Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5203 results about "Metering pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A metering pump moves a precise volume of liquid in a specified time period providing an accurate volumetric flow rate. Delivery of fluids in precise adjustable flow rates is sometimes called metering. The term "metering pump" is based on the application or use rather than the exact kind of pump used, although a couple types of pumps are far more suitable than most other types of pumps.

Medication device

A dispenser for medicaments comprises a first metering pump for insulin and a second metering pump for glucose or glucagon. A controller for both pumps is programmed to maintain a basal supply of insulin, and is responsive to a signal from a separate glucometer to dispense additional insulin or glucose or glucagon as appropriate.

Owner:RICHARDS CYNTHIA C

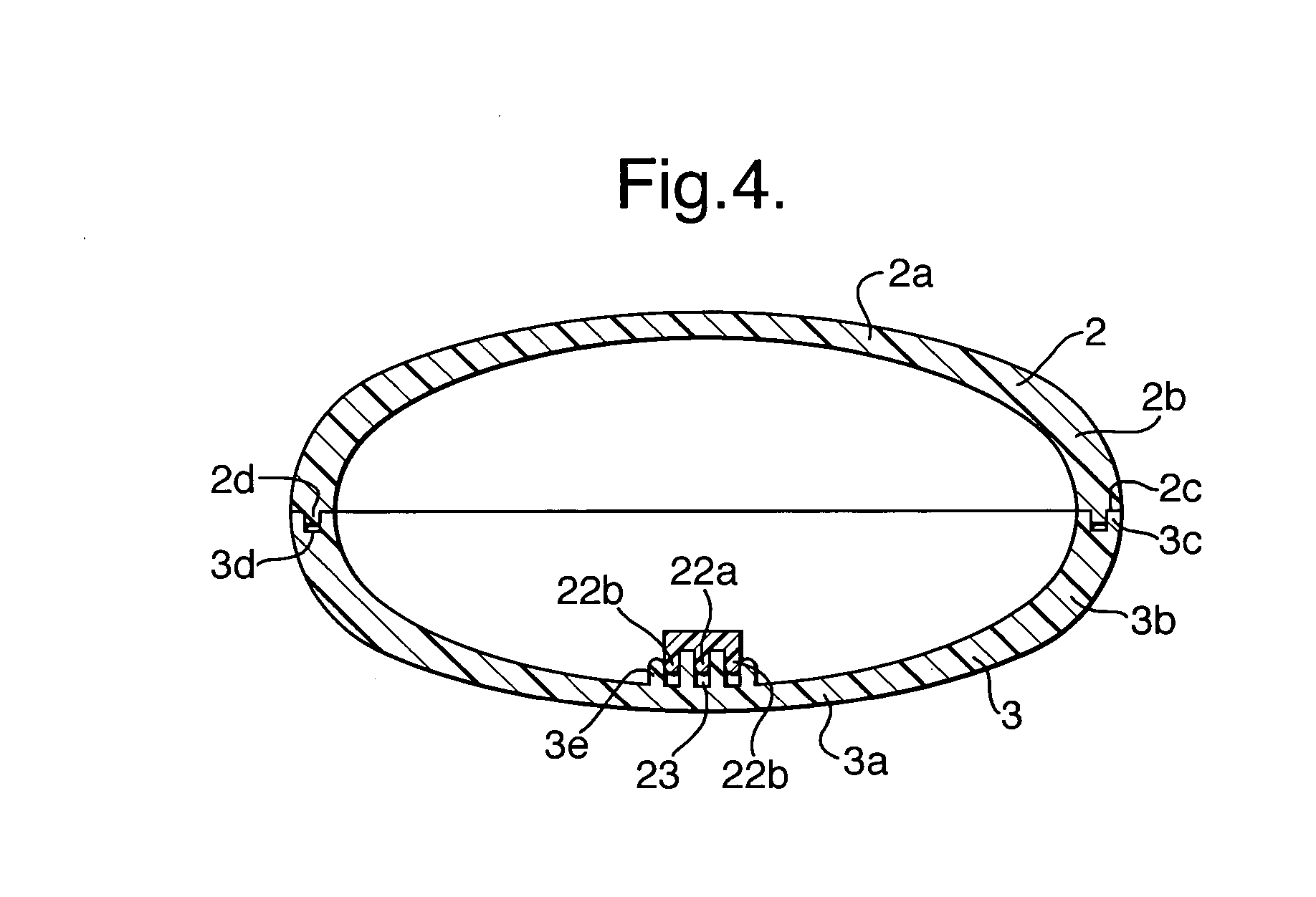

Implantable drug delivery pump

InactiveUS7341577B2Optimize allocationCompact and energy efficientPharmaceutical delivery mechanismMedical devicesPharmaceutical drugMetering pump

The pump includes a metering pump including a rotor, at least two lengths of tubing against which the rotor is movable to urge the drug therethrough, and an outlet port associated with each of the at least two lengths of tubing. In this way, a drug may be supplied to more than one neurological target.

Owner:RENISHAW PLC

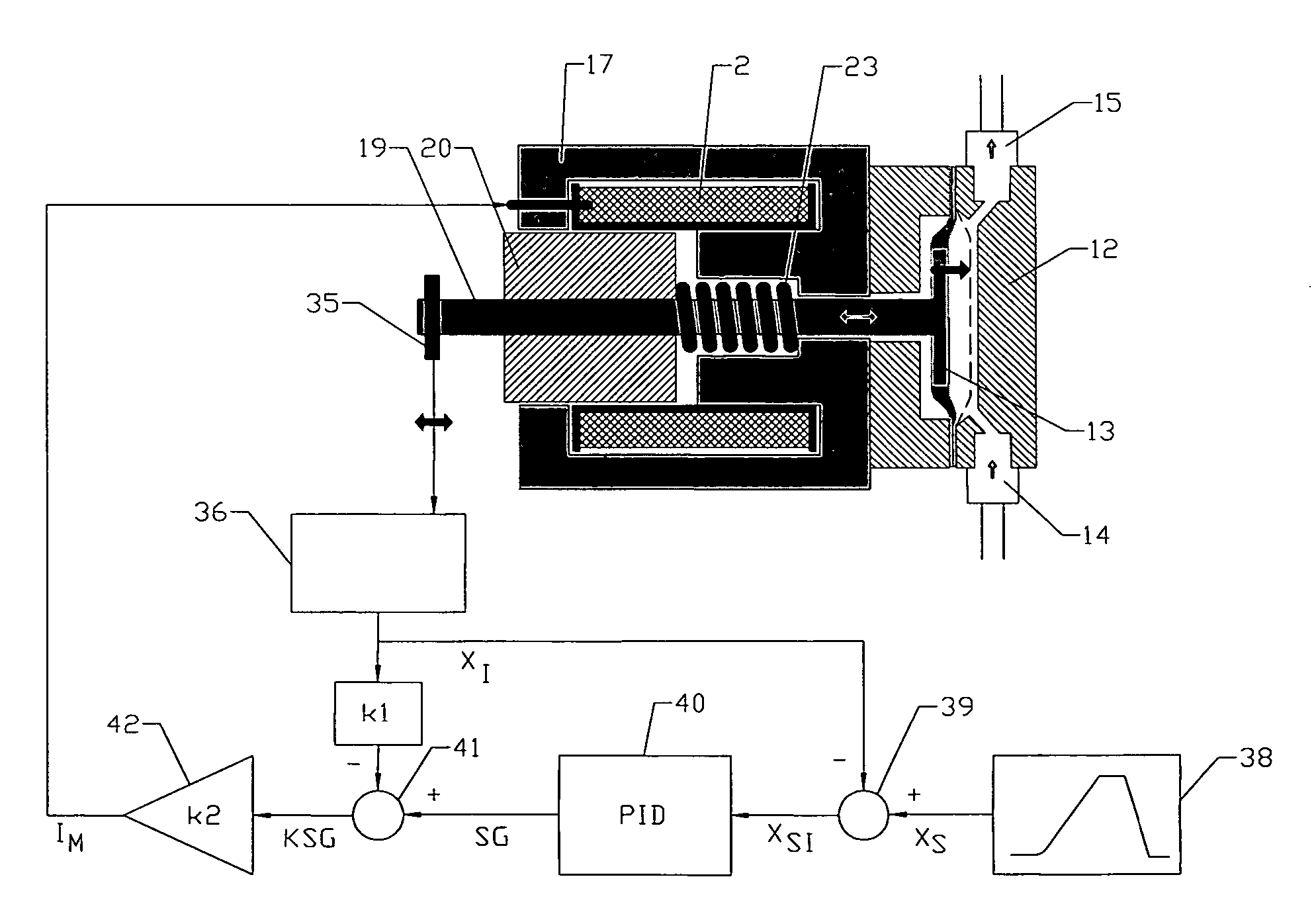

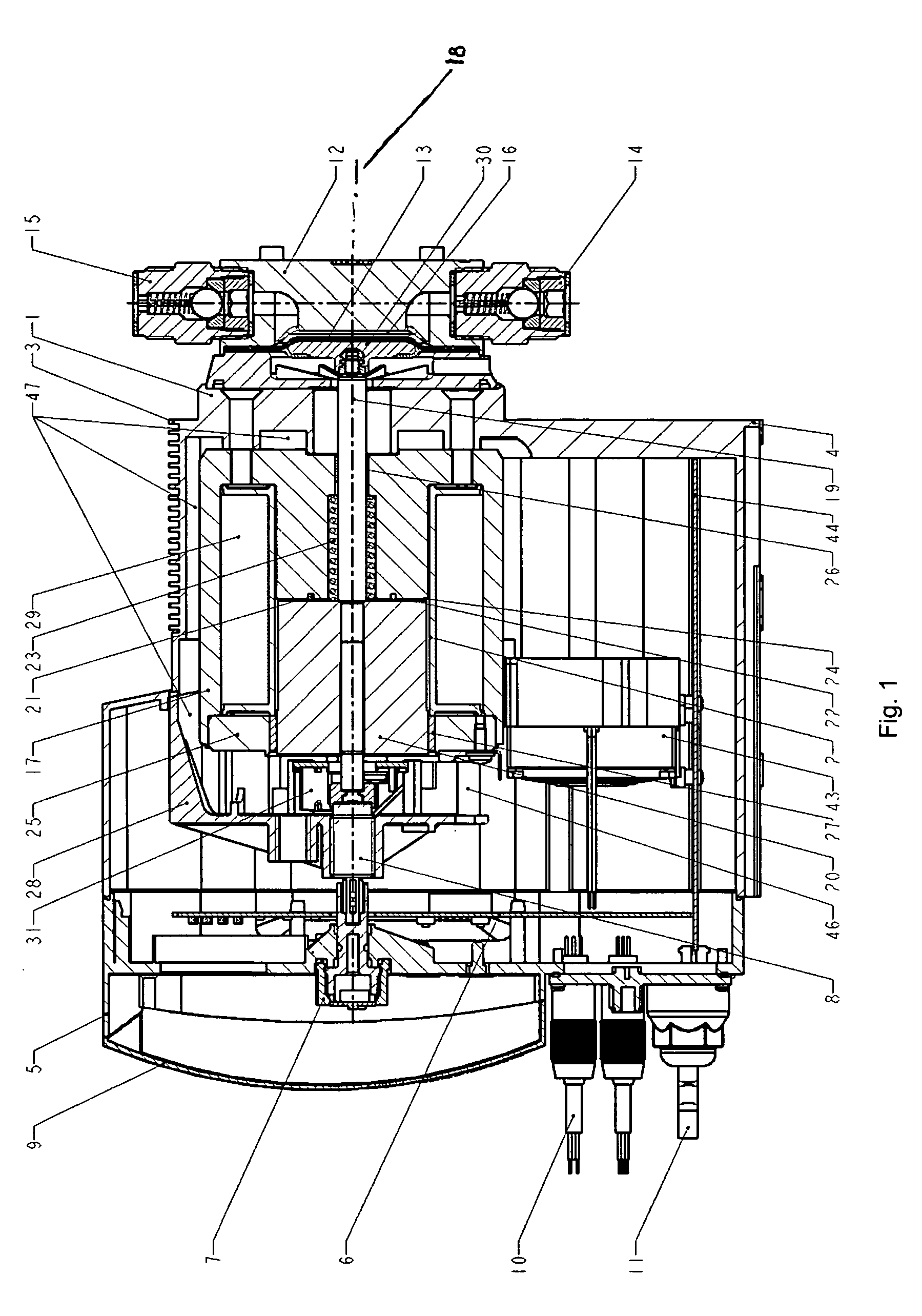

Magnetic drive metering pump

ActiveUS20070040454A1Motor/generator/converter stoppersDC motor speed/torque controlMagnetic tension forceInlet valve

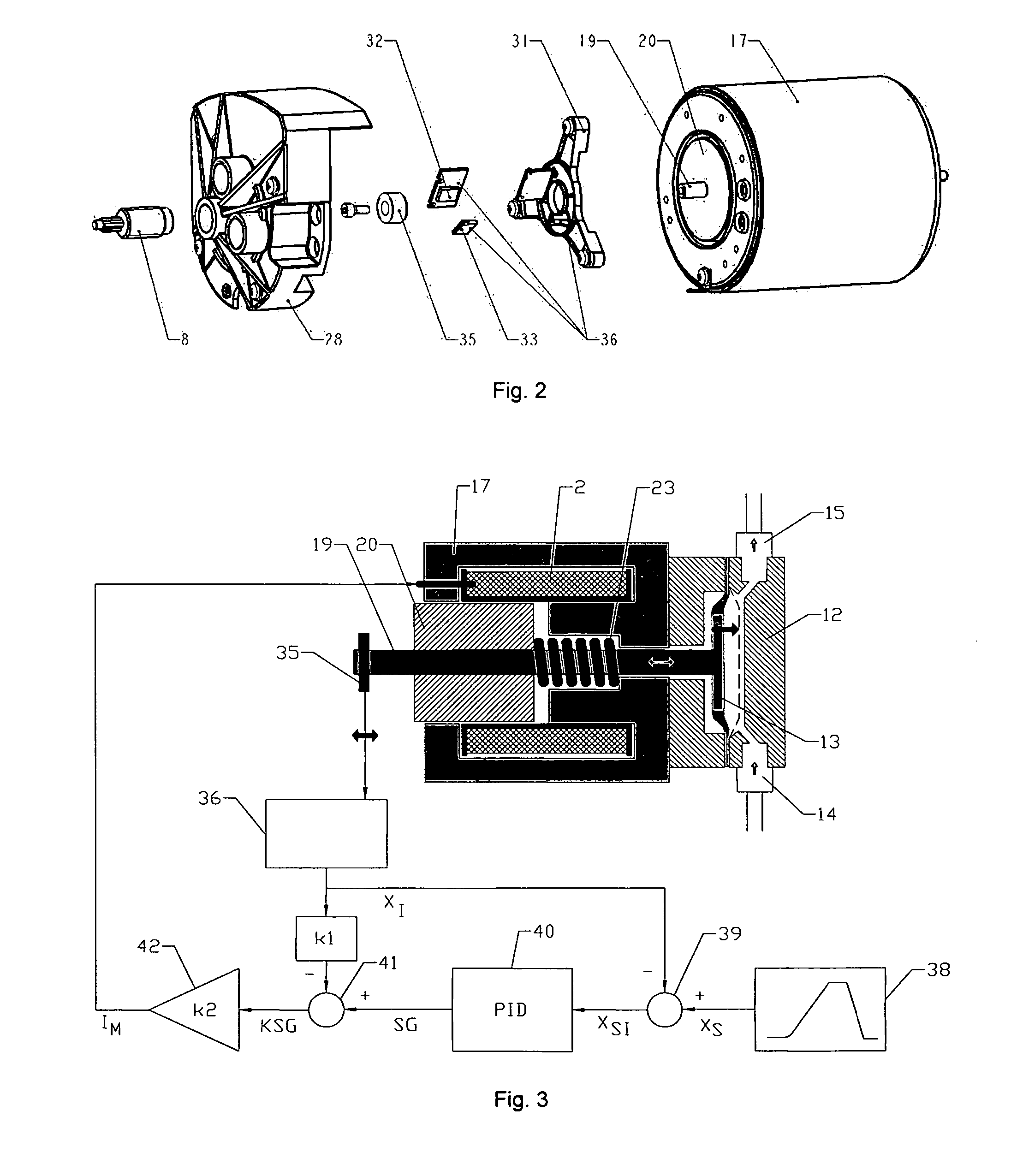

A magnetic drive metering pump in which a movable thrust member fixed to a connecting rod is axially movable in a longitudinal axis in a magnet shroud anchored in a pump housing so that the thrust member with the connecting rod, on electrically driving (actuating) the magnetizing coil, is drawn into the magnet shroud against the force of a recuperating spring, reducing an air gap between the thrust member and an inner face of magnetic shroud, into a bore in the magnet shroud and after deactivating the magnet the thrust member is returned to the starting position by the recuperating spring so that the thrust member and an elastic displacement member actuated thereby on carries out an oscillating motion continued activation and deactivation of the magnetizing coil, which diaphragm cooperates alternately with an outlet and an inlet valve to produce a pump stroke (pressure stroke) and a priming stroke in a metering head arranged in the longitudinal axis. In such a magnetic drive metering pump, a reference element is associated with the module constituted by the thrust member and connecting rod, the position of which reference element is detected by a positional sensor, wherein the positional sensor provides an actual signal which is in a fixed relationship to the position of the reference element, and in that the motion of the unit formed by the thrust member and the connecting rod is influenced as regards control accuracy via a control circuit so that it follows a predetermined nominal profile.

Owner:PROMINENT

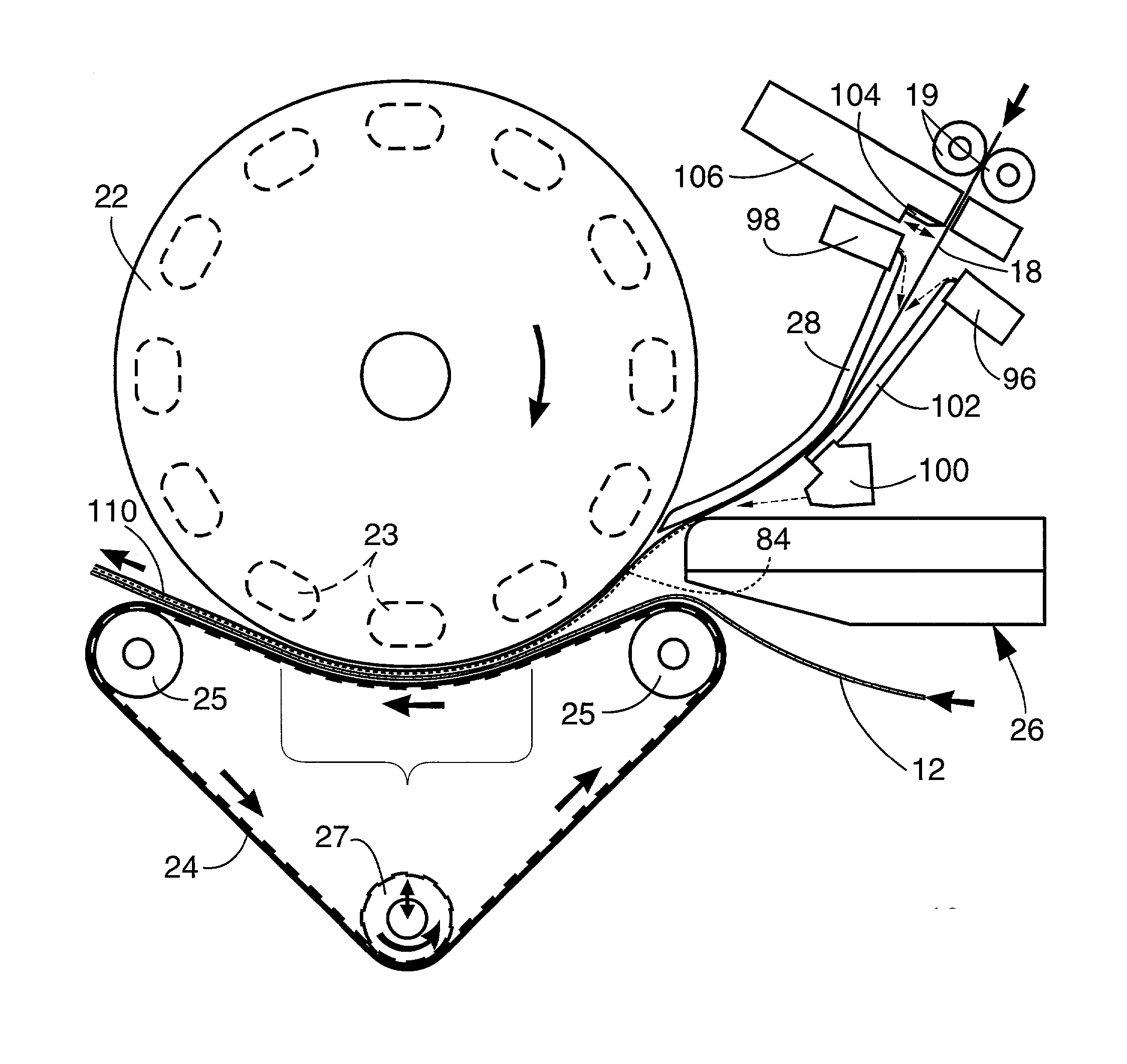

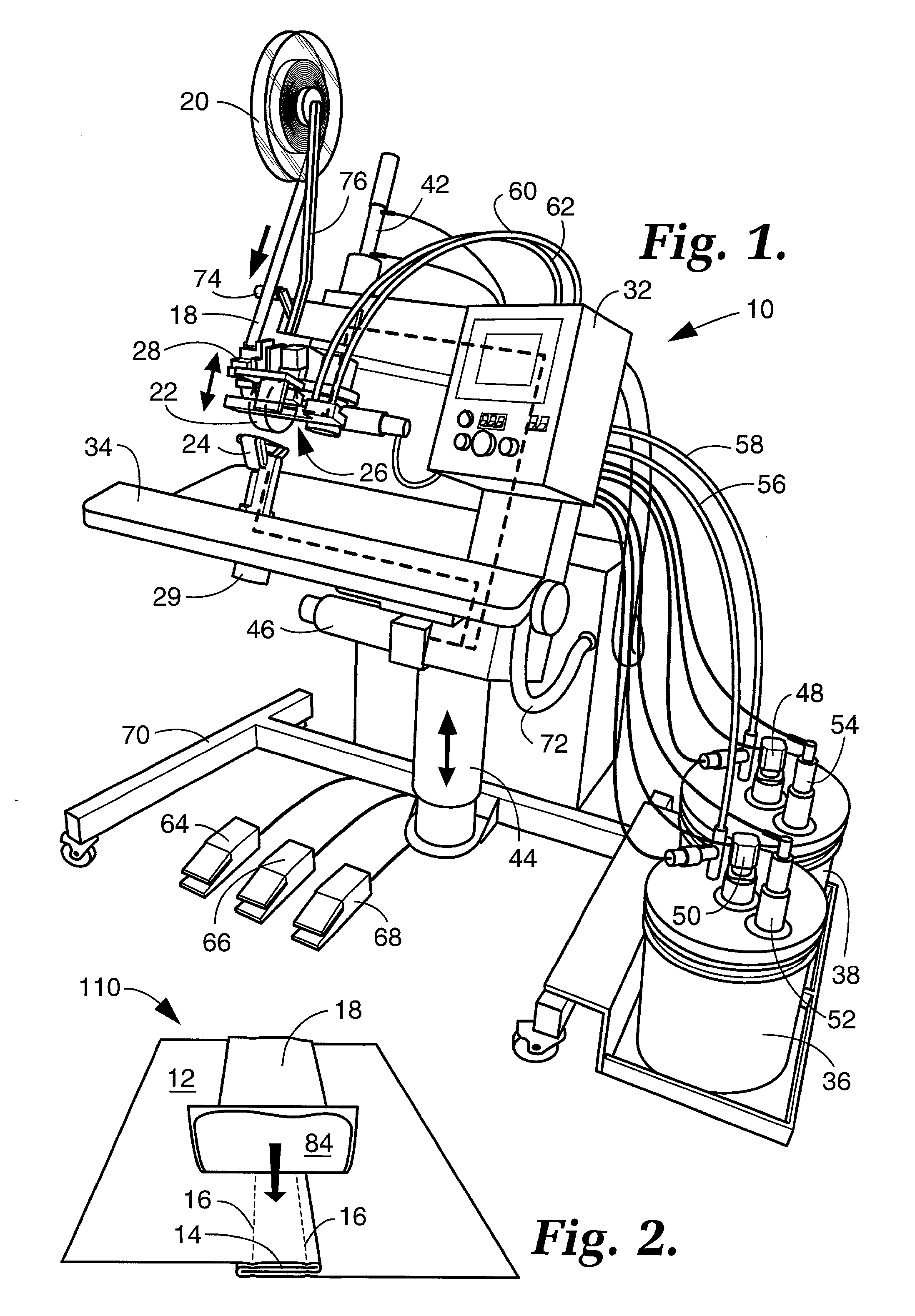

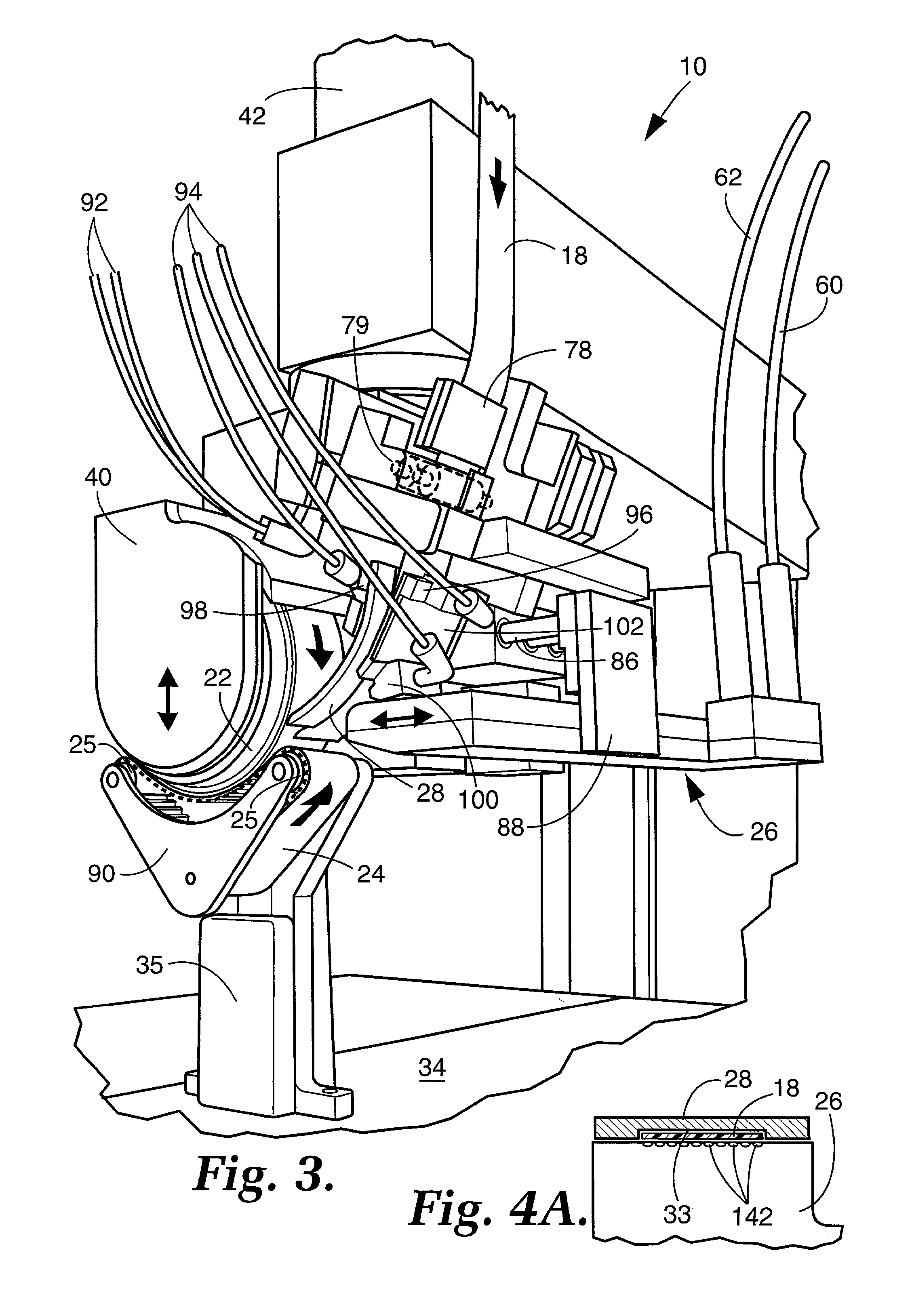

Seam sealing apparatus and process therefor

InactiveUS20030010439A1Easy to cleanWell mixedAdhesive processesManual label dispensersAdhesiveSurgical Gowns

Apparatus and a method for sealing of protective barrier fabric seams in otherwise impermeable articles such as garments, footwear, surgical gowns and the like, are provided, the sealed seams maintaining the imperviousness of the article, including seamed joints, to water, body fluids, pathogens and chemicals. In one pass through the apparatus, a sealed seam in a protective barrier fabric joint, using a curable adhesive sealant, is provided along a predetermined and specified length of the joint. The preferred adhesive is a silicone, most preferably a two-part, thermosetting silicone elastomeric adhesive. Also provided are mixing dies for use, inter alia, in the process which are especially suited for applying the two-part adhesive sealant. In addition, variable-residence-time curing apparatus, which effects variable, controlled, desired cures of the adhesive, all in a one-pass operation, is provided, together with precise metering pumps, especially suited for supplying the seam sealing adhesives in the process of the invention.

Owner:WL GORE & ASSOC INC

Multi-valving sample injection apparatus

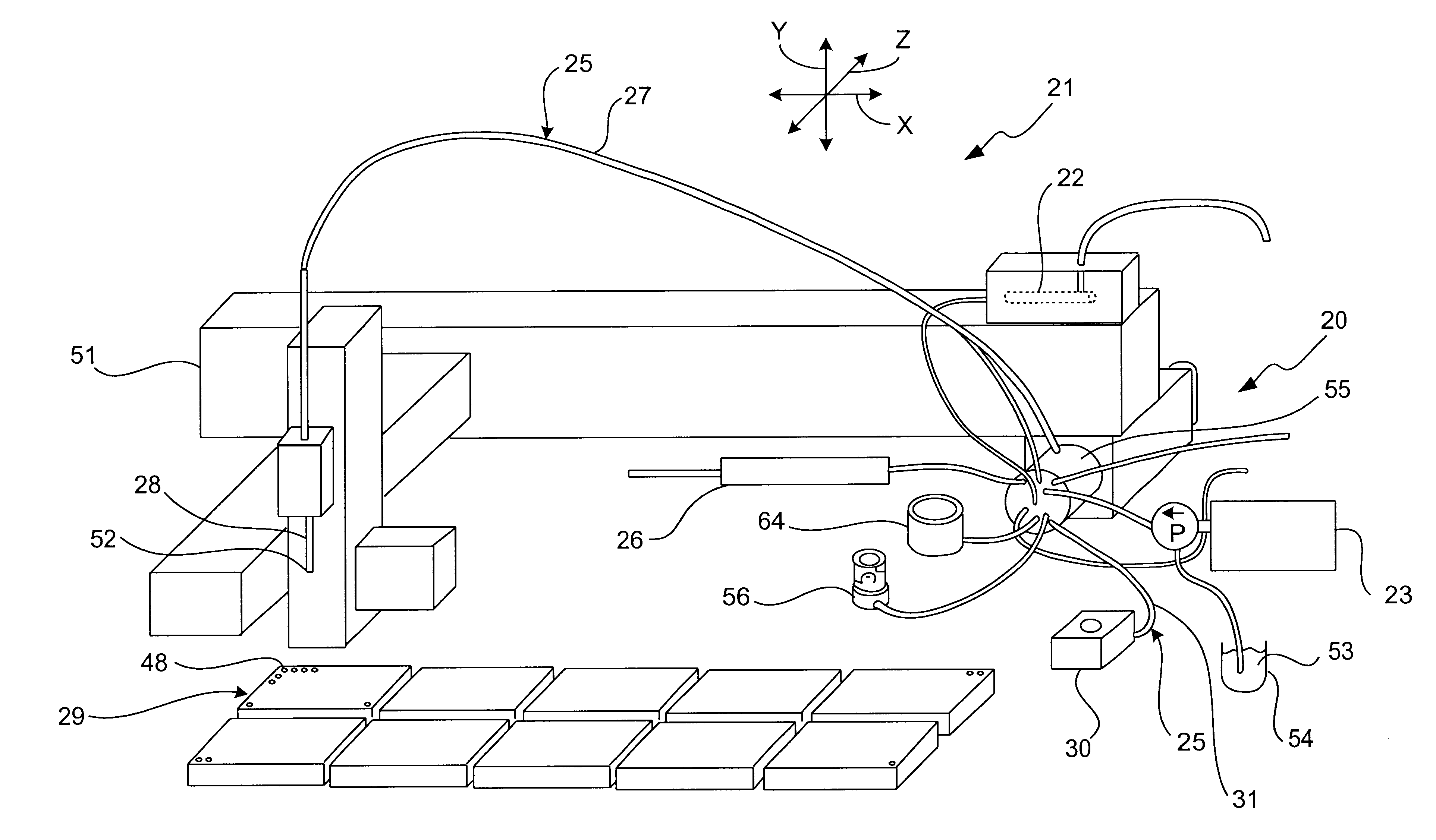

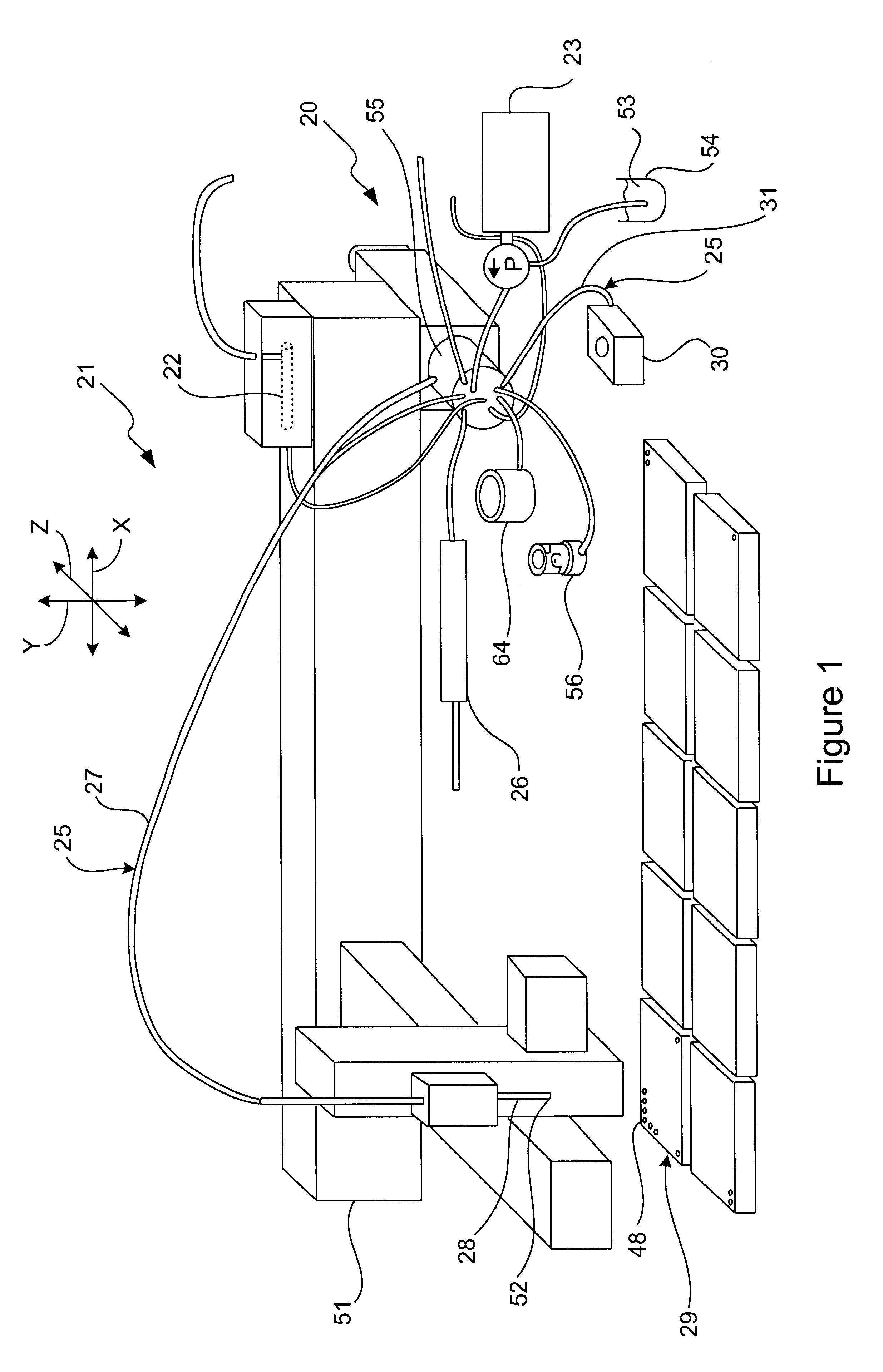

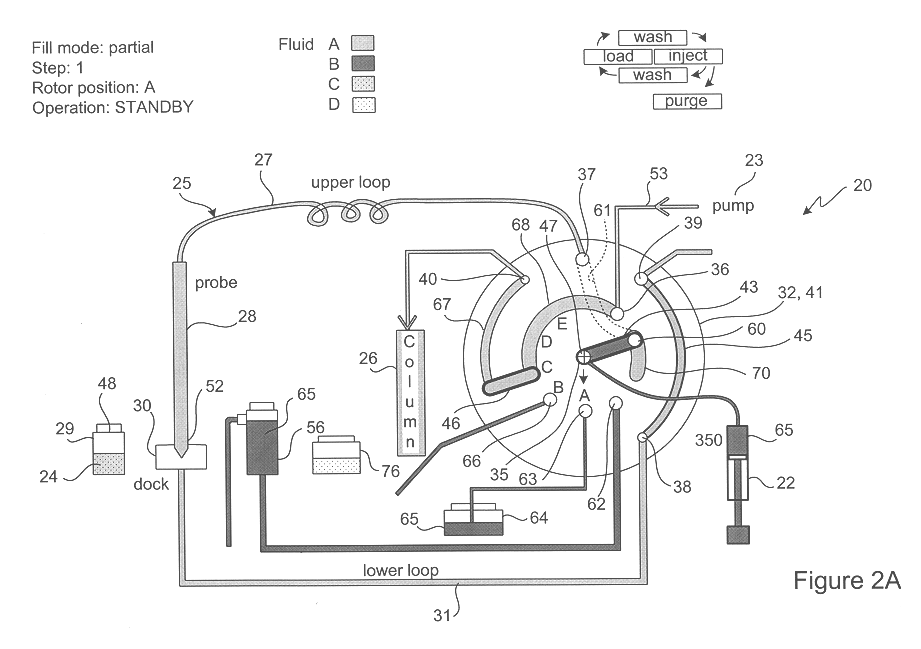

A multi-function valve apparatus for use with a Probe-In-Loop (PIL) architecture sample injection assembly which enables both Partial-Fill and Complete-Fill injections. The rotor element is rotatable about a rotation axis relative the stator between: a Load Position, an Overfill Position, and an Injection Position. In the Load Position, a first bridge channel fluidly couples a metering syringe to the sample loop assembly enabling the probe to aspirate one of a discrete volume of sample into the probe, during a Partial-Fill Mode, and a second volume of sample into the probe, during a Complete-Fill Mode. In the Overfill Position, in the Complete-Fill Mode, a second bridge channel fluidly couples a downstream loop portion to a waste port, and the first bridge channel fluidly couples the metering syringe to an upstream loop portion of the sample loop assembly. This enables the metering pump to dispense the sample from the probe into the downstream loop portion and out the waste port to completely fill the downstream loop portion and the second bridge channel with a substantially precise known volume. In the Injection Position, the second bridge channel fluidly couples the downstream loop portion to the analyzing device to inject the sample into the analyzing device, in either the Partial-Fill Mode or and the Complete-Fill Mode.

Owner:IDEX HEALTH & SCI

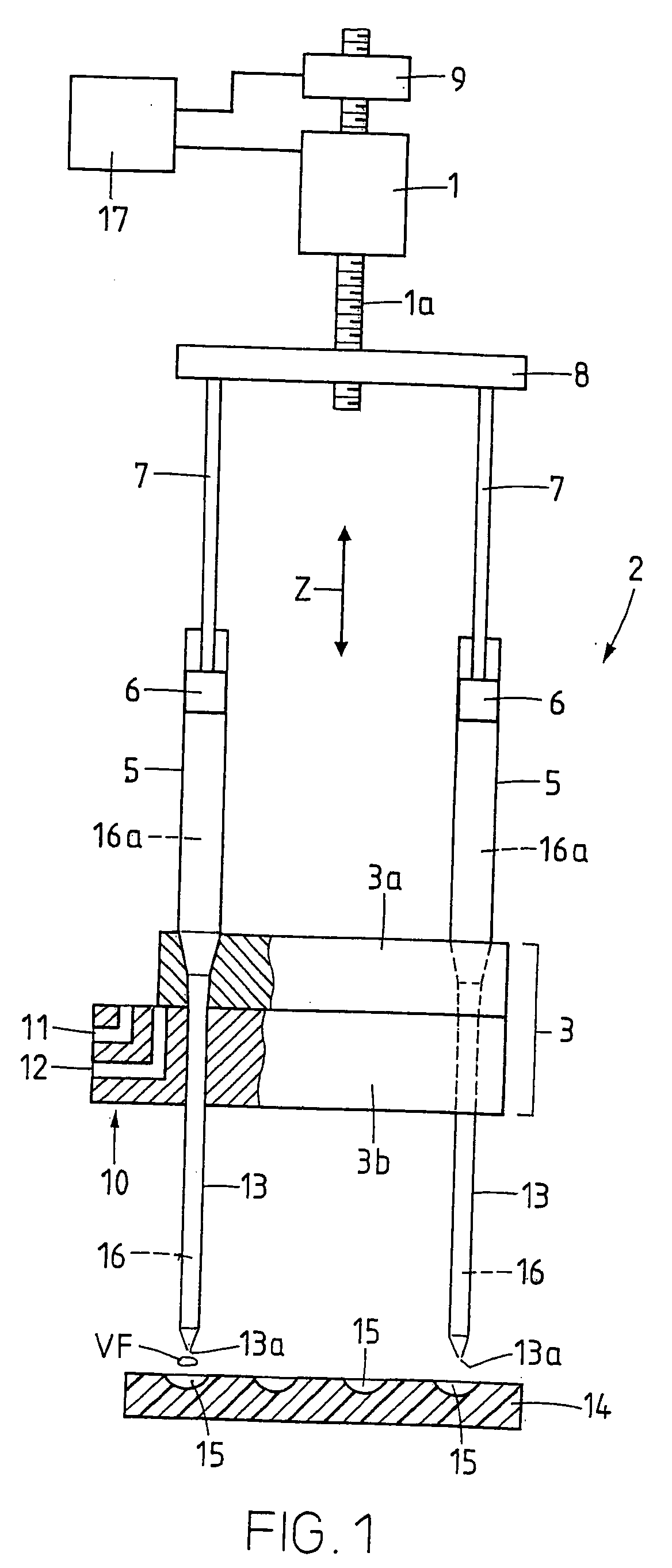

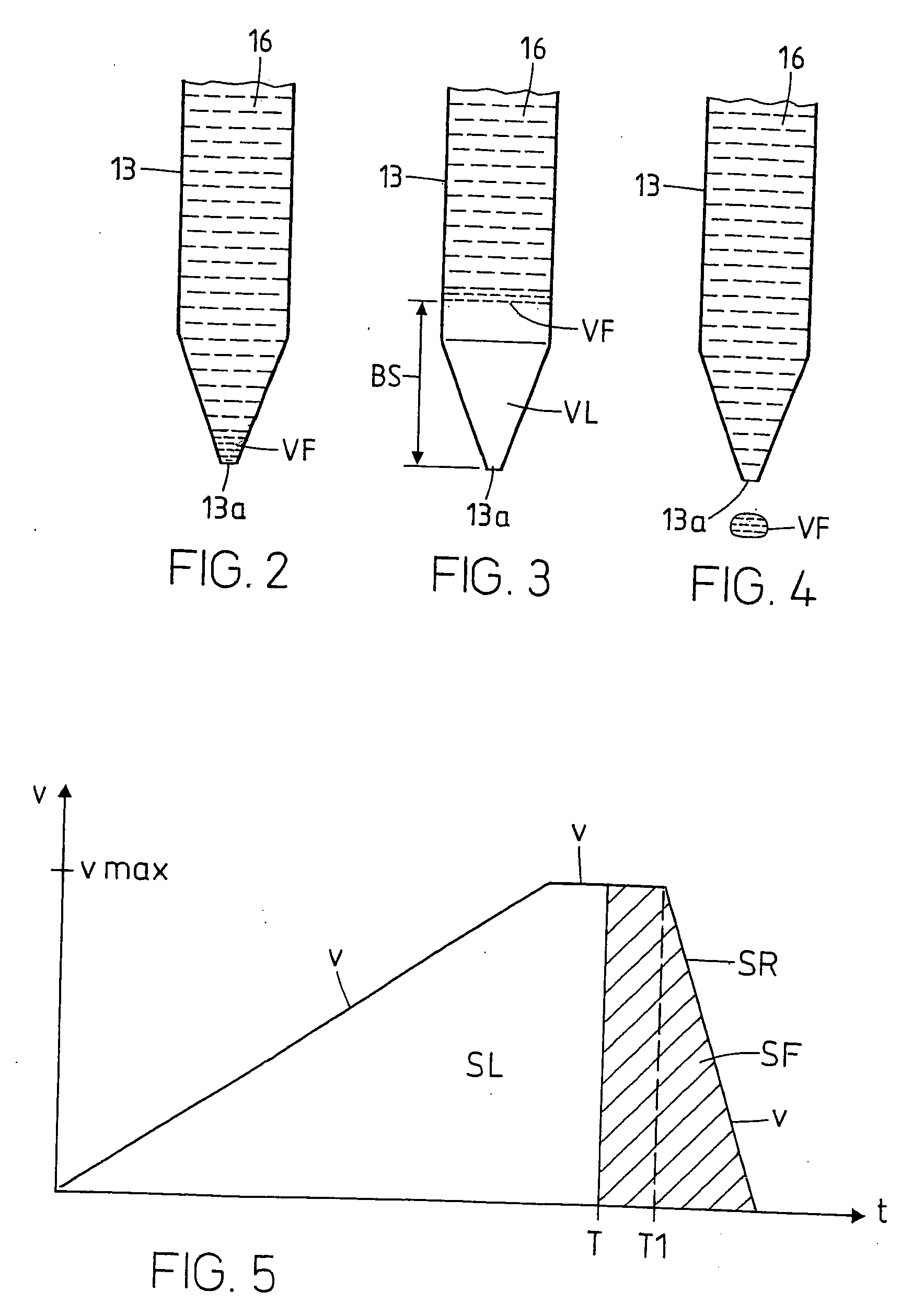

Method and device for dosing small volumes of liquid

InactiveUS20050214172A1Reduce frictional resistanceLower resistanceAnalysis using chemical indicatorsContracting/expanding measuring chambersPipetteMetering pump

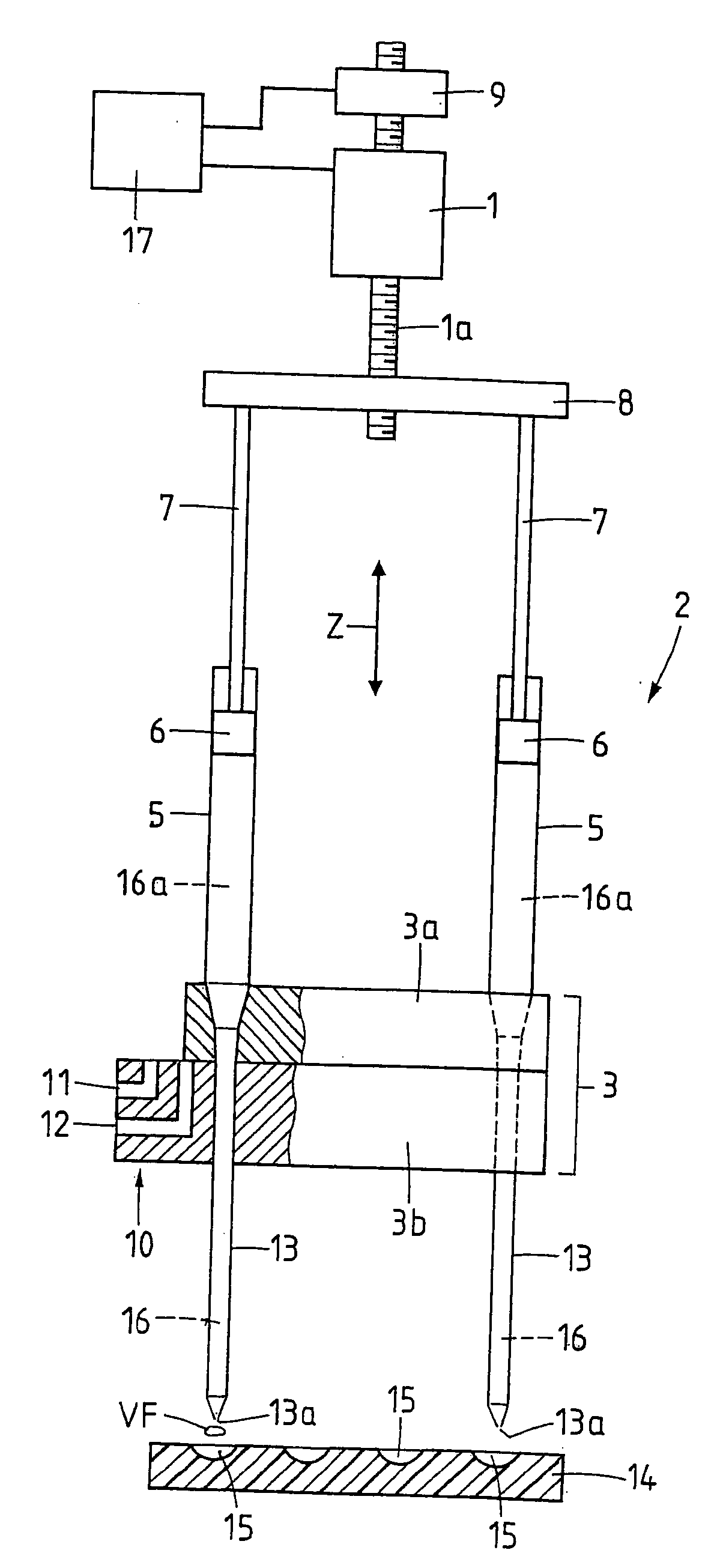

The invention relates to a method for dosing a volume of liquid (VF) of less than 1 !l that is to be dispensed, by means of a dosing pump, in particular a pipette (2). According to said method, a tip (13) is completely filled with a liquid and contains the liquid (16) to be dispensed at least in the vicinity of its outlet (13a), a volume of gas (VL) is drawn into the tip (13) via the outlet (13a) and a volume corresponding to the sum of the volume of liquid (VF) to be dispensed and the volume of gas (VL) is then supplied to the tip (13) in such a way that the volume of liquid (VF) is dispensed via the outlet (13a) in a contactless manner. The device comprises a plurality of dosing pumps that can be simultaneously actuated, in particular pipettes (2), which can be actuated by an injection plunger (6), in addition to a motor (1), which drives the injection plungers (6) and also a valve (3), which is located between the dosing pump and its respective tip (13) in order to fill each system completely with liquid without any gas.

Owner:EPR LABAUTOMATION

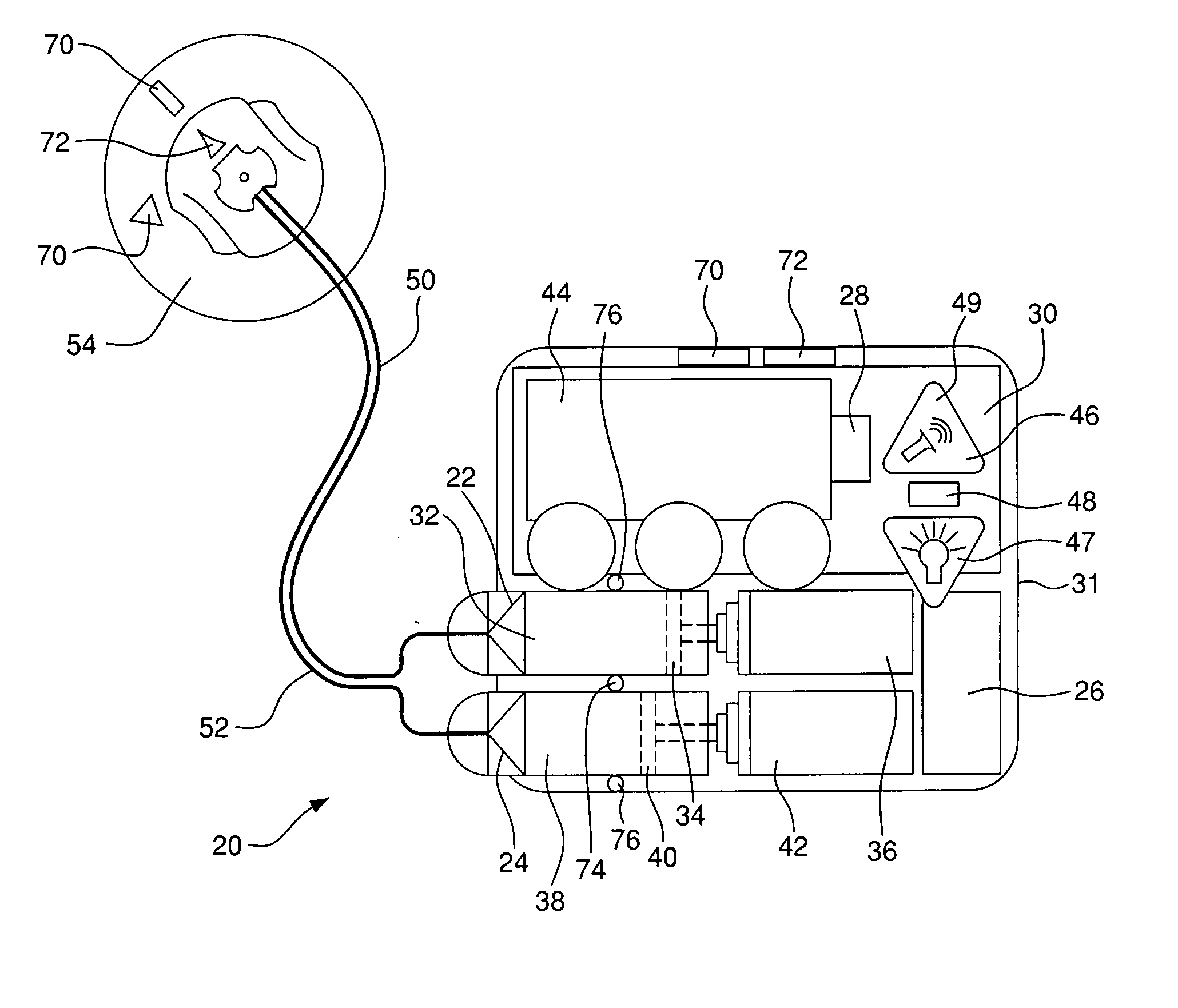

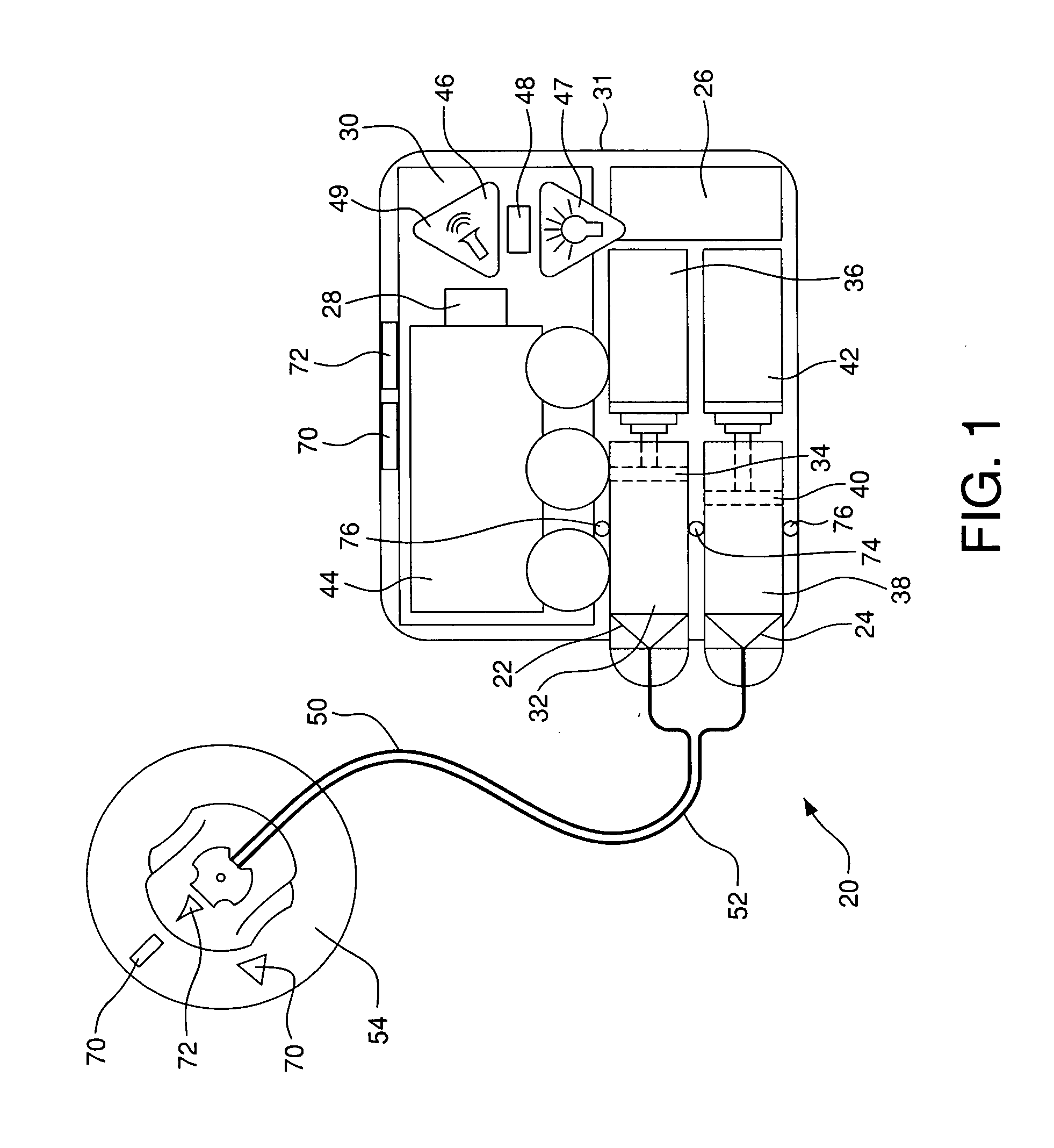

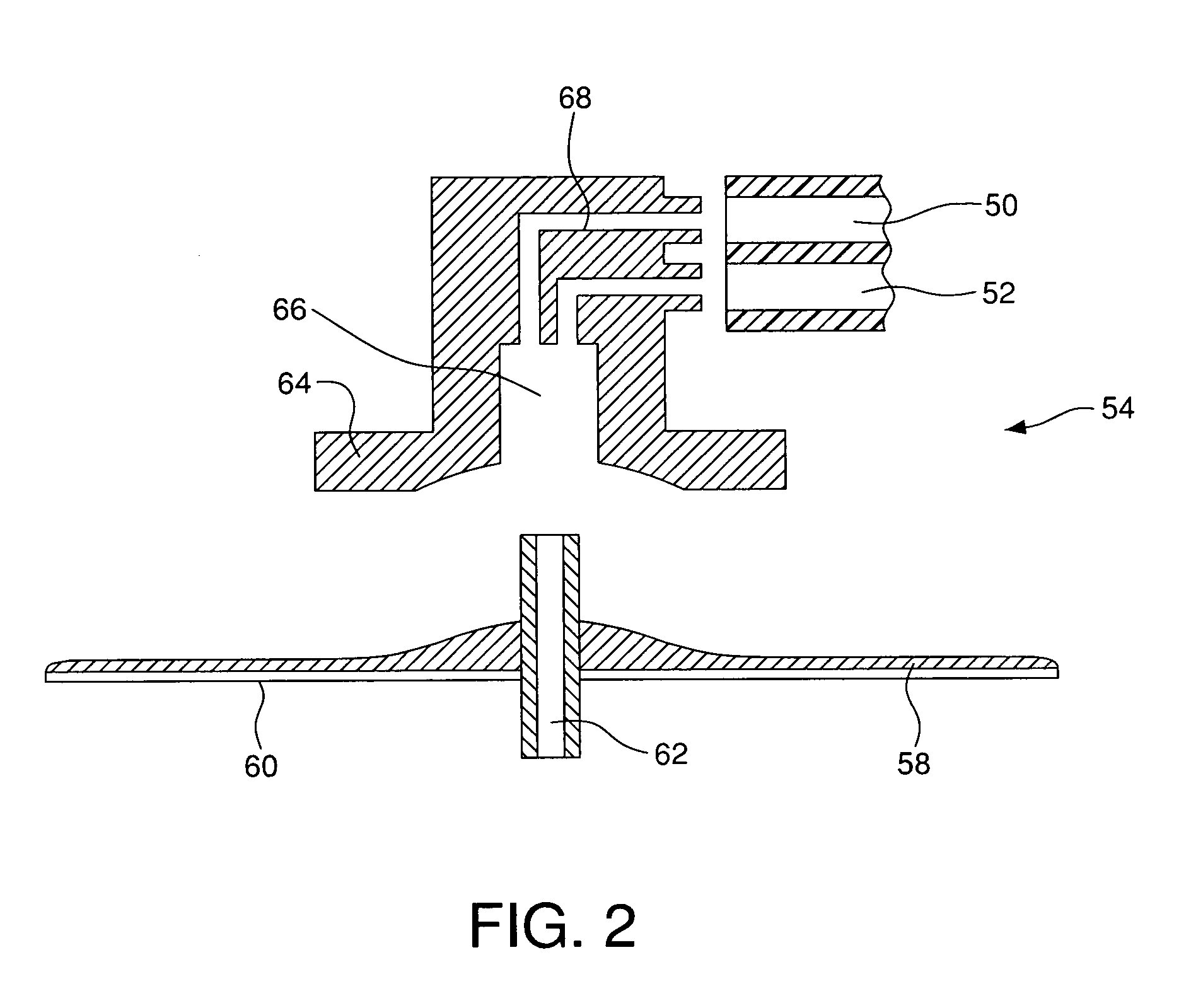

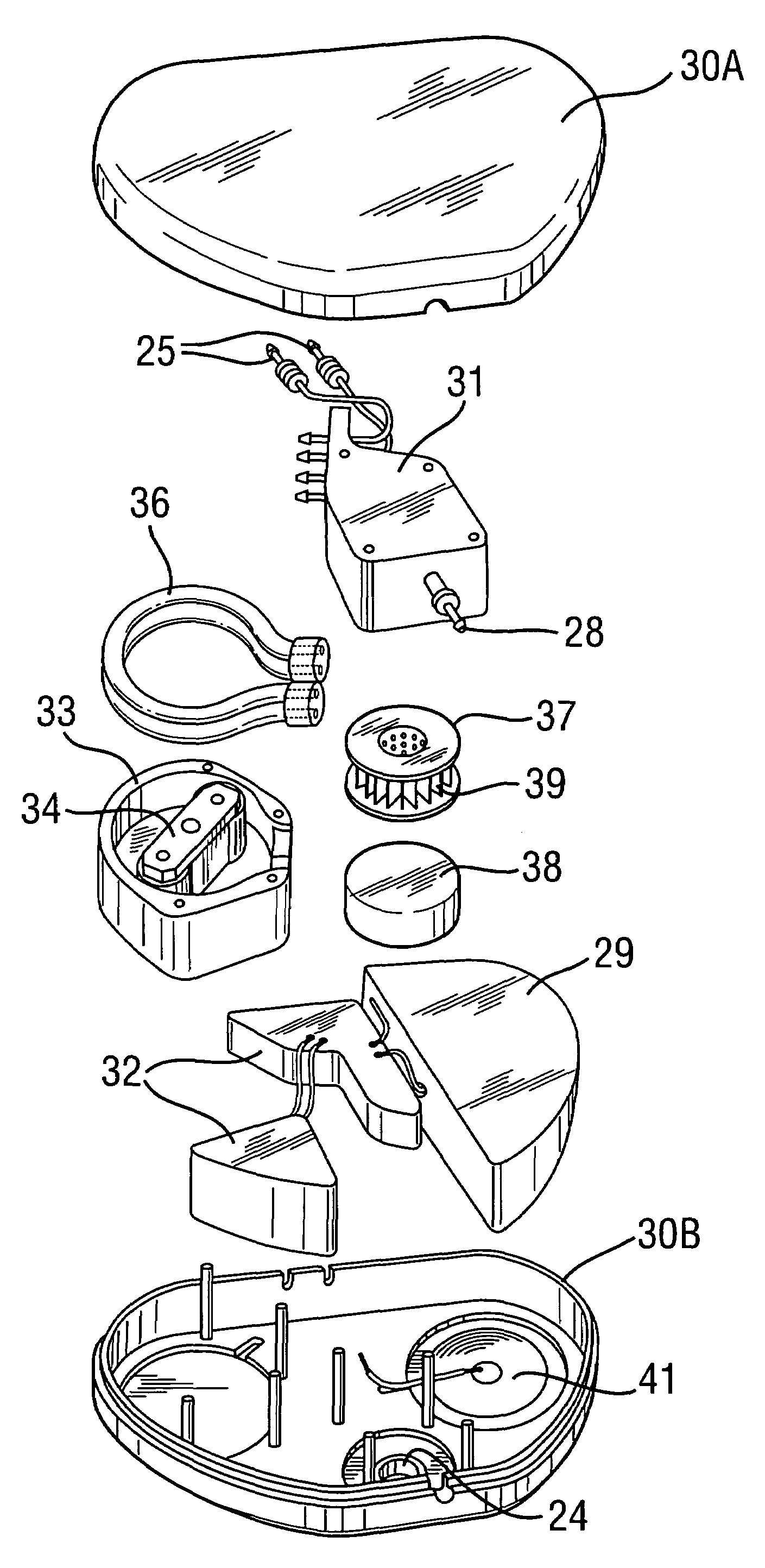

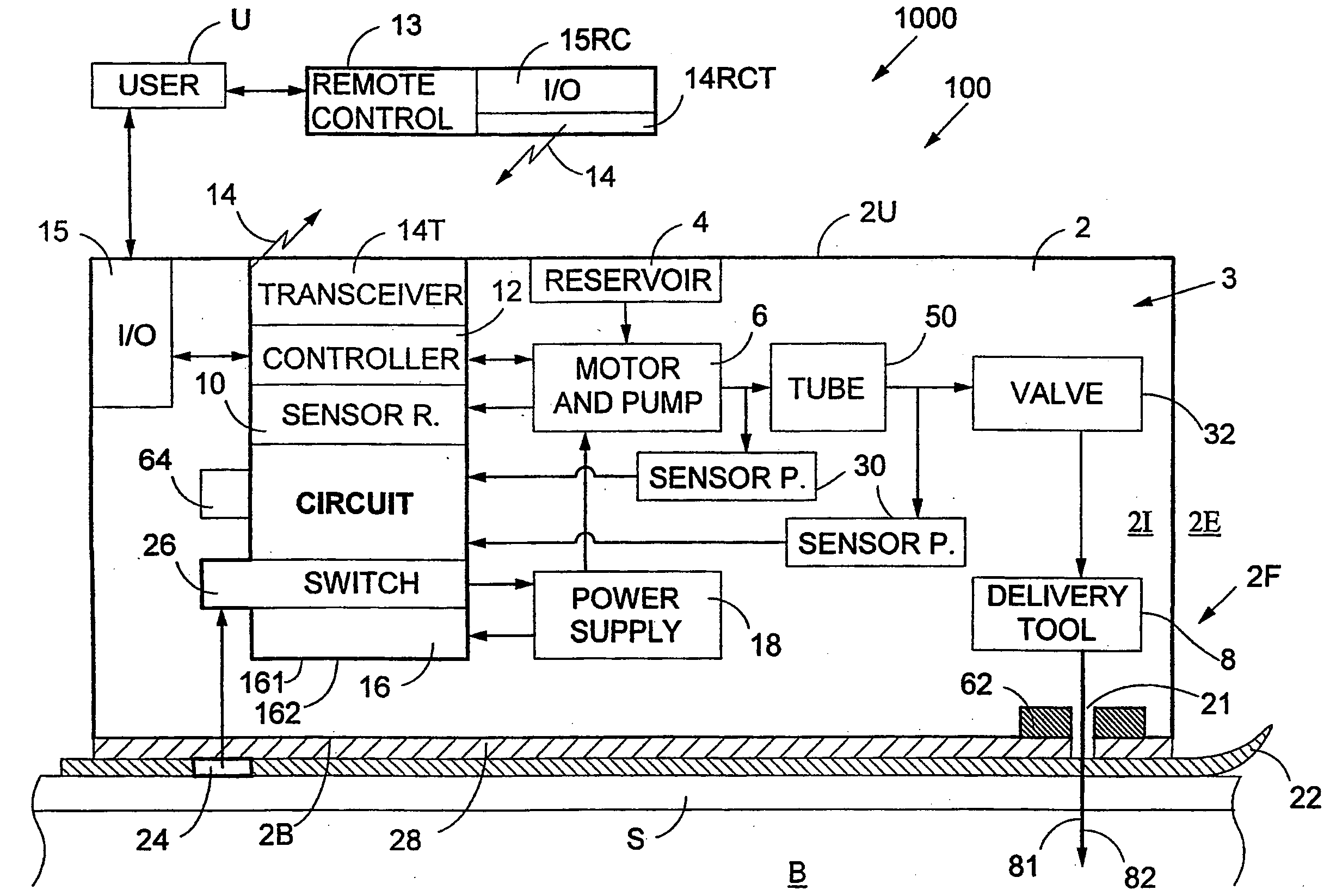

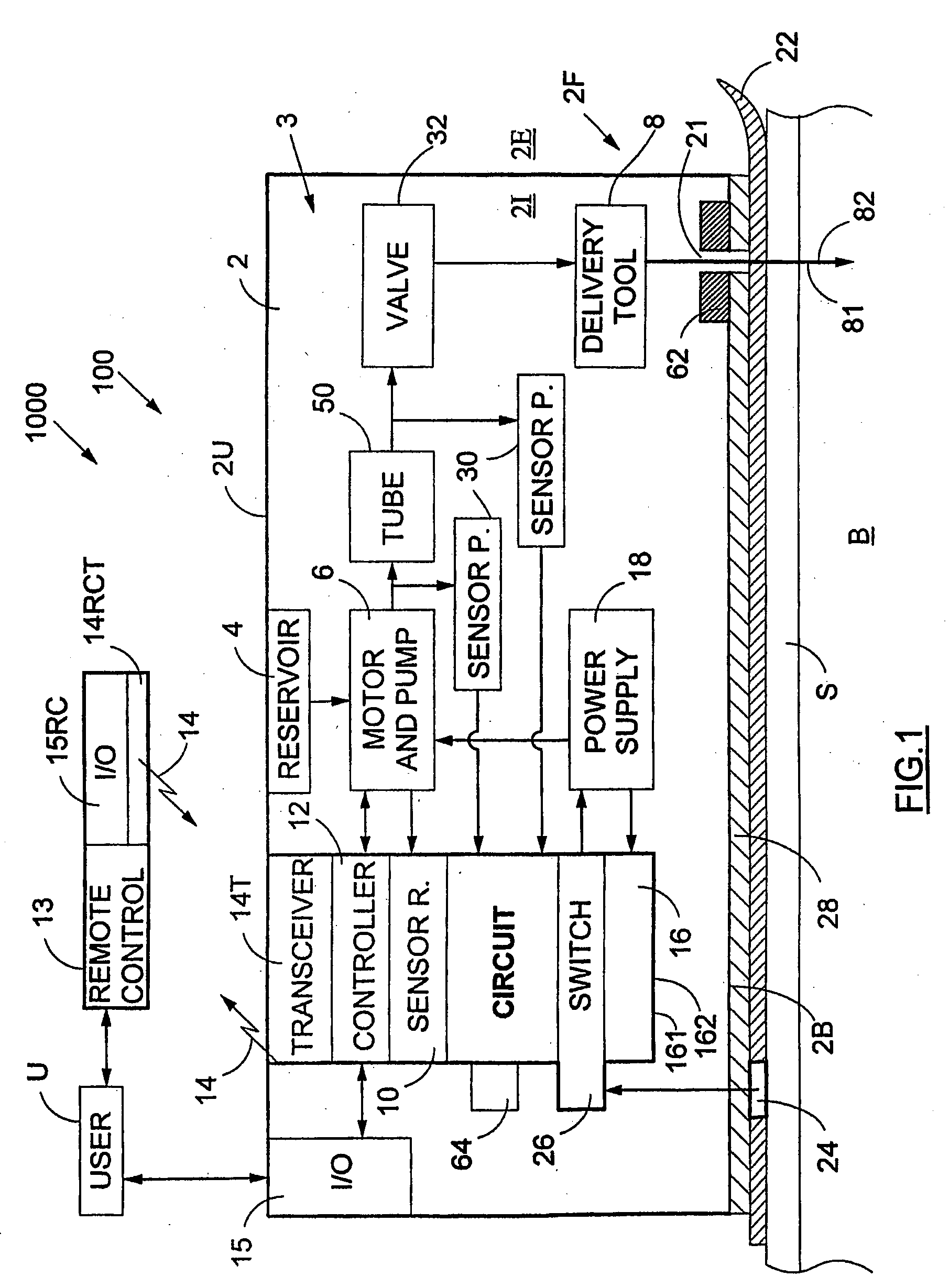

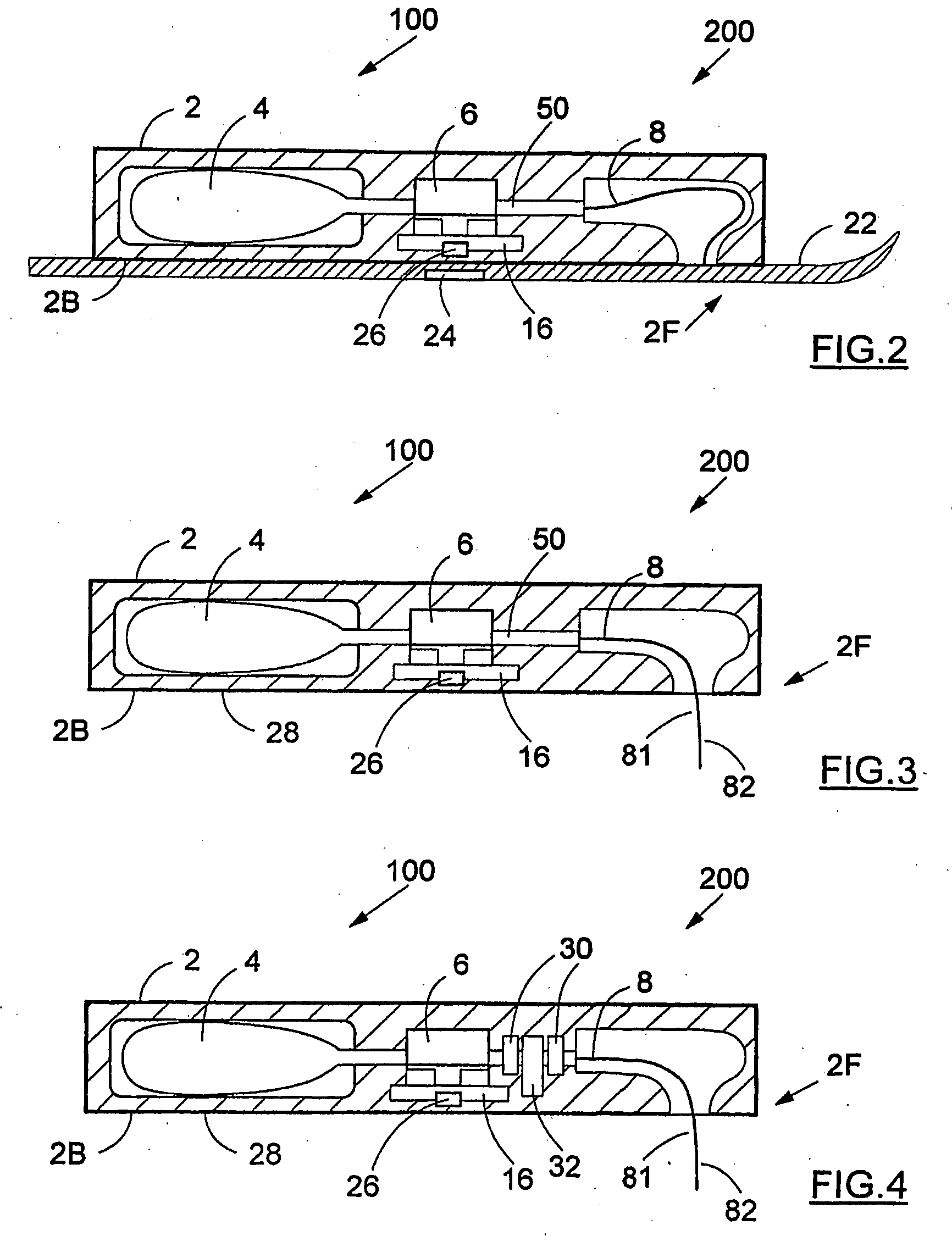

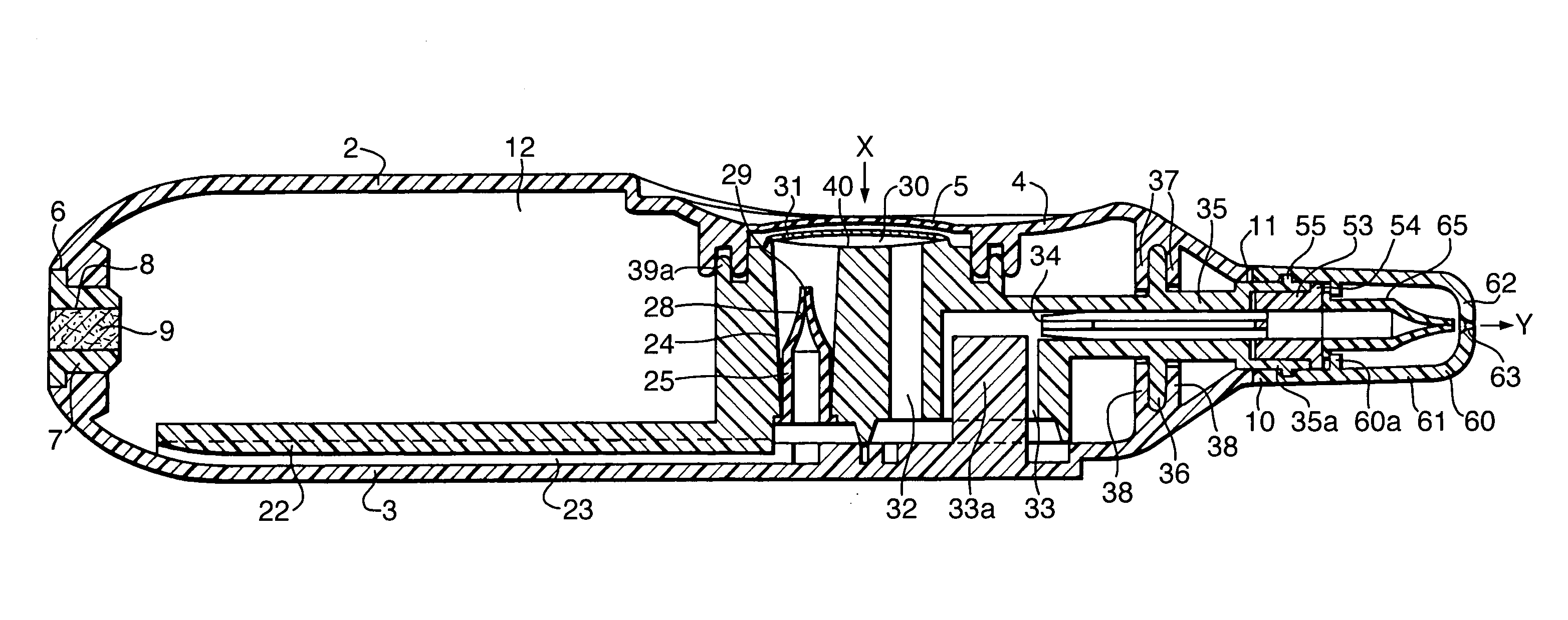

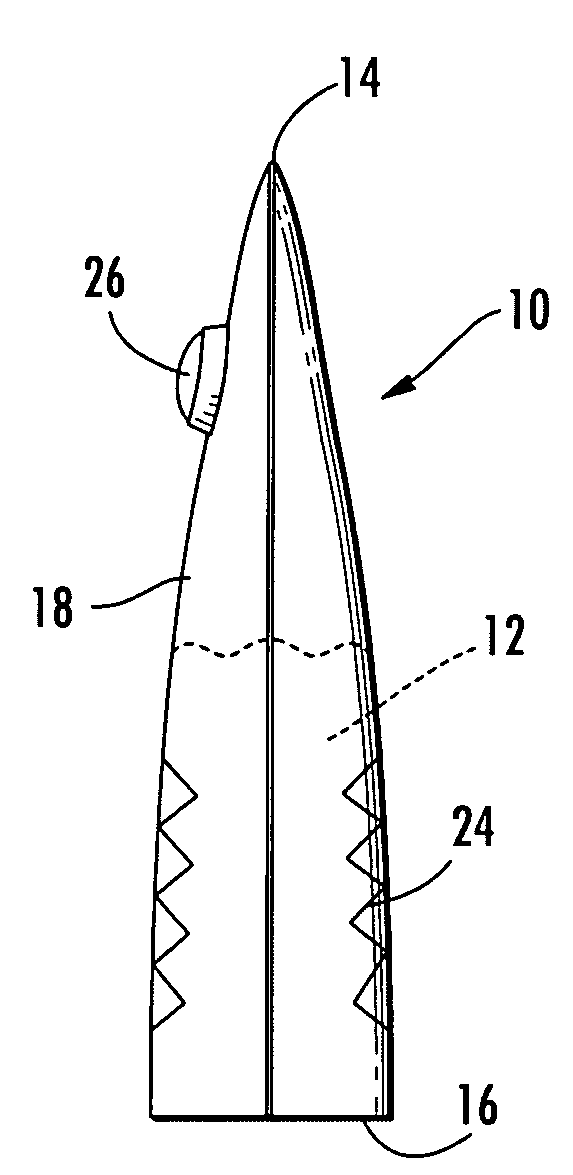

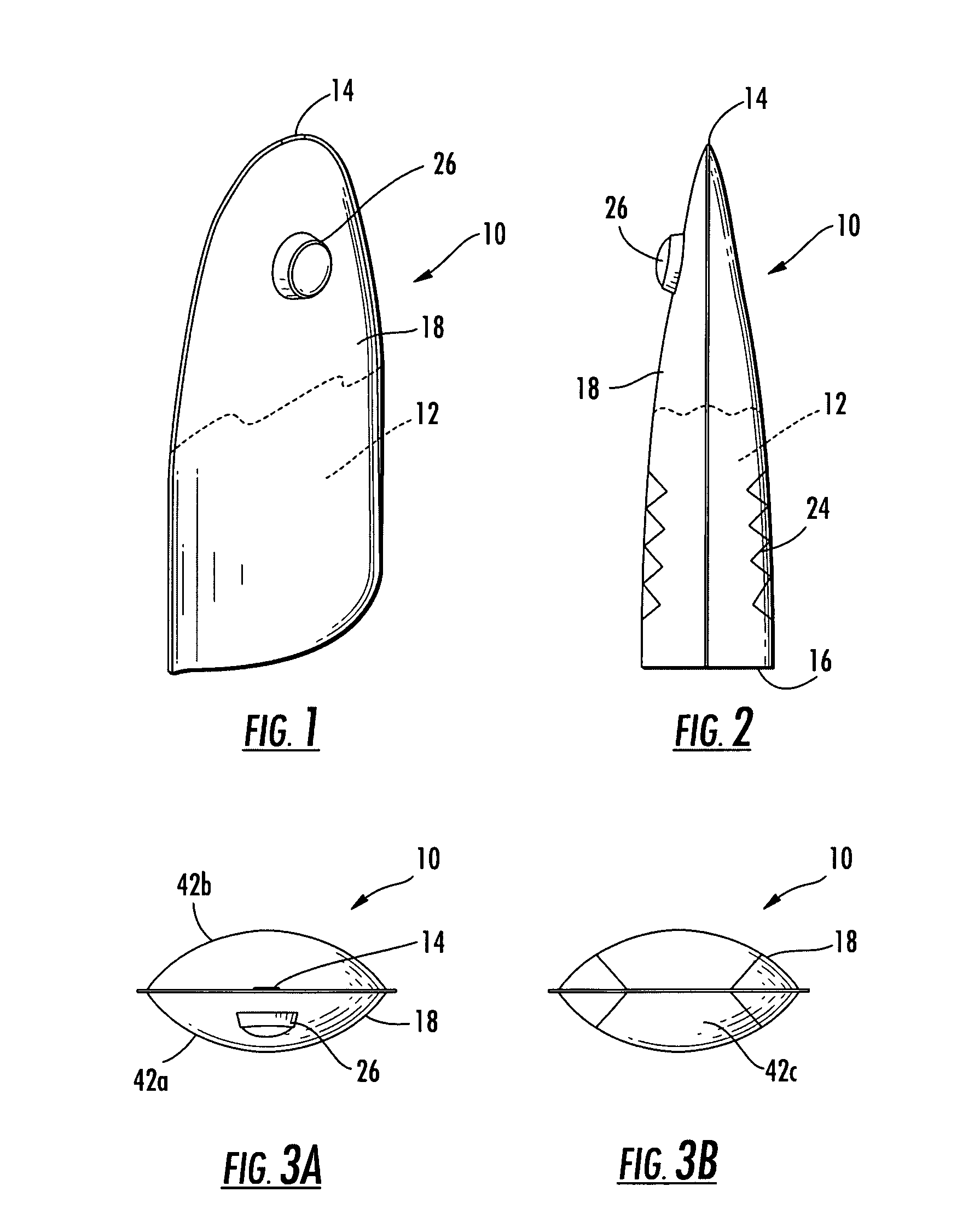

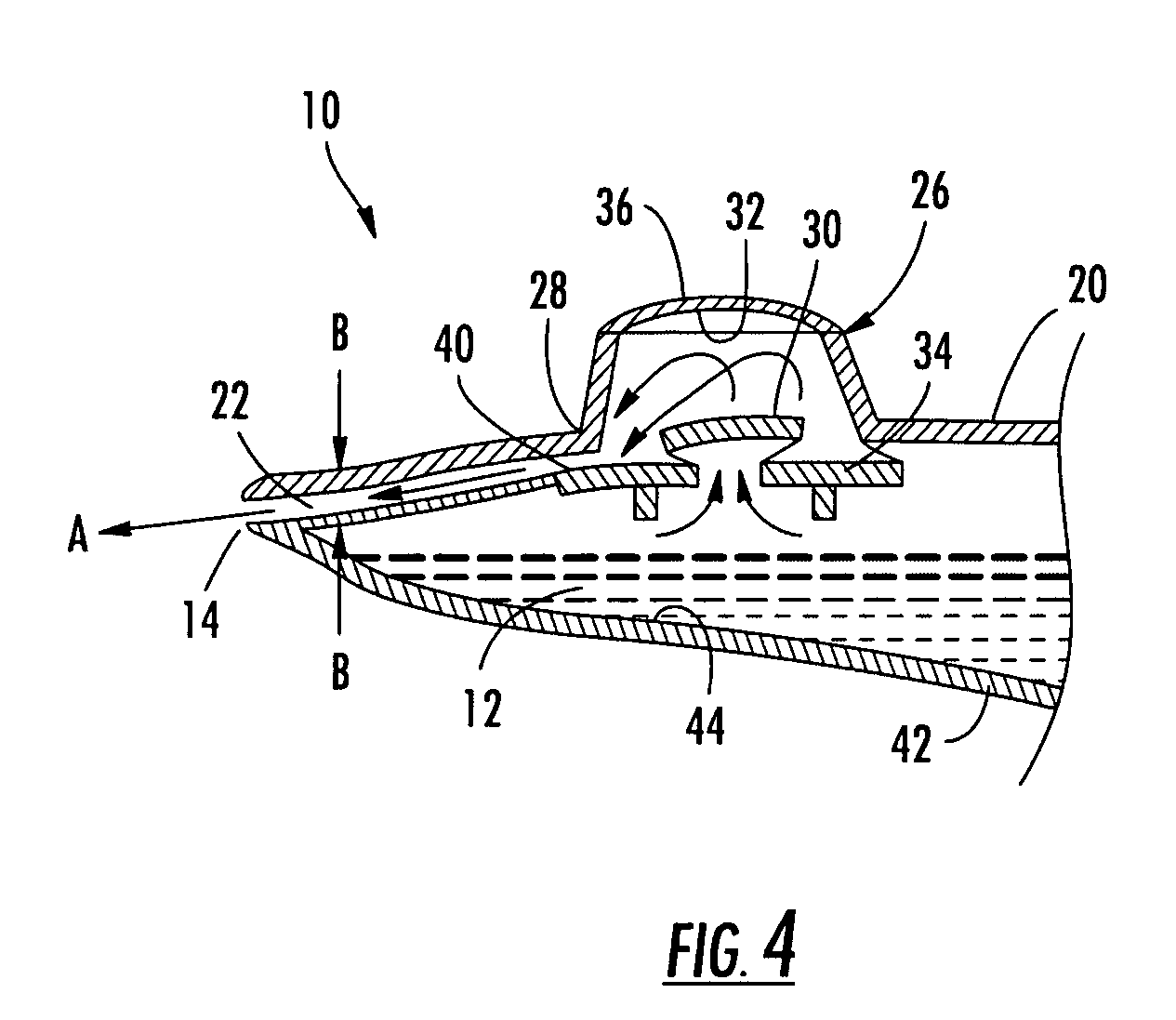

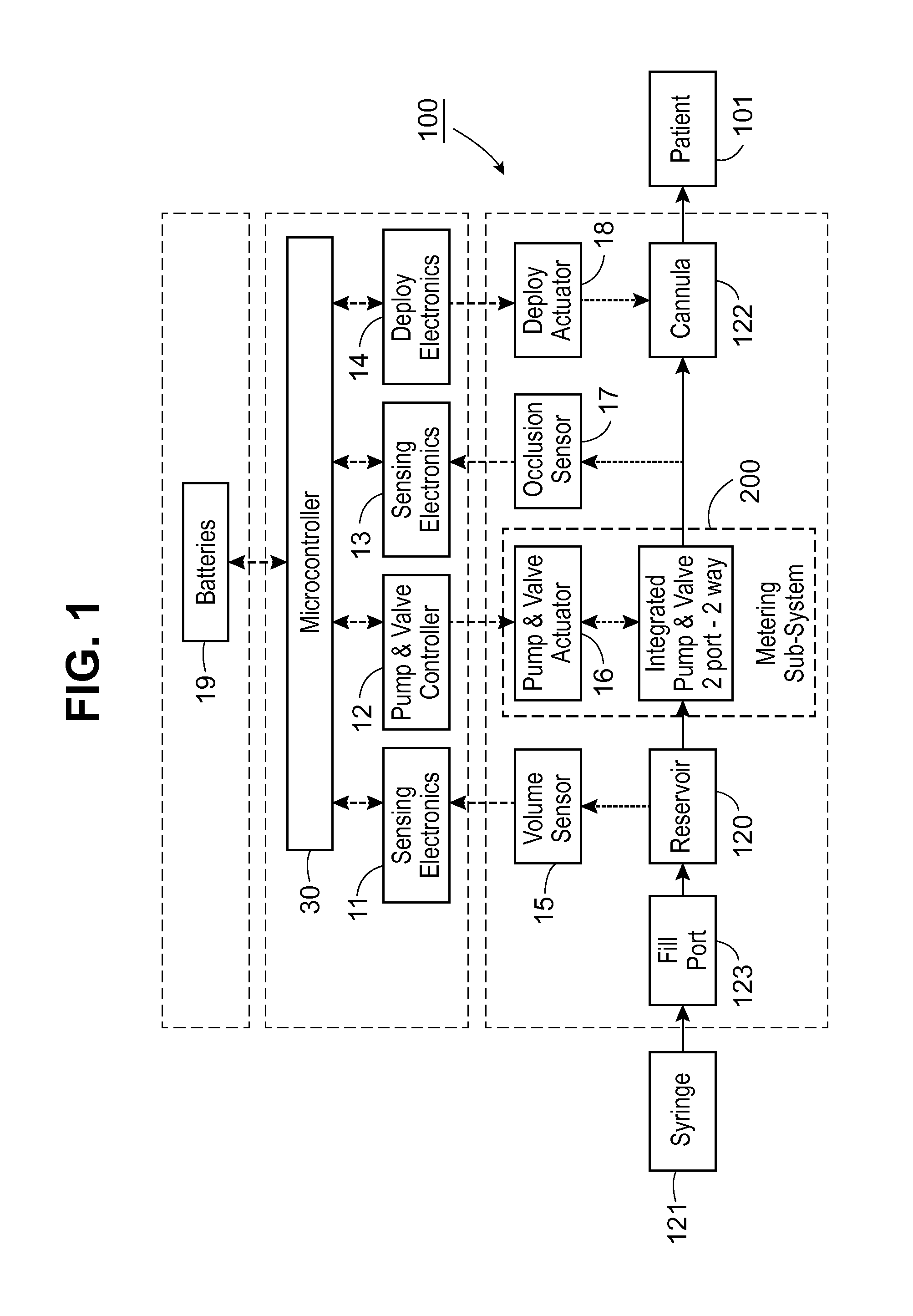

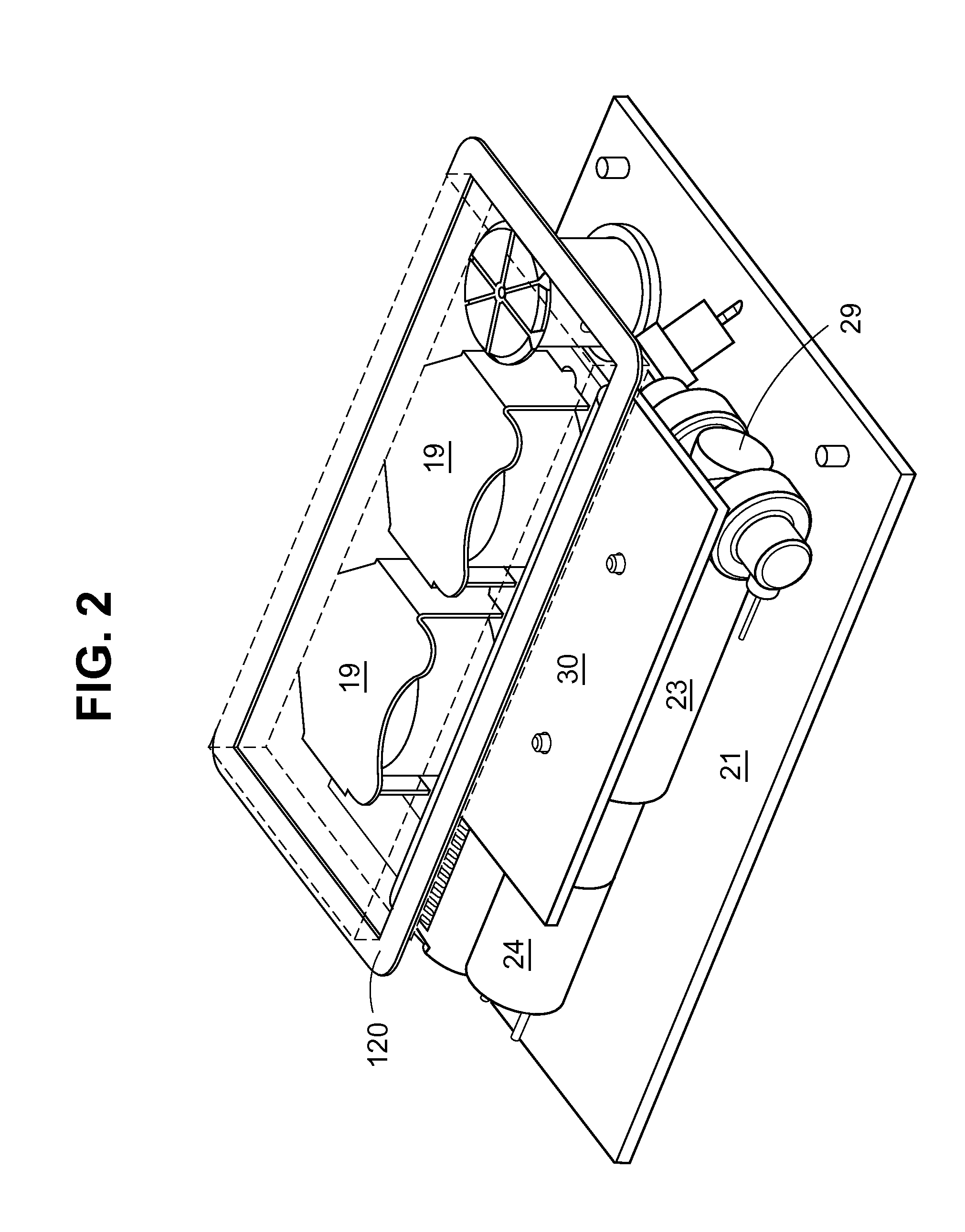

Disposable Dispenser for Patient Infusion

ActiveUS20080234630A1Reduce manufacturing costSafely discardedMedical devicesFlow monitorsAdhesiveMetering pump

Embodiments of the invention are directed to methods and systems associated with a disposable dispenser (100, 200) of therapeutic fluid. Preferred embodiments having a small size of less than about 75 mm in length, less than 50 mm in width and less than about 10 mm in thickness and may be releasably attached to the body (B). In one embodiments, the dispenser draws fluid from a flexible volume-conformable reservoir (4) and operates a dosing and metering pump (6, 61, 62, 63) incorporating a motor to deliver fluid through a fluid delivery tool (8, 81, 82). Disposed on the housing bottom (2B) is a peel-of-tape (22) that when removed, electrically connects a power supply (18) to power the operative components (3) of the dispenser into operation, exposes an adhesive (28) and a window (21) opened in the housing (2), and allows the fluid delivery tool (8) to extend for insertion into the skin (S).

Owner:ROCHE DIABETES CARE INC

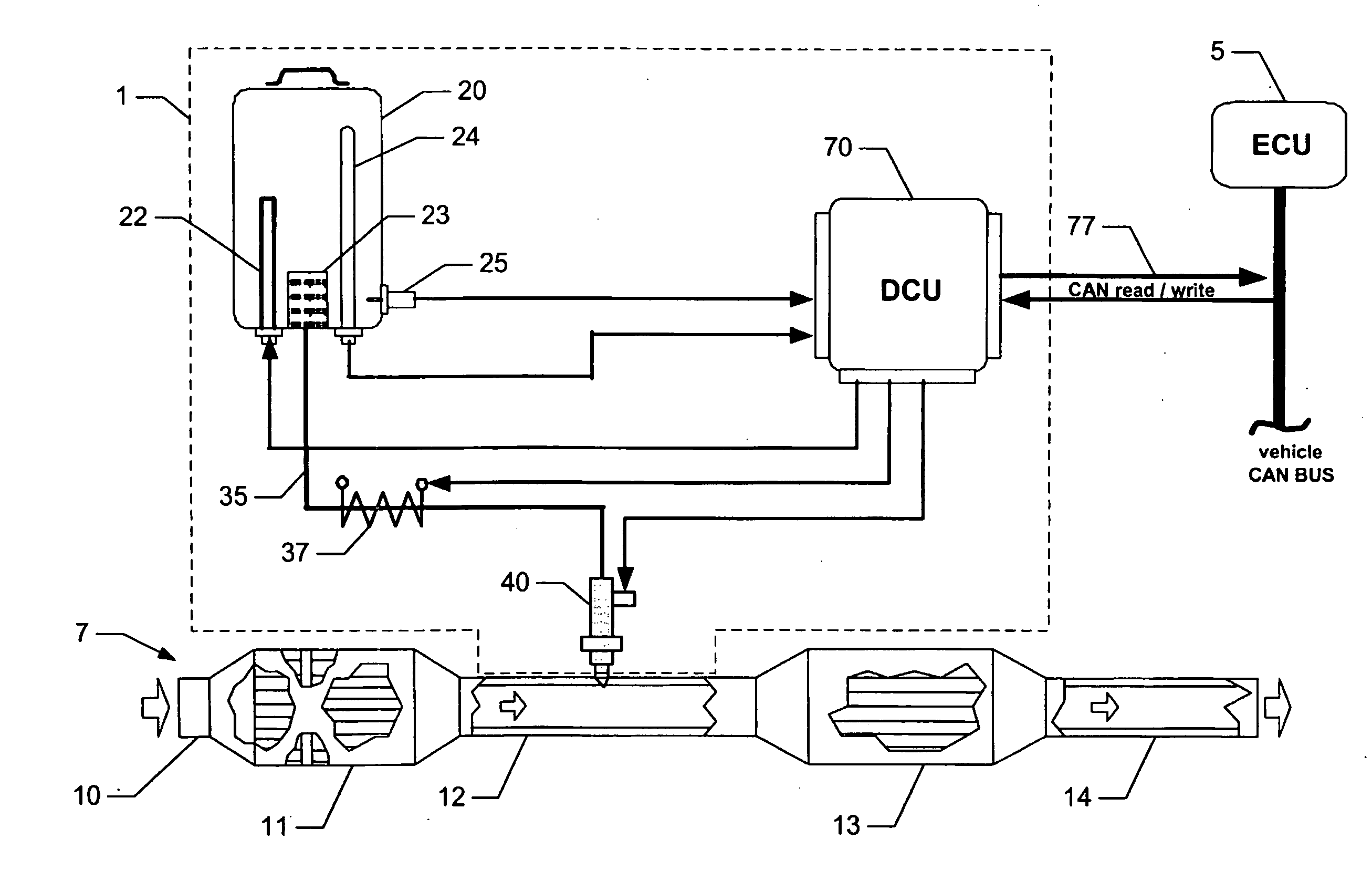

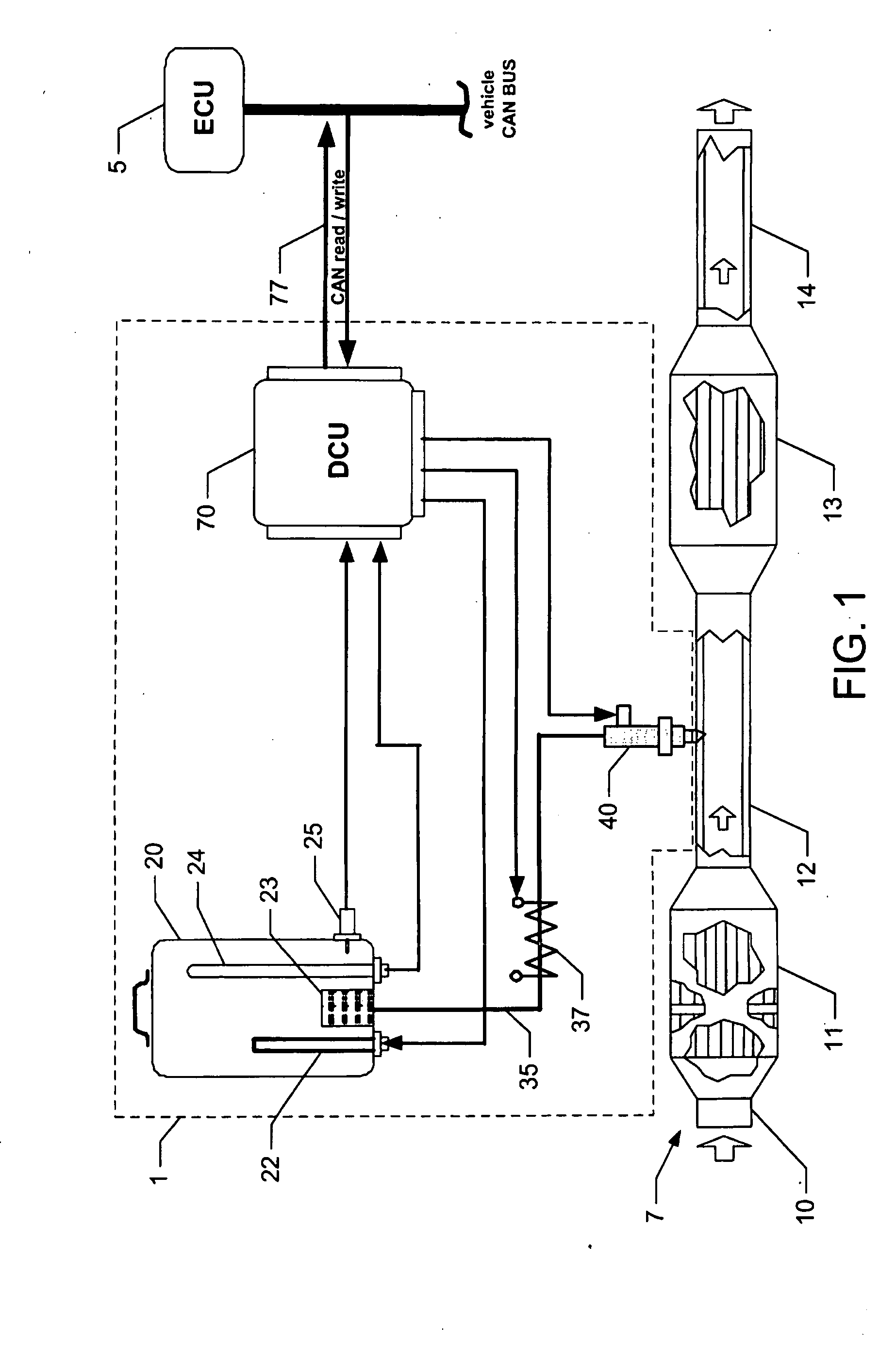

Reagent dosing system and method of dosing reagent

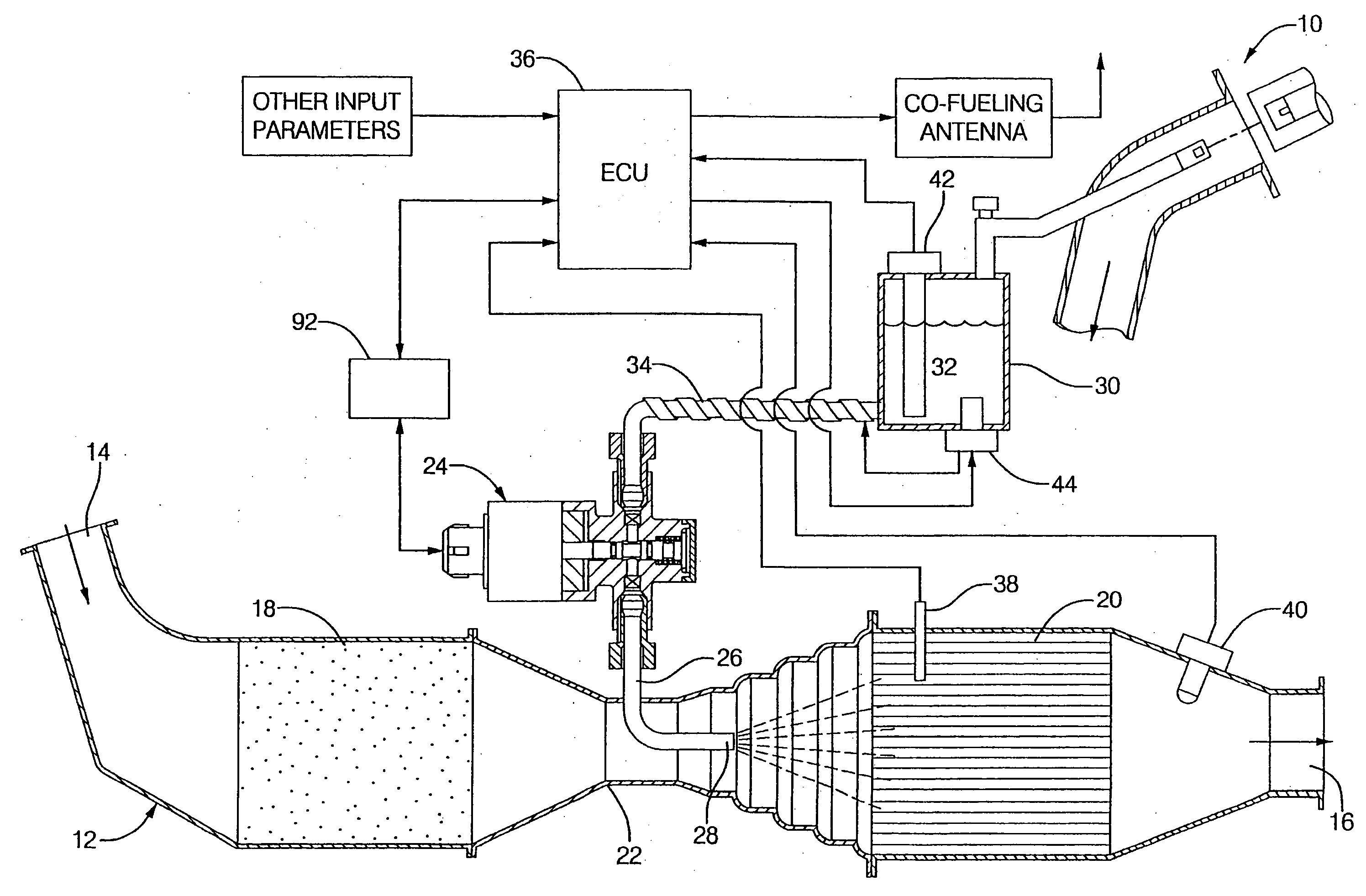

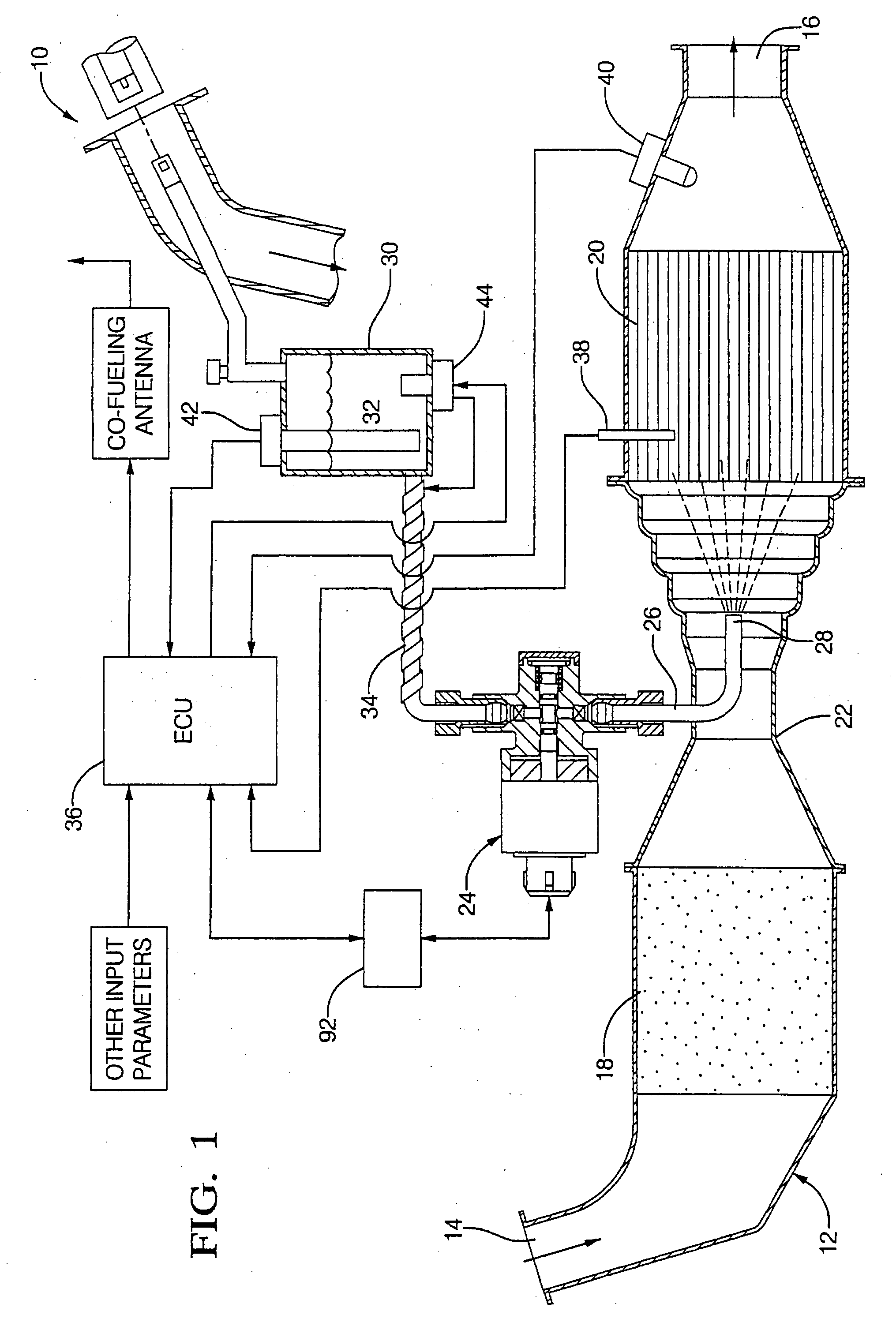

InactiveUS20090301067A1Well mixedInternal combustion piston enginesExhaust apparatusEngineeringInternal combustion engine

A method of dosing a reagent into an exhaust gas stream of an internal combustion engine having an SCR catalyst, the method comprising injecting reagent from a reagent tank into the exhaust gas stream at a position upstream of the SCR catalyst using a reagent injector in accordance with a first dosing schedule in order to remediate a predetermined proportion of NOx in the exhaust gas stream, the first dosing schedule being associated with a first range of engine operating conditions; and injecting reagent from the reagent tank into the exhaust gas stream at a position upstream of the SCR catalyst using a reagent injector in accordance with a second dosing schedule in order to enable heat transfer between the reagent injector and said injected reagent, the second dosing schedule being associated with a second range of engine operating conditions.Dosing in accordance with said first or said second dosing schedule is carried out in dependence on whether engine operating conditions lie within said first or said second range of engine operating conditions, and the proportion of NOx in the exhaust gas stream which is remediated by dosing using said second dosing schedule is less than said predetermined portion. A reagent dosing system is also provided for dosing a reagent into the exhaust gas stream of an internal combustion engine, comprising a reagent tank for storing a supply of reagent, an injector module comprising an atomising dispenser and a positive-displacement metering pump which draws reagent from the reagent tank and delivers it to the dispenser a supply line coupling the reagent tank to the injector module, and a dosing control unit operable to control the injector module to inject reagent into the exhaust gas stream. A priming pump is provided to urge reagent along the supply line toward the injector module under selected conditions.

Owner:DELPHI TECH IP LTD

Effervescent gas bleeder apparatus

InactiveUS7175397B2Positive displacement pump componentsFlexible member pumpsReciprocating motionInlet valve

A diaphragm metering pump suitable for metering an effervescent gas. The pump has a pump head with a product chamber having an inlet end with a one-way inlet valve and an outlet end with a one-way outlet valve. A displaceable diaphragm member defines a boundary of the product chamber. The diaphragm member is capable of being reciprocated to cause pumping displacements. A discharge side is disposed downstream from the outlet valve. A passageway is disposed in fluid communication between the discharge side and the product chamber. A valve is disposed in the passageway. The valve is opened intermittently to allow liquid to re-enter the product chamber in an amount effective to purge gas from the product chamber to prevent loss of prime.

Owner:PULSAFEEDER

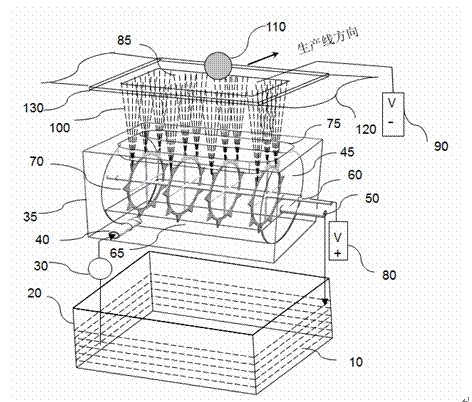

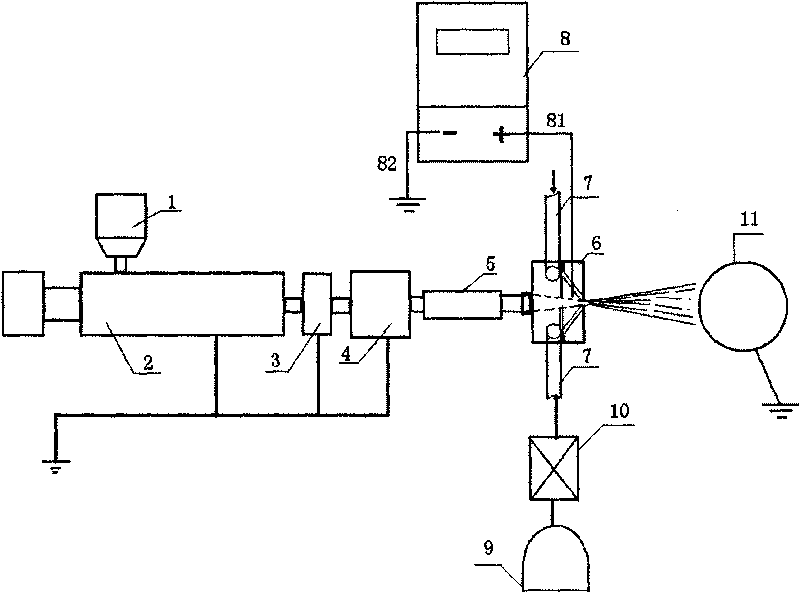

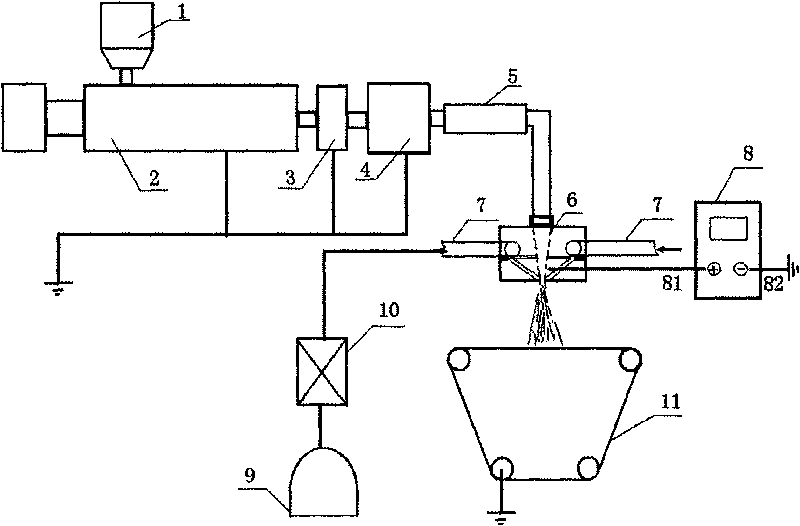

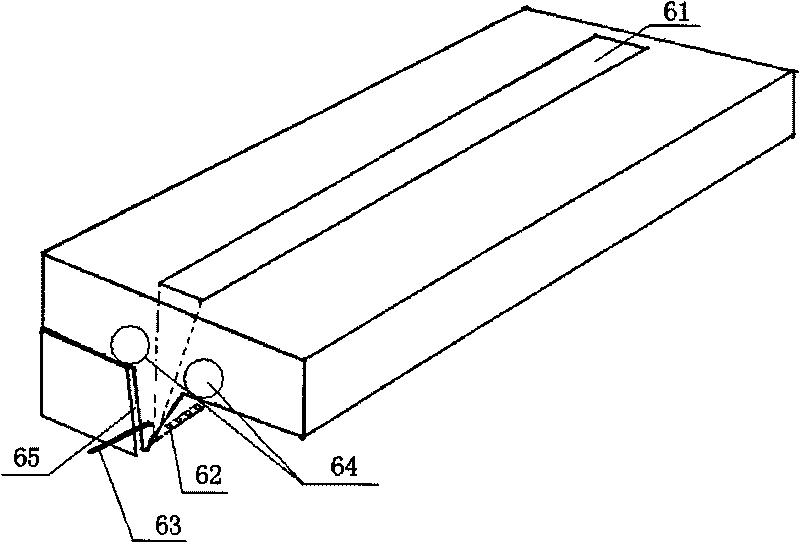

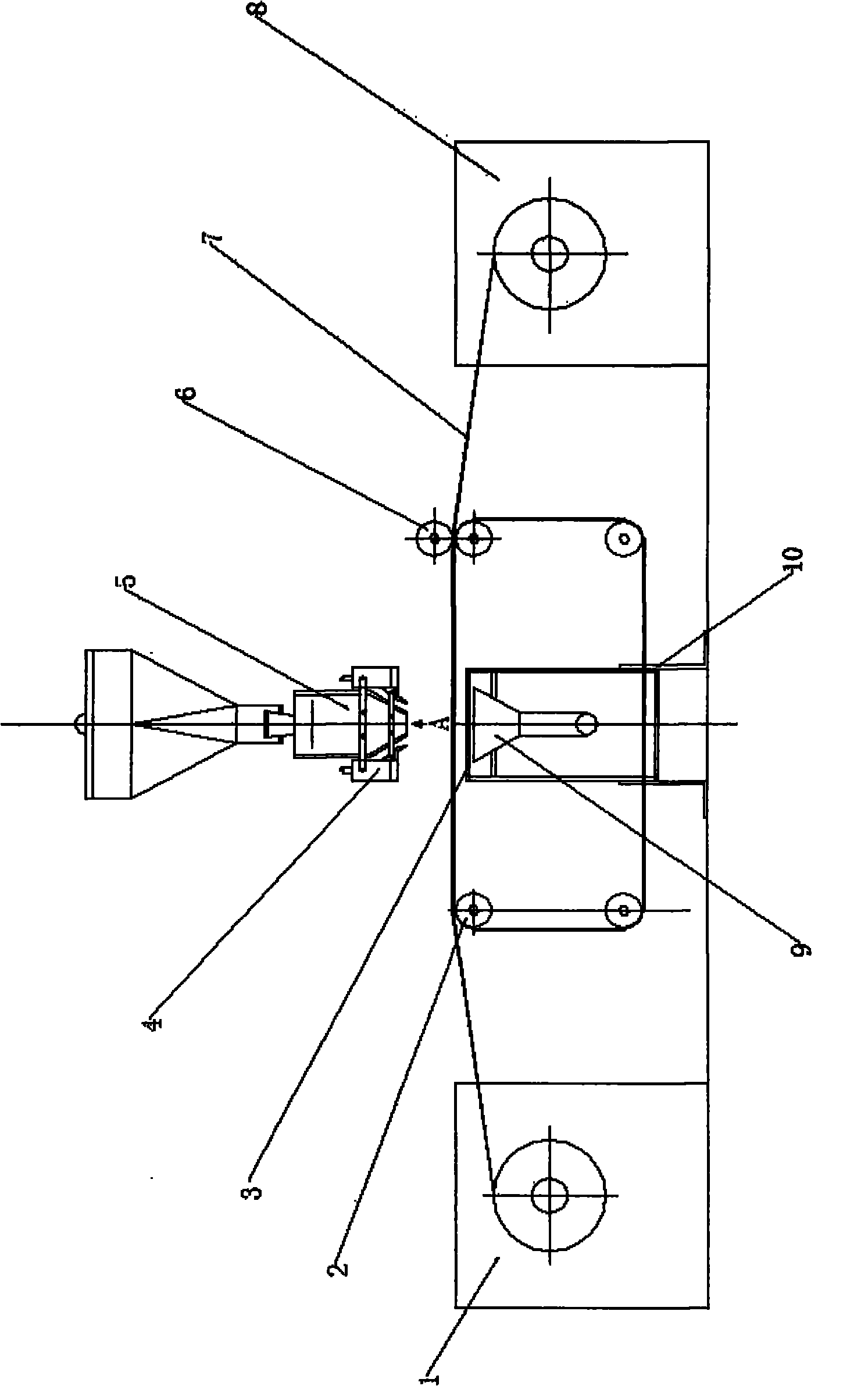

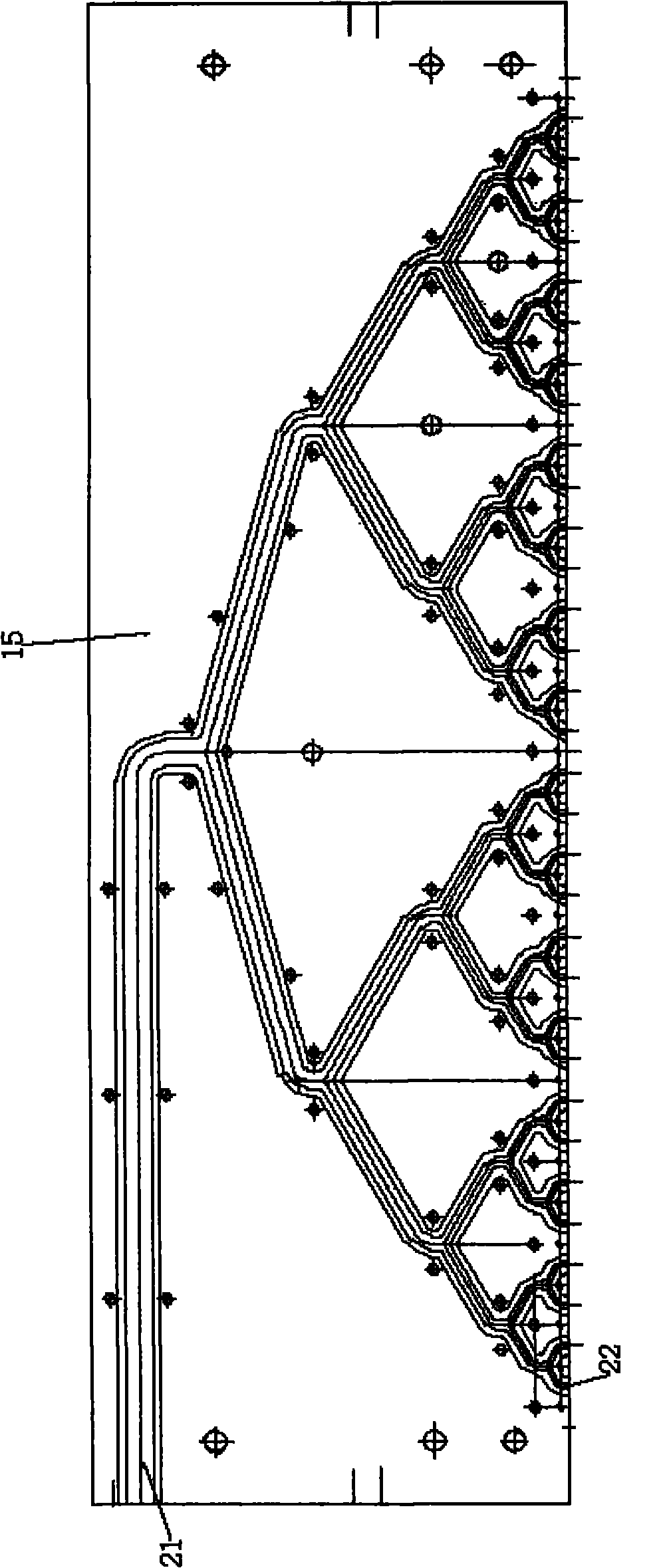

Saw tooth type needle-free electrostatic spinning device

ActiveCN102828259AAvoid cloggingAvoid cleaningSpinnerette packsArtificial thread manufacturing machinesNeedle freeElectrospinning

The invention discloses a saw tooth type needle-free electrostatic spinning device, which comprises a liquid supply system, a spinning system, a power supply system, a receiving system, a transmission system and a control system. The device is characterized in that the spinning system comprises a spinning manifold body, a spinning component and a center shaft; the exterior of the spinning manifold body has a horizontal cuboidal shape, and a horizontal cylindrical cavity is formed in the spinning manifold body; a main body of the center shaft is arranged in the cavity, and the two ends of the center shaft extend from the spinning manifold body, and are connected with the transmission system; the spinning component has an axially continuous or parallel thin rack structure, and points of a rack are outwards arranged on the center shaft, and can be driven by the center shaft to rotate; distances of 1 to 3mm are reserved between the points and the inner wall of the spinning manifold body; a liquid inlet pipe orifice of the spinning manifold body is communicated with a spinning metering pump of the liquid supply system, and an overflow port of the spinning manifold body is connected to a liquid storage device of the liquid supply system through a pipe, and is reserved between the bottom of the spinning component and the center shaft; and rectangular spinning openings are reserved in positions opposite to the highest parts of the spinning component on the upper surface of the spinning manifold body.

Owner:TIANJIN POLYTECHNIC UNIV

Apparatus and method for reductant dosing of an exhaust

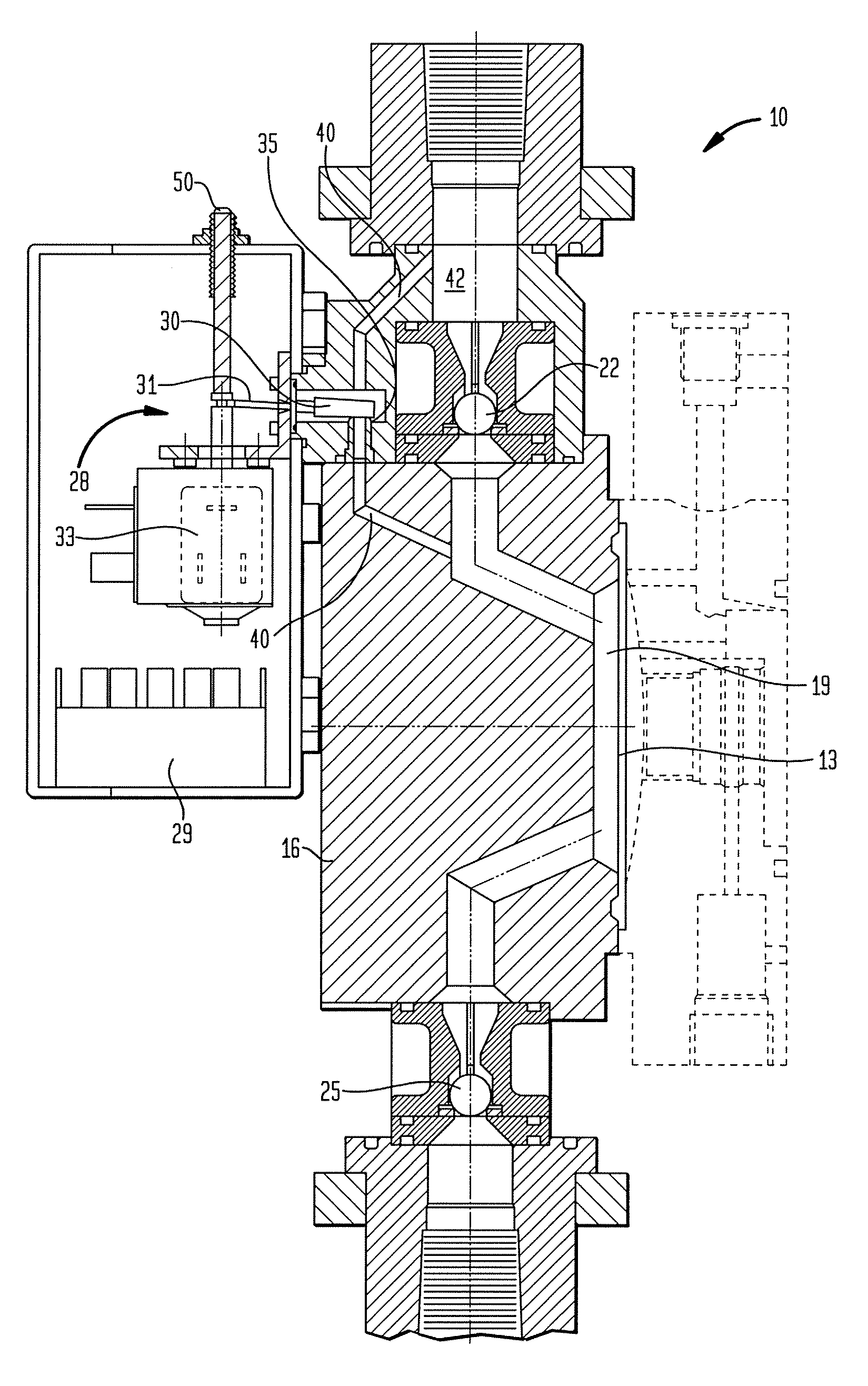

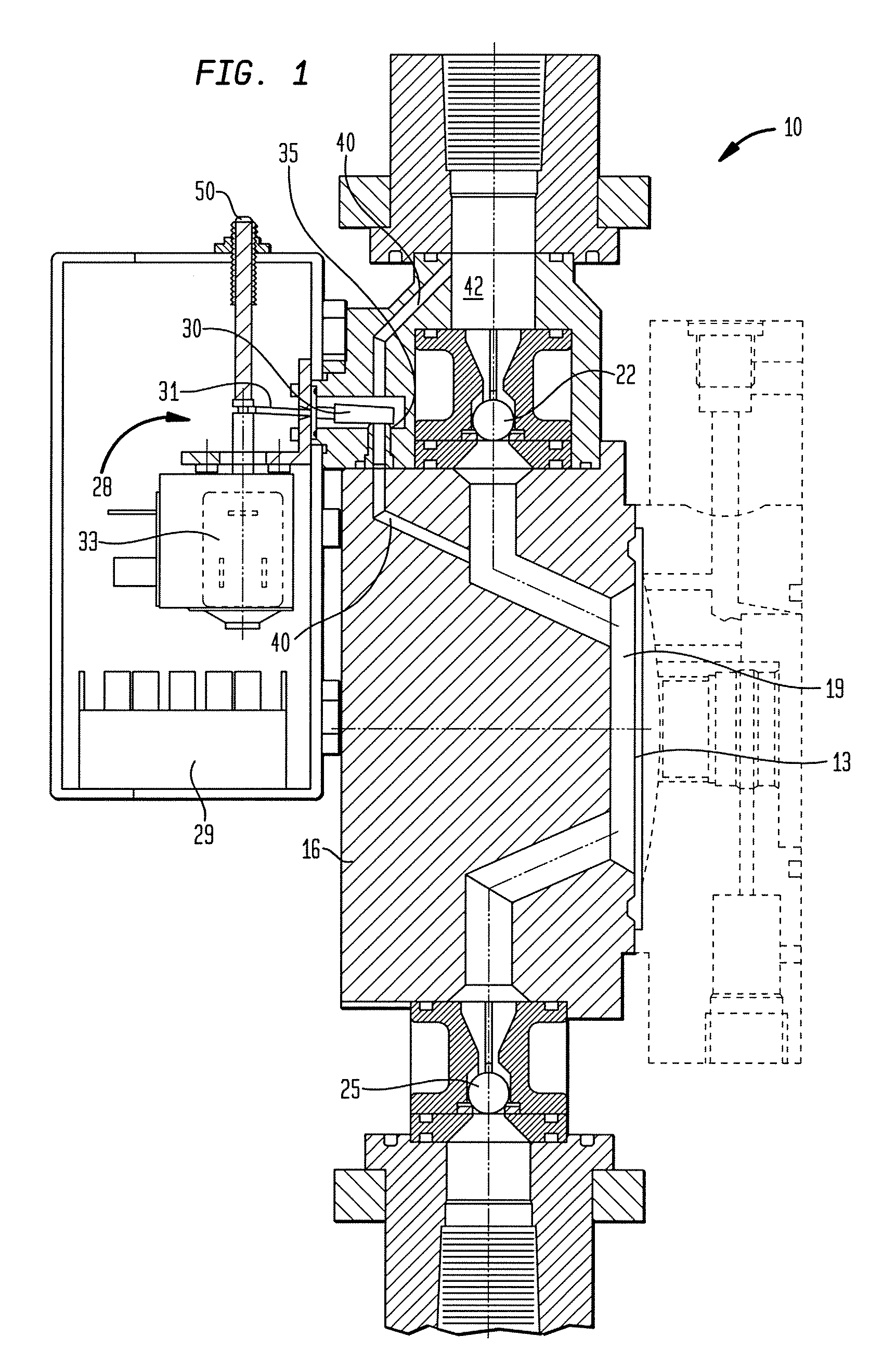

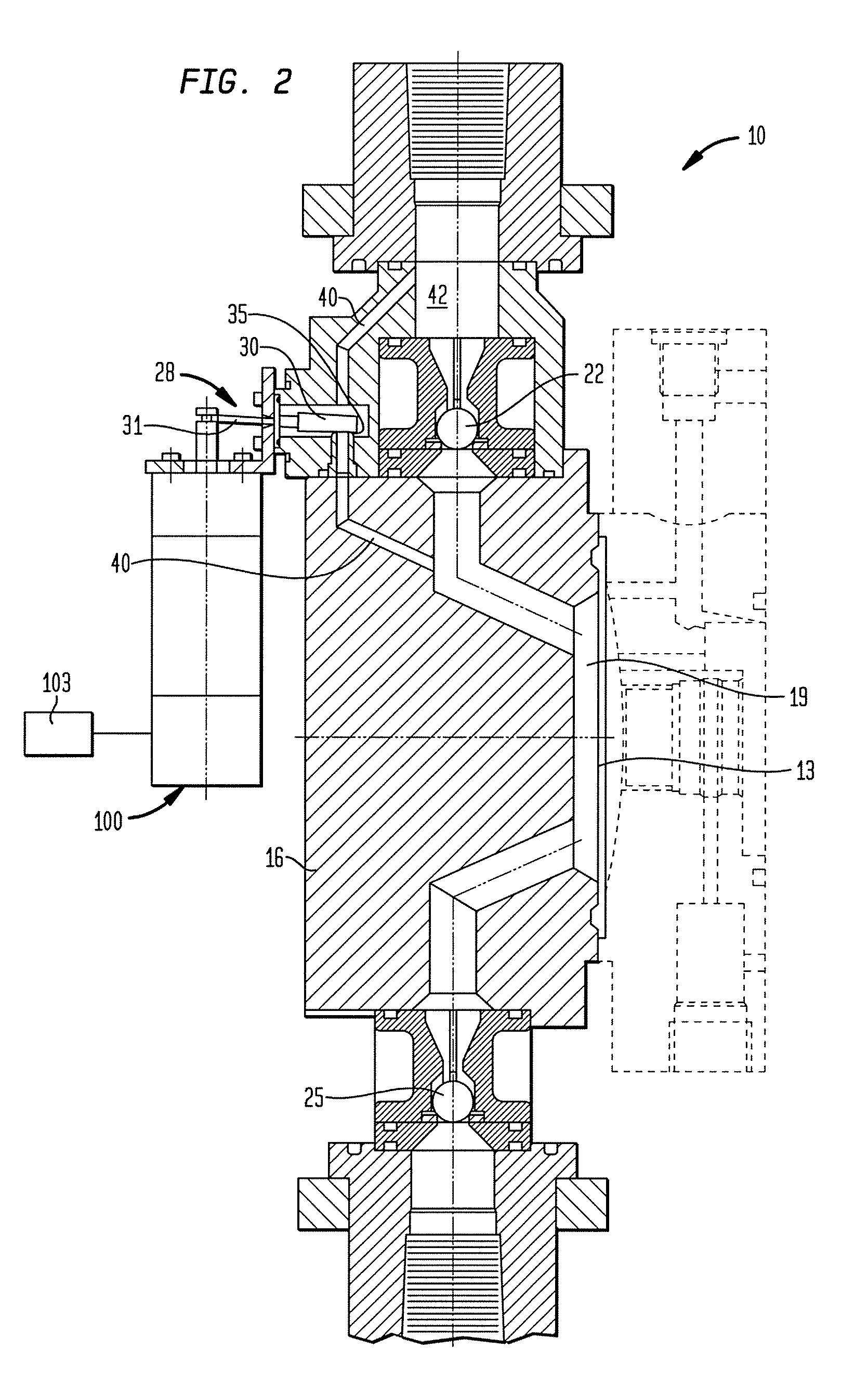

InactiveUS20070295003A1Increase fluid pressureInternal combustion piston enginesExhaust apparatusCombustionEngineering

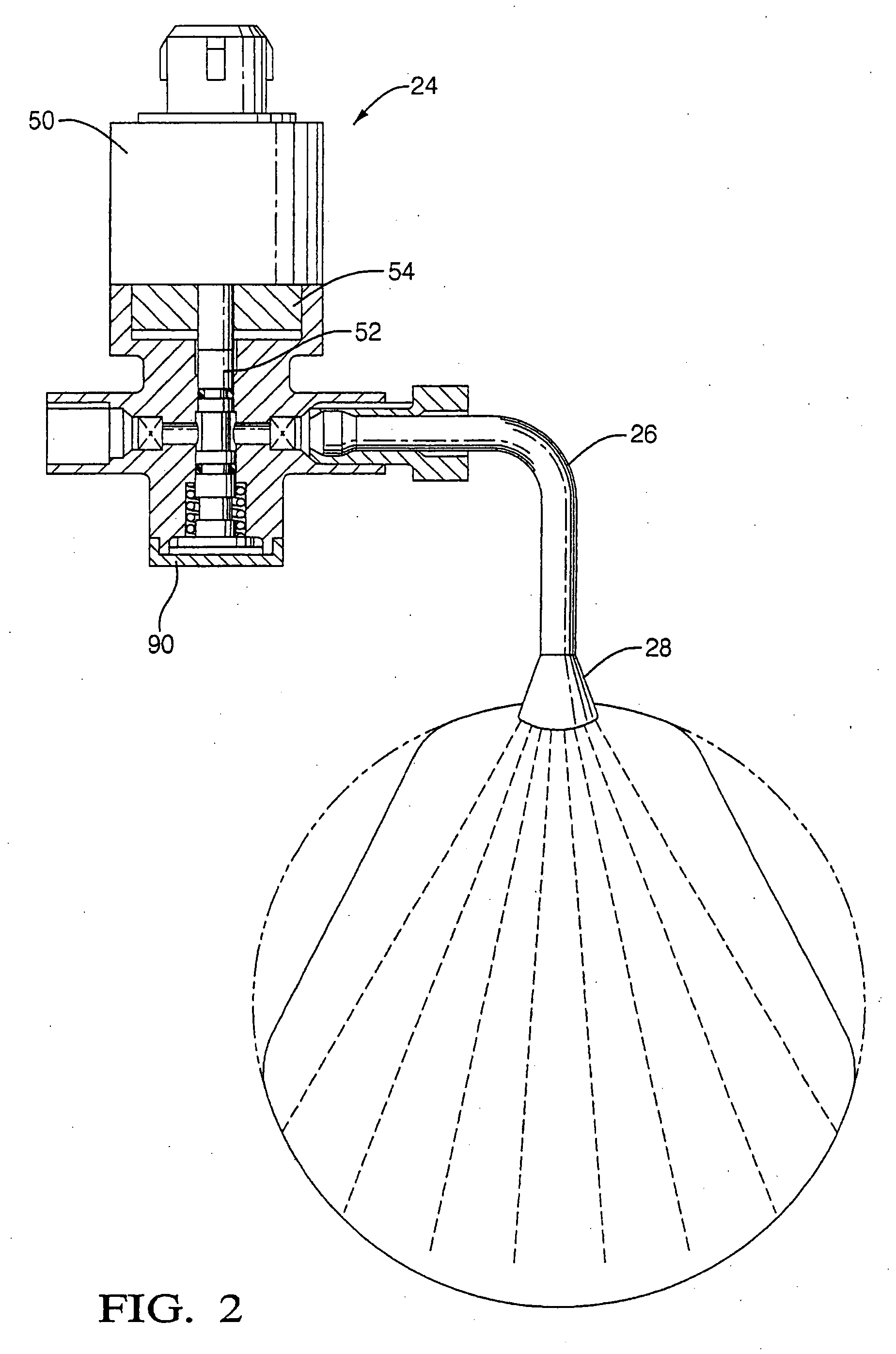

A high-pressure metering pump for providing reductant in a single fluid engine exhaust dosing system, comprising: a solenoid for actuating a piston slidably received within an inner bore of a valve housing of the pump, the inner bore having a pressure chamber with an inlet check valve and an outlet check valve; and wherein movement of the piston causes high pressure reductant to be received at an atomizer of the system, the atomizer being disposed in a location to cause a maximum reduction of undesirable pollutant in the combustion gases of an engine.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

Method for preparing melt-blown polypropylene electret filter material

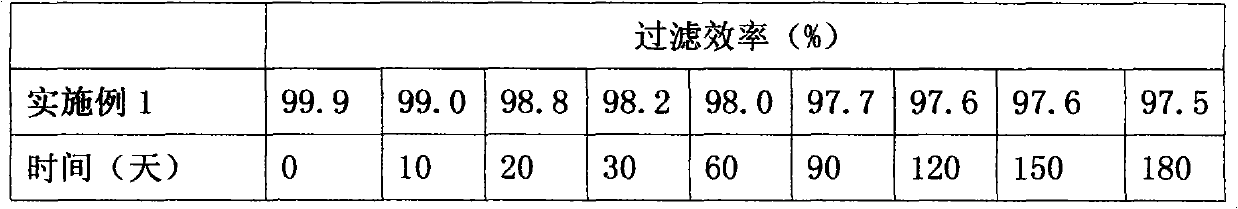

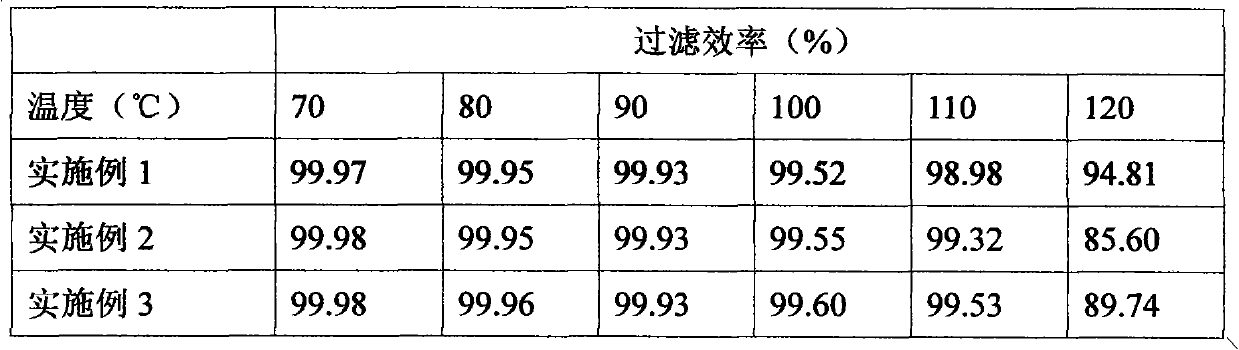

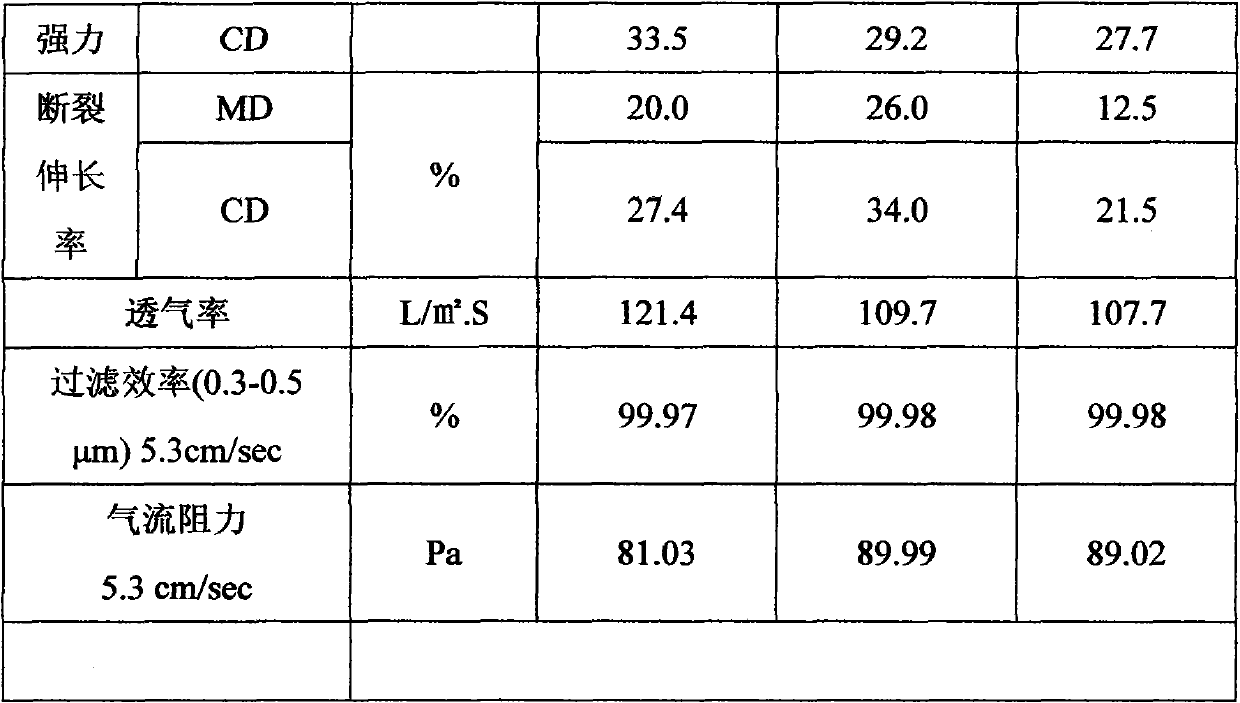

The invention relates to a method for preparing a melt-blown polypropylene electret filter material. The method comprises the following steps of: 1) modification of polypropylene: melting the raw material, polypropylene, and mixing the melt with an additive to obtain modified polypropylene; 2) melt-blown preparation process: a) in a molten state, feeding the modified polypropylene melt into a spinneret plate by using a metering pump; b) extruding the modified polypropylene melt from a spinneret orifice; and c) blowing the melt extruded out from the spinneret orifice into ultrafine fibers by using high-speed hot air to make the fibers fly to a condenser net curtain to form a fiber net through cooling and bonding; and 3), preparation process of an electret: passing the fiber net obtained in step (2) through an electrode of a corona discharge device and obtaining the electret through the discharging of the electrode. The melt-blown electret high-efficiency filter material obtained by the method has the advantages of very high electret charge stability, excellent filtering efficiency, very low pressure loss, long service life and optimal economic benefit.

Owner:HANGZHOU DIANZI UNIV +1

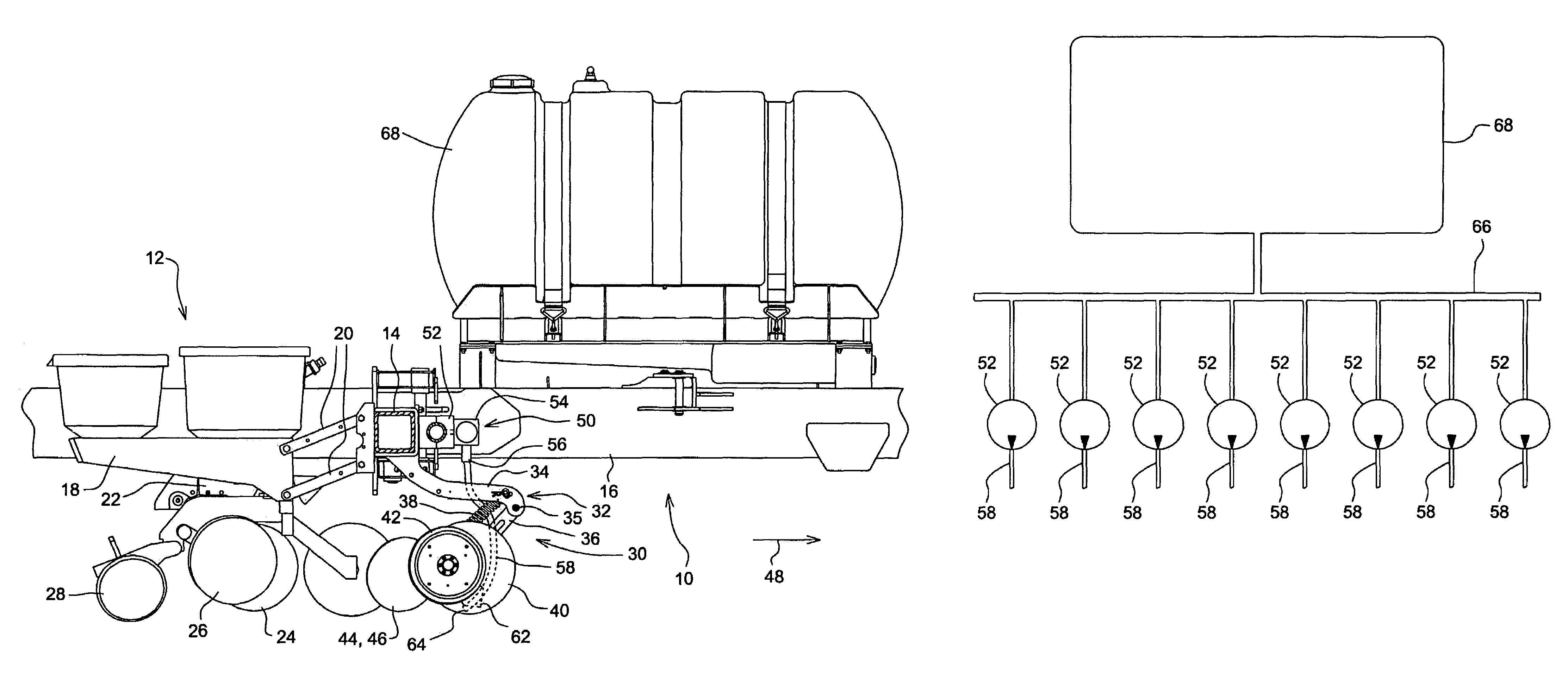

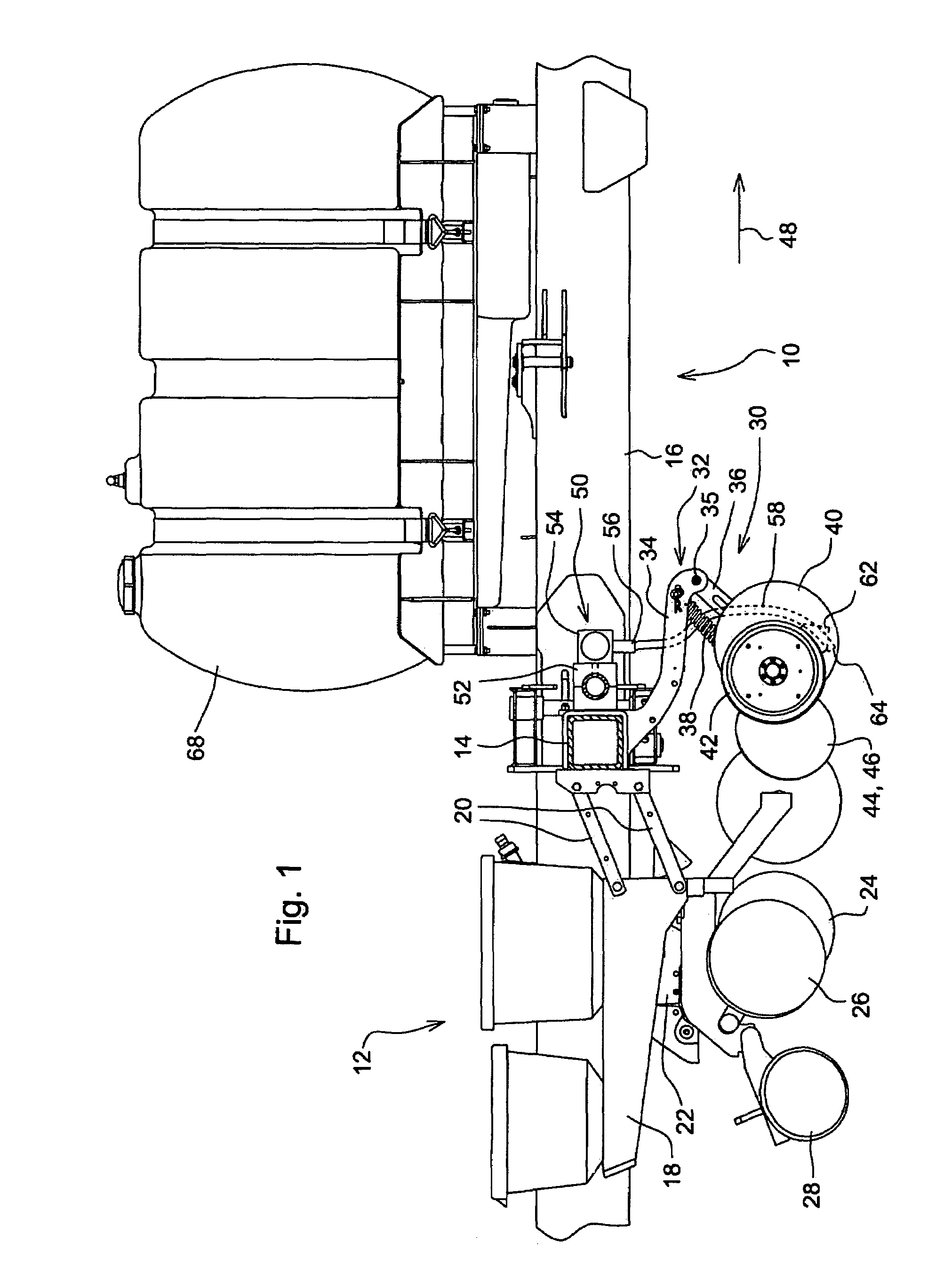

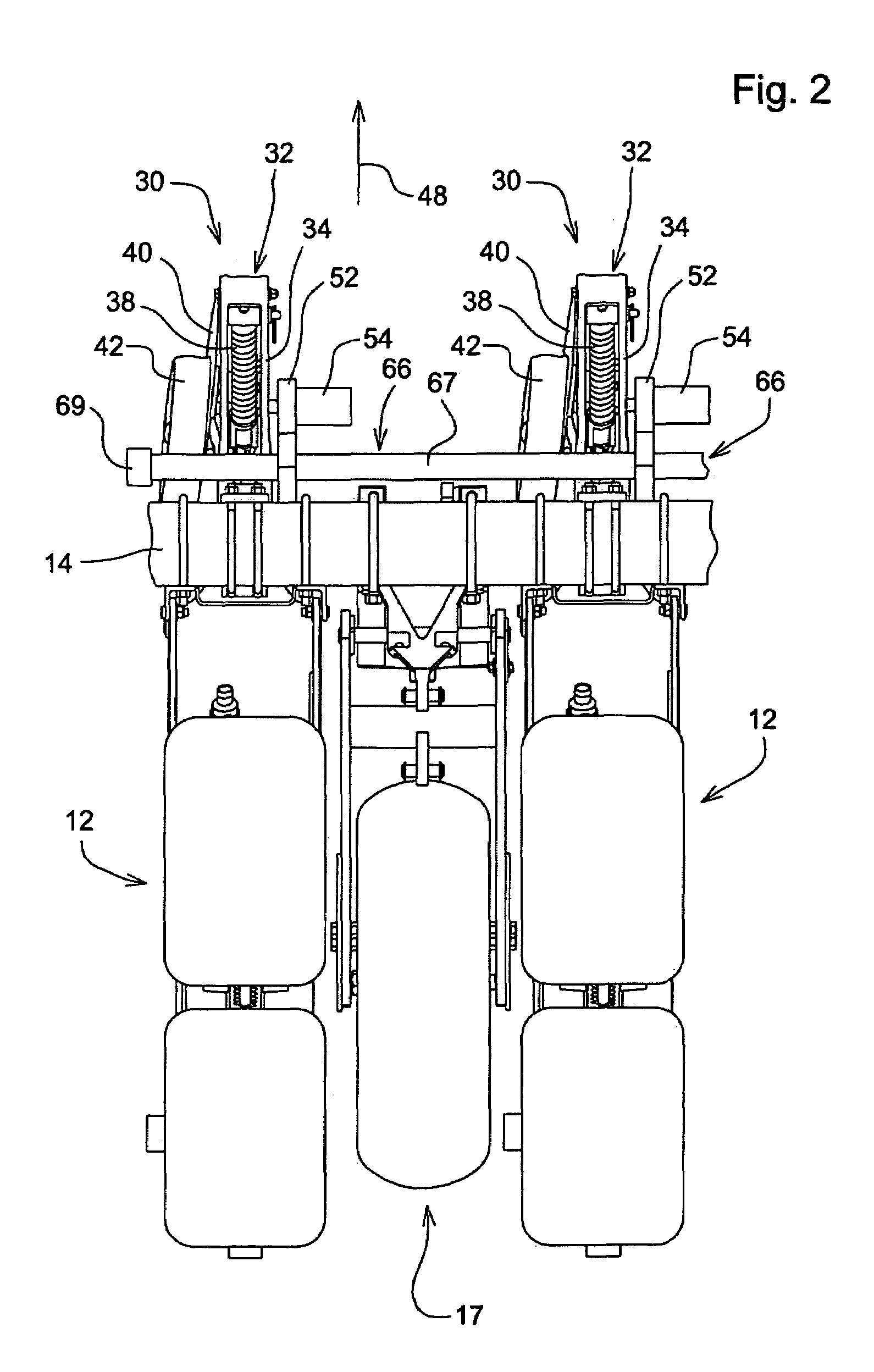

Modular liquid metering system for an agricultural implement

ActiveUS7694638B1Precise applicationOvercome difficultiesPlantingWatering devicesElectricityEngineering

A liquid metering system for an agricultural implement is modular, having individual metering pumps for each crop row. The pumps are individually controlled for precise application of the liquid input and are preferable electrically driven. A common pump is used, making the system modular in that varying sizes of implements can be produced by varying the number of pumps. A common supply line is used to supply a liquid input from a reservoir to the pumps. Each pump is connected to the common supply line. By connecting each pump to the common supply line, the difficulty of routing individual hoses from a central pump to each row unit are overcome.

Owner:DEERE & CO

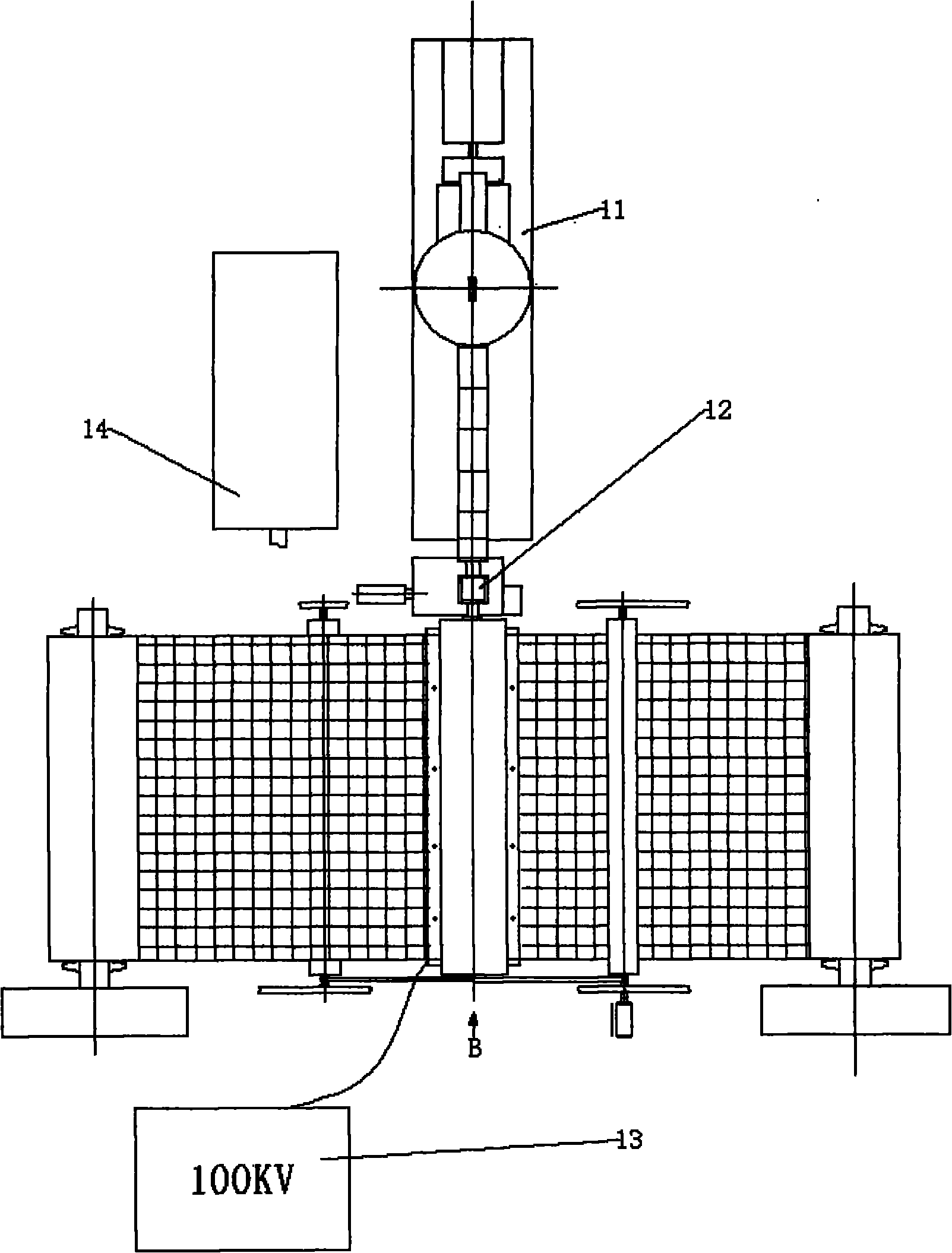

Device and method for manufacturing airflow melting electrostatic spinning nano-fiber non-woven fabric

InactiveCN101709534AThin diameterNarrow distributionSpinnerette packsSpinning head liquid feederFiberManufacturing technology

The invention relates to a device and a method for manufacturing an airflow melting electrostatic spinning nano-fiber non-woven fabric. The device for manufacturing the airflow melting electrostatic spinning nano-fiber non-woven fabric comprises a stock hoper, a screw extruder, a filter, a metering pump, a material path, a melt-blown die head, a hot-air pipeline, an air compressor, a heating device, a high voltage electrostatic generator and a receiving device. The material path is made of high thermal conductivity insulating ceramics. The method for manufacturing the nano-fiber non-woven fabric adopts the device disclosed by the invention and comprises the following processing steps: (1) preparing a polymer melt; (2) jetting nano-fibers by using airflow static electricity; and (3) moulding the non-woven fabric. The method for manufacturing the nano-fiber non-woven fabric of the invention adopts airflow-melting electrostatic spinning technology, avoids a problem of pollution of electrostatic spinning solvent, and is novel environment-friendly non-woven fabric manufacturing technology. In the manufacturing method, high voltage electrostatic is directly acted on the melt-blown die head; the melt has high and uniform charge; and simultaneously by utilizing drafting of the airflow, the prepared nano-fiber has the advantages of thin diameter and narrow distribution. The device can meet production requirements by improving the conventional melt-blown manufacturing device, and has low implementation cost and easy industrialization promotion.

Owner:TIANJIN POLYTECHNIC UNIV

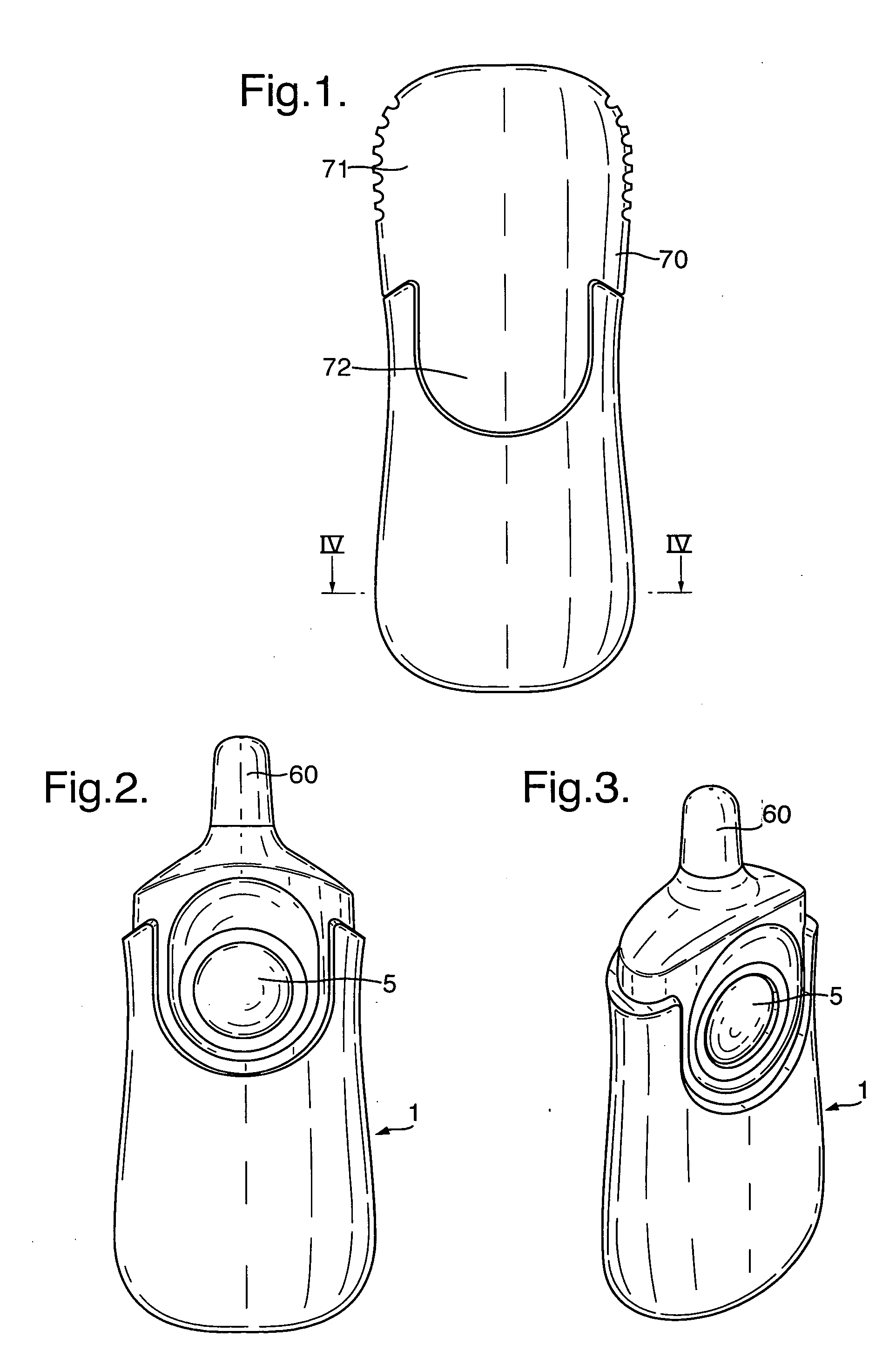

Dispenser for a liquid

A dispenser for a liquid is provided which is particularly, though not exclusively, useful for dispensing liquid medical compositions such as nasal sprays. The dispenser employs at least one, though preferably two, semi-rigid casing halves, defining a liquid reservoir, within which is mounted a bridge member which performs the functions of dip tube, dose metering pump, and outlet orifice. An air inlet may be provided into the reservoir, to allow air to enter as liquid leaves, in which case it may be provided with a liquid-impermeable, and preferably bacteria-impermeable, cover. Other constructions are described in which no such cover need be provided, or in which the need for an air inlet can be avoided altogether.

Owner:THE PROCTER & GAMBLE COMPANY

Dispensing stand-up pouch

InactiveUS20080149666A1Equal volumeEasy and inexpensive to manufactureClosuresLiquid flow controllersEngineeringMetering pump

The stand-up fluid dispensing device (10, 100) includes a container (42) with an outer surface, opening, interior fluid storage region (44) therein and an exterior outer region. A support structure (60) is affixed to the container (42) to maintain the container (42) in an upright condition at all times. Throughout the life of the product and regardless of amount of media (12) in the device (10, 100), it will remain standing upright to better display the package at all times. The support structure (60) is preferably a jacket filled with a gas, such as air. The jacket (60) can include a plurality of pockets (62), such as tubes filled with air. The stand-up fluid dispensing device (10, 100) may also include a metering pump (64) that can include a leakage control mechanism to control the dispensing of media (12) from the device (10, 100).

Owner:POLY D

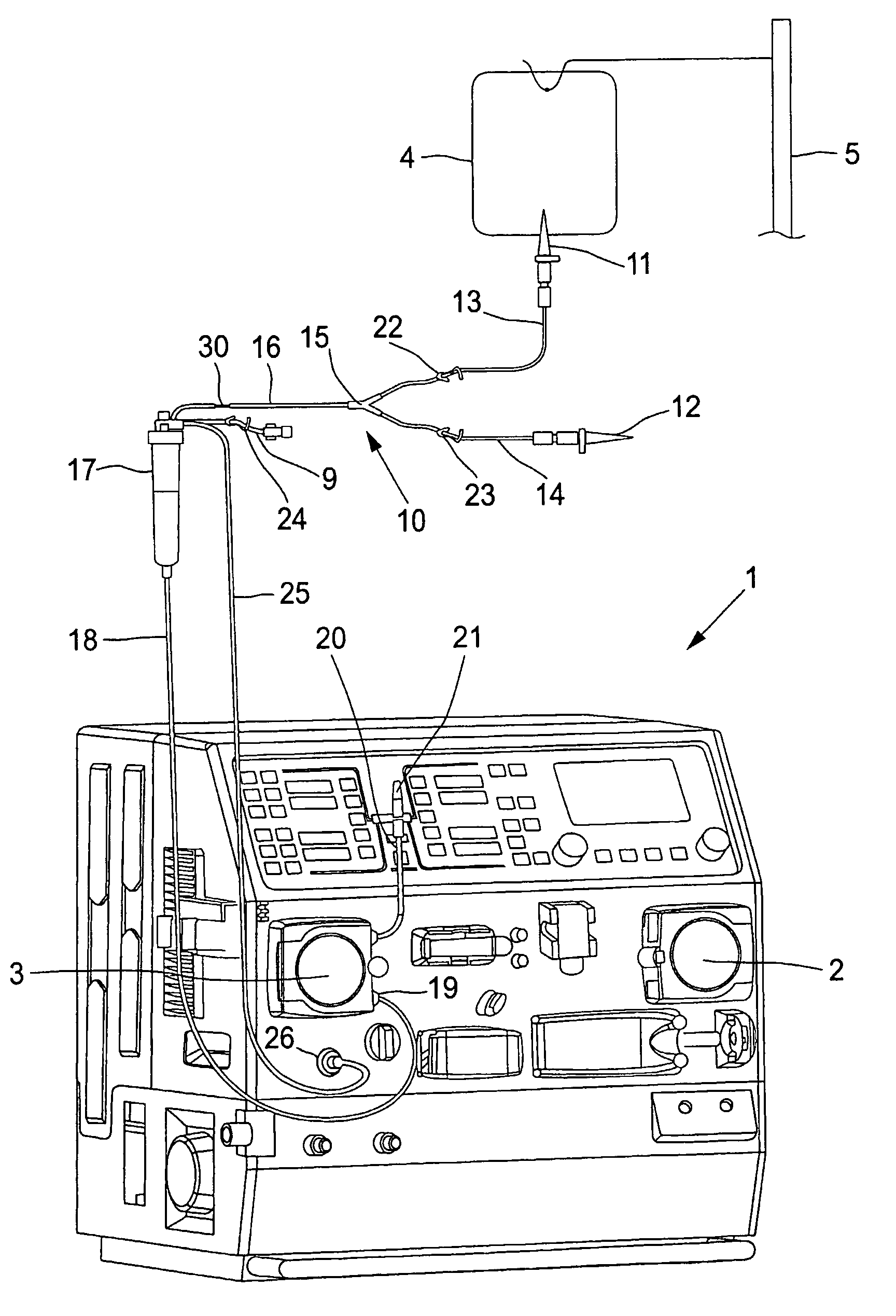

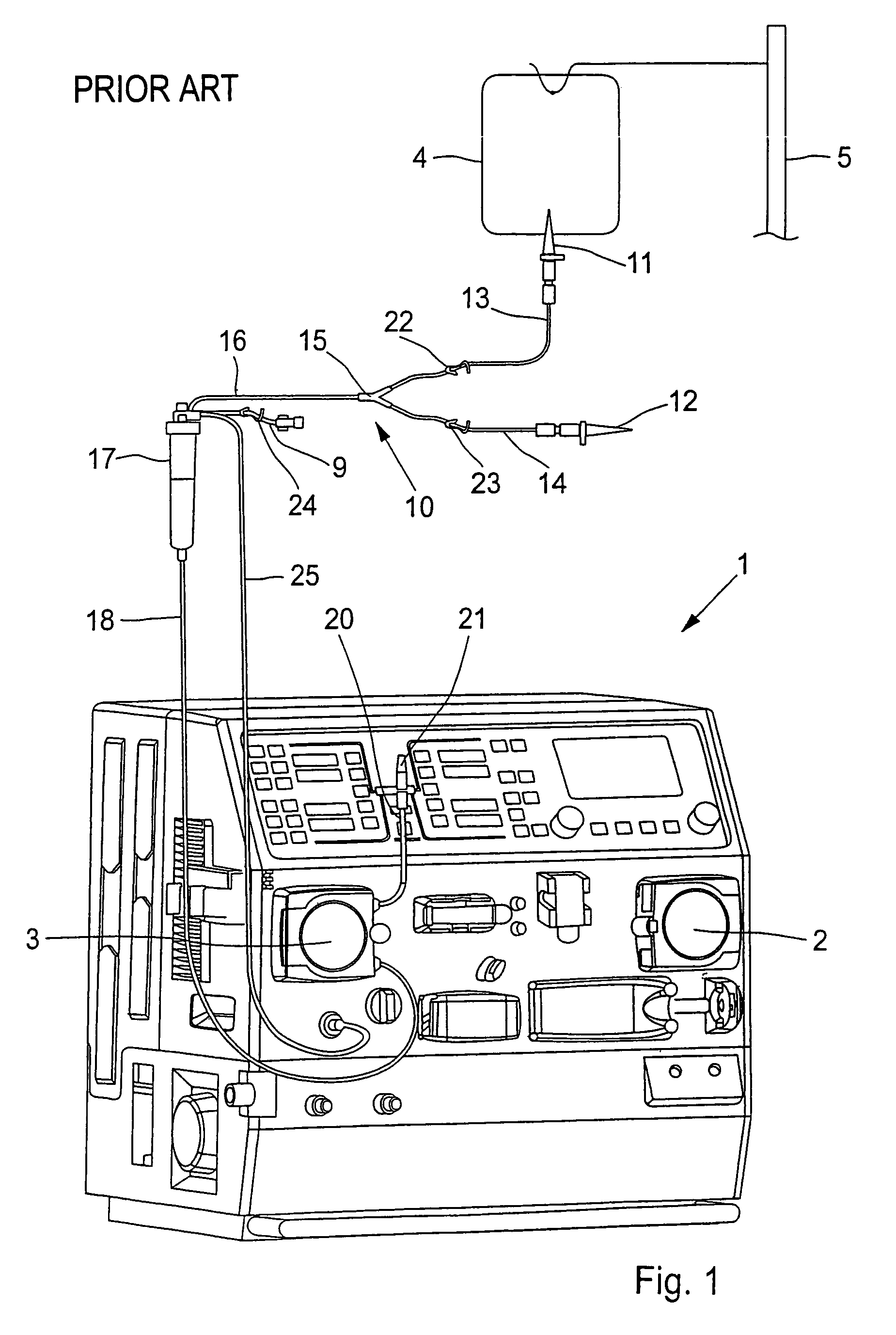

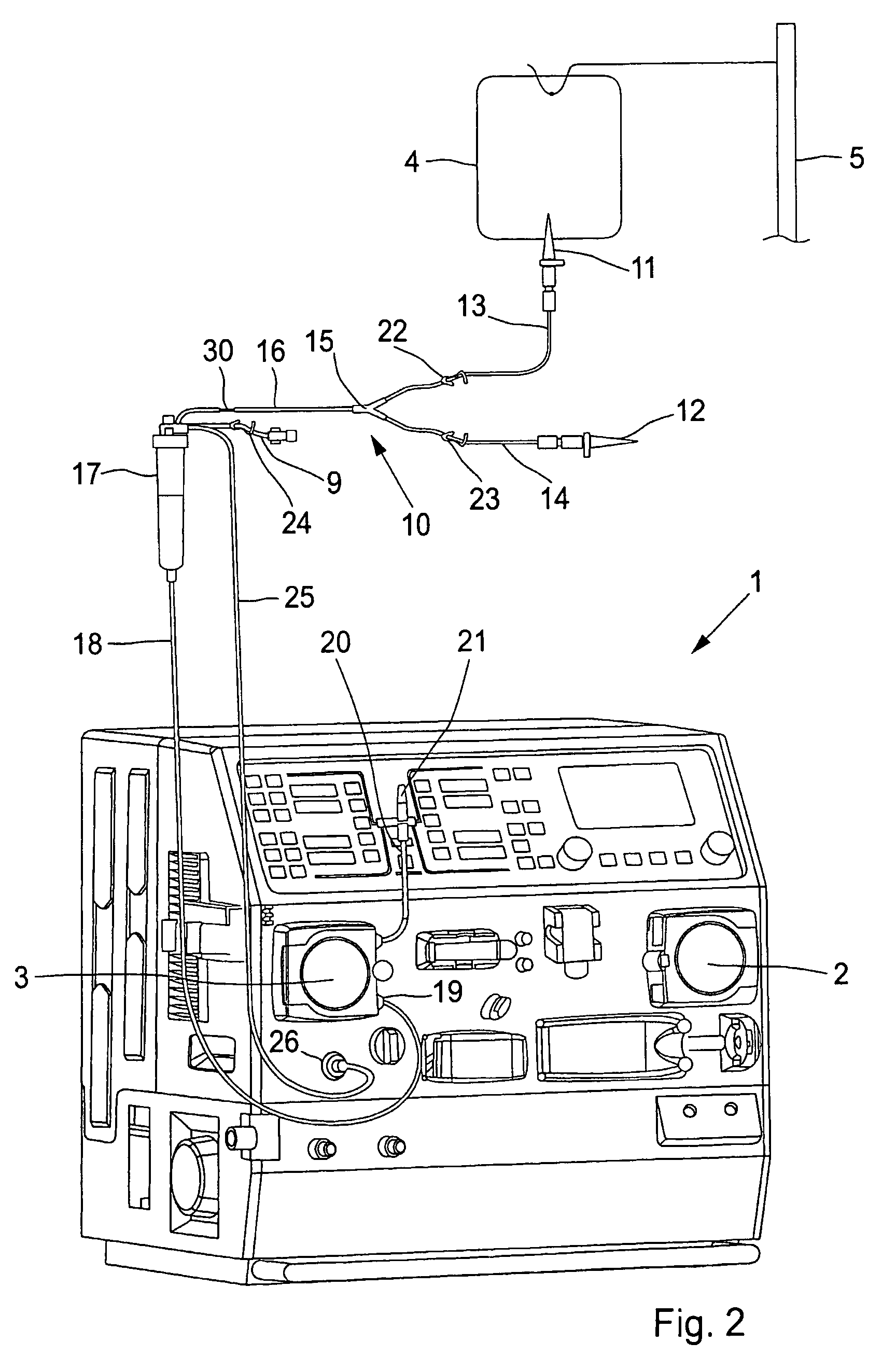

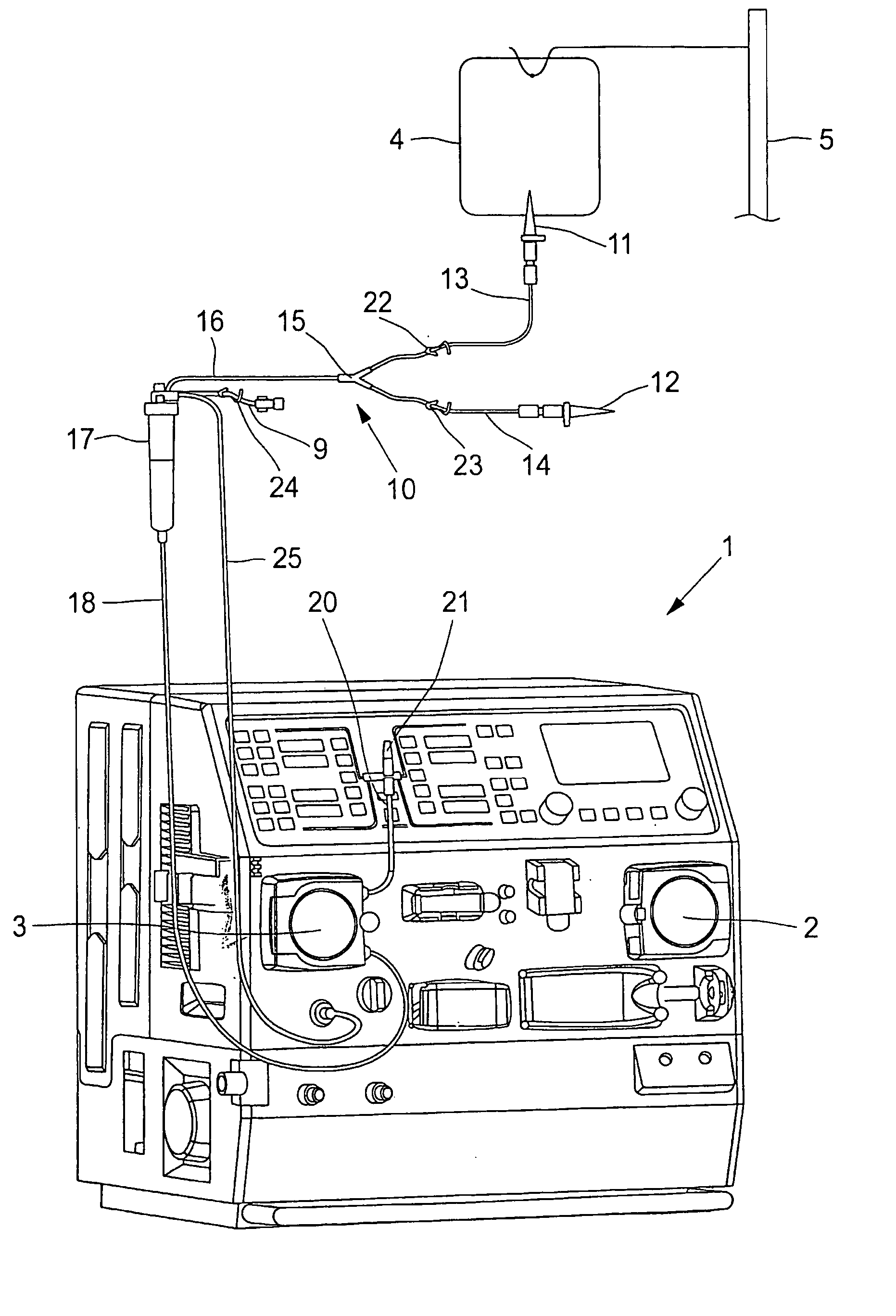

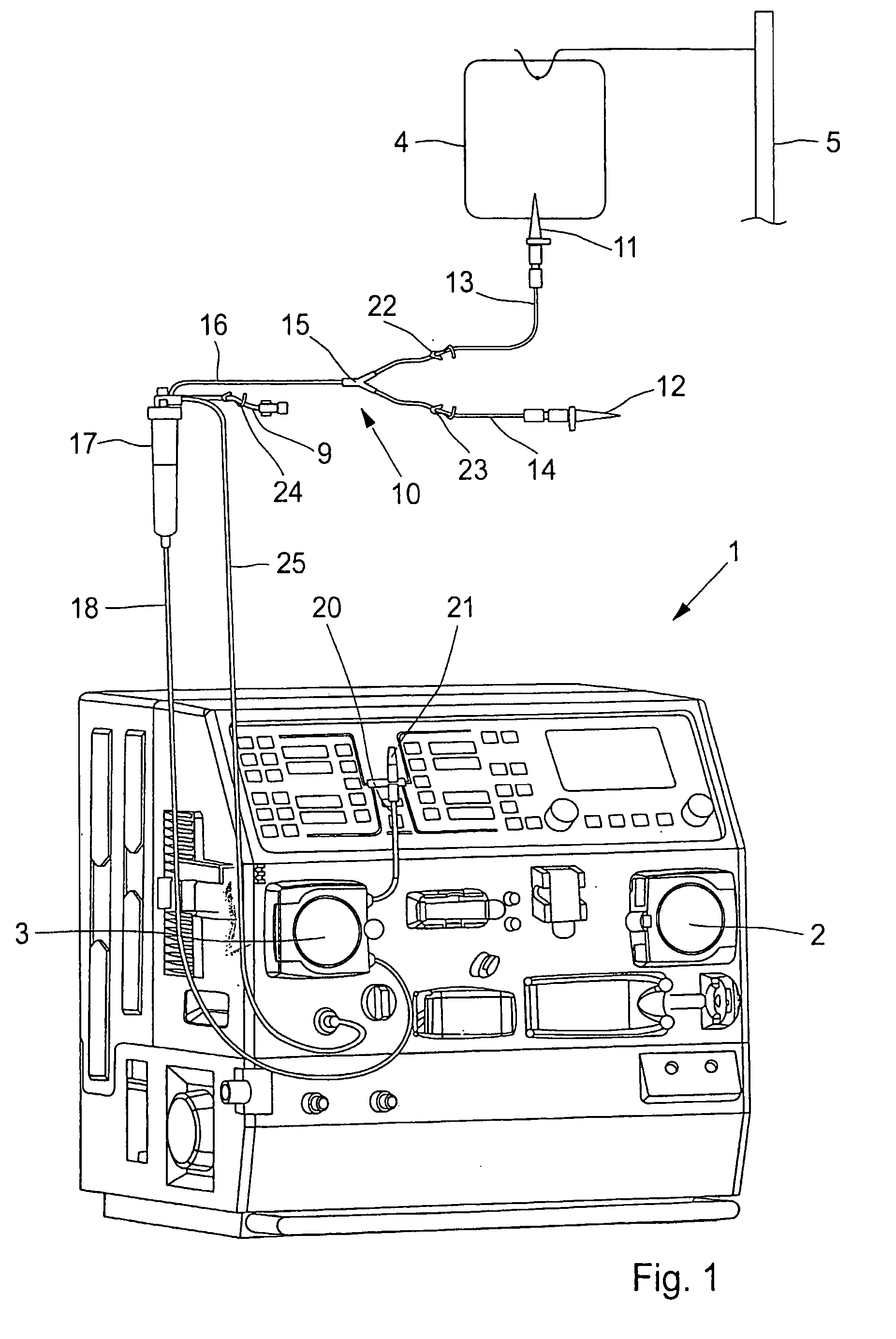

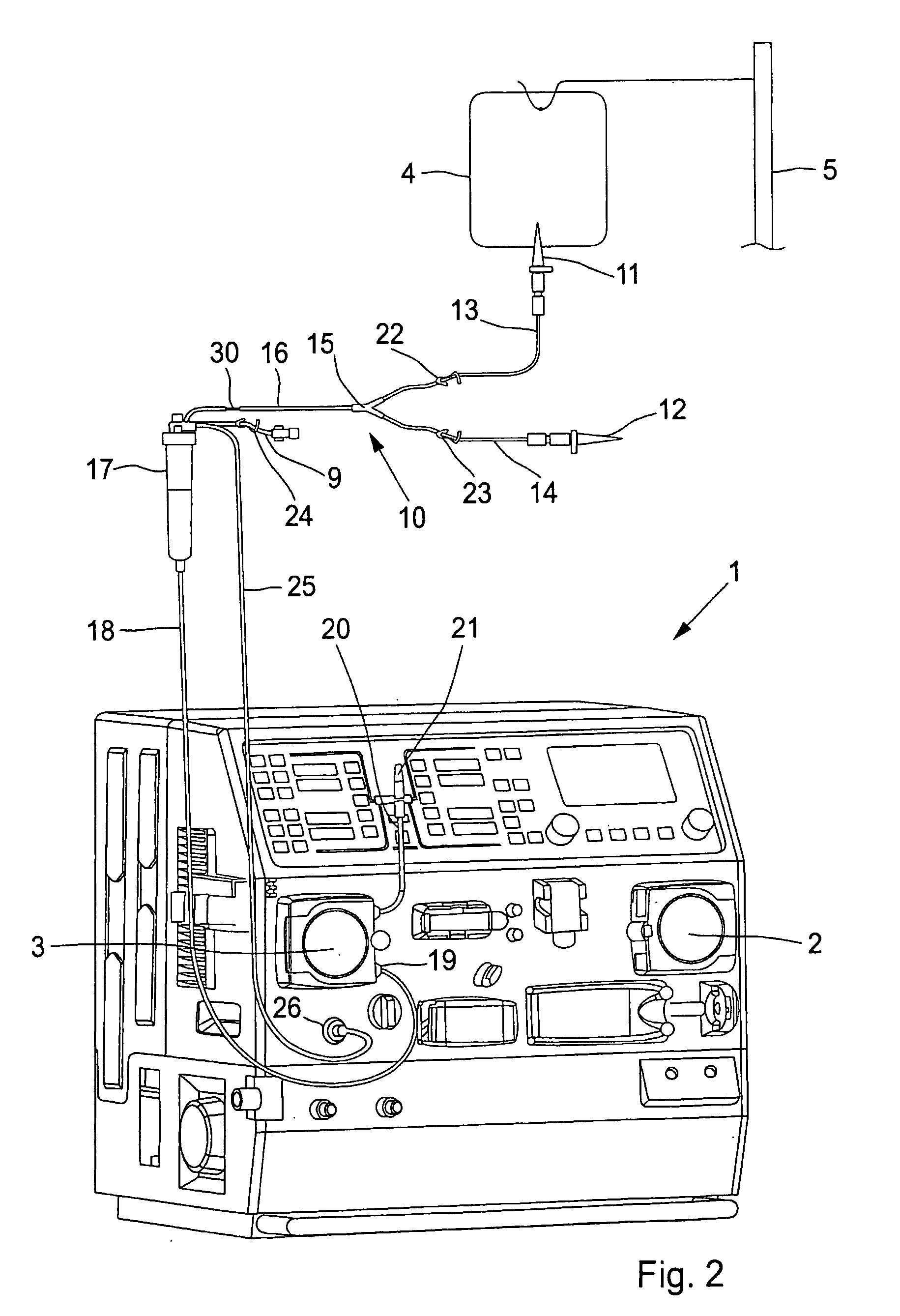

Method and device for monitoring the flow speed of an infusion solution

Method and device for monitoring the flow speed of an infusion solution, such as with hemofiltration or hemodiafiltration. The device has a tube for conducting an infusion solution from a source of infusion solution to a pump device in the form of a metering pump, such as a peristaltic pump or a ceramic pump, and on to an infusion device, such as a drip chamber. The flow speed is determined by the metering pump. The flow speed is monitored separately in that the pressure across a restriction device in the tube is measured. The restriction device can be a separately arranged restriction valve. Alternatively the restriction device is arranged by the tube having a small internal diameter of the order of 0.5 mm in size. The pressure measuring device only needs to measure the absolute pressure with respect to the atmosphere. The hydrostatic pressure due to the infusion bag being hung above the pump and the pressure meter is subtracted in a calculation device.

Owner:GAMBRO LUNDIA AB

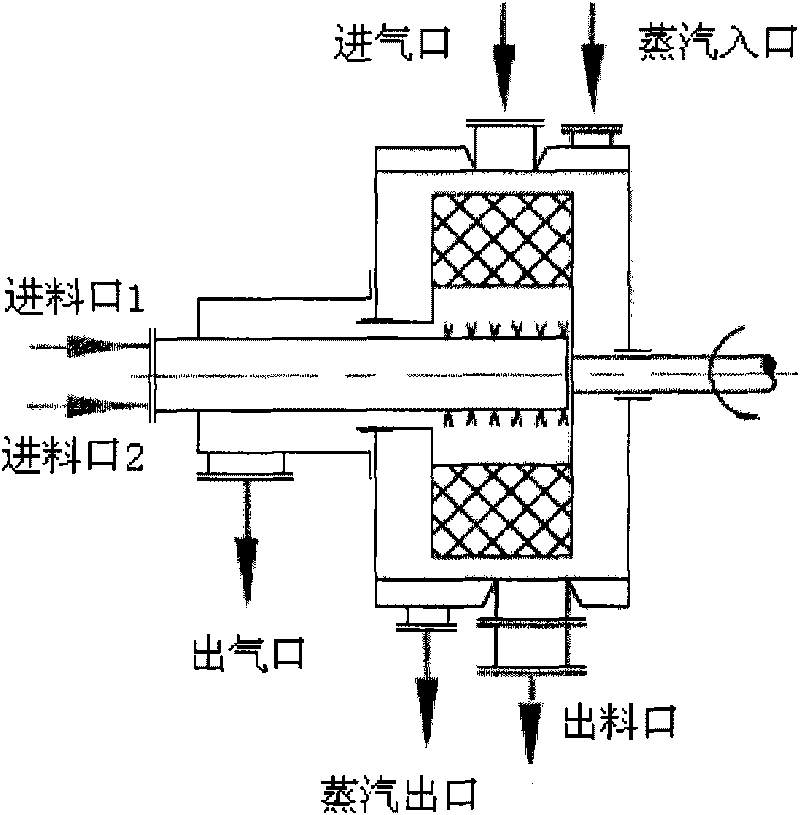

Method for preparing nano iron phosphate

InactiveCN101693531AReduce volumeReduce energy consumptionNanostructure manufacturePhosphorus compoundsPhosphateFerrous salts

The invention relates to a method for preparing nano iron phosphate, belonging to the technical field of the preparation of lithium ion battery cathode materials. The method is characterized by comprising the following steps: inputting an alkaline aqueous solution and a mixed solution formed by one of phosphoric acid or a soluble phosphate solution, one of a water-soluble ferrous salt solution and an oxidant or a ferric salt solution and a water-soluble dispersing agent into a rotating packed bed layer by a metering pump at a certain feeding speed; regulating the rotating speed of the rotating packed bed and controlling the pH value of the reaction system by an alkaline solution; discharging nano iron phosphate particles generated by reaction crystallization from a discharge hole of the rotating packed bed along with the mixed solution; and filtering, washing and drying the nano iron phosphate particles to obtain nano iron phosphate (FePO4.2H2O) powder. The method is simple and has easy operation and high efficiency, and the prepared iron phosphate reaches the nano grade, has uniform particle size and narrow distribution range and is suitable for industrialized production. The nano iron phosphate is a good precursor material for preparing lithium iron phosphate which is used as a cathode material of high-power type lithium ion batteries.

Owner:TSINGHUA UNIV

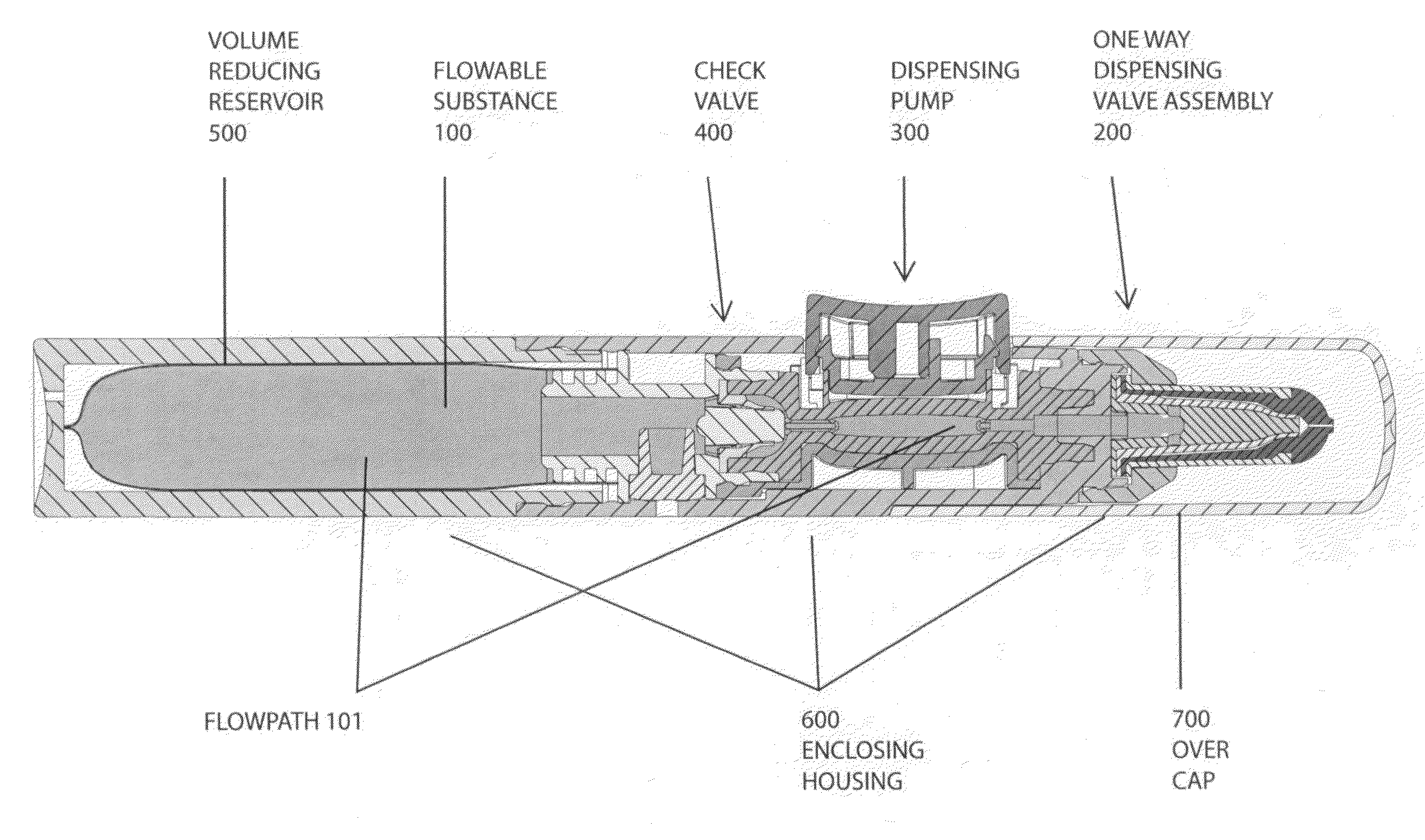

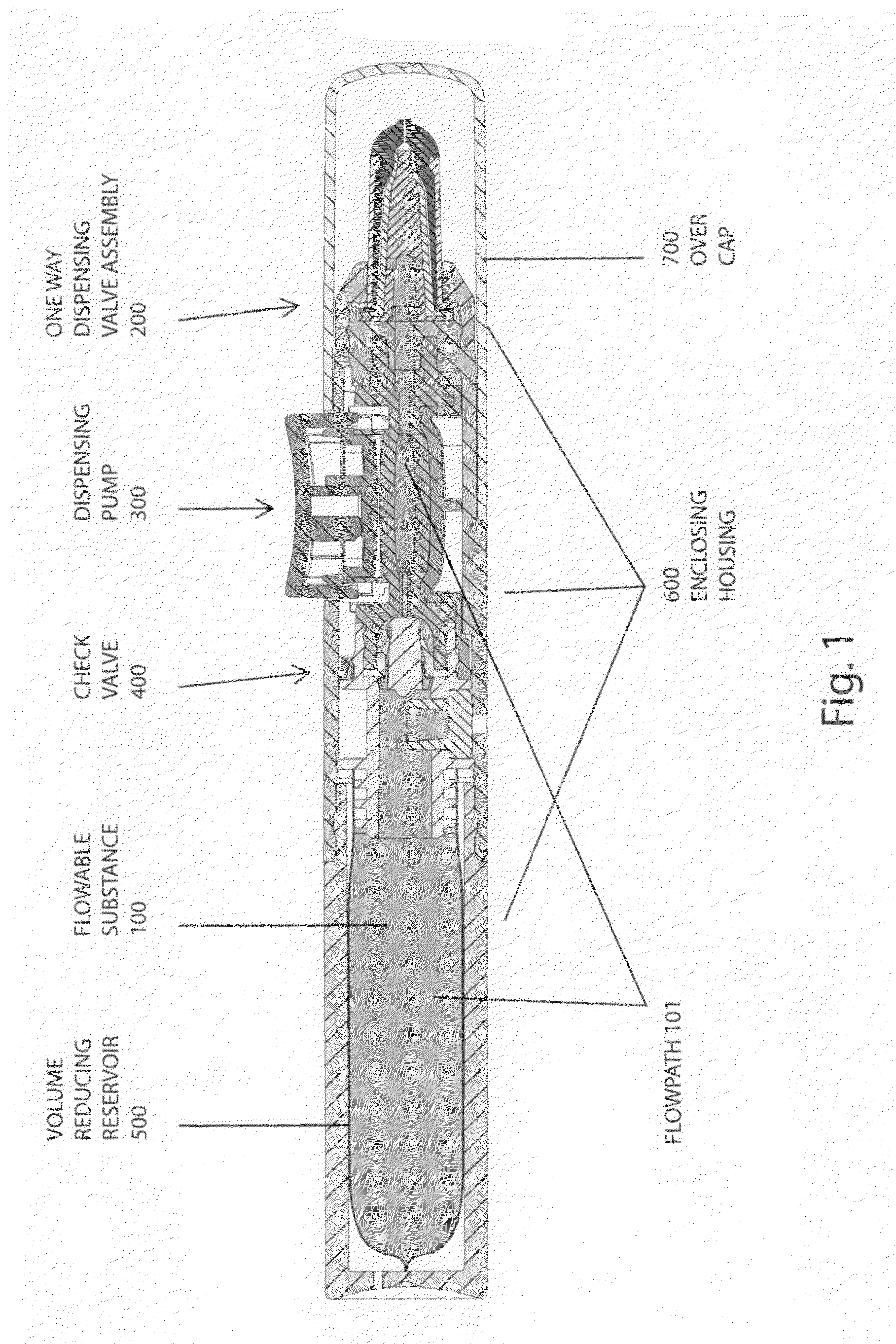

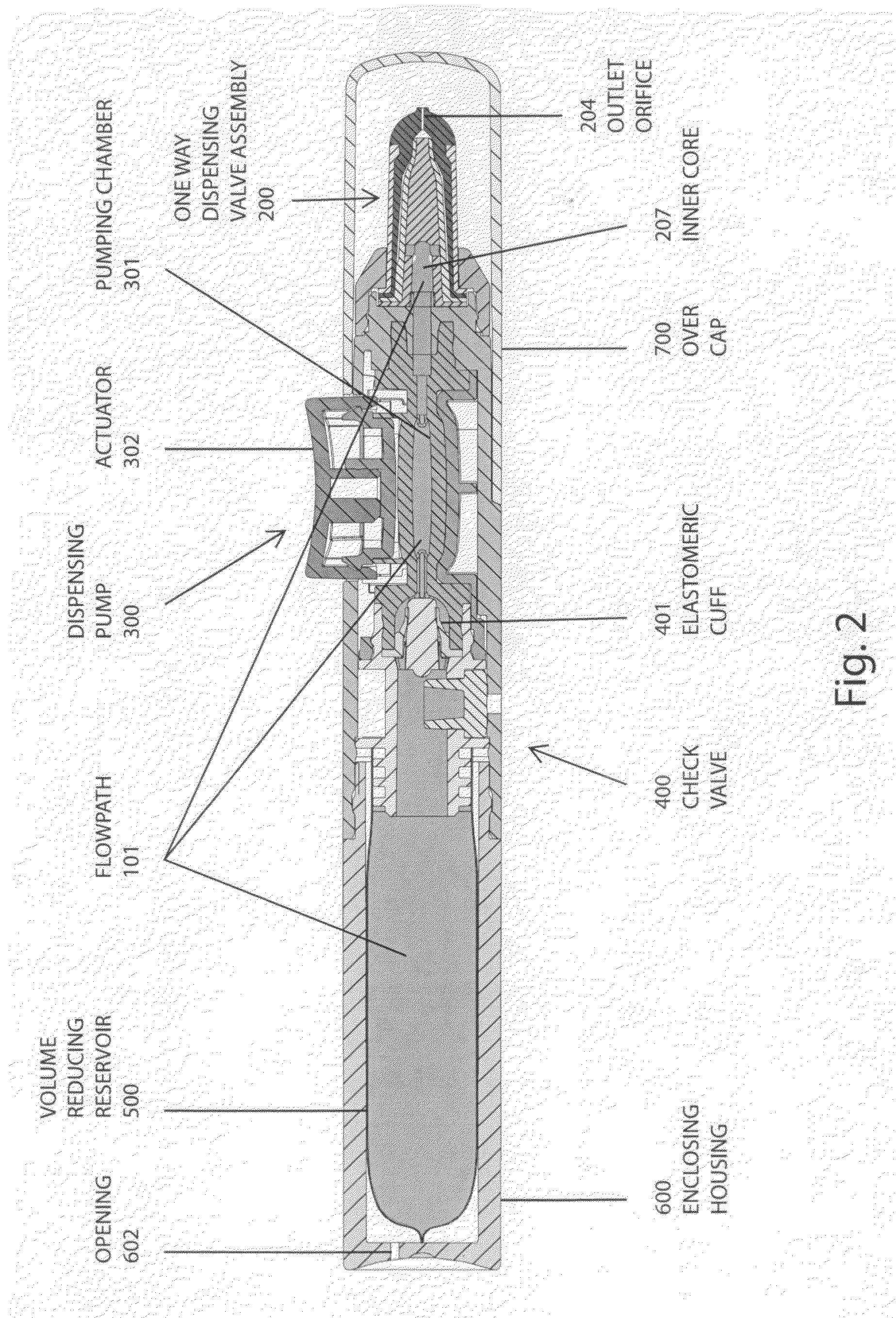

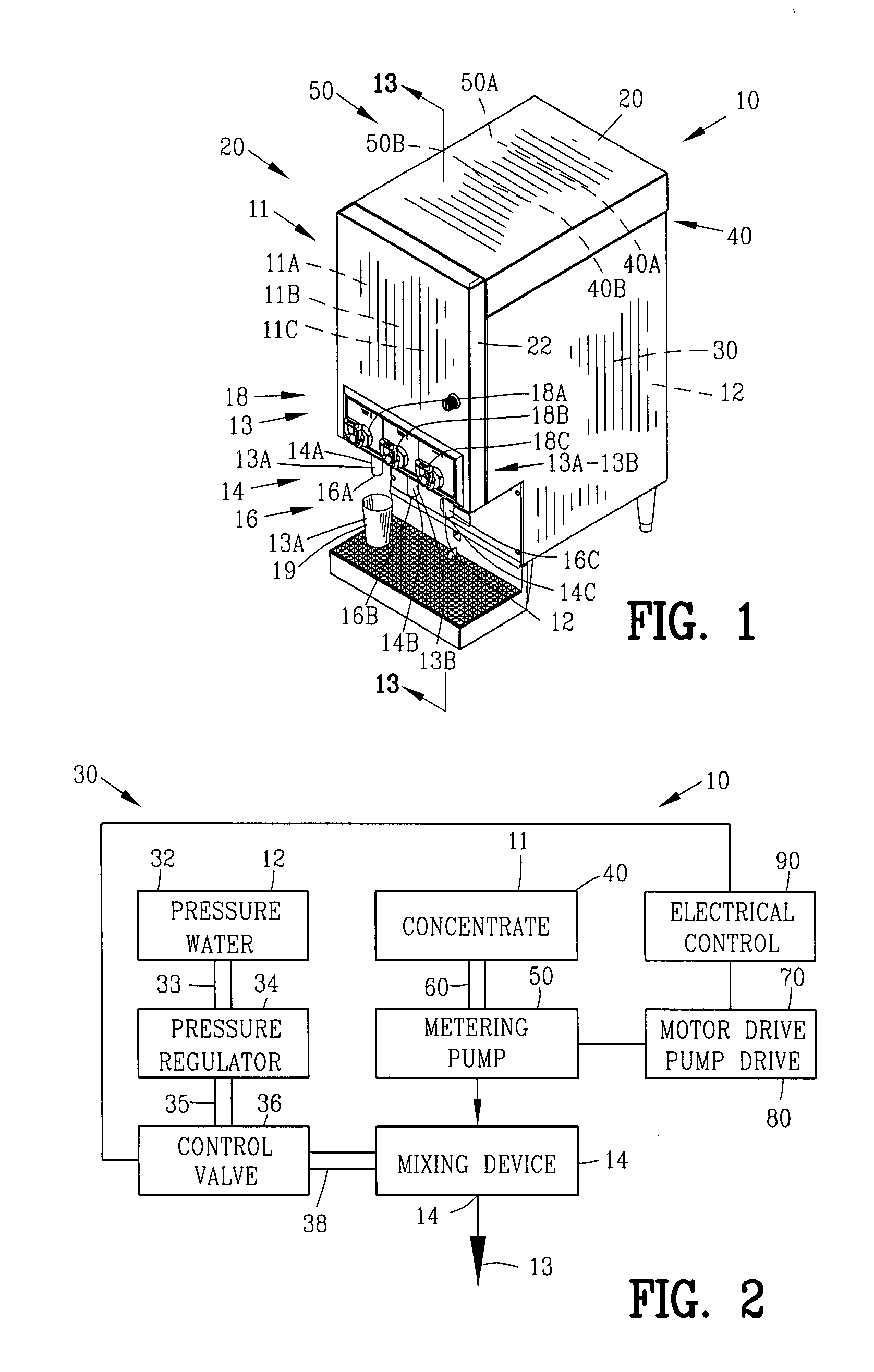

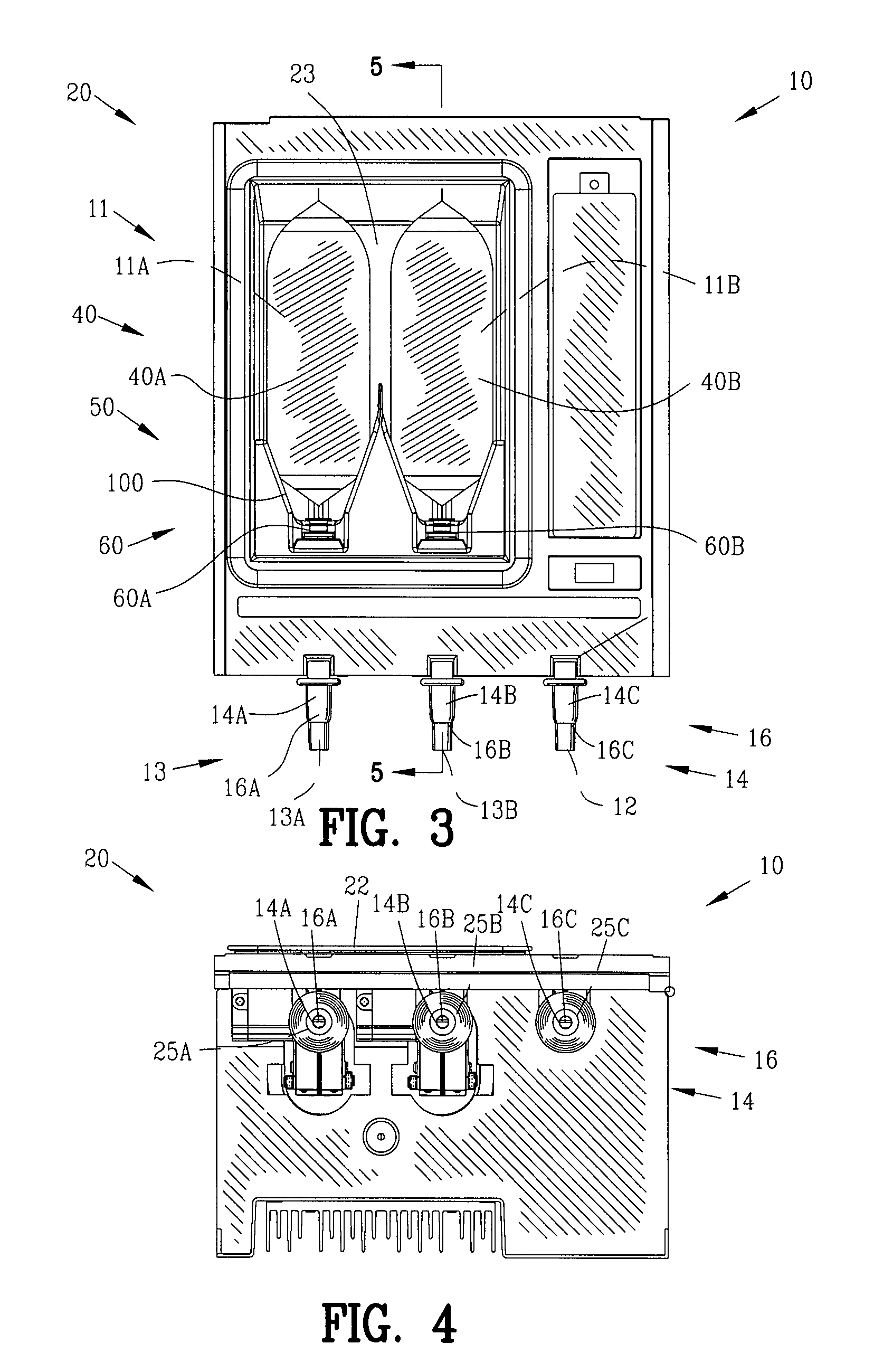

Delivery system for dispensing metered volumes of pure or sterile flowable substances

A sealed delivery system for dispensing metered volumes of a pure or sterile flowable substance is presented. Such system comprises a continuously sealing one-way valve assembly at a distal end, and a volume reducing reservoir at a proximal end, in which a pure or sterile flowable substance can be stored. In operation a user pushes down upon an actuator assembly, acting upon a metering pumping chamber in fluid communication with the reservoir via a check valve. Depression of the actuator causes a dispensing pump to push a metered volume of flowable substance through the continuously sealing one way dispensing valve assembly, and return of the actuator to its home state causes the dispensing pump to pull a metered volume of the contained flowable substance from the volume reducing reservoir and through the check valve.

Owner:RESEAL INT

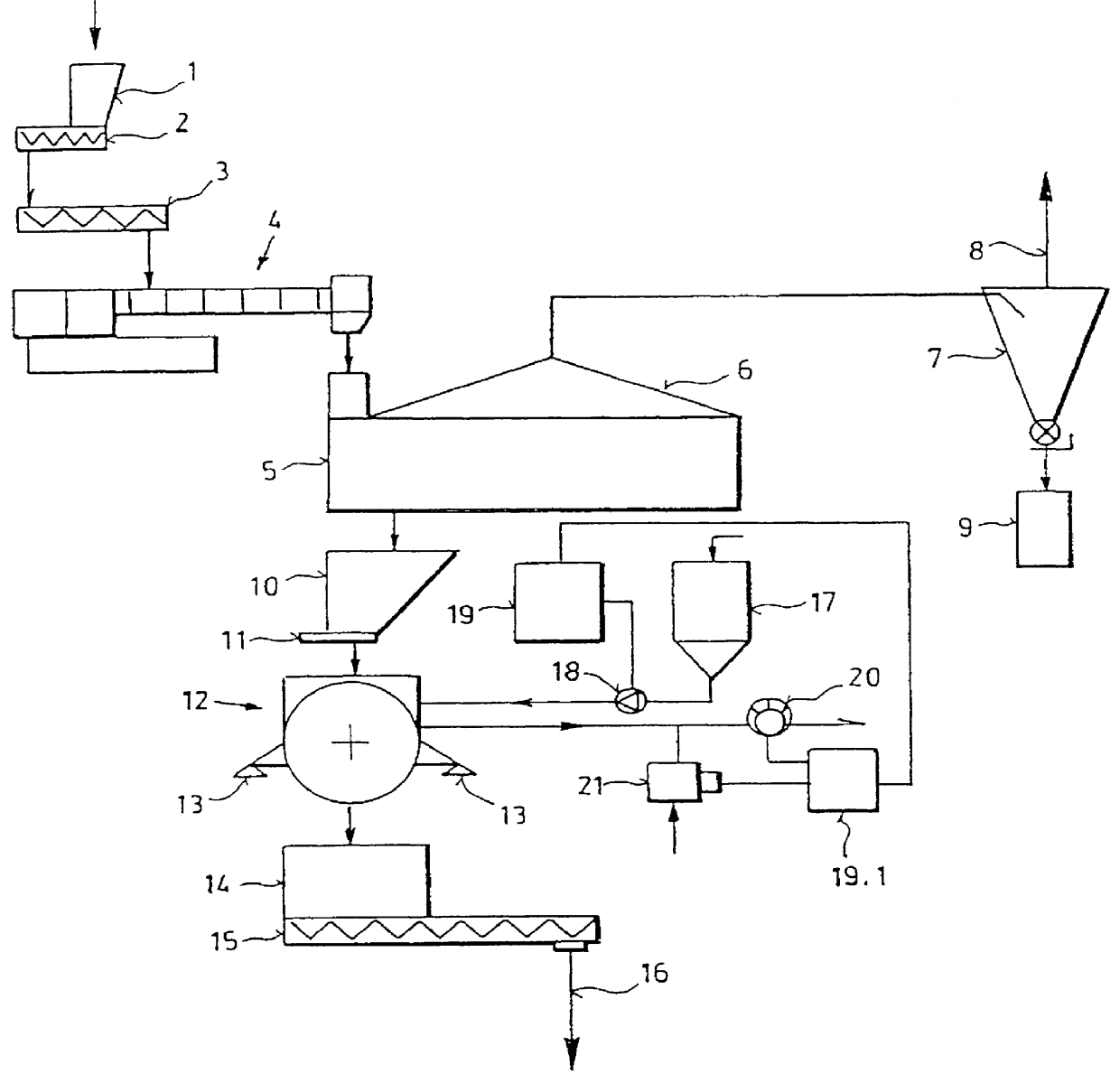

Method of incorporating fatty matter into granulated products

InactiveUS6136353APromote absorptionImprove permeabilityFeeding-stuffAnimal feeding stuffMetering pumpVacuum pump

PCT No. PCT / CH96 / 00265 Sec. 371 Date Dec. 16, 1998 Sec. 102(e) Date Dec. 16, 1998 PCT Filed Jul. 22, 1996 PCT Pub. No. WO98 / 03080 PCT Pub. Date Jan. 29, 1998A method and apparatus for incorporating fatty matter into granulated feed products such as extrudates, pellets and expander pellets with a fat-supplying liquid. Pellets produced in the extruder or expander of press (4) are dried in a dryer (5) and pass through an intermediate container (10) into a mixer (12). Using a metering pump (18) a predetermined amount of fat-supplying liquid is added to the mixer (12) and spread on the surface of product pieces through the mixing process. After a predetermined period of time a vacuum pump (20) generates a negative pressure in the mixer so as to evacuate the air from capillaries or pores of the product pieces. The negative pressure in the mixer is then relieve through an expansion valve (21) so that the air entering into the mixer and into the pores or capillaries of the product pieces transports the fat-supplying liquid on the surface of the product pieces as well as additional fat-supplying liquid into the pores and capillaries, thereby filling them to the extend that a high proportion of approximately 30% fat-supplying liquid is incorporated in the pores of capillaries of the product pieces.

Owner:BUEHLER AG

Method and device for monitoring the flow speed of an infusion solution

Method and device for monitoring the flow speed of an infusion solution, such as with hemofiltration or hemodiafiltration. The device has a tube for conducting an infusion solution from a source of infusion solution to a pump device in the form of a metering pump, such as a peristaltic pump or a ceramic pump, and on to an infusion device, such as a drip chamber. The flow speed is determined by the metering pump. The flow speed is monitored separately in that the pressure across a restriction device in the tube is measured. The restriction device can be a separately arranged restriction valve. Alternatively the restriction device is arranged by the tube having a small internal diameter of the order of 0.5 mm in size. The pressure measuring device only needs to measure the absolute pressure with respect to the atmosphere. The hydrostatic pressure due to the infusion bag being hung above the pump and the pressure meter is subtracted in a calculation device.

Owner:GAMBRO LUNDIA AB

Preparation method for polyvinyl alcohol coarse denier monofilaments

InactiveCN101899722AHigh strengthHigh modulusMonocomponent synthetic polymer artificial filamentMelt spinning methodsFiberState of art

The invention discloses a preparation method for polyvinyl alcohol coarse denier monofilament fibers. The high-strength high-modulus coarse denier polyvinyl alcohol monofilament fibers are prepared by a solid-phase alcoholysis spinning method. The preparation method is characterized in that: polyvinyl alcohol with a low alcoholysis degree under the plasticization of a small amount of water is spun to prepare the coarse denier fibers at a relatively low temperature, and the extraction problem caused by a plasticizer and the problem that the coarse denier (more than or equal to 1,000 D) fibers cannot be produced by a wet spinning method are avoided; the small amount of water is added to make the polyvinyl alcohol in a molten state, the fibers are extruded by a single screw, metered by a metering pump and extruded out of a spinning jet; a small amount of moisture existing can be removed by heating; and the fibers are subjected to drying, multi-level stretching (10 to 16 times) and high-temperature tension and heat shaping to form the high-strength high-modulus fibers. The preparation method makes up defects of the prior art and products sold in the market and meets the requirements on plasticizing, anti-cracking and the like of concrete in building projects.

Owner:SHANGHAI KNP CHEM +3

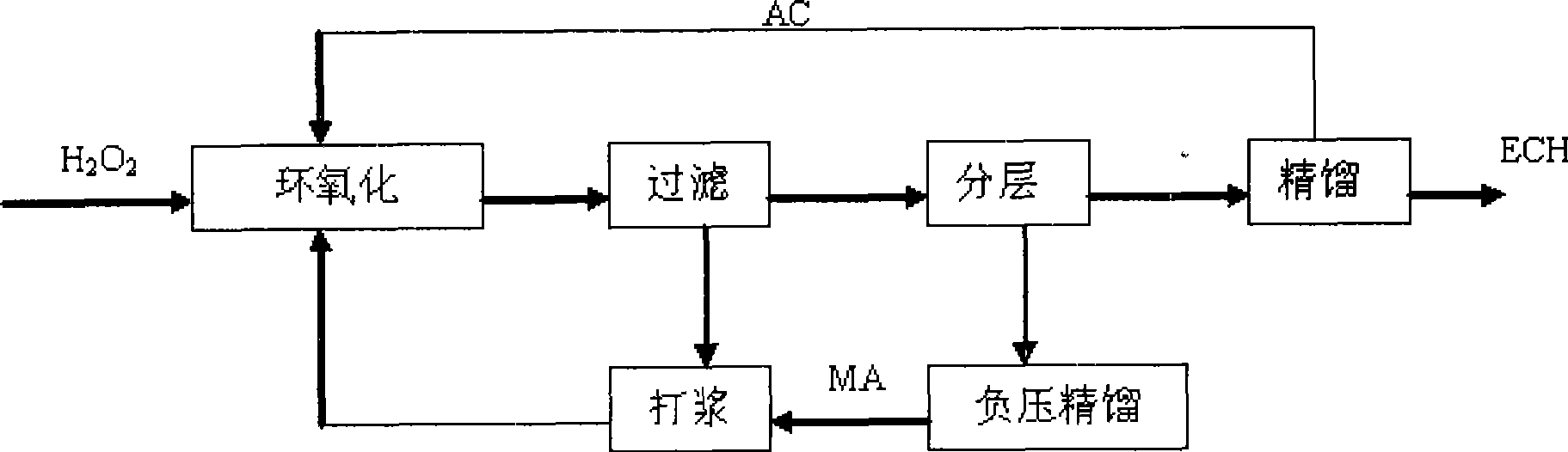

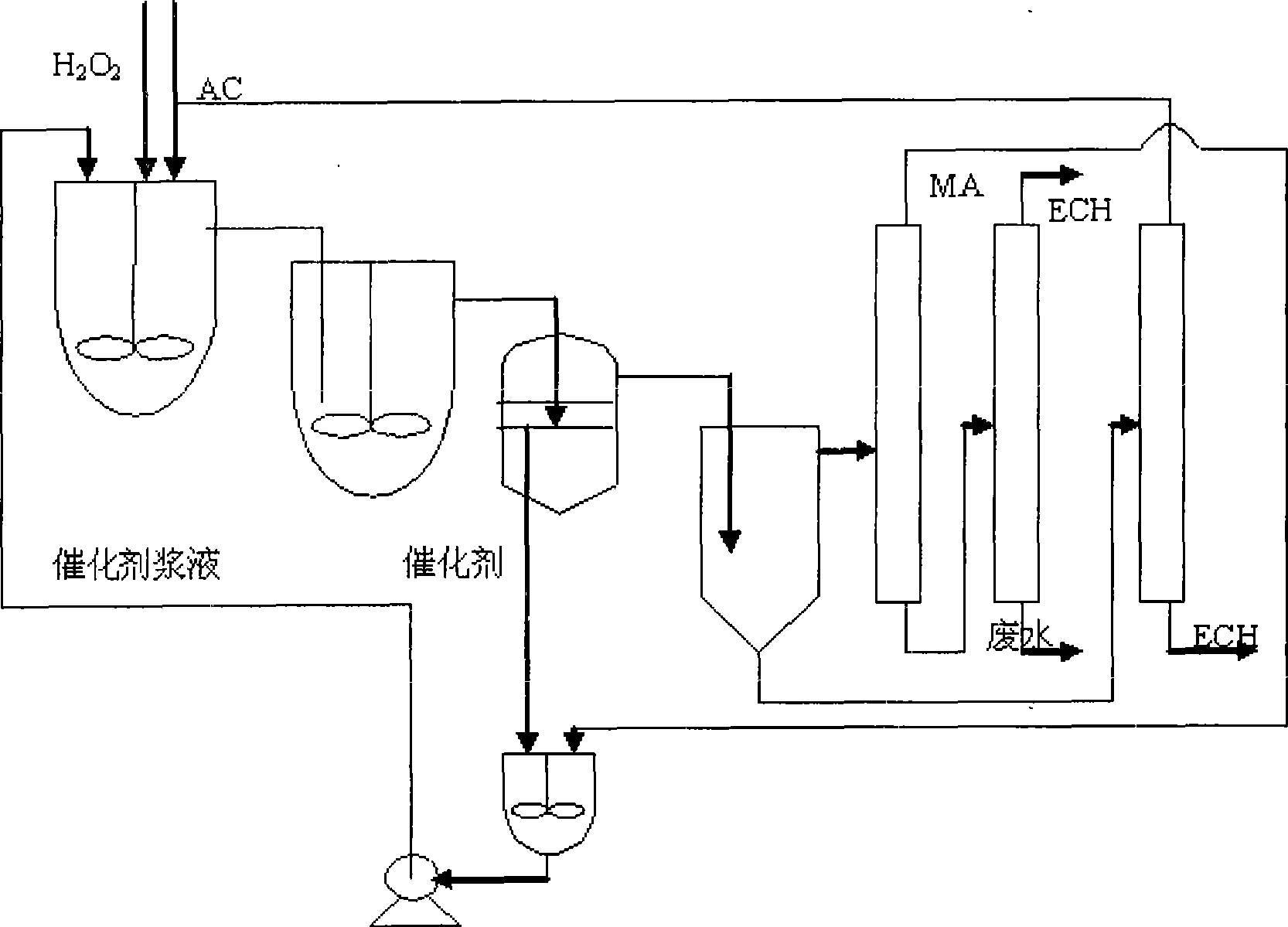

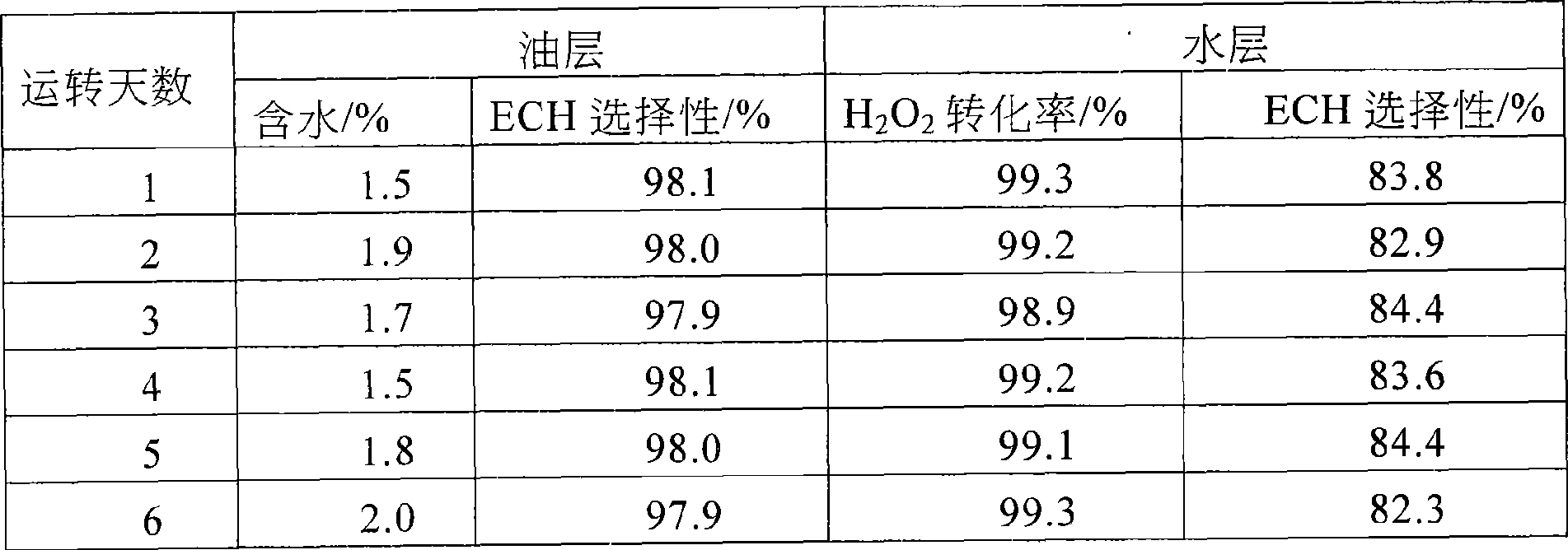

Continuous production method of epoxy chloropropane by hydrogen peroxide process

The invention provides a preparation method of chloroepoxy propane by chloropropene epoxidation. Chloropropene, a solvent and titanium silicalite molecular sieve catalyst fine particles are put in a reaction kettle for reaction at the temperature of 10-80 DEG C. The method is characterized in that the reaction kettle is a single kettle or multistage slurry bed reaction kettles with same or different volumes which are connected in series; the reaction solution needs not to be homogeneous phase, slurry particles of the chloropropene, the solvent and the titanium silicalite molecular sieve catalyst are added to a first stage reaction kettle by a metering pump, hydrogen peroxide is dropwise added to the first stage reaction kettle or each stage of the reaction kettles, the reaction occurs in a weakly acidic condition, materials are subject to oil-water delamination after the reaction to be divided into oil-phase slurry and water-phase slurry; the catalyst is suspended in the water phase, and the oil phase is sent to a rectification tower to separate the chloropropene, the epichlorohydrin and trace methanol; the water phase slurry is filtered, a catalyst filter cake or concentrated slurry is directly beaten by the solvent, and pumped to a first stage epoxidation reaction kettle, the water phase slurry contains the methanol, trace epichlorohydrin and the water which is generated by the reaction and the water which is taken by the hydrogen peroxide, the trace methanol and the epichlorohydrin are separated out by negative pressure rectification, and the recovered methanol is used for preparation of the catalyst slurry. The method has the advantages of simple process, little solvent consumption and high product separation yield, and is available for industrialized production.

Owner:JIANGSU YANGNONG CHEM GROUP +2

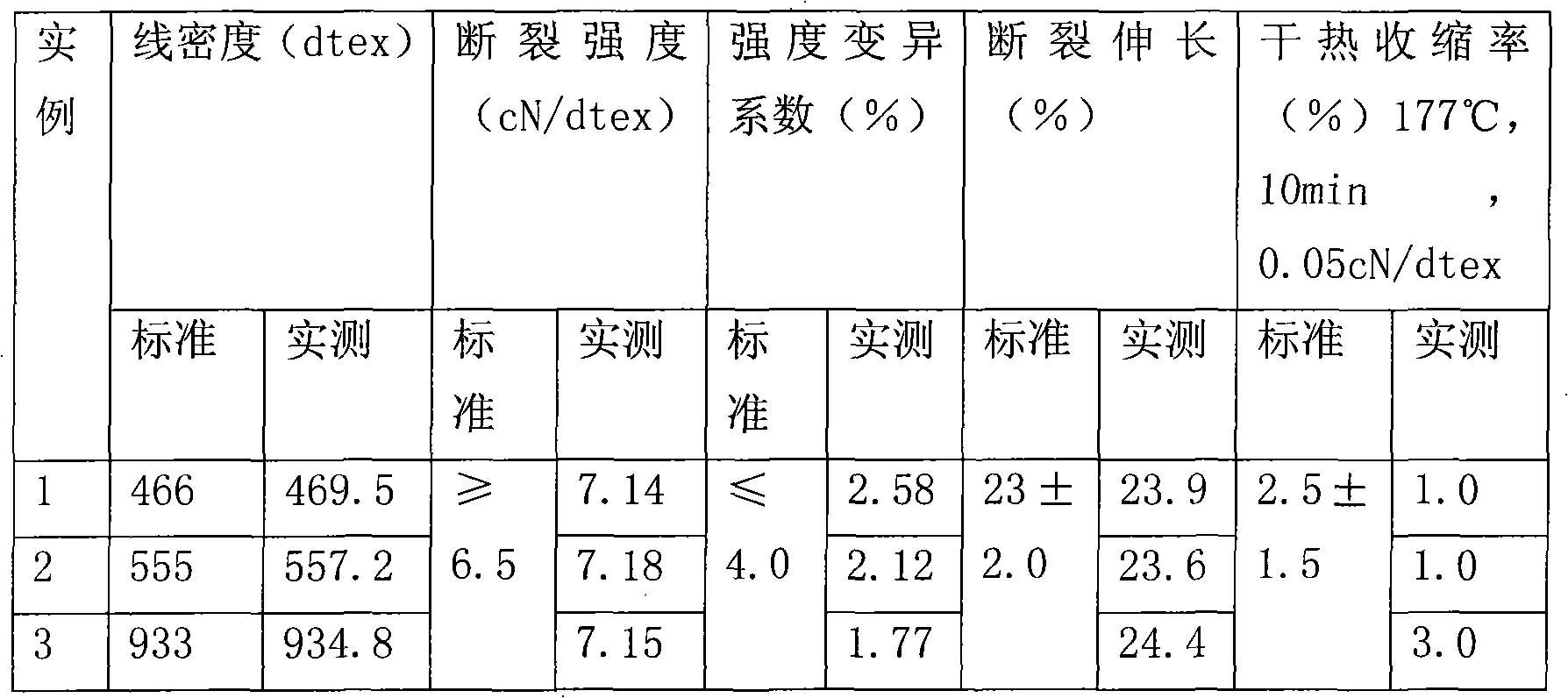

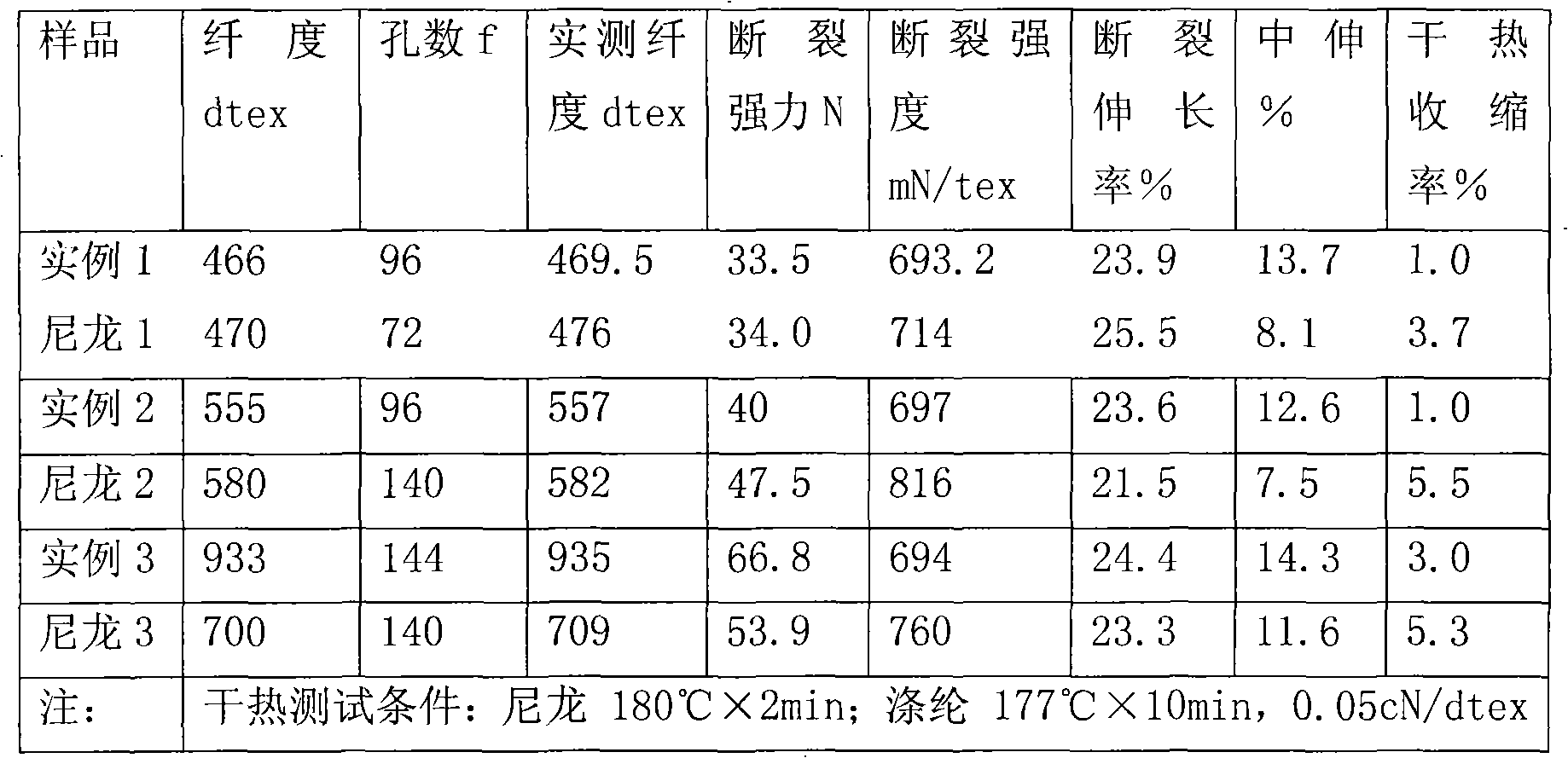

Process for producing polyester industrial fiber for processing safe air bag of automobile

ActiveCN101634052AHeat resistantAging resistantArtificial filament heat treatmentMelt spinning methodsPolyesterEngineering

The invention relates to a process for producing a polyester industrial long fiber for processing a safe air bag of an automobile, which sequentially comprises the following steps: A. processing a polyester slice with high viscosity: enabling the viscosity of the polyester slice to reach 1.0-1.1dl / g; B. melting and spinning: transmitting the polyester slice after solid phase polymerization to a spinning screw rod extruder, melting in a spinning screw rod, entering a spinning assembly by a metering pump and extruding from a fiber spray plate with a diameter of 190 mm to 220 mm to spin fusant, , then heating by a slow cooling heater, carrying out cooling for molding by a side-molding blowing device and then entering a spinning passage; C. stretching and winding: oiling the surface of a fiber and carrying out second-grade high-speed stretching with the total stretching multiple being 5.0 to 5.8, carrying out high-temperature loosing thermoforming at 230 DEG C-250 DEG C and carrying out winding for molding in the range of the winding process speed of 2,500-3,000 m / min to prepare a finished product. The fiber for the safe air bag, which is produced by the process, can completely replace a nylon 66 fiber, is used for spinning terylene safe air bag fabrics and greatly reduces the processing cost.

Owner:ZHEJIANG HAILIDE NEW MATERIAL

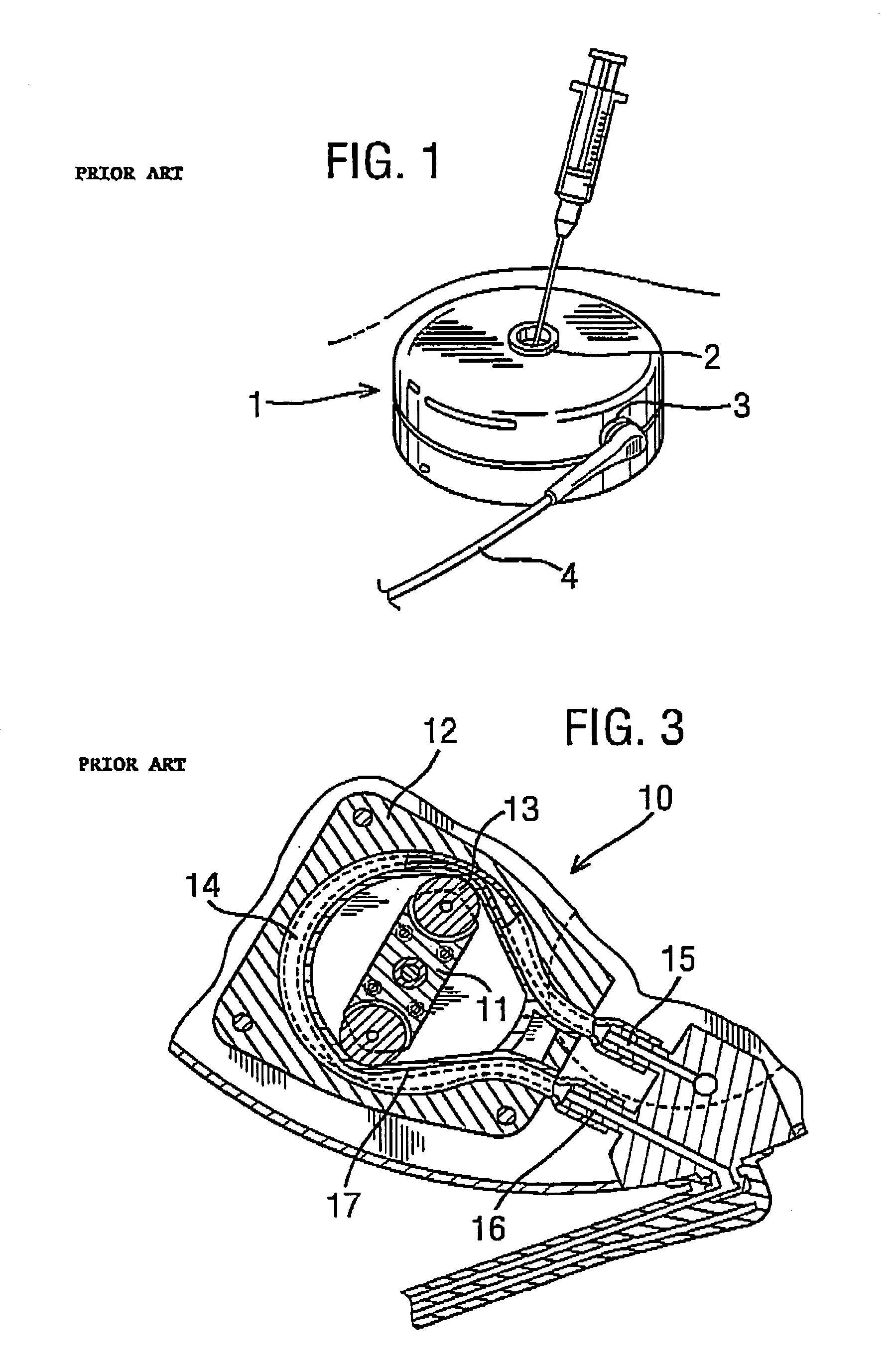

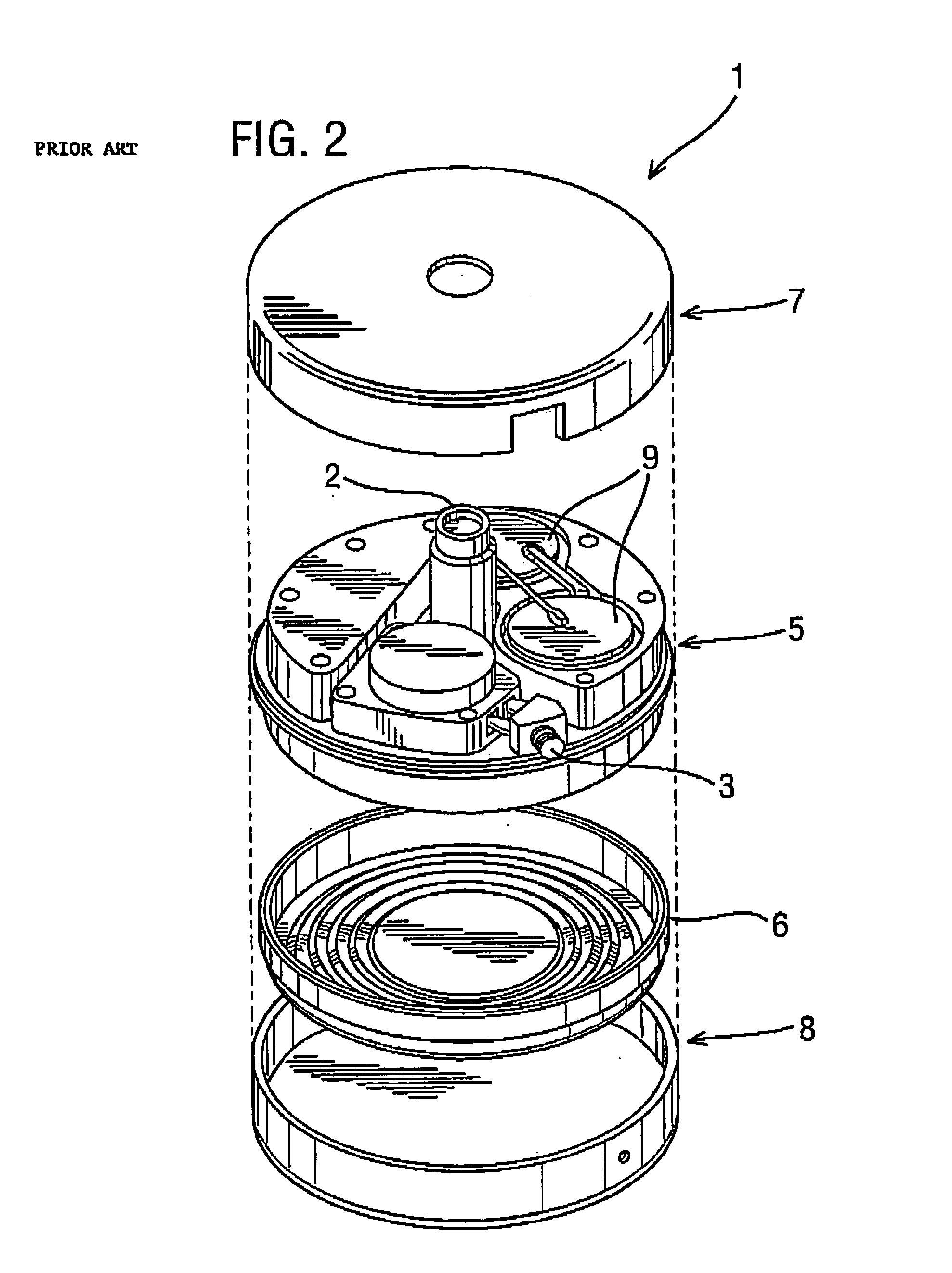

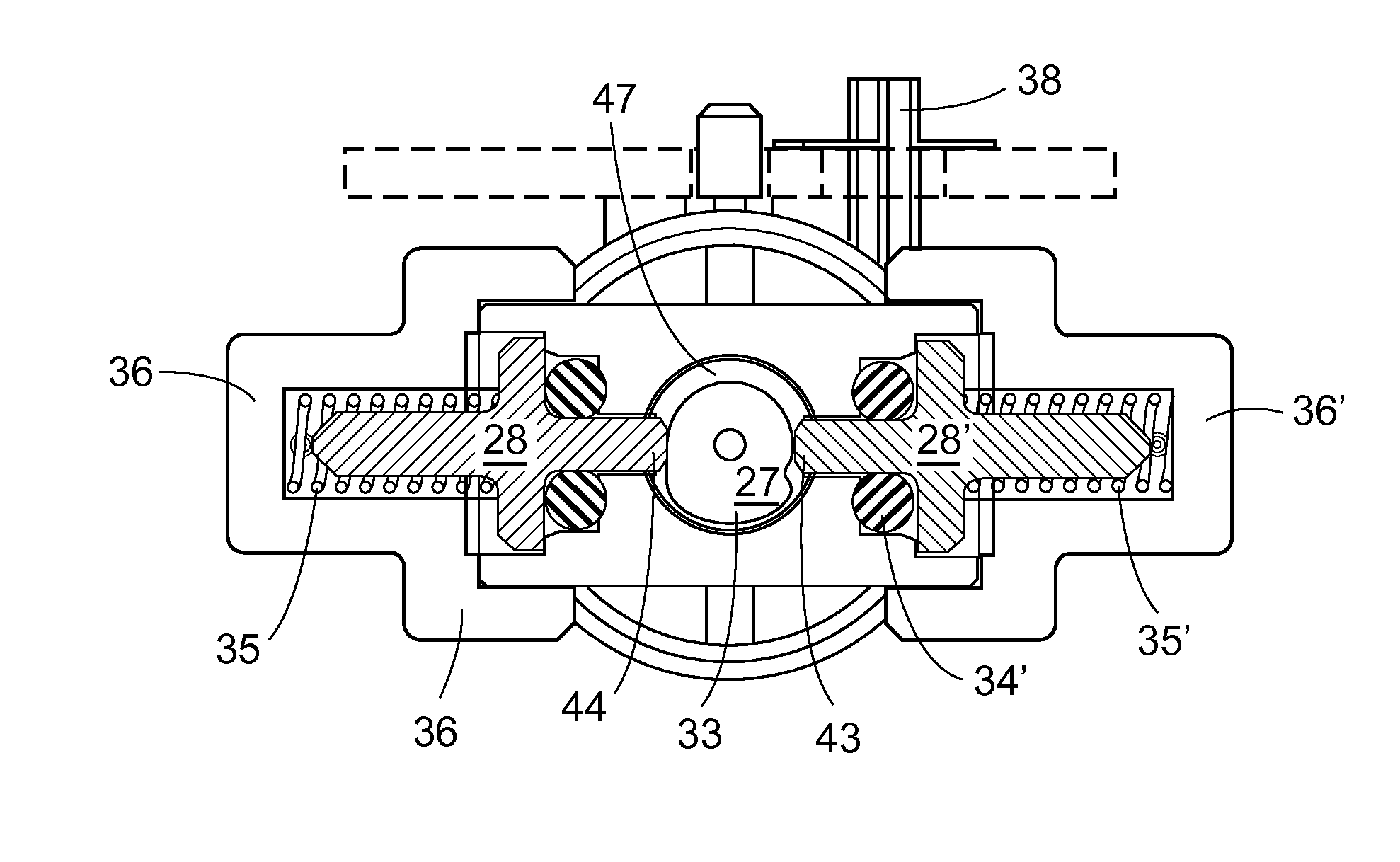

Internal cam metering pump

A micropump according to the invention uses an eccentric cam member rotating within a pump housing to sequentially open and close valves in the pump housing to withdraw fluid from a reservoir and provide metered amounts of the fluid to a cannula port for administration to a patient. The micropump may be used in a disposable pump for continuous infusion of medication such as insulin.

Owner:BECTON DICKINSON & CO

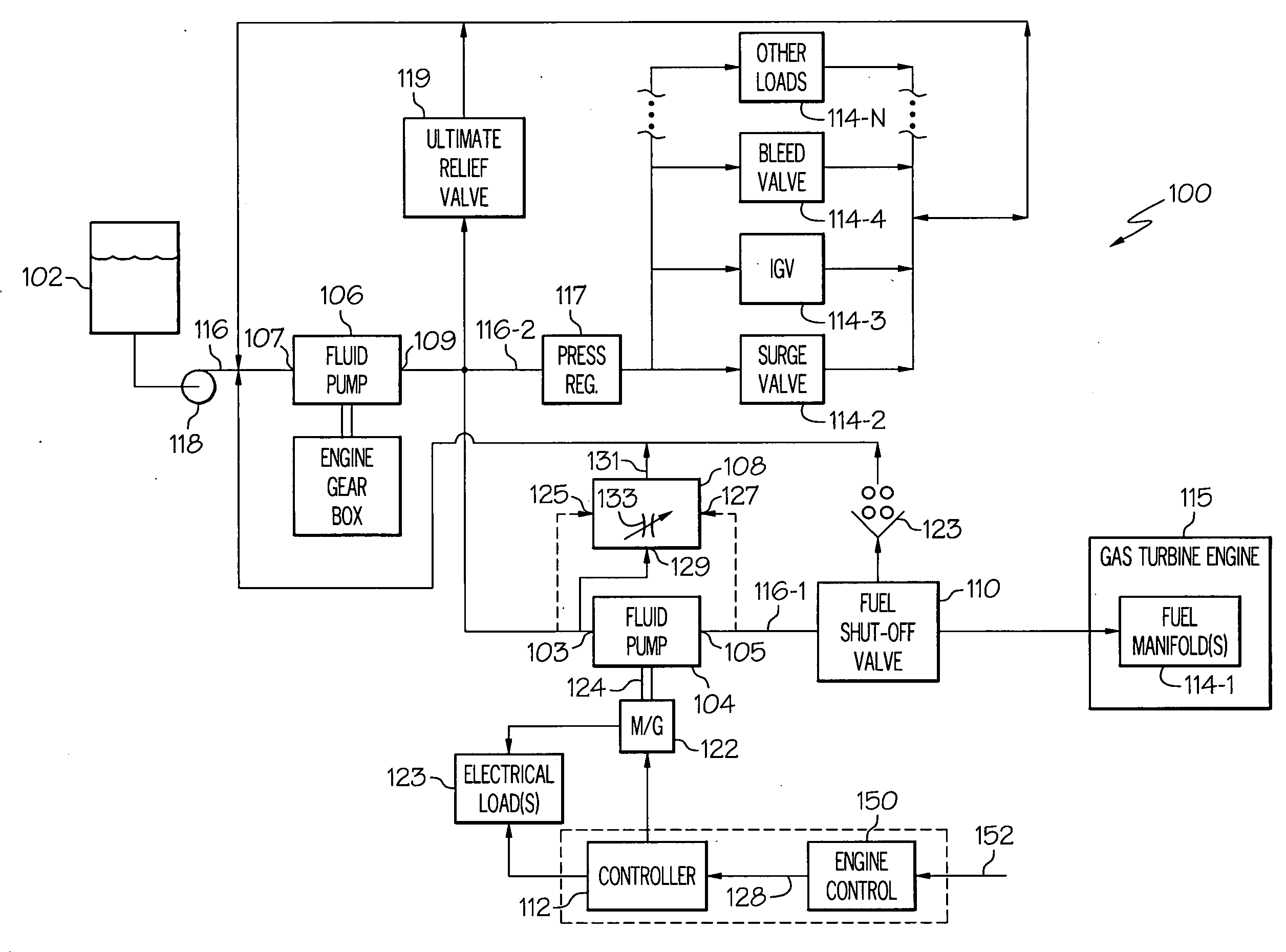

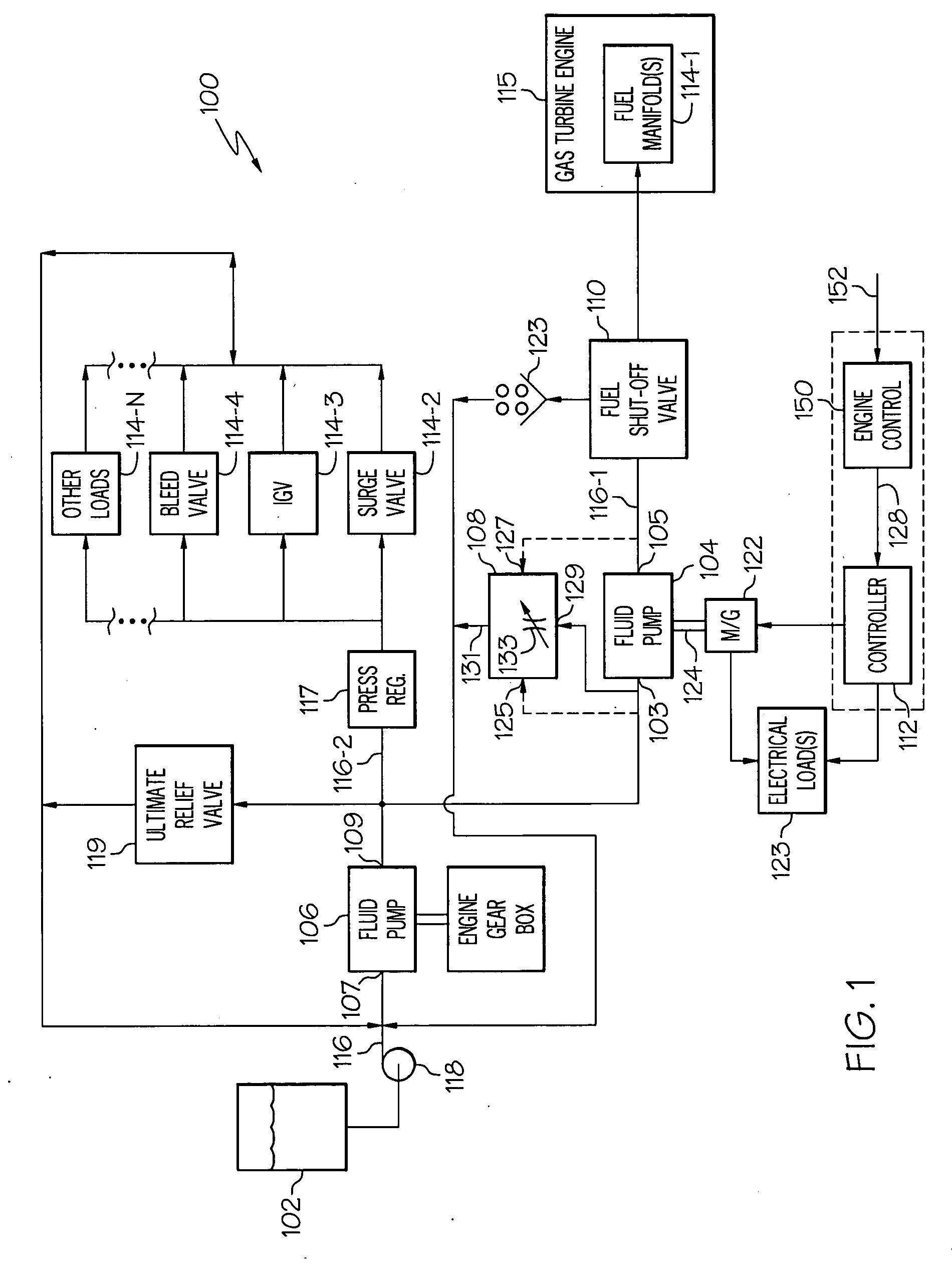

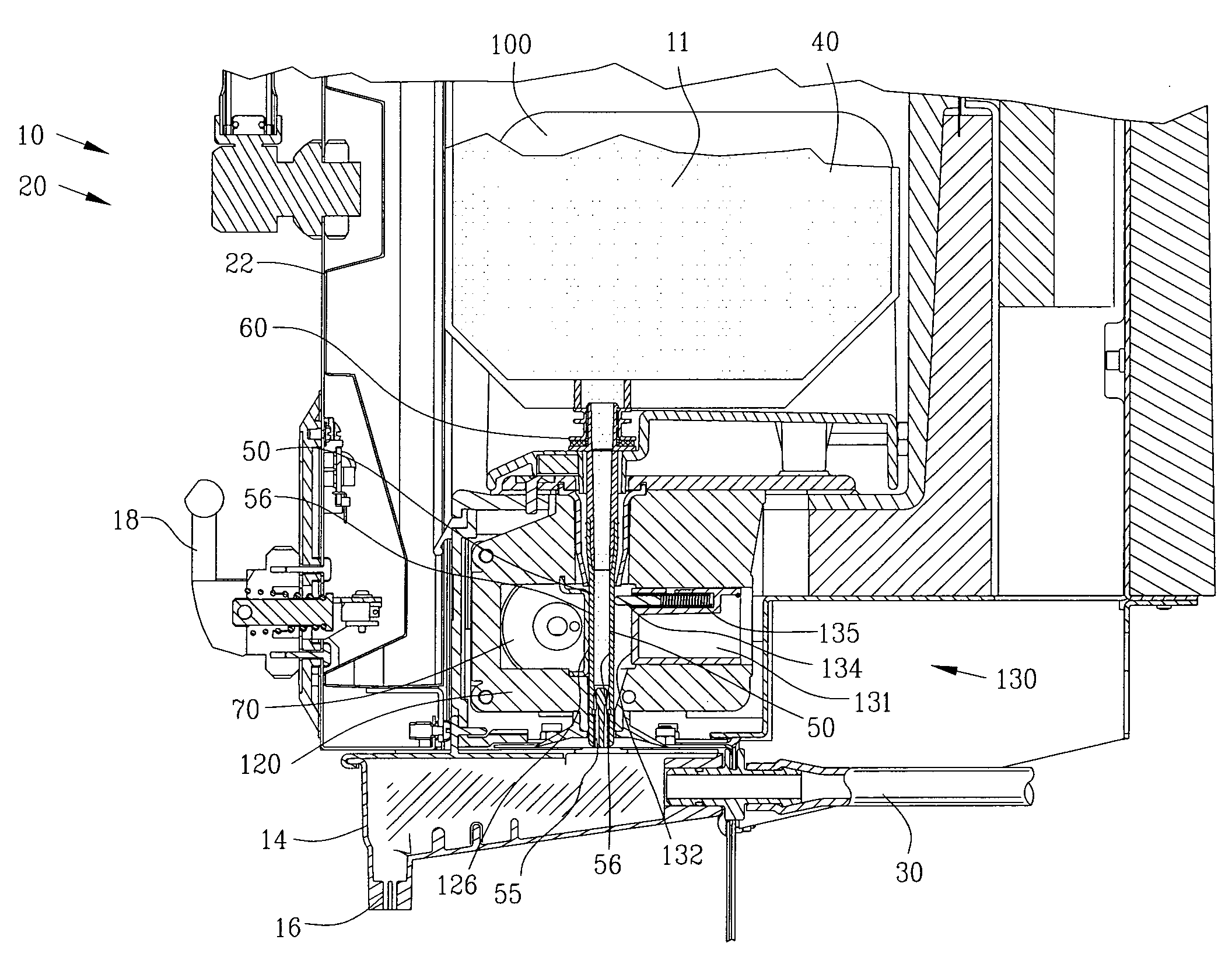

Electric power generating turbine engine fuel supply system

A turbine engine fuel supply system includes a priority flow line, a plurality of secondary fuel loads, a fluid-powered metering pump, a mechanically-driven fuel pump, and an electric machine. The fluid-powered metering pump, upon receiving fuel at its fuel inlet, rotates at a rotational speed, discharges the fuel from its fuel outlet at a flow rate dependent on the rotational speed, and supplies a first drive torque. The mechanically-driven fuel pump receives a second drive torque and, in response, draws fuel into its fuel inlet and discharges the fuel from its outlet to the fluid-powered metering pump fuel inlet to drive the fluid-powered metering fuel pump. The electric machine receives the first drive torque from the fluid-powered metering pump and generates electrical power.

Owner:HONEYWELL INT INC

Method for producing high strength fine-denier polyamide fiber 6 fully drawn yarn

ActiveCN101476169AIncrease draft ratioReduce tensionSpinning head liquid feederMelt spinning methodsYarnHigh intensity

The invention provides a method for producing fine chinlon 6 fully drawn yarn with high strength which includes steps as follows: (1) chinlon 6 slice enters into a screw extruder with electrical heating function through a storage hopper that makes slice showing melt shape; (2) the melt material is pressed in a spinning subassembly through a metering pump quantificationally, and is spout by a spout plate for forming filament bundle in a spining box body; (3) the filament bundle is cooled by side wind through the spinning box body and is cooled further through a corridor; (4) the cooled filament bundle is oiled by an oil roll; (5) oil in the filament bundle is more uniform and has high amplexus degree through confounding; (6) the filament bundle passes through a first group filament guide roll and a second group filament guide roll for drafting forming, then passes through a third filament guide roll to reel. A grade product produced by the method has average more than or equal to 6.0cN / dtex rupture strength that is higher 22% than the product produced by normal method, and has better transparent sense and visual effect, the produced clothes has better flexible sense and handle sense for wearing cosily.

Owner:烟台华润锦纶有限公司

Polyolefin multi-layer porous diaphragm for lithium ion battery and preparation method thereof

InactiveCN102064299AGood heat setting timeLow closed cell temperatureSynthetic resin layered productsCell component detailsPolyolefinBoPET

The invention discloses a diaphragm used for preparing a lithium ion battery. The diaphragm is multilayer material formed by a polyethylene layer and a polypropylene layer which are mutually overlapped, wherein each layer is added with a heat resistant material. The preparation method of the porous diaphragm used for preparing the lithium ion battery comprises the following steps: firstly modifying the surface of a heat resistant inorganic material, uniformly mixing the inorganic material with high boiling point diluent, respectively adding polyethylene and polypropylene as well as the high boiling point diluent mixed with the inorganic material and other auxiliaries into a double screw extruder to be fully plasticized and extruded, preparing a uniform multilayer diaphragm by virtue of a multilayer die head under the control of a metering pump, and carrying out biaxial orientation stretching, washing and extracting, thus the porous diaphragm is obtained. The diaphragm prepared by the invention has higher air permeability and higher anti-puncture strength, more importantly, diaphragm rupturing temperature is higher, obturator temperature is lower, and shrinkage rate is lower, thus the diaphragm prepared by the invention is a novel diaphragm used for the lithium ion battery and has excellent properties.

Owner:FOSHAN JINHUI HIGH TECH OPTOELECTRONICS MATERIAL

Metering pump for dispensing liquid

A pump for metering a liquid is disclosed comprising a flexible tube connected to a container with a pressure relief valve located in the flexible tube. A housing defines an aperture for receiving the flexible tube with a compression surface located adjacent to the aperture. A reciprocating member has a sealing element and a pumping element. A drive moves the sealing element for pinching the flexible tube against the compression surface upstream from the pressure relief valve for trapping liquid between the sealing element and the pressure relief valve. The drive moves the pumping element for collapsing the flexible tube against the compression surface for pumping the trapped liquid to discharge a metered quantity of the liquid from the pressure relief valve.

Owner:SOC DES PROD NESTLE SA

Device for preparing non-woven fabric product continuously with electrostatic spinning method

ActiveCN101985793AEasy to processReduce processing costsSpinnerette packsFilament/thread formingTemperature controlElectrospinning

The invention relates to a device for preparing non-woven fabric products continuously with an electrostatic spinning method, belonging to the field of electrostatic spinning, and mainly comprising a melt body conveying device, a melt body metering pump, an electrostatic spinning die head, a die head temperature control device, a high-voltage static electricity generating device, a collecting device and a bracket, wherein the melt body conveying device is connected with an inlet of the melt body metering pump directly; an outlet of the melt body metering pump is connected with the electrostatic spinning die head; the die head temperature control device is arranged on the electrostatic spinning die head or distributed in the electrostatic spinning die head; the inner part of the electrostatic spinning die head is provided with a distributing passage; the distributing passage distributes a stream of melt body as a plurality of melt bodies uniformly; a spinneret plate of the terminal end of a plurality of the melt bodies is connected with a jet nozzle; the jet nozzle is not a single micro-hole but a hole-slot on a slit; and a passage of hot air is arranged at the outer part of the electrostatic spinning die head. According to the structure of the invention, the manufacturing difficulty of the electrostatic spinning die head is reduced greatly; the fiber diameter is much thinner than that of fiber manufactured by a melt blown method; the fiber quality is better; and modularization production is easy to realize.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com