Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8093 results about "Composite membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin-film composite membranes (TFC or TFM) are semipermeable membranes manufactured principally for use in water purification or water desalination systems. They also have use in chemical applications such as batteries and fuel cells.

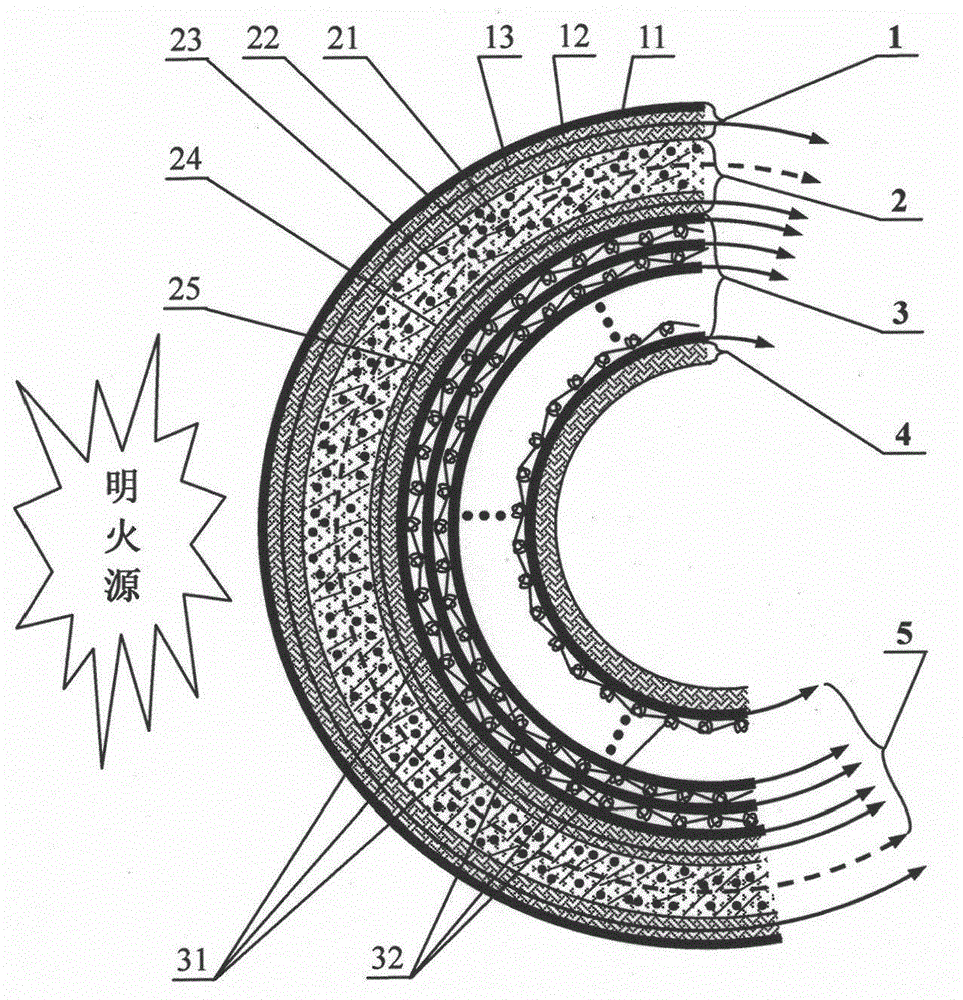

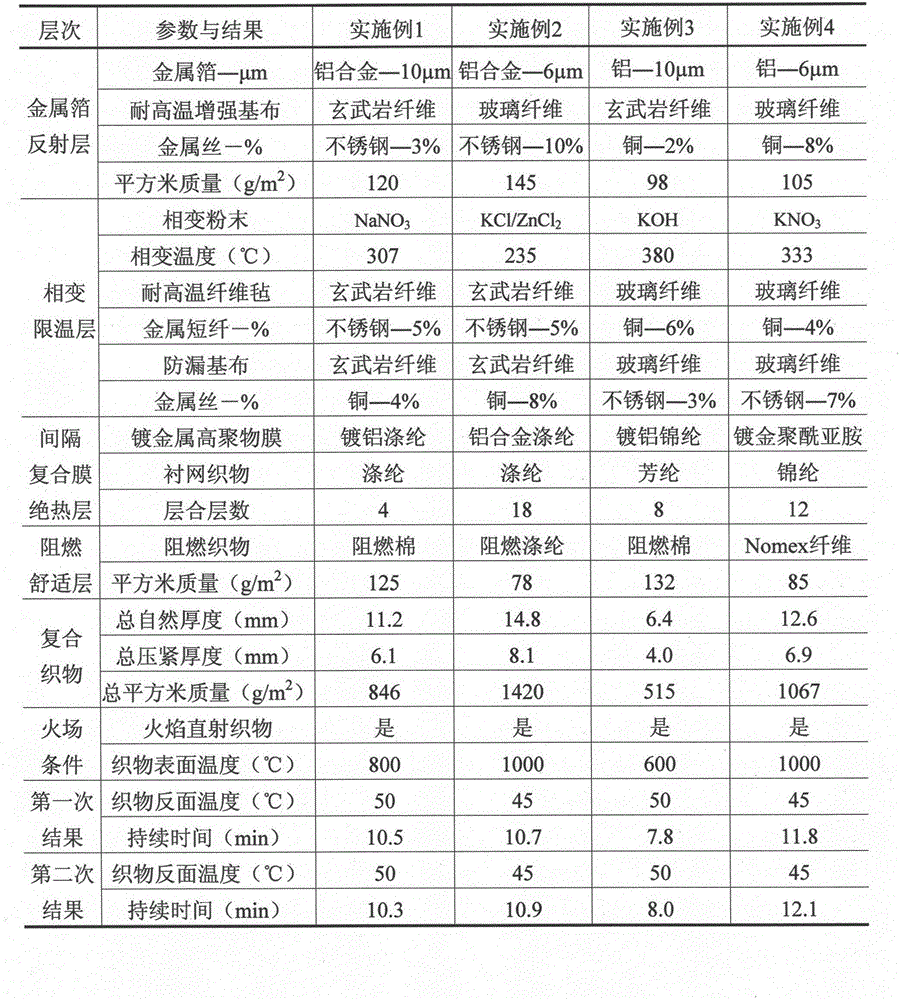

Fire-proof and heat-insulating composite fabric with multi-stage expansion and heat dissipation, preparation method and application

ActiveCN102783741BImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

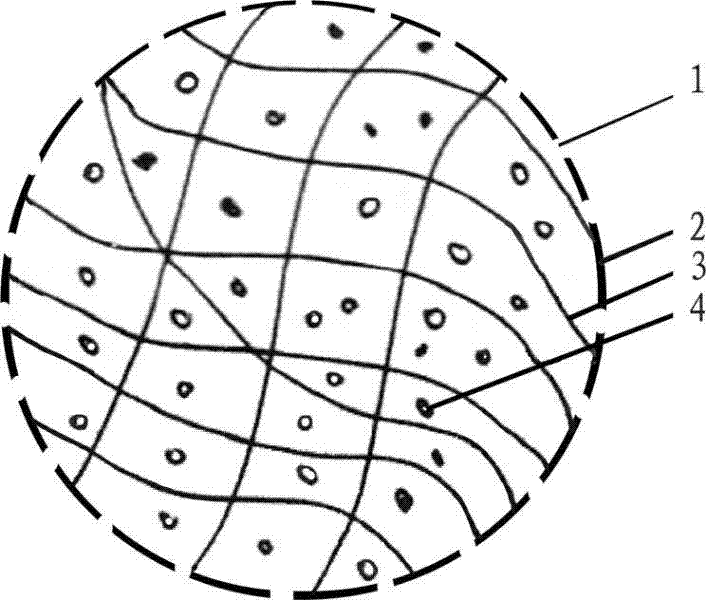

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

Composite membrane and method for making the same

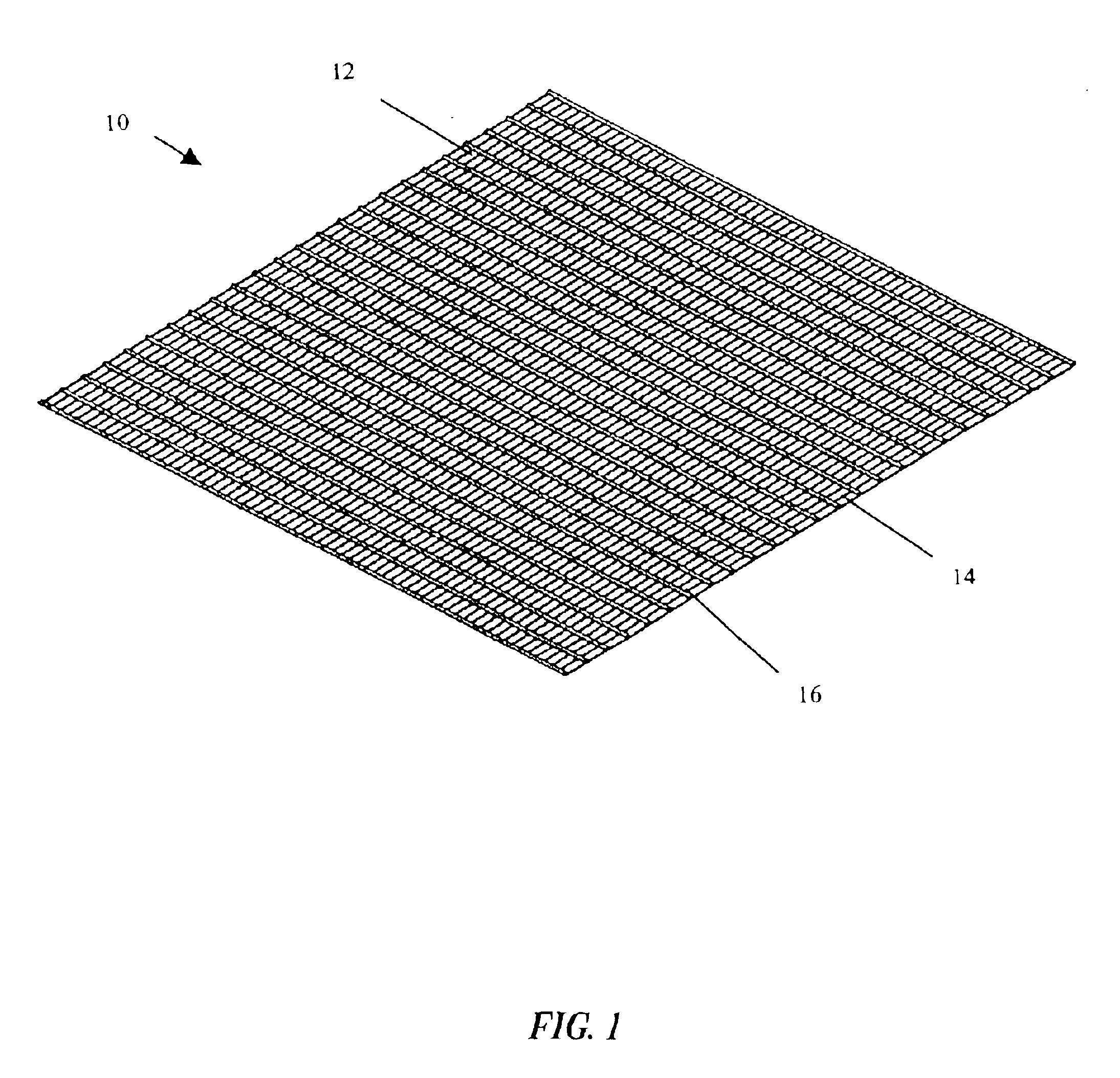

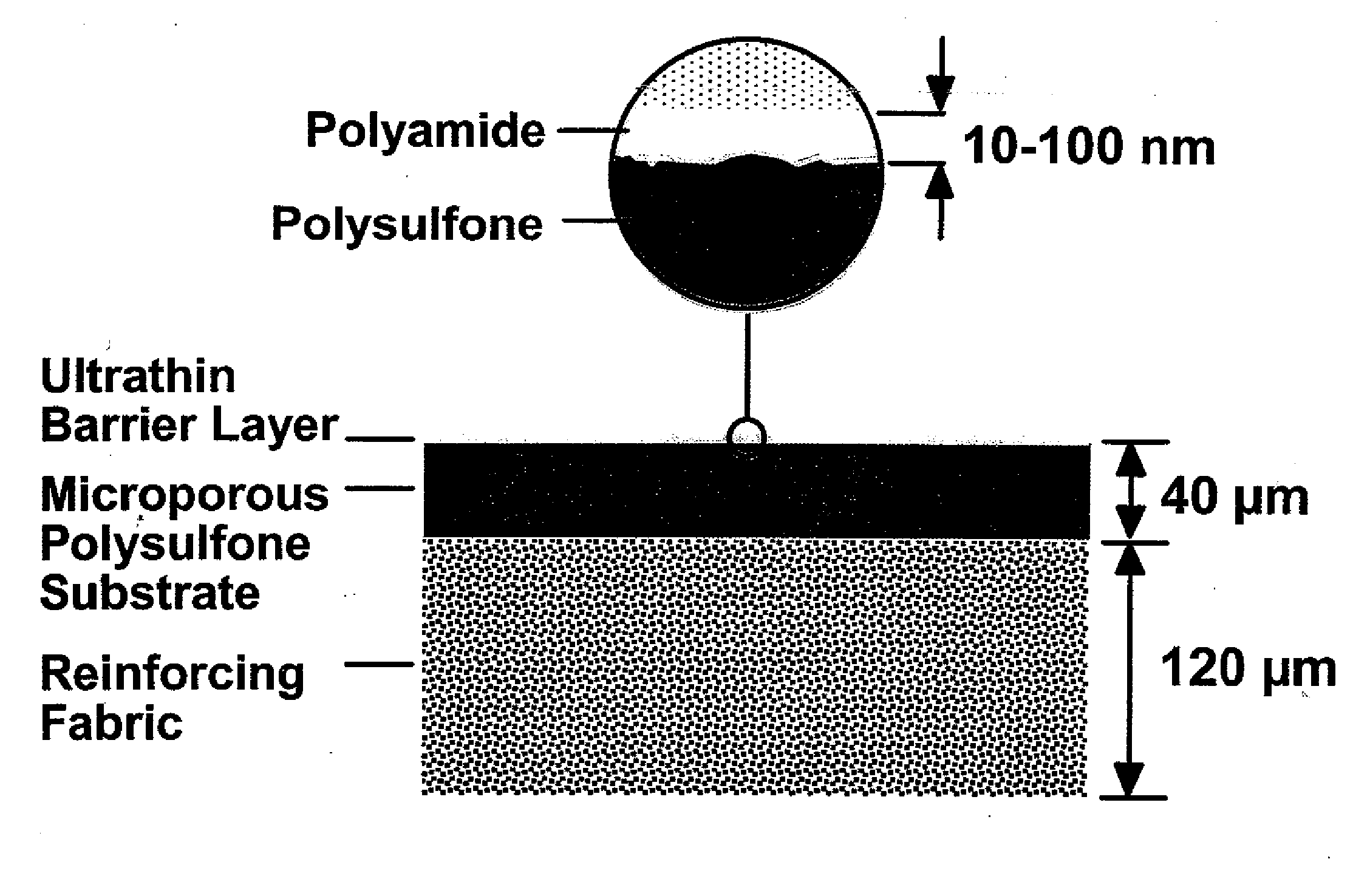

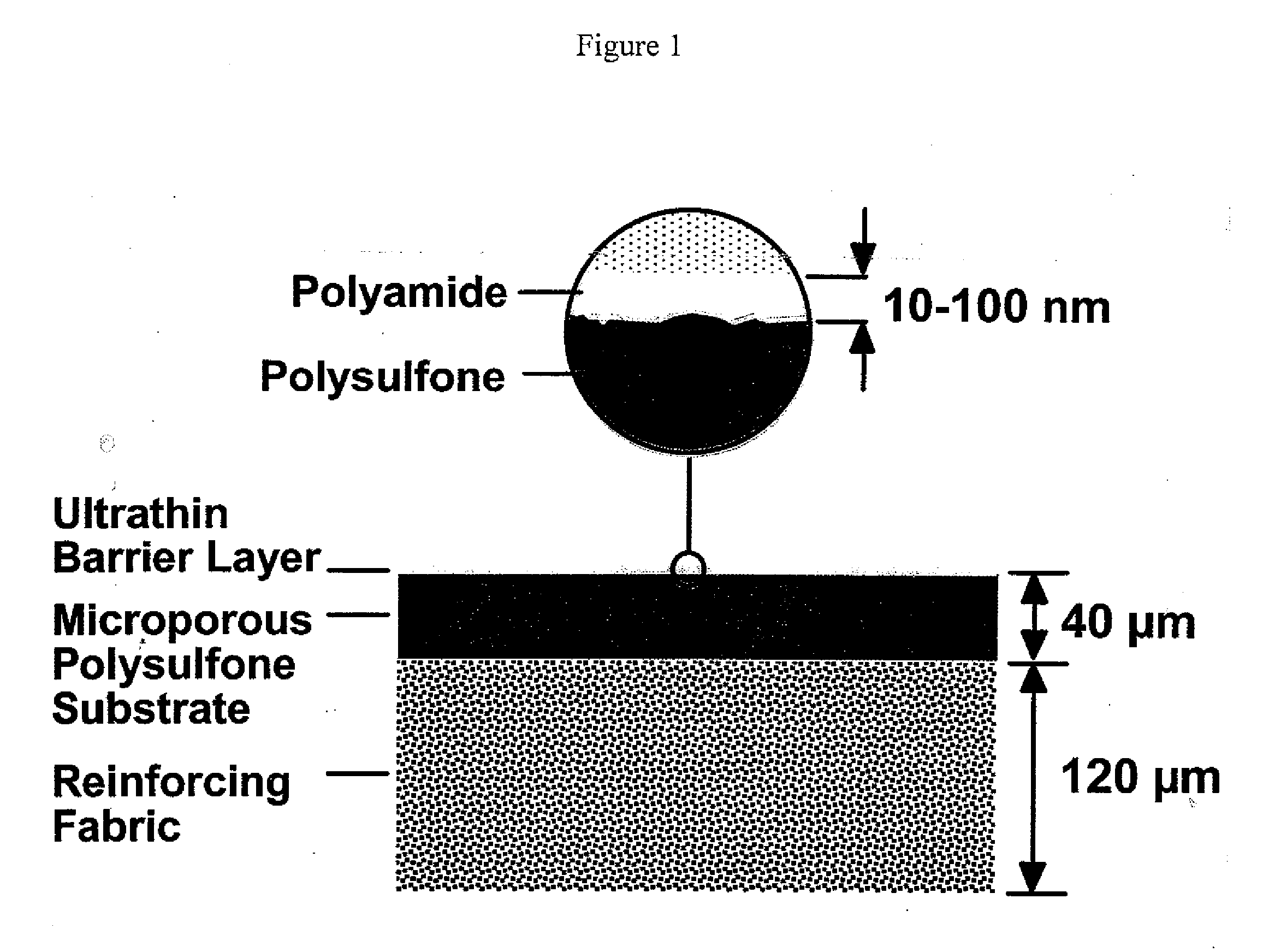

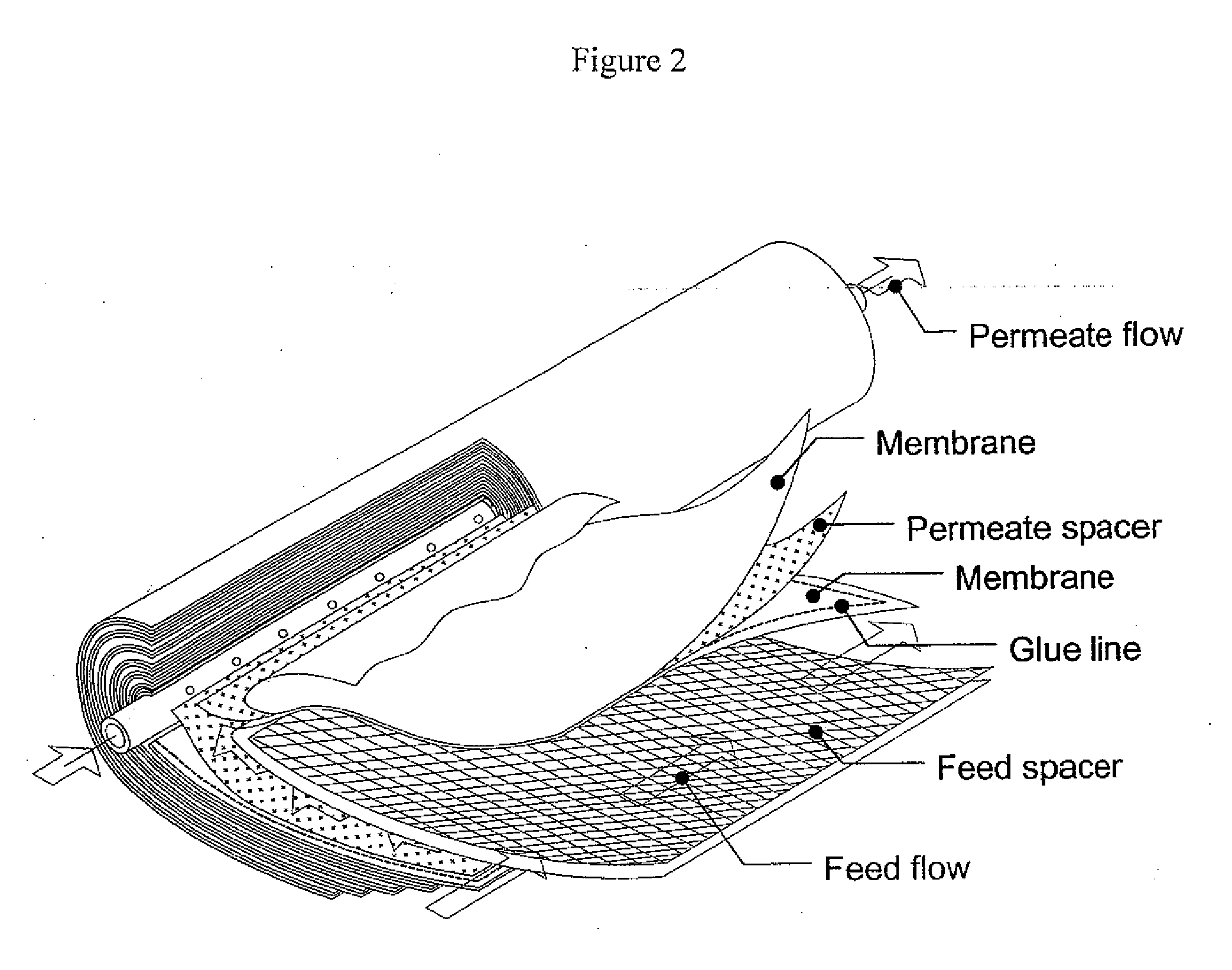

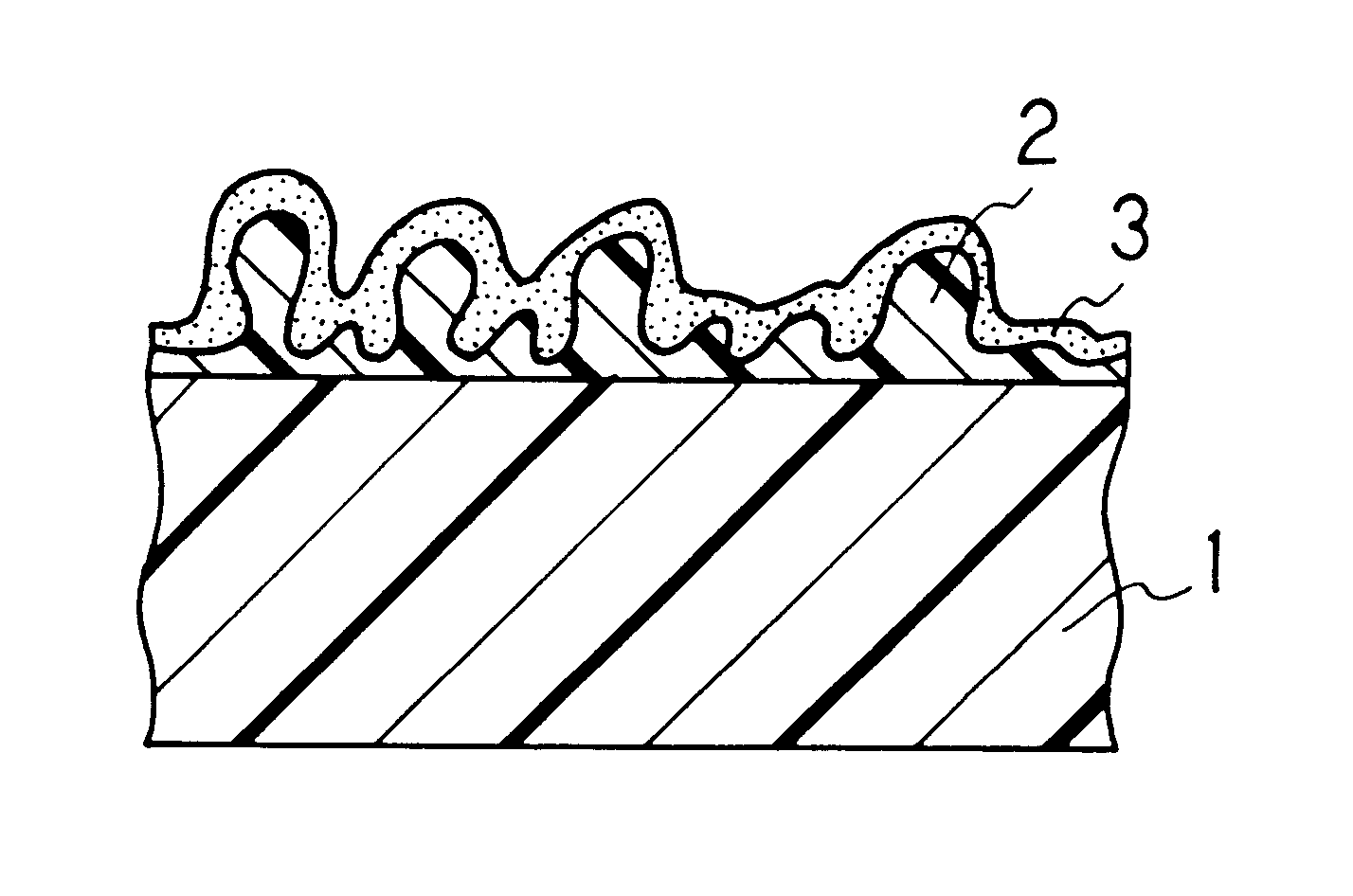

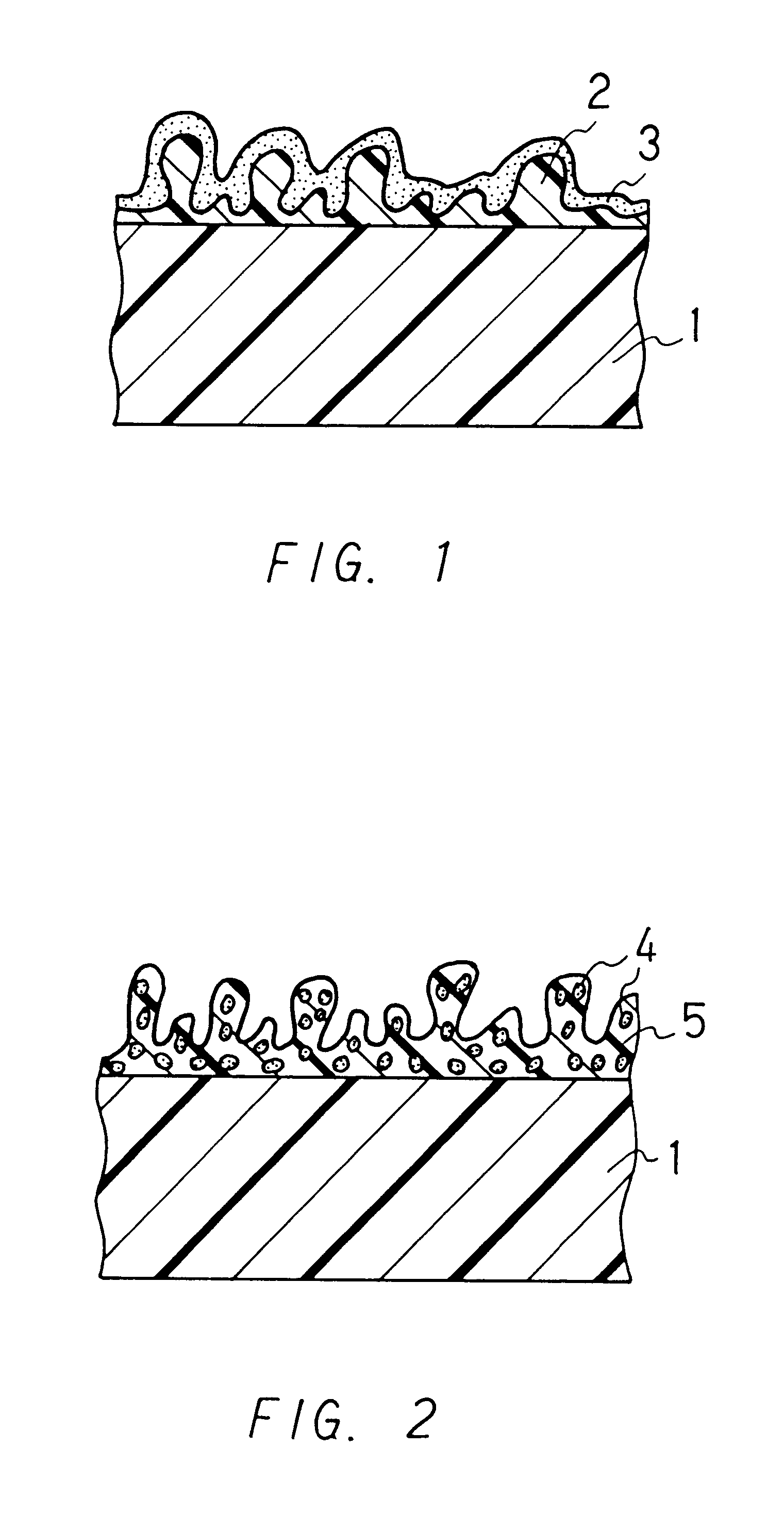

InactiveUS6878278B2Improve throughputEasy to adaptSemi-permeable membranesLoose filtering material filtersPolyamideReverse osmosis

A composite membrane and method for making the same, comprising a porous support and a polyamide surface. The subject membrane provides improved flux and / or rejection rates. The subject membrane is further capable of operating at lower operating pressures. The subject method includes reacting a polyfunctional amine with a polyfunctional acyl halide to form a polyamide. The method includes the step of contacting a complexing agent with the polyfunctional acyl halide prior substantial reaction between the polyfunctional acyl halide and a polyfunctional amine. The subject process is easily adapted to commercial scale manufacturing processes and is particularly suited for making nanofiltration and reverse osmosis composite membranes.

Owner:DOW GLOBAL TECH LLC

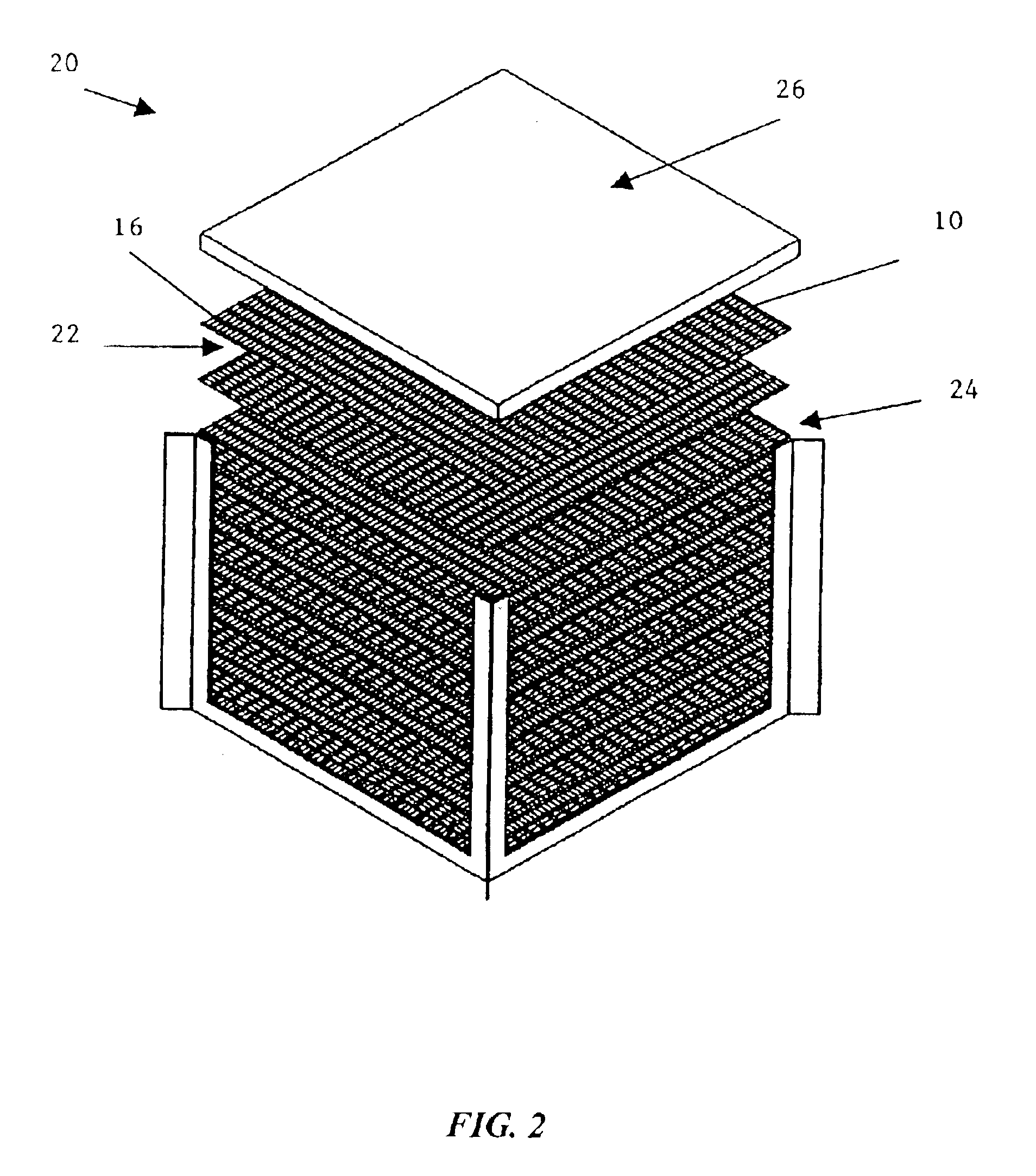

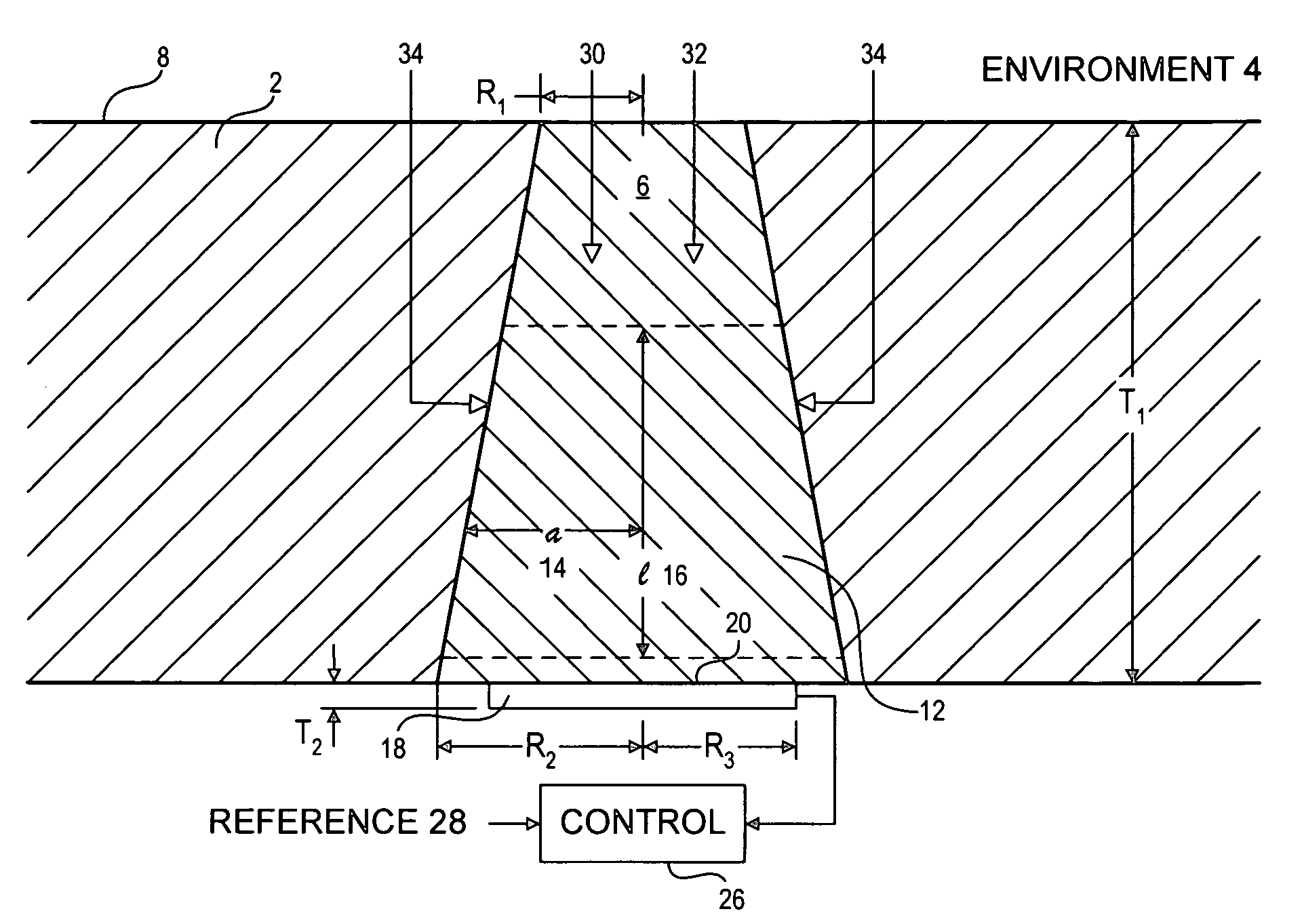

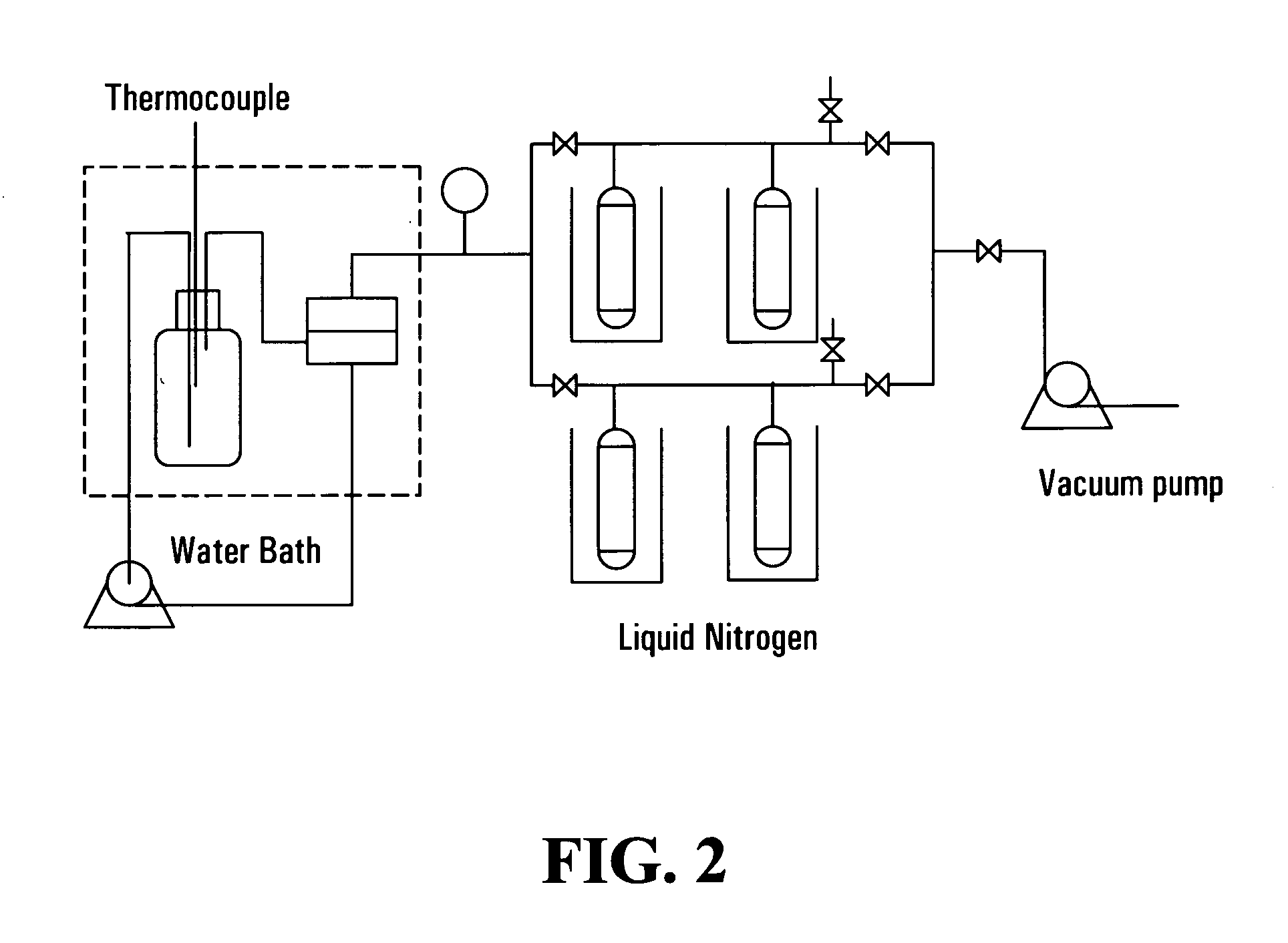

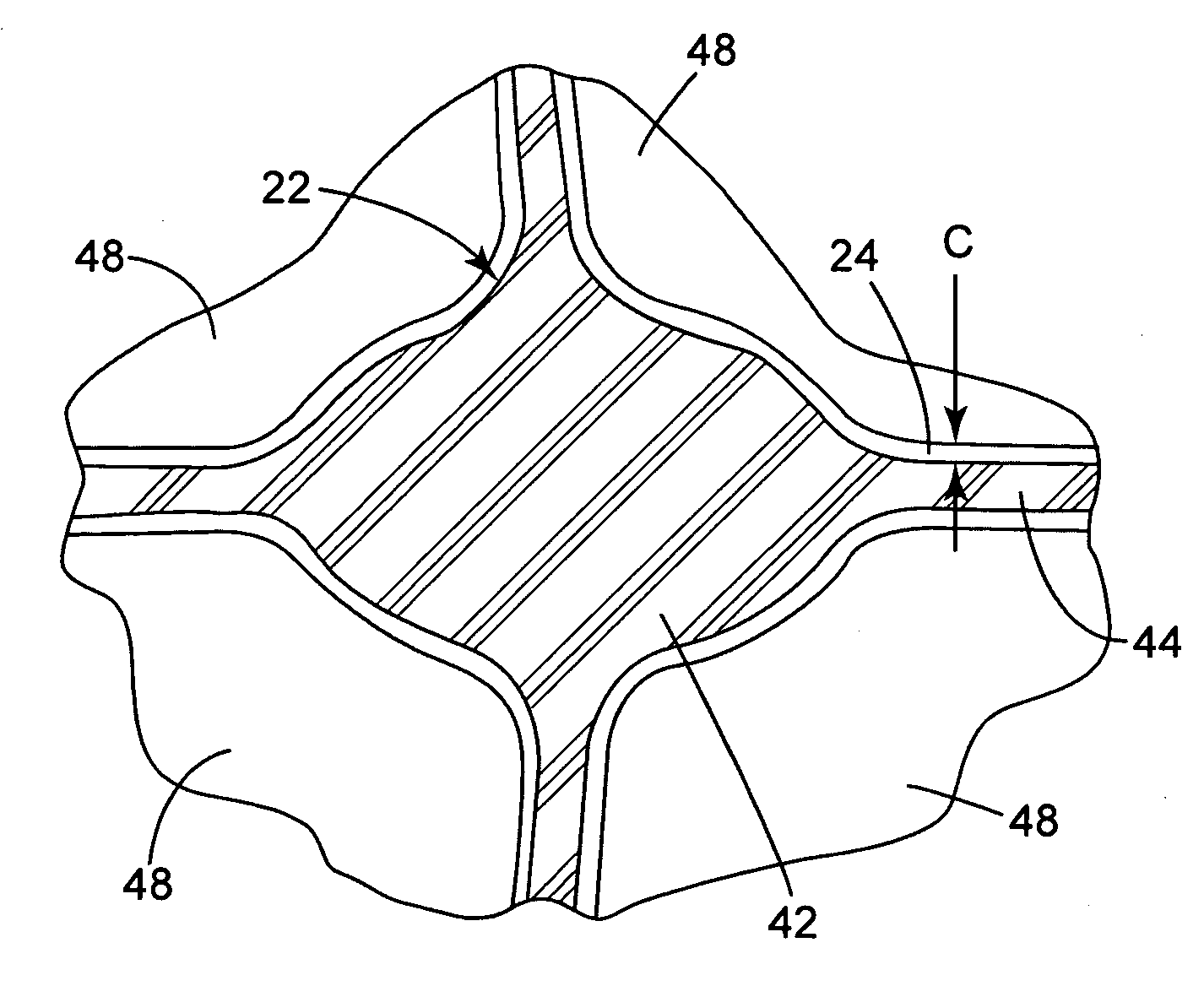

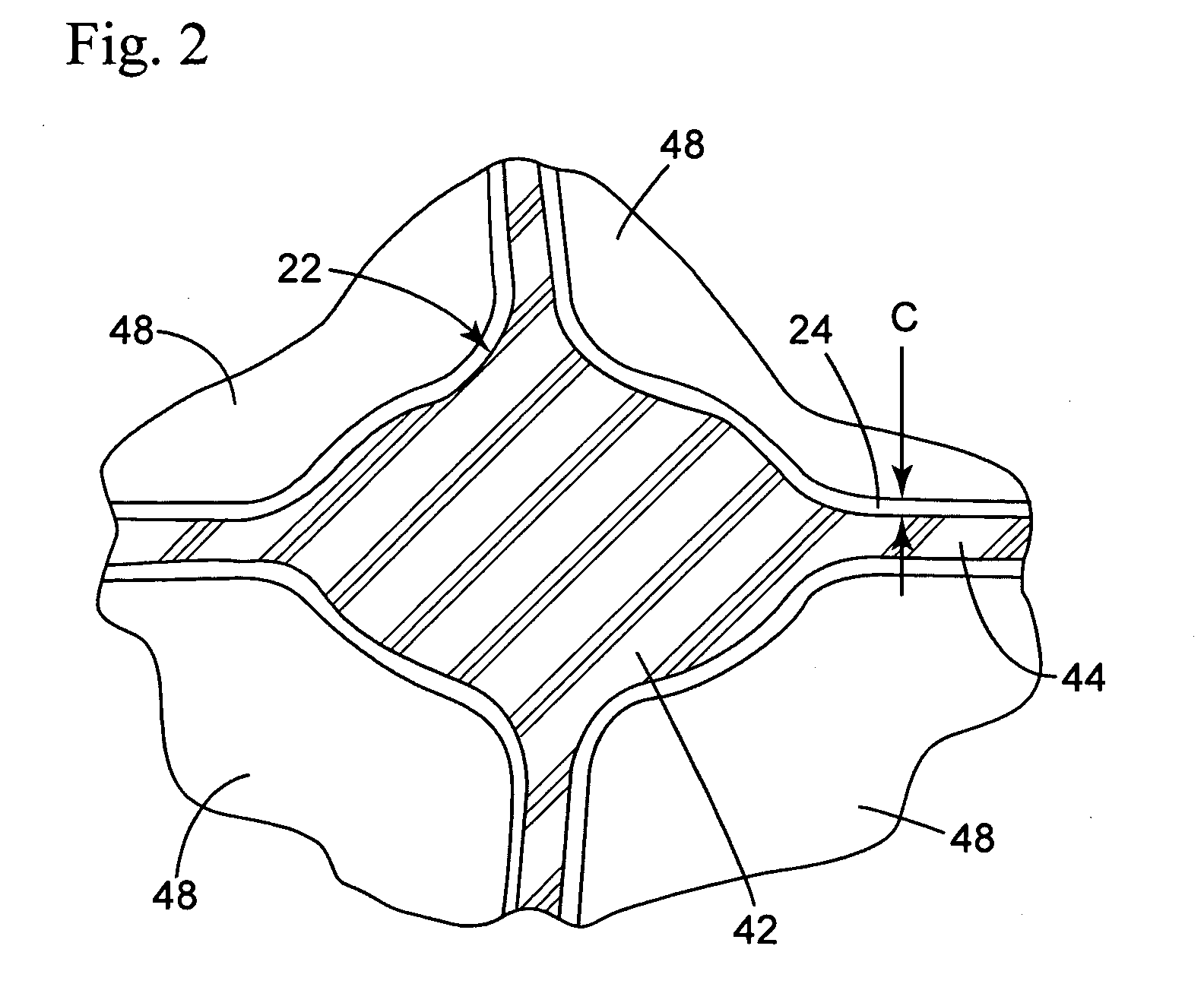

Crosslinked polymer electrolyte membranes for heat and moisture exchange devices

InactiveUS6841601B2Improve permeabilityLow costSpace heating and ventilationIndirect heat exchangersEnergy recoveryMoisture

A unitary humidity exchange cell (HUX) is dislosed that includes at least one composite membrane, disposed between at least one first chamber for flow of the first fluid therethrough and at least one second chamber for flow of the second fluid therethrough. The composite membrane include an at least partially sulfonated humidity-conducting polymer comprising residues derived from at least one arylvinyl monomer; and a reinforcing substrate bonded thereto. The product finds utility in a variety of physical and chemical processes and products whereby moisture or other highly polar liquid or gas transfer, exchange removal or delivery is important. A notable application is the Membrane Energy Recovery Ventilator (MERV) in which both heat, ions and moisture is transferred between two air streams, one intake and one exhaust, from an air-conditioned building.

Owner:TANGREDI PATRICIA

Defect free composite membranes, method for producing said membranes and use of the same

InactiveUS7172075B1Good water permeabilityStrong physical adhesionSemi-permeable membranesSynthetic resin layered productsFruit juiceChemical composition

Owner:ACCORD PARTNER

Reverse Osmosis Membrane with Branched Poly(Alkylene Oxide) Modified Antifouling Surface

InactiveUS20070251883A1Avoid problemsReduce dirtMembranesGeneral water supply conservationHydrogenEnd-group

Composite membranes that exhibit long-term resistance to biofouling comprise a porous support and a crosslinked polyamide discriminating layer having an external surface, the discriminating layer comprising a branched poly(alkylene oxide) (PAO) polymer attached to its external surface. The branched PAO polymer typically has the structure of a molecular comb or brush, and is made by polymerization of a PAO macromonomer of the following formula: RO—[(CHR′)n—O]m-V in which R is hydrogen or a C1-20 aliphatic or aromatic group, V is any group containing a polymerizable site, each R′ is independently hydrogen or a short chain alkyl group, n is an integer of 1-6, and m is an integer of 1 to about 200. The α end group can be either polymerized or copolymerized.

Owner:DOW GLOBAL TECH LLC

Composite reverse osmosis membrane having a separation layer with polyvinyl alcohol coating and method of reverse osmotic treatment of water using the same

InactiveUS6177011B1High Salt RejectionPermit practical desalinationGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisZeta potentialWater use

A reverse osmosis composite membrane that has a high salt rejection, a high water permeability, and a high fouling tolerance, and permits practical desalination at a relatively low pressure is provided by coating the surface of a reverse osmosis membrane of aromatic polyamide with polyvinyl alcohol (PVA), for example, and controlling the surface zeta potential of the separation layer within±10 mV at pH 6. This reverse osmosis composite membrane is electrically neutral and controls the electrical adsorption of membrane-fouling substances having a charge group present in water. Therefore, a high separation property can be maintained without fouling the membrane even if water containing a surfactant or a transition metal component is supplied as raw water.

Owner:NITTO DENKO CORP

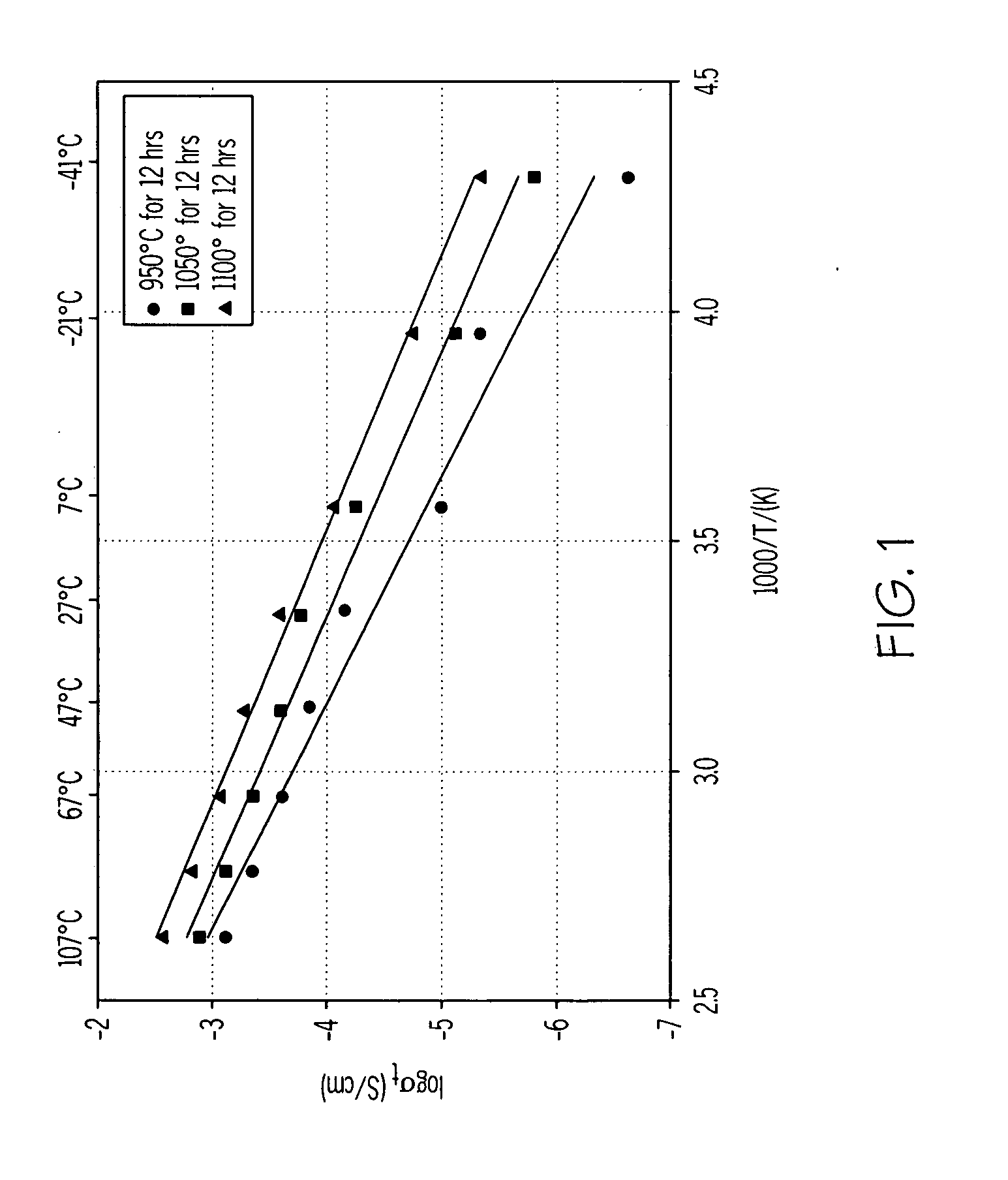

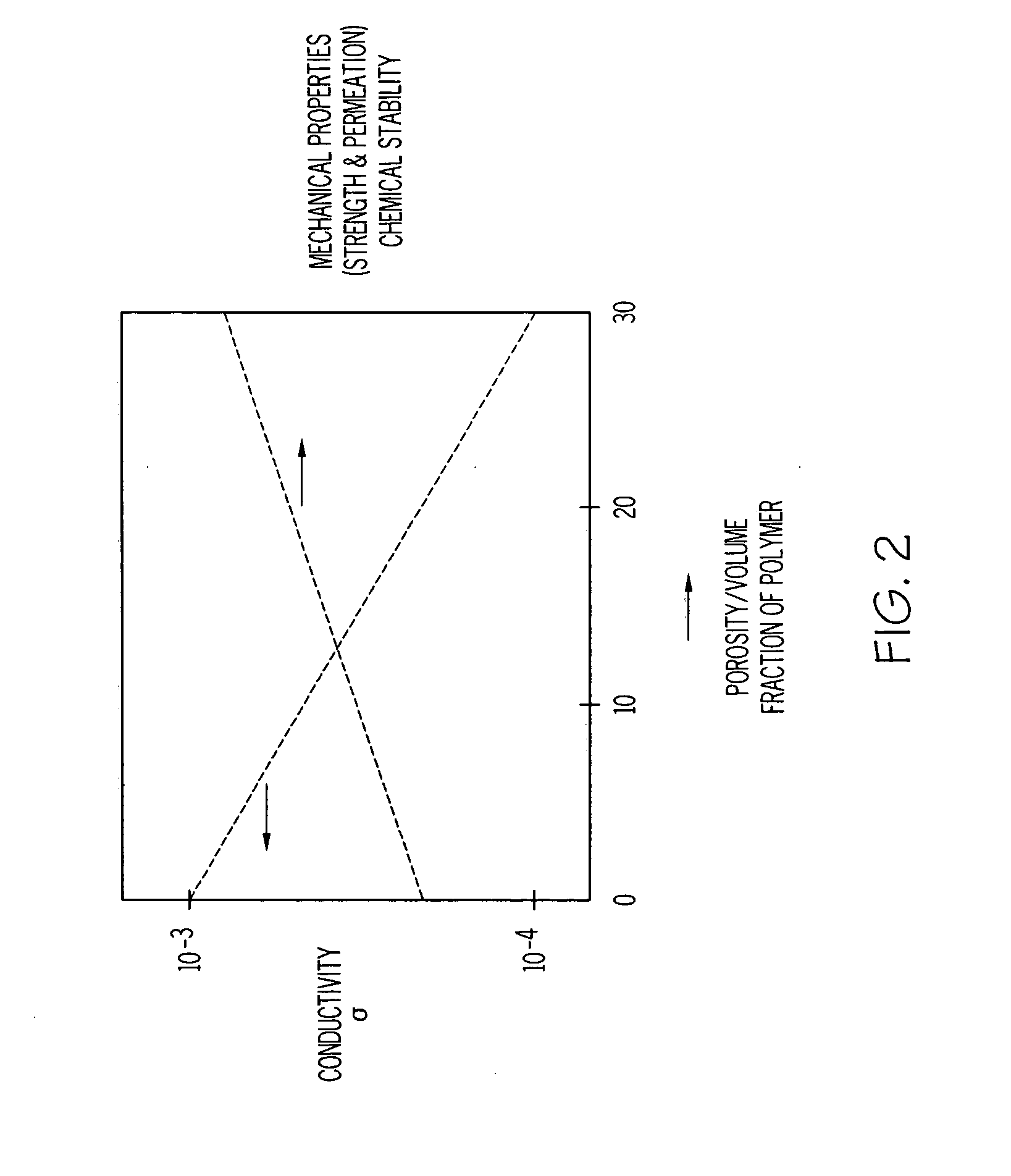

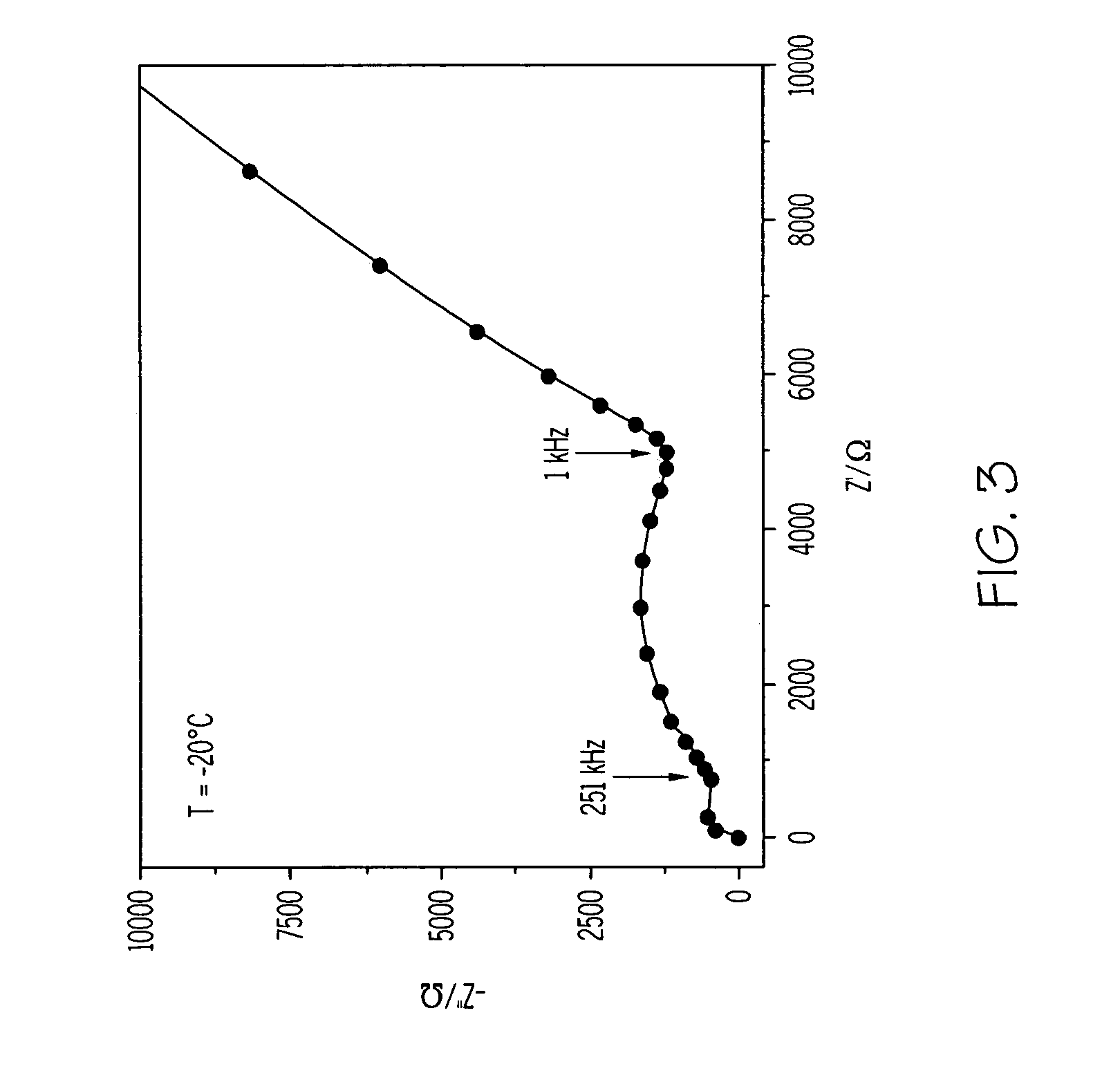

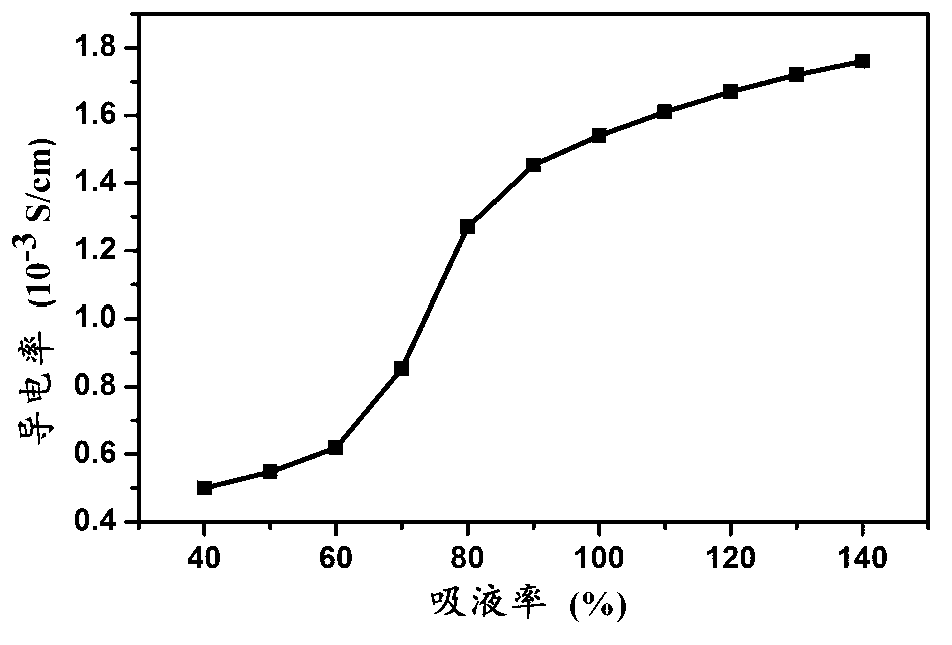

Solid composite electrolyte membrane and method of making

ActiveUS20070117026A1Improve conductivitySolid electrolytesSolid electrolyte cellsPorosityComposite electrolyte

A solid composite electrolyte membrane for use in a lithium battery is provided which exhibits a conductivity ranging from about 10−4 S cm−1 to about 10−3 S cm−1 at ambient temperature. The membrane is formed by providing a glass or glass-ceramic powder formed from a mixture of lithium carbonate, alumina, titanium dioxide, and ammonium dihydrogen phosphate. The powder is mixed with a conditioning agent and at least one solvent, followed by the addition of a binder and one or more plasticizers. The resulting slurry is cast into a tape which is then subjected to a binder burn-off and sintering process to form the membrane. The resulting membrane may be a glass-ceramic composite having a porosity ranging from 0 to 50%, or the membrane may be further infiltrated with a polymer to form a water-impermeable polymeric-ceramic composite membrane.

Owner:UNIV OF DAYTON THE

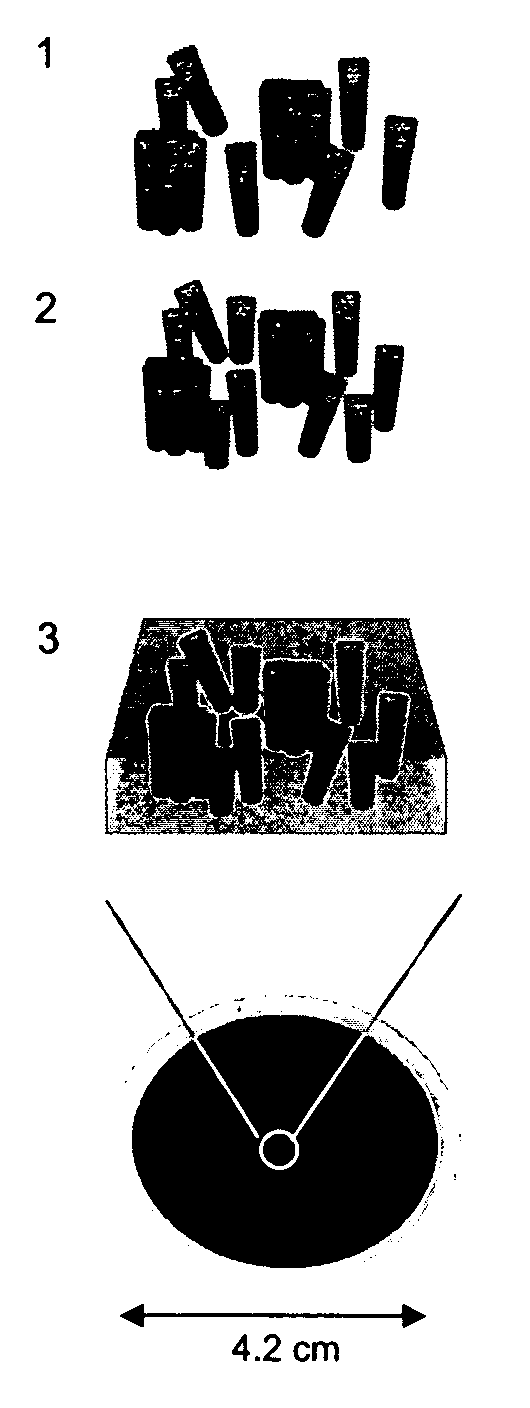

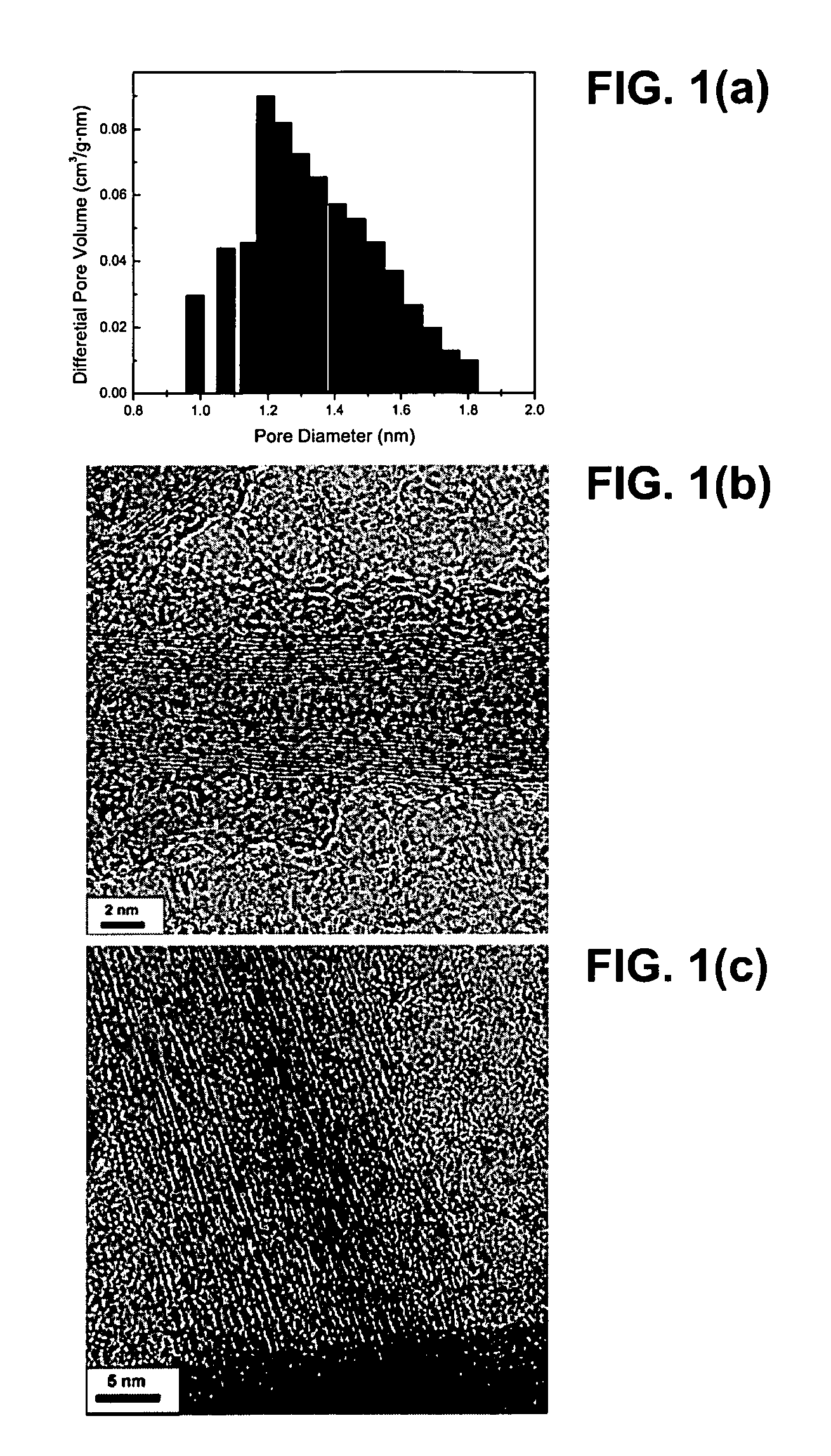

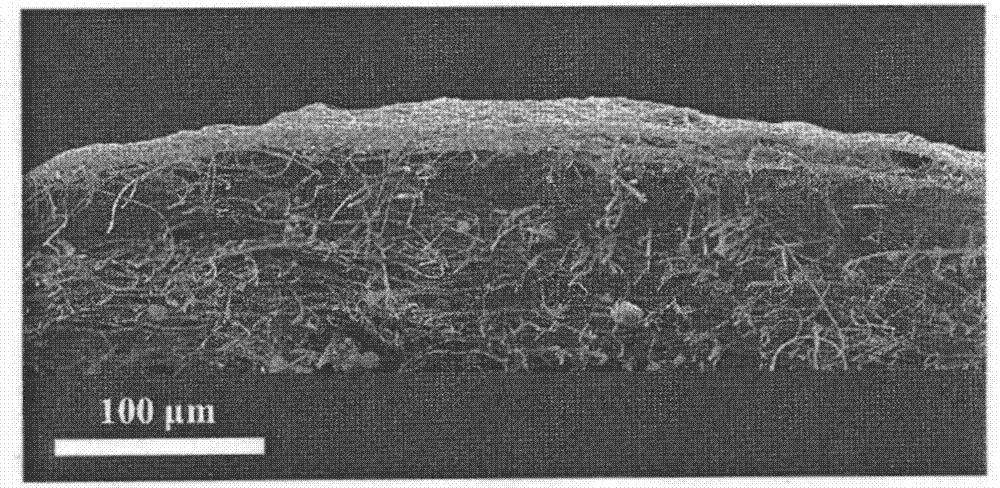

Method for making oriented single-walled carbon nanotube/;polymer nano-composite membranes

ActiveUS20080290020A1Rapid of compoundRapid transportSemi-permeable membranesNanotechFiltrationCarbon nanotube

Nano-composite membranes and methods for making them are described. The nano-composite membranes a made from a layer of oriented carbon nanotubes fixed in a polymeric matrix. Methods for efficient, facile, and inexpensive fabrication of the nano-composite membranes using a filtration method are also described. The carbon nanotubes may also be modified with chemical functional groups to promote their orientation in the carbon nanotube layer or to confer to them other properties.

Owner:VIRGINIA TECH INTPROP INC

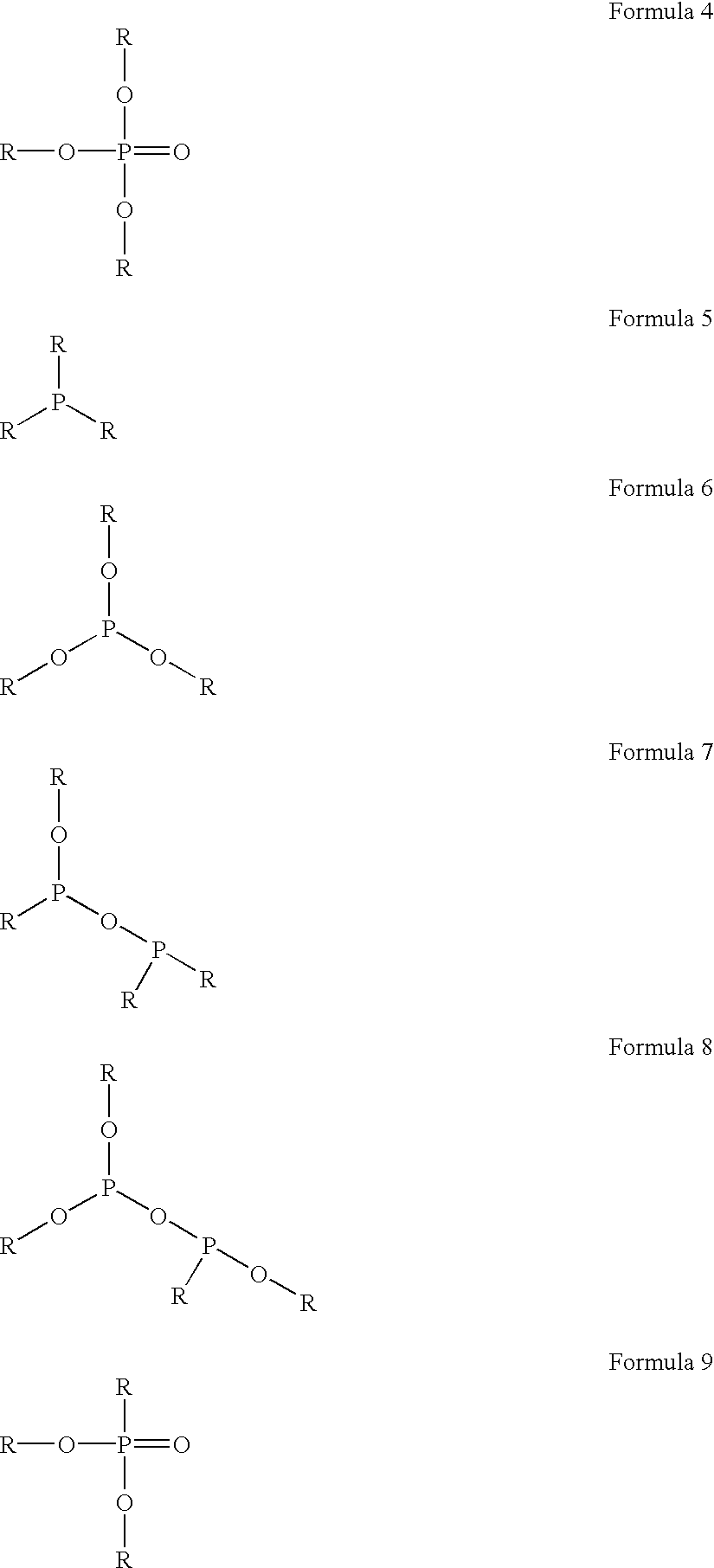

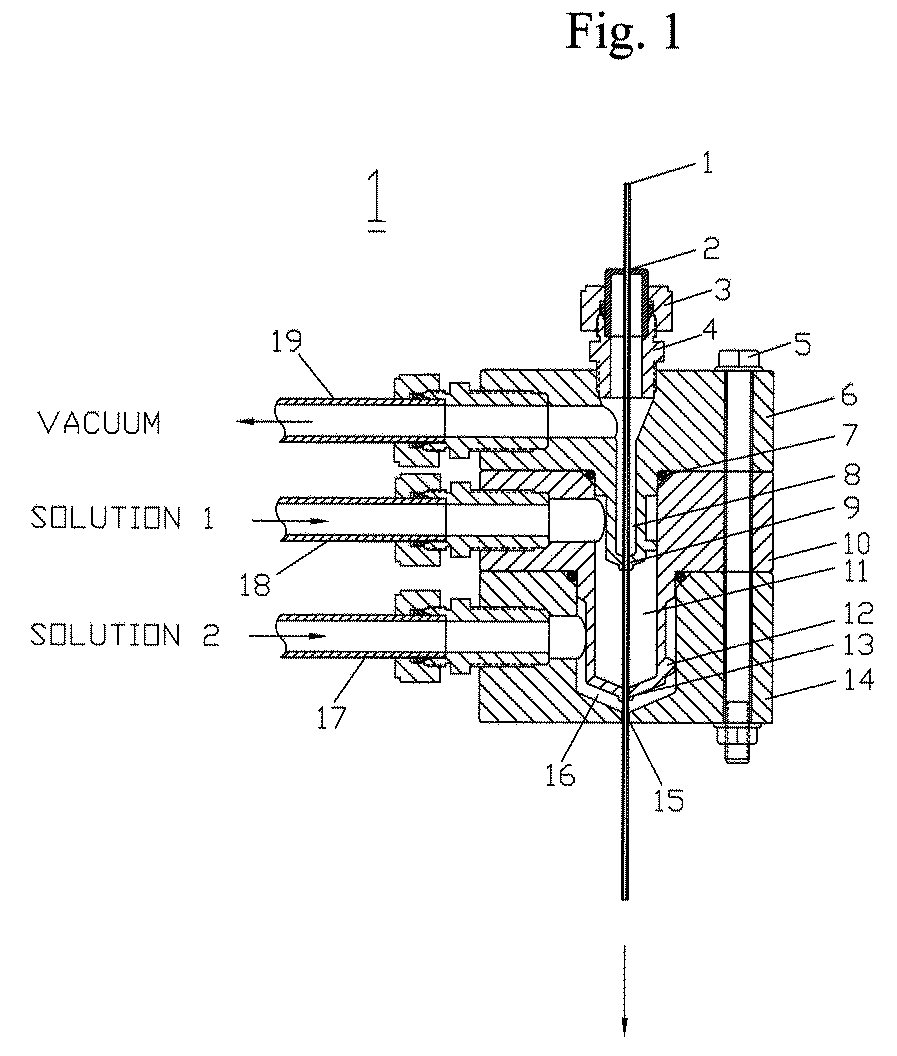

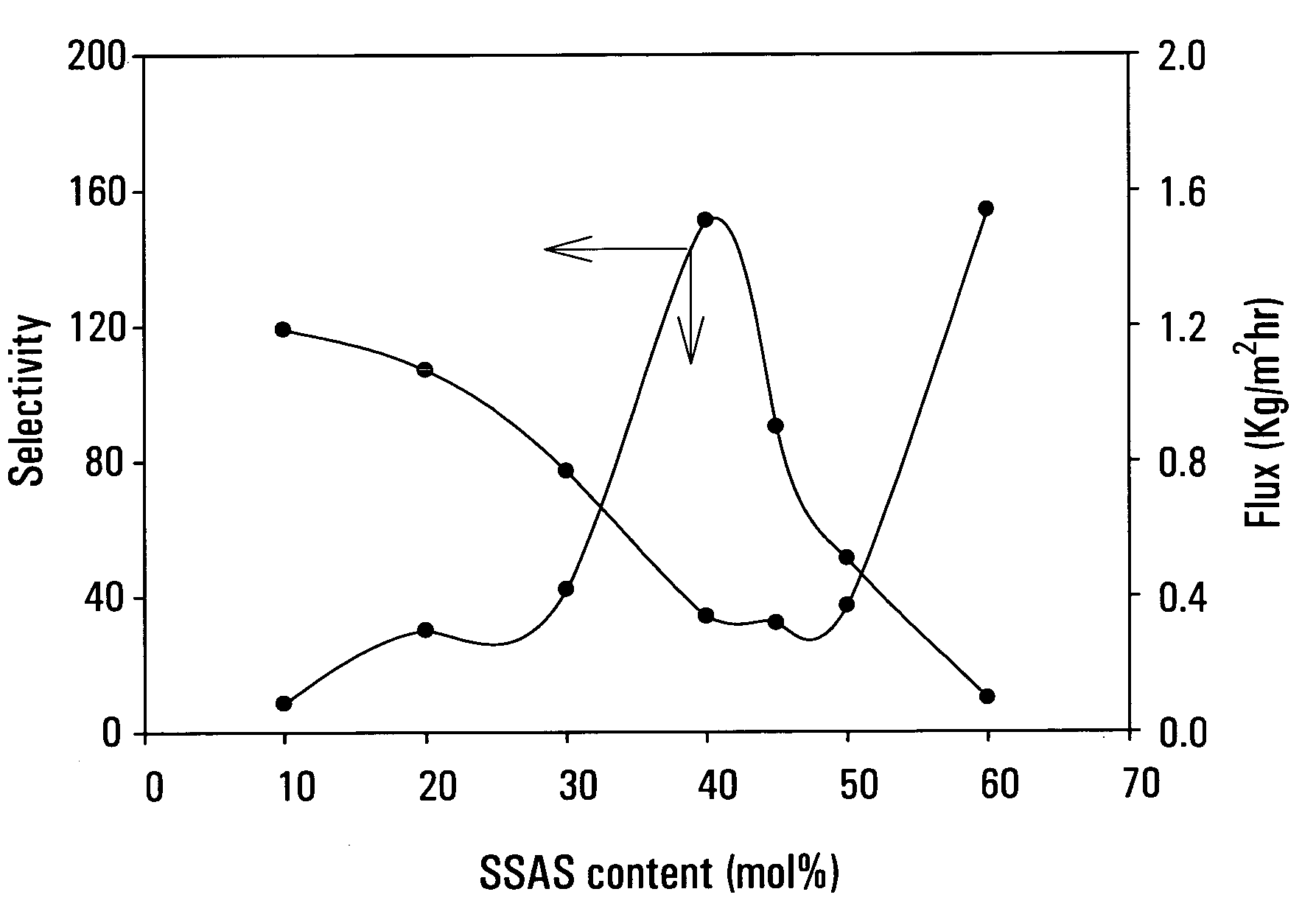

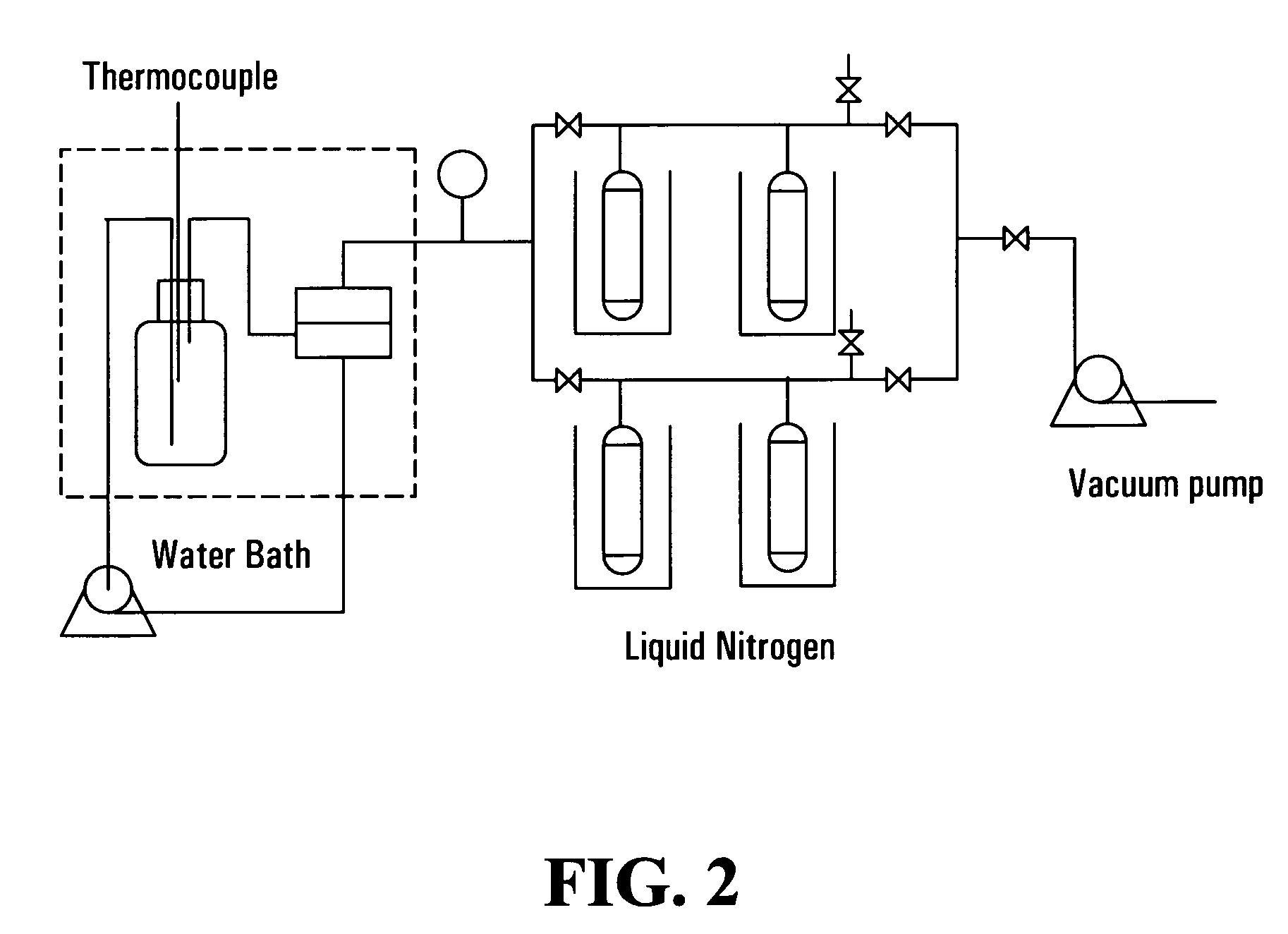

Pervaporation composite membranes

The present application discloses a composite membrane comprising (a) a support member that has a plurality of pores extending through the support member and (b) a cross-linked copolymer comprising (i) a cationic monomer and an anionic monomer and / or (ii) a zwitterionic monomer, which cross-linked copolymer fills the pores of the support member, the cross-linked copolymer having a permeability for a fluid that is dependent on the polarity of the fluid, wherein the permeability increases with increasing polarity.The present application also discloses a process for the preparation of the composite membrane, a pervaporation apparatus comprising the composite membrane, and methods for the use of the composite material in separation and dehydration processes.

Owner:MCMASTER UNIV

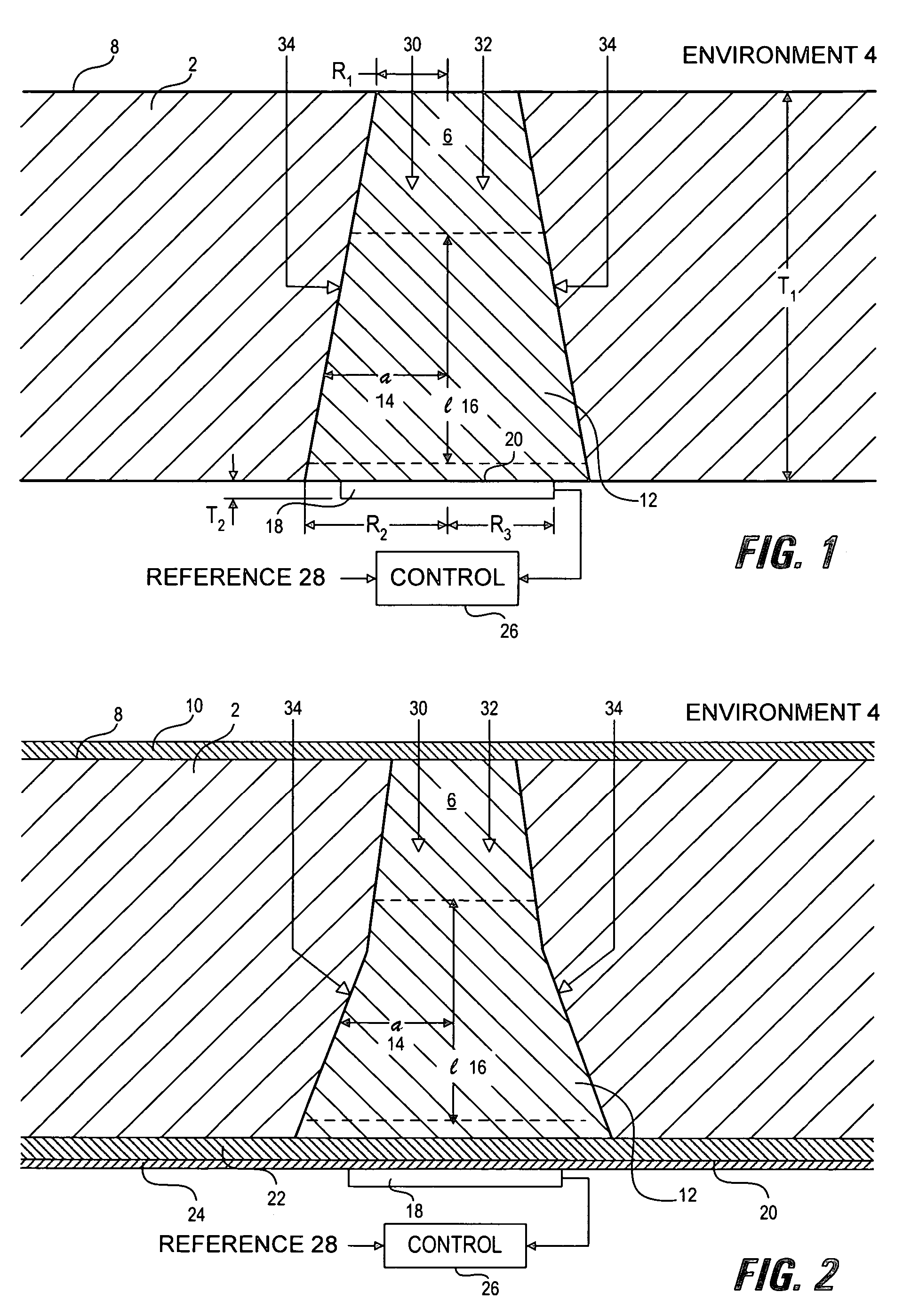

Membrane and electrode structure for implantable sensor

ActiveUS7336984B2Limited accessDiagnostic recording/measuringSensorsEnvironmental designExcess oxygen

The invention is the design of a biological measuring device for the determination of the concentration of biomolecules (e.g. glucose) in an environment which is designed for implantation into an individual or for use in the context of an external apparatus. The device contains a composite membrane that is essentially entirely permeable to oxygen and permeable to larger biomolecules only in discrete hydrophilic regions. The membrane diffusionally limits the access of biomolecules to an enzyme, present in the hydrophilic region that catalyzes the oxidation of the biomolecule to produce hydrogen peroxide. A sensor in communication with the hydrophilic region is used to determine the amount of product produced or the amount of excess oxygen present allowing for the concentration of the biomolecule to be determined.

Owner:RGT UNIV OF CALIFORNIA

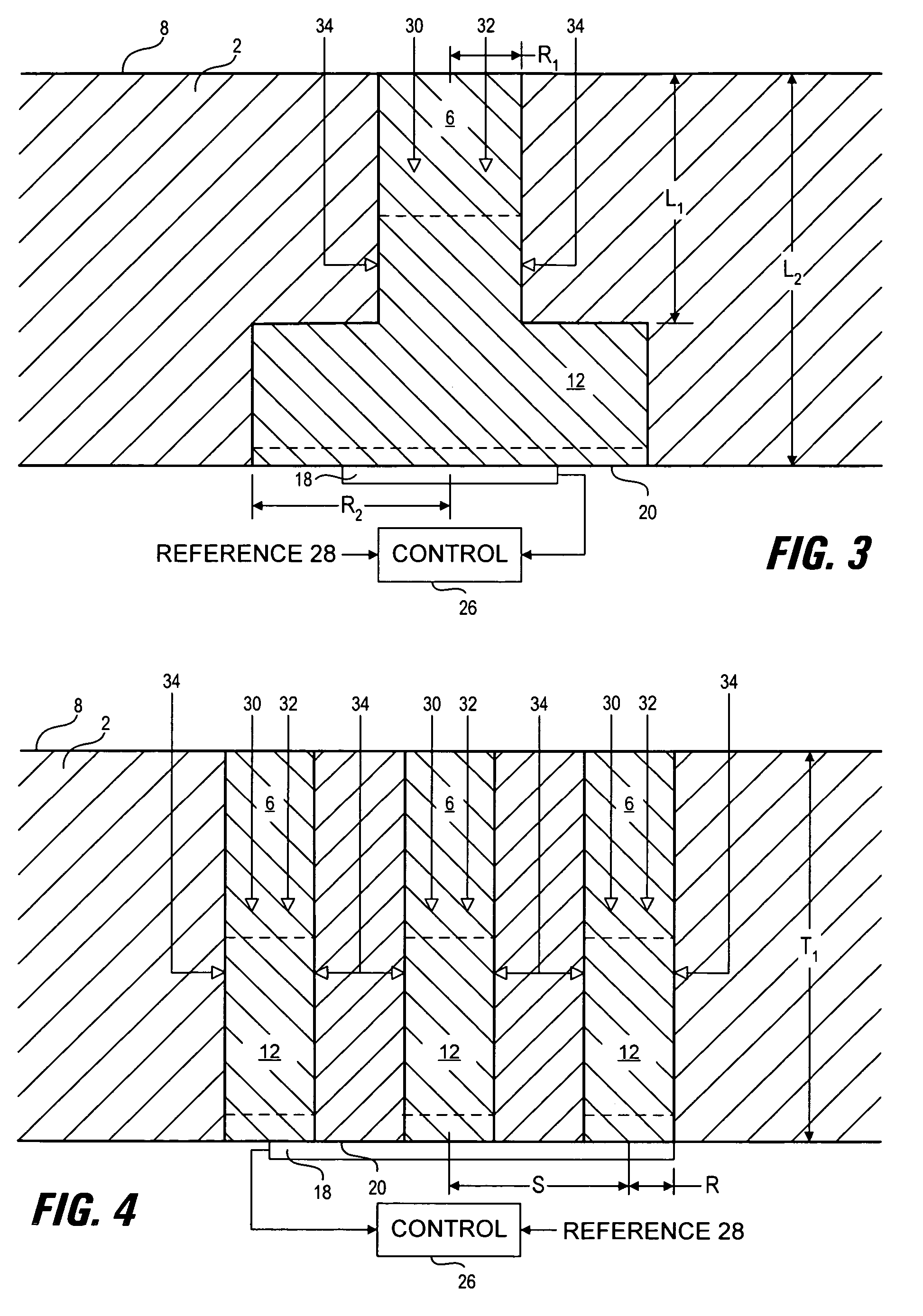

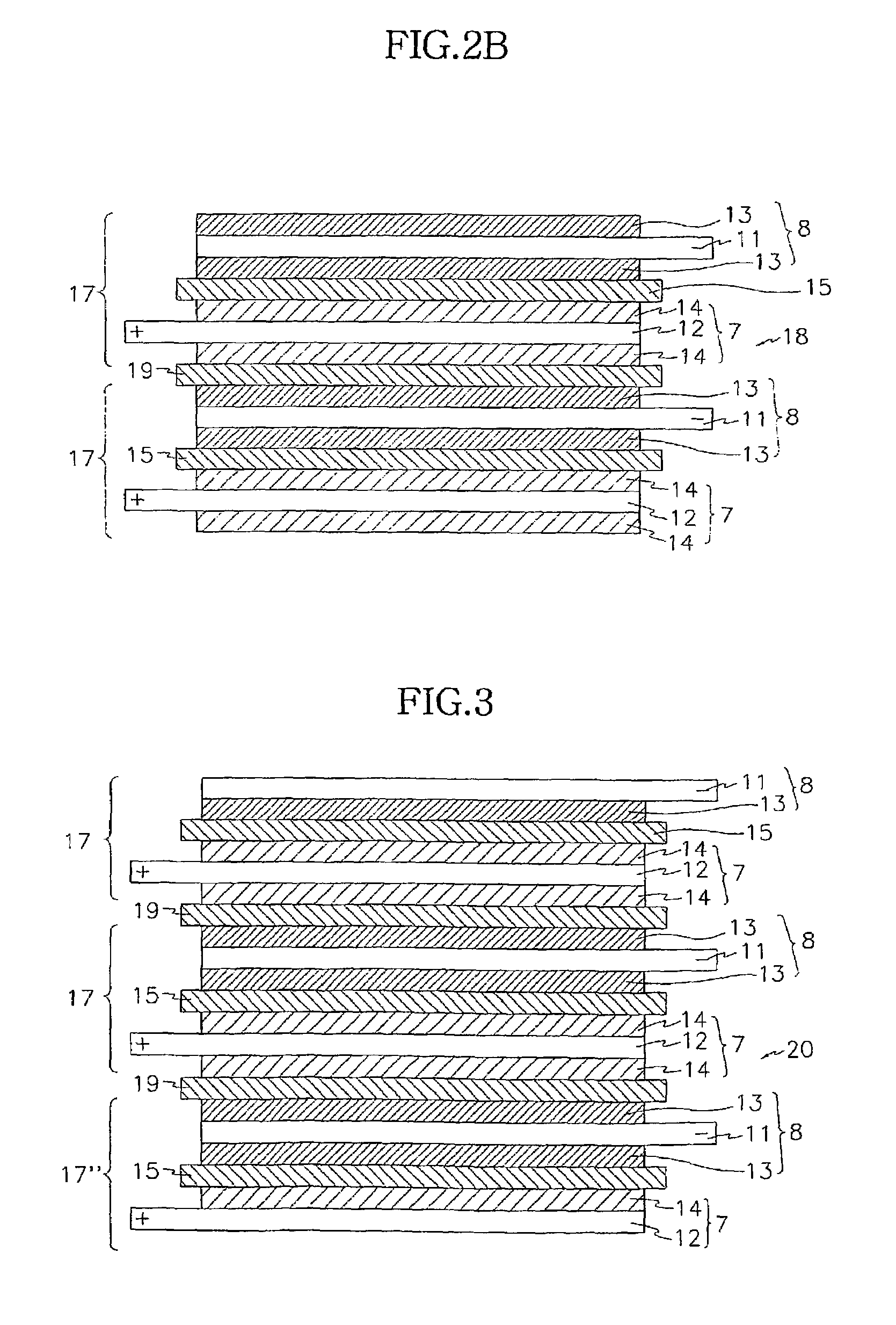

Electrochemical device using multicomponent composite membrane film

InactiveUS7014948B2Easy to manufactureImprove adhesionMembranesSemi-permeable membranesPolymer scienceElectrochemistry

The present invention provides a electrochemical element, wherein a multi-component composite film comprising a) polymer support layer film and b) a porous gellable polymer layer which is formed on either or both sides of the support layer film of a), wherein the support layer film of a) and the gellable polymer layer of b) are unified with each other without an interface between them.

Owner:TORAY BATTERY SEPARATOR FILM +1

Solid polymer electrolyte and process for making same

ActiveUS20070072036A1Enhanced release propertiesIon-exchanger regenerationFinal product manufactureFiberIon exchange

A solid polymer electrolyte membrane having a first surface and a second surface opposite the first surface, where the solid polymer electrolyte membrane has a failure force greater than about 115 grams and comprises a composite membrane consisting essentially of (a) at least one expanded PTFE membrane having a porous microstructure of polymeric fibrils, and (b) at least one ion exchange material impregnated throughout the porous microstructure of the expanded PTFE membrane so as to render an interior volume of the expanded PTFE membrane substantially occlusive; (c) at least one substantially occlusive, electronically insulating first composite layer interposed between the expanded PTFE membrane and the first surface, the first composite layer comprising a plurality of first carbon particles supporting a catalyst comprising platinum and an ion exchange material, wherein a plurality of the first carbon particles has a particle size less than about 75 nm, or less than about 50 nm, or less than about 25 nm.

Owner:WL GORE & ASSOC INC

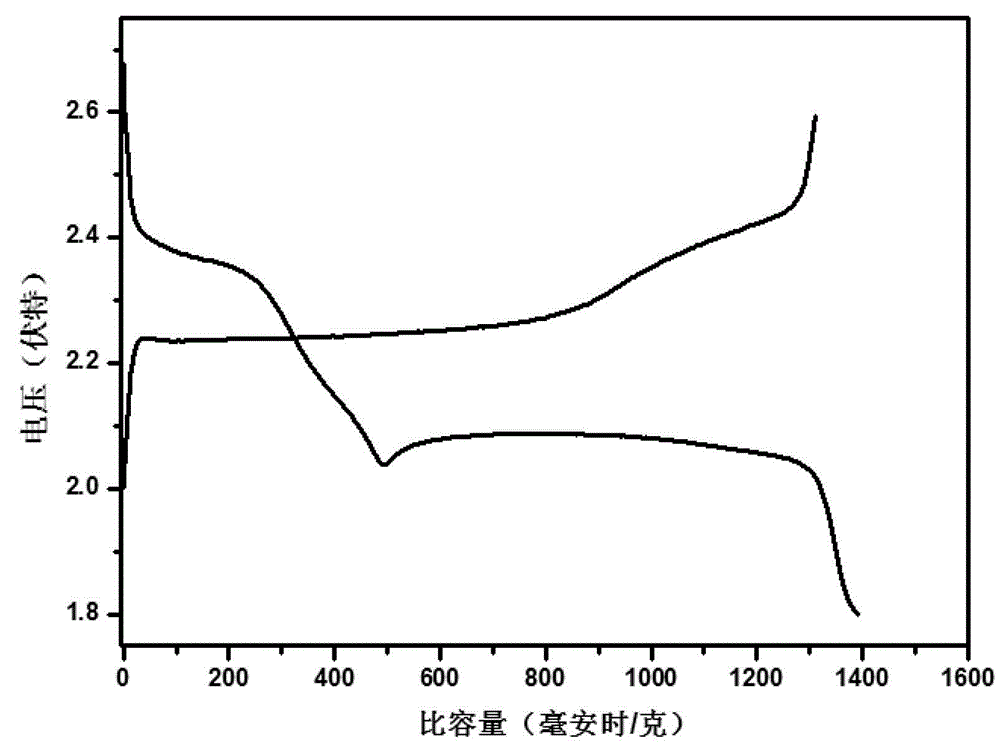

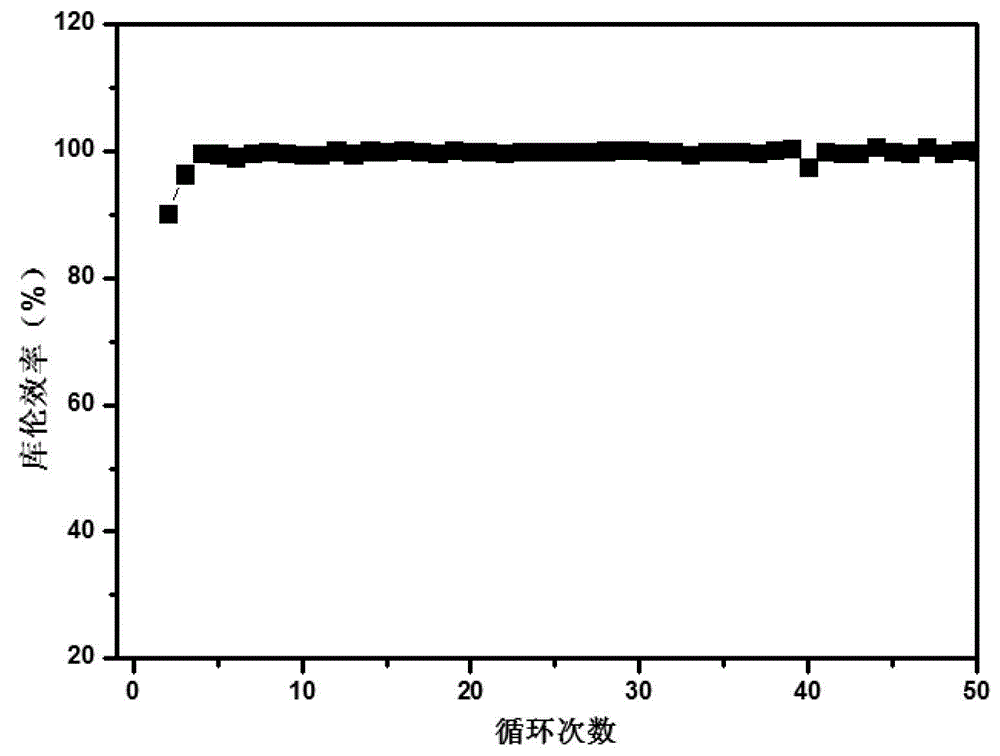

Functional composite membrane for lithium-sulfur battery and preparation method of functional composite membrane

InactiveCN105140447AImproved magnification performanceImprove ionic conductivityLi-accumulatorsCell component detailsLithium–sulfur batteryConductive materials

The invention relates to a functional composite membrane for a lithium-sulfur battery and a preparation method of the functional composite membrane. The composite membrane comprises a membrane for the lithium-sulfur battery and a functional modified layer, wherein the functional modified layer is located on the membrane for the lithium-sulfur battery, and comprises an electronic conductive material and / or inorganic oxides. Compared with the lithium-sulfur battery employing an ordinary battery membrane, the lithium-sulfur battery employing the functional composite membrane with the modified layer has a relatively high specific discharge capacity; the shuttle effect of the lithium-sulfur battery can be suppressed; the coulombic efficiency of the battery is improved; and the cycle performance of the battery is improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

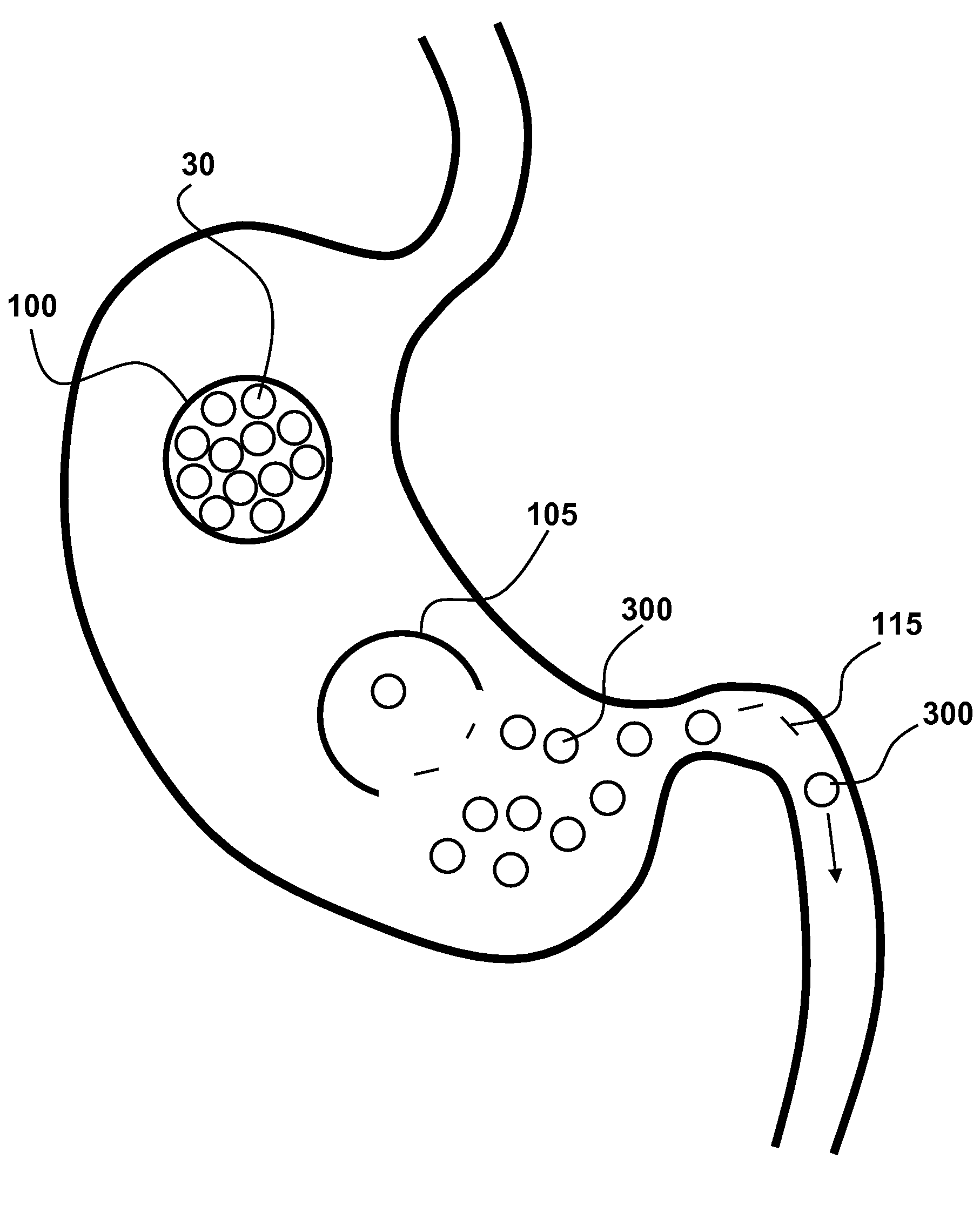

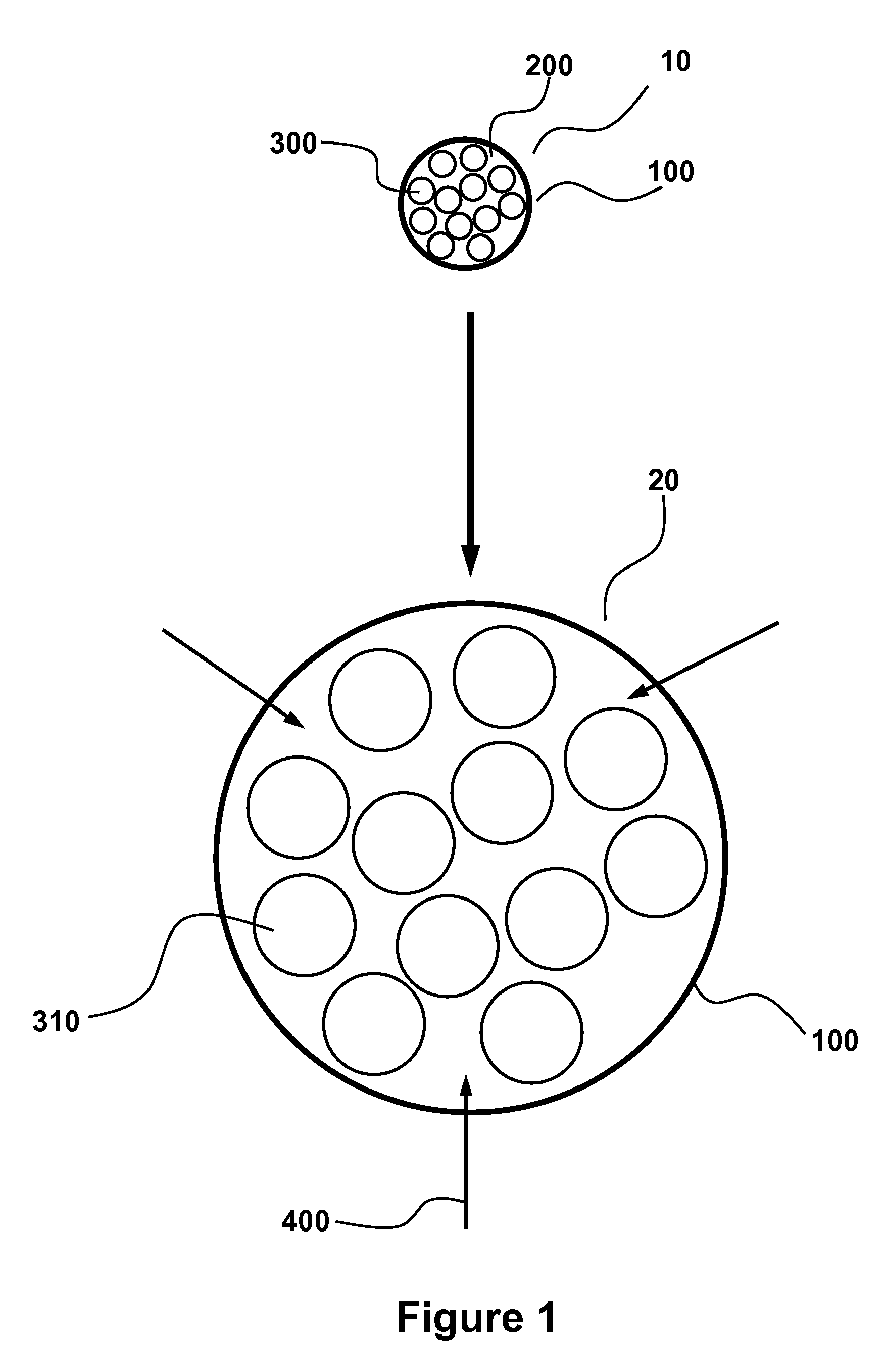

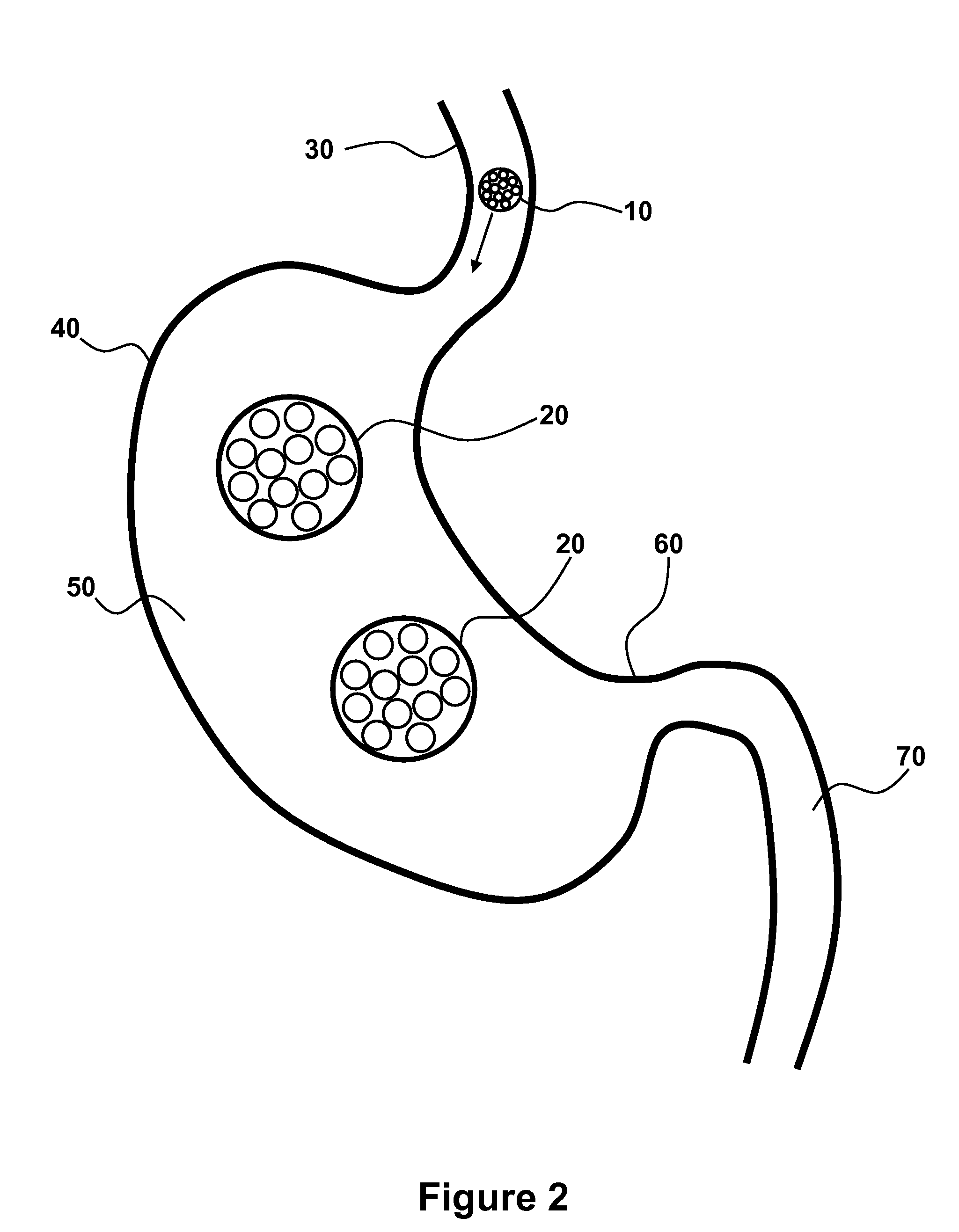

Swallowable Self-Expanding Gastric Space Occupying Device

InactiveUS20090192535A1Suppresses individual 's hungerFilling stomachDilatorsObesity treatmentGastric fluidMembrane configuration

Disclosed is a swallowable self-expanding gastric space occupying device and related methods of making and using the device to control obesity. The device has a membrane through which gastric liquid can pass, wherein the membrane provides an enclosure volume separated from the gastric environment by the membrane. A plurality of self-expanding components is contained in the enclosure volume, so that the components expand in volume upon contact with the gastric fluid, thereby expanding the device from an unexpanded volume to an expanded volume. Composite membranes provide the ability to precisely control how and when the membrane degrades in the stomach, to release the self-expanding components from the enclosure and to ensure that the released pieces are sufficiently small to not obstruct any portion of the gastrointestinal system.

Owner:7L LLC

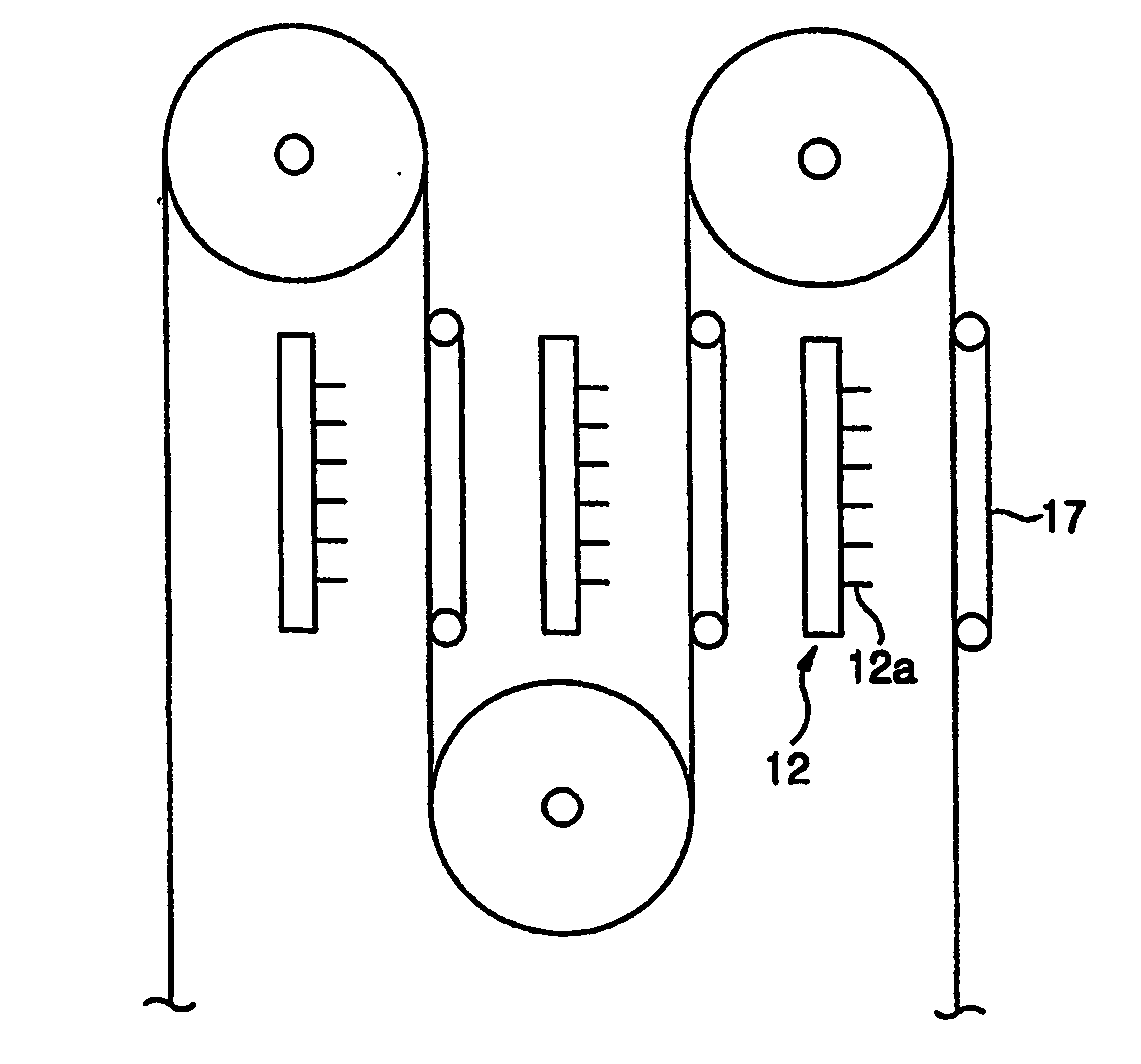

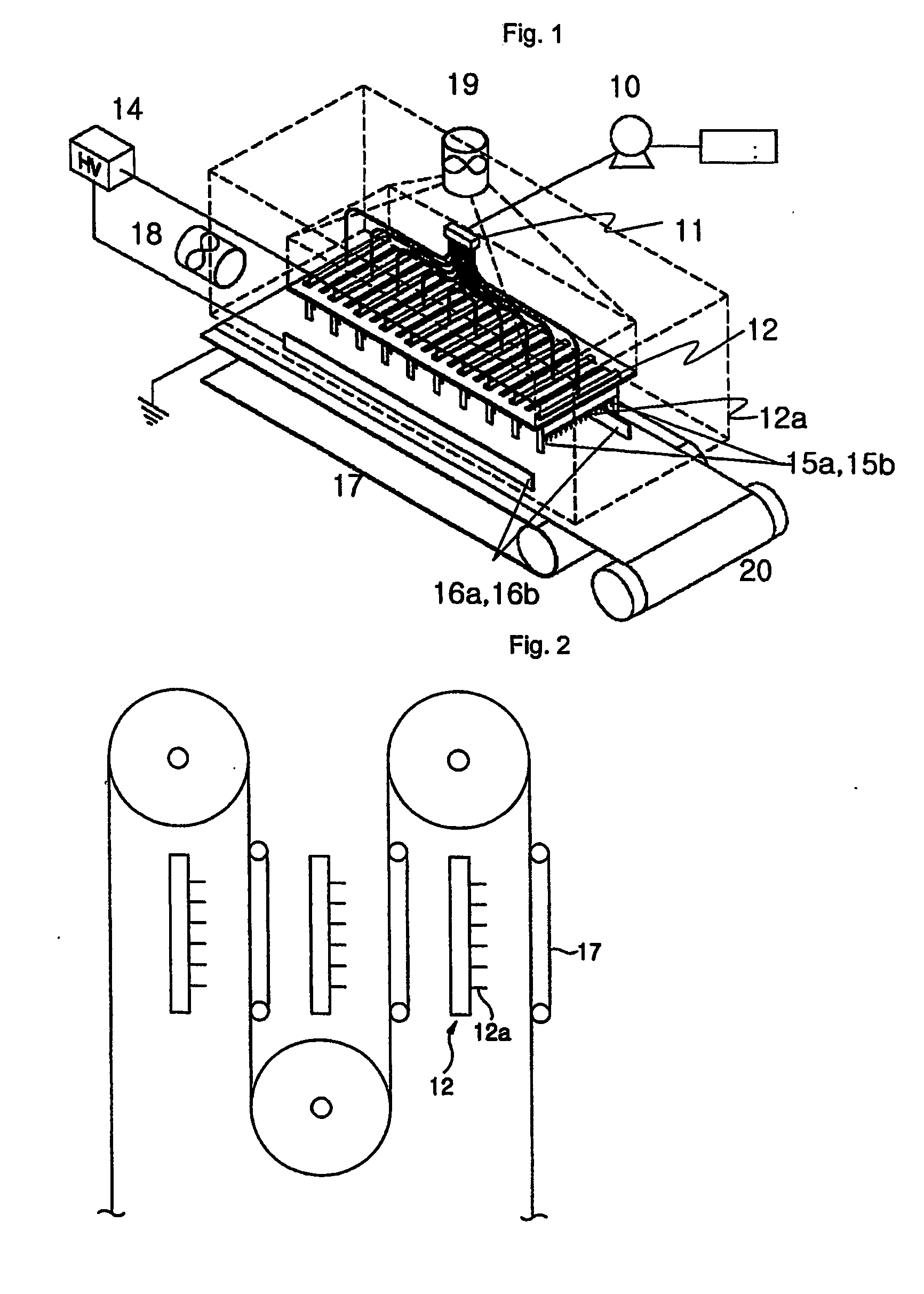

Combination of electrostatic spinning and electrostatic spraying for preparing nanofibre base composite separation membrane

InactiveCN101947415AControl thicknessControl UniformitySemi-permeable membranesFilament/thread formingChemical treatmentPolymer science

Owner:DONGHUA UNIV

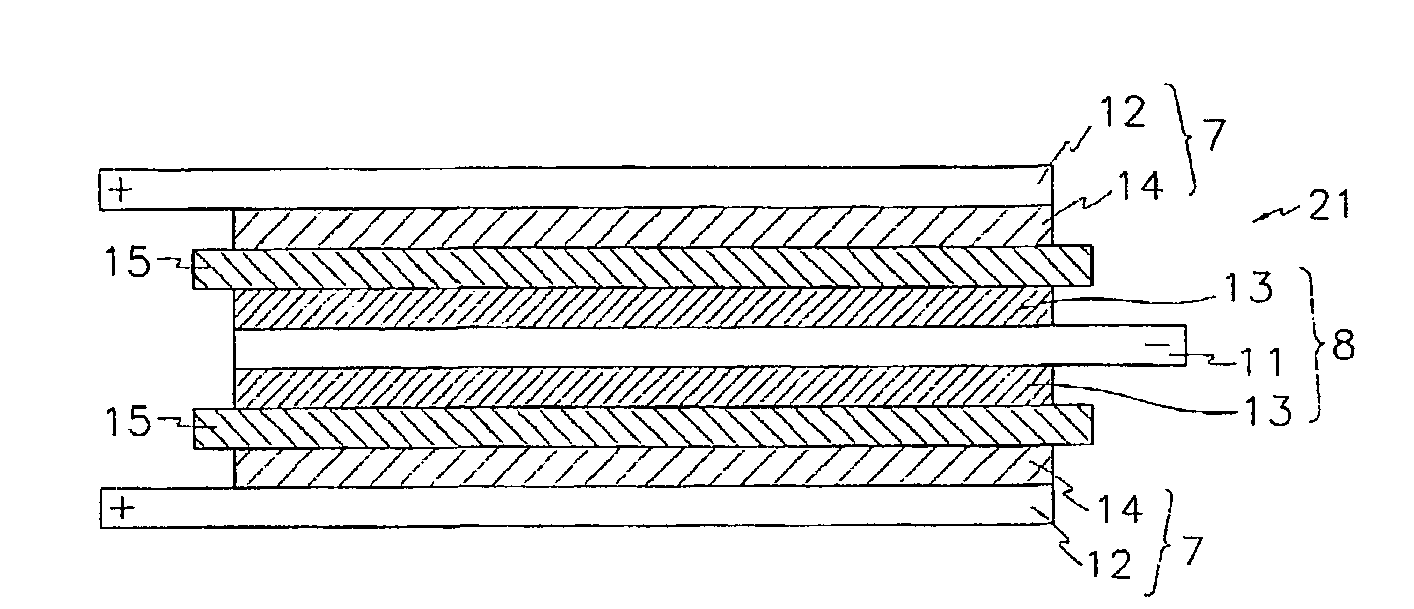

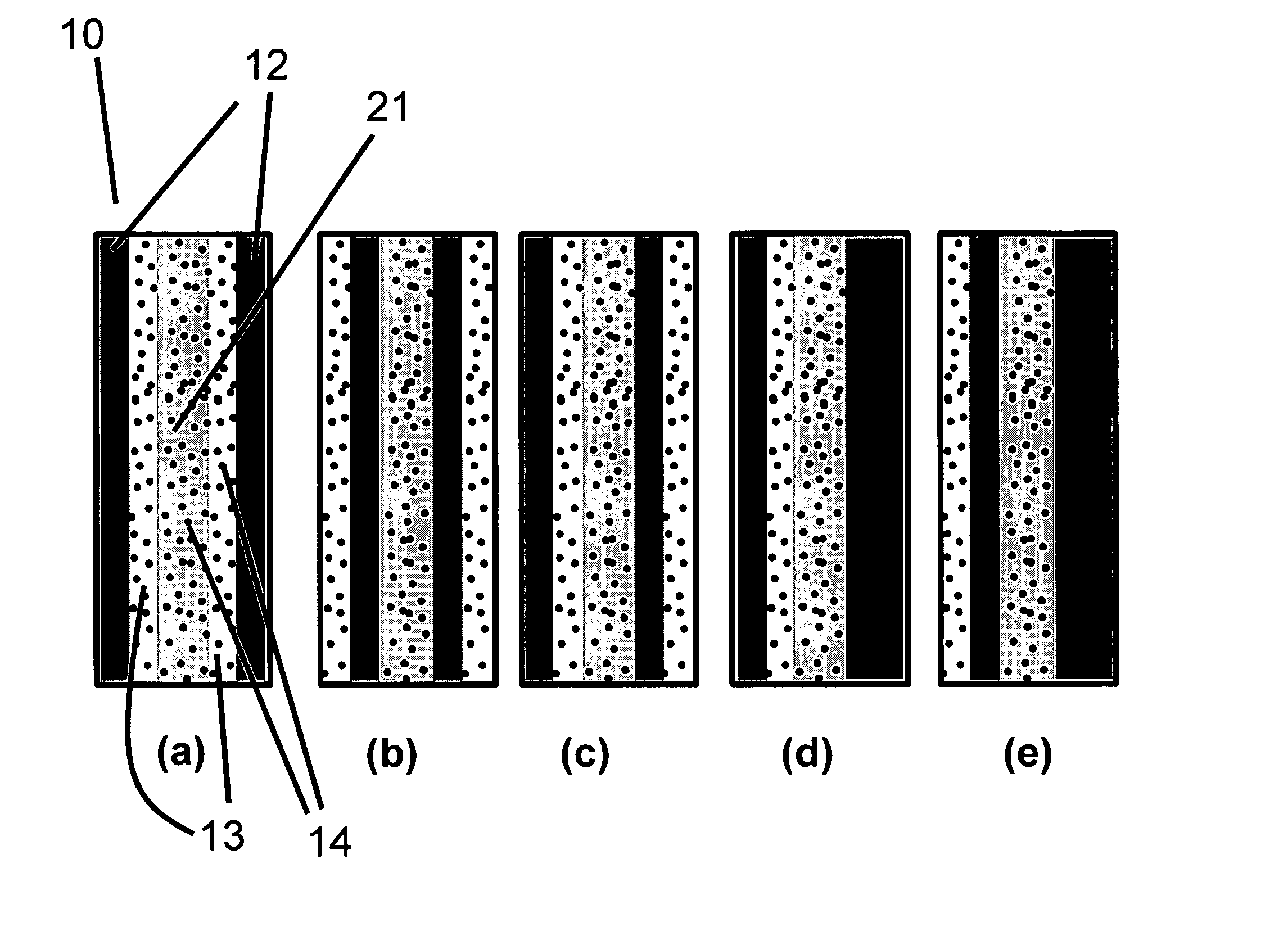

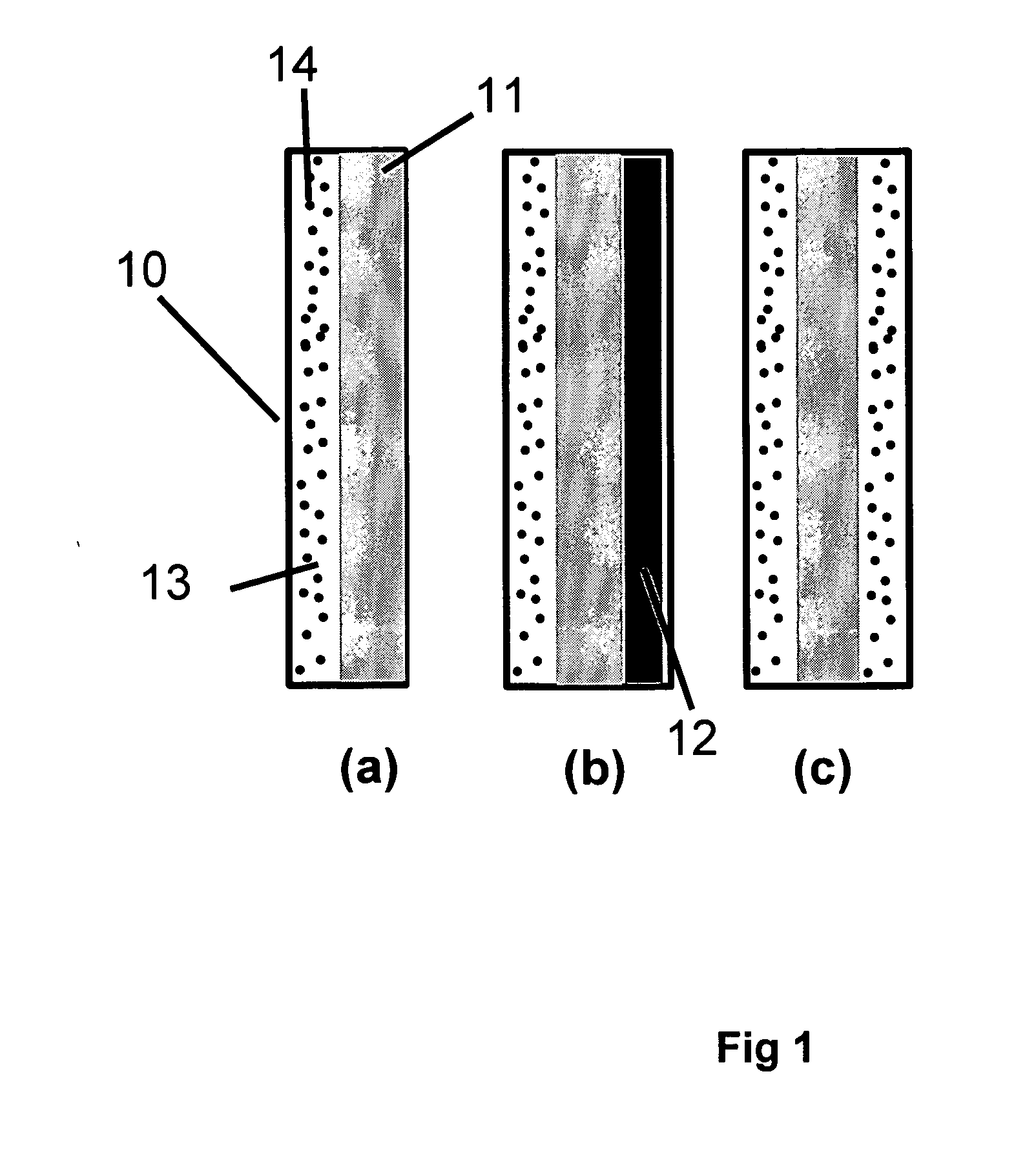

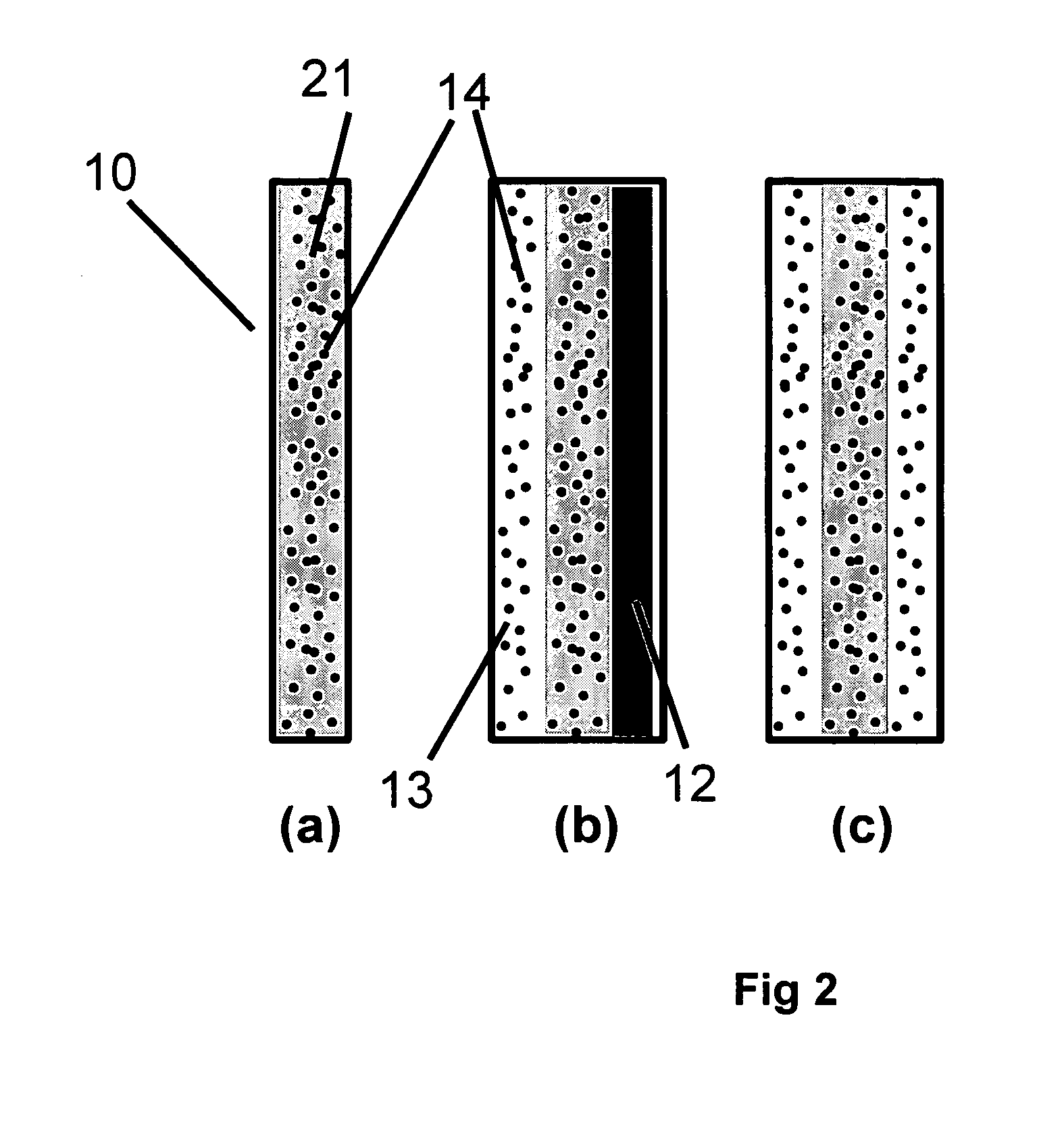

Complex membrane for electrochemical device, manufacturing method and electrochemical device having the same

InactiveUS20060286446A1Improve battery performanceHigh mechanical strengthNanotechSolid electrolytesFiberLithium

A complex membrane for an electrochemical device such as a lithium secondary battery, its manufacturing method, and an electrochemical device having the complex membrane are disclosed. The complex membrane includes a micro-porous polyolefin membrane, and a web-phase porous membrane united to at least one side of the micro-porous polyolefin membrane and composed of nano-fibers. Since the complex membrane is capable of absorbing an electrolyte uniformly, it greatly improves performance of a battery when being used for an electrochemical device. In addition, owing to excellent mechanical strength and good binding capacity to an electrode, it helps to increase a process rate for manufacturing the battery.

Owner:NANOPHIL

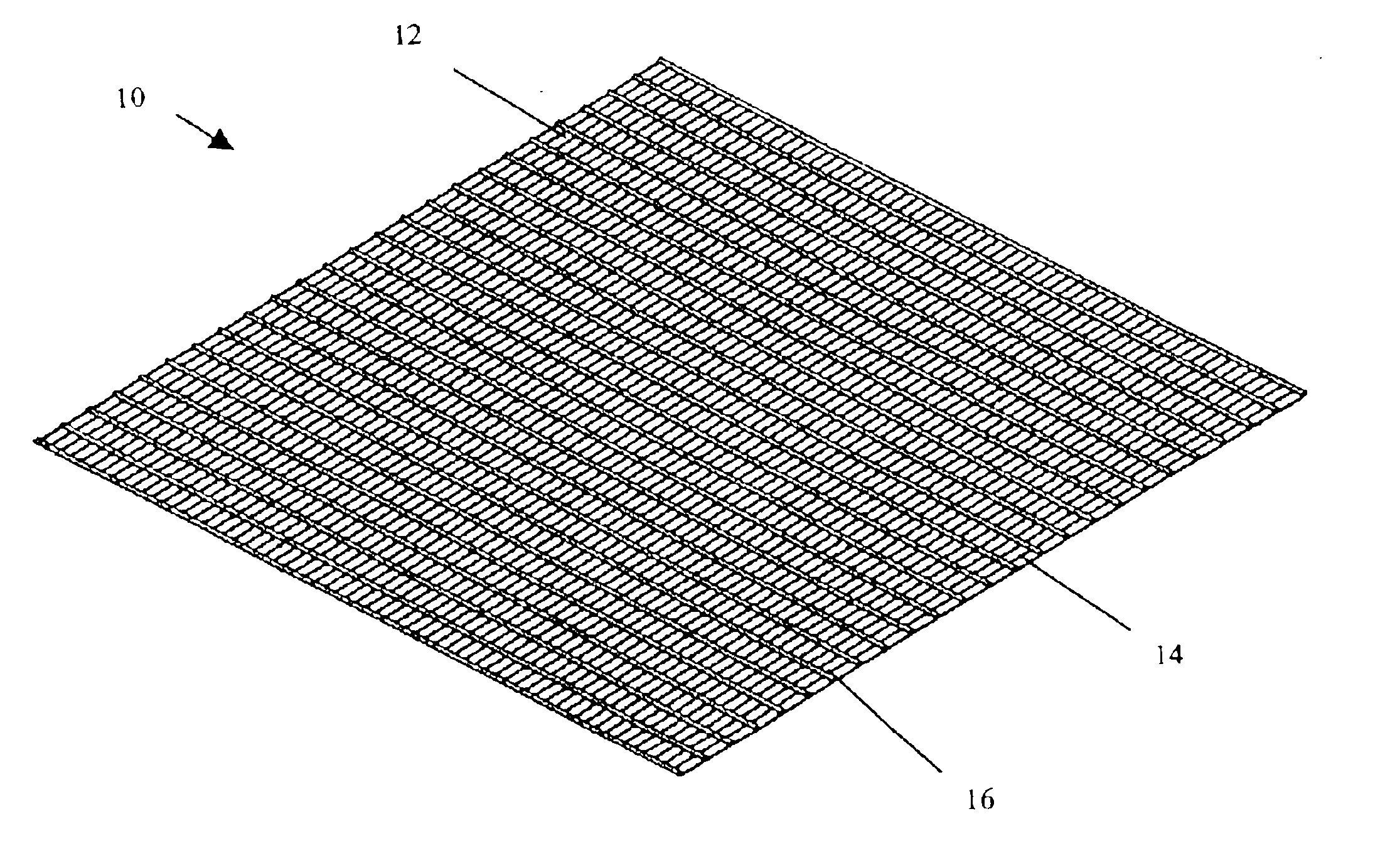

Multilayer composite films and articles prepared therefrom

InactiveUS20060165929A1Improve physical propertiesGood physical propertiesBottlesVehicle componentsElectrical and Electronics engineeringComposite film

Owner:PERFORMANCE MATERIALS NA INC

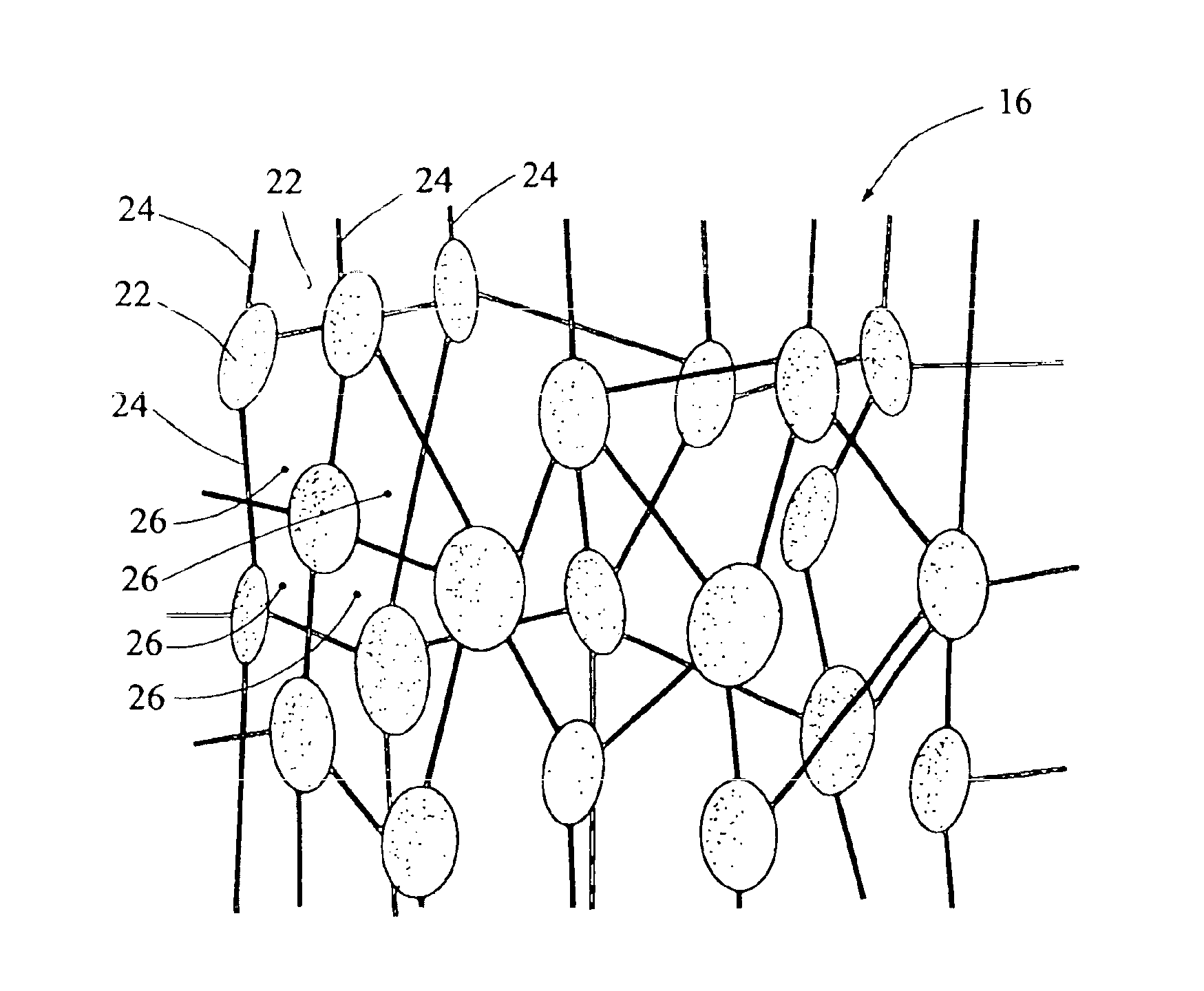

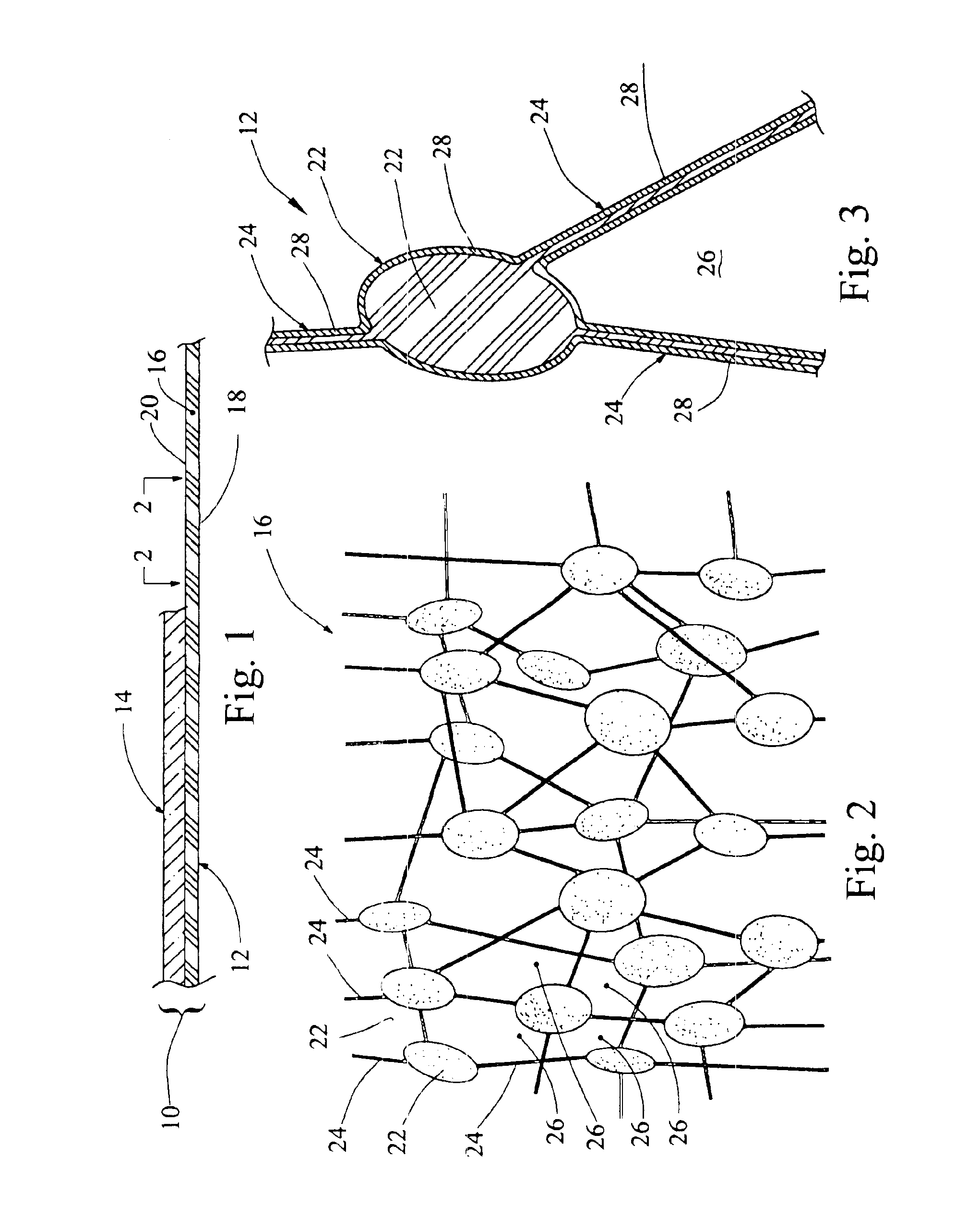

Porous membrane structure and method

A method of treating a membrane comprises the steps of providing a membrane with surfaces that define a plurality of pores extending through the membrane. Providing a dispersion of oleophobic fluoropolymer solids. Stabilizing the dispersion with a stabilizing agent. Diluting the dispersion with a wetting agent. Wetting surfaces which define the pores in the membrane with the diluted and stabilized dispersion. Removing the wetting agent and the stabilizing agent from the membrane. Coalescing the oleophobic fluoropolymer solids of the dispersion on surfaces that define pores in the membrane. A composite membrane comprises a porous membrane having a plurality of interconnecting pores extending through the membrane and made from a material which tends to absorb oils and certain contaminating surfactants. A coating is disposed on surfaces of the nodes and fibrils defining the interconnecting passages in the membrane. The coating comprises oleophobic fluoropolymer solids coalesced on surfaces of the nodes and fibrils to provide oil and surfactant resistance to the composite membrane without completely blocking pores in the membrane. The composite membrane is gas permeable, liquid penetration resistant and capable of moisture vapor transmission at a rate of at least 70,000 gr / m2 day.

Owner:BHA ALTAIR

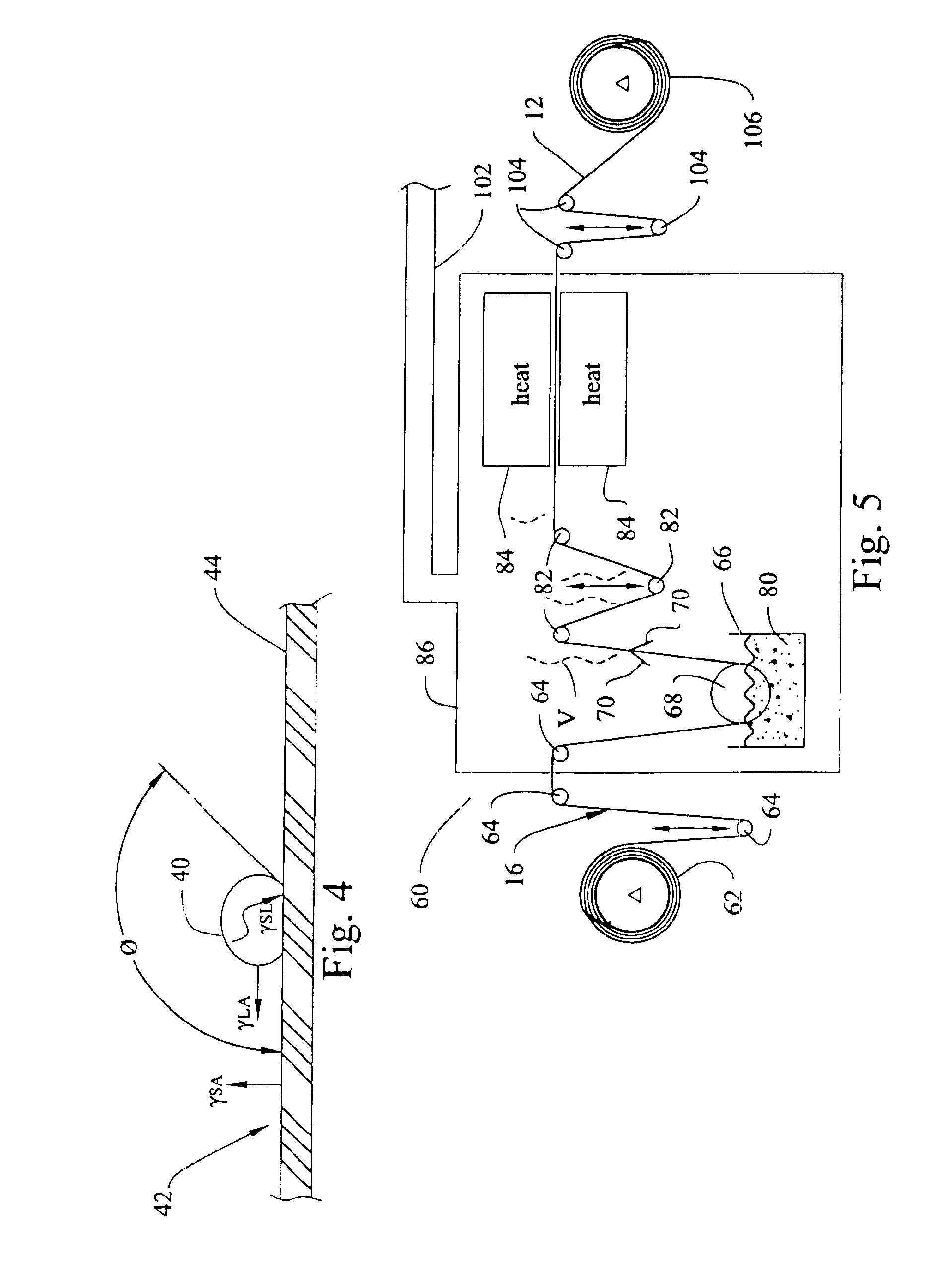

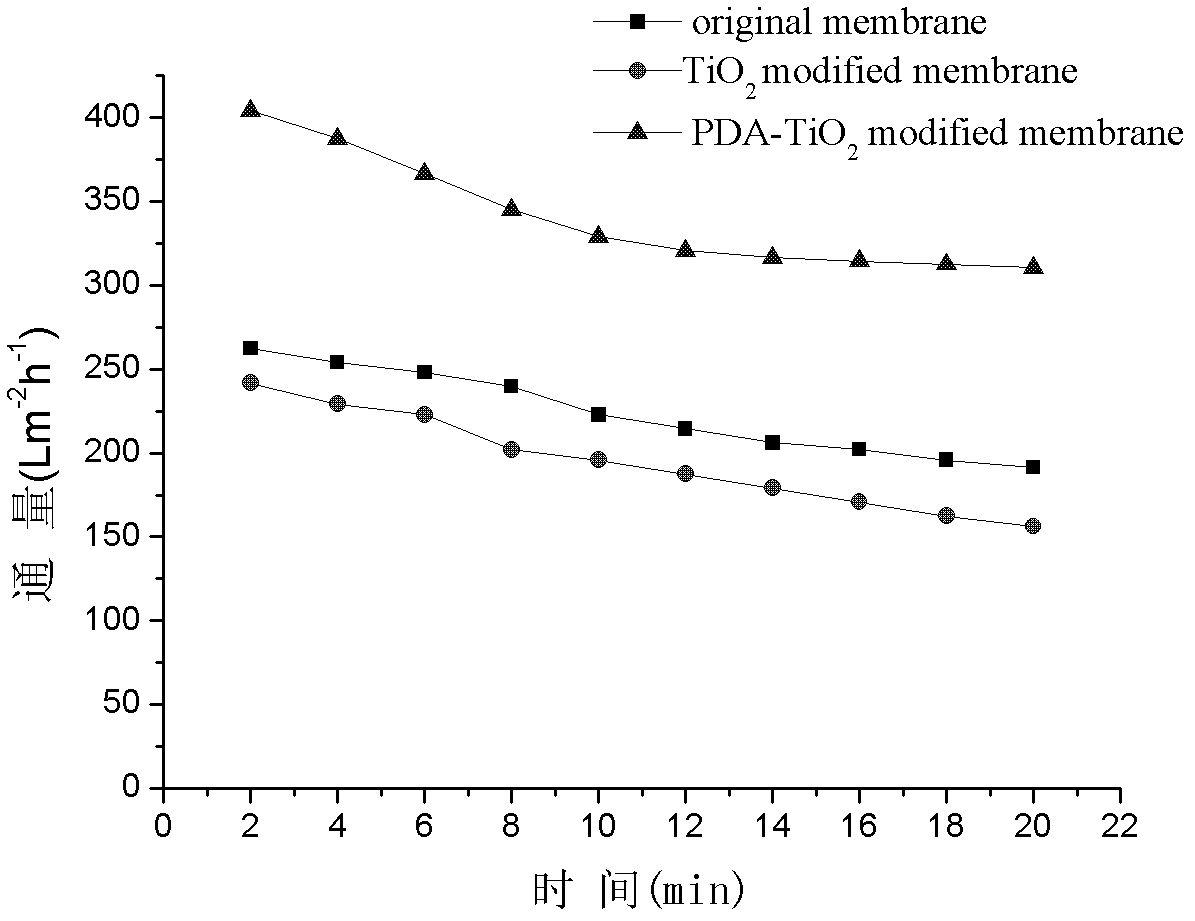

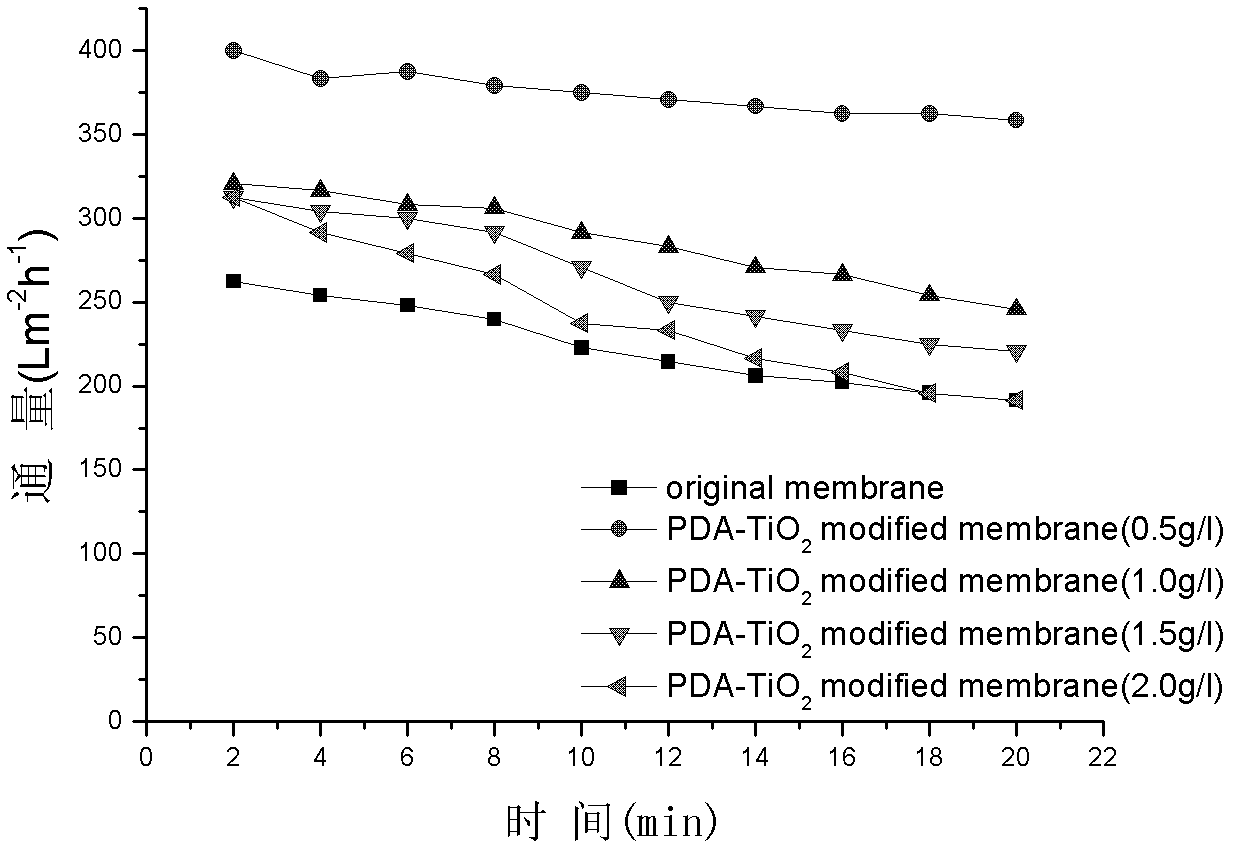

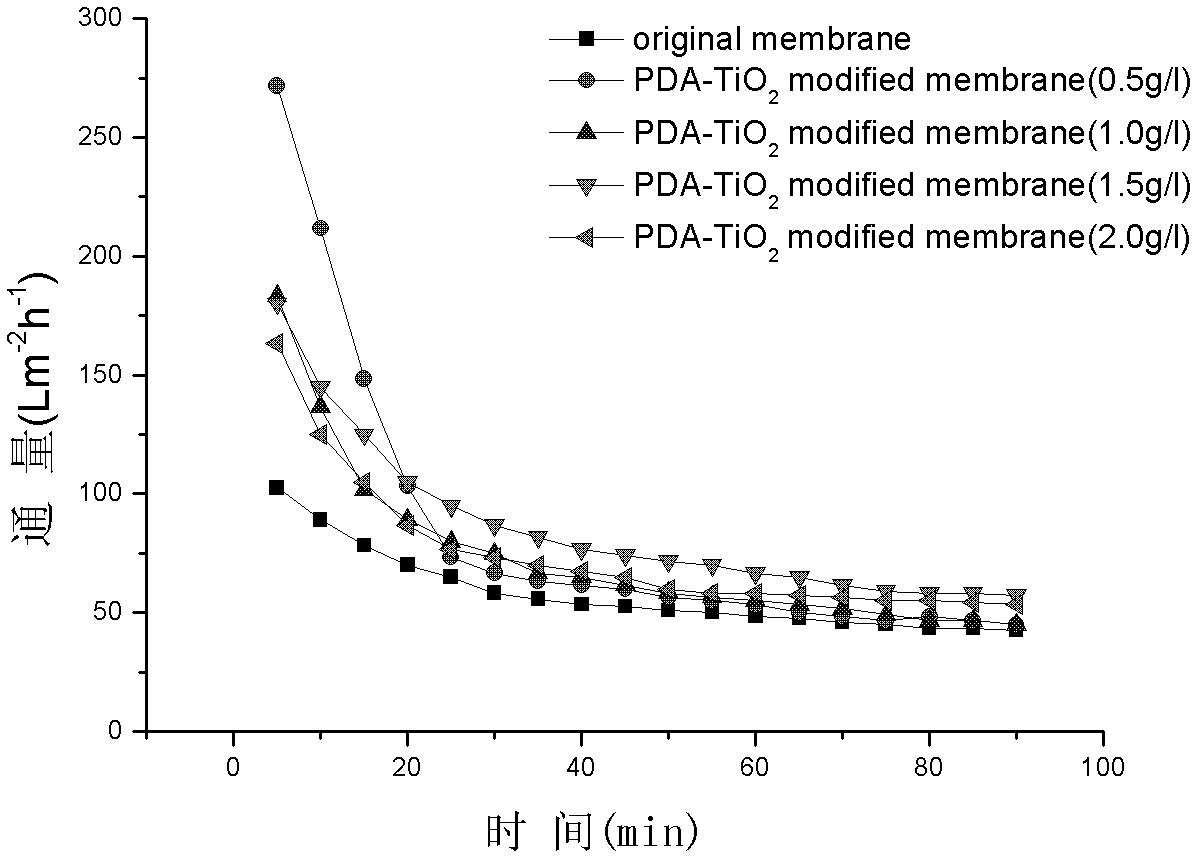

Method for preparing high-flux composite membrane from dopamine-modified nanometer material

InactiveCN102614783AImprove hydrophilicityImprove pollutionSemi-permeable membranesPigment treatment with macromolecular organic compoundsOrganic solventHigh flux

The invention relates to a method for preparing a high-flux composite membrane from a dopamine-modified nanometer material and belongs to the technical field of modification of membrane materials. The method is characterized by comprising the following steps of: forming an active poly-dopamine composite layer on the surfaces of titanium dioxide nanometer grains by utilizing automatic polymerization of dopamine, selecting different concentrations of dopamine-modified titanium dioxide grains, and adding the modified nanometer grains utilized as additives into a membrane casting solution, in which the mass fraction of PVDF (Polyvinylidene Fluoride) is 13% and the mass fraction of PVP (Polyvinyl Pyrrolidone) is 4%, so as to bend and modify according to different proportions, thus obtaining a composite membrane prepared from dopamine-modified nanometer titanium dioxide. The method for preparing the high-flux composite membrane from the dopamine-modified nanometer material, disclosed by the invention, has the advantages that dopamine-modified titanium dioxide can be greatly dispersed in an organic solvent to form a uniform dispersed phase; the additive can be used for effectively improving the hydrophilcity and anti-pollution capability of the high-flux composite membrane; and the dopamine modification method is simple, the condition is gentle, the flux of the prepared membrane is large and the anti-pollution capability is strong.

Owner:DALIAN UNIV OF TECH

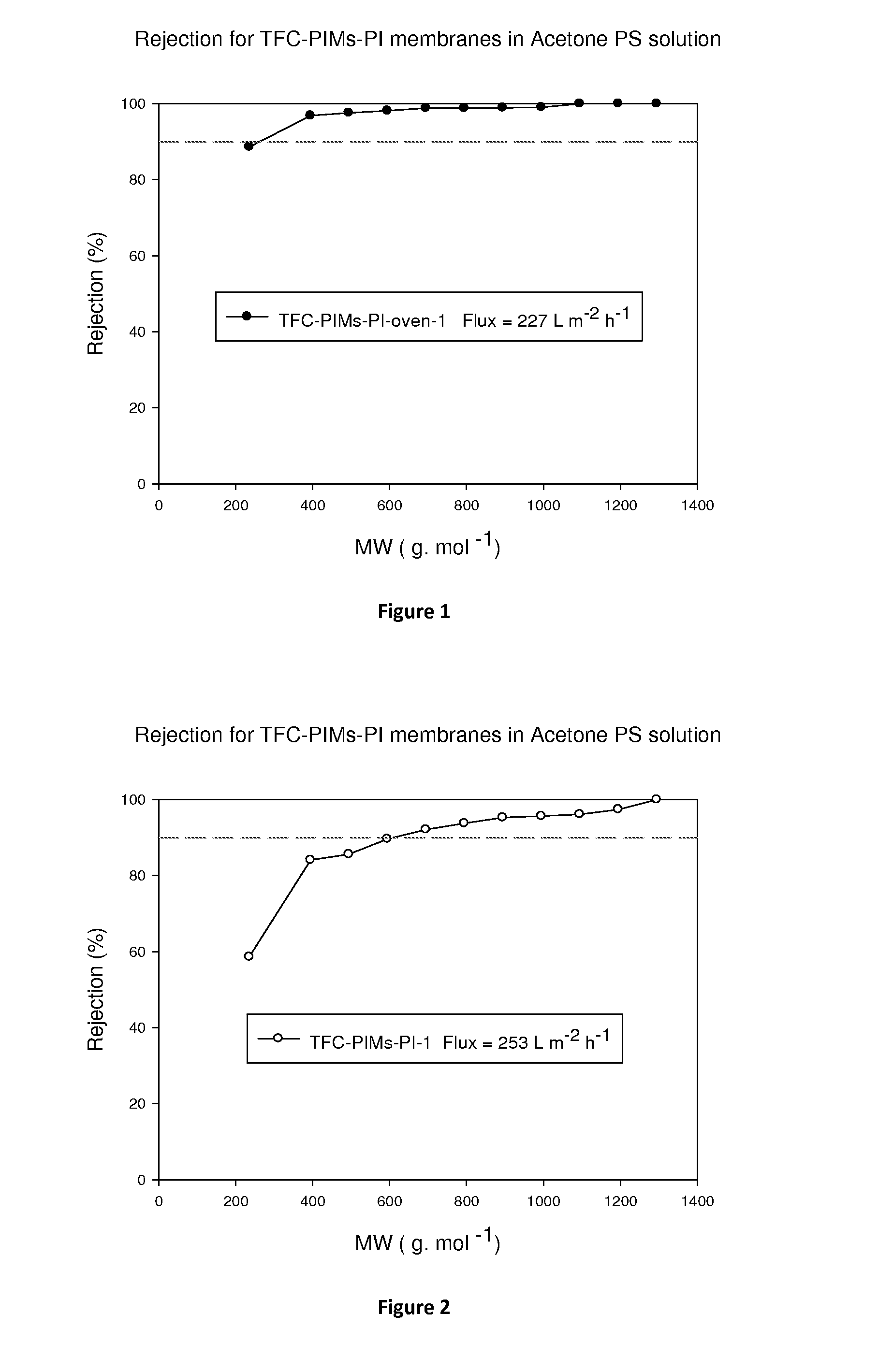

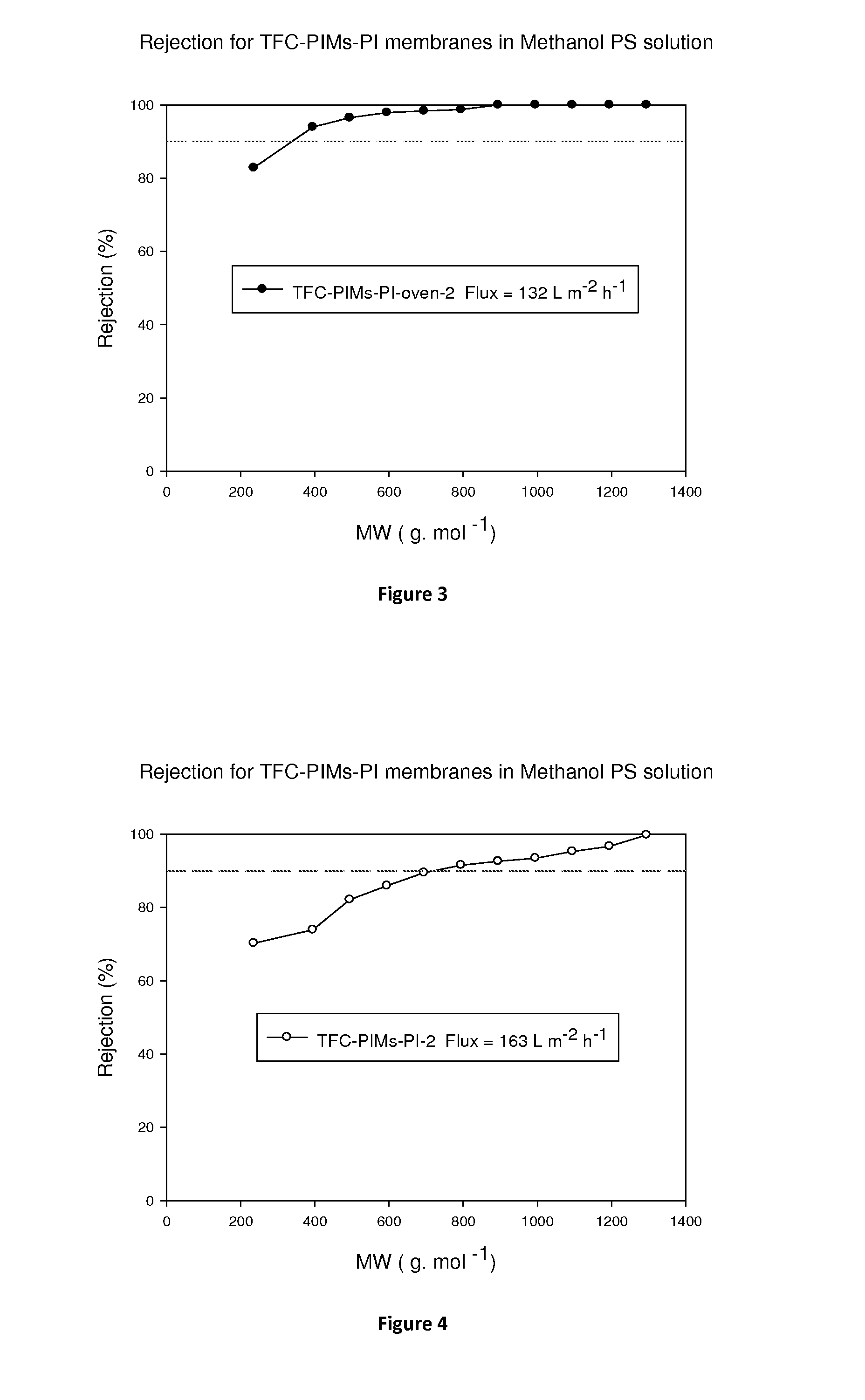

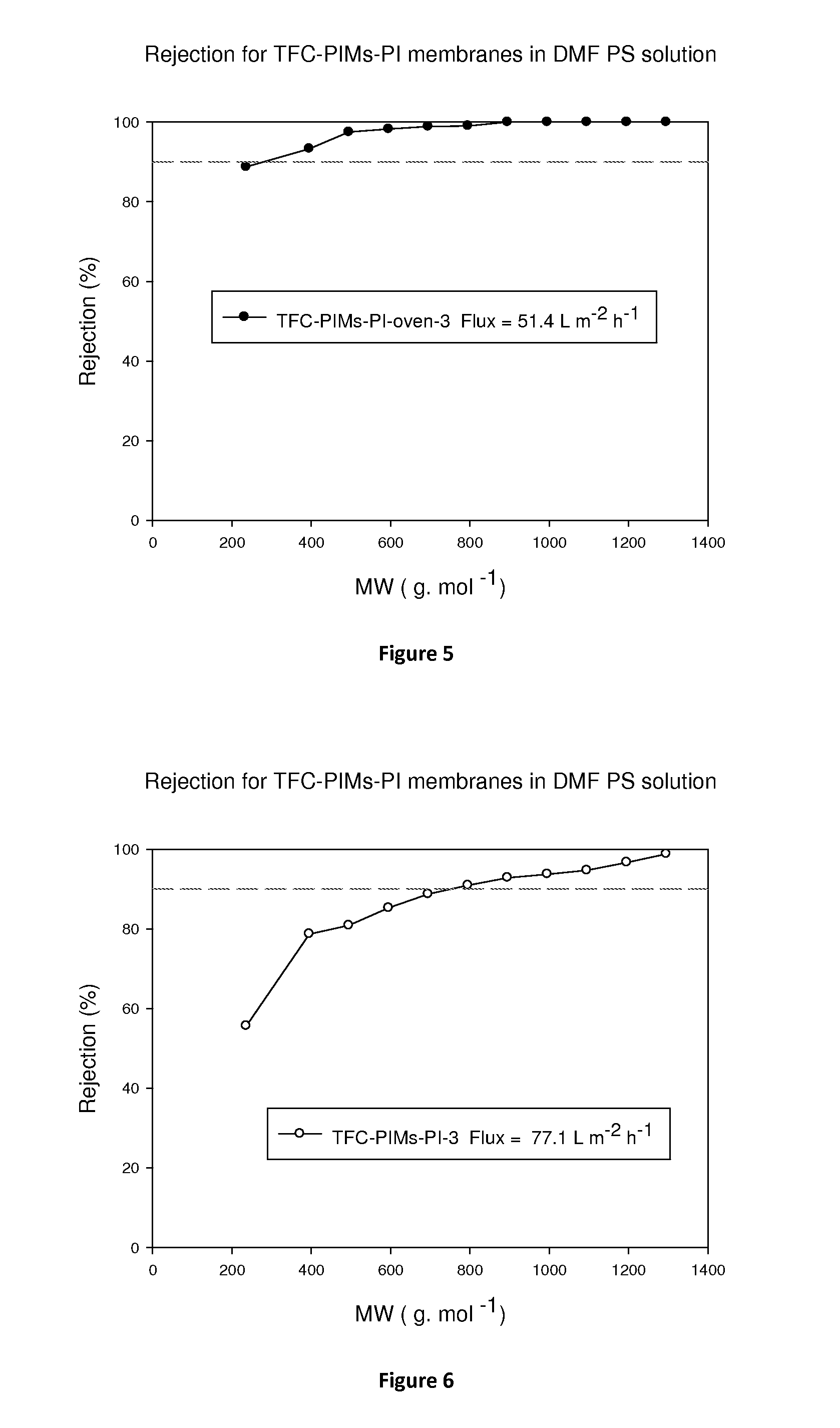

Membranes for separation

ActiveUS20140251897A1Stable in organic solventControl freedomSemi-permeable membranesMembranesOrganic solventProtic solvent

The present invention relates to a composite membrane for gas separation and / or nanofiltration of a feed stream solution comprising a solvent and dissolved solutes and showing preferential rejection of the solutes. The composite membrane comprises a separating layer with intrinsic microporosity. The separating layer is suitably formed by interfacial polymerisation on a support membrane. Suitably, at least one of the monomers used in the interfacial polymerisation reaction should possess concavity, resulting in a network polymer with interconnected nanopores and a membrane with enhanced permeability. The support membrane may be optionally impregnated with a conditioning agent and may be optionally stable in organic solvents, particularly in polar aprotic solvents. The top layer of the composite membrane is optionally capped with functional groups to change the surface chemistry. The composite membrane may be cured in the oven to enhance rejection. Finally, the composite membrane may be treated with an activating solvent prior to nanofiltration.

Owner:IP2IPO INNOVATIONS LTD

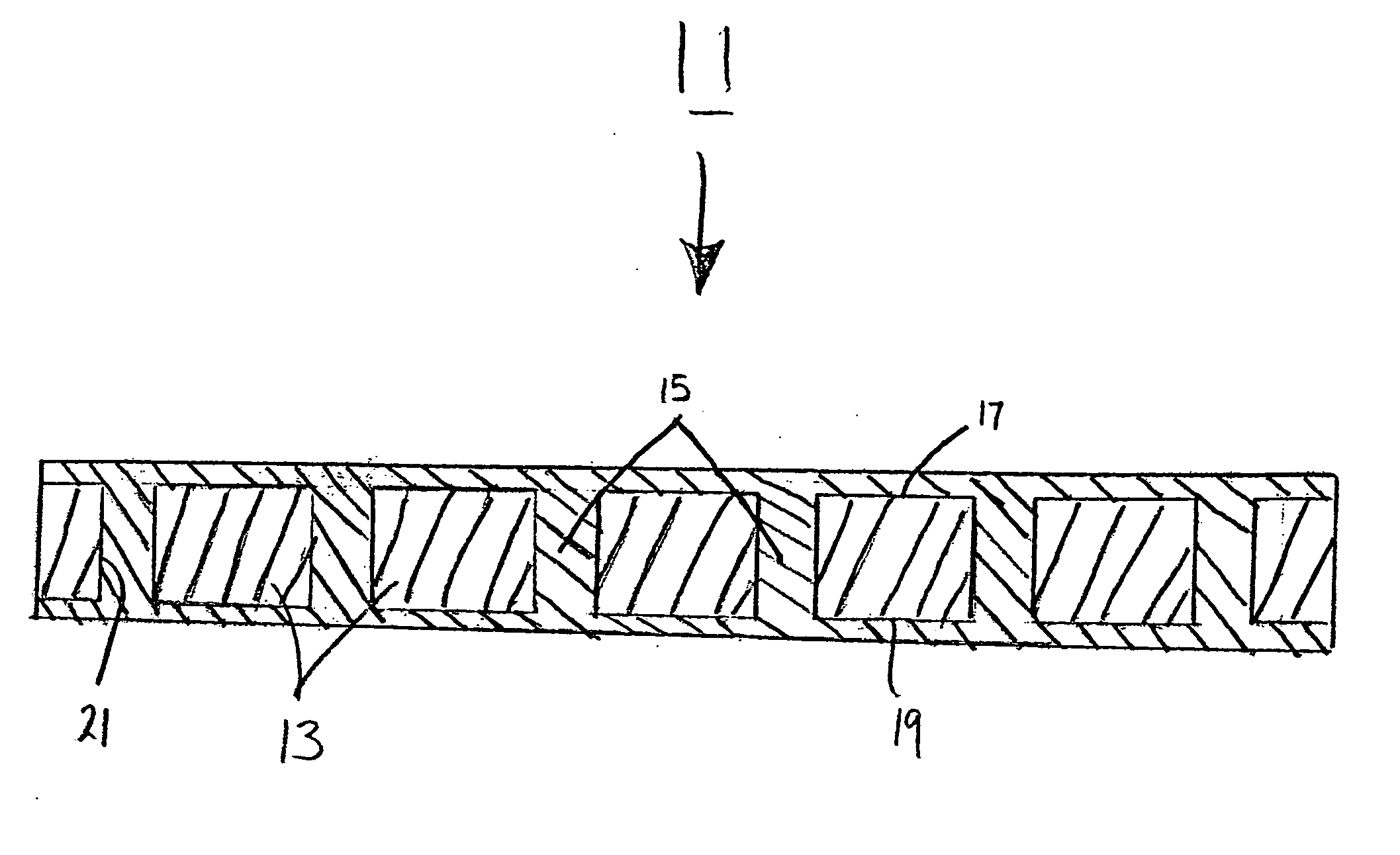

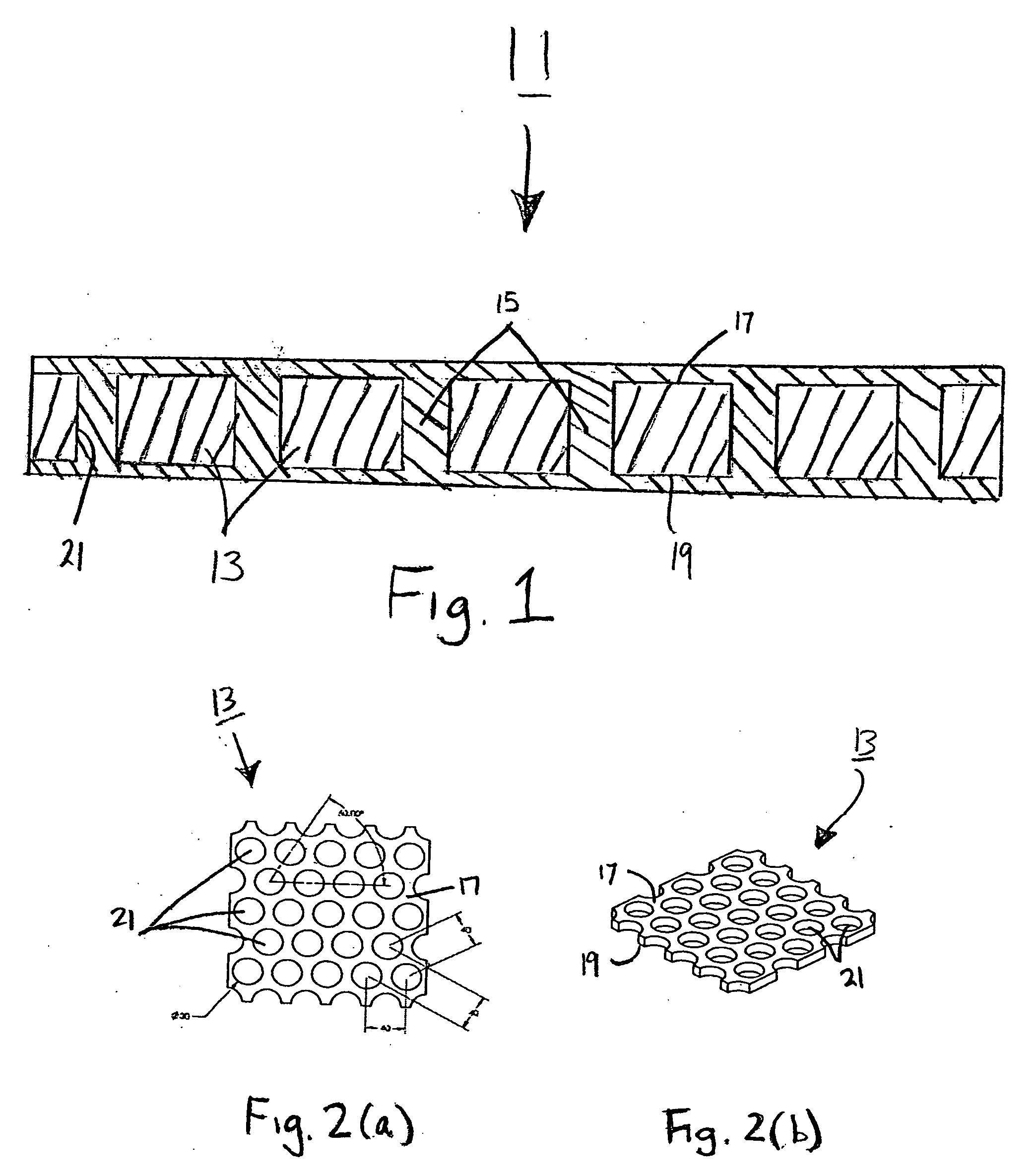

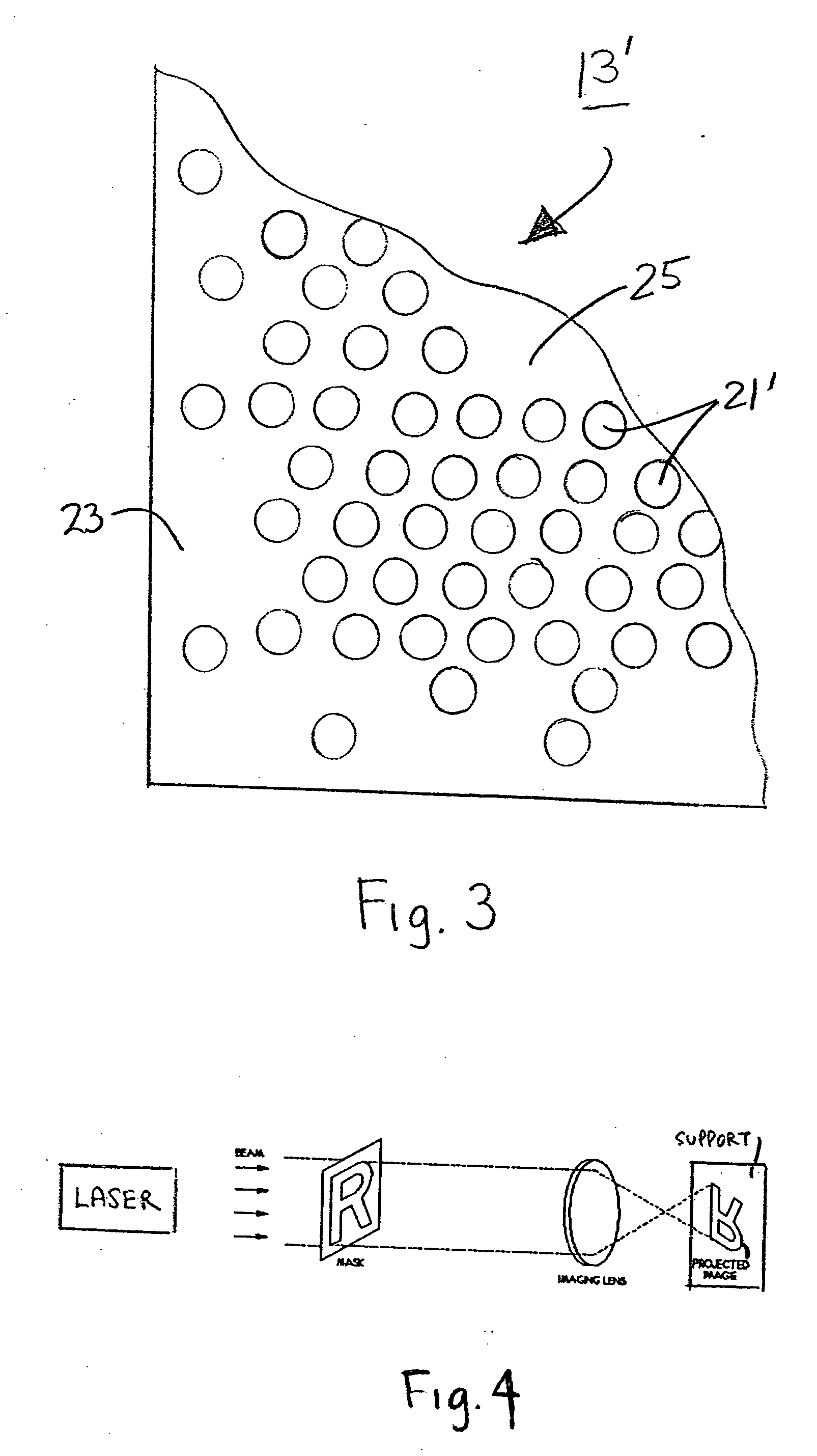

Solid polymer electrolyte composite membrane comprising porous ceramic support

ActiveUS20060183011A1Electrolysis componentsElectrolytic capacitorsPolymer electrolytesIn situ polymerization

A solid polymer electrolyte composite membrane and method of manufacturing the same. The composite membrane comprises a porous ceramic support having a top surface and a bottom surface. The porous ceramic support may be formed by laser micromachining a ceramic sheet or may be formed by electrochemically oxidizing a sheet of the base metal. A solid polymer electrolyte fills the pores of the ceramic support and preferably also covers the top and bottom surfaces of the support. Application of the solid polymer electrolyte to the porous support may take place by applying a dispersion to the support followed by a drying off of the solvent, by hot extrusion of the solid polymer electrolyte (or by hot extrusion of a precursor of the solid polymer electrolyte followed by in-situ conversion of the precursor to the solid polymer electrolyte) or by in-situ polymerization of a corresponding monomer of the solid polymer electrolyte.

Owner:PLUG POWER

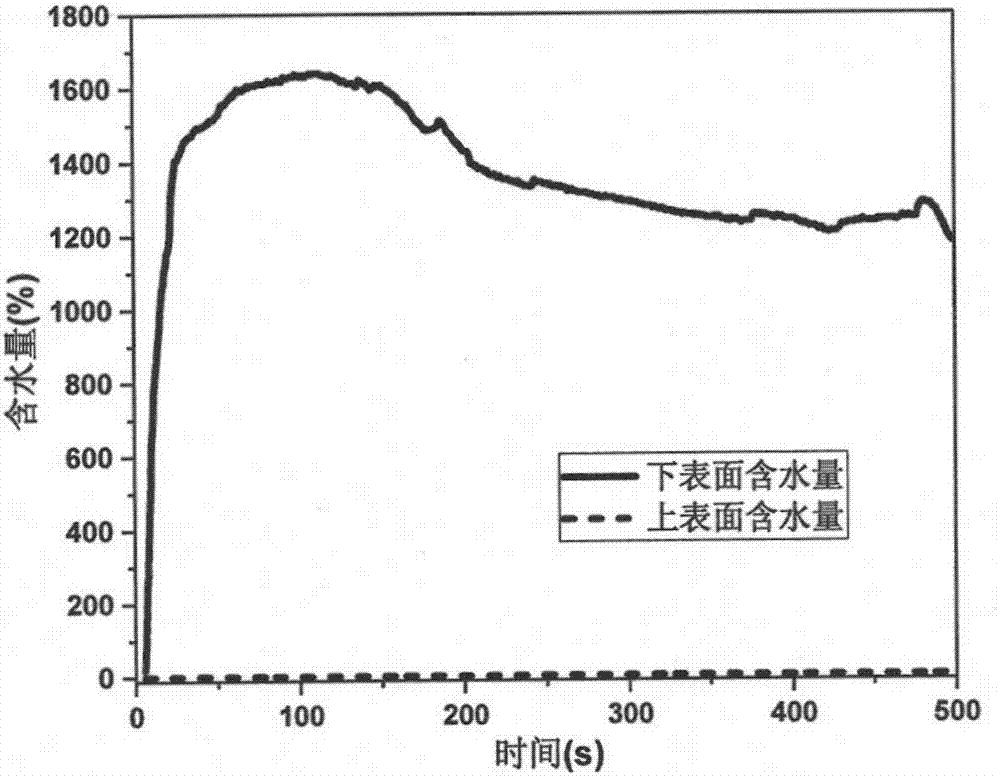

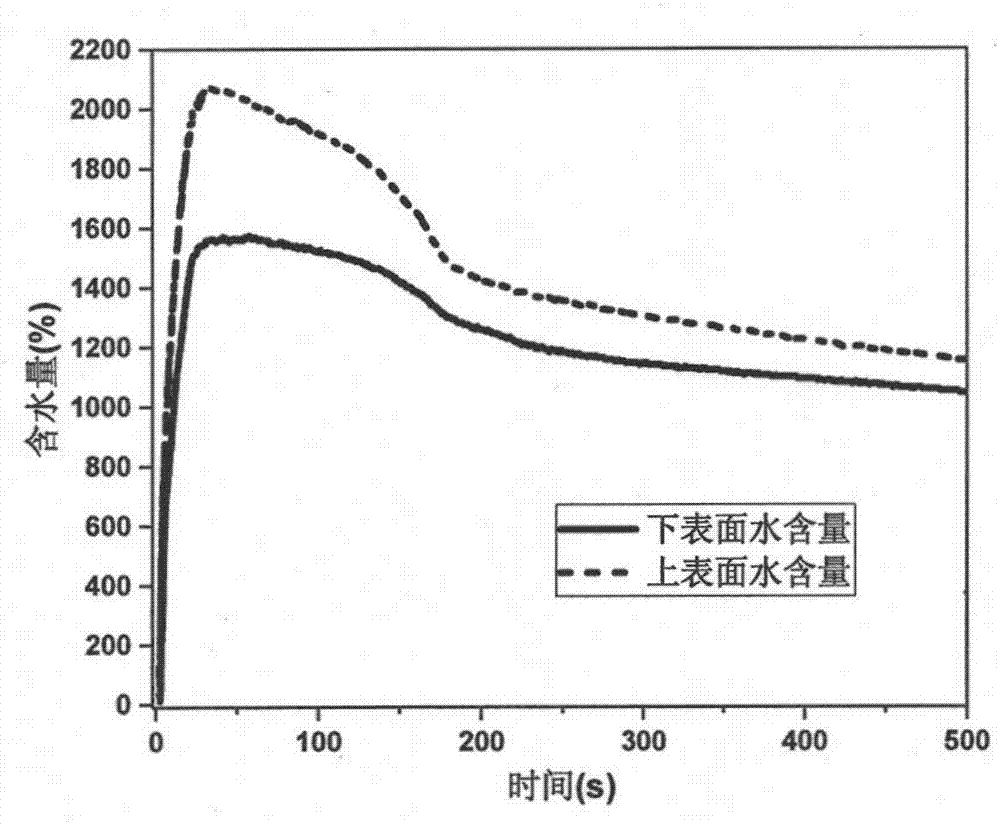

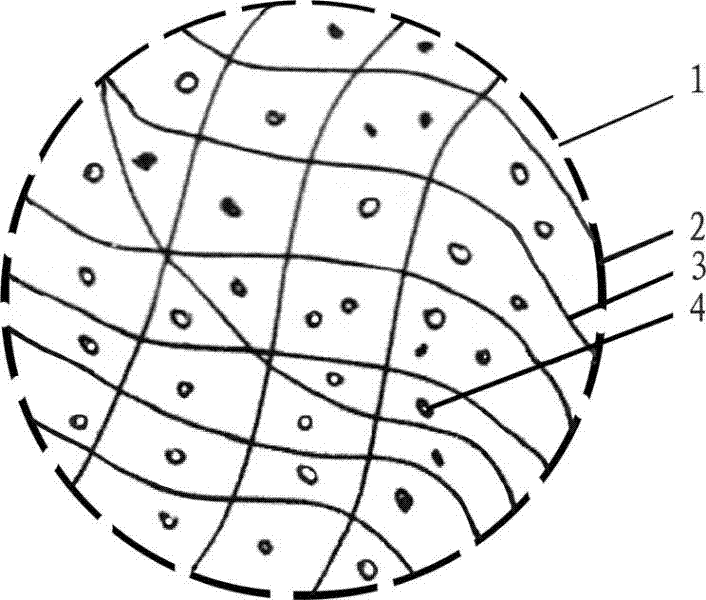

Preparation method of one-way wet conduction nano-fiber multilayer composite membrane with wettability gradient

InactiveCN107059251AExcellent unidirectional moisture transfer performanceWaterproofNon-woven fabricsFiberHydrophobic polymer

The invention discloses a preparation method of a one-way wet conduction nano-fiber multilayer composite membrane with the wettability gradient. The method comprises the following steps that hydrophilic nano materials are dispersed in solvent, the nano materials are dispersed uniformly through ultrasound, a hydrophilic polymer is dissolved in the dispersing agent, a spinning solution A1 is obtained, and a hydrophilic nano-fiber membrane is deposited on a receiving base material through an electrostatic spinning method; hydrophilic nano materials are dispersed in solvent, the nano materials are dispersed uniformly through the ultrasound, a hydrophilic polymer is dissolved in the dispersing agent, and a spinning solution A2 is obtained; a hydrophobic polymer is dissolved in solvent, and a spinning solution B1 is obtained; the two spinning solutions are deposited on the hydrophilic nano-fiber membrane to form at least one diversion layer through the electrostatic spinning method; a hydrophobic polymer is dissolved in solvent, a spinning solution B2 is obtained, a hydrophobic nano-fiber membrane is deposited on the diversion layers through the electrostatic spinning method, and the one-way wet conduction nano-fiber multilayer composite membrane with the wettability gradient is obtained.

Owner:DONGHUA UNIV

Controlled releasing microcapsule for scale prevention, wax prevention or viscosity reduction of oil well

InactiveCN102250604AAchieve slow releaseAchieve long-term effectiveDrilling compositionBorehole/well accessoriesPetrochemicalComponents of crude oil

The invention relates to the technical field of petrochemical engineering, in particular to a controlled releasing microcapsule for scale prevention, wax prevention or viscosity reduction of an oil well. The invention discloses a solid controlled releasing microcapsule for scale and corrosion prevention in the production process of crude oil and wax prevention or viscosity reduction in the production process of the crude oil as well as a preparation method thereof. Filler comprising an inorganic framework and agent components is arranged in a macromolecule composite membrane. The controlled releasing microcapsule has a stable structure comprising an inside inorganic framework support and an outer-layer macromolecular composite membrane wrapping film, can be used for realizing the slow release of the agent and achieving the aim of maintaining the agent effective for a long term as well as the functions of corrosion inhibition and dispersion. With proper volume and density, the controlled releasing microcapsule can be prevented from being taken away by an extraction solution and can be added through a sleeve; and the controlled releasing microcapsule is simple in process and is strong in maneuverability. According to the controlled releasing microcapsule, volatile matters and harmful components which do harm to the human health are avoided; various components can be basically and slowly dissolved; the labor intensity of workers is reduced; and one-time agent addition can ensure stable operation for 30-90 days.

Owner:门正国

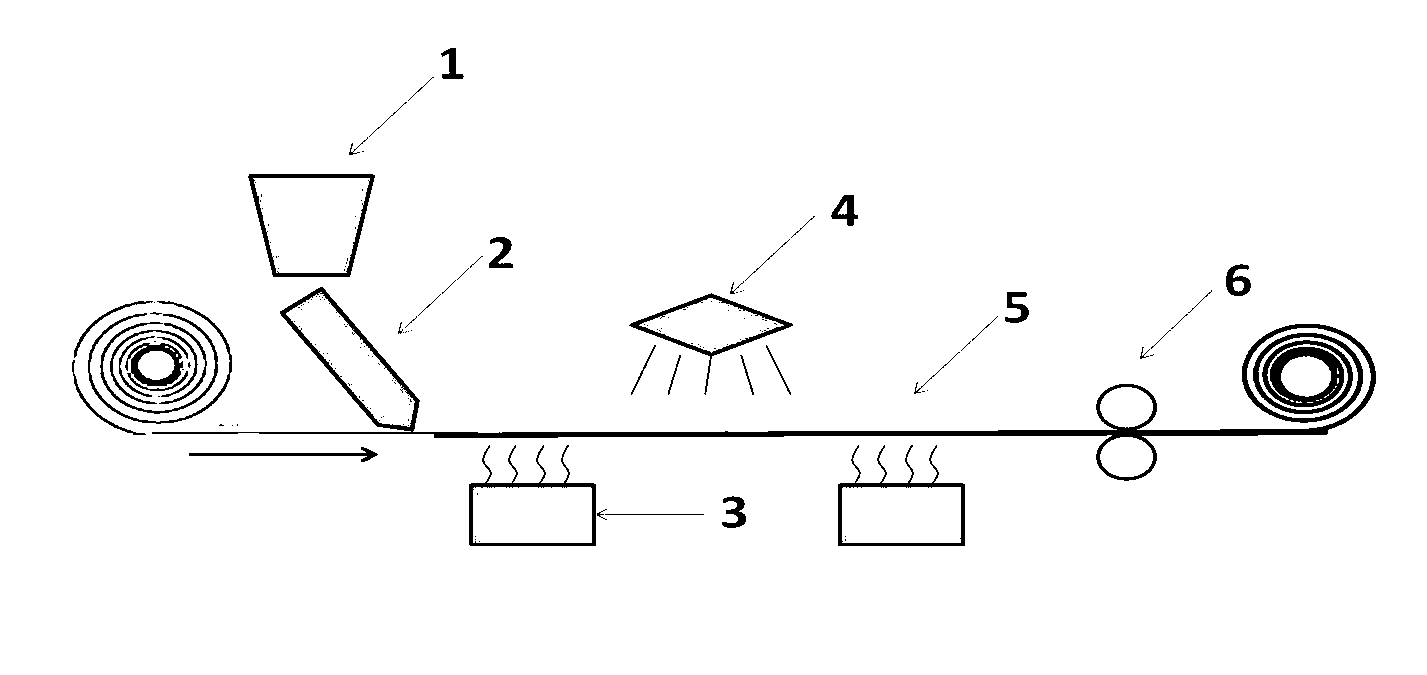

Composite filter membrane with multidimensional pore structure and preparation method thereof

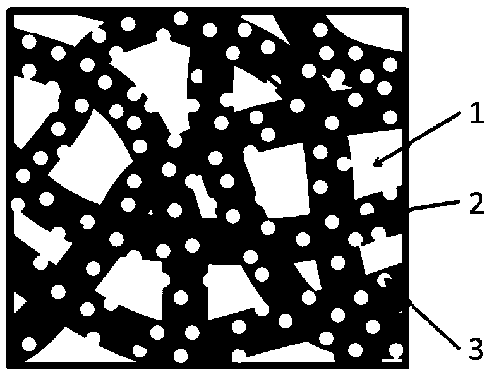

ActiveCN103894077APotential for industrial production application promotionEffective filteringSemi-permeable membranesFiberElectrospinning

The invention provides a composite filter membrane with a multidimensional pore structure and a preparation method thereof. The composite filter membrane comprises nonwoven base cloth and a porous composite nanofiber layer, wherein the nonwoven base cloth and the porous composite nanofiber layer are composited in a manner of hot rolling, and the porous composite nanofiber layer is prepared from a polymer and an additive. The preparation method comprises the following steps: adding the additive into a spinning solution solvent, carrying out ultrasonic treatment to achieve homodisperse, then adding the polymer, and stirring at room temperature until the solution is clear and transparent. A multiple-nozzle electrostatic spinning device is used for electrostatic spinning, and the obtained porous composite nanofibers are directly deposited on the surface of the nonwoven cloth and are composited through a subsequent hot rolling device. The composite filter membrane combines the advantages of common filter materials and nanofiber filter materials, has a good filtering effect, a simple production process and low production cost and is easy to realize large scale production.

Owner:JIANGNAN UNIV

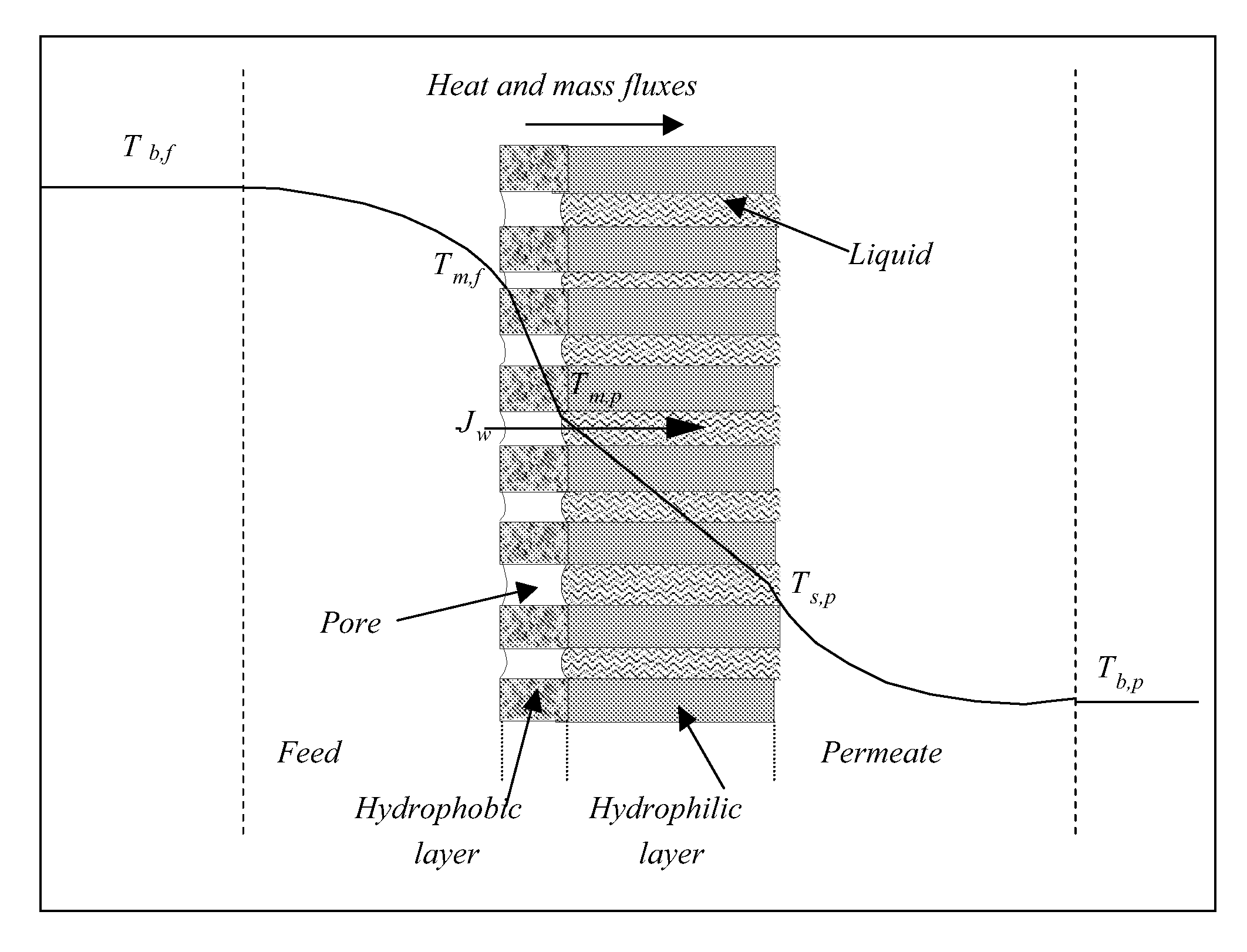

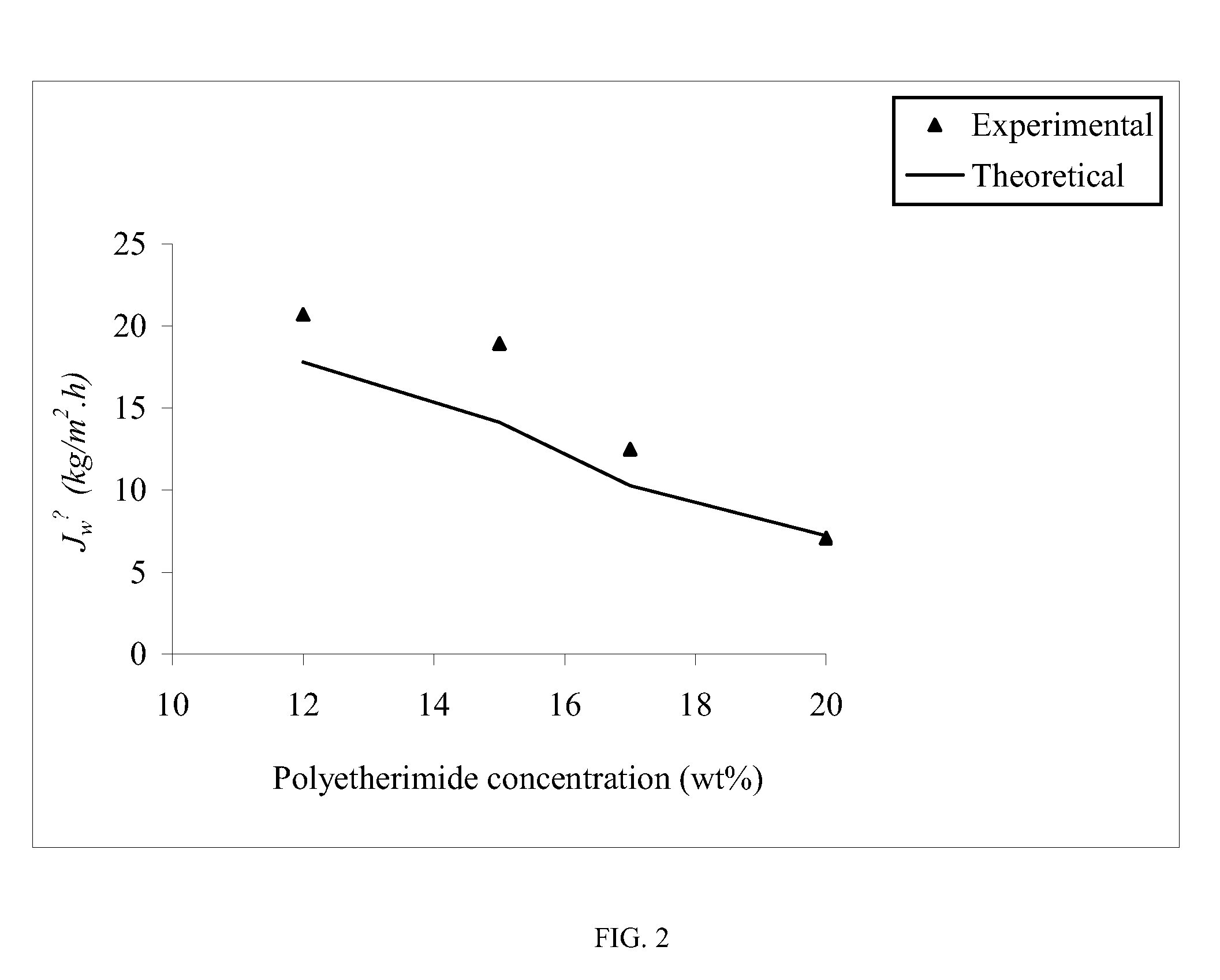

Composite membranes for membrane distillation and related methods of manufacture

ActiveUS20110031100A1Maximizing porosityThickness minimizationMembranesVacuum distillation separationPolymer scienceHydrophilic polymers

The present invention provides composite membranes for membrane distillation and related methods of manufacture. In particular, there is provided a composite hydrophilic / hydrophobic membrane comprising a hydrophilic polymer layer and a hydrophobic polymer layer comprising fluorinated surface-modifying macromolecules, wherein said composite membrane has a high vapour flux. Also provided herein are methods of manufacturing and optimizing the composite membranes and a membrane distillation system comprising the composite membranes.

Owner:MEMBRANE DISTILLATION DESALINATION LTD

Pervaporation composite membranes

The present application discloses a composite membrane comprising (a) a support member that has a plurality of pores extending through the support member and (b) a cross-linked copolymer comprising (i) a cationic monomer and an anionic monomer and / or (ii) a zwitterionic monomer, which cross-linked copolymer fills the pores of the support member, the cross-linked copolymer having a permeability for a fluid that is dependent on the polarity of the fluid, wherein the permeability increases with increasing polarity. The present application also discloses a process for the preparation of the composite membrane, a pervaporation apparatus comprising the composite membrane, and methods for the use of the composite material in separation and dehydration processes.

Owner:MCMASTER UNIV

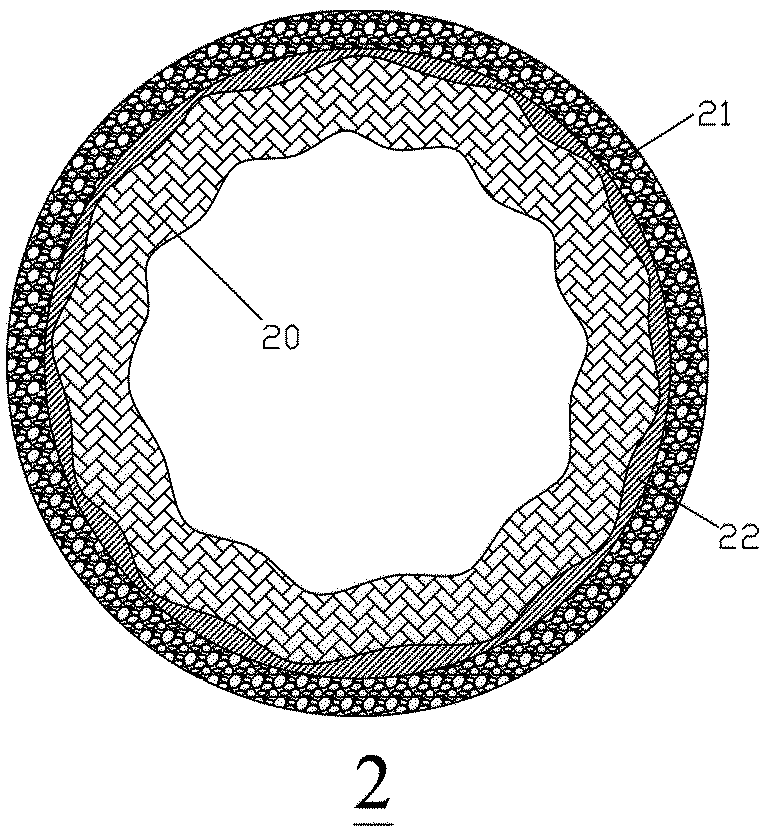

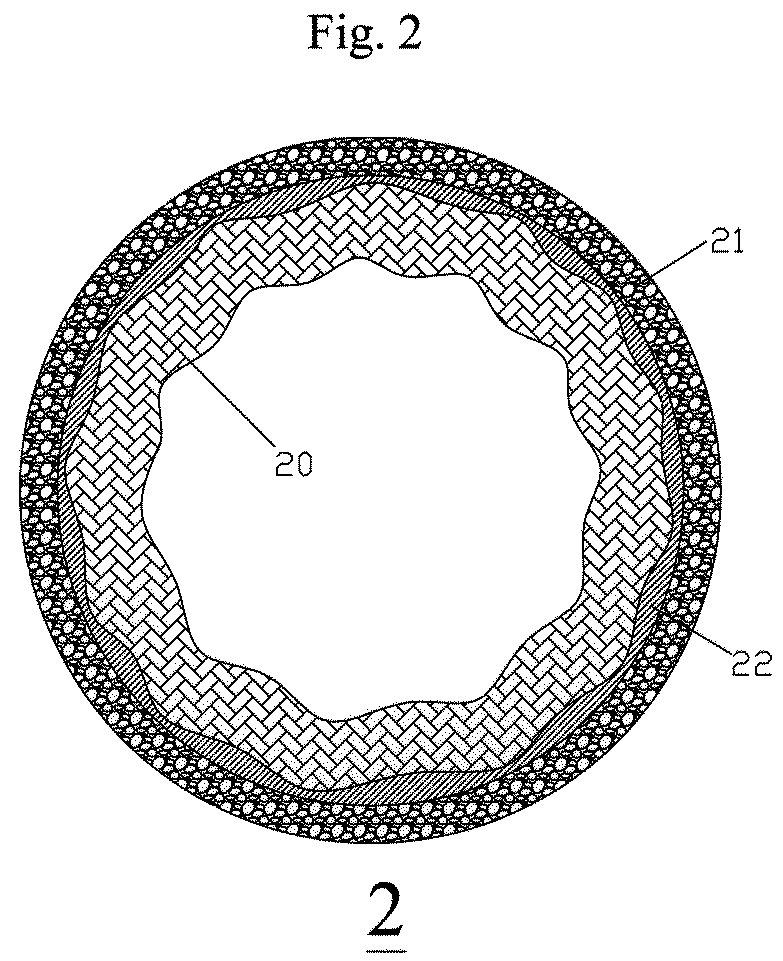

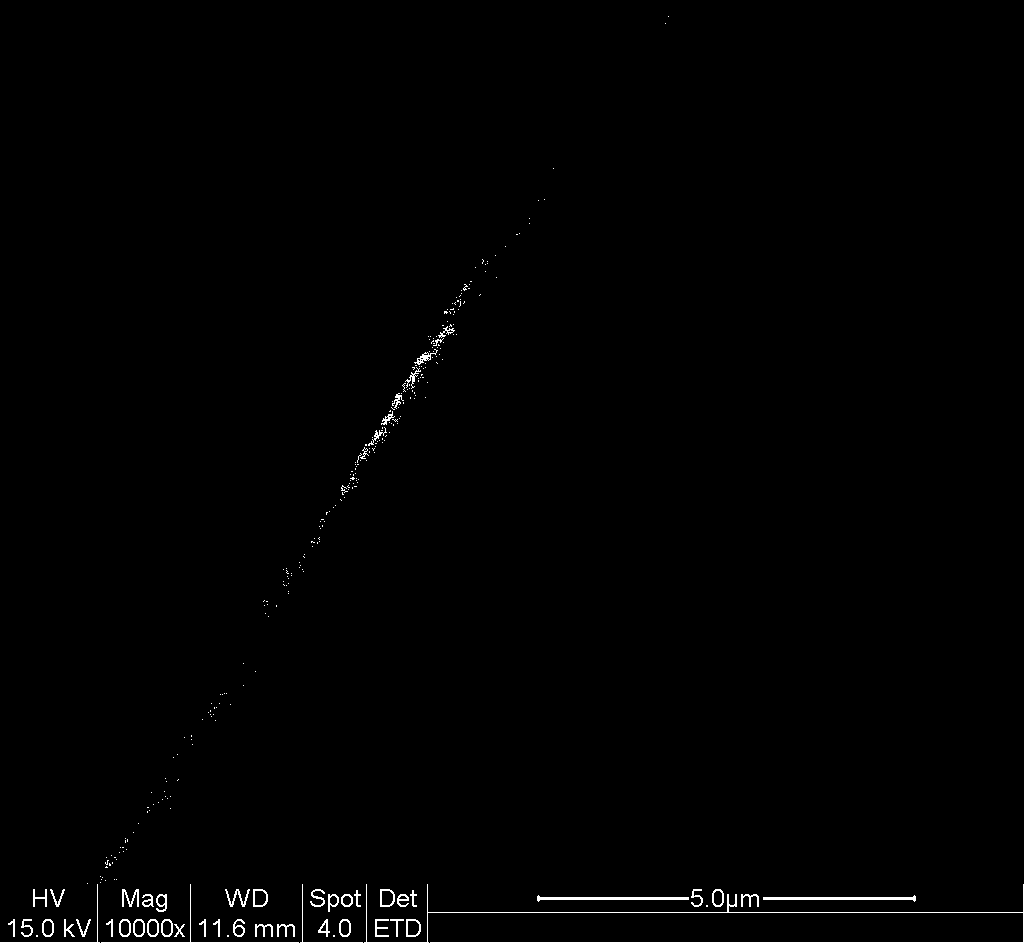

Enhanced graphene oxide hollow fiber composite membrane and preparation method thereof

ActiveCN102600734AImprove hydrophilic abilityImprove hydrophilicitySemi-permeable membranesFiberPolymer science

The invention relates to an enhanced graphene oxide hollow fiber composite membrane and a preparation method of the composite membrane. The composite membrane is characterized in that a supporting layer is a hollow pipe woven by polymer fibers, and a membrane separation layer on a surface is graphene oxide or a mixture of the graphene oxide and polymer resin; and the outer diameter of the hollow pipe woven by the polymer fibers is 1-4mm, and the inner diameter of the hollow pipe woven by the polymer fibers is 0.5-1mm; the thickness of the membrane separation layer is 0.01-1mm; and the membrane pore diameter of the enhanced graphene oxide hollow fiber composite membrane is 1-500nm. The preparation method comprises the following steps: dissolving the polymer resin, an organic additive, an inorganic additive and the graphene oxide into a organic solvent to prepare a membrane preparing solution; coating the membrane preparing solution onto the surface of the hollow pipe woven by the polymer fibers to obtain a blank body of a pre-fabricated composite membrane; and carrying out solidification and formation, rinsing and drying in the air to obtain the enhanced graphene oxide hollow fiber composite membrane. The prepared composite membrane is strong in hydrophilicity, and the water permeability of the composite membrane is greatly improved.

Owner:NANJING UNIV OF TECH

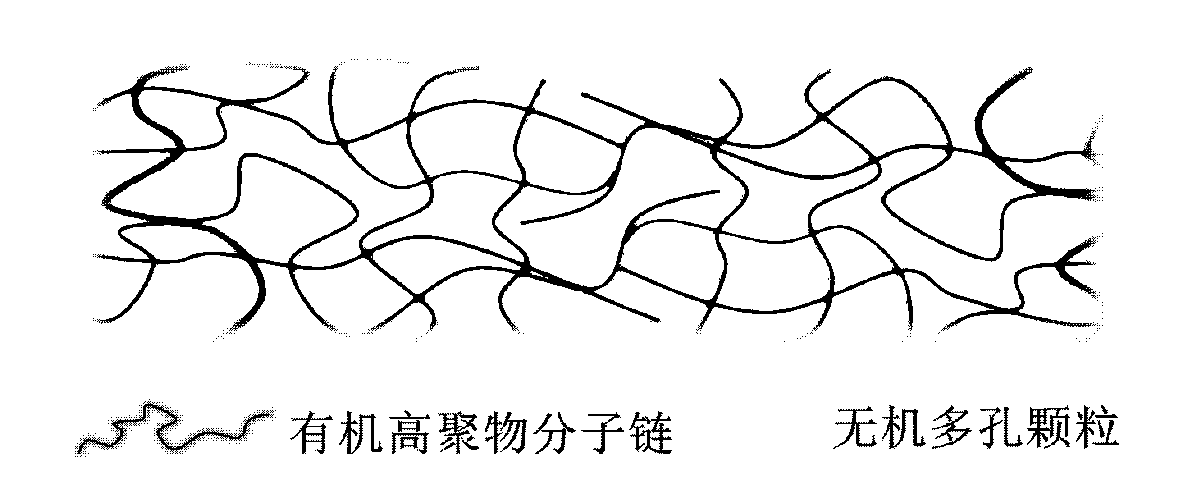

Organic-inorganic composite membrane as well as preparation and application thereof

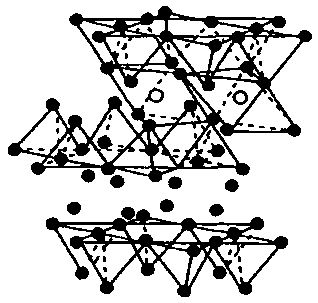

ActiveCN103311486AChange structureImprove thermal stabilityCell component detailsLithium-ion batteryMechanical property

The invention discloses an organic-inorganic composite membrane as well as preparation and application thereof, and belongs to the technical field of preparation of a lithium ion battery material. The organic-inorganic composite membrane is prepared from inorganic particles and a high-molecular polymer, wherein the inorganic particles are evenly embedded and distributed inside the high-molecular polymer, and are selected from layered inorganic materials and / or porous inorganic materials; the mass ratio of the inorganic particles to the high-molecular polymer is (5-20):1; the particle sizes of the inorganic particles are 2-100nm. The organic-inorganic composite membrane disclosed by the invention has good mechanical property and lithium ionic conduction ability after absorbing electrolyte; the composite membrane has excellent safety performance after being prepared into an electric element, and is suitable for being applied to the field of a large battery, especially a large fixation energy storage battery. The organic-inorganic composite membrane is simple and feasible in preparation technology, and conveniently achieves industrial production.

Owner:王海斌

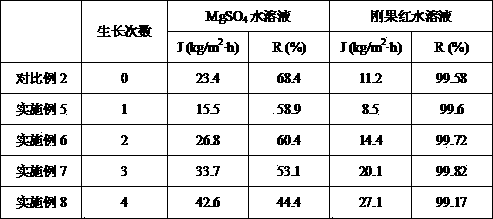

High-flux polyamide/ZIF-8 nanofiltration composite film and preparation method thereof

InactiveCN104209022ASolve the problem of fragmentationImprove permeabilitySemi-permeable membranesInorganic saltsPolymer science

The invention discloses a preparation method of a high-flux polyamide / ZIF-8 nanofiltration composite film. The preparation method comprises the following steps of (1) growing a ZIF-8 type metal-organic framework material on an ultrafiltration bottom film in situ; (2) preparing a polyamide skin layer on the bottom film with ZIF-8 particles through interfacial polymerization; and (3) post-treating a primary composite film to obtain the polyamide / ZIF-8 nanofiltration composite film. A dense skin layer of the nanofiltration film consists of ZIF-8 and polyamide; by virtue of single or multiple in-situ growth, the ZIF-8 particles grow on the surface of the bottom film, and the polyamide skin layer is formed through interfacial polymerization, and the ZIF-8 particles on the surface of the bottom film are embedded into the polyamide layer. By use of a ZIF-8 multi-hole structure and a nano-grade channel size, the nanofiltration separation performance of the polyamide film of the prepared polyamide / ZIF-8 nanofiltration composite film can be improved. On the basis of the in-situ growth method, the operation of firstly synthesizing ZIF-8 and then adding into film preparation liquid is eliminated, so that the film preparation technology is simple; the performance of the polyamide / ZIF-8 film prepared by in-situ growth for multiple times is high; when the nanofiltration composite film is used for separating an inorganic salt aqueous solution system, the permeation flux can be increased; when the nanofiltration composite film is used for separating a congo red aqueous solution, the permeation flux and the retention rate can be increased at the same time.

Owner:BEIJING FORESTRY UNIVERSITY

Composite membrane and method for making

InactiveUS20100167100A1Improve performanceImprove conductivitySemi-permeable membranesMembranesFuel cellsIon exchange

A composite membrane includes a compatibilized porous base membrane and an ion exchange material, which is impregnated into the compatibilized porous base membrane. The base membrane is compatibilized by coating a primer to external and internal surfaces of the porous base membrane and crosslinking the primer. A method for making the membrane, a proton exchange membrane for a fuel cell and a method form making the proton exchange membrane are also provided. The composite membrane is durable, compatible, highly conductive and mechanically stable.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com