Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1806results about "Vibration measurement in fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acoustic vibration analyzing apparatus and acoustic vibration analyzing method, program for analyzing acoustic vibration, and recording medium, readable by computer, on which program for analyzing acoustic vibration is stored

ActiveUS7401000B2Easy to carryReduce in quantityVibration measurement in solidsVehicle testingAnalysis methodAcoustics

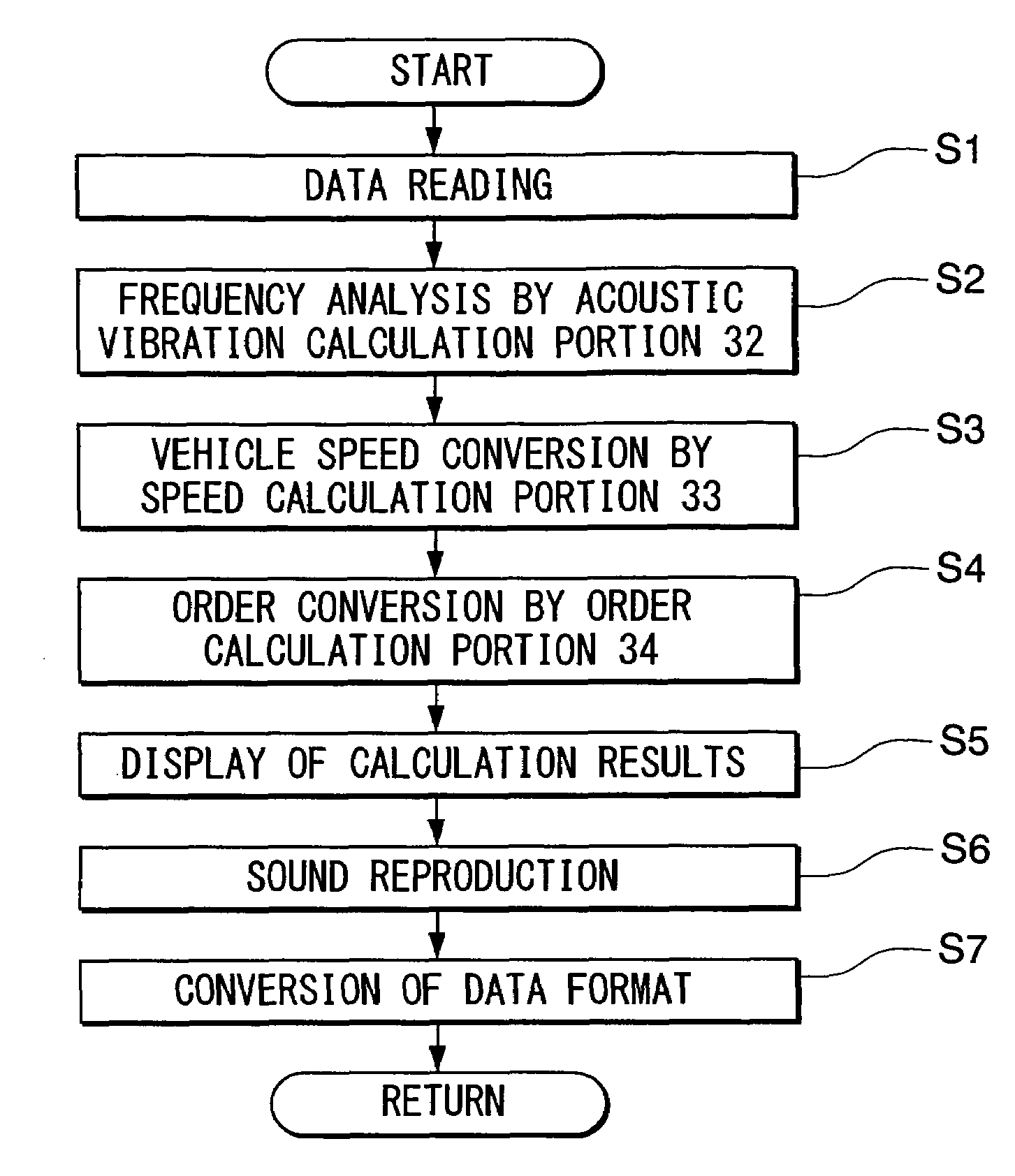

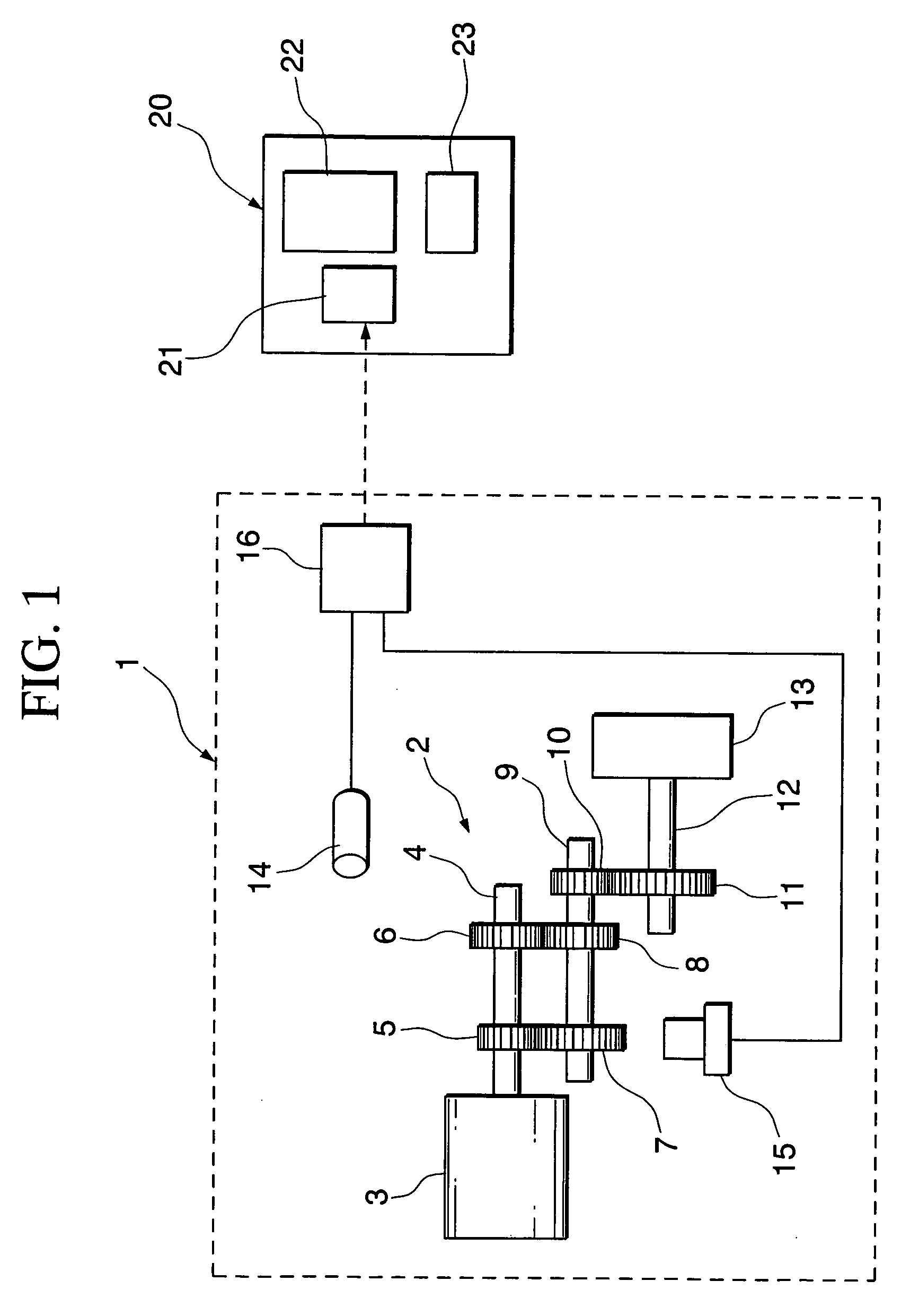

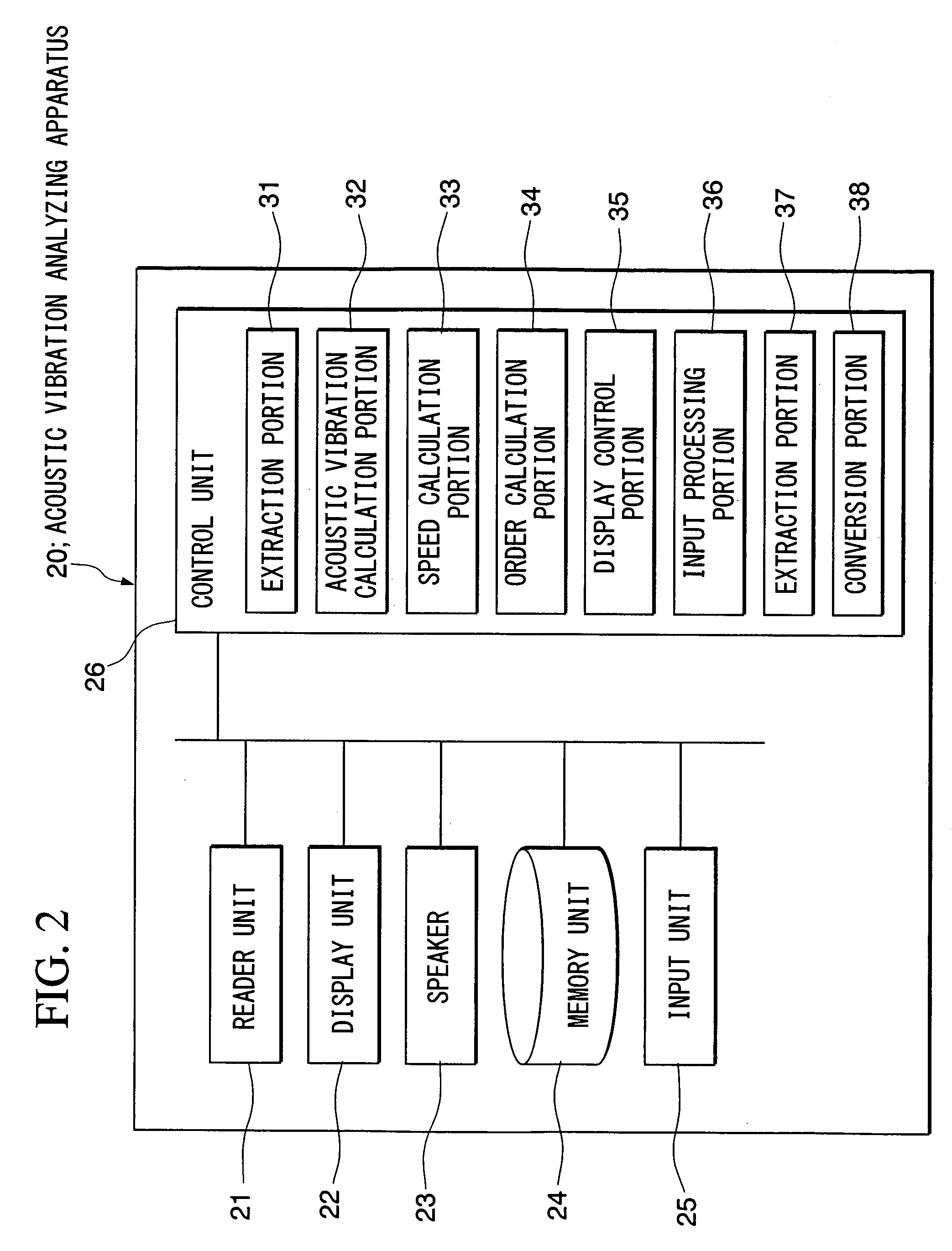

The present invention provides an acoustic vibration analyzing apparatus for carrying out acoustic vibration analysis by picking up data of sounds generated due to rotation of a plurality of gears and data of the number of revolutions of a gear selected from a plurality of gears when a transmission of a vehicle having the plurality of gears operates. The acoustic vibration analyzing apparatus comprises an acoustic vibration calculation portion for analyzing acoustic data in terms of frequency, an order calculation portion for calculating an order in compliance with the specifications of a plurality of gears, a speed calculation portion for calculating the speed of a vehicle, and a display unit for displaying acoustic pressure levels with the order and vehicle speed associated therewith.

Owner:HONDA MOTOR CO LTD

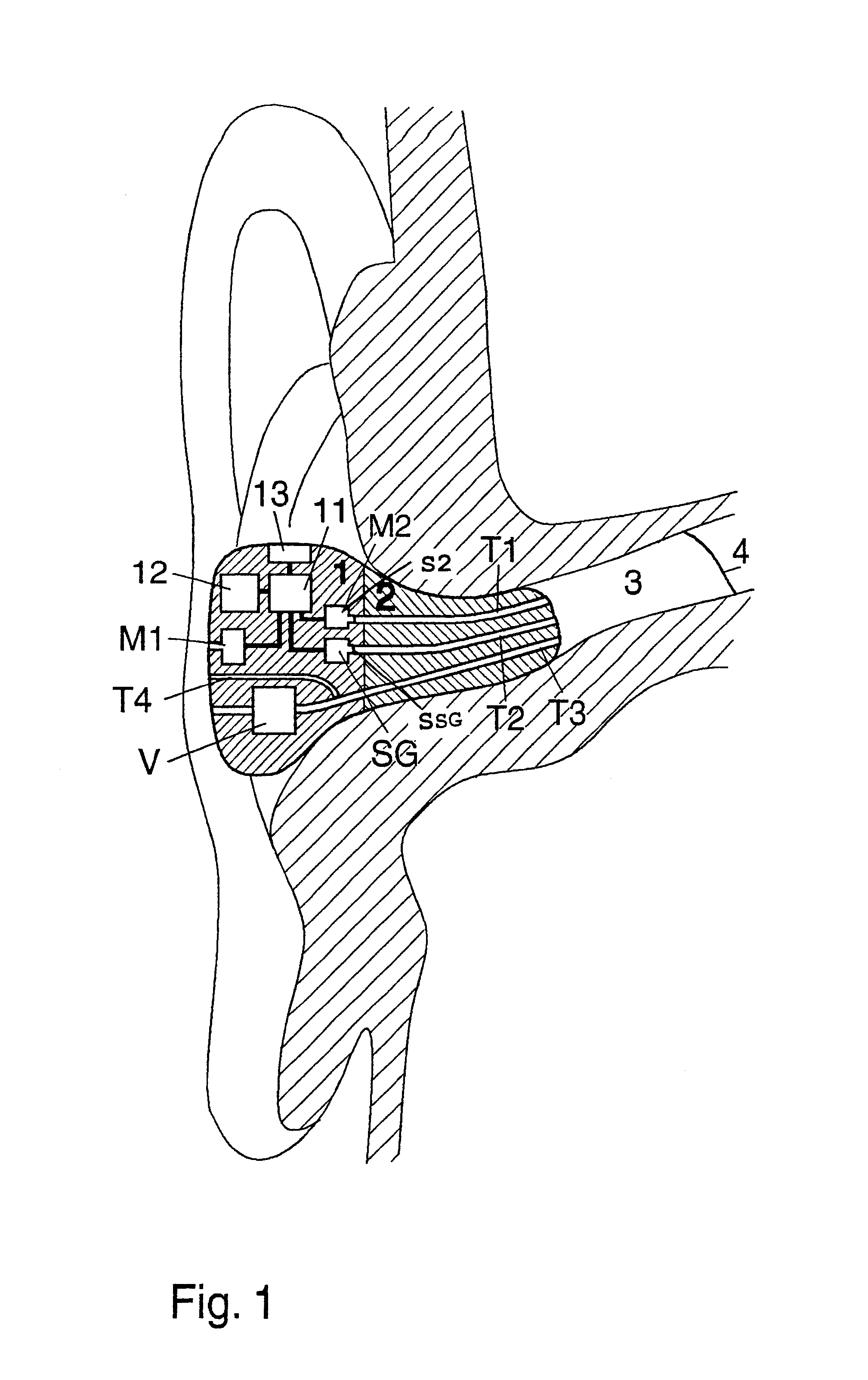

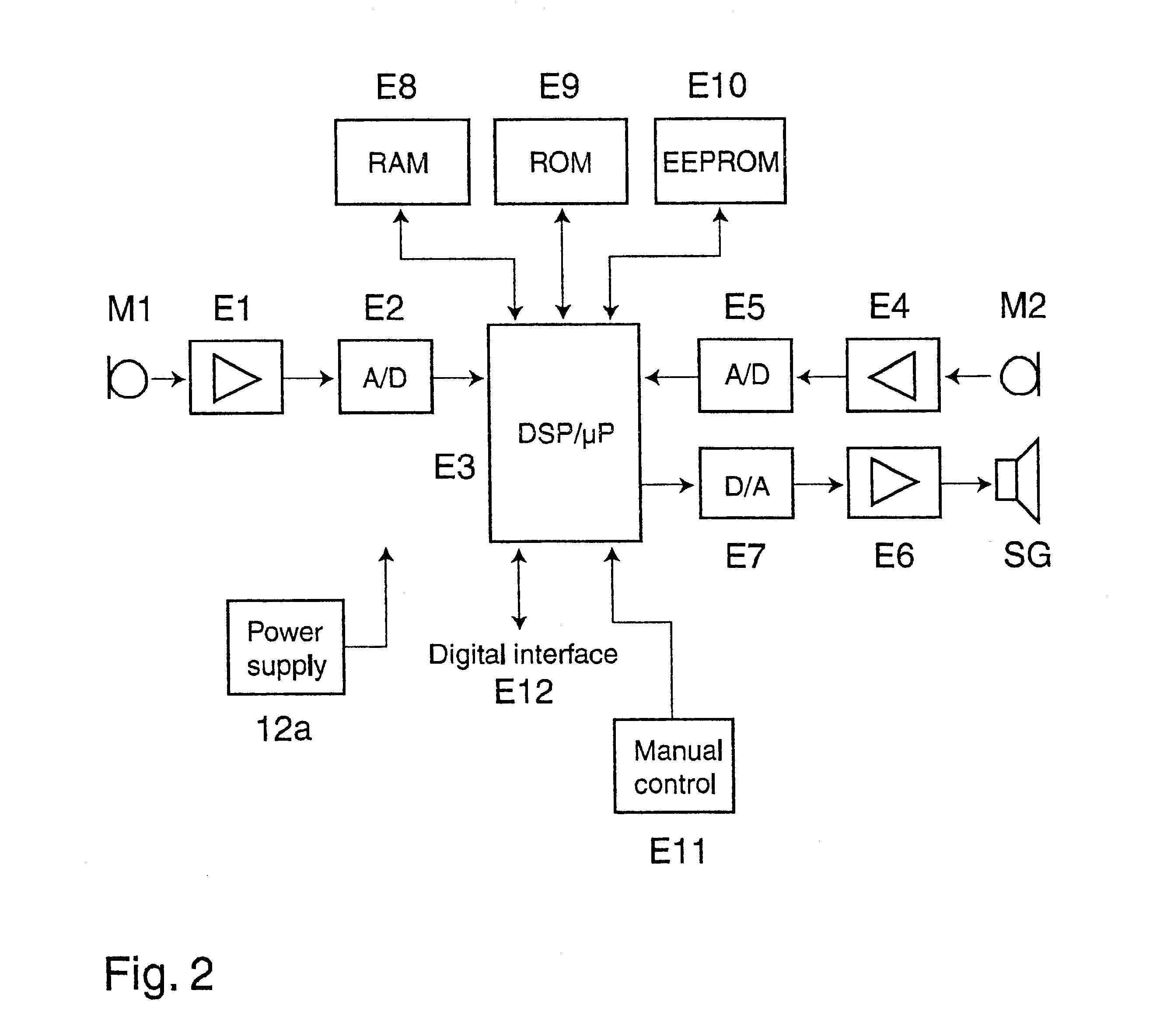

Noise protection verification device

InactiveUS6567524B1Hearing protectionFacilitate communicationVibration measurement in fluidIntra aural earpiecesVocal tractEngineering

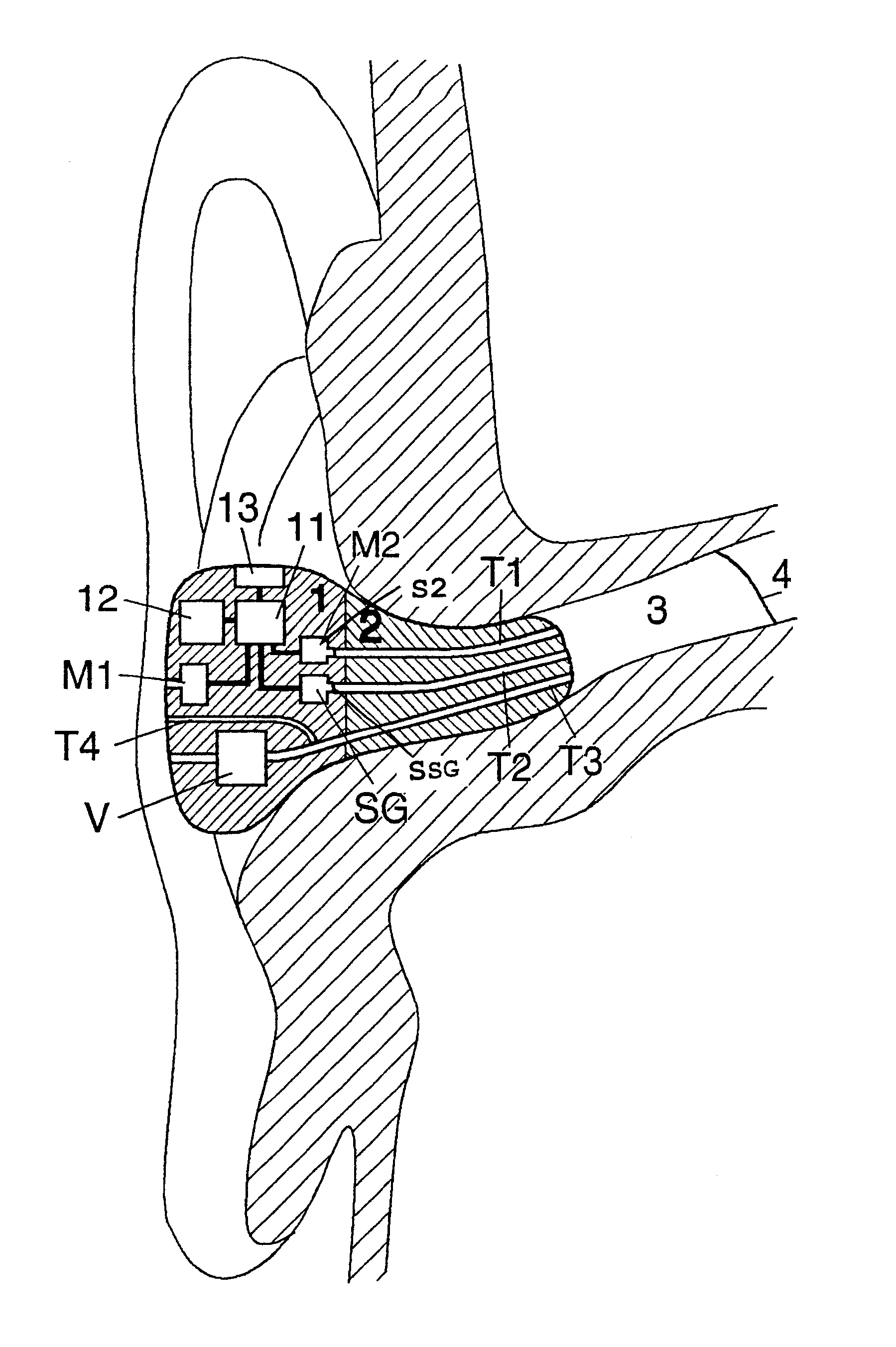

Ear protecting device with a sealing section for acoustically sealing the meatus of a human, includes a sound generator with a sound outlet for being directed toward the user meatus; an inner microphone with a sound inlet from the meatus, arranged for measuring the resulting sound field in the meatus; connected to an electronics unit including a sound analyser coupled to the inner microphone, for analyzing sound characteristics of the resulting sound field in the meatus, producing analyzed sound characteristics; storing part in the electronics unit for storing measured predetermined sound characteristics of a properly functioning ear protecting device; a comparing part in the electronics unit for comparing the inner microphone analyzed sound characteristics with the stored measured predetermined sound characteristics; indicating part coupled to the comparing part for being activated if the analyzed sound characteristics differ significantly from the predetermined sound characteristics.

Owner:HONEYWELL HEARING TECH

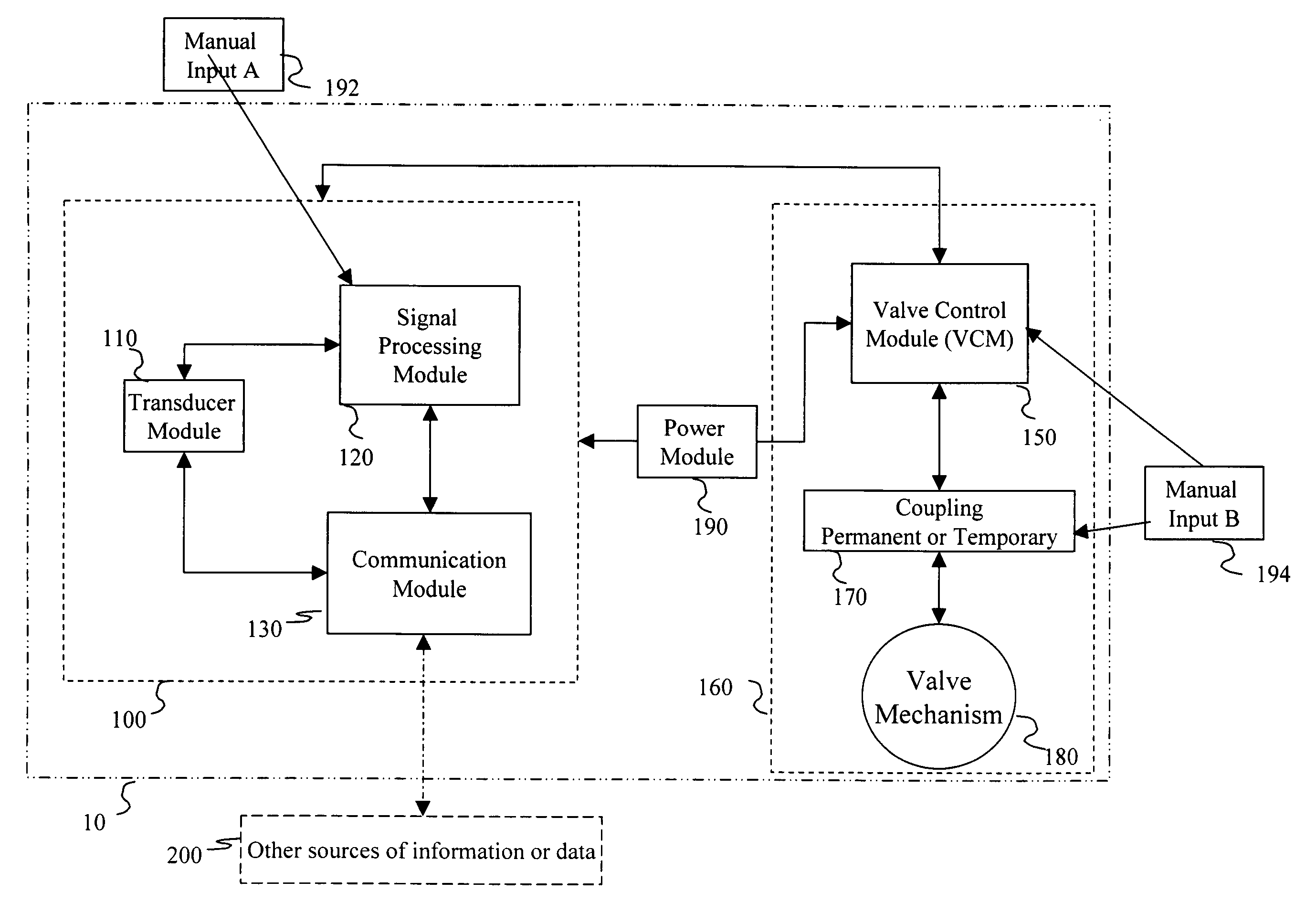

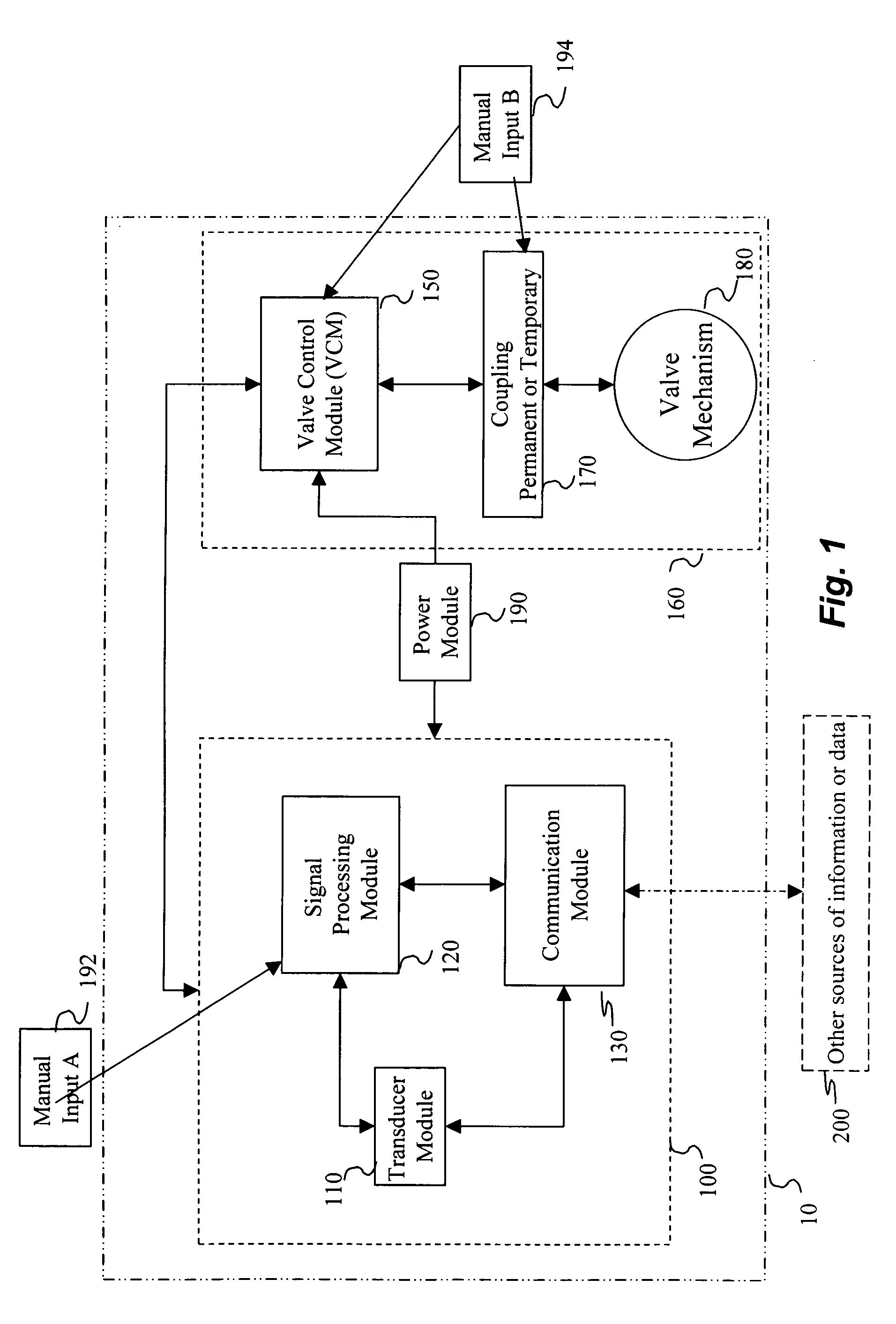

Intelligent valve control methods and systems

InactiveUS20060174707A1ConfidenceQuick couplingDetection of fluid at leakage pointVibration measurement in fluidSmoke detectorsElectricity

A method for determining a burst pipe that requires immediate feeding-valve closing using acoustic and / or vibration sensors coupled to the pipe lor detecting signals, a microprocessor for analyzing signals from said sensors in real-time, a memory coupled to said microprocessor for storing data, including digital signatures acoustic and / or vibration signatures, as well as an actuator electrically coupled to said microprocessor and mechanically coupled to said feeding-valve. When the sensor signals match stored leak-signatures or when a persistent sensor signal produces no match, the system of the present invention initiates a valve closing. To improve detection, signals from other sensors, i.e. water sensors, smoke detectors, heat sensors or acoustic / vibration sensors mounted on other pipes are also used. Some of the said systems have IP addresses and can communicate over the Internet or wirelessly with others.

Owner:ZHANG JACK K

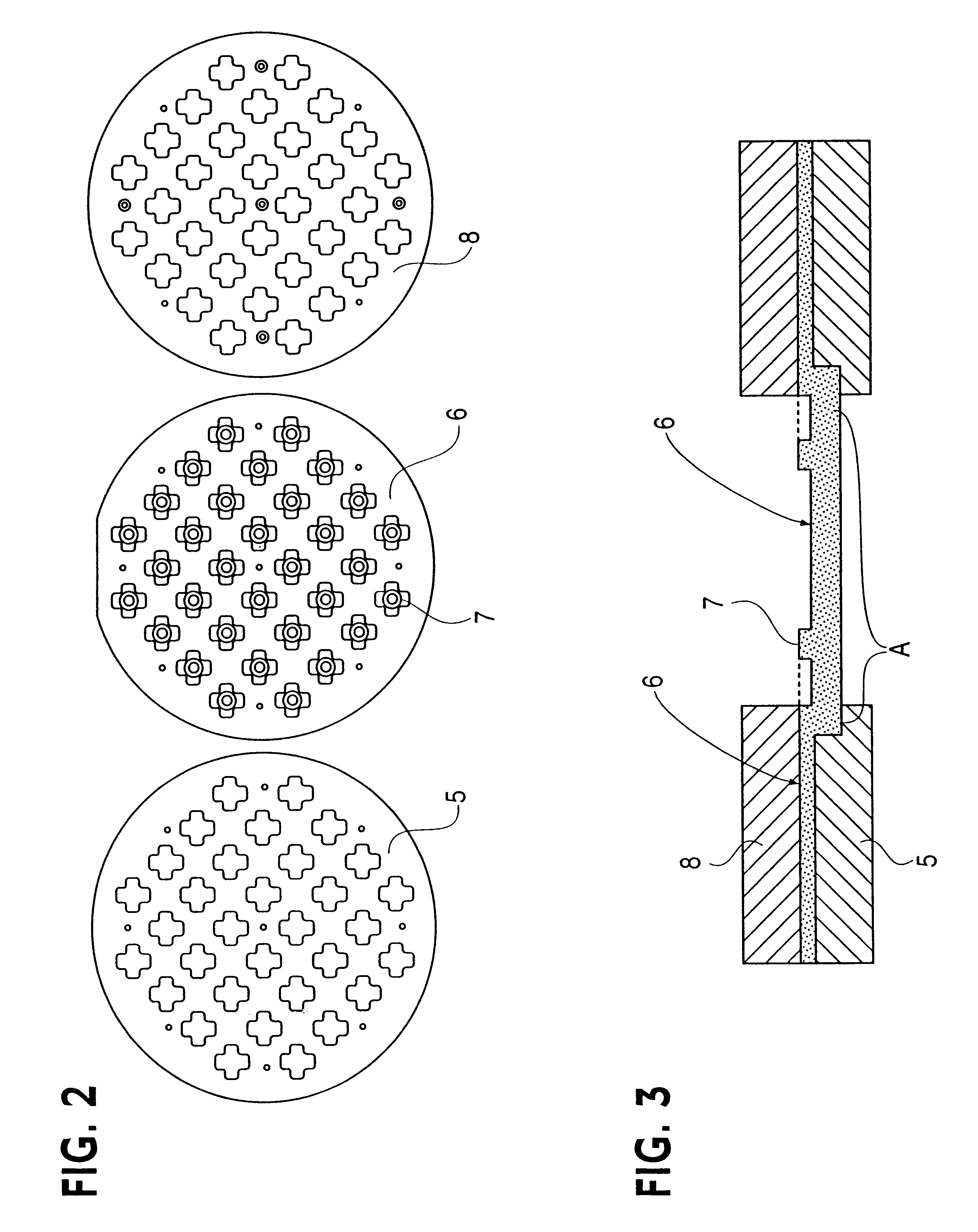

Vibratory transducer

InactiveUS6840109B2Simple and robust mannerSimplifies isolationVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesTransducerEngineering

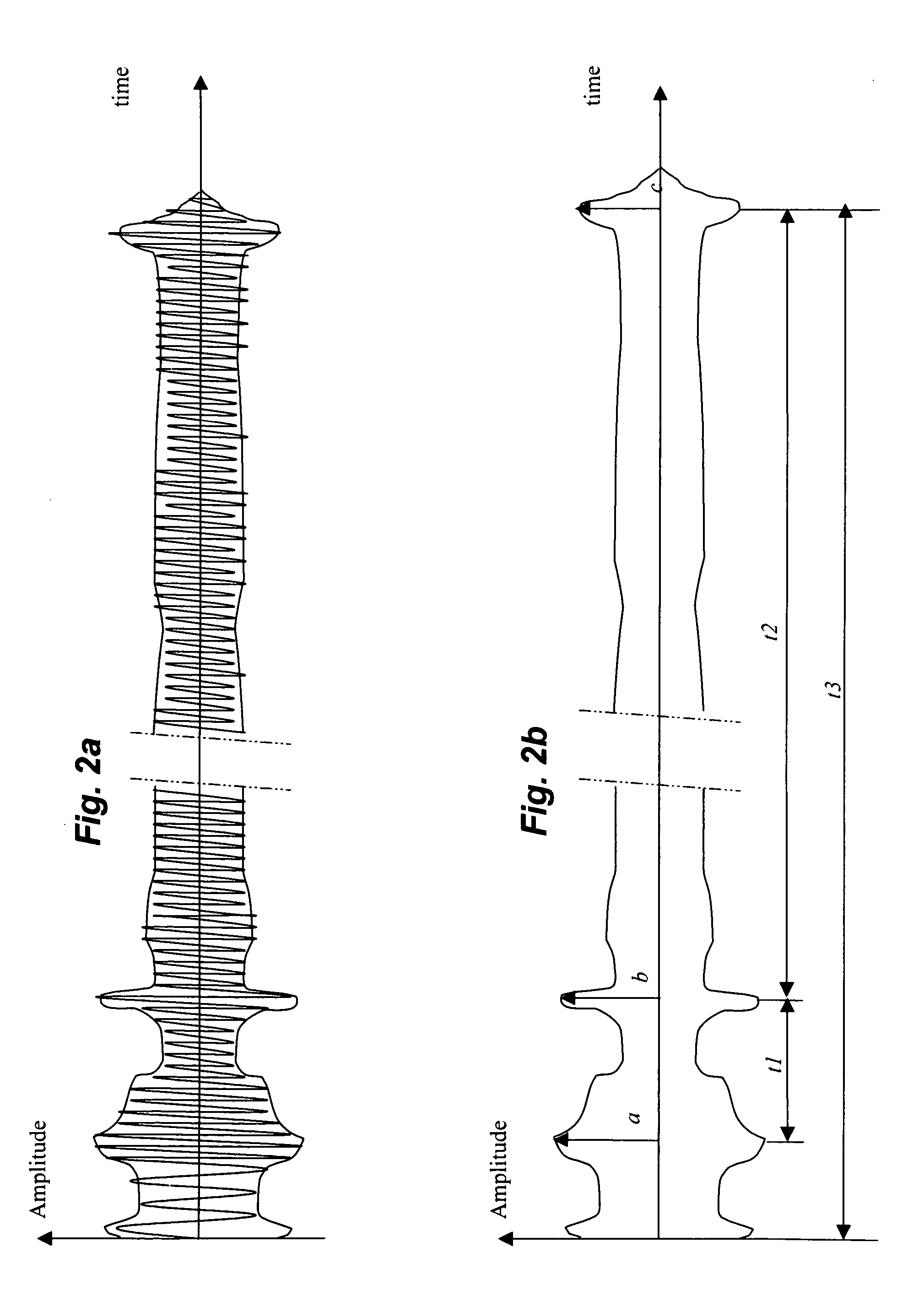

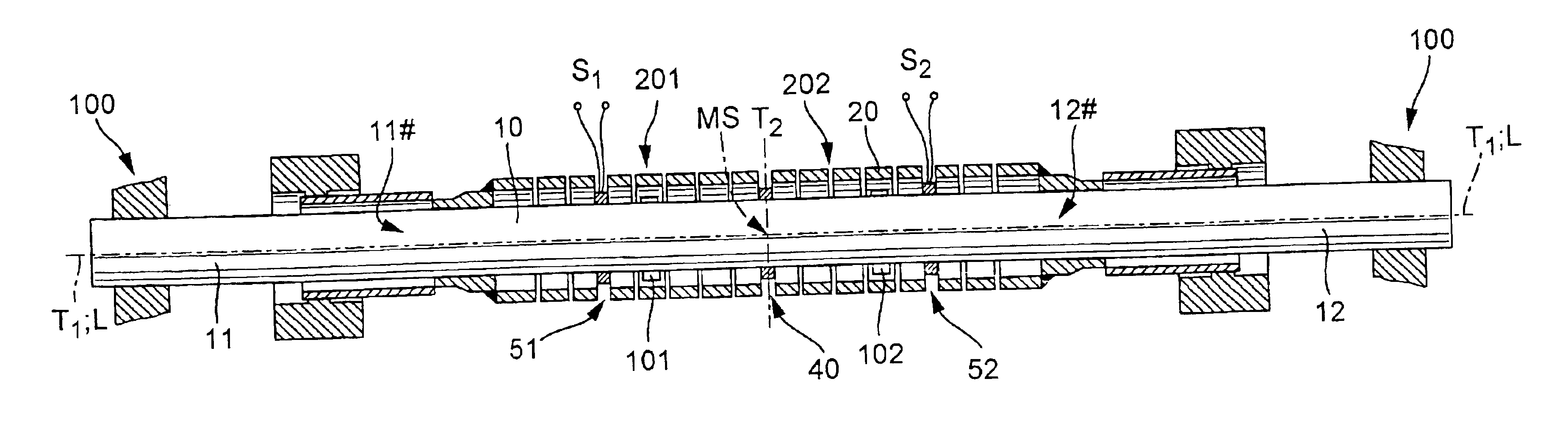

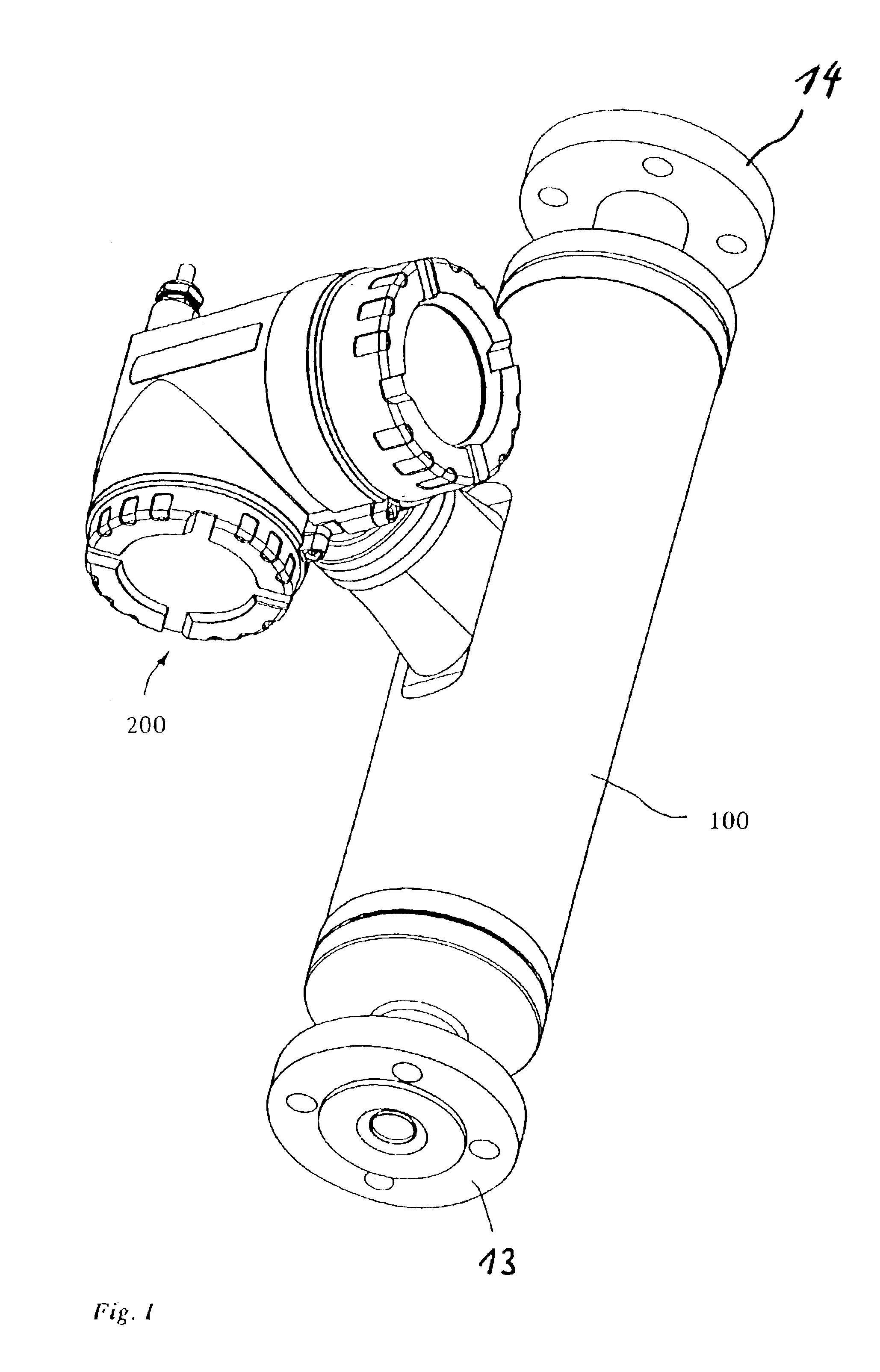

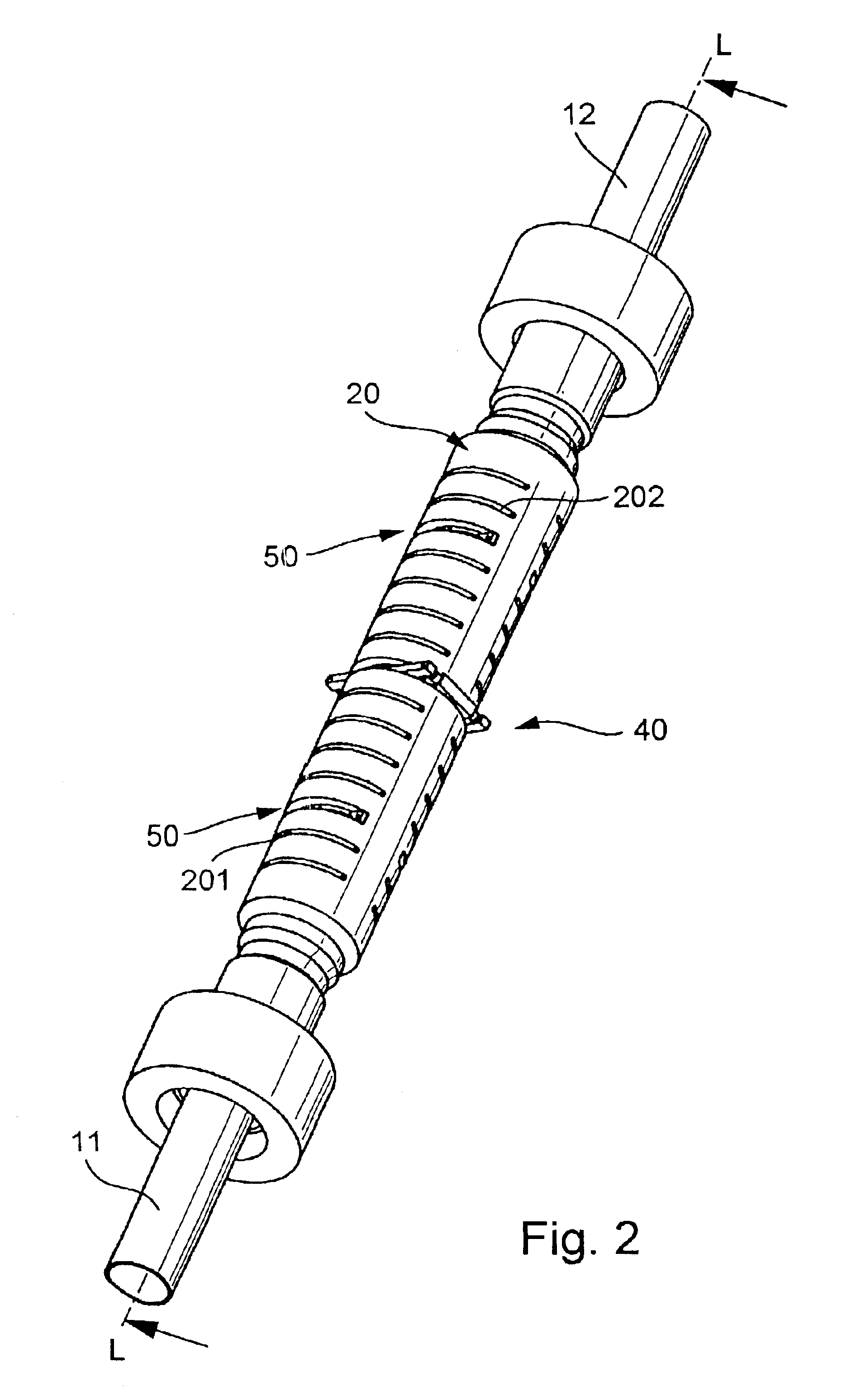

To conduct a fluid, the transducer has a flow tube which in operation vibrated by an excitation assembly. Inlet-side and outlet-side vibrations of the flow tube are sensed by means of a sensor arrangement. To produce shear forces in the fluid, the flow tube is at least intermittently excited into torsional vibrations about a longitudinal flow-tube axis. An internal portion of the transducer, formed at least by the flow tube, an antivibrator, the sensor arrangement, and the excitation assembly and mounted at least on the inlet and outlet tube sections, has a centroid which is located inside the flow tube. The transducer is suitable for use in viscometers or Coriolis mass flowmeter-viscometers. In spite of using only a single straight flow tube, it is dynamically well balanced in operation, and the development of bending moments by the torsionally vibrating flow tube is largely prevented. This also effectively prevents the transducer case or the connected pipe from being excited into sympathetic vibration. Measurement signals representative of mass flow rate are readily distinguishable from measurement signals representative of viscosity, particularly if the sensors used for the viscosity measurement are also used for the mass flow measurement.

Owner:ENDRESS HAUSER FLOWTEC AG

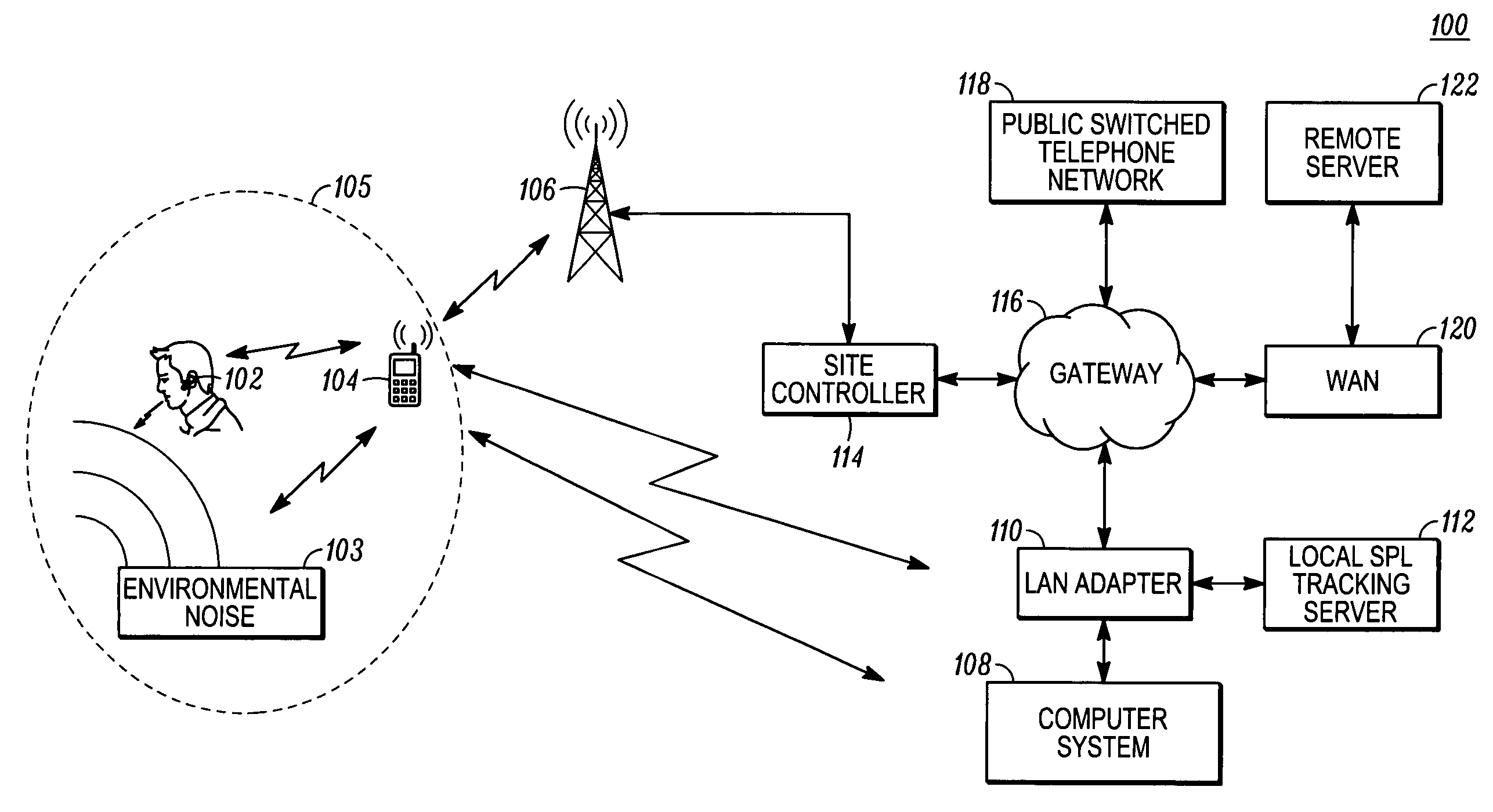

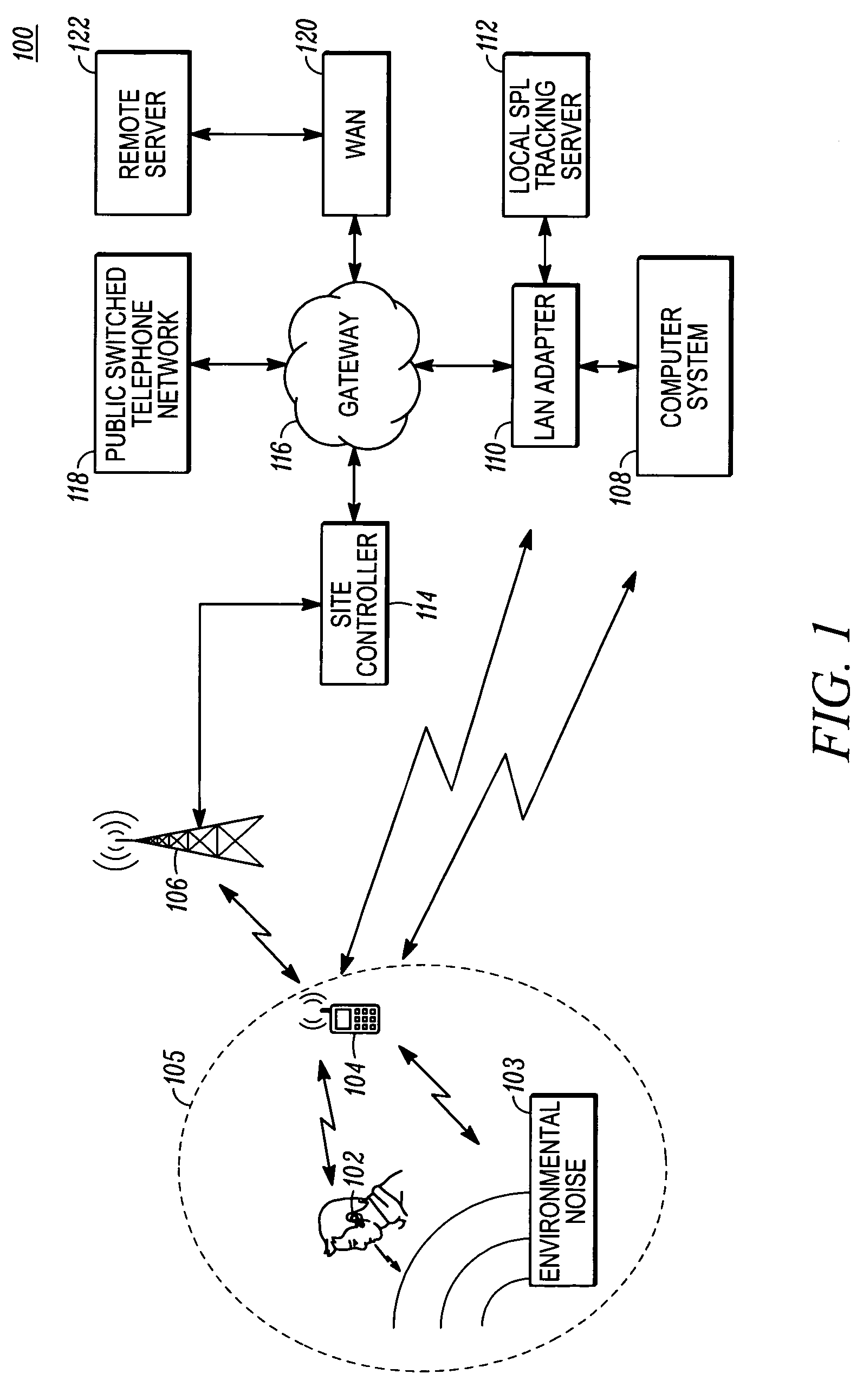

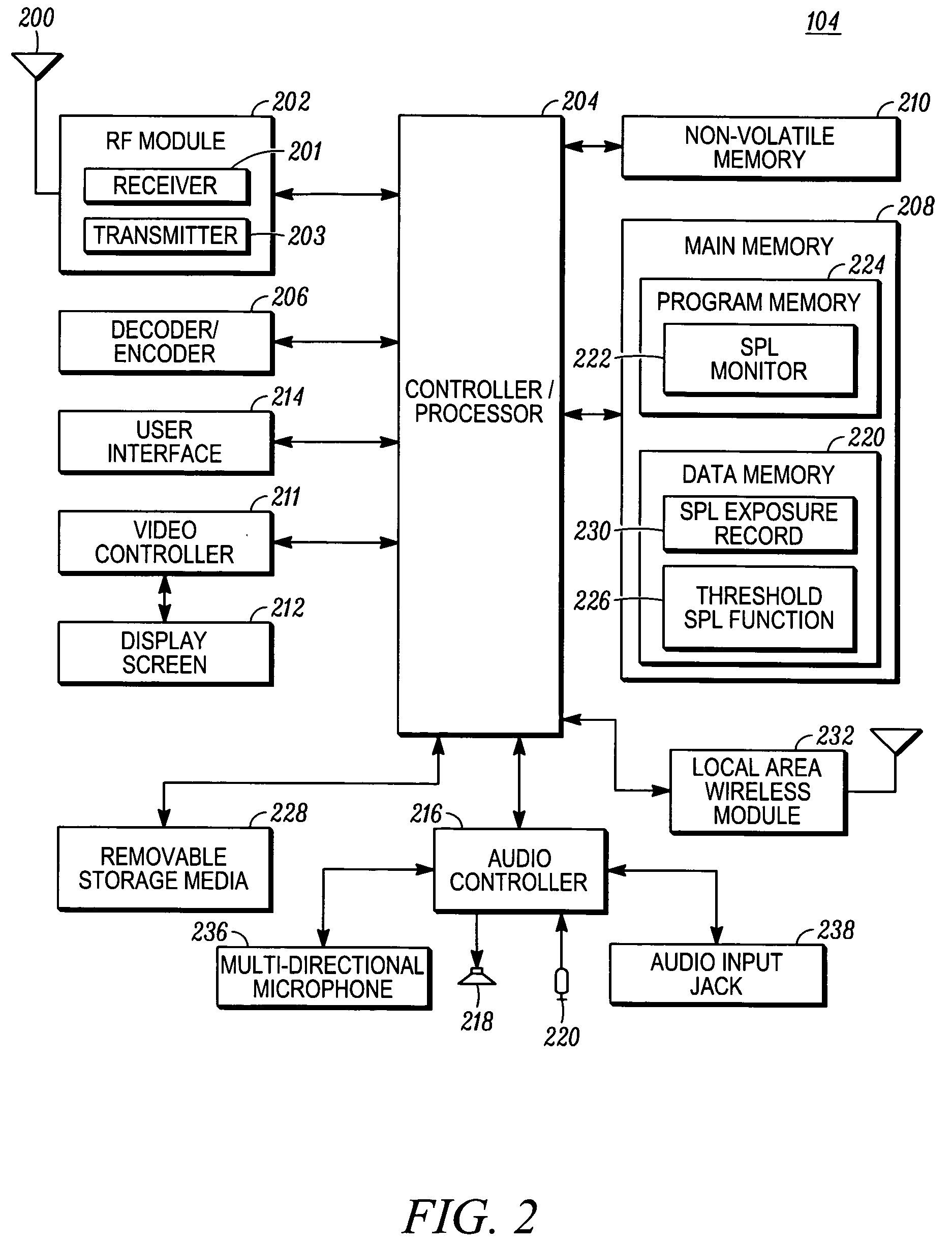

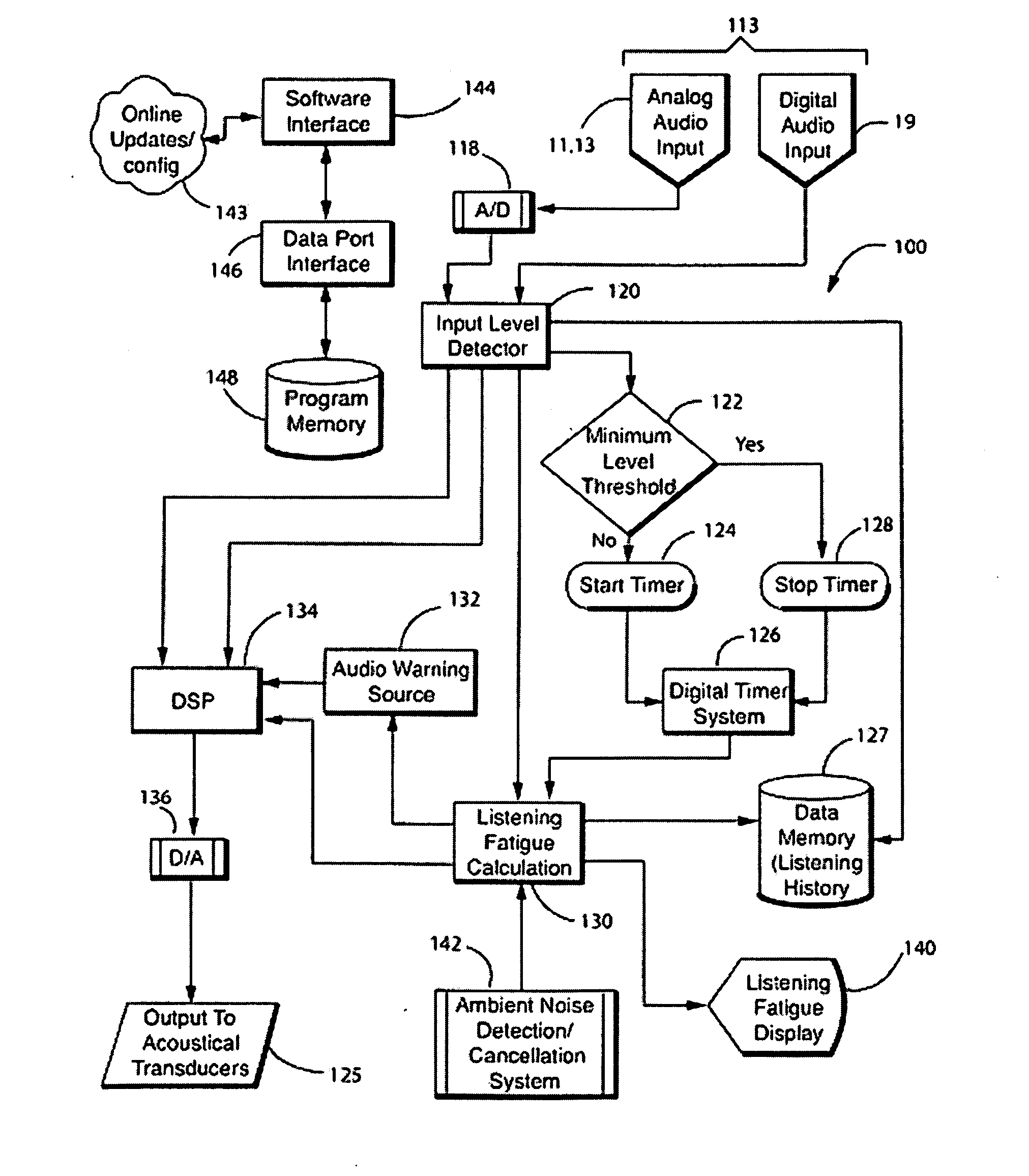

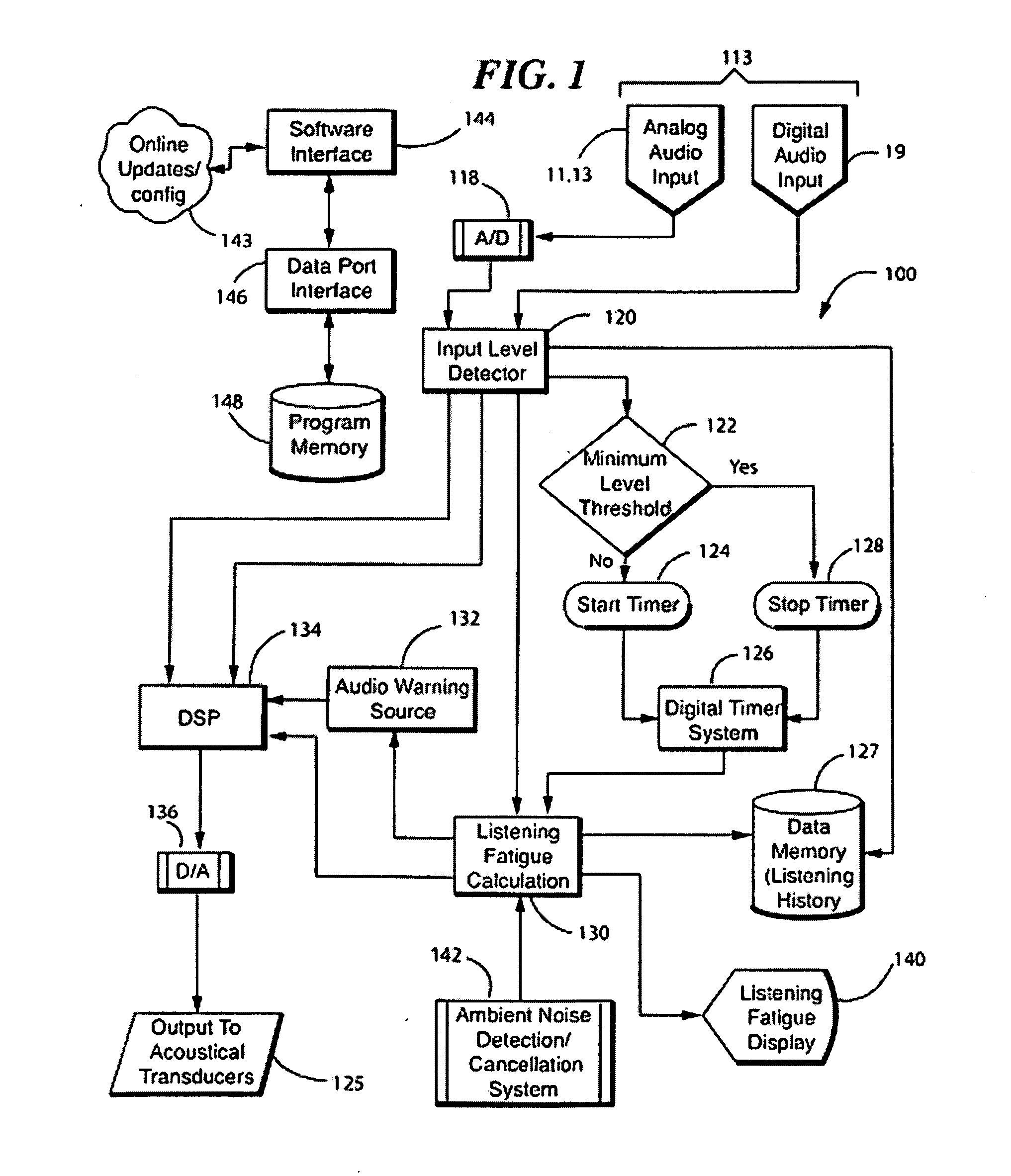

Method for autonomously monitoring and reporting sound pressure level (SPL) exposure for a user of a communication device

ActiveUS20080159547A1Prevent hearing lossVibration measurement in fluidHeadphones for stereophonic communicationTransducerComputer science

A method for monitoring and reporting sound pressure level exposure for a user of a first communication device (104) is implemented in one embodiment when the device measures a sound pressure level (SPL) of the surrounding environment. The device stores at least the SPL measurement in a memory, producing an SPL exposure record, and displays a visual representation of the SPL exposure record on a display screen (212). In another embodiment, the SPL is measured by a second communication device (102) and combined with a known SPL for an output audio transducer (306) of the second device, producing a user sound exposure level. The user sound exposure level is transmitted to the first communication device. The user is notified when the user sound exposure level exceeds a predetermined threshold. A server (112) may also be used to track SPLs over time and recommend corrective action when exposure limits are exceeded.

Owner:GOOGLE TECH HLDG LLC

Hand-held working tool

Owner:HILTI AG

Pipeline monitoring system

InactiveUS20060225507A1Convenient verificationDetection of fluid at leakage pointVibration measurement in fluidMonitoring systemEngineering

Process and apparatus for sensing possible leaks in a pipeline. The pipeline is monitored continuously by acoustic monitoring means, and acoustic events indicating a possible leak are noted. The pipeline is also equipped with temperature monitoring means, and is monitored for temperature either continuously, periodically or on demand. A leak is deemed probable at any location where there is an acoustic event indicating a possible leak, and at approximately the same time, a temperature difference greater than a pre-chosen amount between that location and adjacent locations

Owner:PURETECH VENTURES

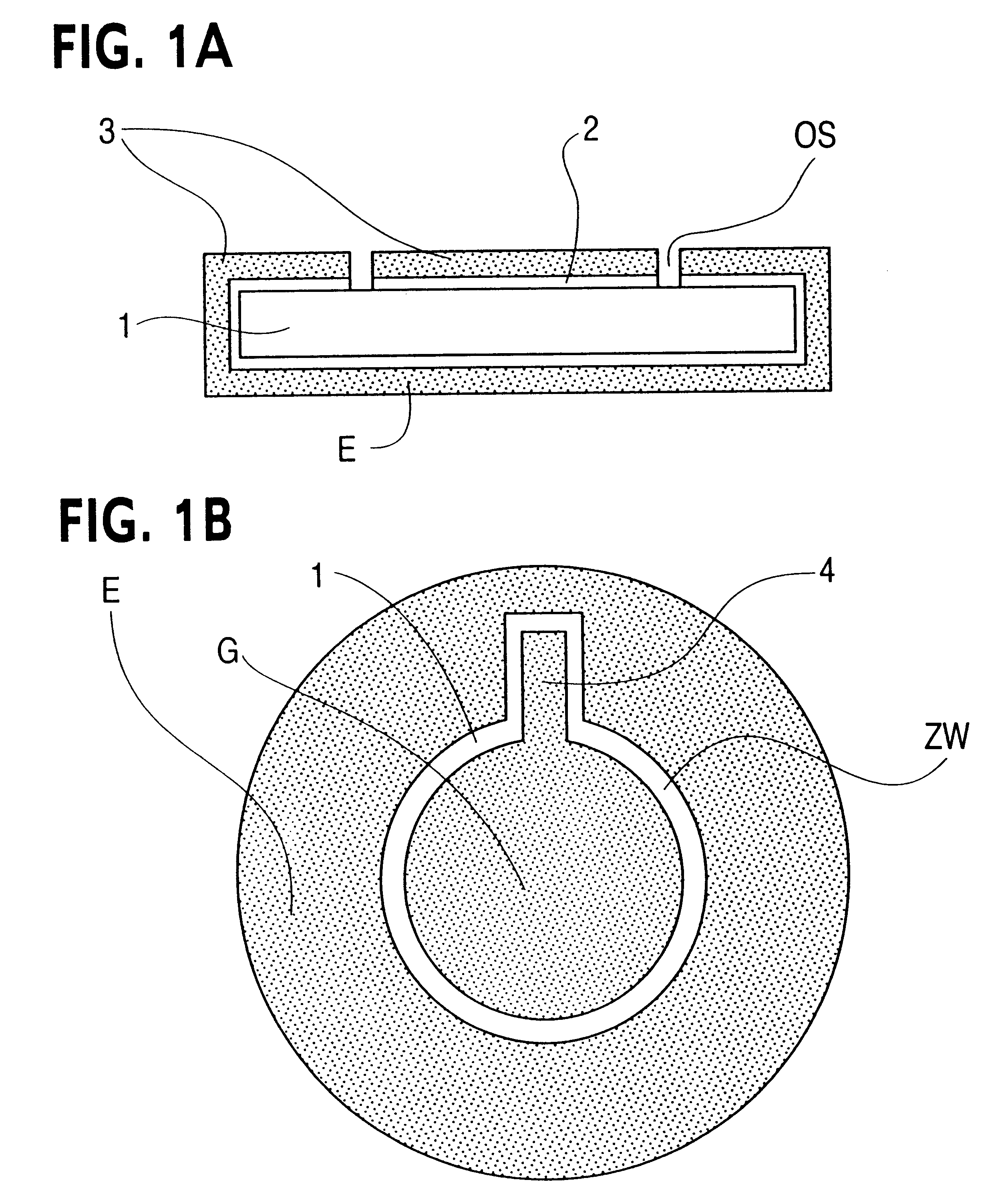

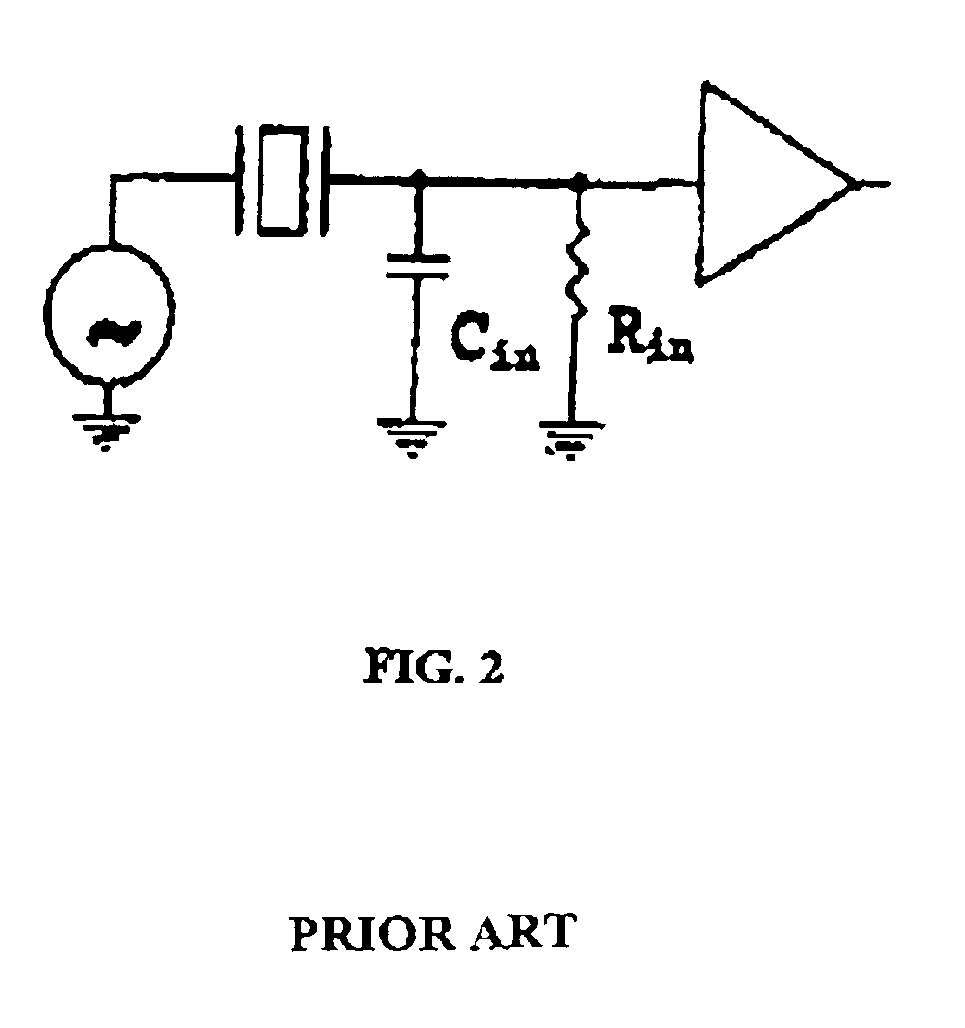

Piezoelectric resonator, process for the fabrication thereof including its use as a sensor element for the determination of the concentration of a substance contained in a liquid and/or for the determination of the physical properties of the liquid

InactiveUS6196059B1Vibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesMeasurement deviceFlow cell

Disclosed is a piezoelectric resonator, a process for the fabrication thereof and its use as a sensor element, which implemented in a through-flow cell, is integratable in a measurement system for the determination of the concentration of a substance contained in a liquid and / or for the determination of the physical properties of the liquid. The piezoelectric resonator is designed plane and is provided on its surface with electric contact areas for an electrode and a counter electrode, which is connectable to a signal source as well as to a measurement device. For measuring, the piezoelectric resonator is brought into contact with the to-be-examined liquid on one side, with the resonator responding to the accumulation of the mass of the to-be-detected substance or to a change in the physical properties of the liquid by changing its resonance frequency and / or oscillation amplitude.The present invention is distinguished by the fact that the piezoelectric resonator is provided with contact electrode areas which is contactable from one single side of the resonator. The resonator is the heart piece of a sensor element, which is integrated in a through-flow cell. The through-flow cell us insertable module-like in a measurement arrangement for determining the concentration of a substance contained in a liquid and / or determining the physical properties of the liquid.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

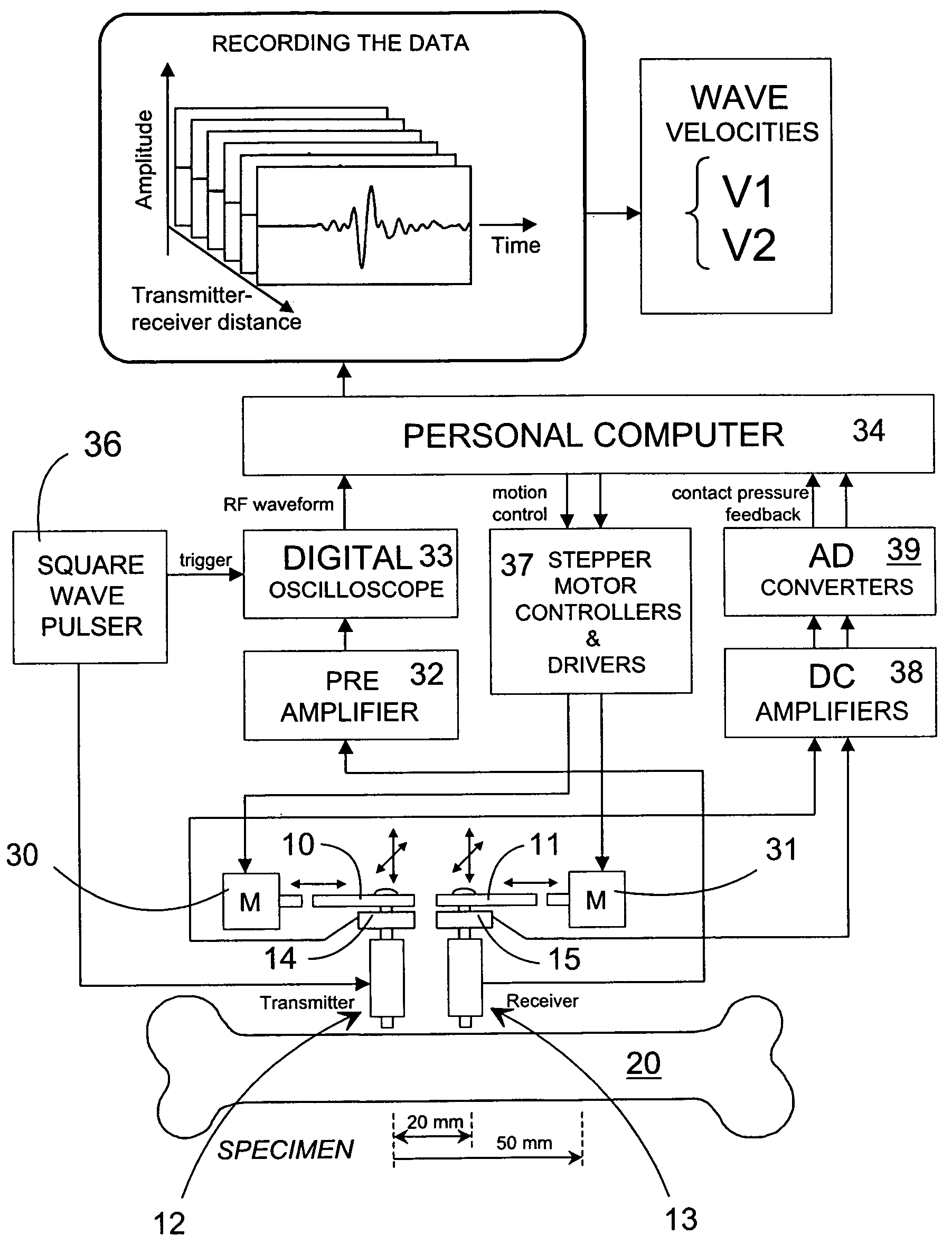

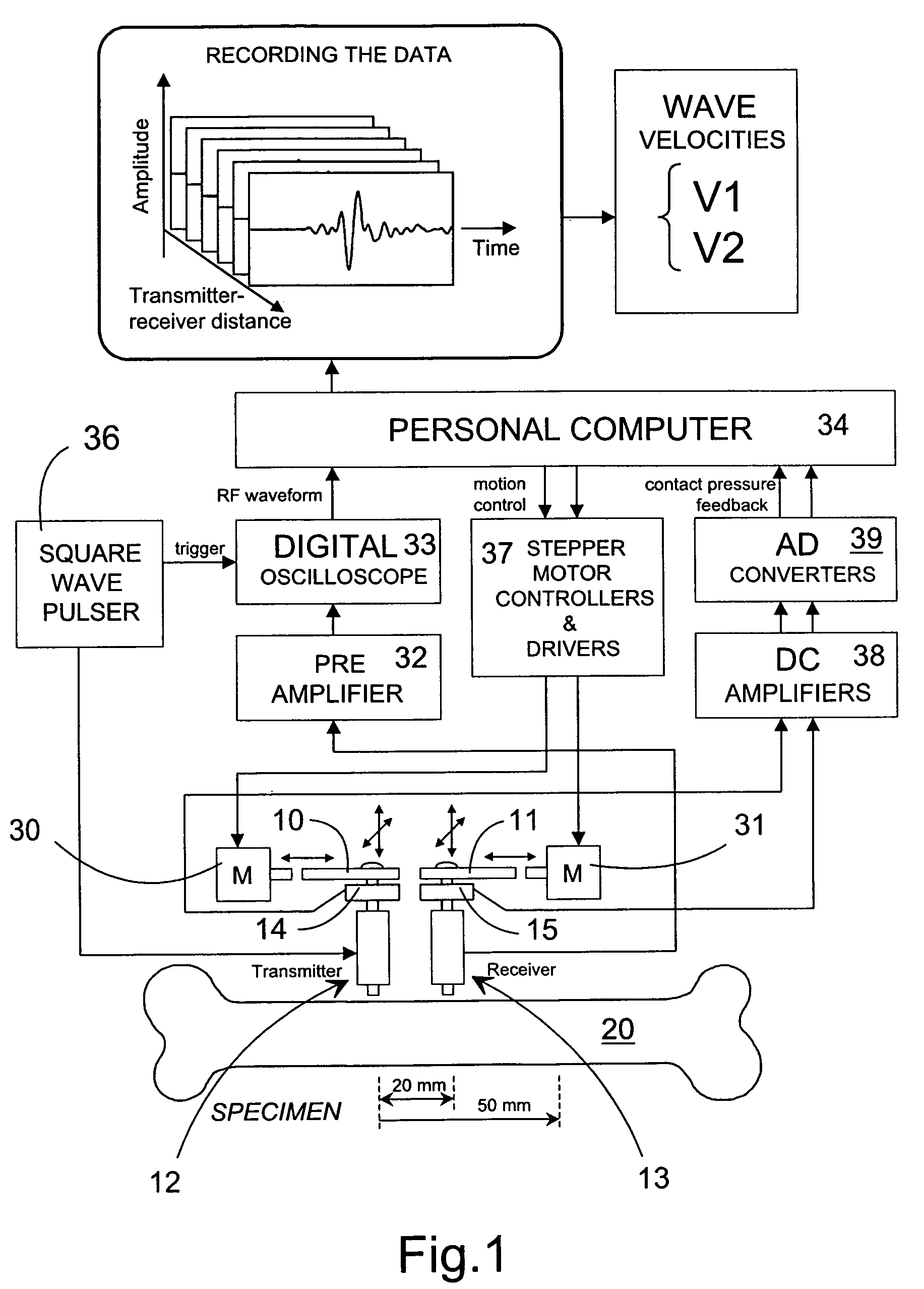

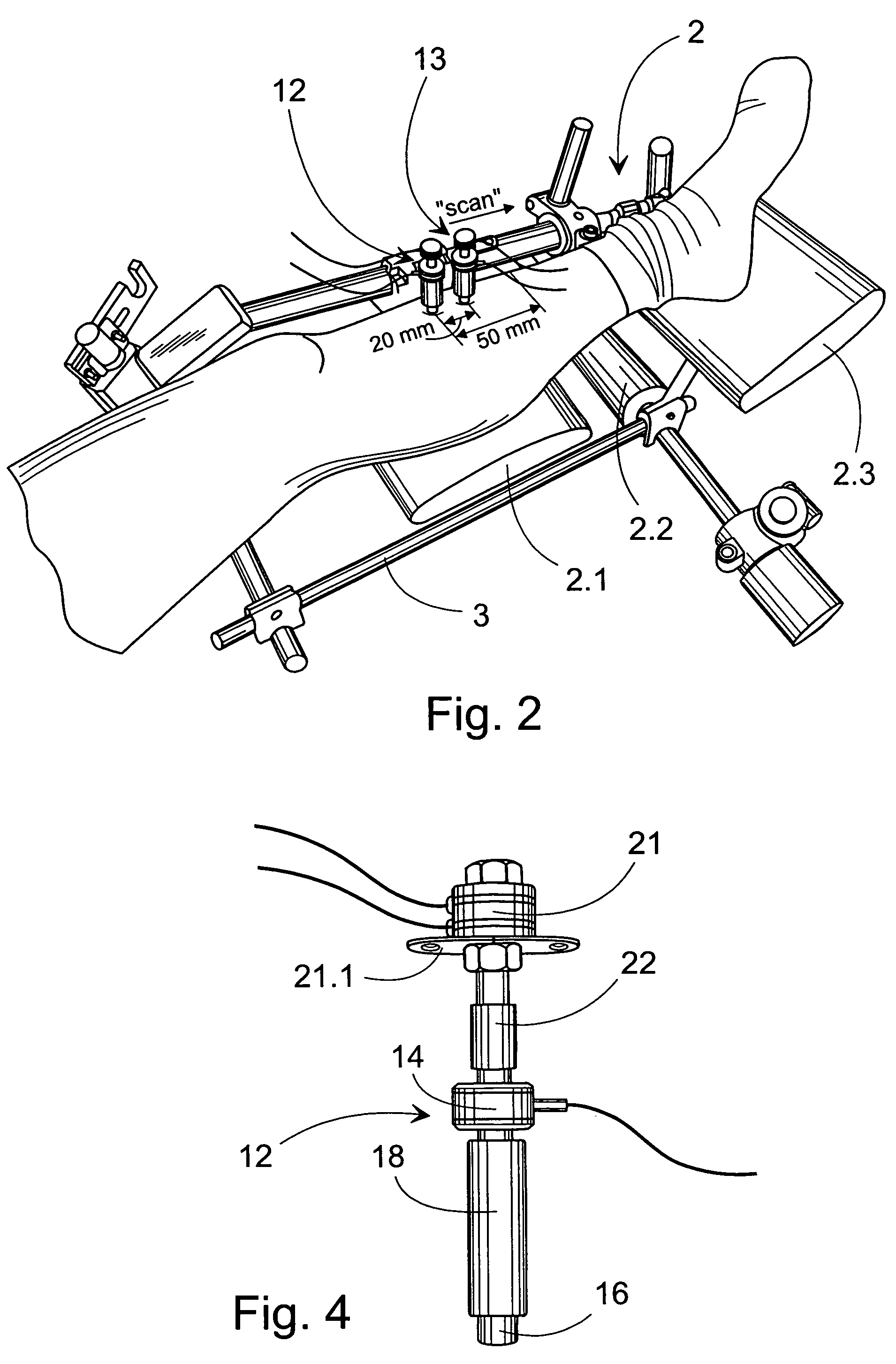

Method and device for the non-invasive assessment of bones

ActiveUS7601120B2Enhanced thickness-dependenceMaterial analysis using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidBone densityTransducer

A method for the in vivo non-invasive characterization of the material and architectural properties of a bone in which an ultrasonic wave is introduced into a bone in such way as to produce one or more guided wave modes within the bone, and the signals emerging from the bone are stored and analyzed to determine the propagation characteristics of the guided wave / s. These measured guided wave propagation characteristics are then processed to obtain estimates of desired bone properties such as cortical thickness, bone density and bone elastic constants. The invention also includes an unltrasound arrangement with movable transducers.

Owner:OSCARE MEDICAL

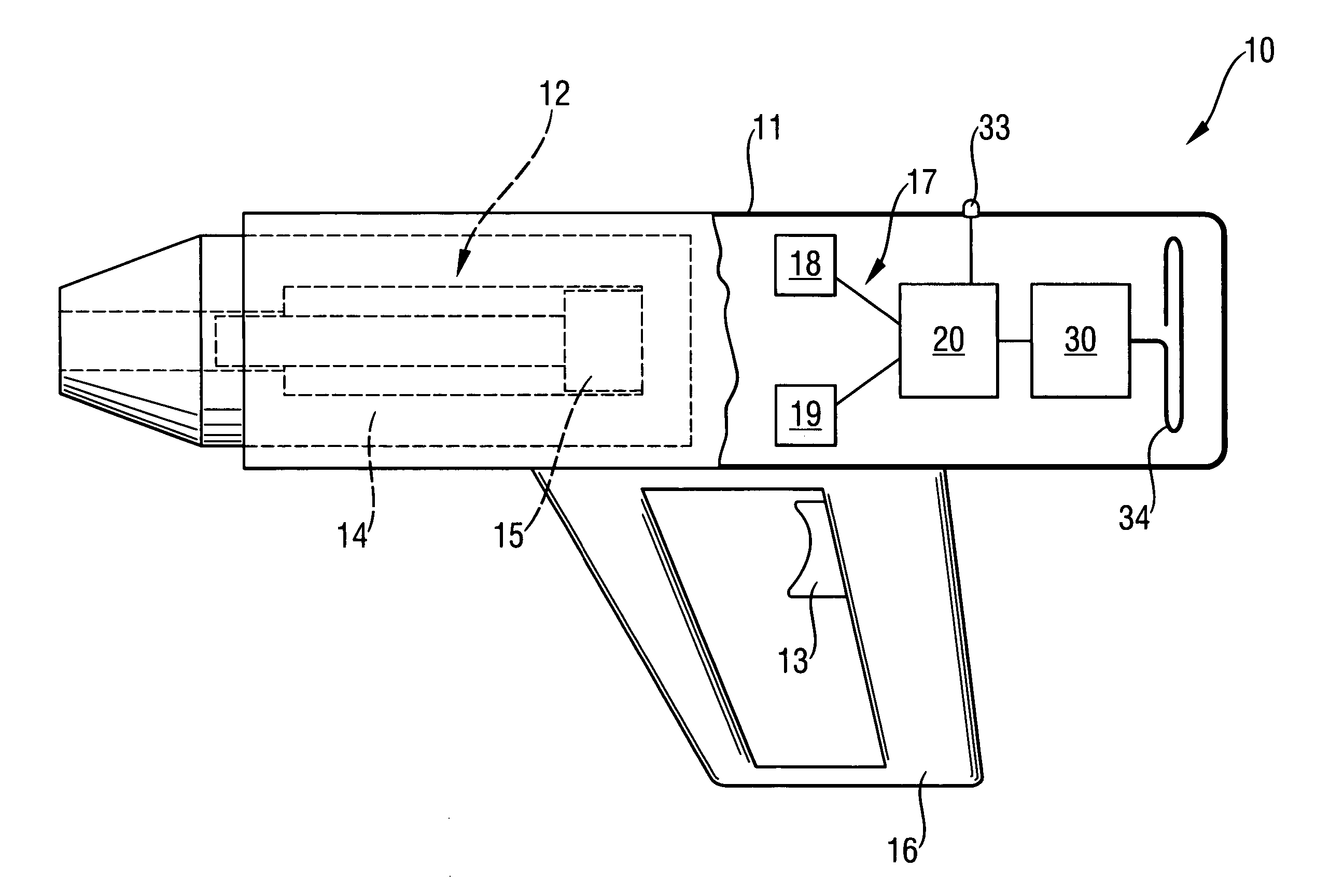

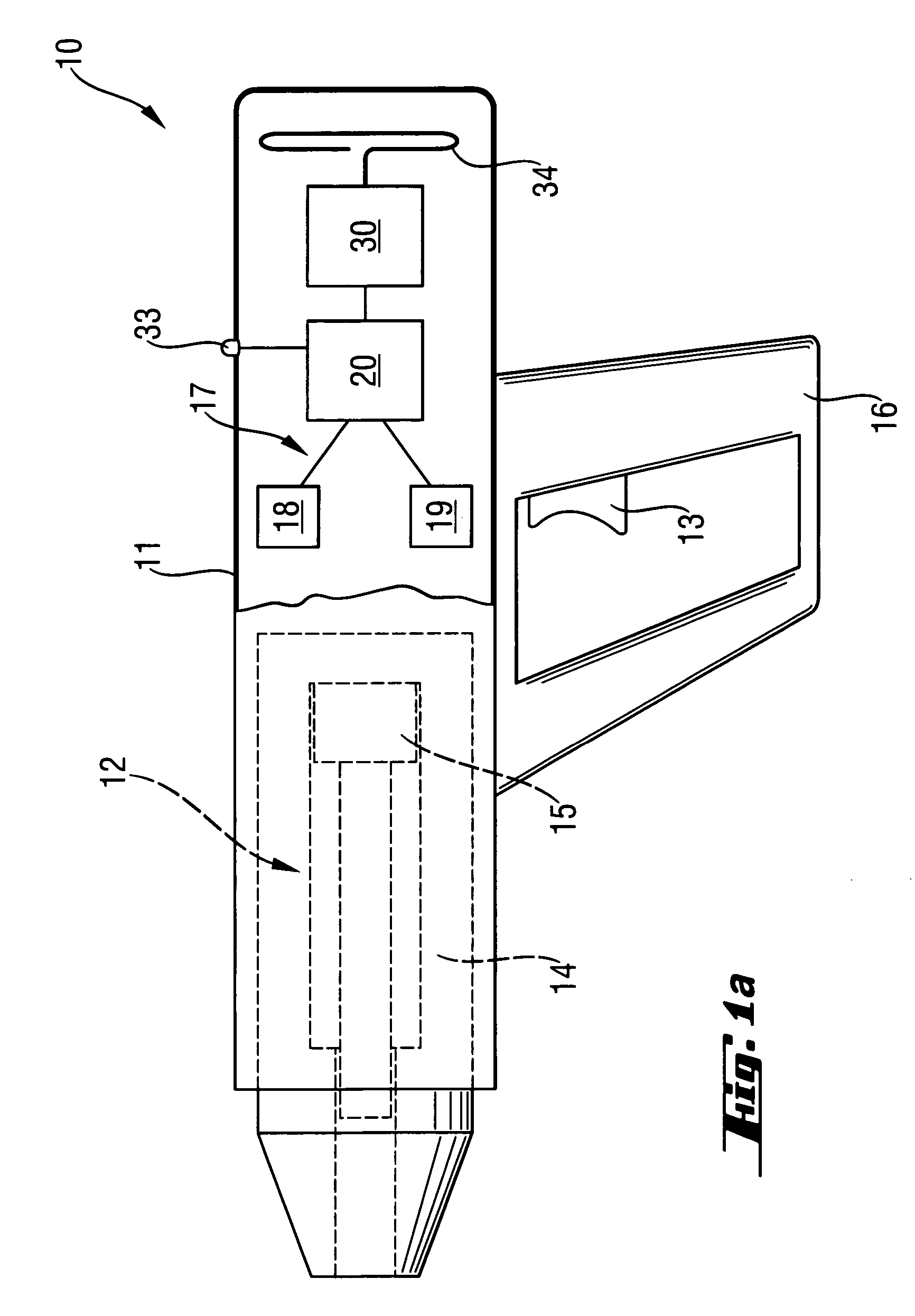

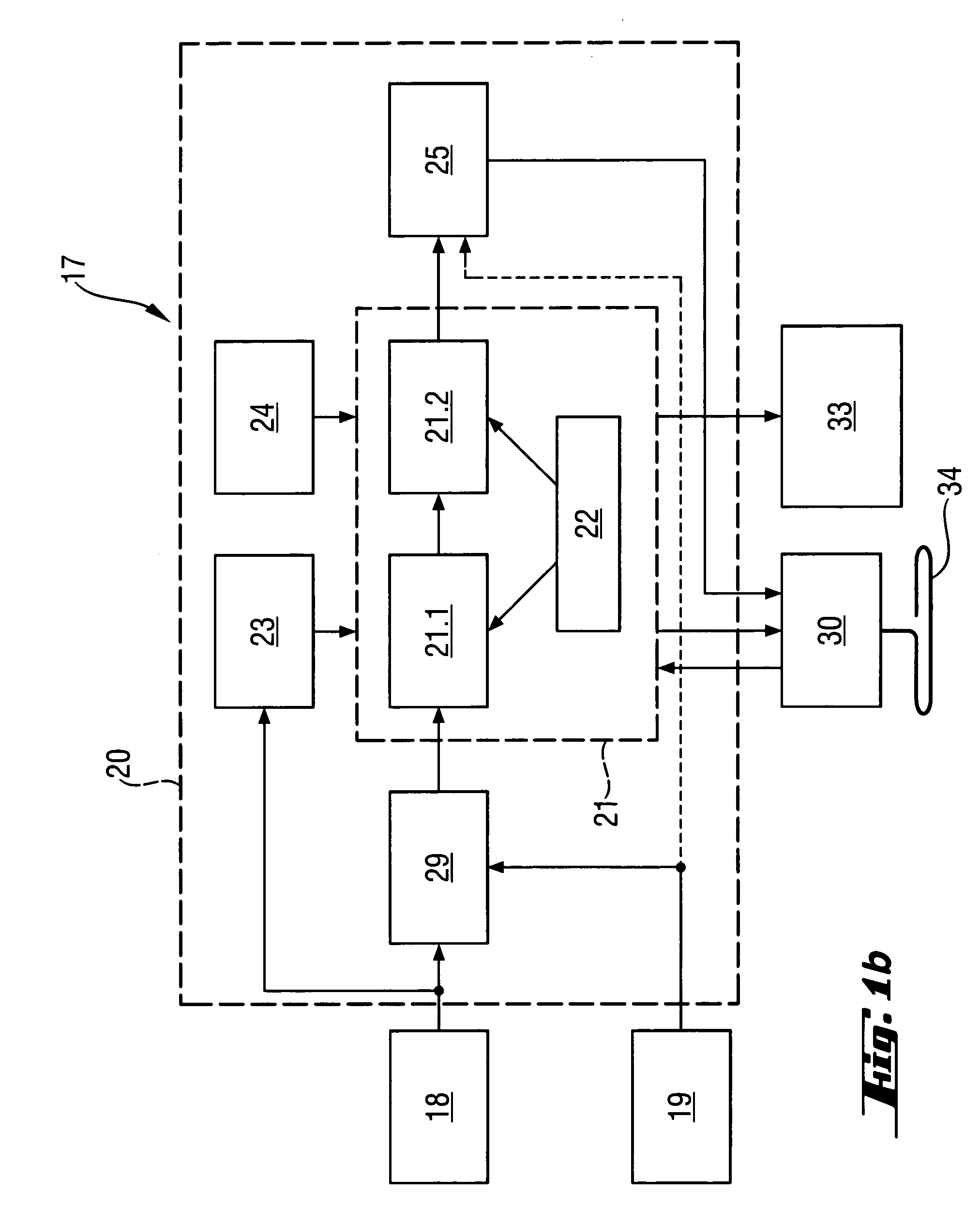

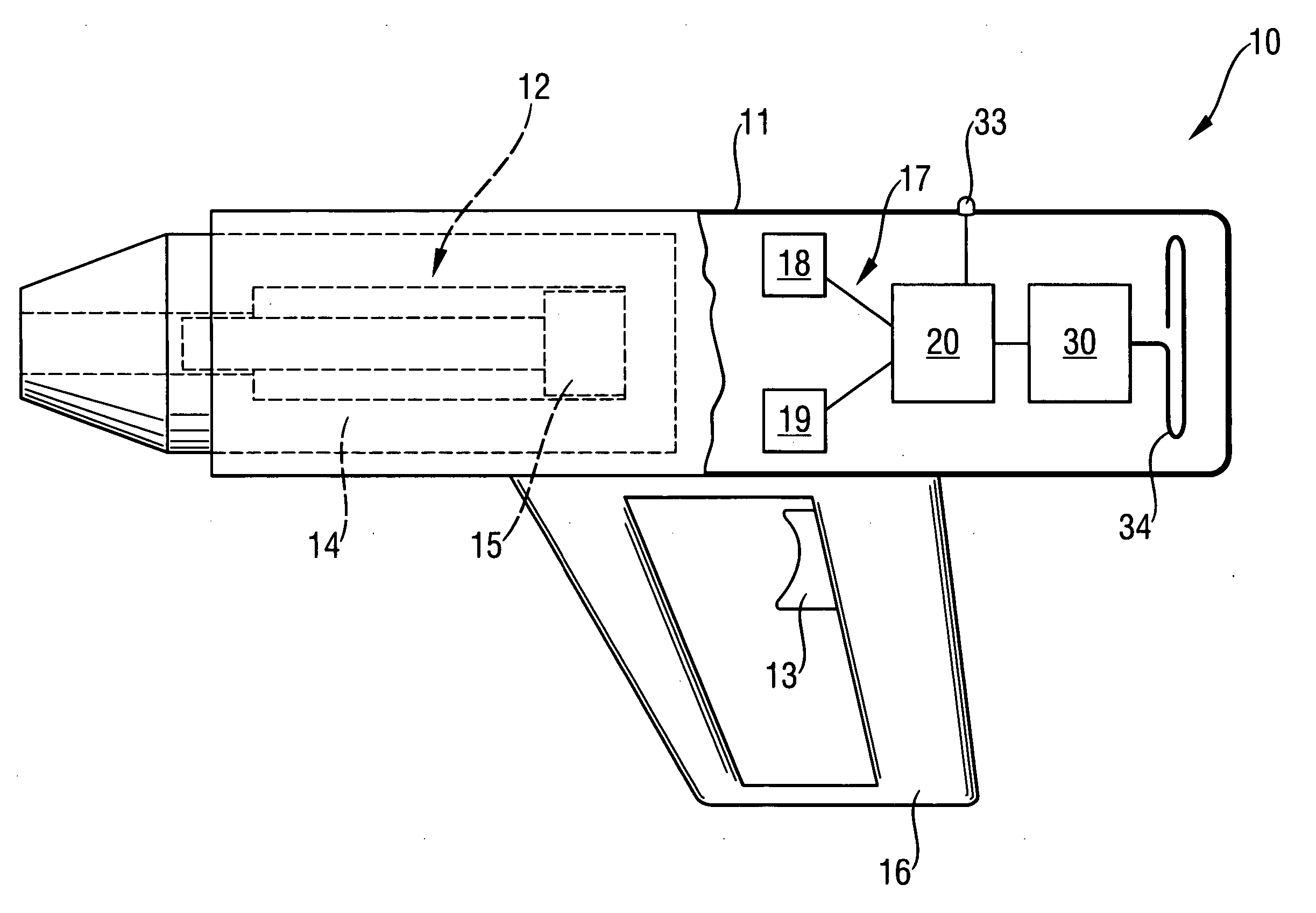

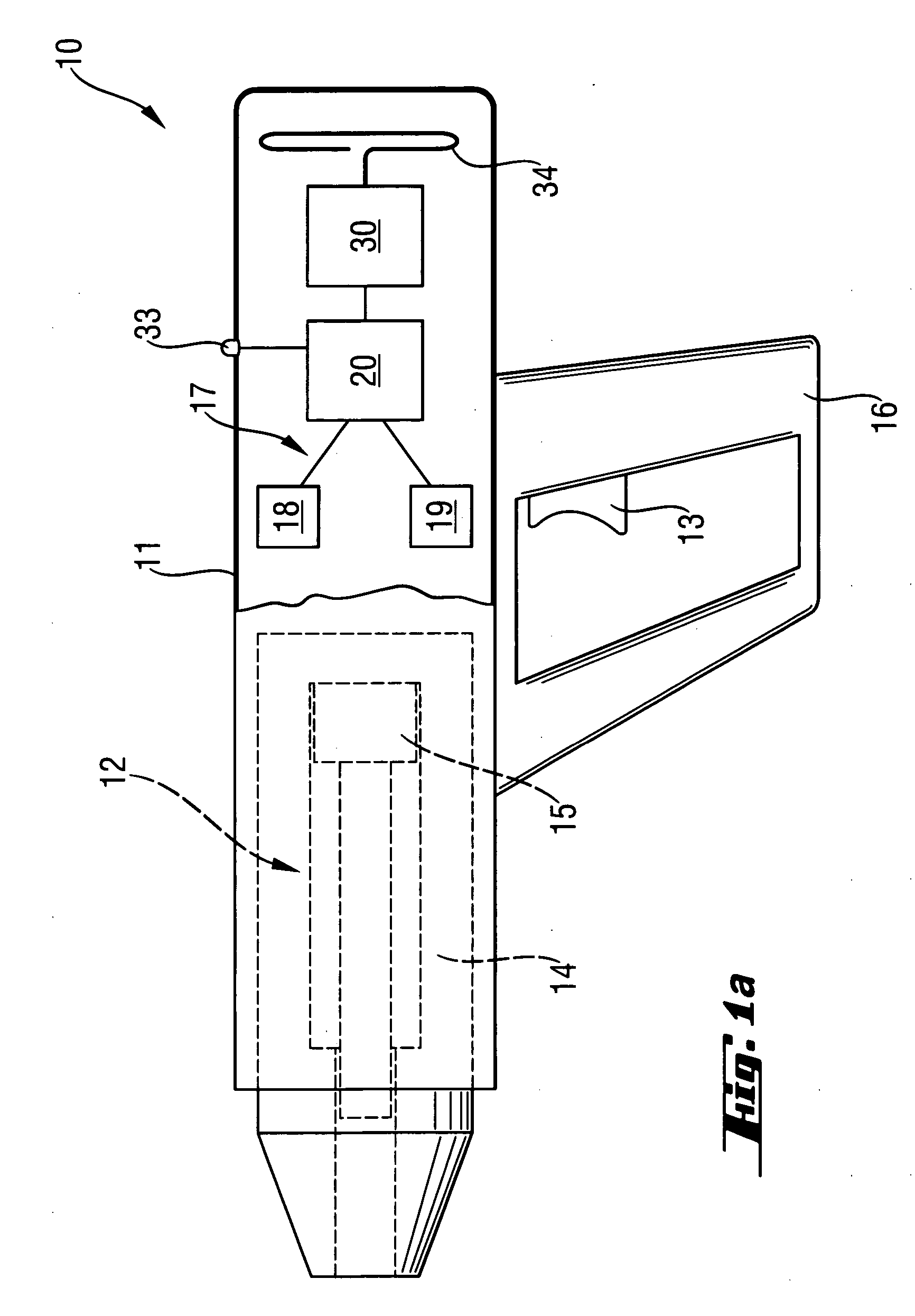

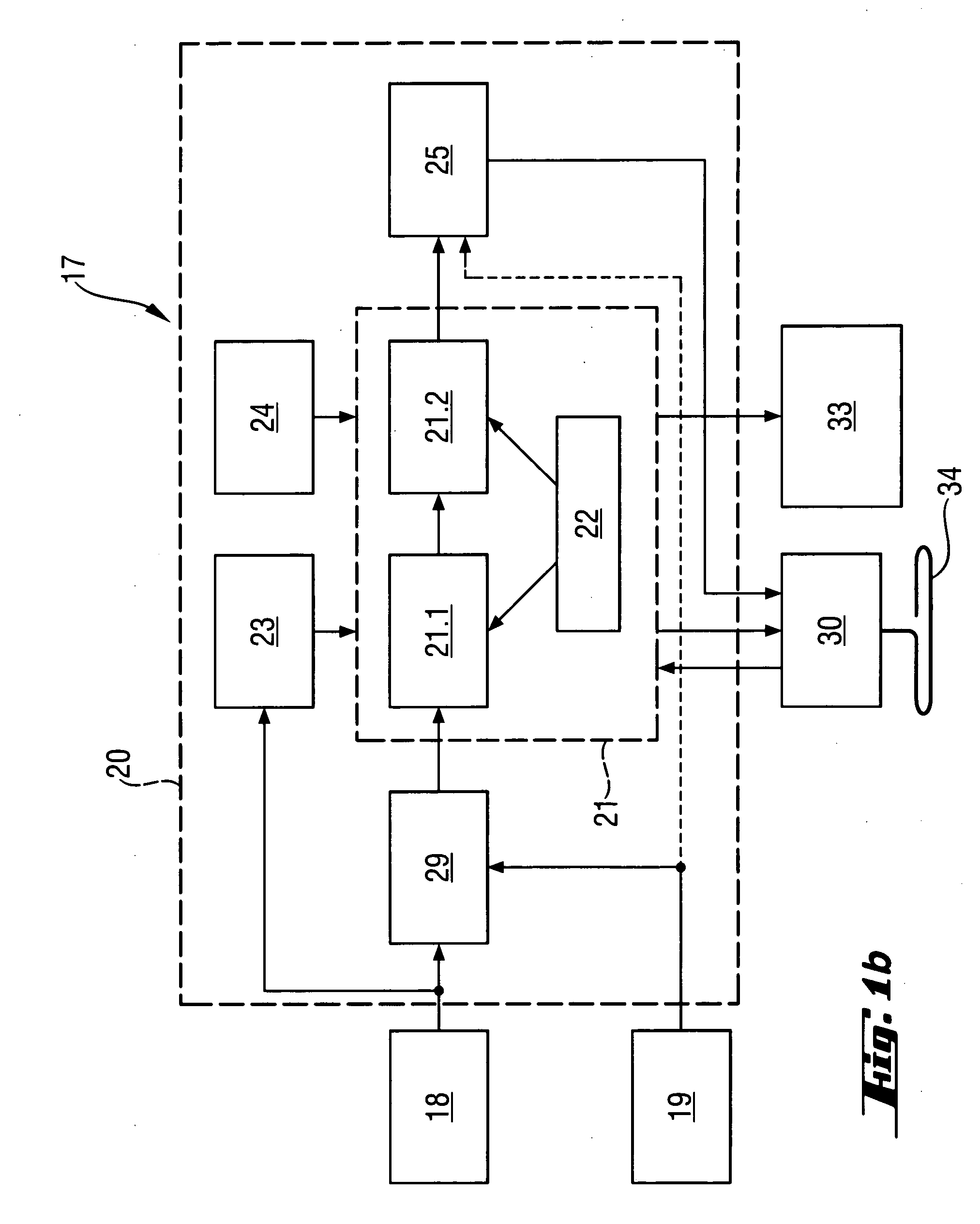

Hand-held working tool

The present invention relates to a hand-held working tool, such as a setting device used for driving fastening elements such as nails, bolts, pins and the like into a surface, or an at least partially percussive hand-held tool having a housing part (11) and a working mechanism such as a setting or striking mechanism arranged inside the housing of the device and having at least one sensing device (17) for sensing acceleration forces occurring during a setting or striking pulse as well as a handle. For improving this type of hand-held working tool (10) an interface (30) for data communication and data output is arranged on the hand-held working tool.

Owner:HILTI AG

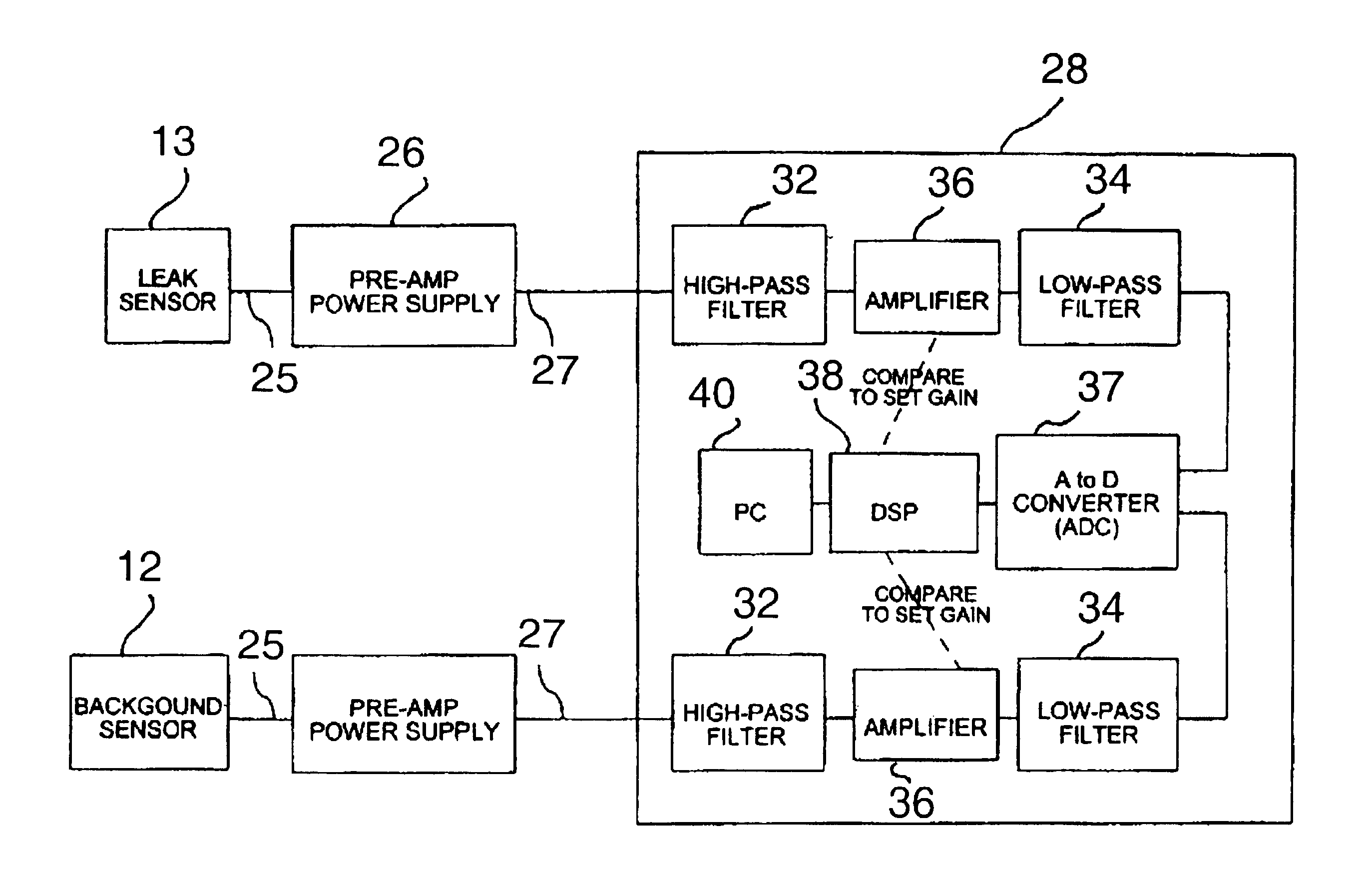

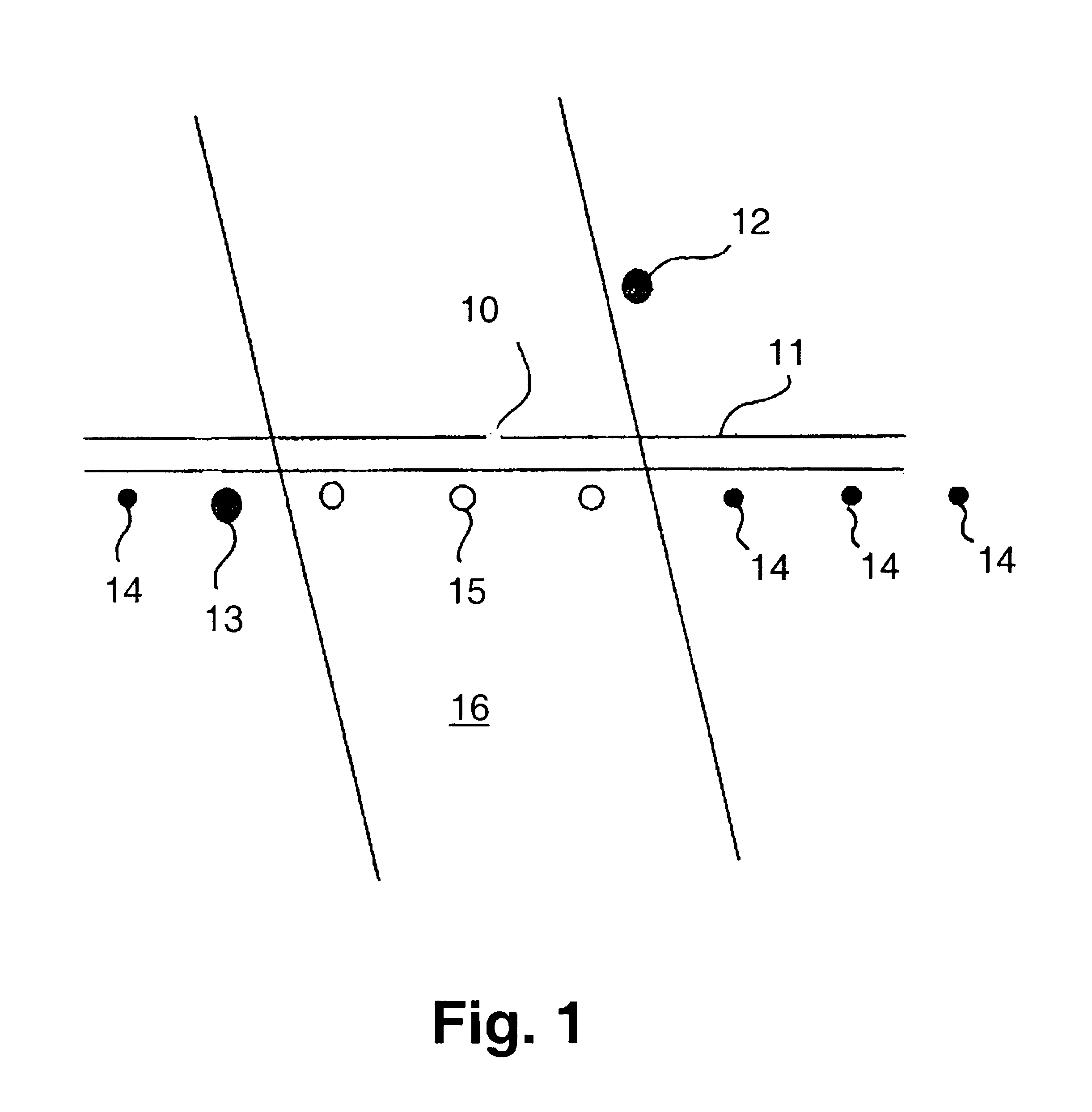

Enhanced acoustic detection of gas leaks in underground gas pipelines

InactiveUS6725705B1Improve efficiencyIncrease the lengthDetection of fluid at leakage pointMaterial analysis using sonic/ultrasonic/infrasonic wavesGas leakEngineering

A method for locating gas leaks from underground gas pipelines in which a first acoustic sensor having a first signal output is positioned in ground disposed substantially above or at a distance from the underground gas pipeline. At least one second acoustic sensor having a second signal output is positioned in the ground at a plurality of locations substantially above the underground gas pipeline. The output signals from the acoustic sensors are measured for each location of the second acoustic sensor and the signals are adaptively filtered to remove common noise signal components. The statistical minima of these rms voltages are determined for both the first output signal and the adaptively filtered second output signals and the differences determined. The location of the second acoustic sensor corresponding to the largest positive said difference is the location closest to the leak site.

Owner:GAS TECH INST

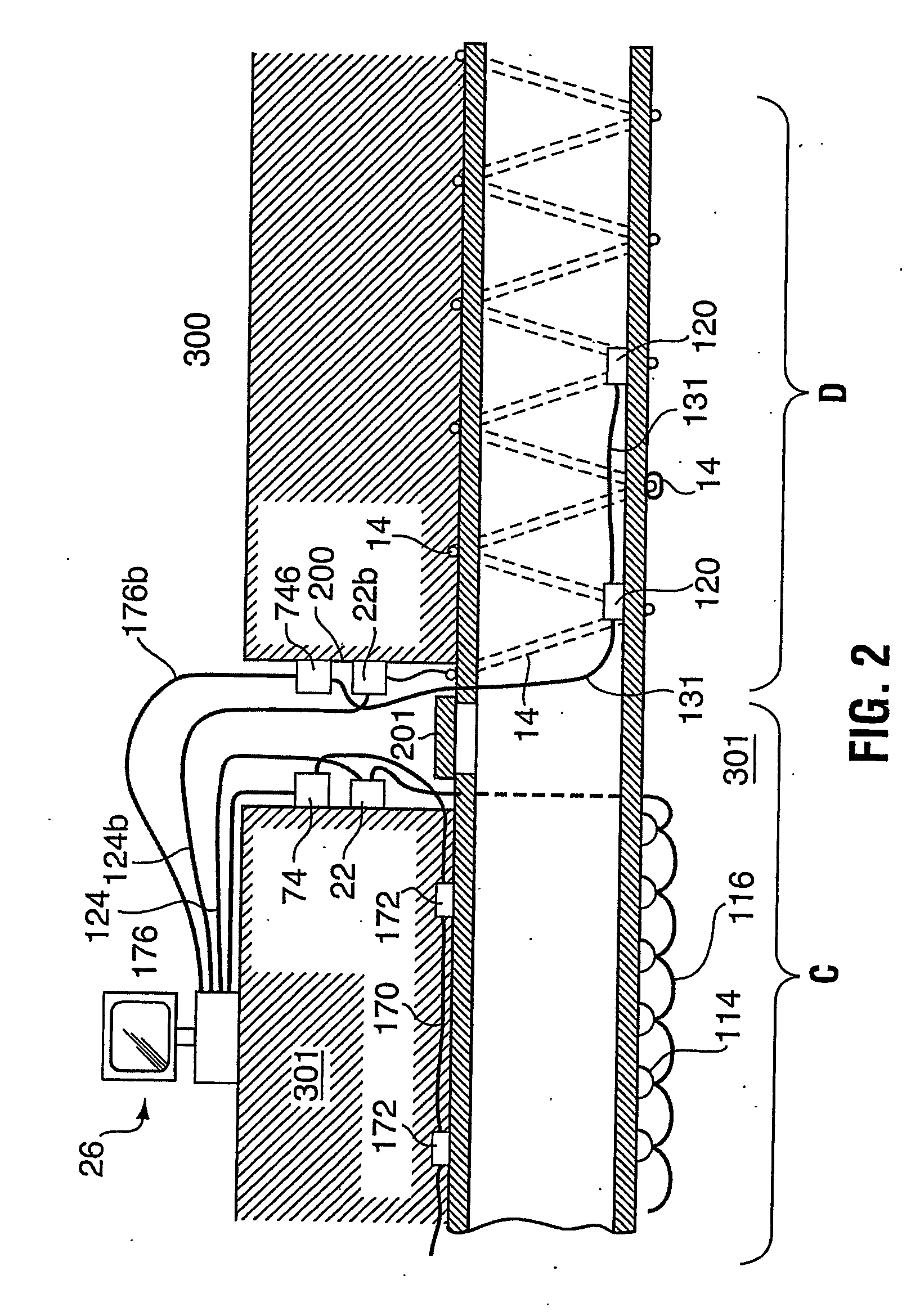

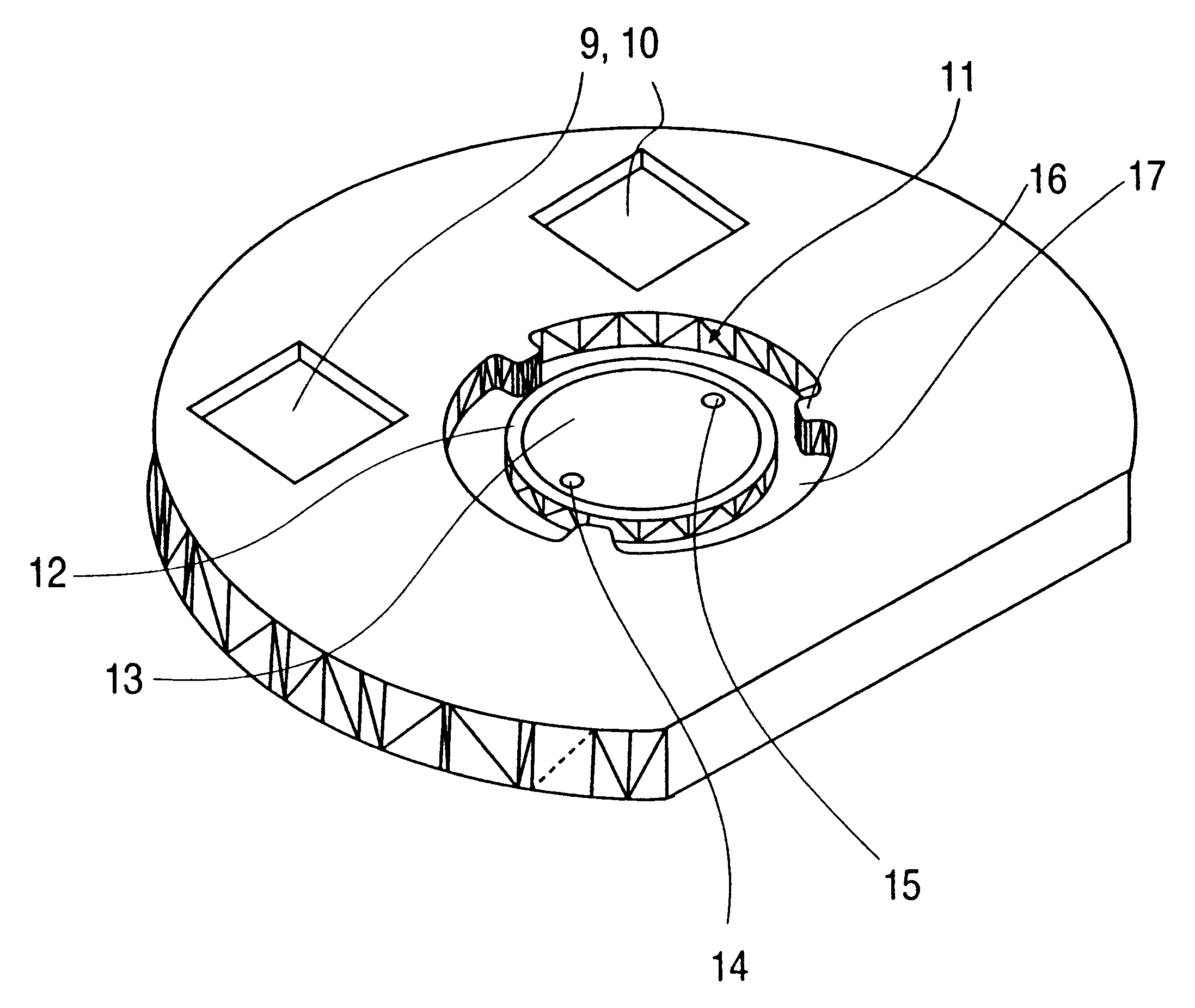

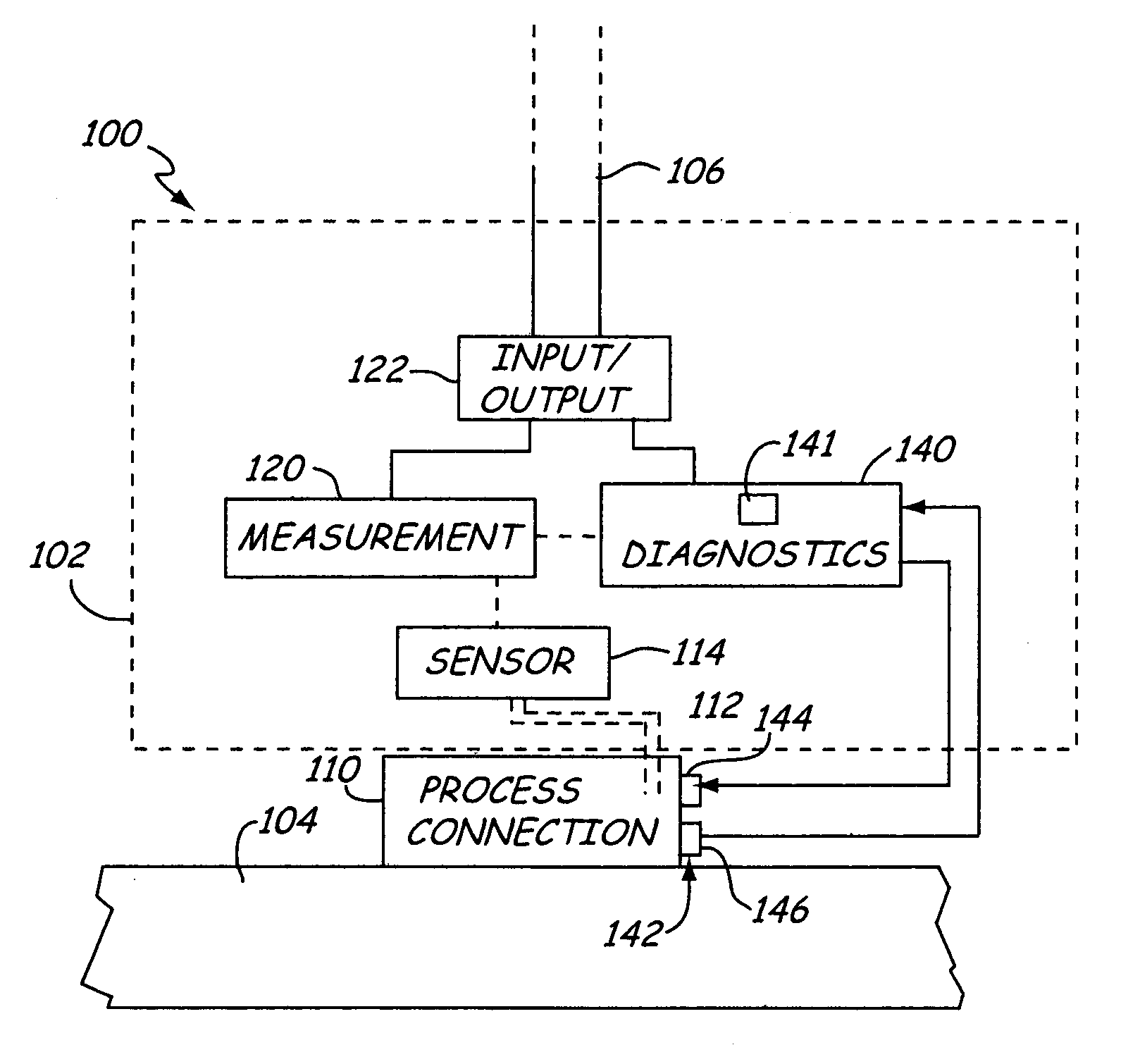

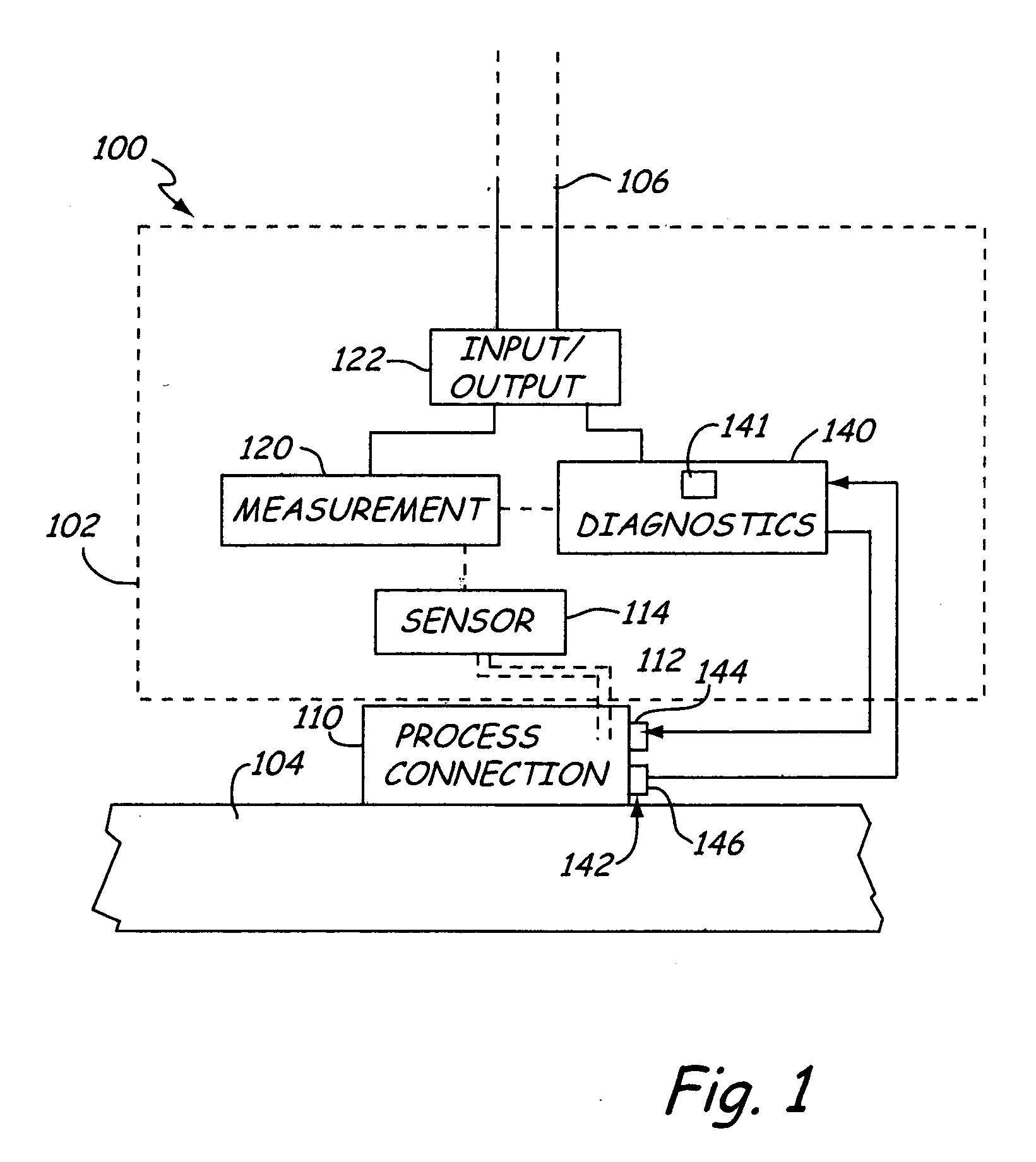

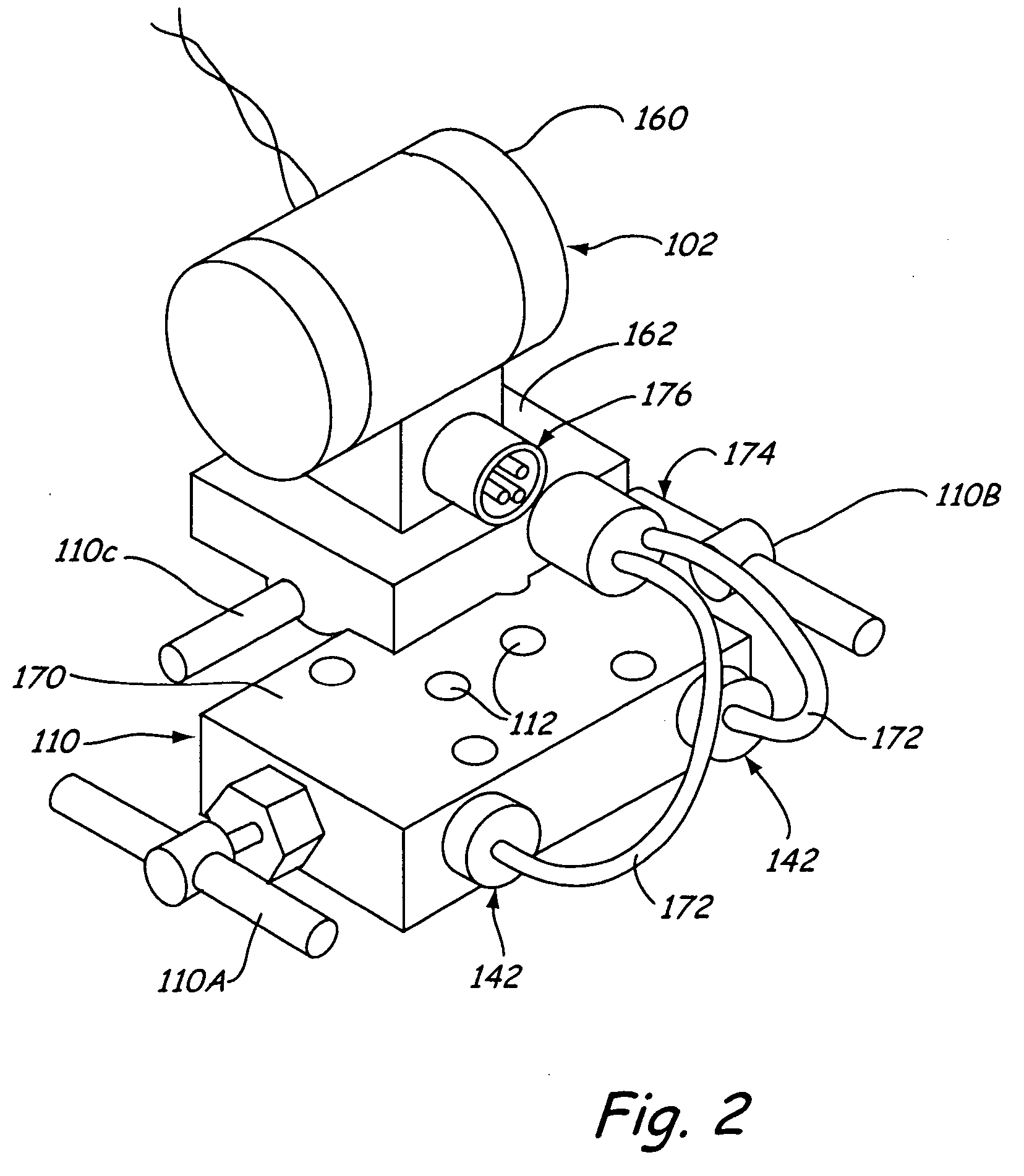

Diagnostics of impulse piping in an industrial process

ActiveUS20050132808A1Analysing solids using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidPipingElectrical and Electronics engineering

Diagnosing operation of an impulse piping line in an industrial process is provided. A vibration source transmits a vibration signal through the piping and a vibration signal receiver receives the vibration signal. The operation of the impulse piping line is diagnosed, such as failure or impending failures, based upon the received vibration signal.

Owner:ROSEMOUNT INC

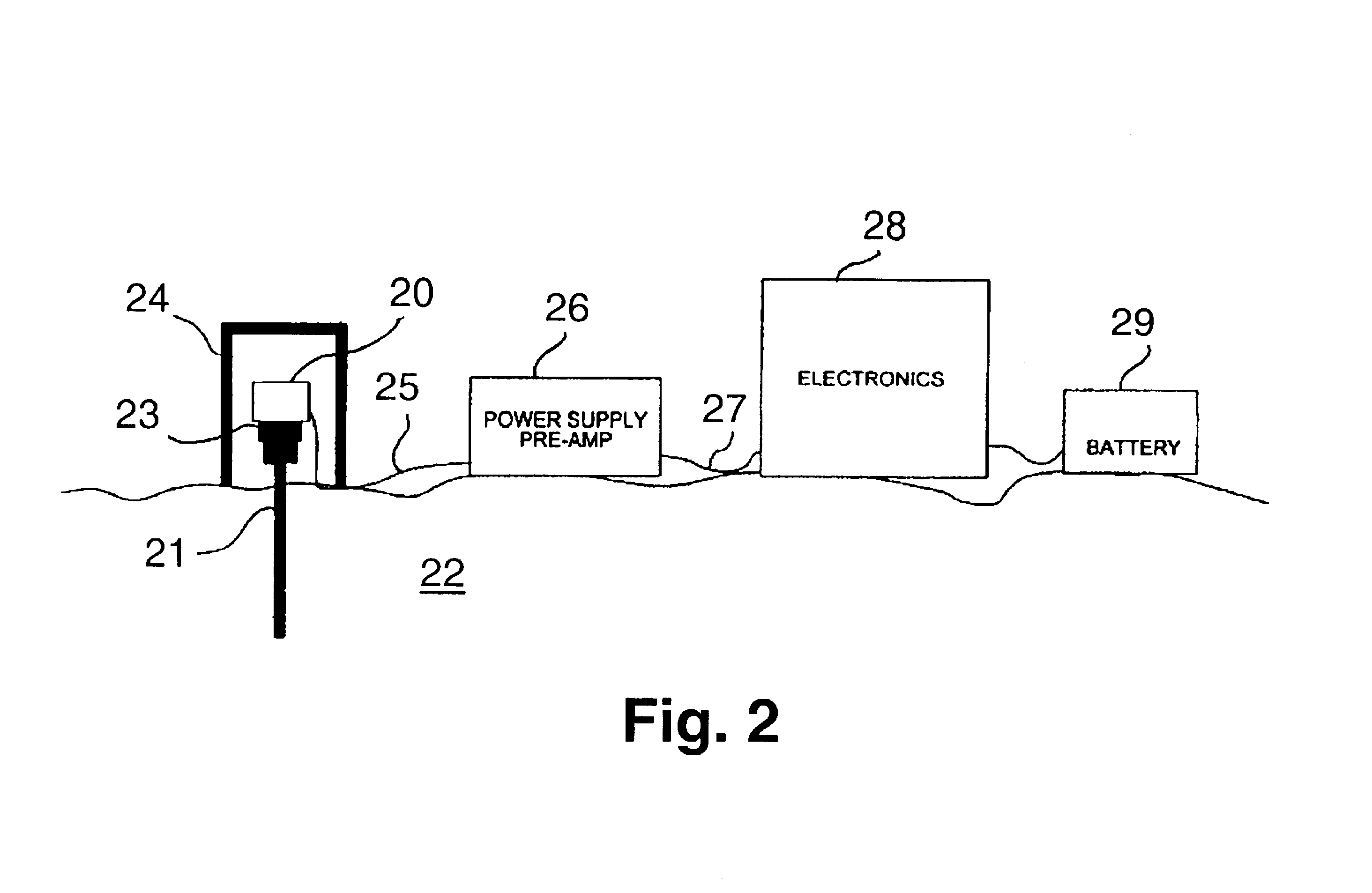

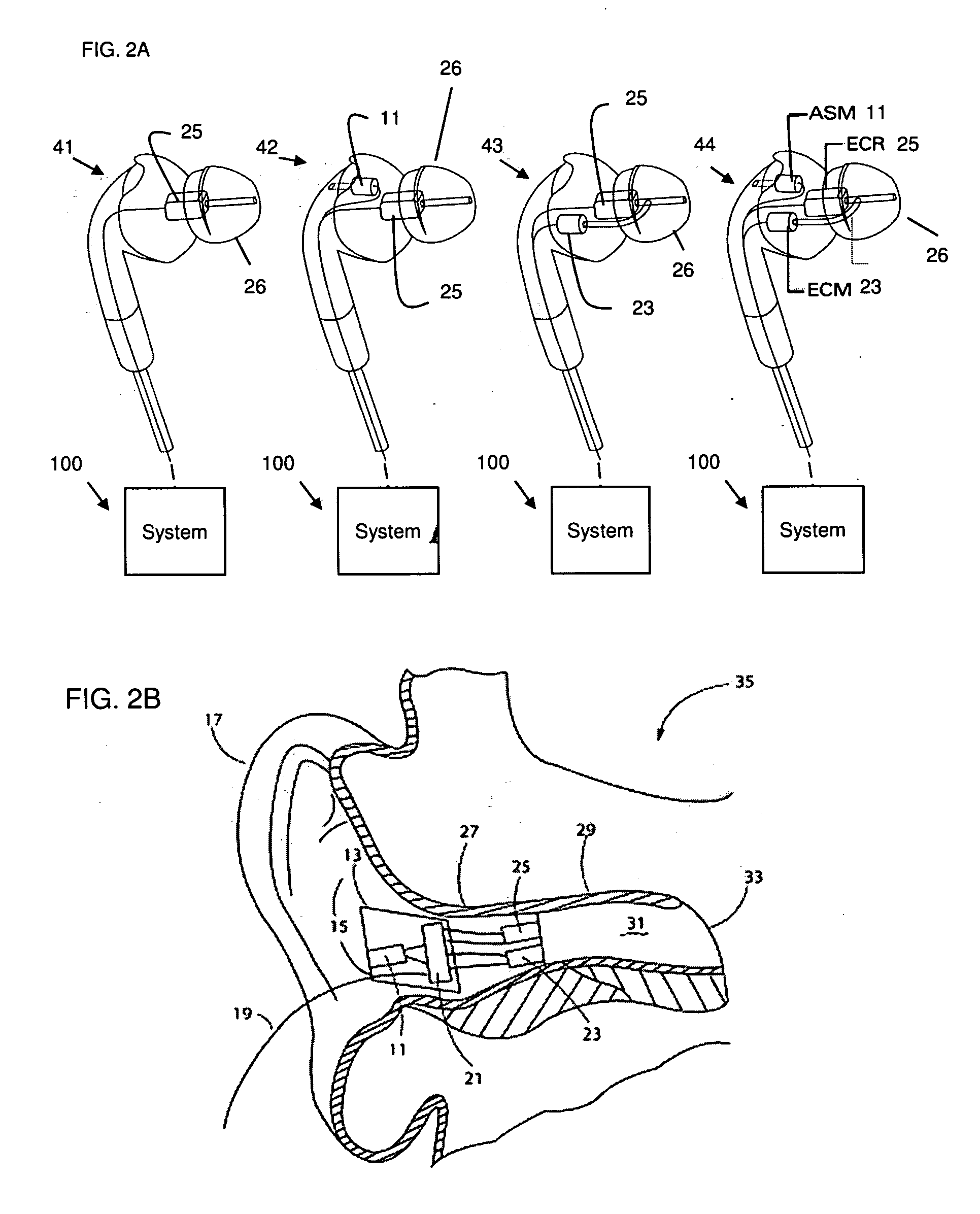

SPL Dose Data Logger System

ActiveUS20100135502A1Reduce hearing damageVibration measurement in fluidDiagnostic recording/measuringWorking environmentEngineering

A method for using an earpiece (800) in a work environment is provided. The earpiece (800) attenuates sound from the work environment to the user's ear. The earpiece (800) includes an ear canal microphone (820) for measuring a sound pressure level in an ear canal of the user. Sound pressure levels are measured periodically while in the work environment. Each measured sound pressure levels is stored in memory (127) of the earpiece with time and location information. The sound pressure level information is downloaded to a database (1704) when the earpiece is removed from the user ear for recharging. The sound pressure level information is analyzed and any potential noise compliance issues in the work environment are identified.

Owner:STATON TECHIYA LLC

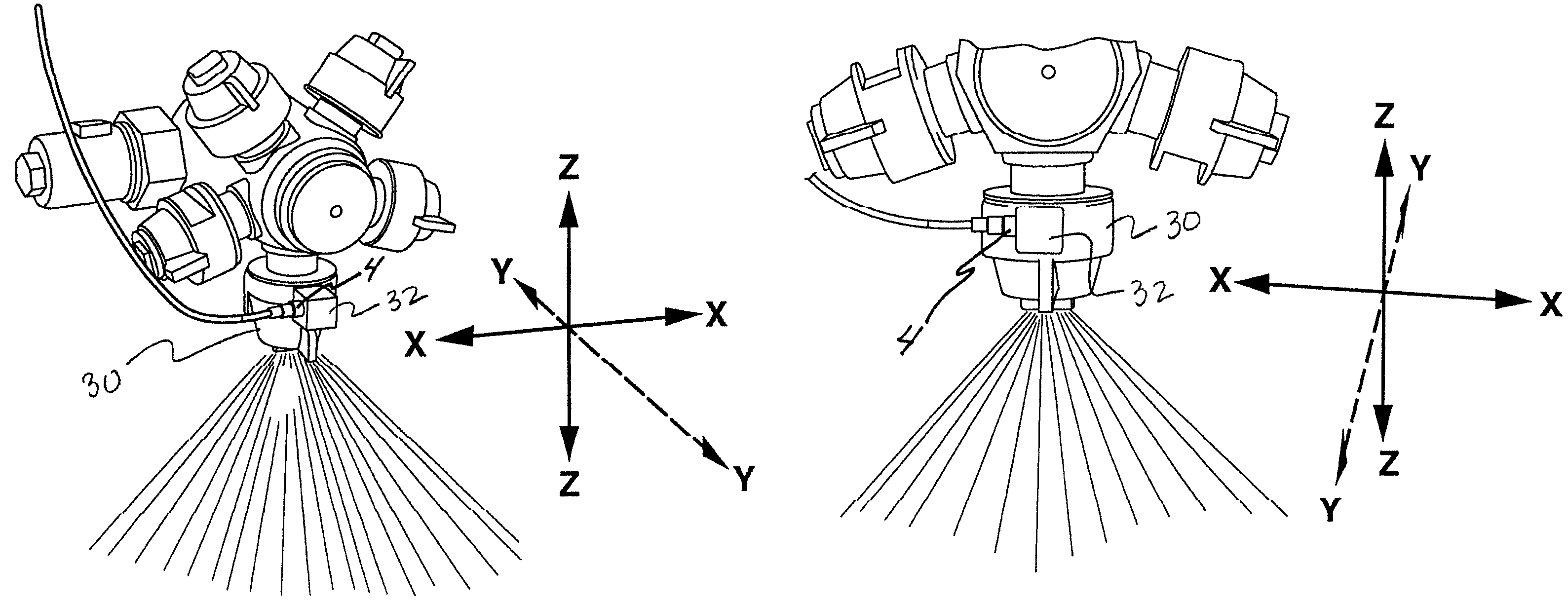

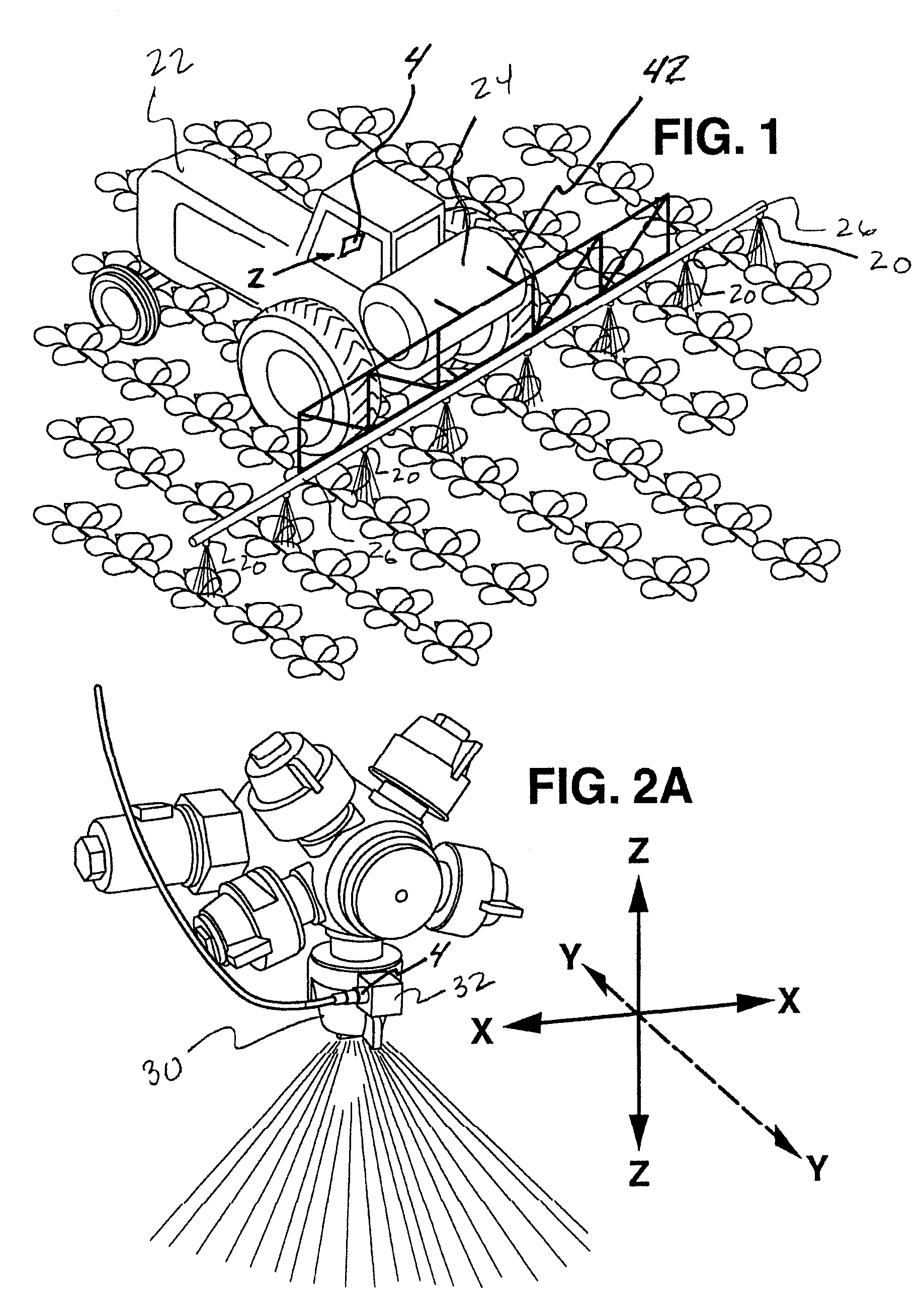

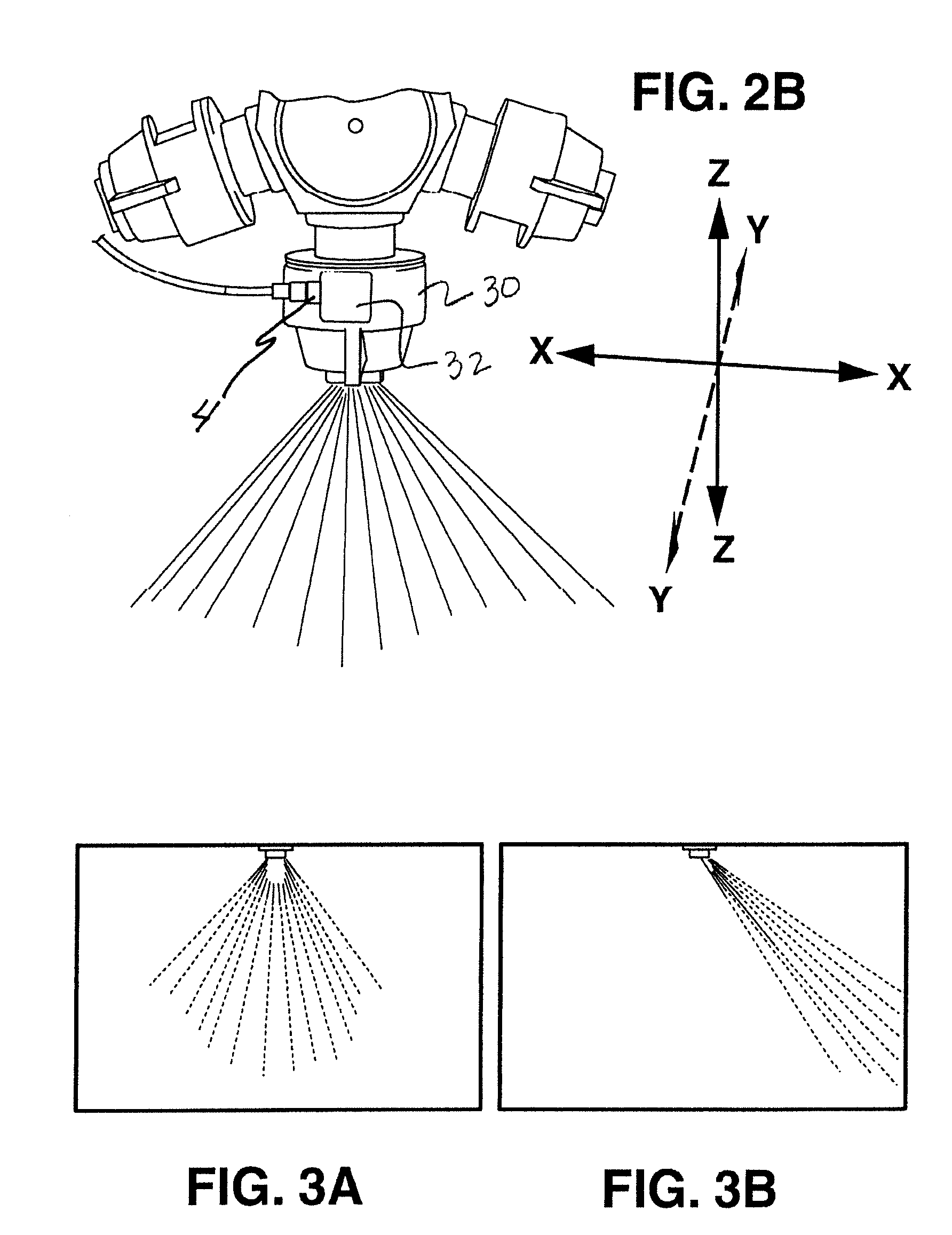

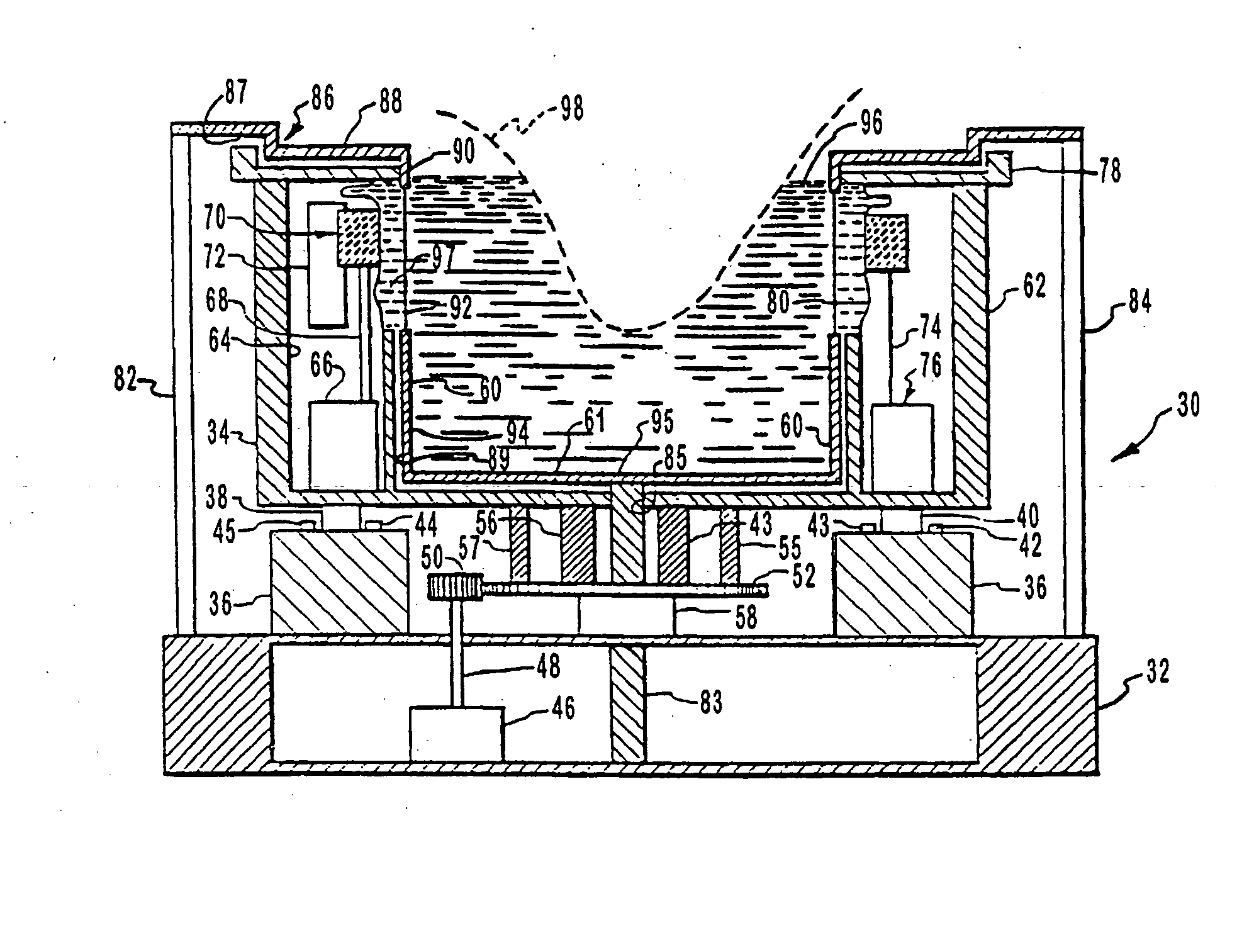

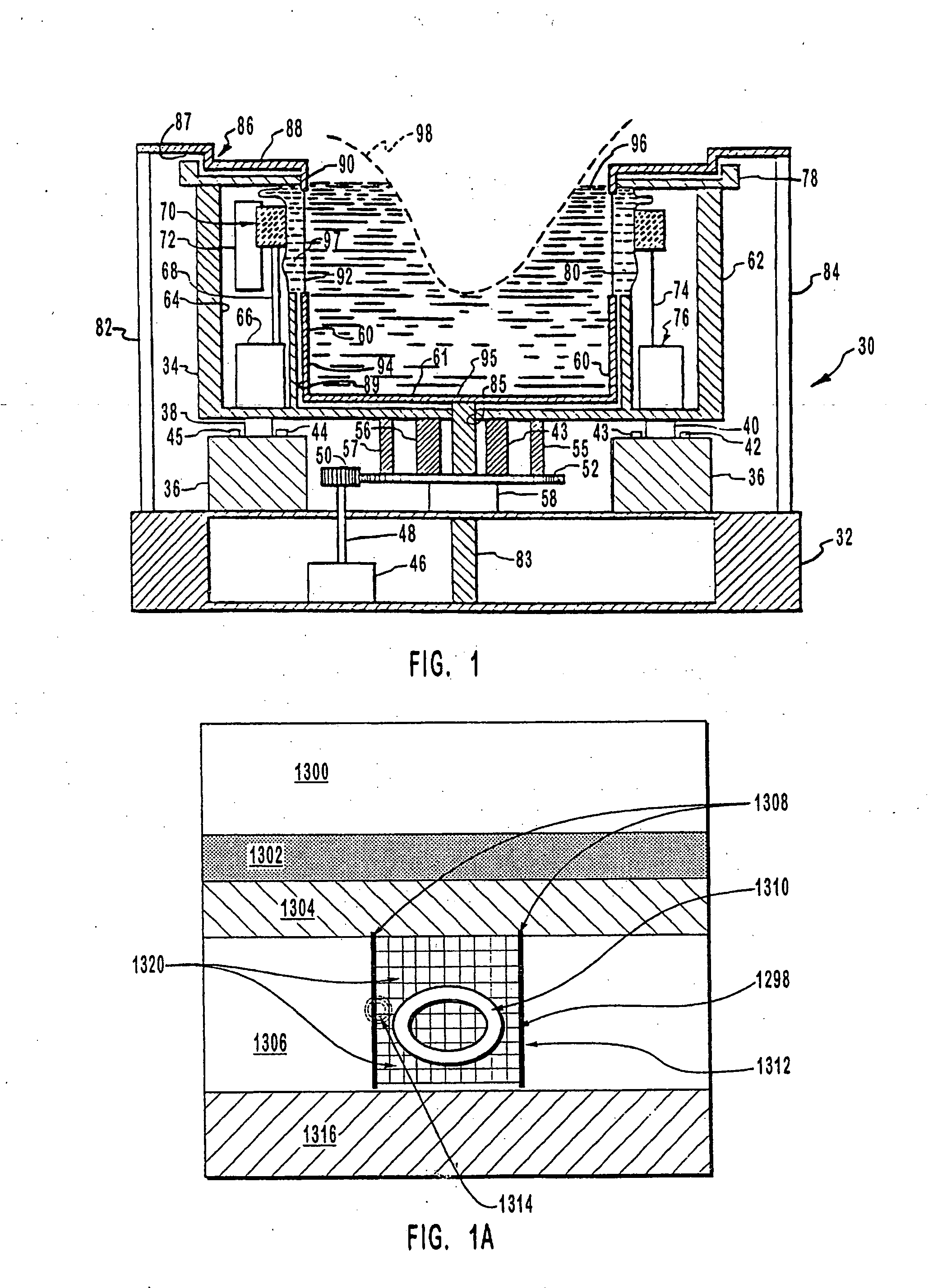

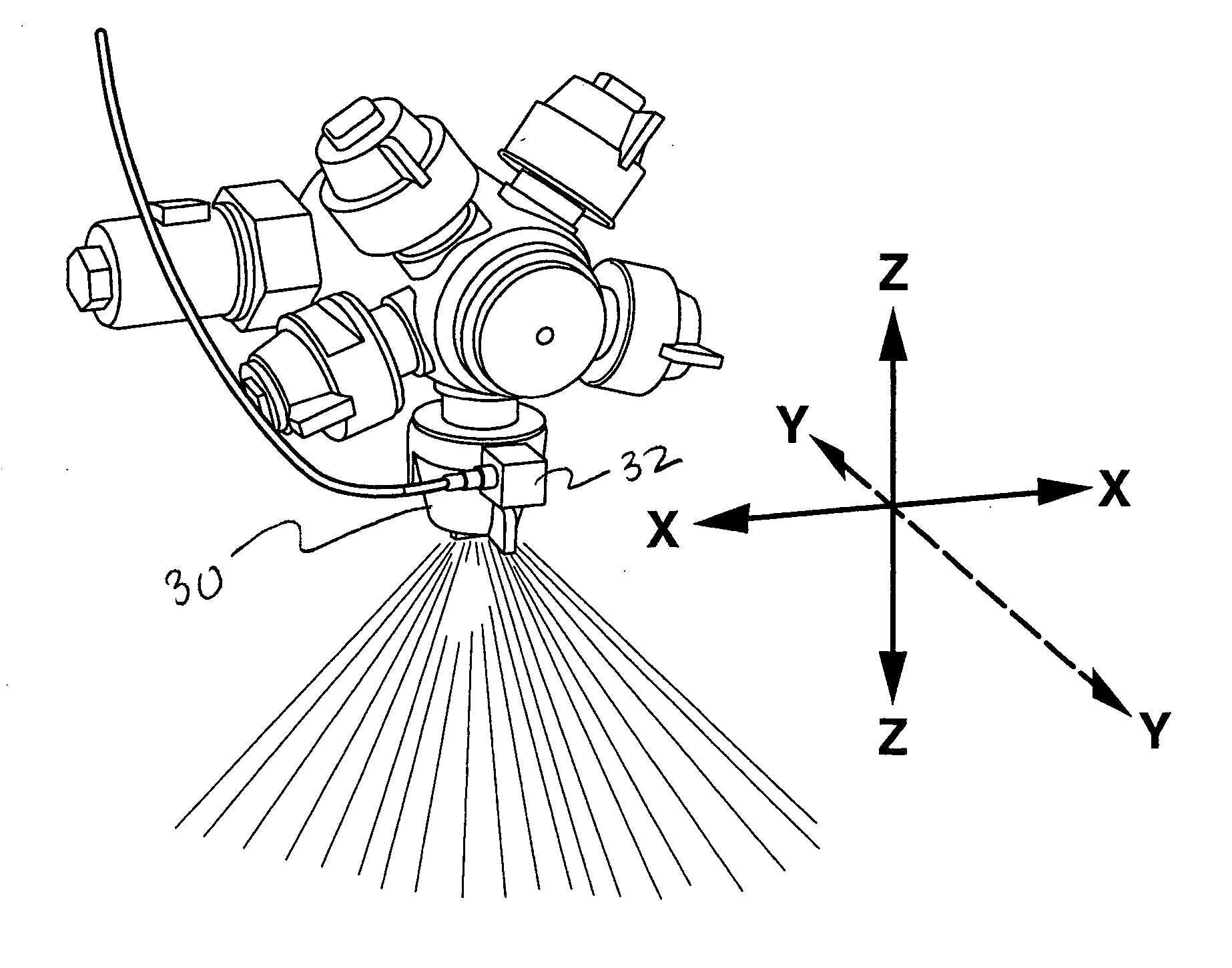

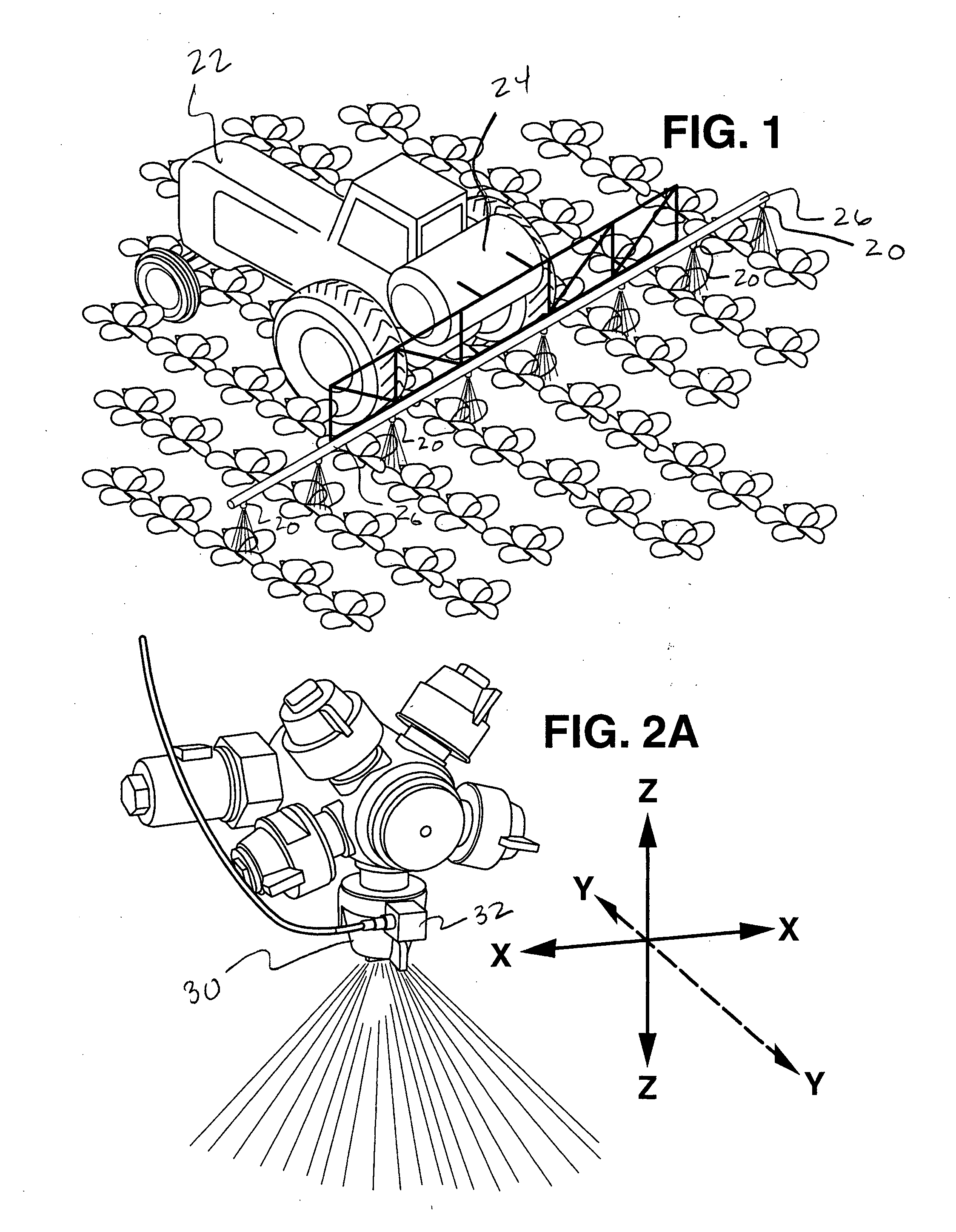

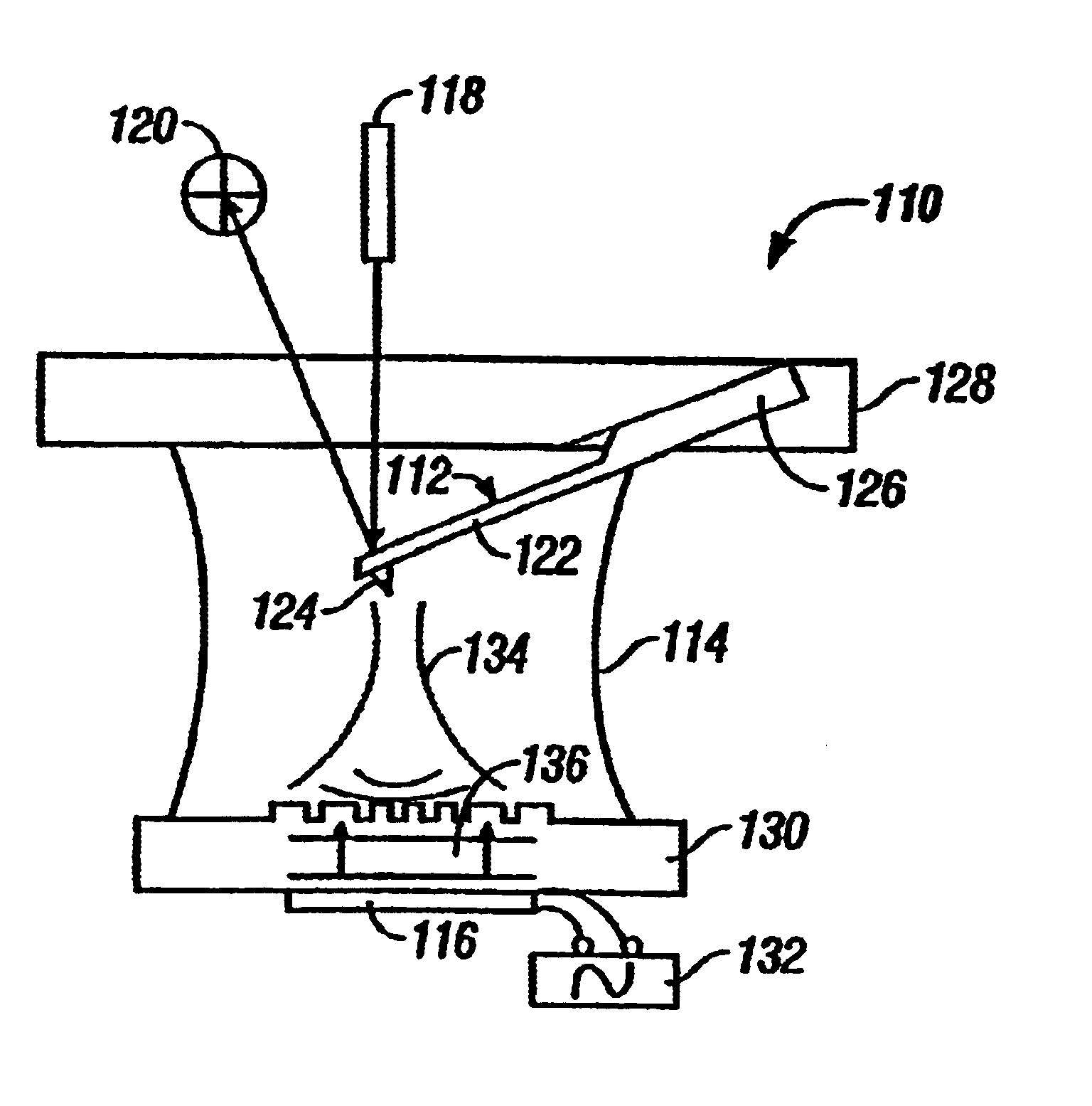

Flow control and operation monitoring system for individual spray nozzles

ActiveUS7311004B2Vibration measurement in solidsVibration measurement in fluidAccelerometerMonitoring system

An apparatus and process for monitoring fluid flow through a nozzle is disclosed. A vibration sensor, such as an accelerometer, is mounted to a nozzle. The vibration output received from the sensor is then analyzed to determine whether or not the nozzle is operating properly. Through the present invention, information can be obtained regarding variations in flow rate, and / or variations in spray pattern and droplet size spectra. If the nozzle flow pulsates, the vibration sensor may also provide information regarding whether the nozzle is pulsating according to a desired frequency duty cycle or waveform.

Owner:CAPSTAN

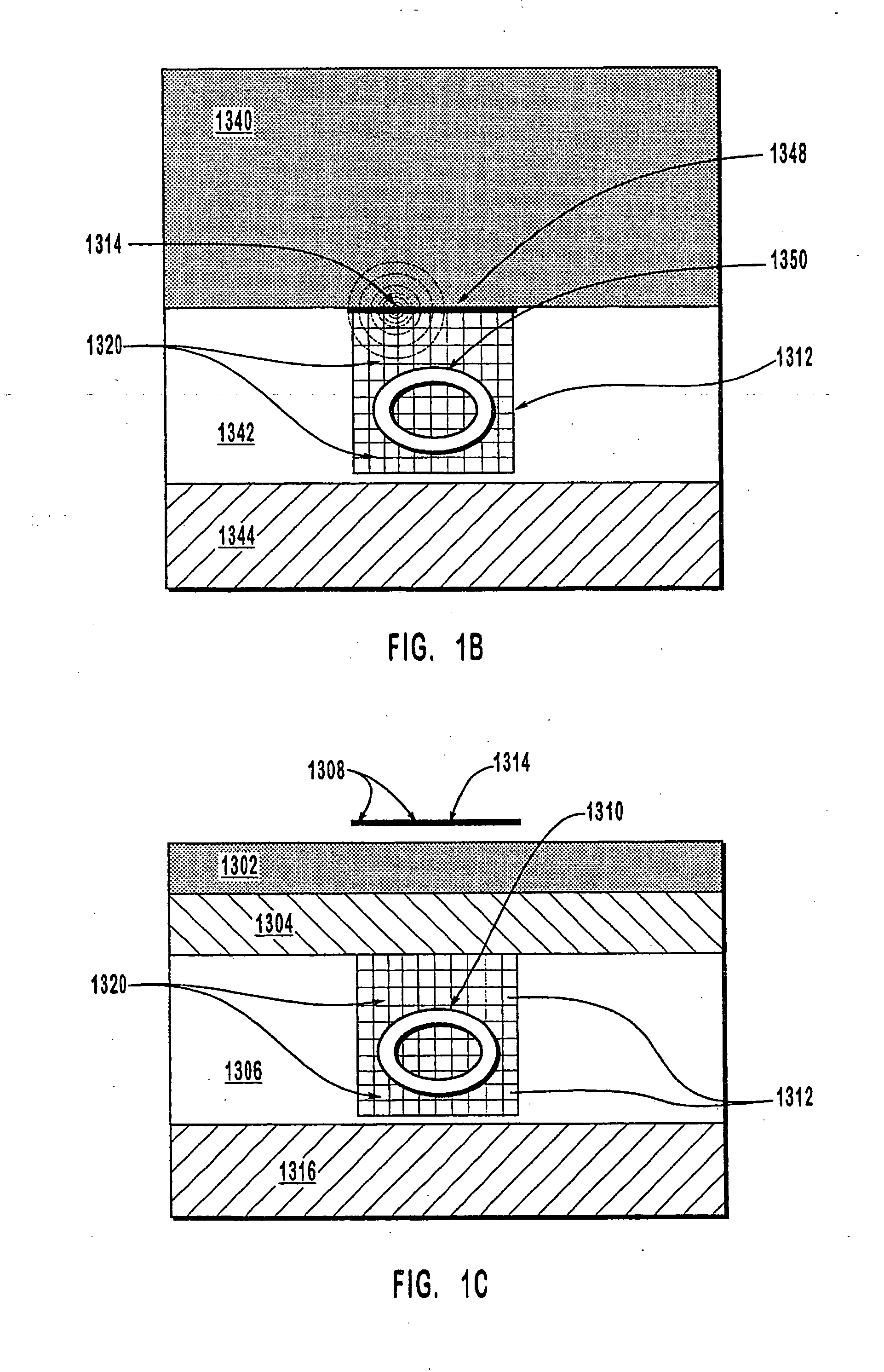

Apparatus and method for imaging objects with wavefields

InactiveUS20070282200A1Vibration measurement in fluidMaterial analysis using microwave meansData setWave field

A transmission wave field imaging method, comprising the transmission of an incident wave field into an object, the incident wave field propagating into the object and, at least, partially scattering. Also includes the measuring of a wave field transmitted, at least in part, through an object to obtain a measured wave field, the measured wave field based, in part, on the incident wave field and the object. Additionally, the processing of the measured wave field utilizing a recursive reconstruction algorithm to generate an image data set representing at least one image of the object.

Owner:QT ULTRASOUND +1

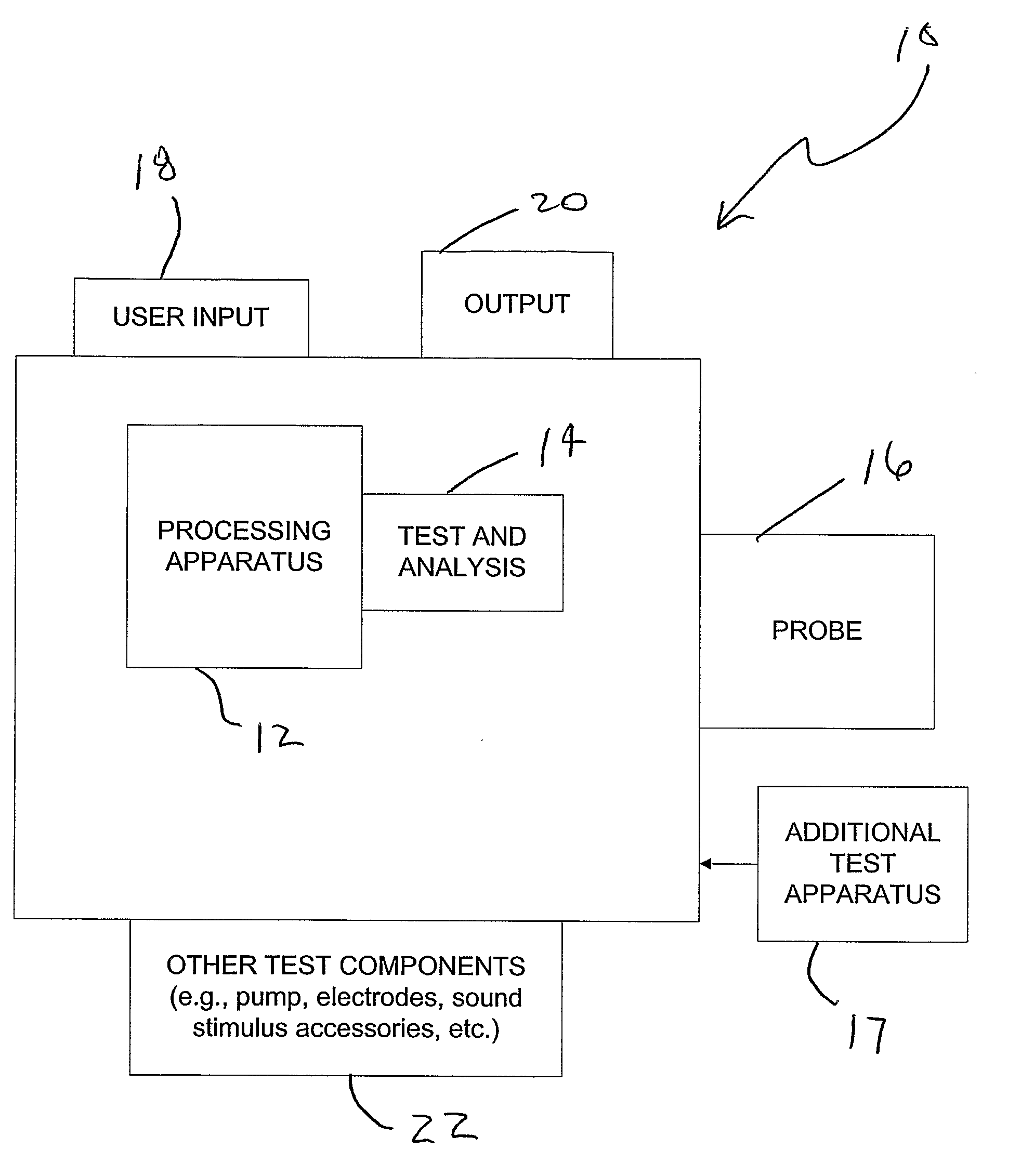

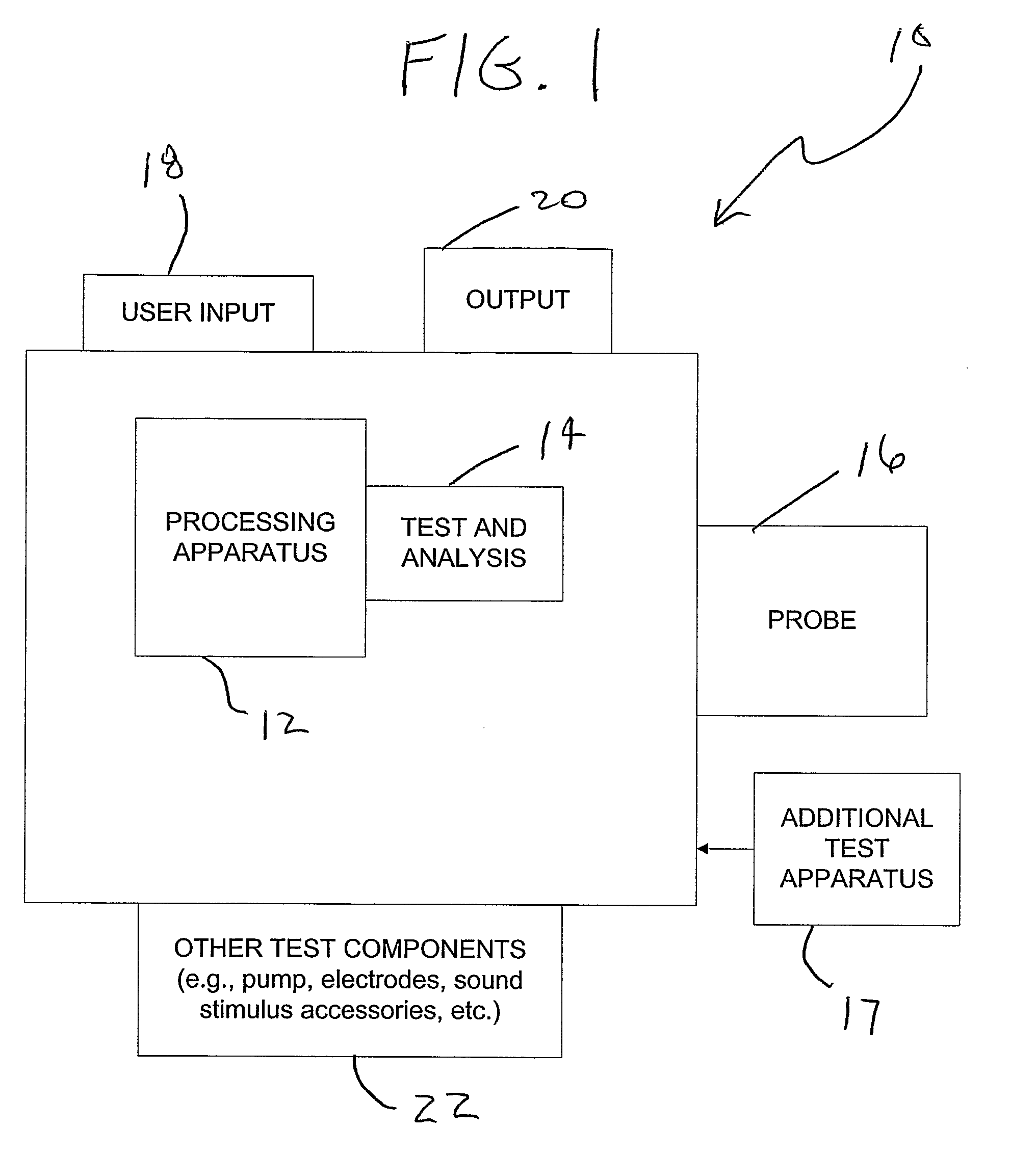

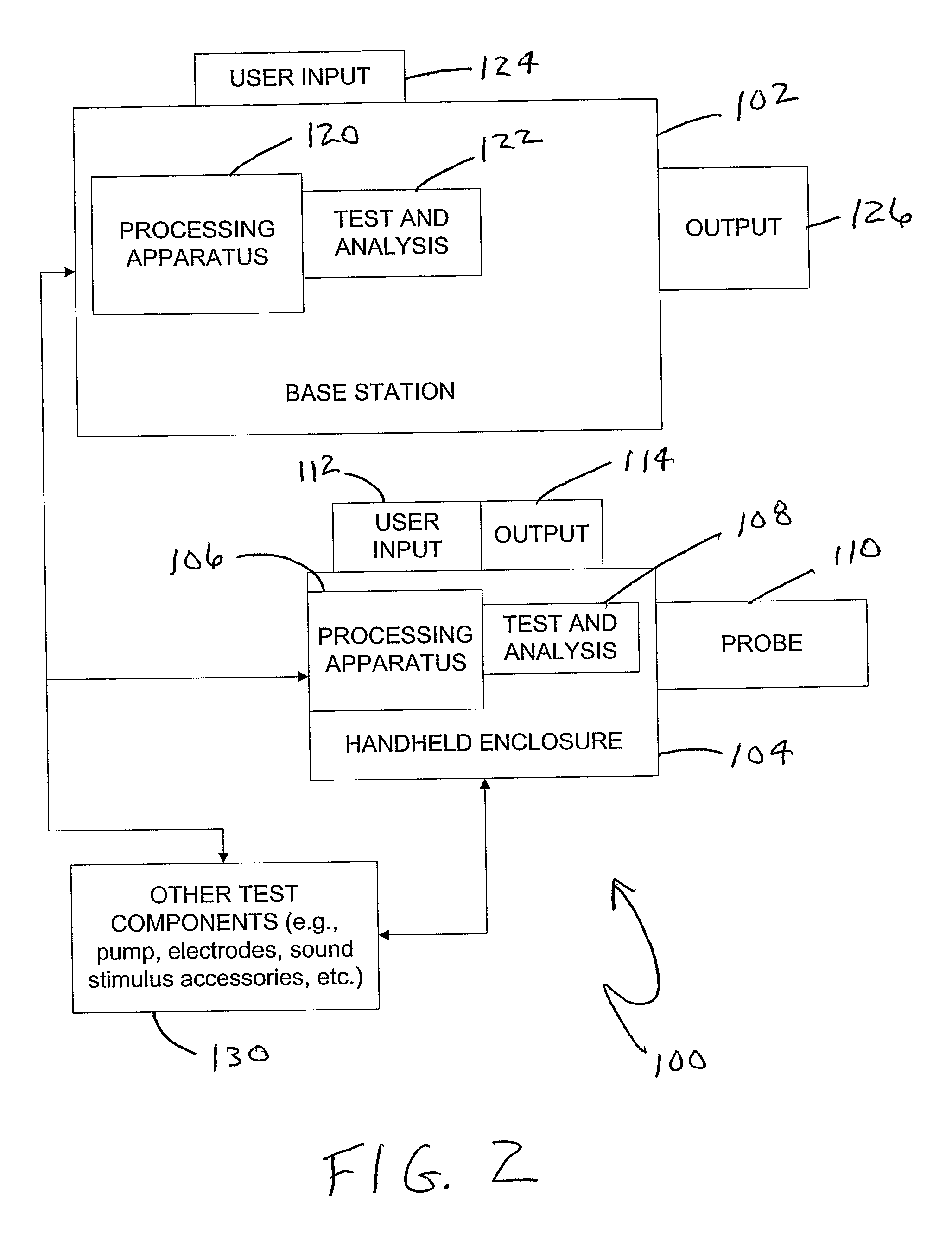

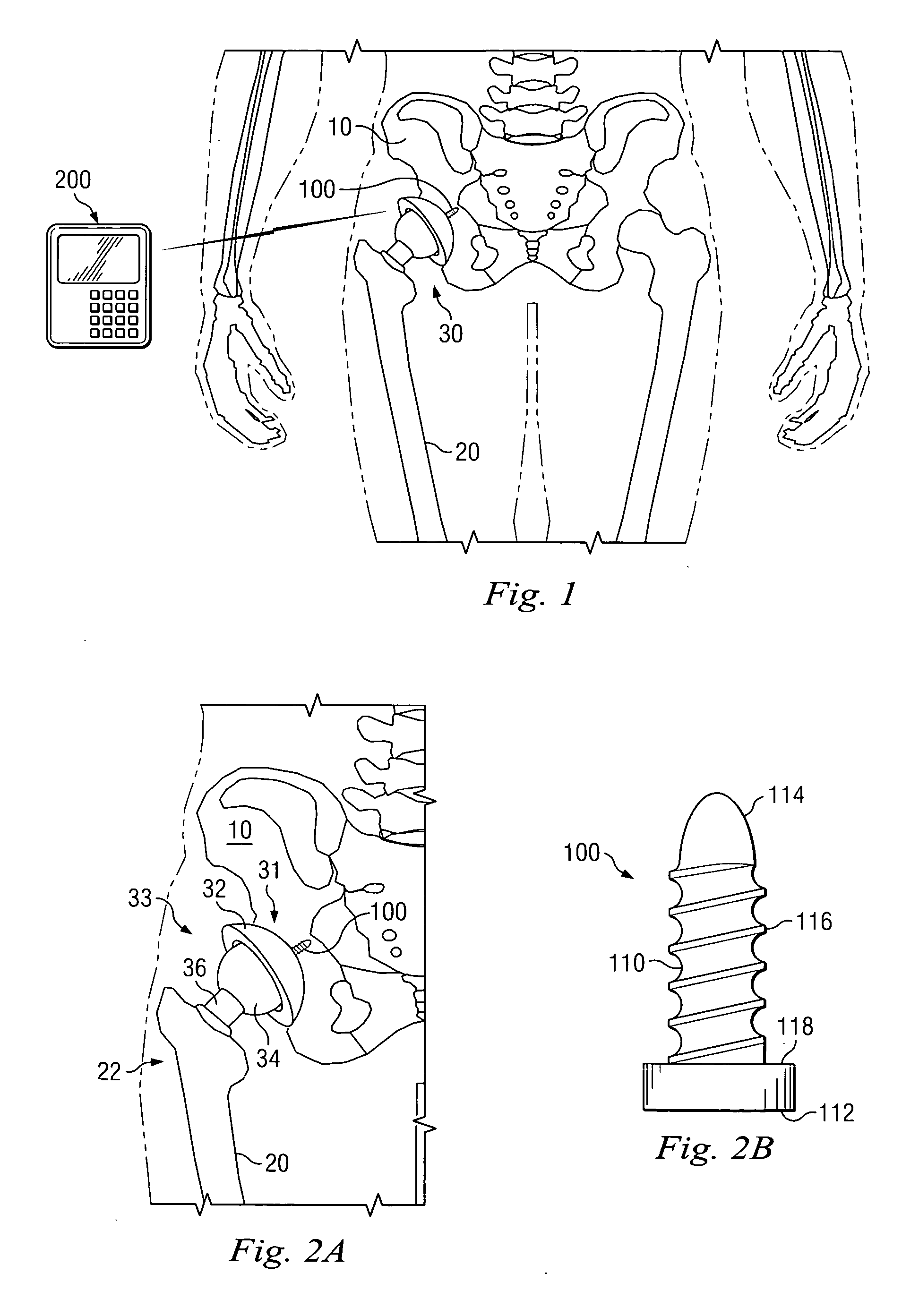

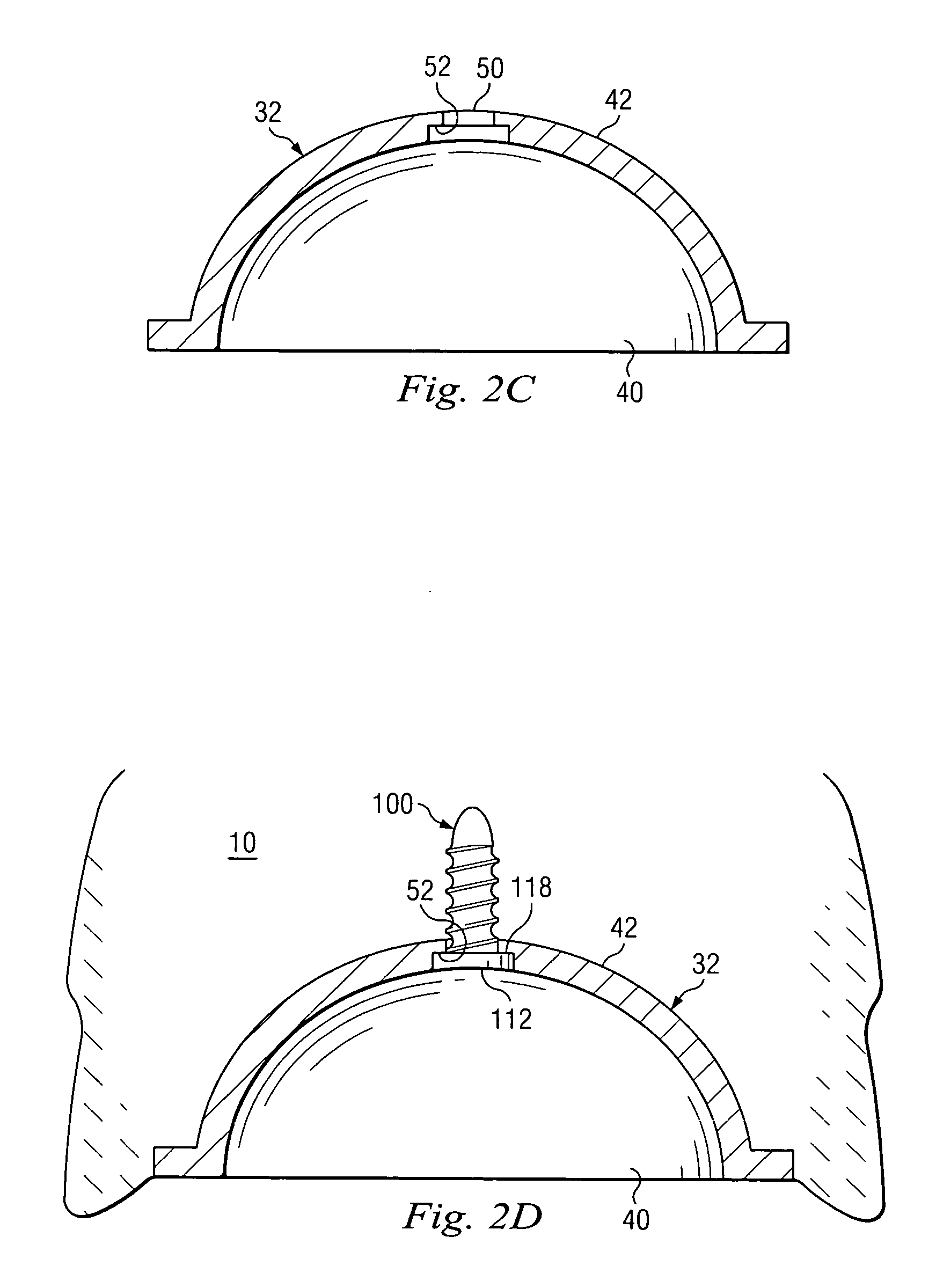

Test Battery System and Method for Assessment of Auditory Function

ActiveUS20080194984A1Improve accuracyImprove reliabilityVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesReflexTest battery

A test battery method and system (10, 100, 200, 225) for use in assessing auditory function (e.g., the screening or diagnosis of impairments, fitting of hearing aids, etc.) is provided which performs one or more auditory tests including, for example, an acoustic reflectance test. Such an acoustic reflectance test may be a reflectance tympanometry test that includes a feedback system to control static pressure in the ear canal. Such acoustic reflectance tests may be used alone or in combination with one or more other auditory tests. Further, for example, such a battery of tests may include middle-ear muscle reflex tests in combination with one or more other auditory or hearing tests.

Owner:SONICOM

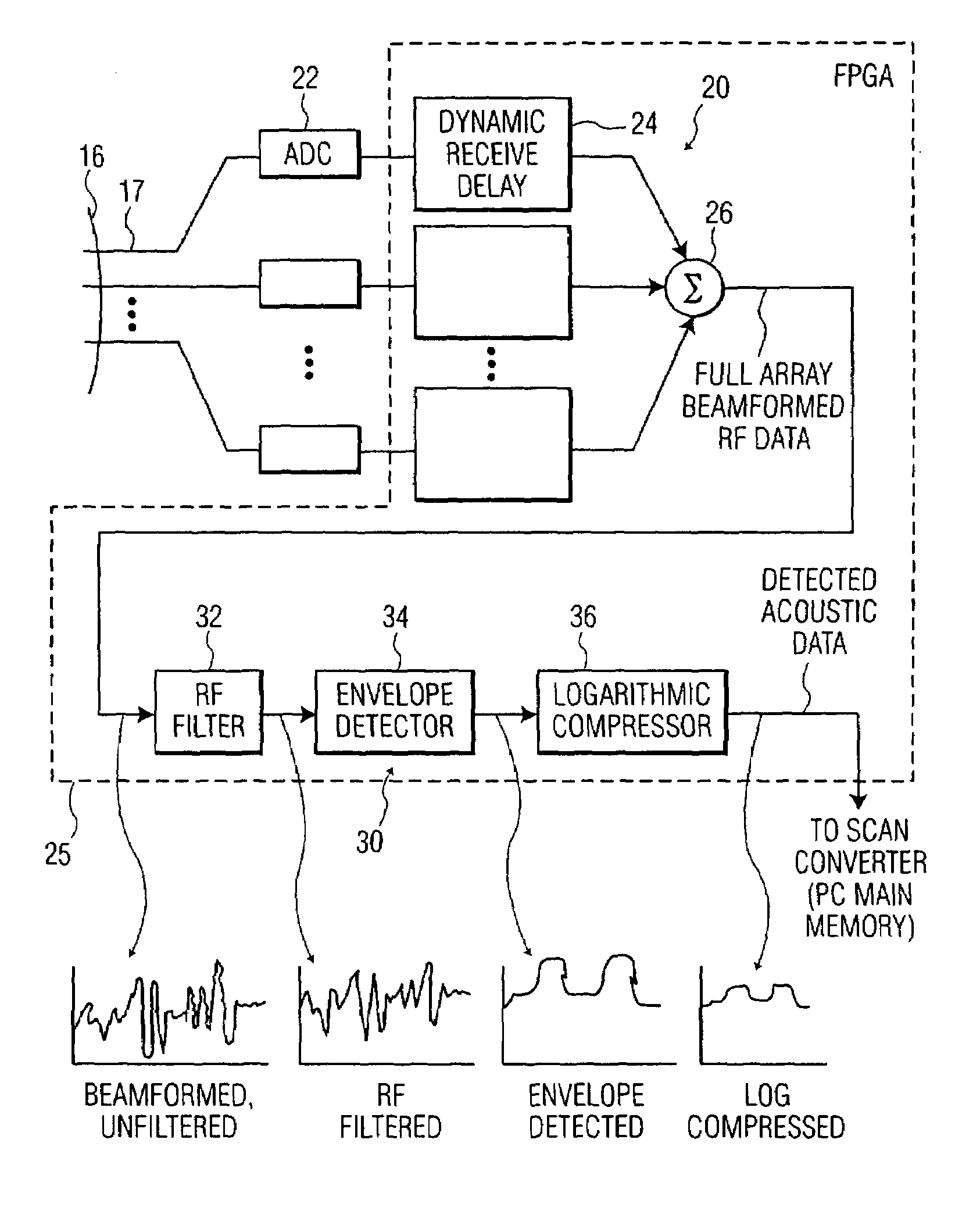

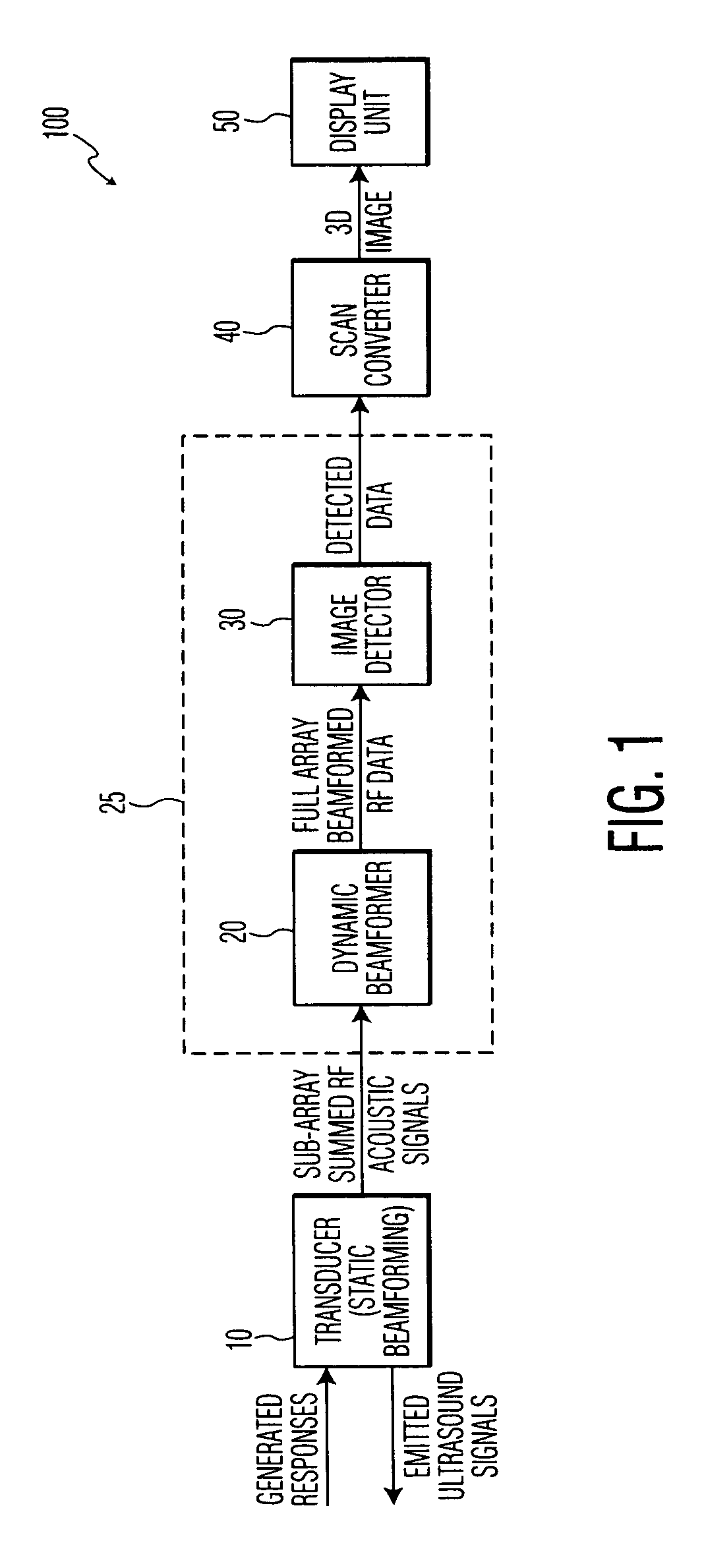

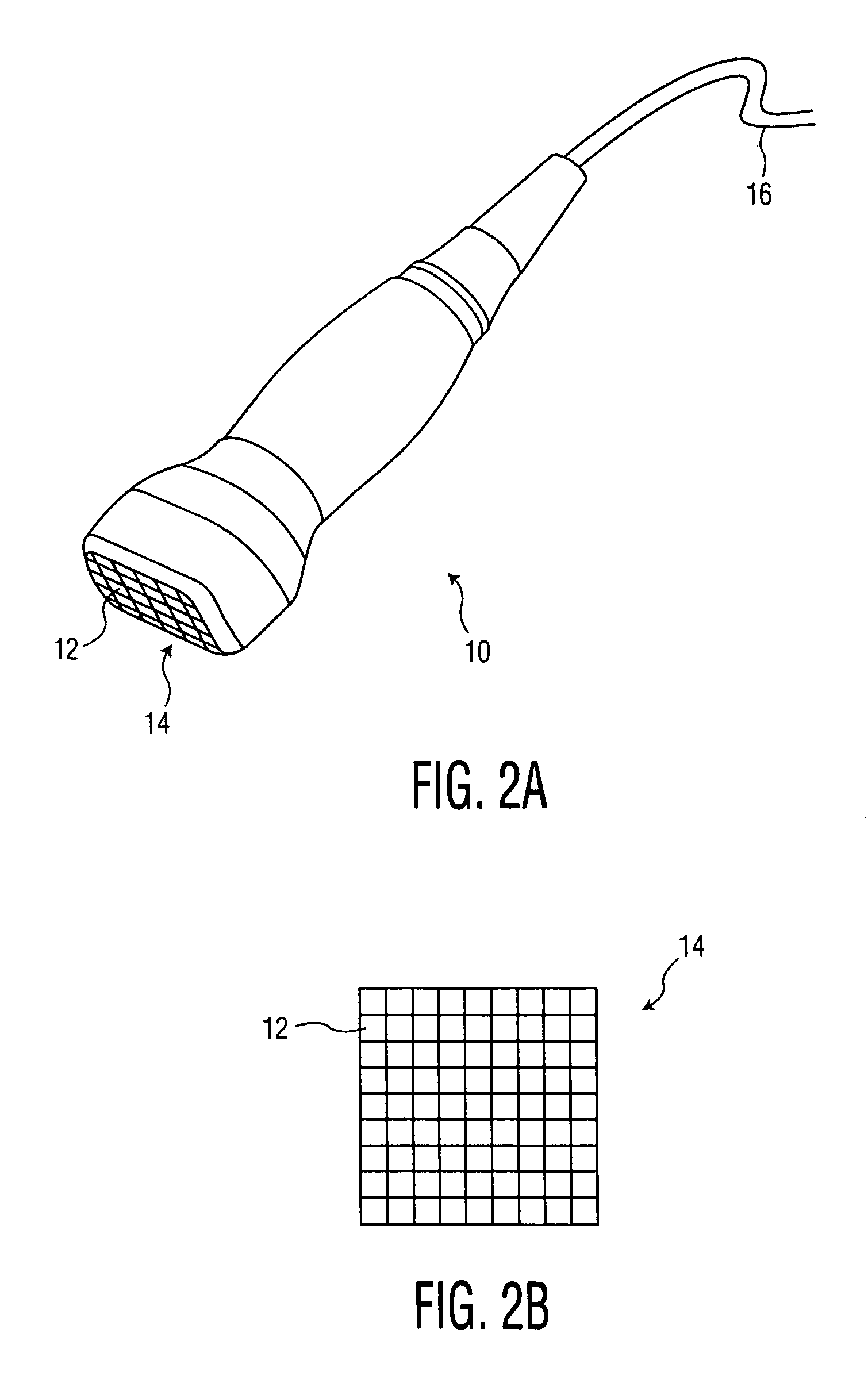

Portable 3D ultrasound system

InactiveUS7141020B2Vibration measurement in solidsVibration measurement in fluidSonificationTransducer

A portable 3D ultrasound device having an ultrasound transducer. The ultrasound transducer includes a transducer array with a plurality of transducer elements arranged in a plurality of dimensions, the transducer array including an emitter to emit ultrasound energy, a receiver to receive responses generated in accordance with the ultrasound energy, a plurality of sub-array beamformers, a signal processor to convert the generated responses into a 3D ultrasound image and a display unit to display the 3D ultrasound image.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

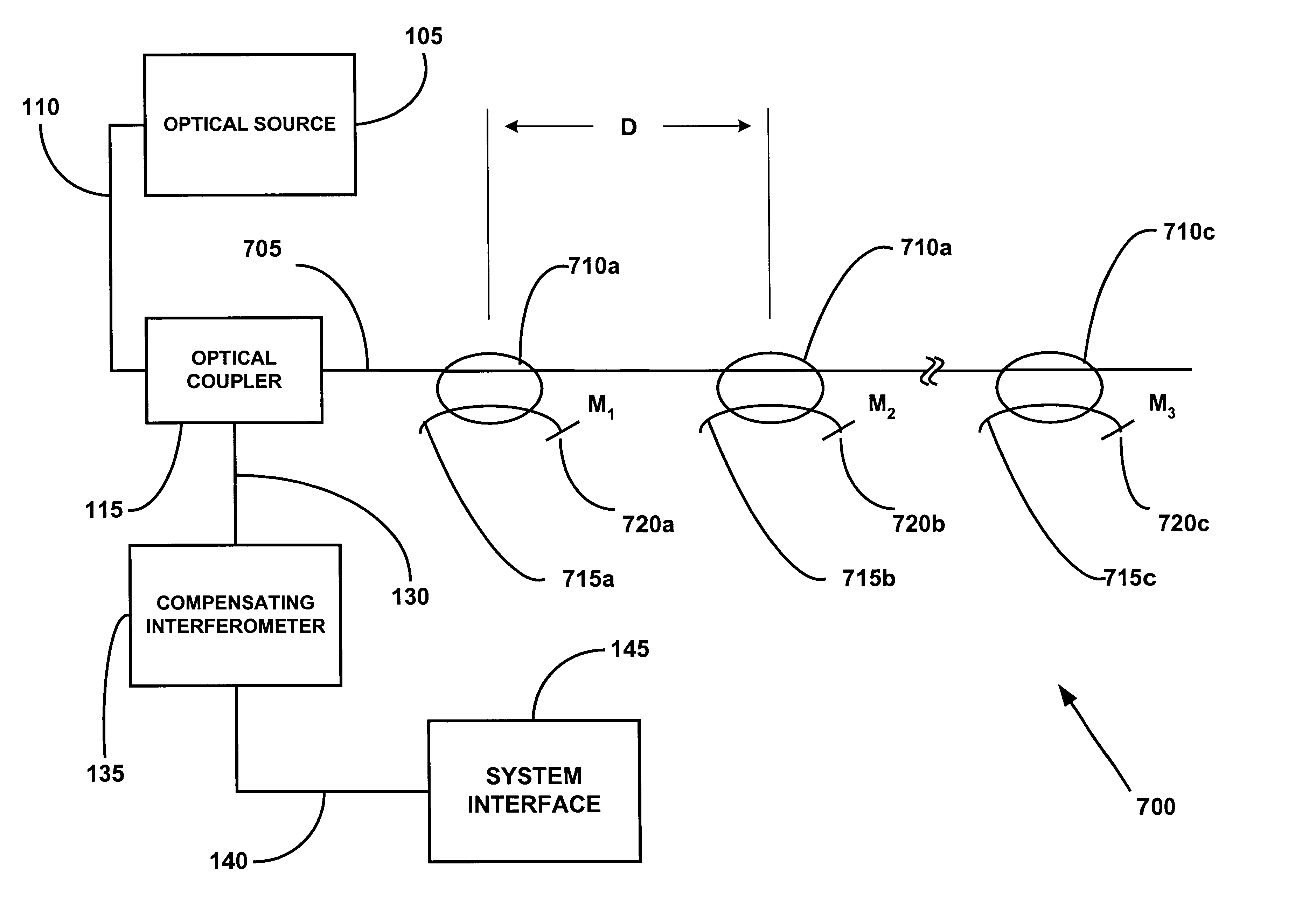

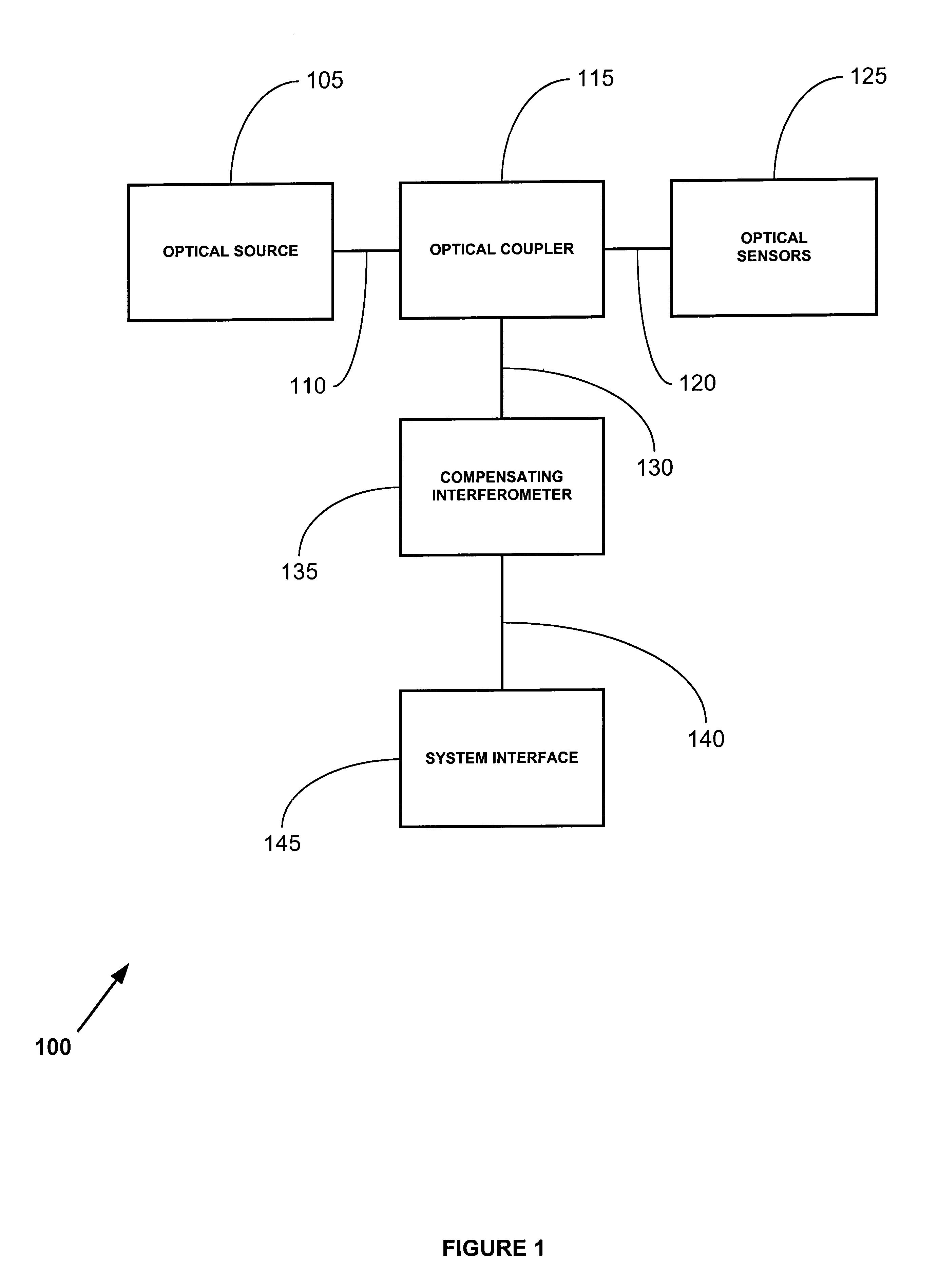

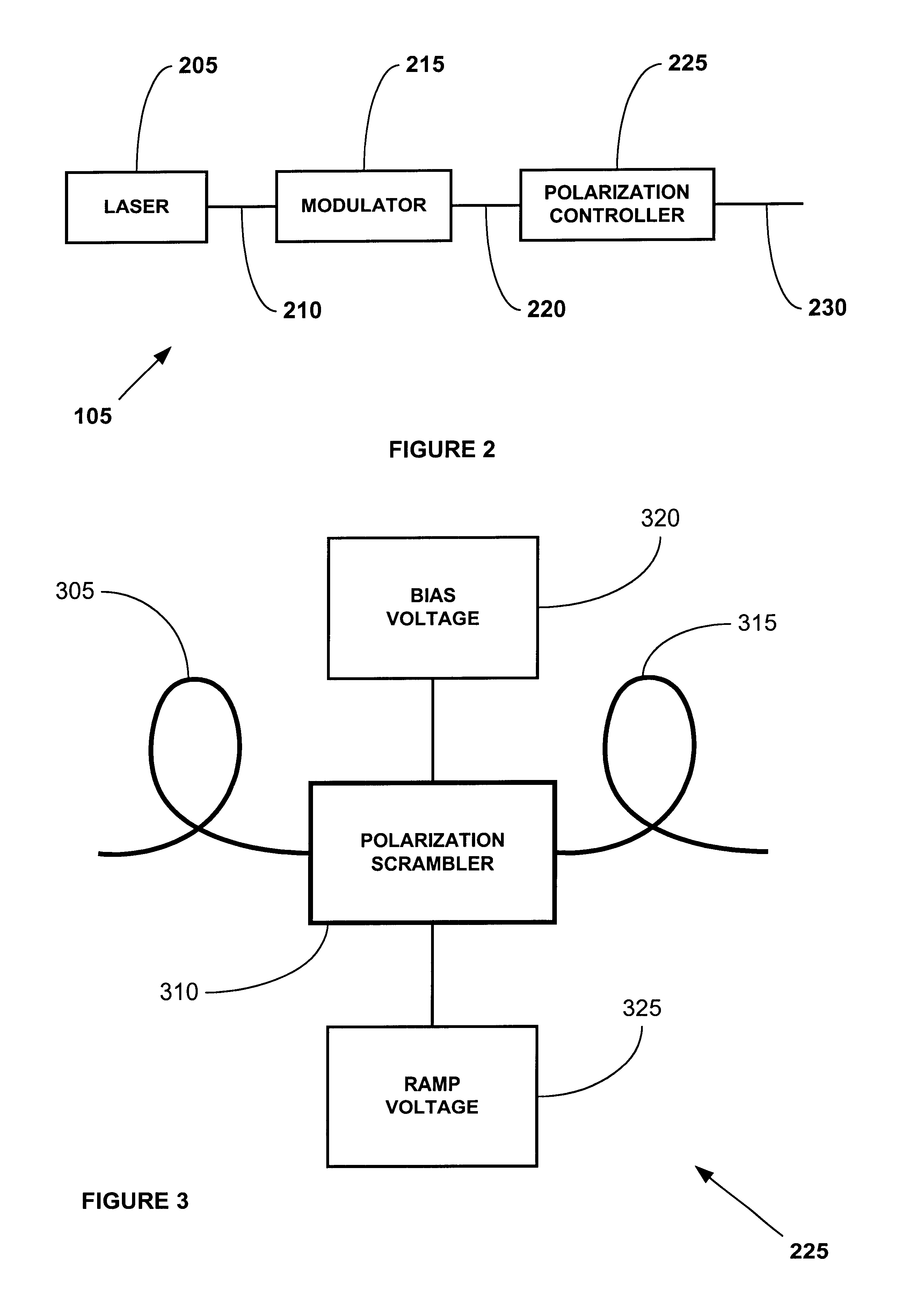

Optical sensing system

InactiveUS6591025B1Improve business performanceRadiation pyrometryVibration measurement in fluidElectrical conductorOptical sensing

A fiber optic acoustic sensor system including an optical conductor having low reflectivity mirrors is provided. Optical sensors are provided by sections of the optical conductor bounded by pairs of the low reflectivity mirrors. Pulses of light are injected into the optical conductor and reflected by the low reflectivity mirrors. The reflected pulses of light are processed using a compensating interferometer to generate interference patterns representative of the environmental conditions acting upon the optical conductor.

Owner:ION GEOPHYSICAL CORP

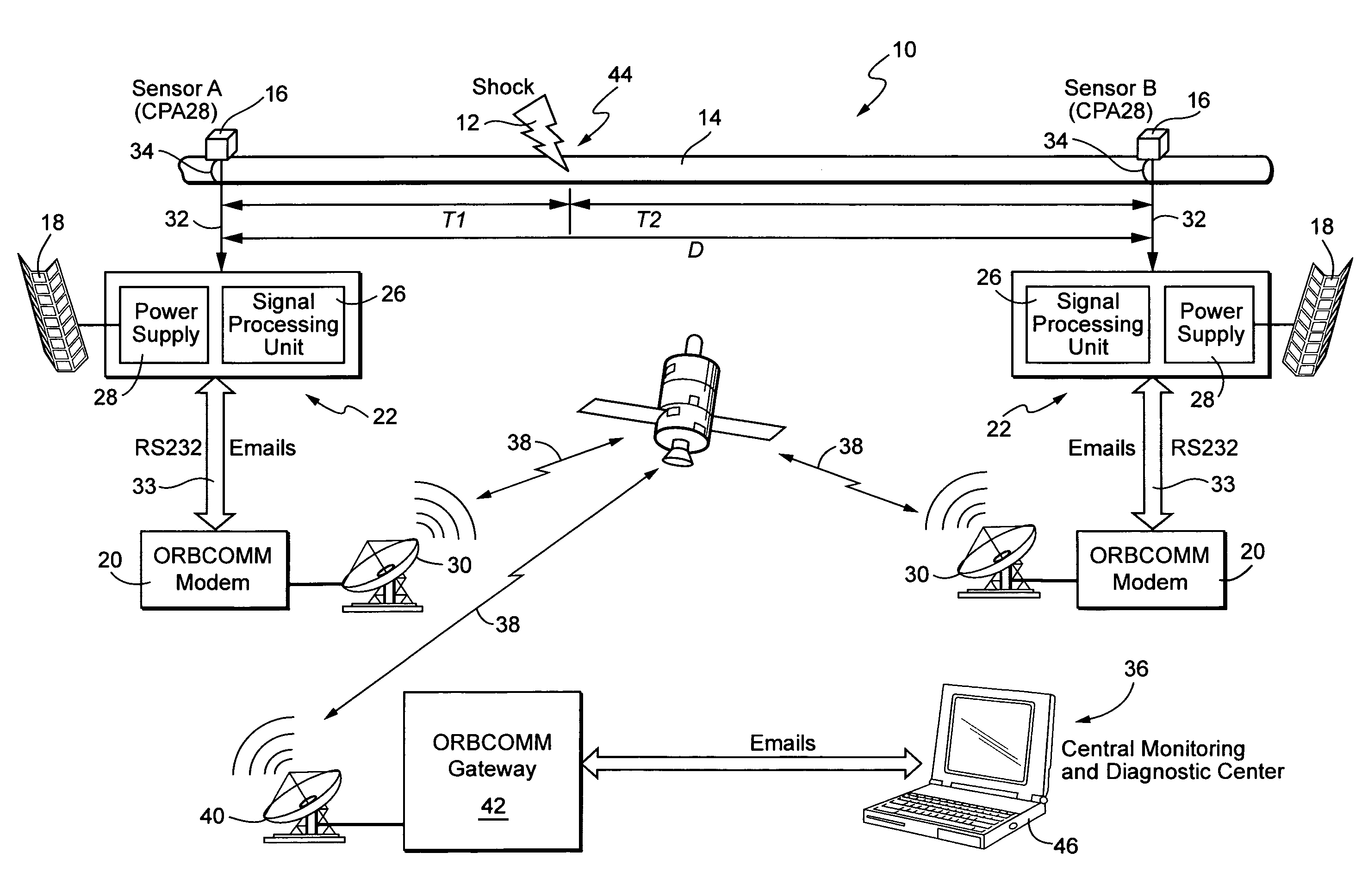

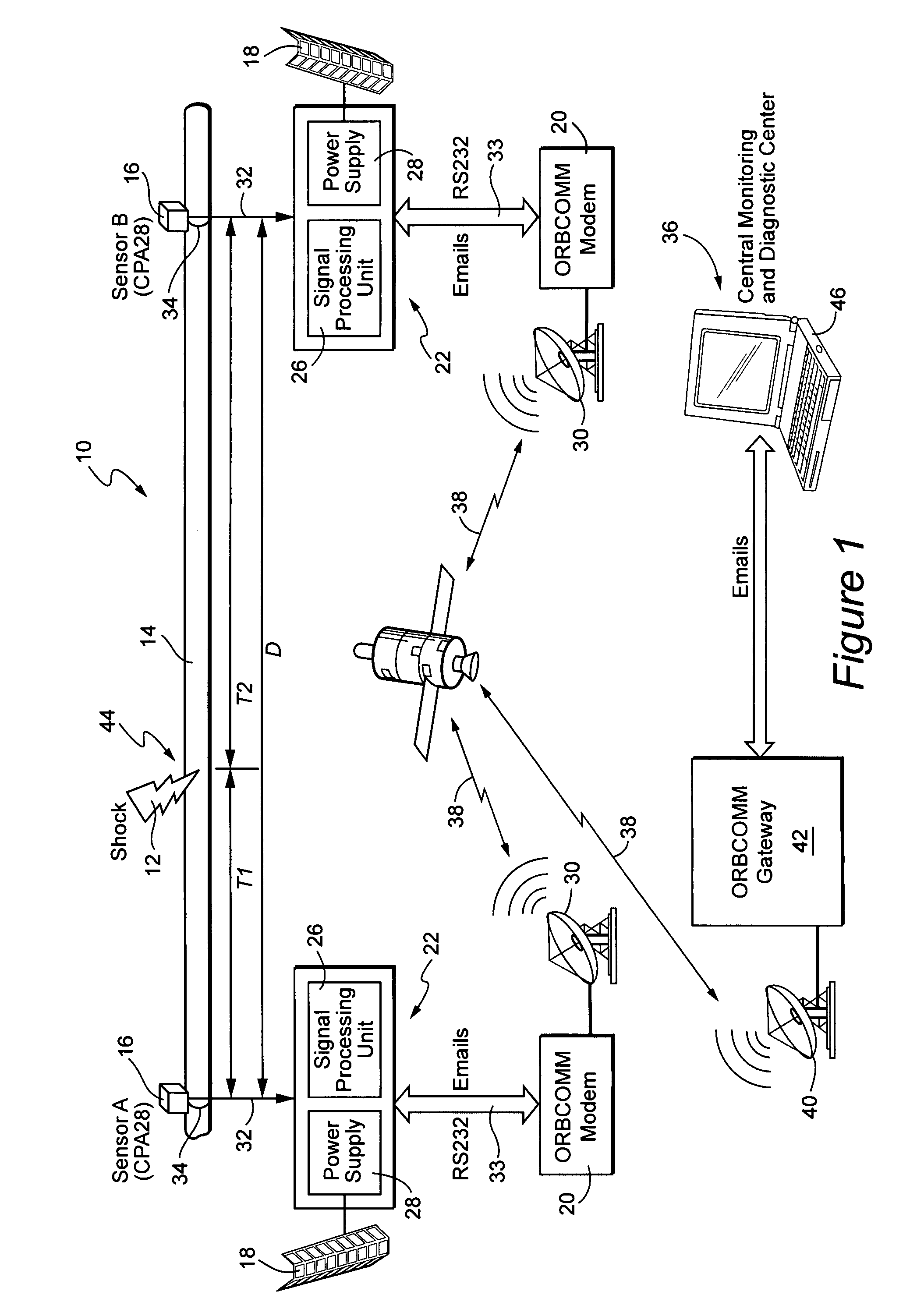

Acoustic impact detection and monitoring system

ActiveUS7607351B2Cost effectiveQuick checkMultiple-port networksVibration measurement in fluidHydrophoneTelecommunications link

A system is disclosed for detecting and locating harmful impacts to pipelines using sensors placed along the pipeline. The exact spacing of sensors is site specific and is set with the goal of maximizing sensor spacing without reducing system performance and reliability. At each sensor location, preferably there are four basic components, i.e., a hydrophone, solar power components, and data processing and communications equipment. Each hydrophone directly measures the acoustic noise fluctuation in a pipe section, which propagates at long distances in the pipeline at the specific speed of sound for the particular type of pipe. If specific signal parameters exceed a programmed threshold, a detection message is generated and transmitted via a communications link to a central monitoring and diagnostic center.

Owner:GENERAL ELECTRIC CO

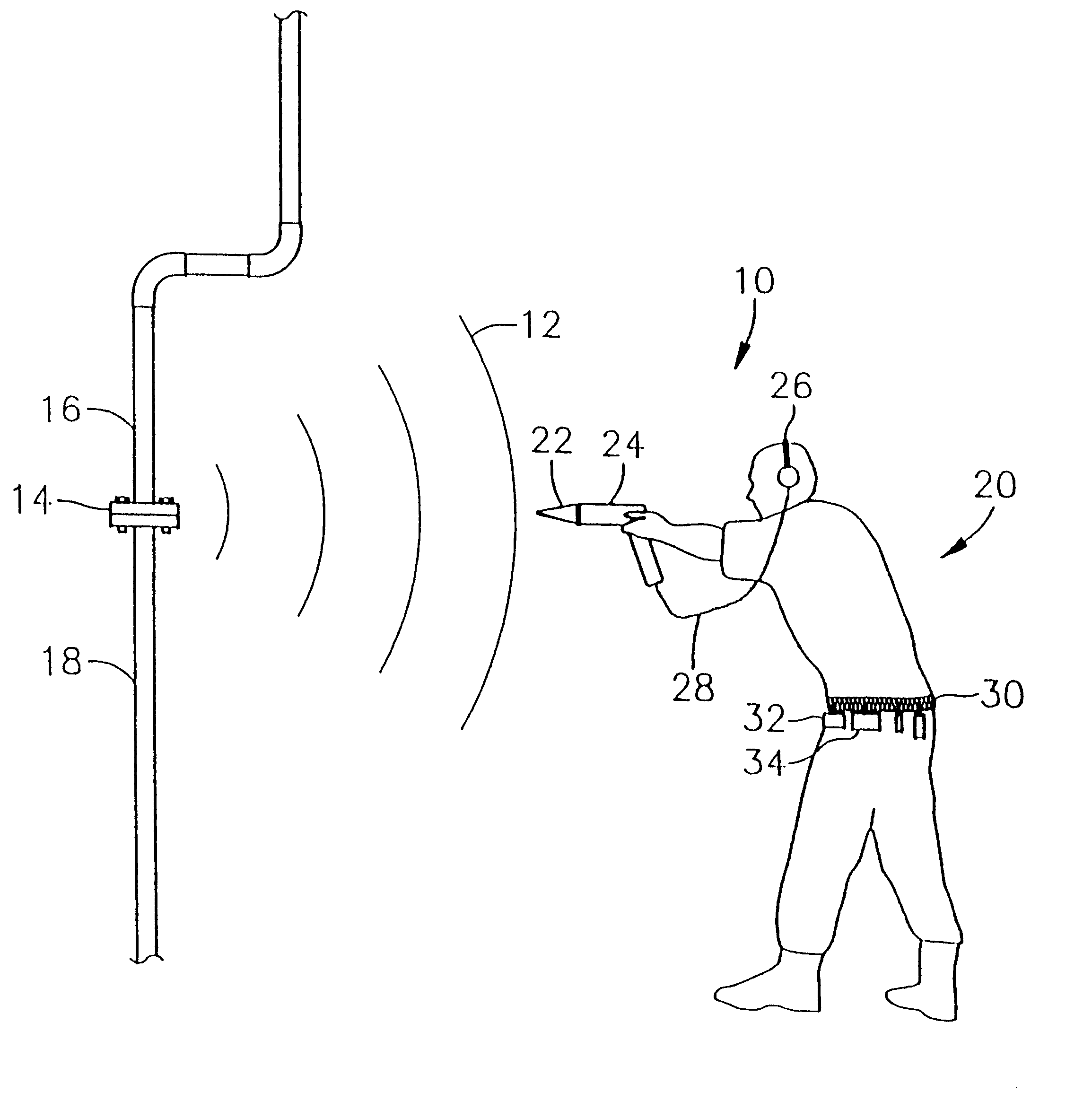

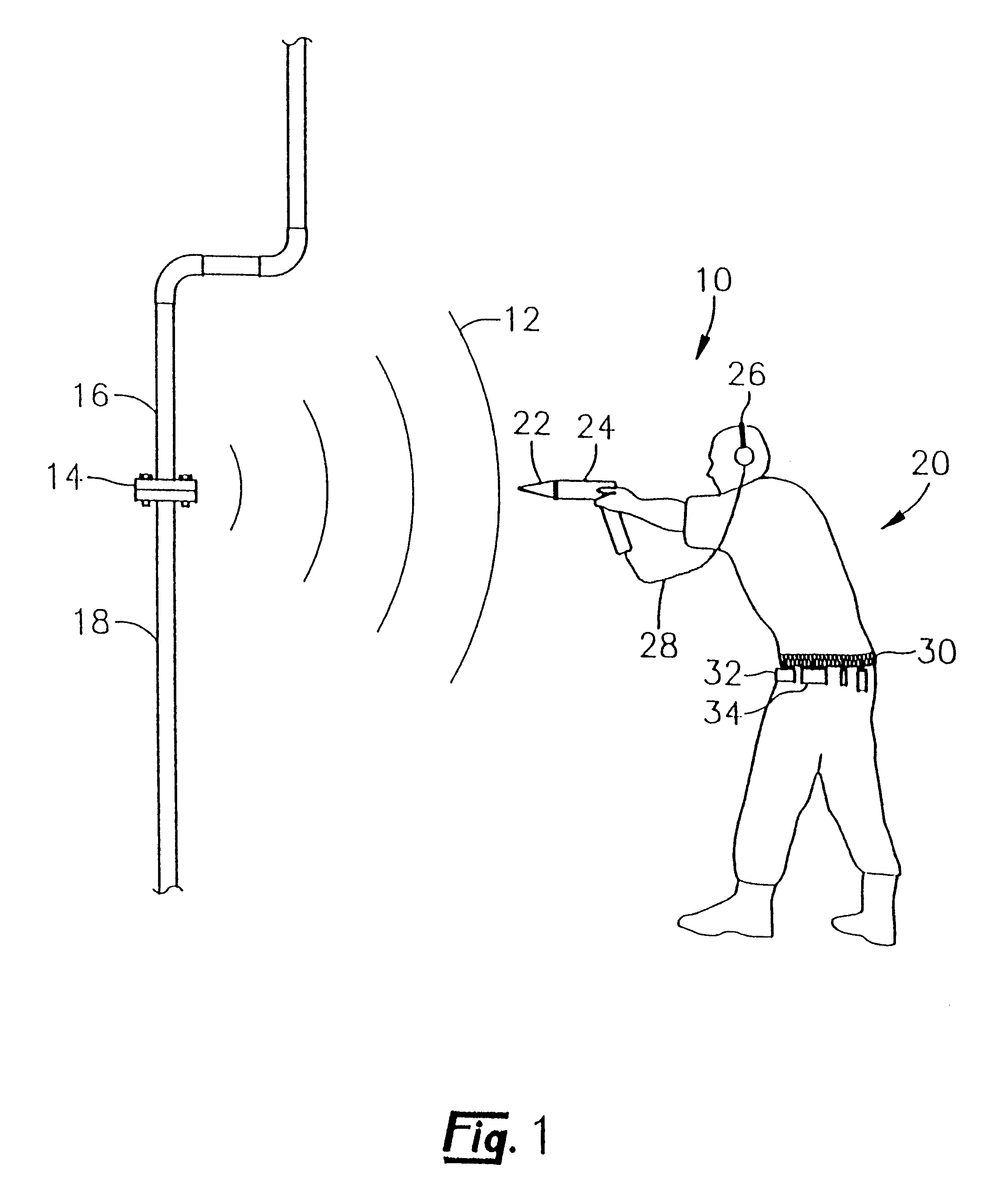

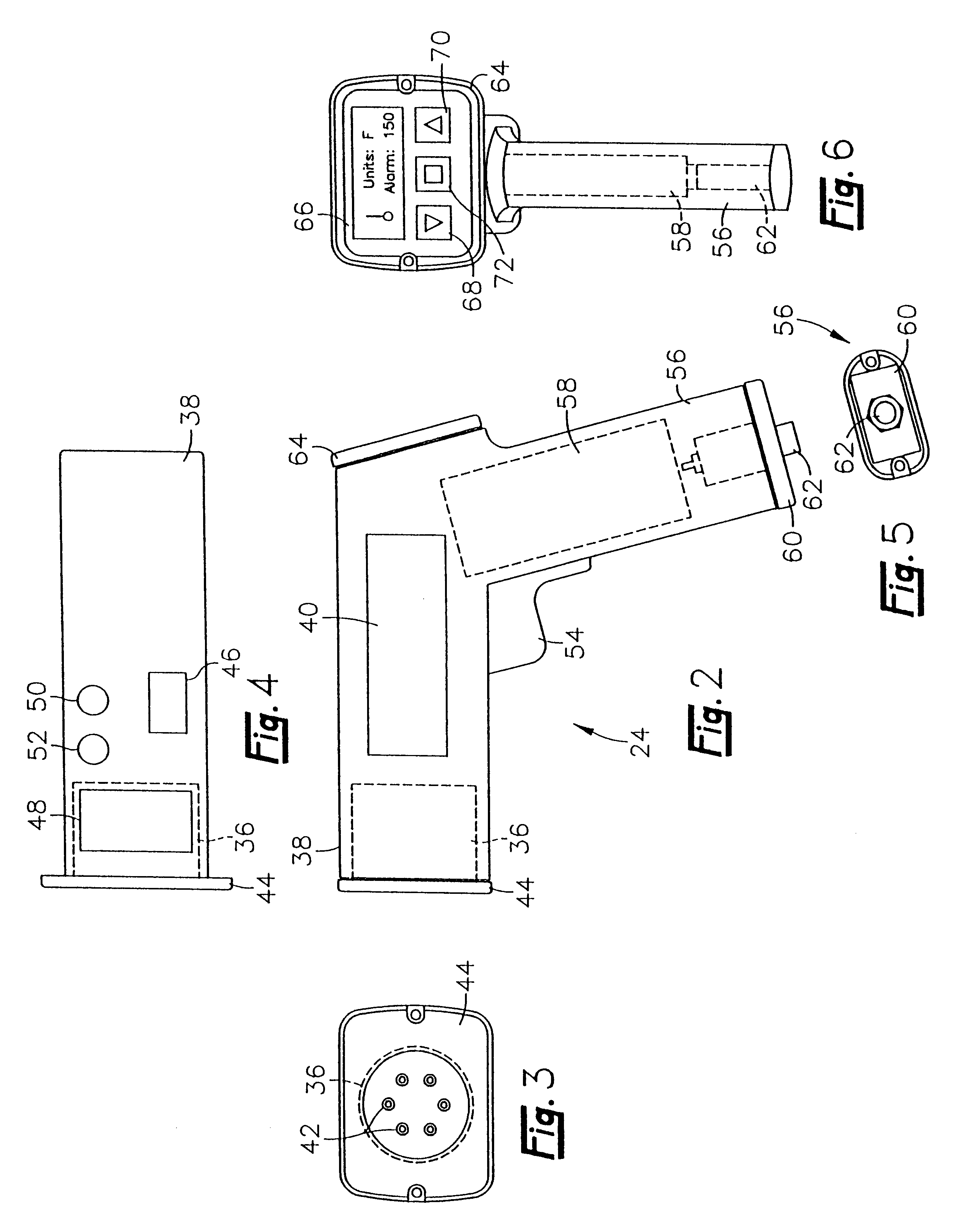

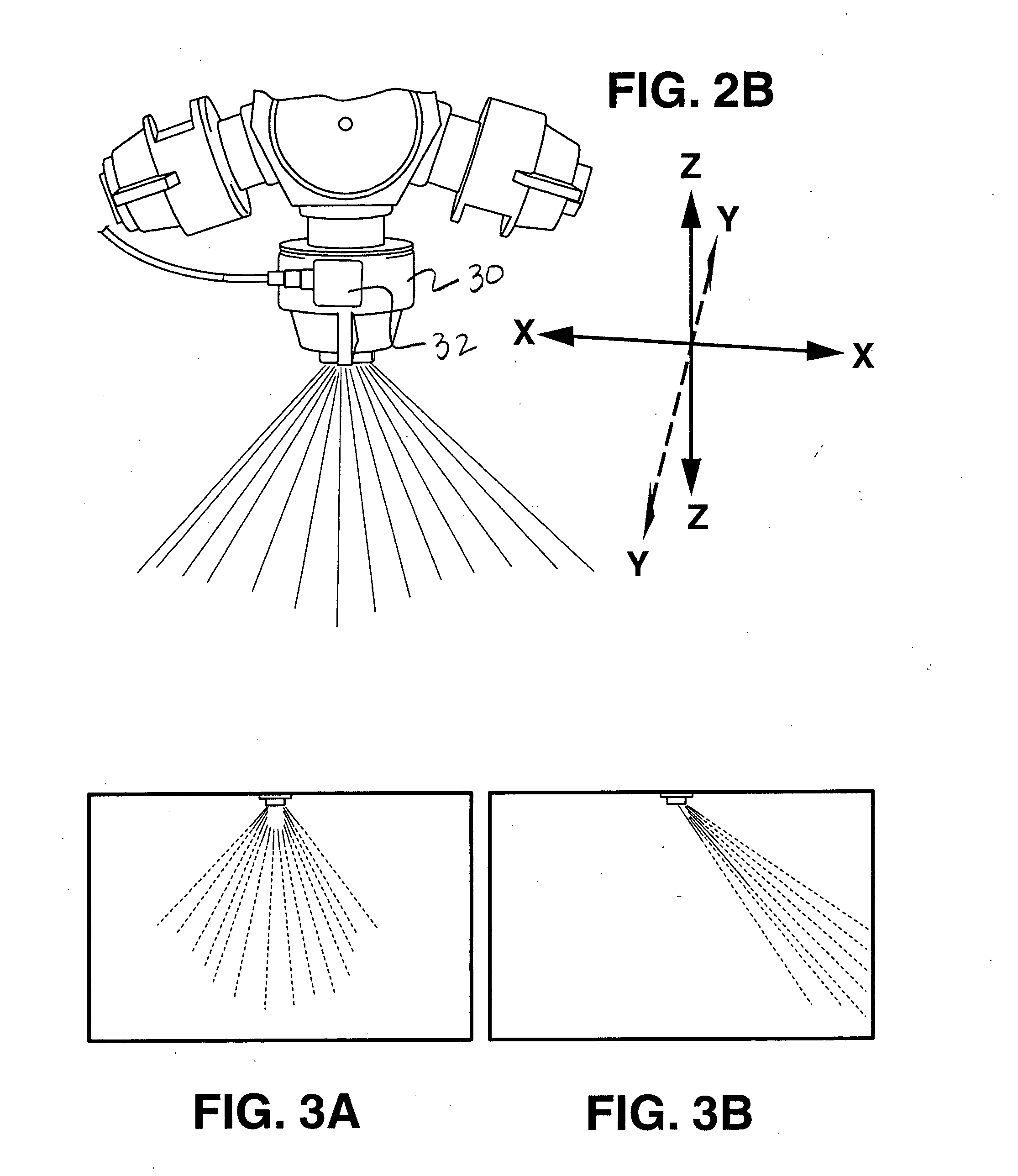

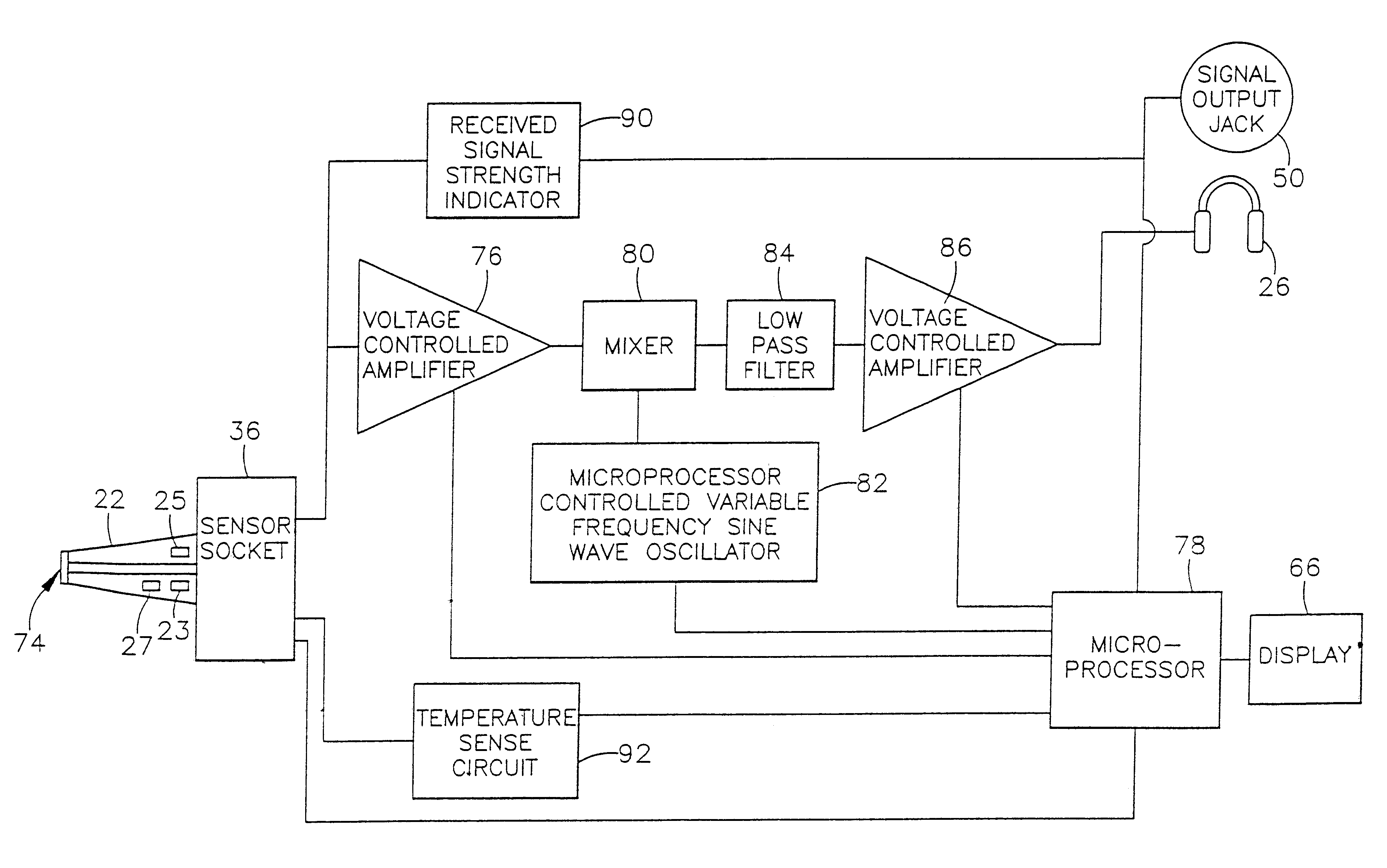

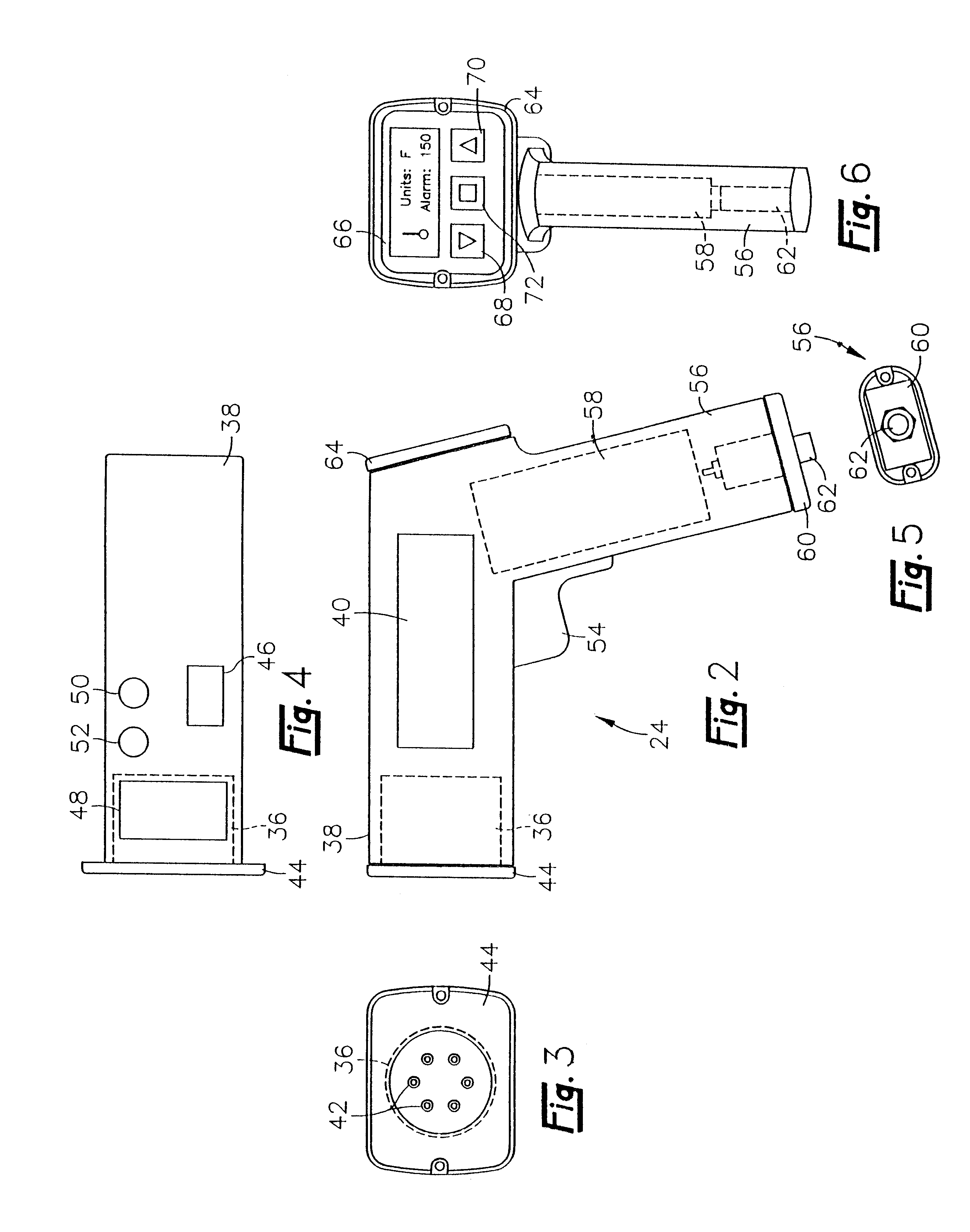

Multiple sensor ultrasonic monitoring device

InactiveUS6220098B1High thermal and ultrasonic conductivityMinimize intrinsic thermal time constantVibration measurement in solidsMachine part testingHand heldMultiple sensor

An ultrasonic monitoring apparatus is provided for use by an operator in detecting ultrasonic vibrations and sound waves. The ultrasonic monitoring apparatus consists of a hand held device with a sensor socket that allows a variety of different types of sensors to be interchangeably installed in the hand held device. These sensors include both contact and airborne ultrasonic sensors as well as a combination temperature and ultrasonic sensor that allows the operator to simultaneously monitor the surface temperature of an object and the ultrasonic vibrations produced by the object. Identification information corresponding to the type of sensor is encoded on the individual sensors. The identification information is read by an identification circuit located in the hand held device. This identification information allows the hand held device to configure itself to operate with the type of sensor installed in the socket.

Owner:COMPUTATIONAL SYST

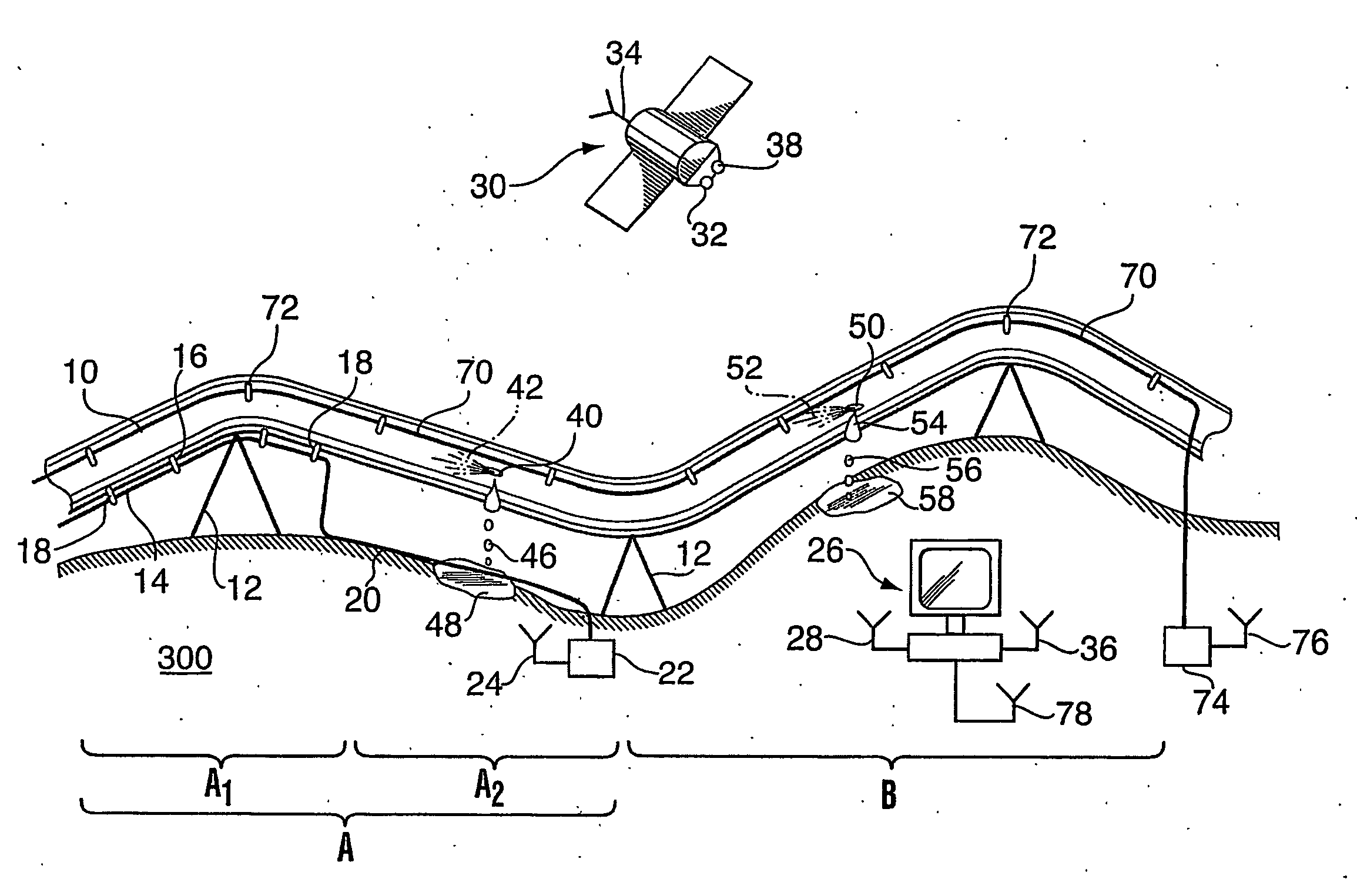

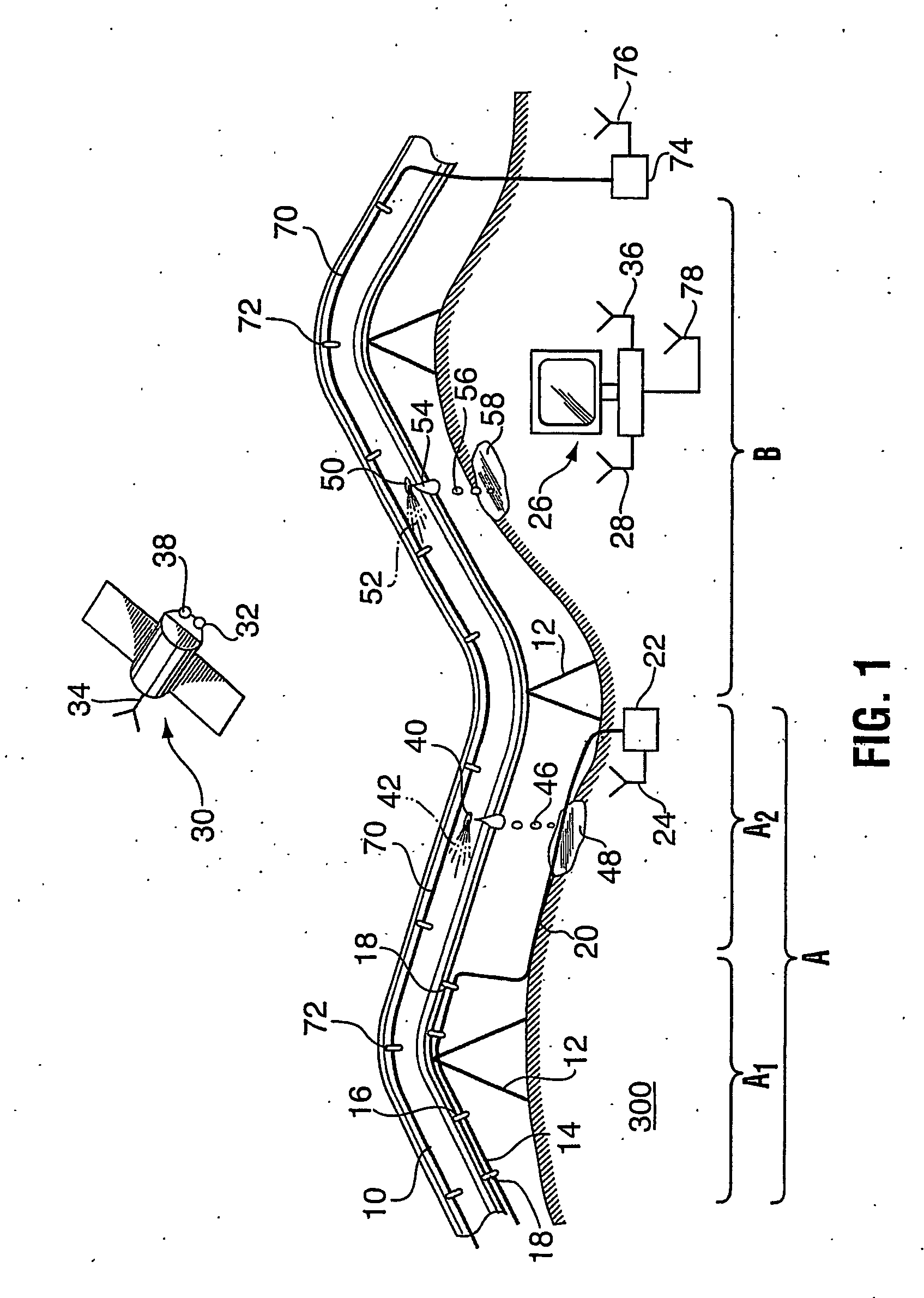

Flow control and operation monitoring system for individual spray nozzles

ActiveUS20050000277A1Vibration measurement in fluidVolume/mass flow measurementAccelerometerMonitoring system

An apparatus and process for monitoring fluid flow through a nozzle is disclosed. A vibration sensor, such as an accelerometer, is mounted to a nozzle. The vibration output received from the sensor is then analyzed to determine whether or not the nozzle is operating properly. Through the present invention, information can be obtained regarding variations in flow rate, and / or variations in spray pattern and droplet size spectra. If the nozzle flow pulsates, the vibration sensor may also provide information regarding whether the nozzle is pulsating according to a desired frequency duty cycle or waveform.

Owner:CAPSTAN

Digital ultrasonic monitoring system and method

InactiveUS6247353B1Easily readable formatVibration measurement in solidsDetection of fluid at leakage pointSonificationDisplay device

A portable digital ultrasonic monitoring system and method for use by an operator in detecting the ultrasonic waves and temperature variations produced by sources such as leaks in pipes, arcing, electrical corona and machinery defects is provided. The digital ultrasonic monitoring system includes a microprocessor based system in a hand held elongate housing that digitally analyzes and stores information received from its sensors. The digital ultrasonic monitoring system provides a referenced decibel output reading of the signal strength of the received ultrasonic signals. In addition, a heterodyned type audio signal that is related to the sensed ultrasonic signals is provided to the operator through a pair of headphones. The portable device has user input keys that allow the operator to select from a variety of different operating modes. A display displays a variety of different readings depending upon the operating mode of the device.

Owner:COMPUTATIONAL SYST

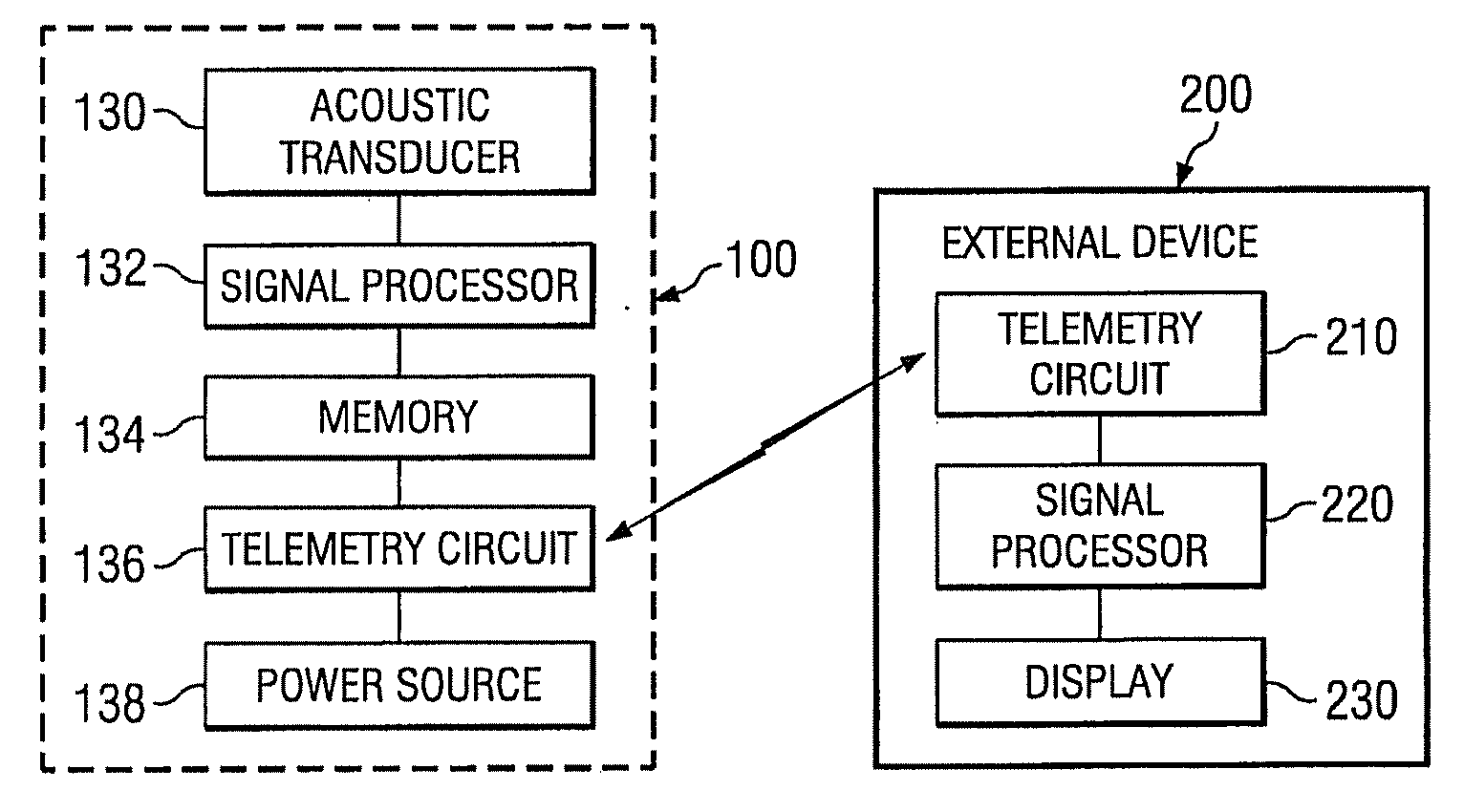

Implantable pedometer

InactiveUS20070179739A1Vibration measurement in solidsVibration measurement in fluidPedometerTelemetry Equipment

An implantable pedometer for measuring the amount of joint use is disclosed. The implantable pedometer includes a sensor adapted for detecting indicators of joint usage. A counter is configured for storing count data corresponding to the number of indicators detected by the sensor and a telemetry circuit is configured for transmitting the count data outside of the body.

Owner:WARSAW ORTHOPEDIC INC +1

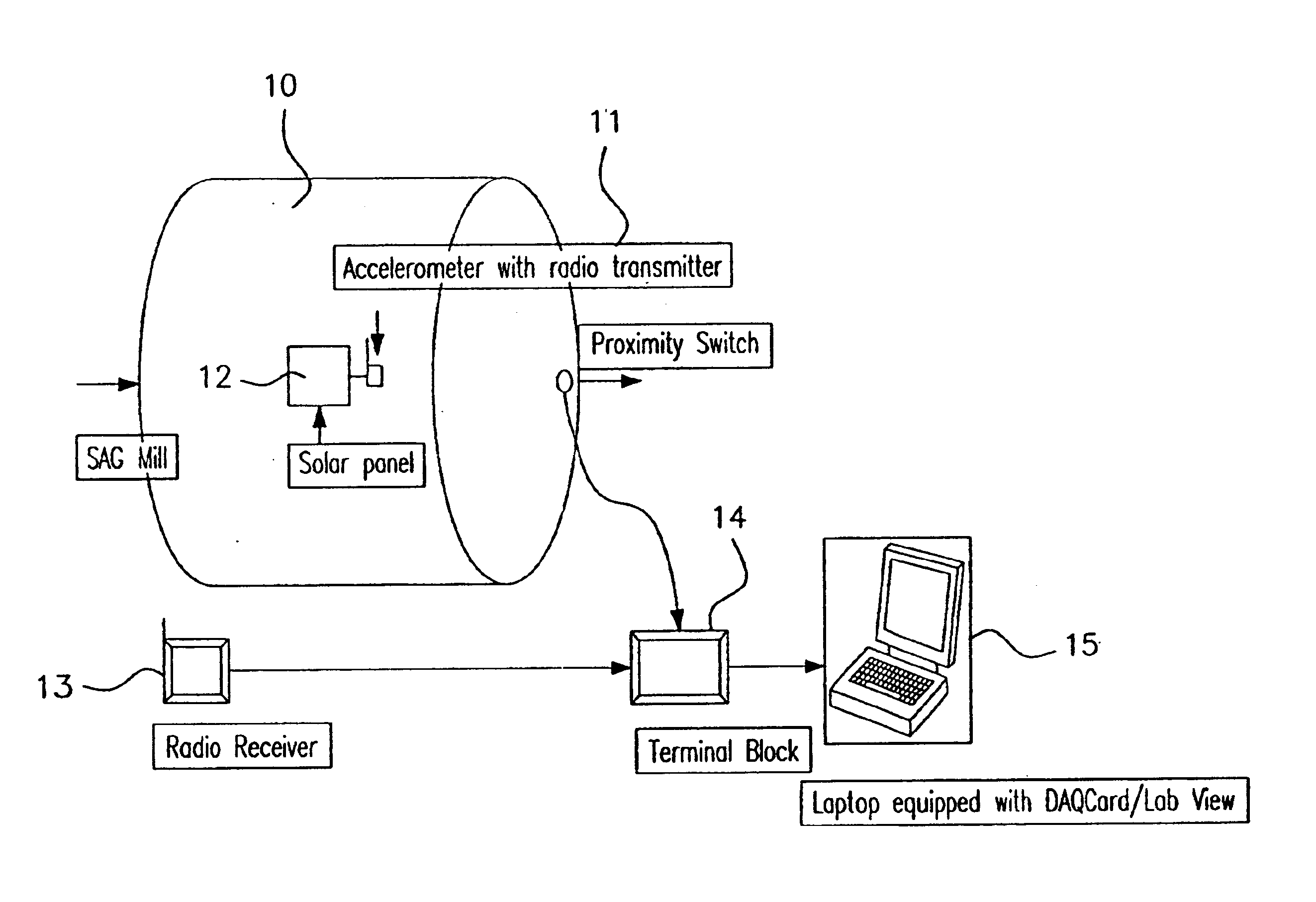

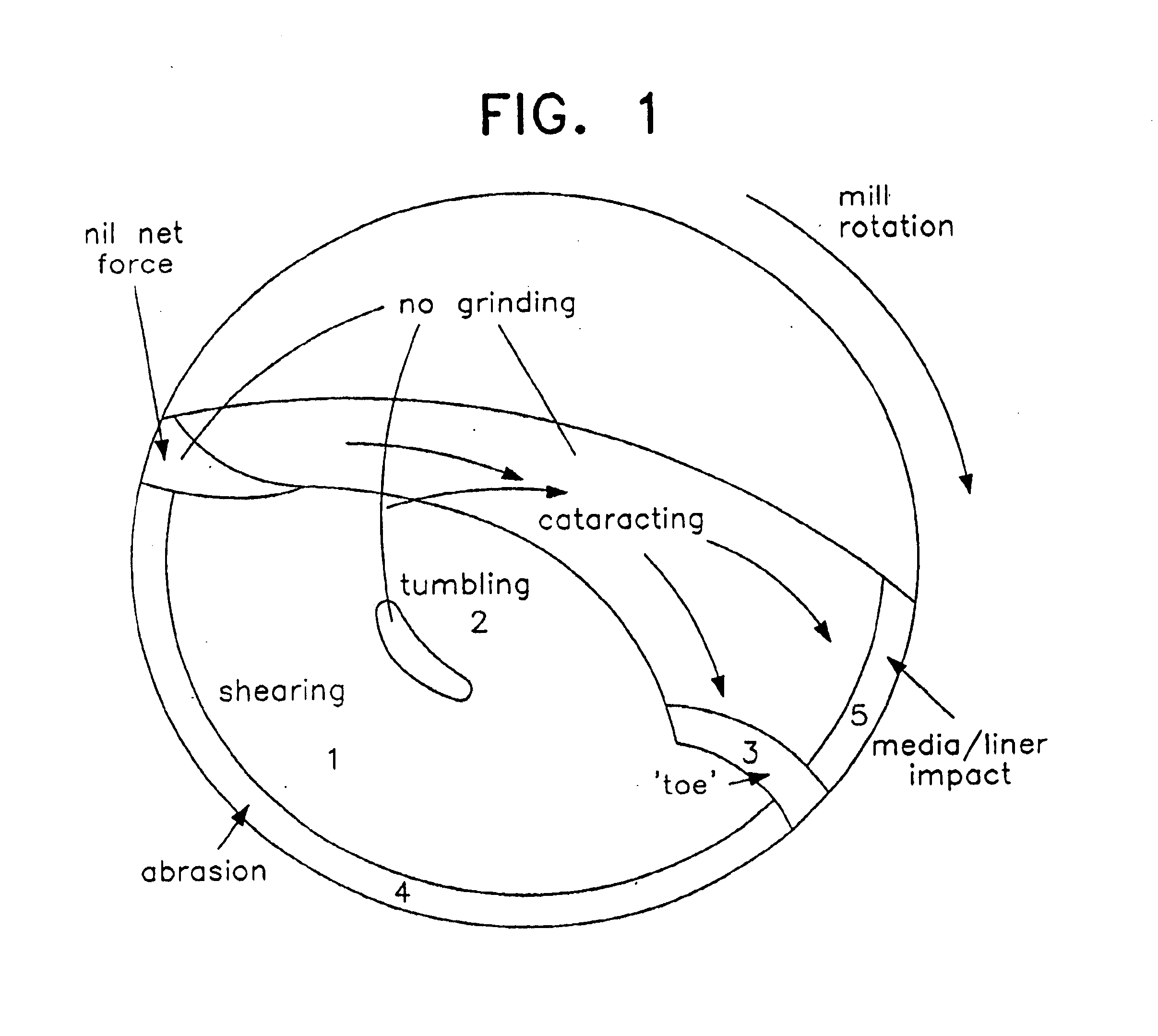

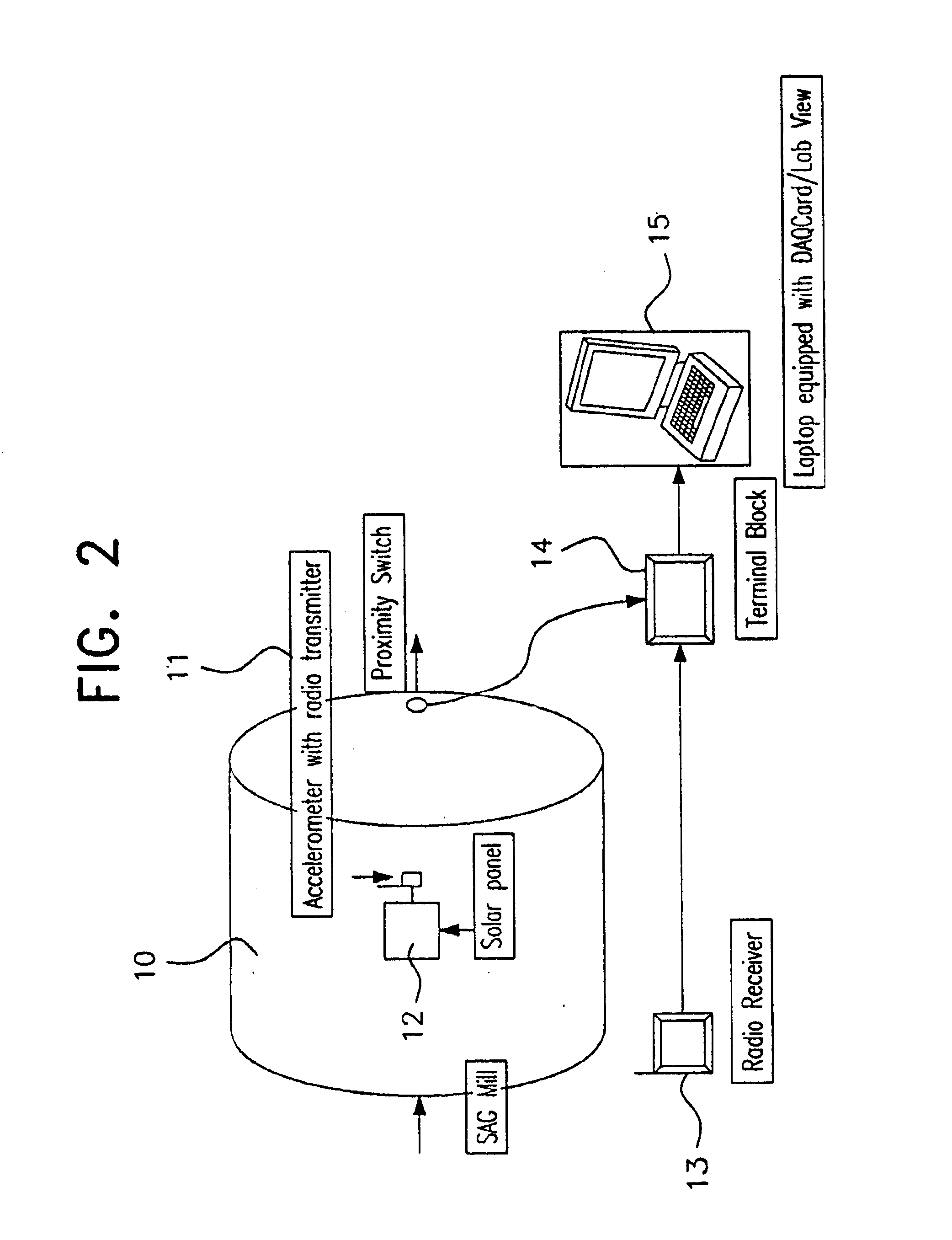

System for monitoring mechanical waves from a moving machine

InactiveUS6874364B1Minimise number/amplitude/frequencyMinimizes valueVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesParticulatesEngineering

A system for monitoring mechanical waves from a machine which in operation has moving particulate matter therein, the system including at least one sensor located on the machine at a location away from the central axis of the machine, the sensors being for sensing acoustic waves and including a transmitter for transmitting signals representing the sensed mechanical waves to a receiver at a location remote from the sensor(s), a data processor connected to the receiver for receiving signals from the receiver which signals represent the mechanical waves and processing the signals to produce output signals for display on a display means, wherein the output signals for display represent one or more parameters indicative of mechanical waves emitted from the machine over a predetermined period of time.

Owner:COMMONWEALTH SCI & IND RES ORG

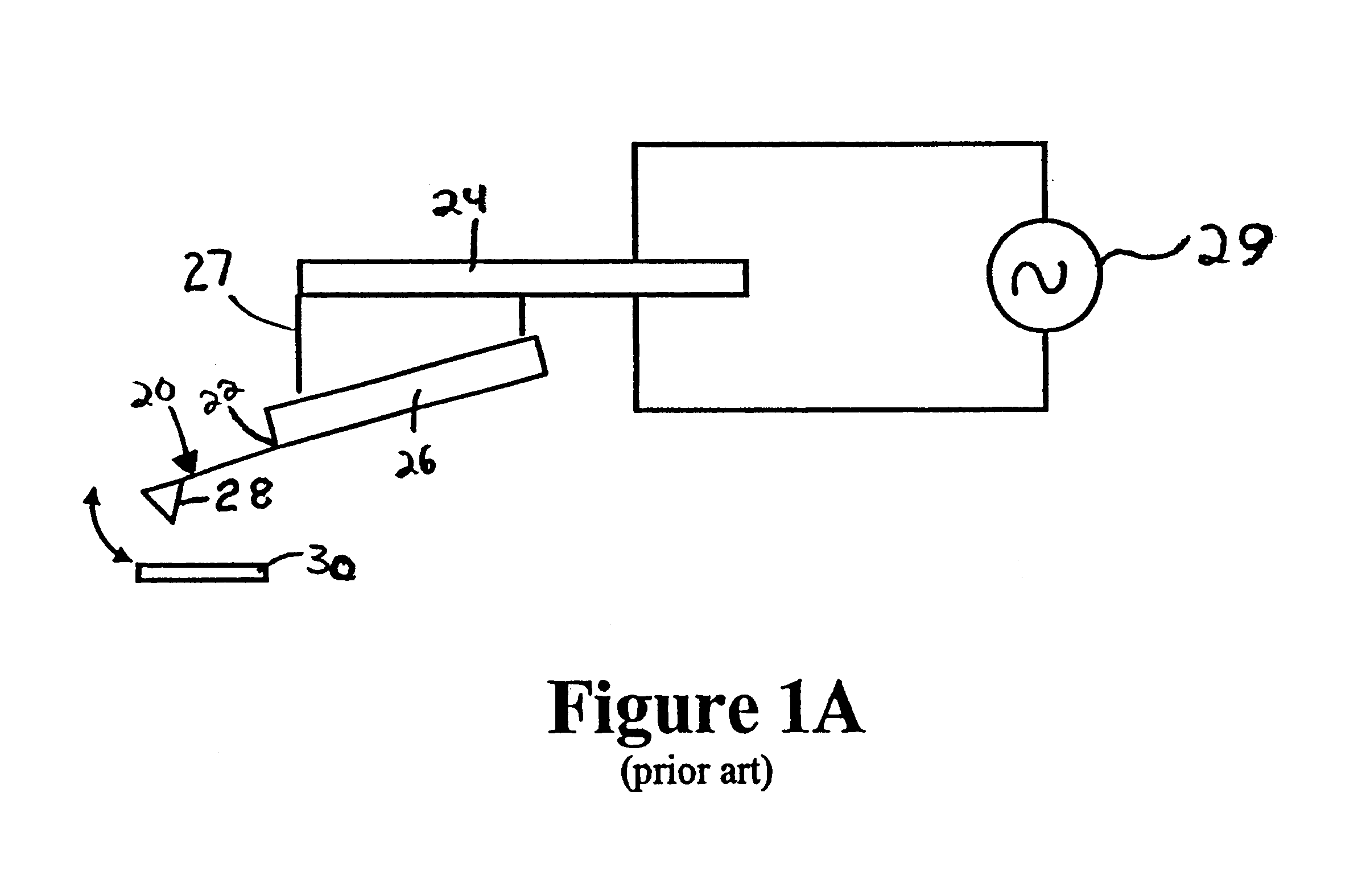

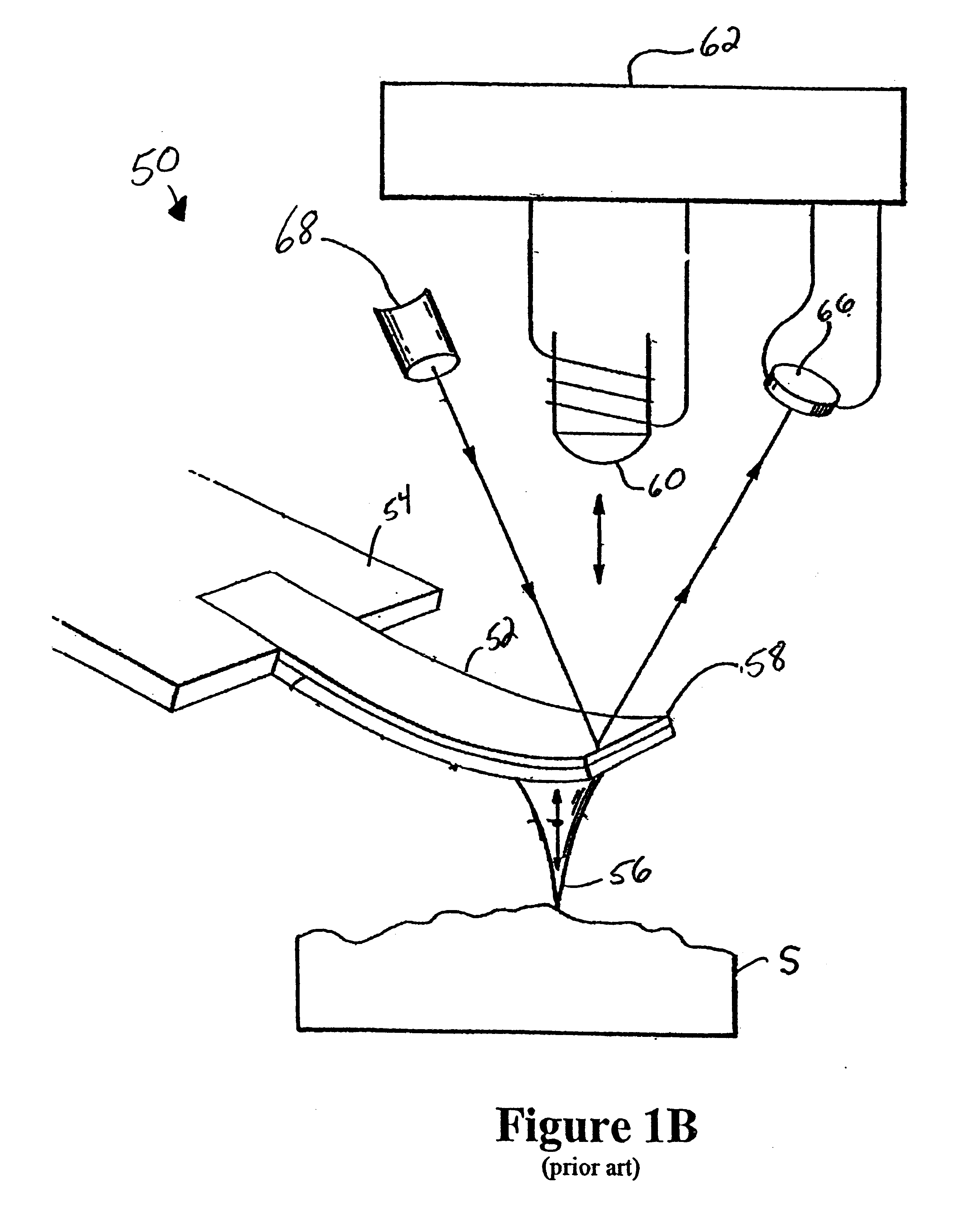

Method and apparatus for the ultrasonic actuation of the cantilever of a probe-based instrument

The cantilever of a probe-based metrology instrument such as an AFM is deflected by directing a beam of ultrasonic energy at the cantilever to apply ultrasonically generated acoustic radiation pressure to the cantilever. The energy is generated by an ultrasonic actuator such as a ZnO transducer driven by a power source such an RF signal generator. The transmitted beam preferably is shaped by focusing, collimation, or the like so that it impinges at least primarily on a region of interest of the cantilever such as the free end. The ultrasonic actuator produces a much better controlled force on the cantilever than can be achieved through the use of a traditional piezoelectric actuator and, accordingly, produces a response free of spurious effects (at least when the cantilever is operating in liquid). It also has a frequency bandwidth in the MHz range.

Owner:GEORGIA TECH RES CORP +1

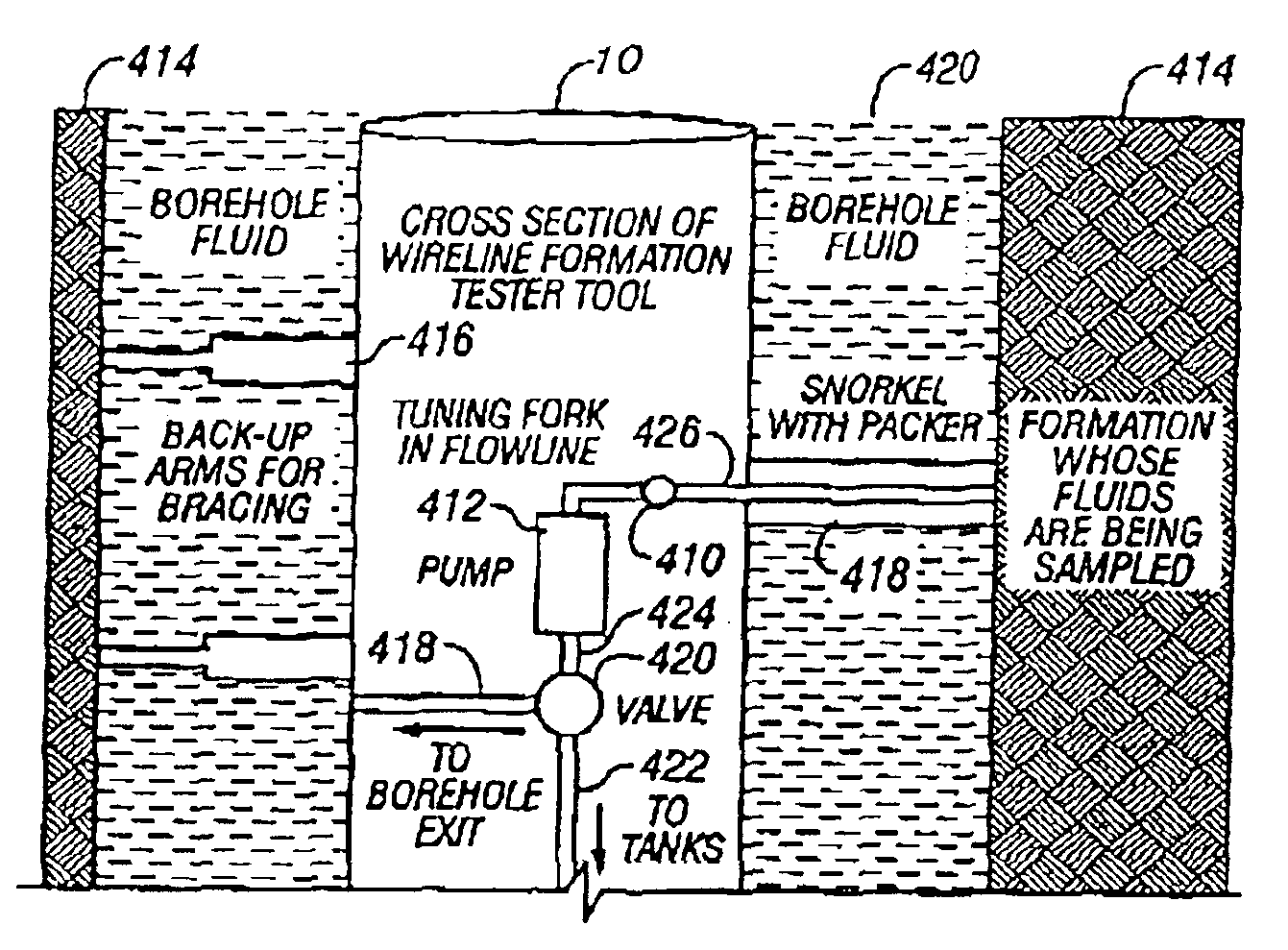

Method and apparatus for downhole fluid characterization using flexural mechanical resonators

InactiveUS6938470B2Avoid contact corrosionInversely to viscosityElectric/magnetic detection for well-loggingAnalysing fluids using sonic/ultrasonic/infrasonic wavesTuning forkFormation fluid

Owner:BAKER HUGHES INC

Method and apparatus for detecting leaks in buried pipes by using a selected combination of geophysical instruments

InactiveUS6667709B1Material analysis using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidEngineeringWave speed

A method and apparatus for detecting and locating leaks in buried pipes is disclosed in which ground penetrating radar, induction, acoustic, and vacuum excavation systems are selected based on soil conditions and then employed in selected combinations. The conductivity and wave speed of the soil are used in the selection process and in the process of detecting and locating a leak based on the measurements obtained from the selected combination of detection systems.

Owner:UNDERGROUND IMAGING TECH +1

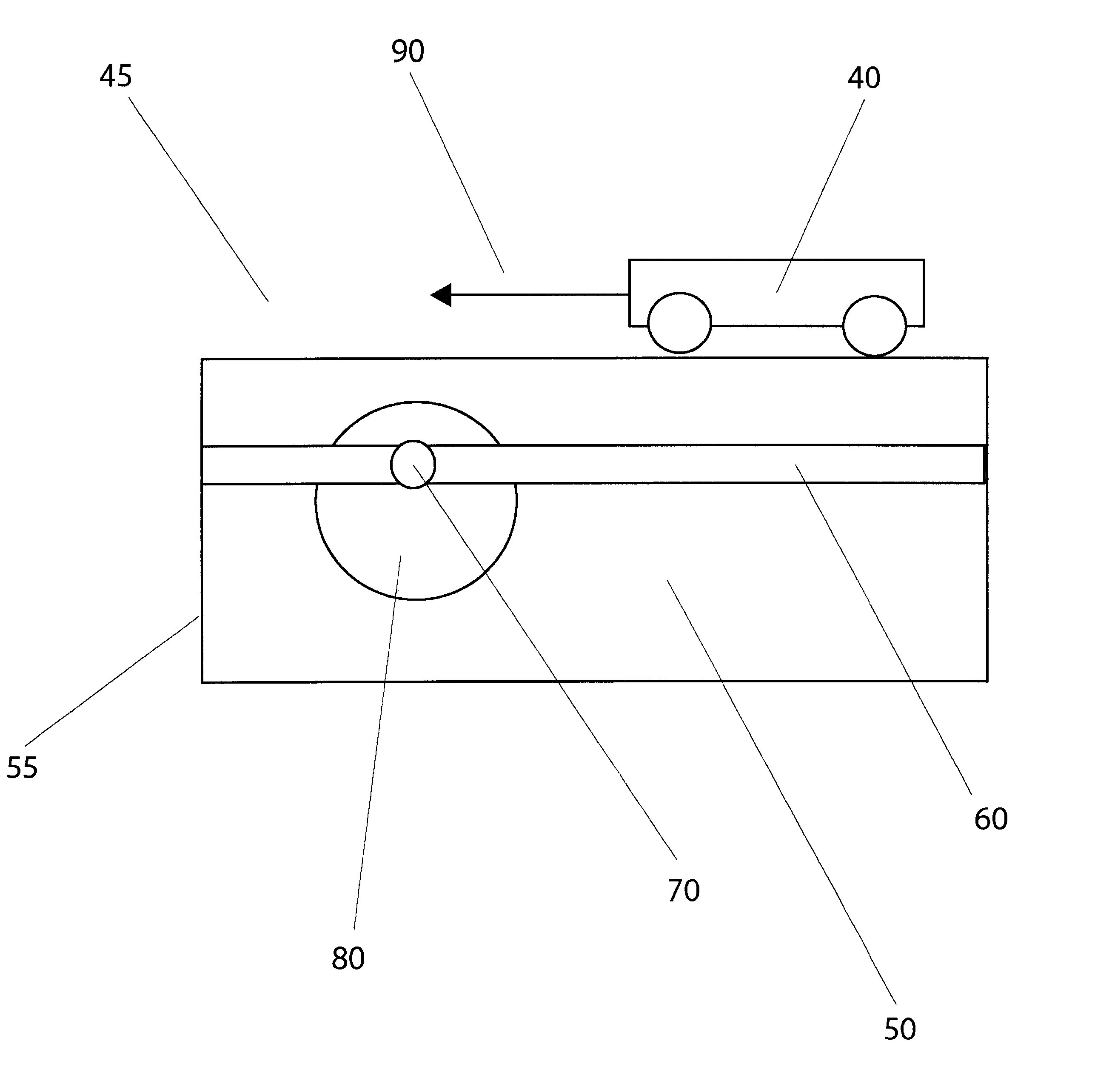

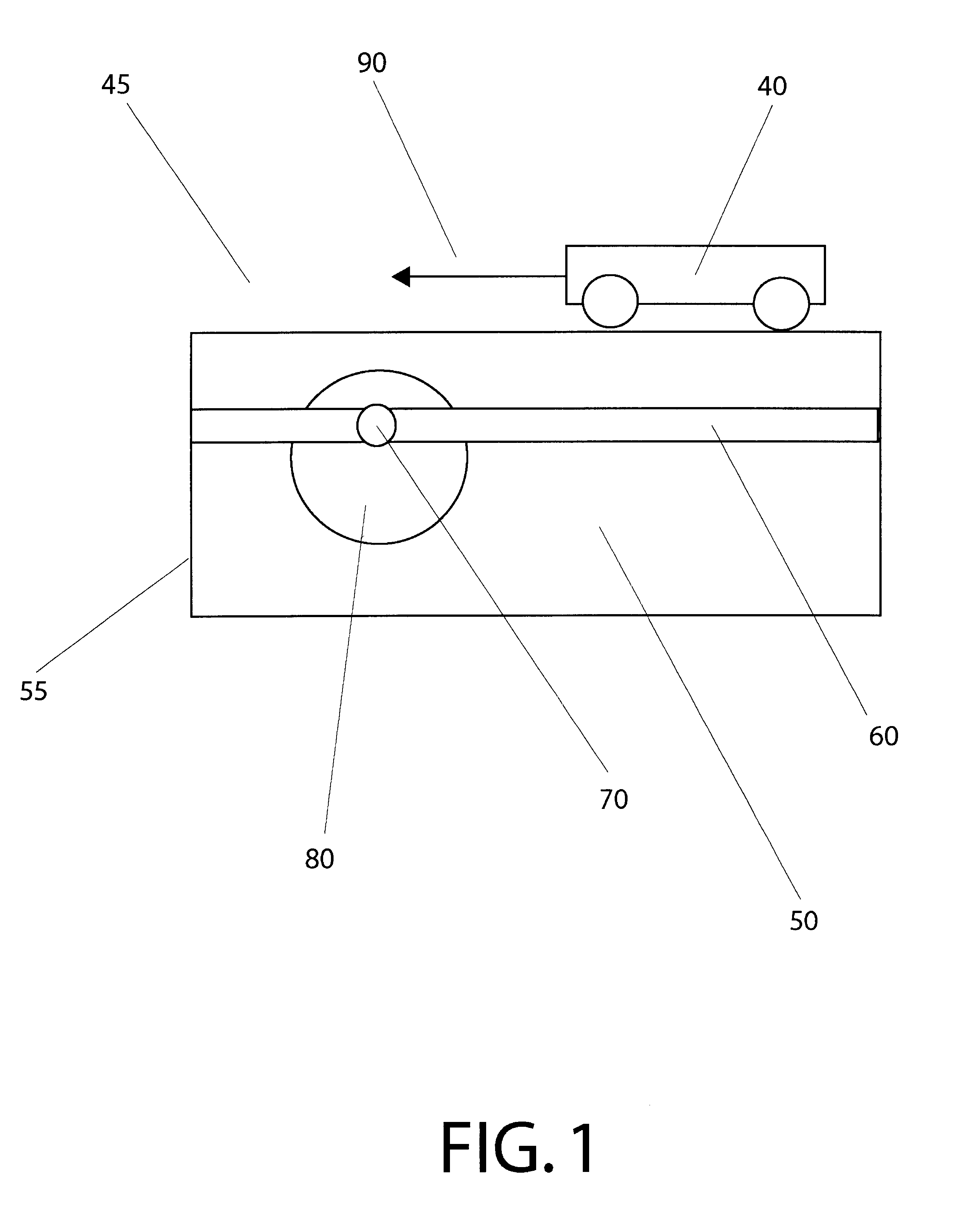

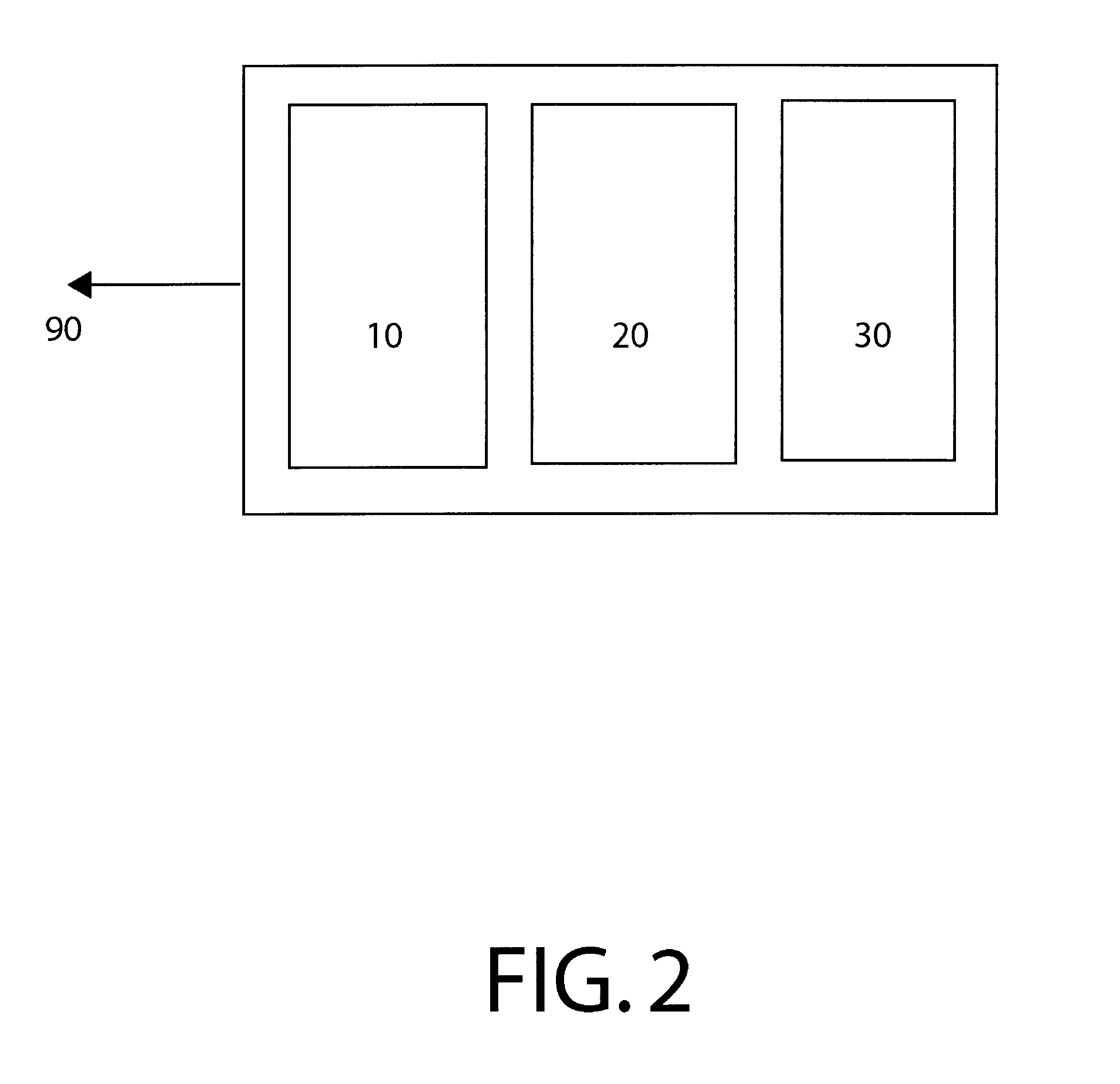

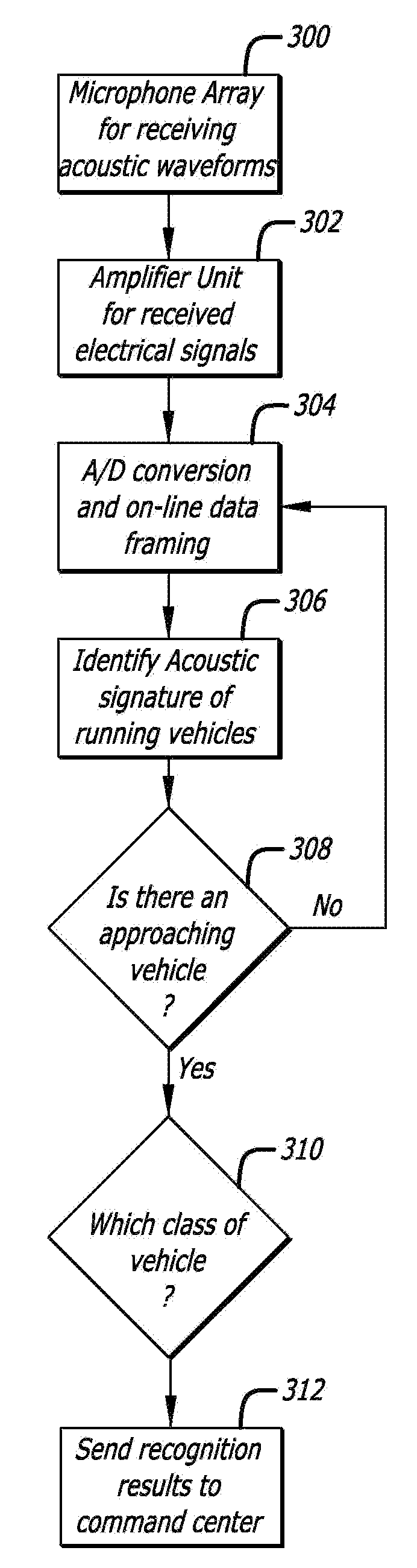

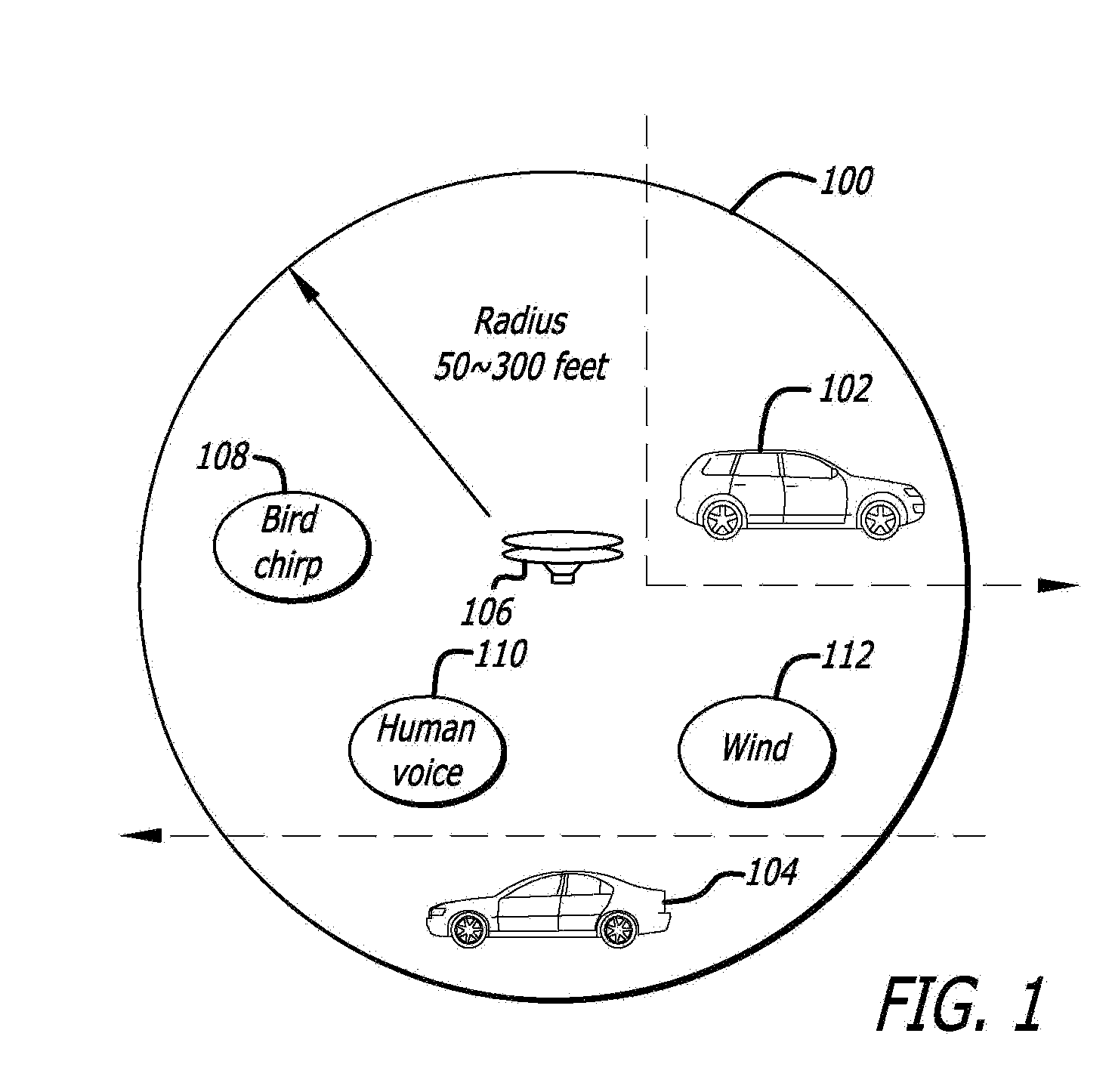

Detection and classification of running vehicles based on acoustic signatures

ActiveUS20090115635A1Analogue computers for vehiclesVibration measurement in fluidFeature vectorSynaptic weight

A method and apparatus for identifying running vehicles in an area to be monitored using acoustic signature recognition. The apparatus includes an input sensor for capturing an acoustic waveform produced by a vehicle source, and a processing system. The waveform is digitized and divided into frames. Each frame is filtered into a plurality of gammatone filtered signals. At least one spectral feature vector is computed for each frame. The vectors are integrated across a plurality of frames to create a spectro-temporal representation of the vehicle waveform. In a training mode, values from the spectro-temporal representation are used as inputs to a Nonlinear Hebbian learning function to extract acoustic signatures and synaptic weights. In an active mode, the synaptic weights and acoustic signatures are used as patterns in a supervised associative network to identify whether a vehicle is present in the area to be monitored. In response to a vehicle being present, the class of vehicle is identified. Results may be provided to a central computer.

Owner:UNIV OF SOUTHERN CALIFORNIA

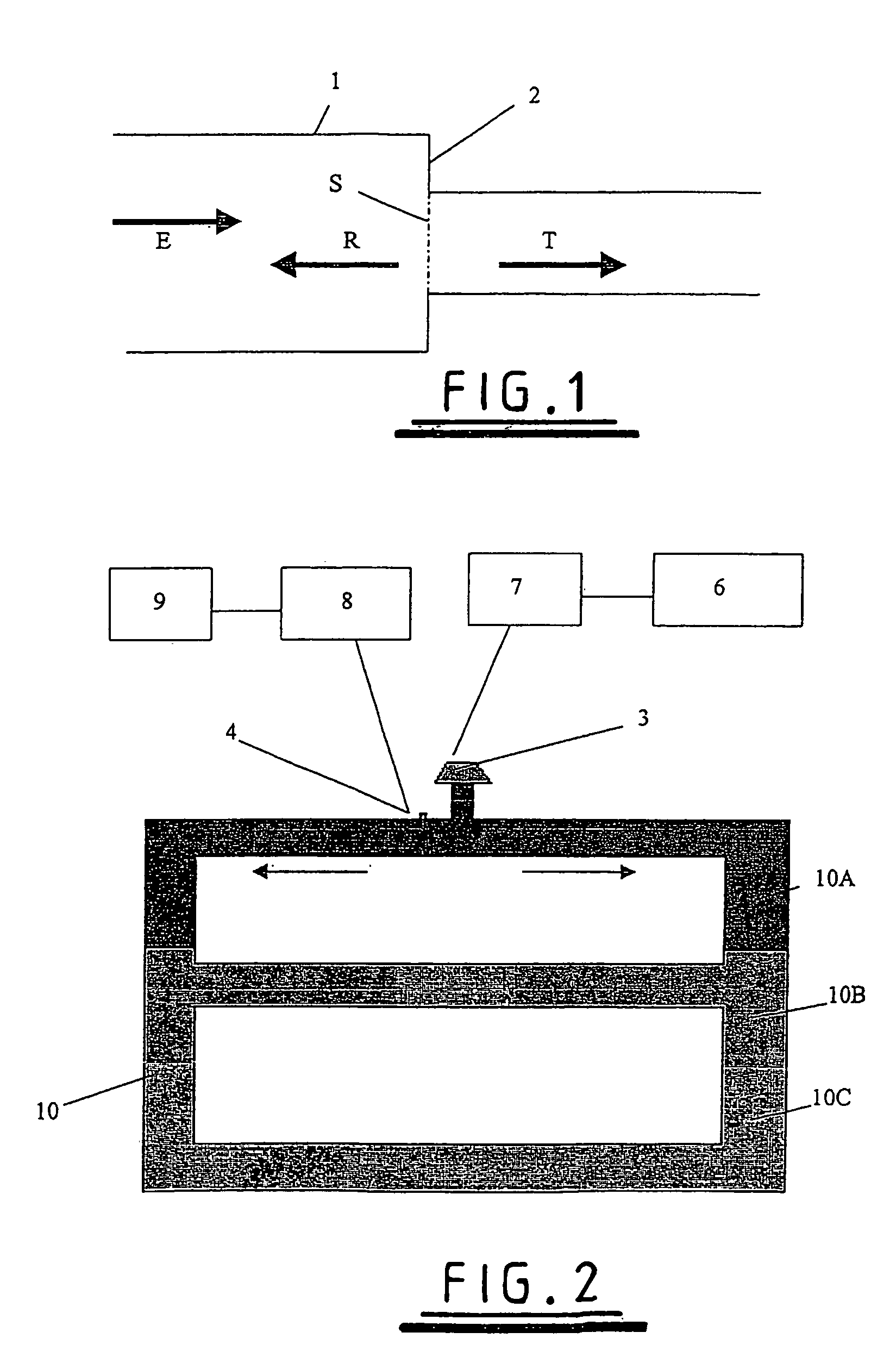

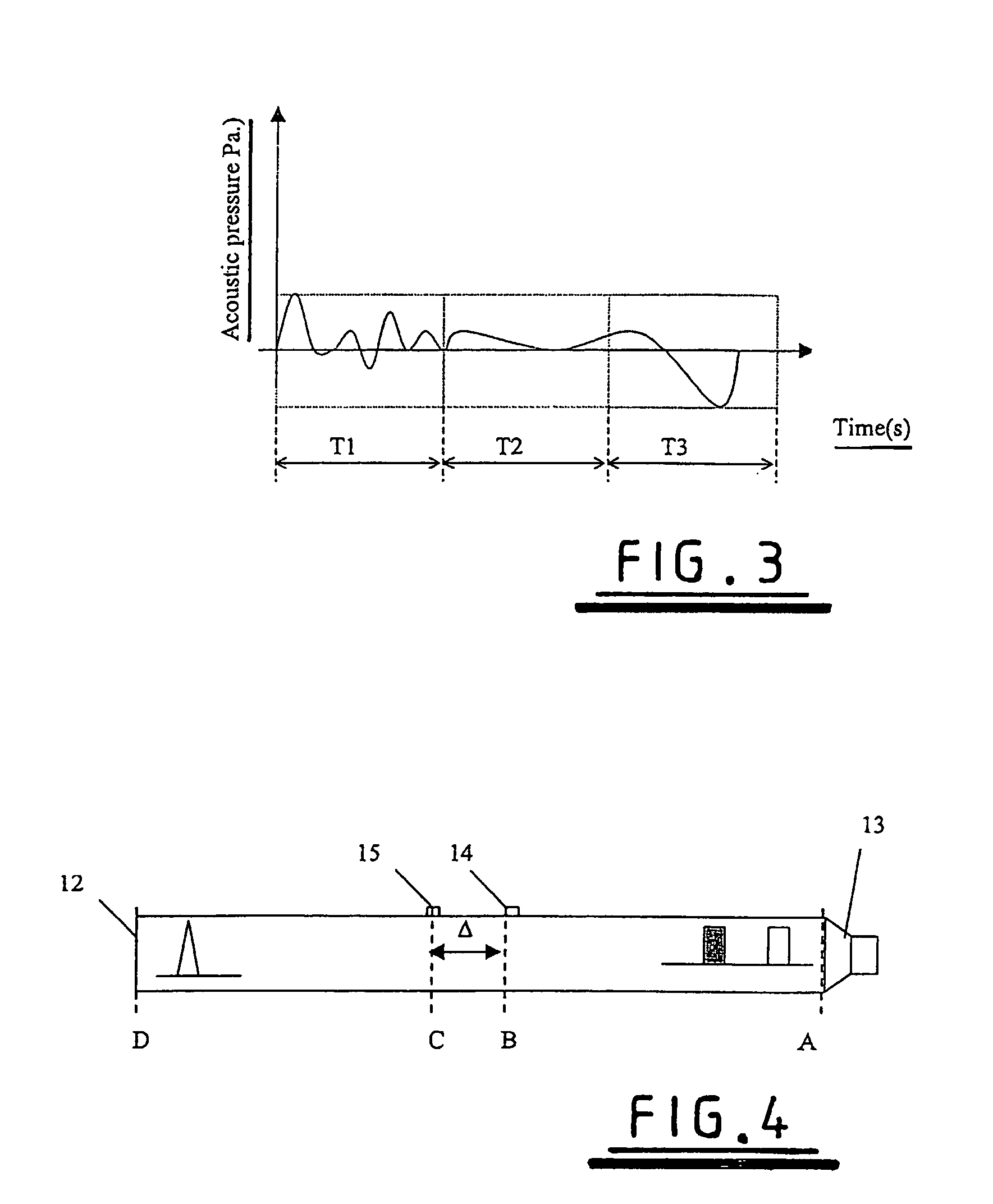

Remote pipeline acoustic inspection

InactiveUS7266992B2Reduce complexityReduce the amount requiredDetection of fluid at leakage pointAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineering

A pipe inspection apparatus comprising an acoustic source (3) for location at a first position in a pipe or pipe network, one or more acoustic or pressure detectors (4) for location at one or more positions in the pipe or pipe network, means for recording and / or displaying a signal detected by the one or more detectors following the generation of an acoustic pulse, and means for allowing the comparison of the detected signal with a predetermined reference signal, differences between the detected and reference signals being indicative of a blockage or leakage in the pipe or pipe network (10).

Owner:UNIV OF MANCHESTER

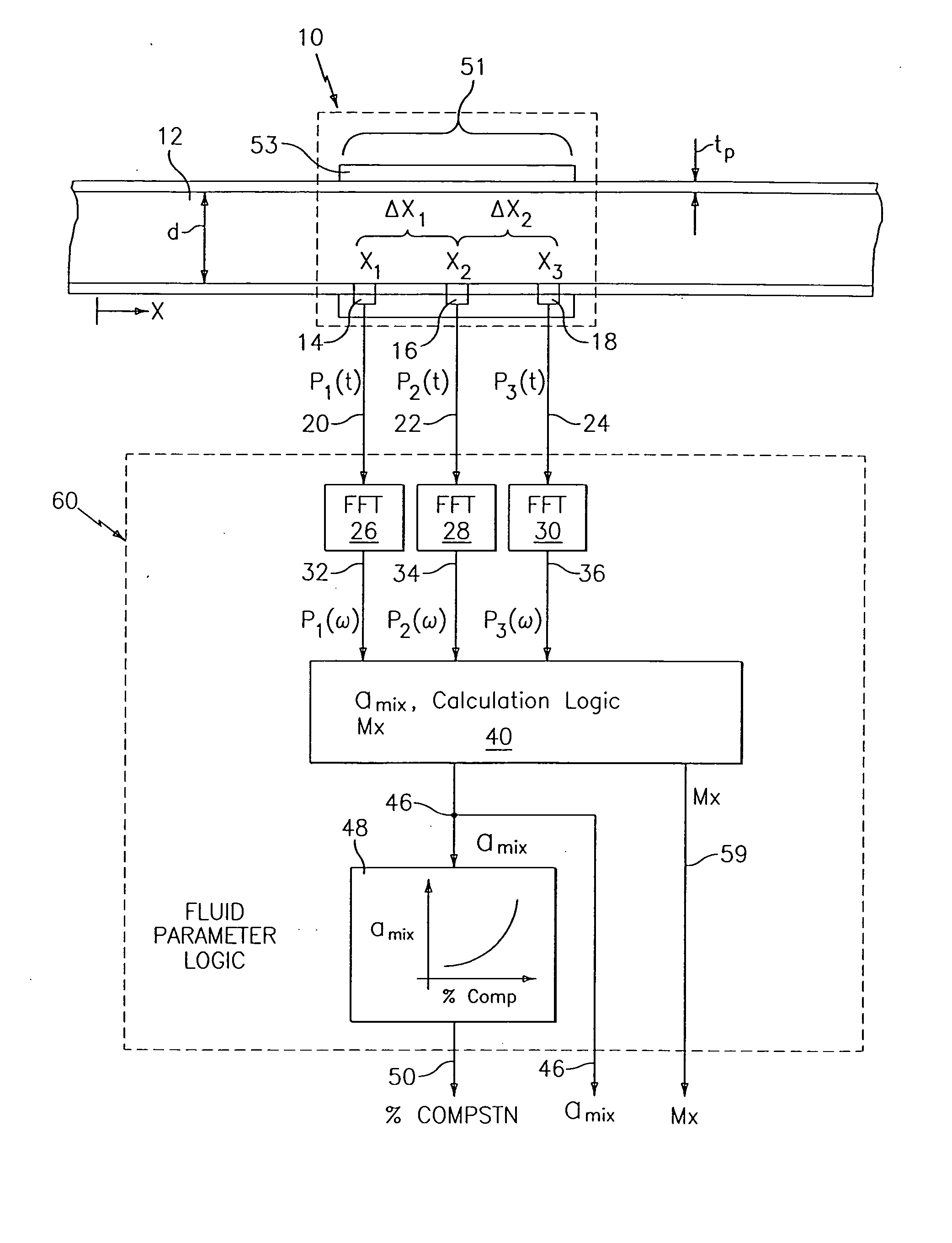

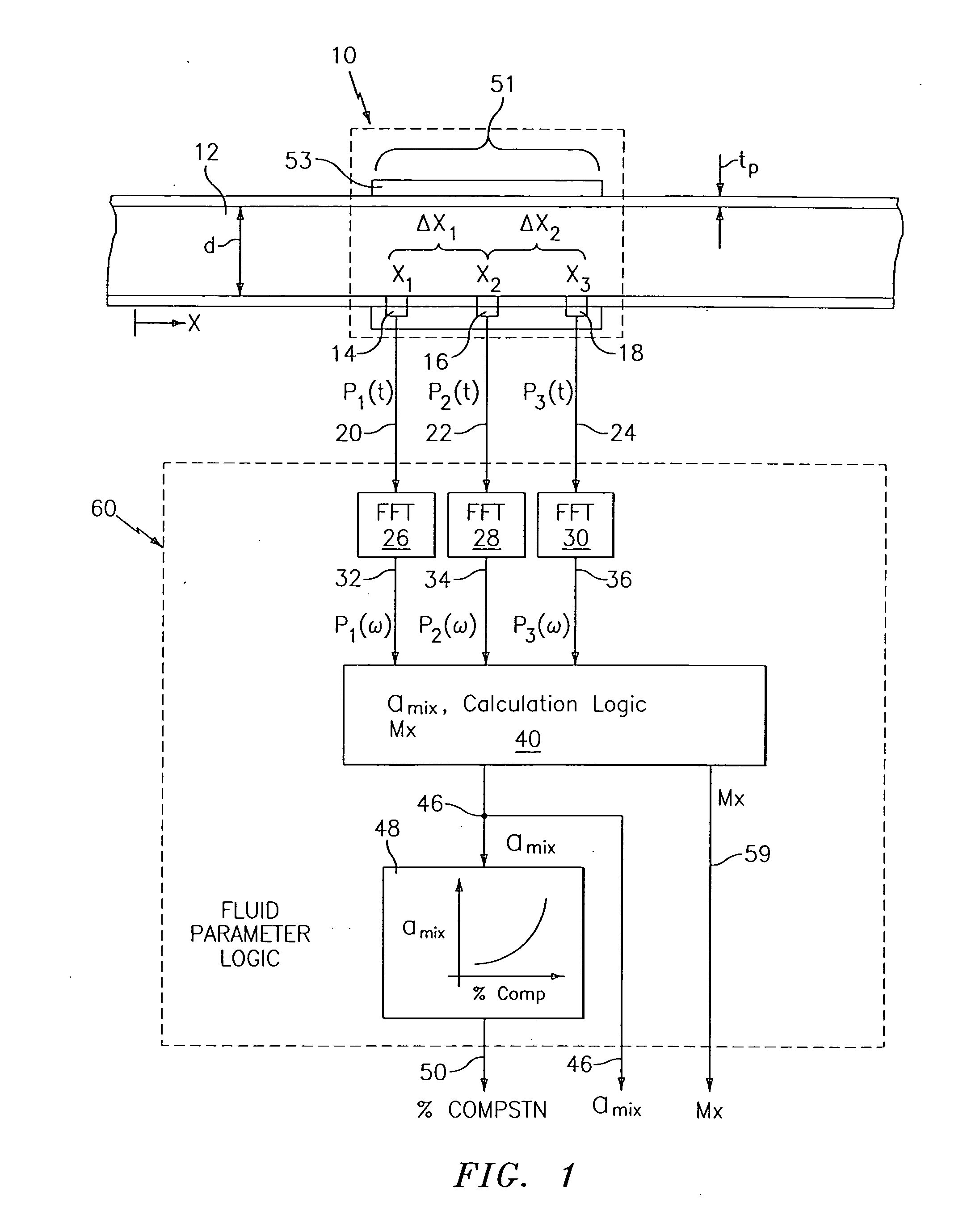

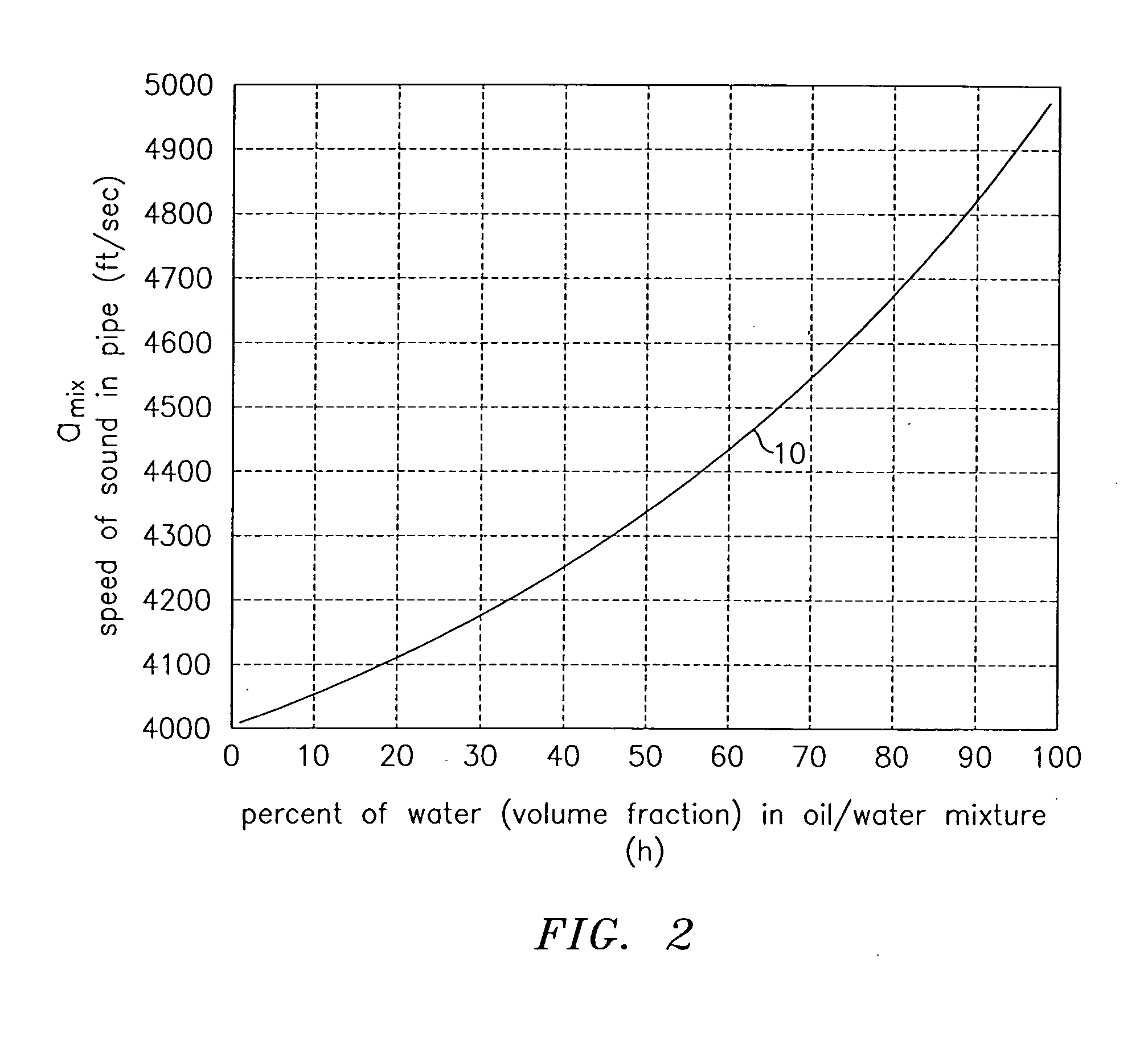

Fluid parameter measurement for industrial sensing applications using acoustic pressures

InactiveUS20050000289A1Less sensitiveImprove measurement reliabilityVibration measurement in solidsVibration measurement in fluidEngineeringOpto electronic

In industrial sensing applications at least one parameter of at least one fluid in a pipe 12 is measured using a spatial array of acoustic pressure sensors 14,16,18 placed at predetermined axial locations x1, x2, x3 along the pipe 12. The pressure sensors 14,16,18 provide acoustic pressure signals P1(t), P2(t), P3(t) on lines 20,22,24 which are provided to signal processing logic 60 which determines the speed of sound amix of the fluid (or mixture) in the pipe 12 using acoustic spatial array signal processing techniques with the direction of propagation of the acoustic signals along the longitudinal axis of the pipe 12. Numerous spatial array-processing techniques may be employed to determine the speed of sound amix. The speed of sound amix is provided to logic 48, which calculates the percent composition of the mixture, e.g., water fraction, or any other parameter of the mixture, or fluid, which is related to the sound speed amix. The logic 60 may also determine the Mach number Mx of the fluid. The acoustic pressure signals P1(t), P2(t), P3(t) measured are lower frequency (and longer wavelength) signals than those used for ultrasonic flow meters, and thus is more tolerant to inhomogeneities in the flow. No external source is required and thus may operate using passive listening. The invention will work with arbitrary sensor spacing and with as few as two sensors if certain information is known about the acoustic properties of the system. The sensor may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

Popular searches

Machine gearing/transmission testing Flow properties Linear/angular speed measurement Machines/engines Level indicators Special data processing applications Indication of measured values Subsonic/sonic/ultrasonic wave measurement Digital computer details Fluid pressure measurement by mechanical elements

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com