Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4521results about "Portable percussive tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

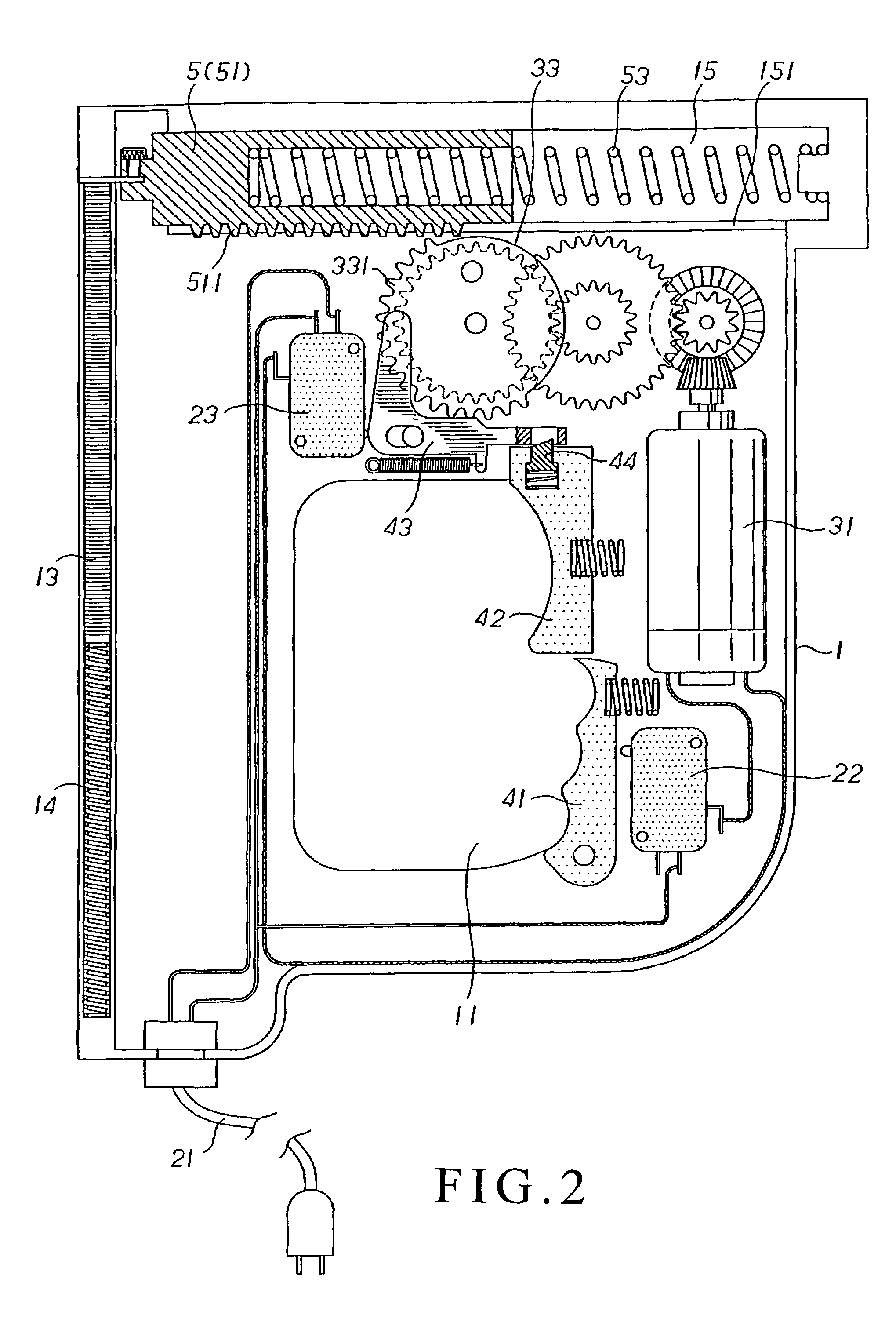

Electrical motor driven nail gun

InactiveUS6705503B1Easy to handleReduce wearStapling toolsReciprocating drilling machinesEngineeringFlywheel

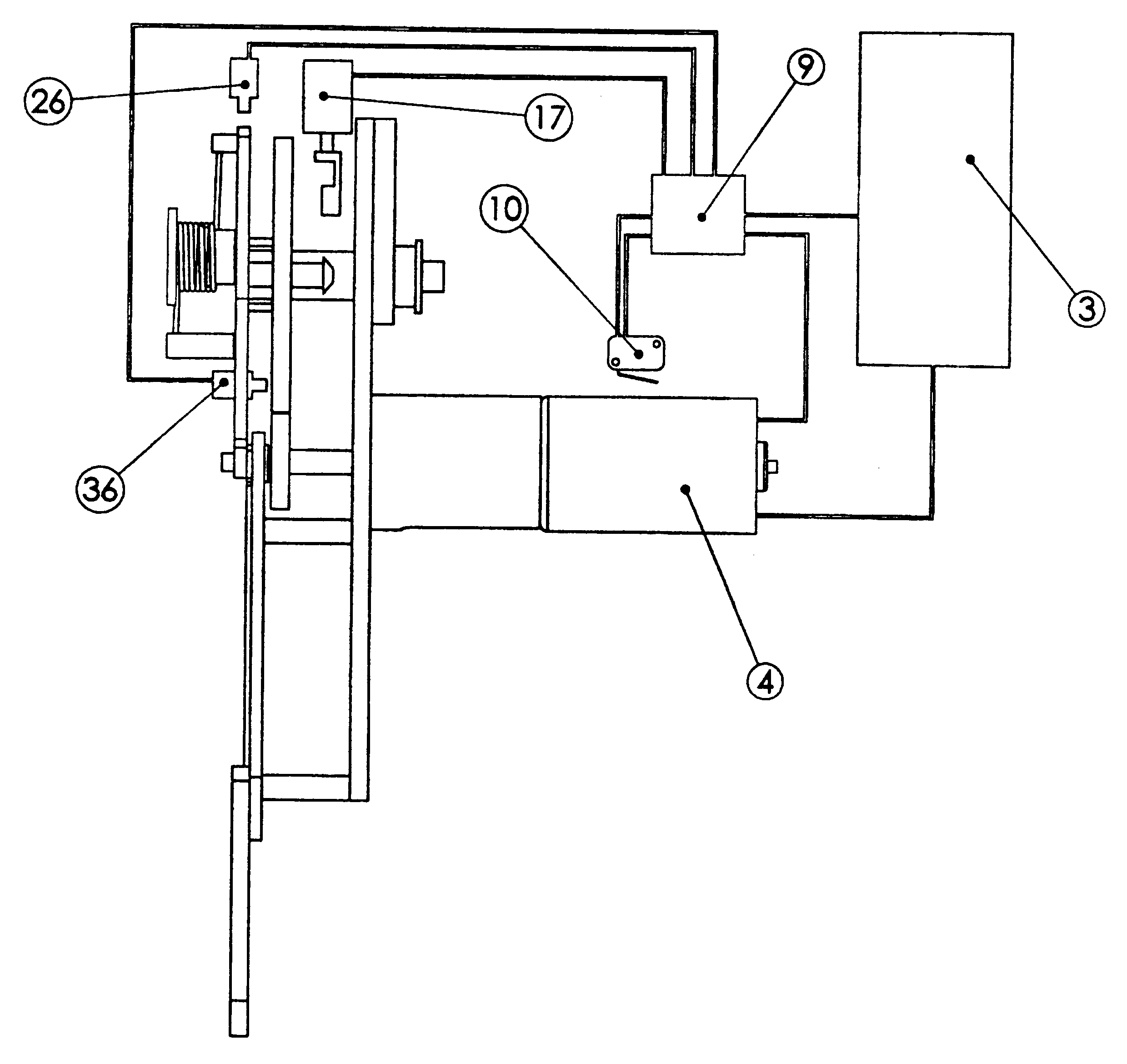

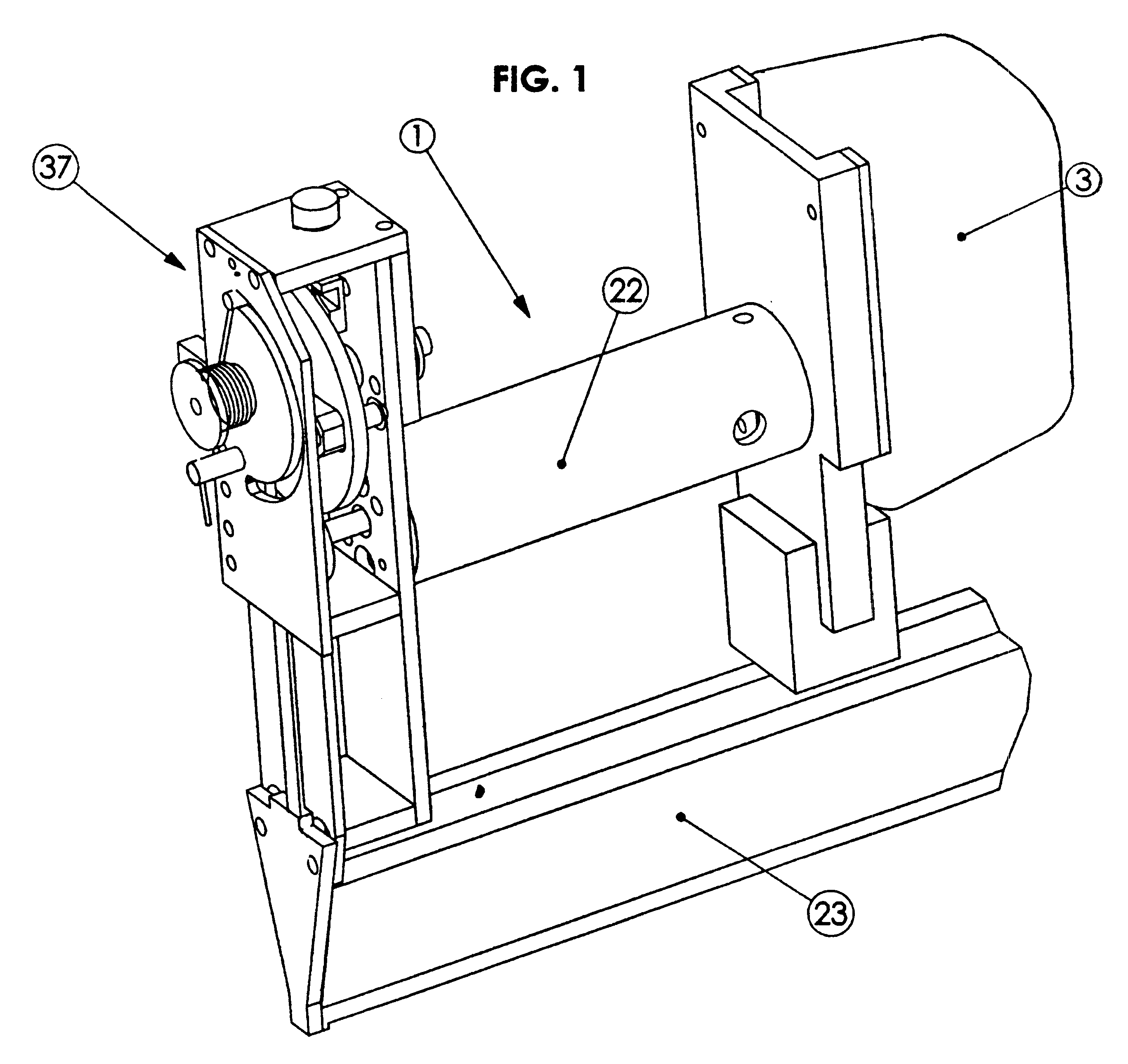

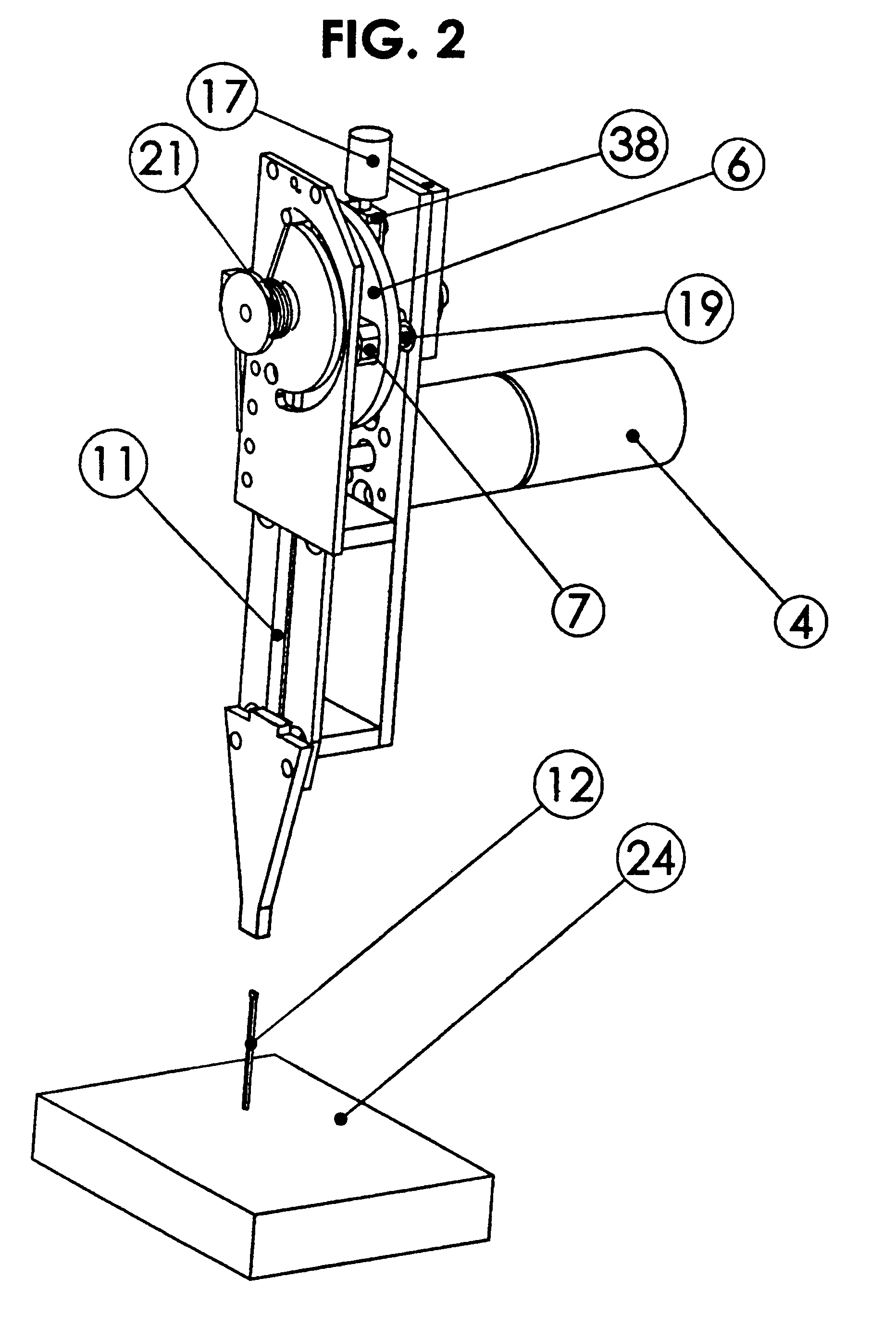

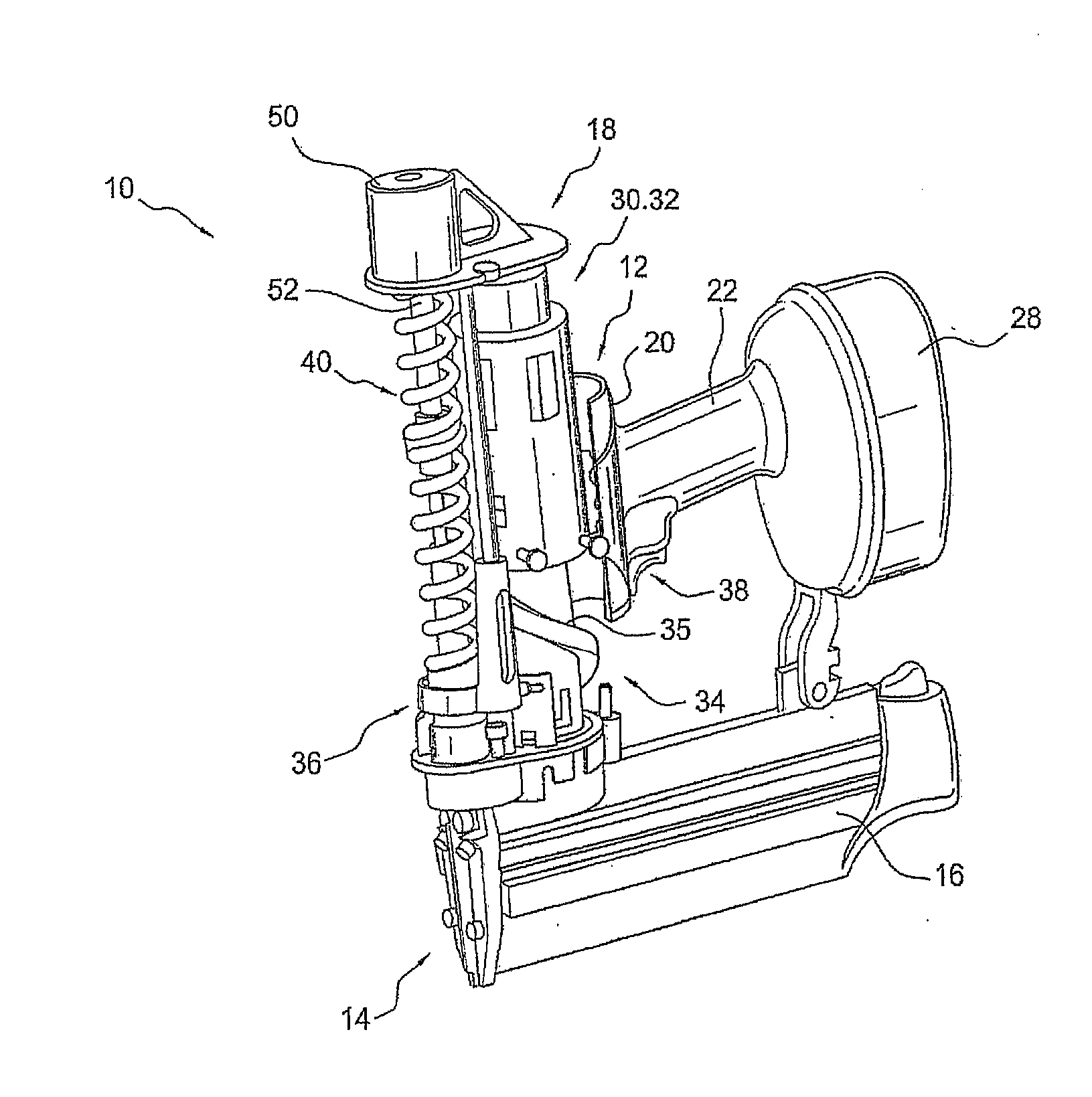

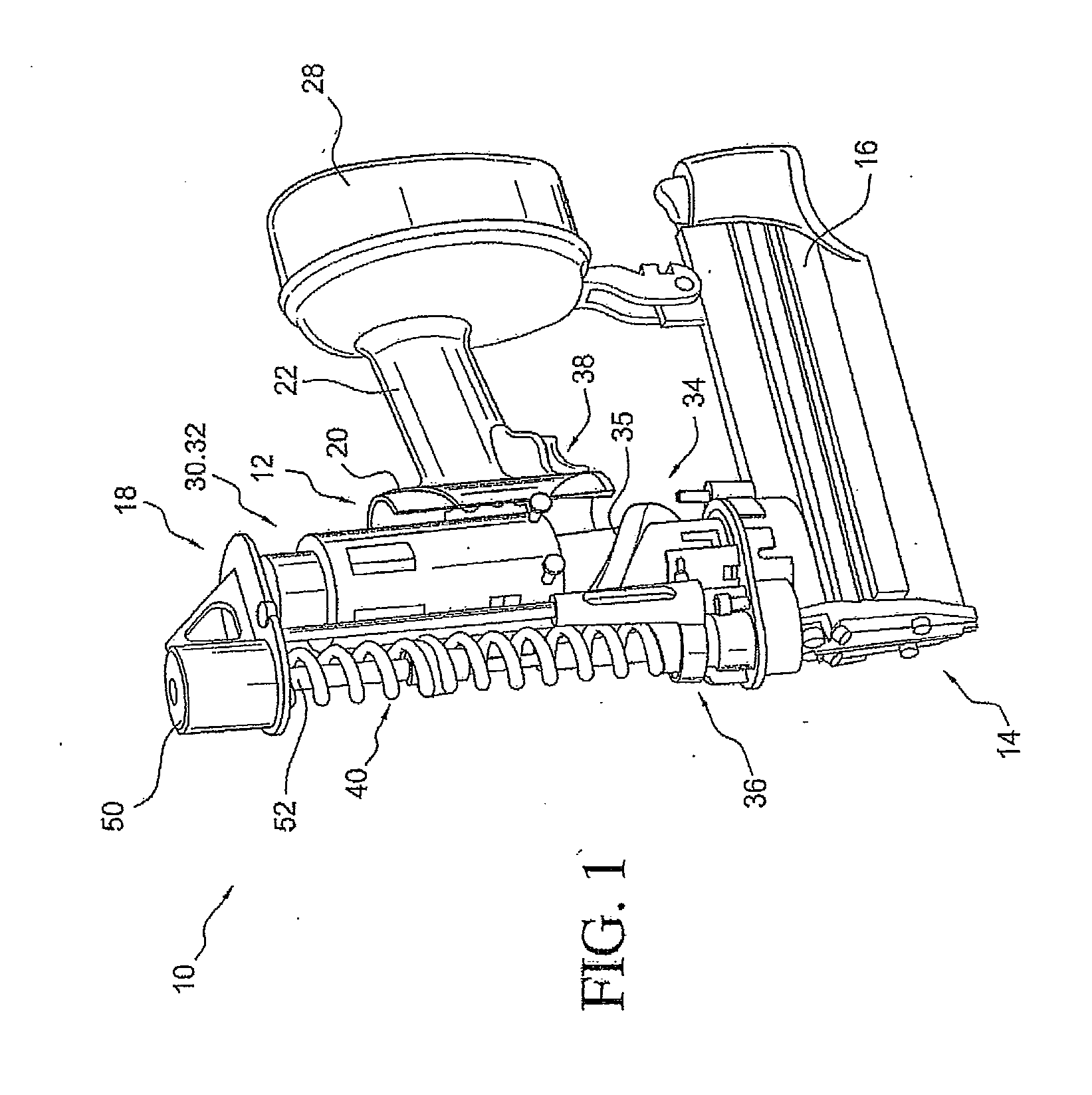

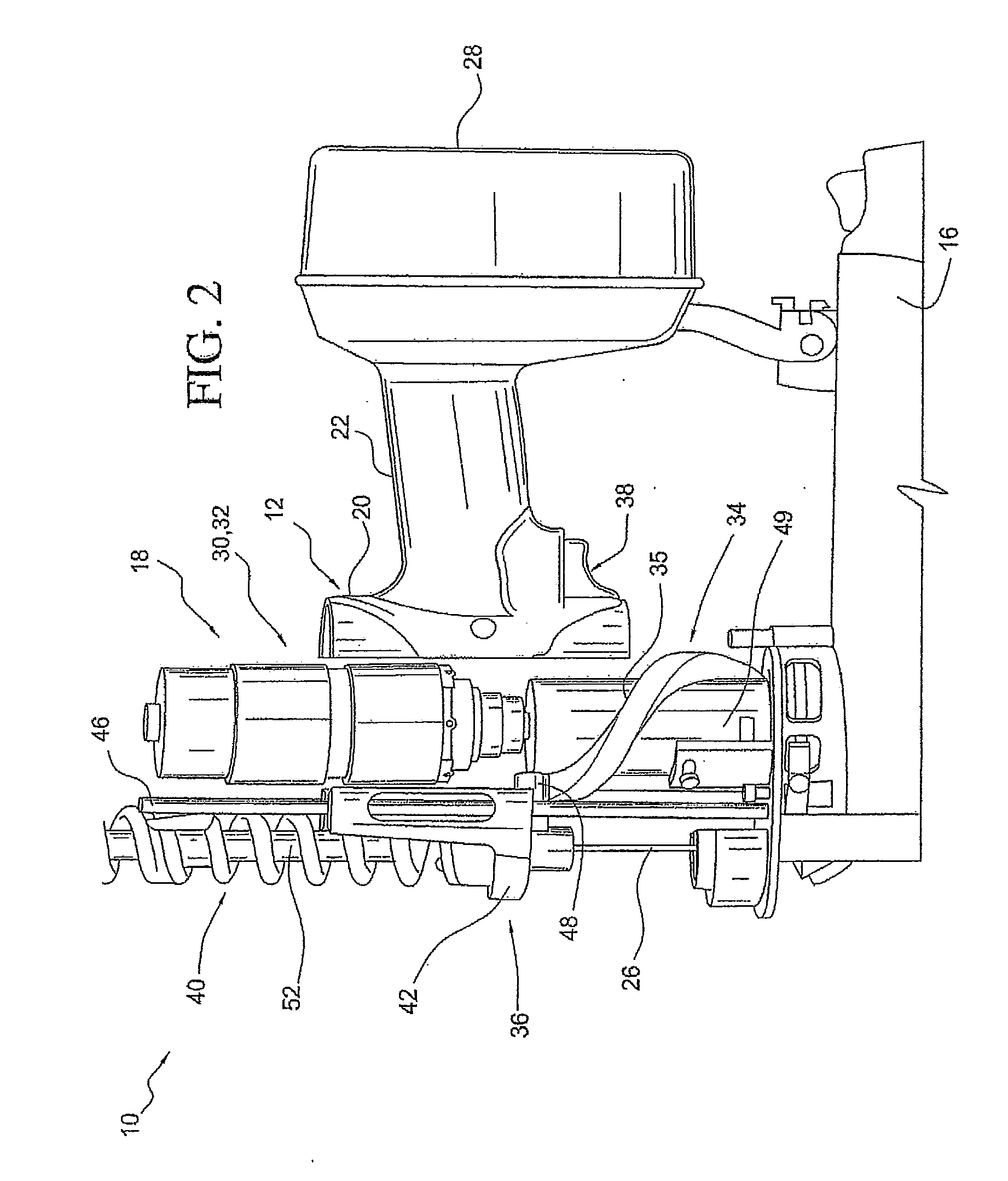

A portable electric nailing gun operating from a power supply. The motor accelerates a flywheel, which at the appropriate energy state is coupled through a mechanism to an anvil acting directly on the nail. The actuation is governed by a control circuit and initiated from a trigger switch. The stored energy delivered from the motor is coupled to the output anvil drives the nail. At least one position of the output anvil is sensed and once the nail is driven, the power is disconnected from the motor. This method uses a direct acting clutch and a harmonic motion nailing mechanism to reduce wear and increase robustness of the nailer. Elastic elements are used to limit stresses during the impact periods. The electrical control circuit and sensors allow precise control and improve safety. The power supply is preferably a rechargeable low impedance battery pack.

Owner:TRICORD SOLUTIONS

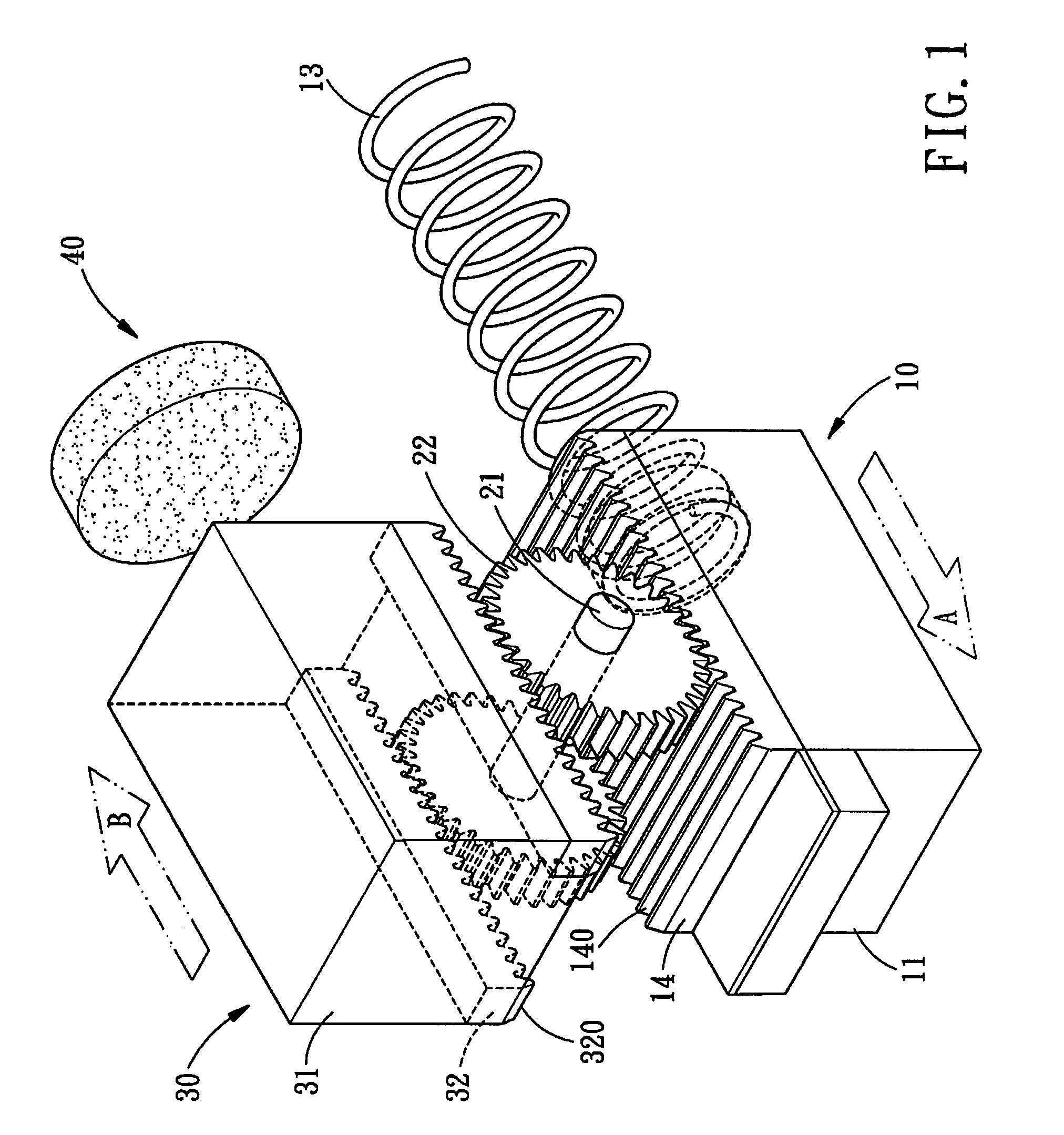

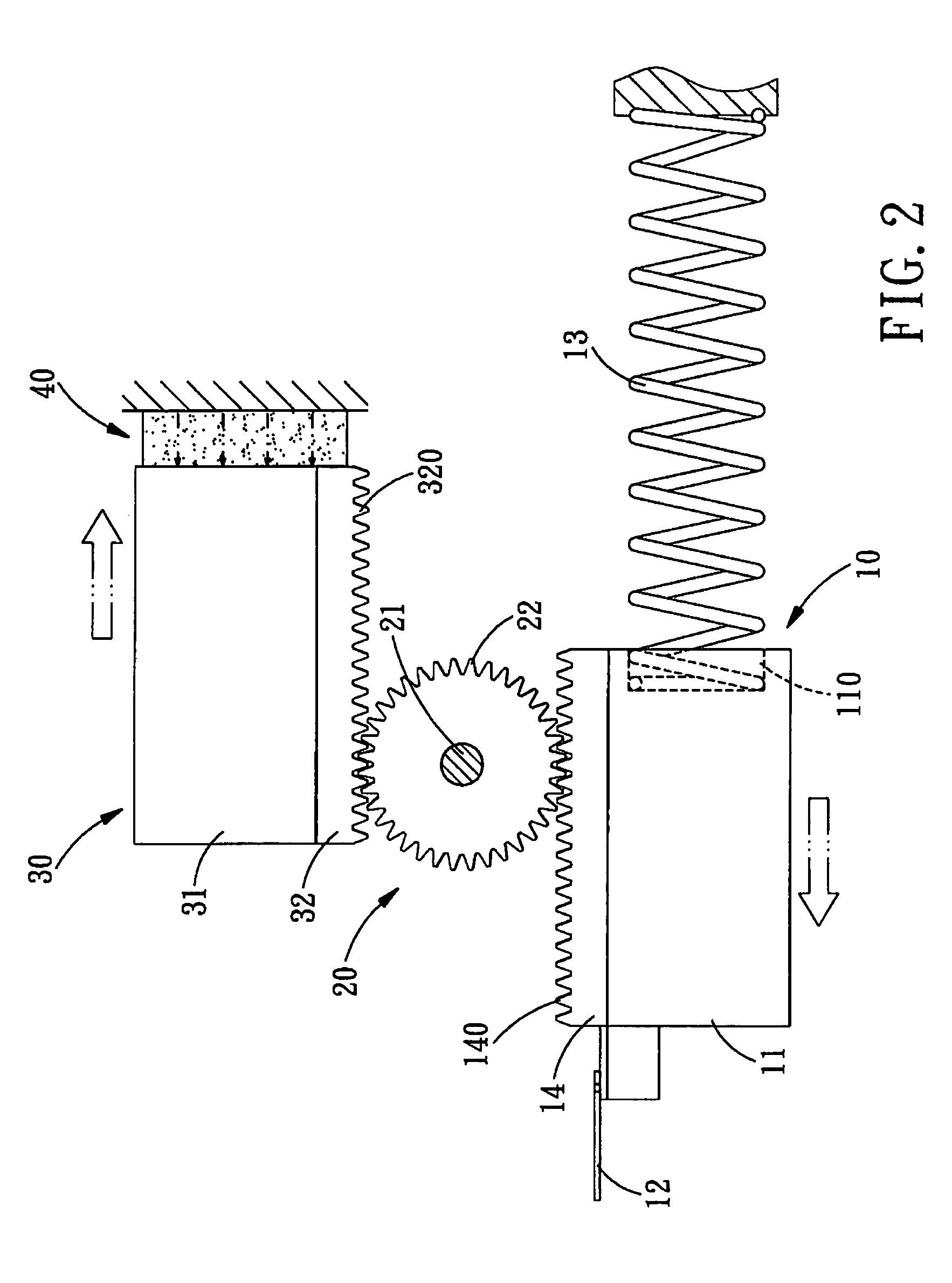

Counterforce-counteracting device for a nailer

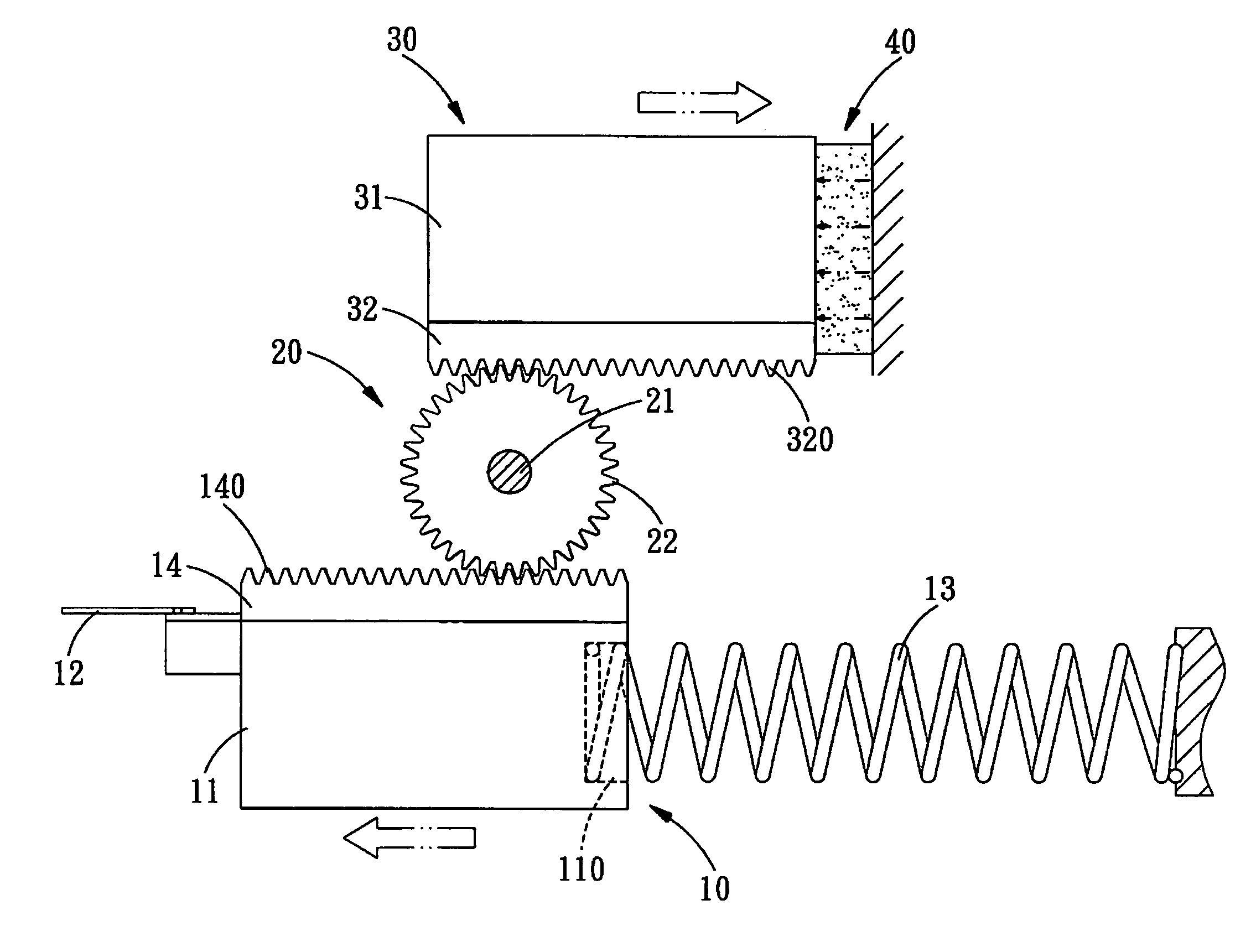

A counterforce-counteracting device for a nailer comprises an active device, a rotating member, and a weight device. The active device drives the rotating member and the weight device to move. After the active device moves, the weight device is driven by the rotating member to produce a counterforce, so as to counteract the counterforce of the nailer. Thereby, such a device is secure and is easy to assemble.

Owner:ORGAN TECH CORP CO LTD

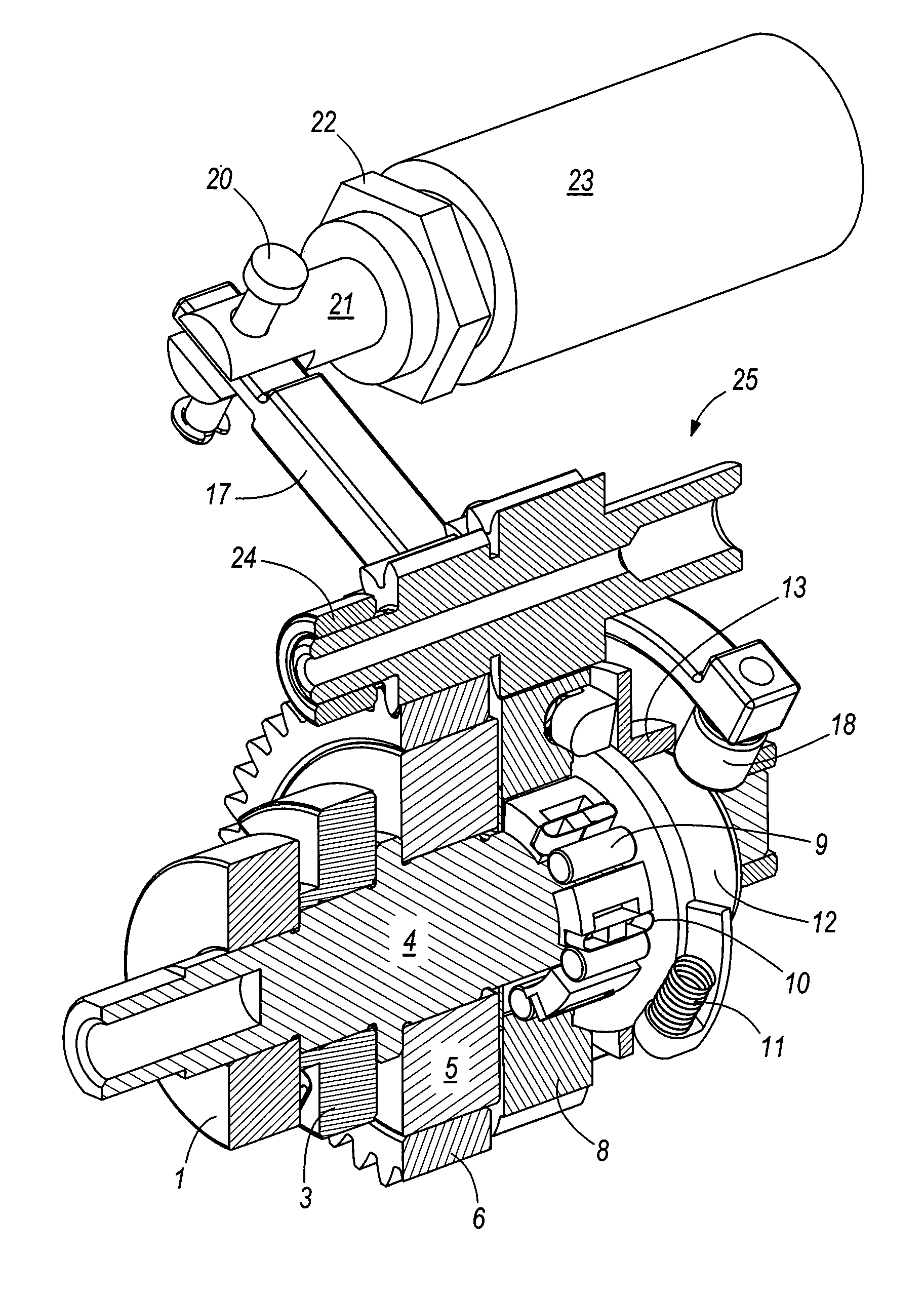

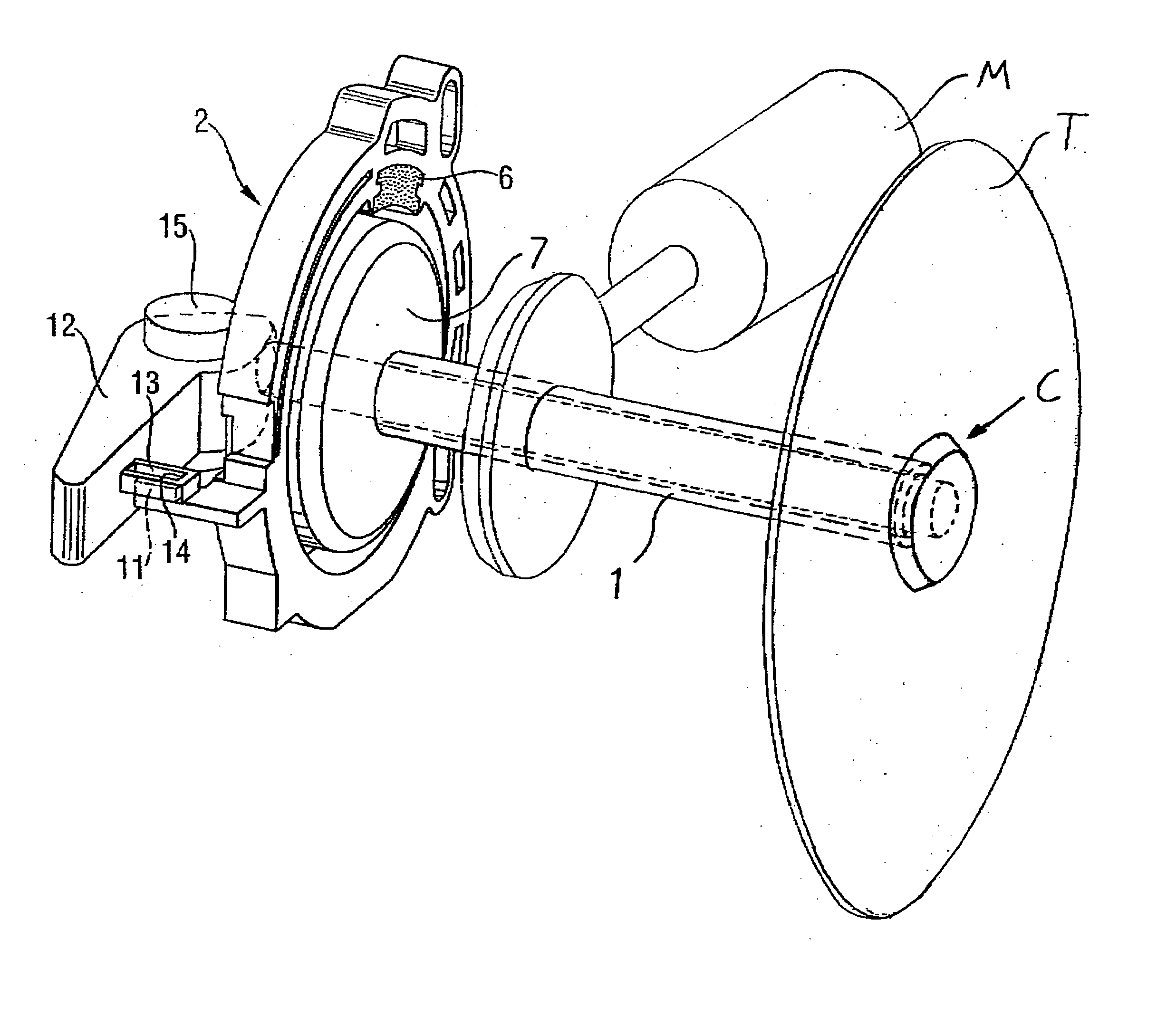

Hammer drill attachment

Power tools of the type under consideration include hammer drills, for example, which are electric or battery powered and includes two modes of operation: a rotation mode and a rotation-hammer mode. A manually operable selector lever enables the hammer drill to be selectively operated in one of the two modes by disengaging and engaging a hammer mechanism. In rotation-hammer mode, the drive shaft of the hammer drill rotates a tool element about a rotational axis and oscillates the tool element along a rotational axis. An attachment mountable within the chuck of a hammer drill prevents a tool element from rotating when the hammer drill is operating in rotation-hammer mode. The hammer drill attachment transfers hammer action, but not rotation, to the tool element. The hammer drill attachment enables dual function power tools to be operated in a hammer only mode to perform a function, for example, chiseling.

Owner:OROZCO JR EFREM

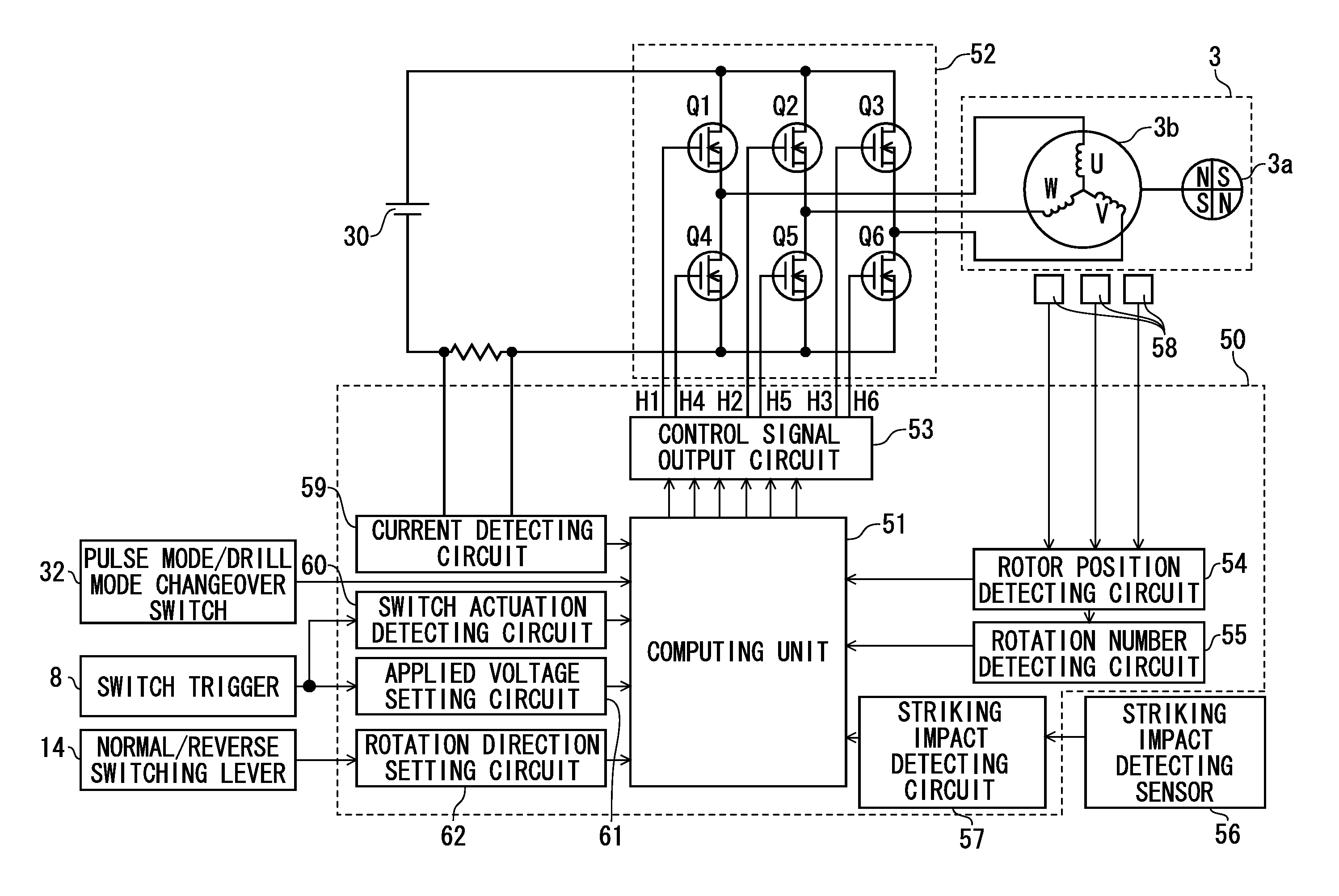

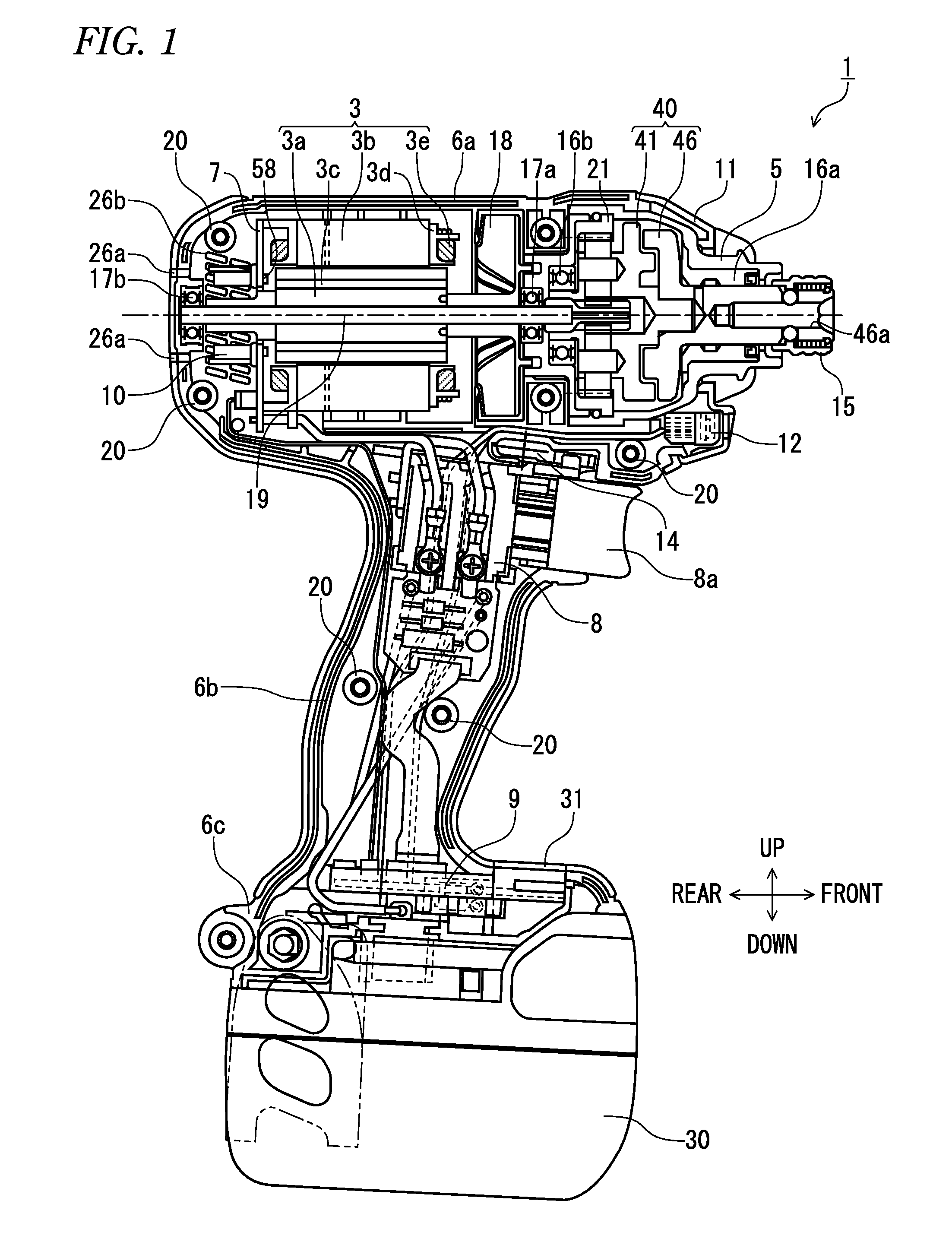

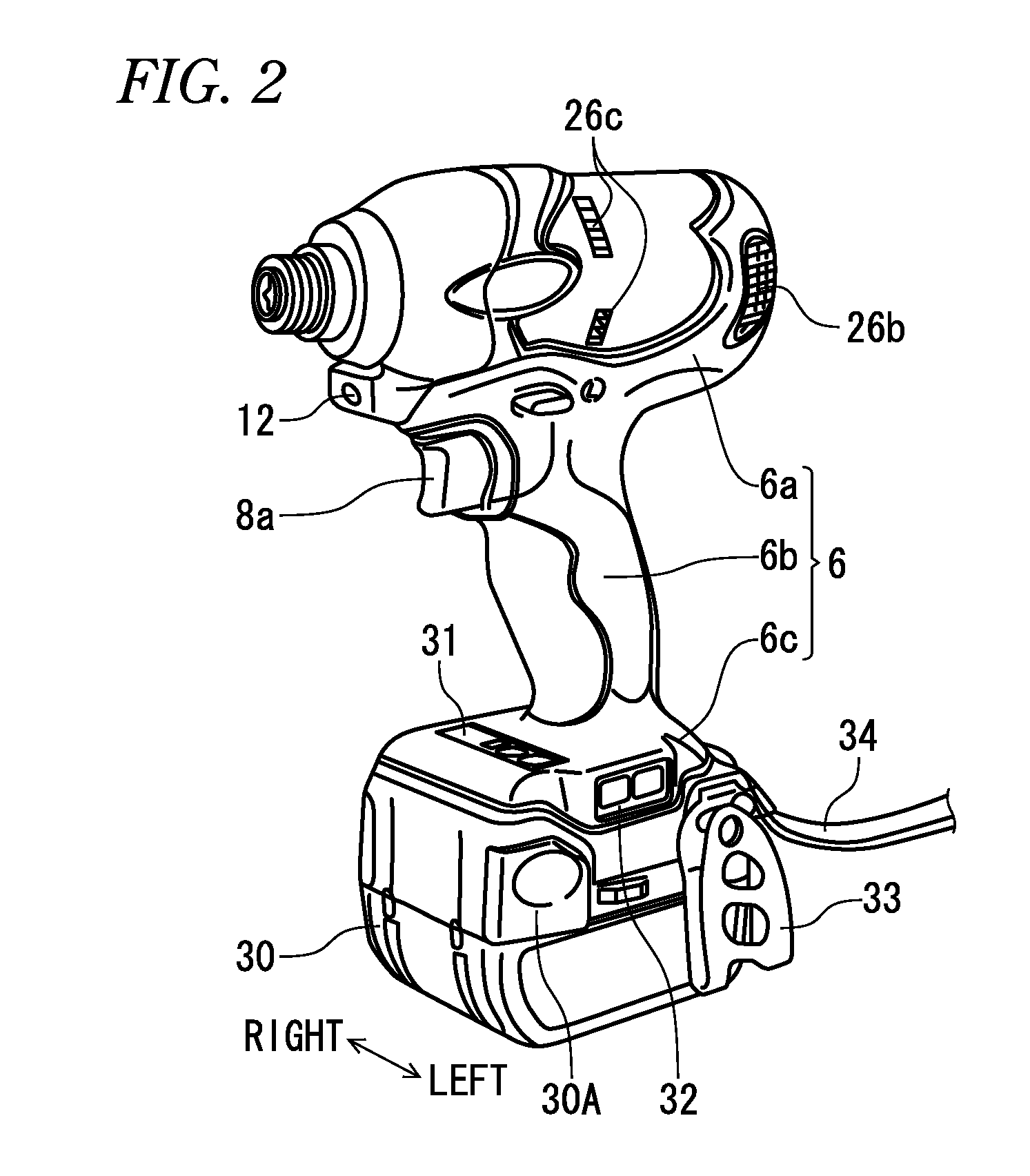

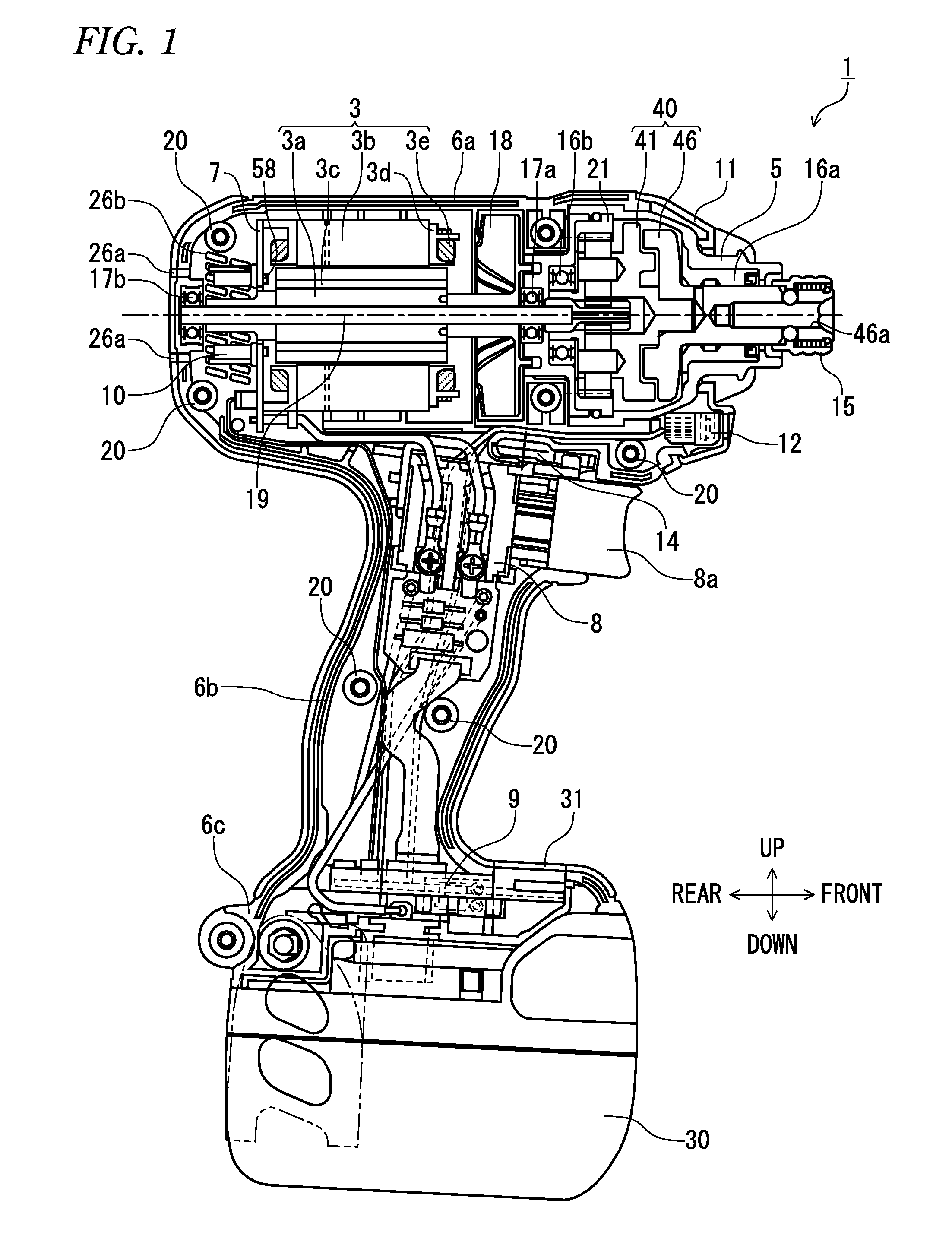

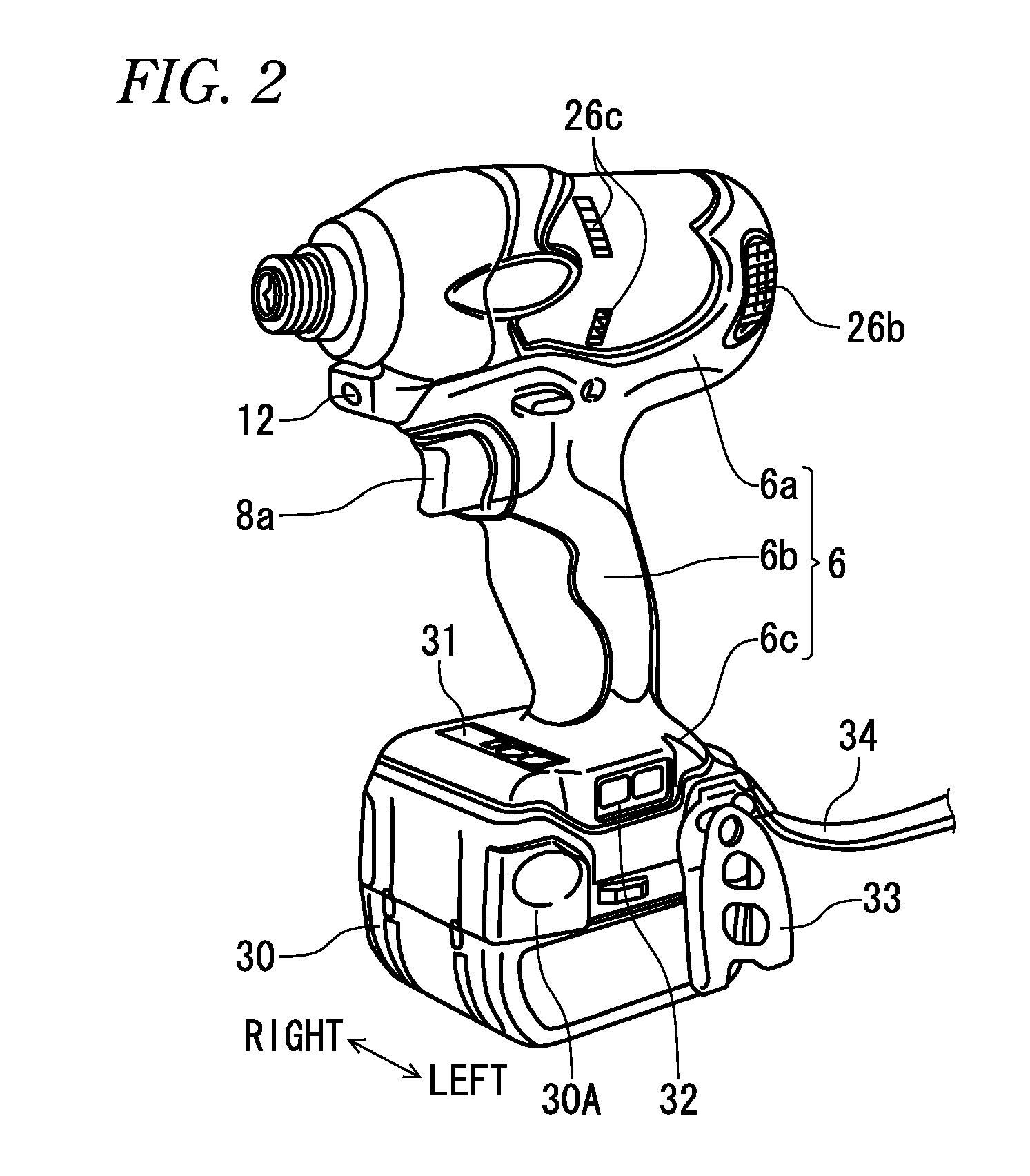

Impact tool

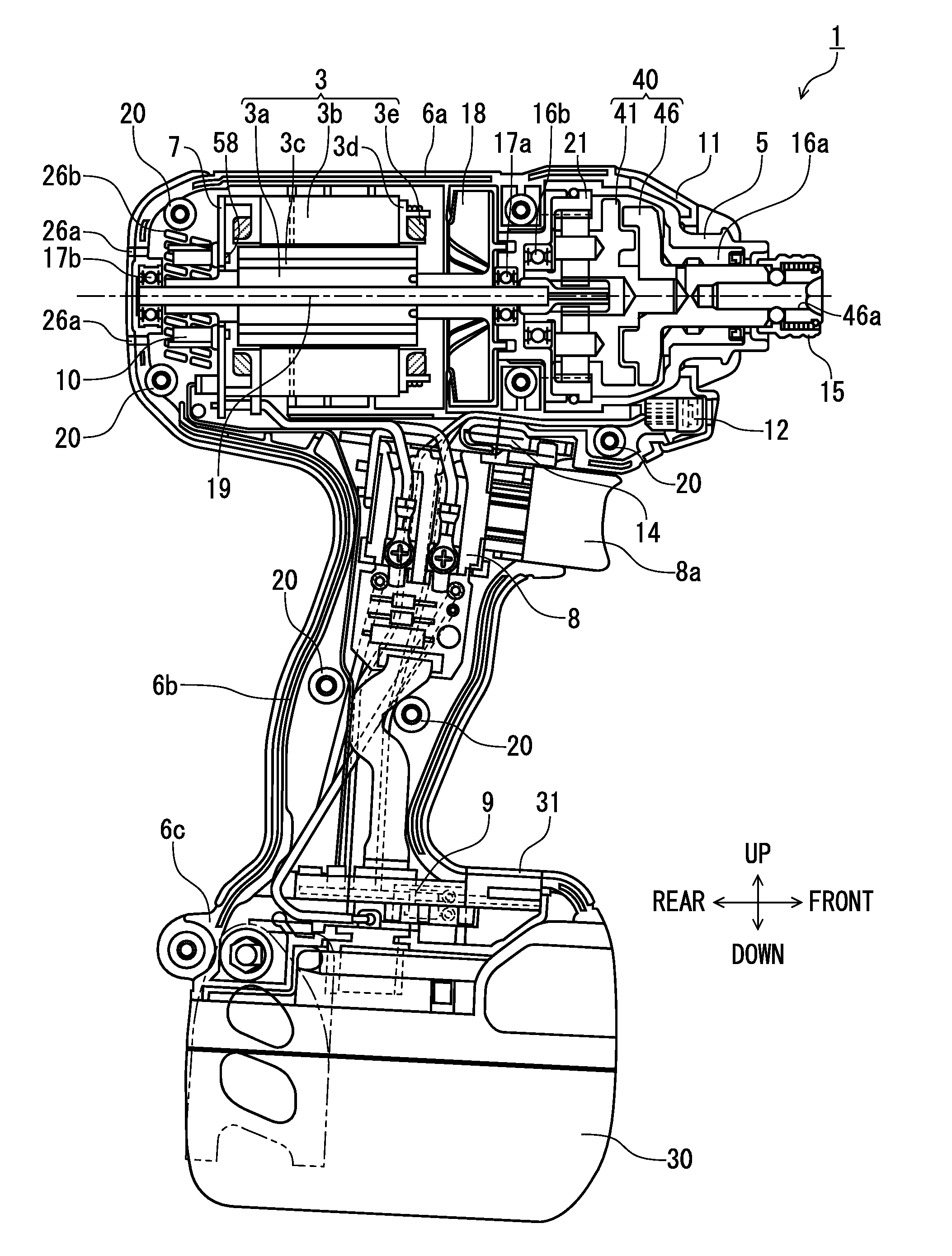

ActiveUS9314908B2Optimization mechanismConstructionsReciprocating drilling machinesEngineeringDriving mode

According to an aspect of the present invention, there is provided an impact tool including: a motor drivable in an intermittent driving mode; a hammer connected to the motor; an anvil to be struck by the hammer to thereby rotate / strike a tip tool; and a control unit that controls a rotation of the motor by switching a driving pulse supplied to the motor in accordance with a load applied onto the tip tool.

Owner:KOKI HLDG CO LTD

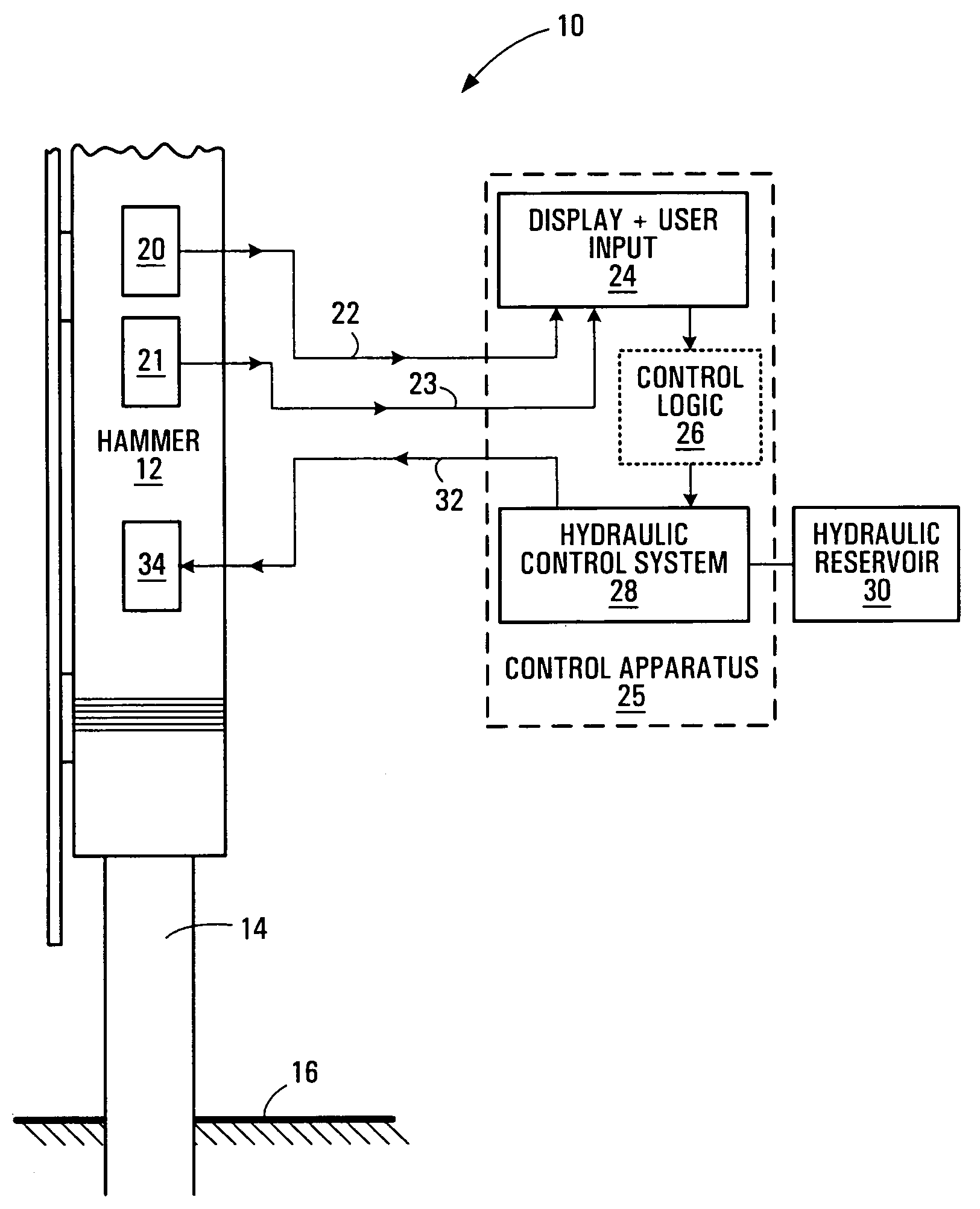

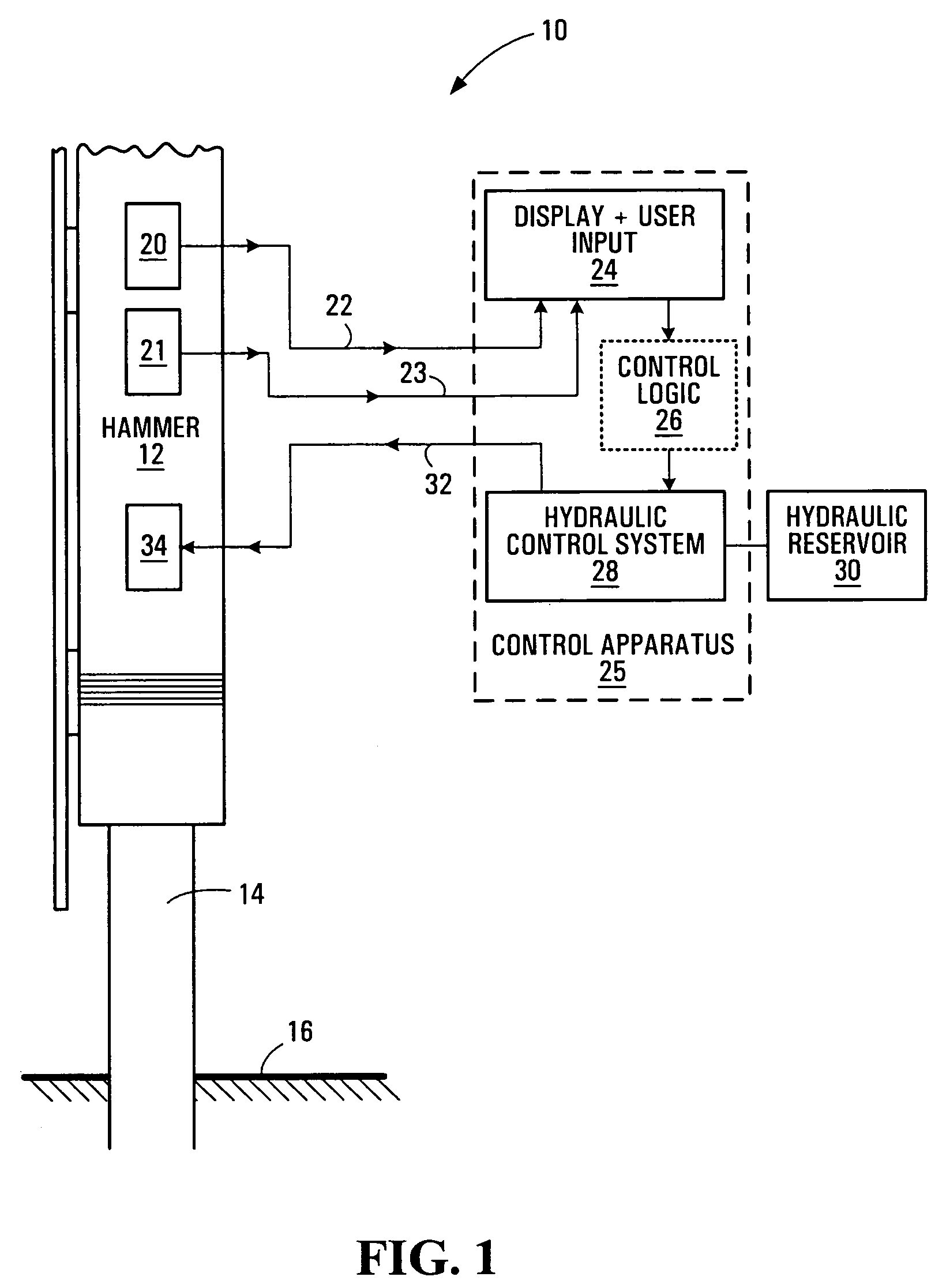

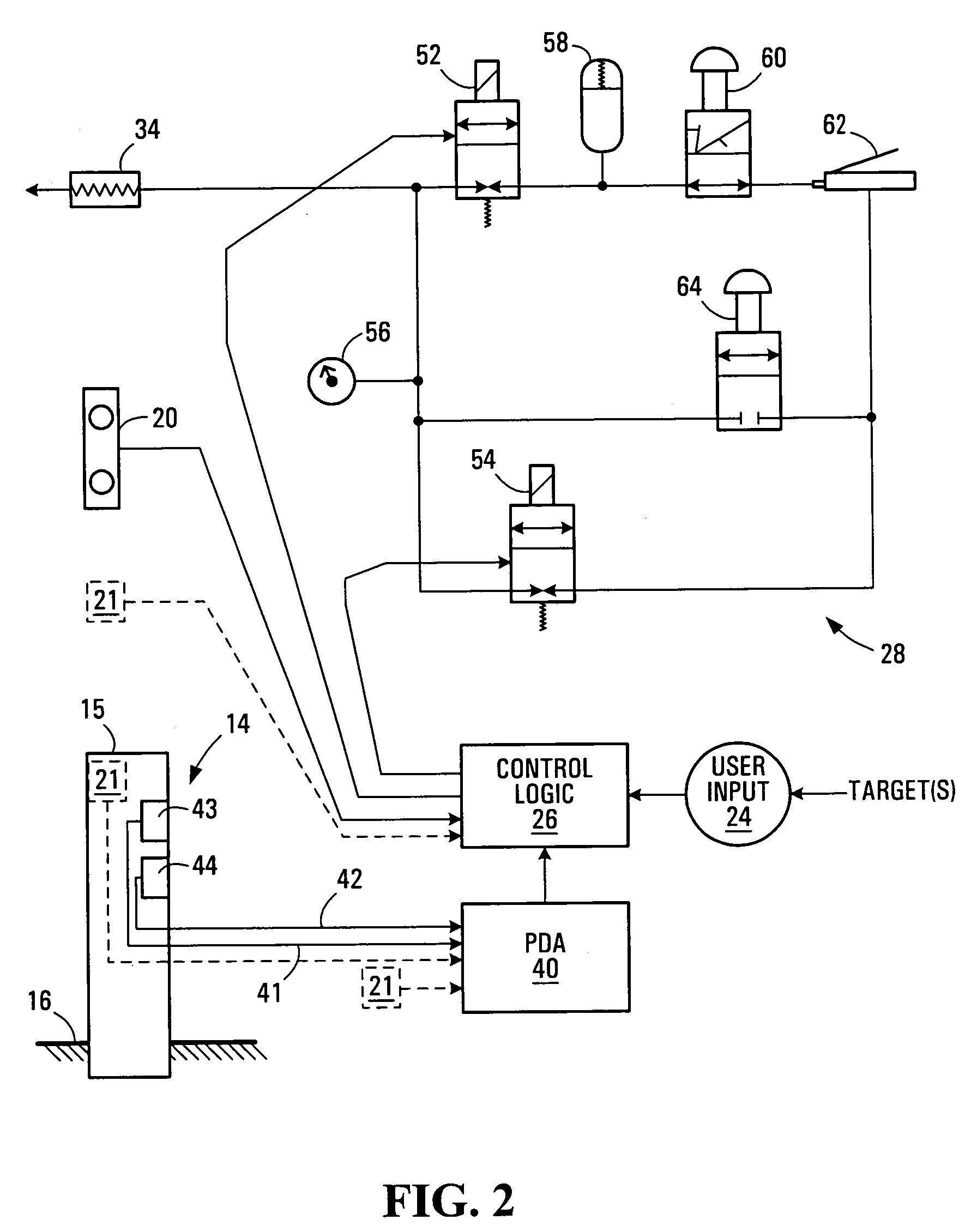

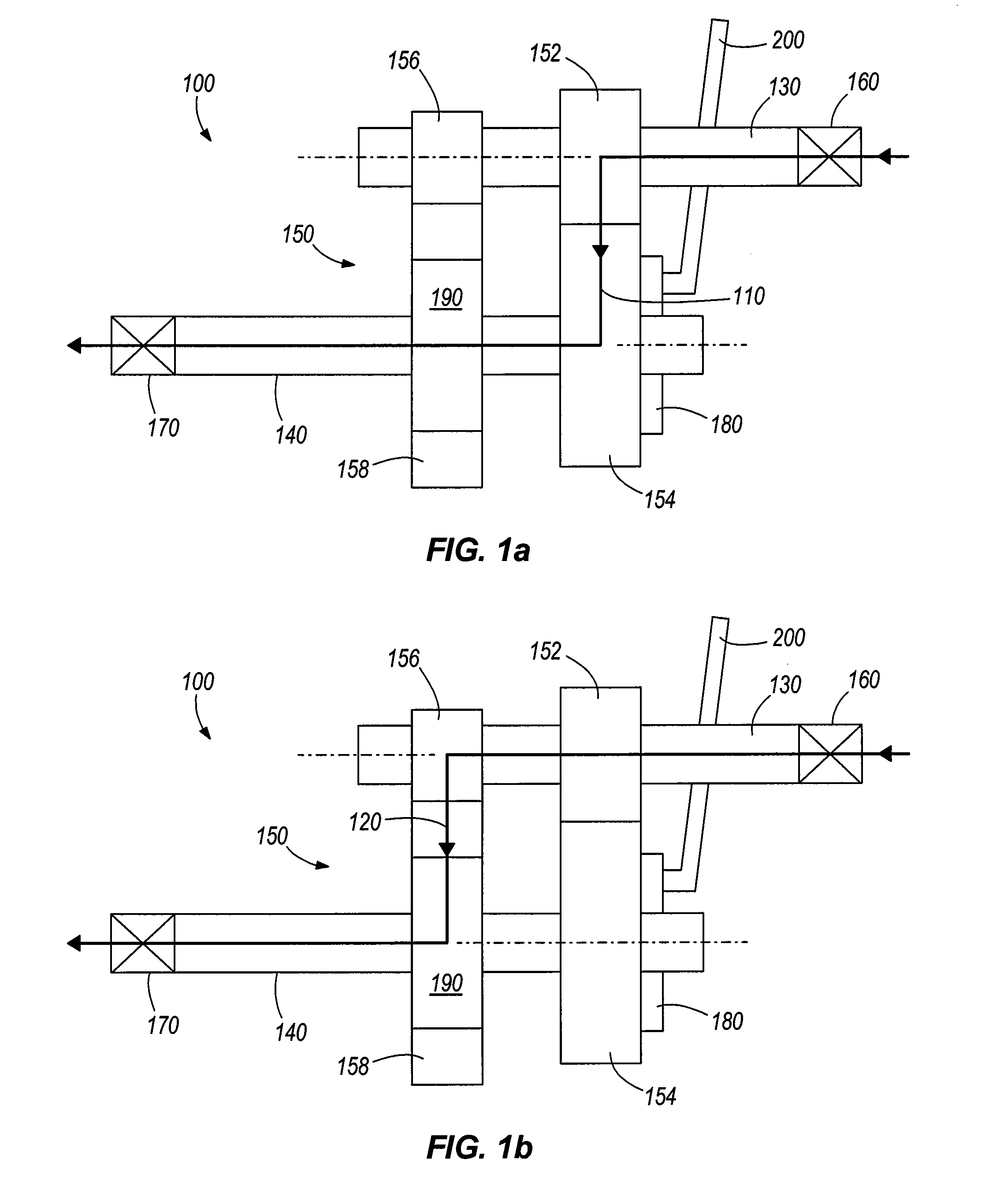

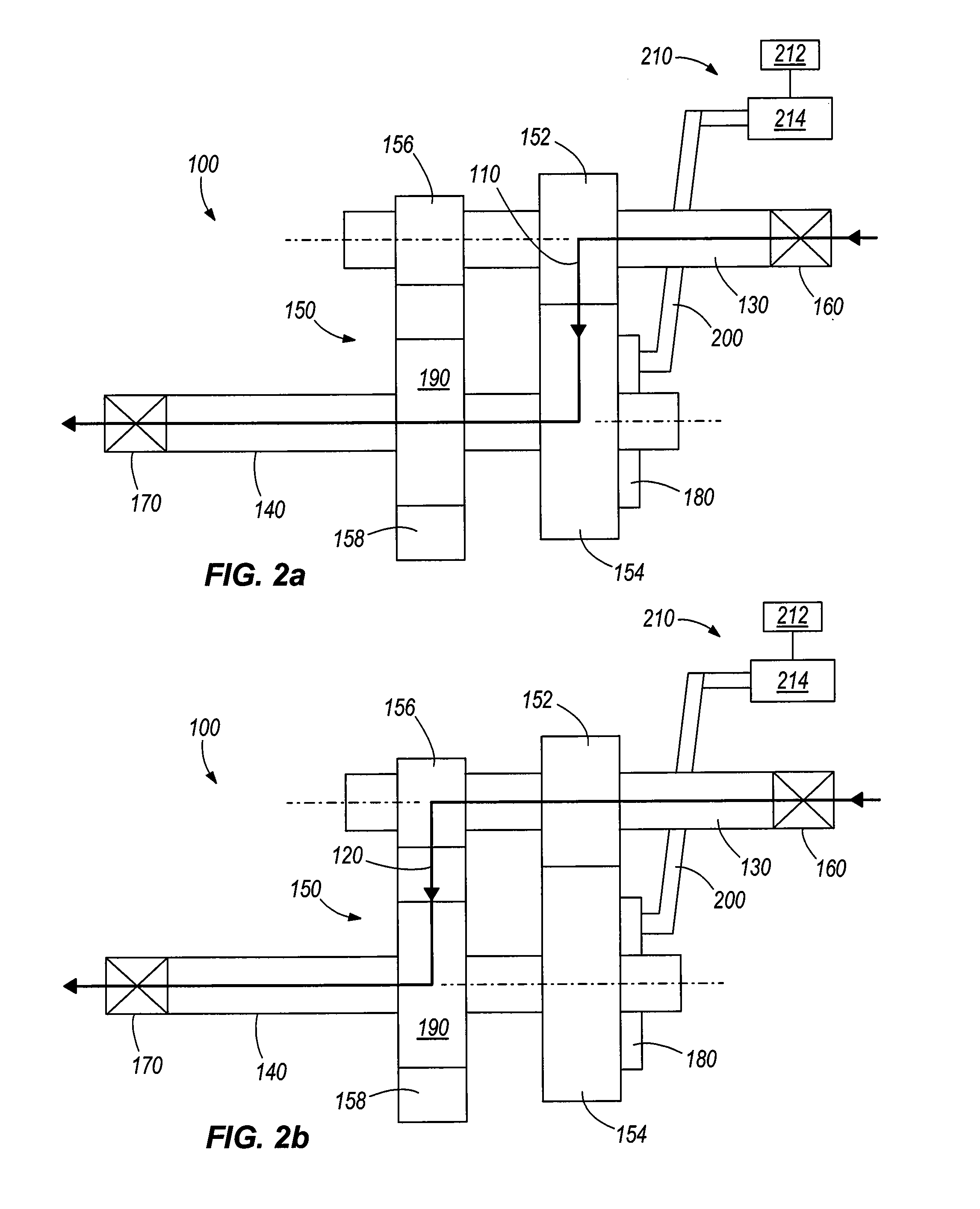

Pile driving control apparatus and pile driving system

ActiveUS7404449B2Reduce impact speedReciprocating drilling machinesDerricks/mastsVibration controlControl system

A pile driving control apparatus for a pile driving system includes a hydraulic control system that controls a throttle of a pile driving hammer, and thereby controls an impact velocity of the hammer with a pile. A controller provides a control signal to the hydraulic control system. Based on the control signal, the hydraulic control system controls an impact velocity of the hammer during a subsequent hammer stroke. The controller may determine one or more control parameters such as sound pressure at a sound control location during a hammer stroke, vibration at a vibration control location during a hammer stroke, an impact force imparted to the pile during a hammer stroke, and / or actual pile capacity of the pile, and provide to the hydraulic control system a control signal based on the determined control parameter(s).

Owner:BERMINGHAM FOUND SOLUTIONS LTD

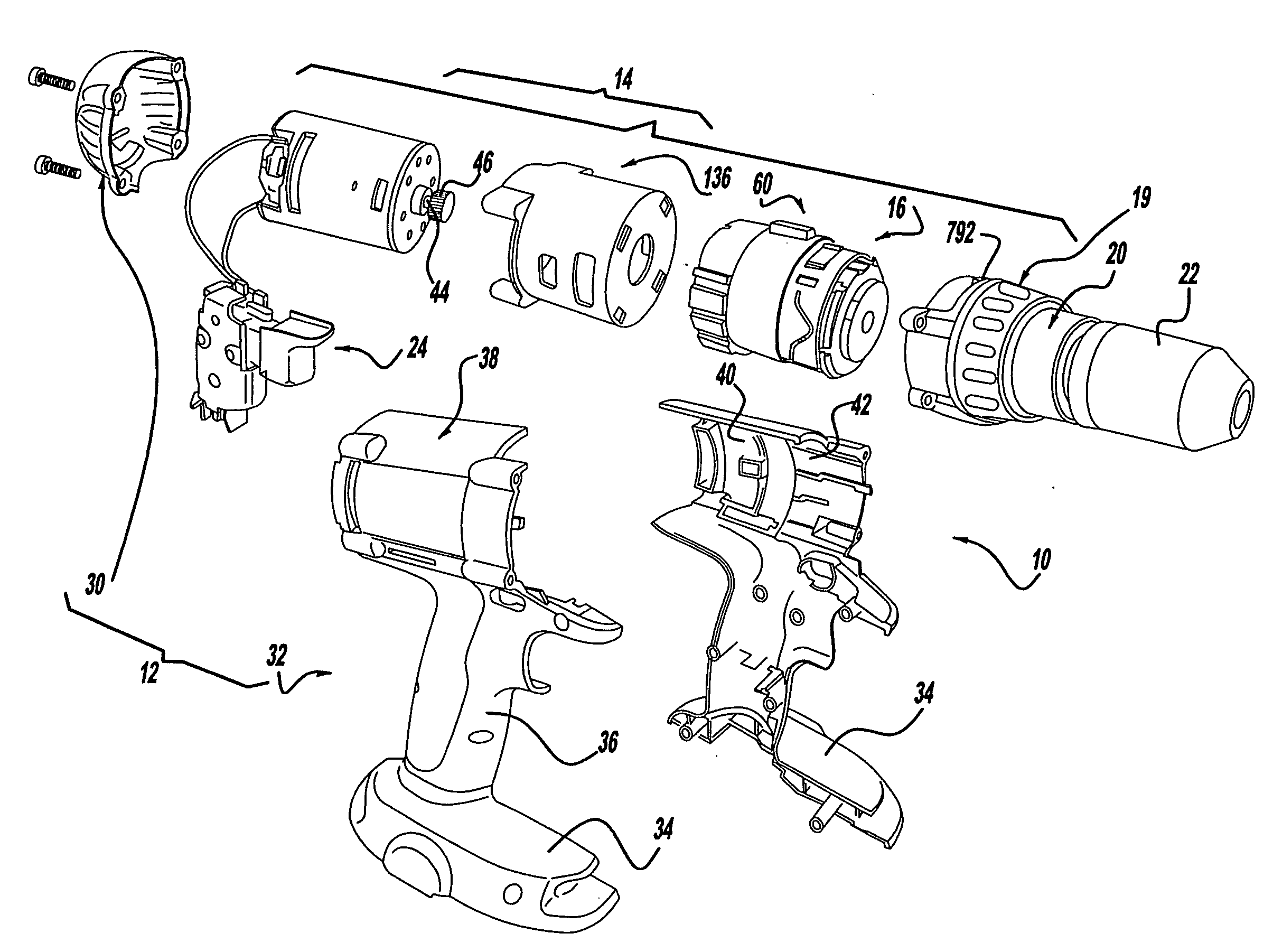

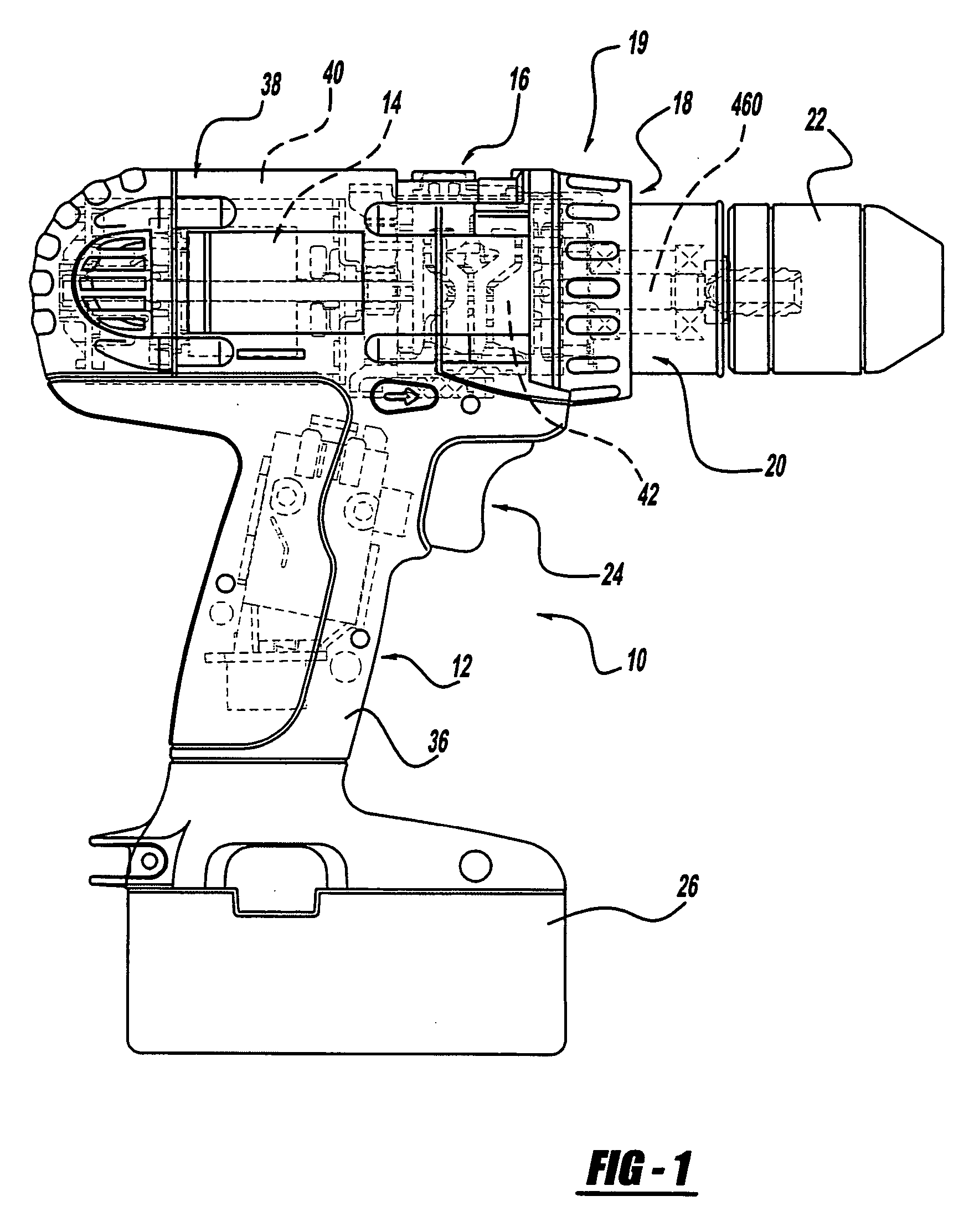

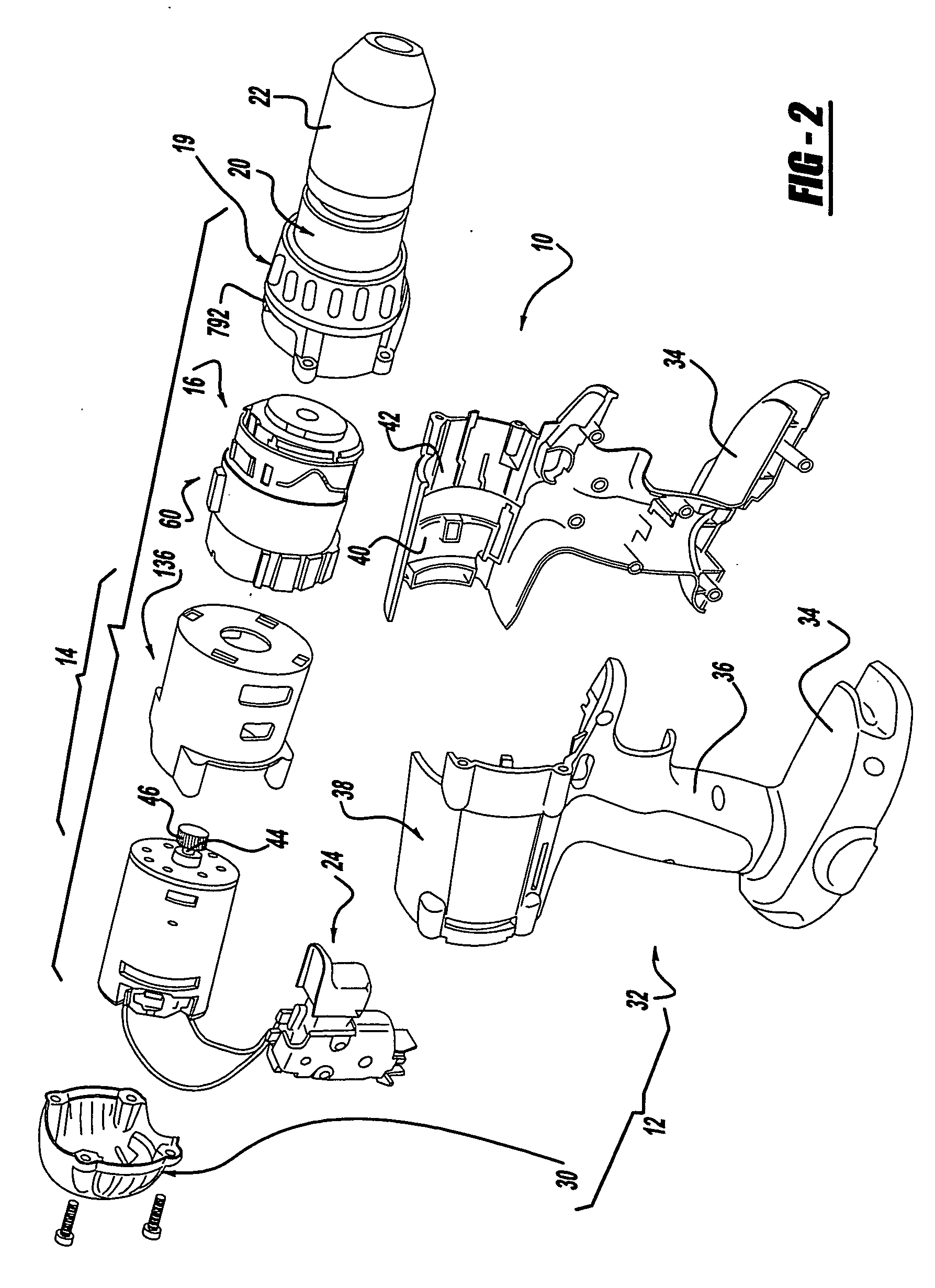

Automatic transmission for a power tool

Owner:TECHTRONIC POWER TOOLS TECHNOLOGY LTD

Power tool

InactiveUS9731410B2Simplify device configurationEasy to understandDrilling rodsConstructionsHand heldEngineering

Owner:MAKITA CORP

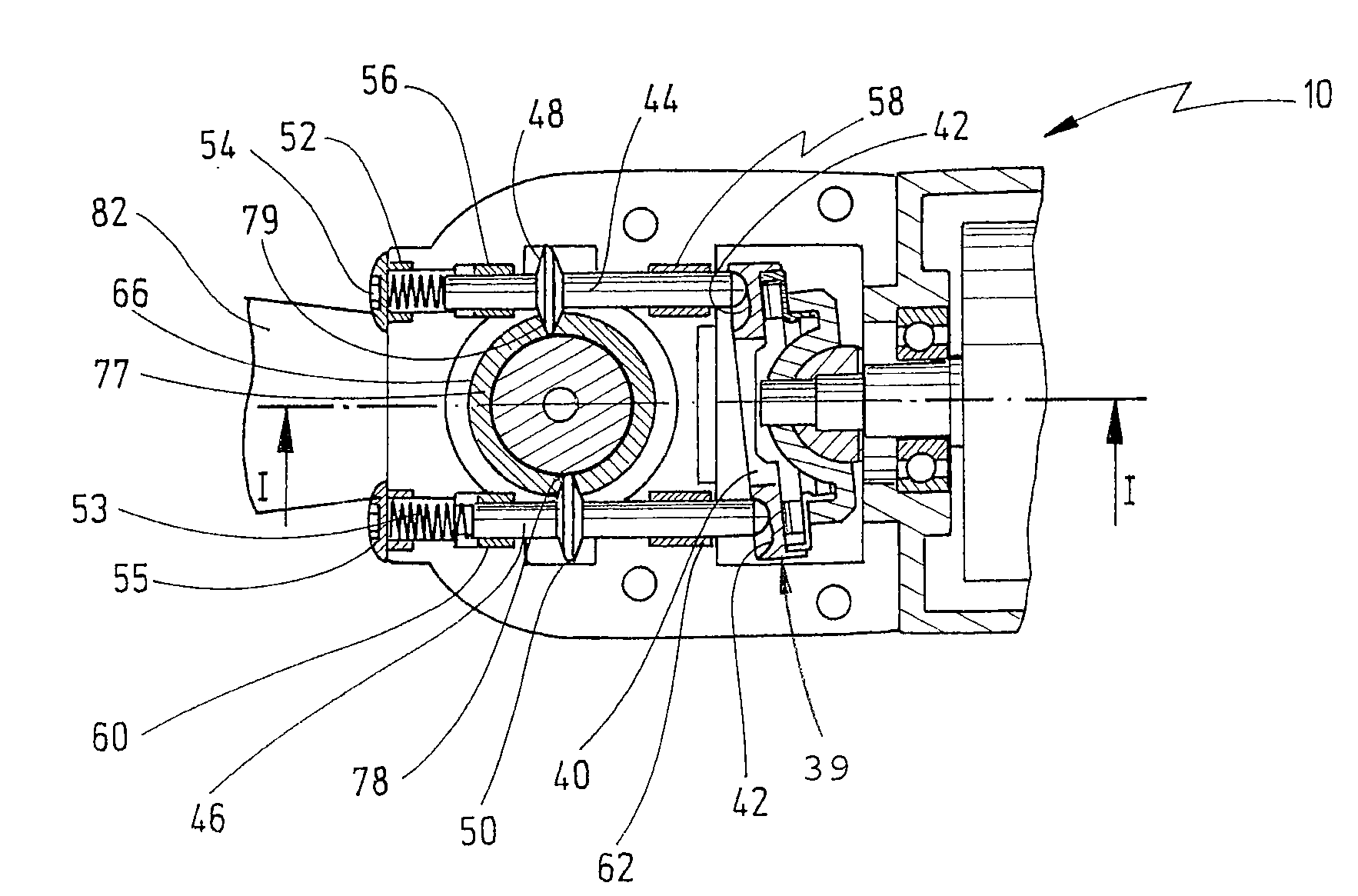

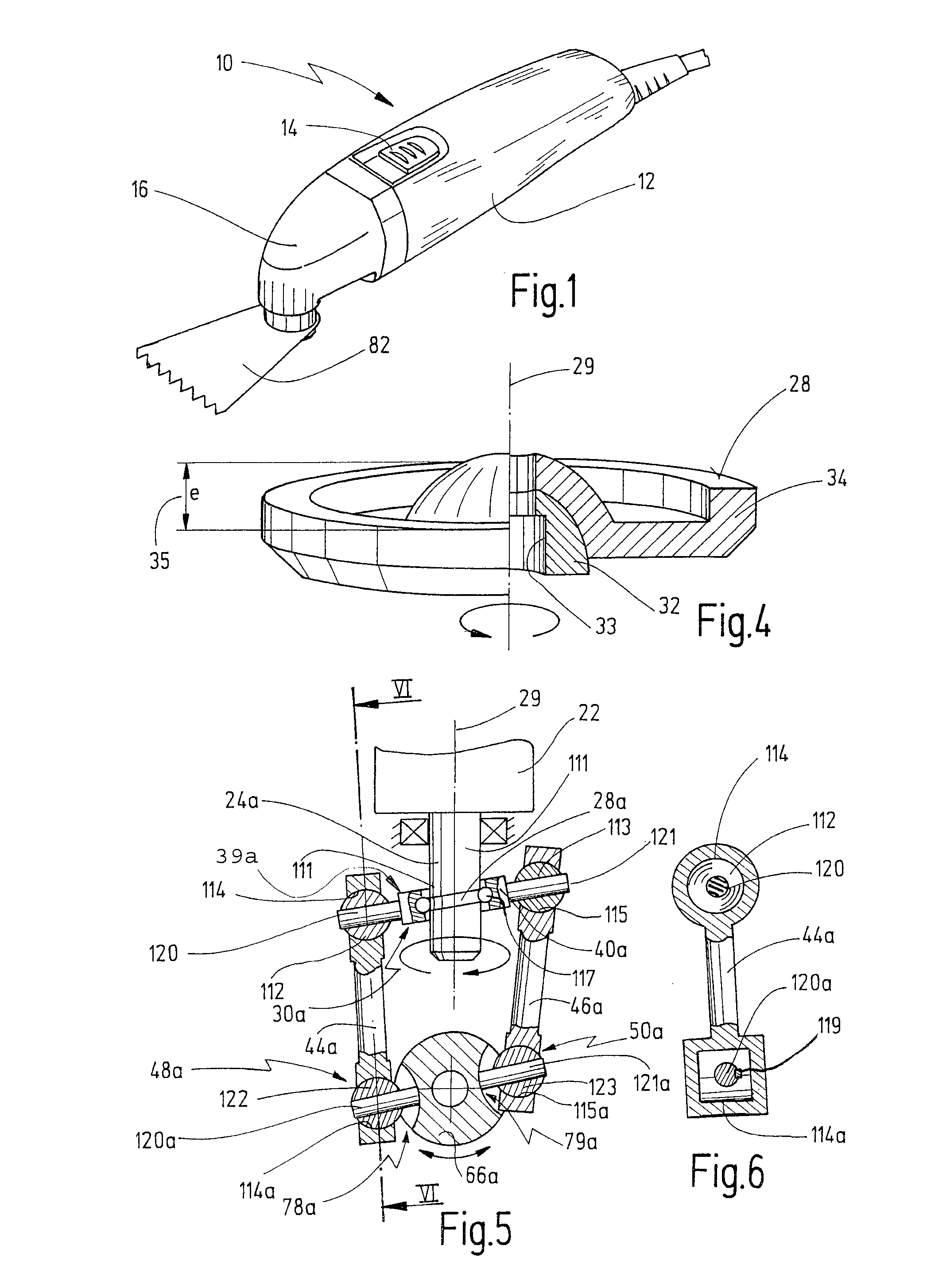

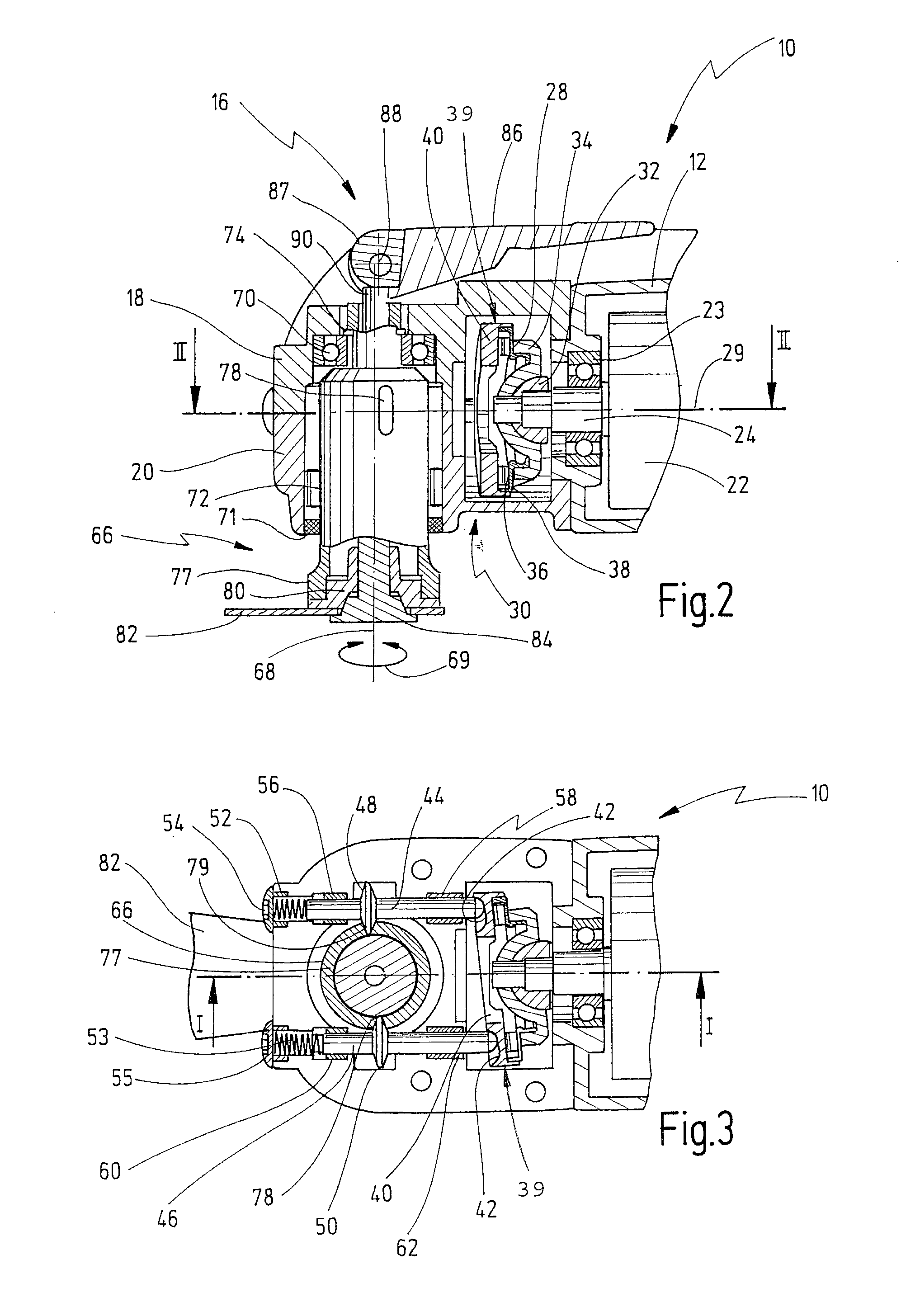

Hand tool machine having an oscillatory drive

A hand tool is disclosed, comprising a housing, a motor shaft being coupled to a drive motor, a working spindle configured for being driven rotatingly oscillatingly about its longitudinal axis, and a coupling element being driven rotatingly by the motor shaft and having a closed guide surface that revolves around the motor shaft. The guide surface is coupled, via transmission means, to at least one driver for driving the latter. The at least one driver is arranged movably relative to the working spindle and engages the working spindle at a circumferential region thereof for driving the latter rotatingly oscillatingly.

Owner:C & E FEIN GMBH & CO KG

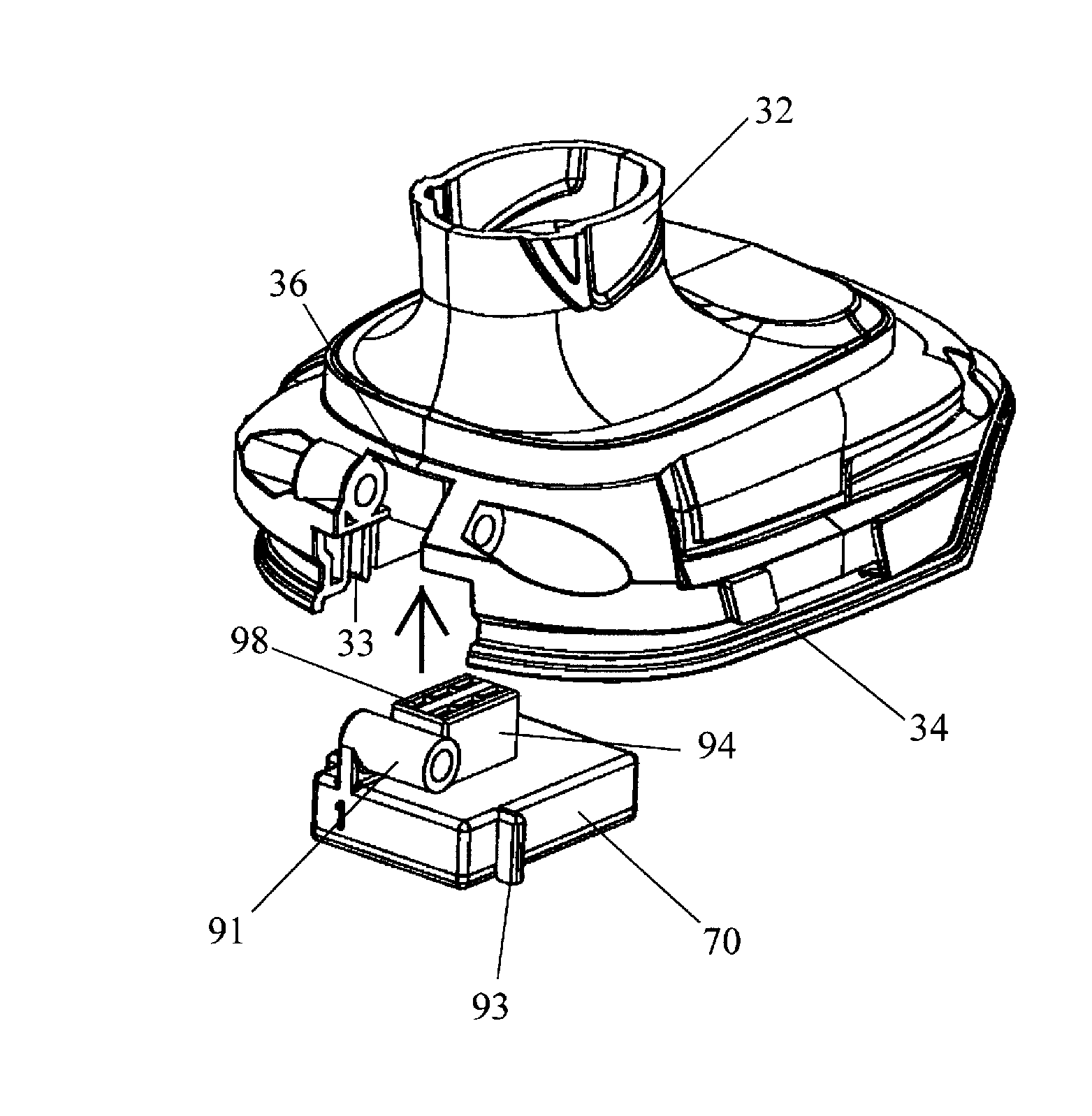

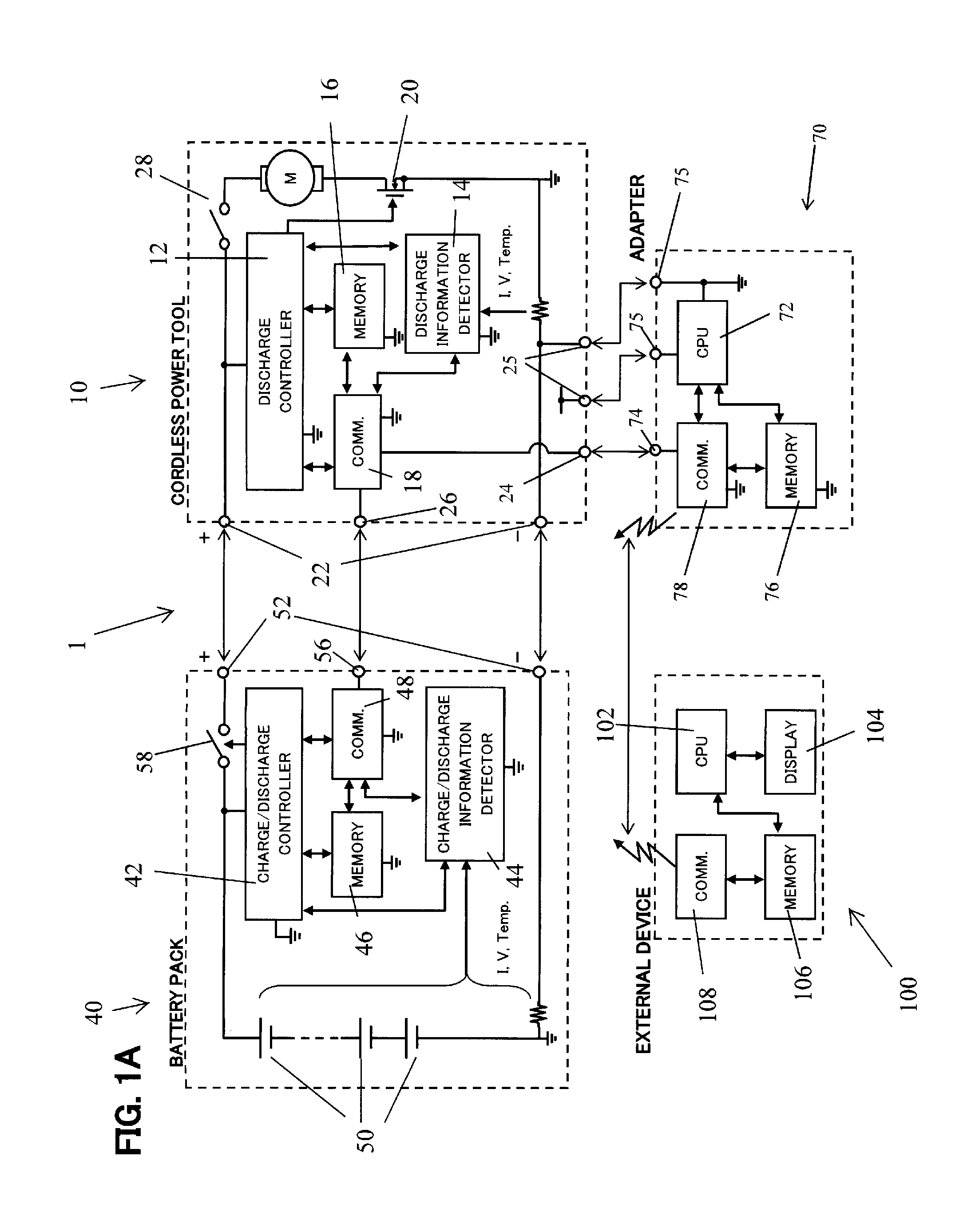

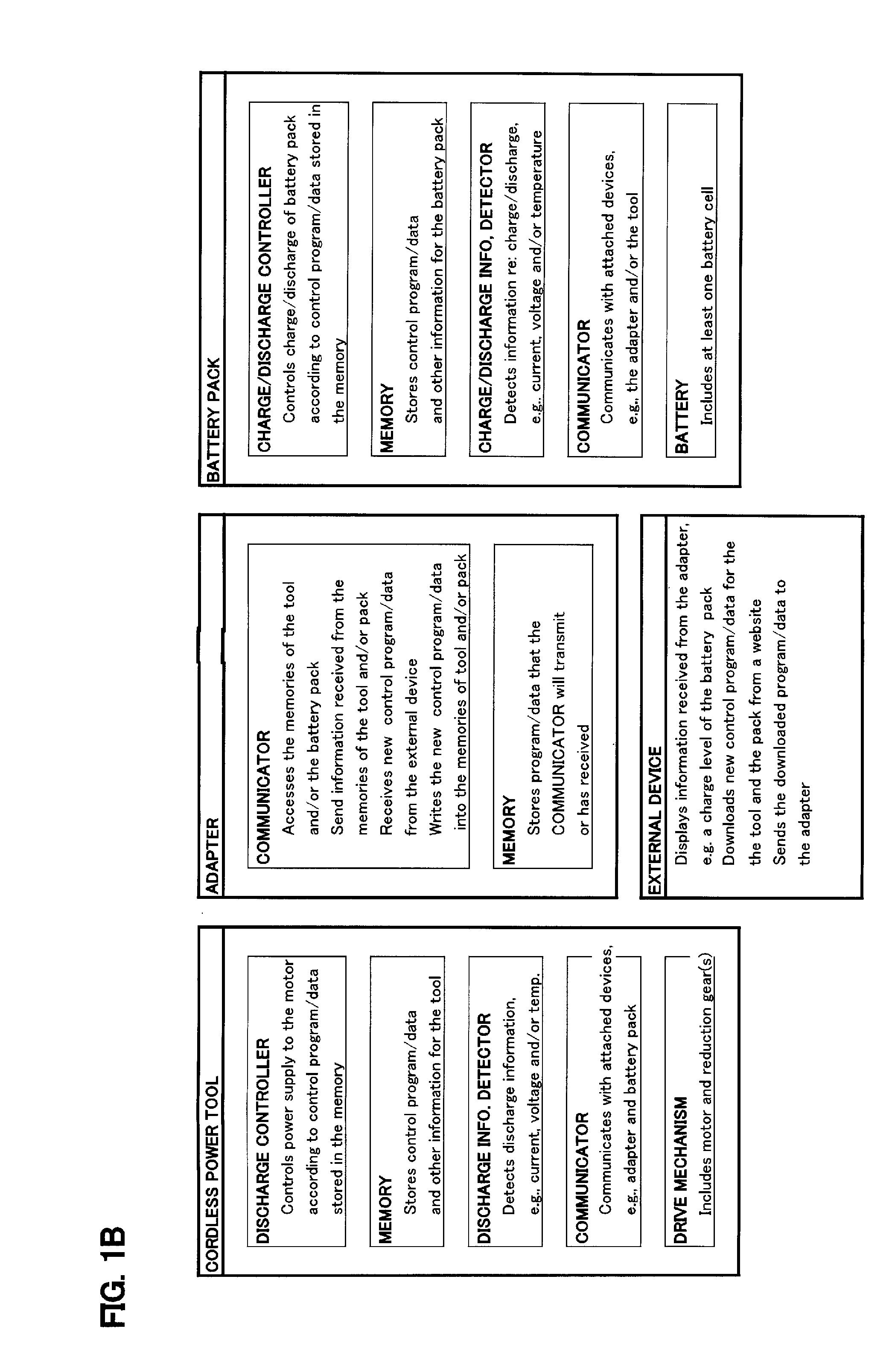

Power tool system and adapter therefor

InactiveUS20140151079A1Stable structureReadily dislodged from the power tool during operationBatteries circuit arrangementsTransmission systemsElectricityEngineering

A power tool system includes a hand-held power tool having a housing with a battery pack interface, an electrically-driven device and a first connector. A battery pack is detachably attached to the battery pack interface and supplies current to the electrically-driven device. An adapter has a second connector physically and electrically connected with the first connector in a detachable manner. The adapter receives power from the battery pack via the hand-held power tool and provides at least one additional electrical function to the hand-held power tool or performs at least one additional electrical function that the hand-held power tool is not otherwise capable of performing. Further, the adapter is at least partially disposed in a space defined in part by the housing and in part by the battery pack when the housing and battery pack are attached to each other.

Owner:MAKITA CORP

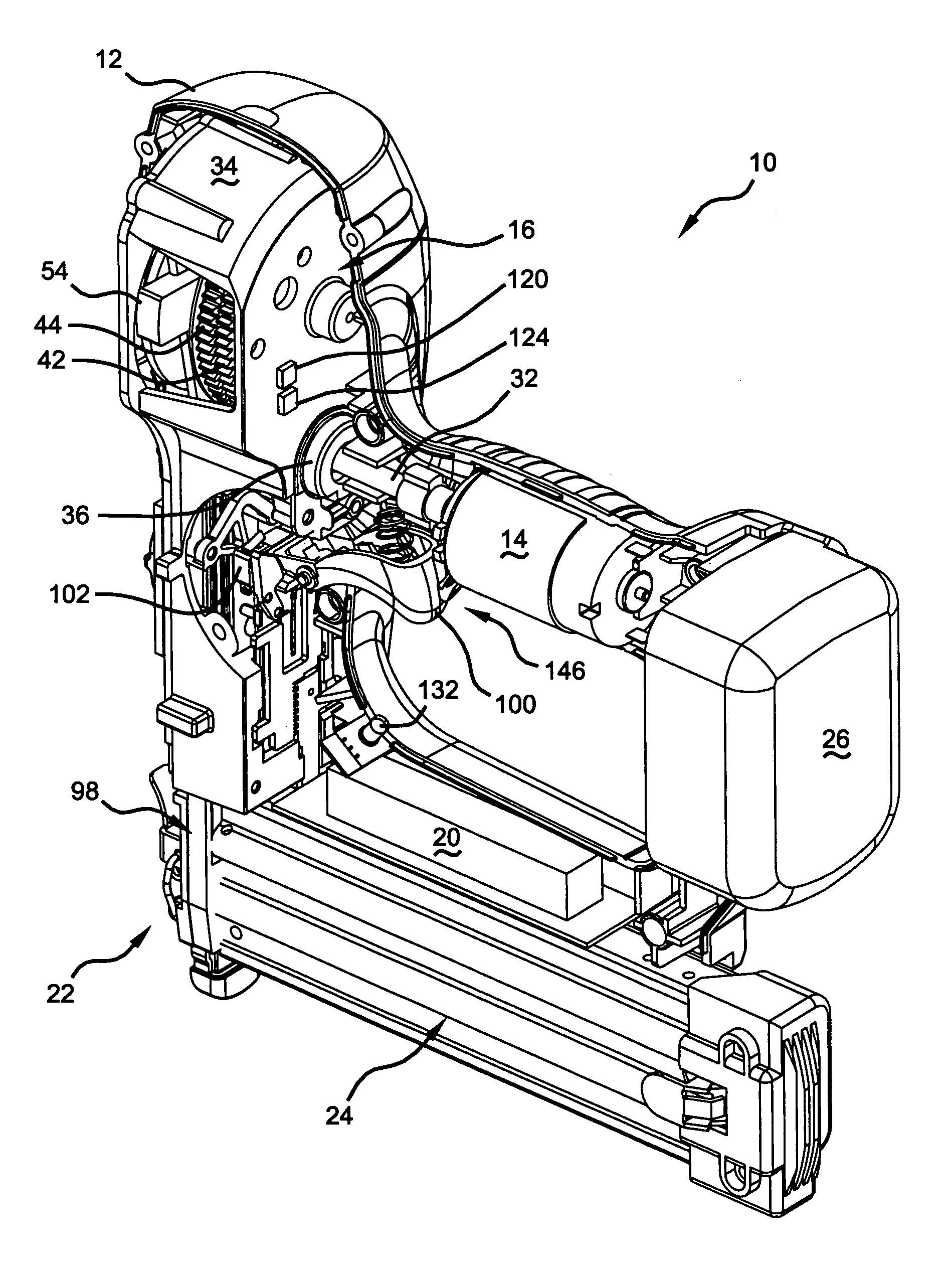

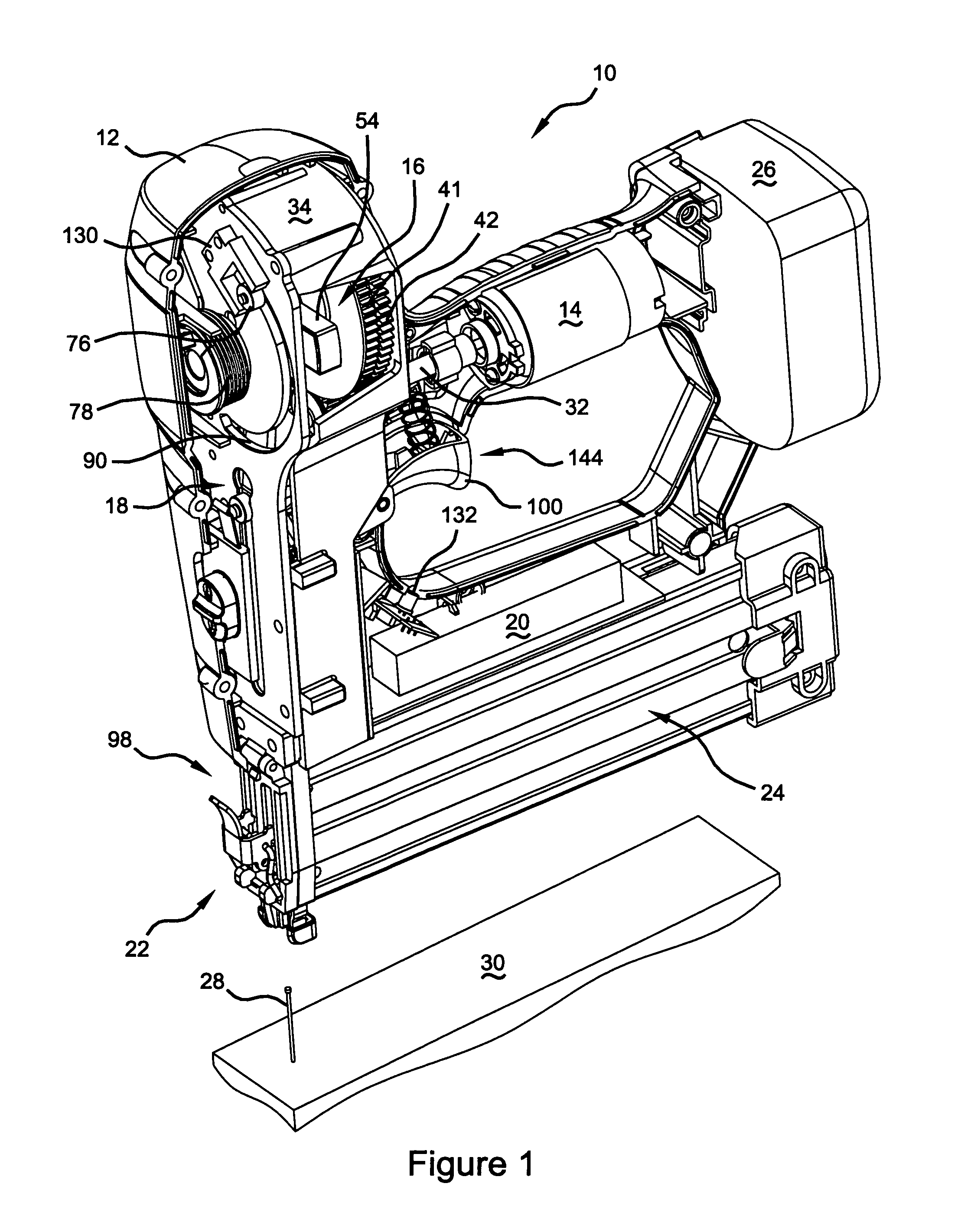

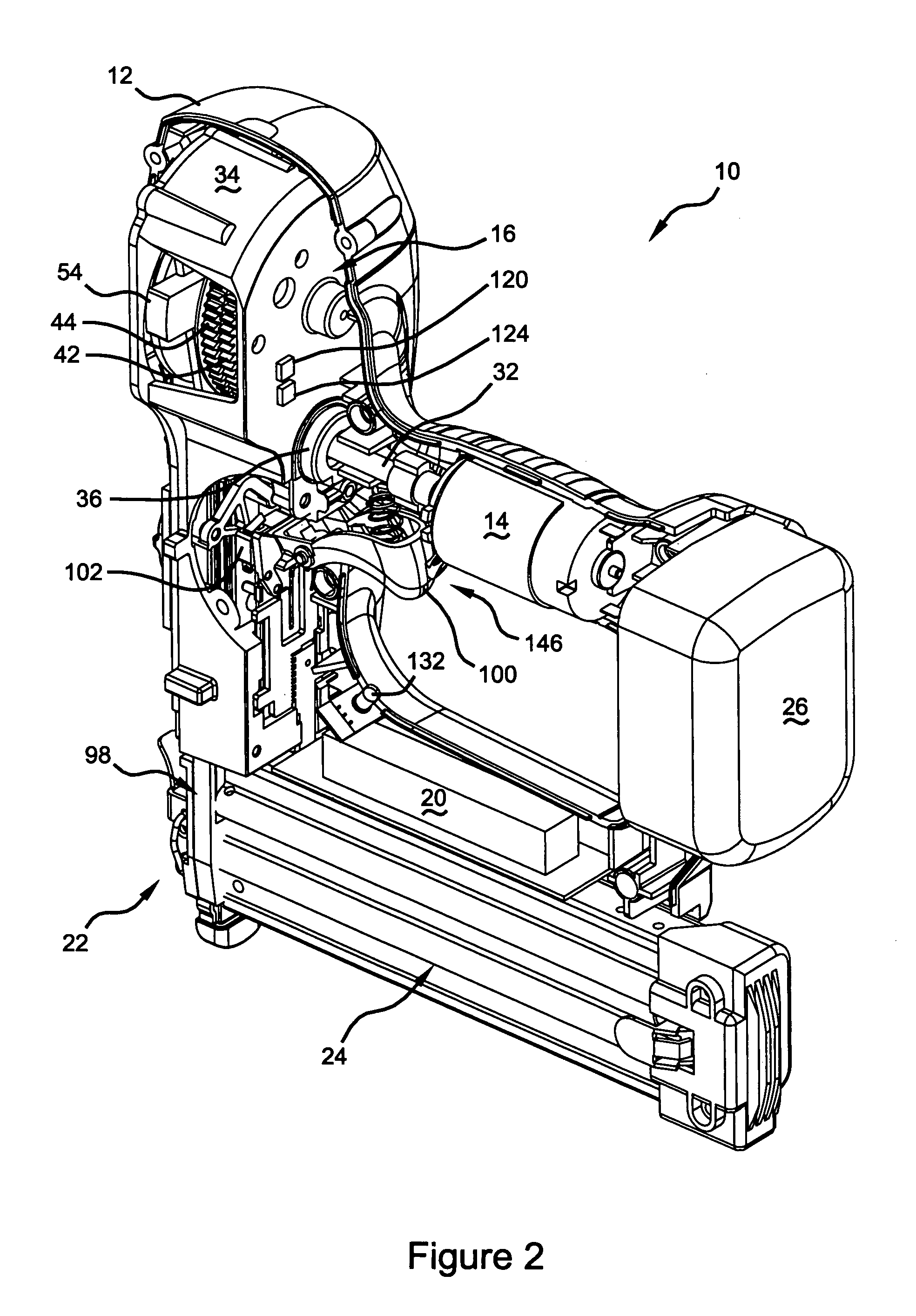

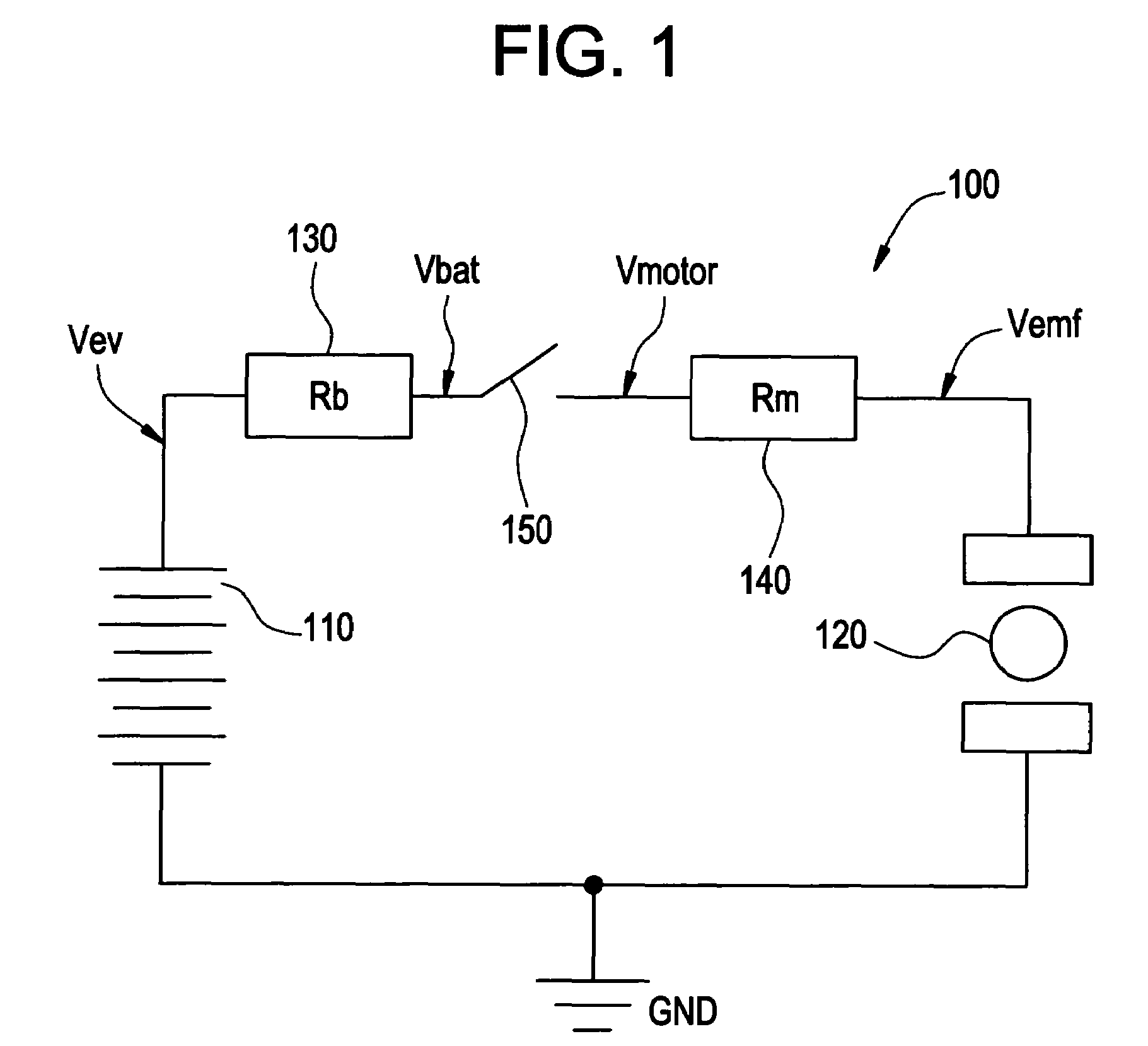

Electronic control of a cordless fastening tool

A fastening tool that drives a fastener into a work-piece. The tool includes a motor that is connected to a transmission. The transmission includes a flywheel. The tool also includes a driver mechanism that is adapted to drive the fastener into the work-piece. The flywheel is connected to the driver mechanism when the flywheel is in a flywheel firing position. The tool includes a control module that detects a flywheel position and compares the flywheel position to the flywheel firing position. The control module also adjusts the flywheel position based on the comparison. The control module ensures that the transmission has enough rotations to ensure that enough momentum can be generated to drive the fastener into the work-piece.

Owner:BLACK & DECKER INC

Hand-held working tool

Owner:HILTI AG

Fastener driving device

A fastener driving device includes a fastener driver, a magazine for carrying a supply of fasteners to the fastener driver, a spring that moves the fastener driver through a drive stroke, and a motor configured to move the fastener driver through a return stroke. The motor is operable upon completion of the drive stroke, to move the fastener driver partially through the return stroke a predetermined amount to partially pre-compress the spring. The motor is further operable to fully compress the spring after receiving a signal for the drive stroke.

Owner:STANLEY FASTENING SYST LP

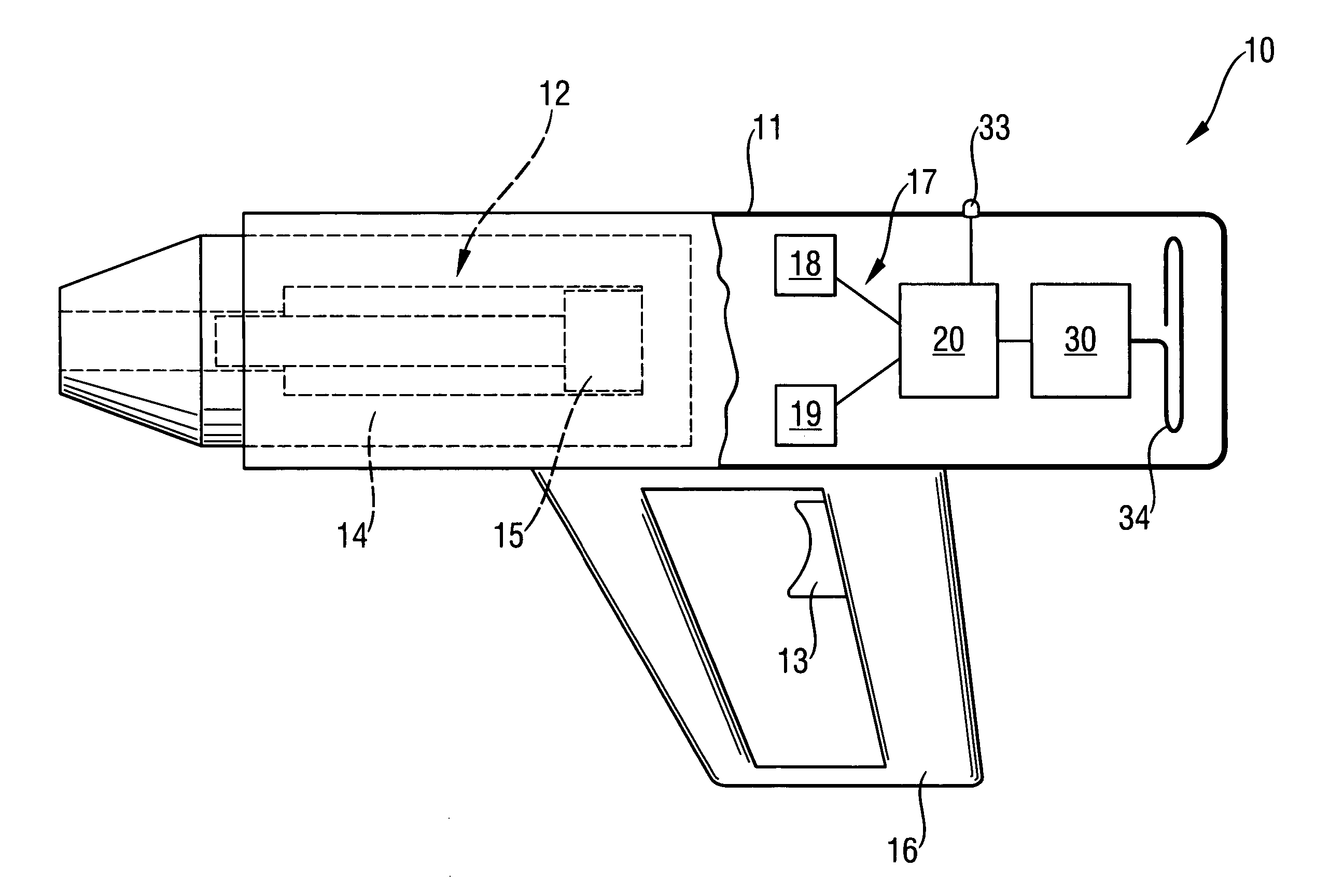

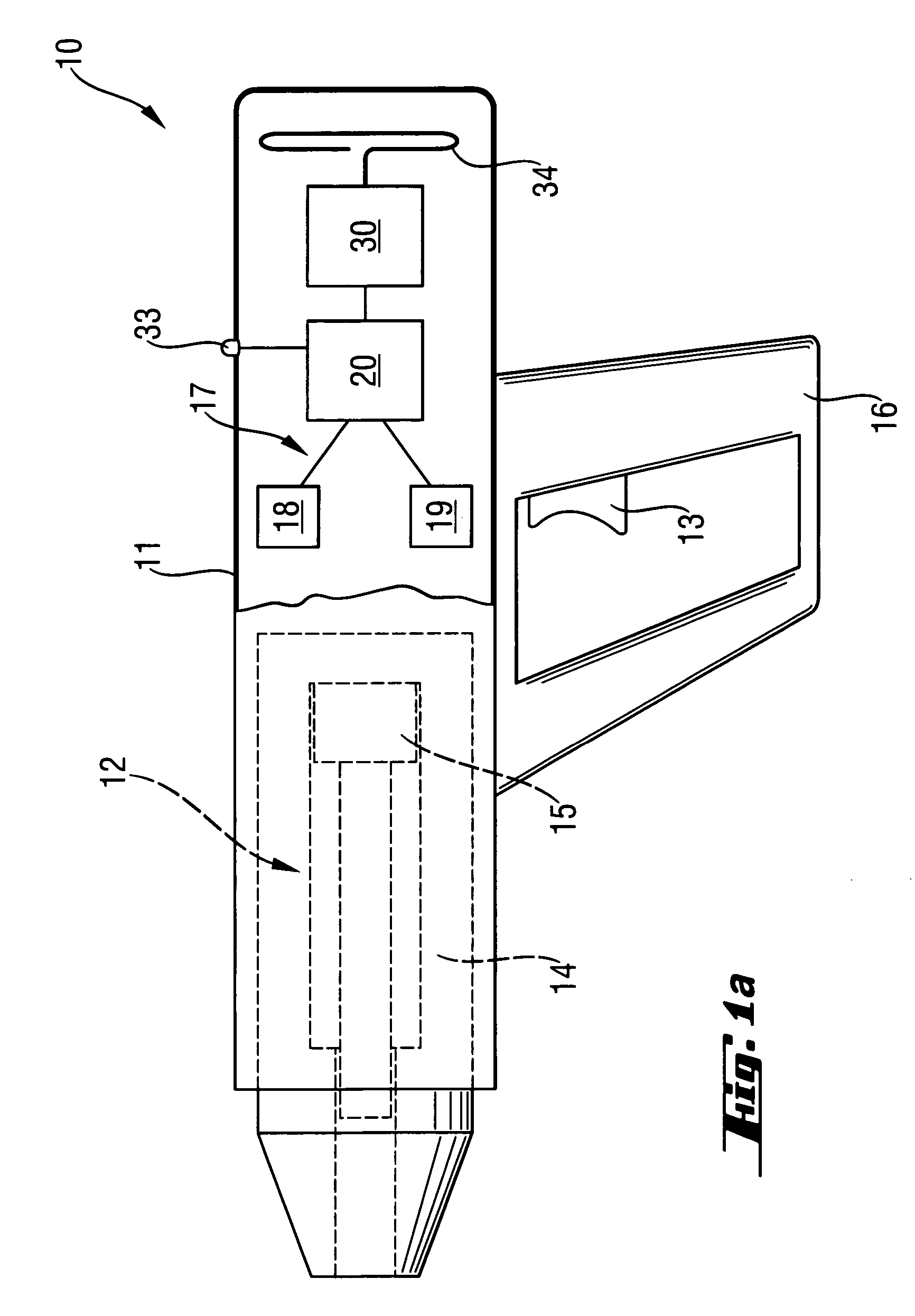

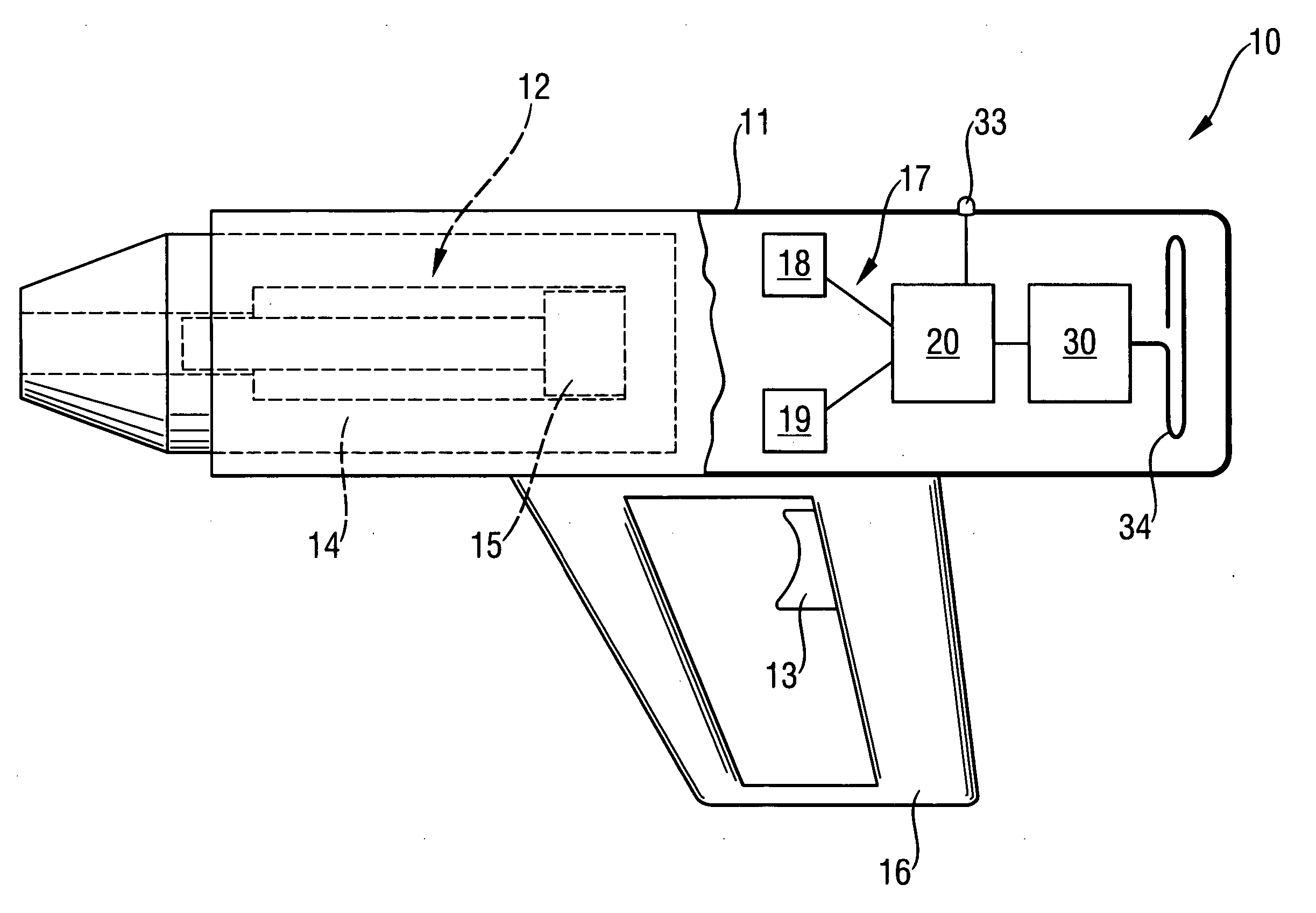

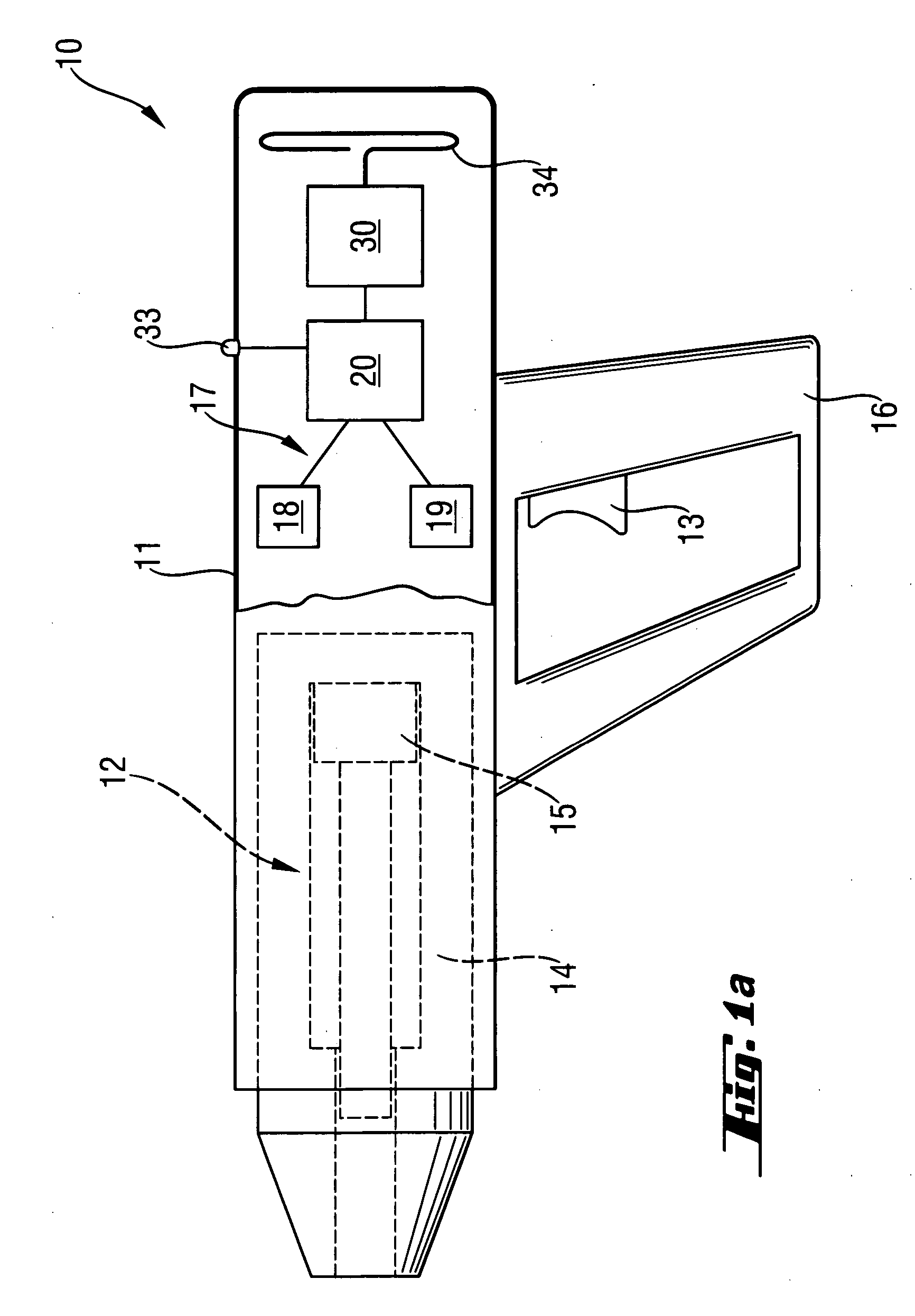

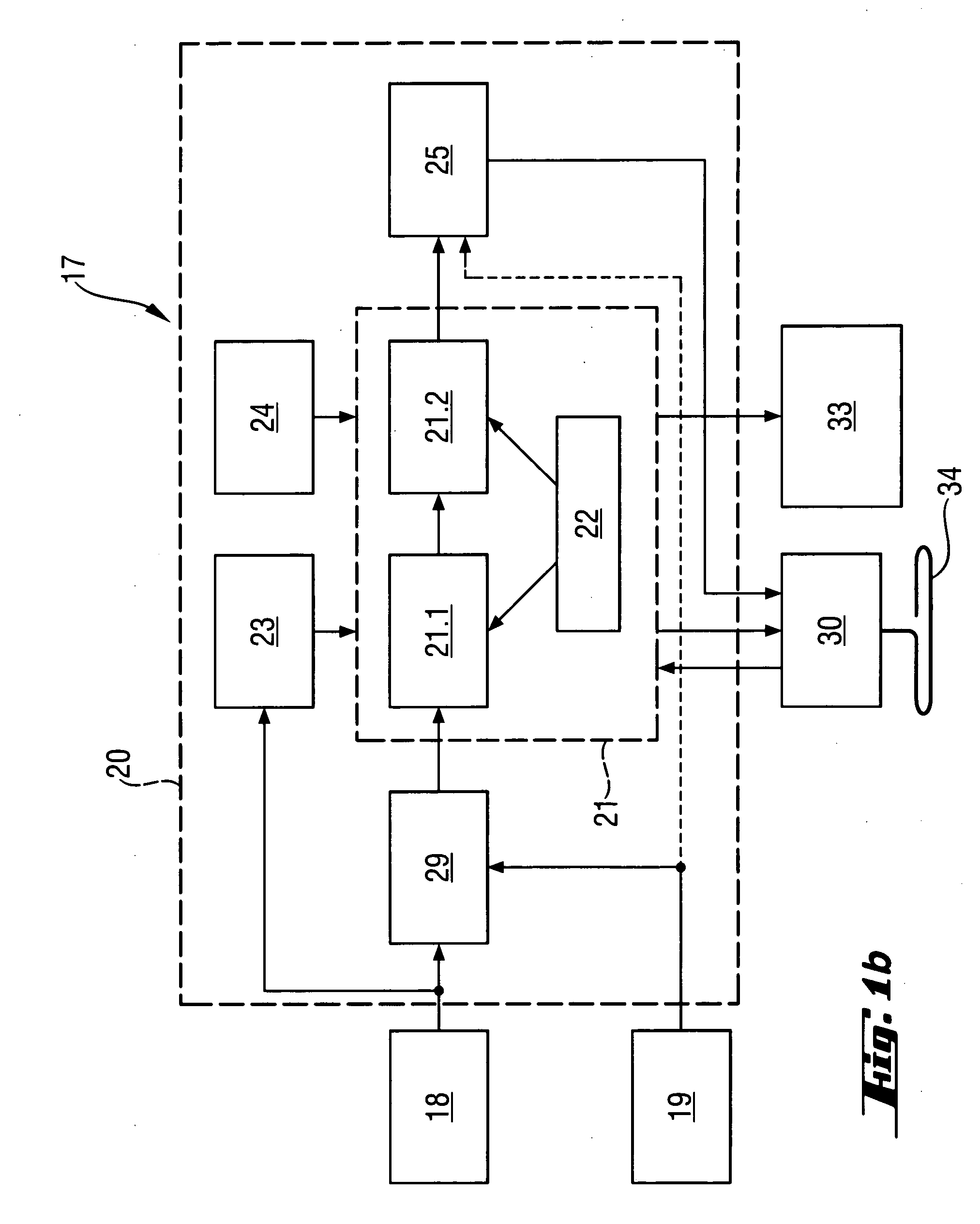

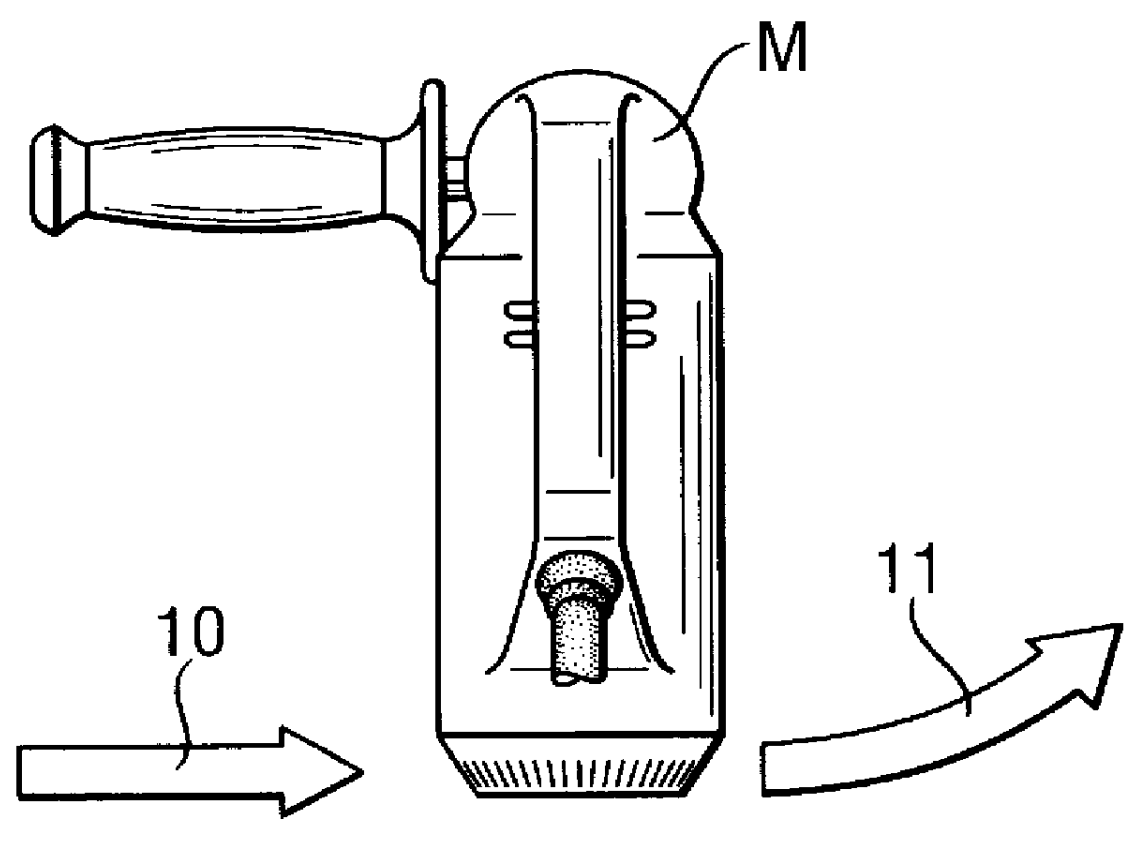

Hand-held working tool

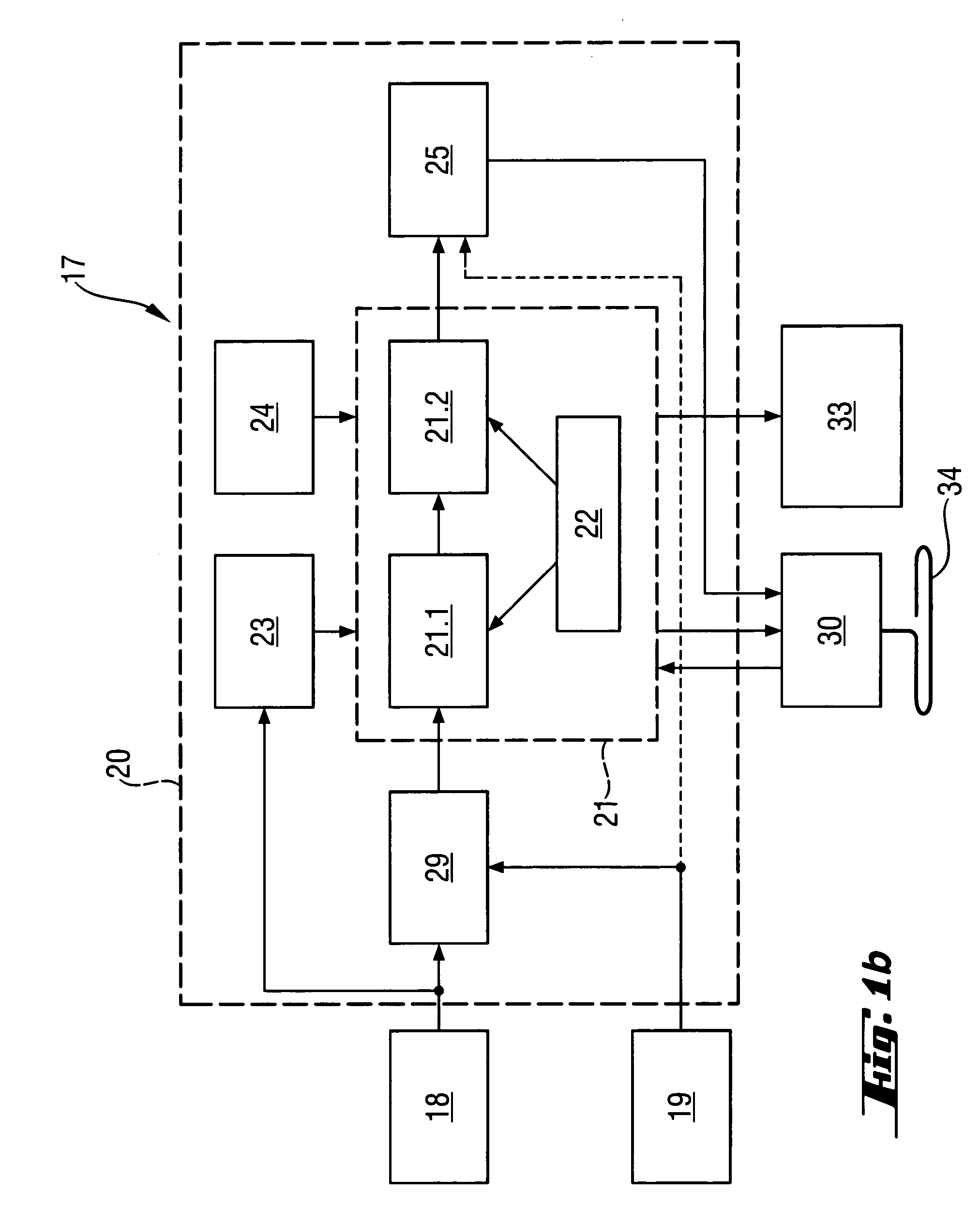

The present invention relates to a hand-held working tool, such as a setting device used for driving fastening elements such as nails, bolts, pins and the like into a surface, or an at least partially percussive hand-held tool having a housing part (11) and a working mechanism such as a setting or striking mechanism arranged inside the housing of the device and having at least one sensing device (17) for sensing acceleration forces occurring during a setting or striking pulse as well as a handle. For improving this type of hand-held working tool (10) an interface (30) for data communication and data output is arranged on the hand-held working tool.

Owner:HILTI AG

Impact tool

ActiveUS20120279736A1Shorten the timeIncrease production capacityReciprocating drilling machinesConstructionsEngineeringDriving mode

According to an aspect of the present invention, there is provided an impact tool including: a motor drivable in an intermittent driving mode; a hammer connected to the motor; an anvil to be struck by the hammer to thereby rotate / strike a tip tool; and a control unit that controls a rotation of the motor by switching a driving pulse supplied to the motor in accordance with a load applied onto the tip tool.

Owner:HITACHI KOKI CO LTD

Hammer drill with a mode changeover mechanism

Owner:BLACK & DECKER INC

Powered Driver

ActiveUS20080221580A1Reduce speedReduce chanceSafety arrangementSurgical needlesGear wheelEngineering

An apparatus and methods are provided to penetrate a bone and associated bone marrow using a powered driver having a gear assembly and a motor. The powered driver may include an indicator operable to show status of a power supply associated with the powered driver. The power supply may include a battery power pack having a diamond shaped cross section. The powered driver may have a handle with a corresponding cross section.

Owner:TELEFLEX LIFE SCI LTD

Hammer drill with a mode changeover mechanism

Owner:BLACK & DECKER INC

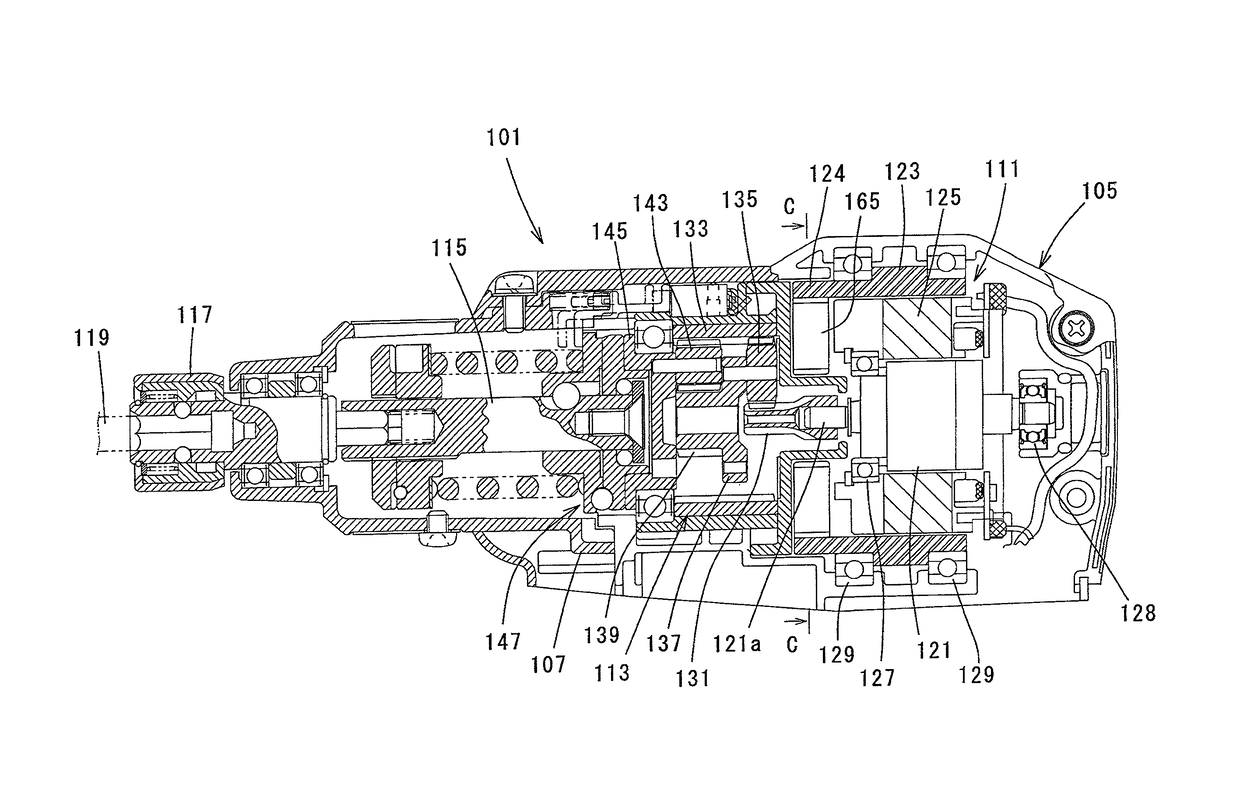

Impact driver having an external mechanism which operation mode can be selectively switched between impact and drill modes

ActiveUS7124839B2Simple structureImprove usabilityReciprocating drilling machinesPortable percussive toolsOperation modeEngineering

An impact driver in which a drill mode can be selected without fail is provided. In a hammer case, a connecting sleeve is provided so as to be slidable back and forth. At the backward position, the connecting sleeve engages with only a first engaging tooth provided on the outer circumference of the hammer for rotating integrally. At the forward position, it engages with both the first engaging tooth of the hammer and a second engaging tooth of an anvil for rotating integrally with both of them, and thus a drill mode is obtained. Further, an operating bolt is provided in the hammer case to be inserted into a concave groove of the connecting sleeve through a guide groove formed in the hammer case. The operating bolt slides the connecting sleeve to the forward or backward position by its movement in the guide groove.

Owner:MAKITA CORP

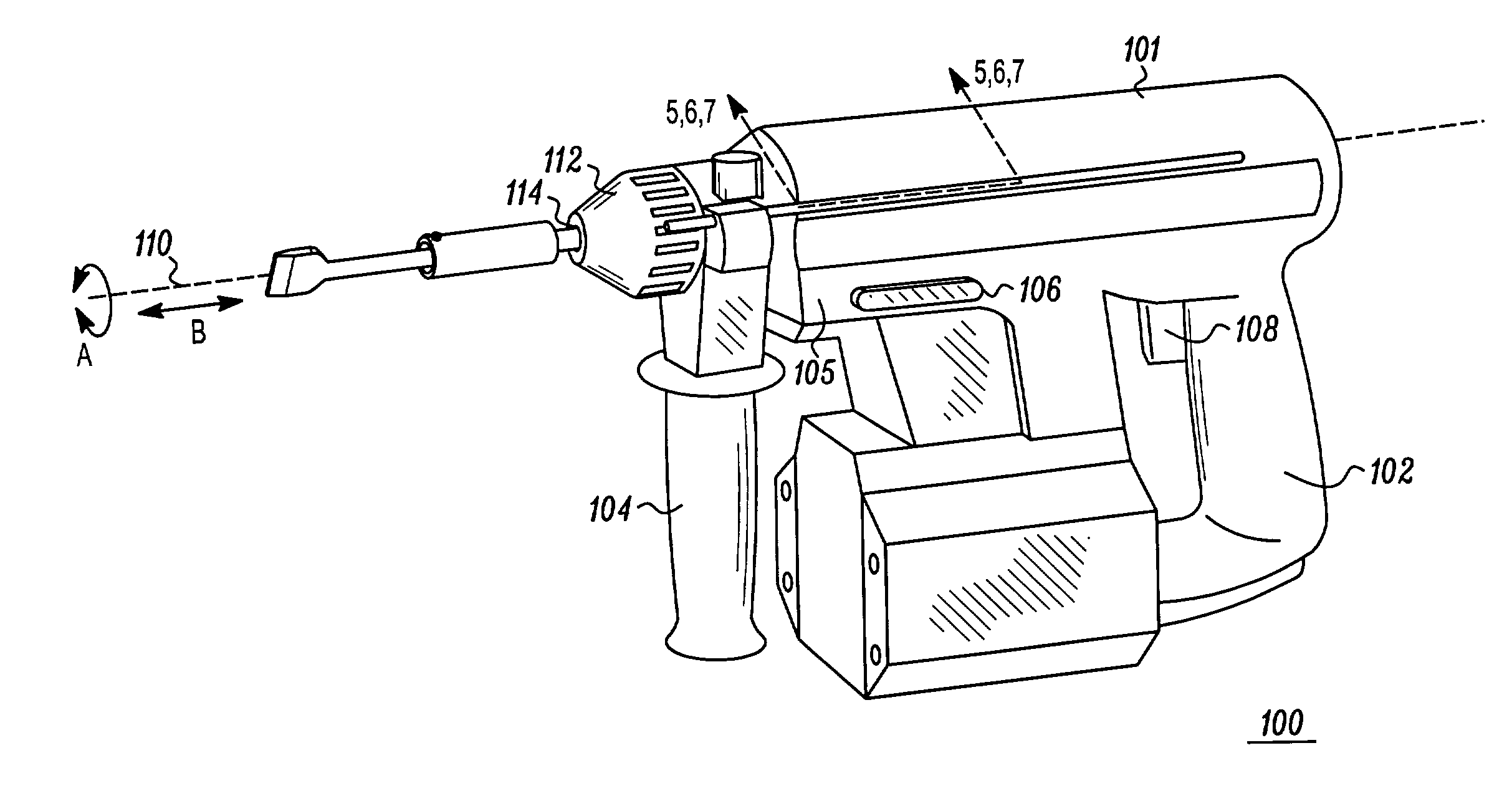

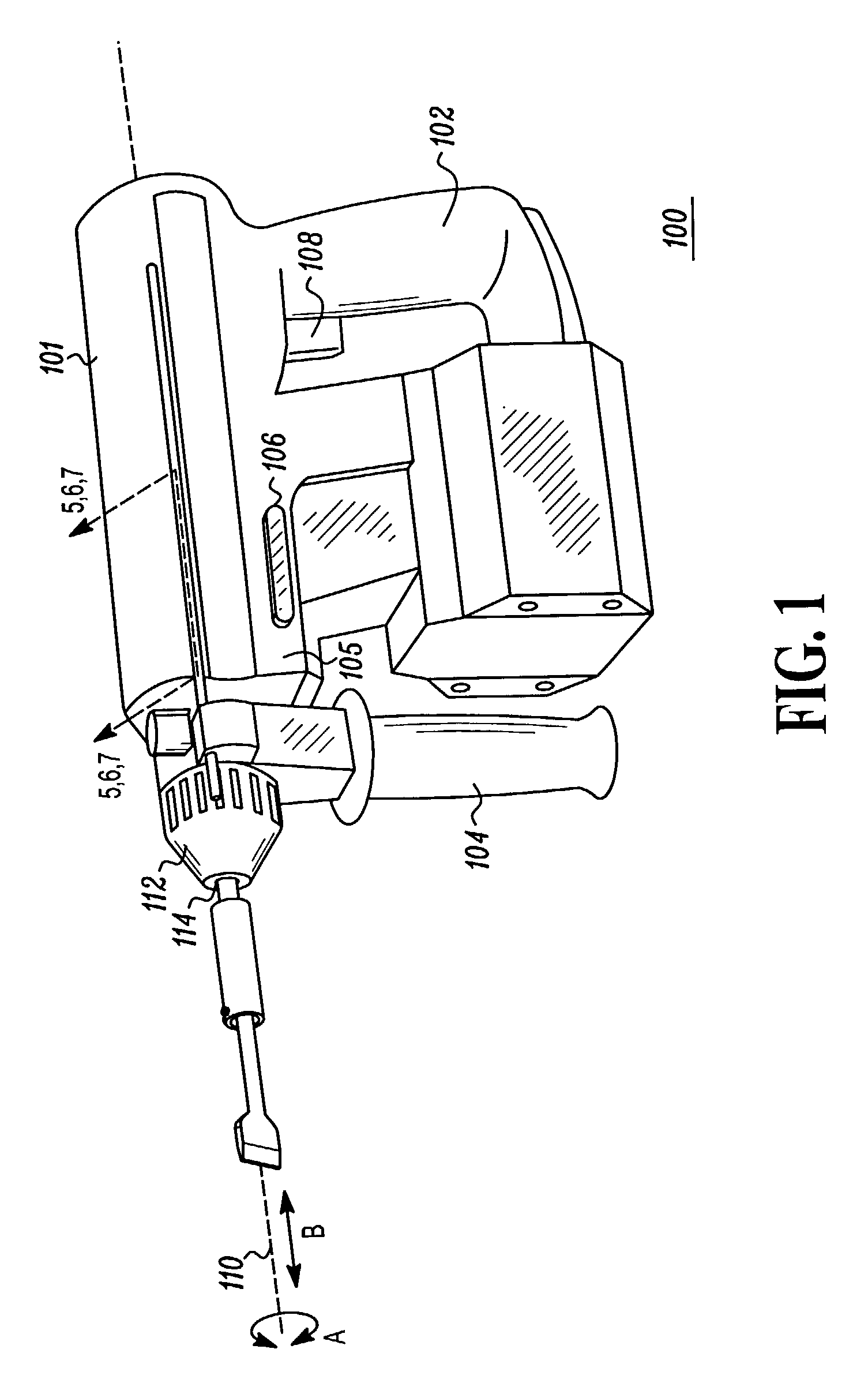

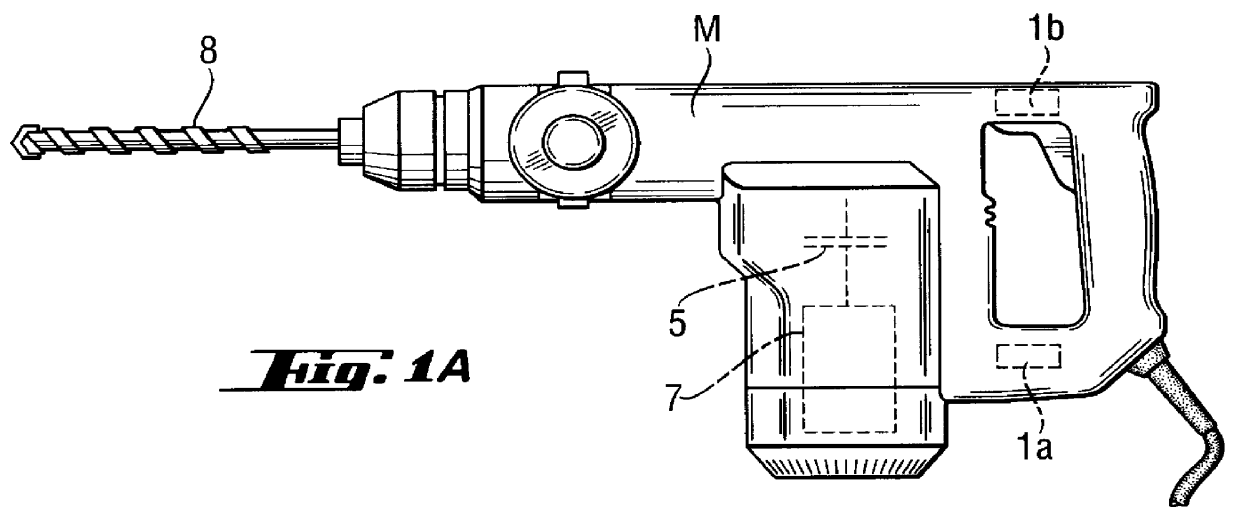

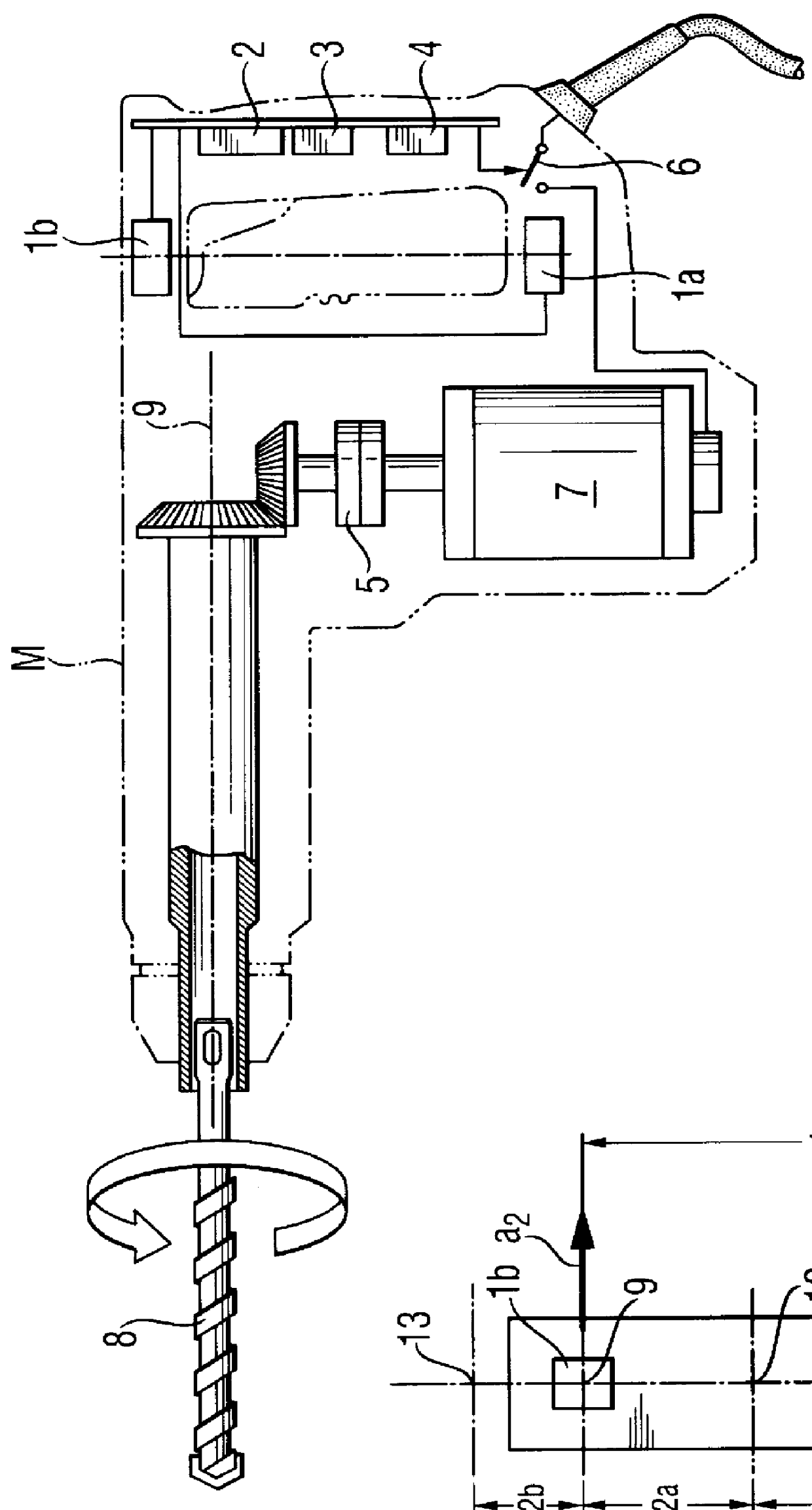

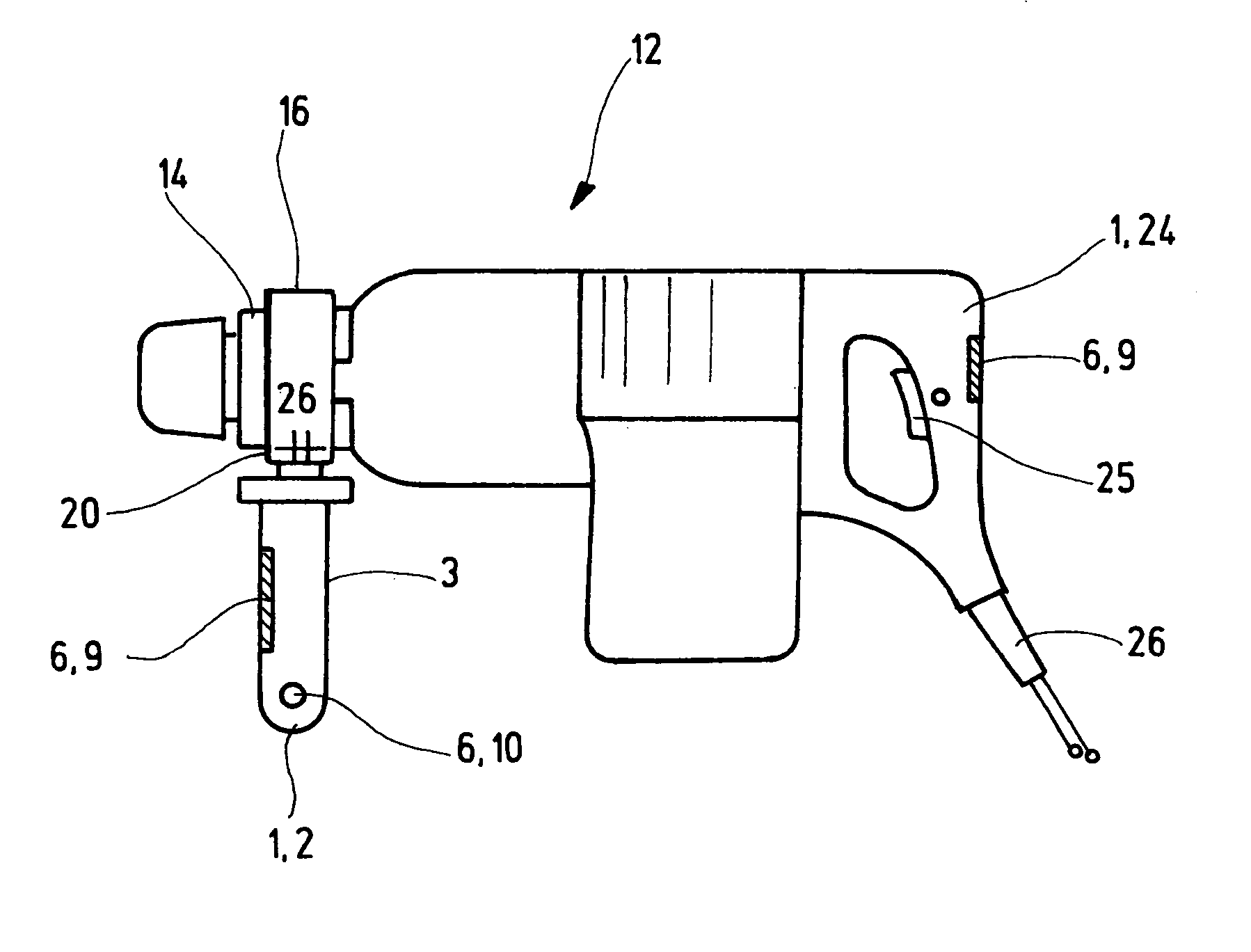

Method of and apparatus for preventing accidents during working with hand-held tools with a rotatable working tool

InactiveUS6111515AAvoid accidentsPortable percussive toolsPortable power-driven toolsElectric machineryHand held

A method of and an apparatus for preventing accidents caused by blockage of a rotatable tool when working with a hand-held tool including the rotatable tool (8), a drive motor (7) for driving the rotatable tool (8), and means (5, 6) for interrupting transmission of a drive torque from the drive motor (7) to the rotatable tool (8) dependent on an operational condition of the hand-held tool, with the method including determining the operational condition of the hand-held tool by measuring displacement of the hand-held tool in space in at least two points of the hand-held tool spatially spaced from each other and spaced from a tool axis; subtracting two obtained displacement measurement variable (a.sub.1, a.sub.2) from each other; and thereafter, calculating an actuation signal that actuates the interrupting means (5, 6); and with the apparatus including sensors and an evaluation circuit for implementing the method.

Owner:HILTI AG

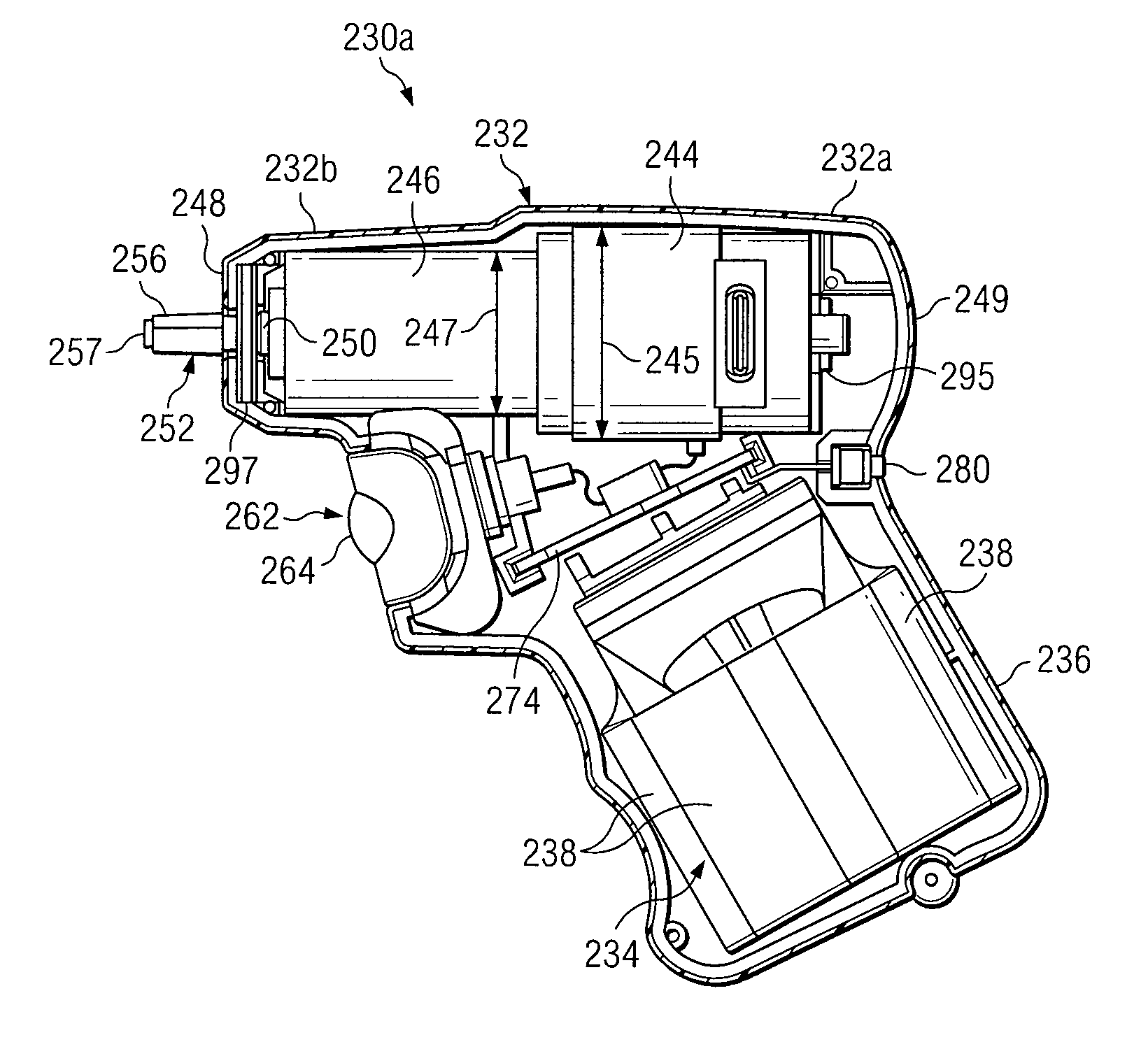

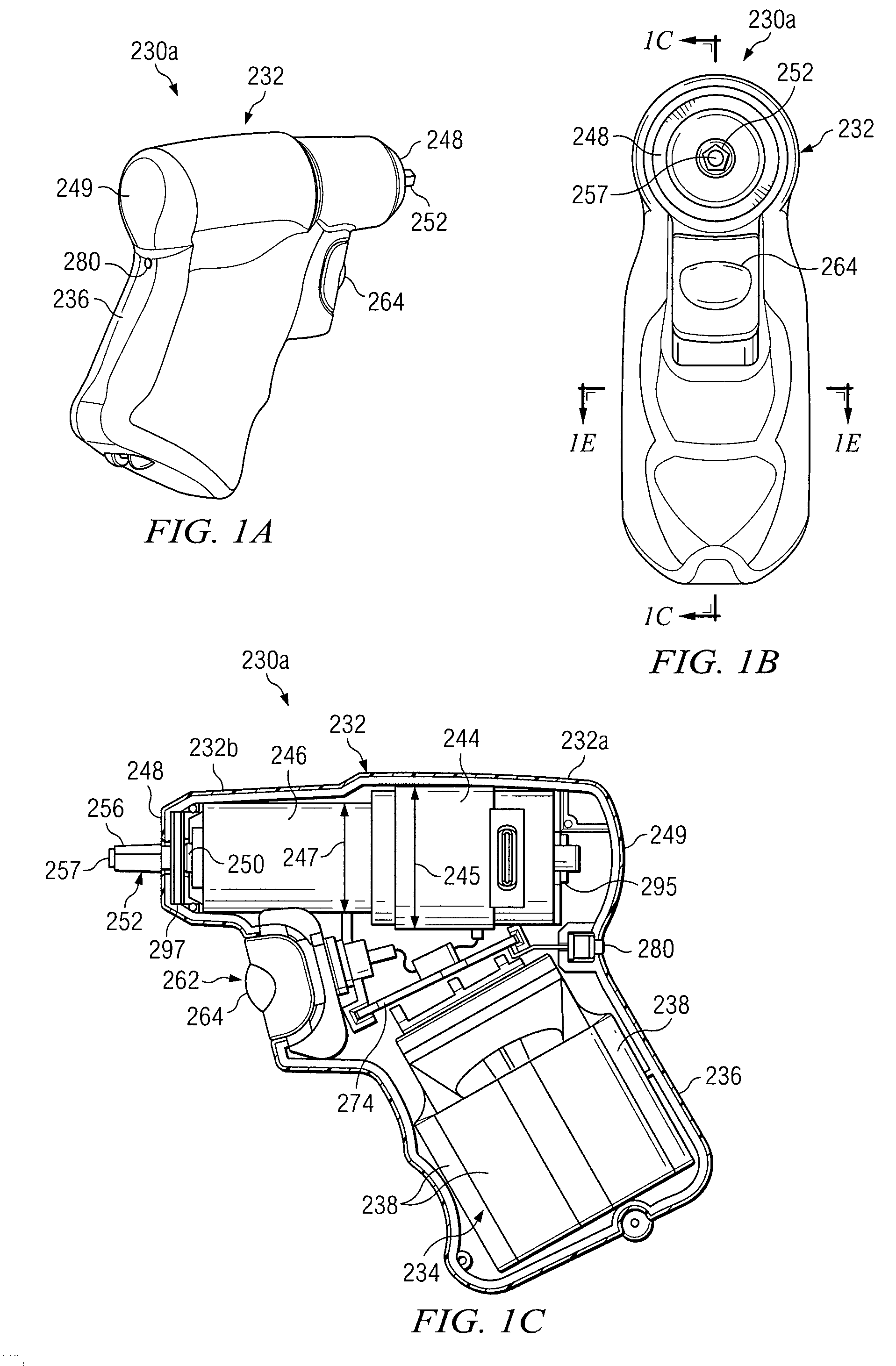

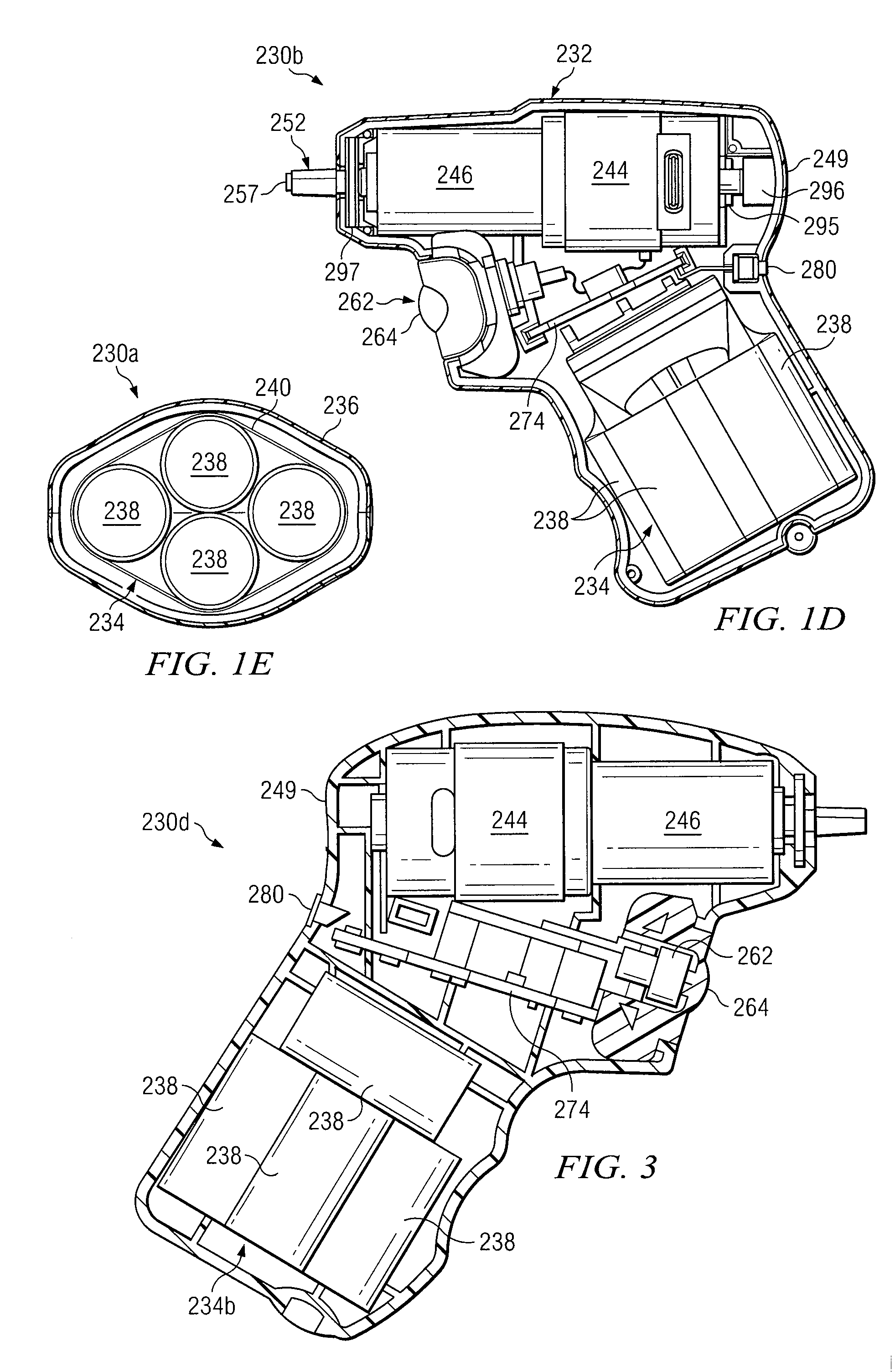

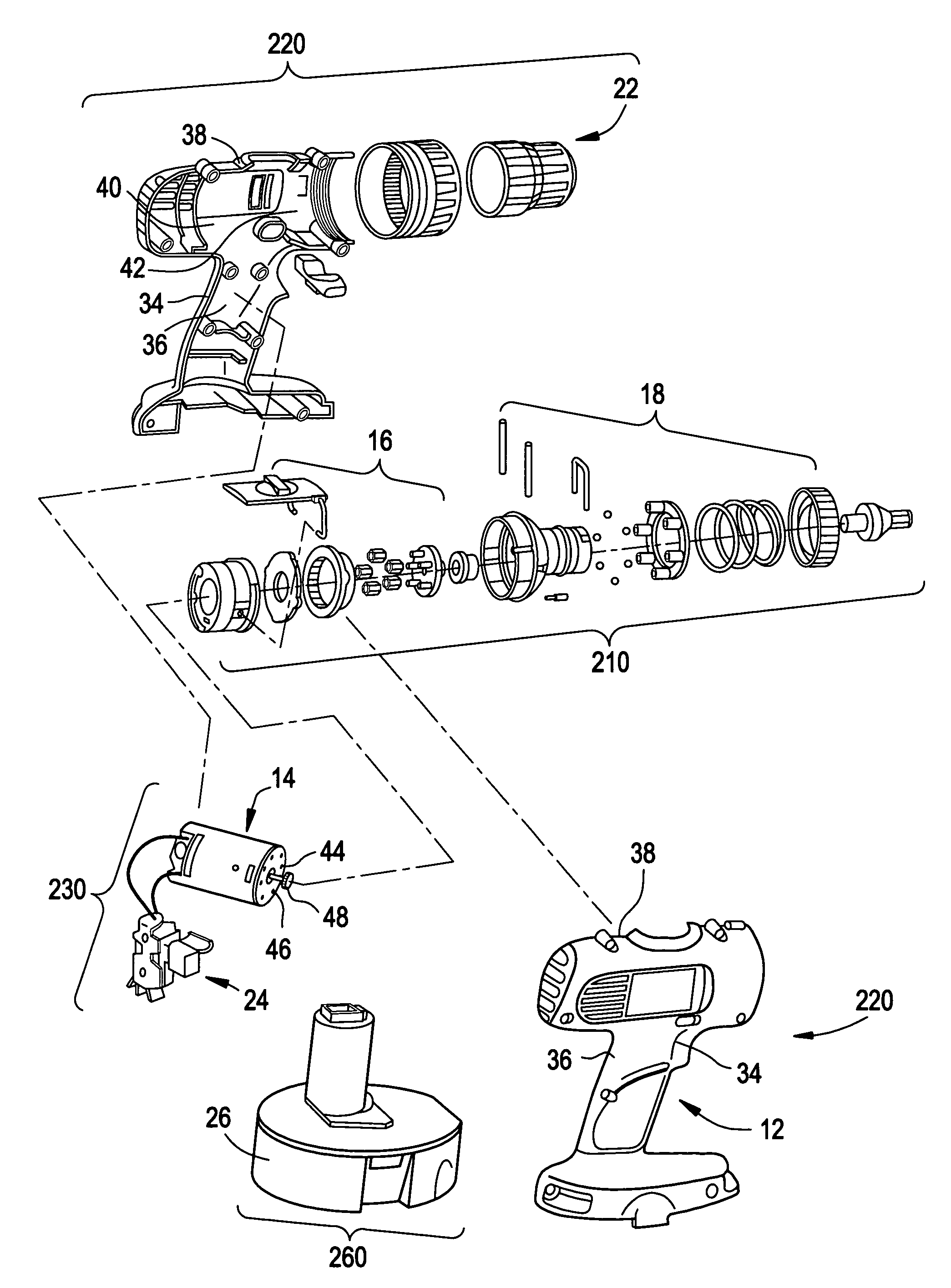

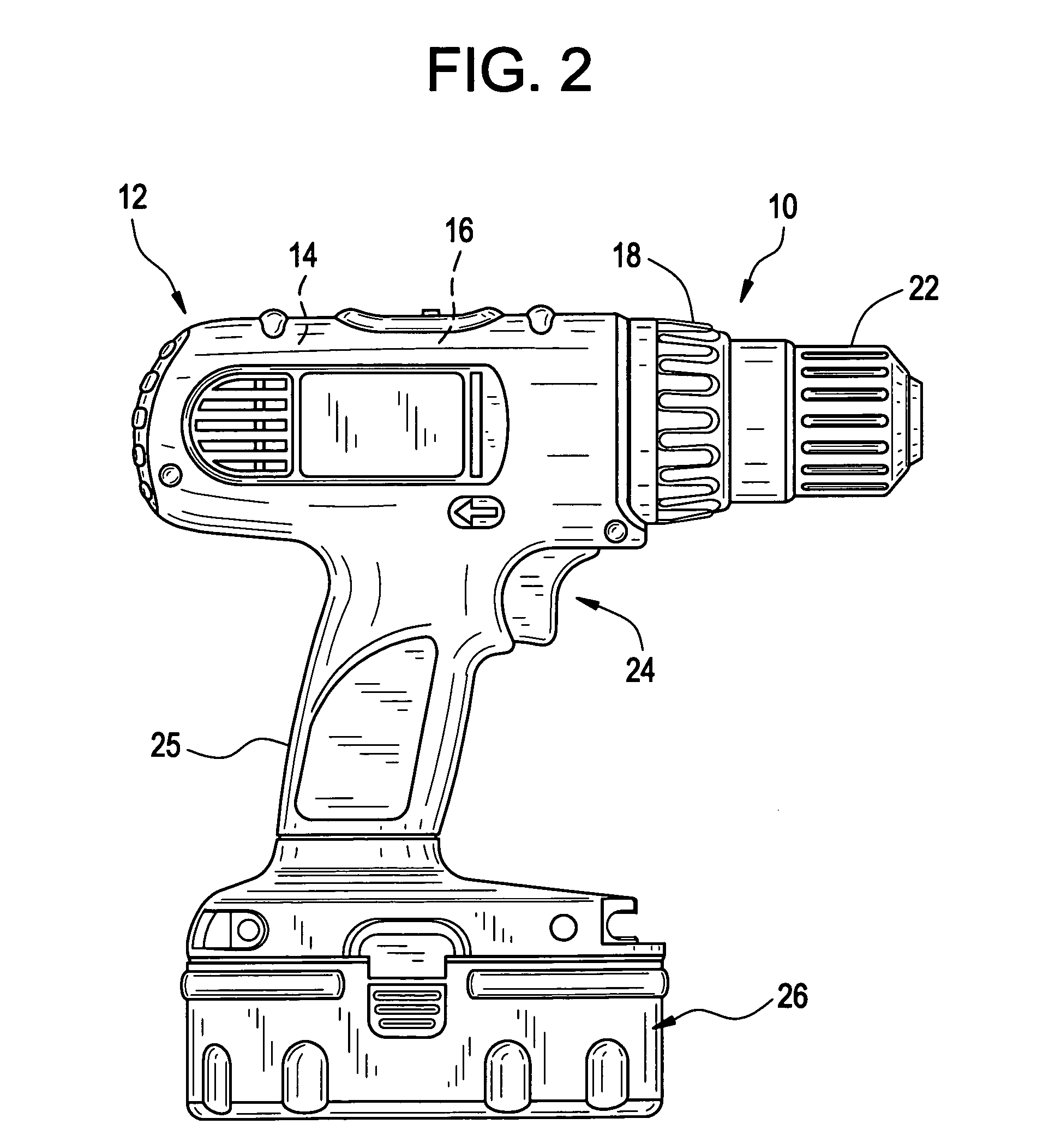

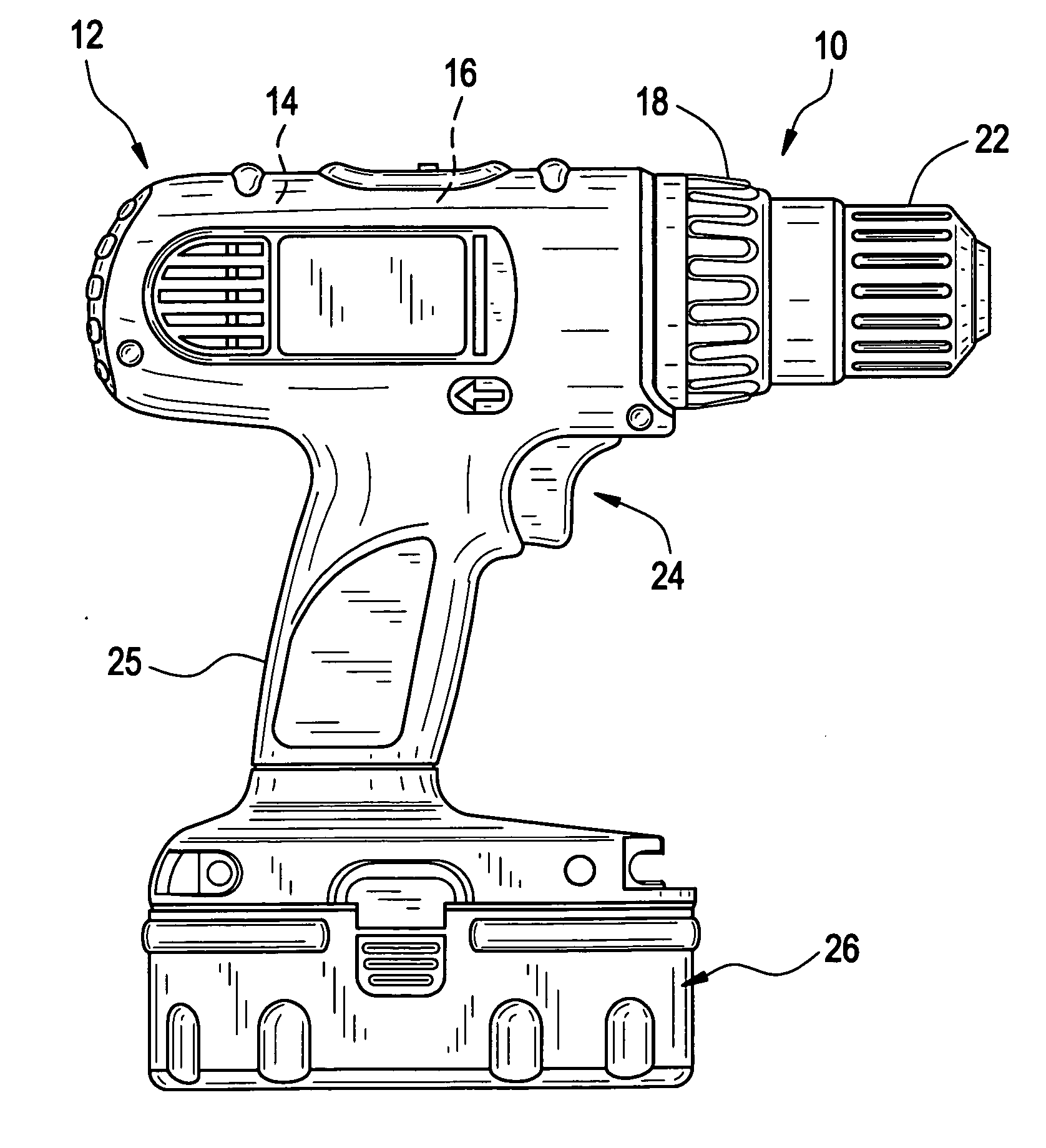

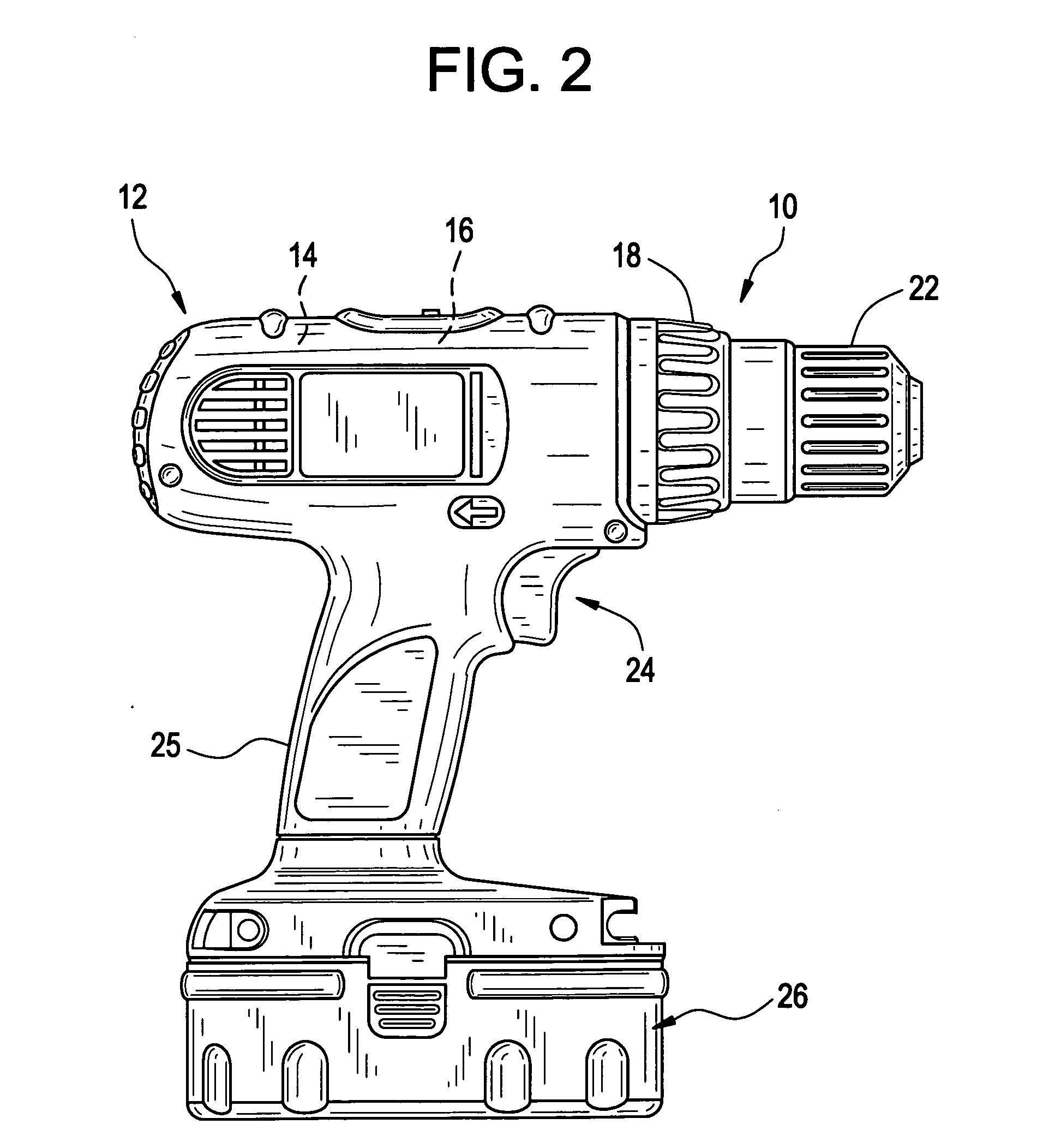

Cordless power tool system with improved power output

An ergonomically efficient cordless power tool system having desired power-to-weight ratios may be configured by reducing weight in one or more constituent weight groups of a given cordless power tool system, while maintaining or improving the total power output of the tool system. An example cordless power tool system may be configured to output a maximum power of at least 475 watts, and have a maximum power output to weight ratio of at least 70 watts per pound (W / lb).

Owner:BLACK & DECKER INC

Ergonomically efficient cordless power tool

An ergonomically efficient cordless power tool system having desired power-to-weight ratios may be configured by reducing weight in one or more constituent weight groups of a given cordless power tool system, while maintaining or improving the total power output of the tool system. An example cordless power tool system may be configured to output a maximum power of at least 475 watts, and have a maximum power output to weight ratio of at least 70 watts per pound (W / lb).

Owner:BLACK & DECKER INC

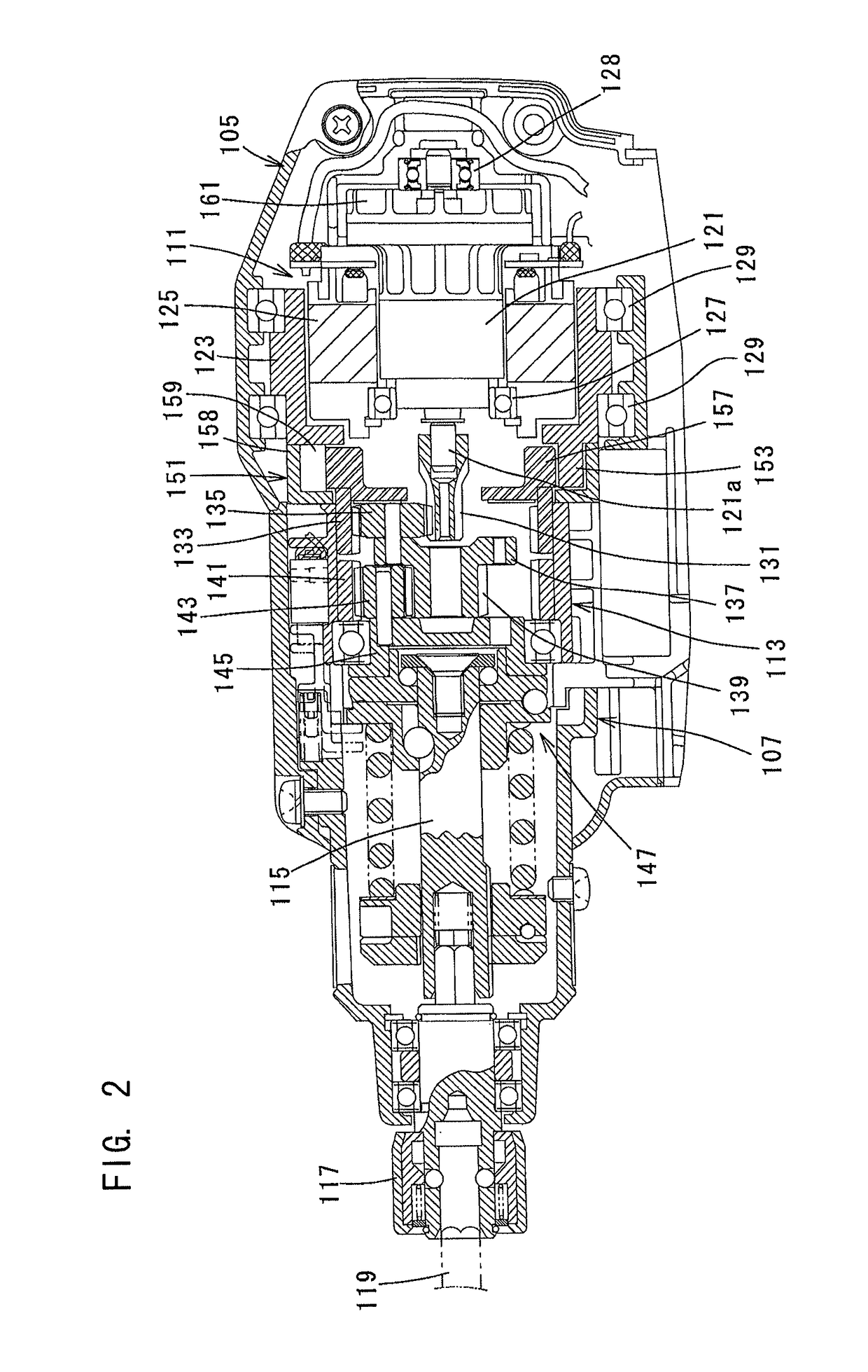

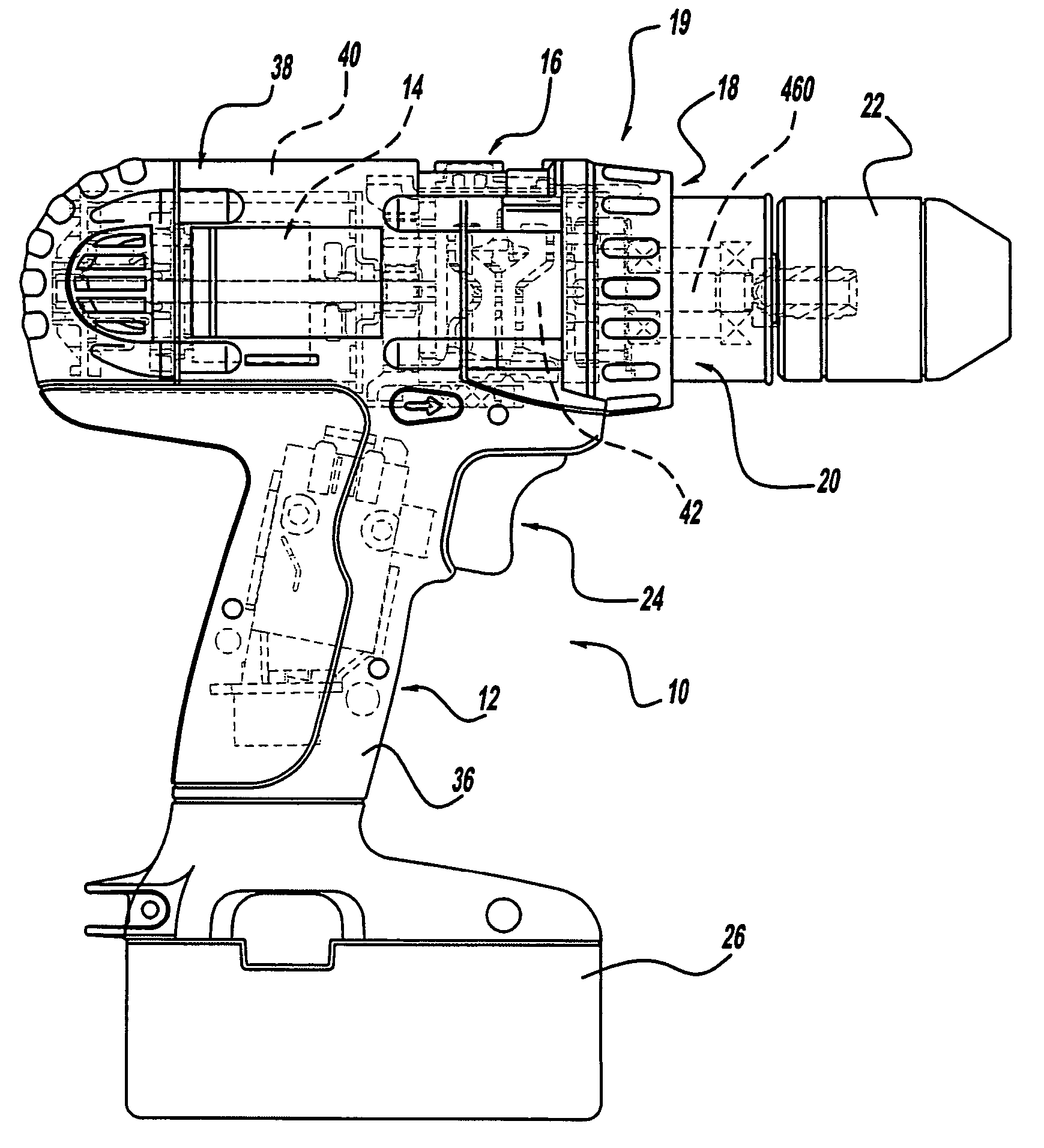

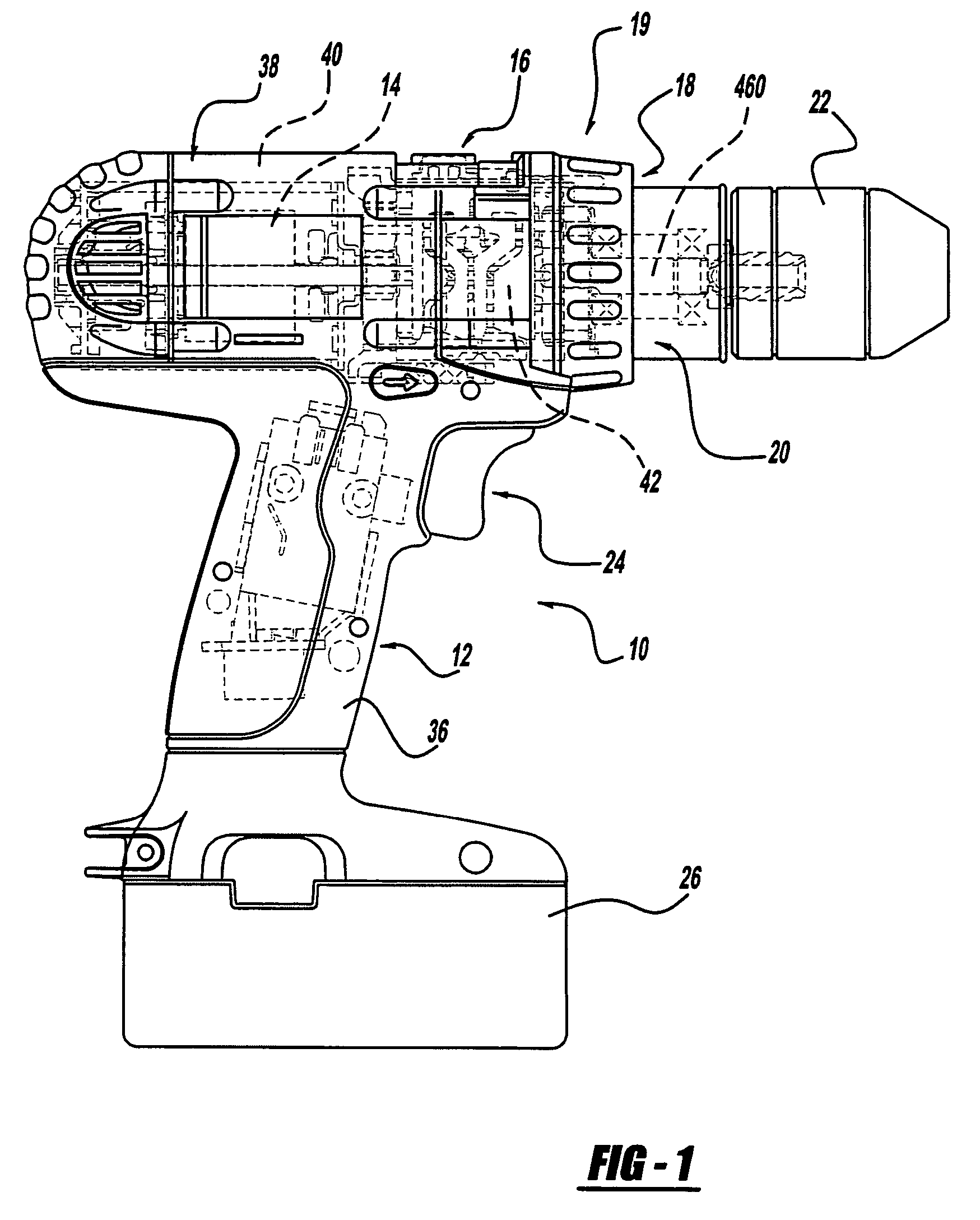

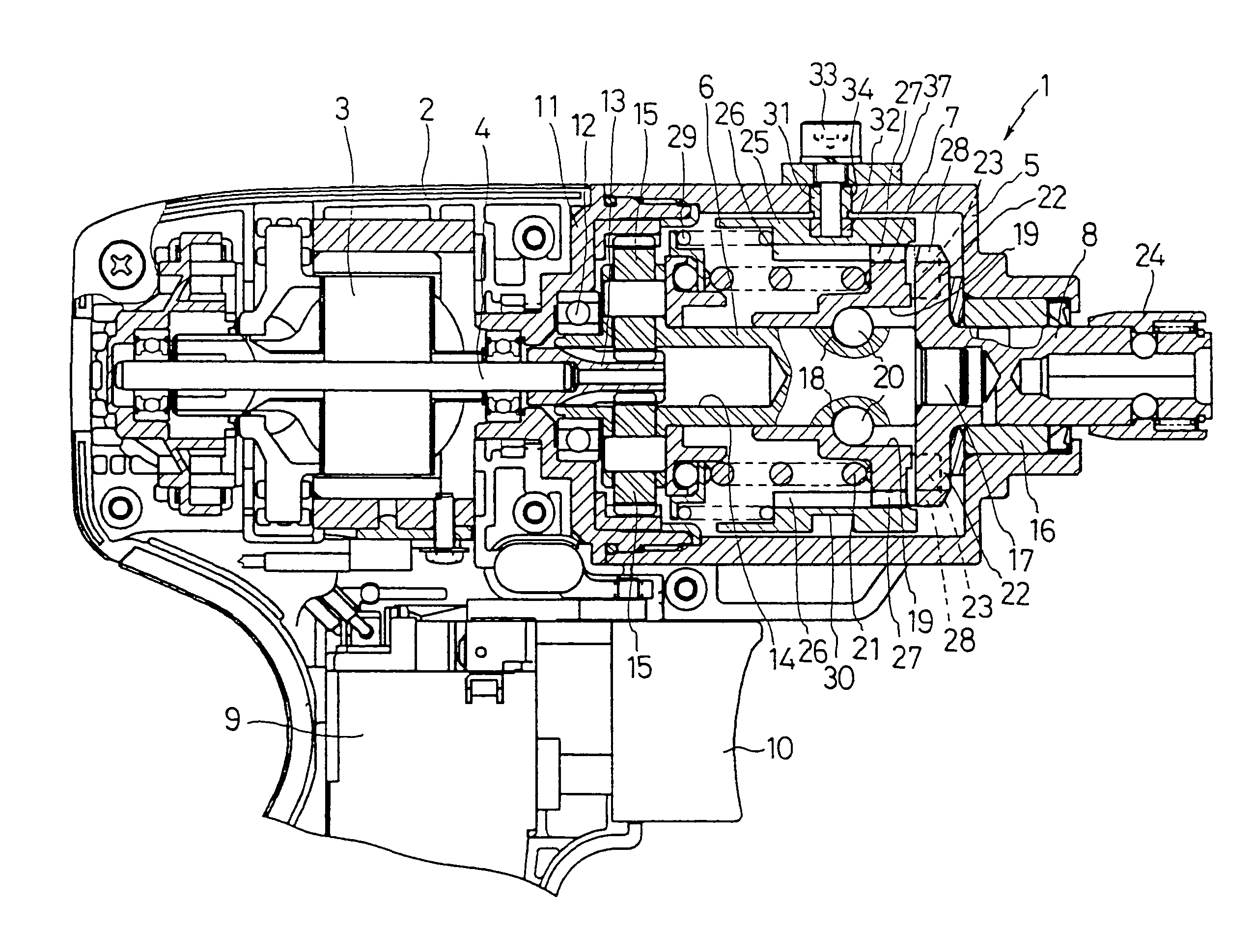

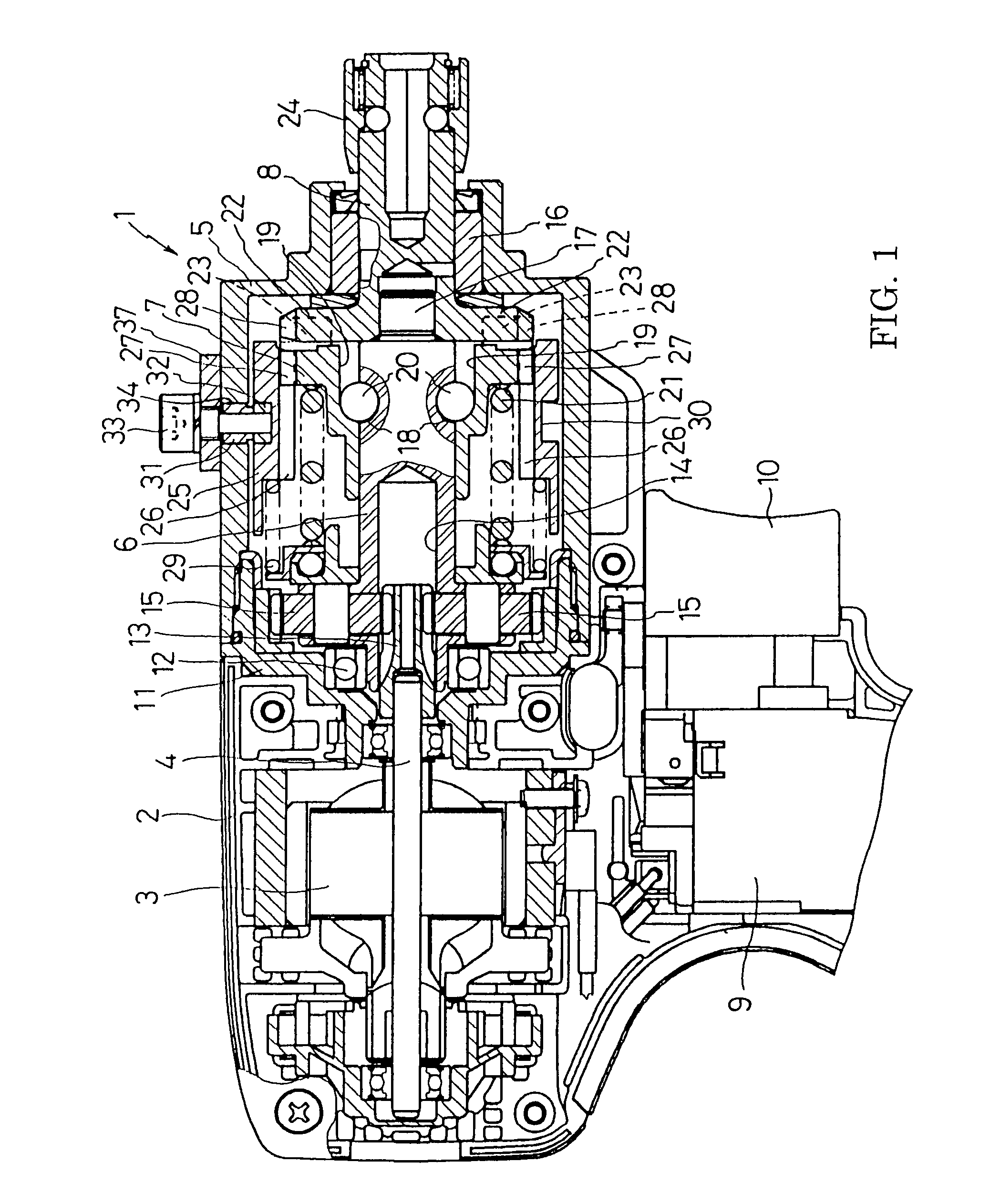

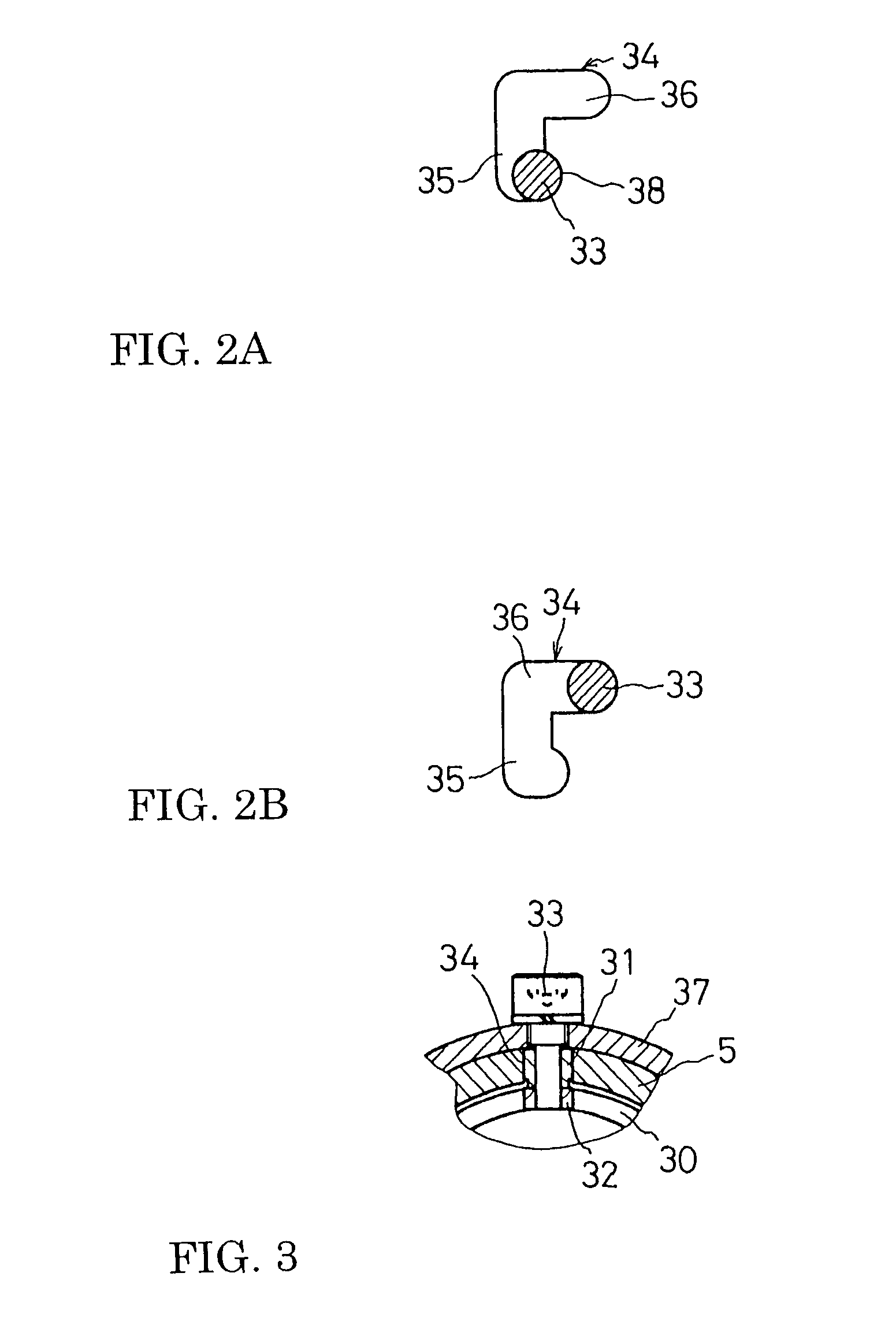

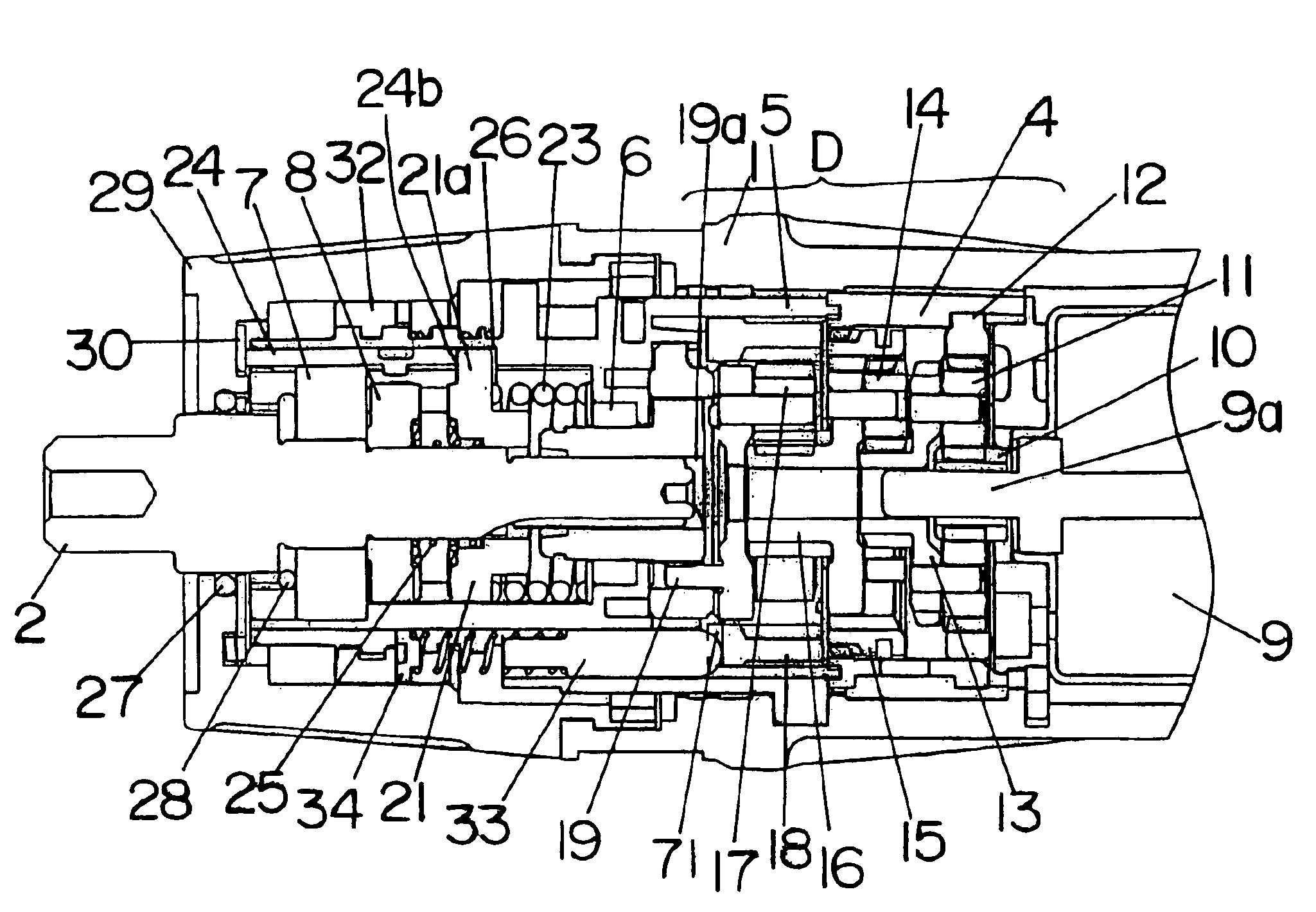

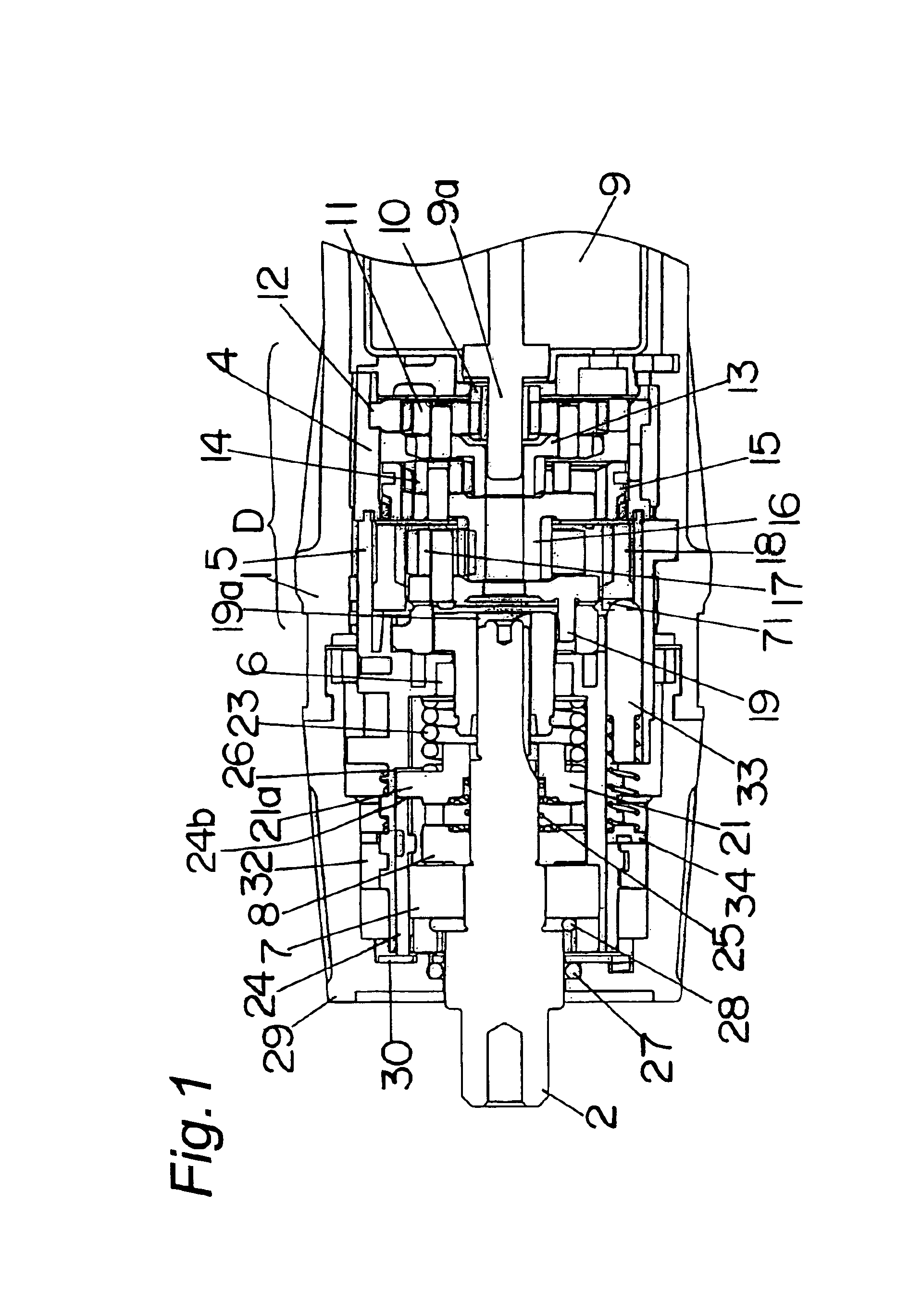

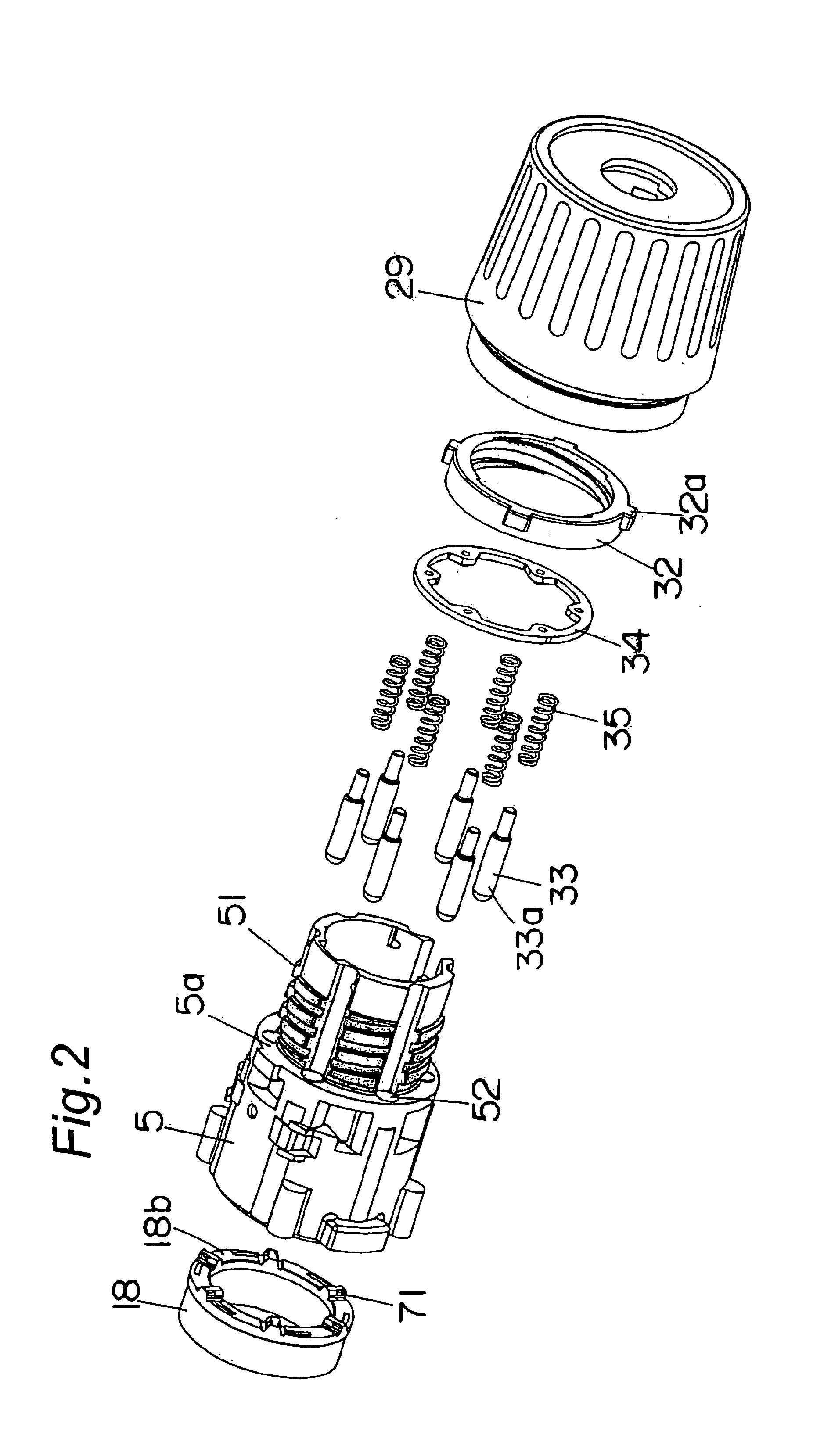

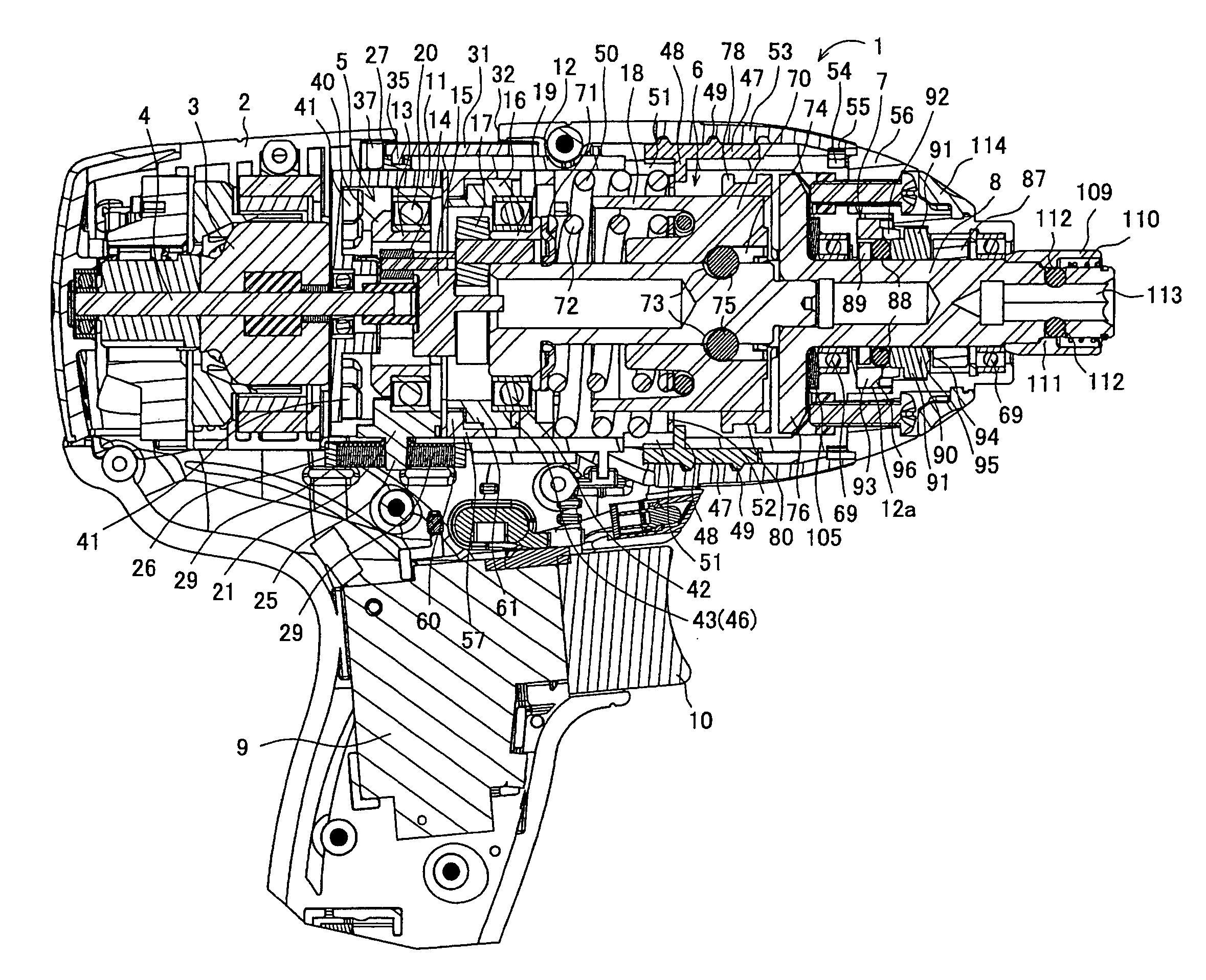

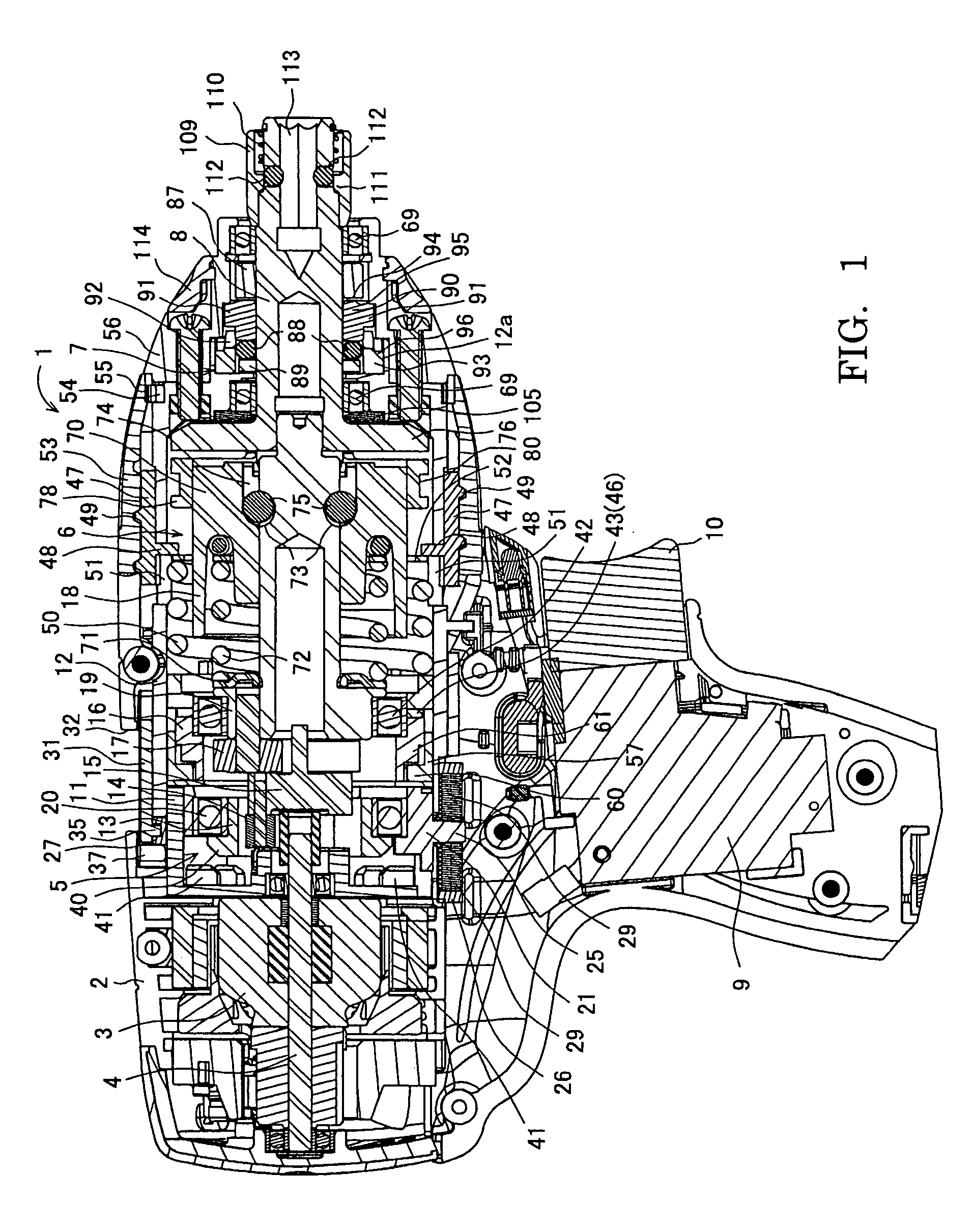

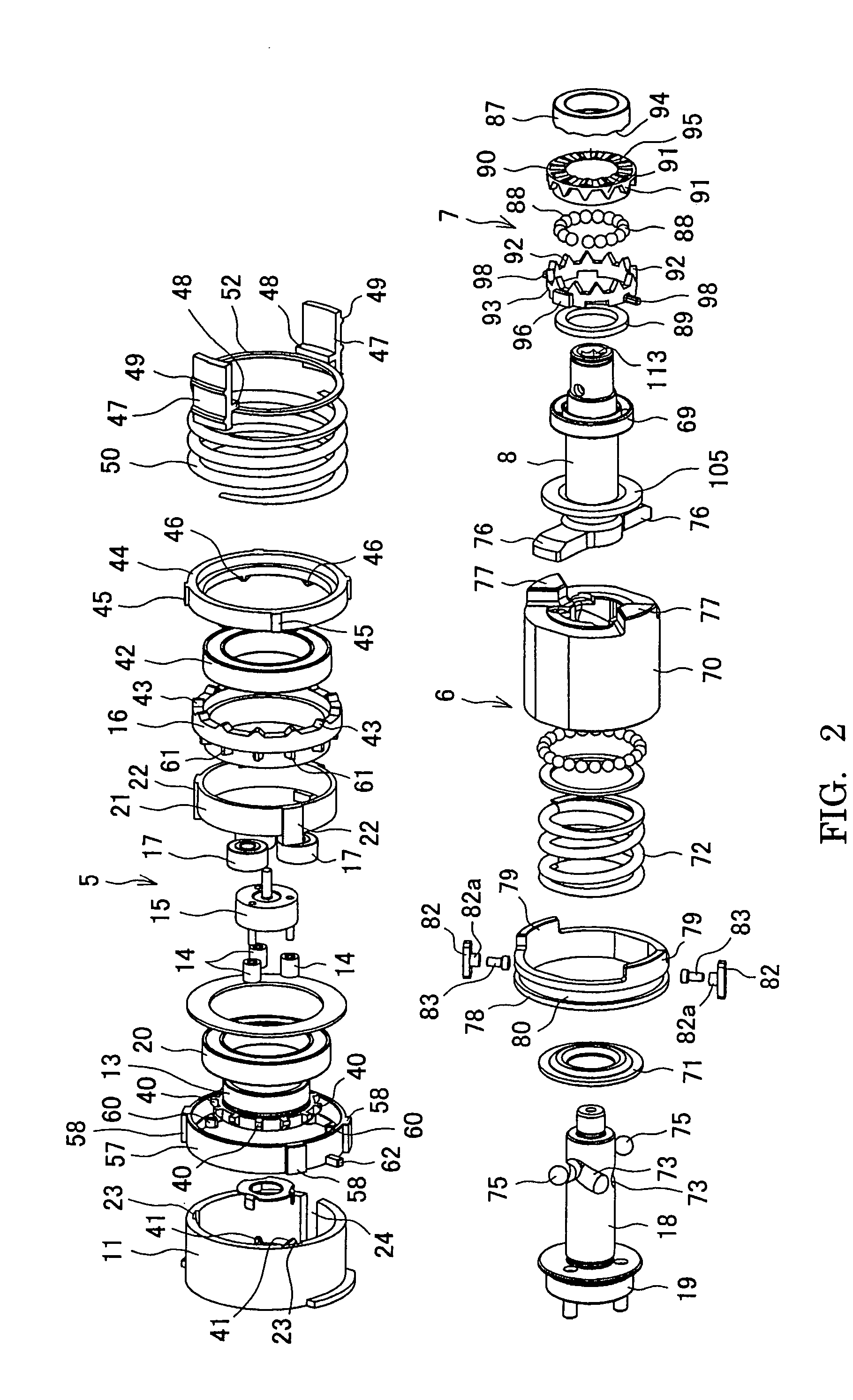

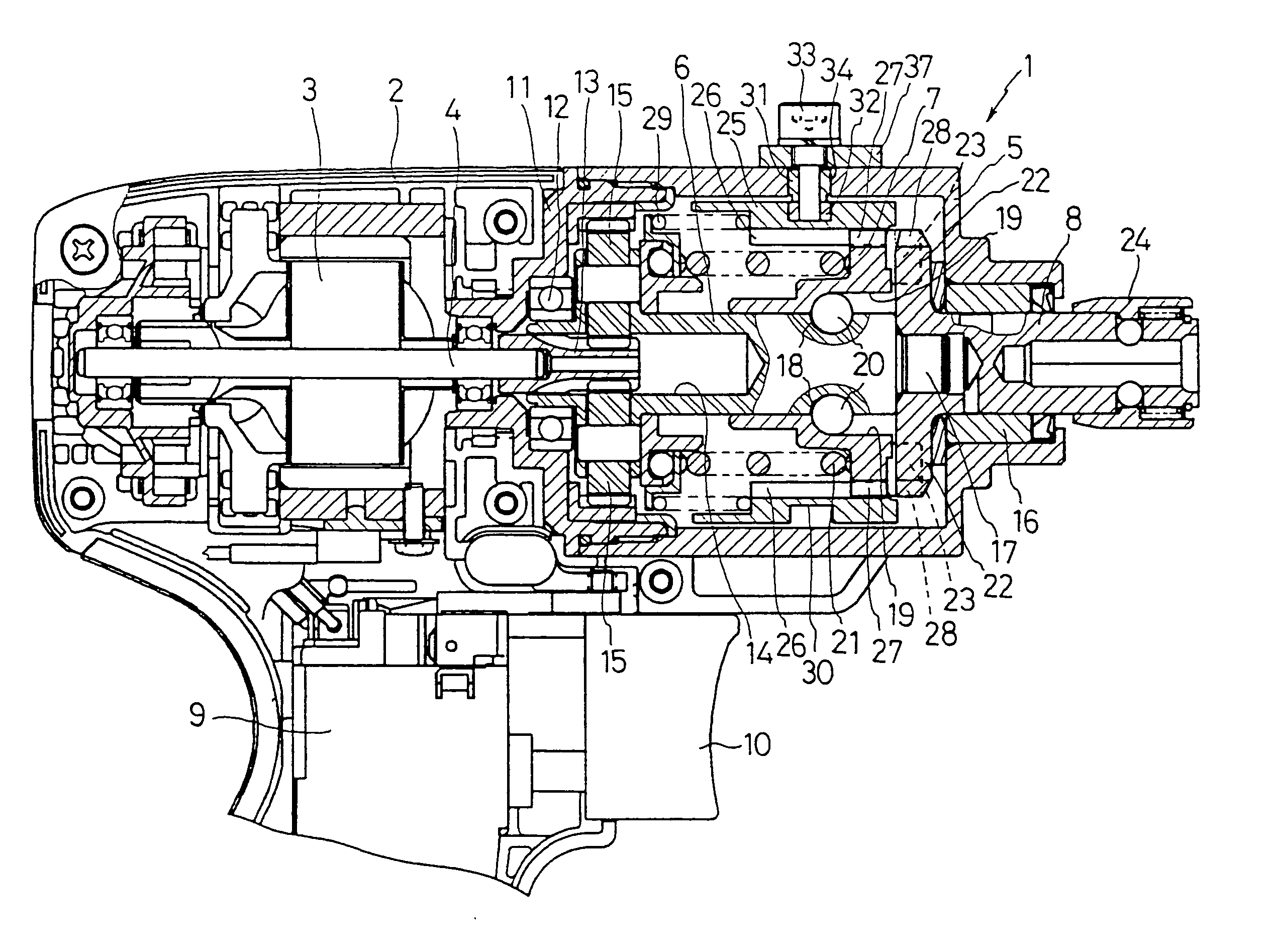

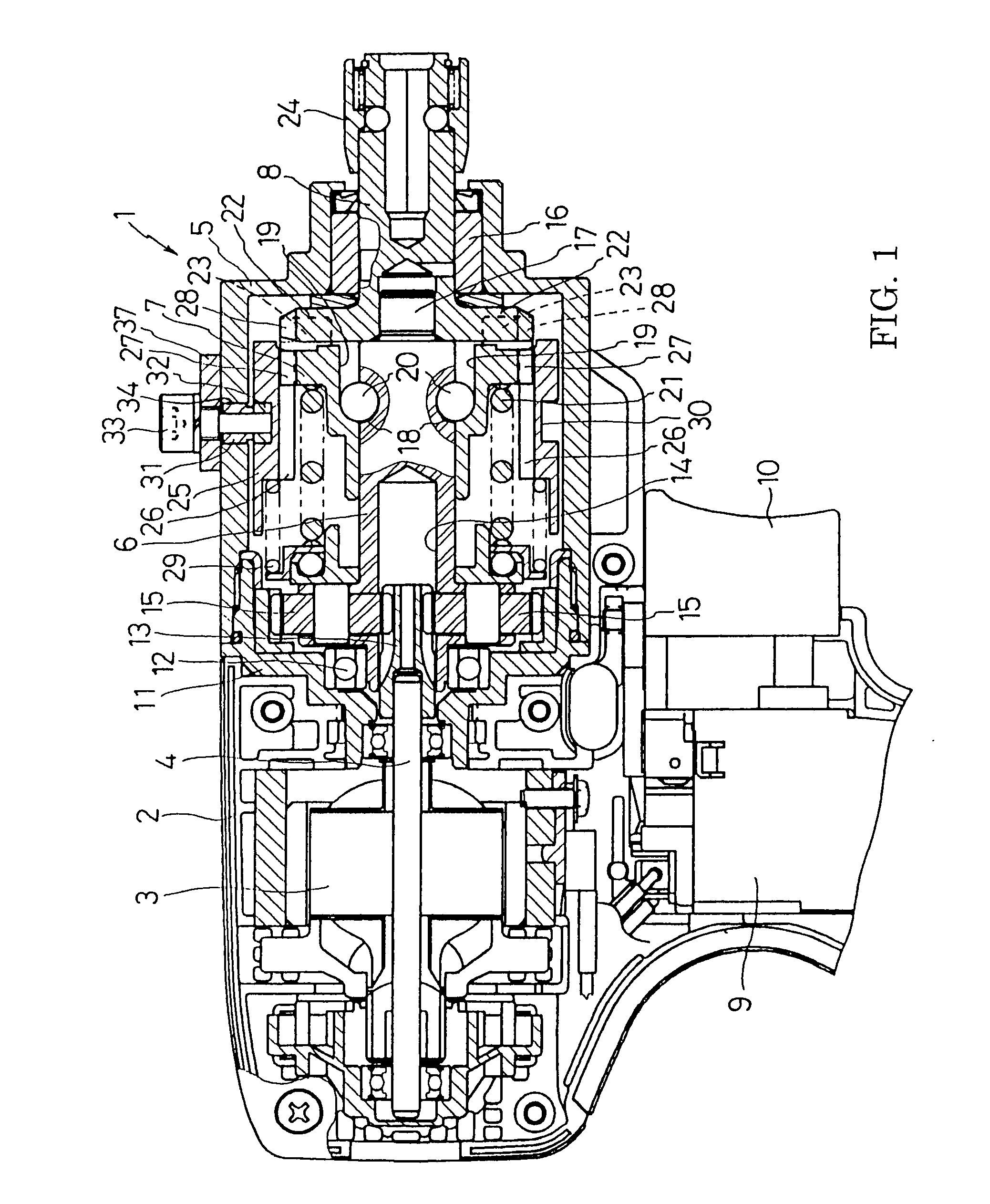

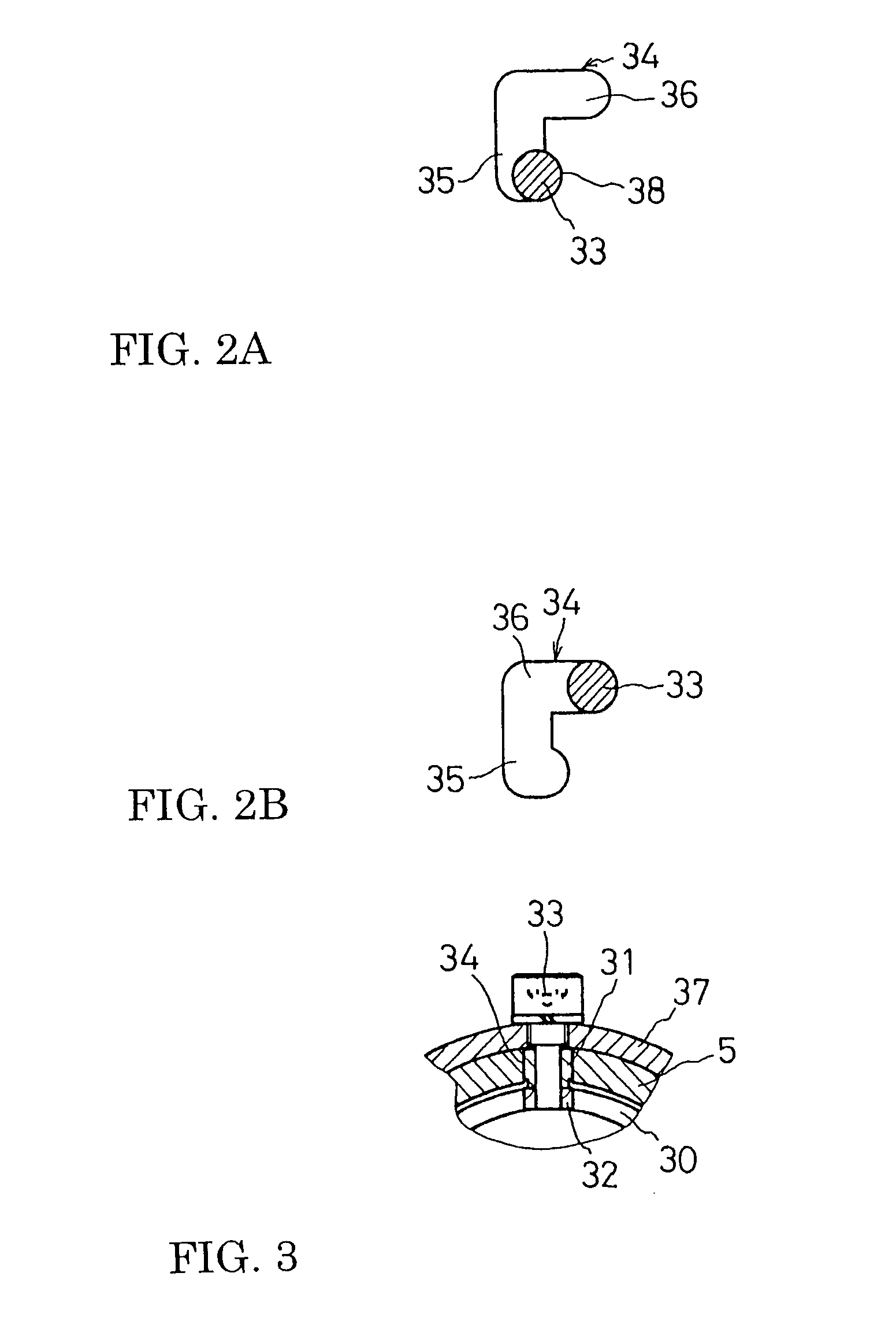

Electrically operated vibrating drill/driver

A vibrating drill / driver includes a motor for driving a spindle about the longitudinal axis thereof, a switching handle supported for rotation about a longitudinal axis thereof, a clutch mechanism for varying a working torque in dependence on rotation of the switching handle, a switching ring having a recess and capable of rotating together with the switching handle, and a switching plate having a tip for engagement in the recess. A vibrating cam mechanism is provided to be operable to undergo a slidable engagement to provide a vibration for the spindle in an axial direction thereof when the tip of the switching plate is engaged in the recess of the switching ring. With the above-described construction, the rotation of the switching handle in one direction causes the vibrating drill / driver to be set in one of a clutch mode, a vibrating mode, and a drilling mode in this order.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Hand-held nailing tool

A handy electric nailing gun includes a firing pin, a firing spring for pushing the firing pin to drive nails into workpiece, an output gear rotatable by a motor through a transmission gear set to retract the firing pin during the first half run of each rotation cycle and to release the firing pin during the second half run of each rotation cycle, and three power switches electrically connected in series between the motor and the power source (AC adapter / rechargeable battery) for operation by the user to control the operation of the motor.

Owner:YIH KAI ENTERPRISE

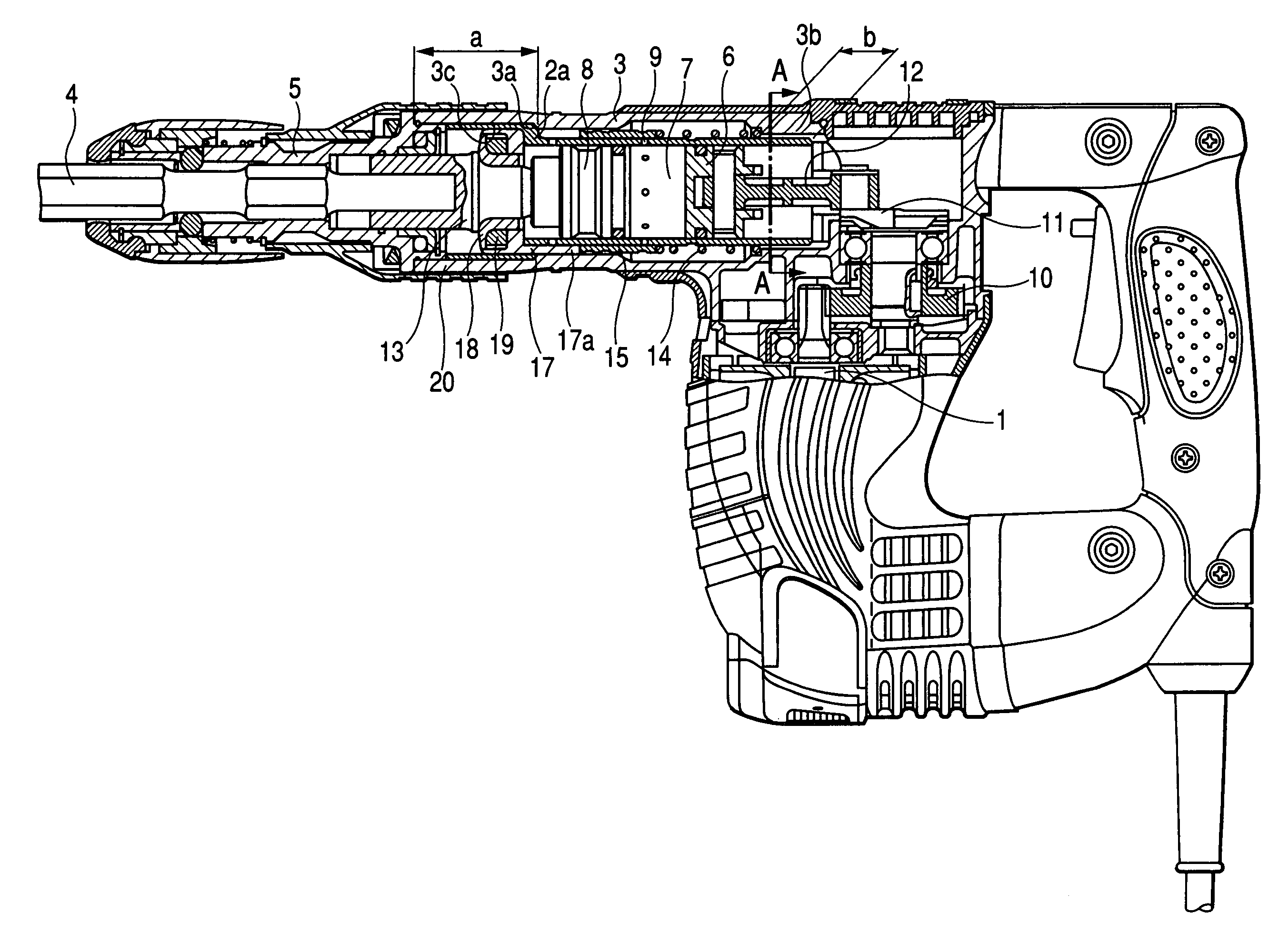

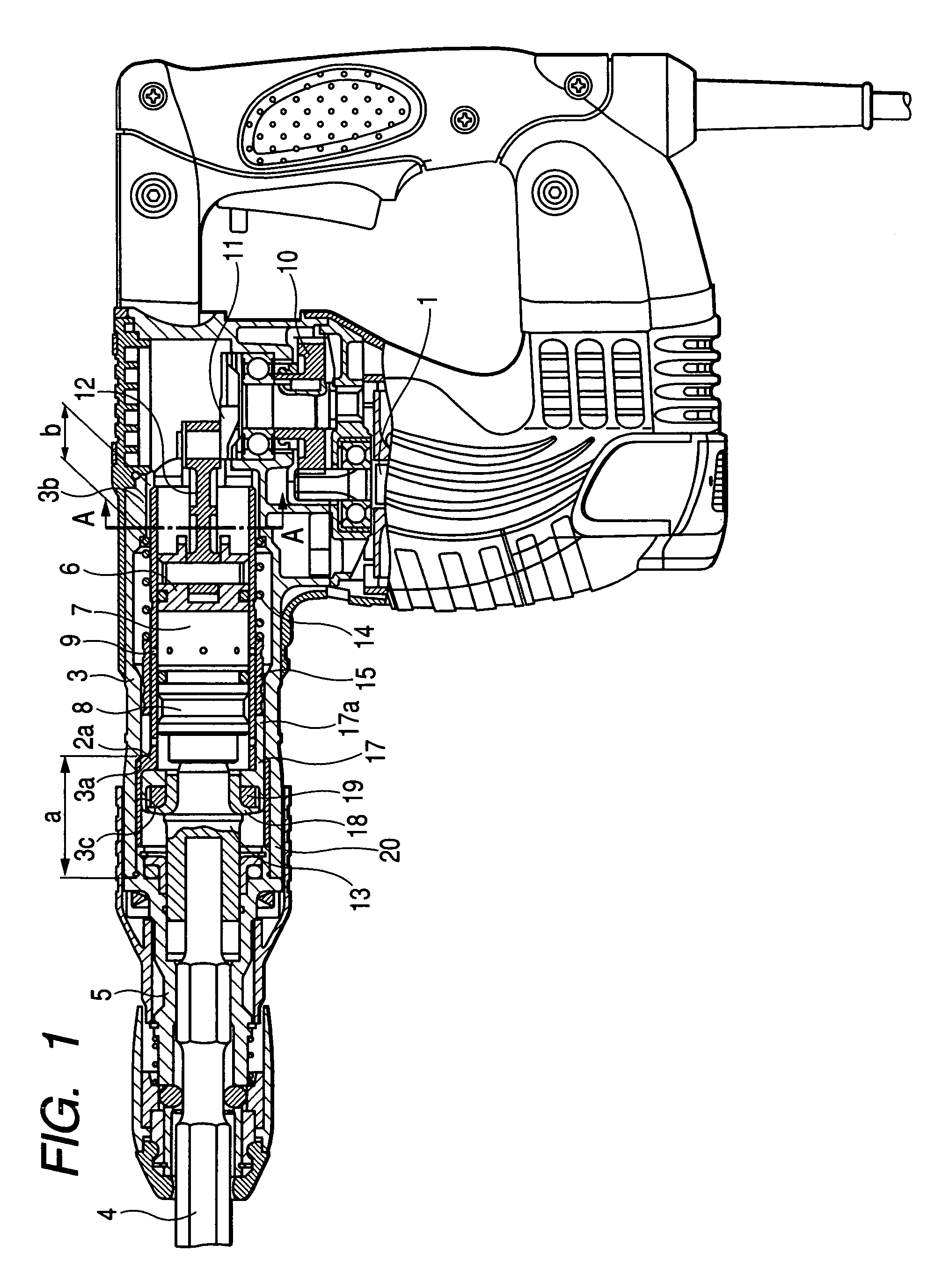

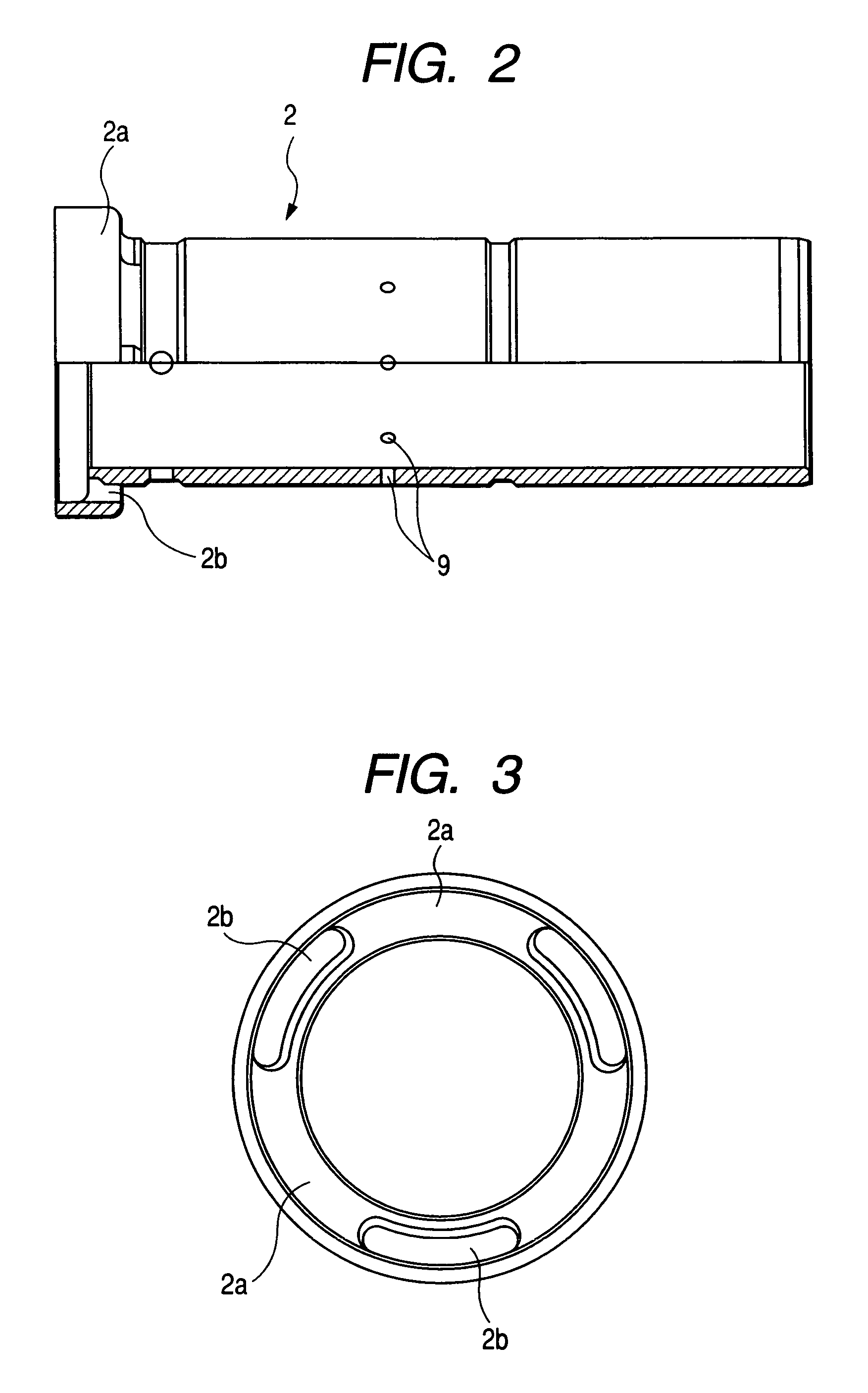

Striking tool

ActiveUS6938705B2Improve performanceEasy to integrateReciprocating drilling machinesPortable percussive toolsMechanical engineering

A projected portion provided at a cylinder and projected in a radius direction is formed at an end face thereof on a side of a tool holding portion, and a holding portion on one side of holding portions for holding an outer periphery of the cylinder by at least two portions remote from each other in an axial direction to position in the radius direction of the cylinder is configured by a guide face having an inner diameter of a dimension substantially the same as an outer diameter of the projected portion and extended over to a contact face brought into contact with the projected portion from an end face of a cylinder case on a side of the tool holding portion.

Owner:KOKI HLDG CO LTD

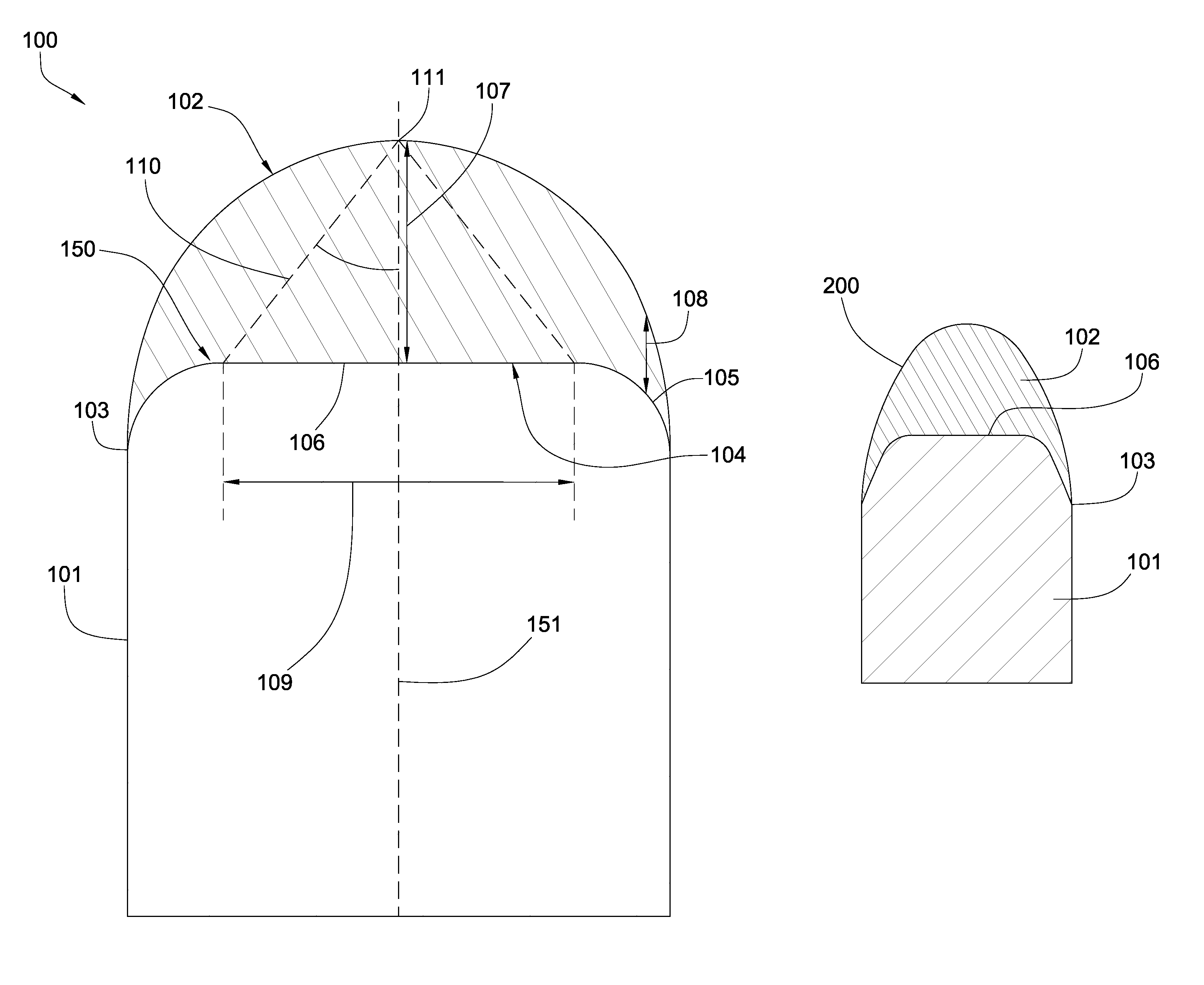

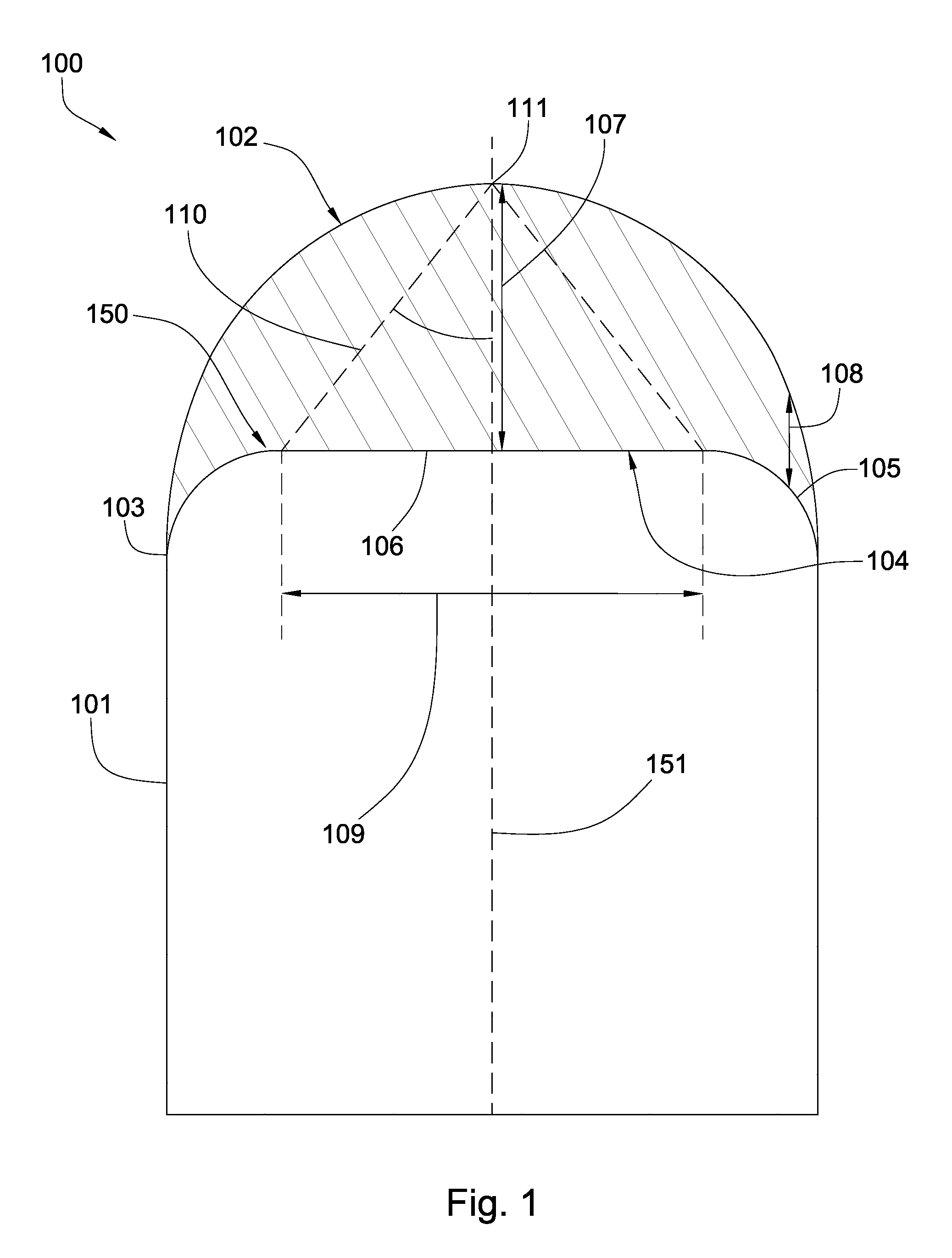

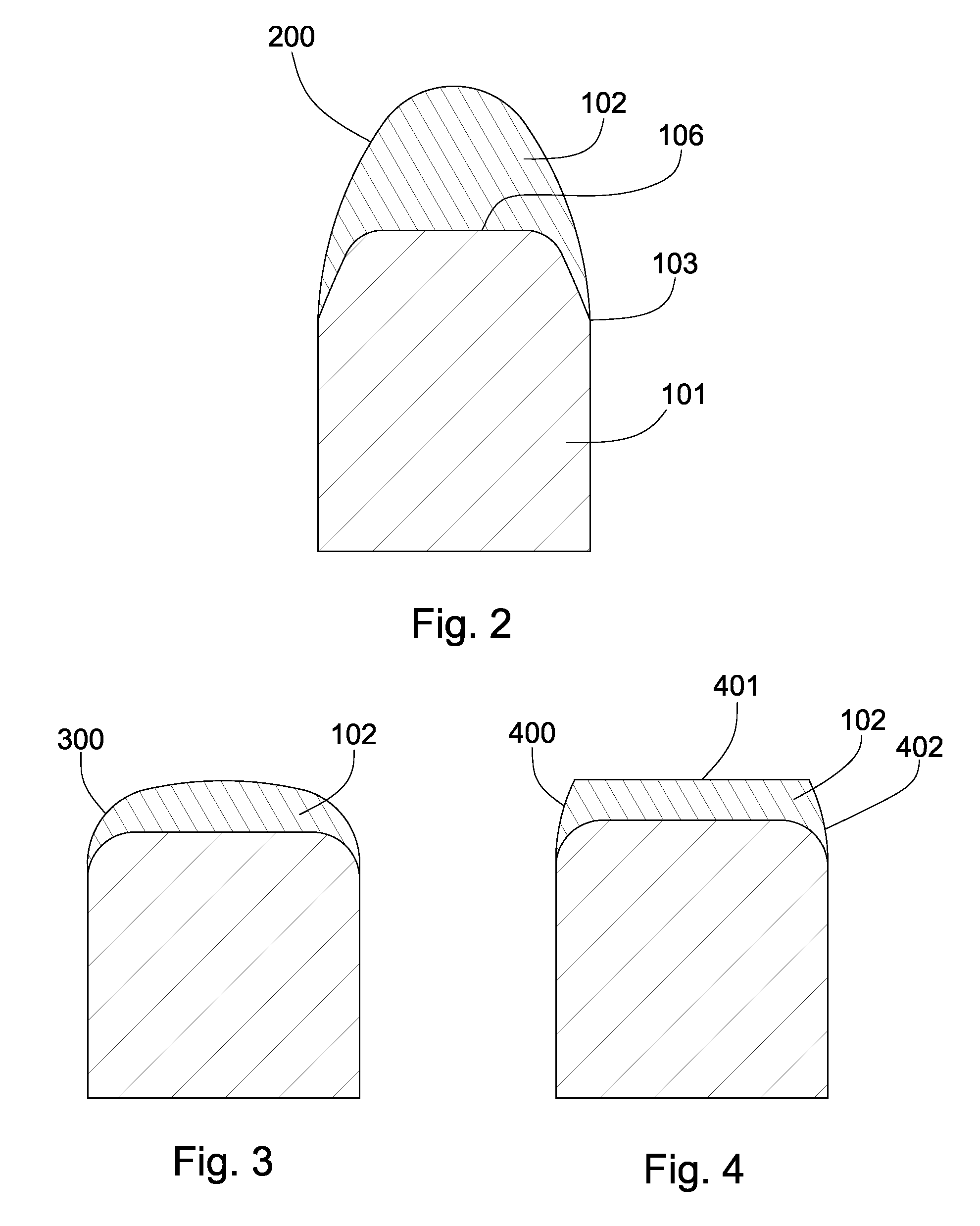

Superhard insert with an interface

In one aspect of the invention, a superhard insert has a carbide substrate bonded to ceramic layer at an interface. The substrate has a generally frusto-conical end at the interface with a tapered portion leading to a flat portion. The central section of the ceramic layer may have a first thickness immediately over the flat portion of the substrate. The peripheral section of the ceramic layer has a second thickness being less than the first thickness covering the tapered portion of the substrate. The ceramic layer may be formed using HPHT technology.

Owner:SCHLUMBERGER TECH CORP

Handle with detecting unit

ActiveUS20050161241A1Fast powerQuick stopDerricks/mastsAuxillary equipmentSoftware engineeringPower tool

Owner:ROBERT BOSCH GMBH

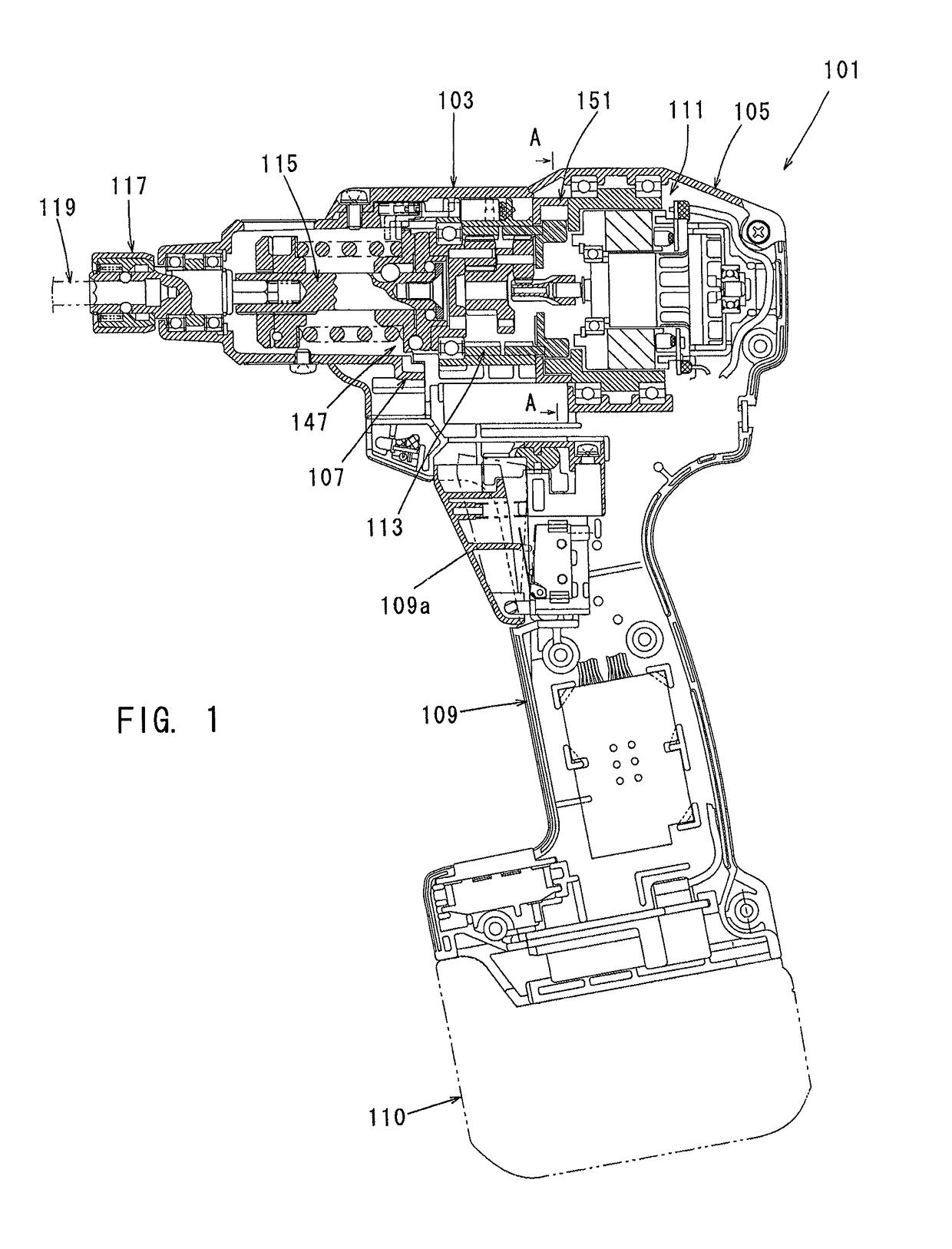

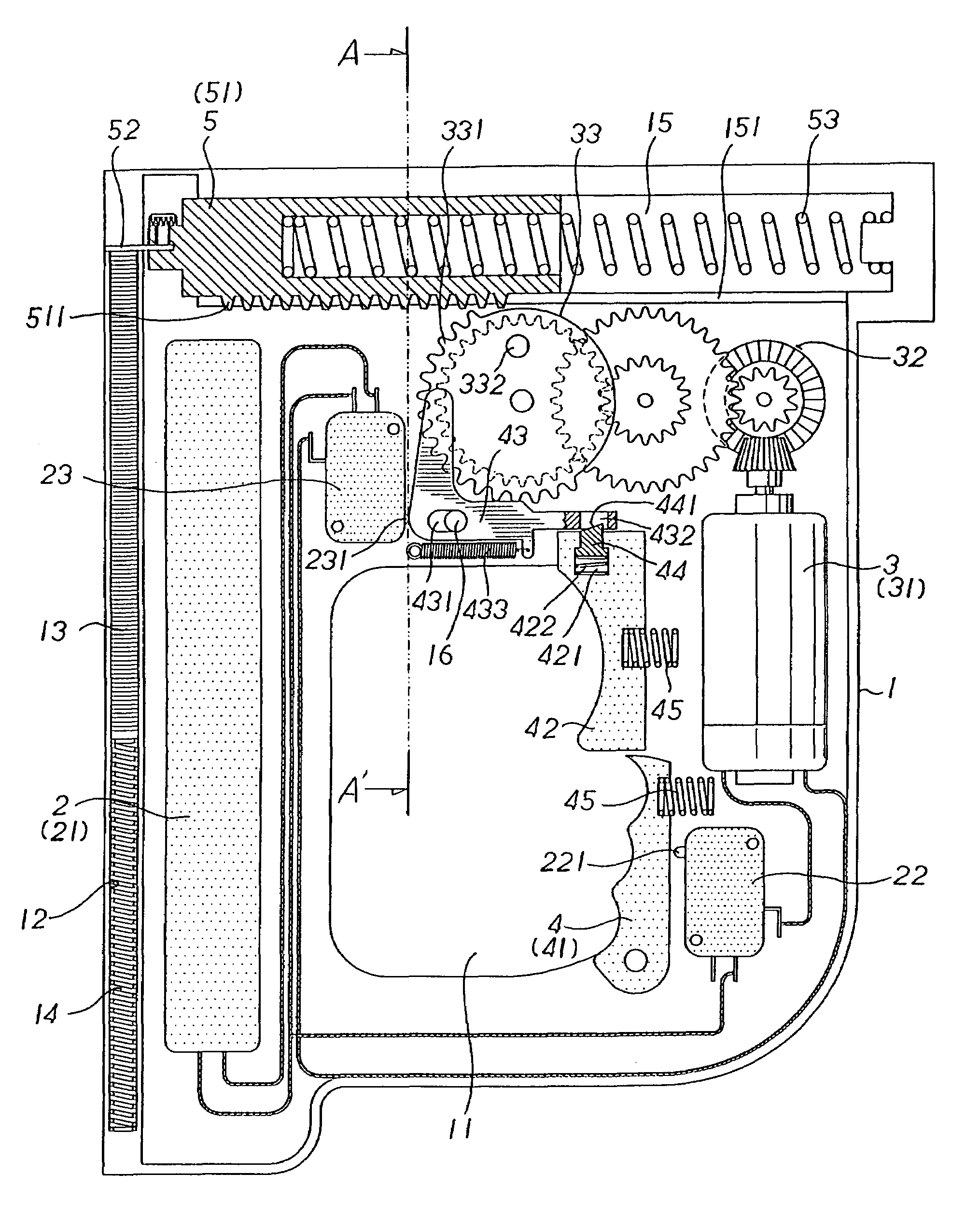

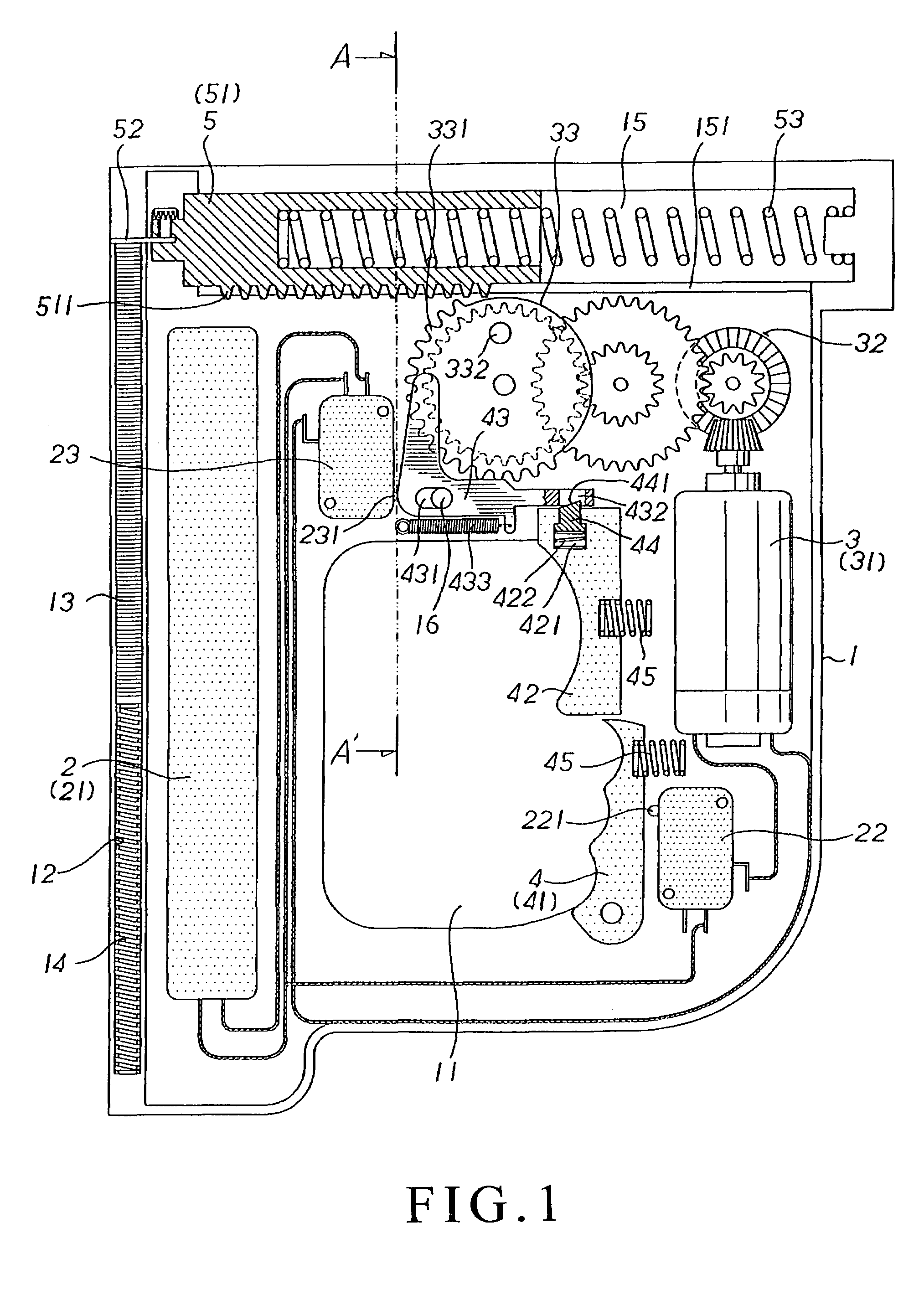

Electric power tool

InactiveUS7308948B2Easy to operateImprove reliabilityDrilling rodsWrenchesElectric power systemOperability

An electric power tool is provided which prevents malfunction with excellent operability even when one operation mode among various modes is selectable. In a gear case of a housing, there are provided a clutch switching groove which engages with a connecting projection of a clutch switching lever, a slit which guides a guide body having a stepped pin which penetrates an impact switching groove to engage with an auxiliary ring, and a percussion switching groove which engages with a connecting projection of a percussion switching lever. In addition, a switching case is externally provided, so that combination of sliding positions of each switching member can be changed. As the switching case can be operated by a switching button, any of all operation modes, which are, a drill mode, an impact mode, a percussion drill mode, and a clutch mode can be selected with the switching button only.

Owner:MAKITA CORP

Impact driver

ActiveUS20050199404A1Simple structureImprove usabilityReciprocating drilling machinesPortable percussive toolsEngineeringMechanical engineering

An impact driver in which a drill mode can be selected without fail is provided. In a hammer case, a connecting sleeve is provided so as to be slidable back and forth. At the backward position, the connecting sleeve engages with only a first engaging tooth provided on the outer circumference of the hammer for rotating integrally. At the forward position, it engages with both the first engaging tooth of the hammer and a second engaging tooth of an anvil for rotating integrally with both of them, and thus a drill mode is obtained. Further, an operating bolt is provided in the hammer case to be inserted into a concave groove of the connecting sleeve through a guide groove formed in the hammer case. The operating bolt slides the connecting sleeve to the forward or backward position by its movement in the guide groove.

Owner:MAKITA CORP

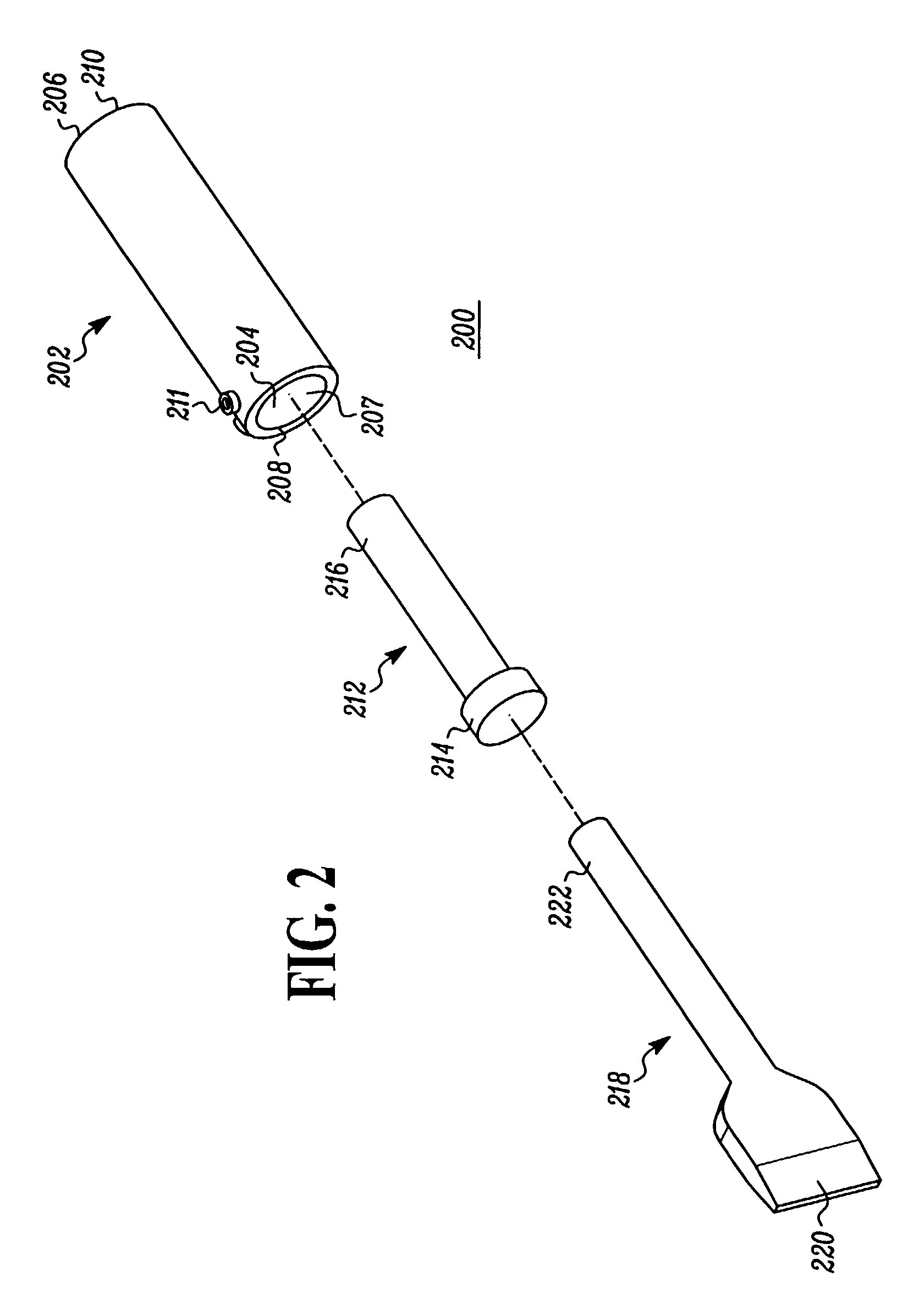

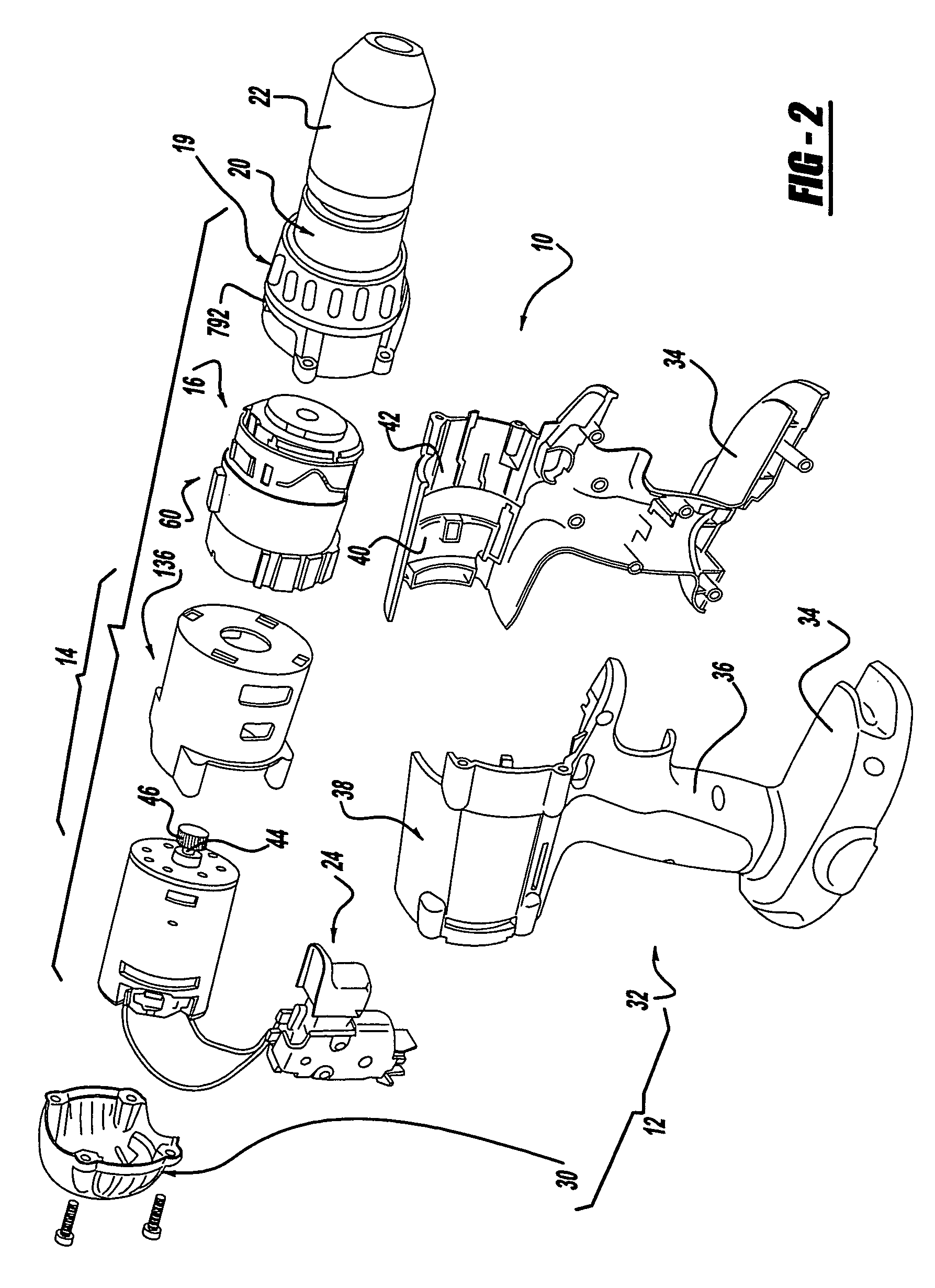

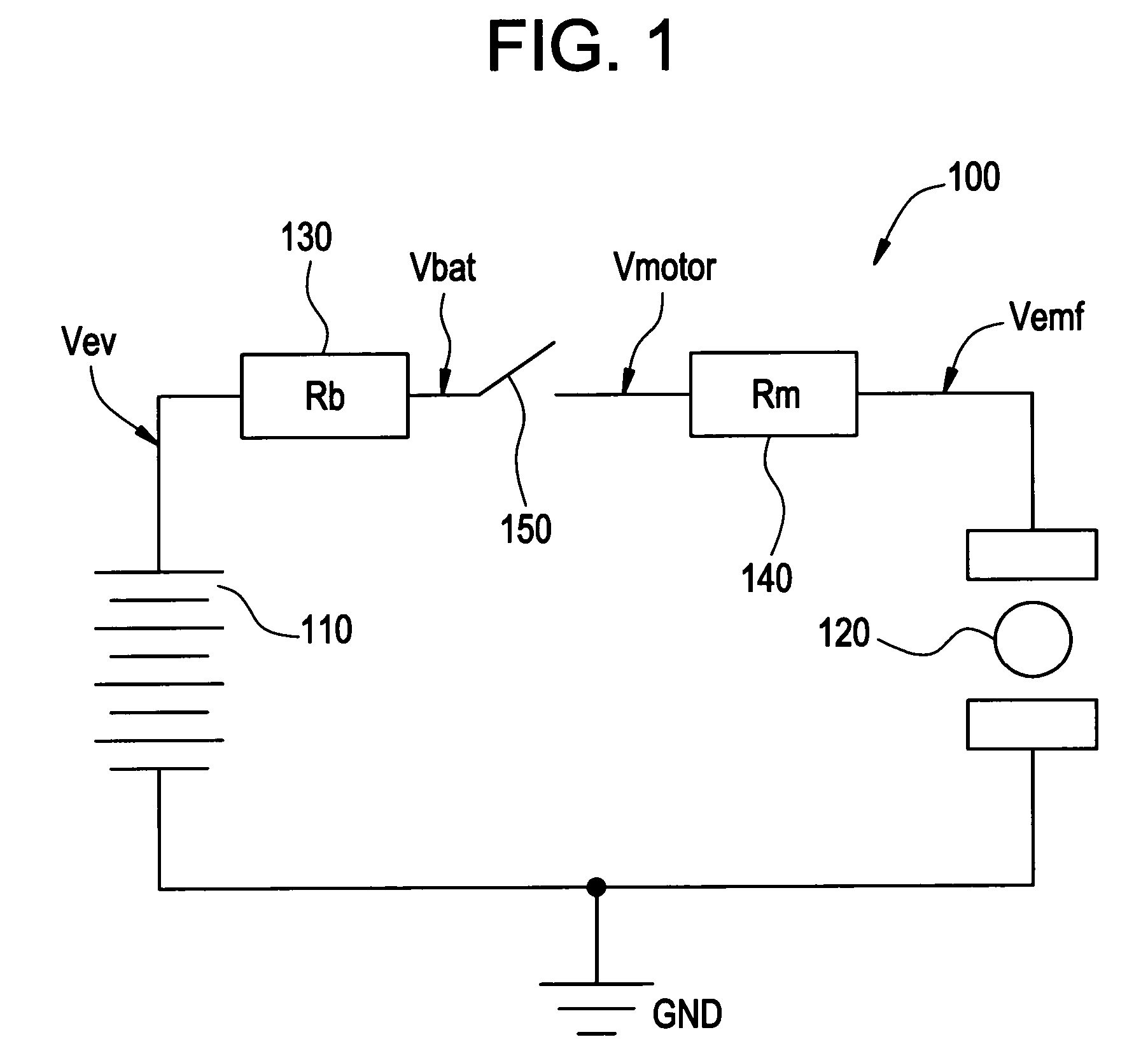

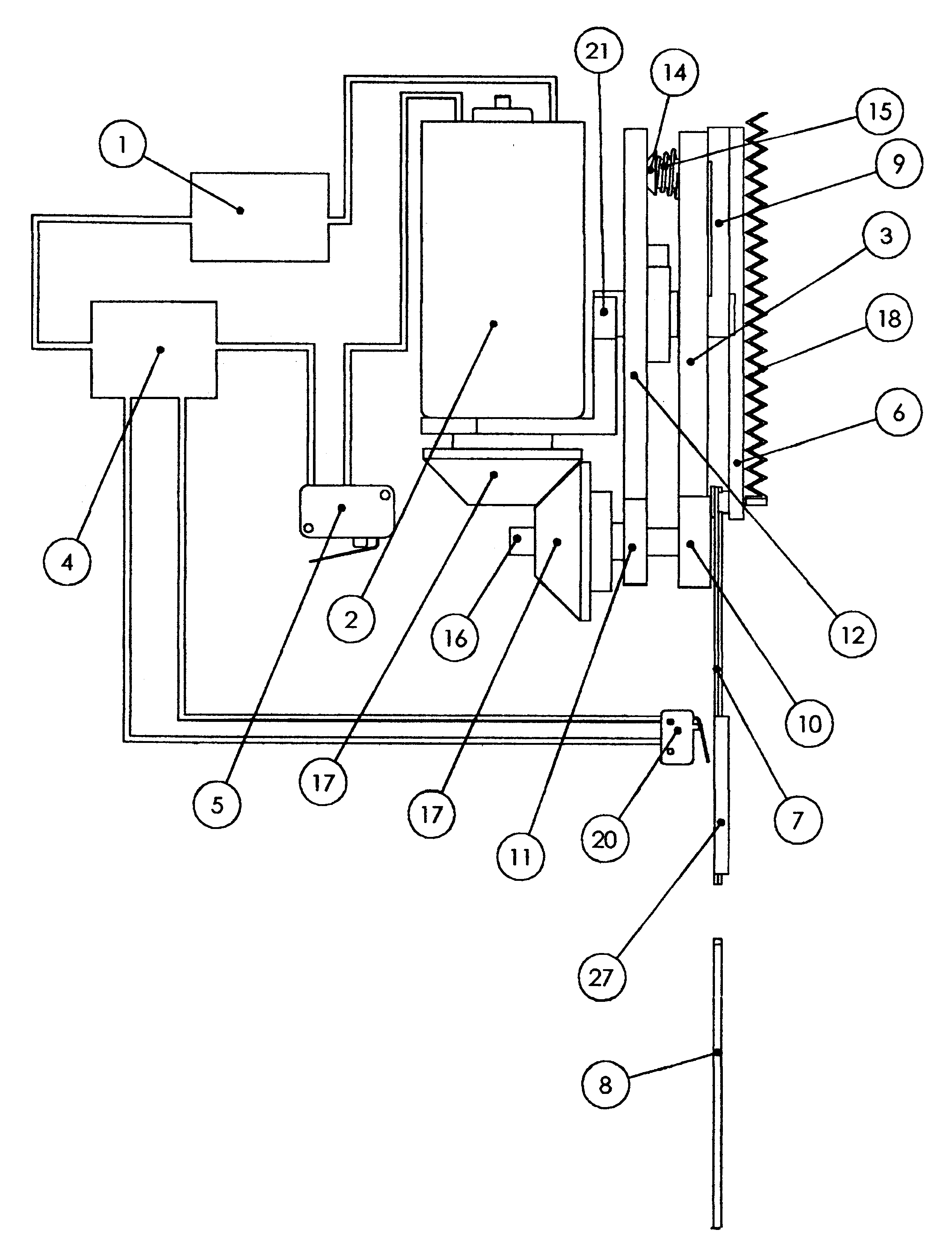

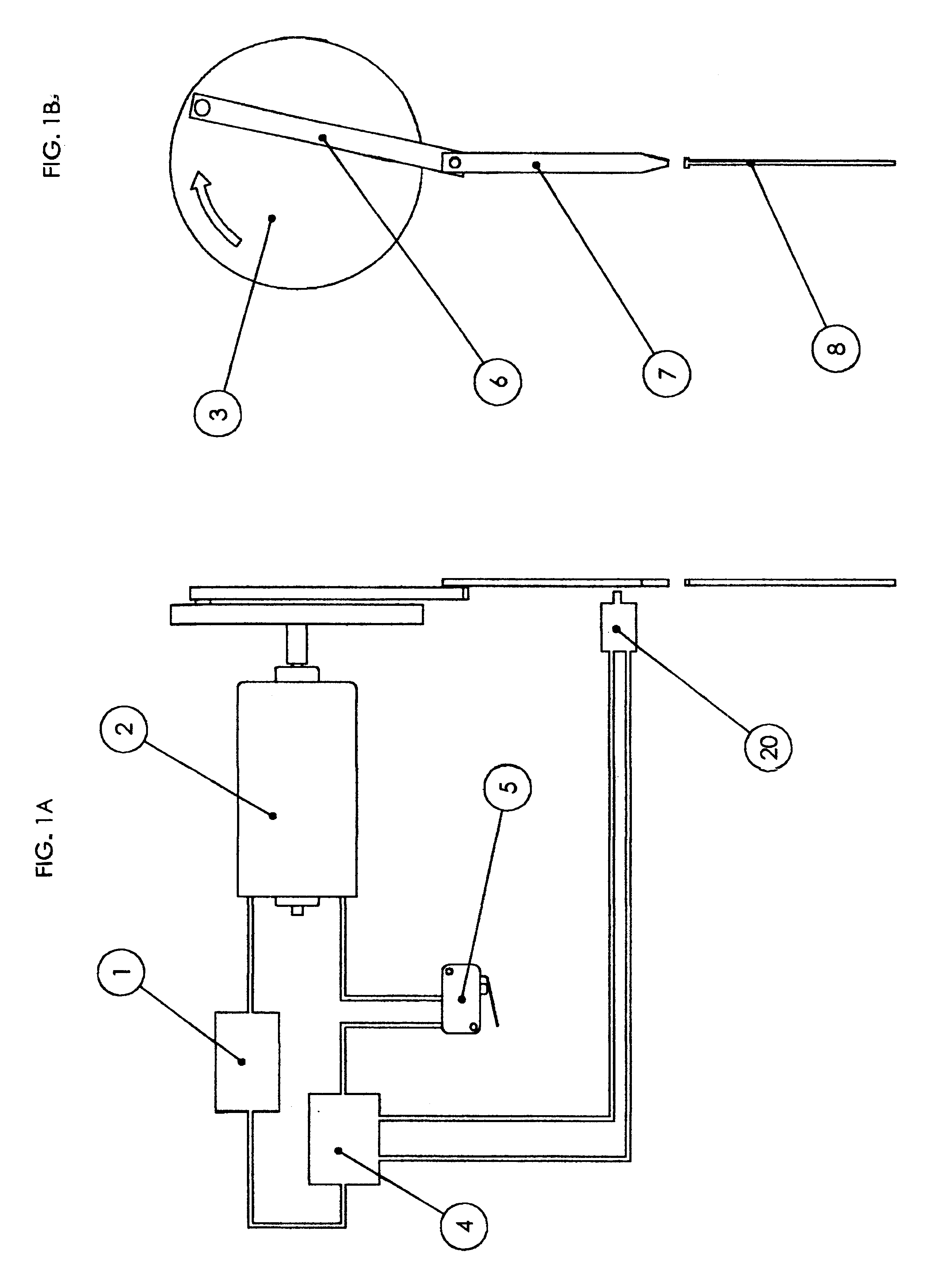

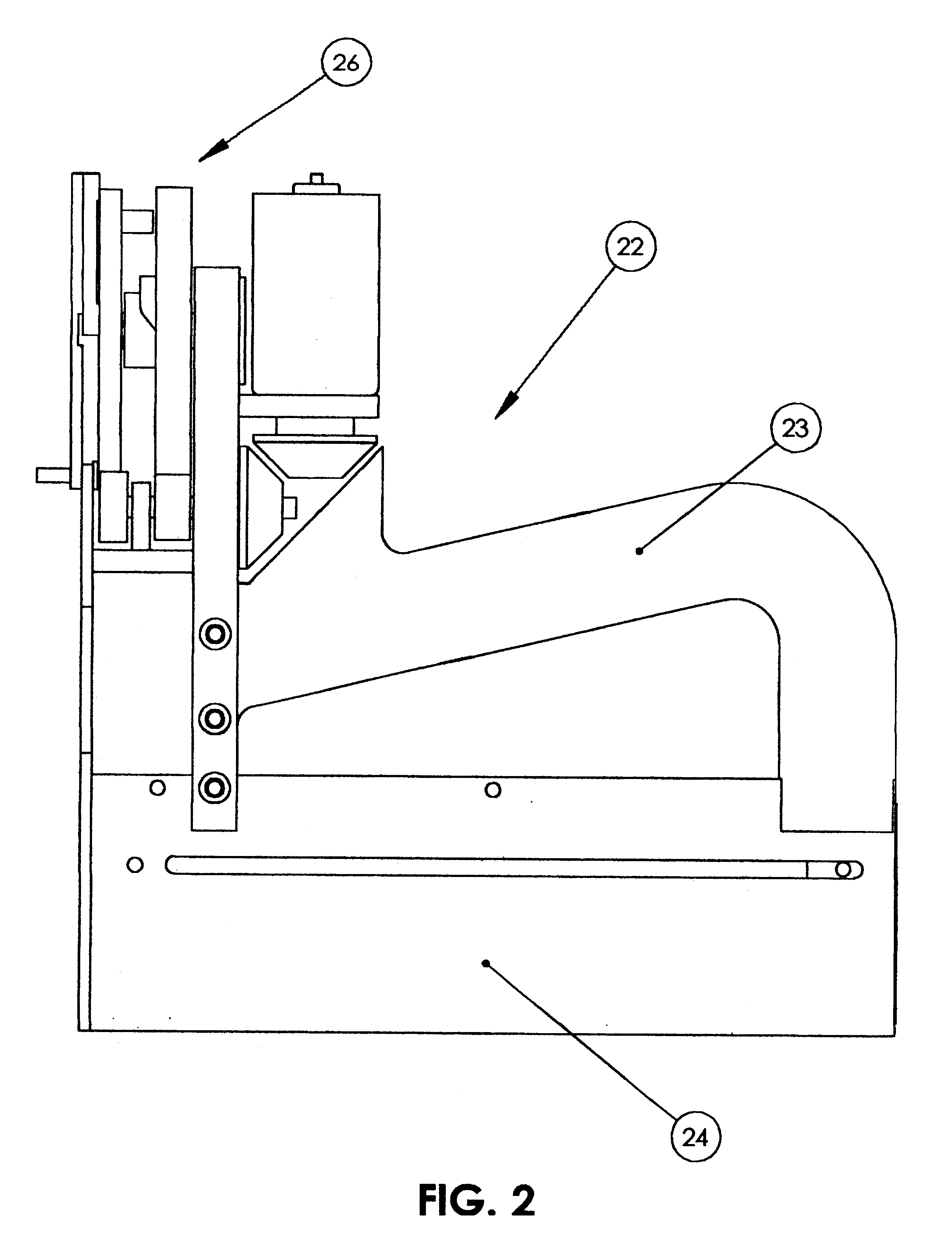

Portable electrical motor driven nail gun

A portable electric nailing gun operating from a power supply. The motor accelerates a flywheel which at the appropriate energy state is coupled through a mechanism to an anvil acting directly on the nail. The actuation is governed by a control circuit and initiated from a trigger switch. The motor accelerates a flywheel that is then clutched to the output anvil causing the nail to be driven. The position of the output anvil is sensed and once the nail is driven, the motor is dynamically braked reducing the excess energy in the flywheel. This method uses a highly responsive motor and power supply which enables the motor to come up to speed, drive the nail and return to a low energy condition in less than 2 seconds. The electrical control circuit and brake allow precise control and improve safety. The power supply is preferably a rechargeable low impedance battery.

Owner:TRICORD SOLUTIONS

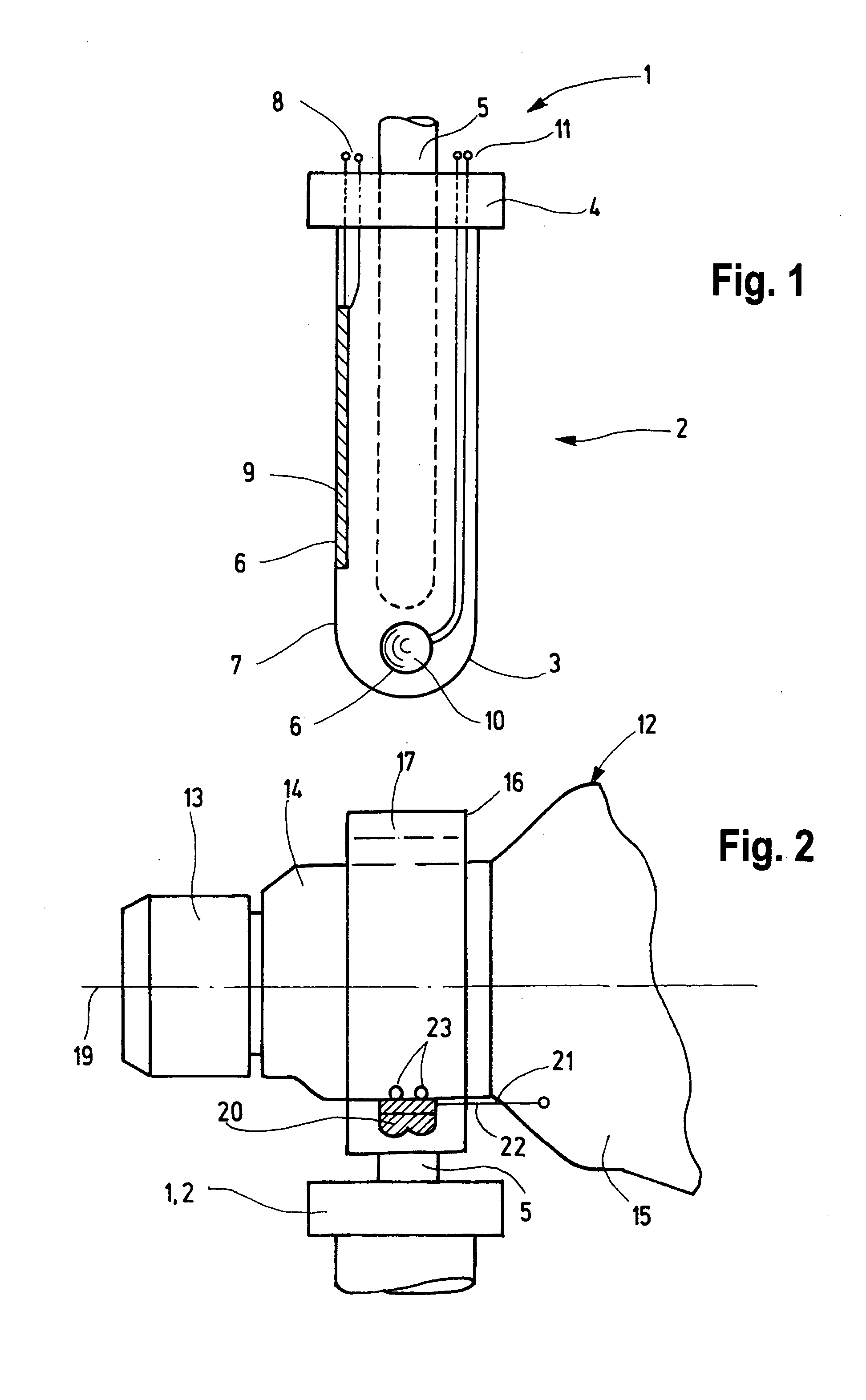

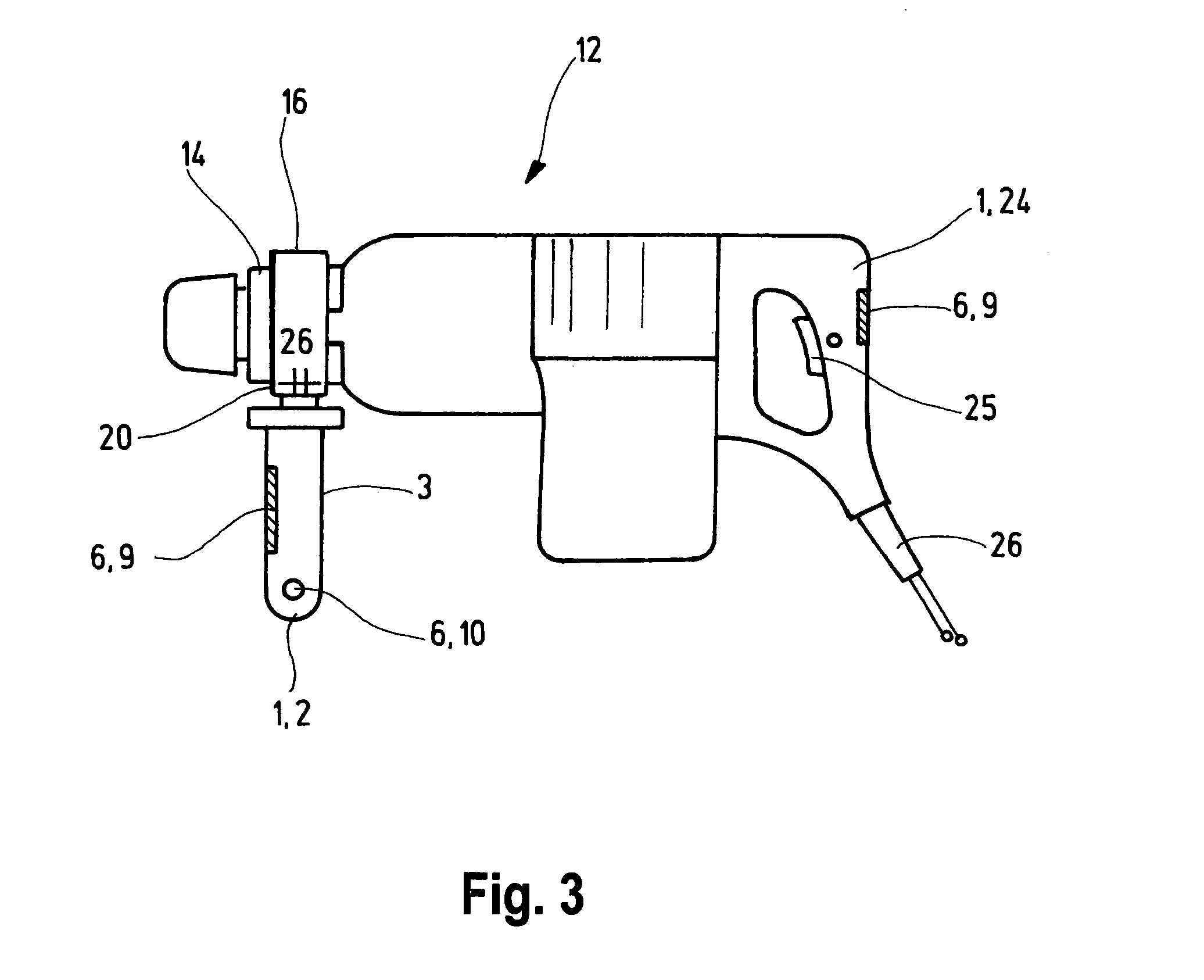

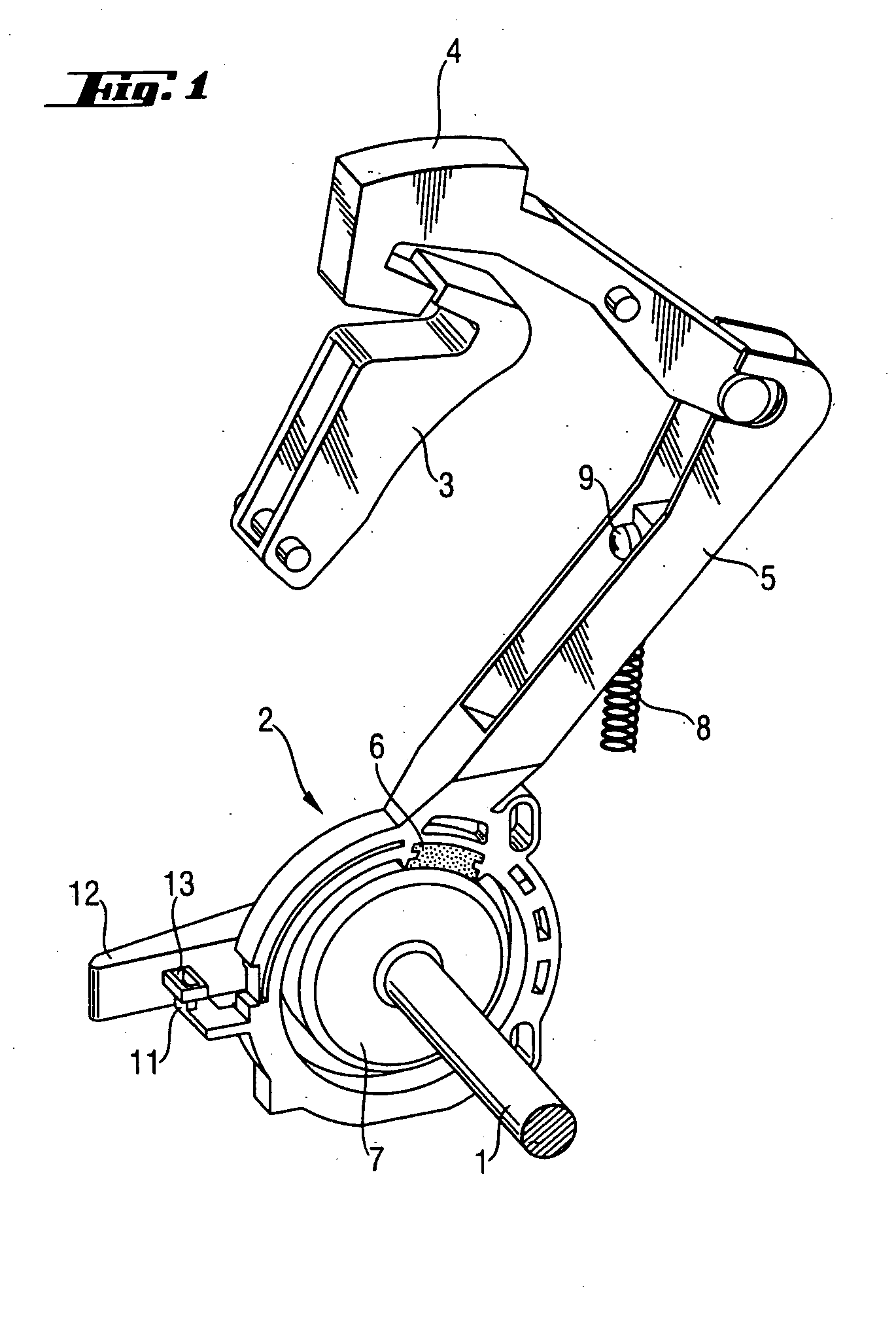

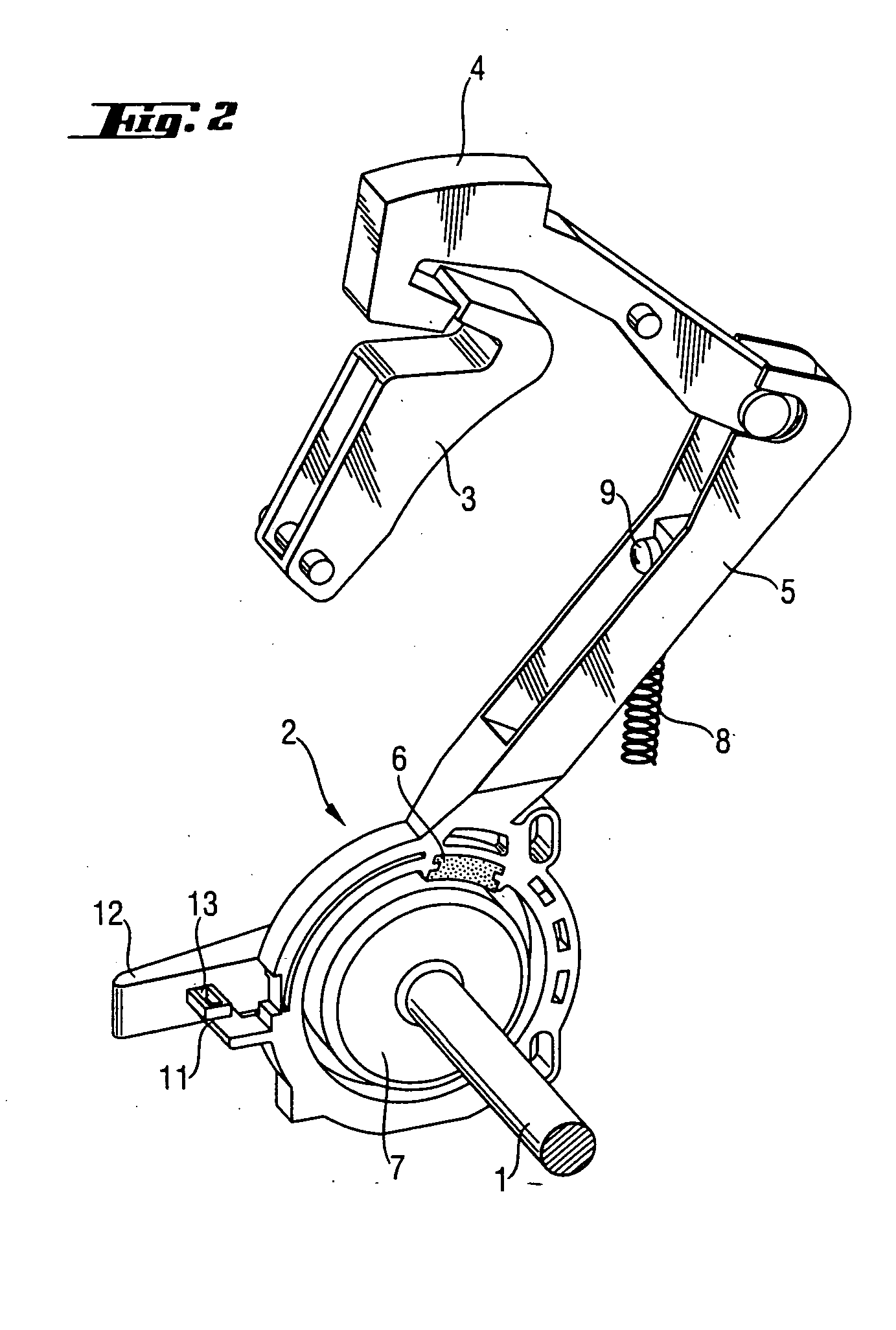

Electric power tool with locking mechanism

InactiveUS20050092149A1Better load distributionLess loadConstructionsReciprocating drilling machinesMotor driveLocking mechanism

An electric power tool has a motor-driven circular tool that can be clamped by means of a clamping device. A mechanical braking device (2) serves to brake the tool. A safety element (4) prevents improper handling of the electric power tool. In a safety position, the safety element (4) prevents the motor from being turned on and activates the braking device (2). In a release position, the safety element (4) allows the motor to be turned on and the braking device (12) is released. An additional locking mechanism prevents that a clamping lever, needed to actuate the clamping device, can be actuated in the clamped state in the safety position. In the release position of the safety element, the locking mechanism is unlocked.

Owner:HILTI AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com