Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7233results about "Automatic control devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

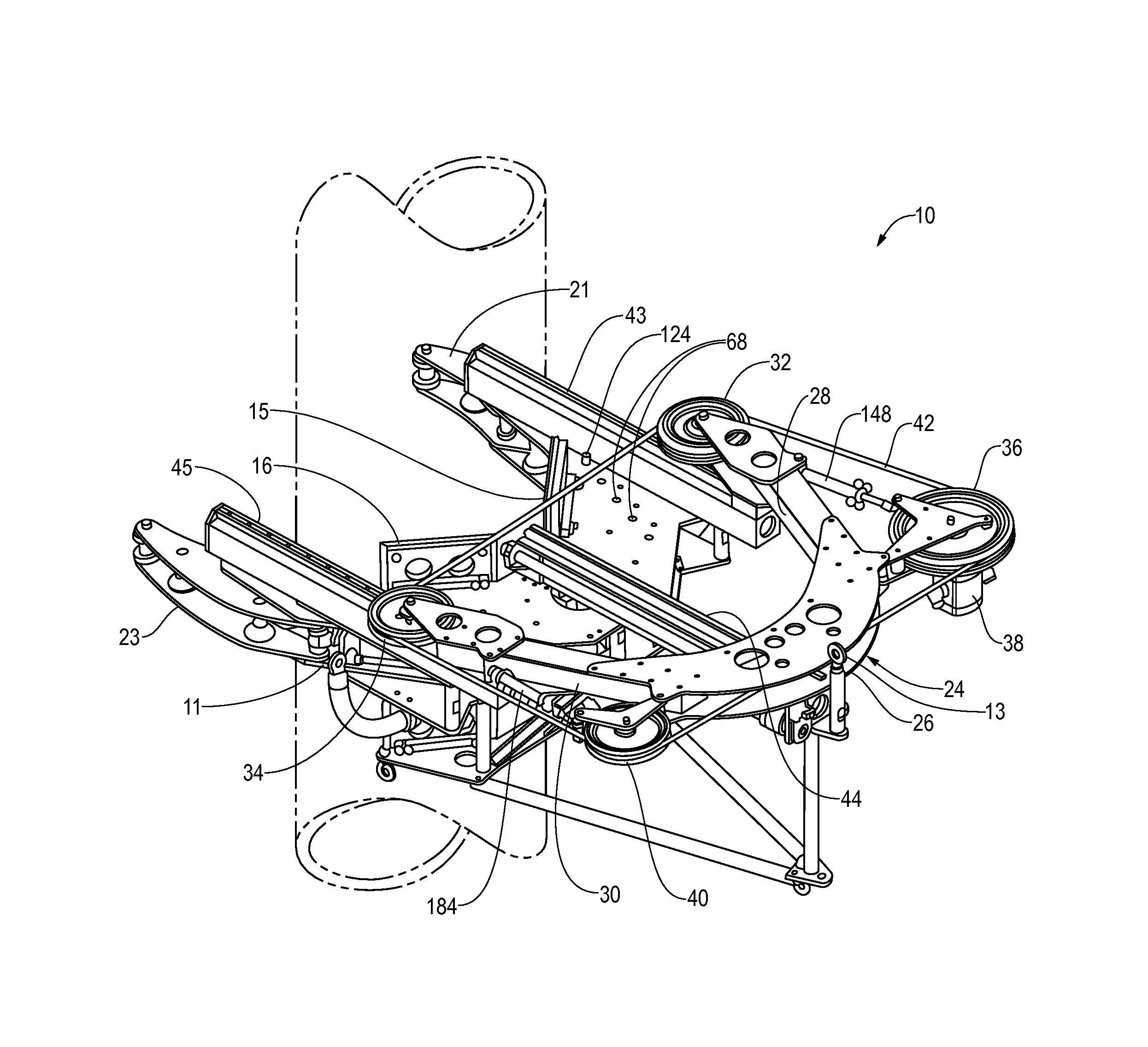

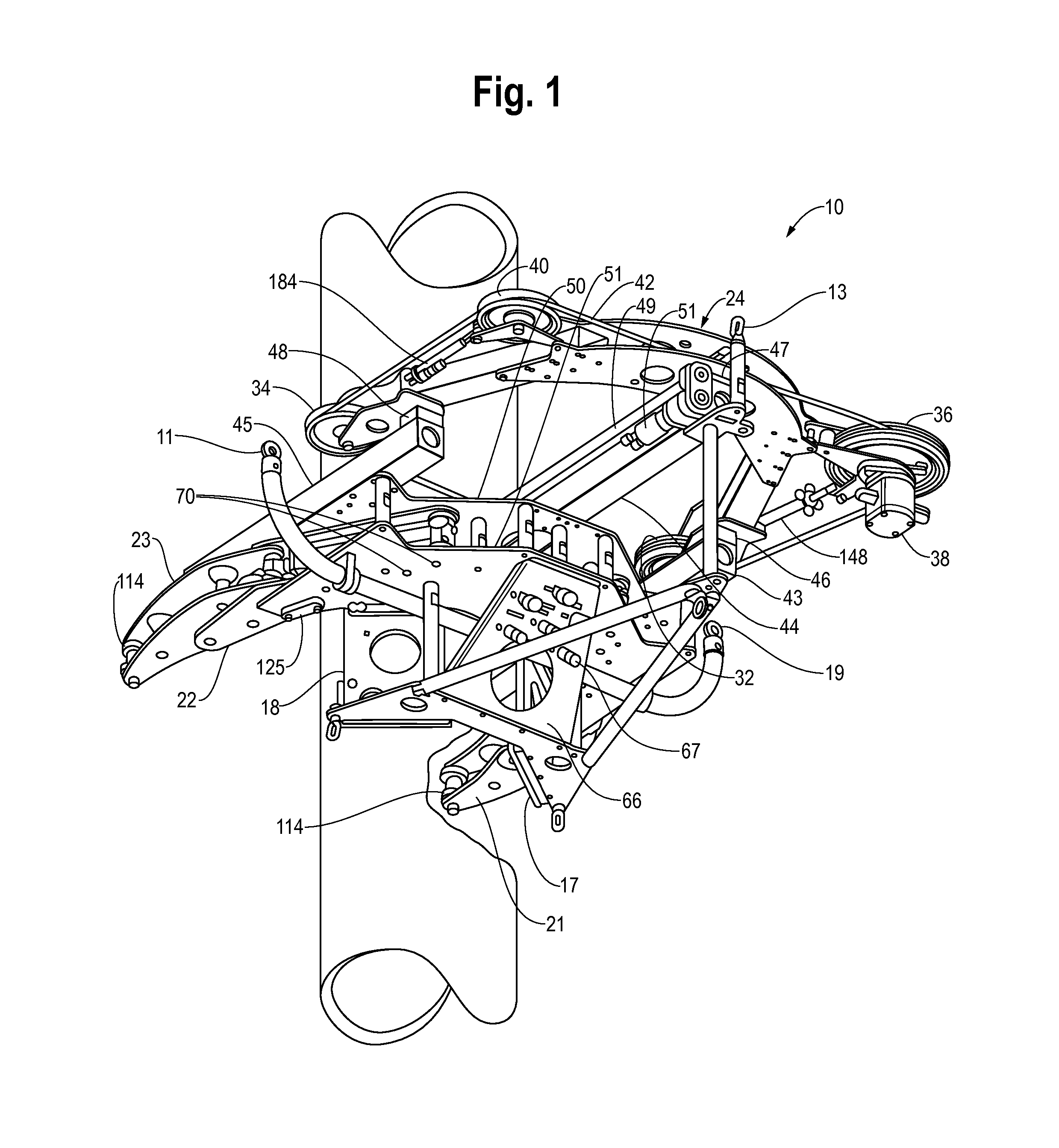

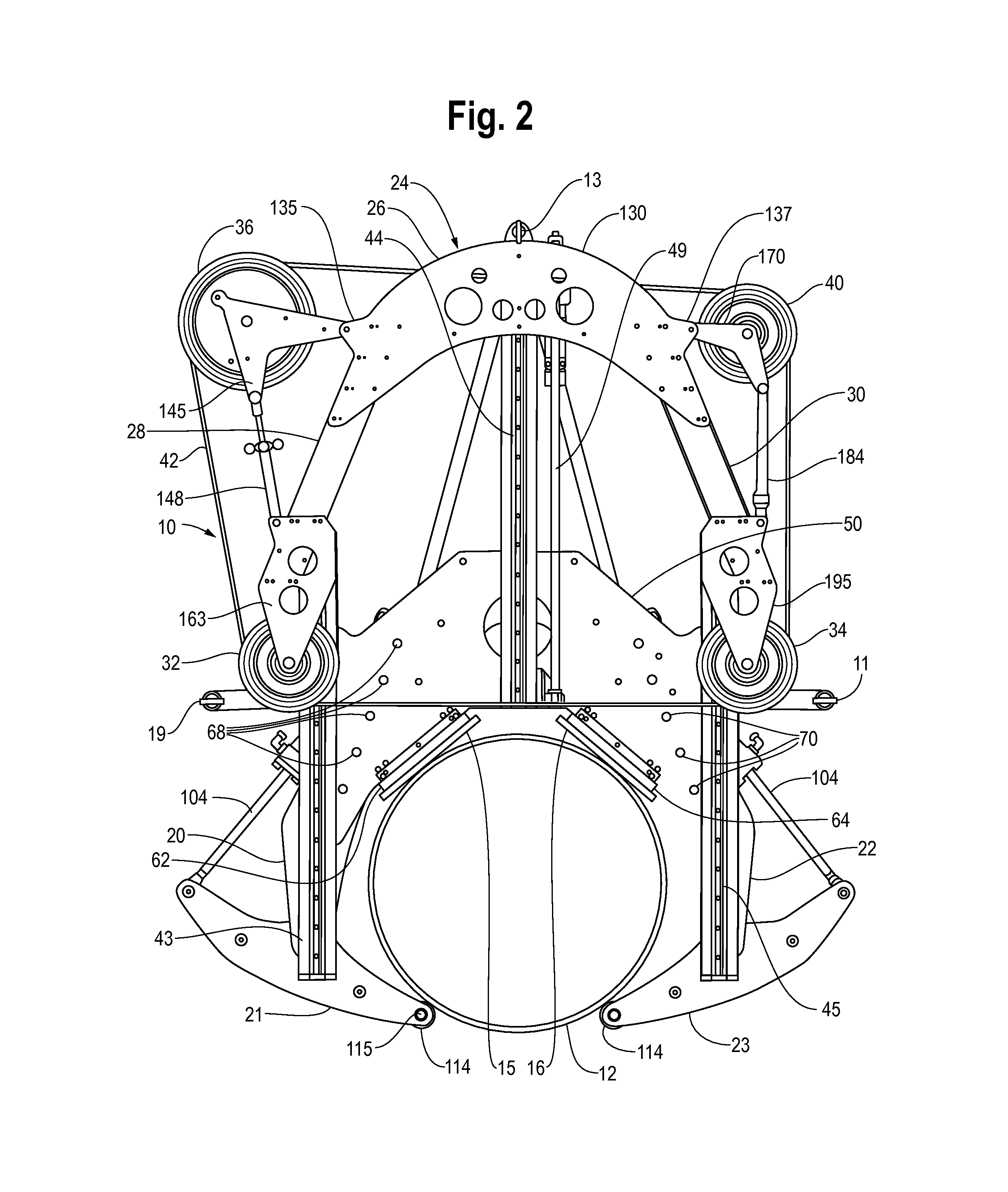

Wire saw

A device for cutting a length of pipe includes a clamp portion for clamping around a length of pipe and a bow moveable with respect to the clamp portion that retains a loop of diamond embedded wire. The device further includes a feed for driving the bow with respect to the clamp portion and a detector for detecting bending of the wire and a control responsive to the detector for controlling feed rates. The device is made of modular parts and has synchronizing arms for clamping around a length of pipe. In one embodiment, the wheels are retained in enclosures with slots through which the cutting wire passes.

Owner:ILLINOIS TOOL WORKS INC

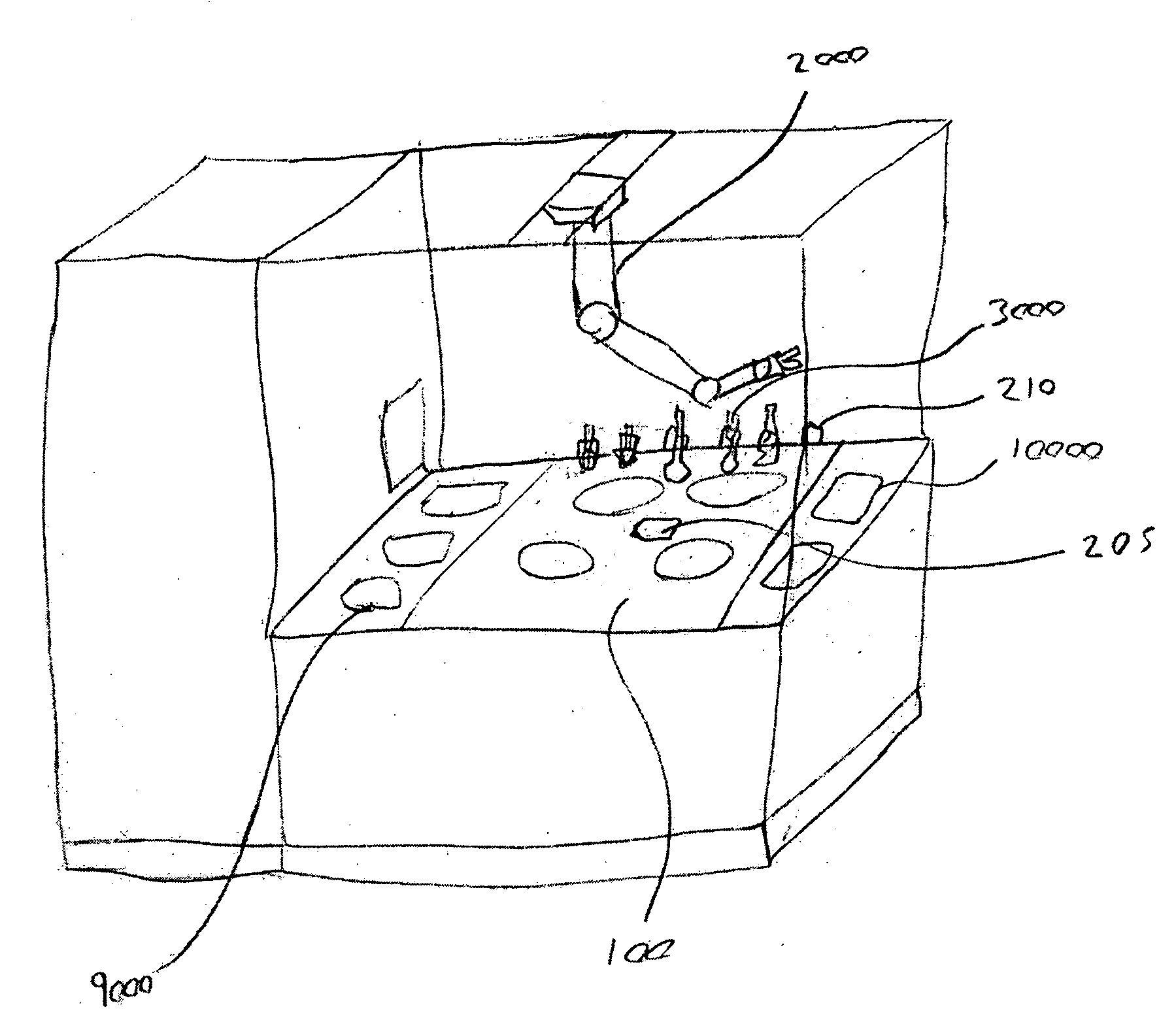

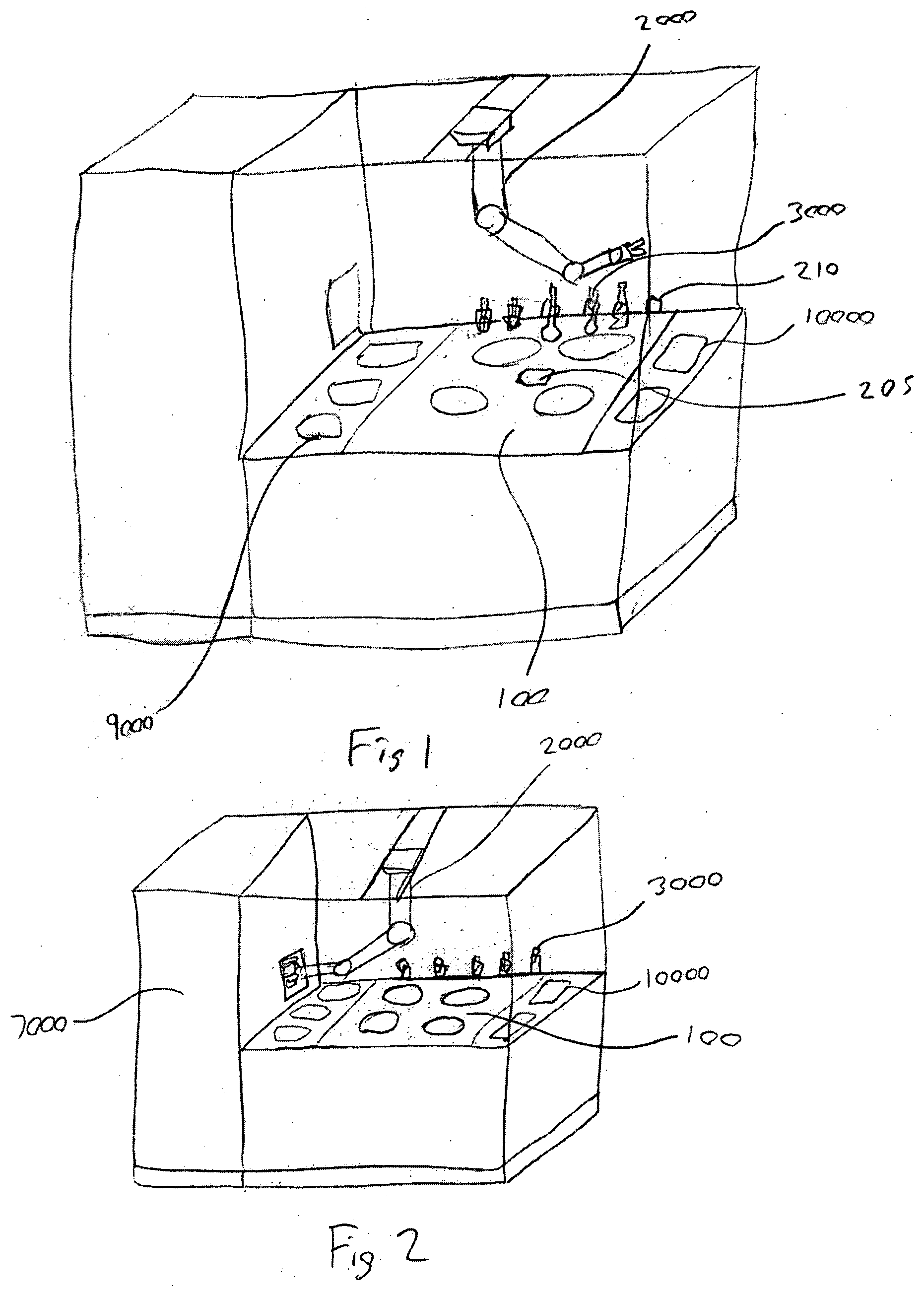

Food preparation system

InactiveUS20050193901A1Eliminate all packaging materialGood for foodFeeding apparatusRoasters/grillsAdditive ingredientControl system

An automated food preparation system is described. It allows precise, automated control of the food preparation process, and has the ability to perform an automated cleanup. It comprises at least one manipulator to process and move ingredients, a control system, an autonomously accessible ingredient storage system, and at least one cooking receptacle.

Owner:BUEHLER DAVID BENJAMIN

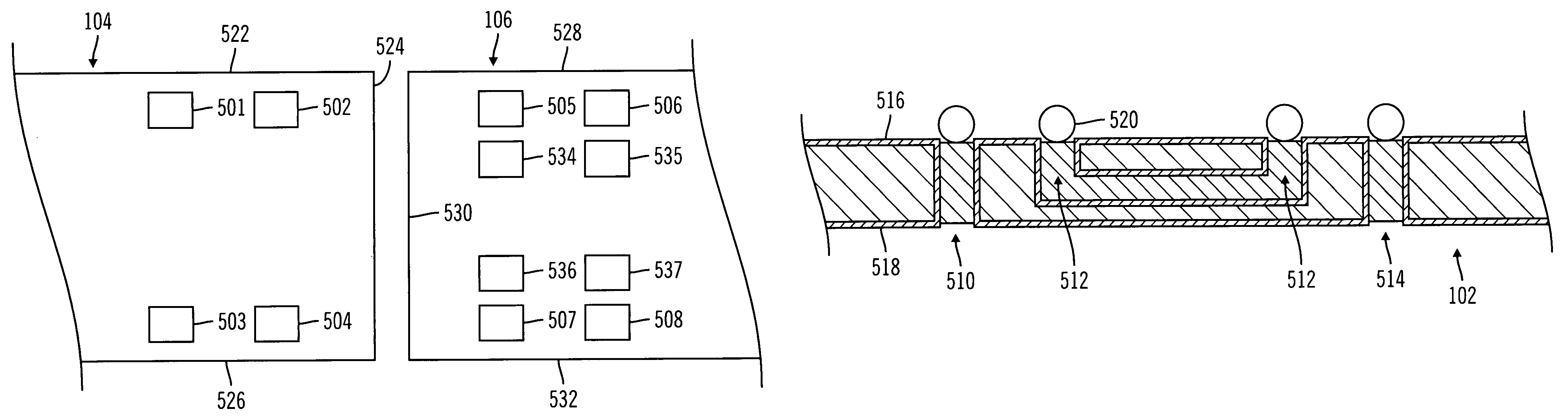

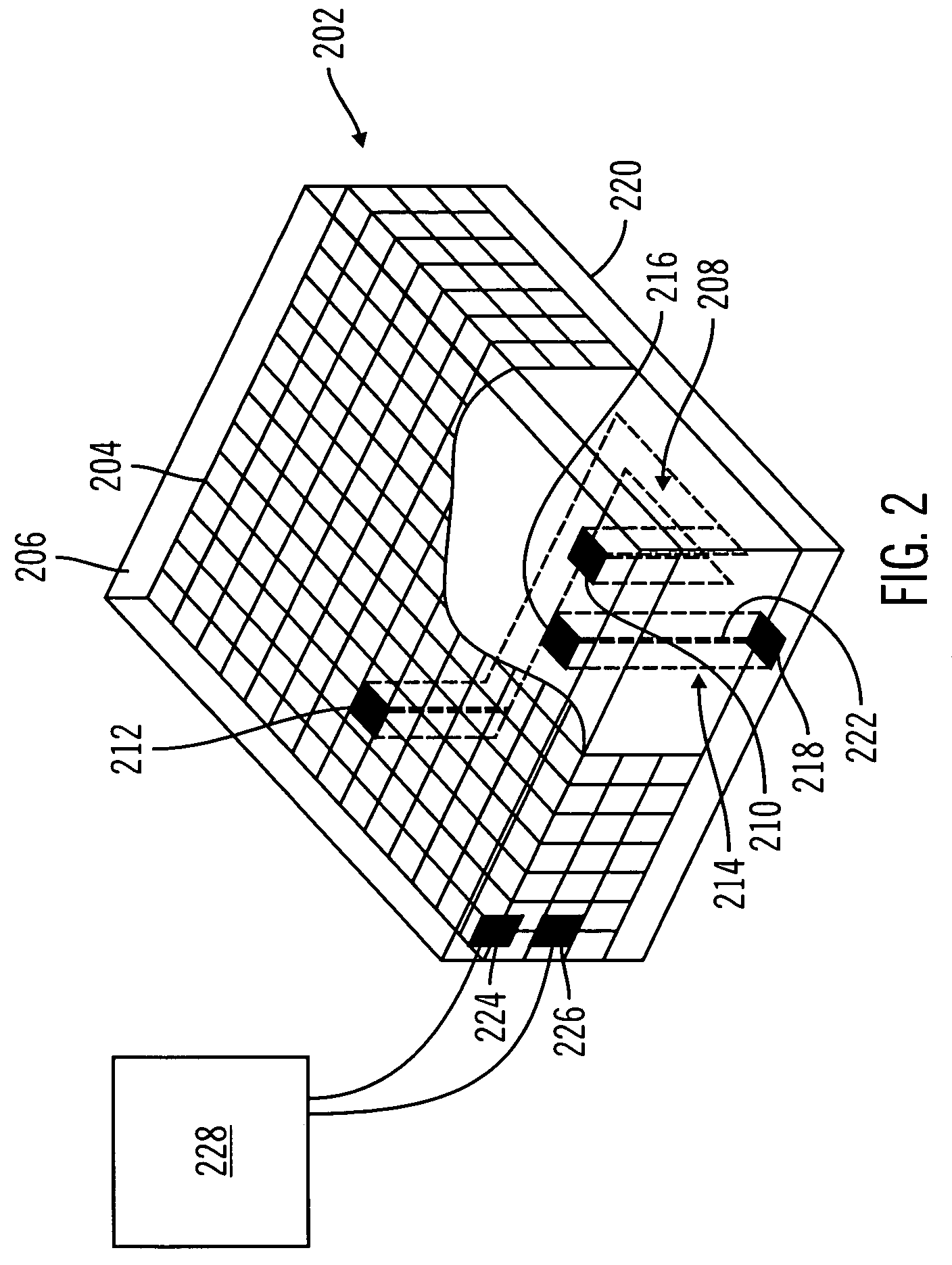

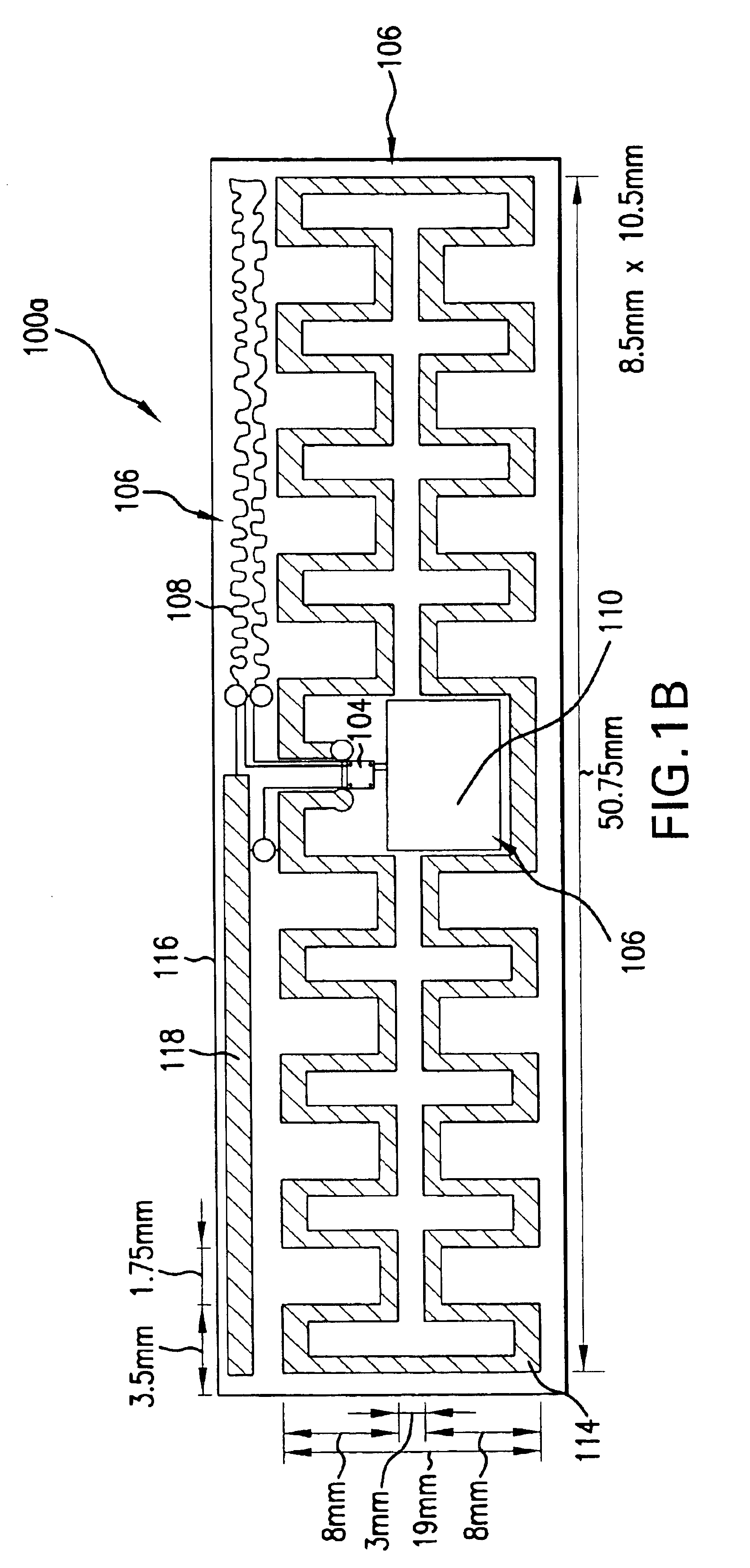

Physically highly secure multi-chip assembly

A physically secure processing assembly is provided that includes dies mounted on a substrate so as to sandwich the electrical contacts of the dies between the dies and the substrate. The substrate is provided with substrate contacts and conductive pathways that are electrically coupled to the die contacts and extend through the substrate. Electrical conductors surround the conductive pathways. A monitoring circuit detects a break in continuity of one or more of the electrical conductors, and preferably renders the assembly inoperable. Preferably, an epoxy encapsulation is provided to prevent probing tools from being able to reach the die or substrate contacts.

Owner:BEIJING PIANRUOJINGHONG TECH CO LTD

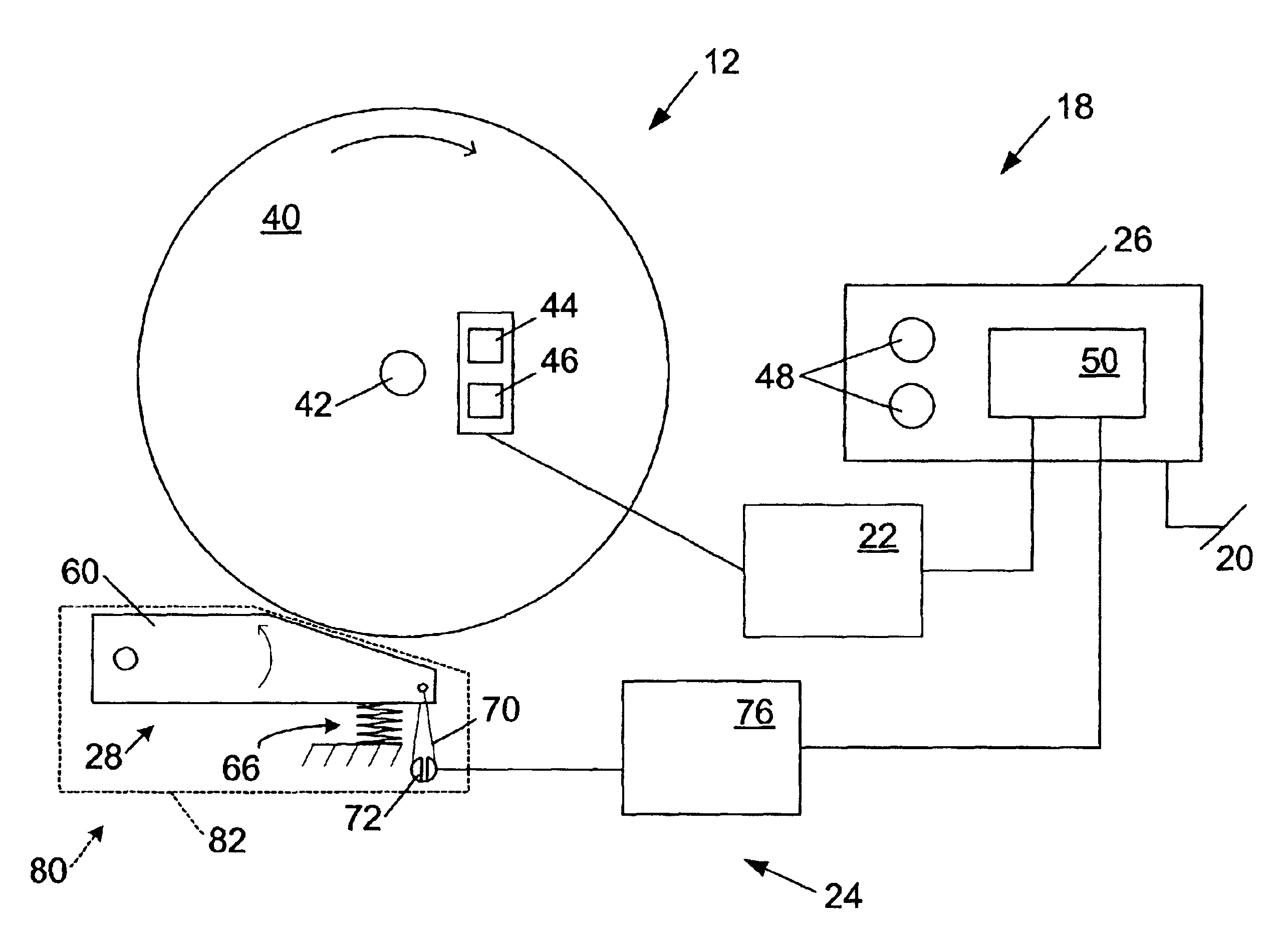

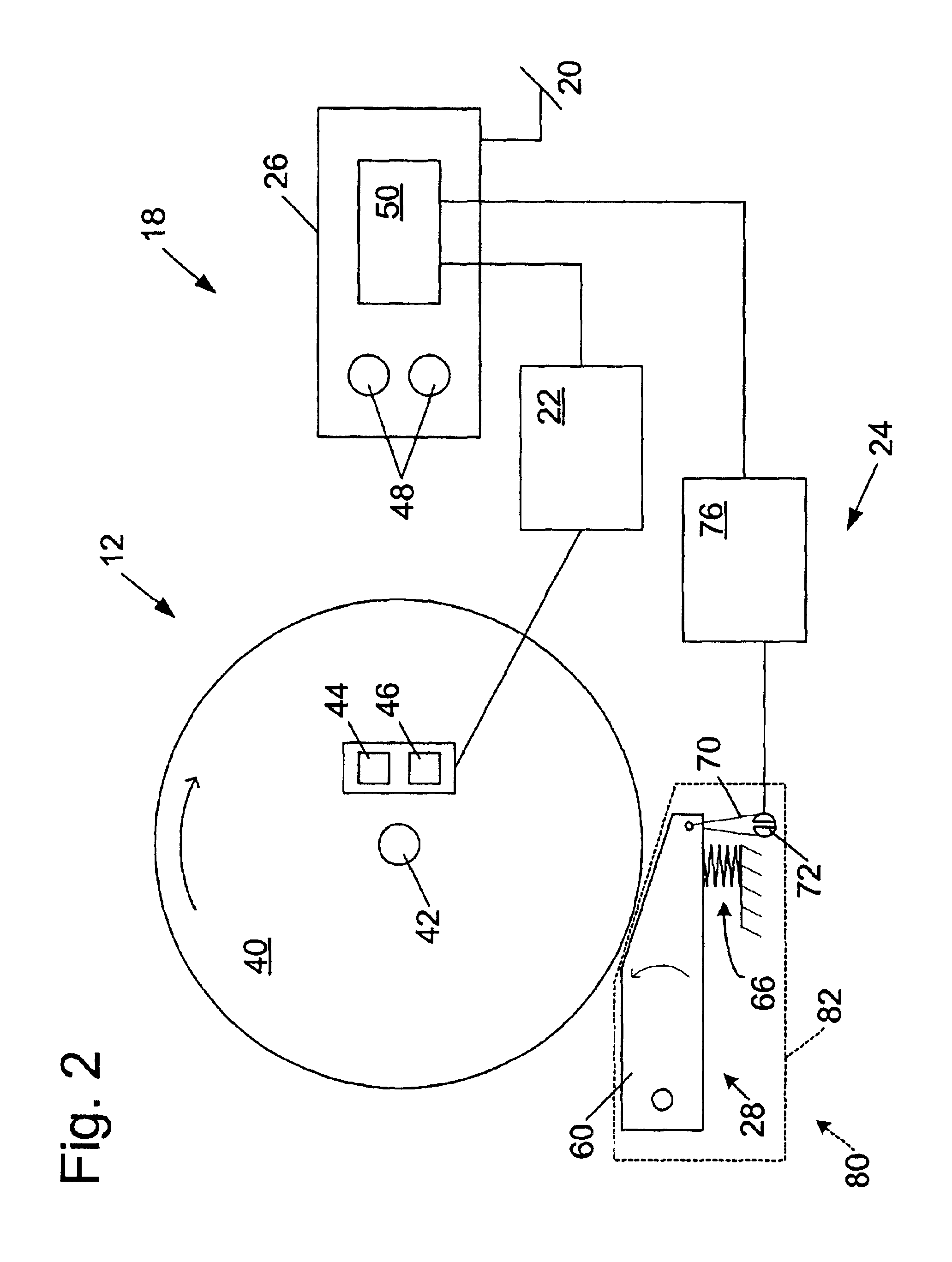

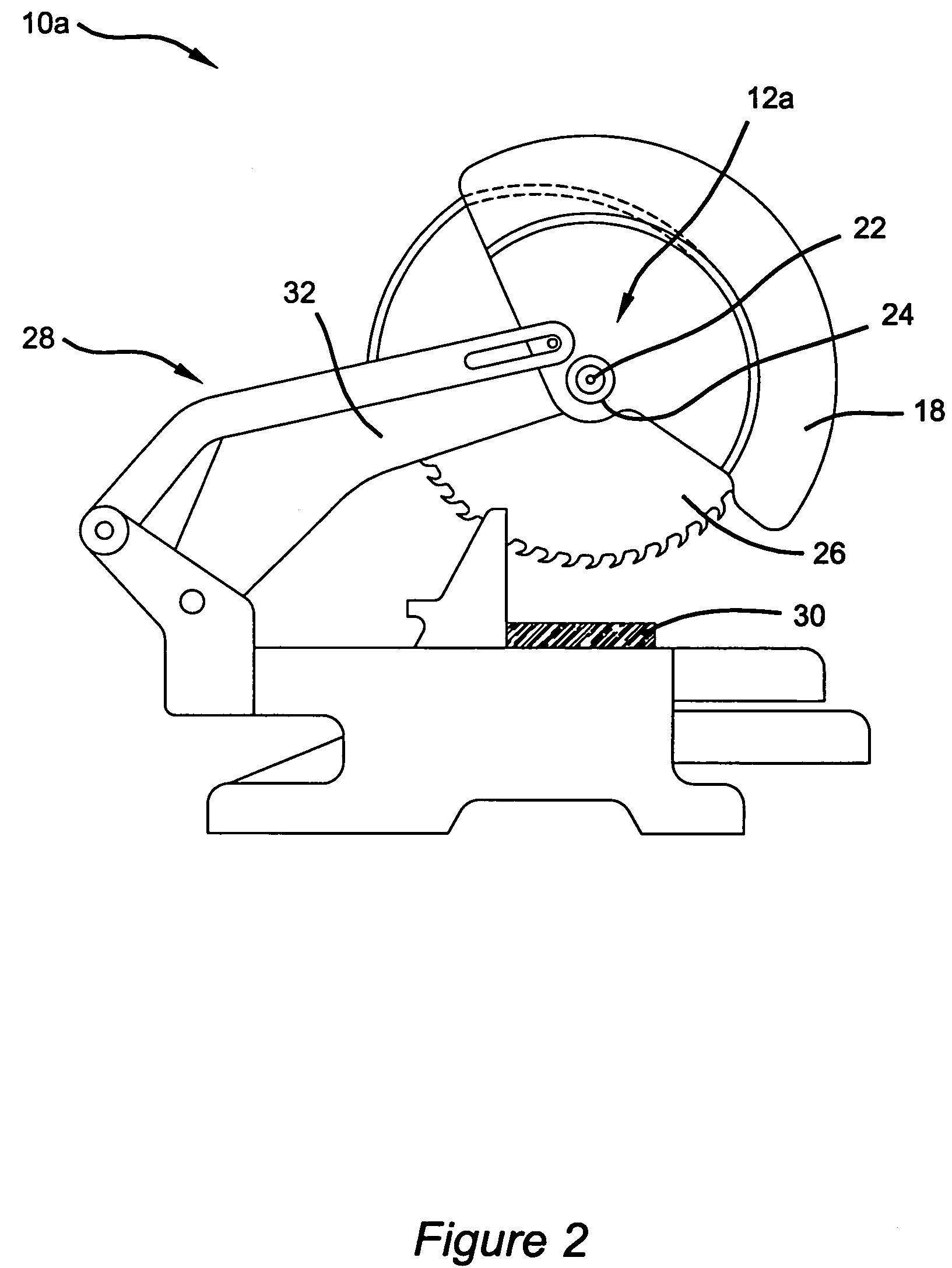

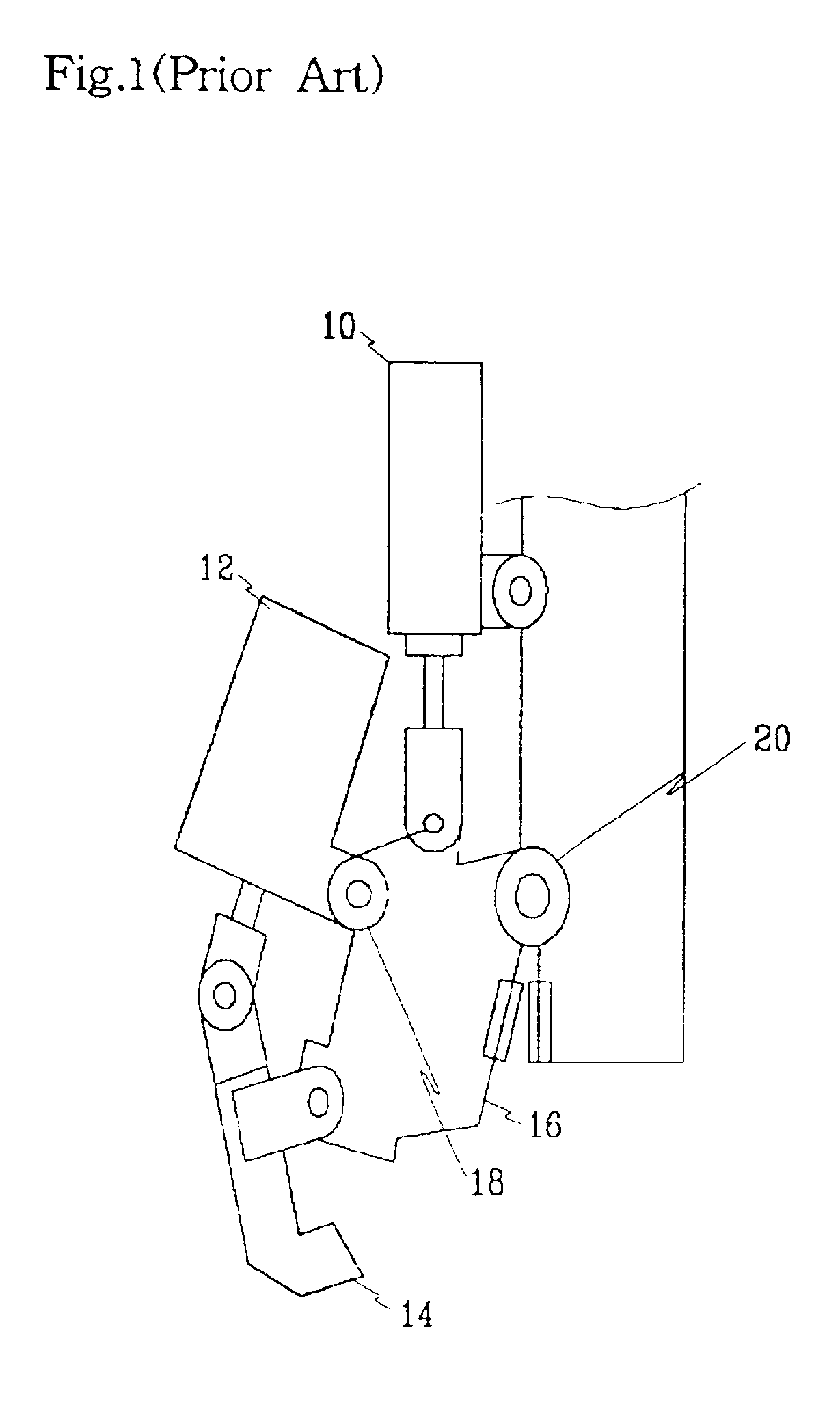

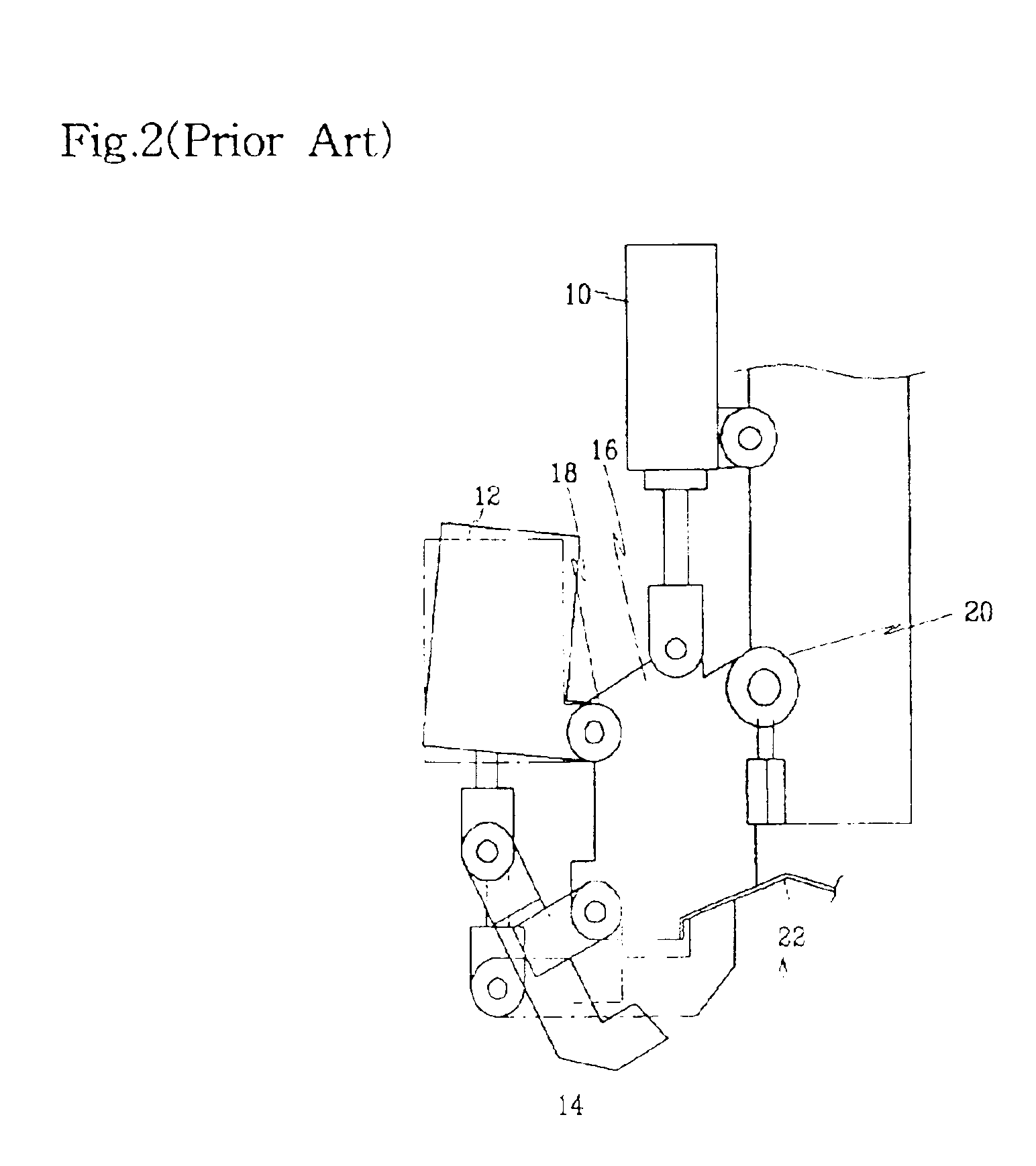

Brake positioning system

InactiveUS6857345B2Multi-purpose machinesEngineering safety devicesEngineeringMechanical engineering

A saw is disclosed having a detection system adapted to detect a dangerous condition between a person and a saw blade, and a brake adapted to stop the saw blade in response to detection of the dangerous condition. The saw further includes a brake positioning system that allows the brake to be positioned in at least two different operable positions to accommodate at least two different blade diameters. The saw may include a system to detect brake-to-blade spacing.

Owner:SAWSTOP HLDG LLC

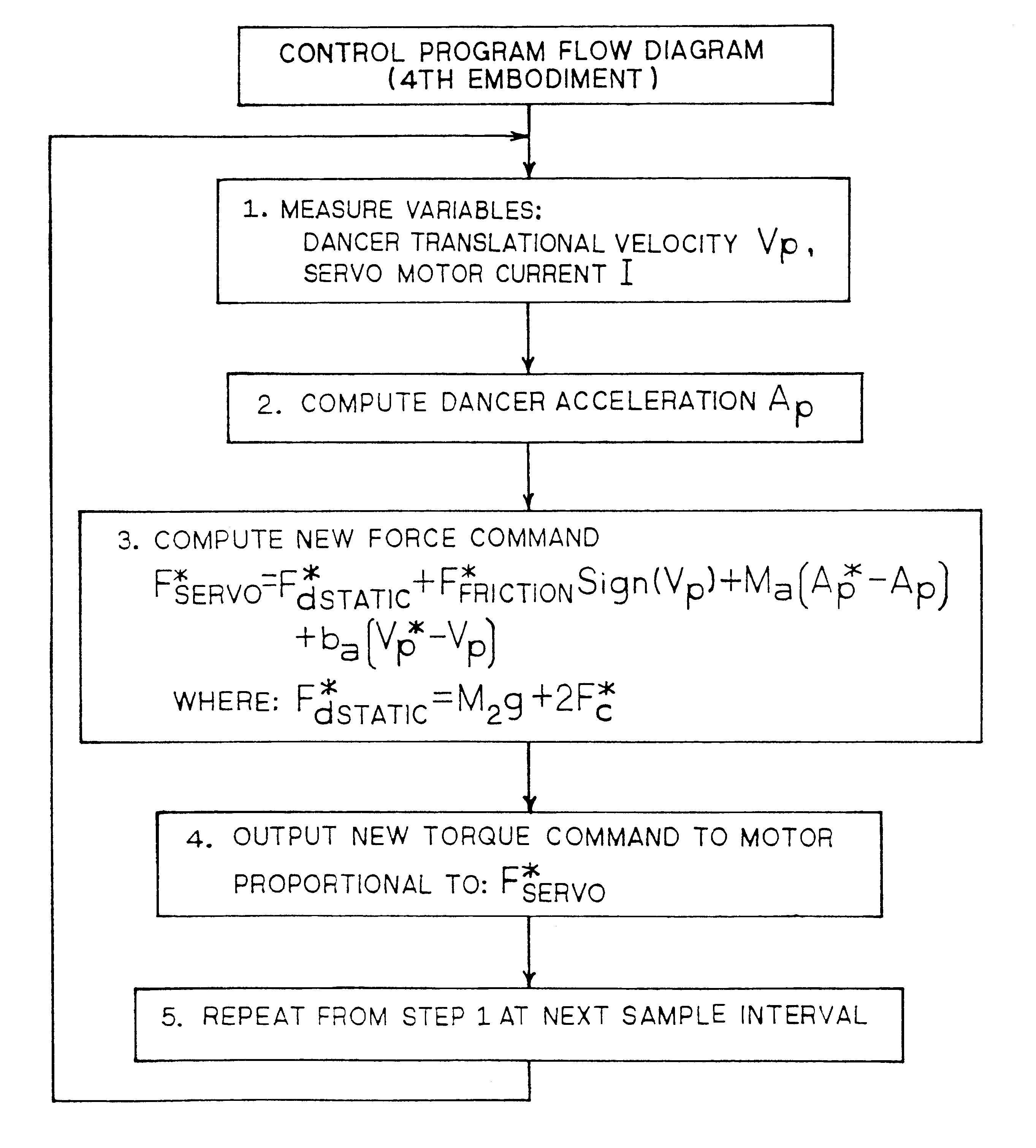

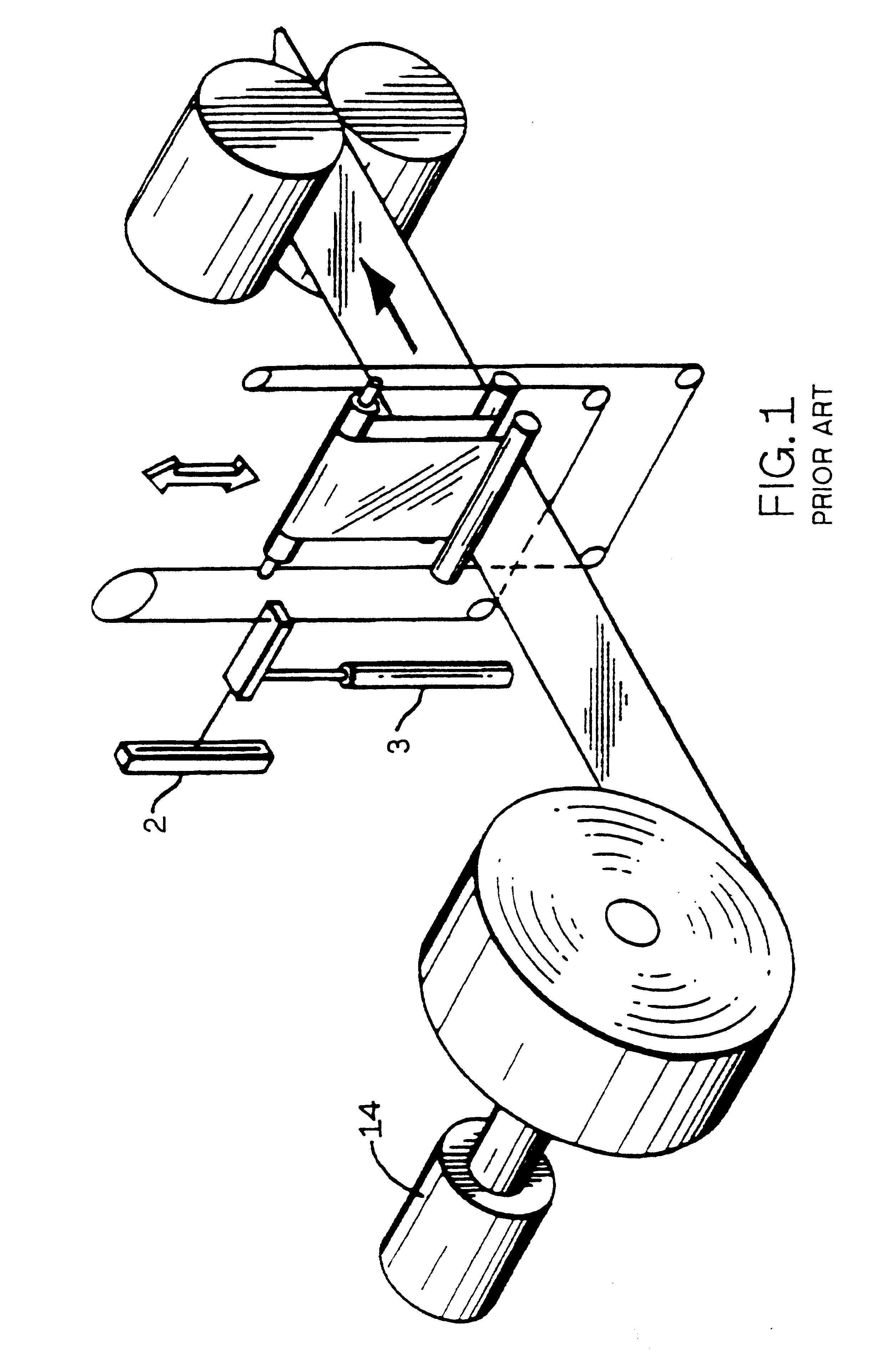

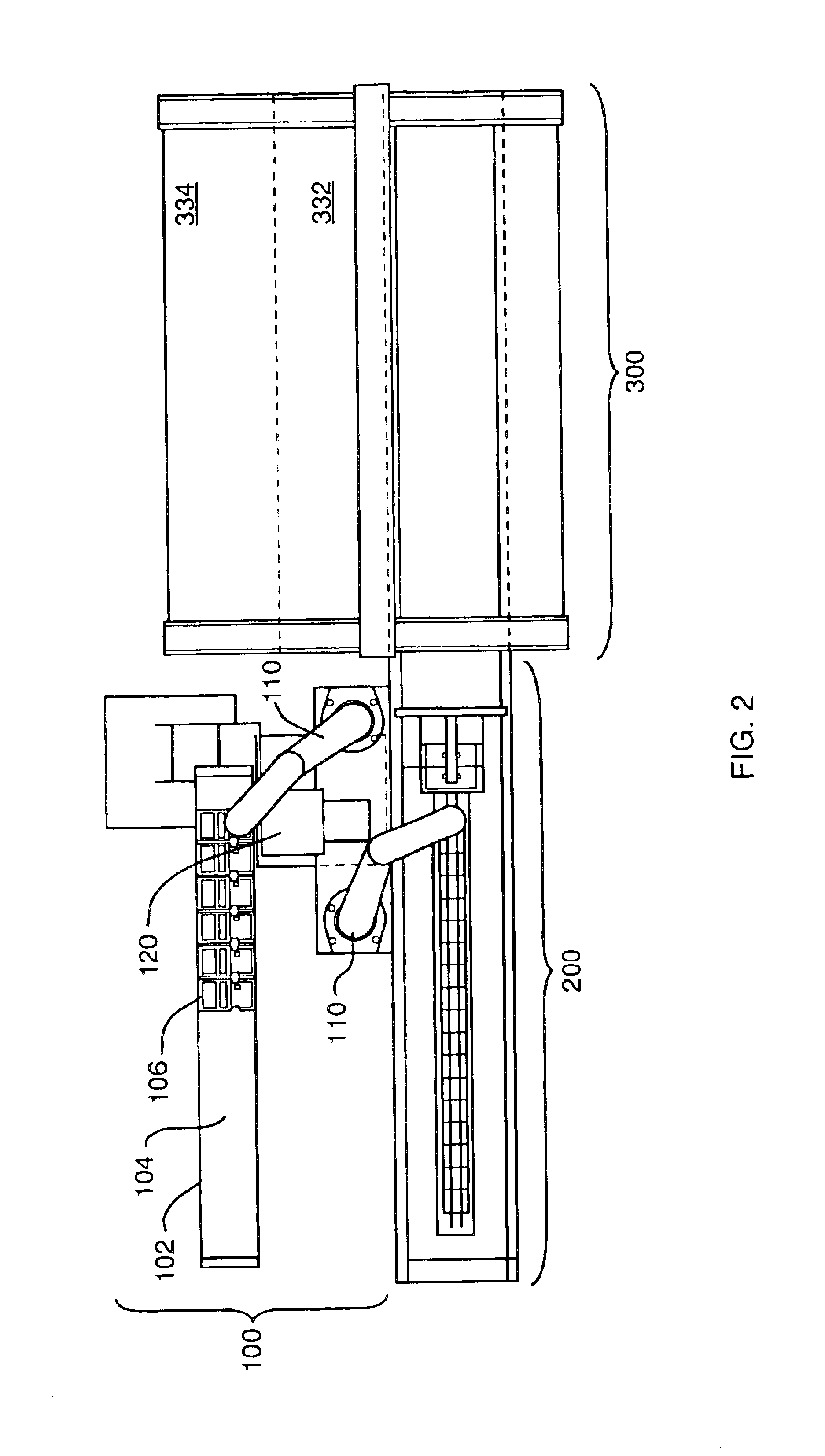

Method and apparatus for controlling web tension by actively controlling velocity and acceleration of a dancer roll

InactiveUS6314333B1The result is accurateAutomatic control devicesPrecision positioning equipmentControl systemEngineering

This invention pertains to processing continuous webs such as paper, film, composites, and the like, in dynamic continuous processing operations. More particularly, it relates to controlling tension in such continuous webs during the processing operation. Tension is controlled in a dancer control system by connecting a corresponding dancer roll to an actuator apparatus or the like, sensing variables such as position, tension, velocity, and acceleration parameters related to the web and the dancer roll, and providing active force commands, in response to the sensed variables, to cause translational movement, generally including a target acceleration, in the dancer roll to control tension disturbances in the web. In some applications of the invention, the dancer control system is used to attenuate tension disturbances. In other applications of the invention, the dancer control system is used to create tension disturbances.

Owner:KIMBERLY-CLARK WORLDWIDE INC

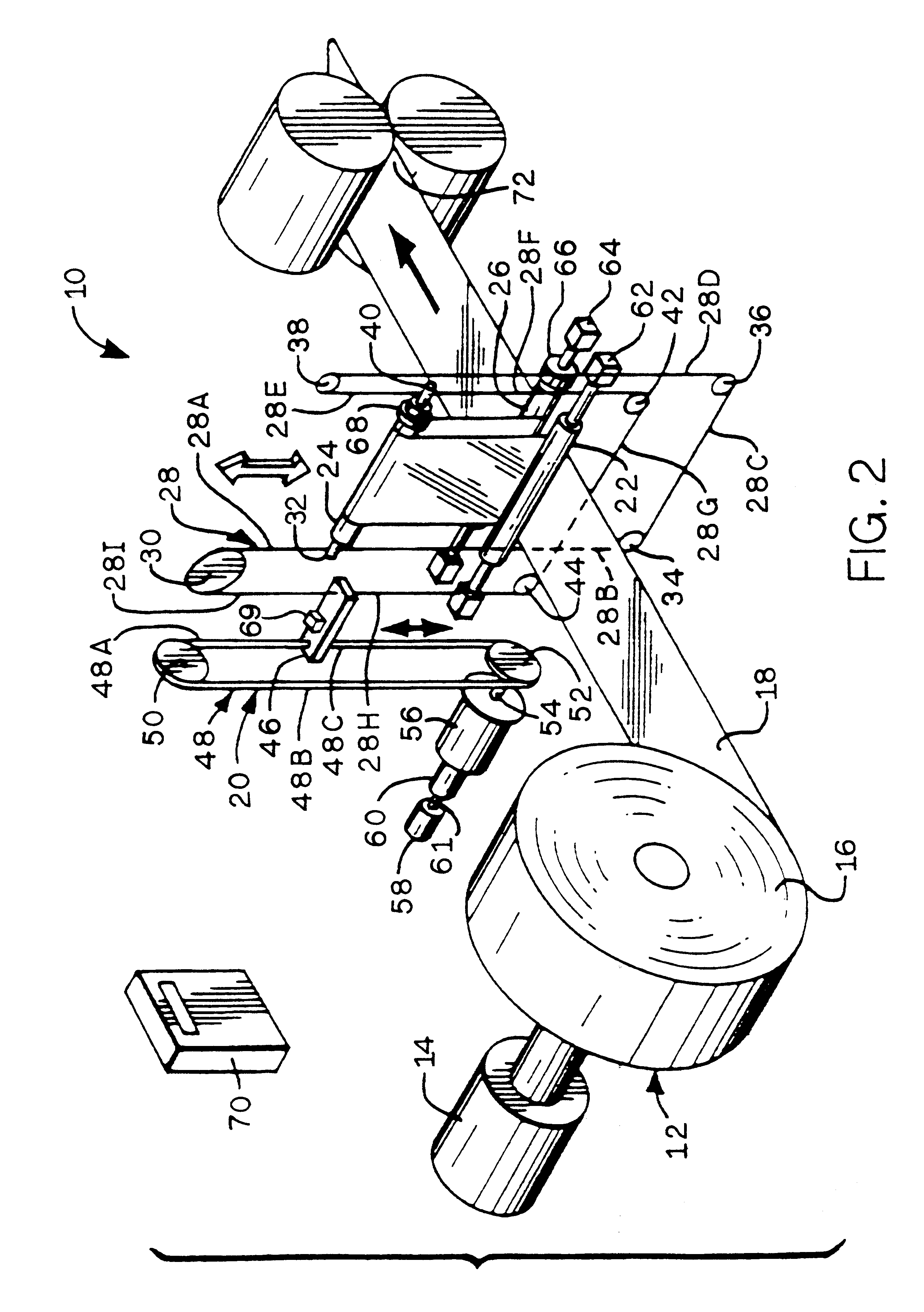

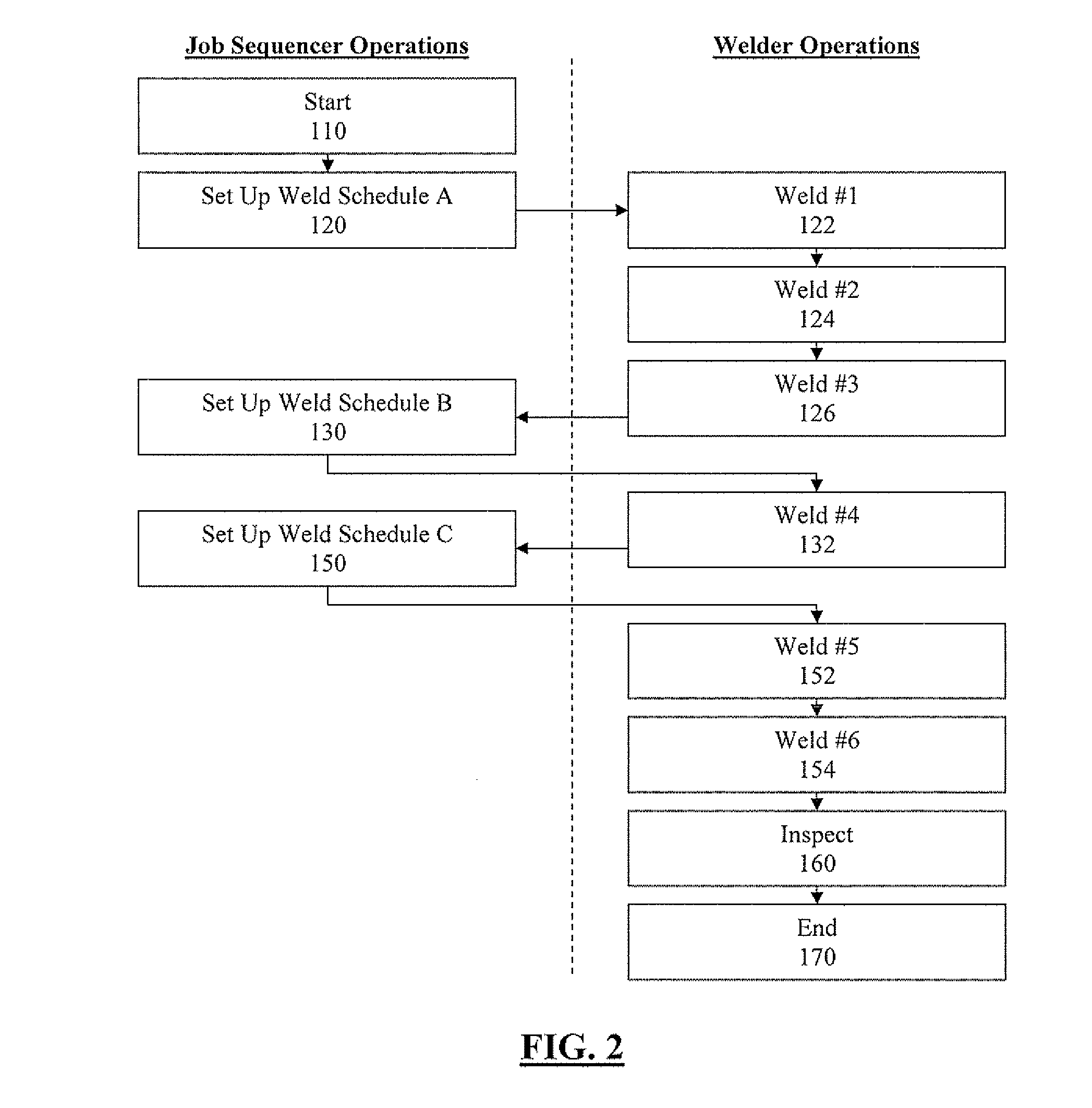

Welding Job Sequencer

A semi-automatic welding work cell, including a welding job sequencer that automatically selects a welding schedule for use by an operator in the semi-automatic welding work cell. The automatic selection may be by way of elapsed time, a detection of welding operations, a detection of the amount of welding wire supplied for the welding operation, or a detection of the amount of energy supplied for the welding operation.

Owner:LINCOLN GLOBAL INC

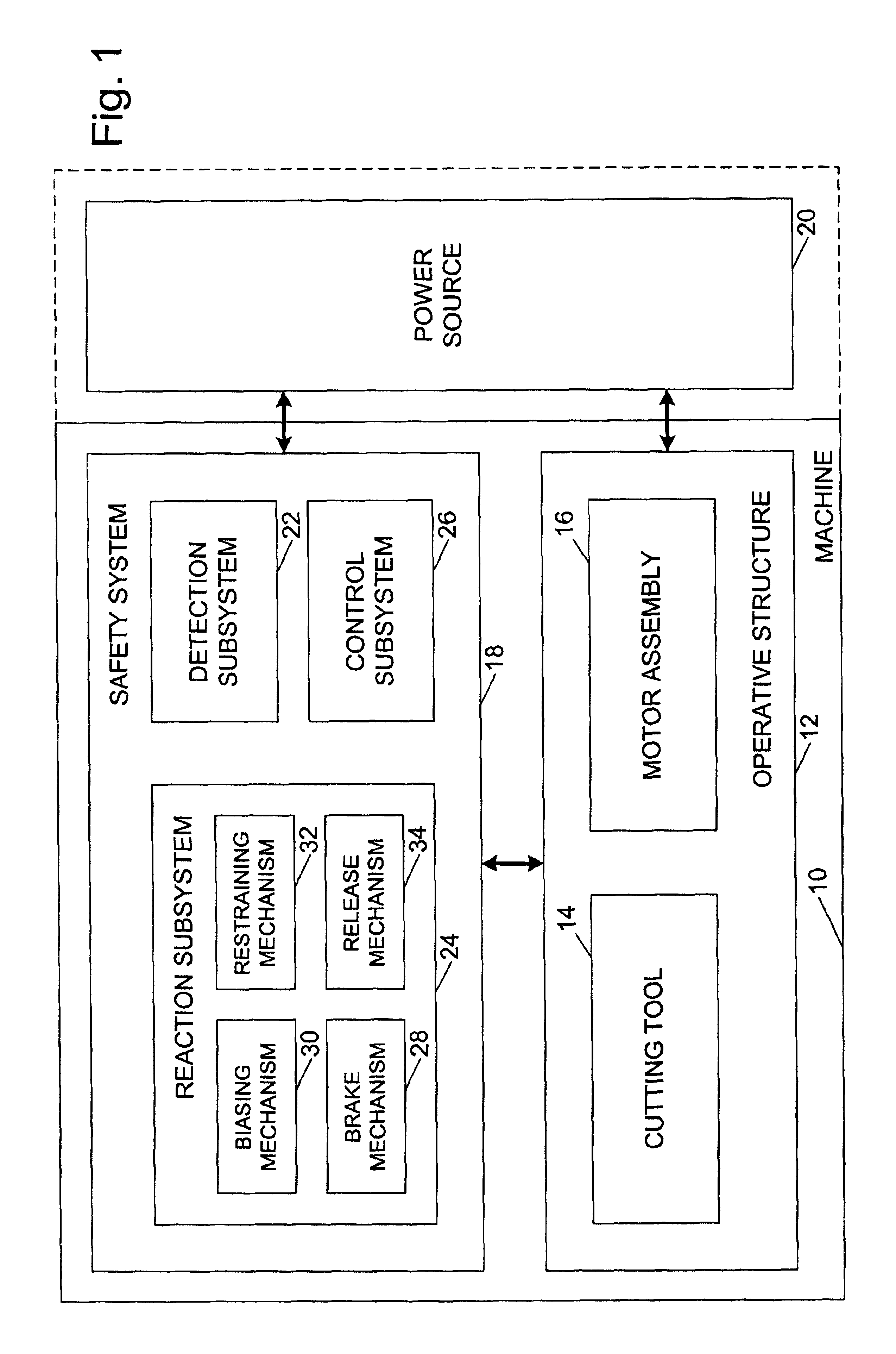

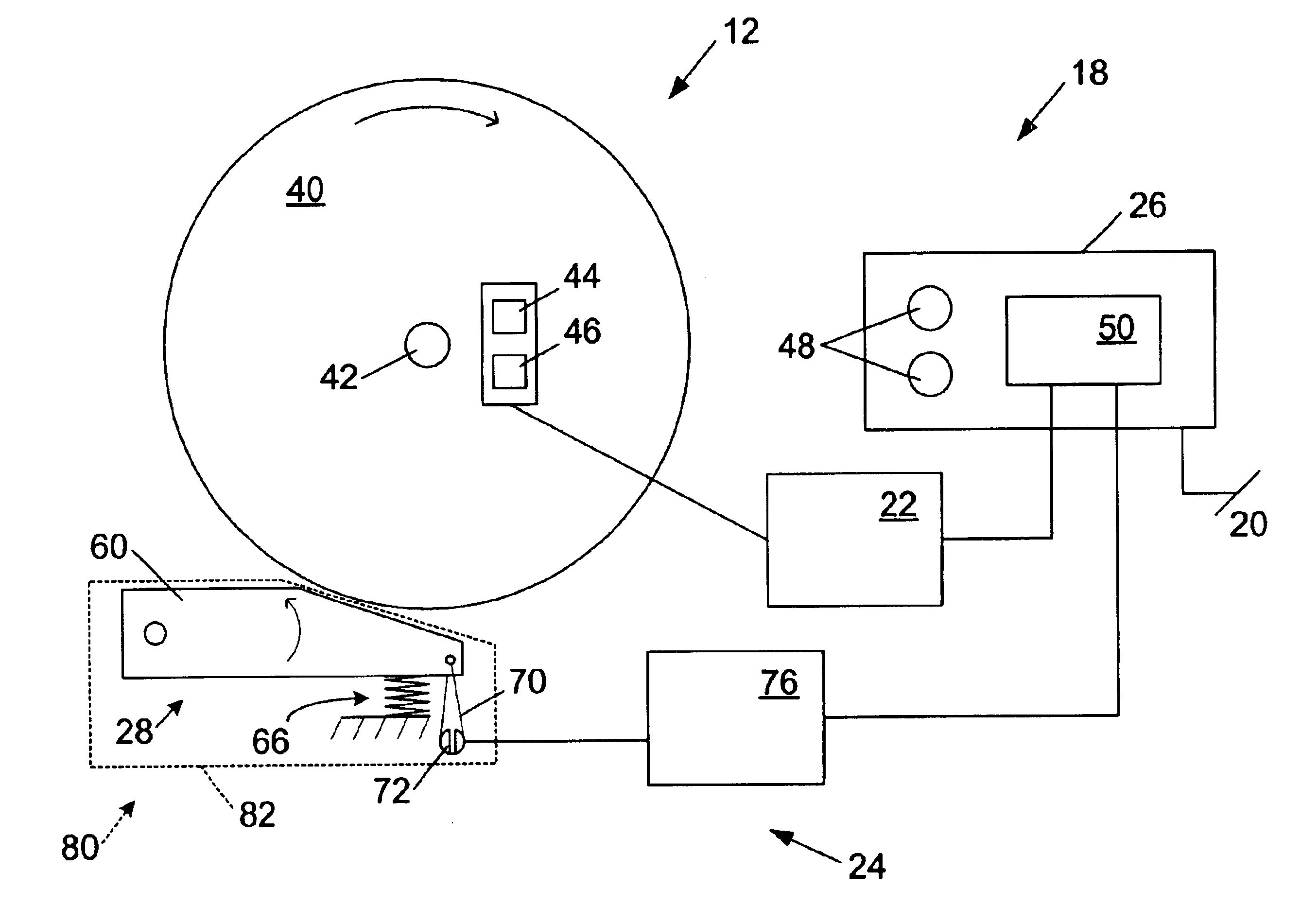

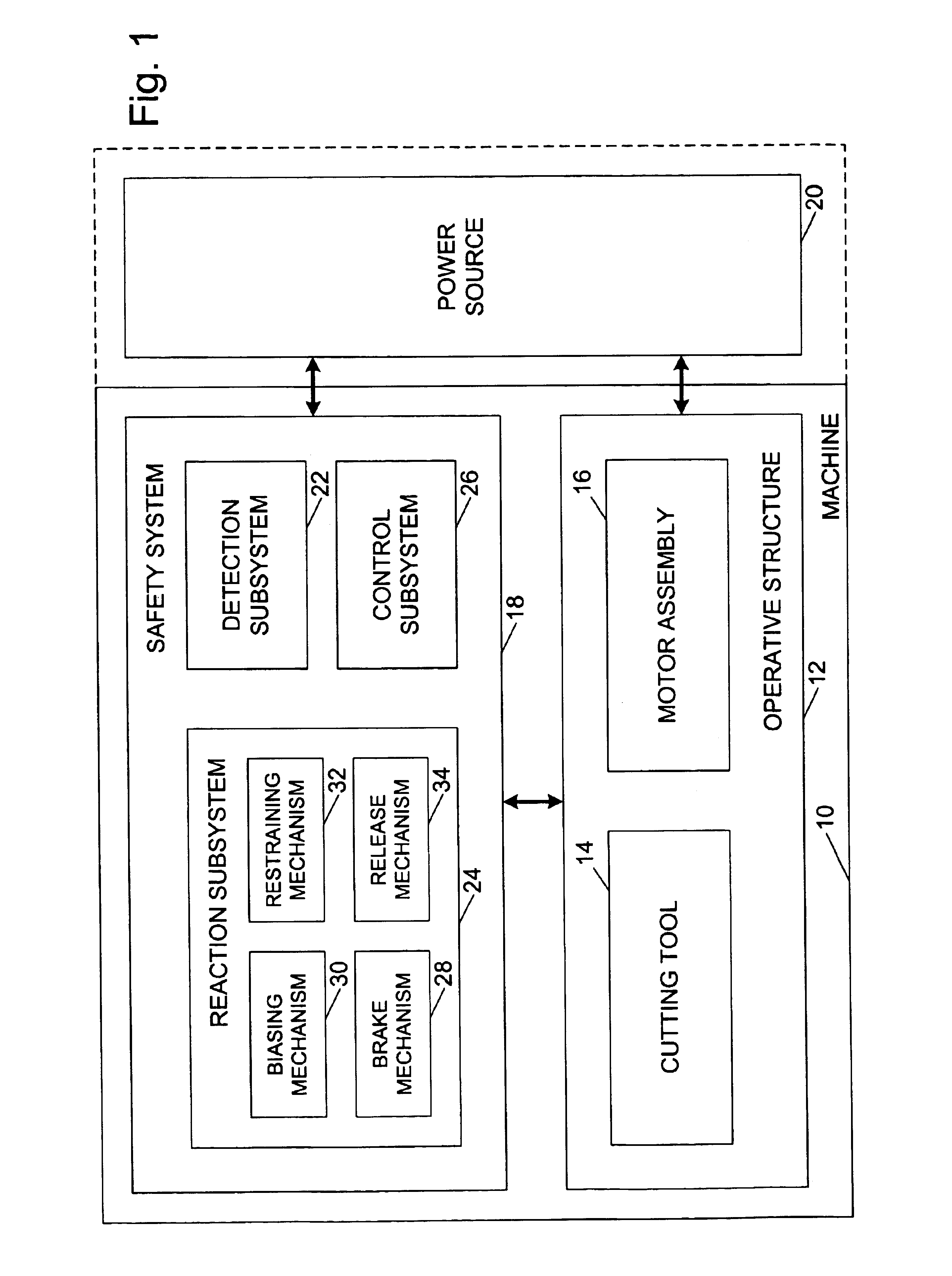

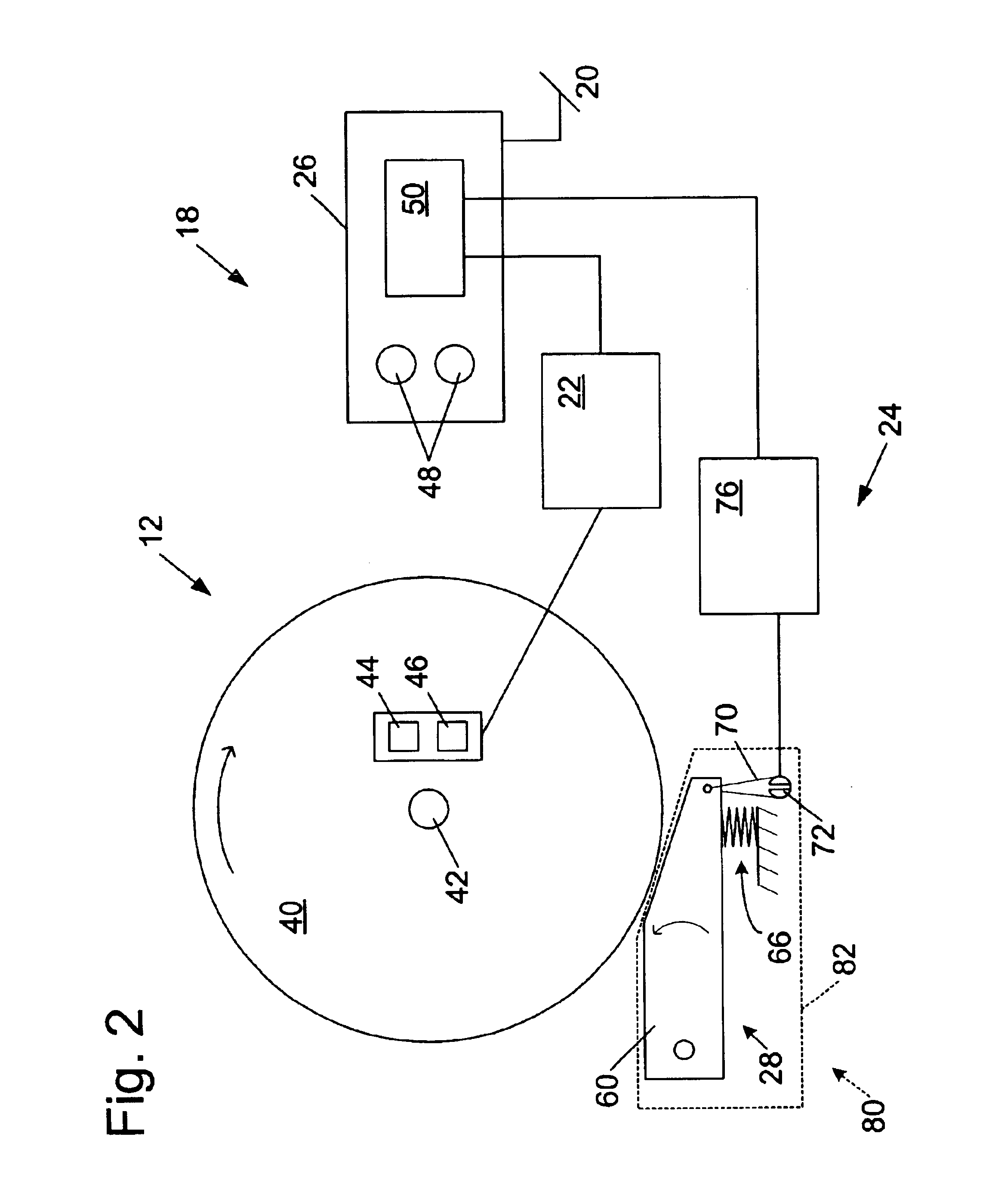

Safety systems for power equipment

A saw with a safety system is disclosed. The safety system includes a detection system adapted to detect contact between a person and a blade while the blade is moving. The safety system further includes a brake system adapted to engage the blade and to stop the blade when the detection system detects contact between the person and the blade.

Owner:SAWSTOP HLDG LLC

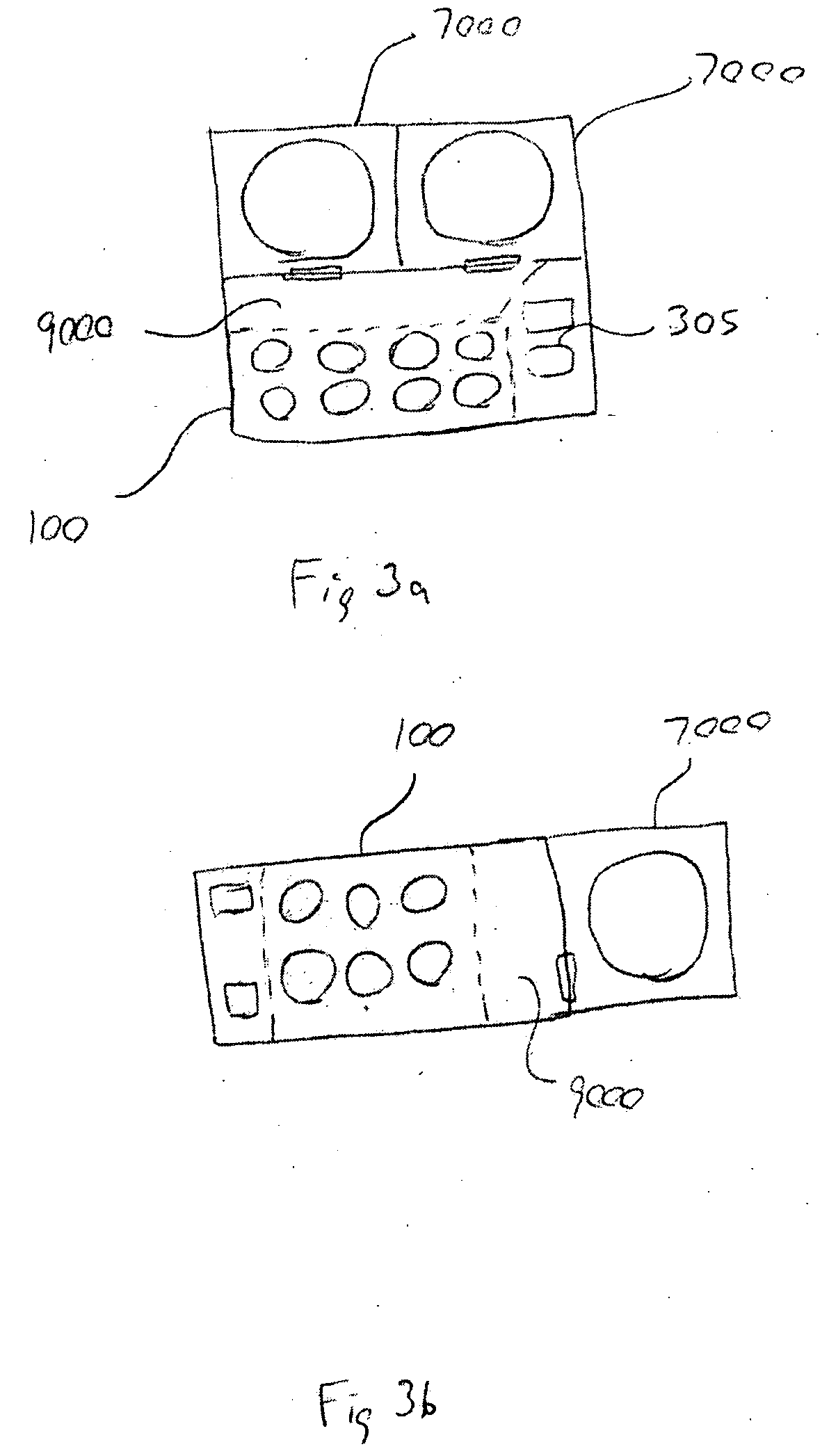

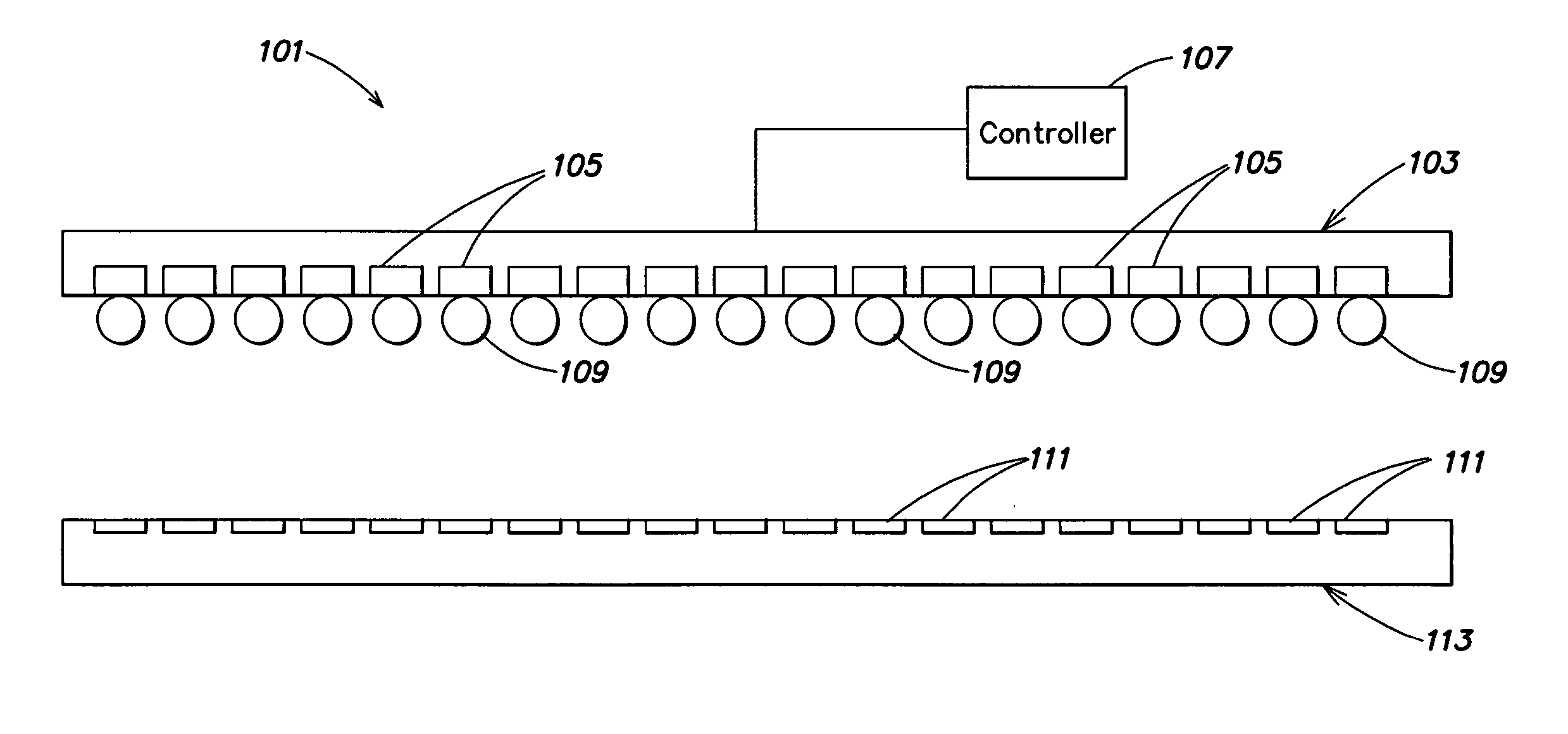

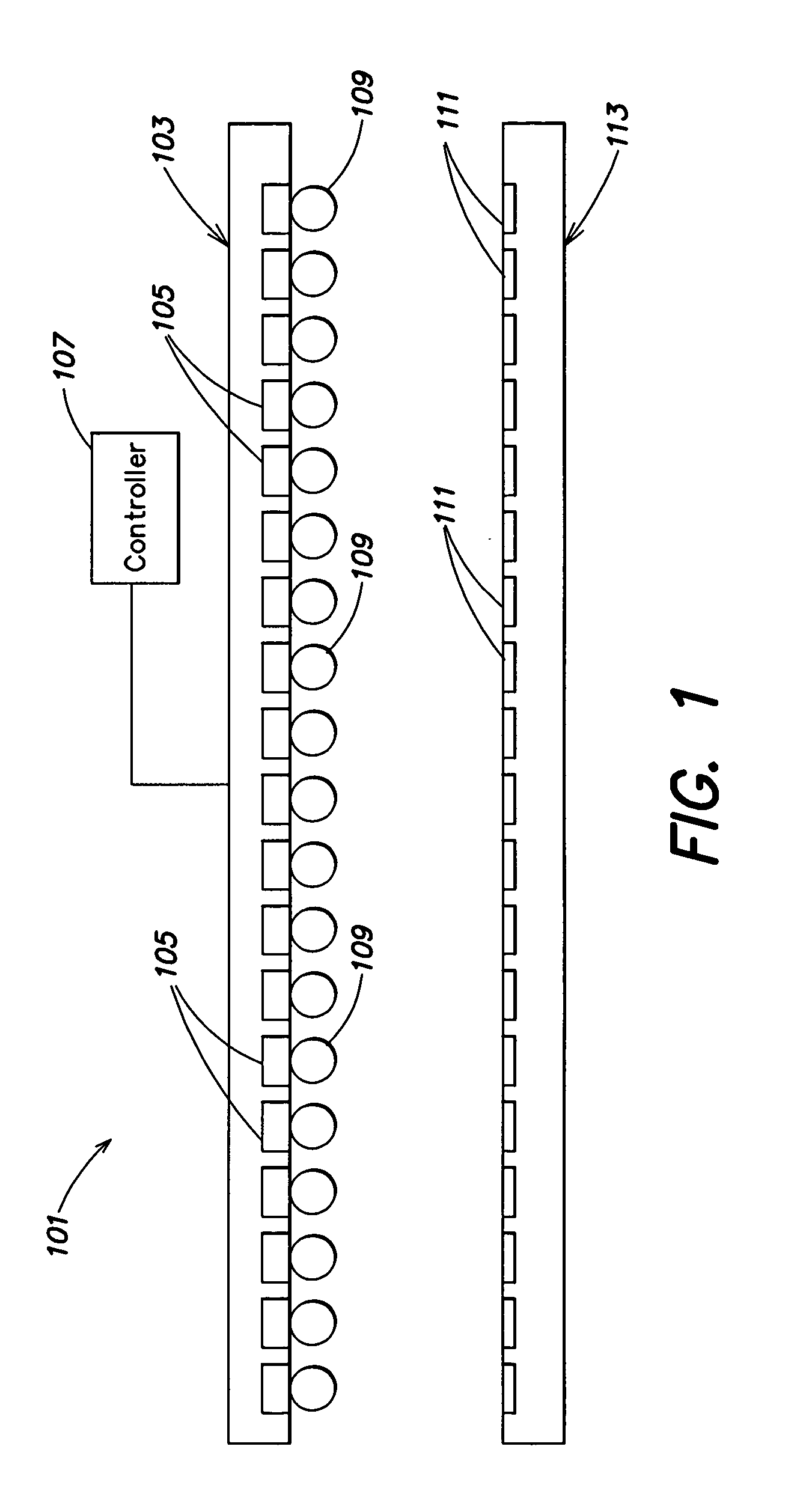

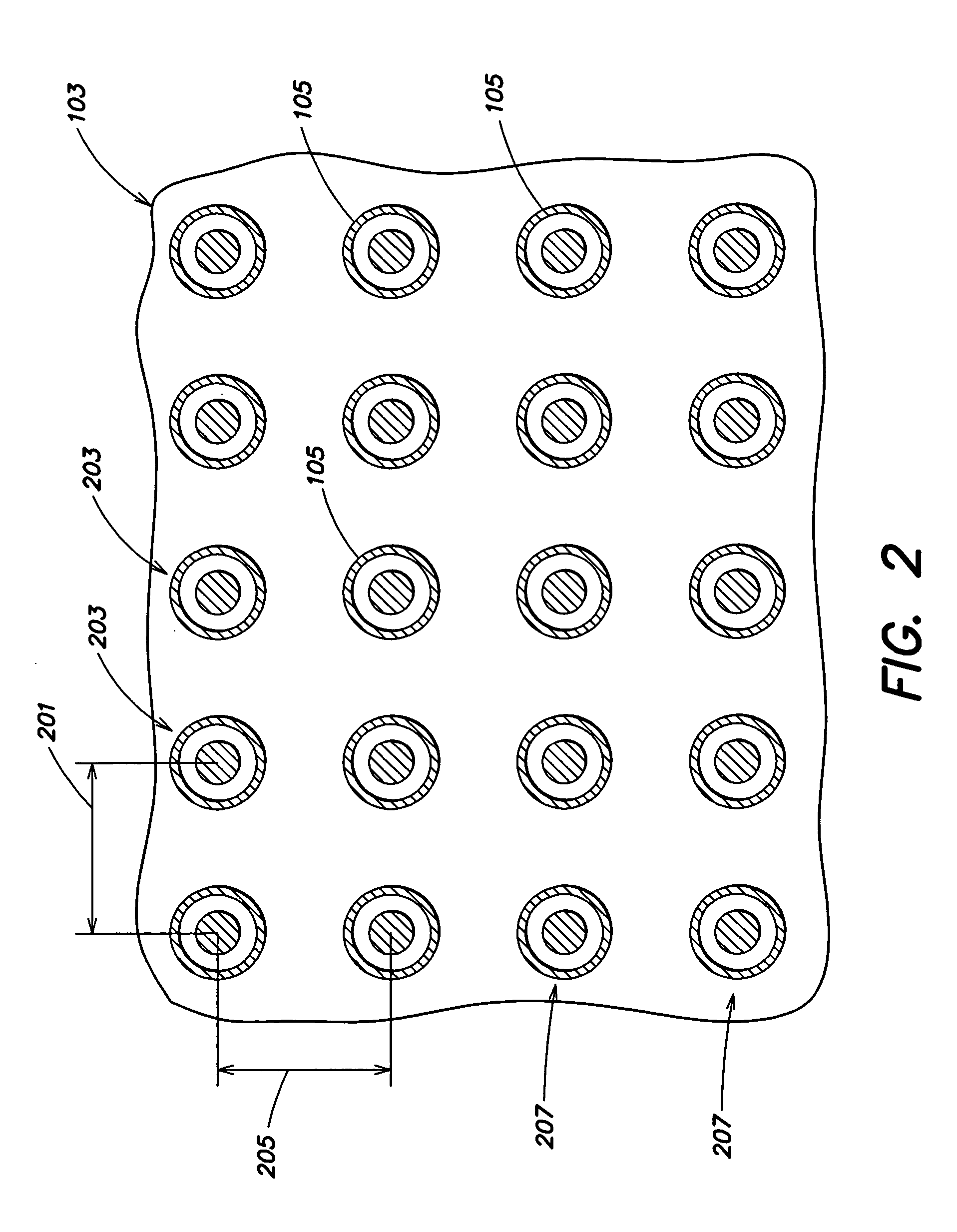

Methods and apparatus for transferring conductive pieces during semiconductor device fabrication

InactiveUS20050232728A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device fabrication

In a first aspect, a programmable transfer device is provided for transferring conductive pieces to electrode pads of a target substrate. The programmable transfer device includes (1) a transfer substrate; and (2) a plurality of individually addressable electrodes formed on the transfer substrate. Each electrode is adapted to selectively attract and hold a conductive piece during transfer of the conductive piece to an electrode pad of a target substrate. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

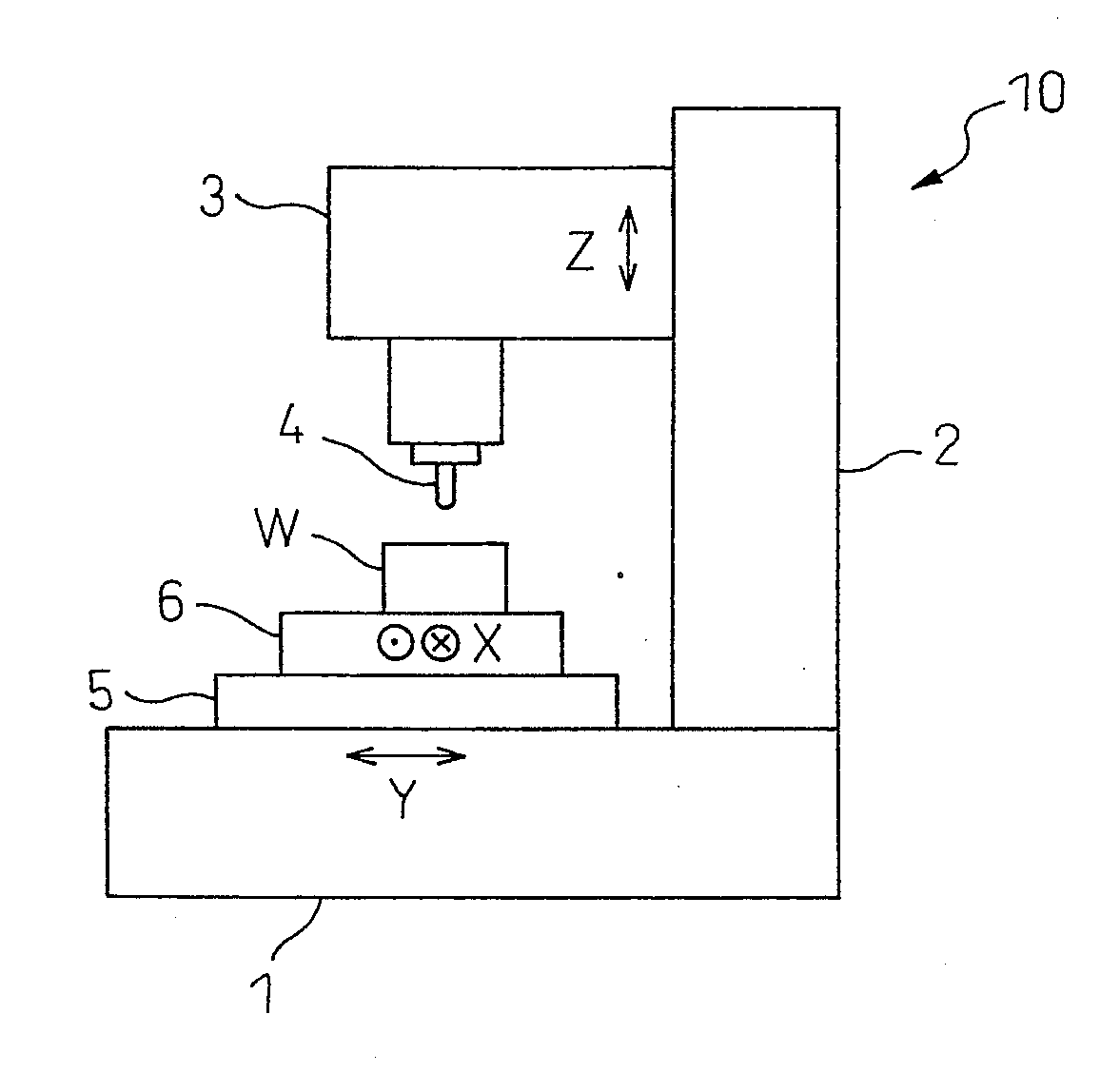

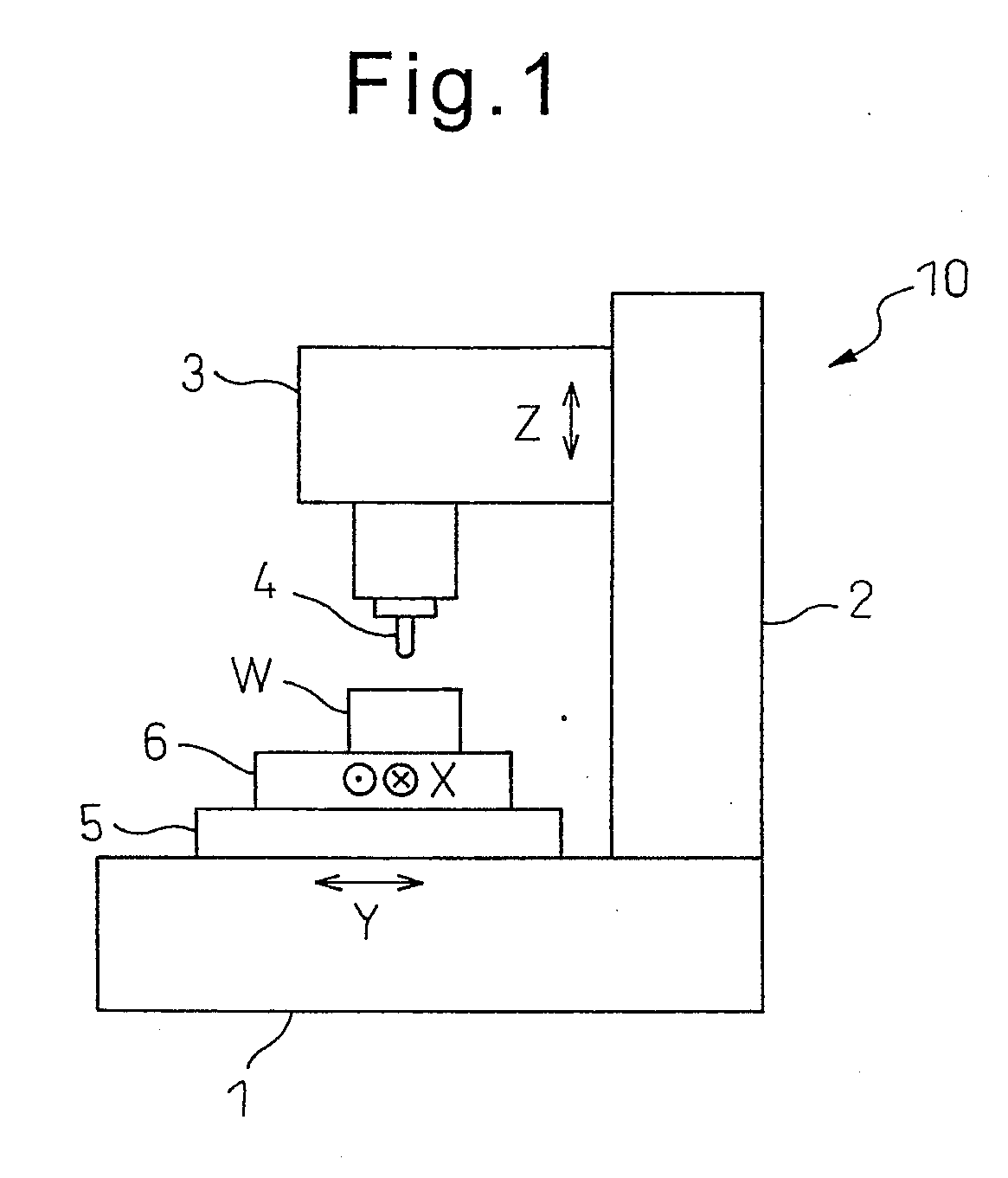

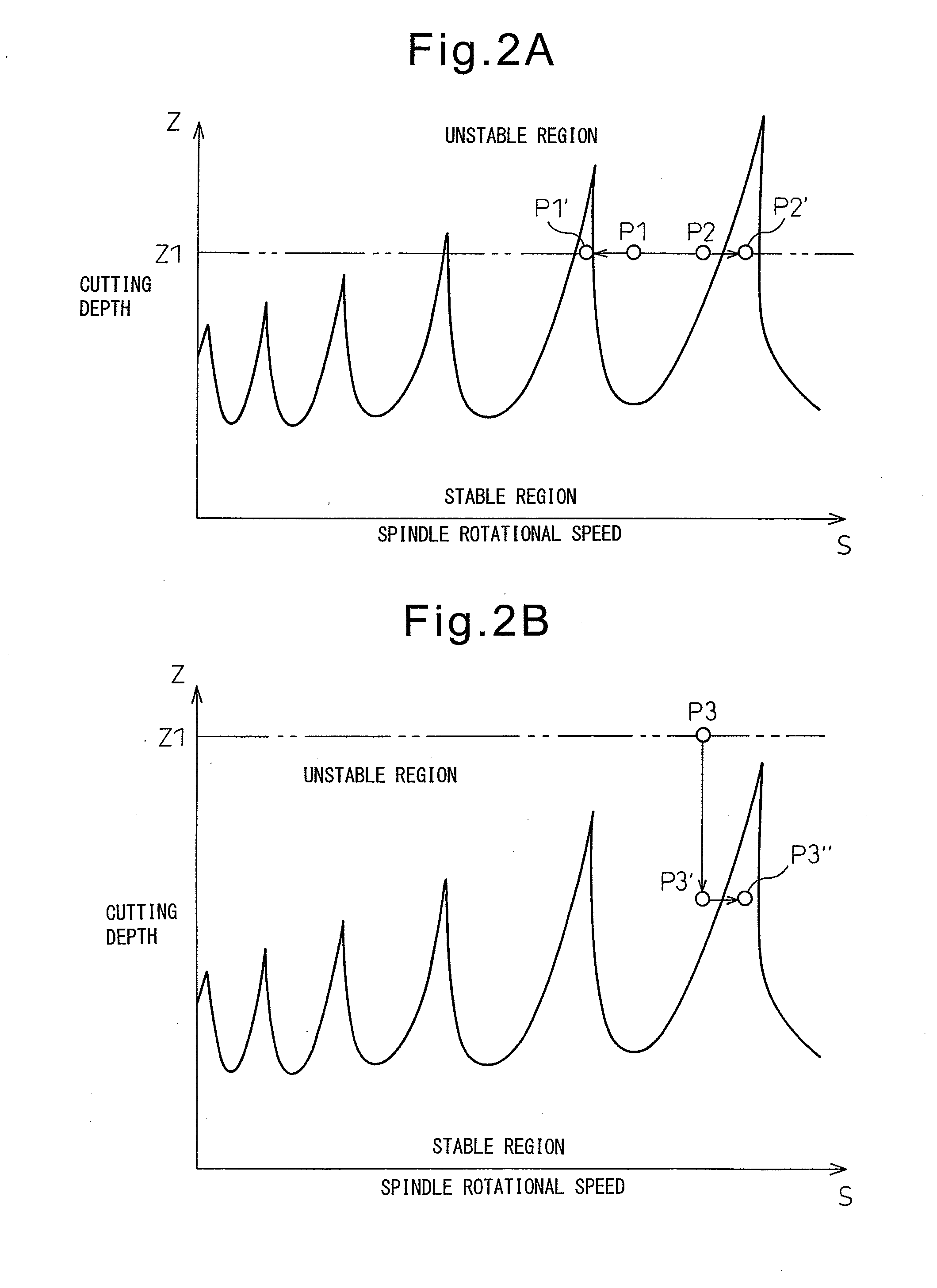

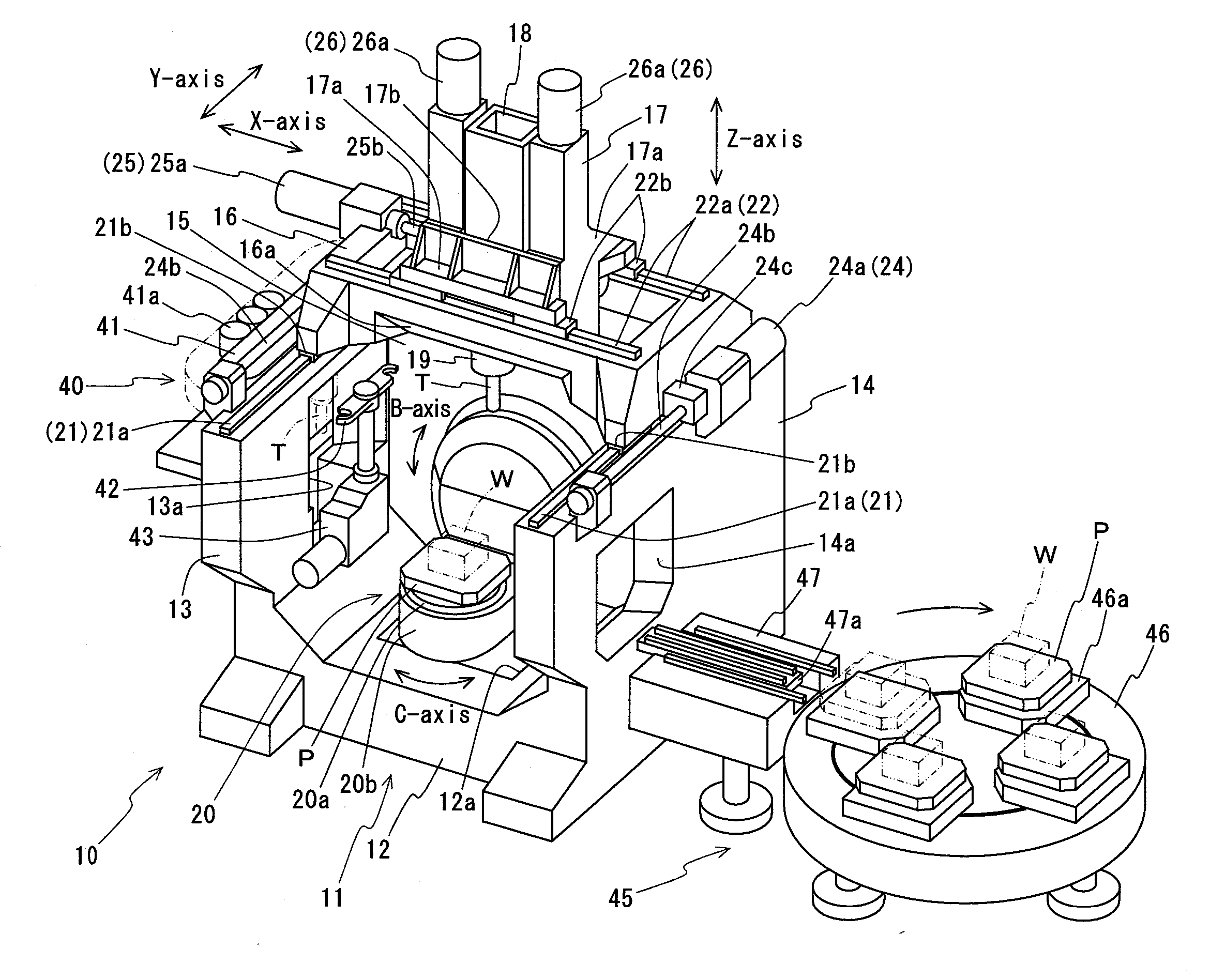

Chatter vibration detection method, chatter viberation avoidance method, and machine tool

A chatter vibration detection method includes acquiring vibration data of a tool (4) at a time of machining a workpiece at a predetermined sampling period (Δt), calculating an autocorrelation coefficient (Rxx′) corresponding to a time required for a cutting edge (4a, 4b) to contact the workpiece (W) several times based on acquired time series vibration data and calculating a period (Tx) of characteristics of the calculated autocorrelation coefficient (Rxx′), and deciding that chatter vibration occurs when a contact period (T1) at which the cutting edge (4a, 4b) contacts the workpiece (W) is not an integral multiple of the calculated period (Tx).

Owner:MAKINO MILLING MASCH CO LTD

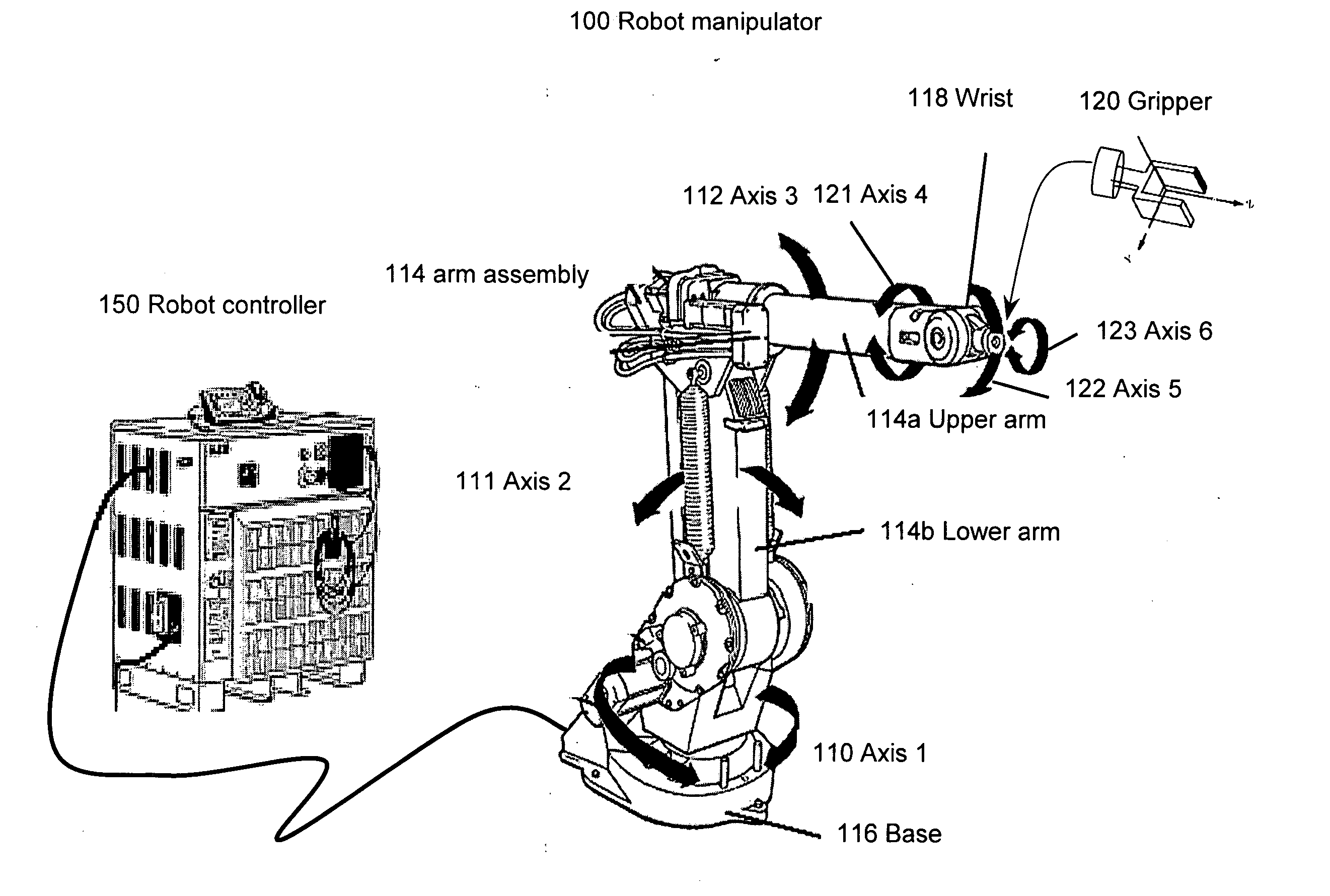

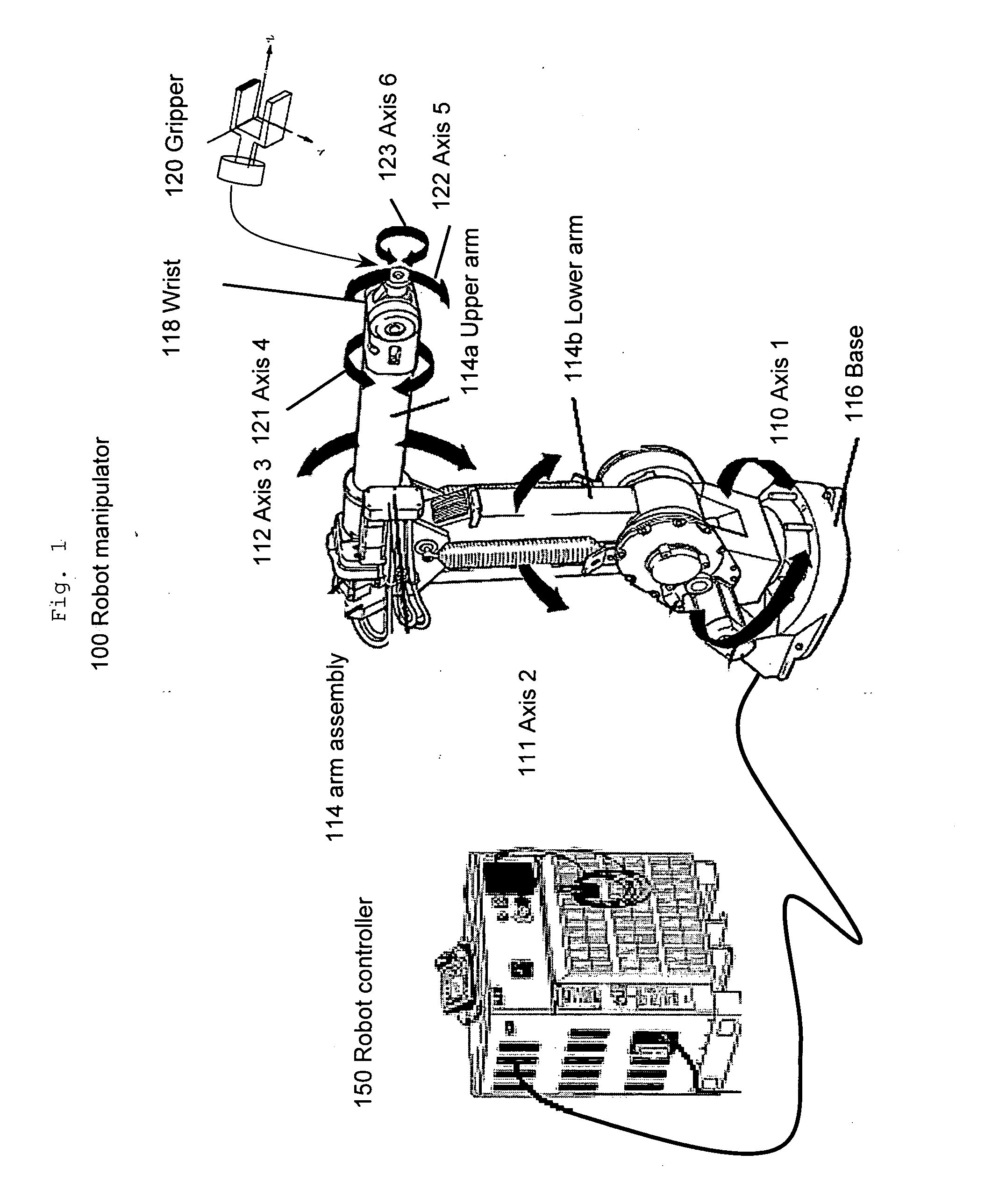

Robotic machining with a flexible manipulator

ActiveUS20060048364A1Control positionProgramme-controlled manipulatorAutomatic control devicesManipulatorEngineering

A robot machining with a flexible manipulator has an end effector which may either hold the tool to perform the machining or the work piece to be machined. A signal representative of a force applied by said tool to said work piece is used to control either the relative motion between the tool and the work piece to give a controlled material removal rate (CMRR) or the relative position between the tool or the work piece to provide deformation compensation or both CMRR and deformation compensation. A force sensor provides the signal for deformation compensation. For CMRR the signal may be obtained from either a force sensor or the current flowing in the motor of the robot's spindle. The force sensor can be mounted either on the robot or together with either the tool or work piece adjacent to the robot.

Owner:ABB RES LTD

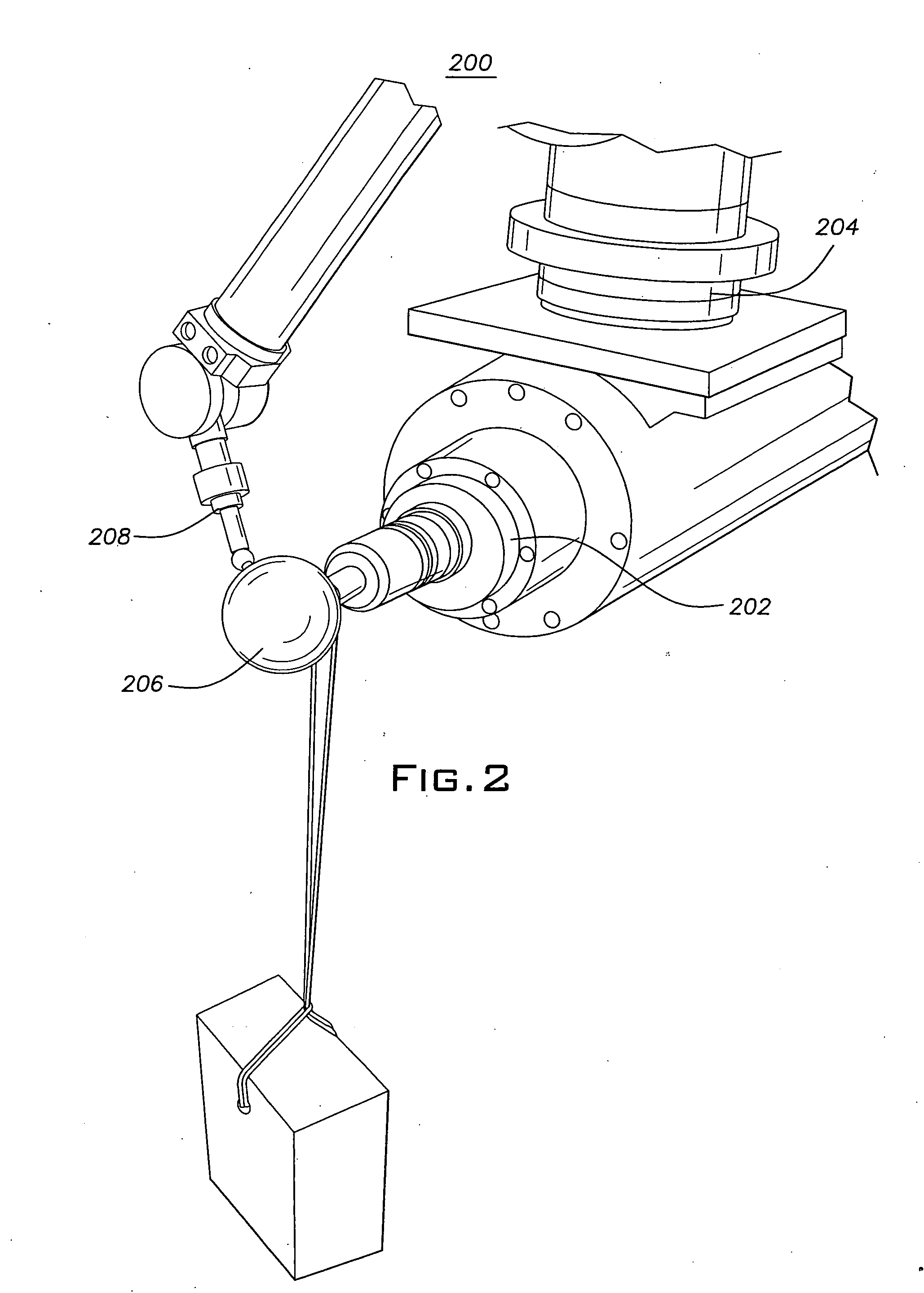

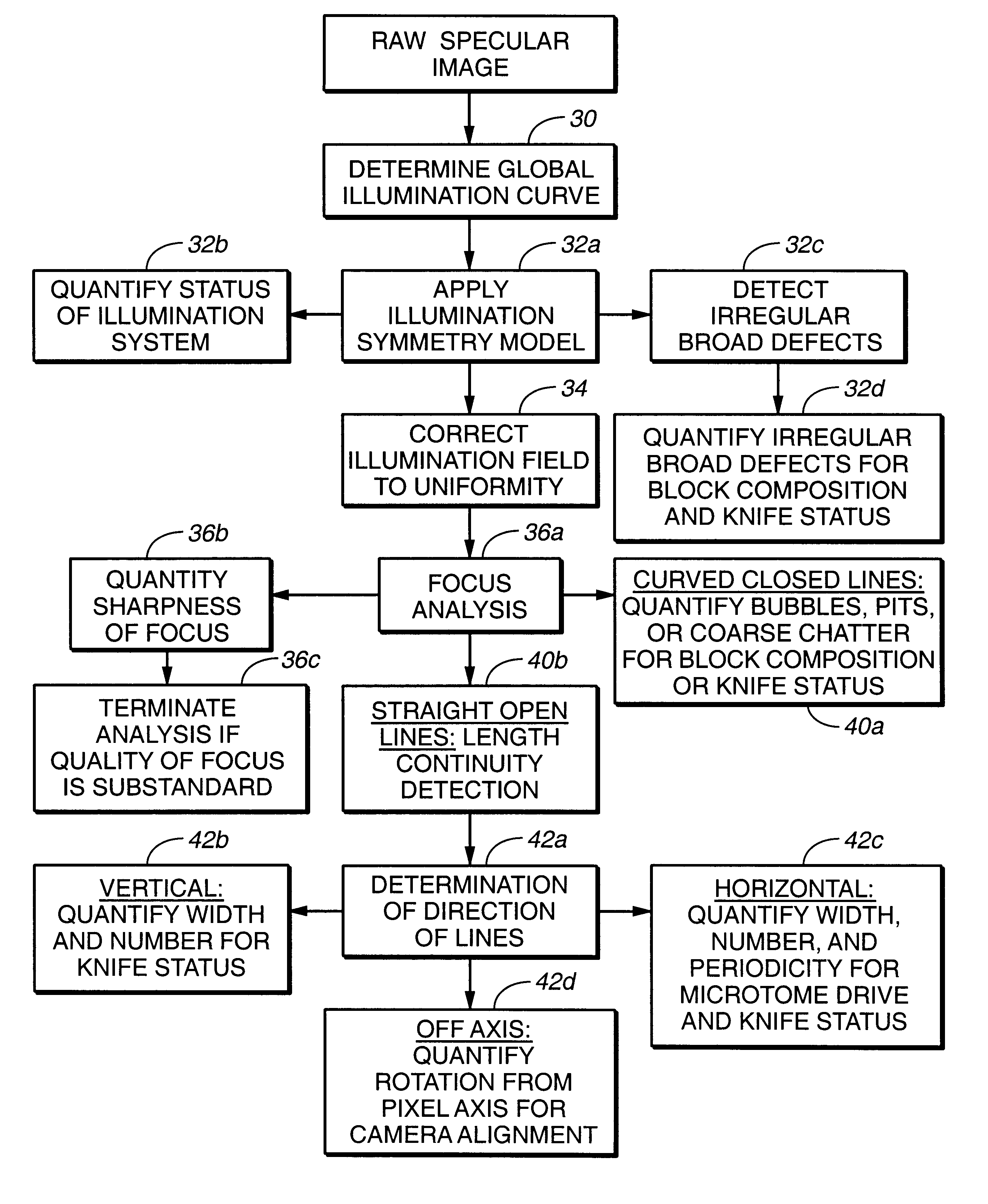

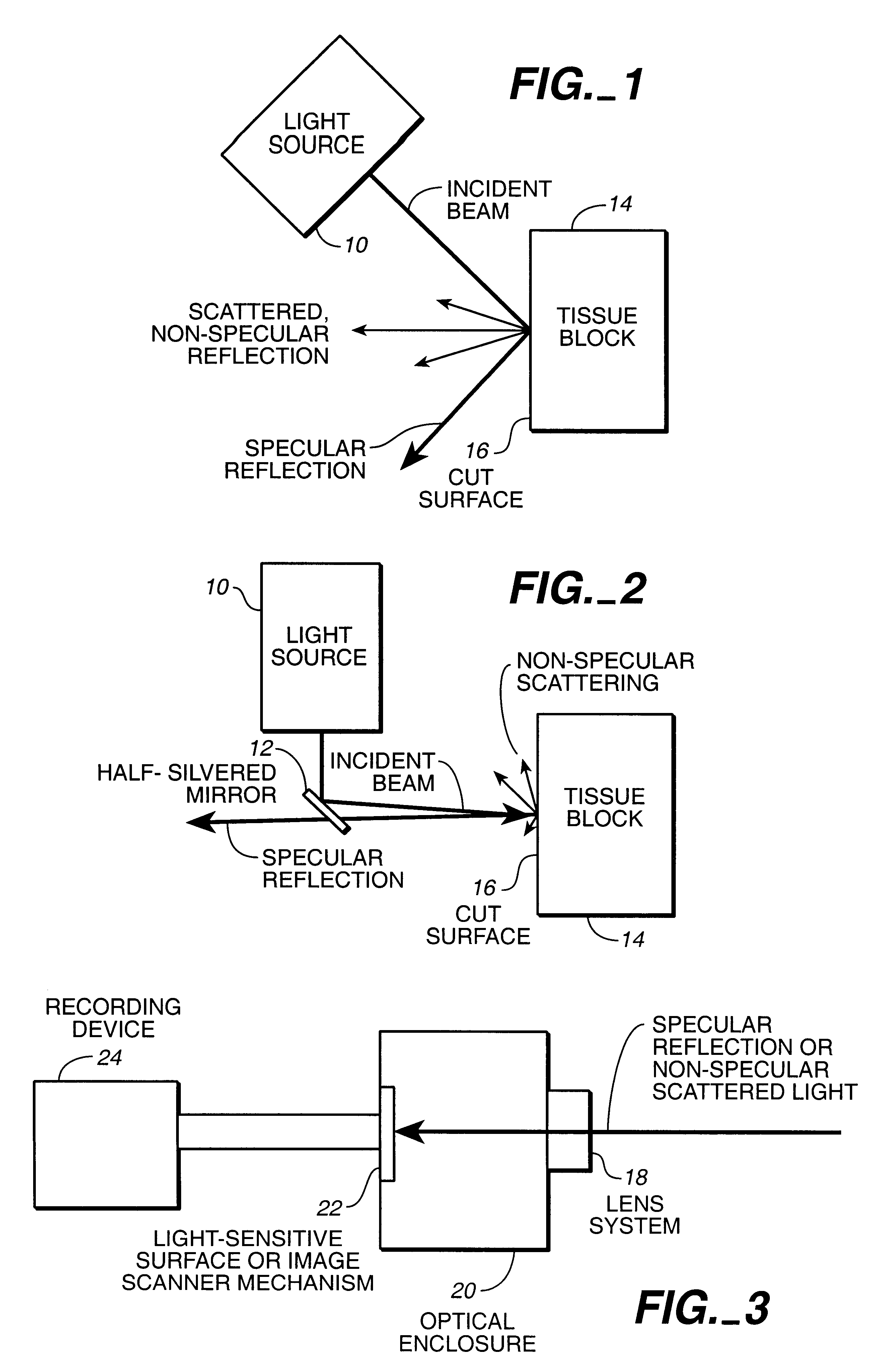

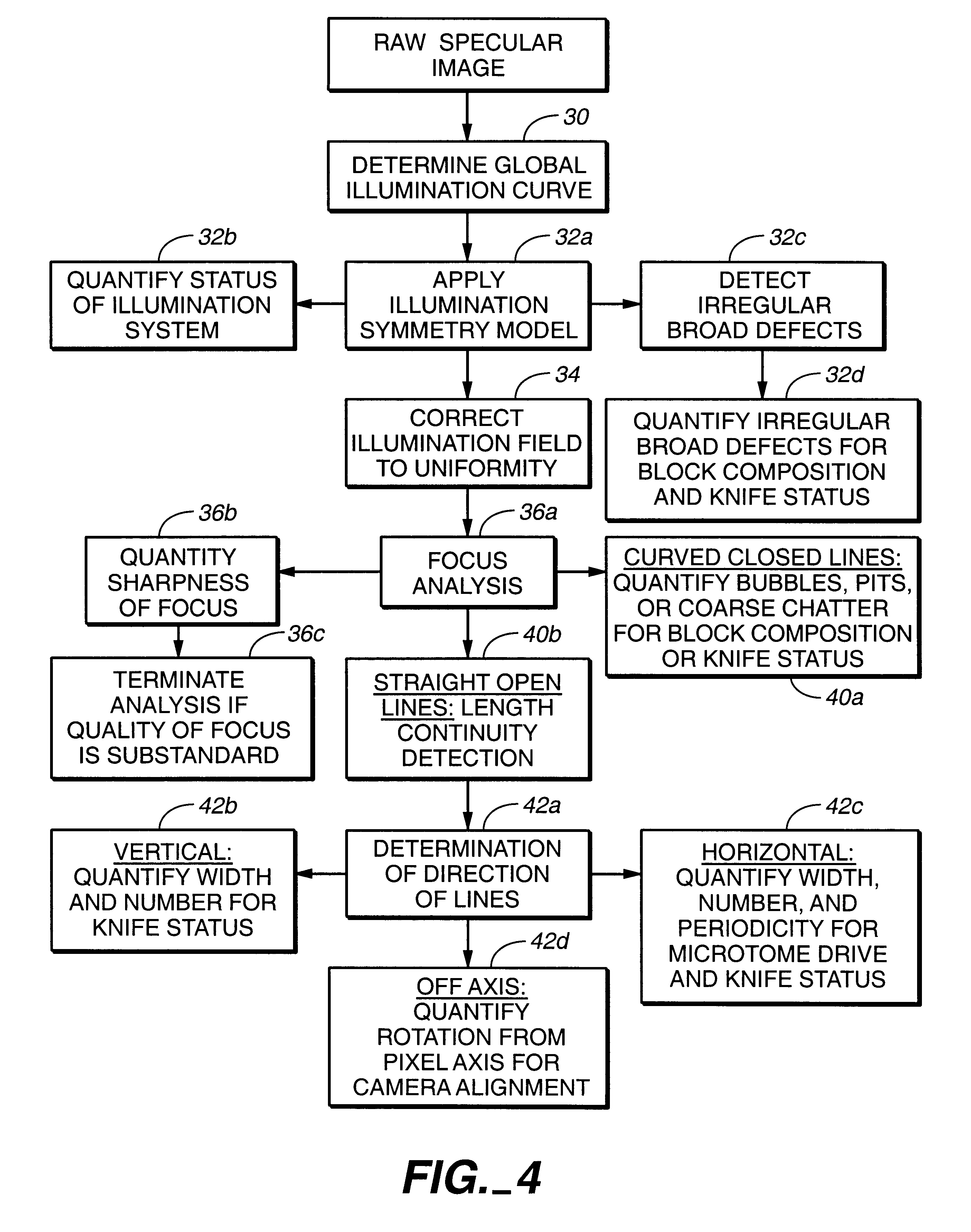

Method and apparatus for measurement of microtome performance

A method and apparatus for monitoring and evaluating the performance and condition of histology laboratory microtomes and microtome accessories including knives, motor drives, and illumination devices. Irregularities in an image of the surface of a block mounted on the microtome are detected and characterized, the block having been subjected to mechanical sectioning by the microtome to produce a cut block face. The image of light reflected from the surface of the block, either specular or non-specular, is recorded and subjected to graphical analysis to extract, quantify, and interpret patterned features, including those indicating anomalies in the function of the microtome, its accessories, or the tissue block itself.

Owner:MICROSCI GROUP

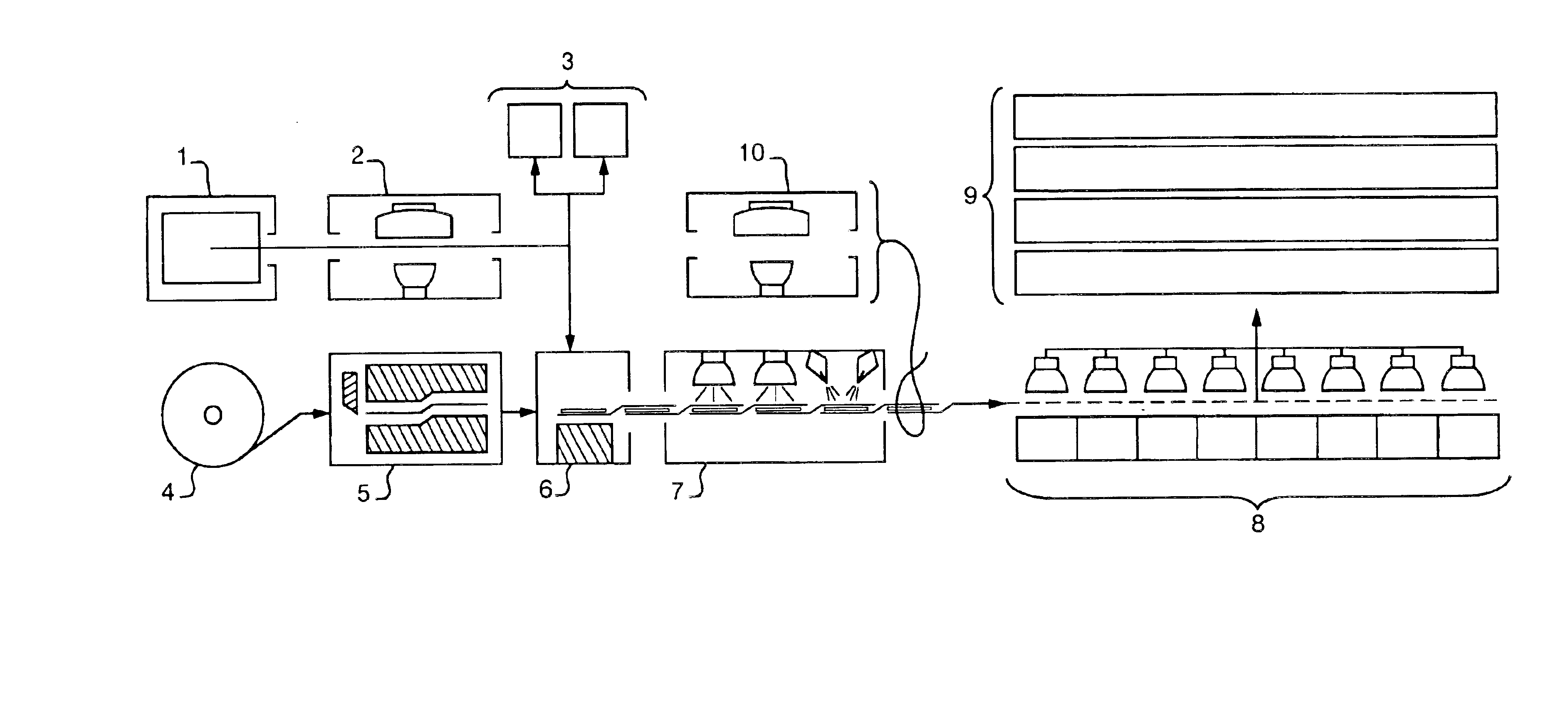

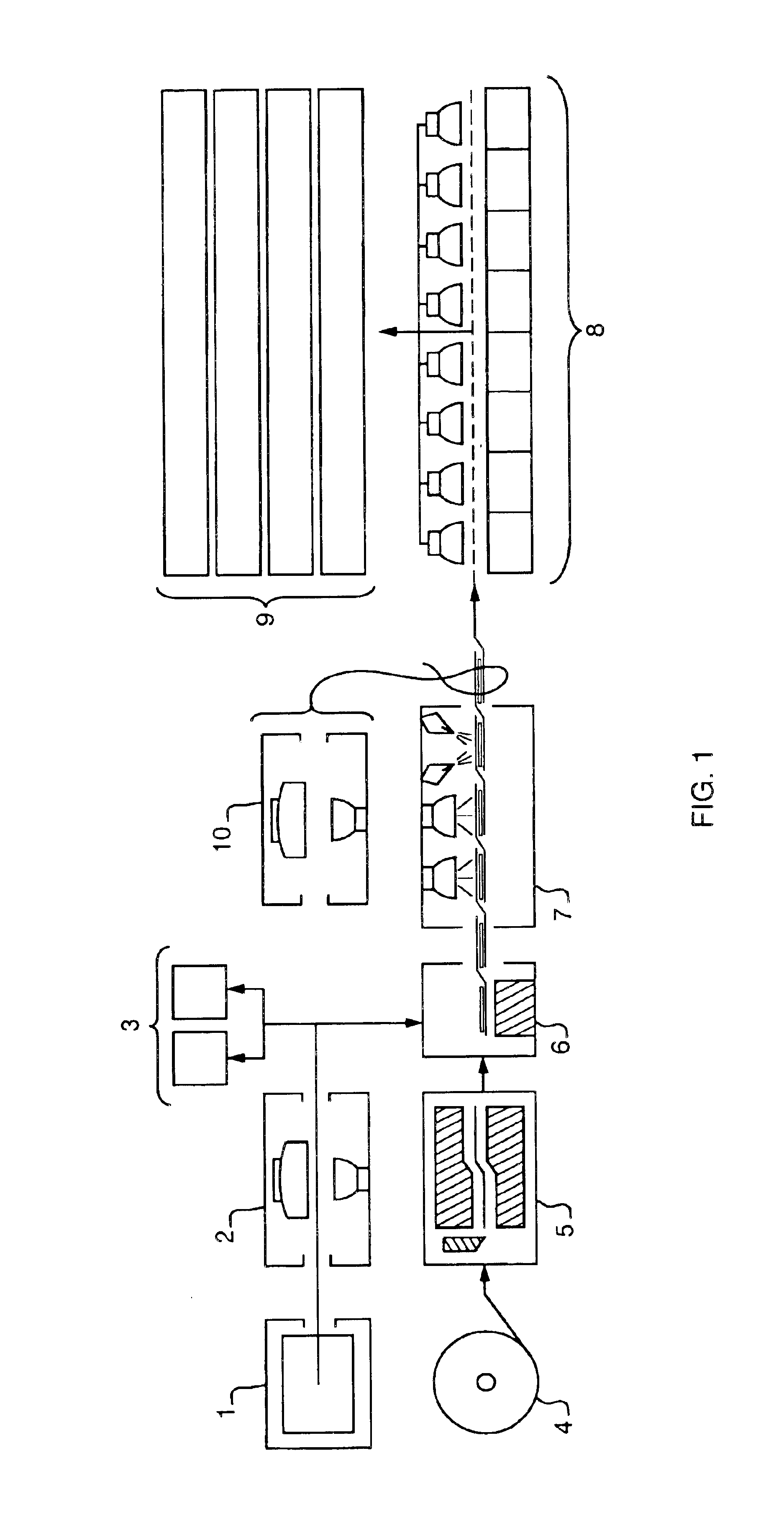

Process and system for sub-dividing a laminated flooring substrate

ActiveUS20070209736A1Good for healthAvoid mistakesMulti-purpose machinesAdjusting equipmentEngineeringControl unit

A process for sub-dividing a laminated flooring substrate into a plurality of laminated flooring planks and a system therefore are described. The process can include providing a laminated flooring substrate having a decorative pattern on a core wherein the decorative pattern can include a plurality of indicators, and independently detecting the indicators with a plurality of detecting devices, each assigned a respective indicator. The detecting devices can individually obtain the position of the detected indicators and a control unit can align a separate saw blade per each position detected. The system includes a cutting unit with individually adjustable saws or an alignment device configured to align the laminated flooring substrate with the saws, to cut the laminated flooring substrate along positions relative to the detected indicators, for example, in the center thereof or off-set therefrom.

Owner:MANNINGTON MILLS

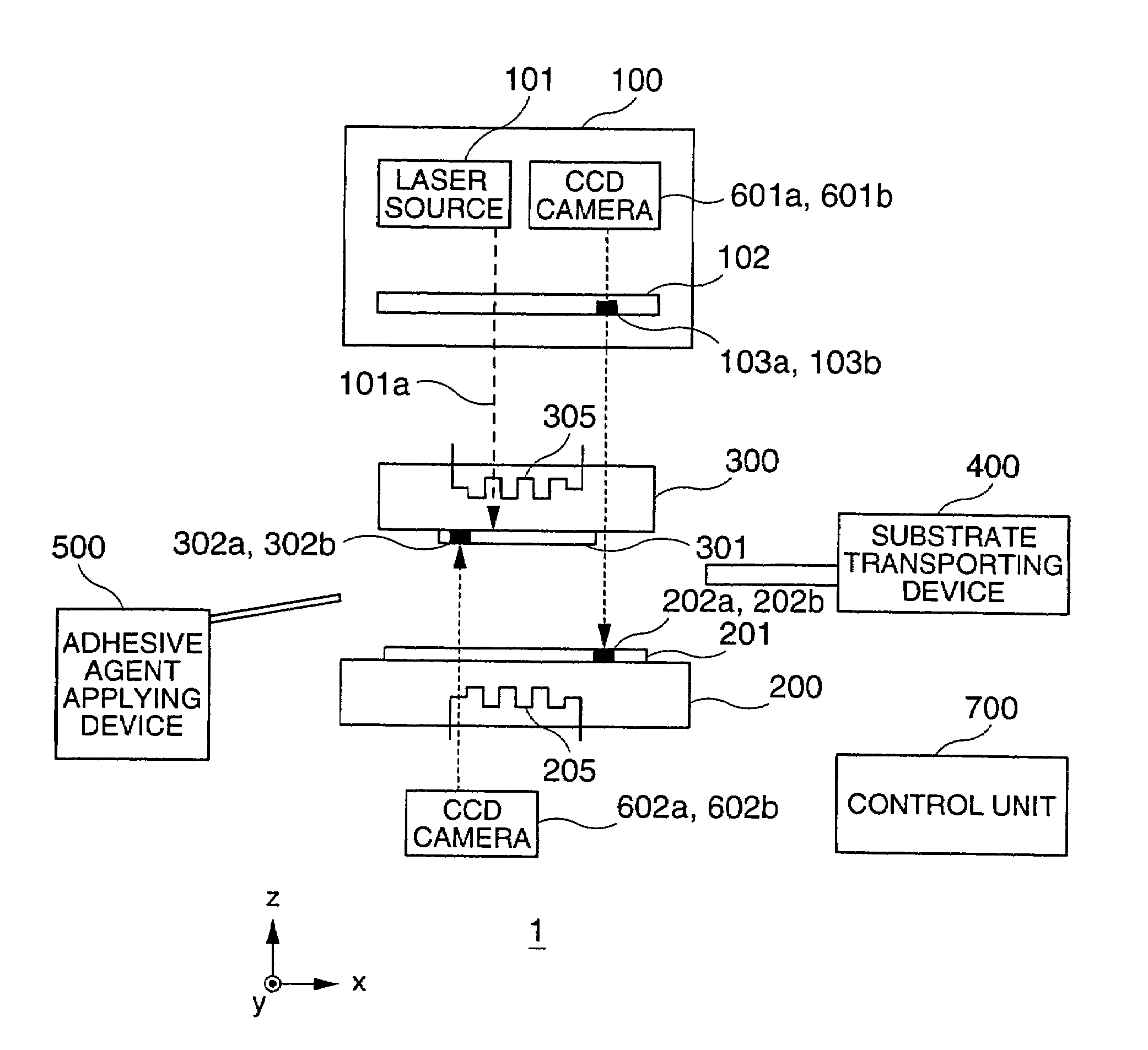

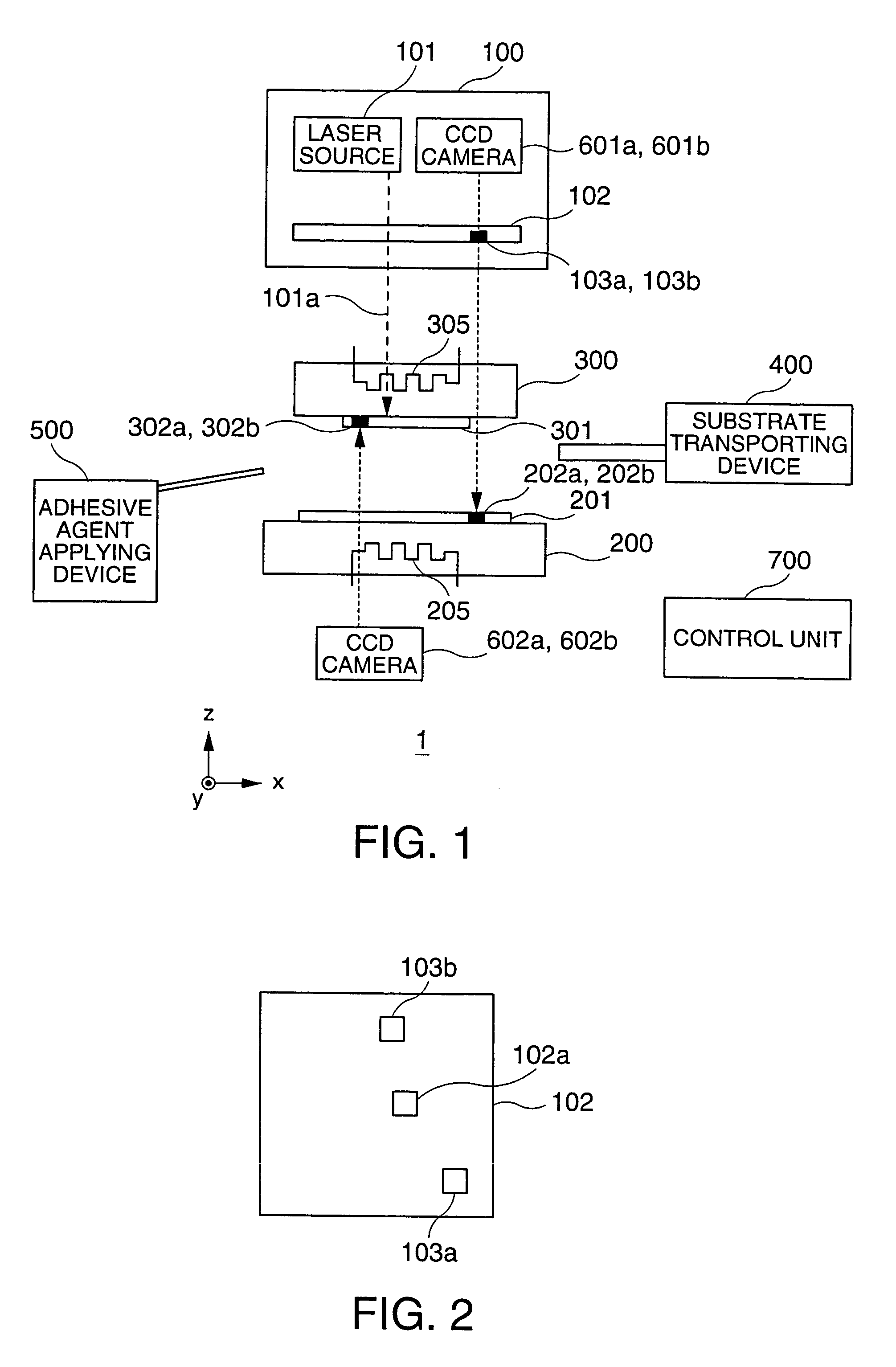

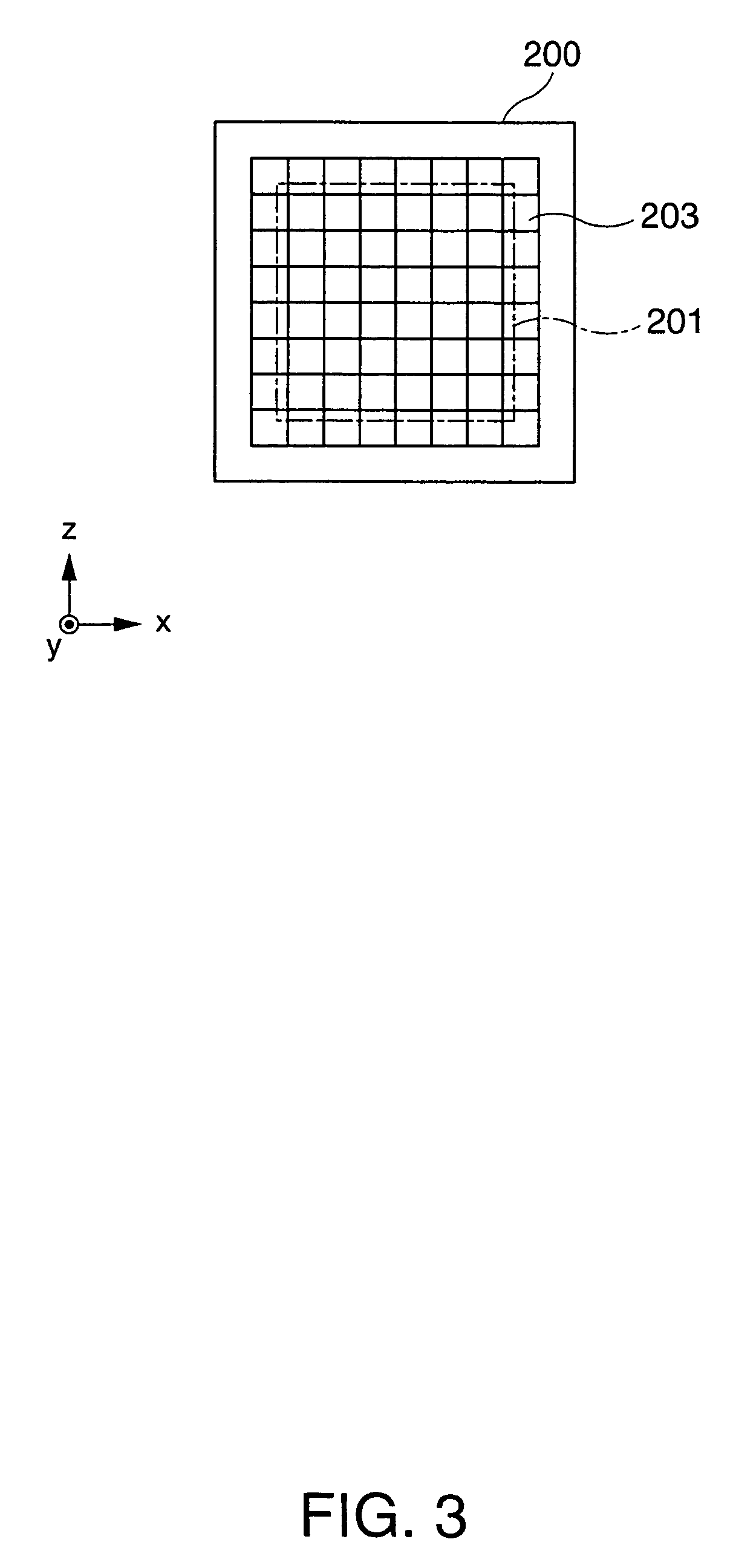

Method of manufacturing electronic device including aligning first substrate, second substrate and mask, and transferring object from first substrate to second substrate, including irradiating object on first substrate with light through mask

ActiveUS7127810B2Easily downsizedEasy to manufactureSolid-state devicesPhotomechanical apparatusOptoelectronicsElectron

A method of manufacturing an electronic device includes providing a mask substrate, a first substrate on which an object to be transferred is formed, and a second substrate to which the object is to be transferred, adjusting positions of the mask substrate, the first substrate and the second substrate so that an alignment mark formed on one of the substrates (a reference substrate) and alignment marks formed on other two of the substrates are aligned with each other, and transferring the object to be transferred from the first substrate to the second substrate, the transferring step including irradiating the object to be transferred from the first substrate with light transmitted through the mask substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

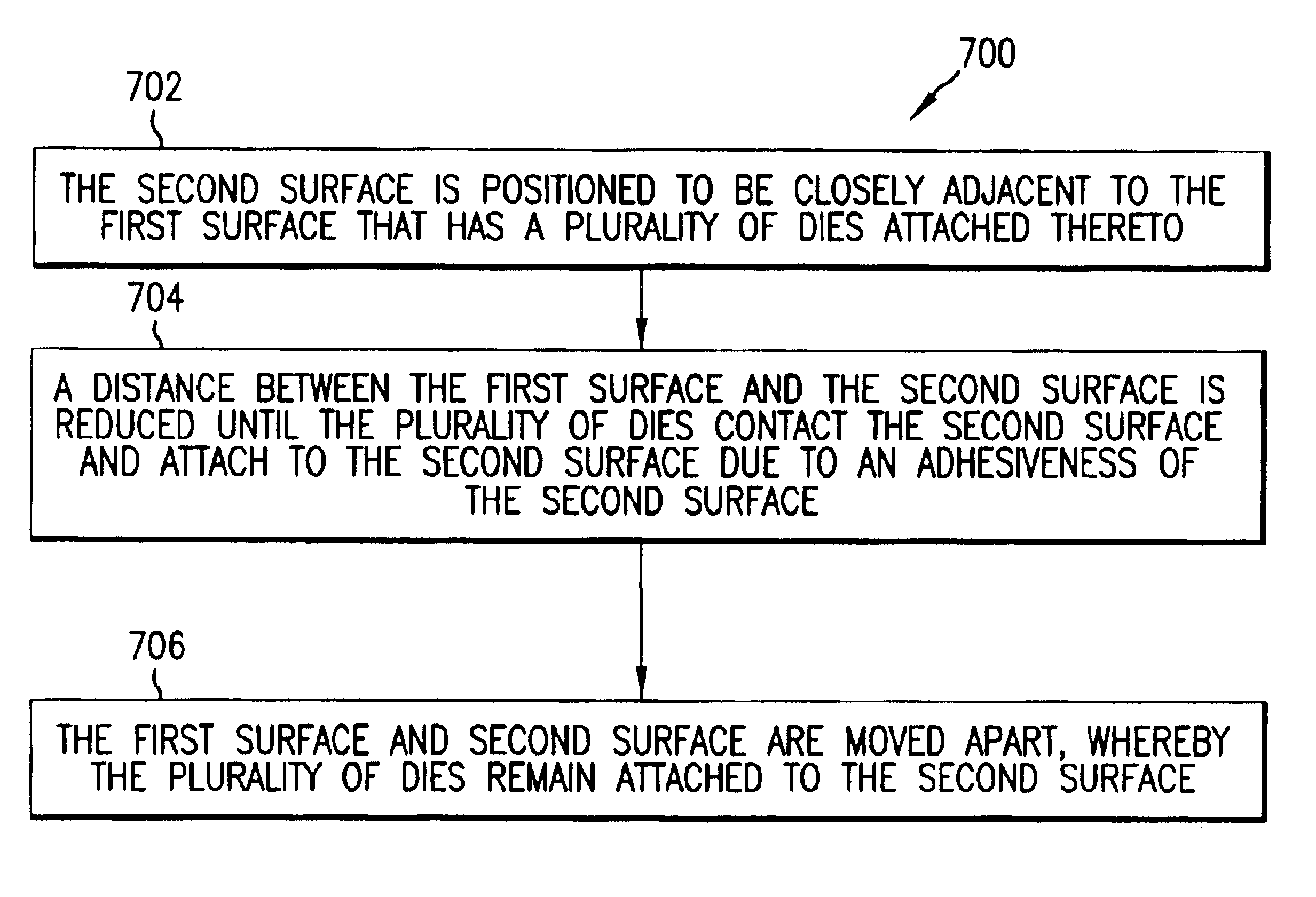

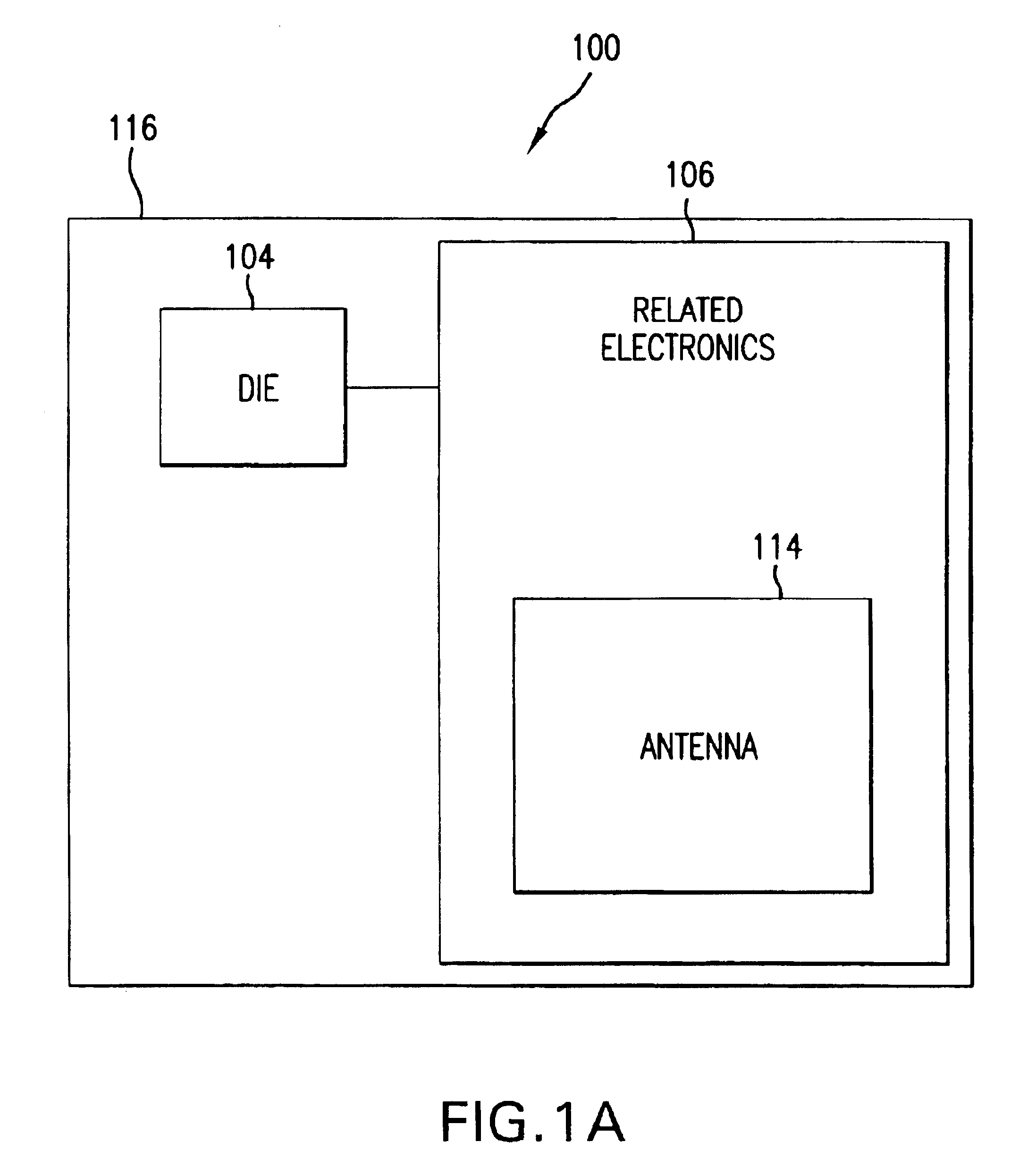

System and method of transferring dies using an adhesive surface

InactiveUS6848162B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringBiomedical engineering

A method and system for transferring a plurality of integrated circuit dies from a first surface to a second surface is described. The second surface is positioned to be closely adjacent to the first surface that has a plurality of dies attached thereto. A distance is reduced between the first surface and the second surface until the plurality of dies contact the second surface and attach to the second surface due to an adhesiveness of the second surface. The first surface and second surface are moved apart. The plurality of dies remain attached to the second surface.

Owner:SYMBOL TECH INC

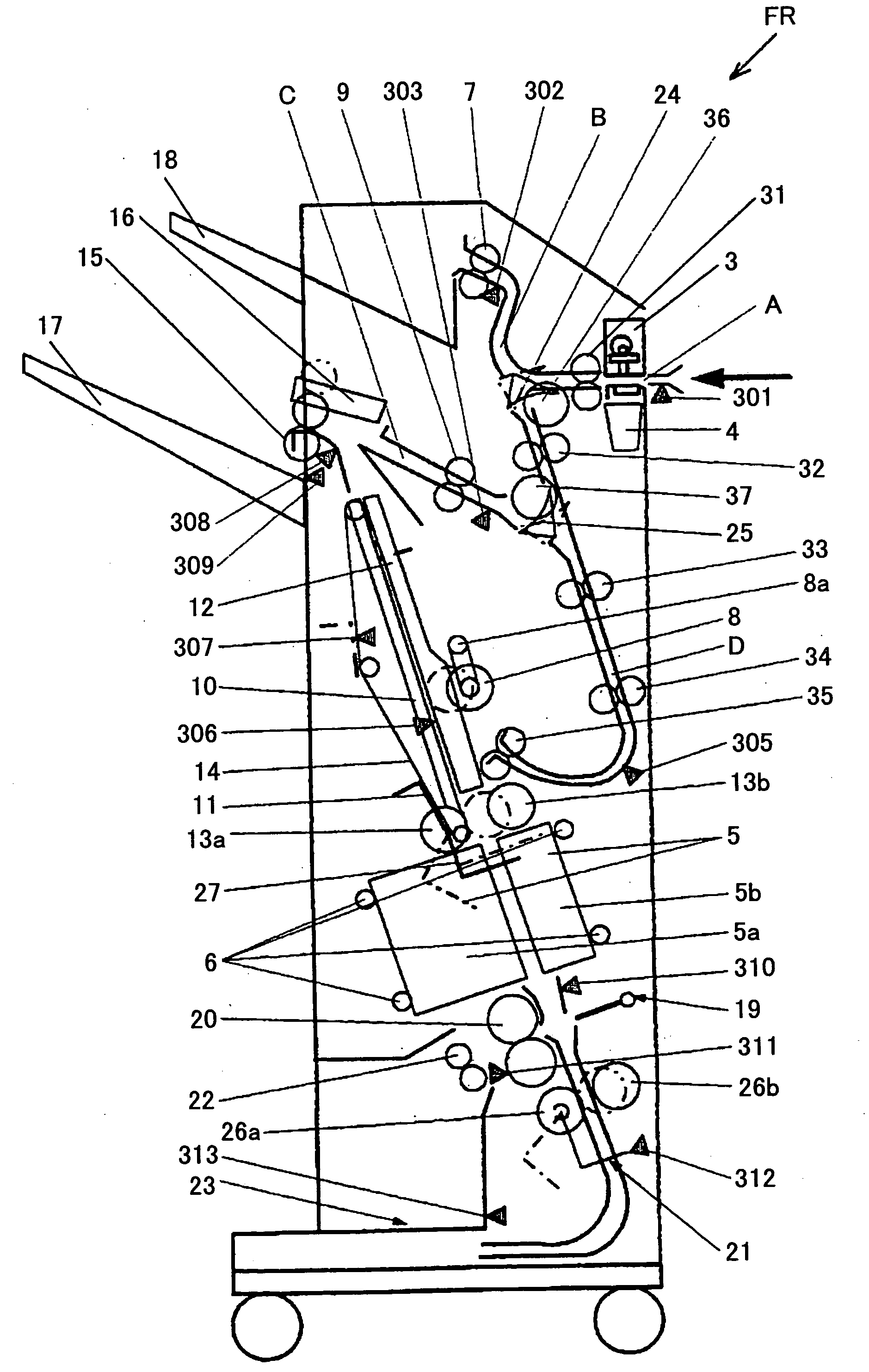

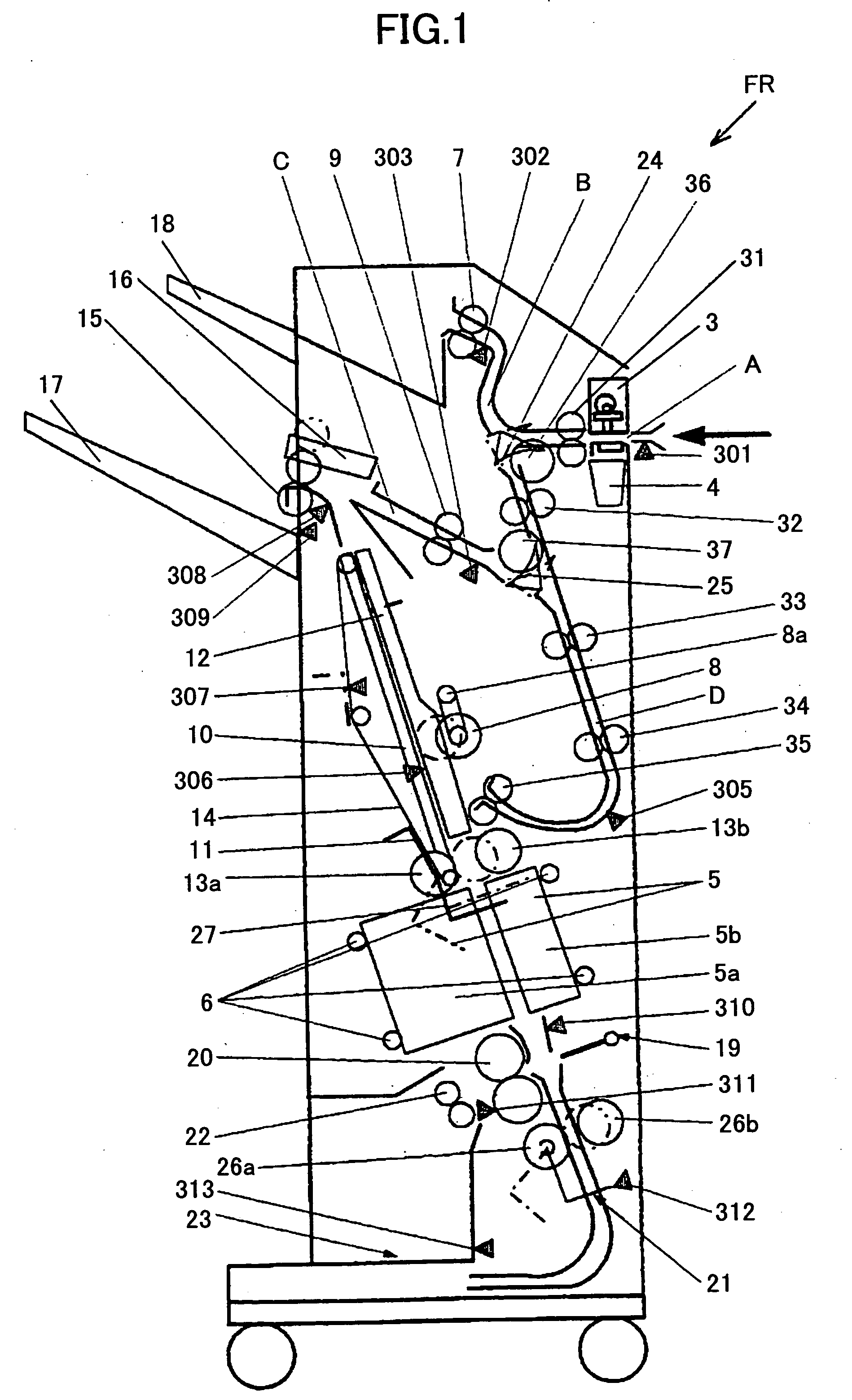

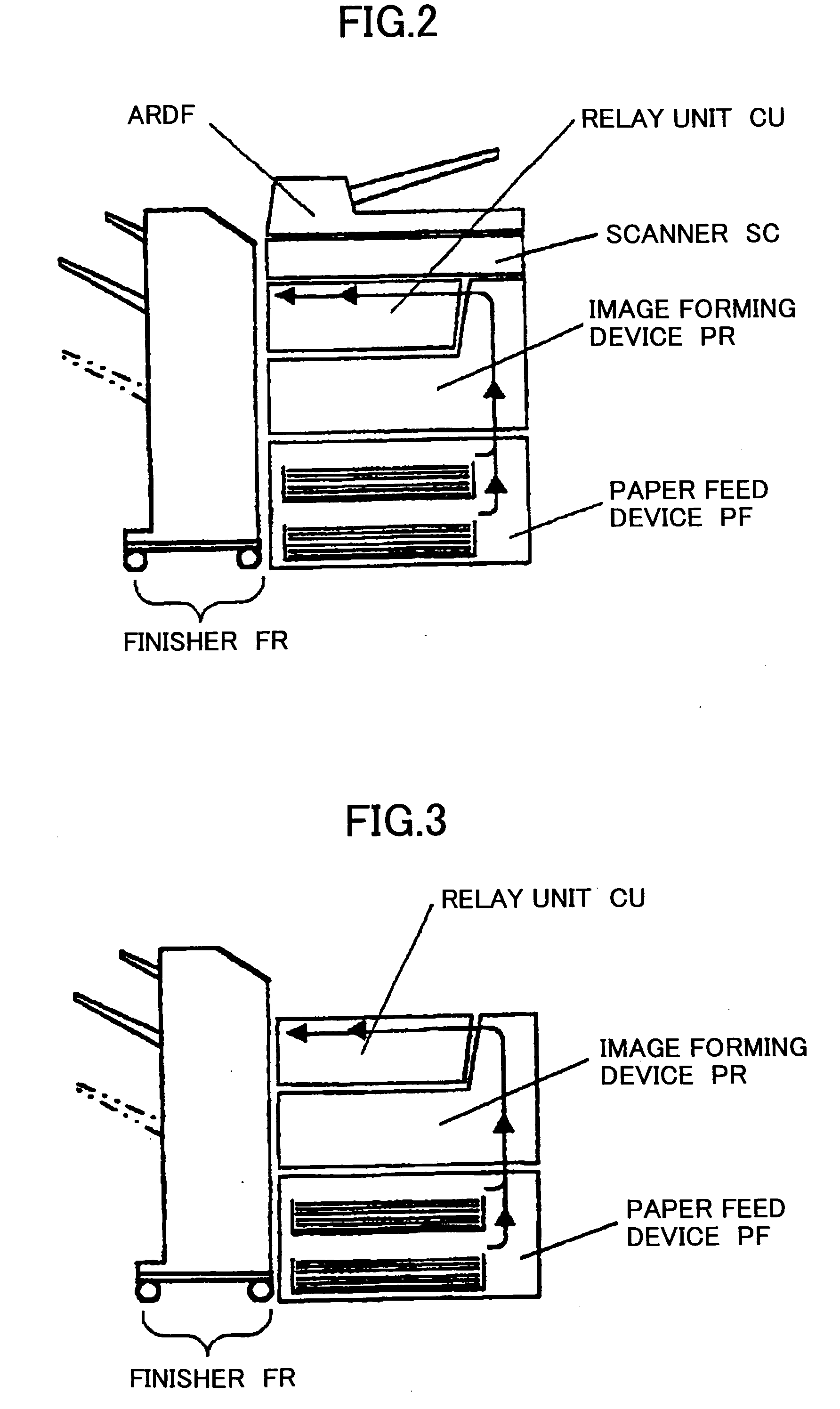

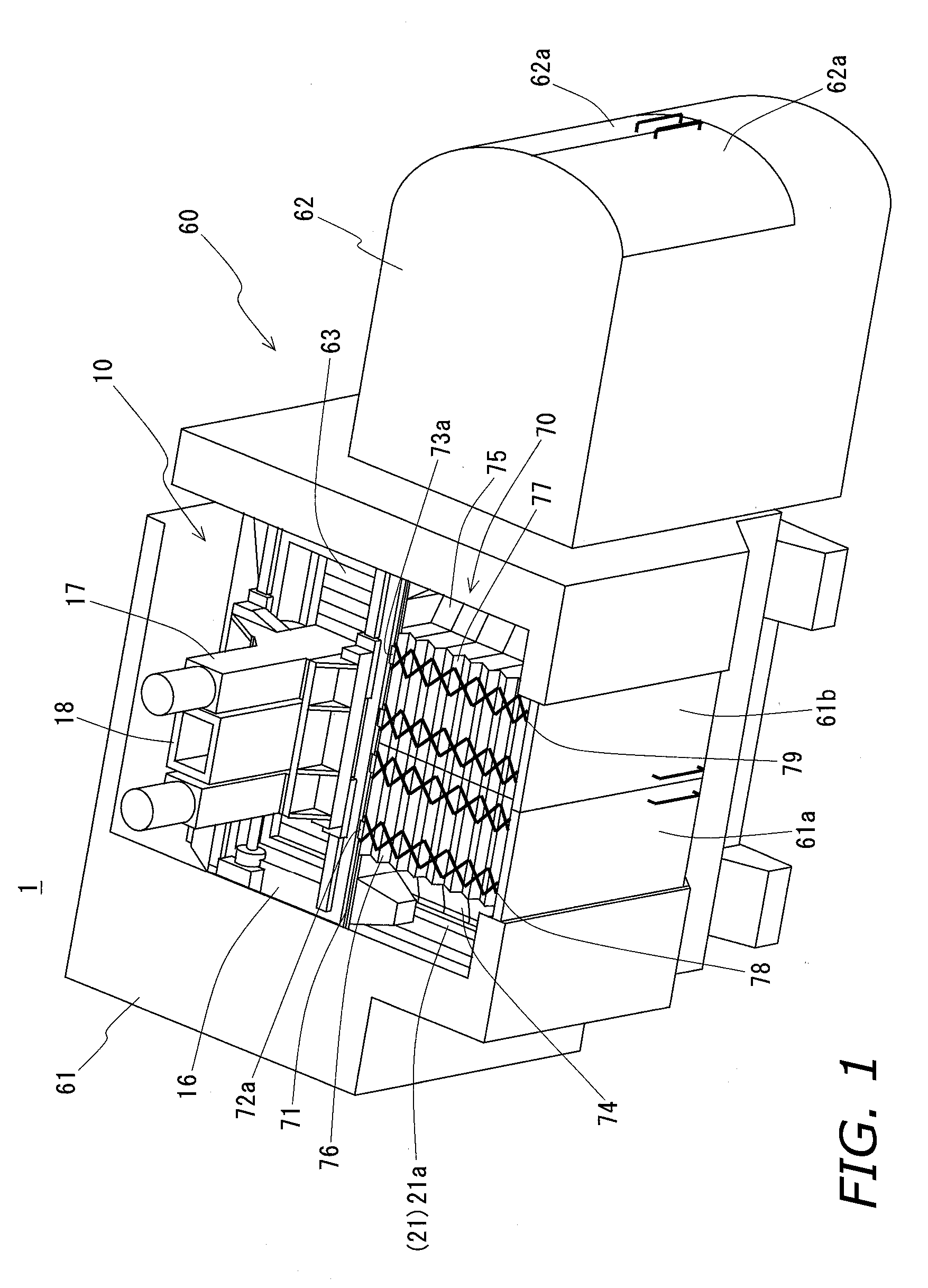

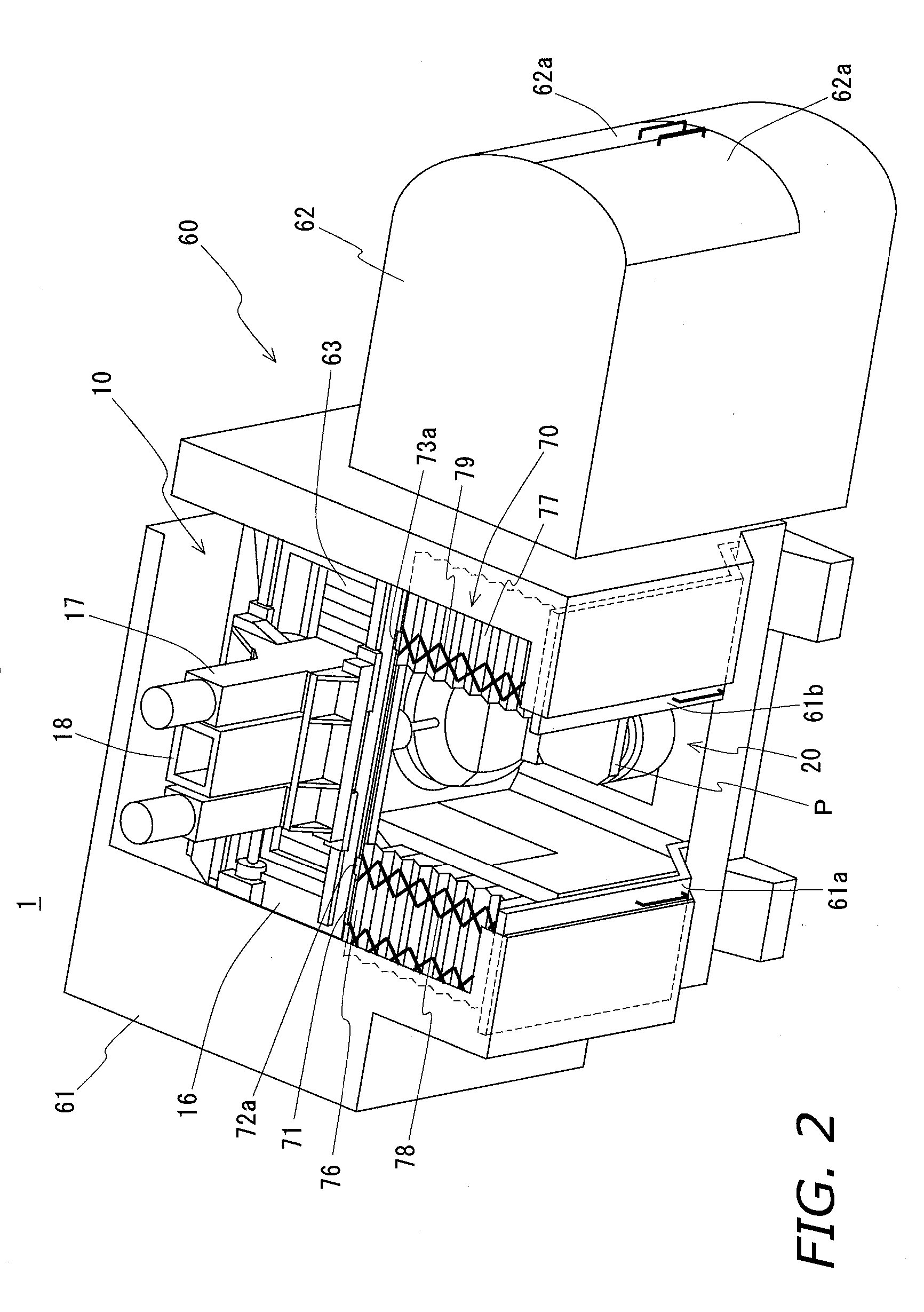

Sheet punch device, sheet processing device, image forming system, program, and recording medium

InactiveUS20050000336A1High-speed sheetGood motor stop precisionAutomatic control devicesFeeding apparatusPunchingEngineering

A sheet punch device for punching a sheet with a punch edge comprises a motor performing a punching operation and a position detection unit detecting a position of the punch edge. A control unit controls the motor and the position detection unit, wherein the control unit causes the position detection unit to detect a position of the punch edge at a time of or prior to a motor stop in a first driving operation of the motor to perform the punching operation, and, when the detected position deviates from a desired position, the control unit performs restarting of the motor so that the punch edge is brought close to the desired position.

Owner:RICOH KK

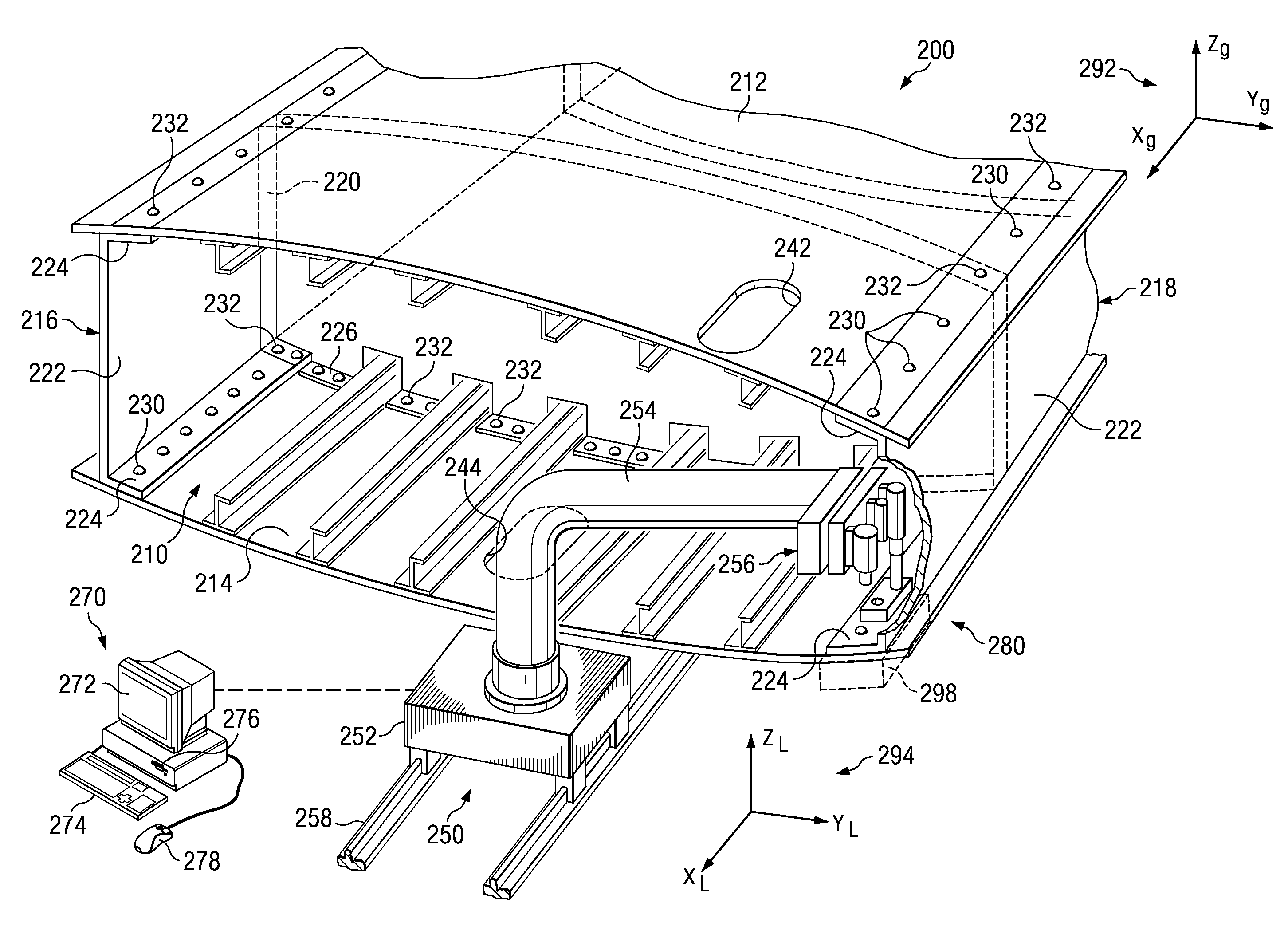

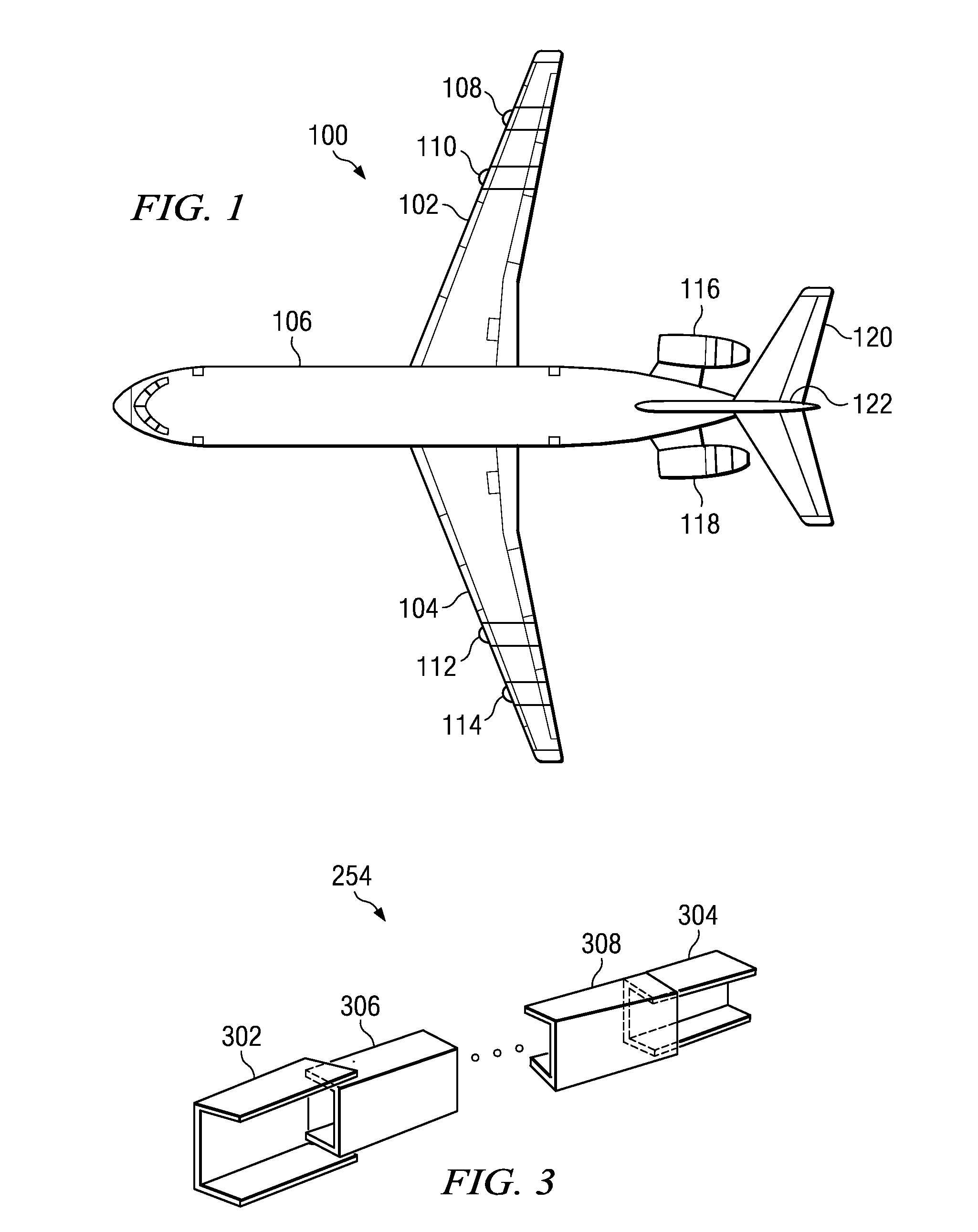

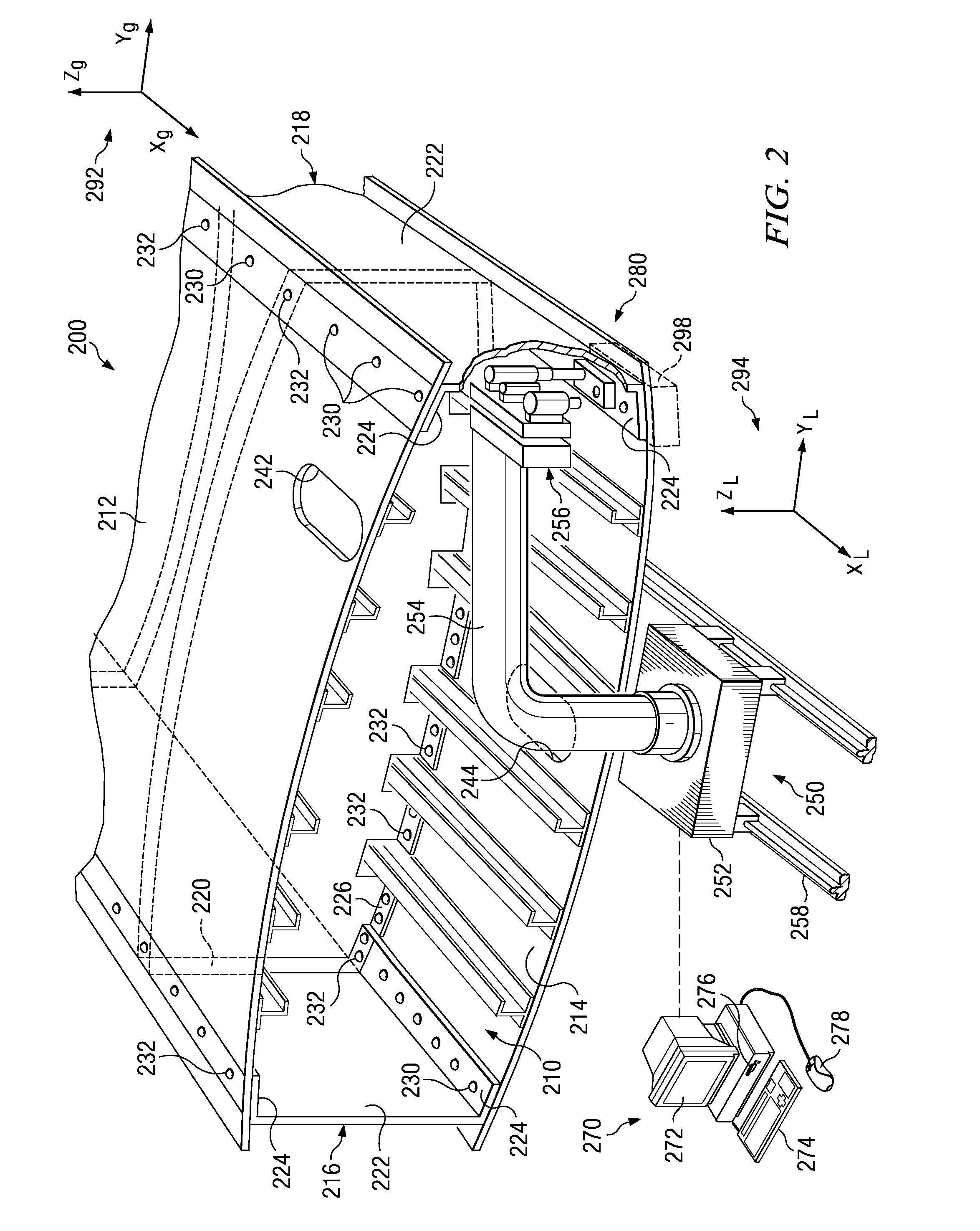

Robot-deployed assembly tool and method for installing fasteners in aircraft structures

ActiveUS20080155807A1Eliminate gapsAircraft componentsAutomatic control devicesFlight vehicleEngineering

An assembly system and method for assembling an aircraft wing box or other structure that may define an interior area accessible through at least one access opening are provided. The method includes inserting a robot having an assembly tool mounted thereto into the interior area through the at least one access opening. The assembly tool may be positioned at a fastener location, and may be clamped to the structure. A hole may be made through the structure, and a fastener may be installed in the hole.

Owner:THE BOEING CO

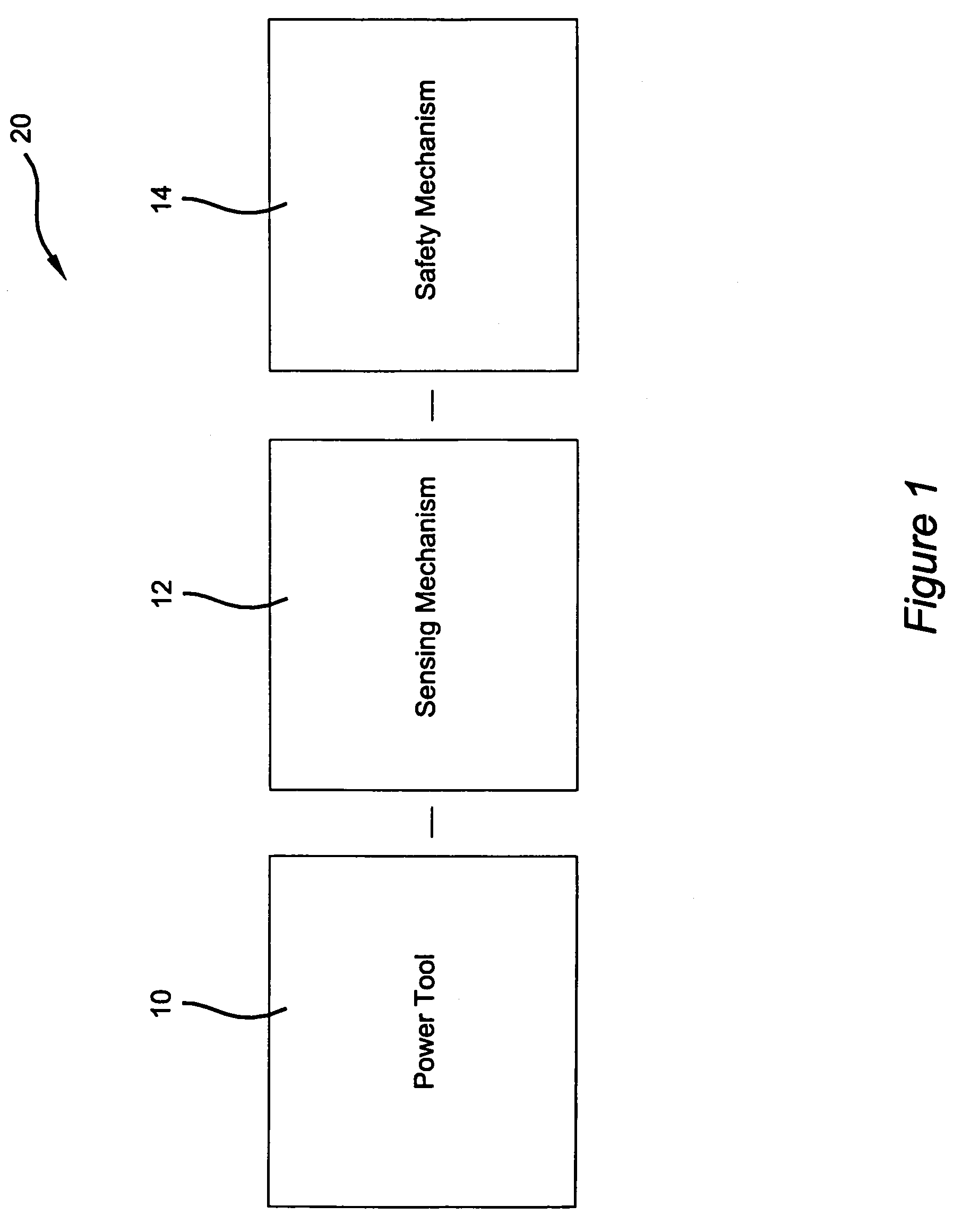

Power tool safety mechanisms

A sensing mechanism (12) for detecting user contact with an active portion (26) of the power tool (10) is provided. In addition, a safety mechanism (14) for preventing prolonged user contact with the active portion (26) of a power tool (10) is provided. The safety mechanism (14) is configured to actuate upon receipt of a signal from the sensing mechanism (12). According to a first aspect, the safety mechanism (14) is arranged to rapidly displace the active portion (26) away from a user extremity. Alternatively, according to a second aspect, the safety mechanism (14) is arranged to rapidly urge an extremity of the user away from the active portion (26) of the power tool (10).

Owner:BLACK & DECKER INC

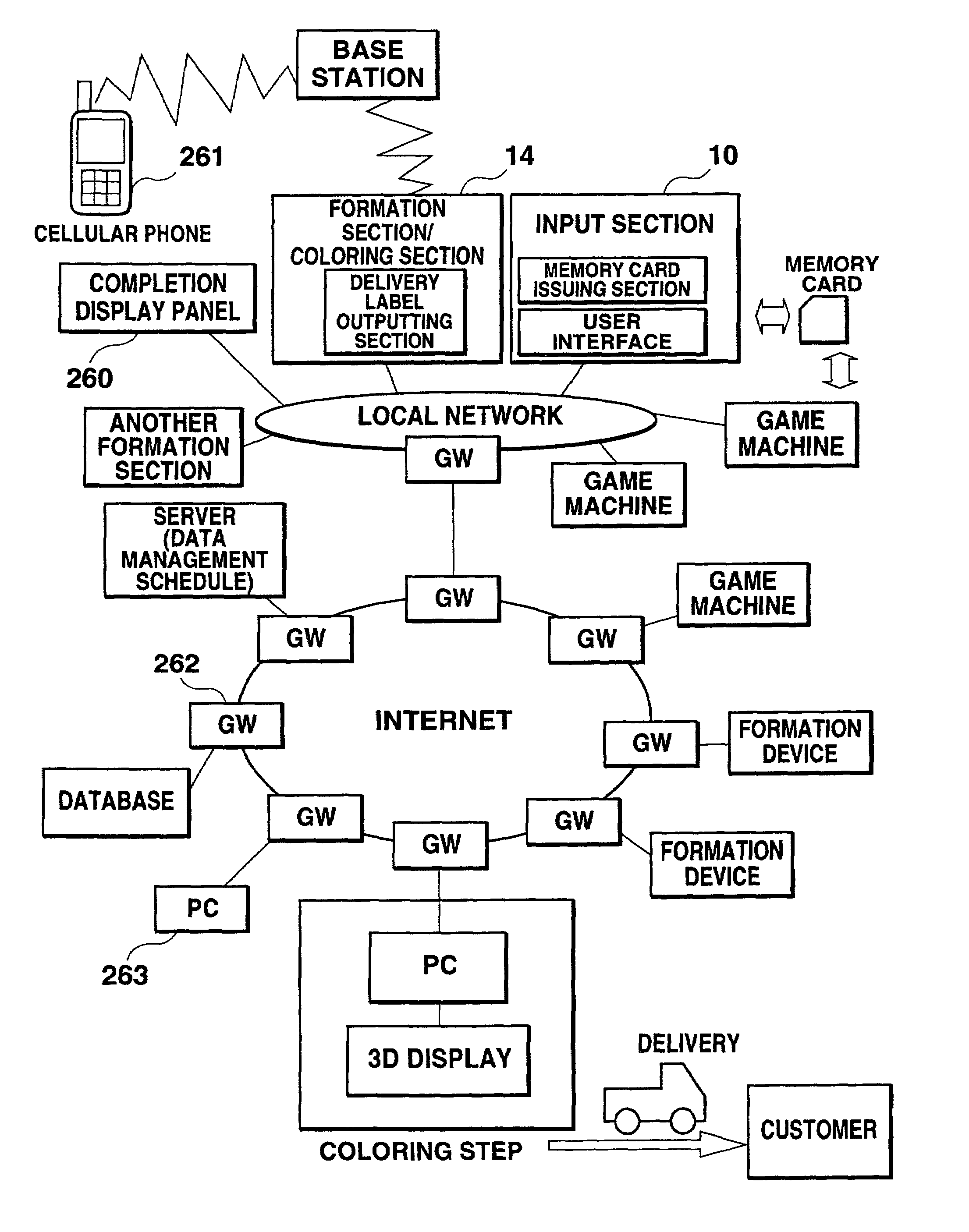

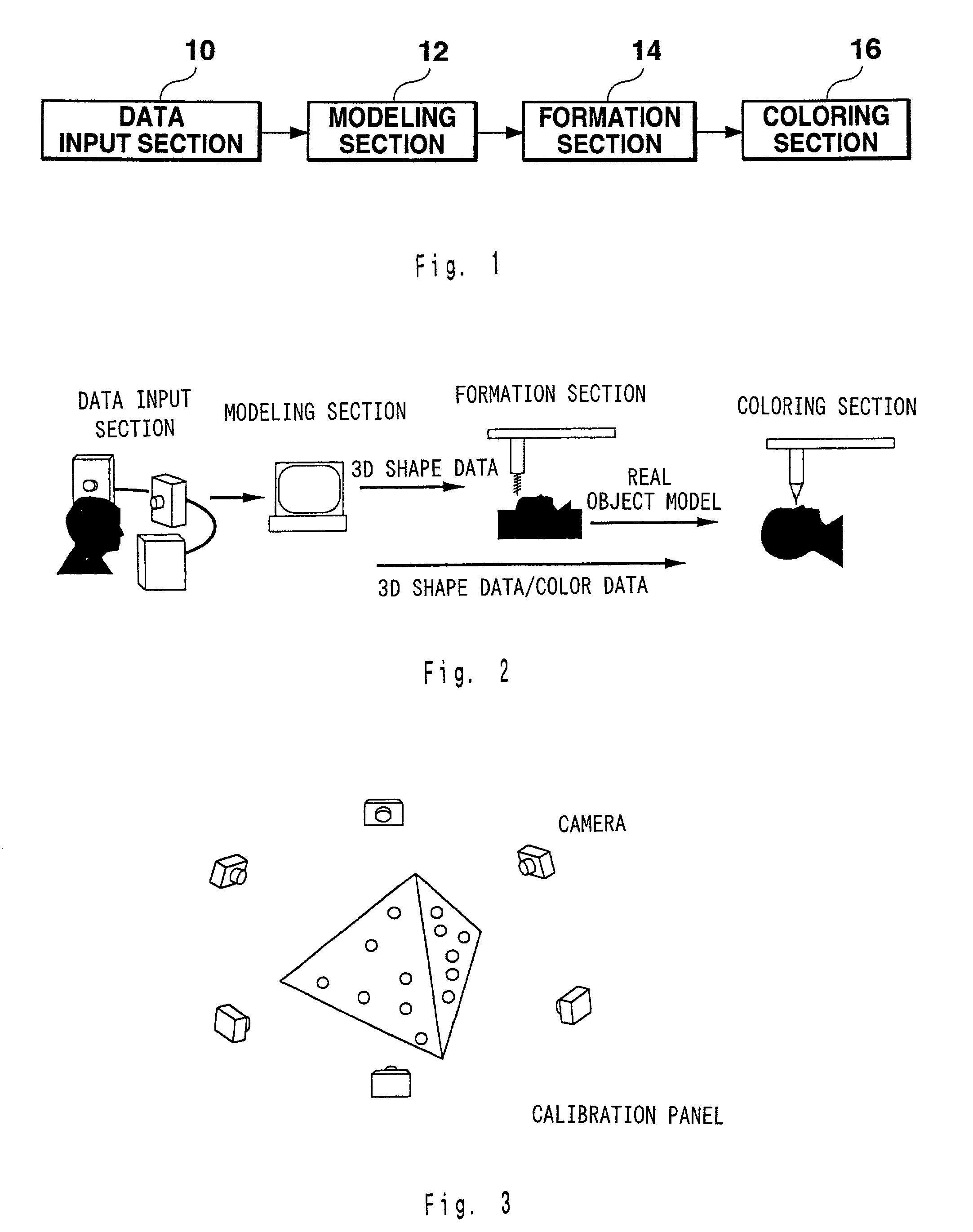

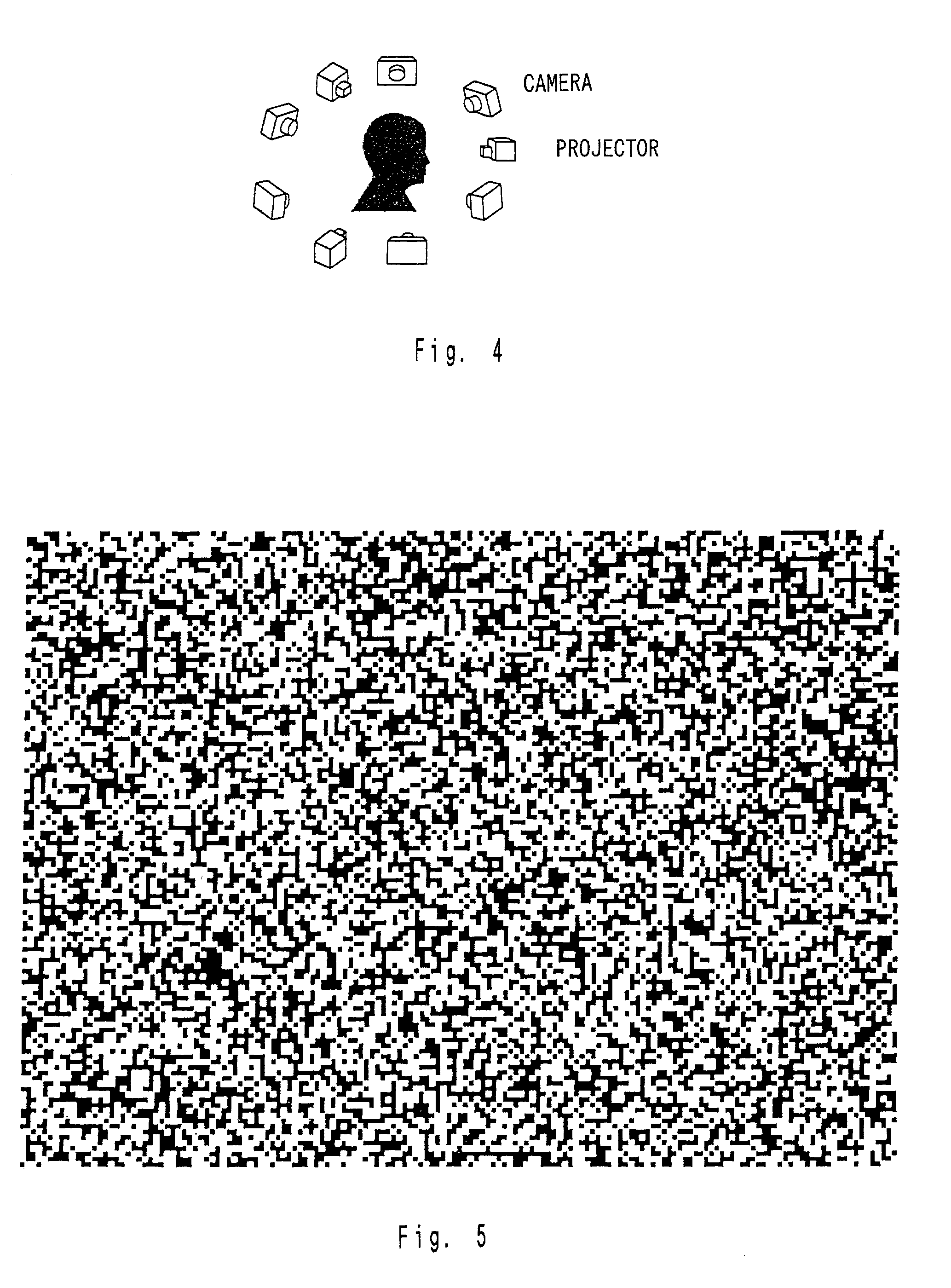

3-D model providing device

InactiveUS7006952B1Efficient and effectiveEffectively and efficiently providingImage analysisDecorative surface effectsThree dimensional shapeMachine learning

For an apparatus effectively providing a real three-dimensional model to a customer, three-dimensional shape data of a target is obtained at a data input section (10). The data is managed by a server which is connected to a network. A suitable formation section (14) is selected to form a real three-dimensional model based on the data. In addition, the formation completion is automatically notified to the customer via a completion display panel (260), a cellular phone (61), or the like.

Owner:DIGIMEDIA TECH LLC

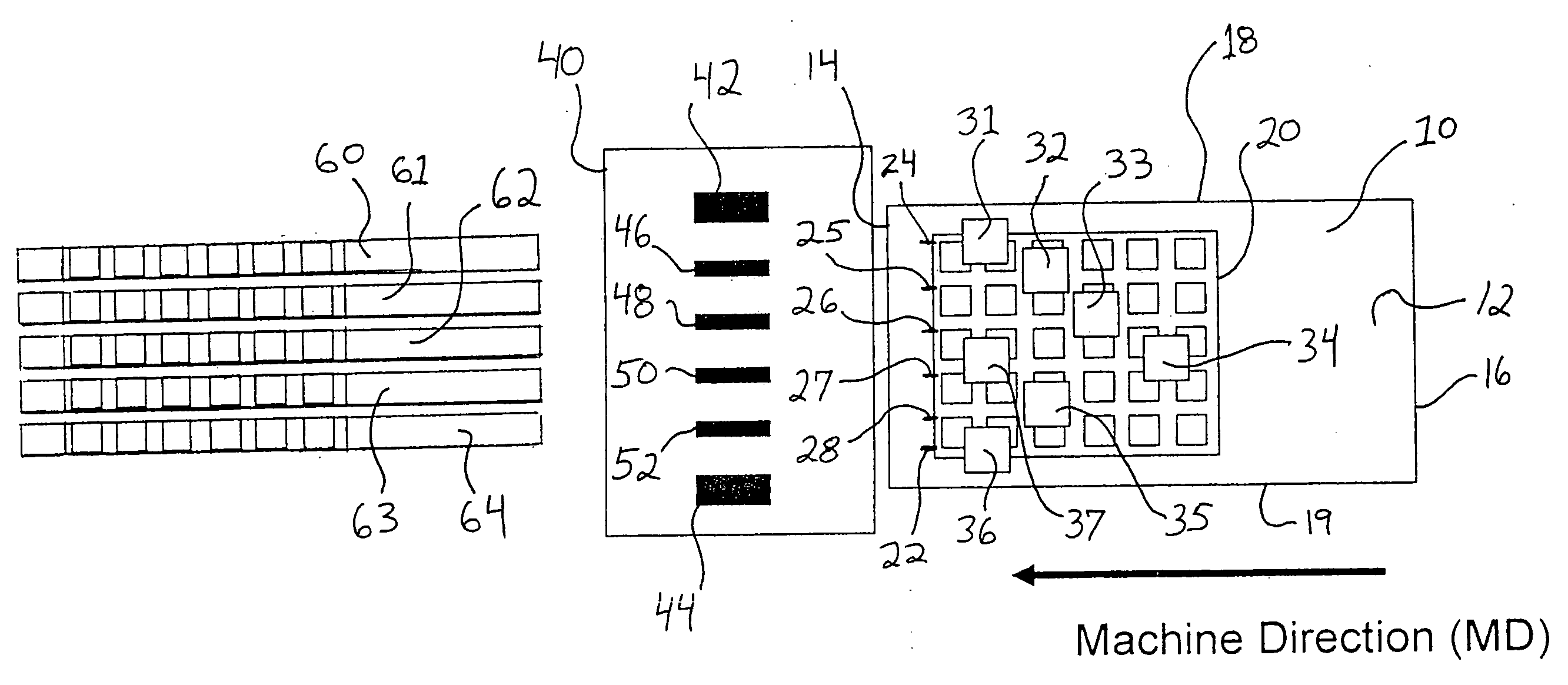

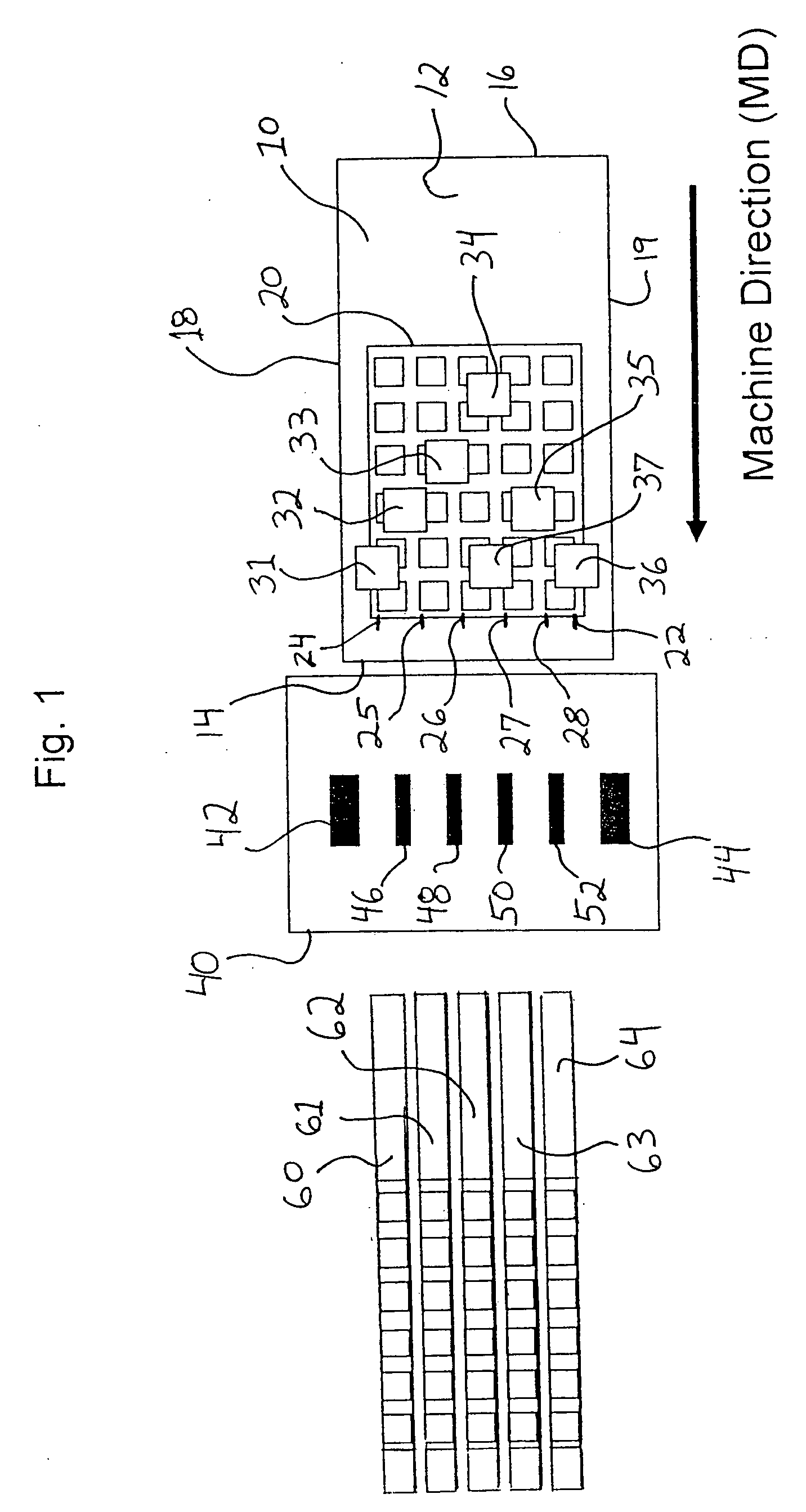

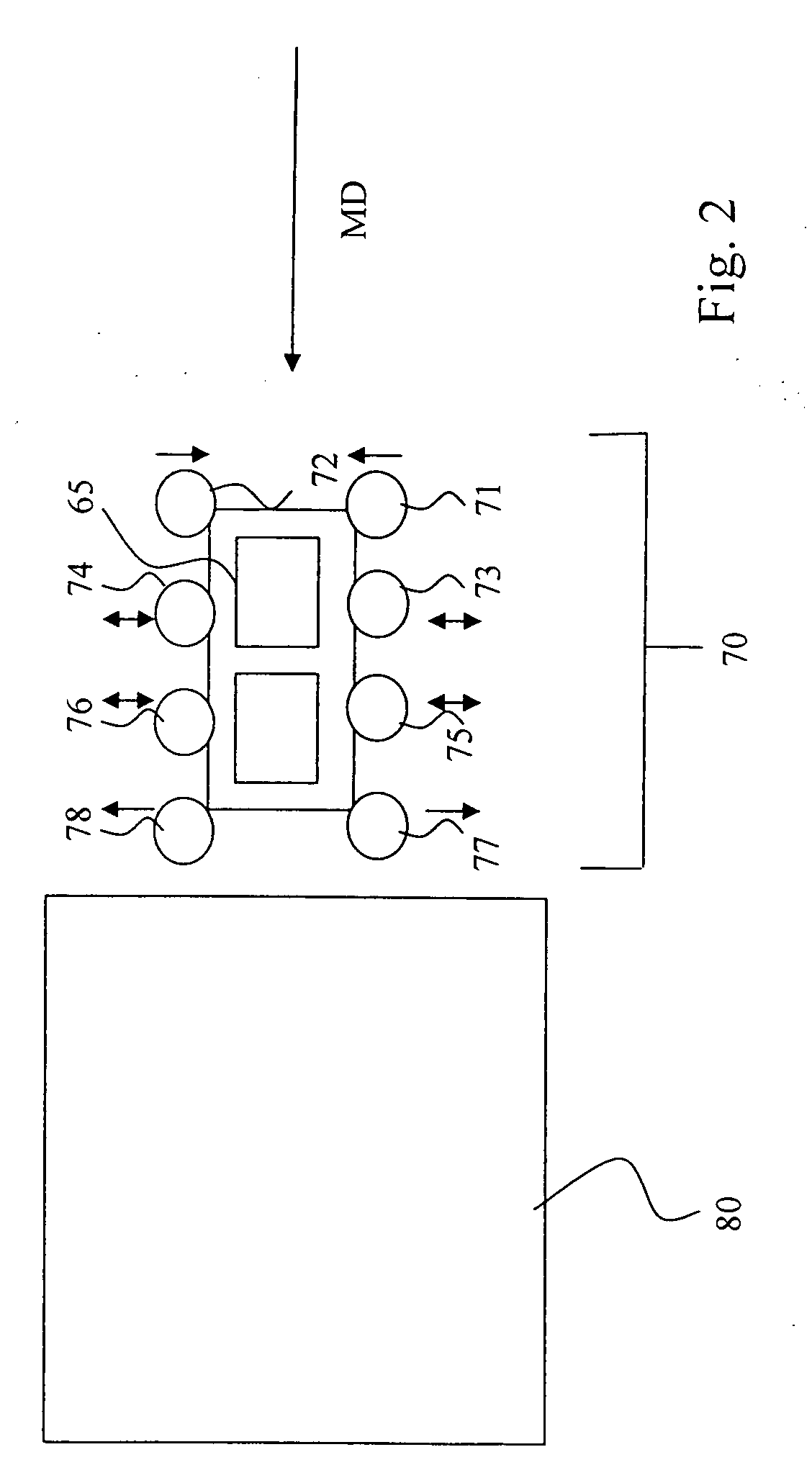

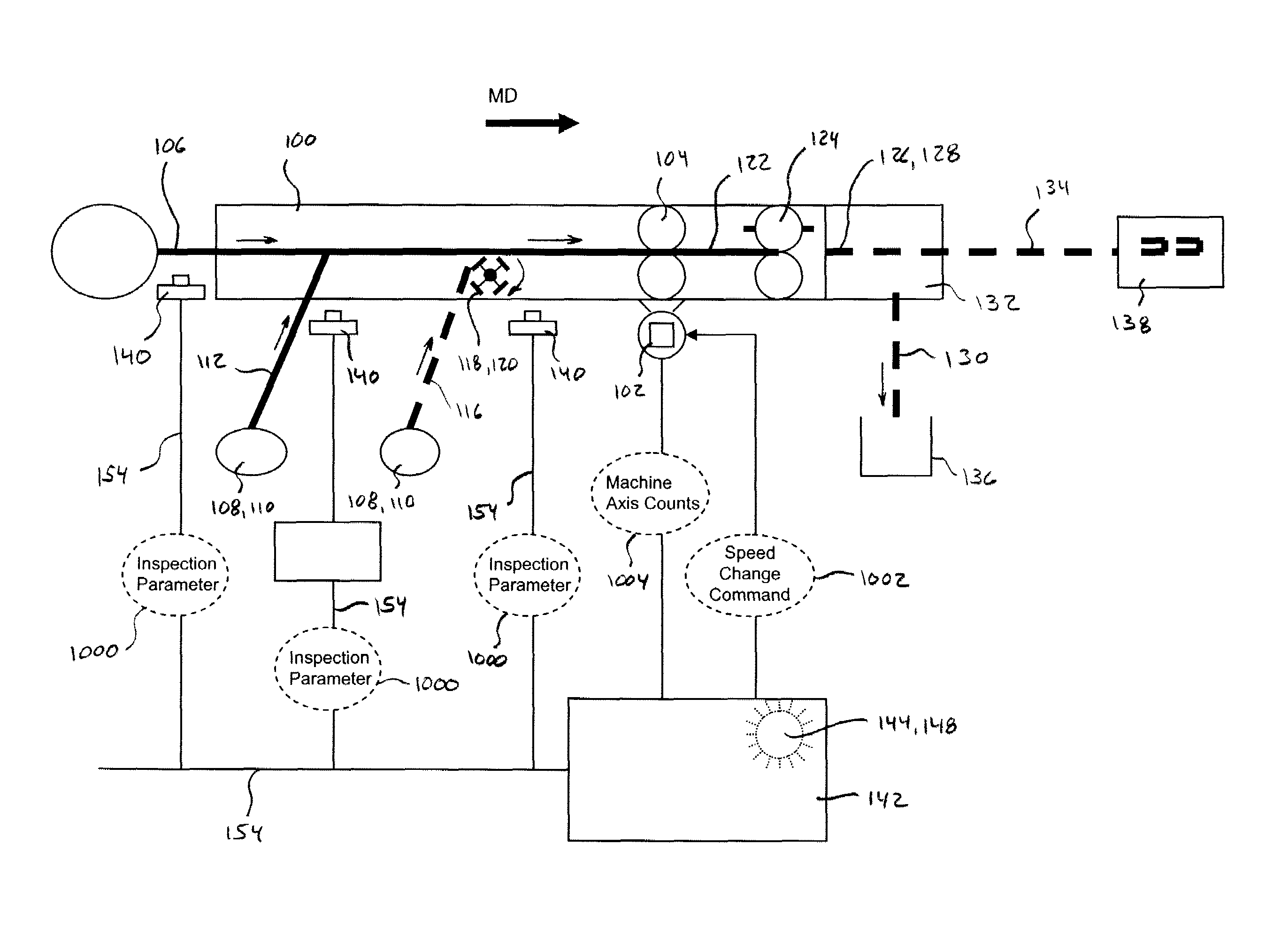

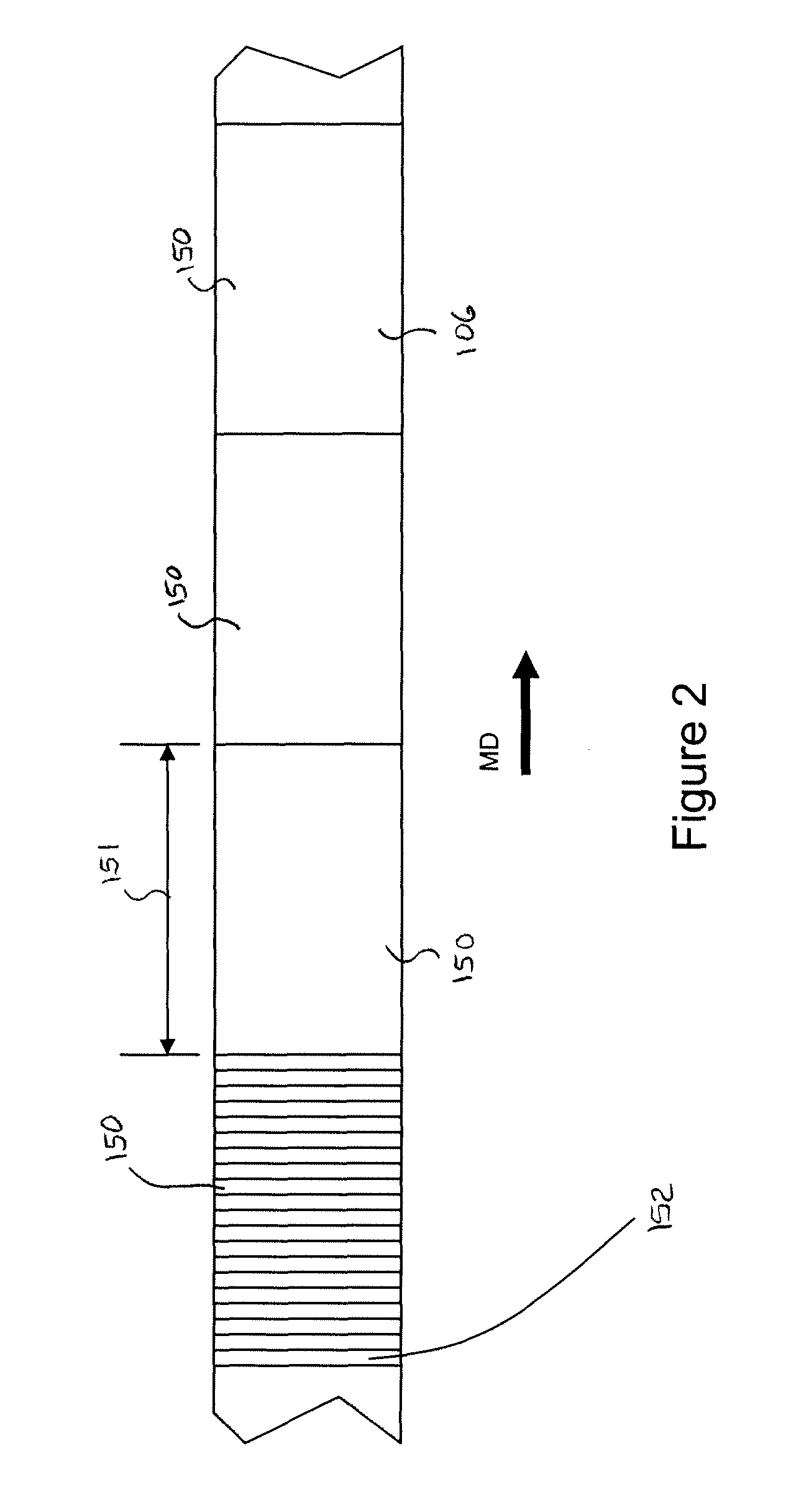

Systems and methods for controlling registration of advancing substrates in absorbent article converting lines

ActiveUS8145343B2Precise applicationMaterial analysis by optical meansMultiple digital computer combinationsControl systemEngineering

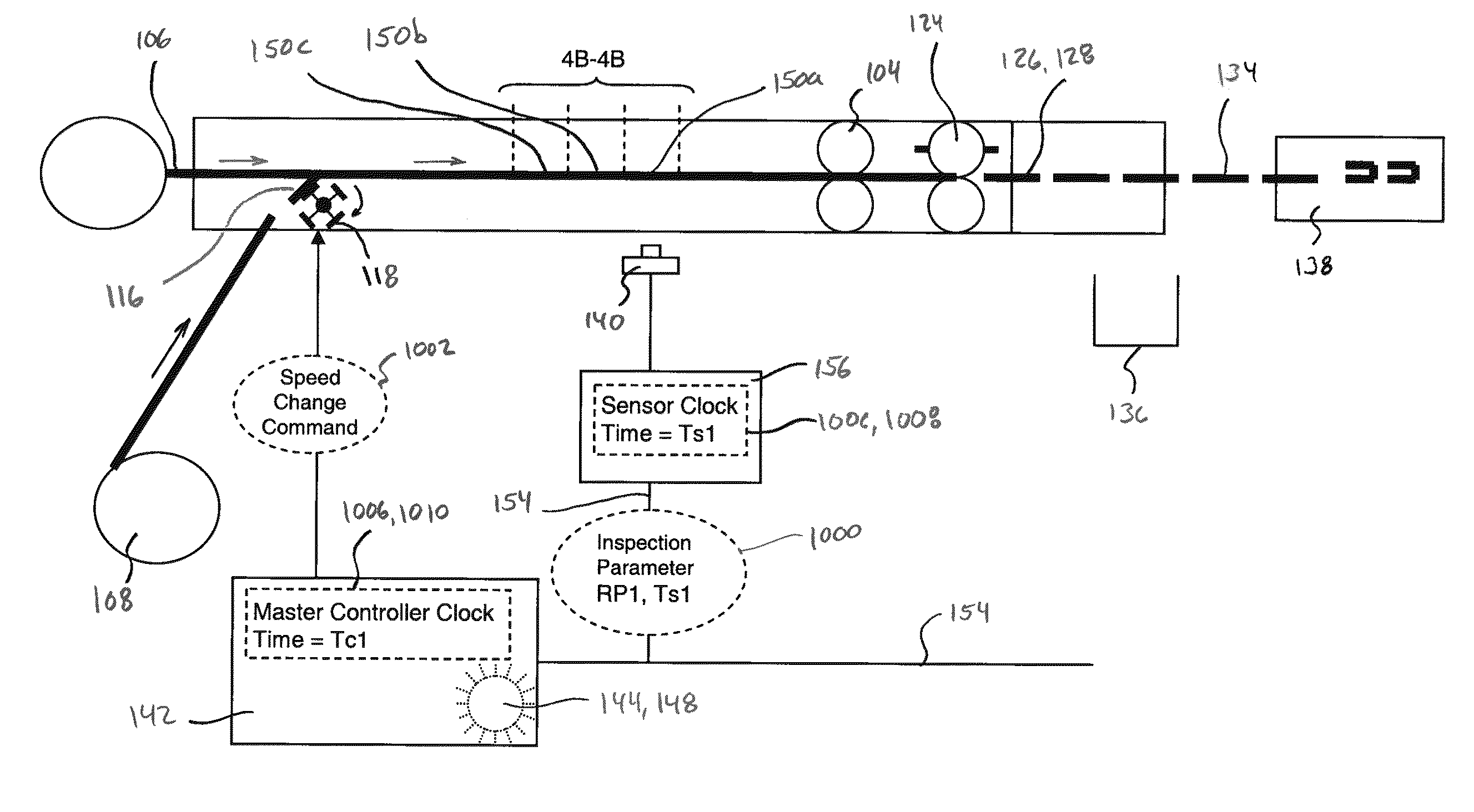

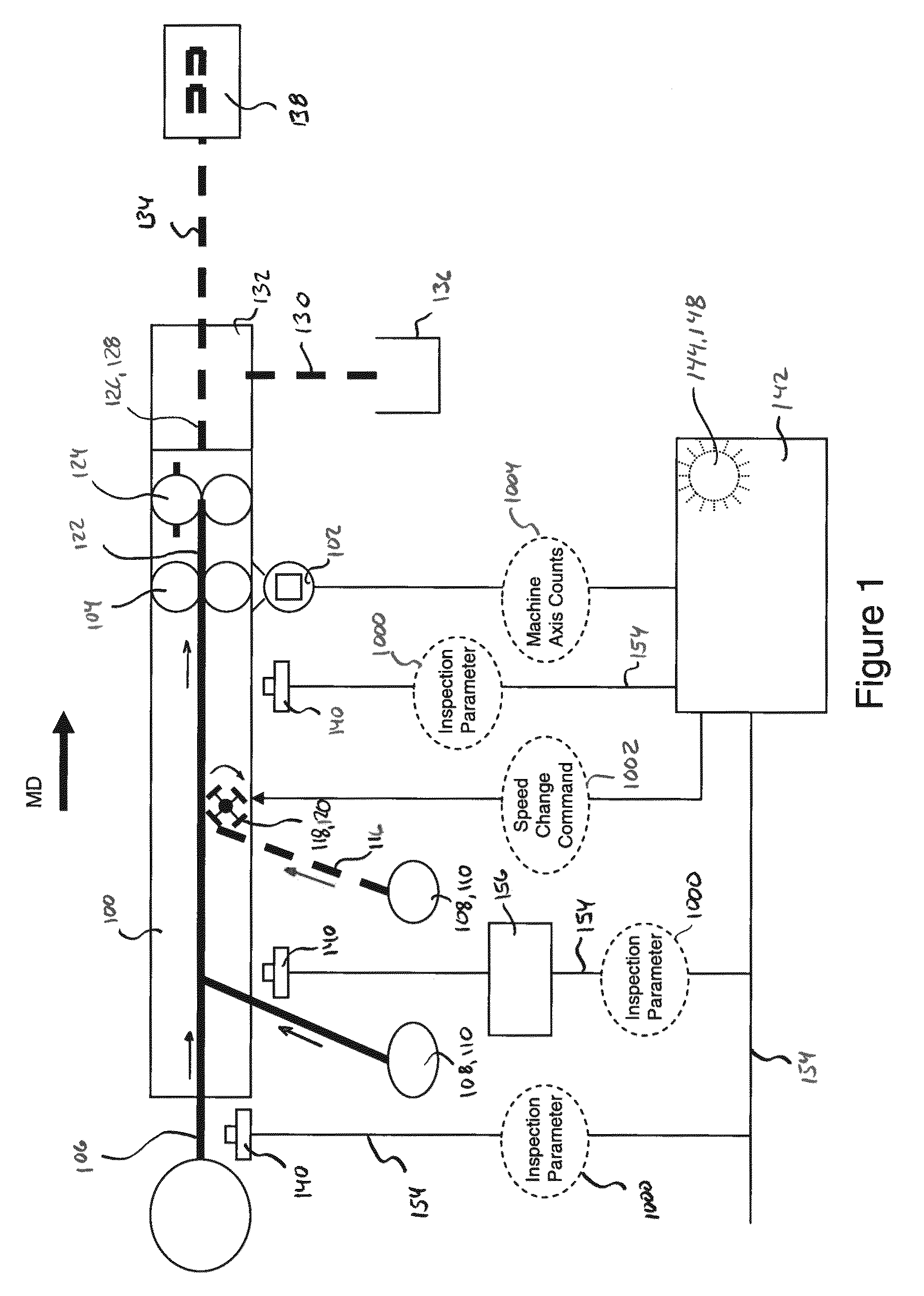

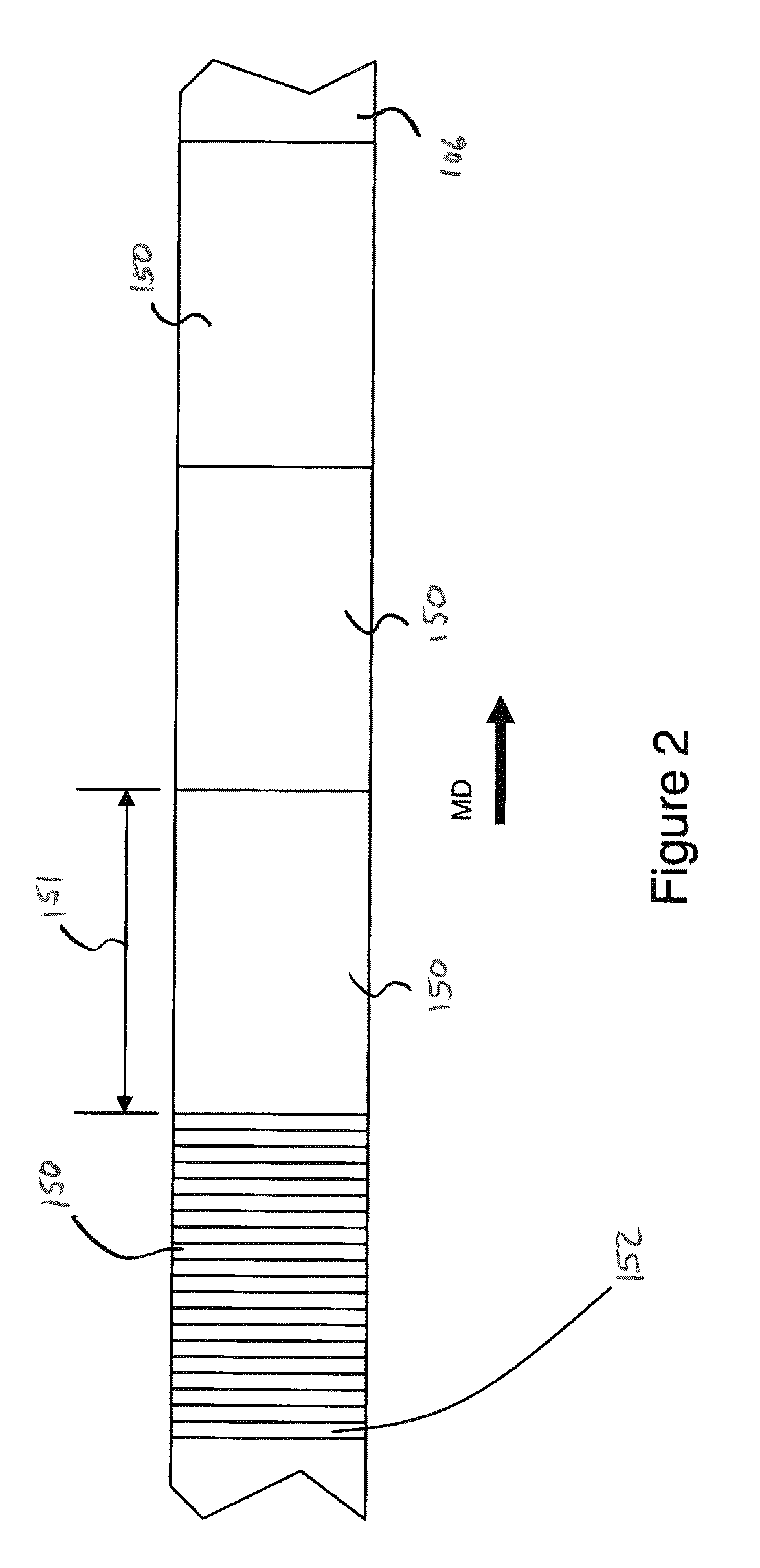

The present disclosure relates to systems and processes for controlling the registration of advancing substrates in absorbent article converting lines. The systems and methods may utilize feedback from technologies, such as vision systems, sensors, remote input and output stations, and controllers with synchronized embedded clocks to accurately correlate registration feature detections and substrate speed control on an absorbent article converting process. The systems and methods may accurately apply the use of precision clock synchronization for both instrumentation and control system devices on a non-deterministic communications network. In turn, the clock synchronized control and instrumentation network may be used to control the substrate speed. As such, the controller may be programmed to track registration features on substrates and components along the converting line without having to account for undeterminable delays.

Owner:PROCTER & GAMBLE CO

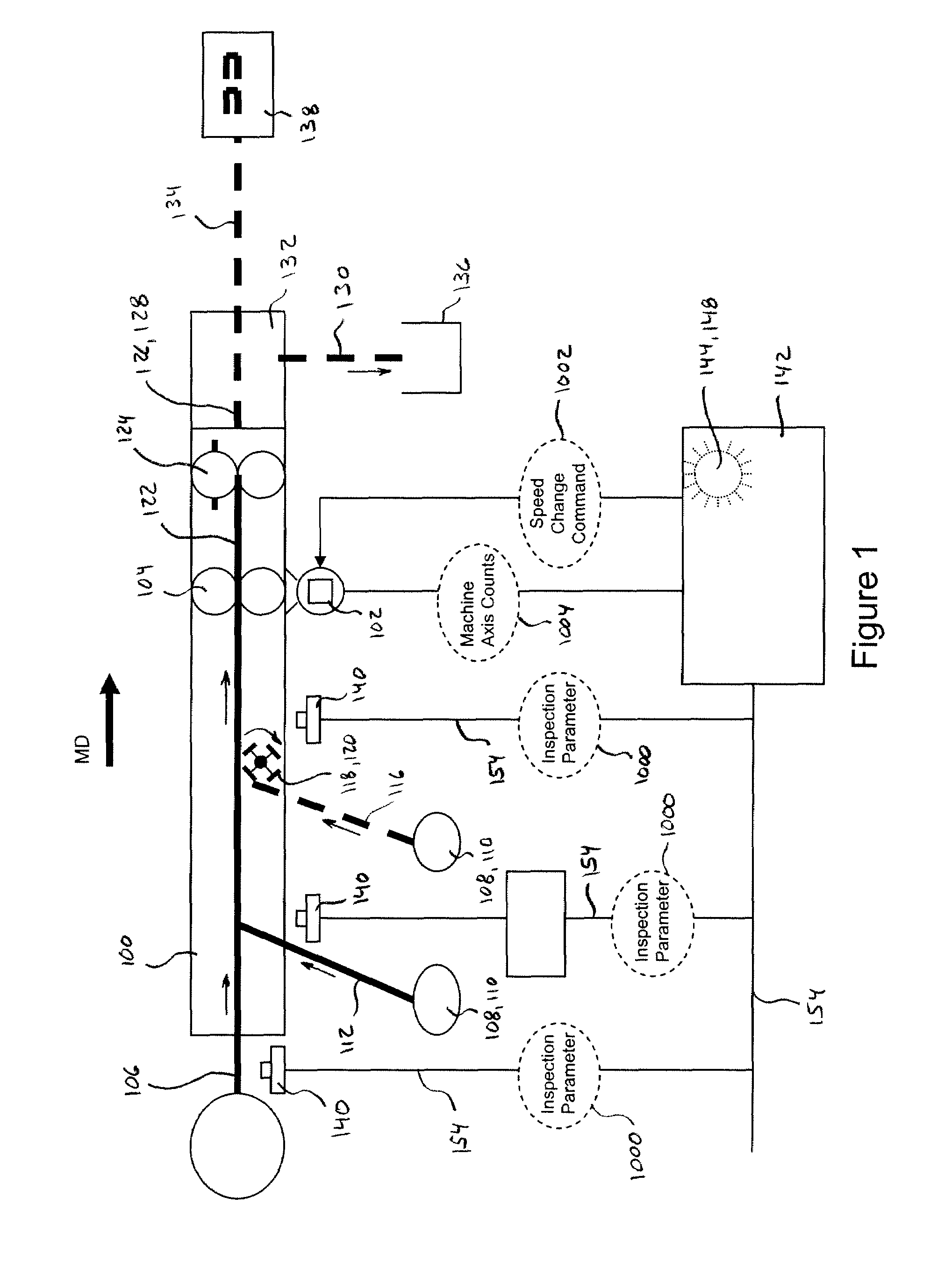

Systems and methods for controlling phasing of advancing substrates in absorbent article converting lines

ActiveUS8145344B2Precise applicationProgramme controlAutomatic control devicesControl systemEngineering

The present disclosure relates to systems and processes for controlling the relative positions or phasing of advancing substrates and / or components in absorbent article converting lines. The systems and methods may utilize feedback from technologies, such as vision systems, sensors, remote input and output stations, and controllers with synchronized embedded clocks to accurately correlate component placement detections and placement control on an absorbent article converting process. The systems and methods may accurately apply the use of precision clock synchronization for both instrumentation and control system devices on a non-deterministic communications network. In turn, the clock synchronized control and instrumentation network may be used to control the substrate position. As such, the controller may be programmed to the relative positions of substrates and components along the converting line without having to account for undeterminable delays.

Owner:THE PROCTER & GAMBLE COMPANY

Machine Tool

ActiveUS20060270540A1Easy maintenanceReduce manufacturing costPlaning/slotting machinesMilling machinesFree rotationSaddle shape

Machine tool simplifying maintenance, reducing manufacturing costs, and enabling high precision machining. The machine tool is equipped with: a bed furnished with a rectangular base, right and left sidewalls provided standing either side of the base, and a rear sidewall provided standing along the back of the base; a table disposed in the space surrounded by the three sidewalls; a first saddle shaped in the form of a rectangular frame shape, provided free to shift back and forth supported on the tops of the left and right sidewalls; a second saddle penetrated by a perpendicular through-hole and arranged free to shift sideways inside the first saddle frame; and a spindle head arranged free to shift perpendicularly inside the through-hole in the second saddle; and a main spindle arranged over the table and supported by the spindle head free to rotate centered on its axis.

Owner:DMG MORI SEIKI CO LTD

Cutter blade position detection mechanism and method of reporting cutter malfunction

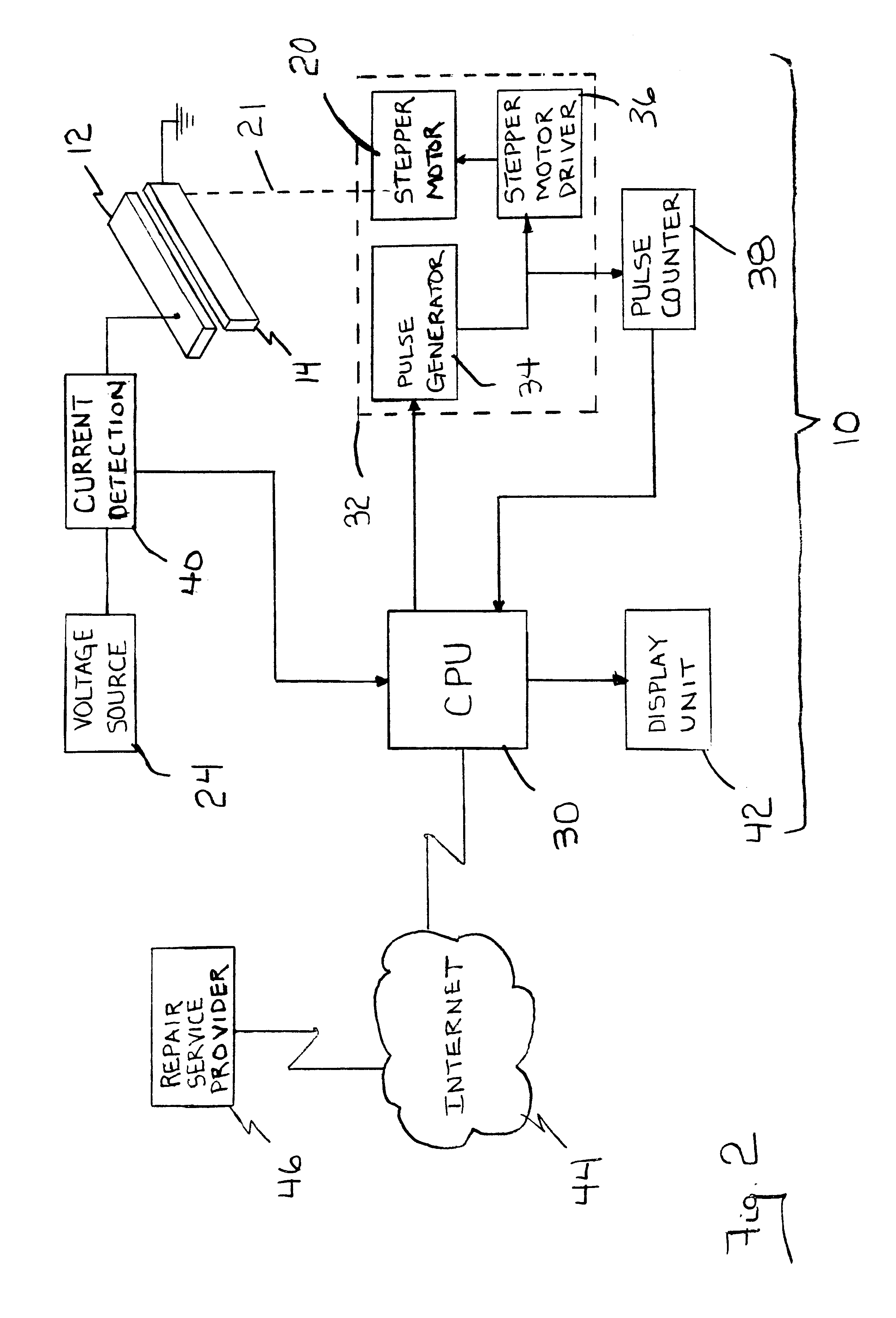

A sheet cutting device utilizing cutter blades as a position detection mechanism and a method of reporting cutter malfunctions is provided. The sheet cutting device including a cutter having a pair of cutter blades, one of the blades connected to a cutter driving mechanism for moving the blade through a cutting cycle, a power source is connected to one of the blades so that a circuit is closed when the blades contact one another, and a current sensing device in connection with the circuit to identify when the blades are in physical contact.

Owner:TOSHIBA GLOBAL COMMERCE SOLUTIONS HLDG

Solar cell stringing machine

Owner:GTAT CORPORATION

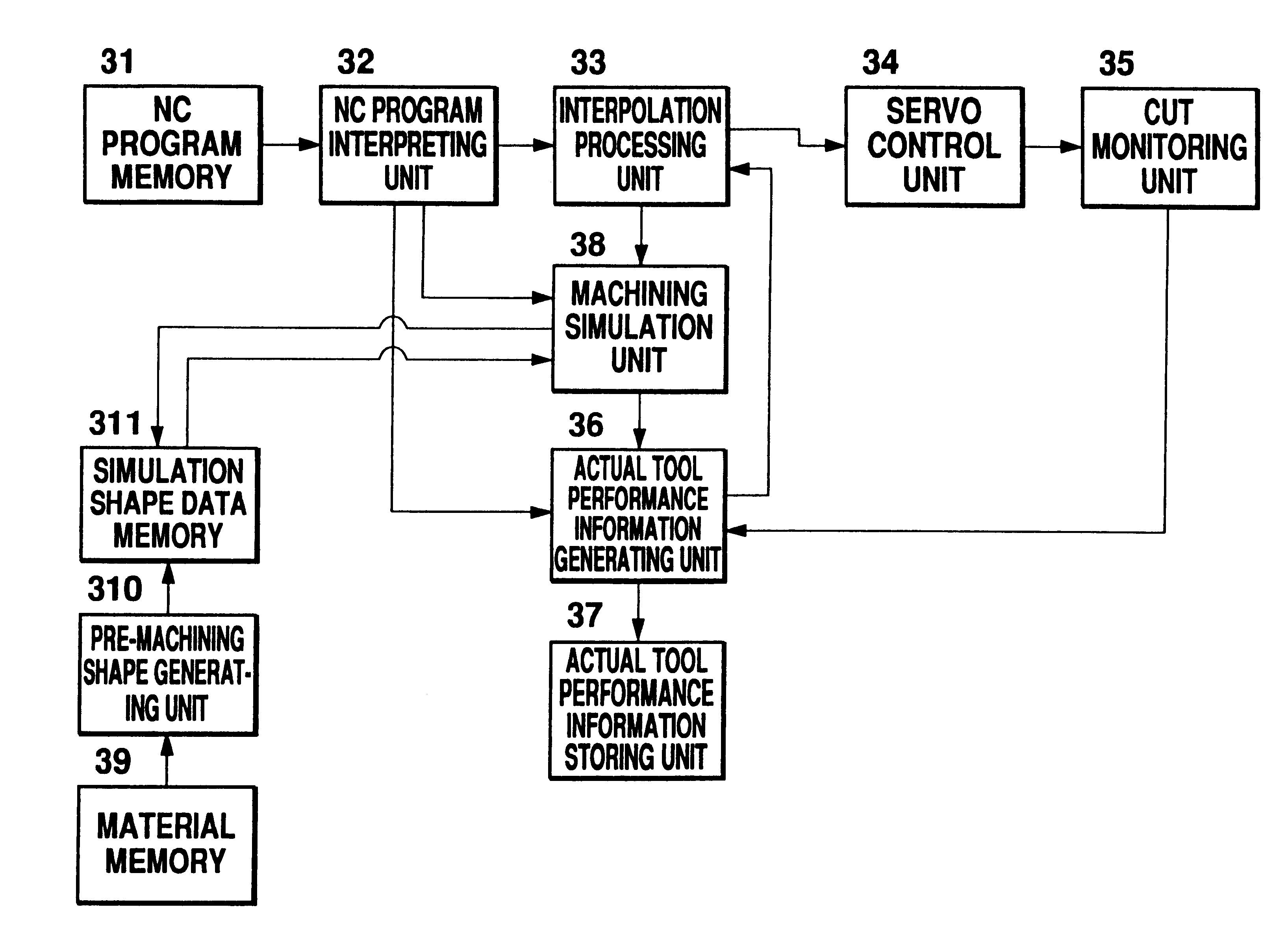

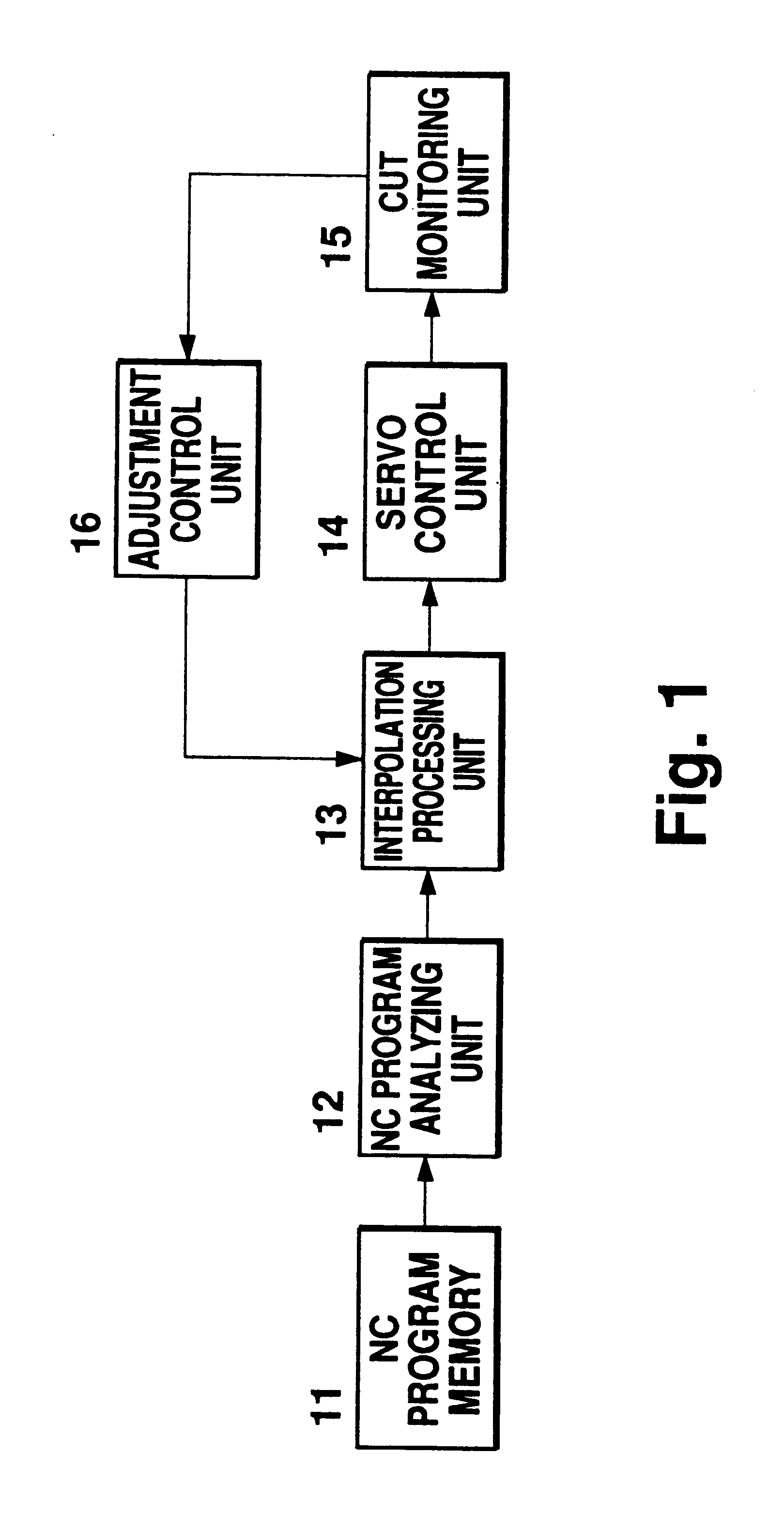

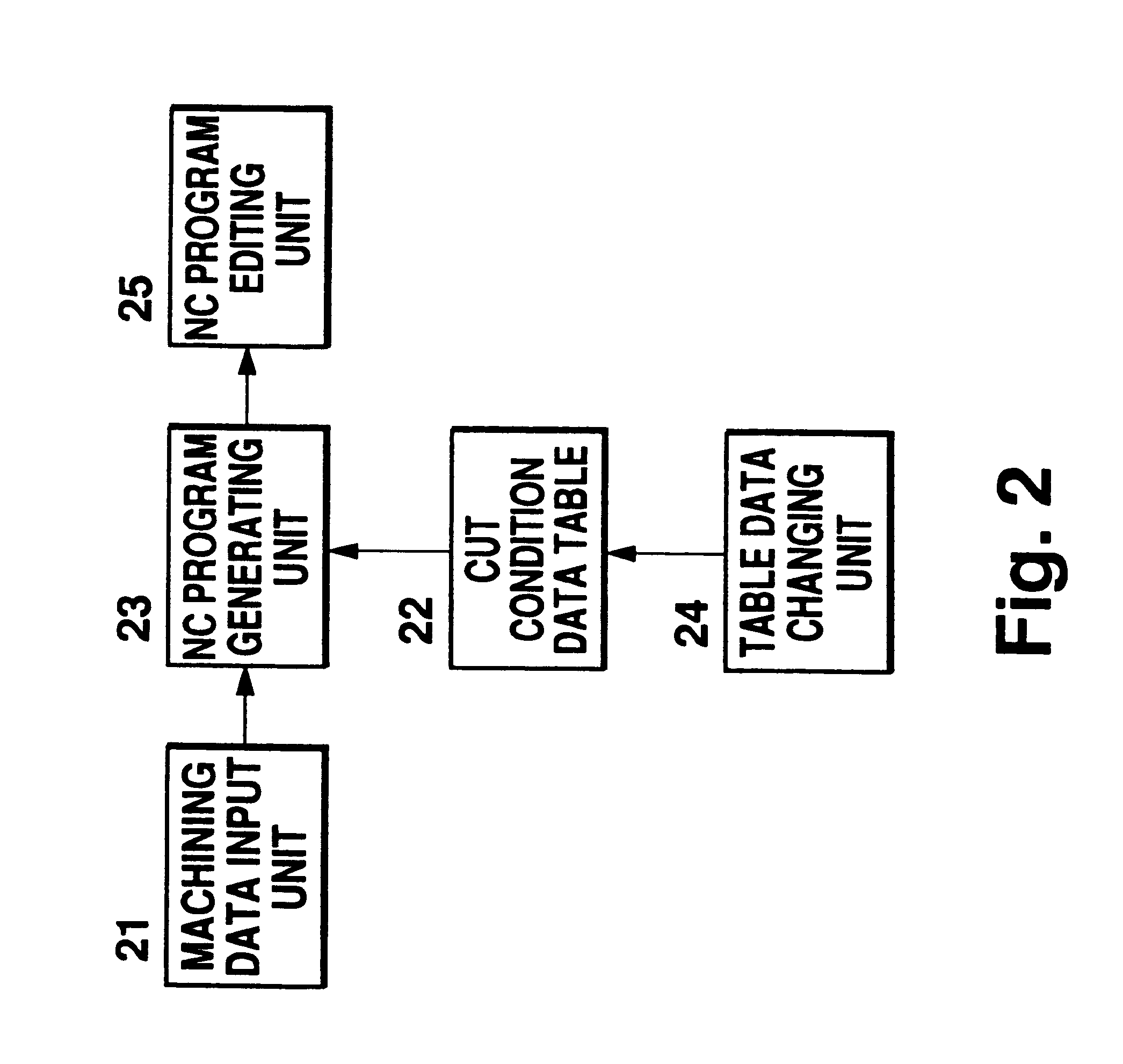

Apparatus for generating a numerical control command according to cut resistance value and cut torque value of machining simulation

InactiveUS6266572B1Solution to short lifeImprove wear resistanceProgramme controlAutomatic control devicesNumerical controlMachine simulation

A method of simulation of NC machining, wherein machining simulation is carried out according to blank shape data, tool shape data and an NC program to modify the NC program or interpolation data by feedforward control so that optimum cutting conditions can be obtained. The simulation result can be used for correcting the NC program and the interpolation data at the next stage. Further, a record of tools used can be generated on the basis of this simulation result.

Owner:OKUMA CORP +3

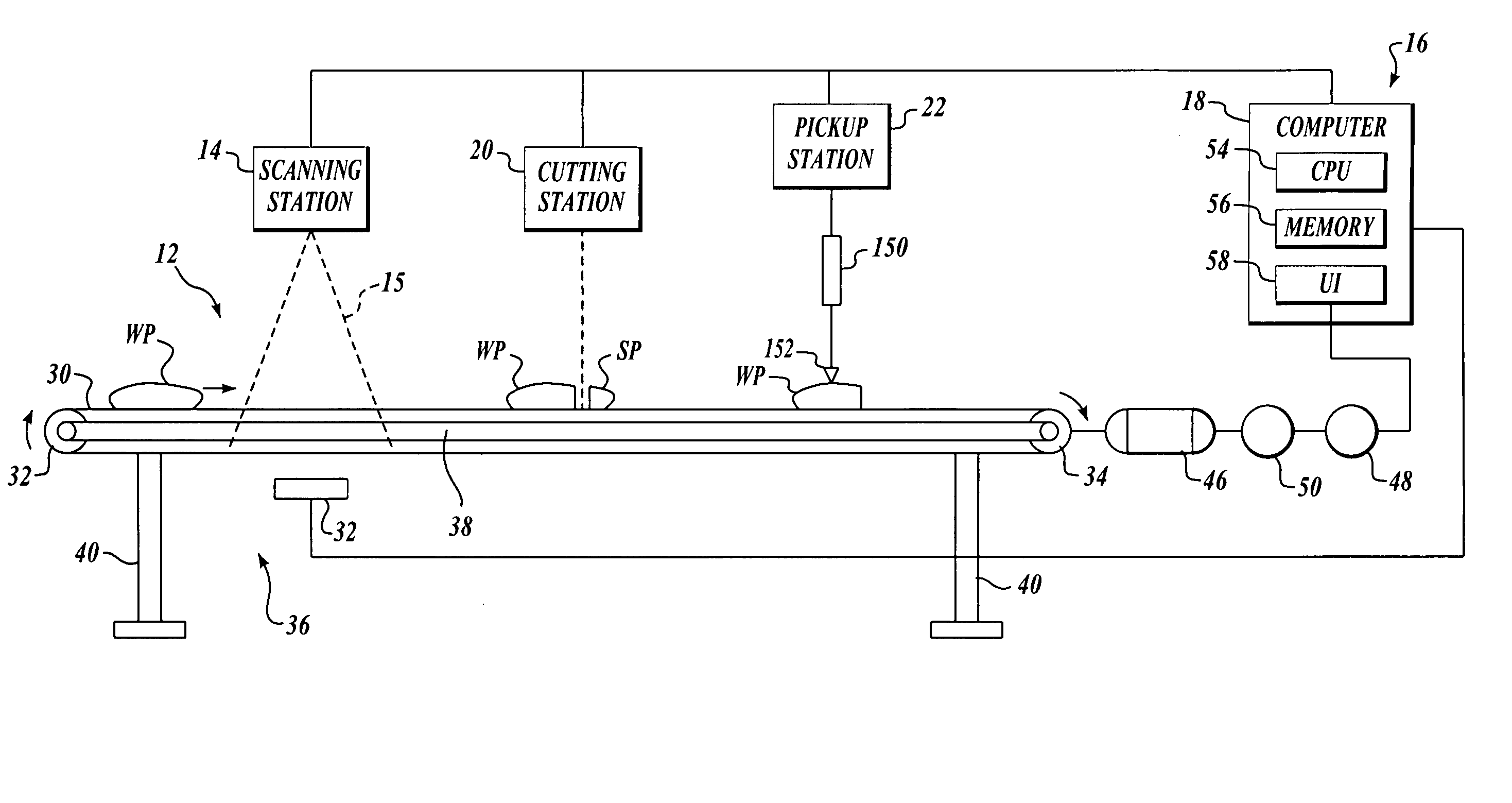

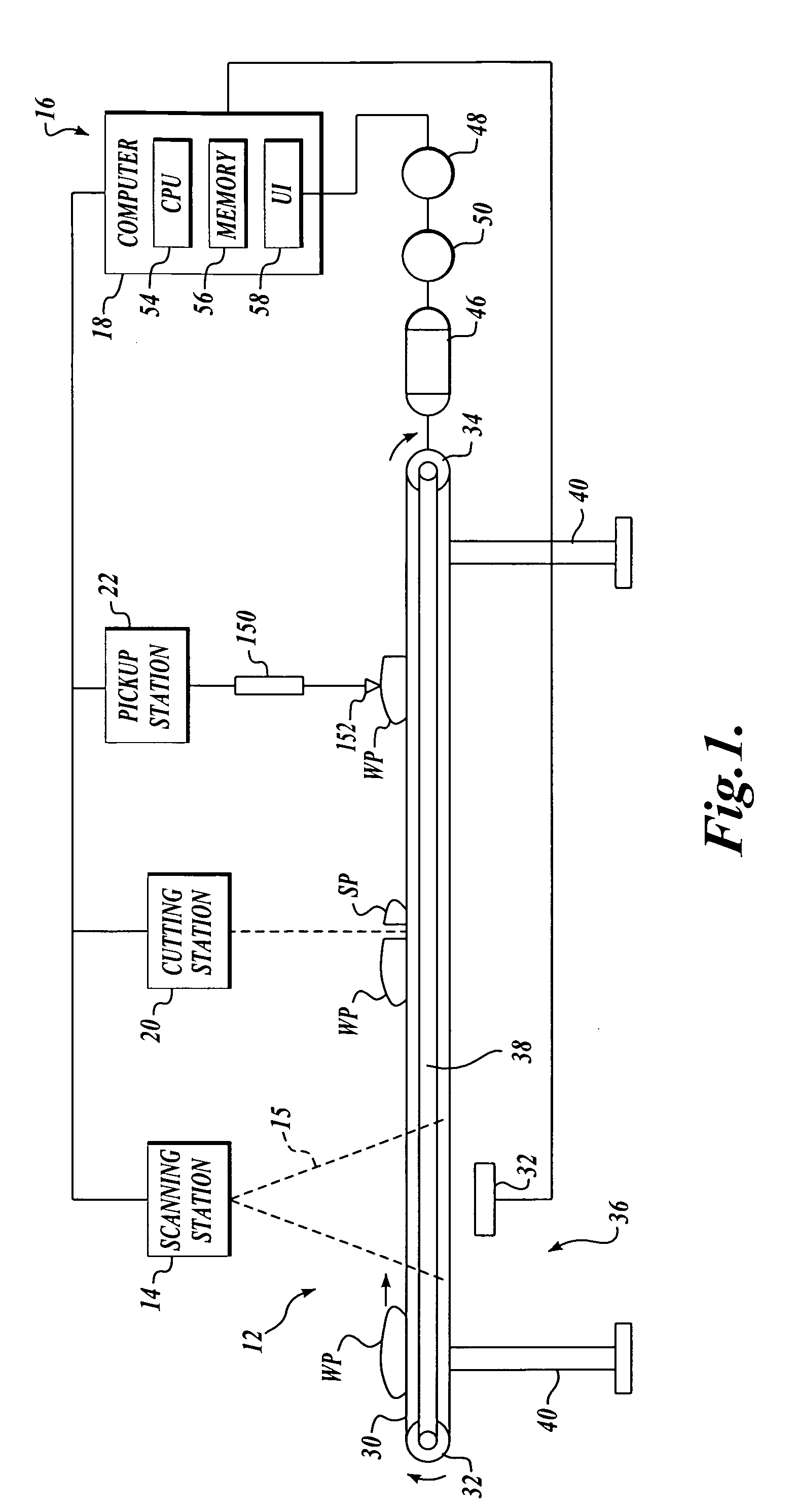

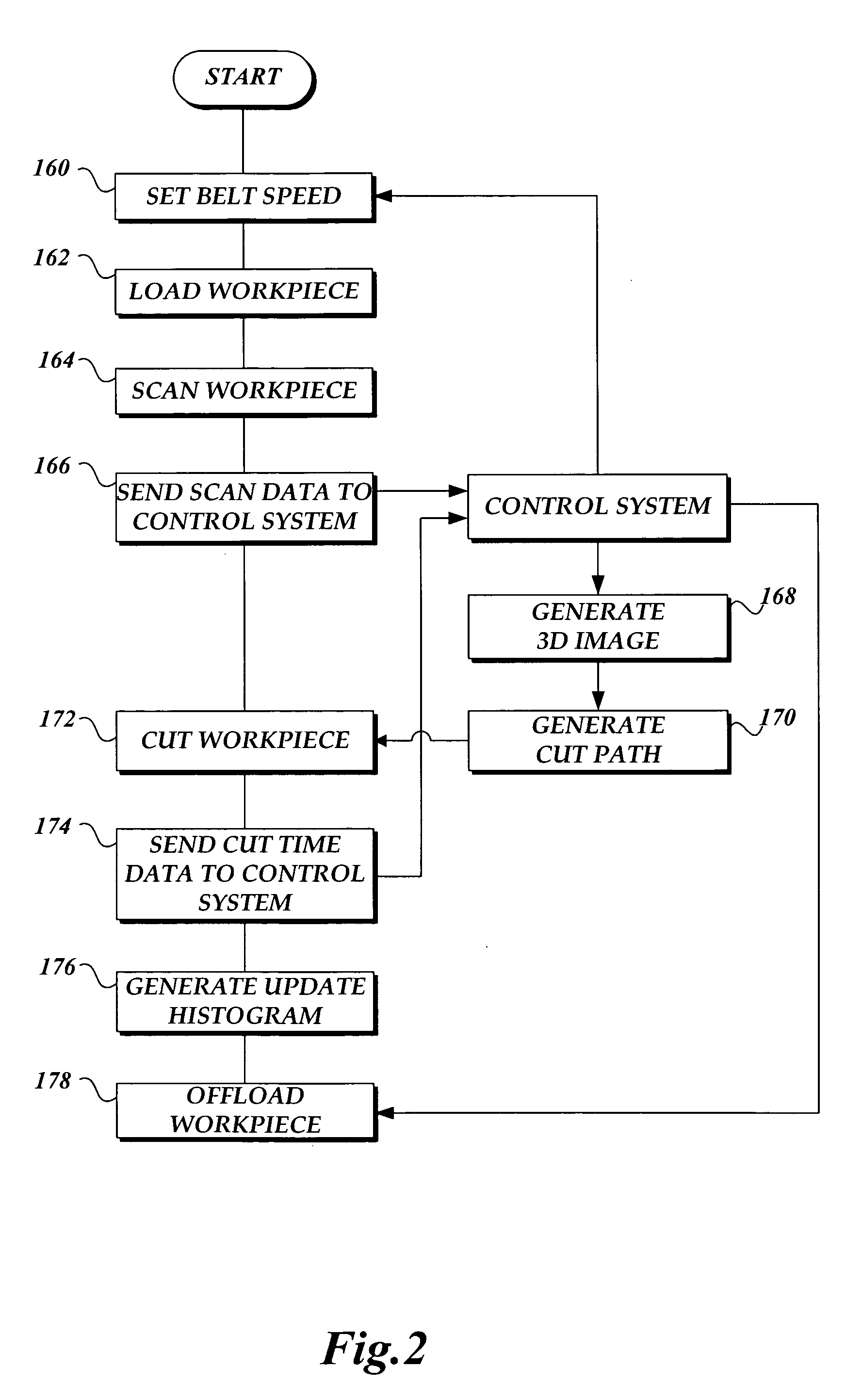

Apparatus and method for portioning using automatic workpiece conveyance speed control

A portioning apparatus (10) includes a powered conveyor (12) for carrying workpieces (WP) past a scanning station (14) and past a cutting station (20). Information from the scanning station pertaining to physical parameters of the workpiece is transmitted to a control system (16) which then determines an optimal cutting strategy for the workpiece, which strategy is implemented at the cutting station (20). The length of time required to portion the workpiece is also determined, and this information is used to ascertain whether the speed of the conveyor (12) is optimal or should be changed.

Owner:JOHN BEAN TECH CORP

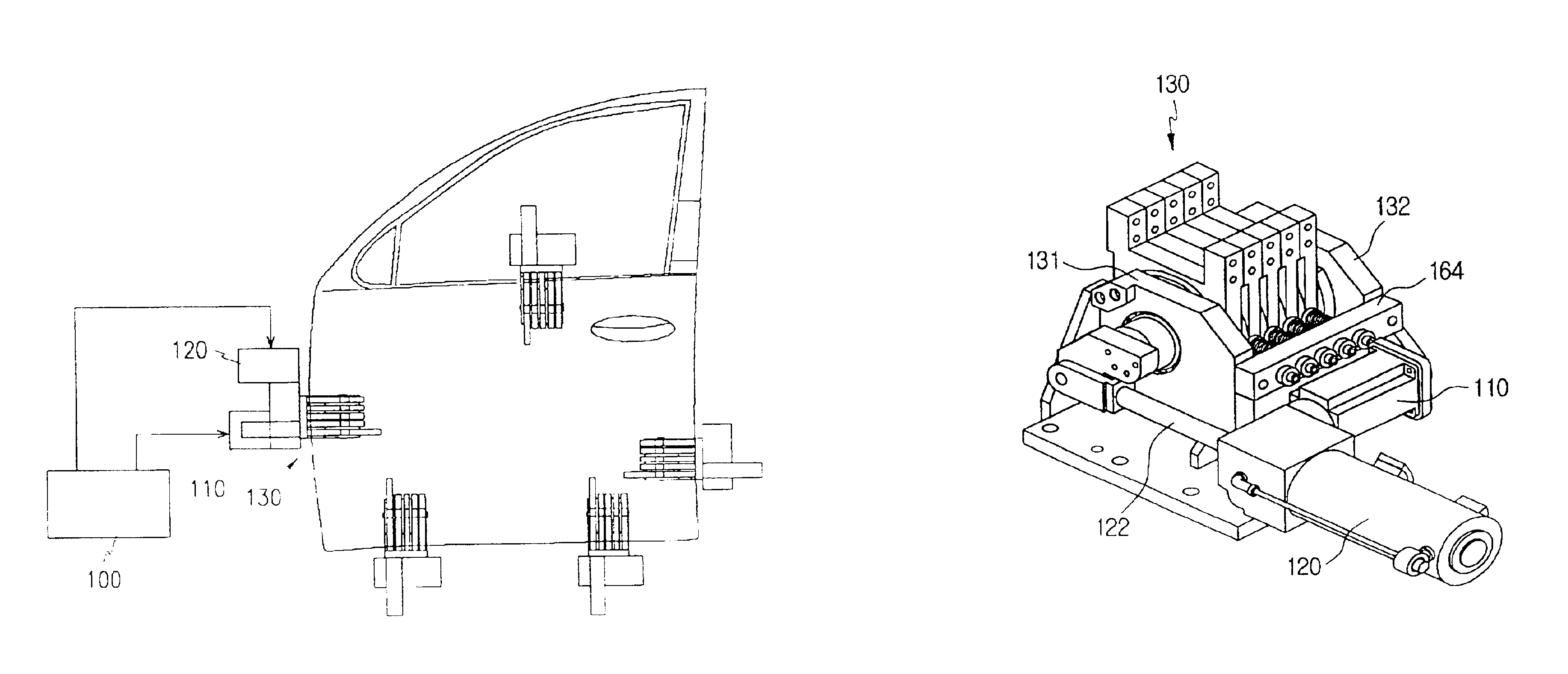

Panel-securing system for various vehicle types

A panel-securing system for various vehicle types is provided, in which various clamps and fingers for different panel shapes may be selected for operation by a single cylinder, the amount of space utilized to install the system is minimized, and parts used in the system are simplified. The panel-securing system for use in a production line for various vehicle types comprises a controller having stored therein panel information for various vehicle types, the controller generating and outputting a locator-selection control signal and a panel-securing control signal corresponding to panel information of the correct vehicle type; a first actuator for selecting a locator corresponding to the locator-selection control signal output by the controller; a second actuator for driving a locator corresponding to the panel-securing control signal output by the controller; and a panel-securing assembly including a plurality of locators, which correspond to panels of the various vehicle types.

Owner:HYUNDAI MOTOR CO LTD

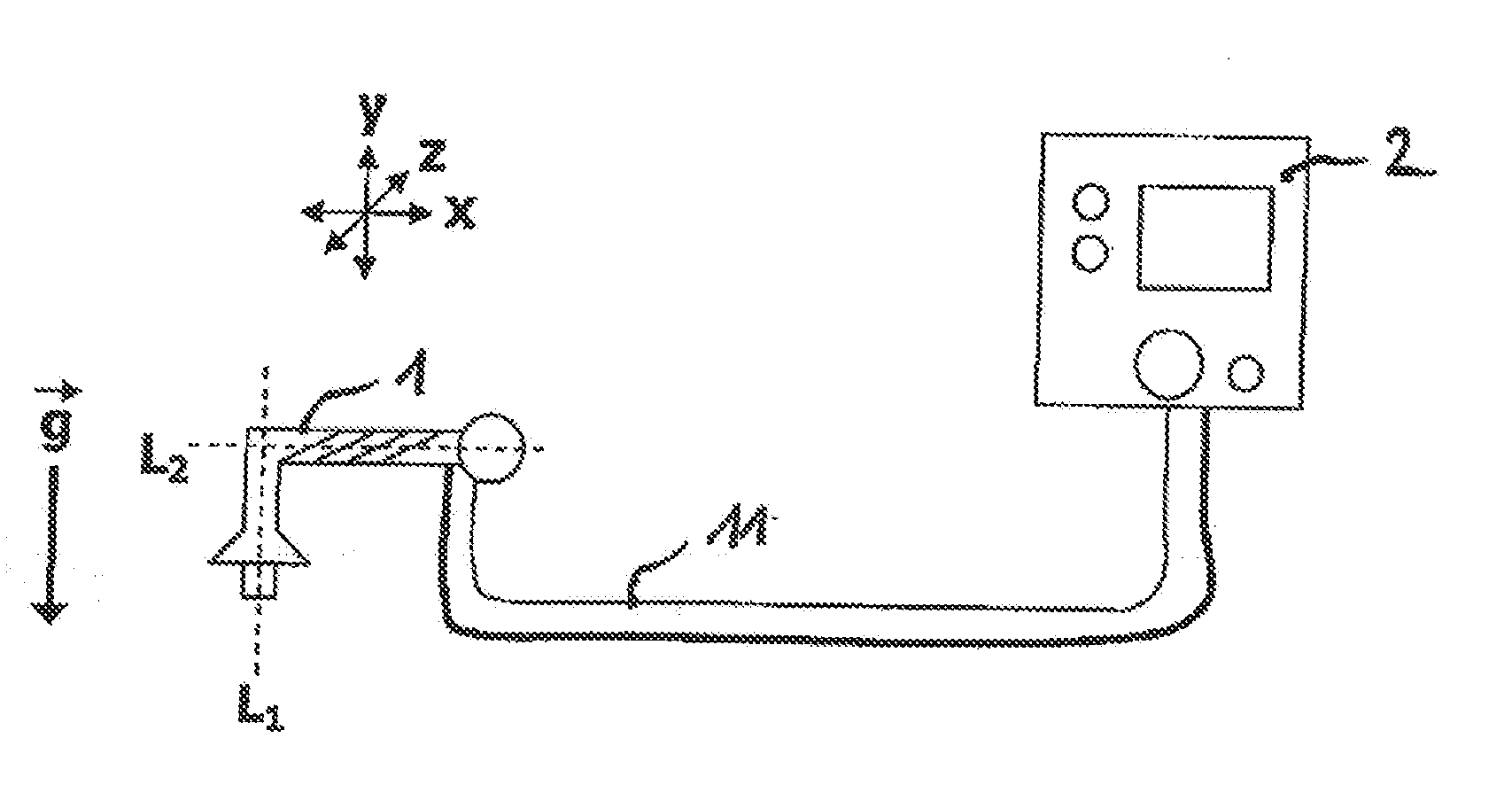

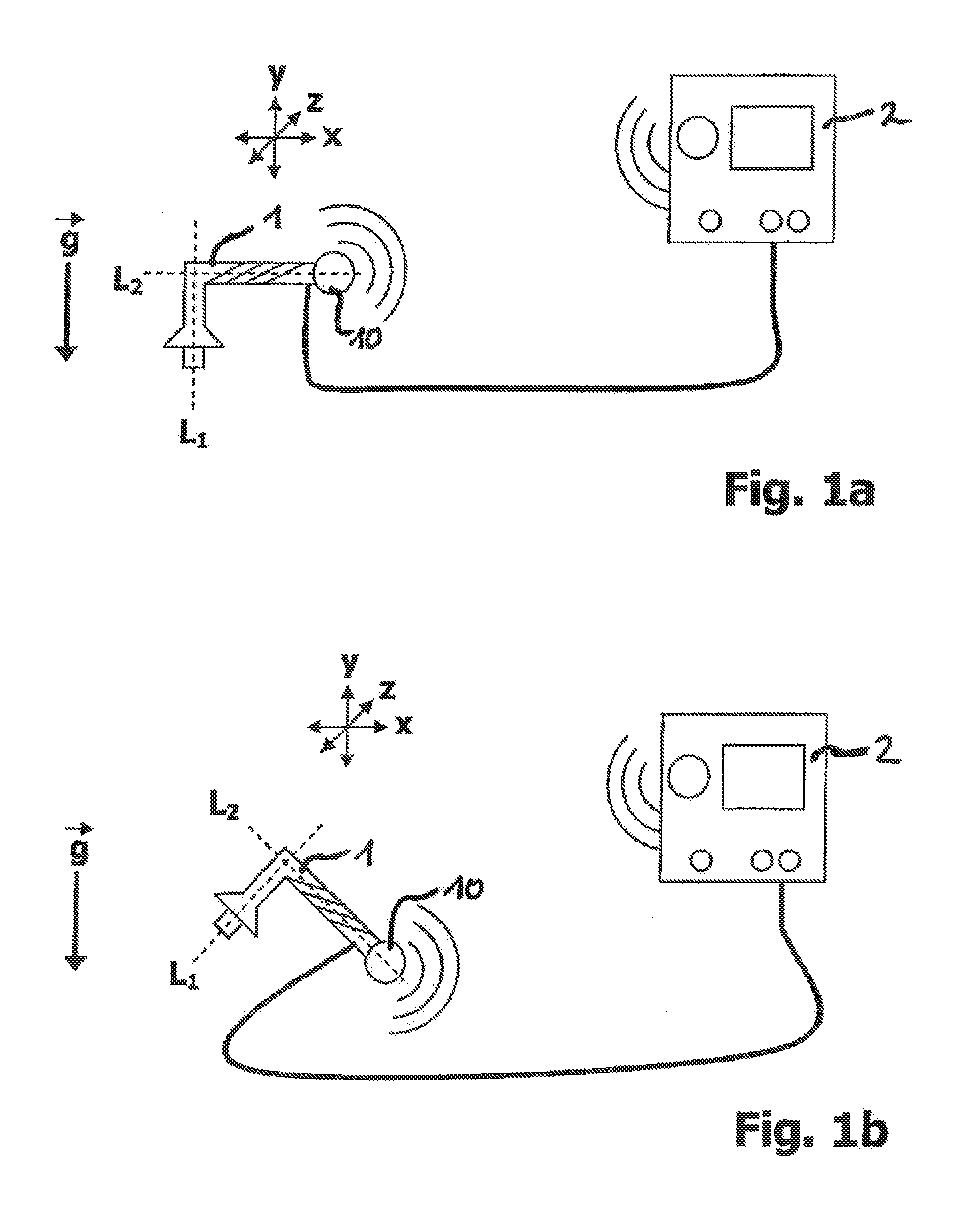

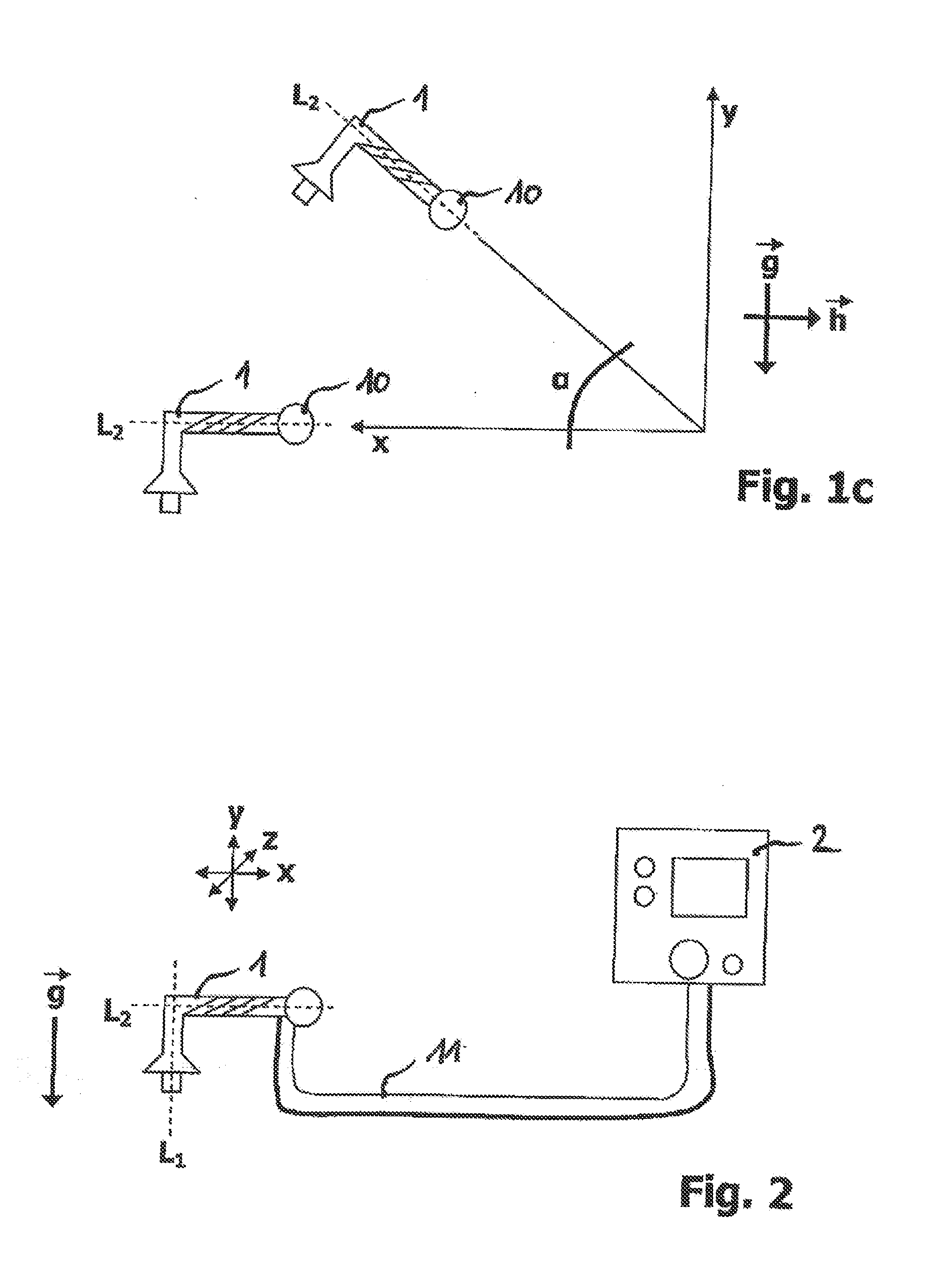

Method for determining a position change of a tool and the tool and the tool control unit

InactiveUS20130081293A1Increase flexibilityFlexibilityAutomatic control devicesWelding/cutting auxillary devicesEngineeringControl unit

A method for determining a position change of a handheld tool in space includes: alignment of an initial tool position with a reference position to determine at least a first position vector of the tool, at least one component of the first position vector being determined by measurement of a component of the gravitational acceleration in the direction of a predetermined axis of the tool;establishing a modification of the tool position during an actual position change by determining at least one angular discrepancy of a second position vector of at least one temporally preceding position vector, at least one component of the second position vector being determined after the position change by measuring the component of the gravitational acceleration in the direction of the predetermined axis of the tool; and providing information relating to the orientation of the tool established from the at least one angular discrepancy.

Owner:DRITTE PATENTPORTFOLIO BET GMBH & CO KG

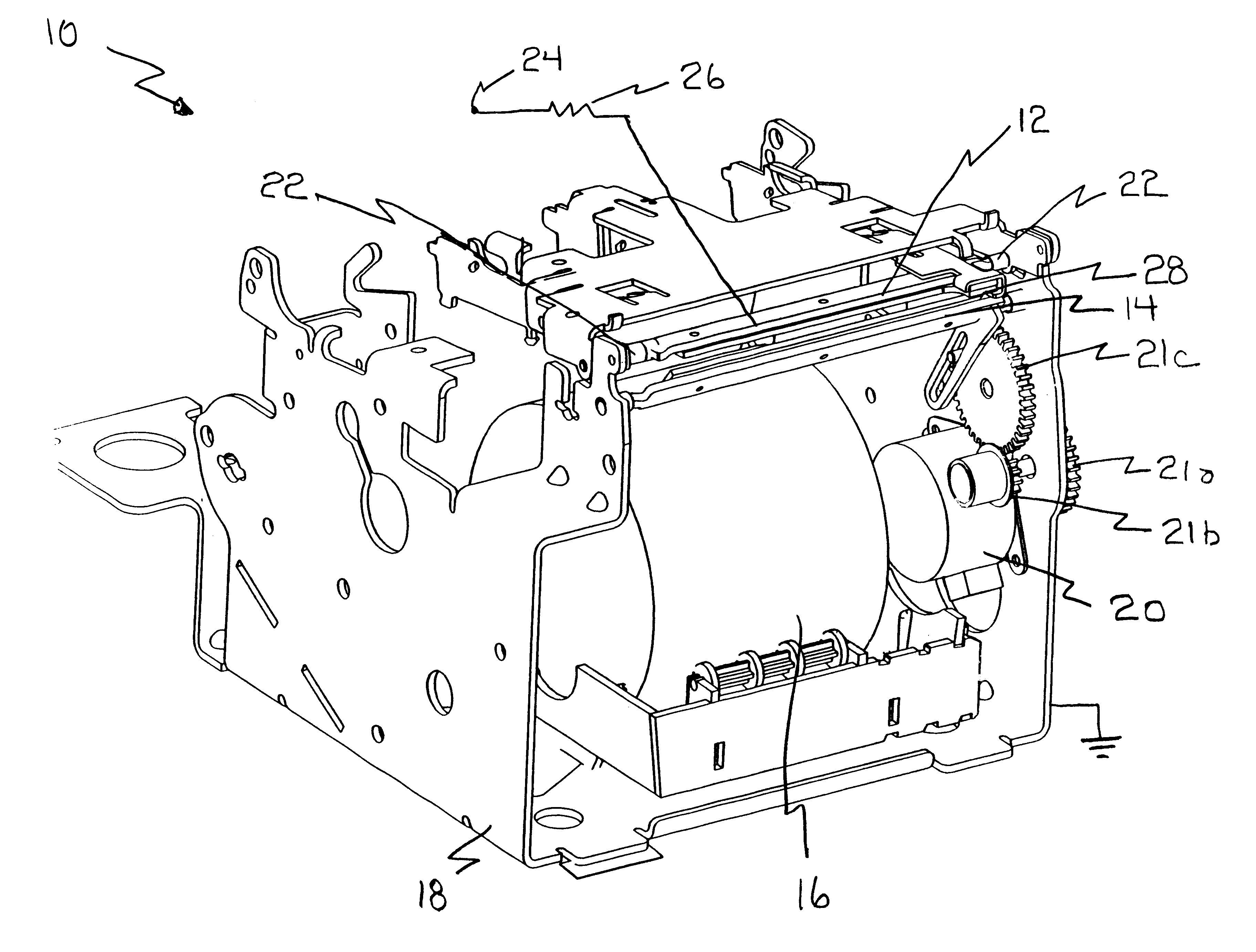

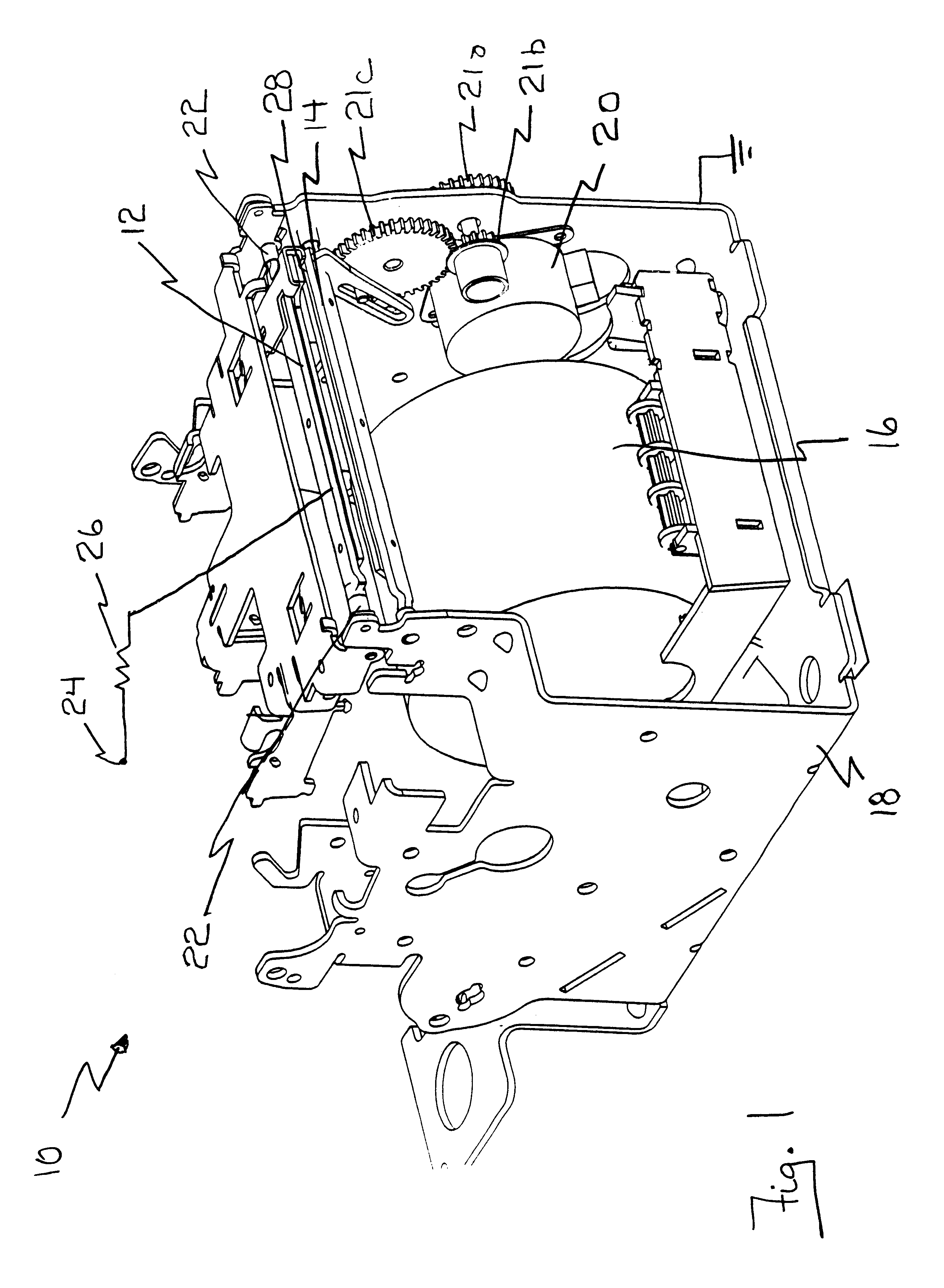

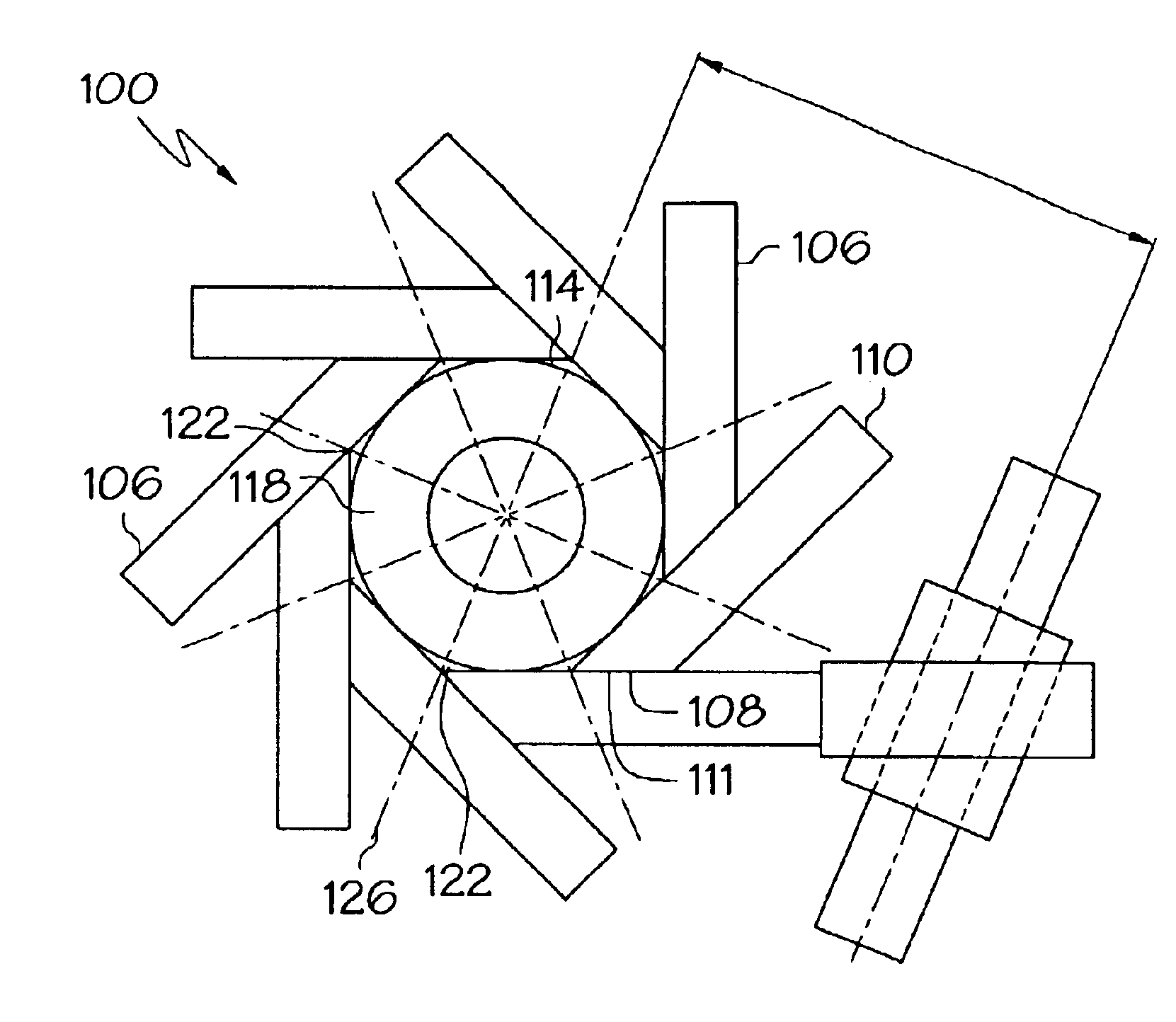

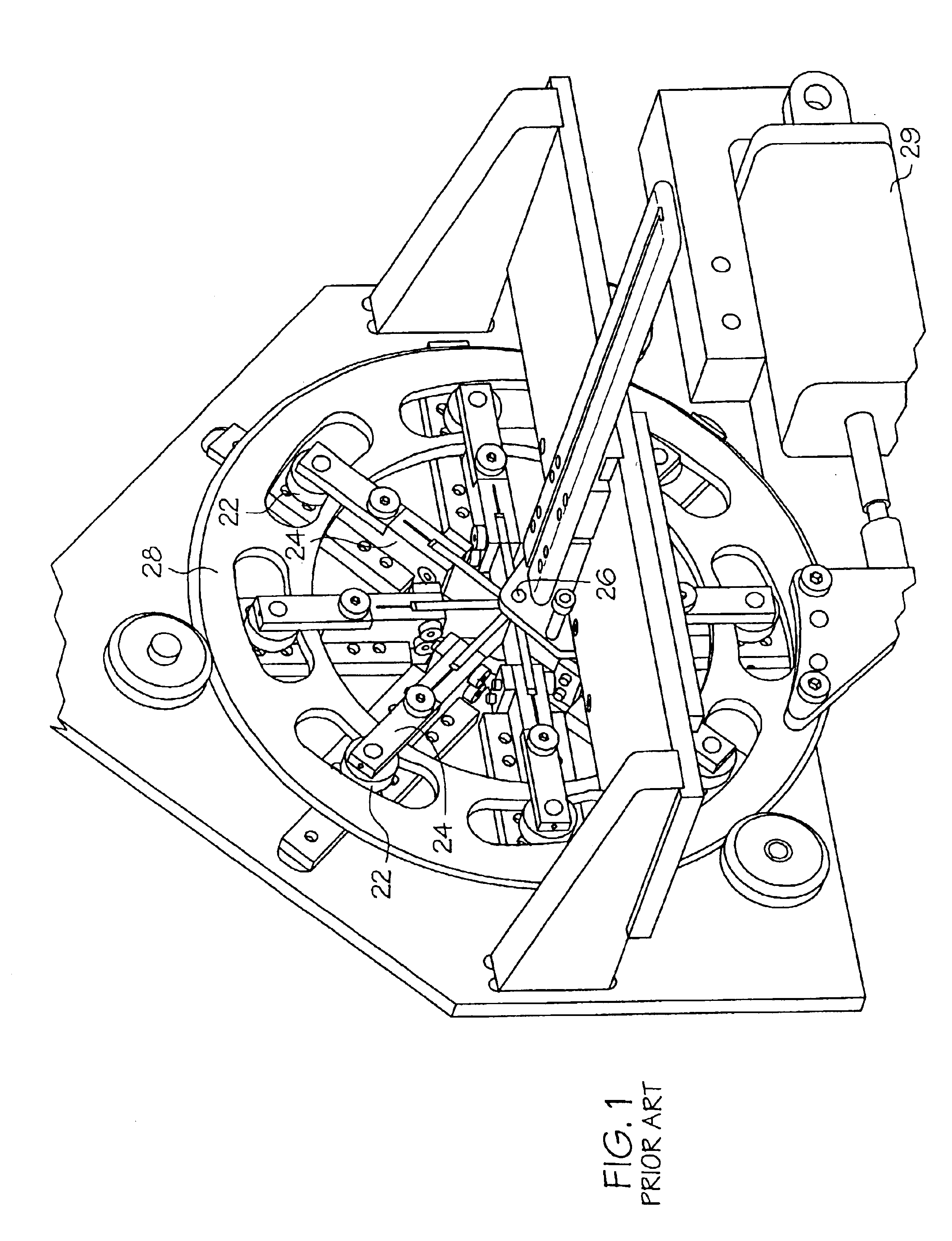

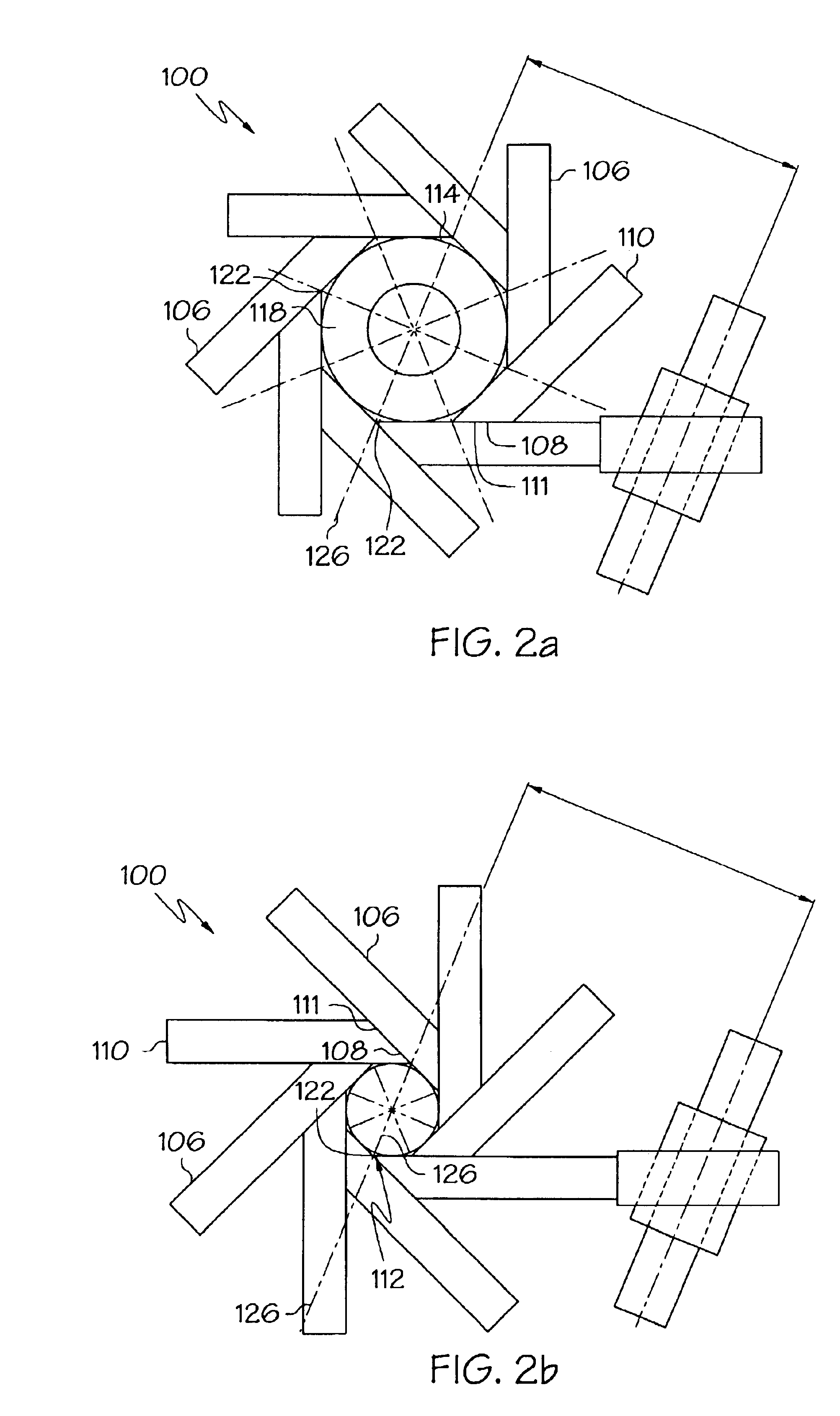

Apparatus for contracting, loading or crimping self-expanding and balloon expandable stent devices

InactiveUS6915560B2Minimizing distortion of and scoringReduce the overall diameterStentsAutomatic control devicesEngineeringKnife blades

An apparatus for manipulating a medical device is formed of at least three coupled movable blades which are disposed about a reference circle to form an aperture whose size may be varied. The aperture capable of being sized to contain a medical device. Each blade is in communication with an actuation device which is capable of moving the blade to alter the size of the aperture. Each blade includes a single radial point which a) lies on the circumference of the reference circle prior to movement of the blade, and b) may be moved only along a radius of the reference circle on movement of the blade.

Owner:BOSTON SCI SCIMED INC +2

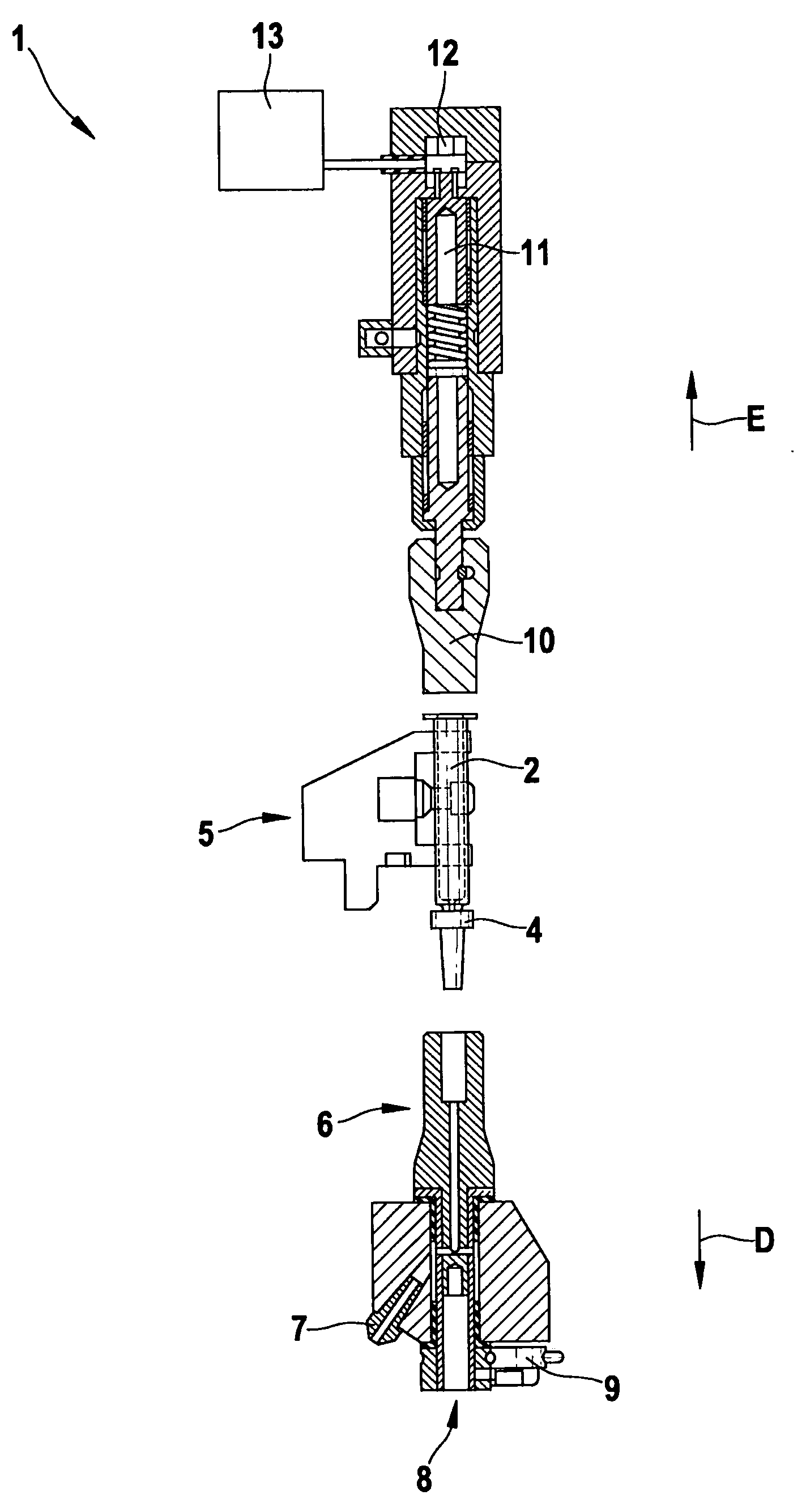

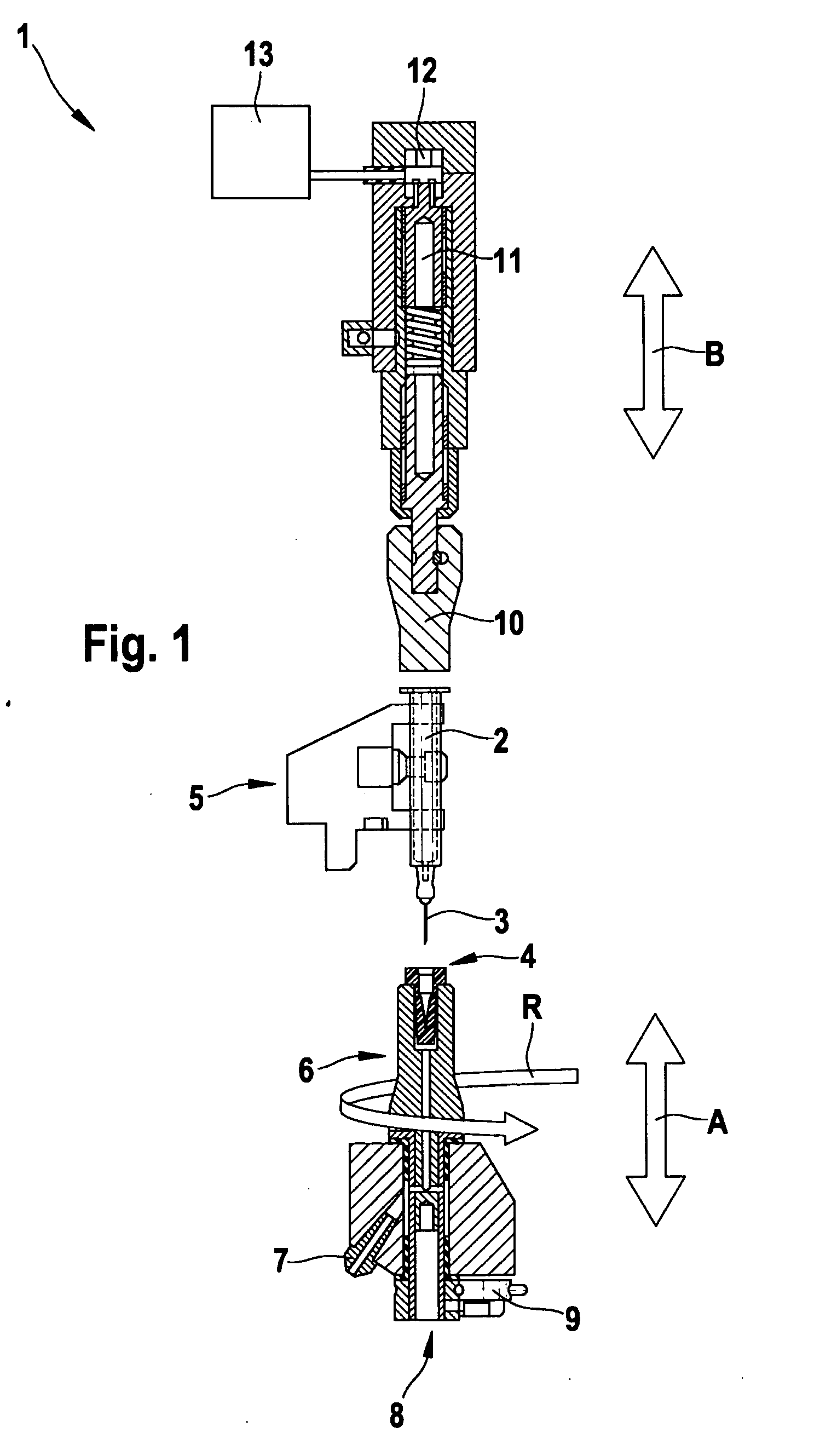

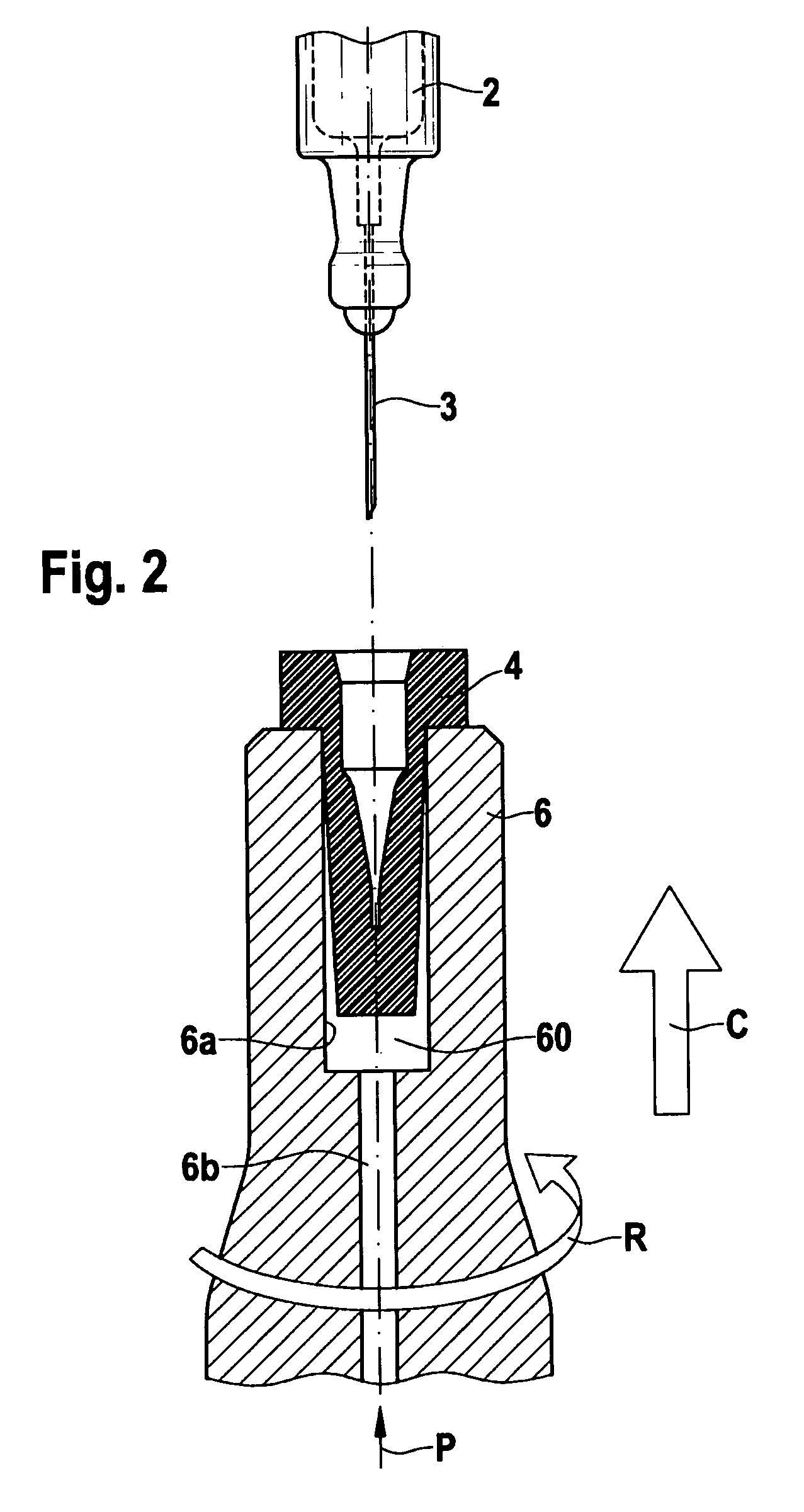

Device and method for mounting a needle guard on a syringe body

InactiveUS20100162548A1Force is smallShort timeAutomatic control devicesMedical devicesNeedle guardCompressed air

The invention relates to a device for mounting a needle guard (4) onto a syringe body (2) that is provided with a needle (3), comprising a retaining device (5) for retaining the syringe body (2), a needle guard receptacle (6) for receiving the needle guard (4), a compressed air system (7) for providing compressed air, a first displacement device (8) for displacing the needle guard receptacle (6) in a vertical direction (A), and a rotation device (9) for at least partially rotating the needle guard receptacle (6), wherein the needle guard receptacle (6) is disposed beneath the retaining device (5), the compressed air being fed to the needle guard receptacle (6) such that the needle guard (4) is suspended on an air cushion (60) in a floating manner, and wherein the needle guard receptacle (6) can be displaced in a vertical direction (A) by means of the first displacement device (8). The invention further relates to a method for mounting the needle guard (4) onto the syringe body (2).

Owner:ROBERT BOSCH GMBH

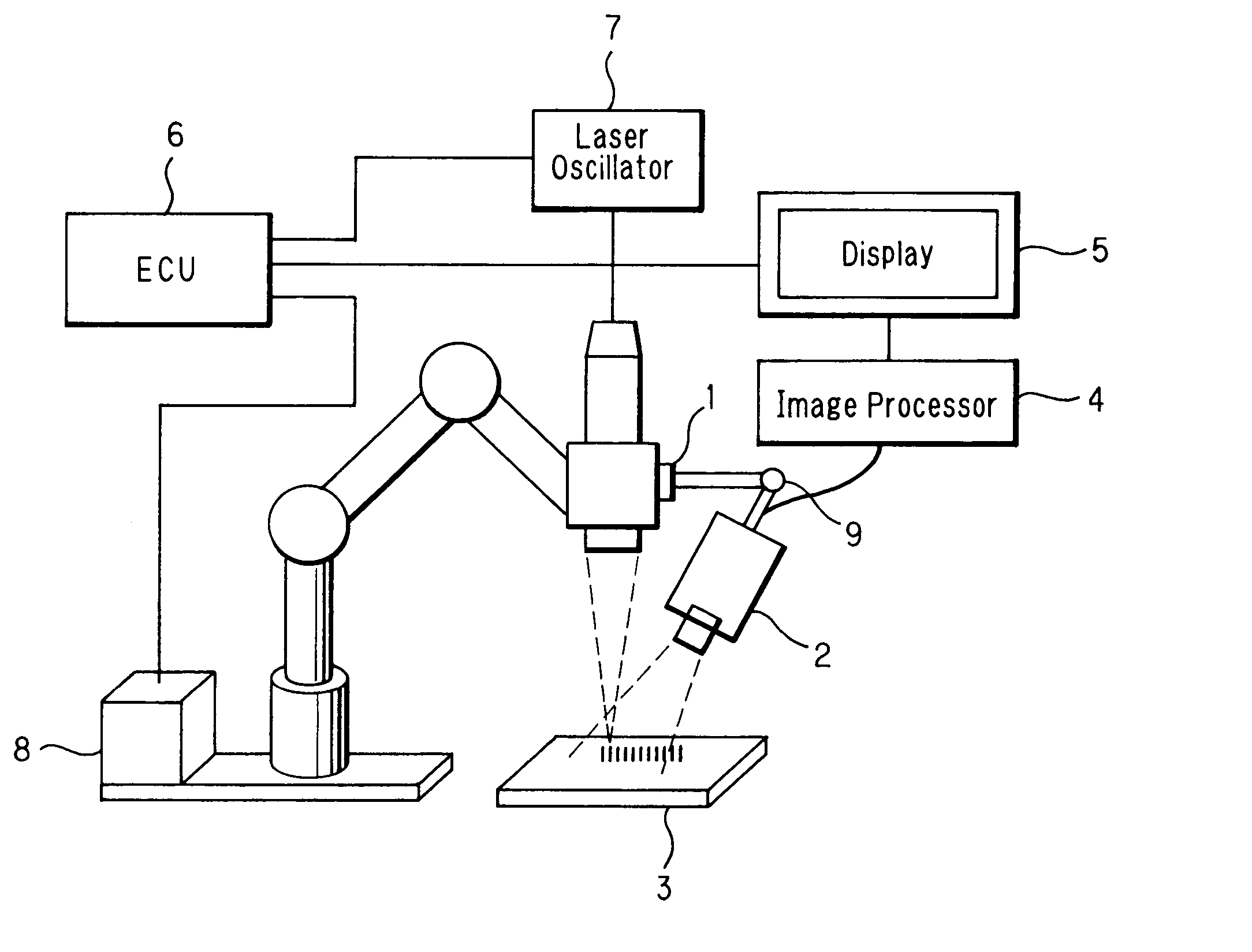

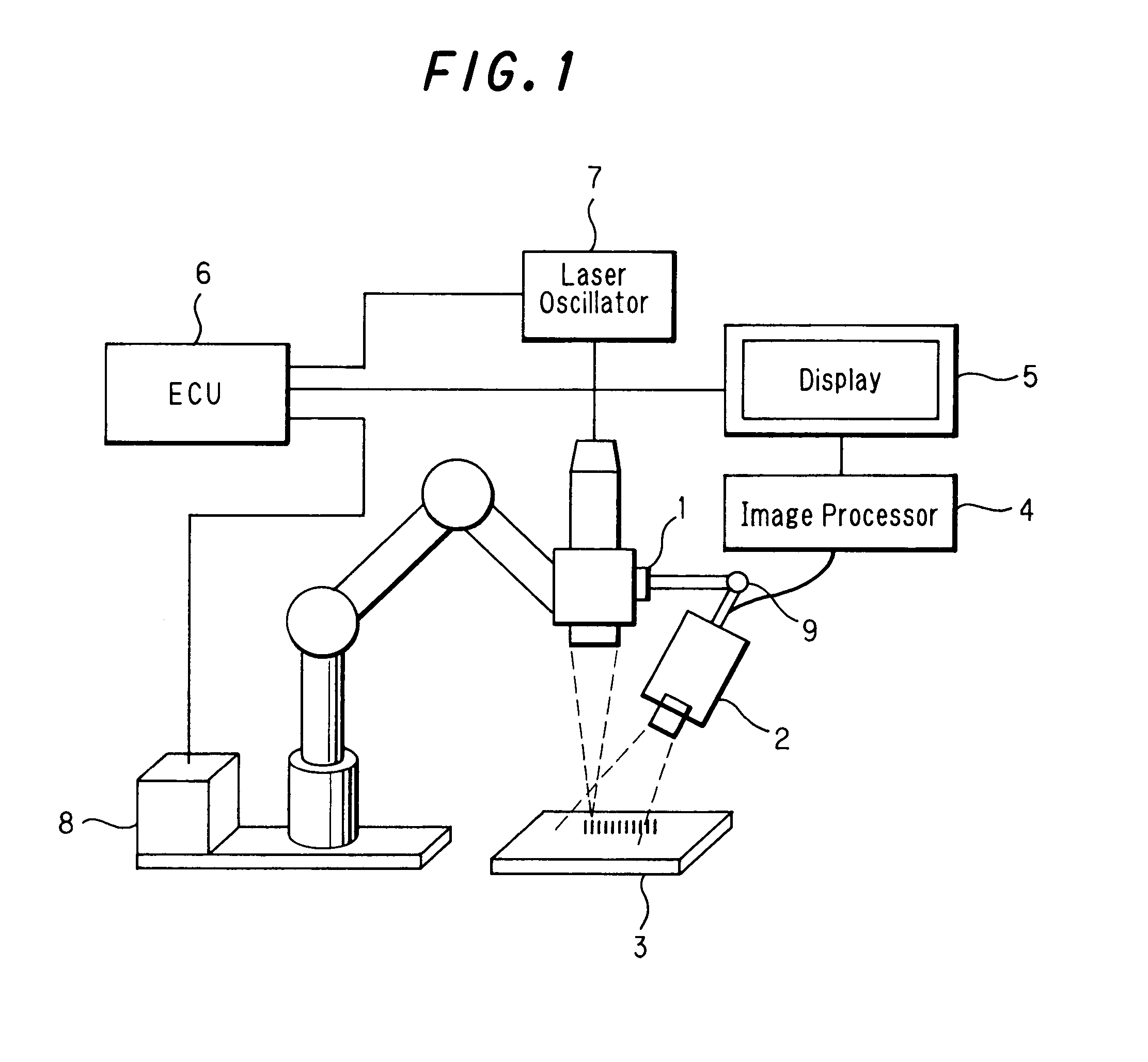

Welding condition monitoring device

InactiveUS20080061113A9Keep distanceIncrease contrastTelevision system detailsAutomatic control devicesEngineeringWide dynamic range

A welding condition monitoring device for monitoring the welding state of a welding work portion by taking an image thereof by an image sensor having a wide dynamic range and capable of taking an image covering a very bright welding portion and relatively dark portion. The monitoring device selectively emphasizes the outputs of the image sensor for any of luminance areas of the image taken by the image sensor using a sensor output characteristic table and can provide an image clearly showing both the very bright welding portion and the dark bead portion with a sufficient contrast allowing an observer to reliably recognize the objects in the image.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com