Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

434 results about "Denim" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

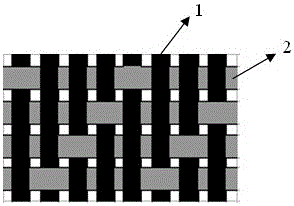

Denim is a sturdy cotton warp-faced textile in which the weft passes under two or more warp threads. This twill weaving produces a diagonal ribbing that distinguishes it from cotton duck. While a denim predecessor known as dungaree has been produced in India for hundreds of years, denim itself was first produced in the French city of Nîmes under the name “serge de Nîmes”.

Internet customization of apparel

InactiveUS20050131571A1Special data processing applicationsMarketingDenimTheoretical computer science

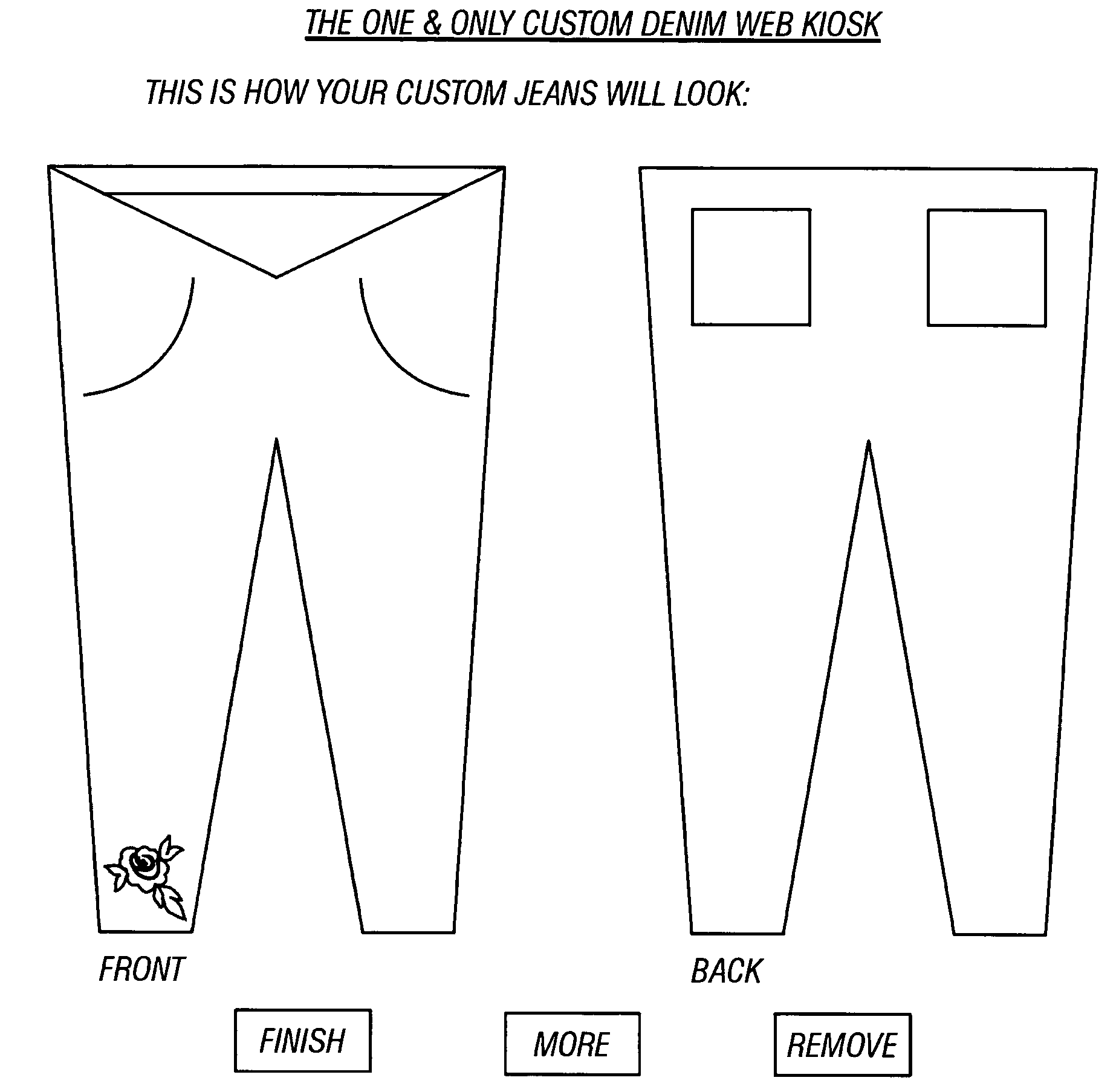

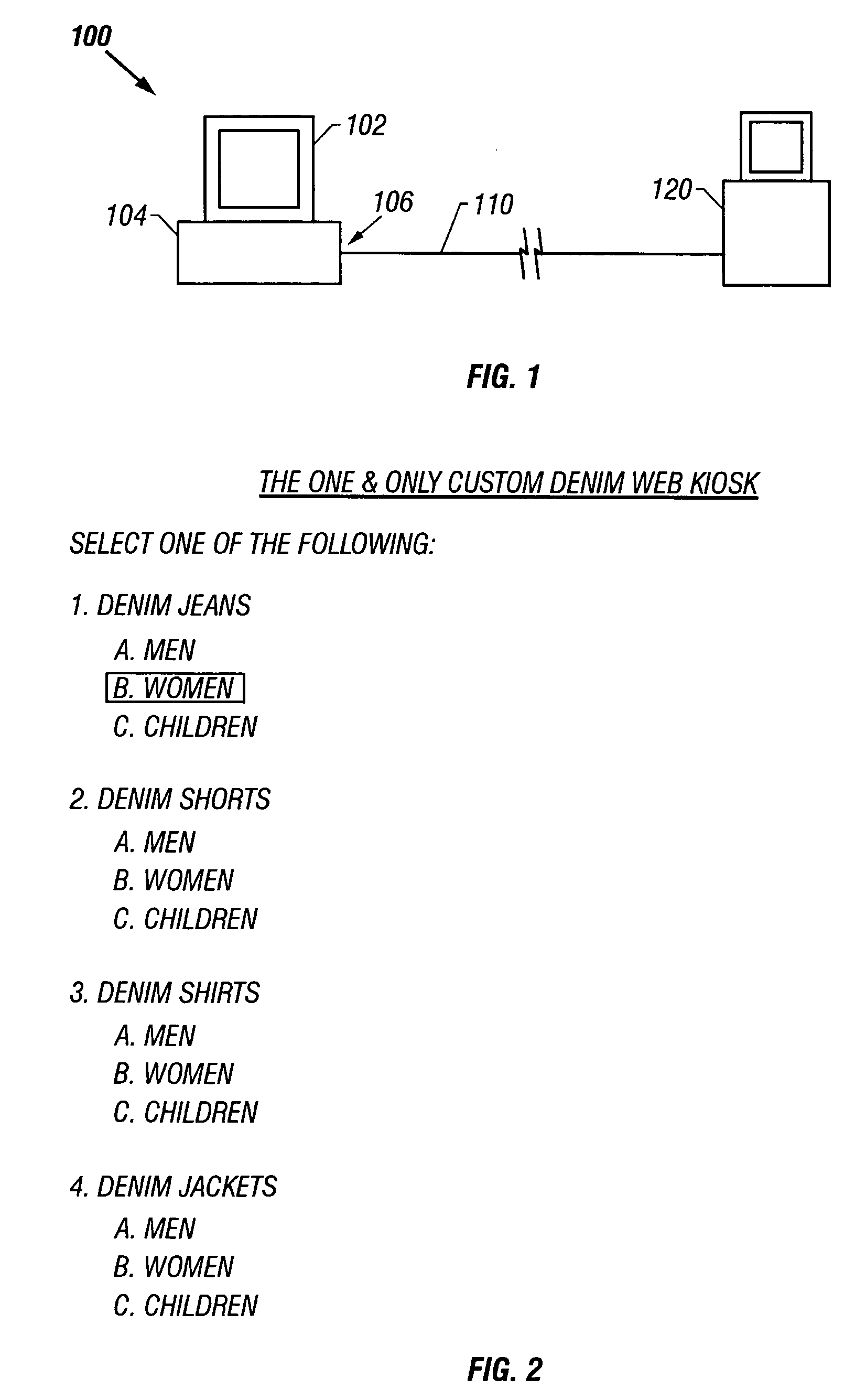

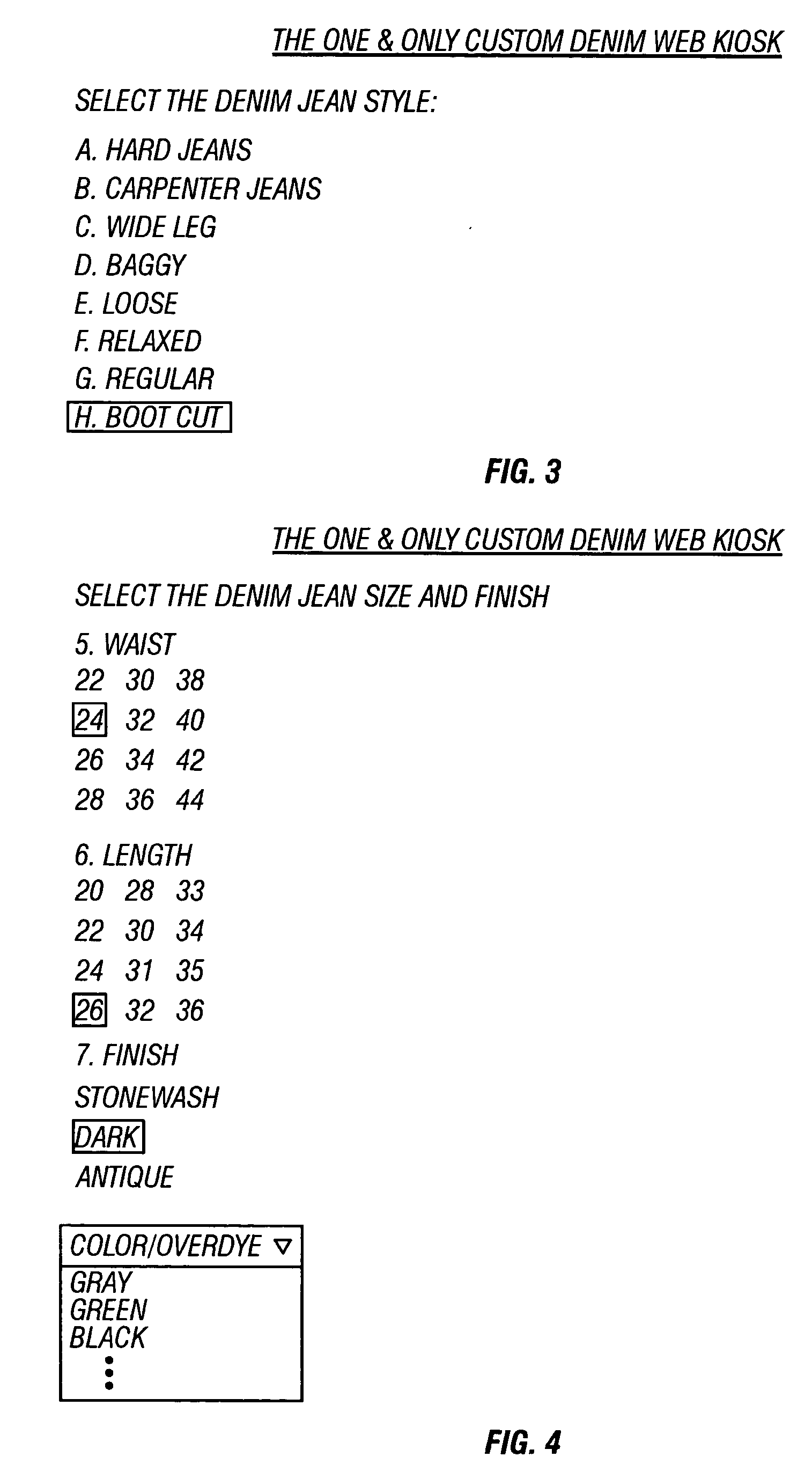

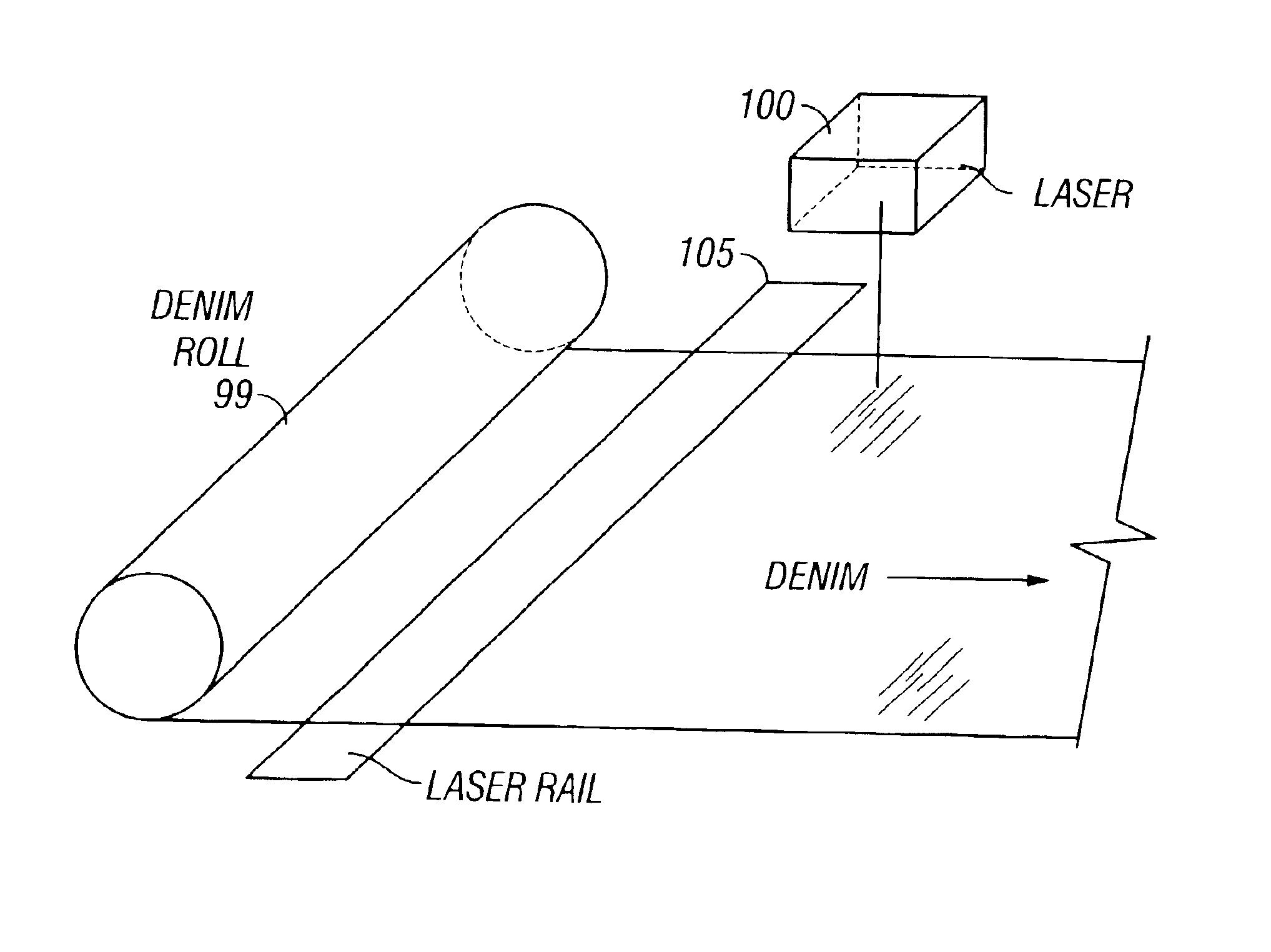

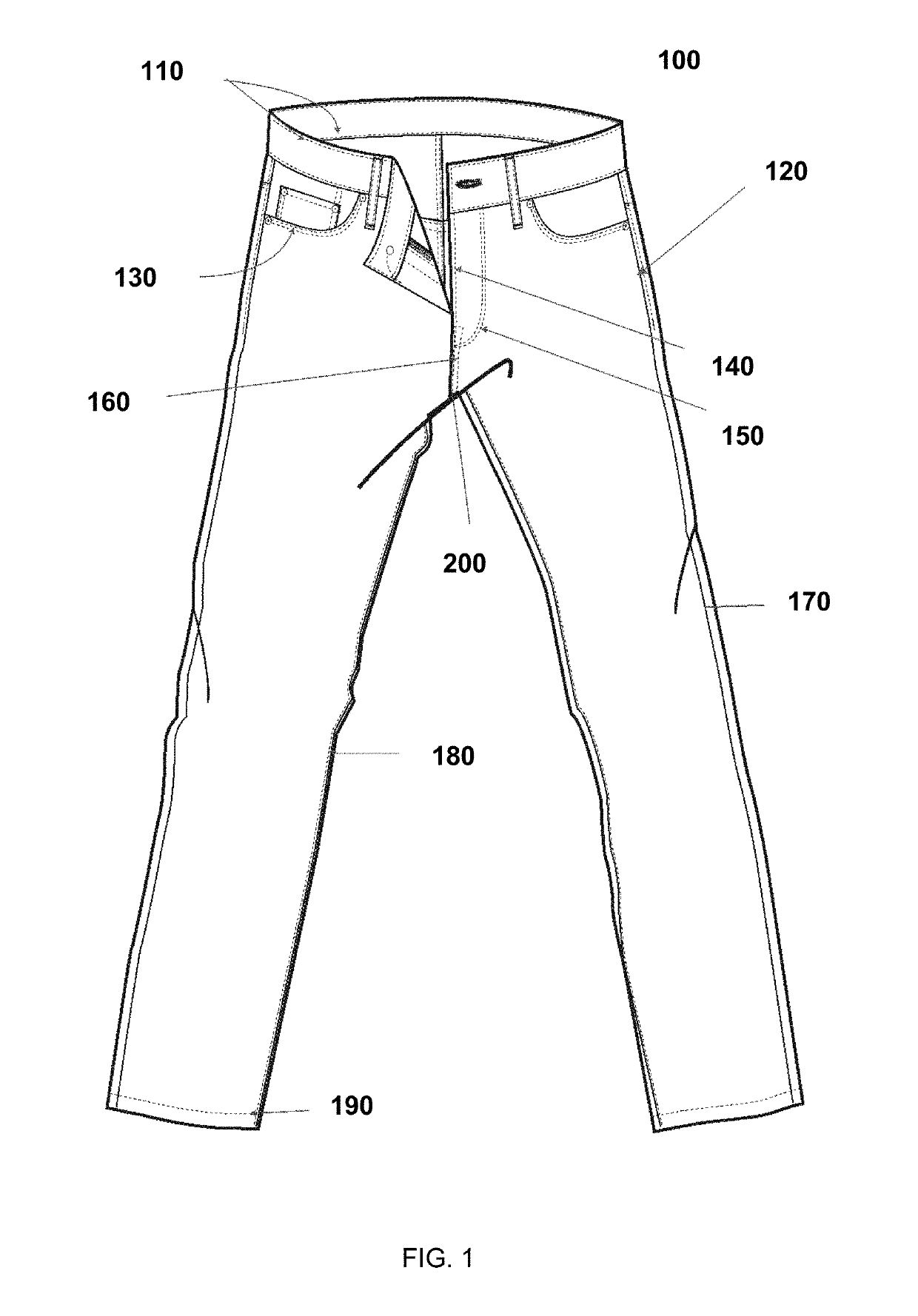

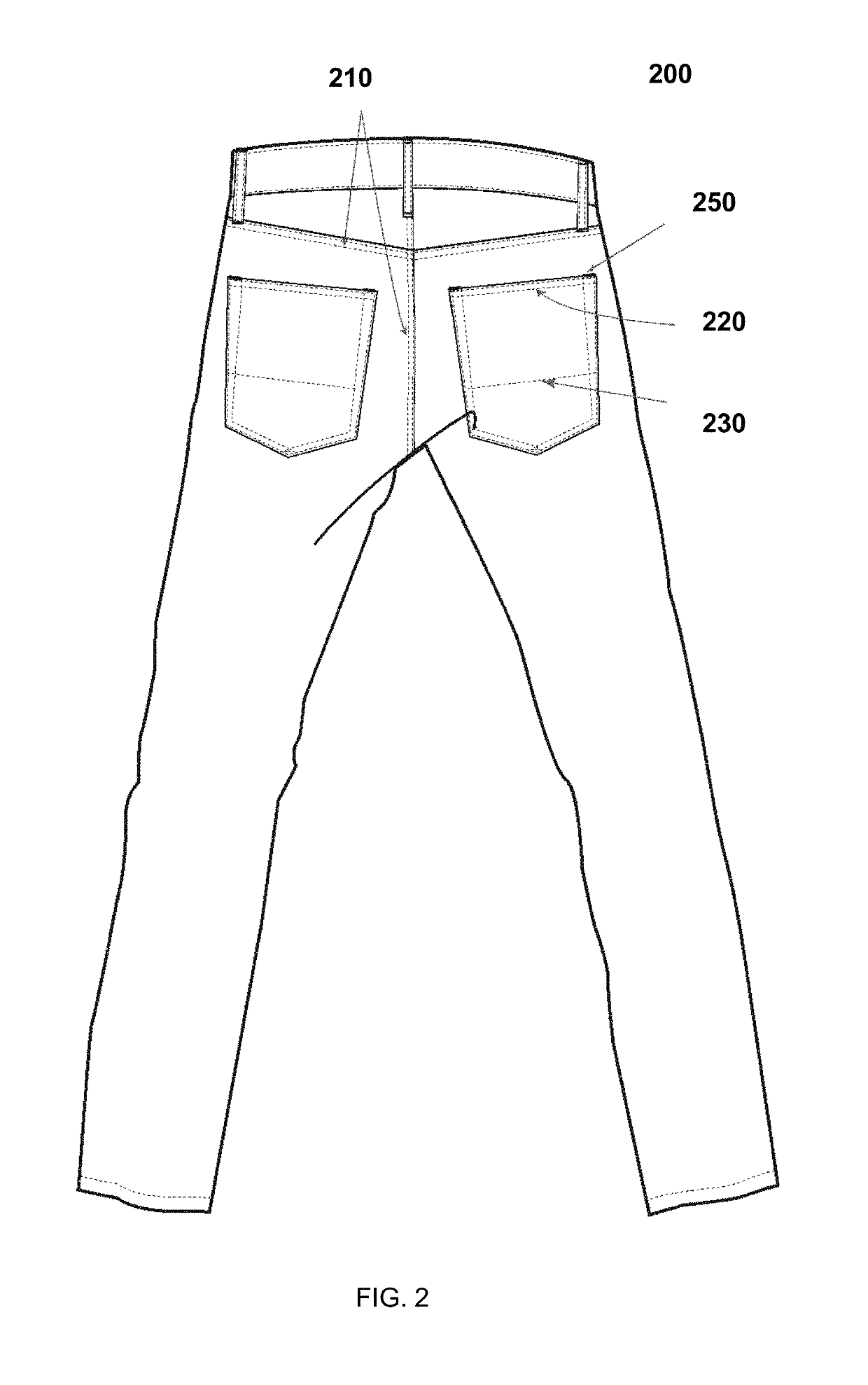

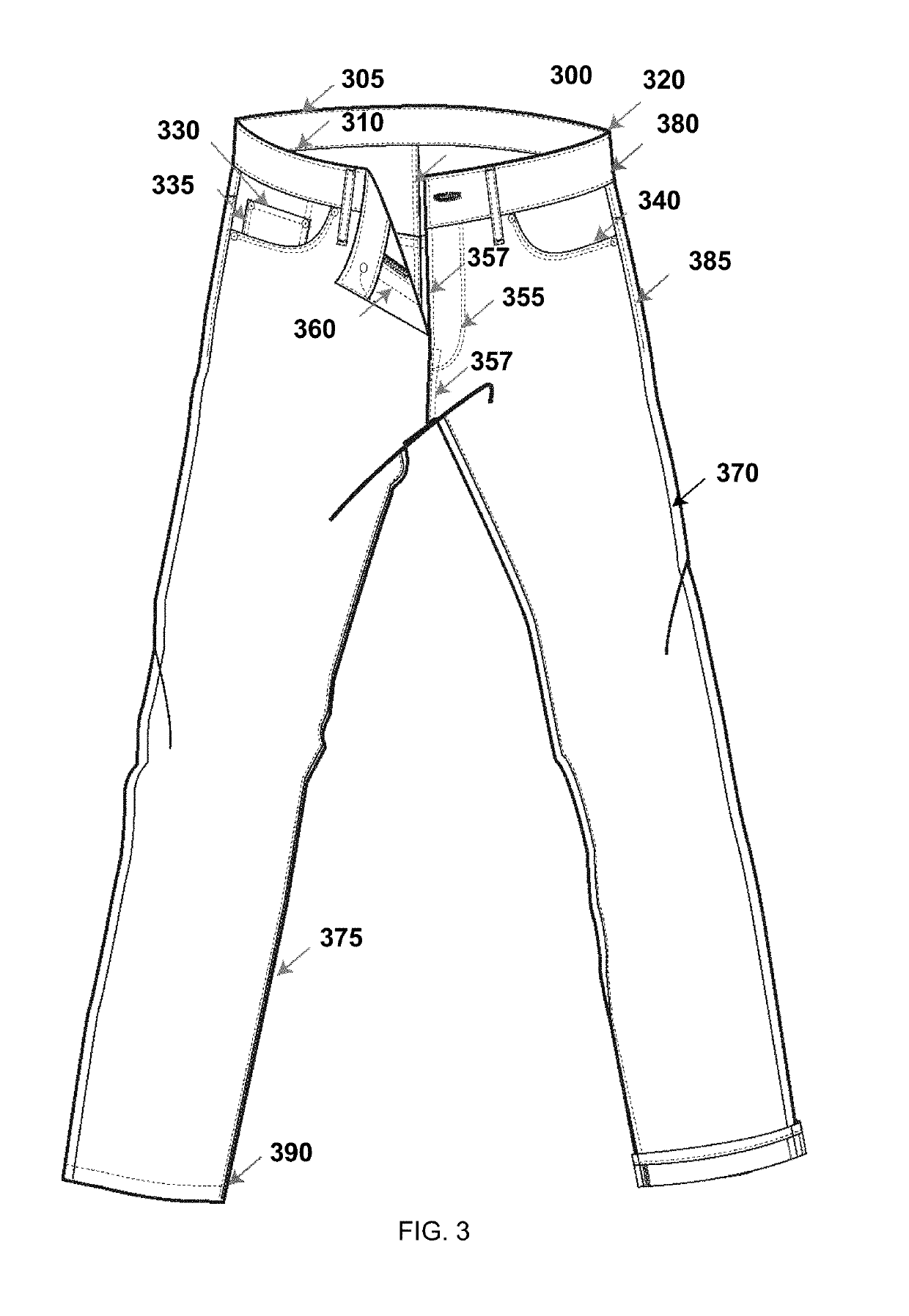

An Internet based technique of allowing customization of denim apparel over the Internet. The user selects custom features for their denim apparel and transmits those features to a computer run by the apparel company. The apparel company displays a facsimile of what the apparel will look like with those custom features. The user can select to purchase that apparel. If so, the company uses a laser to form the custom features on the apparel.

Owner:COSTIN DARRYL

System and method of generating a pattern or image on fabric with linear laser irradiation, fabric made by said method, and products made with said fabric

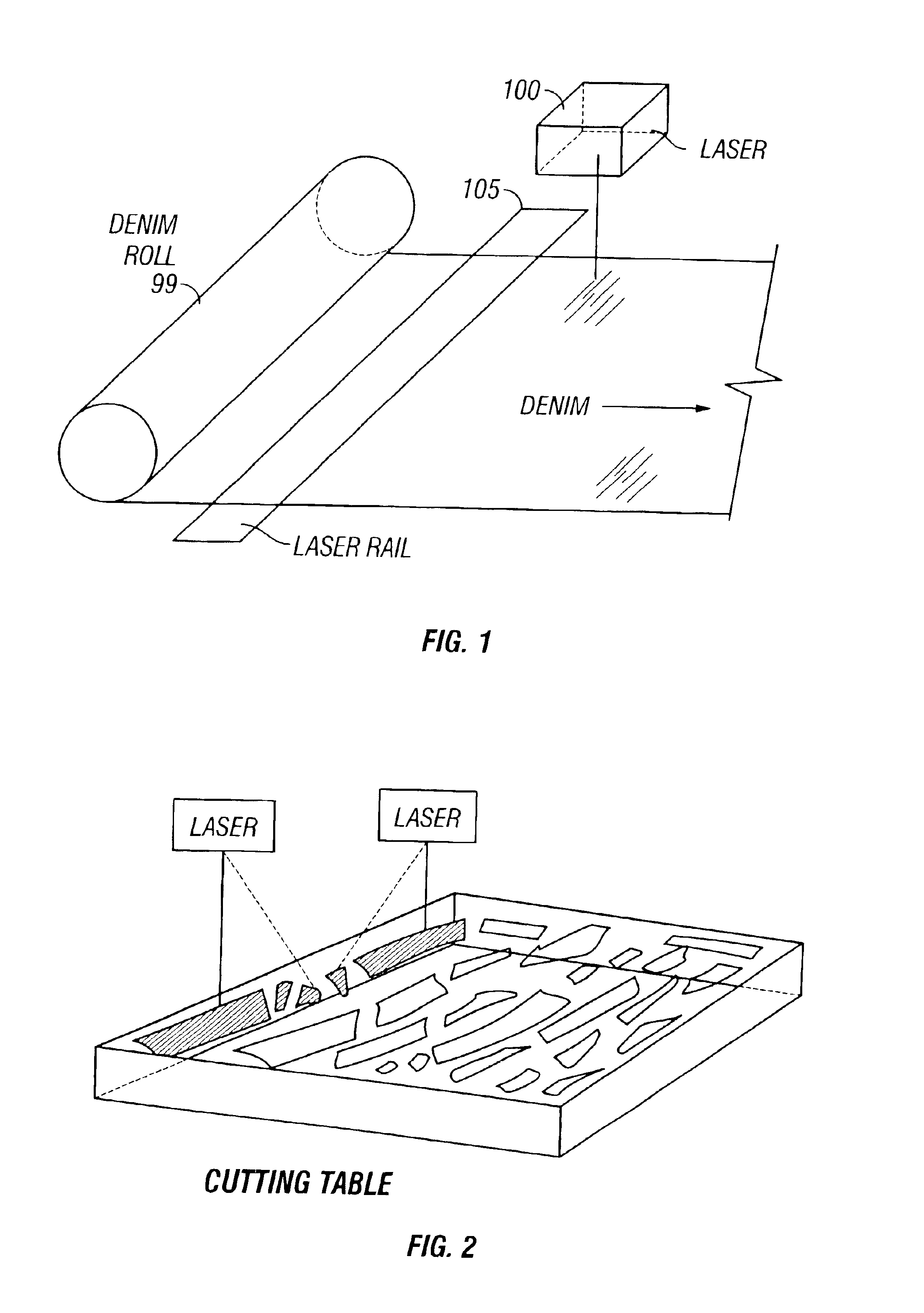

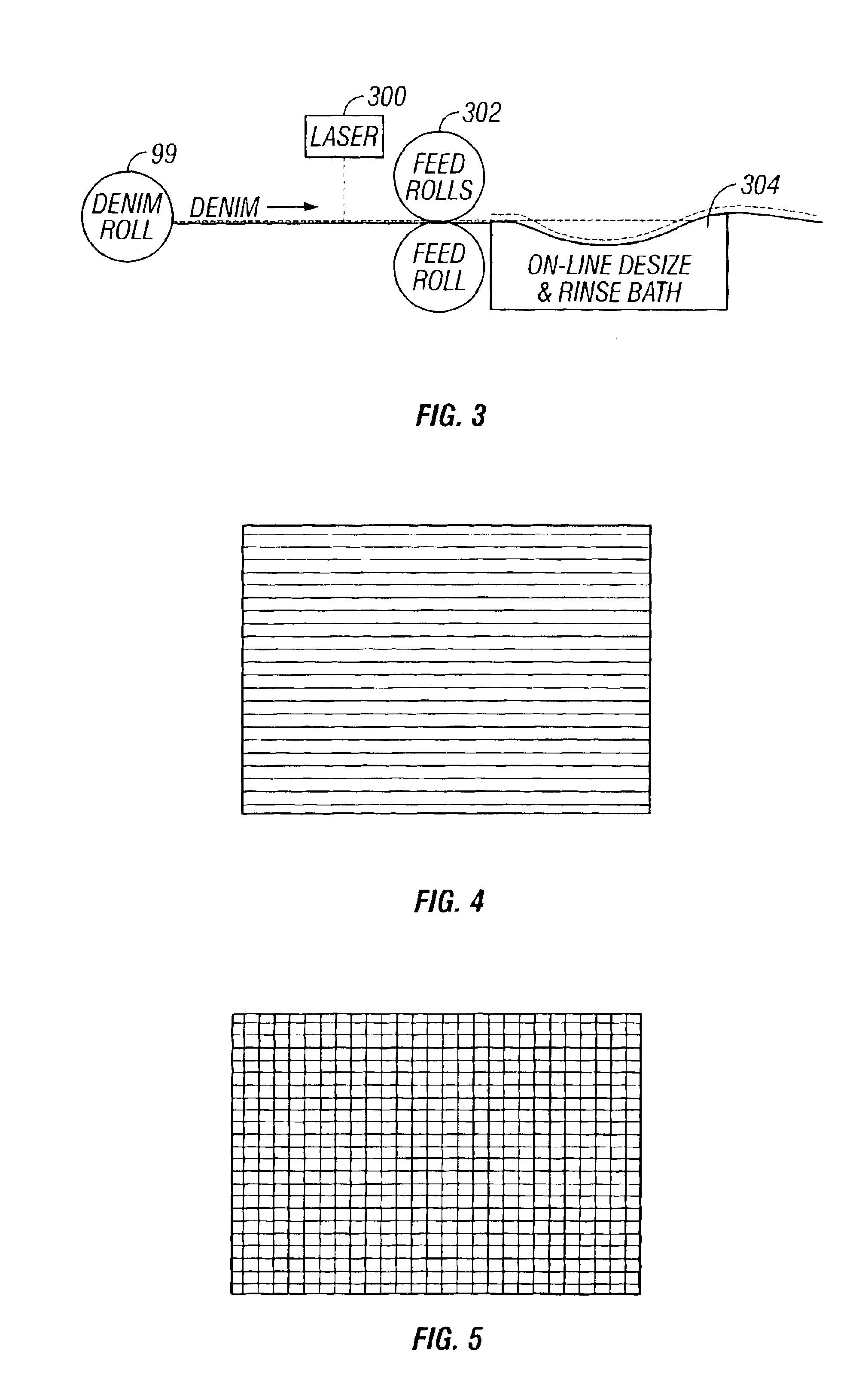

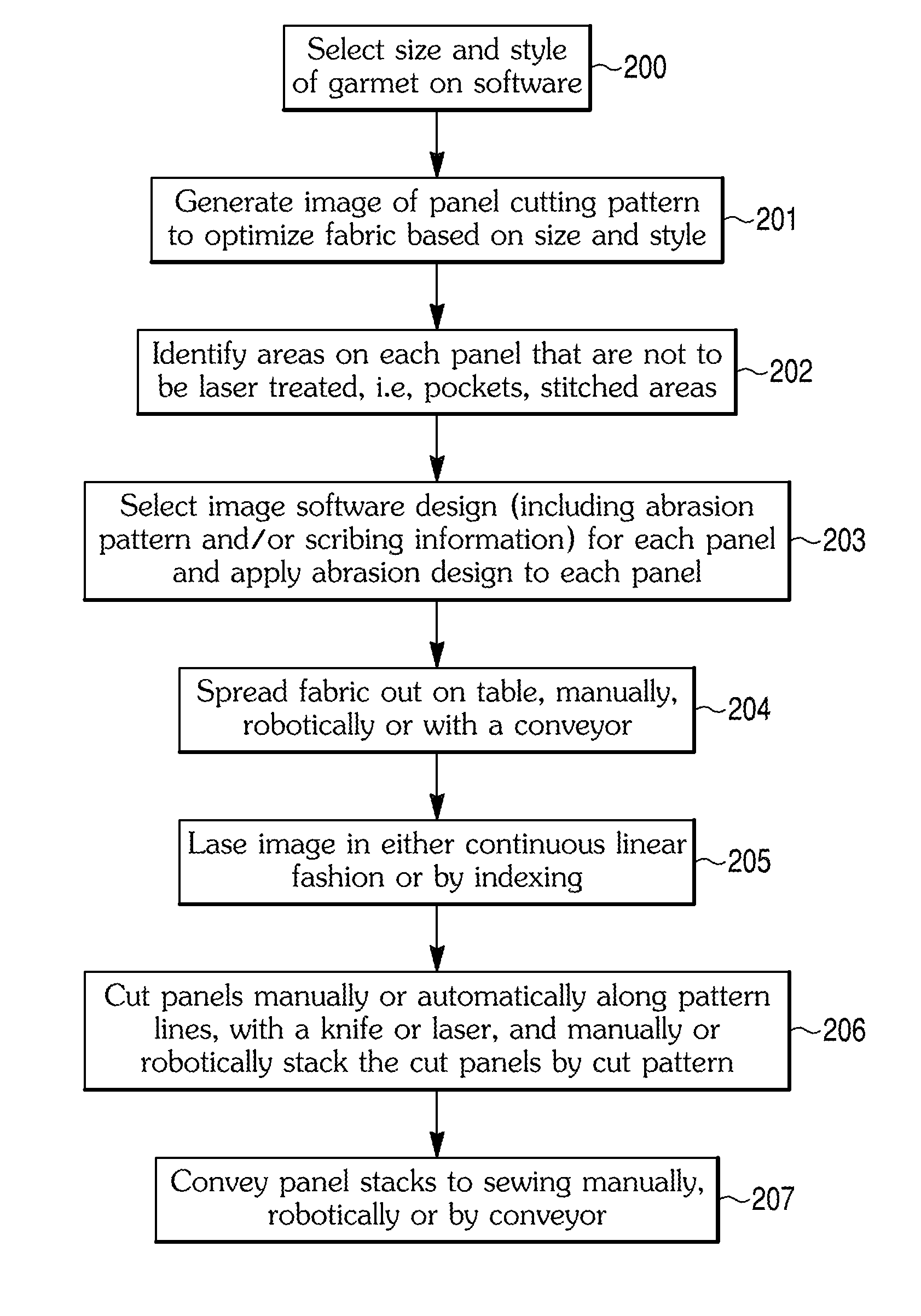

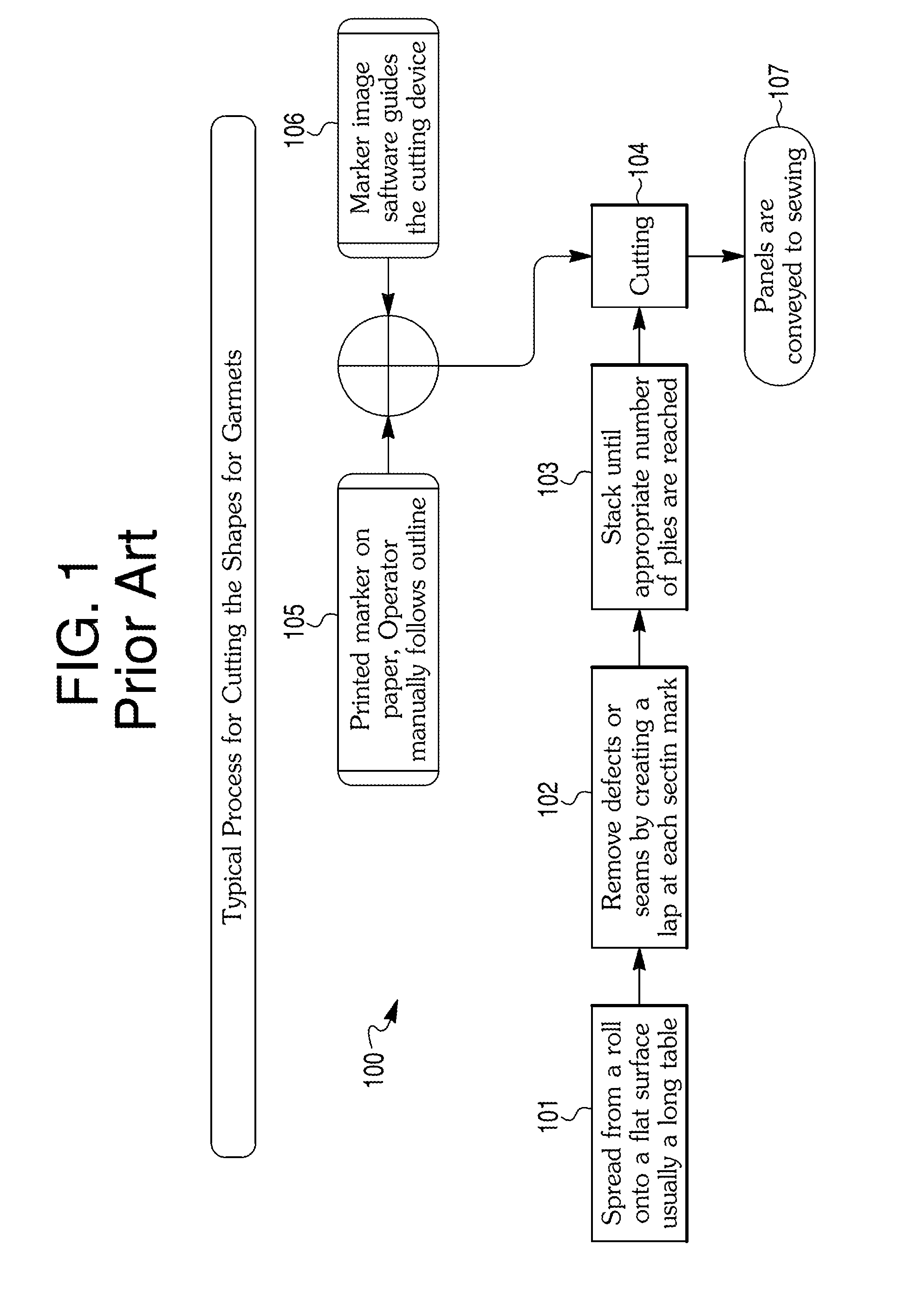

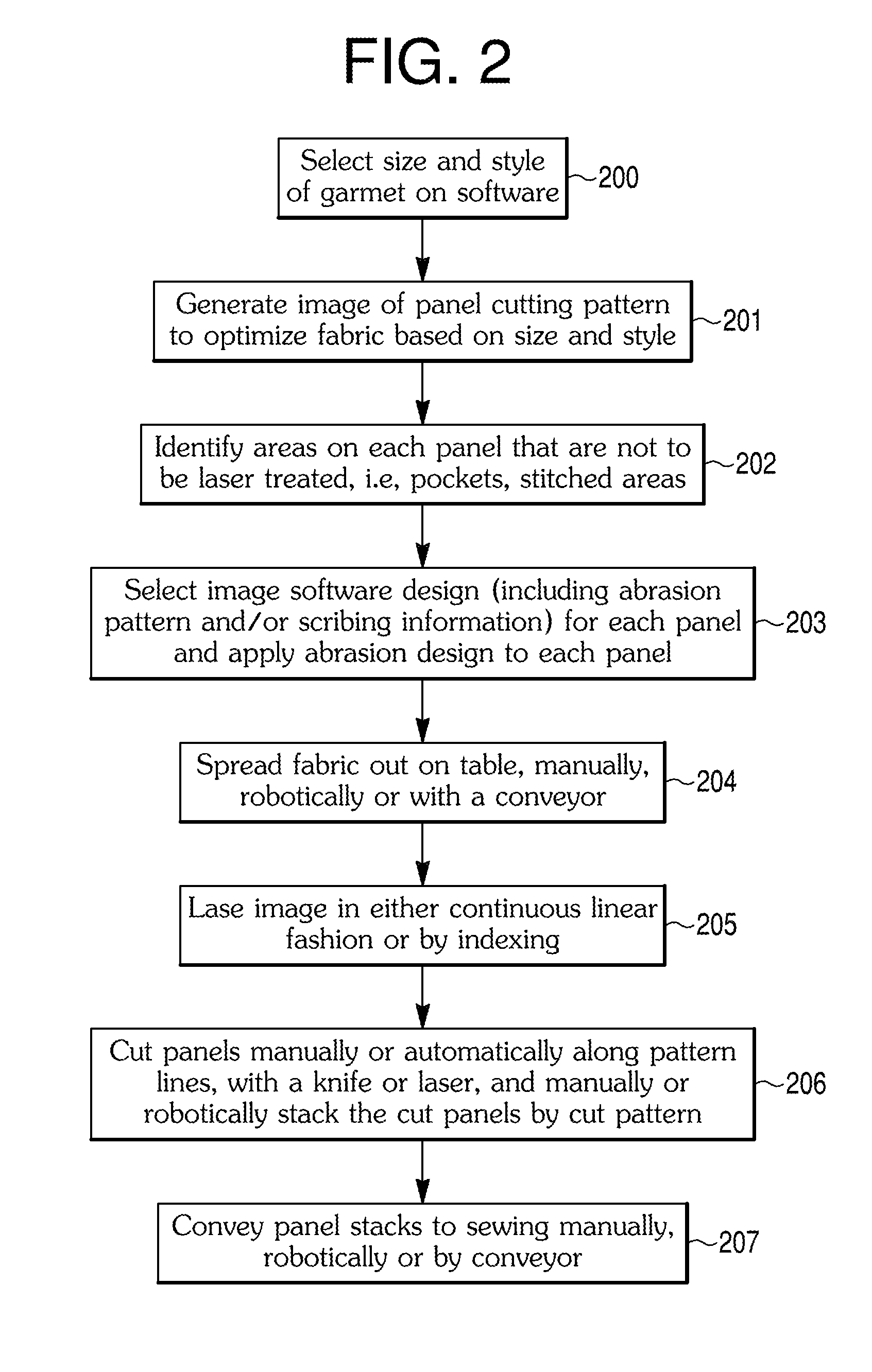

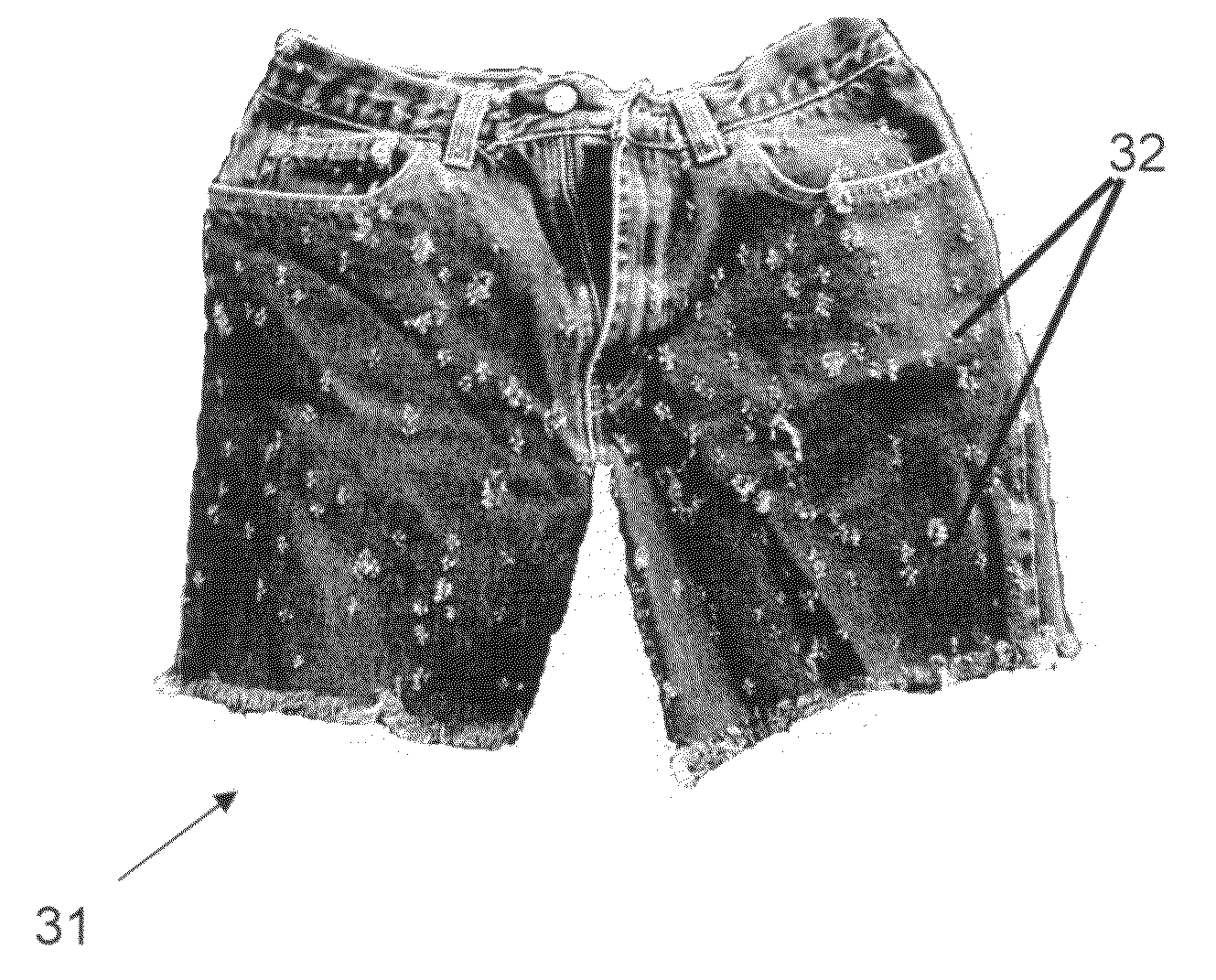

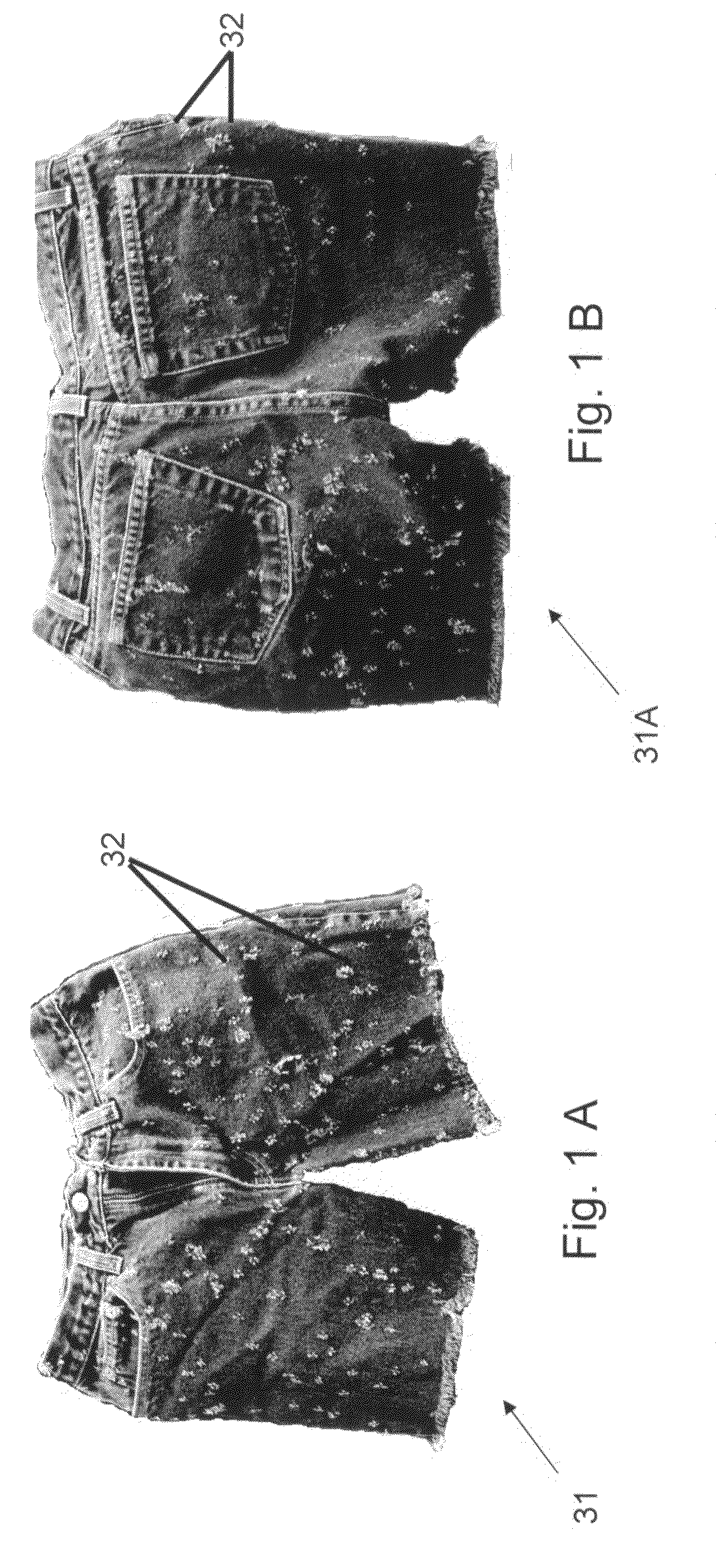

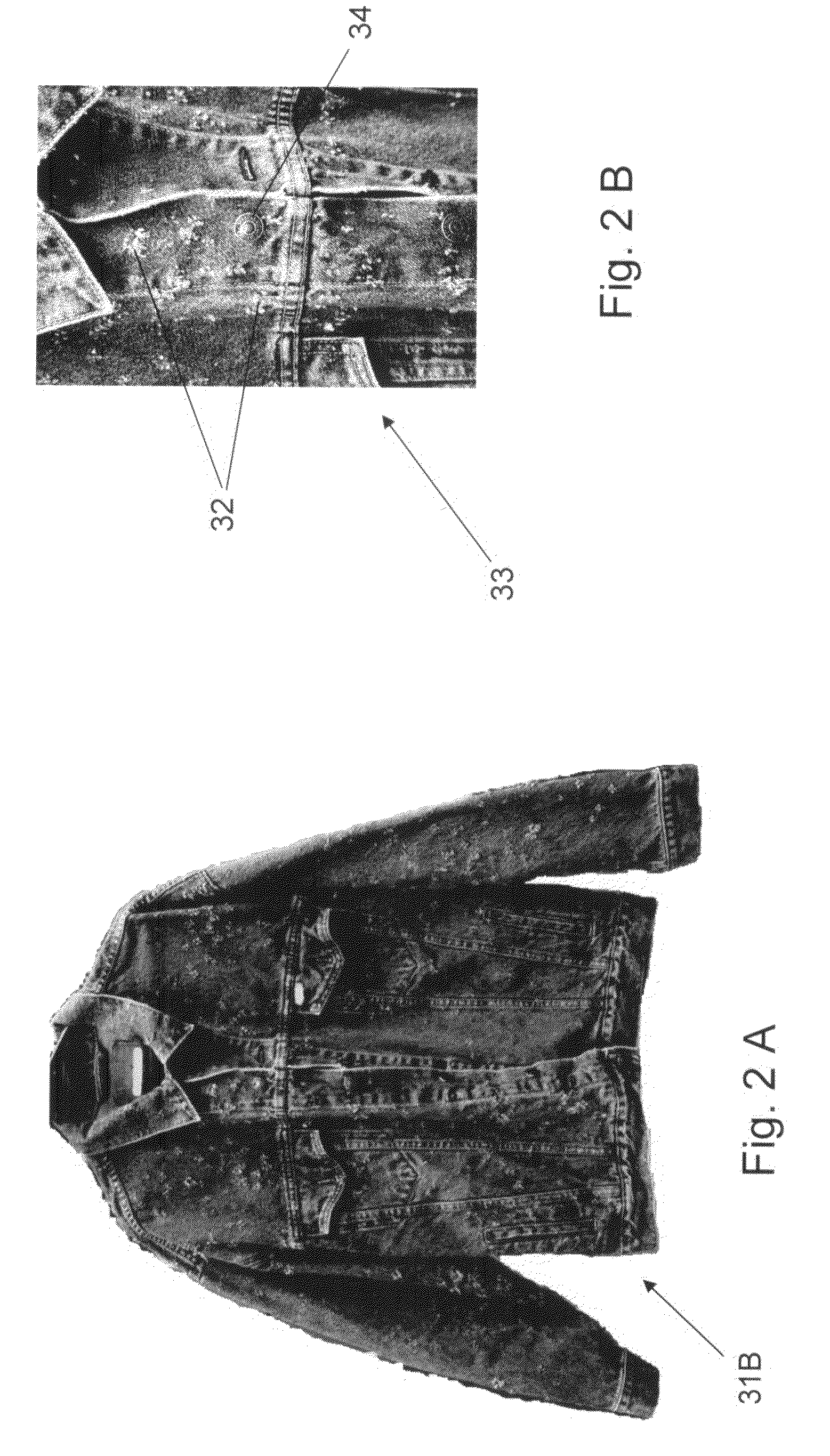

A method of scribing abrasion aesthetics, patterns, images, serial numbers, ply markings and / or other information, such as sizing or care information, on fabric such as denim, before or during the fabric cutting process is provided. The method comprises loading the panel abrasion software, pattern marker software, and fabric scribing software; placing the fabric on a flat surface under at least one laser; laser scribing ply numbers, serial labels, fabric markers, and panel abrasions on the fabric; cutting the fabric into fabric lengths; spreading the pre-abraded and pre-marked fabric lengths on top of each other to create multiple plies in precise alignment; cutting shaped panels along the lines of the pattern marker with a conventional knife, laser, or other appropriate cutting tool; and stacking the abraded, labeled and shaped panels robotically or manually for sewing.

Owner:REVOLAZE LLC

Buck shot blues specially processed denim product and the process methods to make the product

InactiveUS20070205541A1Efficiently provideIncrease heightPattern makingTextile parts treatmentDenimMetal

A process and the resulting uniquely configured product called “Buck Shot Blues”. The base product is a fabric such as denim that has been processed and altered to accomplish an appearance that the fabric has been “blasted” by buck shot or small metal pellets. The resultant fabric has a plurality of holes or apertures in a “blast pattern” that is either specific or random. The holes or apertures after processing are “frayed” from the penetration of the blast elements. The manner of production includes a number of methods, from a simple blast scheme to more complex production processes. An alternative computer controlled manufacturing process is also provided where the individual interacts with the process that produces his garment.

Owner:ALLEN DANN +1

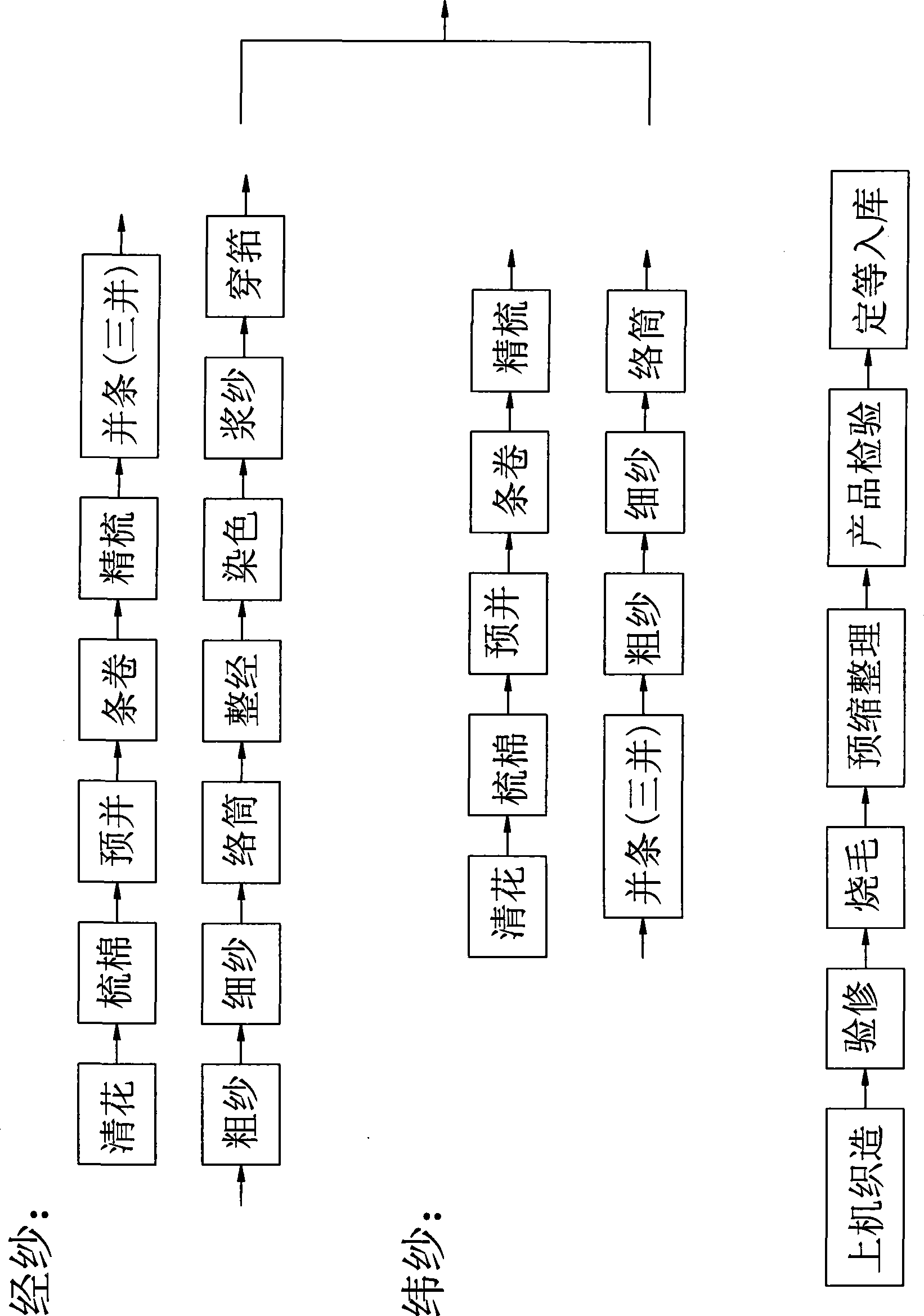

Viloft shengma smooth edge denim and production technology thereof

The invention relates to VILOFT sunn crotataria plain edge jean which comprises the following components by weight percentage: 20-40% of VILOFT fiber, 20-40% of sunn crotataria, 20-40% of one or multiple of cotton fiber, color cotton fiber, prolivon, cashmere, milk fiber, soybean fiber, tencel yarn, flax, silk, etc. In the picking process, the lap pressure is weighted, multi-combing and little beating, combing instead of beating are adopted, the speed of each beater is reduced, and the gauge of the beater and grid bars is enlarged. In the carding process, the lap is fully carded and the card sliver quota is increased; in the drawing process, the clockwise drawing process is adopted, the gauge is enlarged; the pressurizing quantity is improved and the vehicle speed is reduced, the combination process and the three blending combination process are adopted, and the first tension drawing multiple is grasped in a slightly large way; in the spinning process, large postzone roller gauge, small postzone draft multiple and small nip gauge are required, the vehicle speed is reduced, and the pressure is increased. The fabric of the jean has the advantages of environment protection, moderate elastic, soft texture, good luster and drapability, and obviously bamboo joint effect.

Owner:山东万泰创业投资有限公司

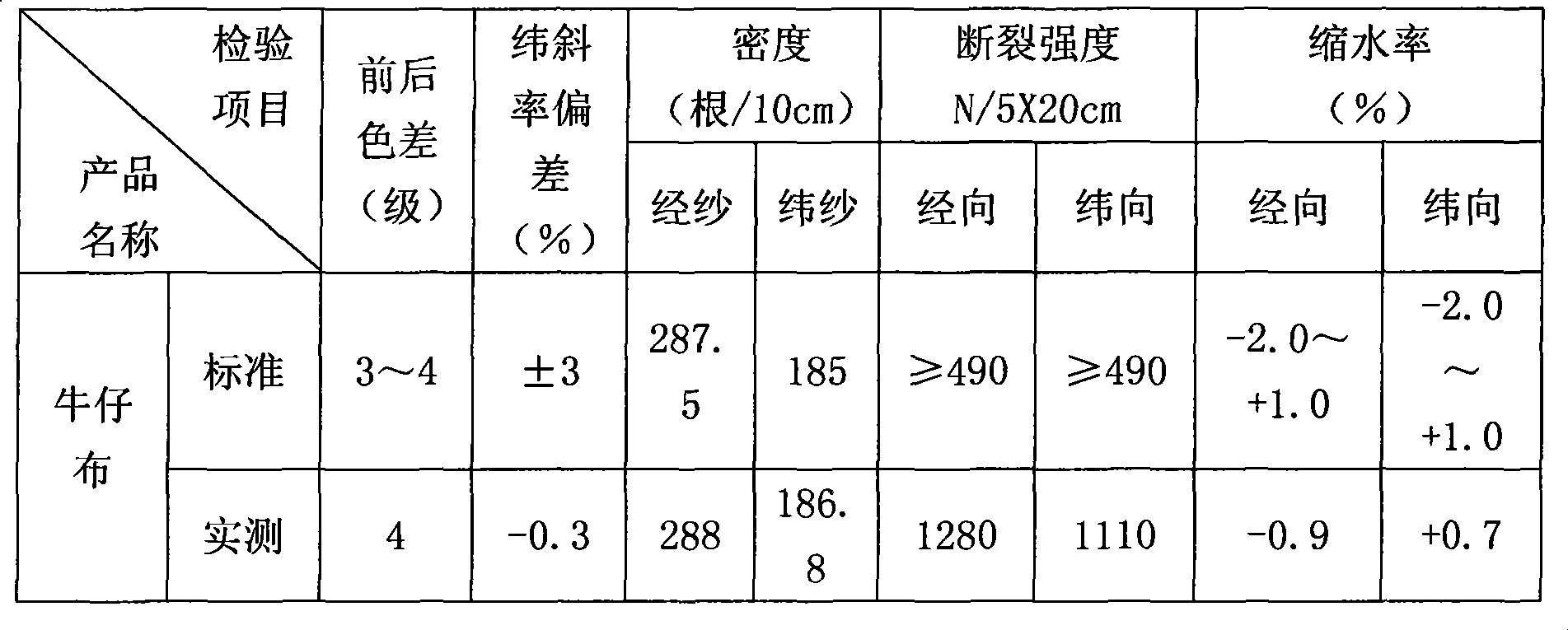

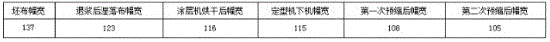

High-elastic low-shrinkage jean cloth and technology for same

The invention discloses high-elastic low-shrinkage jean cloth and a technology for the same. The jean cloth is interweaved by warp yarns and weft yarns in a principle of three warp yarns above and one weft yarn under. The concrete processes are spooling, warping, sizing and dyeing linkage, weaving, checking gray fabric, after-treatment processing, checking finished product and packing. The invention relate to high-elastic low-shrinkage jean cloth and a technology for the same. A 3 / 1 twill-weave is applied; cotton bale T400 warps spandex weft yarns, short fiber pure polyester warps the spandex or blending cotton type warps spandex weft yarns; denier of the spandex is 70D to 105D; draft multiple is 3.5 to 4.5; warp direction tightness of the yarns on a machine is 45% to 75%; weft direction tightness of the yarns on the machine is 38% to 55%; the blank cloth is post-treatment processed according to the concrete processes, so finished product amplification can be narrowed, so weft shrinkage can be reduced; a problem produced during clothing and washing water processing links can be effectively solved; with specific weft-warp yarns, specific weaving machining technology and specific post-treatment process, weft extension of the jean cloth can reach no less than 35%, reversion rate no more than 2.5% and weft shrinkage rate no more than 10%.

Owner:佛山市立笙纺织有限公司

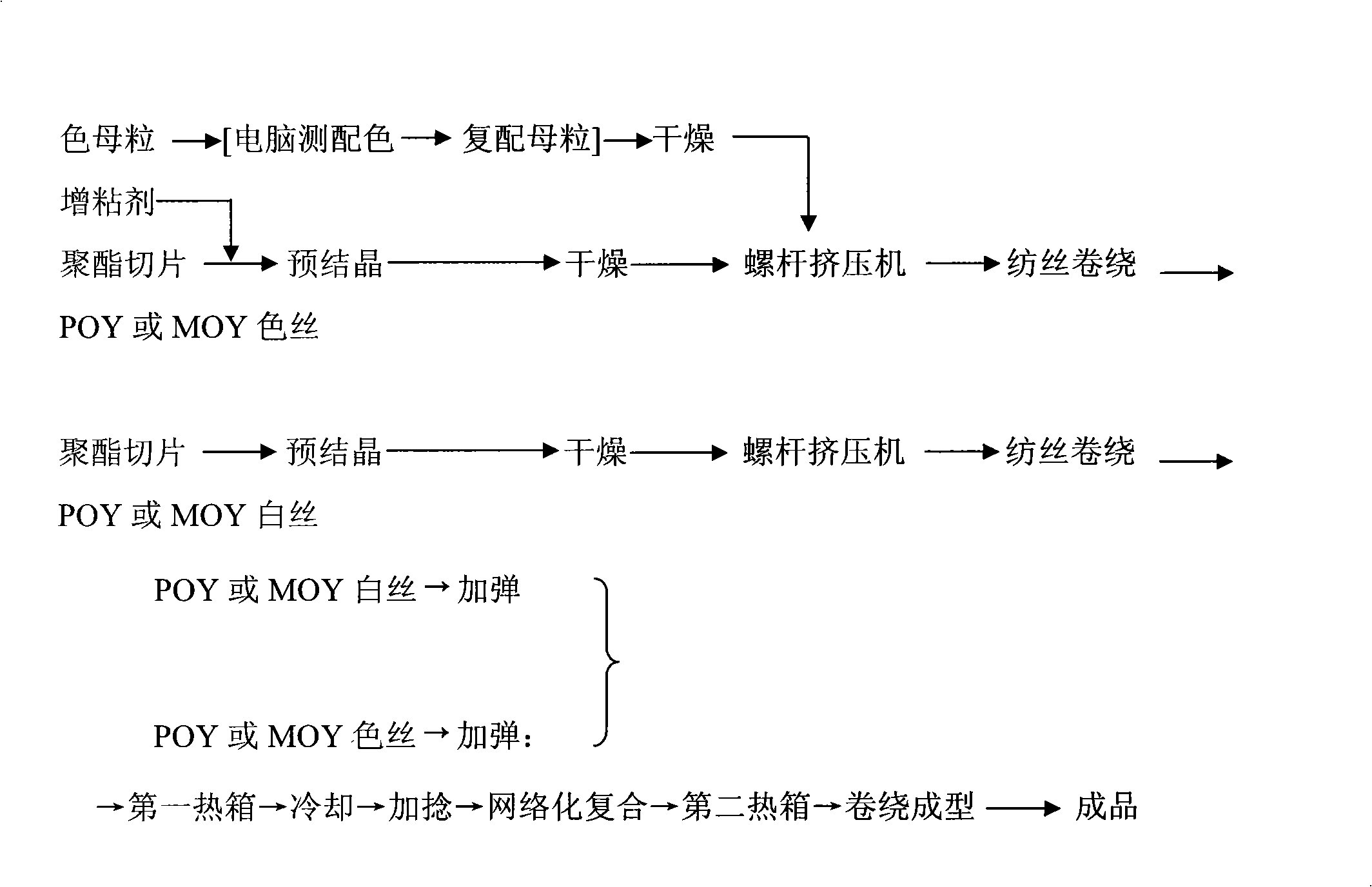

DTY dual-color terylene silk for denim warp thread

InactiveCN101333718ARich varieties and colorsAchieve improvementYarnPigment addition to spinning solutionYarnColor effect

The invention relates to a DTY two-color polyester filament used on the meridian of the denim, which is prepared by the following procedures: (1) color master batch is tested by the computer to be matched color, and then dried, and compound color matched master batch is obtained; (2) a tackifier is added into polyester chips, then the polyester chips are pre-crystallized and dried, then the polyester chips and the compound color matched master batch are both added into a screw extruder to be spun and winded, and a dyed yarn POY or MOY is obtained; (3) the polyester chips are pre- crystallized and dried, then are added into the screw extruder to be spun and winded, and a white yarn POY or MOY is obtained; (4) the dyed yarn POY or MOY and the white yarn POY or MOY are overfeeding textured in variable frequency through slight tension control and networked two-color compound processed, and the DTY two-color polyester filament used on the meridian of the denim is prepared. The DTY two-color polyester filament realizes color matching effect of multicolor and compound color, keeps production processes of colored polyester filament material clean and environmental protective, and realizes the two-color effect of the spun polyester filament and the <color stripping> appearance styles of stone mills and water washing, etc. peculiar to the meridian of the denim.

Owner:SHAOXING UNIVERSITY +1

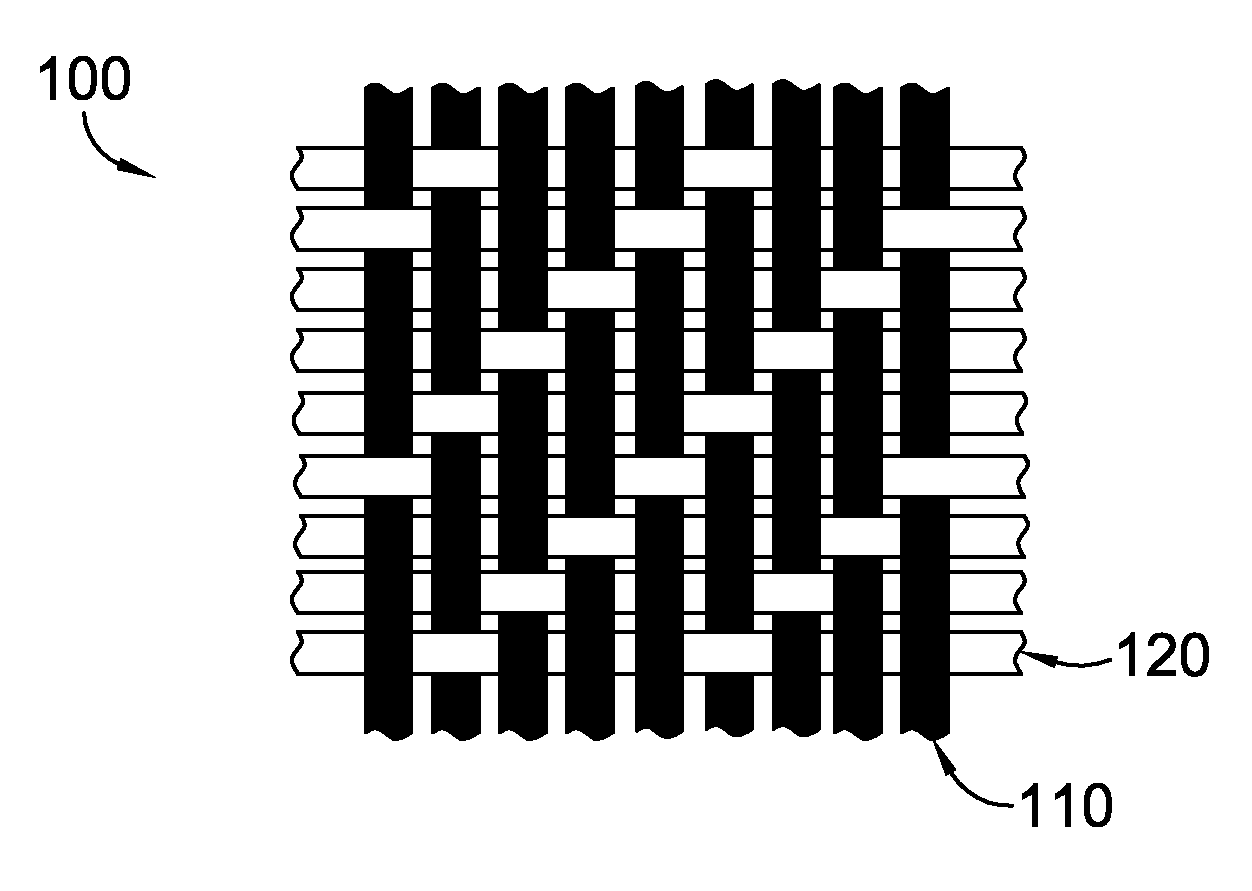

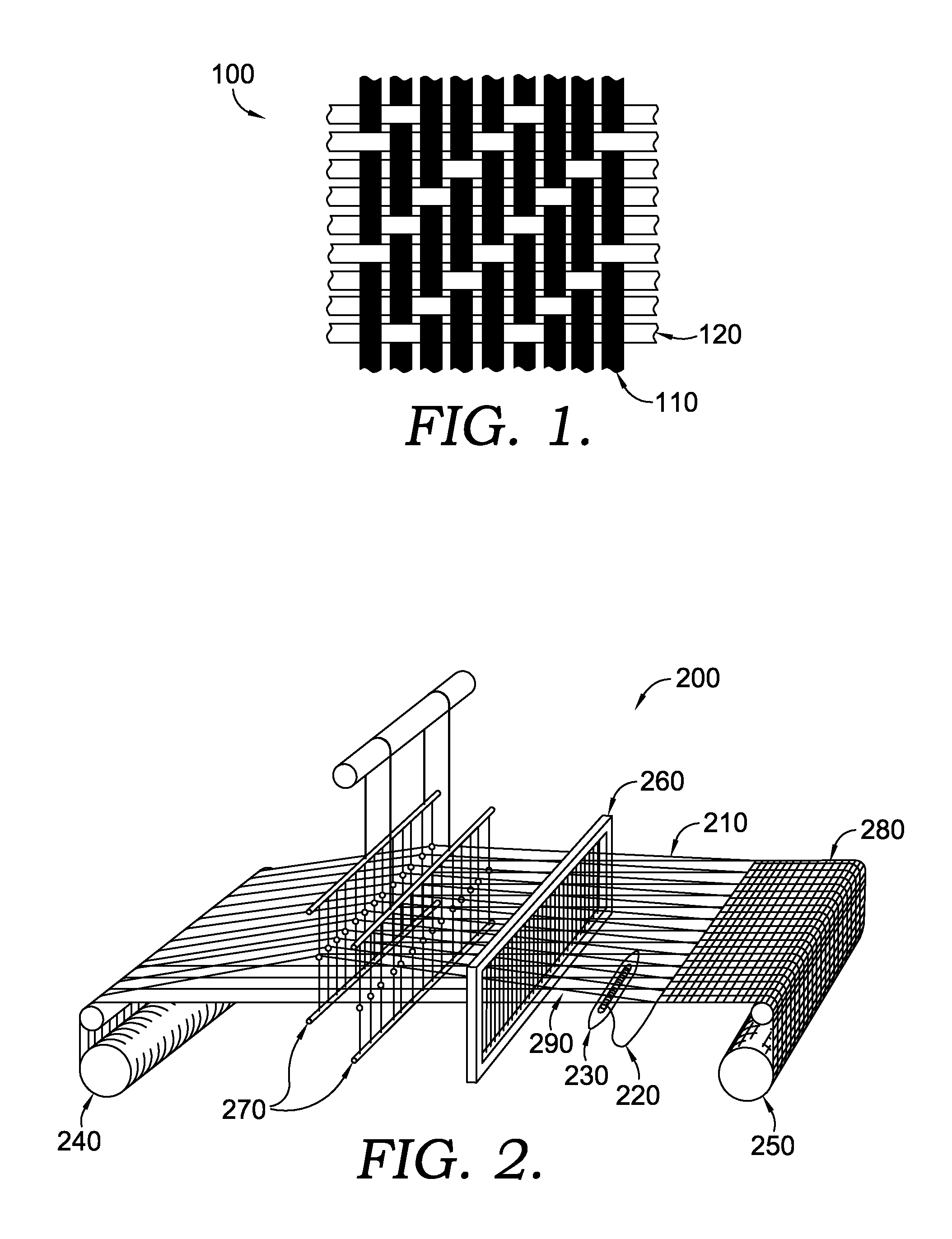

Architectrally Enforced Denim

ActiveUS20130217288A1Light weightSkin stimulationLayered productsWoven fabricsDenimMoisture management

A denim fabric with high tenacity and / or moisture management and / or stretch materials is provided. Proportions of materials in the denim fabric may vary during the weave of the fabric to create different performance zones in the resulting garment with or without assembling different fabric pieces.

Owner:NIKE INC

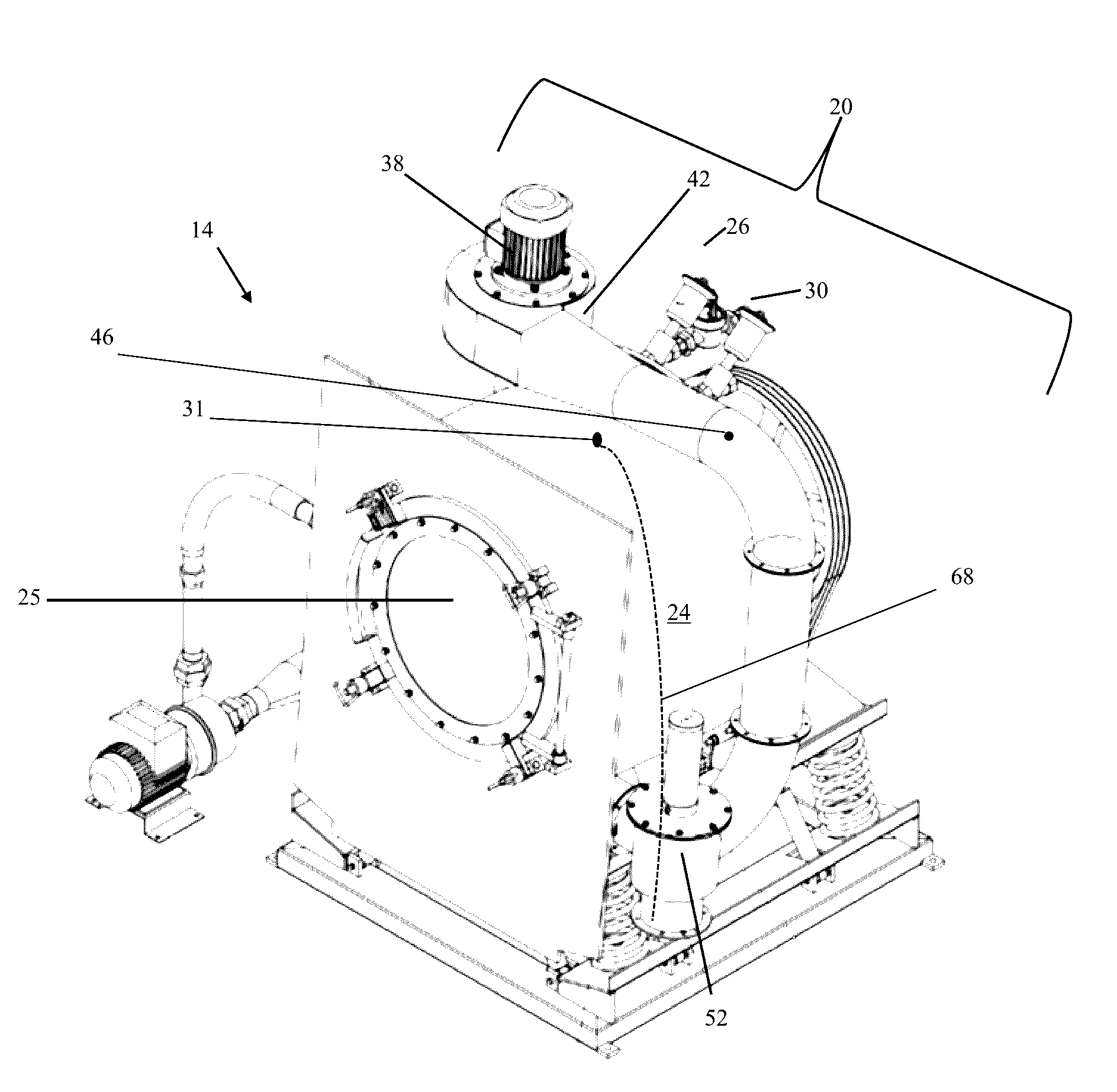

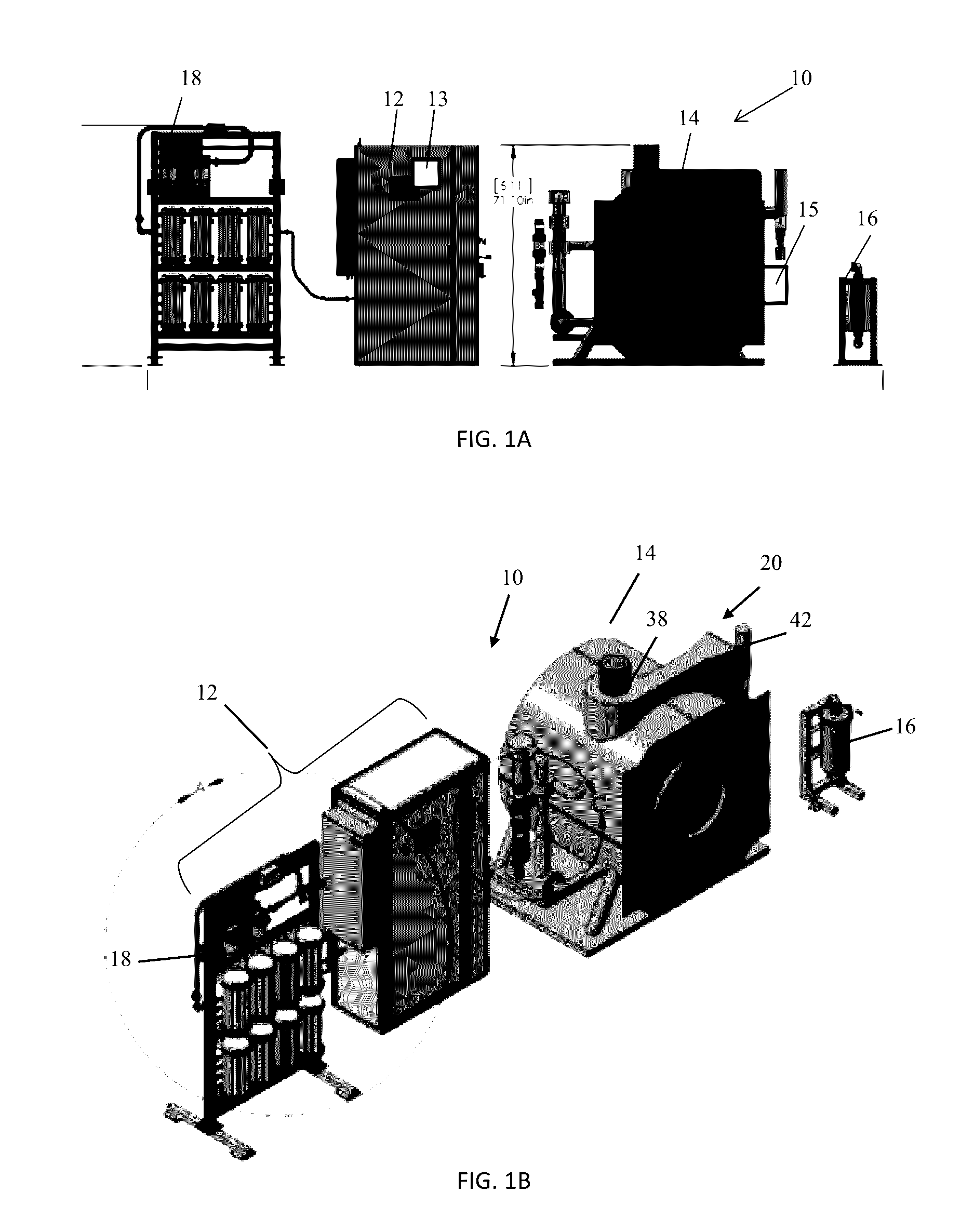

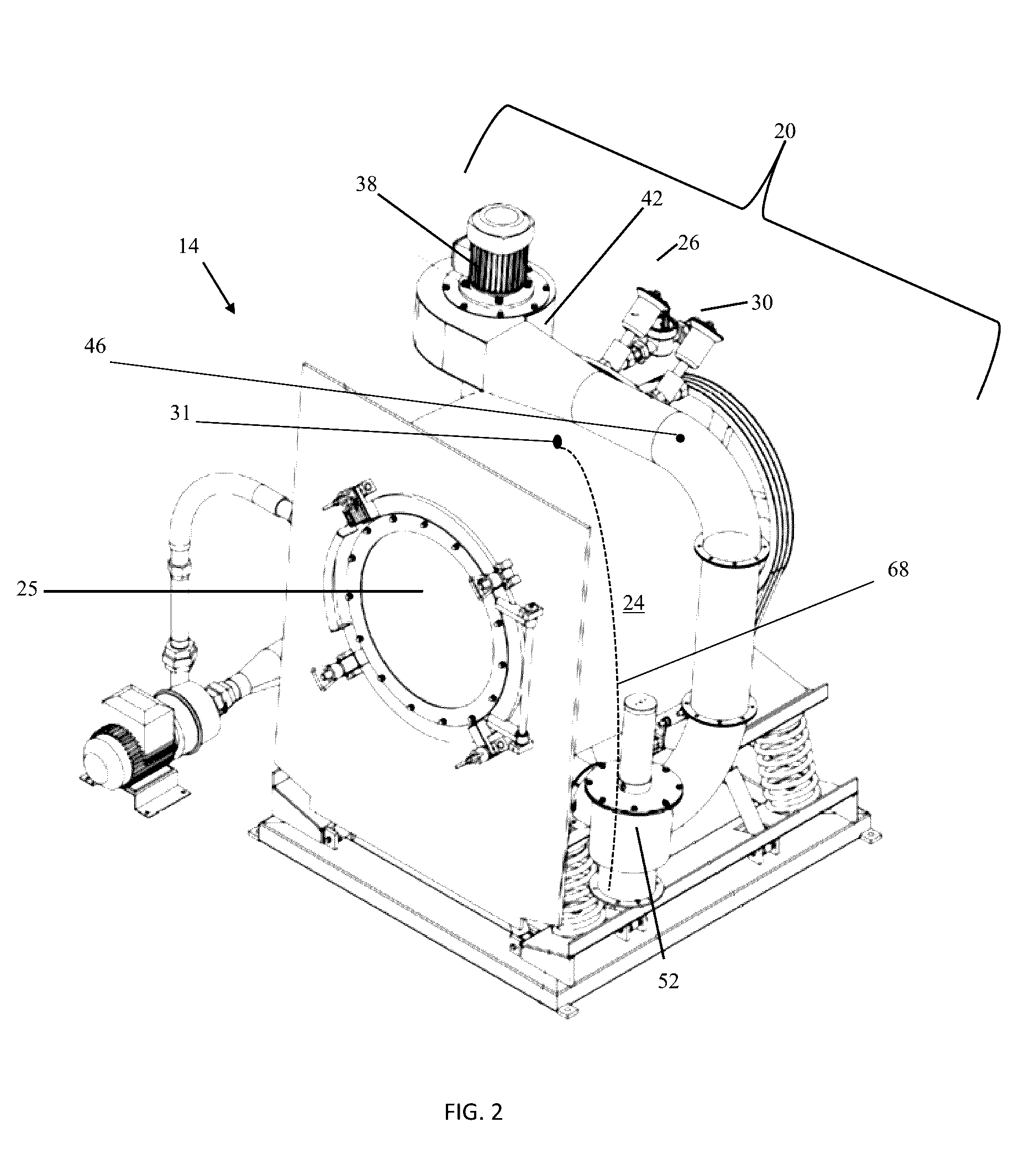

Ozone process for color removal

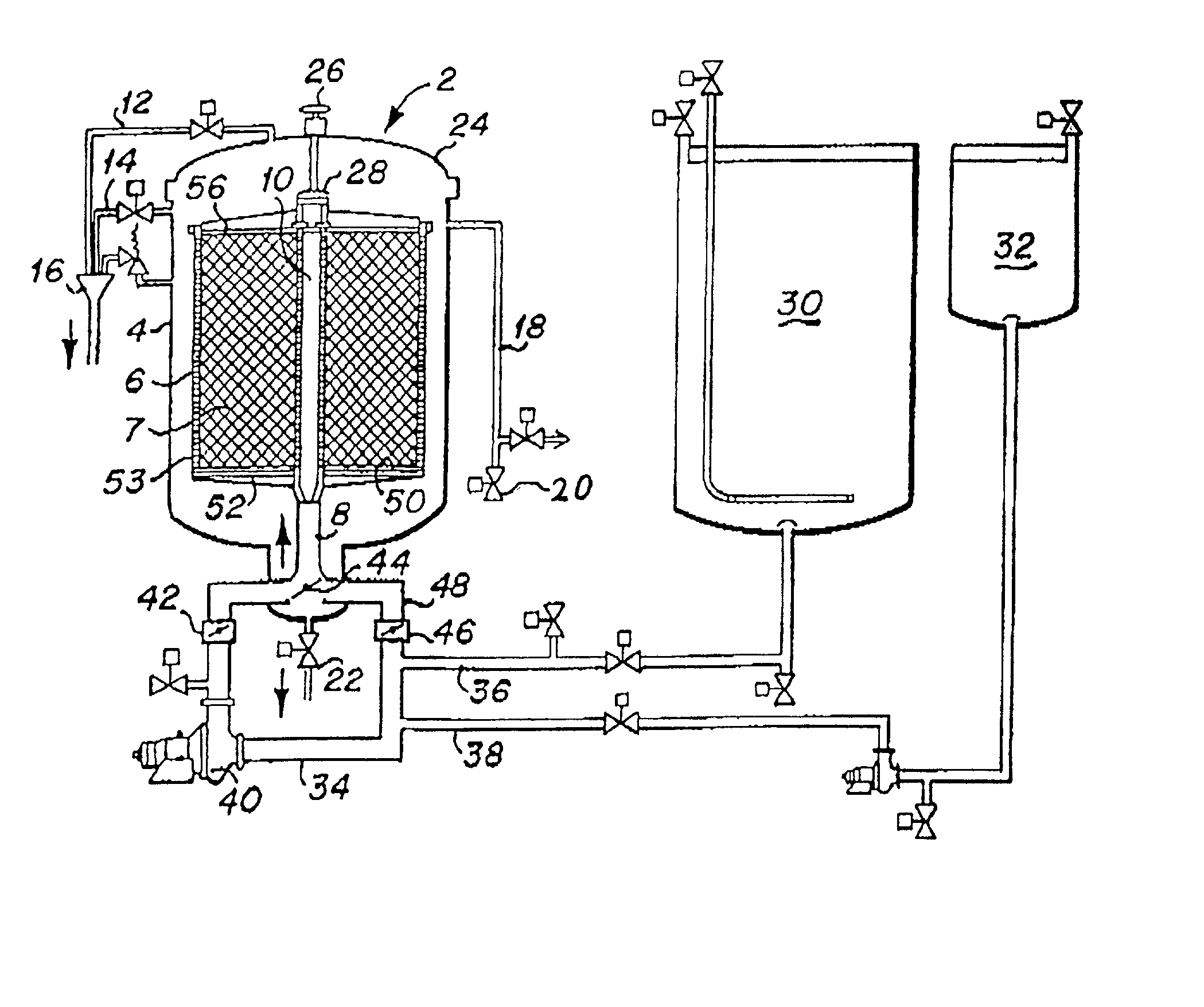

ActiveUS20170016175A1More reliable and reproducibleTextile treatment containersLiquid/gas/vapor article treatmentControl systemWastewater

Embodiments relate generally to methods and systems for bleaching textiles using ozone gas that incorporates a color removal step. In one example, there is provided a hybrid machine that incorporates certain features of a washer, but that also includes an integrated blower for gas distribution inside the machine. There is also provided an ozone dosing control system that allows for maintenance of a constant concentration of ozone in the machine. In one embodiment, the ozone output measured in grams / hour at this constant concentration in conjunction with the weight of product measured being treated may be referred to as the “bleaching factor.” There is further provided a wastewater dye removal step, in which ozone is used to clean the water and remove dyes and other colors that may be deposited via denim or other garments.

Owner:GUARDIAN MFG

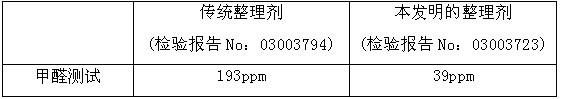

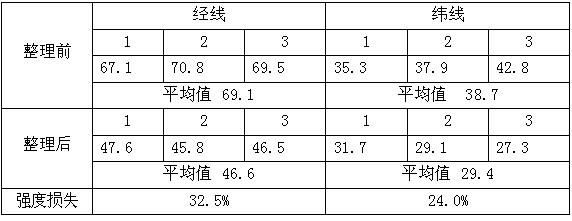

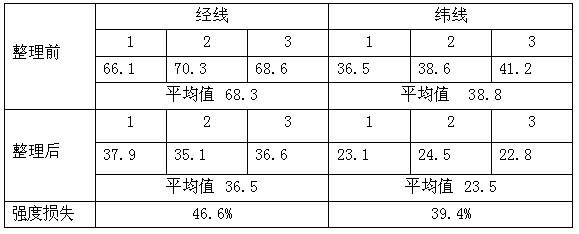

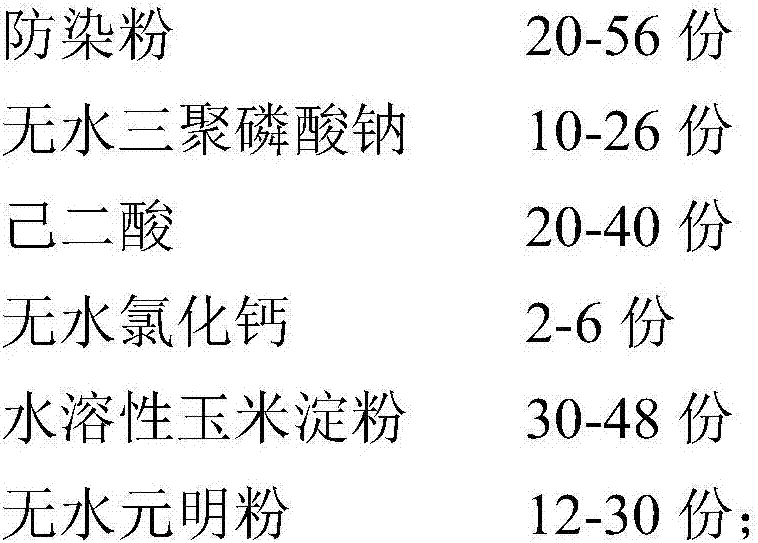

Denim-apparel fold finishing agent and fold finishing method

InactiveCN101851860AReduce formaldehyde contentReduce tear lossFibre treatmentDenimPolyvinyl alcohol

The invention relates to a denim-apparel fold finishing agent and a fold finishing method. The denim-apparel fold finishing agent comprises the following in percentage by weight: 30 to 35 percent of etherification 2D resin, 4 to 5 percent of catalyst, 5 to 10 percent of modified polyvinyl alcohol, 8 to 10 percent of cationic resin, and the balance of deionized water. The denim-apparel fold finishing method comprises the steps of preparing finishing liquid, soaking raw material in the finishing liquid, grasping folds with hands, drying, baking the obtained product in an oven, rubbing the obtained product with hands, spraying potassium permanganate, washing the obtained product with water, and the like. The denim-apparel fold finishing agent has relatively low formaldehyde content, thereby greatly reducing the loss of tearing force. The denim-apparel fold finishing method has the advantages of solving the problem that denim apparel is big in loss of tearing force, maintaining the original hand feel of the denim apparel to the utmost extent, ensuring that the denim apparel is easy to absorb softener and solid folds are easy to finalize and simplifying the production process of solid fold finishing.

Owner:东莞市广利行洗涤原料有限公司

Biological enzyme desizing enzyme wash-bath process of pure cotton and cotton-containing type blended denim clothing

ActiveCN104452315AReduced desizingNo generationBiochemical fibre treatmentDry-cleaning apparatus for textilesState of artDenim

The invention relates to a biological enzyme desizing enzyme wash-bath process of pure cotton and cotton-containing type blended denim clothing. The process comprises the following steps: (1) performing desizing enzyme wash-bath: adding the denim clothing into an industrial washing machine, adding water, heating the water to 40-50 DEG C, adding desizing enzyme wash-bath enzyme into the industrial washing machine, controlling the pH value of the solution to be 6.0-8.0, opening the industrial washing machine, preserving the heat and rotating for 30-90 minutes, discharging the solution and washing for two times with clear water; (2) neutralizing with a reducing agent: adding the clothing on which monkey is sprayed into the industrial washing machine, adding water, heating the water to 25-40 DEG C, adding the reducing agent into the industrial washing machine, controlling the pH value of the solution to be 5.0-7.0, controlling the total hardness of water of the solution to be 70-150 ppm, opening the industrial washing machine, preserving the heating and rotating for 5-20 minutes, discharging the solution and cleaning for 1-2 times with clear water. Compared with the prior art, the process has the advantages that the process is time-saving, simple, easy to control and rational, no toxic or harmful substance is produced, the production efficiency is obviously improved, the product quality is more stable, and the production comprehensive cost is greatly reduced.

Owner:FIBER CHEM BIOLOGICAL CHEM

Printing rubber paste for coating denim and screen mesh printing method using printing rubber paste

InactiveCN102605646AGood bonding and cross-linkingHigh color fastnessDyeing processTextile printerFiber

The invention discloses a printing rubber paste for coating denim and a screen mesh printing method using the printing rubber paste. The printing rubber paste for coating denim comprises, by weight, a component A, a component B and a component C, the component A comprises 15-20 parts of an acrylate adhesive, 5-10 parts of a polyurethane adhesive, 0.5-0.8 parts of an emulsifier, 0.5-2 parts of a thickener, 0.3-0.8 parts of sodium methylene bis-naphthalene sulfonate and 0.5-1 part of a softener, the component B is a crosslinking agent with the weight parts of 0.5-3, and the component C is an assistant with the weight parts of 2-4, wherein the component C can destroy the water proof coating of the coating denim, the component A can be combined with the cloth cover fiber of the denim through the self-crosslinking of the component A, and the component B has an effect on the promotion of the bonding crosslinking of the component A to form a stable reticular structure. The printing rubber paste of the invention can be directly used to print the coating denim, and the good color fastness can be still obtained after washing and stone processing.

Owner:DONGGUAN TONGLING NEW MATERIAL NANO TECH CO LTD

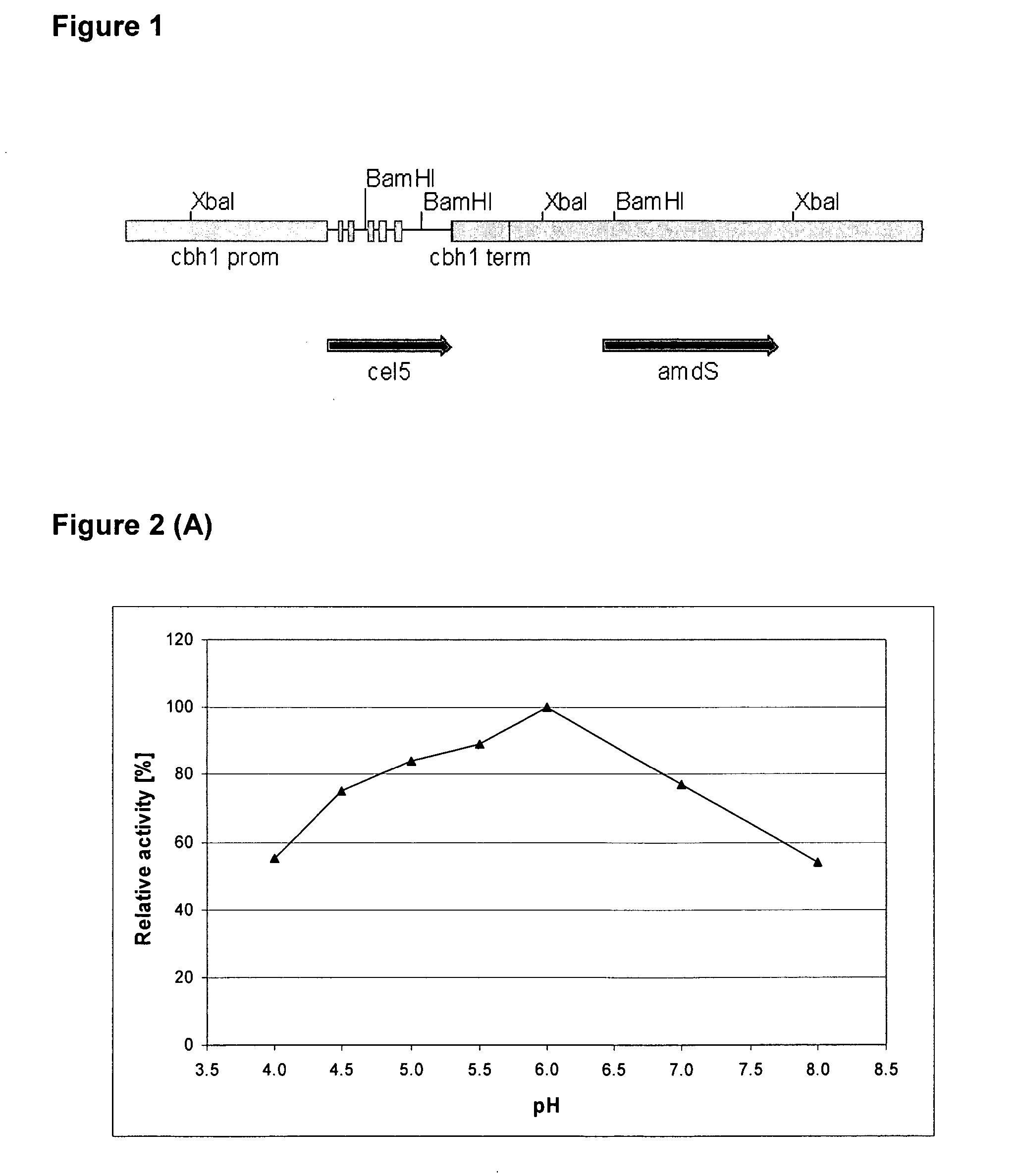

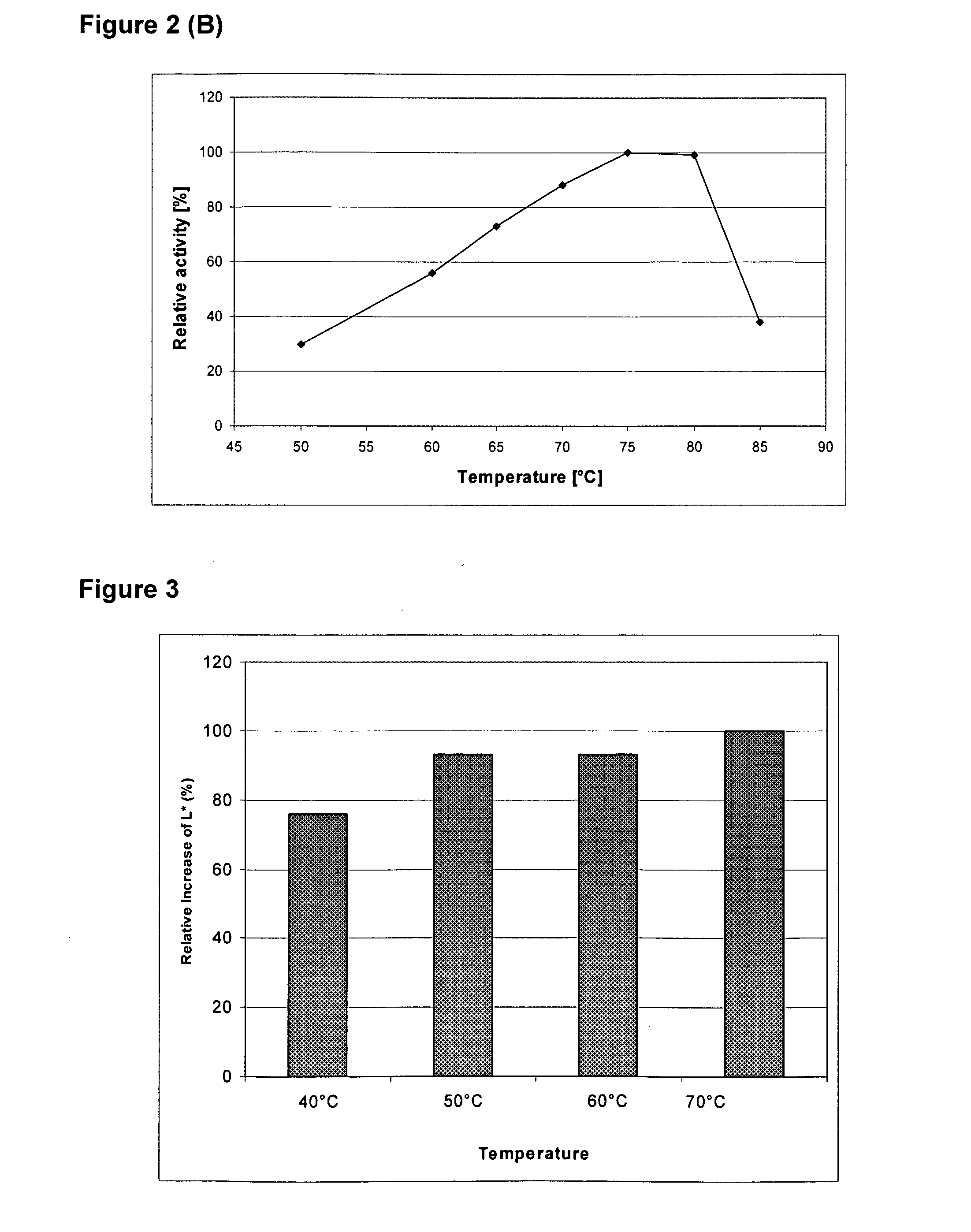

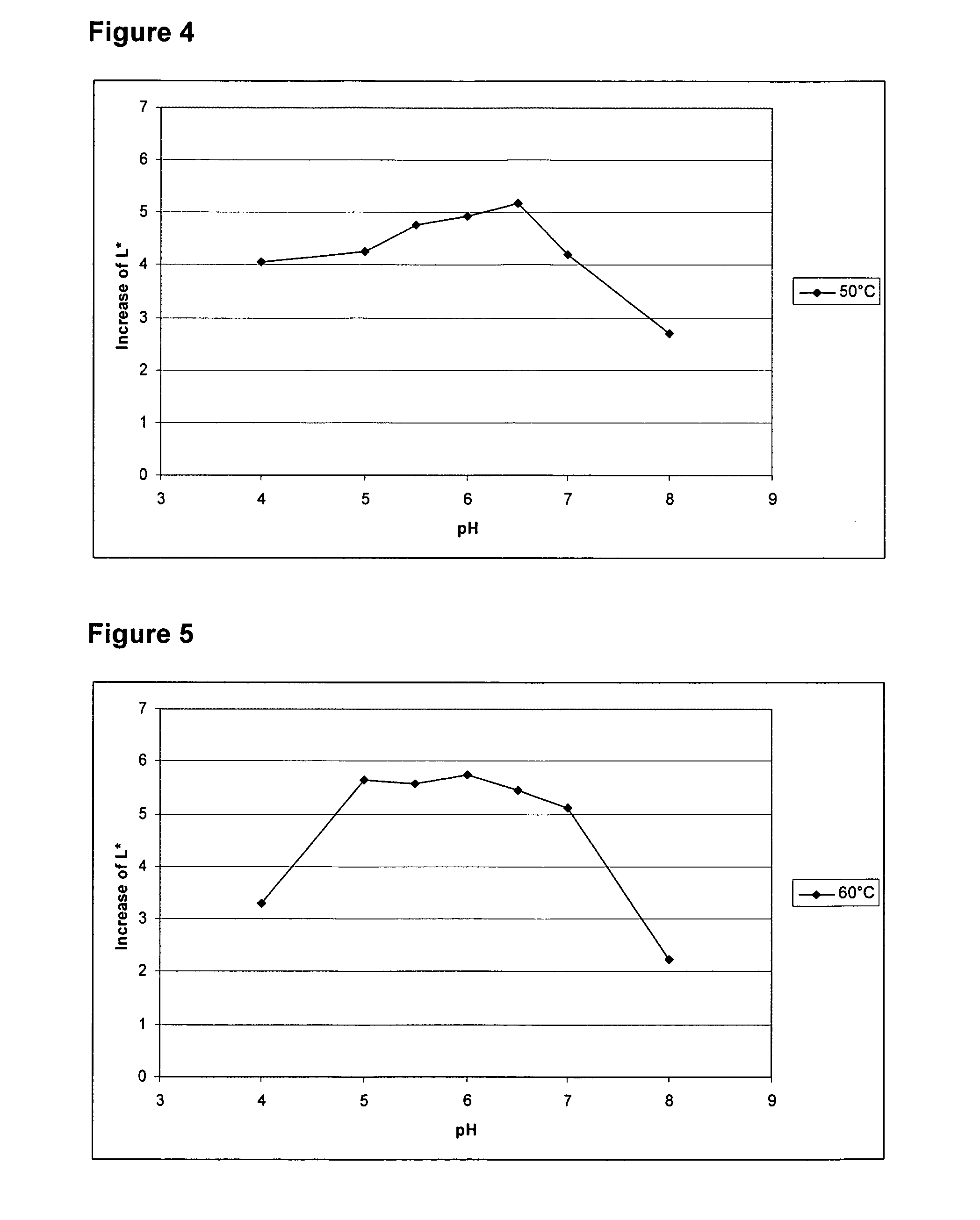

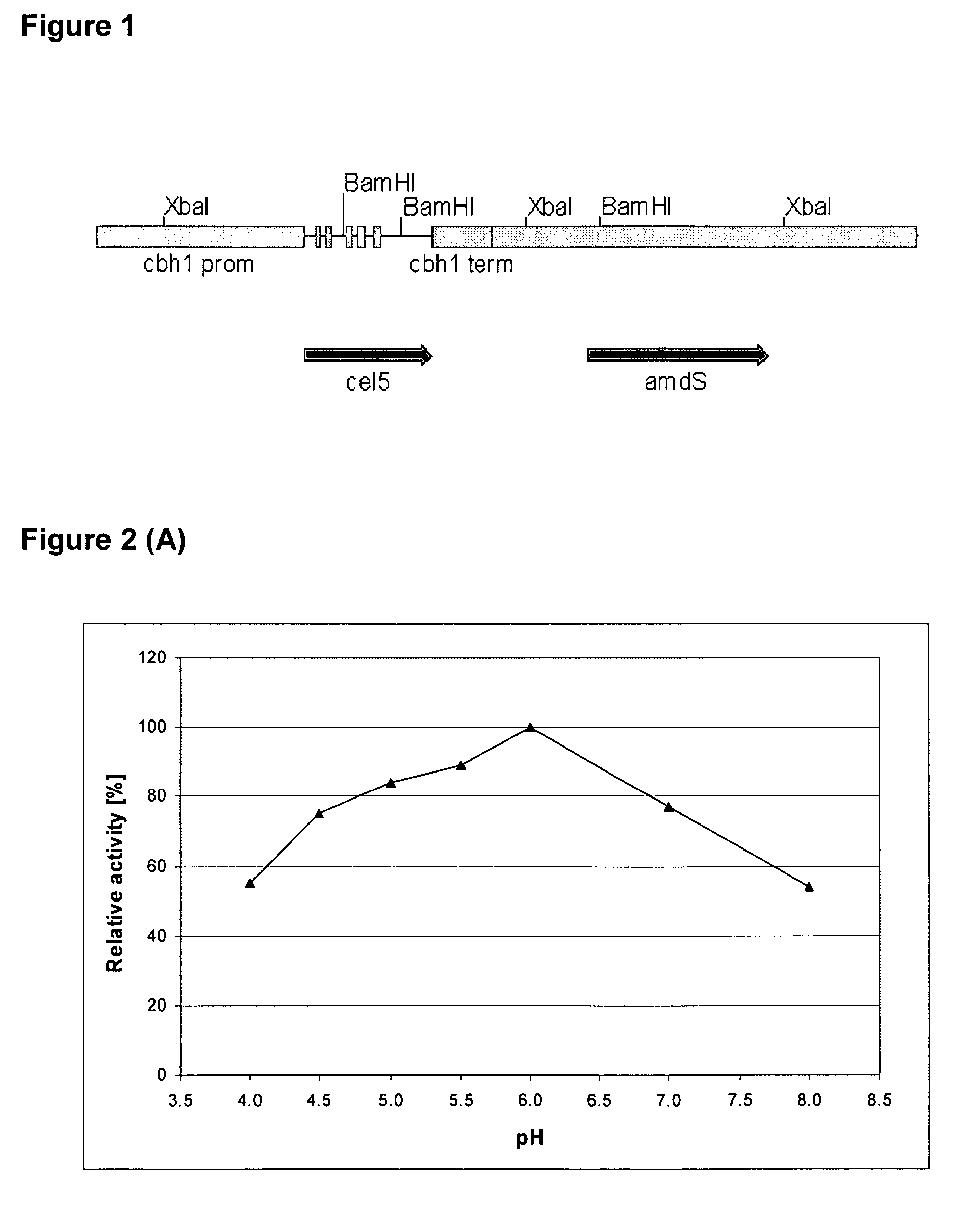

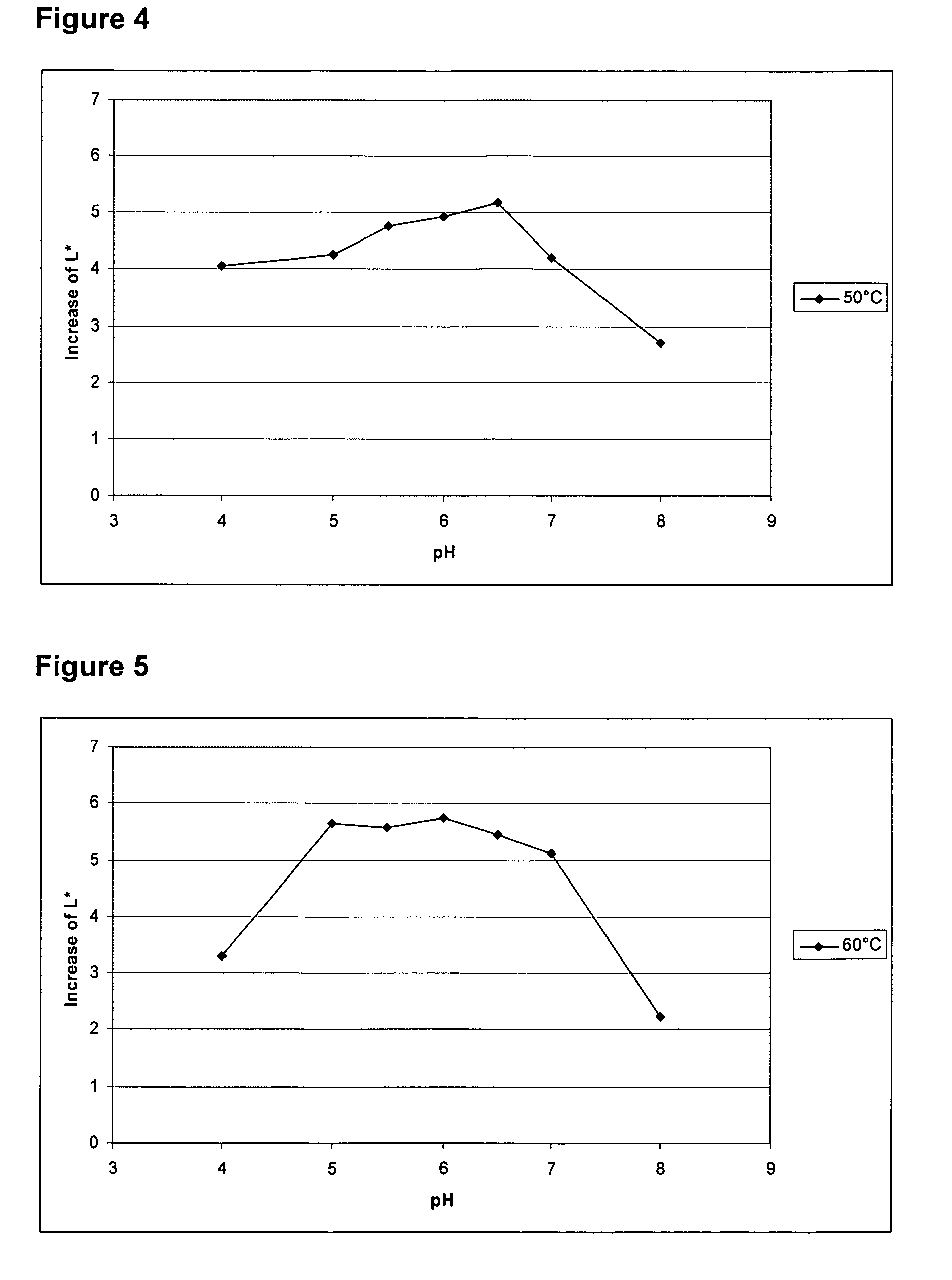

Enzyme fusion proteins and their use

ActiveUS20070244020A1Economical to provideEconomical to useBacteriaSugar derivativesDenimCellulose binding

Cellulase fusion proteins comprising an endoglucanase core region and a heterologous cellulose binding domain are described. The fusion proteins may be produced by recombinant techniques using appropriate polynucleotides, expressing vectors and host cells. The fusion proteins and enzyme preparations thereof are useful in treating cellulosic material, such as textile material, and they are particularly useful in biostoning denim or in biofinishing fabrics and garments. In addition the fusion proteins may be used in pulp and paper industry, oil extraction from plants, detergent compositions, or for improving the quality of animal feed.

Owner:AB ENZYMES OY

Water washing process for denim clothes

InactiveCN106968102AReduce storage pressureQuick removalDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsHigh concentrationDenim

The invention provides a water washing process for denim clothes. The water washing process comprises the following steps: performing pretreatment, enzyme washing, ferment washing, water washing, primary dewatering, primary drying, monkey washing, neutralization treatment, softening, secondary dewatering and secondary drying on the denim clothes, and obtaining a water-washed finished product. The water washing process has the beneficial effects that no odor is generated during neutralizing reduction, so that the air quality in a working environment is not affected; by the use of a high-concentration product, the use amount is small, and the warehousing pressure of a factory is relieved; residual manganese ions can be quickly removed, and thetreatment time is shortened; the color of bleaching liquid can be removed; the number of cleaning times is reduced, and the sewage treatment pressure is relieved; the sewage COD is low; the sand level is clear, and the class of the denim clothes is improved.

Owner:FANCHANG QINGXIN WASHING CO LTD

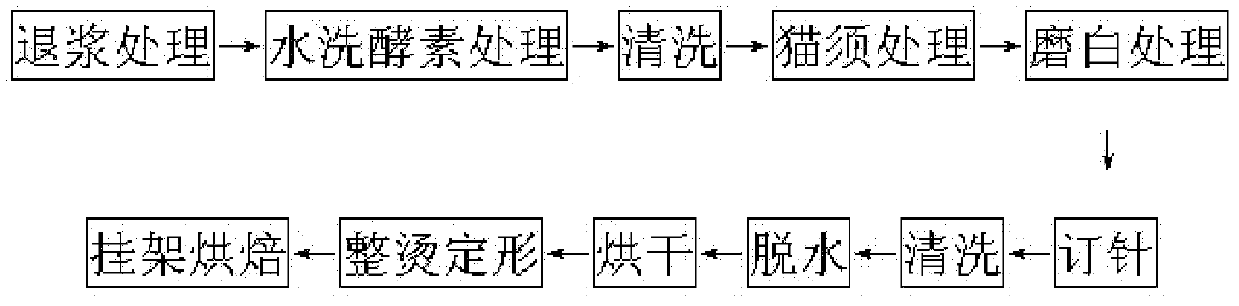

Processing method for enabling denim to present old visual effect

InactiveCN102605583AFade evenlyMeet needsBiochemical fibre treatmentLiquid/gas/vapor removalFiberPolymer science

The invention discloses a processing method for enabling denim to present an old visual effect. The method comprises the following steps: desizing the denim, performing enzymes washing on the denim, after washing the denim, whiskering the denim, milling the denim into white with a millstone, stitching needles, milling the sheared parts by the millstone to form rough edges and holes, then washing, dewatering, drying, ironing, shaping, hanging and drying the denim. The denim is processed by enzymes washing, so that the fading effect of the denim is uniform; the fibres of the denim are free from physical damage and the hand feeling is very soft; the fading effect is uniform; the color and the cloth cover present stone milling and rinsing effects; and the cost is low.

Owner:TAICANG QIDE GARMENT

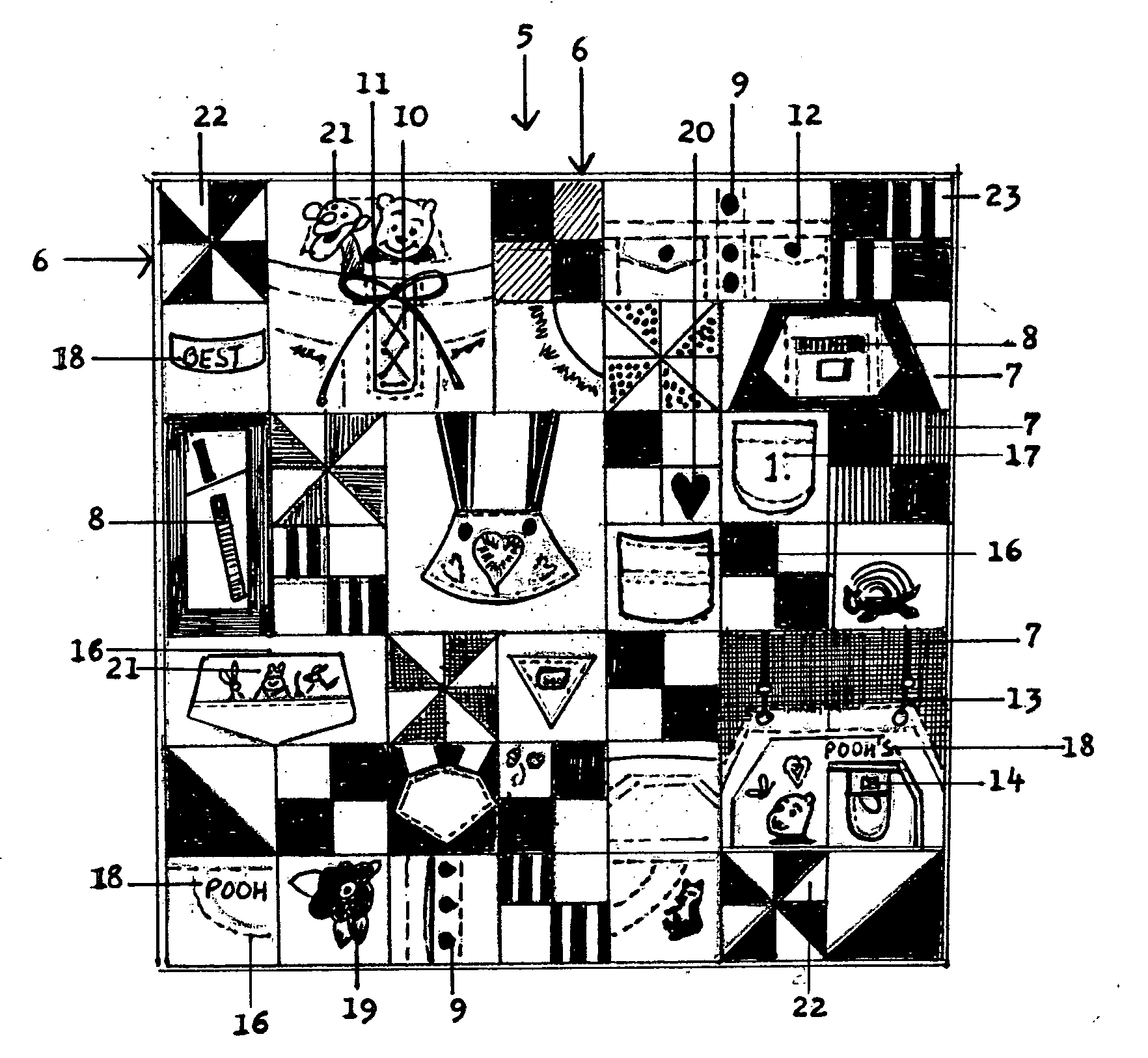

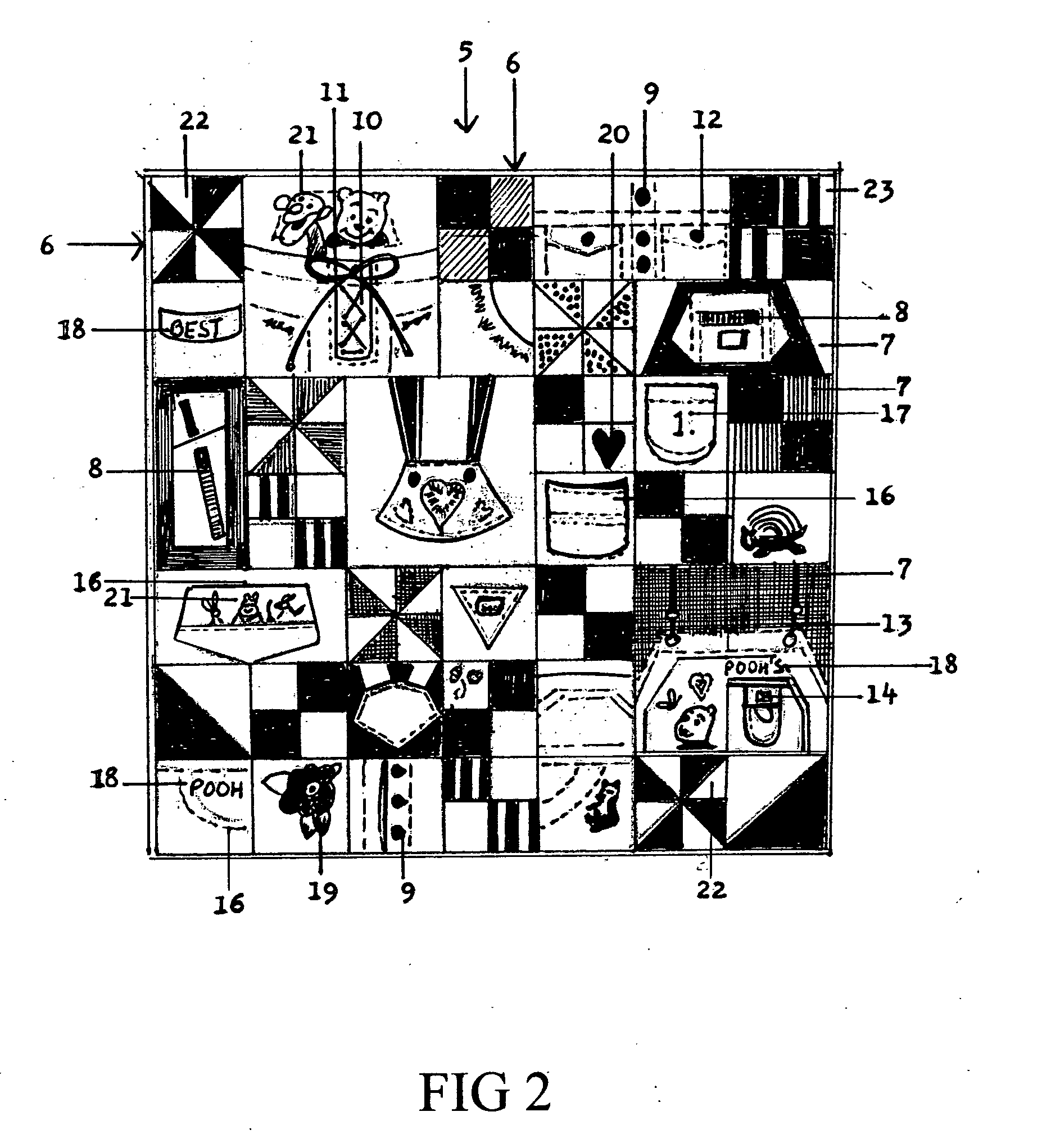

Learning/Play Quilt for development of toddlers' fine motor skills (dexterity): zipping, tying, buttoning, lacing, snapping, hooking, use of Velcro, buckling, and identification of numbers, letters, words and containing pockets for storing small toys in addition to being used as a blanket

The Learning / Play Quilt or Denim / Learning Play Quilt is a compilation of components of children's clothing sewn together to facilitate development or practice of fine motor skills (dexterity) such as zipping, buttoning, lacing, tying, snapping, hooking, use of Velcro, and buckling. The quilt format provides an extensive selection of fine motor skills not found in other formats such as books, vests, dolls and mats, and, at the same time, provides utilitarian uses as a cover for the child in a car seat or stroller. It also features pockets for storage of small toys and treasures. The components of children's clothing also expose children to numbers, letters and words while the embroidery thereon creates a product that is attractive and, therefore, promotes the child's interest in learning. The recommended lap quilt size predisposes its use to places where supervision is more readily available then if used on a bed. This is not only a safety feature but one in which more peer and adult interaction can occur.

Owner:MCELHOE JANICE SWEET

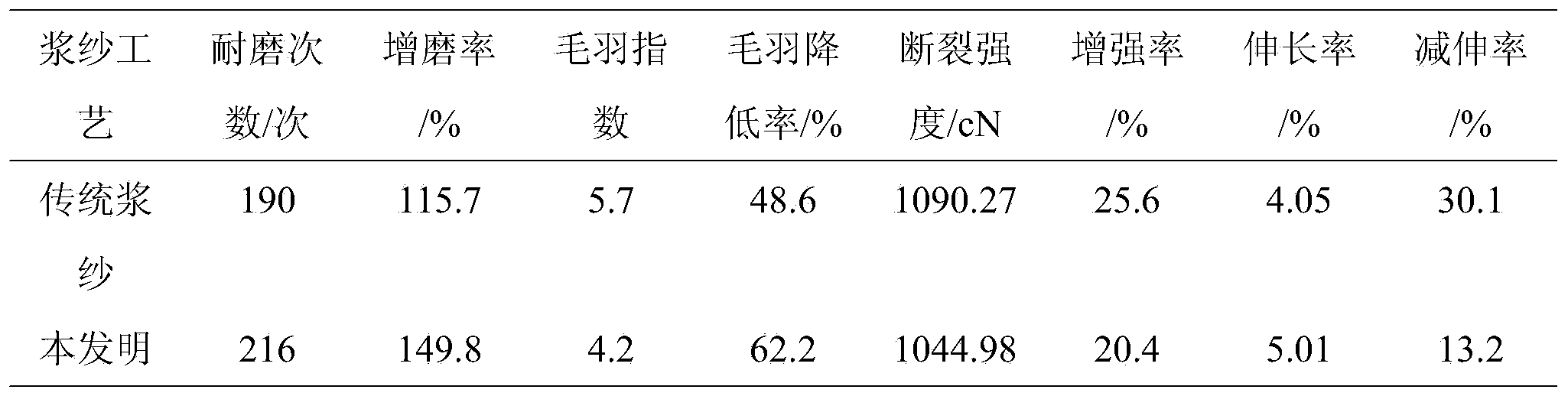

Jean warp sizing slurry and sizing process

ActiveCN103966849AImprove wear resistanceImprove surface propertiesFibre treatmentDenimProcess engineering

The invention provides a jean warp sizing slurry and a sizing process. The slurry is prepared from DSC-14 starch, PVA, LMA-95 synthesis slurry, emulsified oil and a smoothing agent. In comparison with the prior art, the sizing slurry and process ensures that the warp abrasion resistance is greatly improved, the weaving performance is enhanced and the cost is lowered. Besides, the use amount of slurry and pollution are reduced, the existing technological process does not need to be changed significantly, the investment is relatively low and the effect can be taken rapidly.

Owner:ZHEJIANG SANSEN TEXTILE

Silkete cowboy face fabric

InactiveCN101429697AStrong three-dimensional senseIncrease elasticityWoven fabricsYarnFiberPulp and paper industry

The invention provides a mercerized denim fabric, which relates to the field of textile fabric. The fabric comprises warp yarns and weft yarns, wherein the warp yarns adopt purified cotton fibers; and the weft yarns are composite fibers formed by elastic composite fibers and spandex fibers covered by the purified cotton fibers. The mercerized denim fabric has the advantages of reasonable treatment on the fabric, clear and delicate cloth lines with the effect of warp and weft bamboo joints, strong stereoscopic impression, soft and neat hand feel without crinkles, and excellent elastic restoring performance.

Owner:CHANGZHOU OASIS TEXTILE

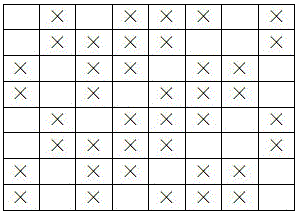

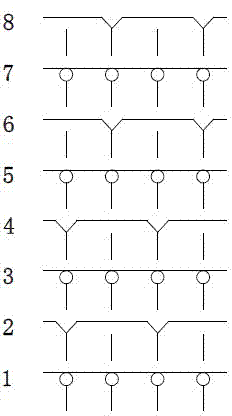

Jean fabric and manufacturing method thereof

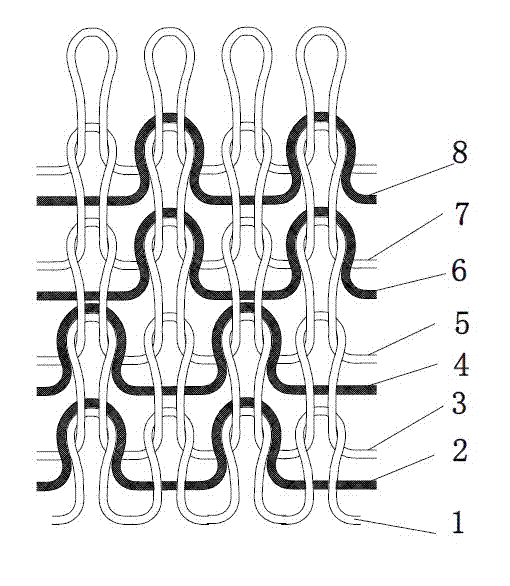

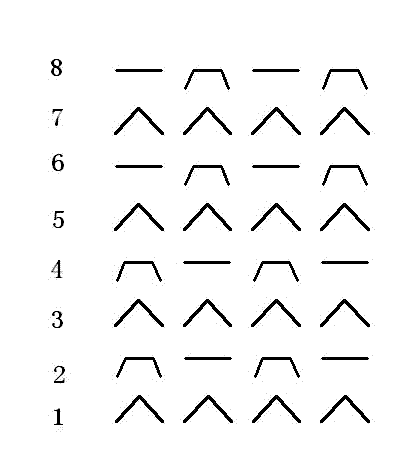

The invention discloses jean fabric which is characterized in that the minimal weave repetition of the jean fabric comprises eight stitch rows and four stitch columns, wherein the first, the third, the fifth and the seventh rows / columns are full-loop weave structures formed by blue yarns and spandex yarns, and the second, the fourth, the sixth and the eighth rows / columns are tuck weave / welt weave interlaced structures formed by hair white yarns. A manufacturing method of the jean fabric comprises the following steps of: dying yarns, weaving, reorganizing and water shaping after unloading. Compared with the prior art, the jean fabric has the following advantages and effects: the jean fabric has coarse texture, is better in elasticity than the common woven jean fabrics, is made of pure cotton, has moisture-absorbing, sweat-removing, antibacterial, deodorant, UV-resistant and warm-keeping effects, is about 190 G in weight, has soft feeling and light weight, can be washed to fade or change the color so as to obtain a desired style of the clothing, and shows both the style of jean fabric and the elegance of knitted fabric.

Owner:JIAXING GANGHENG KNITTING

Process and system for recycling and decoloring denim mercerizing alkali and penetrant

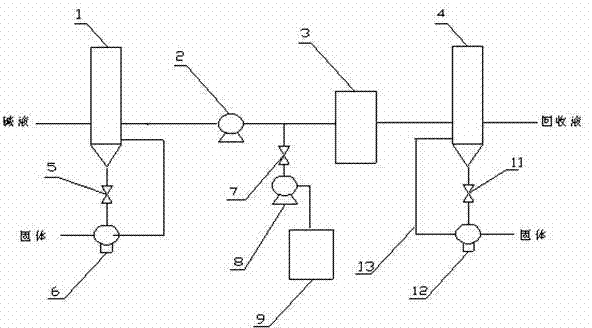

ActiveCN103498312AOxidizingFunctionalTextile treatment machine arrangementsMultistage water/sewage treatmentDenimProcess engineering

The invention discloses a process and system for recycling and decoloring denim mercerizing alkali and penetrant. The process includes the steps that denim mercerizing alkali liquor is placed in a first precipitation tank; the liquor on the upper portion enters a conveying pipeline through a flow pump after precipitation, meanwhile, a metering pump pumps a decolorising agent into the liquor in the conveying pipeline, and then the decolorising agent and the liquor are conveyed to an evaporation concentrator together; the decolorising agent and the liquor enter a second precipitation tank after being evaporated and concentrated; supernatant liquor obtained after precipitation is conveyed to a production line directly; solid substances in precipitation liquor on the lower portion are separated and conveyed to a waste solid storage tank after the precipitation liquor on the lower portion is treated through a centrifugal machine, and clear liquor returns the first precipitation tank and is conveyed backed to the production line. The system comprises the first precipitation tank, the flow pump, the metering pump, a decolorising agent box, the evaporation concentrator and the second precipitation tank. The first precipitation tank, the flow pump, the evaporation concentrator and the second precipitation tank are connected directly through pipelines, and the decolorising agent box is connected to the metering pump below the pipeline where the flow pump and the evaporation concentrator are connected. The process for recycling and decoloring the denim mercerizing alkali and penetrant is simple, the useful alkali and penetrant are recycled, and production cost is greatly reduced.

Owner:SHENZHEN YUEPENG ENVIRONMENTAL PROTECTION TECH

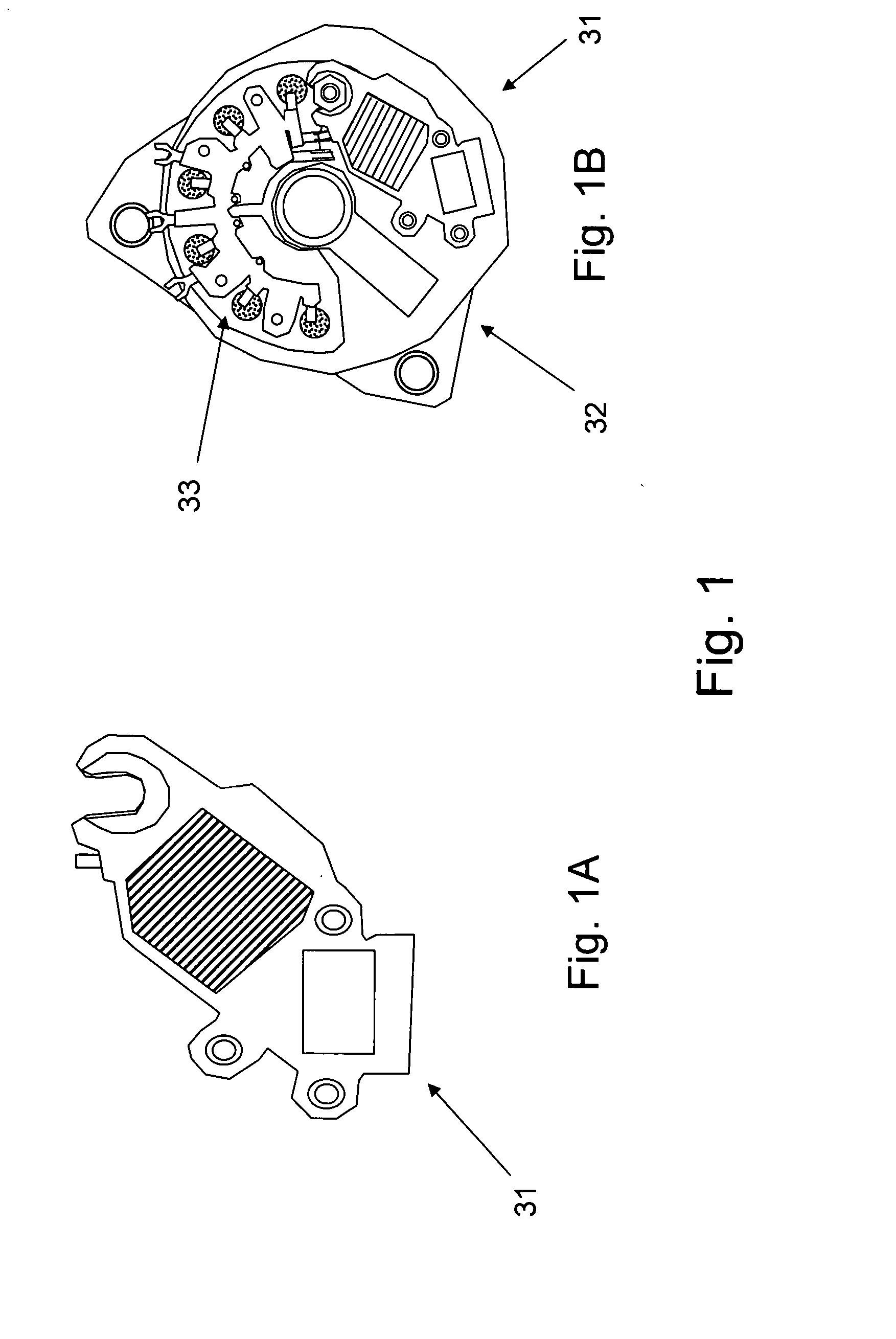

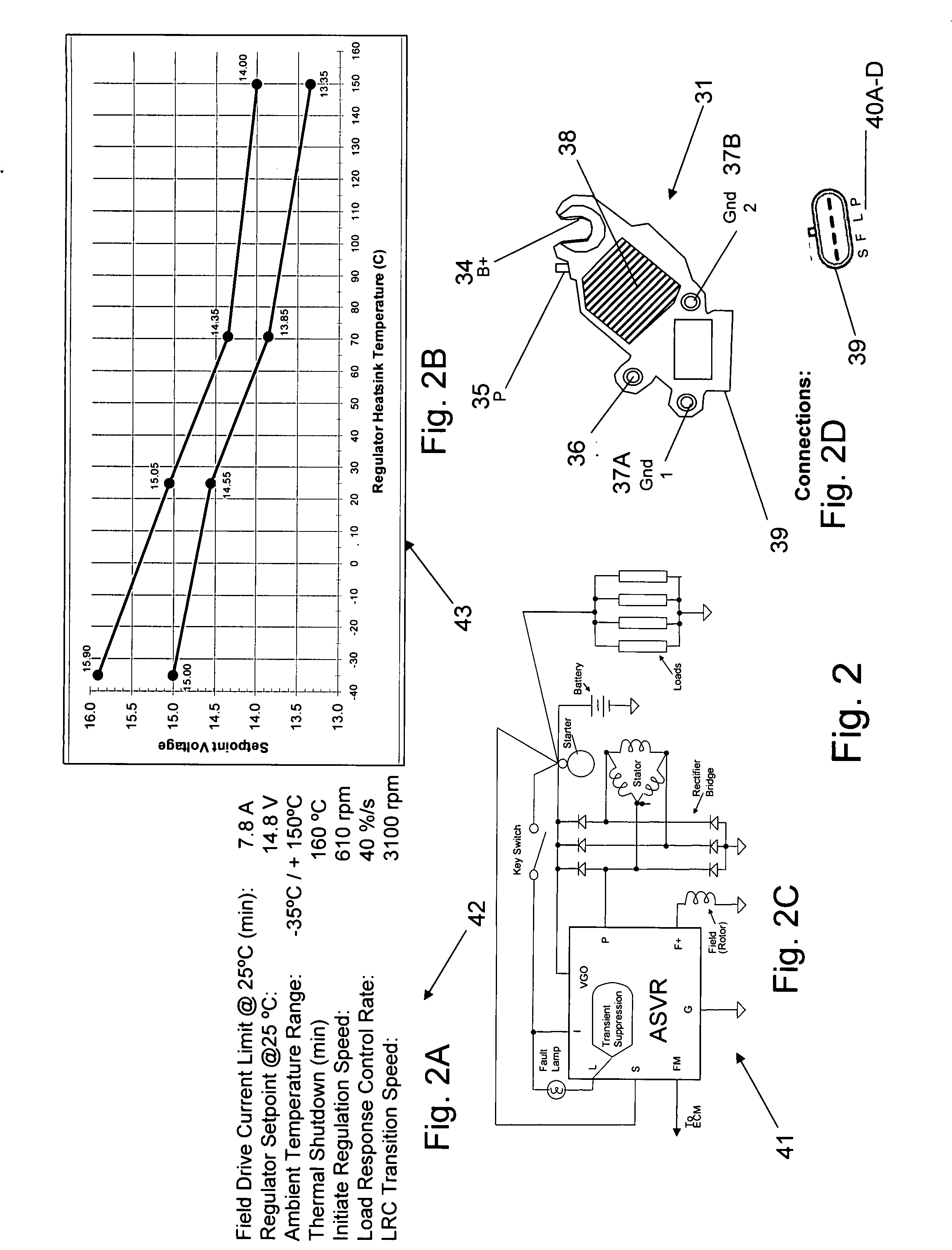

Buck shot blues specially processed denim product and the process methods to make the product

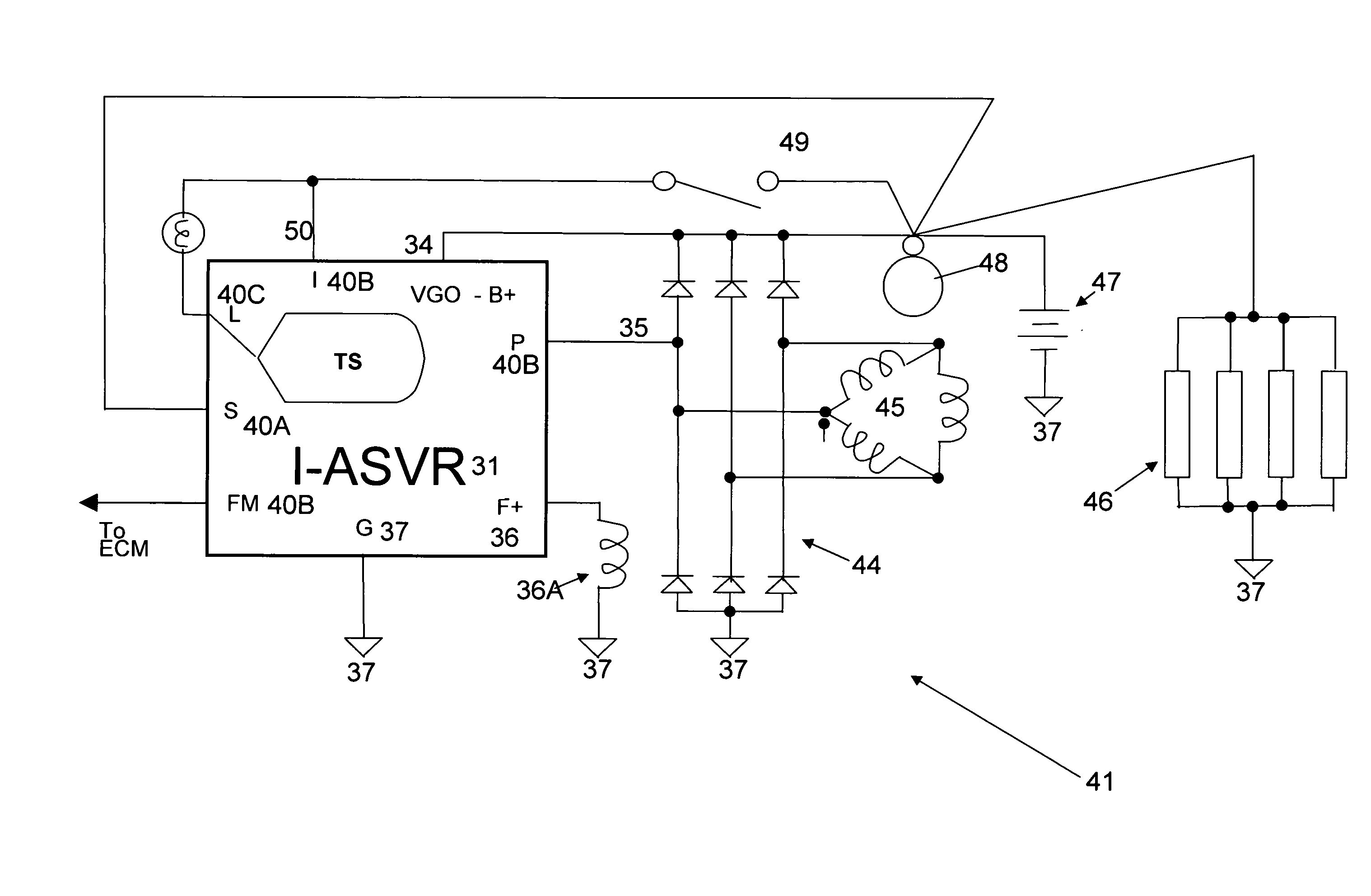

InactiveUS20080054856A1Easy to disassembleEasy to adaptDc network circuit arrangementsBatteries circuit arrangementsDenimAlternator

This device is an Improved Automotive All Silicon Voltage Regulator (I-ASVR) for use in the automotive components re-manufacturing and original equipment alternator product. Particularly this device improves the electrical connections, prevents failures related to poor connections and heat variations, and eliminates failures from transient voltage surges that effect electronic devices. This device may be an improved replacement regulator for re-manufacturing or an original equipment regulator to improve the quality and durability. The device is comprised essentially of four significant changes to a standard voltage regulator: an addition to the electronics of a transient suppression means for the loads; a connection for the battery connection (B+) through a fixed terminal that connects and is sandwiched under the battery stud of the rectifier bridge; the elimination of the soldered B+ terminal that was susceptible to corrosion and failure; and, an improved grounding connection.

Owner:TADITEL US

Desizing, enzyme-washing and bleaching integrated one-bath process

InactiveCN107419510AWater saving realizedRealize water savingDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsWorking fluidProcess engineering

The invention discloses a desizing, enzyme-washing and bleaching integrated one-bath process which includes the steps of (1), adding water and denim garments in an industrial washing machine and starting steam-heating; (2), stopping the steam-heating; (3), adding in desizing and enzyme-washing two-in-one enzyme powder for processing; (4), adding in blenching enzymes for processing; (5), discharging working fluid in the industrial washing machine; (6), adding in water to wash denim garments in the industrial washing machine; (7), discharging bath foam in the industrial washing machine, and (8) dewatering and drying the denim garments to obtain the desized, enzyme-washed and bleached denim garments. By the desizing, enzyme-washing and bleaching integrated one-bath process, denim garments are processed with excellent and unique washing effect, while energy saving and environmental protection are achieved during processing. The desizing, enzyme-washing and bleaching integrated one-bath process is a good choice for washing of denim garments.

Owner:JIANGSU NEW REBA TECH CO LTD

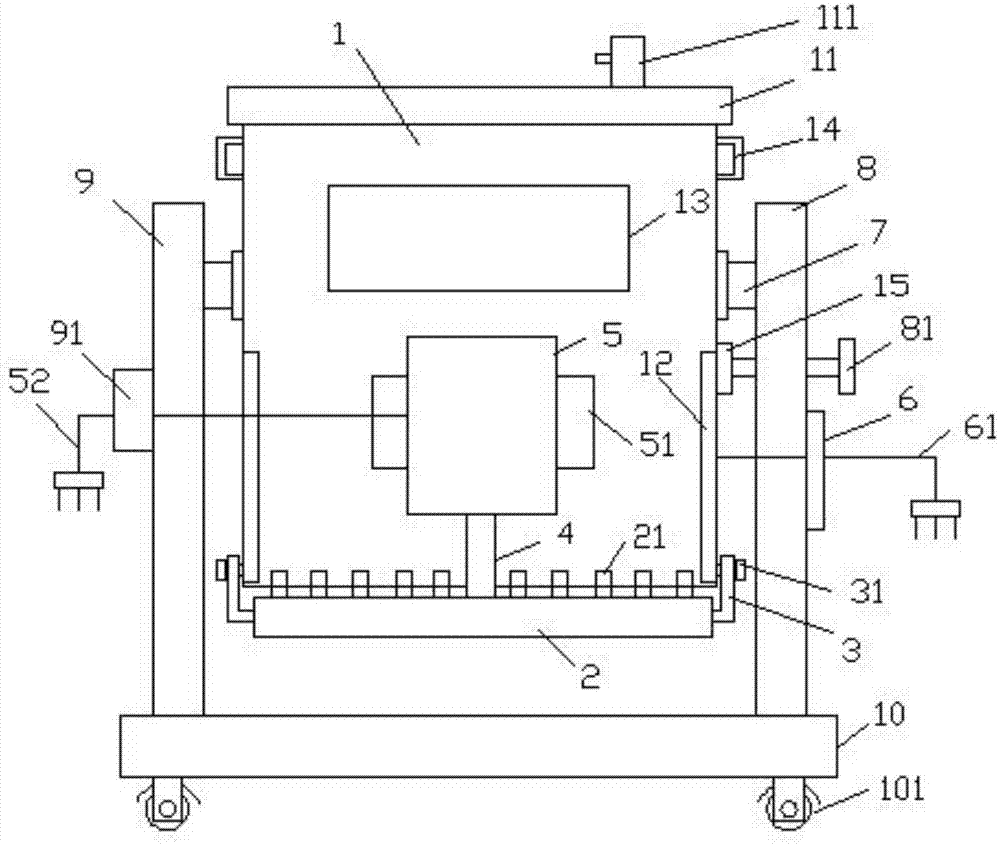

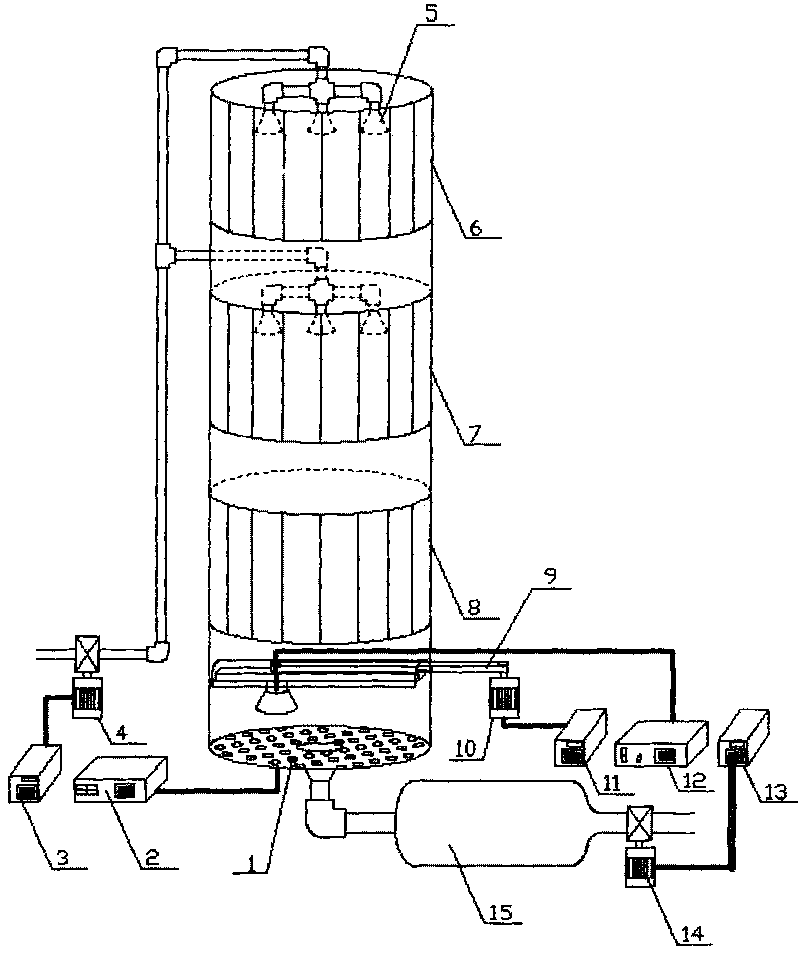

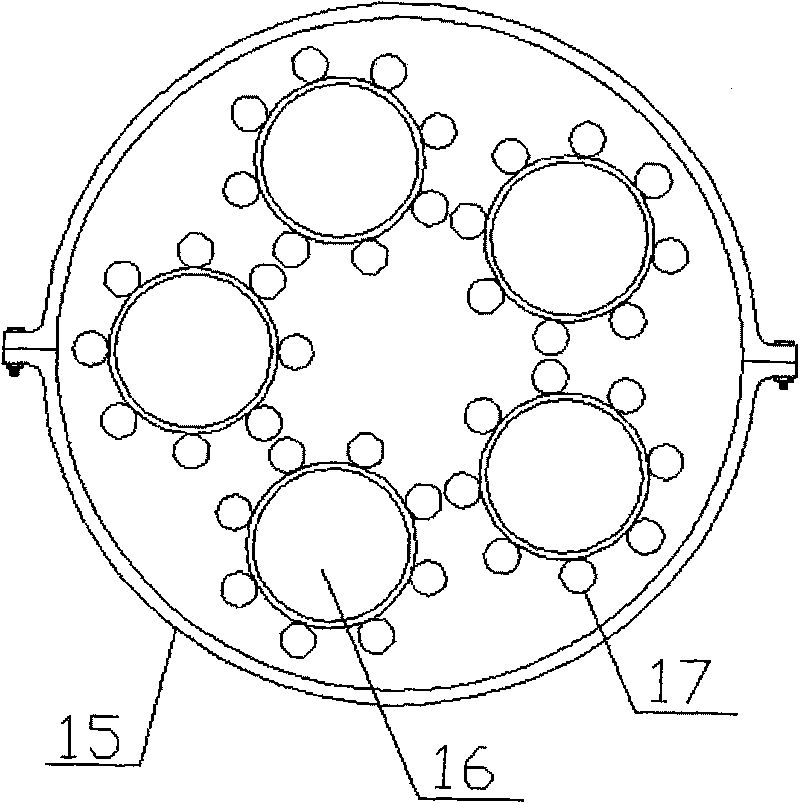

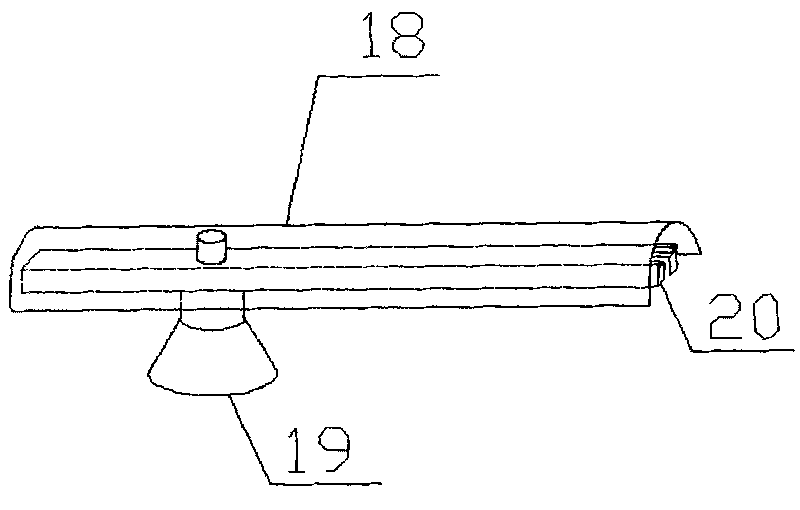

Pneumatic stirring device for dyeing denim fabric

PendingCN107988750AAvoid problems with settling particlesImprove uniformityTextile treatment containersTextile treatment machine arrangementsElectricityDenim

The invention relates to the field of dyeing equipment, in particular to a pneumatic stirring device for dyeing denim fabric. The stirring device can effectively solve the problem of non-uniform stirring of dye liquor, new impurities can be prevented from being generated, and the smooth proceeding of dyeing work is guaranteed. The device structurally comprises a square dyeing barrel, wherein a sealing cover is arranged above the dyeing barrel, a heating block is arranged on the inner side wall of the dyeing barrel, and the heating block is electrically connected with a first external power line; a temperature controller is arranged on the first power line, and a cavity is formed in the bottom of the dyeing barrel; an air inlet pipe communicated with the interior of the dyeing barrel is arranged on the cavity, and the cavity is connected with an air outlet of an air blower through a connecting pipe; the left side and the right side of the dyeing barrel are hinged to a left vertical plate and a right vertical plate through rotary shafts respectively. The device is easy to operate, convenient to use and suitable for various places.

Owner:ZHEJIANG JIE GAO TEXTILE

Enzyme fusion proteins and their use

Cellulase fusion proteins comprising an endoglucanase core region and a heterologous cellulose binding domain are described. The fusion proteins may be produced by recombinant techniques using appropriate polynucleotides, expressing vectors and host cells. The fusion proteins and enzyme preparations thereof are useful in treating cellulosic material, such as textile material, and they are particularly useful in biostoning denim or in biofinishing fabrics and garments. In addition the fusion proteins may be used in pulp and paper industry, oil extraction from plants, detergent compositions, or for improving the quality of animal feed.

Owner:AB ENZYMES OY

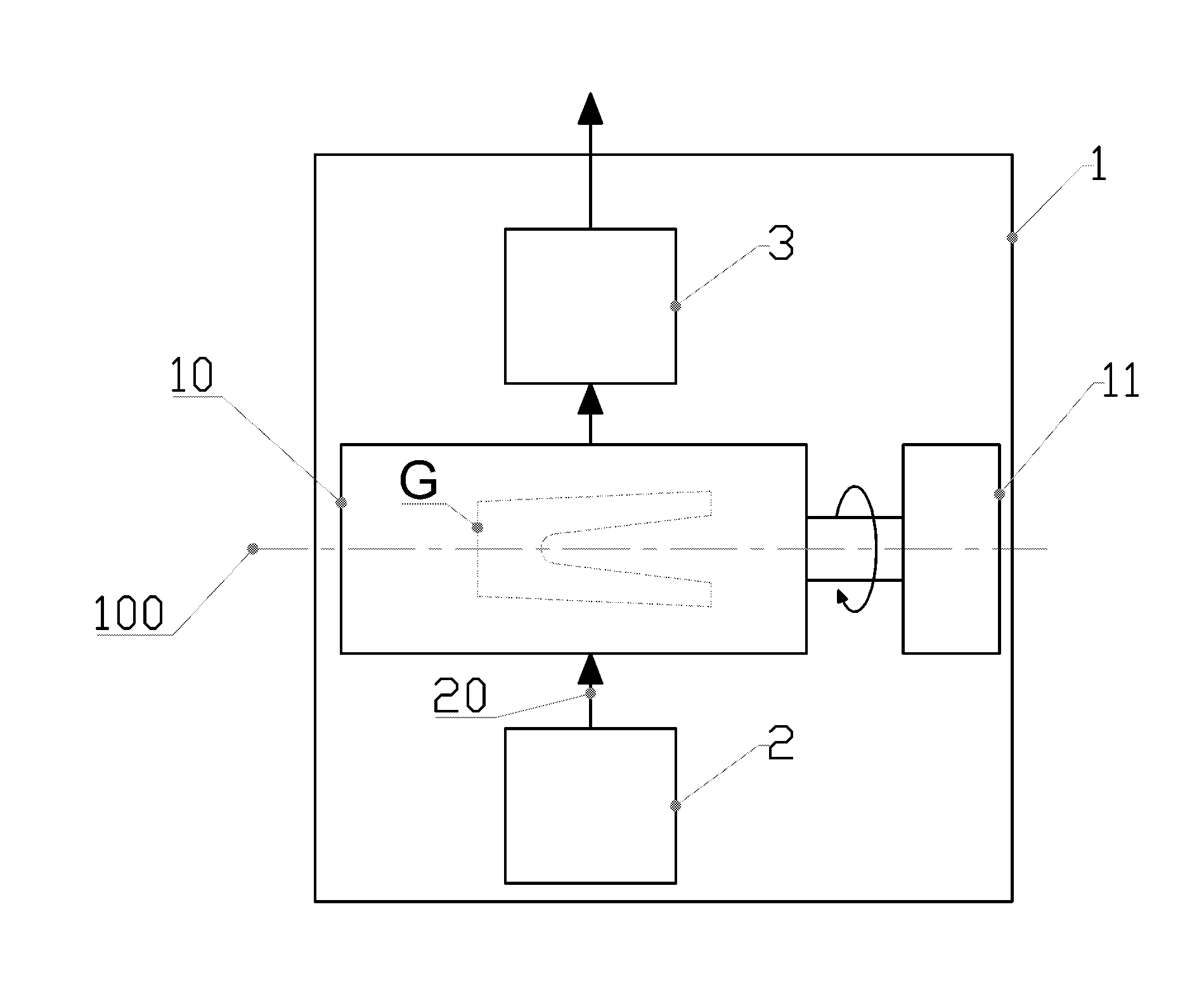

Production process for denim sewage treatment and pretreatment

InactiveCN101759322AReduce the overall heightReduce usageWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsTextile technologyDenim

The invention discloses a production process for denim sewage treatment and pretreatment, and relates to textile technology. The production process organically combines the following four flows: 1, introducing wastewater subjected to pretreatment such as physical sedimentation into a tower biological filter for treatment; 2, performing laser scanning treatment on the sewage for one time; 3, performing ultrasonic treatment on the sewage for one time; and 4, performing ultraviolet irradiation on the sewage for one time; the height of the tower biological filter is reduced greatly; a blast apparatus such as a blast blower is not needed; energy consumption and initial investment are reduced; the main flows of the process treatment are physical treatment flows, the sludge amount is reduced greatly, and the secondary pollution is prevented; and the investment is reduced and the production process is convenient to operate and manage.

Owner:LANYAN GROUP

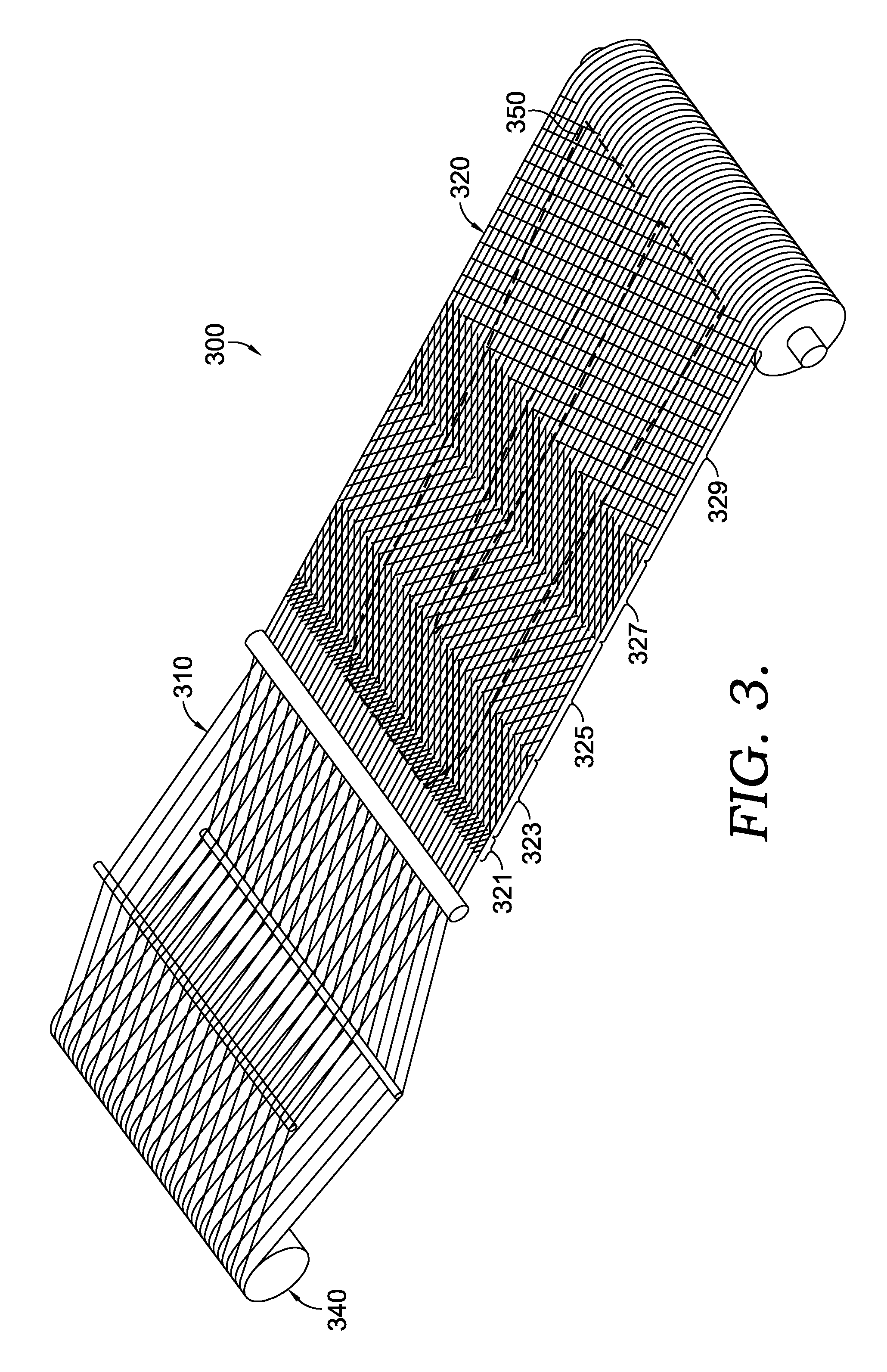

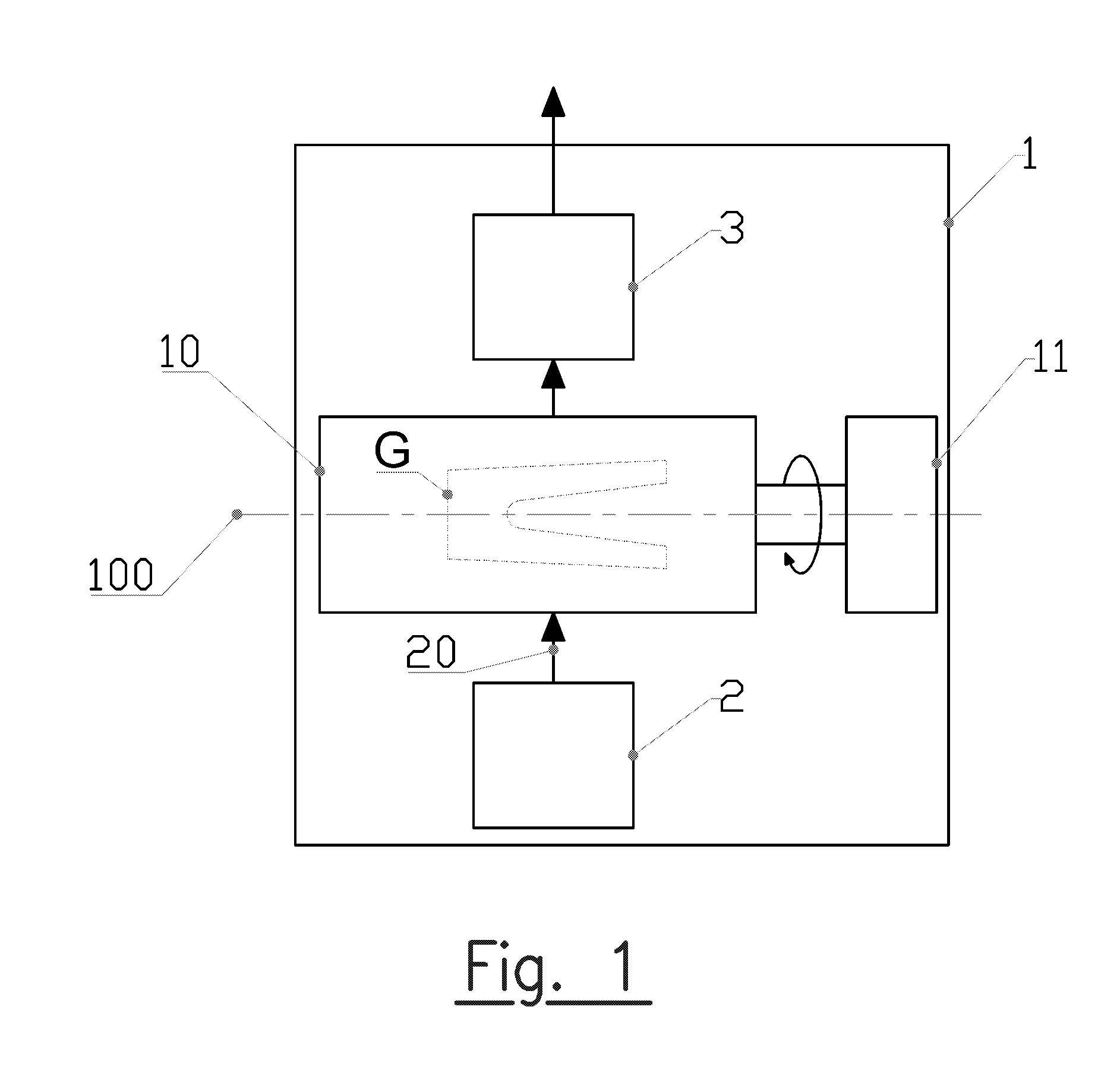

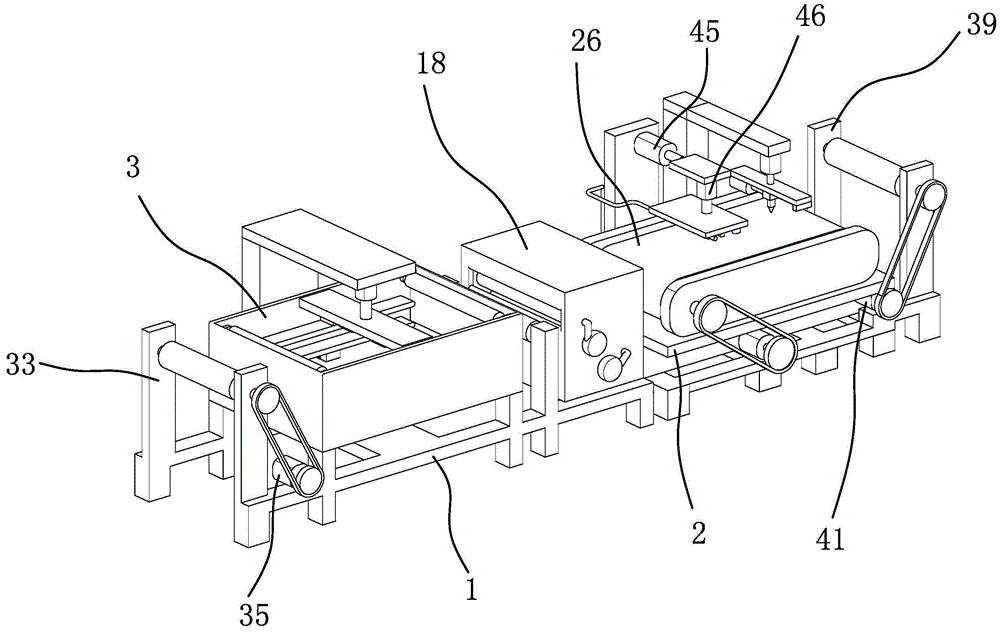

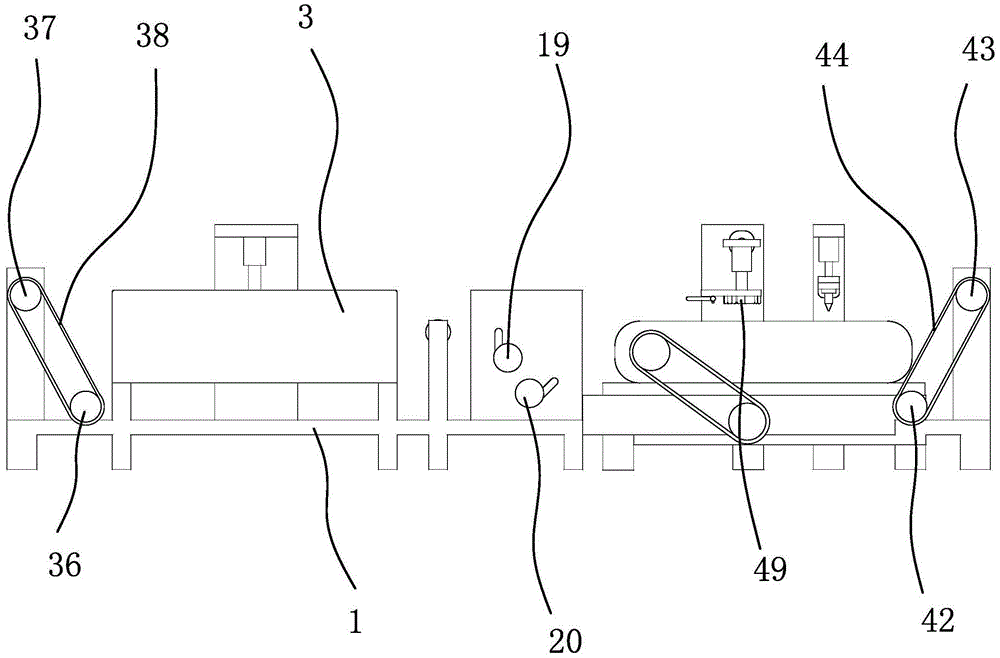

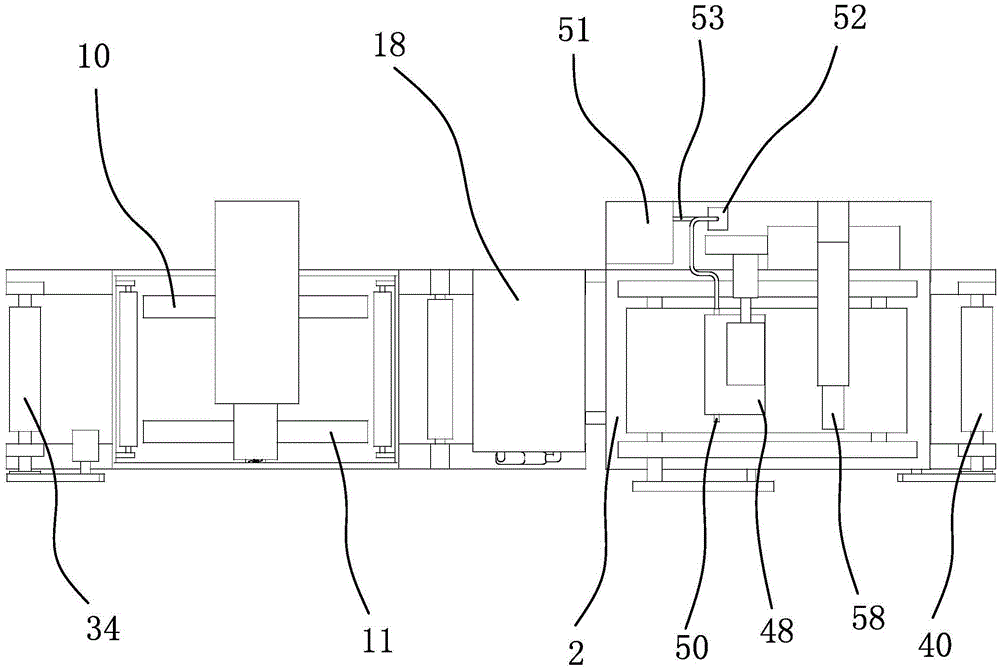

Method and system enabling premature use of a textile garment made of denim fabric

InactiveUS20120276821A1Premature wearSoften the aforementioned garment.Polishing machinesBleaching apparatusPolymer scienceDenim

The invention relates to a method of premature wear of a fabric garment made of a colored denim canvas, wherein the aforementioned garment is placed into a rotating machine including a drum, characterized by the fact that the aforementioned method comprises a step during which the garment is rotated in the drum without being wetted or dampened, ozone gas being injected simultaneously into the interior of the aforementioned drum so as to bleach the aforementioned garment and give it a wear effect.

Owner:RICHARDIERE GILBERT +1

Dyeing device in denim fabric machining device

ActiveCN104894776ADye thoroughlyImprove color adhesionLiquid/gas/vapor removalTextile treatment machine arrangementsState of artDenim

The invention provides a dyeing device in a denim fabric machining device and belongs to the technical field of textile machinery. The problems that the dyeing effect on denim fabrics cannot be significant and the like in the prior art are solved. The dyeing device comprises a first lower clamping block, a second lower clamping block, a first upper clamping block and a second upper clamping block; the first lower clamping block and the second lower clamping block are arranged in a dyeing groove; the first upper clamping block is arranged over the first lower clamping block; the second upper clamping block is arranged over the second lower clamping block; the first lower clamping block and the first upper clamping block are located on one side along the conveying direction of the denim fabrics; the second lower clamping block and the second upper clamping block are located on the other side along the conveying direction of the denim fabrics; a clamping mechanism which can be used for clamping the denim fabrics and enabling the denim fabrics to be located in the tightened state is arranged between the first upper clamping block and the second upper clamping block and the dyeing groove. According to the dyeing device in the denim fabric machining device, the denim fabrics can be located in the tightened state in the dyeing process and accordingly the dyeing effect is improved and the denim fabrics after being dyed can be dried.

Owner:HAINING DENIM WEAVING CO LTD

Yarn formed from recycled cotton and recycled para-aramid, and fabrics made therefrom

Described herein are spun yarns, core spun yarns, and fabrics such as denim fabrics made thereof that contain recycled cotton fibers and recycled para-aramid fibers. The combination of fibers in the yarns and fabrics provide desirable properties such as increased tear strength, breaking strength, and abrasion resistance compared to yarns and fabrics made of 100 wt % cotton.

Owner:GAP INC

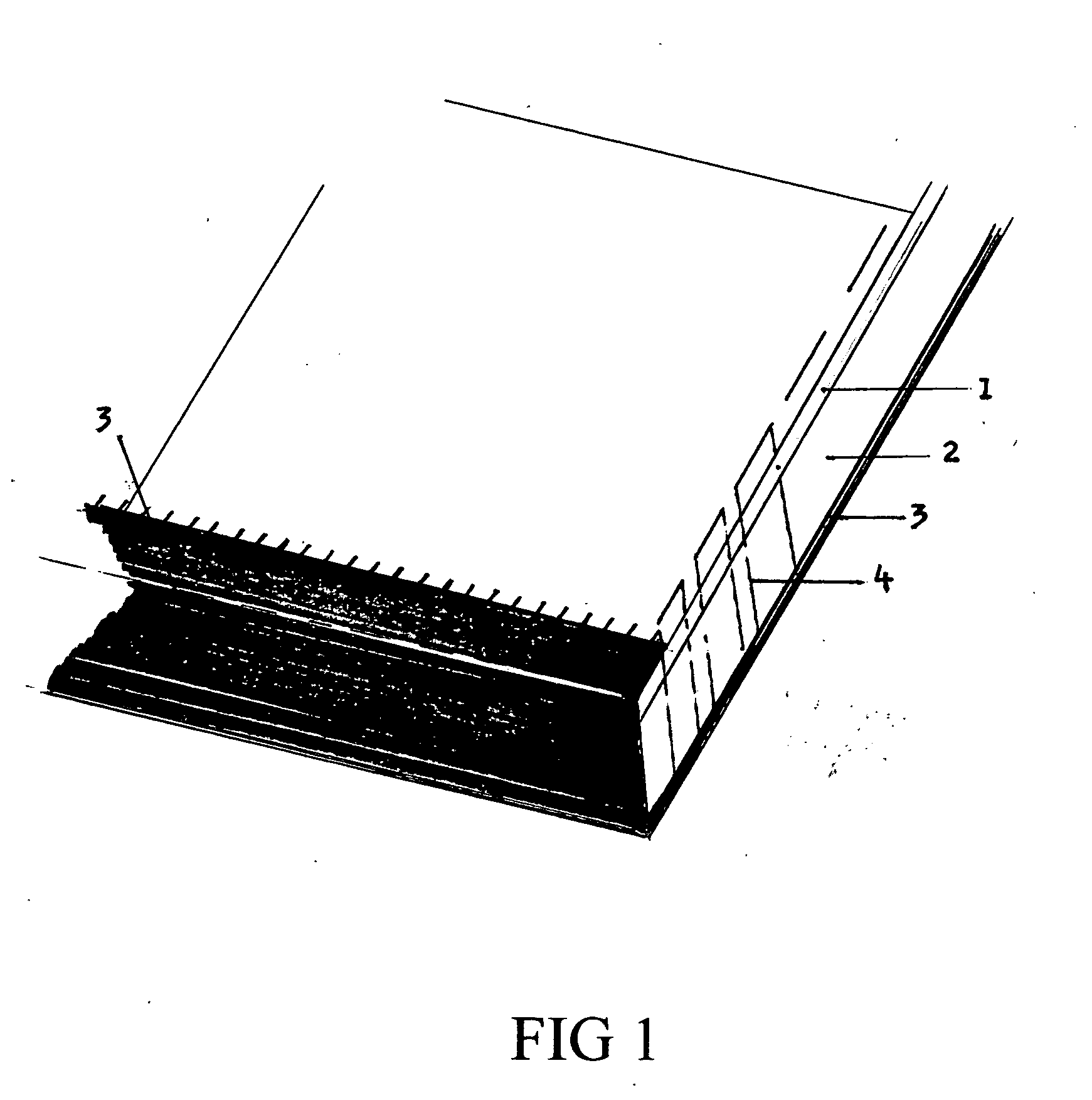

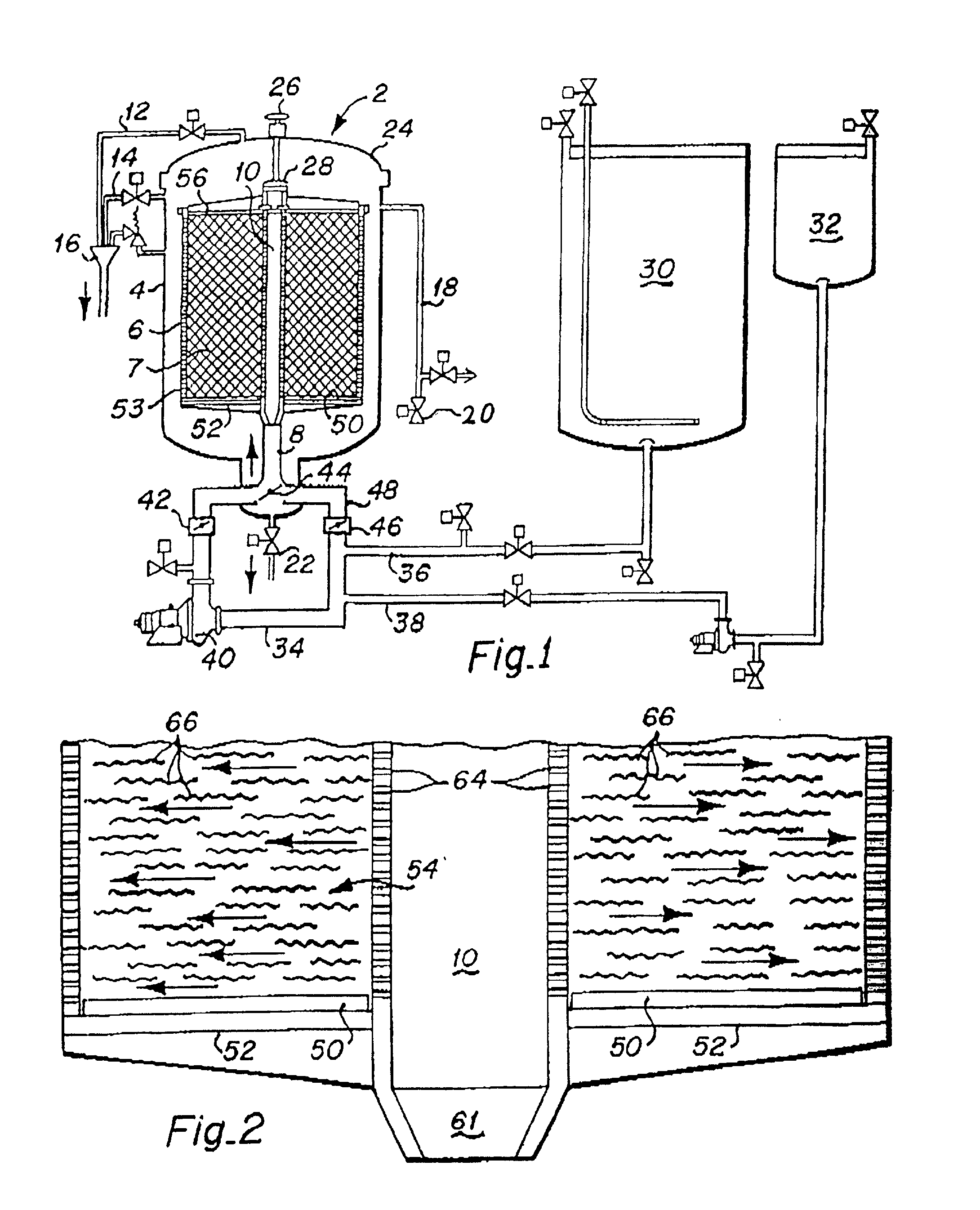

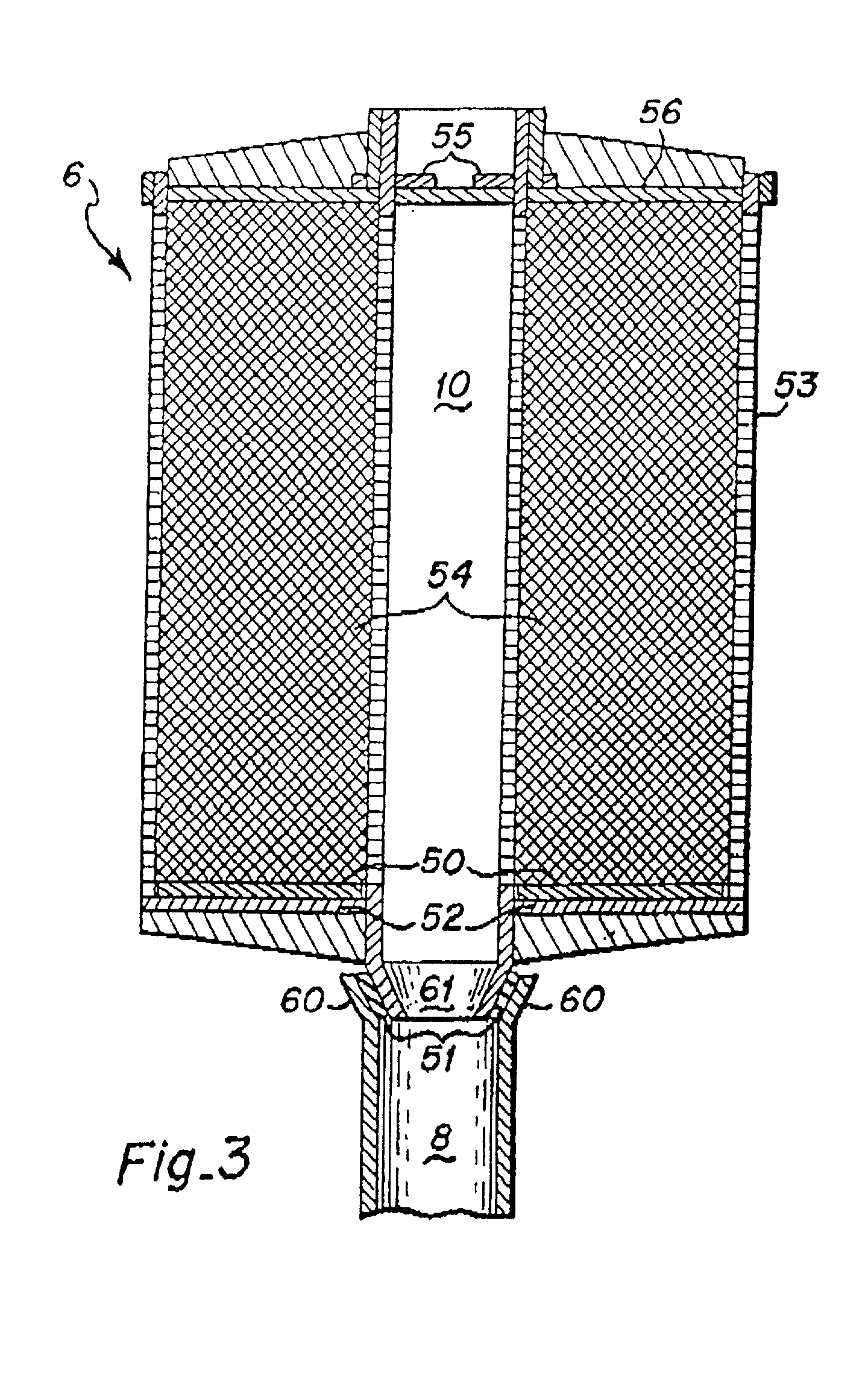

Dye removal from denim scrap with a forced circulation kier

A recycling process for liquid treatment of denim scrap comprising placing denim scrap on a support surface to form a thickness of flat, layered denim scrap. To the top surface is applied a compression plate to form the thickness of denim scrap into a compact cake. Then treatment liquid is passed through the interior of the compact cake in a direction parallel to the surfaces of the scrap, the liquid passing between opposed surfaces of the denim pieces. The denim scrap is preferably cut into relatively uniform sizes having their largest dimension less than about 4 inches. The treatment liquid can be a solvent for oxidized indigo dye, whereby indigo dye is removed from the denim scrap by said liquid; an aqueous solution containing a desizing agent, whereby size is removed from the denim scrap pieces; an aqueous solution containing a reducing agent for indigo dye, whereby dye in the denim pieces is reduced to a soluble, leuco form, dissolves in the solution, and both size and dye are removed from the denim scrap pieces; a solution containing desizing and reducing agent, whereby size and dye is removed from the denim scrap pieces; or an aqueous solution containing a reducing agent for indigo dye, whereby dye in the denim pieces is reduced to a soluble, reduced form, dissolves in the solution, and is removed from the denim scrap pieces; or a sequences of these liquids.

Owner:SSI HOLDCO INC A DELAWARE +1

One-step method jean jacket manufacturing technology

InactiveCN105063872AReduce processing stepsReduce lossSucessive textile treatmentsWeft knittingYarnBobbin

The invention discloses a one-step method jean jacket manufacturing technology. The technology includes the following steps that a, cotton yarn is sorted out through a beam warping machine to complete warping; b, the cotton yarn subjected to warping is conveyed into a dyeing machine for indigo dyeing; c, the cotton yarn subjected to indigo dyeing is conveyed into a yarn dividing machine for yarn dividing; d, the divided cotton yarn is conveyed into a bobbin making machine for a shaft, and the cotton yarn is manufactured into bobbins through the bobbin making machine for the shaft; e, the manufactured bobbins are placed in an automatic knitting machine, and the cotton yarn is knitted into a jean jacket through the automatic knitting machine. By means of the design of the processing steps, in the jean jacket making process, jean does not need to be cut or sewn, the cotton yarn manufactured into the bobbins can be directly made into the jean jacket through the automatic knitting machine, that is, the processing procedures of the jean jacket can be effectively shortened through the one-step method jean jacket manufacturing technology, and loss can be effectively reduced.

Owner:GUANGDONG FORWARD DENIM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com