Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Comfortable to take" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Viscose fiber with plant source anti-bacterial function and aromatic smell, and preparation method thereof

ActiveCN103225123ANo side effectsComfortable to takeArtificial thread manufacturing machinesArtificial filaments from viscoseSide effectMint extract

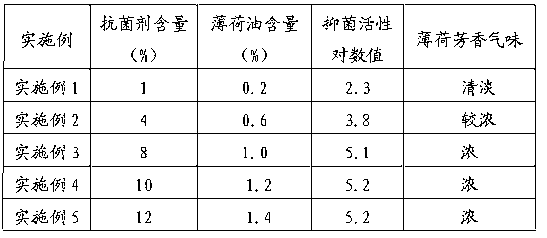

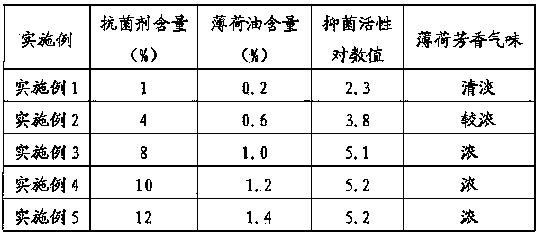

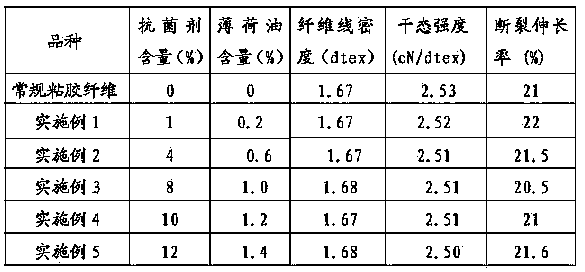

The invention discloses a viscose fiber with a plant source anti-bacterial function and aromatic smell. The viscose fiber is composed of a viscose spinning solution, an anti-bacterial agent and an aromatic agent, wherein the anti-bacterial agent is mixed powder of a mint extract and a isatis root extract, wherein the weight percentage of the mint extract accounts for 40%-80%; and the weight percentage of the isatis root extract accounts for 60%-20%; the aromatic agent is mint oil coated by microcapsules; the anti-bacterial agent accounts for 1%-8% of the mass of methyl cellulose in the viscose spinning solution; the mint oil accounts for 0.2%-1% of the mass of methyl cellulose in the viscose spinning solution; and the viscose fiber is prepared by adopting a wet spinning method by using the viscose spinning solution, the anti-bacterial agent and the aromatic agent. The plant source extracts and the plant source essential oil are used as the anti-bacterial agent and the aromatic agent; and the anti-bacterial agent and the aromatic agent are uniformly distributed in the fiber, so that the anti-bacterial function and the aromatic smell of the fiber are durable. Since the plant source extracts and the aromatic agent are natural substances extracted from the plants, so that the viscose fiber has no side effect to human body.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Viscose fibre with tea anti-bacterial anti-foul function and its preparing method

InactiveCN1944720AWith antibacterial and deodorant functionComfortable to takeMonocomponent cellulose artificial filamentArtifical filament manufactureAnti bacterialViscose fiber

The present invention provides one kind of viscose fiber with antibacterial and antifouling tea component, and the viscose fiber contains antiseptic comprising at least one of natural tea pigment, tea polyphenol and catechin. The powder or solution of at least one of natural tea pigment, tea polyphenol and catechin in the amount of 1-10 wt% is added into viscose spinning fluid to result in lasting antibacterial and antifouling functions. The viscose fiber has also the fragrance of tea, dyeing effect and no side effect on human body, and is suitable for use in making underwear, other costumes and bedding.

Owner:秦如涛

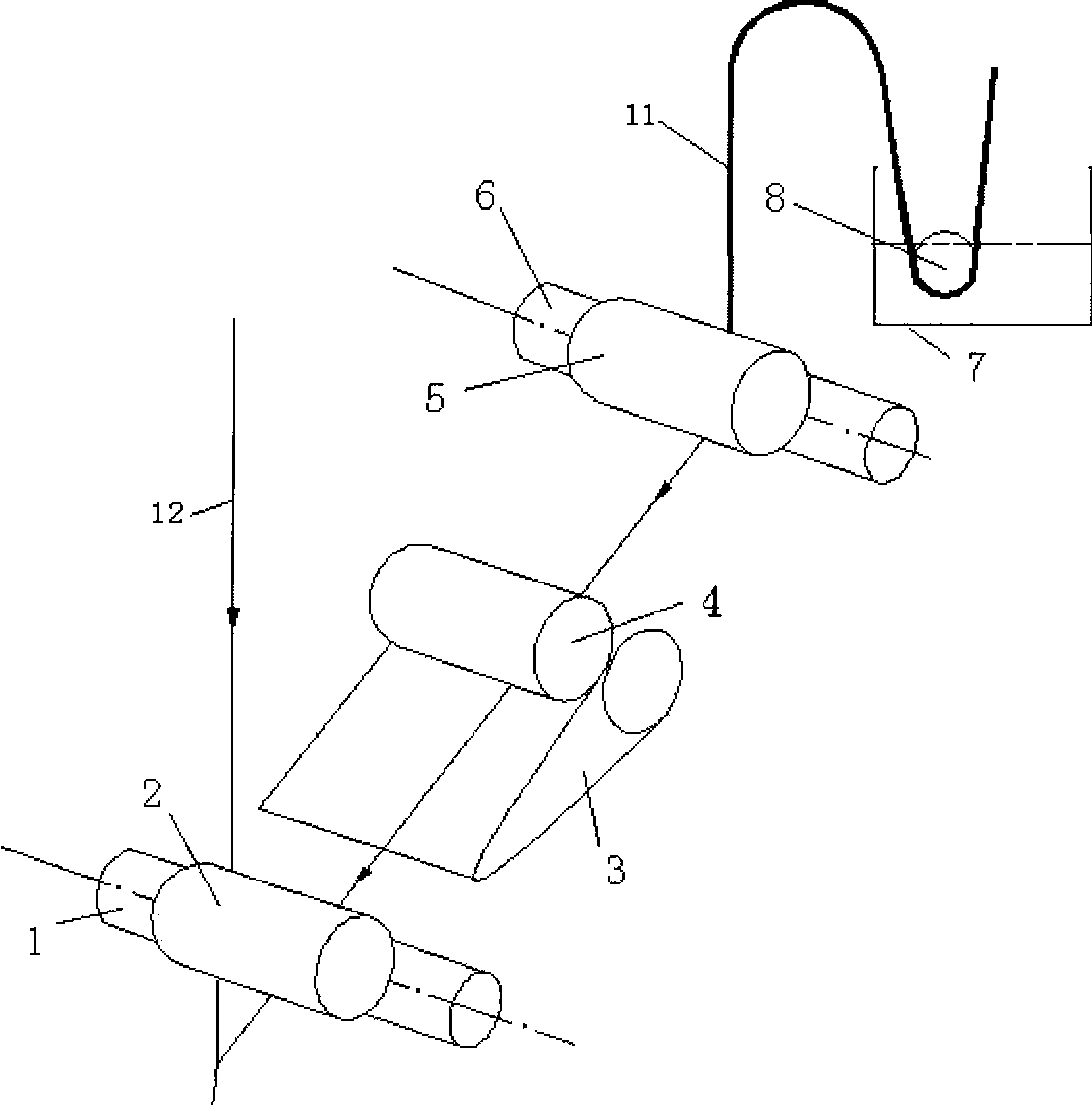

Production technology of viscose extinction monofilament

InactiveCN103215680AImprove spinnabilitySoft touchSpinnerette packsArtificial filaments from viscoseInlet channelExtinction

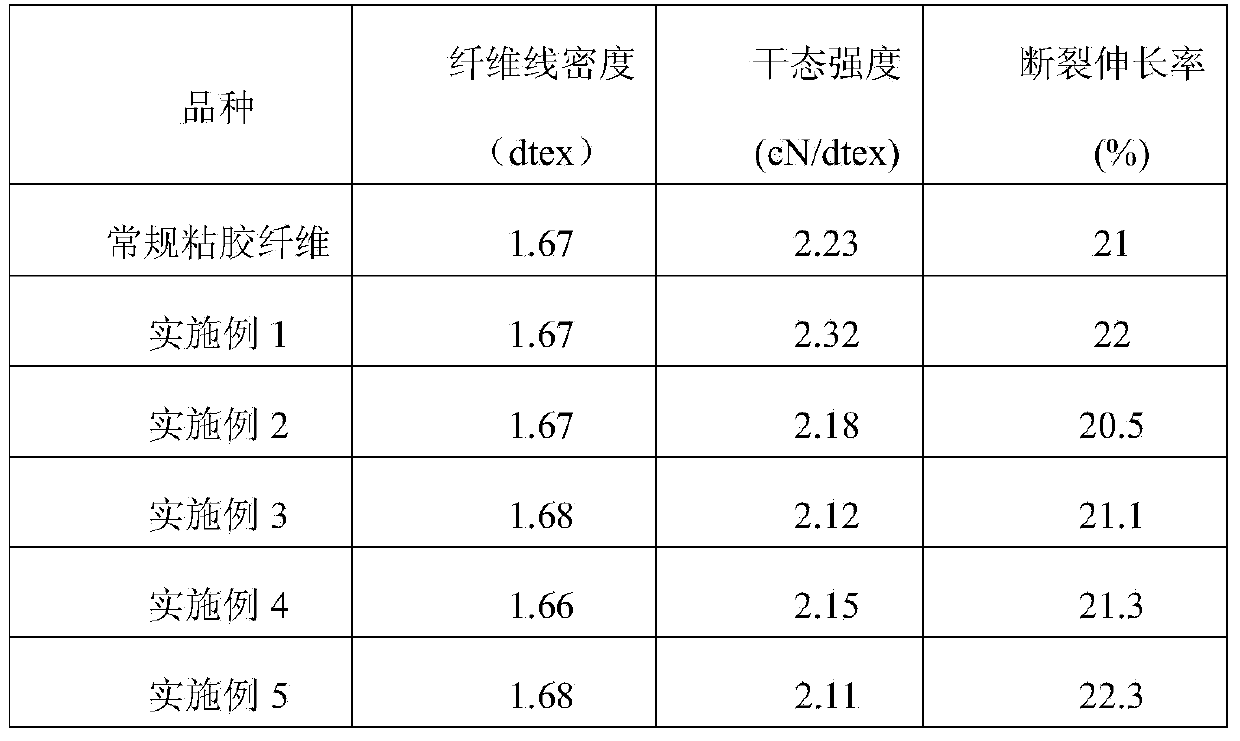

The invention relates to a production technology of viscose extinction monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose extinction monofilament through preparation of a spinning solution, injection before spinning, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) adding a titanium dioxide solution into the spinning solution so that the weight ratio of titanium dioxide to alpha cellulose content in the spinning solution reaches (0.5-5.0):100; and uniformly mixing and feeding for spinning; (C) feeding the spinning solution into a spinning machine, and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, and an inlet channel of the spinneret orifice is in a parabola shape; and (D) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the filament number of the prepared viscose monofilament is 50-6,000D, the strength is high over 75CN, and the requirements on dyeing, weaving and finished product taking are met; and moreover, the viscose extinction monofilament has gentle color and an extinction effect.

Owner:YIBIN HIEST FIBER +2

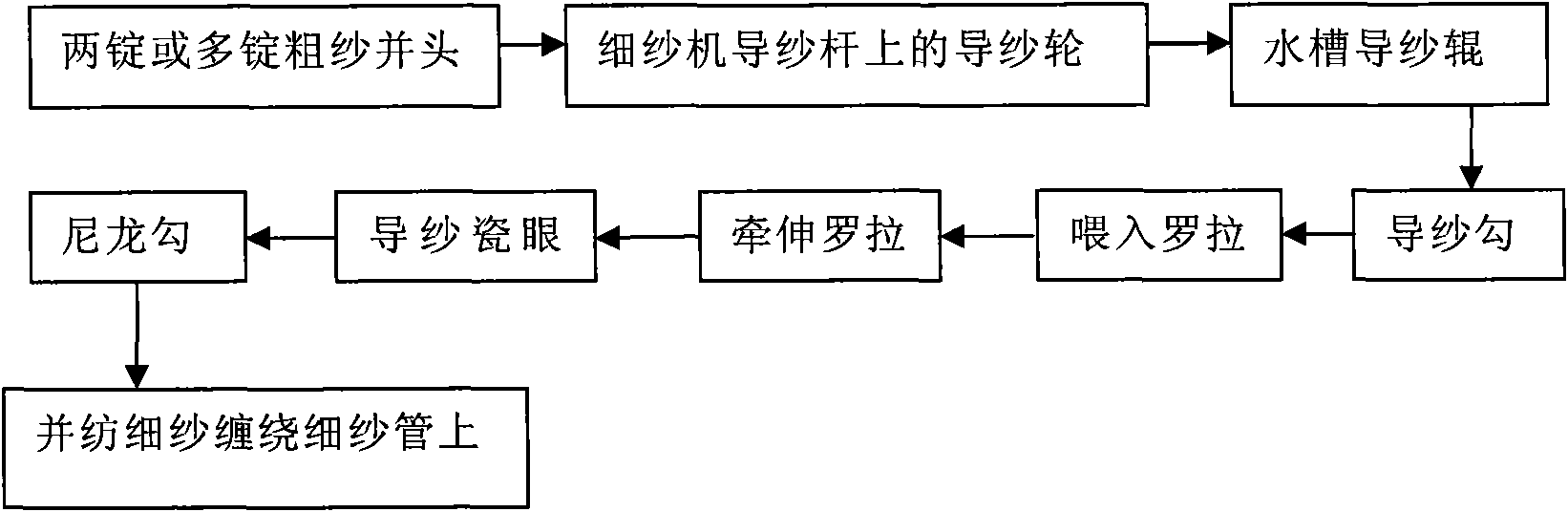

Blending method using hemp fiber as main material

InactiveCN101871147AIncrease the degree of splittingImprove impurity removalHackling machinesBleaching apparatusImpurityMaterials science

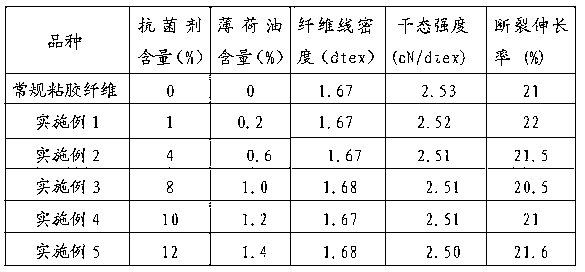

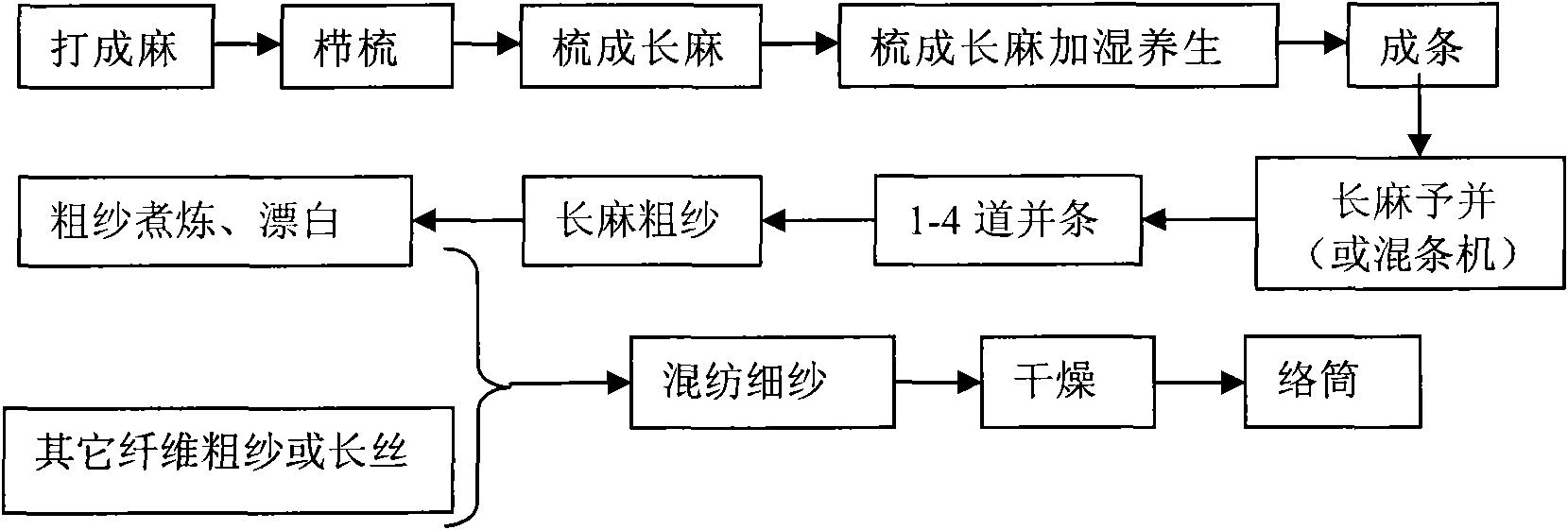

The invention relates to a blending method using a hemp fiber as a main material. The method comprises the following steps of: firstly, processing the hemp fiber into rovings; secondly, mixing the roving yarns of the hemp fiber with the rovings or filaments of other fibers in proportion to form bunch yarns; and finally, spinning the mixed bunch yarns in the second step into spun yarns. The blending method has the advantages of improving the disintegration degree of the hemp fiber and removing impurity without damaging the performance of the blended fibers, ensuring a high spinning yam count and quality of the blended yarns and greatly improving the quality of the blended yarns of the hemp fiber along with simple process.

Owner:肇融亚麻纺织有限公司

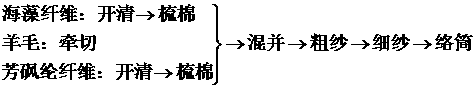

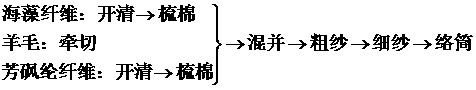

Blended yarns of seaweed fibers, wools and polysulfonamide fibers, shell fabric and production process

ActiveCN103194825AExcellent flame retardant functionImprove high temperature resistanceWeft knittingWarp knittingYarnMoisture absorption

The invention provides blended yarns of seaweed fibers, wools and polysulfonamide fibers, a shell fabric and a production process. The components of the fabrics include, by weight, 25-45% of the seaweed fibers, 0-35% of the wools and 35-75% of the polysulfonamide fibers. The seaweed fibers have natural fire-resistant performance, are good in moisture absorption, and are anti-bacterial and good in affinity with the human skin. The polysulfonamide fibers are also good in the fire-resistant performance; the polysulfonamide fibers have significant advantages in high-temperature heat-resistance, high-temperature strength loss rate and high-temperature dimensional stability as compared with other aramid fibers in the same variety. The wools have the most significant advantages in the fire-resistant performance in natural fibers, are hollow, good in fiber elastic recovery and are capable of heat insulating; and the wools have noble-like performance in the natural fibers. The three varieties of fibers are blended, and strong points are adopted and weak points are overcome; the shell fabric spun by the blended yarns has significant fire-resistant performance, good clothing-adopting performance and comfort, and is adaptable to the fields of superior health-preserving clothing, special protective clothing, special protective apparatuses and the like.

Owner:RUGAO CITY DINGYAN TEXTILE

Blended spinning method of long spinning and damp spinning for bast fibers

The invention provides a method integrated with long spinning, wet spinning and blended spinning for bast fibers. The method comprises the following steps: the bast fibers are scotched into flax; the flax is humidified and soaked for a period of time; the flax is carded into long flax; and the long flax is subjected to matching, silvering, drawing, roving, scouring, bleaching, spinning, drying and winding. The method is characterized in that after the bast fibers are bleached, the obtained rove of the bast fibers and rove or filaments of other fibers are blended on a spinning machine. With the method, blended fibers are not bleached and scoured together with the bast fibers, so the defect that the performance of blended yarn is affected due to the damage of bleaching and scouring agents to the blended fibers in the prior wet spinning and blended spinning is overcome, and the obtained blended yarn has the characteristics of bright and clean yarn body, less hairness, evenness and good wear resistance. In addition, the method can fully play a role in respective advantages of the bast fibers and the blended fibers, complement respective disadvantages of the bast fibers and the blended fibers, has simple process, is favorable for improving the quality of blended yarn of the bast fibers, and realizes the high count, high grade and diversification of varieties of the bast fibers.

Owner:DONGHUA UNIV

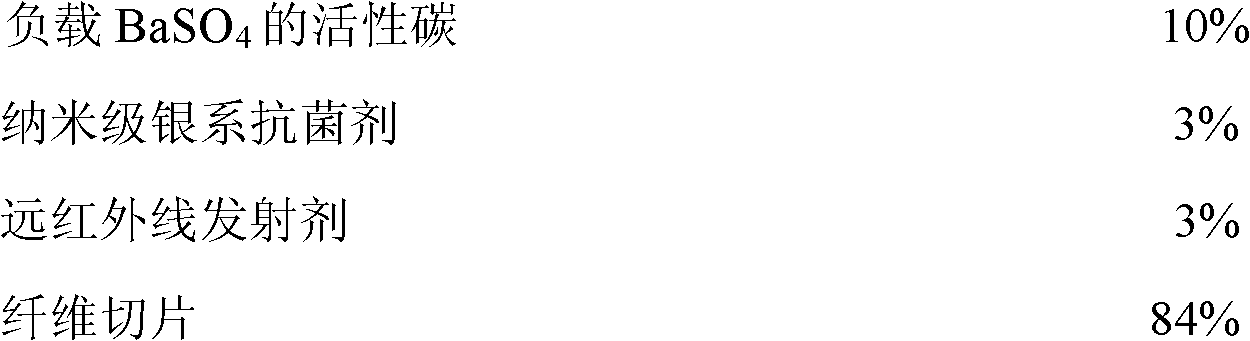

Radiation-proof polyester fiber for emitting negative ions and far infrared rays and preparation method thereof

InactiveCN102220655AComfortable to takeWith Guard BandwidthFilament/thread formingConjugated synthetic polymer artificial filamentsFiberActivated carbon

The invention relates to a radiation-proof polyester fiber for emitting negative ions and far infrared rays and a preparation method thereof. The polyester fiber has the following raw materials according to weight percentages: 0.1-10% of active carbon loaded with BaSO4, 0.1-3% of nanometer silver anti-bacterial agent, 0.1-3% of far infrared-emitting agent, and the balance of fiber slice. The polyester fiber is soft, light and radiation-proof, and has the health functions of emitting the negative ions, the far infrared rays, and the like; the polyester fiber has wide application prospect; and the preparation method of the polyester fiber is simple in operation, has lower cost and low equipment requirement, and is suitable for large-scale production.

Owner:DONGHUA UNIV

Viscose fiber with anti-bacterial function and preparation method thereof

InactiveCN101876090AImprove antibacterial functionComfortable to takeArtificial filaments from viscoseWet spinning methodsSocial benefitsAnti bacterial

The invention provides a viscose fiber with the anti-bacterial function, which comprises viscose fiber and an antimicrobial contained therein. The viscose fiber with the anti-bacterial function is characterized in that the antimicrobial is a natural plant antimicrobial containing sarcandra glabra extractives. A sarcandra glabra extractive solution is added to a viscose filature stock solution, and the addition of sarcandra glabra extractive powder contained in the sarcandra glabra extractive solution is 1-5 percent by mass of the viscose filature stock solution. In the invention, the sarcandra glabra extractives are adopted as the antimicrobial which is evenly distributed in the fiber so that the fiber has lasting anti-bacterial function and dying effect without side effects on human bodies. The viscose fiber with the anti-bacterial function of sarcandra glabra is suitable for making knitted underwear, other clothes and bedding fabrics, has wide range of applications and great economic and social benefits. The preparation method of the invention has reasonable and simple process and is suitable for the industrialized production.

Owner:张继红 +1

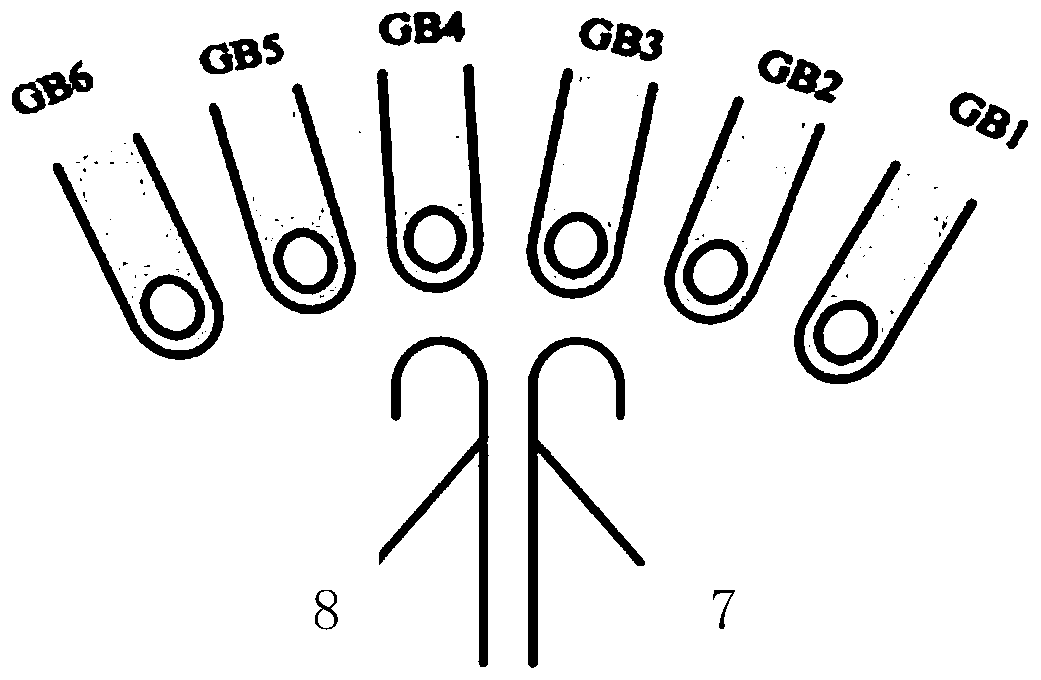

Method for producing elastic spacer fabric through two-needle bar warp knitting machine

InactiveCN104141197AIncrease elasticityComfortable to takeFlat warp knitting machinesSurface layerEngineering

The invention discloses a method for producing an elastic spacer fabric through a two-needle bar warp knitting machine. Guide bars in the warp knitting machine comprises the spacer yarn guiding guide bar, the ground guide bars and the elastic guide bars, wherein the spacer yarn guiding guide bar is arranged at the middle position, the ground guide bars are arranged on the two sides of the spacer yarn guiding guide bar, and the elastic guide bars are arranged on the outer sides of the ground guide bars. The distance between needle bars of the warp knitting machine is correspondingly set according to different applications of the spacer fabric to be produced. Yarns comprise the spacer yarns, the face yarns and the elastic yarns, and the face yarns and the elastic yarns with corresponding thread density are selected according to different surface structures of the spacer fabric. The spacer yarn guiding guide bar penetrates into the spacer yarns, the ground guide bars penetrate into the face yarns, and the elastic guide bars penetrate into the elastic yarns. The face yarns and the elastic yarns are matched to form the upper surface layer and the lower surface layer of the spacer fabric in a knitting mode, and the spacer yarns form the middle interlayer of the spacer fabric in a knitting mode. The spacer fabric produced through the method is good in elasticity, high in reset rate, compact, good in handfeel and high in comfort.

Owner:苏州吴坤纺织品有限公司

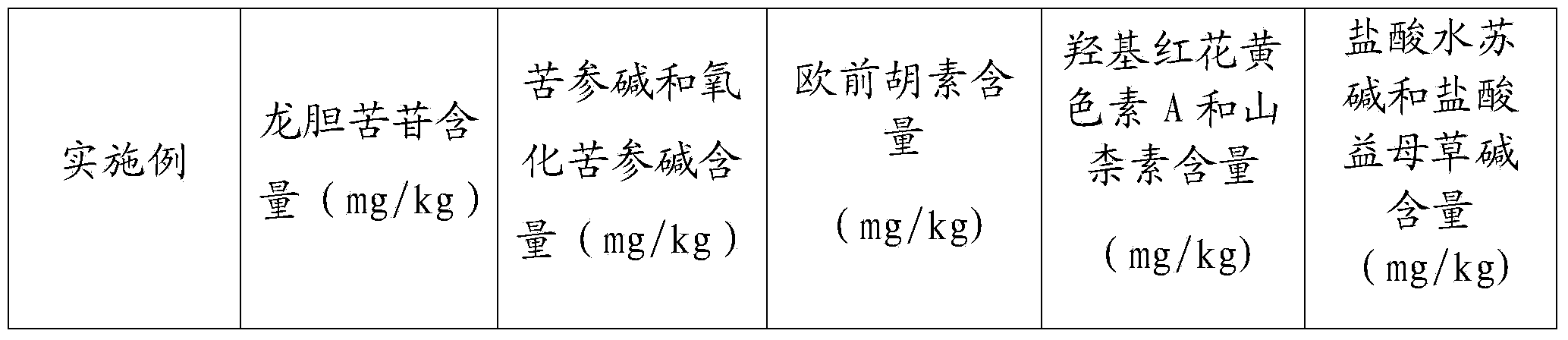

Traditional Chinese medicine composition for preparing woman health-care viscose fiber, prepared health-care viscose fiber and preparation method of health-care viscose fiber

ActiveCN103643333APromote circulationPrevent atherosclerosisArtificial filaments from viscoseWet spinning methodsMotherwortEmulsion

The invention discloses a traditional Chinese medicine composition for preparing a woman health-care viscose fiber, a prepared health-care viscose fiber and a preparation method of the health-care viscose fiber. The traditional Chinese medicine composition comprises the following traditional Chinese medicine components by weight percent: 20-35% of felwort, 15-25% of radix sophorae flavescentis, 15-25% of radix angelicae, 10-20% of flowers carthami and 10-20% of motherwort. The method for preparing the health-care viscose fiber by using the traditional Chinese medicine composition comprises the following steps: dissolving traditional Chinese medicine composition extract powder into an antibacterial health-care solution; heating borneol to melt, and emulsifying into an emulsified liquid; preparing spinning mucilage glue by adopting cellulose pulp as a raw material; adding the antibacterial health-care solution to a viscose solution in any step after yellowing is finished and before spinning is performed, so as to obtain an antibacterial health-care blend viscose solution; spinning and forming, drafting silk and carrying out post-treatment on the antibacterial health-care solution, so as to obtain the health-care viscose fiber; adding a borneol emulsion to the oiling step of after-treatment.

Owner:LINQU XINYUE KNITTING WEAR

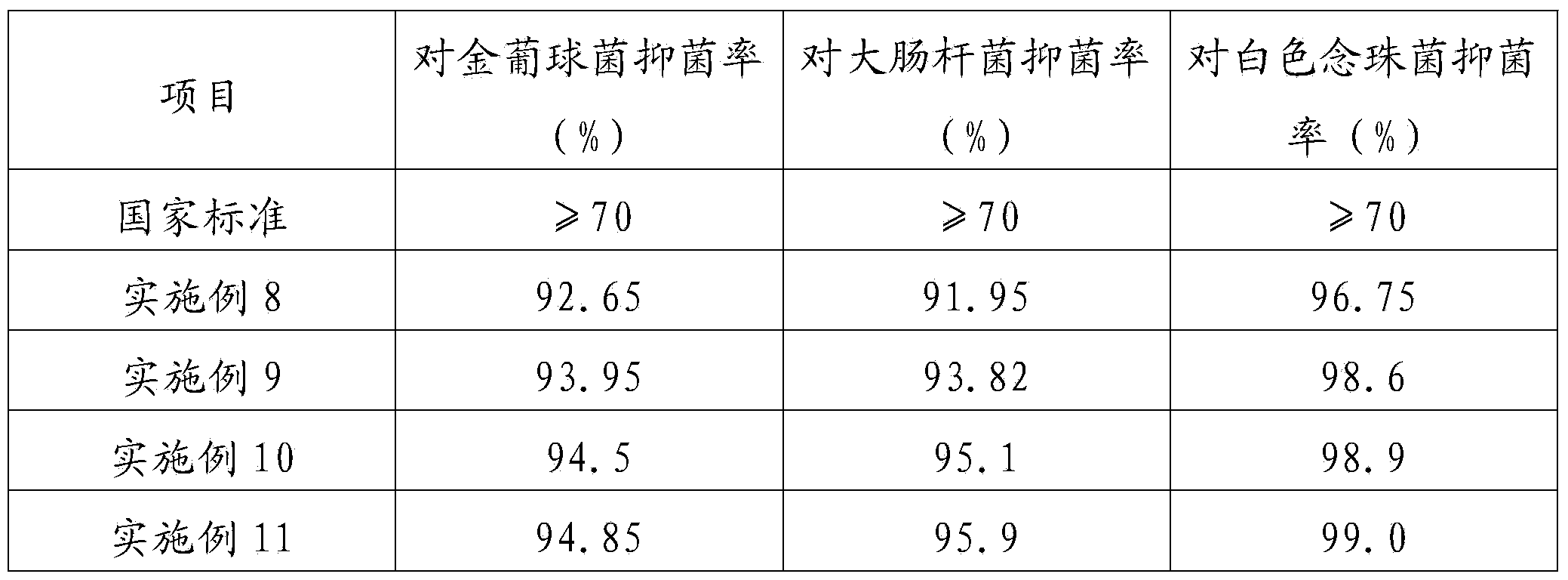

Viscose fiber with antibacterial function of ginkgo leaves and preparation method of viscose fiber

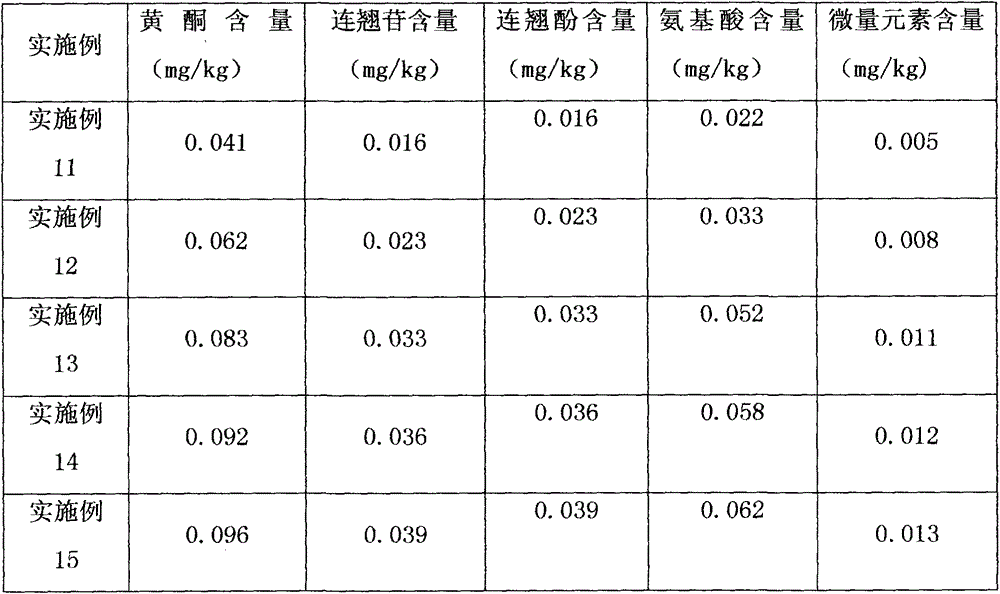

ActiveCN103741245AImprove antibacterial functionComfortable to takeArtificial thread manufacturing machinesArtificial filaments from viscoseGinkgo bilobaGinkgo

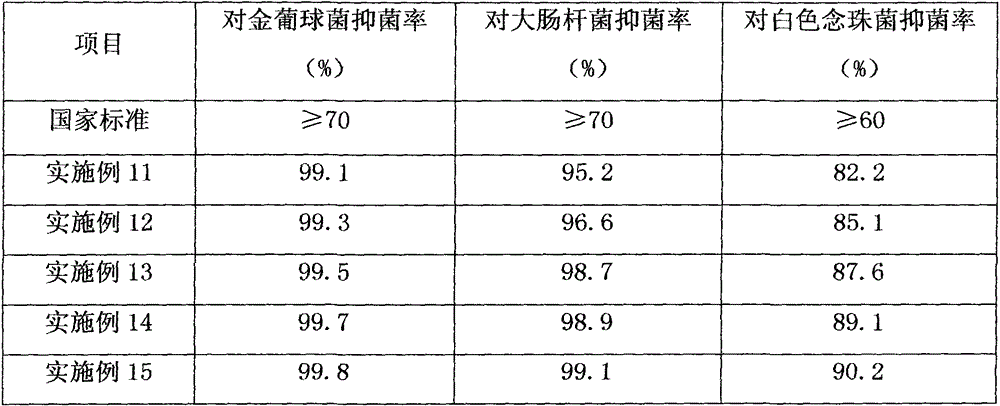

The invention discloses a viscose fiber with an antibacterial function of ginkgo leaves. The viscose fiber contains at least 80wt% of alpha cellulose and at least 3.5mg / Kg of flavonoids, lactone compounds and organic acid substances; the viscose fiber has the bacteria inhibitive rate of larger than or equal to 92% for staphylococcus aureus, the bacteria inhibitive rate of larger than or equal to 91% for Escherichia coli and the bacteria inhibitive rate of larger than or equal to 81% for candida albicans; the fiber is lasting in antibacterial function and has no any side effects on human bodies. The invention also discloses a preparation method of the viscose fiber with the antibacterial function of ginkgo leaves. The method is reasonable and simple in process, suitable for industrial production and capable of sufficiently exerting the unique advantages of lasting antibacterial function of the ginkgo leaves.

Owner:青岛红妮制衣有限公司

Method for designing and manufacturing PTT filament/staple single yarn composite yarn fabric

InactiveCN102051731AImprove performanceNoveltyBiochemical fibre treatmentHeating/cooling textile fabricsSpecial effectsDyeing

The invention provides a method for designing and manufacturing a textile fabric. Polytrimethylene terephthalate (PTT) filament / staple single yarns are manufactured into a novel fiber composite garment fabric by various composite modes such as wrapping, networking and the like, wherein the fabric can exert excellent elasticity of the PTT filaments, has excellent properties of luster, softness, comfortableness and the like of staple single yarns such as mercerized cotton, tencel and the like, has the special effects of wrapped and networked composite yarns, and has excellent performance and novel style; and the method combines weaving parameter design and pretreatment shrinkage, stretching and heat setting process control and the like, and comprises proper raw material preparation, weaving parameter selection, dyeing and after treatment process.

Owner:ZHEJIANG SCI-TECH UNIV

Conductive fiber preparation method and product thereof

The invention discloses a conductive fiber preparation method and a product thereof. The method comprises a step of uniformly coating a prepared conductive material comprising mixed solution of conductive particles or conductive polymer and photosensitive polymer and comprising uniform solution or suspension on the surface of a fiber by a dipping or spraying method, wherein a coating is cured under the irradiation of ultraviolet light, the conductive material is fixed on the surface of the fiber and the fiber is endowed with conductive performance; ultraviolet lamp light is used for irradiation, and the temperature of a lamp box is 25 to 125 DEG C; and in the curing process, the wavelength of the ultraviolet light source is controlled at 280 to 350 nanometers, the power is 150 to 250mW / cm2, and the irradiation time is 2 to 15 seconds. Compared with the prior art, the conductive fiber has the advantages of difficult drop of conductive components, durable conductivity, low resistance, soft handfeel, wearing comfortableness and the like; and the preparation method has simple process and low cost.

Owner:RONGSHENG PETROCHEM +2

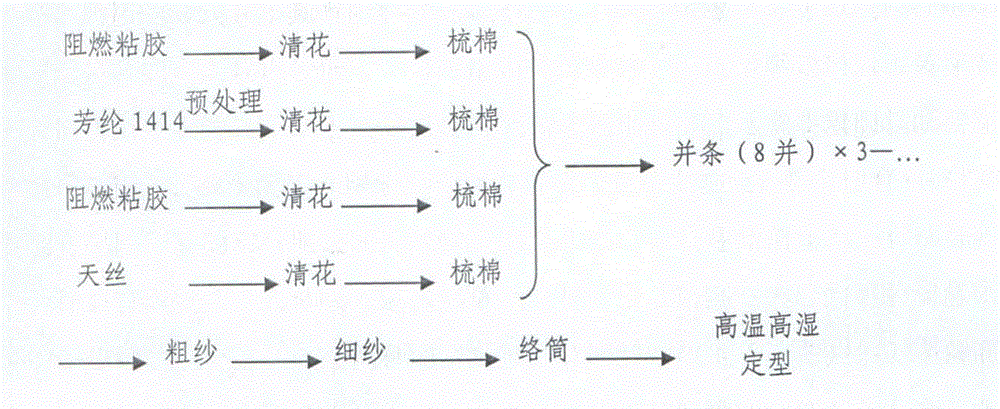

High-strength, flame-retardant and antistatic blended yarn and production method thereof

InactiveCN103541079AStable and durable functionComfortable to takeTextile treatment by spraying/projectingYarnConductive filamentFineness

The invention discloses a high-strength, flame-retardant and antistatic blended yarn and a production method thereof. The high-strength, flame-retardant and antistatic blended yarn is produced in the method comprising the steps that single yarns are formed by 60-80wt% of aramid fibers 1414 and 20-40wt% of cotton fibers in a blended mode through an opening and cleaning procedure, a cotton carding procedure, a drawing procedure, a roving procedure and a spinning procedure, wherein the lengths of the aramid fibers 1414 range from 35mm to 40mm, the line density of the aramid fibers 1414 ranges from 1.65dtex to 1.86dtex, the aramid fibers 1414 are pre-processed through antistatic oil, the lengths of the cotton fibers range from 25mm to 31mm, and the fineness of the cotton fibers ranges from 1.54dtex to 2dtex; finally, 0.5-5wt% of conductive filaments are merged into the single yarns in a winding and cabling procedure, and doubling and twisting are conducted. The high-strength, flame-retardant and antistatic blended yarn makes full use of high orientation and strong inter-chain bonding power of the aramid fibers 1414, good hygroscopicity of the cotton fibers and relatively low specific resistance of the conductive filaments, has the advantages of achieving high strength, flame retardance and resistance to static, and is particularly suitable for industrial textiles with the requirement for a special protection function.

Owner:TAIYUAN UNIV OF TECH

Traditional Chinese medicine composition for preparing male health viscose fibers, prepared health viscose fibers and preparation method thereof

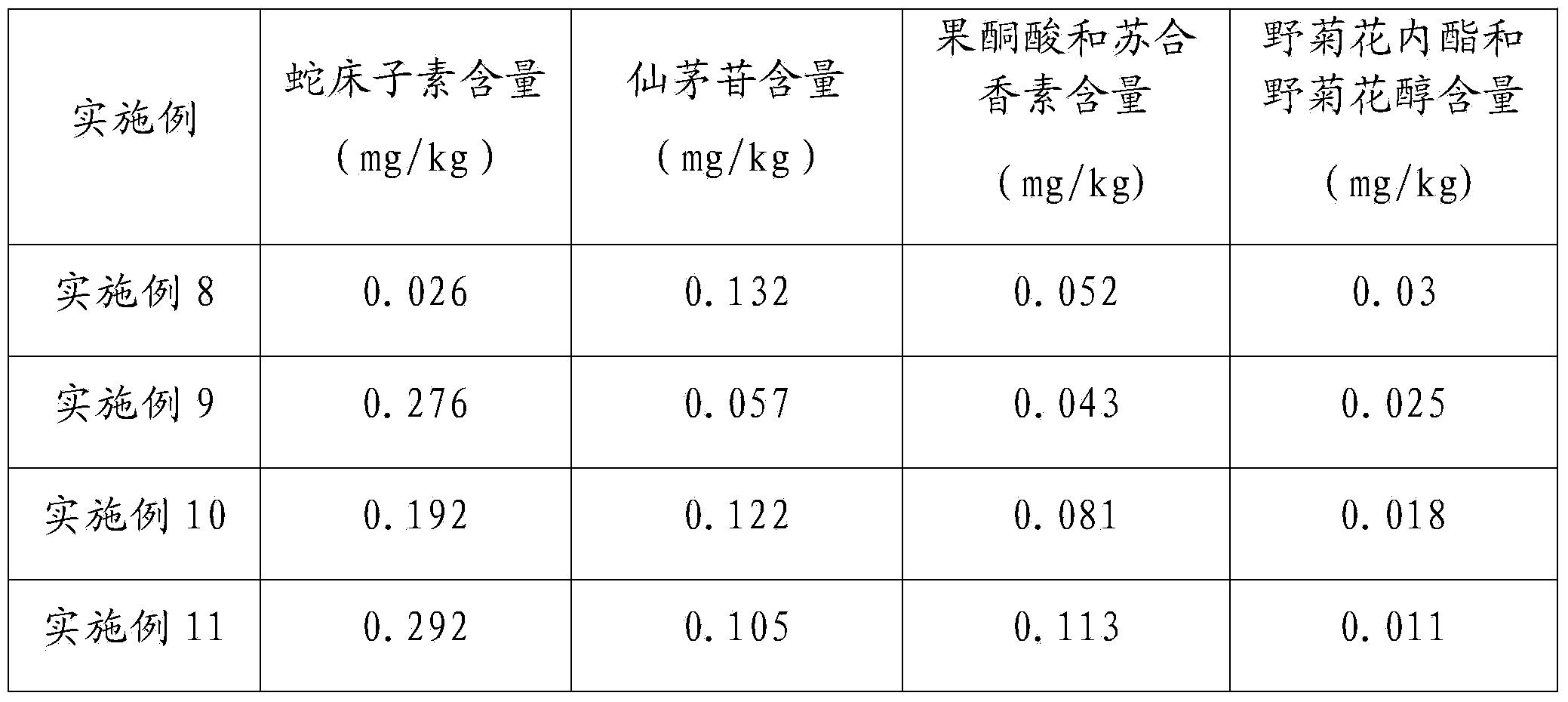

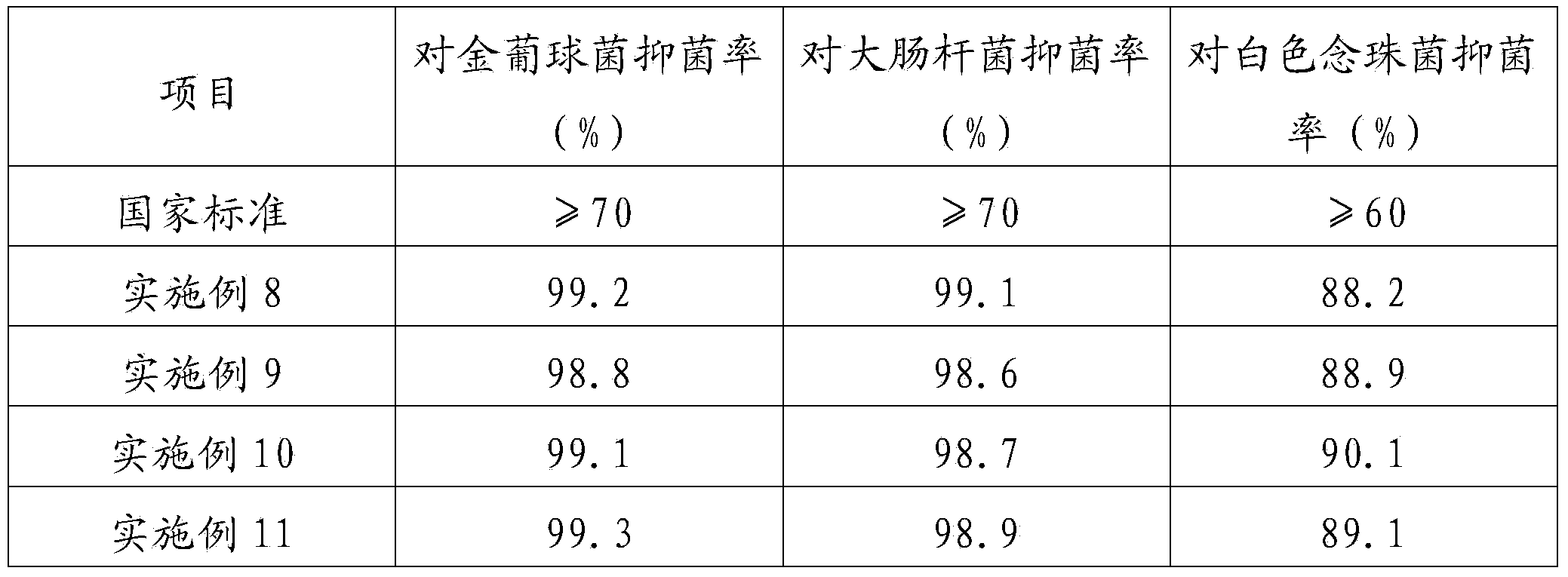

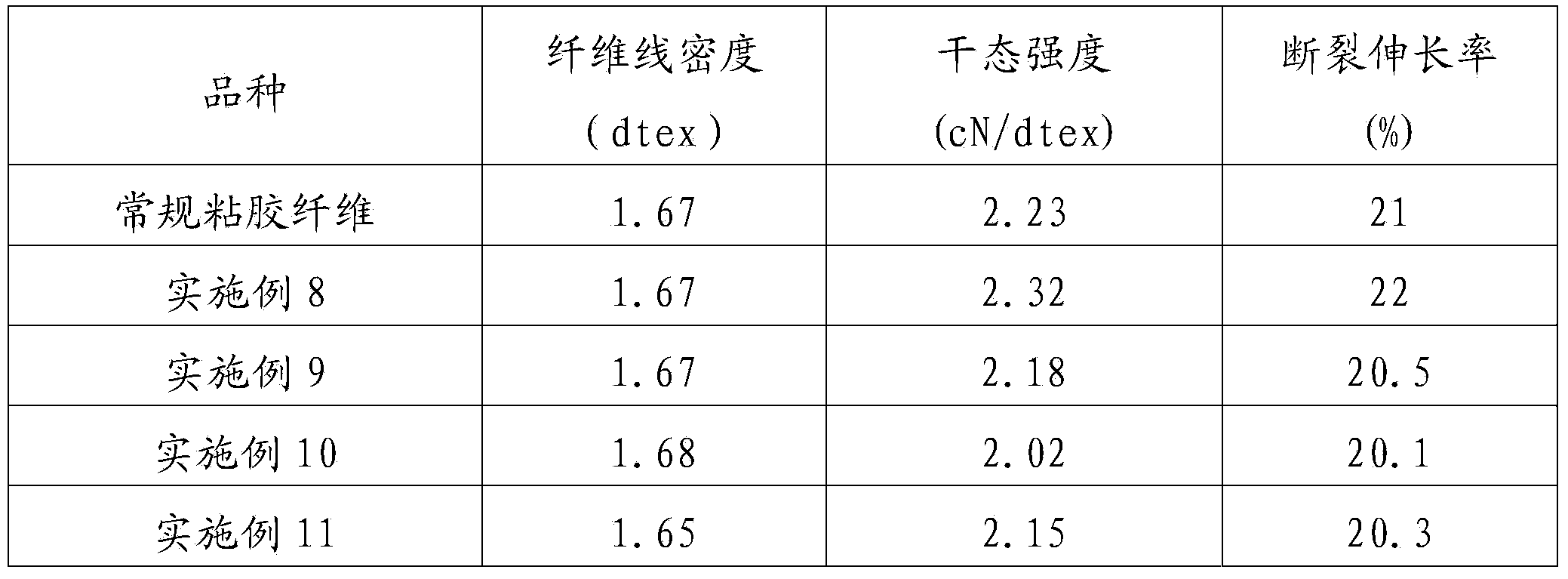

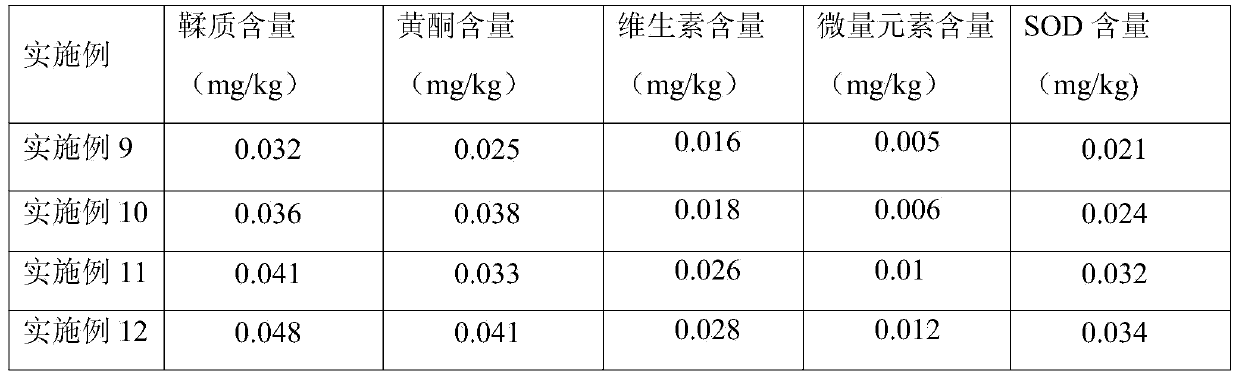

ActiveCN103655960AGood treatment effectGood antibacterial health care performanceHydroxy compound active ingredientsArtificial filaments from viscoseChrysanthemum FlowerViscose

The present invention discloses a traditional Chinese medicine composition for preparing male health viscose fibers, the prepared health viscose fibers and a preparation method thereof. The traditional Chinese medicine composition comprises the following traditional Chinese medicine components, by weight, 25-45% of common cnidium fruit, 25-45% of common curculigo rhizome, 20-40% of beautiful sweetgum fruit, and 10-30% of wild chrysanthemum flower. The method for preparing the health viscose fibers by using the traditional Chinese medicine composition comprises: dissolving traditional Chinese medicine composition extract powder to obtain an antibacterial health solution; heating borneol until being melted, and emulsifying to obtain an emulsifying solution; adopting a cellulose pulp as a raw material to prepare a spinning viscose, and adding the antibacterial health solution to the viscose solution in any steps from the end of yellowing to spinning to obtain an antibacterial health blending viscose solution; and carrying out spinning forming, strand drafting and post-treating on the antibacterial health blending viscose solution to obtain the health viscose fibers, wherein the borneol emulsifying solution is added in the oiling step of post-treating.

Owner:LINQU XINYUE KNITTING WEAR

Aromatic viscose fiber and its making method

InactiveCN1952224AIncrease aromaNo side effectsMonocomponent cellulose artificial filamentArtificial filament heat treatmentDistillationAromatic agent

The invention provides an aroma viscose fiber, characterized in that aromatic agent is made by natural plant pure dew or rip, spinning fluid of viscose fiber comprises original fluid and said aromatic agent, of which the addition is 0.2%-15% of original fluid by weight. The invention provides a production method for the aroma viscose fiber, characterized in that (1) the natural plant pure dew of rip with conventional concentration is concentrated 100% saturated by distillation process and aromatic agent is made after filtering; (2) said aromatic agent with 0.2%-15% of rayon spinning original fluid by weight is added into the original fluid and aroma viscose fiber is obtained by conventional wet spinning and spraying technology. The aroma viscose fiber with persistent aromatic virtue and no adverse effect to human is applied in clothes. The production technology which is rational, simple, low cost, is applied in industrialization manufacture.

Owner:秦如涛

Dyeing and finishing process of PTT filament/staple fiber single yarn composite fabric

InactiveCN102086602AImprove performanceNoveltyBiochemical fibre treatmentDry-cleaning apparatus for textilesSpecial effectsDyeing

The invention relates to a dyeing and finishing technology of a composite fabric, in particular to a dyeing and finishing process of polytrimethylene terephthalate (PTT) filament / staple fiber single yarn composite fabric. The process at least comprises the following steps of: singeing, performing bleaching thermal treatment, drying, preheating and forming, dyeing, drying and thermally forming, inspecting, rolling and packaging. By the process, the novel fiber composite costume fabric, which is good in performance and novel in style, and has good elasticity of a PTT filament, good characteristics of gloss, softness, comfort and the like of staple fiber single yarns, such as mercerized cotton, tencel and the like, and special effects of wrapping and meshing the composite yarns, is prepared by combining weaving parameter design and pretreatment contraction, stretching and thermoforming processes together through proper processes of preparing raw materials, selecting weaving parameters, dyeing and afterfinishing.

Owner:ZHEJIANG SCI-TECH UNIV +1

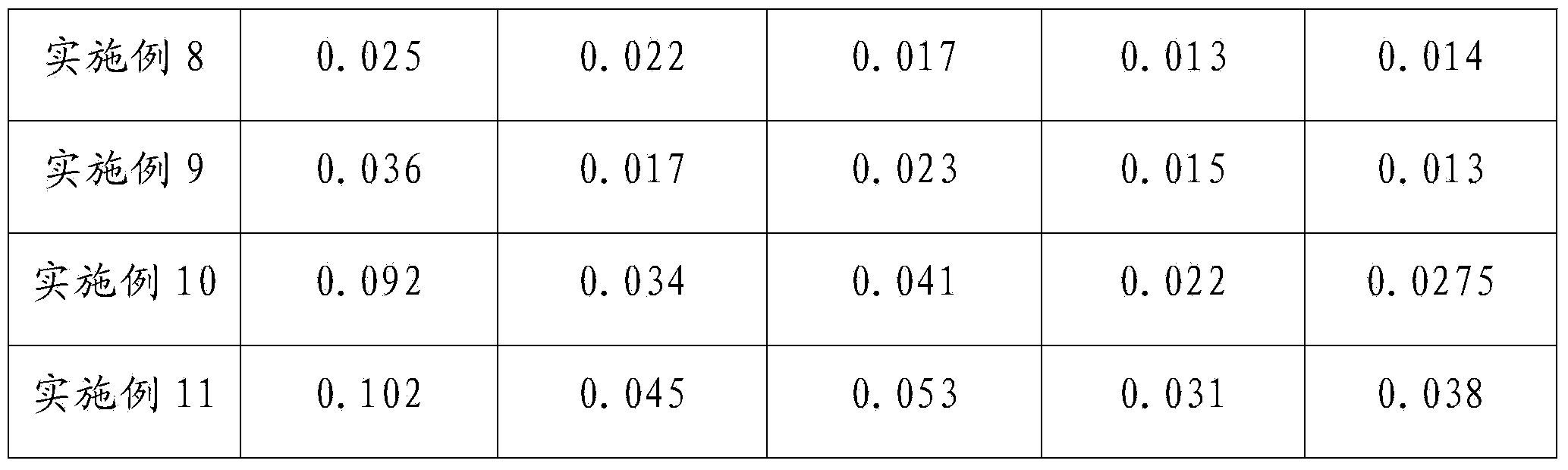

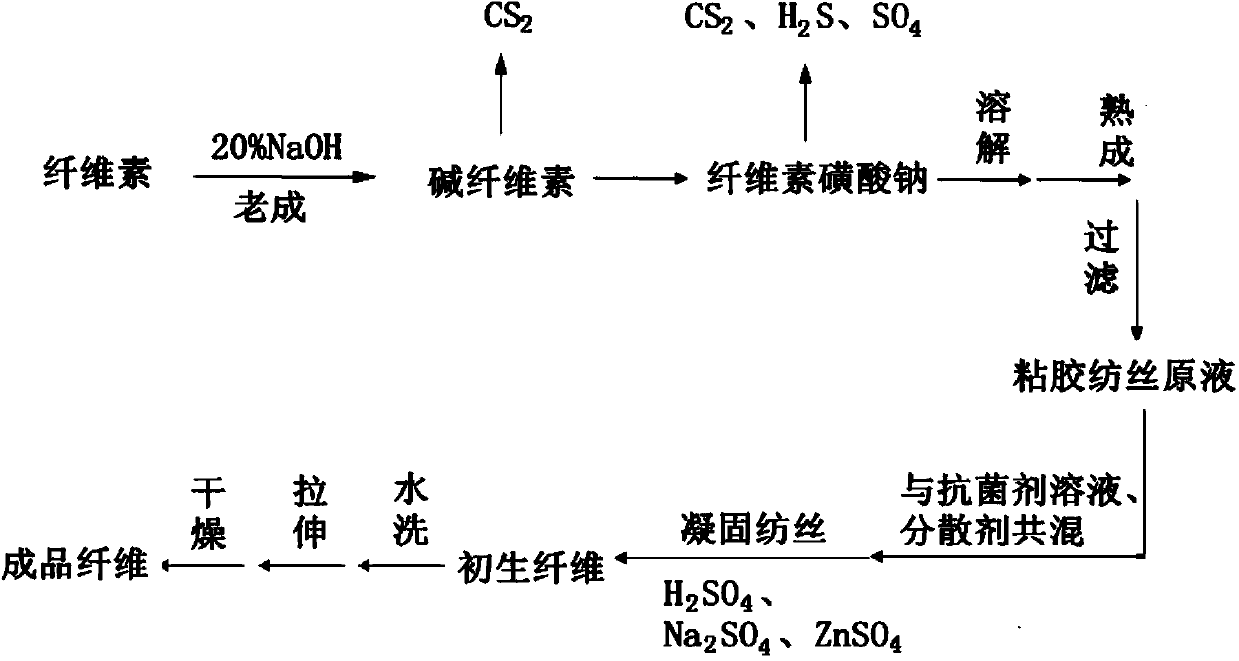

Antibacterial skin care agent composition, viscose fibers prepared from antibacterial skin care agent composition, and preparation method of viscose fibers

InactiveCN103993377ALong-lasting antibacterial skin care functionNo side effectsArtificial filaments from viscoseWet spinning methodsMedicineNatural substance

The present invention relates to functional cellulose fibers, particularly to an antibacterial skin care agent composition, viscose fibers prepared from the antibacterial skin care agent composition, and a preparation method of the viscose fibers. In the prior art, the common viscose fibers do not have the antibacterial skin care effect. Based on the disadvantage in the prior art, the invention provides viscose fibers having a plant antibacterial skin care function, wherein a plant source antibacterial skin care agent composition comprising a rosa laevigata extract, a lophatherum gracile extract and a hippophae rhamnoides extract and adopted as an antibacterial skin care function material, a dispersing agent adopted as an auxiliary material, and cellulose viscose are subjected to co-blending to prepare the viscose fibers having the plant antibacterial skin care function. According to the viscose fibers having the antibacterial skin care function, the composition comprising the rosa laevigata extract, the lophatherum gracile extract and the hippophae rhamnoides extract is adopted as the antibacterial skin care agent, and the antibacterial skin care agent is uniformly distributed in the fibers, such that the antibacterial skin care function of the fibers is lasting; and the composition comprising the rosa laevigata extract, the lophatherum gracile extract and the hippophae rhamnoides extract is the nature substance extracted from the plant, has good compatibility and friendliness with the natural world, and does not has side effect on the human body.

Owner:QINGDAO XUEDA GRP

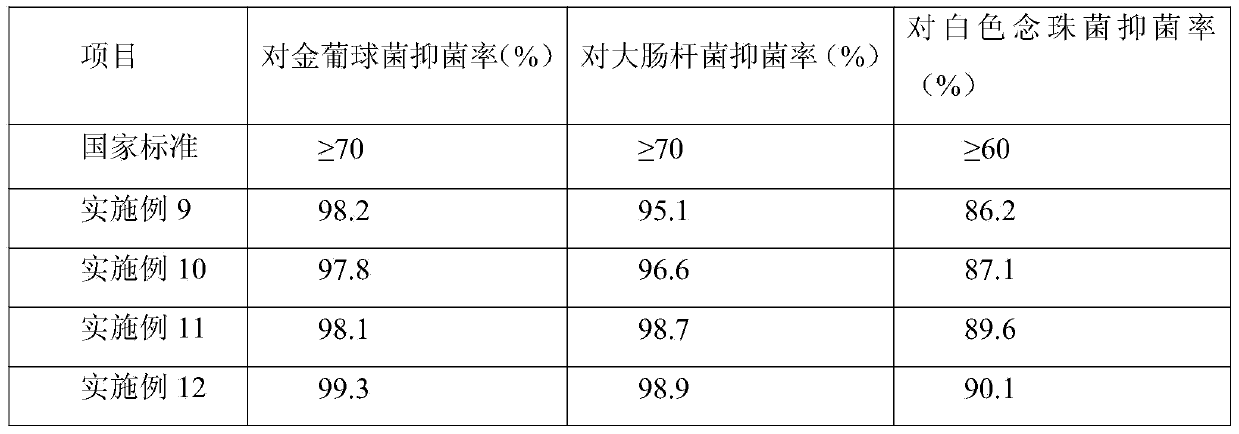

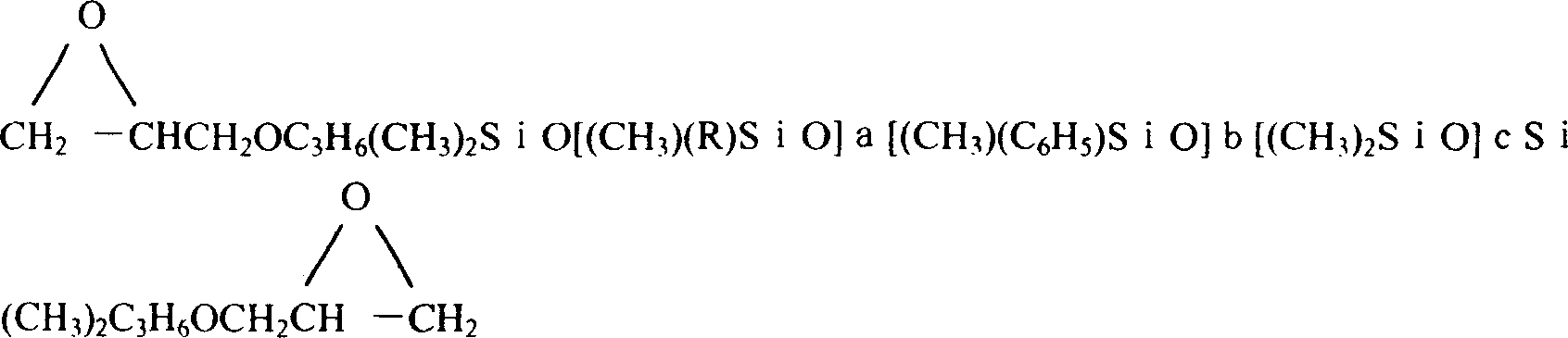

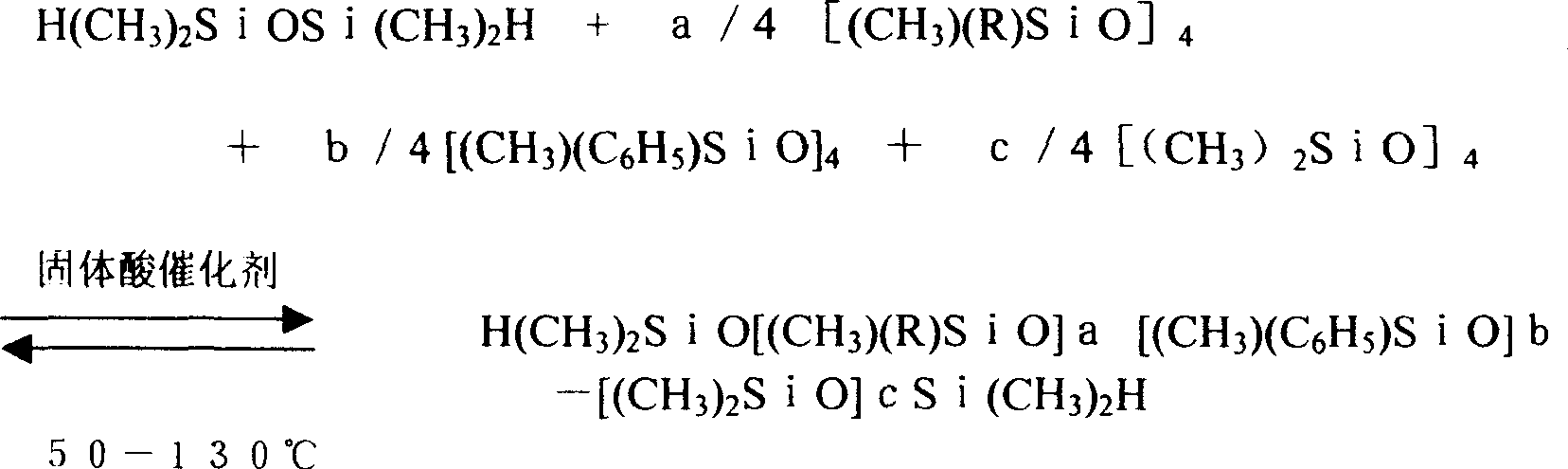

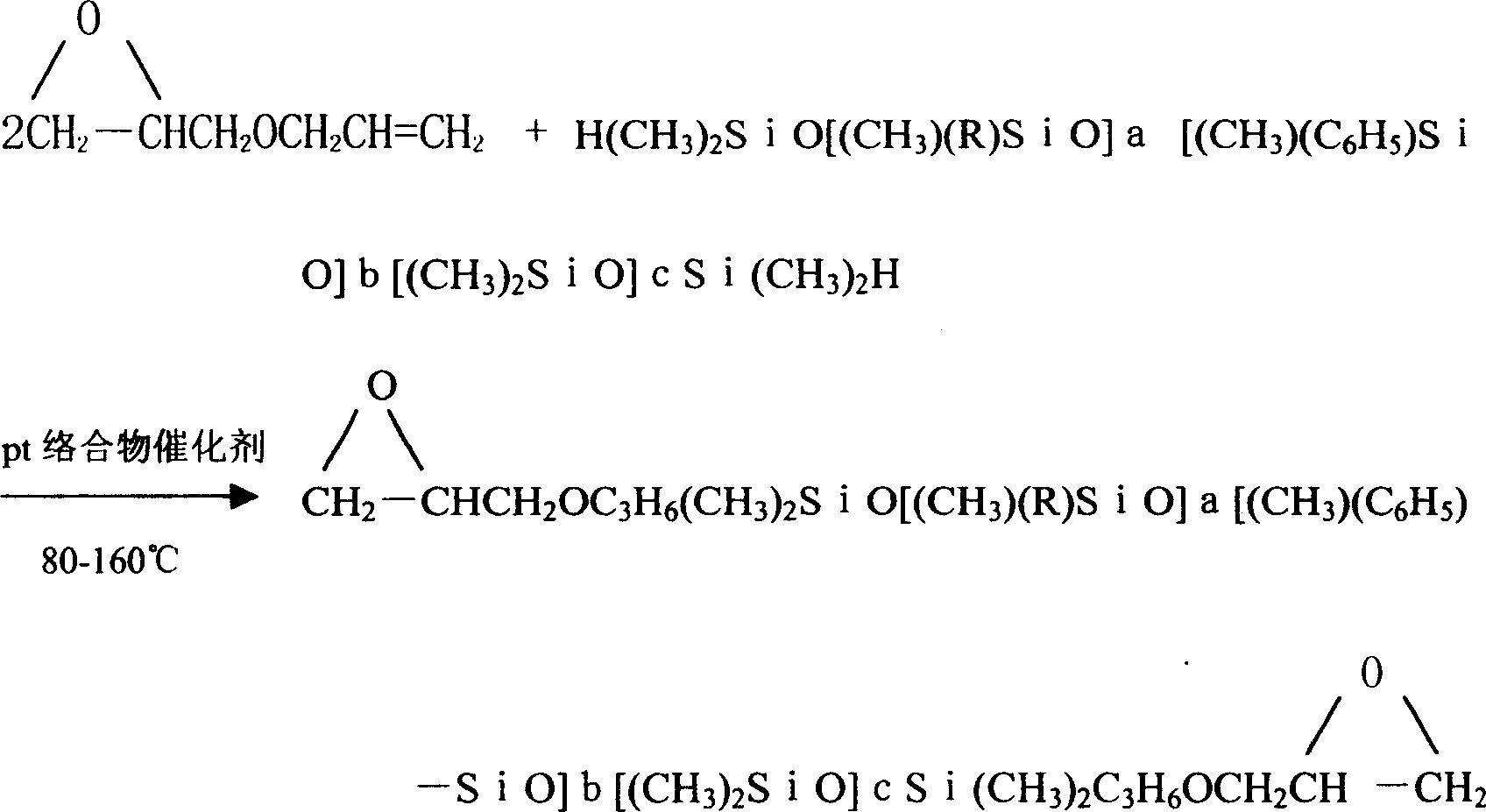

Epoxypropoxy end capped polyether and phenyl comodified polysiloxane, and preparation and use thereof

InactiveCN1982356APromote the development of industrializationNo waste dischargeFibre treatmentEpoxySurface-active agents

An epoxy propyl capped polyether and phenyl modified silicone, its production and use are disclosed. Its advantages include excellent anti-cracking and anti-impact performances and toughness, better hydrophilic and oleophilic properties and antistatic performance. It can be used in polyurethane industry as organic silicon special surface active agent and in textile industry as finishing softening agent.

Owner:山东大易化工有限公司

Method for manufacturing knitted soft composite stabproof vest fabric

InactiveCN101953518AEasy to makeIncrease the accumulation of high-strength fibersWeft knittingLayered productsWarp knittingUltrahigh molecular weight polyethylene

The invention relates to a method for manufacturing a knitted soft composite stabproof vest fabric, which belongs to the field of methods for manufacturing stabproof vest fabrics. The method comprises the following steps of: (1) performing weft knitting spooling or tricot warping by adopting ultrahigh molecular weight polyethylene yarns or aramid fibers as raw materials; (2) knitting the yarns by adopting a circular weft knitting machine and a flat knitting machine or knitting the yarns by adopting a warp knitting machine; (3) washing the knitted fabric obtained by the knitting with cold water and hot water, and then performing coating treatment; (4) layering the finished knitted fabric, ultrahigh molecular weight polyethylene non-woven and a laid fabric; and (5) shearing the layered fabric, serging and quilting seam with rough stitches to obtain the knitted soft composite stabproof vest fabric. The method of the invention has the advantages of improving the shearing resistance of the soft stabproof layer of the obtained fabric, reducing the piercing depth of a cutting edge in the soft stabproof layer and effectively improving the interface strength and uniformity of the coating treatment, along with simplicity and suitability for industrial production; and the obtained fabric is light, soft and comfortable to use.

Owner:DONGHUA UNIV

Viscose fiber with plant source anti-bacterial function and aromatic smell, and preparation method thereof

ActiveCN103225123BNo side effectsComfortable to takeArtificial thread manufacturing machinesArtificial filaments from viscoseSide effectMint extract

The invention discloses a viscose fiber with a plant source anti-bacterial function and aromatic smell. The viscose fiber is composed of a viscose spinning solution, an anti-bacterial agent and an aromatic agent, wherein the anti-bacterial agent is mixed powder of a mint extract and a isatis root extract, wherein the weight percentage of the mint extract accounts for 40%-80%; and the weight percentage of the isatis root extract accounts for 60%-20%; the aromatic agent is mint oil coated by microcapsules; the anti-bacterial agent accounts for 1%-8% of the mass of methyl cellulose in the viscose spinning solution; the mint oil accounts for 0.2%-1% of the mass of methyl cellulose in the viscose spinning solution; and the viscose fiber is prepared by adopting a wet spinning method by using the viscose spinning solution, the anti-bacterial agent and the aromatic agent. The plant source extracts and the plant source essential oil are used as the anti-bacterial agent and the aromatic agent; and the anti-bacterial agent and the aromatic agent are uniformly distributed in the fiber, so that the anti-bacterial function and the aromatic smell of the fiber are durable. Since the plant source extracts and the aromatic agent are natural substances extracted from the plants, so that the viscose fiber has no side effect to human body.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

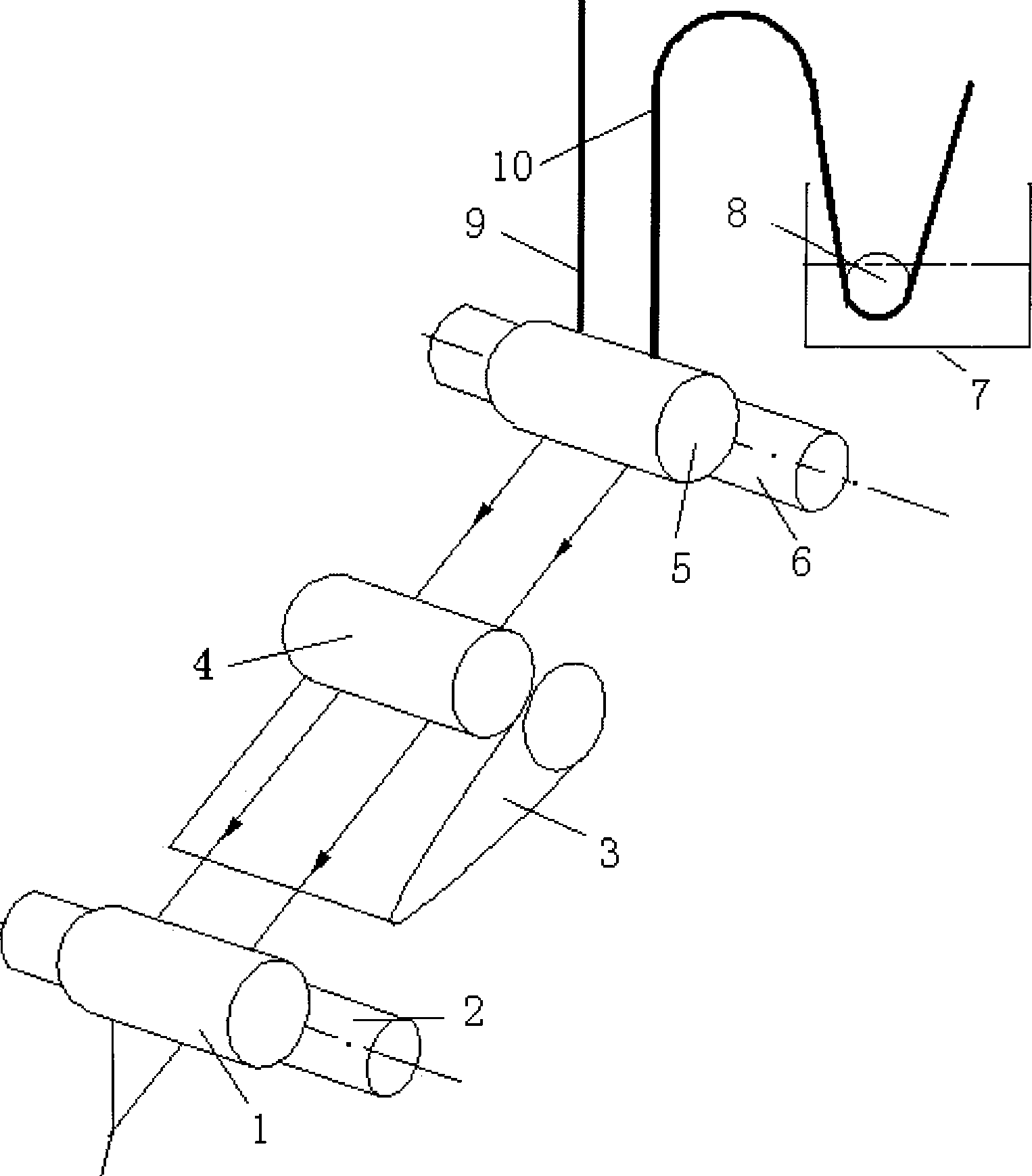

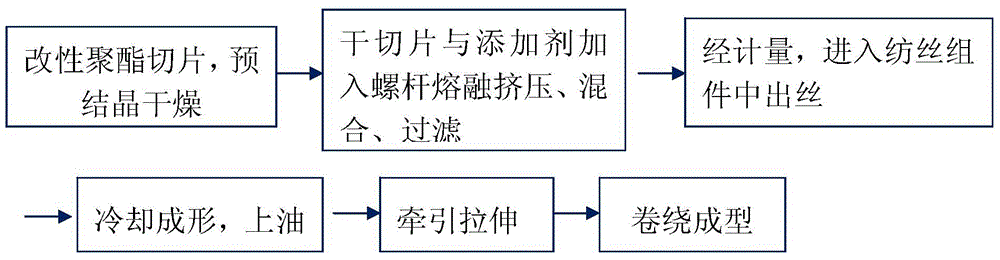

Production process of high-elasticity-feature terylene pre-oriented fibers

InactiveCN104480555AImprove water absorptionImprove sexual functionSpinnerette packsNew-spun product collectionFiberPolyester

The invention provides a production process of high-elasticity-feature terylene pre-oriented fibers. The production process is characterized by comprising the steps of 1) slicing a raw material, namely, modified polyester, conveying the material to a wet material bin to enable pre-crystallizing, and then ventilating and drying to obtain dry slices; 2) feeding the dry slices and an additive into a screw extrusion machine together under a melting condition, filtering and then transferring into a spinning box to obtain a melt; 3) metering the melt through a metering pump, and feeding into a spinning assembly to yield silks; 4) performing slow cooling and side blowing for the silks obtained in step 3) to cool and shape, and then applying oil; 5) pulling, stretching, and thermally shaping; 6) coiling through a coiling head to obtain the high-elasticity-feature terylene pre-oriented fibers. The high-elasticity-feature terylene pre-oriented fibers prepared by the production process have the advantages that the specification is up to 180dtex / 36f, the breaking strength is not less than 1.80cN / dtex, the elongation at break is 200+ / 30; the softness, sense of touch and rebound elasticity are superior to those of the general fibers, and moreover, the water absorbing performance, the oil absorbing performance and the cleaning function are high.

Owner:ZHONGRUN SCI & TECH

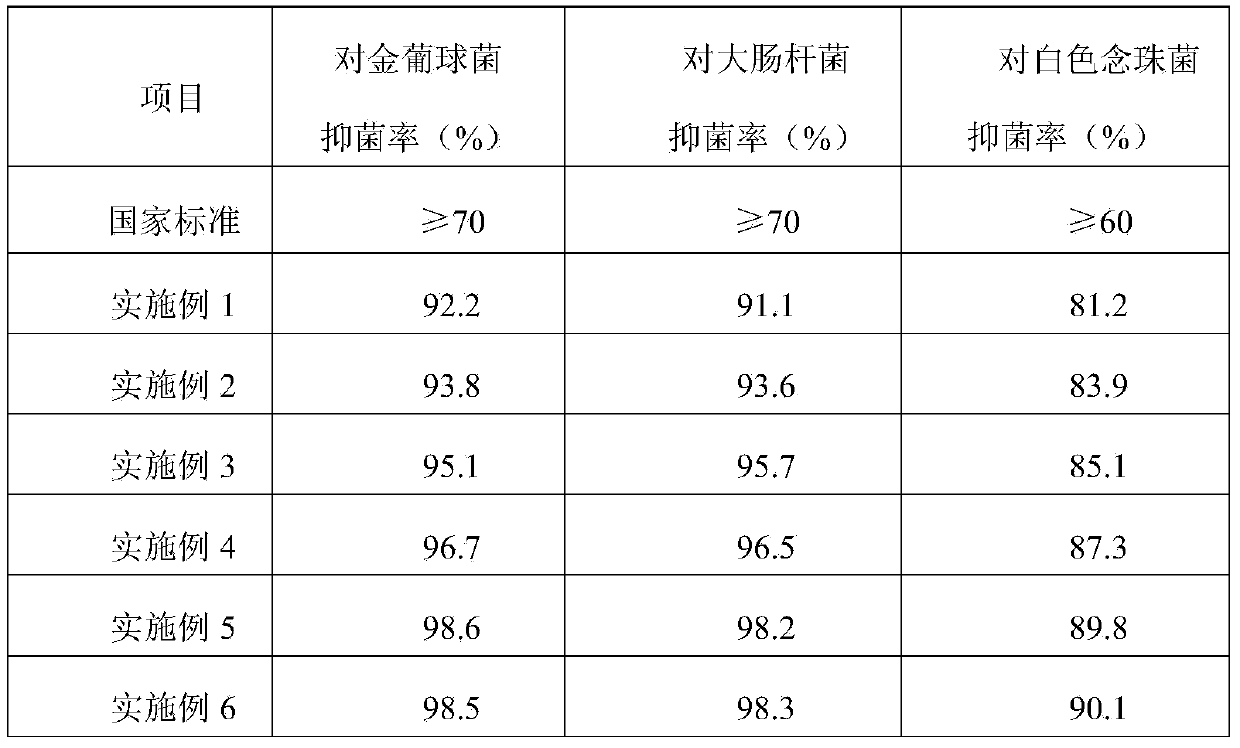

Anti-bacterial, health-caring and skin-beautifying viscose fiber and preparation method thereof

ActiveCN105239185ALong-lasting antibacterial health care and skin beautification functionNo side effectsArtificial filaments from viscoseHuman bodySocial benefits

The invention provides an anti-bacterial, health-caring and skin-beautifying viscose fiber and a preparation method thereof. The viscose fiber includes an anti-bacterial, health-caring and skin-beautifying agent composition including, by weight, 40-50% of apocynum venetum leaves, 30-40% of fructus forsythia and 20-30% of astragalus membranaceus. The preparation method includes the steps of 1) preparing an anti-bacterial, health-caring and skin-beautifying agent solution; 2) preparing a mixture liquid of the anti-bacterial, health-caring and skin-beautifying agent solution and a dispersing agent; 3) preparing the viscose; 4) preparing an anti-bacterial, health-caring and skin-beautifying blended viscose spinning liquid; 5) spinning the anti-bacterial, health-caring and skin-beautifying viscose fiber; and 6) performing after treatment The anti-bacterial, health-caring and skin-beautifying viscose fiber is free of side effect on human body. The fiber is suitable for produce knitted underwear, other clothes and bedding textiles, is wide in available range and has huge economical and social benefit. A blanching process is omitted in the after treatment in the preparation method, so that environment pollution is reduced.

Owner:青岛上雅家居用品股份有限公司

Nanometer pearl poly terephthalate 1, 2-trimethylene glycol ester polyester fiber

InactiveCN101701364AComfortable to takeFiber surface is smooth and coolFlame-proof filament manufactureMelt spinning methodsPropylene glycolPolyethylene terephtalate

The invention relates to nanometer pearl poly terephthalate 1, 2-trimethylene glycol ester polyester fiber which is characterized in that nanometer titanium dioxide, nanometer silver oxide, nanometer pearl powder and nanometer magnesium oxide are added in the process of synthesizing poly terephthalate 1, 2-trimethylene glycol ester polyester to obtain the nanometer modified poly terephthalate 1, 2-trimethylene glycol ester polyester, and the poly terephthalate 1, 2-trimethylene glycol ester polyester can be directly processed with the melt spinning process to obtain the nanometer pearl poly terephthalate 1, 2-trimethylene glycol ester polyester fiber.

Owner:WUJIANG YINGXIANG CHEM FIBER

Pearl skin-care tweed and production technology thereof

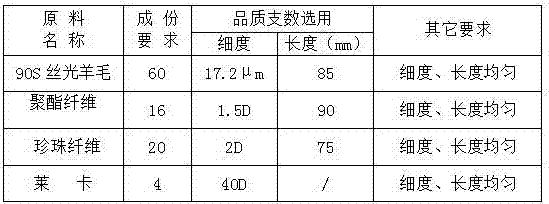

InactiveCN107475859AComfortable to takeComfortable to wearHeating/cooling textile fabricsArtificial filaments from viscosePolyesterUltraviolet

The invention discloses pearl skin-care tweed and a production technology thereof. The skin-care tweed is prepared from 60% of mercerized wool fibers, 16% of polyester fibers, 20% of pearl fibers and 4% of lycra. The production technology of the pearl skin-care tweed comprises the dyeing procedure, the spinning procedure, the weaving procedure and a post-finishing procedure. The pearl fibers have the beauty maintaining and skin caring effects of pearls, and also have the moisture absorption, air permeability and comfortable wearability characteristics of cellulose fibers; the pearl fibers, mercerized wool and the polyester fibers are blended, and the lycra is added, so that the functions, such as beauty maintaining, skin caring, moisture absorbing, air permeability and ultraviolet prevention, of conventional wood fabrics are improved; the fabric has the advantages of being glossy, gorgeous, smooth in hand feeling, friendly to the skin, comfortable and the like, is suitable for wearing as a close-fitting fabric, meets requirements of consumers, and has a wide market space.

Owner:JIANGSU JIANLU WOOLEN

Pearl blended regenerated cellulose fiber and its preparation process and application

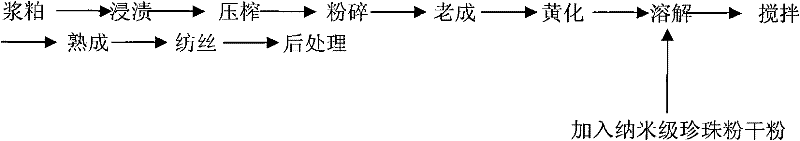

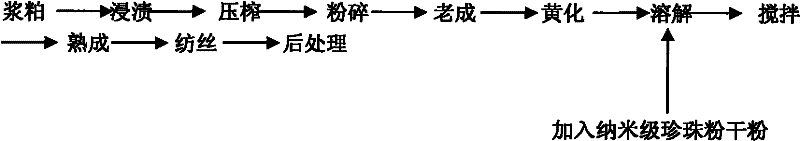

InactiveCN102277639AKeep whitePrevent aging and wrinklingArtificial filaments from viscoseMoisture permeabilityCellulose fiber

The invention discloses a pearl blended regenerated cellulose fiber, its preparation process and application. Calculated by weight percentage, the present invention consists of the following materials: nano-scale pearl powder dry powder: 1%-10%, cellulose: 90%-99%. The preparation process of the present invention is as follows: (1) pulp; (2) dipping; (3) pressing, pulverizing; (4) aging; (5) yellowing; (6) dissolving; (7) adding nano-scale pearl powder dry powder (8) stirring evenly; (9) ripening; (10) spinning; (11) finished product after post-processing. The pearl blended regenerated cellulose fiber prepared by the present invention can be used to prepare short fibers and filaments, and has the advantages of nourishing skin and skin care, whitening skin, anti-ultraviolet rays, moisture absorption and ventilation, comfortable wearing, all-natural and durable.

Owner:湖州珠力纳米材料科技开发有限公司

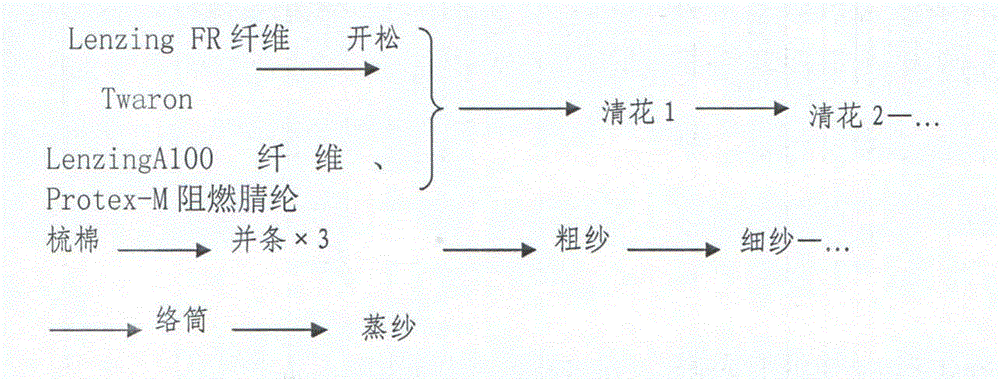

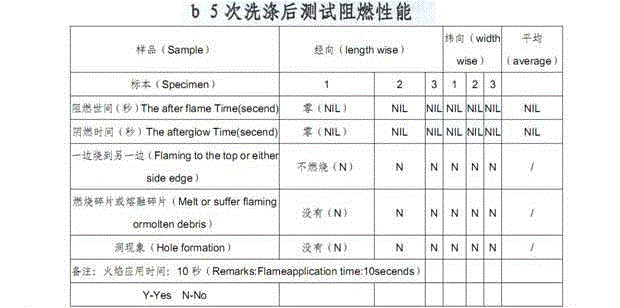

Fire resistant fiber blended yarn and production method thereof

InactiveCN104611796AWith flame retardant functionPermanent flame retardant functionYarnYarnTextile technology

The invention belongs to the technical field of textiles, and particularly relates to a fire resistant fiber blended yarn and a production method thereof. The fire resistant fiber blended yarn comprises, by weight, 30-45% of Lenzing FR fibers, 30-40% of Protex-M fire-resistant acrylic, 15-20% of Lenzing A100 fibers, and 5-10% of Twaron. The production method sequentially comprises the following steps of 1, conducting pretreatment on the Lenzing FR fibers and the Twaron, 2, conducting blowing for the first time, 3, conducting blowing for the second time, 4, conducting cotton carding, 5, conducting drawing, 6, conducting roving, 7, conducting spinning, 8, conducting spooling and 9, conducting yarn steaming. A garment manufactured by the yarn has the permanent fire resistant function, the adopted yarn is safe and environmentally friendly, and no poisonous gas is released; the garment manufactured by the yarn is soft in touch, a user wears the garment comfortably, and the moisture absorption and breathable performance is good; the yarn is formed by evenly mixing the fibers, and the thermal protection and comfort differences caused when the fibers are unevenly mixed at different places of a shell fabric are avoided.

Owner:DEZHOU HUANYUAN ECOLOGICAL TECH

Inelastic lace trimming and production method thereof

ActiveCN103481607AReflect tough textureGood dispersionSynthetic resin layered productsArtifical filament manufactureYarnPolyester

The invention relates to an inelastic lace trimming and a production method of the inelastic lace trimming. A lace layer is combined on inelastic fabric and is formed by weaving polyester and nylon composite yarn and modified nylon yarn, and the mass ratio of the polyester and nylon composite yarn to the modified nylon yarn is 1:1. The production technology is simple in process, and large-scale industrial production can be carried out. The polyester and nylon composite yarn has the weaving and dyeing performance of both polyester and nylon and can be twisted together for weaving production, and thus the polyester and nylon composite yarn not only can show special texture and metal brilliance of metal wires but also is softer and comfortable than the metal wires. Meanwhile, the hard texture of the inelastic trimming can be shown better, and the lace trimming is inelastic fabric and can be widely applied.

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

Preparation method of hydrophilic polyester fibers

The invention discloses a preparation method of hydrophilic polyester fibers. The method comprises the following steps that: a photosensitivepolymer solution with a hydrophilic group is uniformly coated onto the surface of un-oiled or oil-removed polyester fibers by a dipping or spraying method; and under the irradiation of ultraviolet light, the coating is solidified and then the photosensitivepolymer with the hydrophilic group is fixed on the surface of the polyester fibers, wherein the solid content of the coating solution is 1 percent to 50 percent; in the solidifying process of the photosensitivepolymer coating with the hydrophilic group, an ultraviolet light source is controlled to between 280 and 350 nm, the power is controlled to between 150 and 250 mW / cm<2>, and the irradiating time is controlled to between 2 and 15 seconds. Compared with the prior art, the preparation method has the characteristics of simple process, relatively low cost and the like; and the hydrophilic polyester fibers have the advantages that: the coating is not easy to fall off; the hydrophilic performance is long-lasting; the handfeel is soft; clothes made from the fibers are comfortable, and the like.

Owner:RONGSHENG PETROCHEM +2

Treatment technology of copper ammonia fiber imitating shell fabric

InactiveCN109056308APlay the role of "etching"The micro pit effect is obviousWeft knittingLiquid/gas/vapor removalFiberPolyester

The invention relates to a treatment technology of copper ammonia fiber imitating shell fabric. The treatment technology comprises the following steps that (1) a gray fabric is subjected to splittingtreatment by adopting sulfuric acid, and the weight loss ratio of the gray fabric is controlled to be 6-10%; the gray fabric is formed through weaving of yarns blended by polyester fiber and modal fiber, wherein the blending ratio of modal fiber to polyester fiber is (50 to 50)-(70 to 30); (2) the cloth cover pH value of the gray fabric which is subjected to splitting treatment is controlled to be5-7, the gray fabric is subjected to dyeing treatment, and the gray fabric is dried; and (3) the dyed gray fabric is subjected to sand washing, and circular drying, and the copper ammonia fiber imitating shell fabric is obtained. The treatment technology makes the shell fabric woven by yarns formed through blending of polyester and modal fiber have the gloss, the soft feeling, the fluffy feelingand the overhang feeling possessed by the shell fabric similar to copper ammonia fiber shell fabric by improving the shell fabric technology, and the wearability of the shell fabric is better and morecomfortable.

Owner:浙江劲光纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com