Method for preparing polyvinylidene fluoride porous membrane

A technology of polyvinylidene fluoride and porous membrane, which is applied in the direction of chemical instruments and methods, membranes, membrane technology, etc., can solve the problem of unsatisfactory performance and mechanical strength, which affects the application of polyvinylidene fluoride porous membrane, polyvinylidene fluoride Uneven membrane pore structure and other problems, to ensure water flux and strength, improve extensibility and toughness, and good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of polyvinylidene fluoride porous membrane of the present invention is carried out according to the following steps:

[0031] 1) mixing polyvinylidene fluoride resin with diluent; wherein the mass percentage of polyvinylidene fluoride is 30wt%-60wt%, and the mass percentage of diluent is 70wt%-40wt%;

[0032] 2) Put the mixture in step 1) into a high-temperature stirred tank, heat up to 160°C-220°C to form a polymer homogeneous solution, and let it stand for defoaming;

[0033] 3) The polymer homogeneous solution in step 2) is directly scraped and coated on the support net to form a flat membrane or spun into a hollow fiber membrane through a spinneret, and then the obtained flat membrane or hollow fiber membrane is immersed in a cooling liquid to cool, Make the film-forming solution undergo phase separation, and finally solidify to form a film;

[0034] 4) Extracting the diluent in the membrane obtained in step 3) with an alcohol or ether extrac...

Embodiment 1

[0047] The weight average molecular weight is 370,000 polyvinylidene fluoride resin and diphenyl carbonate, its composition is that the mass percentage of polyvinylidene fluoride resin is 30wt%, and the mass percentage of diphenyl carbonate is 70wt%, put into Heat up to 220°C in a high-temperature stirred tank, stir and mix evenly to form a homogeneous polymer solution, and let stand for 24 hours. Then, the polymer homogeneous solution was directly scraped on the support net to form a flat film with a film thickness of 200 μm, and immersed in a cooling liquid bath at 30 ° C to solidify the solution into a film by phase separation. The cooling liquid bath was a water bath. The cured flat film was extracted with ethanol and dried.

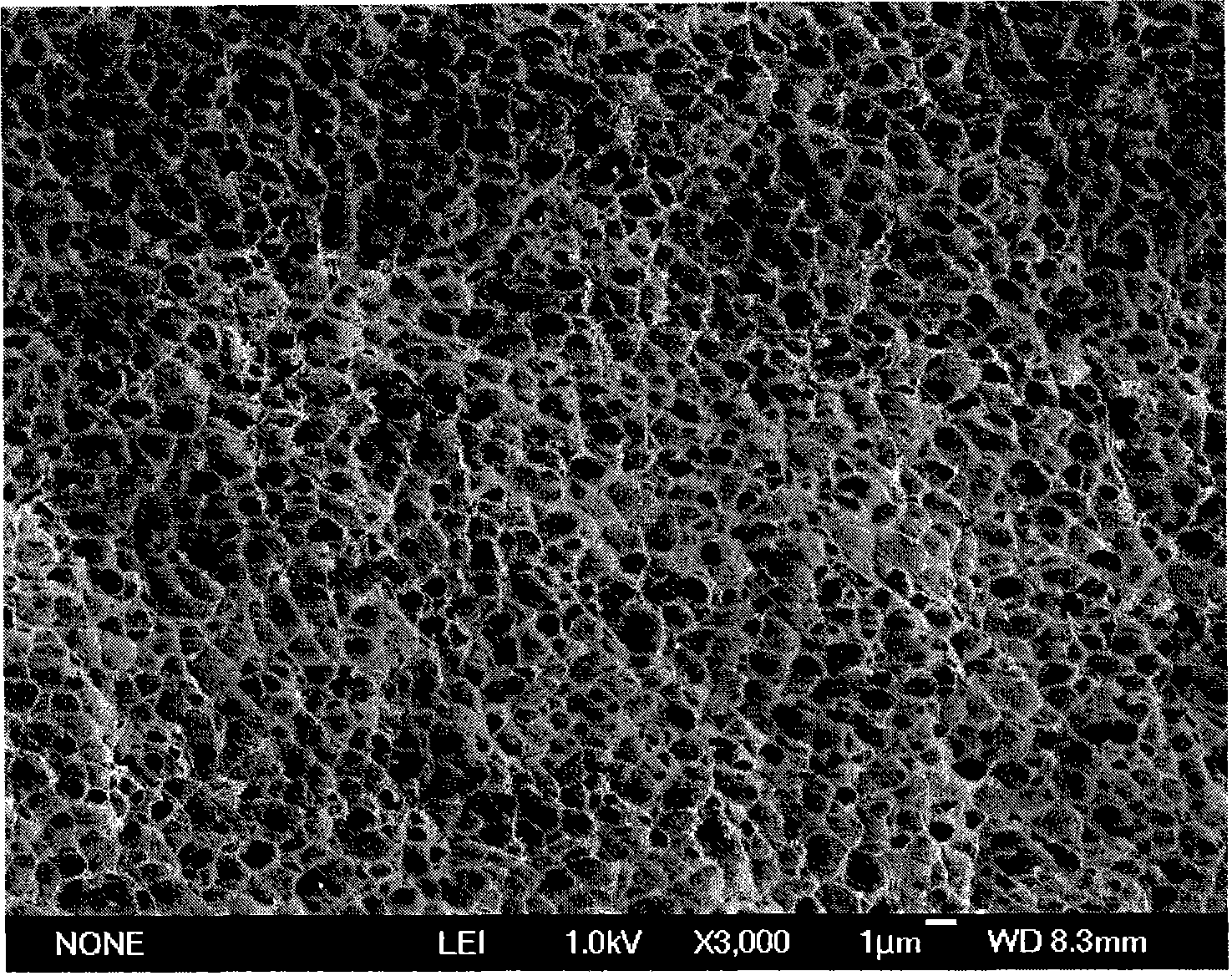

[0048] The cross section of the membrane has a uniform spongy structure with no obvious skin structure on the surface. The membrane pore diameter is about 0.8 μm, the porosity is 76%, the breaking strength is 5.5MPa, the elongation at breaking is 30%...

Embodiment 2

[0050] The weight average molecular weight is 800,000 polyvinylidene fluoride resin and diphenyl carbonate, its composition is that the mass percent composition of polyvinylidene fluoride resin is 40wt%, and the mass percent composition of diphenylcarbonate is 60wt%, put into Heat up to 200°C in a high-temperature stirred tank, stir and mix evenly to form a homogeneous polymer solution, and let stand for 24 hours. Then, the polymer homogeneous solution was directly scraped on the support net to form a flat film with a film thickness of 200 μm, and immersed in a cooling liquid bath at 60 ° C to solidify the solution into a film by phase separation. The cooling liquid bath was a water bath. The cured flat film was extracted with ethanol and dried.

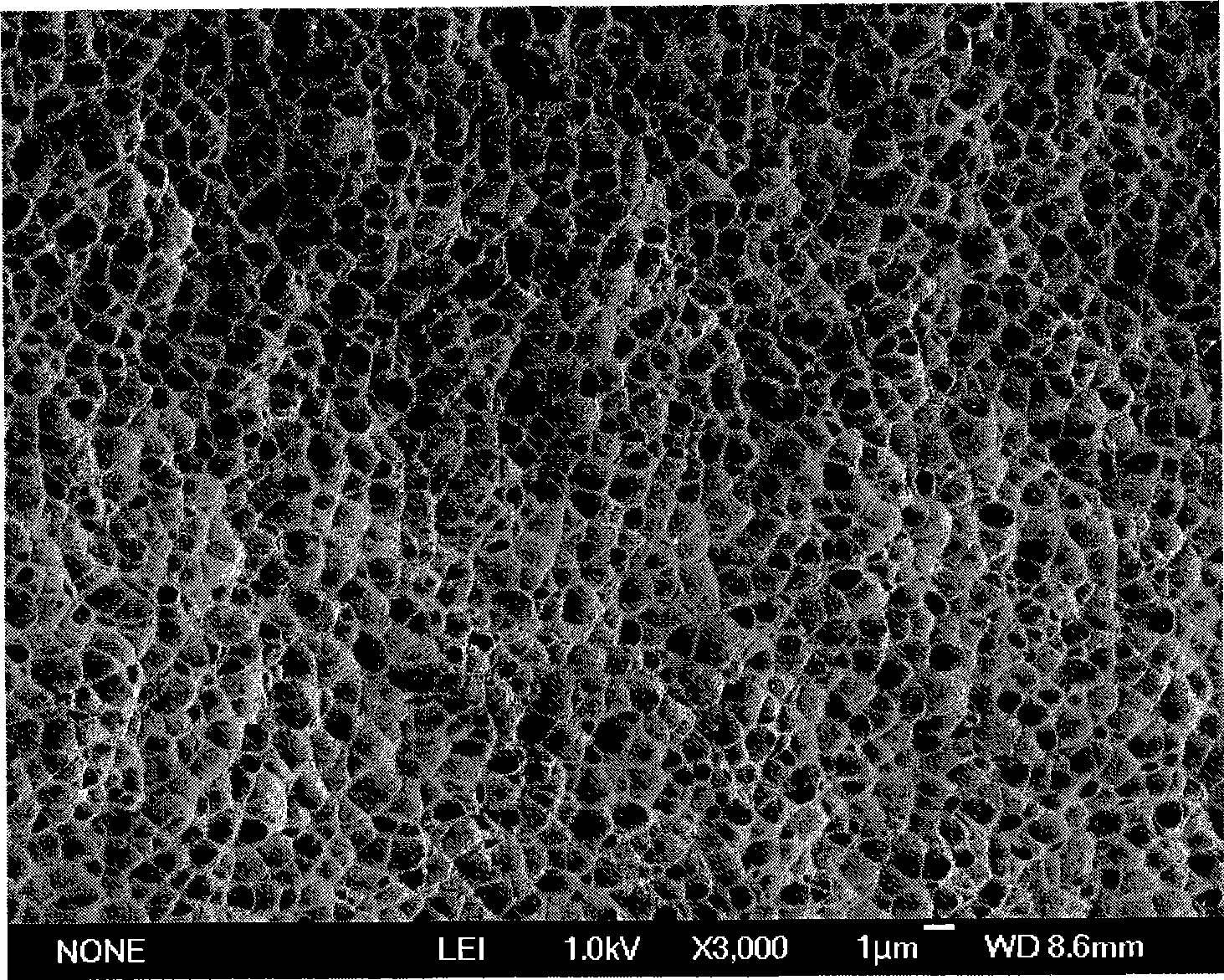

[0051] The cross-section of the membrane is a uniform sponge-like structure, the pore diameter of the membrane is about 0.6μm, the porosity is 70%, the breaking strength is 6.7MPa, the elongation at breaking is 36%, and the pure wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com