Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1760results about "Rivets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

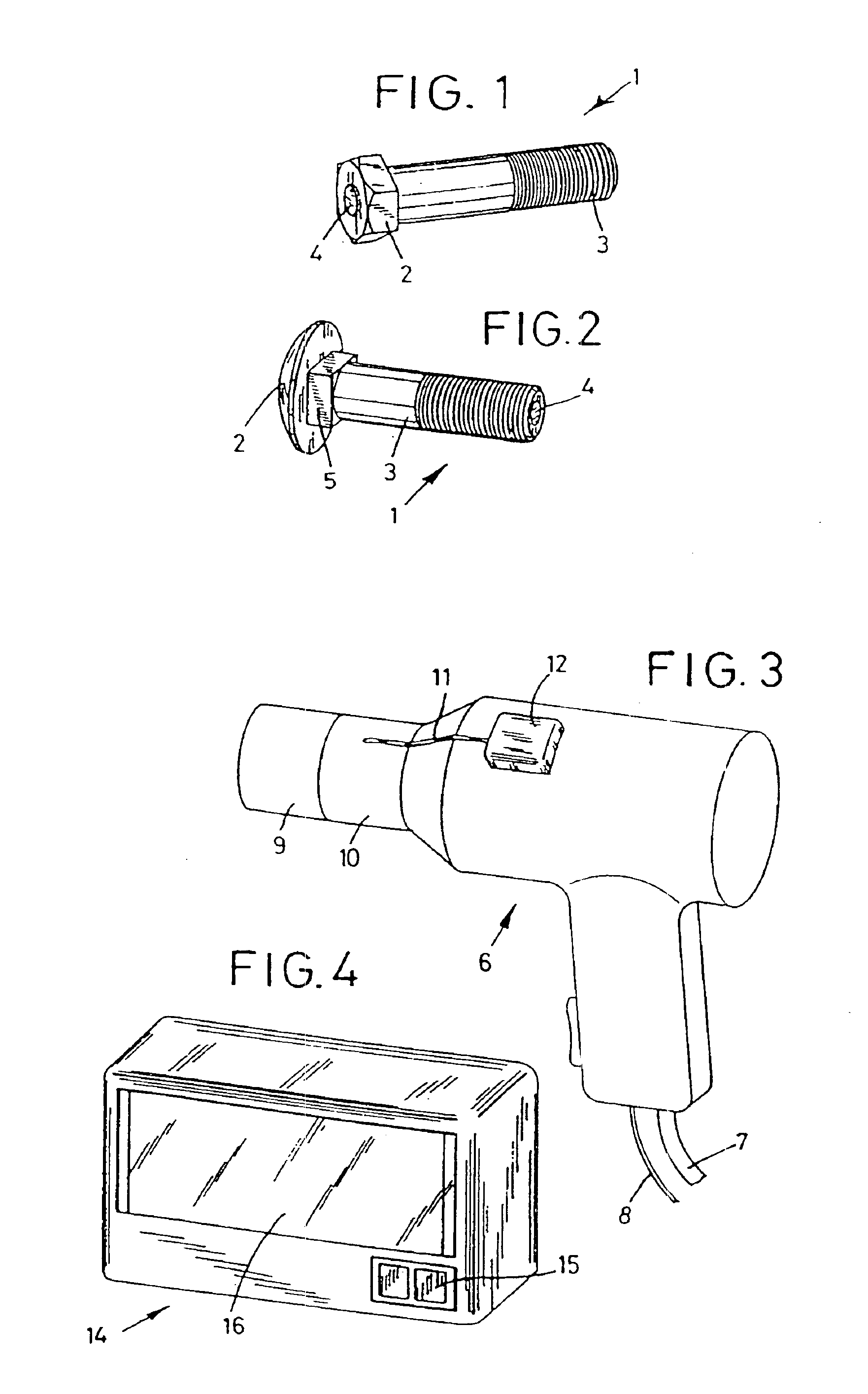

Apparatus for rivetting

Owner:GUNYANG ITT

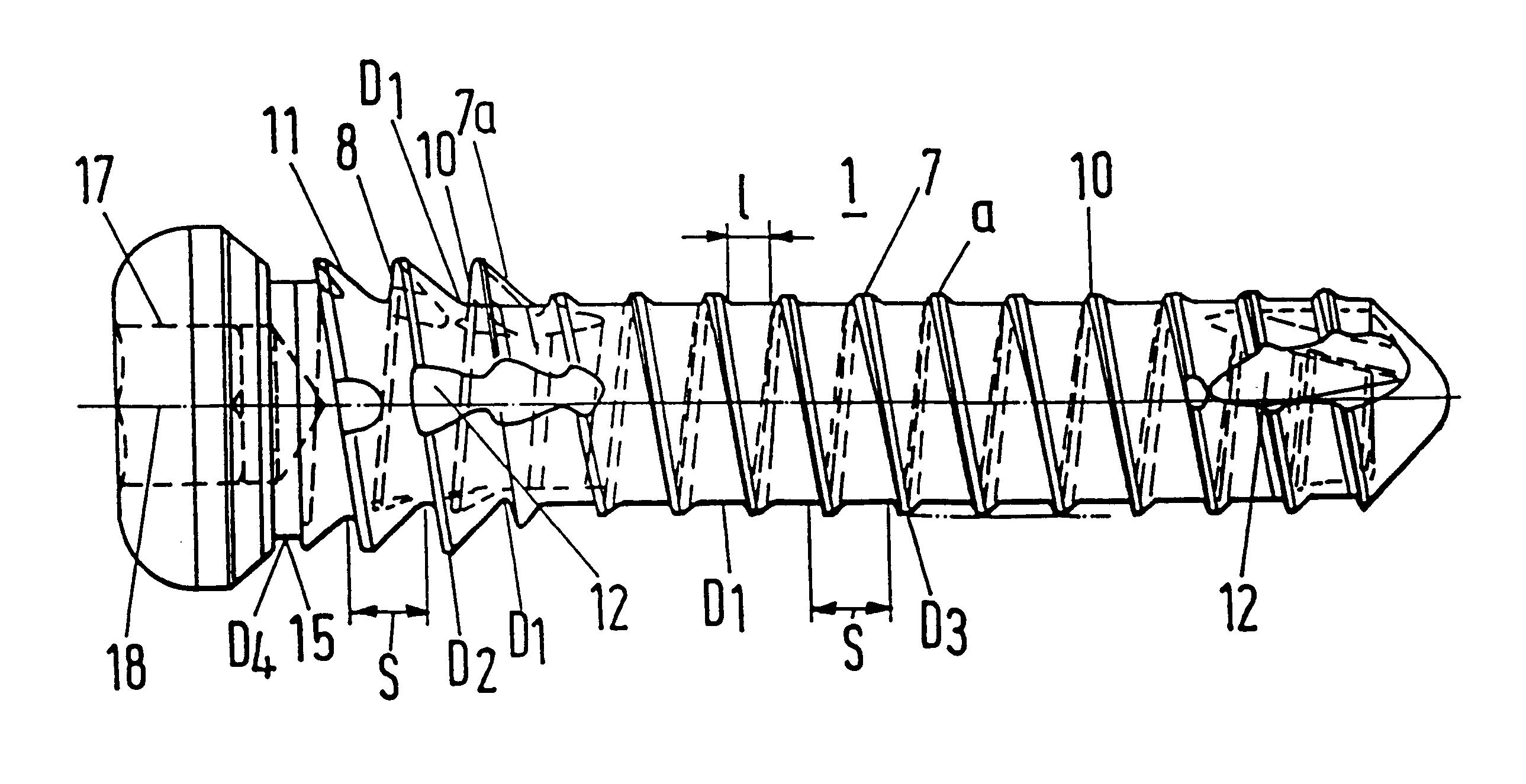

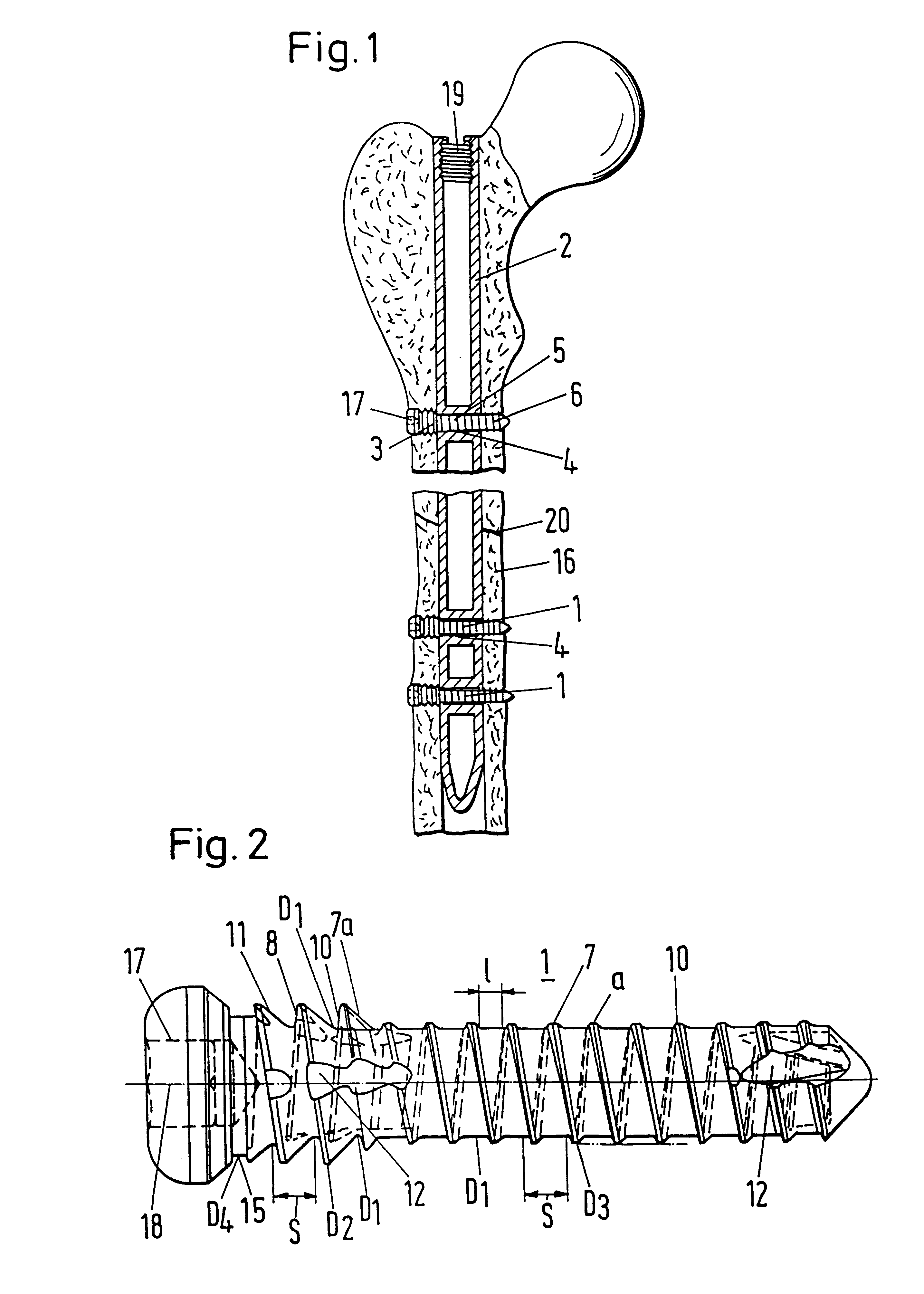

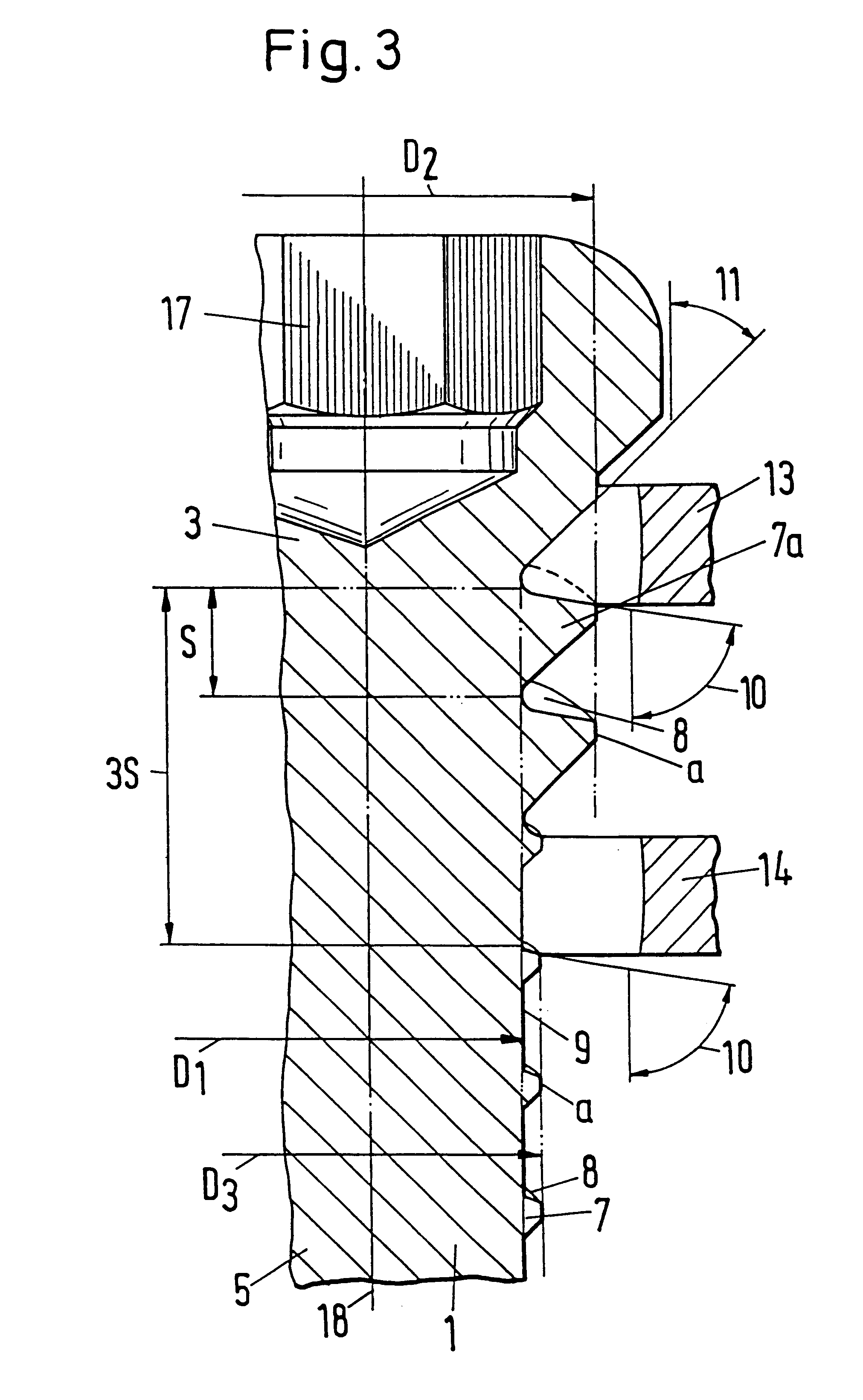

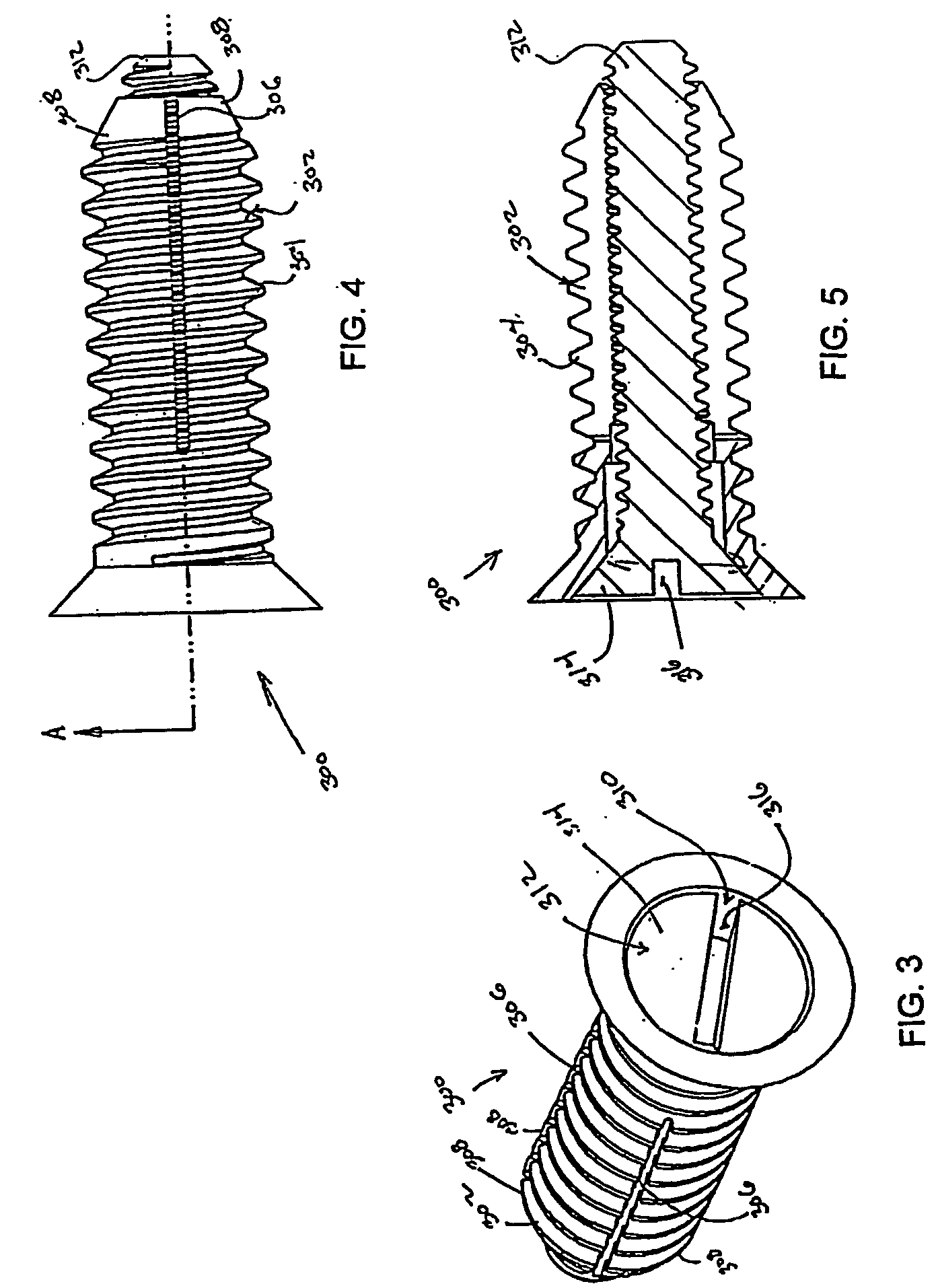

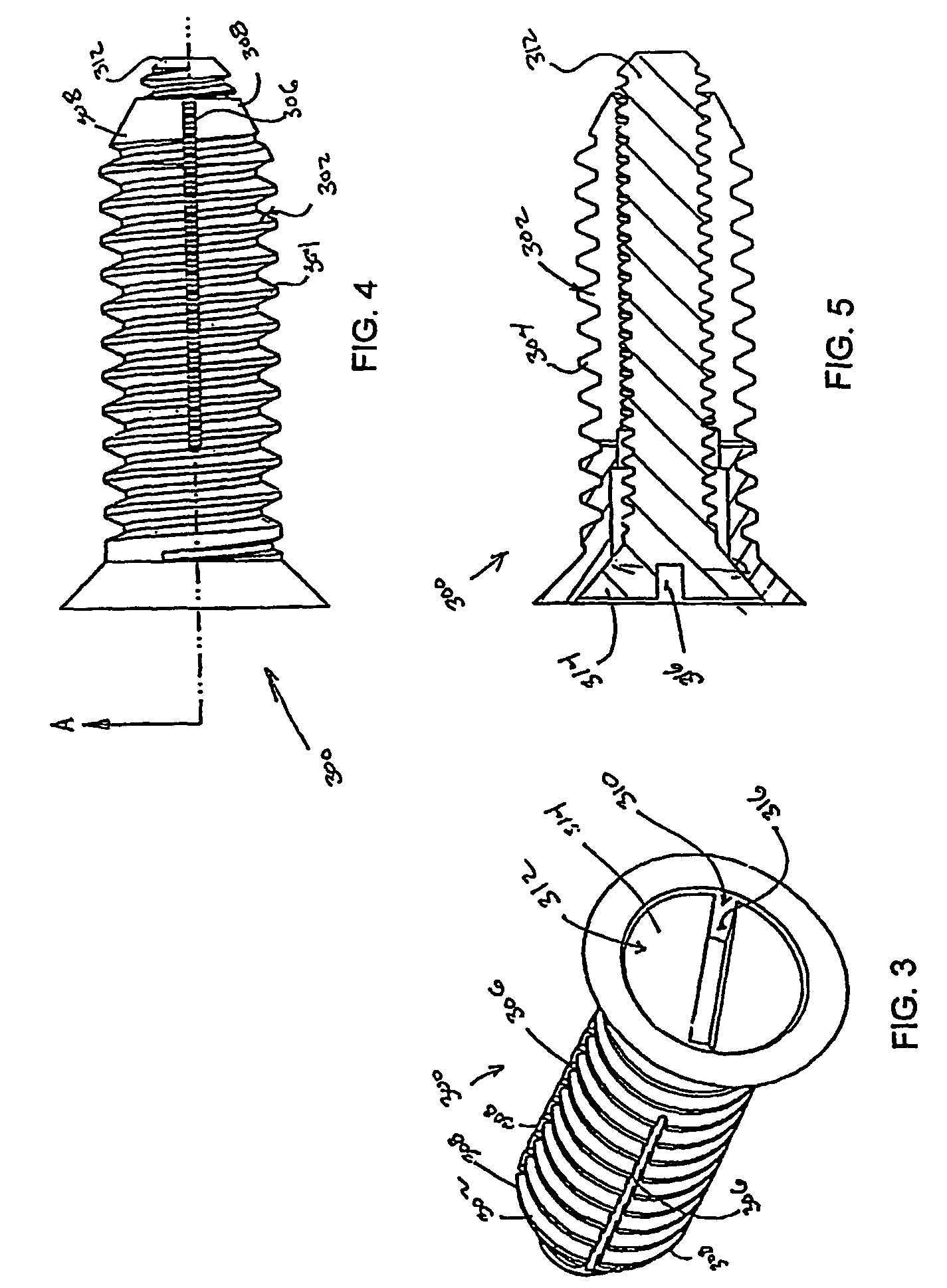

Bone screw for anchoring a marrow nail

A Bone screw for anchoring a marrow nail with transverse bores in a tubular bone. The bone screw had a thread with a pitch S, a core diameter D1 and outer diameter D3. The screw supports the marrow nail with a middle part and is fixed in the bone with a distal part. The thread has a flat cylindrical thread base with a length l>0.3 S. In addition, a second thread with the same pitch S and with the core diameter D1 is present in a proximal head part, but has a greater outer diameter D2>D3 in order to proximally achieve a fixing with a greater thread profile.

Owner:ZIMMER GMBH

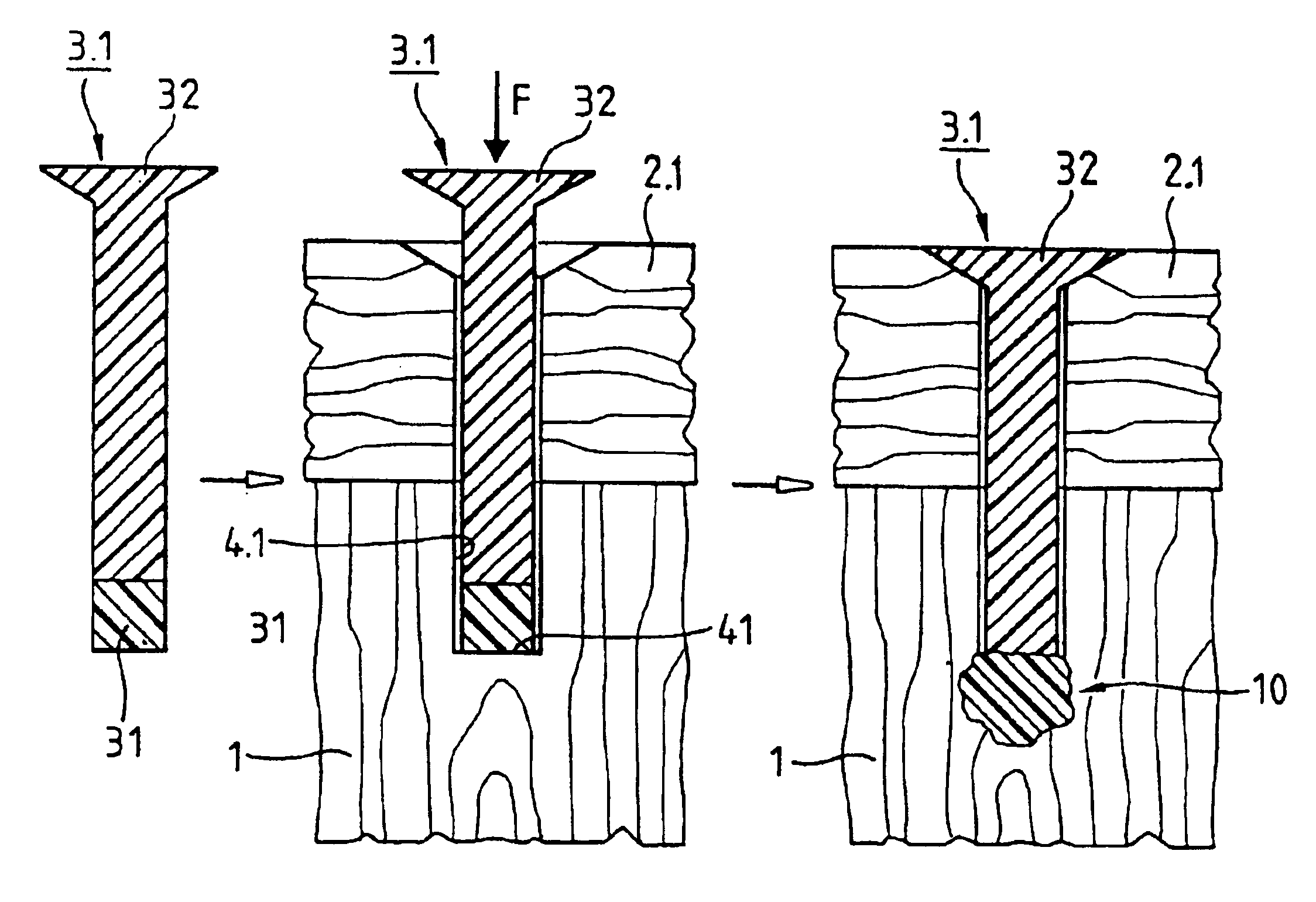

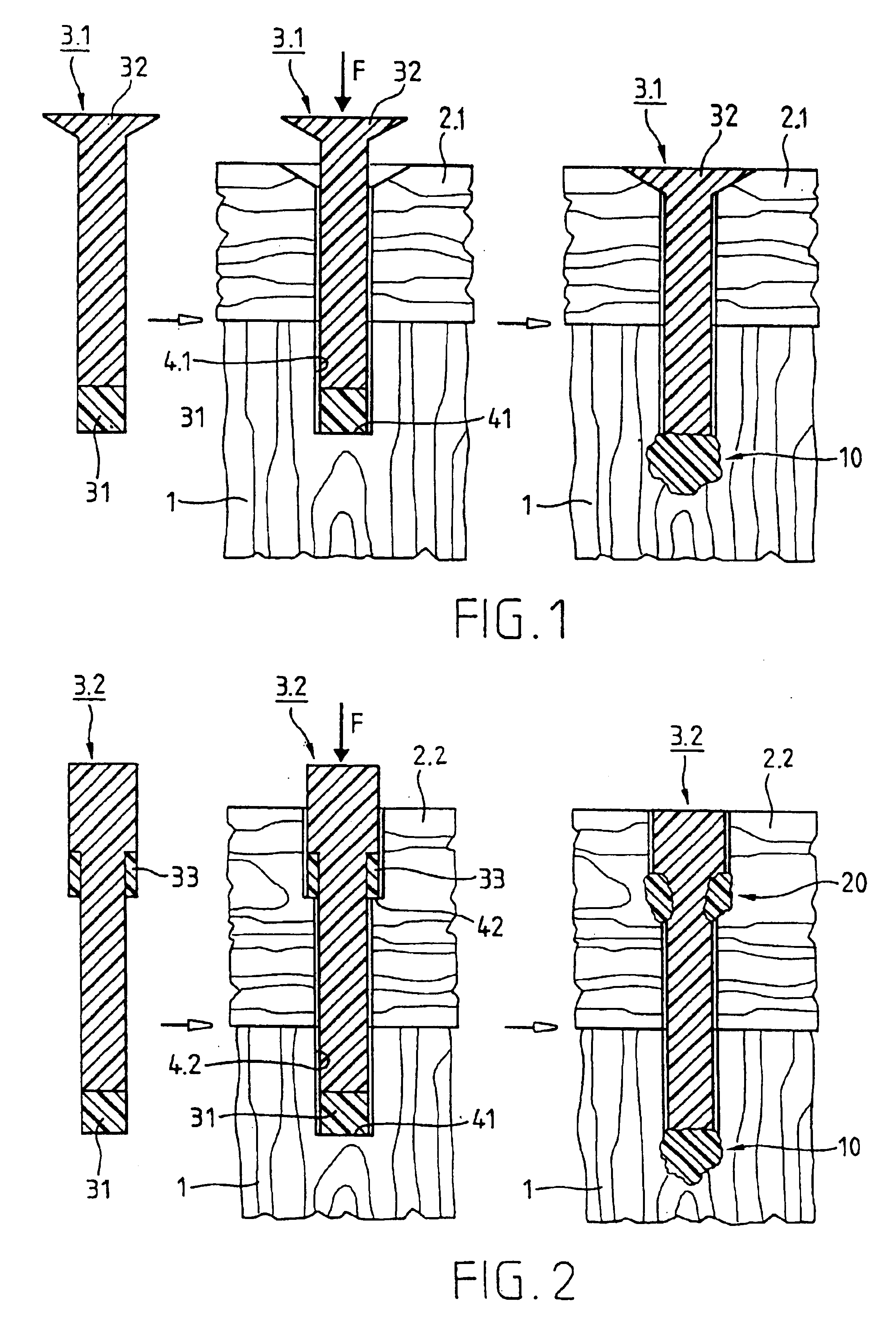

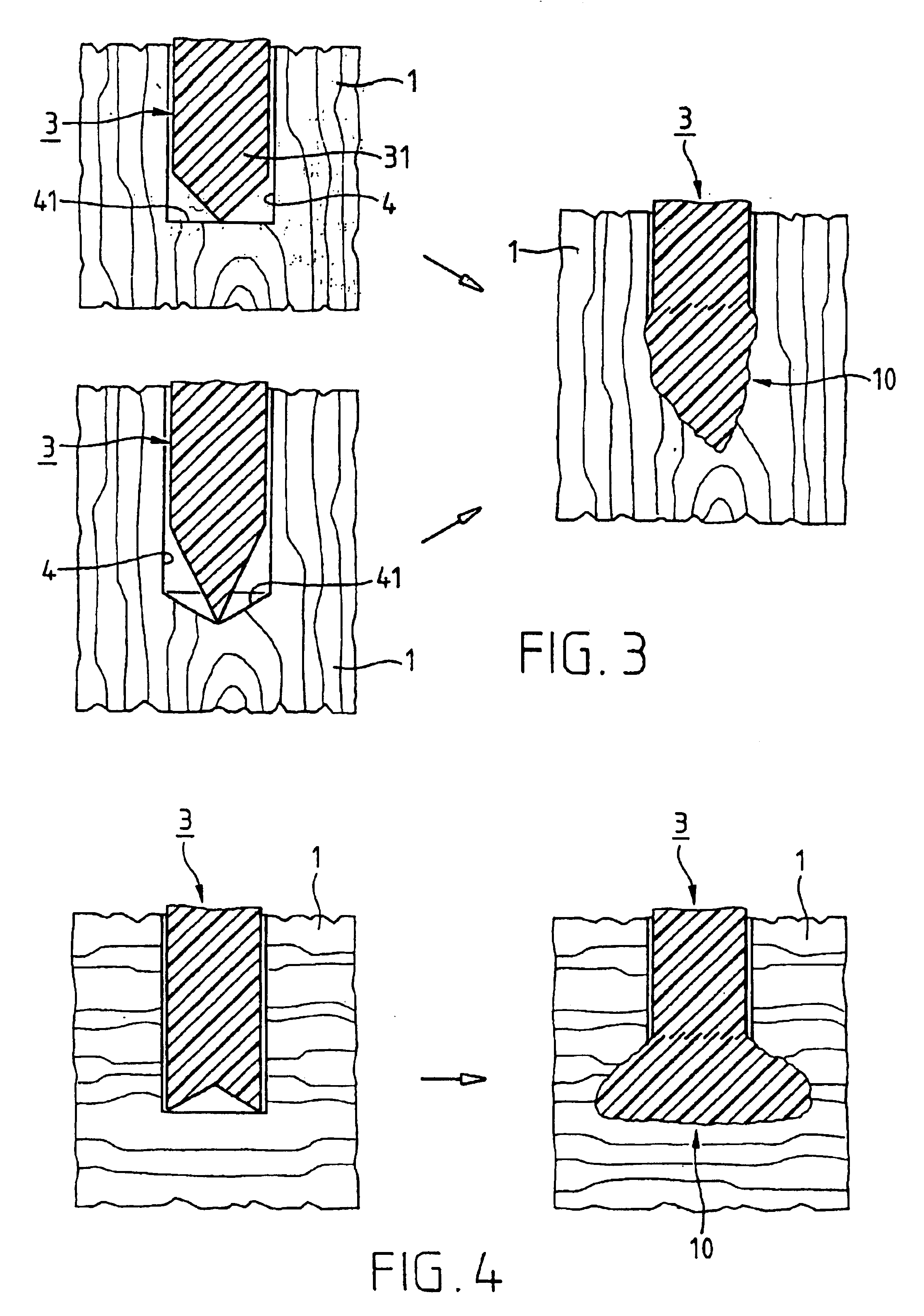

Process for anchoring connecting elements in a material with pores or cavities and connecting elements therefor

InactiveUS6913666B1Easy to reachReduce disadvantagesRivetsCylinder headsEngineeringUltrasonic vibration

A joining pin (3.2) with which two parts (1 and 2) made from a porous material, particularly wood or a wood-like material, are to be joined together, is anchored in the porous material at predetermined anchoring points (31, 33). For this purpose, a bore (4.2) with a closed inner end (41) is made in the parts (1 and 2). The shape of this bore (4.2) is so matched to the joining pin (3.2) that it can be introduced substantially without force expenditure into the bore and is positionable in a first position. At least one predetermined anchoring point (31, 33) between the joining pin (3.2) and the wall of the bore (4.2) is formed when pressure is built up by pressing the joining pin (3.2) with a pressing force (F) more deeply into the bore to a second position. Energy is supplied in a planned manner to the joining pin (3.2) so that at the predetermined anchoring points (31, 33) the thermoplastic material of the joining pin (3.2) is plasticized. The locally plasticized plastic material is pressed by the local pressure into the porous material of the parts and forms local, macroscopic anchors (10, 20). The joining pin (3.2) is, e.g., made entirely from a thermoplastic material and the energy for plasticizing is supplied thereto by ultrasonic vibration.

Owner:WOODWELDING

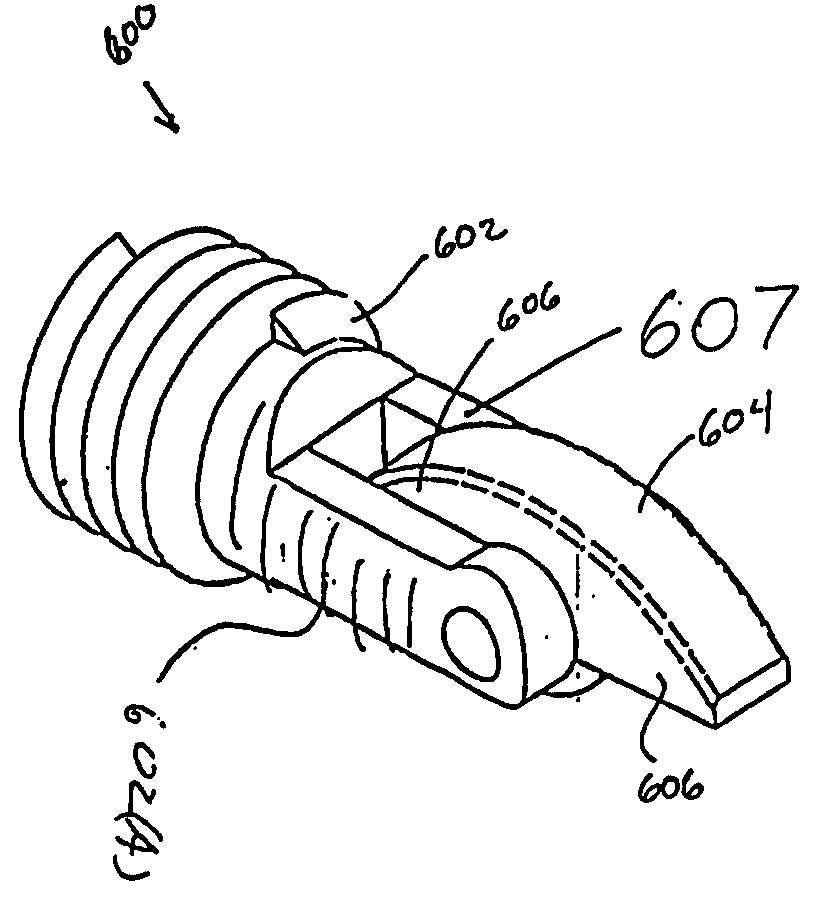

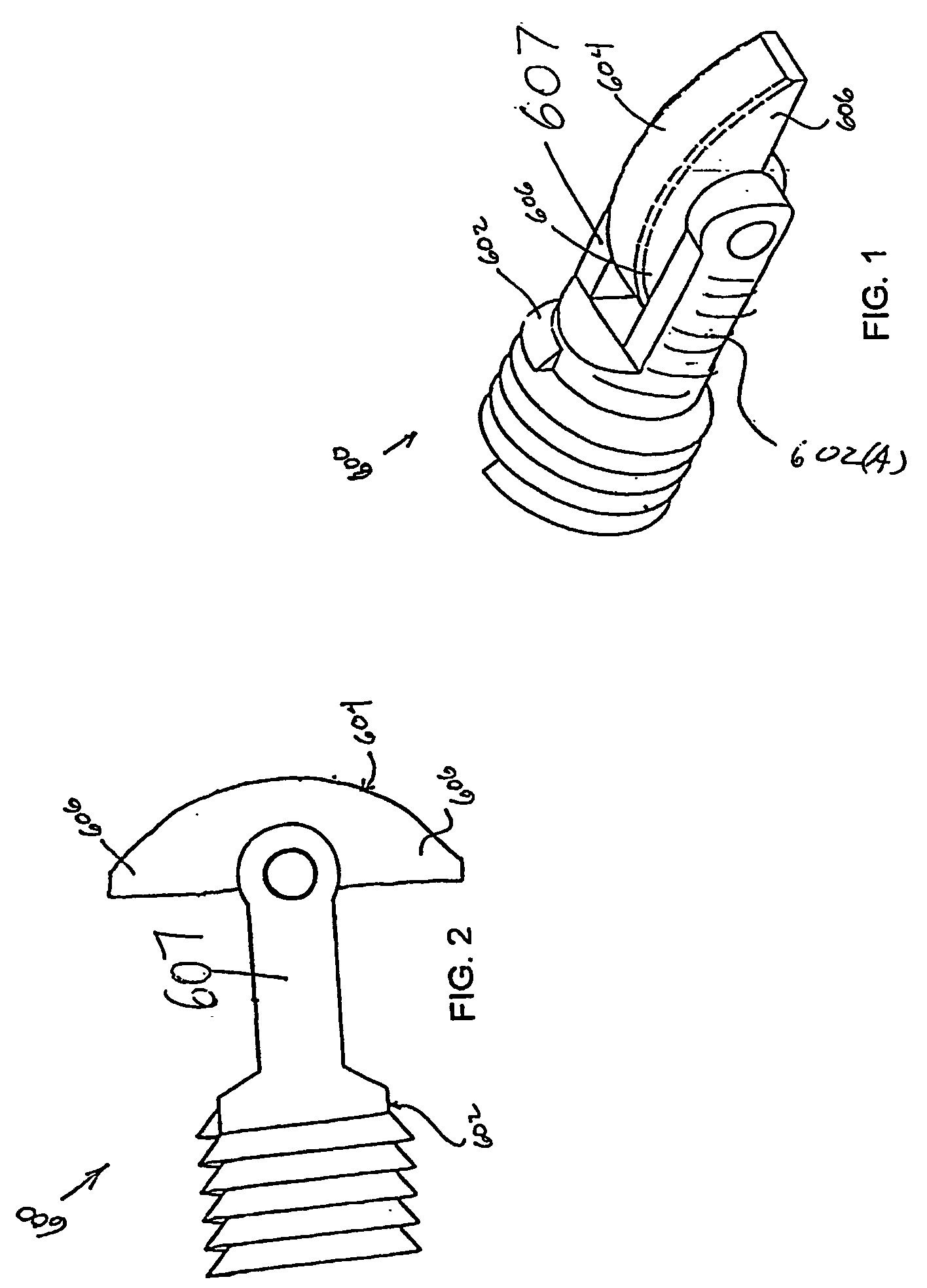

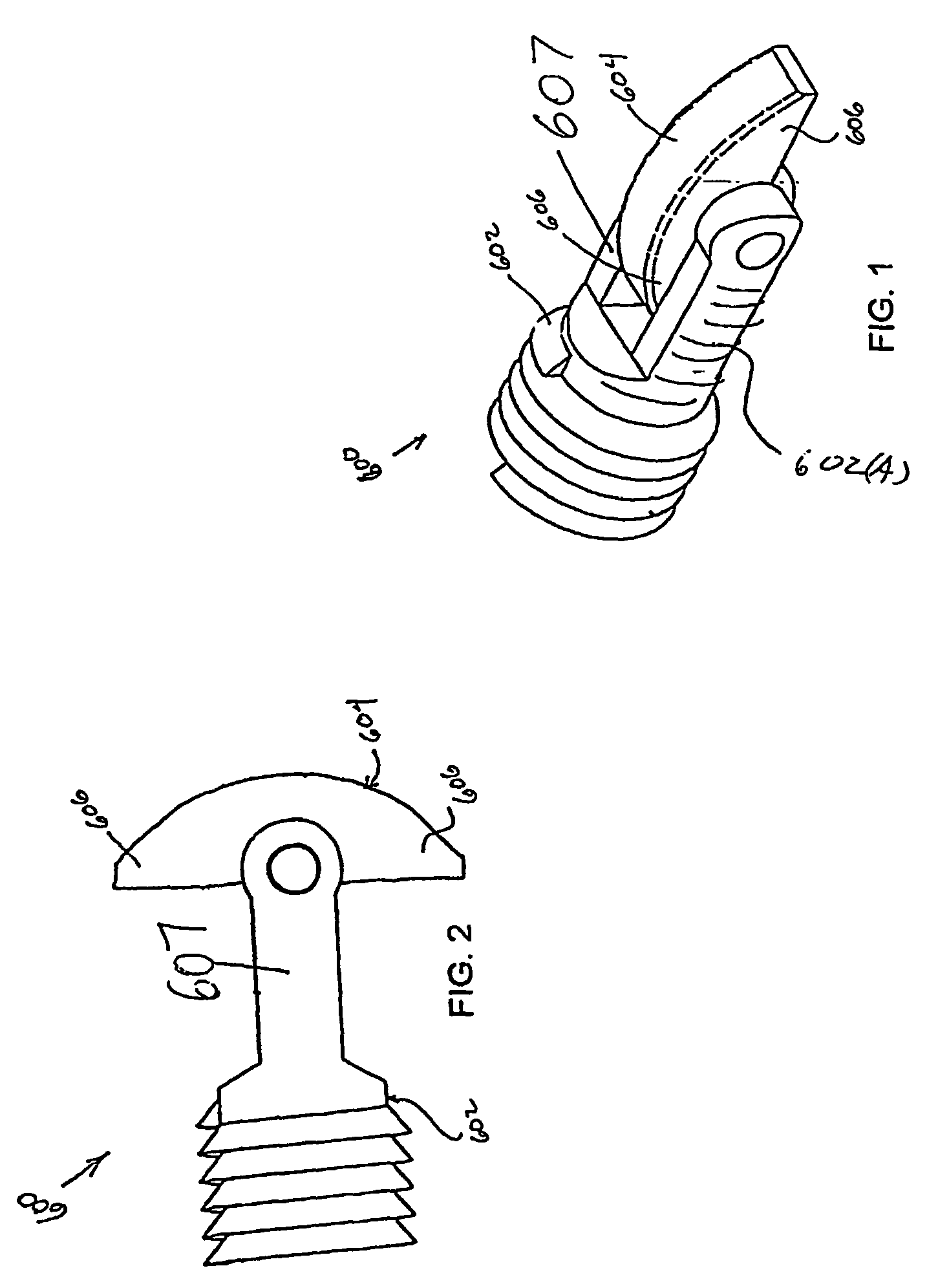

Bone fasteners and method for stabilizing vertebral bone facets using the bone fasteners

InactiveUS20050240188A1Less invasiveLess time-consumingSuture equipmentsInternal osteosythesisVertebral boneBone fragment

Owner:WARSAW ORTHOPEDIC INC

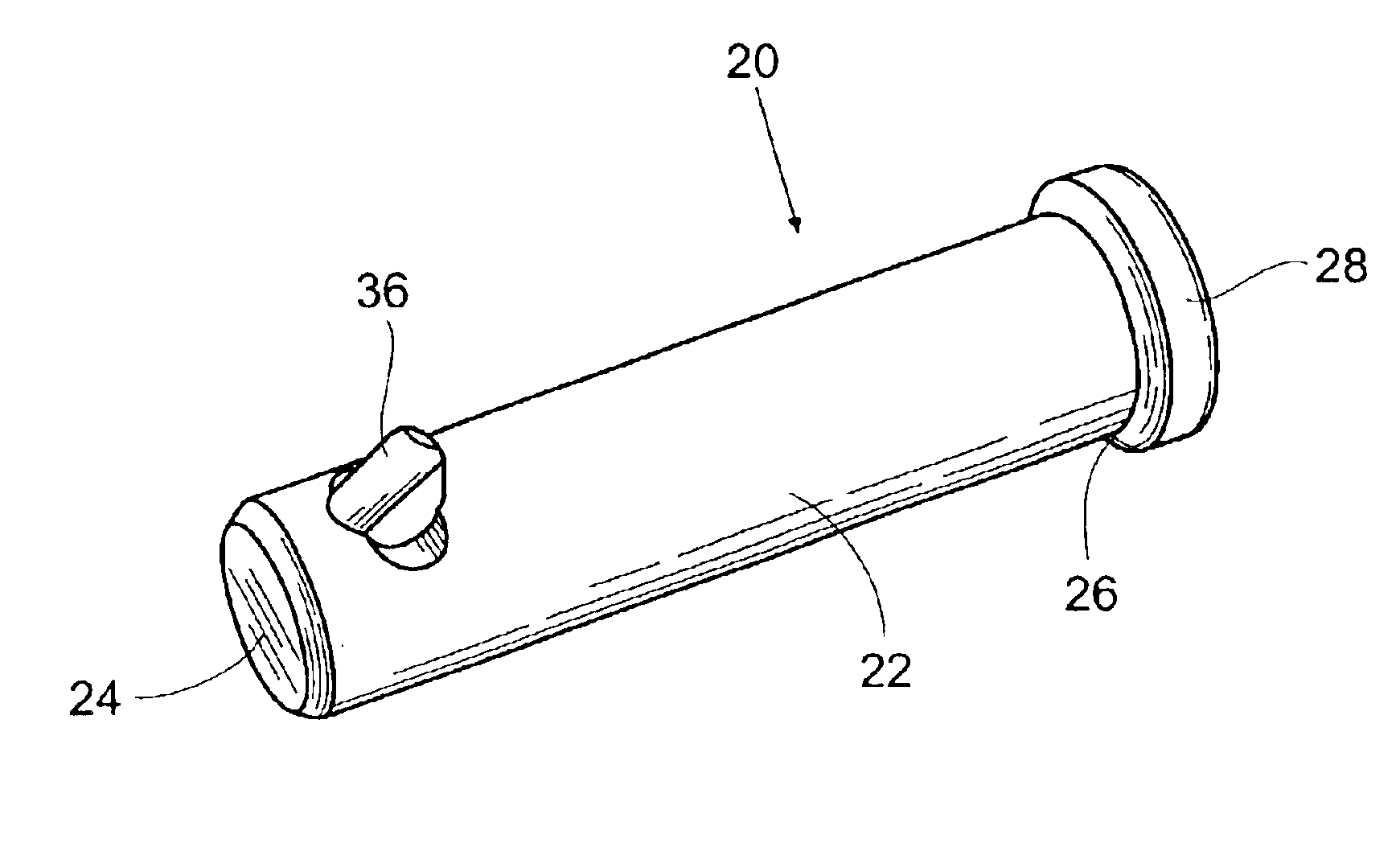

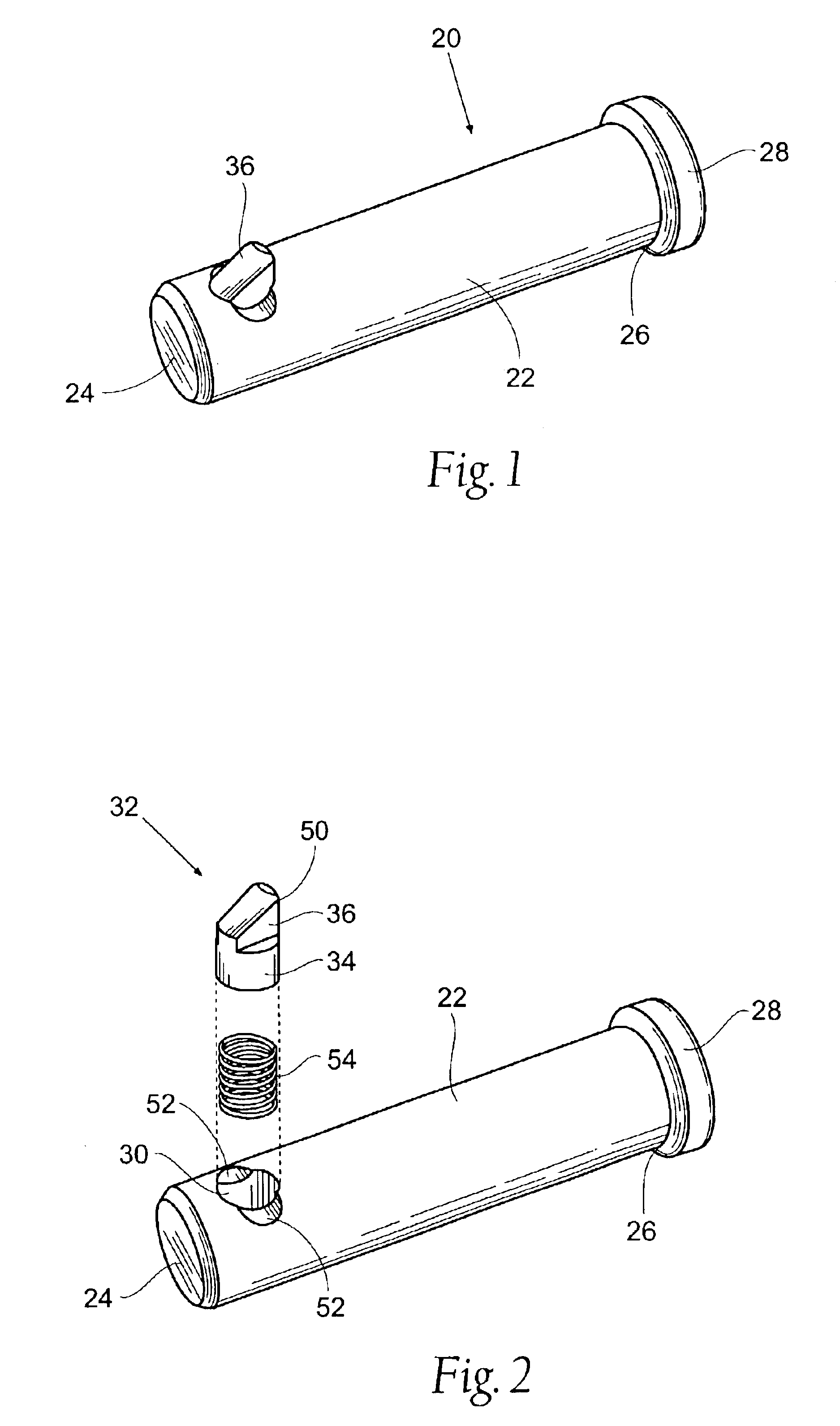

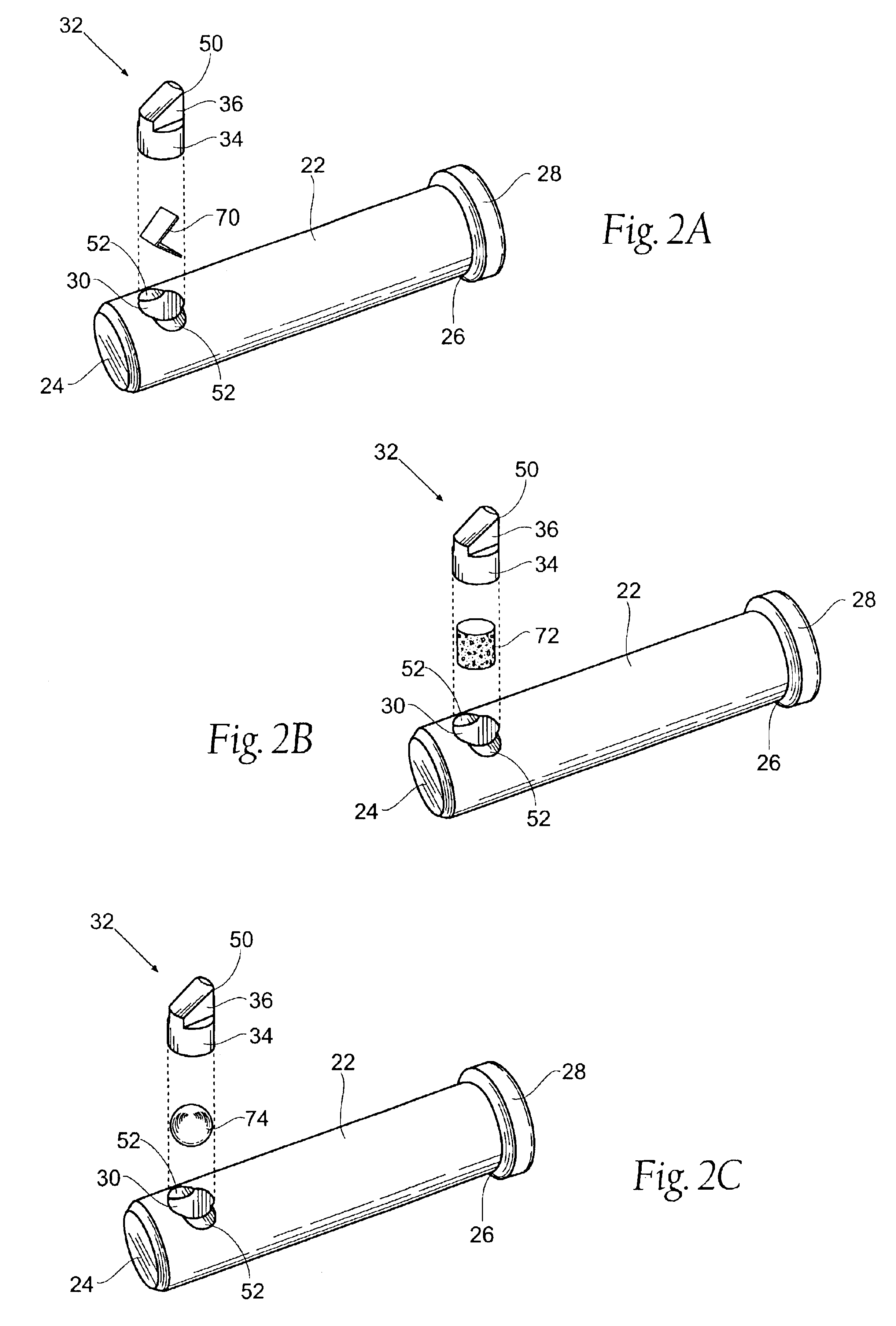

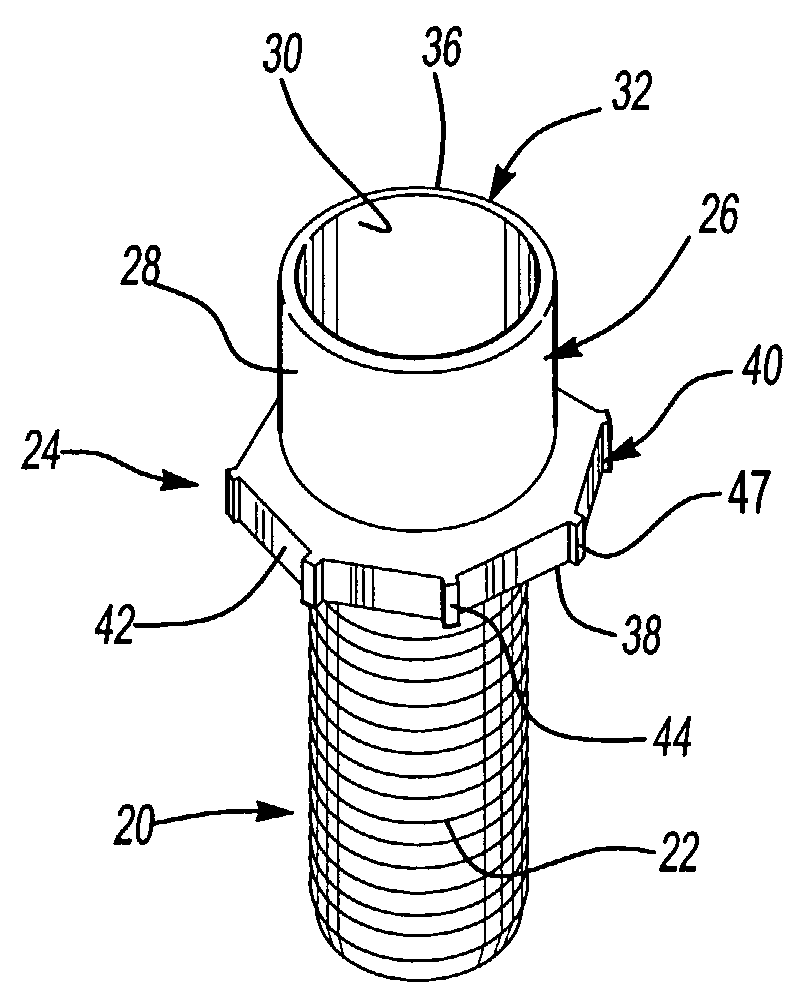

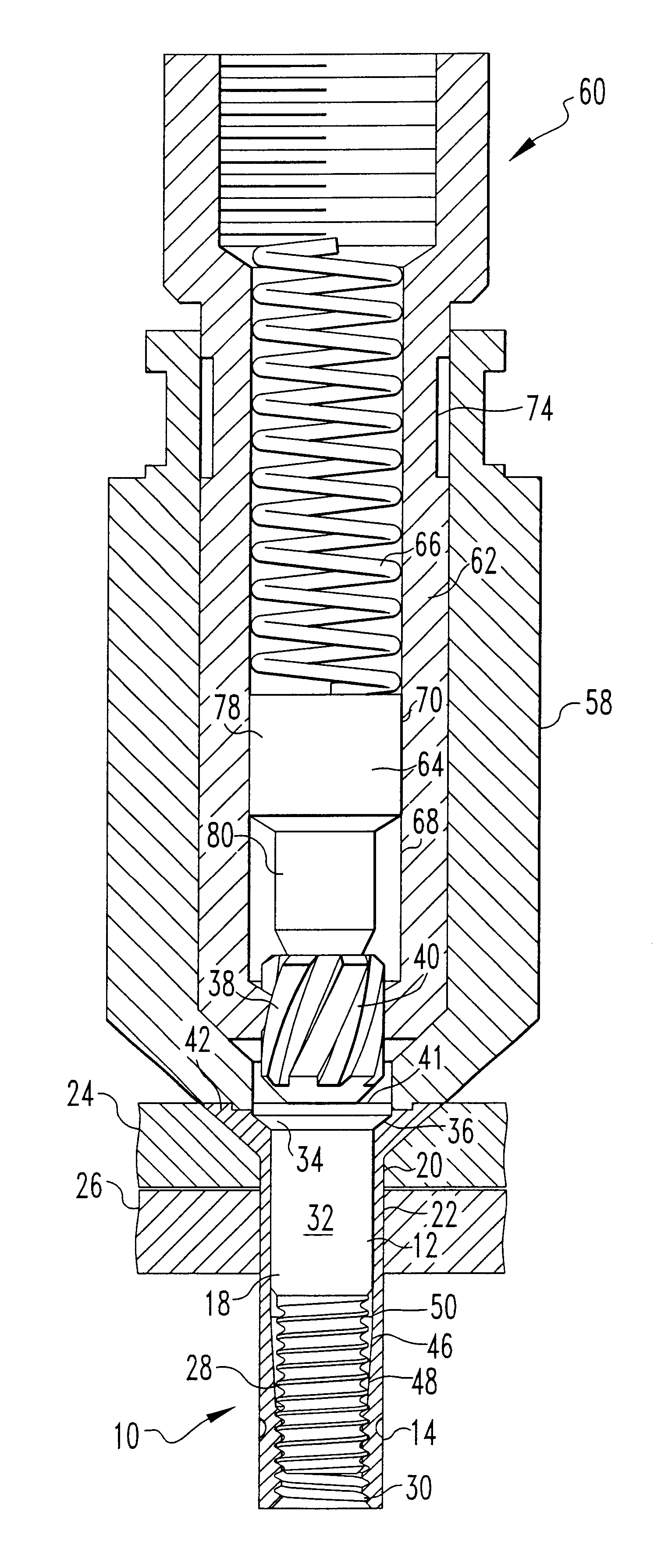

Self-locking pin

A self-locking pin having a shaft, a headed end, and detent means biased in a bore in the pin. The portion of the detent or plunger that extends outwardly from the bore is wedge-shaped, while the portion of the plunger disposed inside the bore is cylindrical. A transitional angle is formed at the point where the configuration of the plunger changes from cylindrical to wedge-shaped. The transitional angle defines shoulders on either side of the plunger. The shaft is staked at points along the perimeter of the bore so that the inwardly extending surface created by the staking abuts the shoulders and prevents the plunger from rotating or being removed from the bore. In an alternate embodiment, the plunger may be rotated to a locked depressed position.

Owner:PIVOT POINT

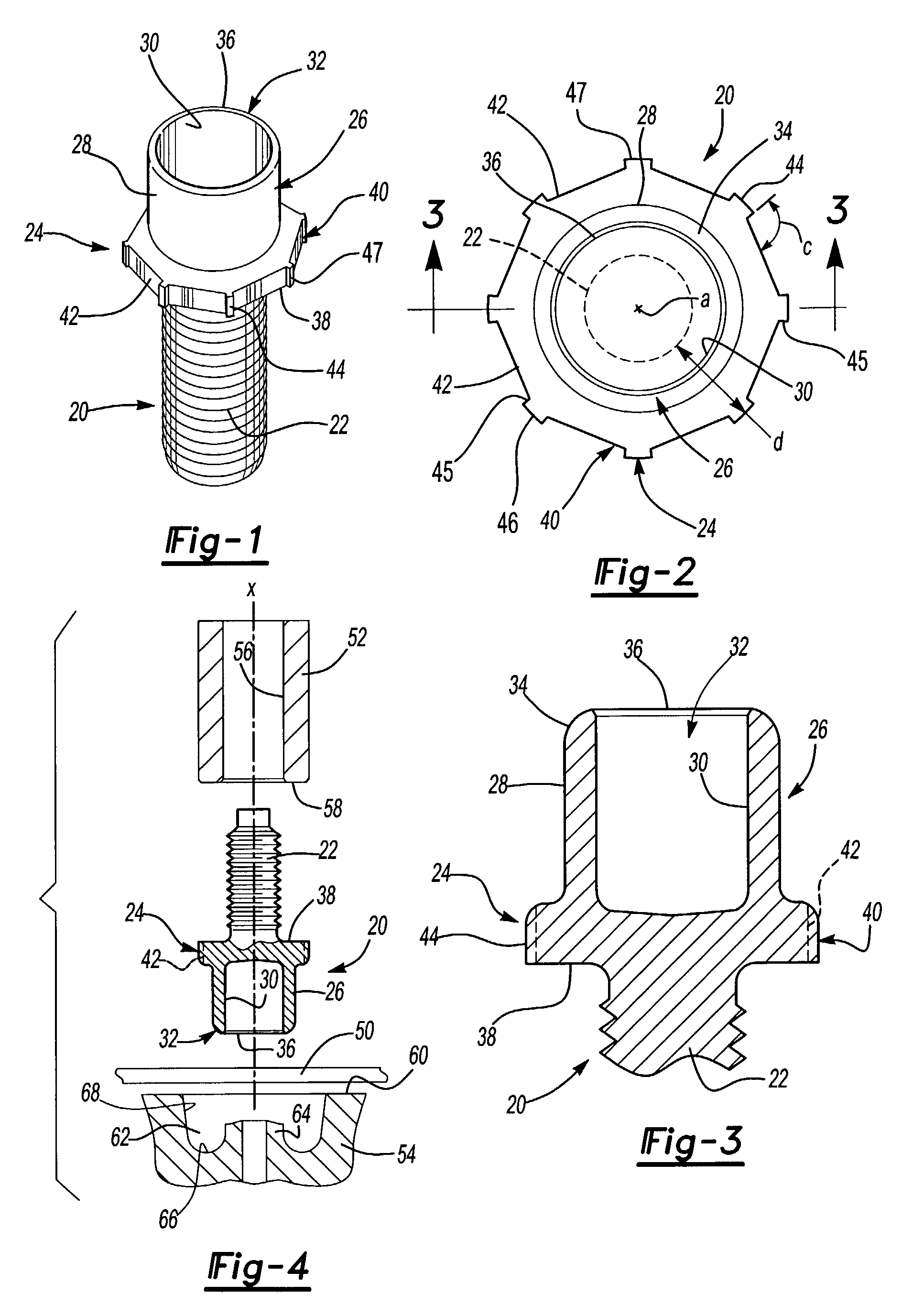

Torque resistant fastening element

A fastening element capable of being attached to a panel by deforming the panel is disclosed. A barrel portion is tubular with an open free end and has an axis defining a circumference. A radial flange portion is integral with the tubular barrel portion opposite the free end and defines a circumferential surface. The radial flange portion includes a plurality of projections spaced apart and extending outwardly from the circumferential surface. Each of the projections defines at least one wall generally perpendicular to the circumference about the axis of the barrel portion.

Owner:PENN AUTOMOTIVE INC

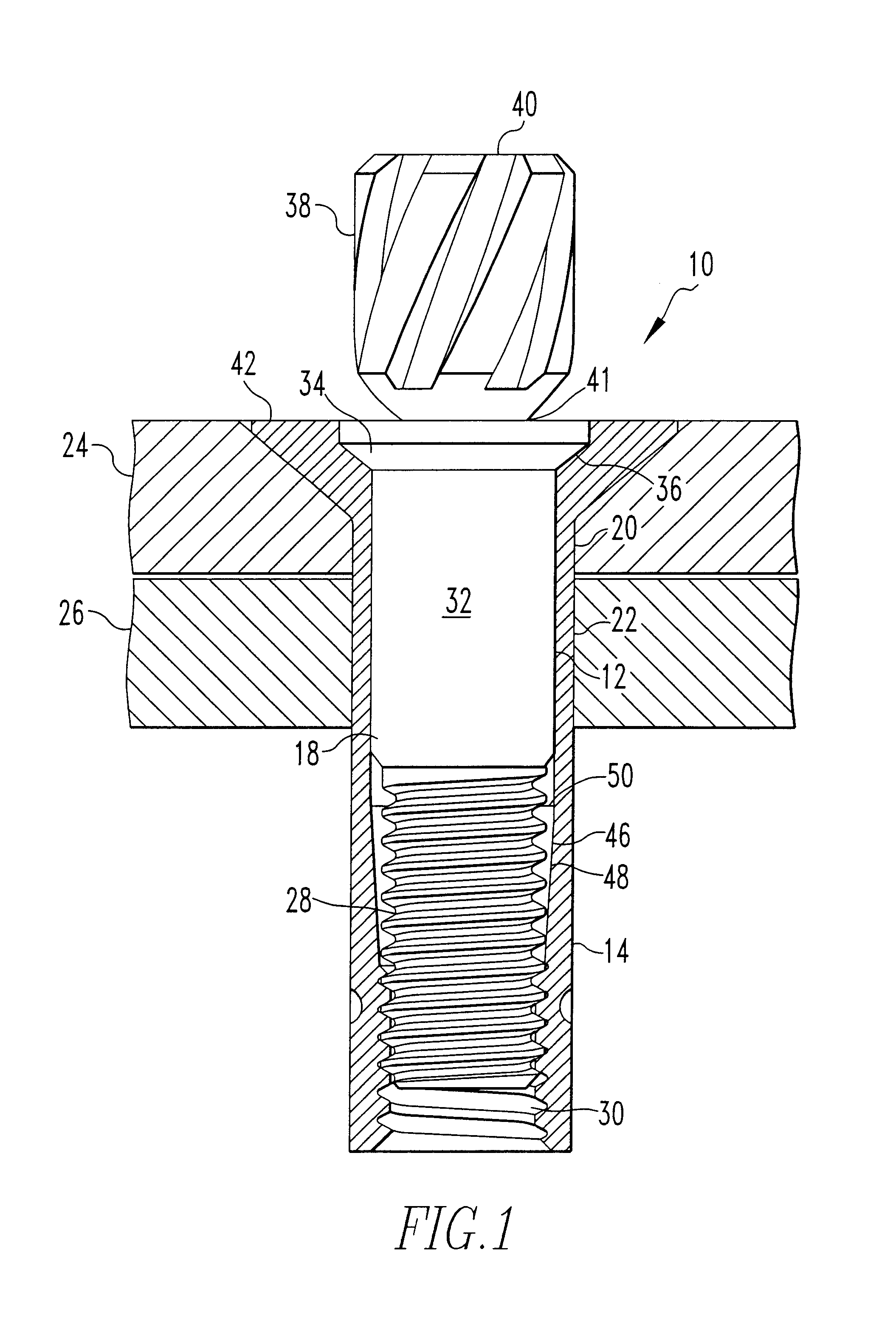

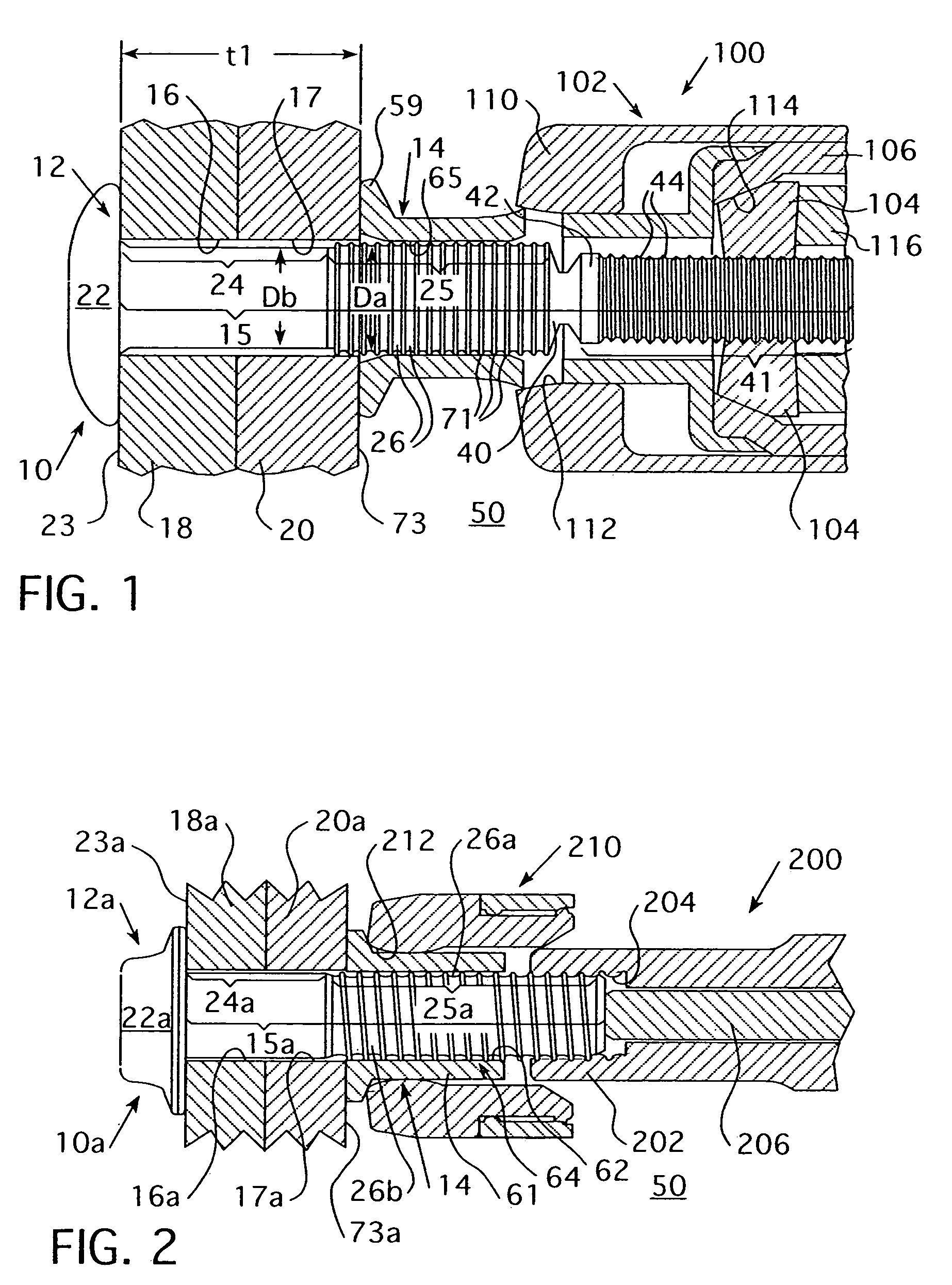

Swage type fastener with low swage load

InactiveUS6325582B1Reduce loadMinimized installation weightRivetsScrewsEngineeringUltimate tensile strength

A two piece fastener system for including a pin member and a collar having an optimized strength with the materials of the pin member and collar having a predetermined shear strength ratio; the collar has a preselected excess volume to provide a desired "overpacking' condition and is of a size whereby after swage it will define a minimum wall thickness; the collar has an outer surface with a contour which in combination with a preselected excess volume results in a reduction in load required to swage the collar and with a pull type fastener providing a breakneck groove of reduced strength whereby severance of the pintail will occur at a reduced load resulting in a reduction in shock or ghost load applied to workpieces including those of a plastic or composite material.

Owner:HUCK INT INC

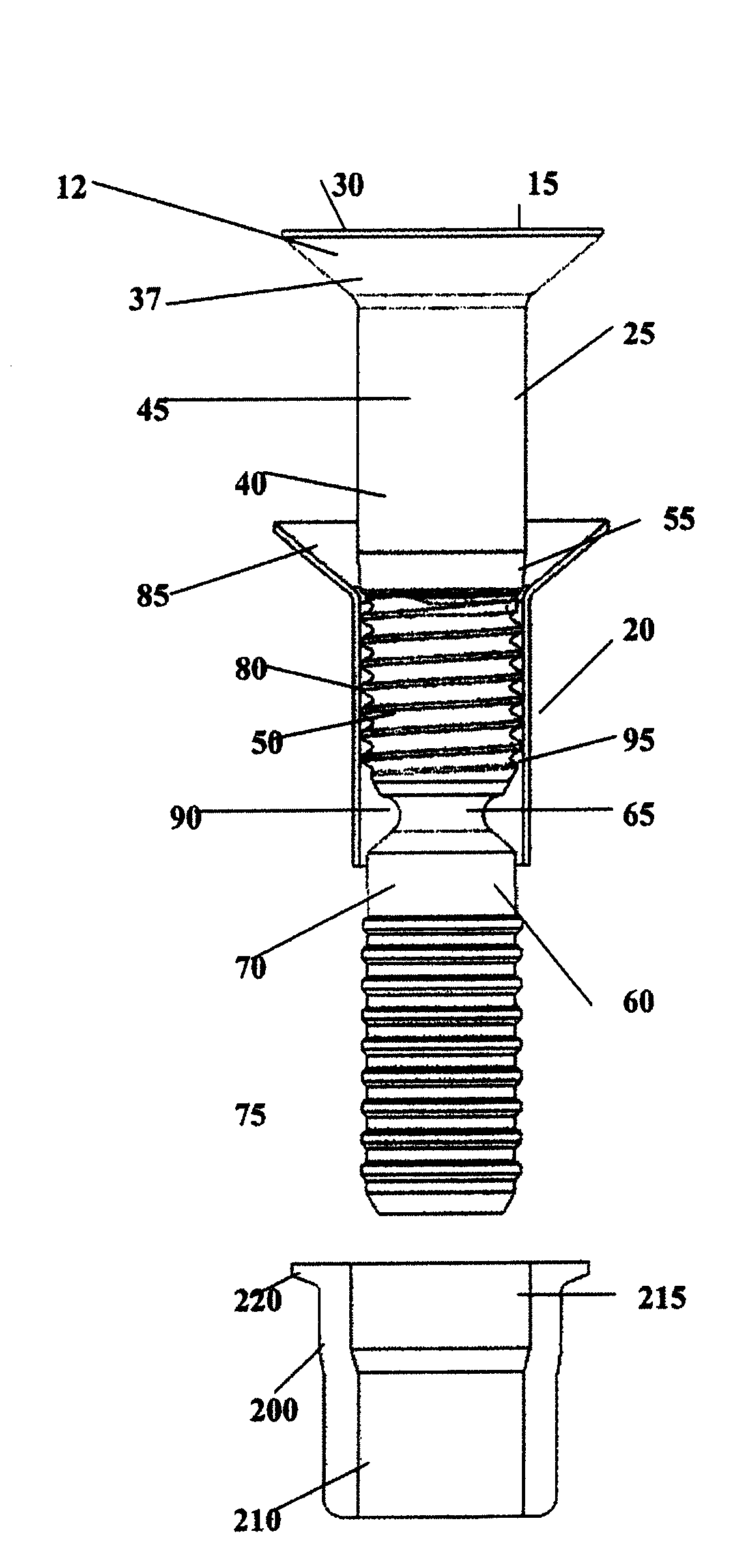

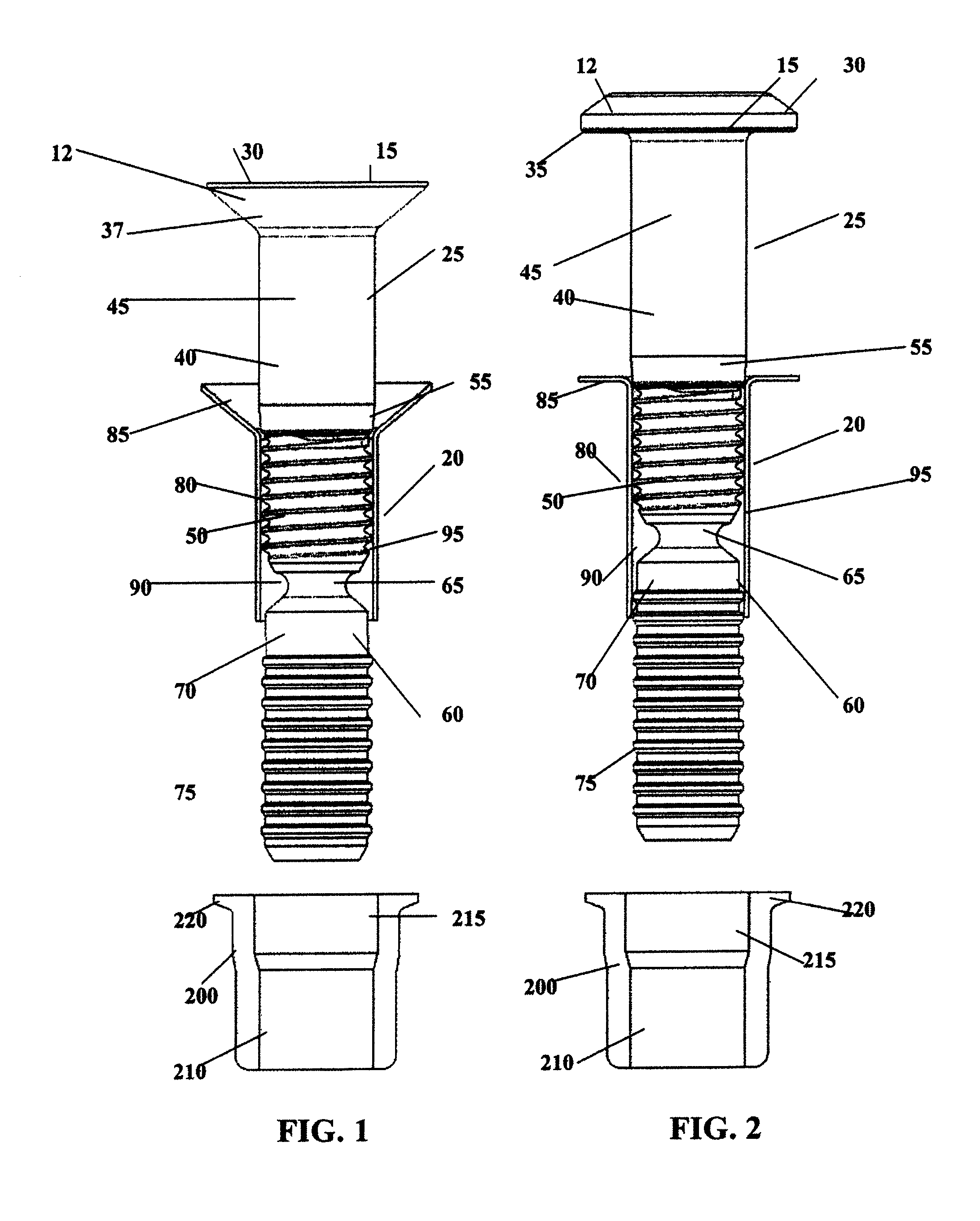

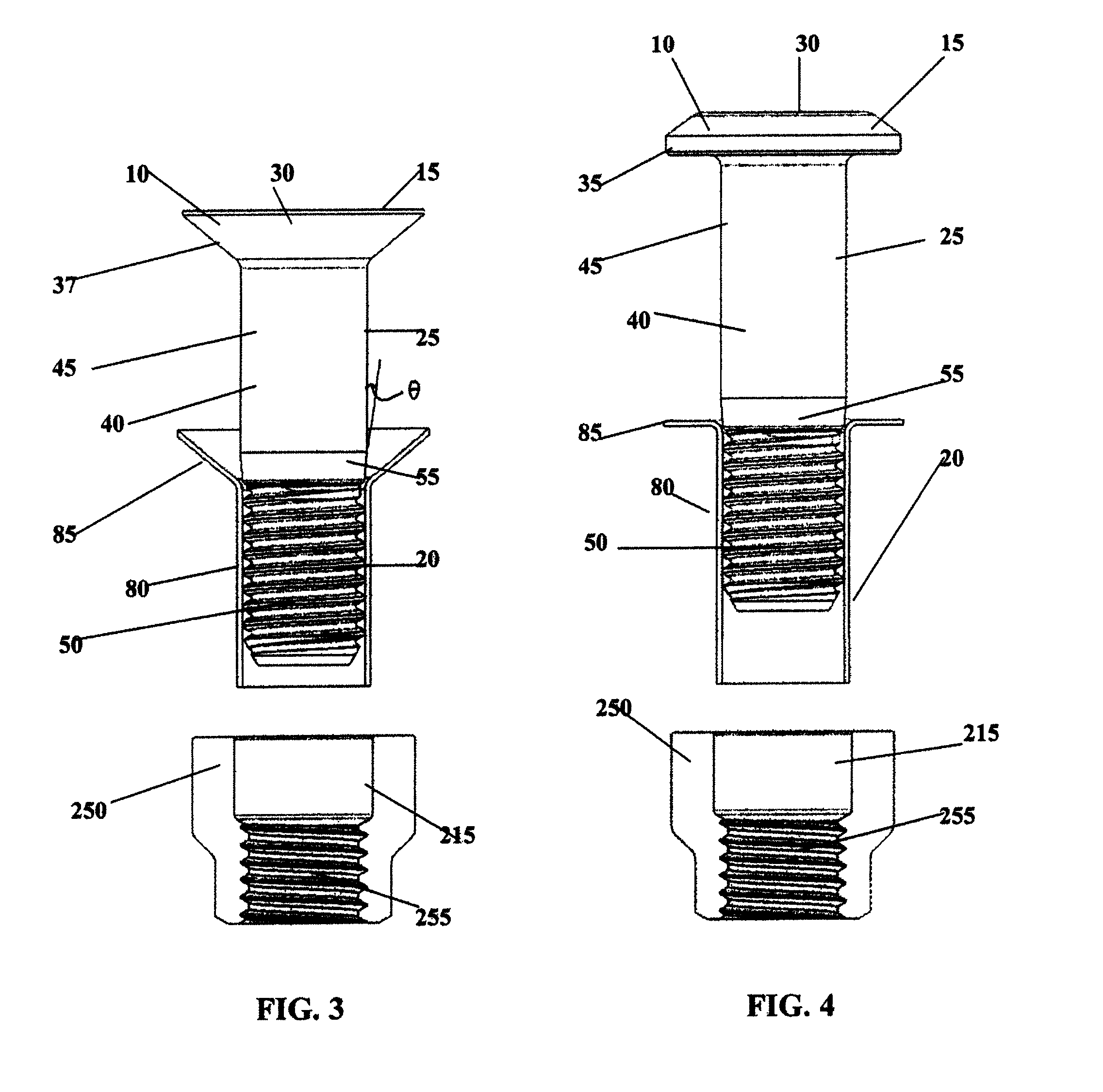

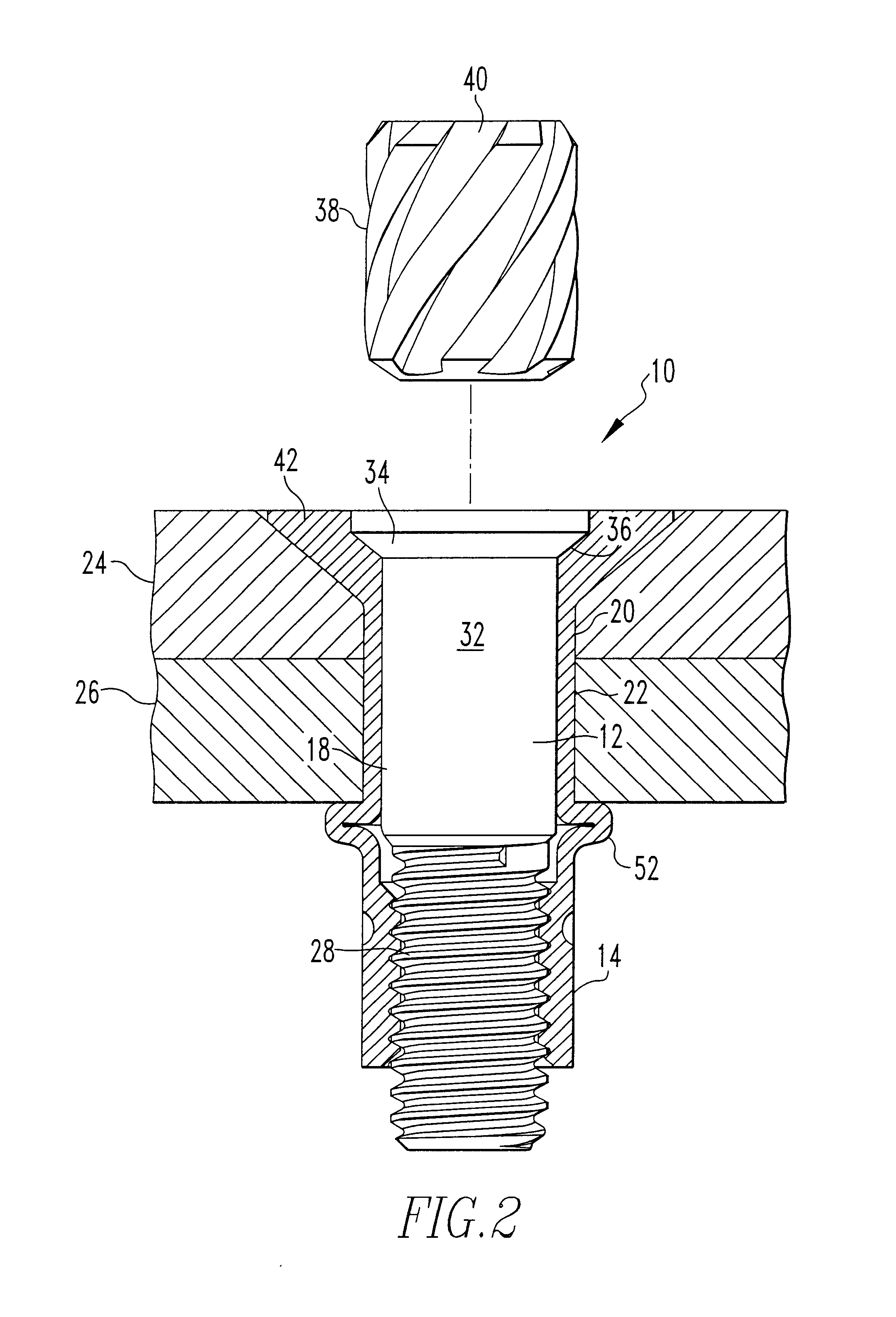

High performance sleeved interference fasteners for composite applications

A fastener adapted to pass through aligned holes through workpieces is disclosed. The fastener includes a pin member having a transition portion wherein the diameter of the transition portion decreases radially as it extends from the smooth cylindrical shank portion to the threaded portion. The fastener may also comprise a sleeve member and a clamping means. The clamping means includes a collar, a nut, or any other possible clamping means. In exemplary embodiments, the workpieces can be formed with a plurality of materials, the materials including composite, metallic, or composite / metallic structures, any combination thereof. In particular embodiments, the fastener has interference capability of 0.0005 to 0.0100 inches in composite structures without risk of composite delamination or damage. As a result of the fastener interference, gaps between the fastener and the structure are eliminated thereby providing good electrical conductivity between components. As a result, the potential for electrical sparks is reduced, providing a safer fastener for use with aerospace applications.

Owner:ALCOA GLOBAL FASTENERS

Fasteners manufactured by three-dimensional printing

InactiveUS20140086704A1Many timesQuick and inexpensive designDeformable pinsPinsEngineeringPrinting press

Owner:A RAYMOND & CO

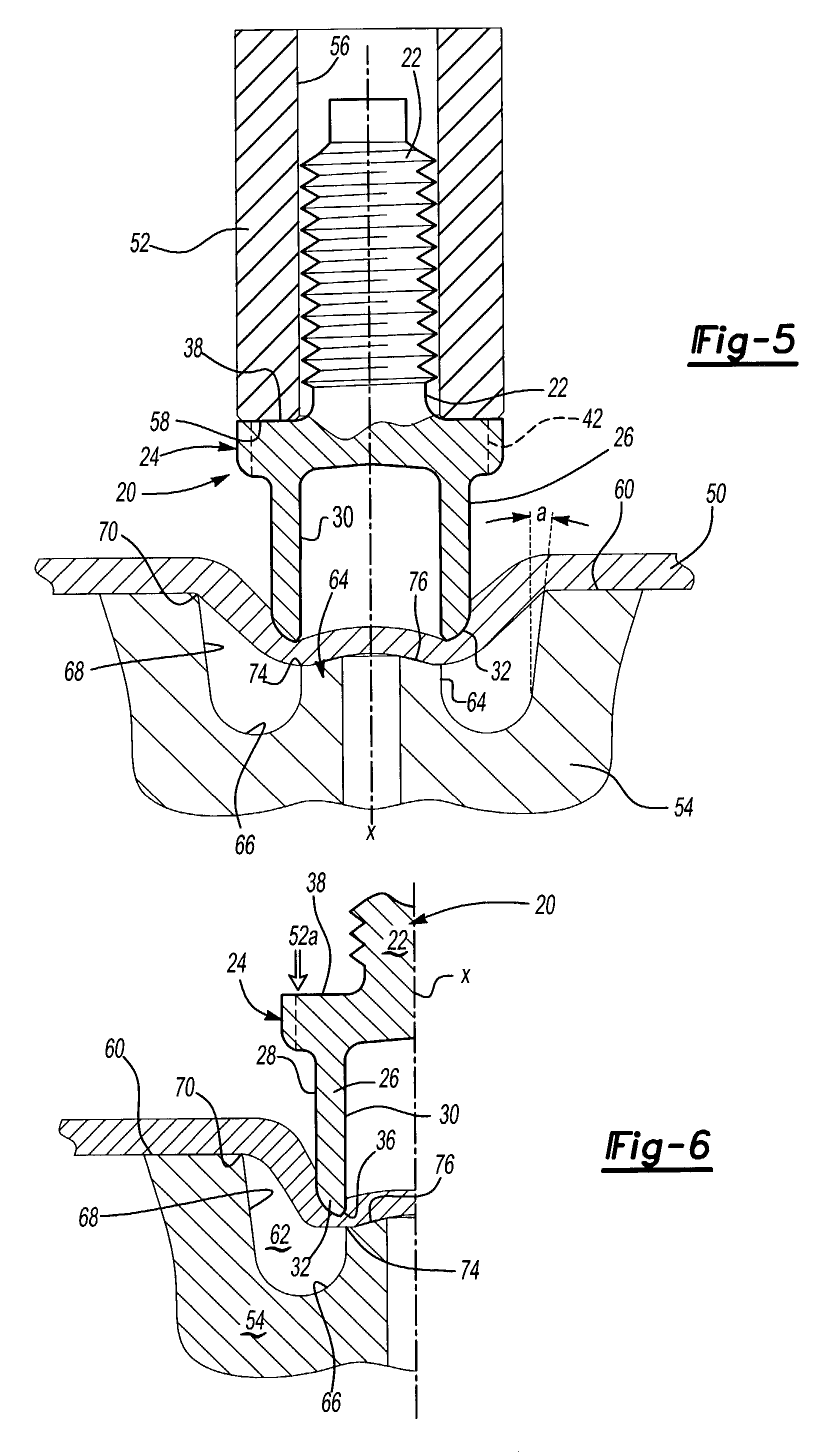

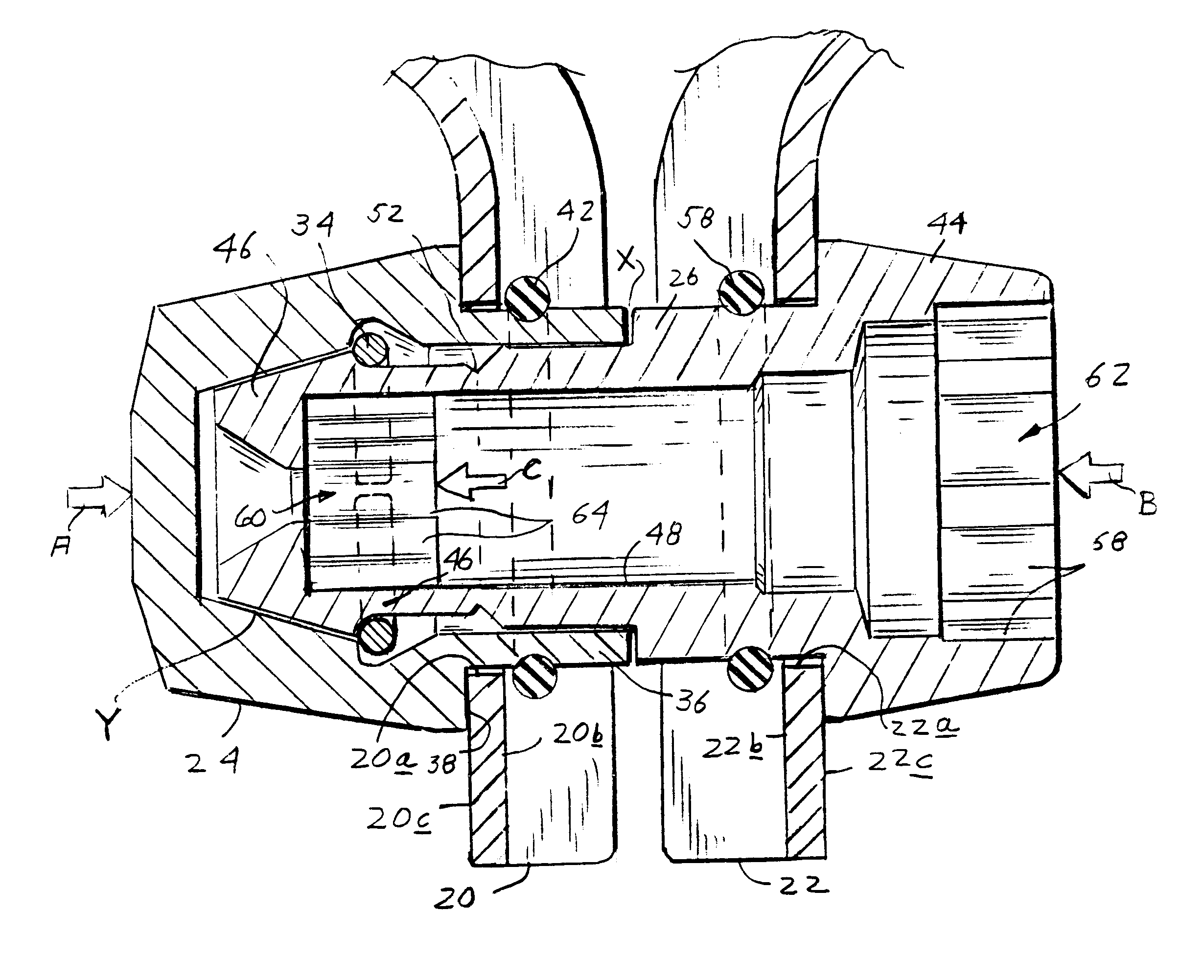

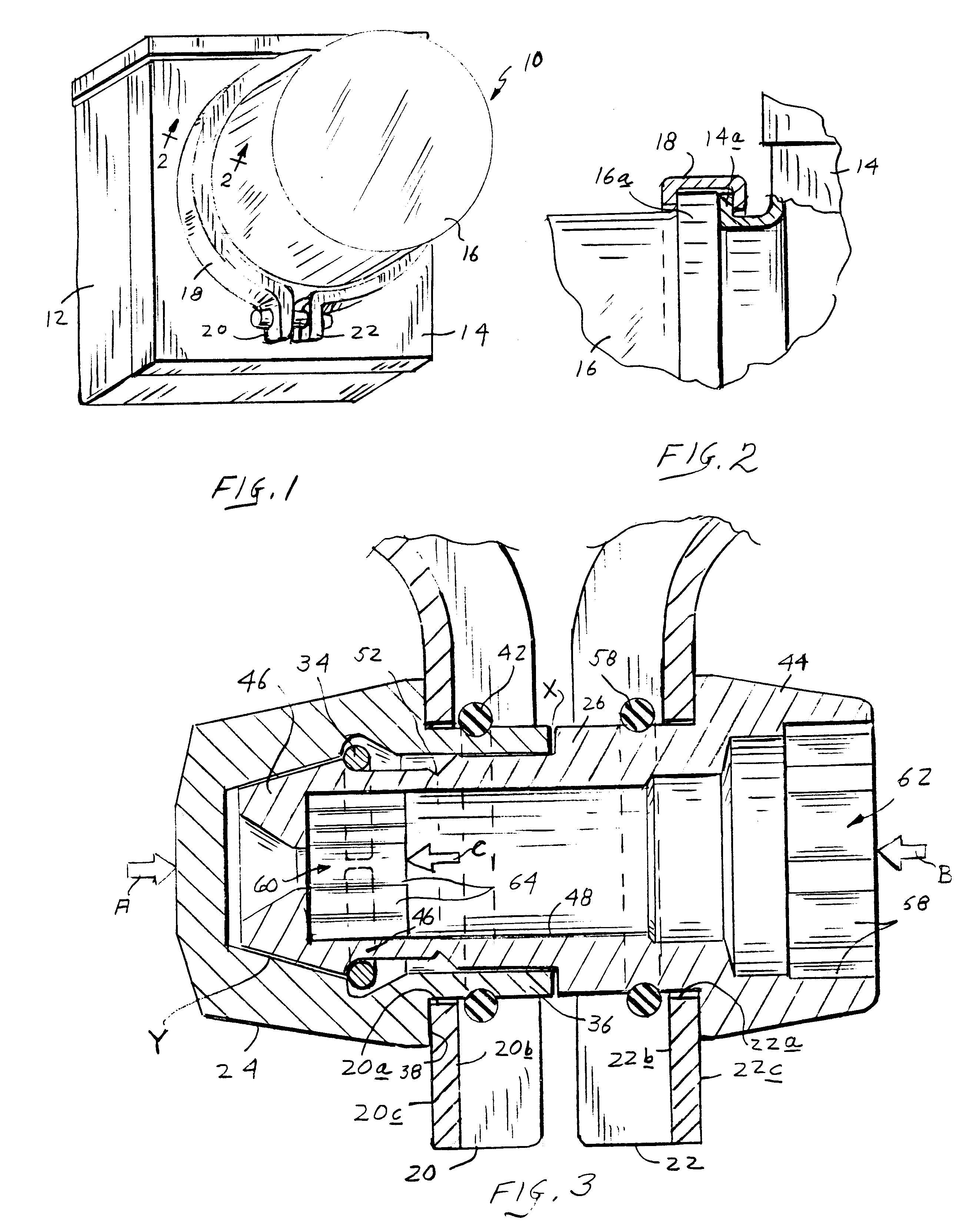

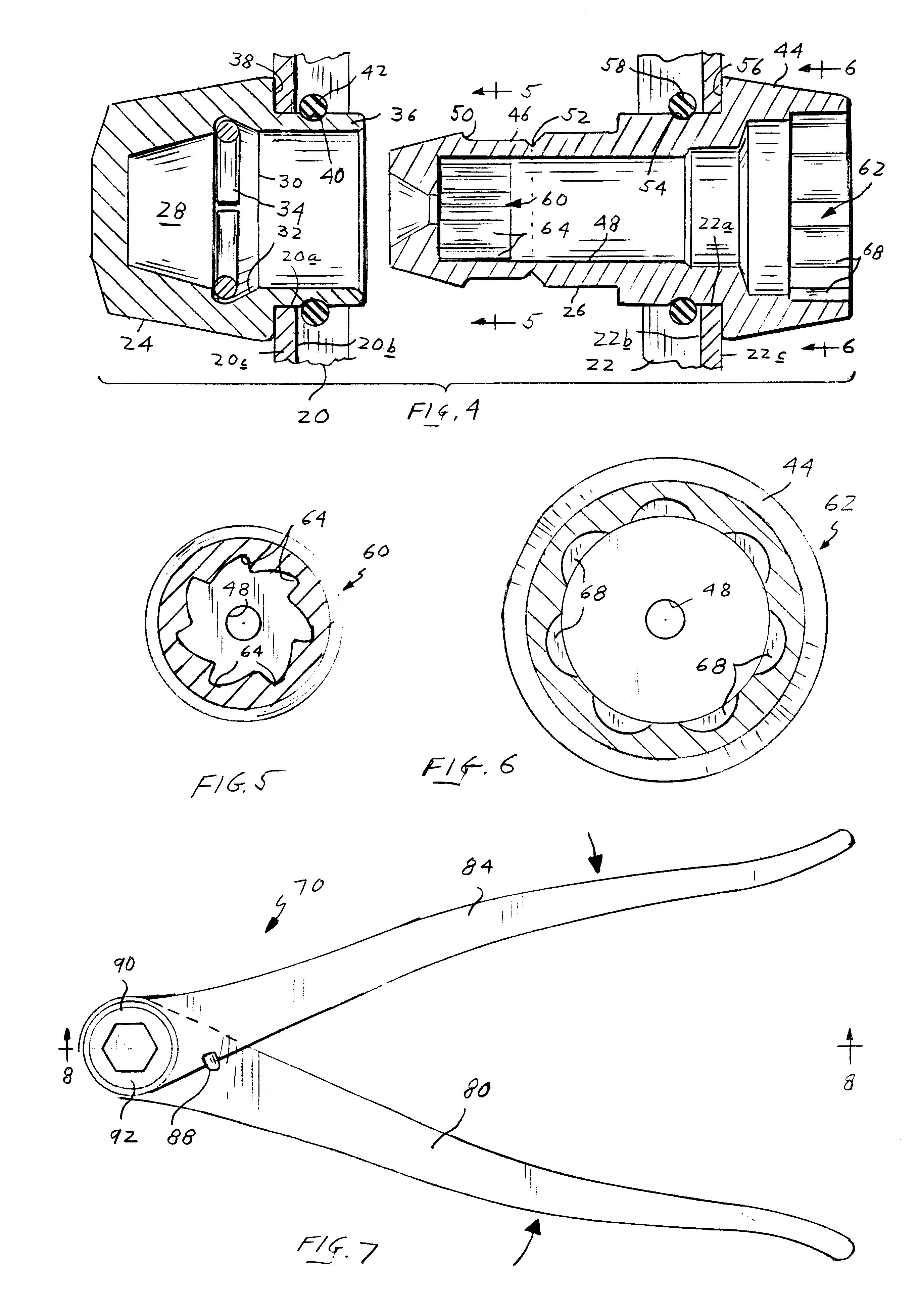

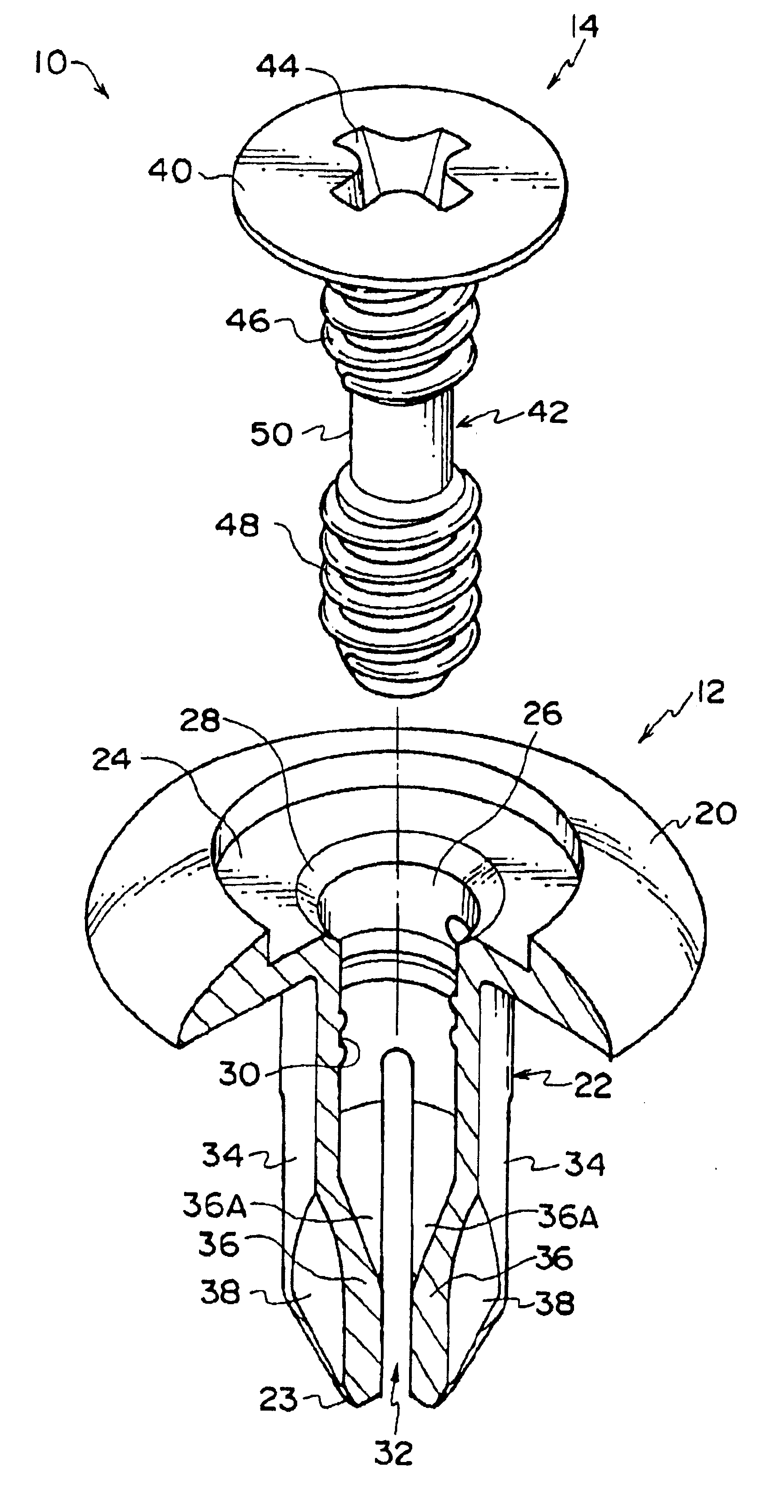

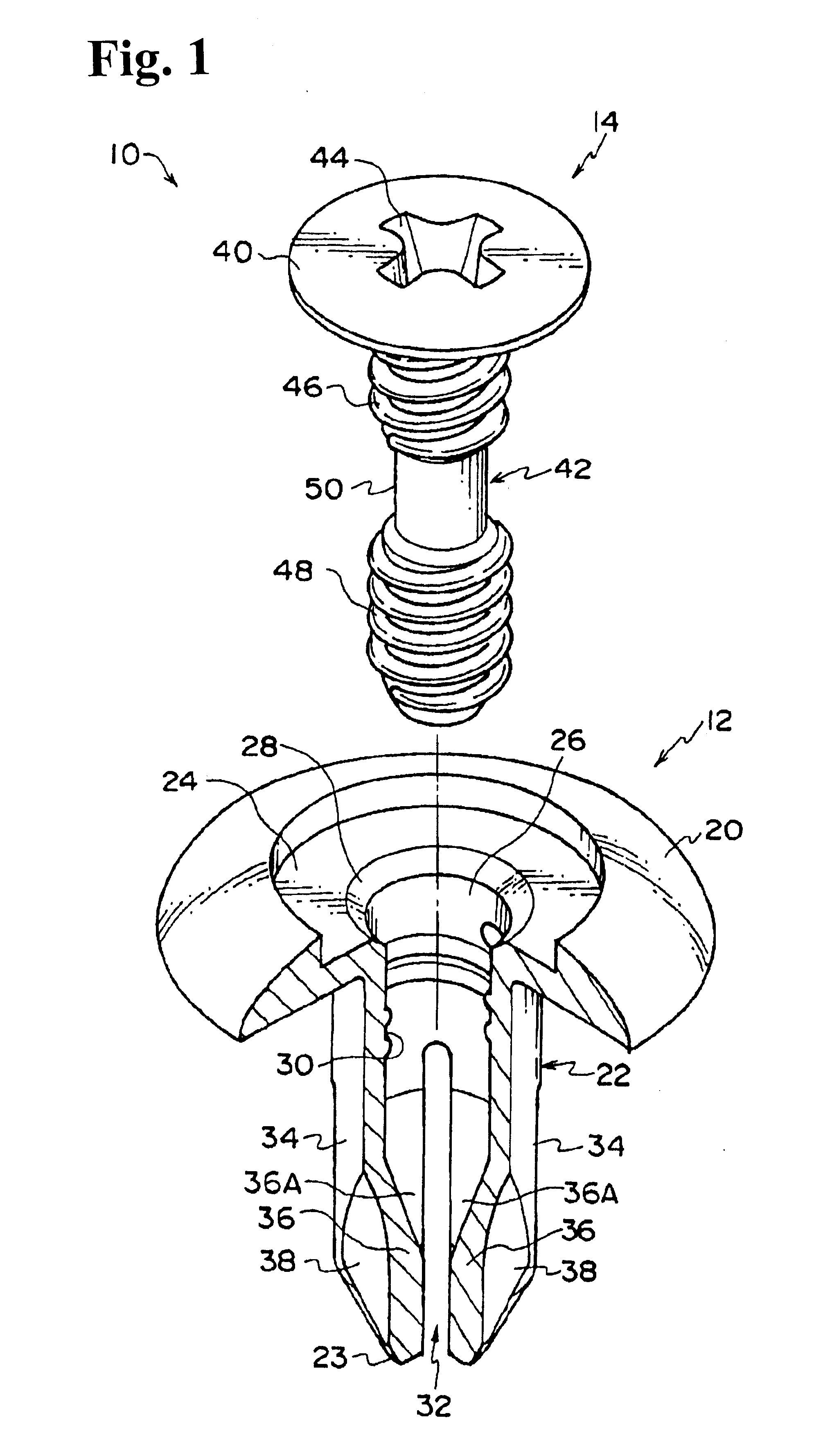

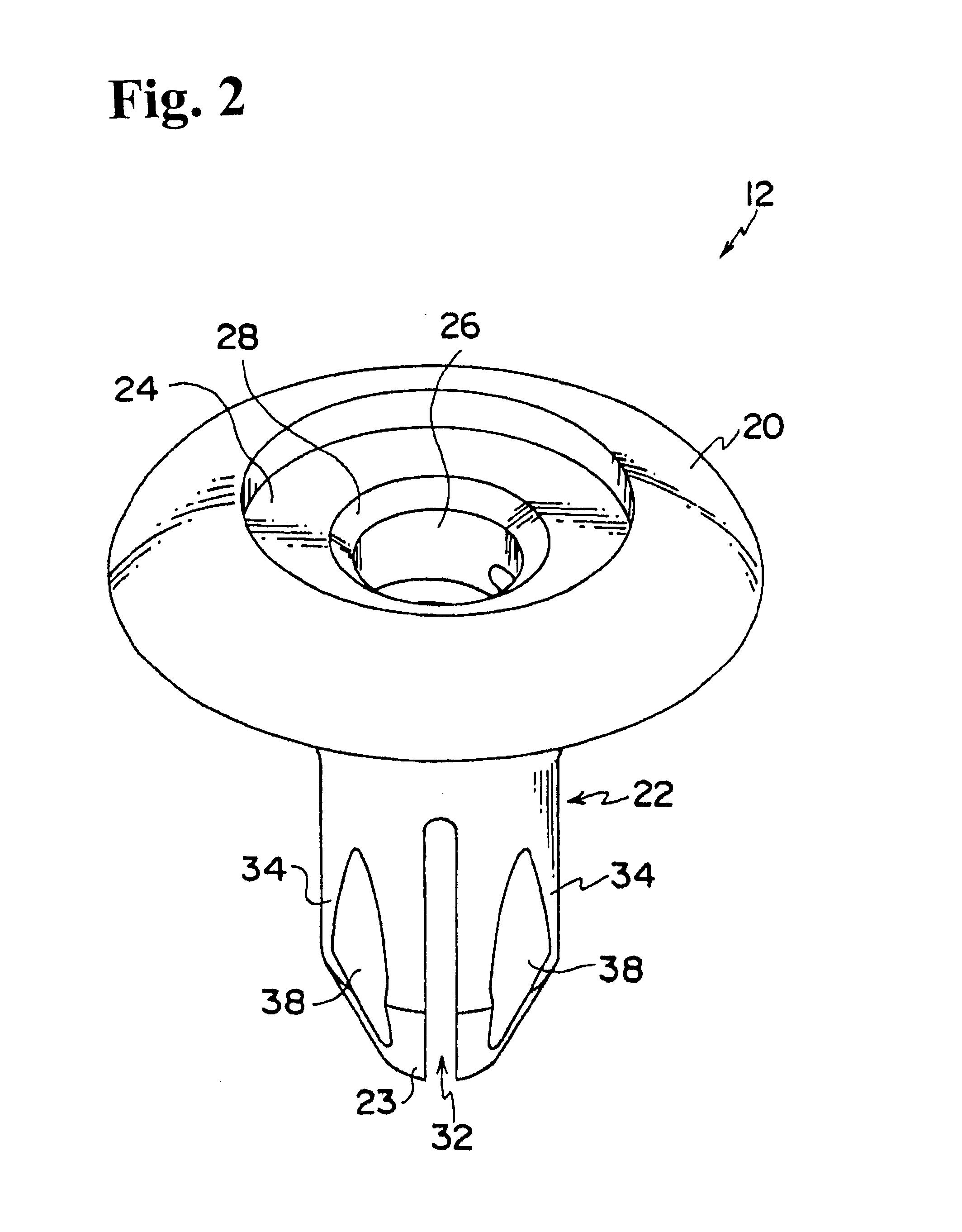

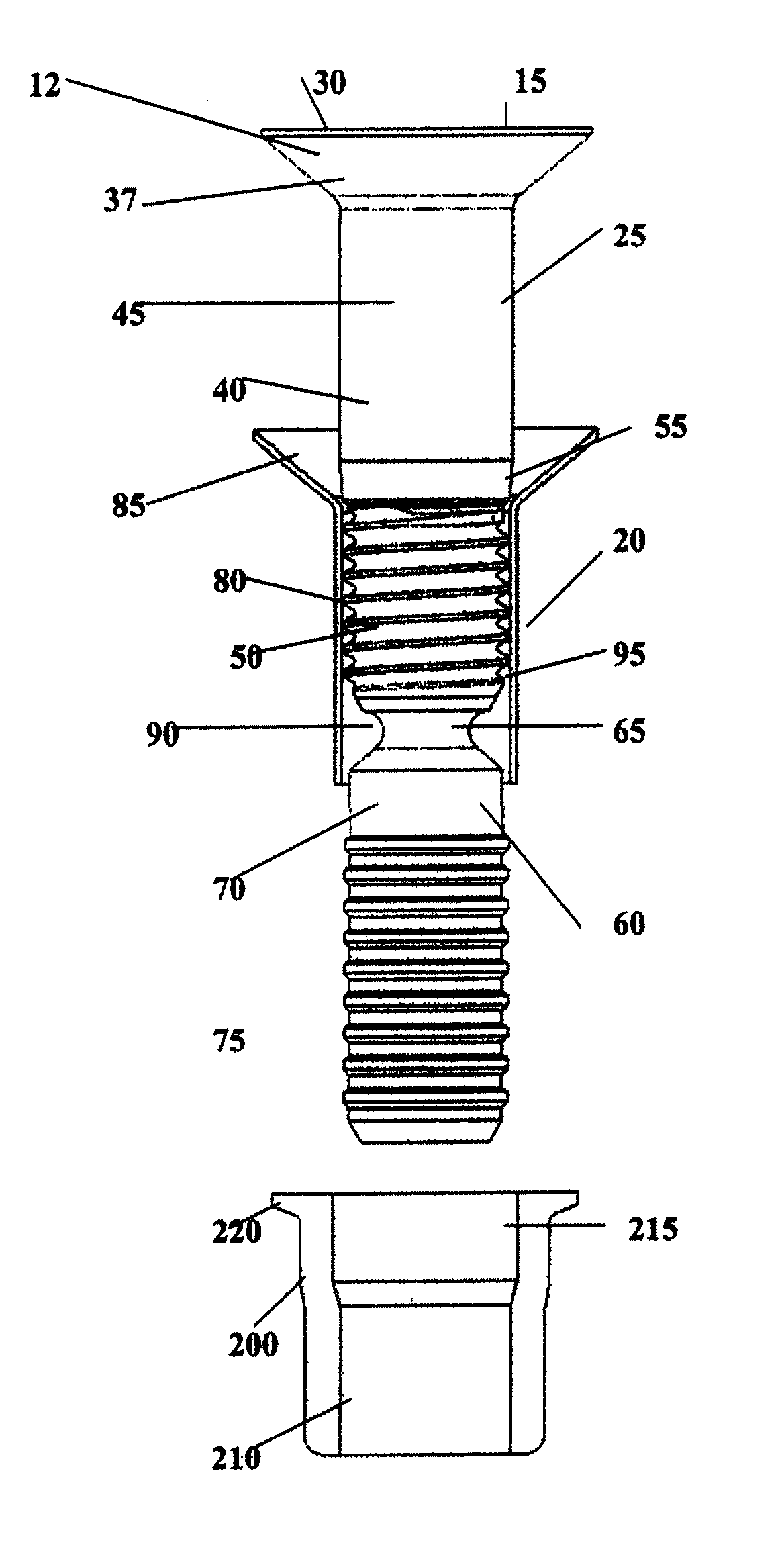

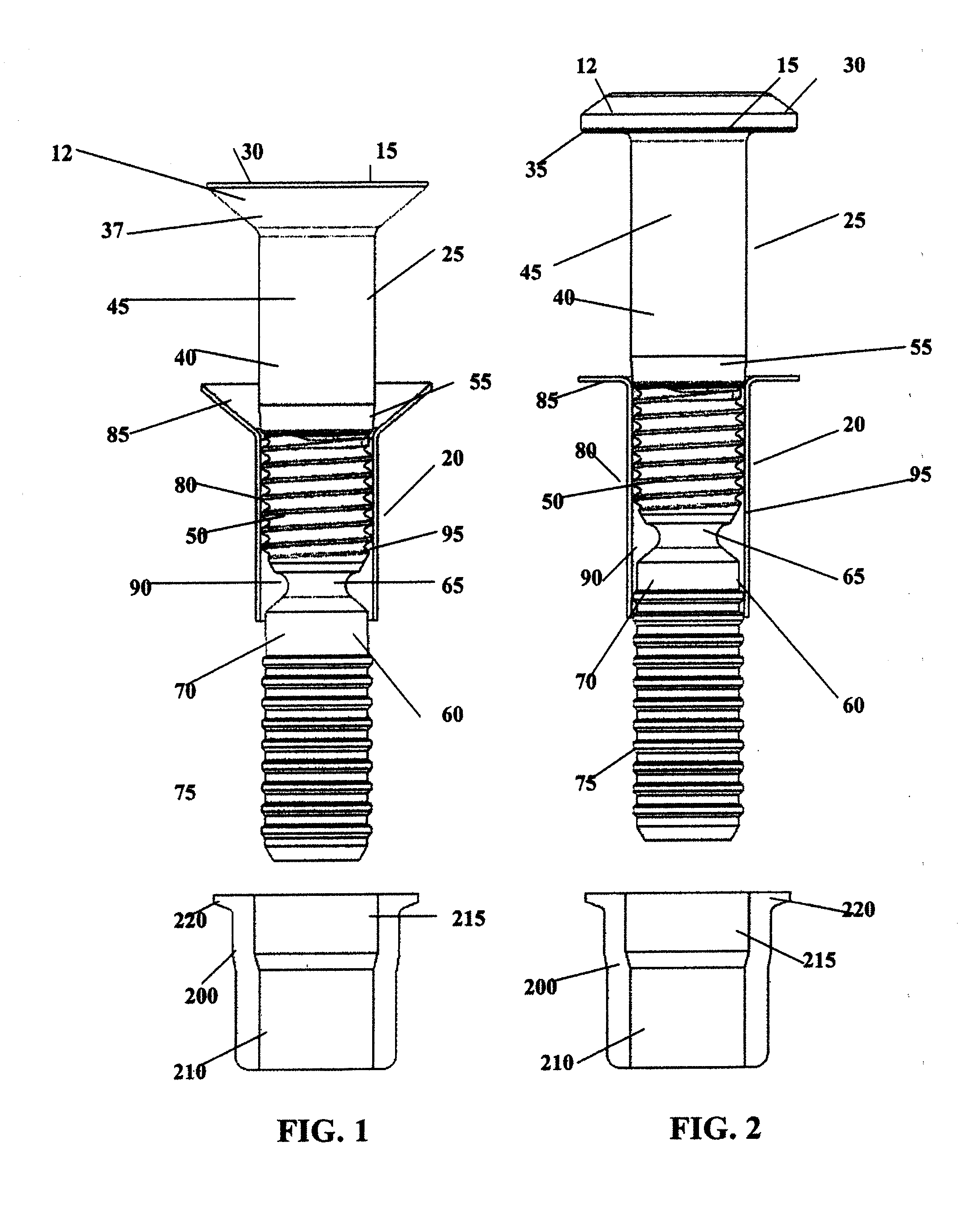

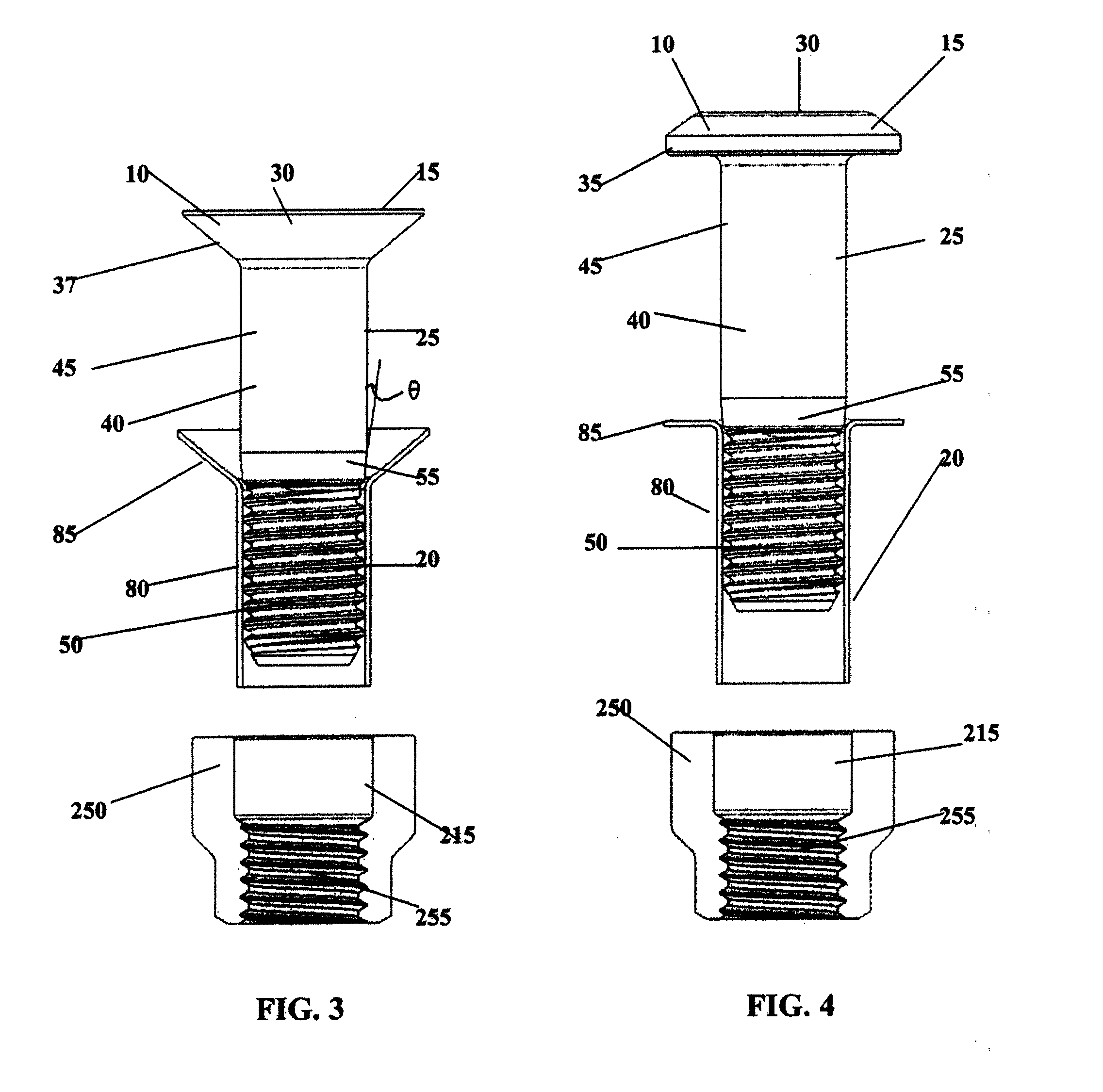

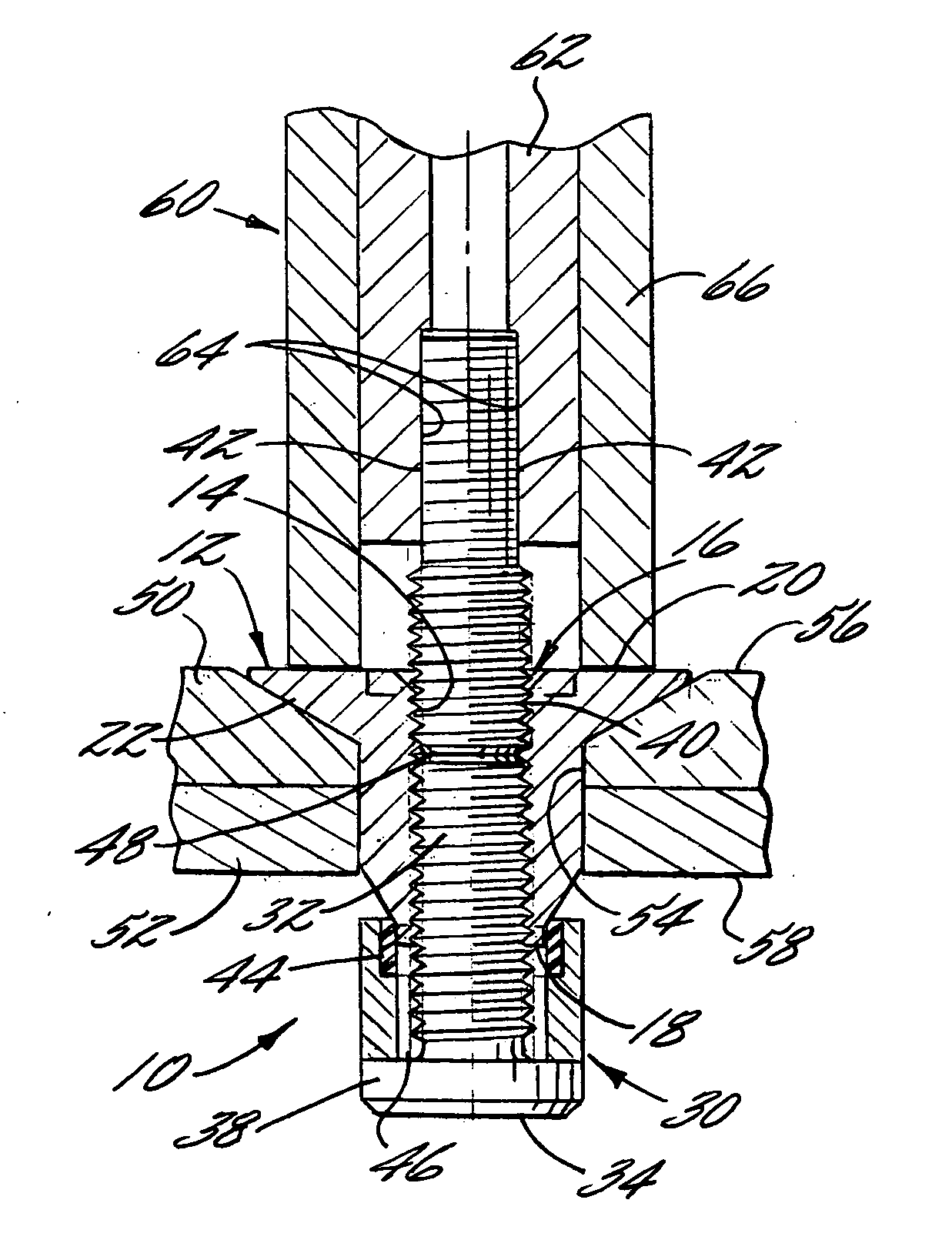

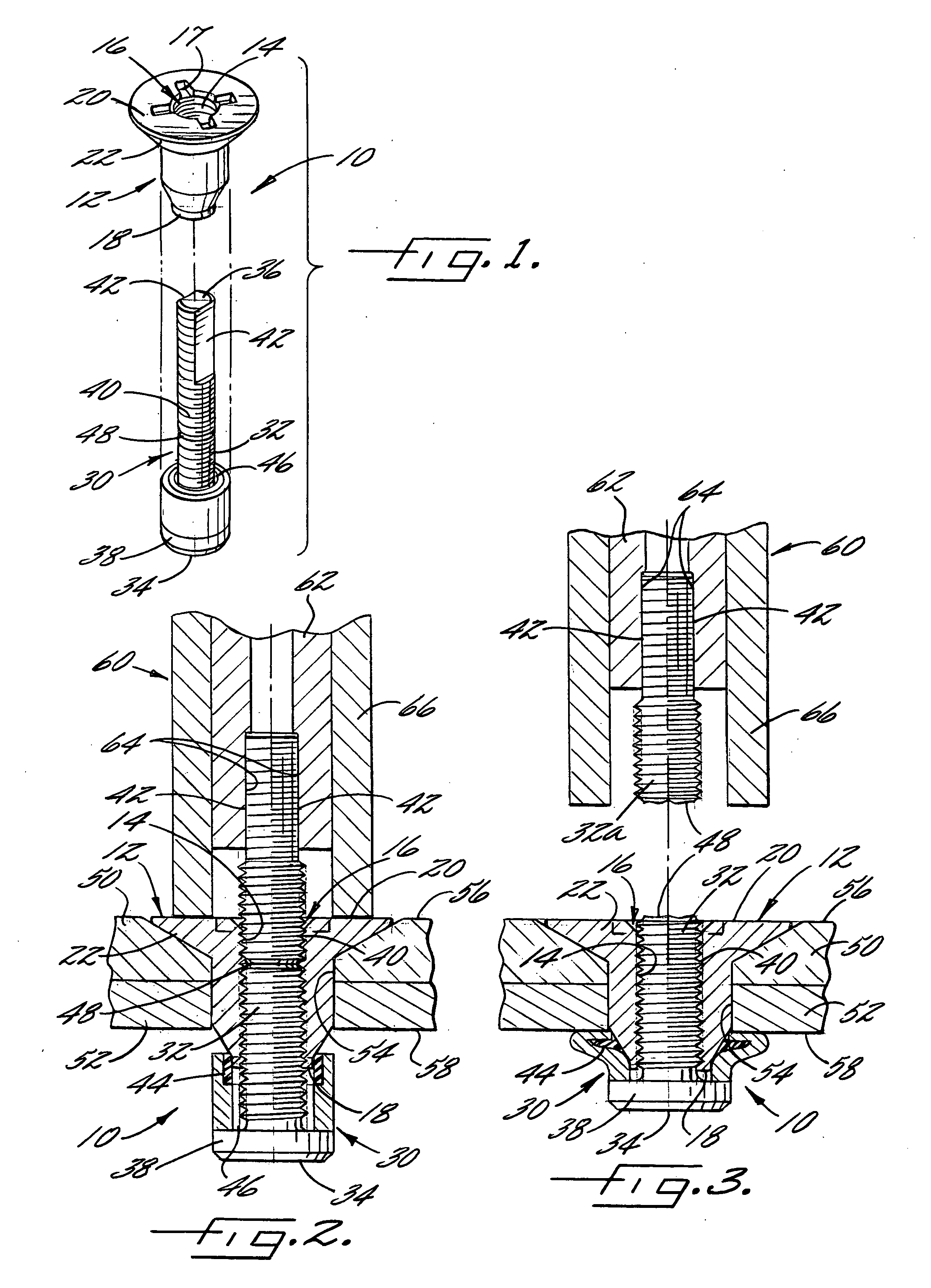

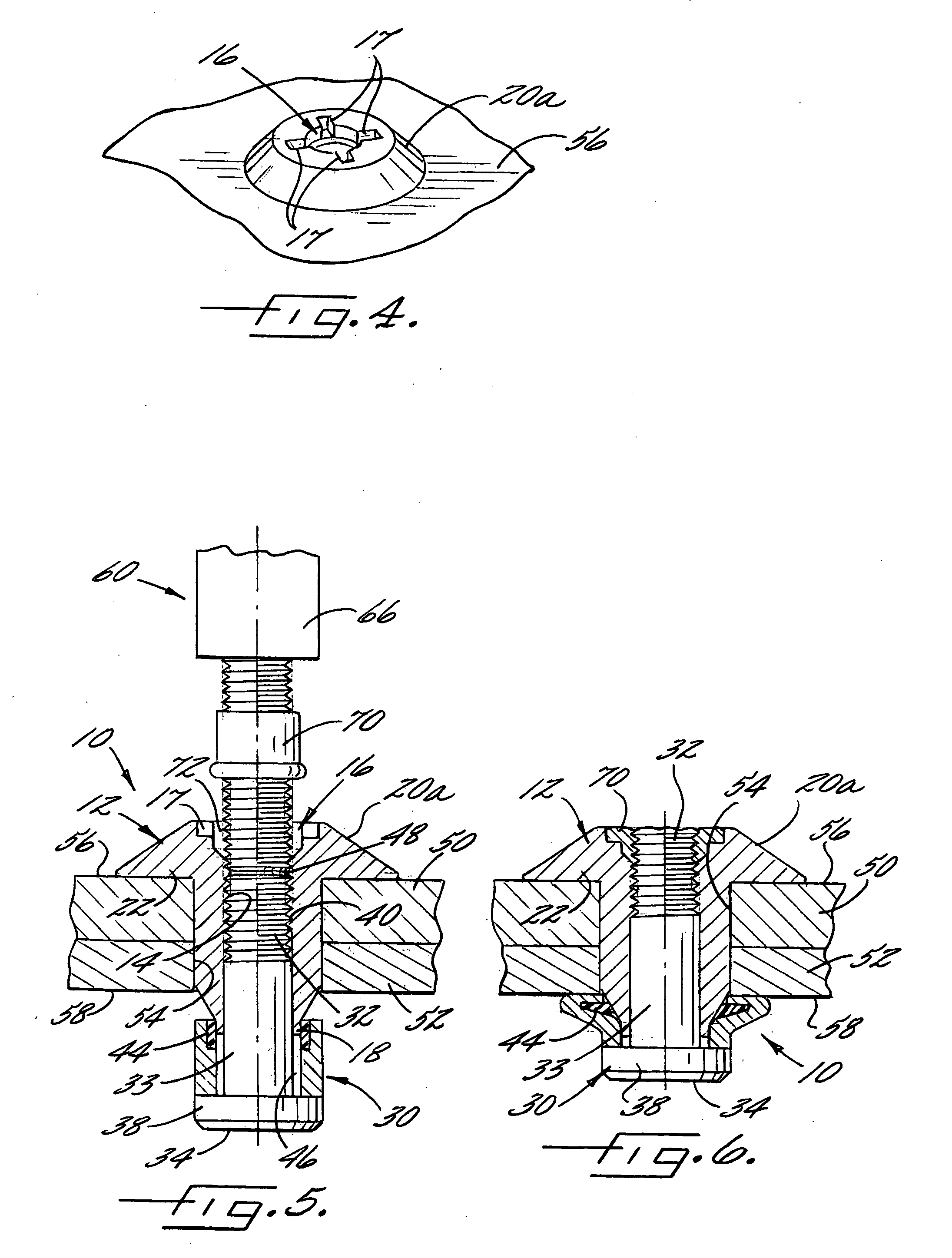

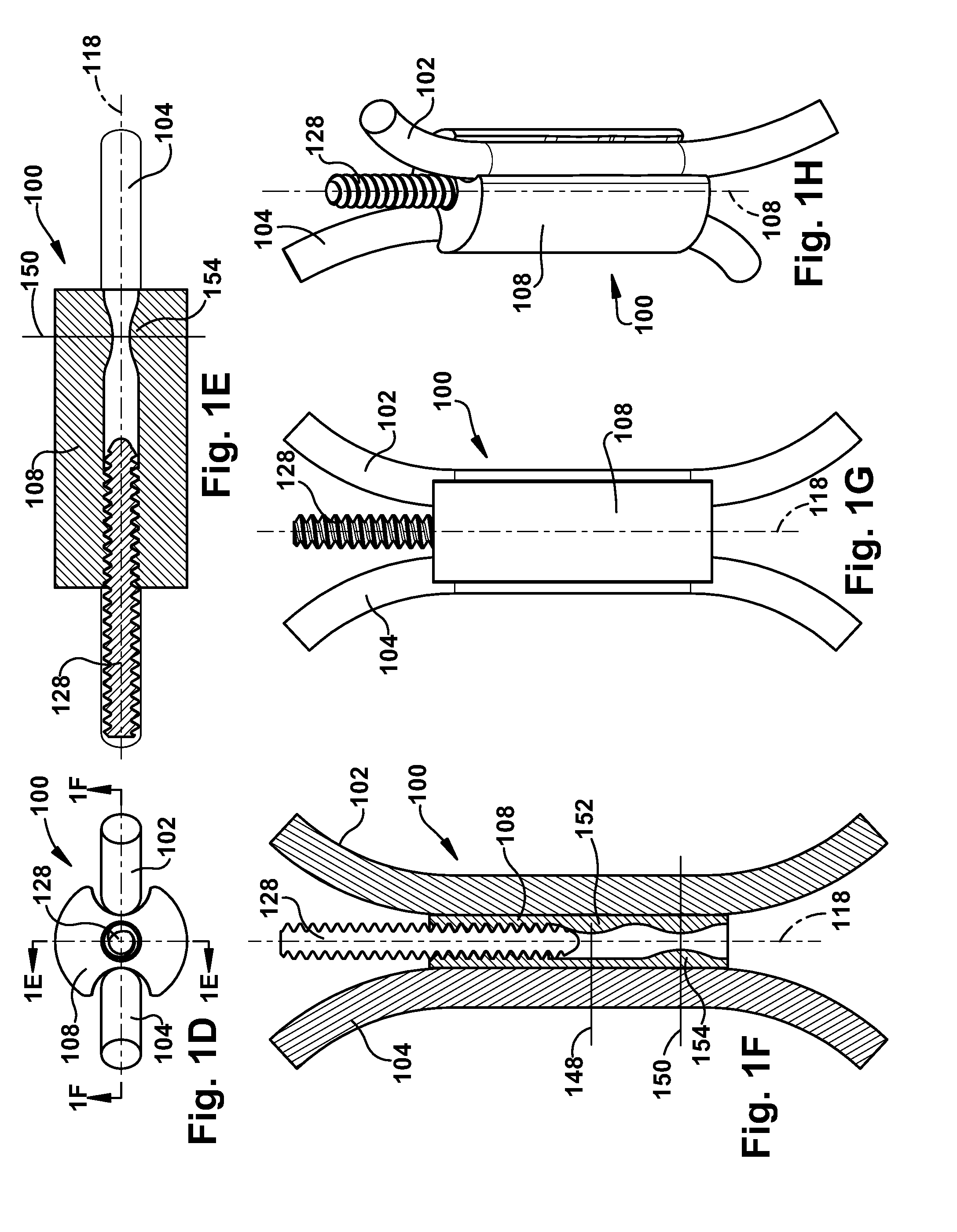

Expandable collet anchor system and method

An expandable collet body and anchor system incorporating a collet body anti-rotation feature and preferably collet body translation arresting means are disclosed. The collet body includes a first end, a first wall portion having at least two fingers, a second end including a head, a second wall portion, an annular protrusion and anti-rotation means where the anti-rotation means engages with an auxiliary structure defining a hole having an internal surface adapted to translationally accept the collet body and operatively function with the collet body anti-rotation means. The auxiliary may include a work piece to be optionally joined to another structure or a sleeve insert locatable in a hole defined by a work piece. Because the collet body is relatively free to translate within the auxiliary structure, a wide spectrum of work piece depths can be engaged with a single length collet body with the use of a stud to radially expand the fingers, thereby engaging a distal structure.

Owner:MCCLURE TRAVIS D

Destructible locking device

A locking device is disclosed for interlocking two members having aligned openings extending therethrough. The device includes a hollow cap and a pin with an enlarged head at one end and a nose at the opposite end. The pin is insertable through the aligned openings of the members, with its nose received in interlocked engagement within the cap, and with the two members captured between the cap and the enlarged head of the pin. A frangible portion of the pin is severable in response to relative rotation between its nose and enlarged head to thereby destructively disassemble the locking device.

Owner:INNER TITE A DIV OF YARA ENG

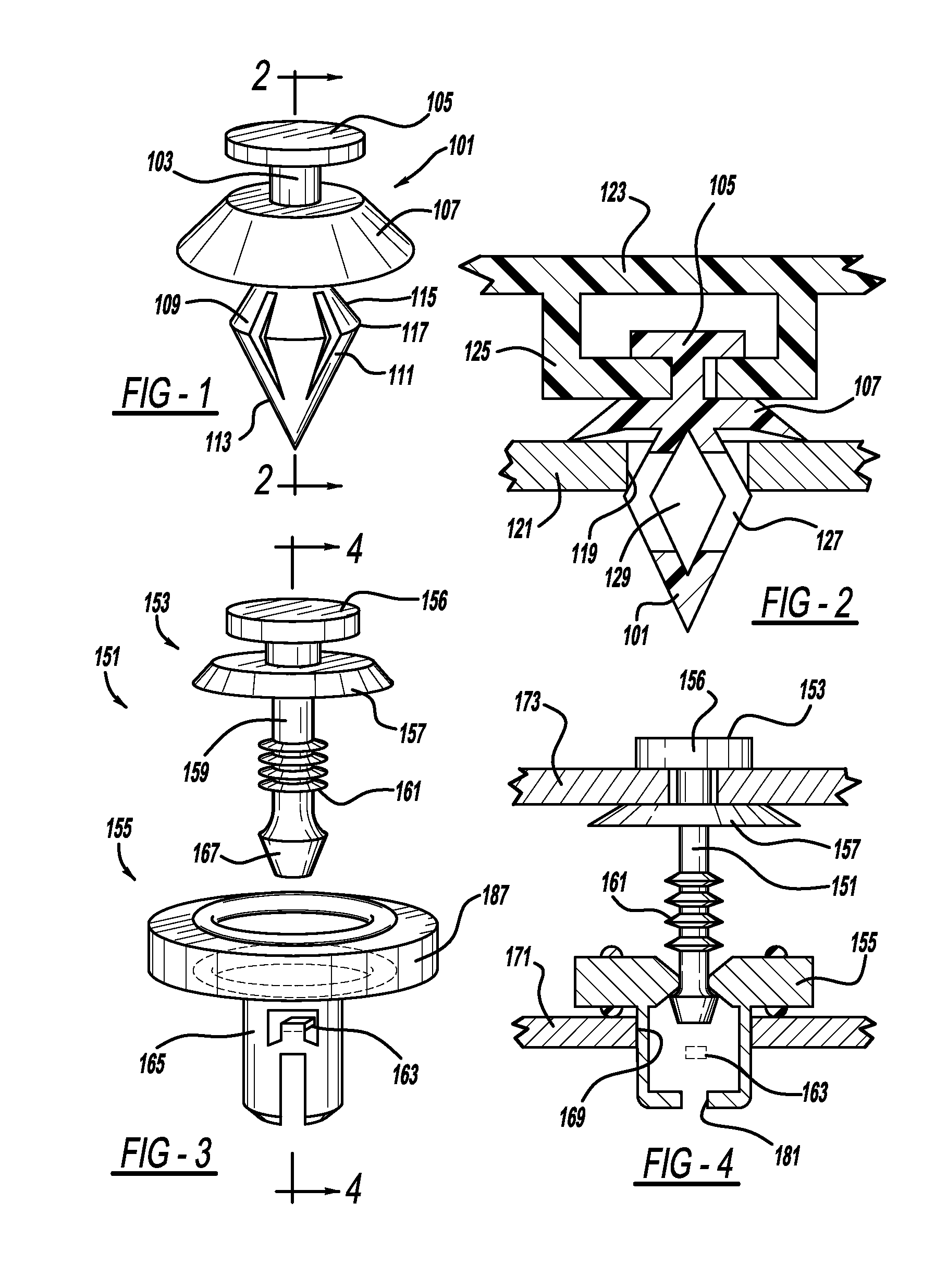

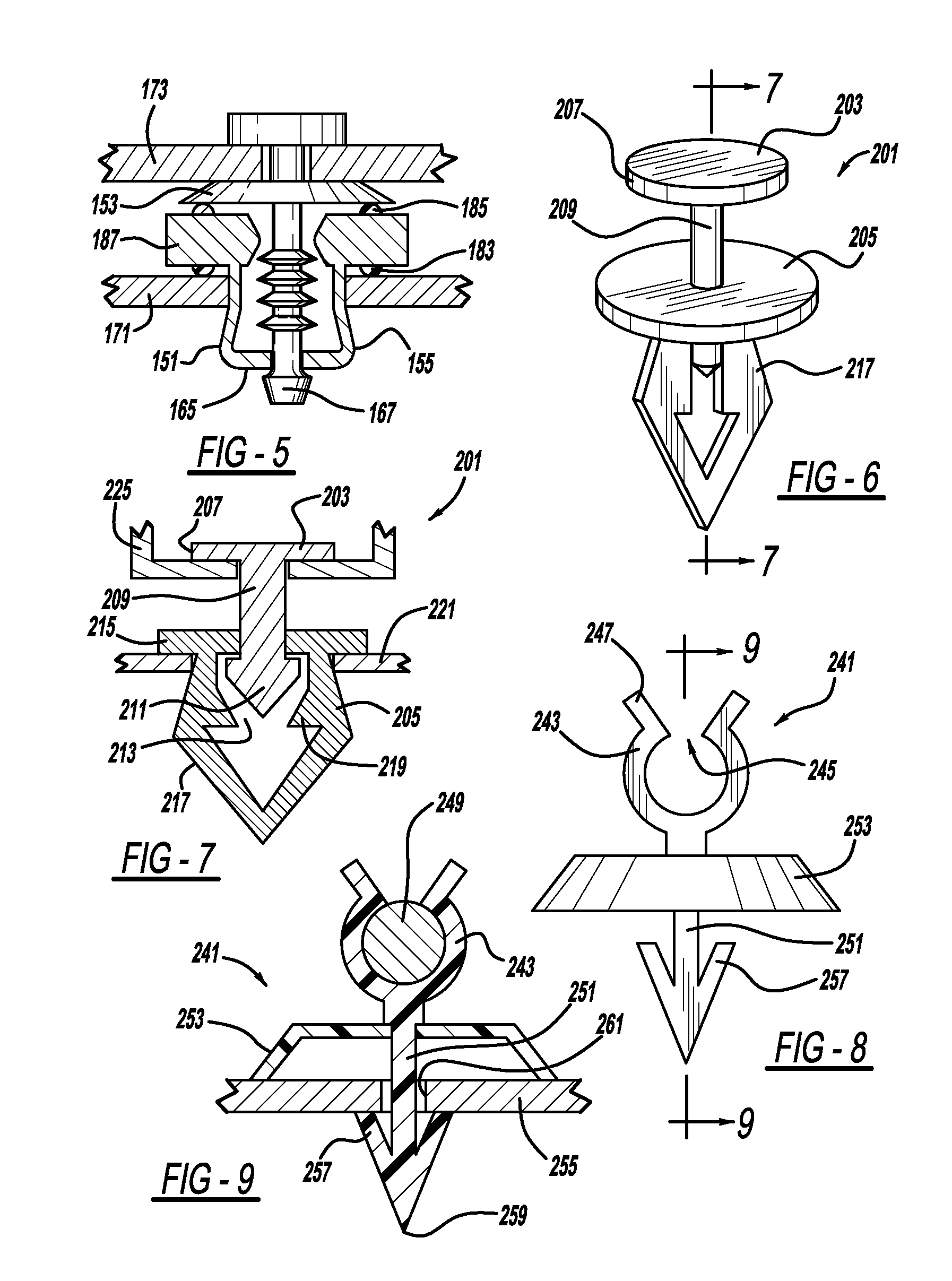

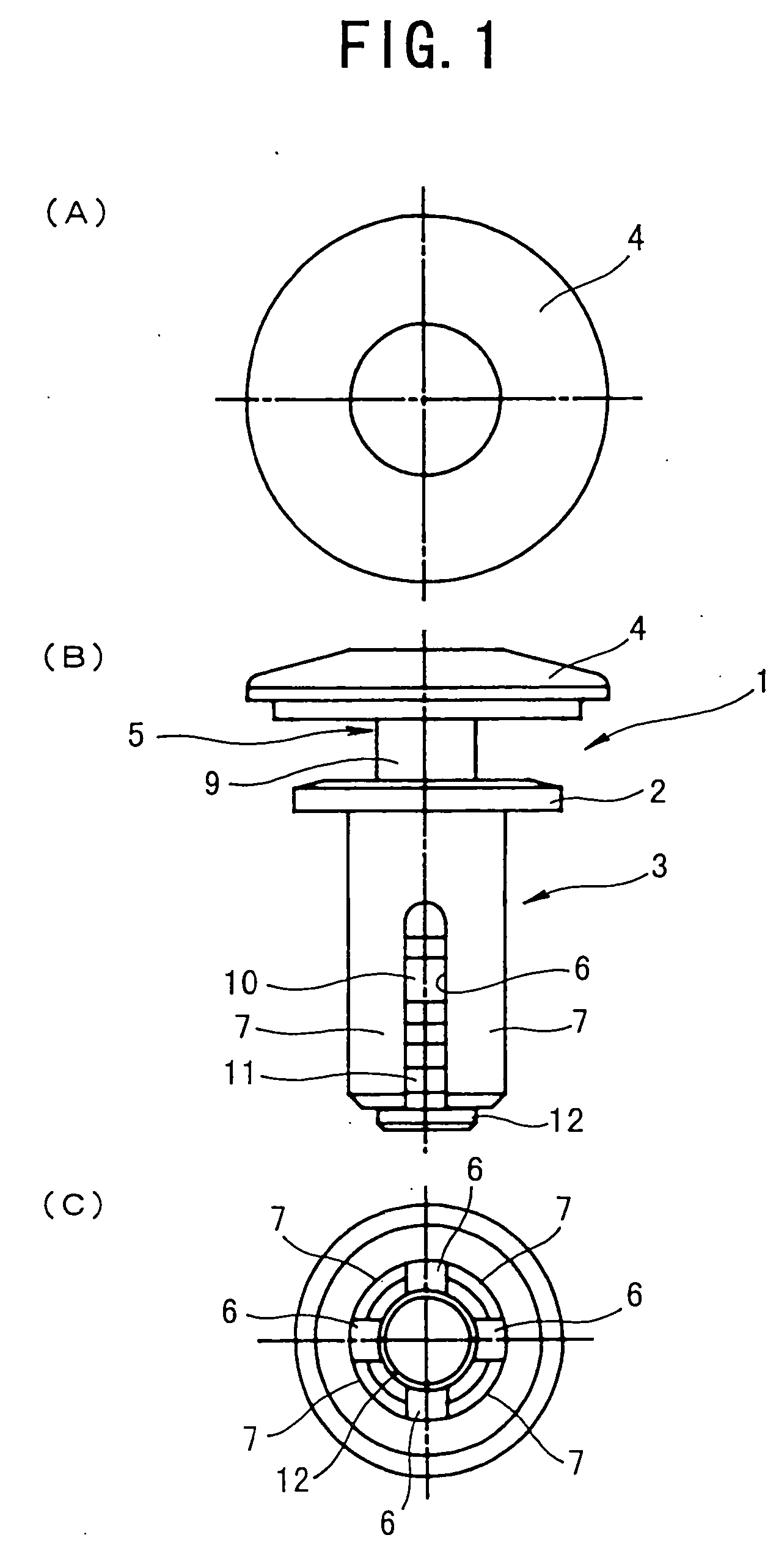

Fastener

A fastener for connecting plate members includes a male member, and a female member to be inserted into mounting holes of the plate members. The female member includes a cylinder body for receiving the main body therein, a projecting portion formed on an outer periphery of the cylinder body at one end thereof, and protruding portions formed at the other end thereof. A first engaging portion is formed on an outer surface of a main body of the male member or an inner surface of the cylinder body, and a second engaging portion engaging the first engaging portion is formed on the inner surface or the outer surface. The second engaging portion has two engaging sections and a smooth surface portion interposed therebetween. When the male member is inserted into the female member, the male member can be easily engaged with the female member.

Owner:NIFCO INC

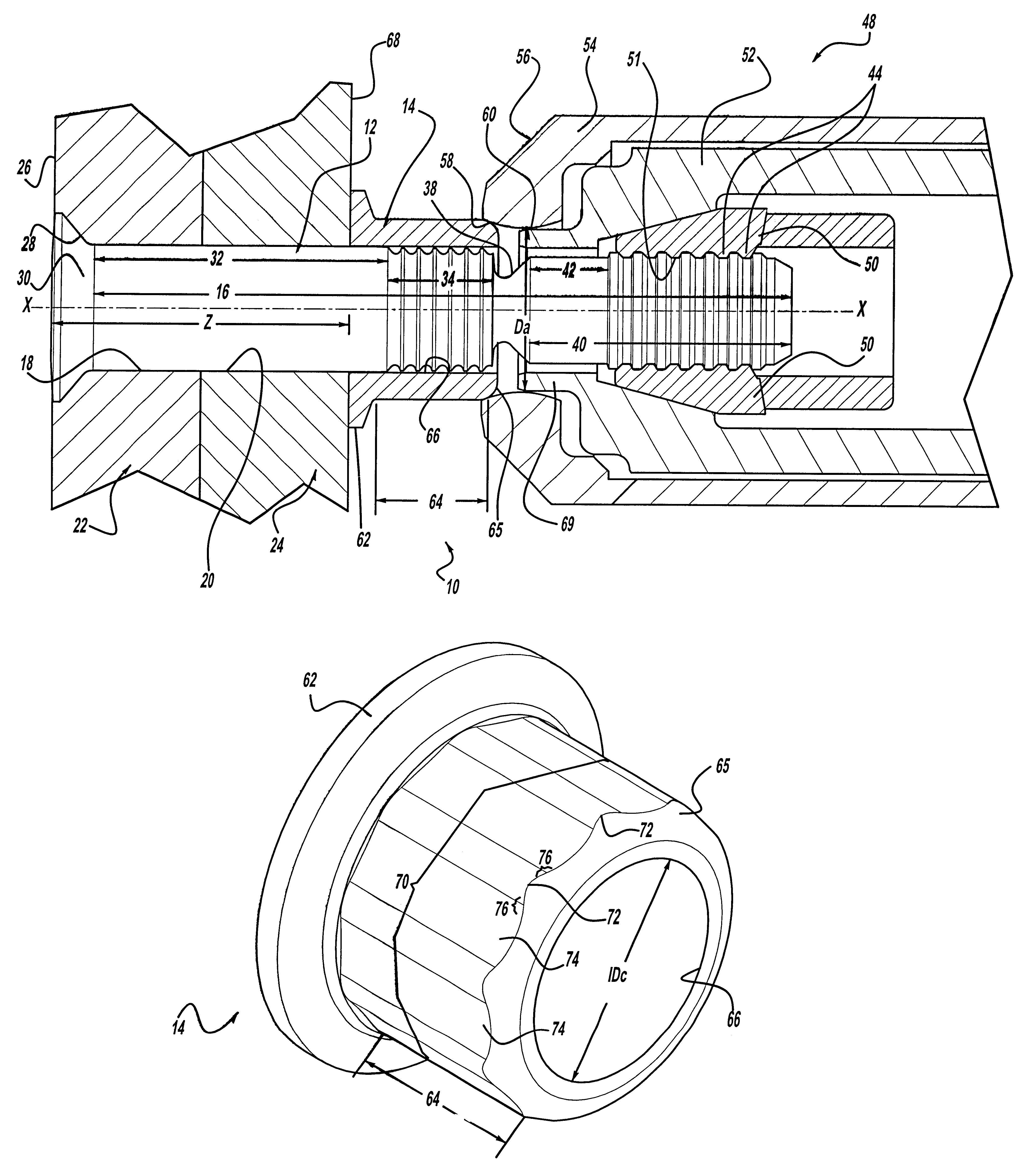

High performance sleeved interference fasteners for composite applications

ActiveUS20080075555A1Minimizing installation forceImprove interferenceRivetsNutsAviationMulti material

A fastener adapted to pass through aligned holes through workpieces is disclosed. The fastener includes a pin member having a transition portion wherein the diameter of the transition portion decreases radially as it extends from the smooth cylindrical shank portion to the threaded portion. The fastener may also comprise a sleeve member and a clamping means. The clamping means includes a collar, a nut, or any other possible clamping means. In exemplary embodiments, the workpieces can be formed with a plurality of materials, the materials including composite, metallic, or composite / metallic structures, any combination thereof. In particular embodiments, the fastener has interference capability of 0.0005 to 0.0100 inches in composite structures without risk of composite delamination or damage. As a result of the fastener interference, gaps between the fastener and the structure are eliminated thereby providing good electrical conductivity between components. As a result, the potential for electrical sparks is reduced, providing a safer fastener for use with aerospace applications.

Owner:ALCOA GLOBAL FASTENERS

Blind fastener and nose assembly for installation of the blind fastener

InactiveUS6868757B2Reduce wall thicknessNot significantly weaken the sleeveRivetsLoad modified fastenersNoseBlind hole

A blind fastener for securing a plurality of workpieces is provided that has a sleeve, and a pin member. In an alternate embodiment, the blind fastener has a sleeve, a pin member and a nut. The sleeves have a head with a plurality of rearwardly sloping recesses disposed therein. The recesses are adapted to be engaged with a plurality of rearwardly sloping nibs disposed on one end of a nose secured to an installation tool. The pin members have a splined head adapted to be engaged with a splined driver secured to an installation tool. Use of the splined head on the pin member, the splined driver, rearwardly sloping recesses on the sleeve, and rearwardly sloping nibs on the nose eliminates camming out of the nibs from the recesses during installation of the blind fastener. A nose assembly for installation of the blind fastener is also provided.

Owner:HUCK INT INC

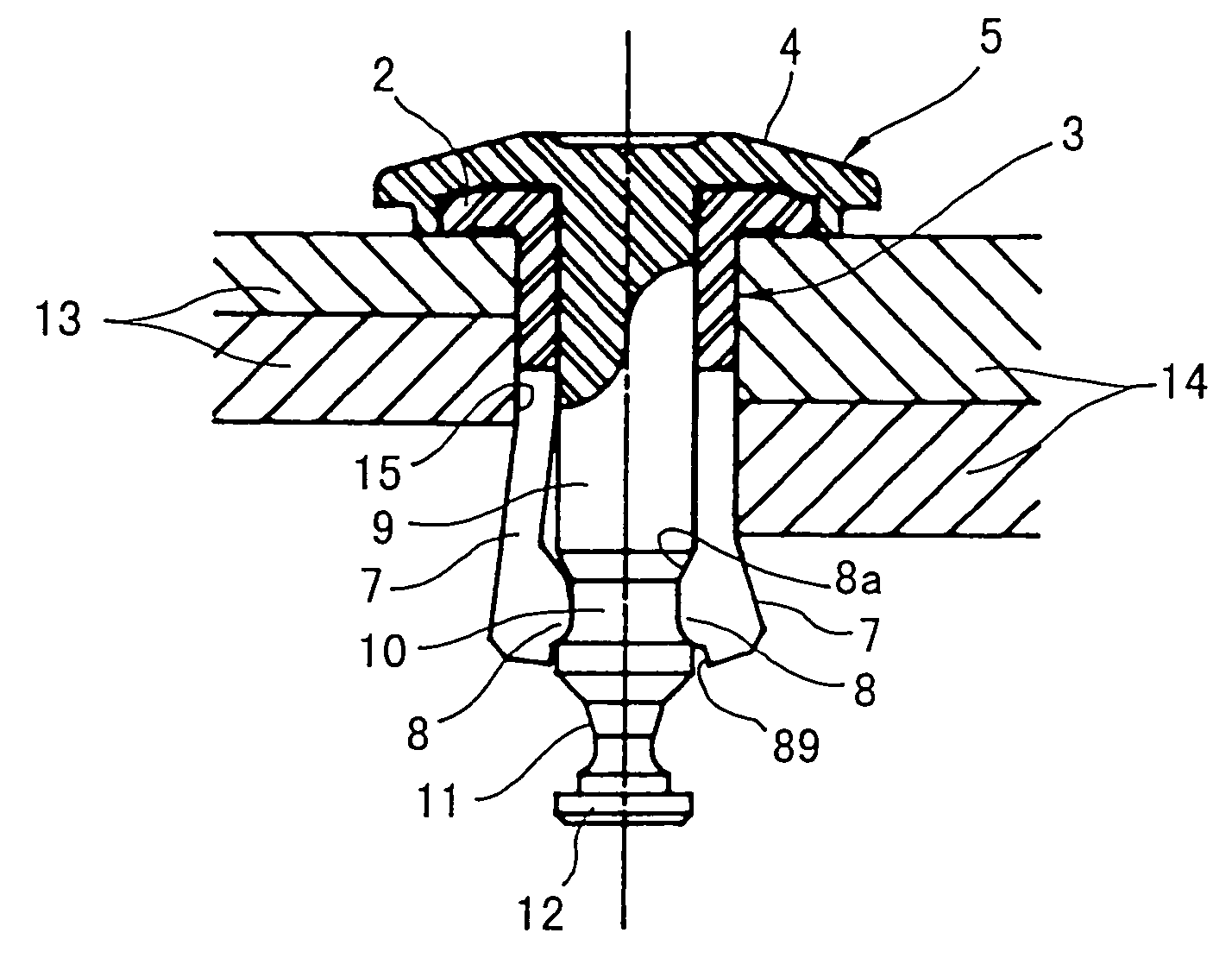

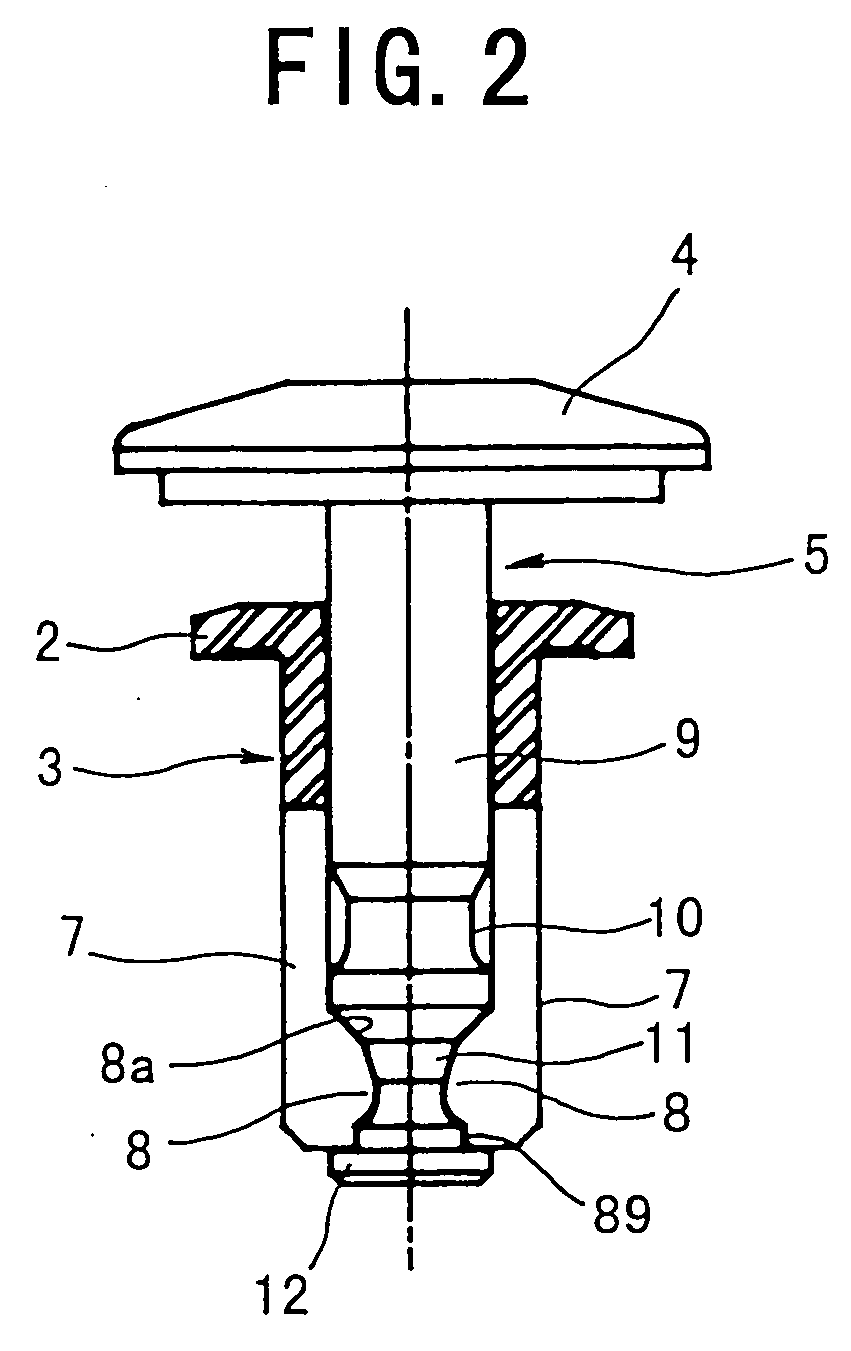

Fastener

InactiveUS20050123372A1Avoid serious impactImprove vibration resistanceRivetsNutsFastenerEngineering

A fastener in which a sleeve 3 and a plug 4 are put into concavo-convex engagement both before and after execution to exert an effect of preventing separation between the two and an effect of preventing loosening therebetween after execution and which can be released by a single action during disassembling. Before execution, the sleeve 3 and the plug 4 press fitted therein are positioned by concavo-convex engagement between a fitting protrusion 8 on the inner periphery of an expanding portion 7 and a neck portion 11 of the plug 4. After execution, the fitting protrusion 8 on the inner periphery of the expanding portion 7 as expanded put into concavo-convex engagement with a neck portion 10 of the plug 4 again, thereby exerting an effect of stopping loosening between the two with respect to vibration, etc. During disassembling, a striking force is given to an end of the plug 4 to release the expanded state by a single action, allowing immediate pulling-away of the fastener 1.

Owner:ZEN KENCHIKU SEKKEI JIMUSHO TOKIOTOKYO

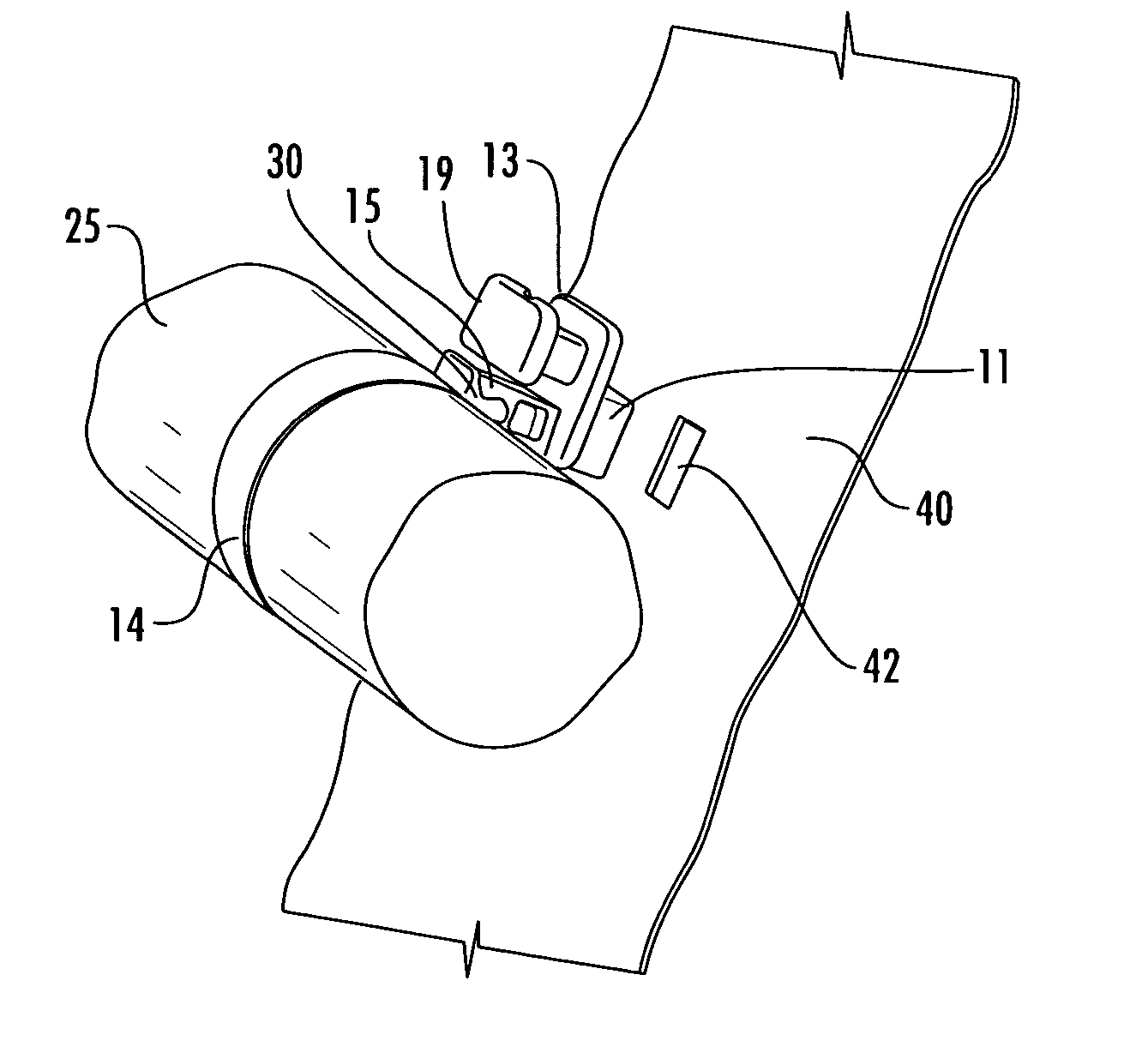

Fastener

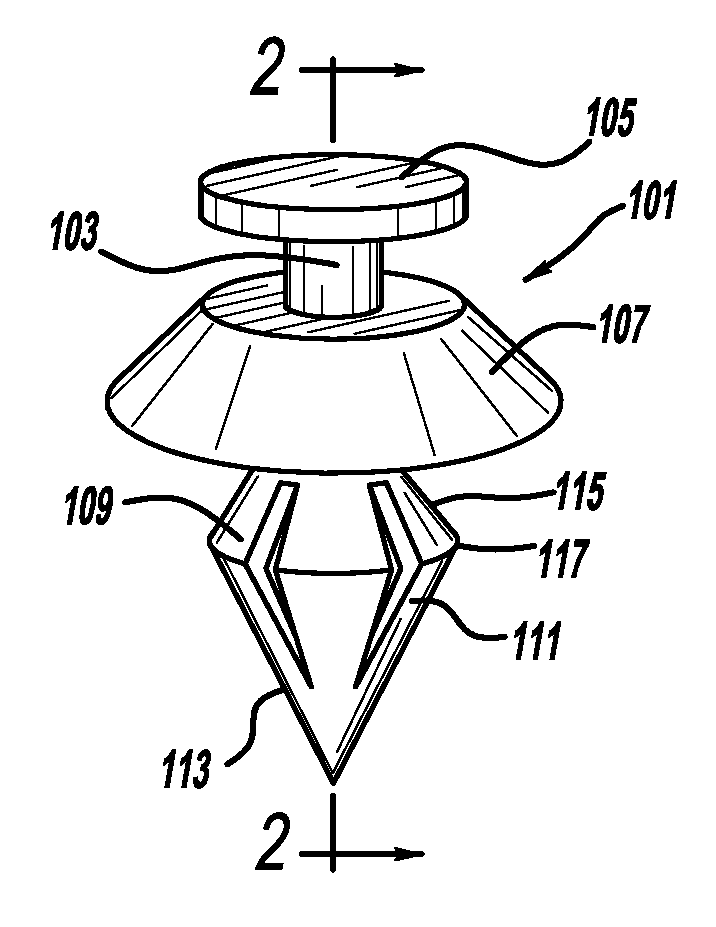

InactiveUS20070126211A1Easy to installHigh retention featureRivetsPedestrian/occupant safety arrangementEngineeringFastener

The invention relates to fasteners adapted for use in automobile air bag attachment systems. The fastener comprises a hook to engage a vehicle structure during installation and a pin to lock the fastener in place. Advantageously, the hook portion may be quickly installed and will support the air bag assembly while allowing any positional adjustments to be made prior to locking the fastener by depressing the pin until it is fully engaged in the vehicle structure. An embodiment of the invention incorporates both a locking method to prevent the fastener from being disengaged and a method of releasing this lock if needed for servicing. Another aspect of the invention provides a method for reducing the likelihood of improperly installed parts by preventing locking when the fastener is in a partially installed configuration.

Owner:ILLINOIS TOOL WORKS INC

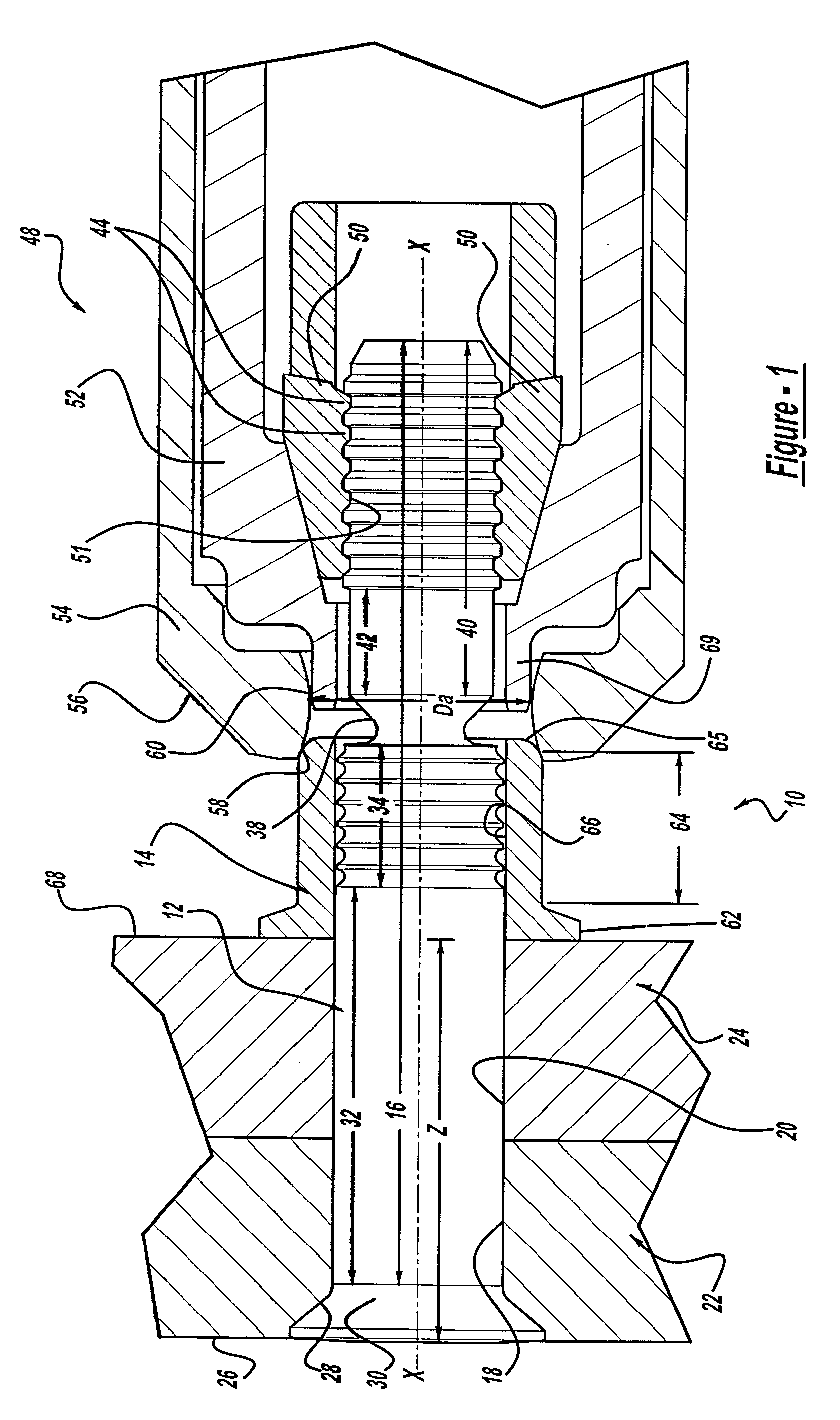

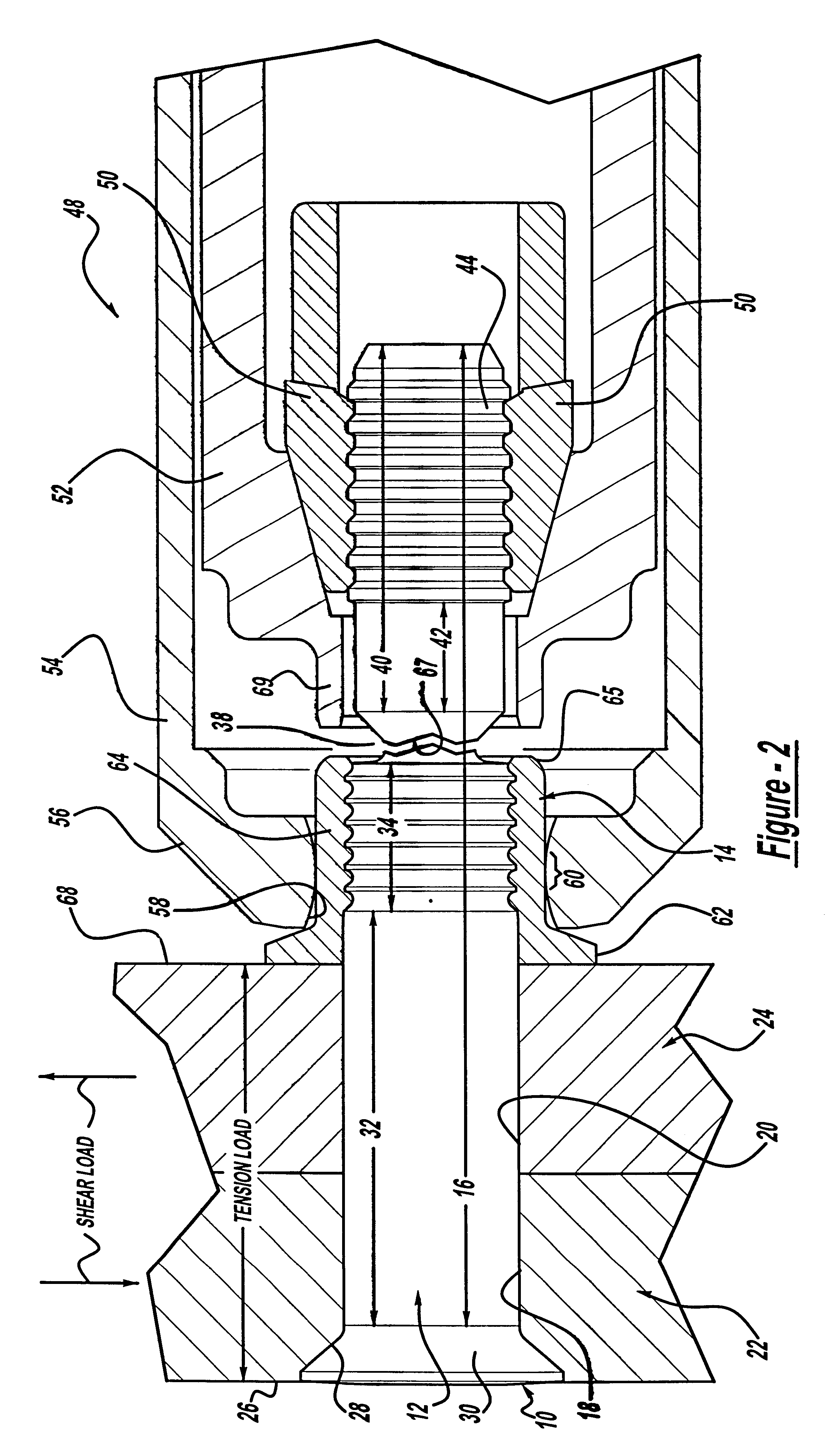

Low swage load fastening system and method

A low swage load fastening system is provided for installing swage-type fasteners to secure a plurality of workpieces together. The fastener includes a pin member having an elongated pin shank to be located in aligned openings in the workpieces. An enlarged head at one end of the pin engages one side of the workpieces. A grooved pin portion extends past an opposite side of the workpieces. A collar includes a shank portion adapted to be swaged into the pin lock grooves in response to a relative axial swage load applied by an installation tool. As one aspect of the system, the collar is as-headed and does not require thermal processing yet provides an optimum balance of reduced collar shank wall thickness and increased hardness, whereby the swage load is minimized. A low swage load thread form for the lock grooves of the pin is also provided, a reduced diameter, relatively short pull portion pin extension, installation tool improvements, and an associated method of use are also disclosed.

Owner:HUCK INT INC

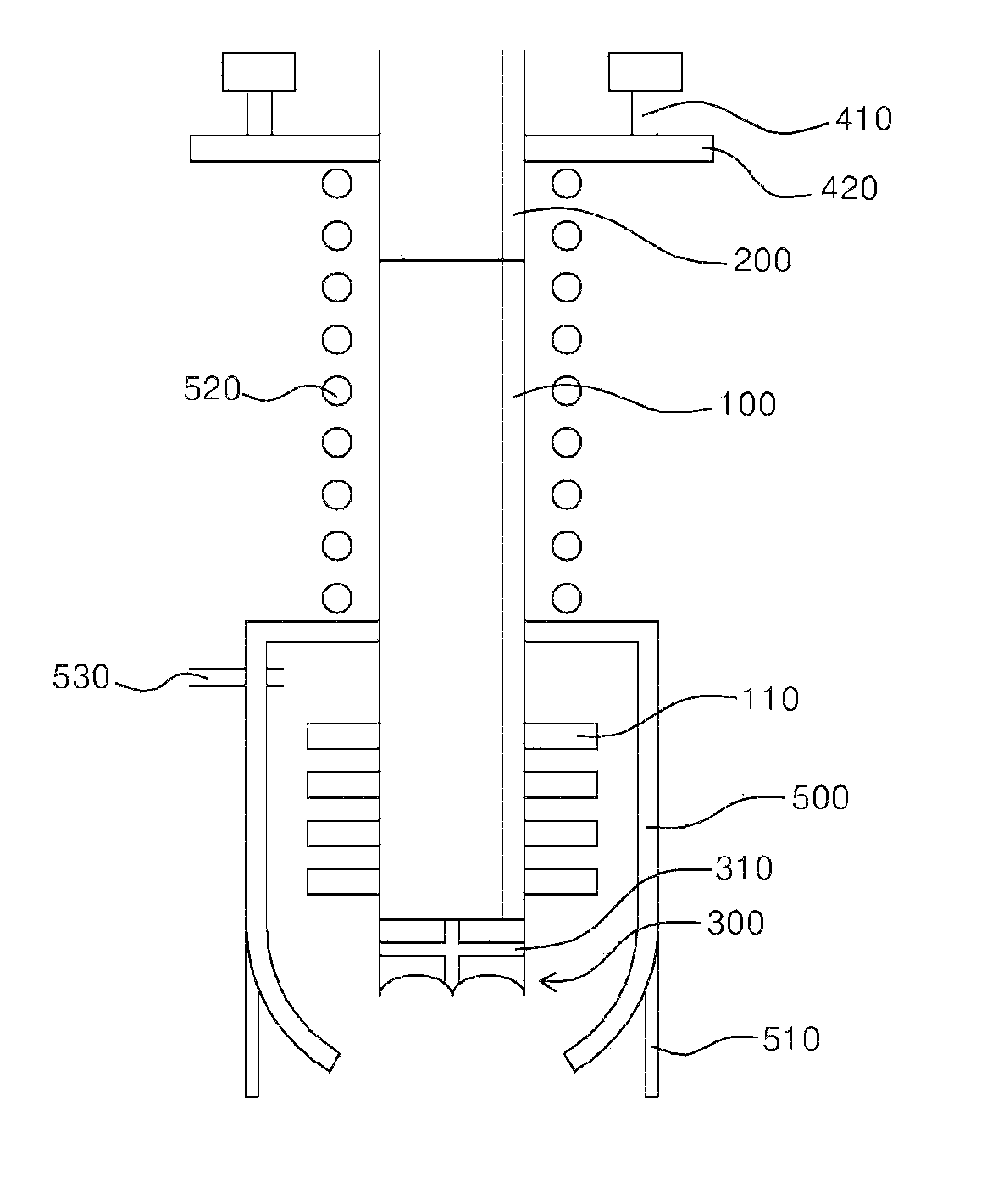

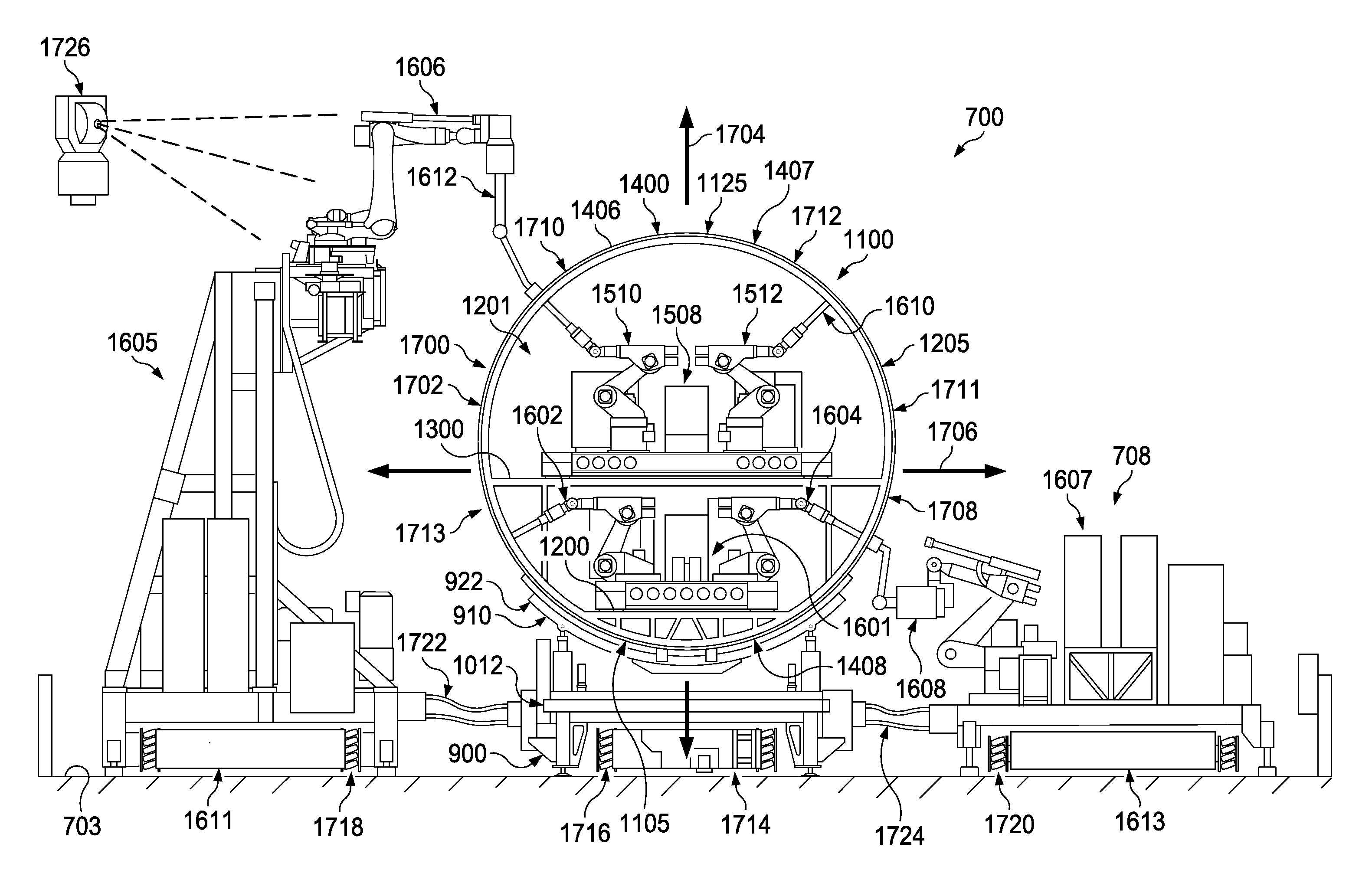

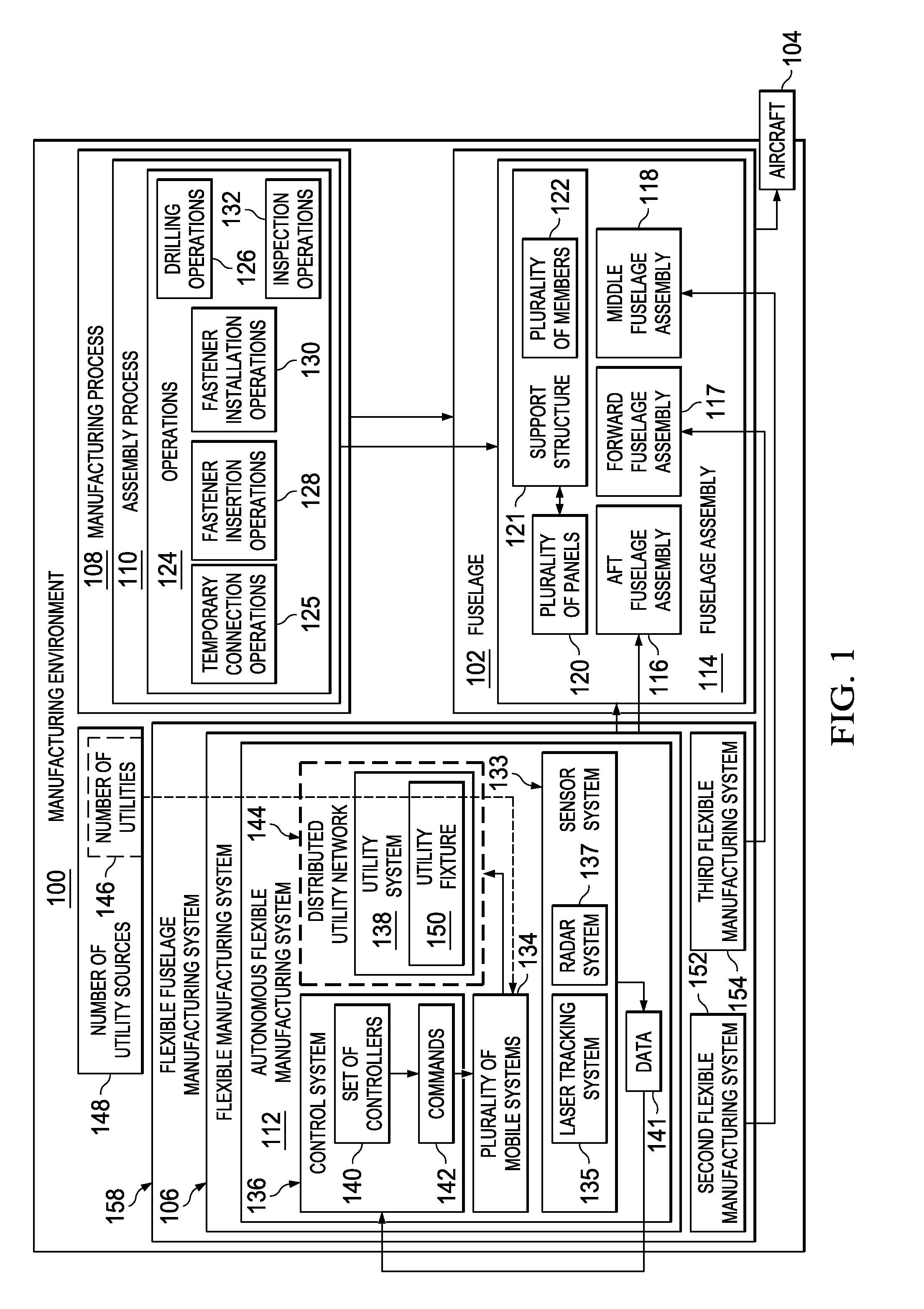

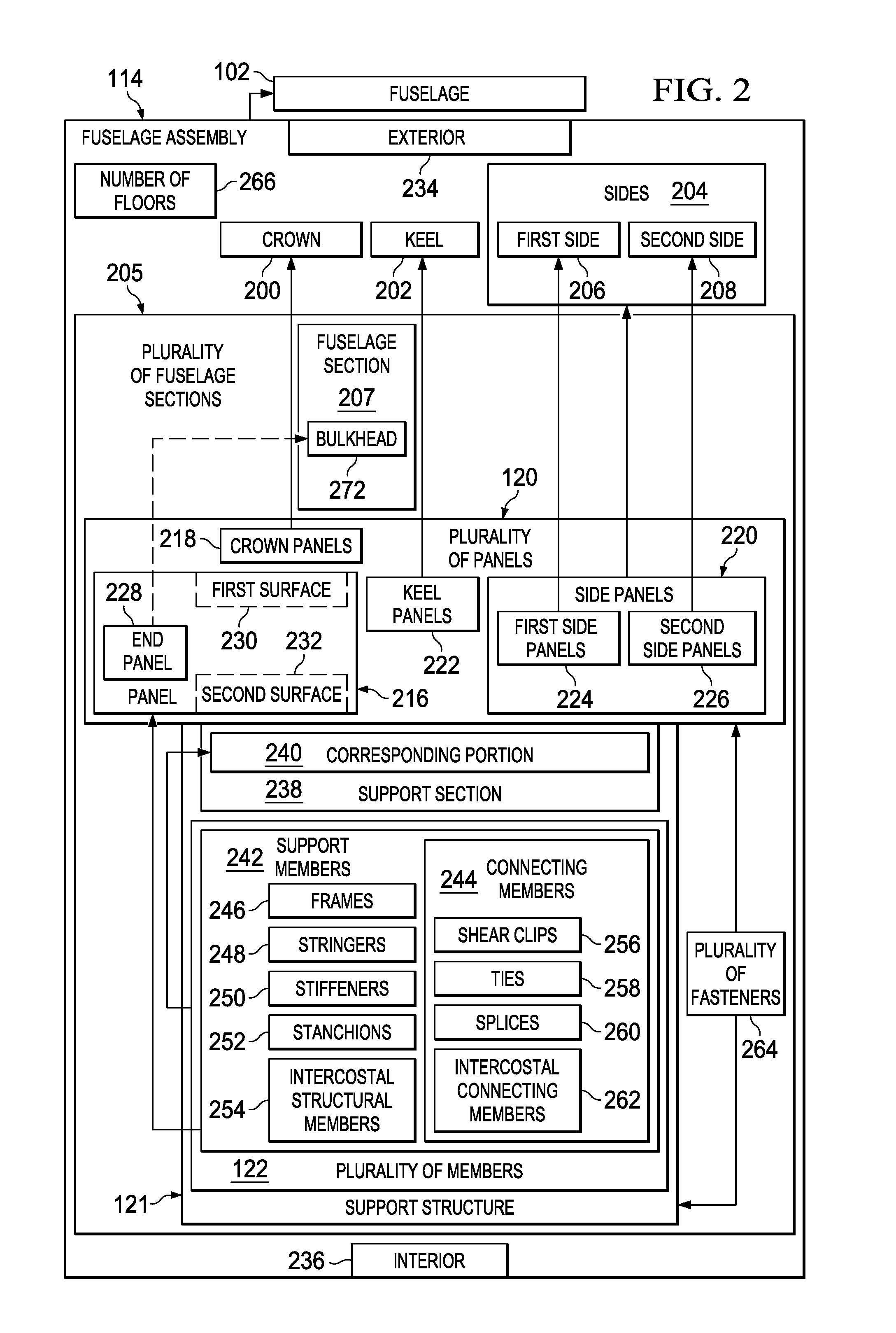

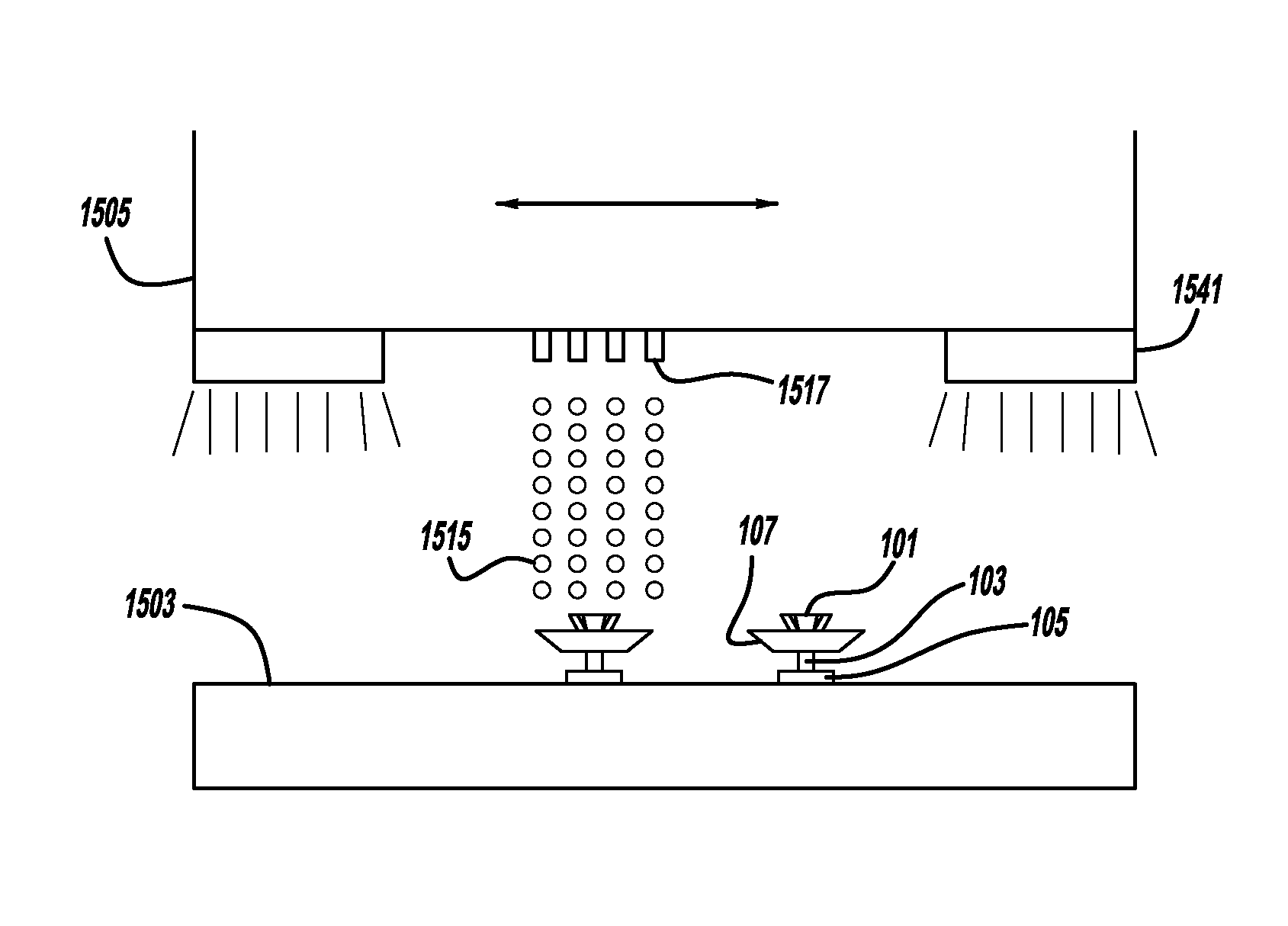

Mobile Platforms for Performing Operations Along an Exterior of a Fuselage Assembly

A method and apparatus for performing an assembly operation. A tool may be macro-positioned relative to an exterior of a fuselage assembly. The tool may be micro-positioned relative to a particular location on the exterior of the fuselage assembly. An assembly operation may be performed at the particular location on the panel using the tool.

Owner:THE BOEING CO

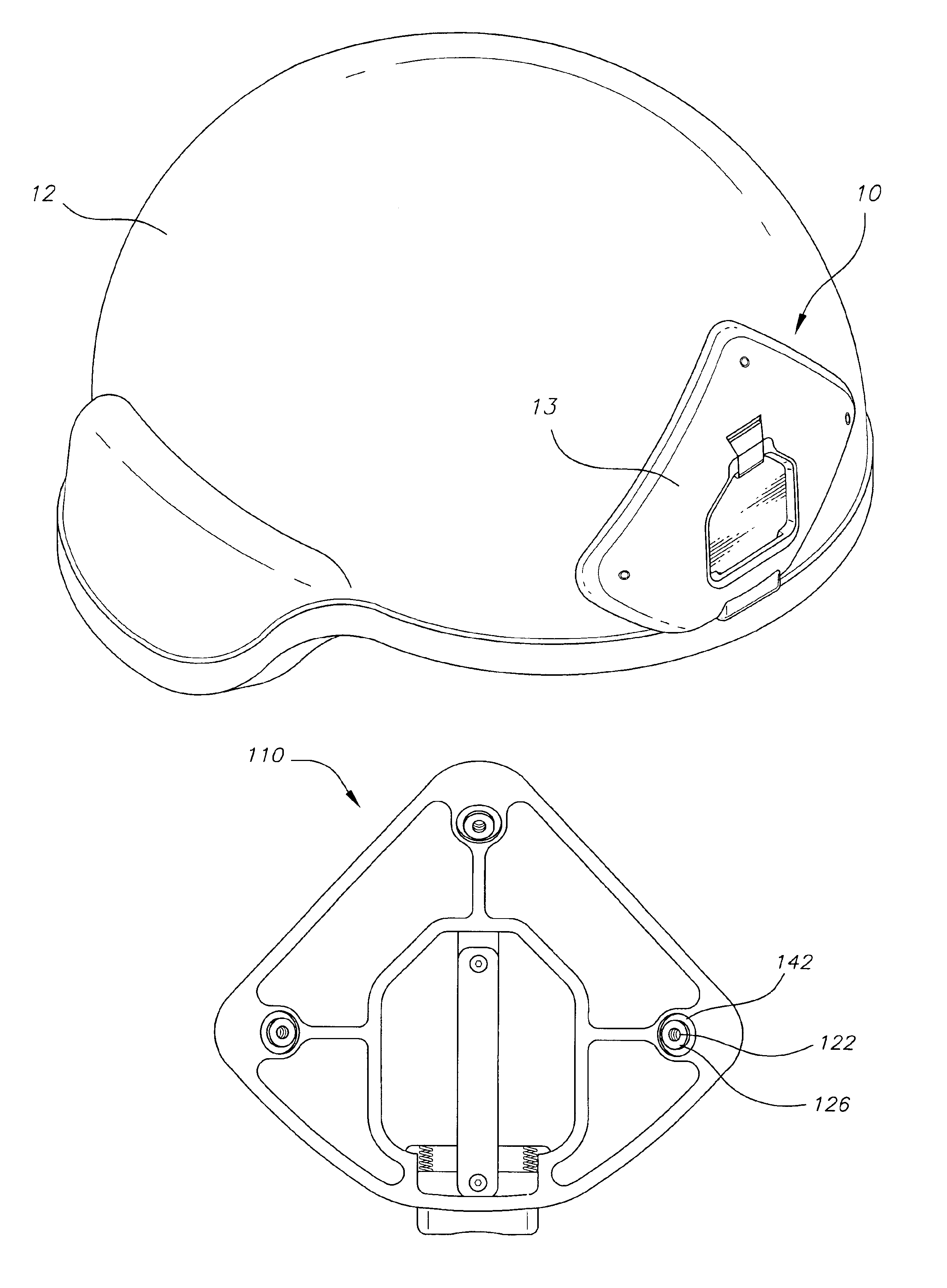

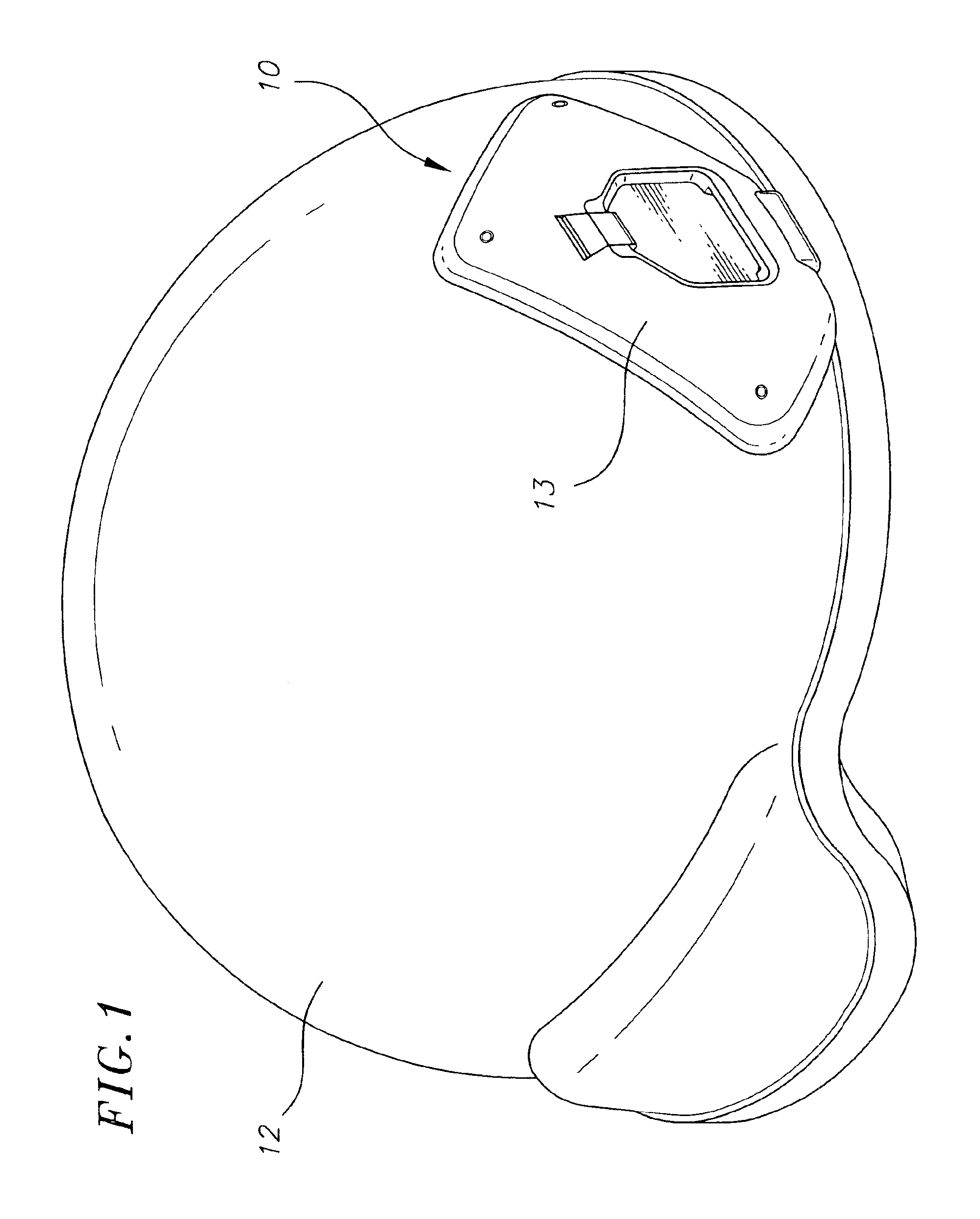

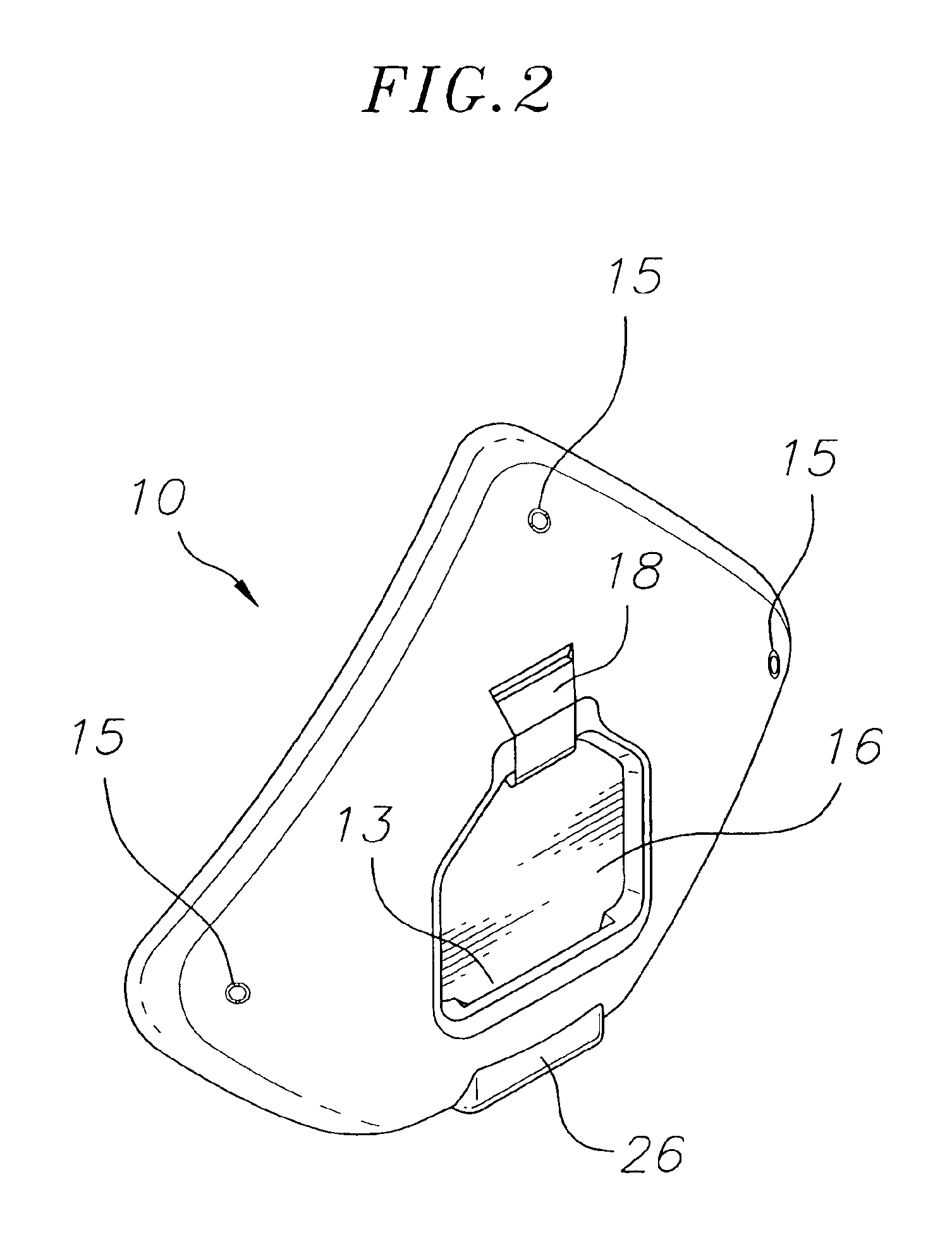

Shroud plate attachment

A shroud plate for headgear is provided that may comprise a shell, an insert, a lock, a release mechanism wherein the shell extends around at least a portion of the insert has a smooth surface with rounded edges and corners and is shaped to match the contour of the headgear, and at least one attachment point wherein the attachment point is laterally movable within a restricted area. Further, the shroud plate may be attachable to headgear at a single attachment point and may be given rotational stability by an elevated ridge or a plurality of legs which may extend over or wrap around an edge of the headgear.

Owner:NOROTOS

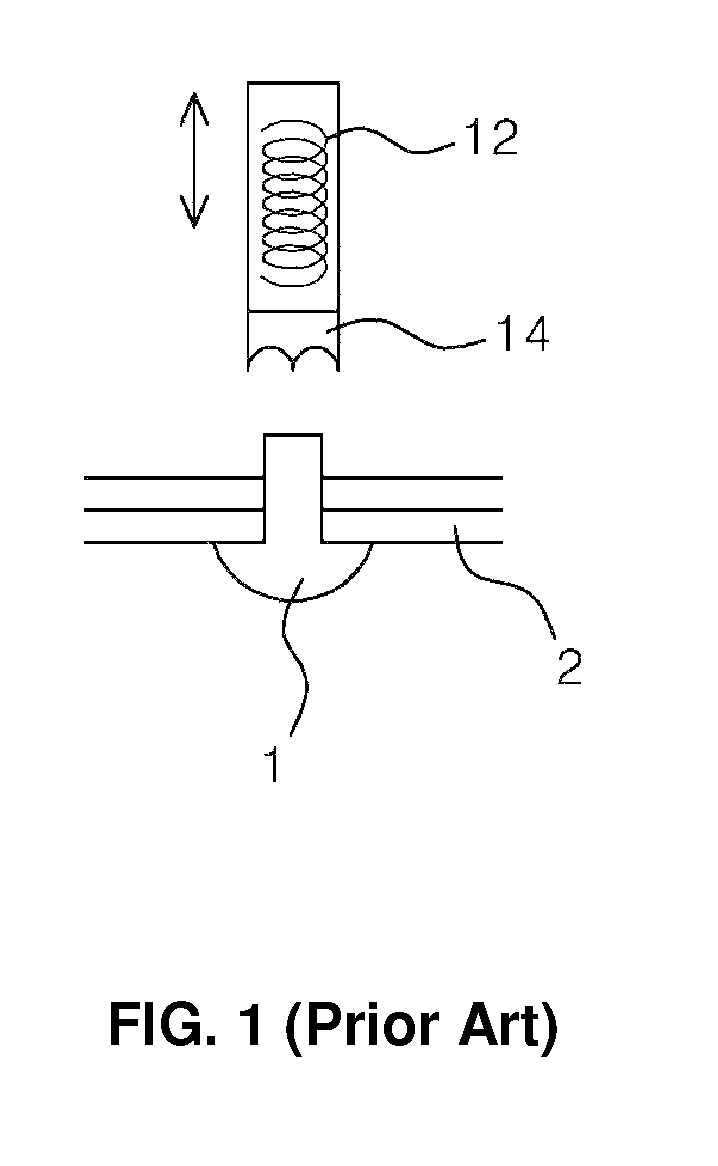

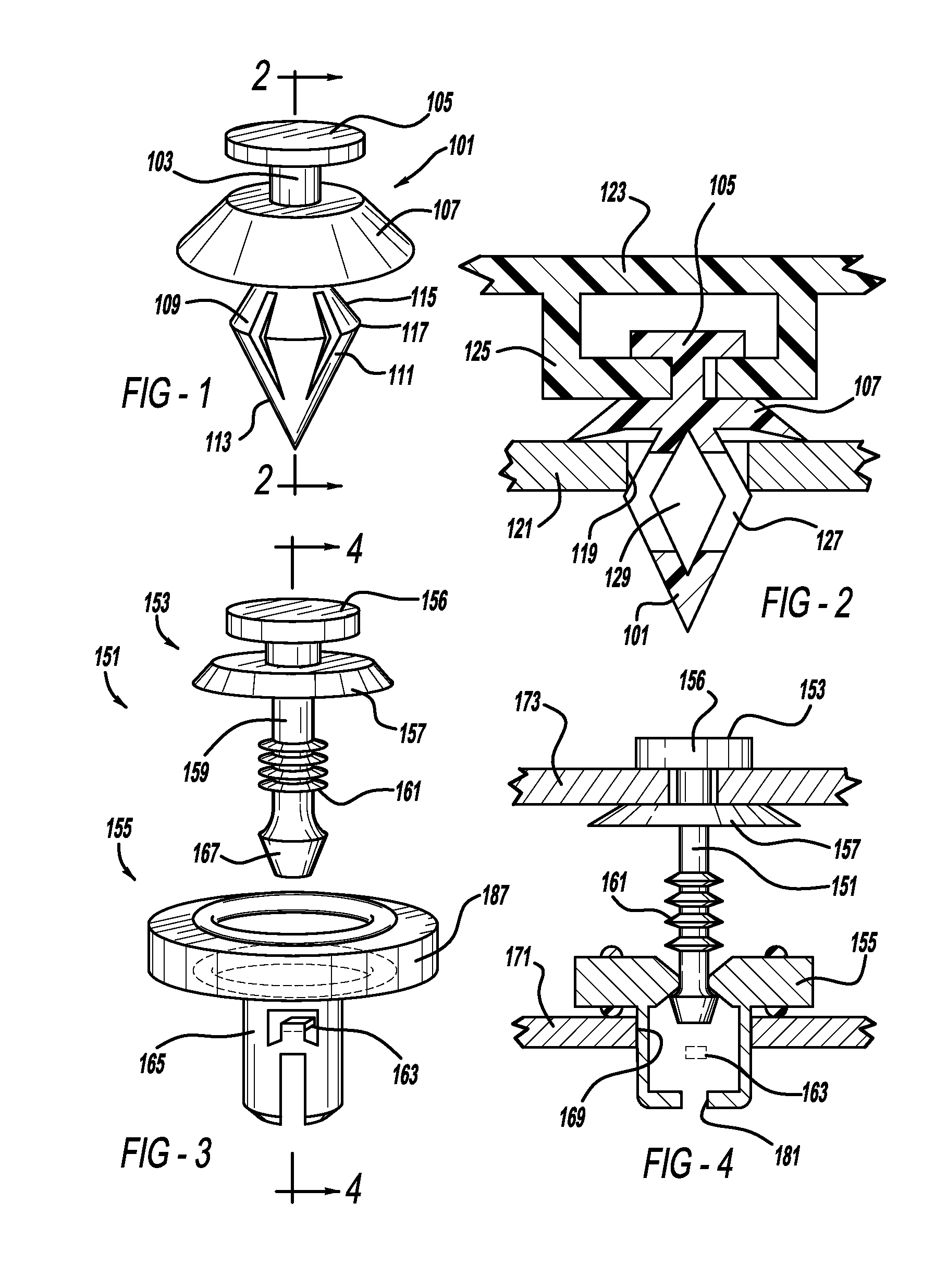

Self-piercing fastening system

ActiveUS7032296B2Obstruct passageIncrease flexibilityRivetsAssembly machinesEngineeringMaterial Perforation

Owner:NEWFREY

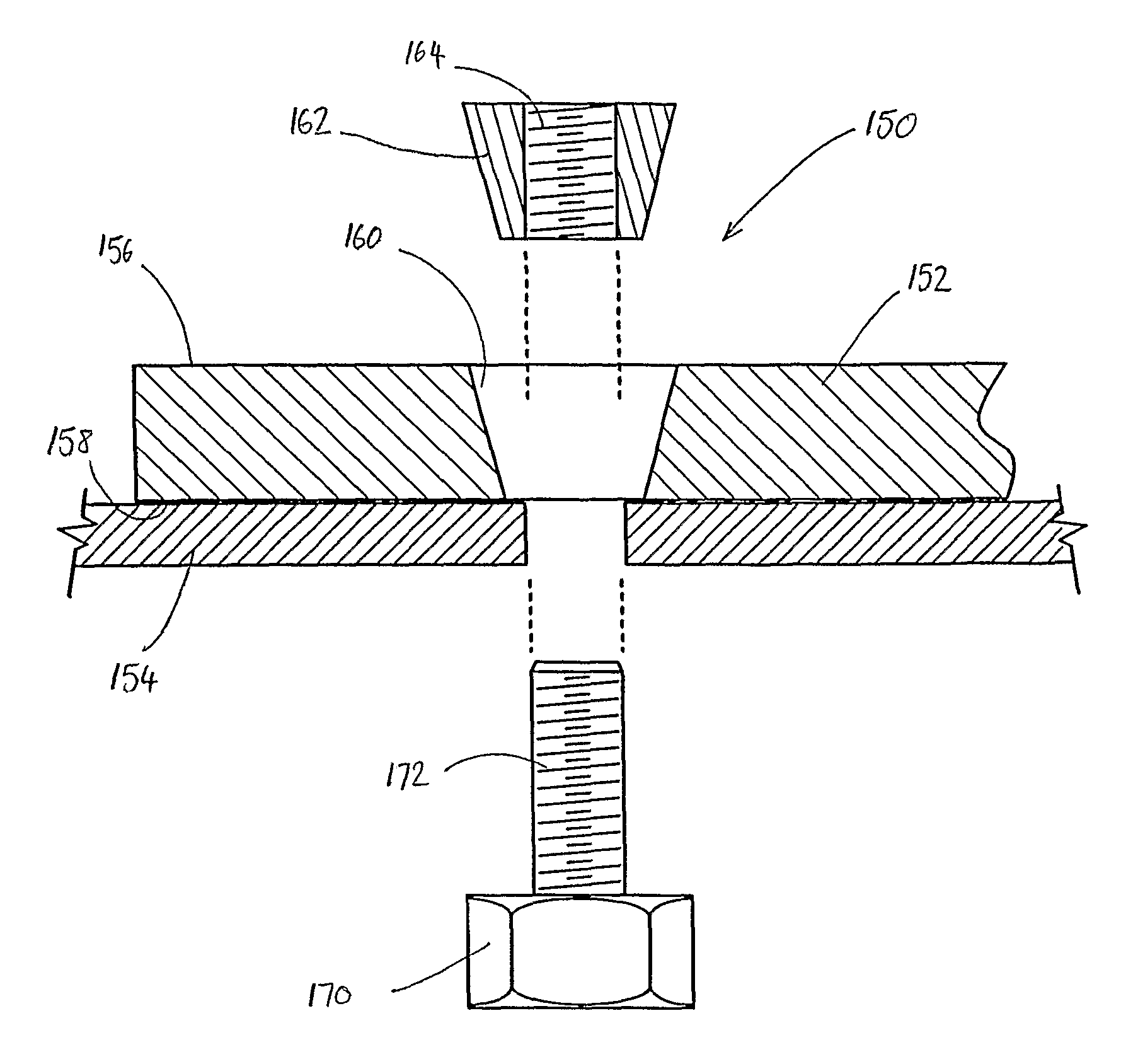

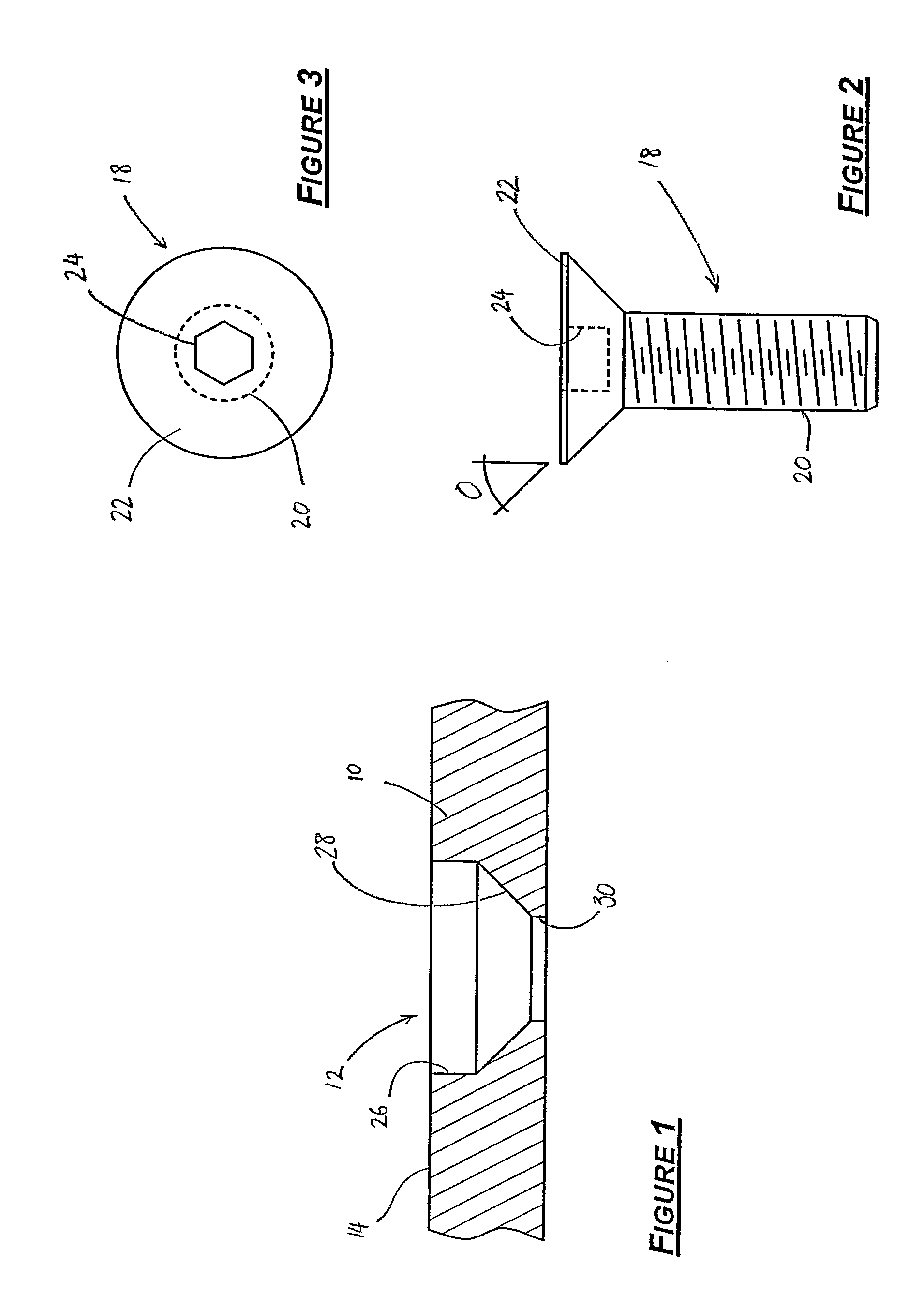

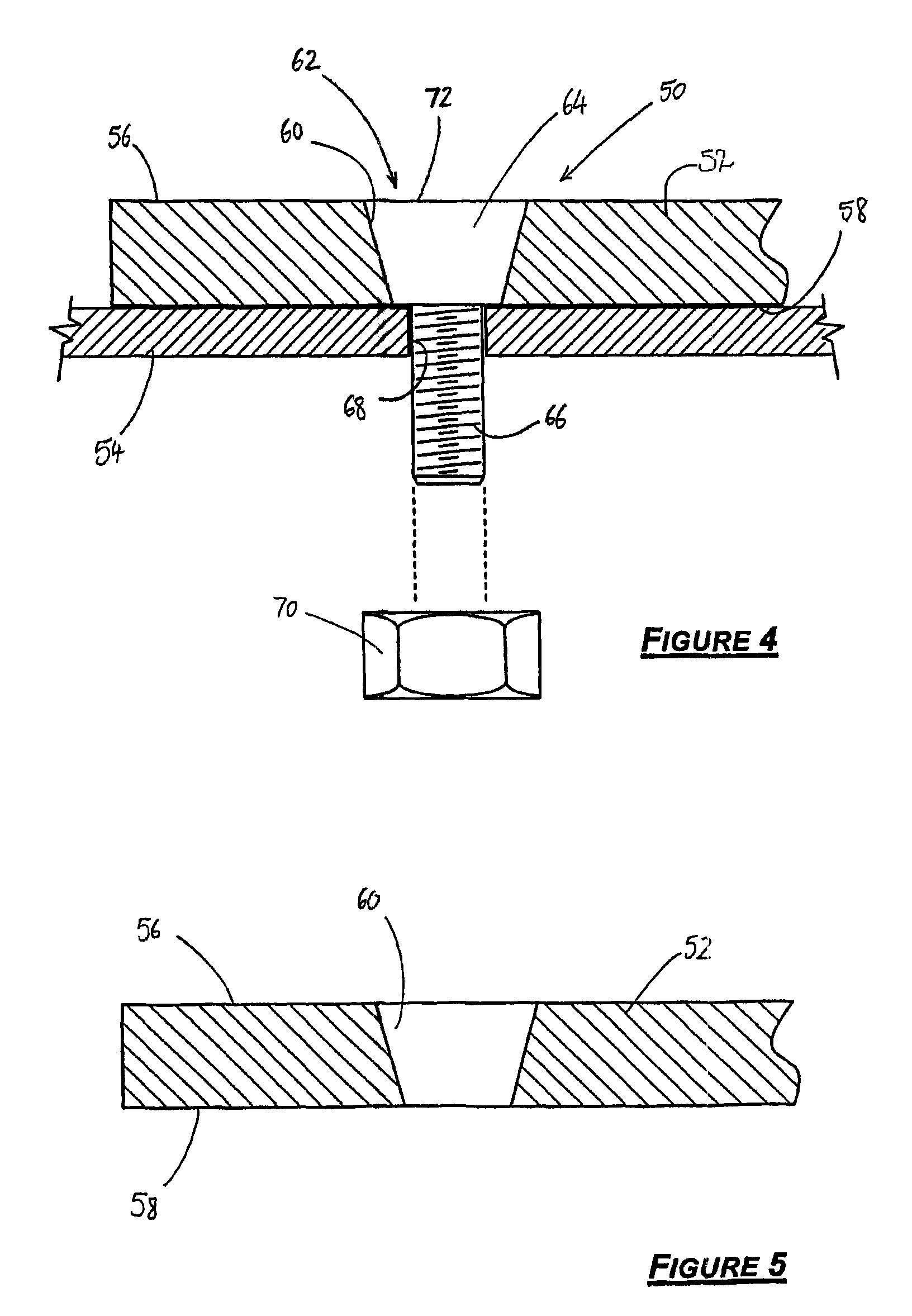

Fastener system for fixing hardened plates

A fastener system for fixing hardened plates includes a fastener element having a frusto-conical head and a threaded shaft portion, wherein a smallest outer diameter of the frusto-conical head is adjacent the threaded shaft, and a largest outer width of the shaft is smaller than a smallest diameter of the head.

Owner:METSO OUTOTEC (FINLAND) OY

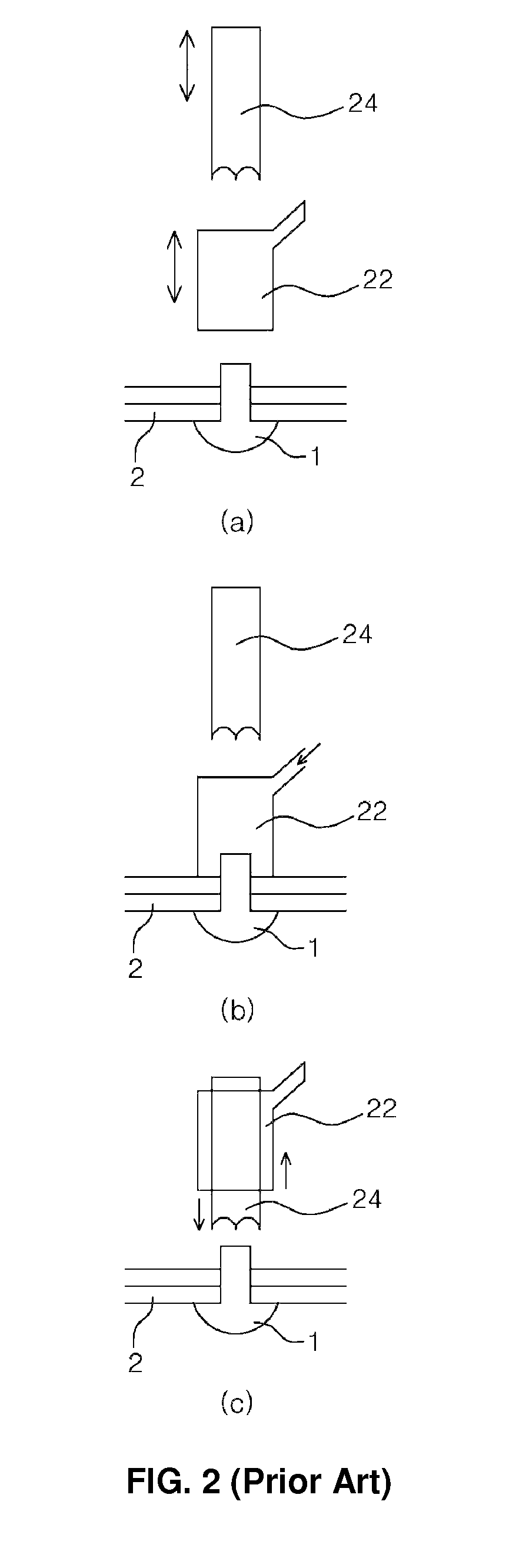

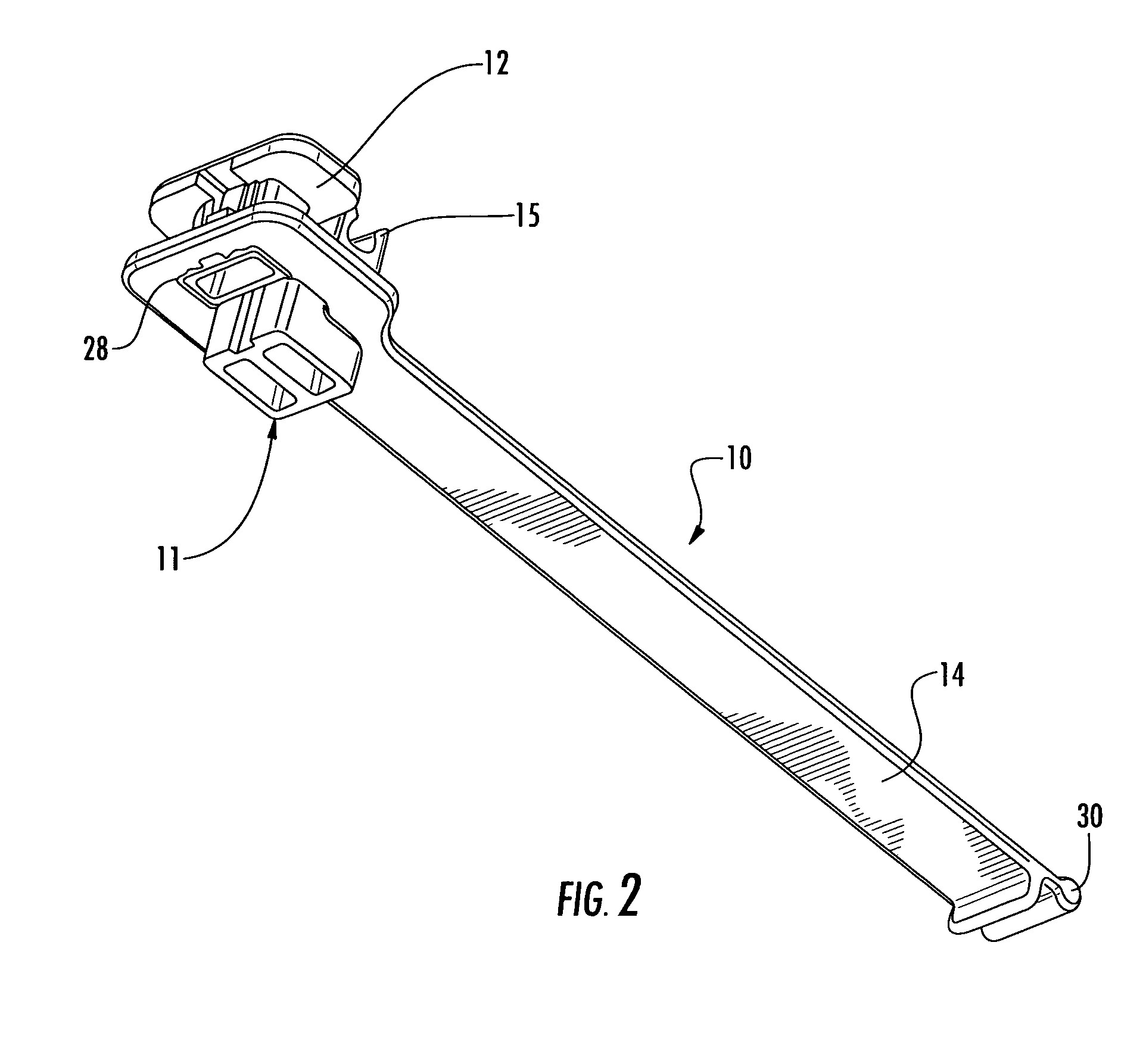

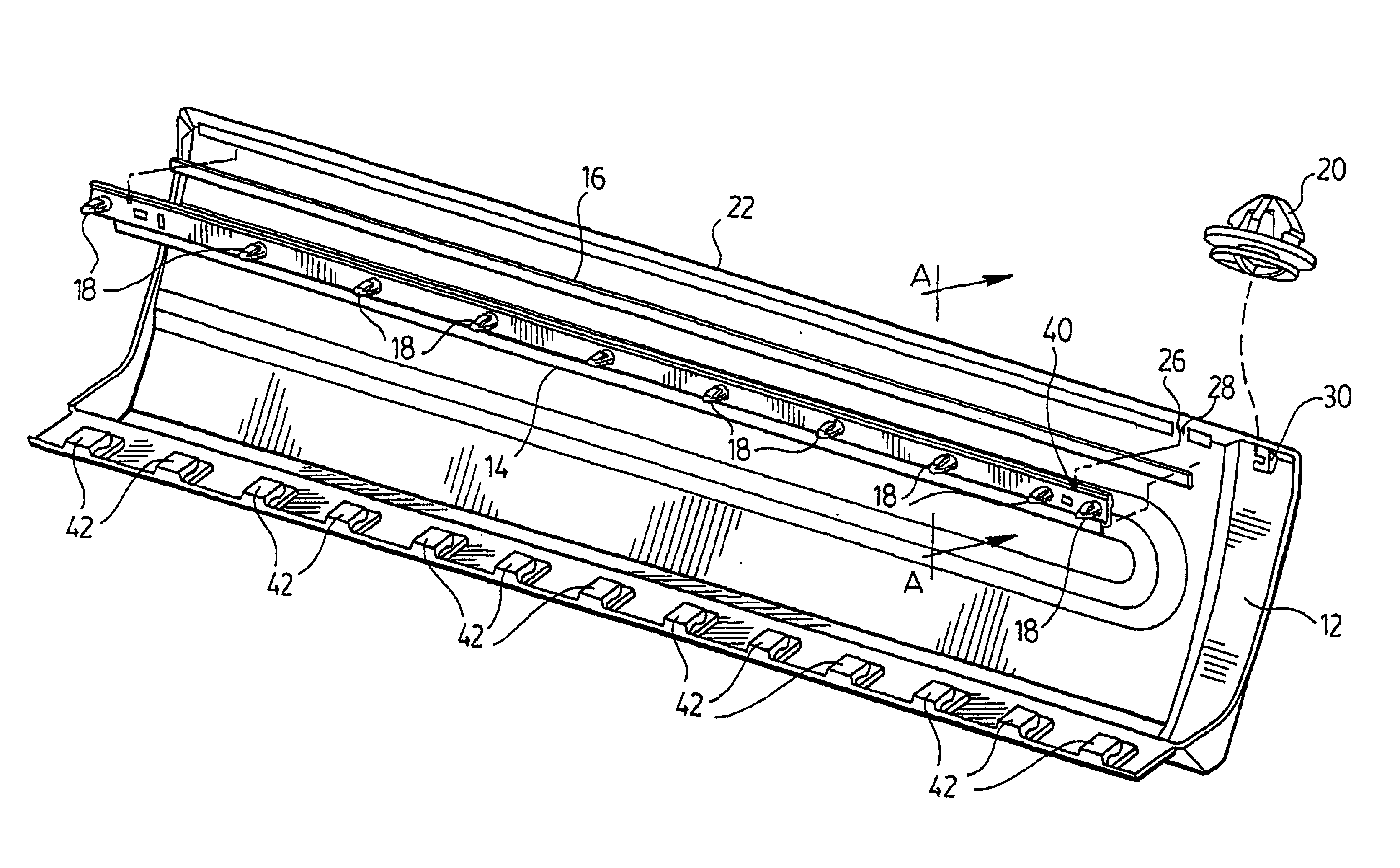

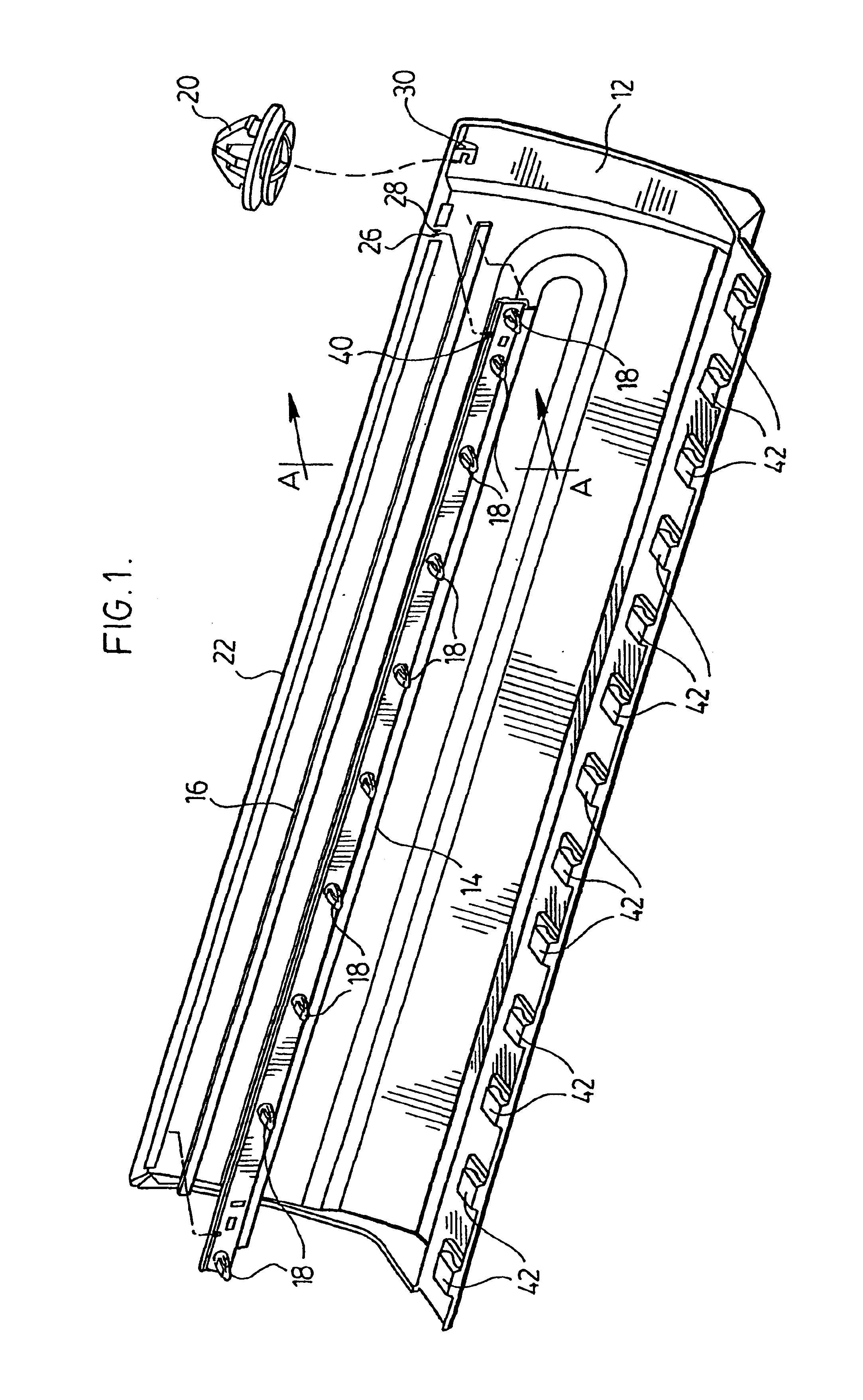

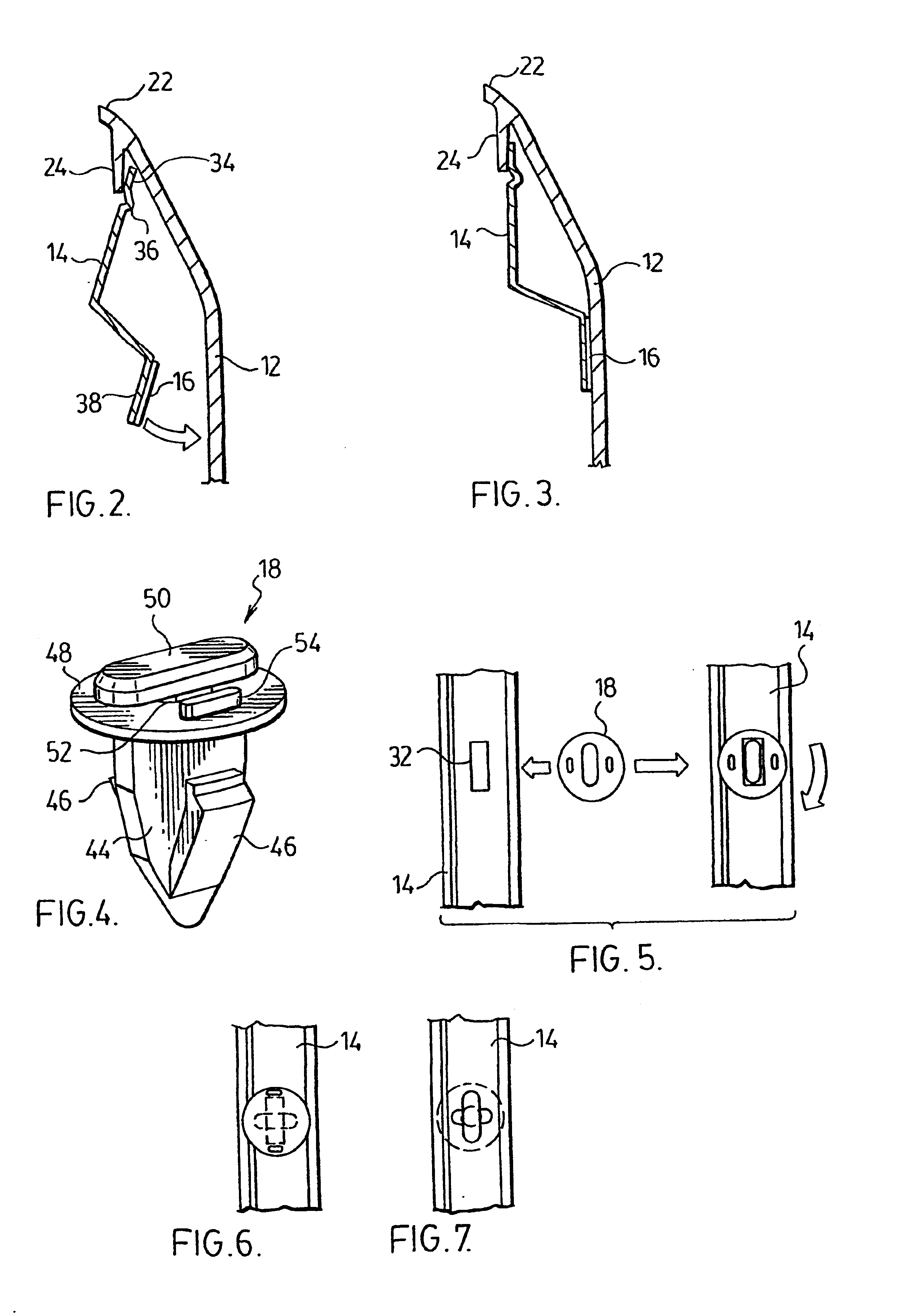

Method of attaching a cladding to a vehicle

A mounting method for mounting a plastic panel (12) to a vehicle substrate provides a support flange (24) on an inner surface of the panel. A reference nodule (28) is positioned on the inner surface of the panel. An elongate bracket (14) has an upper edge (34) thereof engaging the support flange (24). The bracket (14) has a reference notch (40) engaging the reference nodule (28) positioning the bracket (14) relative to the panel (12). A plurality of retainers (18) are mounted on the bracket (14). A double-sided adhesive tape (16) has a first adhesive on a first side thereof compatible for adhesion to the bracket (14) and a second adhesive on a second side thereof compatible for adhesion to the panel (12). The first side of the adhesive tape (16) is applied to the bracket (14) and the second side is applied to the panel (12). The tape (16) allows expansion and contraction movement of the panel (12) while securely retaining the panel (12) to the vehicle substrate.

Owner:DECOMA EXTERIOR TRIM

Bone fasteners and method for stabilizing vertebral bone facets using the bone fasteners

InactiveUS7833255B2Less invasiveLess time-consumingSuture equipmentsInternal osteosythesisVertebral boneBone fragment

Owner:WARSAW ORTHOPEDIC INC

Hybrid fastener apparatus and method for fastening

InactiveUS20060062650A1Reduce galvanic corrosionEnhanced electrical continuityRivetsNutsFiberBiomedical engineering

A fastener and method for fastening structural members wherein the fastener comprises a metallic stem defining a shank extending between first and second ends, the stem defining a deformable first head at the first end of the shank, and a resin-fiber composite sleeve defining the second end of the shank. The sleeve defines an aperture longitudinally extending through the sleeve, and a portion of the sleeve has a cross-sectional dimension greater than a cross-sectional dimension of the aperture through the structural members. Tensile strength of the composite sleeve is increased by incorporation of a support washer into the composite sleeve and / or by substantially orienting the fibers of the resin-fiber sleeve composite in the longitudinal direction of the sleeve.

Owner:THE BOEING CO

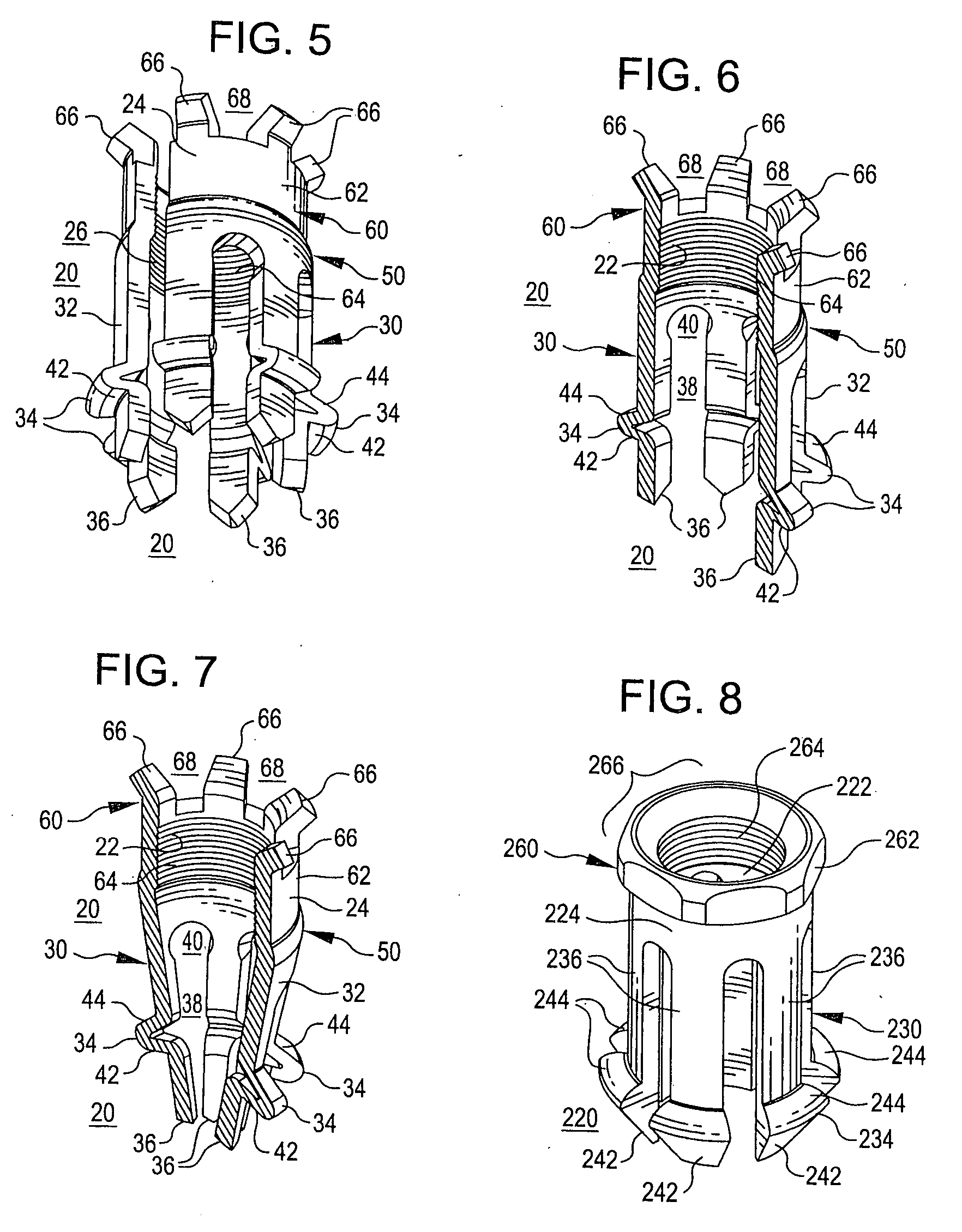

Expandable fastener assembly with deformed collar

At least one embodiment generally relates to an installation assembly for an opening in a workpiece that includes a swaged collar, an inner member, and an outer member. The swaged collar has a first end, a second end, and a main body extending between the first end and the second end. The main body includes an inner surface defining a passageway through the collar. The inner member has a mandrel section for expanding the outer member. The inner member is used to expand the outer member and to keep the outer member in an expanded state.

Owner:FATIGUE TECH

Method of making fasteners by three-dimensional printing

Owner:A RAYMOND & CO

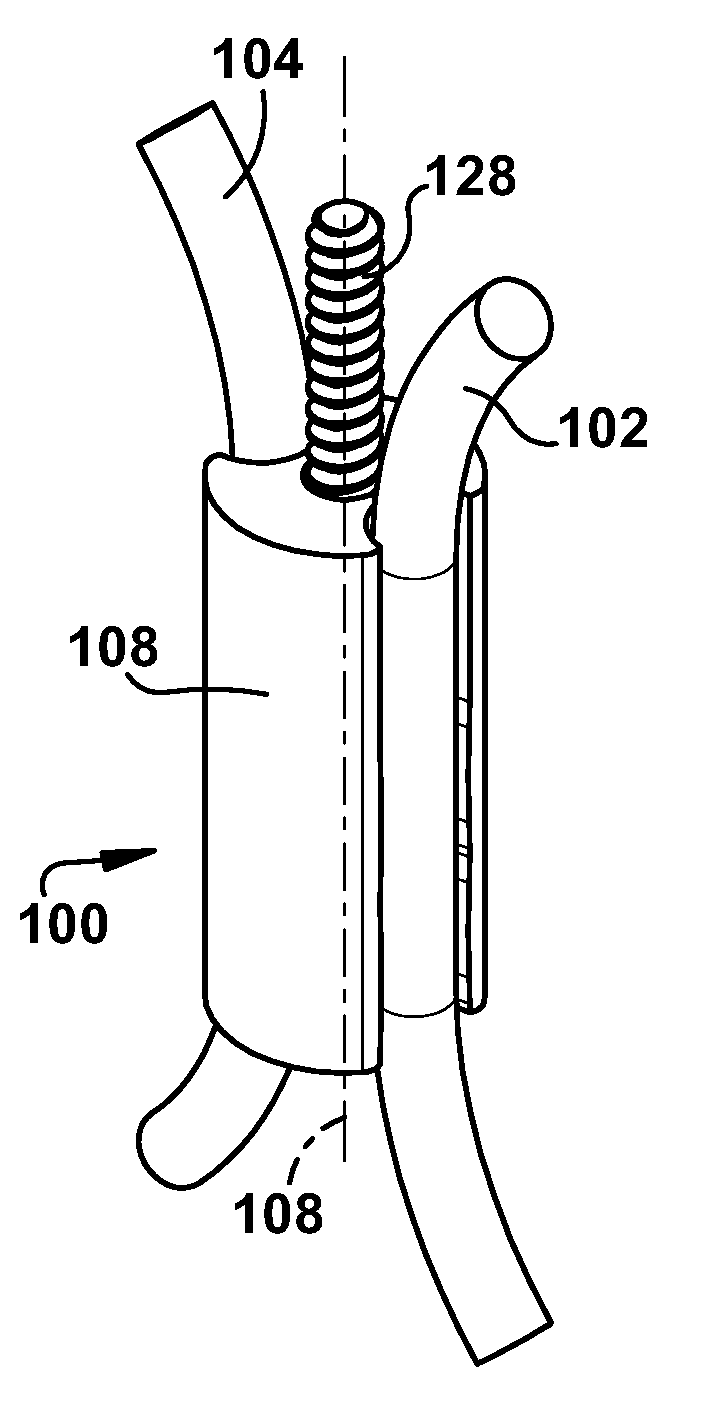

Self-expanding blind fastener with mechanical lock

A blind fastener for clamping sheet components and including a mechanical lock to prevent loosening of the fastener. The fastener is self-expanding following insertion and engagement of the threaded stem. The fastener includes an internally threaded nut body, an externally threaded stem threadably received within the nut body, and a lock sleeve matingly receiving the nut body. Carried on the stem is an expandable sleeve which expands to engage the underside of the material. Rotation of the stem following insertion of the assembly into the aperture will draw the stem head and expandable sleeve against the backside for the material causing the sleeve to expand outwardly. In addition, the locking sleeve is pushed beneath the expansion sleeve wedging between the threaded stem and expansion sleeve. This mechanical lock is resistant to vibration locking the fastener against loosening.

Owner:METALDYNE CORP

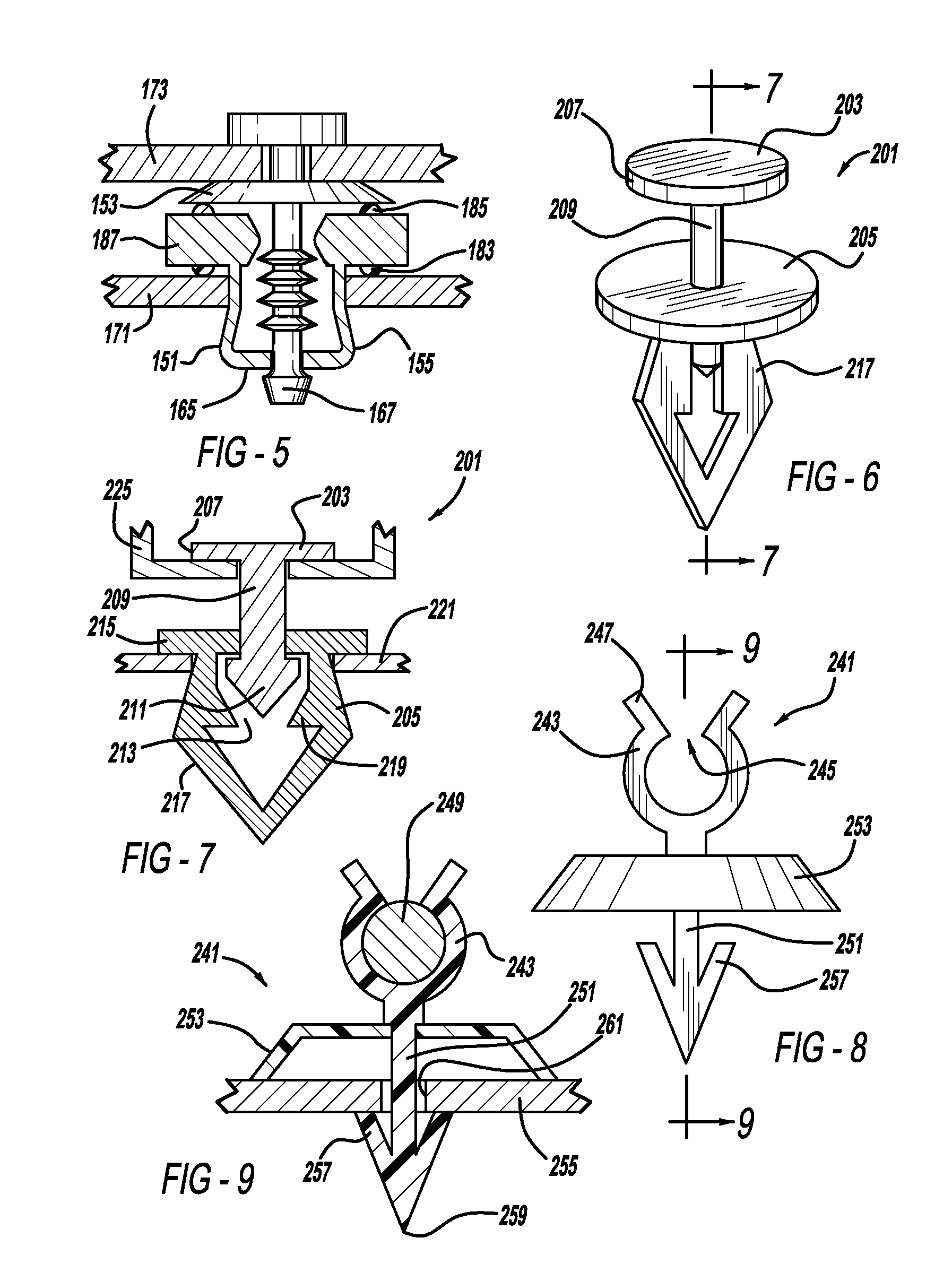

Apparatus and method for sequentially anchoring multiple graft ligaments in a bone tunnel

An apparatus for anchoring at least two graft ligaments within a longitudinal bone tunnel includes a longitudinal sleeve having at least two radially spaced ligament-contacting surfaces located in lateral opposition to a sleeve inner lumen. The sleeve is configured for at least partial insertion into the bone tunnel with each graft ligament positioned laterally adjacent a different ligament-contacting surface. The graft ligaments are at least partially located between the bone tunnel and the sleeve. An actuating member has longitudinally separated proximal and distal actuating member ends. An asymmetrically offset profile is defined by at least one of the sleeve and the actuating member. The asymmetrically offset profile has a plurality of longitudinally spaced engagement thresholds. The actuating member is inserted longitudinally into the sleeve to cause frictional engagement of each graft ligament with both the bone tunnel and at least one ligament-contacting surface. The frictional engagement of each graft ligament is temporally spaced apart from the frictional engagement of at least one other graft ligament. The temporal spacing is provided by the plurality of engagement thresholds. A method of anchoring at least two longitudinally extending graft ligaments within a bone tunnel is also provided.

Owner:THE CLEVELAND CLINIC FOUND

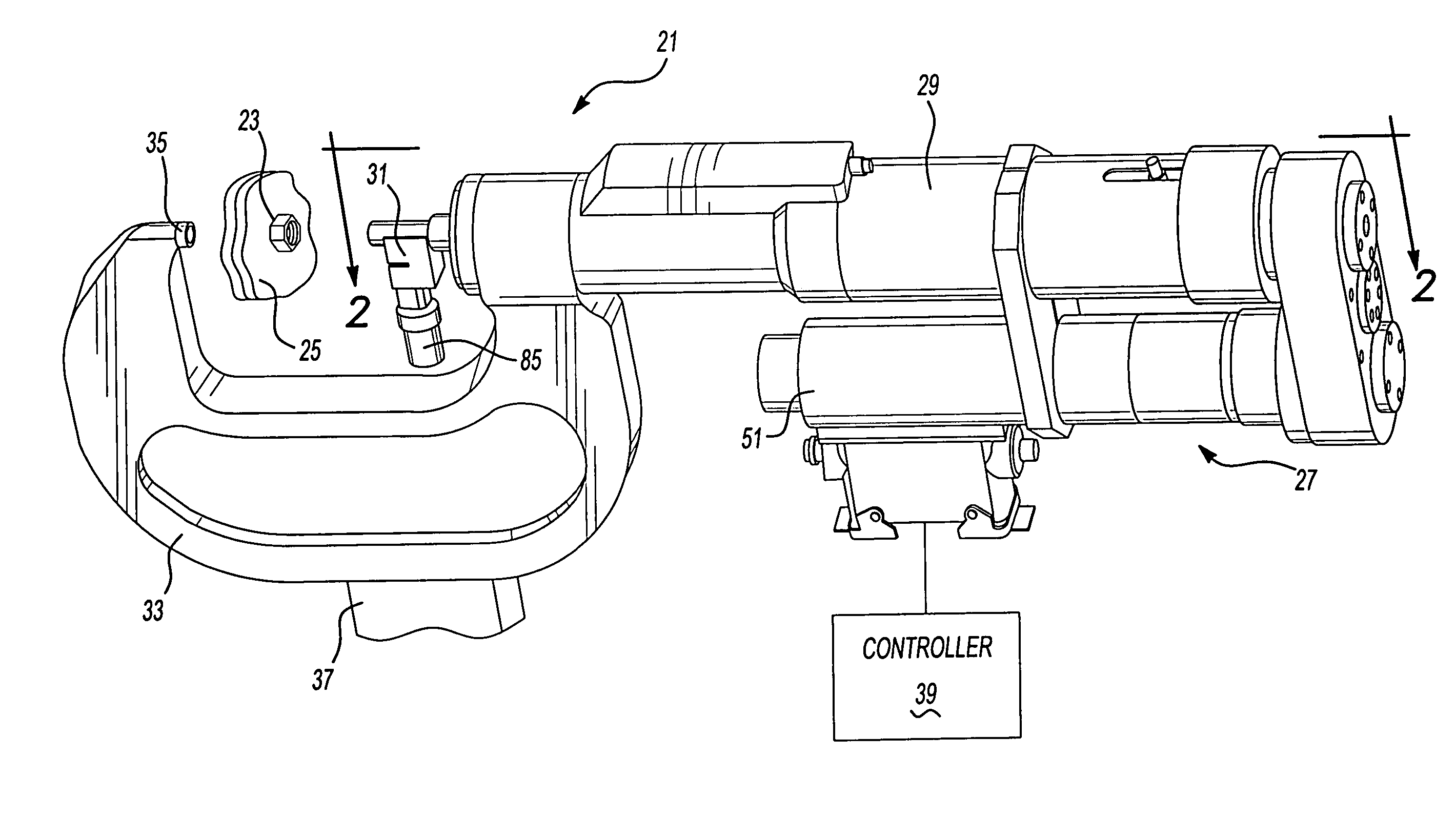

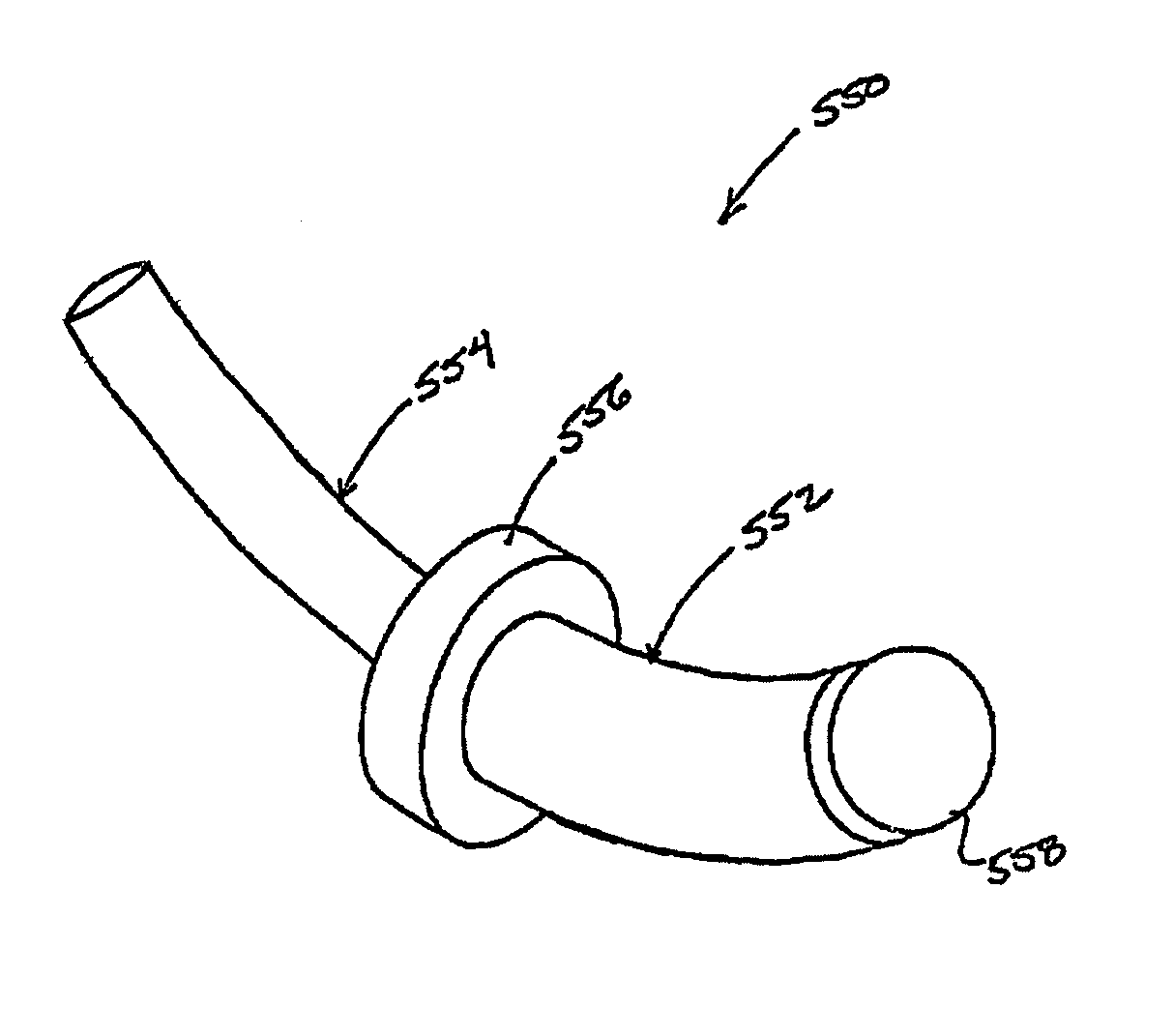

Wire mesh heat shield isolator

A substrate such as a heat shield for a vehicle is provided with a unitary compressed wire mesh bushing or isolator formed in place though a bore in the substrate. The bushing is formed by supporting an uncompressed or partially compressed wire mesh sleeve, optionally including a grommet or spacer, on a mandrel positioned within the bore; the mandrel is surrounded on either side of the bore by outer sleeves forming a molding cavity on each side of the substrate, and a slidable tamp is disposed in each outer sleeve and moved towards each other to compress the mesh within the bore and provide the unitary bushing.

Owner:ACS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com