Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2669results about "Artificial thread manufacturing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

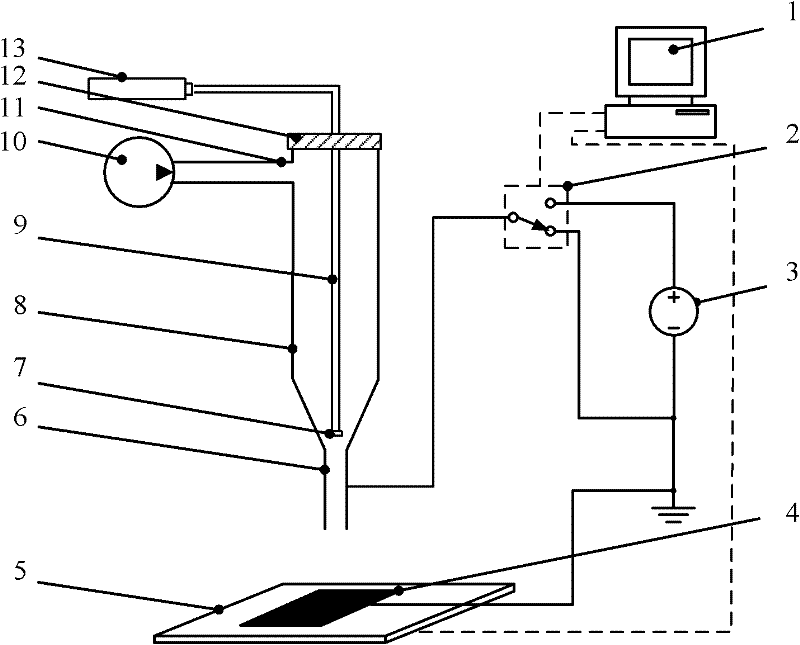

Apparatus and methods for electrospinning polymeric fibers and membranes

InactiveUS6713011B2Easy to controlLarge specific surface areaElectric discharge heatingConfectioneryFiberElectrospinning

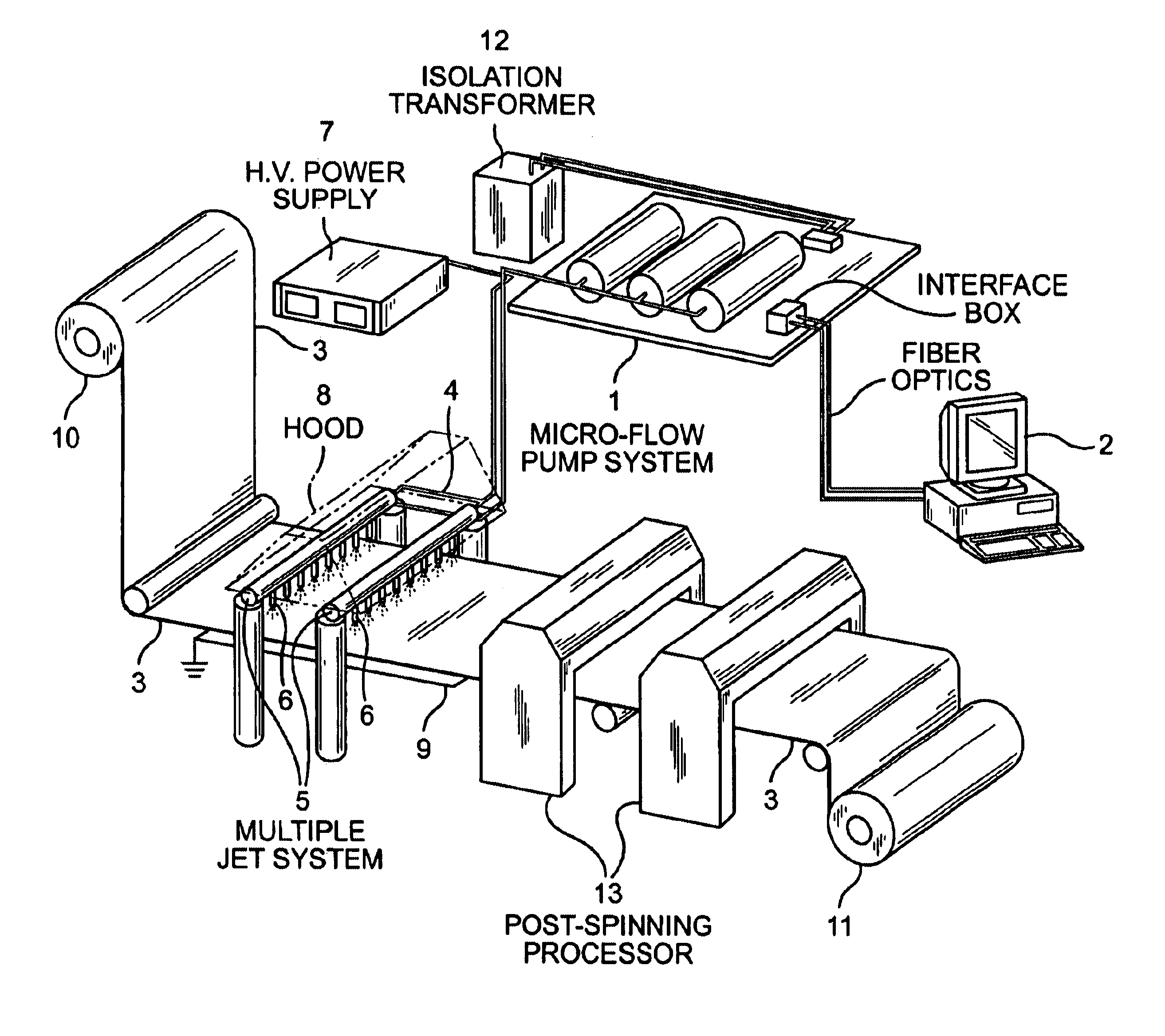

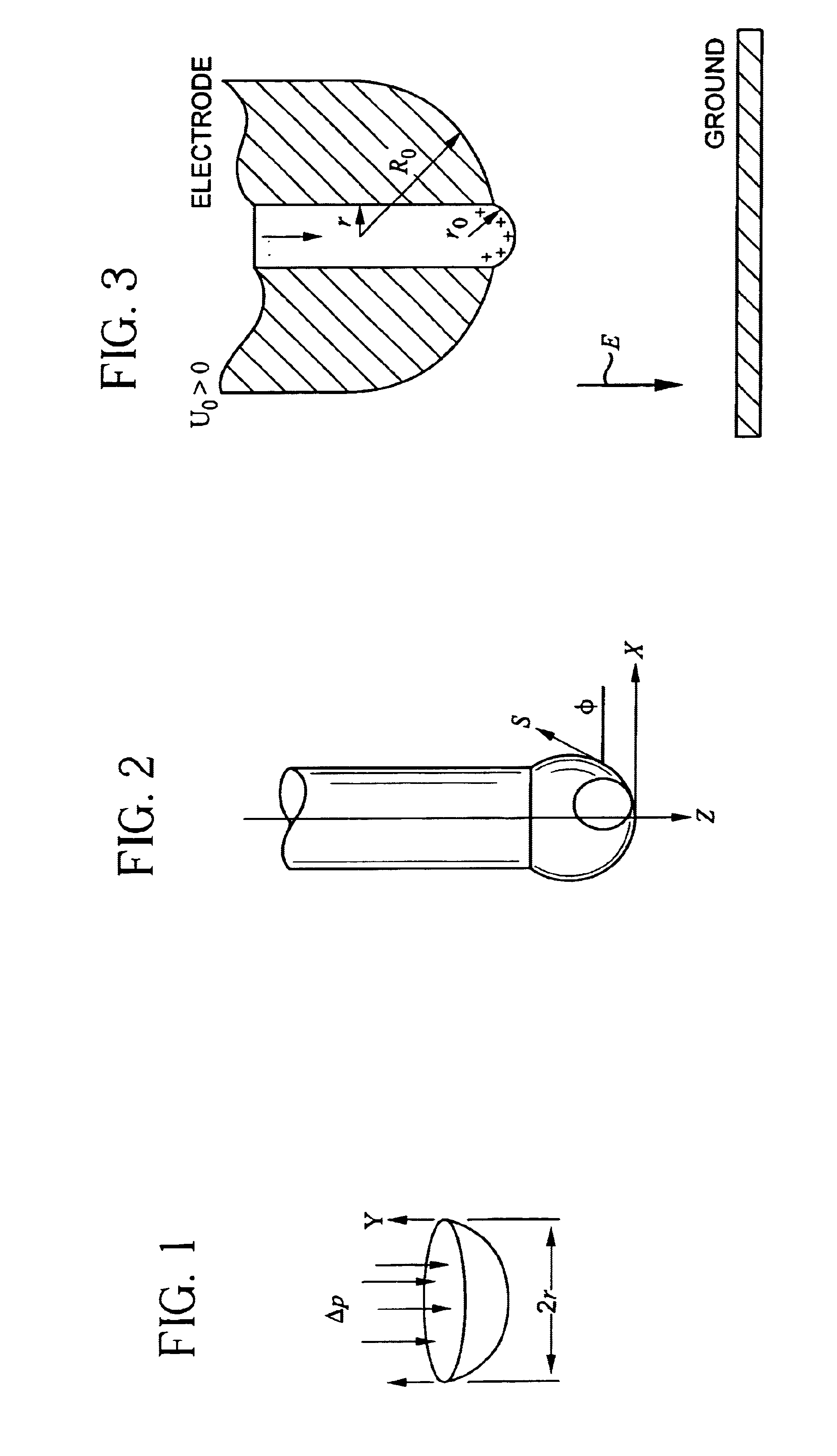

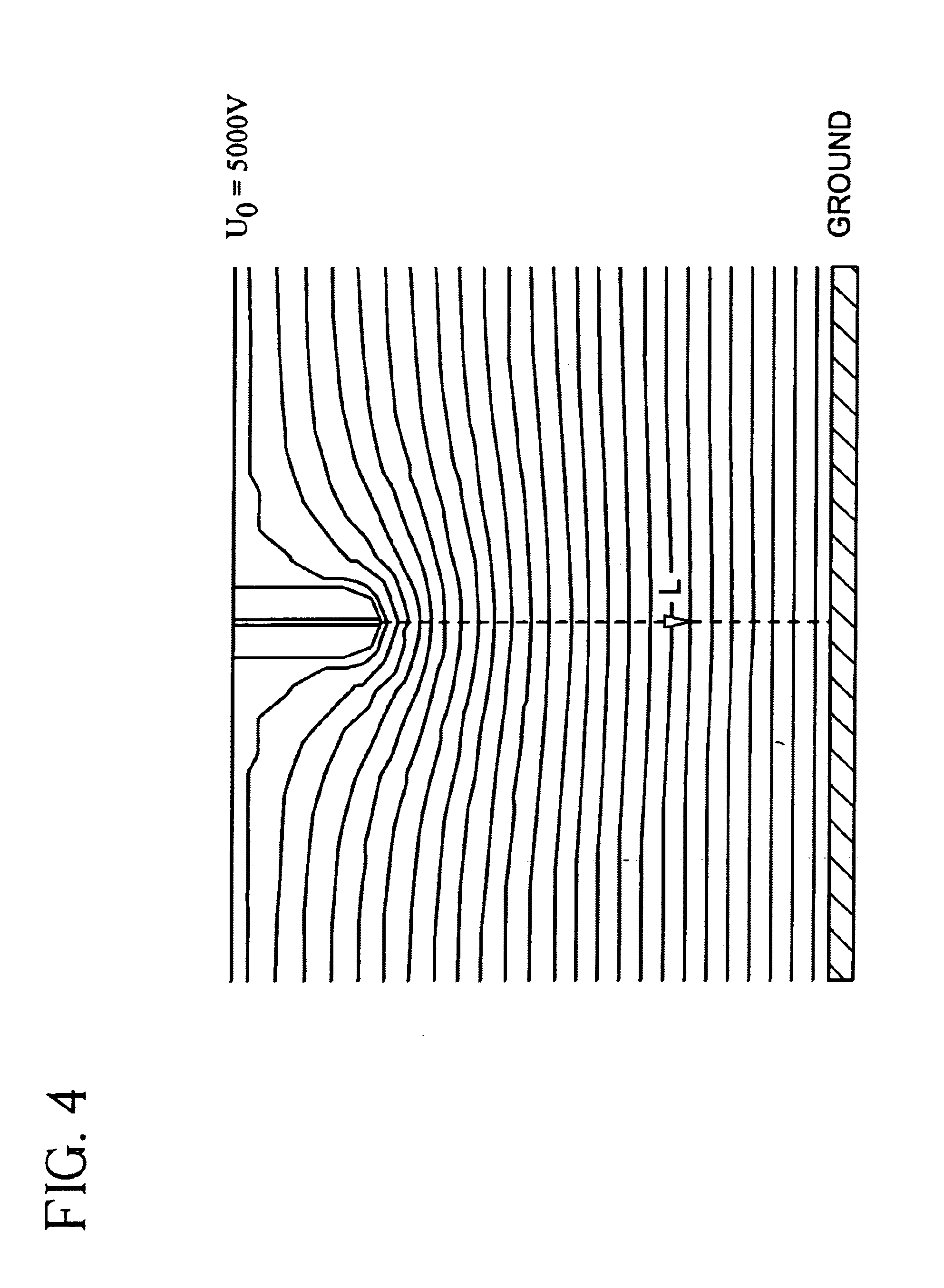

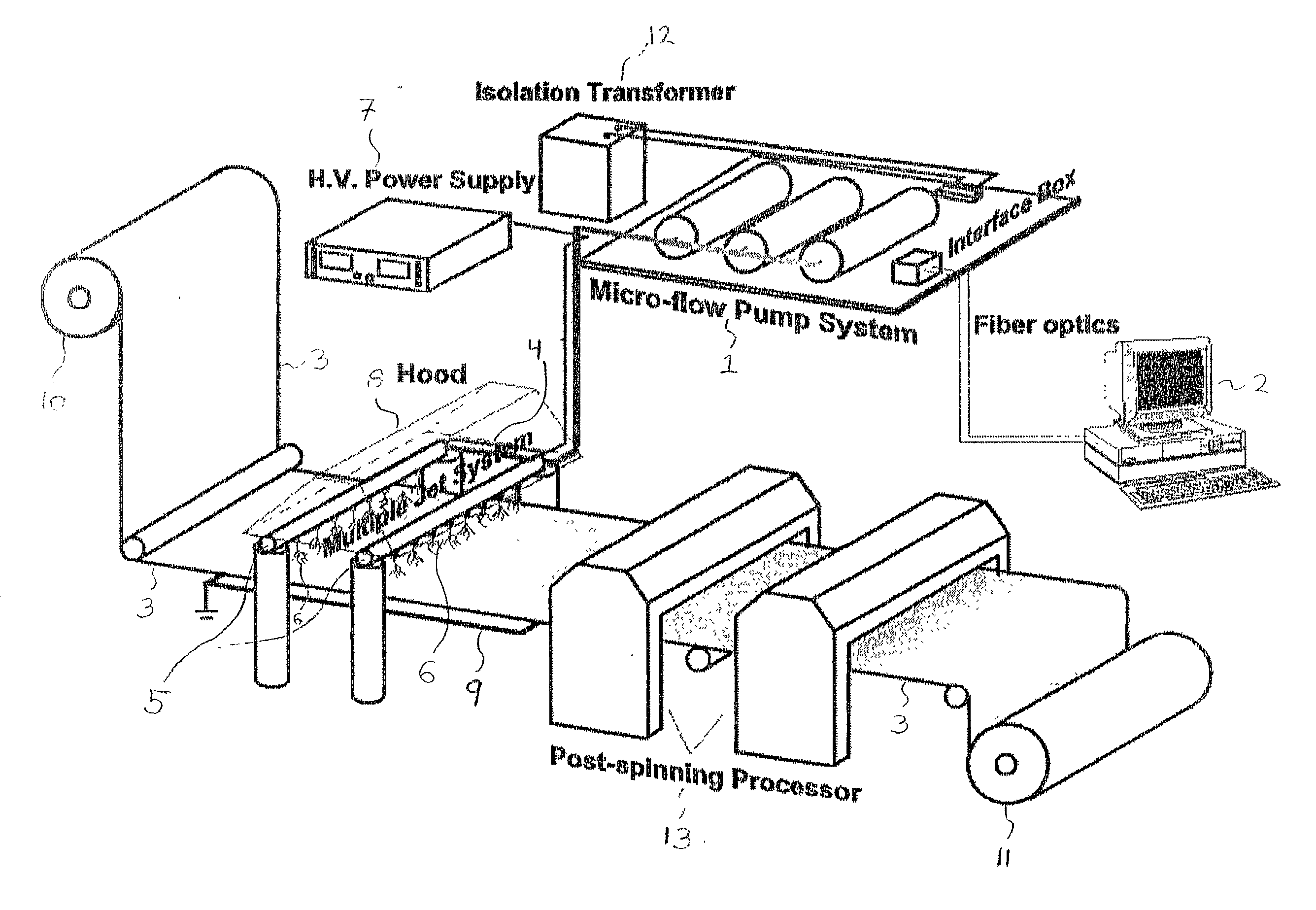

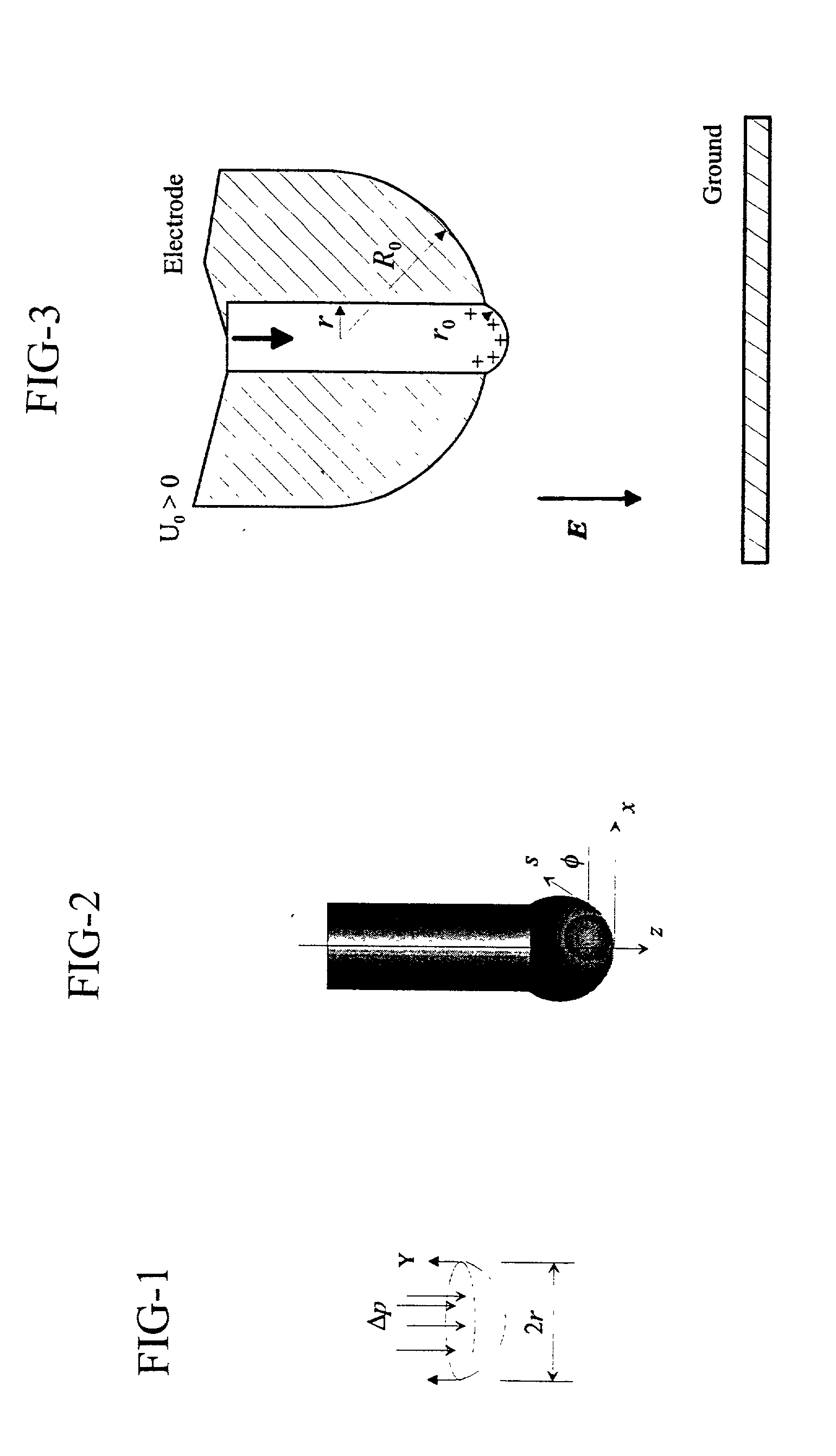

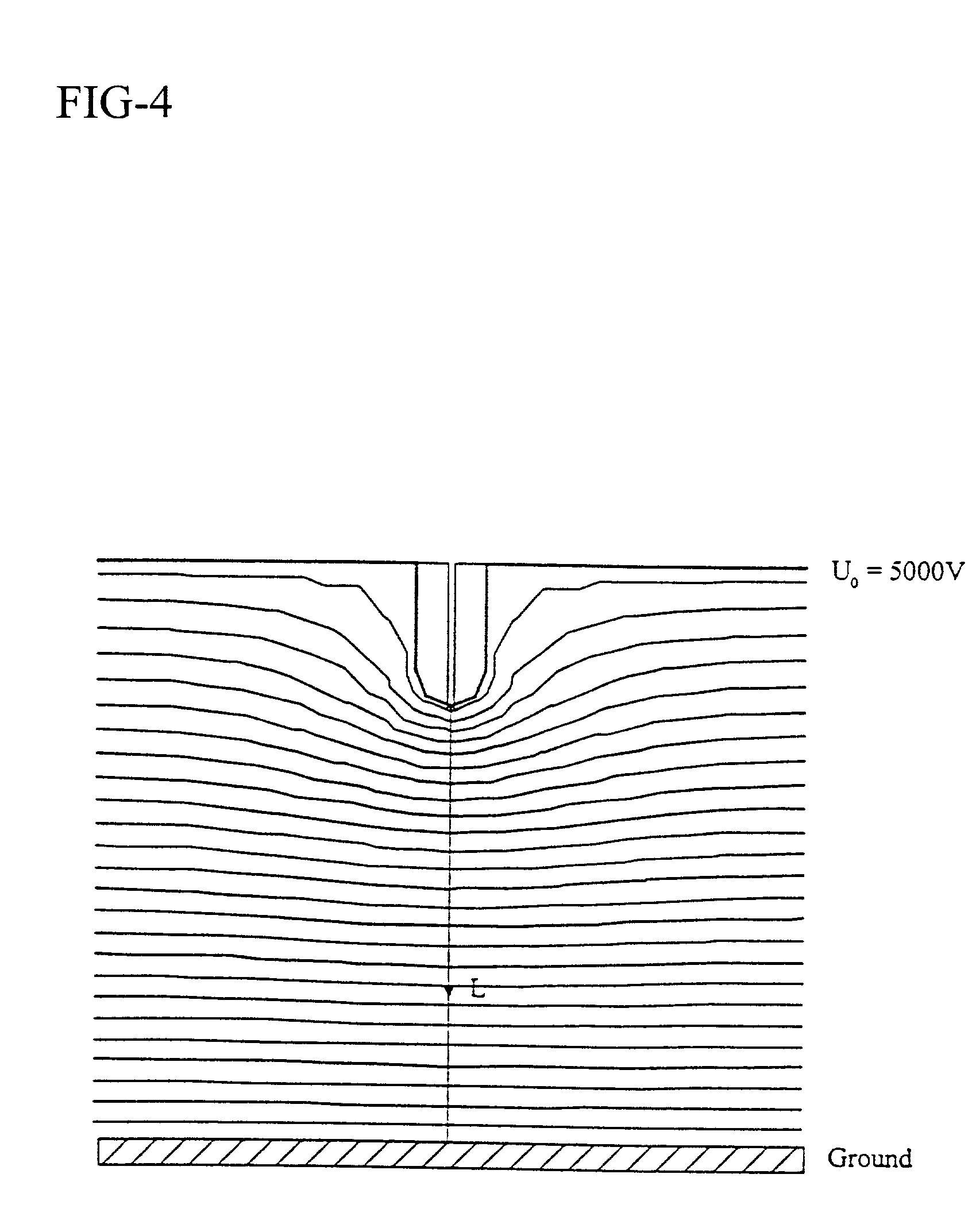

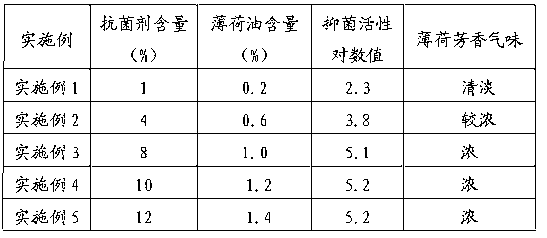

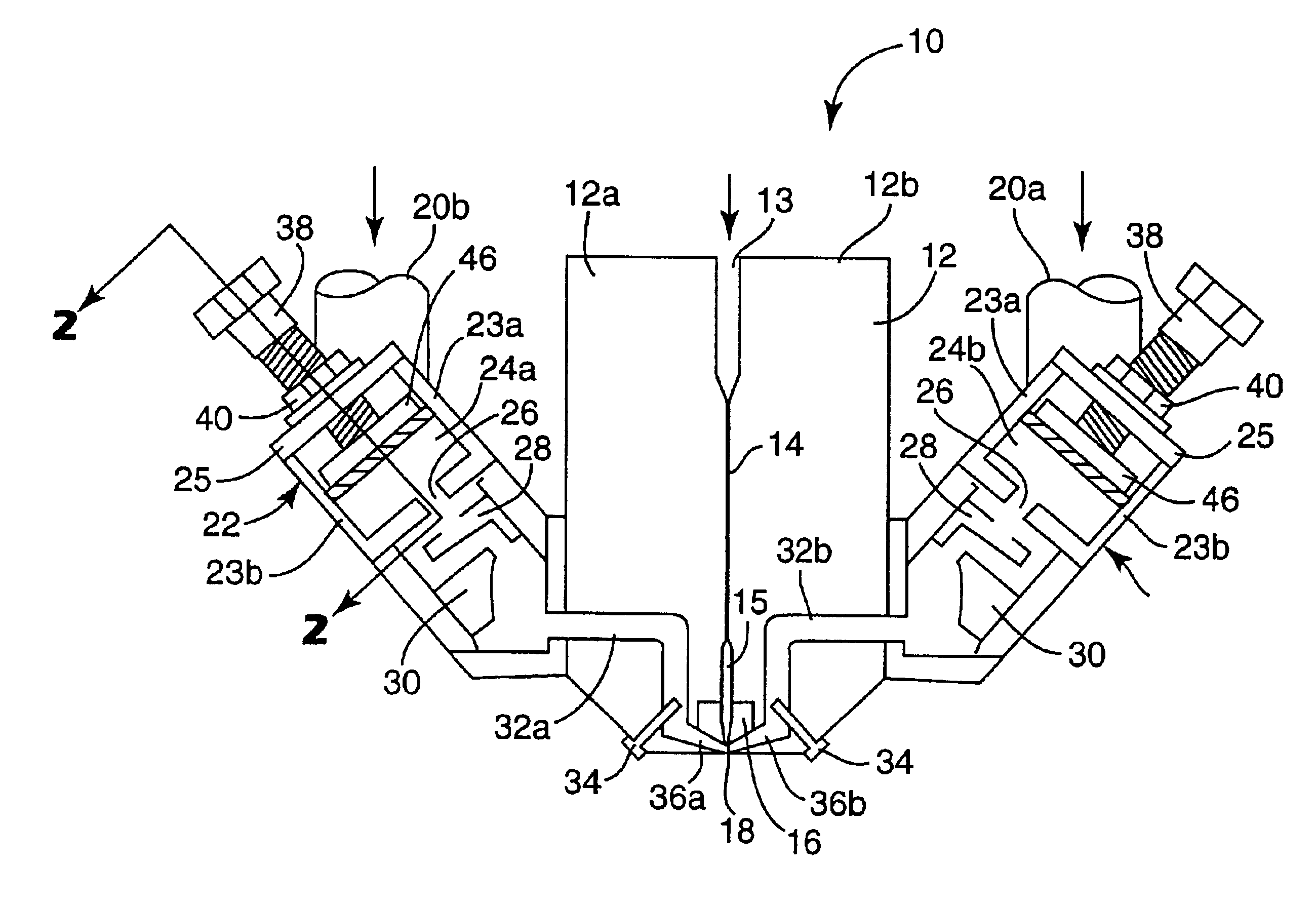

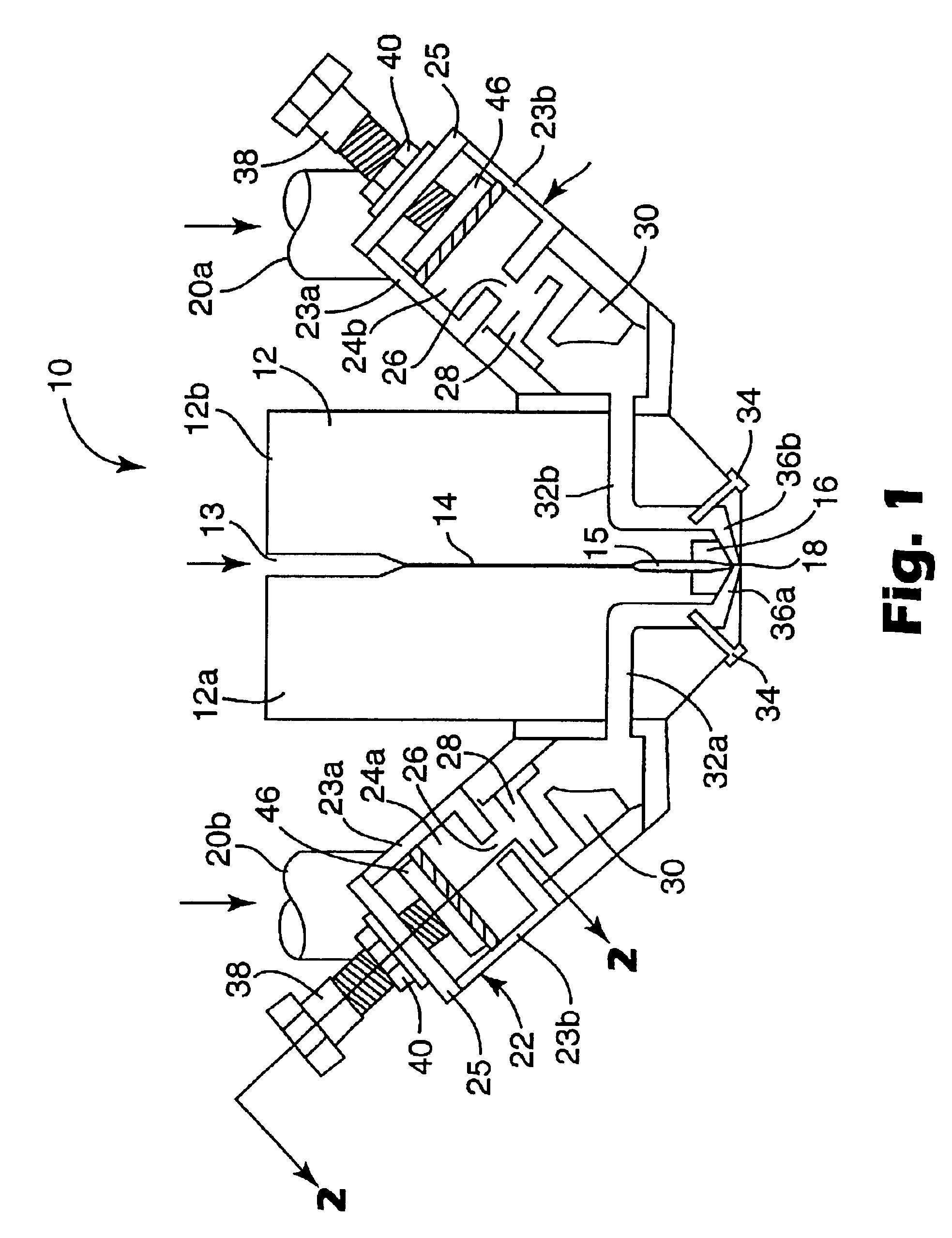

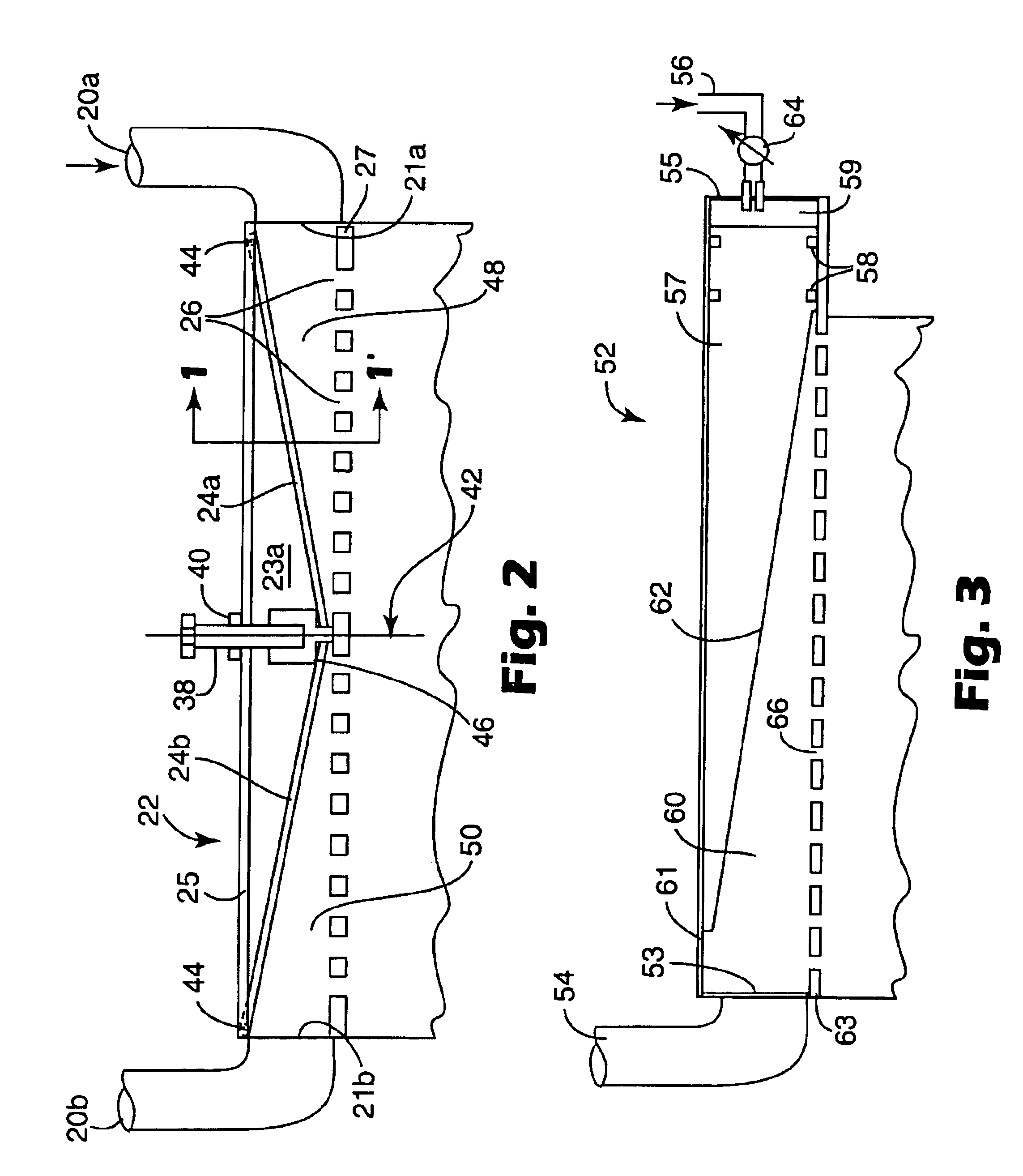

An apparatus and method for electrospinning polymer fibers and membranes. The method includes electrospinning a polymer fiber from a conducting fluid in the presence of a first electric field established between a conducting fluid introduction device and a ground source and modifying the first electric field with a second electric field to form a jet stream of the conducting fluid. The method also includes electrically controlling the flow characteristics of the jet stream, forming a plurality of electrospinning jet streams and independently controlling the flow characteristics of at least one of the jet streams. The apparatus for electrospinning includes a conducting fluid introduction device containing a plurality of electrospinning spinnerets, a ground member positioned adjacent to the spinnerets, a support member disposed between the spinnerets and the ground member and movable to receive fibers formed from the conducting fluid, and a component for controlling the flow characteristics of conducting fluid from at least one spinneret independently from another spinneret.

Owner:RES FOUND THE

Apparatus and methods for electrospinning polymeric fibers and membranes

An apparatus and methods for electrospinning polymer fibers and membranes are described. The methods include in one aspect electrospinning a polymer fiber from a conducting fluid containing the polymer in the presence of a first electric field established between a conducting fluid introduction device and a ground source and modifying the first electric field with a second electric field to form a jet stream of the conducting fluid. In another aspect the methods include forming an electrospinning jet stream of the conducting fluid and electrically controlling the flow characteristics of the jet stream. In yet another aspect the methods include forming a plurality of electrospinning jet streams of the conducting fluid and independently controlling the flow characteristics of at least one of the jet streams. The apparatus for electrospinning includes a conducting fluid introduction device containing a plurality of electrospinning spinnerets for delivering the conducting fluid, a ground member positioned adjacent to the spinnerets, a support member disposed between the spinnerets and the ground member and movable to receive fibers formed from the conducting fluid, and a means for controlling the flow characteristics of conducting fluid from at least one spinneret independently from the flow characteristics of conducting fluid from another spinneret. An improved conducting fluid introduction device which includes a plurality of spinnerets, each for independently delivering a controlled quantity of conducting fluid at a controlled pressure or flow rate, the spinnerets being charged at an electric potential and being disposed relative to each other to normally interfere with the electric field produced by adjacent spinnerets, each of the spinnerets having a tip at which conducting fluid exits configured to have an electrostatic field strength at each tip stronger than the liquid surface tension at each of the tips is also described.

Owner:RES FOUND THE

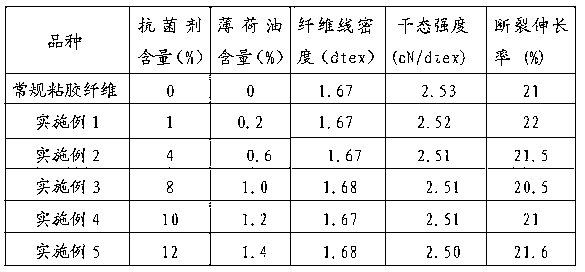

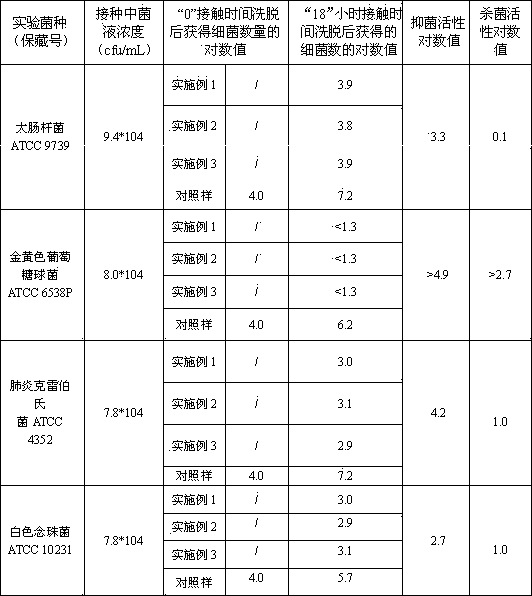

Viscose fiber with plant source anti-bacterial function and aromatic smell, and preparation method thereof

ActiveCN103225123ANo side effectsComfortable to takeArtificial thread manufacturing machinesArtificial filaments from viscoseSide effectMint extract

The invention discloses a viscose fiber with a plant source anti-bacterial function and aromatic smell. The viscose fiber is composed of a viscose spinning solution, an anti-bacterial agent and an aromatic agent, wherein the anti-bacterial agent is mixed powder of a mint extract and a isatis root extract, wherein the weight percentage of the mint extract accounts for 40%-80%; and the weight percentage of the isatis root extract accounts for 60%-20%; the aromatic agent is mint oil coated by microcapsules; the anti-bacterial agent accounts for 1%-8% of the mass of methyl cellulose in the viscose spinning solution; the mint oil accounts for 0.2%-1% of the mass of methyl cellulose in the viscose spinning solution; and the viscose fiber is prepared by adopting a wet spinning method by using the viscose spinning solution, the anti-bacterial agent and the aromatic agent. The plant source extracts and the plant source essential oil are used as the anti-bacterial agent and the aromatic agent; and the anti-bacterial agent and the aromatic agent are uniformly distributed in the fiber, so that the anti-bacterial function and the aromatic smell of the fiber are durable. Since the plant source extracts and the aromatic agent are natural substances extracted from the plants, so that the viscose fiber has no side effect to human body.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Attenuating fluid manifold for meltblowing die

InactiveUS6861025B2Quality improvementUniform physical propertiesSpinning head liquid feederConfectioneryDistribution characteristicEngineering

Melt blown nonwoven webs are formed by supplying attenuating fluid to a meltblowing die through an attenuating fluid distribution passage whose distribution characteristics can be changed while the die and manifold are assembled. By adjusting the distribution characteristics of the passage, the mass flow rate of attenuating fluid to channels in the meltblowing die and the temperature of the attenuating fluid at the die outlets can be made more uniform.

Owner:3M INNOVATIVE PROPERTIES CO

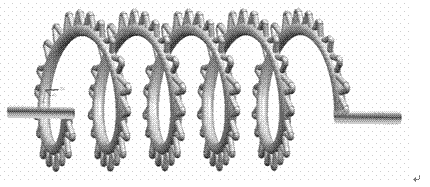

Saw tooth type needle-free electrostatic spinning device

ActiveCN102828259AAvoid cloggingAvoid cleaningSpinnerette packsArtificial thread manufacturing machinesNeedle freeElectrospinning

The invention discloses a saw tooth type needle-free electrostatic spinning device, which comprises a liquid supply system, a spinning system, a power supply system, a receiving system, a transmission system and a control system. The device is characterized in that the spinning system comprises a spinning manifold body, a spinning component and a center shaft; the exterior of the spinning manifold body has a horizontal cuboidal shape, and a horizontal cylindrical cavity is formed in the spinning manifold body; a main body of the center shaft is arranged in the cavity, and the two ends of the center shaft extend from the spinning manifold body, and are connected with the transmission system; the spinning component has an axially continuous or parallel thin rack structure, and points of a rack are outwards arranged on the center shaft, and can be driven by the center shaft to rotate; distances of 1 to 3mm are reserved between the points and the inner wall of the spinning manifold body; a liquid inlet pipe orifice of the spinning manifold body is communicated with a spinning metering pump of the liquid supply system, and an overflow port of the spinning manifold body is connected to a liquid storage device of the liquid supply system through a pipe, and is reserved between the bottom of the spinning component and the center shaft; and rectangular spinning openings are reserved in positions opposite to the highest parts of the spinning component on the upper surface of the spinning manifold body.

Owner:TIANJIN POLYTECHNIC UNIV

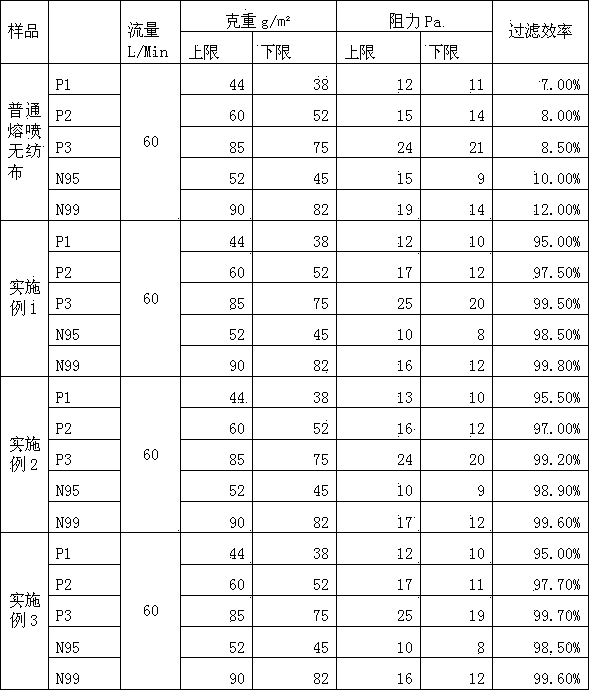

Long-acting electrostatic holding meltblown polypropylene electret and preparation method and application thereof

ActiveCN111235666AImprove filtration efficiencyImprove adsorption capacityArtificial thread manufacturing machinesMembrane filtersPolypropyleneHigh polymer

The invention belongs to the field of high polymer materials, and provides a long-acting electrostatic holding meltblown polypropylene electret and a preparation method and an application thereof. Themeltblown polypropylene electret provided by the invention contains blended master batch and meltblown polypropylene; the master batch contains a matrix material, an electret filler, a modifier, a dispersing agent, a coupling agent and an antioxidant, wherein the matrix material is polypropylene; the electrets filler is tourmaline and / or a fluorine-containing polymer, and the modifier is a nucleating agent. The meltblown polypropylene electret provided by the invention is obtained by adding the master batch into the meltblown polypropylene for spinning and by passing through a corona electrets, and the obtained meltblown polypropylene electrets material is stable in charge storage, high in filtering efficiency and high in temperature resistance.

Owner:道恩高材(北京)科技有限公司 +2

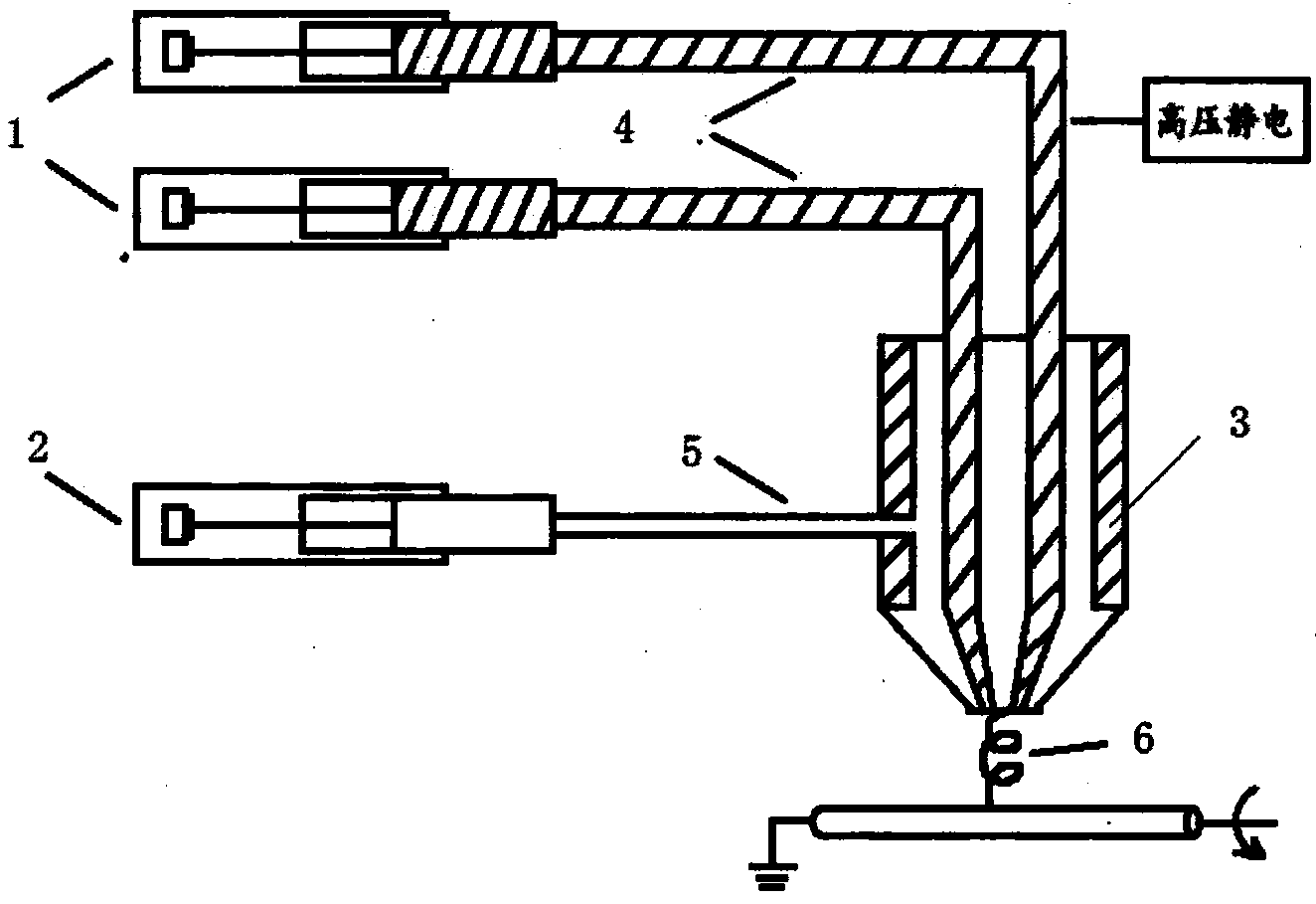

Method for preparing drug sustained release nanofibers

InactiveCN103966680AAdjustable structureControlled release rateArtificial thread manufacturing machinesFilament/thread formingFiberLiquid storage tank

The invention provides a method for preparing drug sustained release nanofibers. The method is characterized by including the specific steps that (1) drug-carried micro-spheres are arranged in an organic solvent to be evenly stirred and vibrated to obtain core layer spinning solutions; (2) degradable solutes and volatile solvents are evenly mixed to prepare surface-layer spinning solutions; (3) the surface-layer spinning solutions and the core layer spinning solutions are injected into a surface-layer liquid storage tank and a core layer liquid storage tank of a coaxial spinning jet respectively, coaxial electrostatic spinning is carried out at the room temperature, and the volatile solvents in the surface-layer spinning solutions volatilize to form through holes in the spinning process to obtain the drug sustained release nanofibers with the porous surface layer and the drug-carried micro-sphere wrapped core layer. By means of the method, the obvious multi-stage drug release system is achieved, and the drug-carried micro-spheres are released in the core layer firstly to enter a hole channel in the surface layer and finally enter damaged target components of the nanofibers to give play to drug effects. The method is simple in operation and gentle in reaction condition. A drug sustained release curve is well controlled, and the drug using efficiency is improved.

Owner:DONGHUA UNIV

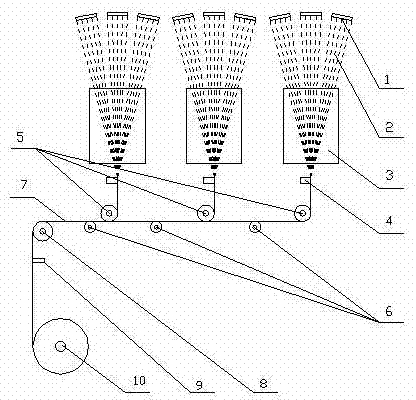

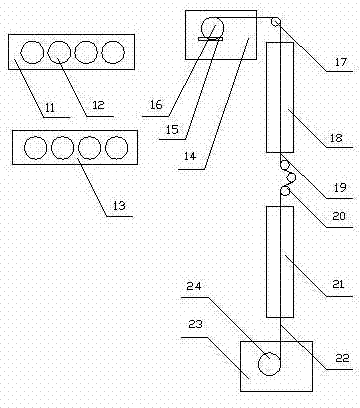

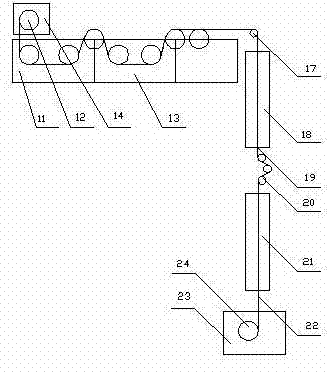

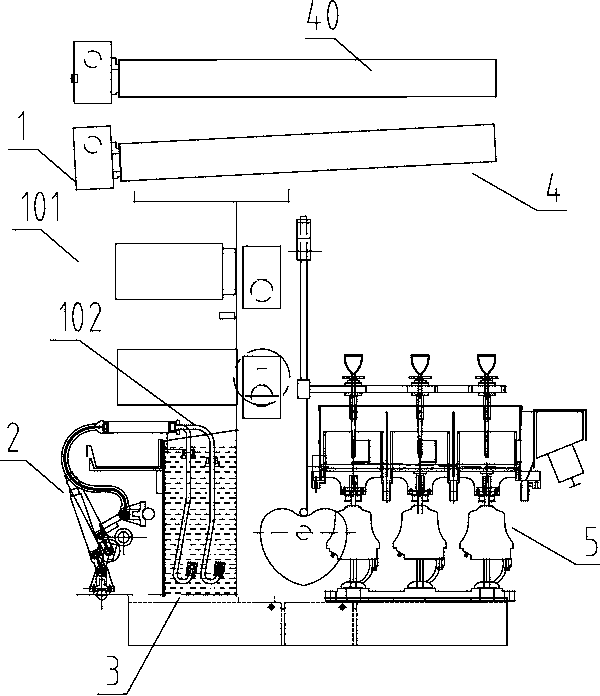

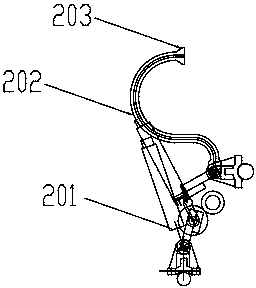

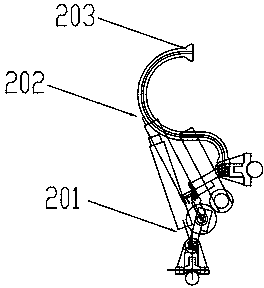

Array multi-nozzle electrospinning device

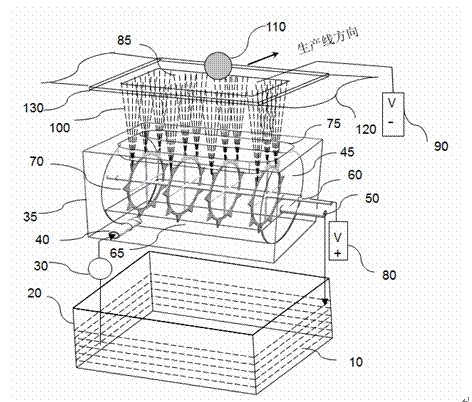

InactiveCN101586288ARealize mass productionEasy to disassembleArtificial thread manufacturing machinesFilament/thread formingFiberEngineering

The present invention discloses an array multi-nozzle electrospinning device, including an electrospinning liquid supply apparatus, an electrospinning liquid spinning apparatus, a receiving electrode plate, an electrospun fiber transport apparatus and a high voltage electrostatic generator, the electrospinning liquid spinning apparatus includes effusers and nozzles, the nozzles are array-arranged; the electrospun fiber transport apparatus includes a feed roller apparatus and a discharge roller apparatus disposed on two ends of the receiving electrode plate respectively; the electrospun fiber receiving material is transported to the space between the electrospinning liquid spinning apparatus and the receiving electrode plate by the feed roller apparatus, and the discharge roller apparatus transports the received electrospun fiber out; the invention provided device can produce electrospun fiber membrane in large scale, and can produce both single polymer electrospun fiber membrane and multiple polymers blended layered electrospun fiber membrane for one time, and can obtain a electrospun fiber membrane with specific topological pattern by changing electrospun fiber receiving material conveniently, which satisfies various application requirements of electrospun fiber materials.

Owner:JIANGSU CHANGJIYONG BIOTECH CO LTD

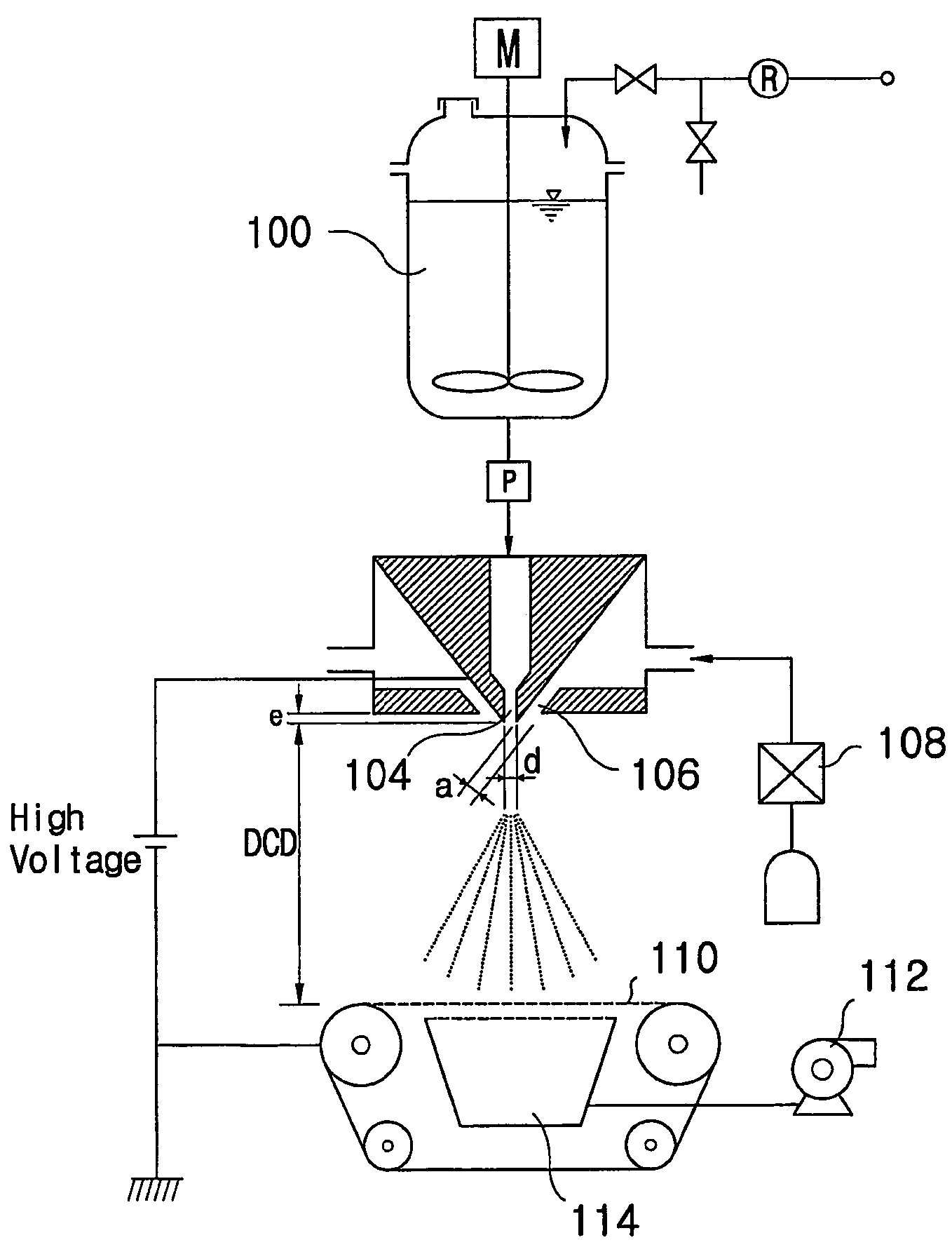

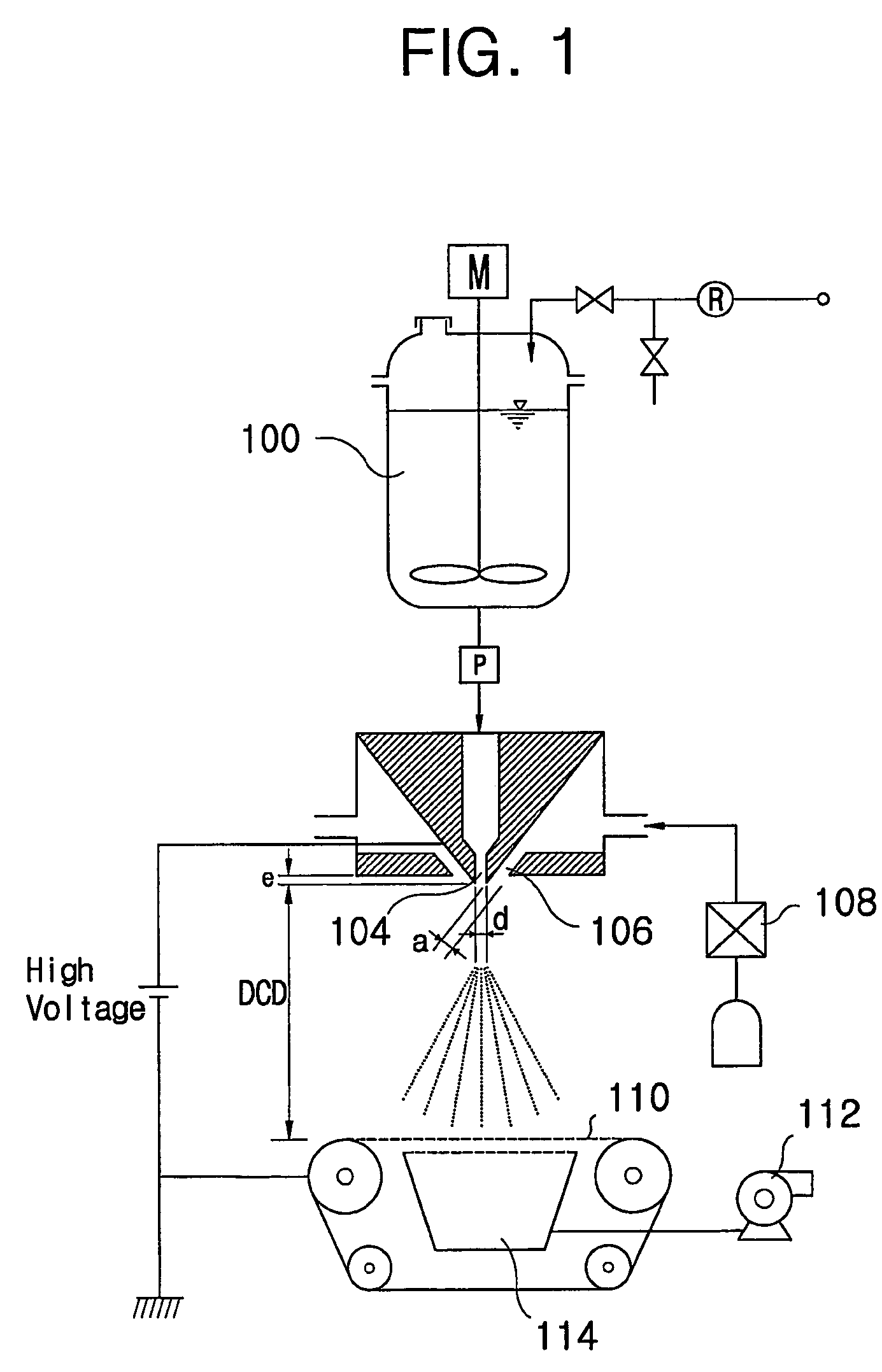

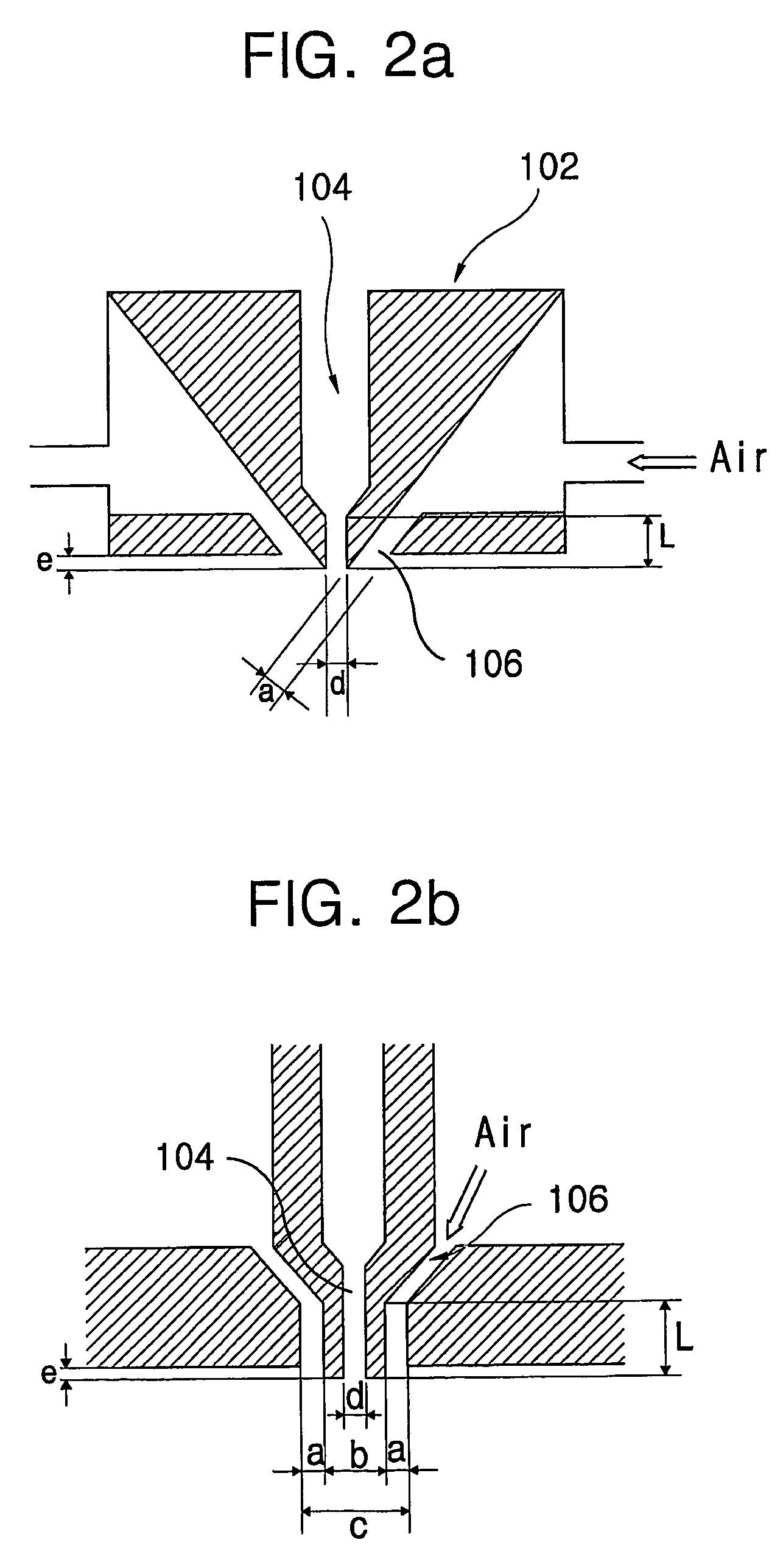

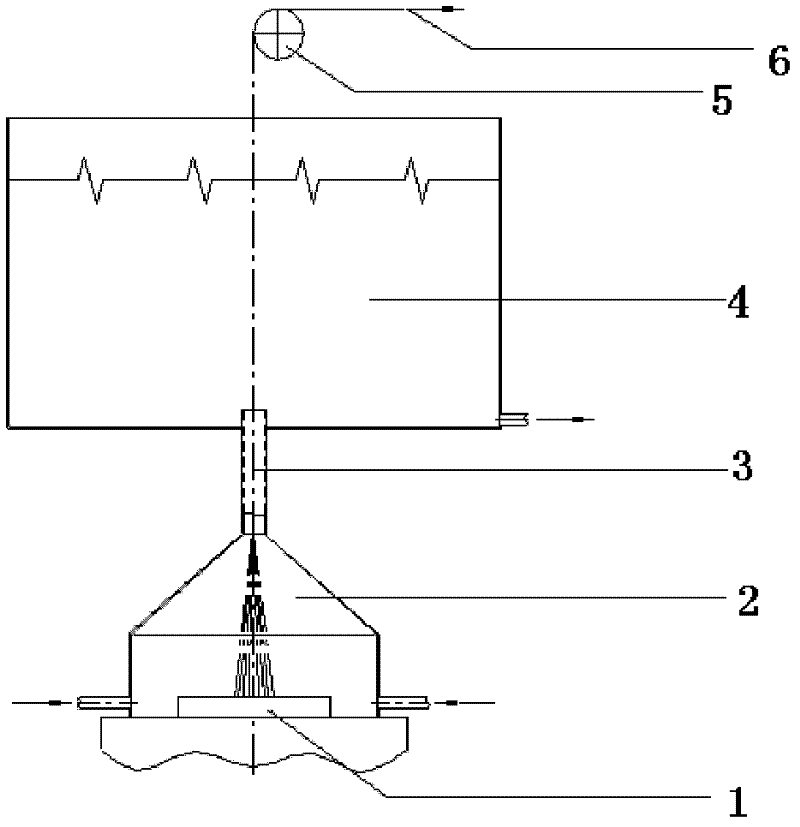

Manufacturing device and the method of preparing for the nanofibers via electro-blown spinning process

ActiveUS7618579B2Easily realizedElectric discharge heatingWood working apparatusThermoplasticNanofiber

The invention relates to a nanofiber web preparing apparatus and method via electro-blown spinning. The nanofiber web preparing method includes feeding a polymer solution, which is a polymer dissolved into a given solvent, toward a spinning nozzle, discharging the polymer solution via the spinning nozzle, which is charged with a high voltage, while injecting compressed air via the lower end of the spinning nozzle, and collecting fiber spun in the form of a web on a grounded suction collector under the spinning nozzle, in which both of thermoplastic and thermosetting resins are applicable, the solution does not need to be heated and electrical insulation is readily realized.

Owner:DUPONT SAFETY & CONSTR INC

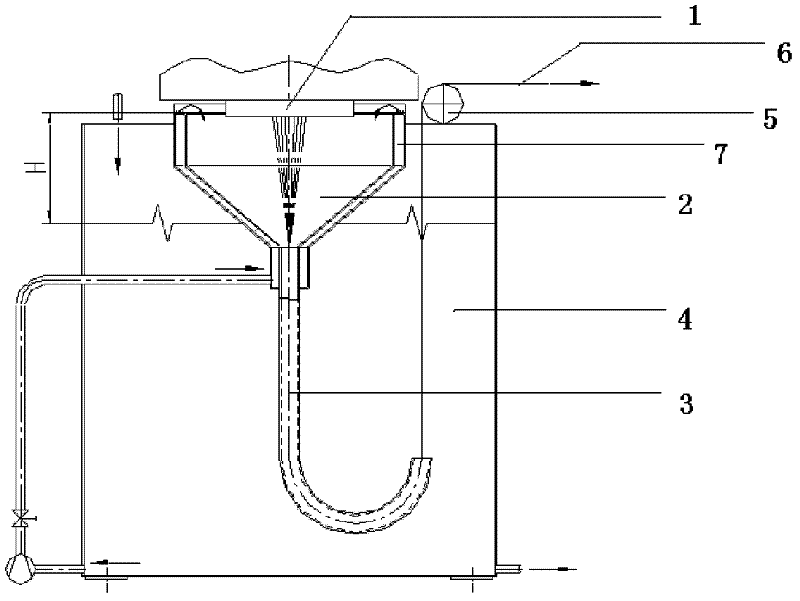

Porous bubble electrostatic spinning device

InactiveCN102660783ARealize large-scale productionIncrease productivityArtificial thread manufacturing machinesFilament/thread formingSprayerAir pump

A porous bubble electrostatic spinning device comprises a liquid storage tank, a high pressure electrostatic generator, an air pump, a sprayer, and a dash receiver, wherein the sprayer is connected with the air pump through an air duct, the dash receiver is connected with a grounded electrode, an opening is arranged at the upper end of the liquid storage tank, the liquid storage tank is connected with the high pressure electrostatic generator through a metal electrode, the liquid storage tank is internally provided with a middle flat plate, and a plurality of small holes with adjustable diameters are formed in the middle flat plate in a penetrating way. As the small holes are formed in the middle flat plate, solution in the liquid storage tank generates a large quantity of bubbles through the plurality of small holes under the action of the air pump. When filed stress is greater than surface tension of the solution, and jet flow is ejected from the top of the bubbles and is deposited on the dash receiver to form a large amount of nanofiber. The porous bubble electrostatic spinning device can produce the nanofiber in a large scale, so that according to the device, the production efficiency is high, the production cost is low, the equipment is simple, the operation is easy, the adaptability is high and the requirement of batch production can be met.

Owner:SUZHOU UNIV

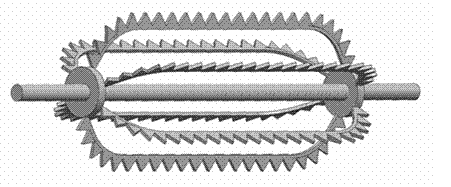

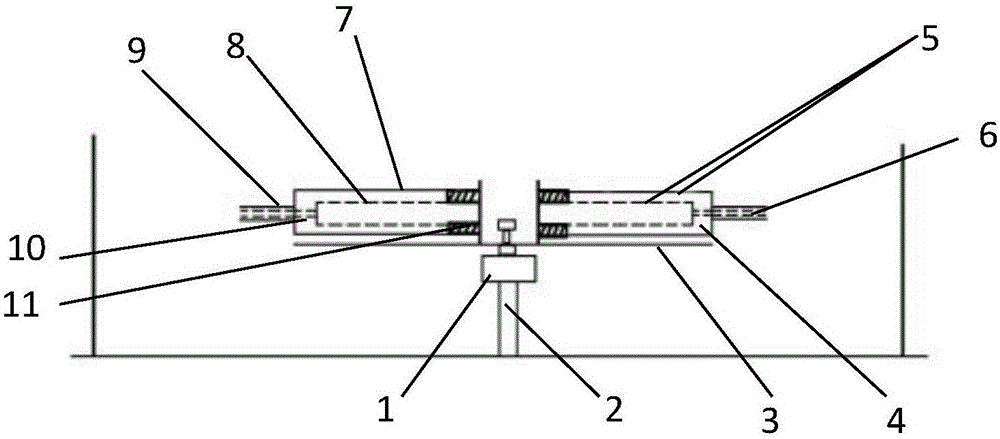

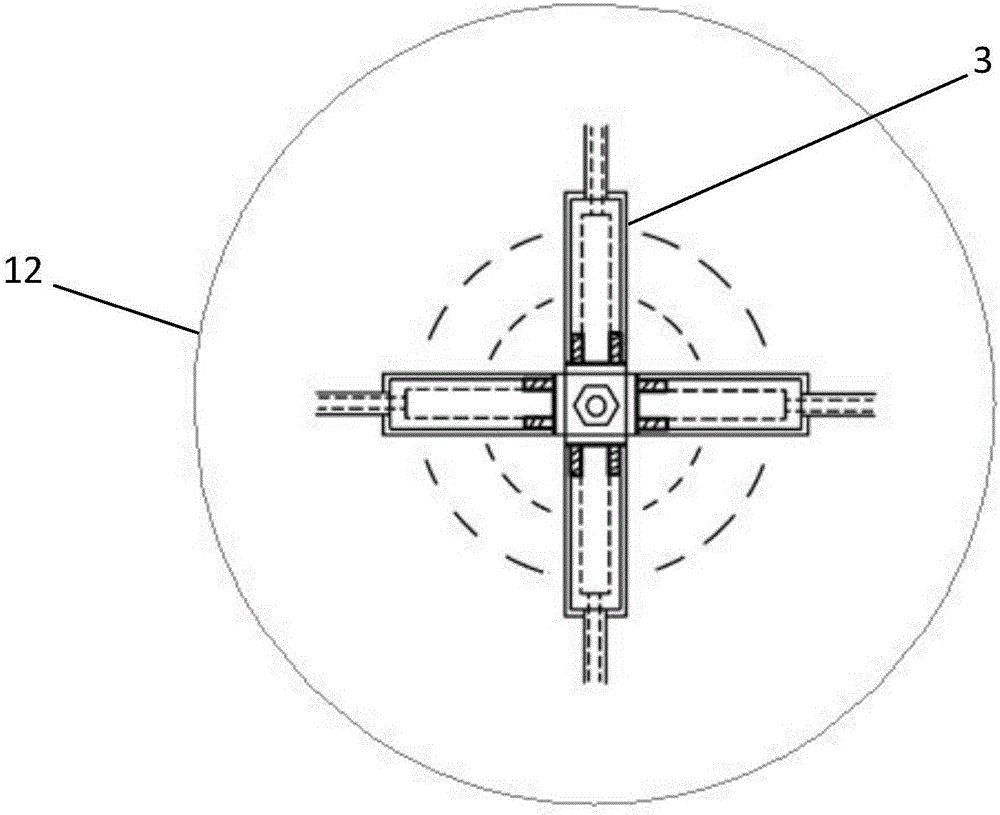

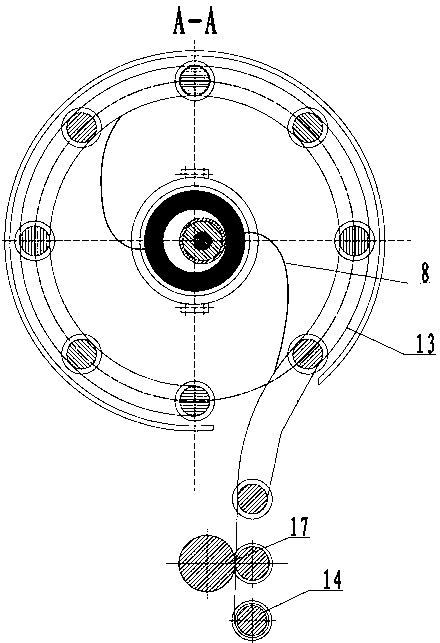

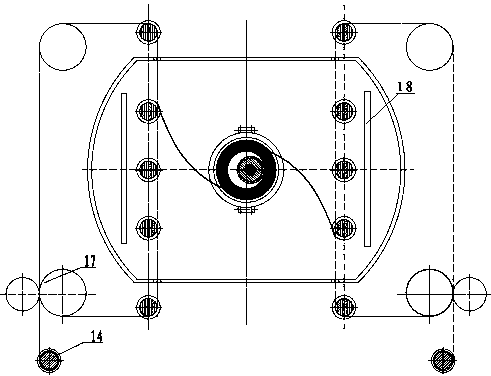

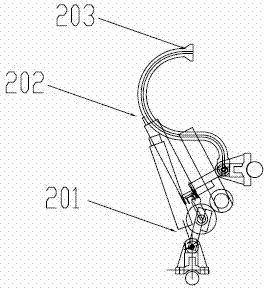

Coaxial centrifugal spinning device and method

InactiveCN106222767AStable productionGuaranteed suitabilityArtificial thread manufacturing machinesFilament/thread formingEngineeringSpin speed

The invention discloses a coaxial centrifugal spinning device and method. The device comprises a direct-current motor, a supporting device, a spinning support, coaxial centrifuge tubes, spinning needle heads and a receiving device, wherein the direct-current motor is fixed to the supporting device, the spinning support is directly and fixedly connected with an output shaft of the direct-current motor, the coaxial centrifuge tubes are fixed to the spinning support, and under the action of the direct-current motor, the spinning support drives the coaxial centrifuge tubes to rotate at high speed; each coaxial centrifuge tube comprises an outer layer centrifuge tube and an inner layer centrifuge tube, each spinning needle head comprises an outer layer needle head and an inner layer needle head, during spinning, a spinning solution or melt in the outer layer centrifuge tubes and the inner layer centrifuge tubes is tossed out under the action of centrifuge force, an outer layer solution wraps an inner layer solution, and superfine fiber of a skin-core structure is formed due to centrifuge force drafting, solvent volatilization and phase separation. The coaxial centrifugal spinning device is simple, high in spinning speed and production efficiency and capable of producing coaxial superfine fiber on a large scale.

Owner:TIANJIN POLYTECHNIC UNIV

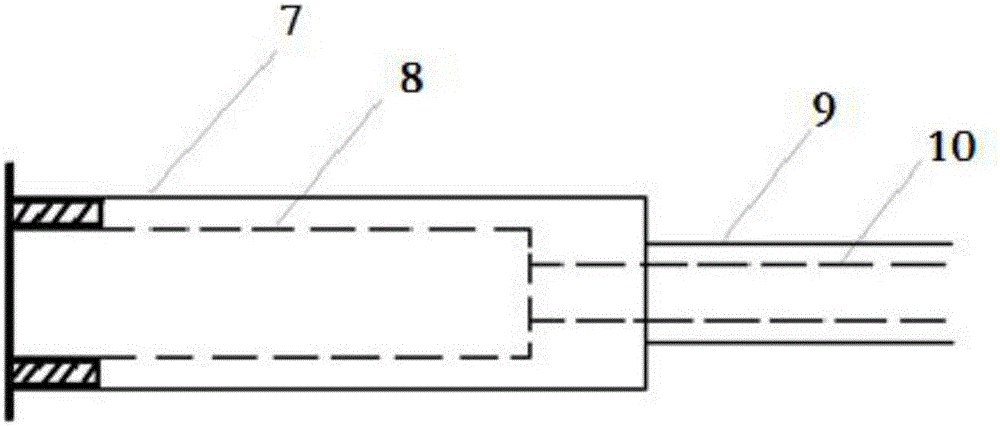

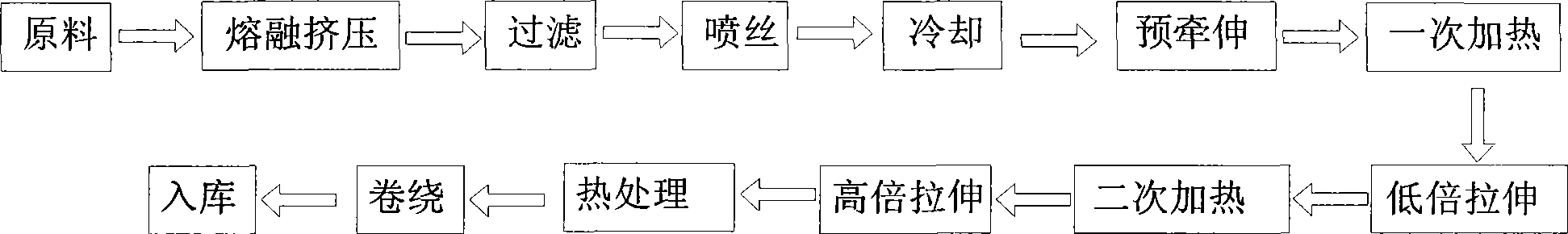

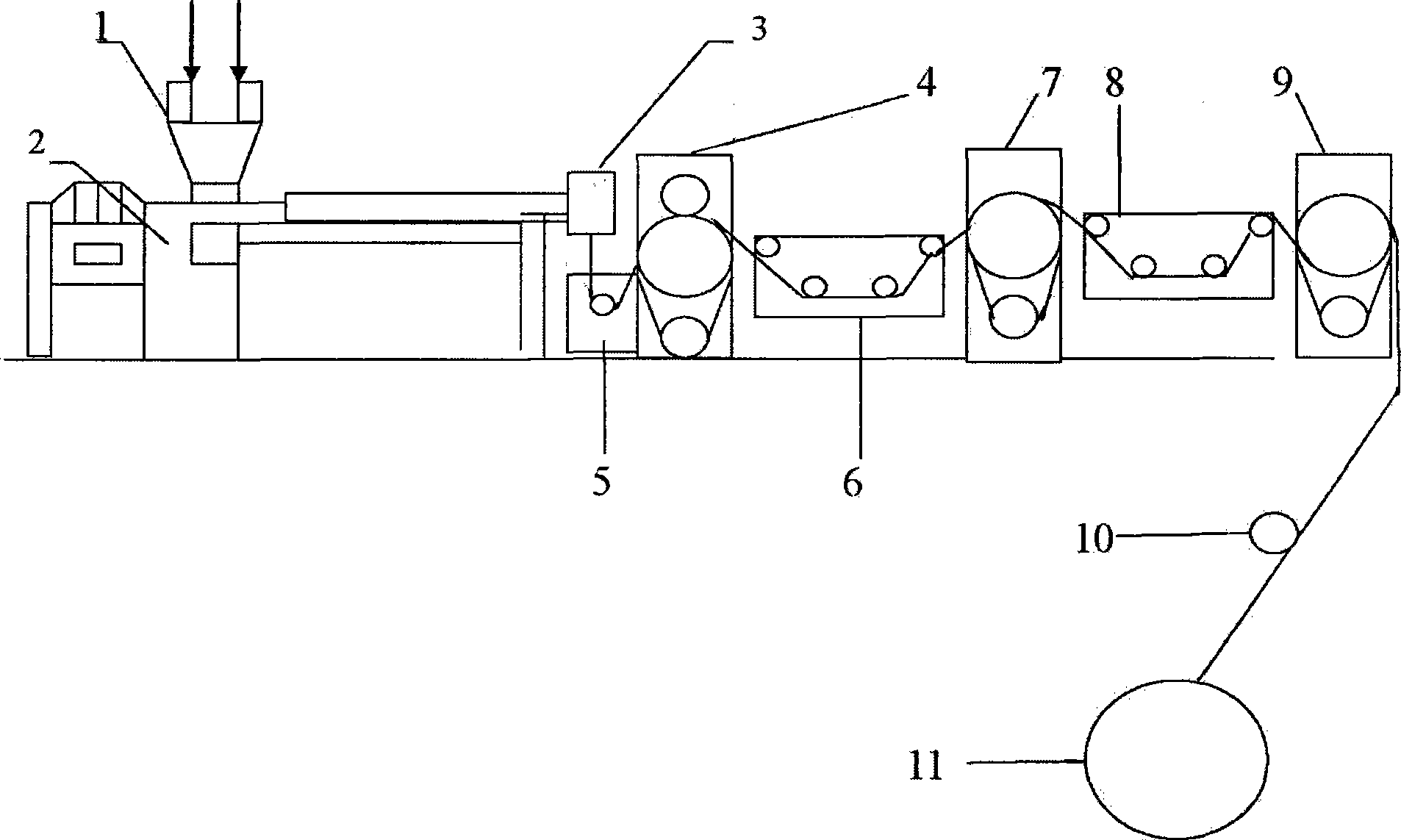

Method and equipment for preparing ultrahigh molecular weight polyethylene fibers

InactiveCN101935894AContinuous productionShort processArtificial thread manufacturing machinesMelt spinning methodsFiberYarn

The invention discloses a method and equipment for preparing ultrahigh molecular weight polyethylene fibers. The method comprises the following steps of: blending and melting ultrahigh molecular weight polyethylene and a modifier to prepare a granular or powdery modified ultrahigh molecular weight polyethylene raw material; melting and extruding the raw material by using an extruder to form melt of which a flow rate is 0.01 to 0.2 grams per 10 minutes, feeding the melt to a spinning mould by using a melt pump to form melt strips, and cooling and pre-stretching the melt strips to obtain primary yarns; and stretching the primary yarns in a plurality of stages to obtain the ultrahigh molecular weight polyethylene fibers. The equipment comprises the extruder, the melt pump, the spinning mould, a cooling channel, a three-roller tractor, a primary hot-stretching box, a first seven-roller tractor, a secondary hot-stretching box, a second seven-roller tractor, a rinsing trough, a drying box and a winder which are arranged sequentially. The method and the equipment have the characteristics of continuous production capability, relatively shorter process flow, relatively fewer equipment components, no need of solvent, low production cost and the like.

Owner:王庆昭

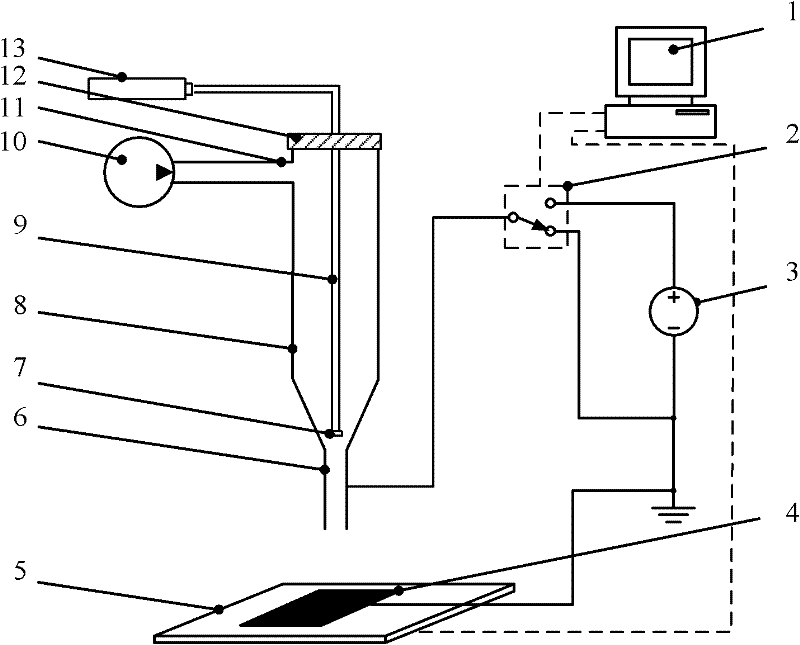

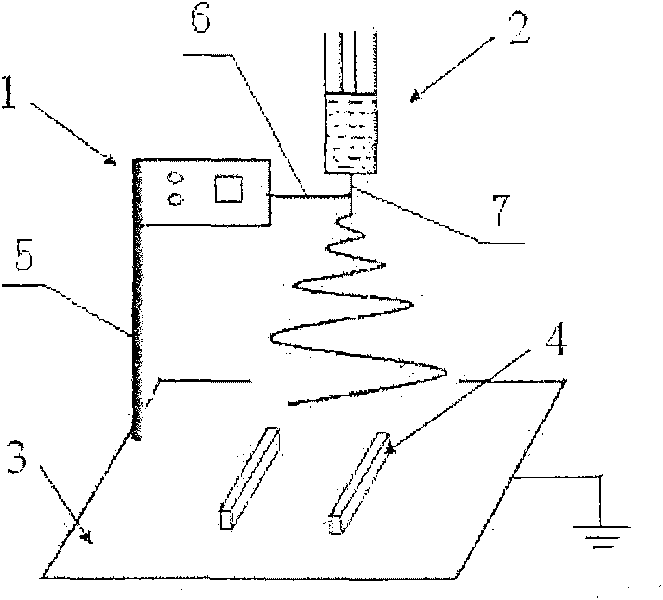

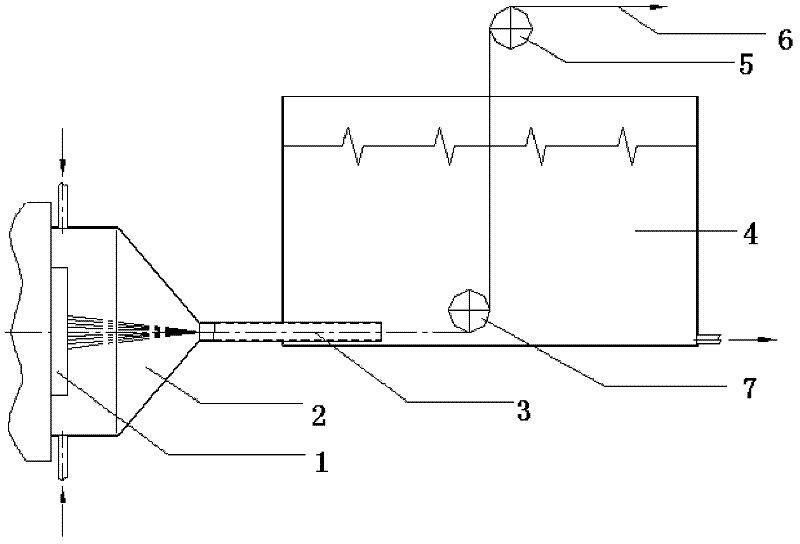

Laser-guided electrospinning direct writing device

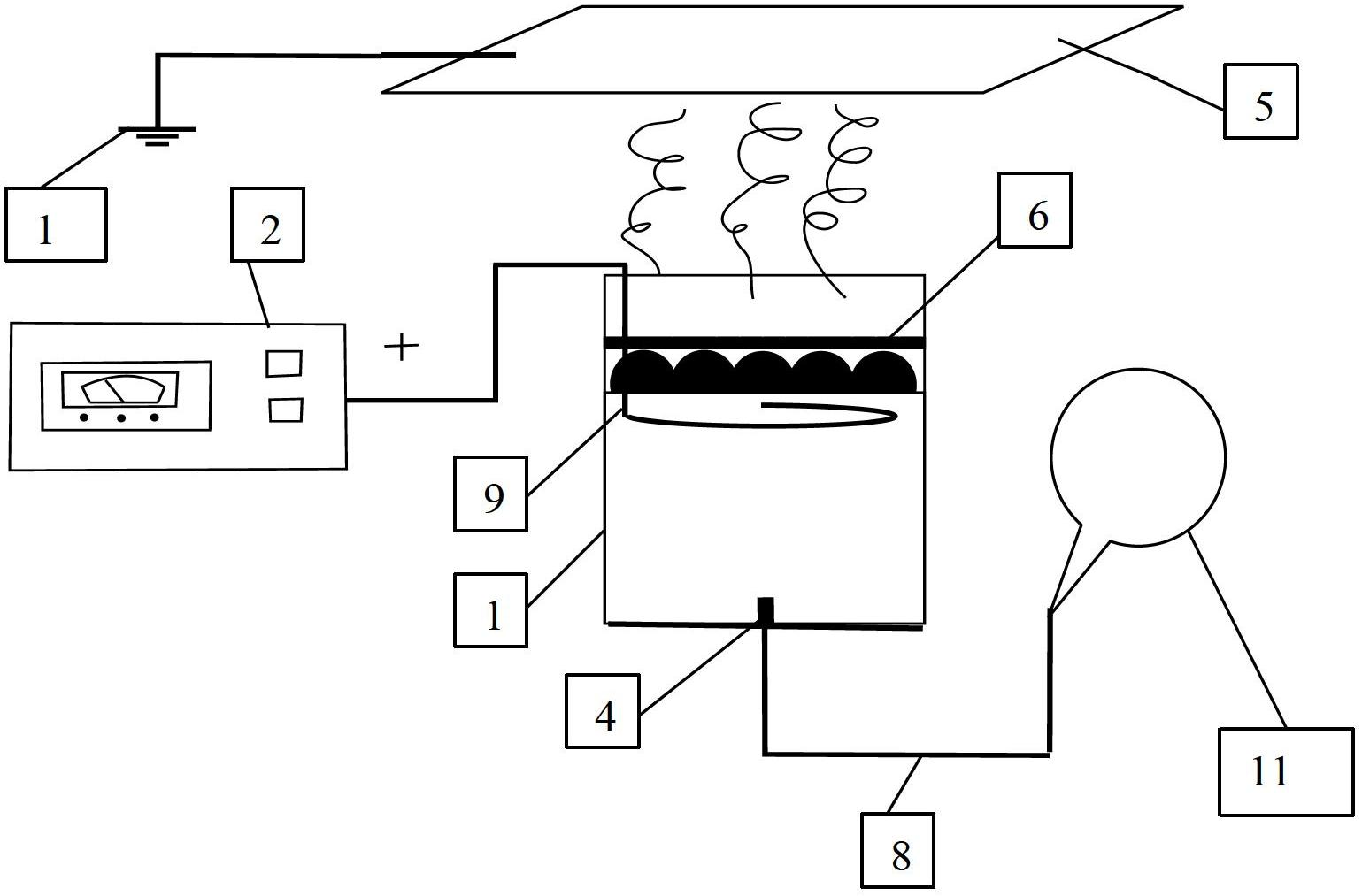

InactiveCN102162175AImprove stabilityExtend exercise timeSpinnerette packsSpinning head liquid feederComing outElectrical conductor

The present invention provides a laser-guided electrospinning direct writing device capable of realizing long-time controllable preparation and precise positioning of single uniform micro / nanostructure. The device is provided with a controller, a high-voltage relay, an electrostatic high-voltage [power] source, a hollow nozzle, a collimating focusing lens set, optical fibers, a sealing adjusting part, a laser, a solution feed pump, a solution feed pipe, a collecting board and a motion platform, wherein the controller is connected with the high-voltage relay; ends of the high-voltage relay are respectively connected with the electrostatic high-voltage [power] source, the collecting board and a conductor nozzle arranged at the front end of the hollow nozzle; the sealing adjusting part is in a sealing connection with the rear end of the hollow nozzle; the optical fibers pass through the center of the sealing adjusting part and are fixedly connected with the sealing adjusting part; the collimating focusing lens set is arranged at the front end of the optical fibers; the rear end of the optical fibers comes out of the hollow nozzle and is connected with the laser; the solution feed pump is communicated with the hollow nozzle through the solution feed pipe; and the collecting board is fixed on the motion platform and faces the hollow nozzle. The laser constraints the disordered motion of spinning jet flow and guides the spinning jet flow to deposit at the laser spot of the collecting board.

Owner:XIAMEN UNIV

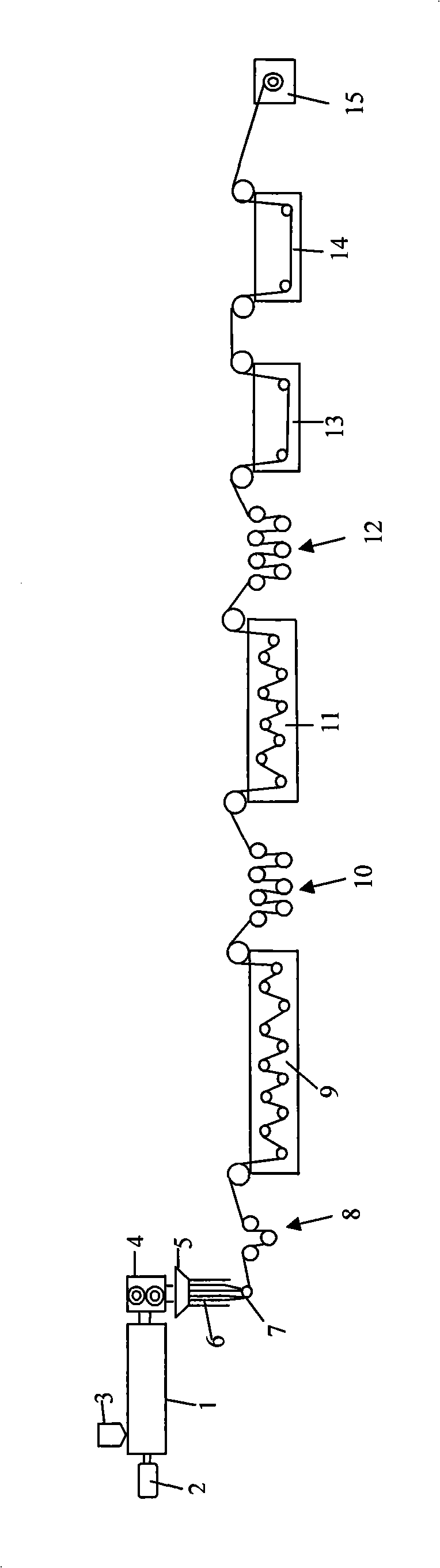

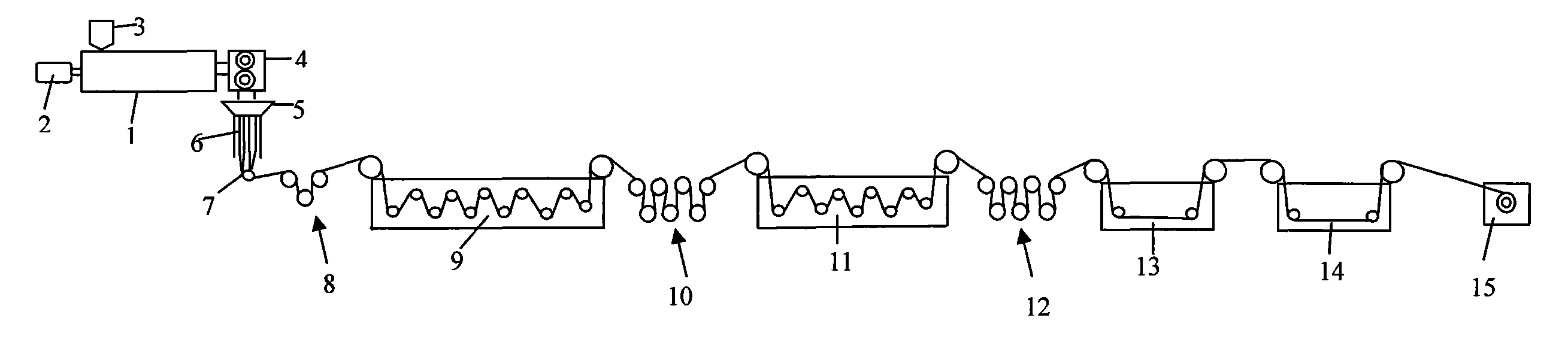

Method and apparatus for producing high strength, high modulus polyethylene filament by melt drawing

ActiveCN101476170AImprove featuresHigh strengthArtificial thread manufacturing machinesArtificial filament heat treatmentPolymer scienceHigh intensity

The invention discloses a method for producing polythene fiber with high strength and high modulus by melting fiber drawing and a device thereof. The method includes steps as follows: blend composition of polythene with super high molecular weight and three element blend composition of polythene with super high molecular weight are used as raw material, the raw material is spout fibre adobe after melted through a screw extruder, the fibre adobe is preset drafted after cooling, then low power drafted after once heating, then high power drafted after twice heating, finally is processed heat processing for obtaining polythene fiber with high strength and high modulus. The screw extruder, a cooling mechanism, a drafting machine processing preset drafting, an once heating mechanism, a low power drafting machine, a twice heating mechanism, a high power drafting machine, a heat processing mechanism, a winding reeling machine are arranged in the device orderly. The invention provides a producing method with simple technique, short producing flow, low cost and no pollution aiming at problem that UHMWPE melting spout fibre process has difficult to spin, and provides a device with compact equipment and easy to operate.

Owner:闫镇达

Method for producing color composite polyester yarn through one step

The invention discloses a method for producing a color composite polyester yarn through one step. Spinning positions are utilized to divide different areas, and the synchronous different-path spinning of pre-oriented yarns (POY) and fully-drawn yarns (FDY) and strand combined yarn networking are compounded together, so that four processing links of stock solution coloring, spinning, drawing and networking are completed through a one-step method. The production technological process is short, the production efficiency is high, energy consumption and loss are small, pollutant discharge is reduced, and the method is ecological and environmental-friendly.

Owner:ZHEJIANG HUAXIN ADVANCED MATERIALS

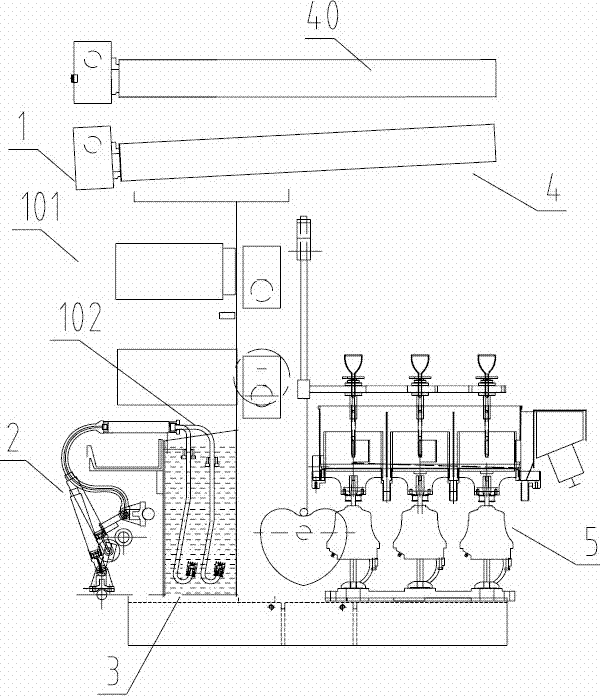

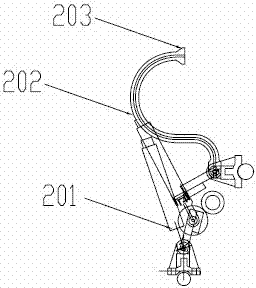

Preparation method of continuous filament of asphalt-based carbon fiber

InactiveCN103046165ASmall diameterIncrease the number of filamentsNew-spun product collectionArtificial thread manufacturing machinesFiber bundleCarbonization

The invention discloses a preparation method of a continuous filament of an asphalt-based carbon fiber, and belongs to the field of carbon fiber production. The preparation method solves the problems that the existing spinning speed is lower, the fiber bundle damage is large, the infusibility efficiency is low, and doubling and embrittlement are easy. The preparation method comprises the specific process steps that a, spinning asphalt is extruded into fines by spinning position fusion, humidified, oiled and bundled to form a protogenic asphalt fiber bundle; b, double roller stranding and tensioning are conducted; c, the asphalt fiber bundle is wound on a spinning roller sleeve; d, an asphalt fiber reel is immersed in an oxidability liquid phase, and a liquid-phase oxidized fiber bundle reel is obtained; e, the reel is immersed in a high-temperature-resistant oil solution; the filament is unreeled and rollers are removed at a low speed; the oxidized fiber bundle continuously enters a continuous infusible furnace and a continuous low-temperature pre-carbonization furnace to form a pre-carbonization fiber bundle reel; and f, drawing heat treatment is conducted through a continuous carbon-fiber high-temperature carbonization furnace and a graphitization furnace, and then the continuous filament of the asphalt-based carbon fiber is obtained.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

Nano-silver antibacterial melt-blown non-woven fabric and production method thereof

ActiveCN104047114AHigh strengthAvoid breakingFilament forming substance formingArtificial thread manufacturing machinesPolyesterNonwoven fabric

The invention relates to nano-silver antibacterial melt-blown non-woven fabric and a production method thereof. The nano-silver antibacterial melt-blown non-woven fabric is characterized in that the fabric contains hybrid nanoscale antibacterial powder, a non-woven fabric base stock can be polypropylene, polyester or polyphenylene sulfide, the hybrid nanoscale antibacterial powder is formed in a way that nanoscale zirconium phosphate and silver nitrate are exchanged in water to form silver phosphate, zinc oxide needs to be added in the exchange process, and the antibacterial powder has the proportion of ingredients as follows: 2-5 percent of the silver nitrate, 90-95 percent of the zirconium phosphate and 1-5 percent of the zinc oxide. The nano-silver antibacterial melt-blown non-woven fabric has excellent inhibition and stop effects on escherichia coli, staphylococcus aureus, Candida albicans and the like, and can filter various particles with the pm (particulate matter) over 2.5 in current air haze, the filter efficiency is over 95 percent, and the antibacterial ratio is over 99 percent; the fabric is tested by sgs (Societe Generale de Surveillance); the prepared nano-silver antibacterial melt-blown non-woven fabric is good in strength, not easy to break, soft and comfortable.

Owner:李文博 +1

Low-melting-point sheath-core-type polylactic acid composite fiber and preparation method thereof

InactiveCN105133082AHigh elastic recovery rateIncrease added valueArtificial thread manufacturing machinesFilament/thread formingFiberAfter treatment

The invention relates to a low-melting-point sheath-core-type polylactic acid composite fiber and a preparation method thereof and belongs to the field of double-component composite fibers. In the composite fiber, low-melting point polylactic acid is employed as a sheath layer and spinning-grade polylactic acid is employed as a core layer, wherein the core layer is completely wrapped by the sheath layer. The weight of the sheath layer accounts for 25-40% of the total weight of the composite fiber. The invention also provides the preparation method of the composite fiber, which comprises the steps of performing drying cut sheets, double-component melt distribution spinning, and fiber cooling, solidifying and winding to prepare raw filaments of the sheath-core-type polylactic acid composite fiber, and then performing after treatment to produce the sheath-core-type polylactic acid composite fiber. By means of the characters that the sheath-core-type polylactic acid composite fiber is good in loosen property and is high in elasticity recovery rate, the composite fiber can be subjected to thermal binding to form non-woven cloth, which can be widely applied as disposable sanitary materials and indoor decorative materials, thereby greatly improving additional value and market competitiveness of polylactic acid fibers.

Owner:北京普利玛科技有限责任公司

Manufacturing method for superlow shrinkage type PET industrial yarn

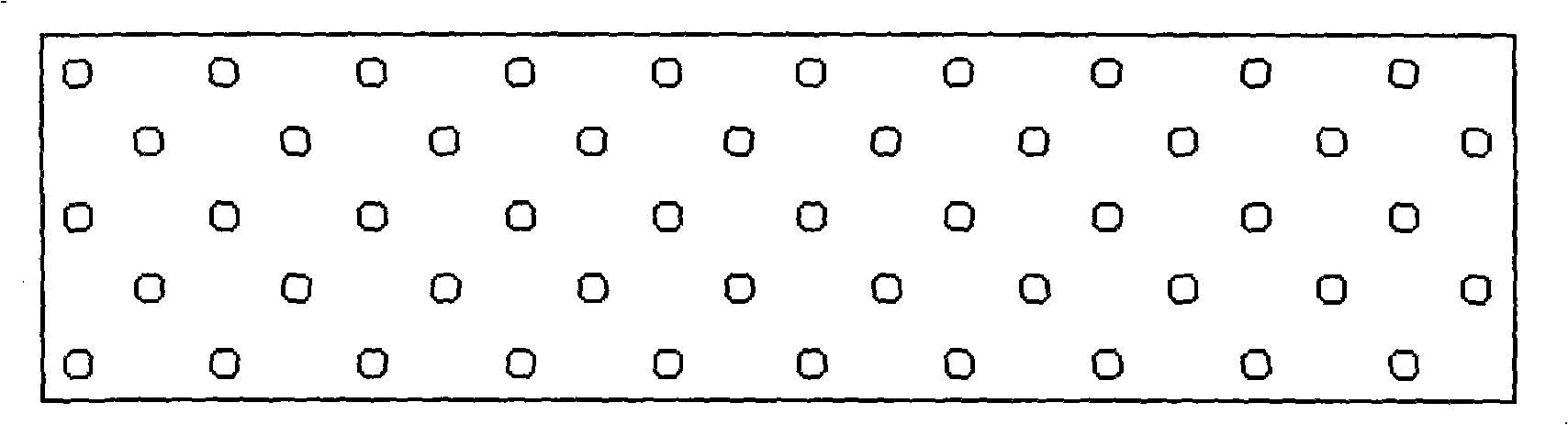

ActiveCN102797056AGuaranteed positionControl and reduce dwell timeArtificial thread manufacturing machinesMelt spinning methodsFiberYarn

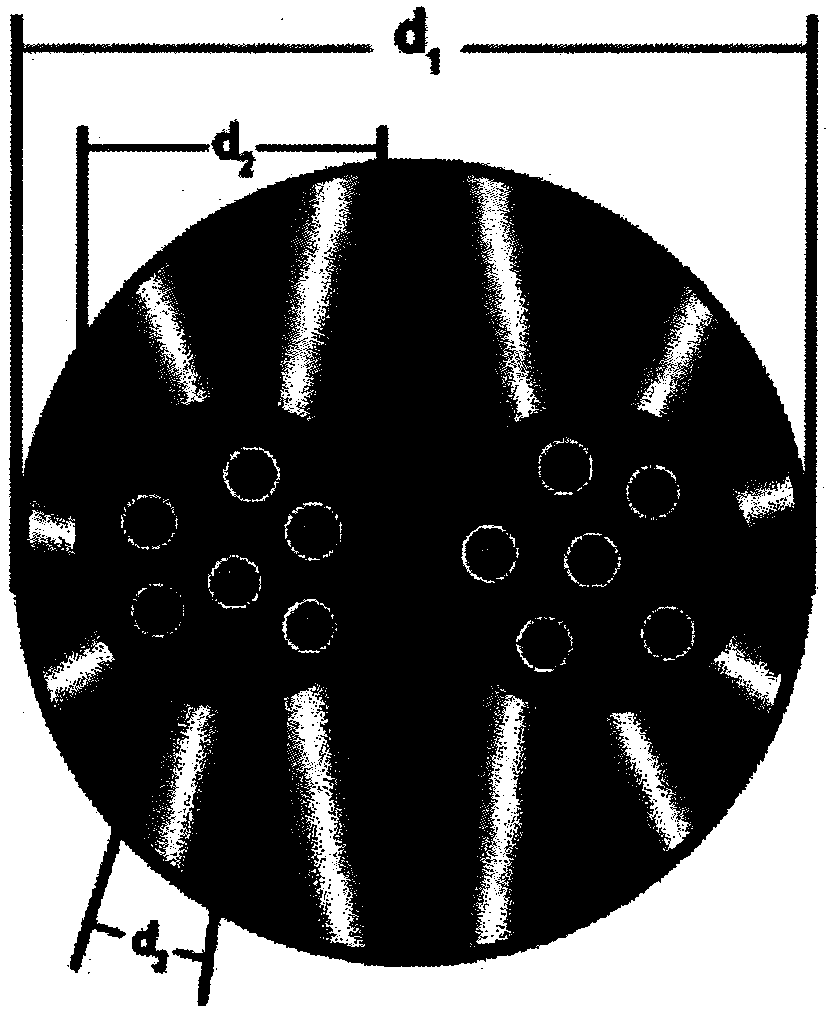

The invention relates to a manufacturing method for superlow shrinkage type PET industrial yarn, which is characterized in that the superlow shrinkage type PET industrial yarn is manufactured through selecting and controlling cooling conditions, and the technological process is as follows: hyperviscous melting to polyester raw materials, metering, spanning, cooling, oil supplying, stretching, hot shaping, and reeled forming. For lowing the irregularity and shrinkage percentage of fiber, a slow cooling device is arranged in the production of industrial yarn, a precooling device adopted is a hollow stepped ring-shaped belt comprising an upper part and a lower part, through holes with the diameters of 5 to 7 mm are uniformly distributed in the upper part of the ring-shaped belt, through holes with the diameters of 3 to 4 mm are uniformly distributed in the lower part, and the hole arrangement densities are the same. The natural target of the PET industrial yarn is as follows: the fracture strength is equal or greater than 7.0 cN / dtex, the breaking elongation is 20.0 plus or minus 1.5 percent, and the dry heat shrinkage percentage under the test conditions of 170 DEGC, 0.05cN / dtex reaches 1.9 plus or minus 0.25 percent.

Owner:JIANGSU HENGLI CHEM FIBER

Preparation method and device of dual different-shrinkage combined filament yarn

InactiveCN102140700AFluffy appearanceFull of layersArtificial thread manufacturing machinesArtificial filament heat treatmentSpinningEngineering

The invention relates to a preparation method and device of dual different-shrinkage combined filament yarn. The device comprises a first spinning component, a second spinning component, a lower spinning reel, an upper spinning reel, a first hot roll, a second hot roll, a first redirector, a doubling machine, a netting device and a winding roll, and is characterized by also comprising a third hot roll, a fourth hot roll and a second redirector. The preparation method is characterized in that one part of yarn output by the second spinning component is input to the doubling machine through the first hot roll and the second hot roll; the other part of yarn output by the second spinning component is input to the doubling machine through the third hot roll, fourth hot roll and second redirector; and after the doubling machine merges all the input yarn, the yarn is processed by the netting device and the winding roll, thereby finally obtaining the dual different-shrinkage combined filament yarn. The looped piles formed on the surface of the dual different-shrinkage combined filament yarn are more stratified; and the loops with different sizes are tangled, so that the combined filament yarn looks fluffier, and the formed fabric is plumper and has stereo perception.

Owner:DONGHUA UNIV

Spinning technology of four-spinning-roller semi-continuous high-speed spinning machine

InactiveCN103409820AReduce in quantityReduce manufacturing costArtificial thread manufacturing machinesWet spinning methodsSpinningIndustrial engineering

The invention relates to a spinning technology of a four-spinning-roller semi-continuous high-speed spinning machine, and belongs to the technical field of semi-continuous spinning machine spinning. The spinning technology comprises glue supply, thread forming, spinning and winding, wherein spinning is finished through a spinning device, the spinning device comprises four spinning rollers transversely arranged opposite to the operation surface of a spinning surface and are surrounded by threads, and drafting, solidification and acid removing are finished through rotating of the spinning rollers in the step of spinning. The spinning technology of the four-spinning-roller semi-continuous high-speed spinning machine solves the problems that a semi-continuous spinning machine in the prior art is insufficient in thread reaction, and therefore the spinning speed can not be increased, and production efficiency and product quality can not be given consideration to; the arrangement directions of the spinning rollers can be changed to increase the spinning speed of the spinning machine without changing structures of other parts of the original four-spinning-roller semi-continuous high-speed spinning machine, the threads can move farther and can more sufficiently react in an acid bath, and both production efficiency and product quality are given consideration to.

Owner:YIBIN HIEST FIBER +2

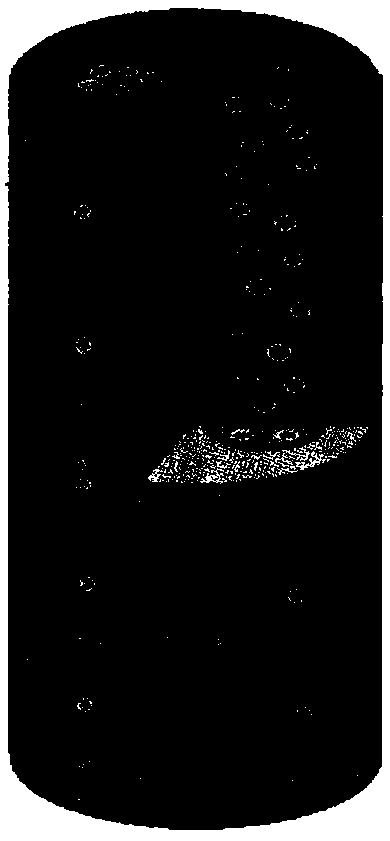

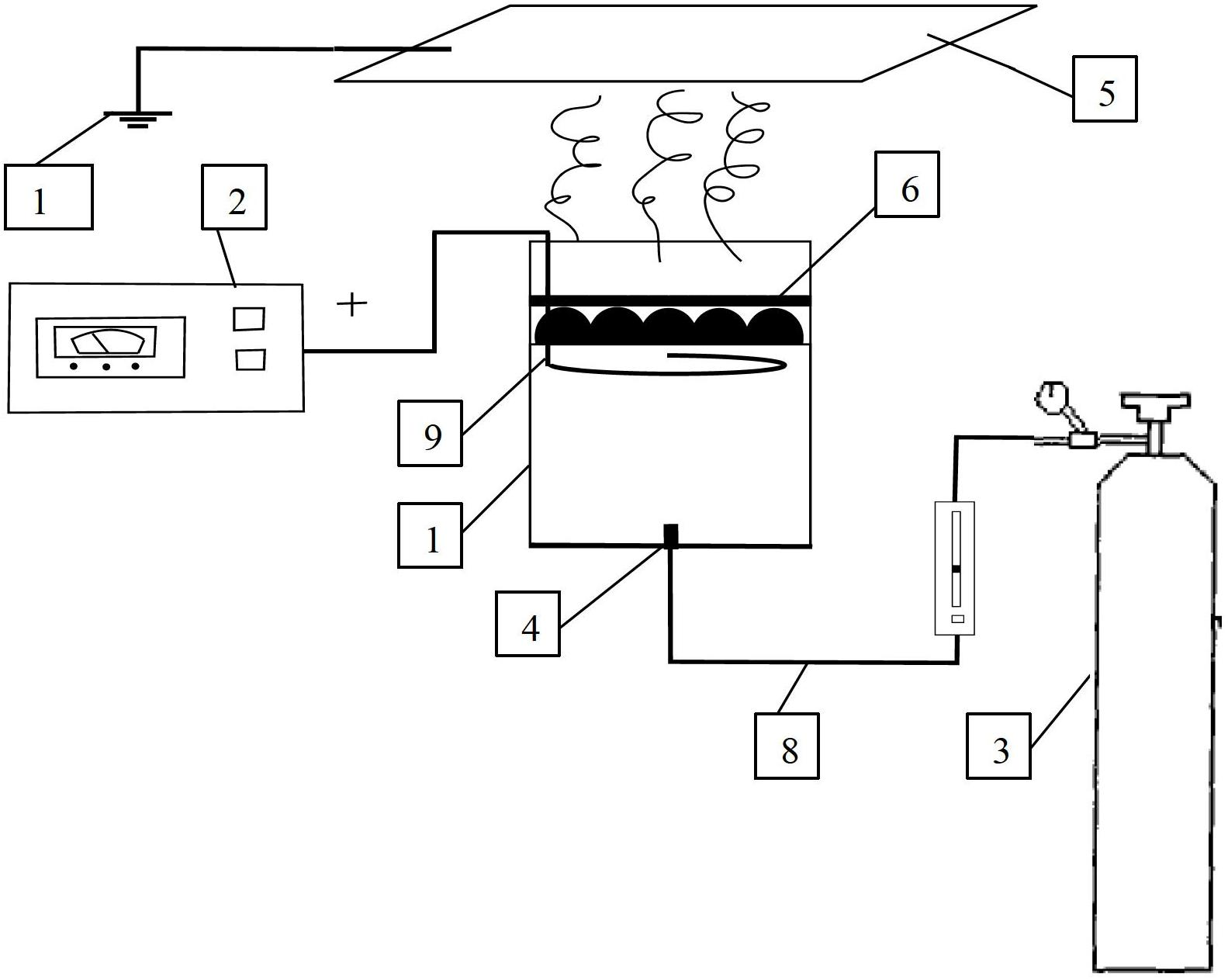

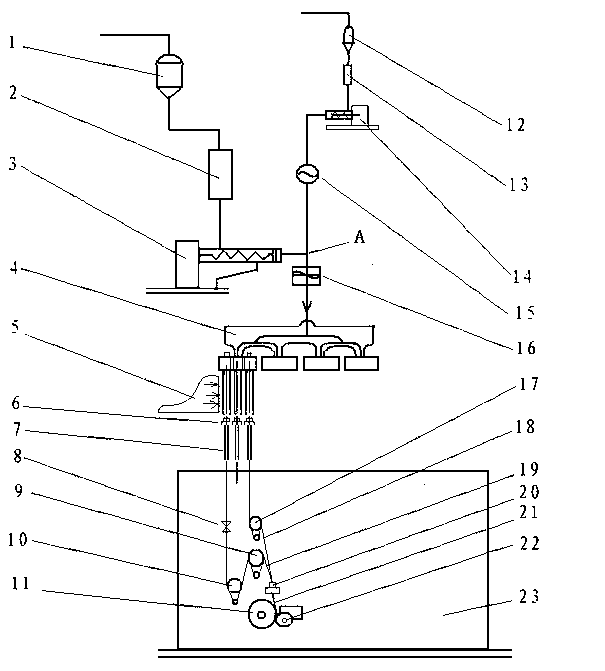

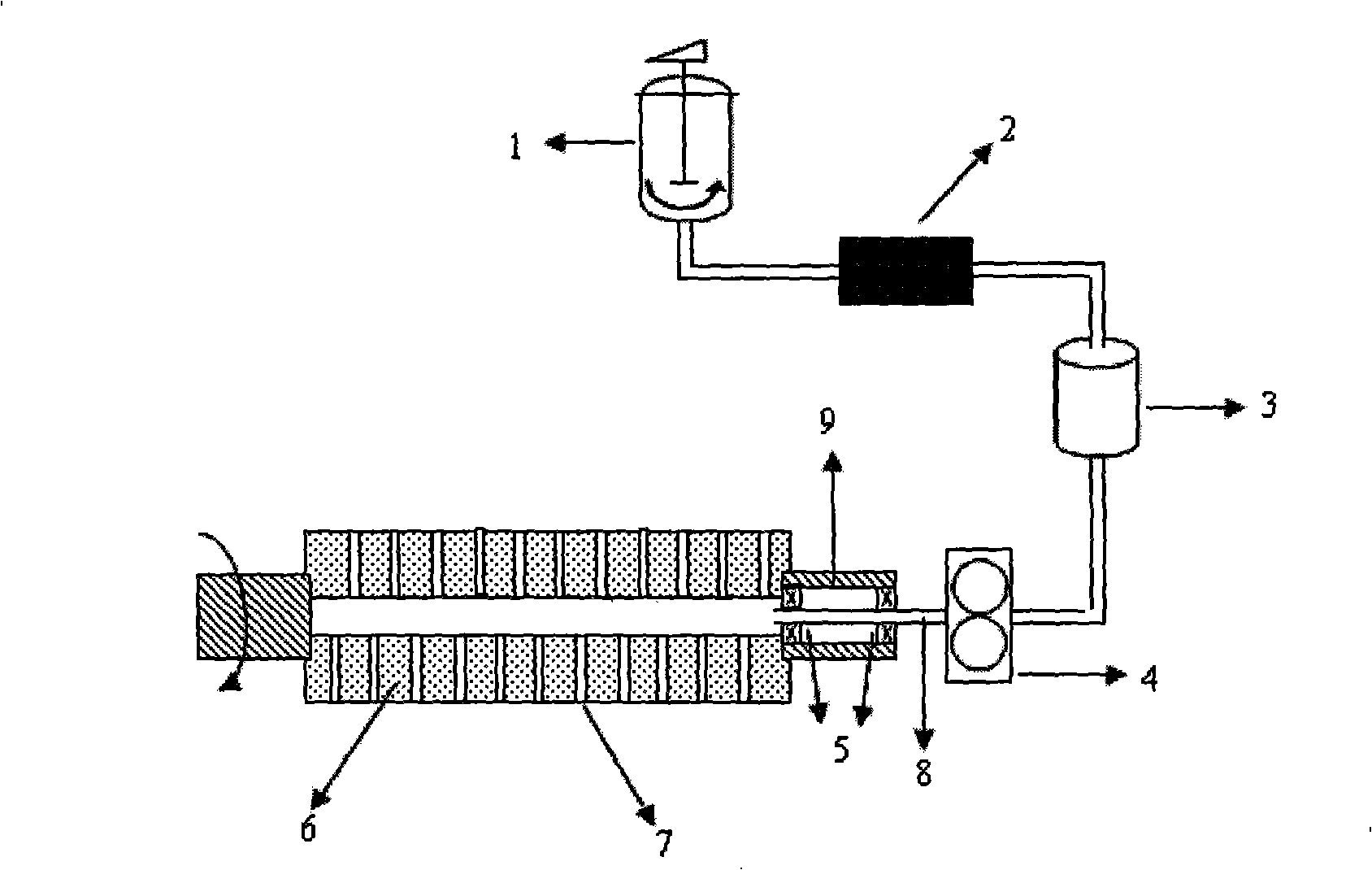

Method for producing continuous high-efficiency nano fibre nonwoven fabric and production device thereof

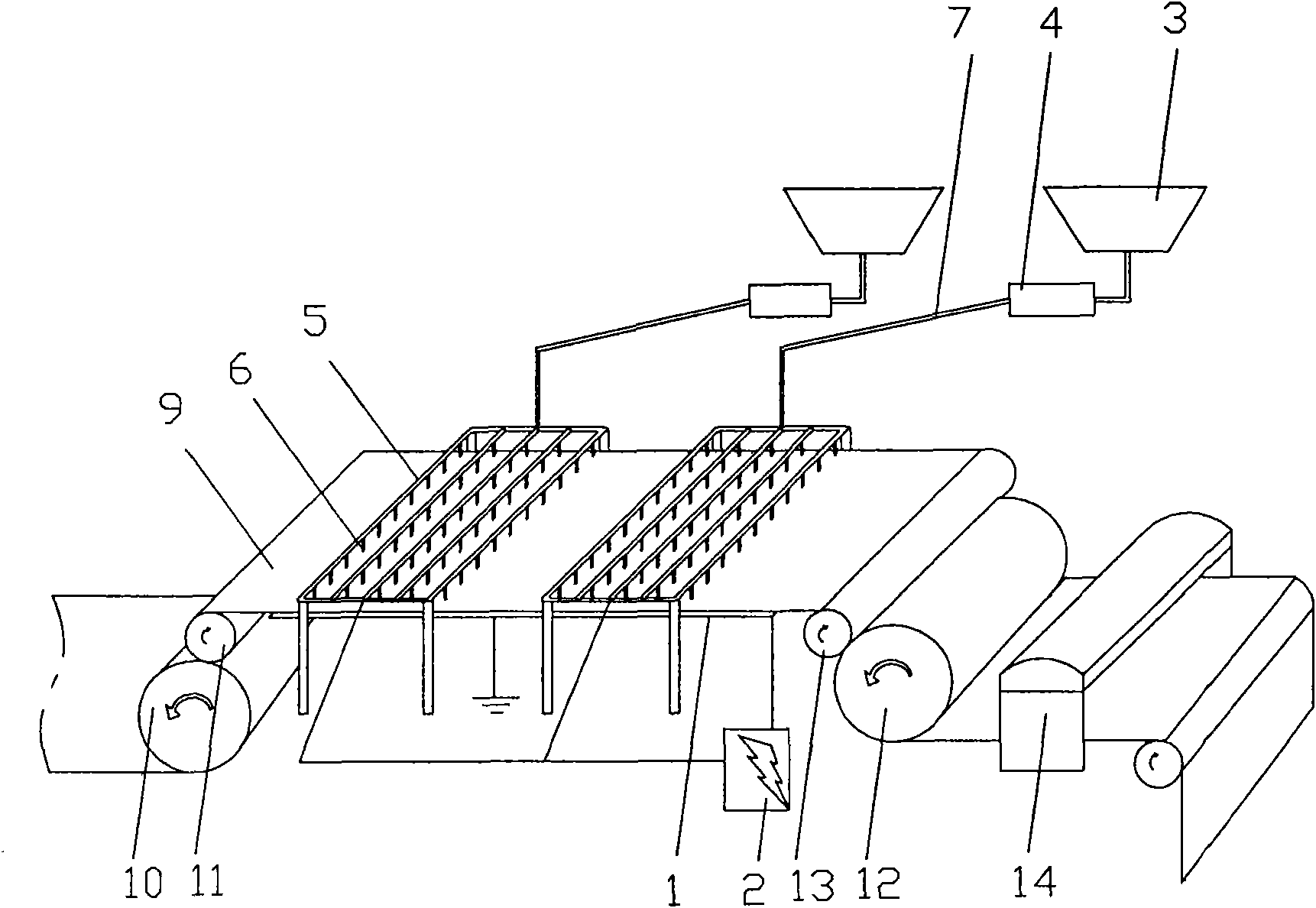

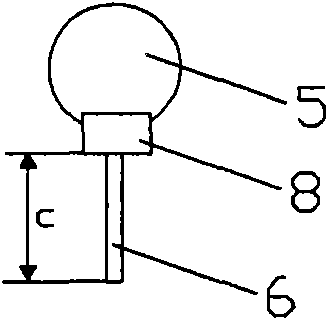

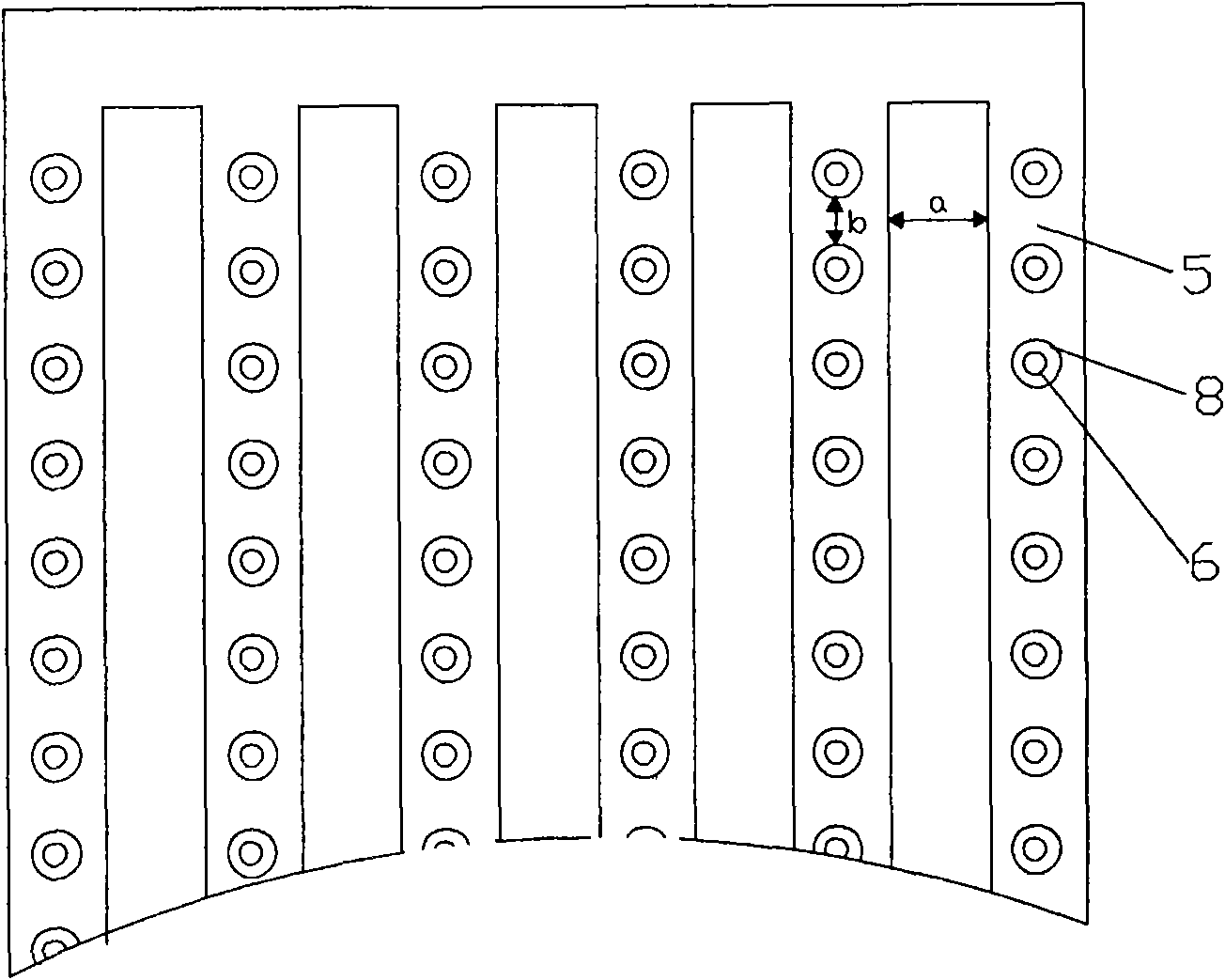

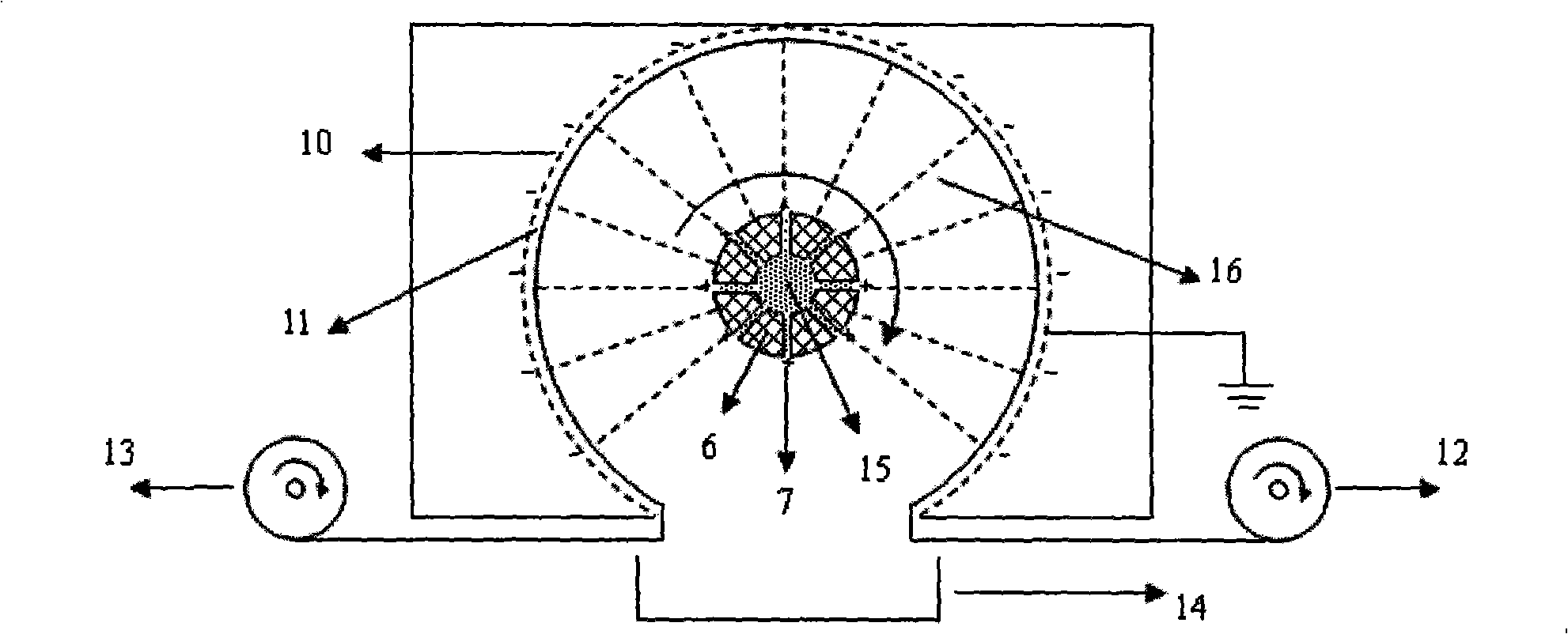

InactiveCN101298724AEvenly distributedAvoid uneven distribution of the jet (16) on the surface of the metal drumSpinnerette packsArtificial filament recoveryElectrospinningNanofiber

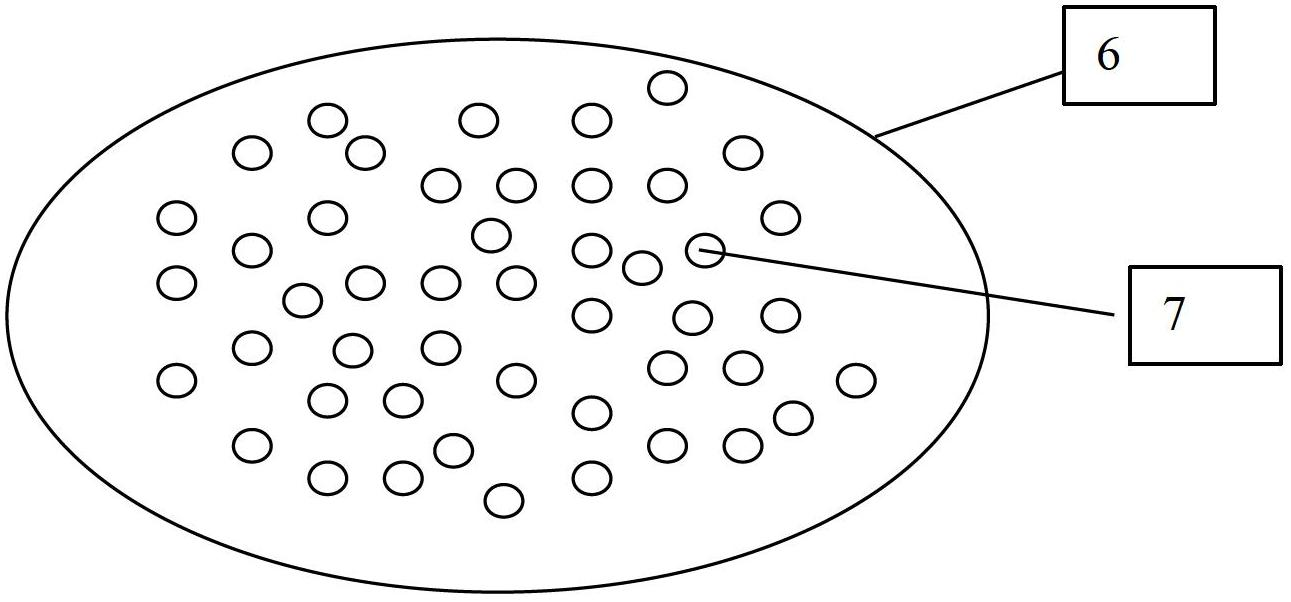

The invention relates to continuous high efficiency nano spinning solution (15), a nanofiber nonwovens manufacturing method and a manufacturing device which not only has high manufacturing efficiency but form better thickness of the nanofiber nonwovens. The manufacturing device comprises a solution supply system, a solution feeding pipe (8), a connecting mechanism and a metal roller (6); a metal strainer (10) and a fiber receiving web (11) which have the same shaft with the metal roller are sequentially arranged on the outside of the metal roller (6), an unreel roller (12) and a winding roller (13) are arranged on the fiber receiving web (11), and pores (7) are cut on the hollow metal roller (6). The manufacturing method includes the steps: (1), polymer spinning solution (15) is prepared; (2), an electric field is arranged between the metal roller (6) and metal strainer (10); (3), the metal roller (6) is revolved at a certain speed; (4) a measuring pump (4) is led to the metal roller (6) for even internal inputting; (5), the nanofiber is received. The invention is good for the scale manufacturing of static spinning.

Owner:DONGHUA UNIV

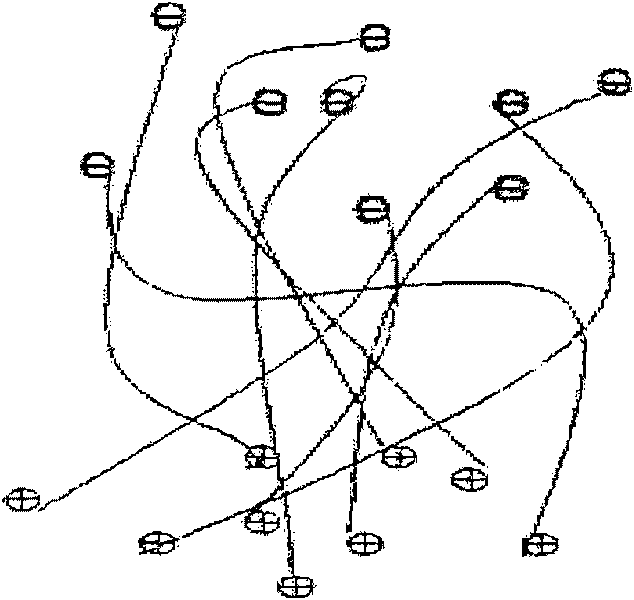

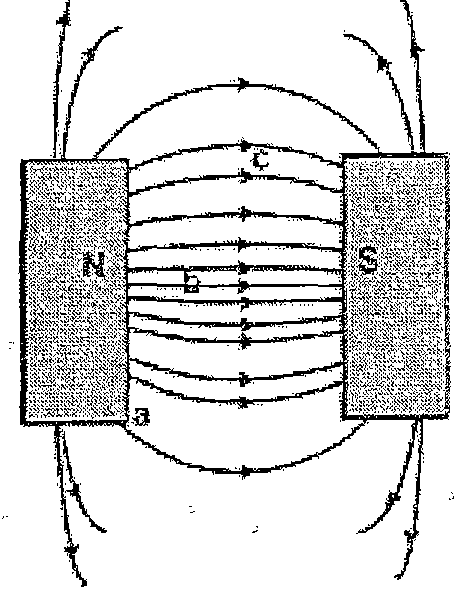

Device and method for preparing oriented polysulfonamide superfine fiber by using magnetized electrostatic spinning method

InactiveCN101724919AEasy to operateHighly repeatableArtificial thread manufacturing machinesFilament/thread formingSpinningElectrospinning

The invention relates to a device and a method for preparing an oriented polysulfonamide PSA superfine fiber by using a magnetized electrostatic spinning method. The device comprises a DC (Direct Current) high-voltage power supply, an injector, and a receiver which is obtained by arranging a pair of parallel permanent magnets on an aluminum foil receiver; two leads are respectively led from the anode and the cathode of the DC high-voltage power supply, wherein one lead is connected with the aluminum foil receiver, and the other lead is connected with a spinning nozzle of the injector. The method comprises the steps of: adding an oil-phase magnetic Fe3O4 solution to a polysulfonamide spinning solution to obtain a magnetized polysulfonamide PSA spinning solution, and processing the magnetized polysulfonamide PSA spinning solution under the action of a magnetic filed to obtain an oriented superfine fiber with the fiber diameter distribution of 100-500 nm. The method has the advantages of simple operation, high replication degree and easy popularization.

Owner:SHANGHAI UNIV

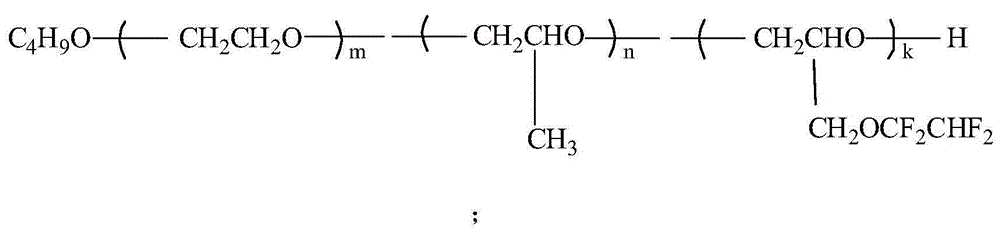

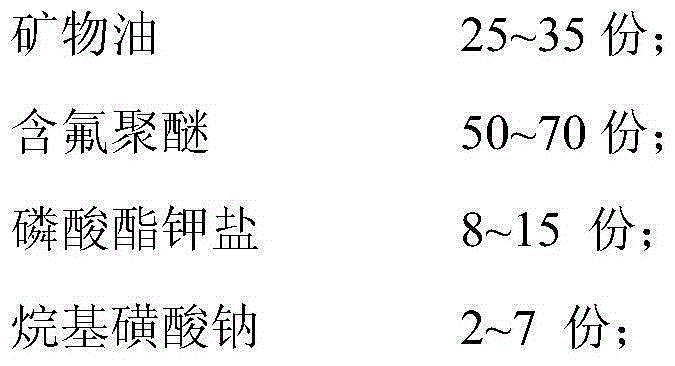

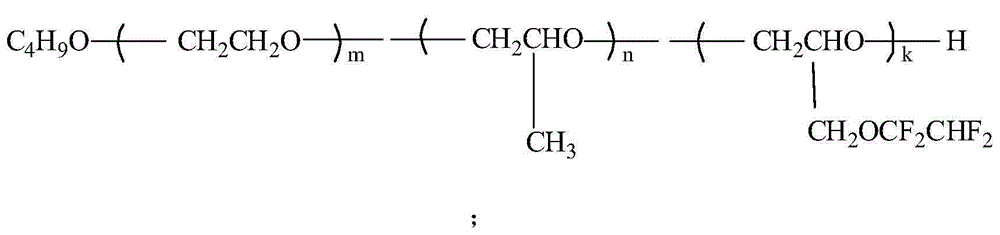

Super-soft superfine polyester fiber and preparation method thereof

ActiveCN105019059ASoft lusterConvenient careArtificial thread manufacturing machinesFibre typesPolyesterPolymer science

The invention relates to a super-soft superfine polyester fiber and a preparation method thereof. The super-soft superfine polyester fiber is mainly prepared by the steps of melt spinning of polyester through spinneret holes, application of an oiling agent and high-speed winding, wherein the oiling agent at least comprises fluorine-containing polyether, the mass of which is more than or equal to 45% of that of the oiling agent, the fluorine-containing polyether is a random copolymer of ethylene oxide, [(1,1,2,2-tetrafluoroethoxy) methyl] oxirane and propylene oxide, and the structural formula of the random copolymer is shown in the specification. The preparation method comprises the steps of metering, extruding, cooling, oiling, stretching, heat setting and high-speed winding of polyester, thereby obtaining the super-soft superfine polyester fiber. As the filament fineness of the super-soft superfine polyester fiber is very high, a fabric has advantages of specially soft and fine hand feeling, soft luster, comfortableness, breathability and good appearance texture and is easy to care, thus being popular with users more and more.

Owner:江苏轩达高分子材料有限公司

Cellulose fiber, preparation method thereof and equipment

ActiveCN102477591AHigh strengthSmall denierArtificial filaments from cellulose solutionsArtificial thread manufacturing machinesPolymer scienceSpinning

The invention relates to the field of chemical fibers, in particular to a cellulous fiber, a preparation method thereof and equipment. The cellulose fiber mainly comprises cellulous, is prepared by the solidifying liquid co-current drawing and spinning technology, and meets the following conditions that the tension breakage strength of the fiber is higher than or equal to 2.0cN / dtex, the fineness of the fiber is equal to or smaller than 1.67dtex, the content of S elements in the fiber is smaller than or equal to 100ppm, the fibrillation index (F.I.) of the fiber is smaller than or equal to 2. In addition, the cellulose fiber is free of chemical compositions relevant to fibrillation treatment resistance. The invention further relates to the preparation method of the cellulous fiber and the equipment. The cellulose fiber is high in strength, low in fineness and free of fibrillation tendency, the preparation method is simple, and is easy to control and applicable to large-scale industrialized production, and the equipment is simple in structure, skillful in design and stable in condition.

Owner:CHINESE TEXTILE ACAD

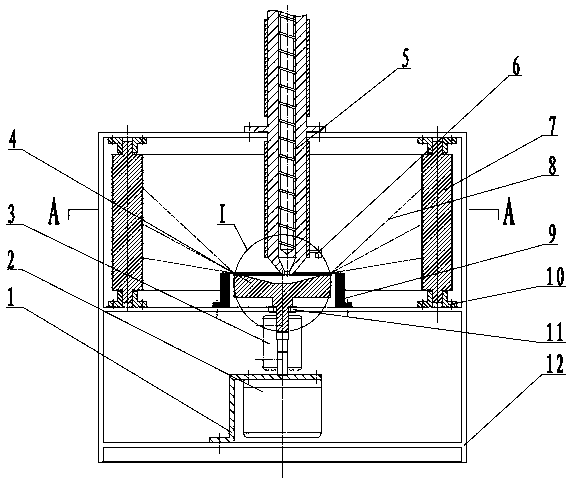

Device for preparing nanofibers by differential split-flow centrifugal spinning method

InactiveCN103305947ARealize continuous centrifugal spinningDegree of controlArtificial thread manufacturing machinesFilament/thread formingElectric machineryEngineering

The invention discloses a device for preparing nanofibers by a differential split-flow centrifugal spinning method. The device mainly comprises a motor support, a high-speed motor, a coupling, a rotator, a continuous feed device, an infrared temperature sensor, a conveyer belt roller set, an electromagnetic heater, a roller bearing block, a rotator bearing, a spinning manifold, conveying cord fabric, a rolling device and a take-up device. The motor support is fixedly arranged on the bottom bin of the spinning manifold and is used for fixing the high-speed motor; the rotator is driven to rotate at a high speed by the high-speed motor through the coupling and the rotator bearing; the continuous feed device is fixedly arranged at the top end of the spinning manifold; a discharge hole of the continuous feed device is arranged at the upper end of the rotator in an eccentric way, and a small interval is kept between the discharge hole and the upper end of the rotator. By combining a fluid differential structure and a reinforced fluid reduced conical surface, the control on the reduced degrees and centrifugal forces of fluids with different viscosity is realized, and meanwhile, a simple and efficient solution is provided to batch nanofiber preparation of solution or melt by the continuous feed device, an indirect heating device and the continuous take-up device.

Owner:QINGDAO ZHONG KE HAO TAI NEW MATERIAL SCI & TECH +1

Semi-continuous high-speed spinning machine

ActiveCN103290501AEasy to operateControllableNew-spun product collectionArtificial thread manufacturing machinesEngineeringMechanical engineering

The invention relates to spinning equipment, in particular to a semi-continuous high-speed spinning machine. The semi-continuous high-speed spinning machine comprises a rack, a glue supply device, a strip forming device, a spinning device and a winding device, wherein a spinning roller of the spinning device is horizontally arranged relative to an operating surface of a spinning surface. The operating surface of the spinning surface is a horizontal working surface in a spinning surface area, and the fact that the spinning roller is horizontally arranged relative to the operating surface of the spinning surface refers to that the spinning roller is horizontally installed relative to spinning workers when the spinning workers face towards the winding device. According to the semi-continuous high-speed spinning machine, the spinning roller is horizontally arranged relative to the operating surface of the spinning surface, and two ends of the horizontally arranged spinning roller are fixed, so that the spinning speed can be increased on the basis of the semi-continuous high-speed spinning machine, the spinning roller is ensured to rotate stably without shaking, and the problems of intertwining and breakage of strips caused by shaking of the spinning roller during spinning are solved.

Owner:YIBIN HIEST FIBER +2

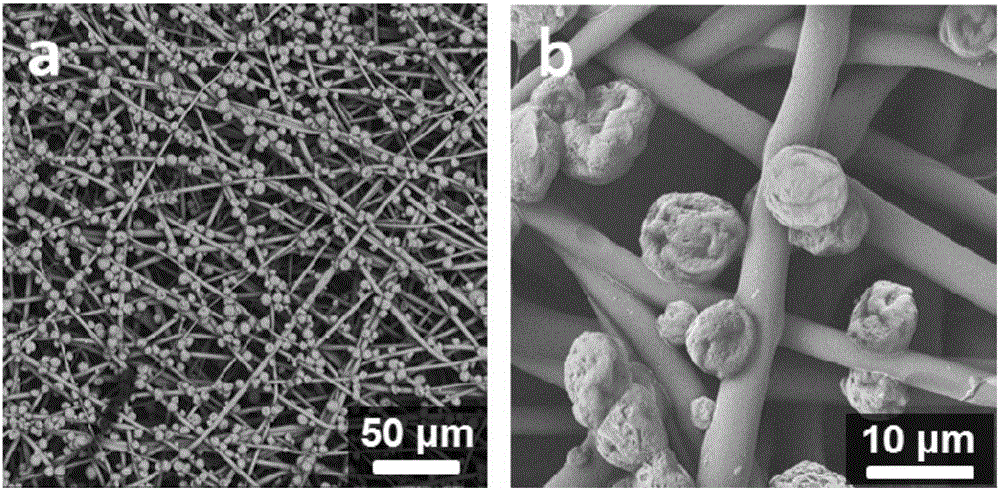

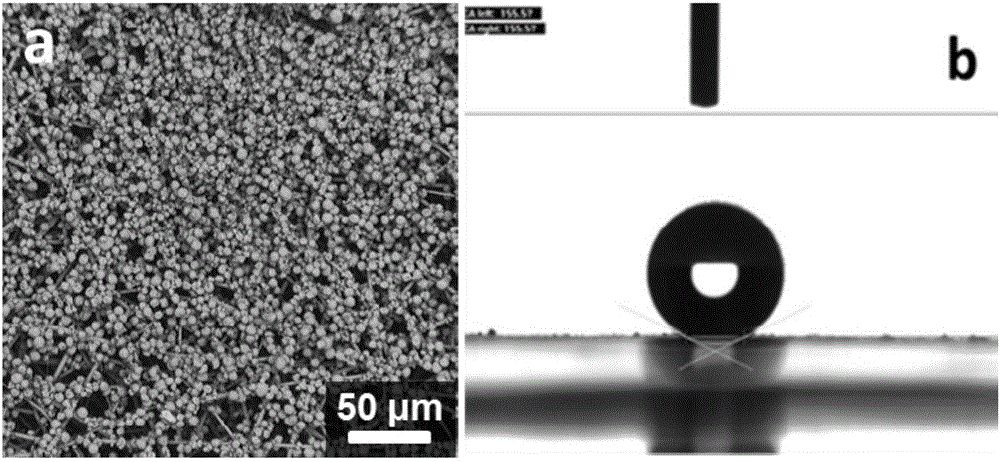

Water scour-resistant superhydrophobic composite membrane and preparation method and application thereof

InactiveCN106167551AExcellent superhydrophobic propertiesImprove water erosion resistanceArtificial thread manufacturing machinesElectro-spinningFiberSuperhydrophobe

The invention belongs to the field of high polymer materials and discloses a water scour-resistant superhydrophobic composite fiber membrane and a preparation method and application thereof. A composite fiber membrane is prepared into high polymer fibers by adopting a hydrophobic high polymer material through an electrospinning technology; homogeneous or heterogenic hydrophobic high polymer material solution coats the fiber membrane through an electrospinning technology; the composite fiber membrane is subjected to physical or chemical crosslinking treatment, and finally the superhydrophobic composite fiber membrane which is composed of the fibers and microspheres and has the surface provided with a micro-nano structure is obtained. The diameters of the fibers in the water scour-resistant superhydrophobic composite fiber membrane are 100 nm to 20 [mu]m, and the microsphere dimension is 1-30 [mu]m. The micro-nano structure formed by the fibers and the microspheres in the composite fiber membrane is fixed, so that the water scour-resistant superhydrophobic composite fiber membrane has excellent superhydrophobic and scour-resistant performances, can be applied to the fields such as oil-water separation, self-cleaning, antifreezing and antibiosis and have a huge economic benefit potential.

Owner:SOUTH CHINA UNIV OF TECH

Flame-retardant antibacterial artificial wig hairline

ActiveCN106245156AWith temperature and weather resistanceRich in colorWigsFlame-proof filament manufacturePolyesterMasterbatch

The invention discloses a flame-retardant antibacterial artificial wig hairline, which comprises, by weight, 80-90% of a polyester material, 5-11% of a flame retardant agent, 2.5-6% of an antibacterial agent, 0.3-3% of a dispersing agent, 0.2-0.5% of an antioxidant, and 2-5% of color masterbatch. According to the present invention, the flame-retardant antibacterial artificial wig hairline has characteristics of high simulation degree, flexible hairline, diverse color, flame retardant property, antibacterial property, no fused drop, environmental protection and the like, and can replace the expensive human hairline. The invention further discloses a manufacturing method of the flame-retardant antibacterial artificial wig hairline, wherein the manufacturing method comprises: pre-treating a polyester raw material, carrying out blending granulation on the polyester material, the antibacterial agent, the flame retardant agent, the dispersing agent and the stabilizer by using a double-screw extruder to obtain a flame-retardant antibacterial slice, carrying out melt spinning on the slice, carrying out high-temperature shaping treatment, carrying out washing and drying, and carrying out other steps.

Owner:见喜新材料股份有限公司

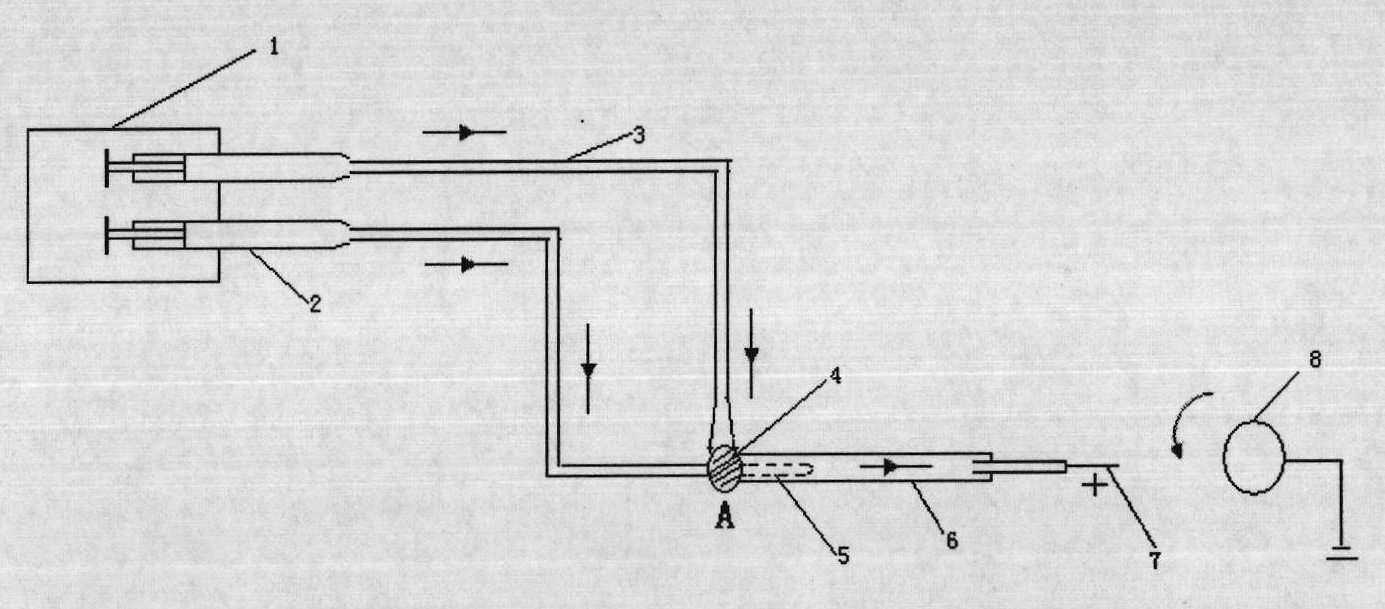

Microfluid electrostatic spinning device

InactiveCN101994162ASimple structureEasy to operateArtificial thread manufacturing machinesFilament/thread formingFiberComposite nanofibers

The invention belongs to the field of spinning field and discloses a microfluid electrostatic spinning device which comprises a dual-channel injection pump, a microfluid device, a high voltage power supply and a roller receiving device, wherein the microfluid device is additionally arranged to the traditional electrostatic spinning device; and the injection pump is the dual-channel injection pump which is capable of individually controlling the boosting speed of a dual-channel injector. Multi-component composite nanofibre with a predicted structure can be woven by the microfluid electrostatic spinning device, and is unique in structure and function. The microfluid electrostatic spinning device ensures that accurate control for proportion of all components of the composite nanofibre, which is realized by the traditional electrostatic spinning technique, can be realized. The microfluid electrostatic spinning device has simple structure, and is convenient in operation and short in technique procedure.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com