Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1226 results about "Surface friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

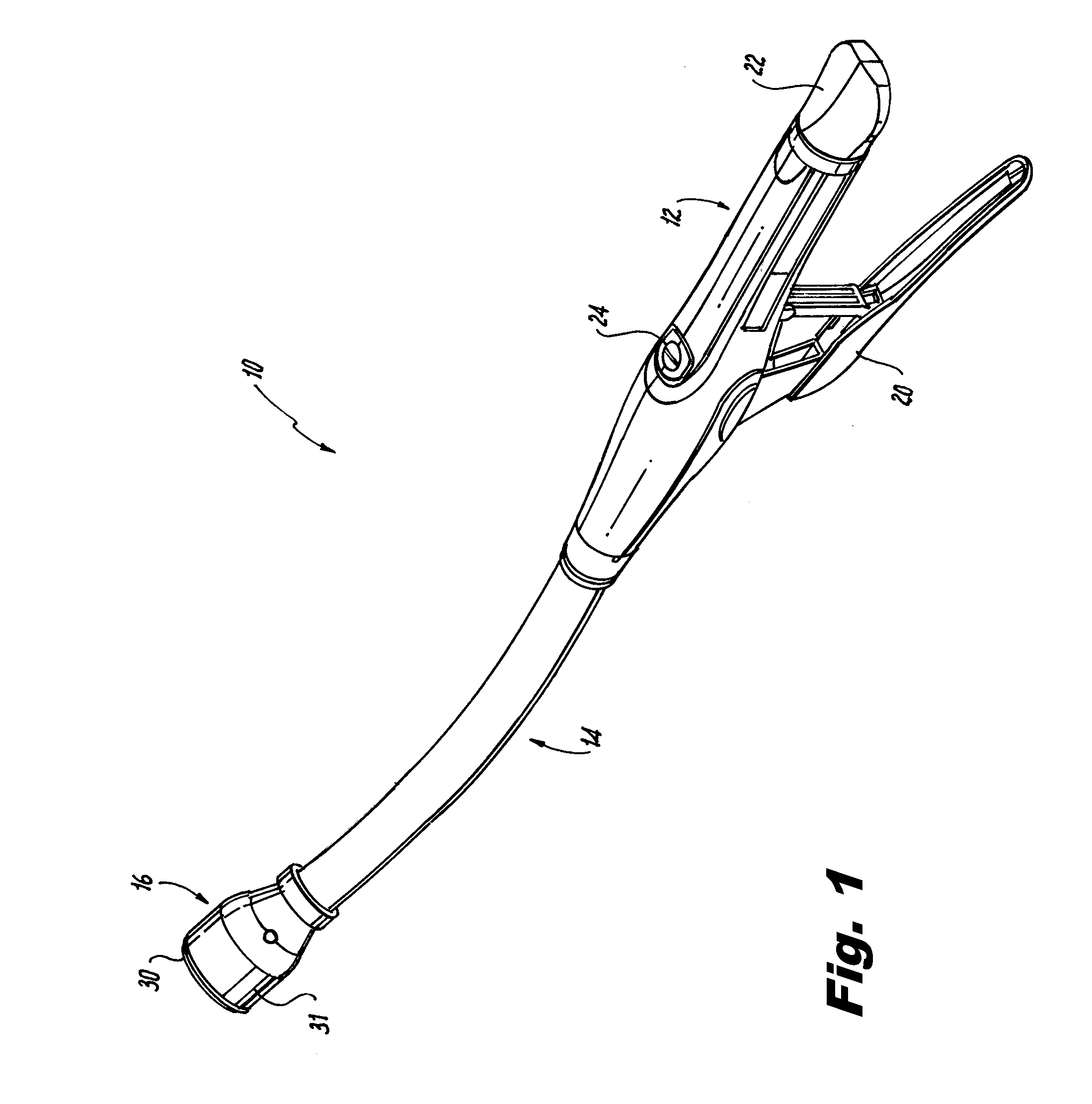

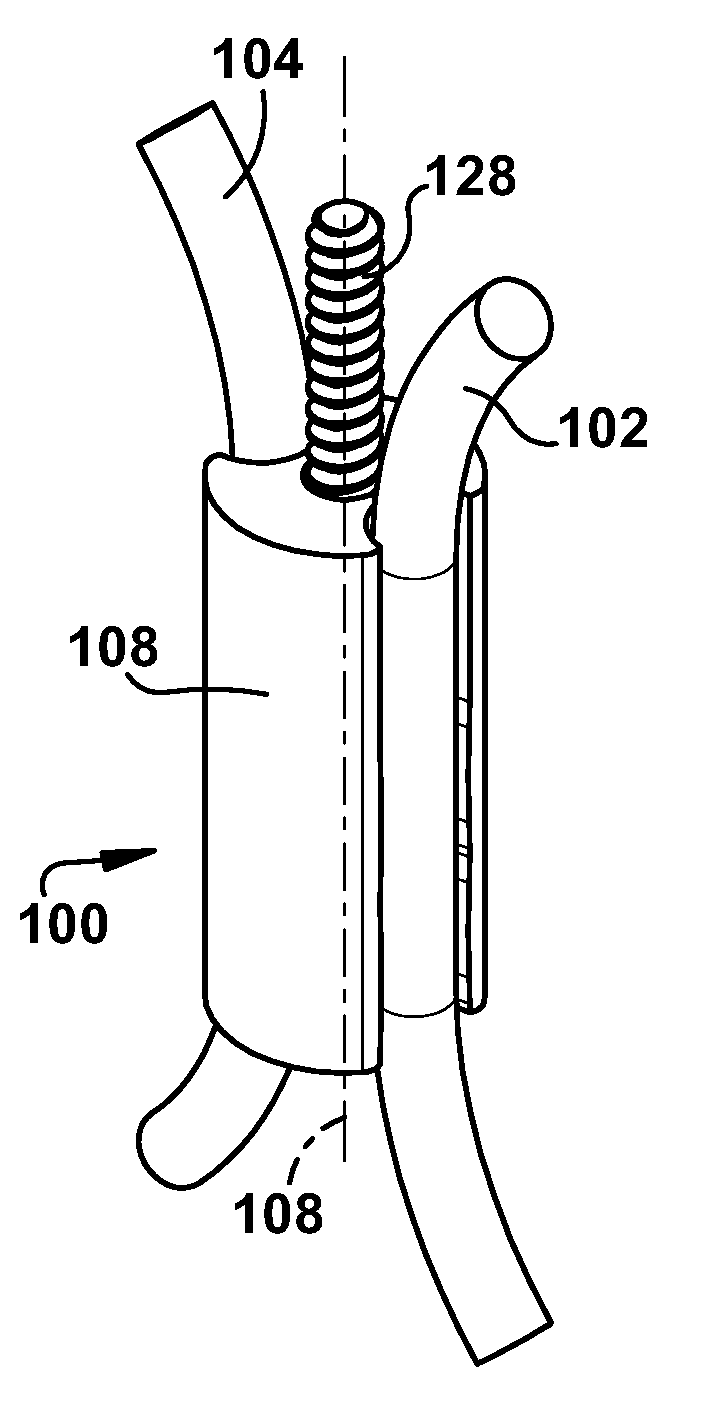

Multilumen body for an implantable medical device

A splined multilumen body for use in elongated medical devices is provided for carrying multiple conductors, wires or cables to multiple device components along the device body. Open lumens may be provided through which medical devices or therapies may be delivered. The multilumen body is constructed from a generally tubular outer member having inward-radiating splines that mate with outward-radiating splines on a generally tubular inner member. Lumens formed between sets of mated splines isolate conductors carried therein. Interaction of mated splines provides good torque transfer between outer and inner members. Materials for fabricating outer and inner members may be selected to achieve desired torque transfer properties, flexibility, and surface friction.

Owner:MEDTRONIC INC

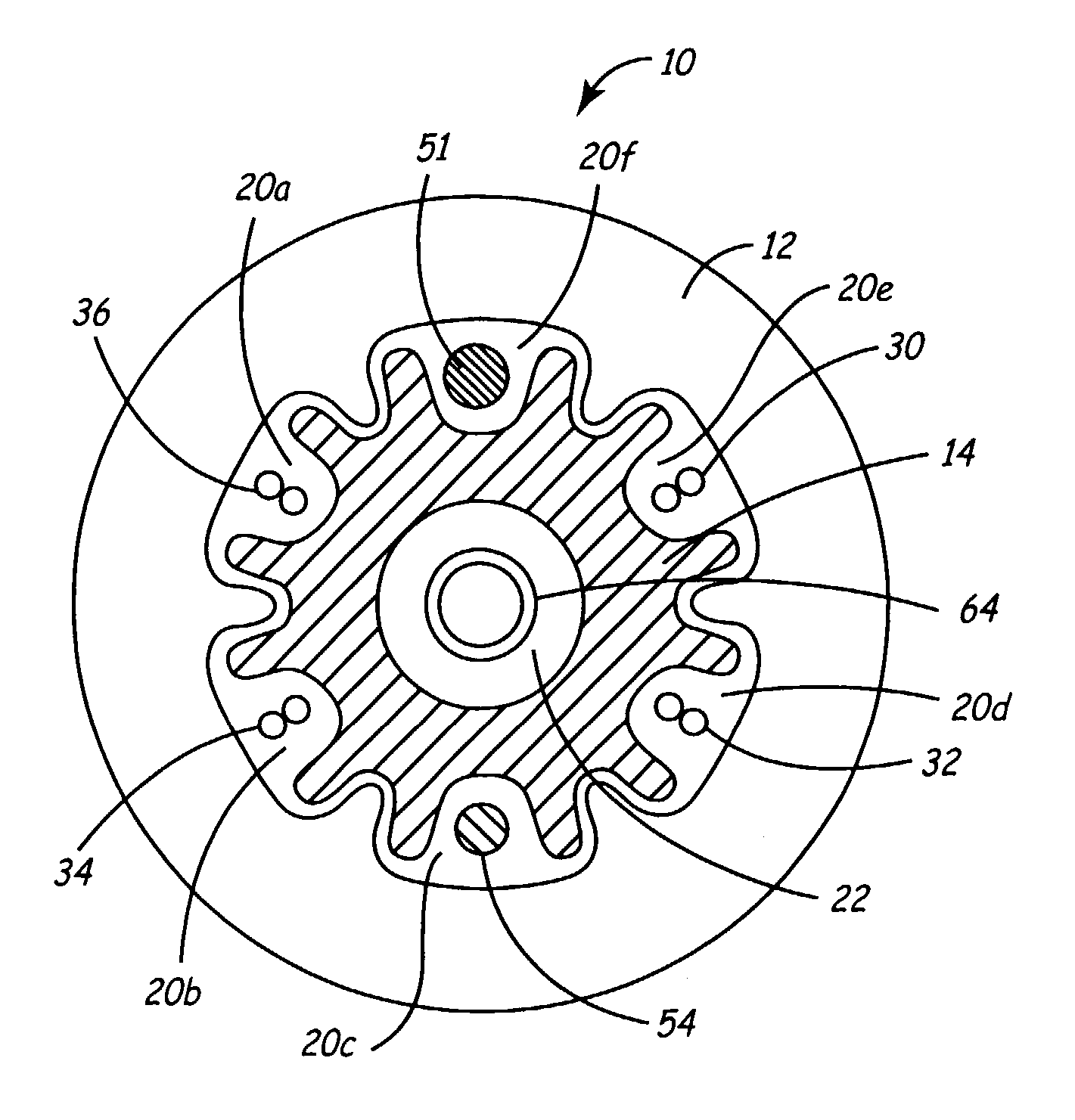

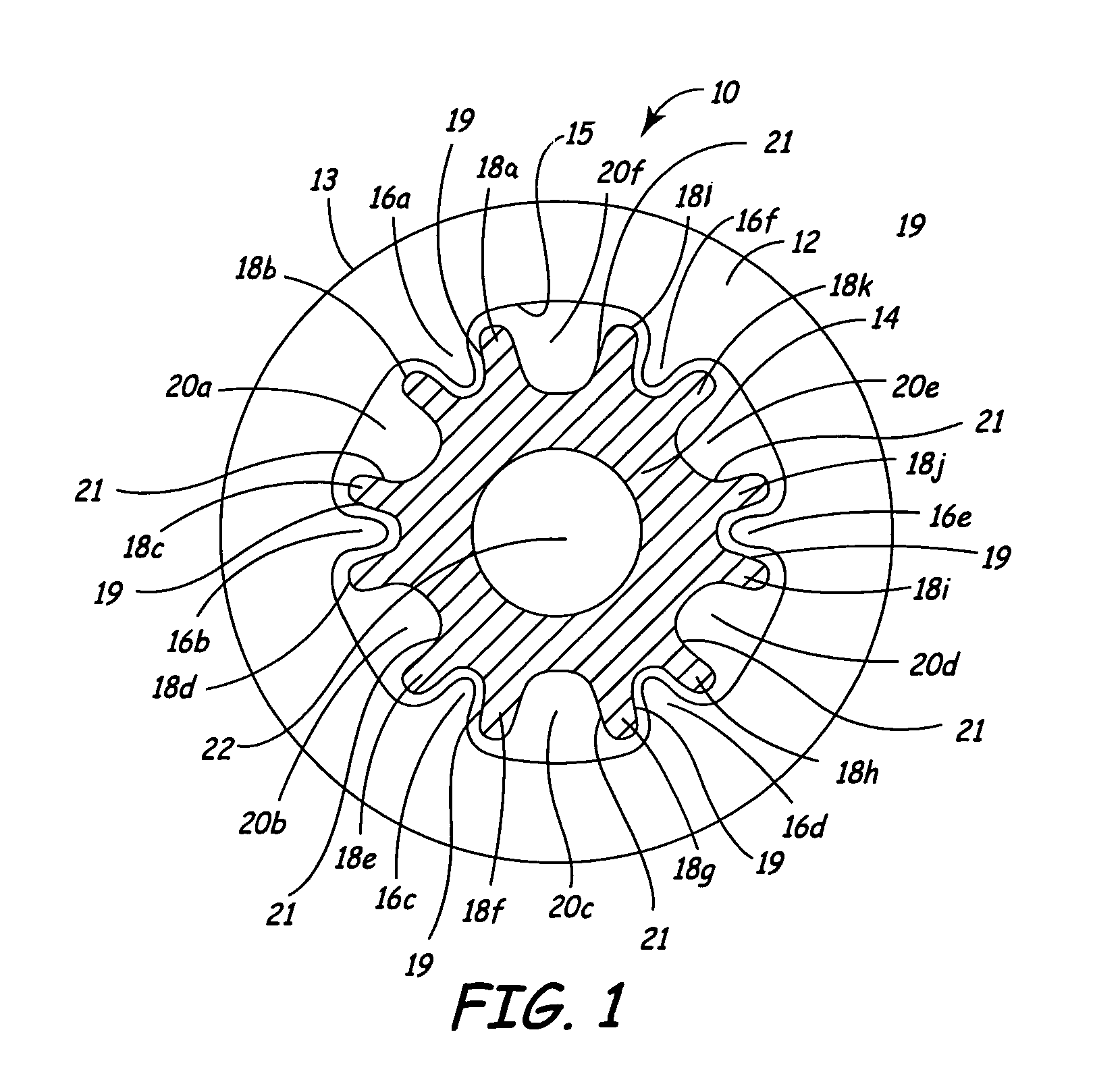

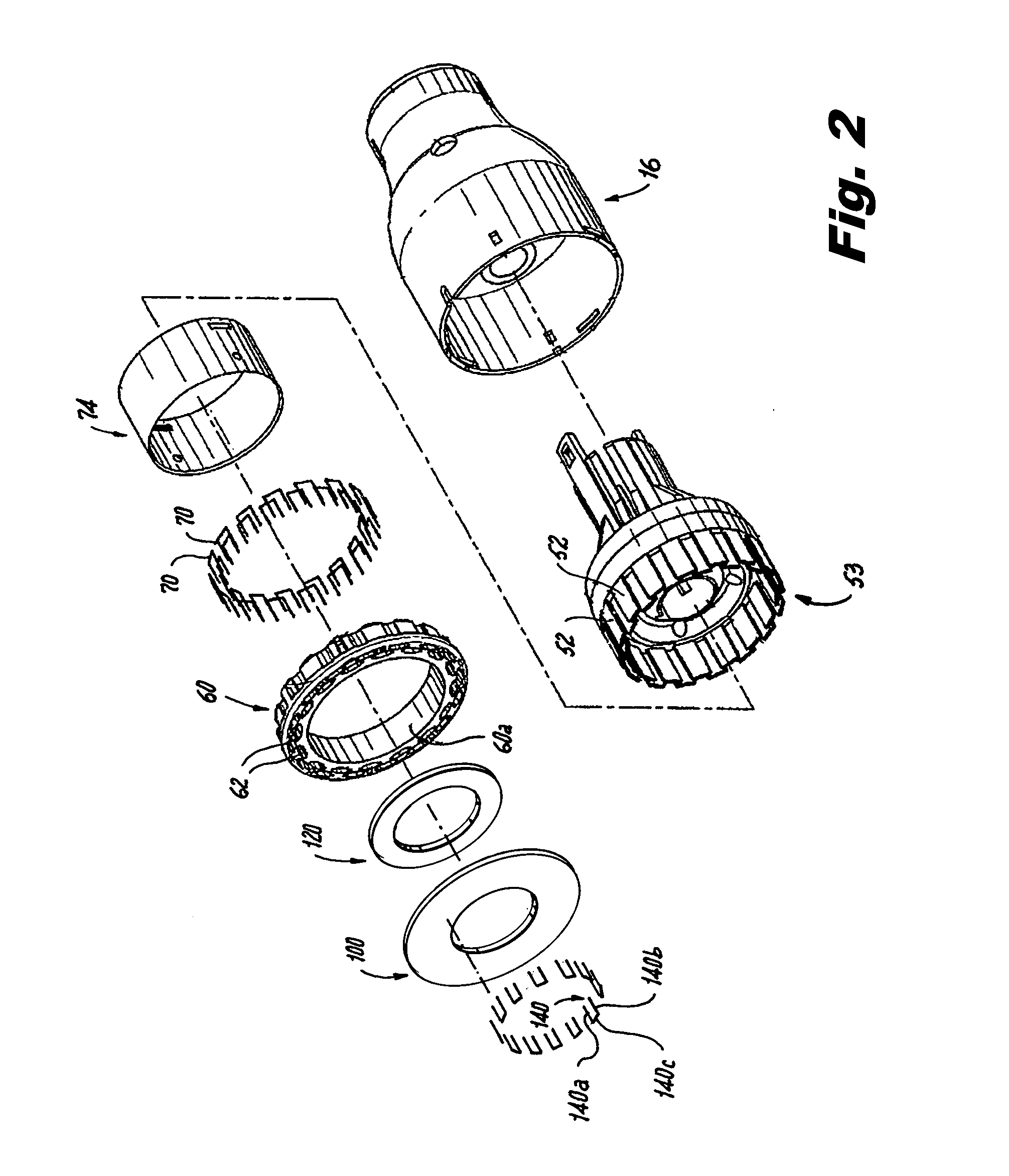

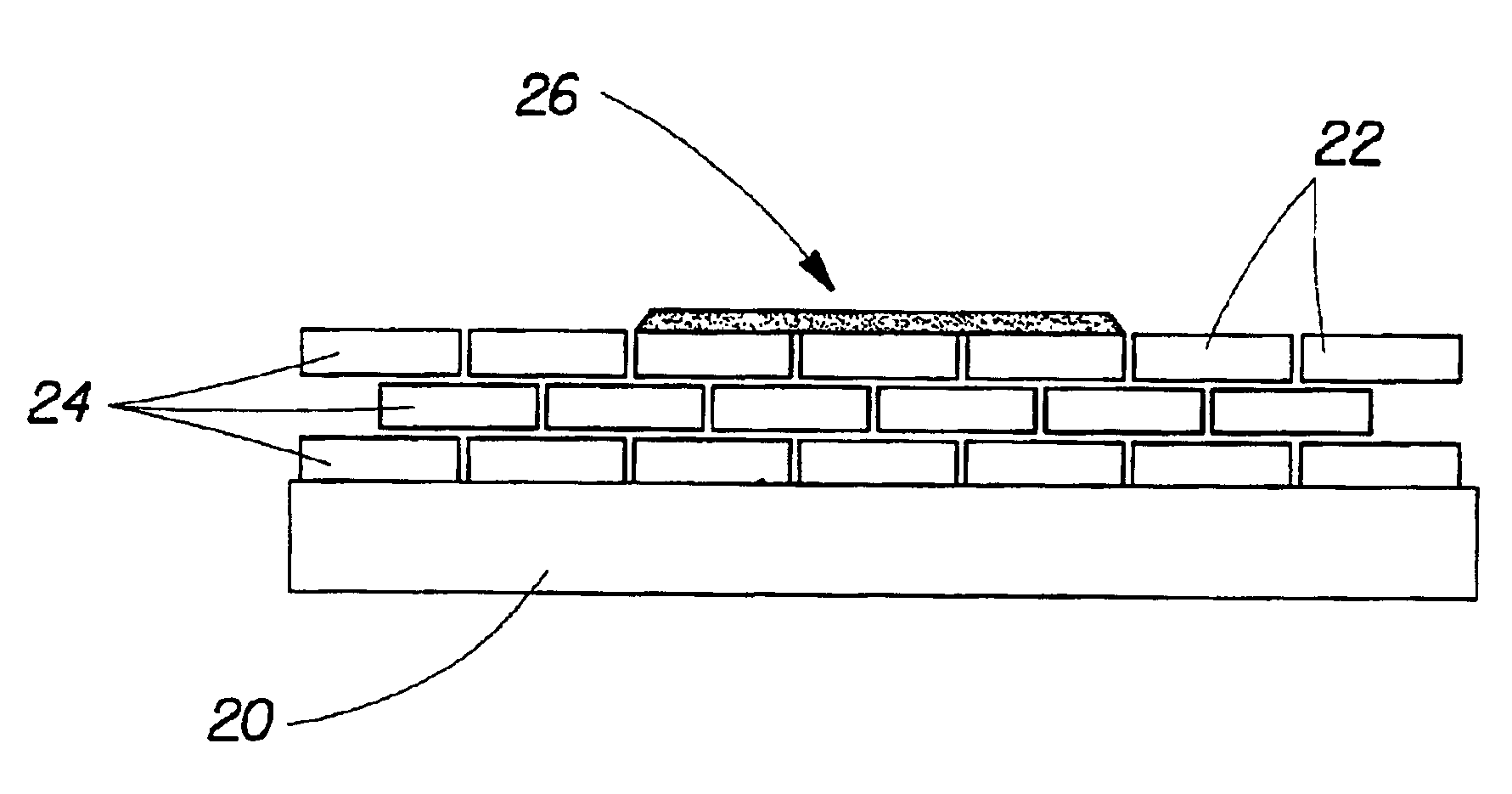

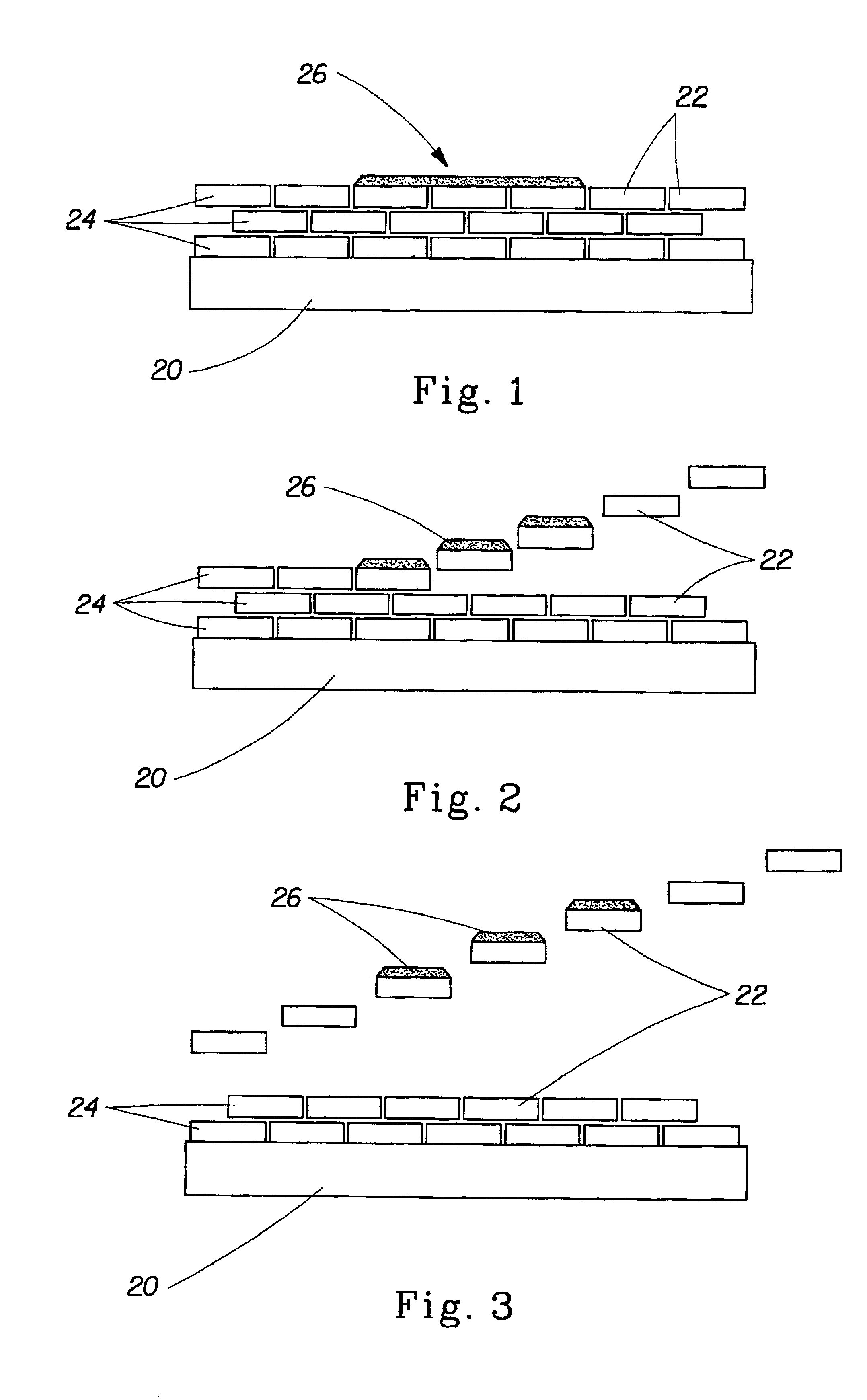

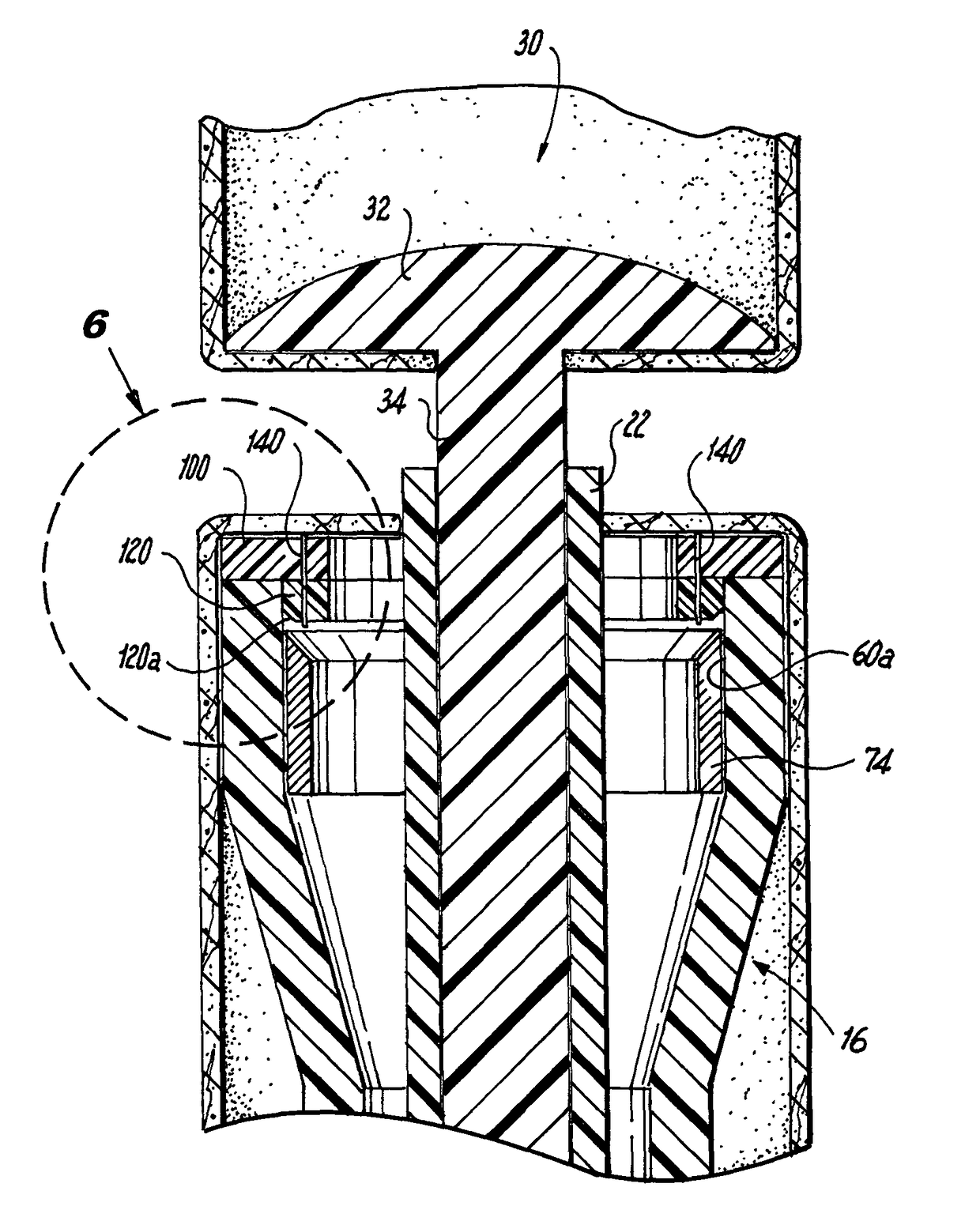

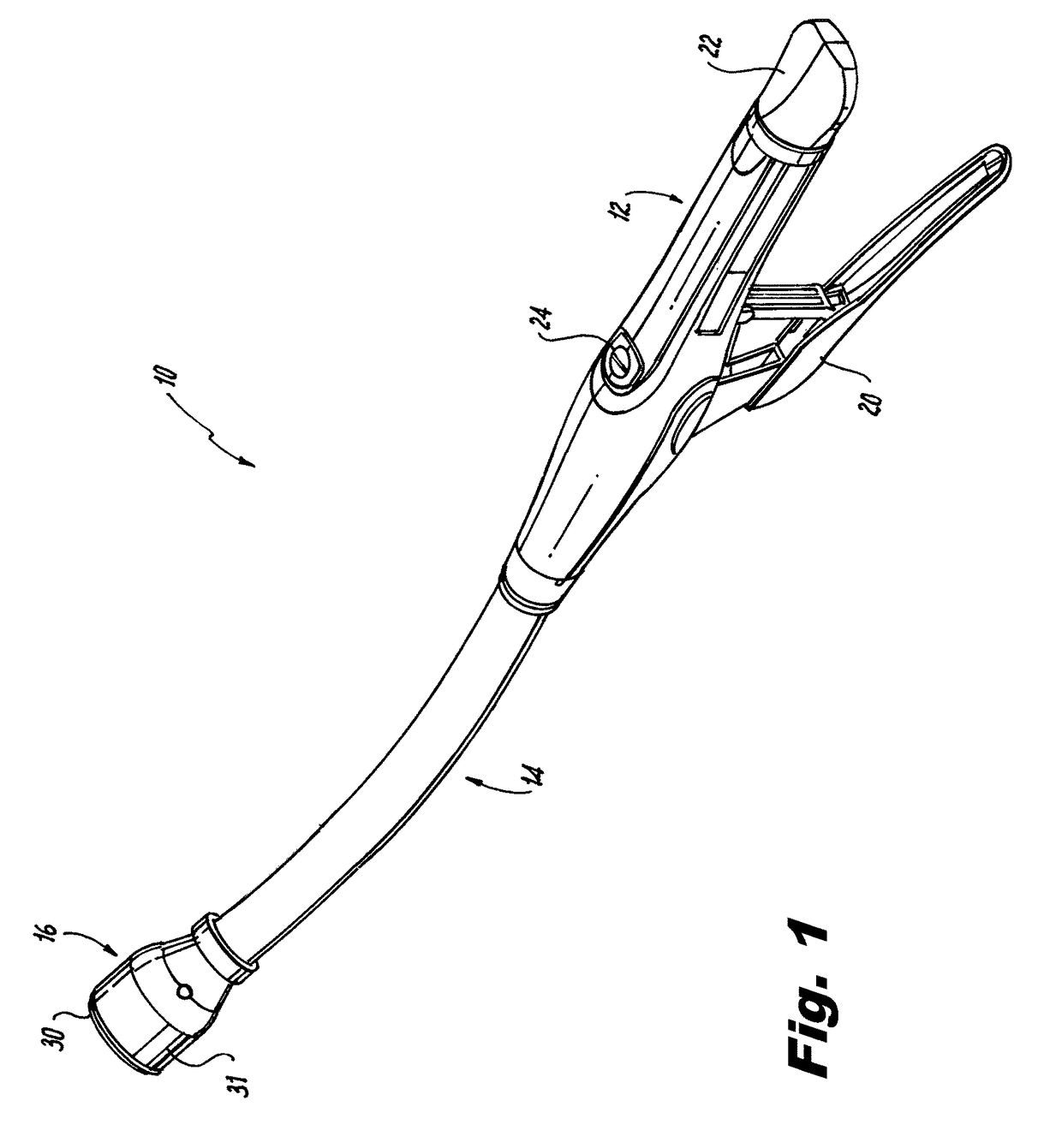

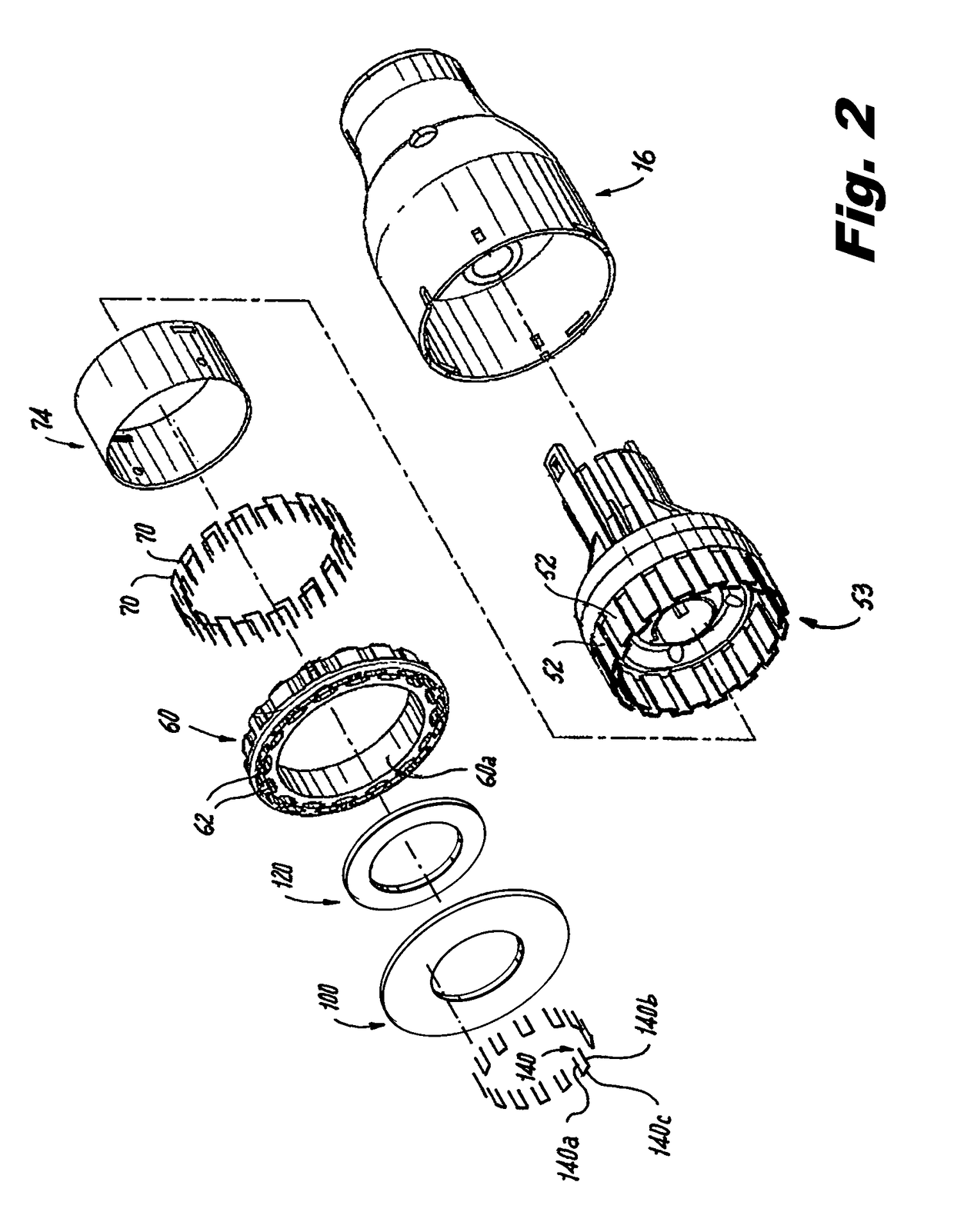

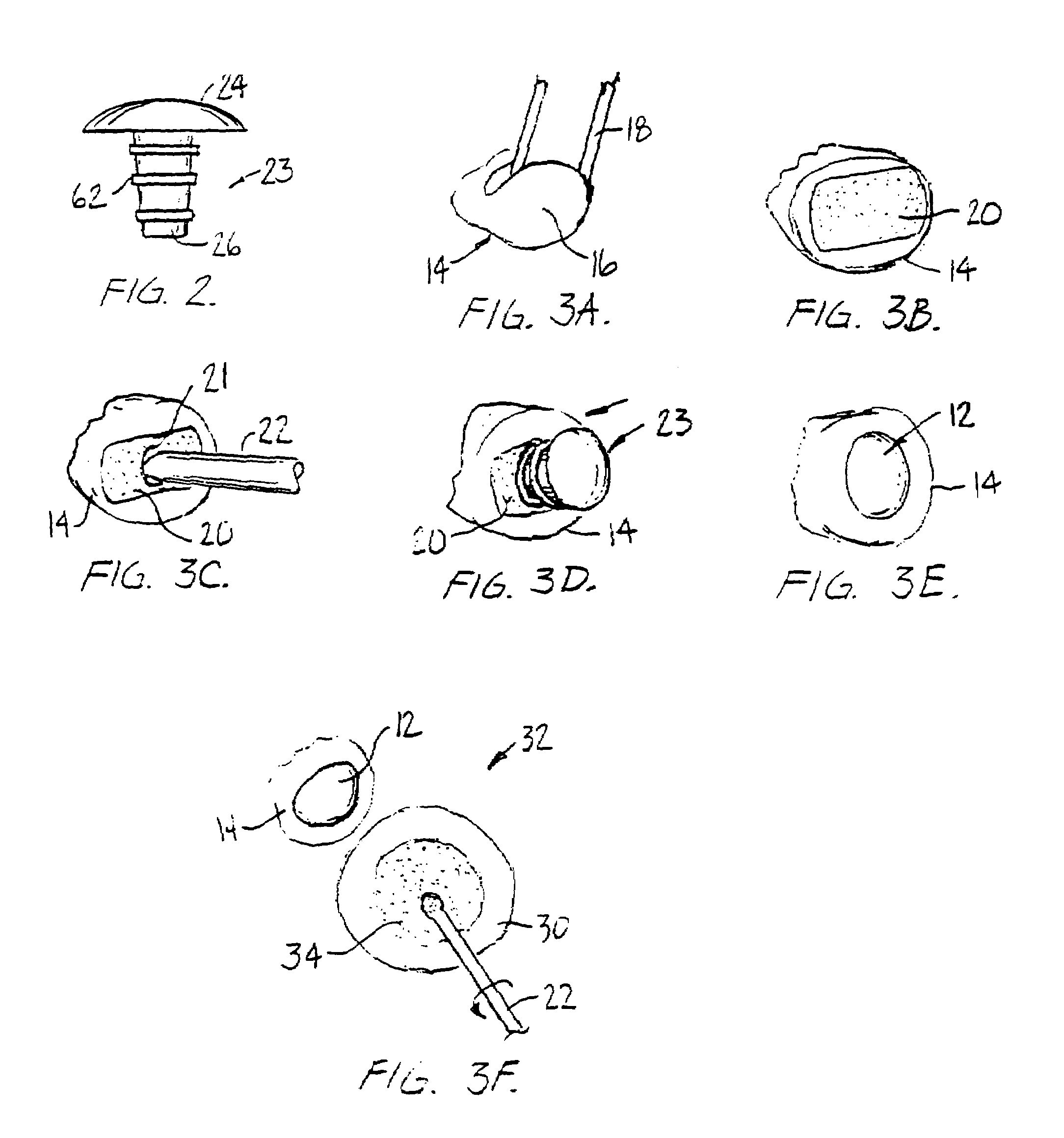

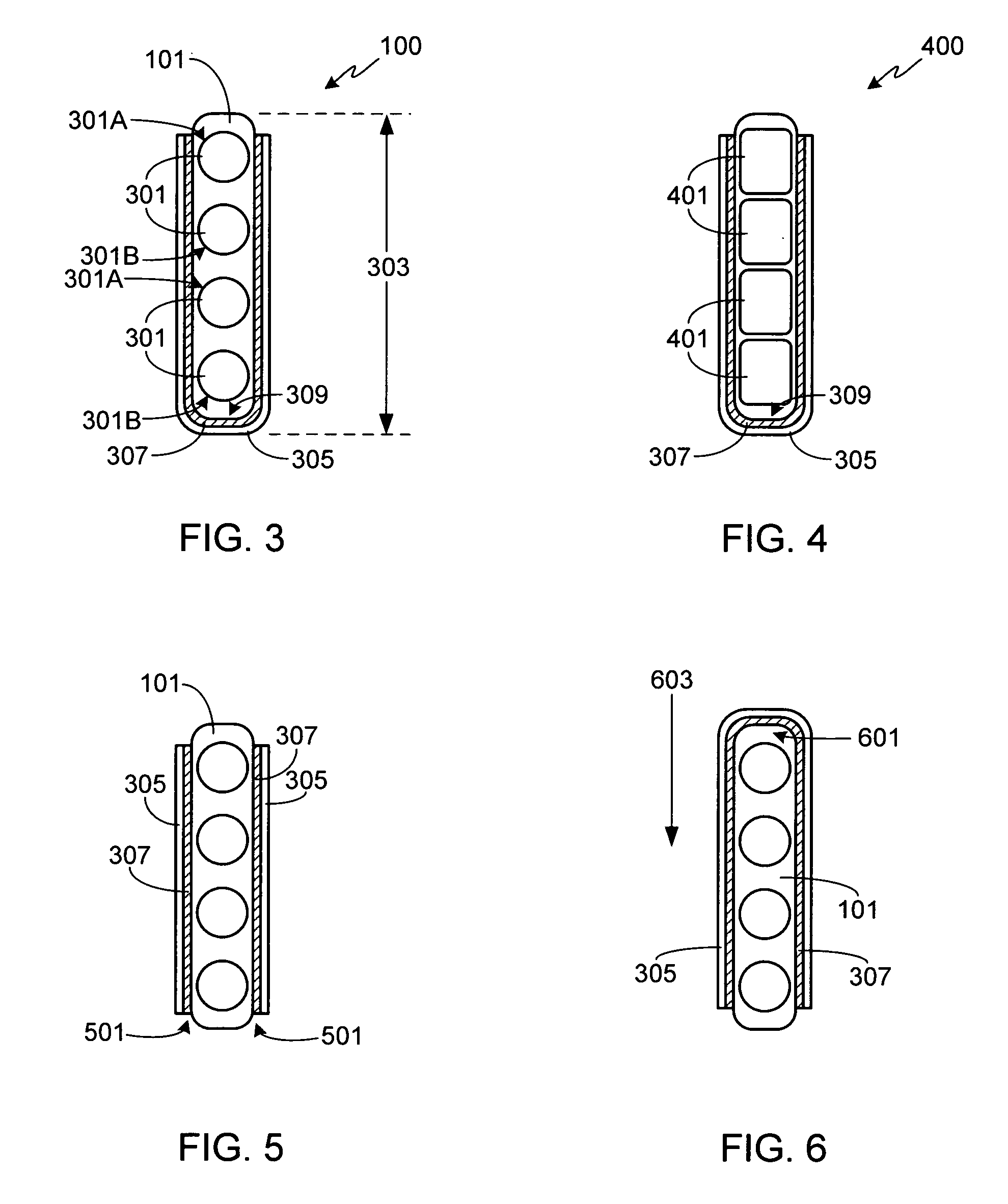

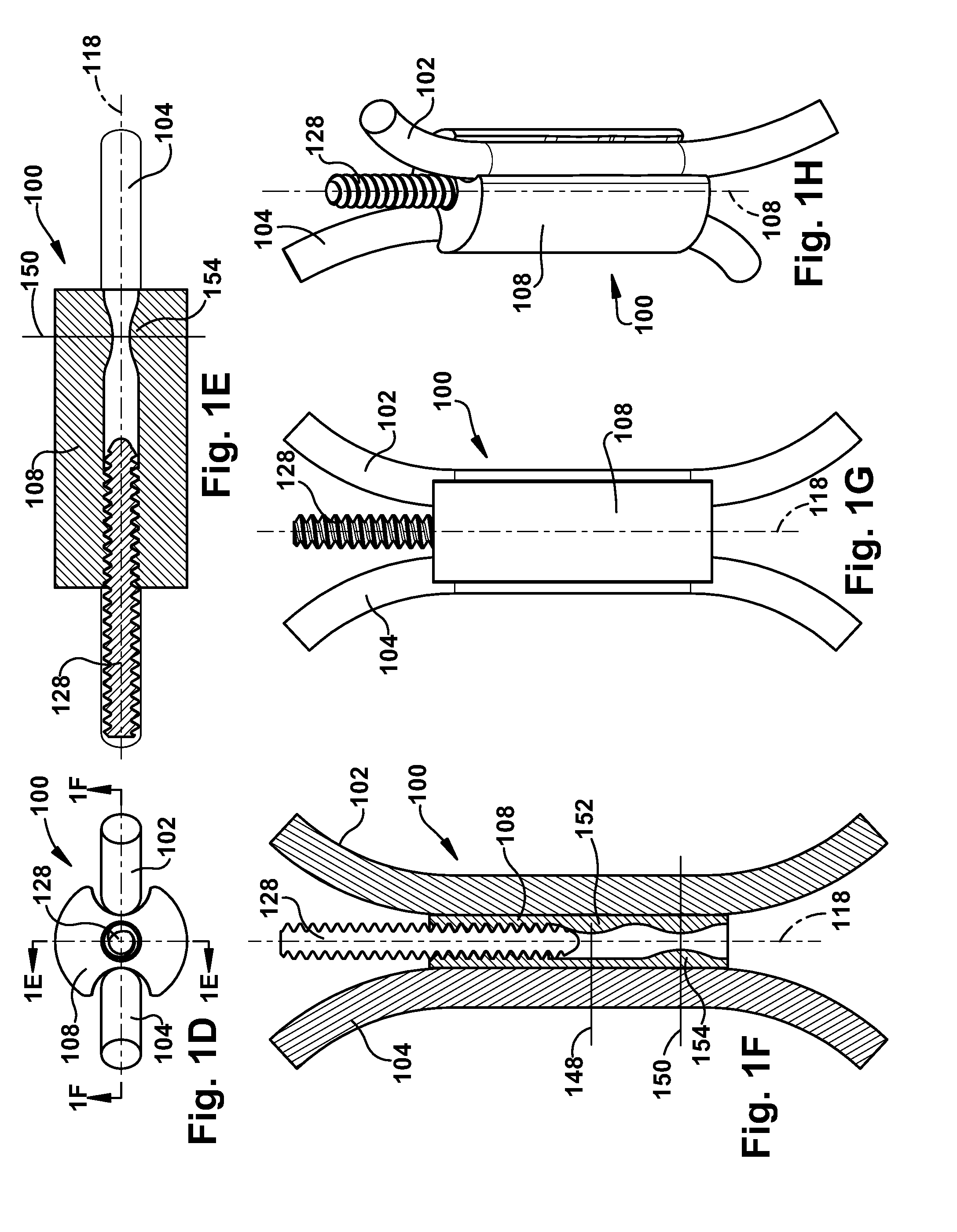

Circular surgical stapling device including buttress material

A buttress material and mounting structure assembly is provided for use with a circular surgical stapling device. The assembly comprises a ring-like mounting structure sized to have an outer diameter that frictionally engages a radial inner surface of a staple cartridge assembly, wherein the mounting structure is disposed within the radial inner surface of the staple cartridge assembly; an annular buttress material overlaying a tissue facing surface of the staple cartridge assembly, the annular buttress material defining an outer radial terminal edge extending radially beyond a pair of annular arrays of staple receiving slots, and a radial inner terminal edge extending across the mounting structure; and at least one suture securing the buttress material to the mounting structure.

Owner:TYCO HEALTHCARE GRP LP

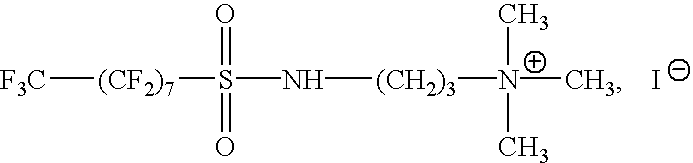

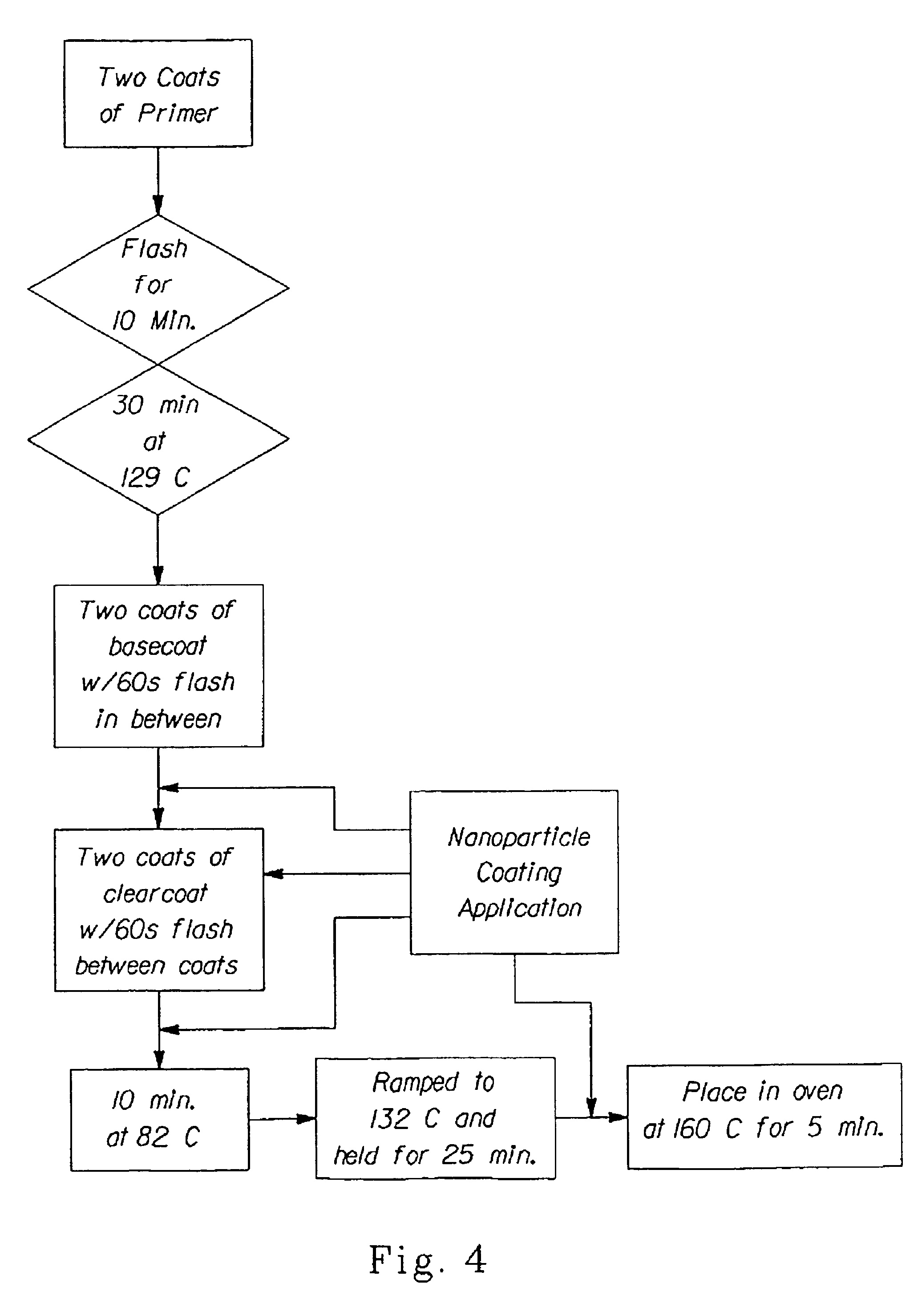

Enhancement of color on surfaces

InactiveUS6872444B2Easy to controlGood removal effectInorganic/elemental detergent compounding agentsPigmenting treatmentNanoparticleMaterials science

Coating compositions, methods and articles of manufacture comprising a nanoparticle system employing same to impart surface modifying benefits for all types of soft surfaces, and in some cases, hard surfaces, are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to the modified surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that, in some embodiments, may include at least one of the following improved surface properties: cleaning, wettability, liquid strike-through, comfort, stain resistance, soil removal, malodor control, modification of surface friction, reduced damage to abrasion and color enhancement, relative to the surfaces unmodified with such nanoparticle systems.

Owner:THE PROCTER & GAMBLE COMPANY

Circular surgical stapling device including buttress material

A buttress material and mounting structure assembly is provided for use with a circular surgical stapling device. The assembly comprises a ring-like mounting structure sized to have an outer diameter that frictionally engages a radial inner surface of a staple cartridge assembly, wherein the mounting structure is disposed within the radial inner surface of the staple cartridge assembly; an annular buttress material overlaying a tissue facing surface of the staple cartridge assembly, the annular buttress material defining an outer radial terminal edge extending radially beyond a pair of annular arrays of staple receiving slots, and a radial inner terminal edge extending across the mounting structure; and at least one suture securing the buttress material to the mounting structure.

Owner:TYCO HEALTHCARE GRP LP

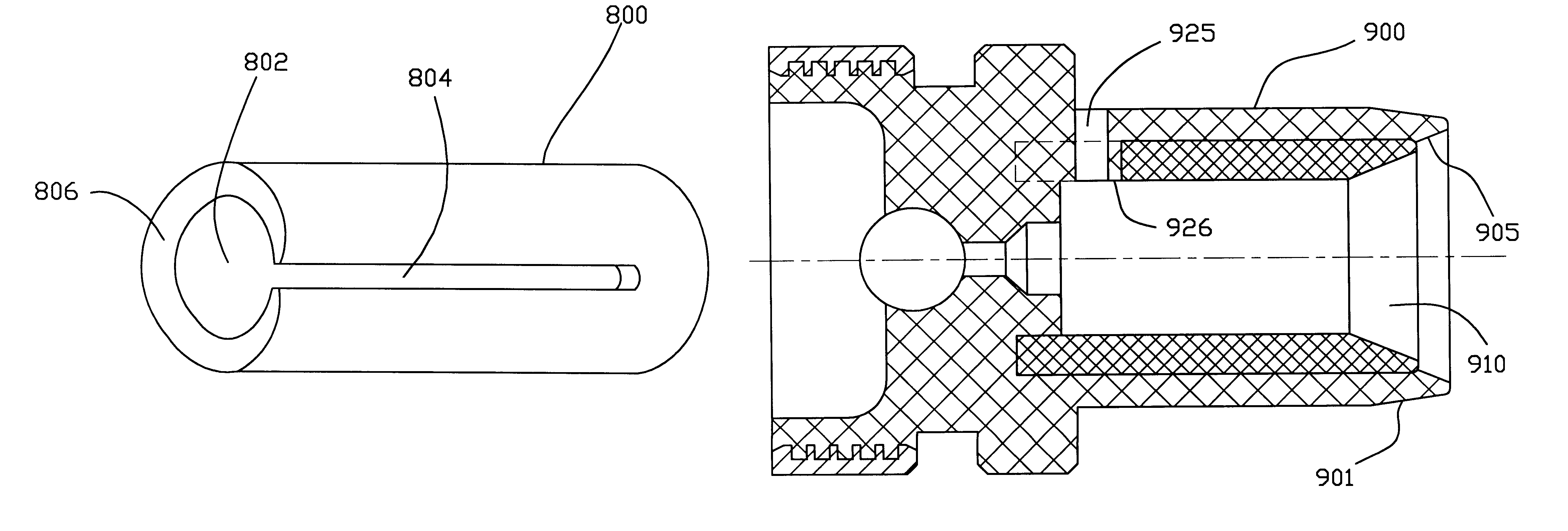

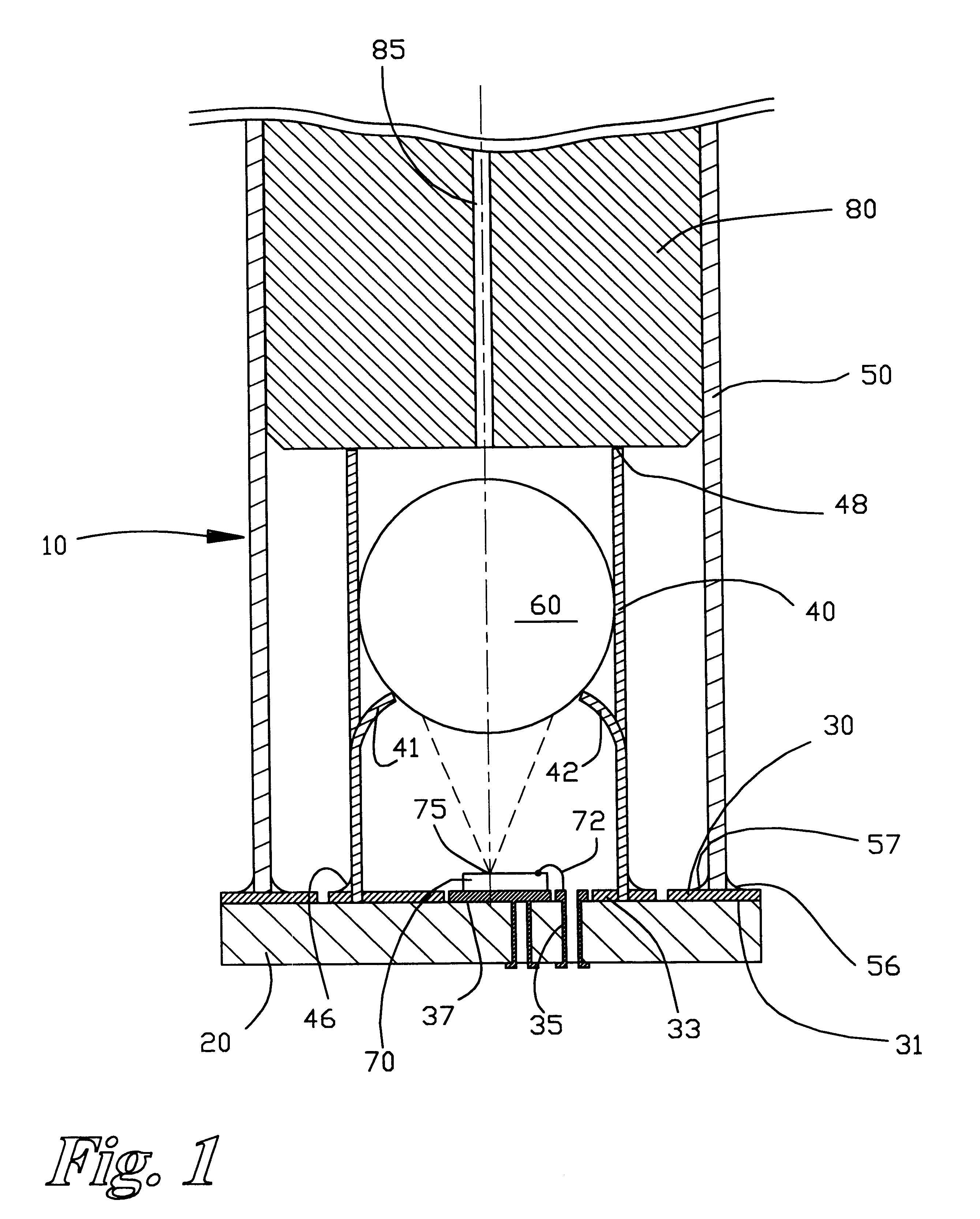

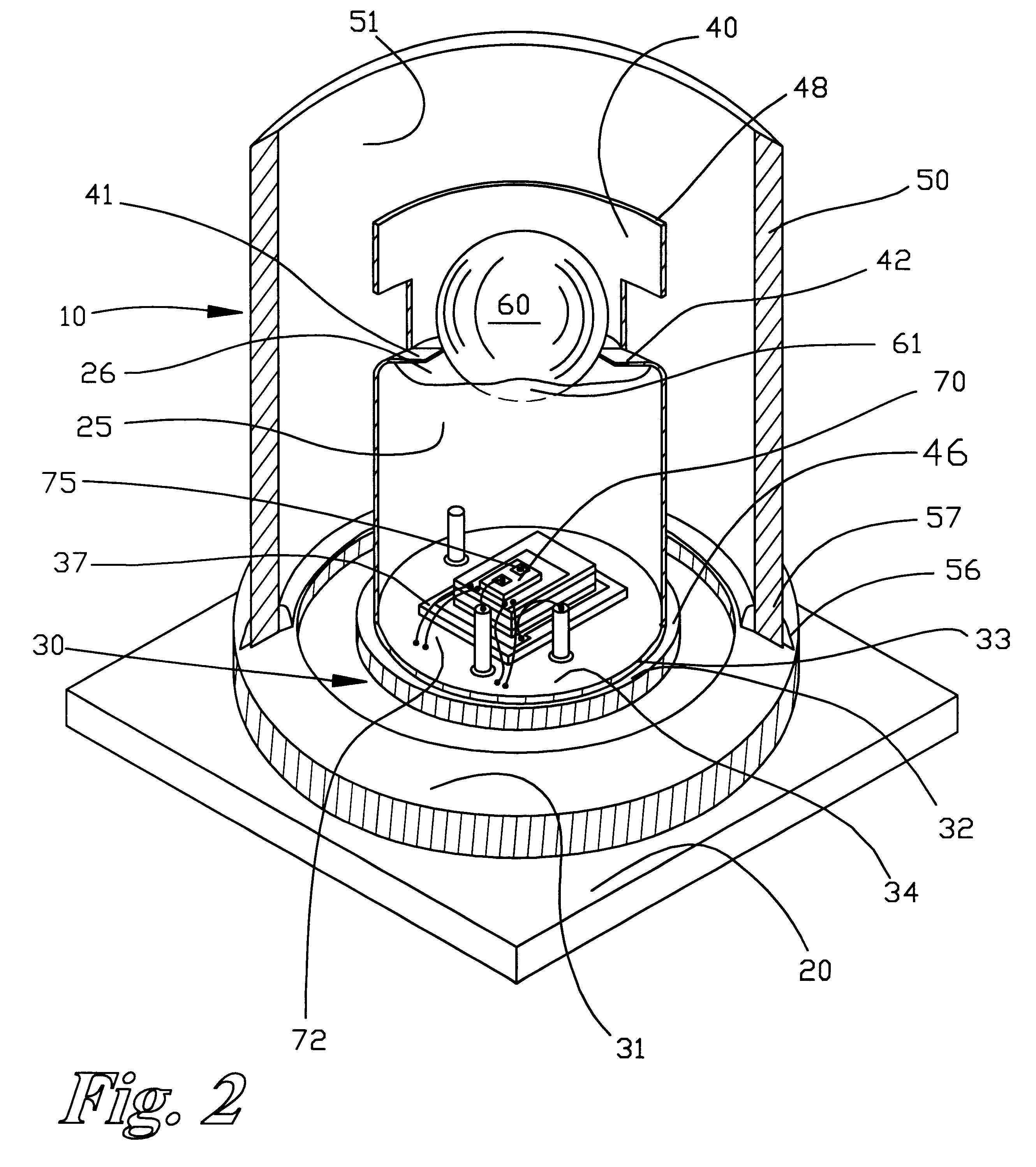

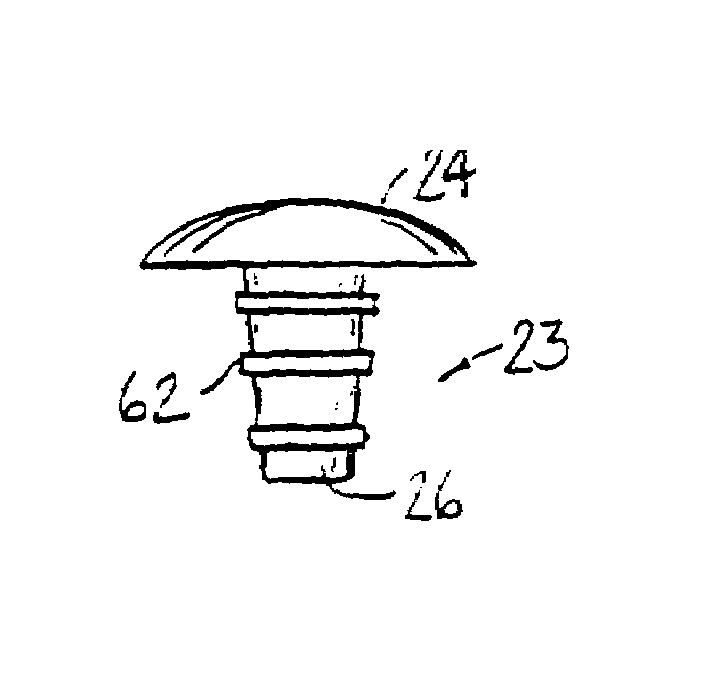

Optical package with alignment means and method of assembling an optical package

InactiveUS6283644B1Easy alignmentQuickly and inexpensively manufacturedSolid-state devicesCoupling light guidesFiberAdhesive

An optical package is provided including a housing having first and second ends. A ferrule receiving bore is formed in the first end, and an optics cavity is formed in the second end. The optics cavity and the ferrule receiving bore are axially aligned with one another along an optical axis defined by the package. A mounting cap is inserted over the optics cavity and frictionally engages an outer surface of the housing. The end cap includes an endplate and a substrate having an optical device mounted thereon. The ferrule receiving bore includes a longitudinal slot extending generally parallel to the axis of the bore providing radial flexibility to the outer wall. Additionally, a split sleeve is provided for accepting a fiber optic connector ferrule. The split sleeve being insertable and expandable in a ferrule receiving bore of an optical package housing. The split sleeve being retained in the ferrule receiving bore with an adhesive.

Owner:STRATOS INT

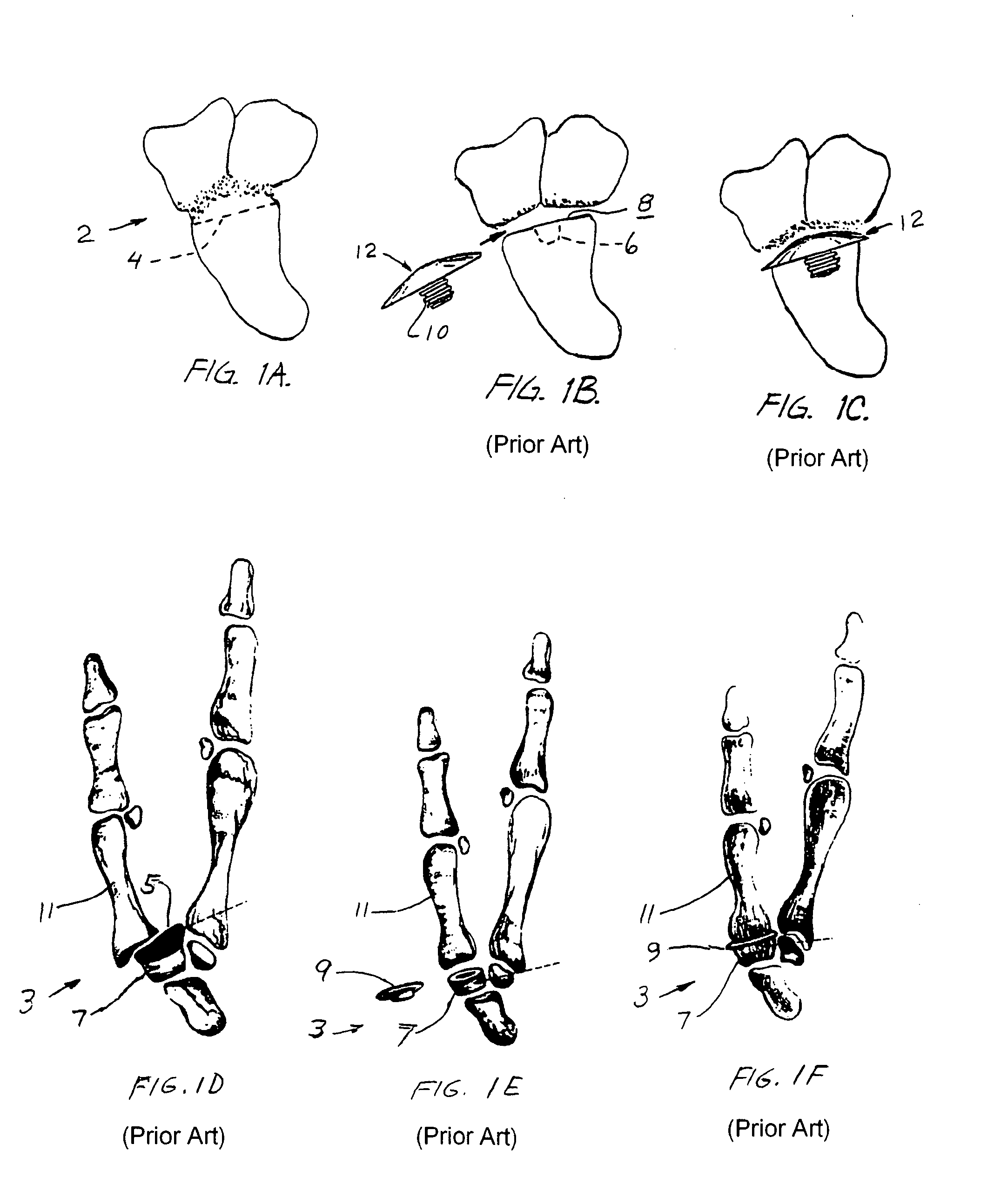

Joint treating method

InactiveUS7128763B1Stimulate and promote formationKeep movingJoint implantsArticular surfacesFibrocartilage

A method for treating a non-weight bearing arthritic joint involves resecting at least one of the opposed joint surfaces to expose a cancellous bone surface. A bioresorbable implant is mounted to one of the joint surfaces so that the resected joint surface rubs against the surface of the implant. This causes the fibroblast to change into fibrocartilage at the resected bone surface as the implant is resorbed thereby effectively replacing the implant with fibrocartilage during such resorption.

Owner:BLATT GERALD

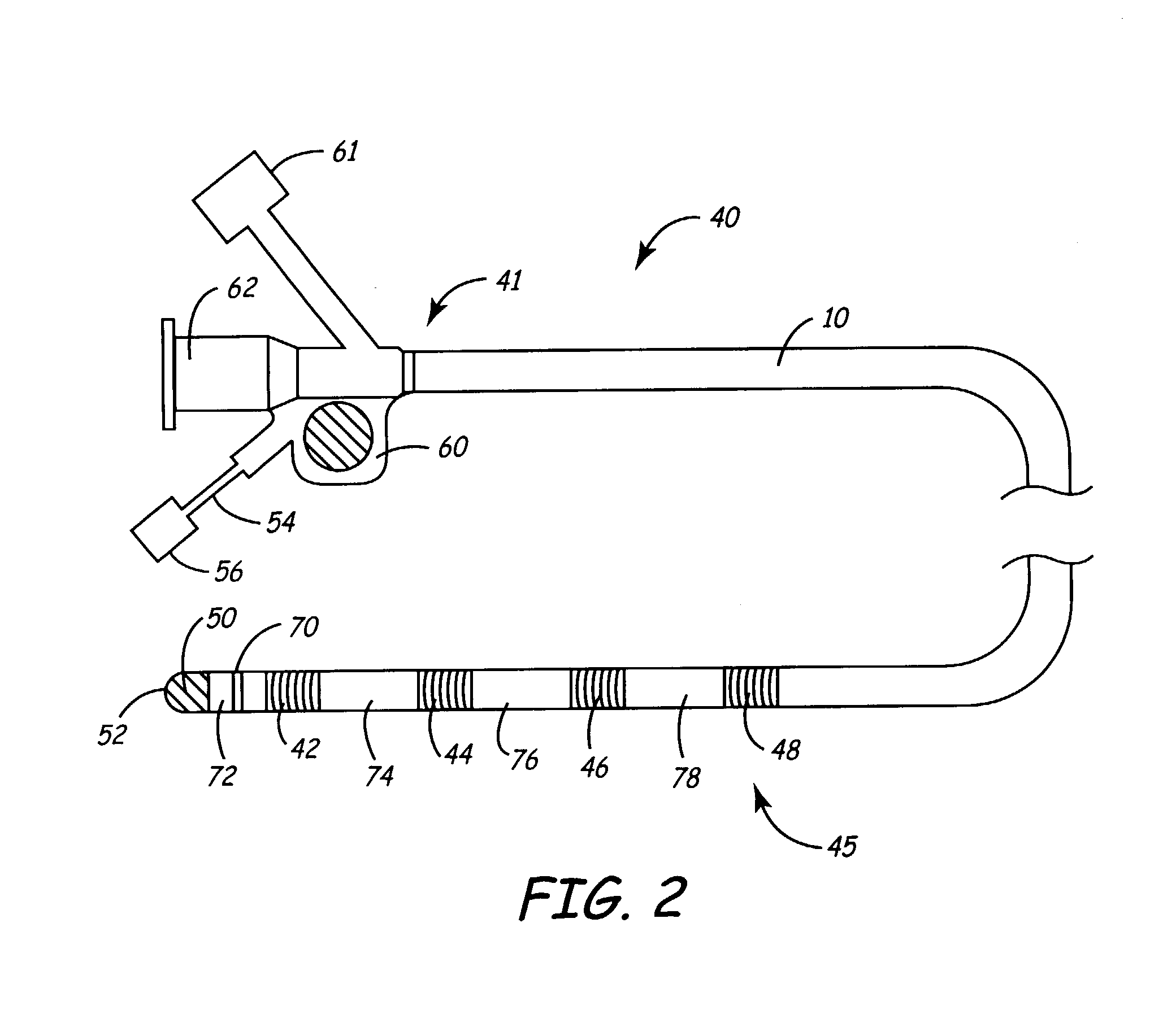

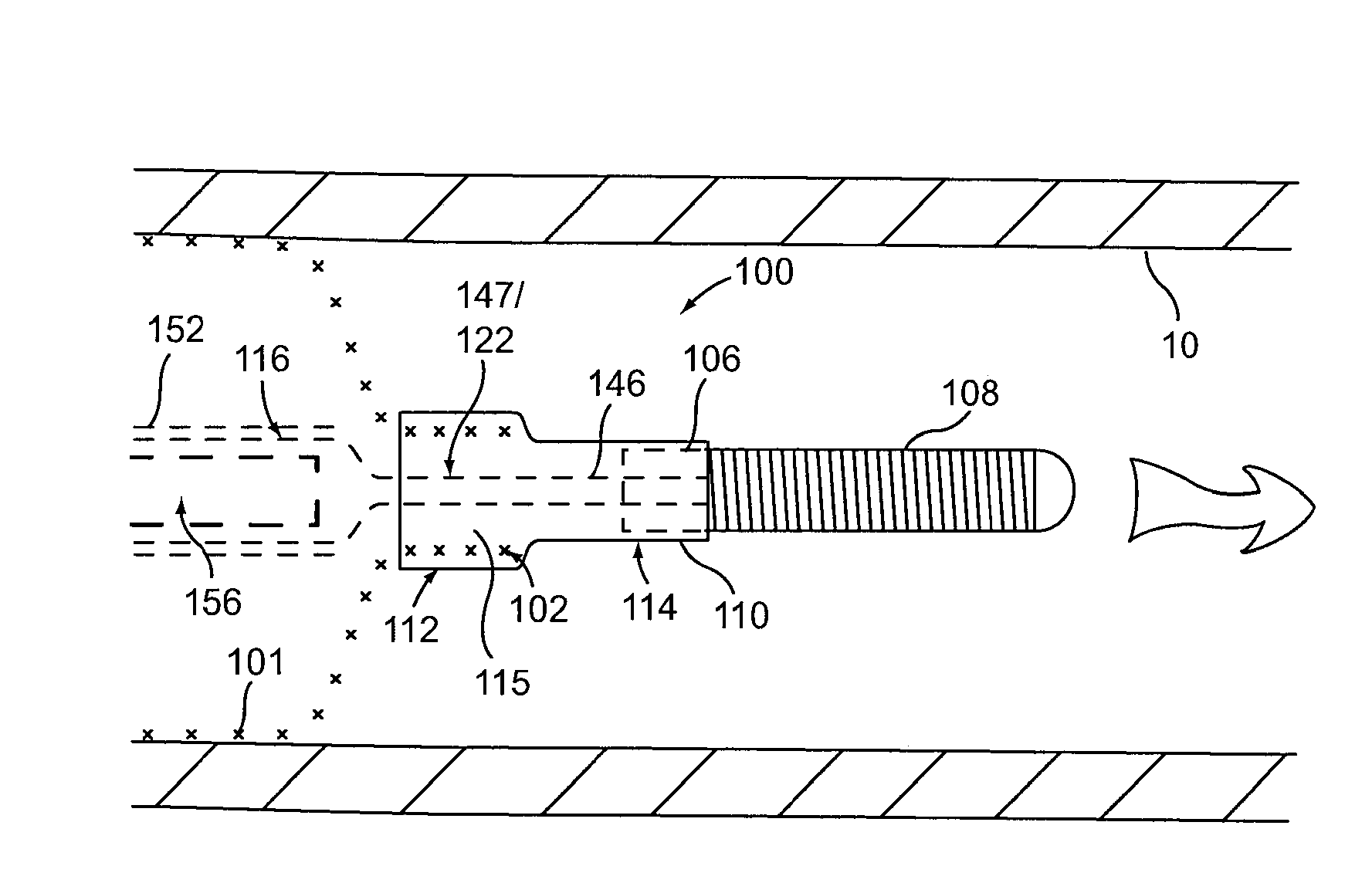

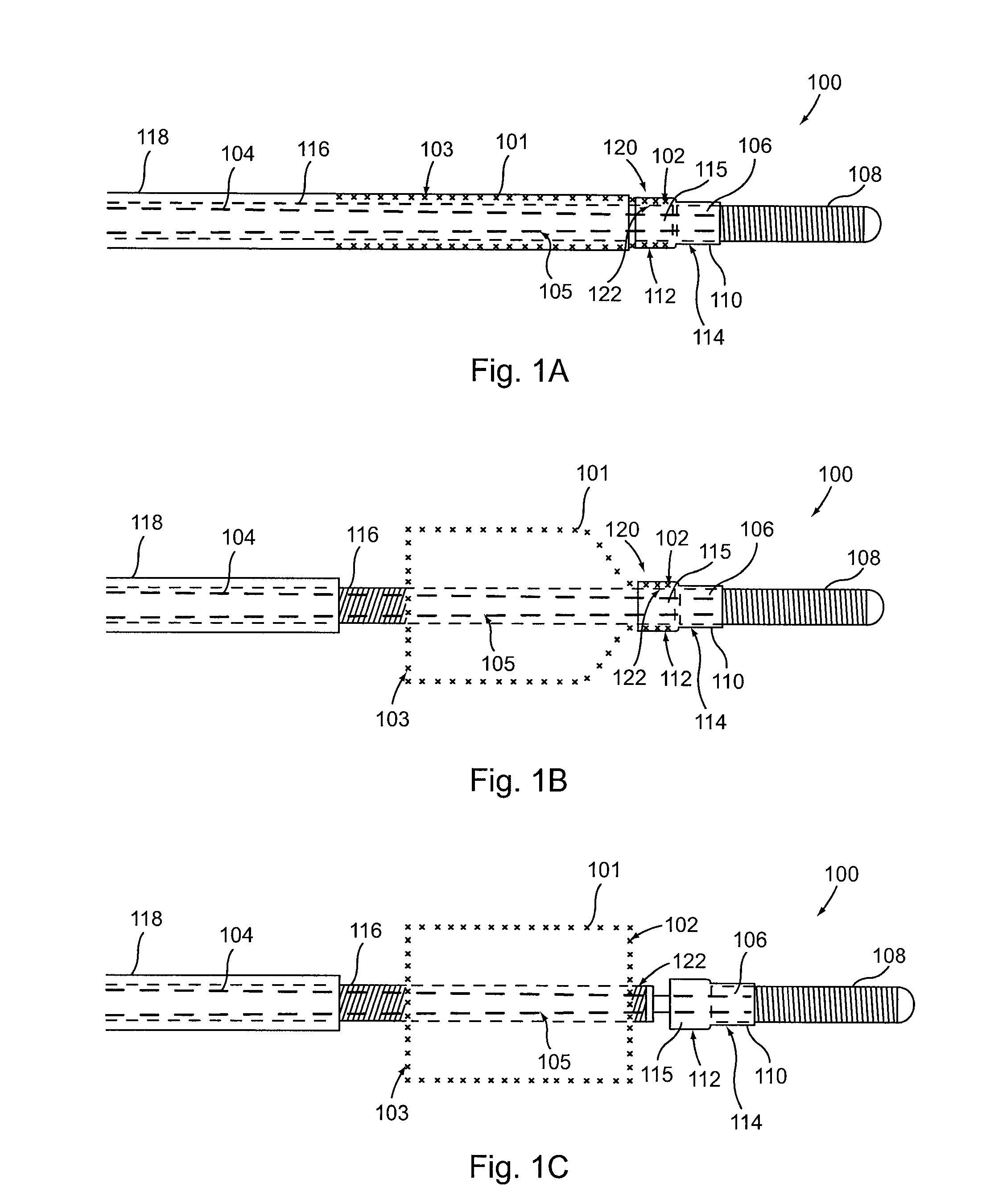

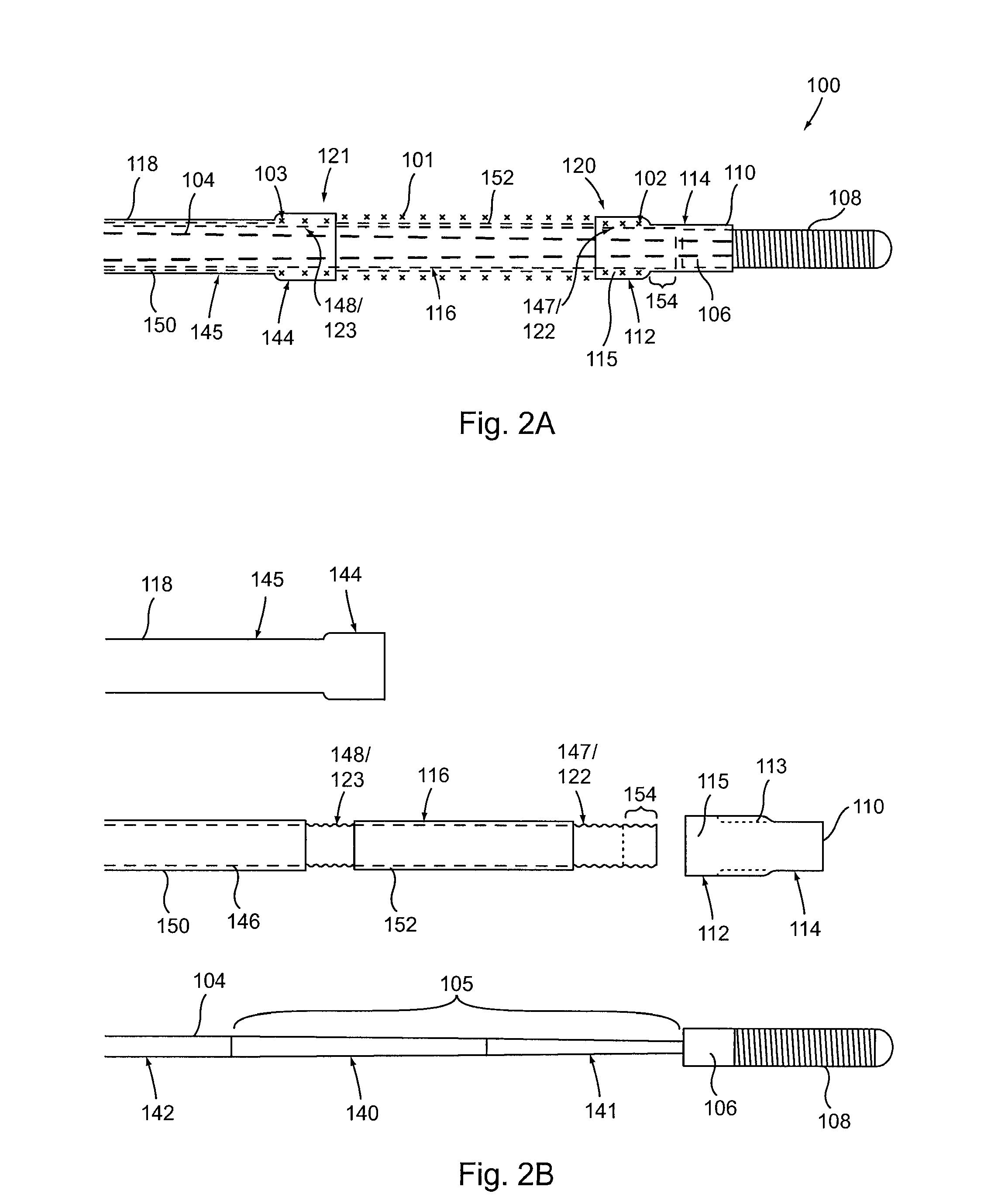

Friction-Release Distal Latch Implant Delivery System and Components

InactiveUS20090264978A1Increase flexibilityIncrease thrustStentsBlood vesselsBiomedical engineeringDelivery system

Provided herein are systems, devices and methods for the delivery of medical implants. A distal end portion of the implant is coupled with a delivery device by surface friction between the implant and an underlying surface such that the distal end portion is frictionally locked and maintained in the appropriate position and state prior to delivery. When positioned within the patient at the proper location, the state of frictional lock can be released to free the distal end portion of the implant from the delivery device.

Owner:TYCO HEALTHCARE GRP LP

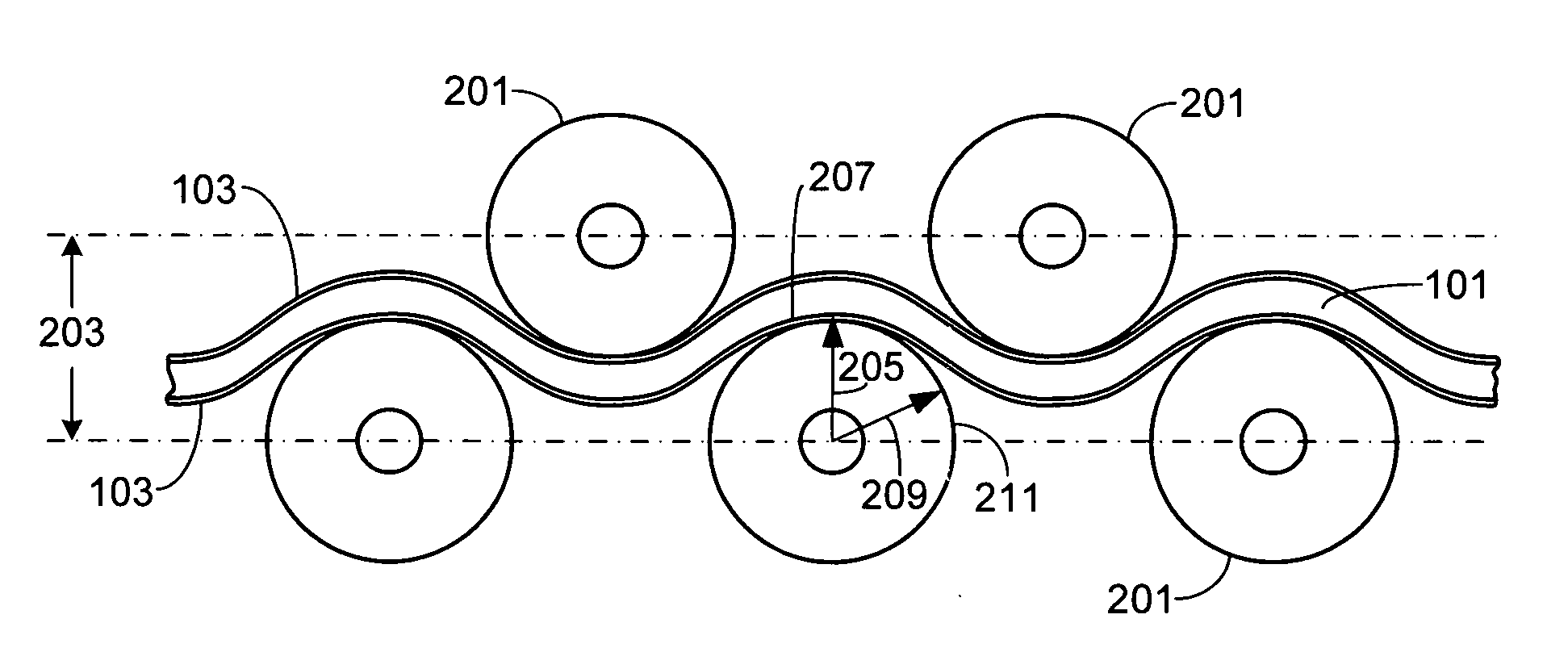

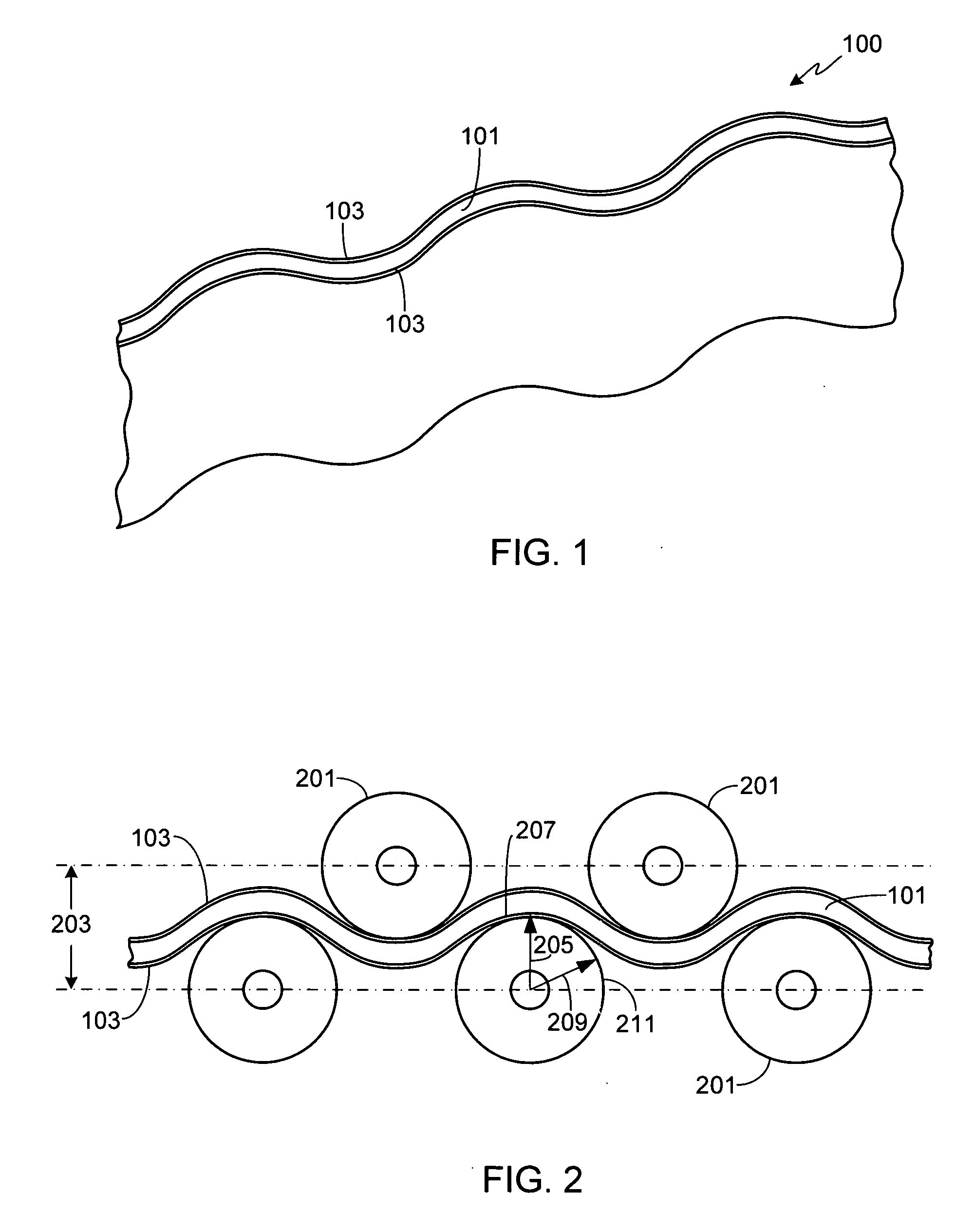

Liquid cooling manifold with multi-function thermal interface

ActiveUS20100104938A1Cell temperature controlCell component detailsCompressible materialThermal management system

A liquid cooling manifold assembly for use in the thermal management system of a battery pack is provided. The liquid cooling manifold assembly includes a coolant channel portion through which the coolant channels run, and a dual layer thermal interface interposed between the coolant channel portion and the cells of the battery pack. The outer material layer of the dual layer thermal interface is comprised of an electrically non-conductive, high dielectric material that is preferably tear resistant, deformable and has a high tensile strength and a relatively low surface friction. The inner material layer of the dual layer thermal interface is comprised of a highly compressible material.

Owner:TESLA INC

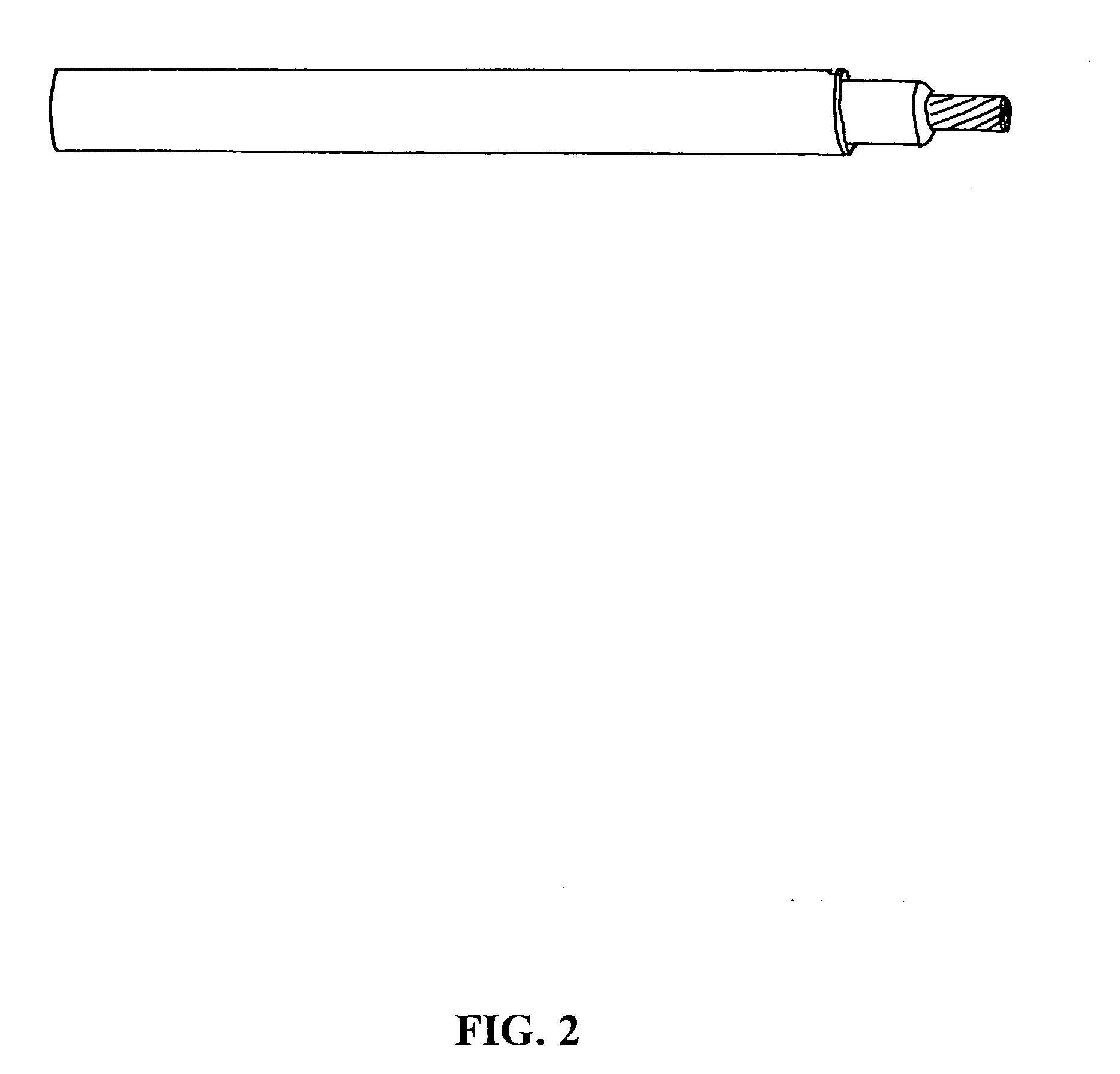

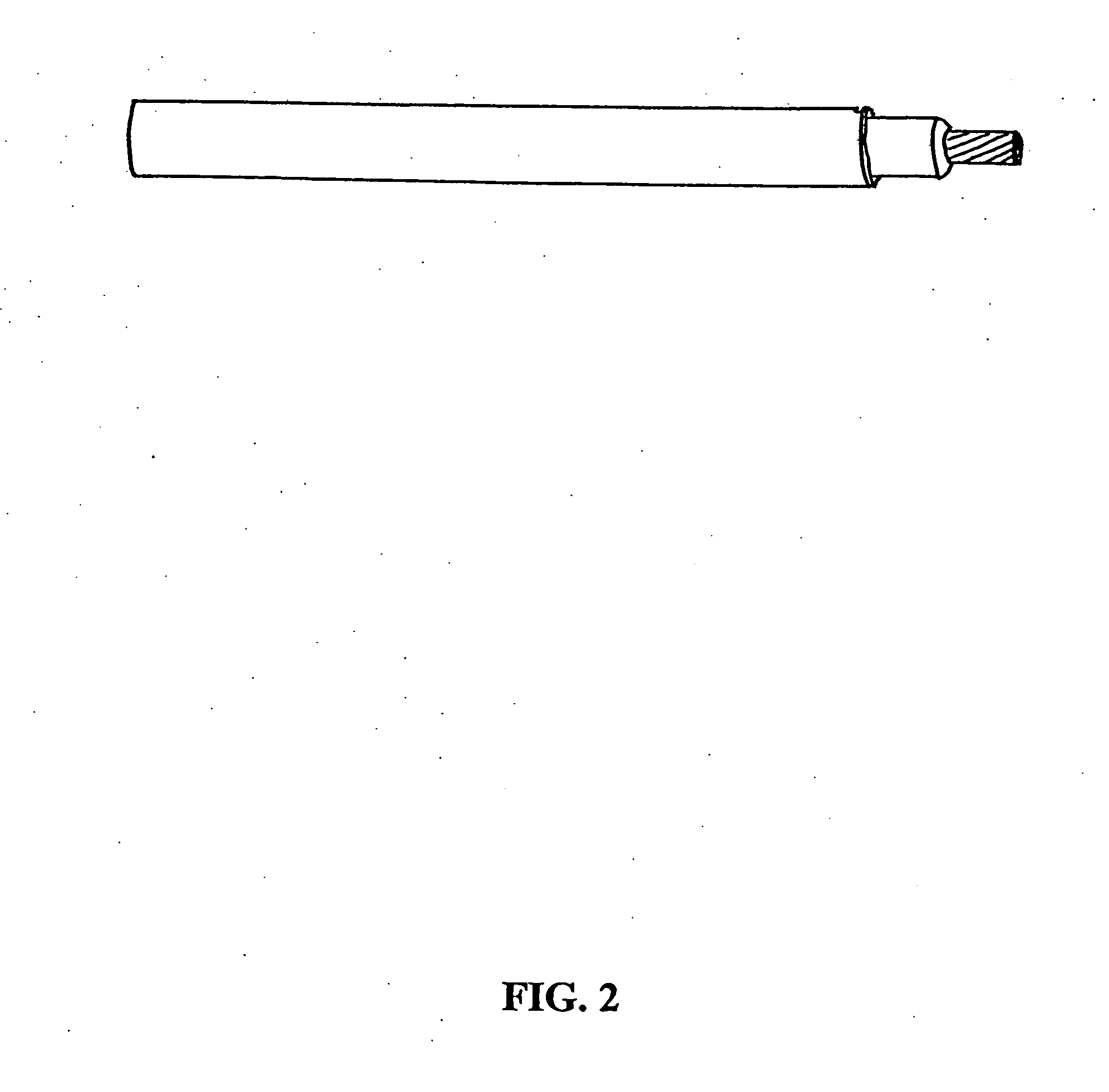

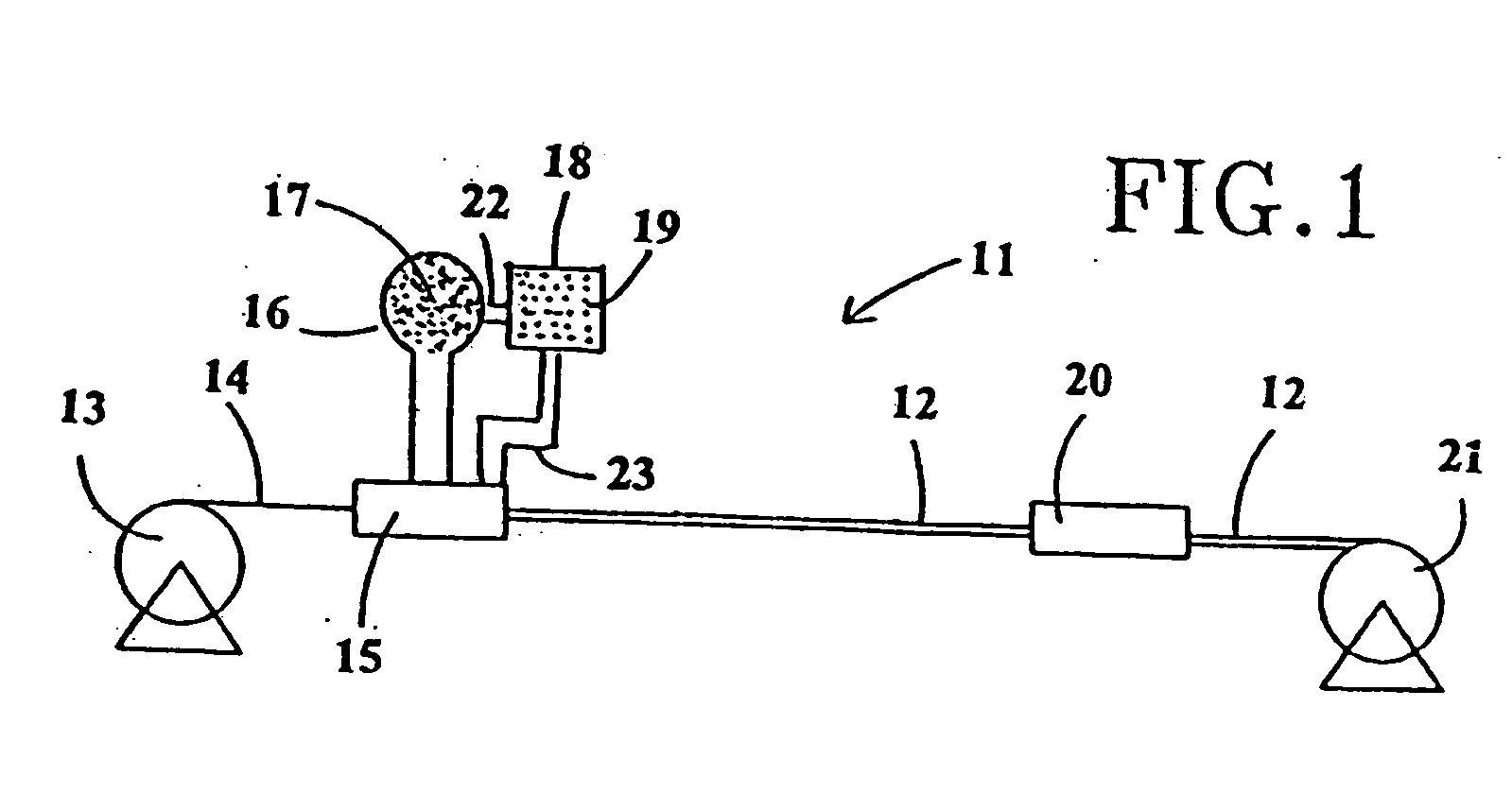

Electrical cable having a surface with reduced coefficient of friction

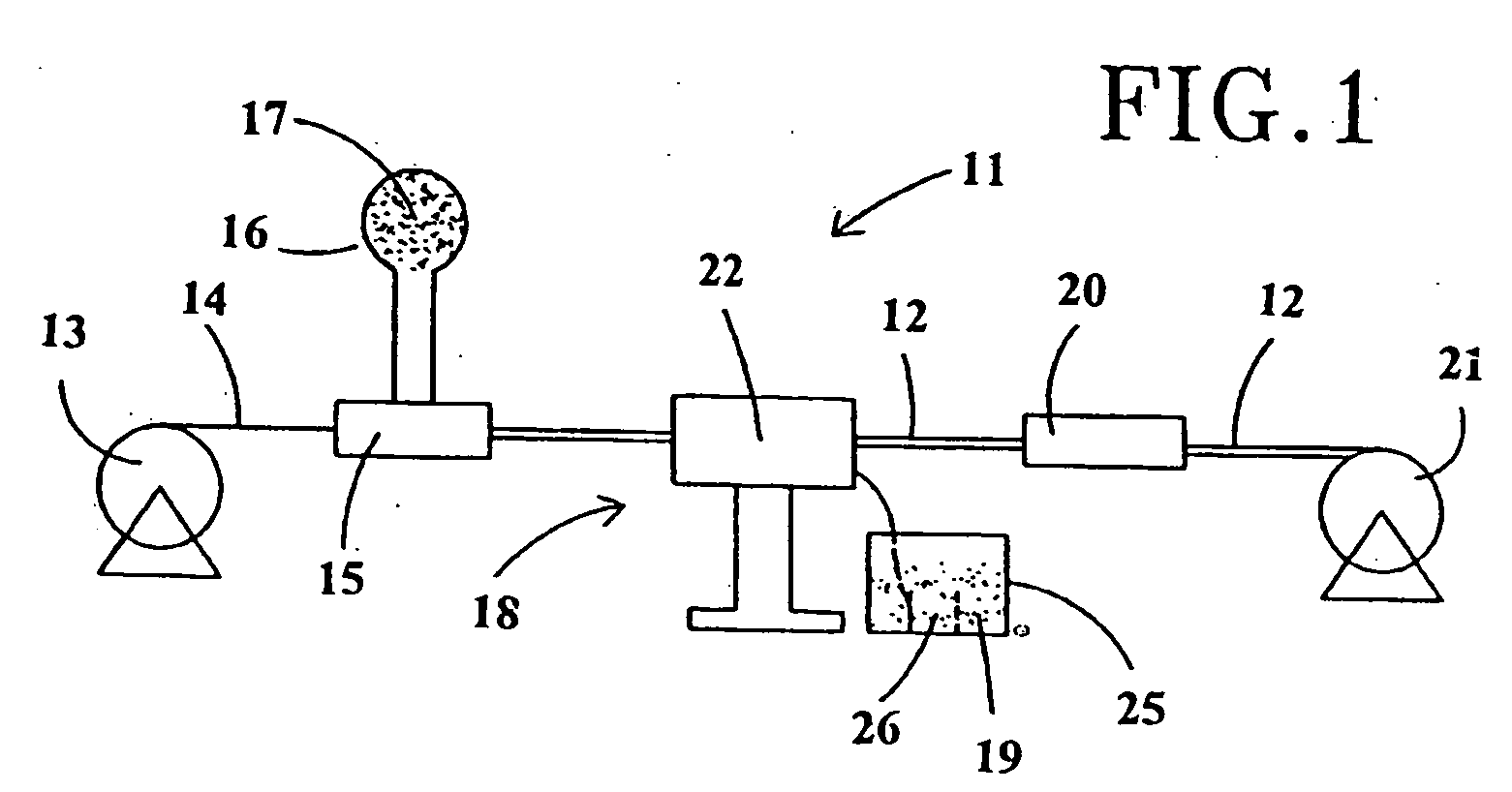

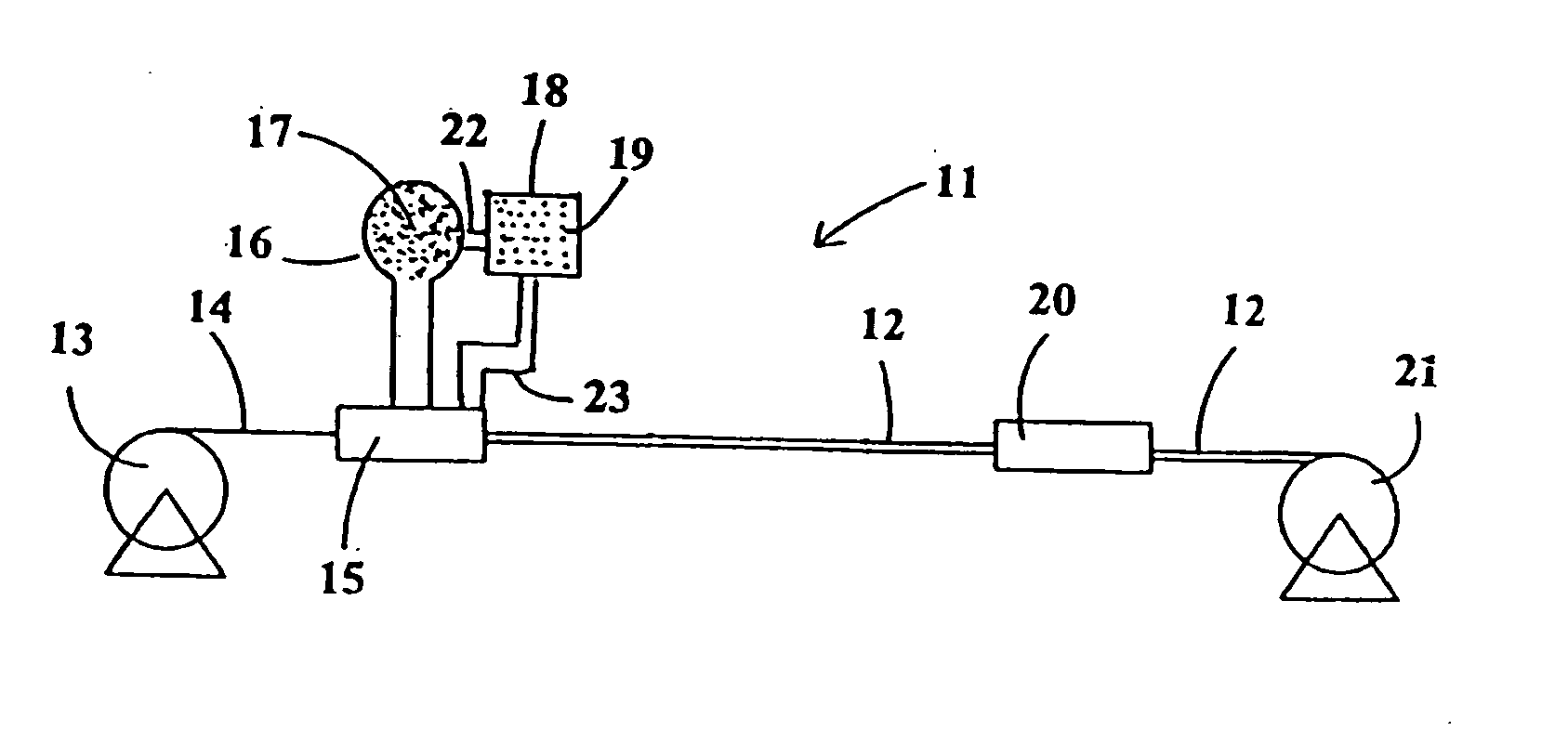

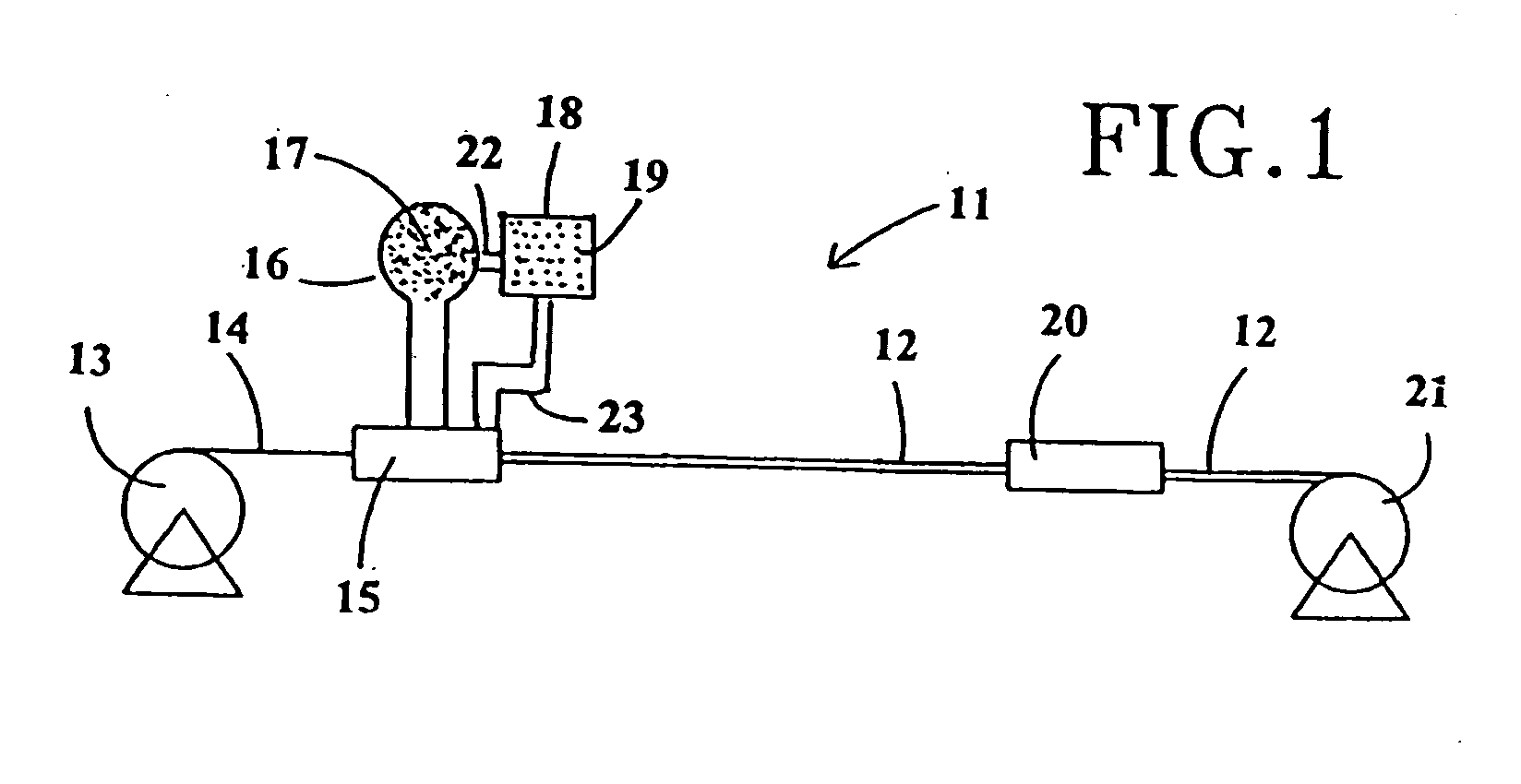

ActiveUS7411129B2Reduce coefficient of frictionEasy to installPlastic/resin/waxes insulatorsLiquid organic insulatorsElectrical conductorPlastic materials

The present invention includes a cable having reduced surface friction and the method of manufacture thereof having steps in which a conductor wire is coated with a mixture of a plastic material and lubricating material and in which the coated conductor wire is cooled. The cable includes at least one conductor core and at least one coating of plastic material and incorporates a lubricating material in and / or on the plastic material. The equipment for the manufacturing of electrical cable includes a reel for supplying a conductor wire to an extruding head, which is connected to tanks containing plastic material and lubricating material for coating the conducting wire, and a reel for taking up the cable.

Owner:SOUTHWIRE CO LLC

Long lasting coatings for modifying hard surfaces and processes for applying the same

InactiveUS6955834B2Improve smoothnessImprovement in wetting and sheetingInorganic/elemental detergent compounding agentsOrganic anion exchangersMetallurgyDefect repair

Materials for coating, coating compositions, methods and articles of manufacture comprising a nanoparticle system or employing the same to impart surface modifying benefits for all types of inanimate hard surfaces are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to modified hard surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that include at least one of the following improved surface properties: wetting and sheeting, quick drying, uniform drying, soil removal, self-cleaning, anti-spotting, anti-soil deposition, cleaner appearance, enhanced gloss, enhanced color, minor surface defect repair, smoothness, anti-hazing, modification of surface friction, release of actives and transparency, relative to hard surfaces unmodified with such nanoparticle systems. Actively curing the coating composition on the hard surfaces, including, but not limited to by radiative heating the air surrounding the hard surface with the coating thereon can be used to increase the durability of the hard surface coating.

Owner:THE PROCTER & GAMBLE COMPANY

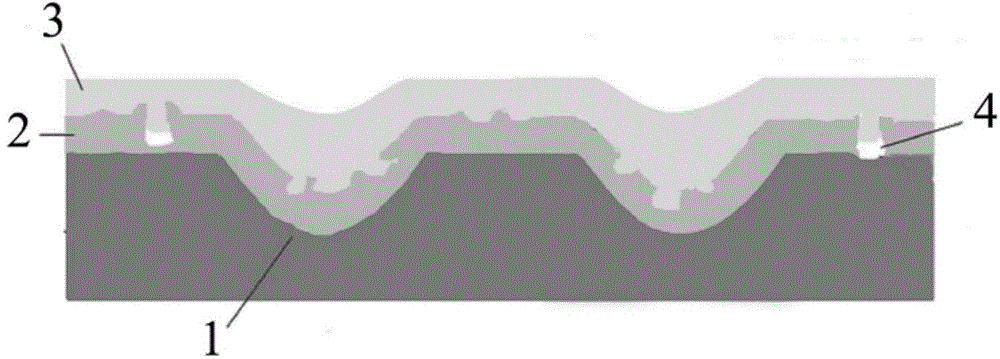

Composite wear-resistant antifriction coating on titanium alloy surface and preparation method thereof

InactiveCN104480511AImprove wear resistanceHigh bonding strengthSurface reaction electrolytic coatingOxide ceramicPlasma electrolytic oxidation

The invention discloses a composite wear-resistant antifriction coating on a titanium alloy surface and a preparation method thereof. The coating comprises a laser texturing surface, an oxide ceramic layer and a self-lubricating coating which are connected in sequence, wherein micropore arrays are uniformly distributed on the laser texturing surface; the oxide ceramic layer is a hard oxide ceramic coating; and the self-lubricating coating is a MoS2 coating, PTFE (polytetrafluoroethylene) coating or graphite coating. In the invention, the laser surface texturing technology is combined with the plasma electrolytic oxidation technology, and a texturing / ceramization composite coating is prepared on the titanium alloy surface which is then coated with a solid lubricant to improve the friction performance of the surface.

Owner:NANJING UNIV OF SCI & TECH +1

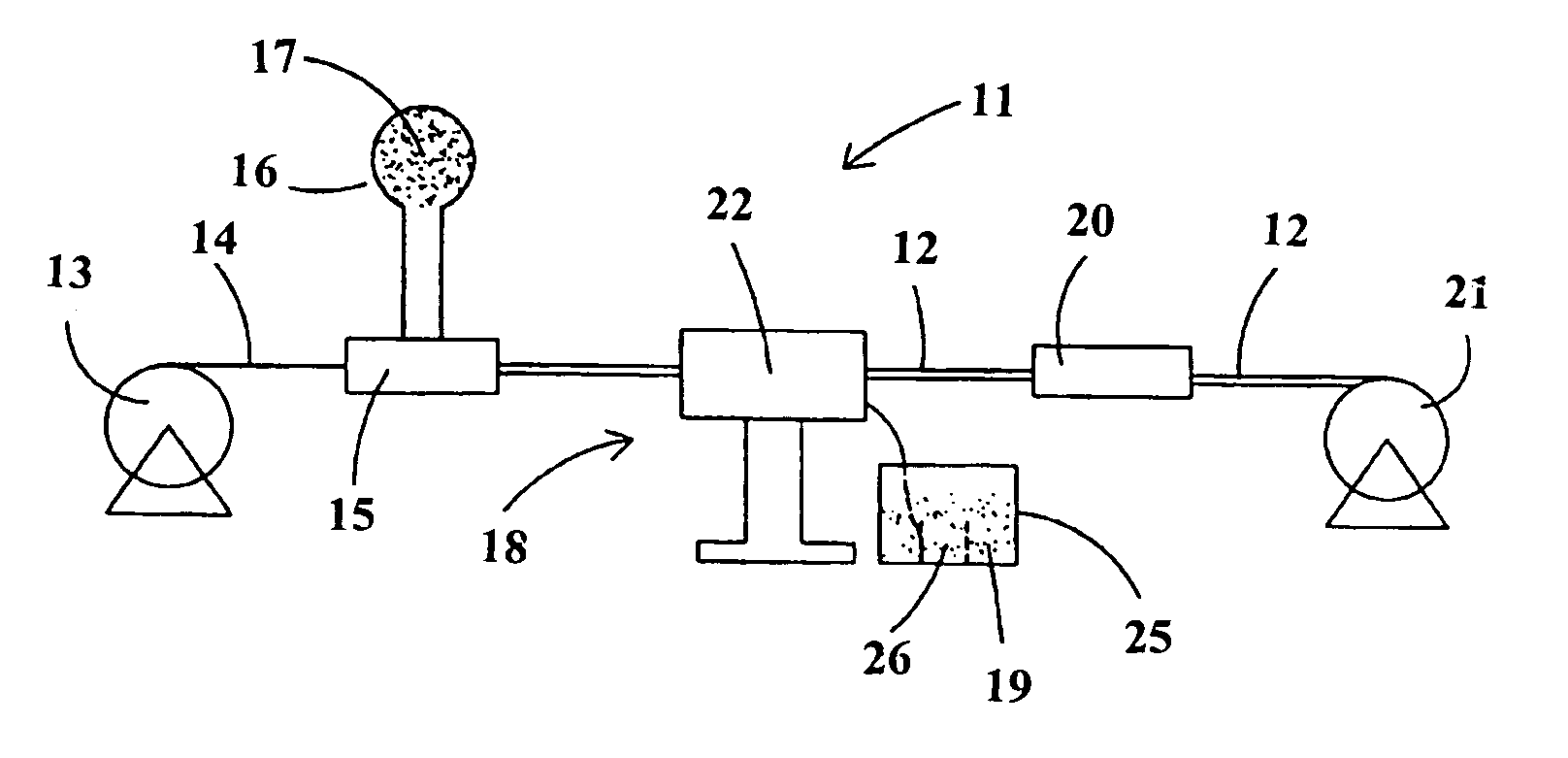

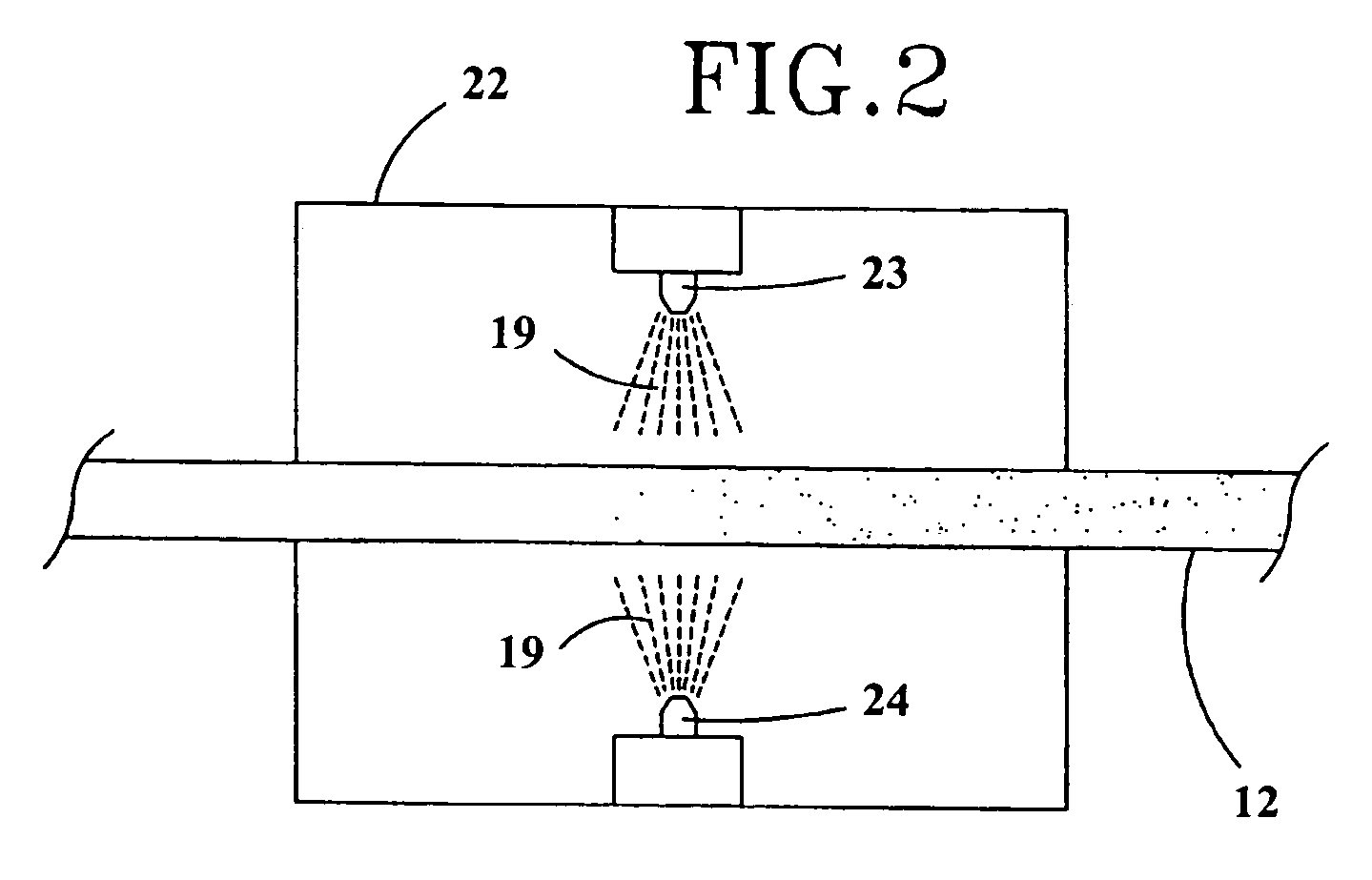

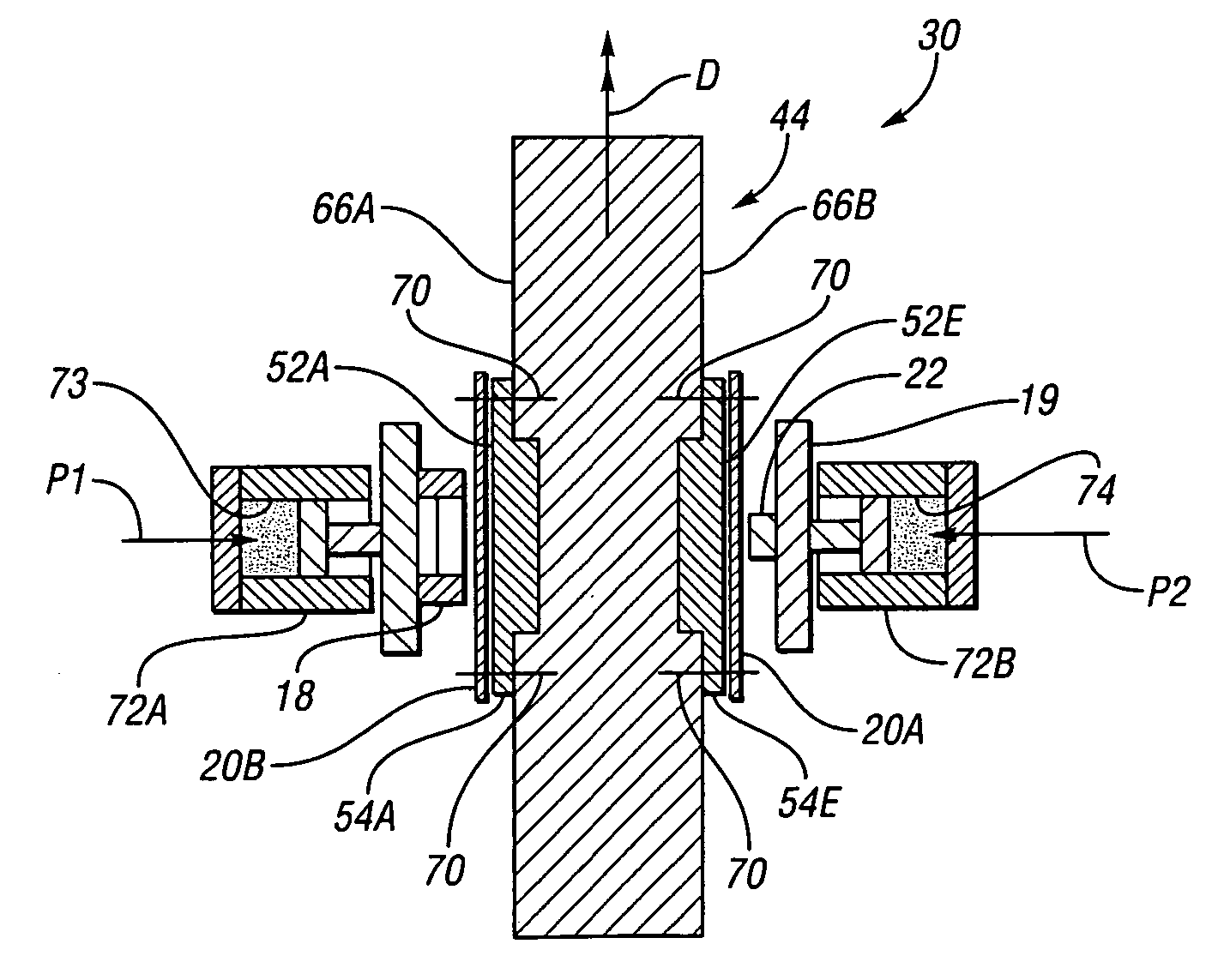

Electrical cable having a surface with reduced coefficient of friction

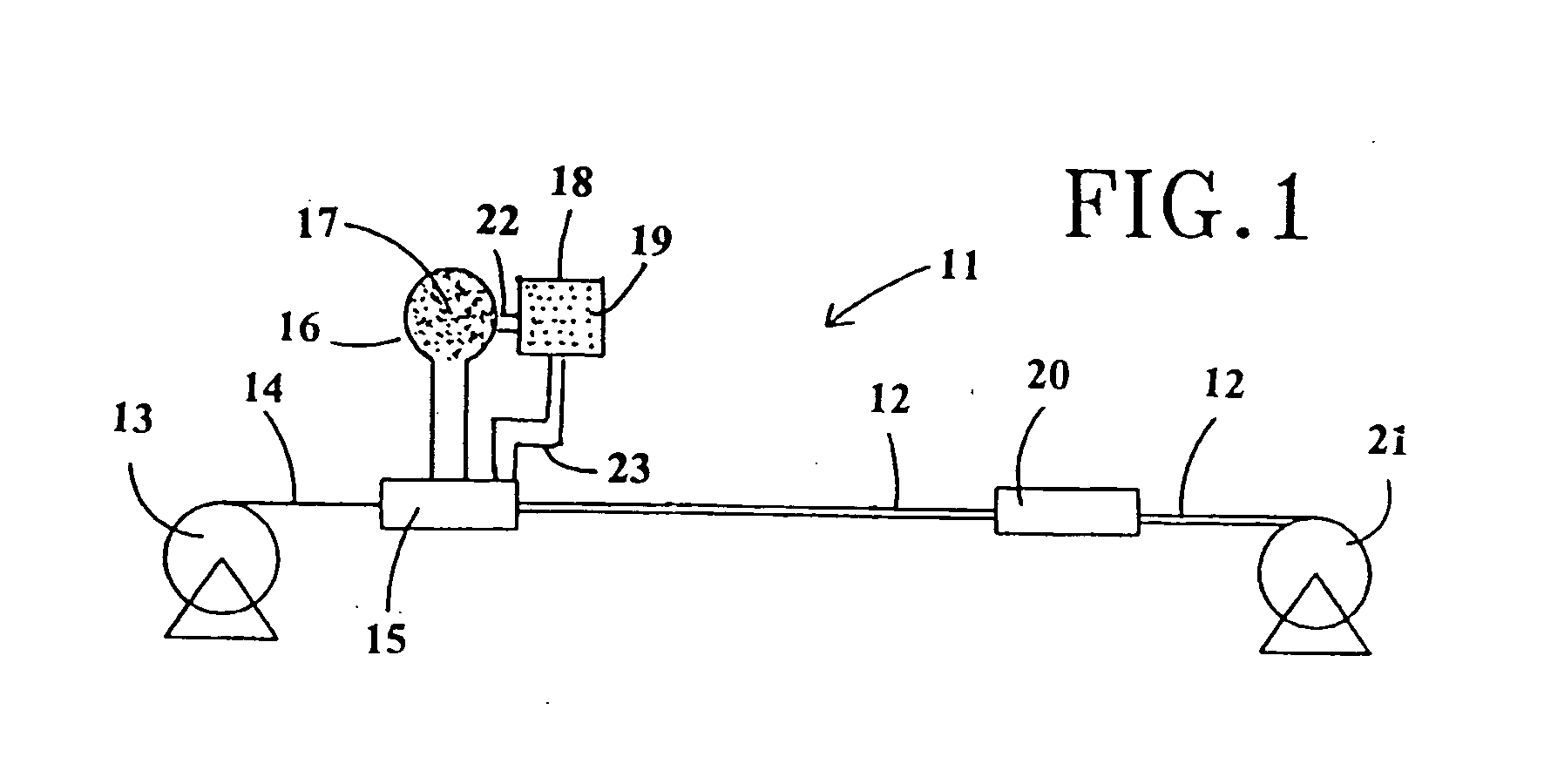

InactiveUS20060088657A1Reduce coefficient of frictionEasy to installLiquid organic insulatorsSpraying apparatusElectrical conductorPlastic materials

The present invention includes a cable having reduced surface friction and the method of manufacture thereof including steps in which a conductor wire is coated with a first plastic material, coated with a second plastic material and the coated conductor wire then cooled, and includes a step in which a lubricating material is applied to the surface of the cooled, coated cable. The cable includes at least one conductor core and at least one coating of plastic material and incorporates a lubricating material on the exterior coating. The equipment for the manufacturing of the electrical cable includes a reel for supplying a conductor wire to an extruding head, which is connected to tanks containing plastic materials for coating the conducting wire, a reel for taking up the cable, and a device for the application of a lubricating material onto the surface of the cable.

Owner:SOUTHWIRE CO LLC

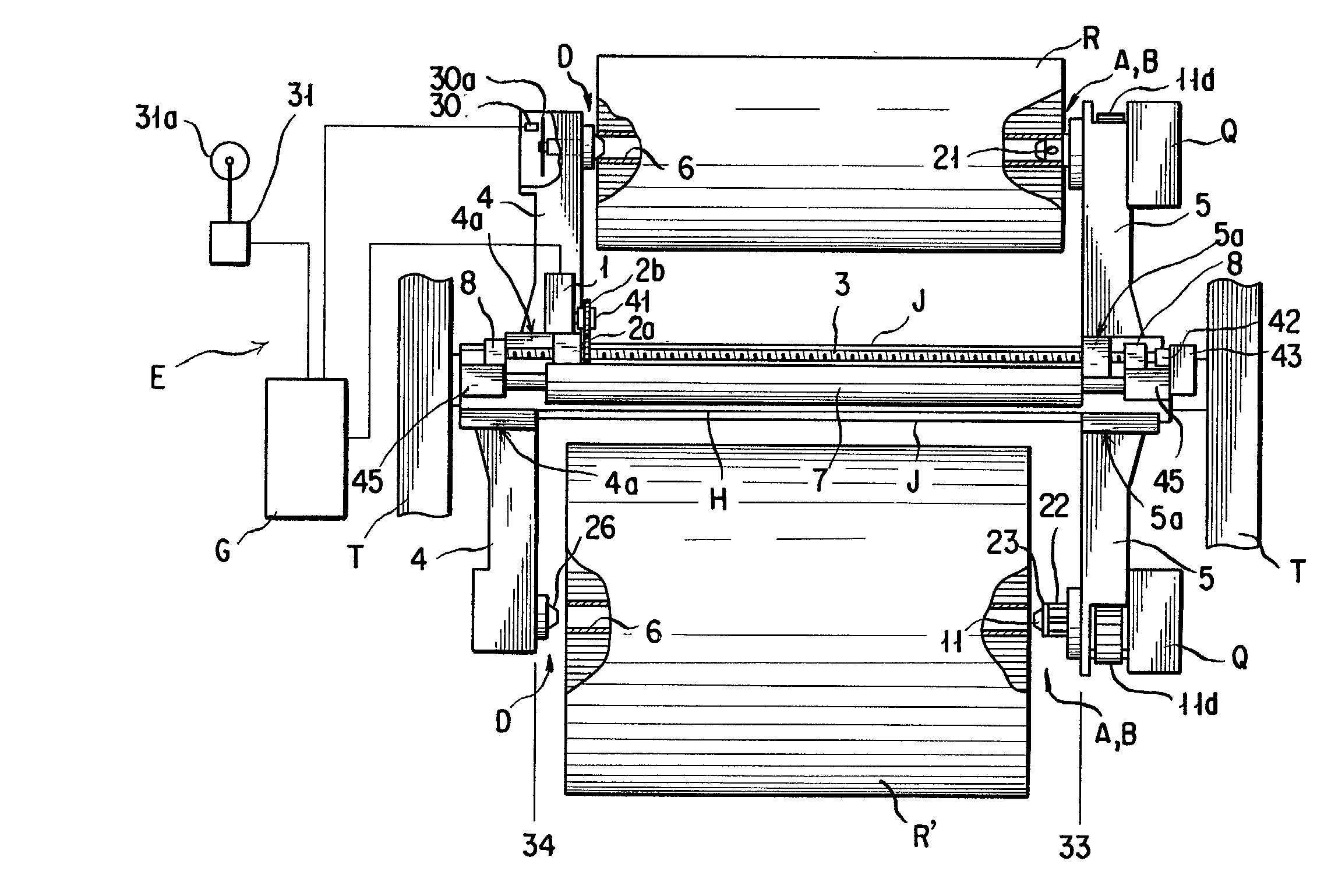

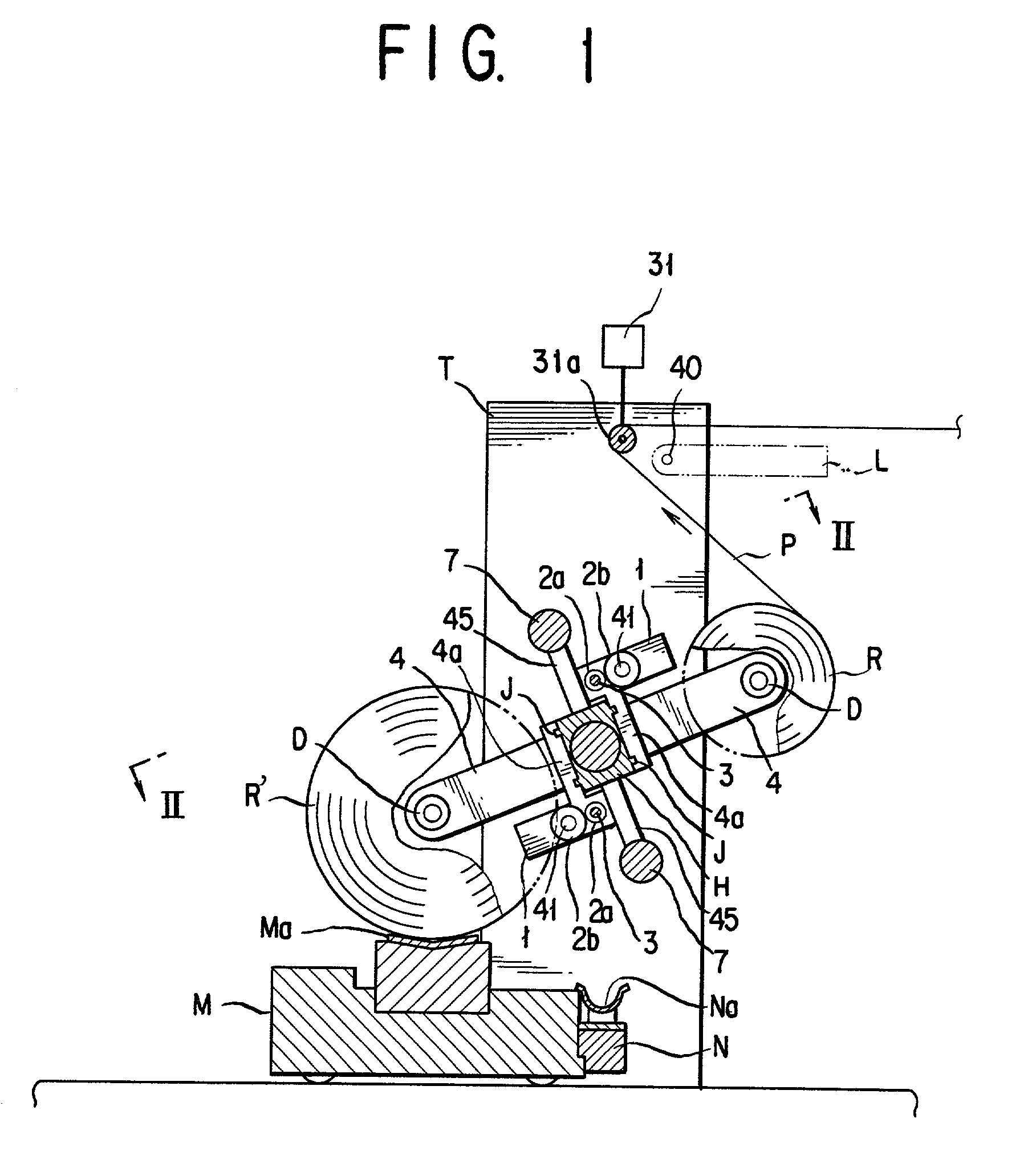

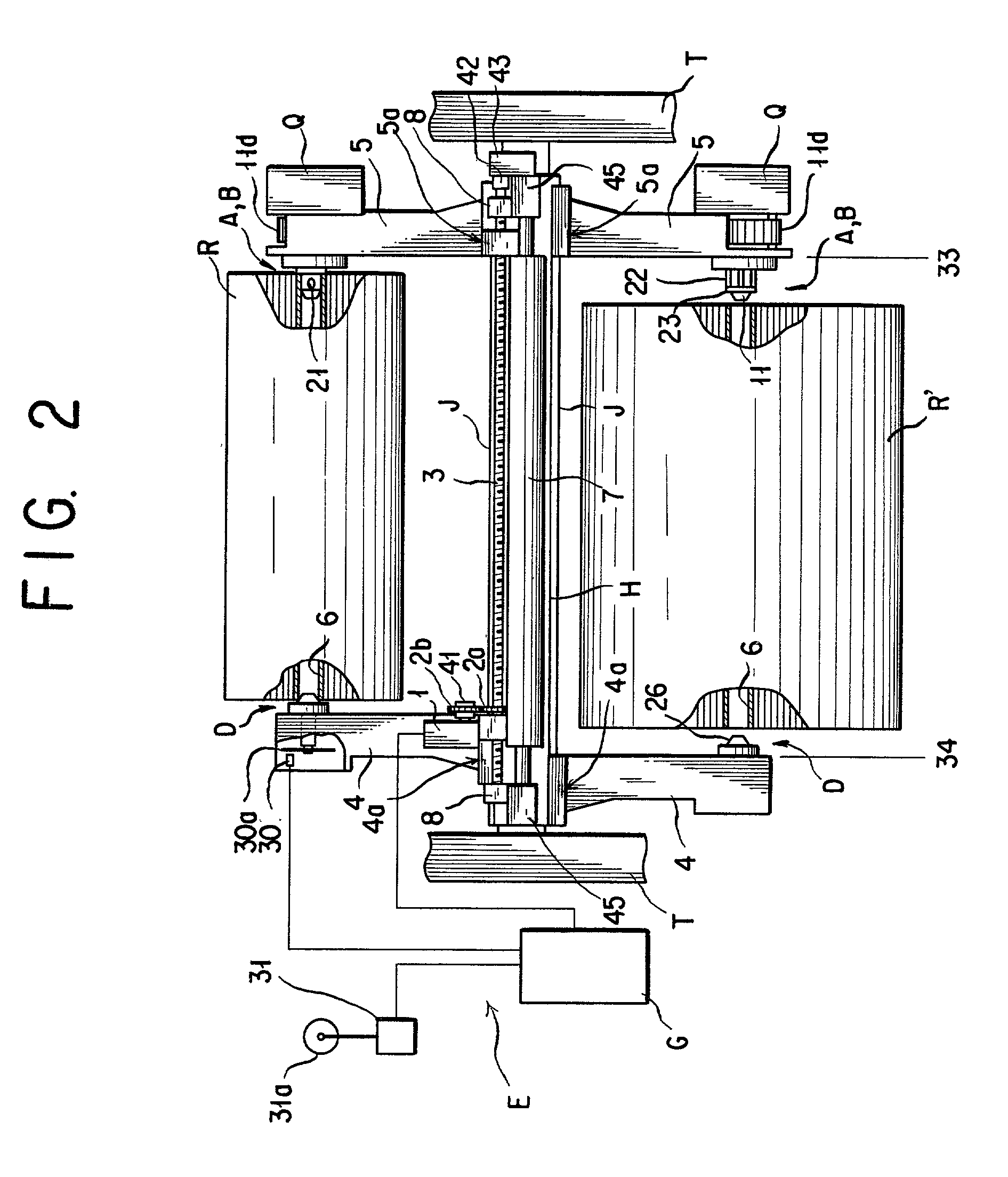

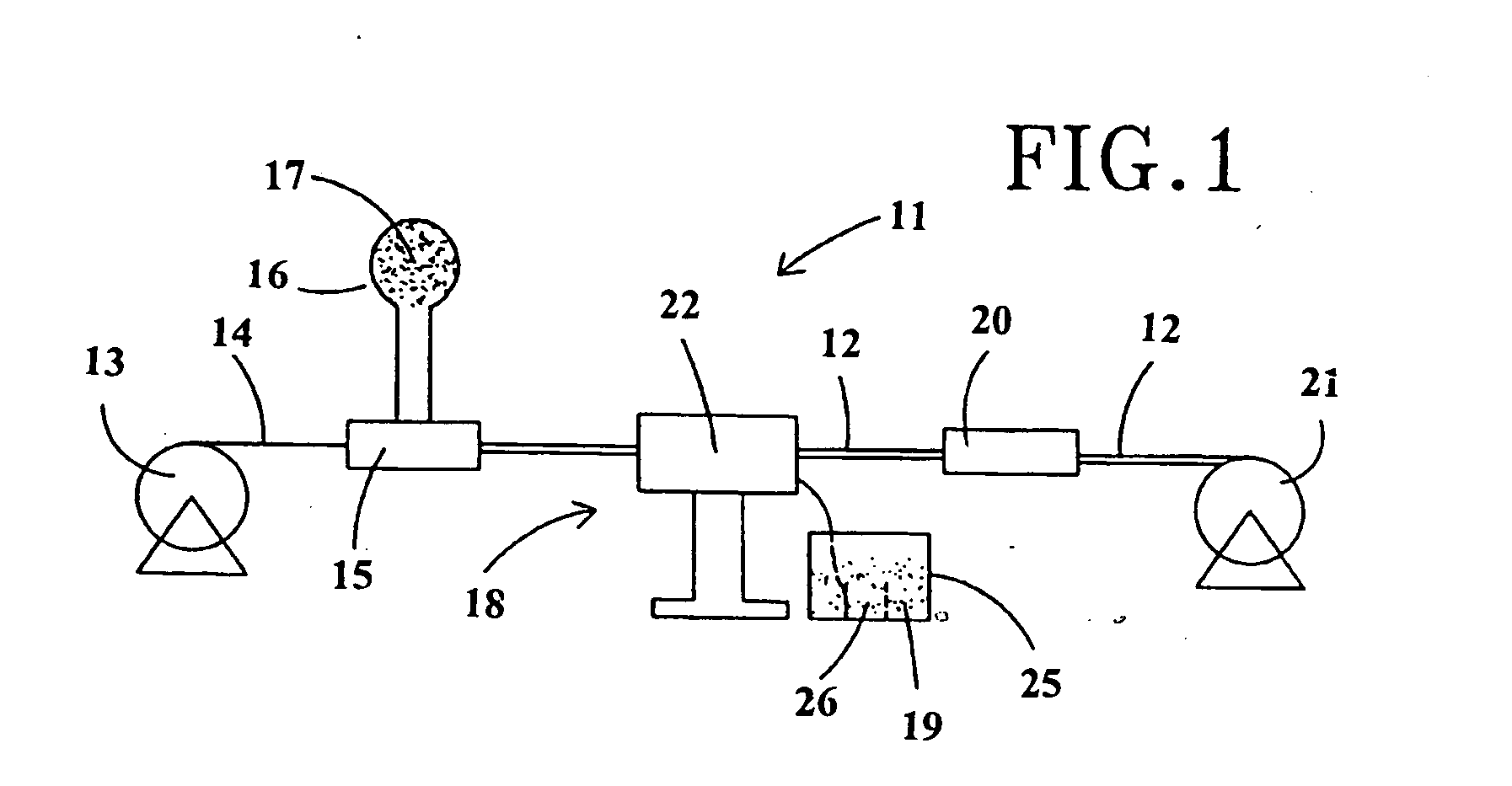

Web infeed for a rotary printing press

InactiveUS20020130214A1Compact structureWithout riskFilament handlingArticle deliveryDetentEngineering

A rotary beam has mounted thereon a pair of carrier arms for rotatably supporting a roll of web from which the web is fed into the press, and another such arm pair for supporting another such web roll to which the web is to be spliced upon consumption of the first web roll. One of each pair of carrier arms has rotatably mounted thereto a hollow spindle to be partly inserted in the tubular core of the web roll. The hollow spindle has detents arranged at circumferential spacings thereon for fluid pressure actuation into frictional engagement with the inside surface of the web roll core. The other of each carrier arm pair has a second spindle rotatably mounted thereto which is to be held endwise against the web roll core via a spring-loaded end cap. How hard the web roll core is urged against the first spindle by the second spindle, resisting the unwinding of the web therefrom, depends upon whether the second spindle is held fast against the end cap or spaced therefrom by the spring. The second spindle is sprung away from the end cap upon decrease of the web roll diameter to a predefined limit, in order to mitigate tension on the web being paid out.

Owner:TOKYO KIKAI SEISAKUCHI LTD

Electrical cable having a surface with reduced coefficient of friction

InactiveUS20060065430A1Reduce coefficient of frictionEasy to installLiquid organic insulatorsInsulated cablesElectrical conductorPlastic materials

The present invention includes a cable having reduced surface friction and the method of manufacture thereof including steps in which a conductor wire is coated with a first plastic material and with a mixture of a second plastic material and lubricating material and the coated conductor wire cooled. The cable includes at least one conductor core and at least two coatings of plastic material and incorporates a lubricating material in and / or on the outer layer of plastic material. The equipment for the manufacturing of the electrical cable includes a reel for supplying a conductor wire to an extruding head, which is connected to tanks containing plastic material and lubricating material for coating the conducting wire, and a reel for taking up the cable.

Owner:SOUTHWIRE CO LLC

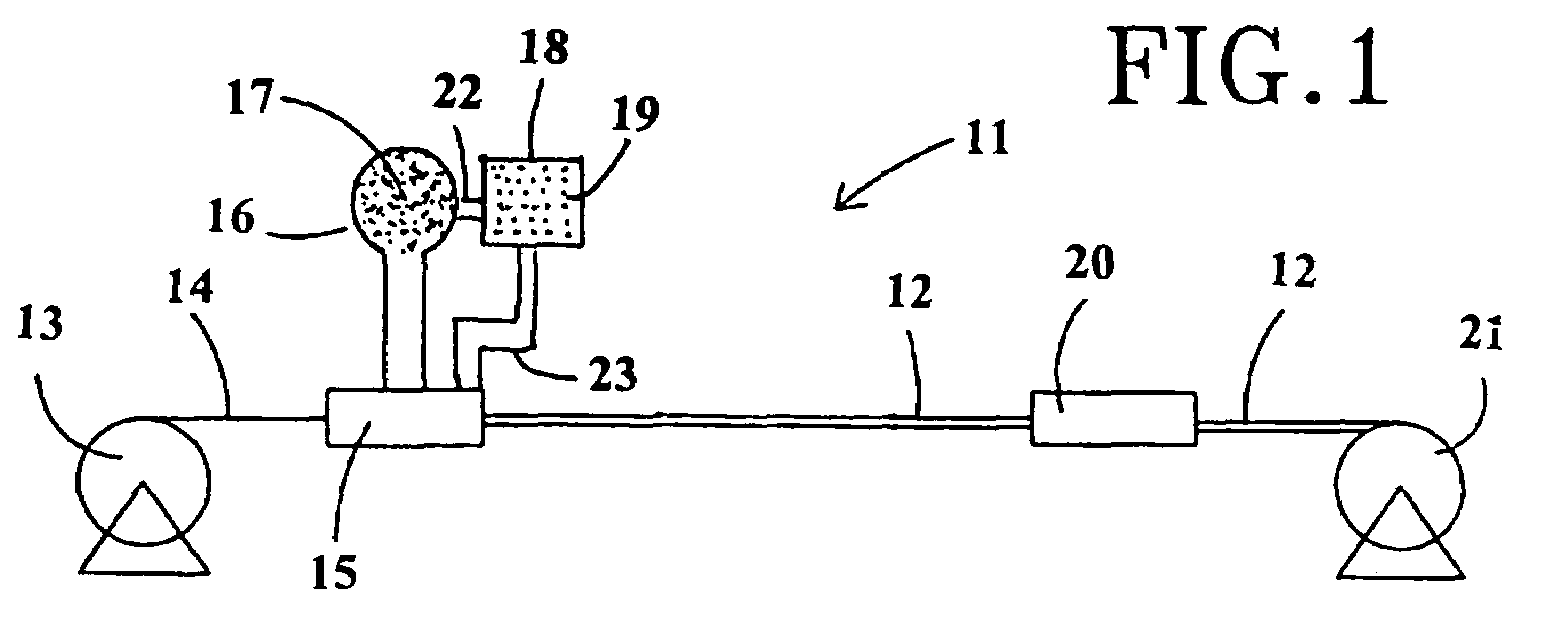

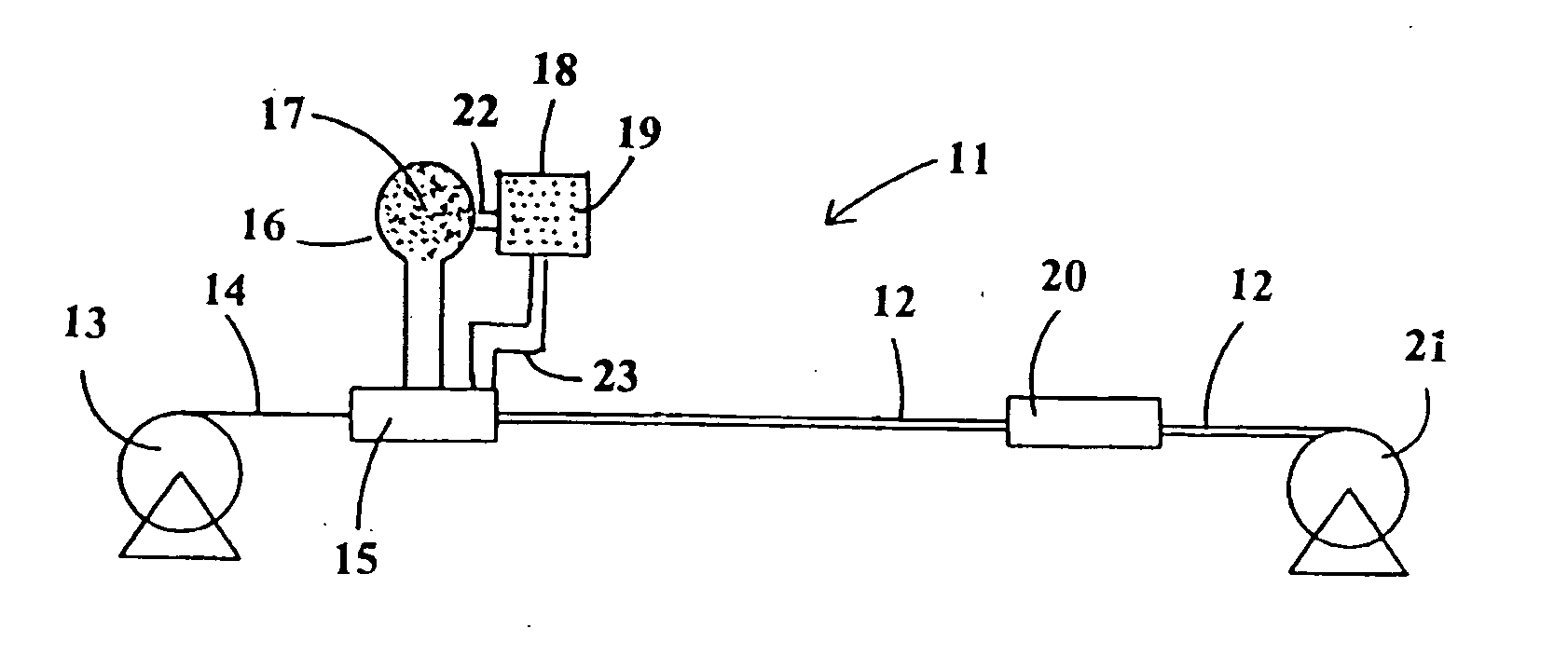

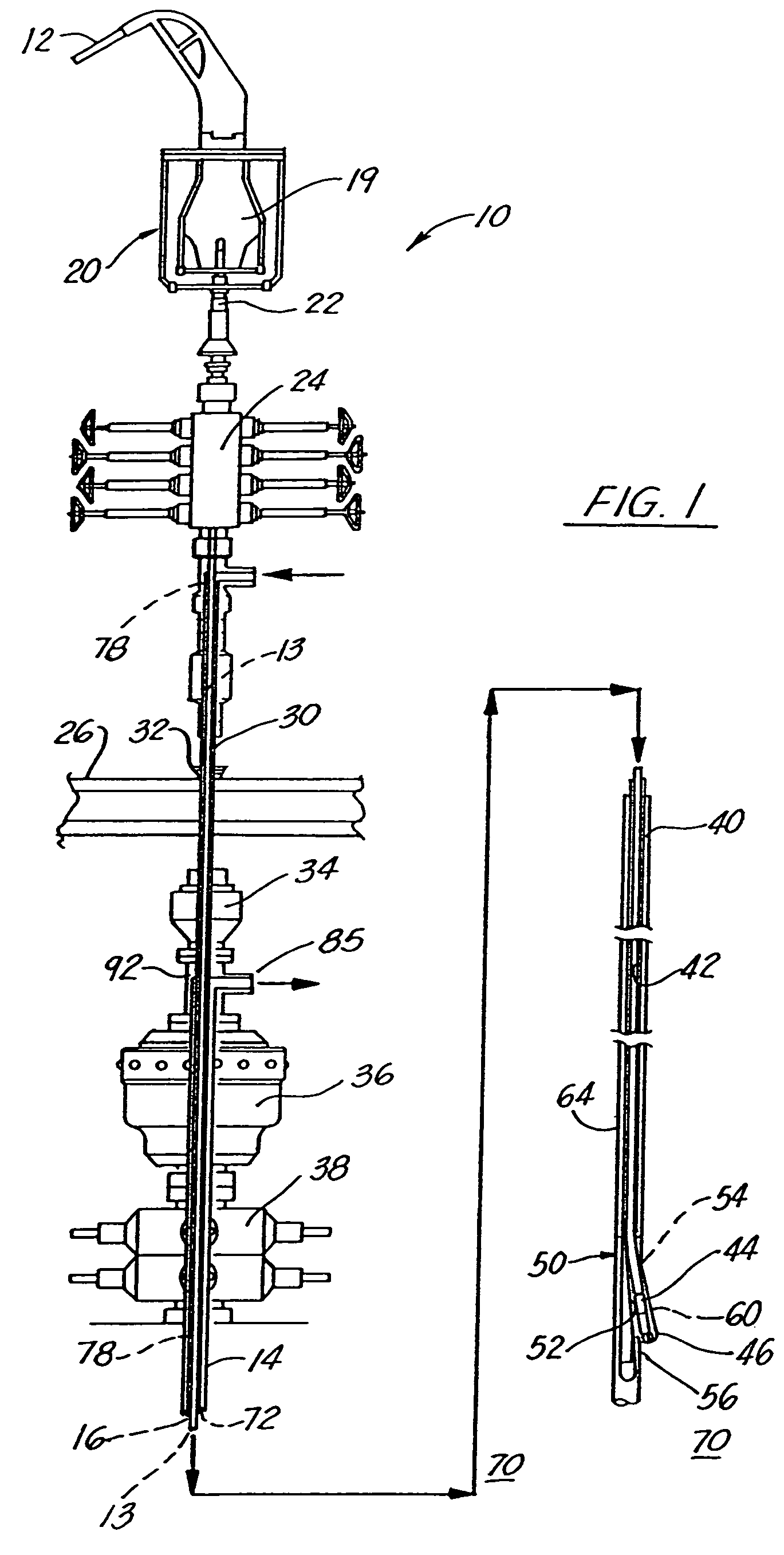

Method and system for hydraulic friction controlled drilling and completing geopressured wells utilizing concentric drill strings

InactiveUS7185718B2High injection rateHigh pressure lossArtificial islandsDrilling rodsWell drillingCasing string

A method and system of drilling straight directional and multilateral wells utilizing hydraulic frictional controlled drilling, by providing concentric casing strings to define a plurality of annuli therebetween; injecting fluid down some of the annuli; returning the fluid up at least one annulus so that the return flow creates adequate hydraulic friction within the return annulus to control the return flow within the well. The hydraulic friction should be minimized on the injection side to require less hydraulic horsepower and be maximized on the return side to create the desired subsurface friction to control the well.

Owner:GARDES ROBERT

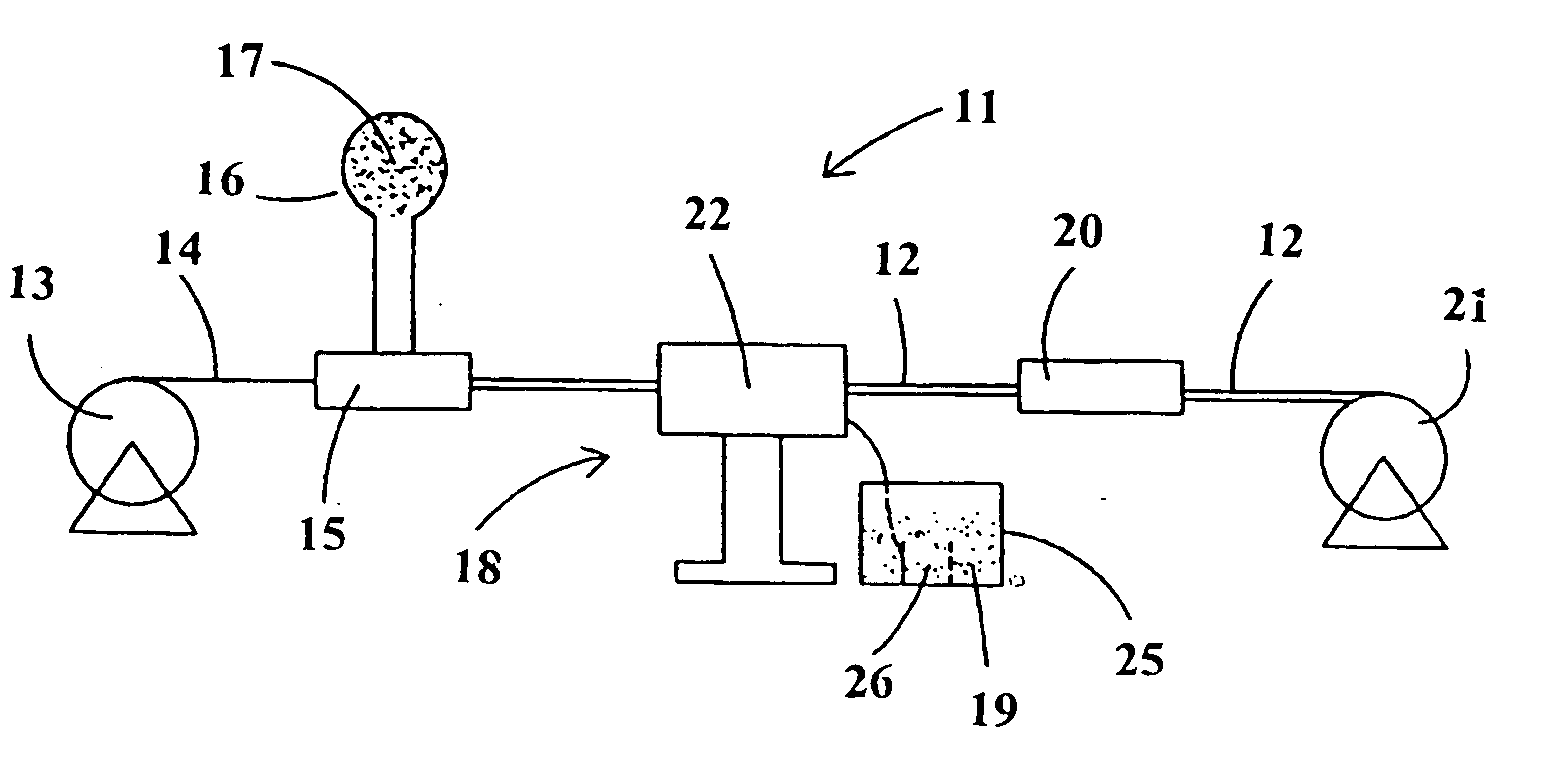

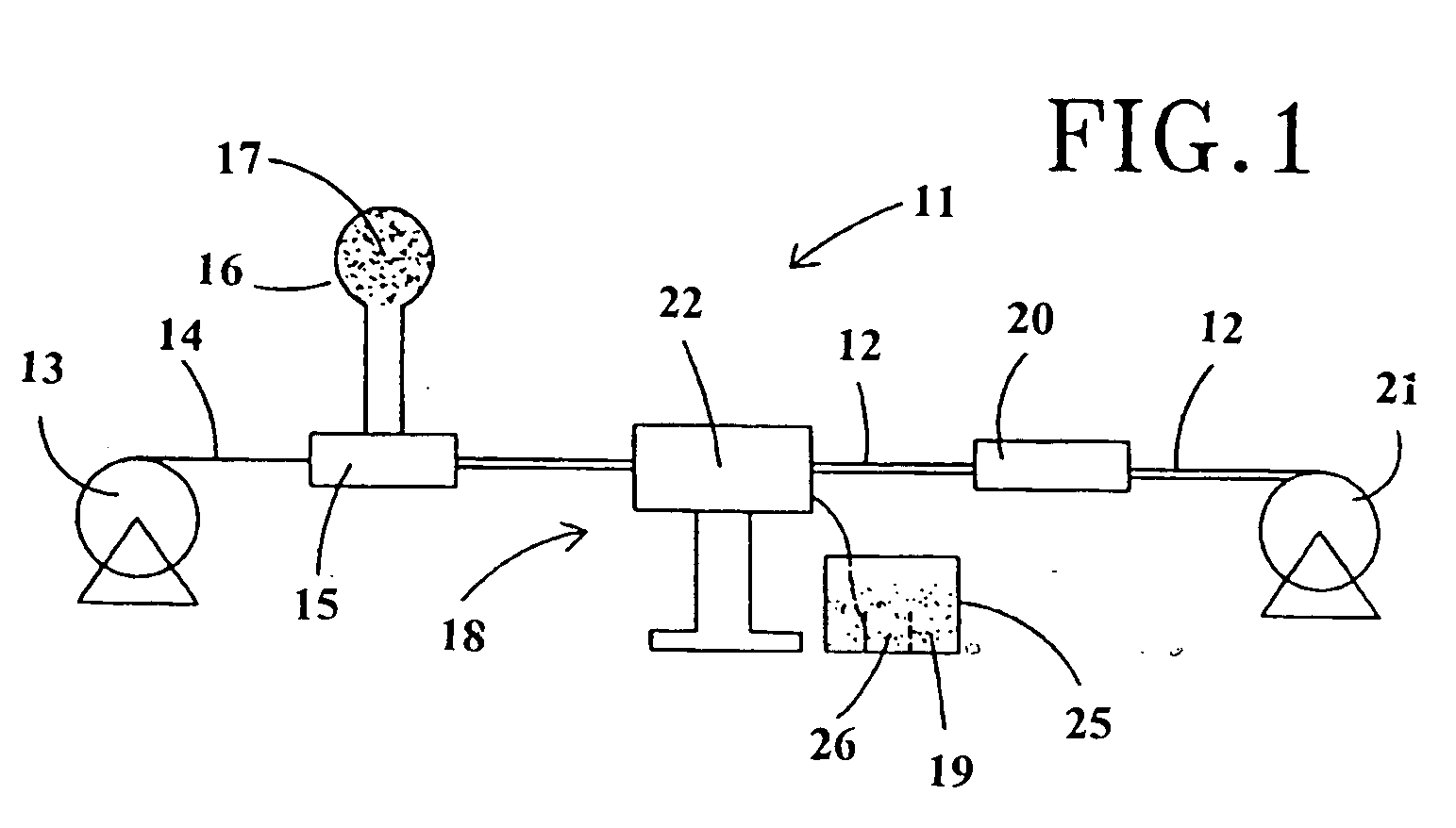

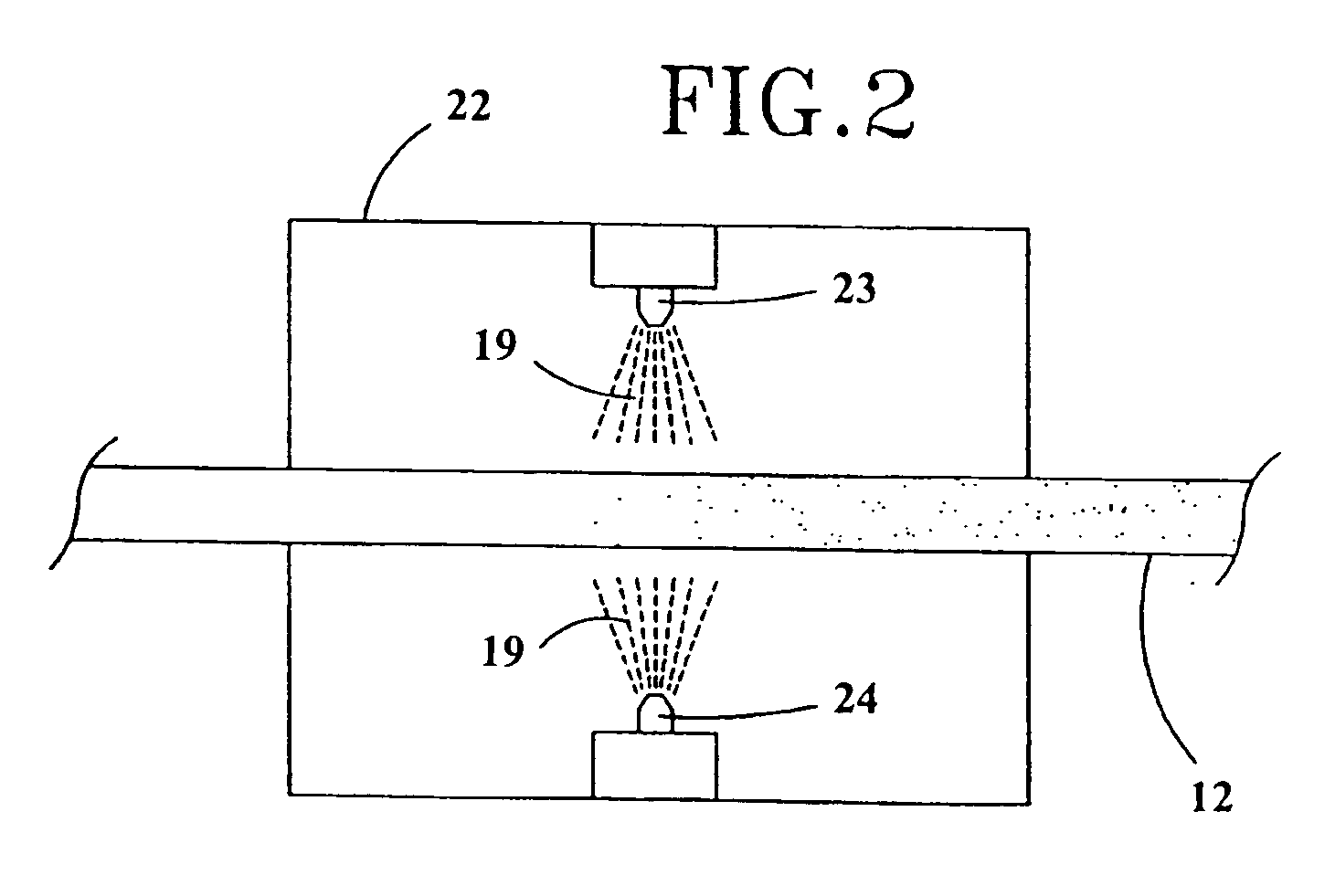

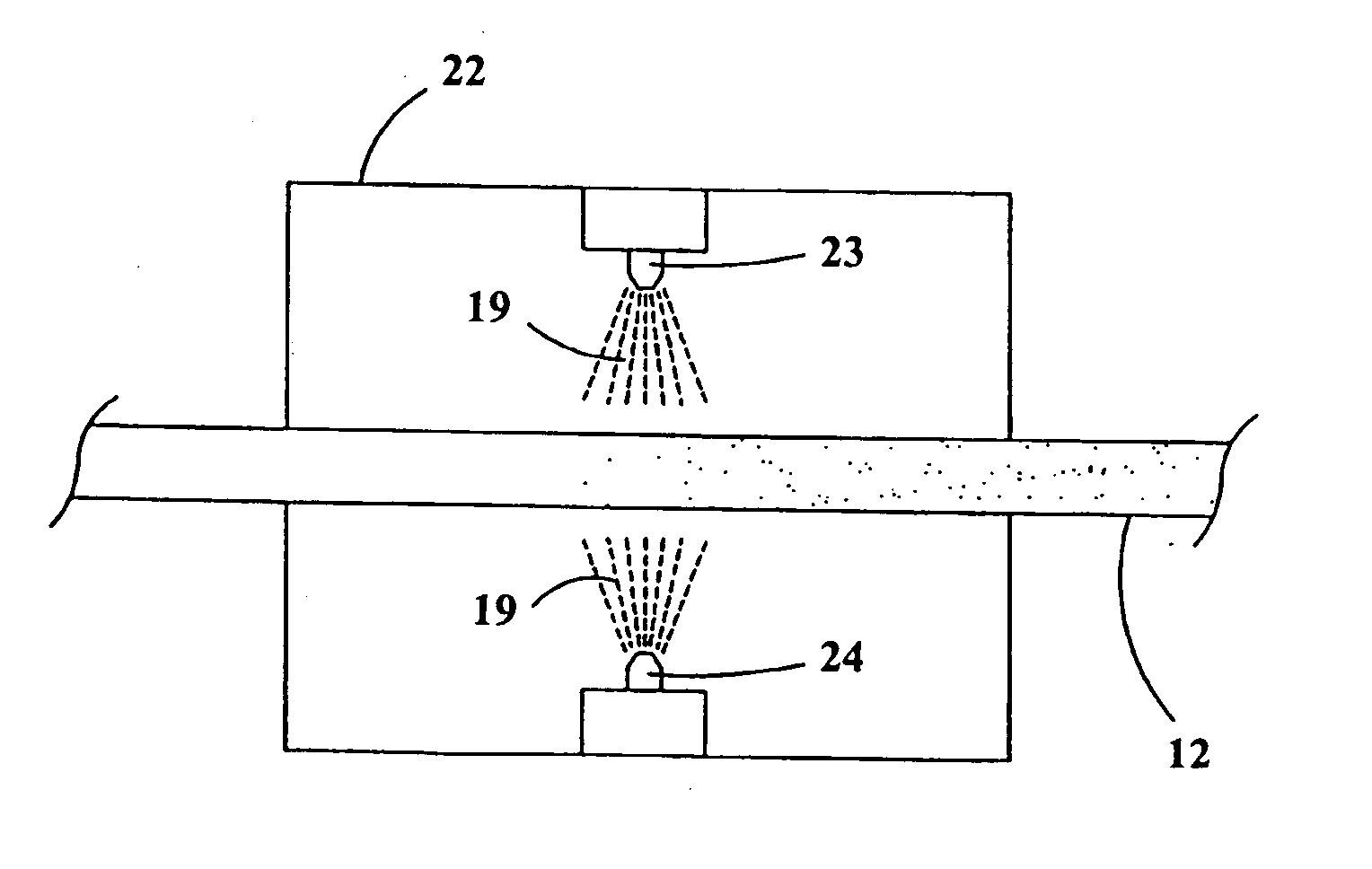

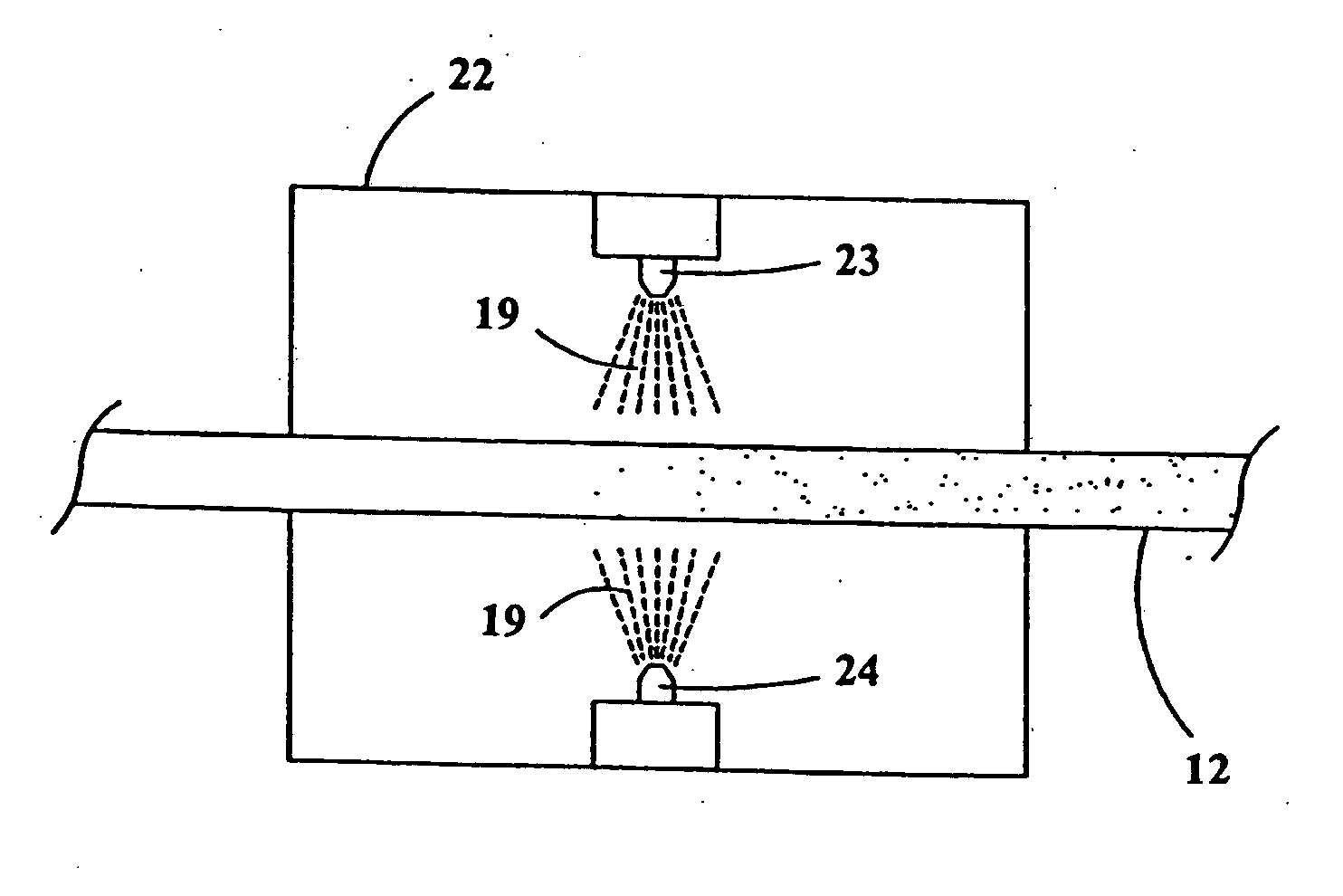

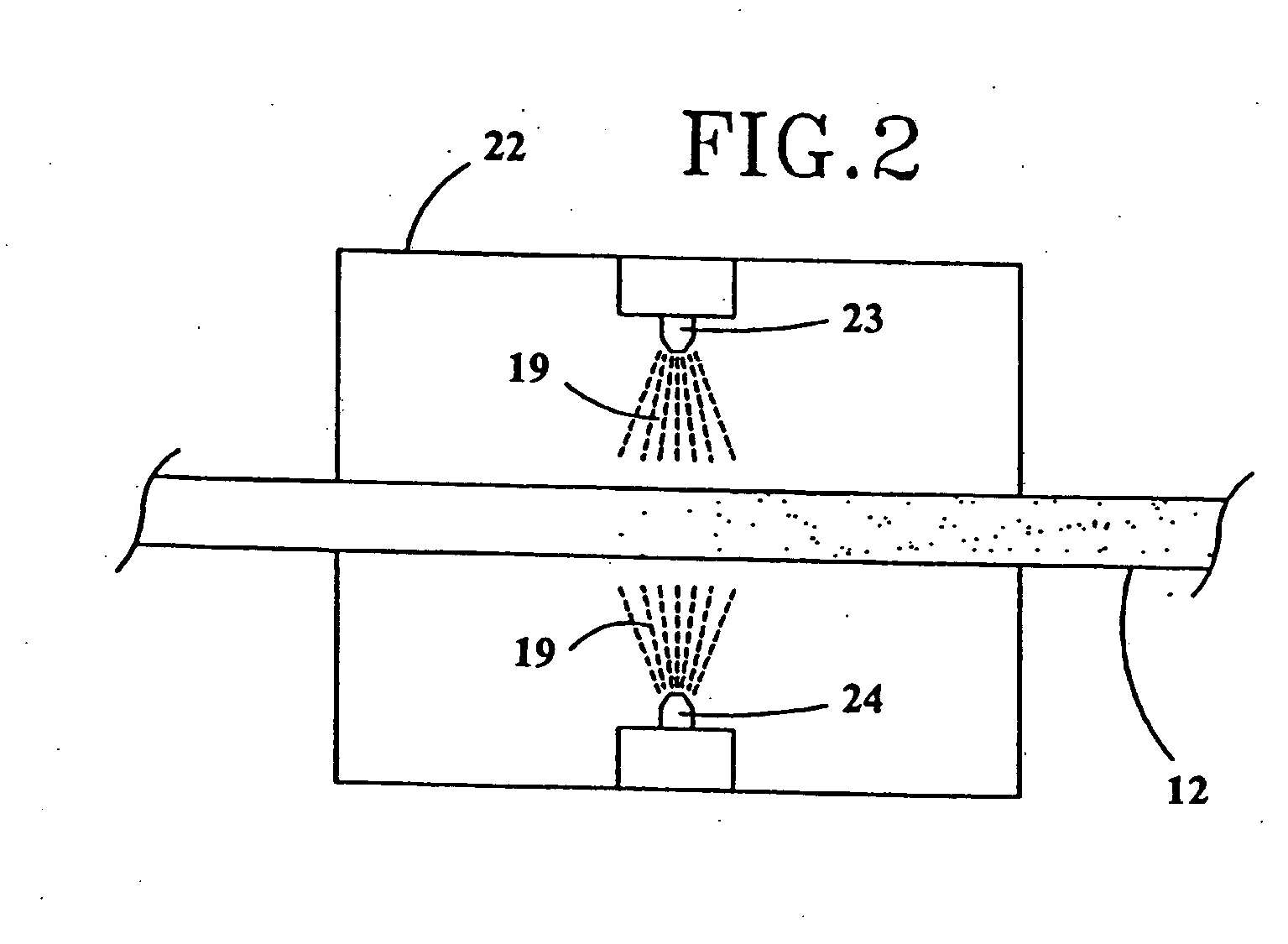

Electrical cable having a surface with reduced coefficient of friction

InactiveUS20060068086A1Reduce coefficient of frictionEasy to installSpray nozzlesLiquid spraying apparatusWire rodElectrical conductor

The present invention includes a cable having reduced surface friction and the method of manufacture thereof having steps in which a conductor wire is coated with a plastic material and in which the plastic material is cooled, and includes a step in which the lubricating material is applied to the surface of the cable. The cable includes at least one conductor core and at least one coating of plastic material and incorporates a lubricating material on the exterior coating. The equipment for the manufacturing of electrical cable includes a reel for supplying a conductor wire to an extruding head, which is connected to a tank containing plastic material for coating the conducting wire, a reel for taking up the cable, and a device for the application of a lubricating material onto the surface of the cable.

Owner:SOUTHWIRE CO LLC

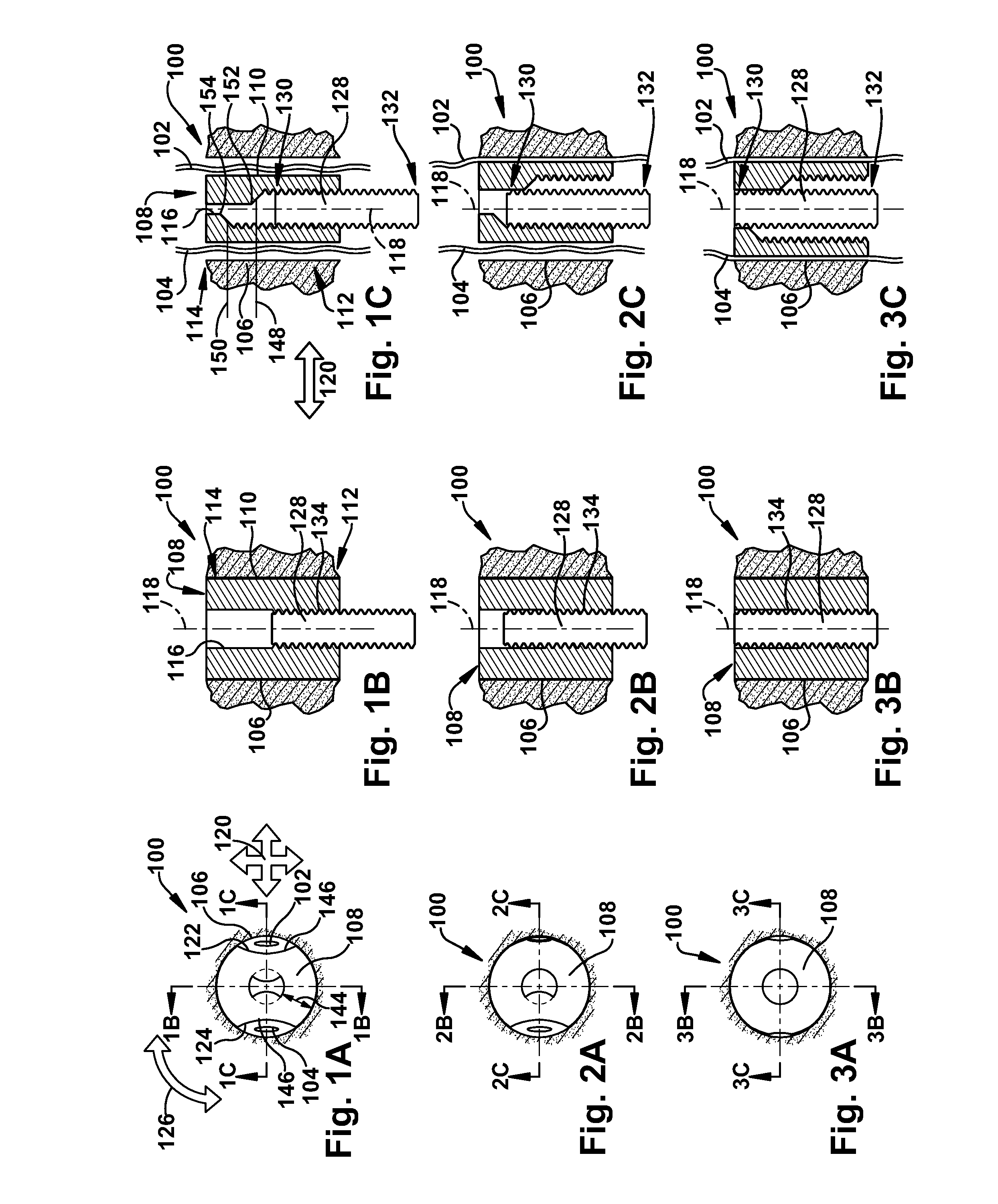

Apparatus and method for sequentially anchoring multiple graft ligaments in a bone tunnel

An apparatus for anchoring at least two graft ligaments within a longitudinal bone tunnel includes a longitudinal sleeve having at least two radially spaced ligament-contacting surfaces located in lateral opposition to a sleeve inner lumen. The sleeve is configured for at least partial insertion into the bone tunnel with each graft ligament positioned laterally adjacent a different ligament-contacting surface. The graft ligaments are at least partially located between the bone tunnel and the sleeve. An actuating member has longitudinally separated proximal and distal actuating member ends. An asymmetrically offset profile is defined by at least one of the sleeve and the actuating member. The asymmetrically offset profile has a plurality of longitudinally spaced engagement thresholds. The actuating member is inserted longitudinally into the sleeve to cause frictional engagement of each graft ligament with both the bone tunnel and at least one ligament-contacting surface. The frictional engagement of each graft ligament is temporally spaced apart from the frictional engagement of at least one other graft ligament. The temporal spacing is provided by the plurality of engagement thresholds. A method of anchoring at least two longitudinally extending graft ligaments within a bone tunnel is also provided.

Owner:THE CLEVELAND CLINIC FOUND

Electrical cable having a surface with reduced coefficient of friction

InactiveUS20060068085A1Reduce coefficient of frictionEasy to installLiquid organic insulatorsSpray nozzlesWire rodElectrical conductor

The present invention includes a cable having reduced surface friction and the method of manufacture thereof having steps in which a conductor wire is coated with a plastic material and in which the plastic material is cooled, and includes a step in which the lubricating material is applied to the surface of the cable. The cable includes at least one conductor core and at least one coating of plastic material and incorporates a lubricating material on the exterior coating. The equipment for the manufacturing of electrical cable includes a reel for supplying a conductor wire to an extruding head, which is connected to a tank containing plastic material for coating the conducting wire, a reel for taking up the cable, and a device for the application of a lubricating material onto the surface of the cable.

Owner:SOUTHWIRE CO LLC

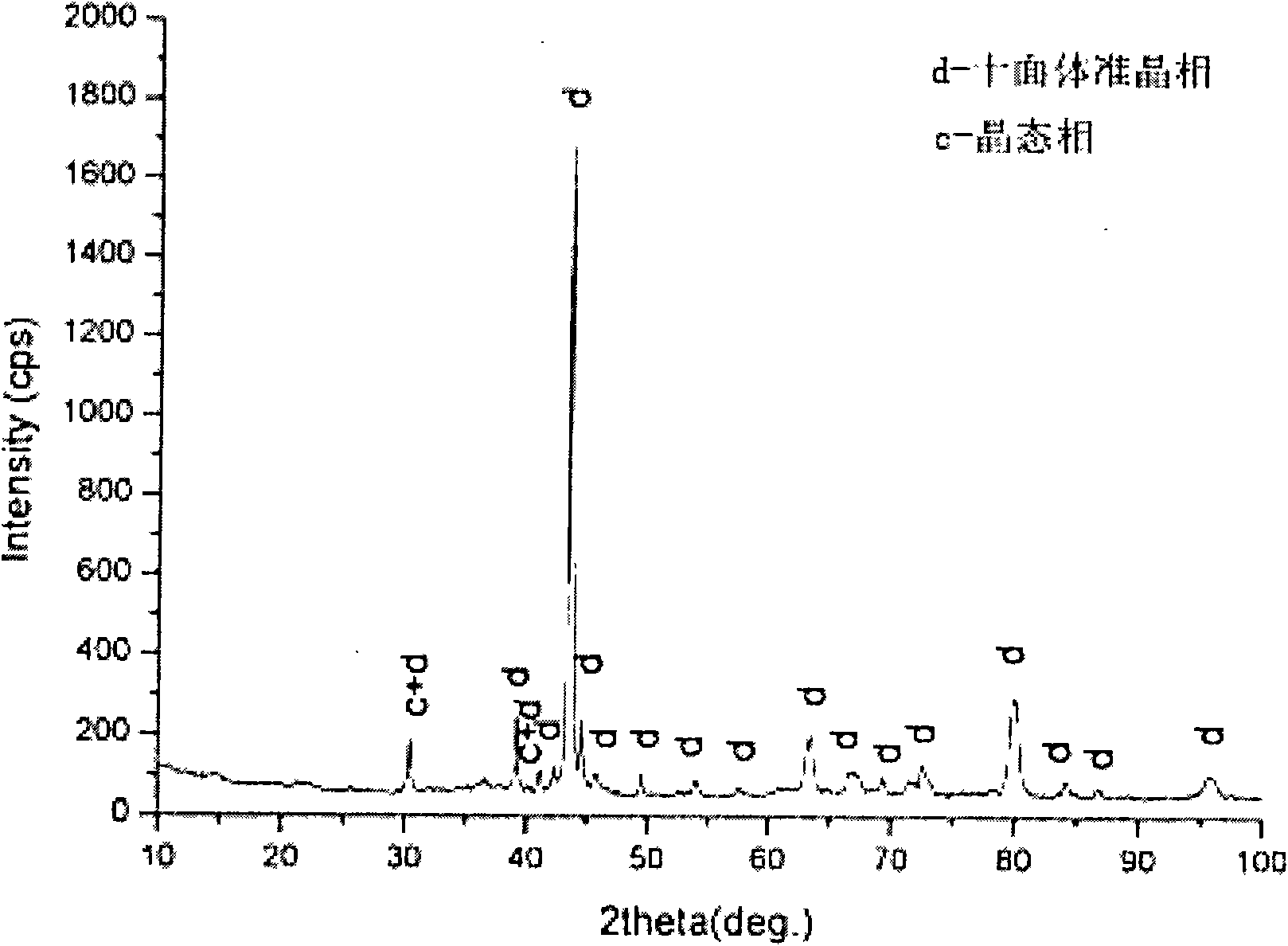

Non-stick pan coating layer and preparation method thereof

The invention provides a non-stick pan coating layer and a preparation method thereof. The coating layer comprises Al-Cu-Fe-Cr-B quasicrystalline alloy which has components as follows by the atomic percentage: 70-90 of Al, 1-15 of Cu, 5-15 of Fe, 5-15 of Cr, and the balance of B and unavoidable impurity. The method comprises the specific steps as follows: (1) smelting alloy materials with a spraying device at a temperature of 900-1100 DEG C to prepare alloy powder; (2) spraying the alloy coating layer on a boiler basal body with a plasma spraying device, with a main gas feed rate of 65 L / min, a secondary gas feed rate of 20-30 L / min, an arc current of 550-590A, an arc voltage of 45-60V, a powder delivering amount of 10-15 g / min, and a coating layer thickness of about 100-200 micro. At a cooking temperature, the invention has the advantages of stable chemical property, large rigidness, lower cost than Teflon or organic silicon, low surface friction coefficient, and the like.

Owner:鞠汉清

Apparatus for weighting golf club shaft

InactiveUS7704160B2Increased durabilityLimit on characteristicRod connectionsFriction grip releasable fasteningsHand heldGolf Ball

An apparatus for selectively adding weight to the hollow shaft of a hand-held implement. One embodiment includes an upper cylindrical member, a lower member, and an expansion ring that fits between the upper and lower members. These components are sized slightly smaller than the inside diameter of a hollow shaft, such as a golf club shaft. Each component includes an axial bore, through which a screw with an elongated barrel extends. The axial bore of the upper member is enlarged at its upper terminus to receive the cap of the screw, and the axial bore of the lower member is threaded to receive the screw. This assembly is inserted into a hollow shaft, and as the screw is tightened, the lower member is drawn into the upper member, compressing the expander ring axially causing it to expand radially until a friction fit with the inside surface of the hollow shaft is achieved.

Owner:BALANCE CERTIFIED GOLF

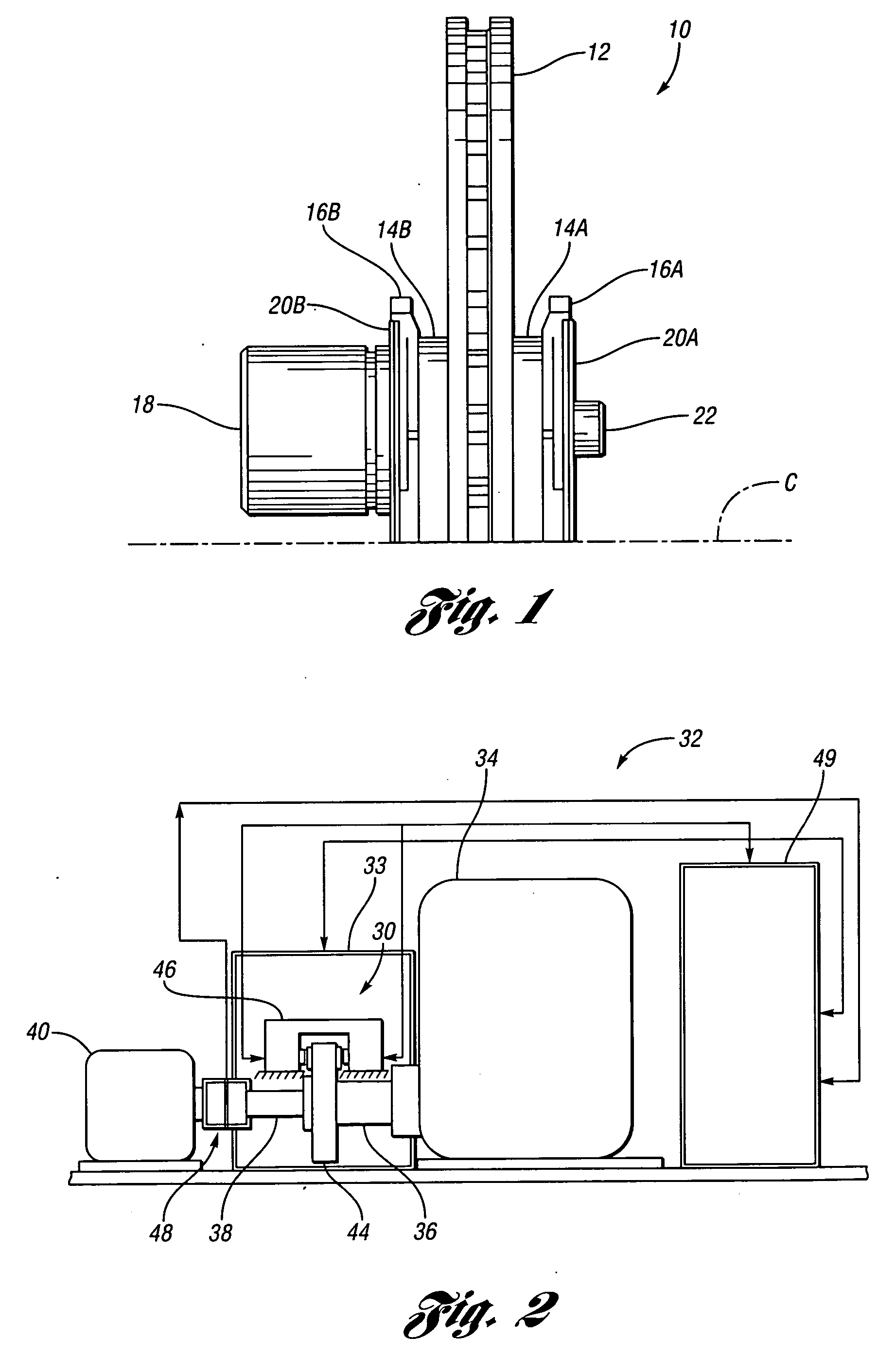

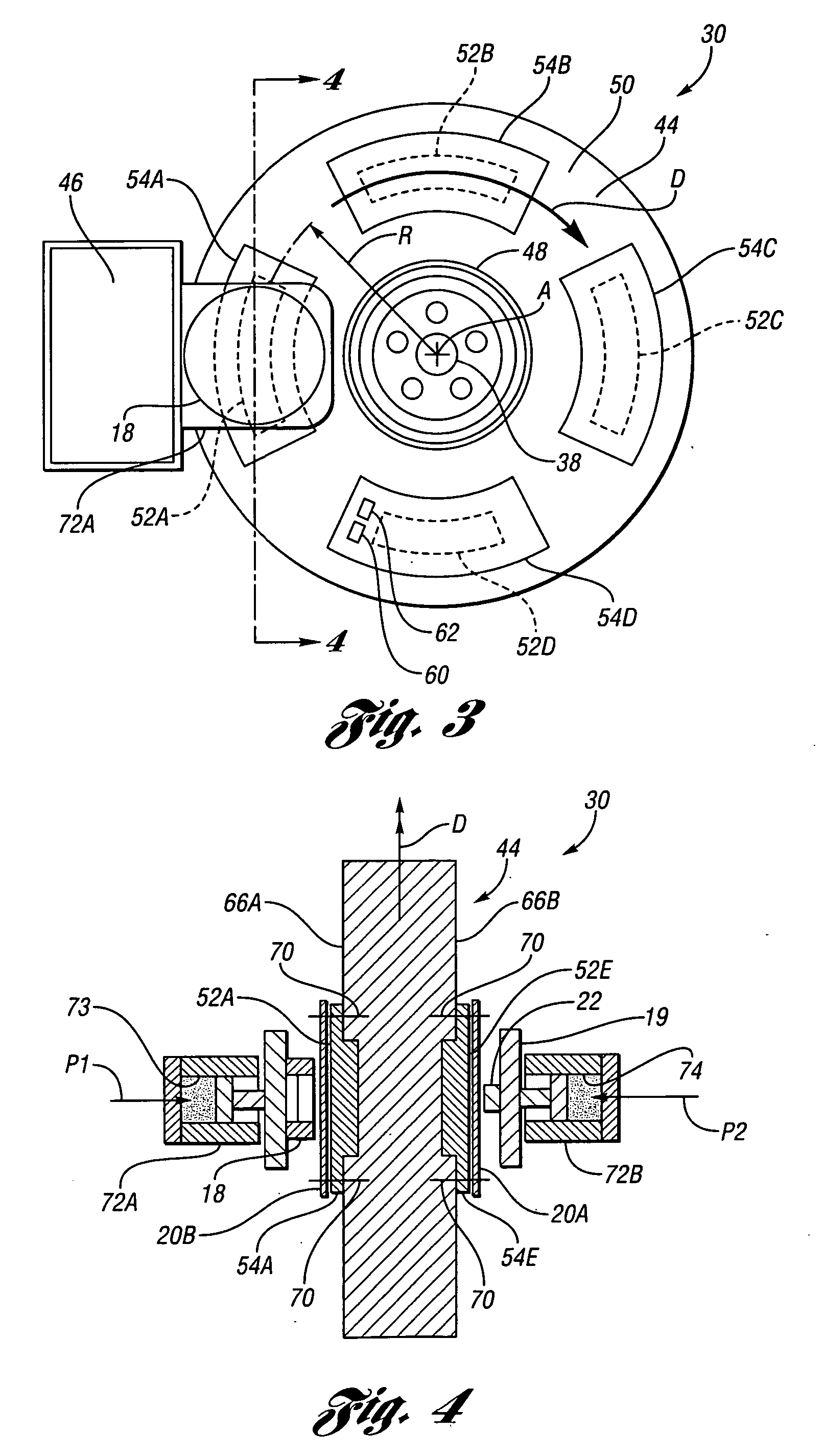

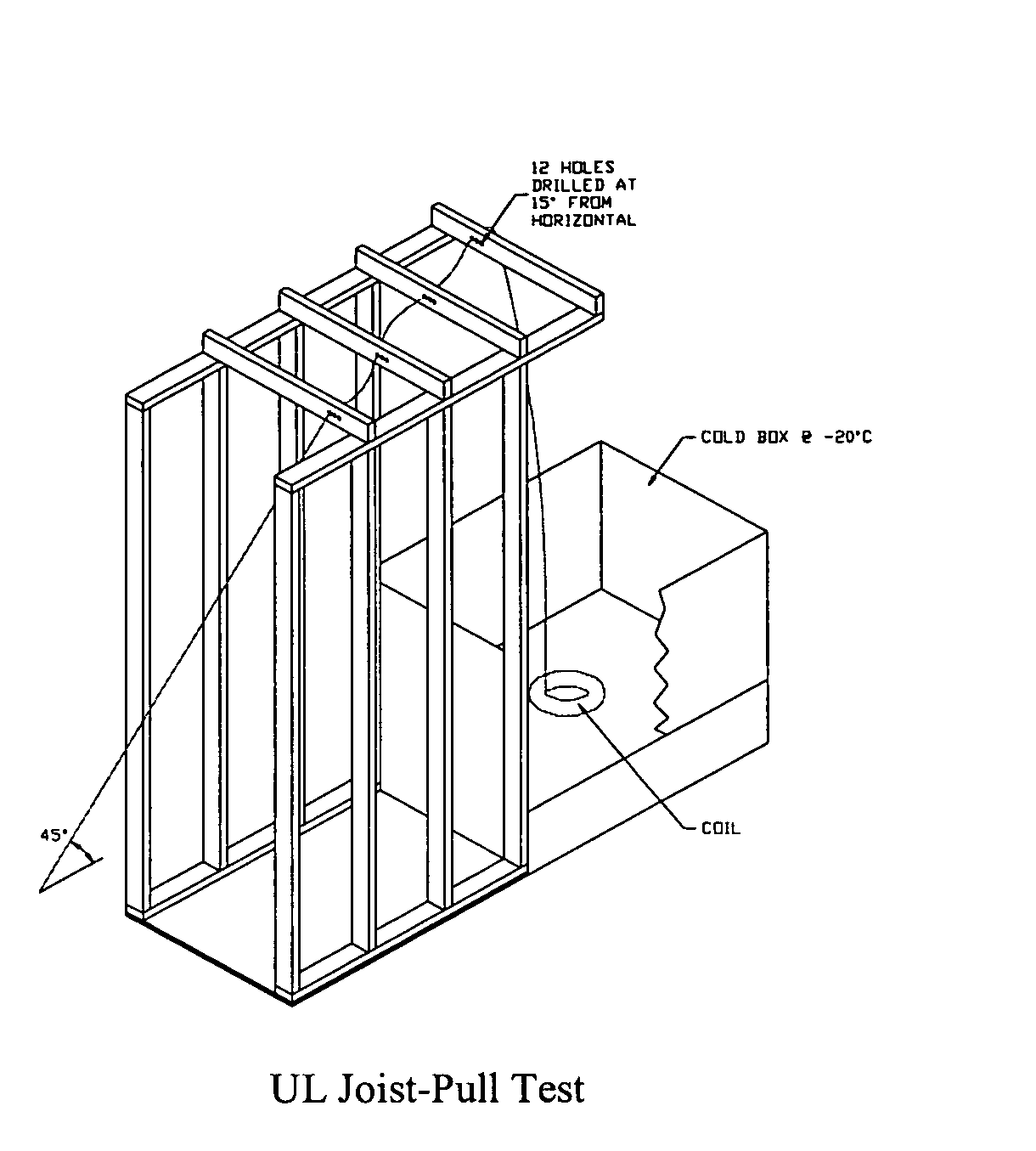

Test apparatus and method of measuring surface friction of a brake pad insulator material and method of use of a brake dynamometer

ActiveUS20070068220A1Easy to measureEasy to testUsing mechanical meansInvestigating abrasion/wear resistanceDynamometerEngineering

A test apparatus for measuring surface friction of a damping material such as brake pad insulator material includes a rotor configured to support the damping material for rotation therewith, an actuator pressurizable to apply axially-inward force to the damping material and a stator configured to support the actuator. A sensor determines the force applied to the actuator and a torque cell is axially aligned with the rotor for measuring torque of the rotor in relation to force applied to the damping material. The calculation of surface friction of the damping material is possible based on the measured load and torque. A method of measuring surface friction of a brake pad insulator material as well as a method using a brake dynamometer is also presented.

Owner:WOLVERINE ADVANCED MATERIALS

Electrical cable having a surface with reduced coefficient of friction

InactiveUS20060249298A1Reduce coefficient of frictionEasy to installPlastic/resin/waxes insulatorsInsulated cablesElectrical conductorPlastic materials

The present invention includes a cable having reduced surface friction and the method of manufacture thereof including steps in which a conductor wire is coated with a first plastic material, coated with a second plastic material and the coated conductor wire then cooled, and includes a step in which a lubricating material is applied to the surface of the cooled, coated cable. The cable includes at least one conductor core and at least one coating of plastic material and incorporates a lubricating material on the exterior coating. The equipment for the manufacturing of the electrical cable includes a reel for supplying a conductor wire to an extruding head, which is connected to tanks containing plastic materials for coating the conducting wire, a reel for taking up the cable, and a device for the application of a lubricating material onto the surface of the cable.

Owner:SOUTHWIRE CO LLC

Electrical cable having a surface with reduced coefficient of friction

InactiveUS20060065428A1Reduce coefficient of frictionEasy to installPlastic/resin/waxes insulatorsInsulated cablesElectrical conductorPlastic materials

The present invention includes a cable having reduced surface friction and the method of manufacture thereof having steps in which a conductor wire is coated with a mixture of a plastic material and lubricating material and in which the coated conductor wire is cooled. The cable includes at least one conductor core and at least one coating of plastic material and incorporates a lubricating material in and / or on the plastic material. The equipment for the manufacturing of electrical cable includes a reel for supplying a conductor wire to an extruding head, which is connected to tanks containing plastic material and lubricating material for coating the conducting wire, and a reel for taking up the cable.

Owner:SOUTHWIRE CO LLC

Electrical cable having a surface with reduced coefficient of friction

InactiveUS20060157303A1Reduce coefficient of frictionEasy to installInsulated cablesLubricating pumpsElectrical conductorPlastic materials

The present invention includes a cable having reduced surface friction and the method of manufacture thereof including steps in which a conductor wire is coated with a first plastic material, optionally coated with a second plastic material and the coated conductor wire then cooled, and includes a step in which a lubricating material is applied to the surface of the cooled, coated cable. The cable includes at least one conductor core and at least one coating of plastic material and incorporates a lubricating material on the exterior coating. The equipment for the manufacturing of the electrical cable includes a reel for supplying a conductor wire to an extruding head, which is connected to tanks containing plastic materials for coating the conducting wire, a reel for taking up the cable, and a device for the application of a lubricating material onto the surface of the cable.

Owner:SOUTHWIRE CO LLC

Electrical cable having a surface with reduced coefficient of friction

InactiveUS20060251802A1Reduce coefficient of frictionEasy to installCoatingsSpecial surfacesElectrical conductorEngineering

The present invention includes a cable having reduced surface friction and the method of manufacture thereof including steps in which a conductor wire is coated with a first plastic material and with a mixture of a second plastic material and lubricating material and the coated conductor wire cooled. The cable includes at least one conductor core and at least two coatings of plastic material and incorporates a lubricating material in and / or on the outer layer of plastic material. The equipment for the manufacturing of the electrical cable includes a reel for supplying a conductor wire to an extruding head, which is connected to tanks containing plastic material and lubricating material for coating the conducting wire, and a reel for taking up the cable.

Owner:SOUTHWIRE CO LLC

Electrical cable having a surface with reduced coefficient of friction

InactiveUS20060249299A1Reduce coefficient of frictionEasy to installInsulated cablesCoatingsElectrical conductorPlastic materials

The present invention includes a cable having reduced surface friction and the method of manufacture thereof including steps in which a conductor wire is coated with a first plastic material and with a mixture of a second plastic material and lubricating material and the coated conductor wire cooled. The cable includes at least one conductor core and at least two coatings of plastic material and incorporates a lubricating material in and / or on the outer layer of plastic material. The equipment for the manufacturing of the electrical cable includes a reel for supplying a conductor wire to an extruding head, which is connected to tanks containing plastic material and lubricating material for coating the conducting wire, and a reel for taking up the cable.

Owner:SOUTHWIRE CO LLC

Electrical cable having a surface with a reduced coefficient of friction

InactiveUS20070243761A1Reduce coefficient of frictionMinimizing required installation pulling forceLiquid organic insulatorsSecuring/insulating coupling contact membersElectrical conductorFrictional coefficient

Owner:SOUTHWIRE CO LLC

Electrical cable having a surface with reduced coefficient of friction

InactiveUS20060151196A1Reduce coefficient of frictionEasy to installPlastic/resin/waxes insulatorsInsulated cablesElectrical conductorPlastic materials

The present invention includes a cable having reduced surface friction and the method of manufacture thereof including steps in which a conductor wire is coated with a first plastic material and with a mixture of a second plastic material and lubricating material and the coated conductor wire cooled. The cable includes at least one conductor core and at least two coatings of plastic material and incorporates a lubricating material in and / or on the outer layer of plastic material. The equipment for the manufacturing of the electrical cable includes a reel for supplying a conductor wire to an extruding head, which is connected to tanks containing plastic material and lubricating material for coating the conducting wire, and a reel for taking up the cable.

Owner:SOUTHWIRE CO LLC

Electrical Cable Having a Surface With Reduced Coefficient of Friction

InactiveUS20080066946A1Reduce coefficient of frictionEasy to installPlastic/resin/waxes insulatorsInsulated cablesWire rodElectrical conductor

The present invention includes a cable having reduced surface friction and the method of manufacture thereof including steps in which a conductor wire is coated with a first plastic material and with a mixture of a second plastic material and lubricating material and the coated conductor wire cooled. The cable includes at least one conductor core and at least two coatings of plastic material and incorporates a lubricating material in and / or on the outer layer of plastic material. The equipment for the manufacturing of the electrical cable includes a reel for supplying a conductor wire to an extruding head, which is connected to tanks containing plastic material and lubricating material for coating the conducting wire, and a reel for taking up the cable.

Owner:SOUTHWIRE CO LLC

Electrical cable having a surface with reduced coefficient of friction

InactiveUS20060191621A1Reduce coefficient of frictionEasy to installInsulated cablesCoatingsWire rodElectrical conductor

The present invention includes a cable having reduced surface friction and the method of manufacture thereof including steps in which a conductor wire is coated with a first plastic material and with a mixture of a second plastic material and lubricating material and the coated conductor wire cooled. The cable includes at least one conductor core and at least two coatings of plastic material and incorporates a lubricating material in and / or on the outer layer of plastic material. The equipment for the manufacturing of the electrical cable includes a reel for supplying a conductor wire to an extruding head, which is connected to tanks containing plastic material and lubricating material for coating the conducting wire, and a reel for taking up the cable.

Owner:SOUTHWIRE CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com