Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

950results about "Thread cutting feeding devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

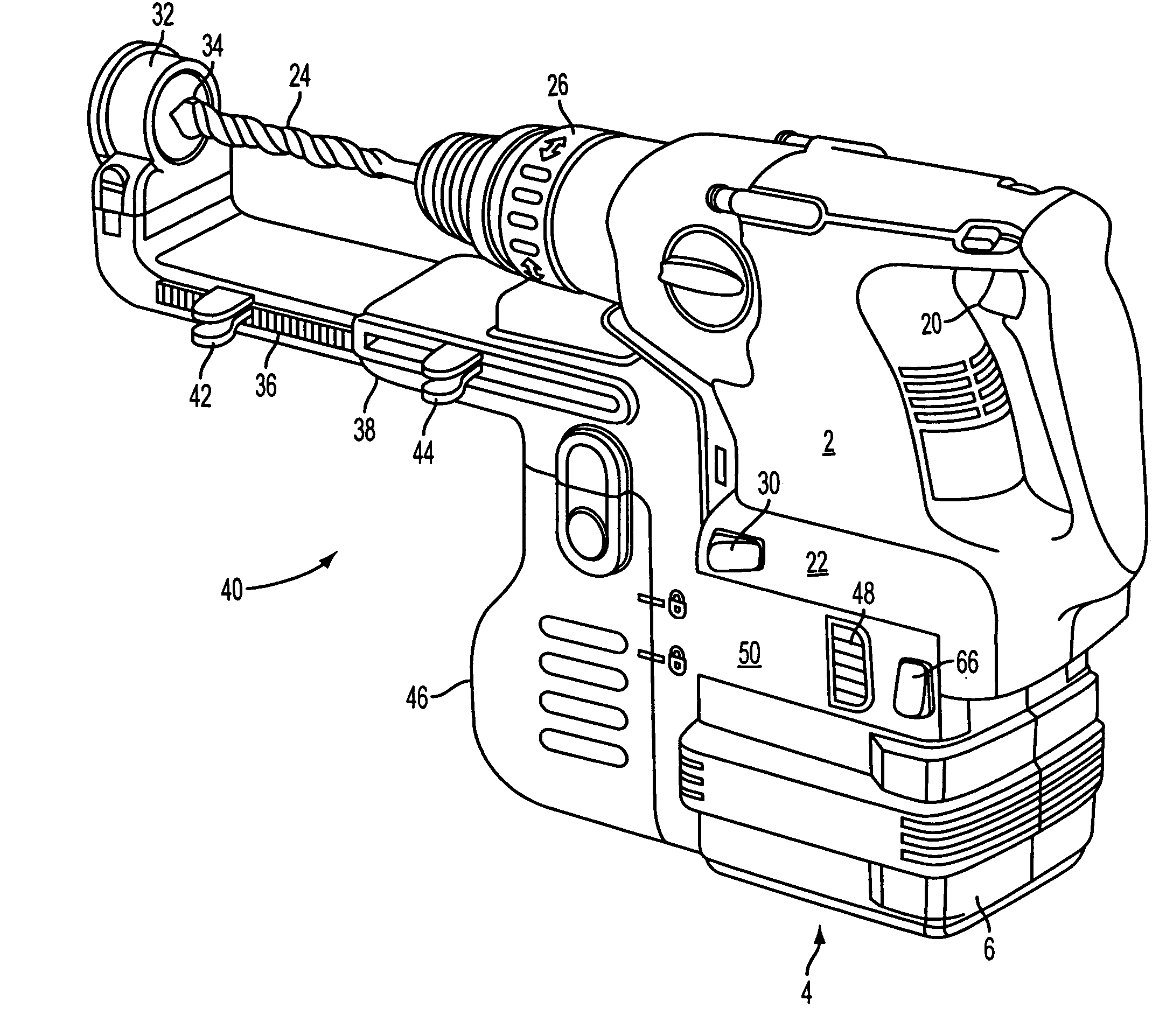

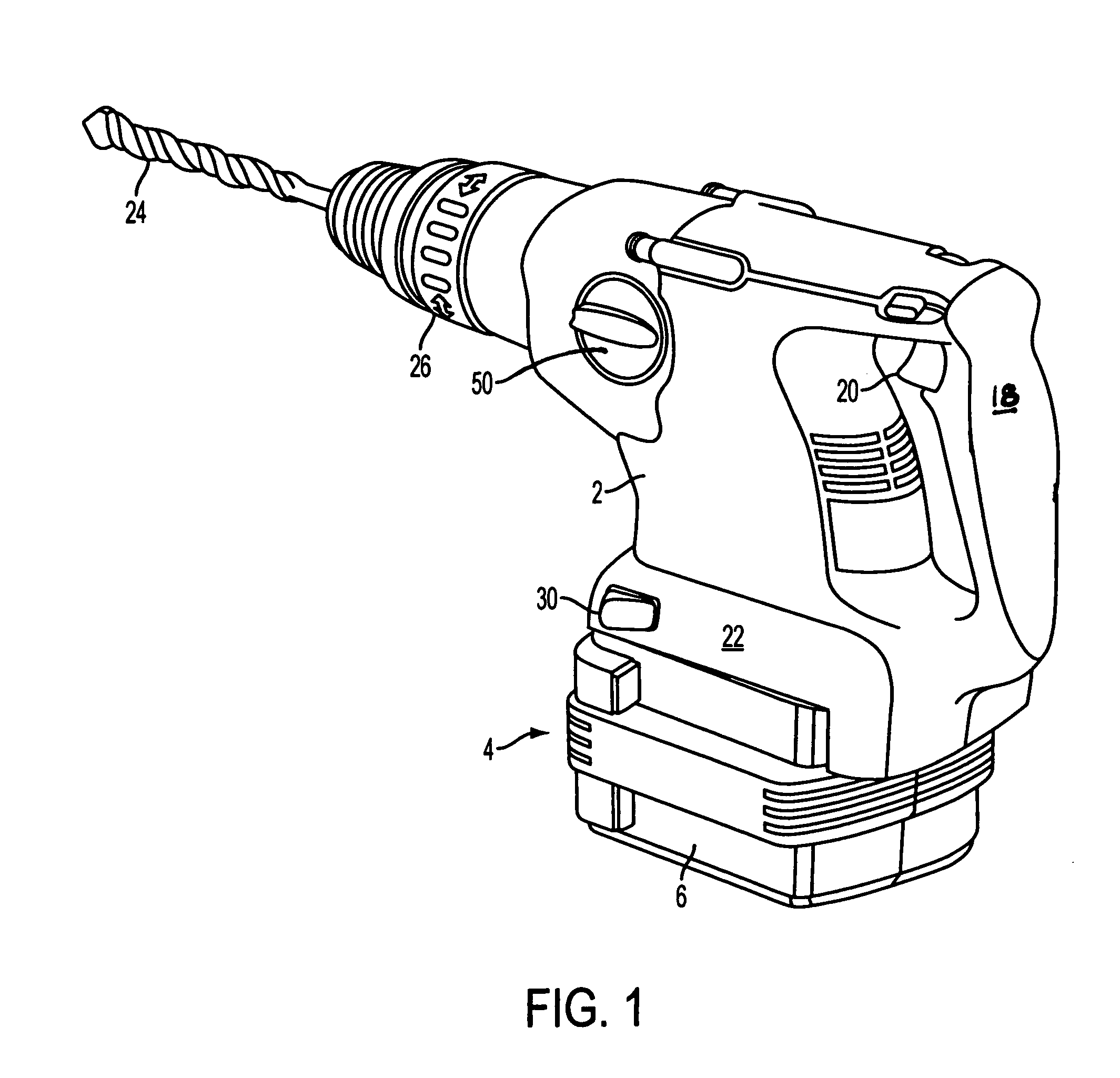

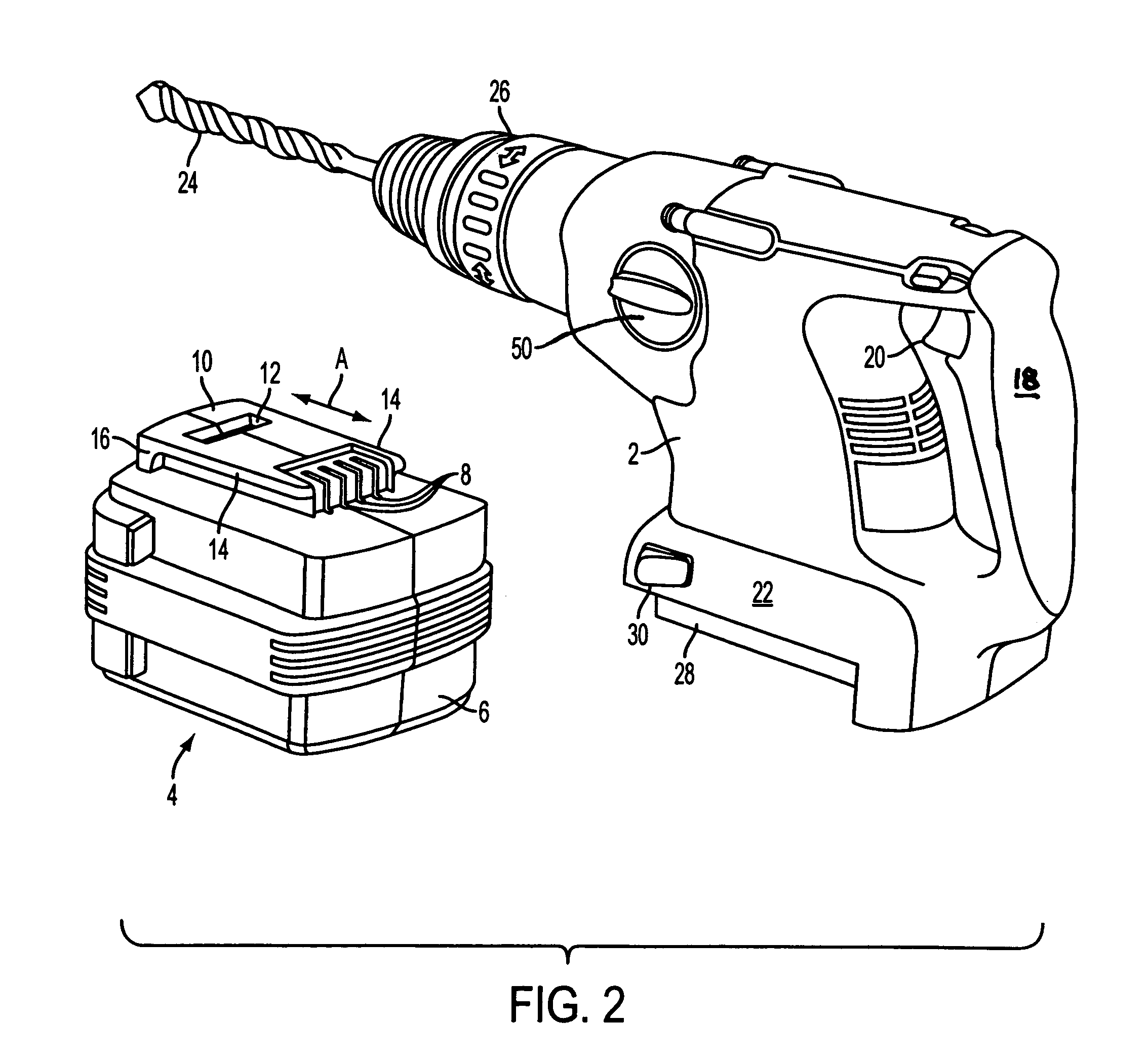

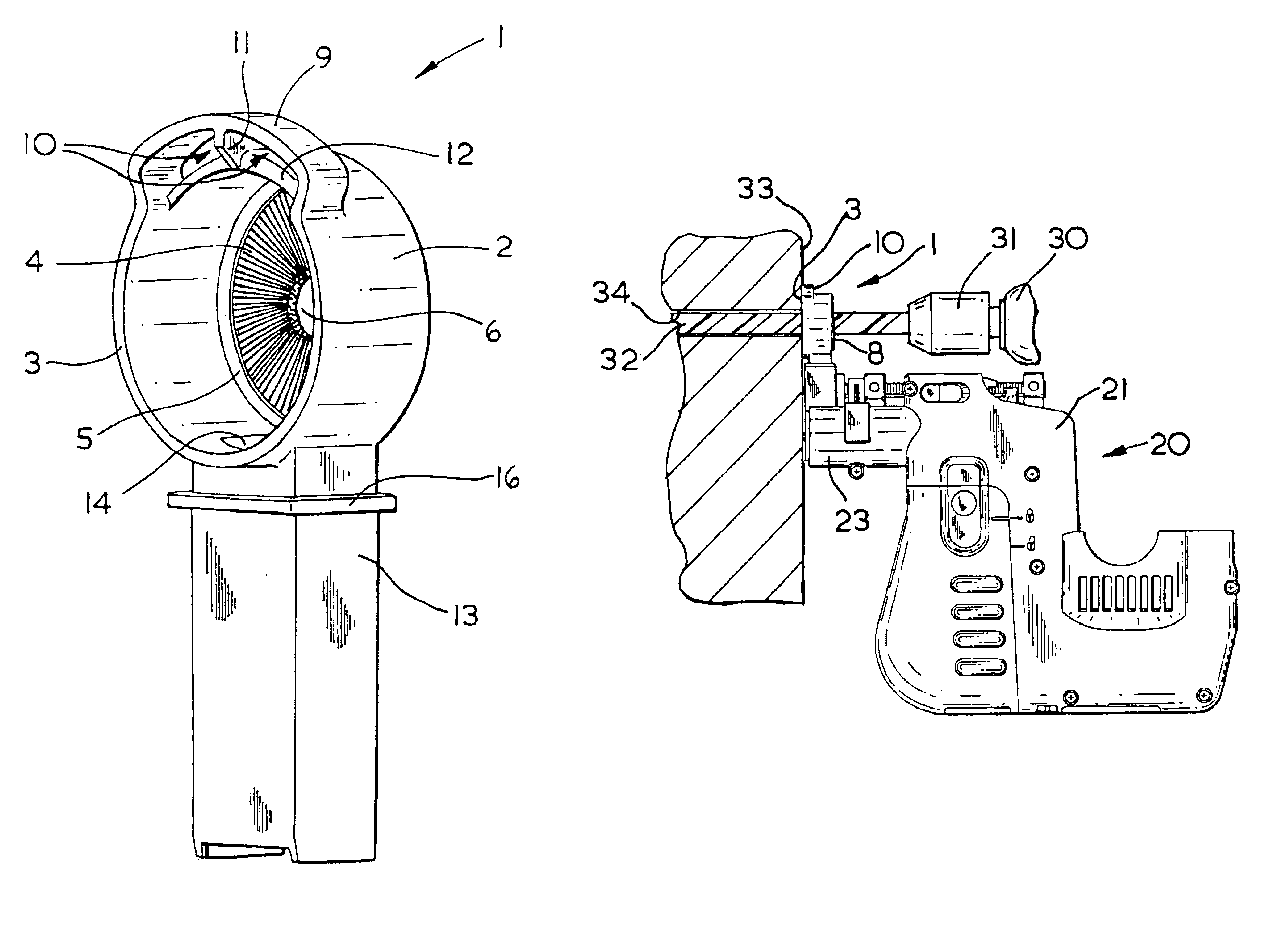

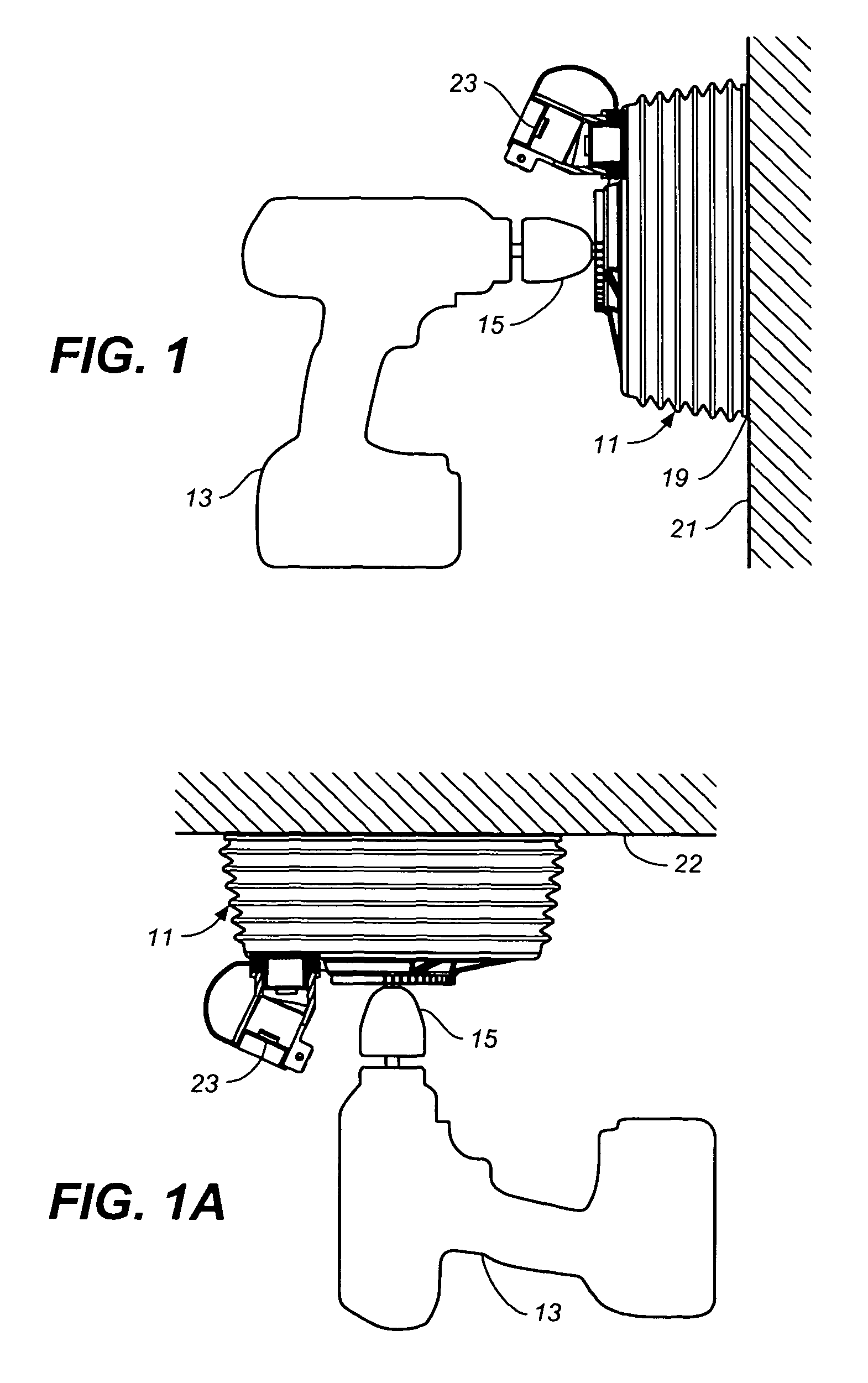

Cordless hand held power tool with powered accessory

Owner:BLACK & DECKER INC

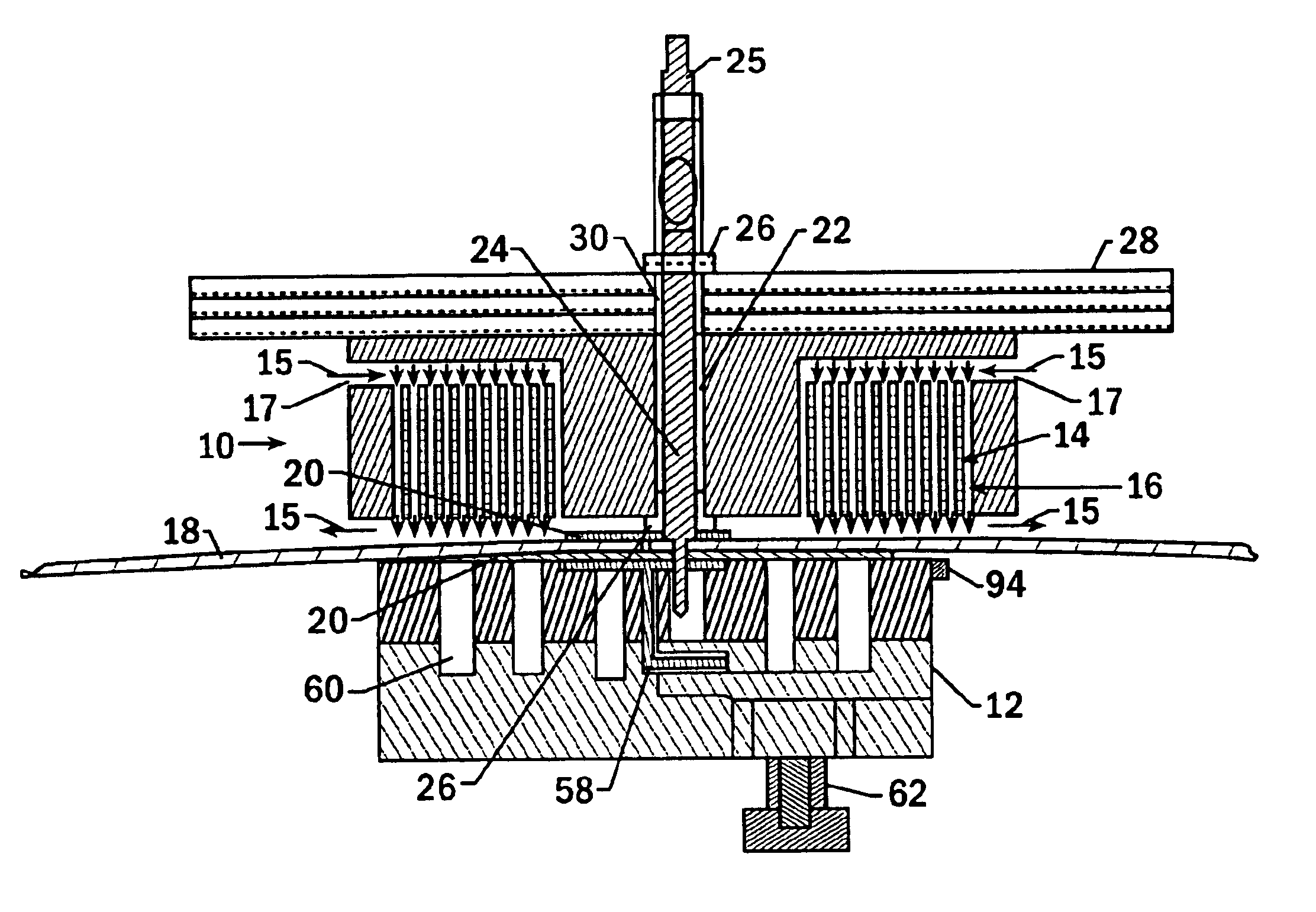

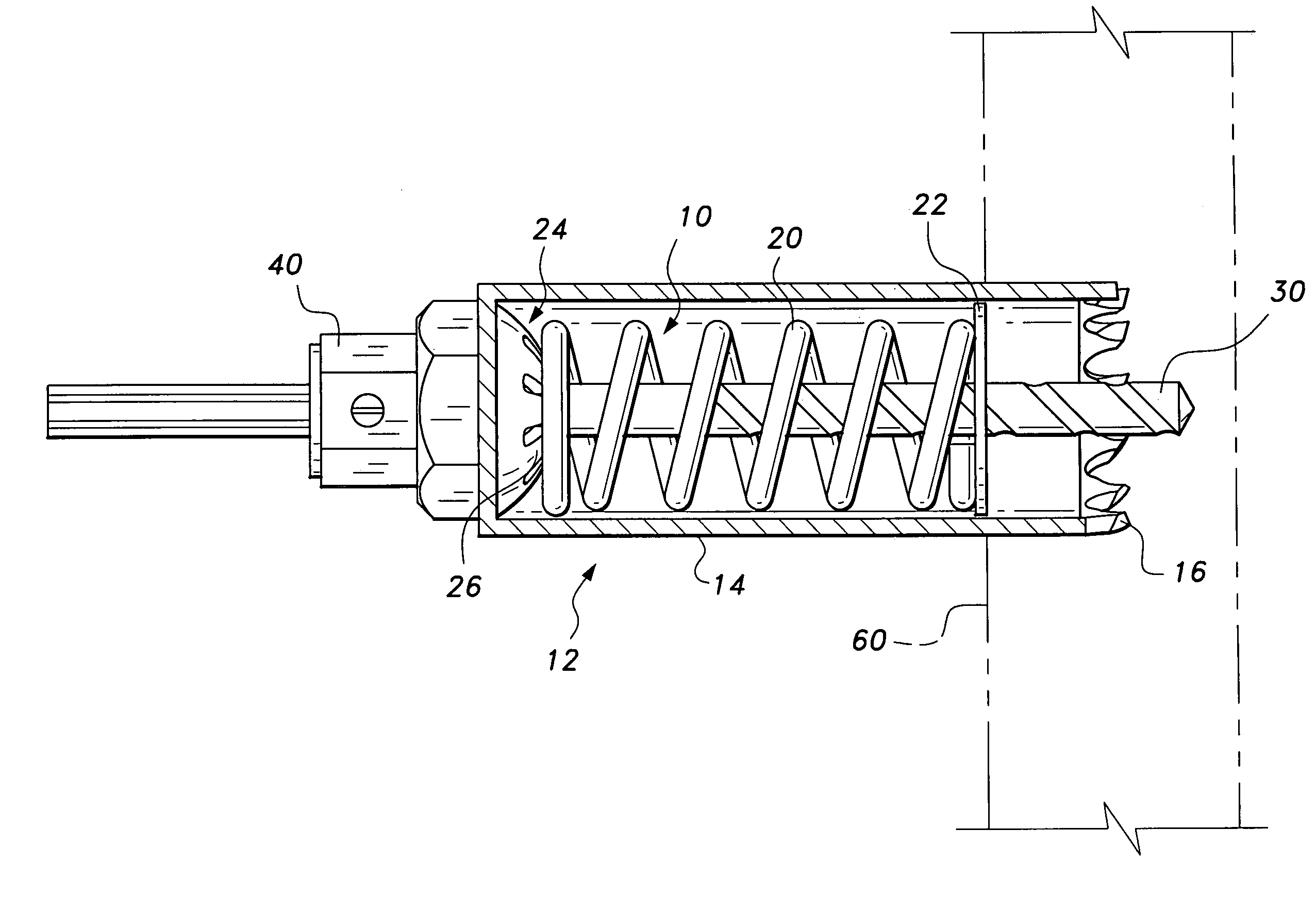

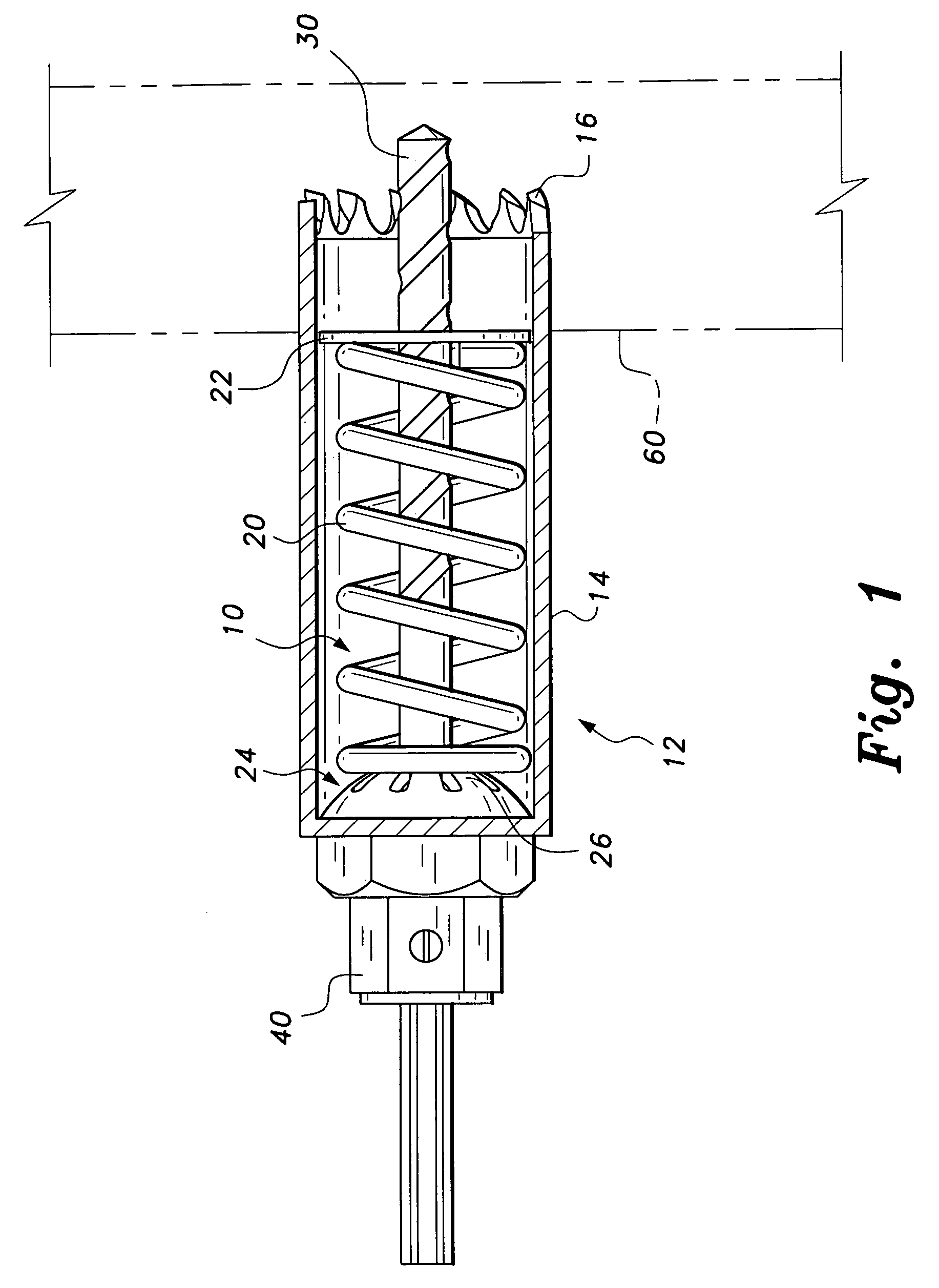

Machining mechanical parts with a hollow cylindrical tool

ActiveUS20060291970A1Simple processAvoid high frequency noiseThread cutting feeding devicesDrilling rodsWood shavingsMechanical components

The present invention relates to a device for machining mechanical parts by means of a hollow cylindrical tool presenting a distal end with a free edge that is shaped to perform machining when said tool is rotated about its axis. In accordance with the invention, the hollow cylindrical tool is fitted internally with a transverse member forming a shaving-breaker, and said hollow cylindrical tool is secured axially to a distal end of a hollow cylindrical spindle, said hollow cylindrical spindle being mounted to rotate about its own axis on a support plate, and being driven externally by rotary drive means mounted on said support plate, and said hollow cylindrical spindle having a proximal end facing and directly adjacent to a hollow cylindrical endpiece secured to said support plate and connected to a suction hose, such that the machining shavings can be evacuated internally by passing successively through the hollow cylindrical tool going round the transverse member forming a shaving-breaker, through the hollow cylindrical spindle, through the hollow cylindrical endpiece, and through the suction hose.

Owner:ROMER INC

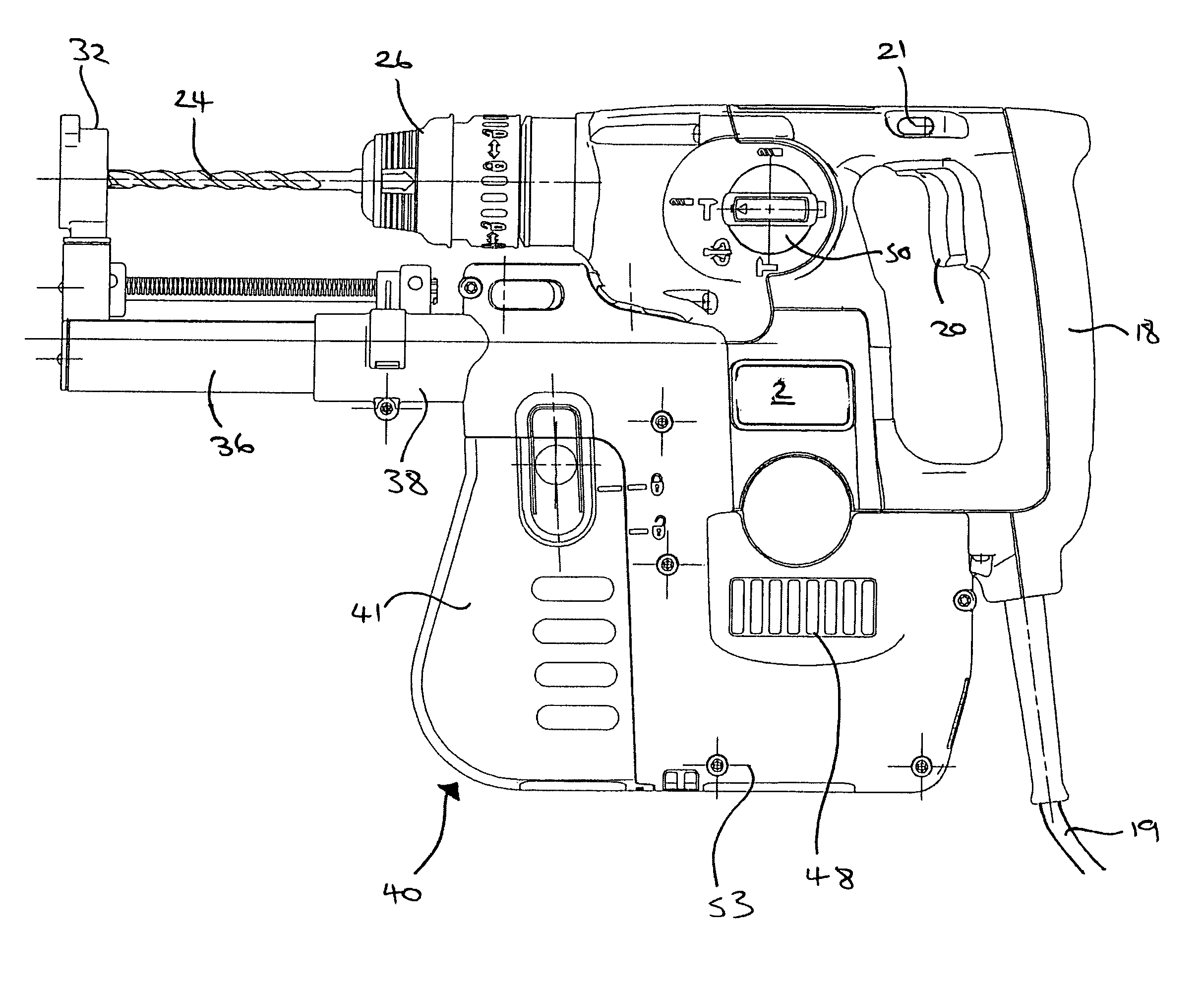

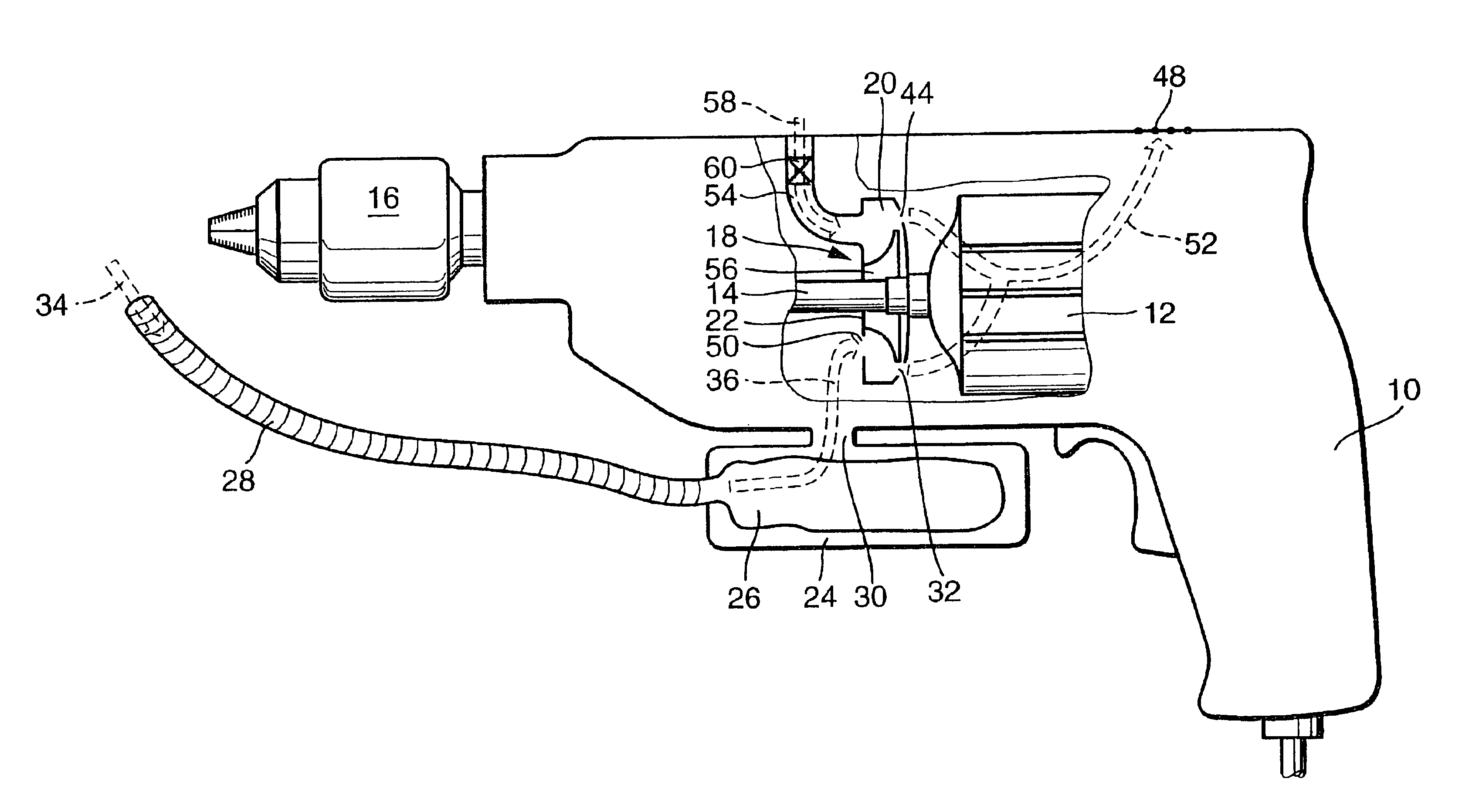

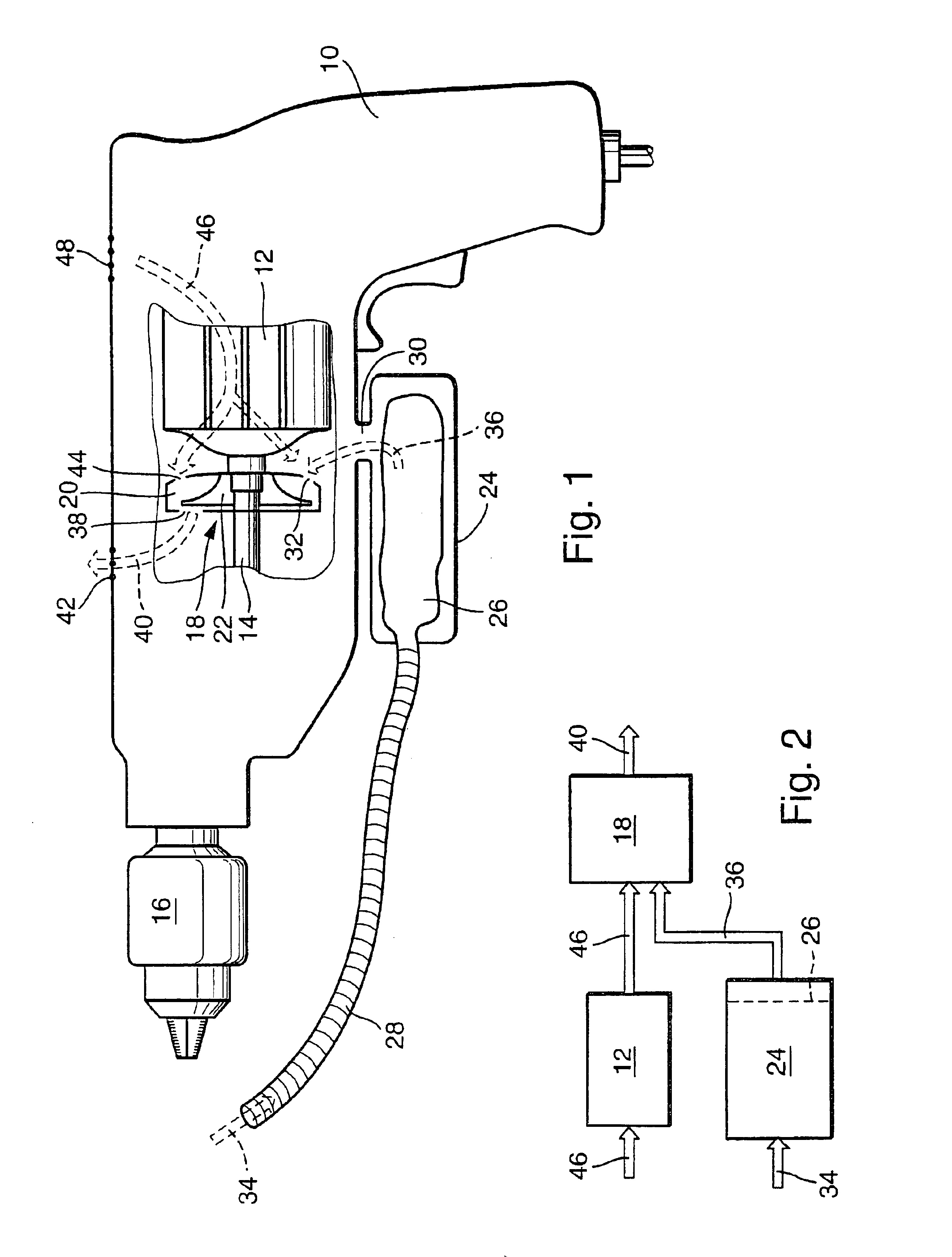

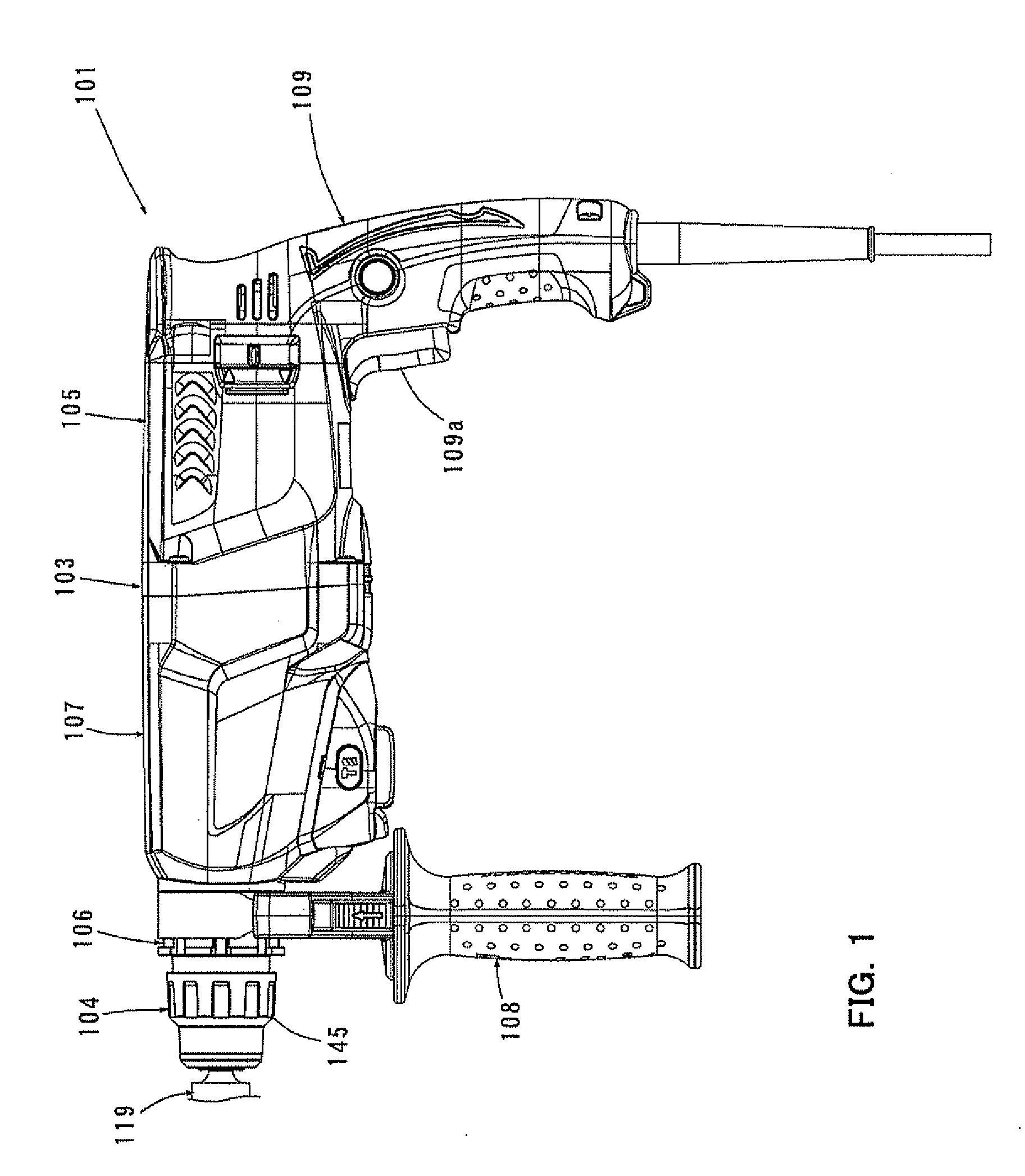

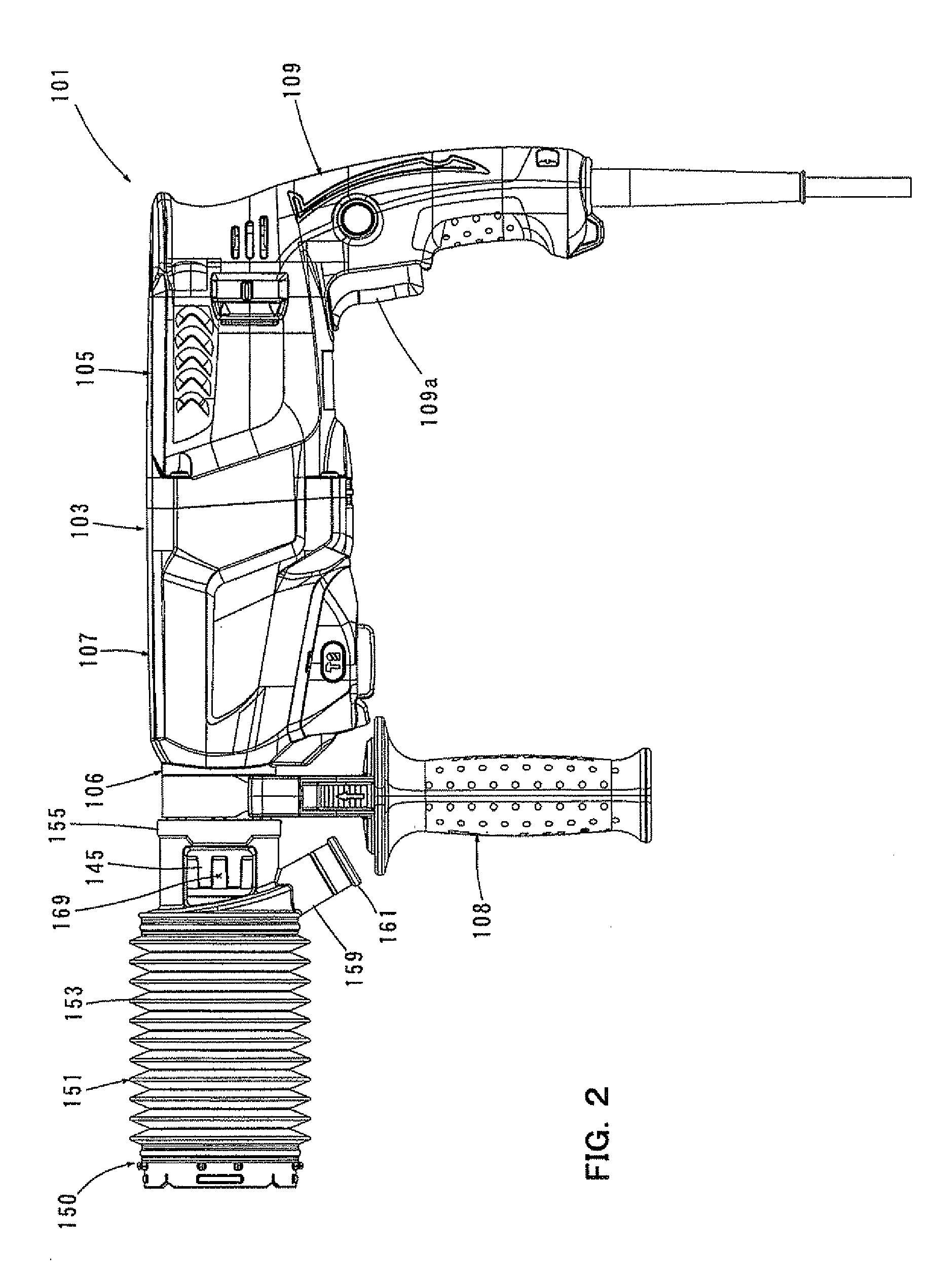

Hand held drilling and/or hammering tool with dust collection unit

InactiveUS7017680B2Efficient processEasy to installThread cutting feeding devicesDrilling rodsHand heldElectrical connection

Owner:BLACK & DECKER INC

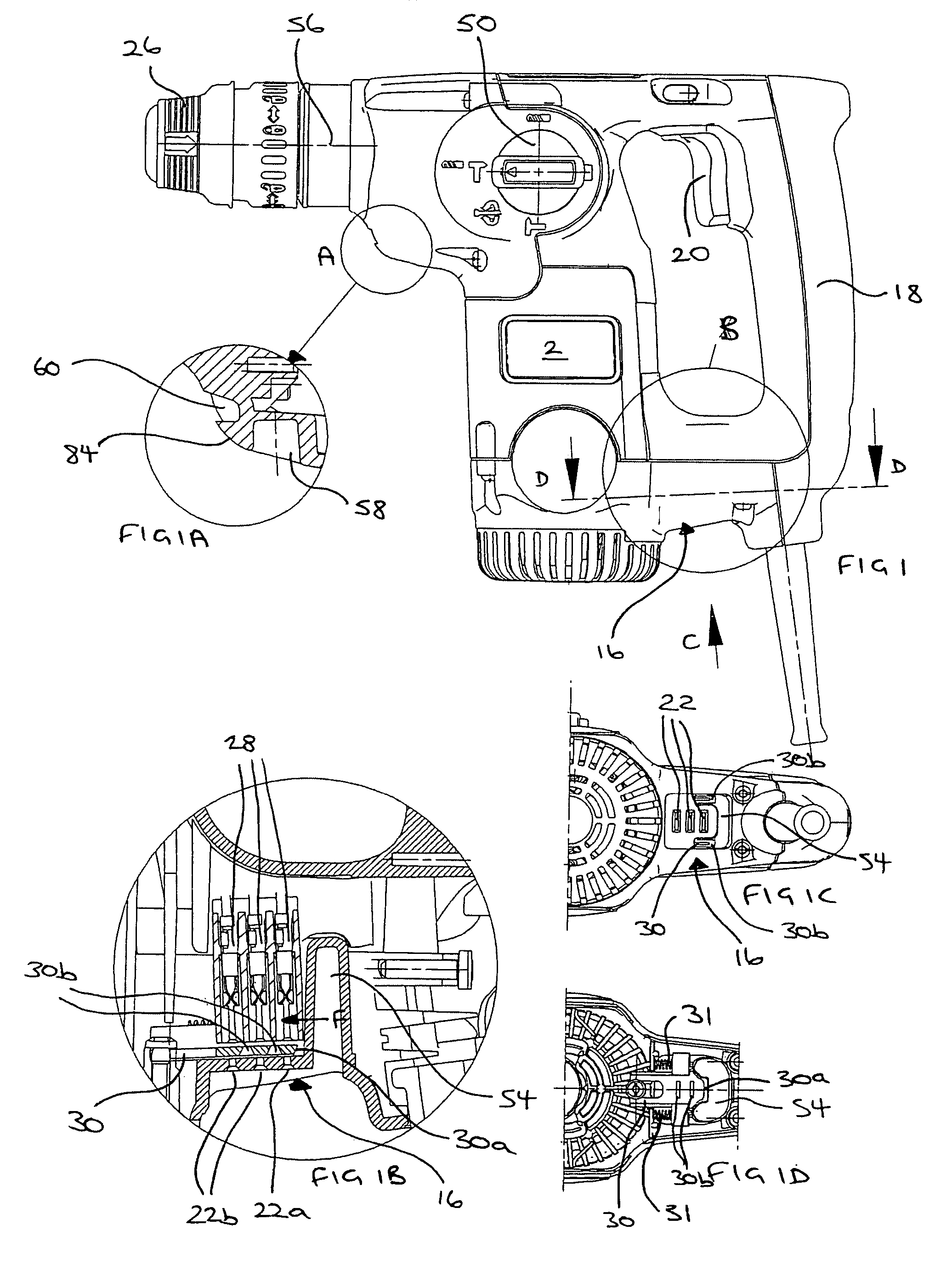

Hand-held power tool with a dust suction module

InactiveUS20050281627A1Minimal flow lossPrevent penetrationThread cutting feeding devicesDrilling rodsPower toolAirflow

Owner:HILTI AG

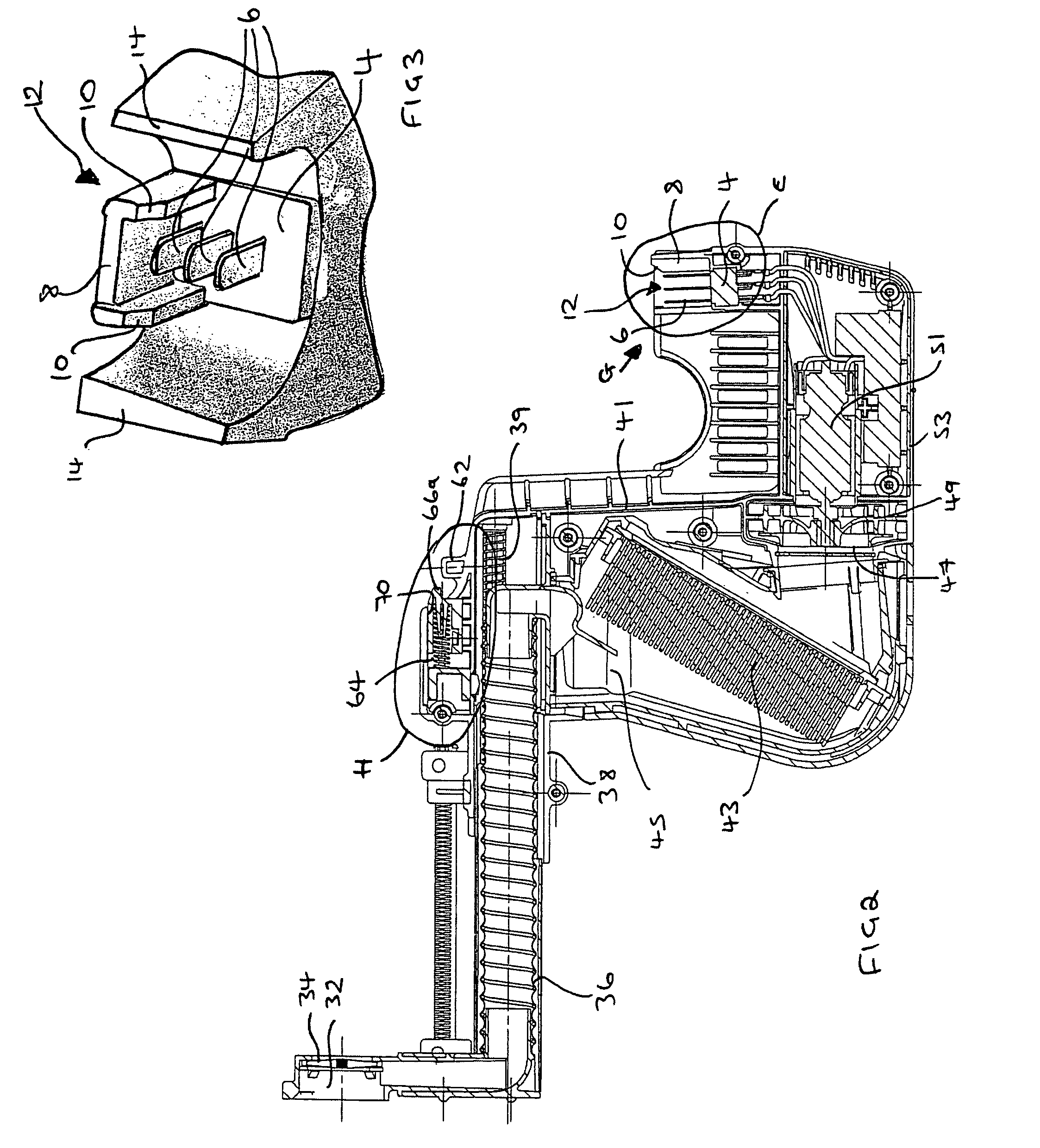

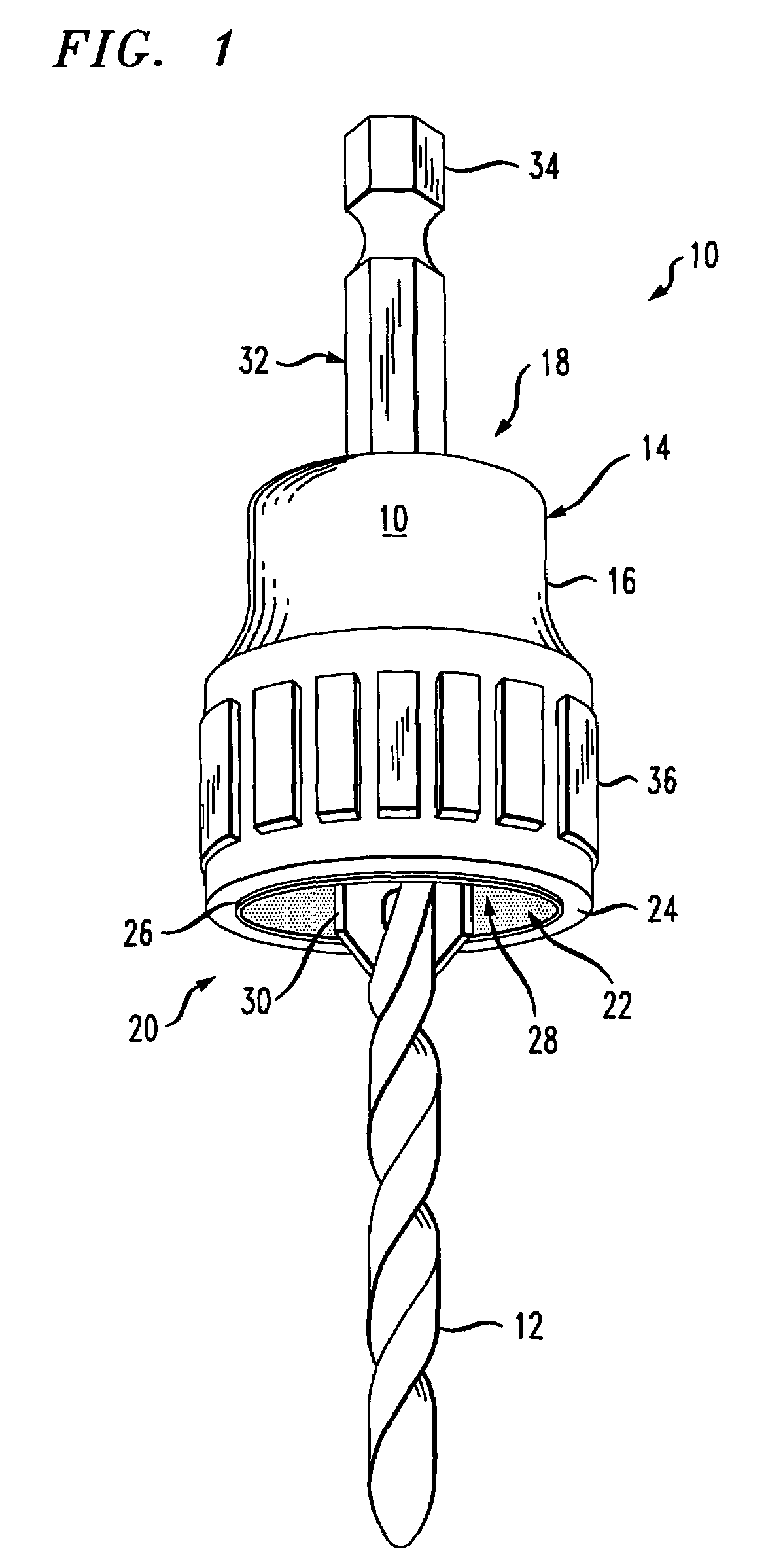

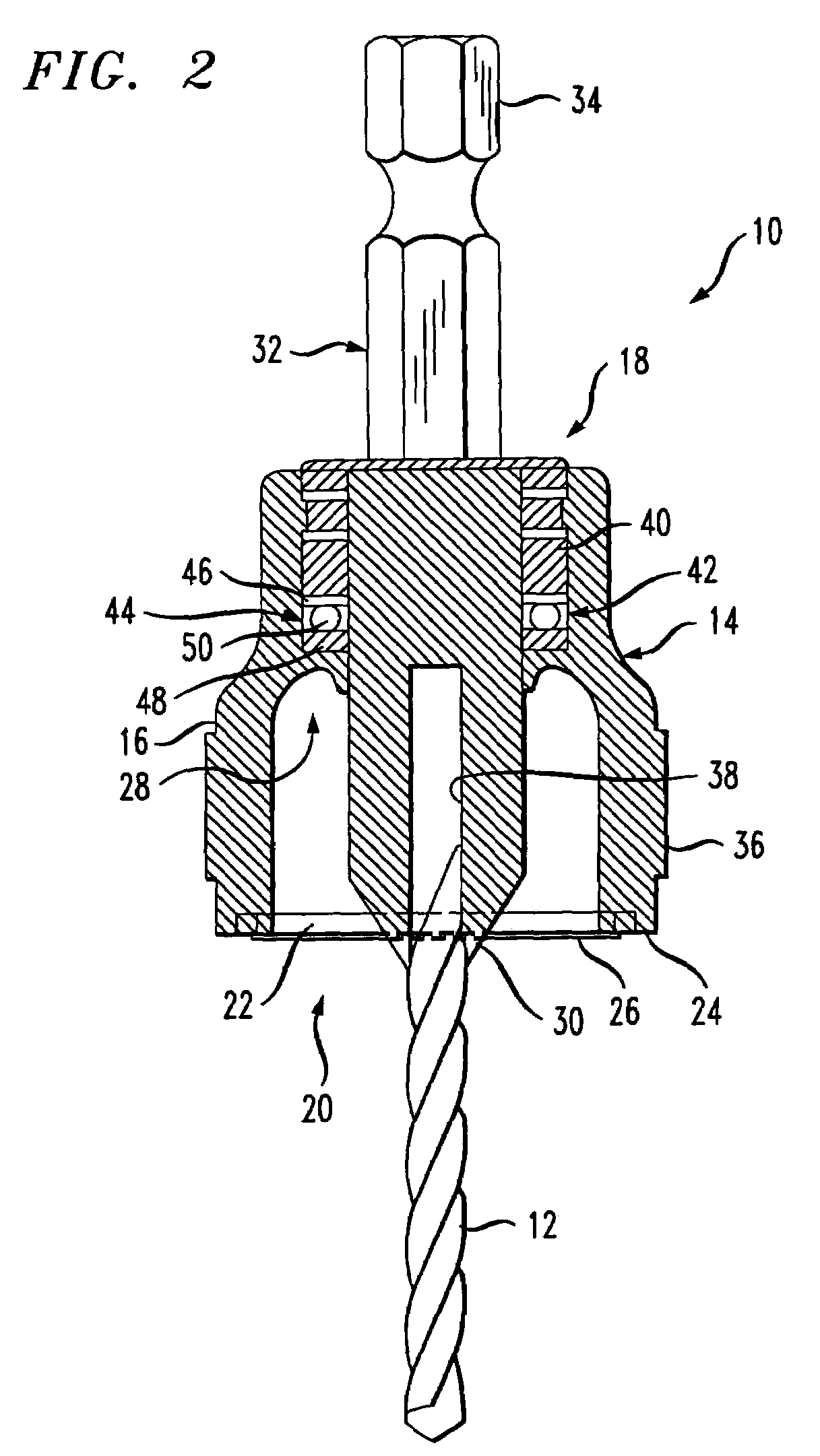

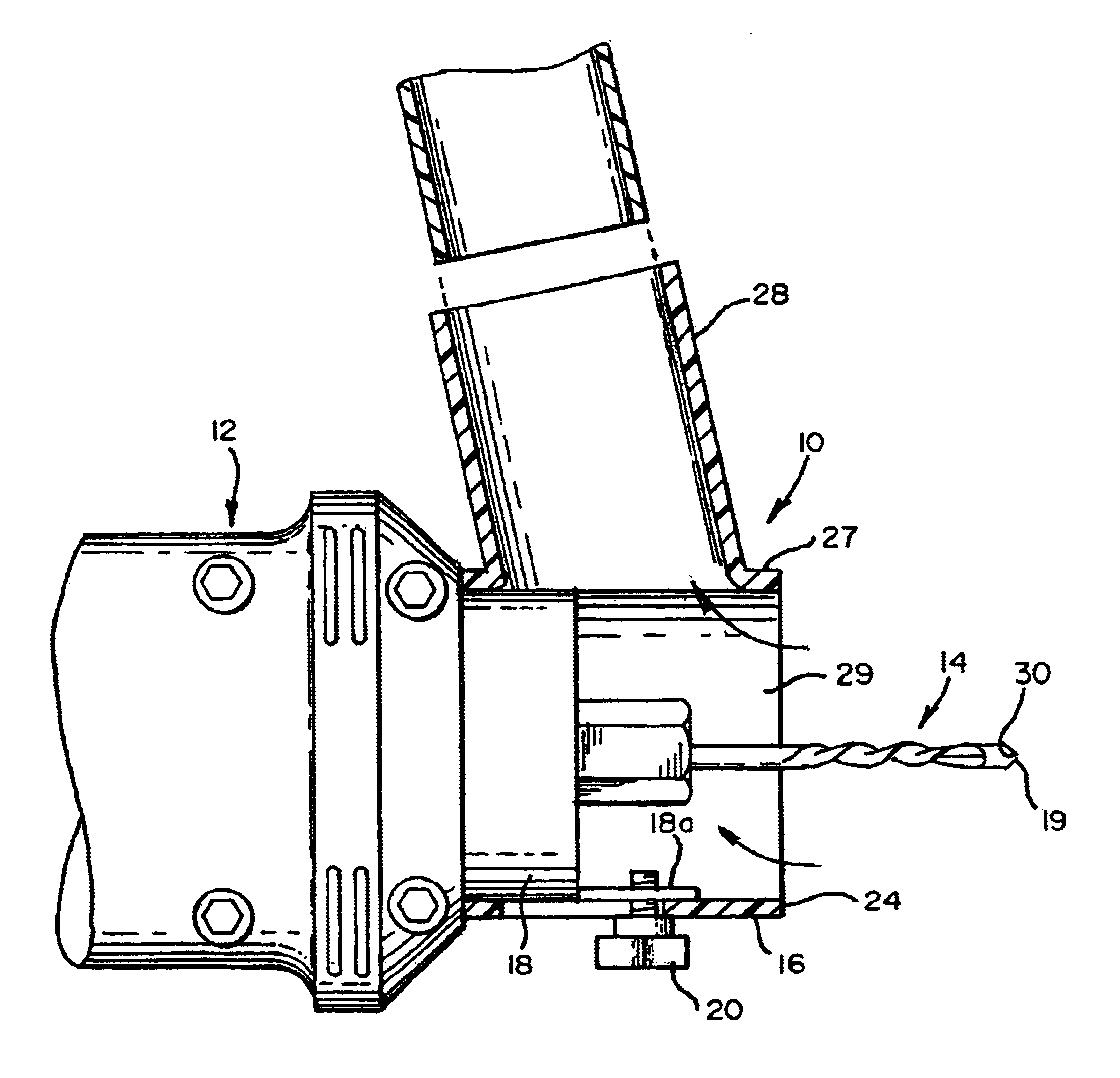

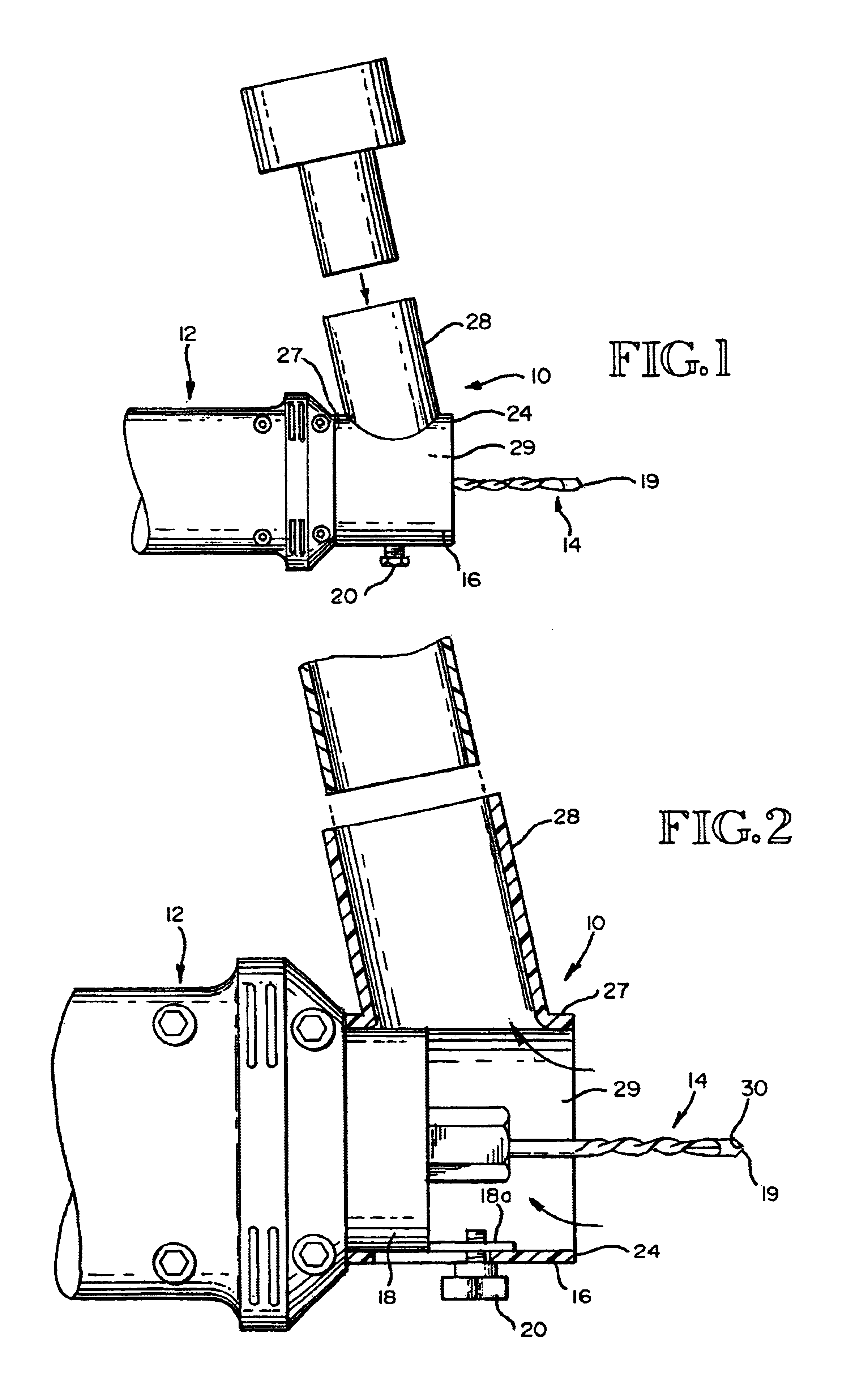

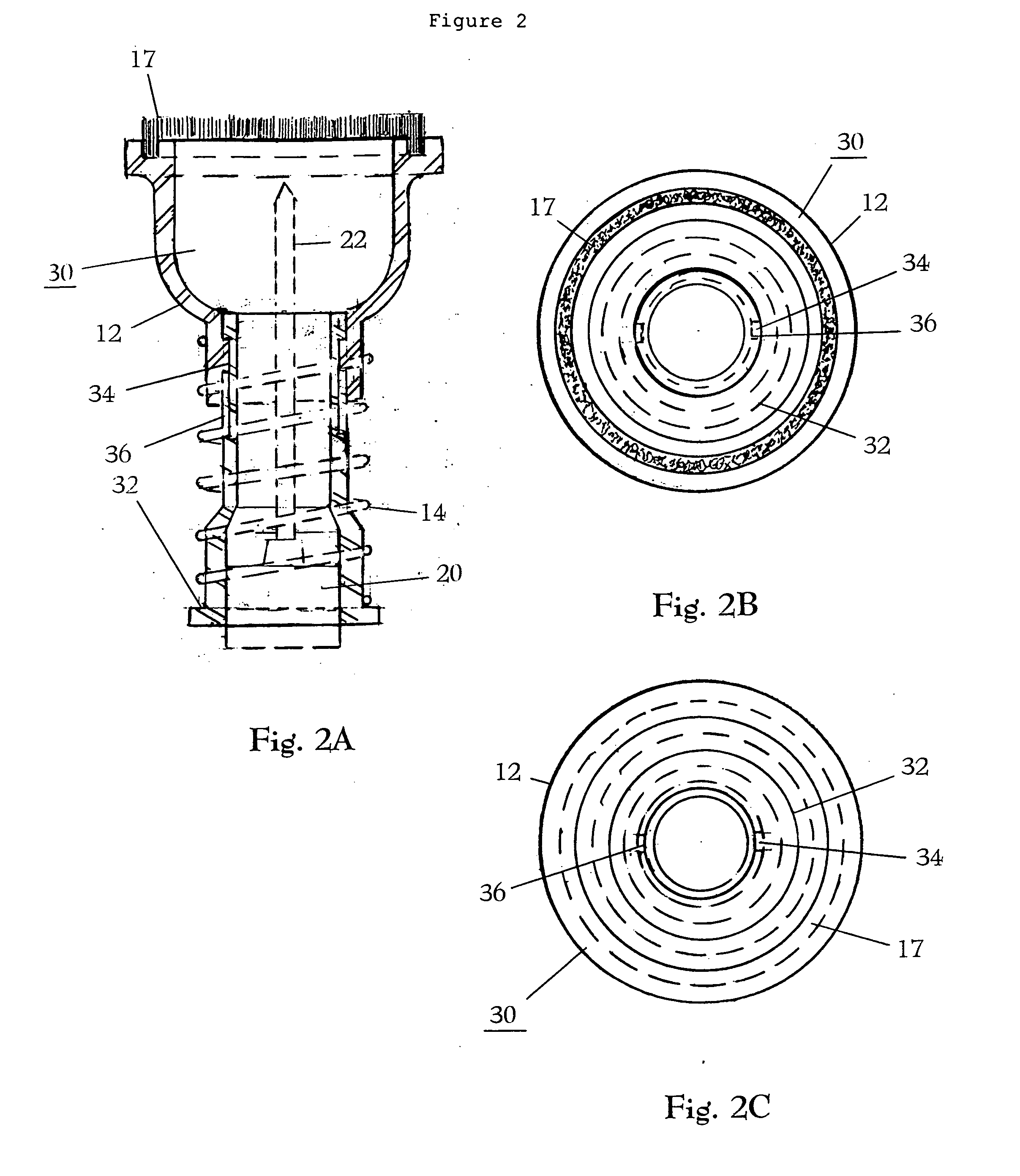

Depth limiting device and hole forming apparatus containing the same

ActiveUS7258513B2Facilitates and promotesAvoid damageThread cutting toolsDrilling/boring measurement devicesEngineeringMechanical engineering

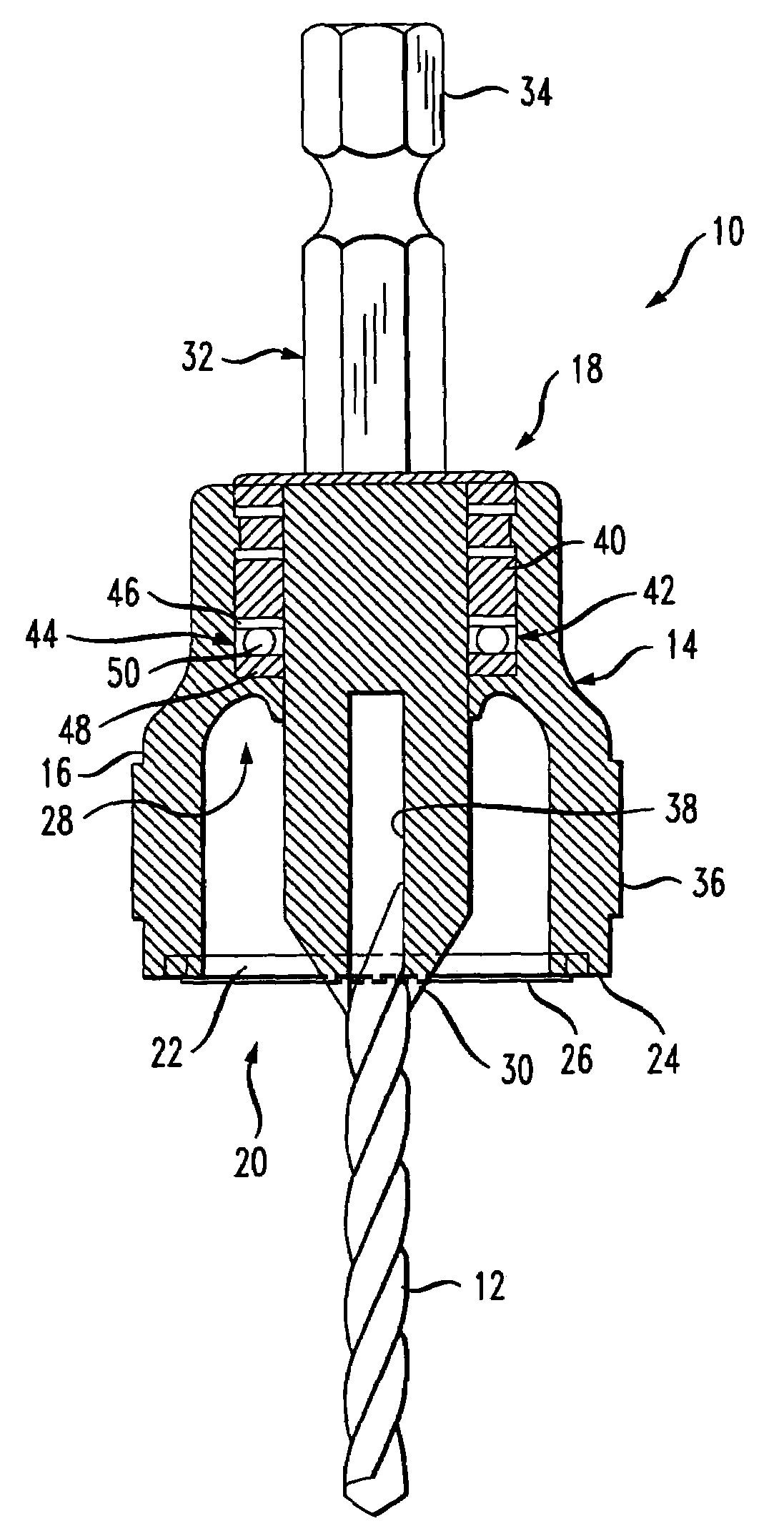

A depth limiting device includes a stop collar having a an open end portion and an workpiece engaging portion extending along the open end portion thereof for contacting a workpiece; a spindle extending axially through the shell, the spindle including a first end extending from the exterior of the stop collar for attachment to a hole forming apparatus, and an second end interior to the stop collar for attachment to a hole forming bit, wherein the attached hole forming bit projects through the open end portion of the stop collar at a predetermined length corresponding to the desired depth of the hole in the workpiece; and a bearing assembly operatively associated with the stop collar and the spindle for isolating the rotation of the spindle from the stop collar whereby the stop collar ceases to rotate when contacting the workpiece without generating sufficient frictional contact to mar or otherwise damage the workpiece.

Owner:FAR NORTH

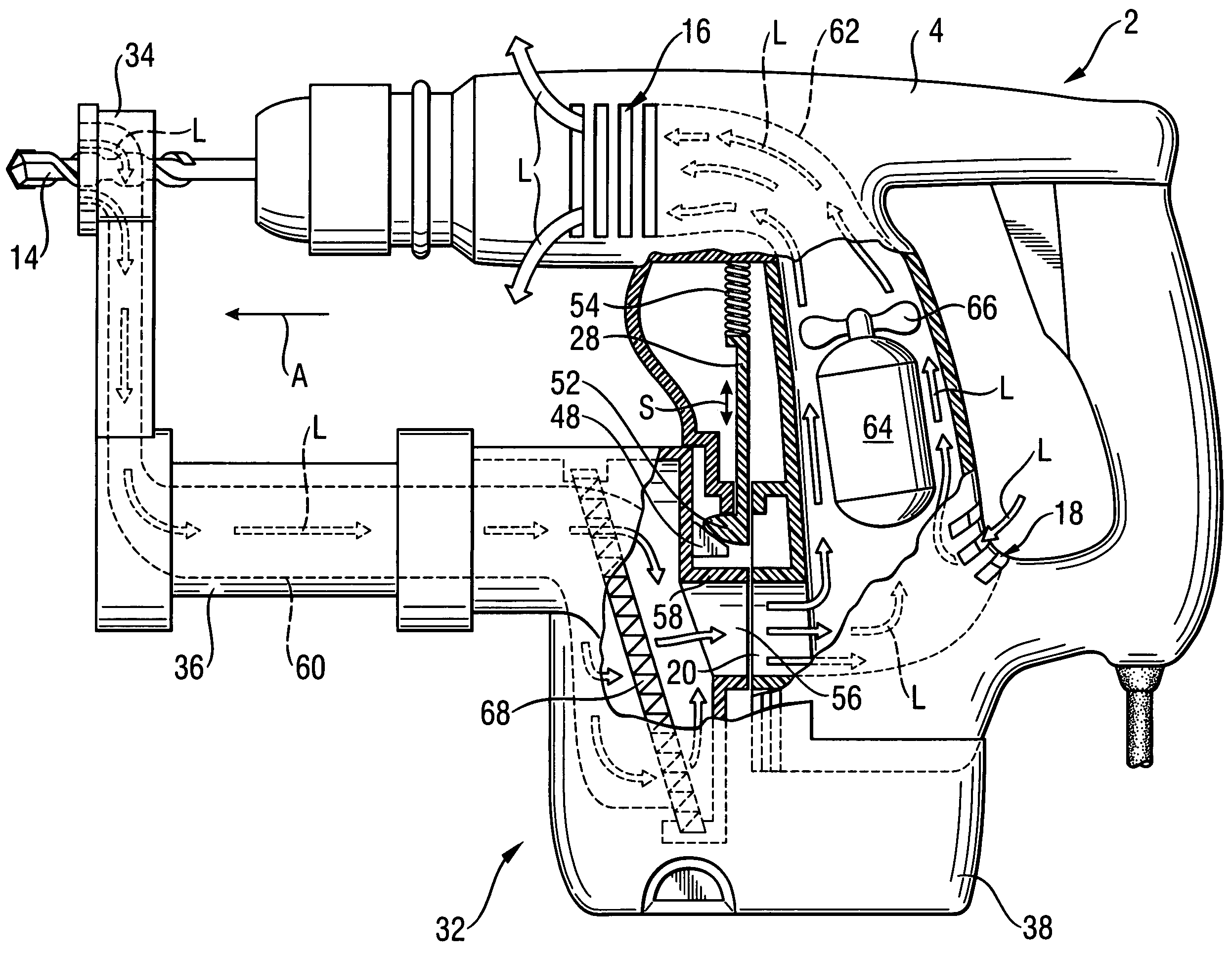

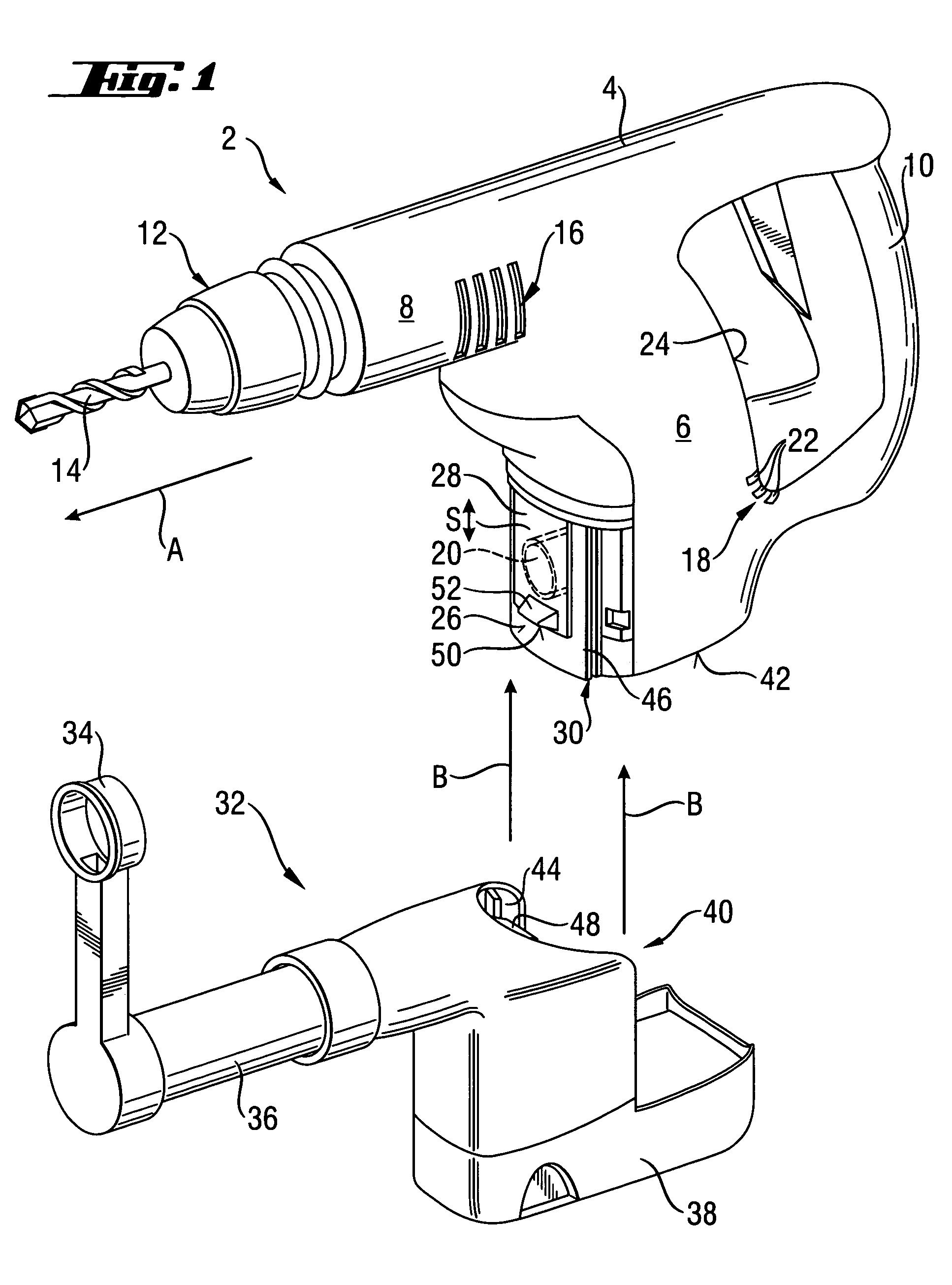

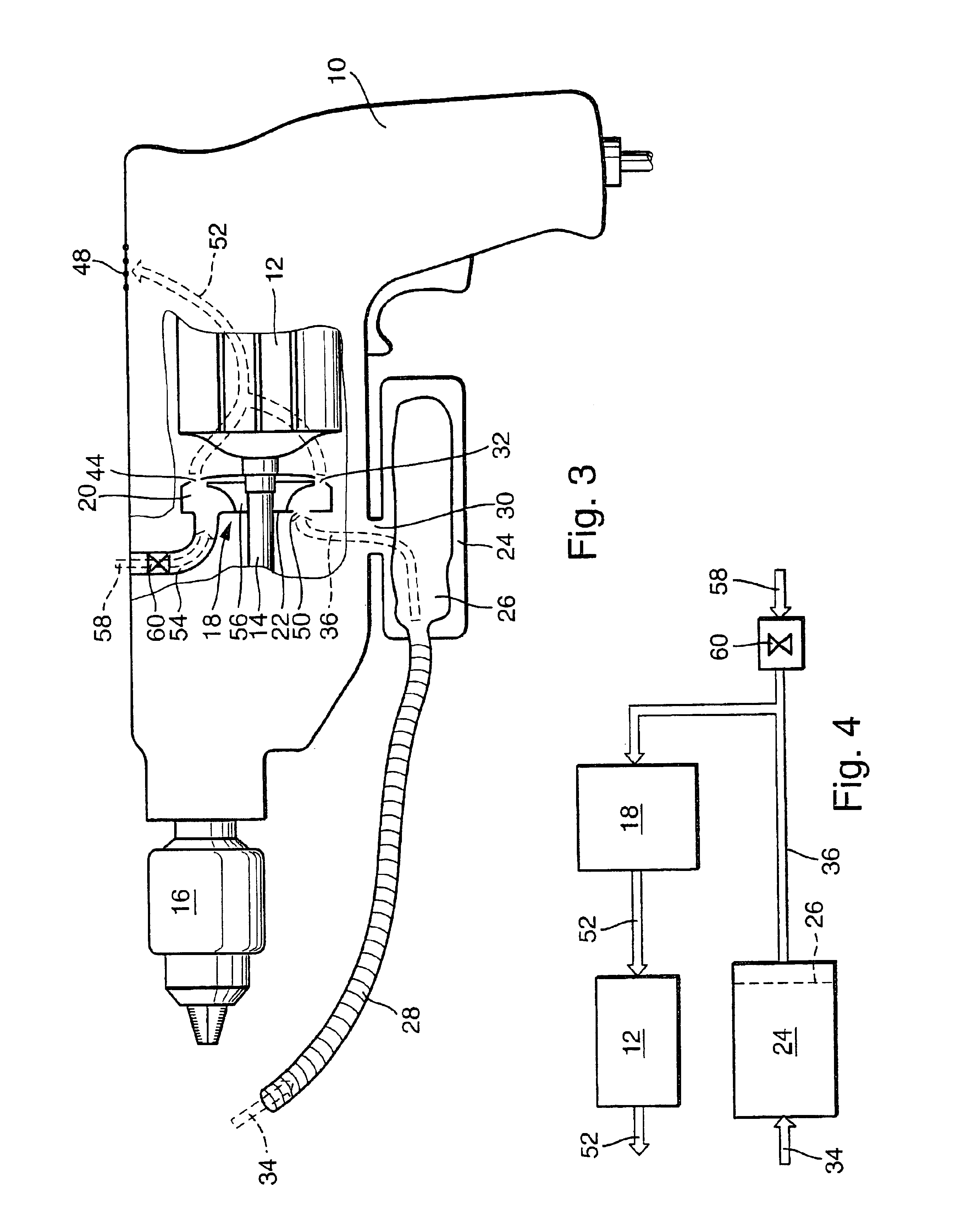

Hand-held power tool with a dust suction module

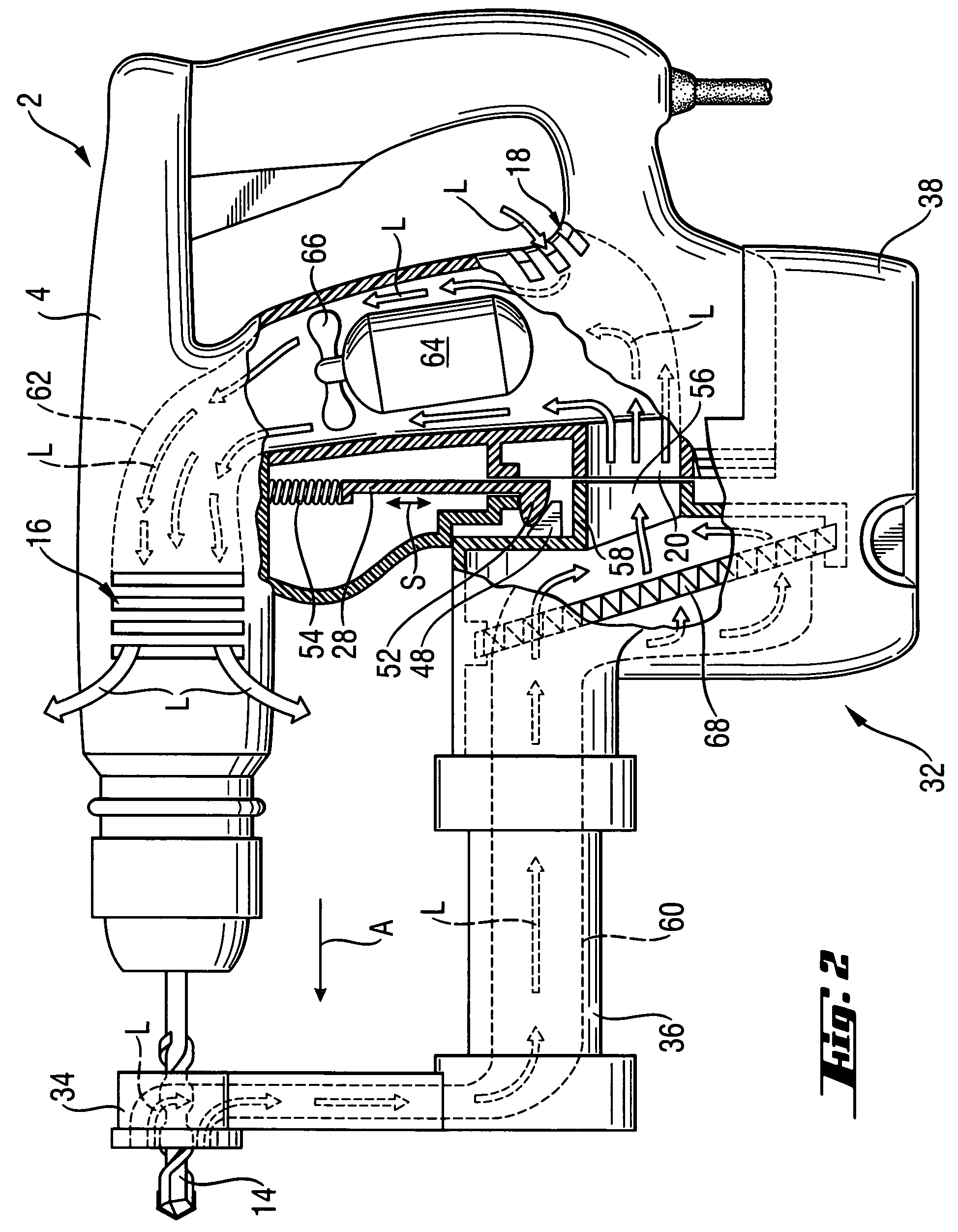

InactiveUS7354226B2Cost-effectiveAccurate guidanceThread cutting feeding devicesDrilling rodsSeparated stateHand held

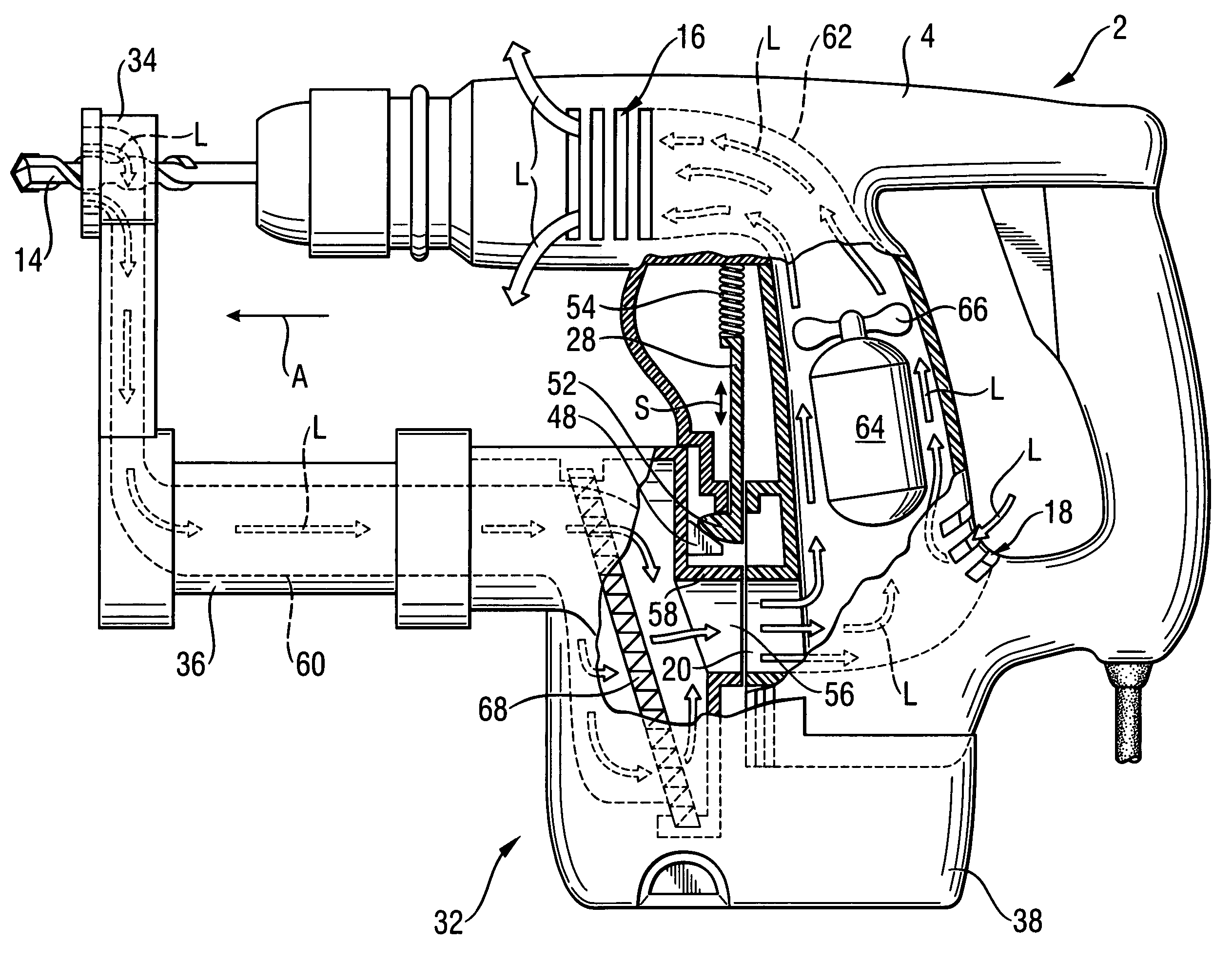

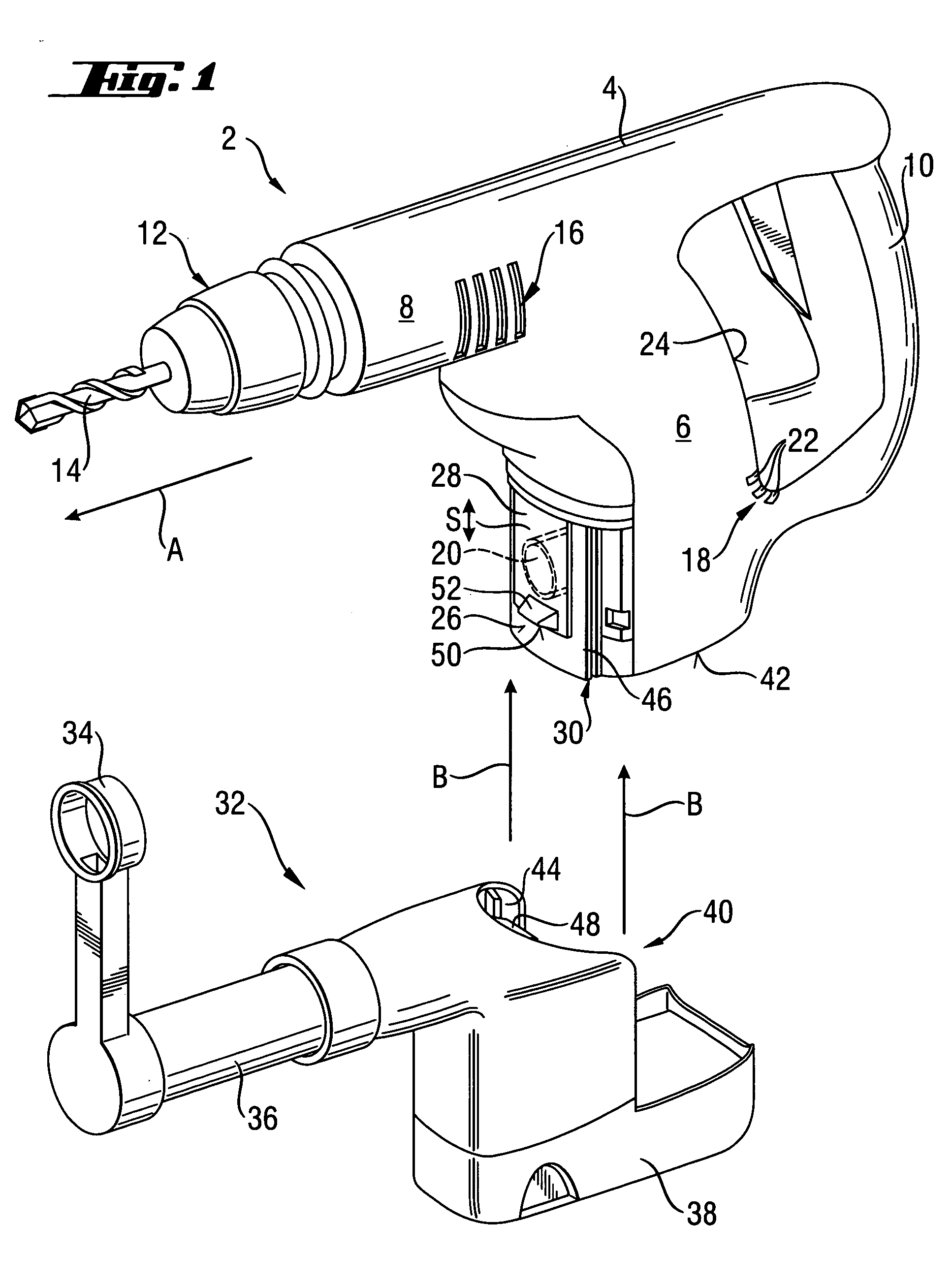

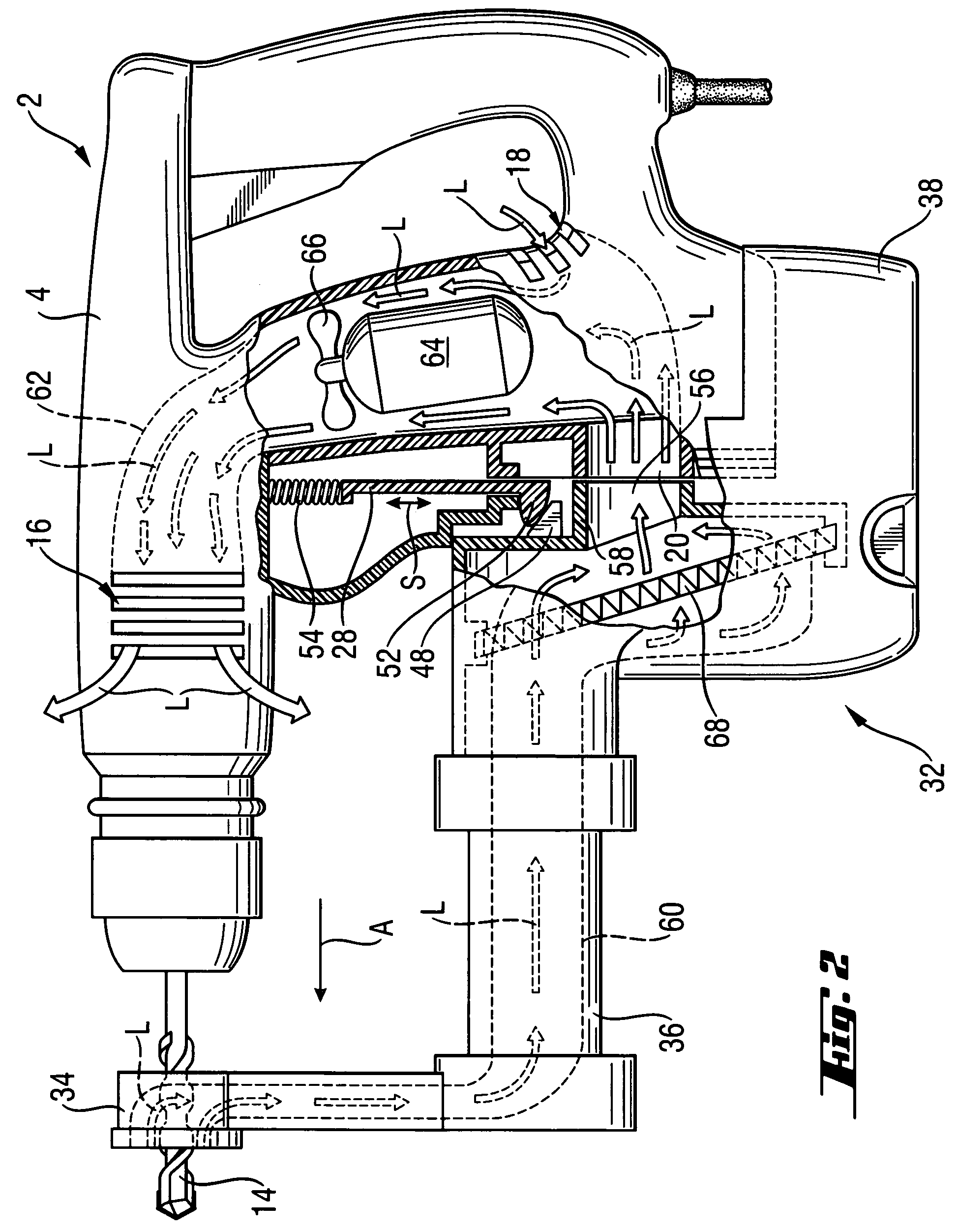

A hand-held power tool (2) connectable with a dust suction module (32) includes a motor (64) and an air flow generator (66) which for cooling the motor (64) is located, together with the motor (64), in air flow path (62) between an air inlet and an air outlet (16) both formed in the tool housing, (4, 6), with an air inlet having a side opening (18) and a connection opening (20) connectable with the suction path (60) of the dust suction module (32) and the dust suction module (32) having a suction conduit (58) for connecting the suction path (60) with the air flow path (62) and adjoining the connection opening (20) in a connected condition of the dust suction module (32) with the power tool, and with the power tool (2) further having a closing member provided on the connection opening (20), operable by the dust suction module (32), and having, in an attached position of the dust section module (32), an open position, and having a closed position in the detached condition of the dust suction module (32).

Owner:HILTI AG

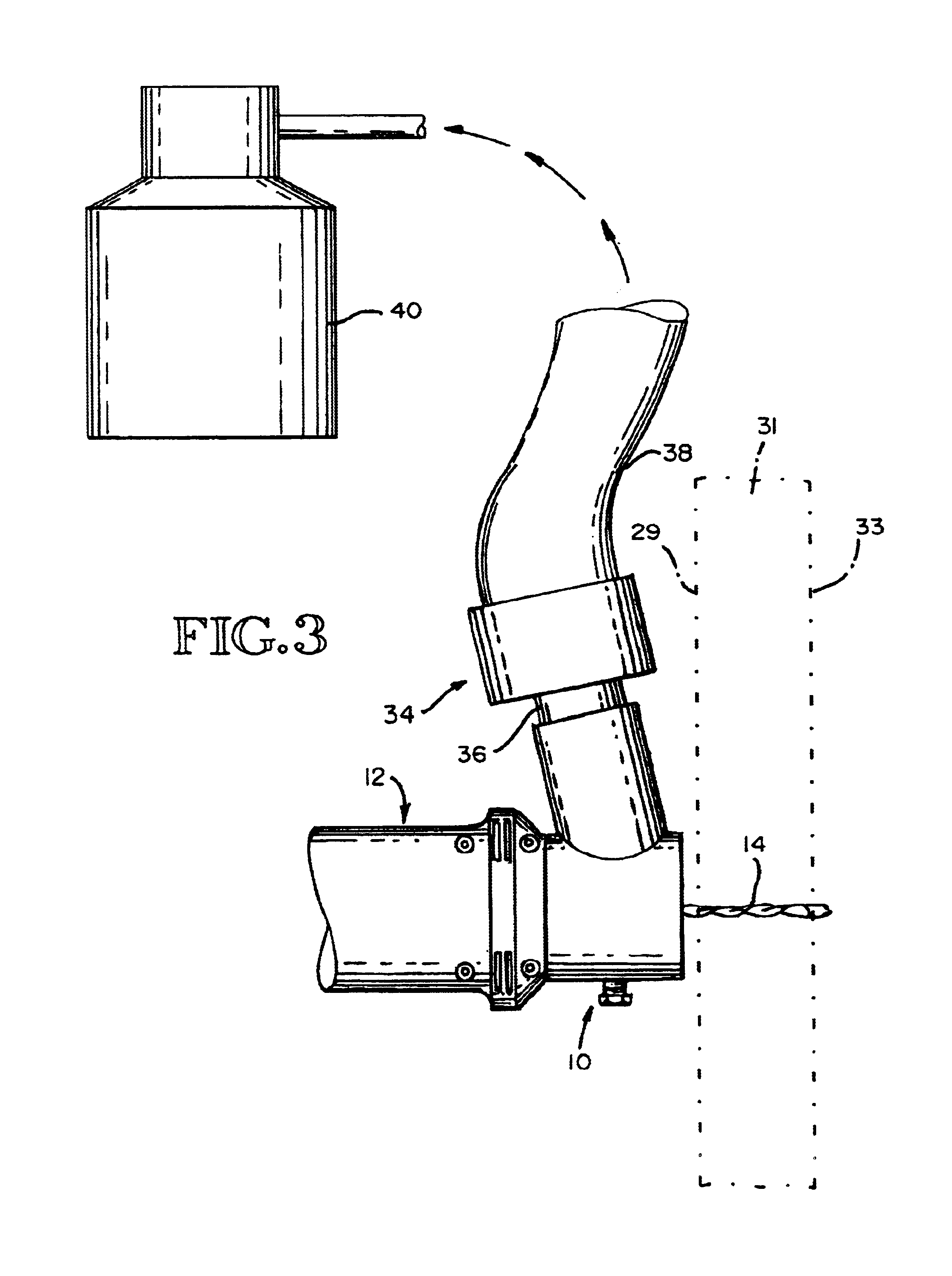

Dust collector attachment for a spiral power tool

The dust attachment which is used with a spiral saw power tool includes a first attachment portion which at a rear end has a substantially dust-tight fit with a mounting head portion of the tool. The other (forward) end extends beyond a forward edge of the mounting head portion, but such that the spiral saw bit extends beyond the forward edge of the attachment portion by a distance which is slightly greater than that of the thickness of the workpiece. An attaching member such as a screw secures the dust attachment portion to the tool. An dust exit tube extends from a side surface of the attachment portion and communicates with the interior of the attachment portion. The dust exit tube extends at an angle away from the attachment portion toward the rear end thereof.

Owner:WEISS STEPHEN F

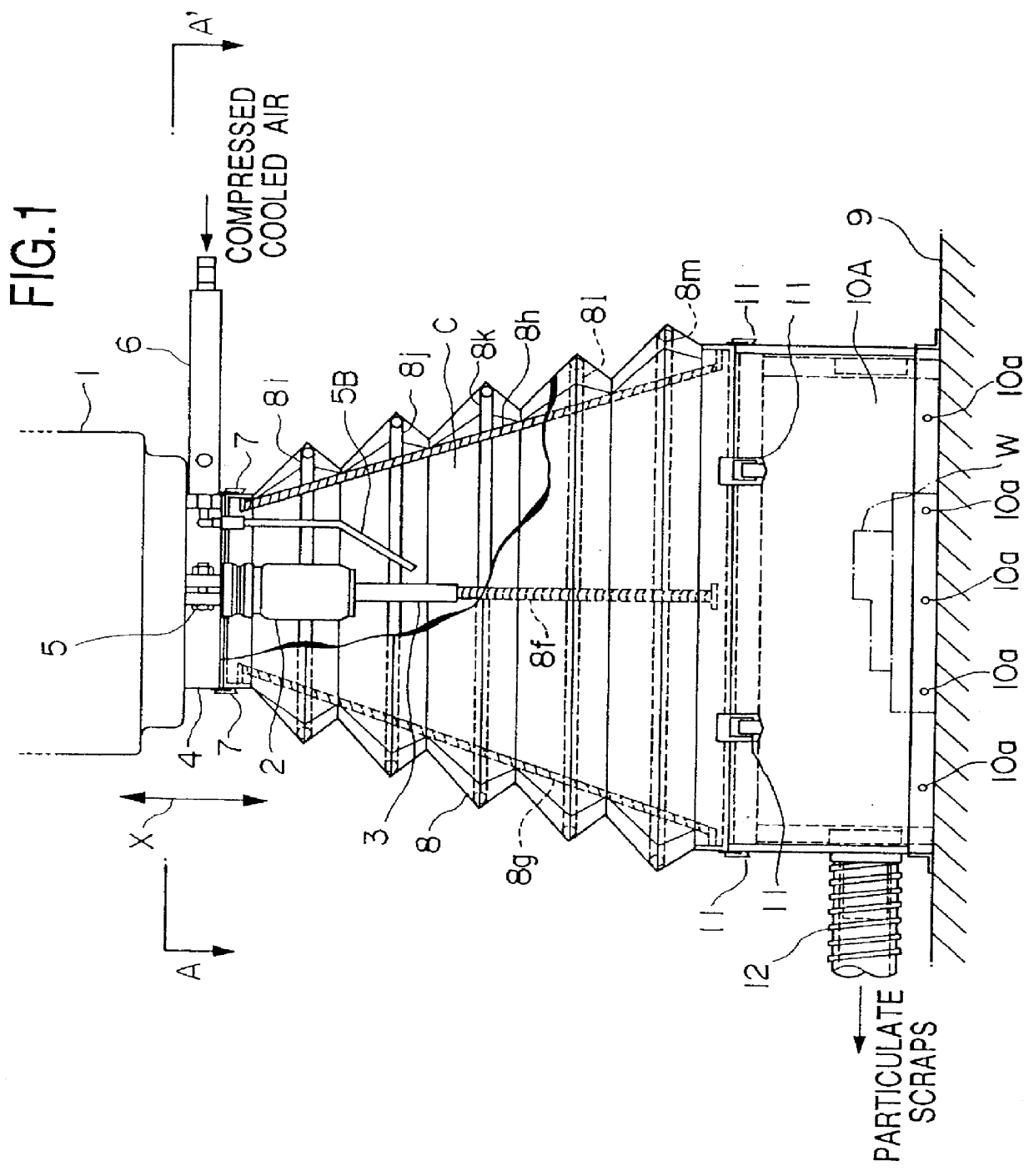

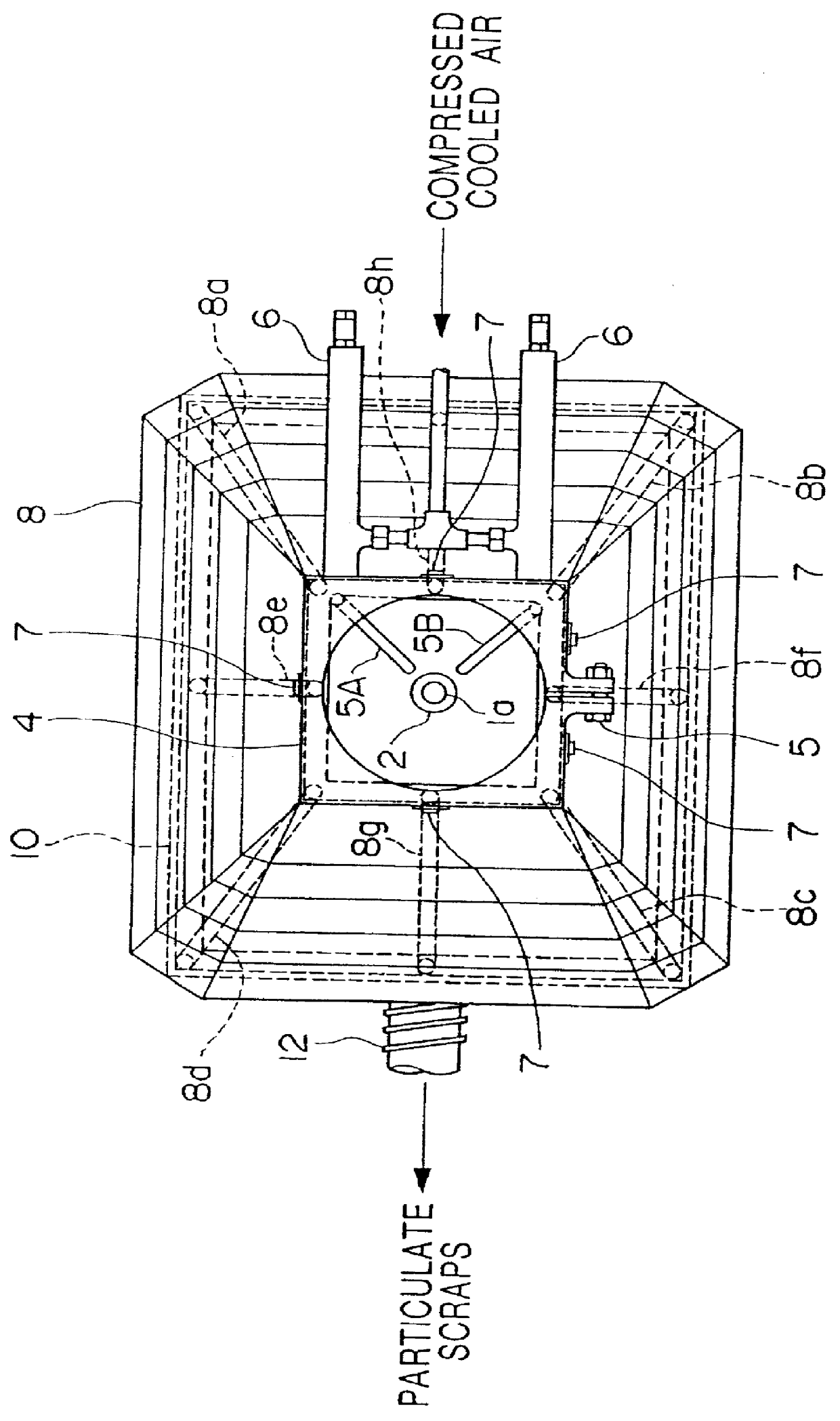

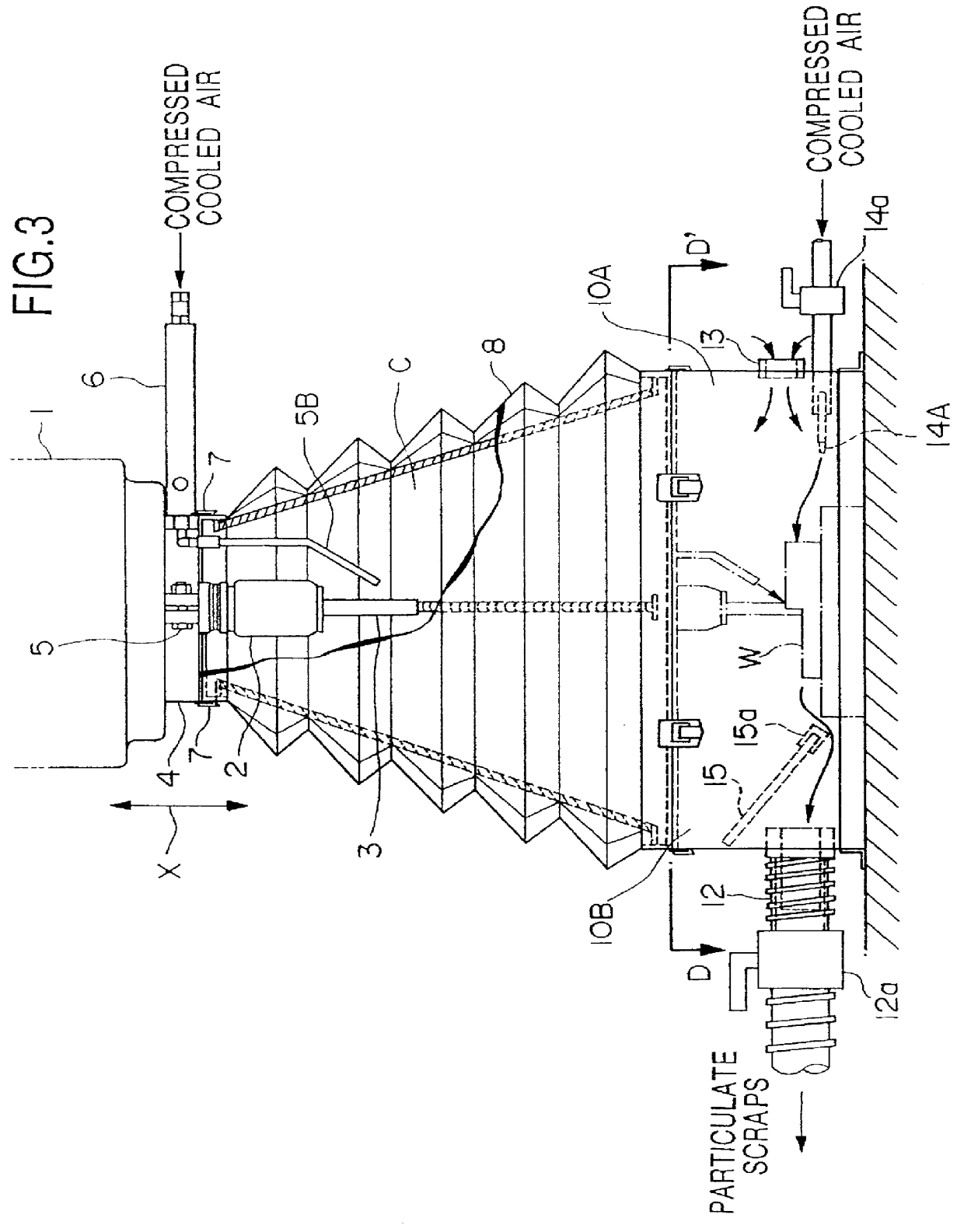

Machine tool

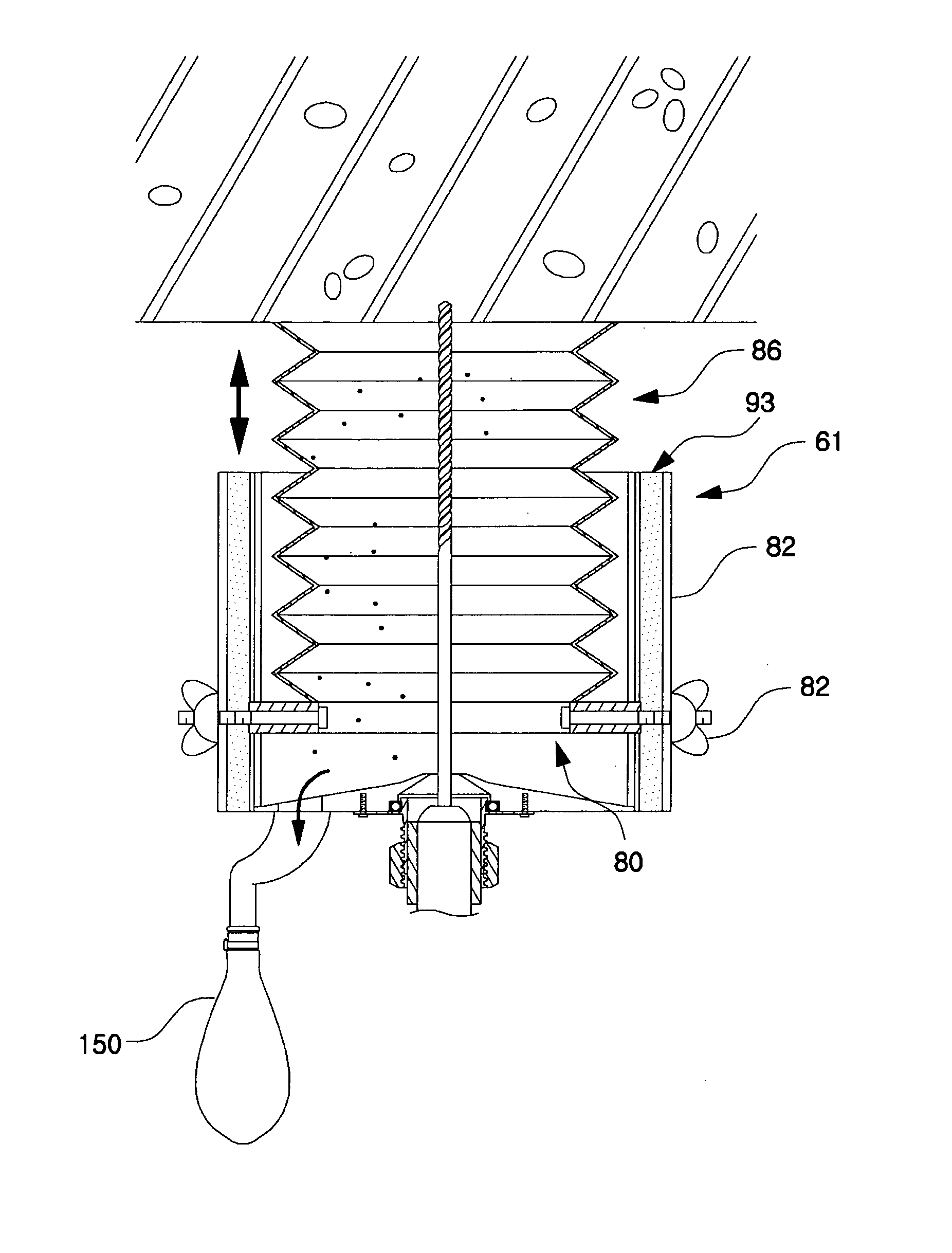

PCT No. PCT / JP97 / 02496 Sec. 371 Date Mar. 3, 1998 Sec. 102(e) Date Mar. 3, 1998 PCT Filed Jul. 18, 1997 PCT Pub. No. WO98 / 03302 PCT Pub. Date Jan. 29, 1998In order to process a solid processed object with a simple construction, and to process a solid and flat work while effectively collecting particulate scraps, in a machine tool for processing work in which a working table on which the work is mounted and a spindle in which a cutter is installed move relatively to each other, a bellow which telescopes freely is provided, one open end of which connects to the spindle head so as to surround the spindle, and the other open end of which connects to a working table in such a manner as to surround the work.

Owner:TOKO KABUSHIKI KAISHA

Dust extraction shroud for a power tool

A dust extraction shroud for a drill, which surrounds a drill bit and which lies adjacent the work surface, comprises a body portion defining a first inlet adapted to engage the work surface and to surround the location at which said bit penetrates the surface. The shroud body further defines a first outlet connected to a source of suction and a third inlet for allowing the bit to pass through said body portion. A first sealing means is arranged in said third inlet for surrounding said bit and resisting the flow of air. Wherein said body portion includes at least one protruding portion defining a second inlet between said protruding portion and an adjacent part of said body, and on a side of said protruding portion remote from the first inlet. The second inlet admits air to enter said body portion and travel to the first outlet.

Owner:BLACK & DECKER INC

Suction device

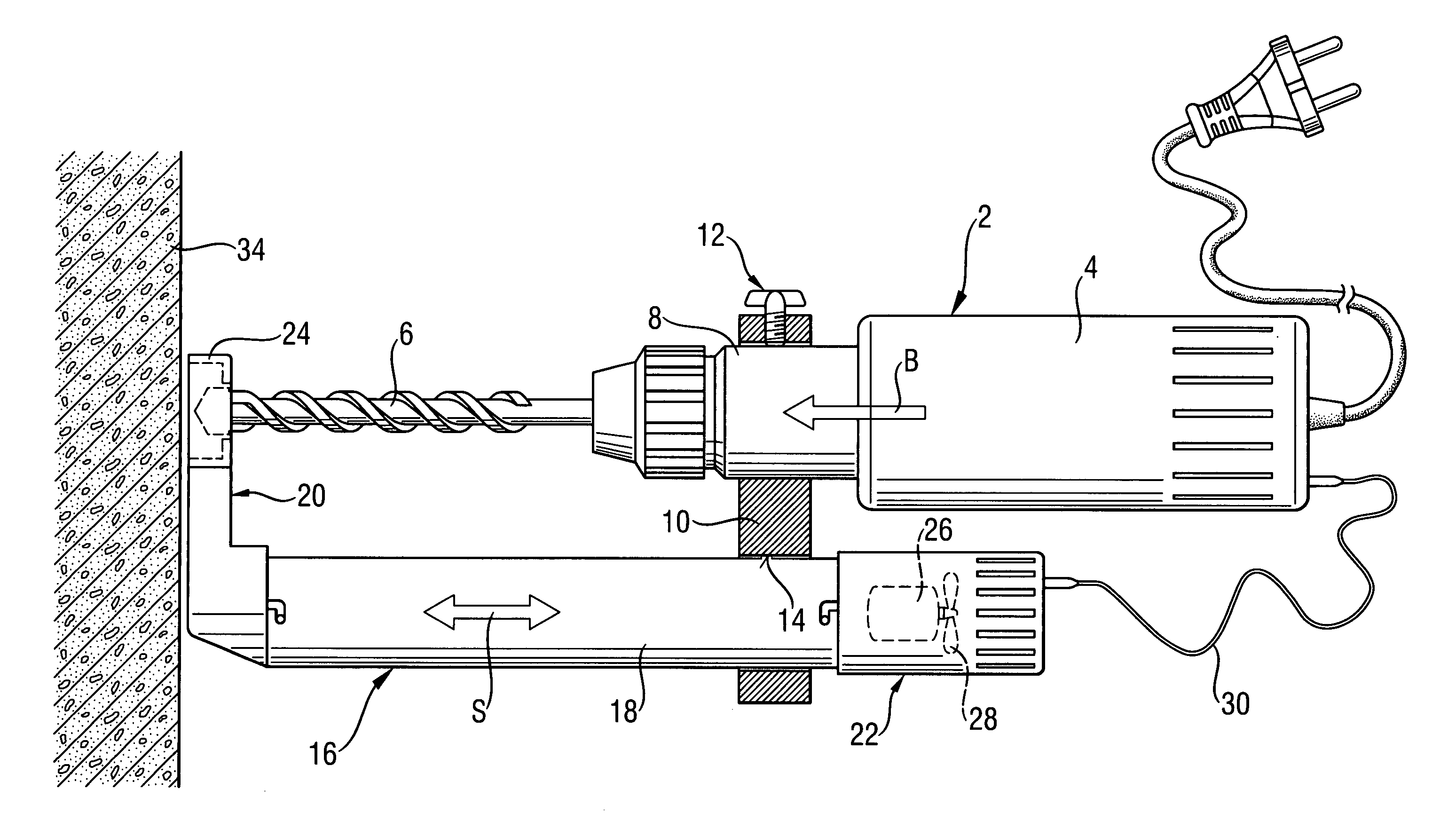

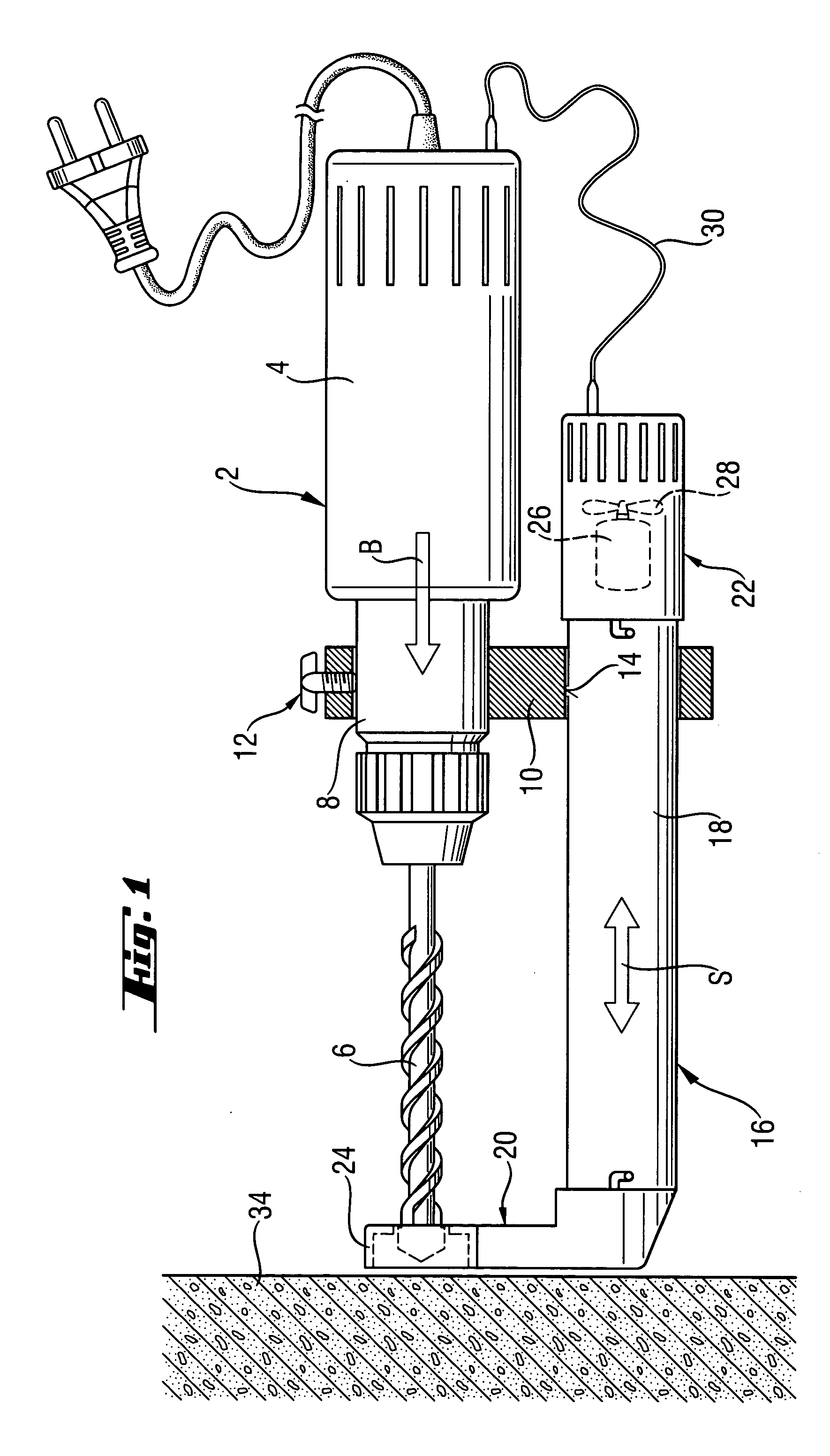

InactiveUS7281886B2ConstantMaximal suction performanceDrilling/boring measurement devicesThread cutting feeding devicesEngineeringGuide tube

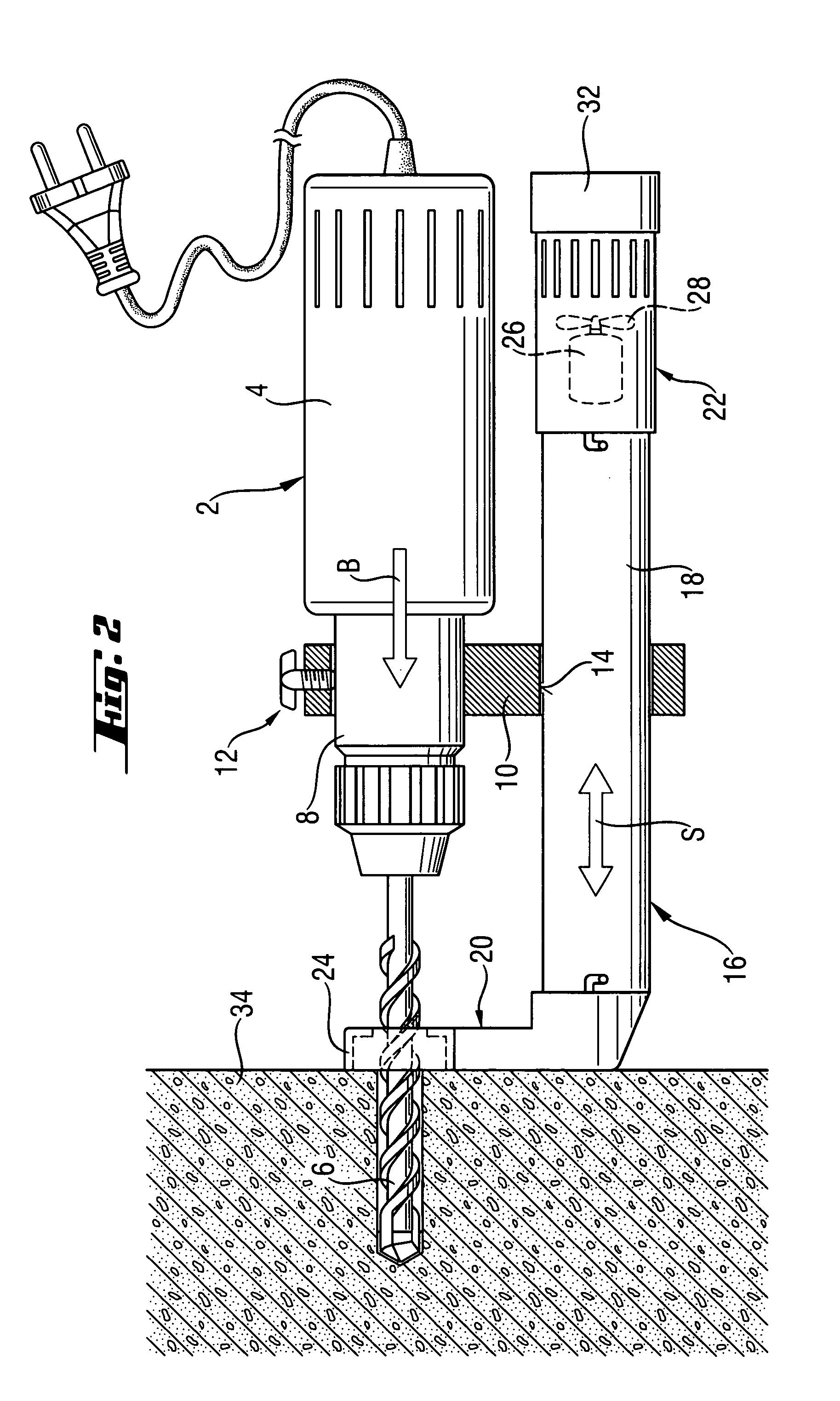

A suction device that is used with a power drilling tool for aspirating material removable during operation of the drilling tool, and which includes a suction head (20) displaceable relative to the drilling tool (2) in a direction opposite a drilling direction (B) of the drilling tool (2), and an aeration device (22) fixedly connected by a suction conduit with the suction head (20) for joint displacement therewith.

Owner:HILTI AG

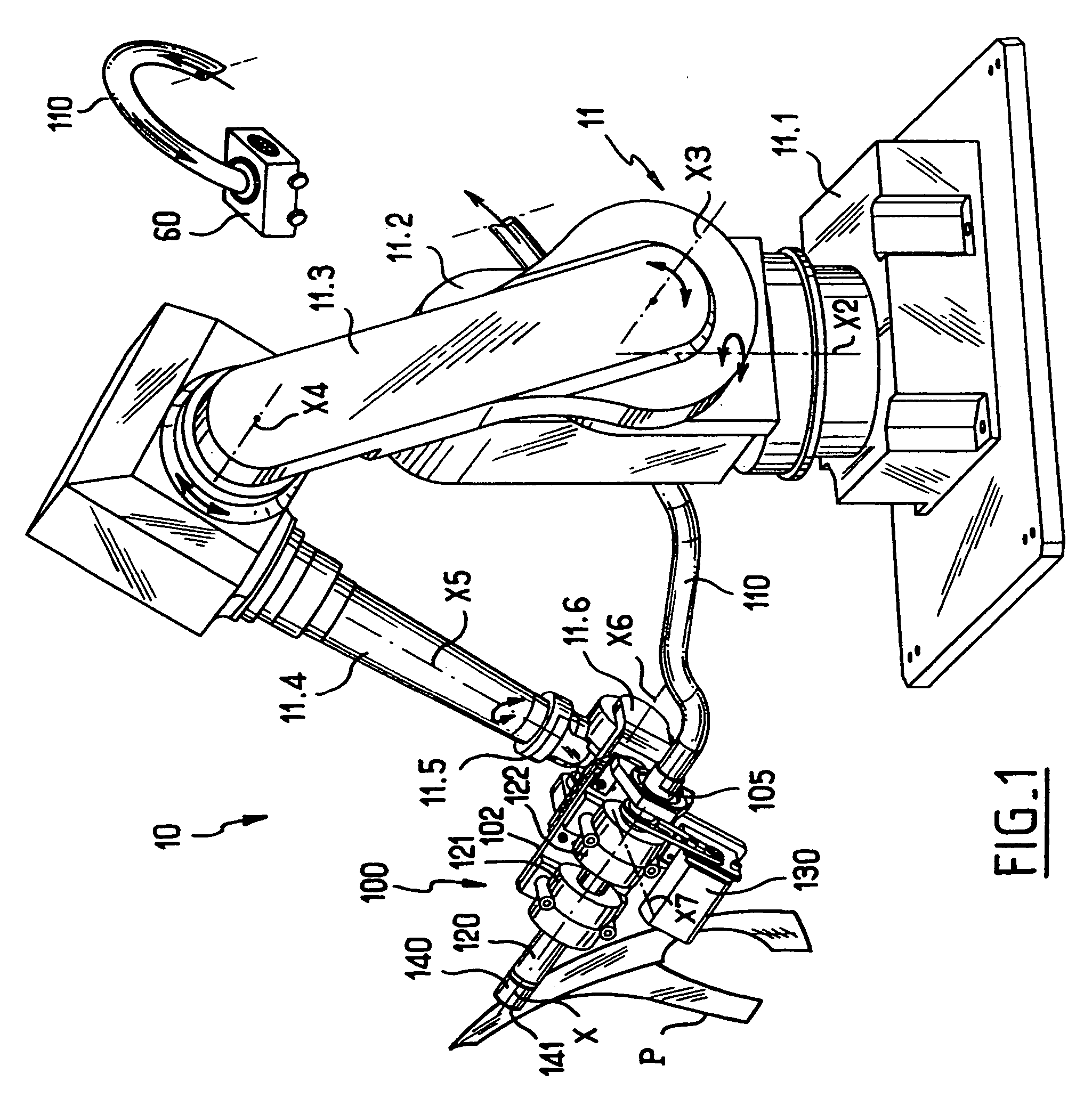

Toolhead for multi-axis machine tools

ActiveUS7220088B2Easy to getSmall and lightAircraft componentsDrilling/boring measurement devicesTransducerEngineering

Owner:JOBS SPA

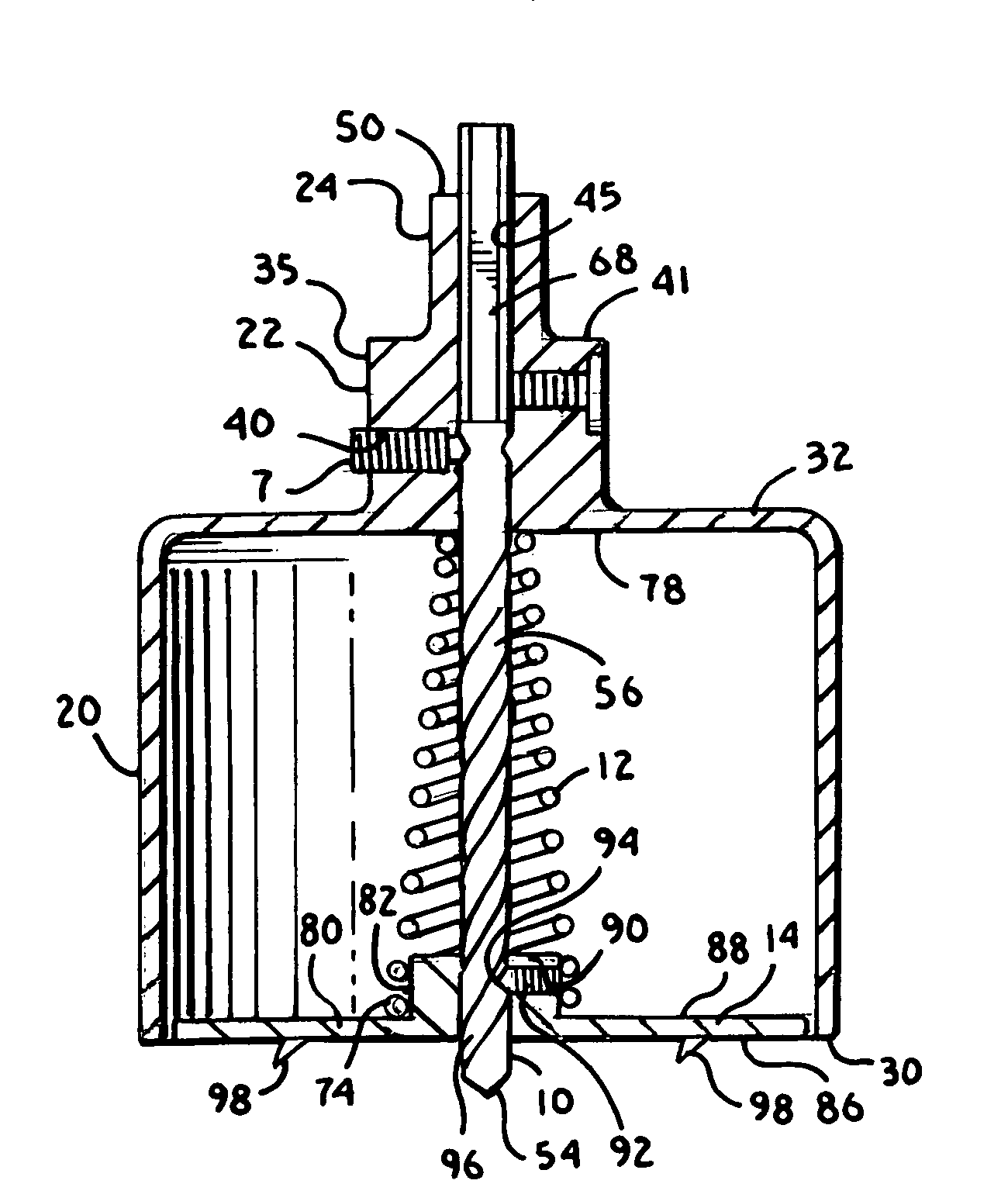

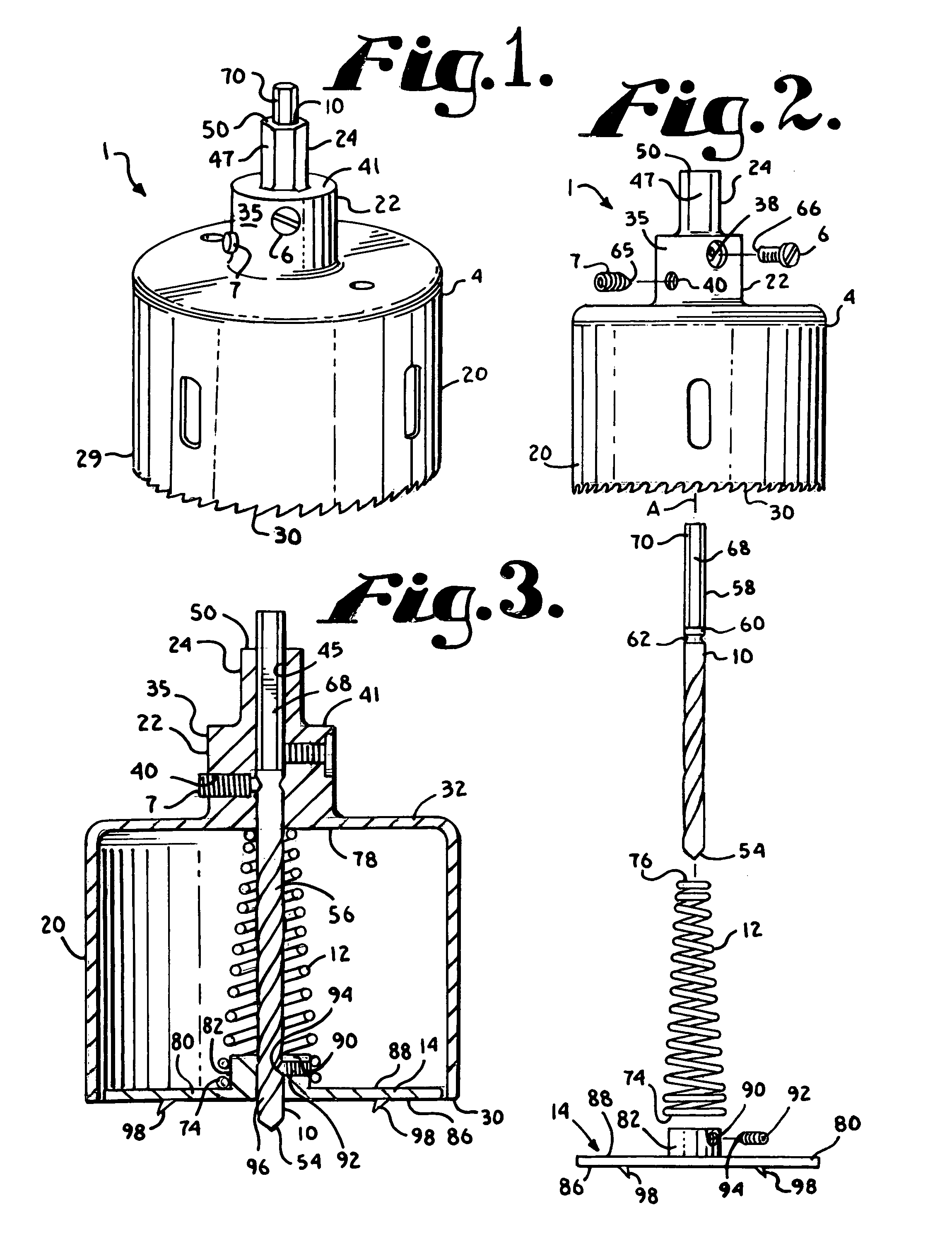

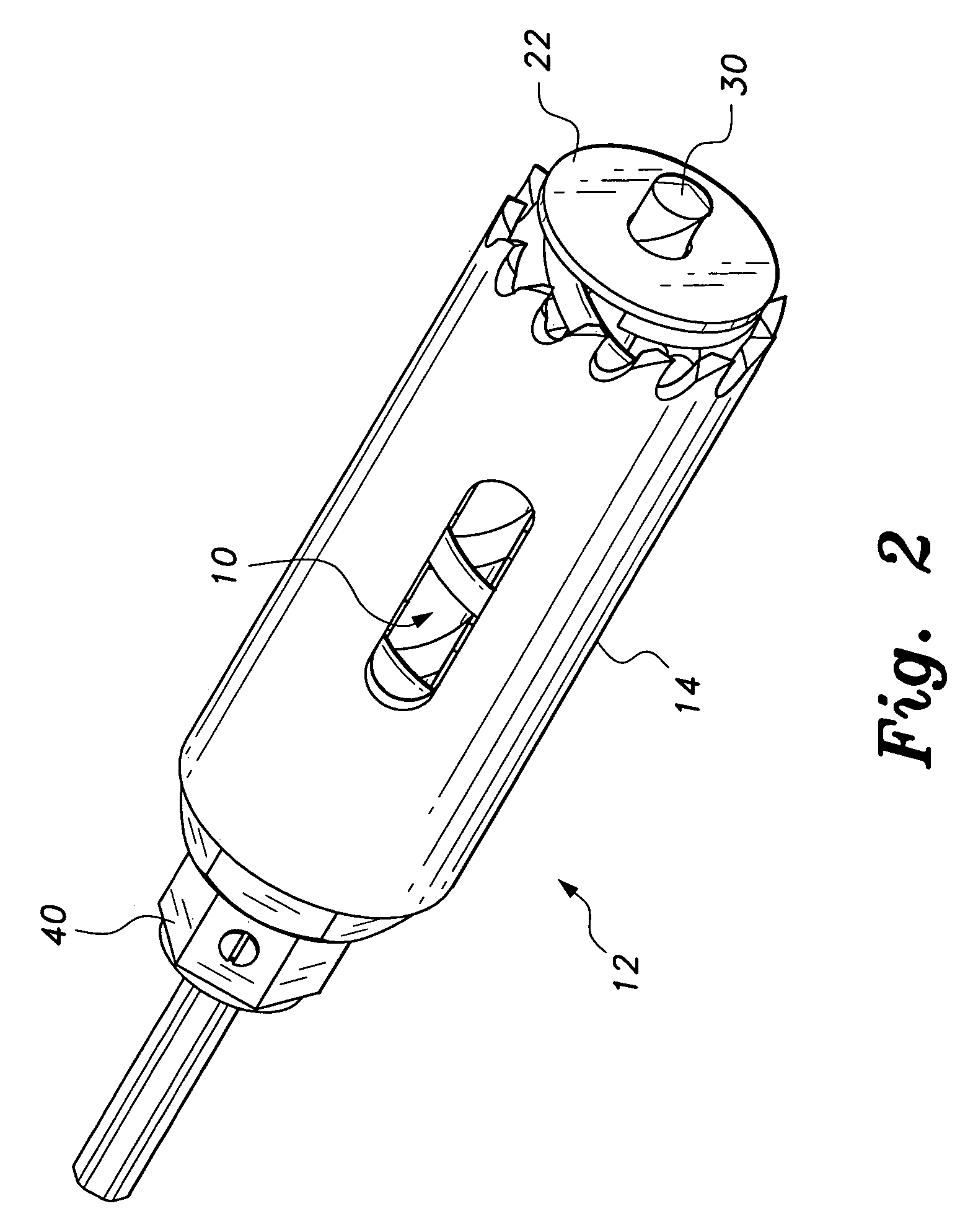

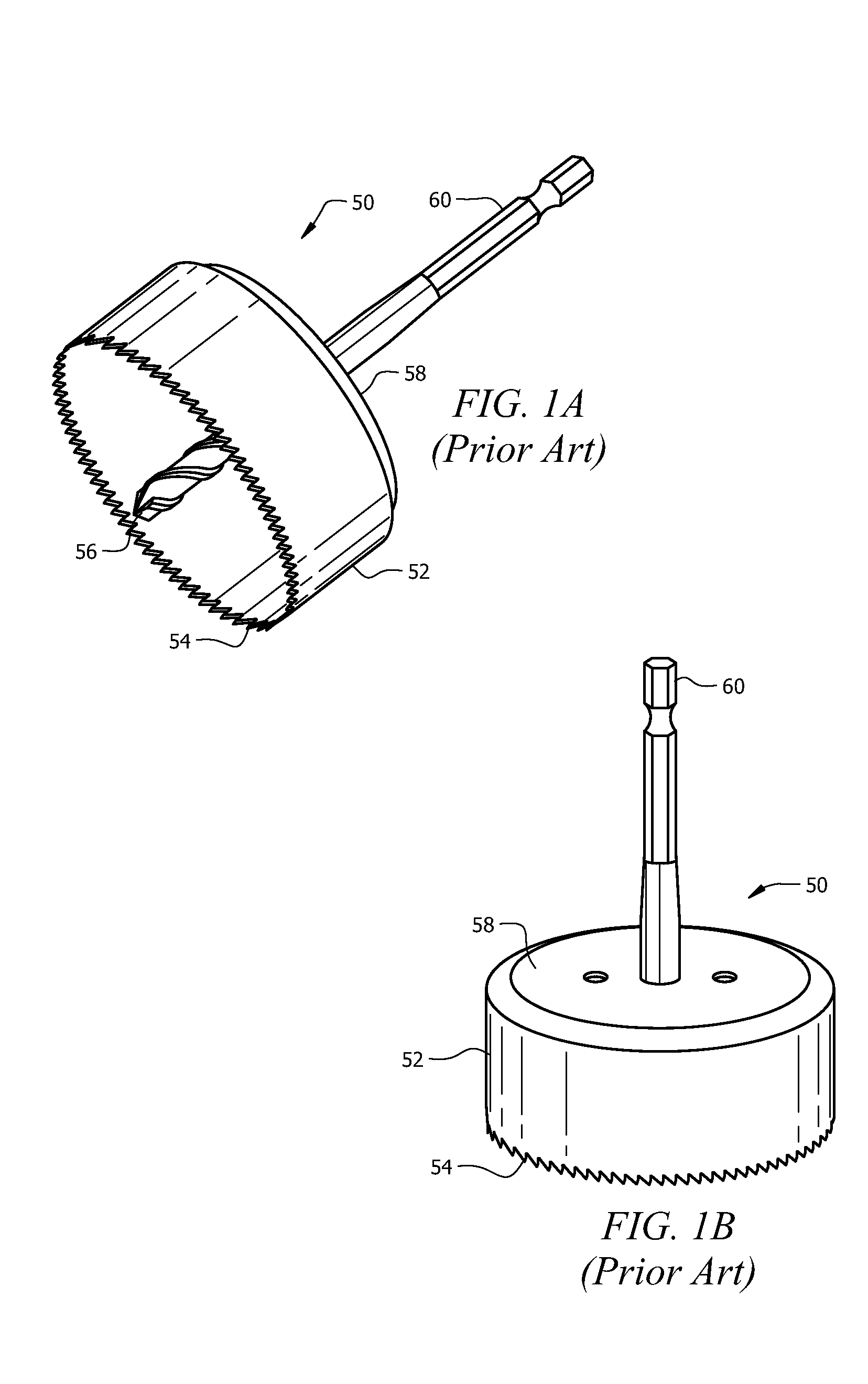

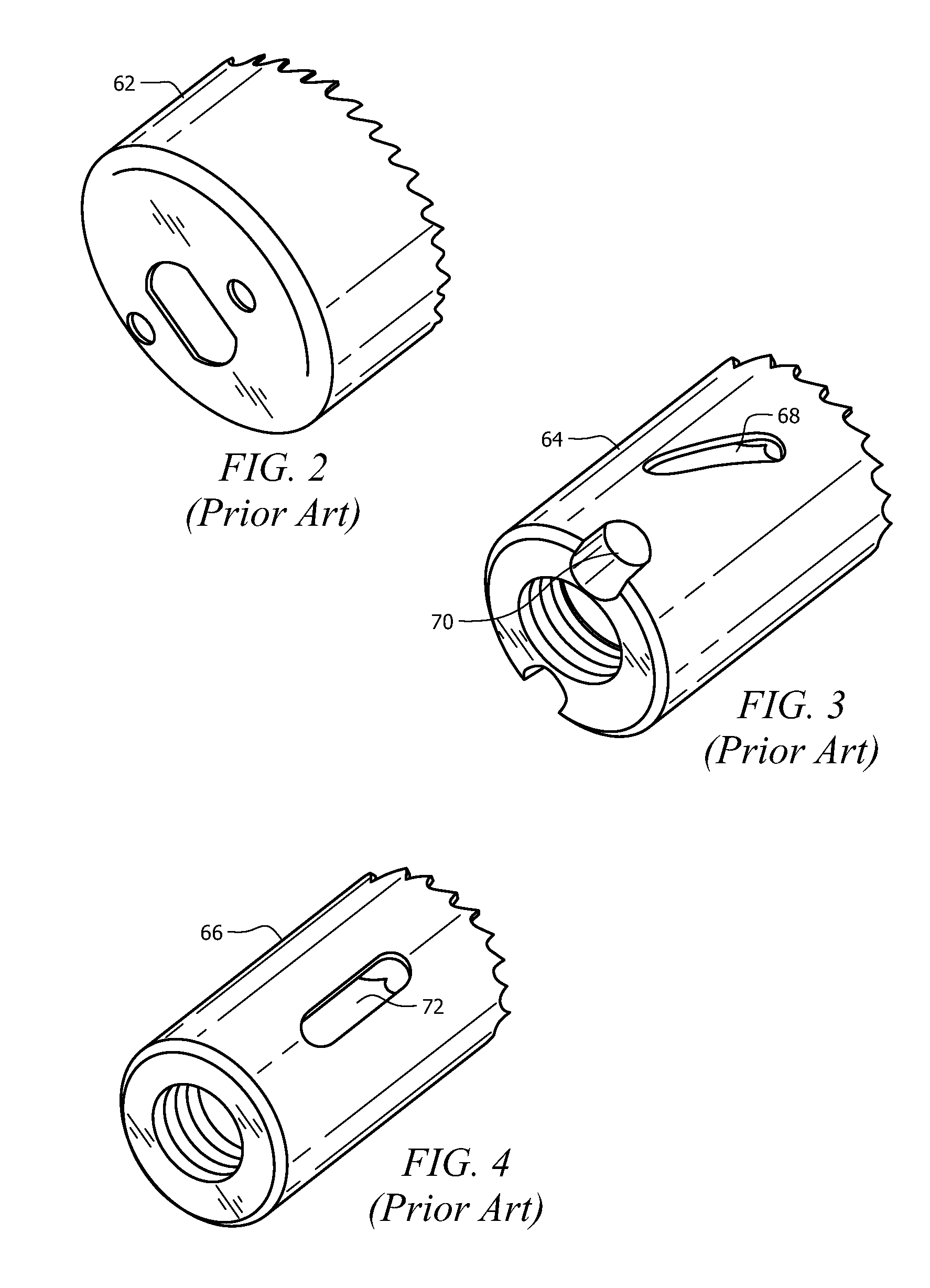

Hole saw having efficient slug removal

InactiveUS7658576B1Reduce frictional contactUniform forceThread cutting feeding devicesTransportation and packagingHole sawEngineering

A hole saw having efficient slug removal preferably includes a saw cup, a shank portion and a pilot cutting device. A cutting surface is formed on an open end of the saw cup. An inside surface of the saw cup is given a low friction treatment and preferably an outside surface thereof. The shank portion is retained on a closed end of the saw cup. The pilot cutting device is preferably a drill, but other cutting devices may also be used. A second embodiment of a hole saw having efficient slug removal preferably includes a saw cup, a shank portion and a pilot cutting device. The saw cup includes a prior art saw cup, at least two side openings and a cutting surface. The at least two side openings are formed through the prior art saw cup to remove a substantial portion of a side wall.

Owner:CAPPYS CONCEPTS

Hand tool comprising a dust suction device

The dust removal device comprises a fan (18), a dust collection receptacle (24), and a suction passage (28). The dust collection receptacle (24) equipped with a dust filter (26) is located in the path of air flow (34, 36) between the suction passage (28) and the fan (18). The dust is therefore filtered out of the air stream before it reaches the fan, which prevents dust-induced wear. It is also possible to use the same fan for engine cooling as well as dust removal.

Owner:ROBERT BOSCH GMBH

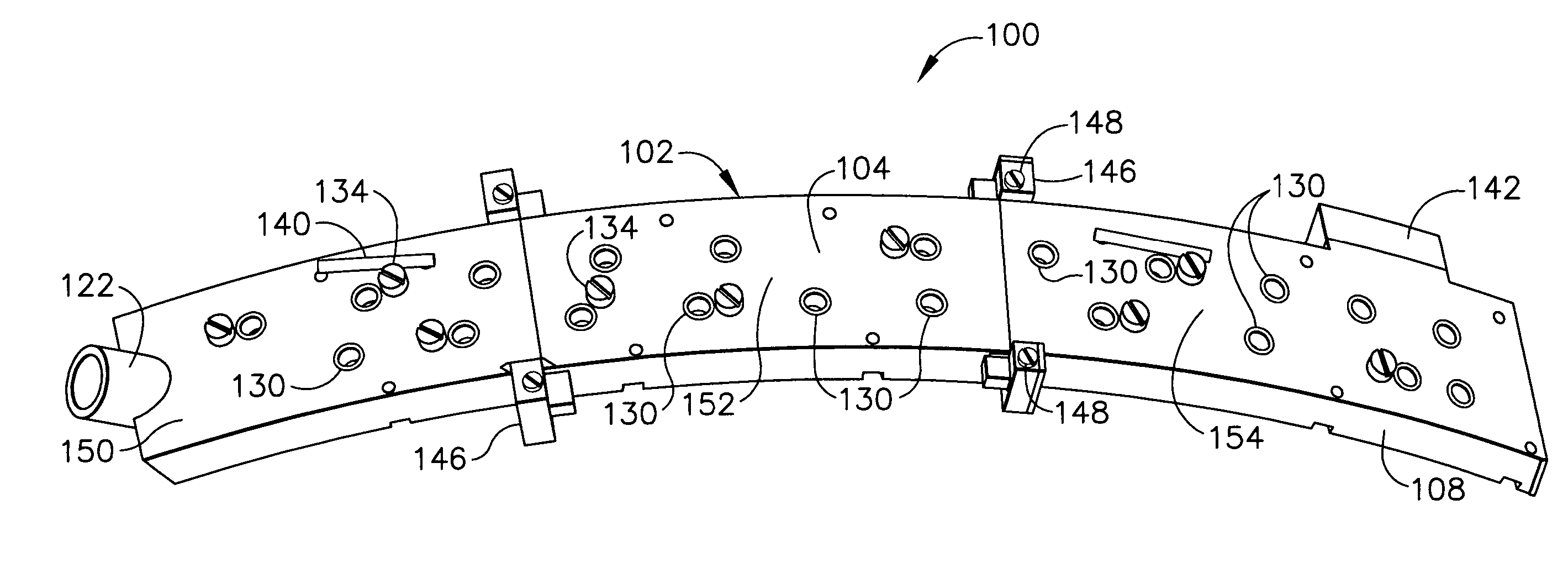

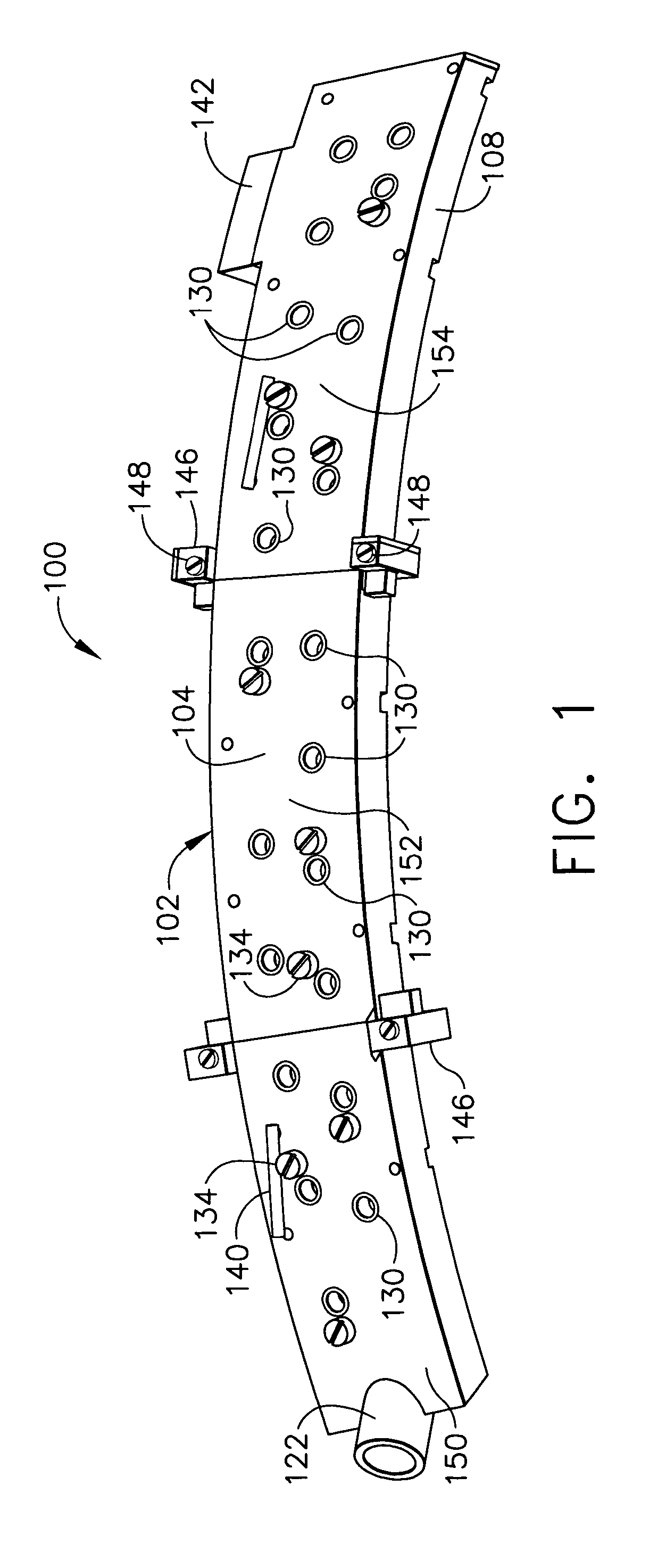

Drill template with integral vacuum attach

A drill template includes a vacuum housing with a skirt having a CAD-formed contact surface formed to an exact fit with a mold line surface of a structure. The drill template includes at least one drill guide bushing extending through the vacuum housing from a top surface to an interior surface of the vacuum housing; a vacuum port integral to the vacuum housing; and at least one index hole for positioning and aligning the vacuum housing on the structure. Index holes extend from the top surface through to the CAD-formed contact surface of the vacuum housing. A CAD-formed edge of part locator is formed according to a CAD solid model of the aircraft fuselage and fits to a precise location of the structure for precisely positioning the template on the structure. A vacuum port provides vacuum to the interior of the vacuum housing for removing drilling debris and dust.

Owner:THE BOEING CO

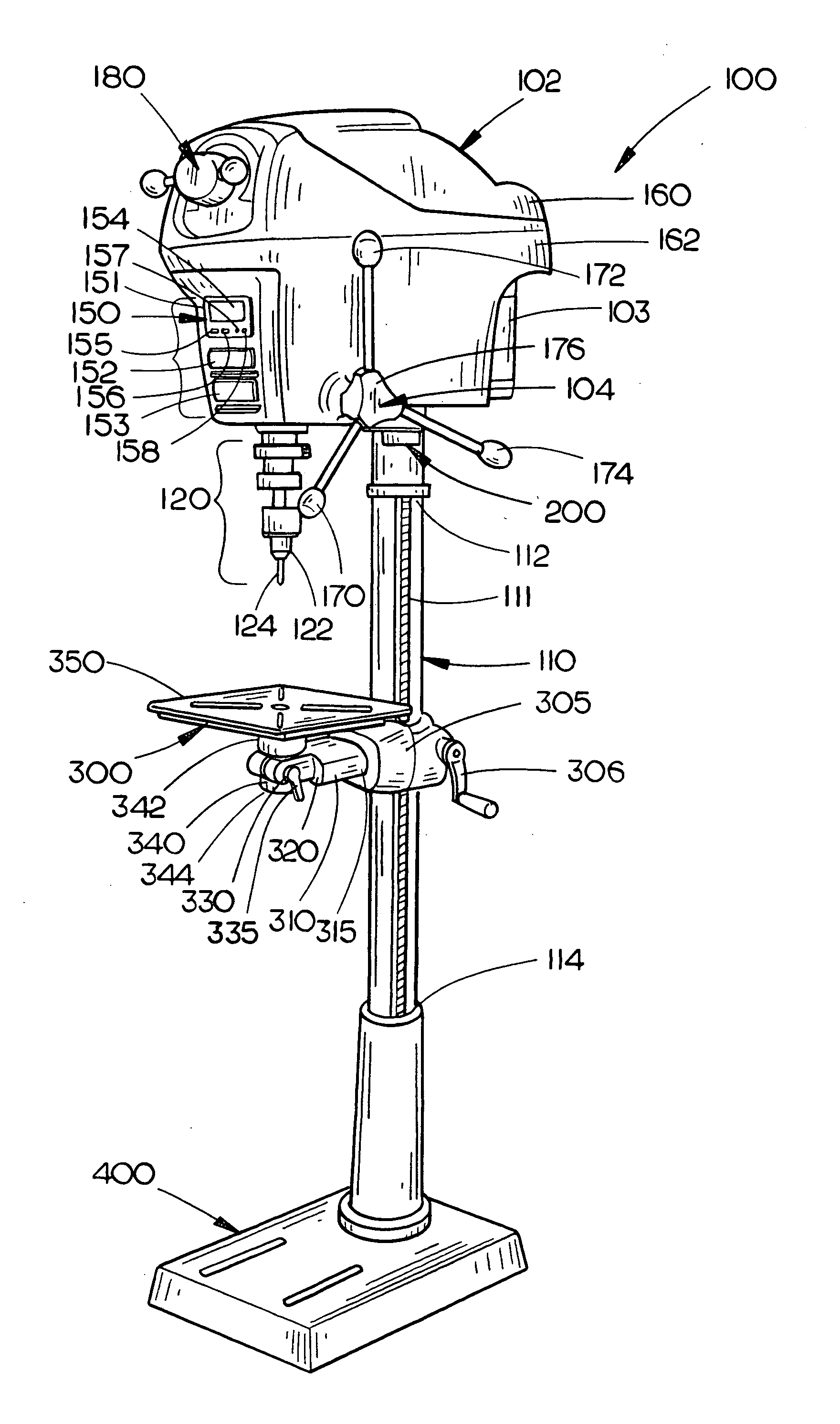

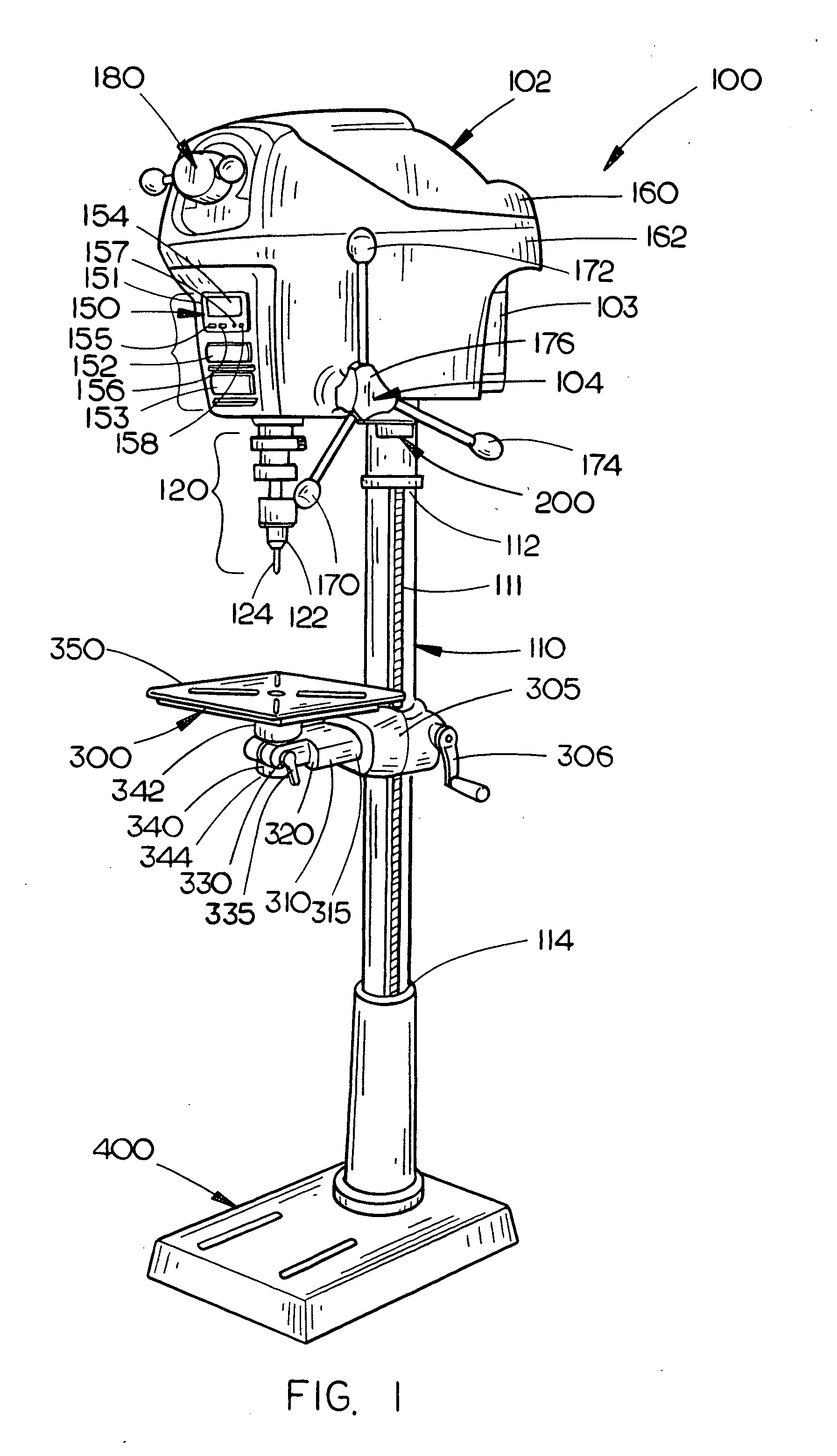

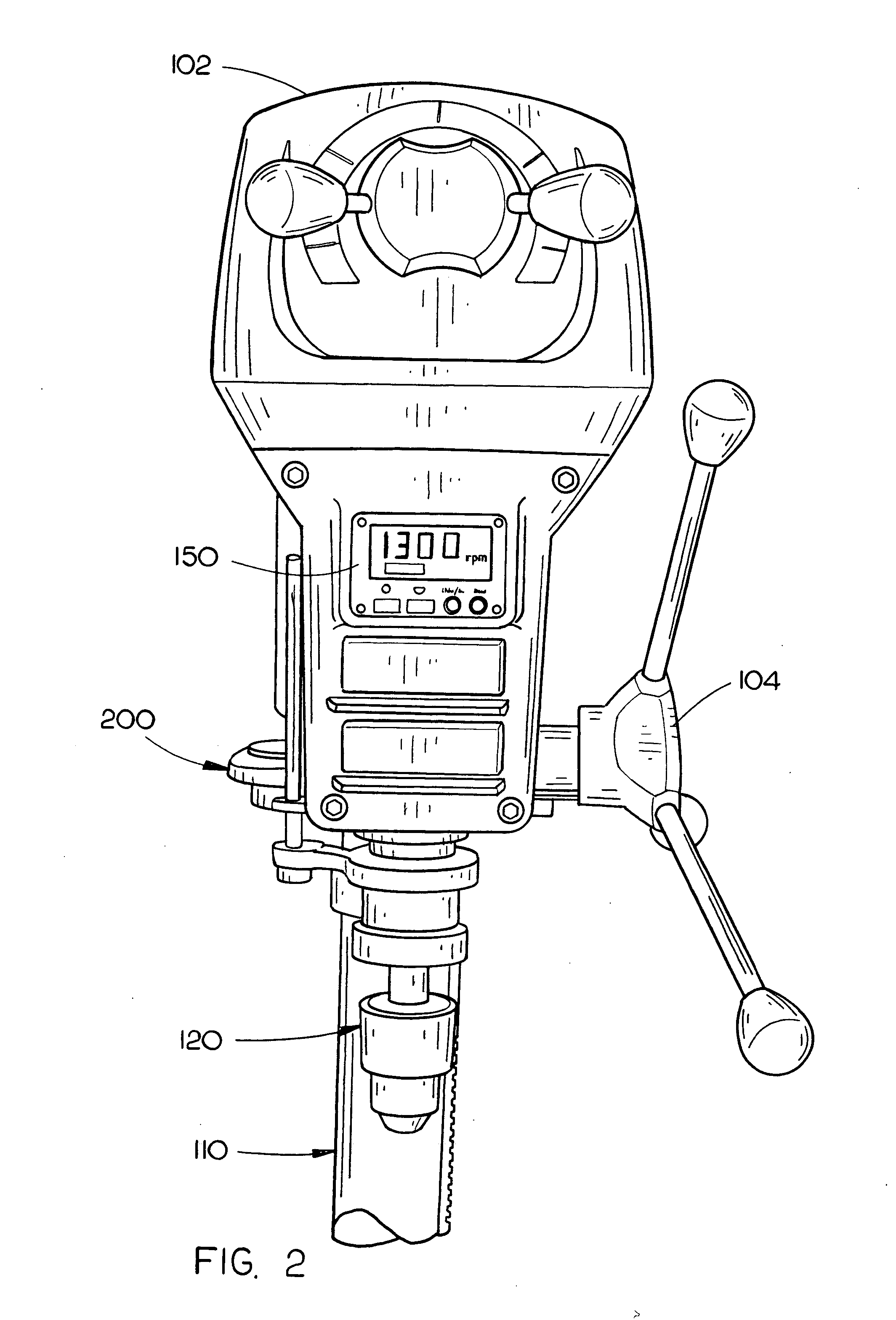

Drill press

InactiveUS20060104731A1Improve efficiencyEasy to operateDrilling/boring measurement devicesThread cutting feeding devicesControl systemEngineering

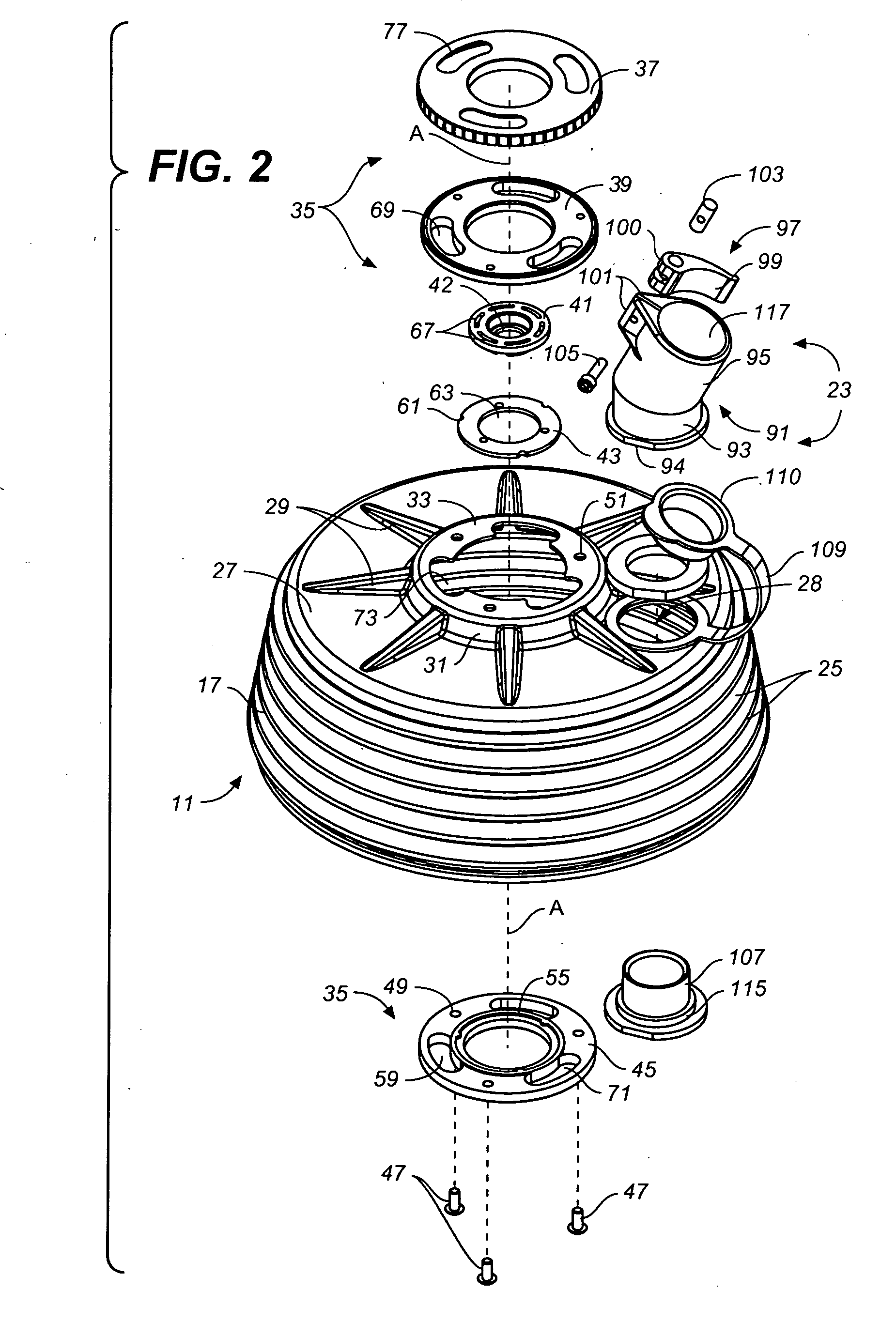

A power tool control system connected with a drill press provides a system for determining operational settings for the drill press and / or structural factors of a workpiece to be operated upon by the drill press. For instance, the power tool control system may establish a visual indication of the axis of operation of the drill press upon a workpiece and / or determine the thickness, structural composition, and / or moisture content of a workpiece. The determined axis of operation and / or structural factor is utilized to determine the operational settings of the power tool.

Owner:CHANG TYPE INDAL

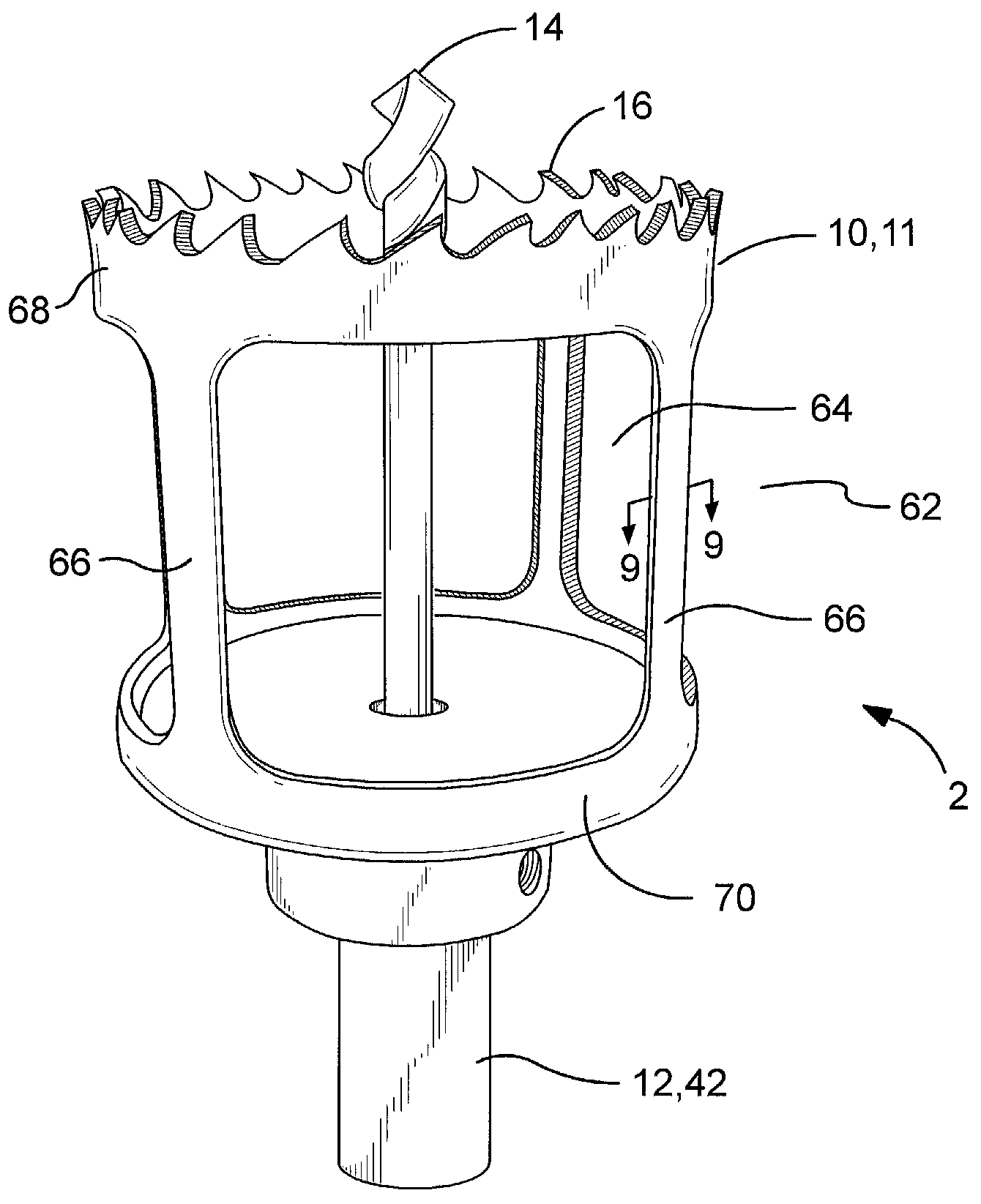

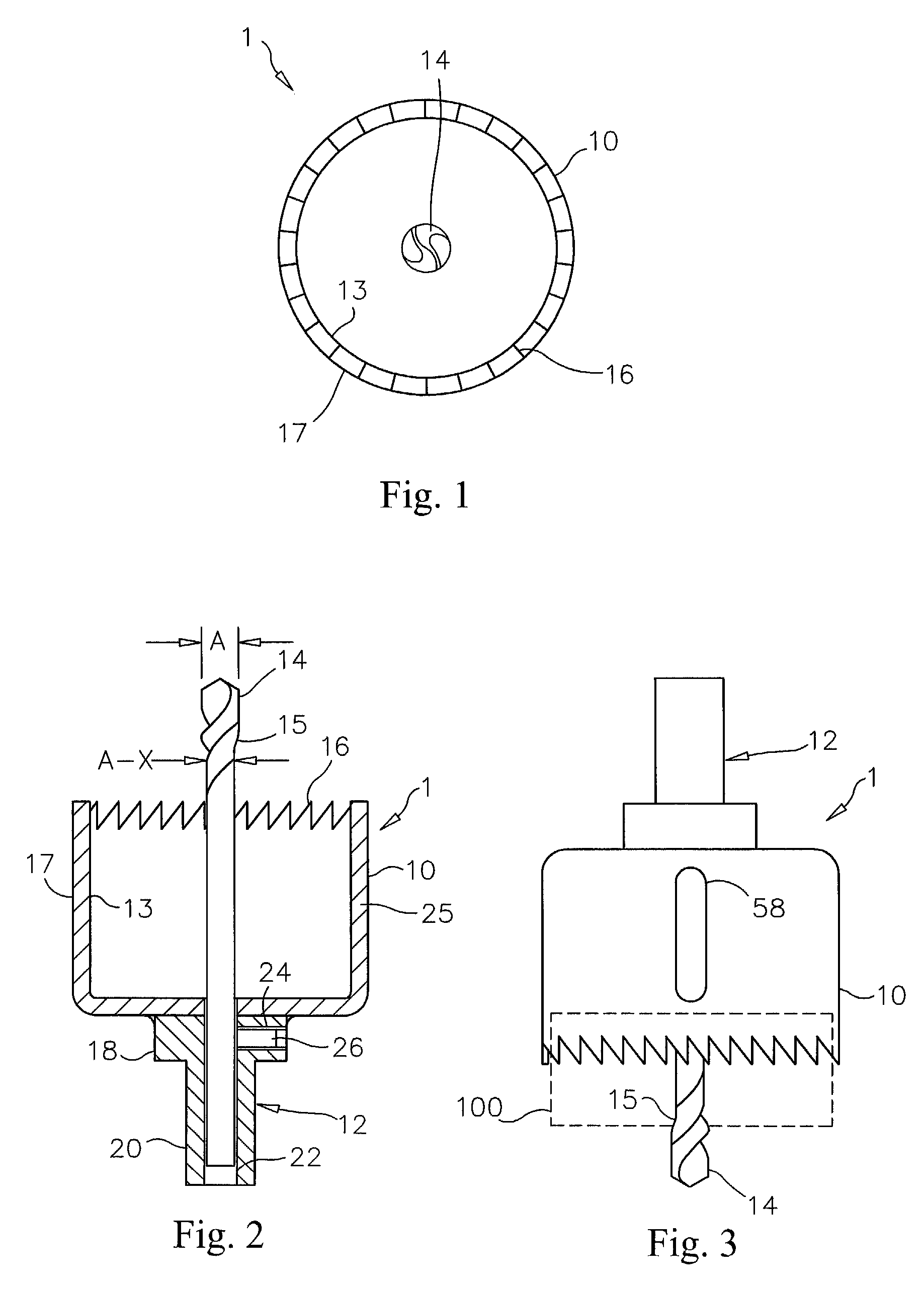

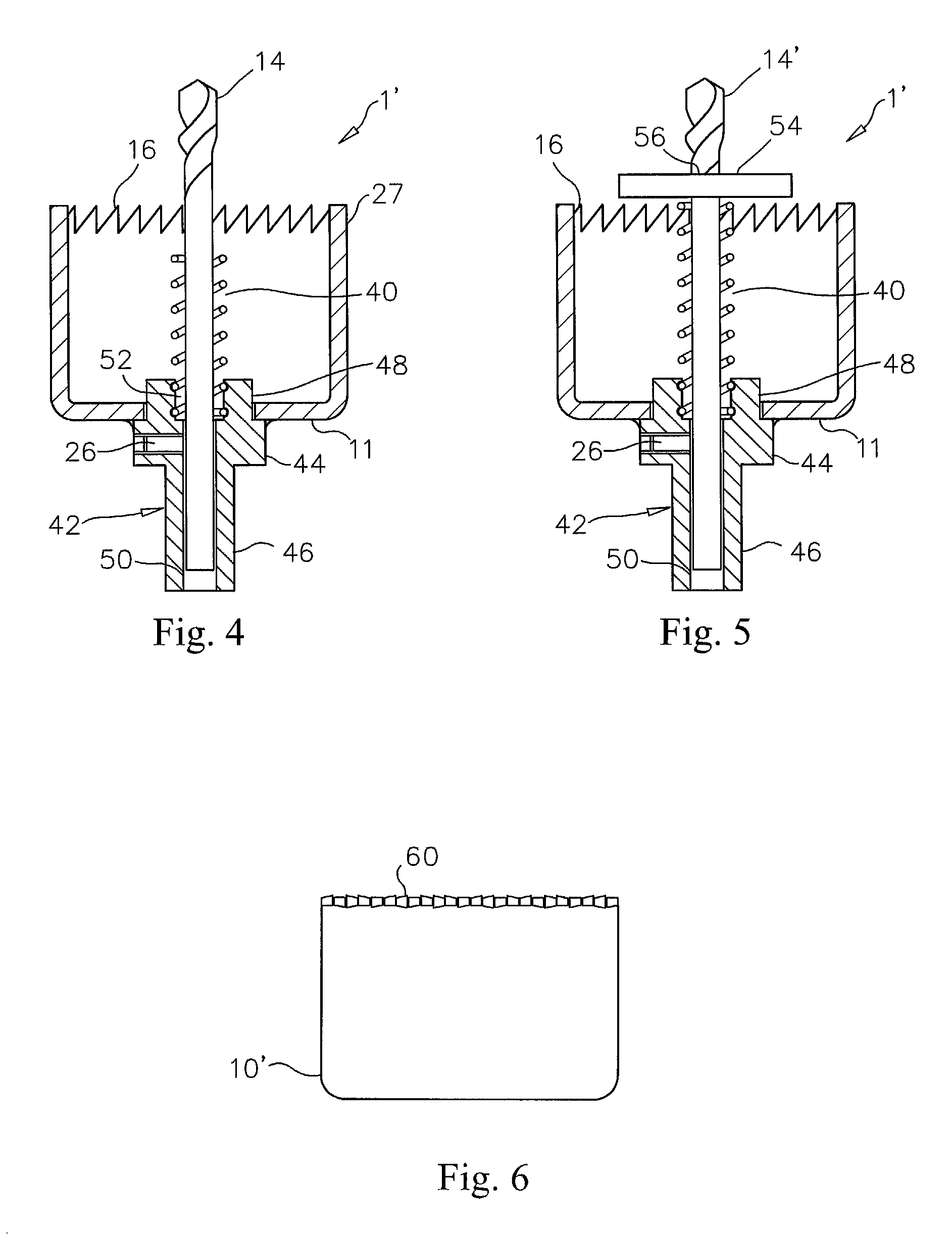

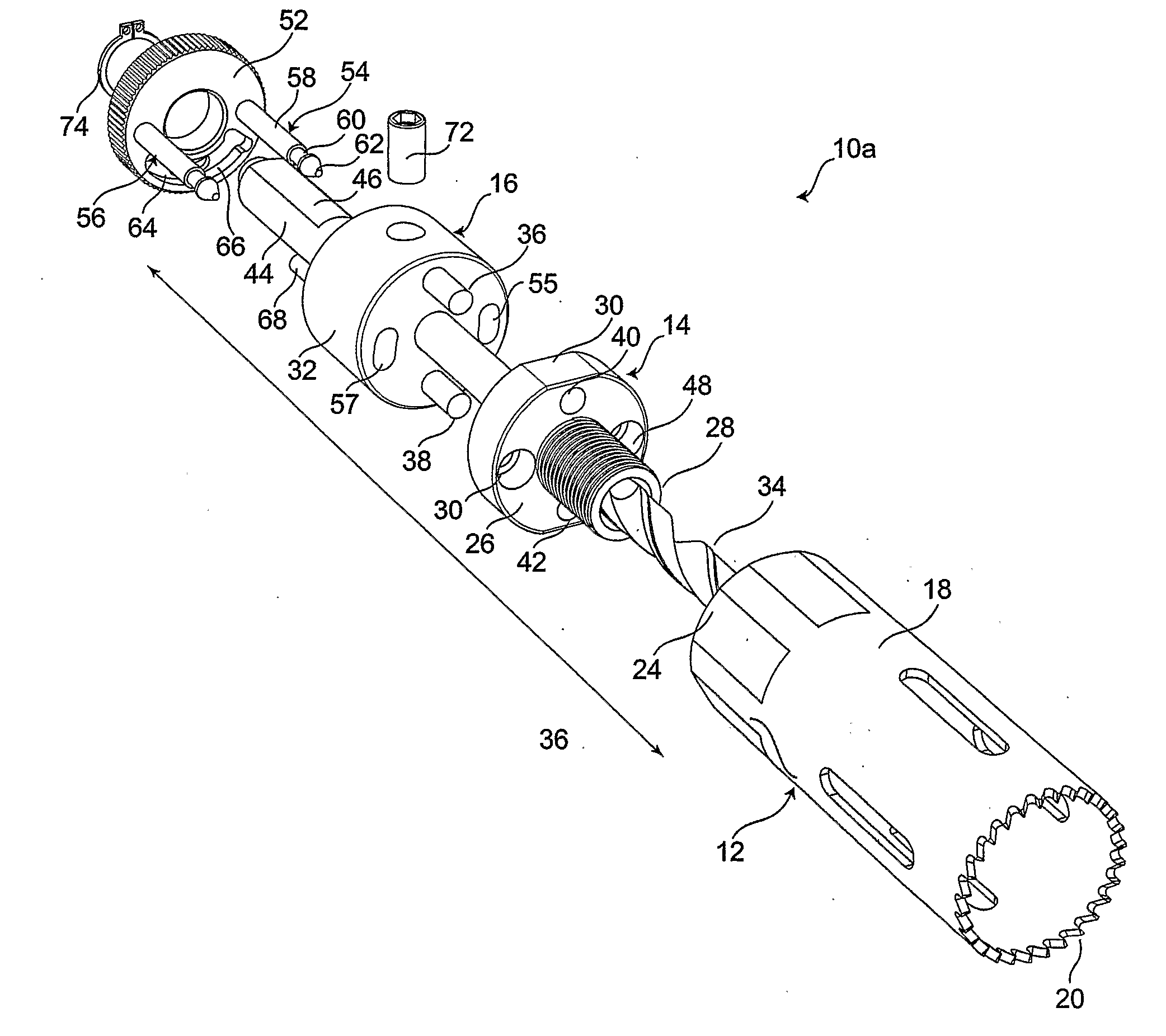

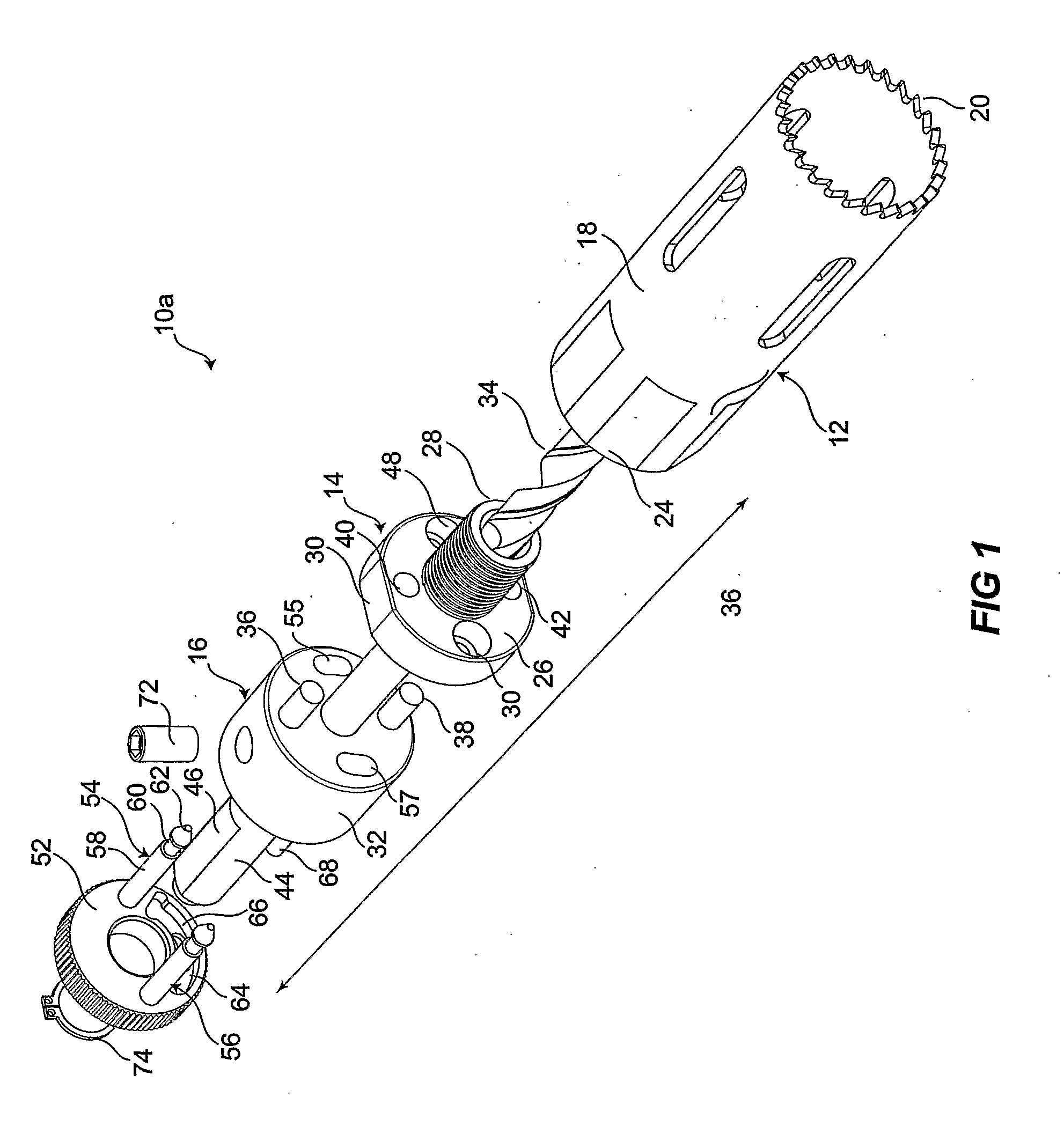

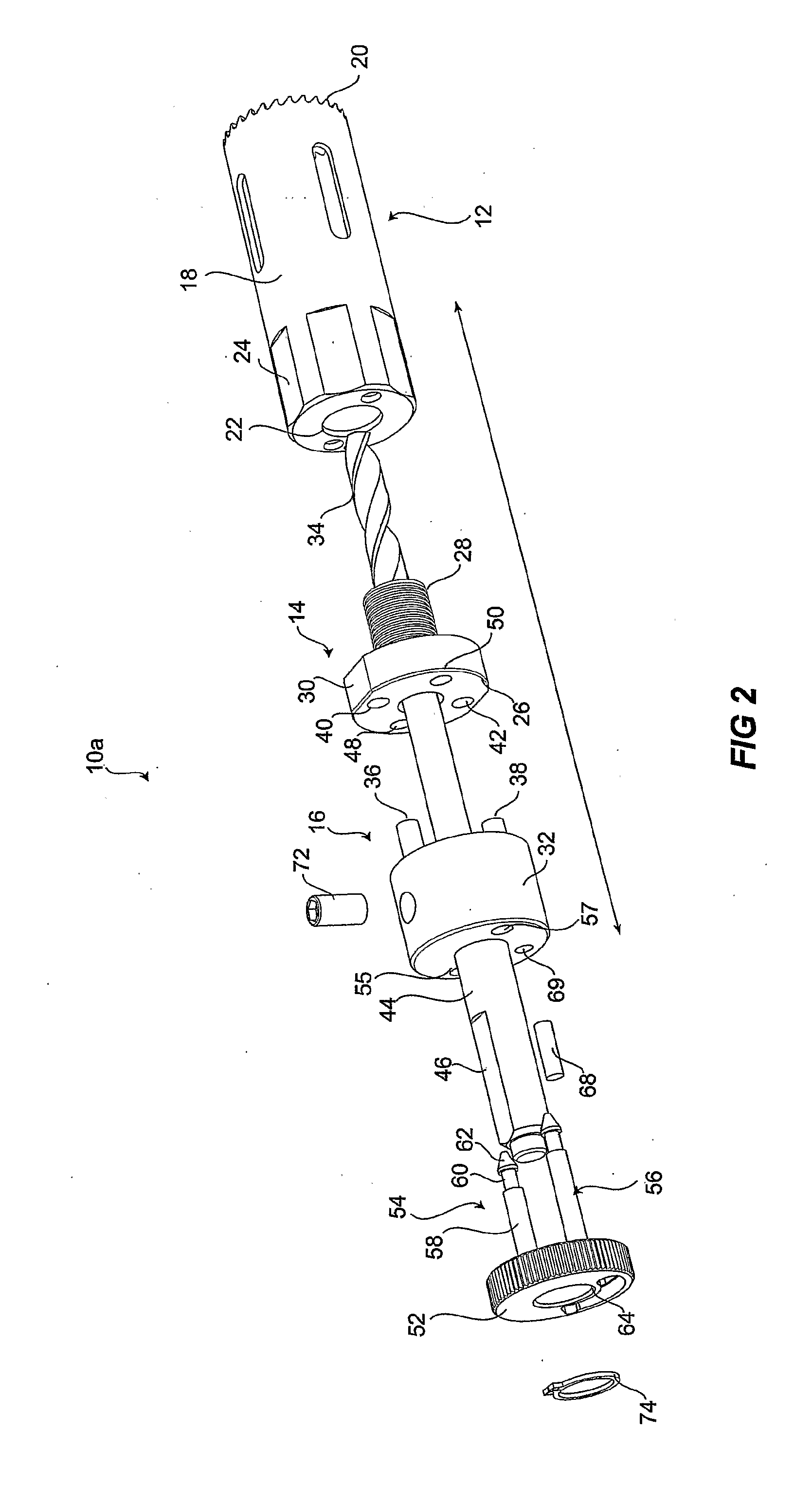

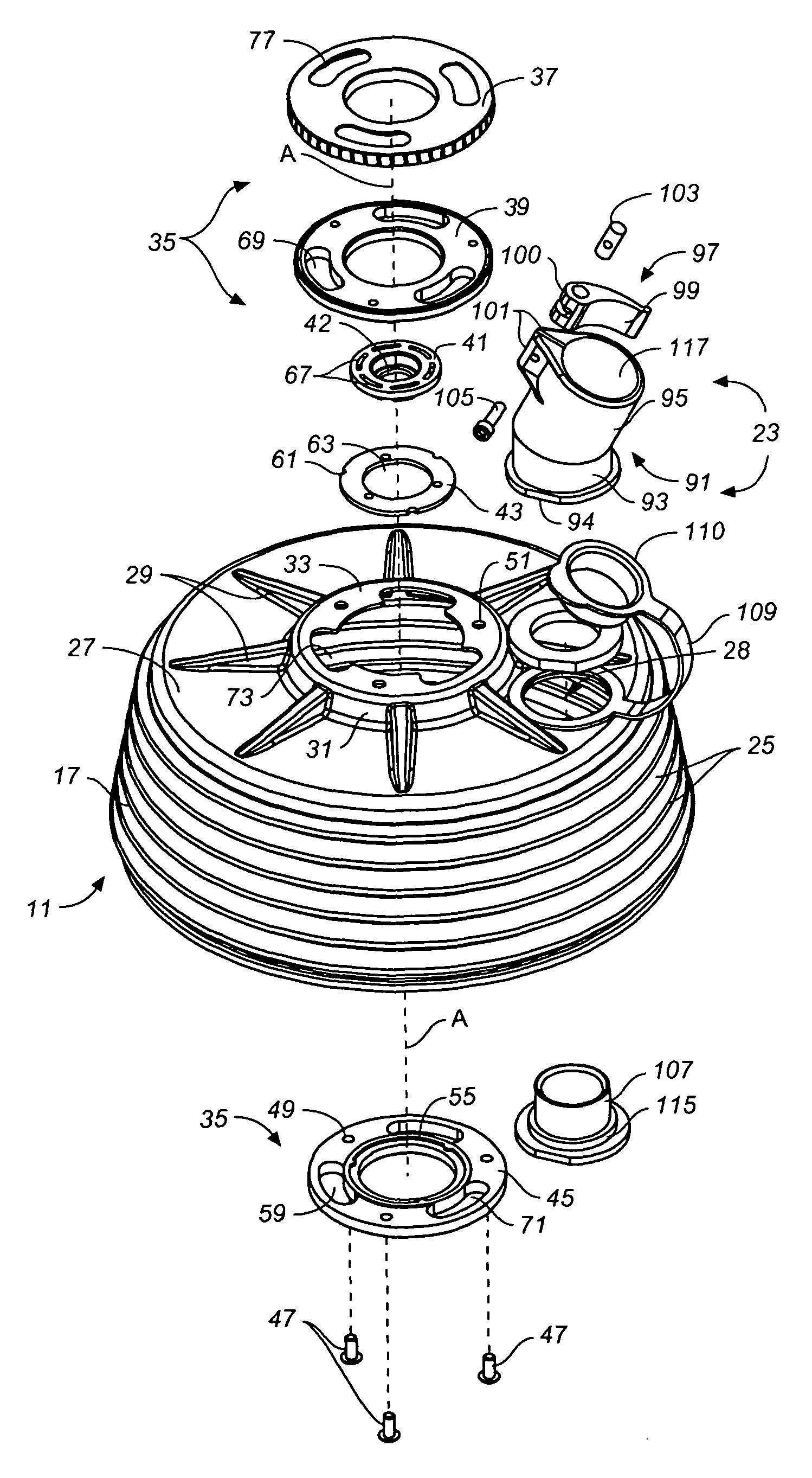

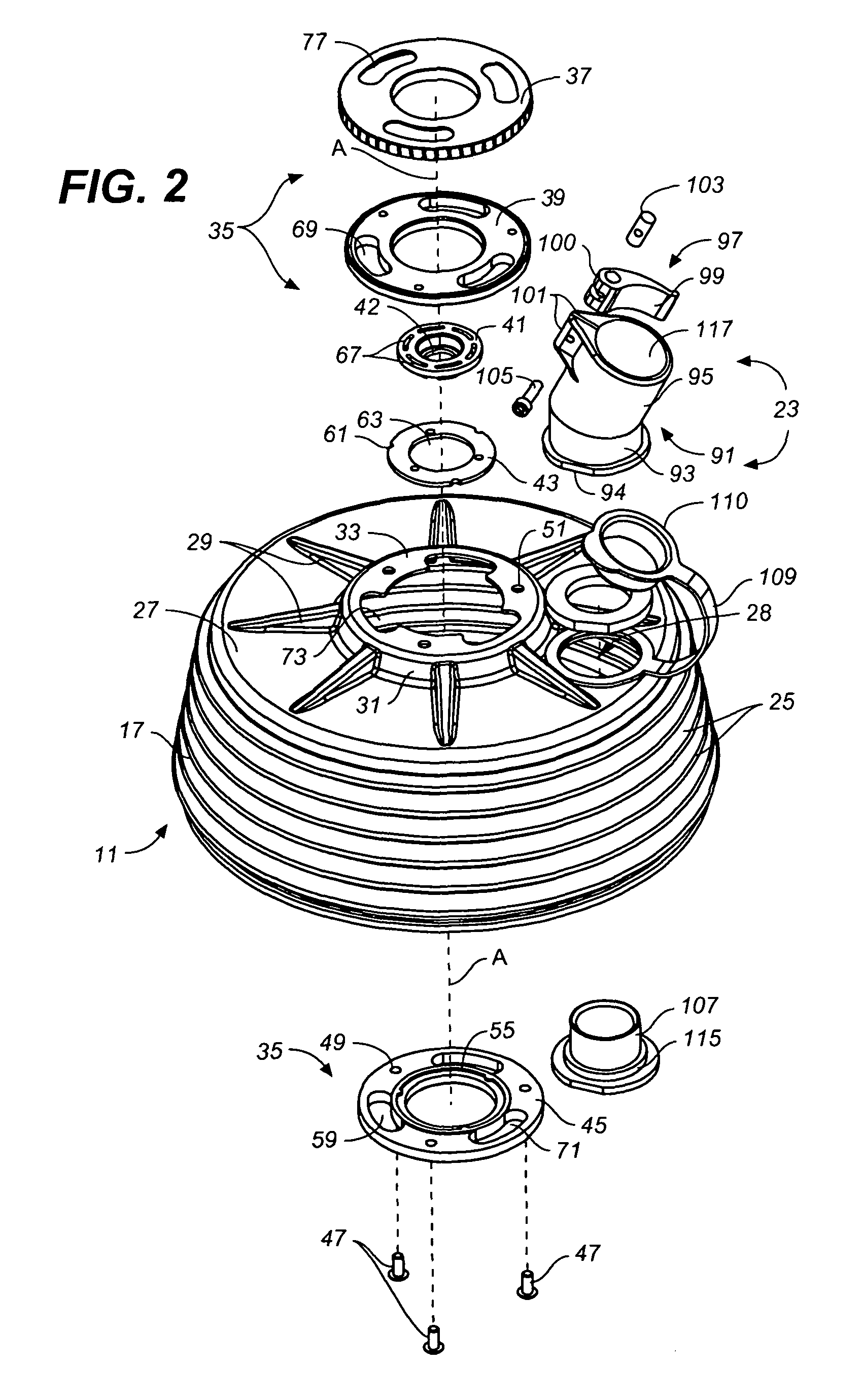

Hole saw assembly including drive shafts supported by a rotatable annulus

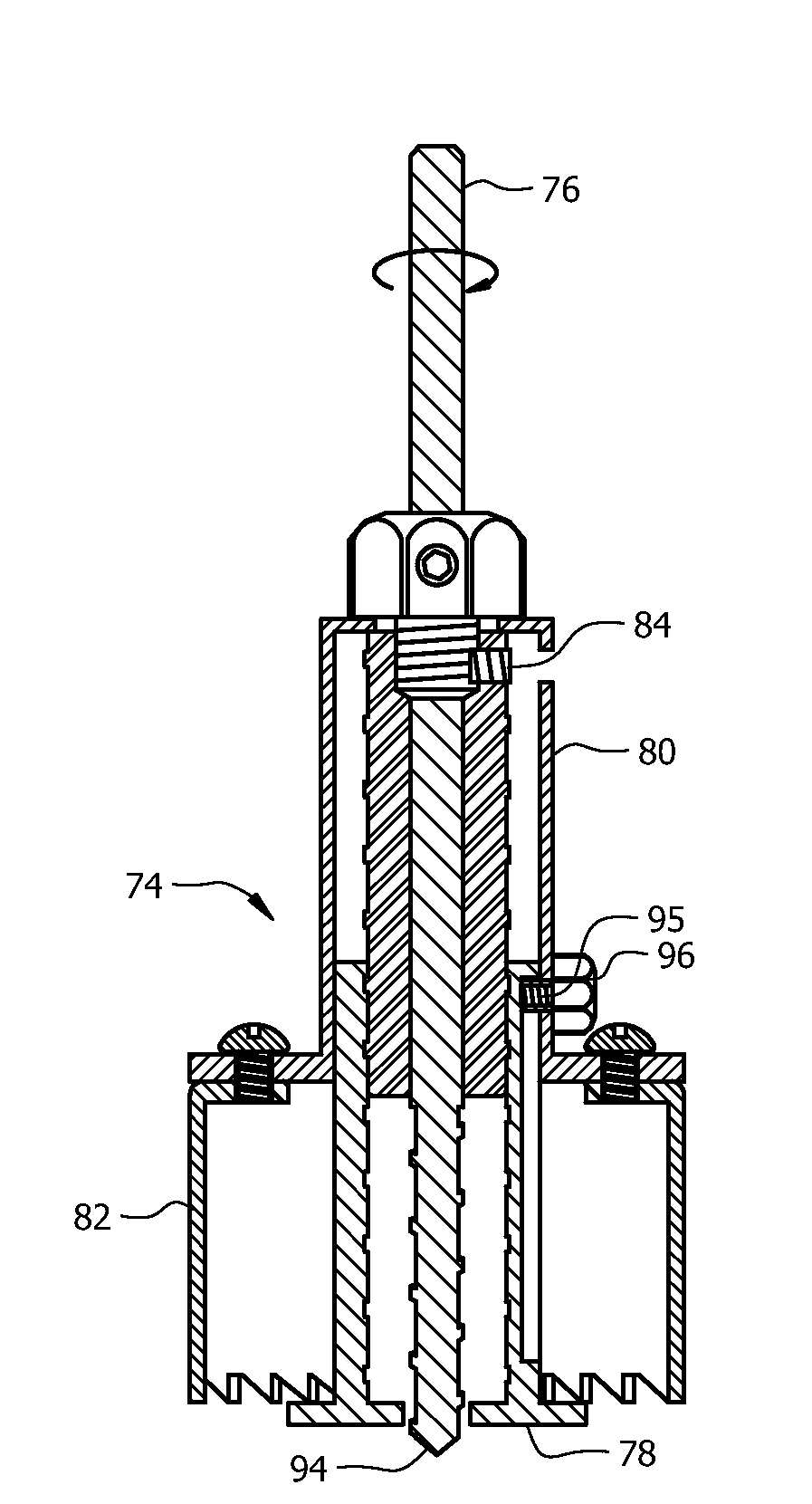

ActiveUS20100067995A1Avoid relative motionThread cutting feeding devicesThread cutting machinesDrive shaftHole saw

A hole-saw assembly including a hole-saw having at one end a plurality of cutting teeth and at the other end a base having two holes therethrough. two shafts. The assembly includes a mandrel coaxially aligned with said hole-saw and including a body having two bores therethrough, and an annulus located on top of the body which is coaxially aligned with said mandrel and hole saw. The annulus includes two shafts co-axial with the mandrel bores, and is rotatable around its longitudinal axis from a first to a second position. In the first position the annulus shafts are aligned with the base holes allowing the shafts to be freely insertable and removable and in the second position the shafts are misaligned to lock the shafts to the base. In one embodiment the mandrel bores are shaped to accommodate rotation of the shafts, and in a further embodiment, the shafts are configures to rotate within circular mandrel bores. Such an arrangement allows the hole-saw and the mandrel to be easily and quickly mountable and demountable.

Owner:KEIGHTLEY KYM JOHN

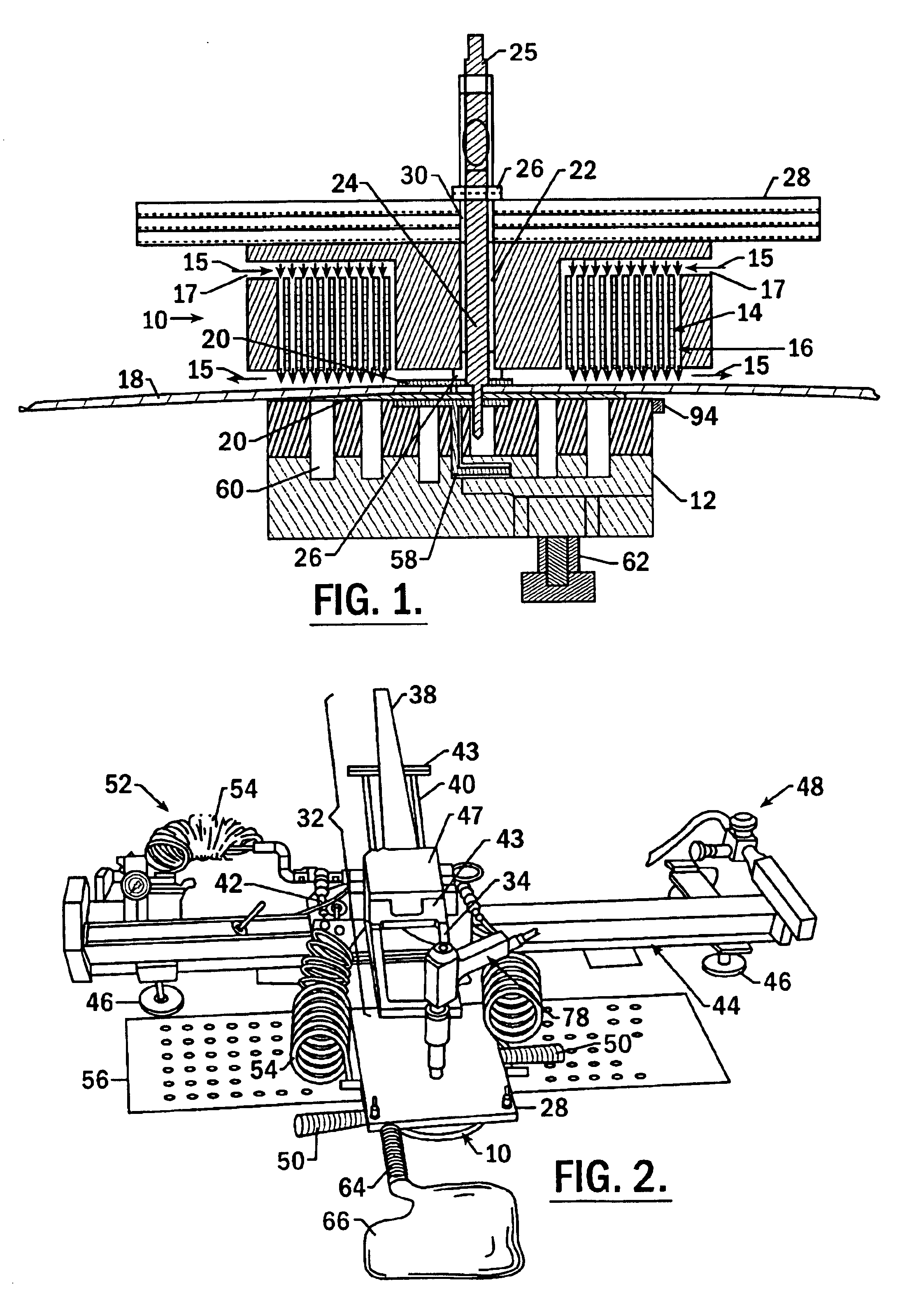

Apparatus and method for drilling holes and optionally inserting fasteners

InactiveUS6905291B2Shorten the timeReduce expensesAircraft componentsDrilling/boring measurement devicesEngineeringSealant

The method and apparatus for drilling holes and optionally inserting fasteners of the present invention provide for efficiently drilling holes through a multiple-layer structure because the layers are securely held together during the drilling by an electromagnet and a clamp, each on opposite sides of the structure. The electromagnet and clamp hold the layers together so tightly that burrs do not form within the holes and debris does not accumulate between the layers and, therefore the layers do not have to be disassembled after drilling. In addition, the apparatus and method of the present invention provide for initially drilling the hole with a countersink and for inserting a fastener into the hole, through the electromagnet, immediately after drilling the hole, such that the hole does not have to be revisited after reassembly and drying of the sealant in order to drill a countersink and / or insert a fastener.

Owner:THE BOEING CO

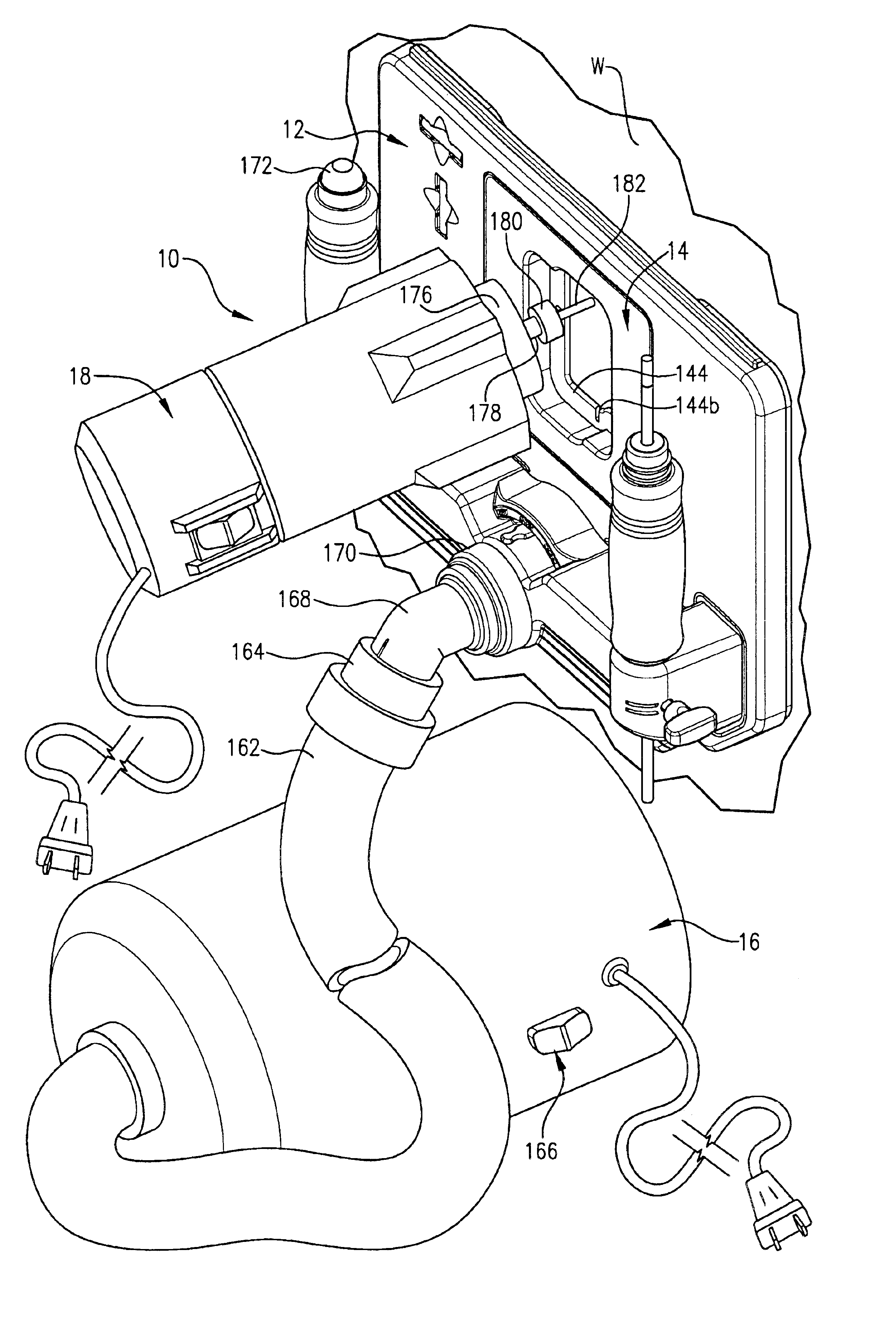

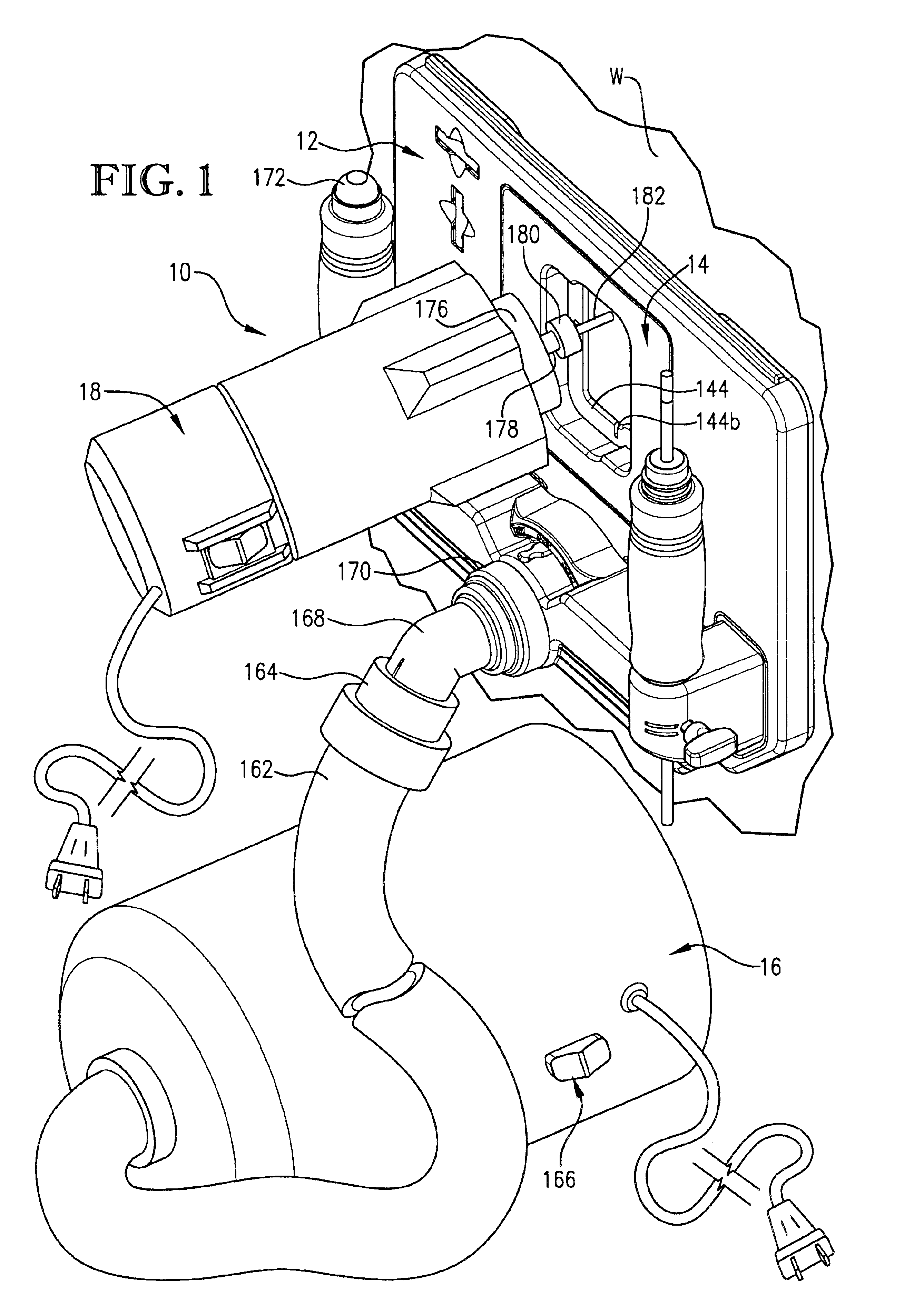

Hole cutting tool

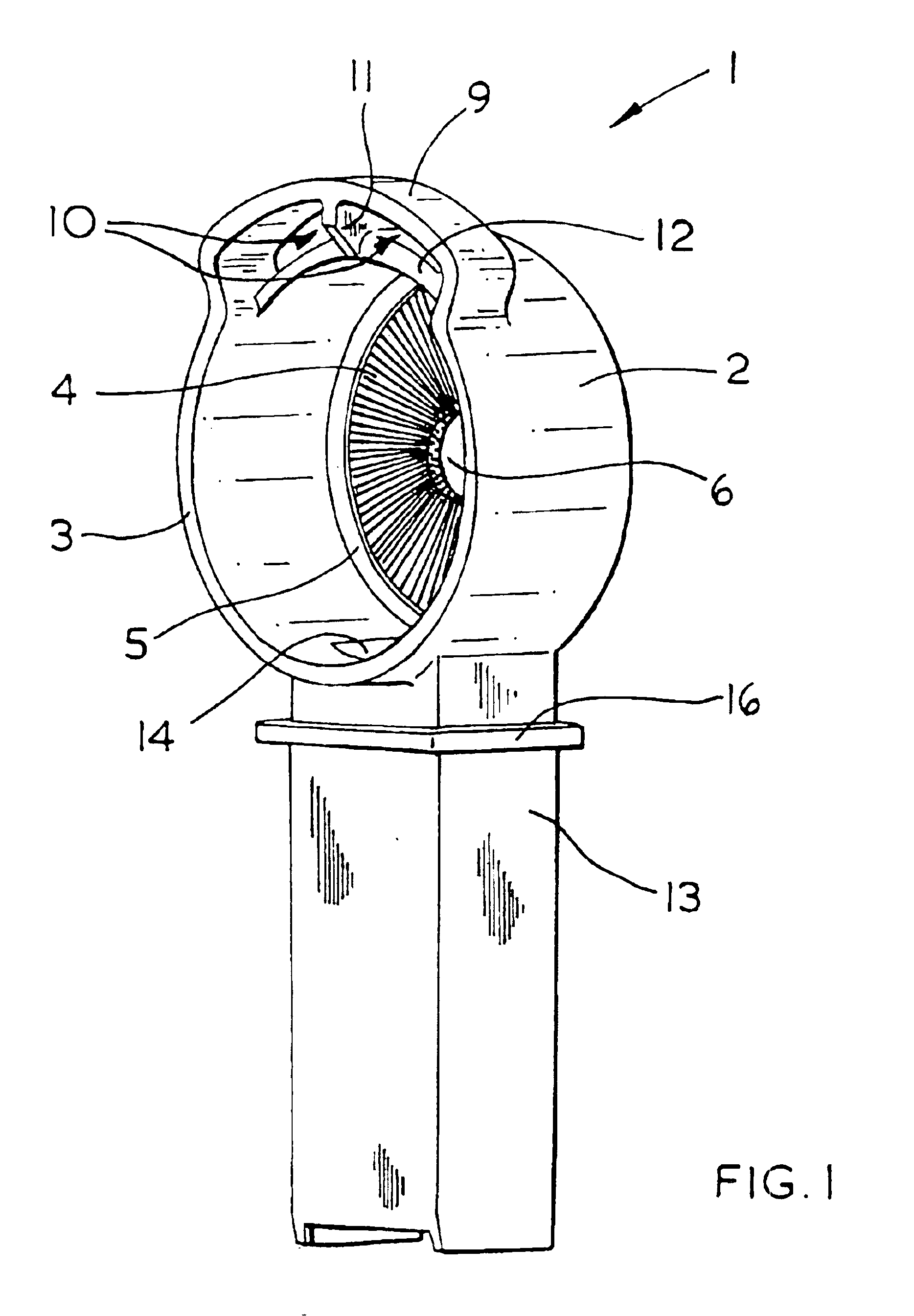

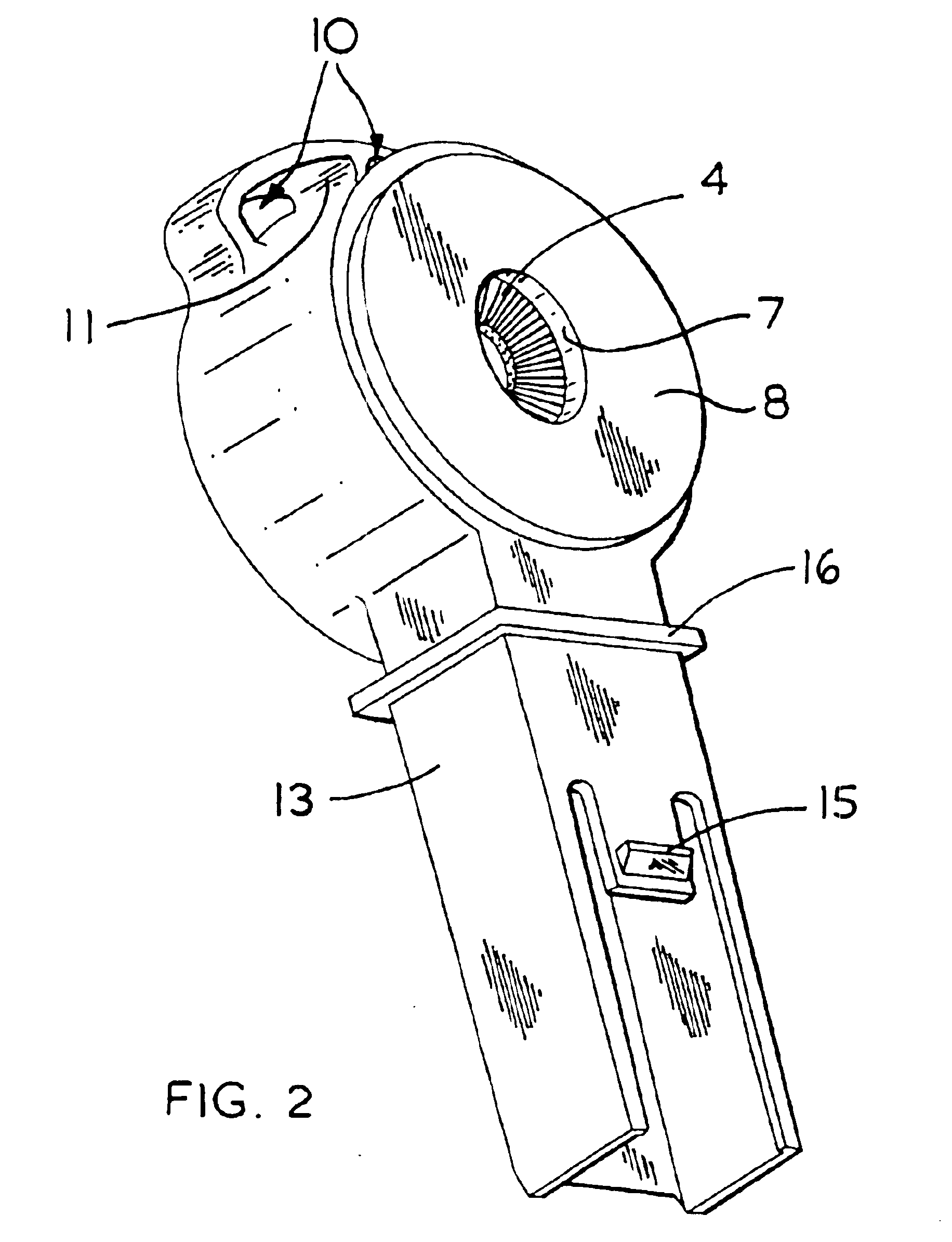

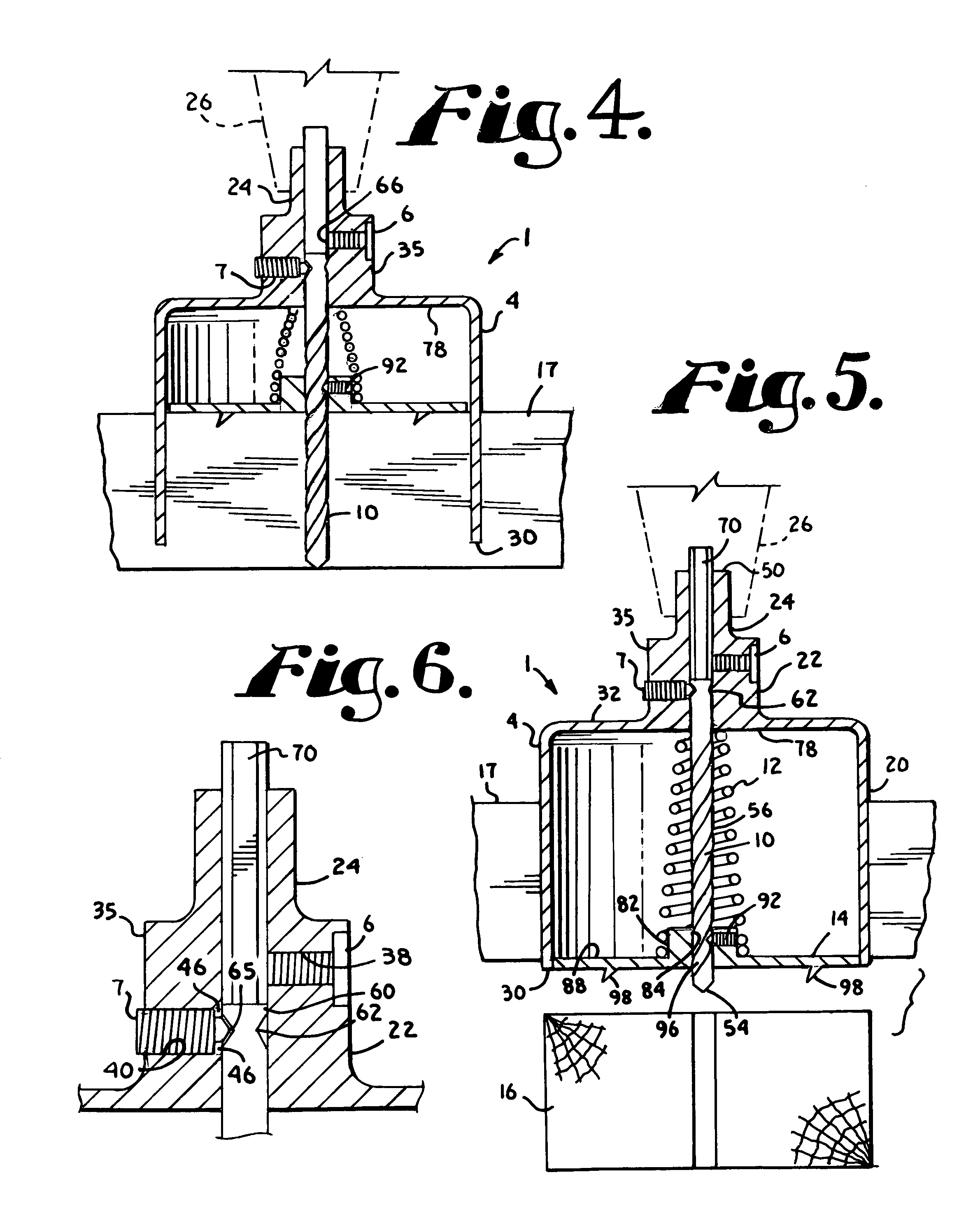

InactiveUS6851900B2Drilling/boring measurement devicesThread cutting feeding devicesDust particlesGasket

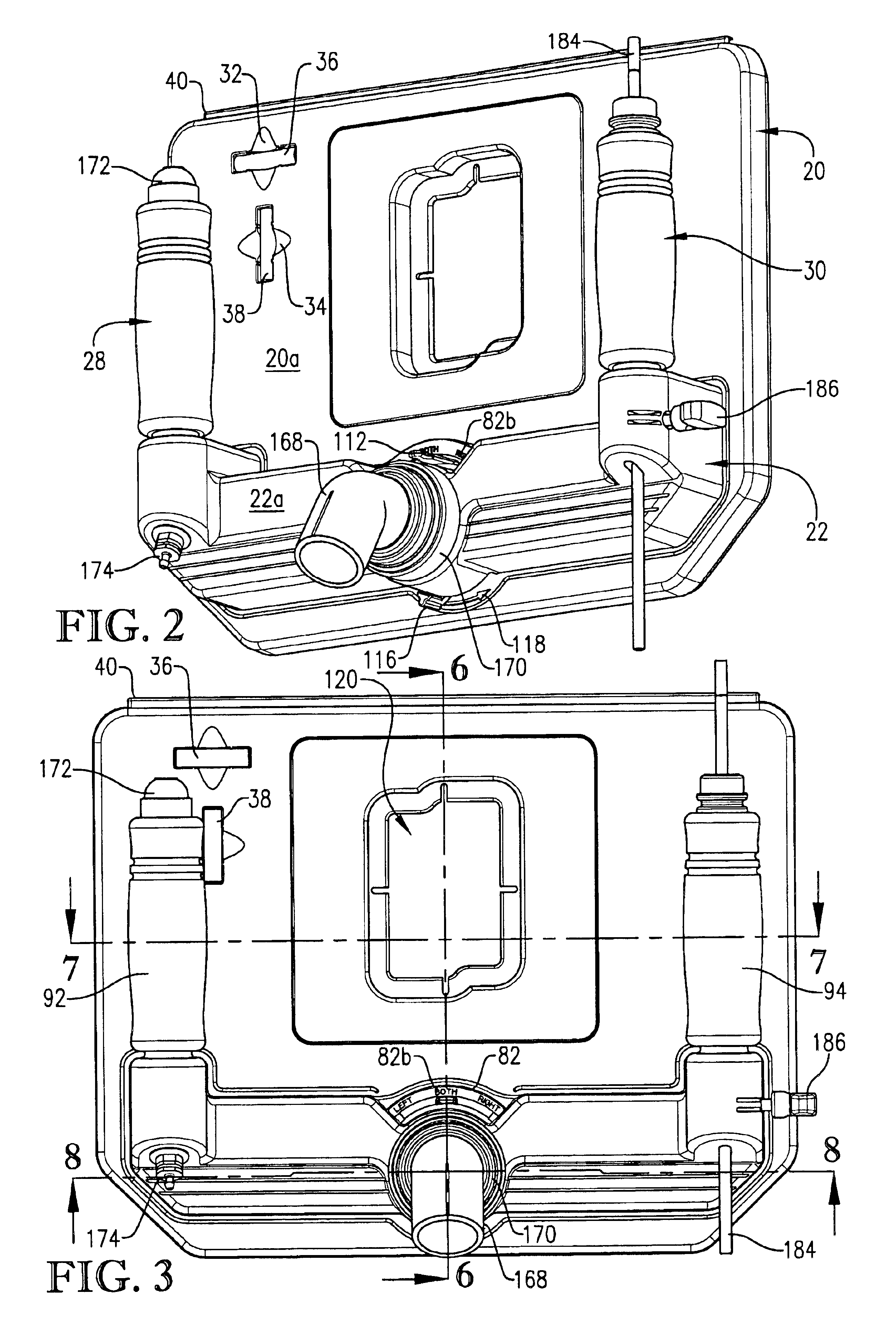

A hole cutting tool (10) configured for cutting an accurately located and precisely shaped hole in a surface, such as a wall (W) of a finished residential or commercial building is disclosed. The tool (10) provides a frame assembly (12) which is self-adhering to the surface (W) and carries removable templates (14, 146-152) for handsfree use in cutting an accurately located and precisely shaped hole. The unique frame assembly (12) provides multiple selectable, pneumatically isolated suction chambers (50,52) that enable the self-adhesion function even when the frame assembly (12) is placed over existing holes in the surface (W). The suction chambers (50,52) are formed in part by a unique corrugated gasket (56) that enables the frame assembly (12) to self-adhere to porous surfaces. The removable template (14) enables dust particles created during the cutting process to be simultaneously vacuumed away regardless of the orientation of the template (14) relative to the frame assembly (12).

Owner:PYTHON PERFECT CUTTER

Debris shield for a rotary tool or machine

ActiveUS20070065242A1Eliminate needReduce needDrilling/boring measurement devicesThread cutting feeding devicesHole sawEngineering

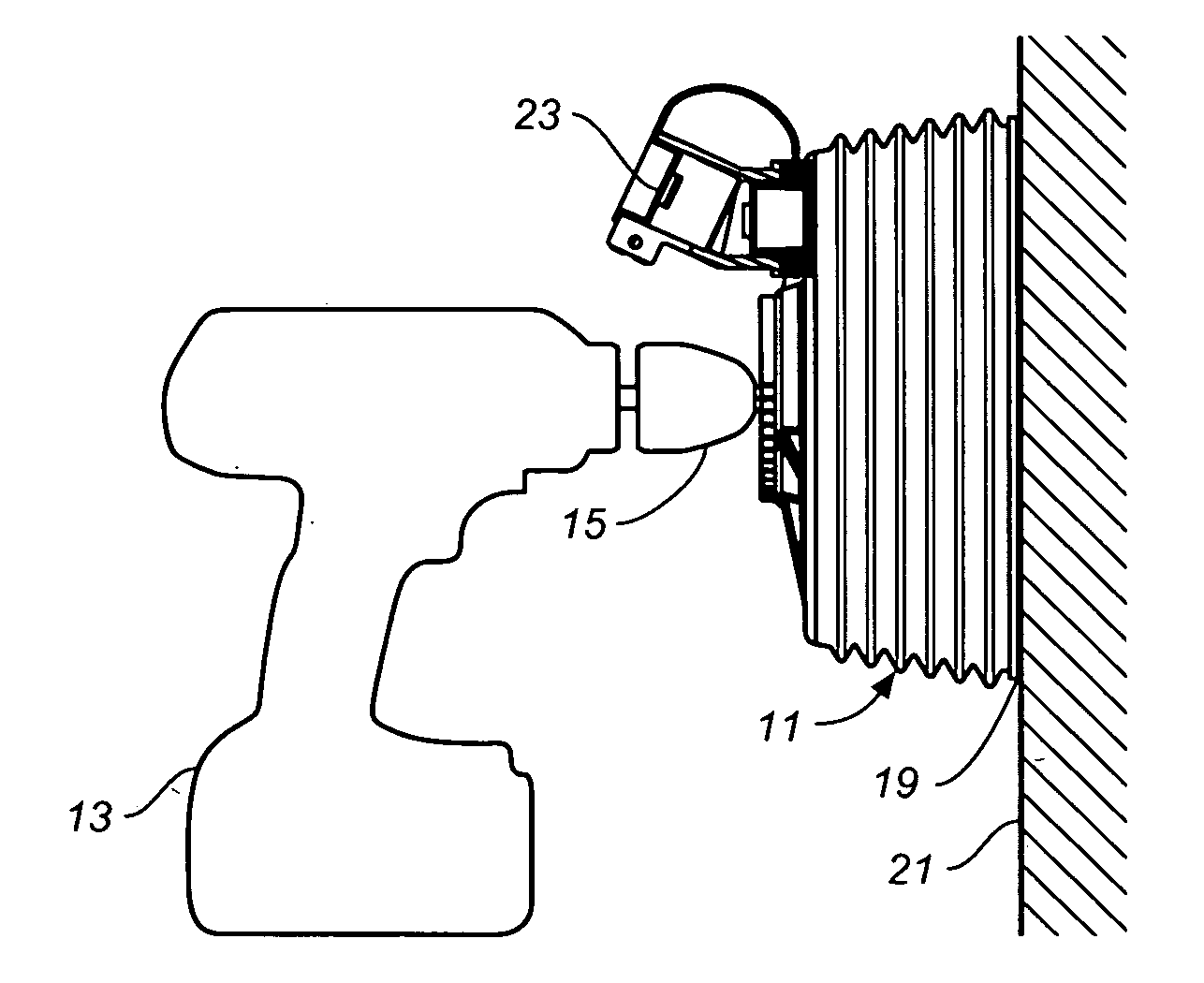

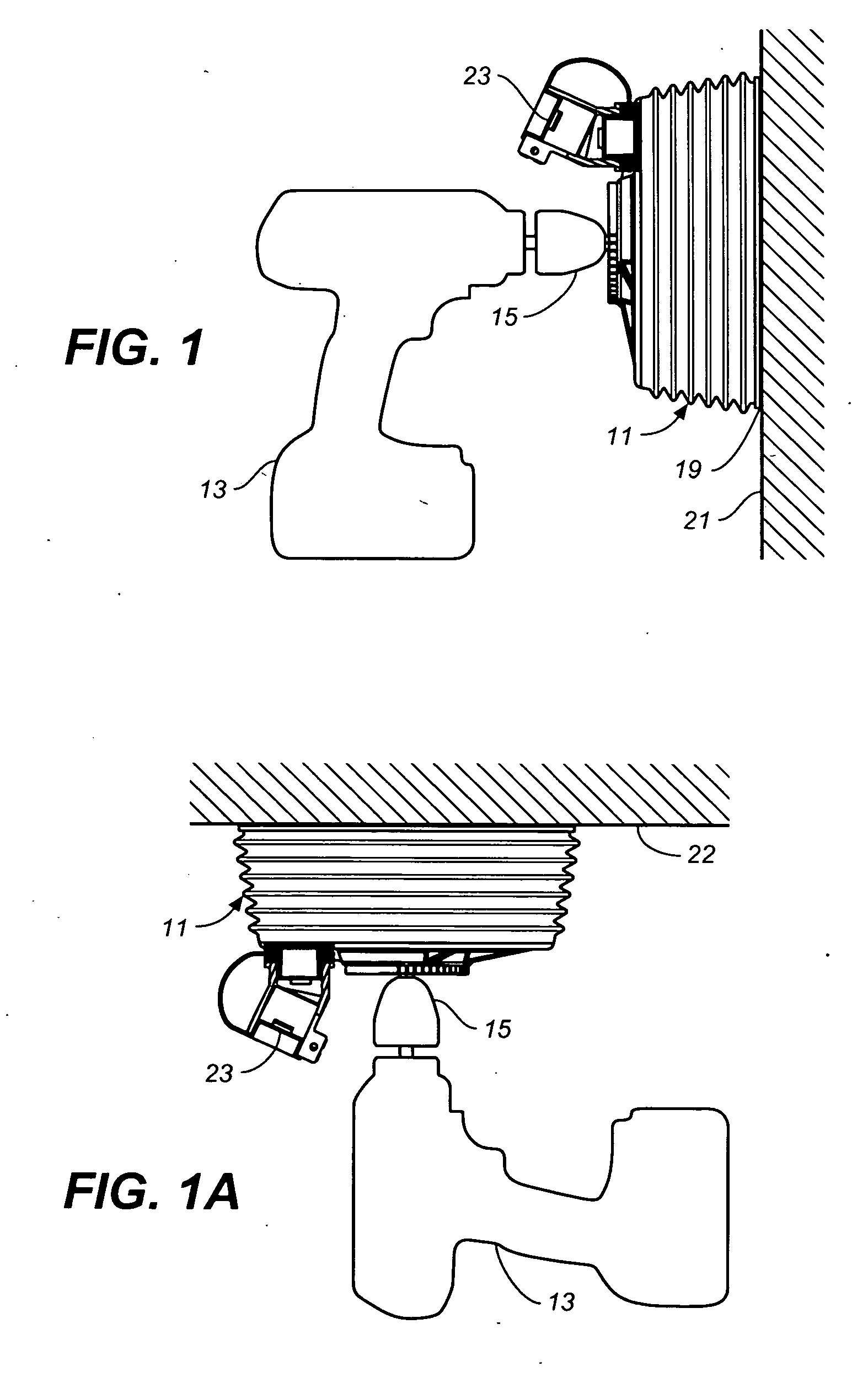

A debris shield for a rotary tool or machine for collecting debris generated while cutting or drilling holes in a work surface has a debris collection housing having a top structure, side walls depending from said top cover structure to form a debris collection chamber, an open bottom with a surface contact rim, and a compression axis extending through the housing's top structure and bottom opening. In one aspect of the invention, the debris collection housing is a bellows housing with a vacuum port, and has a shank-holding and vent assembly in top structure of the bellows housing for receiving and rotatably holding the shank of a rotary surface working implement such as a drill bit, spade bit or hole saw. In another aspect of the invention the debris collection housing can be either a bellows type housing or rigid housing, and can have a vacuum port or not. In this aspect of the invention, the housing is provided with a chuck-arbor assembly having a chuck end and an arbor end rotatably mounted in the top structure of said debris collection housing so that it lies on a rotary axis that is substantially parallel to the compression axis of said debris collection housing. The chuck end of said chuck-arbor assembly is situated within said housing for receiving and holding the arbor end of a surface working implement, and the arbor end of said chuck-arbor assembly projects above the top structure of said housing such that the arbor end of said chuck-arbor assembly can be inserted into the chuck of a rotary tool such as a handle drill. In one embodiment, compression along the compression axis is provided by means of a bellows type housing; in another embodiment compression is provided by a chuck-arbor assembly having a spring loaded shaft which is slidably mounted in the top structure of the housing, such that the chuck end of the chuck-arbor assembly can be made to advance against the restoring force of the spring loaded shaft toward a work surface.

Owner:SKRADSKI THOMAS J

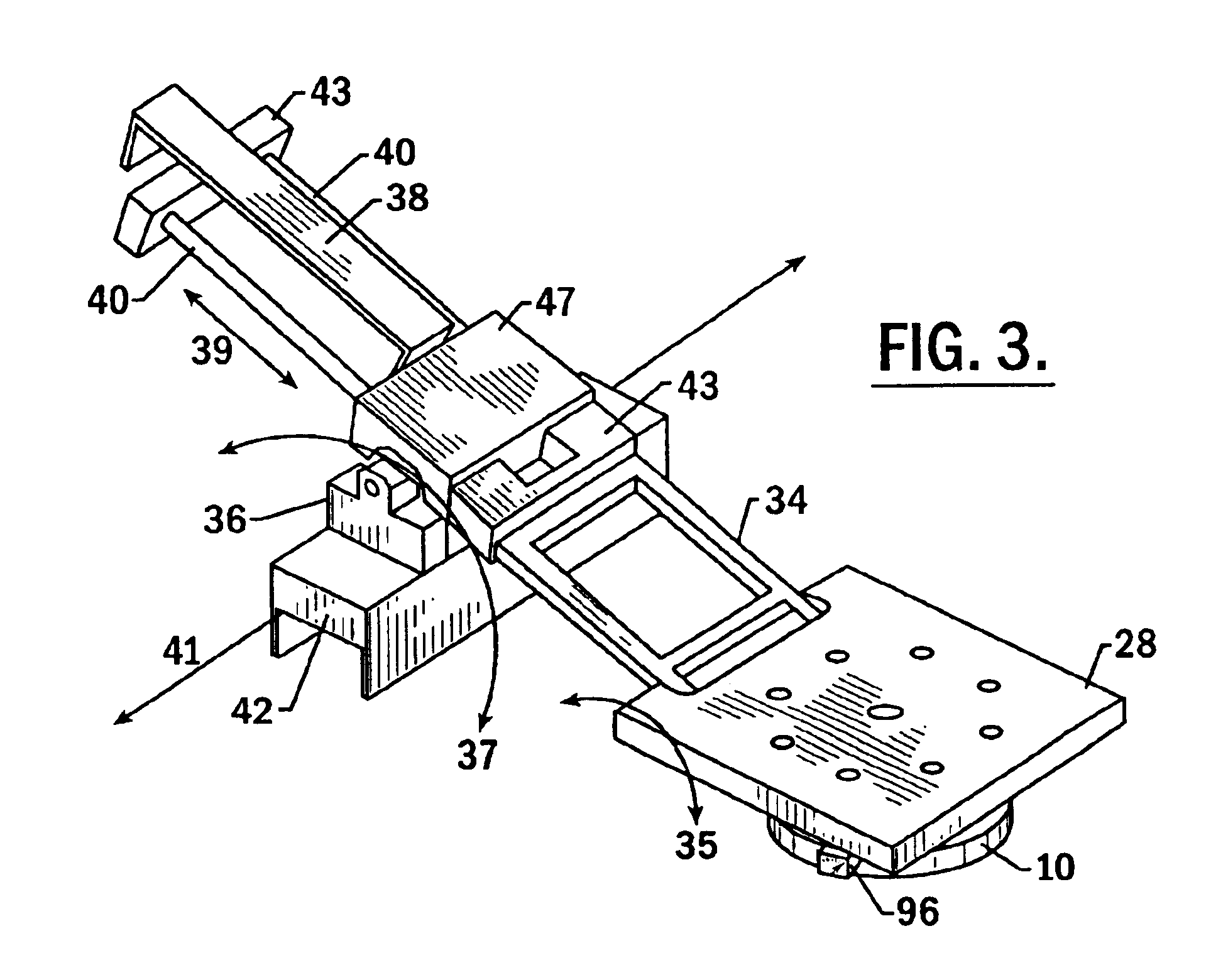

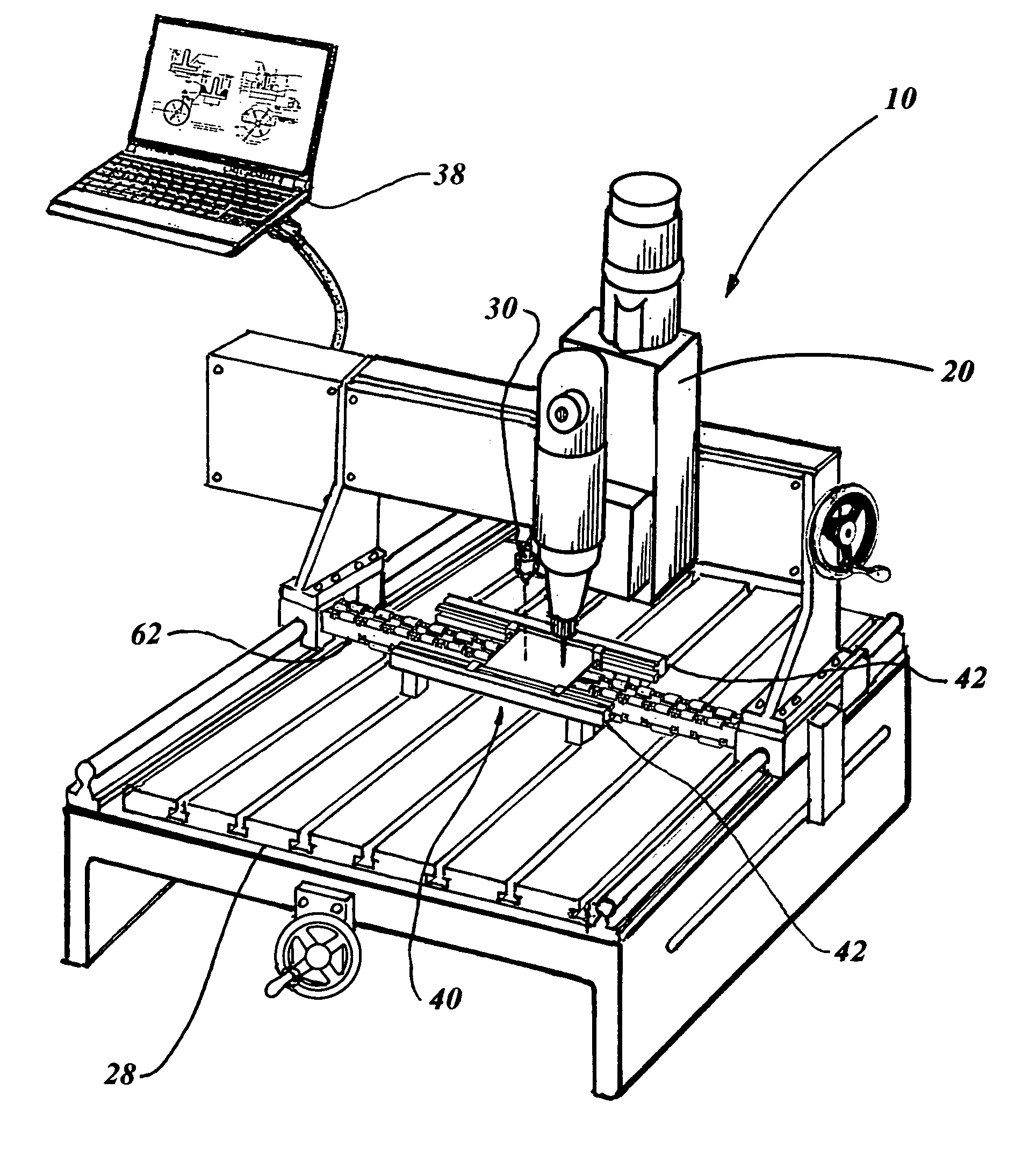

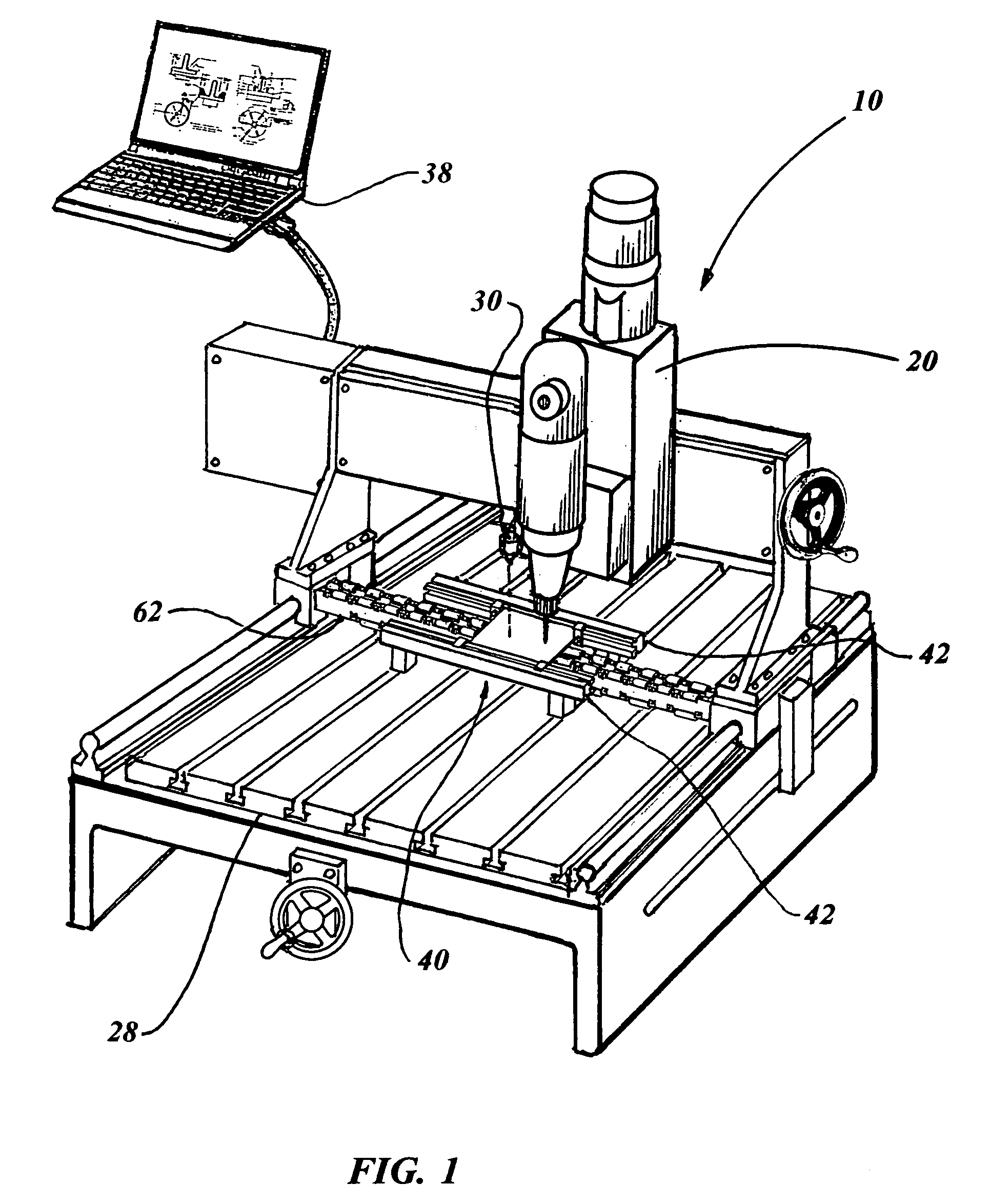

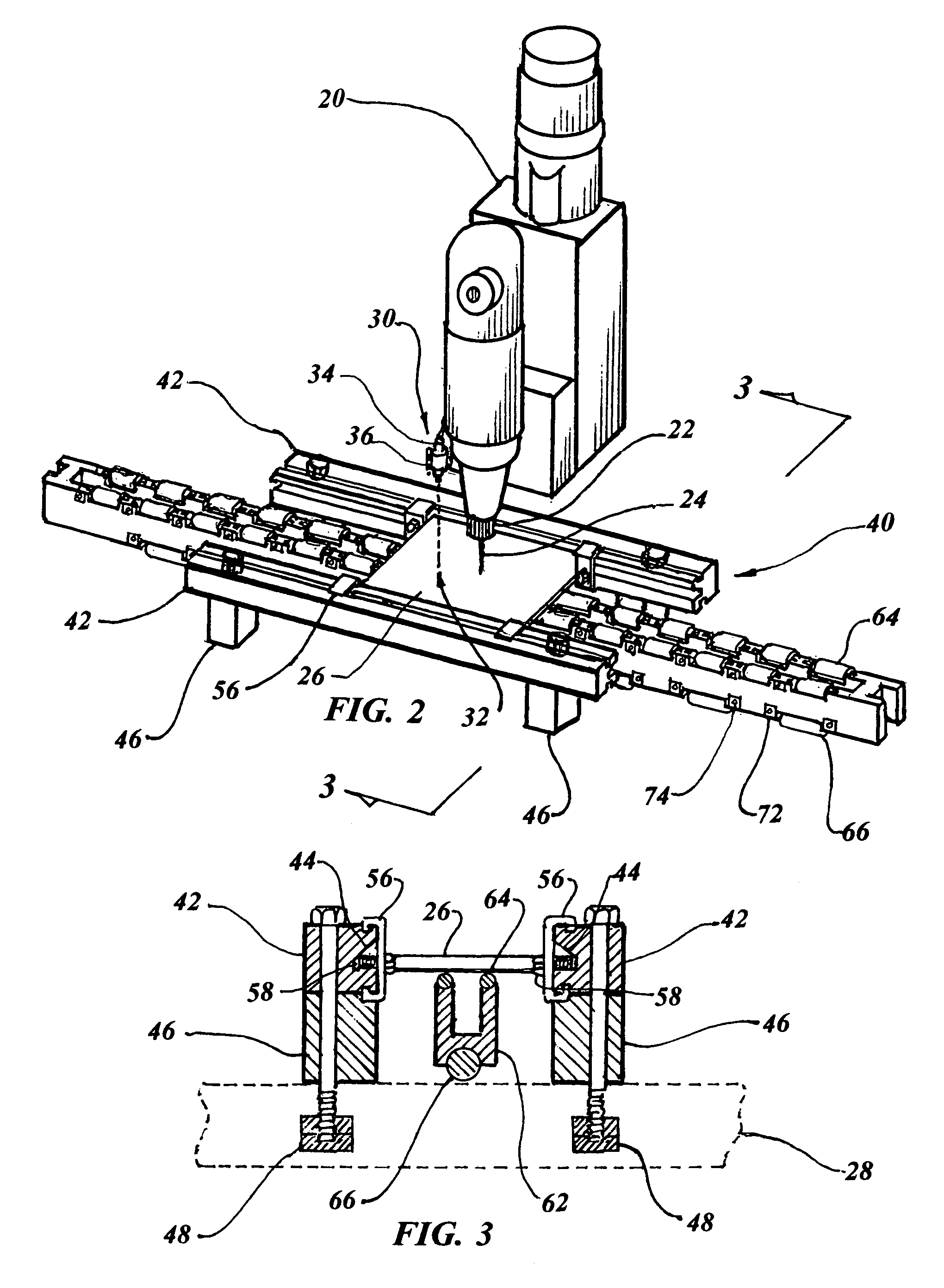

Thin plate drilling and milling machine

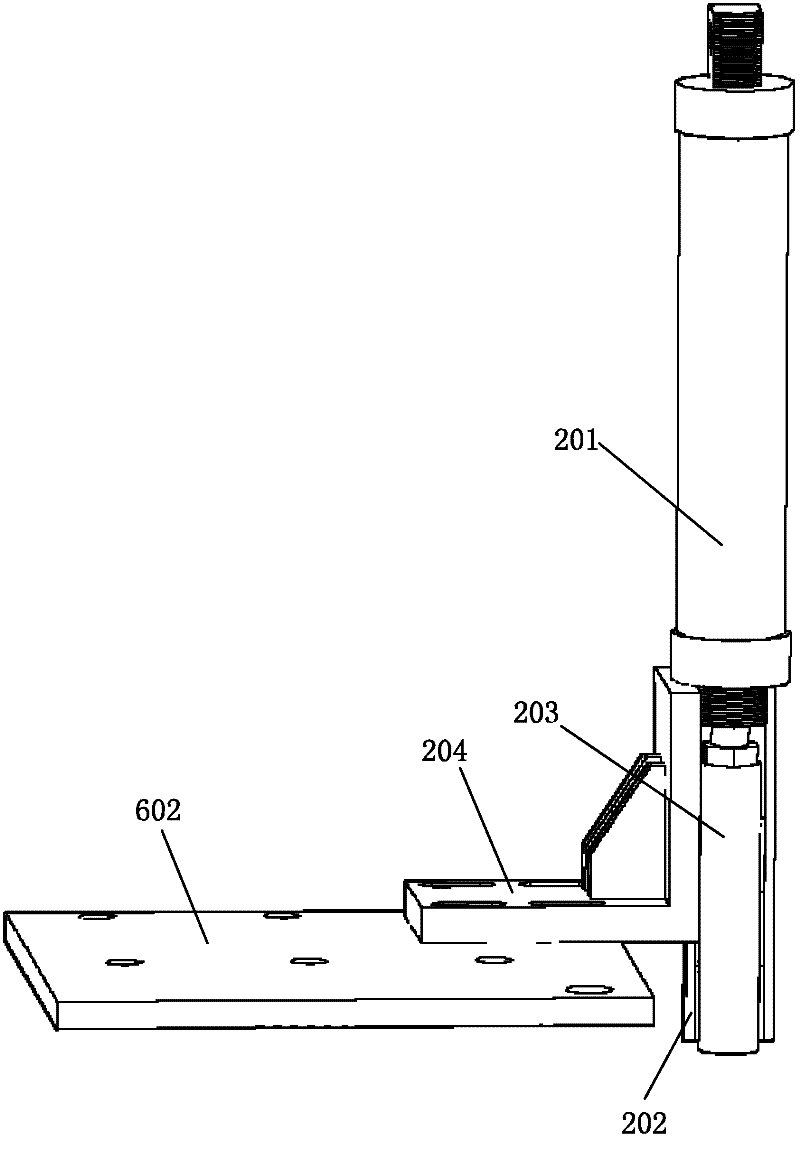

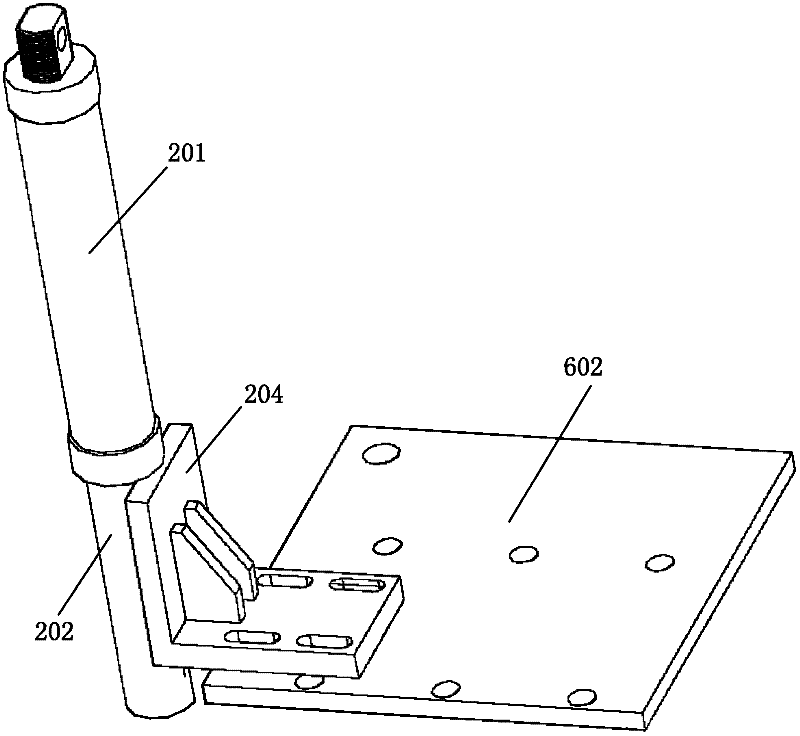

InactiveUS7467449B1Avoid scratchesEasy to slideDrilling/boring measurement devicesThread cutting feeding devicesEngineeringLaser beams

A CNC drilling and milling machine comprised of a movable drill motor platform (20) with a laser reference point finder (30) in the form of a laser (34) that is attached to the machine adjacent a spindle (22). The reference point is aligned on the workpiece (26) with an identical reference located in a CNC computer (38). A workpiece holder (20) has two opposed bars (42) attached to a T-groove base of the drilling and milling machine, with each bar having a longitudinal notch (44) for holding the edges of a workpiece (26). A plate compression support and debris collecting member (62) collects debris and provides support for the workpiece (26). The entire platform is moved to drill or mill at predetermined computer selected positions, having the initial reference point (32) located with the calibrated laser beam.

Owner:LEE S PETER +1

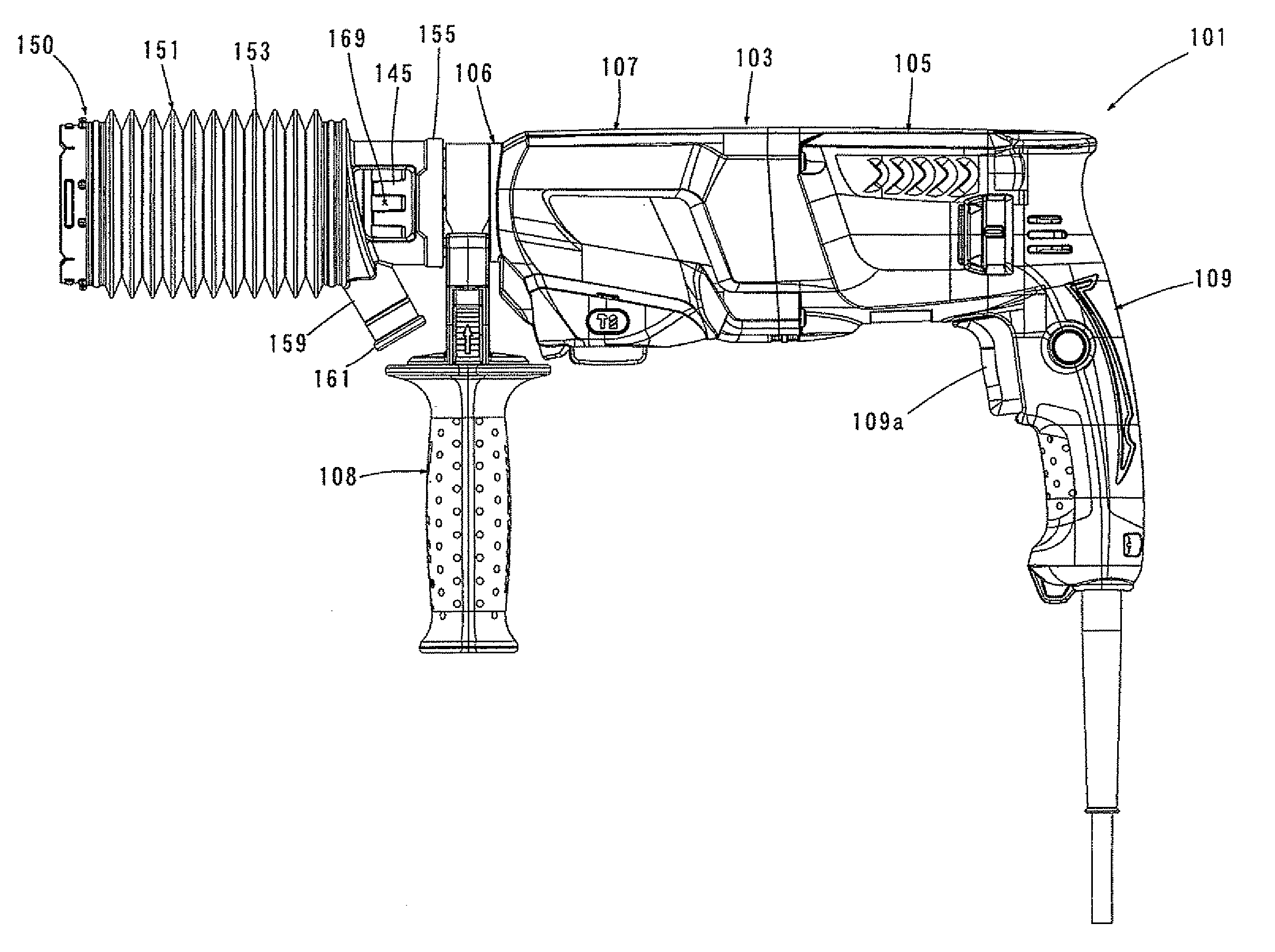

Dust collecting attachment

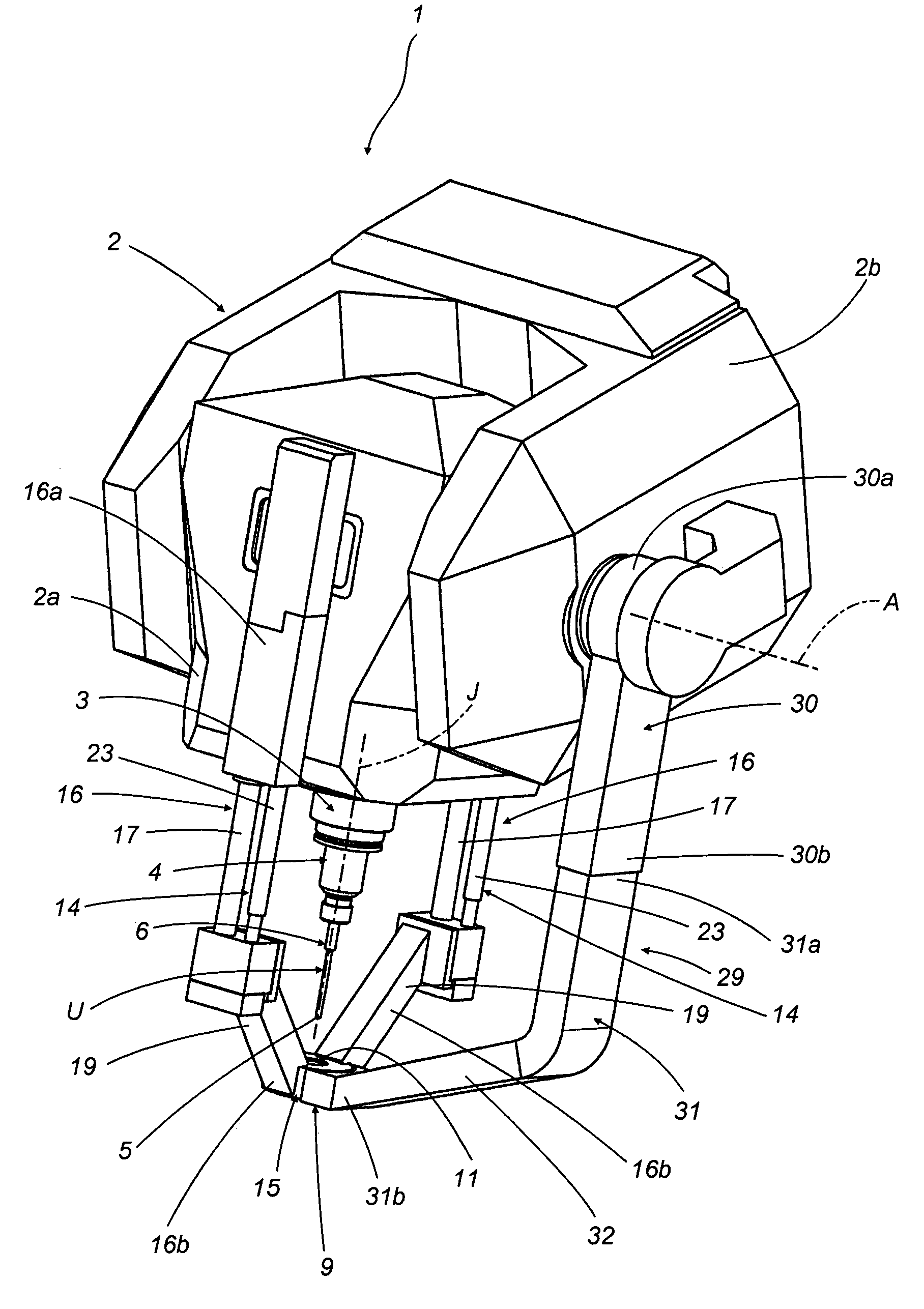

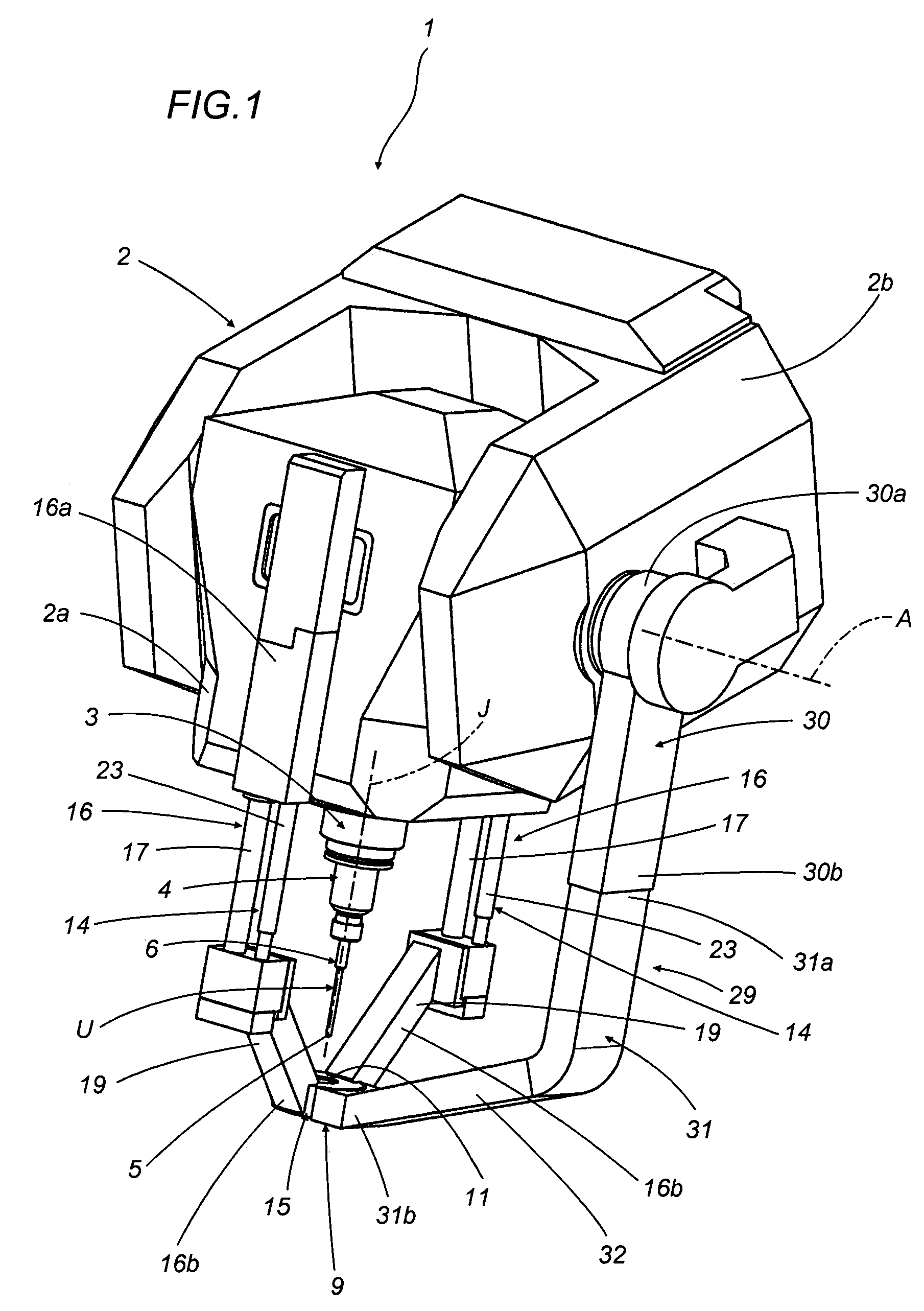

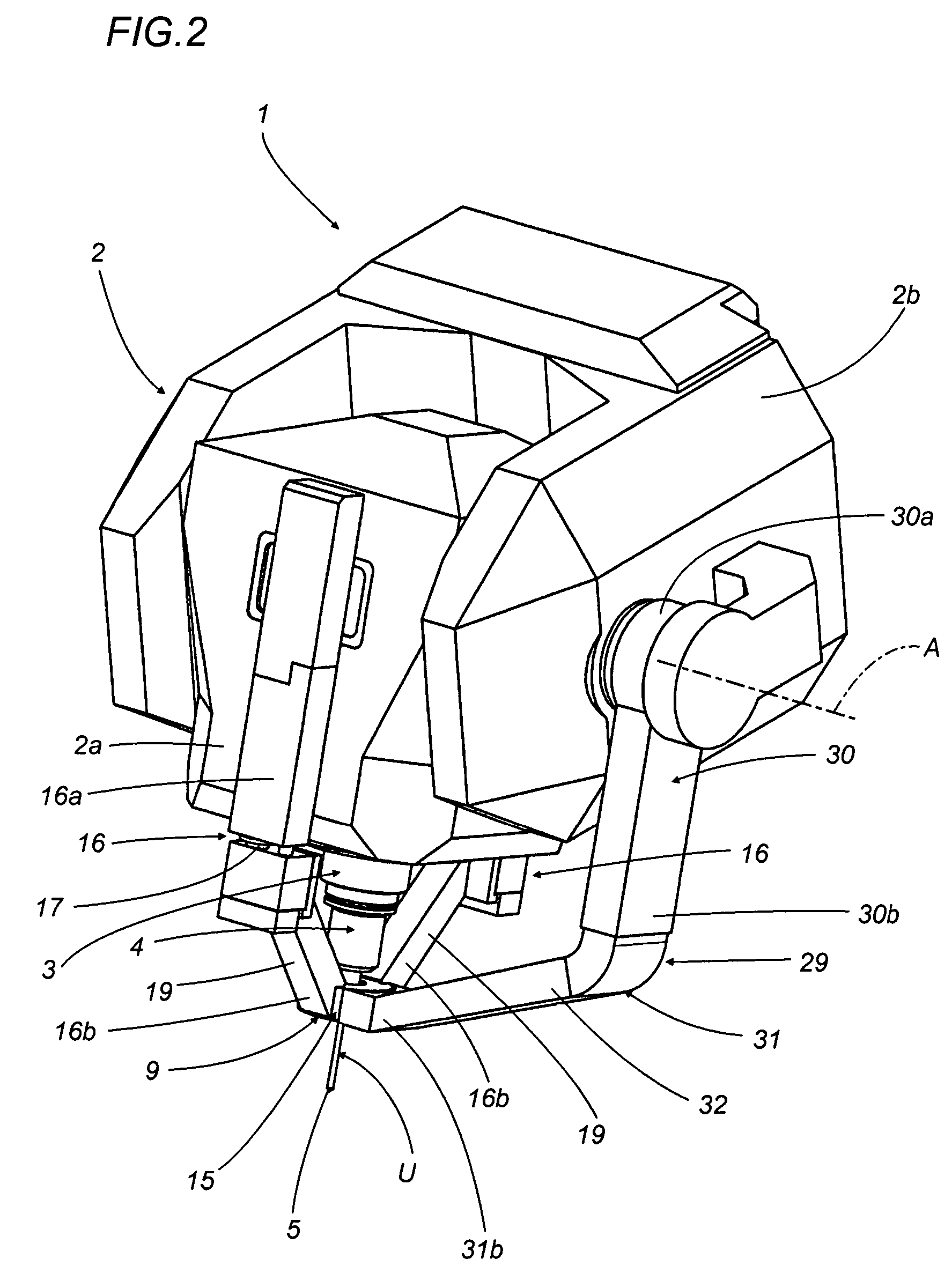

ActiveUS20110008118A1Improve usabilityEasy to replaceThread cutting feeding devicesPortable percussive toolsDrill bitElectrical and Electronics engineering

A technique for allowing a user to operate an operating member disposed in a front end region of a power tool in the state in which a dust collecting attachment designed to be attached to the front end region of the power tool is left attached to the power tool. The dust collecting attachment is used on a power tool having an operating member for removal and / or bit angle setting of a tool bit coupled to a front end region of a tool body. The dust collecting attachment has a dust collecting member which can be attached to the front end region of the tool body. The dust collecting member has an opening formed in a region which faces the operating member in the state in which the dust collecting member is attached to the tool body, and the operating member can be operated by user's finger through the opening.

Owner:MAKITA CORP

Hole saw with waste plug ejector

Owner:EISERER CECIL +1

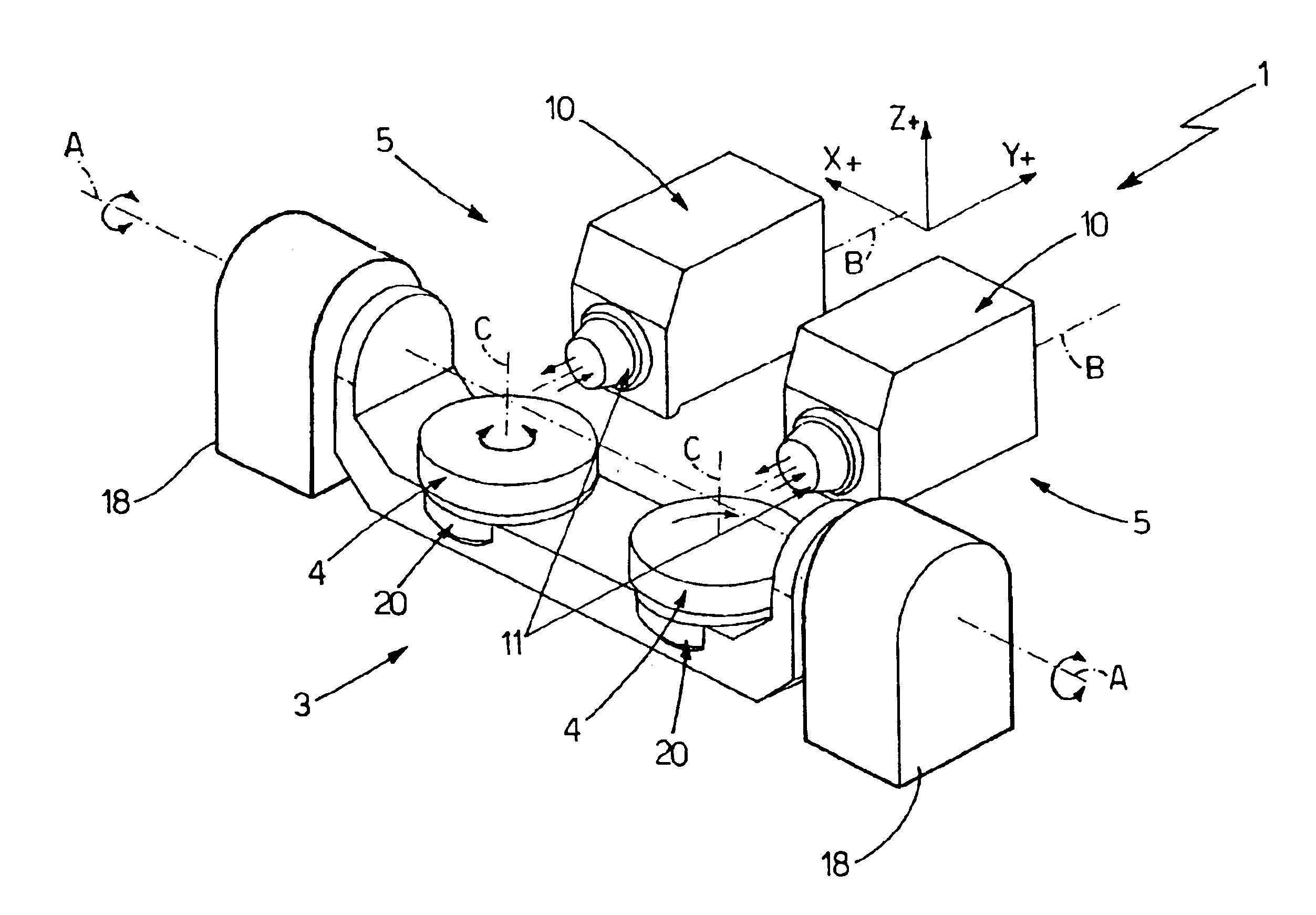

Numerical-control milling machine

InactiveUS6865788B2Drawback can be obviatedThread cutting feeding devicesThread cutting machinesRotational axisEngineering

A numerical-control milling machine having a supporting frame; a worktable fitted to the supporting frame so as to oscillate about a substantially horizontal first axis of rotation, and in turn having two rotary platforms, each for accommodating a workpiece; and two independent work units, each of which is fitted movably to the supporting frame, alongside the worktable, is positioned facing a corresponding platform, and provides for machining the workpiece on the platform; the two work units selectively operating either asynchronously, to machine the workpieces fixed to the two platforms independently of each other, or synchronously to perform the same machining operations simultaneously on the workpieces fixed to the two platforms.

Owner:O M V OFF MEC VENETE

Portable drilling machine

InactiveUS20060147284A1Preventing a dust collector from interferingIncrease spacingThread cutting feeding devicesDrilling/boring measurement devicesEngineeringDrilling machines

A portable drilling machine includes a housing; a drill chuck positioned on a front surface of the housing; a drill bit detachably coupled to the drill chuck; a driver positioned inside the housing to provide either the drill bit or the drill chuck with a rotational driving force; an anti-dust cover having a rear anti-dust cover formed in a cup shape with a drill through-hole formed in a central region of a bottom surface of the rear anti-dust cover and a front anti-dust cover formed in a tube shape to be coupled to the rear anti-dust cover, the front anti-dust cover being adapted to move towards the bottom surface of the rear anti-dust cover when acted on by pressure towards the housing and return to original position when the pressure is removed; and a dust collector having a retainer for detachably coupling the rear anti-dust cover to an outer surface of either the housing or the drill chuck. The rotational motion of the drill bit is not interfered with by the dust collector, and the dust collection space is increased.

Owner:LEE SEOK JAE

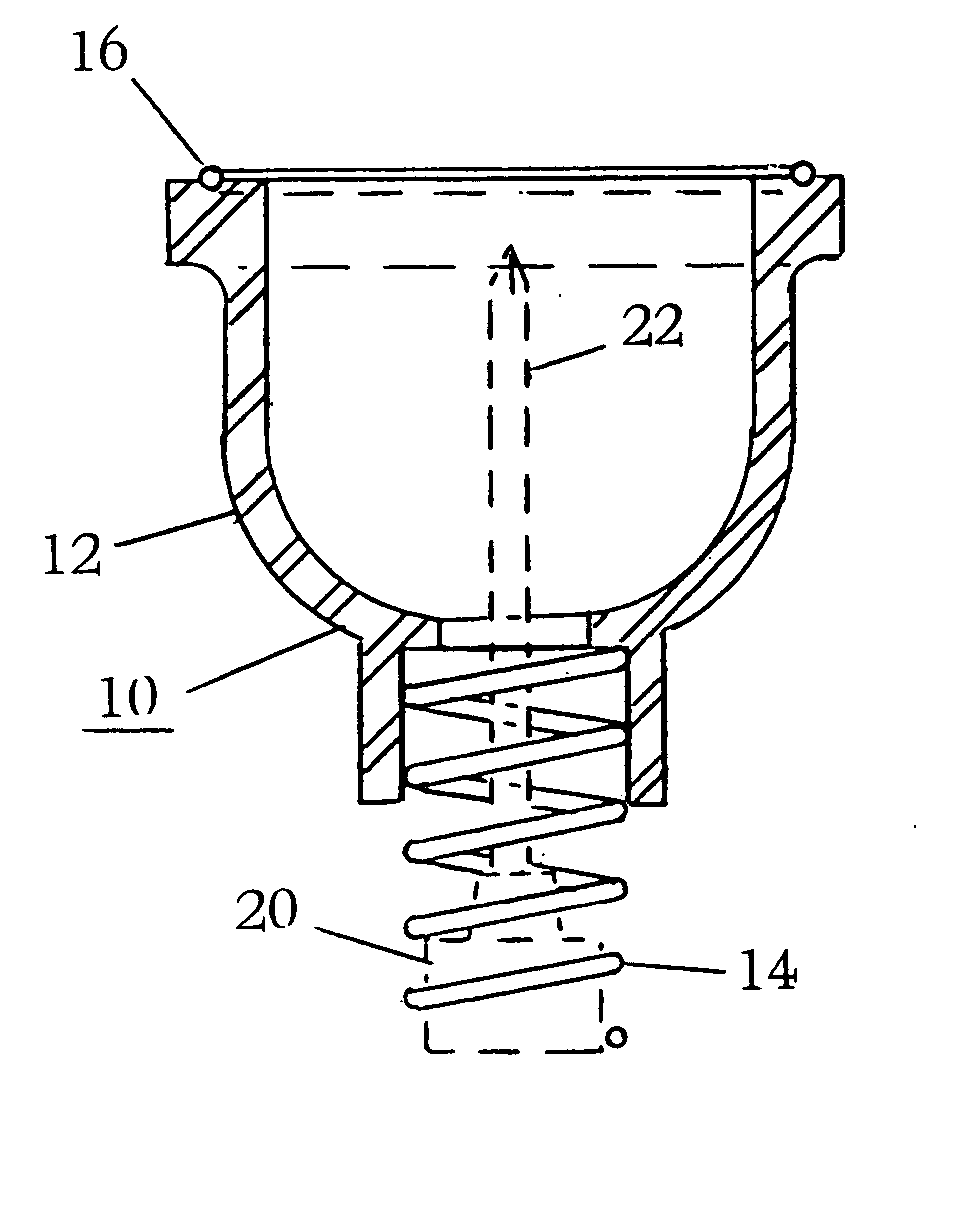

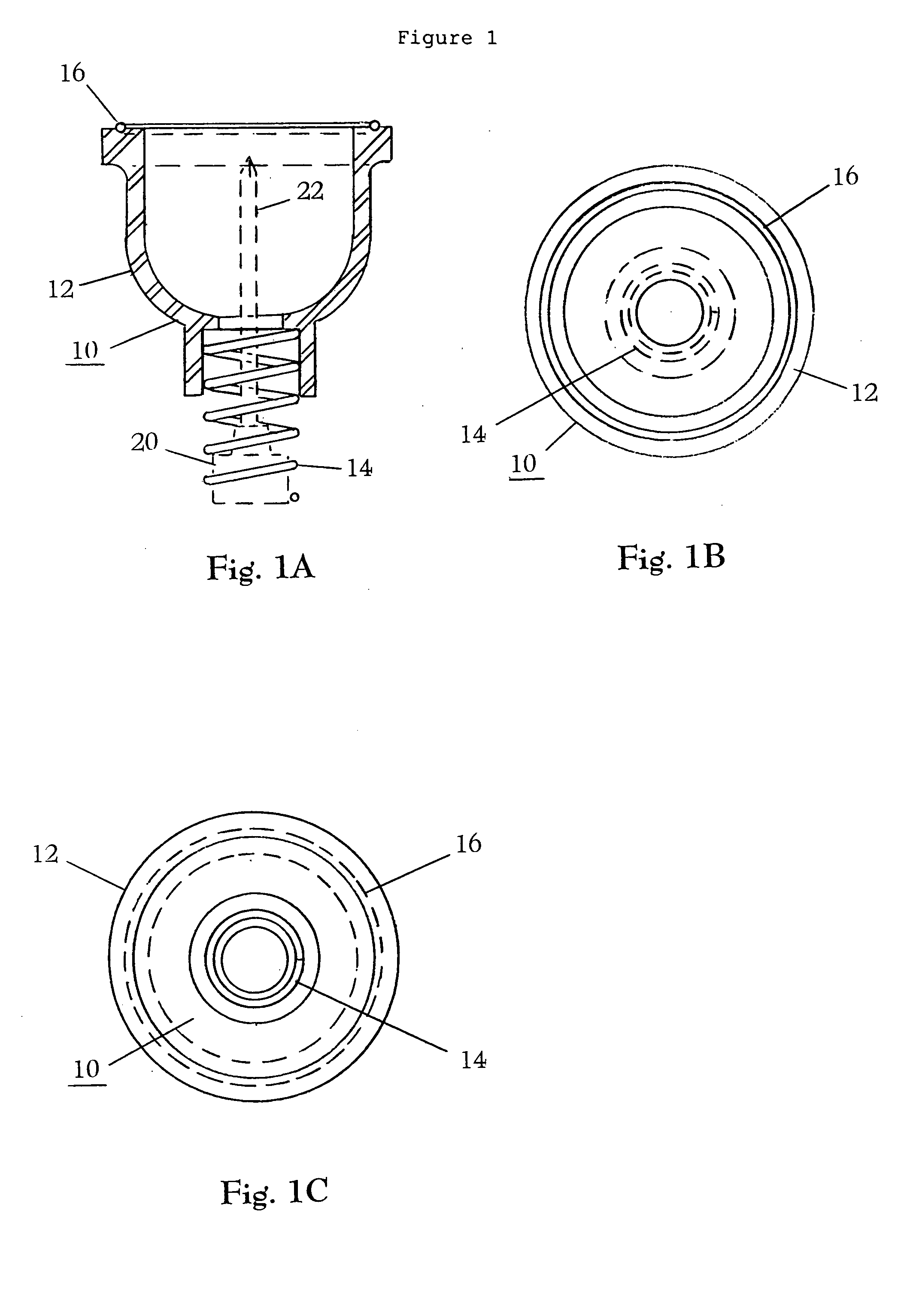

Debris shield for a rotary tool or machine

ActiveUS7901164B2Eliminate needReduce needDrilling/boring measurement devicesThread cutting feeding devicesEngineeringDrill bit

A debris shield for a rotary tool or machine for collecting debris generated while cutting or drilling holes in a work surface has a debris collection housing having a top structure, side walls depending from said top cover structure to form a debris collection chamber, an open bottom with a surface contact rim, and a compression axis extending through the housing's top structure and bottom opening. In one aspect of the invention, the debris collection housing is a bellows housing with a vacuum port, and has a shank-holding and vent assembly in top structure of the bellows housing for receiving and rotatably holding the shank of a rotary surface working implement such as a drill bit, spade bit or hole saw.

Owner:SKRADSKI THOMAS J

Hole saw slug removal device

InactiveUS7160064B2Simple designMinimal expenseThread cutting feeding devicesTransportation and packagingCircular discHole saw

The hole saw slug removal device is a device constructed to fit within a hole saw that provides for automatic ejection of waste slugs from within the hole saw. The hole saw slug removal device generally consists of two discs affixed on either end of a compression spring. The device is then inserted into the hole saw, and one disc retains the compression spring within the hole saw by locking onto the drill bit or against the inner surface of the hole saw. Upon operation of the hole saw, the spring compresses and the other disc is pushed down by the force of the sawing. After the sawing is completed, the spring decompresses, and the disc is pushed forward, automatically ejecting the waste slug that has become trapped within the hole saw. The slug removal device may lack one disc and instead be permanently affixed to a hole saw.

Owner:JASSO ABELARDO

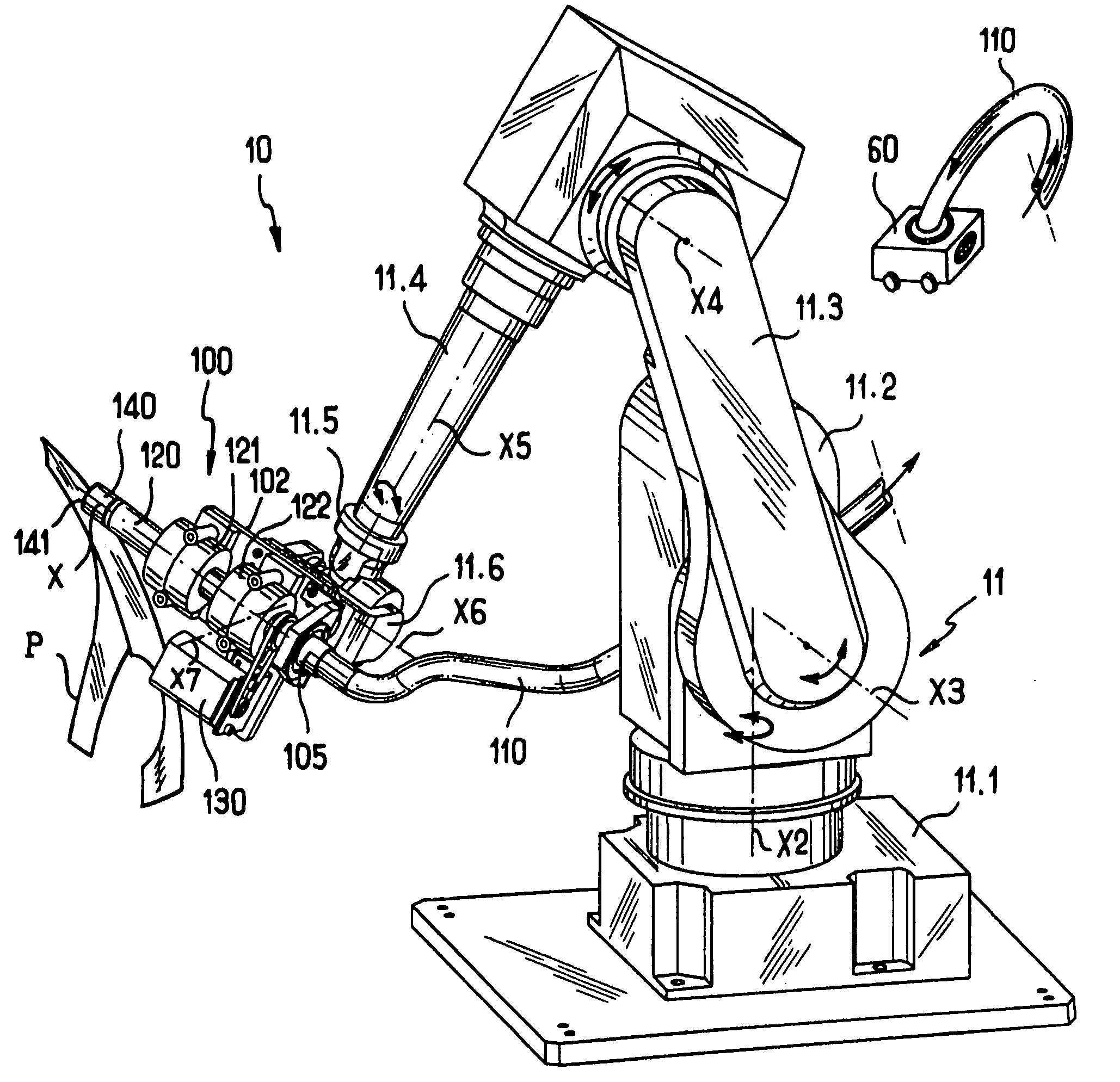

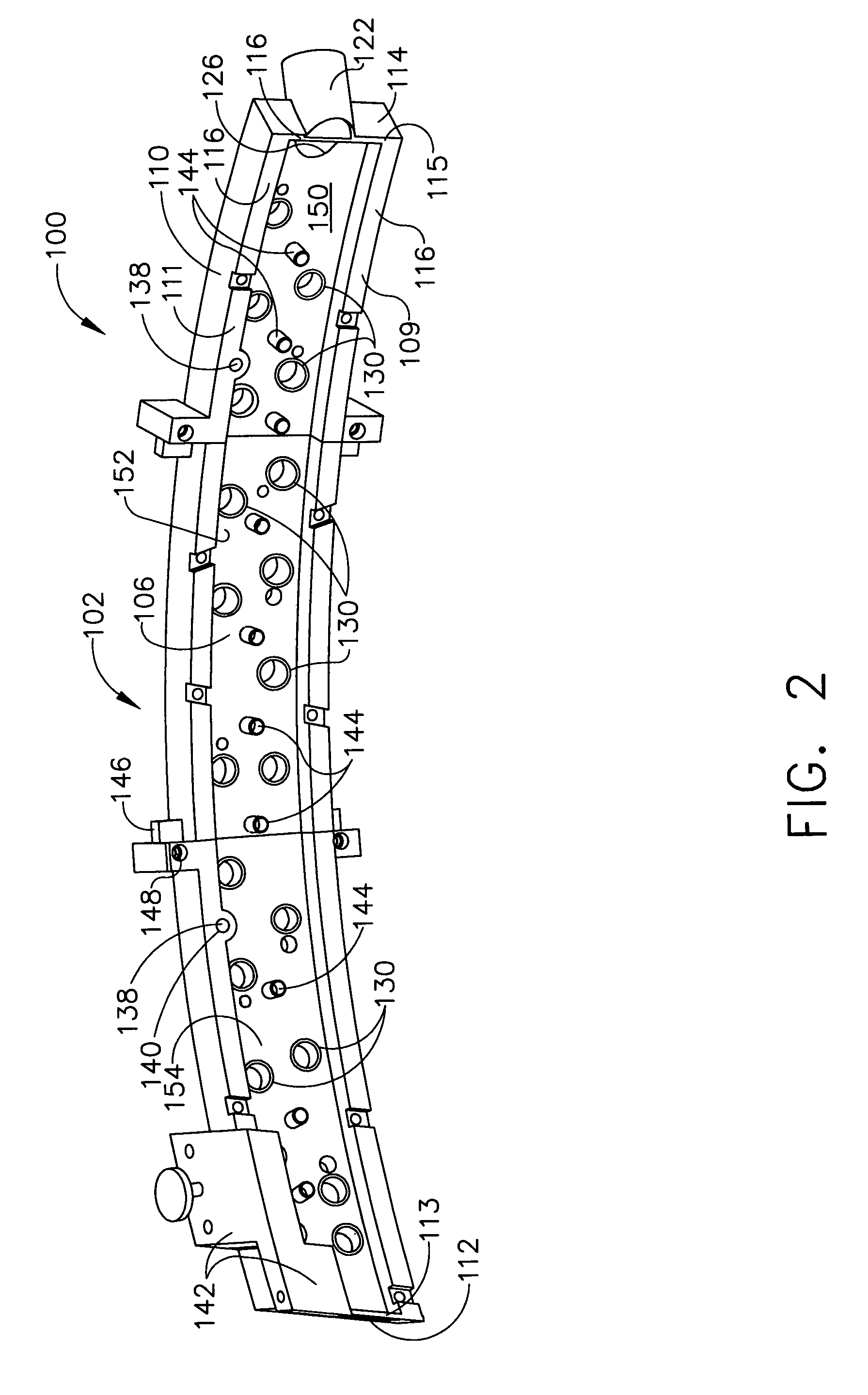

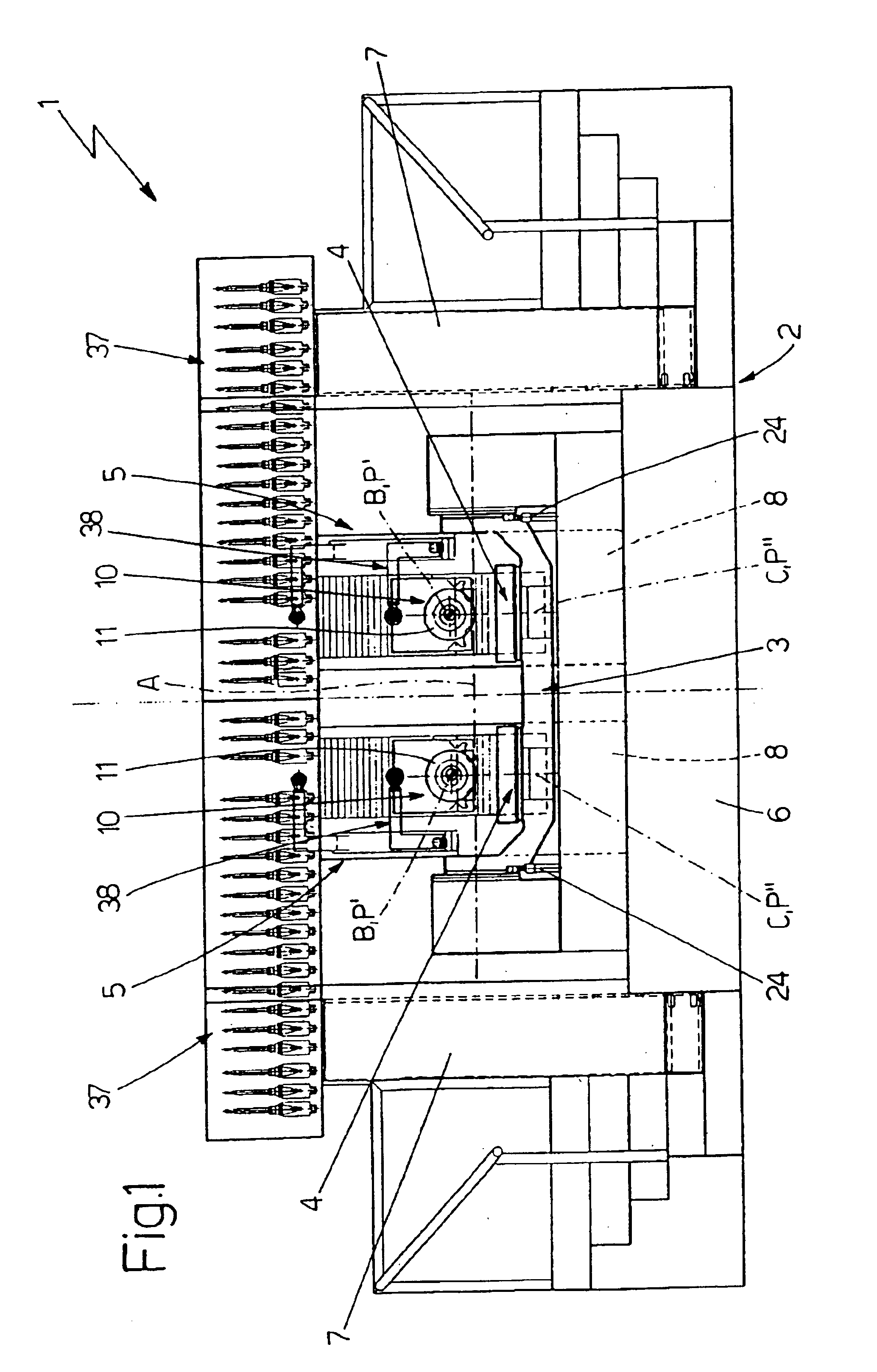

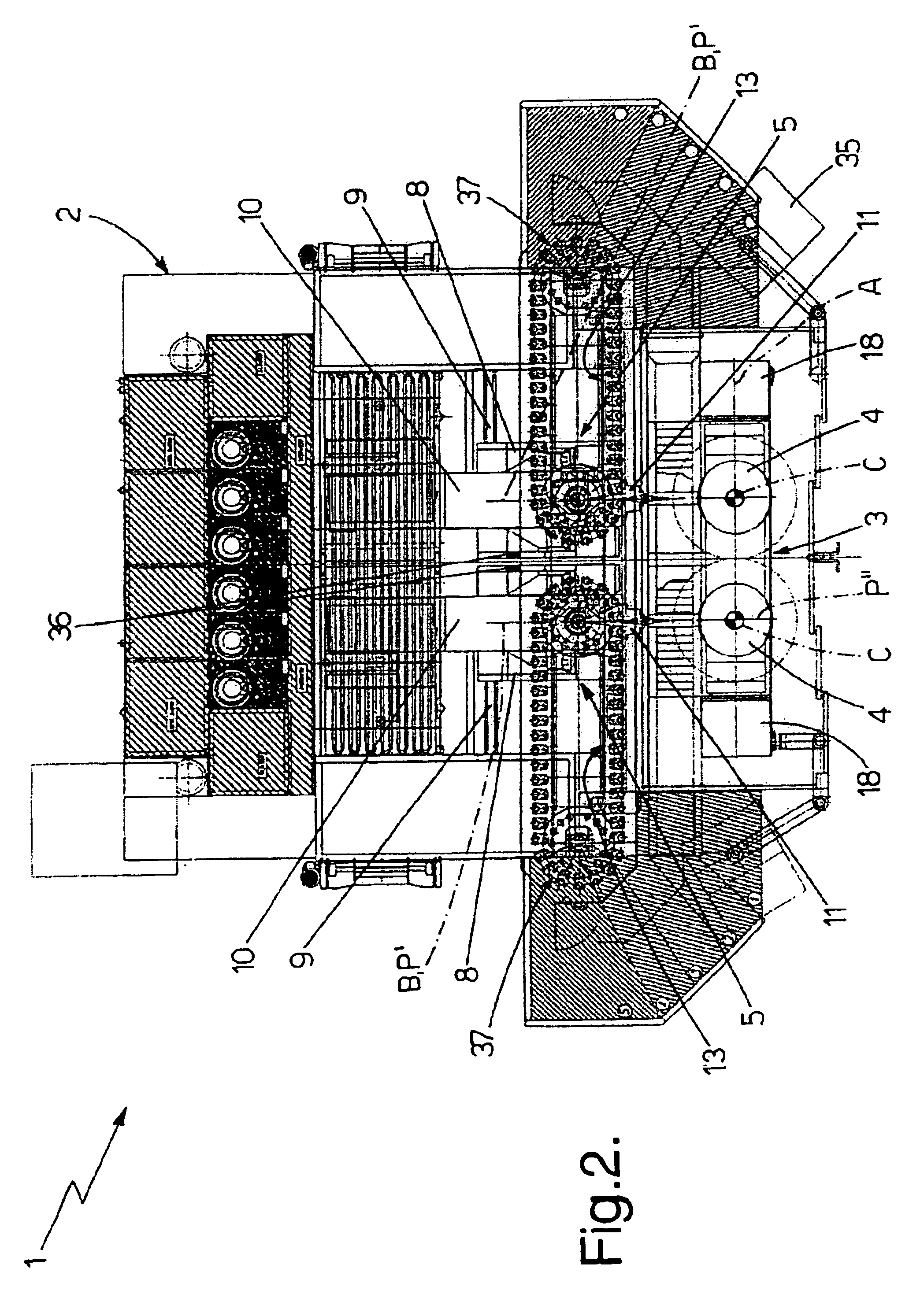

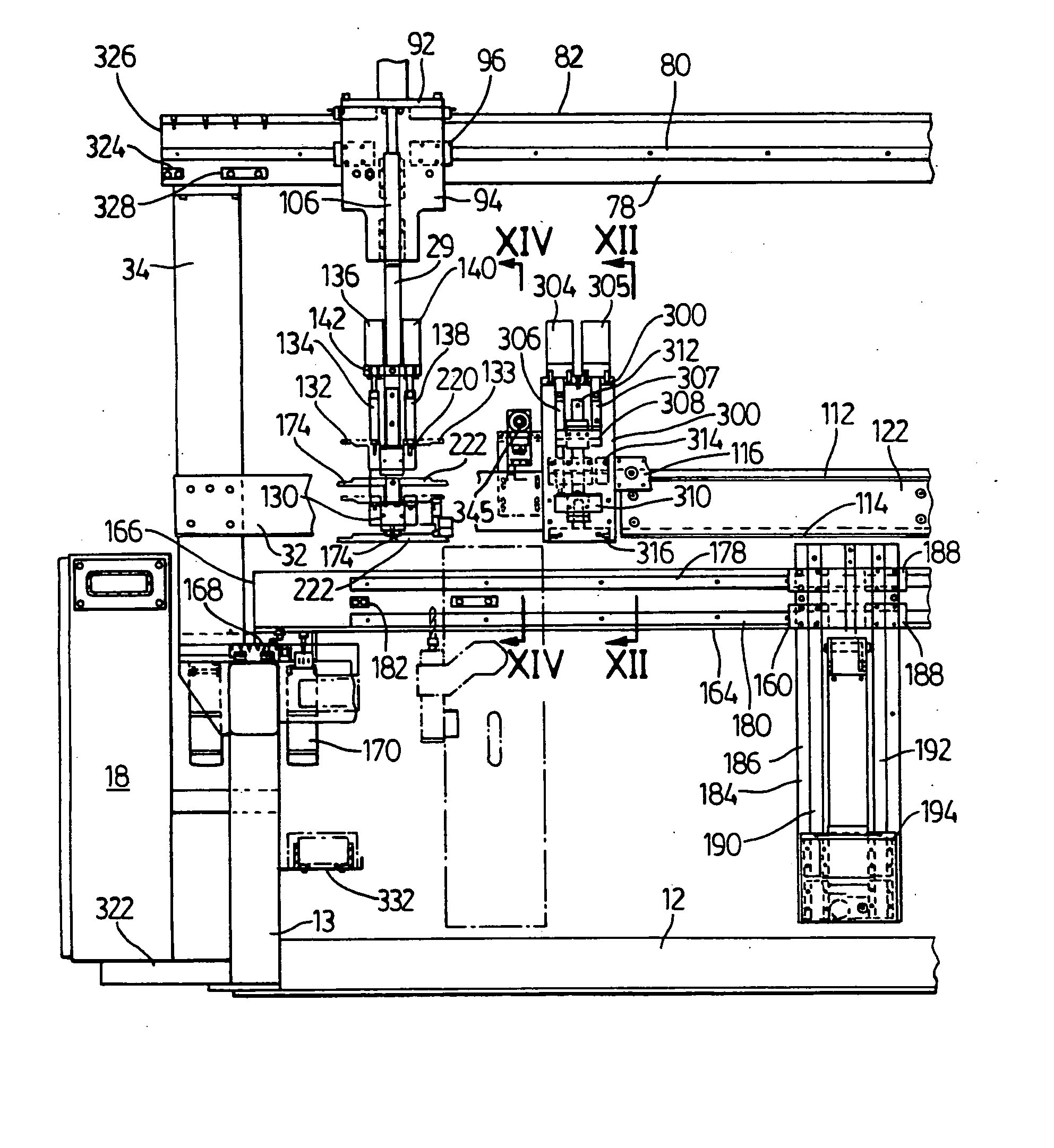

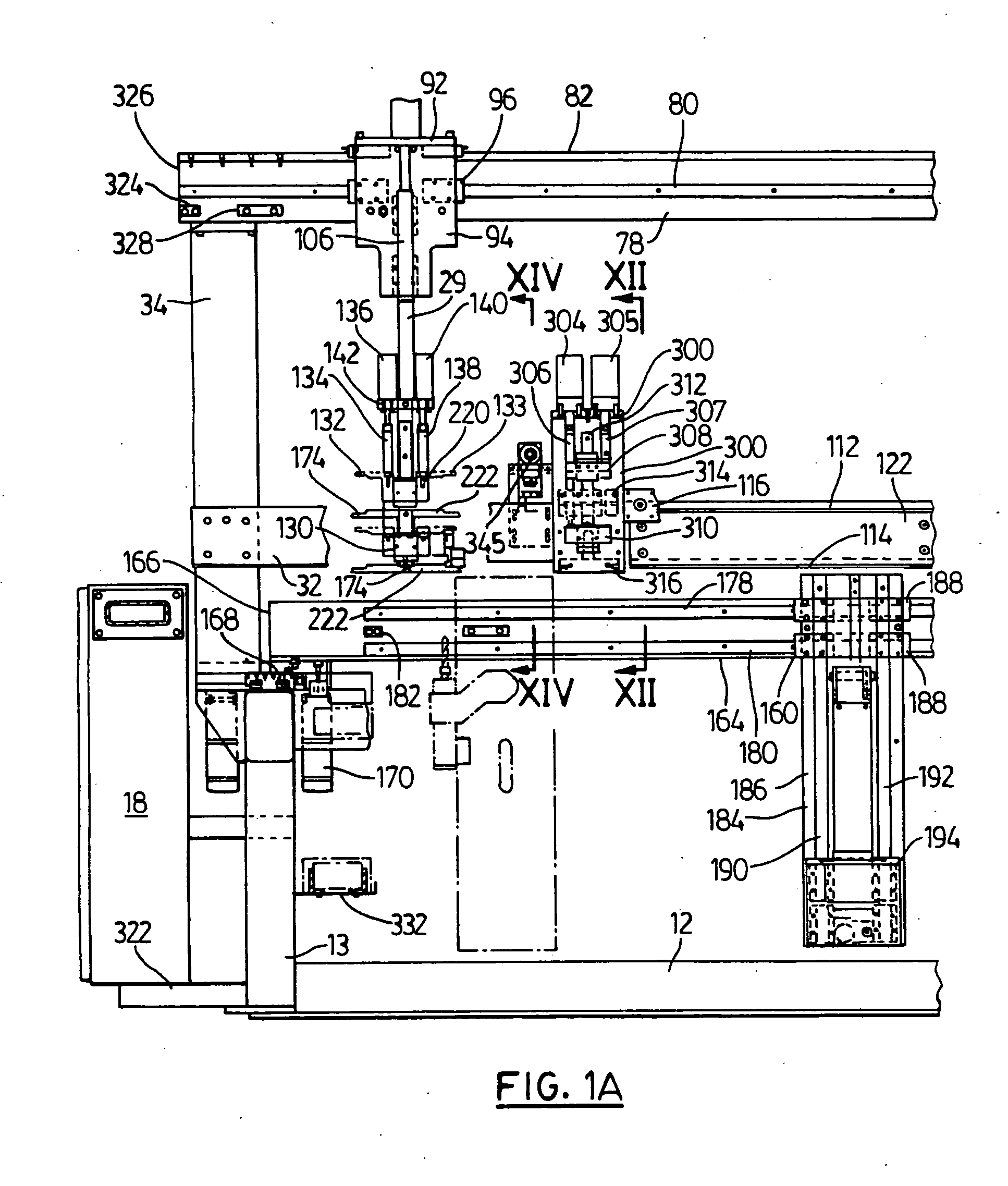

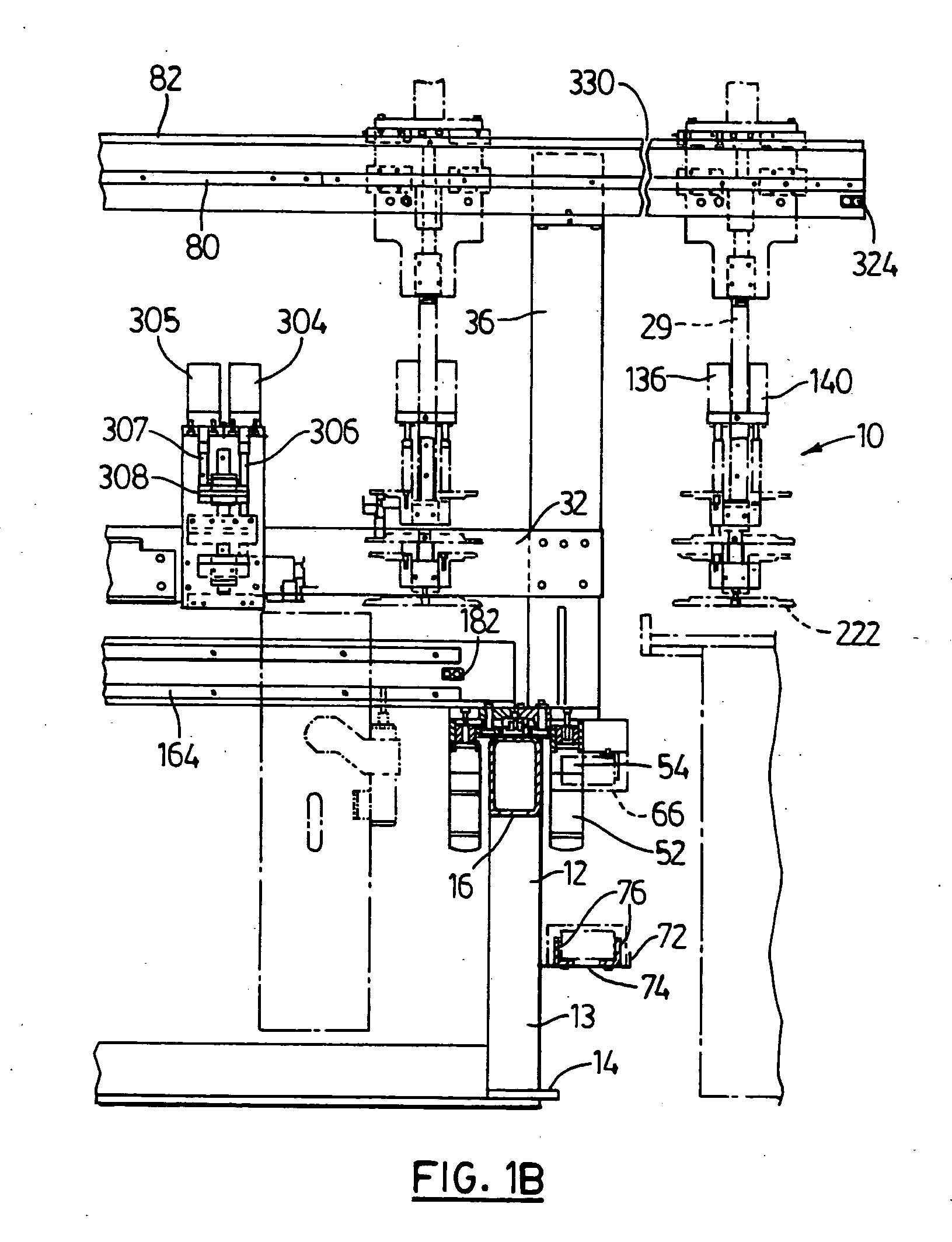

Apparatus and method for manufacturing plastic frameworks such as window frames

InactiveUS20050257361A1Reduce manufacturing costEfficient and flexibleAutomatic control devicesThread cutting feeding devicesProduction lineEngineering

A production line and a method for carrying out machining and cleaning operations on rectangular framework, such as window frames, is provided. Initially, elongate plastic frame members are welded together in a plastic frame welding machine, thereby forming two rectangular frameworks located one above the other. These are moved to a framework processing machine along separate predetermined paths where the first path being located above the second path. The paths are provided by horizontally extending guide arrangements on the machine which has at least one power tool for carrying out machining operations, this tool being supported by a transporting mechanism capable of moving the tool both horizontally and vertically. Machining steps are carried out on the two frame works while they are held one above the other in the processing machine. The frameworks are then moved to a weld cleaning machine along respective upper and lower paths and further processing operations including weld cleaning steps are carried out in this machine.

Owner:PRO LINE AUTOMATION SYST

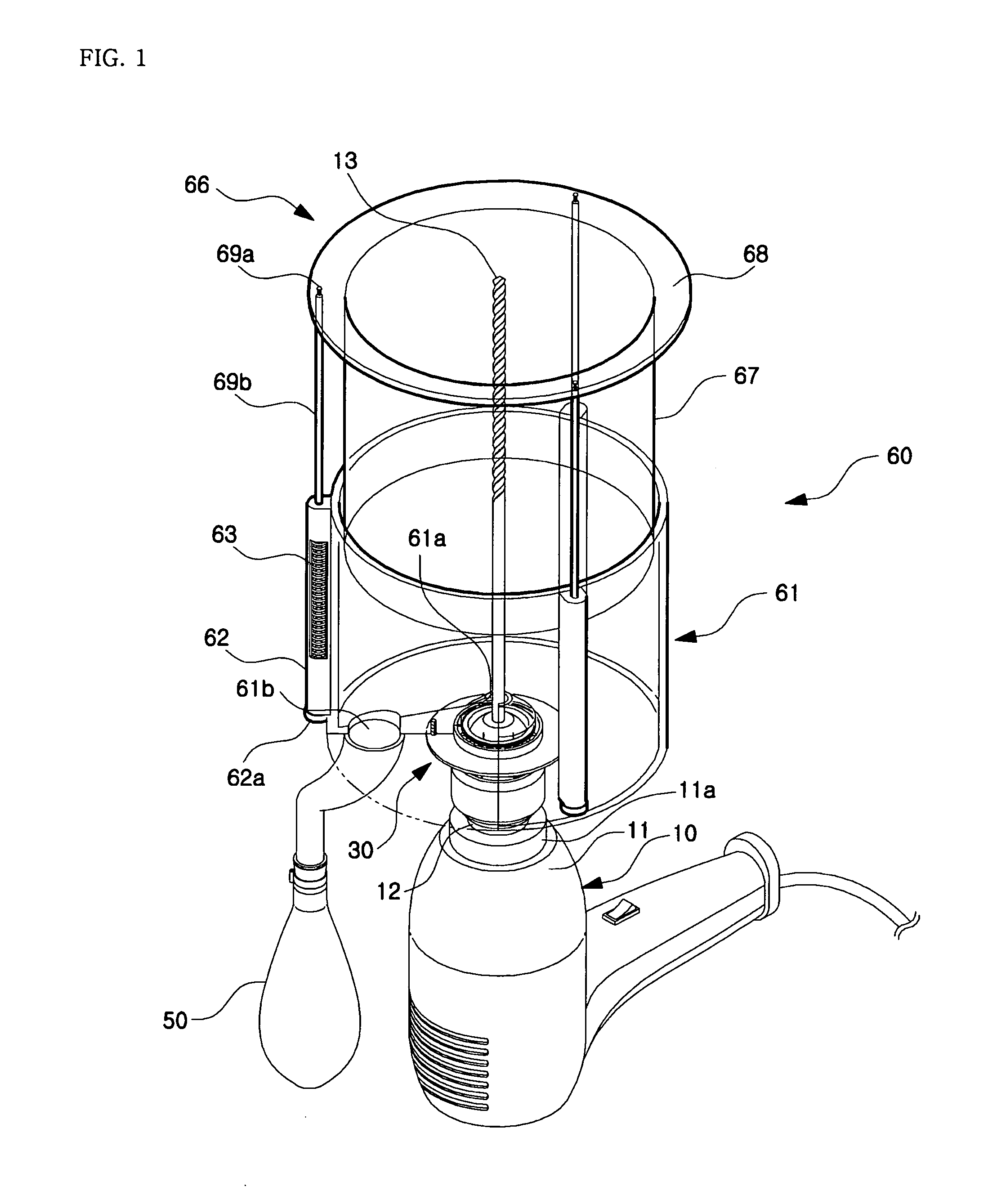

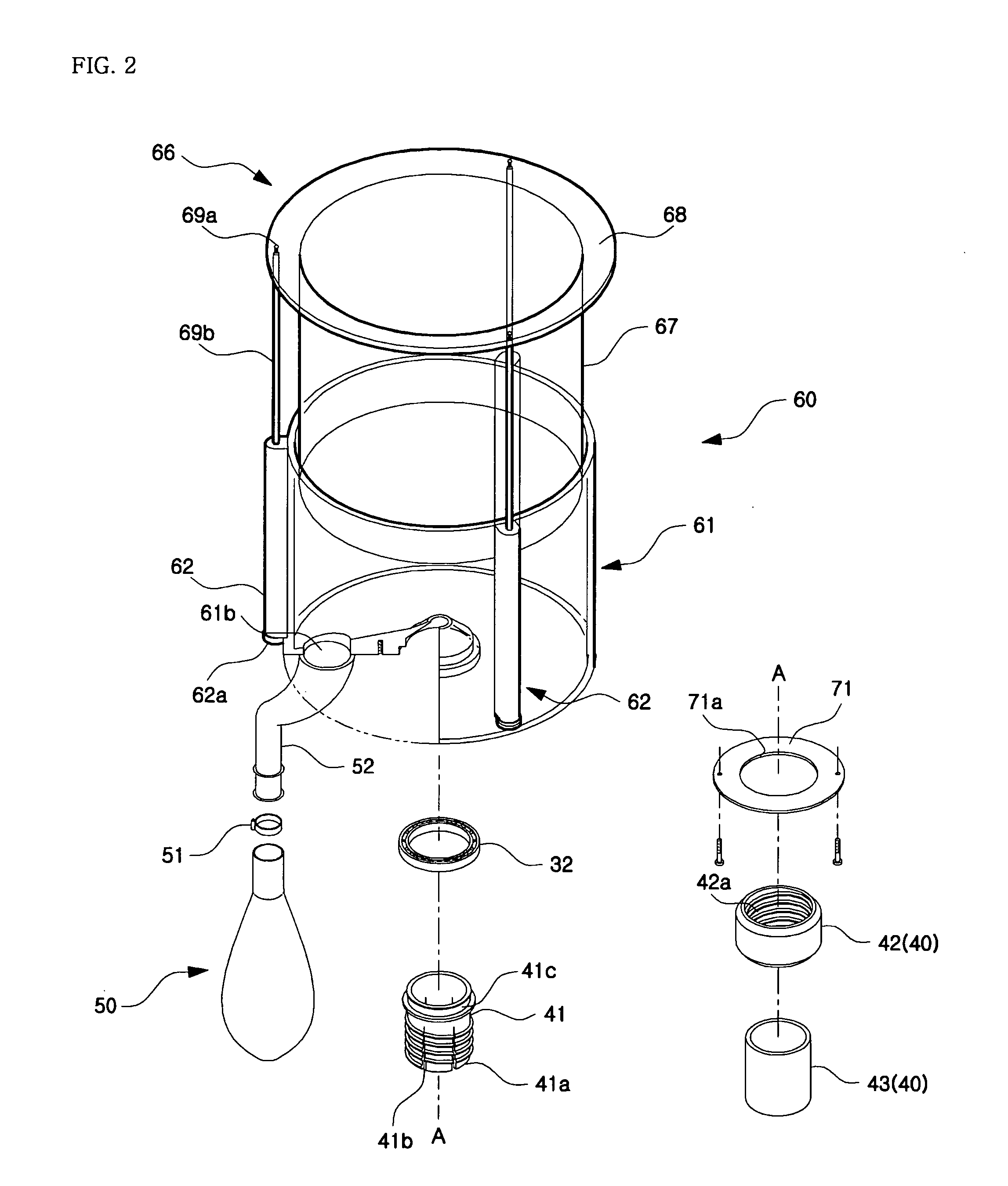

Hole saw and slug remover

ActiveUS20100086372A1Readily apparentThread cutting feeding devicesTransportation and packagingHole sawEngineering

A hole saw with slug remover including a top cylindrical housing; a bottom cylindrical housing attached to the top cylindrical housing, the bottom cylindrical housing having teeth for cutting; a pilot drill extending through the top cylindrical housing and bottom cylindrical housing; a drive screw rotatably affixed to the top cylindrical housing, the drive screw having a threaded exterior; and an ejection plunger engaging the threaded exterior of the drive screw wherein the ejection plunger is forced downward to eject a slug when the drive screw rotates counter-clockwise and is forced upward when the drive screw rotates clockwise.

Owner:WERNER TRAVIS E

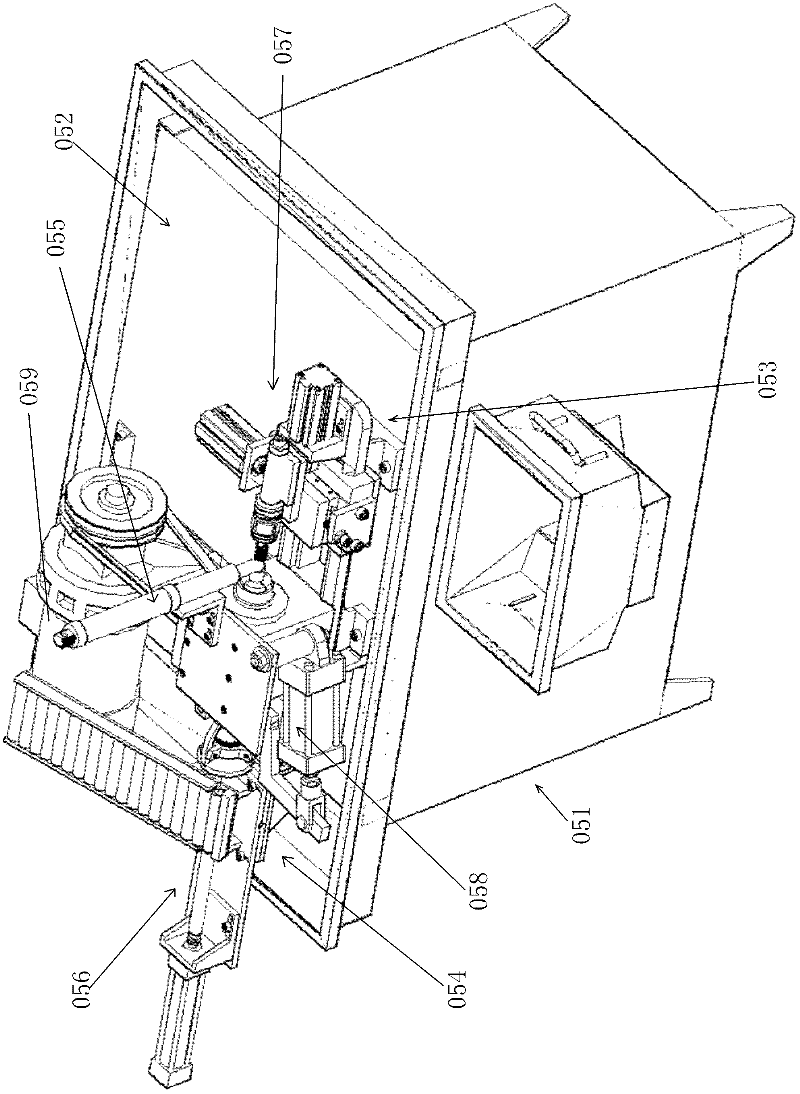

Automatic tapping machine

InactiveCN102310237AQuality improvementHigh precisionThread cutting feeding devicesThread cutting machinesProgrammable logic controllerEngineering

The invention discloses an automatic tapping machine and relates to a processing device used for processing internal screw threads. The automatic tapping machine disclosed by the invention comprises a PLC (Programmable Logic Controller) control circuit, a machine base 051, a marble slab 052, an instrument lathe 053, a positioning adjustment device 054, a limiting device 055, a feed device 056, a tapping device 057, a clamping device 058 and a deceleration motor 059, wherein the marble slab is arranged on the machine base, the positioning adjustment device and the instrument lathe are fixed onthe marble slab, and the deceleration motor is arranged at one side of the instrument lathe. Being controlled by the PLC control circuit, the feed device quickly conveys workpieces, the limiting device ensures the workpieces to be accurately clamped, and the tapping device completes the accurate positioning of screw taps and is matched with the clamping device to complete the tapping process. Theinvention aims to provide the automatic tapping machine to solve the technical problem that manual intervention is needed in the processes of feeding, positioning, clamping, tapping and loosening, and through the invention, the processing speed and the processing accuracy are improved.

Owner:莱州市山普管件制造有限公司

Protective sheild for a tool

InactiveUS20050013674A1Avoid injuryDrilling/boring measurement devicesThread cutting feeding devicesEngineeringFront and back ends

A protective shield for a drilling or cutting tool having a cylindrical-shaped housing that has a front end and a back end, the front end able to fit flush against a working surface; and a spring having a first end and a second end, the first end able to receive the back end of the cylindrical-shaped housing and the second end able to receive a drilling or cutting tool chuck; the cylindrical-shaped housing able to receive debris from the drilling or cutting tool operation.

Owner:VIDAL ROBERT J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com