Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

273 results about "Alpha-Cellulose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alpha Cellulose is the building blocks of wood pulp, it is essentially made up of multiple sugar molecules bonded together to form a chain.

Composites containing cellulosic pulp fibers and methods of making and using the same

InactiveUS6270883B1Reduce discolorationDiscoloration is significantly reduced or avoidedSynthetic resin layered productsNon-woven fabricsCellulose pulpPolymer chemistry

Reinforced composites containing cellulosic pulp fibers dispersed in a matrix, wherein the matrix comprises a thermoplastic polymeric material melting above 180° C. and the cellulosic pulp fibers have an alpha-cellulose purity greater than 80% by weight. Methods of making and using the reinforced composites.

Owner:RAYONIER PERFORMANCE FIBERS +1

Organic biomass fractionation process

InactiveUS20030041982A1Economical and efficientLow costPretreatment with acid reacting compoundsWaste based fuelFractionationNitration

A method for fractionating fibrous biomass comprising cellulose, hemicellulose and lignin components to separate said lignin, cellulose and hemicellulose from one another comprises: (a) shredding said fibrous biomass; (b) concurrently with or subsequent to said shredding, contacting said biomass with an aqueous solution of a nitrate ion source at a concentration of about 0.1-0.3% at a temperature in the range of about 60° to about 80° C. to initiate nitration of the lignin component of said biomass; (c) submerging said partially nitrated biomass in an aqueous solution of a nitrate ion source in the presence of an aluminum compound at a temperature within the range of about 75-100° C. for a time sufficient to complete the nitration of said lignin component; (d) contacting the nitrated biomass produced in step (c) with an alkaline extraction liquor comprising NH4OH at an initial concentration sufficient to solubilize said nitrated lignin component and said hemicellulose component from said cellulose component of said biomass; e) recovering said cellulose from said extraction liquor containing said solubilized nitrated lignin and hemicellulose components, wherein said cellulose comprises at least about 88% alpha cellulose; (f) treating said extraction liquor with an acid to precipitate lignin contained therein, and (g) separating said lignin from soluble hemicellulose in said extraction liquor. The recovered cellulose component comprises at least 88% alpha cellulose and is useful as a starting material for the production of ethanol.

Owner:PRIOR ERIC S

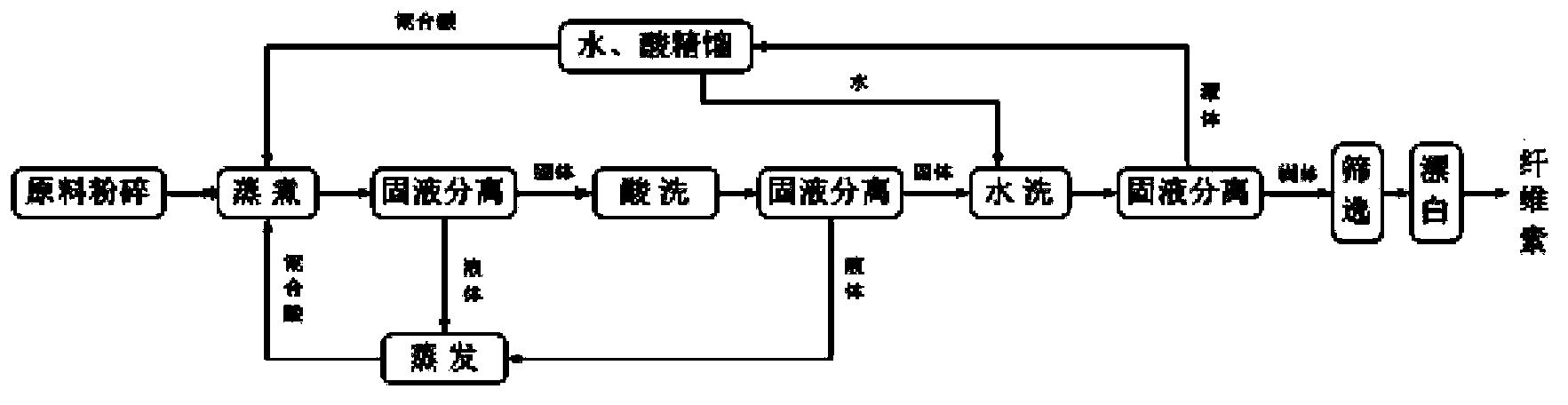

Technology for extracting cellulose from biomass raw materials

ActiveCN103898782AHigh purityReduce cooking timePulp bleachingPulping with acid salts/anhydridesAcetic acidOrganic acid

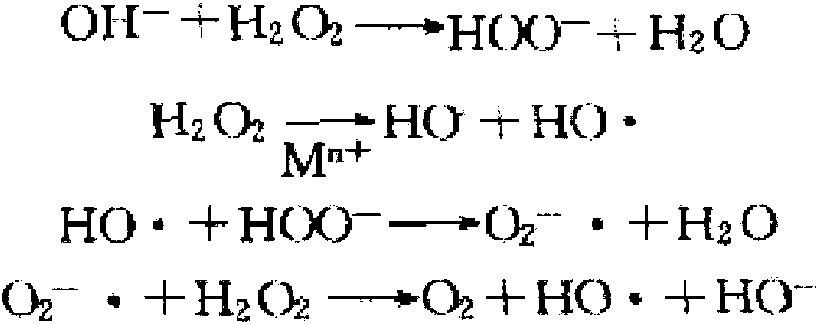

The invention relates to a cellulose extracting technology, and specifically relates to a technology that utilizes organic acids to extract cellulose from biomass raw materials in the presence of a hydrogen peroxide catalyst. The technology comprises the following steps: in the presence of a hydrogen peroxide catalyst, utilizing an organic acid to cook biomass raw materials, wherein the organic acid is composed of formic acid with a concentration of 70 to 95 wt% and acetic acid with a concentration of 70 to 95 wt%; extracting and screening so as to obtain screened cellulose pulp; and further bleaching the screened pulp so as to obtain the target cellulose; wherein the cellulose is dissolving pulp or industrial cellulose. The alpha-cellulose content of the cellulose obtained by the method provided by the invention is more than 90 wt%. The technology has the advantages of simple route and low energy consumption.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

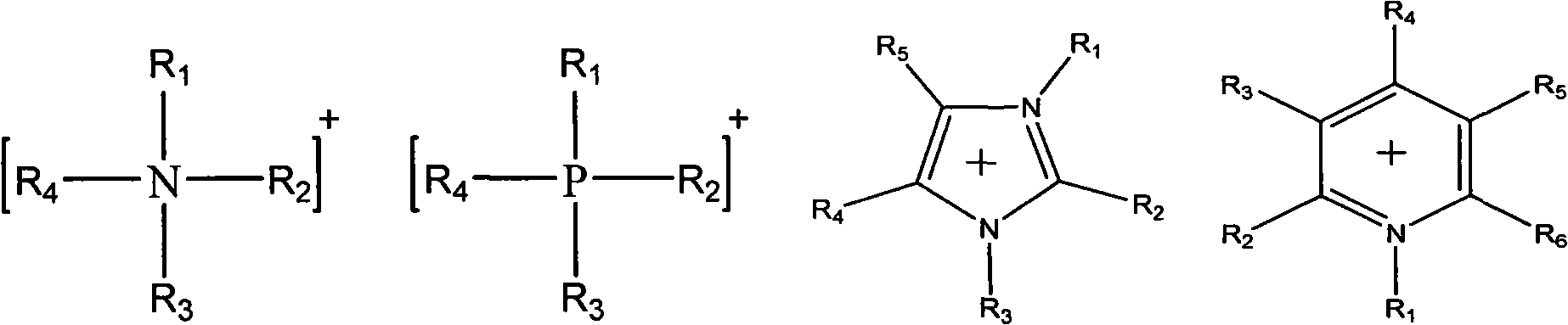

Flame retardant cellulose fiber and preparation method thereof

InactiveCN101608348ASuitable for processingEasy to useFlame-proof filament manufactureMonocomponent cellulose artificial filamentMass ratioCellulose fiber

The invention discloses a flame retardant cellulose fiber and a preparation method thereof. The fiber has the components of fire retardant and cellulose which have the mass ratio of 10-25:100; wherein the fire retardant is novel phosphorus fire retardant having the average grain diameter being less than 1mum; the cellulose is wood pulp or cotton pulp having the polymerization degree of 400-1000 and alpha-cellulose content being more than or equal to 90%. According to the components with the mass ratio of the fiber, the preparation method of the fiber comprises the technique as follows: 1. preparation of flame retardant spinning solution as the following: according to the mass ratio, firstly adding the fire retardant into ionic liquid at the normal temperature, and leading the fire retardant to be uniformly dispersed in the ionic liquid under mechanical agitation; then adding the cellulose into the mixed ionic liquid to be fully dissolved with the dissolving temperature of 70-110 DEG C to prepare flame retardant spinning solution; ensuring the mass ratio between the cellulose and the ionic liquid to be 5-35:95-65: 2. preparation of the flame retardant cellulose fiber: preparing the flame retardant cellulose fiber according to the conventional spinning process flow.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing flame-proof viscose fiber

InactiveCN101215726ASimple and convenient filteringFilter is not easy to clogFlame-proof filament manufactureMonocomponent cellulose artificial filamentPolymer scienceEmulsion

The invention discloses a process for preparing flame retarding cellulose viscose, which adopts pyrophosphate exchange reaction flame retardant particle whose mean particle diameter is <= 1.0um, non-ionic surface active agent, dispersing agent and solvent water to mix and obtain flame retardant emulsion, each percentage by weight is pyrophosphate exchange reaction flame retardant 20-45 wt%, non-ionic surface active agent 5-10 wt% and dispersing agent 0.5-1.0 wt%, and residue is solvent water. The process for preparation comprises adding pyrophosphate exchange reaction flame retardant of flame retardant emulsion which is corresponded to alpha cellulose 15-30 % into spinning original liquid which is filtered to mix, shaping spinning by adopting spinning bath which is low acid, low salt, low temperature and high zinc. The spinning original liquid of the invention has simple and convenient preparation, fiber does not contain halogen elements, which avoids environmental pollution, when in burning, the invention is not melted, while charring only happens to keep the original shape of fiber, the invention prevents dripping which is melted in high temperature from scalding human body, and flame retardant is distributed evenly in adhesive, which can not smolder after leaving fire and easy to be self-extinguished.

Owner:CHTC HELON

Method for producing dissolving pulp by oxygen continuous digesting method

InactiveCN101333778AReduce the degree of polymerizationAchieve continuous cookingPaper material treatmentCyclonic separationCooking methods

The invention relates to a production method for preparing a dissolving pulp by an oxygen-dissolving and continuous-cooking method, which applies the preparation of cotton linters in the production of viscose fibers in the textile industry, and the method comprises the following steps of: I. cotton linter pretreatments: including cotton linter loosening, cyclone separation and dust removal, feeding, two-roll grinding treatment, etc. to the cotton linters by a two-roll pulping machine; and II. oxygen dissolving and continuous cooking: a horizontal continuous cooking digester is adopted to realize the continuous, fast and low-pollution preparation of dissolving cotton pulp through the actions of high temperature, alkali, oxygen or hydrogen peroxide. The horizontal continuous cooking digester includes a pre-reaction bin, a two-roll gauge, a feeding screw, a T-shaped tube, a continuous-cooking tube and a cold discharge device. The method can effectively solve the problems of: cutting, tearing and cell primary wall breakage to the cotton linters by dry method after feed preparation, physical and chemical stripping to mass impurities in the cotton linters, fast accumulation reduction of the cotton linters in a continuous-cooking device and the purification of alpha cellulose under fast accumulation reduction, recycling of waste heat in the production link, and reduction of total amount of COD in a black liquor, and the method has advantages of even cooking and short cooking cycle.

Owner:宜宾长毅浆粕有限责任公司

Antibacterial viscose containing artemisia argyi oil component and production method of antibacterial viscose

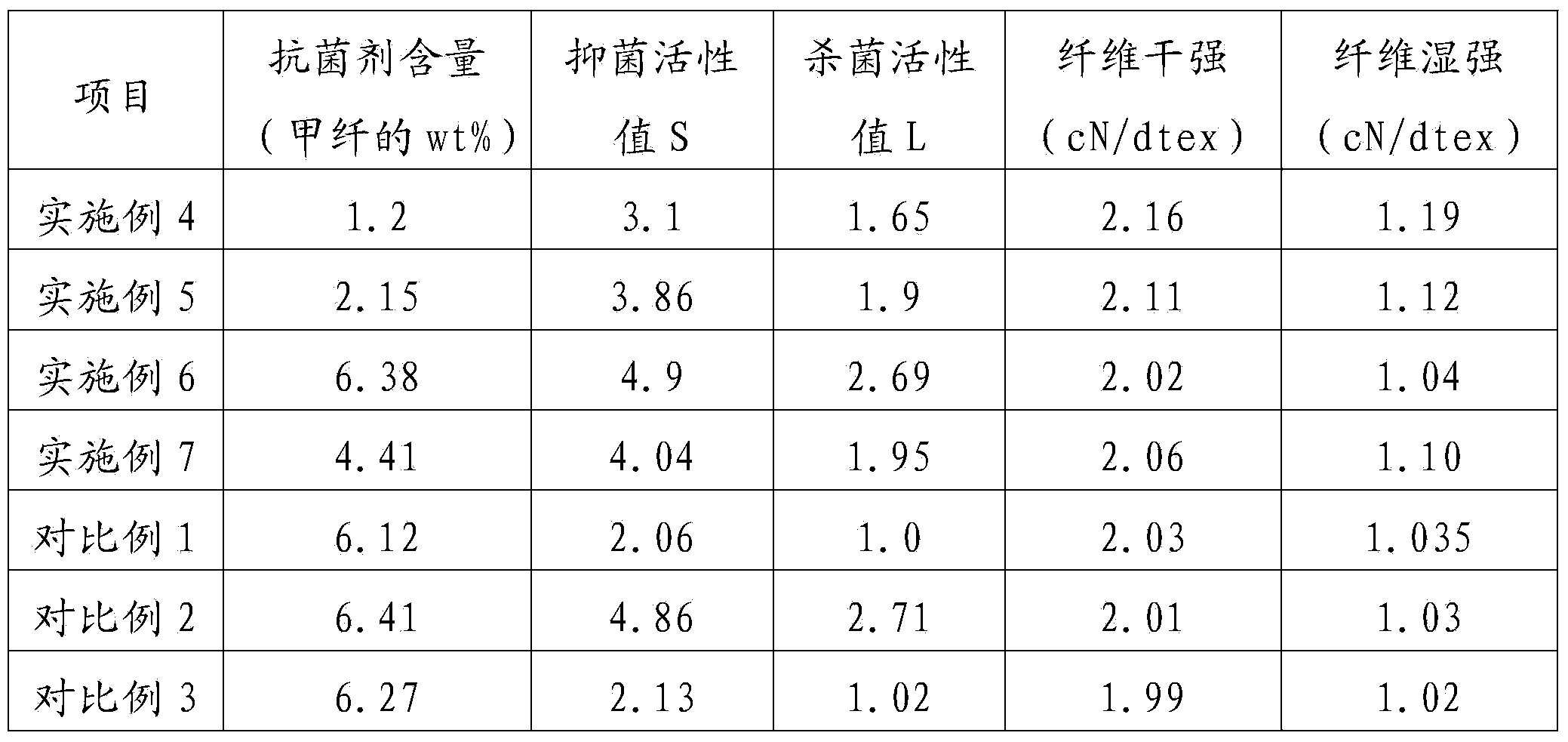

ActiveCN103556250AHigh antibacterial rateImprove durabilityArtificial filaments from viscosePolymer scienceAnti bacterial

The invention relates to antibacterial viscose containing an artemisia argyi oil component and a production method of the antibacterial viscose. The antibacterial viscose takes an artemisia argyi oil microcapsule as an antibacterial agent and a spinning solution is composed of the artemisia argyi oil microcapsule and mucilage glue, wherein the adding ratio of the artemisia argyi oil microcapsule is 10%-30% of alpha cellulose in the mucilage glue and the antibacterial property index are as follows: the antibacterial value is more than 4.0 and the sterilization value is 2.7. The production method of the antibacterial viscose containing the artemisia argyi oil component comprises the following steps: preparing artemisia argyi emulsion, preparing the artemisia argyi oil microcapsule, preparing the mucilage glue, preparing the spinning solution, and spinning and molding. The antibacterial viscose not only has the advantages of maintaining water absorption and air permeability of common viscose and being comfort to wear, but also has high antibacterial rate and good endurance; meanwhile, the antibacterial viscose has a good skin-caring effect and can be widely applied to home textile articles, underwear, sports shirts and the like.

Owner:潍坊欣龙生物材料有限公司

Method for manufacturing modal fiber

ActiveCN101545150AHigh strengthBrightly dyedArtificial filaments from viscoseInternational standardDissolution

The invention discloses a method for manufacturing modal fiber, which comprises basification reaction, ageing reaction, yellowing reaction, dissolution of viscose glue, filter of the viscose glue, defoaming of the viscose glue, ripening of the viscose glue, wet spinning, drawing and other related process steps. The method adopts cellulose pulp with alpha cellulose content of less than 95 percent as a raw material, uses common equipment for producing common viscose glue short fiber, and adopts the technology to control a simple and practical special process formulation and a spinning drawing mode to manufacture the modal fiber capable of reaching international standards. The method has the advantages of little investment, easily obtained and low-cost raw materials, high productivity and simple process operation; and the manufactured modal fiber has good quality and stable performance.

Owner:杭州奥通新材料智能科技有限公司

Methods of making composites containing cellulosic pulp fibers

InactiveUS20020000683A1Reduce discolorationDiscoloration is significantly reduced or avoidedSynthetic resin layered productsLaminationFiber-reinforced compositeCellulose pulp

Reinforced composites containing cellulosic pulp fibers dispersed in a matrix, wherein the matrix comprises a thermoplastic polymeric material melting above 180° C. and the cellulosic pulp fibers have an alpha-cellulose purity greater than 80% by weight. Methods of making and using the reinforced composites.

Owner:RAYONIER PERFORMANCE FIBERS

Method for preparing Nano SiO2 fire retardant viscose fiber, and film

ActiveCN101050559ASimple processEasy to operateFlame-proof filament manufactureArtificial filaments from viscoseFire retardantSodium sulfate

The present invention relates to a preparation method of nano SiO2 fire-retardant viscose fiber and film, specially, it relates to a preparation method of fire-retardant viscose fiber formed from cellulose and SiO2 and organic-inorganic polymer nano composite membrane made of cellulose and SiO2. Said method includes the following steps: adding silicone sol with a certain mass into a viscose solution whose composition contains alpha-cellulose whose mass percentage content is 6-9% and sodium hydroxide whose mass percentage content is 5-6%; fully stirring and mixing them at 10-50 deg.C, deforming so as to obtain viscose-silicone sol solution, then adding said viscose-silicone sol into a coagulation acid bath prepared by using sulfuric acid, sodium sulfate, zinc sulfate and water, coagulating at 10-100 deg.C, spinning so as to obtain nano SiO2 fiber-retardant viscose fiber, utilizing coating process so as to obtain organic-inorganic polymer nano composite membrane of cellulose / SiO2.

Owner:QINGDAO UNIV

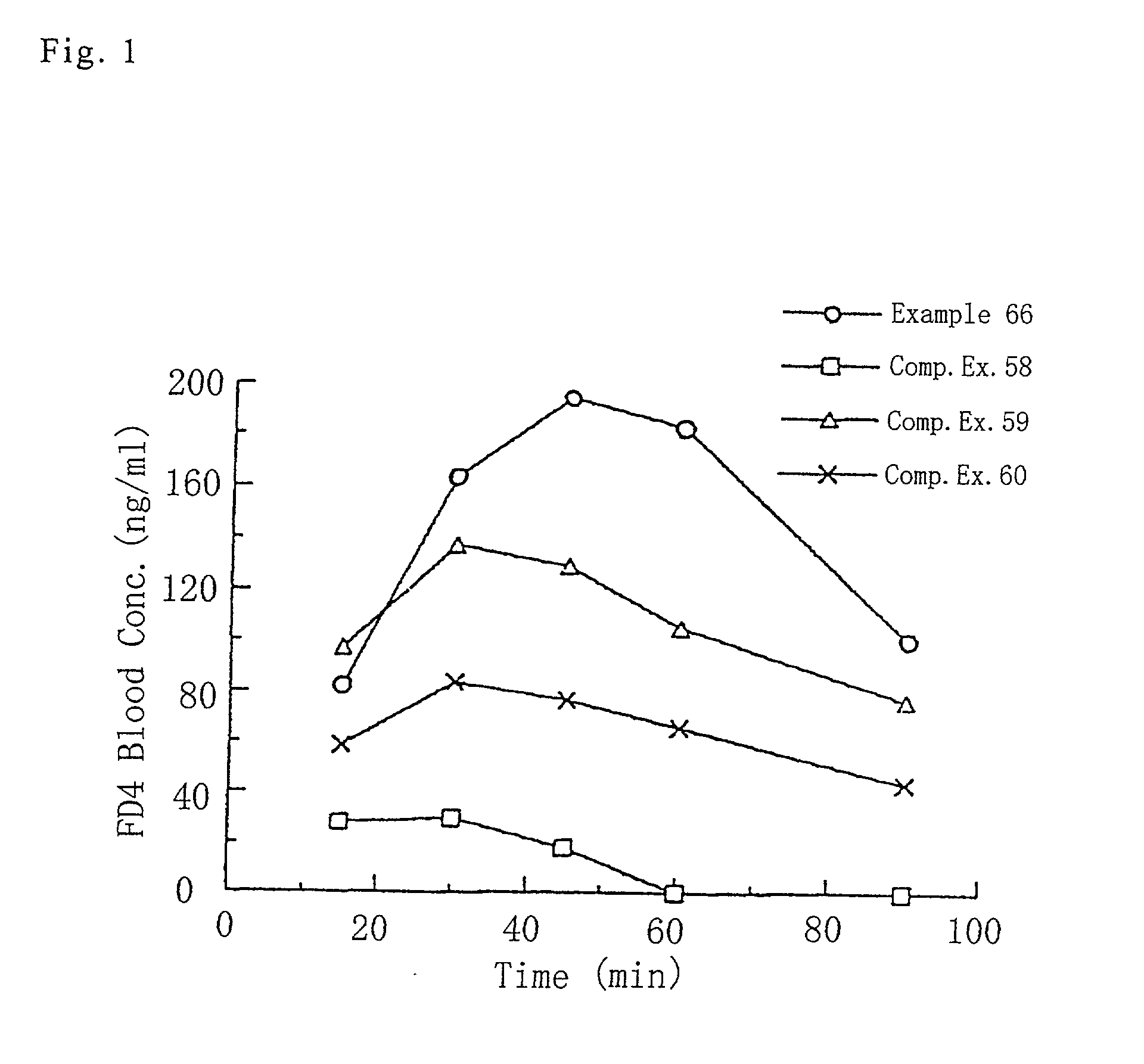

Powdery composition for nasal administration

InactiveUS20020012688A1Promote absorptionHigh maximum blood concentrationPowder deliveryMicrocapsulesNasal cavitySolubility

The present invention relates to a powdery composition for nasal administration, which is characterized in that (1) the composition contains (i) a drug, (ii) a water-absorbing and gel-forming base material such as hydroxypropyl cellulose or hydroxypropylmethyl cellulose and (iii) a water-absorbing and water-insoluble base material such as crystalline cellulose or alpha-cellulose, (2) wherein the amount of the water-absorbing and gel-forming base material is about 5-40 wt % based on the total of the water-absorbing and gel-forming base material and the water-absorbing and water-insoluble base material, and (3) wherein the drug is unevenly dispersed more on / in the water-absorbing and water-insoluble base material than on / in the water-absorbing and gel-forming base material. The present invention provides the powdery composition for nasal administration excellent in absorption of the drug from the nasal cavity and having an extremely increased maximum blood concentration comparing a conventional composition for nasal administration even for a drug having a high solubility in water, a drug having a high lipophilicity or a peptide / proteinaceous drug having a large molecular weight.

Owner:TEIJIN LTD

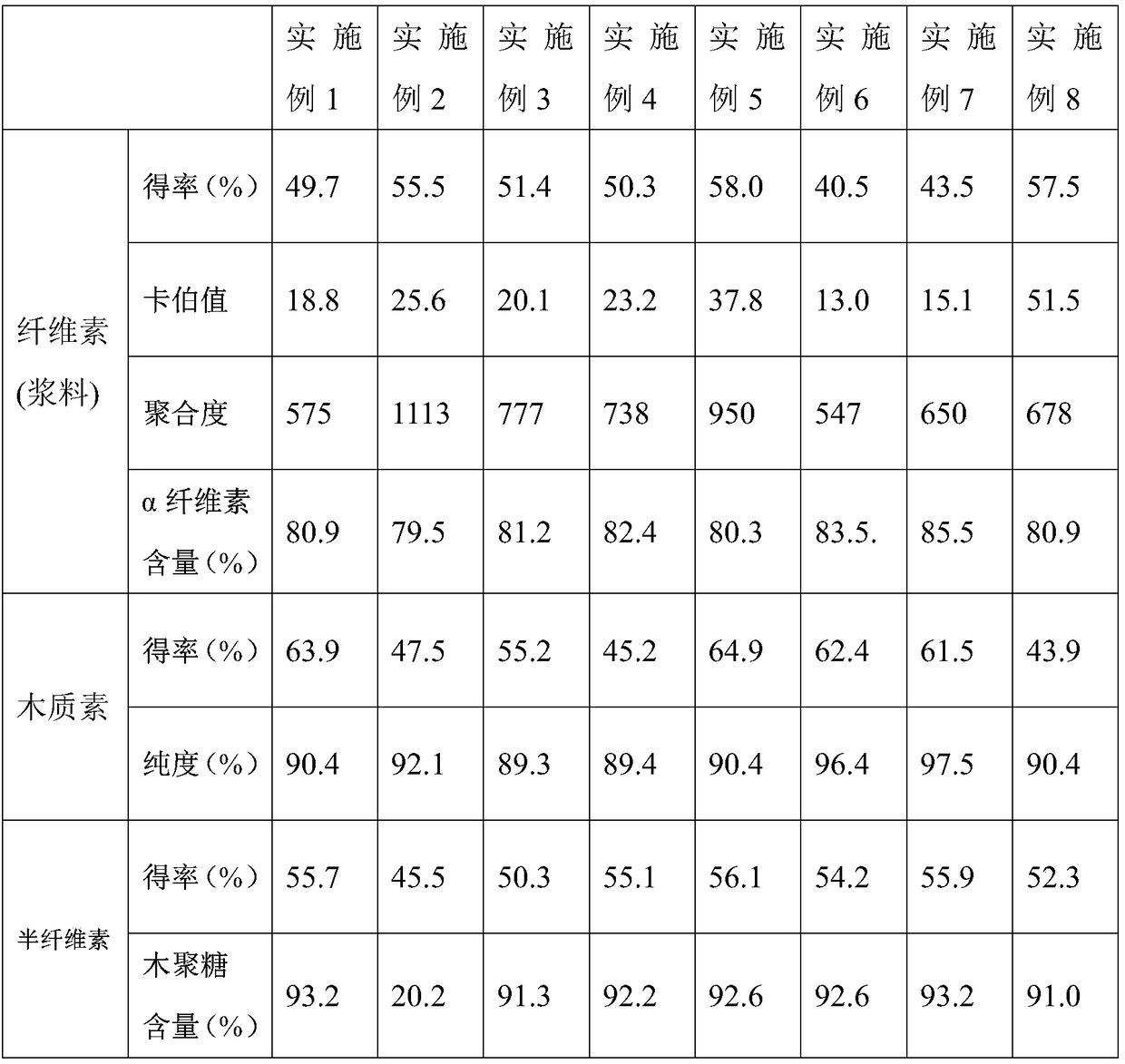

Method for separating three components of cellulose, hemicellulose and lignin in plant fiber raw materials

The invention discloses a method for separating three components of cellulose, hemicellulose and lignin in plant fiber raw materials. The method comprises the following steps of heating, steaming andboiling the plant fiber raw materials by a lactic acid / choline chloride low-eutectic solvent in a pressurizing or normal-pressure way, selectively dissolving out the lignin and hemicellulose, and washing the remaining insoluble matters, so as to obtain the cellulose; adding water into a dissolution solution of the low-eutectic solvent containing lignin and hemicellulose, the lignin is separated out, washing and separating, so as to obtain the lignin; separating the remaining water solution of low-eutectic solvent containing the hemicellulose in a nanofiltration way, so as to obtain the hemicellulose; concentrating and dewatering the water solution of the low-eutectic solvent, so as to recycle. The method has the advantages that the components of the plant fiber raw materials can be fully separated, so as to obtain the cellulose with content of alpha-cellulose greater than 79.5% and polymerizing degree of 1,113, the lignin with purity greater than 89%, and the hemicellulose with yield rate greater than 45%; the production energy consumption is low, the property of the obtained slurry is excellent, and the industrialized application prospect is realized.

Owner:NANJING FORESTRY UNIV

Method for producing high-wet-modulus regenerated cellulose fibers from bamboo pulp

ActiveCN103556281AMeet needsReduce the degree of polymerizationArtificial filaments from viscoseAfter treatmentDegree of polymerization

The invention discloses a method for producing high-wet-modulus regenerated cellulose fibers from bamboo pulp. The method comprises a gum making step and a spinning step, and specifically comprises the following steps: with the bamboo pulp having the alpha cellulose content of greater than or equal to 90% and a degree of polymerization in the range from 400 to 500DP as a raw material, subjecting the bamboo pulp to alkali steeping, and adding BerolVisco388 which is produced by Akzo Nobel Company of Sweden and accounts for 0.1-0.2% of the weight of the alpha cellulose in the bamboo pulp in the alkali steeping step to obtain an alkali cellulose; subjecting the alkali cellulose to crushing, squeezing, aging, yellowing, dissolving, filtering, defoaming and ripening to form a spinning solution for spinning; reacting the spinning solution with a spinning bath to obtain primary filaments; and then subjecting the primary filaments to negative drafting, cutting, after treatment and drying processes to obtain finished product fibers. The method provided by the invention realizes the production of the high-wet-modulus regenerated cellulose fibers from the bamboo pulp with low polymerization degree and low alpha cellulose. Besides, the high-wet-modulus regenerated cellulose fibers are greatly improved in wet-and-dry strength and wet modulus, and meets the definition requirements of modal fibers in BISFA (Bureau International pour la Standardisation des Fibres Artificielles) standards.

Owner:唐山三友集团兴达化纤有限公司

Composite pulp of paper pulp and cotton linter and preparation method thereof

ActiveCN102182090AAchieve recyclingReduce pollutionPaper recyclingPulp bleachingSteepingDissolving pulp

The invention provides a preparation method of composite pulp of paper pulp and cotton linter for viscose. By utilizing the method, the unique performances of fibers such as bamboos, woods, bast fibers, bagasse and the like can be combined with the excellent performances of cotton; any other two or more than two of raw materials such as the paper pulp or the bamboos, the woods, the cotton, the bast fibers and the like can be steamed and cooked independently and can be composited and prepared into dissolved pulp at a bleaching stage after being subjected to a series of process treatments. The varieties of the paper pulp used in the invention are not limited from production methods and raw materials and can be unbleached pulp or bleached pulp; through alkali steeping treatment, the difficulty in steaming and cooking the paper pulp is reduced, the prepared dissolved pulp has high content of alpha cellulose and the steeping liquor can be cyclically utilized; and by utilizing the method, the pollution in the pulping process is less and the cyclic utilization of the alkali liquor can be realized.

Owner:潍坊欣龙生物材料有限公司

Production technology of viscose extinction monofilament

InactiveCN103215680AImprove spinnabilitySoft touchSpinnerette packsArtificial filaments from viscoseInlet channelExtinction

The invention relates to a production technology of viscose extinction monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose extinction monofilament through preparation of a spinning solution, injection before spinning, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) adding a titanium dioxide solution into the spinning solution so that the weight ratio of titanium dioxide to alpha cellulose content in the spinning solution reaches (0.5-5.0):100; and uniformly mixing and feeding for spinning; (C) feeding the spinning solution into a spinning machine, and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, and an inlet channel of the spinneret orifice is in a parabola shape; and (D) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the filament number of the prepared viscose monofilament is 50-6,000D, the strength is high over 75CN, and the requirements on dyeing, weaving and finished product taking are met; and moreover, the viscose extinction monofilament has gentle color and an extinction effect.

Owner:YIBIN HIEST FIBER +2

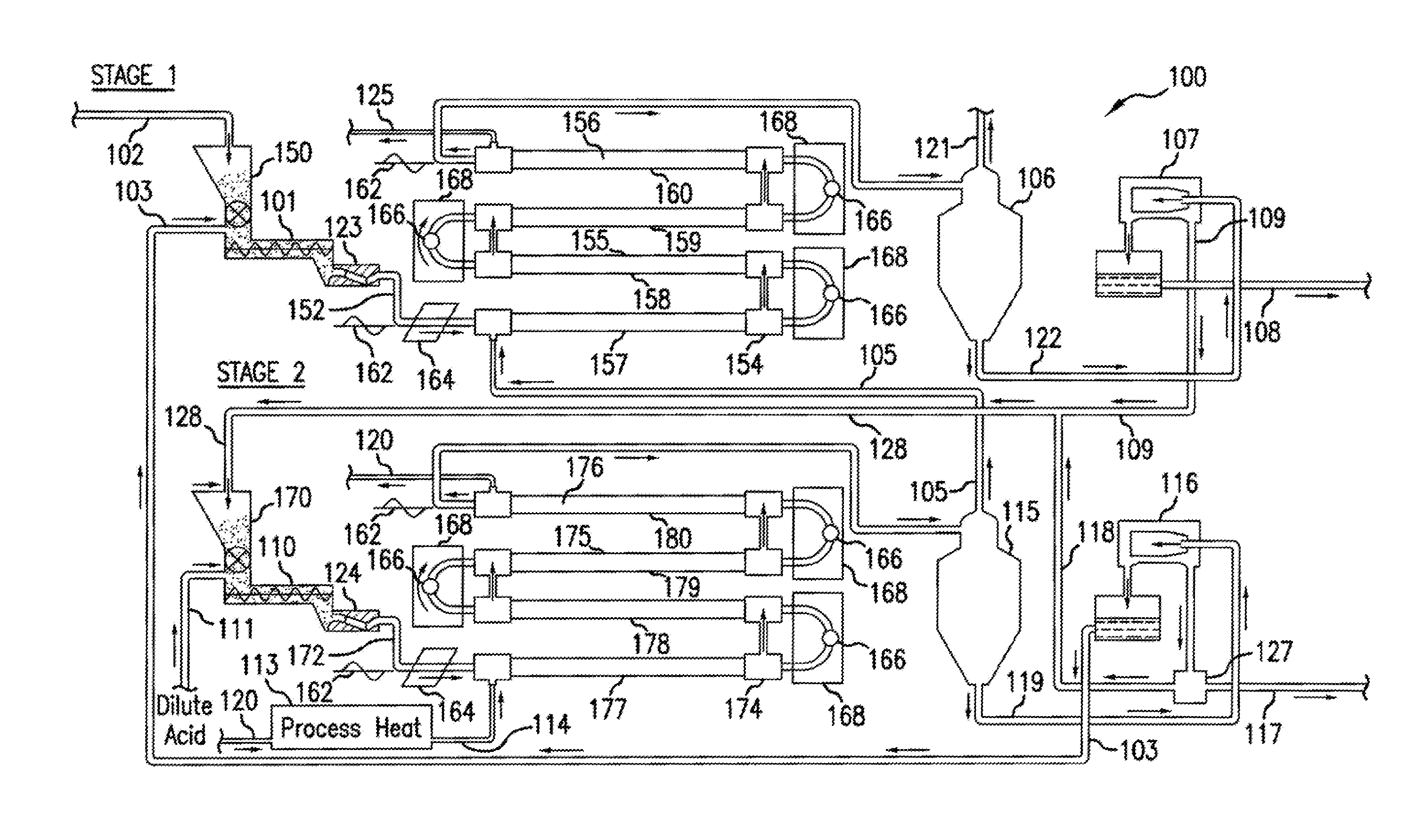

Self-contained, high efficiency cellulose biomass processing plant

InactiveUS20110060132A1Improve efficiencyImprove operationSolid waste disposalTransportation and packagingEnergy supplyHigh effectiveness

A self-contained, high efficiency cellulose biomass processing plant includes sources of quantum-based wave energy to facilitate the dilute acid hydrolysis of hemi-cellulose and alpha-cellulose bond. The sources of quantum-based wave energy supply one or more of, and suitably a combination of ultrasonic waves, ultraviolet waves, magnetic waves and direct current to facilitate fracture of the intermolecular bonds. An integrated plant is also provided which combines the cellulose biomass processing plant with apparatus for converting high protein residue into a finished high grade protein product. Due to the high efficiency resulting from use of quantum-based wave energy, the plant uses less energy, and can be small and portable.

Owner:LEWIS TED C

Cellulose acetate semipermeable membrane and process for producing the cellulose acetate semipermeable membrane

InactiveUS6372136B1Improve filtration rateSemi-permeable membranesHollow filament manufactureAcetic acidCellulose acetate

To provide a cellulose acetate semipermeable membrane having a high filtration rate and high mechanical strength and which is hardly degraded by microorganisms, the present invention provides a cellulose acetate semipermeable membrane containing a cellulose acetate having an alpha-cellulose content of not less than 99% by weight, a 6 wt / vol % viscosity of 20 to 220 mPa.s at 25±1° C. and an acetylation degree of 58 to 62%. The cellulose acetate semipermeable membrane is suitable particularly as a hollow fiber membrane.

Owner:DAICEL CHEM IND LTD

Eucalyptus dissolving pulp and production method thereof

InactiveCN102493256AReduce productionReduce pollution loadPretreatment with water/steamNatural cellulose pulp/paperSulfateDissolving pulp

The invention discloses a eucalyptus dissolving pulp and a production method thereof, wherein the eucalyptus dissolving pulp is prepared after the steam prehydrolysis, sulfate cooking, oxygen delignification and D0EoPD1 bleaching of eucalyptus pieces, the whiteness is not less than 88%, the alpha cellulose is not less than 94.5%, the pentosan is not higher than 3.0%, the dynamic viscosity is 9-25mPa s, the ash content is not higher than 0.1%, and the iron content is not higher than 15mg kg<-1>. The production method of the eucalyptus dissolving pulp comprises the following steps that: the eucalyptus pieces undergo the steam prehydrolysis, and the P- factor of the steam prehydrolysis is 300-800; the sulfate cooking is carried out after the steam prehydrolysis of the eucalyptus pieces to obtain the pulp; the eucalyptus chemical pulp undergoes the D0EoPD1 bleaching after the oxygen delignification; and after the bleaching, the pulp is washed, dried and processed into the eucalyptus dissolving pulp.

Owner:湖南骏泰新材料科技有限责任公司 +1

High-whiteness bamboo-charcoal viscose fiber and manufacturing method thereof

ActiveCN101709512AHigh whitenessAntibacterial and antibacterialArtificial filaments from viscoseYarnOptoelectronics

The invention provides a manufacturing method of a high-whiteness bamboo-charcoal viscose fiber, which comprises the following steps: soaking the raw materials mainly comprising bamboo chemical fiber pulp, squeezing, pulverizing, aging, sulfidizing, dissolving, degassing, filtering, spinning into yarn, post-processing and drying; and in the course of processing, adding nano white-crystal pulp, wherein the nano white-crystal pulp accounts for 0.5-10% of the alpha cellulose by weight. In the invention, the nano white-crystal pulp is added in the course of manufacturing the bamboo-charcoal viscose fiber to manufacture the high-whiteness bamboo-charcoal viscose fiber. The prior bamboo-charcoal viscose fiber can be only black or grey; however, the high-whiteness bamboo-charcoal viscose fiber has high whiteness which is greater than or equal to 60%. The high-whiteness bamboo-charcoal viscose fiber can be colored with various dyes, and has the functions of bacterial inhibition, far infrared emission and negative oxygen-ions, thereby having wide application range.

Owner:吉林化纤股份有限公司

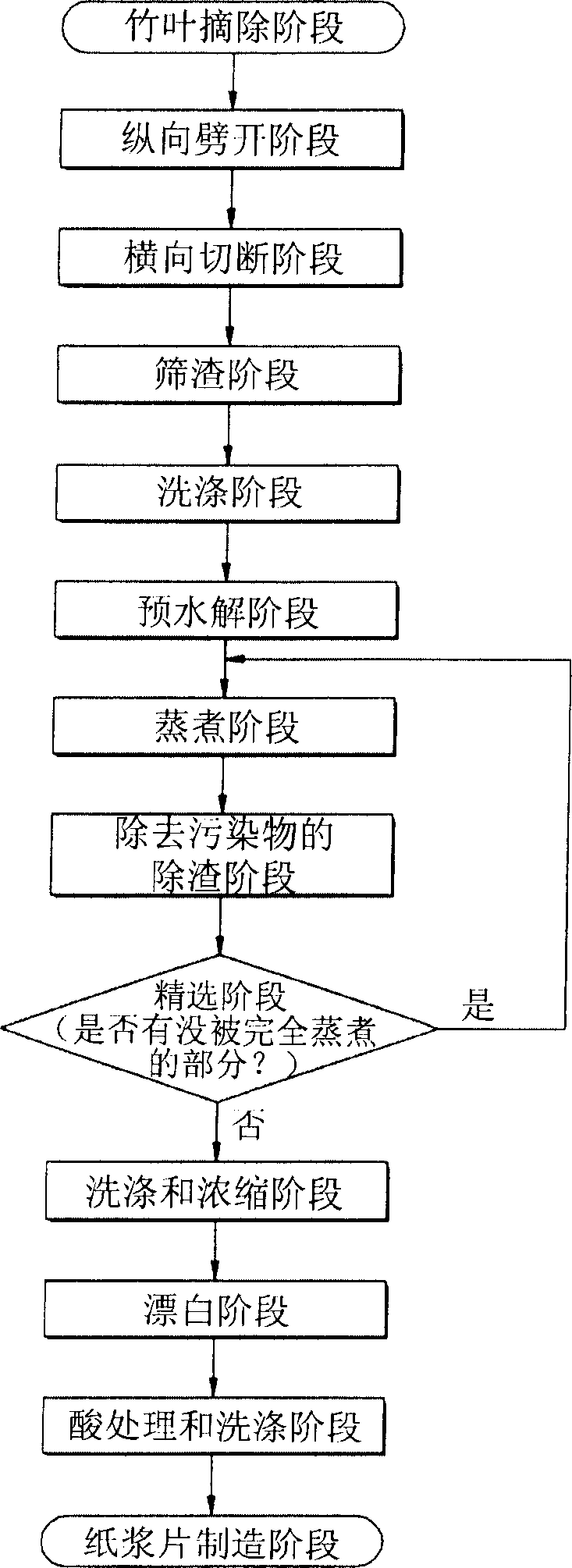

The production method and pulp maked bamboos

InactiveCN1854388AHigh yieldPretreatment with water/steamWashing/displacing pulp-treating liquorsPulp and paper industryCellulose pulp

The present invention relates to a kind of method that utilizes bamboo to make paper pulp, relate to firstly splitting bamboo vertically and transversely and then going through the process of screening and washing to reduce the consumption of medicines in the process of prehydrolysis and pulping and make it easy to react, thereby A method of making pulp from bamboo and its pulp that can produce better-quality, higher-yield dissolving pulp, and that can prevent the generation of dioxins by using the bleaching method of ECF or TCF. Since the anthraquinone caustic soda method using anthraquinone as a catalyst is used in the cooking process, the effects of improving delignification and pulp quality and increasing pulp yield are obtained. Also, the content and degree of polymerization of α-cellulose can be arbitrarily adjusted according to the characteristics of the man-made fibers produced as desired by adjusting the conditions of prehydrolysis, cooking and bleaching. At the same time, by recovering xylose produced in the dissolving pulp manufacturing process, it is used to manufacture xylitol, seasoning, furfural, etc., thereby contributing to the improvement of resource utilization and economic efficiency of waste.

Owner:李权革

Method for preparing bamboo pulp by full-liquid-phase prehydrolysis sulfate displacement cooking process

ActiveCN102182086AReduce pollutionSolve pollutionPretreatment with water/steamPulp bleachingBlack liquorSulfate

The invention discloses a method for preparing bamboo pulp by a full-liquid-phase prehydrolysis sulfate displacement cooking process, which comprises the following steps: preparing materials, washing the materials, prehydrolysizing, cooking, washing, screening, bleaching, regulating polymerization degree, dechlorinating and conducting acid treatment. According to the preparation method, after the cooking is finished, for the obtained pulp, the content of alpha cellulose is more than or equal to 95%, the pepentosan is more than or equal to 4%, and the average polymerization degree is 550-650; after the acid treatment is finished, for the obtained pulp, the content of alpha cellulose is more than or equal to 94%, the pentosan is less than or equal to 3.0%, the average polymerization degree is 400-500, and the white degree is 86-89%. The method has the following advantages: the whole set of technology of full-liquid-phase prehydrolysis, full-liquid-phase cooking, hydrolyzate recovering and recovered black liquid displacement cooking, not only is the waste water pollution degree is alleviated, the temperature rising time and steam amount are saved, the trebling effects of energy saving, emission reduction and yield increasing are achieved, and the problems that the waste water pollution is serious, the energy consumption is high and the output is low in the pulp prepared by the current prehydrolisis sulfate method.

Owner:SICHUAN YONGFENG PAPER MAKING JOINT STOCK

Production method for preparing bamboo dissolving pulp by utilizing natural-color unbleached bamboo pulp in a modifying way

ActiveCN101736637AShort processShorten the production cyclePulp de-wateringPulp beating/refining methodsDissolving pulpAlpha-Cellulose

The invention discloses a production method for preparing bamboo dissolving pulp by utilizing natural-color unbleached bamboo pulp in a modifying way, overcoming the defect of poor reaction property of products prepared by an alkali refining method. The production method comprises the following steps of: concentrating and dewatering dredged natural-color unbleached bamboo pulp, and delivering to a double-helix roller type pulp grinder; continuously dewatering in the pulp grinder, and adding liquid medicine; continuously concentrating and kneading the pulp and mixing the pulp with the liquid medicine in the pulp grinder; then delivering the pulp to a stewing machine; and after stewing is completed, conducting subsequent procedures including washing and bleaching till paper making. The invention reduces the preparation cost, enhances the quality of products and increases resource supplying sources; in addition, the bamboo pulp prepared by the production method not only has higher content of alpha-celluloses, but also has good reaction property, and is suitable for filament and staple fibers.

Owner:YIBIN GRACE GROUP CO LTD

Bamboo fiber dissolving pulp and production technology thereof

InactiveCN102978993AHigh in celluloseHigh in alpha-cellulosePulping with inorganic basesNon-woody plant/crop pulpSulfatePapermaking

The invention discloses bamboo fiber dissolving pulp and a production technology thereof. Bamboo is used as a material in production by using the technology, and the technology adopts the following production procedures of: preparing bamboo wood, hydrolyzing bamboo sheets in advance, performing displacement cooking of sulfate, washing and dressing in a sealing way, performing ECF (extracellular fluid) bleaching and refining, and papermaking by pulp. The displacement cooking and the ECF bleaching are used for producing the bamboo fiber dissolving pulp; a product is good in quality, high in yield, high in alpha-cellulose content, low in pentosan content, few in ashes and impurities, and even in viscosity, good in reacting property, high in whiteness, and not easy to yellow. The production of subsequent procedures is facilitated; and the bamboo fiber dissolving pulp is bleached by ClO2 without chlorine element, and the damage to the environment can be greatly reduced.

Owner:四川银鸽竹浆纸业有限公司

Stewing process for preparing wood dissolving pulp by natural-color unbleached wood pulp in a modifying way

ActiveCN101736632AShort processShorten the production cyclePaper material treatmentDissolving pulpProcess conditions

The invention discloses a stewing process for preparing wood dissolving pulp by utilizing natural-color unbleached papermaking-grade wood pulp in a modifying way, overcoming the defect of poor reaction property of products prepared by an alkali refining method. The stewing process conditions of natural-color unbleached wood pulp in a stewing device are as follows: liquor ratio is 1:2.5-7.0; alkali charge includes 10-50% of NaOH and 0.1-50% of Na2S; a temperature increasing condition comprises the following steps of: increasing temperature to 115-130 DEG C for 30-60 minutes, and keeping the temperature for 30-120 minutes; continuously increasing the temperature to 135-150 DEG C for 30-60 minutes, and keeping the temperature for 120-180 minutes; after the temperature is kept, continuously increasing the temperature to 165-175 DEG C, and keeping the temperature for 30-180 minutes; after the temperature is kept, reducing the temperature, and discharging; and stewing to end after the discharging. The wood pulp produced by the stewing process not only has higher content of alpha-celluloses, but also has good reaction property, and is suitable for filament and staple fibers.

Owner:YIBIN GRACE GROUP CO LTD

Nano bamboo charcoal anti-bacterial fiber and production method thereof

InactiveCN101440534AImprove adsorption capacityGood moisture absorptionMonocomponent cellulose artificial filamentWet spinning methodsSlurryRenewable resource

The invention relates to a nanometer bamboo charcoal viscose antibacterial fiber and a method for producing the same, in particular to a wet-spinning method for producing the nanometer bamboo charcoal viscose antibacterial fiber. Nanometer bamboo charcoal antibacterial liquid slurry is prepared after mixing nanometer silver and nanometer bamboo charcoal. The nanometer bamboo charcoal antibacterial liquid slurry is mixed with alpha cellulose to prepare the nanometer bamboo charcoal viscose antibacterial fiber through the wet-spinning according to a viscose process production method. The nanometer bamboo charcoal viscose antibacterial fiber has the advantages that the bamboo charcoal is a renewable resource which is rich, can be produced through adjusting part of the process conditions by using the prior equipment, and passes through a test and a detection with the antibacterial rate of more than 98 percent; and the nanometer bamboo charcoal viscose antibacterial fiber has stronger handfeel than that of the prior terylene, and better comfort in wearing and use, and is widely applied to transportation, environmental protection, medical treatment and other industries.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

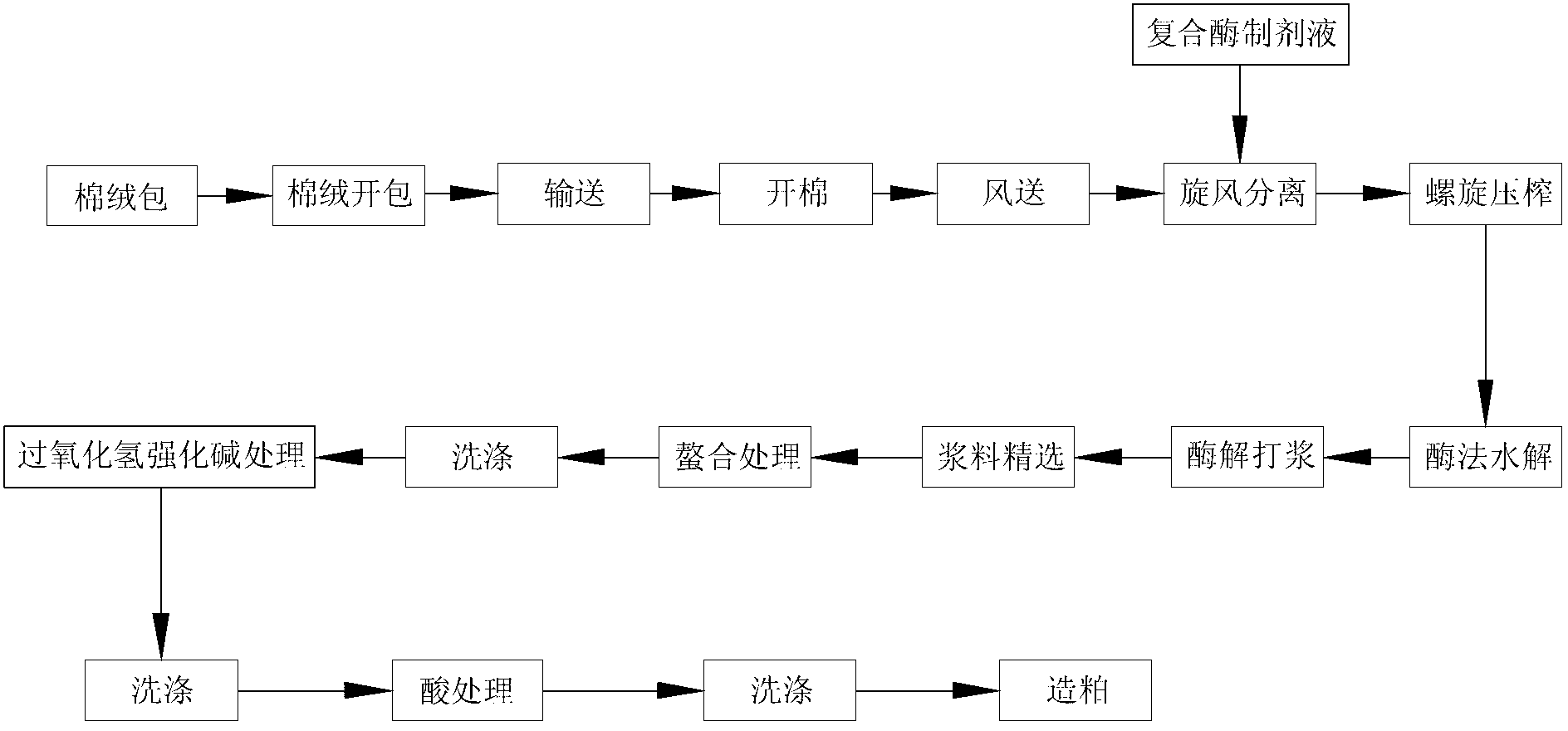

Complex enzyme preparation and technique for preparing dissolving pulp by using same

ActiveCN103061181ALoose structureEnhancement and effectPaper material treatmentChemical oxygen demandCellulose fiber

The invention relates to the technical field of production of regenerated cellulose fiber, in particular discloses a complex enzyme preparation applied in the preparation of dissolving pulp and a technique for preparing the dissolving pulp by using the enzyme preparation. The complex enzyme preparation is divided into a complex enzyme preparation I and a complex enzyme preparation II, wherein the complex enzyme preparation I mainly consists of feruloyl esterase, lipase and the like; and the complex enzyme preparation II mainly consists of xylanase, cellulase and the like. The complex enzyme preparation is applied in the technique for purifying alpha-cellulose and preparing the dissolving pulp; and the technique comprises the following steps of impurity removal for raw materials, enzyme method pretreatment, enzymolysis pulping, chelation treatment, alkali hydroxyl active oxygen cooking, acid treatment, washing, sand removal and pulp mixing. The method has the simple preparation technique, and adopts the complex enzyme preparation to treat the raw material pulp so as to effectively remove lignin, hemicellulose, pectin substance and waxiness and to reduce the degree of polymerization of the alpha-cellulose; the energy consumption is low under the normal pressure condition; the COD (Chemical Oxygen Demand) value of the pulping waste water is low; the yield of the dissolving pulp is high; the alpha-cellulose has high content and uniform degree of polymerization; and the production requirements of viscose can be satisfied.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

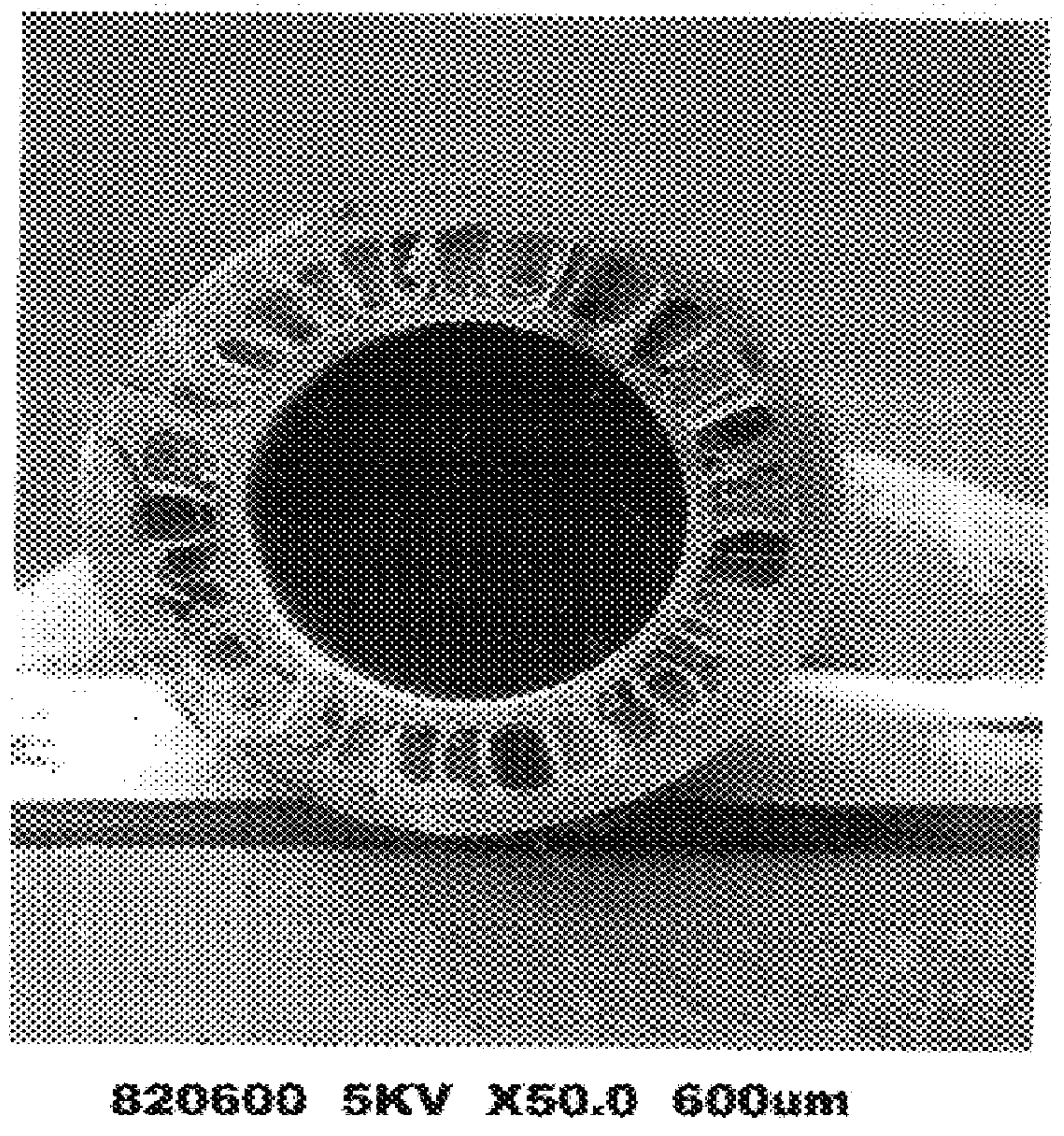

Wound Dressing

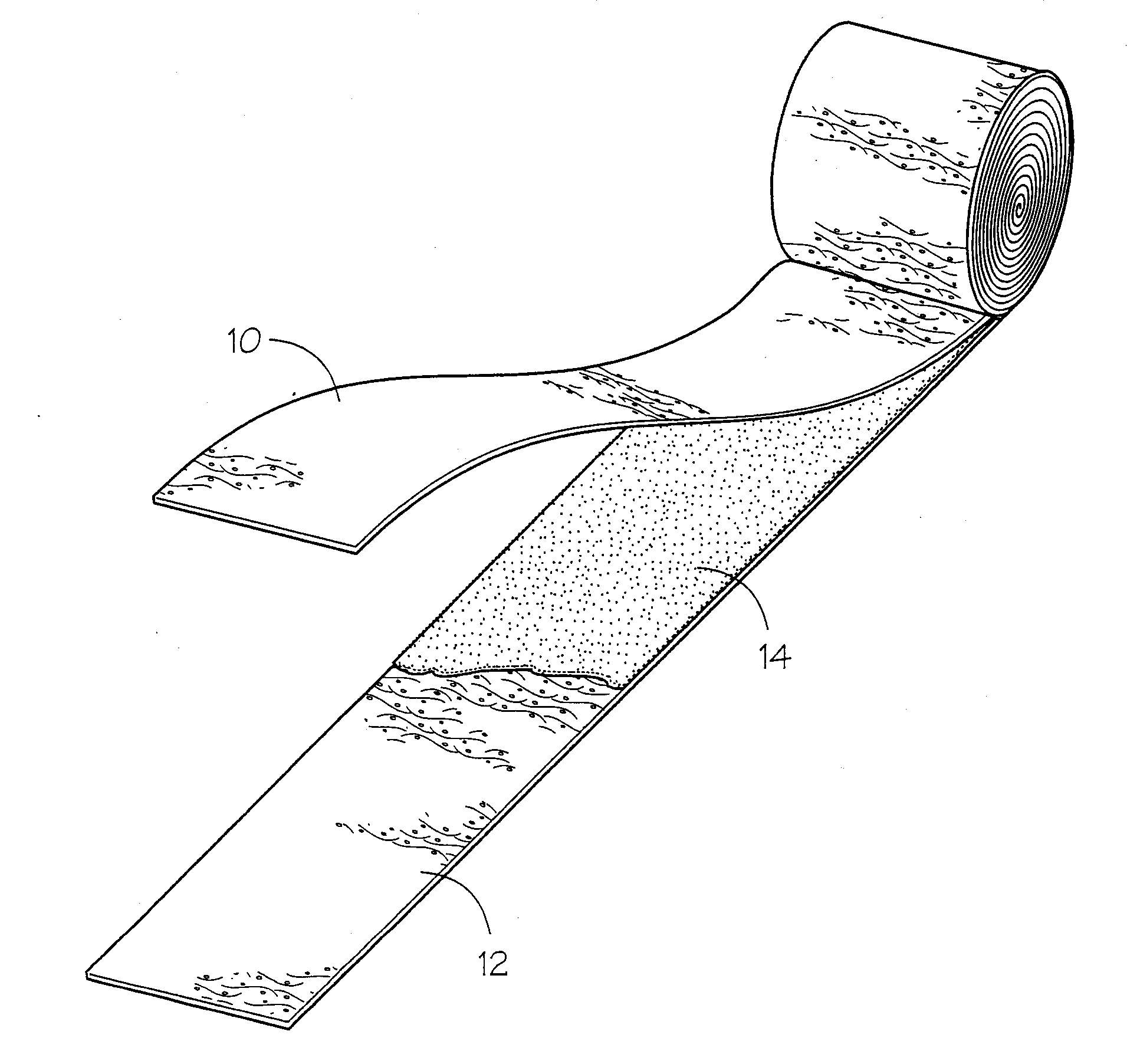

InactiveUS20130012857A1Raise the ratioRapid hemostatic, analgesic, antimicrobial and accelerated wound healing propertiesNon-adhesive dressingsPharmaceutical delivery mechanismWound dressingSource material

A microfibrillar cellulose substrate having a defined morphology and optimized concentrations of free radicals formed by milling a source material containing alpha cellulose with non-metalic cutting surfaces into a sterilized fine powder with a particle size of approximately 20 to 35 micrometers. A gauze selected from the group consisting of a woven, nonwoven, and extruded netting substrate for supporting the microfibrillar cellulose substrate. The microfibrillar cellulose substrate may be carried between a first layer of the gauze and a second layer of the gauze by affixing the first and second gauze layers closed around their perimeter.

Owner:NORTH AMERICAN RESCUE PRODS

Preparation method of temperature regulating fiber

ActiveCN104831388APhase change performance is maintained for a long timeNot easy to loseArtificial filaments from viscoseHeat-exchange elementsFiltrationKetone

The invention discloses a preparation method of a temperature regulating fiber. The method comprises the following steps: 1, carrying out two-stage dipping, squeezing, crushing, ageing, yellowing reaction, filtration, deaeration and maturation on cellulose pulp to obtain a spinning solution; 2, packaging phase change paraffin in the honeycomb micropores of a packaging material honeycomb silica to prepare phase change particles, adding an osmotic agent, an emulsifier and a ketose cross-linking agent, and uniformly mixing to prepare a phase change emulsion; 3, fully mixing the phase change emulsion with the spinning solution to prepare a phase change spinning solution, wherein the addition amount of the phase change particles is 5-25wt% of alpha-cellulose in the spinning solution; and 4, carrying out spinning formation on the phase change spinning solution, and post-processing to obtain the temperature regulating fiber. The phase change fiber prepared in the invention has the advantages of stable phase change temperature, good phase change performance, long service life and high physical and mechanical performances.

Owner:湖州珠力纳米材料科技开发有限公司

Antibacterial regenerated cellulose fiber and preparation method thereof

ActiveCN103668520ABiodegradablePromote degradationArtificial filaments from viscoseWet spinning methodsBiocompatibility TestingCellulose fiber

The invention discloses an antibacterial regenerated cellulose fiber and a preparation method thereof, and the antibacterial cellulose fiber contains 0.5 ~ 10wt% of chitosan quaternary ammonium salt, the preparation method comprises the following steps: (1) preparing the chitosan quaternary ammonium salt with deionized water and sodium hydroxide into an antibacterial solution; (2) using cellulose pulp as a raw material to prepare spinning viscose; (3) adding the antibacterial solution to a viscose solution of any step from the yellowing step to before spinning, with the adding amount of the chitosan quaternary ammonium salt being 0.5 ~ 10% of the weight of alpha cellulose in the viscose solution, to obtain an antibacterial spinning viscose solution; and (4) obtaining the antibacterial regenerated cellulose fiber by coagulating bath spinning and drawing molding of the antibacterial spinning viscose solution, and then refining and drying. The antibacterial regenerated cellulose fiber simultaneously has biodegradability, biocompatibility, safety and antibacterial property and other excellent properties, and has better moisture absorption and moisture preservation, crease resistance and softness.

Owner:赛得利(盐城)纤维有限公司

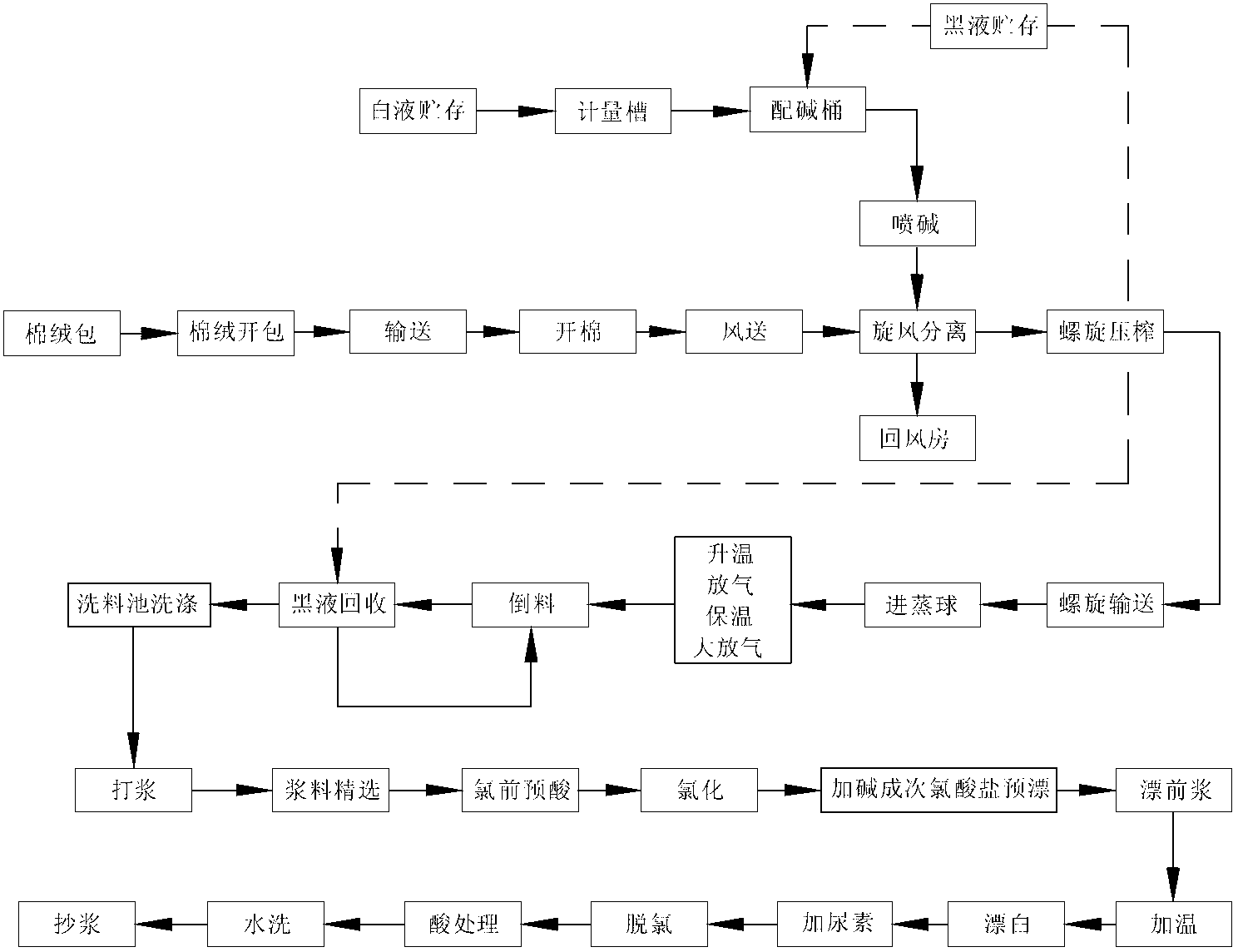

Production process of cotton pulp for cellulose triacetate

ActiveCN101597870AEmission reductionReduce pollutionPulp bleachingPulping with inorganic basesCellulose acetateWastewater

The invention relates to a production process of cotton pulp for cellulose triacetate, in particular to a simple production process of cotton pulp using cotton linter as a raw material; in the whole pulping process, the wastewater COD discharge is as low as 20250-25050mg / l, so that the environmental pollution and sewage treatment pressure can be reduced; on the conditions of stable polymerization, high whiteness and alpha cellulose content, uniform fiber length and proper compactness, the product has low content of methylene dichloride extract and metallic ions, low ash content and low dust, thus being applicable to the industry for producing cellulose triacetate.

Owner:山东银鹰化纤有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com