Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3649results about How to "Good water permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite water permeable brick

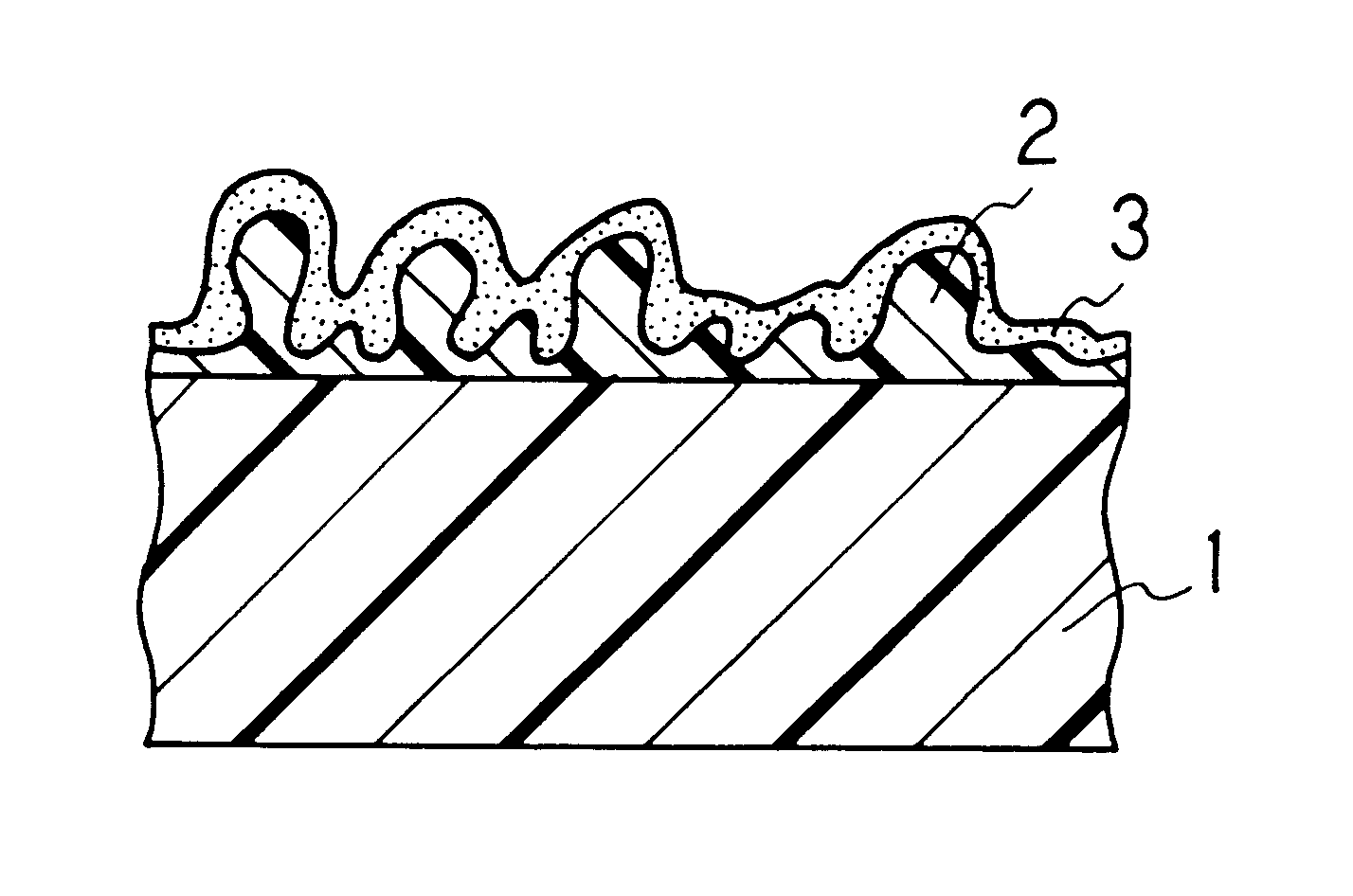

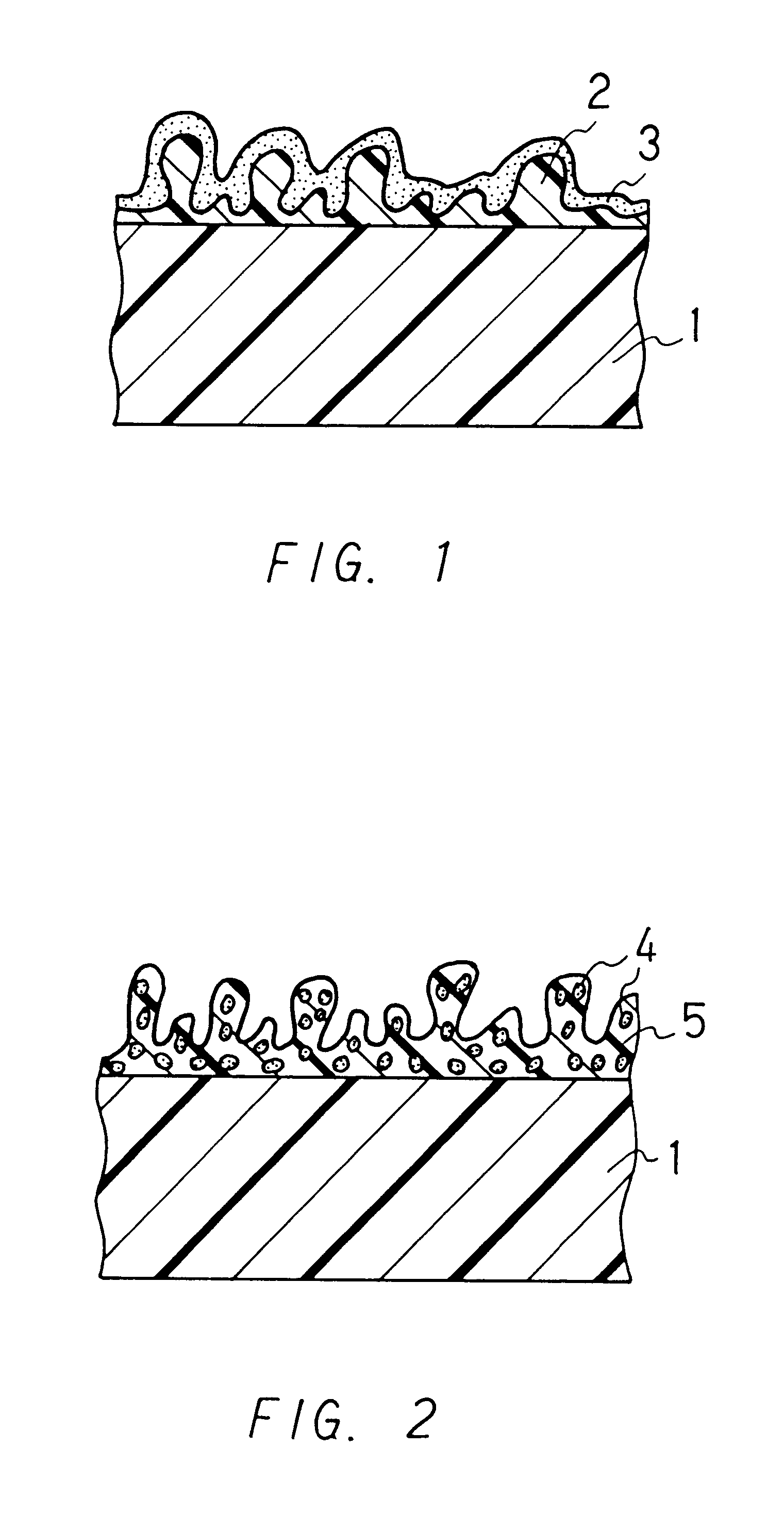

InactiveCN1966861AGood water permeabilityLow costSingle unit pavingsClimate change adaptationBrickAdhesive

A composite water permeable brick comprises water permeable surface and base closely combined together with aggregate and adhesive coating the aggregate, with the adhesive of the said water permeable surface including at least hydrophilicity adhesive. It can keep fine water permeability, with the brick surface fine and close and reduced in cost.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Composite reverse osmosis membrane having a separation layer with polyvinyl alcohol coating and method of reverse osmotic treatment of water using the same

InactiveUS6177011B1High Salt RejectionPermit practical desalinationGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisZeta potentialWater use

A reverse osmosis composite membrane that has a high salt rejection, a high water permeability, and a high fouling tolerance, and permits practical desalination at a relatively low pressure is provided by coating the surface of a reverse osmosis membrane of aromatic polyamide with polyvinyl alcohol (PVA), for example, and controlling the surface zeta potential of the separation layer within±10 mV at pH 6. This reverse osmosis composite membrane is electrically neutral and controls the electrical adsorption of membrane-fouling substances having a charge group present in water. Therefore, a high separation property can be maintained without fouling the membrane even if water containing a surfactant or a transition metal component is supplied as raw water.

Owner:NITTO DENKO CORP

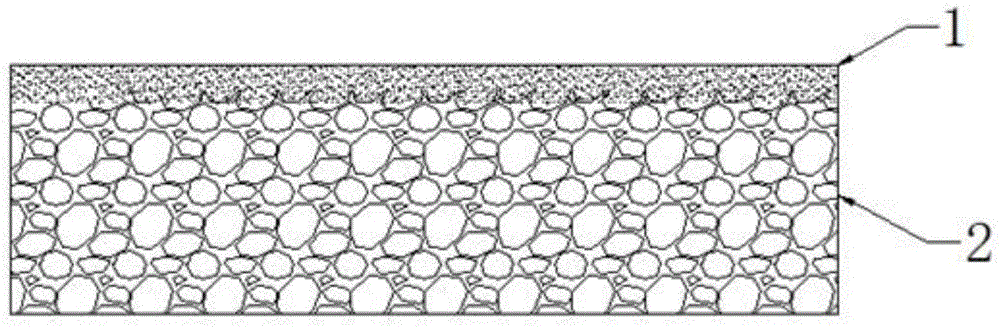

Water permeable brick and preparation method thereof

ActiveCN104452525AHigh porosityHigh strengthSolid waste managementSidewalk pavingsSolid componentBrick

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

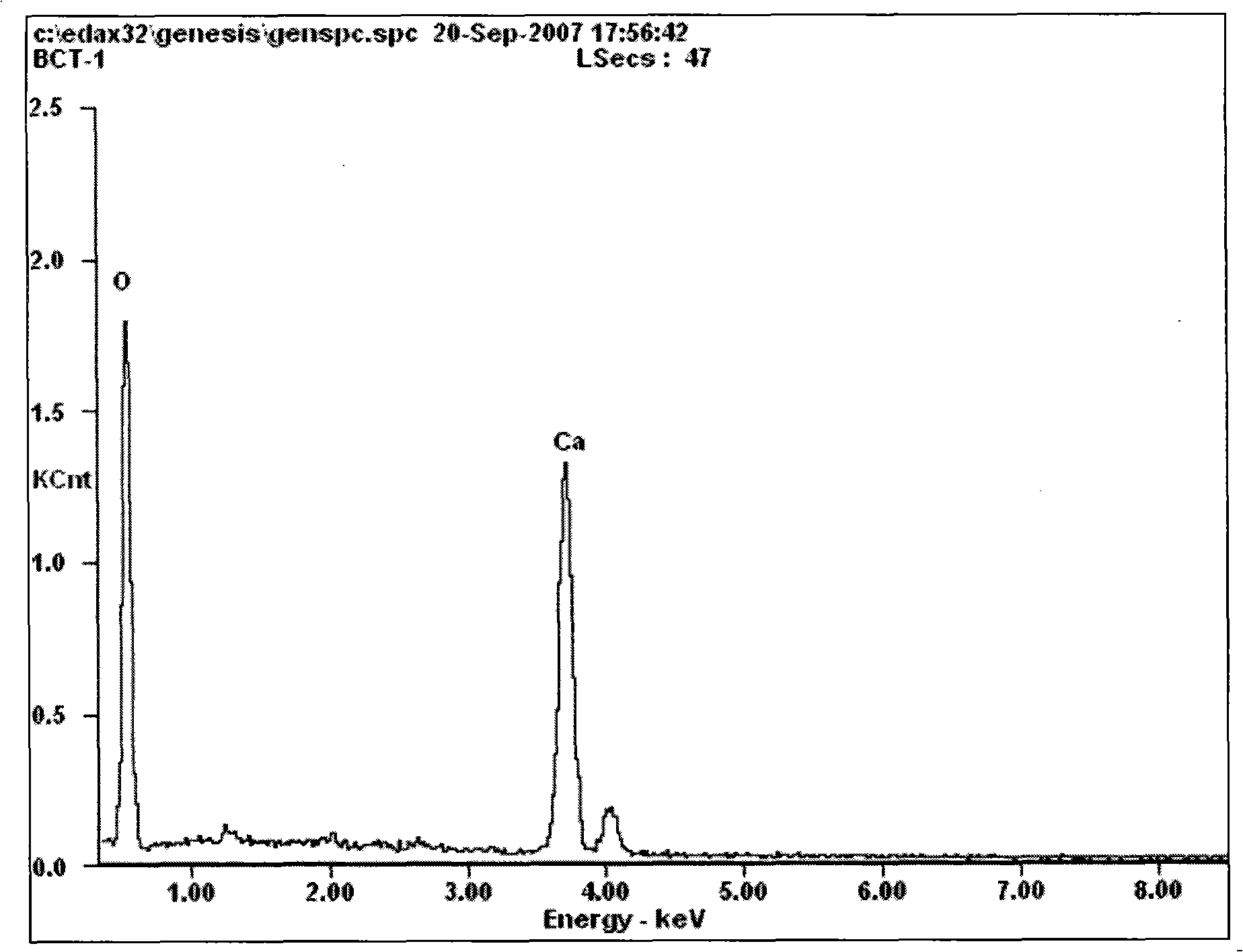

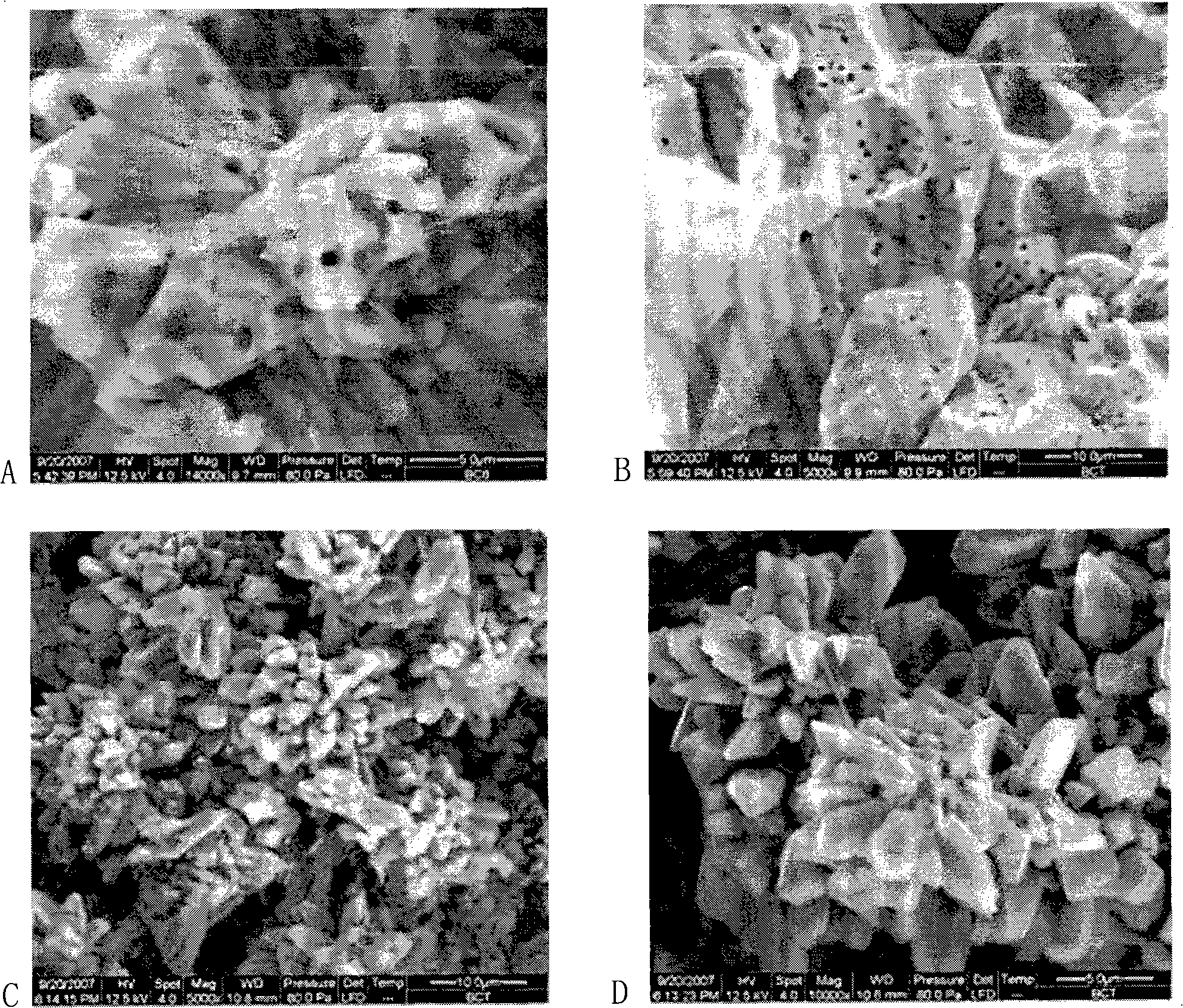

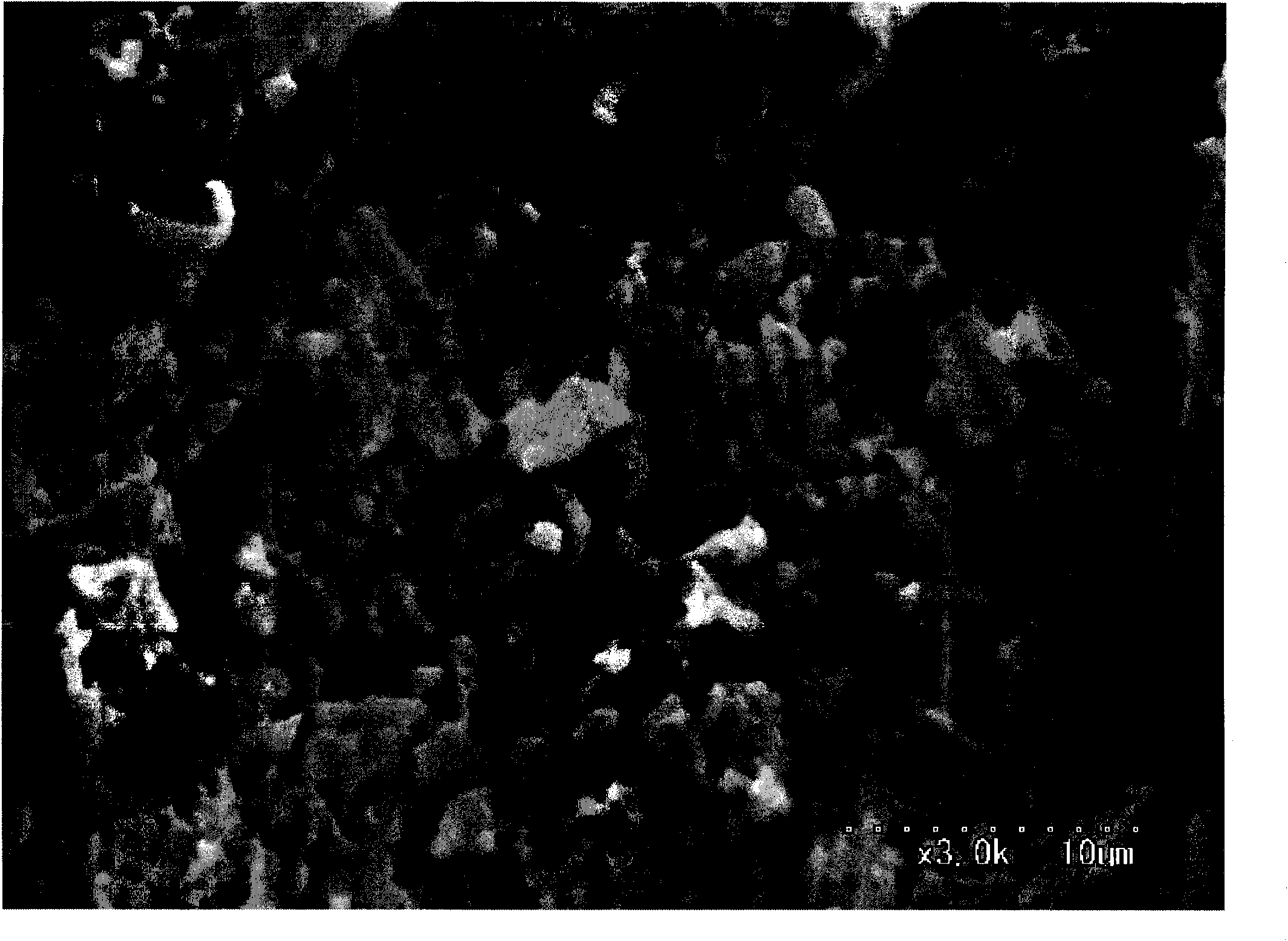

Microorganism cause concrete or concrete, producing method and application thereof

InactiveCN101270369ADoes not hinder precipitationApplicable treatmentBacteriaMicroorganism based processesMicroorganismEnvironmental hazard

The invention discloses a microbiogenic cement and concrete and a production method thereof, which mainly mixes the Bacillus pasteurii solution for producing urease and an admixture of containing urea and mineral calcium salt and obtains the microbiogenic cement after reacting in a certain condition; adds admixture such as sand etc. into the mixture of mixing the bacterial solution and the mixture and reacts to generate the microbiogenic concrete. The microbiogenic cement or concrete of the invention can be used on protection and restoration of masonry ancient architectures and repair of cracks on concrete building or treatment of liquescent sandy soil. The invention provides a permanent method of safety, effectiveness and without environmental hazard for repair and strengthening technology of large quantity of civil architecture and structure; the invention has the advantages of the good effects, the good weatherability, the good permeability of gas and the good permeability of water and being especially suitable for treatment of the sandy soil; the invention is safe and environmental-friendly, and belongs to the environmental-friendly restoring material.

Owner:TSINGHUA UNIV

Permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste and preparation

The invention discloses permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste and preparation. The permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste is characterized in that recycled coarse aggregates and ceramsites are taken as coarse aggregates of concrete, an appropriate amount of pretreated industrial and agricultural solid waste such as industrial waste, agricultural waste, household garbage and the like is taken as an admixture, a cementing agent is prepared from cement, water, a superplasticizer and a reinforcement material, and the materials are mixed with a preset stirring process and preparation method, so that ecological concrete with good mechanical property, permeable property and durability is produced. According to the concrete, the waste utilization rate is up to about 80%, the concrete is environment-friendly, locally available materials can be used, the economic benefit is remarkable, ceramist pore is smaller, and sewage can be continuously and stably treated, so that the concrete is commonly used in water environment comprehensive improvement engineering; and besides, the concrete has light weight, high strength and good water permeability and can be also used in permeable pavement engineering such as a sidewalk, a parking lot and the like as well as plant engineering such as ecological riverway slope protection, roof landscape planting and the like.

Owner:YANGZHOU UNIV

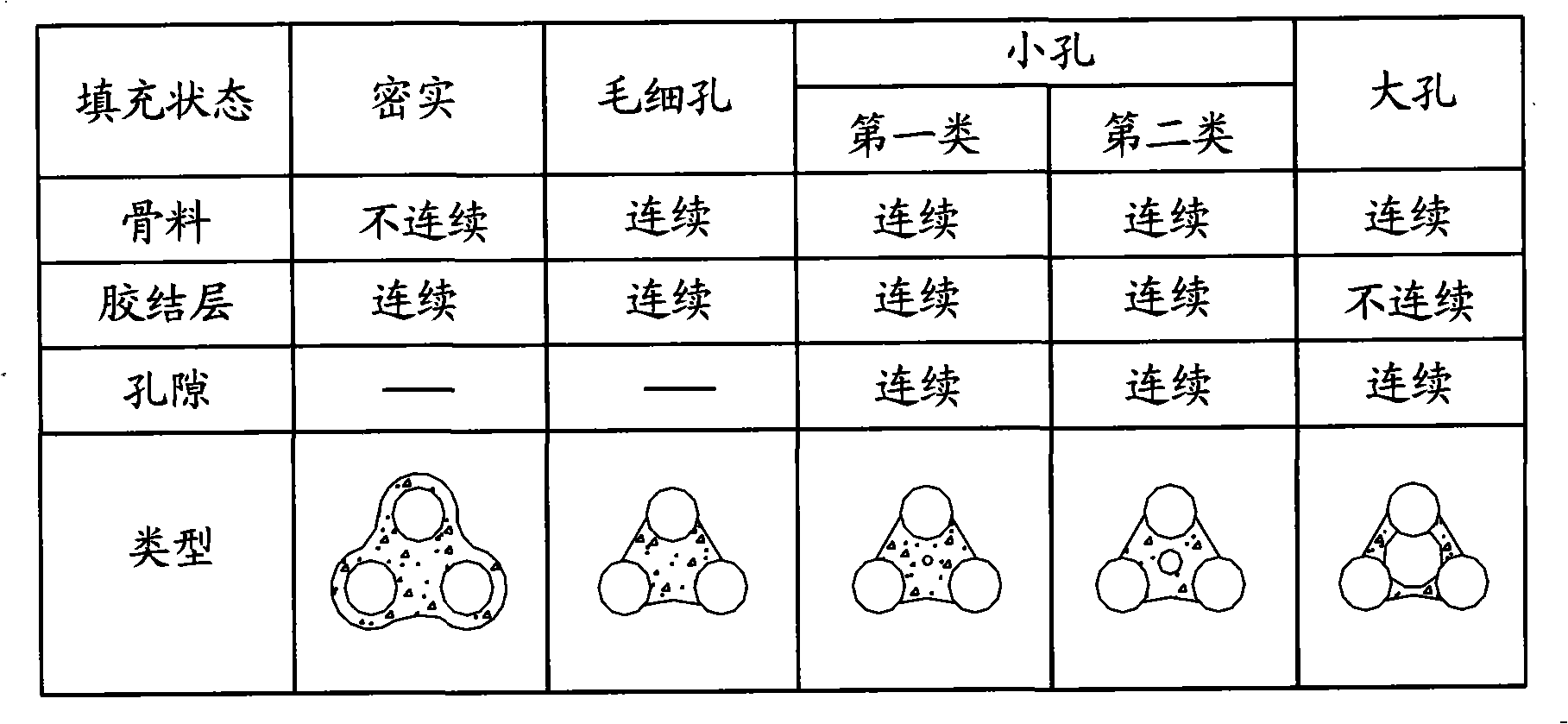

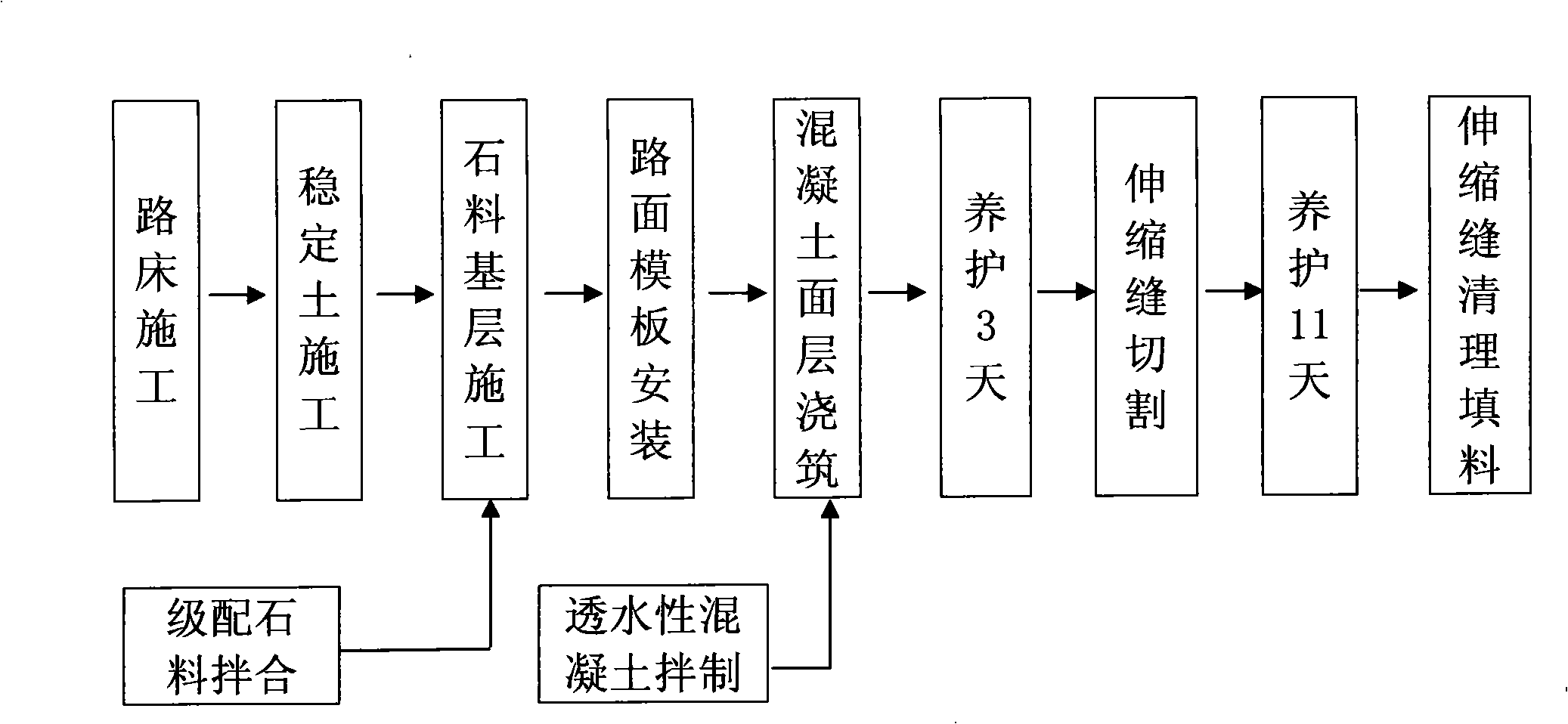

Water permeable concrete and pavement construction method

InactiveCN101293763AHigh strengthGood water permeabilityIn situ pavingsSolid waste managementFlexural strengthRoad surface

The invention discloses permeable concrete and a pavement construction method. The permeable concrete comprises the following components: 1350 to 1800 parts of broken stones, 90 to 150 parts of water, 300 to 350 parts of cement, 10 to 70 parts of mineral powder, 10 to 70 parts of silicon ash and 0.3 to 7 parts of water reducing agent; if necessary, organic intensifying agent can be added. The construction method comprises the following steps: permeable concrete is mixed, poured and cured, an expansion joint is cut, and the filling and the other processes are performed. Concrete pavement prepared by the method has higher strength and water permeability, and the compression strength can reach or exceed 30 MPa; the flexural strength is above 4 MPa; the coefficient of water permeability is more than or equal to 1 mm / s; the requirements for the permeable concrete pavement can be fully satisfied. The permeable concrete is suitable for the construction of permeable concrete pavement, squares and parking lots; by adopting the method, the consumption of cement is small, the construction is simple, and the method is favorable for being popularized.

Owner:HENAN GUOJI CONSTR GRP +1

Method for preparing polyvinylidene fluoride porous membrane

ActiveCN101362057AGuaranteed StrengthGuaranteed high water fluxSemi-permeable membranesMembranesHollow fibreFiber

Owner:TSINGHUA UNIV

Weatherable water-permeable material and its uses

The invention discloses a weatherability permeable material, which consists of aggregate and adhesive, wherein the aggregate is one of natural quartz sand, coal ash, melt slag, artificial quartz sand or their random composition with diameter at 0.07mm-1. 6mm; the adhesive is one of epoxide resin, polyurethane resin and acroleic acid resin or their composition with good weatherability; the optical stabilizer, anti-oxidizer and adhesive are added in the raw material, which improves weatherability obviously; the permeable resin is added in the aggregate as well as inorganics, which improves permeability effectively.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

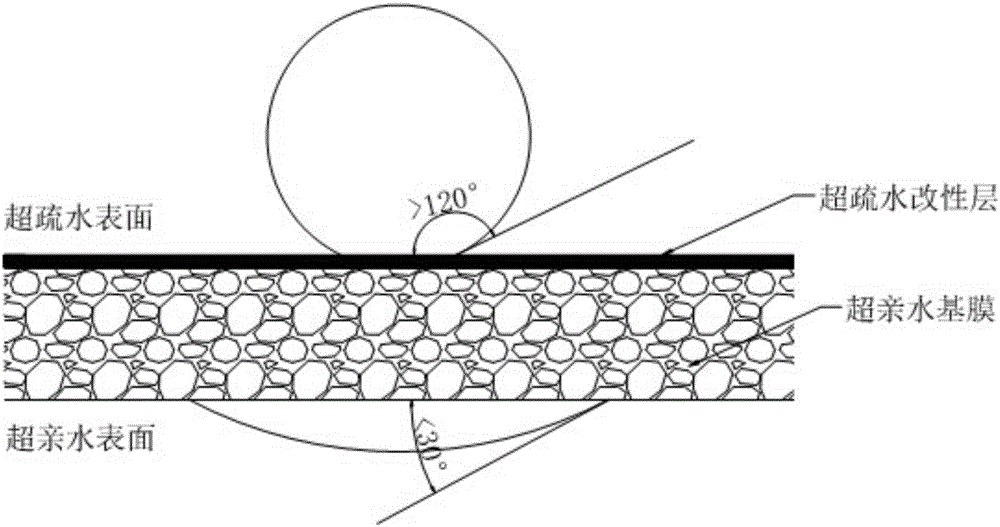

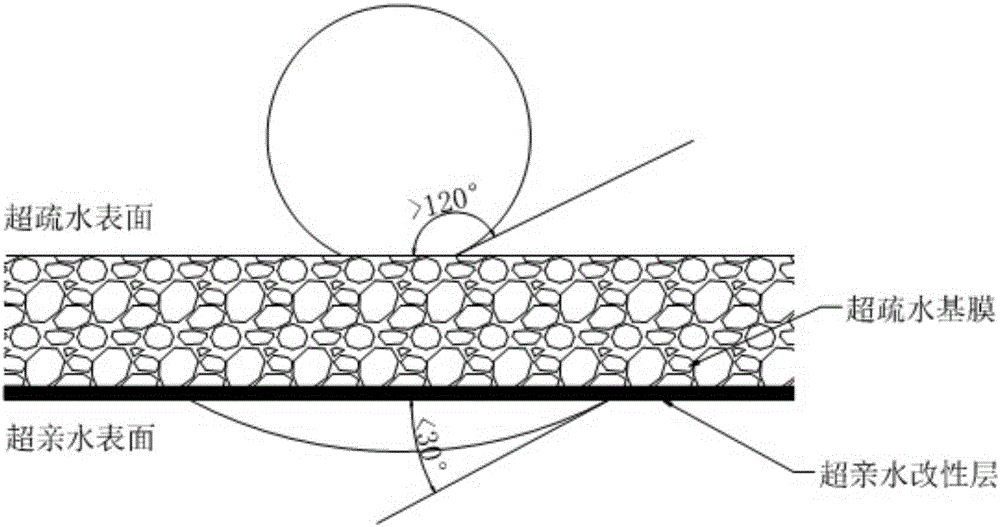

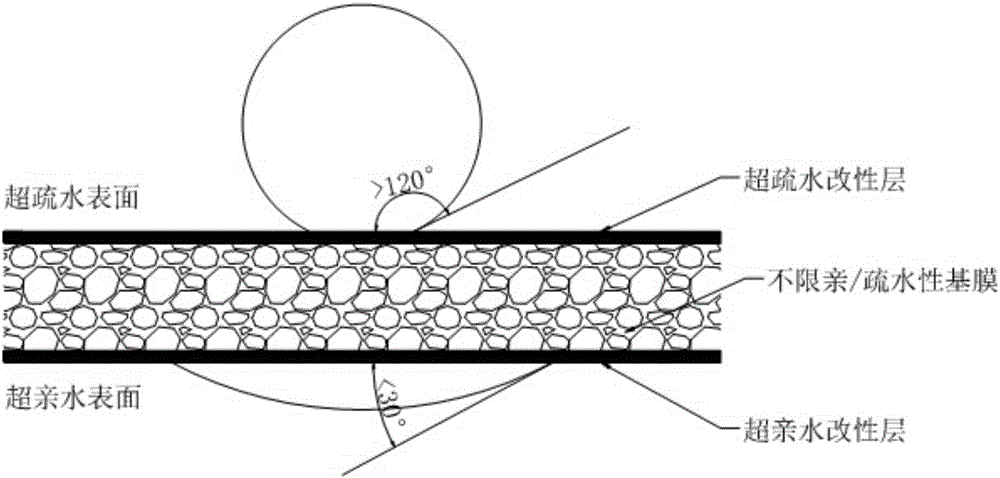

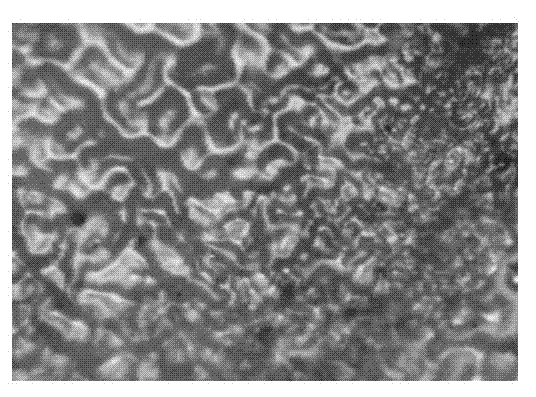

Asymmetric ultra-hydrophilic/hydrophobic dual-property polymer membrane and preparation method thereof

ActiveCN106268355AImprove anti-pollution performanceReduce adhesionMembranesSemi-permeable membranesPore diameterHollow fiber membrane

The invention relates to a membrane separation technique and aims at providing an asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane and a preparation method thereof. According to the asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane, a base membrane is a flat sheet membrane or a hollow fiber membrane, one side of the base membrane is a hydrophilic side, the water contact angle of the hydrophilic side is not greater than 30 degrees, the other side of the base membrane is a hydrophobic side, and the water contact angle of the hydrophobic side is not smaller than 120 degrees. The prepared asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane is of the type of the flat sheet membrane or the hollow fiber membrane and belongs to an ultra-micro filter membrane category, and the pore diameter range of the membrane is 0.01-2.0 microns. Therefore, the hydrophilic and hydrophobic properties on double sides are different, one side is hydrophilic, the other side is hydrophobic, and the asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane shows asymmetric hydrophilic / hydrophobic properties and is a novel water treatment membrane.

Owner:ZHEJIANG UNIV

Compound bio-fertilizer containing ardealite and application thereof

InactiveCN101693641AFacilitate absorption and utilizationImprove the immunityBio-organic fraction processingOrganic fertiliser preparationGypsumWater content

The invention provides a compound bio-fertilizer containing ardealite and application thereof. Compound bio-fertilizer is obtained through following steps: adjusting pH value of the ardealite to 4-5 via lime water, drying and crushing to 200-400 sections; drying animal manure, cutting crop straws into sections and then drying; mixing and fermenting the ardelite, the animal manure and the crop straws; controlling cultivation temperature to be at 28-32 DEG C after medium sterilization, sequentially inoculating various beneficial microorganisms, respectively cultivating the same, mixing mixed bacteria with prepared fermenting mixture by weight ratio of 1:300-1000 after completing cultivation, adding water to adjust water content to 35-45%, stirring the water , stacking the mixture for 3-5 days for co-fermentation, further adding water to adjust water content to 20-30%, and then crushing to obtain the compound bio-fertilizer. The compound bio-fertilizer is mainly applied to field crops and applied to improving saline-alkali soil, acid soil and coastal soil structures.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Nano-composite environment-friendly water permeable brick and production method thereof

InactiveCN103290753AGuaranteed compression performanceGood water permeabilitySingle unit pavingsCeramic shaping apparatusEnvironmental resistanceBrick

The invention discloses a nano-composite environment-friendly water permeable brick and a production method thereof. The nano-composite environment-friendly water permeable brick comprises a concrete bottom layer and a mortar surface layer arranged on the concrete bottom layer, wherein the concrete bottom layer and the mortar surface layer are compounded to form an integrated structure; the concrete bottom layer is prepared from the following raw materials in parts by weight: 20-40 parts of cement, 10-20 parts of water, 5-15 parts of fly ash, 50-65 parts of recycled aggregate, 50-65 parts of natural coarse aggregate, 65-85 parts of sand and 0.05-0.2 part of water-reducing agent; and the mortar surface layer is prepared from the following raw materials in parts by weight: 70-100 parts of cement, 5-20 parts of nano-TiO2, 30-60 parts of water, 200-400 parts of sand and 0.1-1.0 part of water-reducing agent. The nano-composite environment-friendly water permeable brick disclosed by the invention is integrally formed and has the advantages of high compressive strength, high flexural strength, good water permeability and good water retention, and a ground surface laid by the nano-composite environment-friendly water permeable bricks can timely dredge and drain rainwater, is conductive to growth of surrounding vegetation and can effectively supplement groundwater, reduce the pressure of a municipal drainage system and reduce the influence of surface gathered water on the traffic; and the nano-composite environment-friendly water permeable brick has a photocatalytic self-cleaning function and can decompose and remove organic stains on the surface of the brick and beautify the urban environment.

Owner:CHINA STATE CONSTR HAILONG TECH CO LTD

Cement concrete permeable brick, permeable road and production methods thereof

InactiveCN101671987AComply with quality deviationMitigate the heat island effectSingle unit pavingsClimate change adaptationPondingBrick

The invention relates to a cement concrete permeable brick, a cement concrete permeable road and production methods thereof. At present, most of urban construction adopting the rigid hardened ground has the problems of dust blowing at a fine day, water accumulation and impermeable ground at a rainy day, no groundwater level supplement, no relief of urban heat island effect, and the like. The invention aims to develop a cement concrete permeable brick, a cement concrete permeable road and production methods thereof. The cement concrete permeable brick is formed by pressing and molding a base material layer and a surface material layer, and both the base material layer and the surface material layer contain cement, sand, stone, water adsorbing resin, asphalt powder, diffusant and a water reducing agent. The production method of the permeable brick is realized by molding the permeable brick by a computer full-automatic building block forming machine; and the production method of the cement concrete permeable road is realized by directly pressing the cement concrete permeable road through a road roller. The invention can achieve the aims of water adsorption, water retention, permeability and practicability, can be widely used for a highway, an airport runway, a roadway, a footway, a square, garden construction, and the like and solve the problem of road icing.

Owner:SHAANXI SUNSHINE RAIN ECOLOGICAL TECH

Fertilizer for saline-alkali soil and preparation method of fertilizer

InactiveCN104262046AHigh in nutrientsLow bulk densitySuperphosphatesCalcareous fertilisersAlkali soilSoil organic matter

The invention relates to a fertilizer for saline-alkali soil. The fertilizer is prepared from the following raw materials in parts by weight: 5-20 parts of humic acid, 0.3-1 part of microorganisms, 6-16 parts of farmyard manure, 15-40 parts of straws, totally 5-10 parts of calcium superphosphate, ferrous sulfate, coal ash, furfural residues and flue gas desulfurization gypsum, 6-14 parts of a nitrogen fertilizer, 2-4 parts of a phosphatic fertilizer and 2-3 parts of a potassic fertilizer. The invention further relates to a preparation method of the fertilizer for saline-alkali soil. The fertilizer for saline-alkali soil, which is provided by the invention, has the beneficial effects that the fertilizer for saline-alkali soil has the characteristics of being low in cost and simple in preparation method, can be used for effectively improving the condition of saline-alkali soil, reducing the content of salt of soil and the pH value and increasing the content of organic matters in soil, and is particularly suitable for being applied to the saline-alkali soil.

Owner:瑞昊(北京)环境工程集团有限公司

Pervious concrete and construction method thereof

ActiveCN104402339AImprove workabilityIncreased intensityIn situ pavingsRoad surfaceUltimate tensile strength

The invention discloses pervious concrete and a construction method thereof. The pervious concrete comprises the following raw materials in percentage by weight: 13.1-15.9% of cement, 12.7-15.6% of river sand, 59.6-66.0% of stones, 3.7-3.9% of water and 4.5-5.0% of admixtures, wherein the admixtures comprise the following raw materials in percentage by weight: 45-50% of ultrafine mineral powder, 15-20% of heavy calcium carbonate, 15-20% of gypsum powder, 3-5% of polypropylene fiber, 5-10% of a polycarboxylate water reducing agent, 4.2-8.4% of adhesive powder and 2-5% of a pigment. The pervious concrete provided by the invention has relatively high water permeability, strength and durability; after the pervious concrete is applied to a practical engineering, the pervious concrete can greatly improve the problem of poor drainage of a hardened road surface, so that the development of the pervious concrete can be promoted.

Owner:TIANYUAN CONSTR GROUP

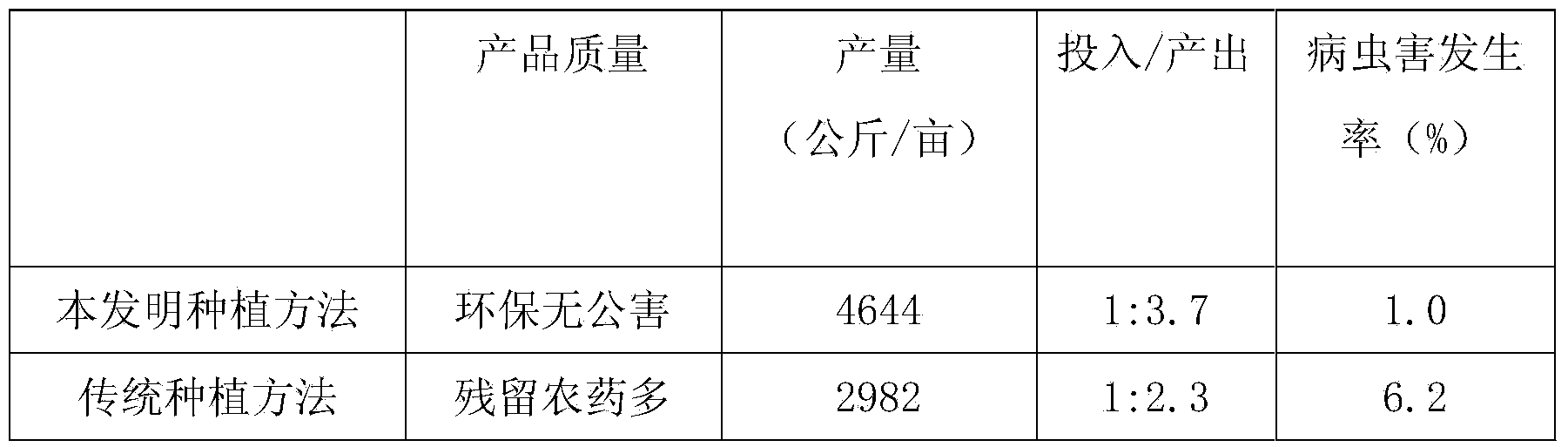

Method for growing watermelons

InactiveCN103798019AImprove water retentionGood water permeabilityBiocideAnimal repellantsDiseaseSugar

The invention discloses a method for growing watermelons. The method includes the steps of processing seeds and accelerating germination, sowing and raising seedlings, applying base fertilizer on the whole land, transplanting the seedlings, performing field management, harvesting and the like. The method for growing watermelons is easy to operate, convenient to manage, good in growth vigor of watermelons, high in disease resistance, uniform in result nature and high in yield, the yield per mu can reach 4000 kg to 5000 kg, the watermelons are large, good in quality, high in sugar content, bright in flesh color, delicate in flesh and high in water content and commodity value, and therefore the method has great significance for increasing income of melon farmers.

Owner:HEXIAN CHANGJIU AGRI DEV

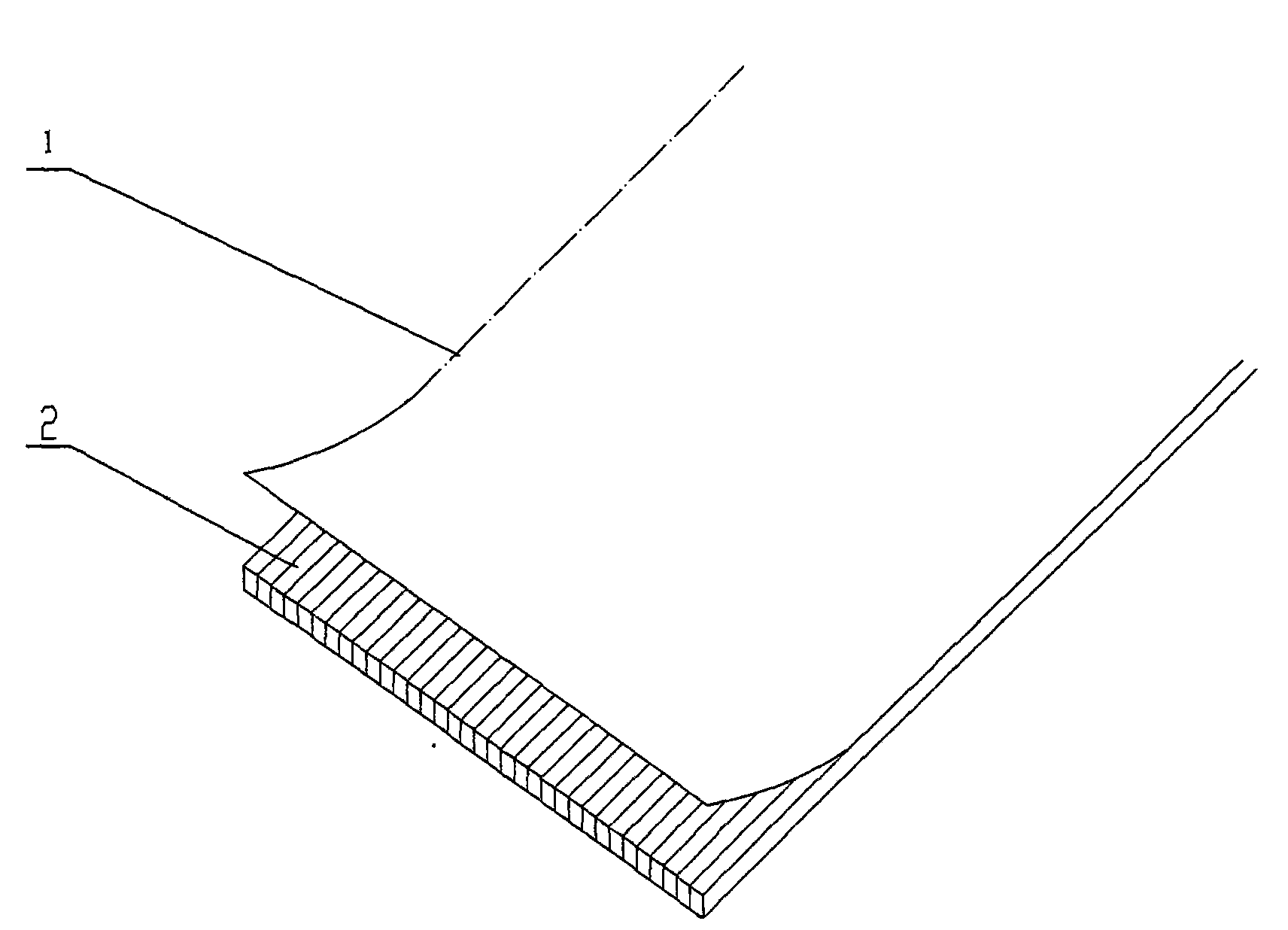

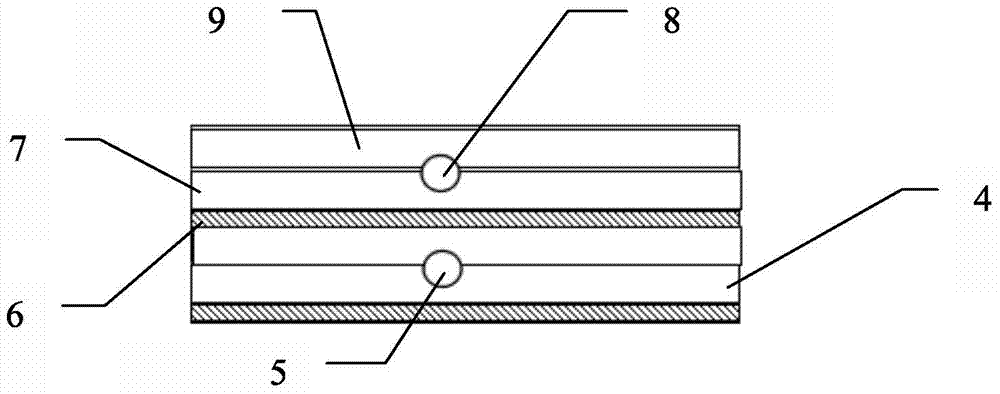

Drainage plate for silt consolidation, filter cloth and drainage plate core

The invention is the improvement on a longitudinal drainage plate for silt consolidation, filter cloth and a drainage plate core, which is characterized in that fibrous hot-pressed microporous filter cloth is planar filter cloth hot-rolled by a flat roller, the filter cloth is adhered to the surfaces of convex ribs of the drainage plate core through thermal thawing or a chemical way, the filter cloth adopts silk reeling and hot-press forming separation technology, and the drainage plate core is made of co-polypropylene, thereby overcoming the disadvantages of the prior art; and the aperture of the filter cloth can be adjusted according to treated silt, the drainage plate is difficult to block, the engineering on a soft foundation after the treatment cannot have the settlement after the construction and has smooth drainage and high drainage efficiency, and the plate core has long effective service life.

Owner:JIANGSU XINTAI GEOTECHNICAL TECH CO LTD

Self-cleaning water permeable brick and preparation method thereof

InactiveCN101445340AWide variety of sourcesImprove pollutionSolid waste managementEcological environmentBrick

The invention discloses a self-cleaning water permeable brick comprising a surface material and a base material. The base material is weighed according to weight percentage, comprising 68.4 percent to 77.5 percent of rubble or building rubbish granule or slag, 10 percent to 25 percent of cement, and 5.3 percent to 12 percent of water. The surface material is weighed according to weight percentage, comprising 66.7 percent to 71.8 percent of high-intensity sand, 10.8 percent to 26.5 percent of cement, 3.4 percent to 10.4 percent of water, and 0.1 percent to 1.0 percent of nanometer titanium dioxide. The surface material and the base material are compacted together to form an integrated water permeable brick. The invention further discloses a preparation method of the self-cleaning water permeable brick. The method comprises the following steps: 1) the base material and the surface material are weighed, respectively premixed and then stirred as raw materials for standby application; 2) molding is carried out; 3) steam curing is carried out; and 4) liquid titanium dioxide is sprayed. Road surfacing of the self-cleaning water permeable brick in the invention can reduce water permeable hole plugging and surface pollution, thereby having the effects of road surface temperature decrease and high-efficient sterilization, regaining circulatory system of natural soil air and water, preventing soil pollution and improving ecological environment.

Owner:程卫国

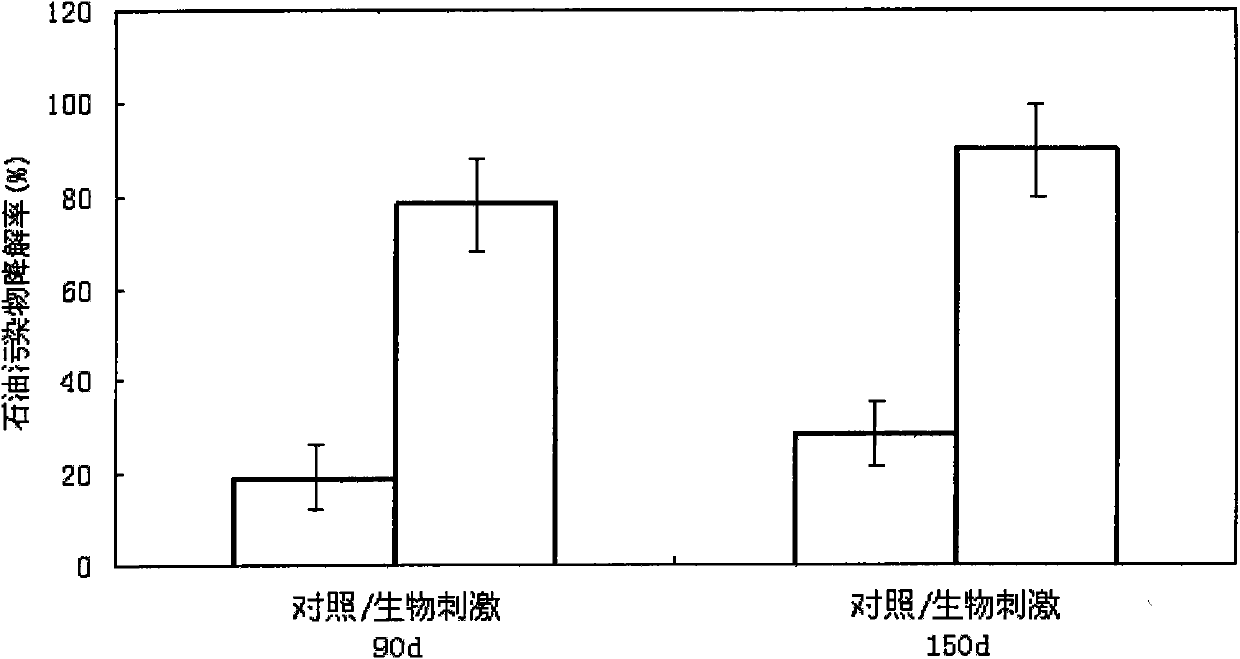

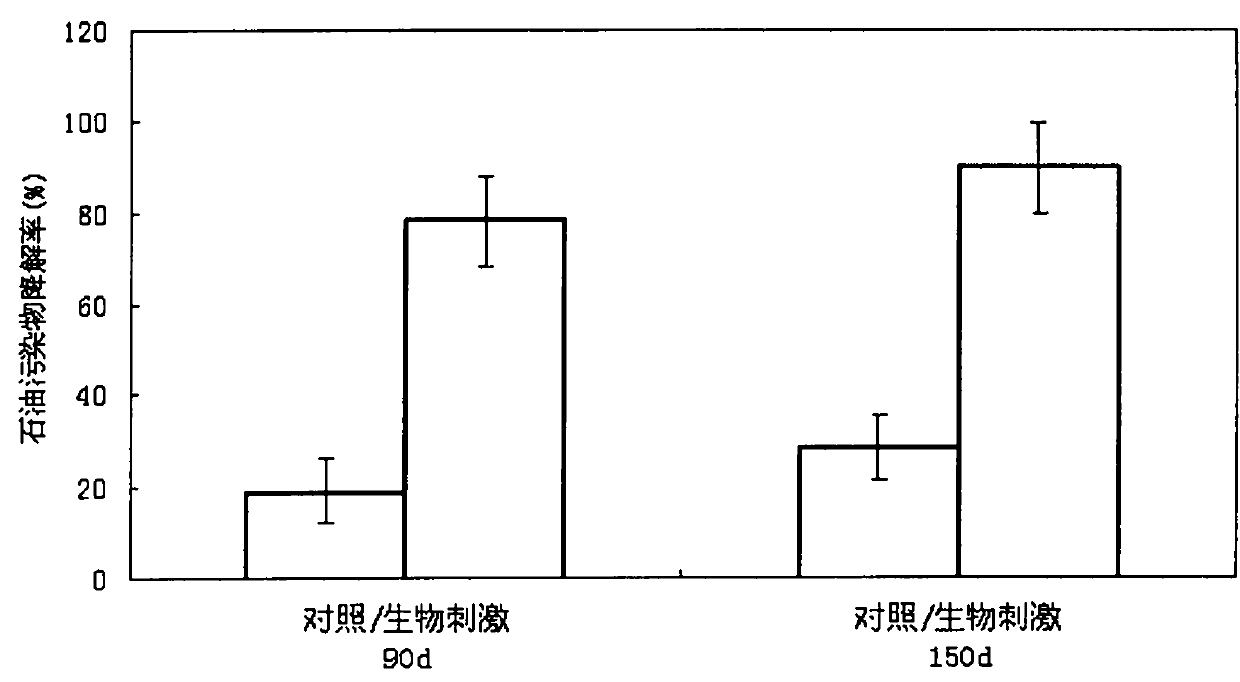

Biostimulation method for remediation of oil-polluted soil

InactiveCN101947544AImprove the environmentReduce viscosityContaminated soil reclamationBiostimulationBio degradation

The invention discloses a biostimulation method for remediation of oil-polluted soil. In the method, on the premise of not adding an oil pollutant biodegrading bacterial agent, a soil conditioner is added to improve the soil environment, reduce soil stickiness, increase the soil permeability, adjust the water-retaining capacity of the soil, adjust inorganic and organic nutrients necessary for local microbe growth, maintain the pH value of the soil close to neutrality, promote oil pollutant degrading microbes in the soil to grow and propagate, and improve the oil pollutant degrading efficiency of the local microbes; by planting plants, the microenvironment of the soil near root systems of the plants is improved, the plants secrete organics with low molecular weight such as amino acid to the root systems so as to stimulate the massive propagation of the local microbes and indirectly promote oil pollutant degradation by the microbes of the root systems; and the biostimulation method has the advantages of accelerating the remediation of the oil-polluted soil and restoring the original state of the soil.

Owner:SINOPEC PETROLEUM ENG DESIGN

Sintered water permeable brick and preparation method thereof

ActiveCN106087631AImprove water permeabilityLittle tortuousnessSingle unit pavingsPaving detailsBiomass fuelsSurface layer

The invention discloses a sintered water permeable brick and a preparation method thereof, and belongs to the technical field of sintered ceramics. According to the water permeable brick, structural pug in a surface layer is composed of, by weight, 45-65% of structural fine aggregates, 20-30% of plastic high-temperature binders and 15-25% of water, pore forming pug in the surface layer is composed of, by weight, 20-50% of pore forming agent aggregates, 45-80% of plastic pore adding binders and 0-5% of biomass fuel internal combustion catalysts, and a blank of a secondary surface layer is composed of, by weight, 70-75% of coarse structural aggregates, 10-15% of plastic high-temperature binders, 0-5% of pore adding agent coarse aggregates and 10-15% of water. A blank of the surface layer and the blank of the secondary surface layer are prepared firstly, the blank of the surface layer contains the orderly distributed structural pug and the pore forming pug, and then single-shaft extrusion forming, drying and sintering are conducted to obtain the water permeable brick. The water permeable brick has high water permeable rate, high strength, high abrasion resistance and durability and is a paving material with excellent ecological and environmental functions.

Owner:四川绿岛环境工程有限公司

Saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer and use thereof

InactiveCN105384579AGood water permeabilityImprove breathabilityExcrement fertilisersBioloigcal waste fertilisersAlkali soilPotassium

The invention relates to saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer. The saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer has a low cost and high fertilizer efficiency, is economic and environmentally friendly, improves a soil water binding capacity and permeability, and has functions of keeping fertility, slowly releasing fertilizer and reducing paddy rice salinization. The saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer comprises biomass charcoal, chicken manure, pyroligneous liquor, fermented soybean meal and potassium humate. The biomass charcoal is prepared by thermal cracking charring of biomass raw materials under anoxic conditions. The saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer can be used for paddy rice plantation, can improve a saline-alkali soil environment and can improve an organic paddy rice yield.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Ceramic material with multi-stage duct structure and manufacture method thereof

InactiveCN101885620ALow costMeet environmental protection requirementsSolid waste disposalFurniture waste recoveryMetallurgyDecomposition

The invention provides a ceramic material with a multi-stage duct structure and a manufacture method thereof. The ceramic material is characterized by being provided with a plurality of macropores with millimeter grade, tens of middle pores with millimeter grade exist on the walls of the macropores, micropores with sizes less than microns exist on the walls of the middle pores. The ceramic material is manufactured by using 10-50 percent by mass of waste and 20-60 percent by mass of natural porous mineral and matching with 10-30 percent by mass of clay through the steps of adding water for mixing, forming, drying, preheating and sintering at a temperature of 1000-1200 DEG C, wherein the waste can be expanded at high temperature or has large ignition lost and easy decomposition and volatilization. The ceramic material has excellent water-absorbing and water-retaining properties, better water permeability, excellent absorption and filtration and light weight, and can be used as a water-absorbing material, a water-retaining material, a water permeating material, a sound insulating material, a heat insulating material, an indoor deodorizing material, an absorbing material, a filtering material and the like to be widely applied to various fields.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

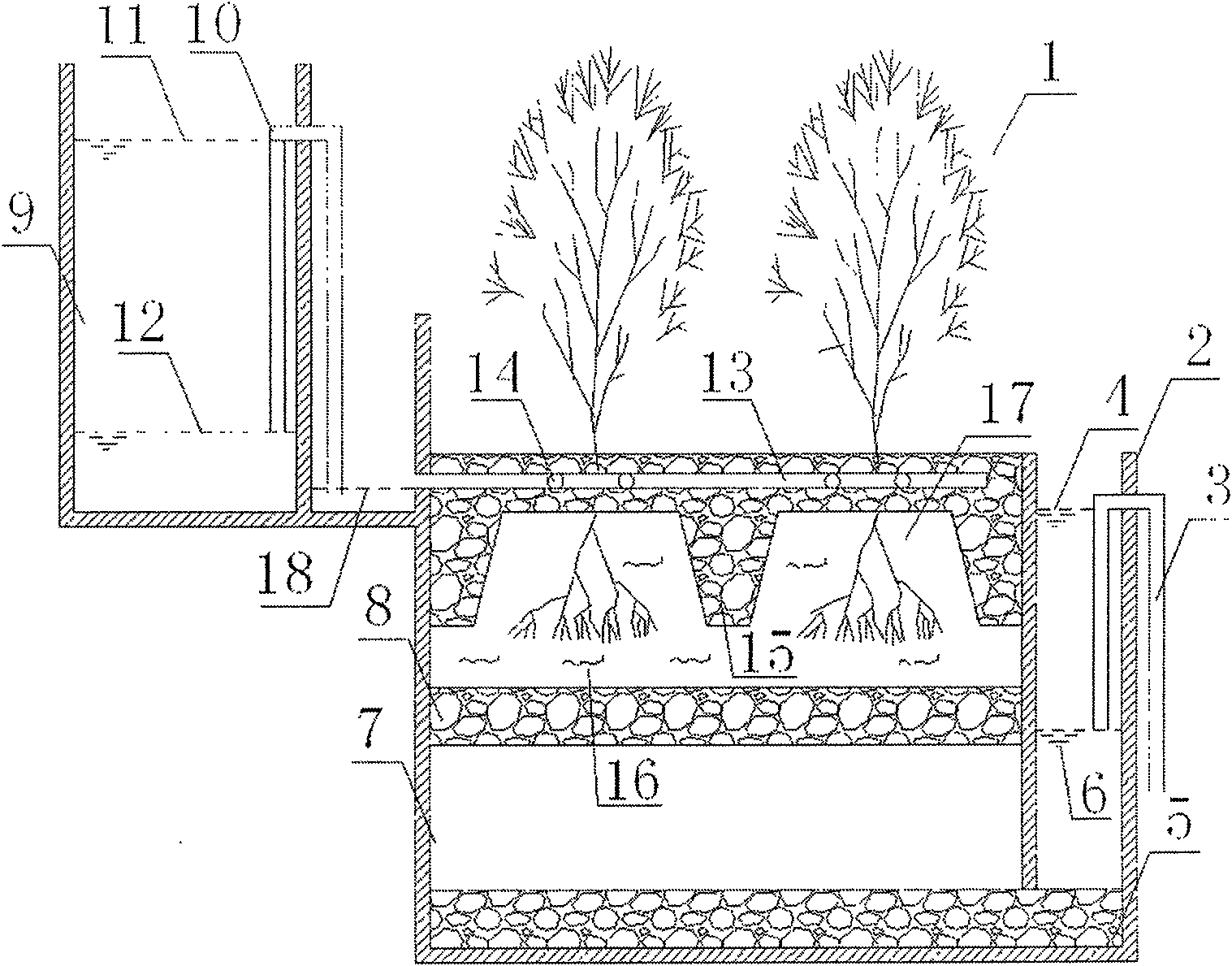

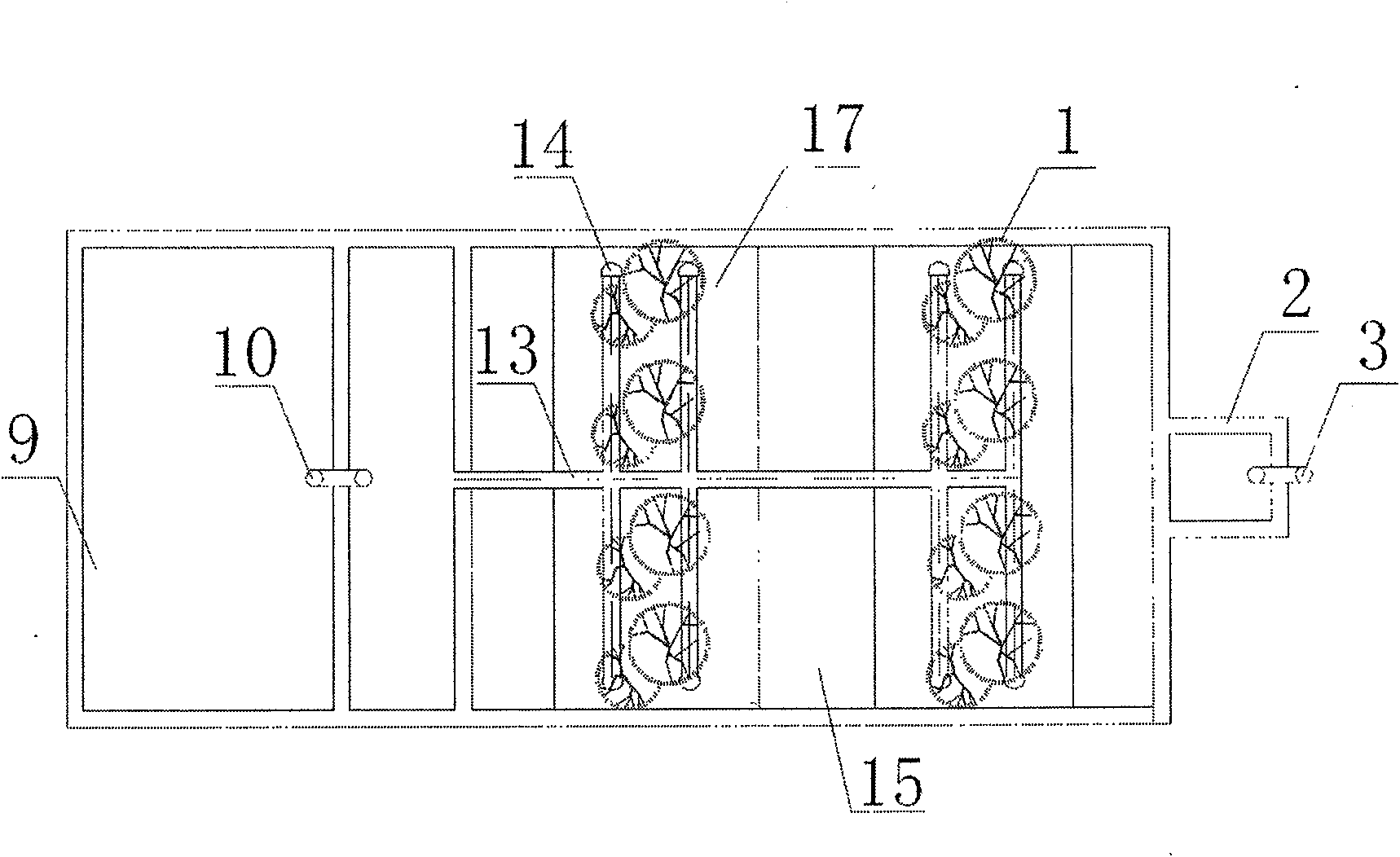

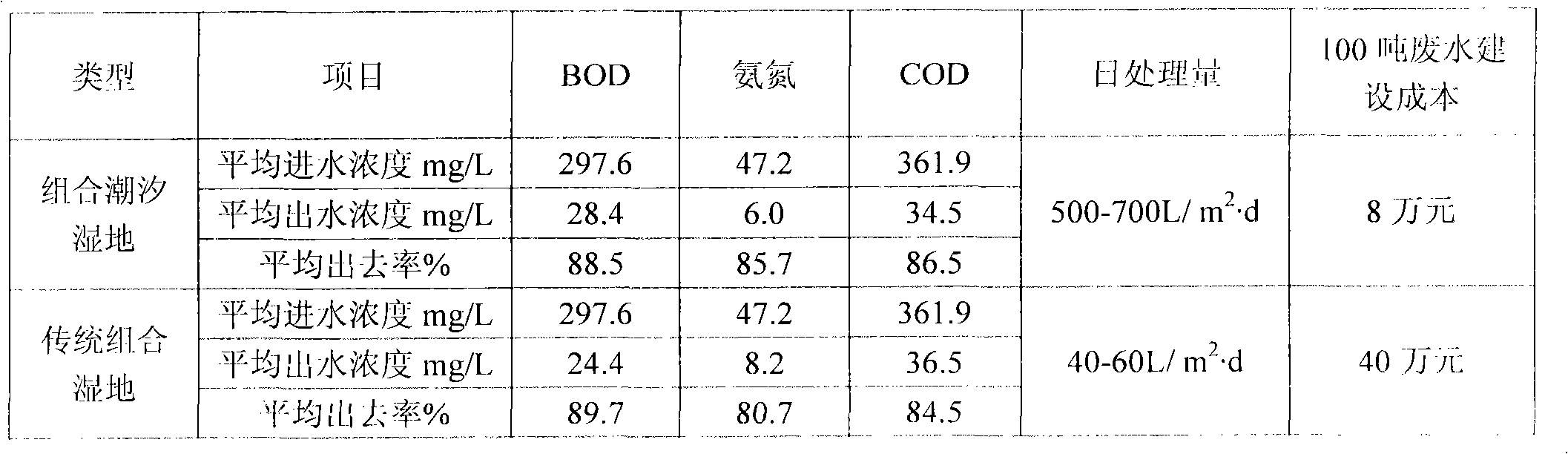

Sewage treatment system and method for combined tidal flow artificial wetland

InactiveCN101671092AGuaranteed contact areaGuaranteed timeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentConstructed wetlandSiphon

The invention discloses a sewage treatment system for combined tidal flow artificial wetland, belonging to the technical field of sewage treatment. The system comprises a non-powered automatic water charging device (9), an artificial wetland bed and a non-powered automatic water discharging device (2), wherein the non-powered automatic water charging device (9) is positioned above the artificial wetland bed and is communicated with the artificial wetland bed through a siphon water inlet pipe (10); the artificial wetland bed is provided with a water discharging layer (5), a denitrification reinforcing layer (7), a reinforcing reaeration layer (8) and an aerobic ecological sand layer (17) from the bottom up; and the non power automatic water discharging device (2) and the artificial wetlandbed form a connector and are connected with each other through the bottom water discharging layer (5). The invention further discloses a sewage treatment method using the system, comprising two stepsof waterflooding absorption and emptying reaeration. Compared with the traditional combined wetland, the sewage treatment system for the combined tidal flow artificial wetland increases daily sewage treatment amount and reduces construction cost.

Owner:CHINA AGRI UNIV

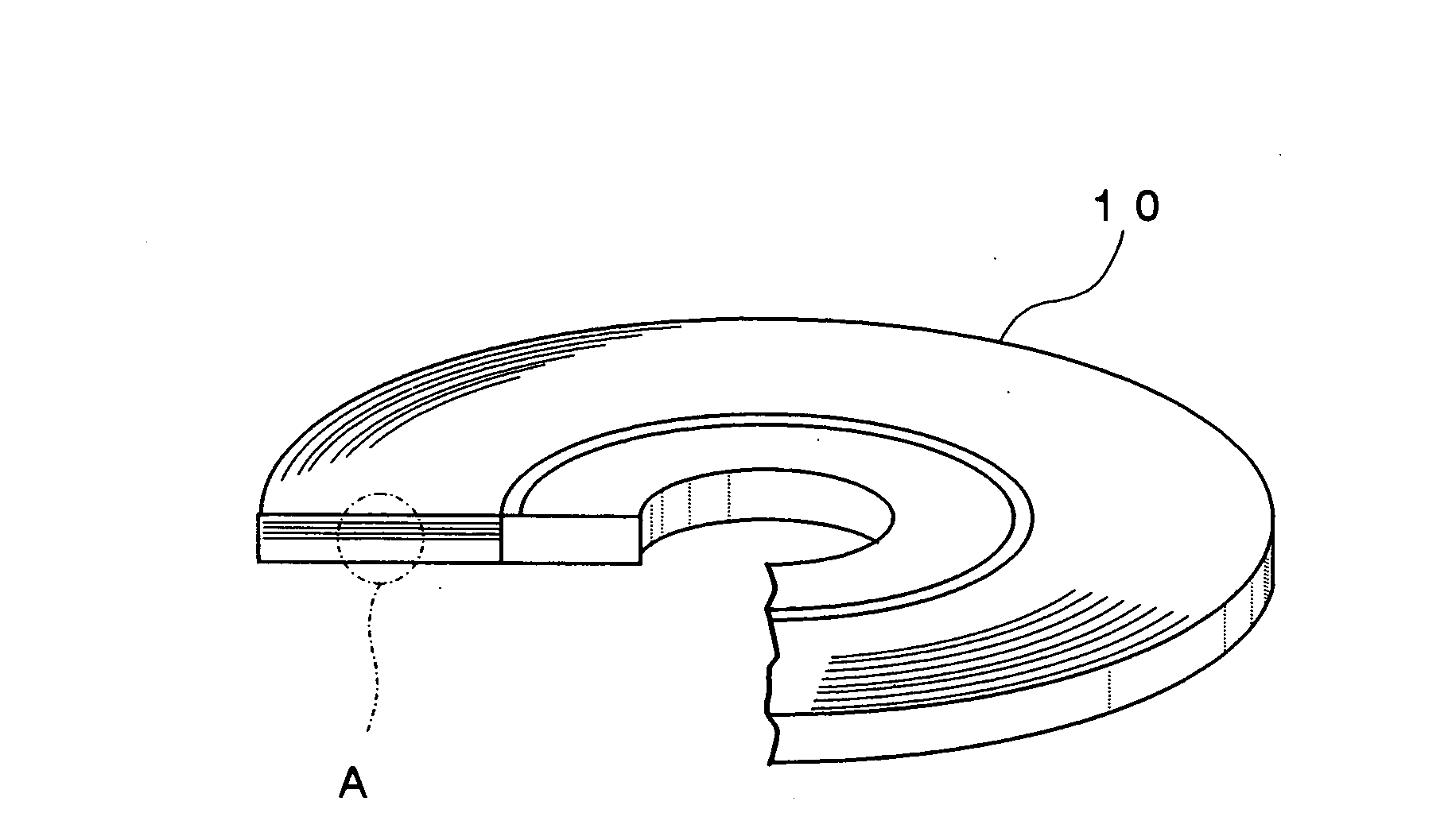

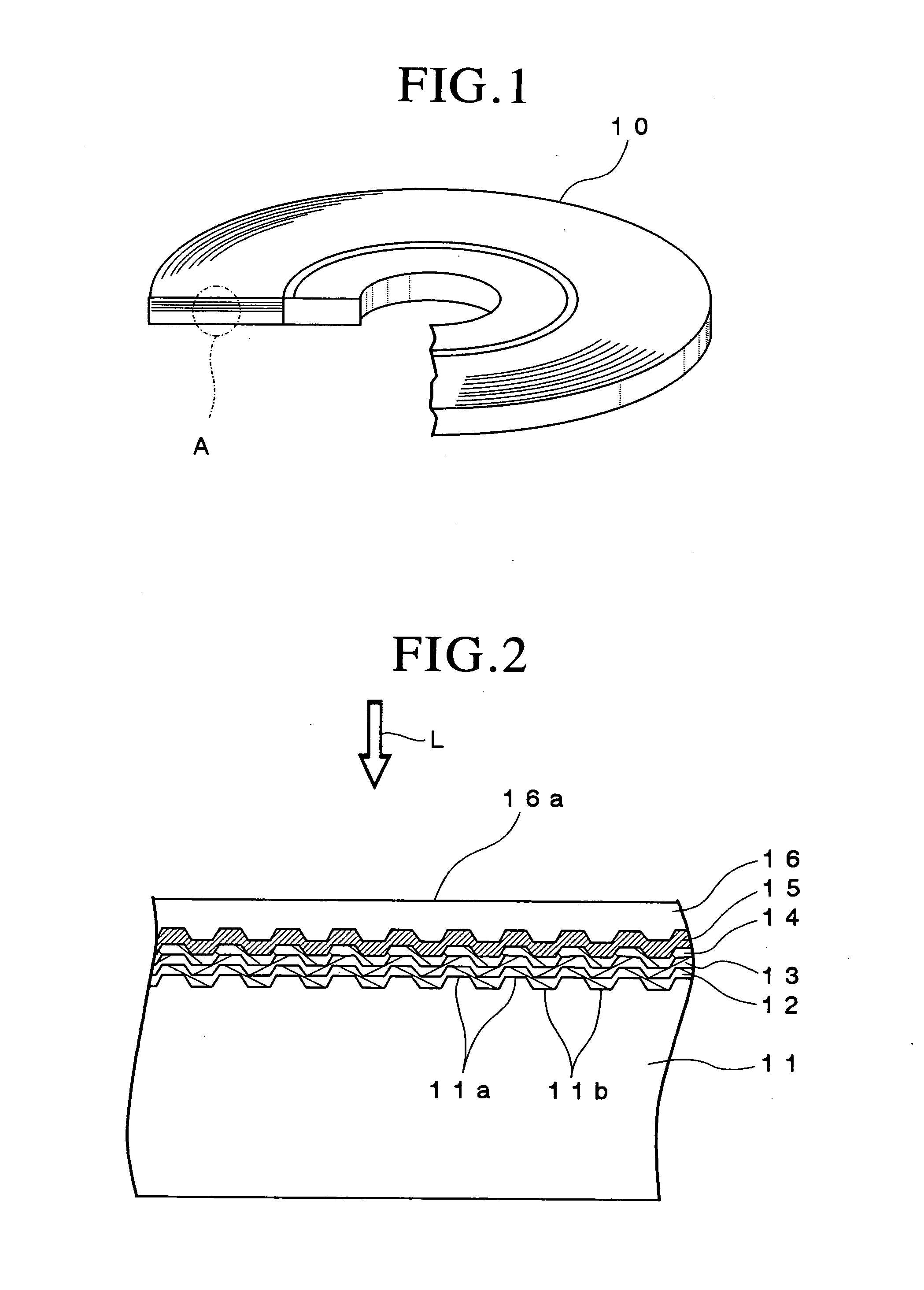

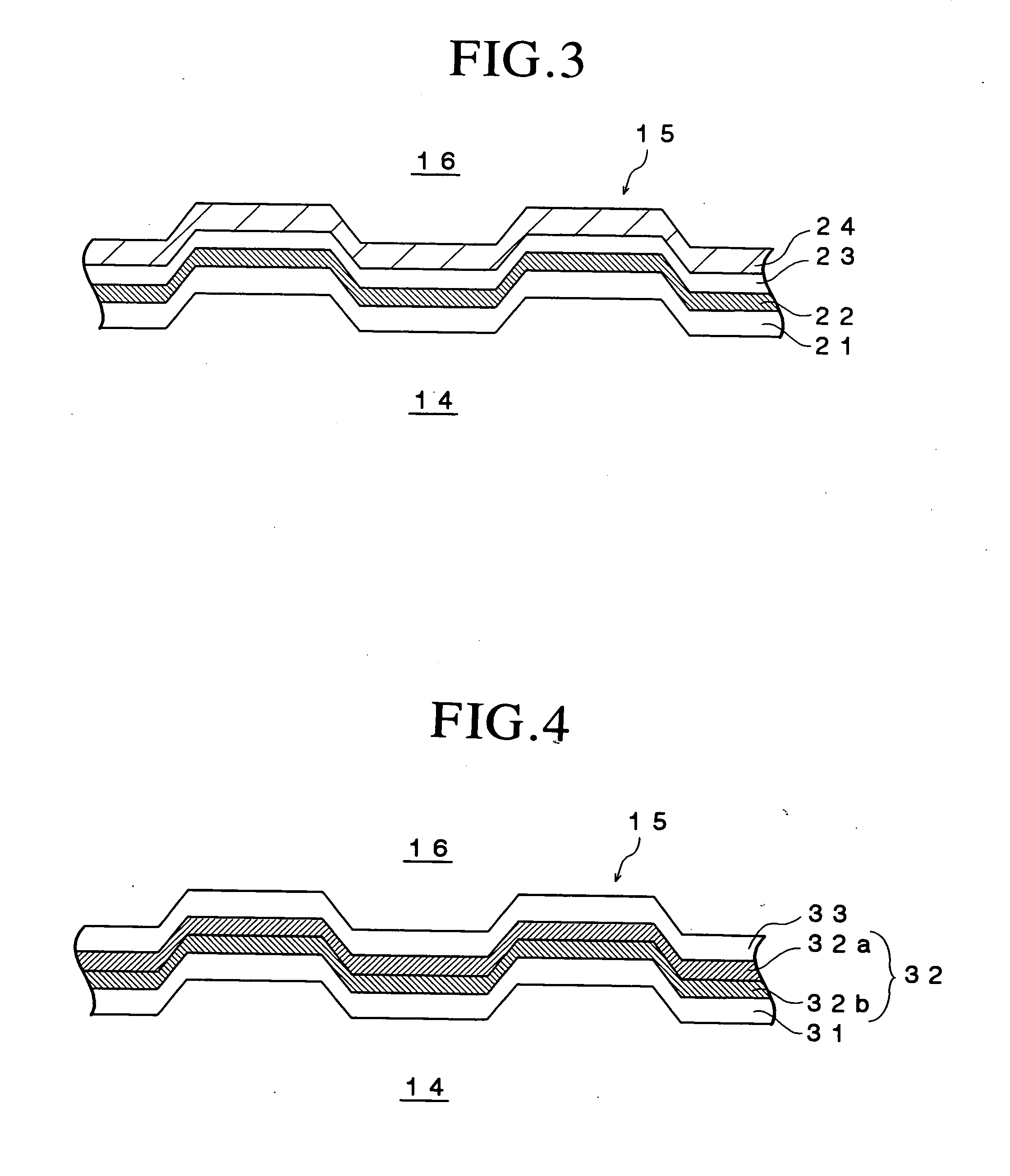

Optical recording medium

InactiveUS20040180171A1Avoid layeringGood water permeabilityLayered productsRecord information storageOptical recordingReflective layer

An optical recording medium includes a support substrate, a light transmission layer whose one surface constitutes a light incidence plane through which a laser beam is projected, an information recording layer formed between the support substrate and the light transmission layer, a reflective layer formed between the information recording layer and the support substrate, a water proof layer formed between the reflective layer and the support substrate and containing a mixture of ZnS and SiO2 as a primary component, and a corrosion resistant layer formed between the water proof layer and the reflective layer. According to the thus constituted optical recording medium, it is possible to effectively prevent a reflective layer from being corroded and has excellent storage reliability.

Owner:TDK CORPARATION

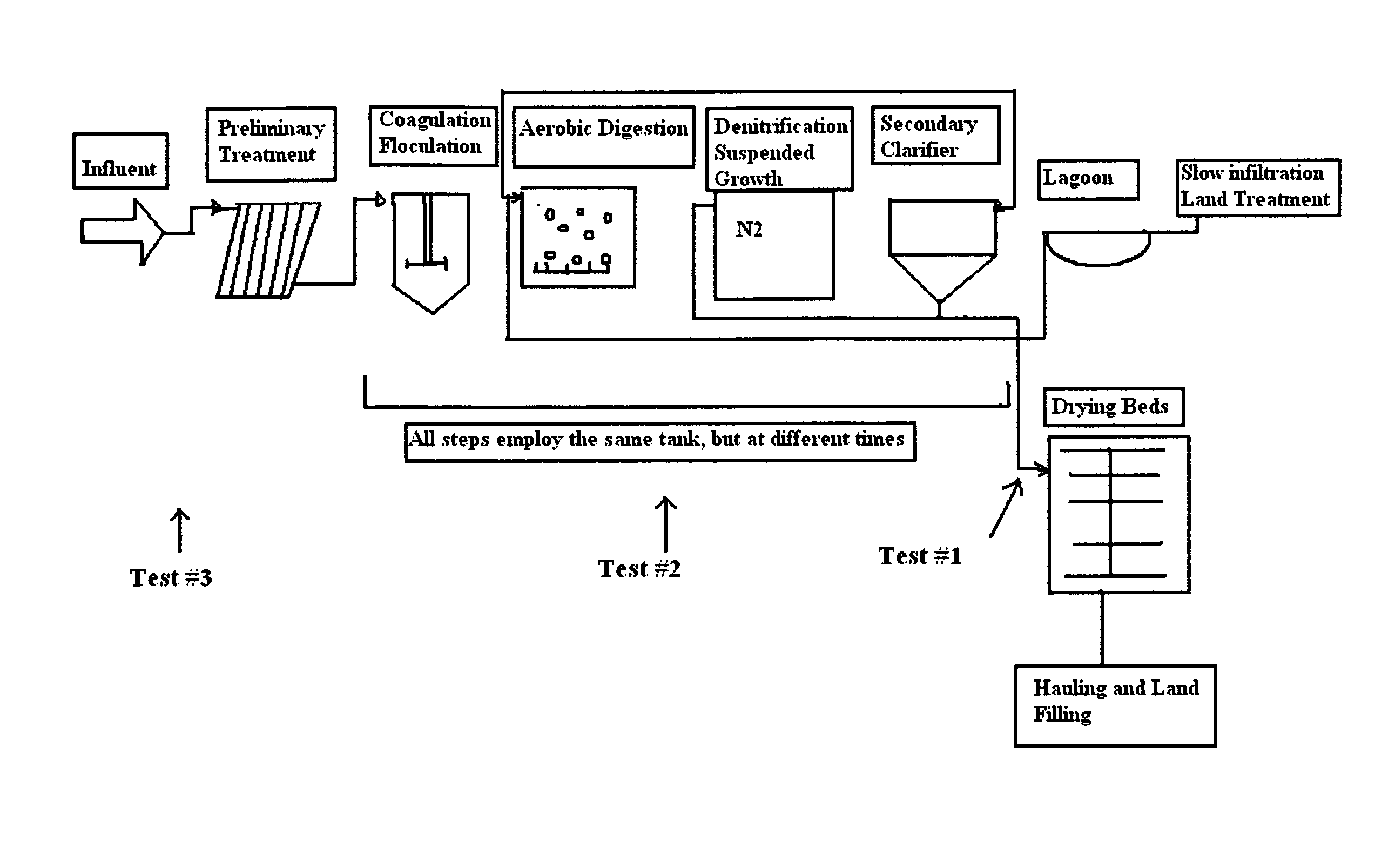

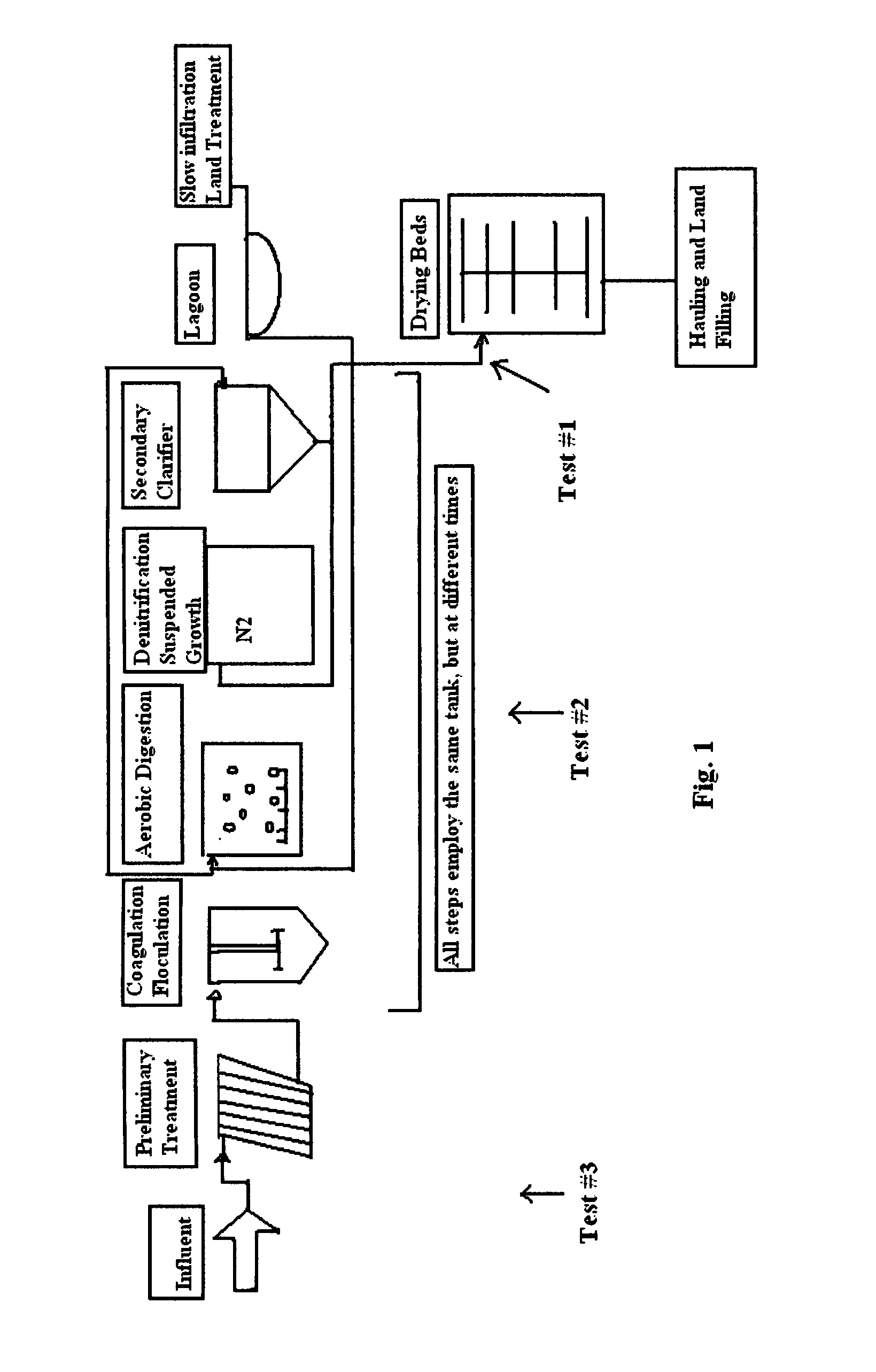

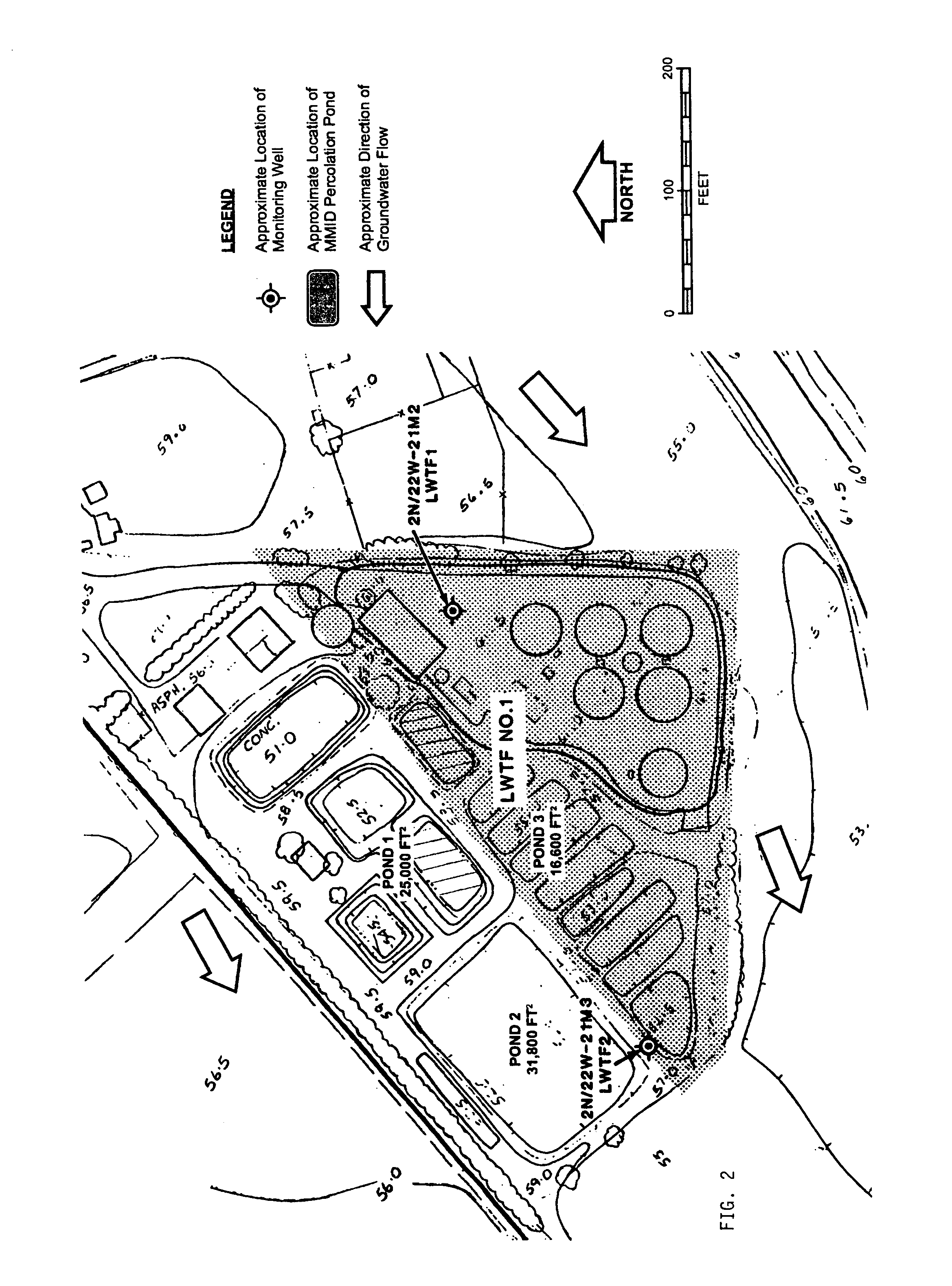

Wastewater chemical/biological treatment plant recovery apparatus and method

ActiveUS7416668B1Minimal capital cost expenditureLand cost is not prohibitiveBio-organic fraction processingSedimentation separationSludgeWastewater

A chemical / biological wastewater treatment plant method and apparatus employing rapid sludge chemical dewatering technology in conjunction with an environmental biological system for treating the separated treated wastewater by land applying it for plant consumption, and / or passing it through aqueous plant or microbial reduction of the dissolved solids and ammonia for BOD compliance to produce water of sufficient quality to meet open stream and ocean effluent discharge requirements; and disposing of the high BTU low moisture solids.

Owner:EARTH RENAISSANCE TECH

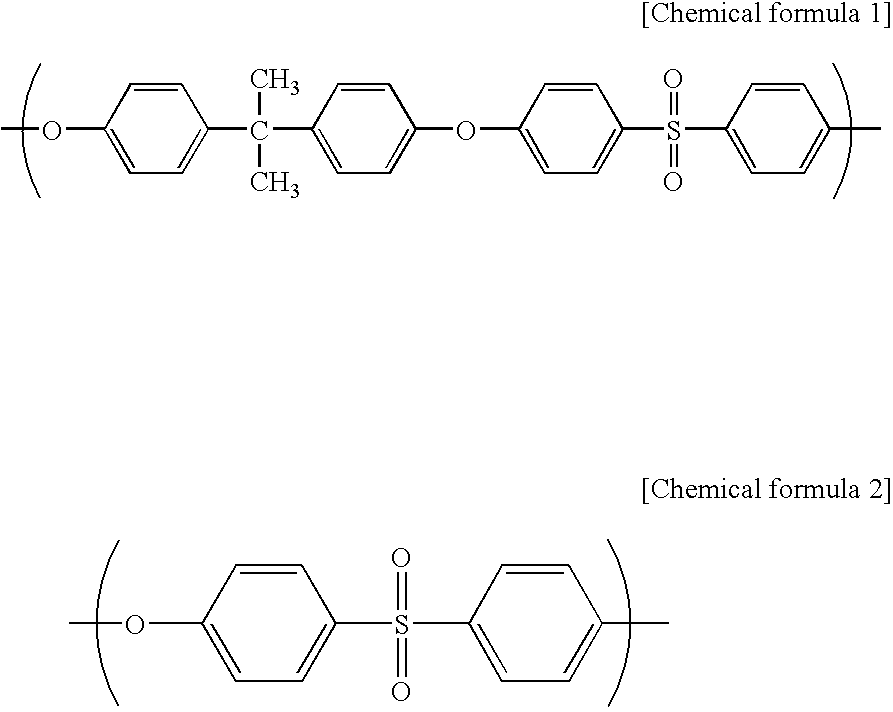

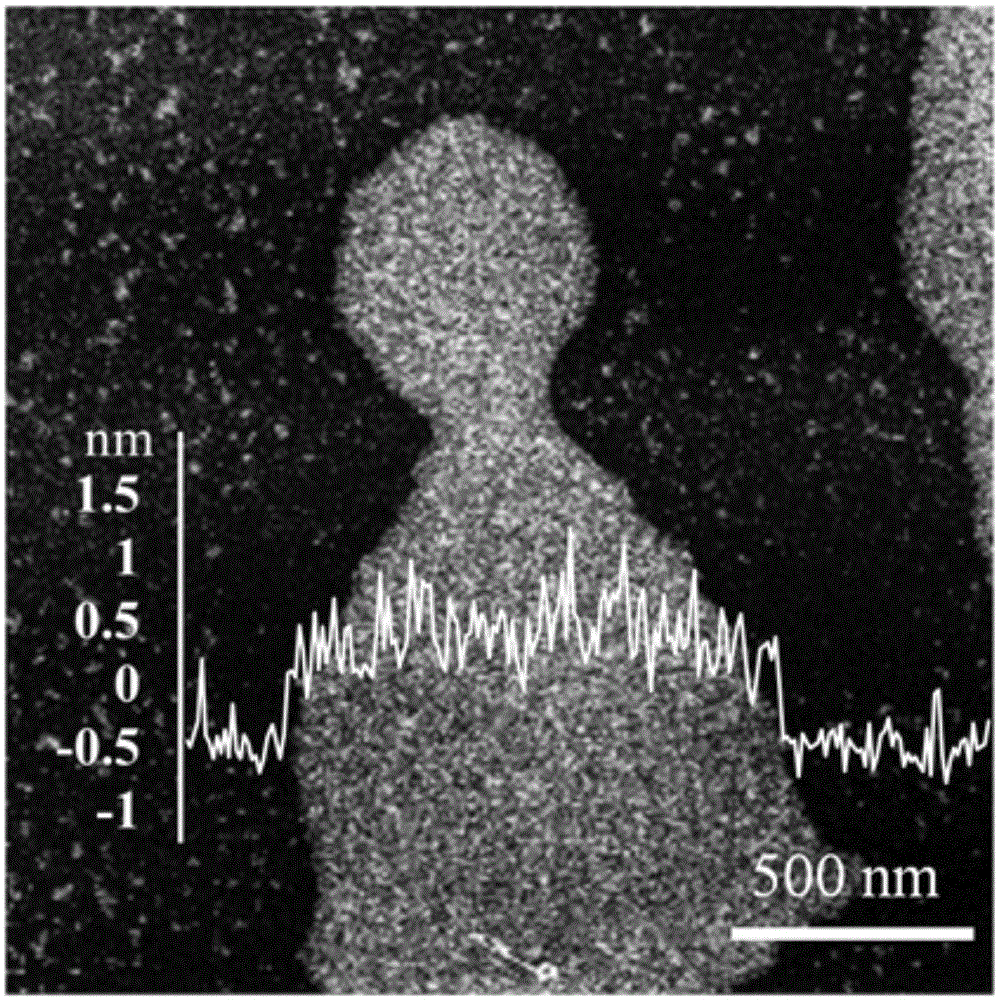

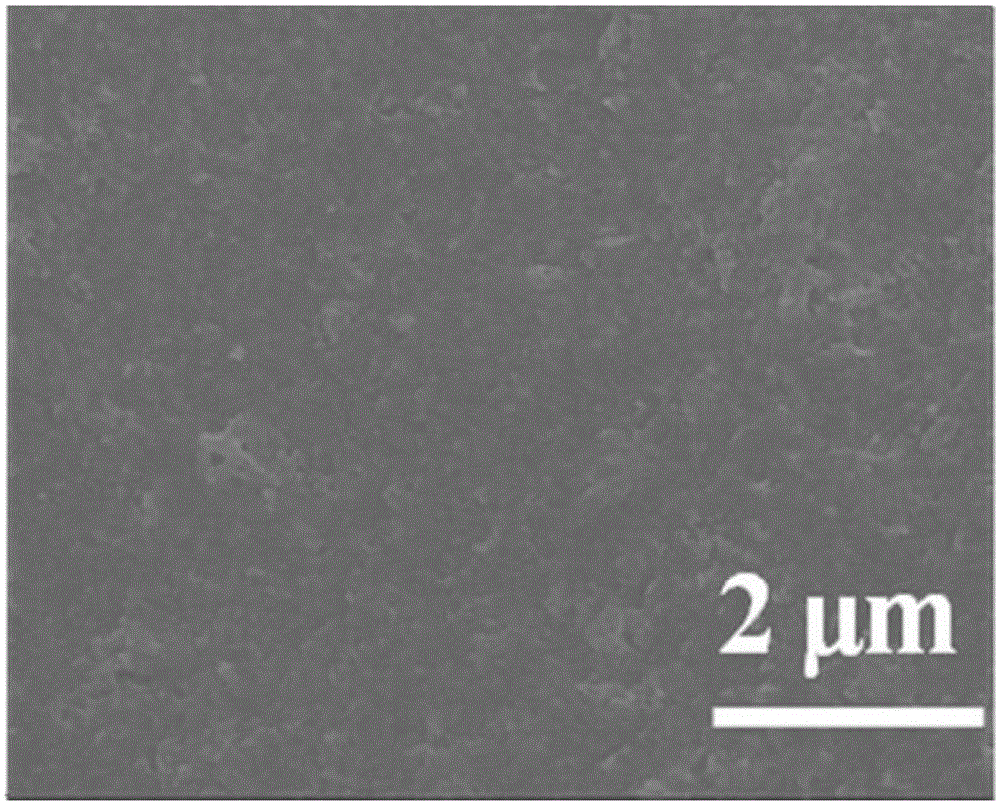

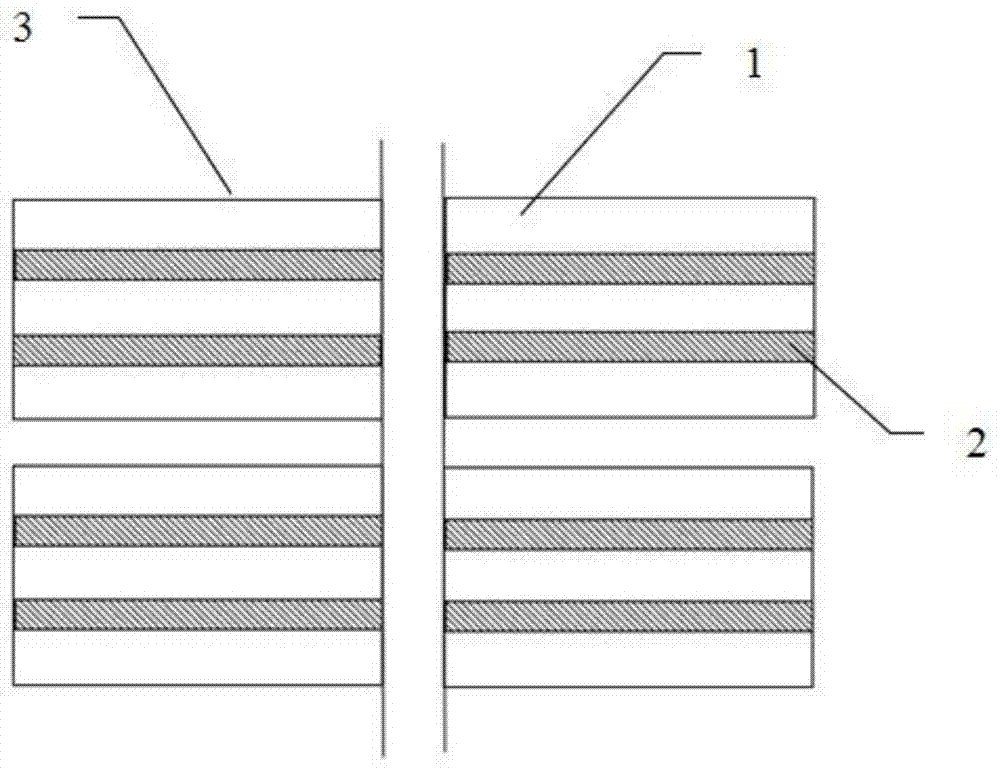

Polysulfone Type Selectively Permeable Hollow Fiber Membrane Module and Process for Manufacturing the Same

ActiveUS20080044643A1Light weightImprove performance stabilityMembranesSemi-permeable membranesPolymer scienceHydrophilic polymers

The invention relates to a hollow fiber membrane module comprising polysulfone type selectively permeable hollow fiber membranes which contain a polysulfone-based resin and a hydrophilic polymer as main components, wherein (A) the content of the hydrophilic polymer in the uppermost layer of the inner surface of the hollow fiber membrane is at least 1.1 times larger than the content of the hydrophilic polymer in the proximate layer of the inner surface of the membrane, and (B) the content of the hydrophilic polymer in the uppermost layer of the outer surface of the hollow fiber membrane is at least 1.1 times larger than the content of the hydrophilic polymer in the uppermost layer of the inner surface of the membrane. The hollow fiber membrane module is exposed to a radioactive ray, on condition that the oxygen concentration of an ambient atmosphere around the hollow fiber membrane is from 0.001 to 0.1%, and that the moisture content of the hollow fiber membrane to the weight thereof is from 0.2 to 7 mass %.

Owner:NIPRO CORP

Method for manufacturing and sintering brick permeable to water with urban sewage sludge and wet-discharged coal ash

The invention provides a method for producing and sintering a water permeable brick by utilizing municipal sludge and wet fly ash. The method is characterized by comprising the following steps that: 1. the raw materials are mixed; 2. the brick is formed; 3. the brick is dried; and 4. the brick is sintered. The method has the advantages that: 1. resources are saved, the environment is protected, and the social benefit is good; 2. organic matter in the mud and the unburned carbon in the fly ash are taken as internal combustion, the resources are saved; the product has high intensity and good permeability of water; 3. the method has good social and environmental benefits in the aspects such as supplementation of urban groundwater, adjustment of urban climate and purification of air; and 4. the production technology is simple, the production cost is low and the method has good economical benefit.

Owner:NANCHANG UNIV

Adjustable and controllable ultrathin two-dimensional nano g-C3N4 film, and preparation method and application thereof

ActiveCN105148744AHighly corrosiveStrong mechanical propertiesSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisAir atmosphereThin membrane

The invention belongs to the technical field of separating film materials, and discloses an adjustable and controllable ultrathin two-dimensional nano g-C3N4 film, and a preparation method and application thereof. The preparation method comprises the following steps of performing heat treatment on dicyandiamide or cyanurtriamide under an inert atmosphere to obtain caked g-C3N4; pulverizing the caked g-C3N4 and calcining under an air atmosphere to obtain g-C3N4 powder; dispersing the g-C3N4 powder in solvent to obtain g-C3N4 two-dimensional nanosheet solution; adding electrolyte solution for modifying; depositing a g-C3N4 two-dimensional nanosheet on a porous carrier of which the pore diameter is greater than 200 nanometers to form a two-dimensional g-C3N4 ultrathin film; and drying to remove the solvent so as to obtain the adjustable and controllable ultrathin two-dimensional nano g-C3N4 film loaded on the porous carrier. The g-C3N4 film is high in water permeability and high in separation efficiency, and has a wide application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Groove-type planting method of nano-selenium Chinese yam

ActiveCN103931386ASuitable for growthIncrease selenium contentBio-organic fraction processingOrganic fertiliser preparationOrganic manureOrganic fertilizer

The invention discloses a groove-type planting method of nano-selenium Chinese yam. Deep soil is crushed and made to float to be mixed with cultivated soil through a deep plowing technology, by adding a certain amount of biological-organic fertilizer containing nano-selenium, the soil is fertile, loose, rich in organics, and is more suitable for growth of the Chinese yam, the selenium content of the Chinese yam is increased, and the nutrition and medicinal value of the Chinese yam are increased. A plurality of U-shaped planting grooves are arranged for planting the Chinese yam, the Chinese yam can transversely grow along the U-shaped planting grooves and is easy to plant and harvest, labor intensity is relieved, and production cost is reduced. Meanwhile, the planting grooves are made of materials with mesh holes, palm bark is laid inside the planting grooves, the breathability and water permeability of the planting grooves can be effectively improved, and waterlogging and droughts are both effectively prevented. A double-layer planting method is adopted, the utilization area of land is effectively increased, and production and income are both increased largely.

Owner:哈威光电科技(苏州)有限公司

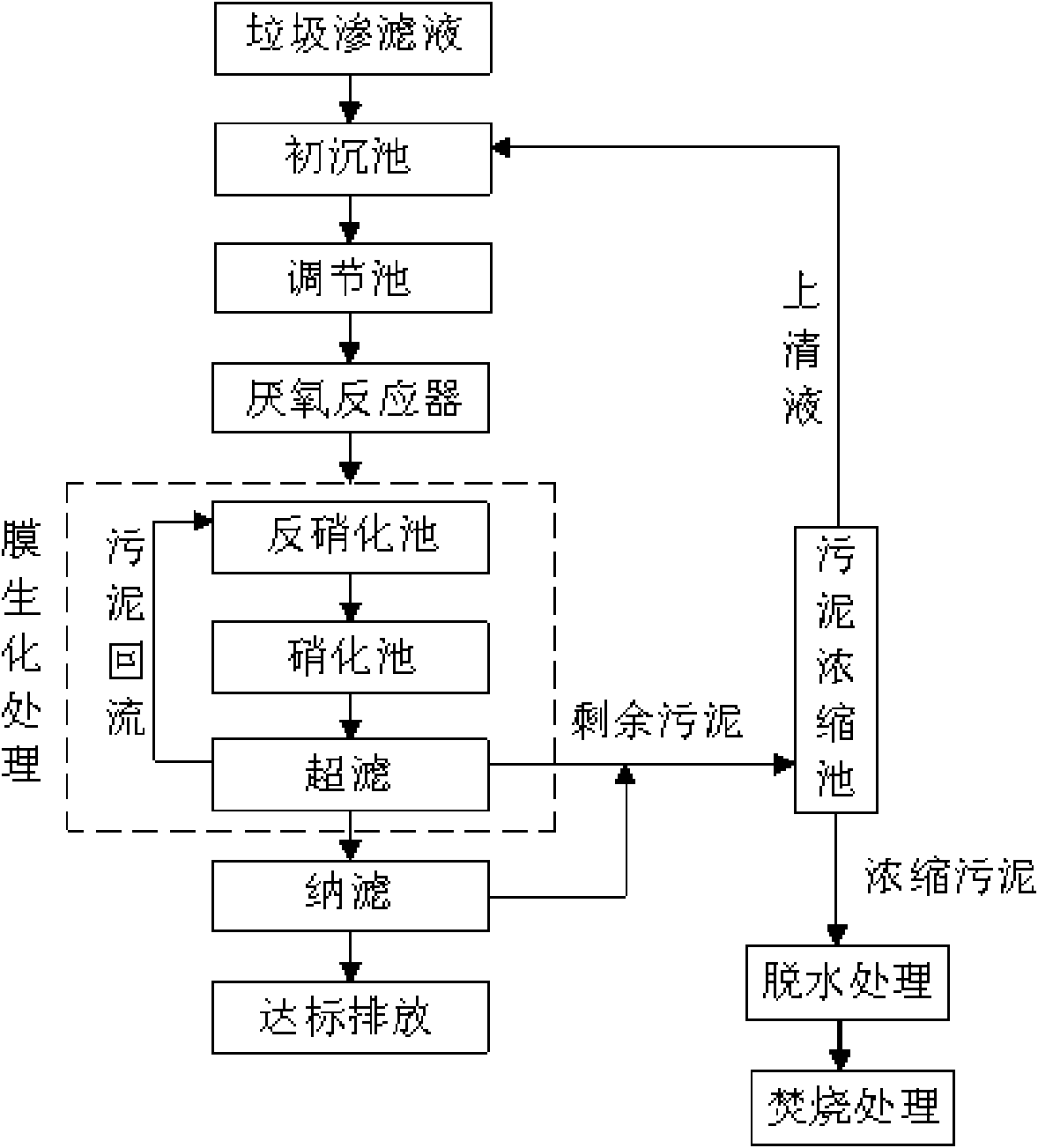

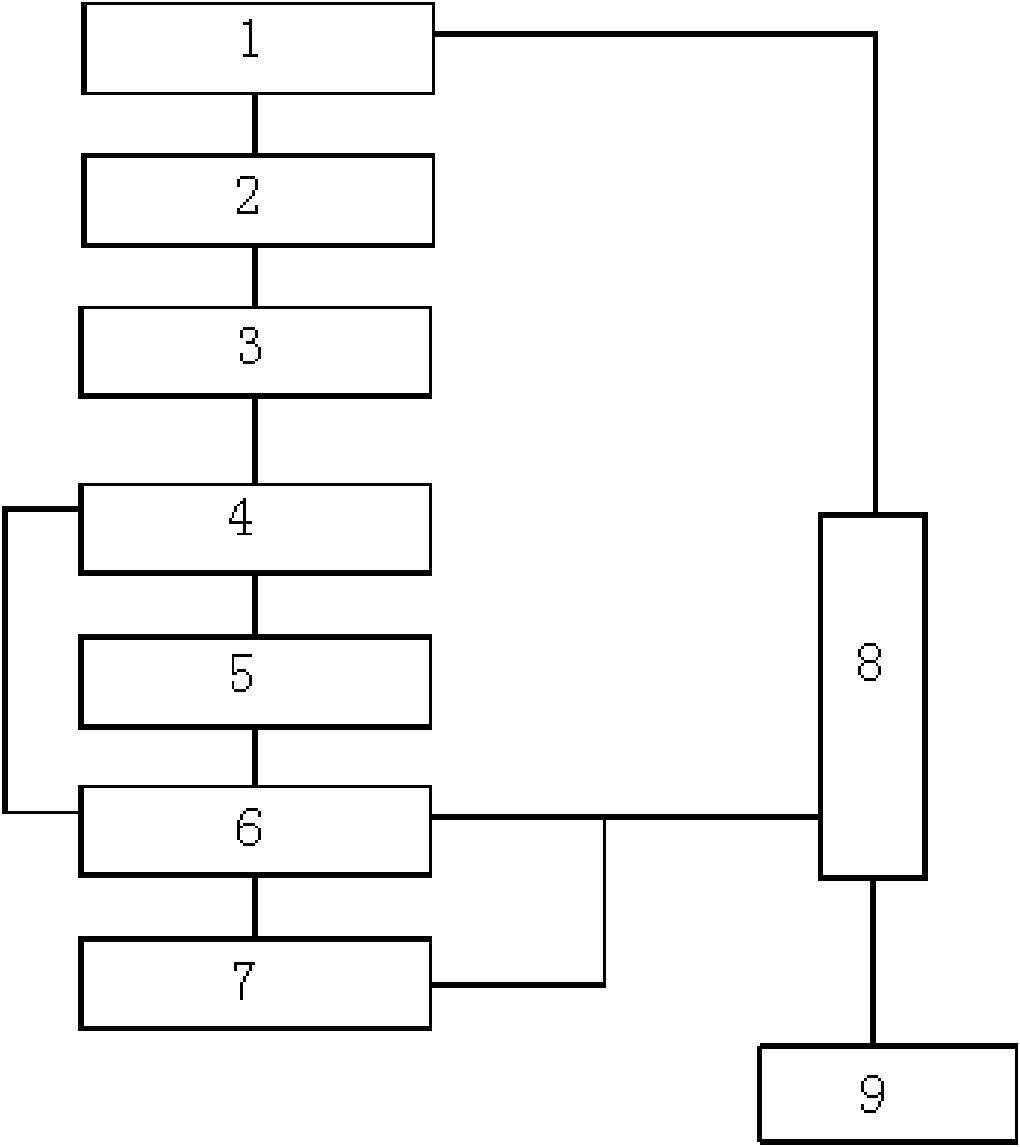

Method and device for treating garbage percolate

ActiveCN101597131AAchieving zero emissionsRelieve stressSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesHigh concentrationAfter treatment

The invention discloses a method and a device for treating garbage percolate, wherein the method comprises the steps of pretreatment, anaerobic treatment, membrane biochemical treatment, nanofiltration treatment, sludge treatment and the like; the device comprises a primary sedimentation tank (1) and an adjusting tank (2), the adjusting tank (2) is connected with an anaerobic reactor (3), the anaerobic reactor (3) is connected with a denitrification tank (4), and the denitrification tank (4) is communicated with a nitrification tank (5); and the nitrification tank (5) is connected with an ultrafiltration apparatus (6), and the ultrafiltration apparatus (6) is connected with a nanofiltration device (7). The method and the device achieve COD degradation of high-concentration wastewater so that the COD of high-concentration COD of 50,000 reaches about 50 after treatment and reaches the standard of industrial reuse water, thus the method and the device achieve zero discharge of the percolate, initiate a new attempt to treat high-concentration percolate, and fill up the domestic blank.

Owner:汕头市澄海洁源垃圾发电厂有限公司

Clay-based compound sand consolidating material

ActiveCN102229804APermeableReduce evaporationOrganic fertilisersSoil conditioning compositionsSoil scienceEngineering

The invention discloses a clay-based compound sand consolidating material and belongs to the technical field of sand prevention and consolidation. The clay-based compound sand consolidating material is made of clay, sodium silicate, lewis acid, organic polymer and the like according to a certain ratio. The material is added with water to form solution at certain concentration by adding water, andthe solution is sprayed onto the surface of sand and naturally dries in an open environment to form a consolidated skin; or the clay and sand are uniformly mixed according to a certain ratio and pilled in grids, then solution prepared from the sodium silicate, lewis acid, organic polymer and water is sprayed onto the surface of the grids and naturally dries in an open environment to form consolidated skin, and thus, sand preventing and consolidating clay grids are formed. The consolidated skin of the sand consolidating material disclosed by the invention has high pressure strength, high waterpermeability, high weather resistance, and good sand consolidating effect; and the raw materials are readily available, the sand consolidation process is simple, the cost is low and the clay-based compound sand consolidating material is suitable to be promoted in a large area in desert regions.

Owner:NORTHWEST NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com