Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1058results about "Planing/slotting machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

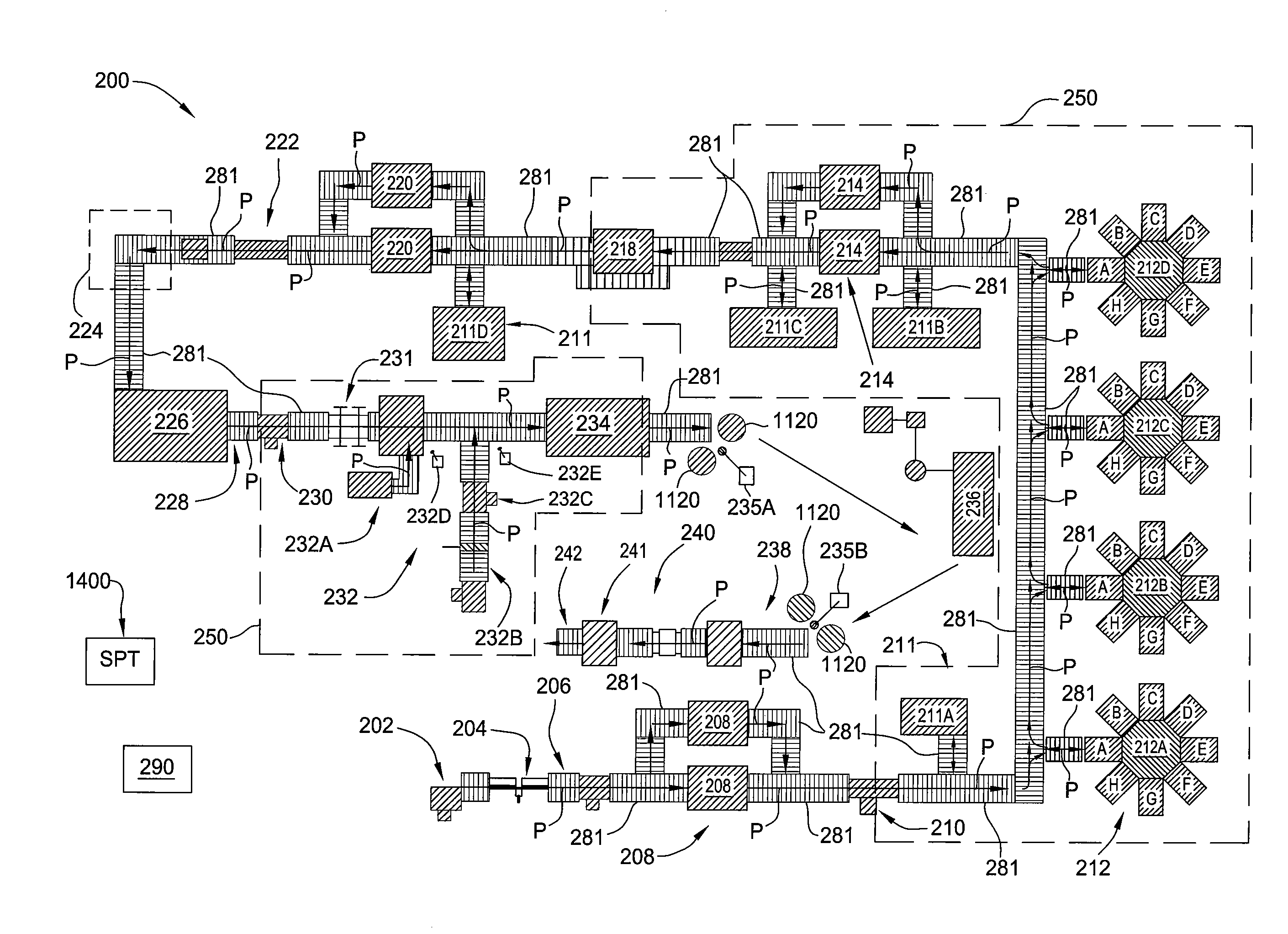

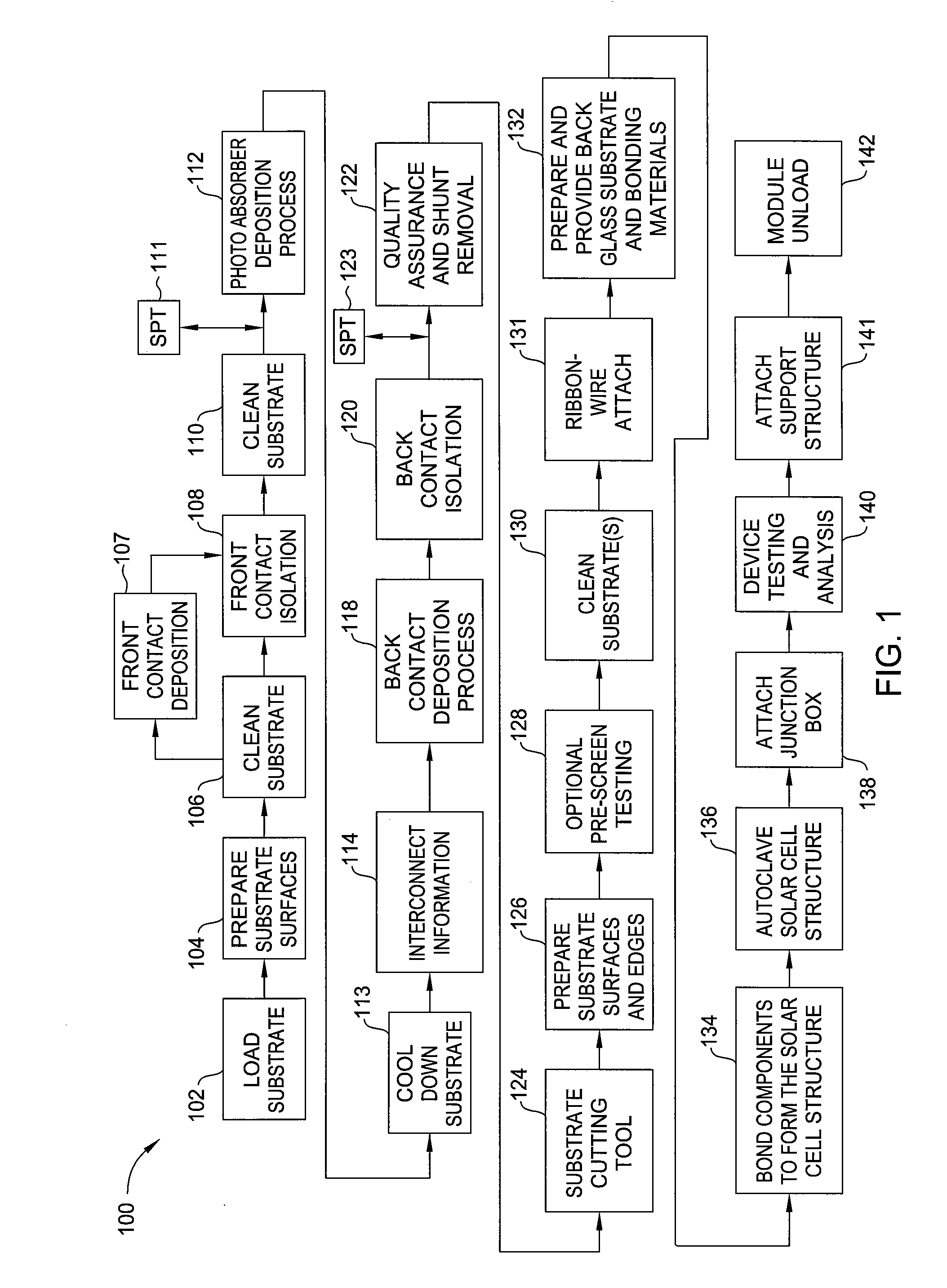

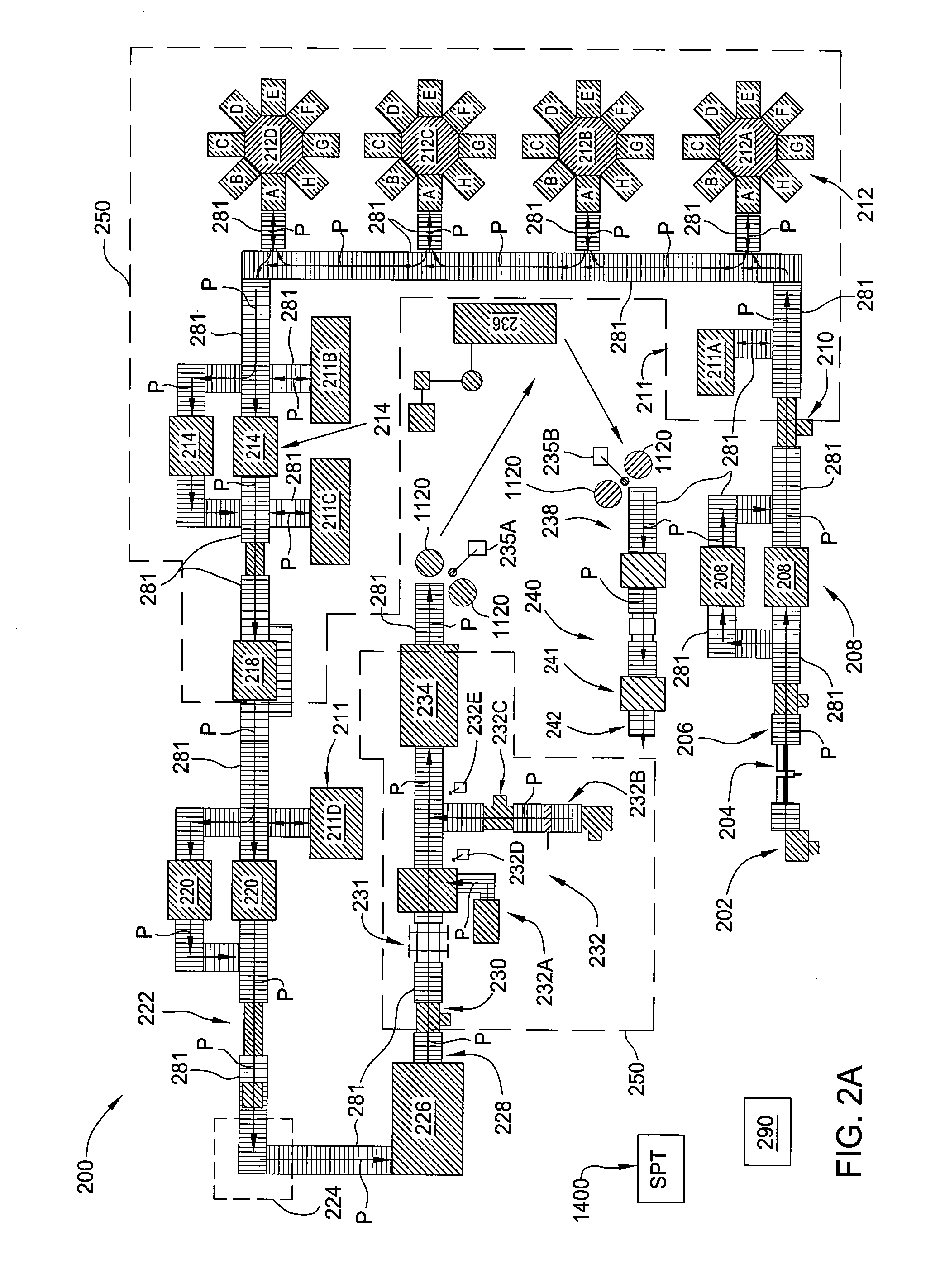

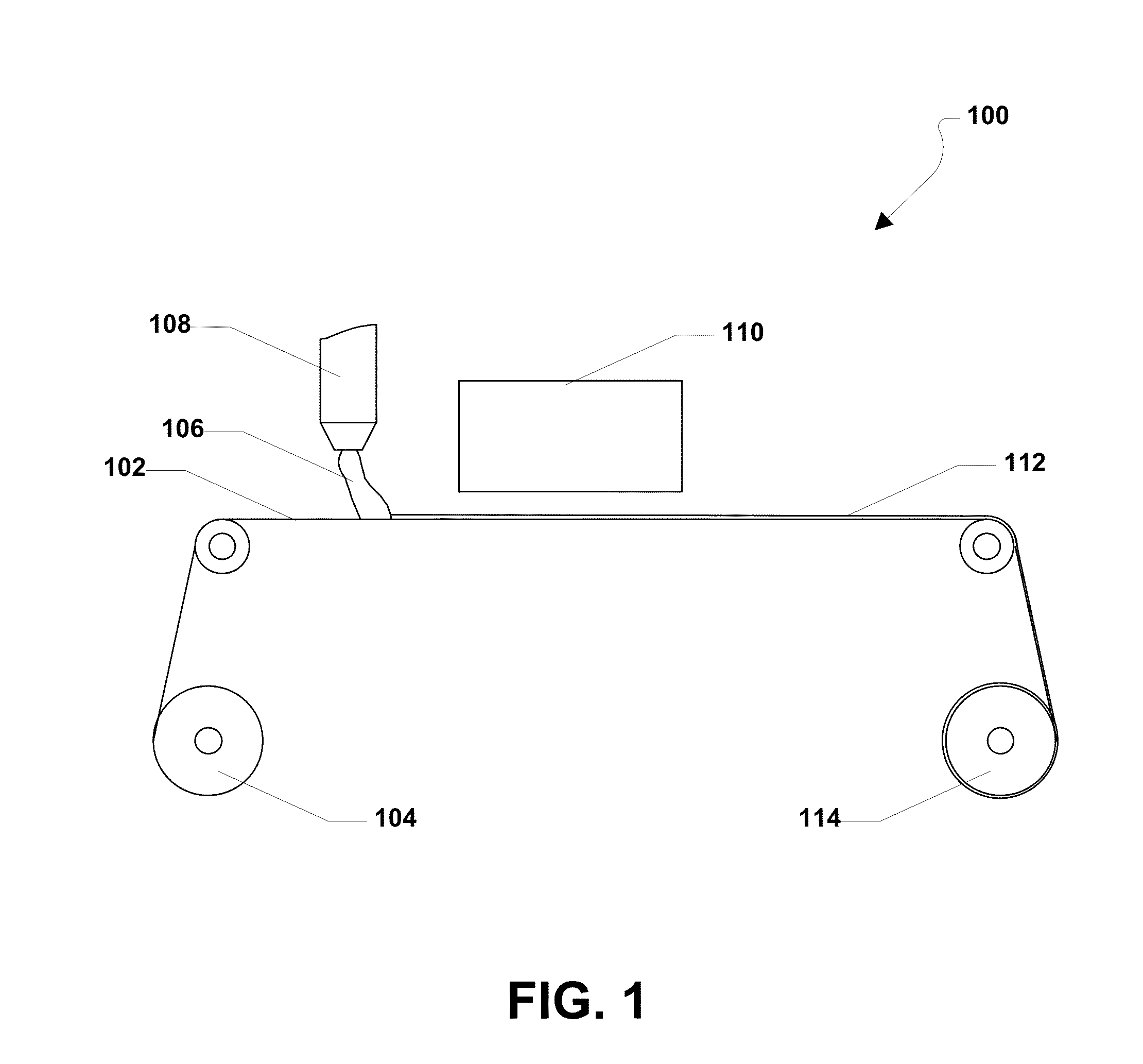

Photovoltaic production line

InactiveUS20090077805A1Improve bindingPhotovoltaic monitoringWave amplification devicesProduction lineQuality assurance

The present invention generally relates to a system that can be used to form a photovoltaic device, or solar cell, using processing modules that are adapted to perform one or more steps in the solar cell formation process. The automated solar cell fab is generally an arrangement of automated processing modules and automation equipment that is used to form solar cell devices. The automated solar fab will thus generally comprise a substrate receiving module that is adapted to receive a substrate, one or more absorbing layer deposition cluster tools having at least one processing chamber that is adapted to deposit a silicon-containing layer on a surface of the substrate, one or more back contact deposition chambers, one or more material removal chambers, a solar cell encapsulation device, an autoclave module, an automated junction box attaching module, and one or more quality assurance modules that are adapted to test and qualify the completely formed solar cell device.

Owner:APPLIED MATERIALS INC

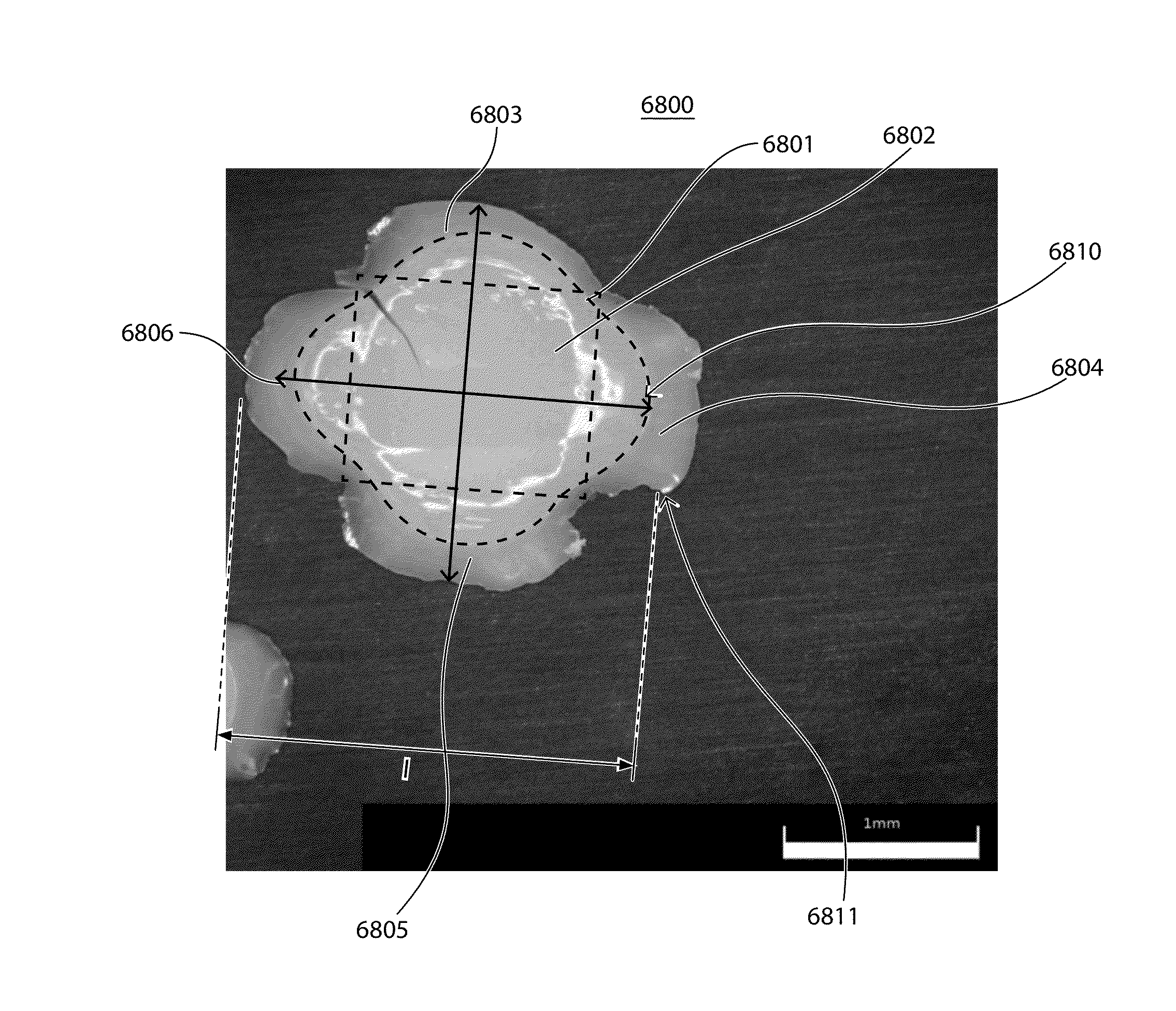

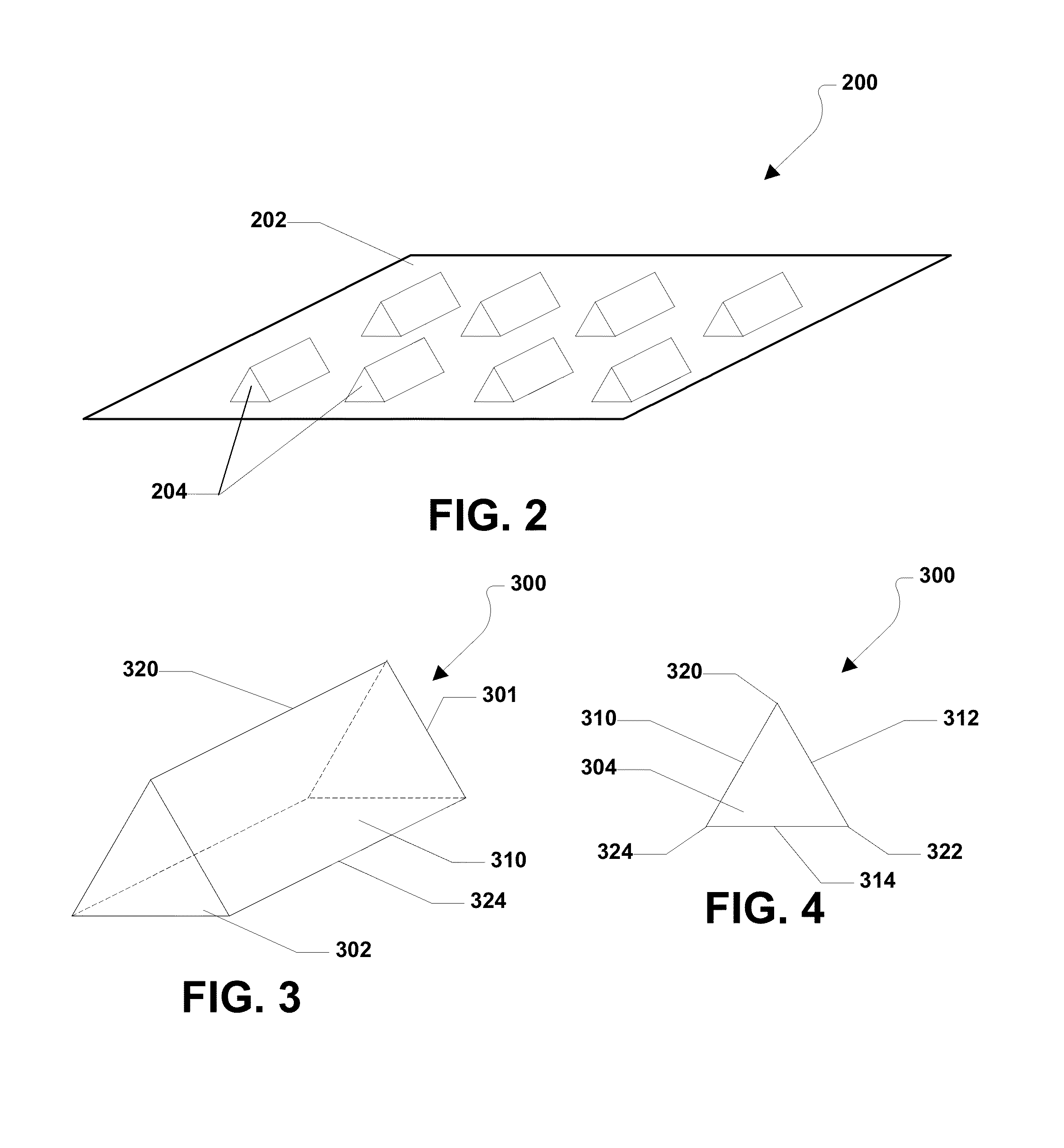

Abrasive particles having complex shapes and methods of forming same

An abrasive grain is disclosed and may include a body. The body may define a length (l), a height (h), and a width (w). In a particular aspect, the length is greater than or equal to the height and the height is greater than or equal to the width. Further, in a particular aspect, the body may include a primary aspect ratio defined by the ratio of length:height of at least about 2:1. The body may also include an upright orientation probability of at least about 50%.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

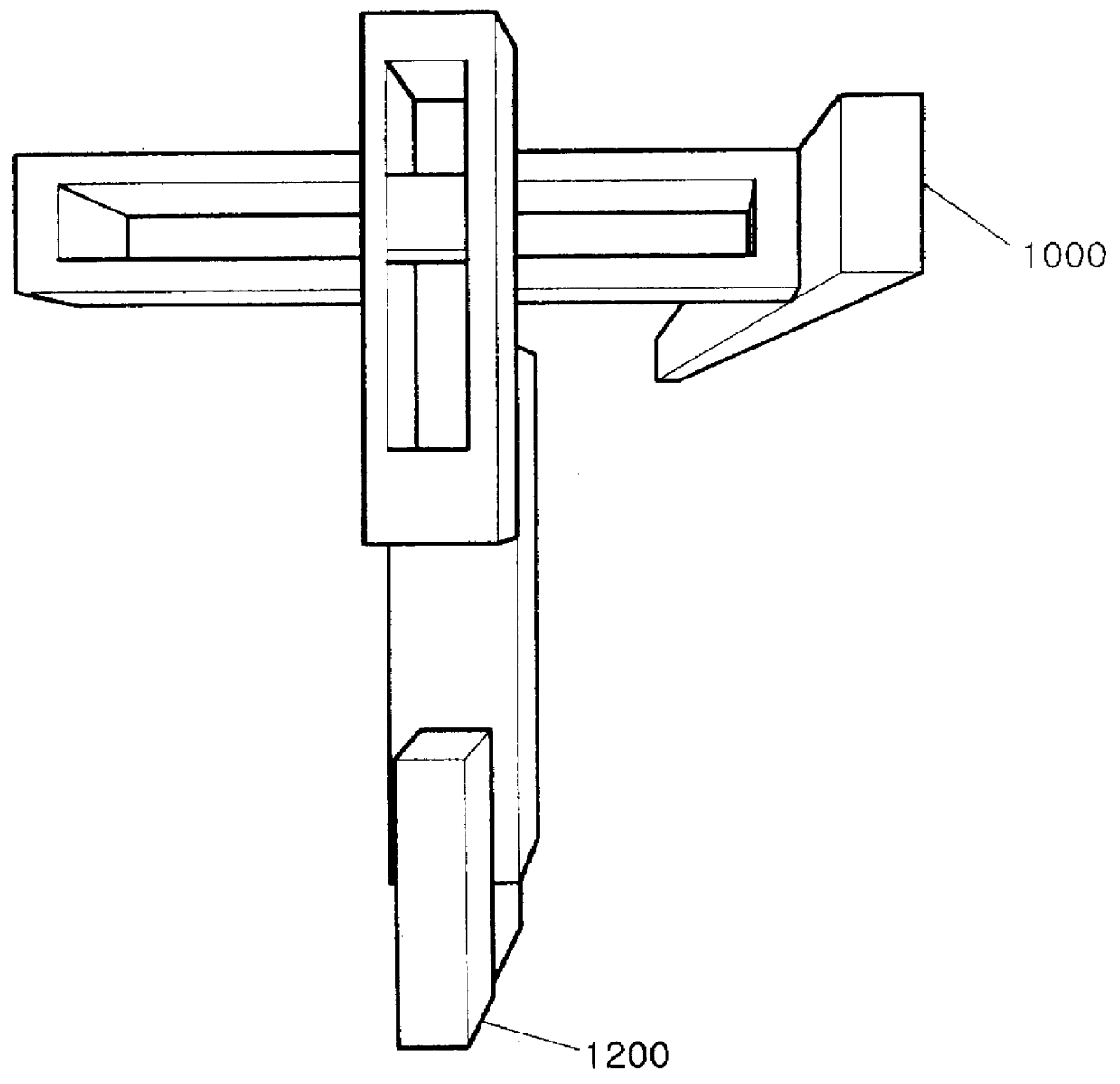

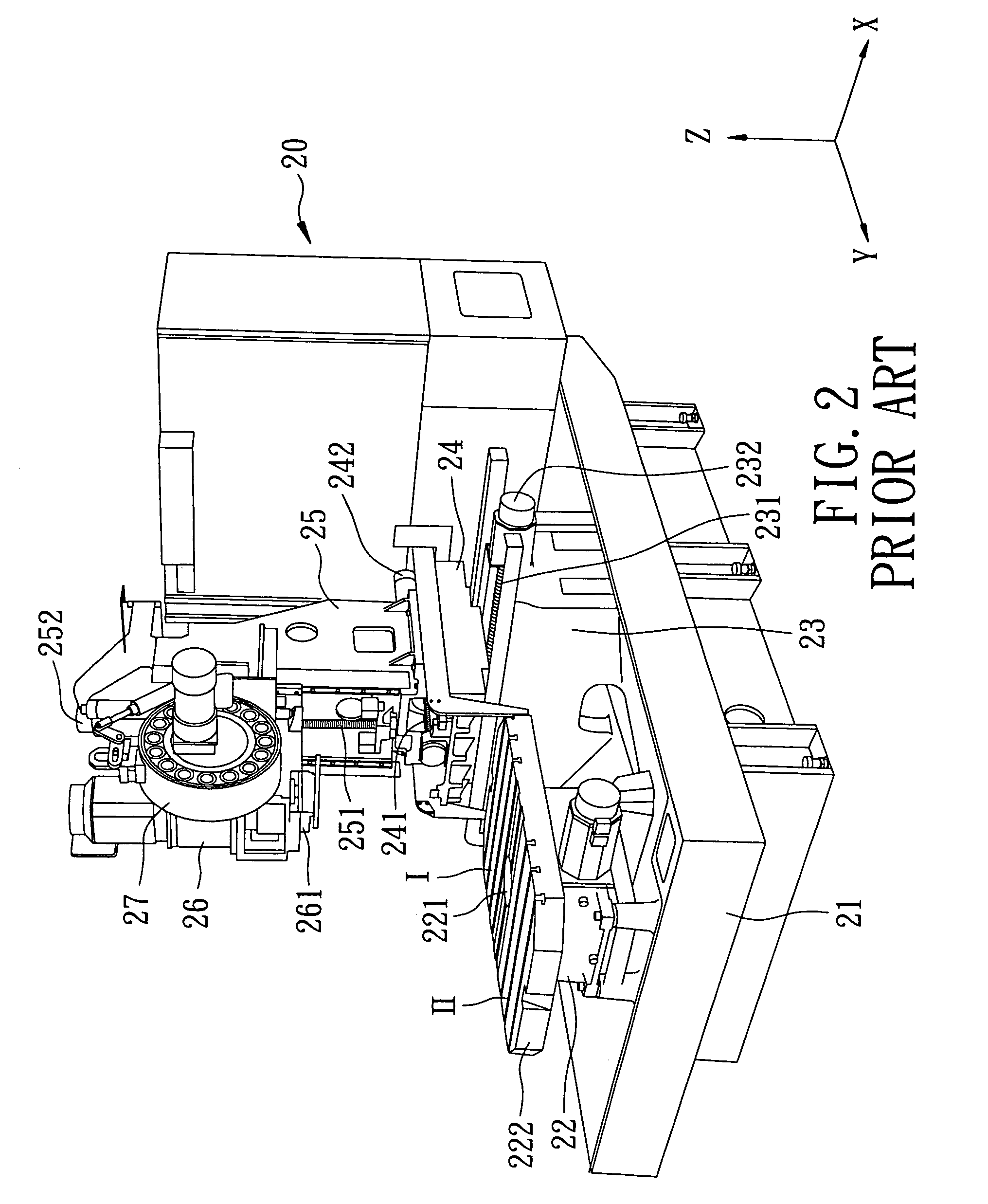

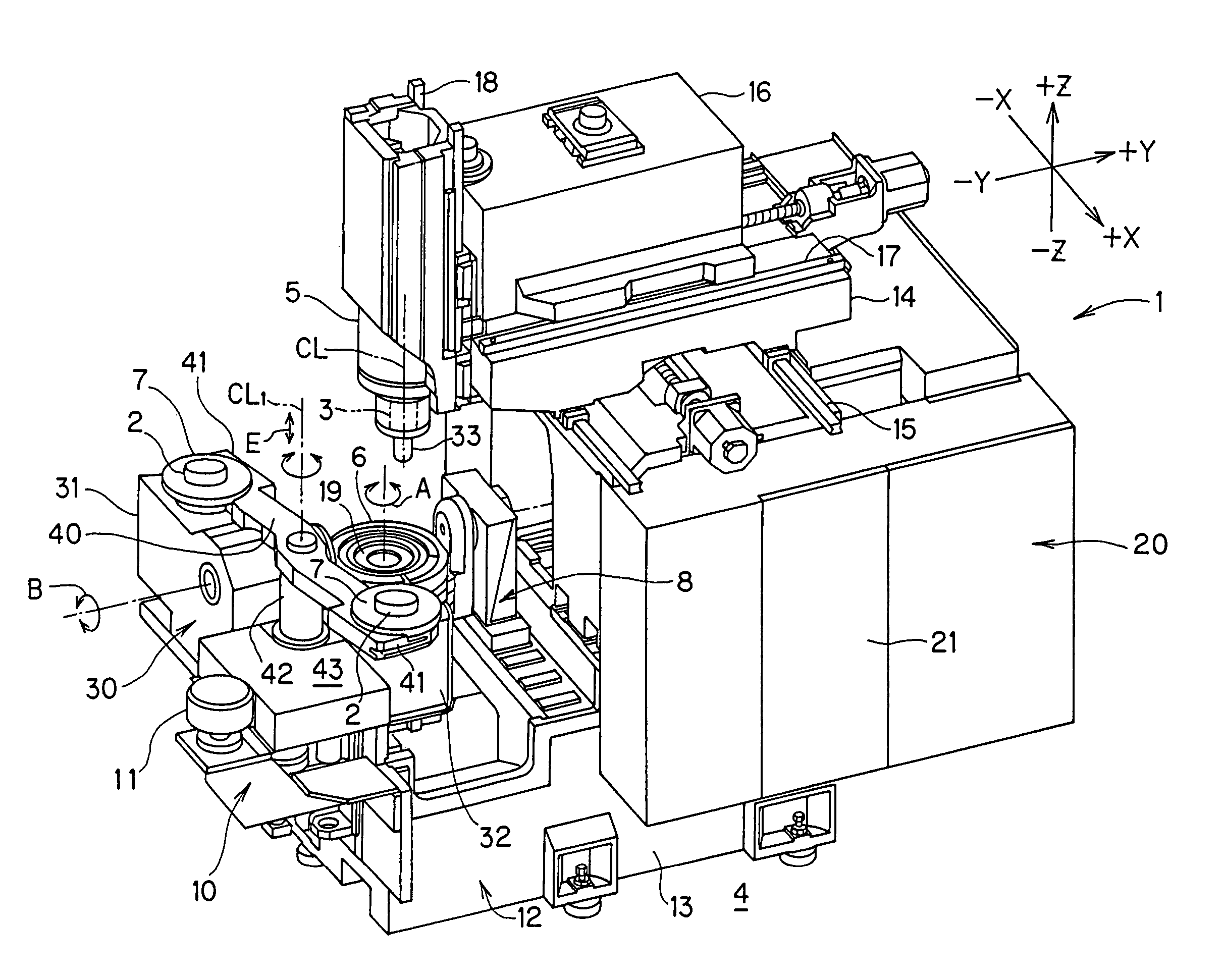

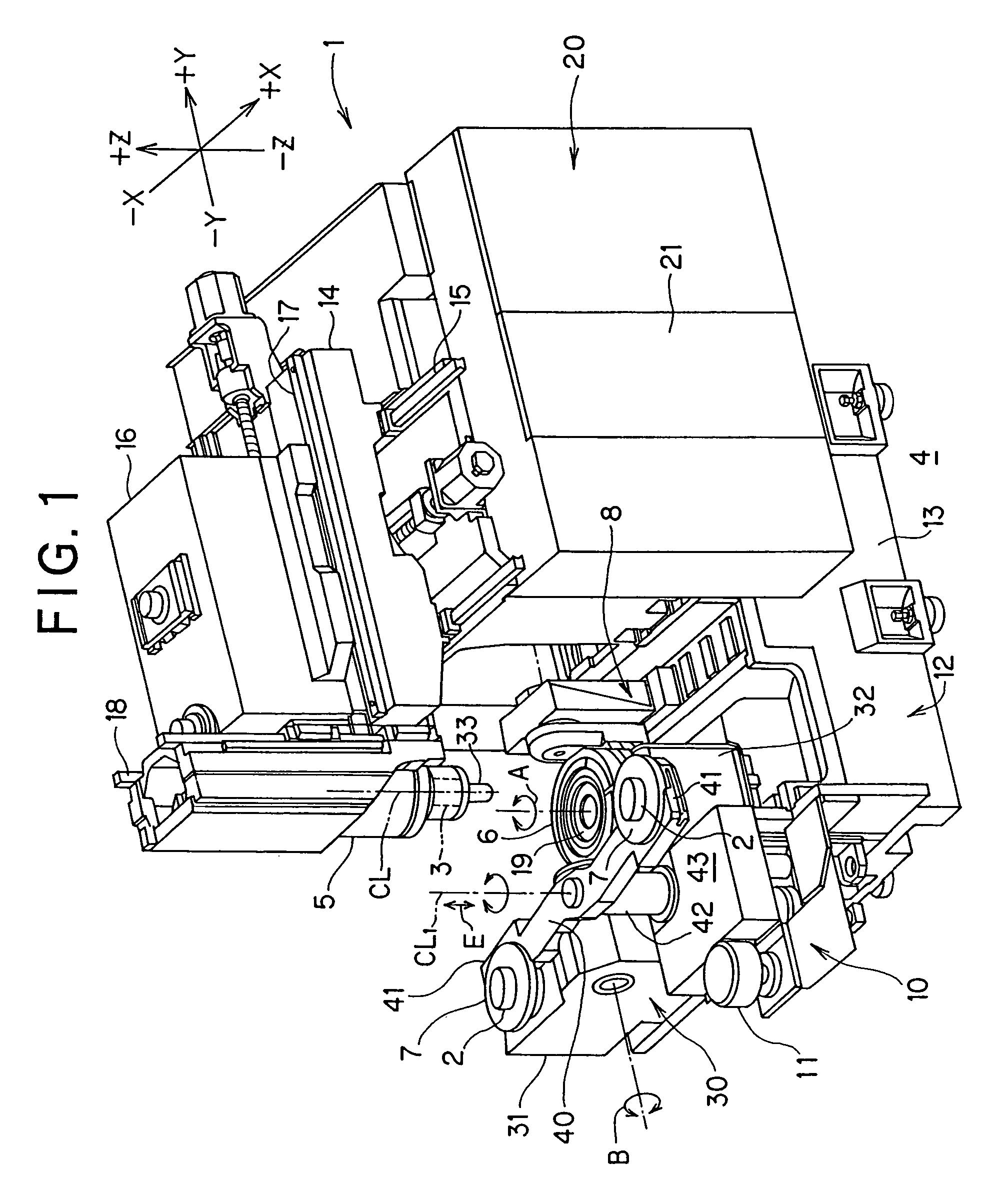

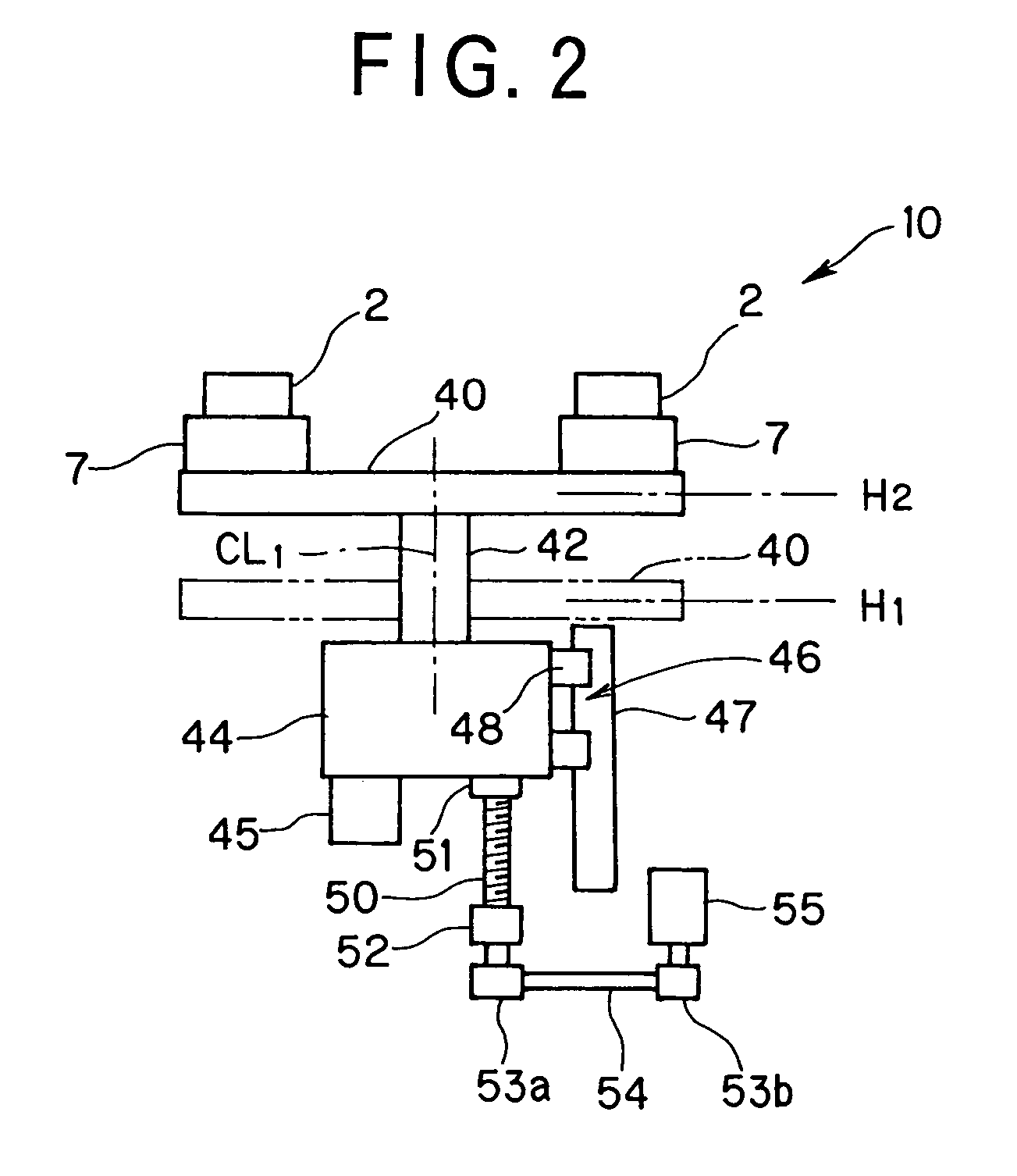

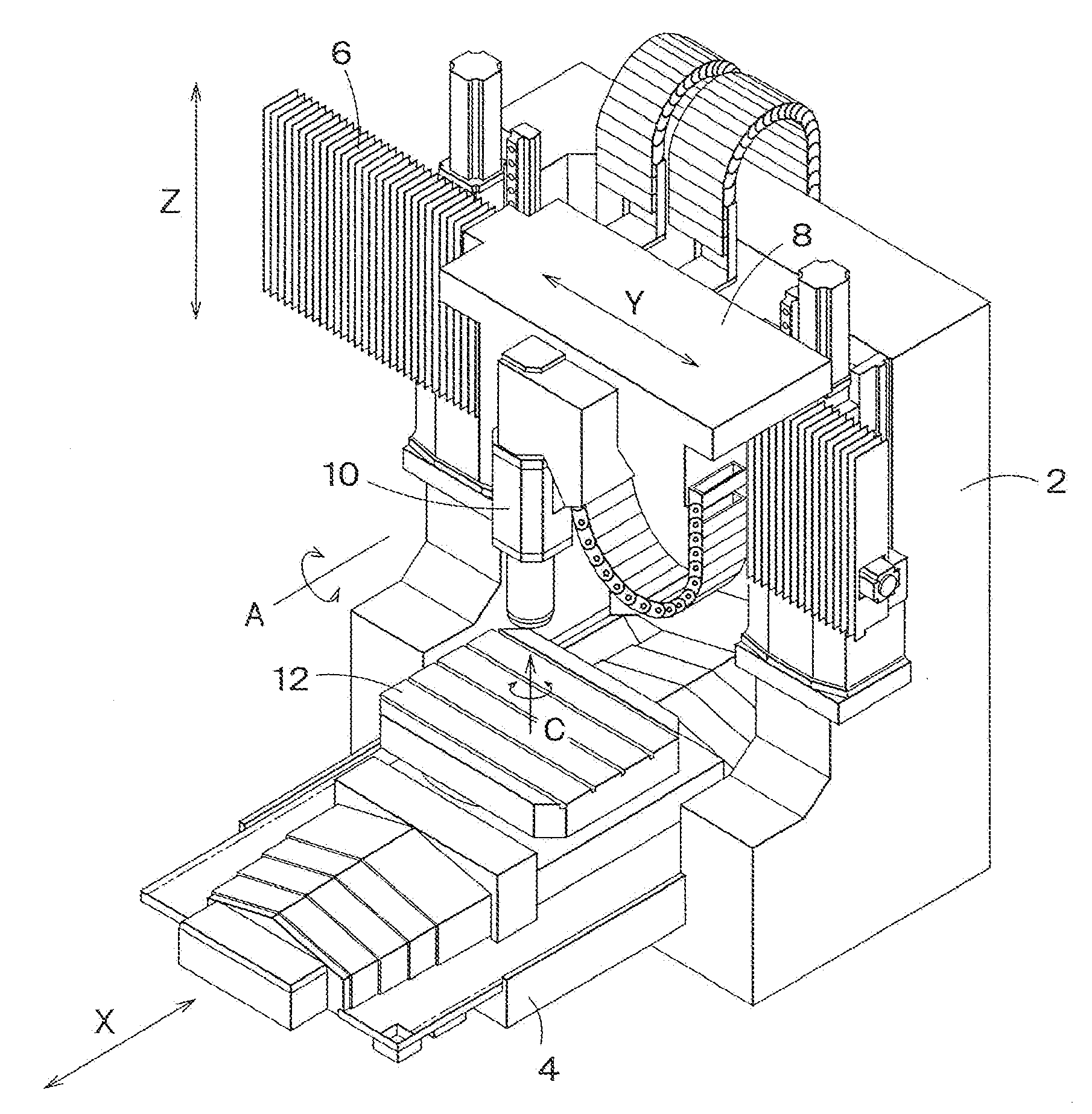

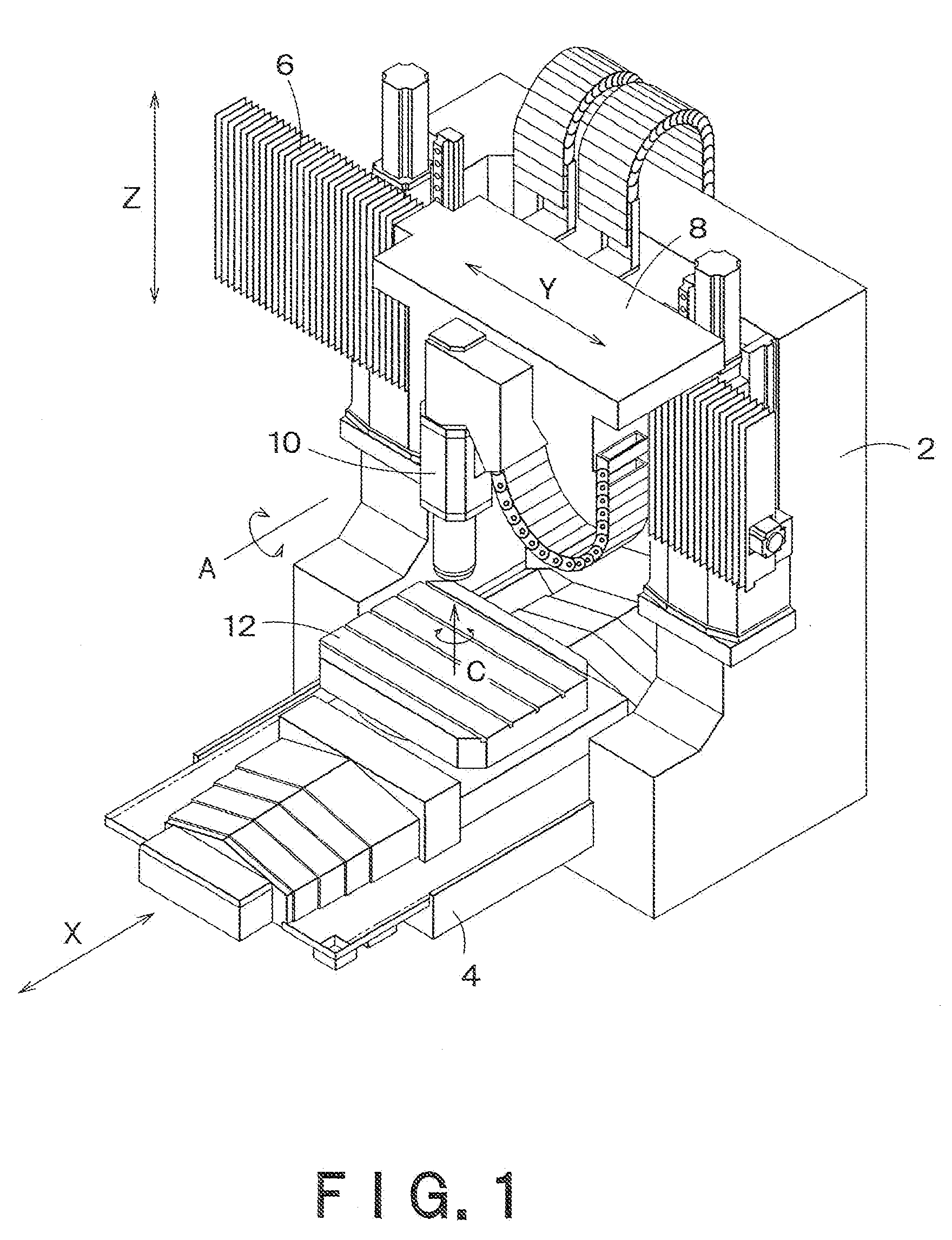

Machine Tool

ActiveUS20060270540A1Easy maintenanceReduce manufacturing costPlaning/slotting machinesMilling machinesFree rotationSaddle shape

Machine tool simplifying maintenance, reducing manufacturing costs, and enabling high precision machining. The machine tool is equipped with: a bed furnished with a rectangular base, right and left sidewalls provided standing either side of the base, and a rear sidewall provided standing along the back of the base; a table disposed in the space surrounded by the three sidewalls; a first saddle shaped in the form of a rectangular frame shape, provided free to shift back and forth supported on the tops of the left and right sidewalls; a second saddle penetrated by a perpendicular through-hole and arranged free to shift sideways inside the first saddle frame; and a spindle head arranged free to shift perpendicularly inside the through-hole in the second saddle; and a main spindle arranged over the table and supported by the spindle head free to rotate centered on its axis.

Owner:DMG MORI SEIKI CO LTD

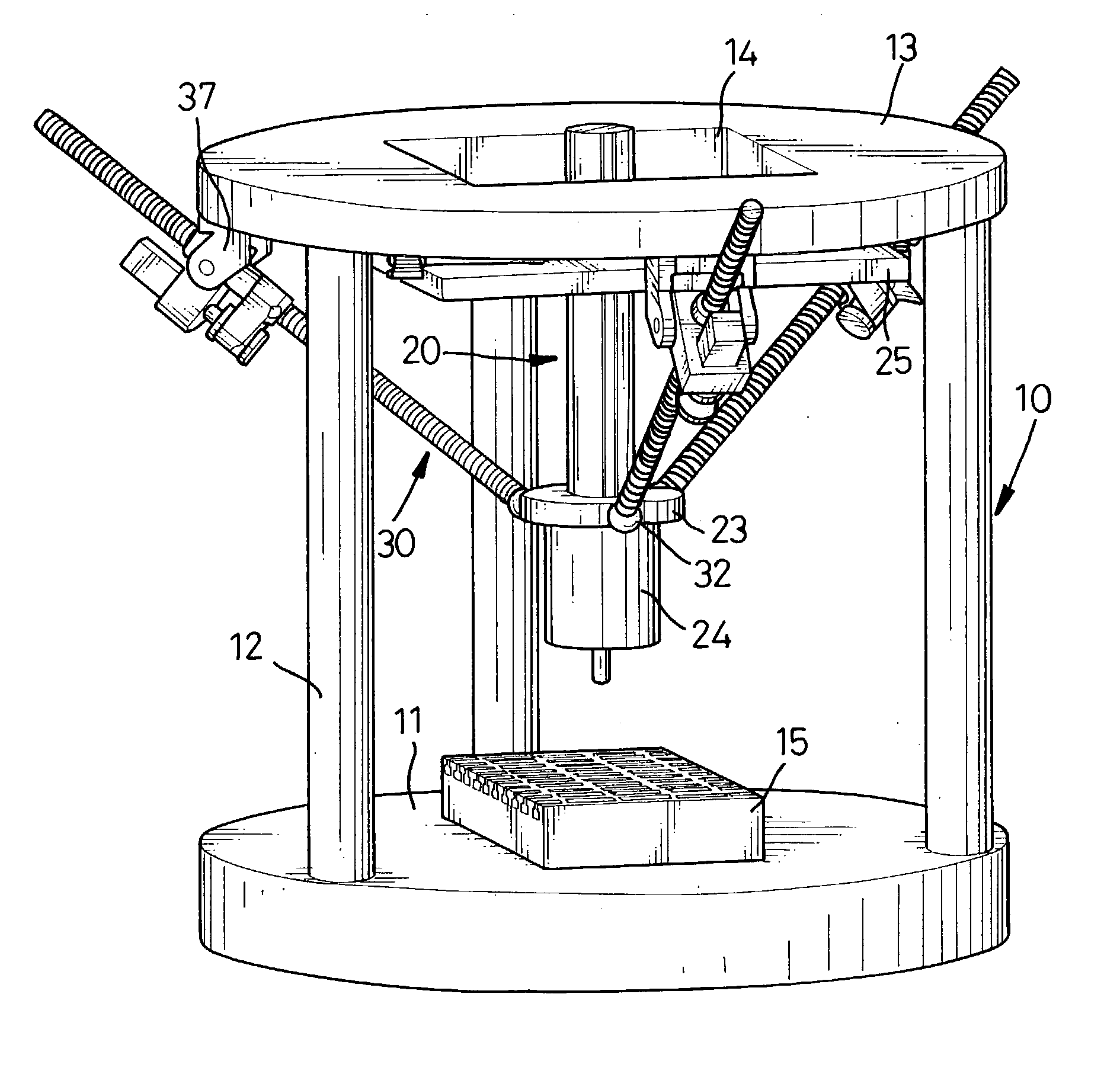

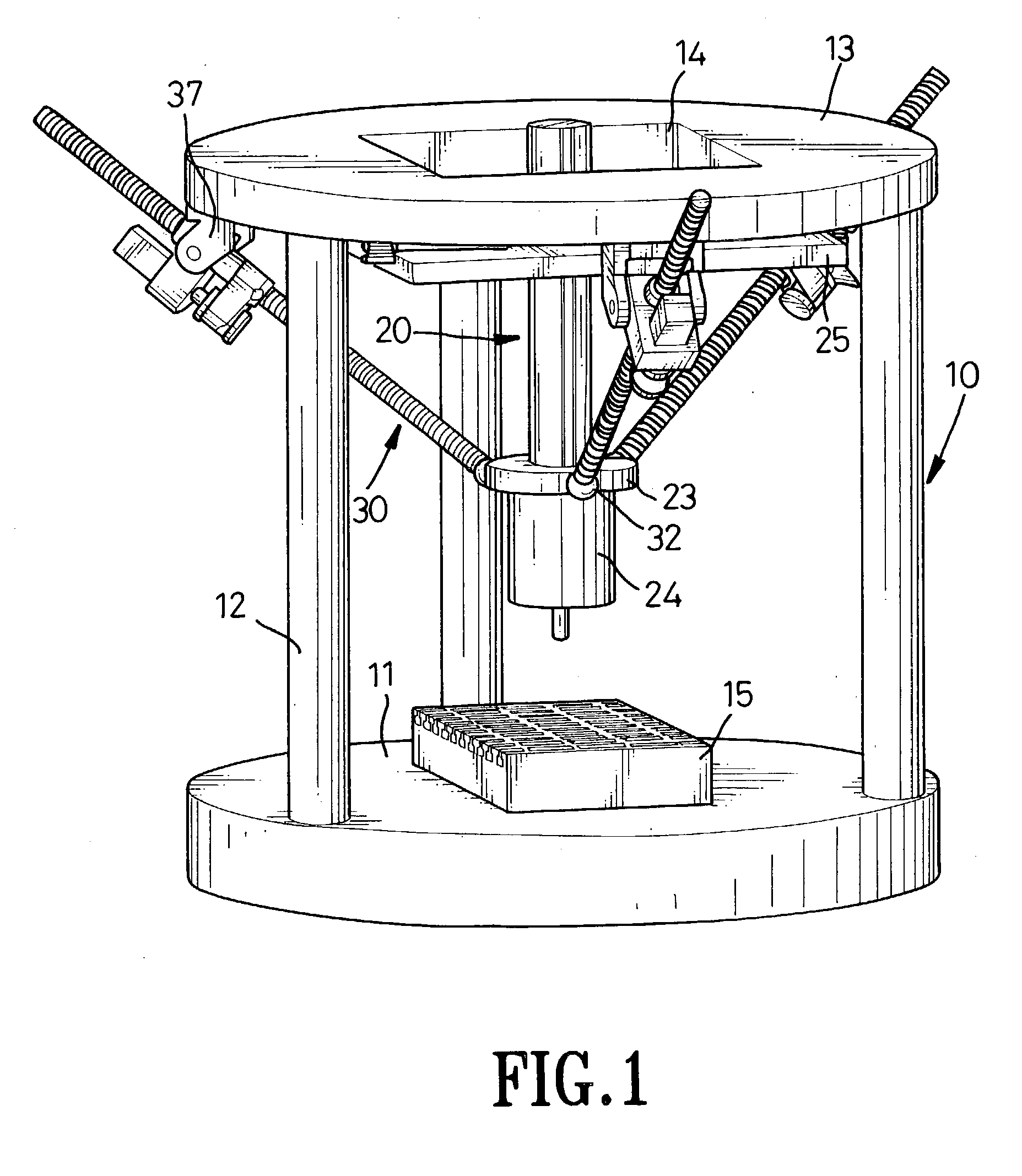

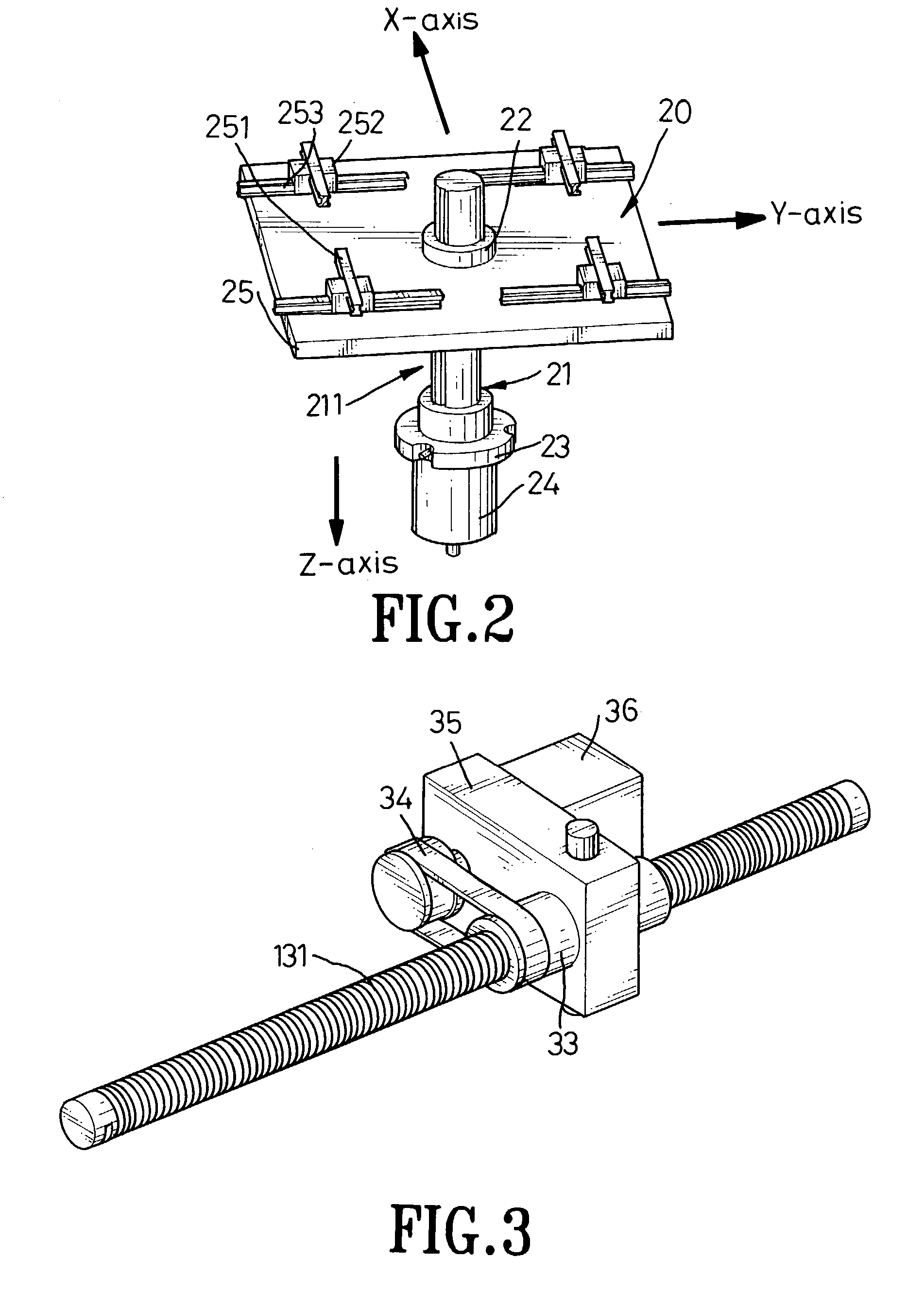

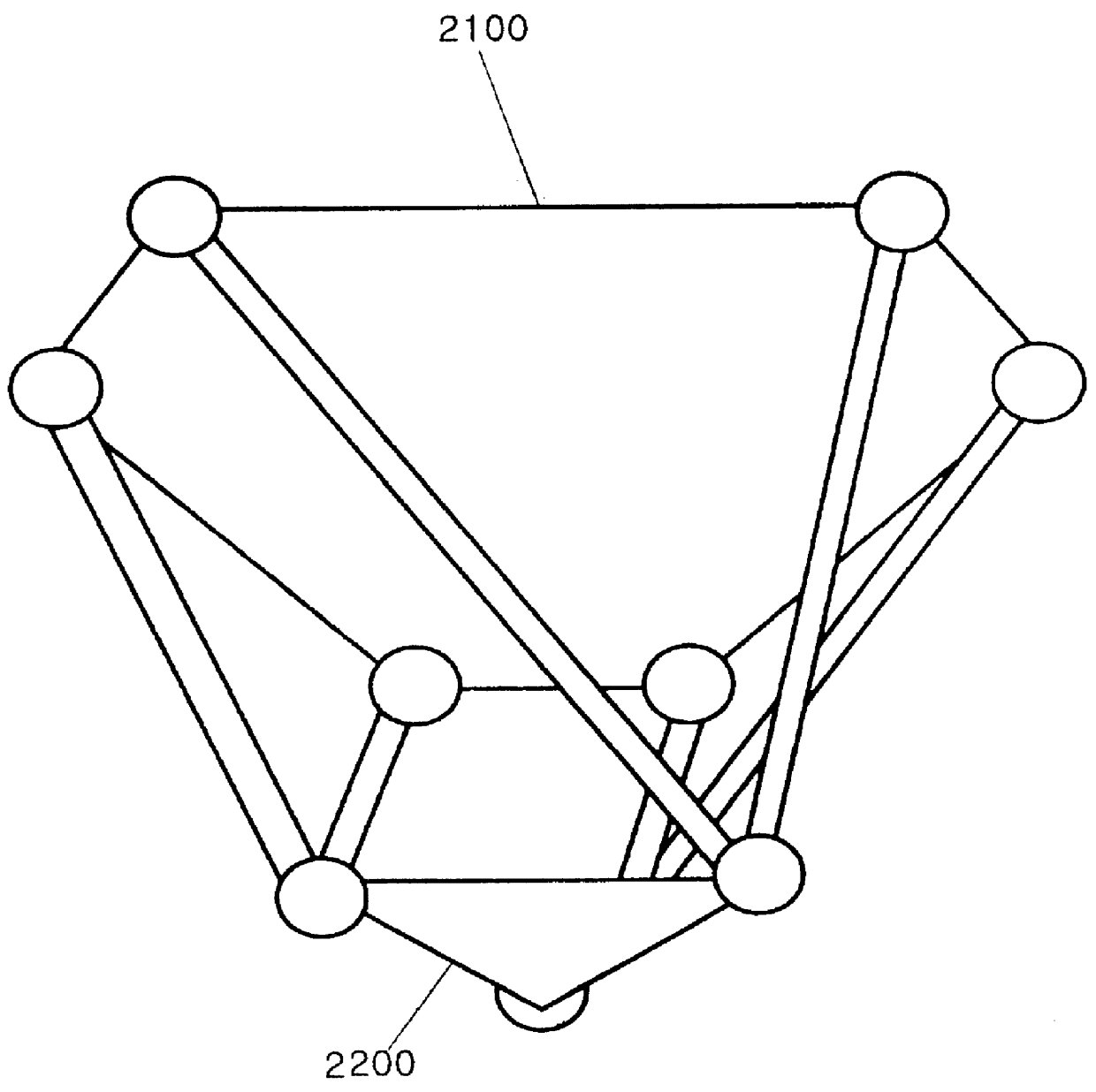

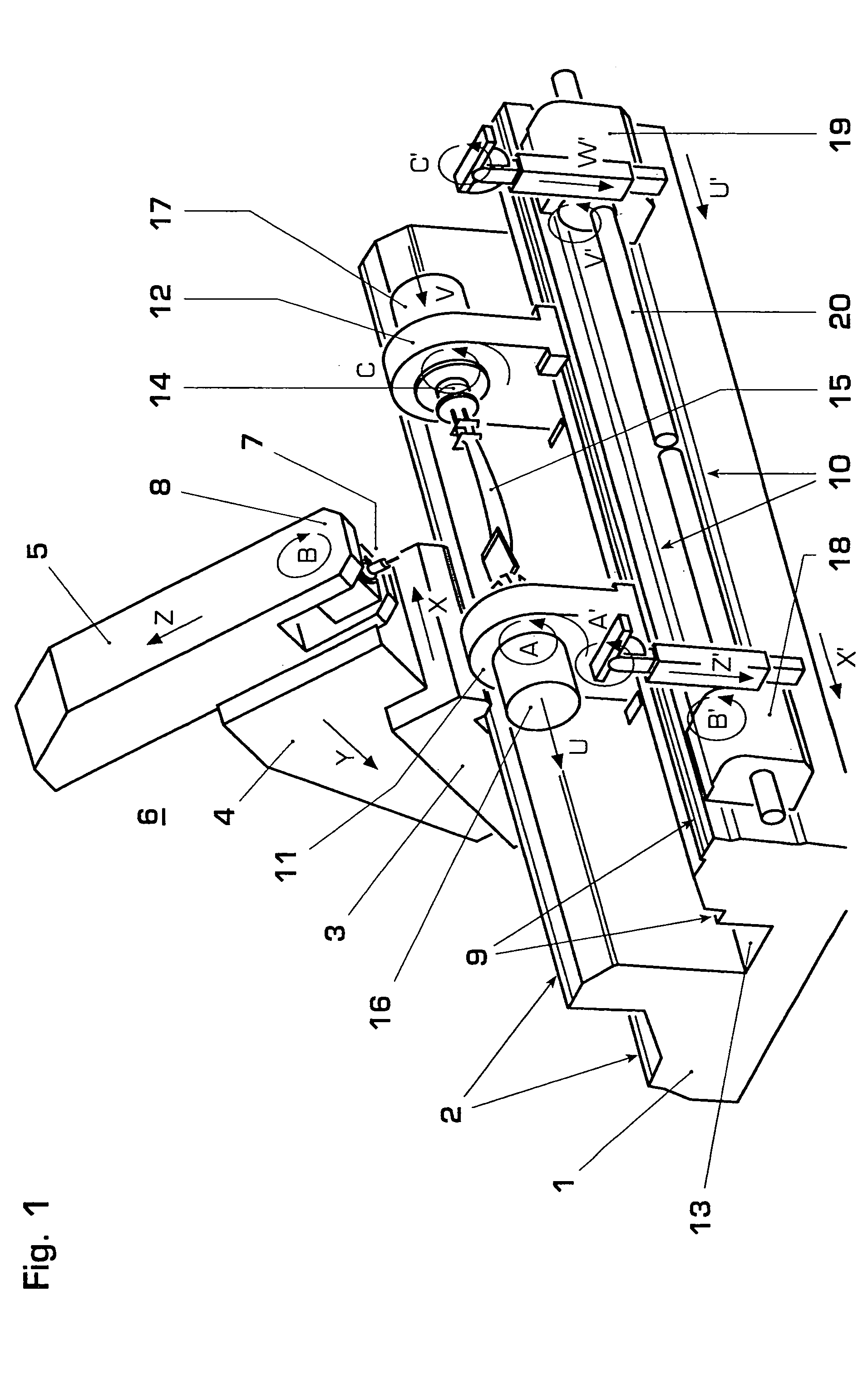

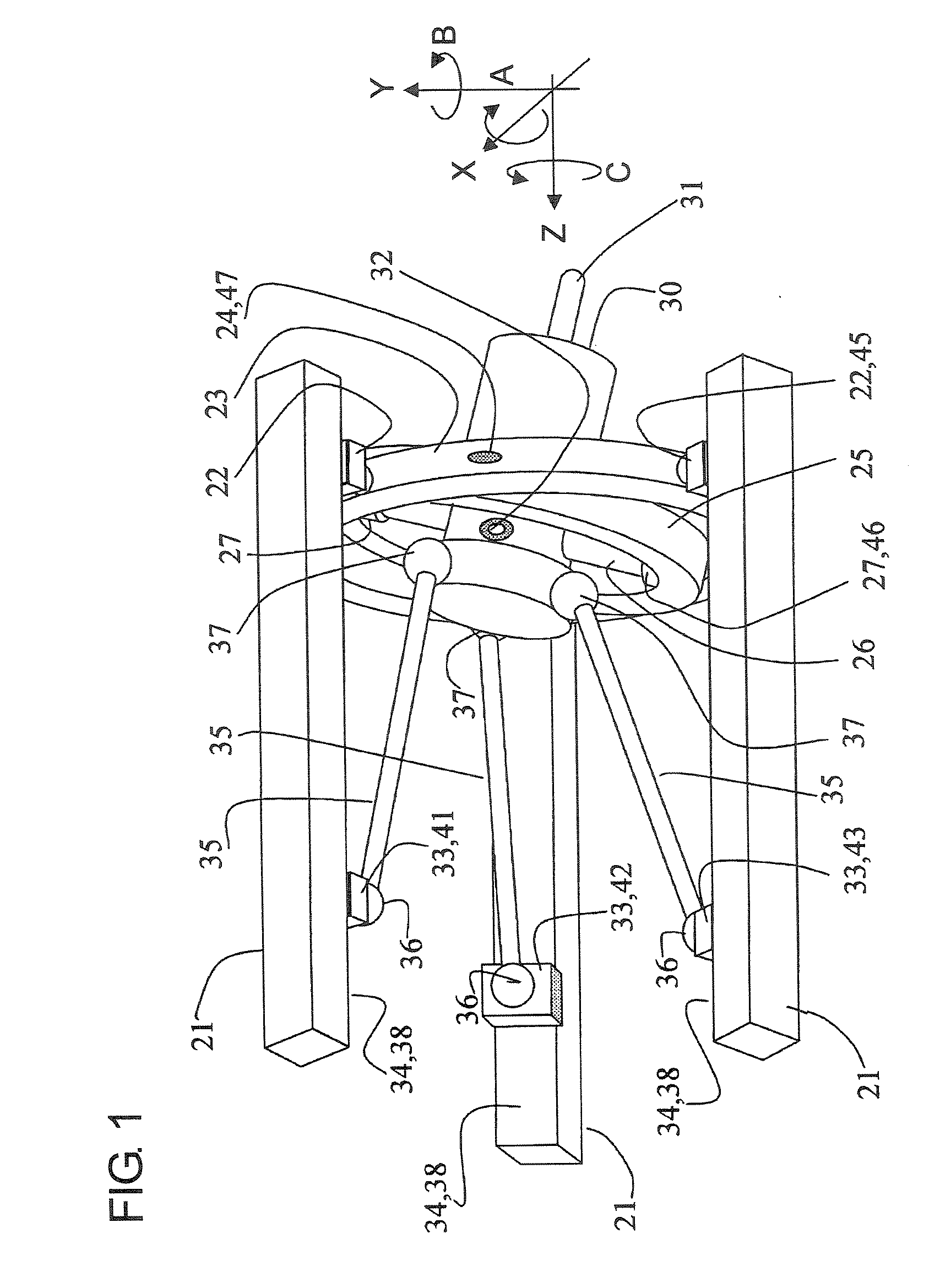

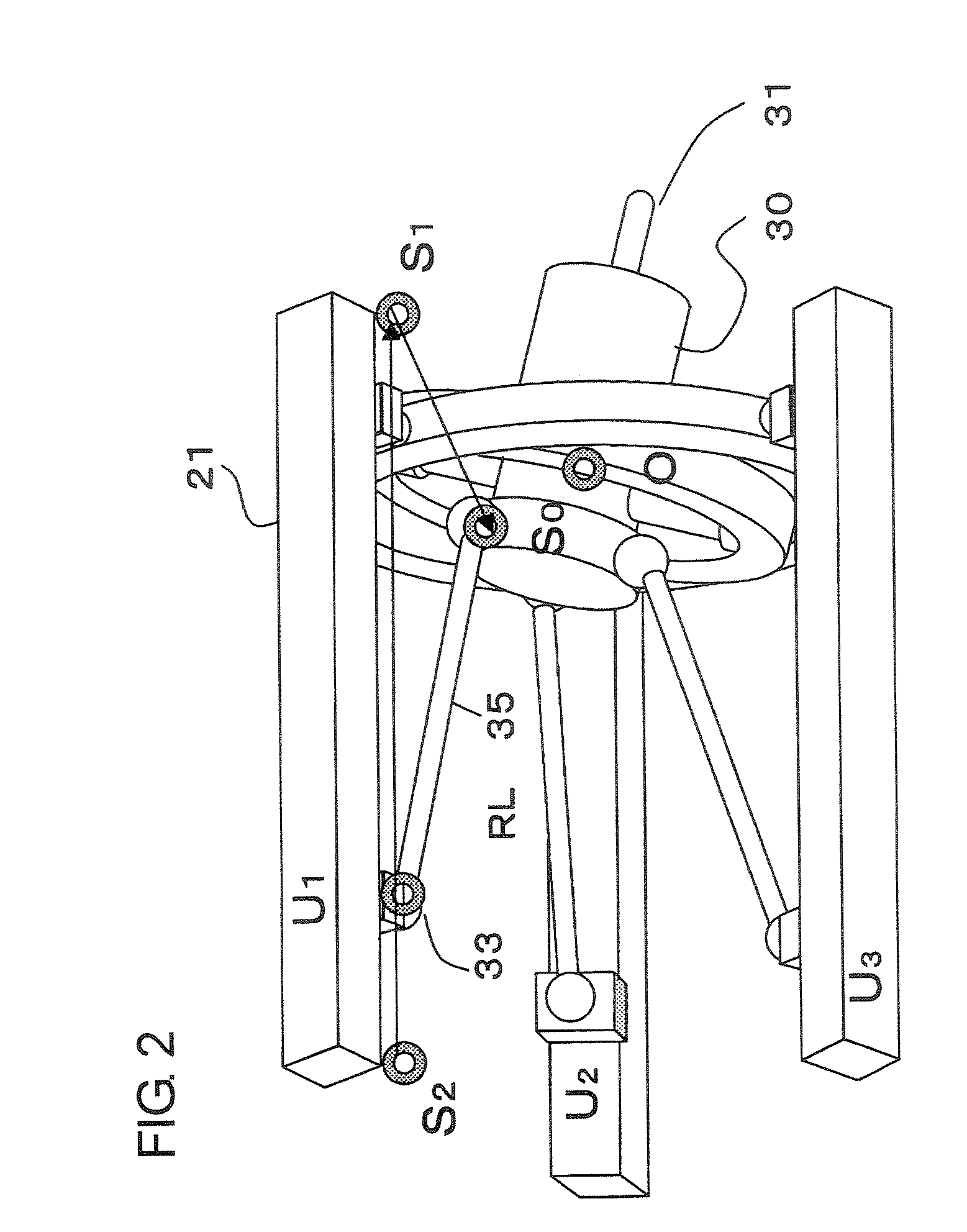

Multi-axis cartesian guided parallel kinematic machine

A multi-axis Cartesian guided parallel kinematic machine has a frame, a base platform, a multi-axis Cartesian guiding mechanism assembly, multiple driving strut assemblies and a motion platform. The motion platform is connected to the base platform through the driving strut assemblies and the multi-axis Cartesian guiding mechanism assembly. The multi-axis Cartesian guiding mechanism assembly has multiple linear guiding mechanisms and rotary guiding mechanisms that are in-serial linked and arranged in orthogonal to each other according to the Cartesian coordinate system. The multiple driving strut assemblies are in-parallel connected to the base platform and the motion platform using pivot joints. Each driving strut assembly is a telescoping strut assembly or a sliding strut assembly. When the driving strut assemblies are actuated, the motion platforms can be driven to a desired position in the Cartesian workspace with a controllable platform orientation relative to the frame.

Owner:CHEN JENG SHYONG

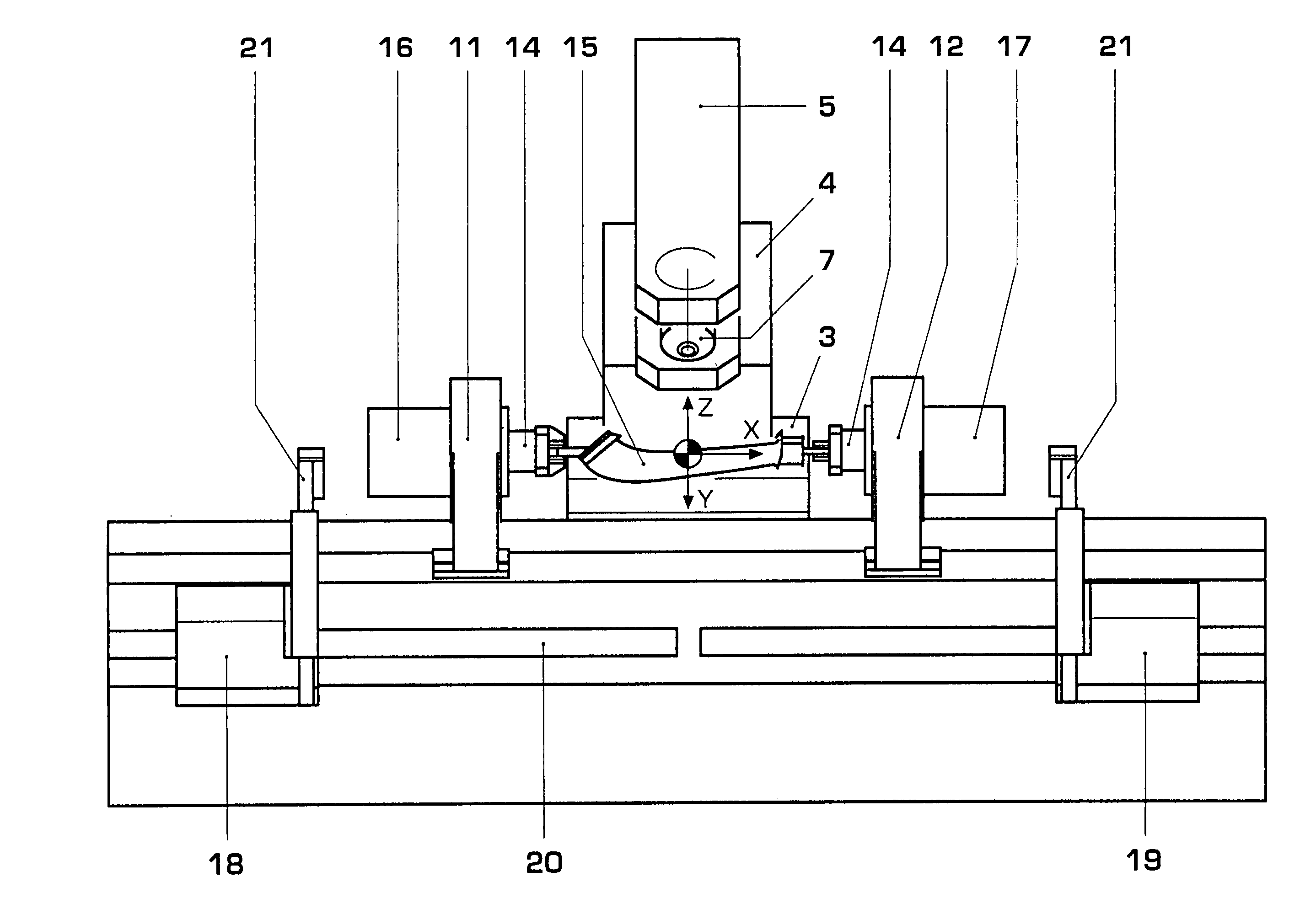

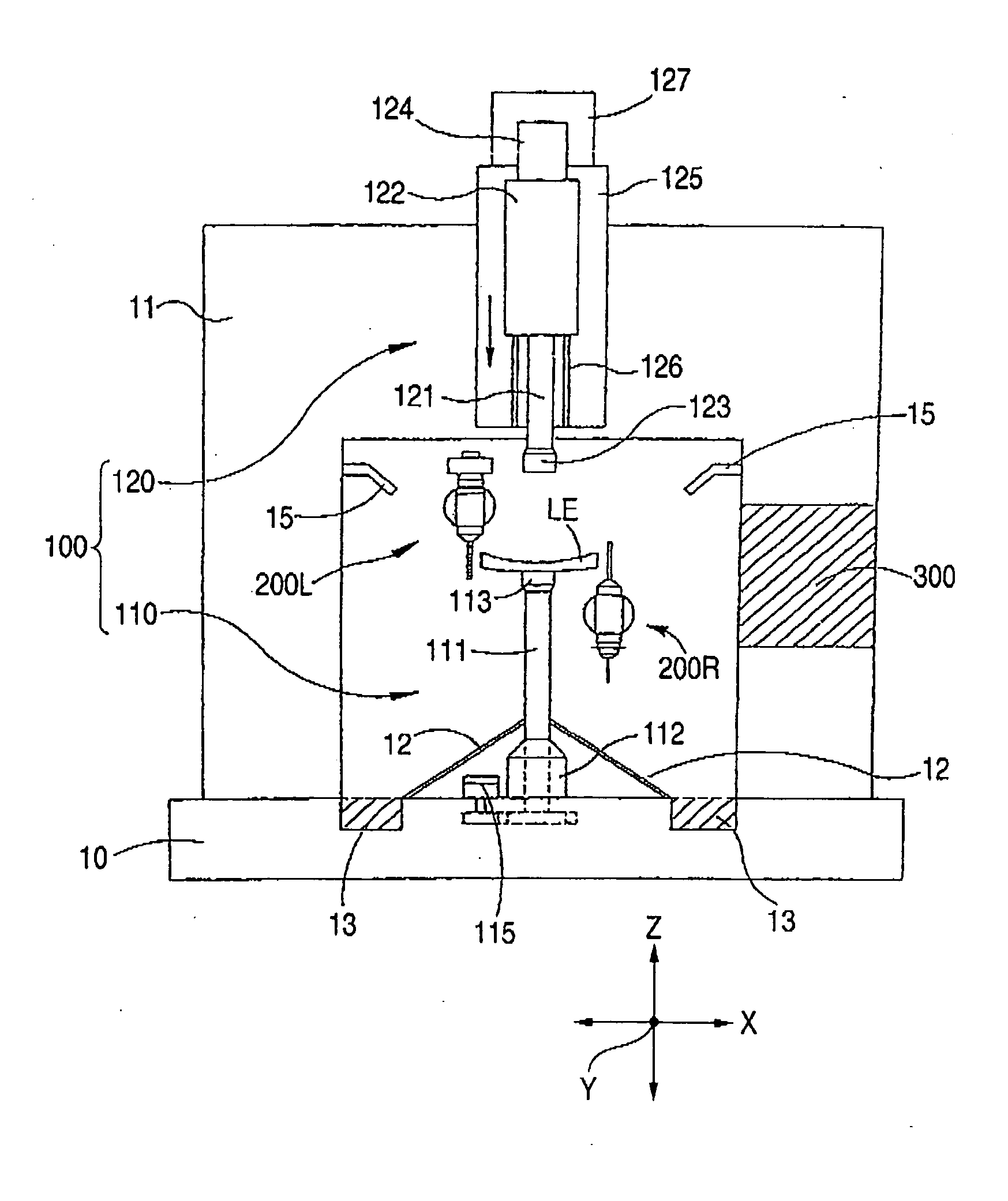

Parallel mechanism for multi-machining type machining center

InactiveUS6135683AImprove robustnessMeasurement/indication equipmentsPlaning/slotting machinesActuatorMachining

A six-degree-of-freedom parallel mechanism is provided for expanding a grade of a spindle. The parallel mechanism has a spindle that turns round a workpiece at a tilting angle of 90 DEG in a workspace, to thereby allow a machining for both vertical and horizontal planes of the workpiece, and a vertical turning process, by a single machining center. A six-axis multi-machining type machining center embodying the parallel mechanism of the present invention is also disclosed. An over-actuated multi-machining type machining center further including over-actuated actuators is presented to solve a problem of driving joints' singularity caused by the parallel mechanism.

Owner:SEOUL NAT UNIV R&DB FOUND

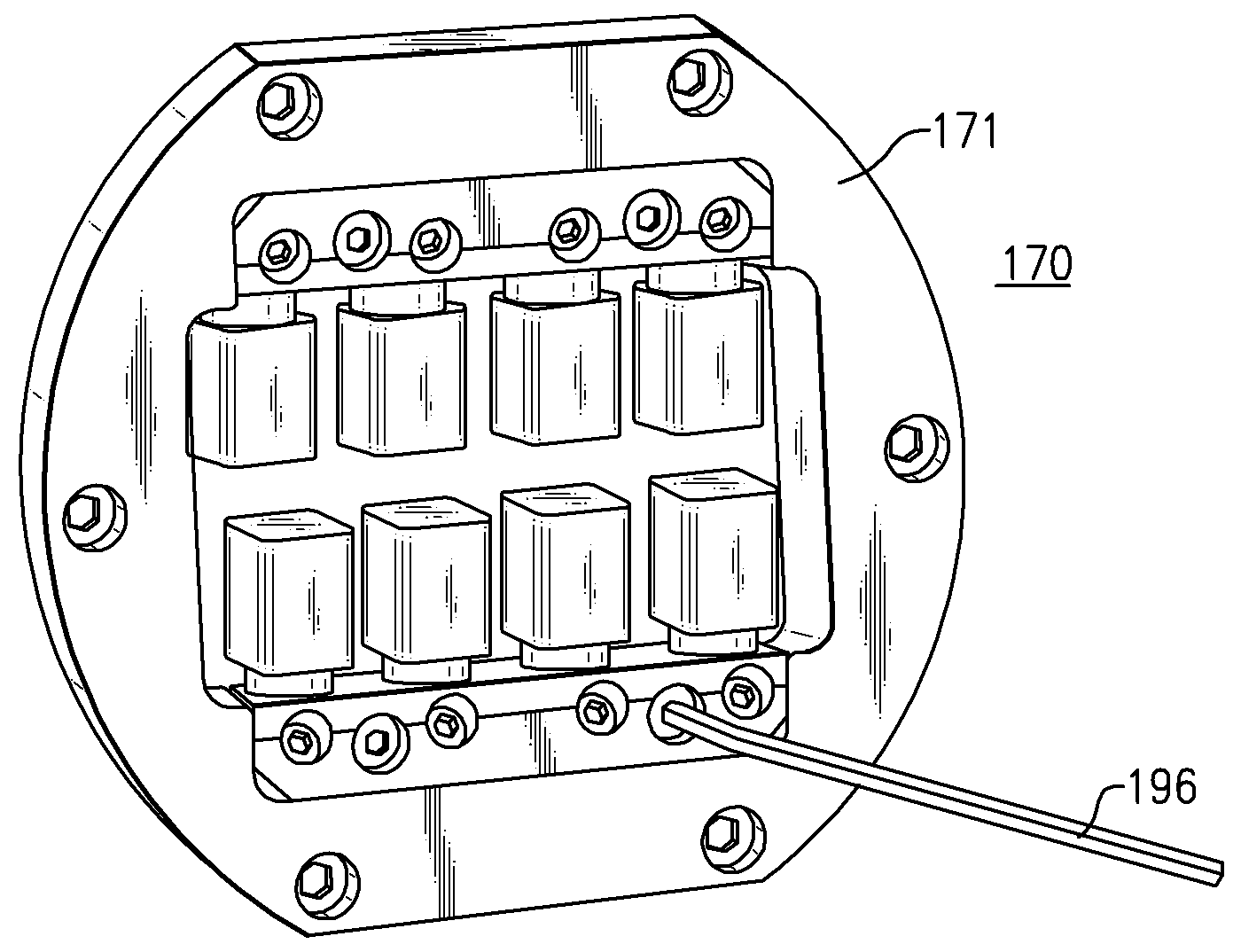

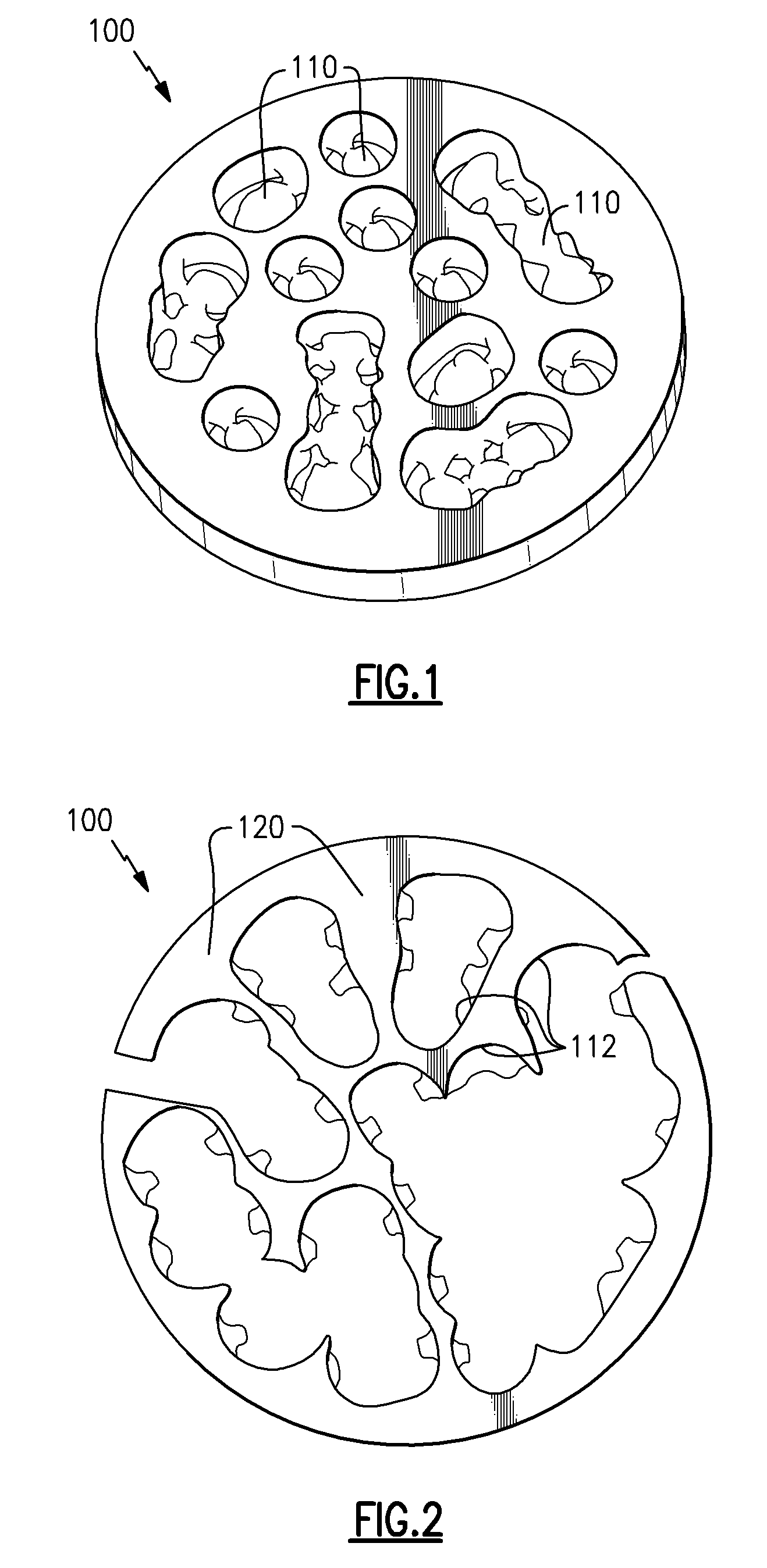

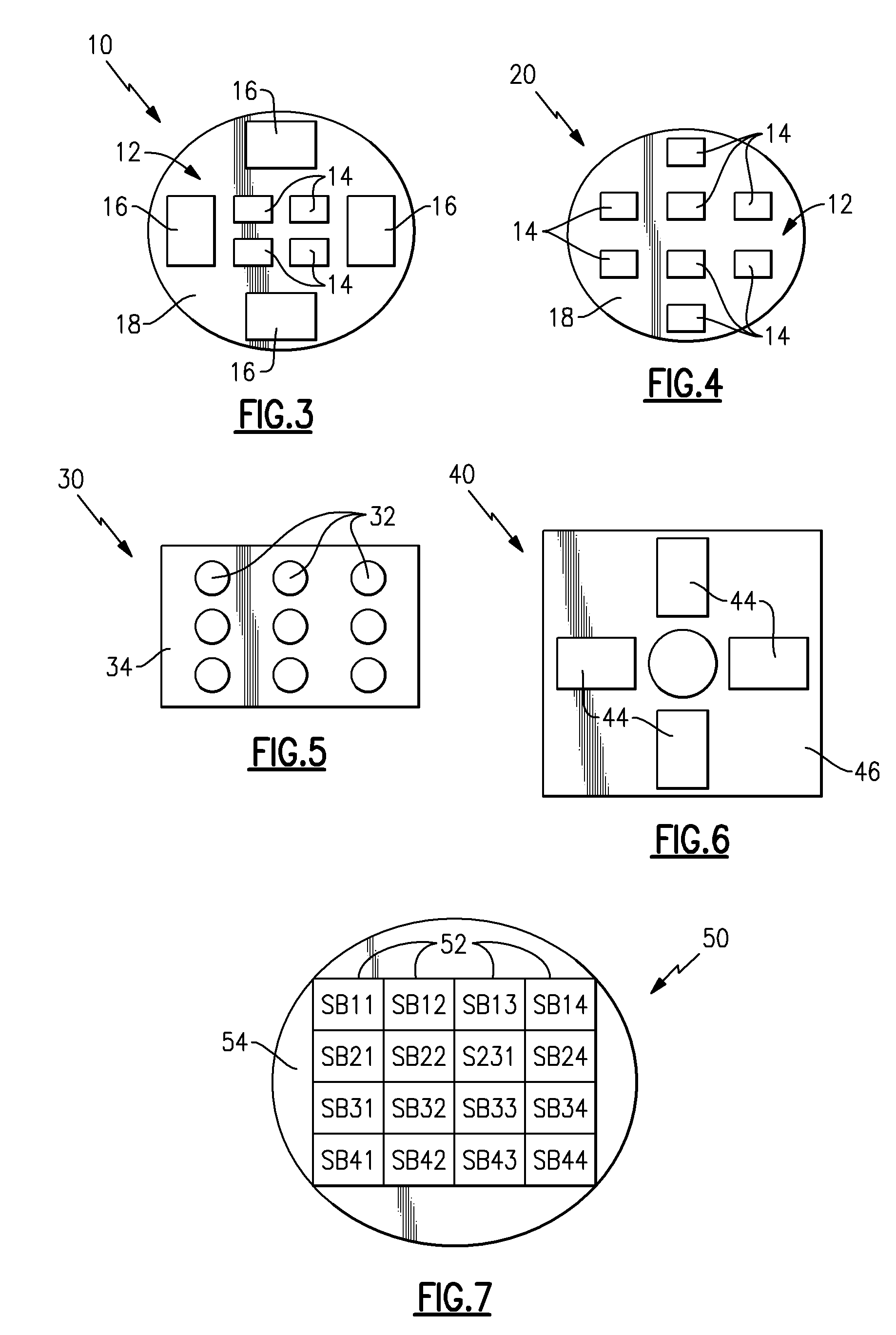

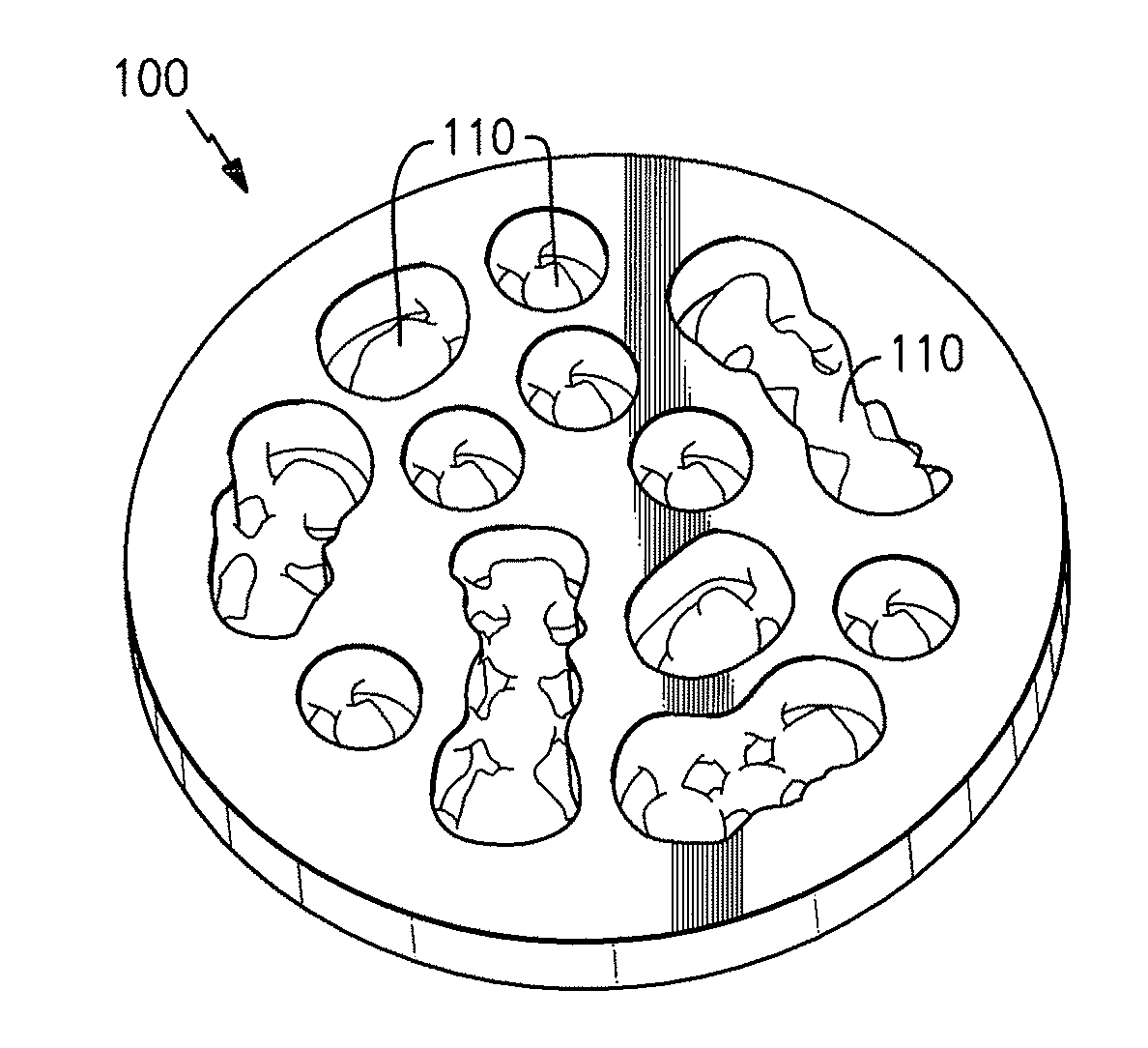

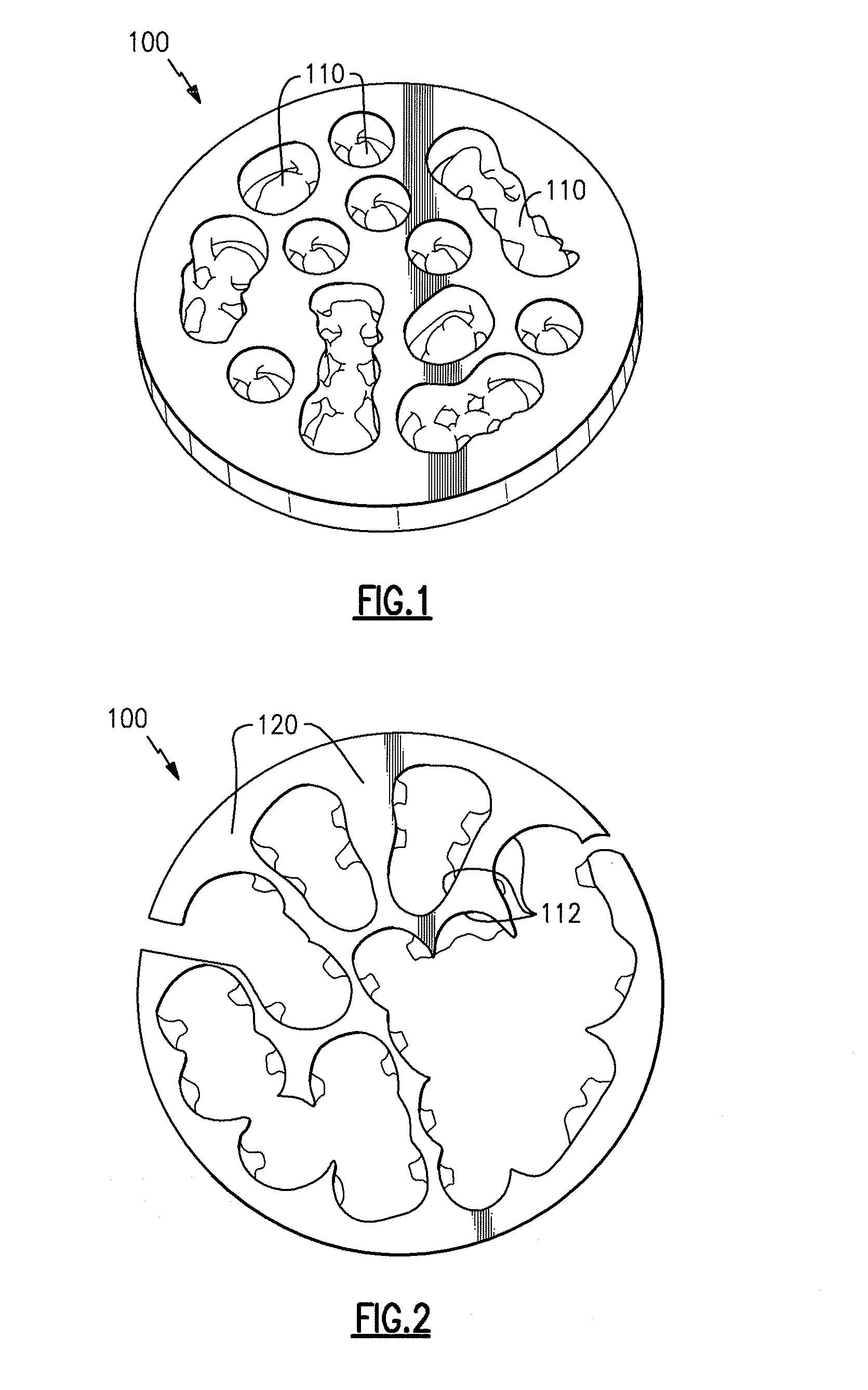

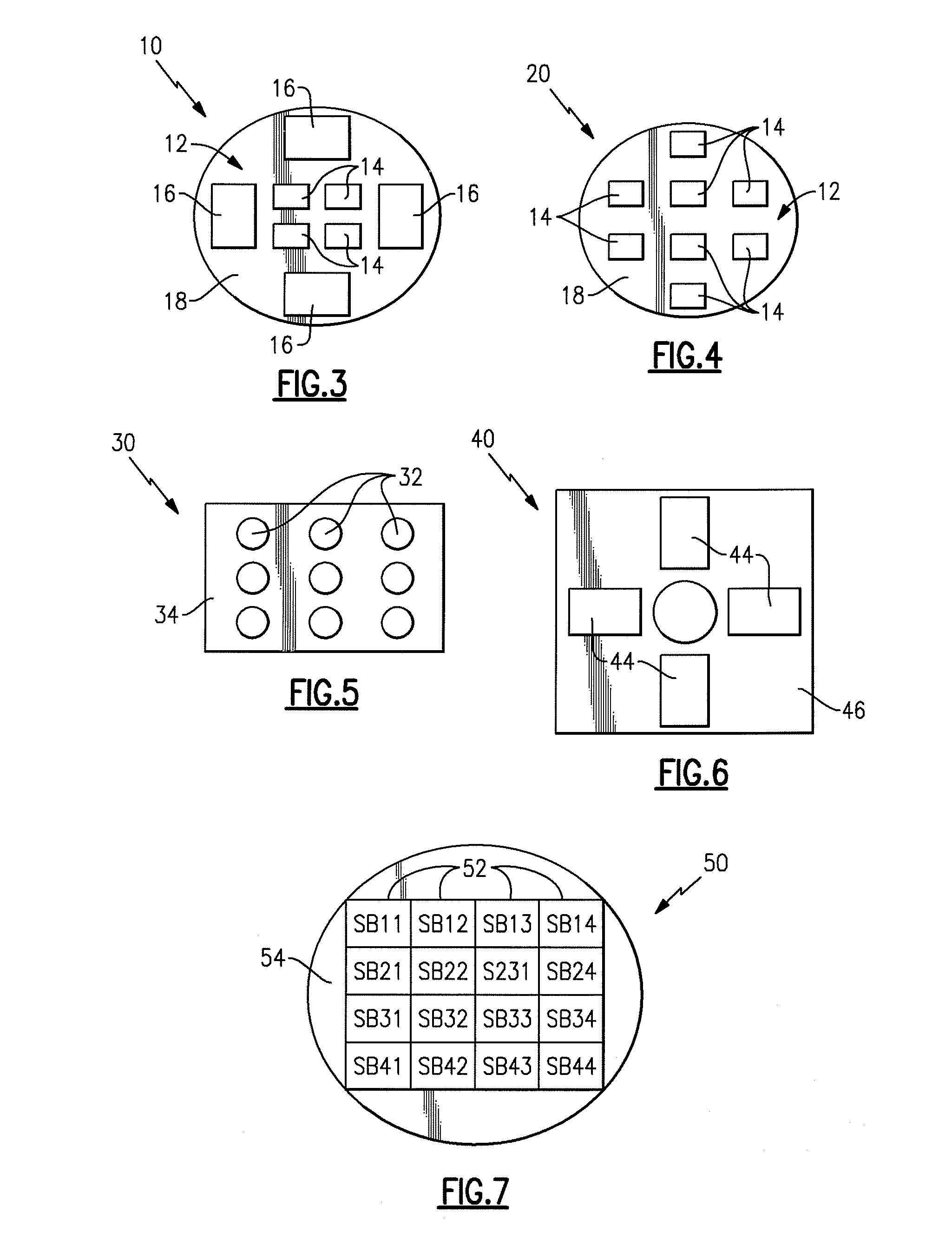

Addressable matrices/cluster blanks for dental cad/cam systems and optimization thereof

ActiveUS20090130634A1Maximum interchangabilityMaximum flexibilityDwelling equipmentDental toolsEngineering

A cluster mill blank includes a framework constructed to cooperate with a blank holder of an existing CAD / CAM system, and a plurality of sub-blanks attached to the framework forming an addressable matrix or cluster blank. CAD / CAM systems including such a framework, as well as associated methods are described.

Owner:IVOCLAR VIVADENT AG

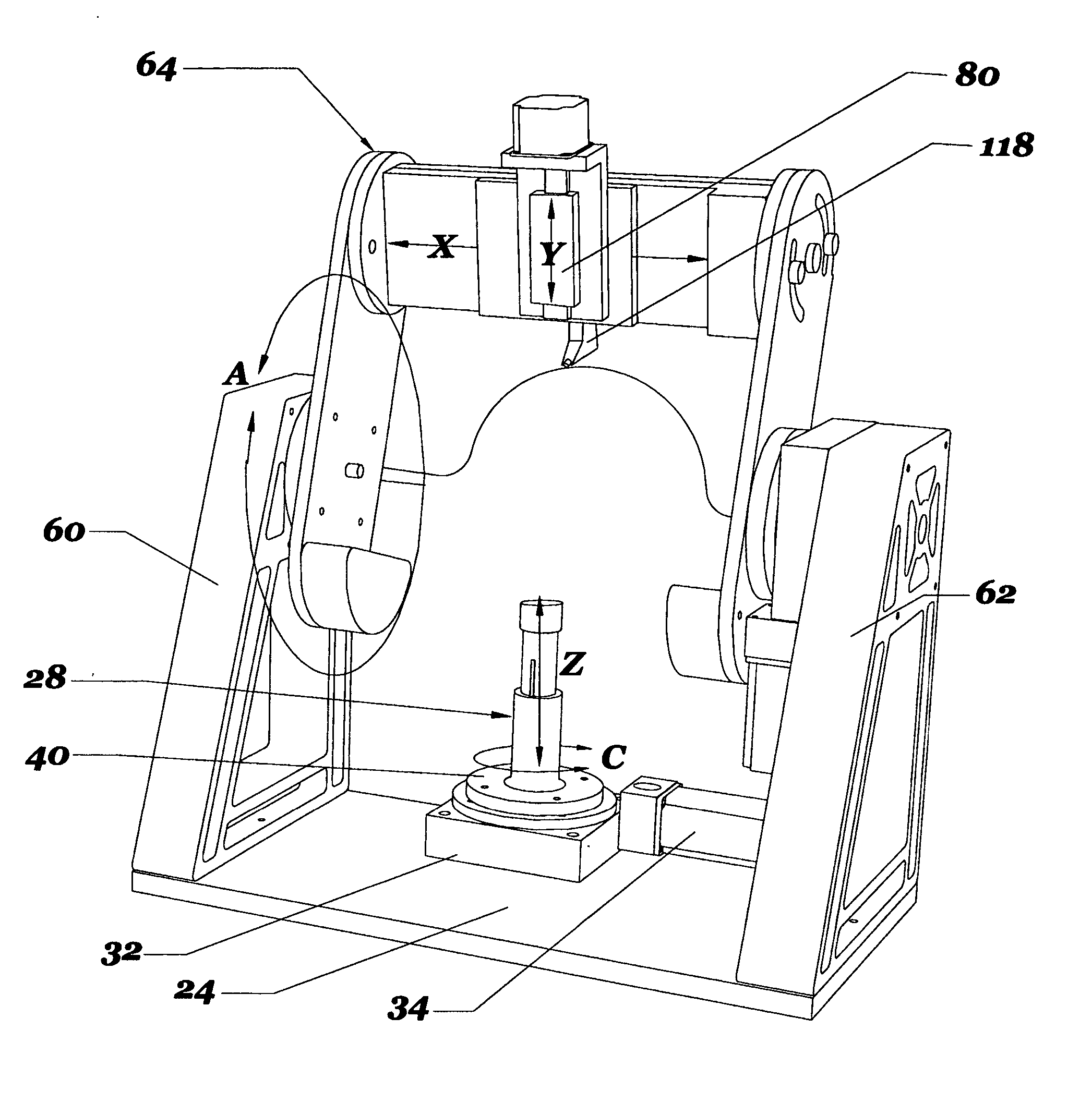

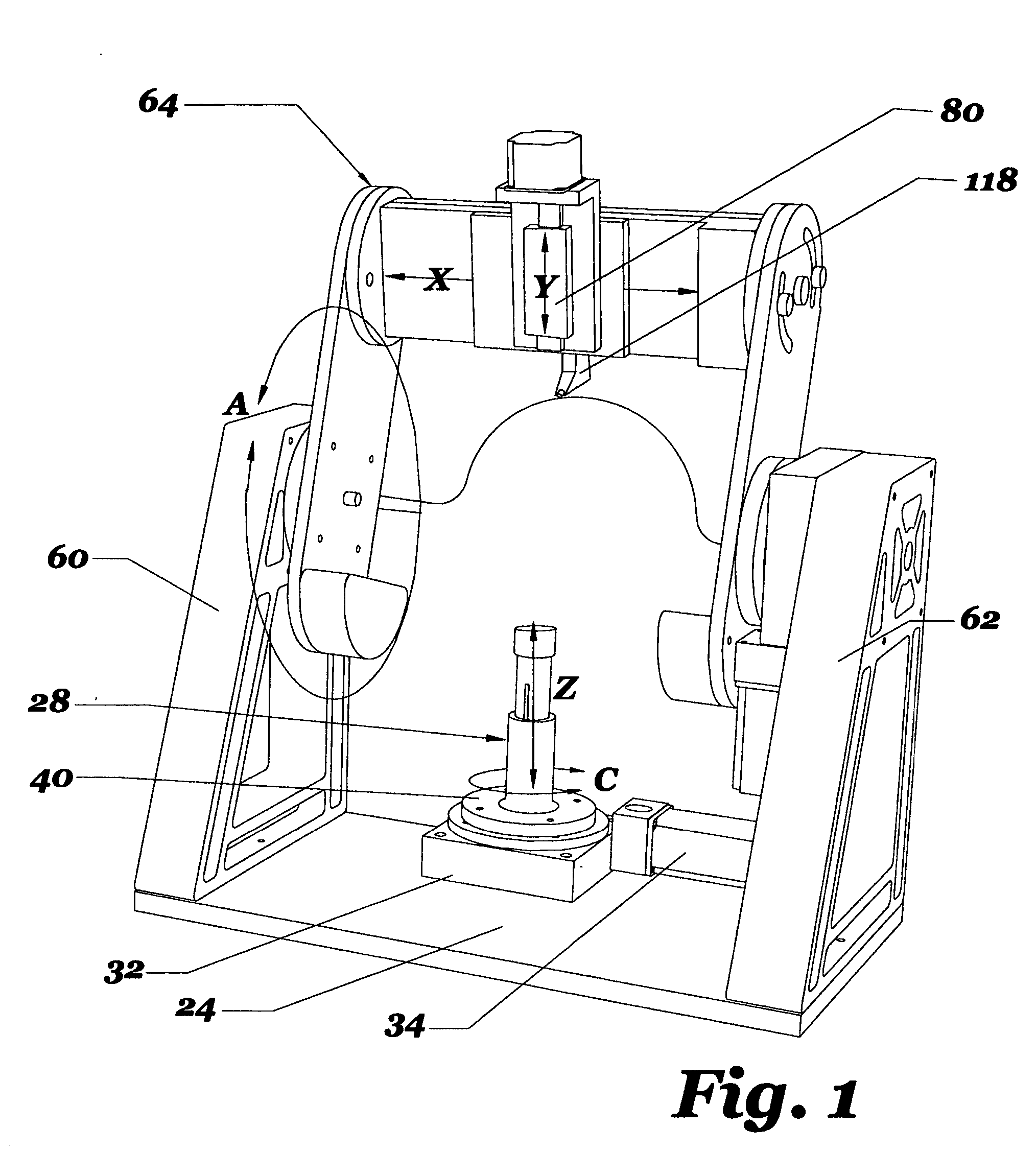

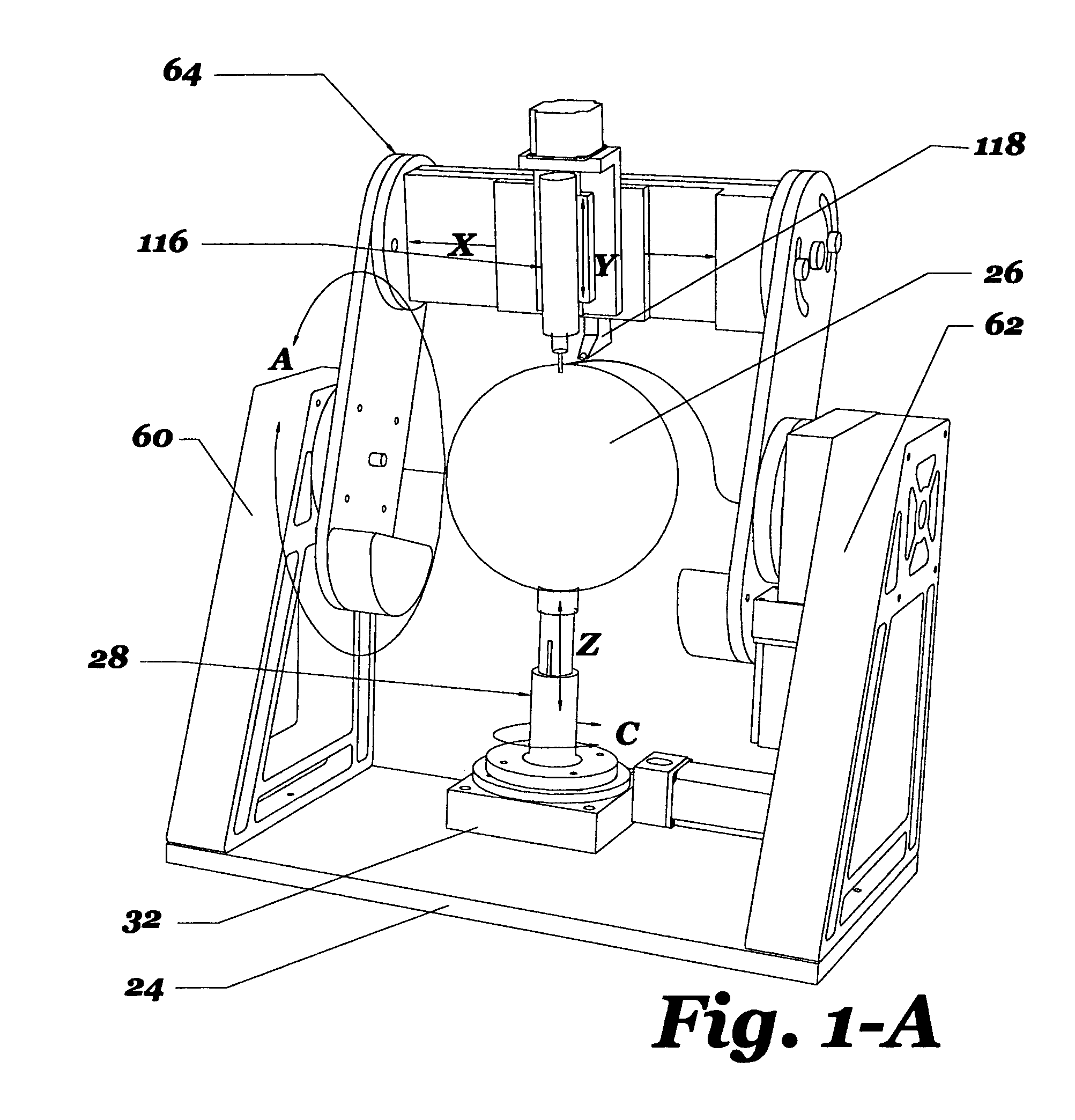

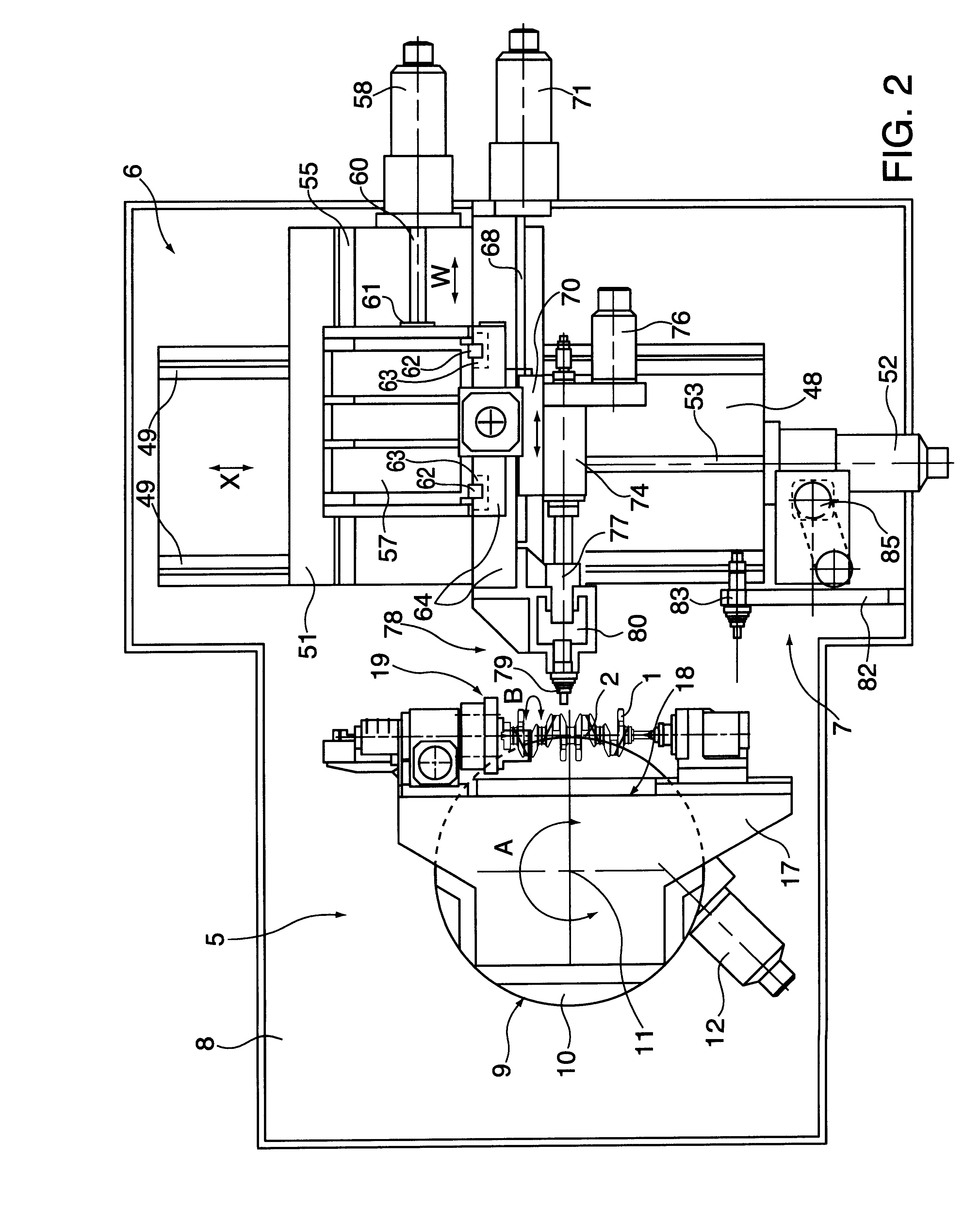

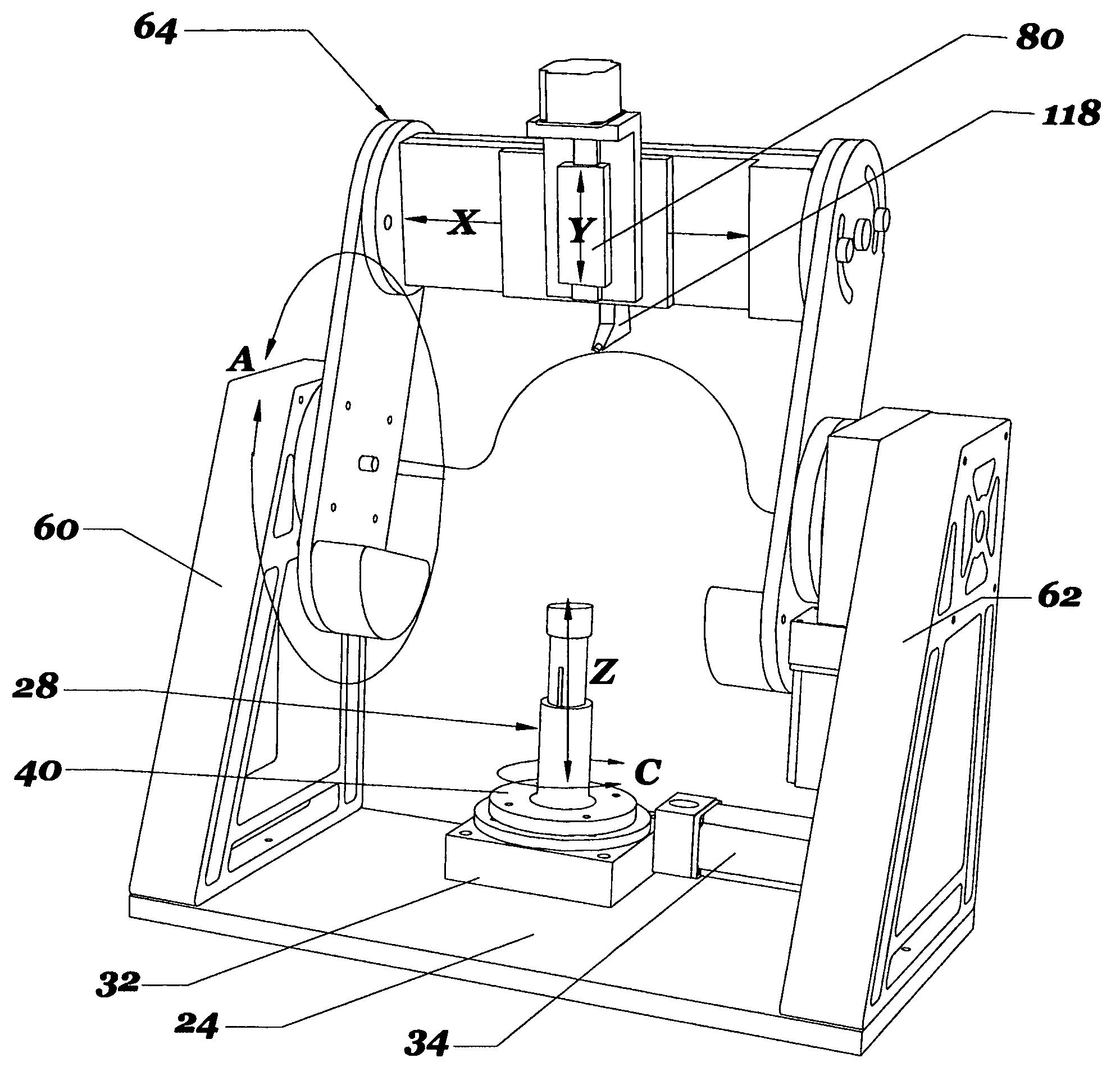

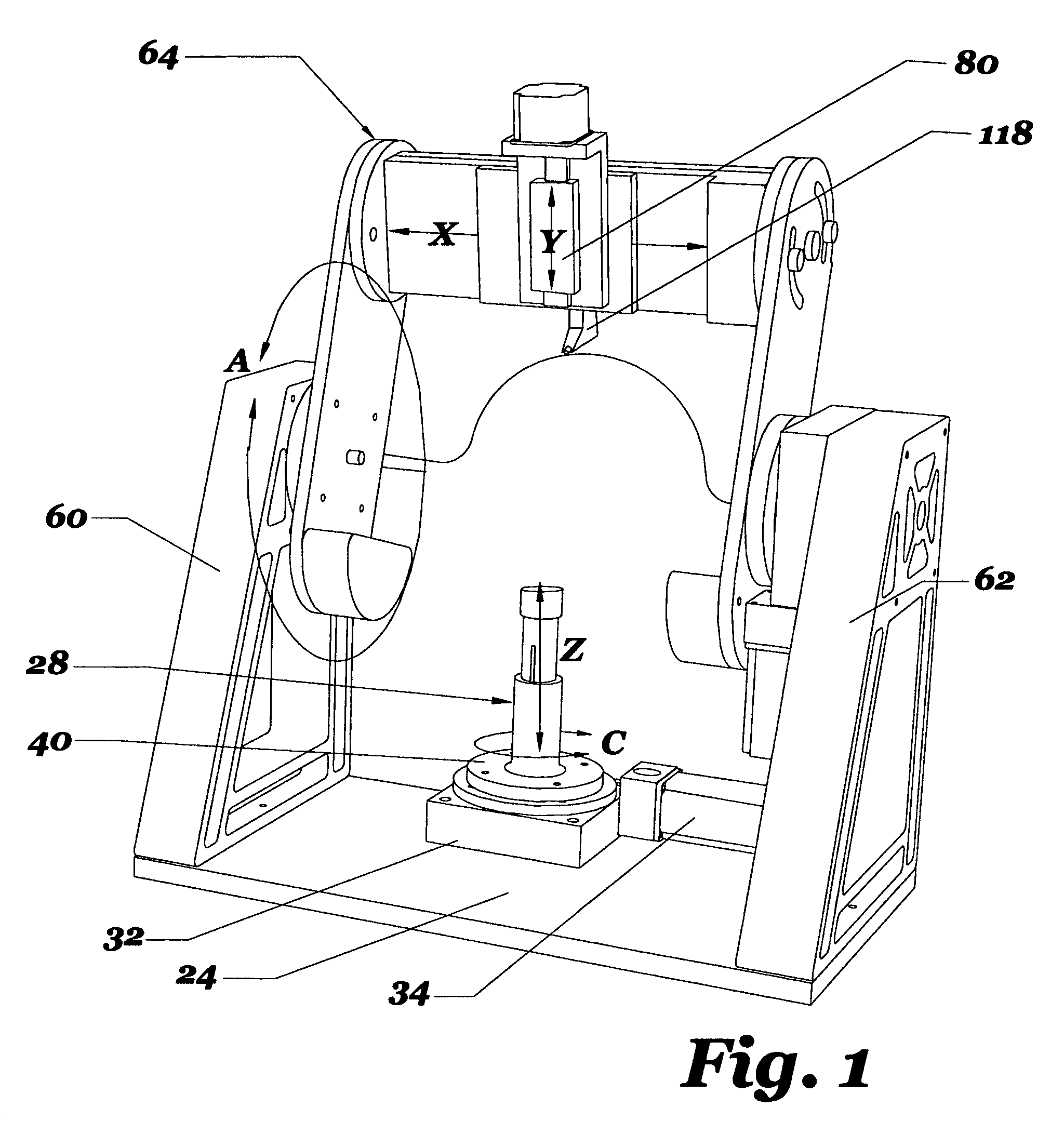

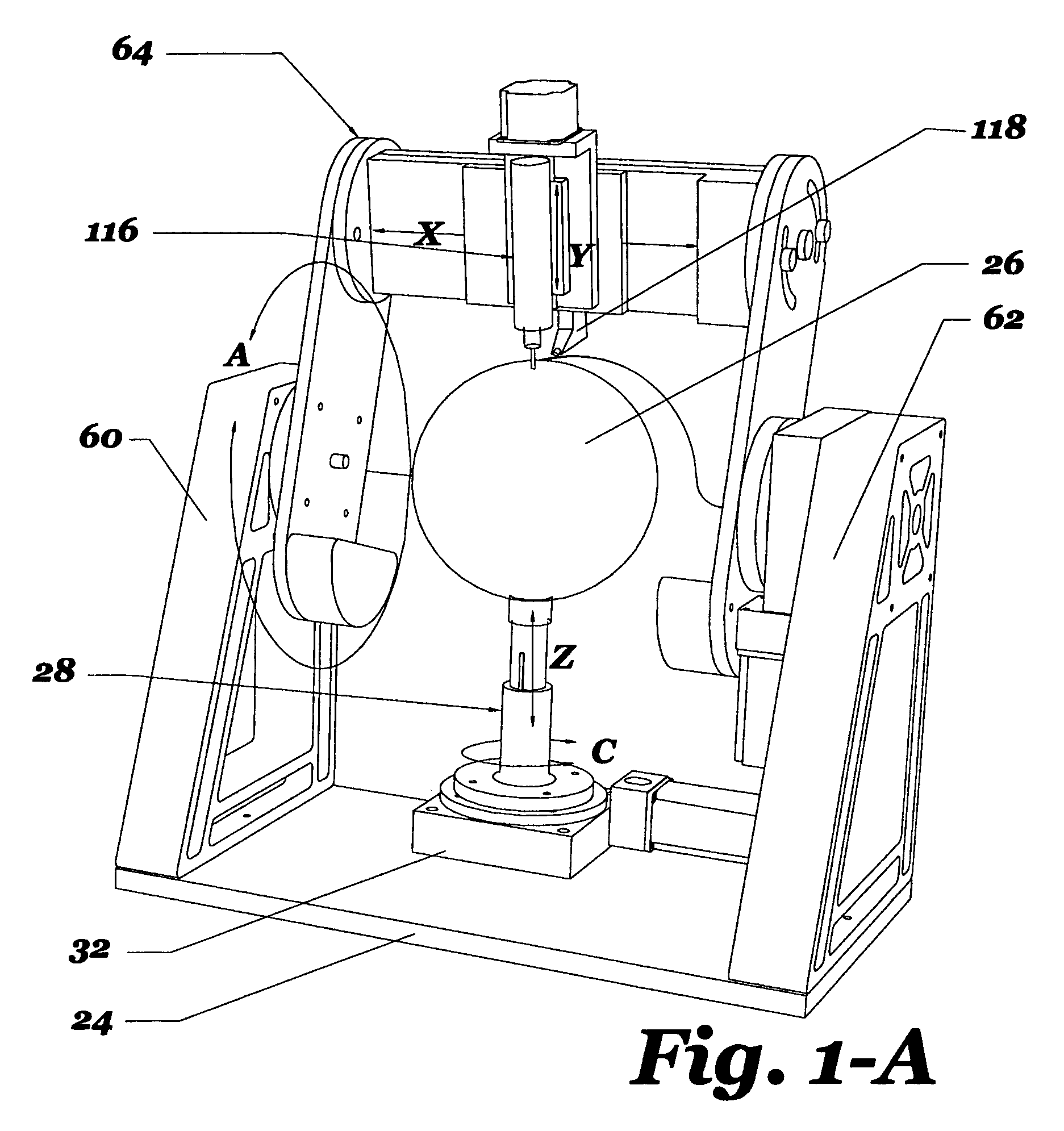

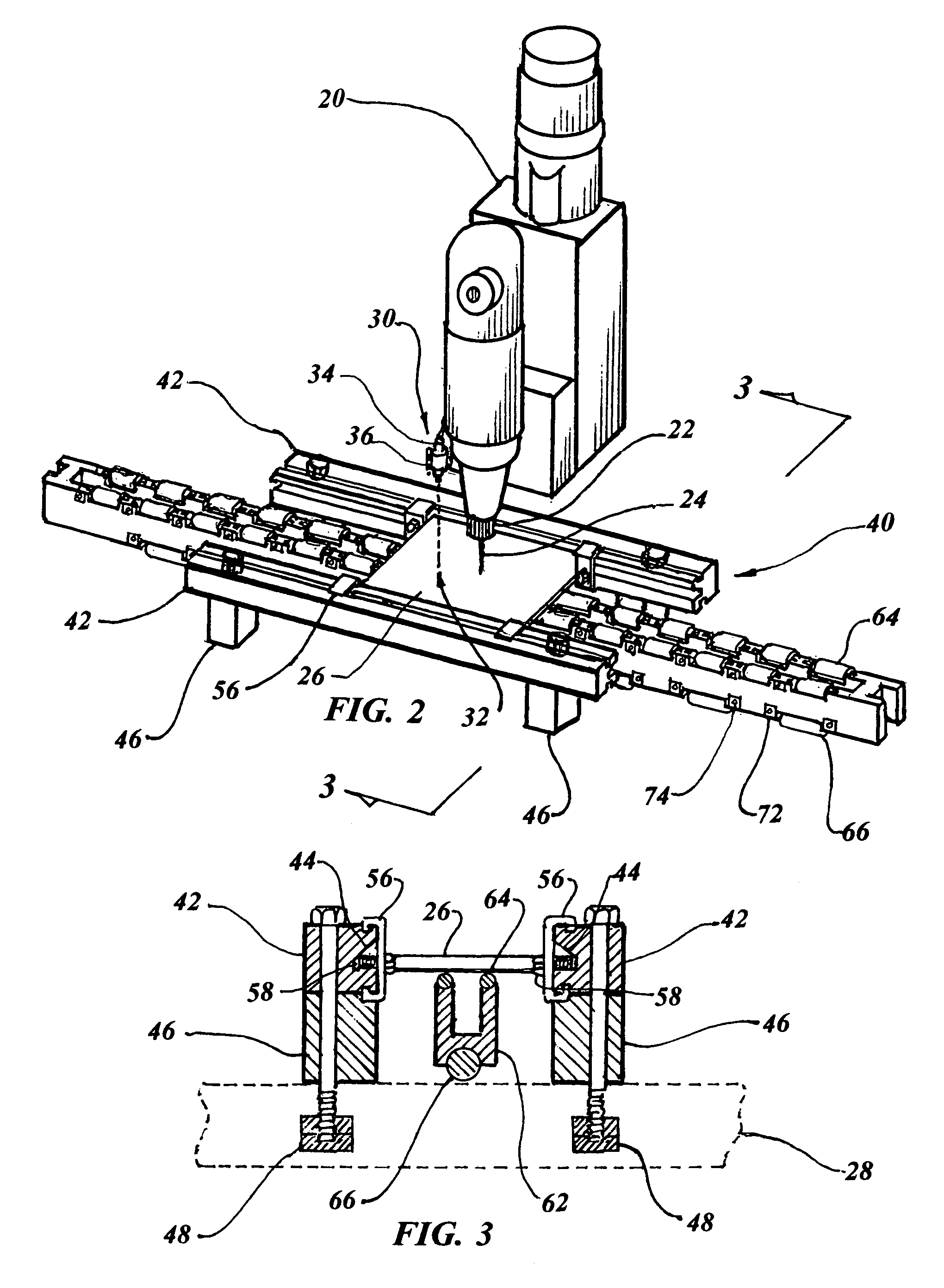

Multi-axis, processor-controlled, toolhead positioner

InactiveUS20060242818A1Programme-controlled manipulatorPlaning/slotting machinesRotational axisEngineering

A multi-axis, computerized numerically-controlled (CNC) toolhead positioning device with six degrees of freedom of movement while utilizing only five axes of movement, comprising a rotating workpiece mount assembly (28) and a rotating gantry (64) with a mounted toolhead assembly base (80). Perpendicular rotational axes about a mounted workpiece (26) provide the capability to perform specific toolhead operations on the arcuate surface of the workpiece (26), subject to the type of mounted toolhead assembly. The computer (120) uses CNC software to integrate operator instructions, machining operations, and the sequence of operations into an automatic and coherent machining package.

Owner:PRECISION SPHERICAL

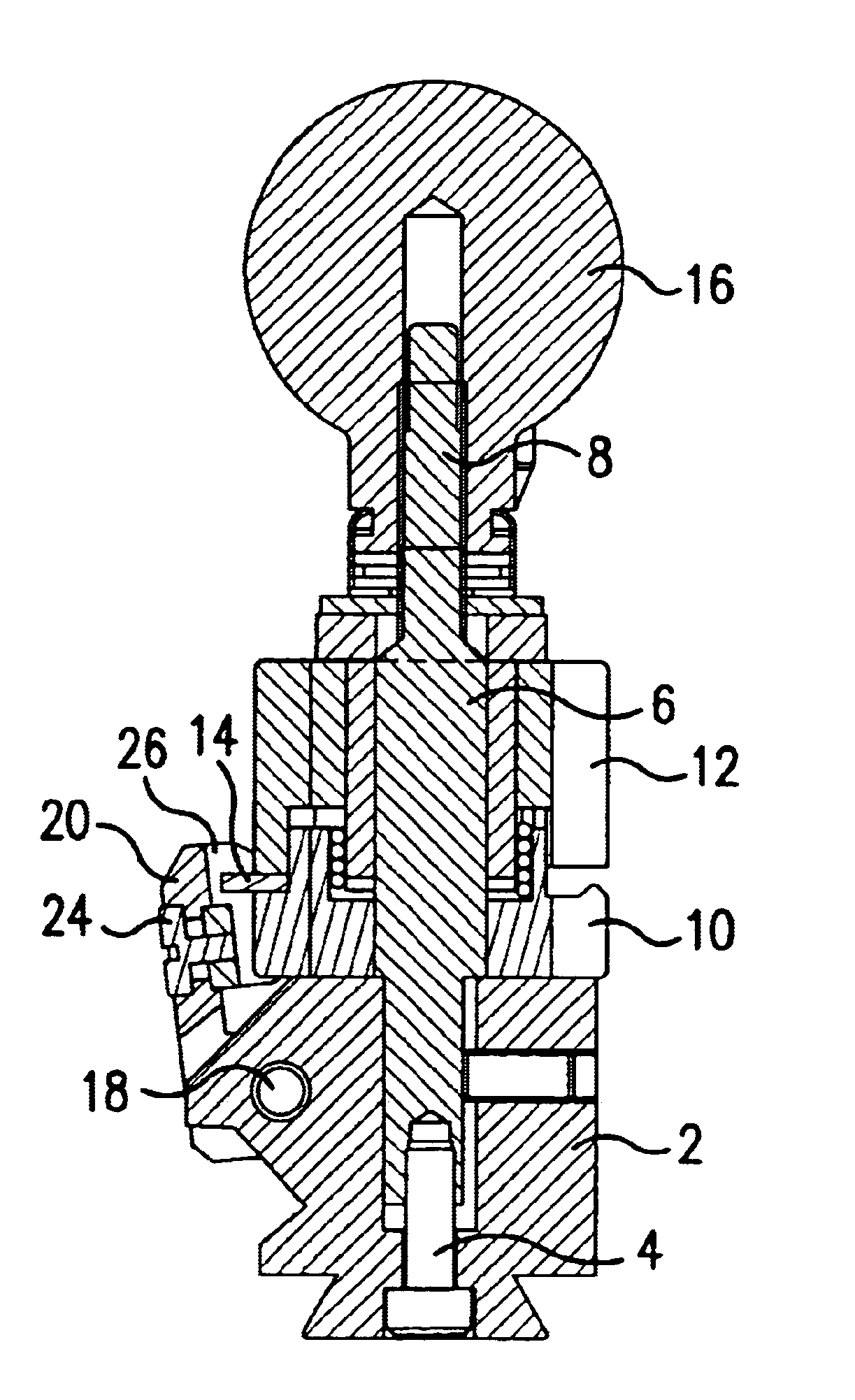

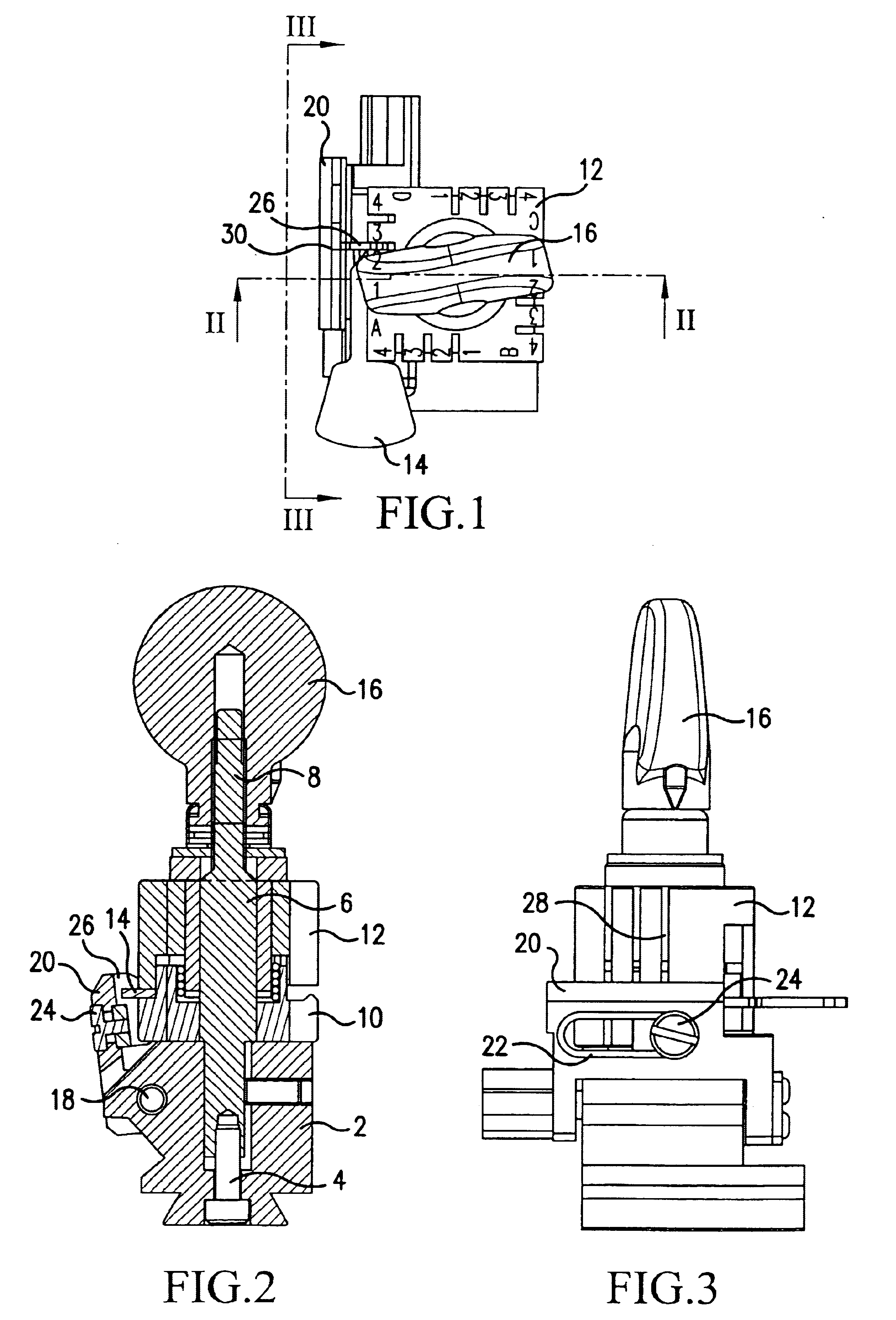

Clamp for a key duplicating machine

Owner:SILCA SPA

Cutting insert and cutting insert holder therefor

A milling cutter for machining camshafts includes a rotary disc and an annular row of cutting bits mounted in pockets formed in the disc. Each cutting bit includes a top surface having a pair of diagonally spaced raised portions. Cutting edges are formed where the top surface and the raised portions intersect side surfaces of the bit. The pockets are arranged along an edge of the disc where a cylindrical outer periphery of the disc intersects an end face of the disc. Each pocket is configured with an internal cavity for receiving a raised portion of an inactive cutting portion of the respective bit.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

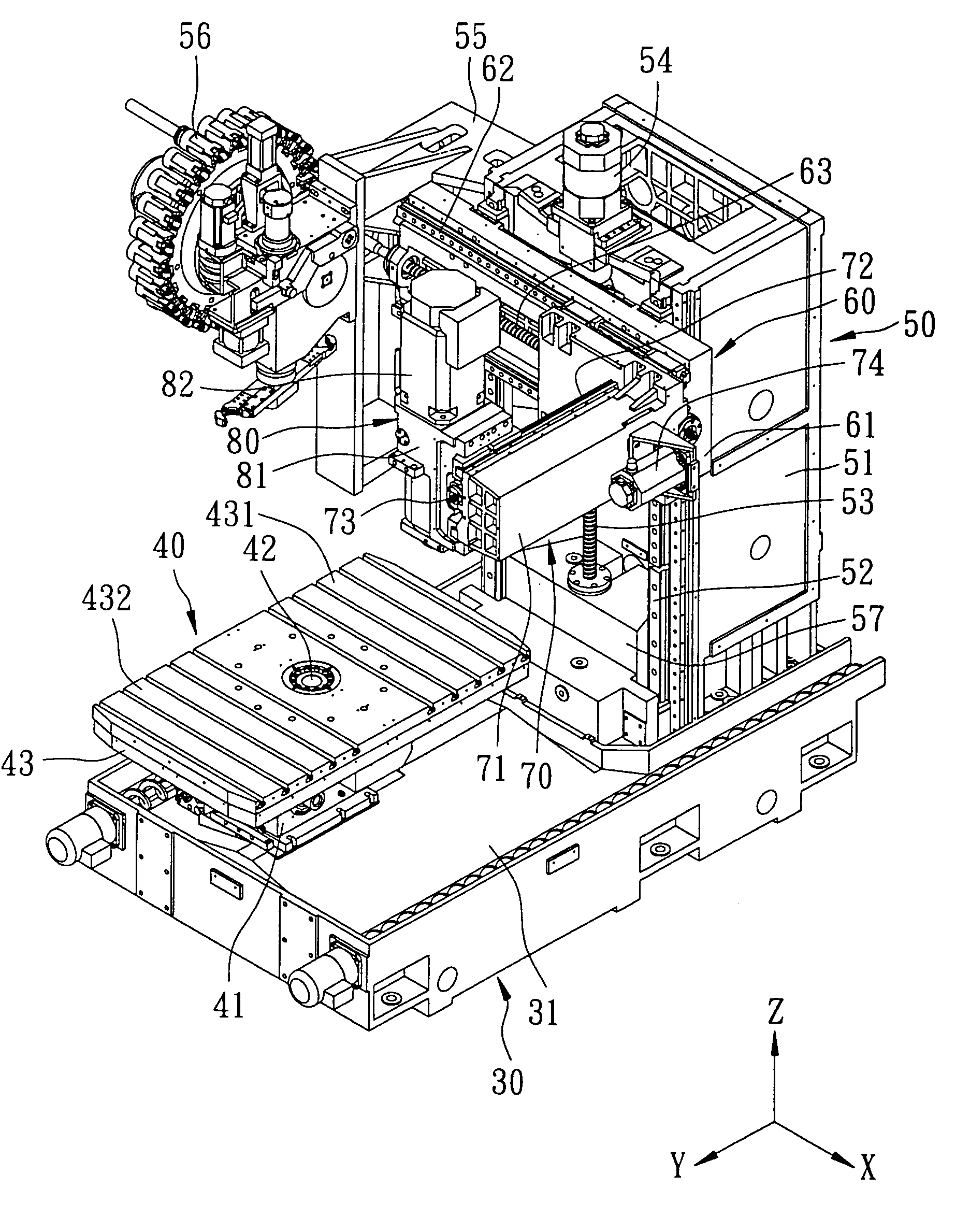

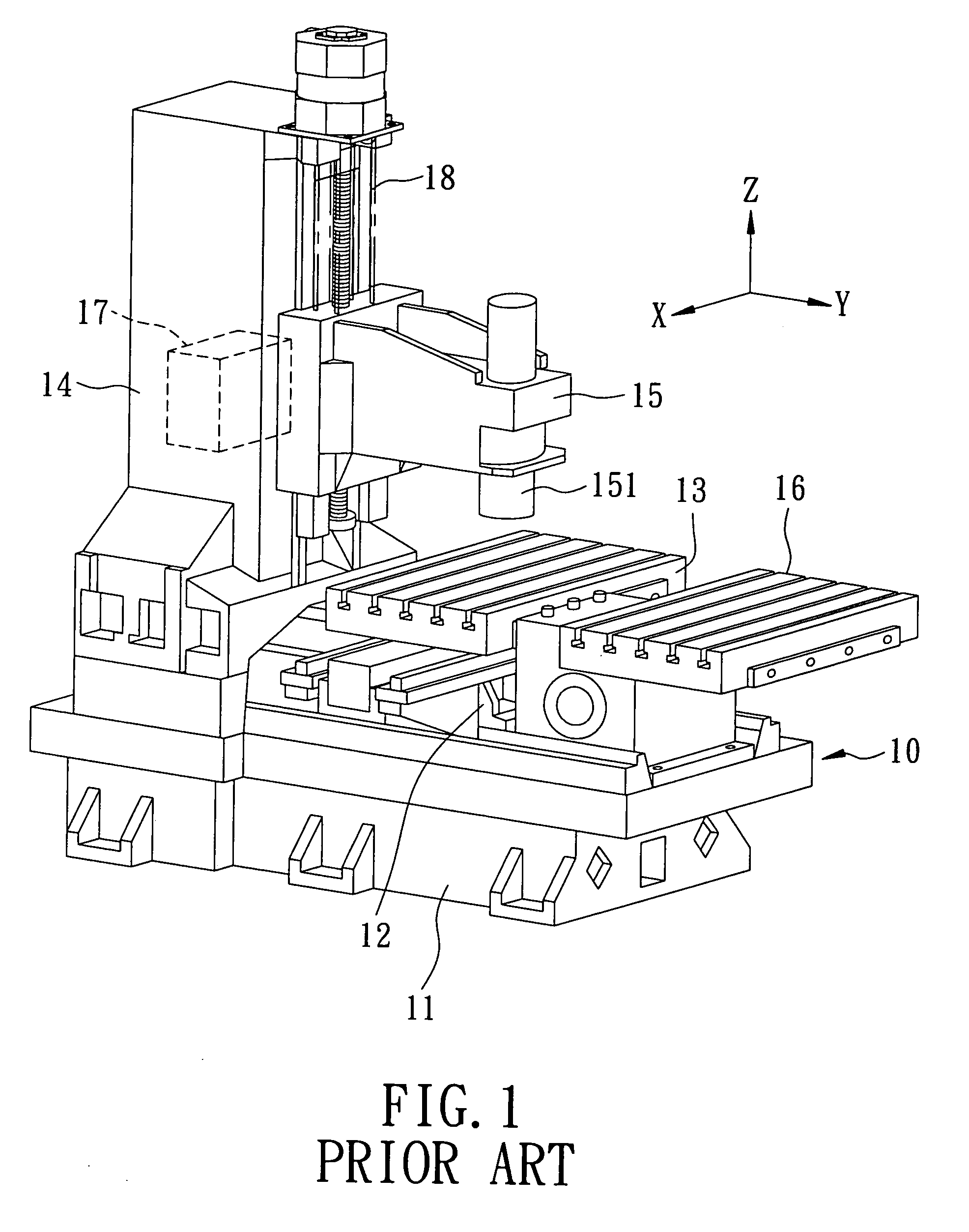

CNC machine tool

InactiveUS7147595B1Reduce loadUnnecessary movementPlaning/slotting machinesMilling machinesNumerical controlEngineering

A CNC machine tool includes a worktable supporting two workpieces and rotatable on a base so as to exchange the positions of the workpieces. A post member is fixed on the base. A first horizontal rail unit is movable vertically on the post member. A second horizontal rail unit is movable on the first horizontal rail unit along a first horizontal direction. A spindle head unit is movable on the second horizontal rail unit along a second horizontal direction perpendicular to the first horizontal direction.

Owner:CHEN HSI KUAN

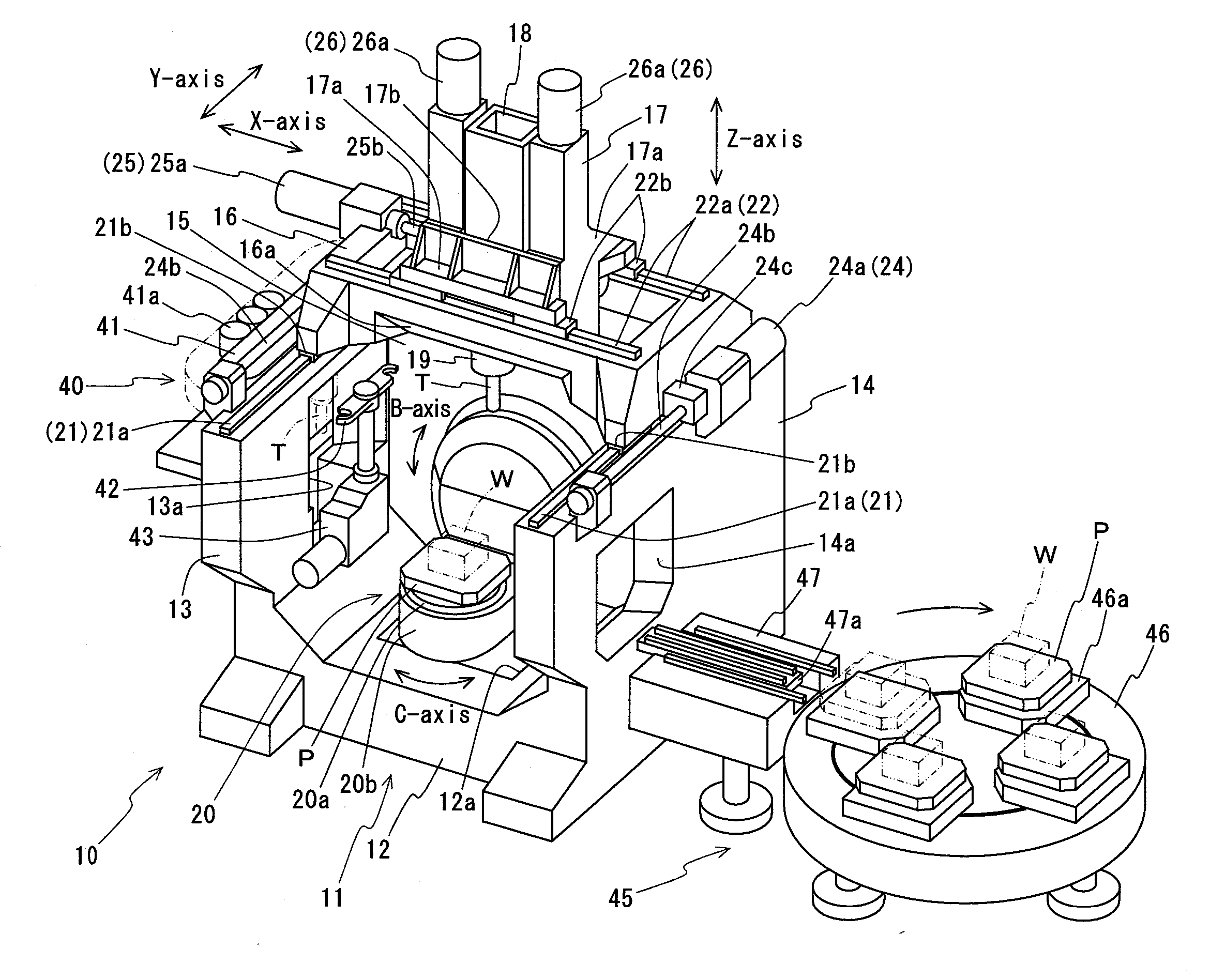

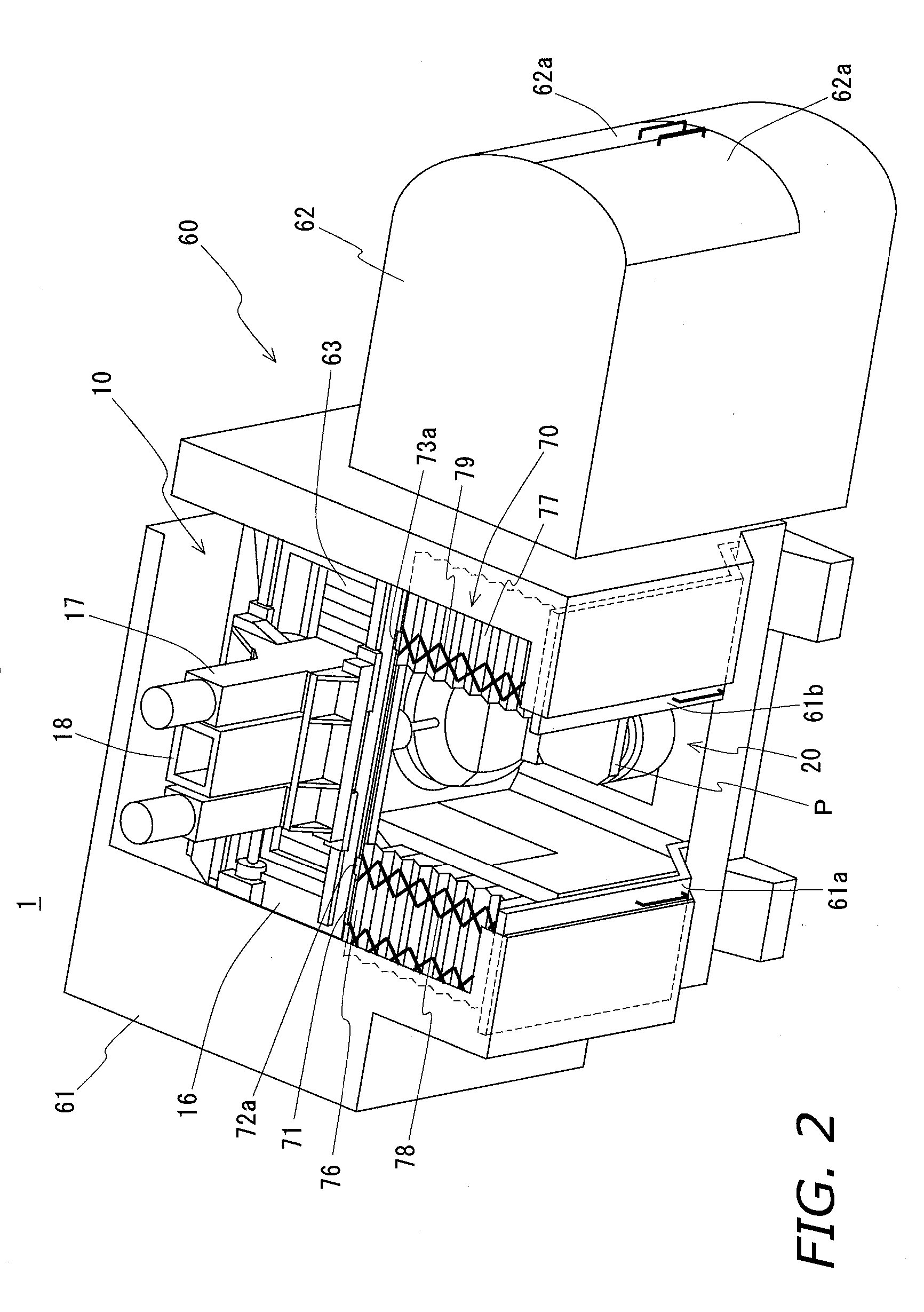

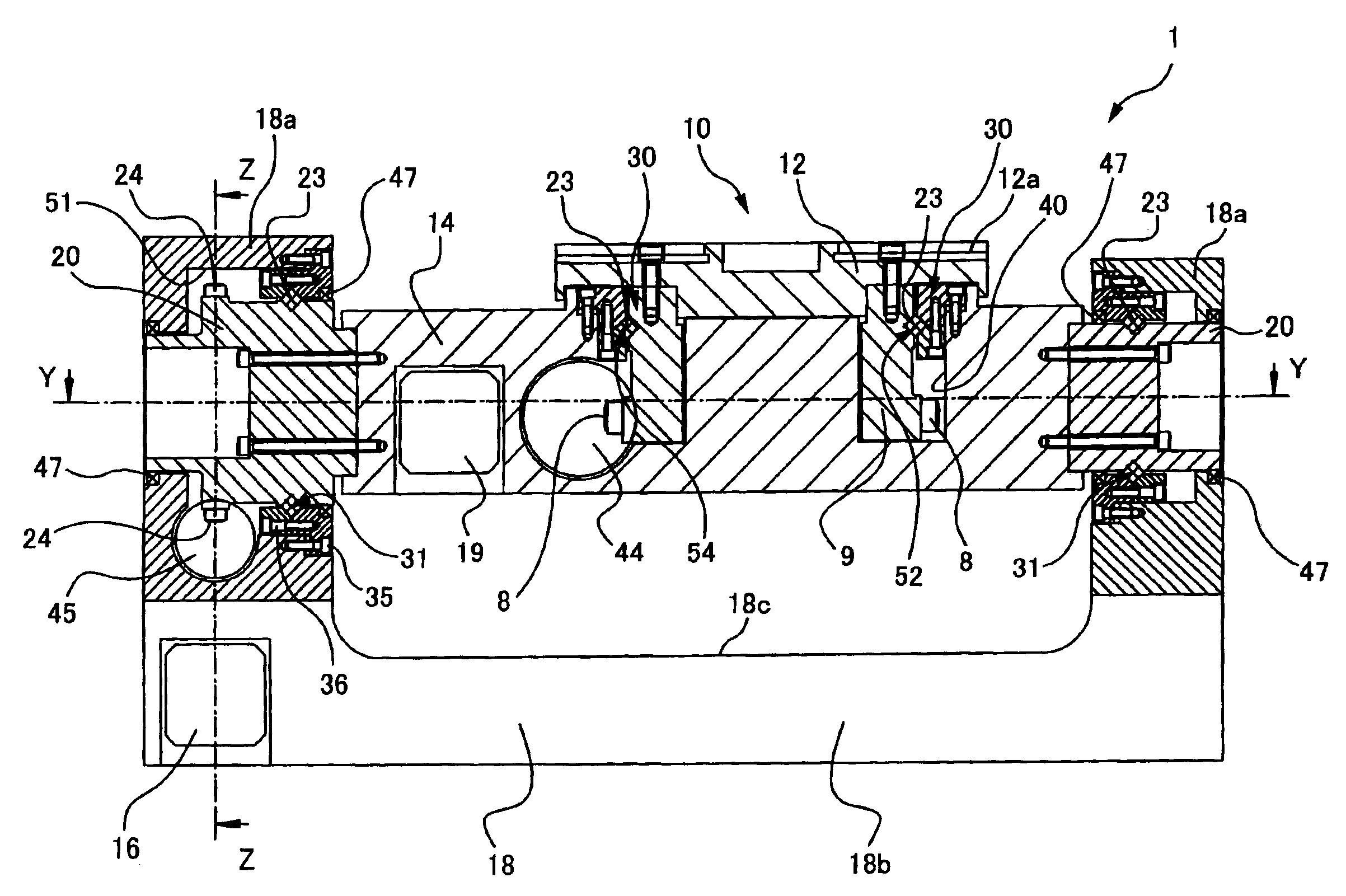

Machine tool and pallet changer for machine tool

InactiveUS7013544B2No longer be changedSimple and compact structureLathesAutomatic/semiautomatic turning machinesTransverse axisMachine tool

An APC is provided in a five-axis controlling vertical machining center. A spindle head is movable in three mutually transverse axes directions to a workpiece. A table disposed below swings to be positioned and is directed upwardly and indexed. A pallet setup base is provided outside a machining area. A pallet change arm has pallet grip portions for gripping and releasing the pallets. The arm makes a swivel motion and makes an ascending and descending motion. Thus, the pallet is transferred between the table and the pallet setup base and is received and discharged to the table and the pallet setup base.

Owner:MORI SEIKI HITECH

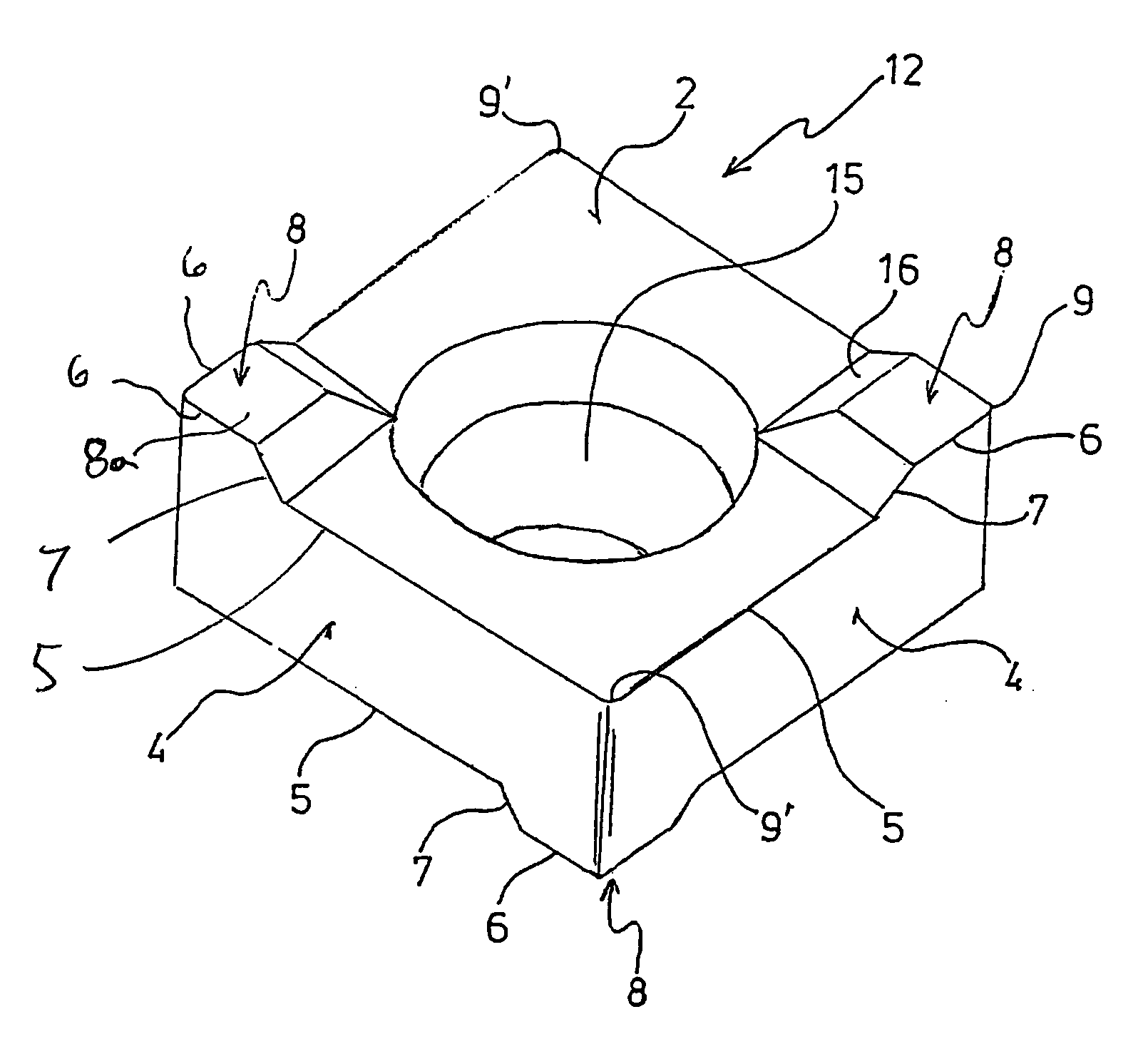

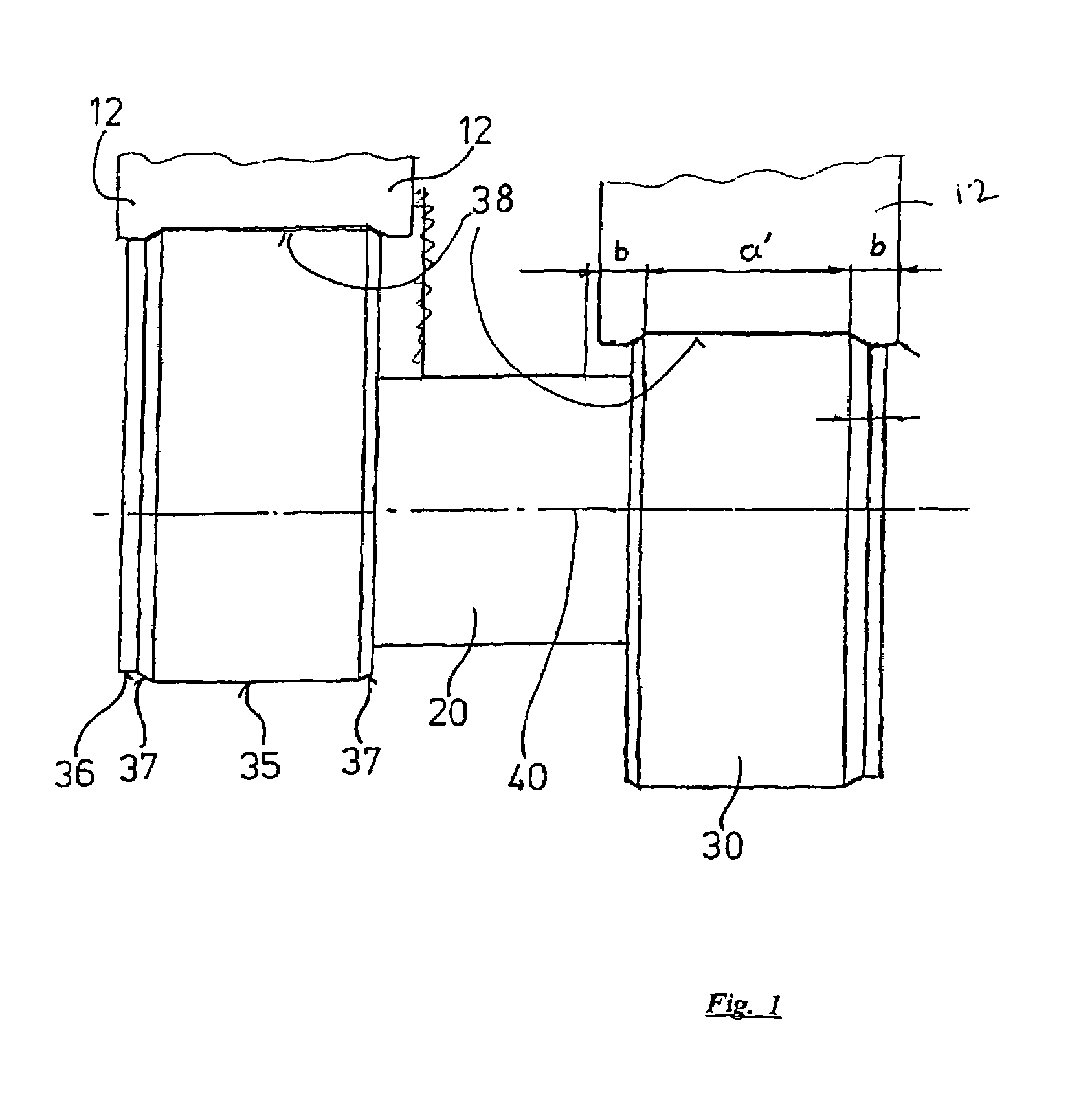

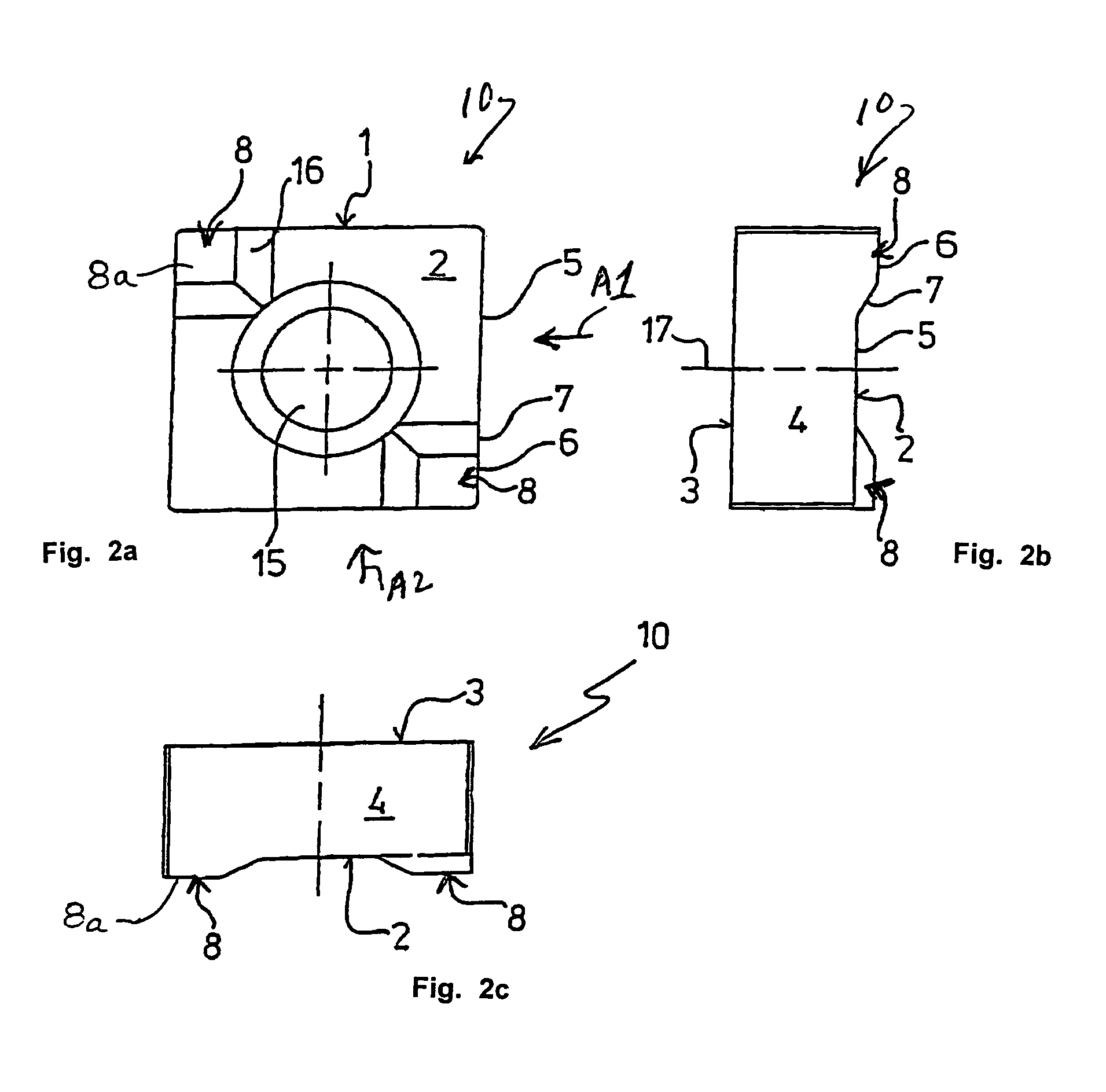

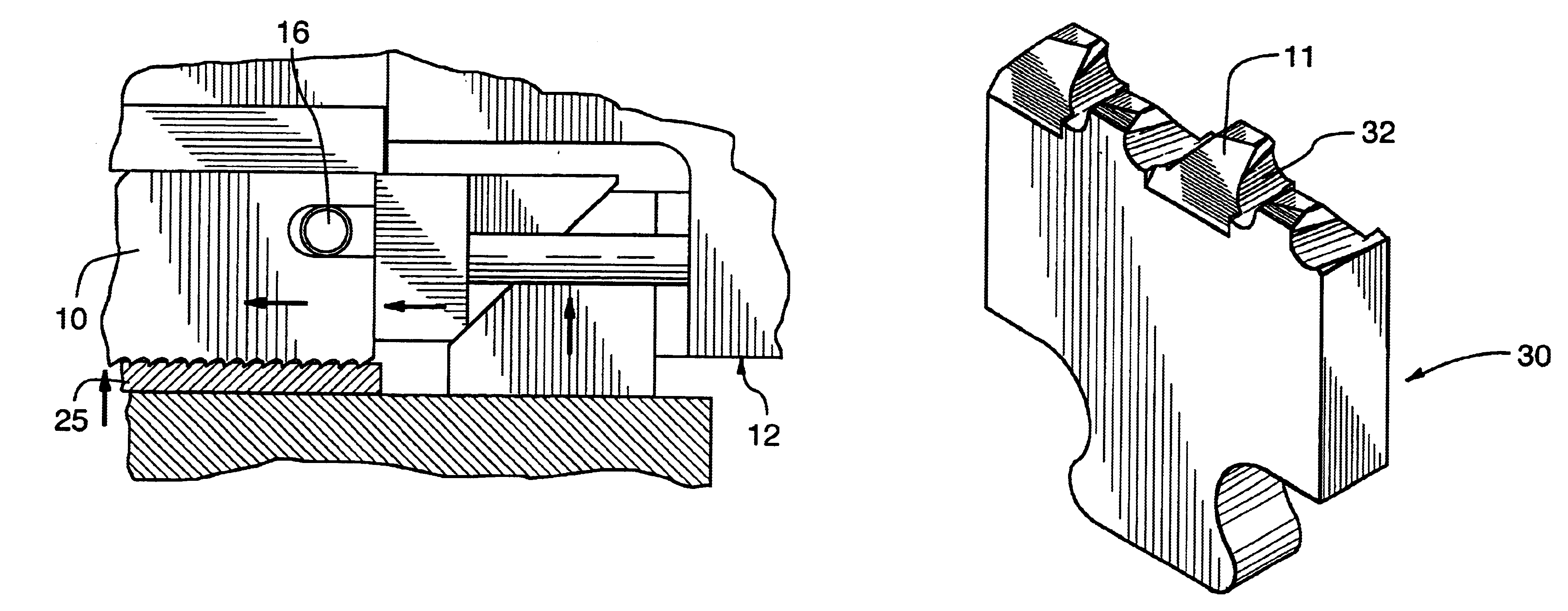

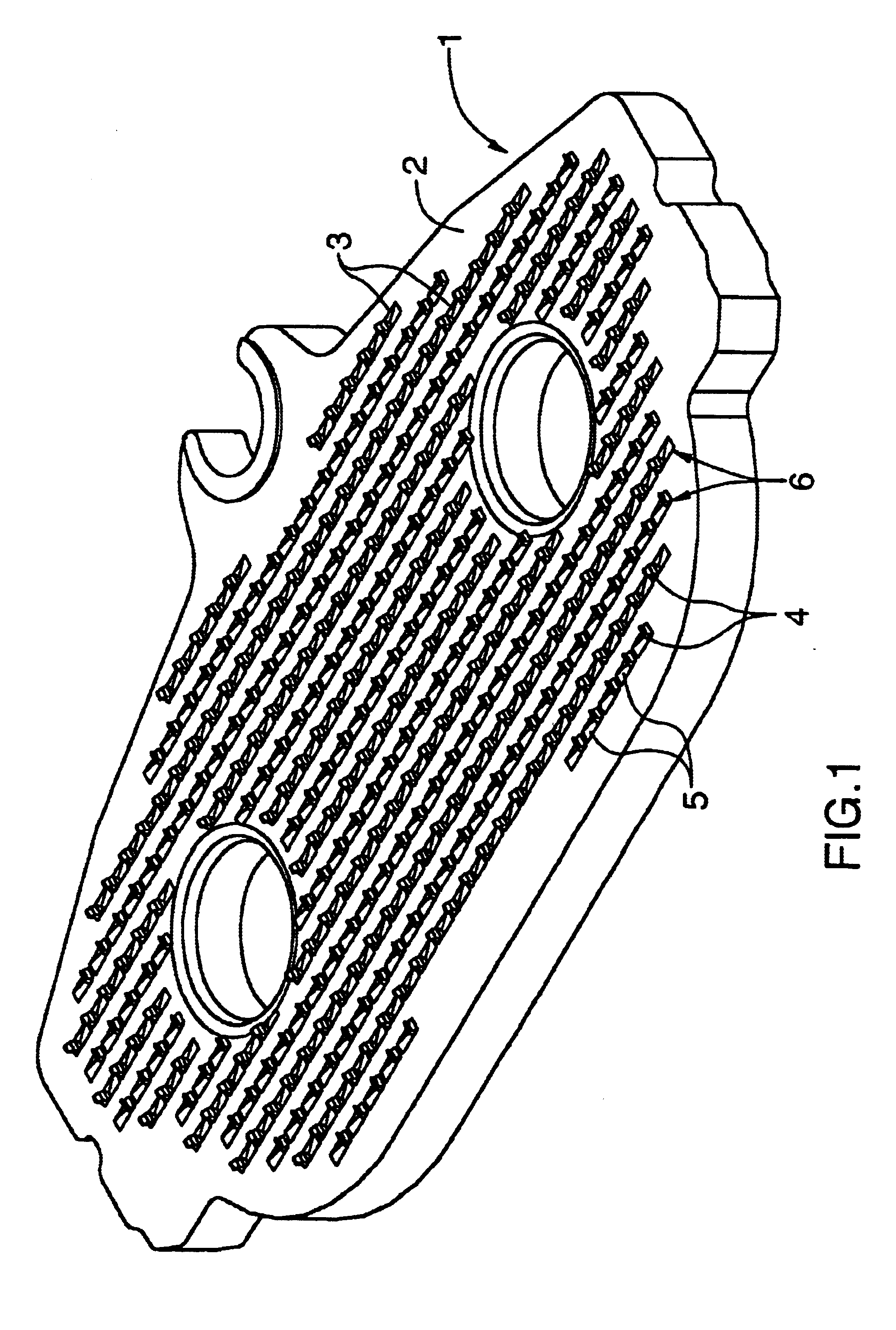

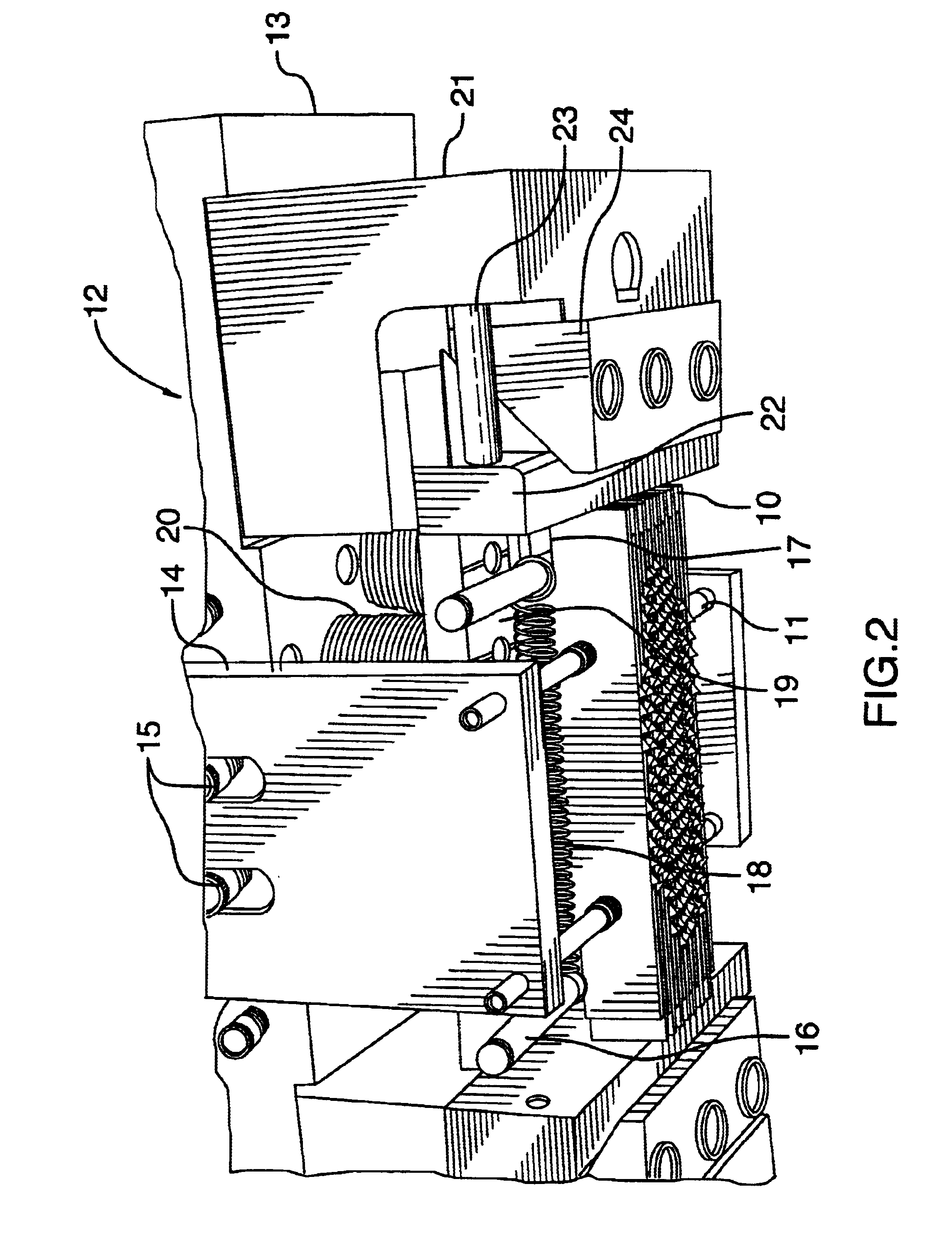

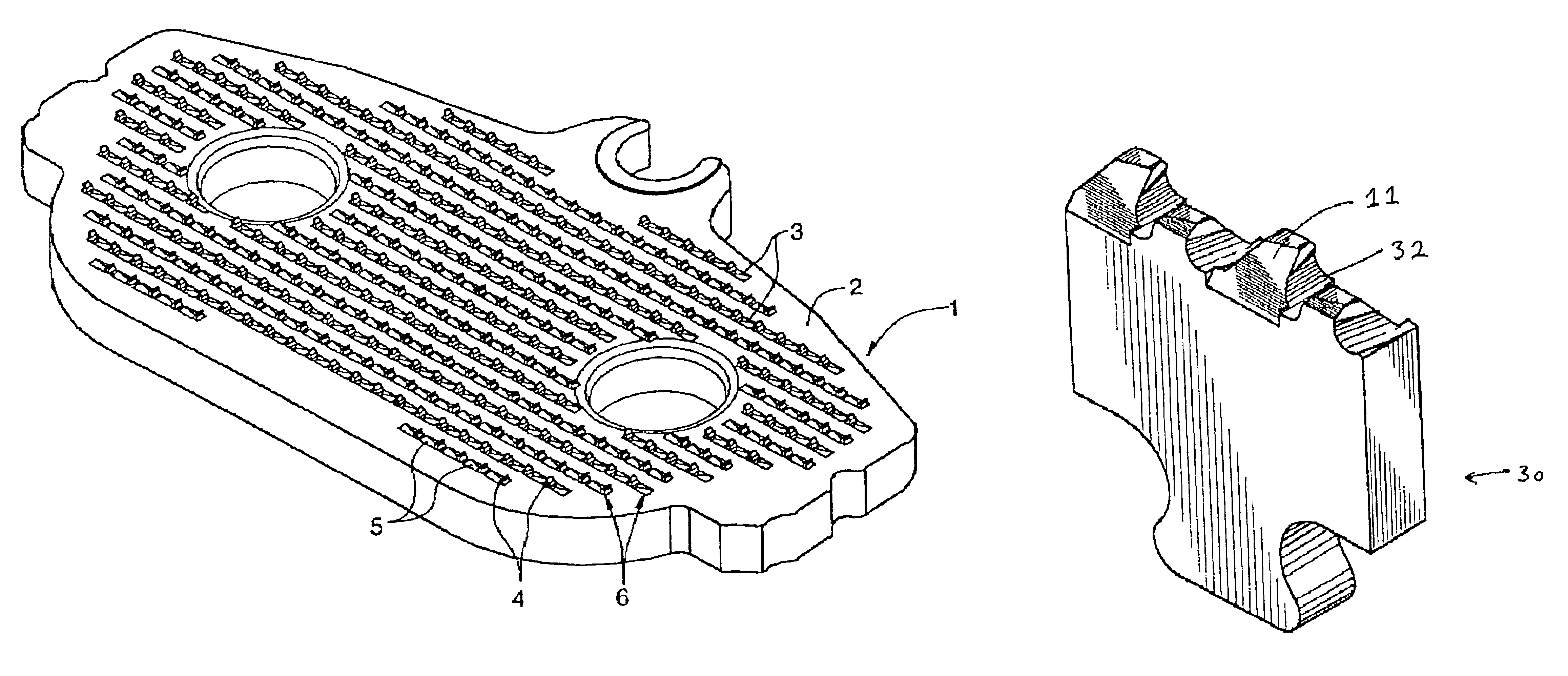

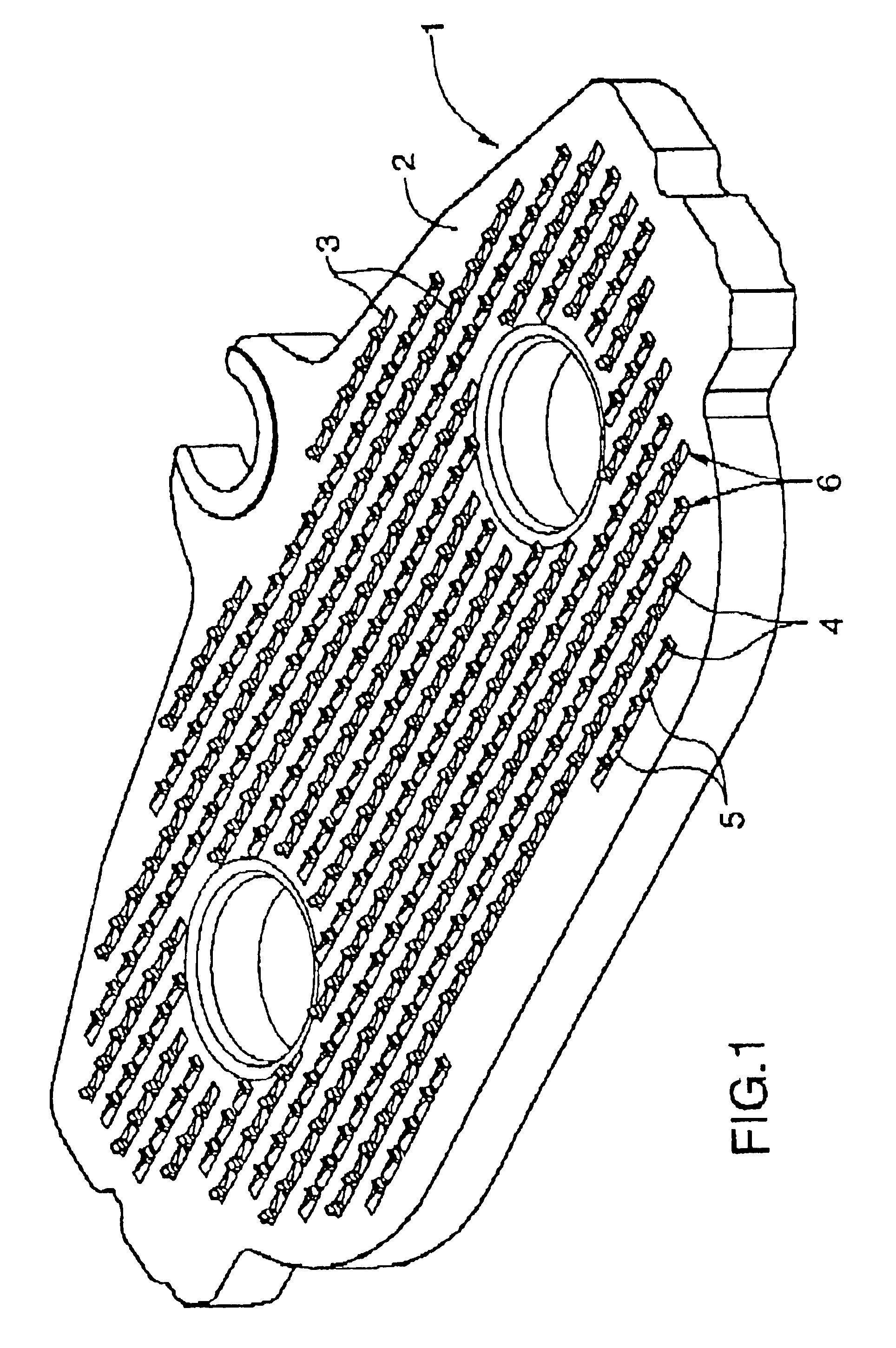

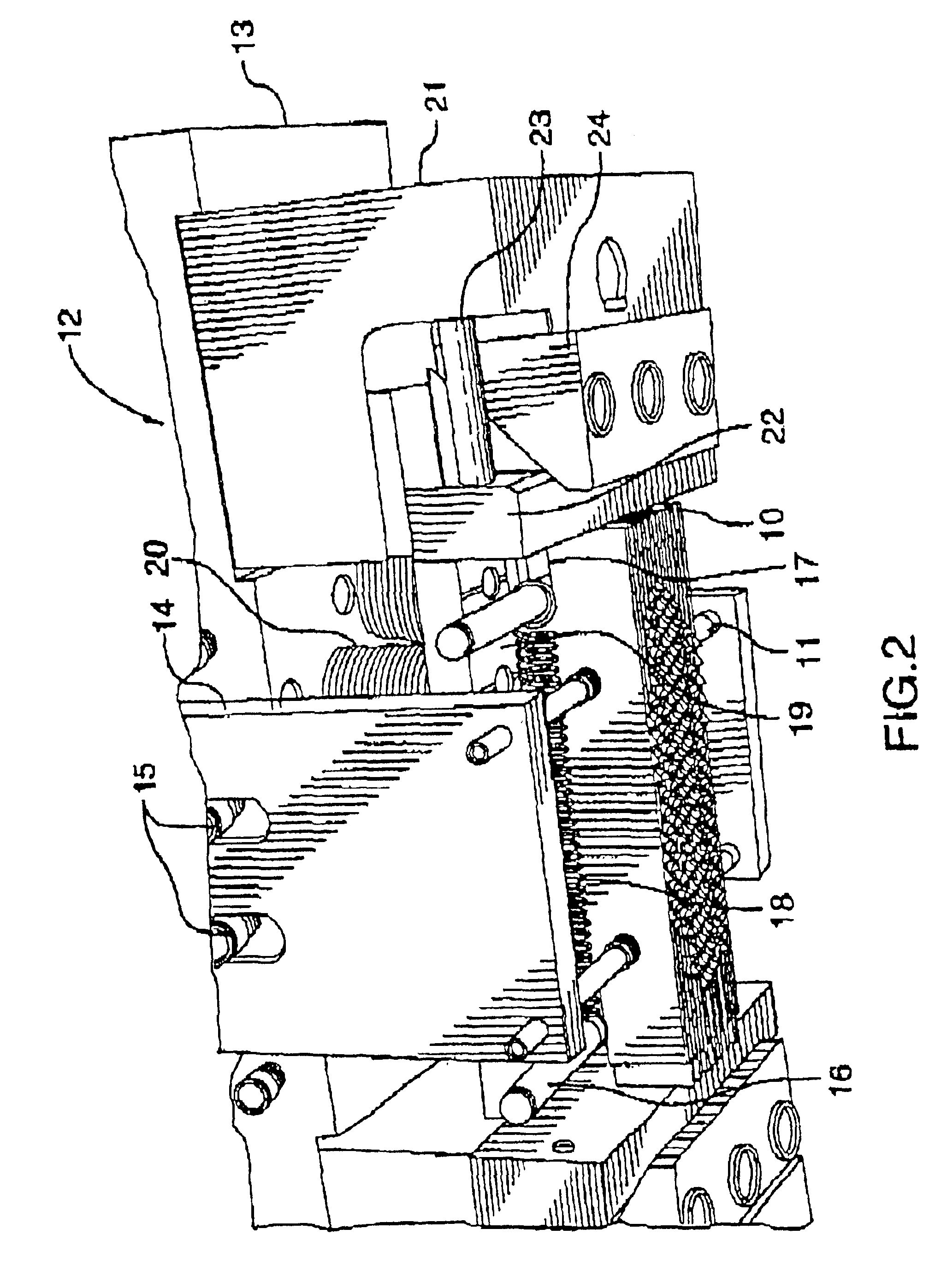

Apparatus for manufacturing a brake plate

InactiveUS6843095B2Improve bindingImprove structural strengthSpringsPlaning/slotting machinesBiomedical engineering

The invention is a plate for holding a friction material in a brake assembly. The plate preferably comprises a contact surface for attaching the friction material to the plate, a second surface opposing the contact surface; and a plurality of retaining structures formed on the contact surface, each retaining structure comprising a projecting member extending from a point between the contact surface and the second surface, so that the member extends outwardly from the contact surface for engagement with the friction material.

Owner:NUCAP IND

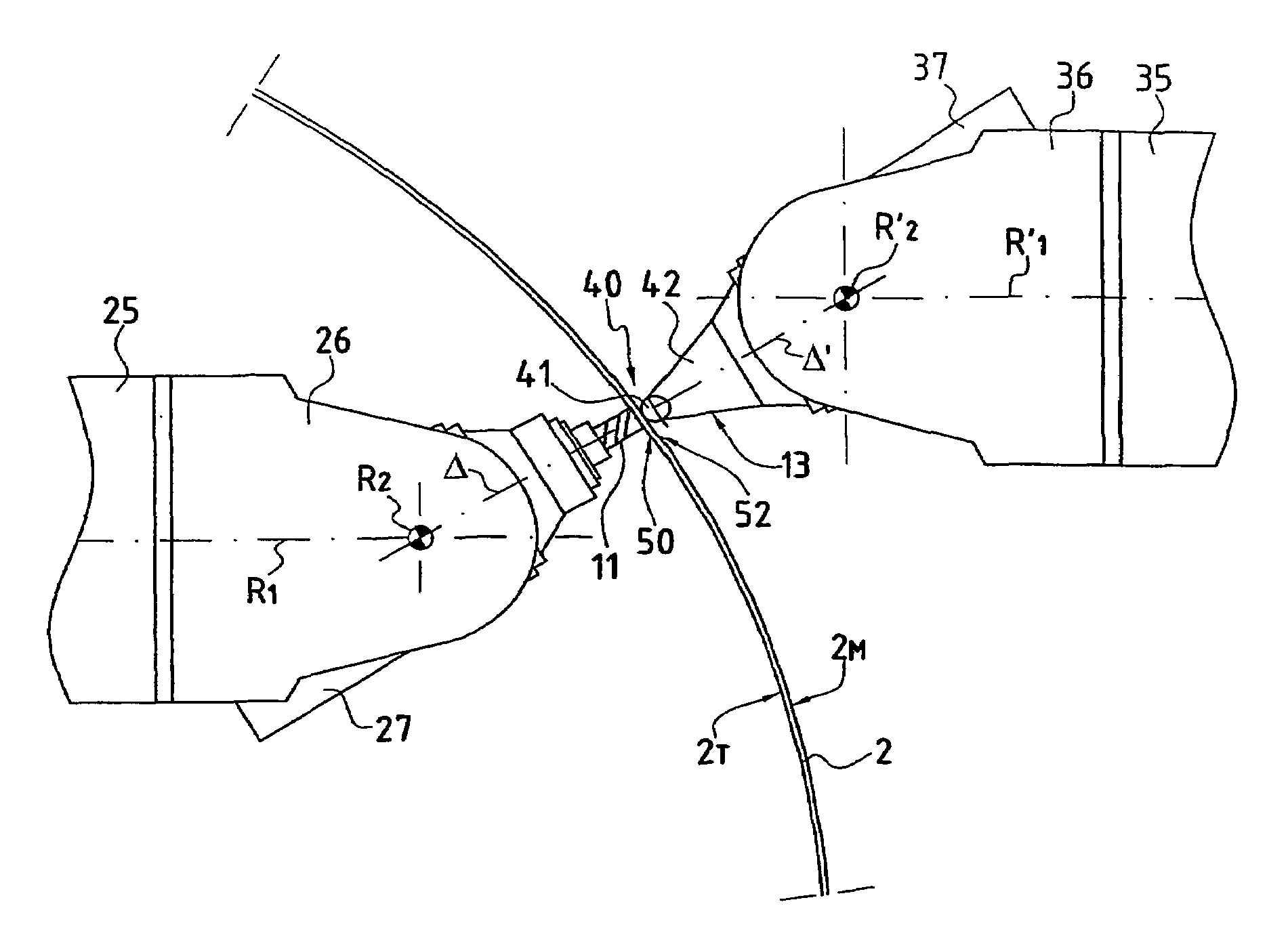

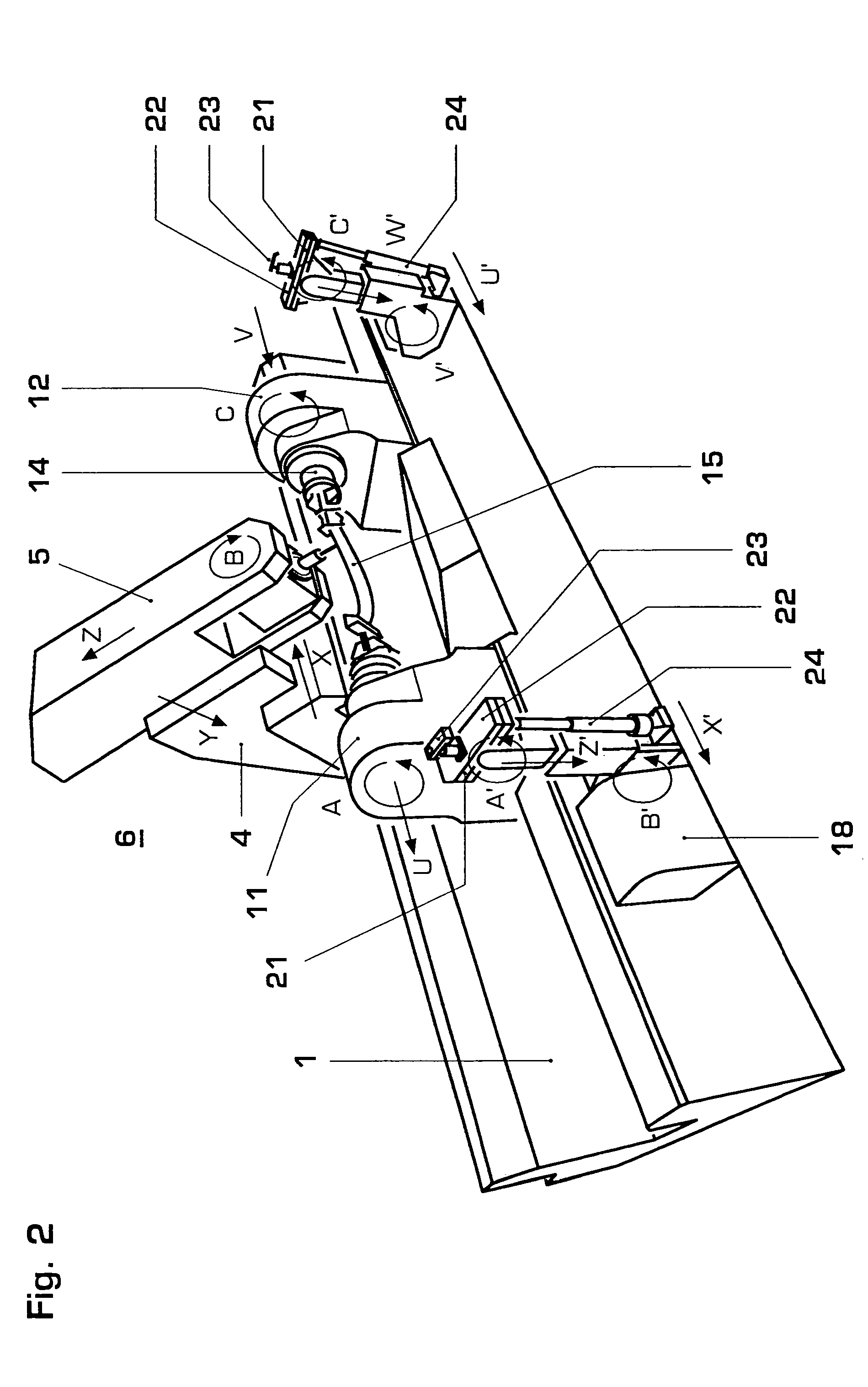

Process and a device for the machining of panels

ActiveUS7682112B2Considerable precisionEasy to useFinal product manufactureEfficient propulsion technologiesEngineeringFace sheet

Owner:AIRBUS OPERATIONS (SAS) +1

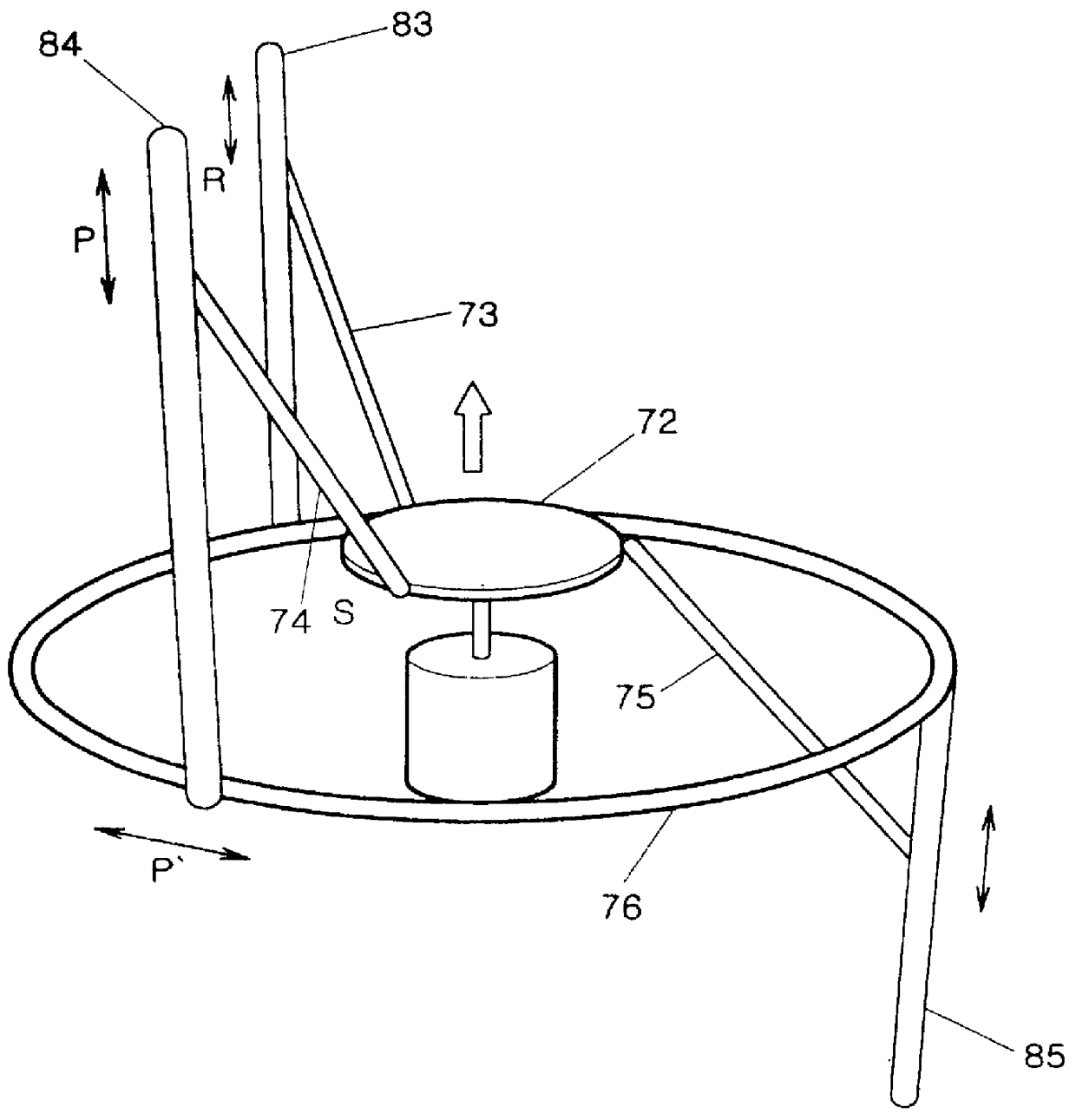

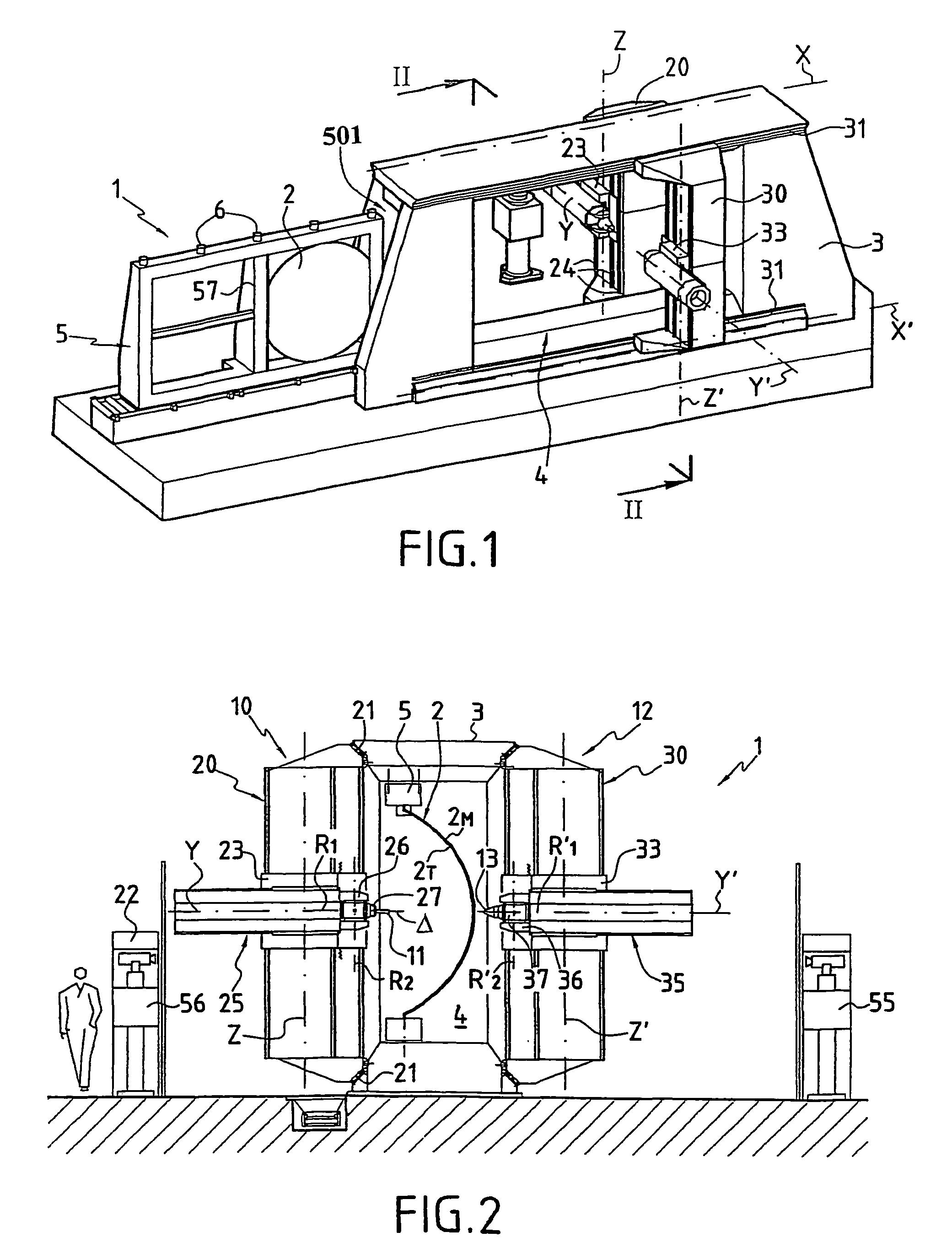

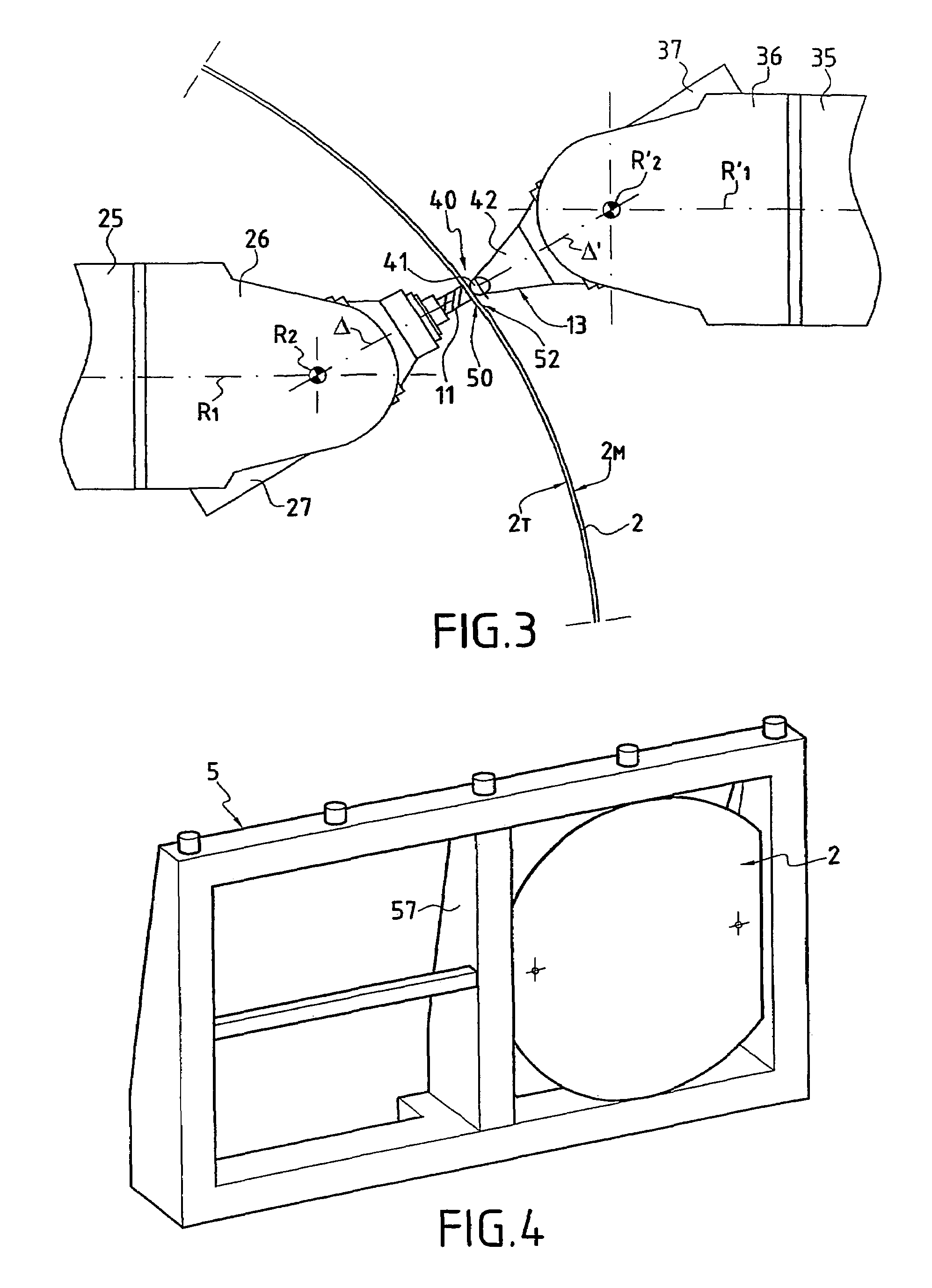

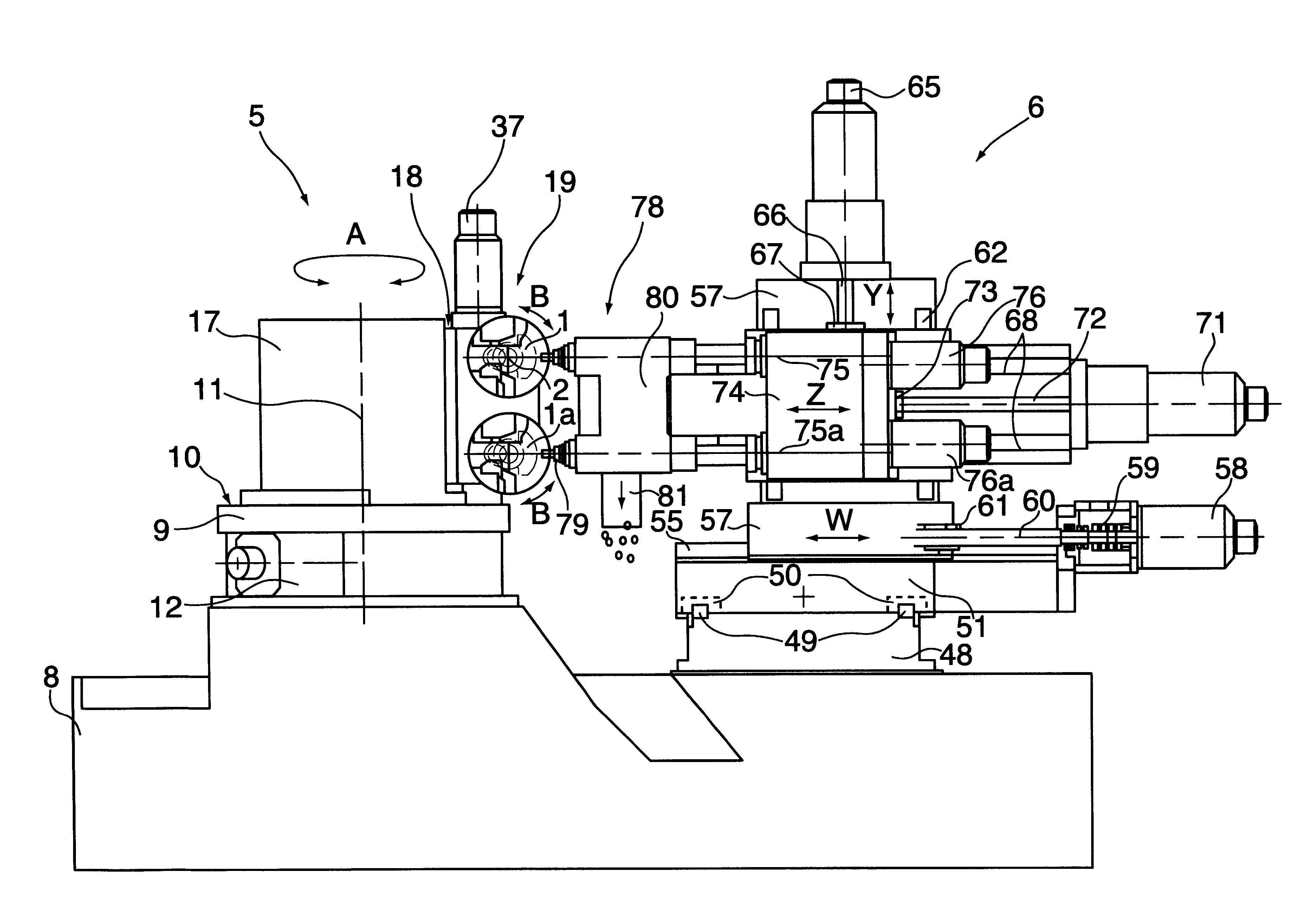

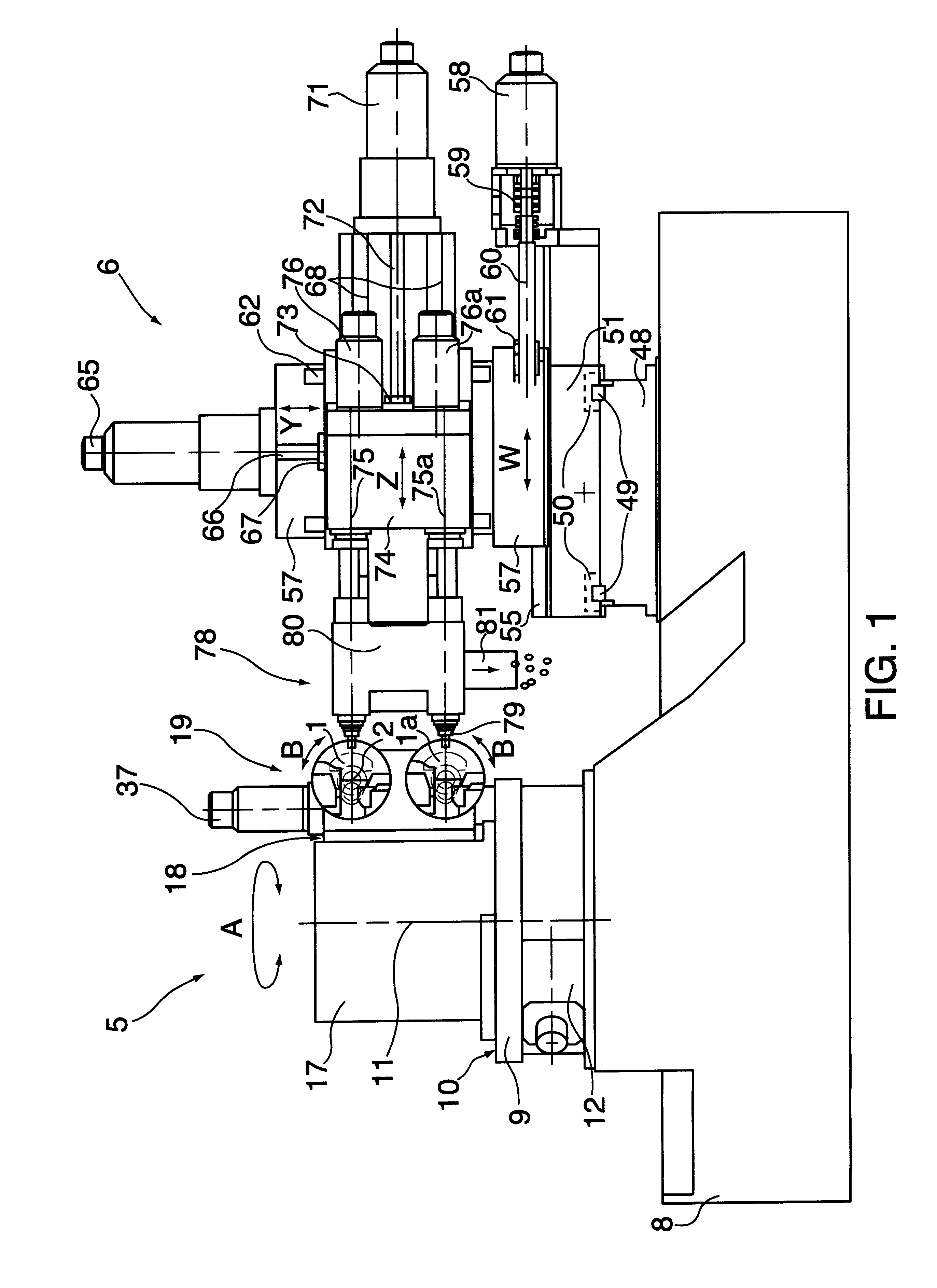

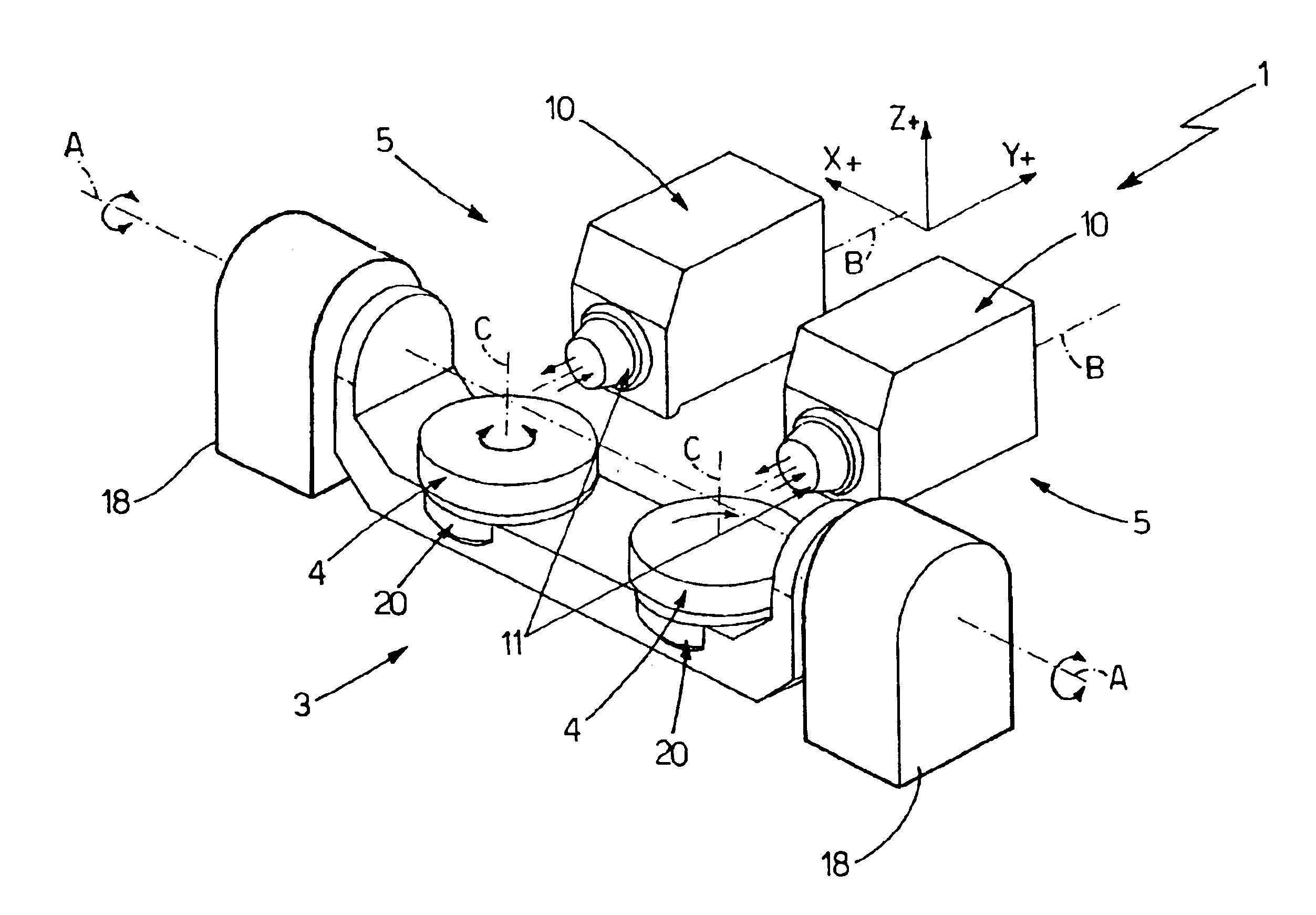

Machine for drilling oil holes in crankshafts

InactiveUS6203478B1Remove complicationsEliminate investmentCrankshaftsThread cutting machinesEngineeringCo ordinate

A machine for drilling oil-holes in crankshafts and the corresponding procedure. It can be used to drill one, two or more crankshafts per cycle. Each crankshaft can revolve on its own axis. The unit described is mounted on a horizontally-faced rotary table with vertical rotating axis, to place the crankshafts at different angles to the Z axis of the machining module, maintaining the horizontal position of the longitudinal axes of the crankshafts. Facing the unit is the machining module, provided with two horizontal spindles, drill tool-holders, with their corresponding guide bushings and parallel to each other, one on top of the other, at the same distance as the two crankshafts. The module has movement in three co-ordinates: axis X (horizontal-transverse), Y (vertical ) and Z (horizontal-presenting tools). A fourth axis W, (with additional module and independent action), moves parallel to Z and carries the guide bushings. It is provided with an automatic changeover, (tool+bushing or just the bushing), incorporating simultaneously the pair of spindles.

Owner:ETXE TAR SA

Multi-axis, processor-controlled, toolhead positioner

InactiveUS7185412B2Programme-controlled manipulatorPlaning/slotting machinesRotational axisEngineering

Owner:PRECISION SPHERICAL

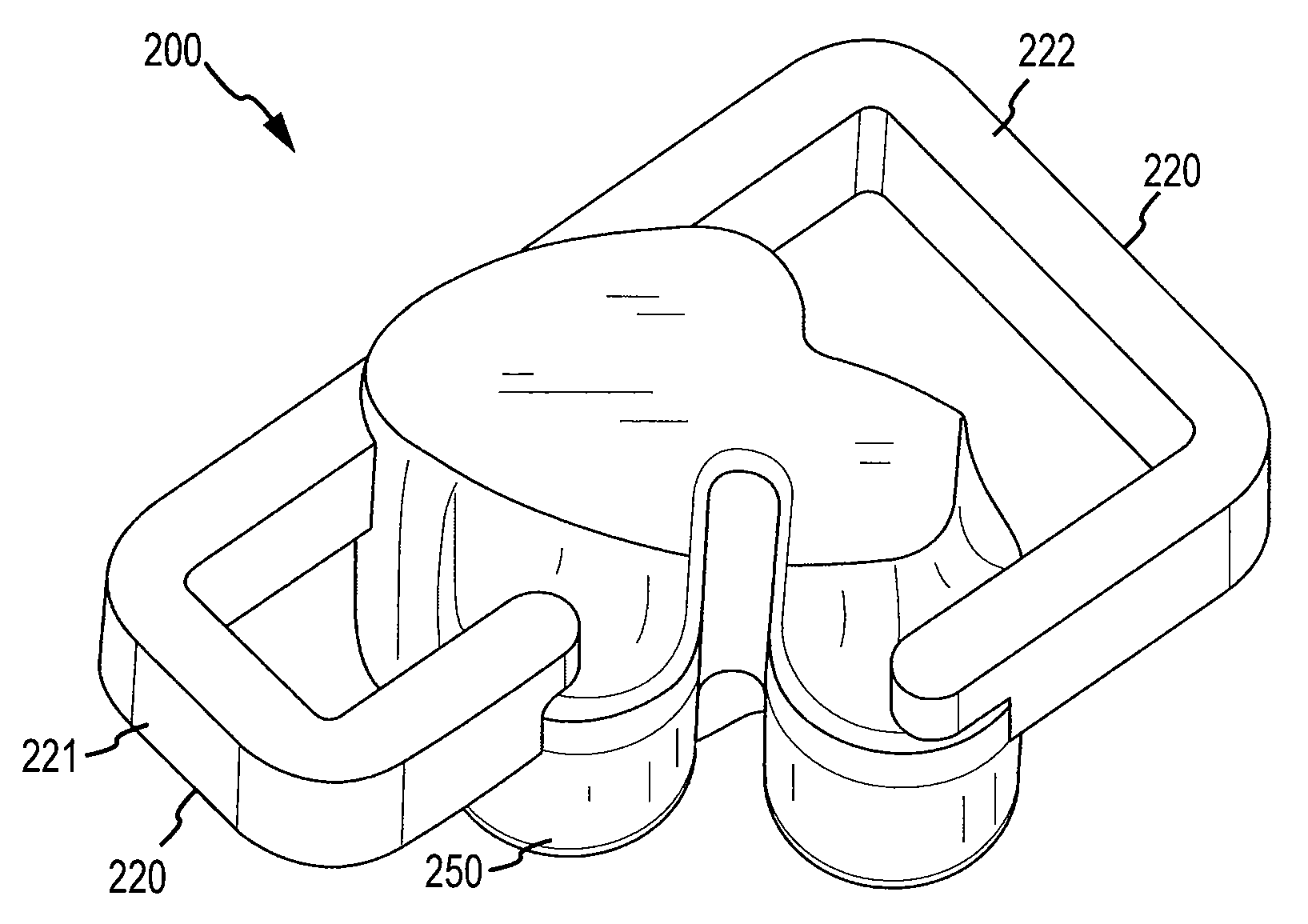

Hole cutting tool

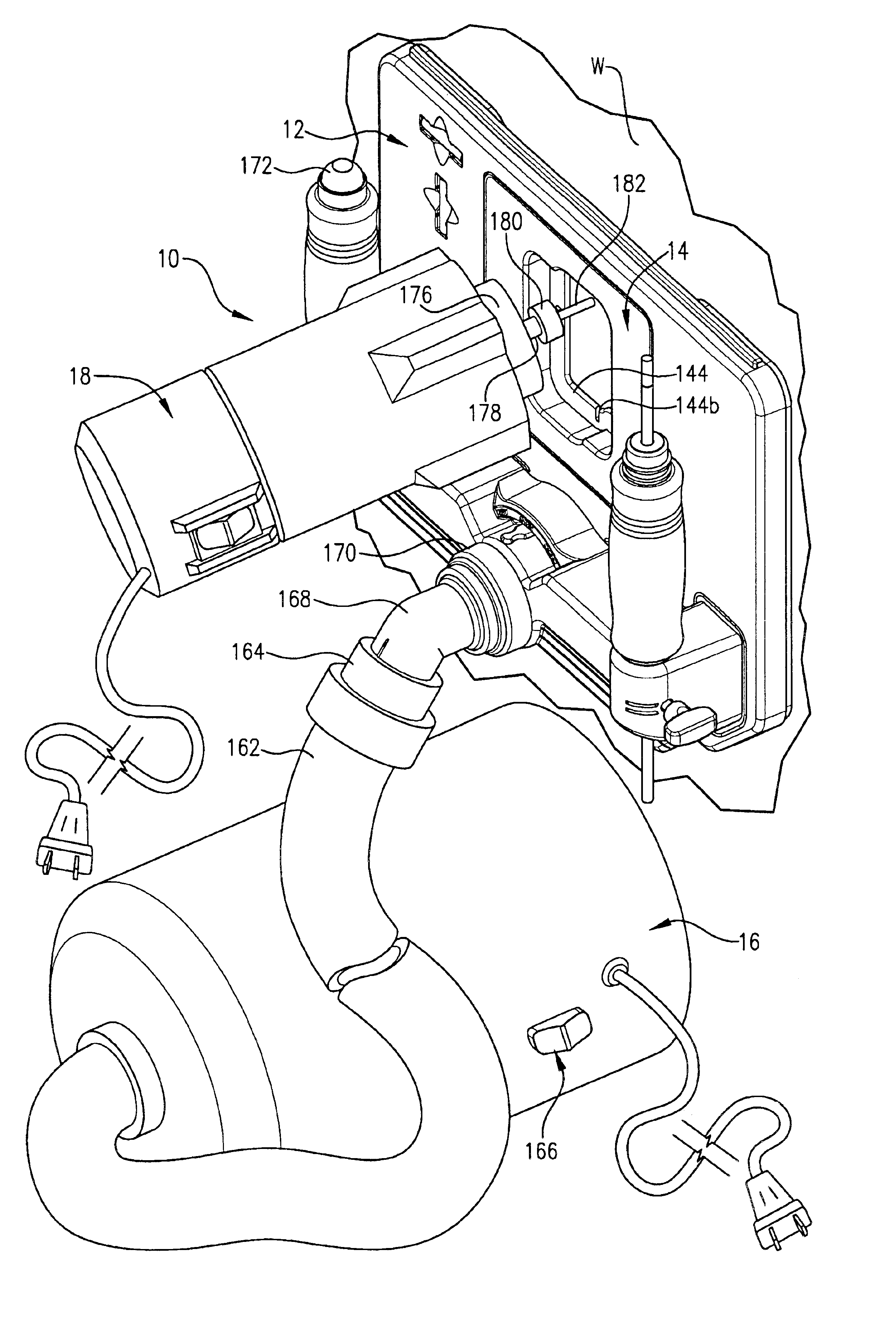

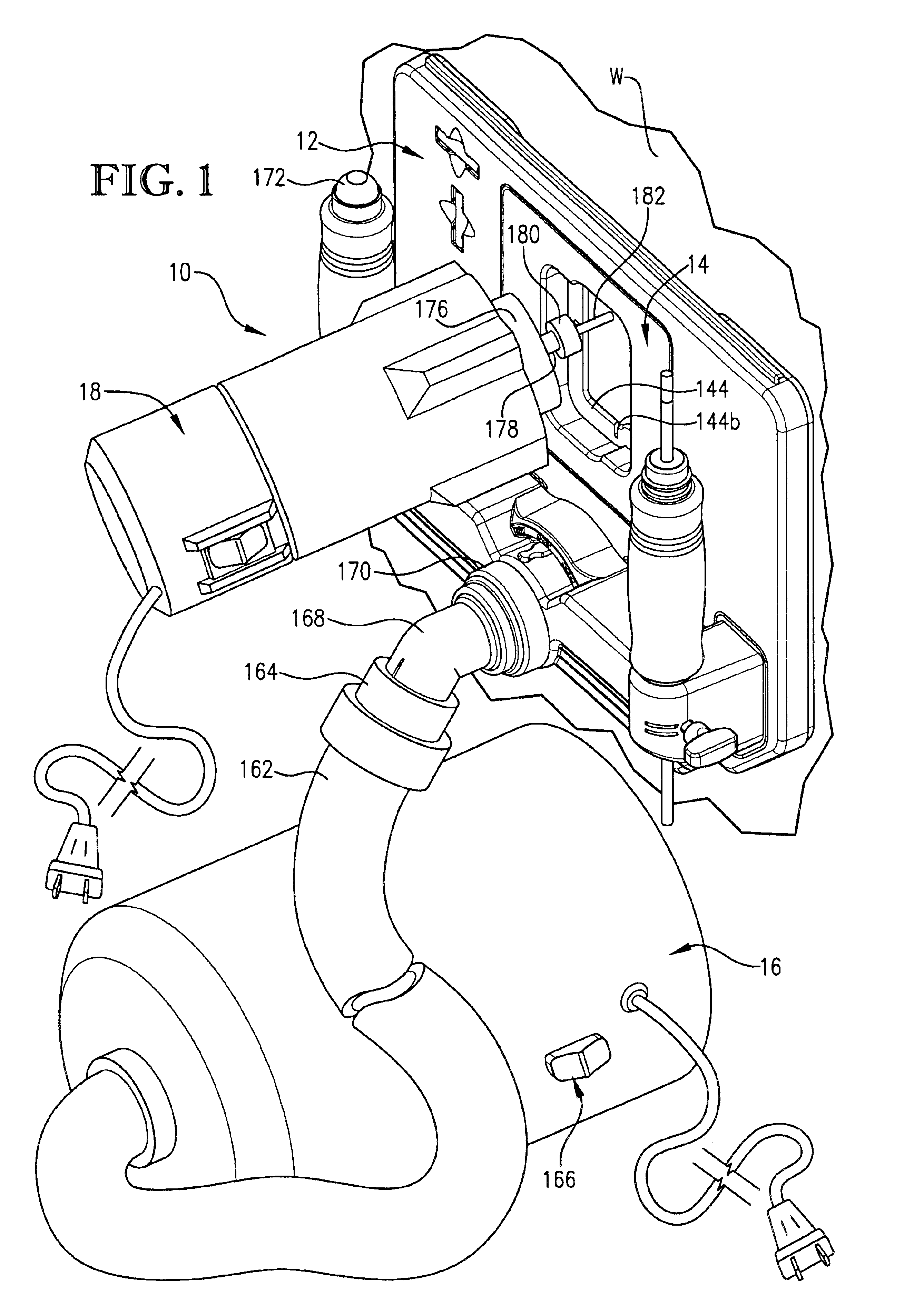

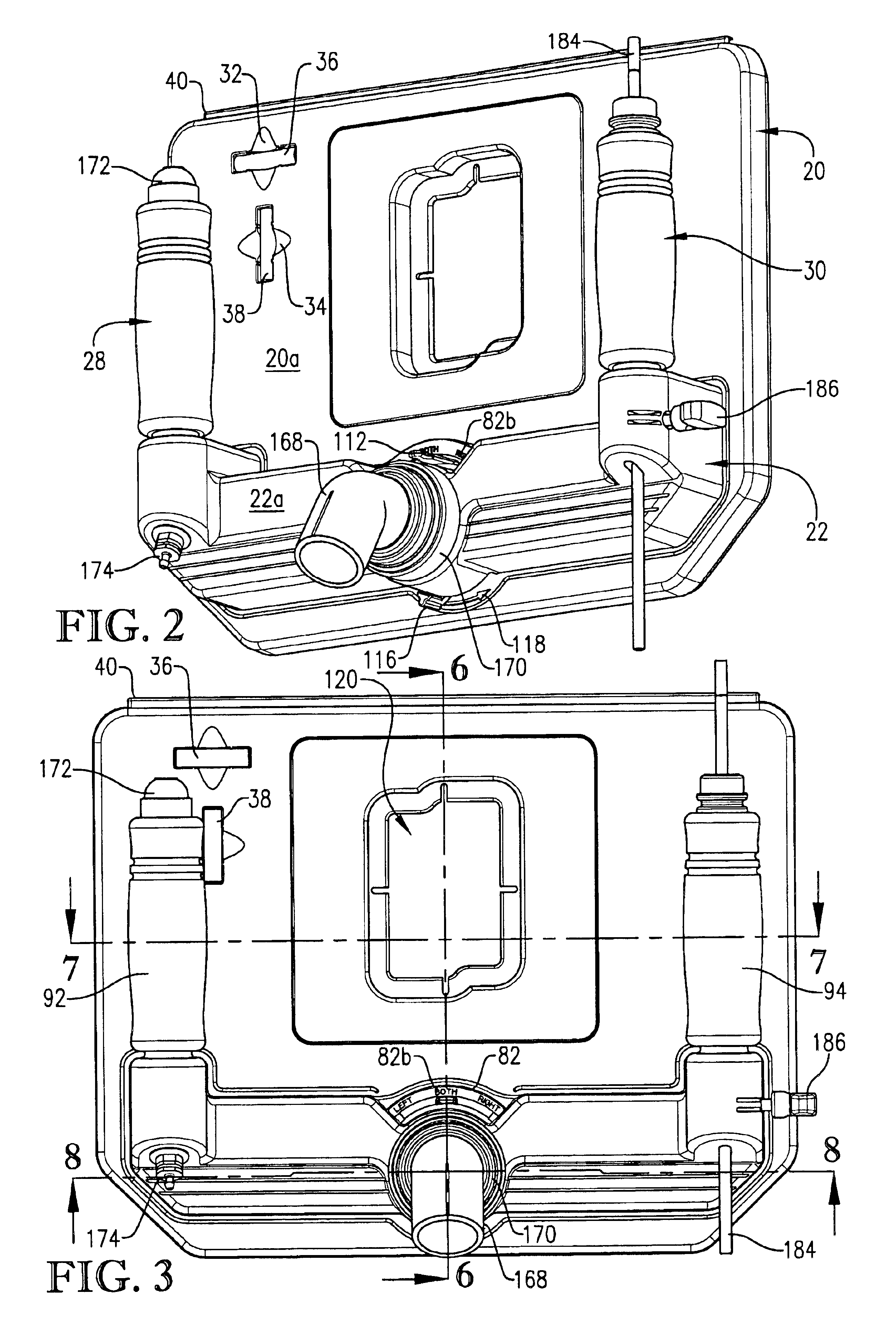

InactiveUS6851900B2Drilling/boring measurement devicesThread cutting feeding devicesDust particlesGasket

A hole cutting tool (10) configured for cutting an accurately located and precisely shaped hole in a surface, such as a wall (W) of a finished residential or commercial building is disclosed. The tool (10) provides a frame assembly (12) which is self-adhering to the surface (W) and carries removable templates (14, 146-152) for handsfree use in cutting an accurately located and precisely shaped hole. The unique frame assembly (12) provides multiple selectable, pneumatically isolated suction chambers (50,52) that enable the self-adhesion function even when the frame assembly (12) is placed over existing holes in the surface (W). The suction chambers (50,52) are formed in part by a unique corrugated gasket (56) that enables the frame assembly (12) to self-adhere to porous surfaces. The removable template (14) enables dust particles created during the cutting process to be simultaneously vacuumed away regardless of the orientation of the template (14) relative to the frame assembly (12).

Owner:PYTHON PERFECT CUTTER

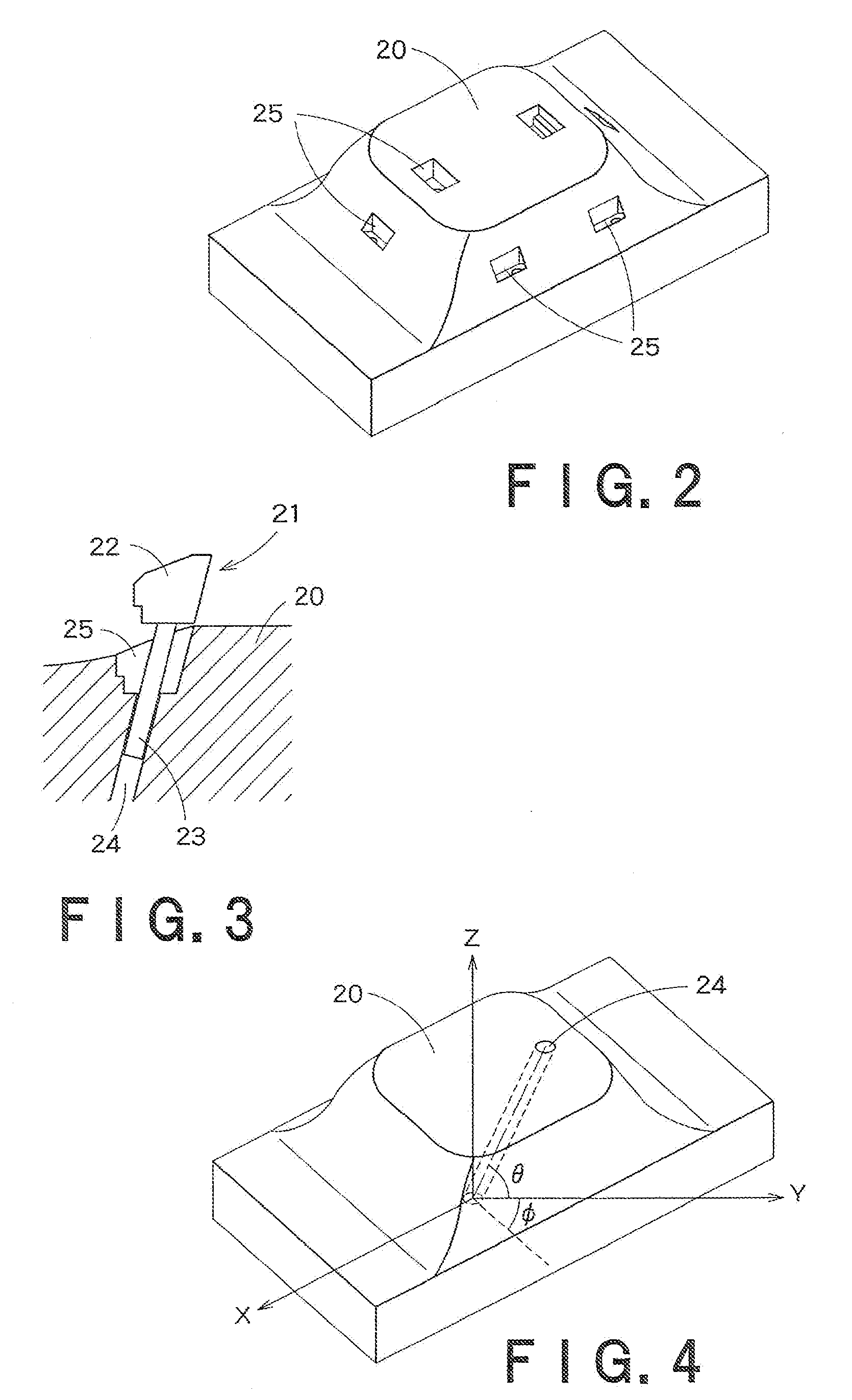

Position ensuring system for oblique machining in five-axis machine tool

ActiveUS20080114485A1Improve machine efficiencyTake advantage ofProgramme controlAngles/taper measurementsData preparationControl theory

There is provided a position ensuring system for oblique machining in a five-axis machine tool which, based on the inclination and the direction of an inclined hole to be machined, carries out measurement of an error in the pivot angle of a spindle head and an error in the rotation angle of a table before initiating machining of the hole, and can automatically correct the pivot angle of the spindle head and the rotation angle of the table upon machining of the hole, thereby precisely ensuring the position of the spindle head and the position of the table in the machining.The position ensuring system includes: an A-axis calibration means for measuring a displacement angle, which is an error between a target value and a measured value of the pivot angle of the spindle head about the A-axis as the spindle head is pivoted to meet the inclination angle of an inclined hole to be machined in a workpiece, and correcting the pivot angle about the A-axis in such a manner that the displacement angle as measured with the corrected pivot angle as a target value fall within a tolerable range, before initiating machining of the workpiece, the measurement of displacement angle being carried out for all the inclined holes to be machined by execution of a measurement program prepared based on data on the shapes, including the inclination angles and the directions, of the inclined holes to be machined; a corrected data storage means for storing the corrected pivot angle about the A-axis for each of the inclined holes to be machined; and an A-axis control means for reading out the corrected pivot angle about the A-axis for each inclined hole upon executing a machining program for the workpiece by means of an NC apparatus, and instructing the corrected pivot angle about the A-axis to pivot the spindle head when executing oblique machining of the inclined hole.

Owner:TOSHIBA MASCH CO LTD

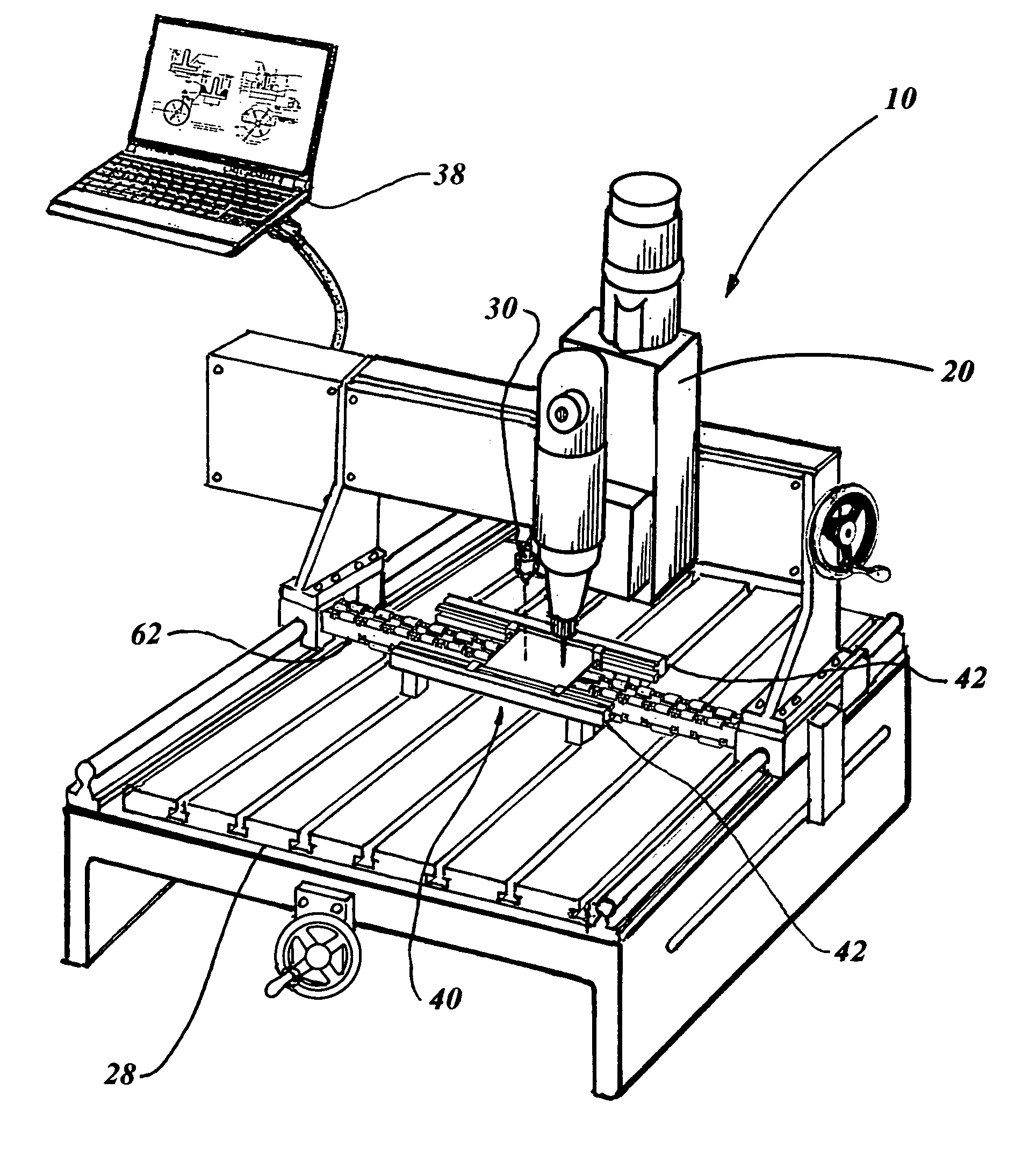

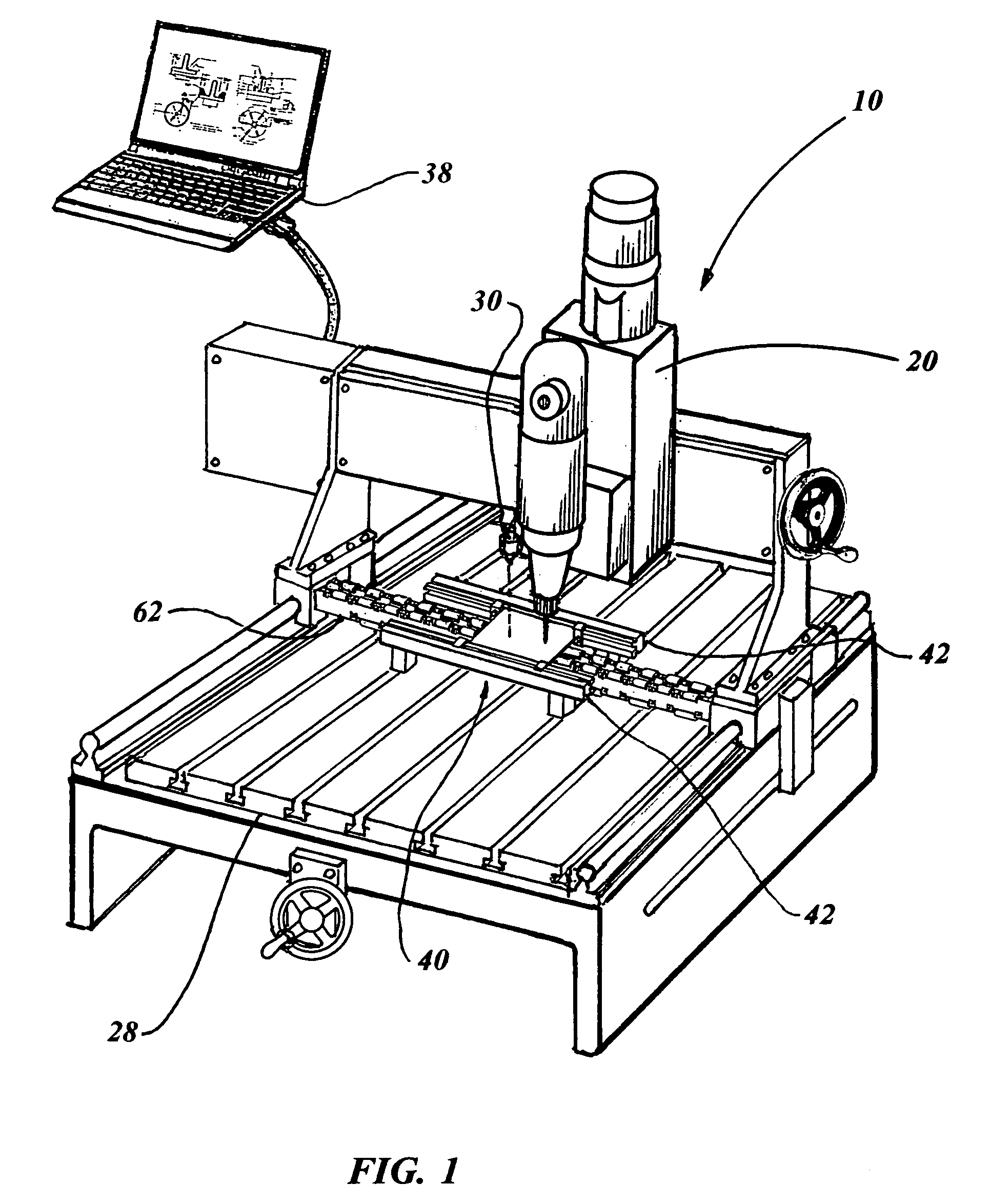

Thin plate drilling and milling machine

InactiveUS7467449B1Avoid scratchesEasy to slideDrilling/boring measurement devicesThread cutting feeding devicesEngineeringLaser beams

A CNC drilling and milling machine comprised of a movable drill motor platform (20) with a laser reference point finder (30) in the form of a laser (34) that is attached to the machine adjacent a spindle (22). The reference point is aligned on the workpiece (26) with an identical reference located in a CNC computer (38). A workpiece holder (20) has two opposed bars (42) attached to a T-groove base of the drilling and milling machine, with each bar having a longitudinal notch (44) for holding the edges of a workpiece (26). A plate compression support and debris collecting member (62) collects debris and provides support for the workpiece (26). The entire platform is moved to drill or mill at predetermined computer selected positions, having the initial reference point (32) located with the calibrated laser beam.

Owner:LEE S PETER +1

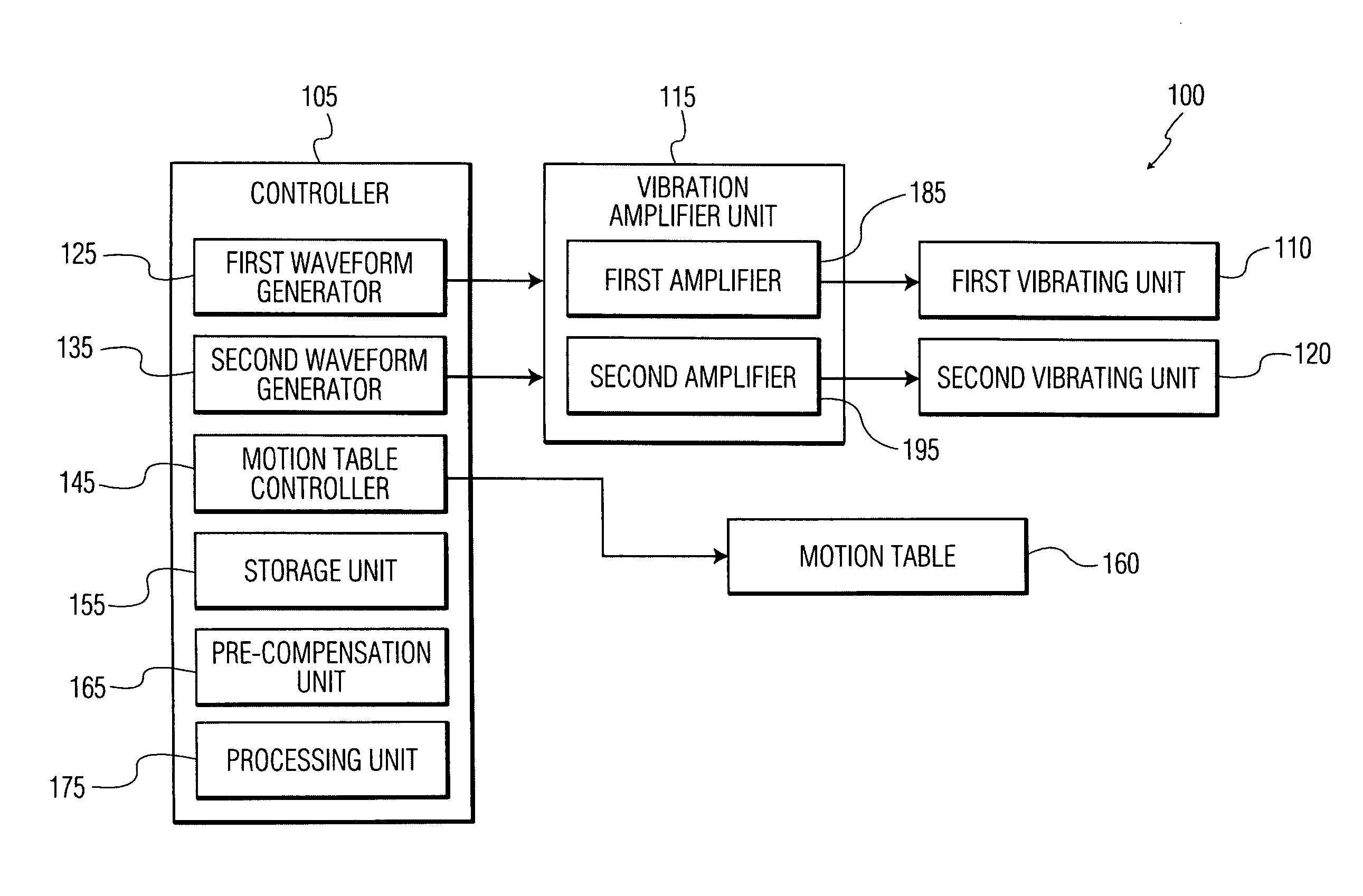

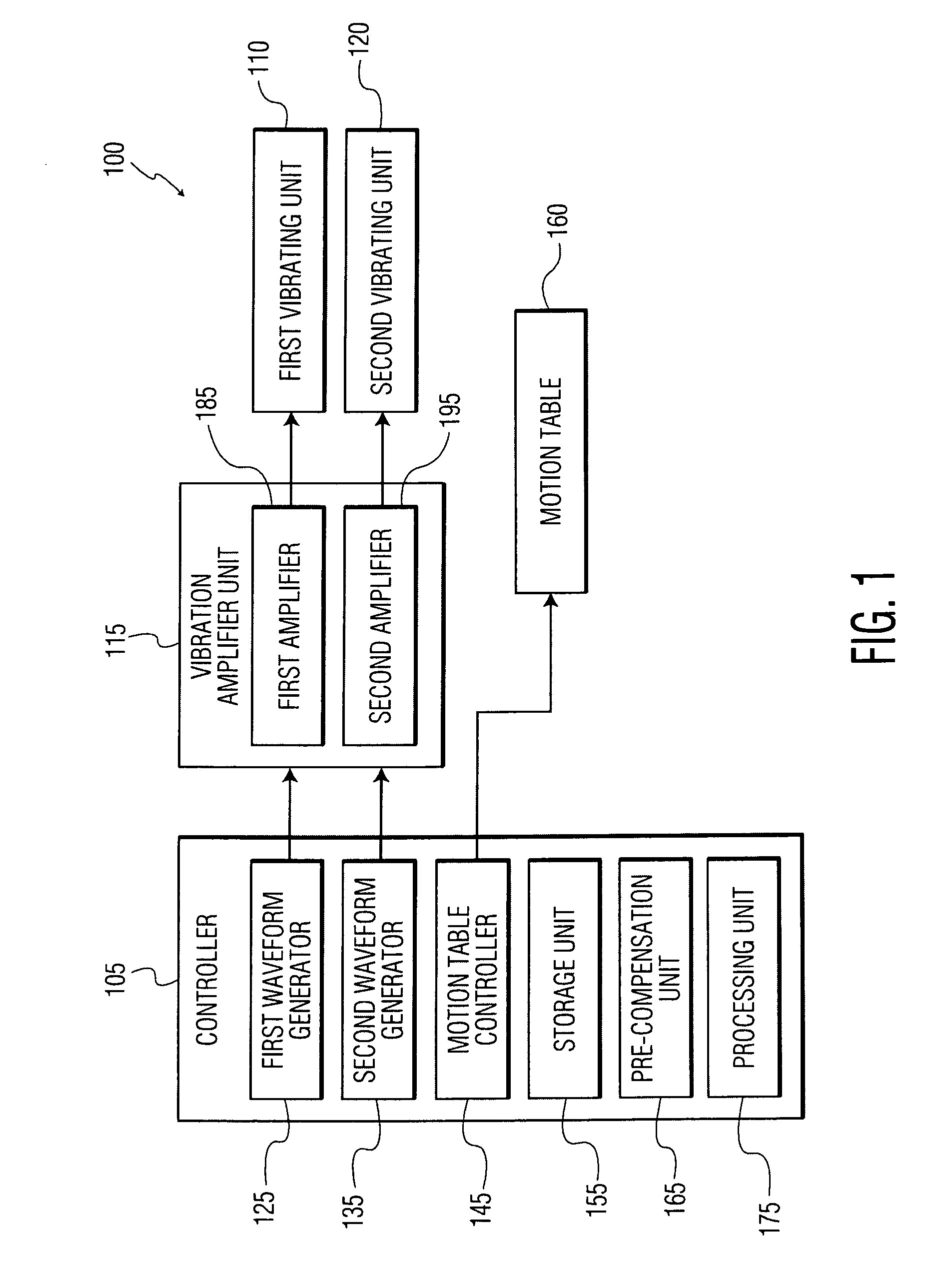

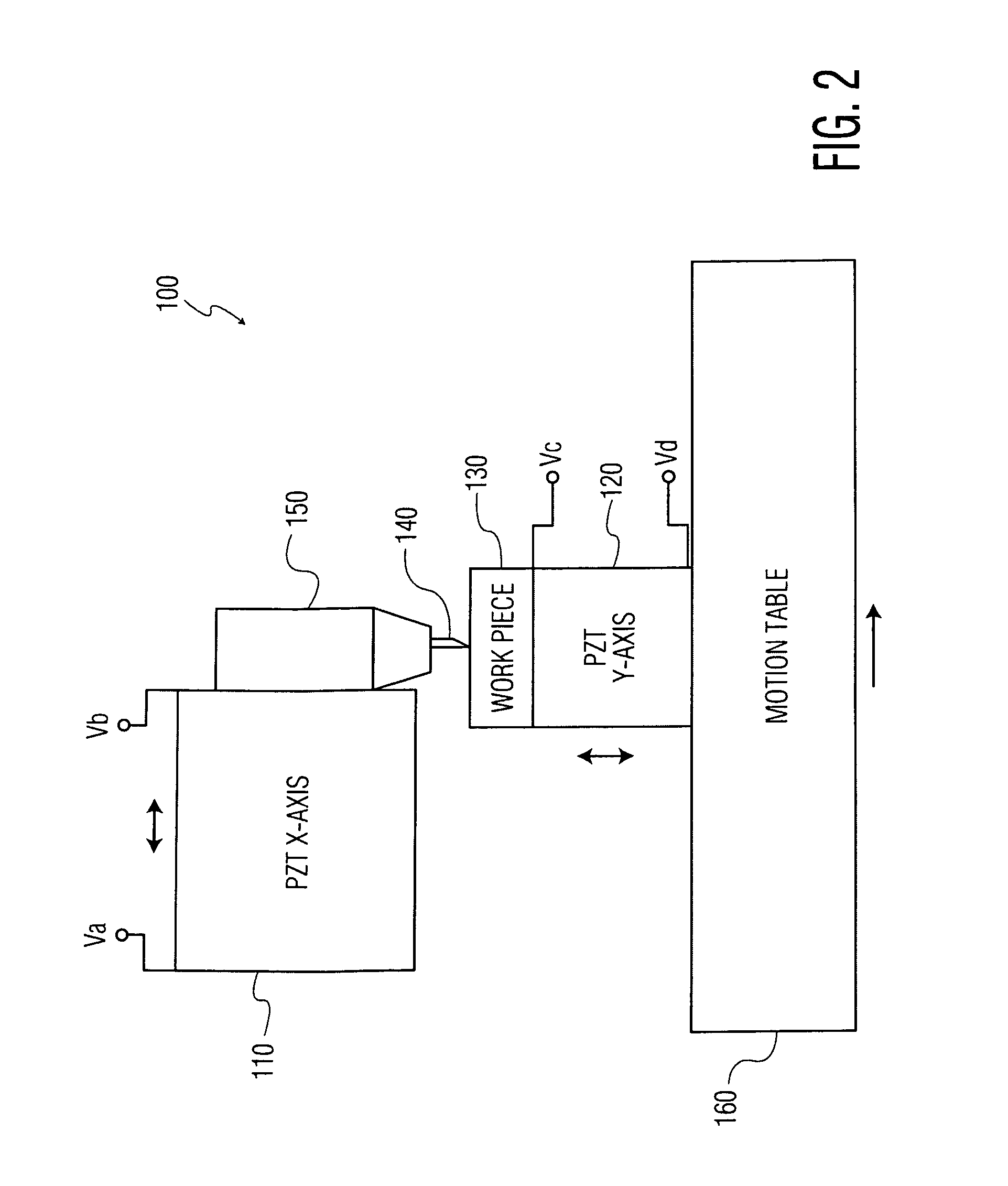

Method and apparatus for vibration machining with two independent axes

InactiveUS20070052326A1Piezoelectric/electrostriction/magnetostriction machinesWorkpiecesEngineeringMechanical engineering

A vibration machining apparatus and method of use. The vibration machining apparatus includes a cutting tool and a motion stage coupled to one of the cutting tool or the workpiece to move the cutting tool relative to the workpiece. A tangent to a machine path and a normal to the surface of the workpiece define a vibration plane. The vibration machining apparatus further includes a first vibrating unit coupled to one of the cutting tool or the workpiece to vibrate it along a first vibrational direction, substantially in the vibration plane, and a second vibrating unit coupled with one of the cutting tool or the workpiece to vibrate the one of the cutting tool or the workpiece coupled to the second vibrating unit along a second vibrational direction, different from the first direction and substantially in the vibration plane.

Owner:PANASONIC CORP

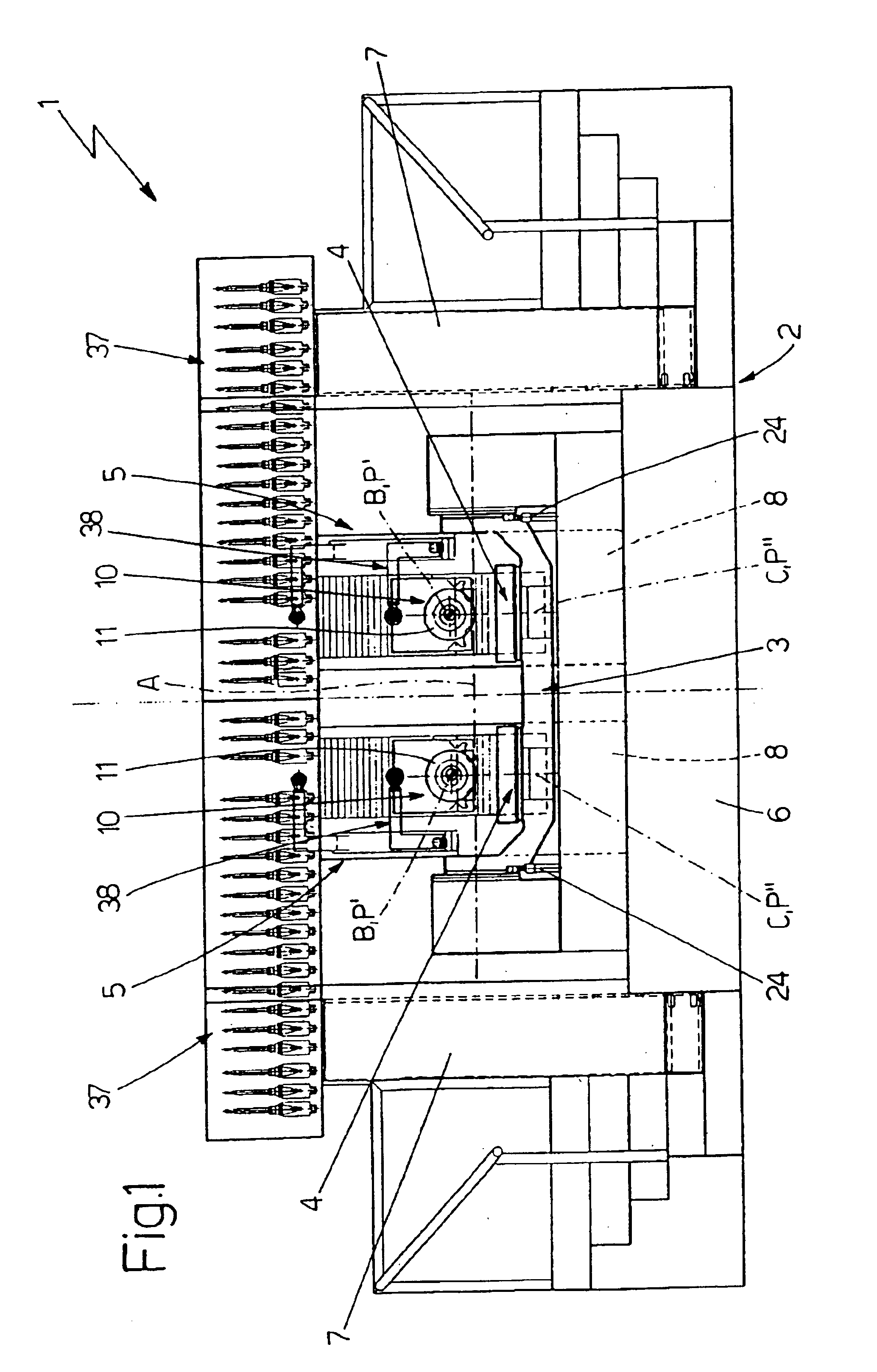

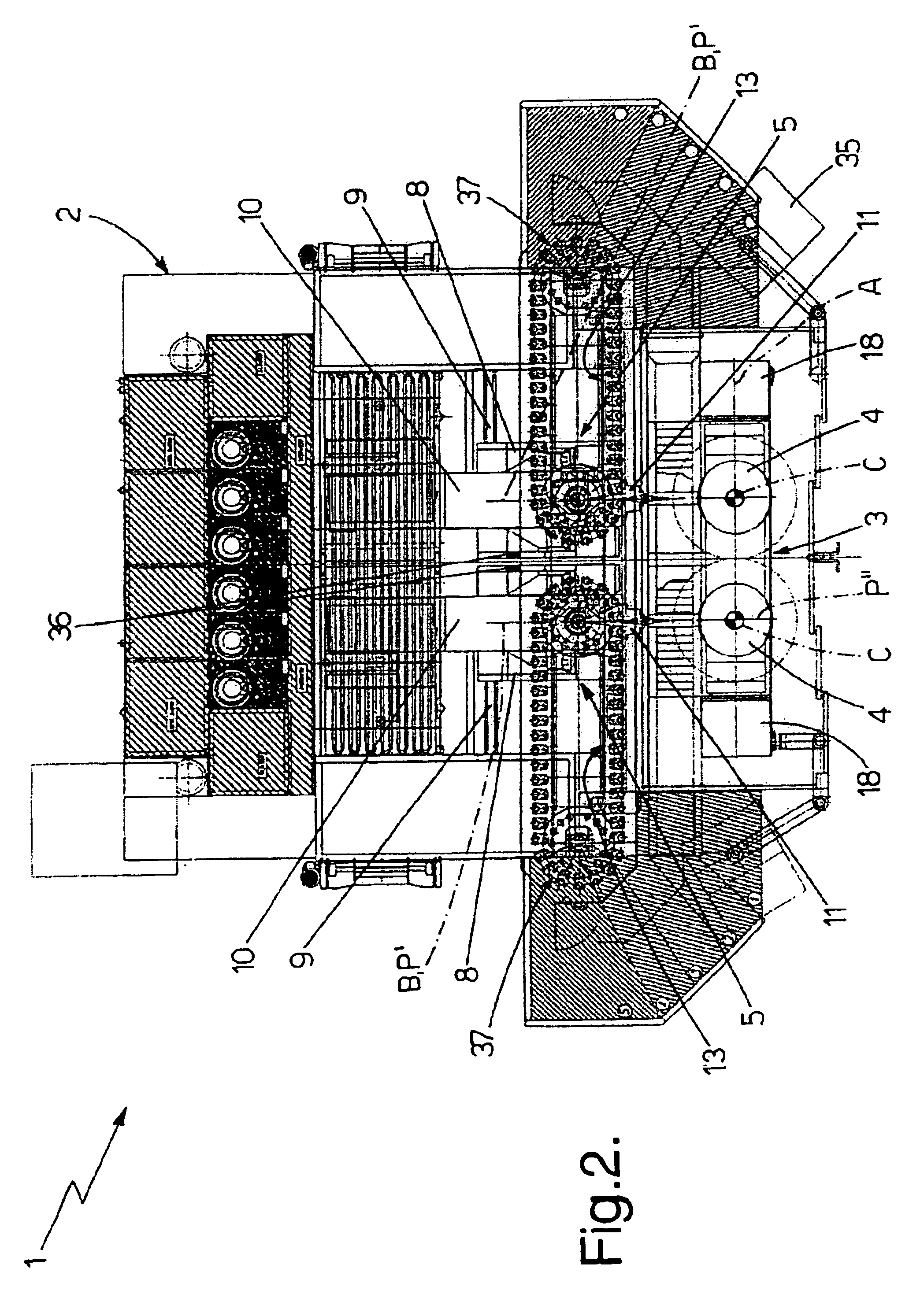

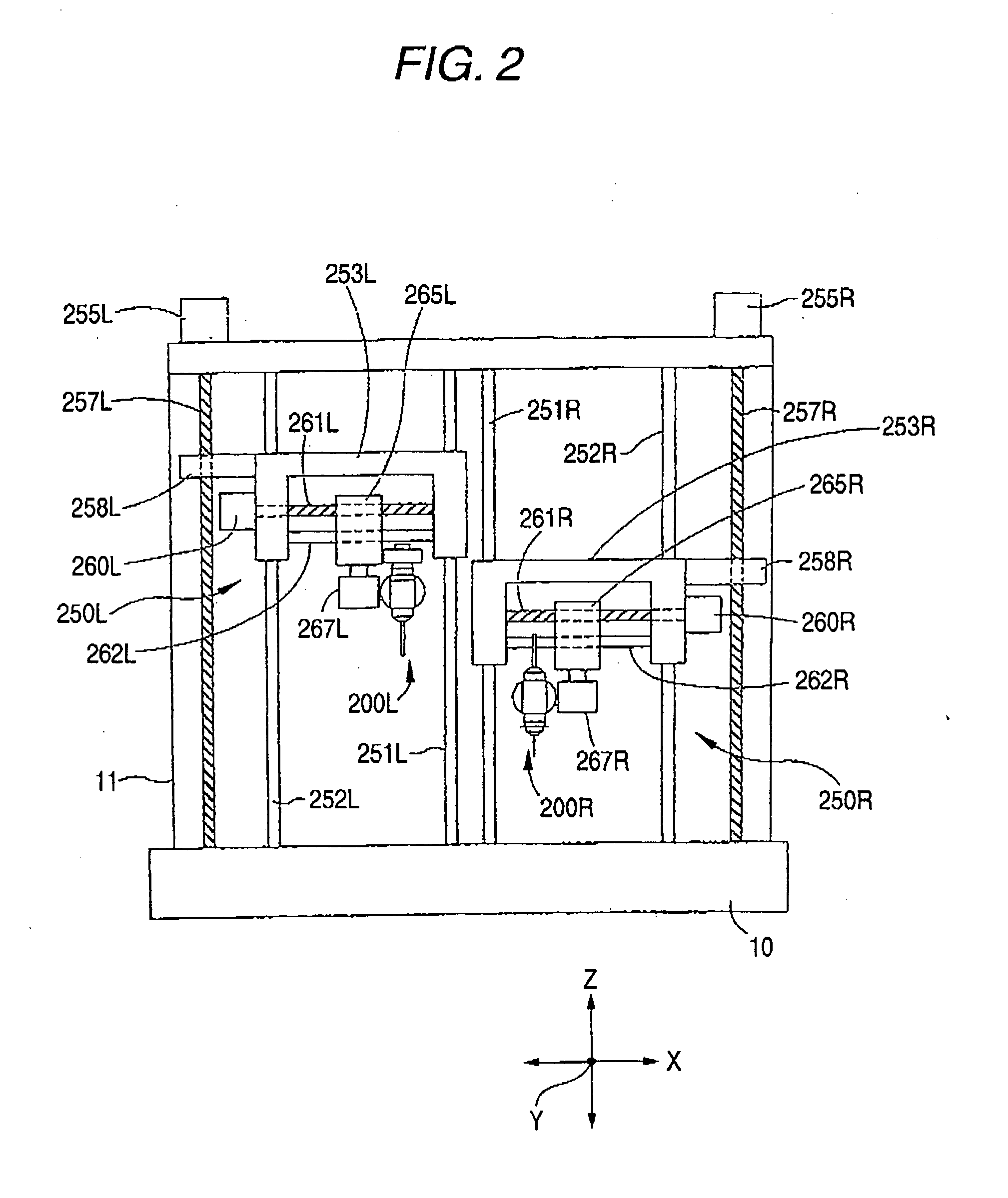

Numerical-control milling machine

InactiveUS6865788B2Drawback can be obviatedThread cutting feeding devicesThread cutting machinesRotational axisEngineering

A numerical-control milling machine having a supporting frame; a worktable fitted to the supporting frame so as to oscillate about a substantially horizontal first axis of rotation, and in turn having two rotary platforms, each for accommodating a workpiece; and two independent work units, each of which is fitted movably to the supporting frame, alongside the worktable, is positioned facing a corresponding platform, and provides for machining the workpiece on the platform; the two work units selectively operating either asynchronously, to machine the workpieces fixed to the two platforms independently of each other, or synchronously to perform the same machining operations simultaneously on the workpieces fixed to the two platforms.

Owner:O M V OFF MEC VENETE

Inclining and rotating table apparatus

ActiveUS6955345B2Improve accuracyPrecision positioning equipmentRoller bearingsRotary stageEngineering

An inclining and rotating table apparatus comprises a rotating table device having a rotating table, and a support base for rotatably supporting the rotating table having a shaft body provided perpendicular to a rotation axis of the rotating table, and a base for rotatably supporting the rotating table device using the shaft body. A table surface of the rotating table is inclined by making the rotating table device rotate. A first V-shaped groove is directly formed in the shaft body along its rotating direction. The base has a second V-shaped groove opposing the first V-shaped groove. A cross roller bearing is structured by providing rolling bodies, which are placed in contact with the first and second V-shaped grooves and are capable of rolling therebetween, between the shaft body and the base, and arranging a rolling axis of a rolling body perpendicular to that of an adjacent rolling body.

Owner:SANKYO SEISAKUSHO

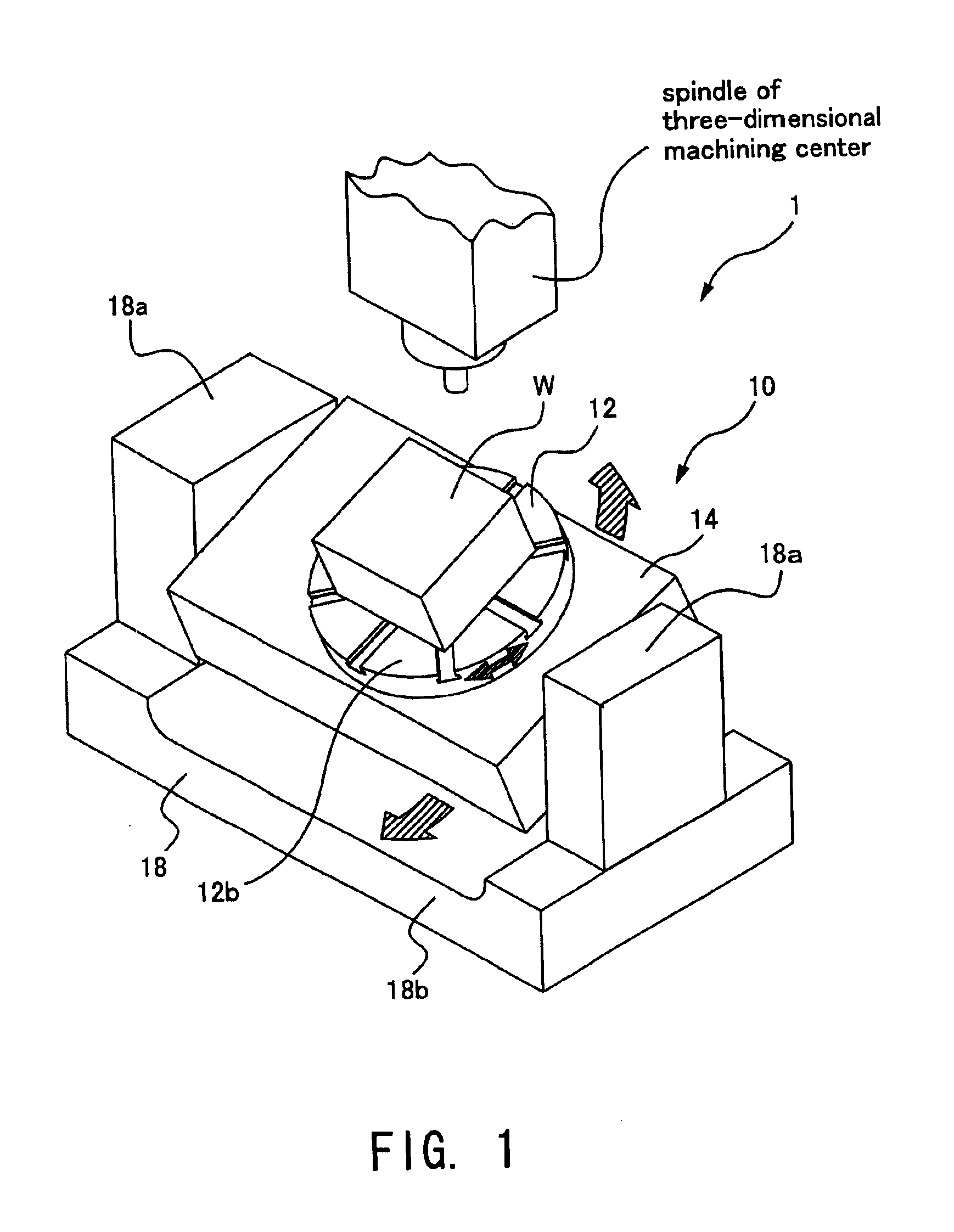

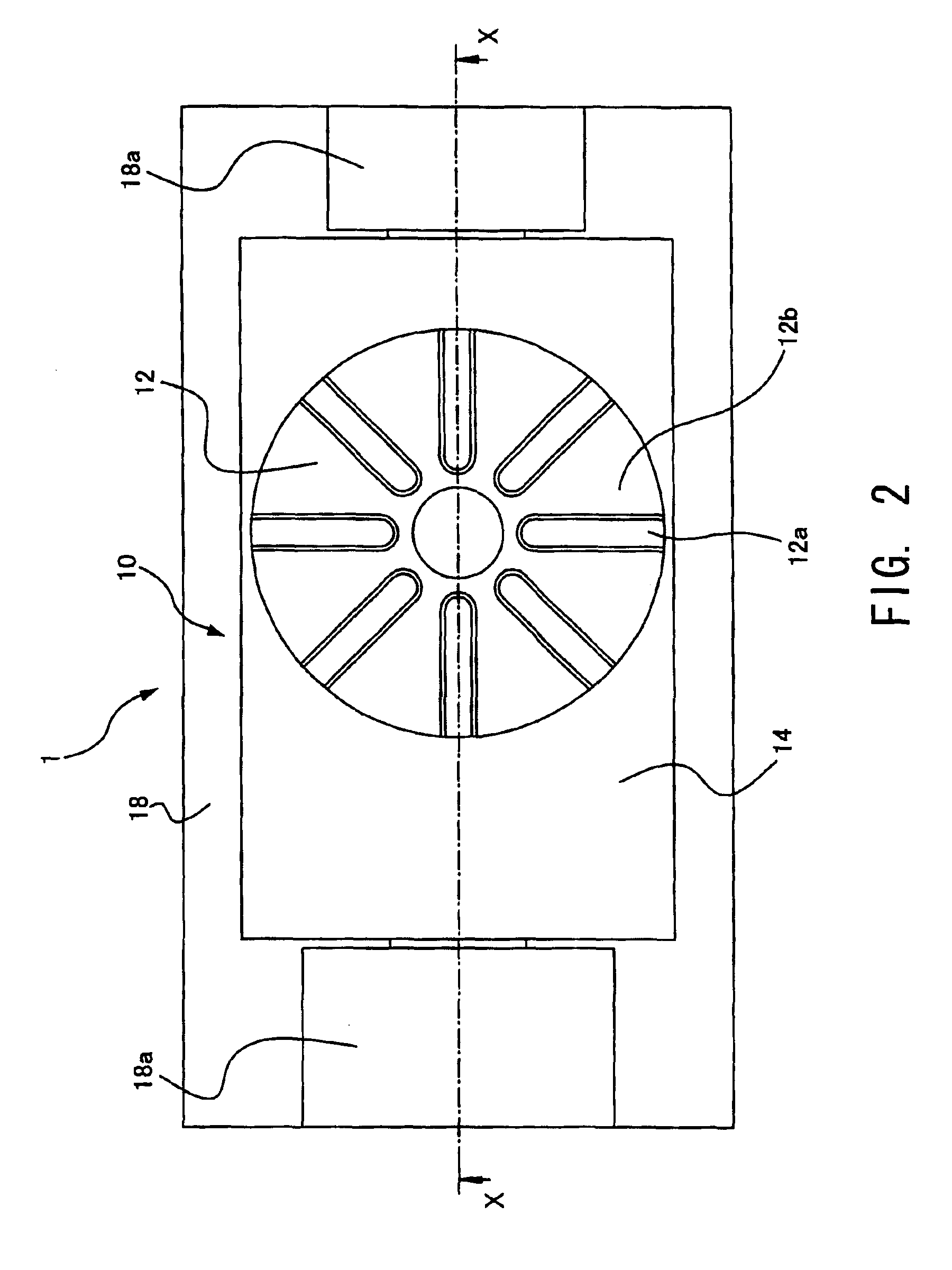

Method and apparatus for machining a blank from all directions in a machine tool or milling machine

InactiveUS7261500B2Simple processLow costTurbinesPlaning/slotting machinesEngineeringSpatial direction

The corresponding machine tool or milling machine for carrying out the method described has a milling spindle which is displaceable in three spatial directions and with which the workpiece can be machined in a machining region, the machine tool or milling machine having at least one mounting slide, with which the workpiece, for the first machining step, can be mounted in gripping adapters. Furthermore, the machine tool or milling machine has at least one rocker, with which the partly machined workpiece can be mounted by means of at least one special gripping adapter in the first, finally machined region of the workpiece for the second machining step.

Owner:ALSTOM TECH LTD

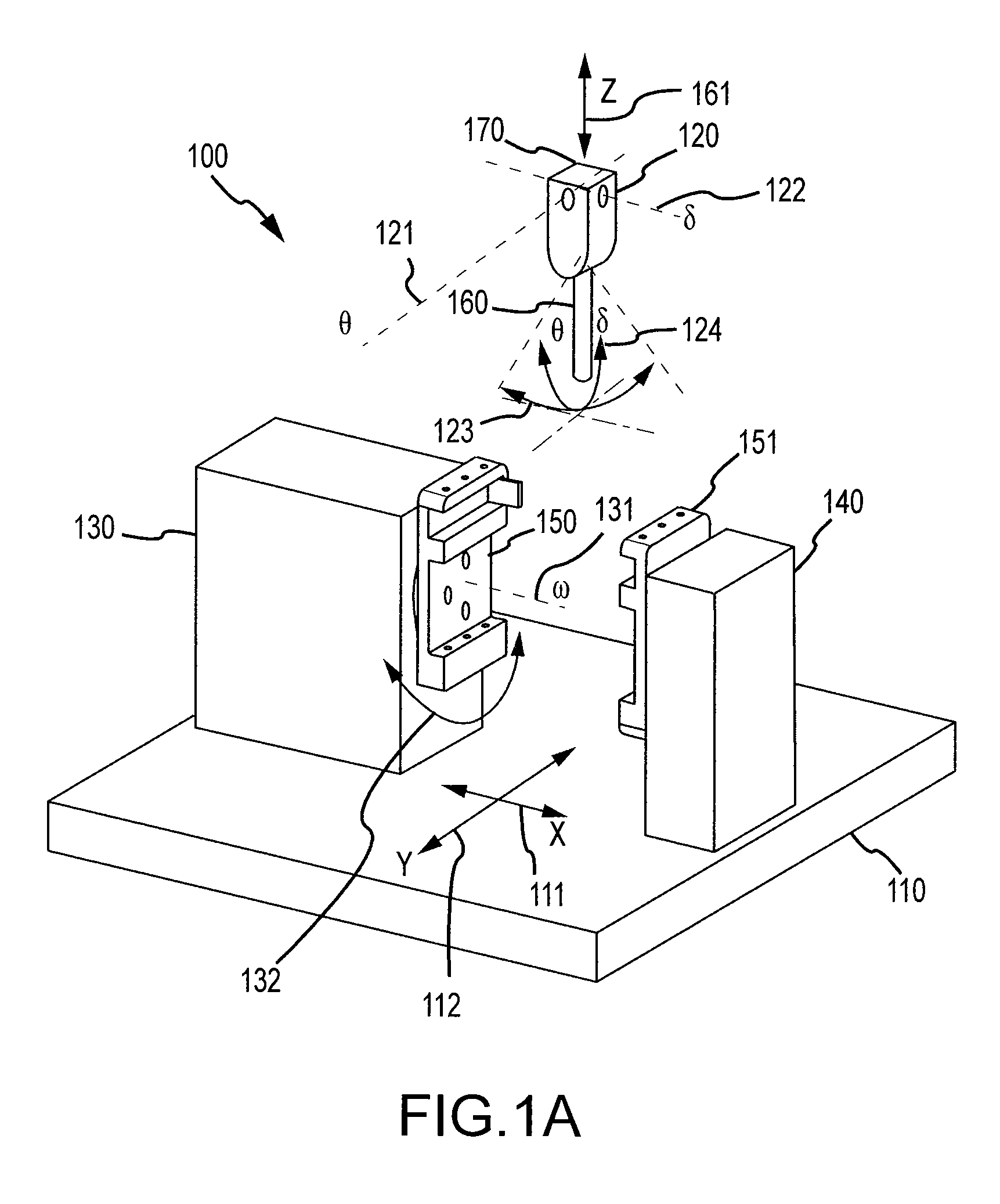

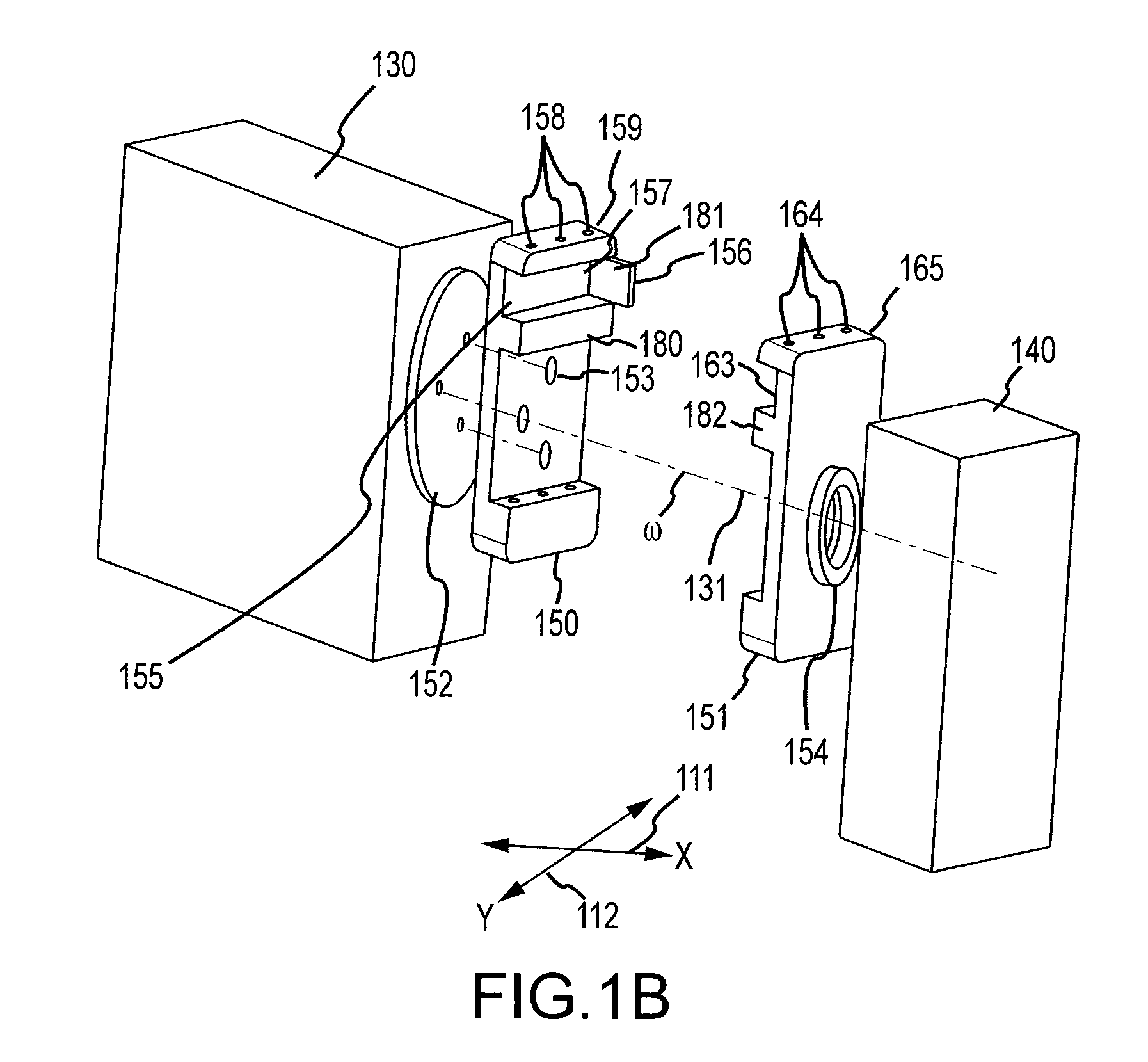

Arthroplasty systems and devices, and related methods

ActiveUS8460303B2Improve positionCorrect formatThread cutting machinesJoint implantsNumerical controlBiomedical engineering

Systems for manufacturing arthroplasty jigs are disclosed. The systems include positioning components for positioning an arthroplasty jig blank in a machining device (e.g., a computer numerical control (CNC) machine). Arthroplasty jig blanks that may be used in the systems can include an arm fixture component configured to be coupled to the positioning component. Coupling the arm fixture component to the positioning component positions the jig blank body for machining by the machining device. In addition, positioning components, arthroplasty jig blanks, and methods for making arthroplasty jig blanks are disclosed.

Owner:HOWMEDICA OSTEONICS CORP

Brake plate and method and apparatus for manufacturing same

InactiveUS6910255B2Improve bindingImprove structural strengthSpringsMetal rolling stand detailsEngineeringMechanical engineering

The invention is a plate for holding a friction material in a brake assembly. The plate preferably comprises a contact surface for attaching the friction material to the plate, a second surface opposing the contact surface; and a plurality of retaining structures formed on the contact surface, each retaining structure comprising a projecting member extending from a point between the contact surface and the second surface, so that the member extends outwardly from the contact surface for engagement with the friction material.

Owner:NUCAP IND

Addressable Matrices/Cluster Blanks for Dental CAD/CAM Systems and Optimization Thereof

ActiveUS20090023112A1Maximum interchangabilityMaximum flexibilityDwelling equipmentDental toolsEngineeringCam

A cluster mill blank includes a framework constructed to cooperate with a blank holder of an existing CAD / CAM system, and a plurality of sub-blanks attached to the framework forming an addressable matrix or cluster blank. CAD / CAM systems including such a framework, as well as associated methods are described.

Owner:IVOCLAR VIVADENT AG

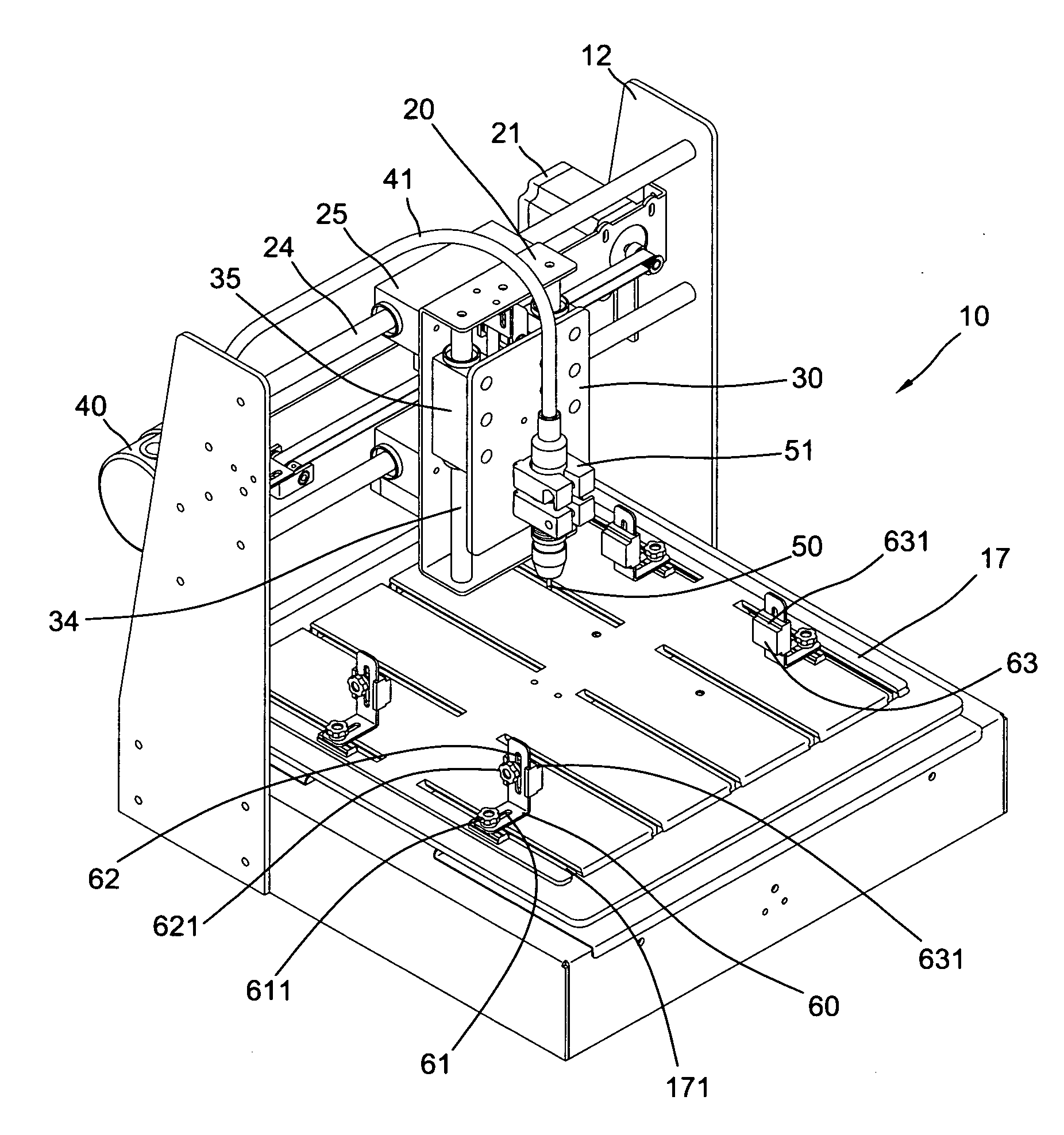

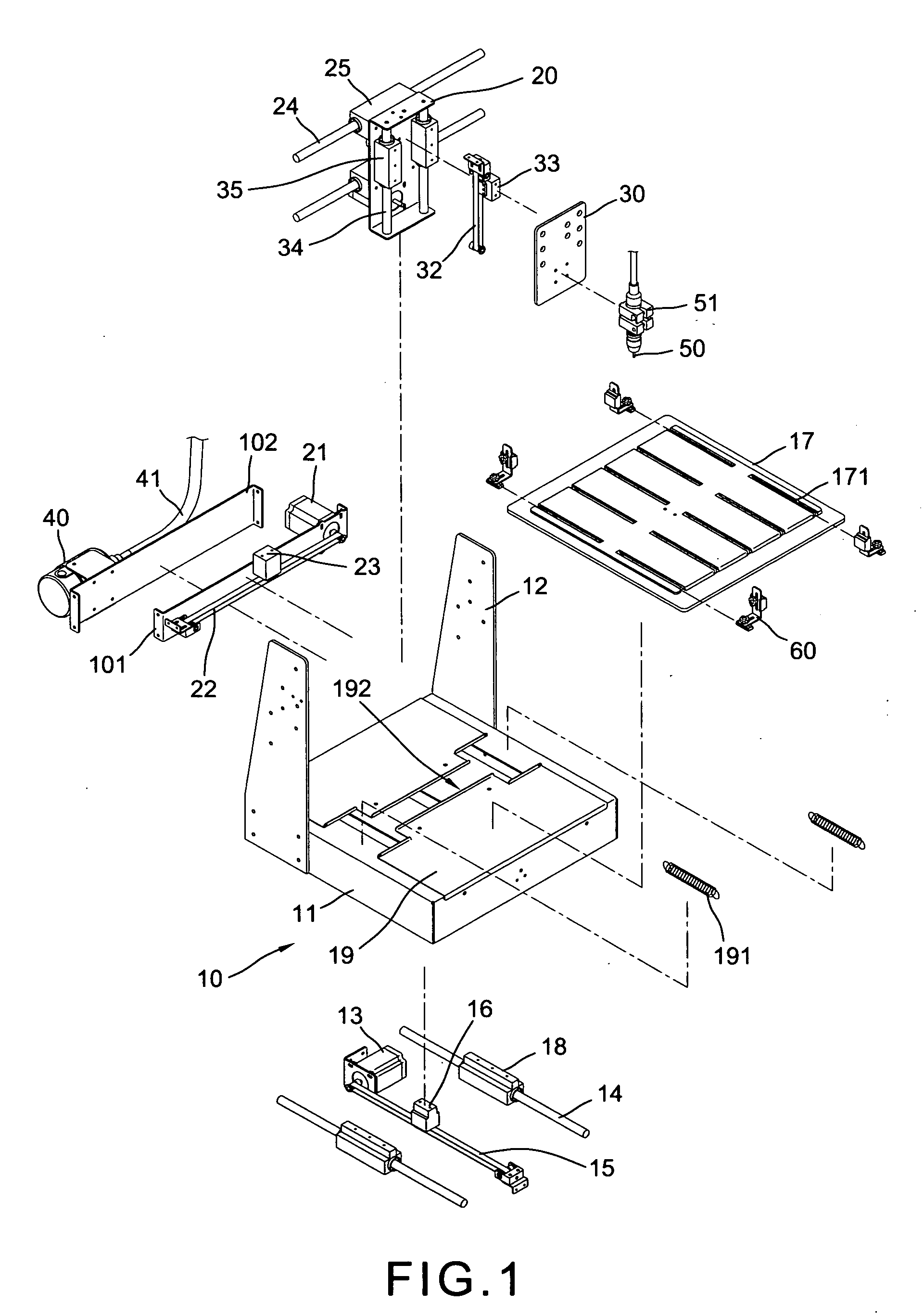

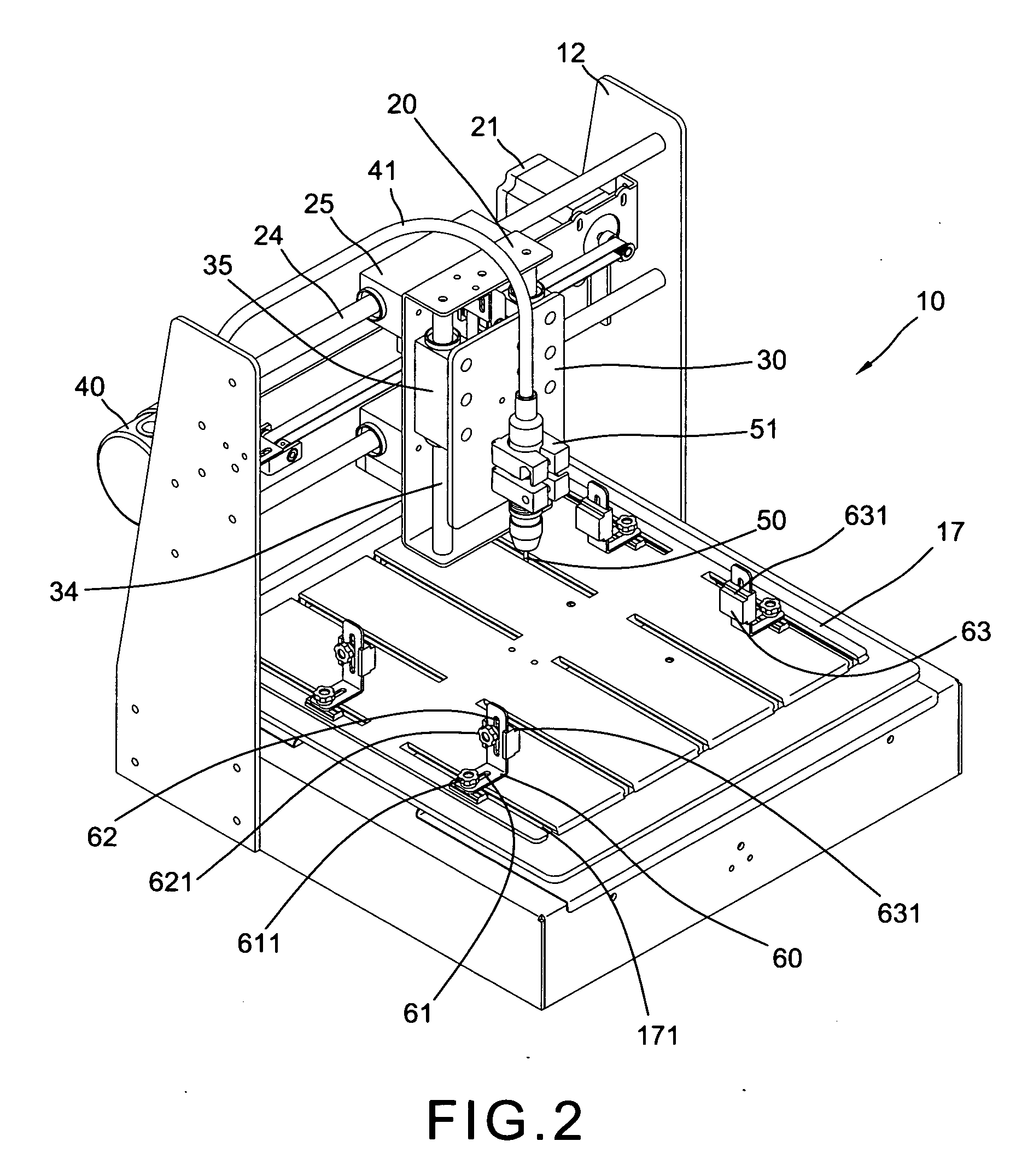

Compact engraving machine

An engraving machine includes a base with two side panels extending upward from two sides of the base, and a top board is driven horizontally by a motor in the base. A horizontal frame is movably mounted on two rods connected between the two side panels by a motor. A vertical frame is located on a front side of the horizontal frame and is movable along two rods in vertical direction by another motor. The horizontal frame, the vertical frame and the top board are movable along X, Y and Z directions by three independent motors. A chuck is connected to the vertical frame and secures an engraving tool which is driven by a main motor connected between the two side panels. The object to be engraved is secured on the top board and engraved by the engraving tool in X, Y and Z directions.

Owner:CHEN YUEHTING

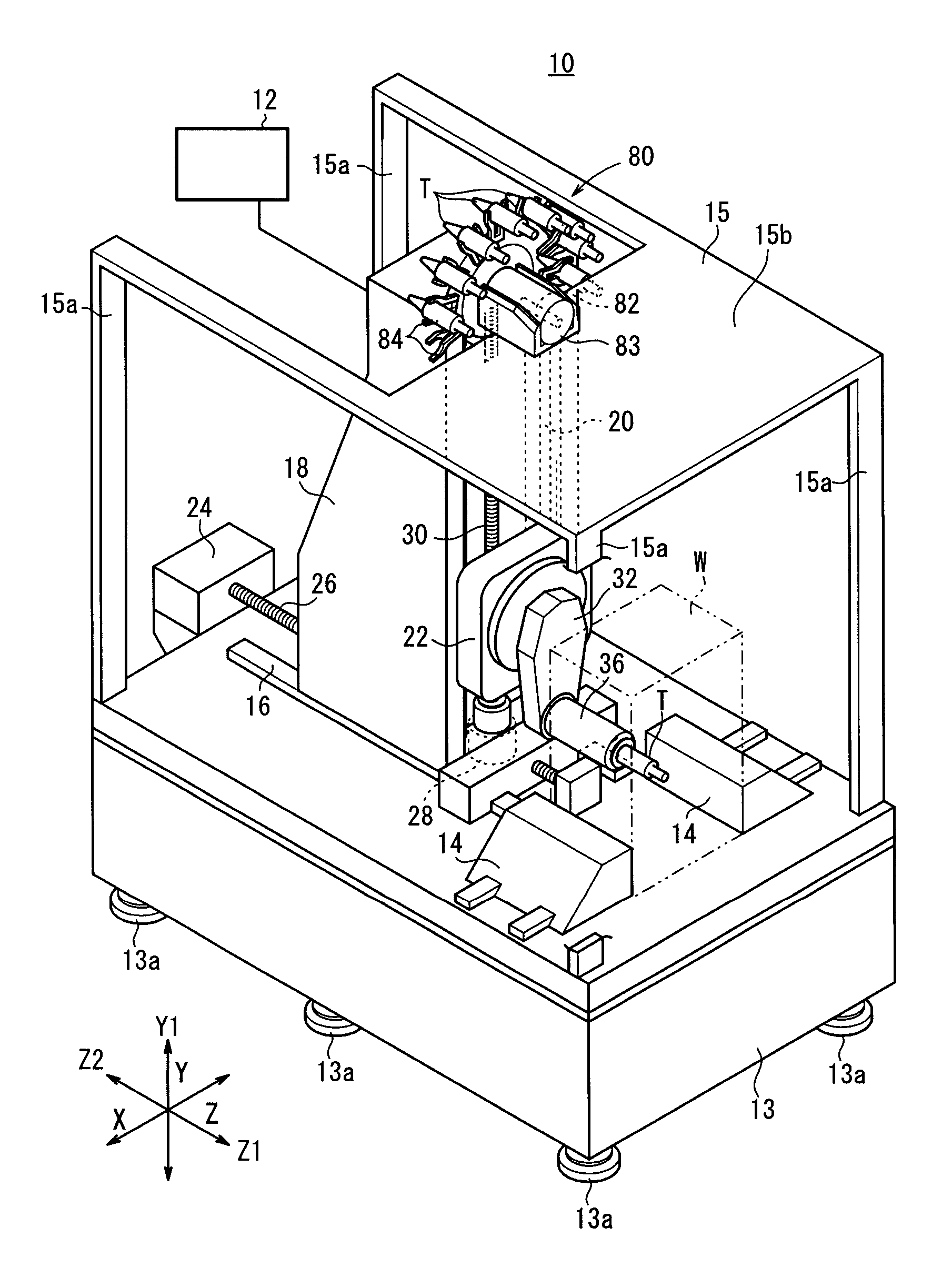

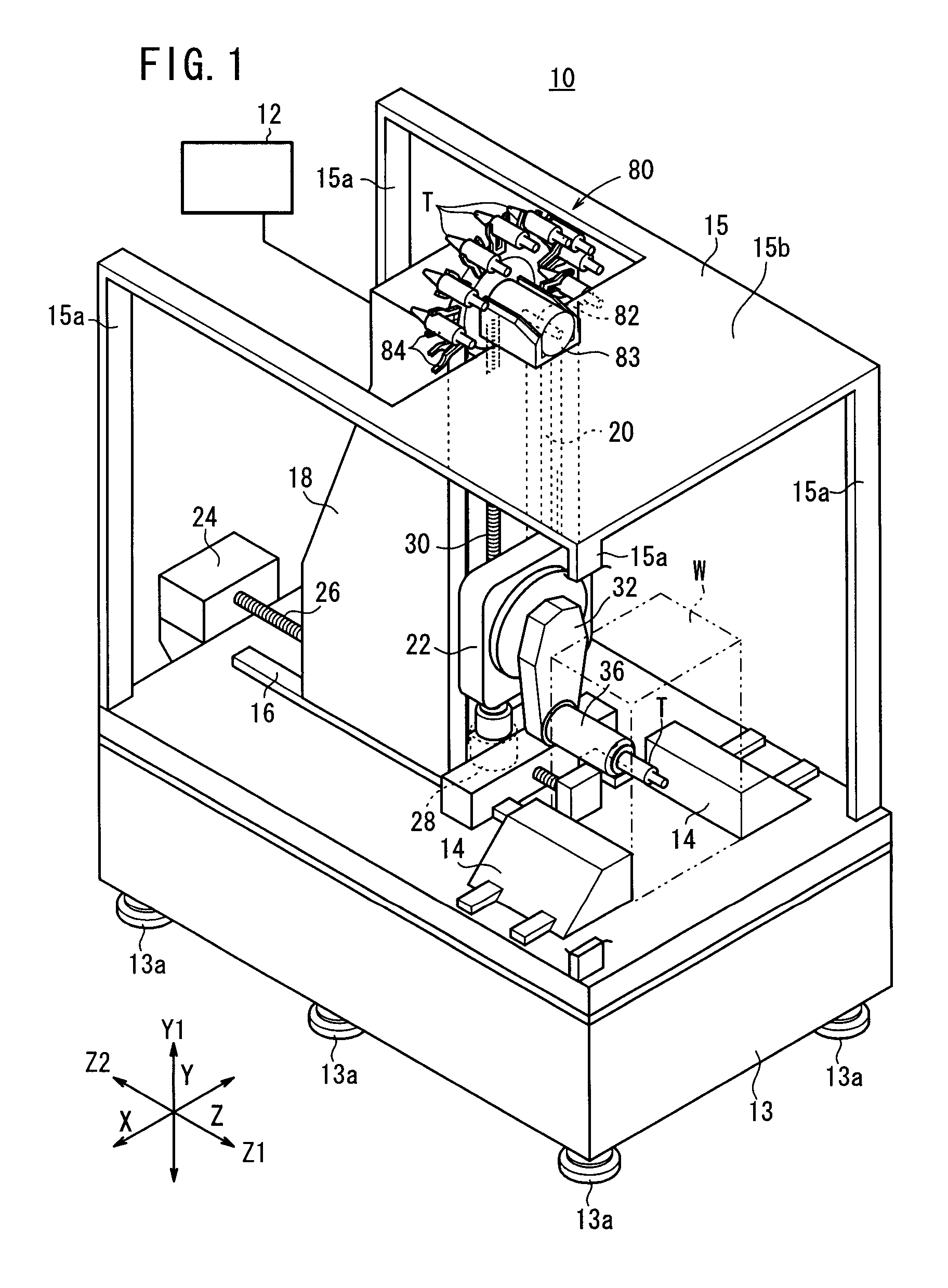

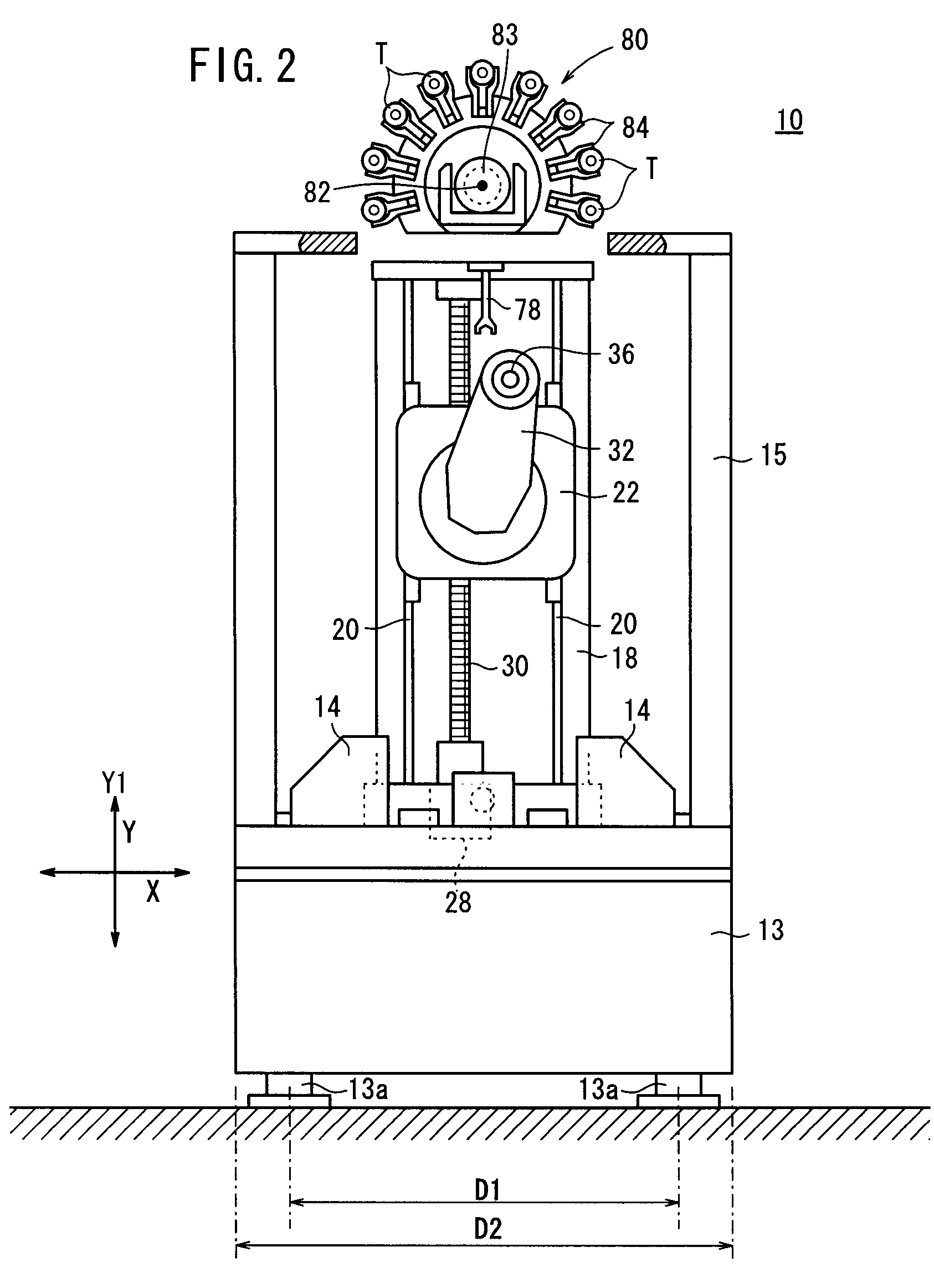

Machine tool and method of controlling machine tool

InactiveUS20090053004A1Compact structureImprove space efficiencyAttachable milling devicesTool changing apparatusVertical planeEngineering

A machine tool (10) has a Z table (18) sliding in the Z direction in a horizontal plane, a support body (22) provided on the Z table (18) and sliding in the vertical direction, a rotation arm (32) supported at the support body (22) and endlessly rotatable in a vertical plane facing work (W), an arm motor (34) for rotating the rotation arm (32), a processing spindle (36) rotatably supported and placed at a position of a distance R from the center C of rotation of the rotation arm (32), and a spindle motor (38) for rotating the processing spindle (36).

Owner:HONDA MOTOR CO LTD

Three degree of freedom parallel mechanism, multi-axis control machine tool using the mechanism and control method for the mechanism

InactiveUS20070248428A1Easy to controlImprove responseProgramme-controlled manipulatorMechanical apparatusKinematicsUniversal joint

In a three degrees of freedom parallel mechanism, a spindle head is carried by first and second movable support members to be movable along a Z-axis and to be pivotable along each of A and B-axes. The spindle head is jointed through three rods to drive sliders which are movable along three parallel linear guides secured stationarily. For jointing, there are employed spherical joints and universal joints. Kinematic parameters used in converting each command position of the movable body to target operational positions for three actuators of the Z, A and B-axes are compensated based on inversely converted command positions and inversely converted actually measured positions which have been gathered with the spindle head being located at positions of a suitable number, so that the kinematic parameters can be updated to those newest.

Owner:JTEKT CORP

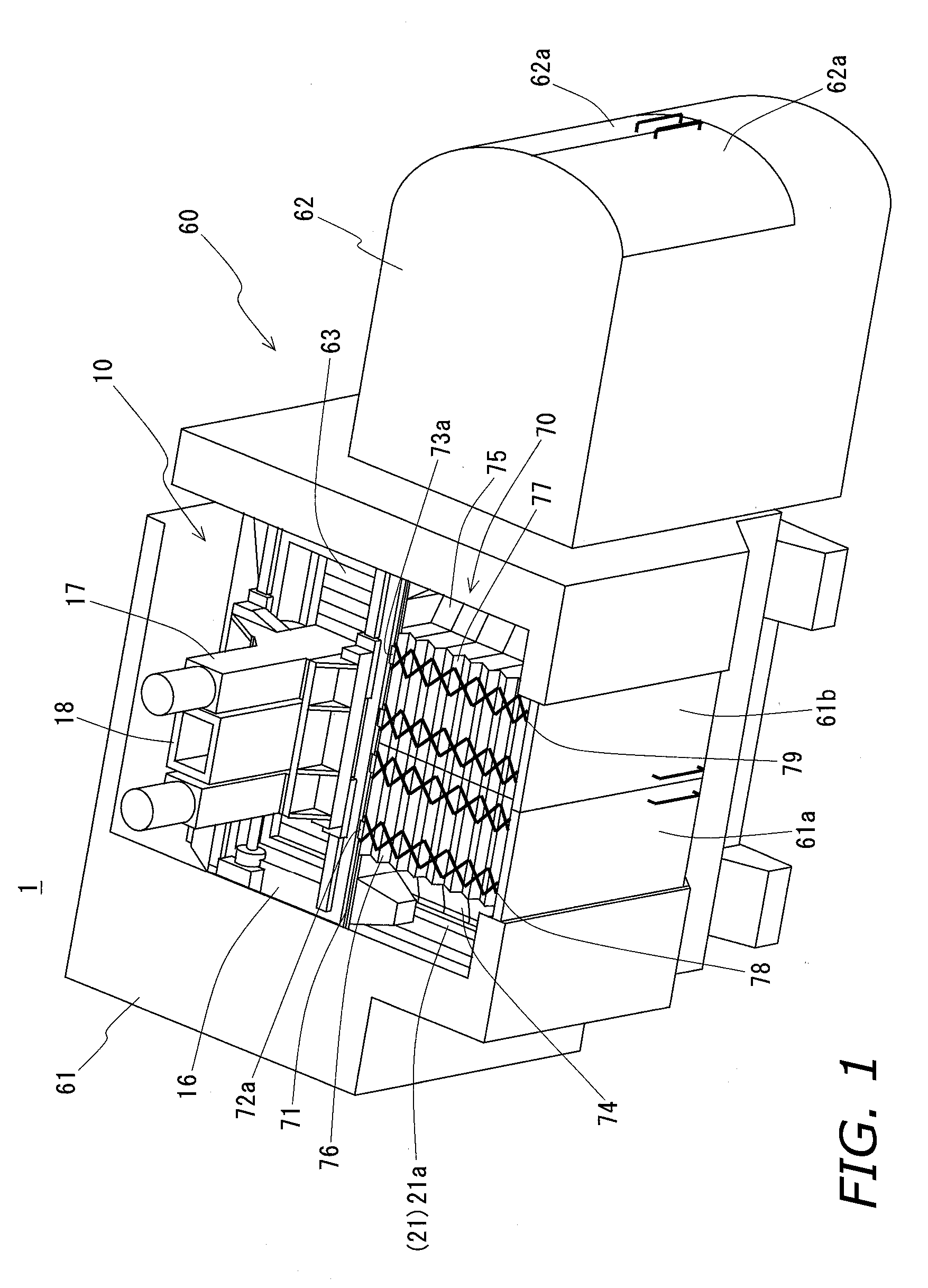

Eyeglass lens processing apparatus

An eyeglass lens processing apparatus for processing a periphery of an eyeglass lens, the apparatus includes: a lens chuck shaft that holds and rotates the lens; an end mill that processes the periphery of the lens; an end mill tilting unit that varies a tilt of the end mill with respect to the lens chuck shaft; an end mill moving unit that relatively moves the end mill with respect to the lens held by the lens chuck shaft; a target lens shape input unit that inputs an target lens shape; a lens measuring unit that detects a position of a processing edge of the lens based on the input target lens shape; a memory that stores a beveling shape including a beveling tilt angle on a front surface side of the lens and a beveling tilt angle on a rear surface side of the lens; and a control unit that controls the end mill tilting unit and the end mill moving unit to perform a roughing process on the lens using the end mill based on the input target lens shape and to perform a beveling process on the roughing-processed lens using the end mill based on the detected position of the processing edge and the stored beveling shape.

Owner:NIDEK CO LTD

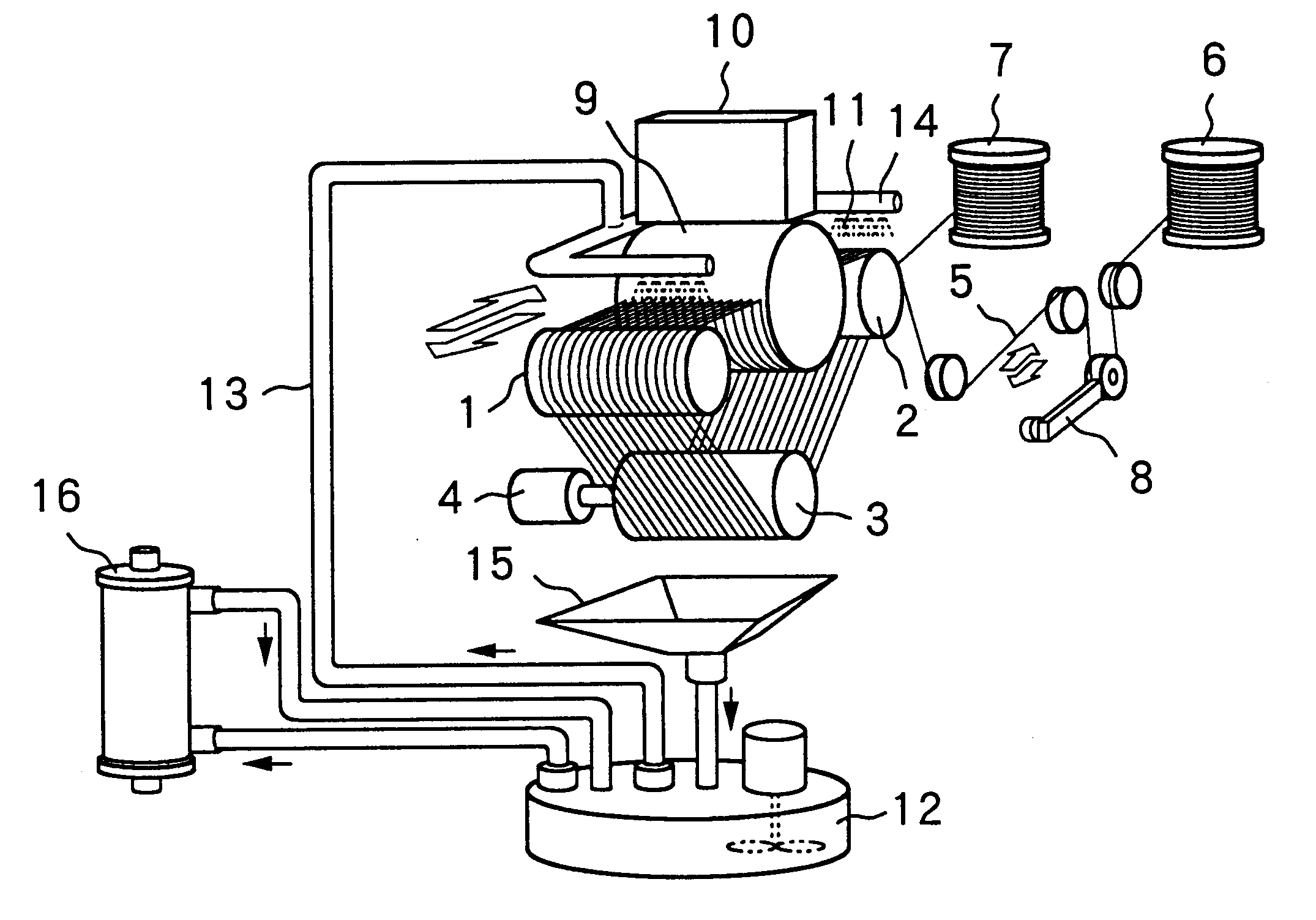

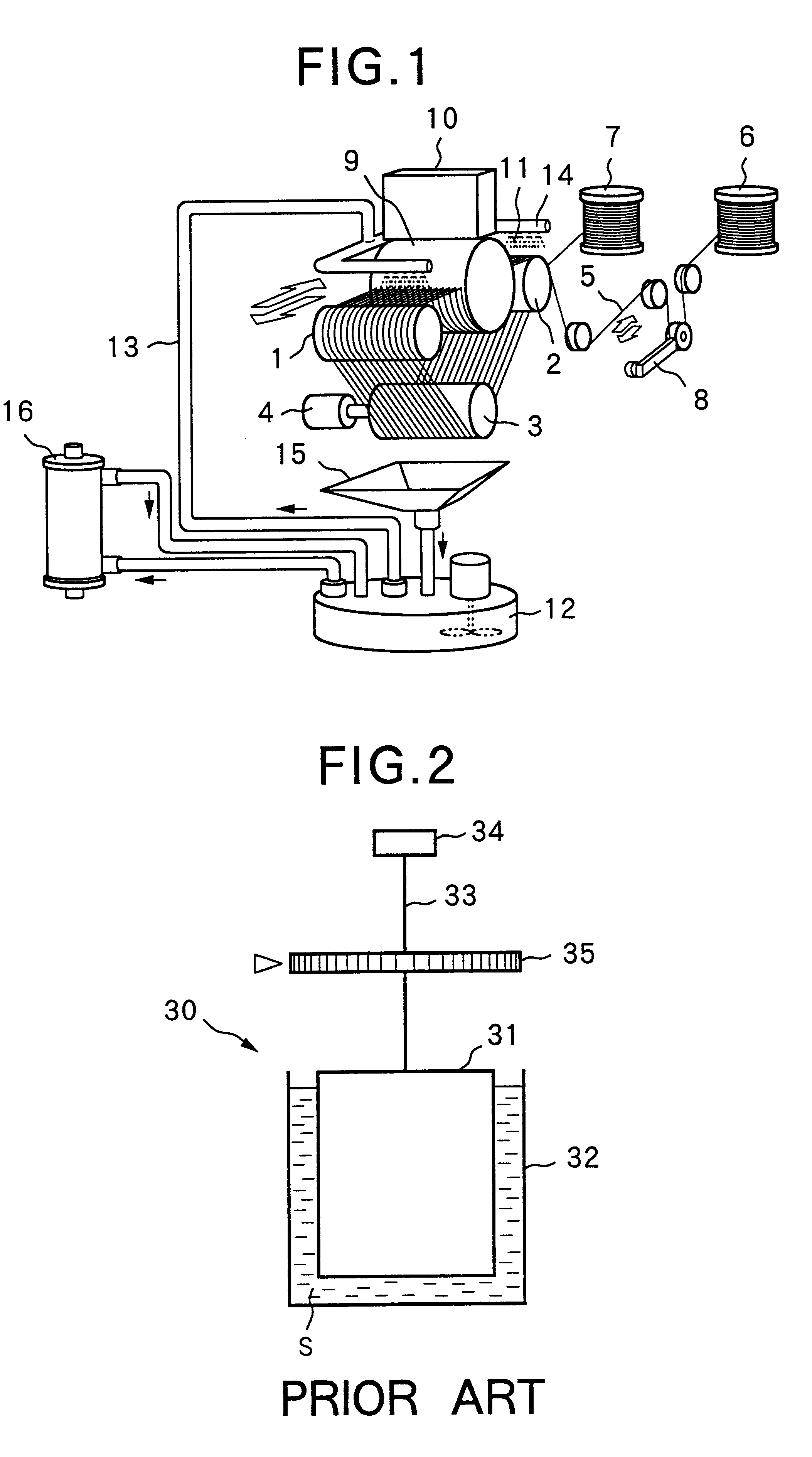

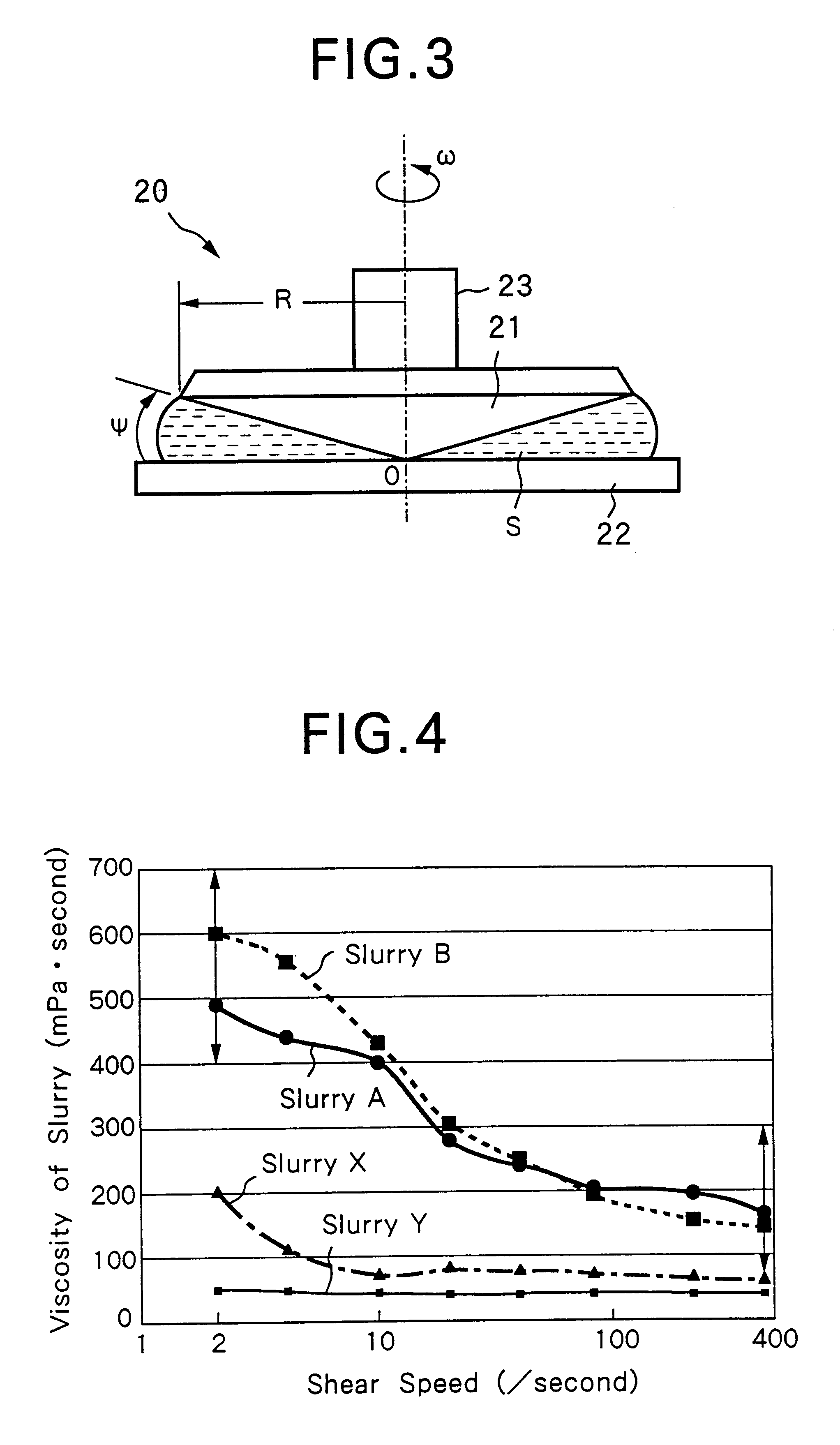

Slurry useful for wire-saw slicing and evaluation of slurry

Slurry useful for wire-saw slicing has viscosity adjusted to 400-700 mPa.second at a shear speed of 2 / second and of 50-300 mPa.second at a shear speed of 380 / second. The viscosity of slurry is measured using a cone and plate type viscometer which can measure viscosity at different shear speeds. Since the slurry sufficiently flows into inner parts of grooves formed in an ingot and consumed for wire-saw slicing due to the viscosity controlled in response to the shear speed, the ingot can be efficiently sliced to wafers or discs.

Owner:SUPER SILICON KENKYUSHOKK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com