Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11291 results about "Process control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic process control in continuous production processes is a combination of control engineering and chemical engineering disciplines that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. It is implemented widely in industries such as oil refining, pulp and paper manufacturing, chemical processing and power generating plants.

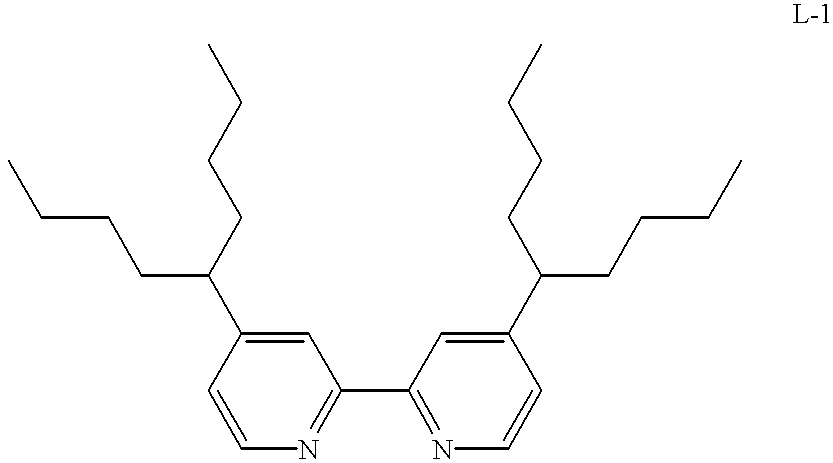

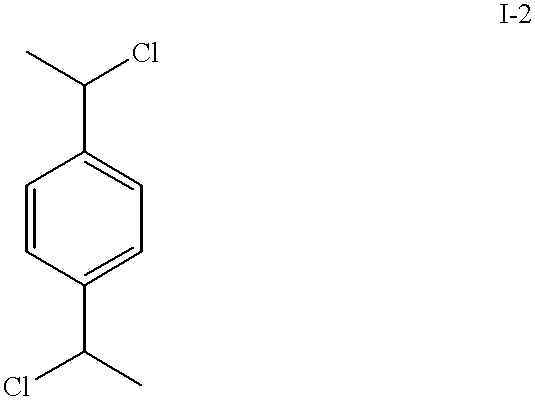

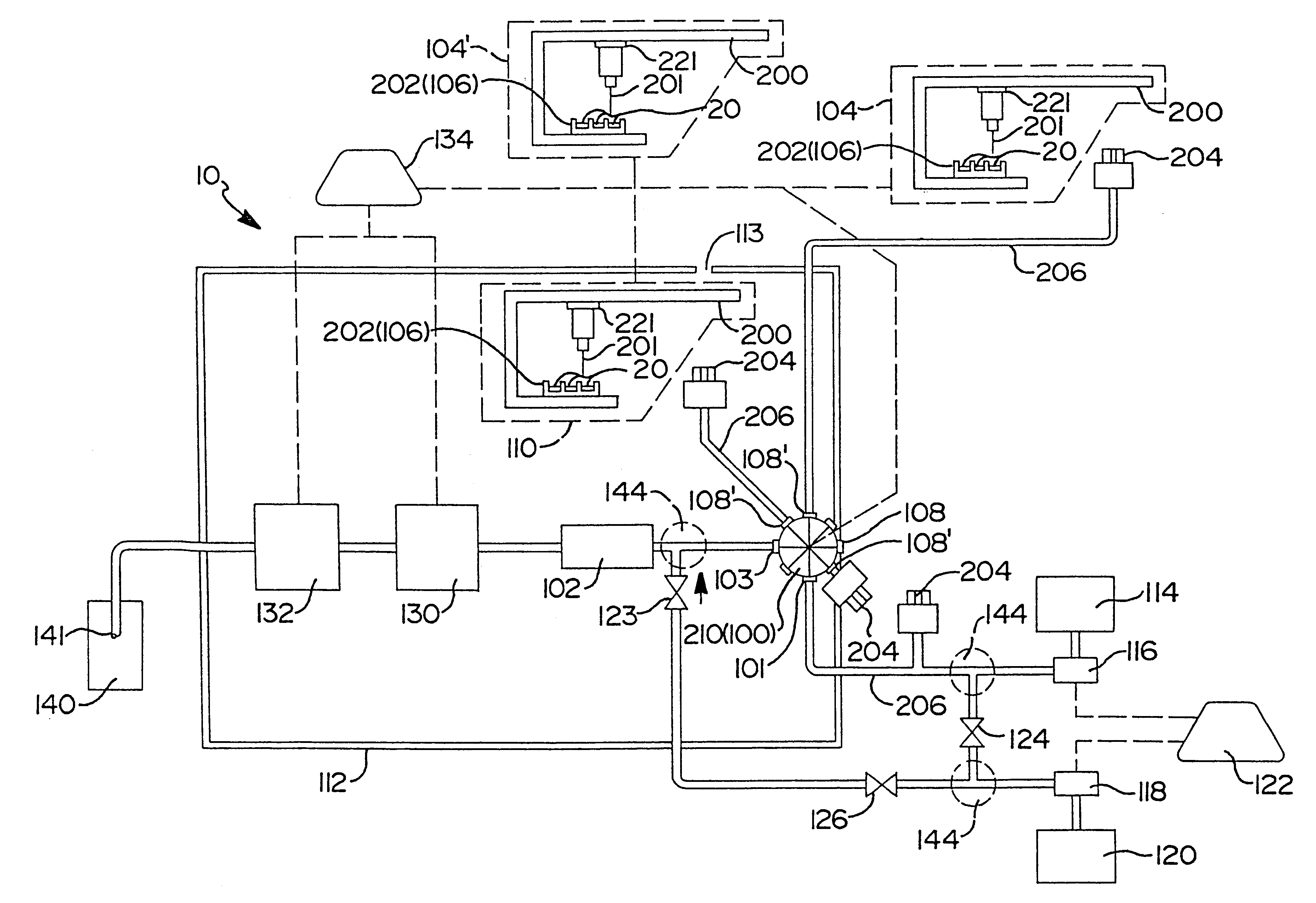

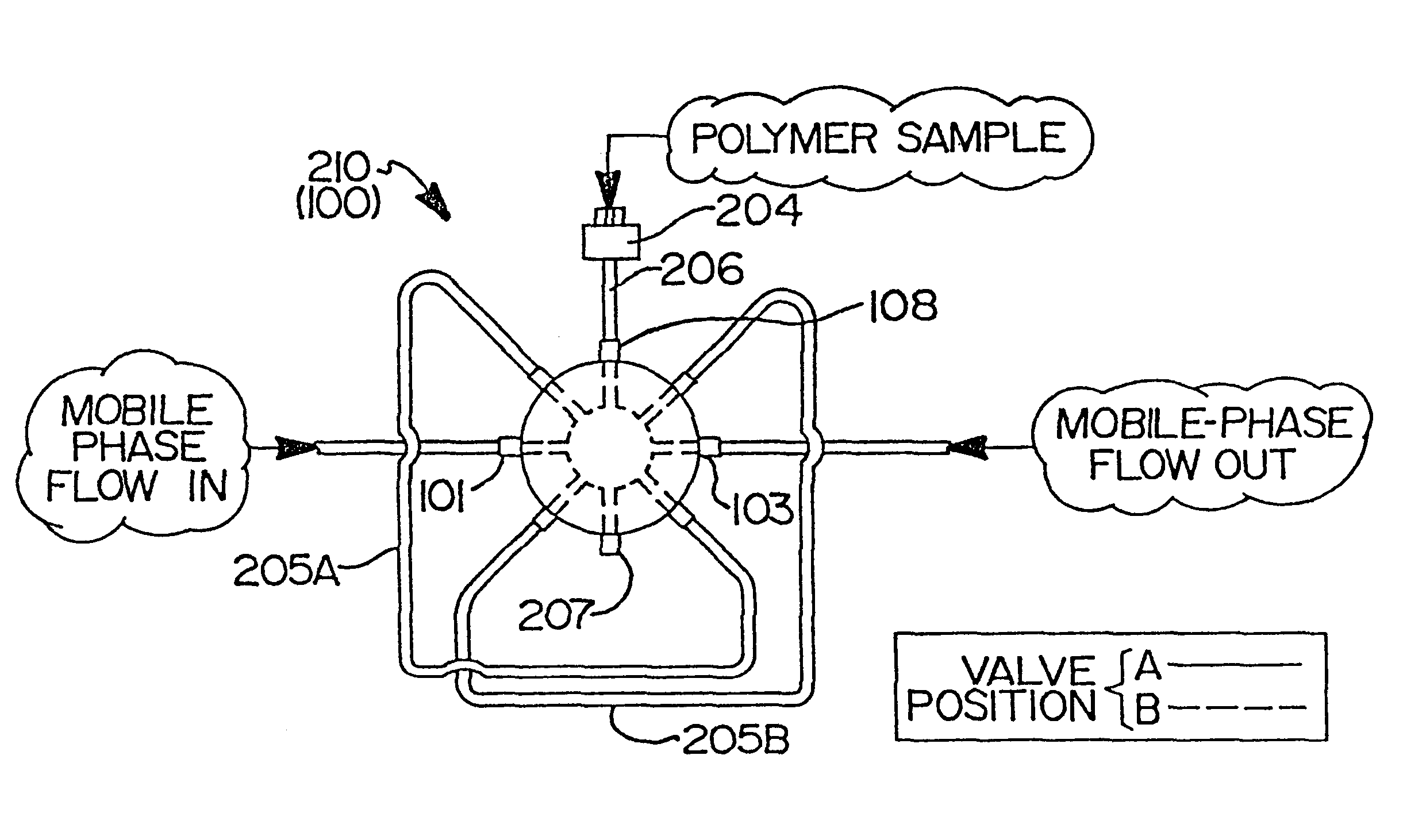

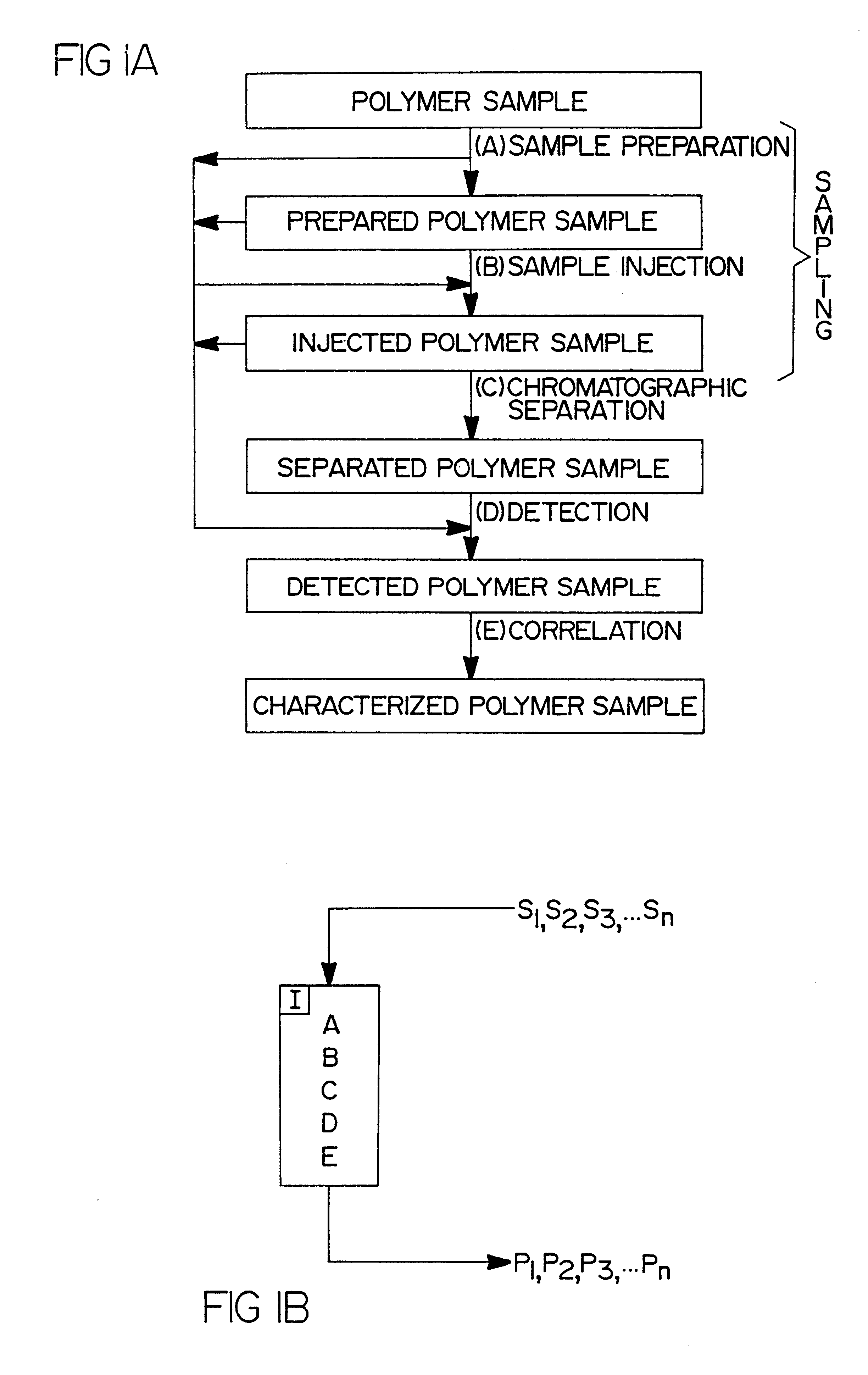

Flow-injection analysis and variable-flow light-scattering methods and apparatus for characterizing polymers

InactiveUS6175409B1Avoid backlogImprove throughputSequential/parallel process reactionsSamplingFlow injection analysisPolymer

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. The described methods, systems, and devices have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

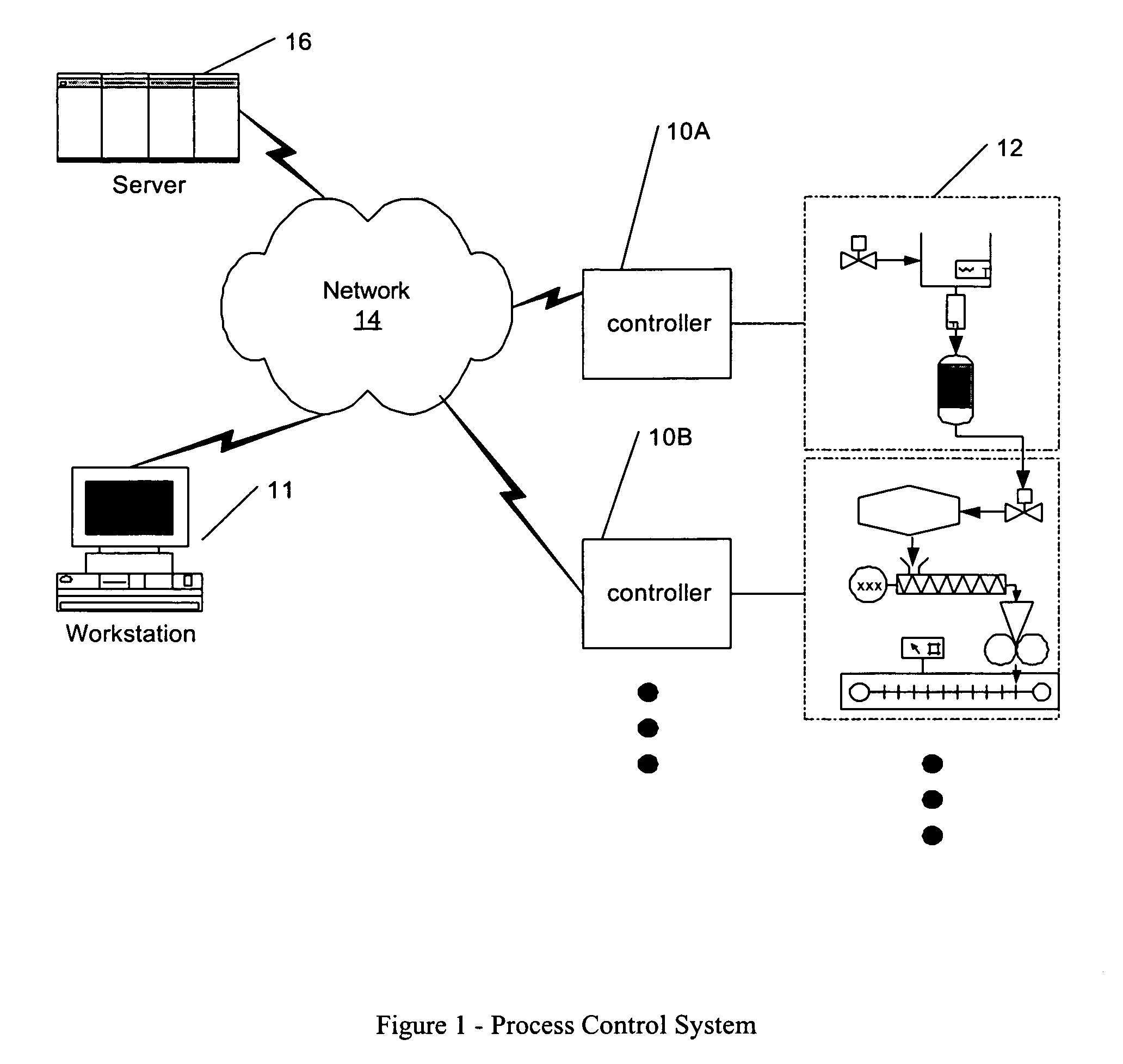

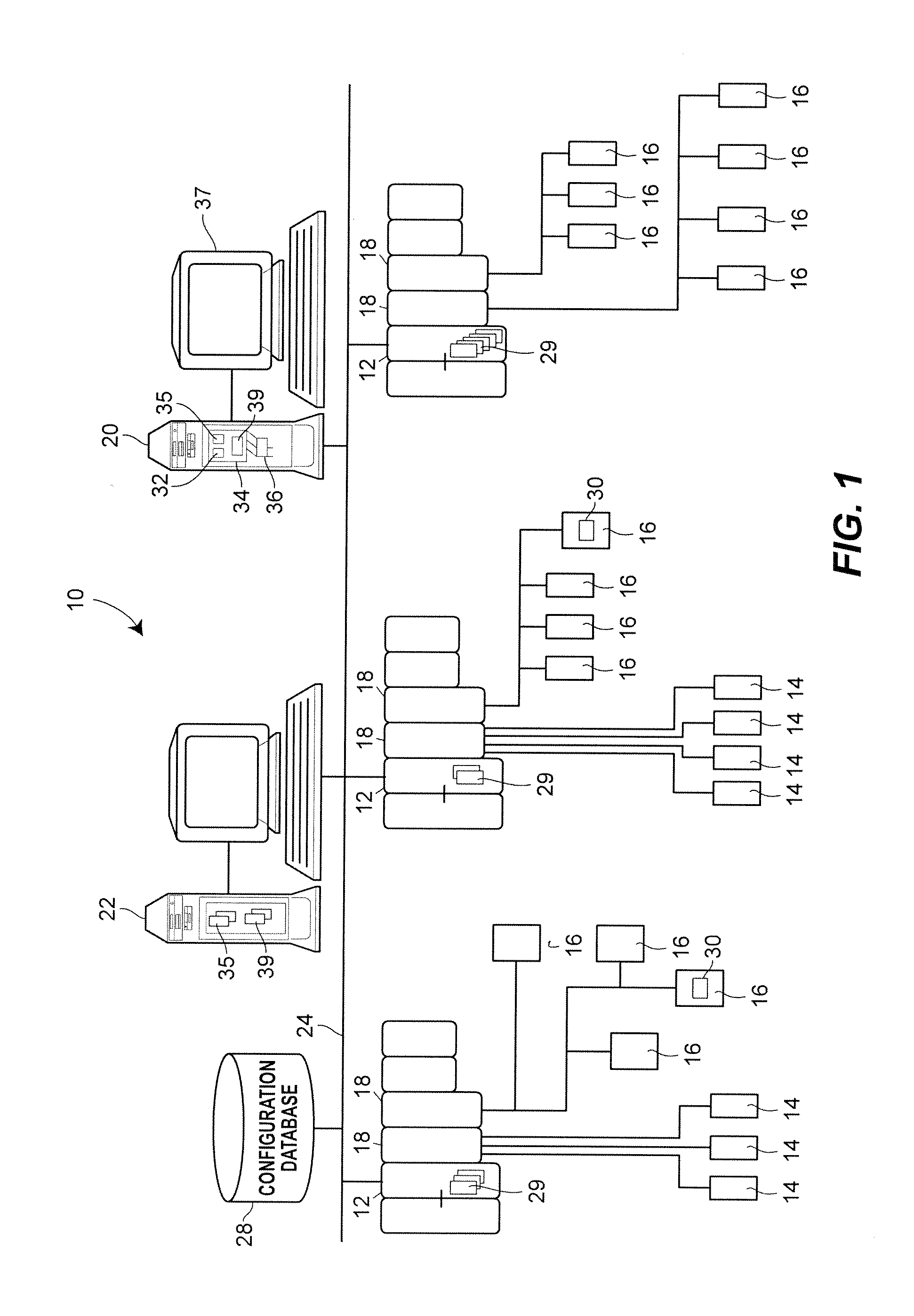

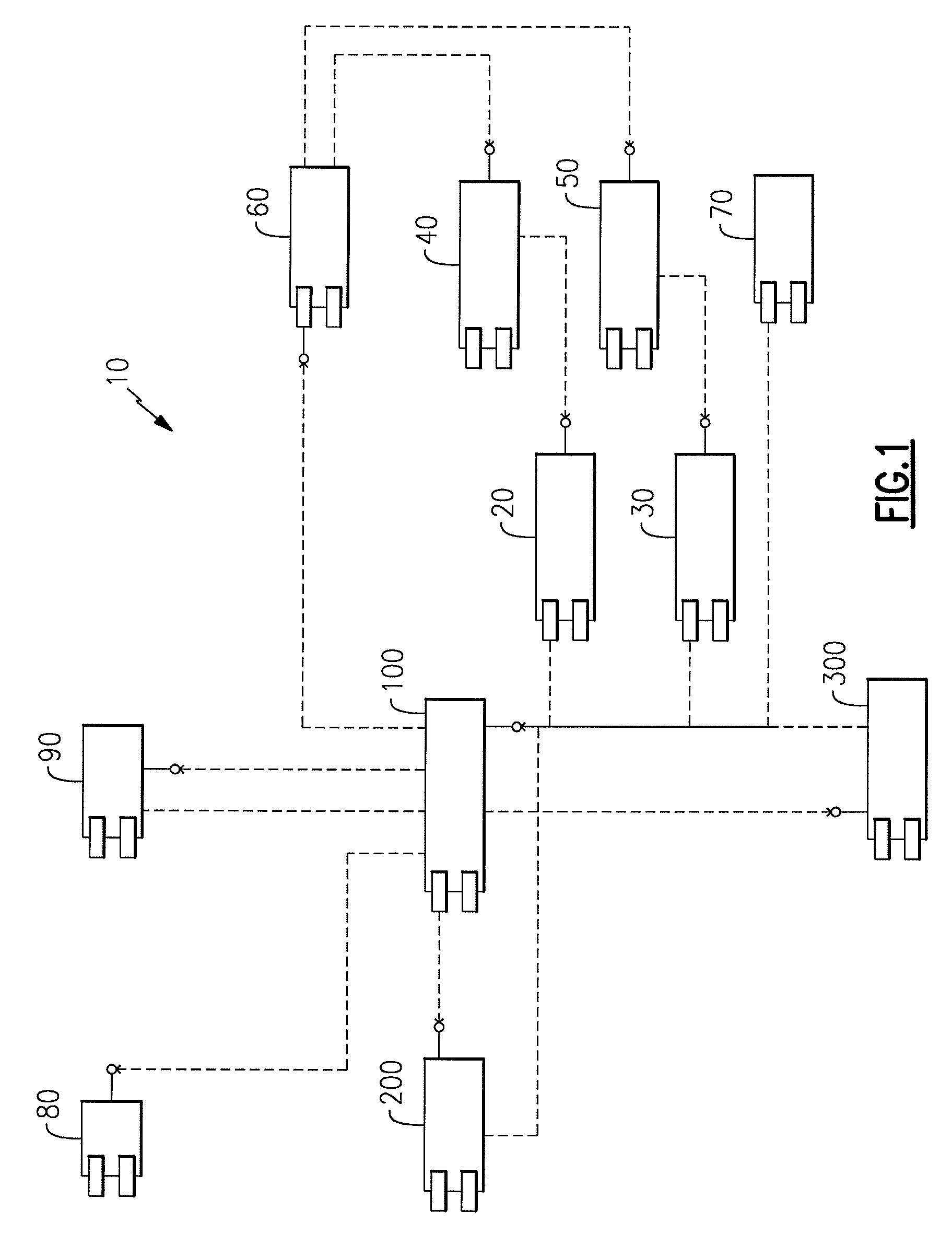

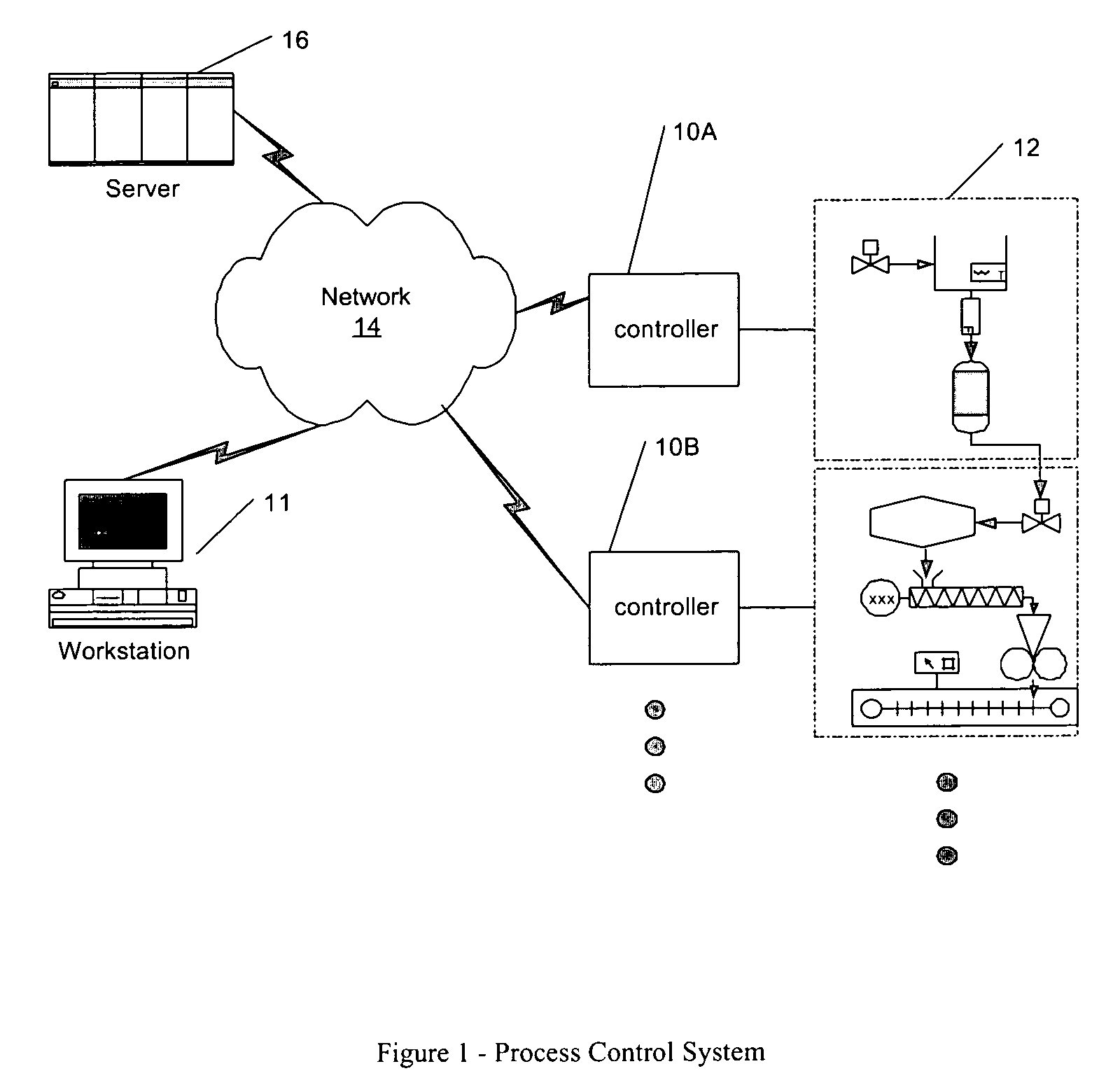

Process control configuration system with connection validation and configuration

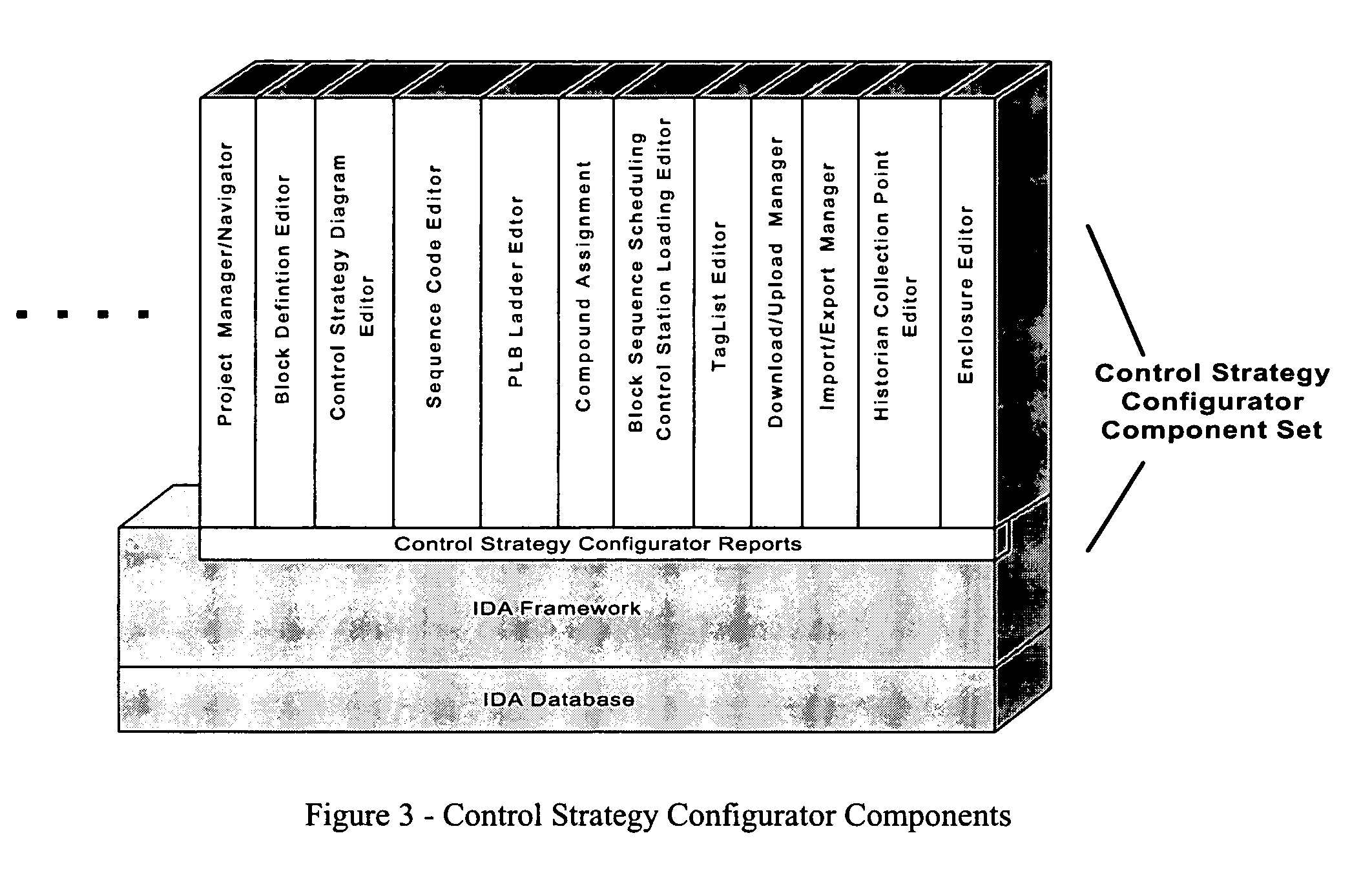

Connection objects or other such data structures facilitate establishing and configuring connections between objects that model components in a process control system. A first set of data structures (e.g. the object connection type structures) identify valid types for component-to-component pairings and the respective roles of each component in the pairing (e.g., parent or child, source or sink). A second set of data structures (e.g., the parameter connection type structures) supply similar information for parameter-to-parameter connections. Together, these data structures can be used, for example, to validate component-to-component connections suggested by the user and to automatically configure parameter-to-parameter connections. Actual connections, both at the component or parameter level, are reflected using parameter overrides within the parameterized object model—with which the connection objects are constructed.

Owner:SCHNEIDER ELECTRIC SYST USA INC

High-temperature characterization of polymers

InactiveUS6260407B1Avoid backlogImprove throughputSequential/parallel process reactionsComponent separationElutionChromatography column

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. In preferred high-temperature embodiments, the polymer sample is maintained at a temperature of not less than about 75° C. during sample preparation, loading into a liquid chromatography or flow-injection analysis system, injection into a mobile phase of a liquid chromatography or flow-injection analysis system, and / or elution from chromatographic column. The described methods, systems, and device have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

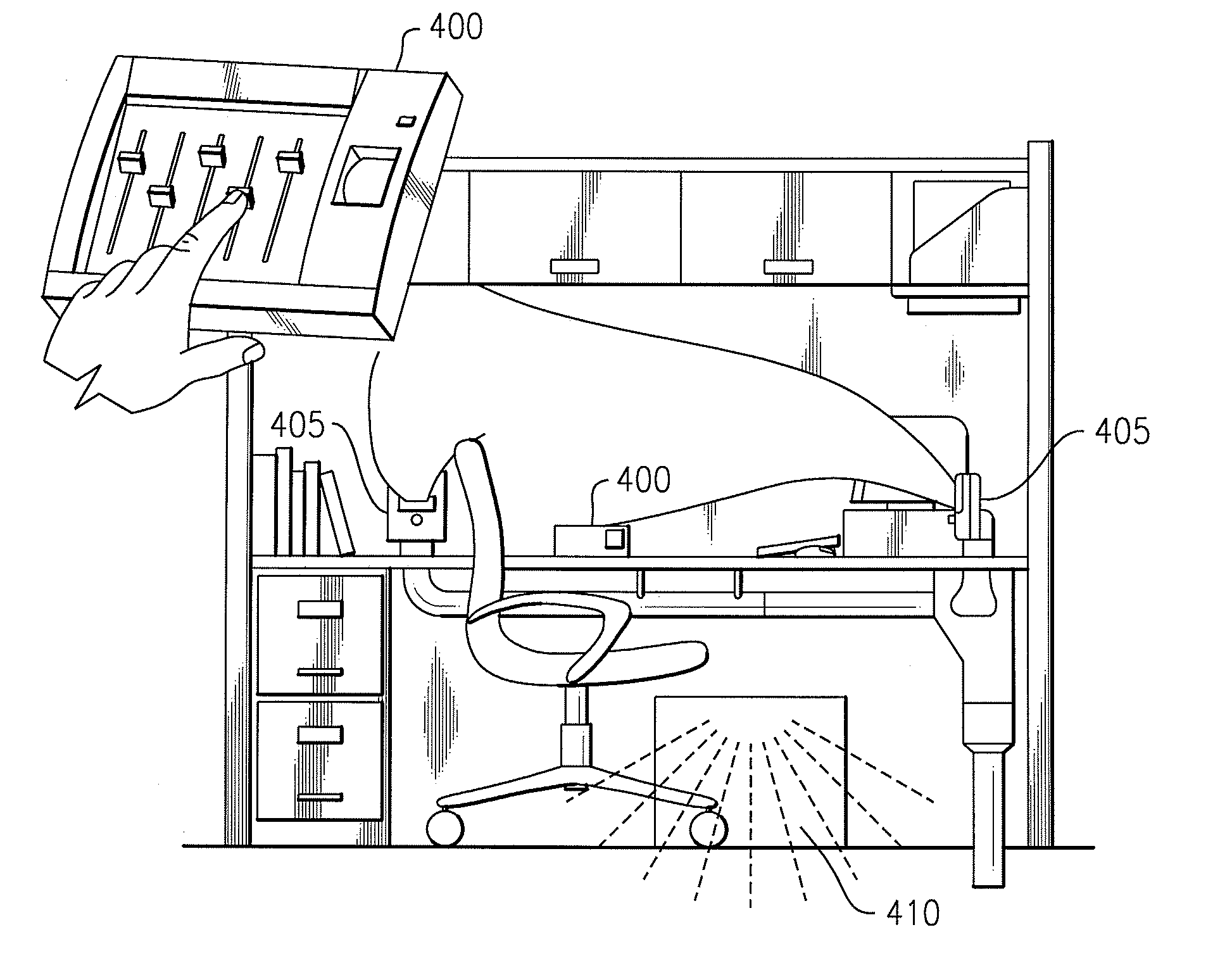

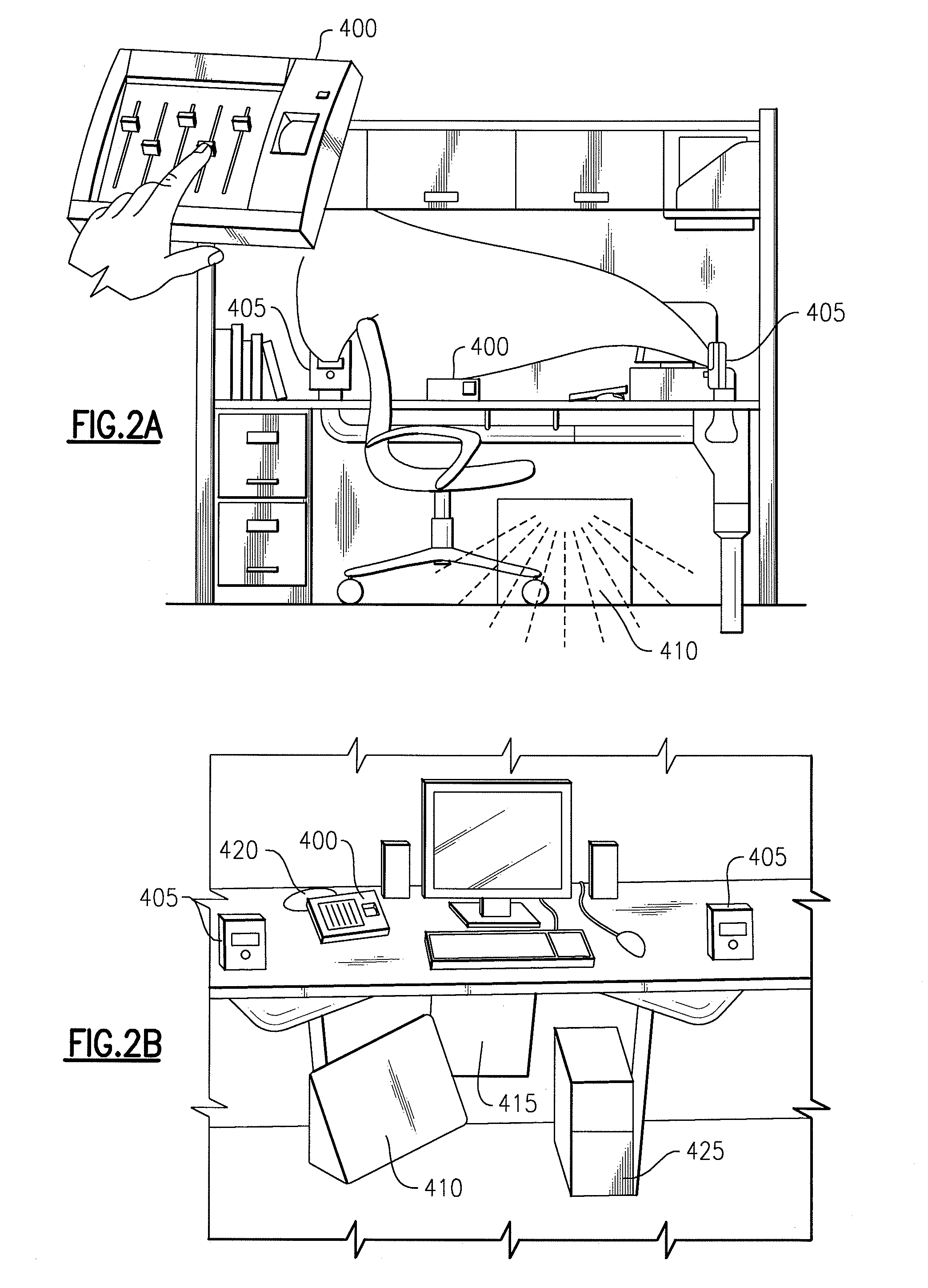

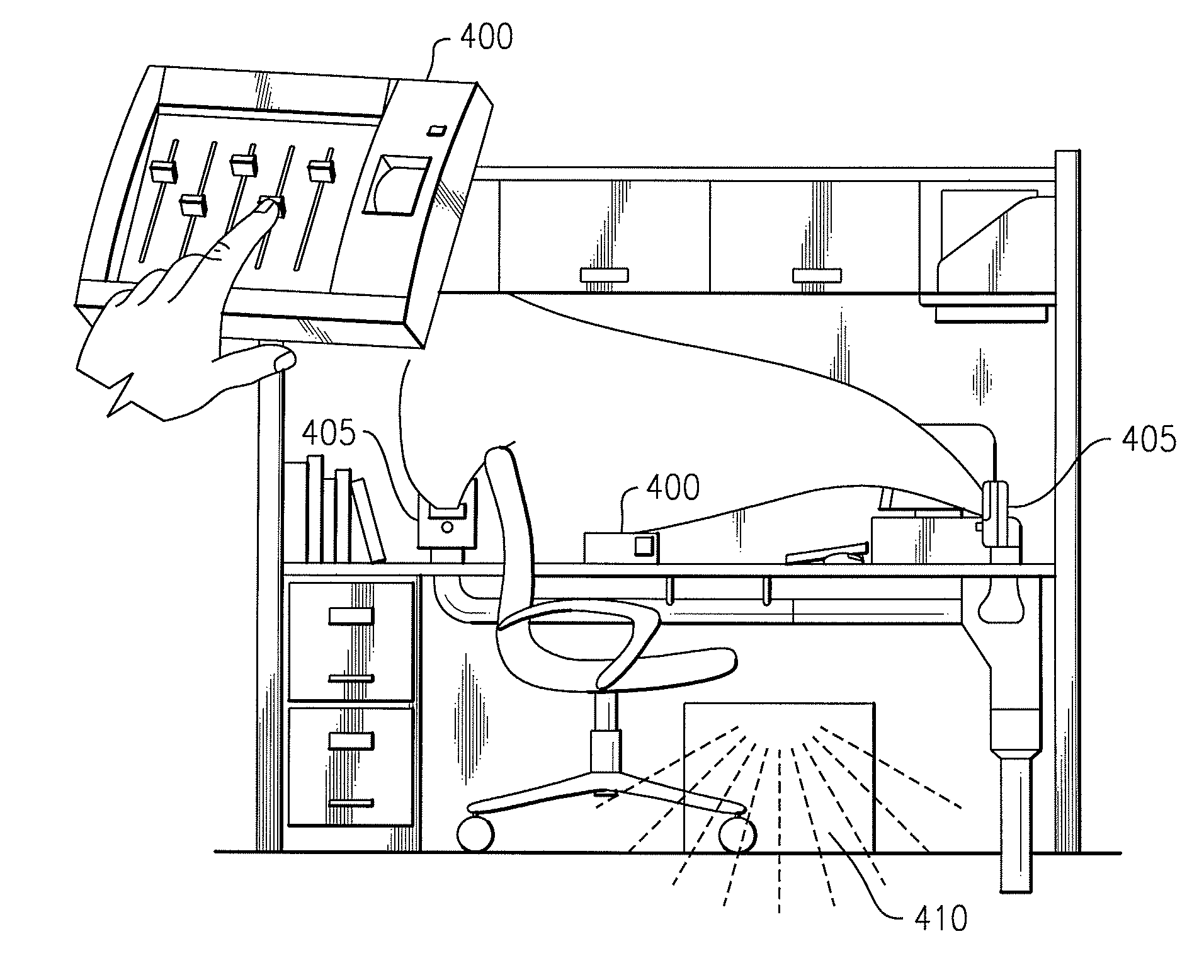

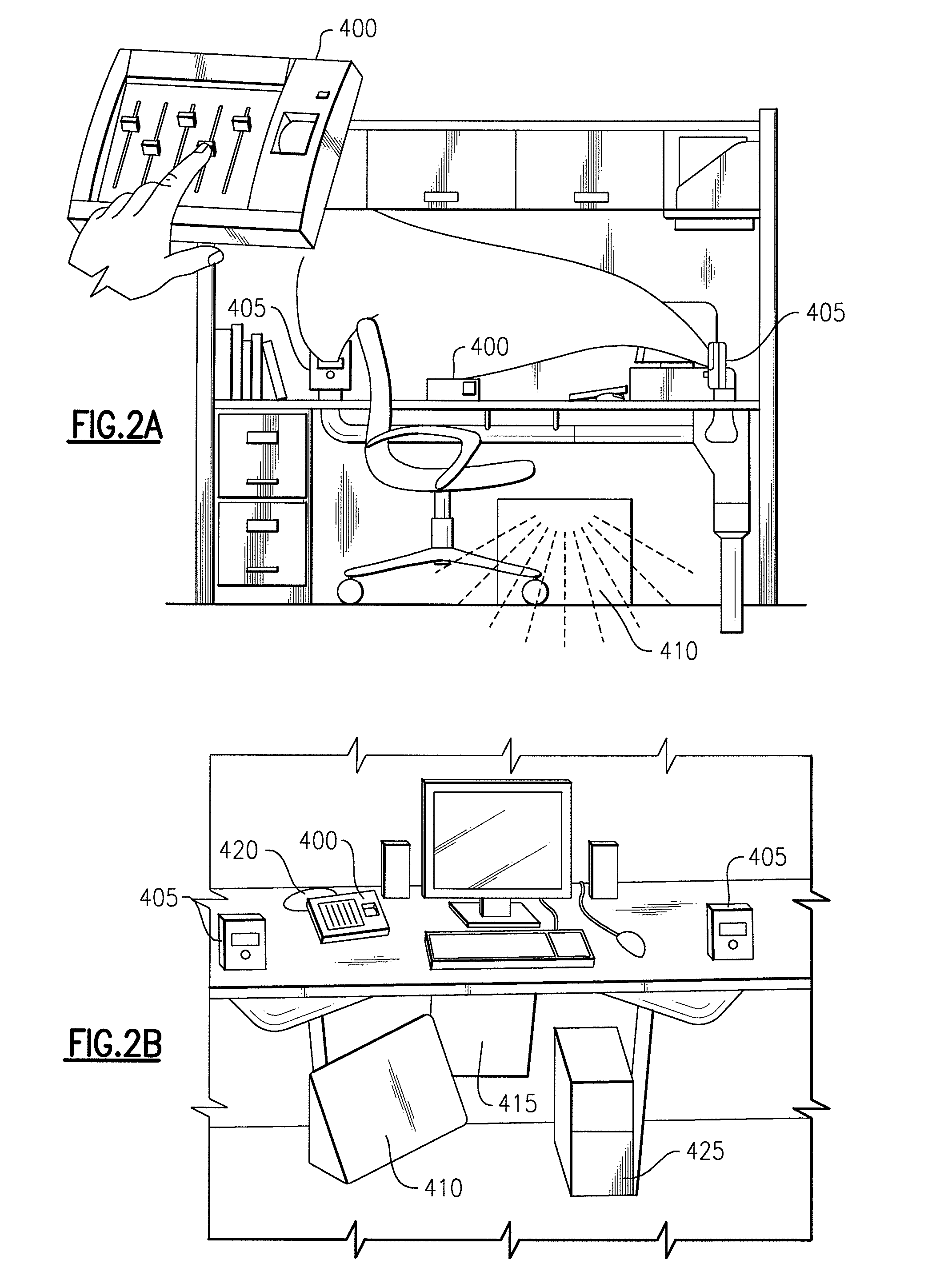

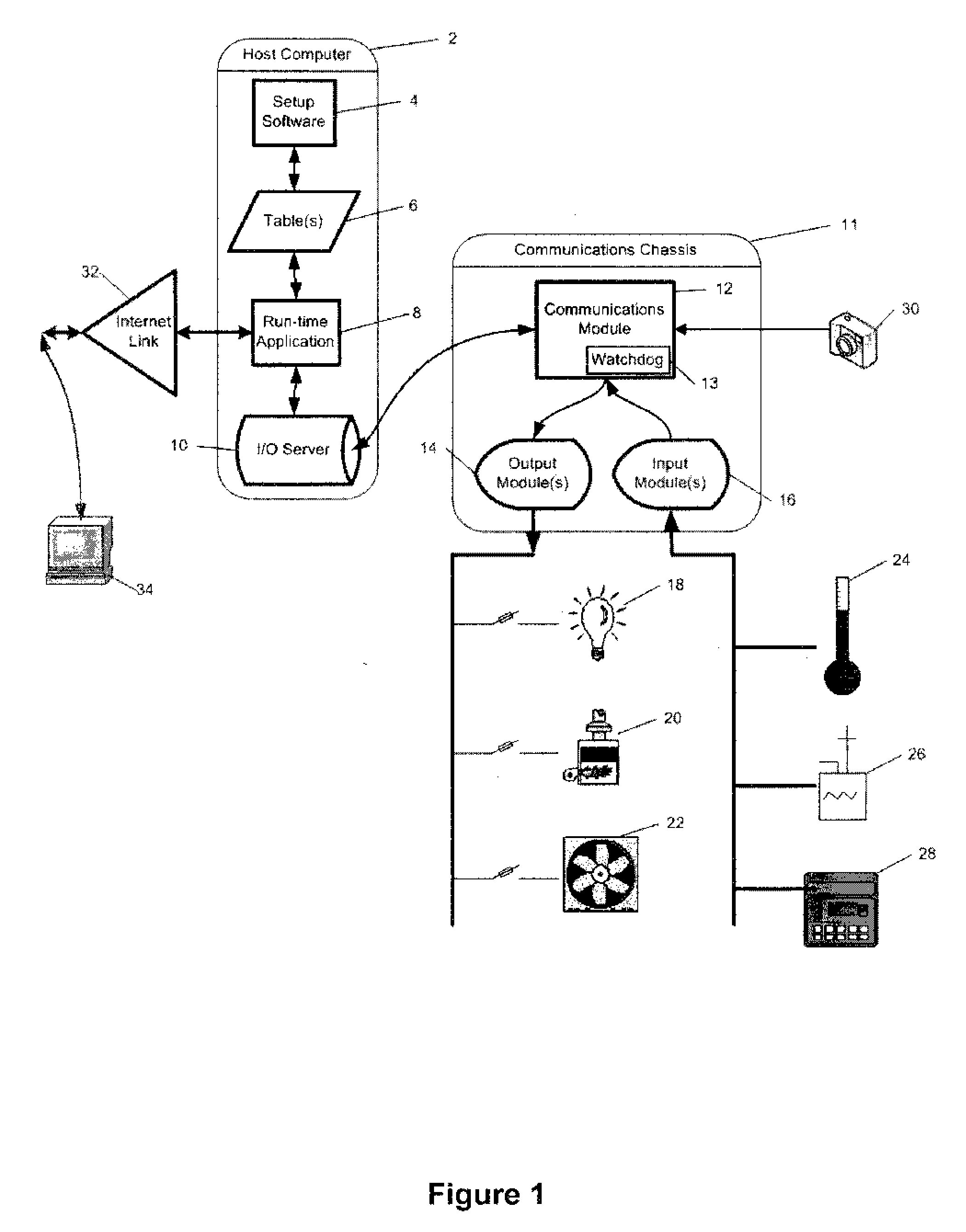

Open Web Services-Based Indoor Climate Control System

InactiveUS20080281472A1Improve productivityCost of sameProgramme controlSampled-variable control systemsReal-time Control SystemWeb service

The present invention relates generally to a building automation system, and, more particularly, to an Internet-centric, open, extensible software and hardware framework supporting all aspects of control and monitoring of a smart building ecosphere. The present invention further relates to an “intelligent,” real-time control system capable of both autonomous process control and interaction with system users and system administrators, which is configured to accommodate functional extensions and a broad array of sensors and control devices. The system allows individuals to communicate, monitor and adjust their personal environmental preferences (temperature, light, humidity, white noise, etc.) much like they would in an automobile, via the Internet. The system is equipped with an occupancy sensor that recognizes the presence and identity of the individual. A built-in expert system can make decisions based on data from multiple sources so that the system can alter its activity to conserve energy while maintaining users' comfort.

Owner:SYRACUSE UNIVERSITY

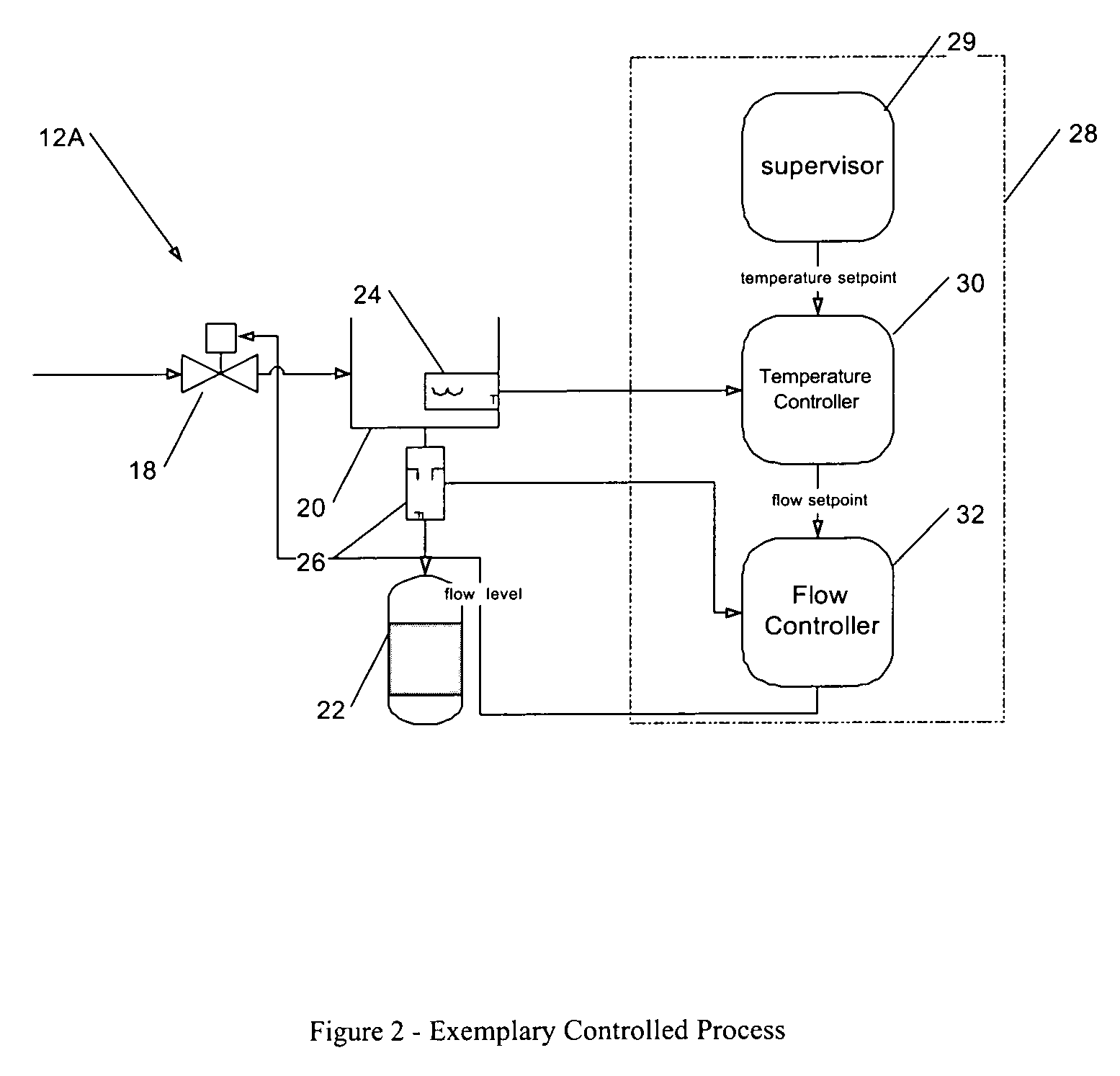

System for real-time economic optimizing of manufacturing process control

InactiveUS6038540AEasy to operateEasy to deployMarket predictionsComplex mathematical operationsProcess measurementSelf adaptive

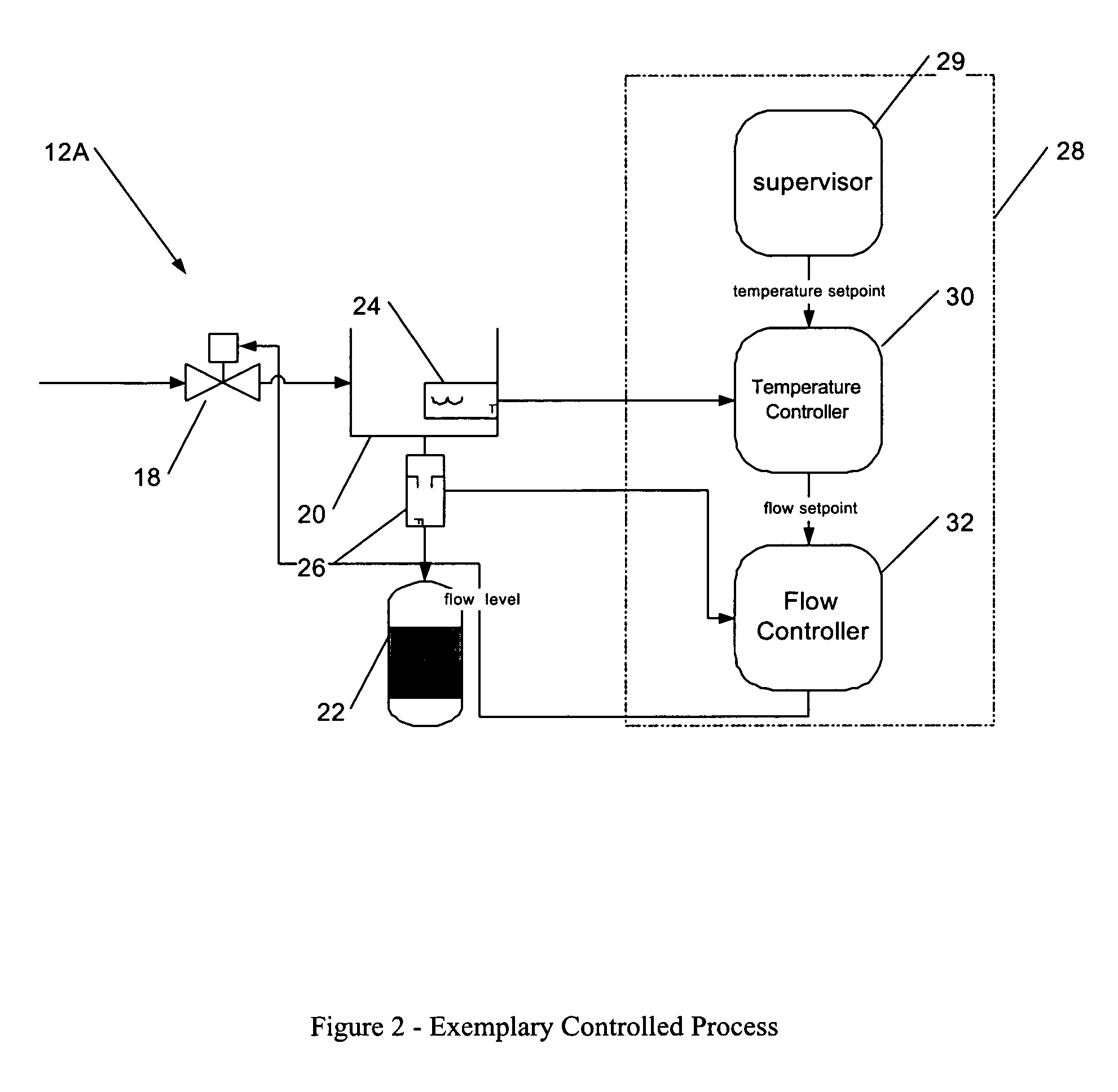

The present invention provides an adaptive process control and profit depiction system which is responsive to both process measurement input signals, economic inputs, and physical environment inputs. The process control system features an interactive optimization modeling system for determining manipulated process variables (also known as setpoints). These manipulated process variables are used to position mechanisms which control attributes of a manufacturing system, such as a valve controlling the temperature of a coolant or a valve controlling the flow rate in a steam line.

Owner:DOW GLOBAL TECH LLC

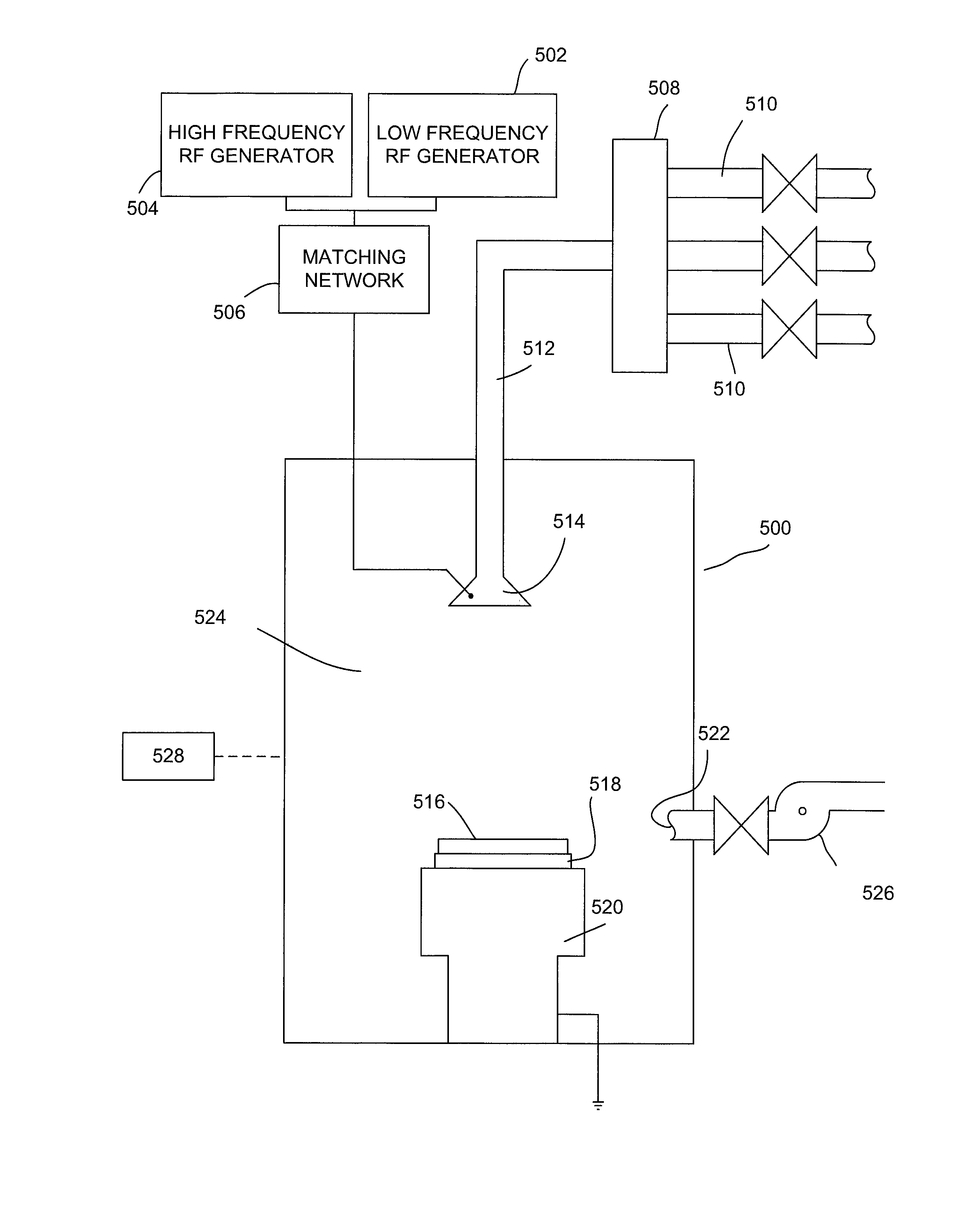

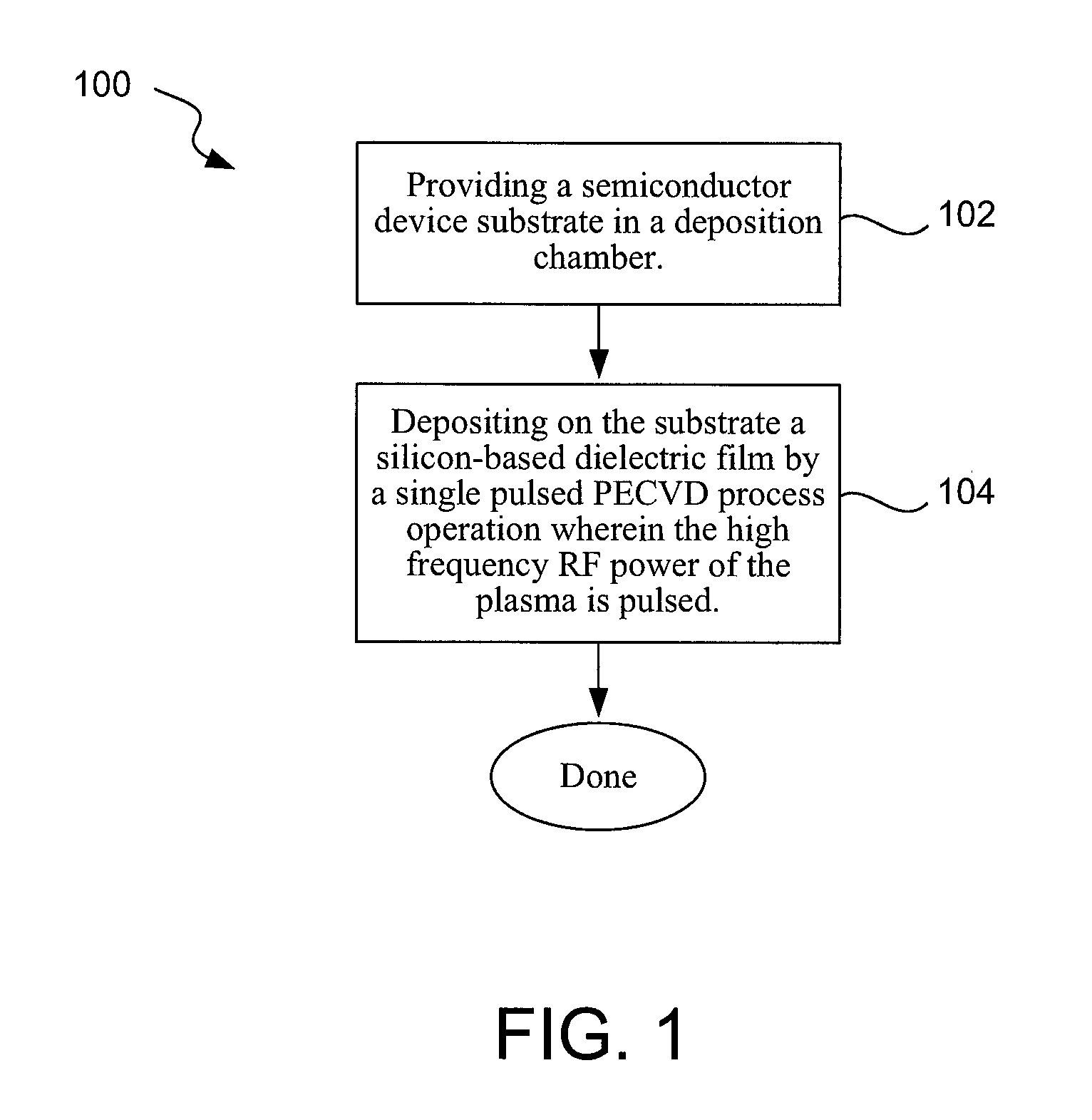

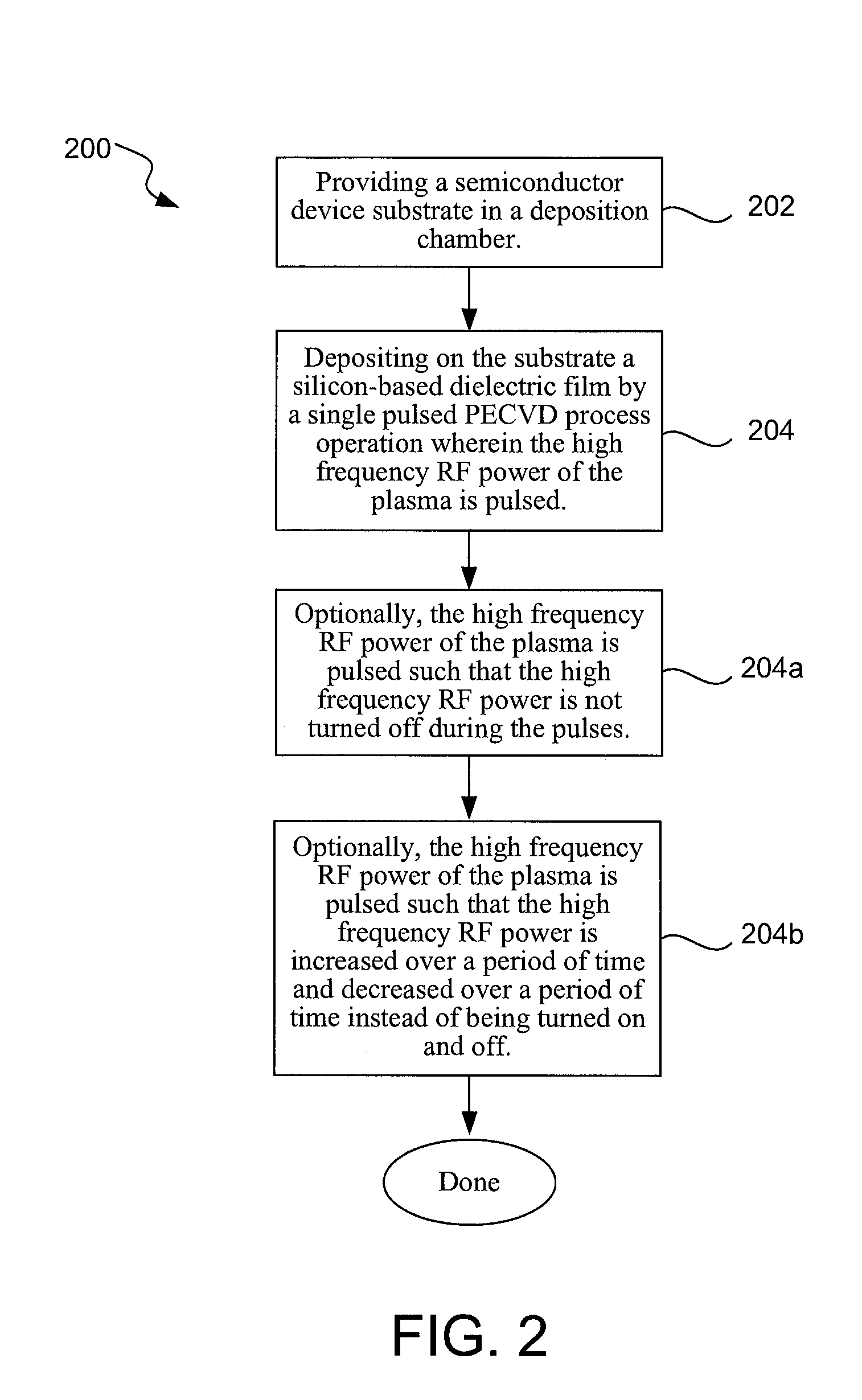

Method for improving process control and film conformality of PECVD film

ActiveUS7745346B2More controllable depositionIncrease depositionLiquid surface applicatorsSemiconductor/solid-state device manufacturingDielectricEngineering

A method for forming a silicon-based dielectric film on a substrate with a single deposition process operation using pulsed plasma enhanced chemical vapor deposition (PECVD) wherein the high frequency radio frequency power of the plasma is pulsed, allows enhanced control, efficiency and product quality of the PECVD process. Pulsing the high frequency RF power of the plasma reduces the deposited film thickness per unit time the high frequency RF power of the plasma is on. This yields silicon-based dielectric films that are both thin and conformal.

Owner:NOVELLUS SYSTEMS

Dynamic User Interface for Configuring and Managing a Process Control System

ActiveUS20120029661A1Reduce the number of timesImprove convenienceElectric controllersIgnition automatic controlControl systemComputerized system

A process control management method in a computer system for configuring and supervising a process plant includes providing an interactive user interface to manage a plurality of objects in the process plant, where each of the plurality of objects corresponds to a physical or logical entity in the process plant, including generating a navigation pane to display a set of selectable items, each in the set of selectable items corresponding to a respective one of the plurality of objects, and generating a command pane to display a set of selectable controls, each in the set of selectable controls corresponding to a task to be performed on at least one of the plurality of objects in the process plant; receiving a selection of one of an item in the set of selectable items via the navigation panel and a control in the set of selectable controls via the command panel; determining an operational context based on the received selection, wherein the operational context corresponds to one of a range of actions applicable to the selection if the selection is an item selection, or a range of items to which the selection is applicable if the selection is a control selection; and adjusting one of the navigation pane or the command pane according to the operational context, including displaying a subset of selectable items in the navigational pane, wherein each in the subset of selectable items is within the range applicable to the selection, if the selection is a control selection, and displaying a subset of selectable controls in the command pane, wherein each in the subset of selectable controls is within the range applicable to the selection, if the selection is an item selection.

Owner:FISHER-ROSEMOUNT SYST INC

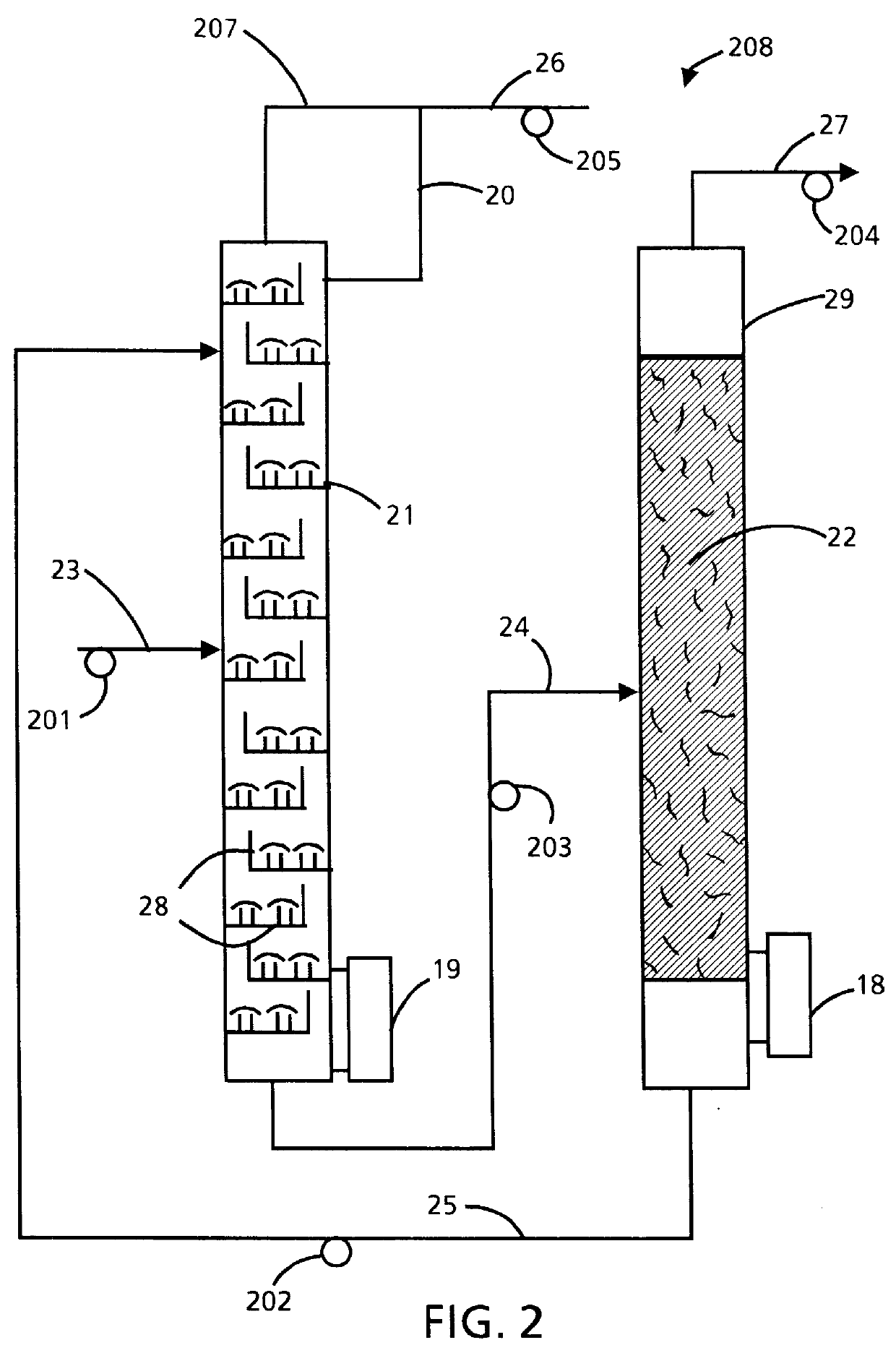

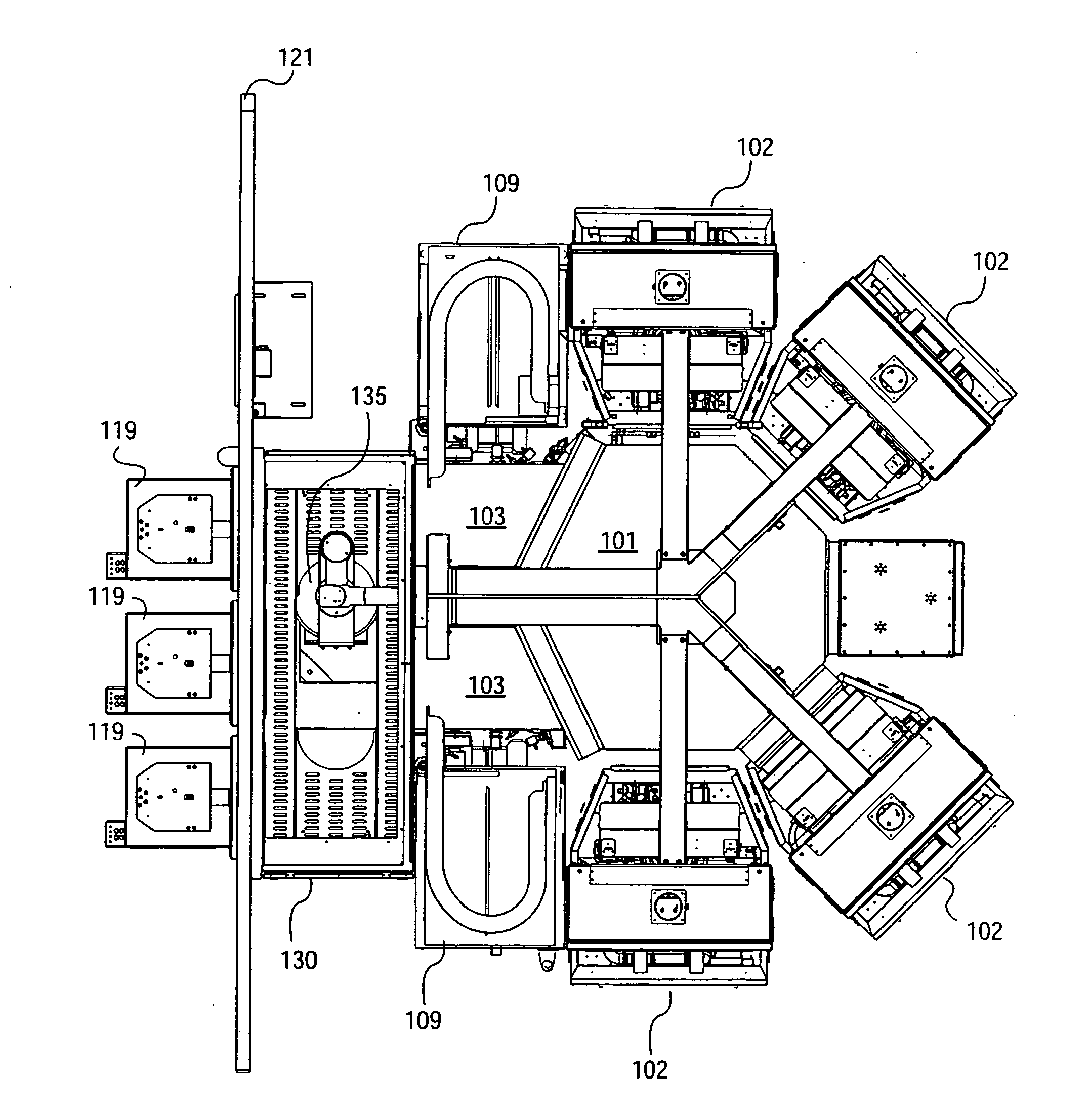

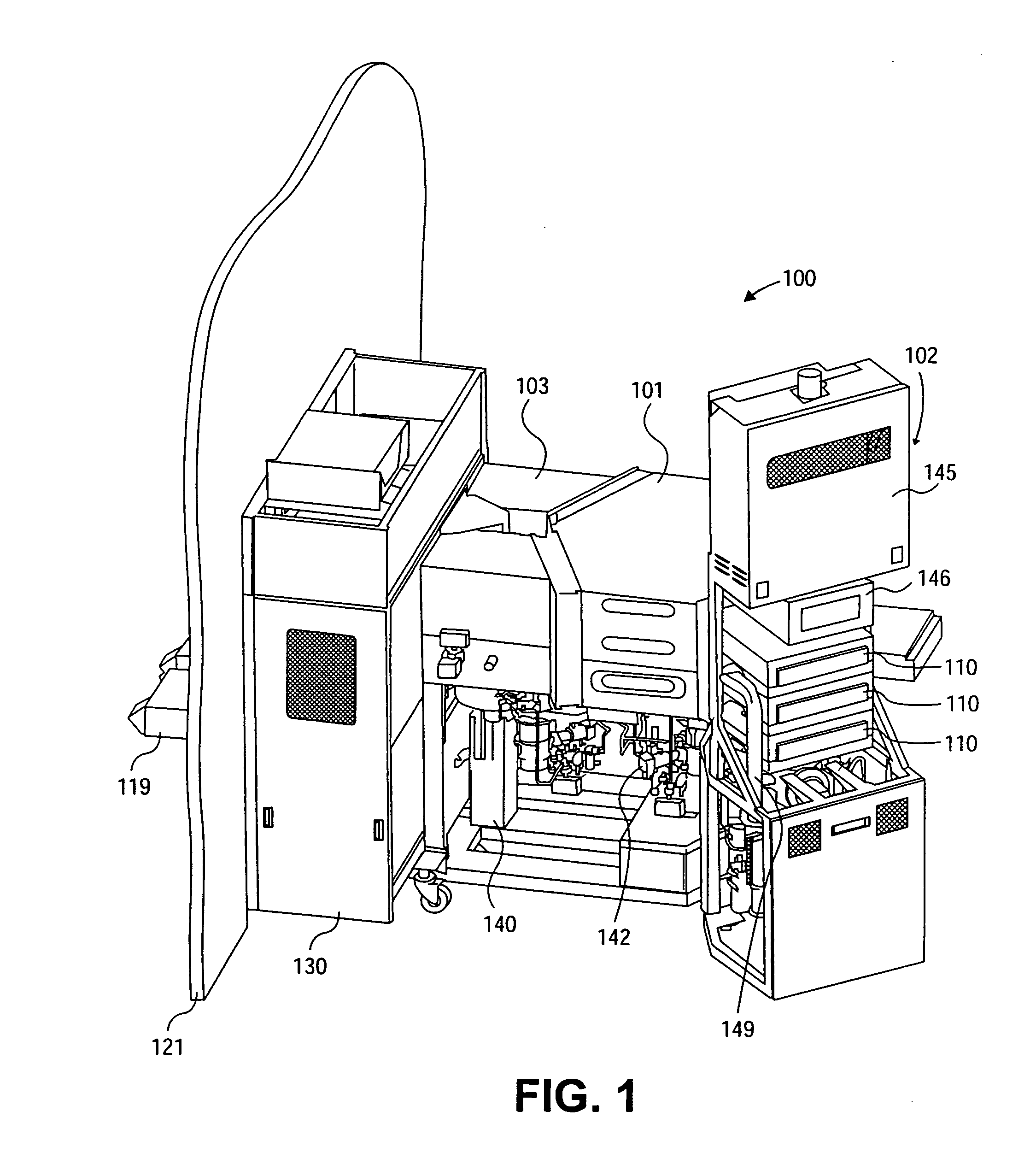

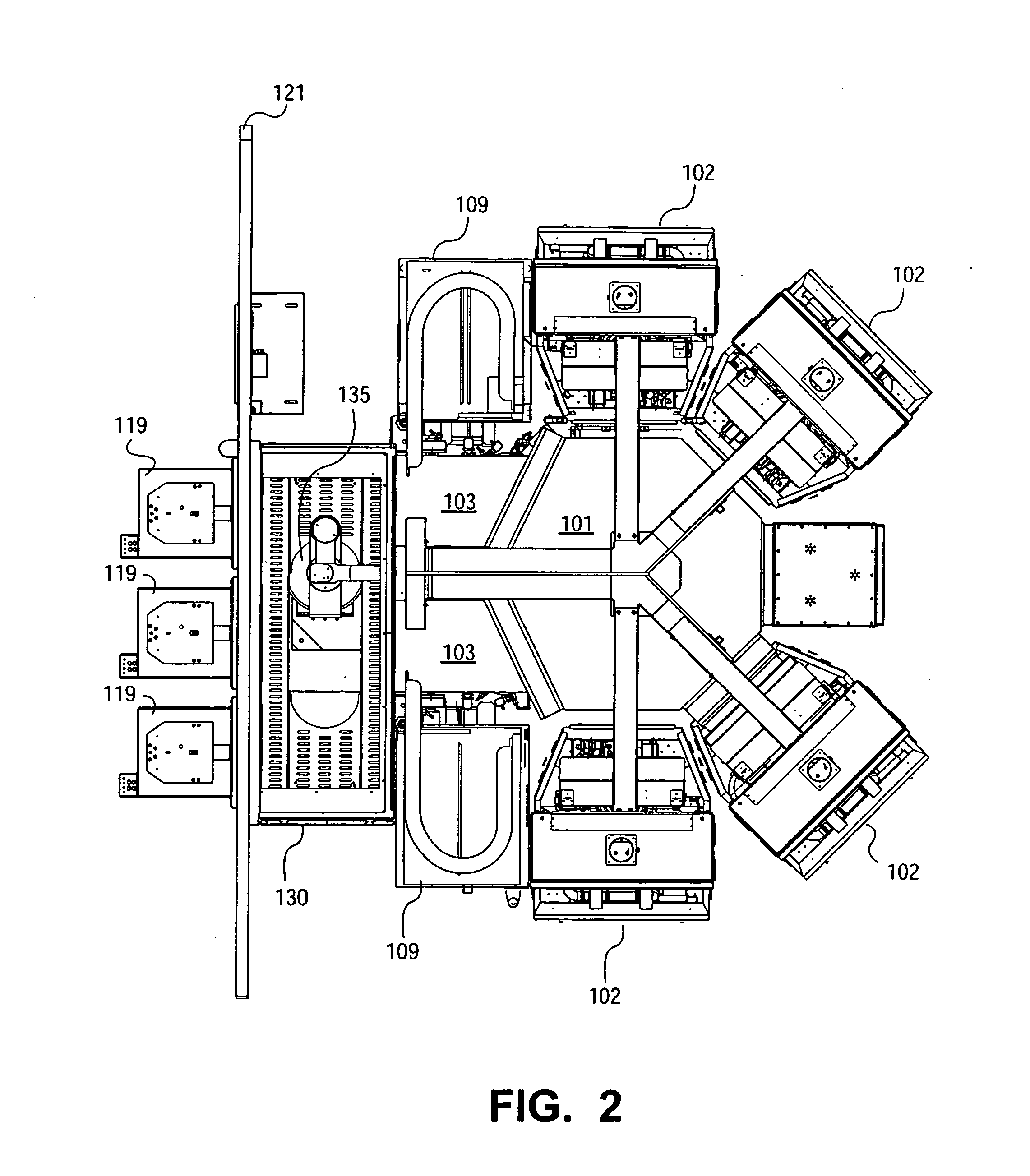

Massively parallel atomic layer deposition/chemical vapor deposition system

InactiveUS20050274323A1Improve generally axi-symmetric gas flowMinimizing vertical heightChemical vapor deposition coatingMassively parallelGas phase

A method and apparatus for the use of individual vertically stacked ALD or CVD reactors. Individual reactors are independently operable and maintainable. The gas inlet and output are vertically configured with respect to the reactor chamber for generally axi-symmetric process control. The chamber design is modular in which cover and base plates forming the reactor have improved flow design.

Owner:AIXTRON INC

Open web services-based indoor climate control system

InactiveUS7904209B2Improve productivityCost of sameProgramme controlSampled-variable control systemsReal-time Control SystemWeb service

The present invention relates generally to a building automation system, and, more particularly, to an Internet-centric, open, extensible software and hardware framework supporting all aspects of control and monitoring of a smart building ecosphere. The present invention further relates to an “intelligent,” real-time control system capable of both autonomous process control and interaction with system users and system administrators, which is configured to accommodate functional extensions and a broad array of sensors and control devices. The system allows individuals to communicate, monitor and adjust their personal environmental preferences (temperature, light, humidity, white noise, etc.) much like they would in an automobile, via the Internet. The system is equipped with an occupancy sensor that recognizes the presence and identity of the individual. A built-in expert system can make decisions based on data from multiple sources so that the system can alter its activity to conserve energy while maintaining users' comfort.

Owner:SYRACUSE UNIVERSITY

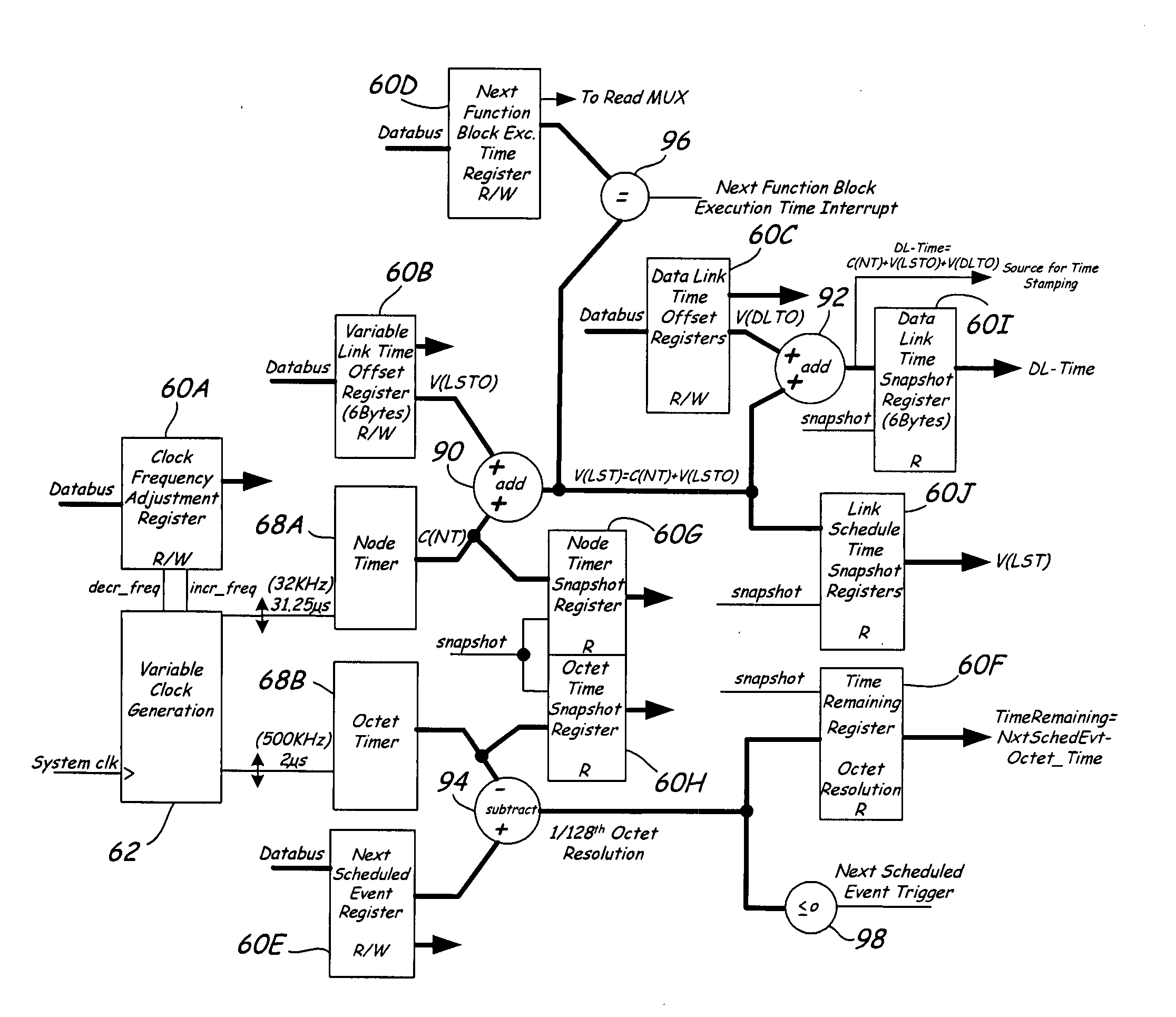

Communication controller with automatic time stamping

ActiveUS20060026314A1Programme controlInput/output to record carriersControl systemCommunication control

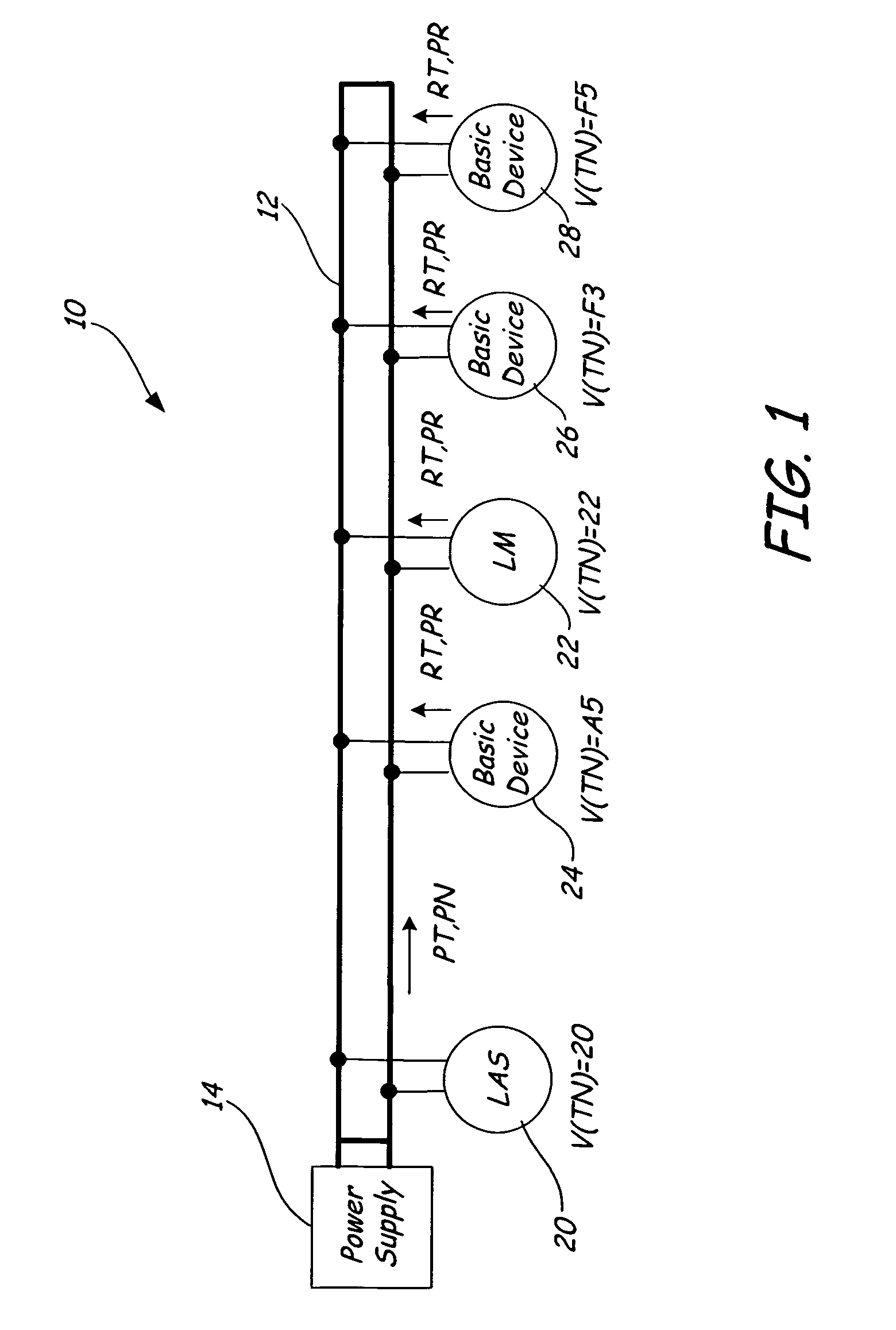

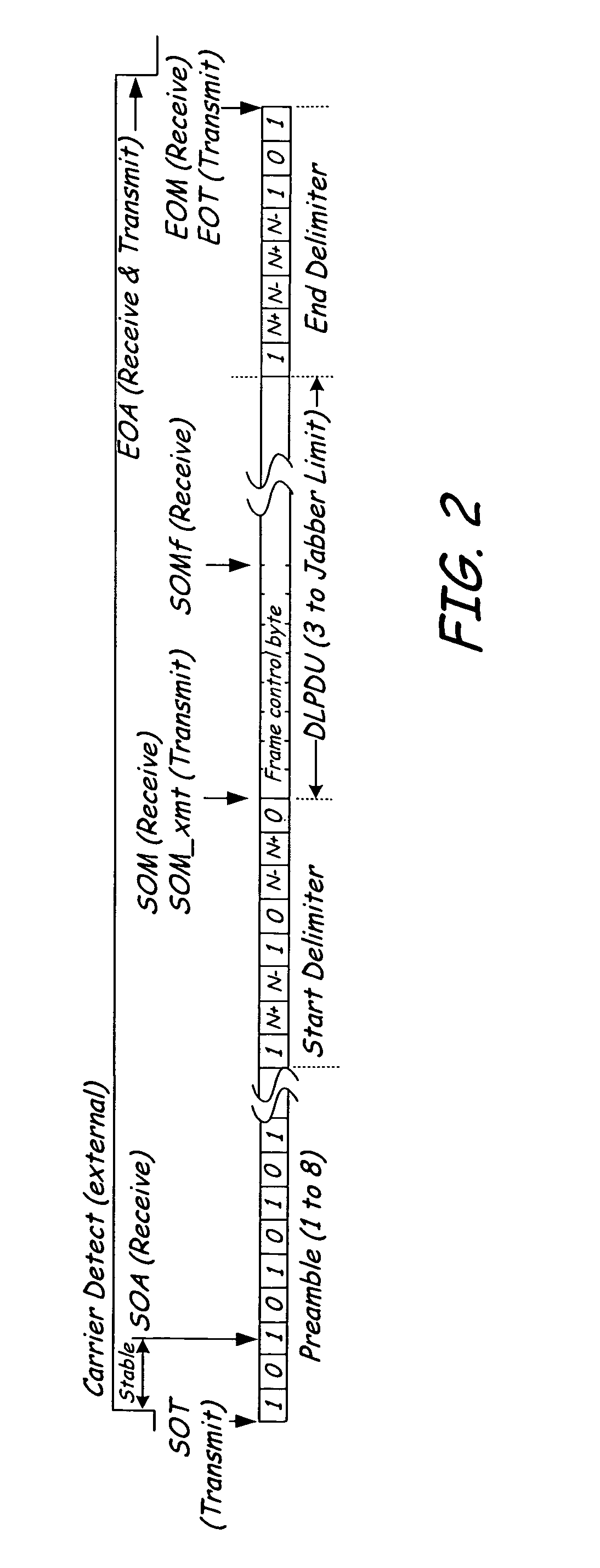

Devices in a process control system communicate by data messages over a communication medium segment. Each device includes a communication controller that automatically time stamps events associated with received and transmitted messages.

Owner:FISHER-ROSEMOUNT SYST INC

Indirect calibration of polymer characterization systems

InactiveUS6294388B1Avoid backlogImprove throughputIon-exchange process apparatusSamplingPolymer characterizationFlow injection analysis

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. The described methods, systems, and devices have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

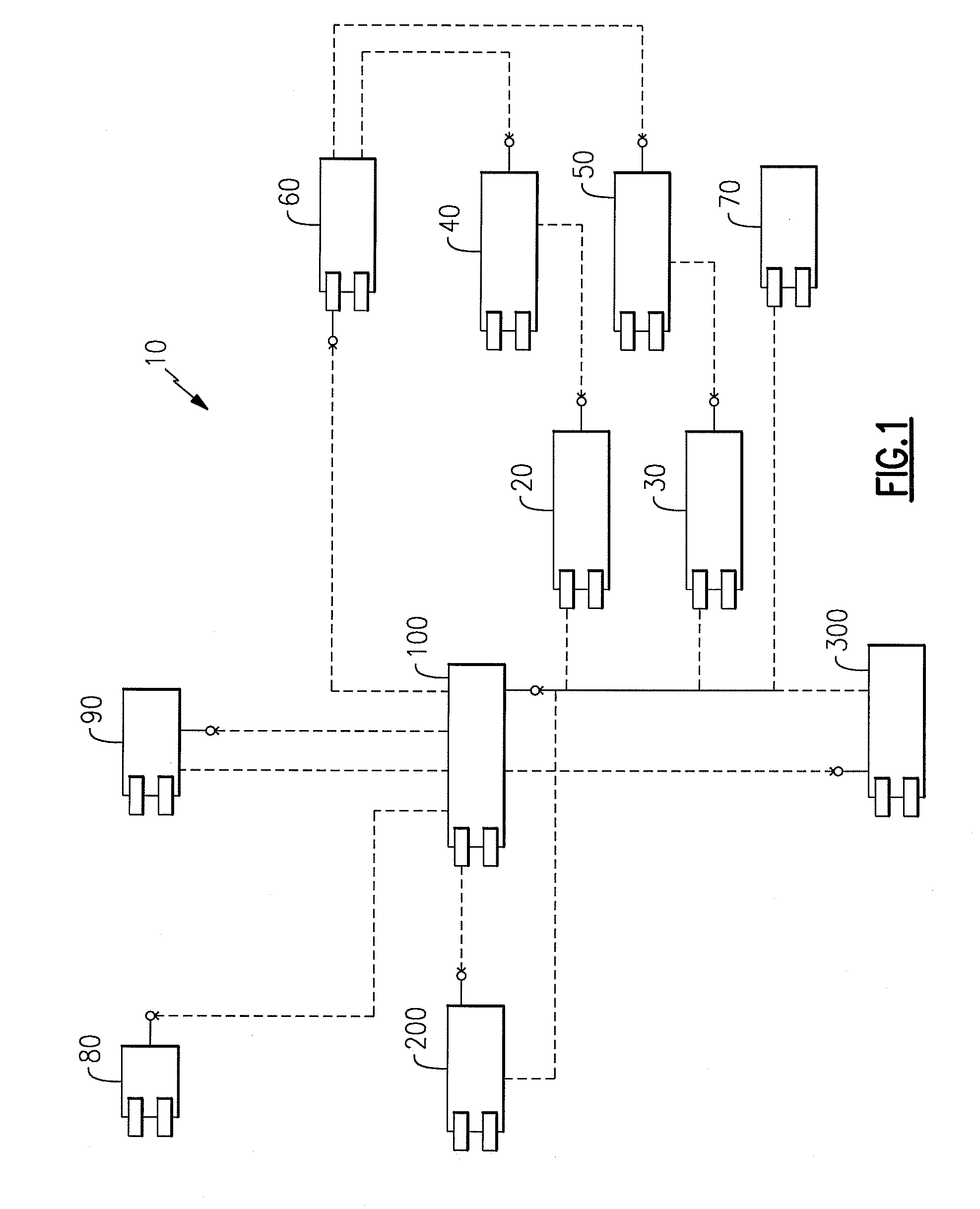

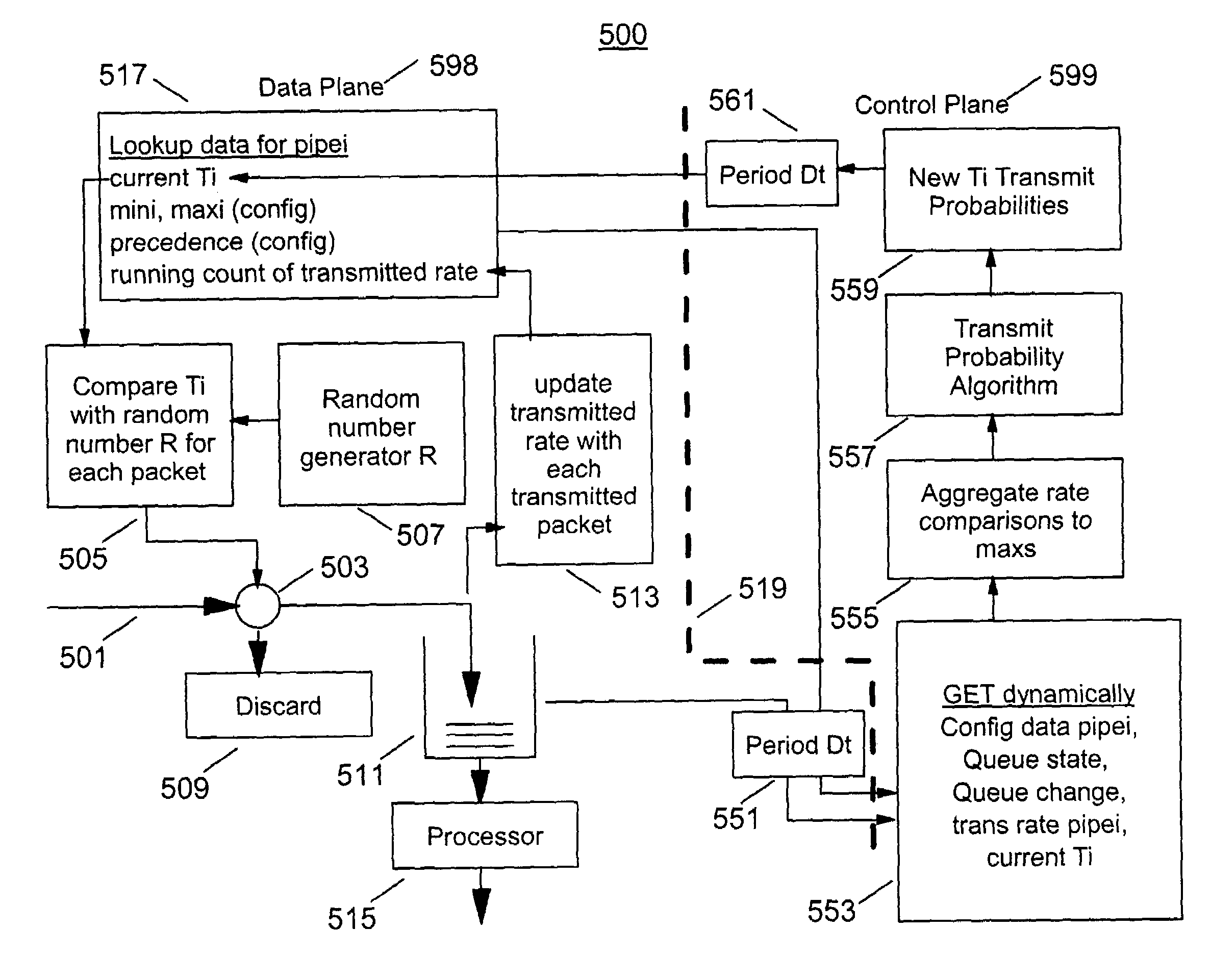

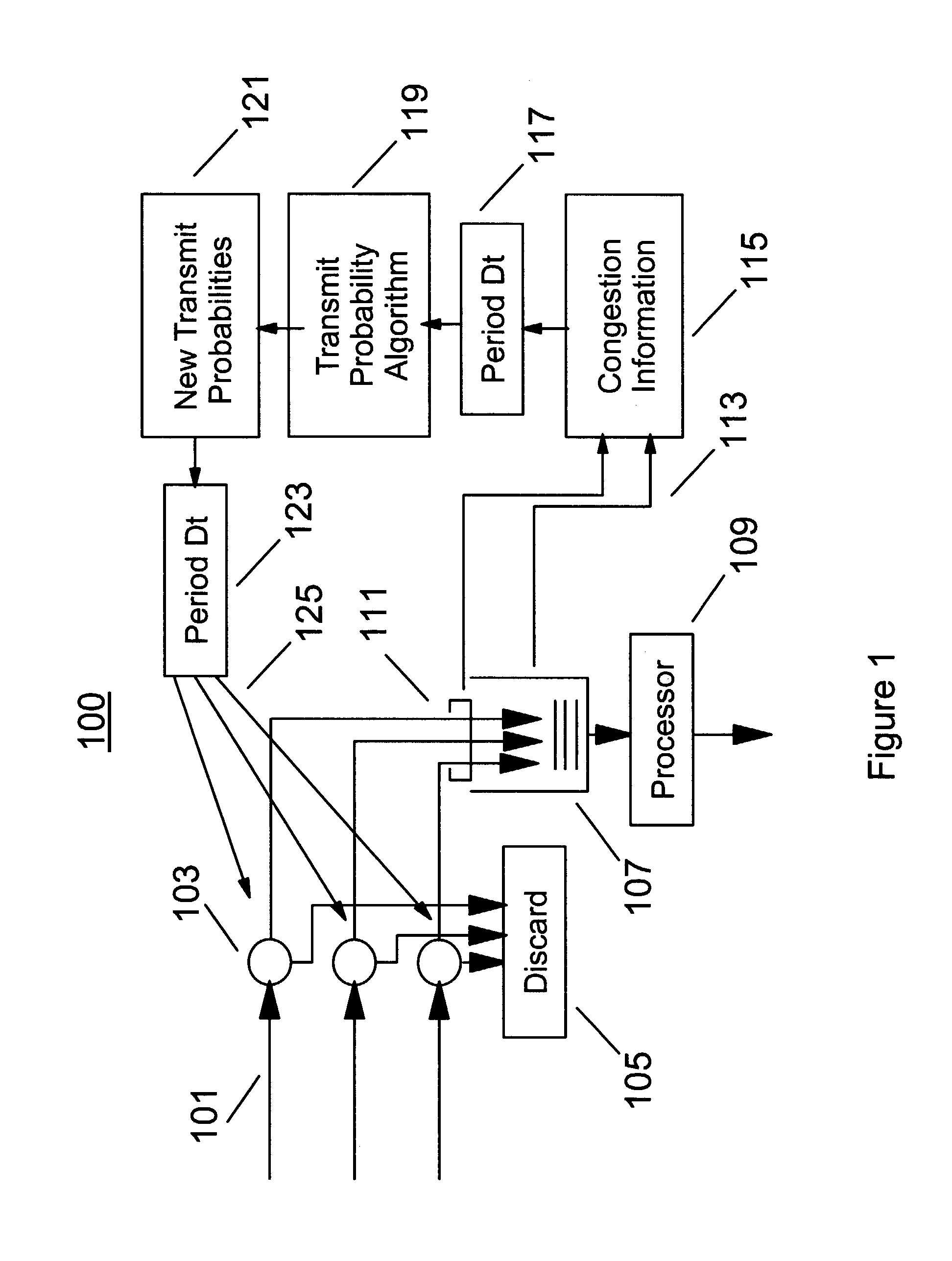

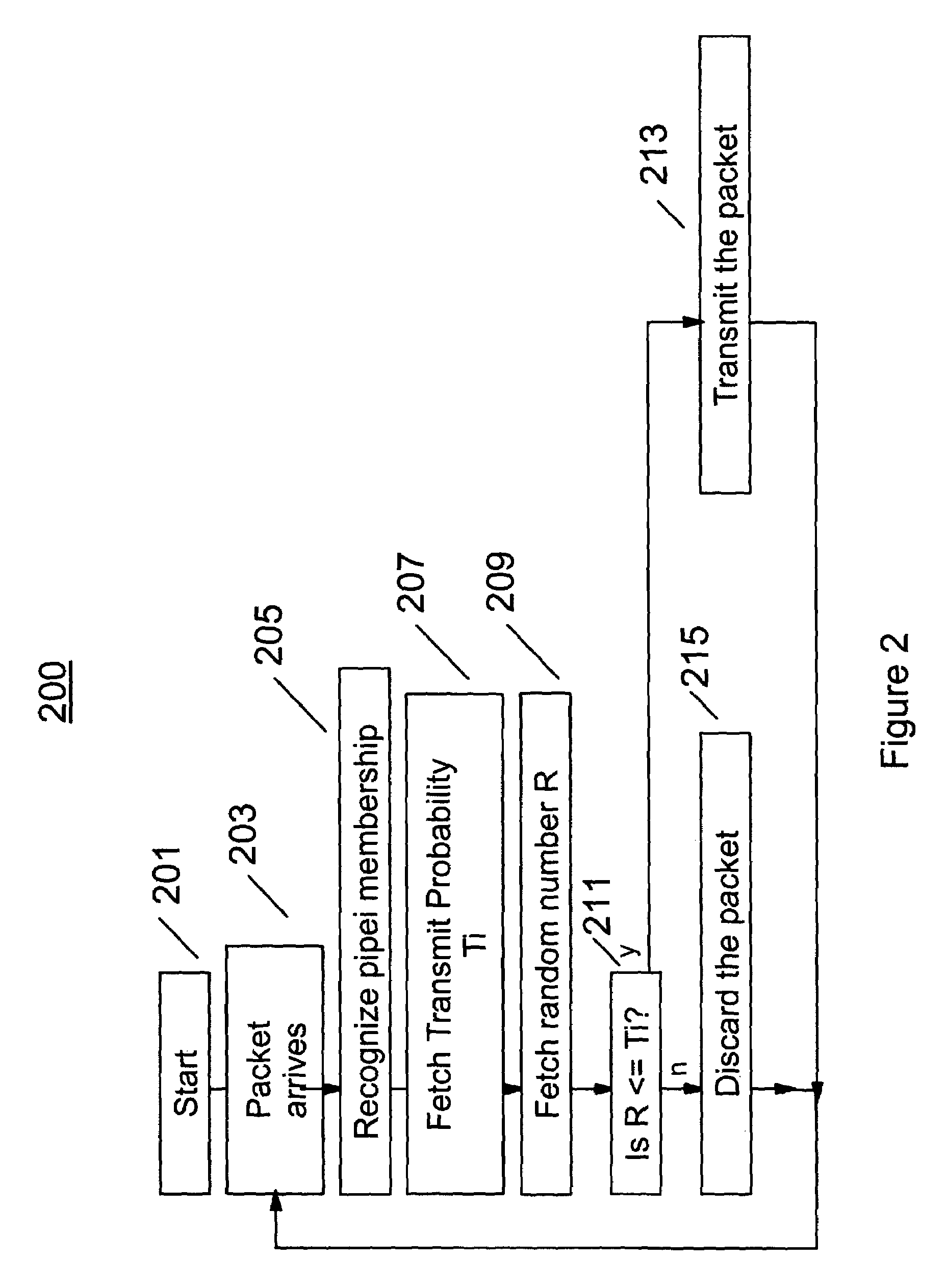

System and method for automatic management of many computer data processing system pipes

ActiveUS7710874B2Attenuation bandwidthReduce information required can be stored in algorithm processorError preventionFrequency-division multiplex detailsComputer data processingComputer science

A process control method and system including partitioning transmit decisions and certain measurements into one logical entity (Data Plane) and partitioning algorithm computation to update transmit probabilities into a second logical entity (Control Plane), the two entities periodically communicating fresh measurements from Data Plane to Control Plane and adjusted transmit probabilities from Control Plane to Data Plane. The transmit probability may be used in transmit / discard decisions of packets or instructions exercised at every arrival of a packet or instruction. In an alternative embodiment, the transmit probability may be used in transmit / delay decisions of awaiting instructions or packets exercised at every service event.

Owner:TWITTER INC

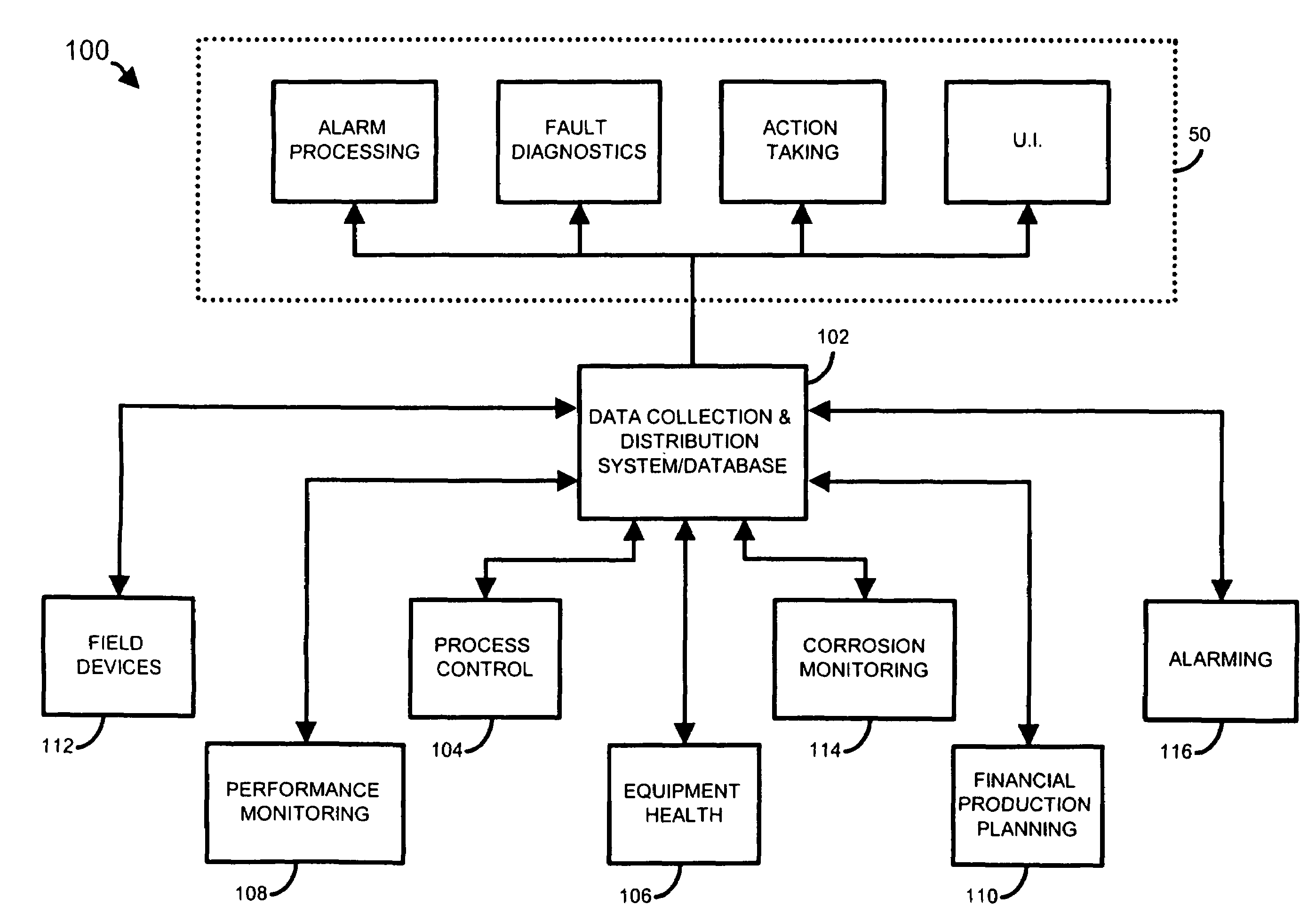

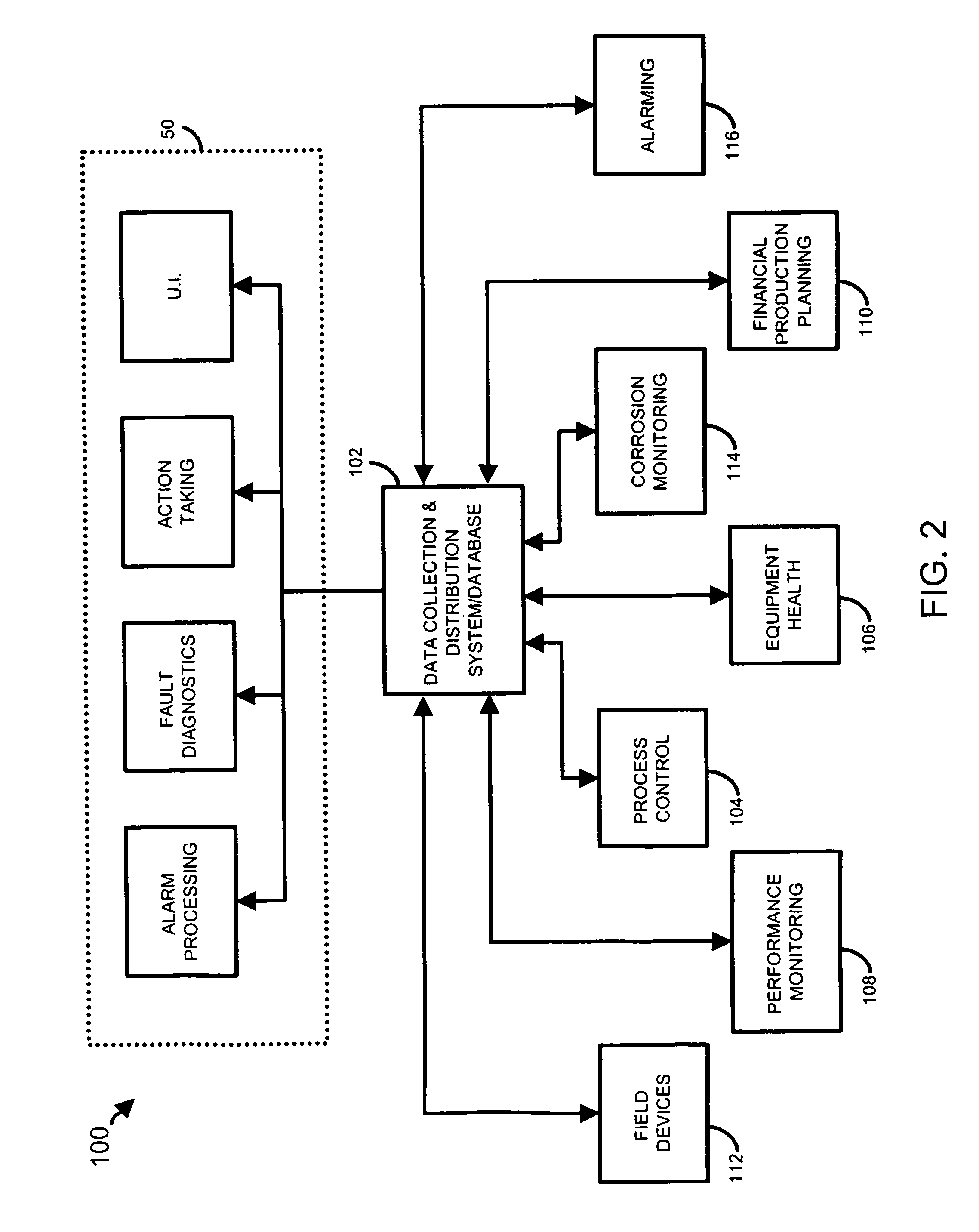

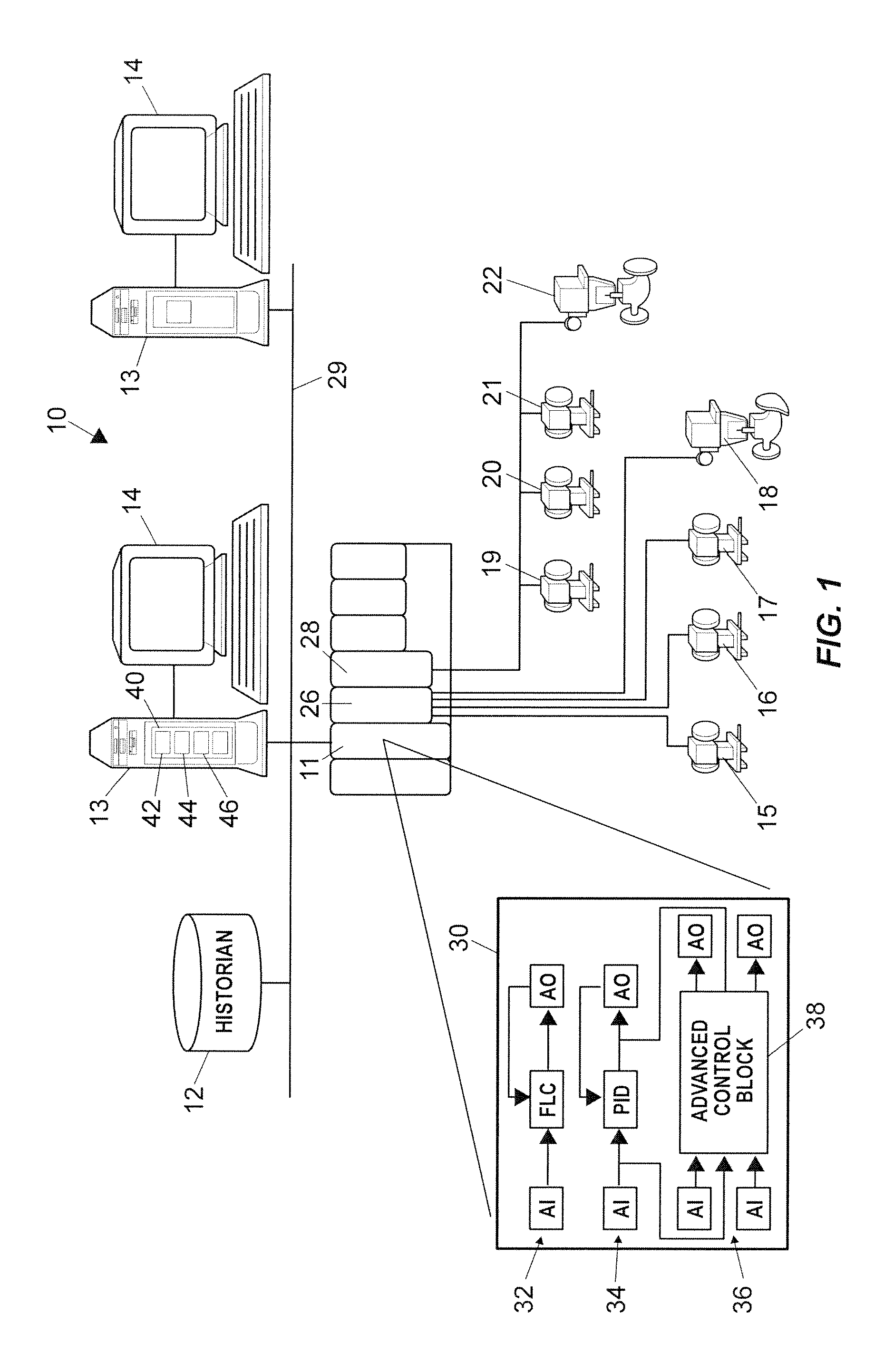

Method and apparatus for performing a function in a plant using process performance monitoring with process equipment monitoring and control

InactiveUS7206646B2Easy to operateBetter stateSafety arrangmentsCatalytic crackingProcess equipmentOptimal control

A process control system uses a data collection and distribution system and an asset utilization suite to collect data or information pertaining to the assets of a process plant from various sources or functional areas of the plant including, for example, the process control functional areas, the maintenance functional areas and the process performance monitoring functional areas. This data and information is manipulated in a coordinated manner by the data collection and distribution system and is redistributed to other applications where this it is used to perform overall better or more optimal control, maintenance and business activities. Information or data may be collected by maintenance functions pertaining to the health, variability, performance or utilization of a device, loop, unit, area, etc. and this information may then be sent to and displayed to a process operator or maintenance person to inform that person of a current or future problem. A user interface is provided that enables users to access and manipulate the expert engine to optimize plant operation or cause optimization of plant operation, to get information about the operation of the plant, etc. Furthermore, applications, such as work order generation applications may automatically generate work orders, parts or supplies orders, etc. based on events occurring within the plant.

Owner:FISHER-ROSEMOUNT SYST INC

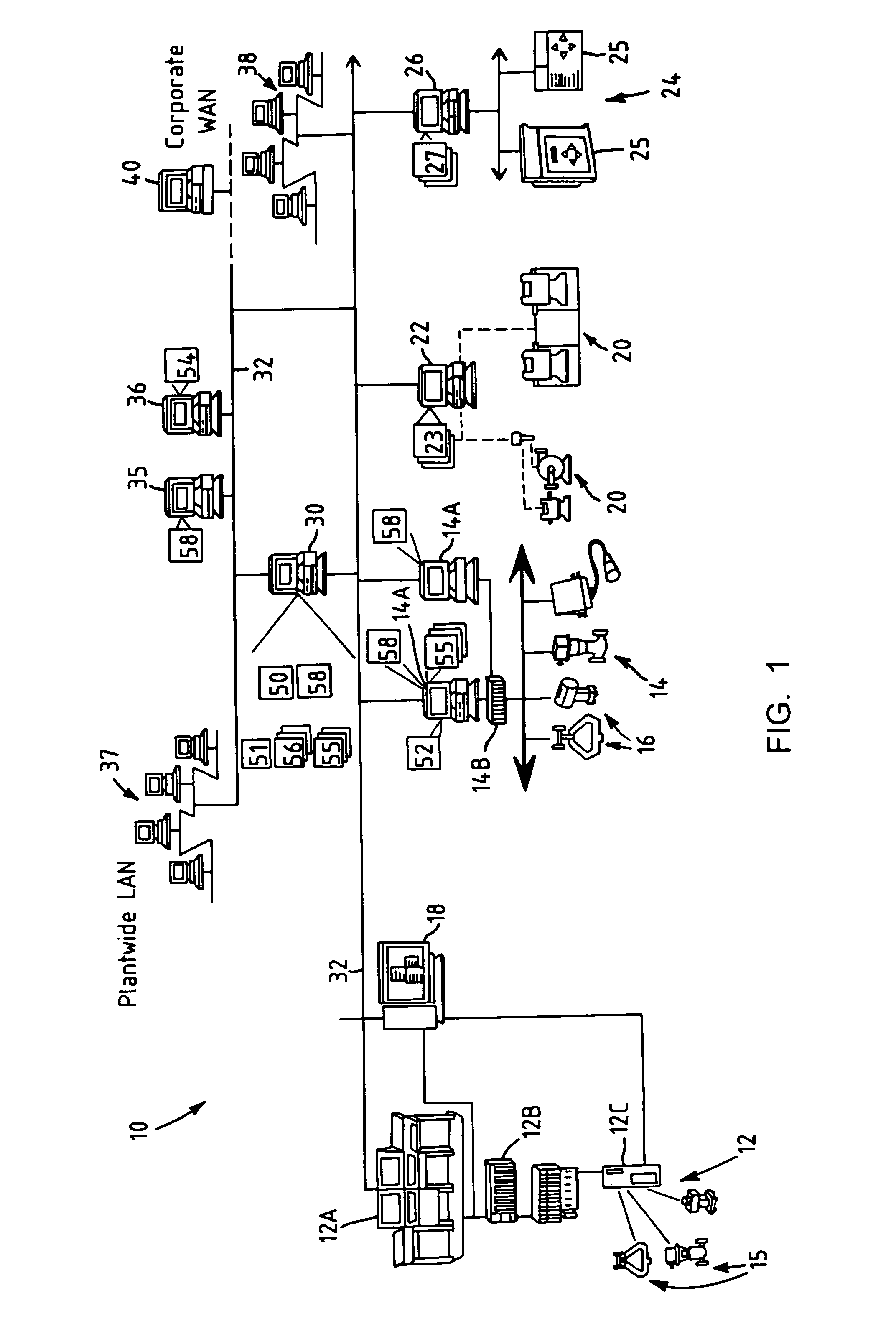

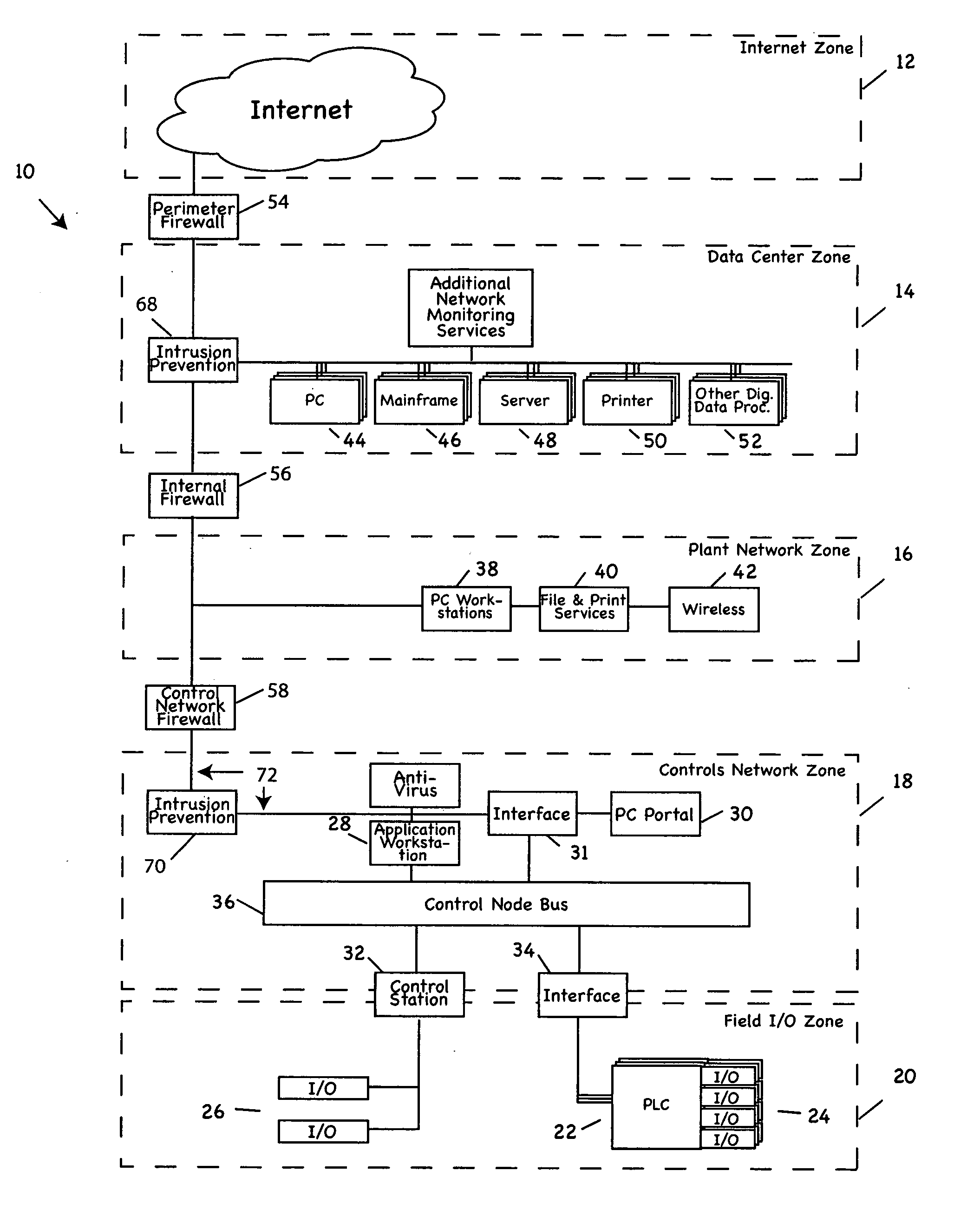

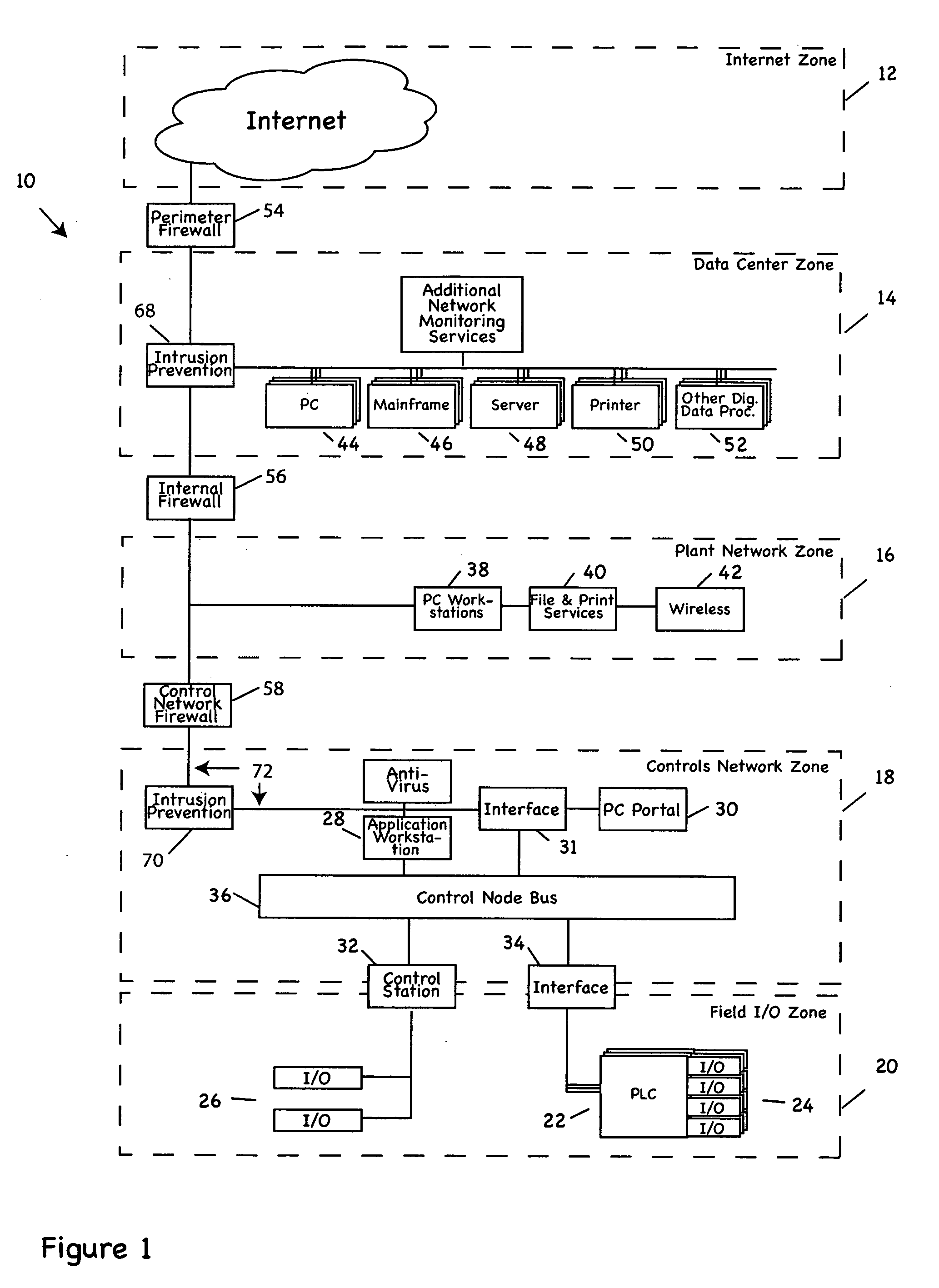

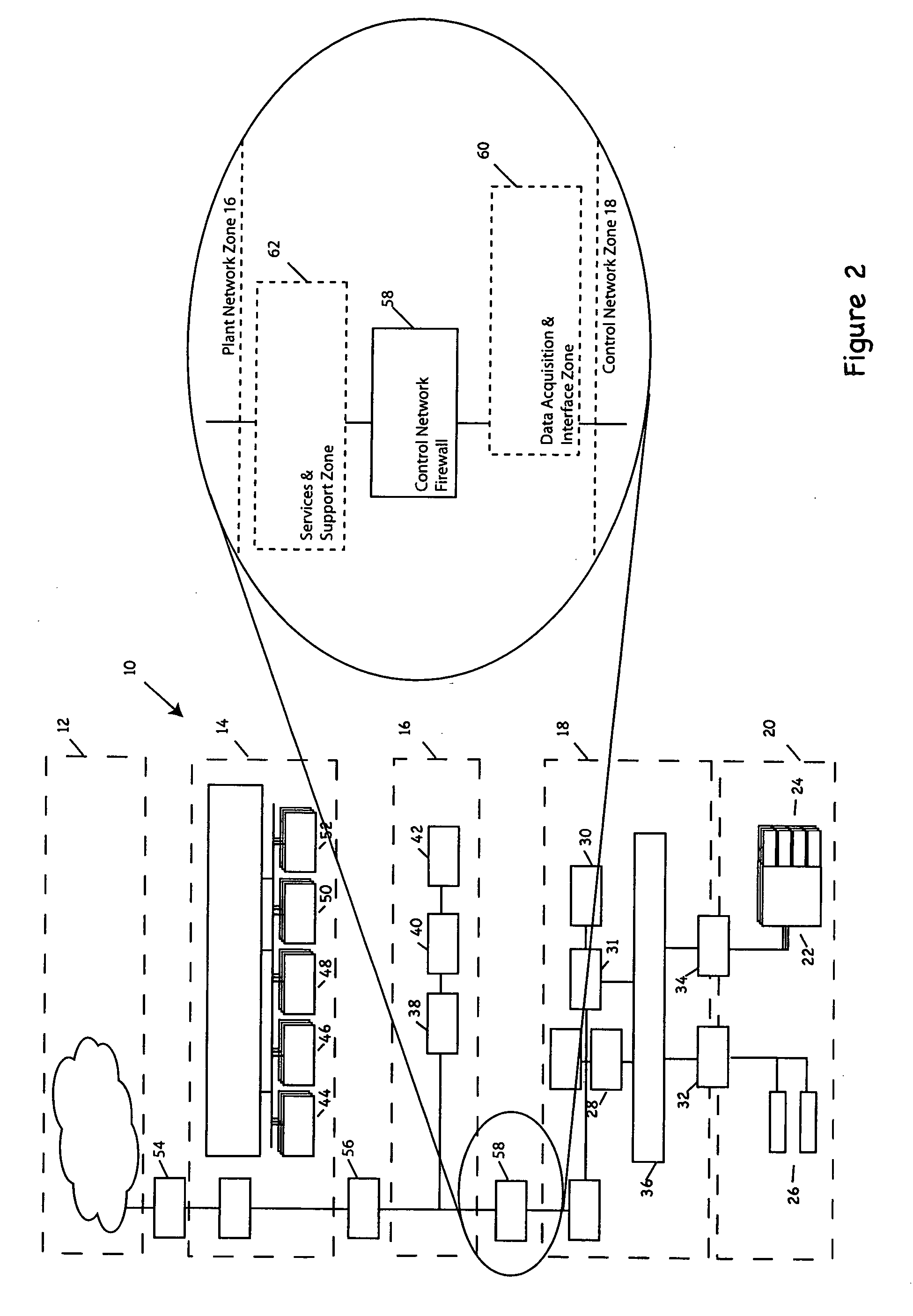

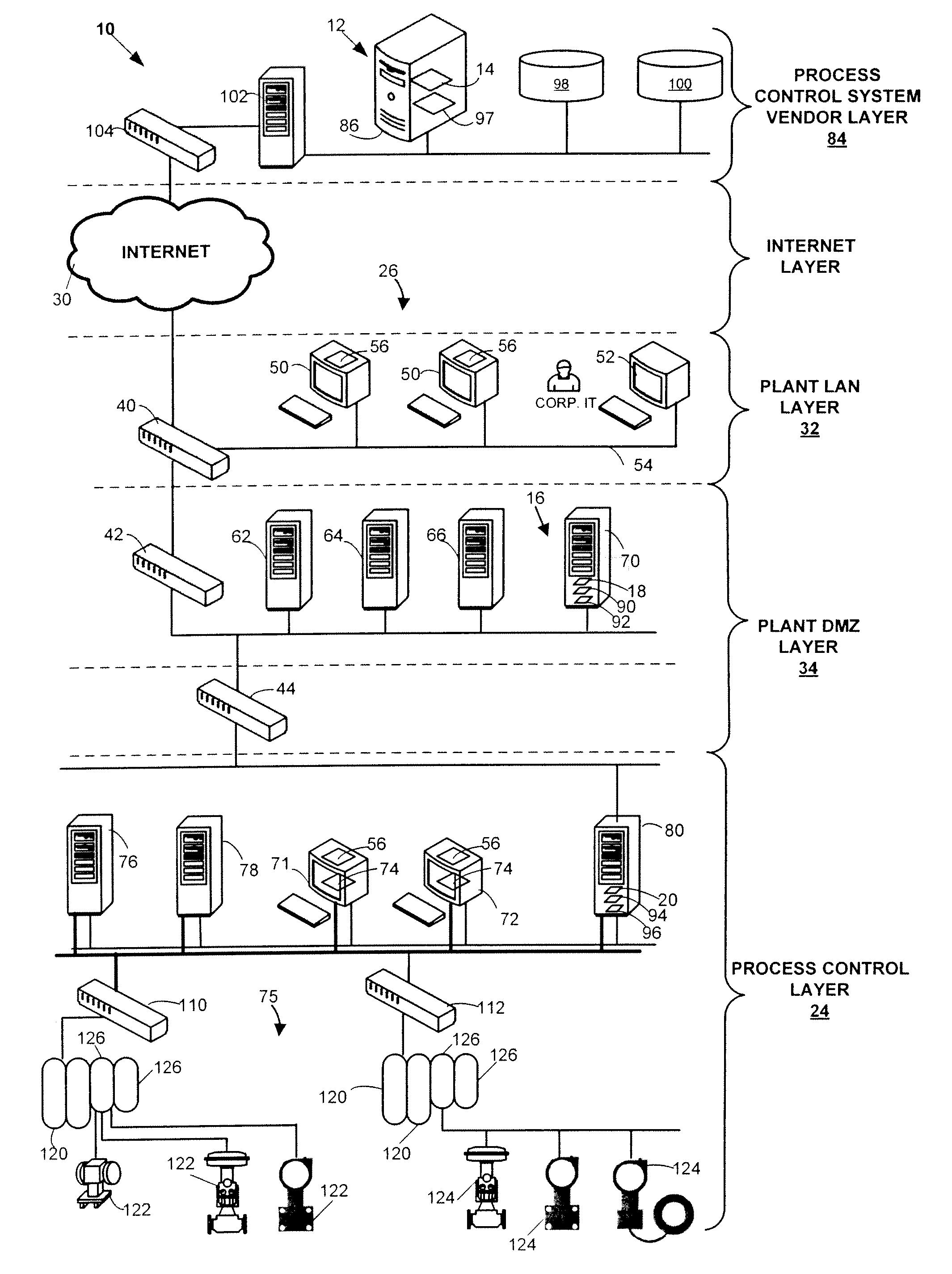

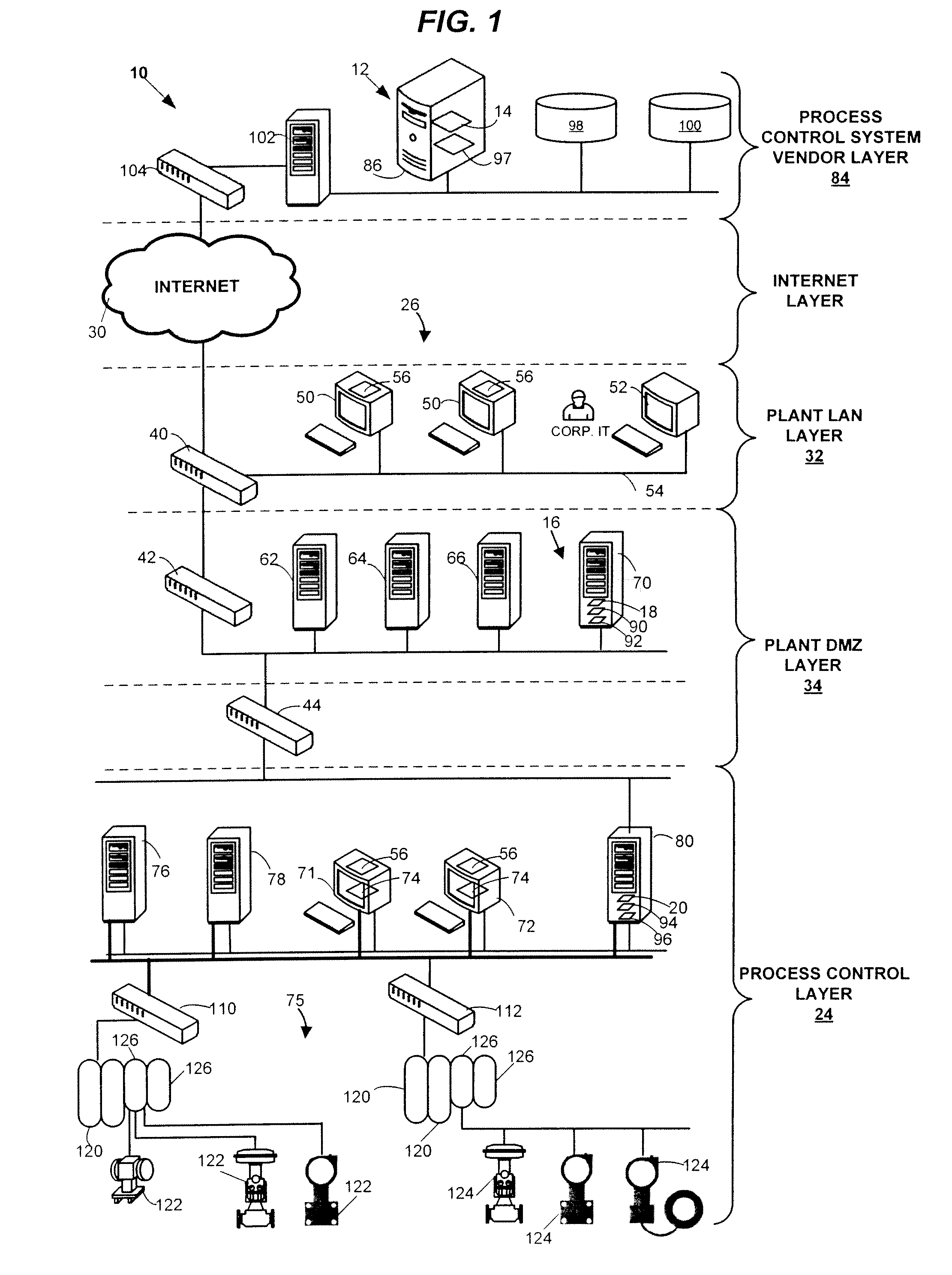

Process control methods and apparatus for intrusion detection, protection and network hardening

ActiveUS20060053491A1Memory loss protectionError detection/correctionEnvironmental control systemIntrusion prevention system

The invention provides an improved network and methods of operation thereof for use in or with process control systems, computer-based manufacturing or production control systems, environmental control systems, industrial control system, and the like (collectively, “control systems”). Those networks utilize a unique combination of firewalls, intrusion detection systems, intrusion protection devices and / or other devices for hardening (e.g., security against hacking, intrusion or other mischievous conduct) and / or intrusion detection. The networks and methods have application, by way of example, in plants, sites and other facilities in which networks that support control systems interface with corporate, business or other networks.

Owner:SCHNEIDER ELECTRIC SYST USA INC

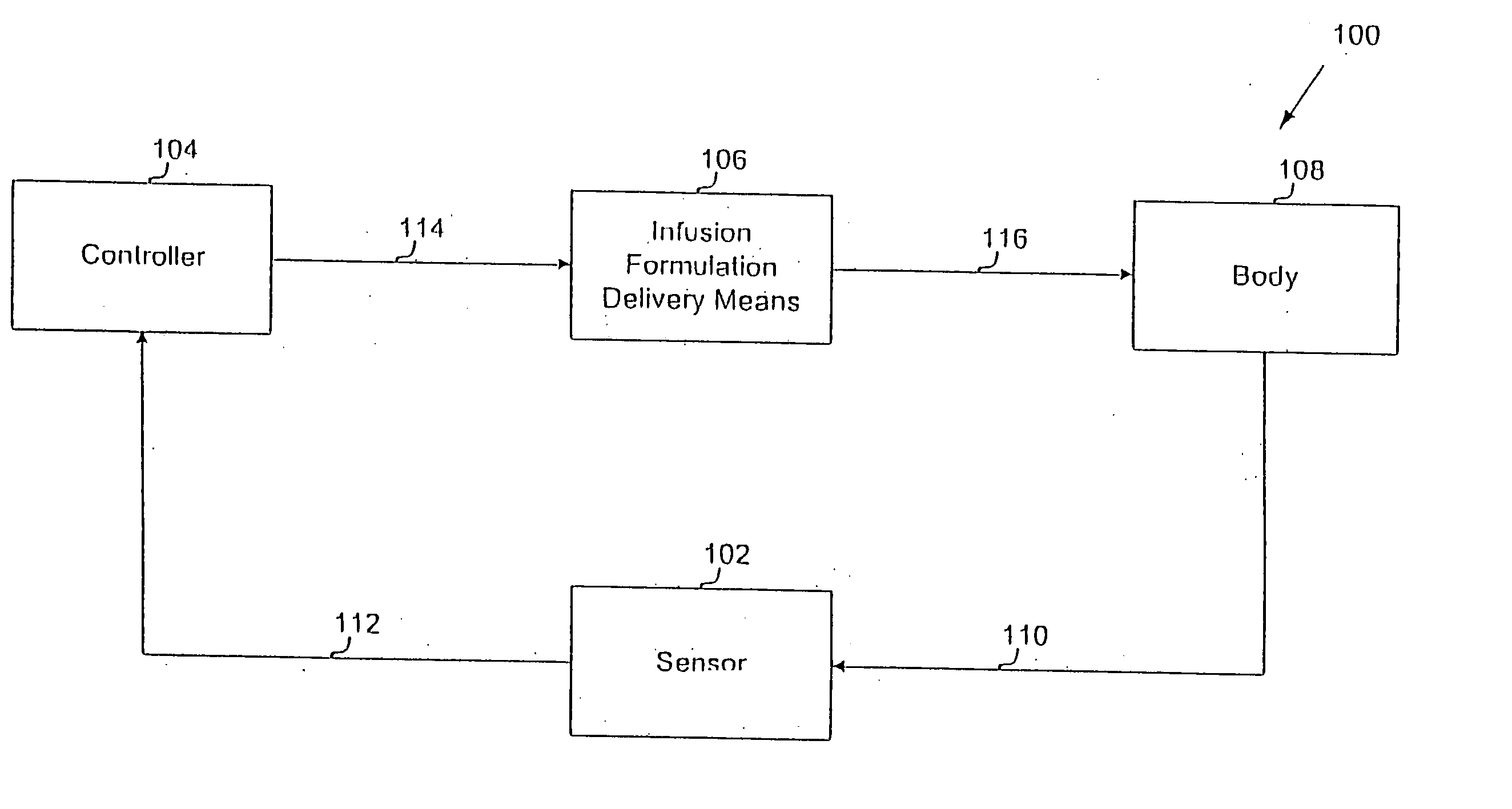

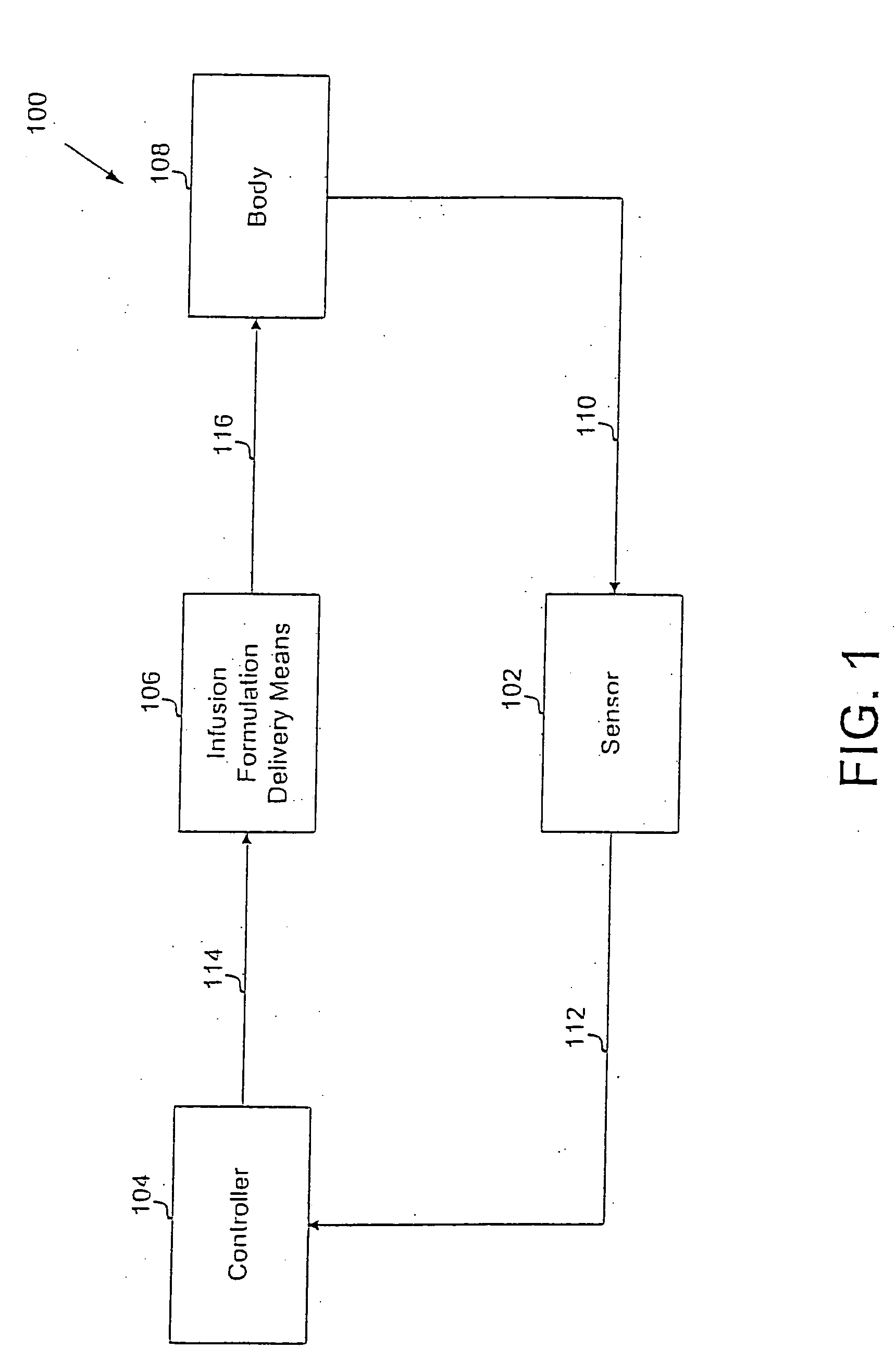

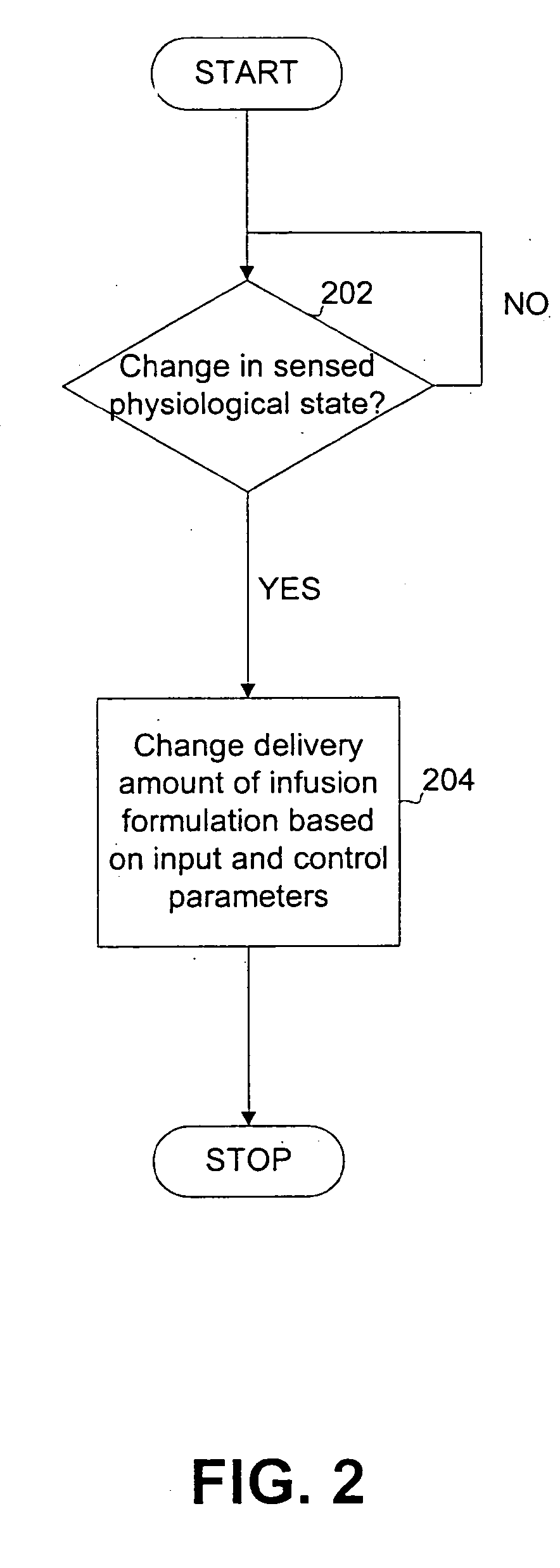

System and method for providing closed loop infusion formulation delivery

ActiveUS20040220517A1Accurate calculationAccurately determineHealth-index calculationDrug and medicationsBasal rateMedicine

A system and method for providing closed loop infusion formulation delivery which accurately calculates a delivery amount based on a sensed biological state by adjusting an algorithm's programmable control parameters. The algorithm calculates a delivery amount having proportional, derivative, and basal rate components. The control parameters may be adjusted in real time to compensate for changes in a sensed biological state that may result from daily events. Safety limits on the delivery amount may be included in the algorithm. The algorithm may be executed by a computing element within a process controller for controlling closed loop infusion formulation delivery. The biological state is sensed by a sensing device which provides a signal to the controller. The controller calculates an infusion formulation delivery amount based on the signal and sends commands to an infusion formulation delivery device which delivers an amount of infusion formulation determined by the commands.

Owner:MEDTRONIC MIMIMED INC

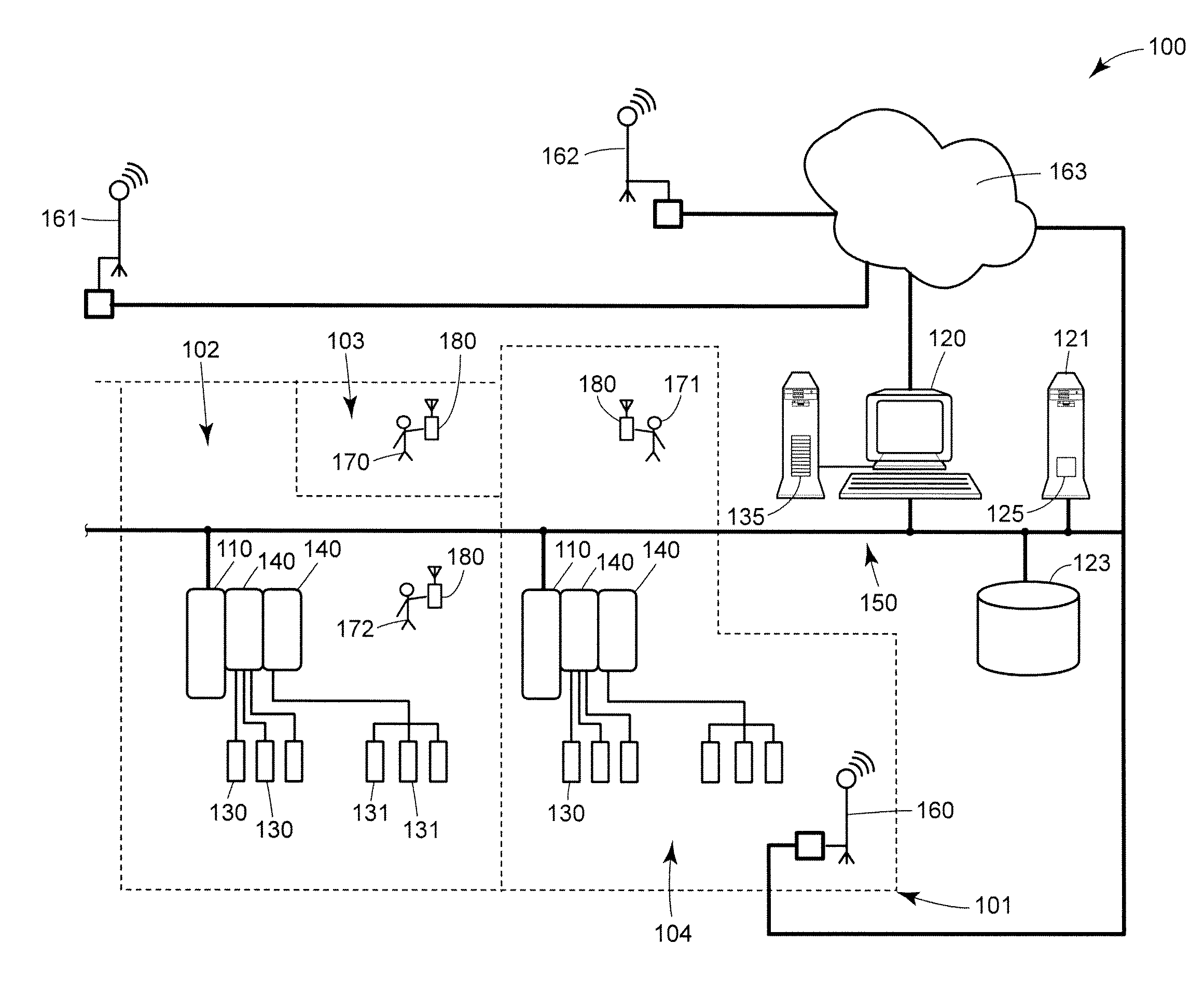

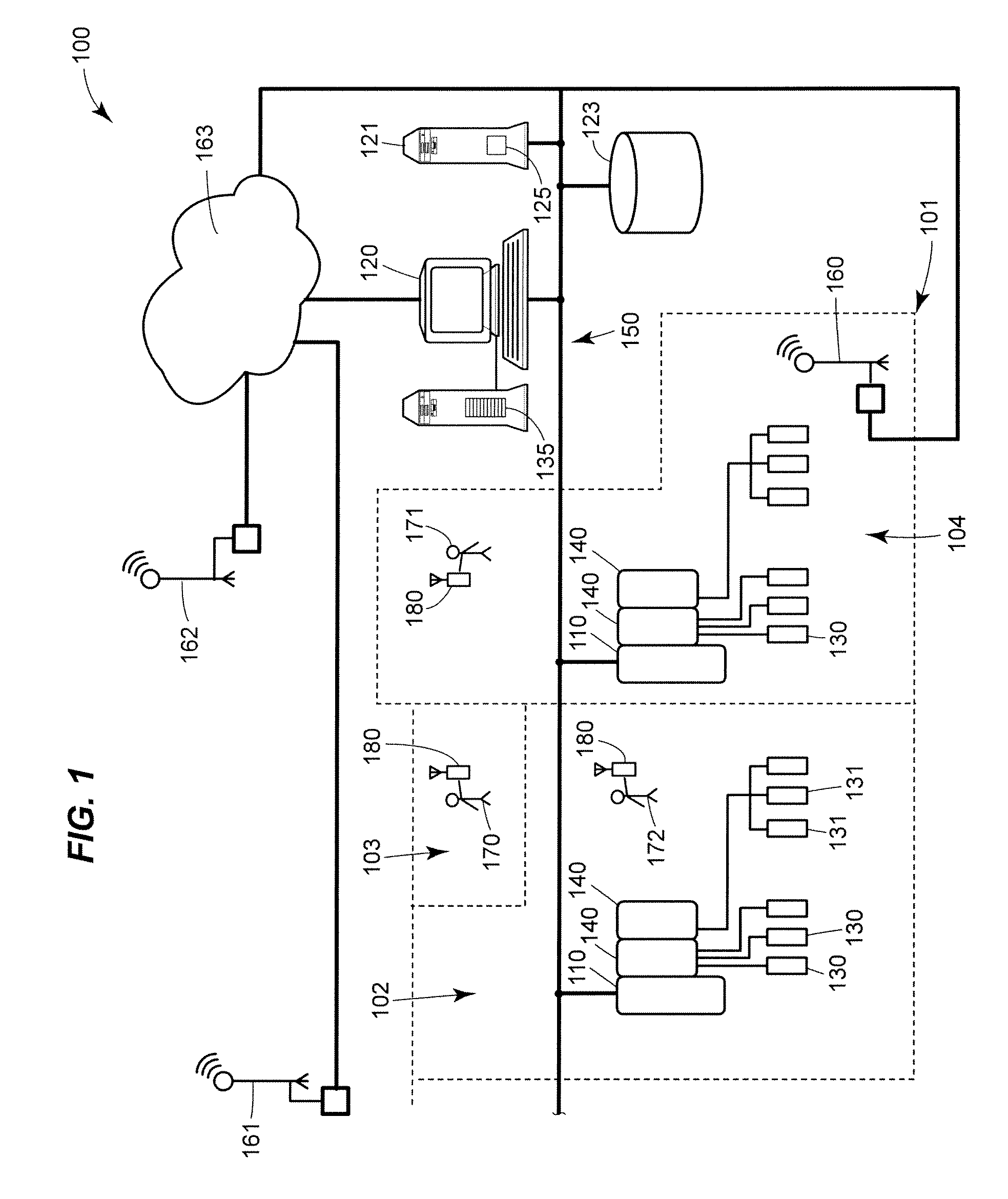

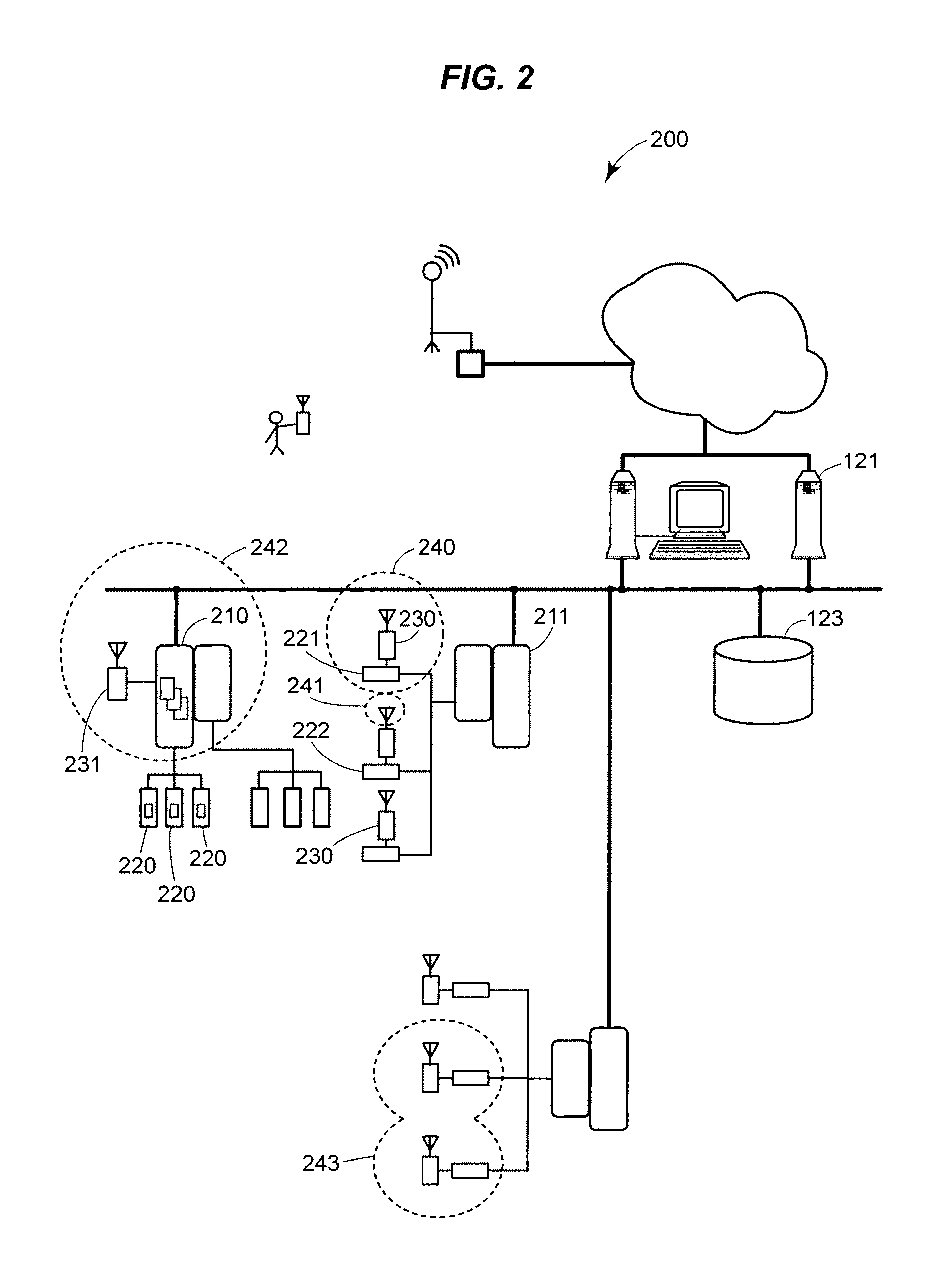

Location Dependent Control Access in a Process Control System

ActiveUS20090065578A1Avoid changeProvide securityIndividual entry/exit registersTotal factory controlControl systemPosition dependent

A method of accessing an element in a process control environment using a portable communicator includes defining a plurality of control areas within the process control environment, determining a position of a user operating a portable communicator with respect to one or more of the control areas, establishing an identity of the user, and selectively allowing the user to access an element within the process control environment via the portable communicator depending on the determined position of the user with respect to the one or more control areas and on the identity of the user.

Owner:FISHER-ROSEMOUNT SYST INC

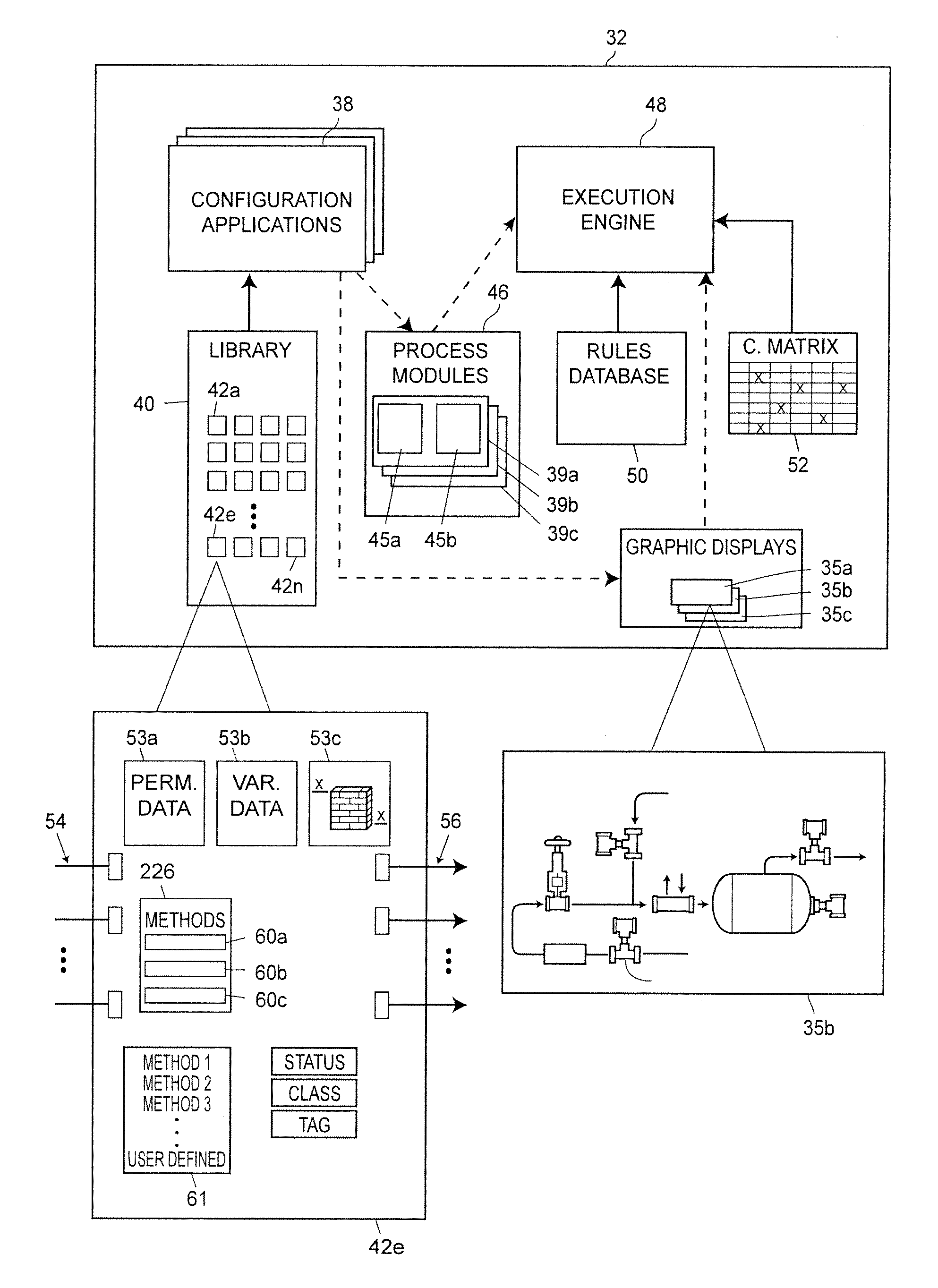

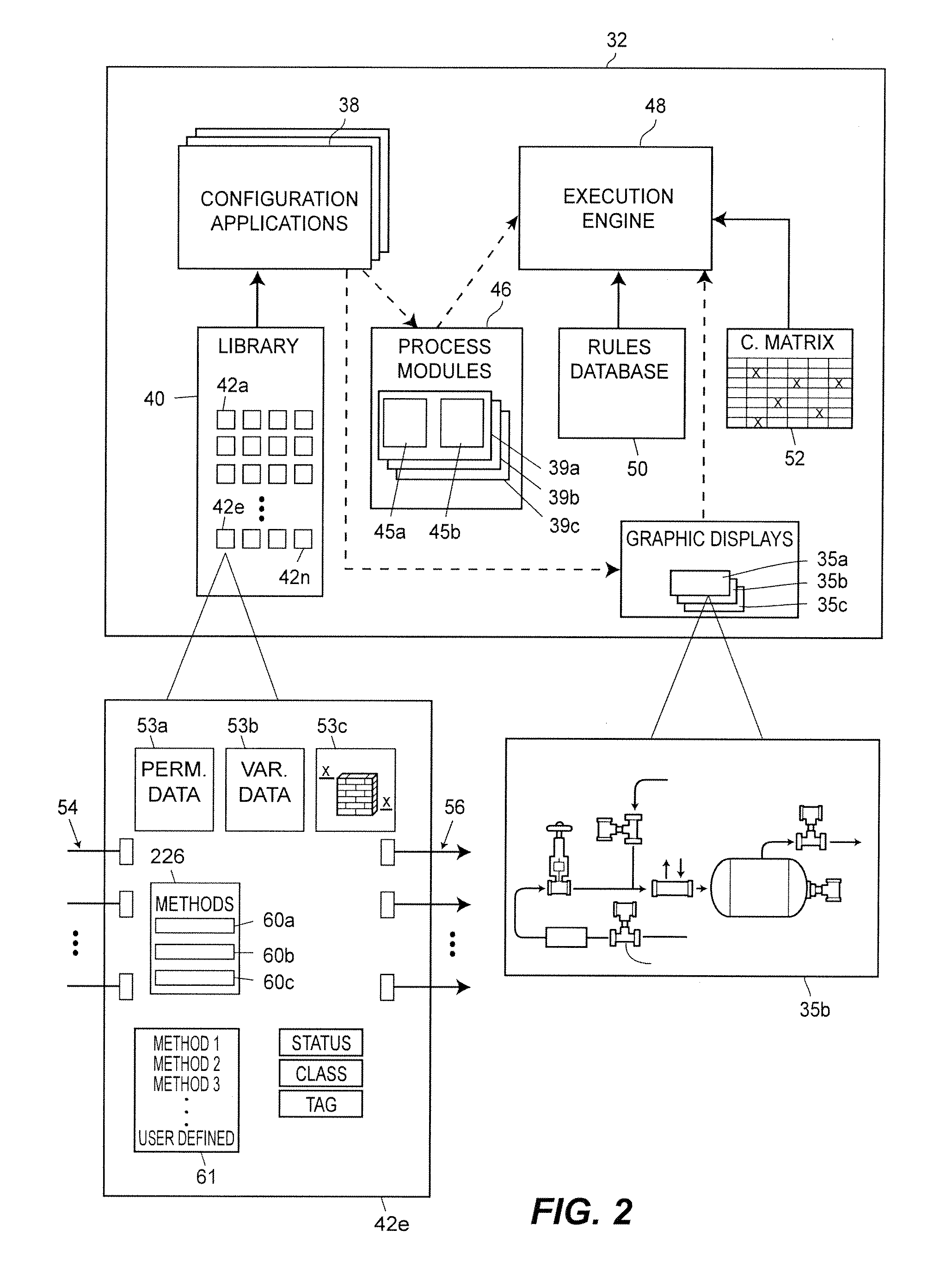

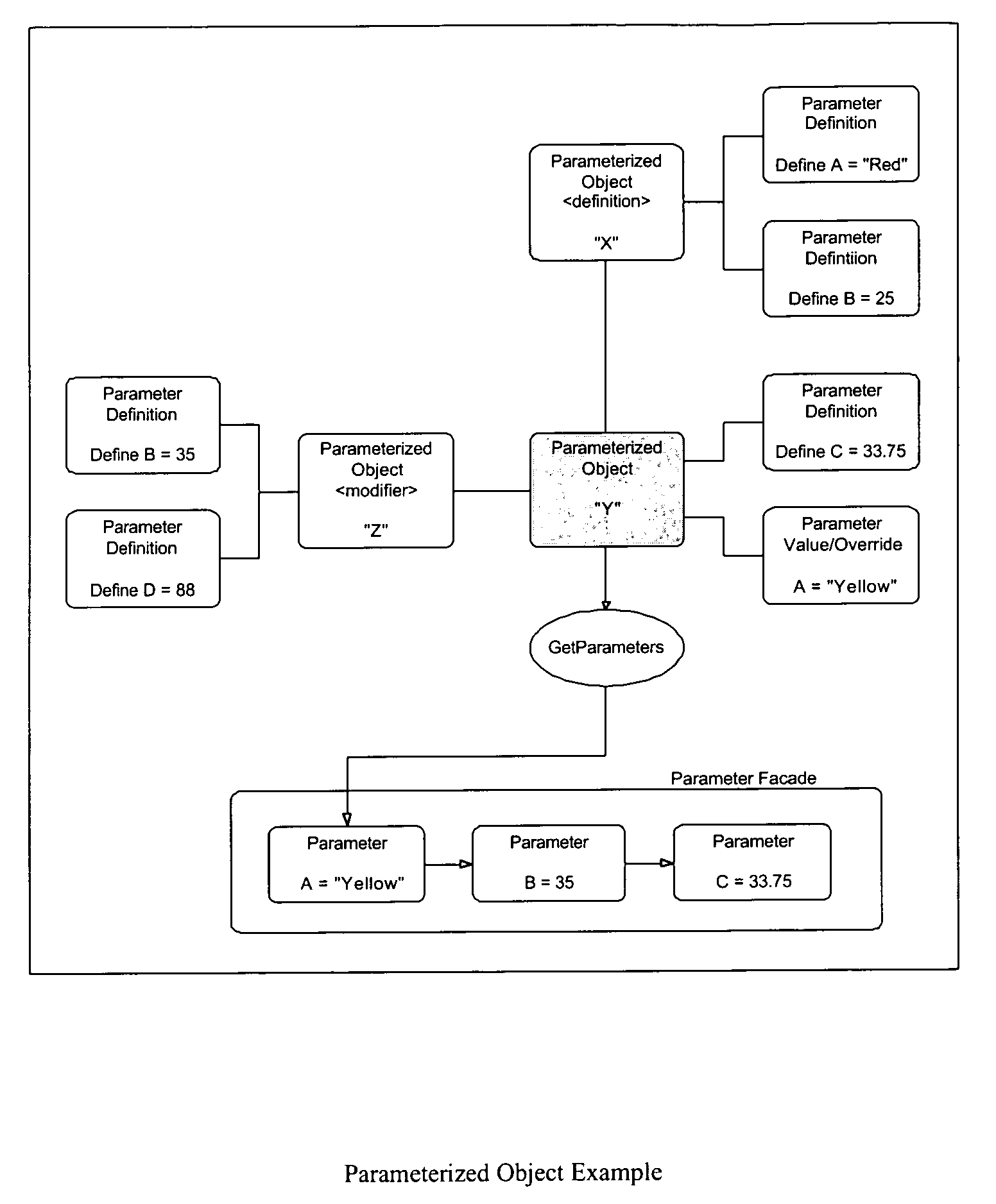

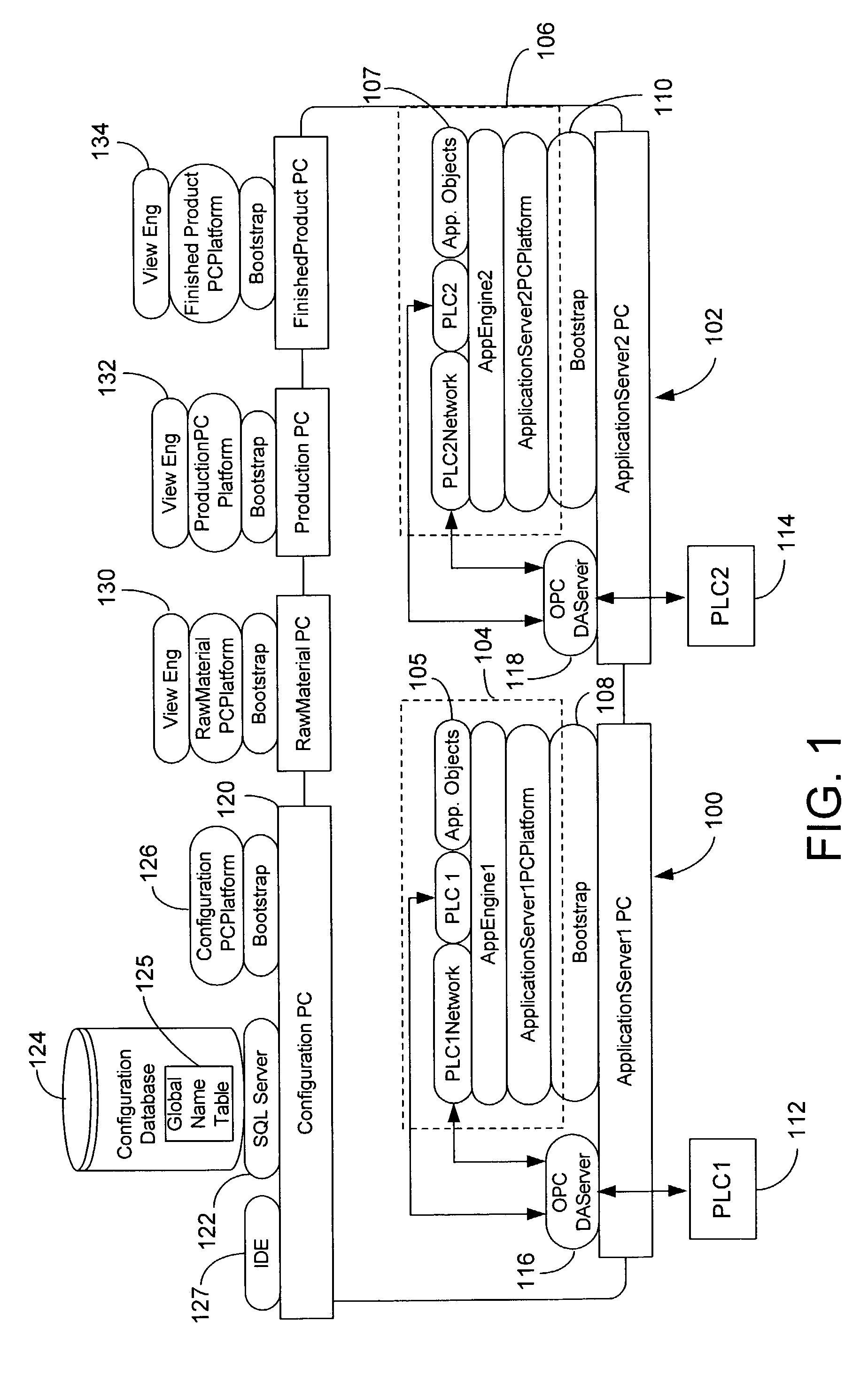

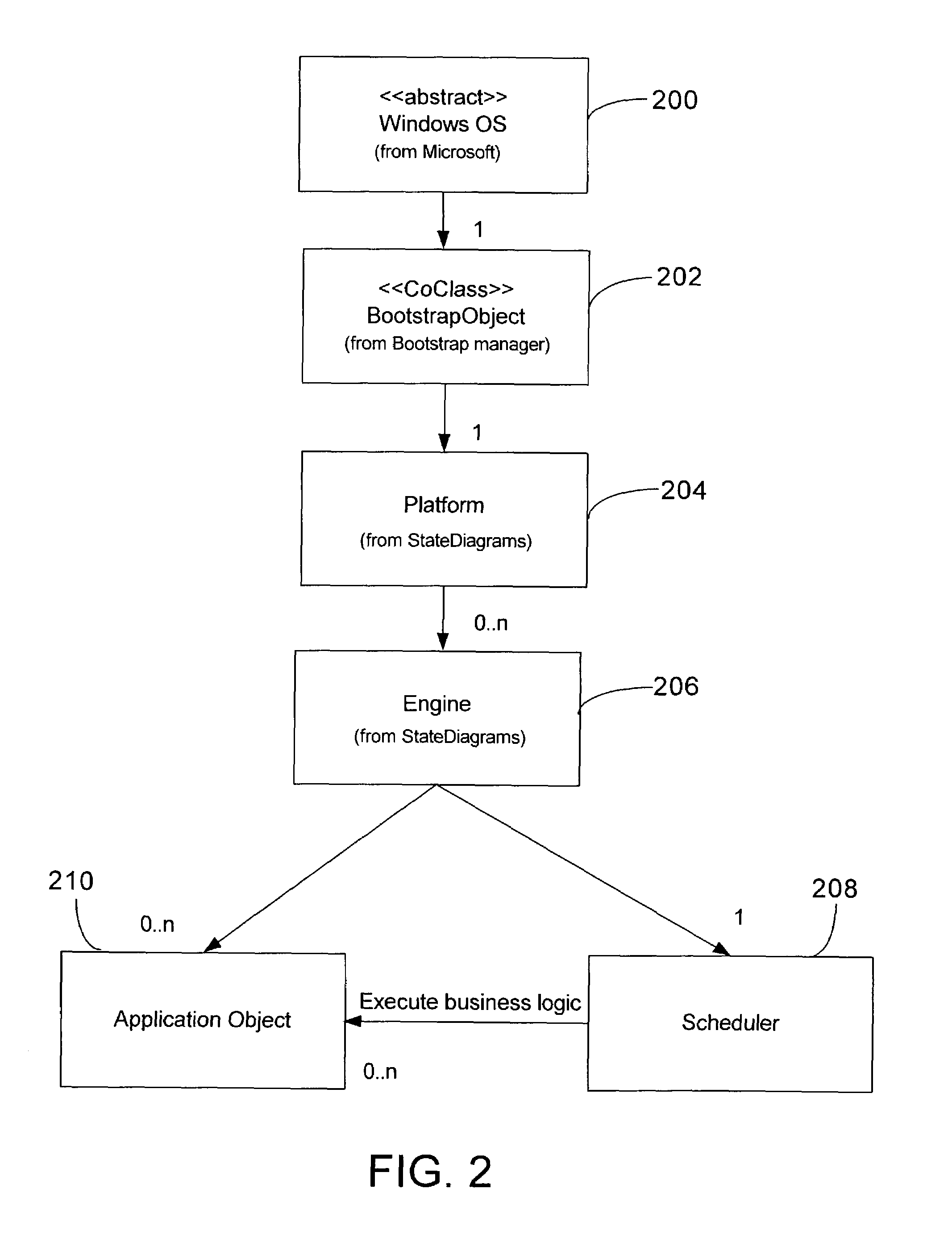

Process control configuration system with parameterized objects

InactiveUS7096465B1OptimizationConfiguration of process controlProgramme controlProgram loading/initiatingControl systemModel system

A process control system is configured via manipulation of objects that model system components, e.g., sensors, blocks, control processors, historians, workstations, etc. Individual objects include parameters that characterize the underlying components and / or the behavior of the objects themselves. These parameters are derived from the “parents,” from which the objects are created. Derived characteristics need not be defined explicitly but, rather, are defined implicitly or by reference. These derived characteristics may be overridden for an individual object and, thereby, its progeny. Although objects have class-like characteristics (i.e., insofar as they are definitional in nature), they can be created at configuration time, without the need for recompilation.

Owner:SCHNEIDER ELECTRIC SYST USA INC

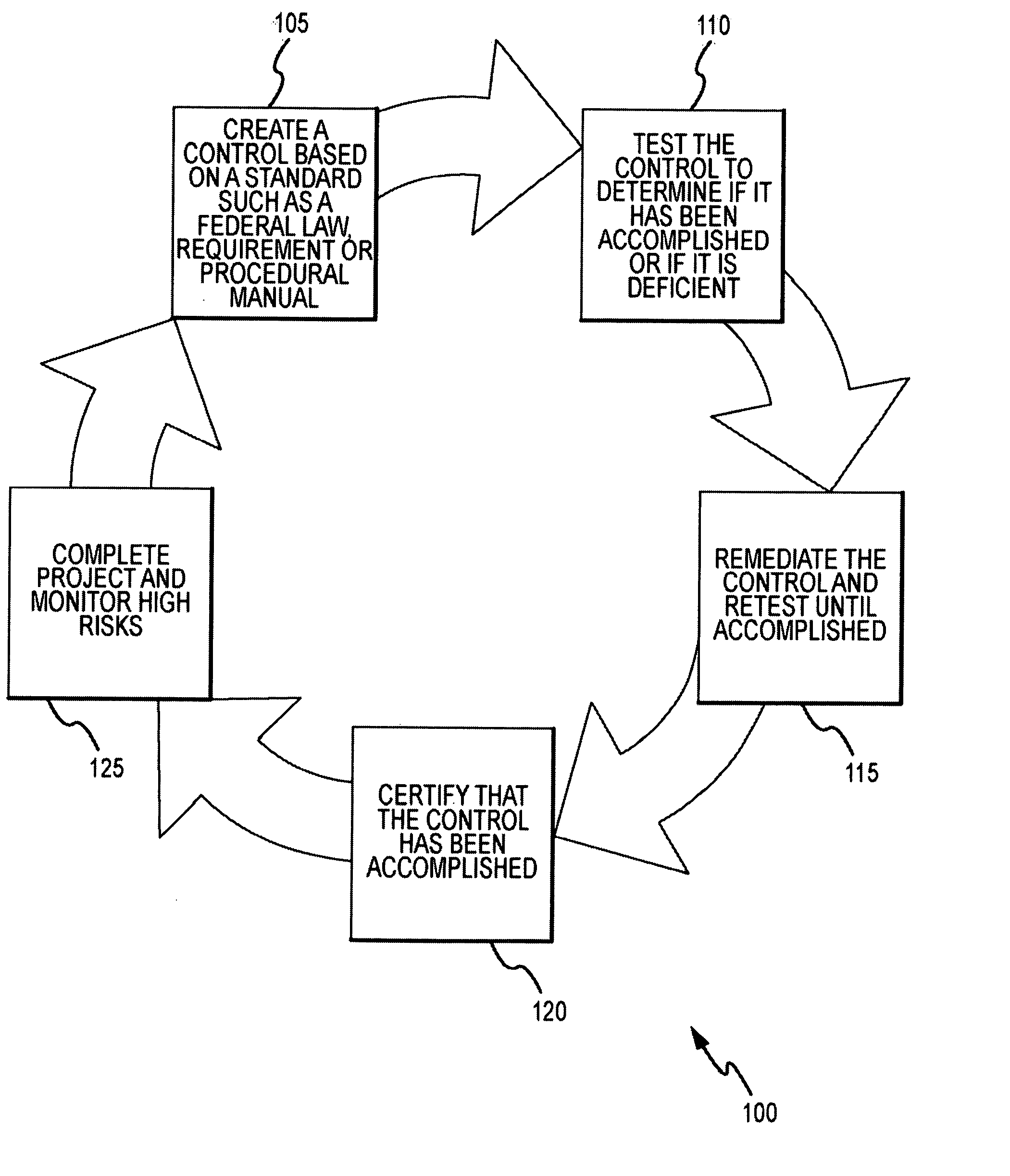

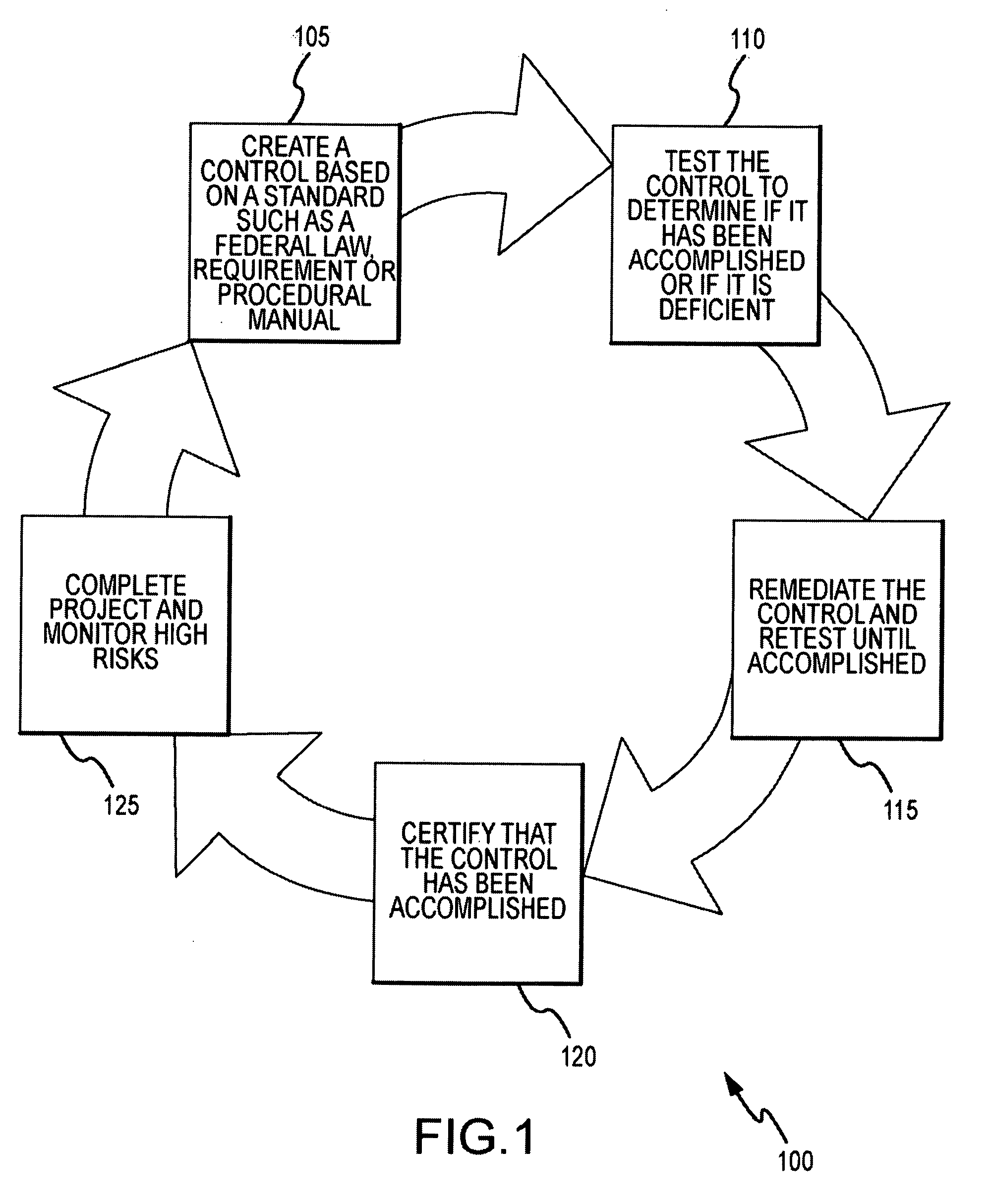

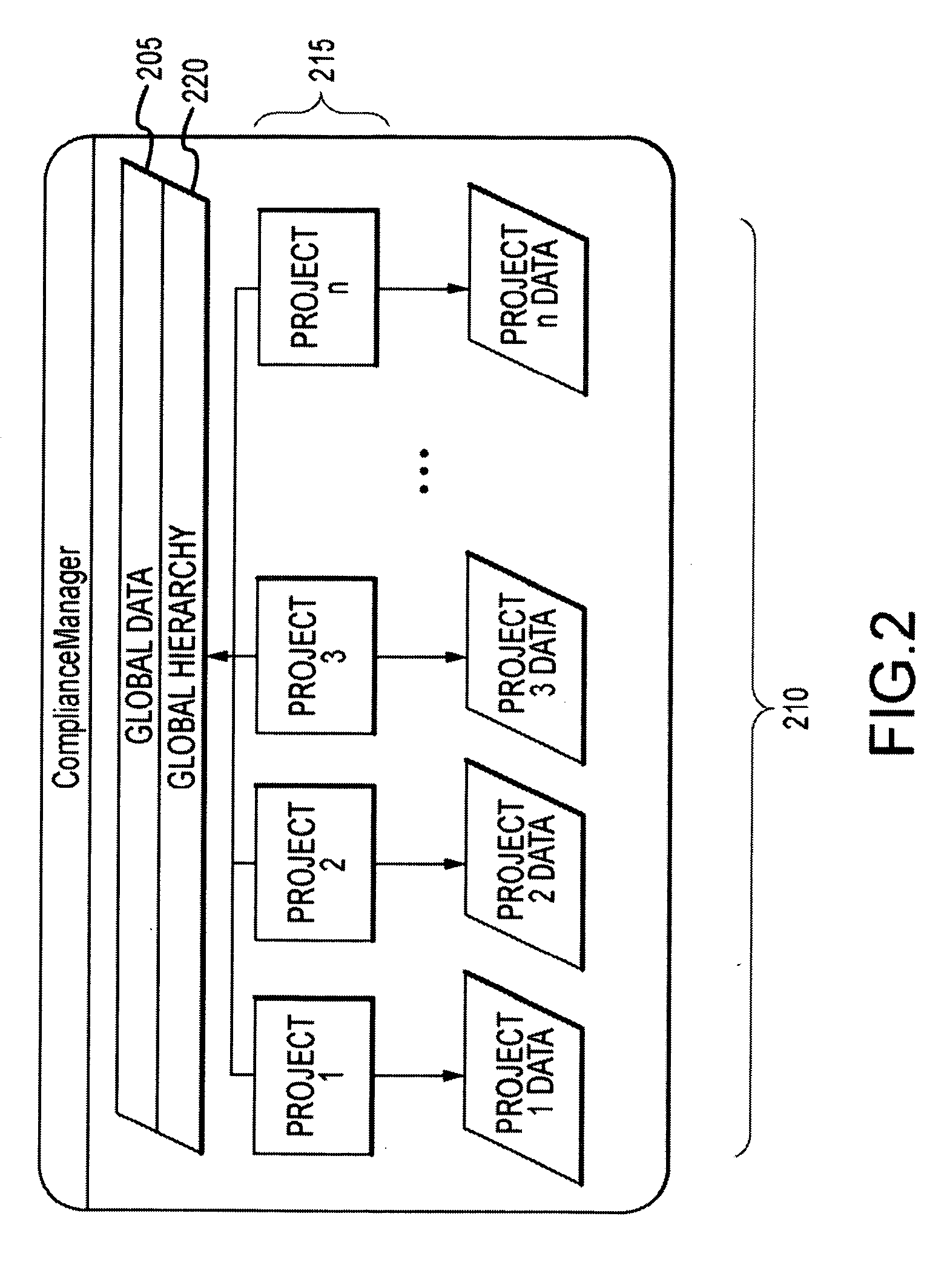

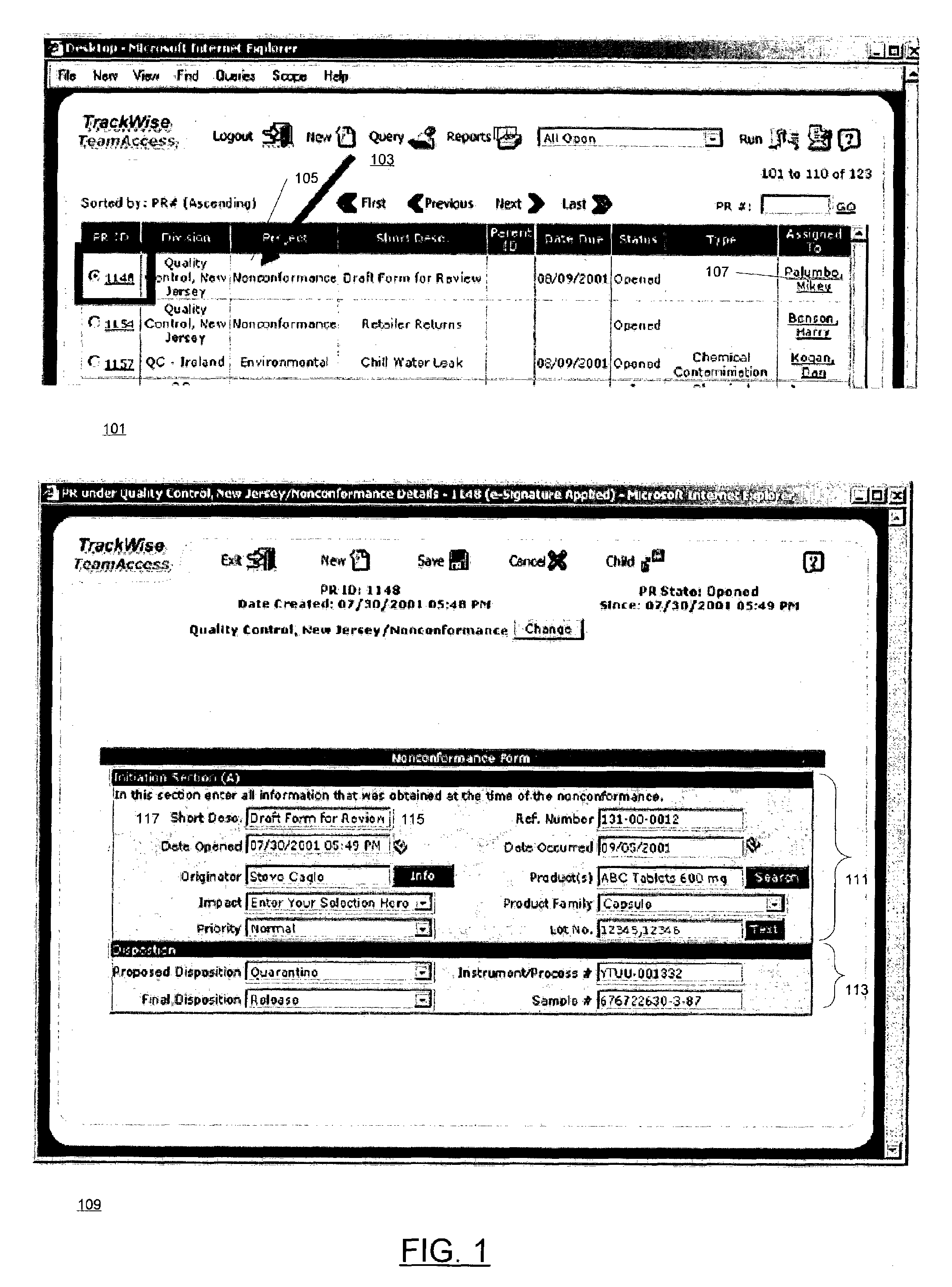

System and method for project process and workflow optimization

InactiveUS20080077530A1Improve complianceUser identity/authority verificationComputer security arrangementsSoftware engineeringProcess control

A system and method for process control and management is disclosed. Various features and applications of the present invention may be suitably adapted to manage, control or otherwise improve compliance and / or project workflow processing. In representative applications, the present invention provides a system and method for control, management, verification, certification and communication of compliance standards.

Owner:MARK BUSINESS INTELLIGENCE SYST

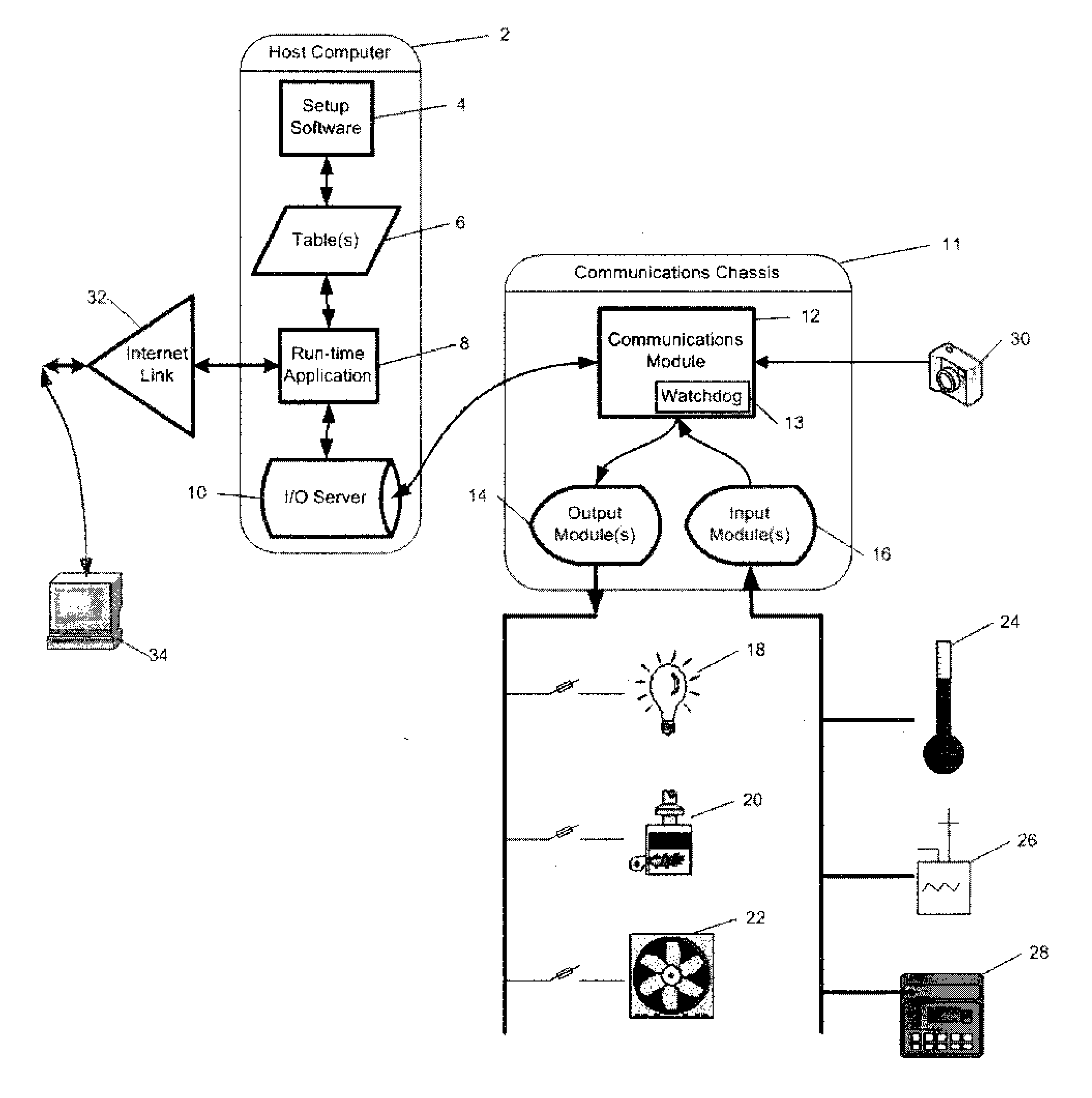

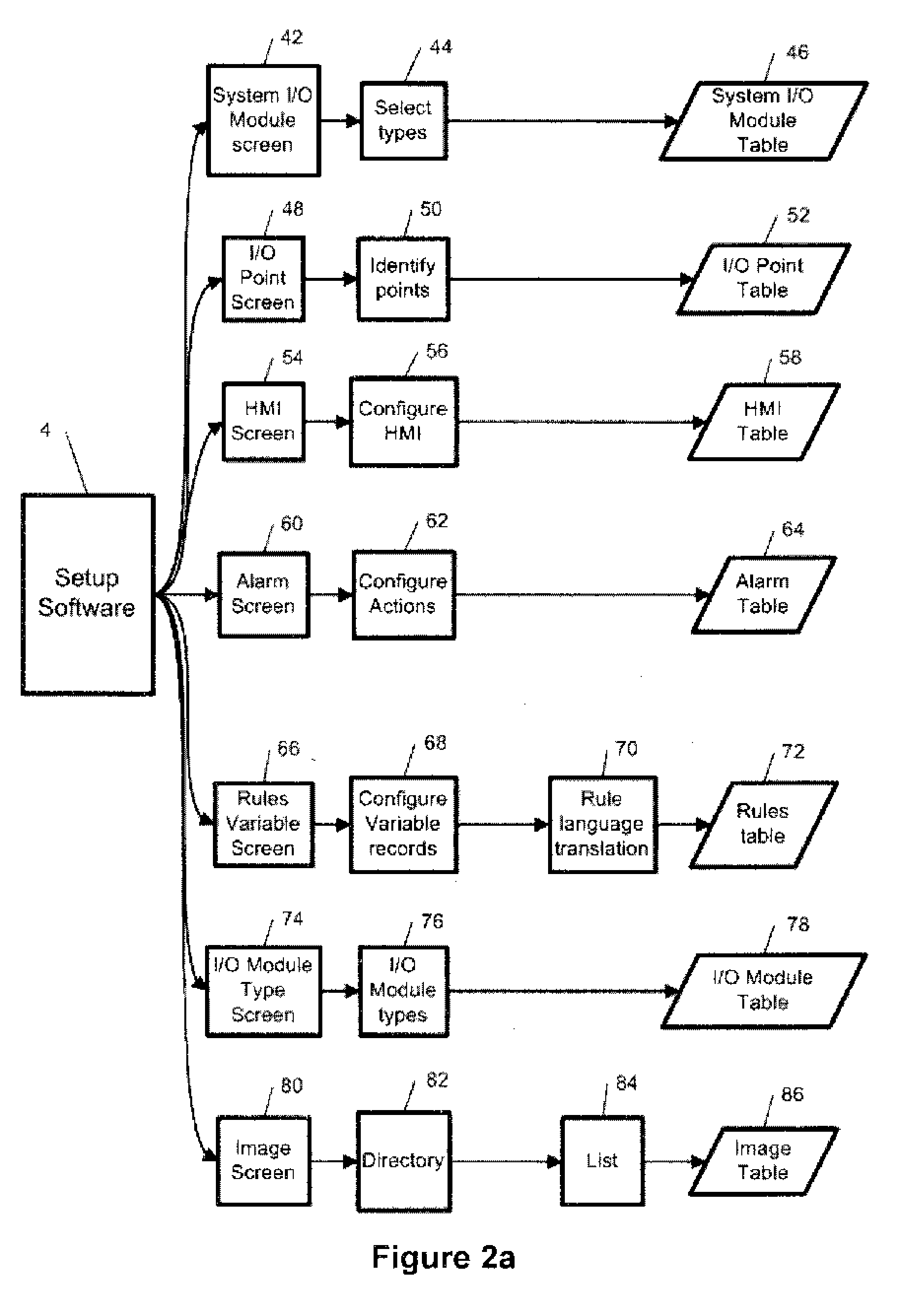

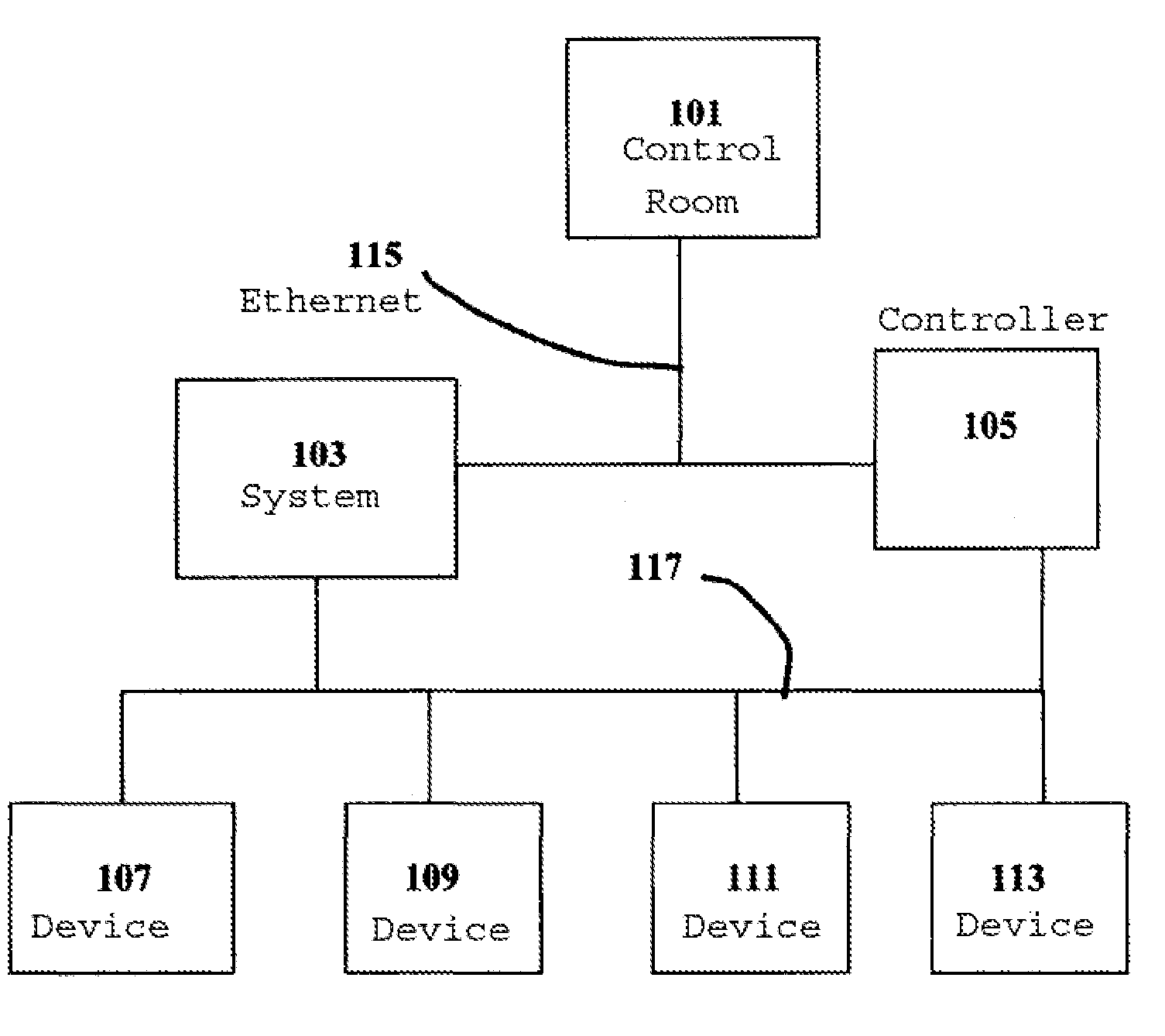

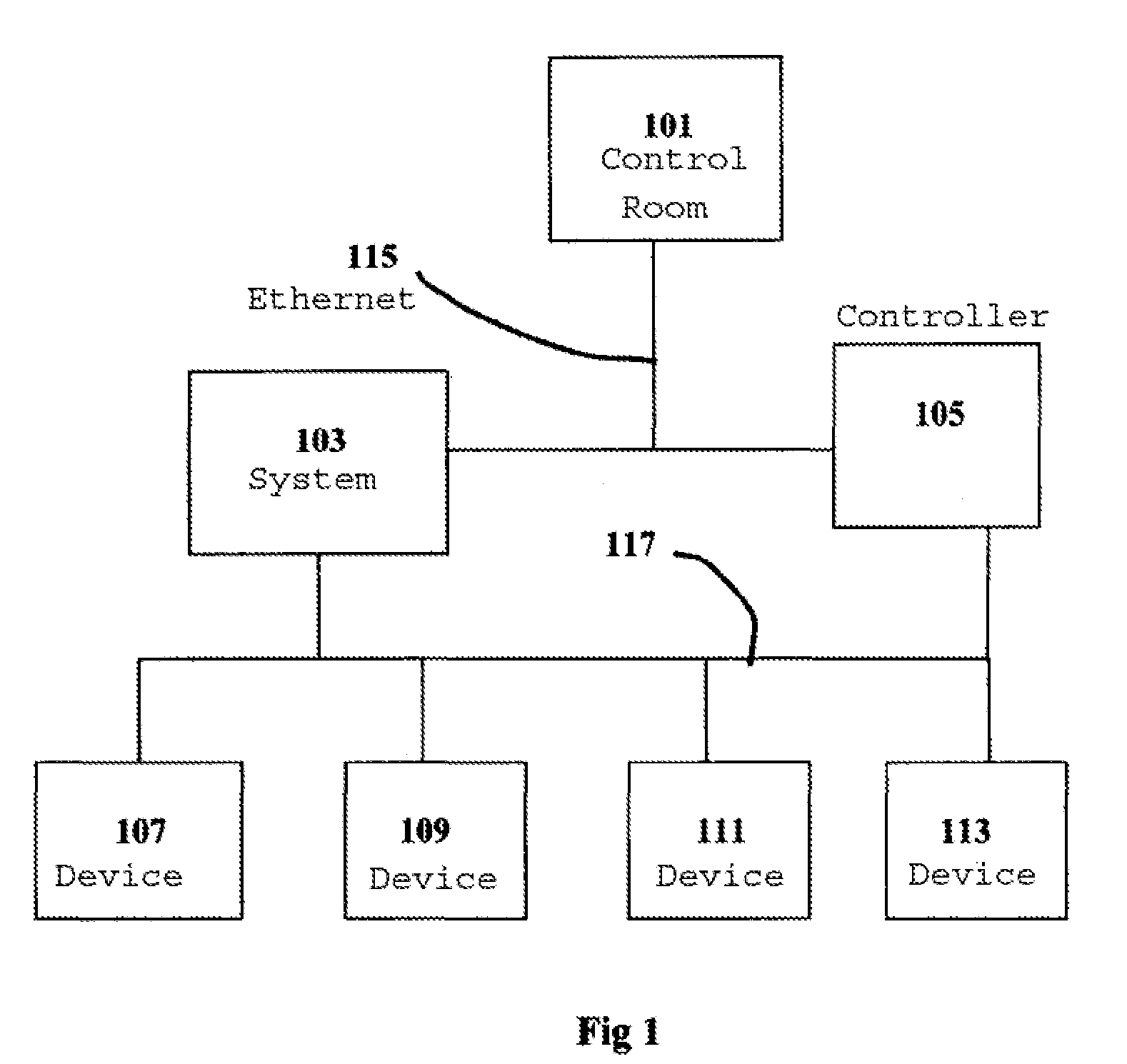

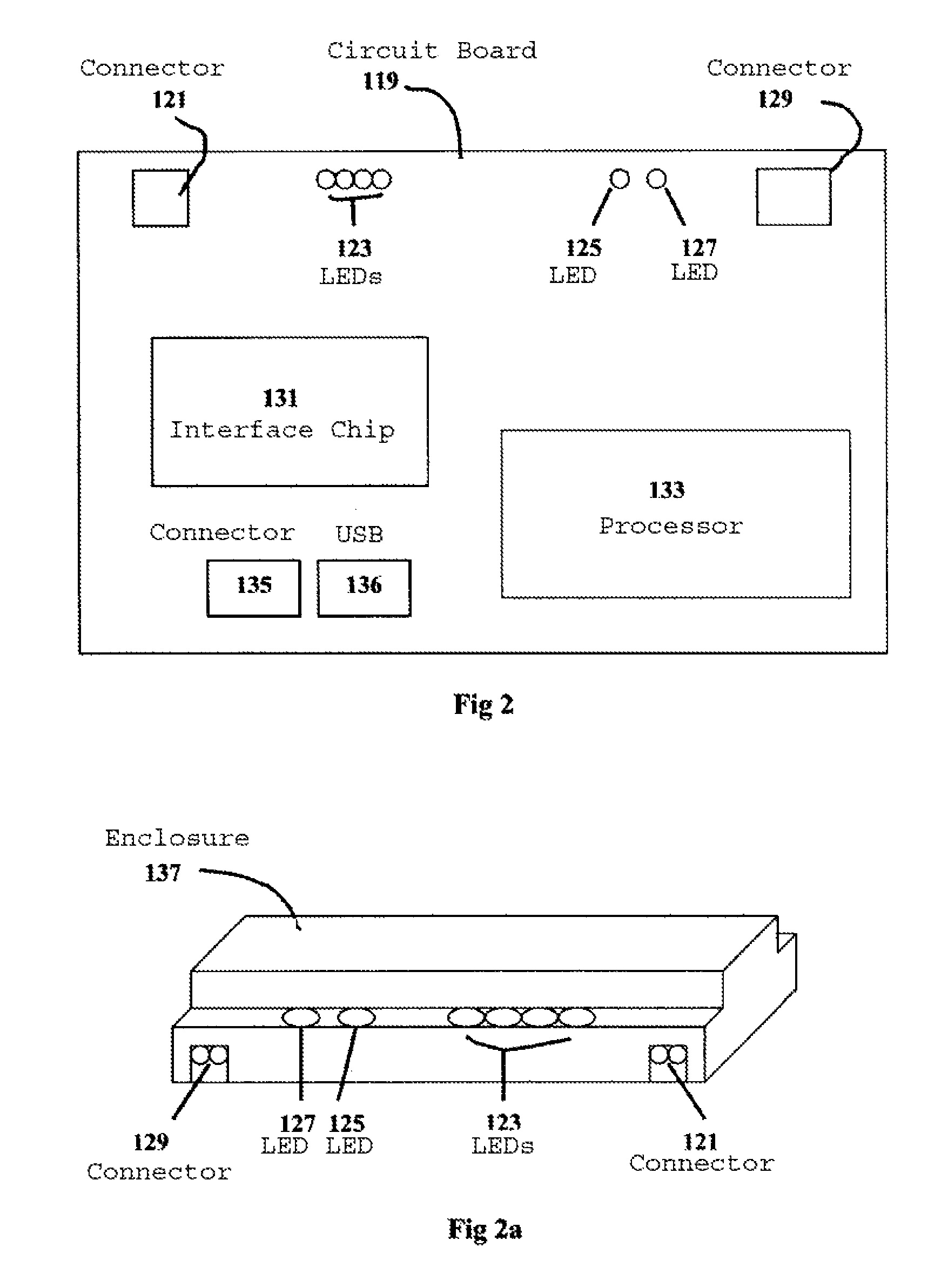

Method and apparatus for tabular process control

InactiveUS20060253205A1Eliminate input/output address configurationEnhances earlyNatural language translationComputer controlAutomatic controlData acquisition

The invention discloses methods and apparatus based on tabular concepts which greatly simplify the configuration, maintenance and run-time operations of a broad range of electronic equipment control systems, including, but not limited to: (a) industrial controls, (b) supervisory control and data acquisition, such as heating, ventilation and air conditioning, and (c) home automation, including systems or stand-alone equipment, such as video recording devices. The tabular concepts of the invention are applied in three primary stages, namely (i) data input or configuration, including automated data population, (ii) generic operating rule application to tables of rules data variables, and (iii) English (or other) language translations of the current rule sets, for ease of verification. By each of these methods alone and through combination of all of these methods, the current invention makes the configuration and operation of automated equipment easily accessible to persons who do not have technical skills in either process control, automation, or software programming. Development of software for automatic control of equipment is also greatly simplified by these inventions.

Owner:GARDINER MICHAEL

Diagnostic access system

InactiveUS7975184B2Reduce user costsEasy to useError detection/correctionDigital computer detailsData processing systemDiagnostic data

Owner:GOFF DONALD +2

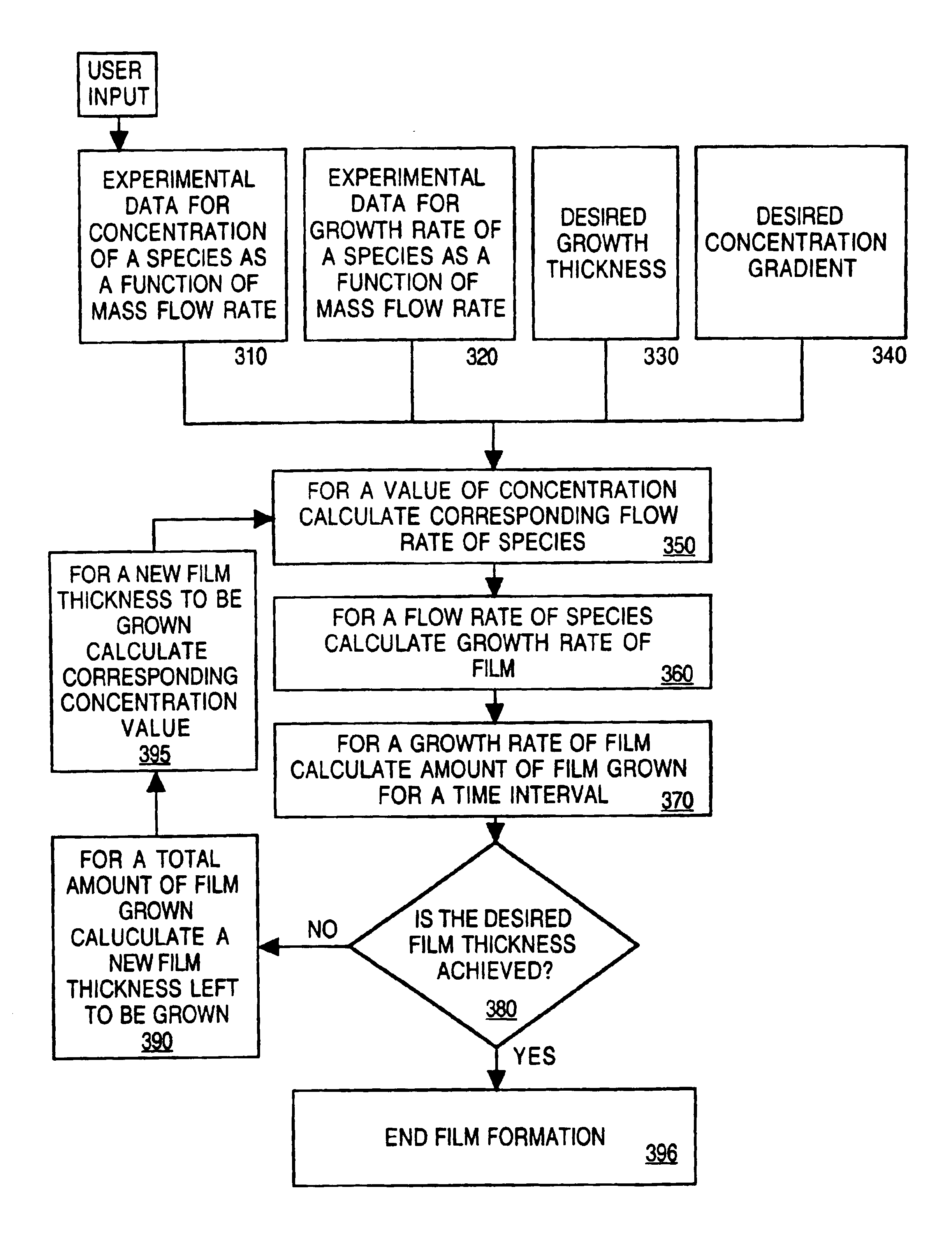

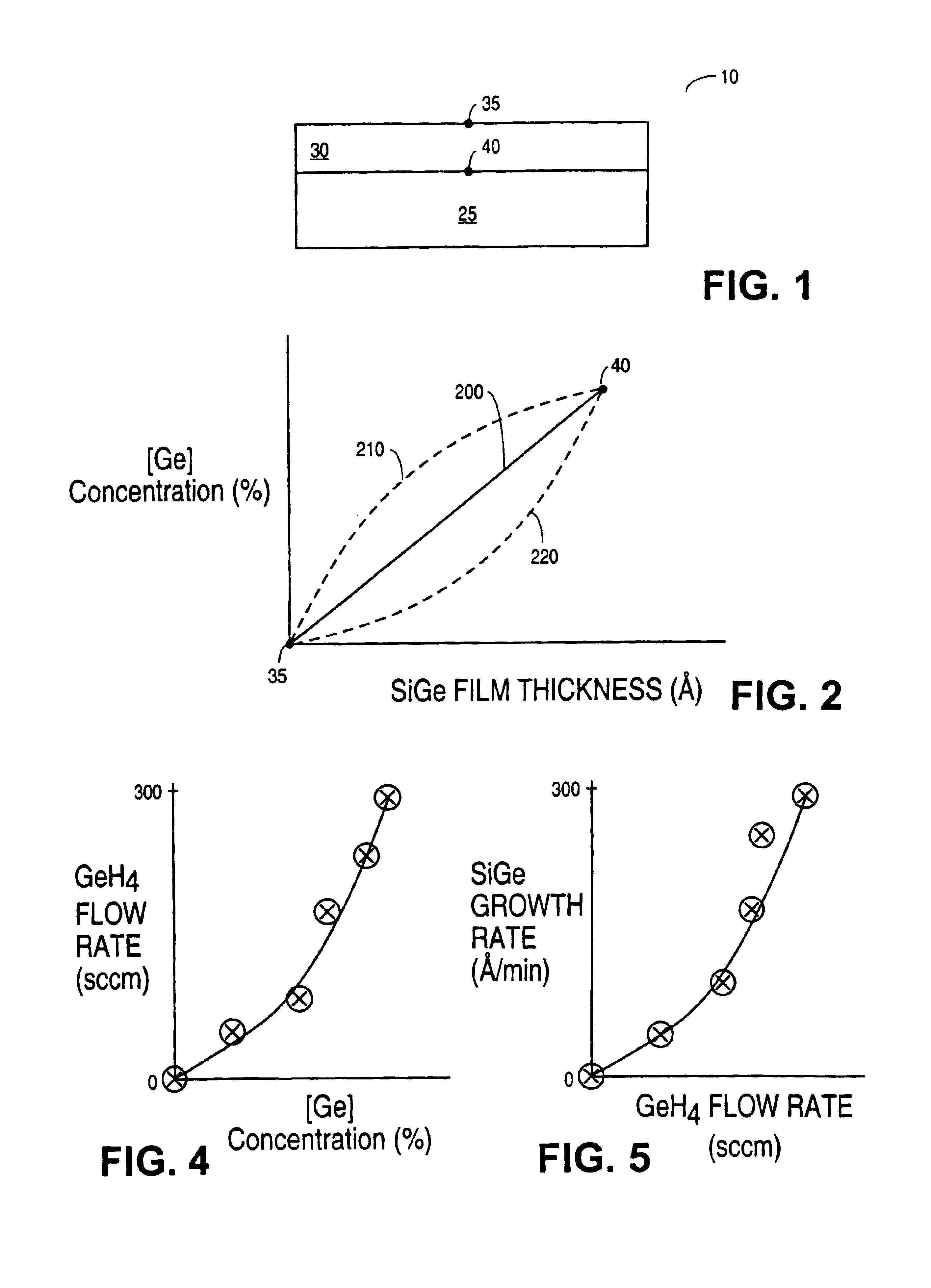

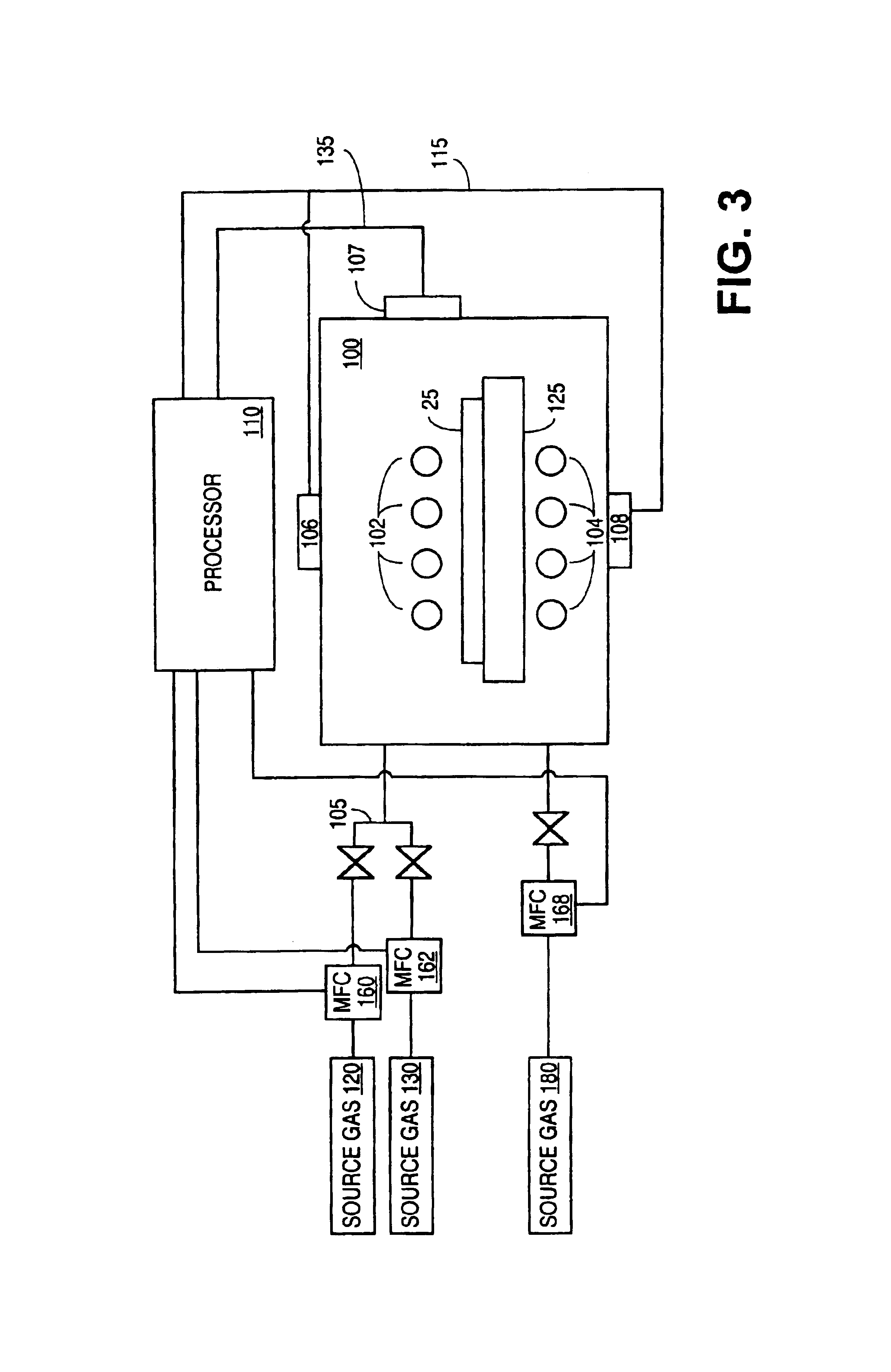

Method for CVD process control for enhancing device performance

InactiveUS6911401B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringProcess control

A method implemented by one or more processors, including receiving first information relating a plurality of flow rates of a species to corresponding concentrations of the species within films generated using the flow rates; receiving a desired concentration profile of the species within a desired film; and generating a plurality of process steps that, when performed, would form the desired film with the desired concentration profile by controlling the flow rate of the species based, in part, on the first information and the desired concentration profile, wherein a first concentration of the species at a first point in the desired concentration profile differs from a second concentration of the species at a second point in the desired concentration profile. A computer-readable medium, system and apparatus are also disclosed.

Owner:APPLIED MATERIALS INC

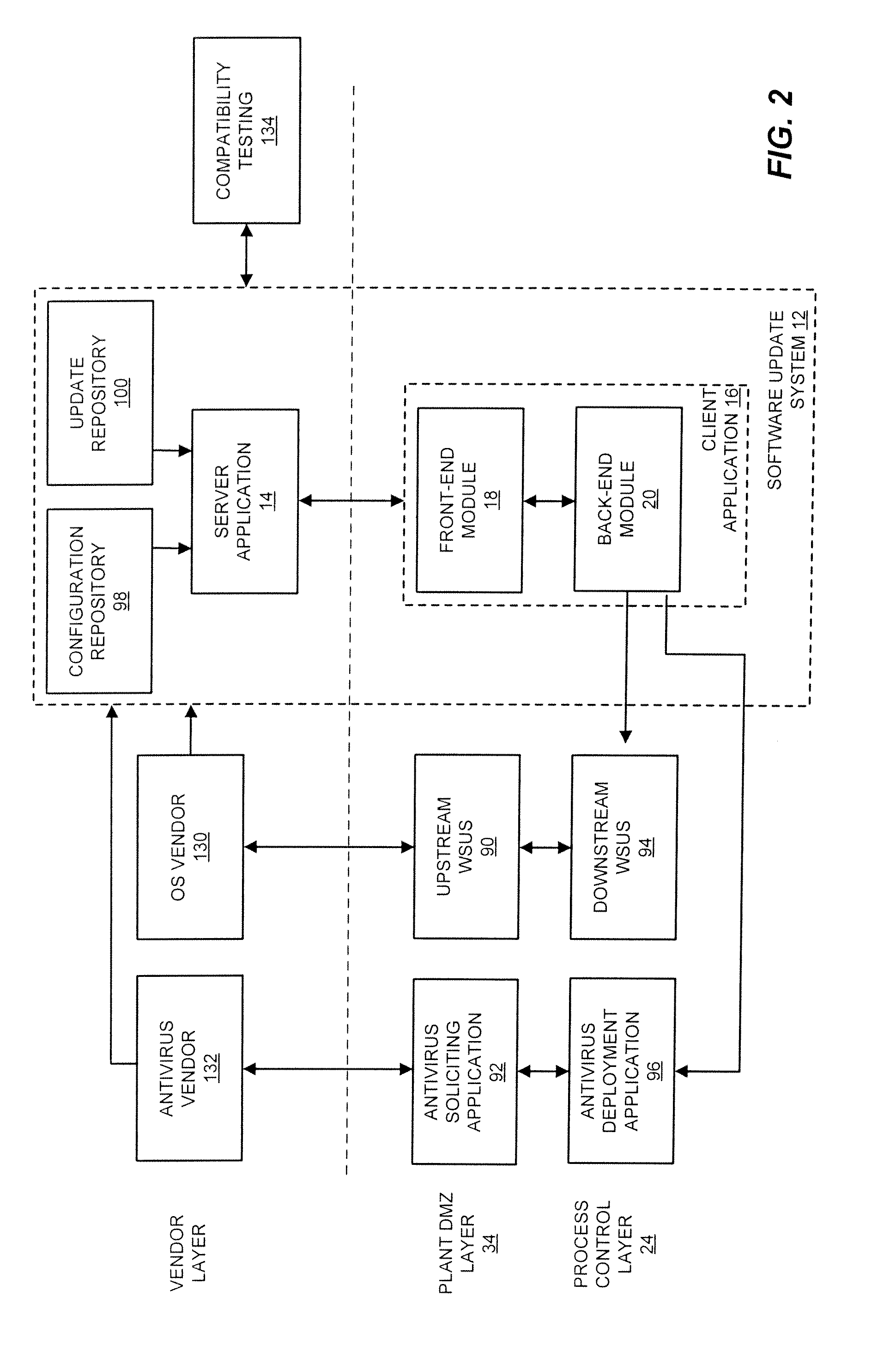

Automated Deployment of Computer-Specific Software Updates

ActiveUS20110078675A1Specific program execution arrangementsMemory systemsSoftware updateControl system

A software update system automatically deploys software updates, approved by a provider of a process control system, to computer hosts that execute the process control system. The software update system includes a client application that generates a request for software updates applicable to the computer hosts and initiates automatic deployment of the software update to the host, and a server application that provides software update data to the client application in response to the request.

Owner:FISHER-ROSEMOUNT SYST INC

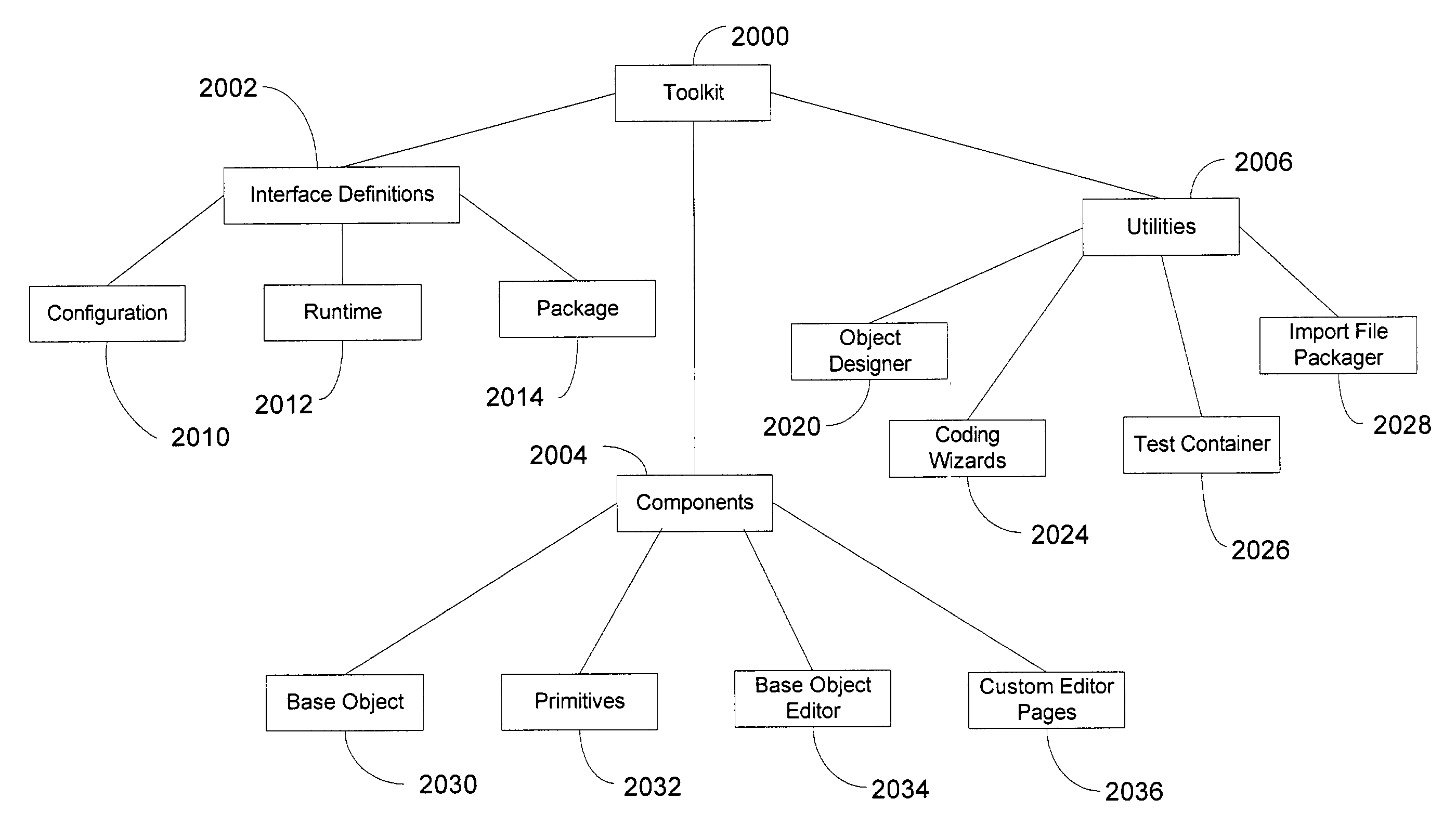

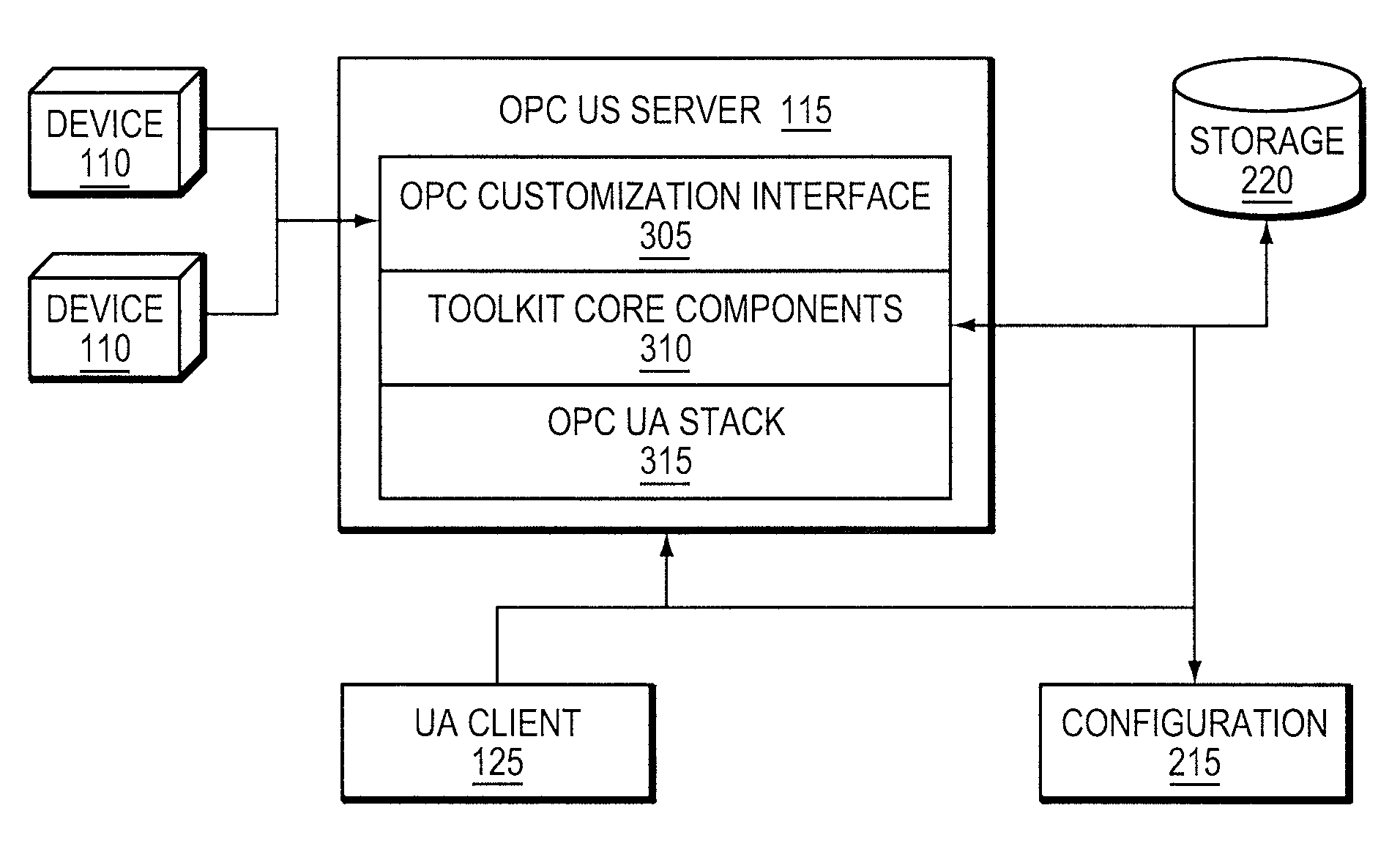

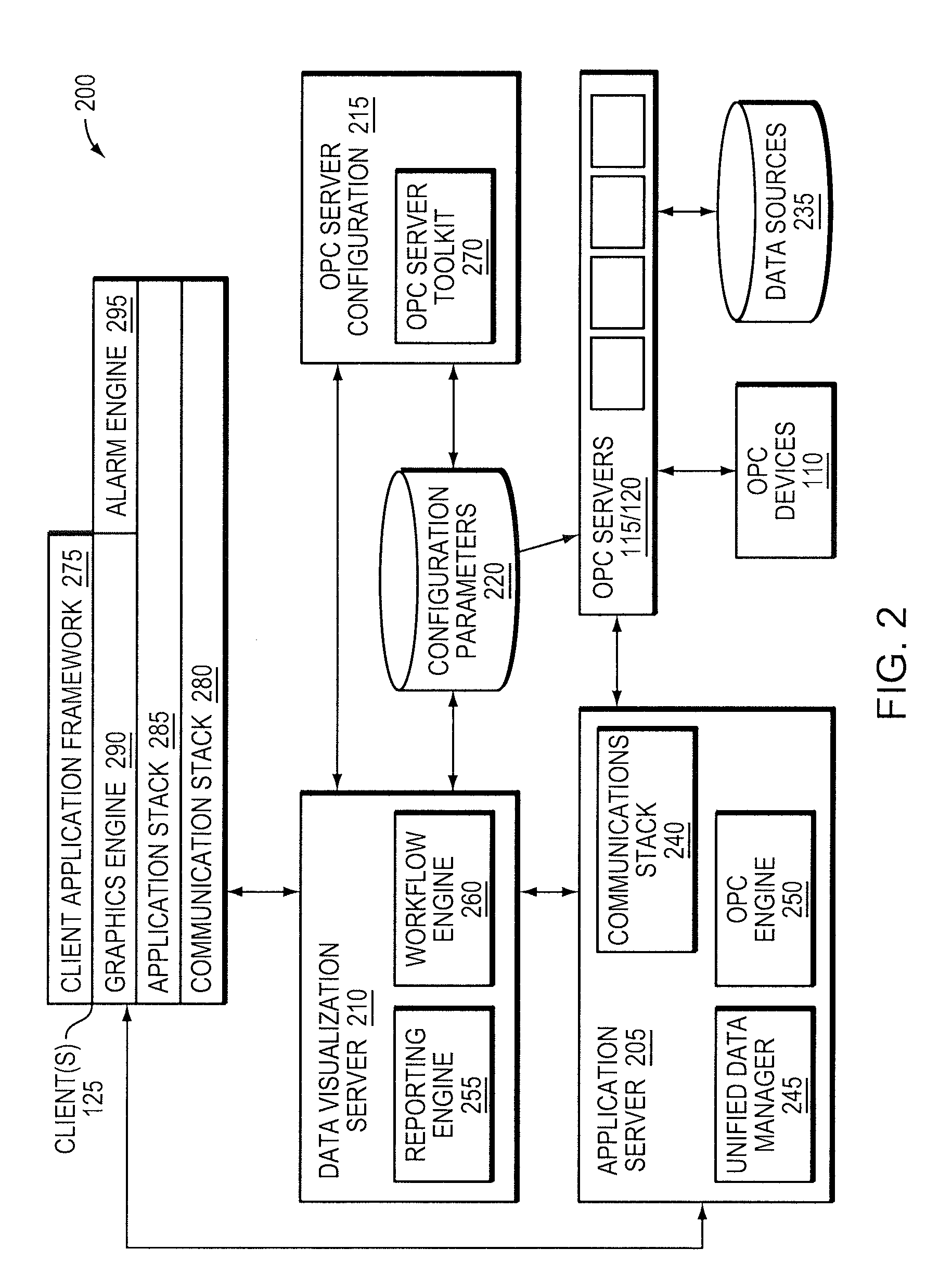

Customizable system for creating supervisory process control and manufacturing information applications

ActiveUS7086009B2Enhanced product offeringIntegration changesSoftware designSoftware simulation/interpretation/emulationThird partyDocumentation procedure

An extensible base process control and manufacturing information application development and execution software suite is disclosed that facilitates streamlined third party (e.g., OEM) development of derivative applications for particular vertical markets. The suite includes an object design toolkit that provides object template derivation tools for accessing and editing a set of base object templates. The objects derivable from the base templates include at least application objects deployed upon lower level hosting component objects of a supervisory process control and manufacturing information application. The toolkit also includes development tools for creating new base object templates that are added as extensions of the set of base object templates.In addition to the toolkit, the suite includes a set of marketing package customization tools facilitating seamlessly integrating changes by developers to the extensible base development and execution software suite. The marketing package customization tools include electronically editable base user documentation.

Owner:SCHNEIDER ELECTRIC SOFTWARE LLC

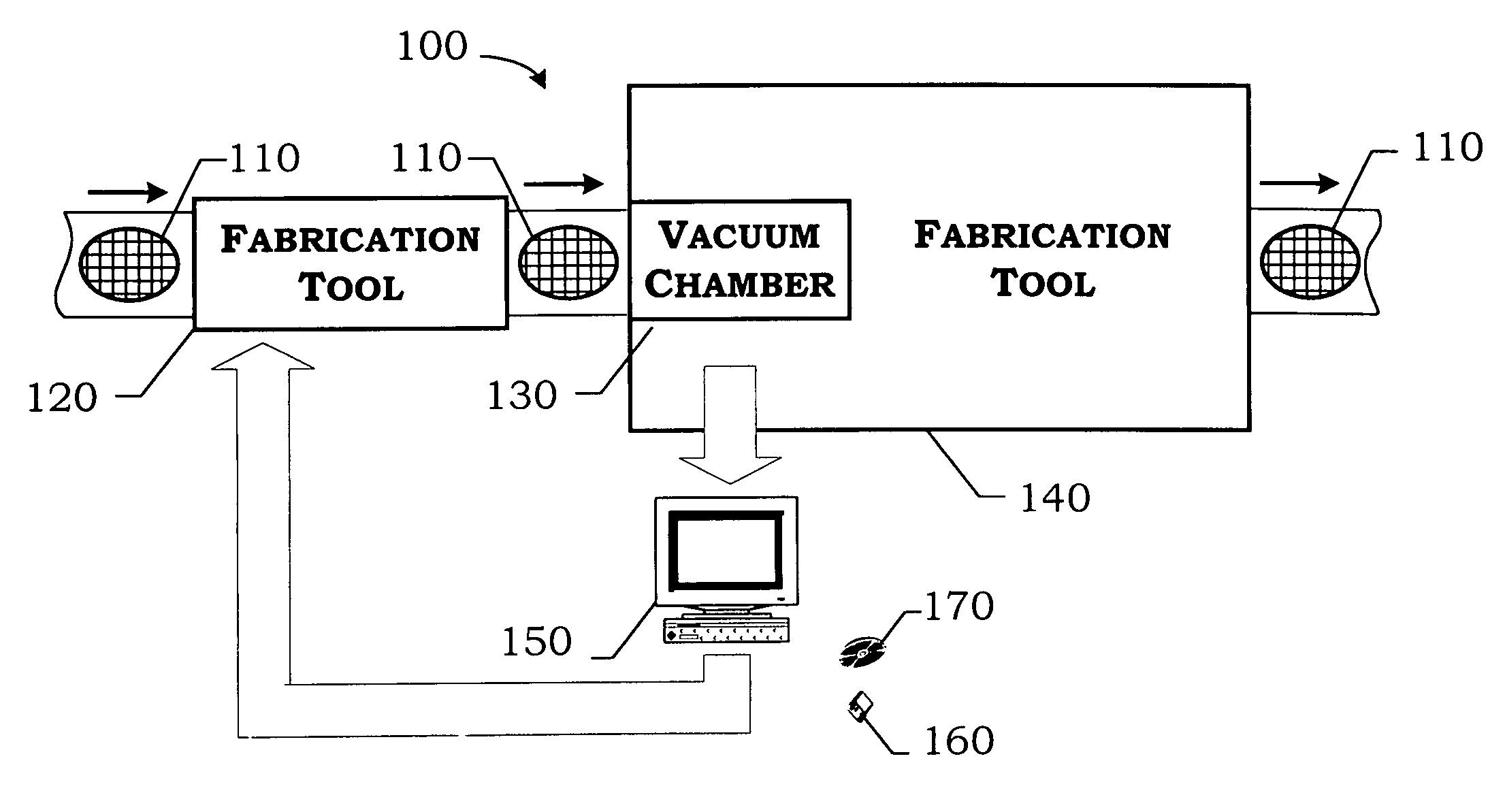

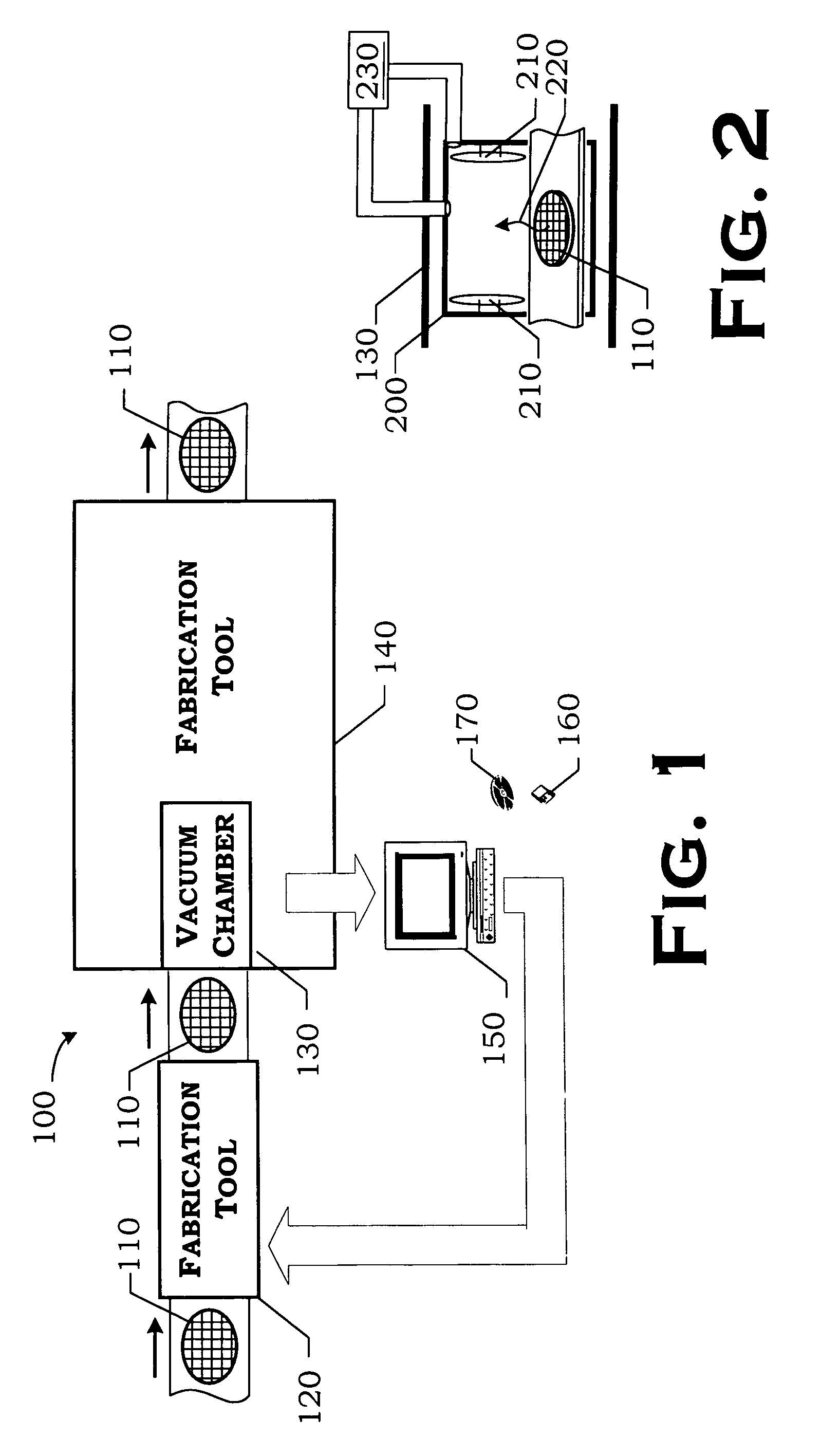

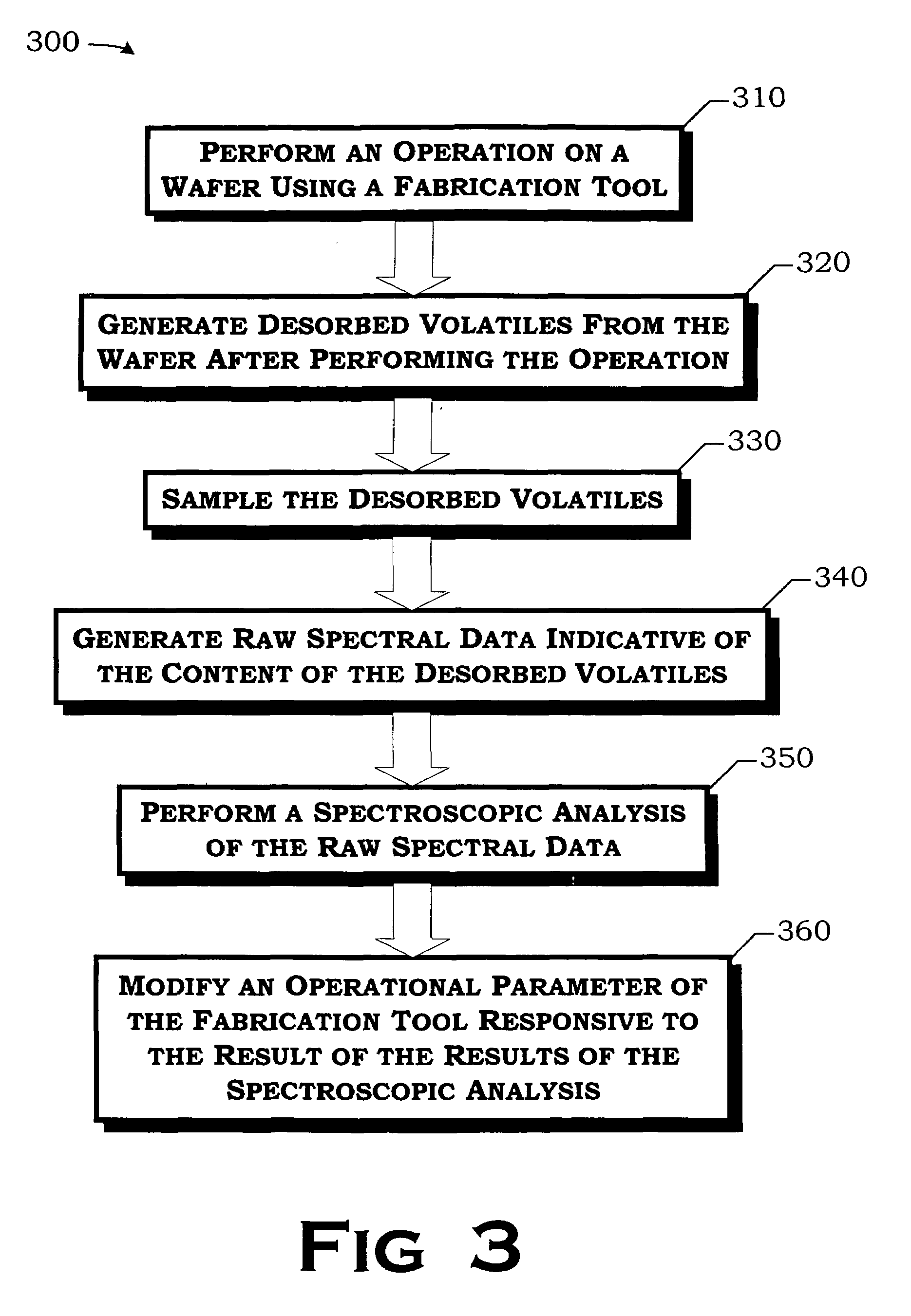

Closed loop residual gas analyzer process control technique

InactiveUS6955928B1Reduce the amount requiredSemiconductor/solid-state device testing/measurementSolid-state devicesResidual gas analyzerClosed loop

A technique for use in fabricating an integrated circuit are disclosed. The method generally begins by performing an operation on a wafer using a fabrication tool. Next, volatiles are desorbed from the wafer. The desorbed volatiles are sampled and raw spectral data indicating the content of the desorbed volatiles is generated. The raw spectral data is subjected to a spectroscopic analysis. An operational parameter of the fabrication tool is then modified responsive to the result of the results of the spectroscopic analysis. In one particular aspect of the invention, a controller receives the raw spectral data and processes the raw spectral data to determine the presence of a residual material on the wafer. The controller then controls the process flow operation to reduce the amount of the residual material on the wafer responsive to the results of processing the raw spectral data. Other aspects of the invention include the apparatus implementing the process flow and the controller itself.

Owner:TAIWAN SEMICON MFG CO LTD

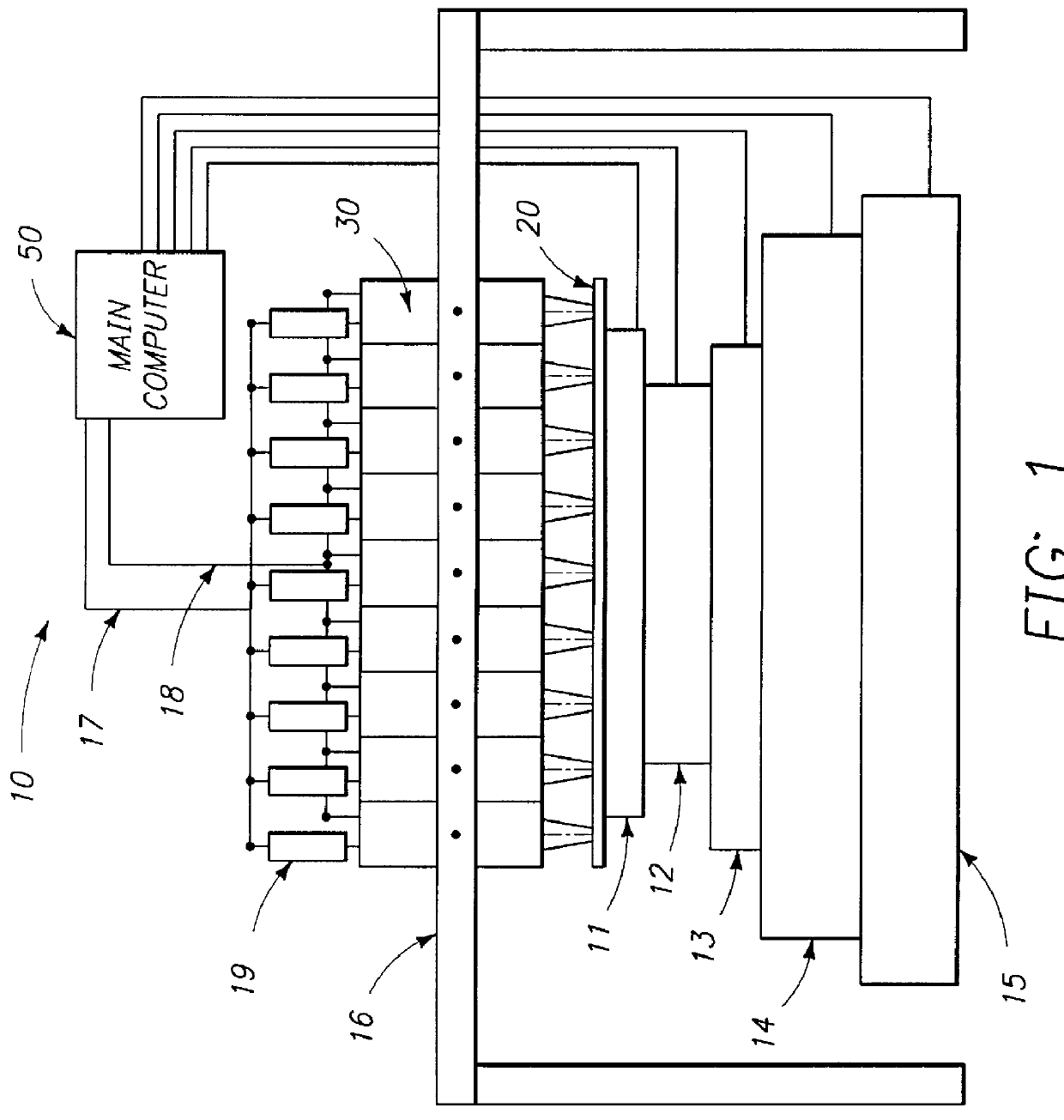

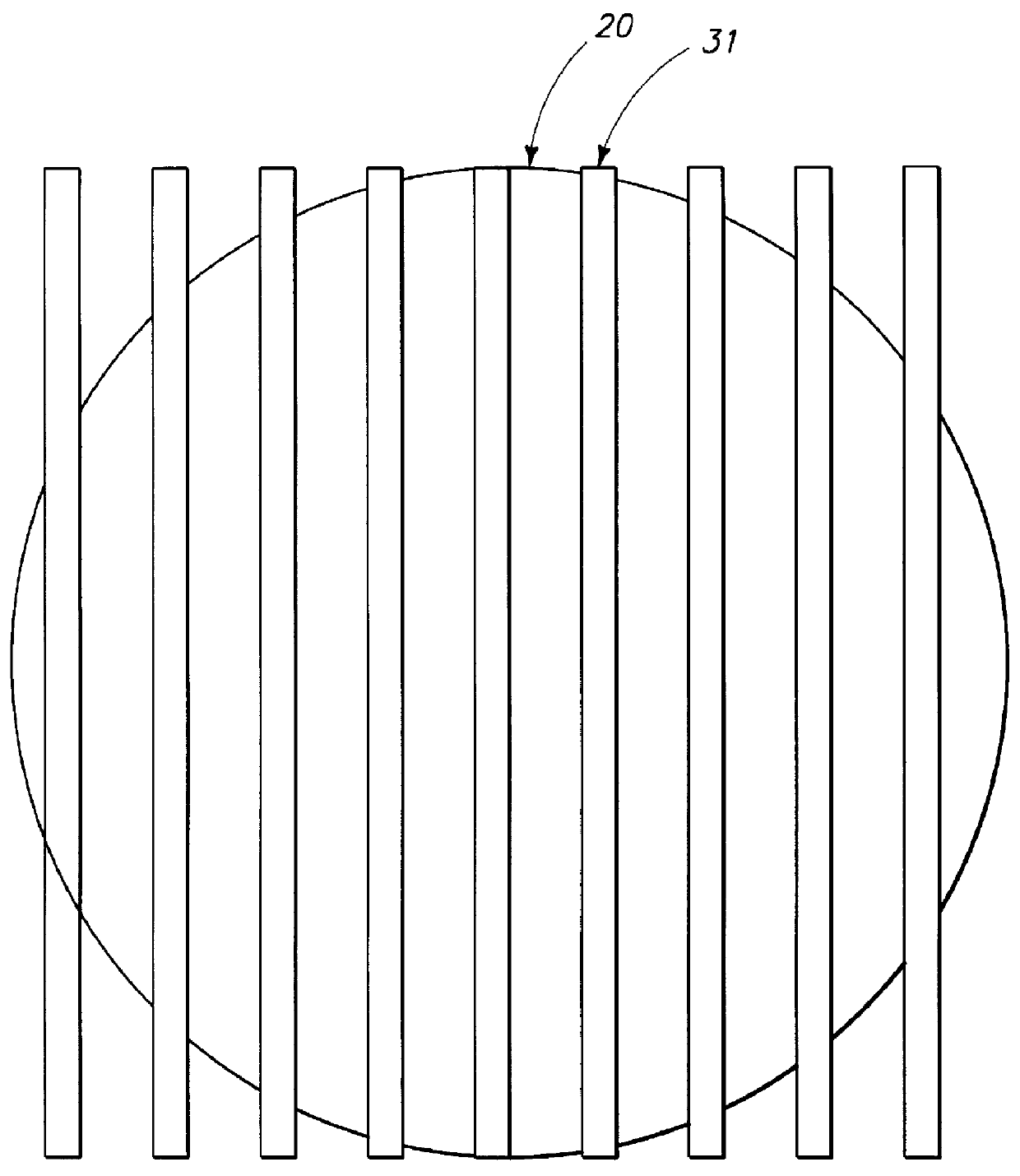

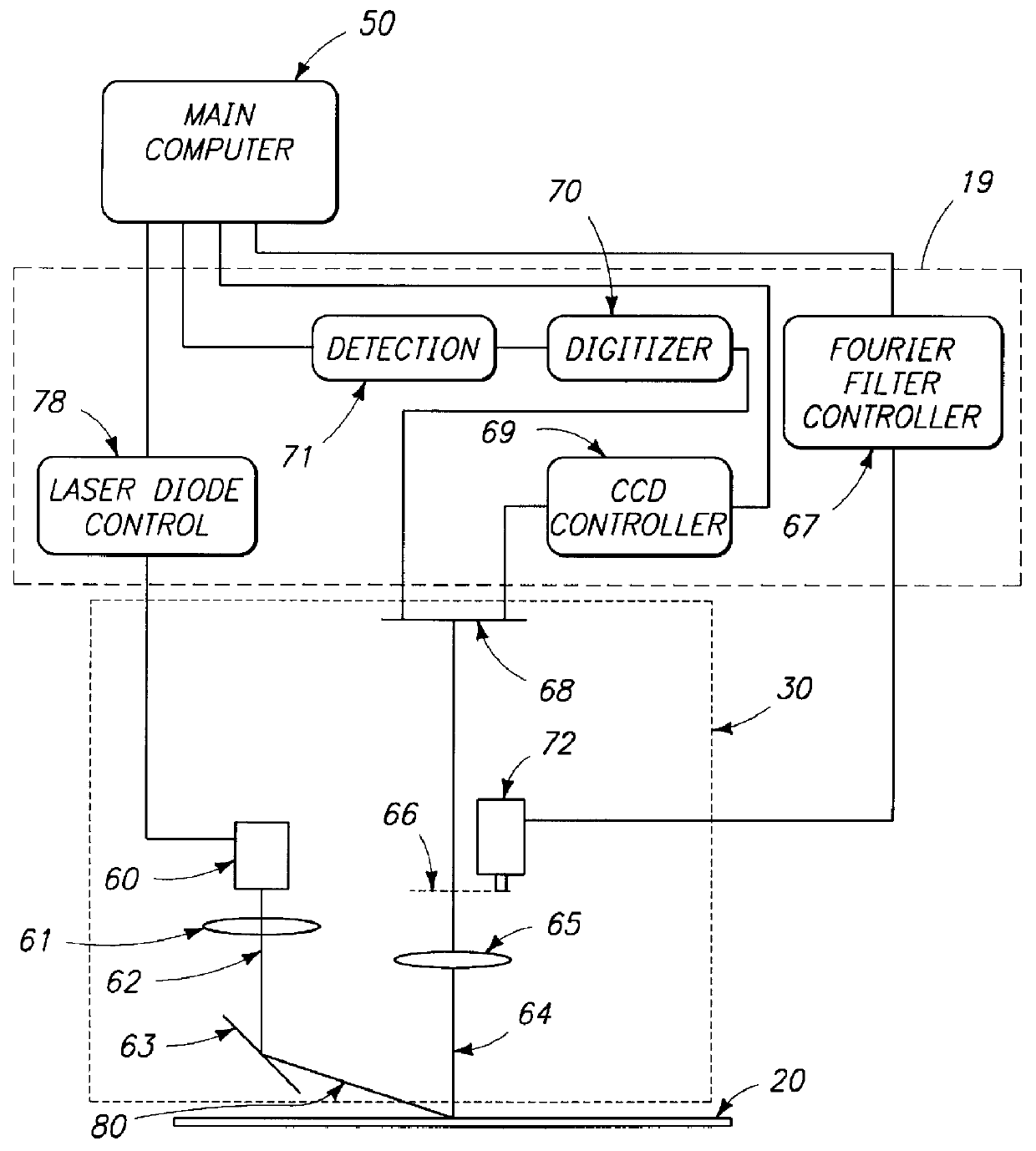

System and method for inspecting semiconductor wafers

InactiveUS6020957ALow costFaster throughputSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingGratingImage subtraction

A method for inspecting semiconductor wafers is provided in which a plurality of independent, low-cost, optical-inspection subsystems are packaged and integrated to simultaneously perform parallel inspections of portions of the wafer, the wafer location relative to the inspection being controlled so that the entire wafer is imaged by the system of optical subsystems in a raster-scan mode. A monochromatic coherent-light source illuminates the wafer surface. A darkfield-optical system collects scattered light and filters patterns produced by valid periodic wafer structures using Fourier filtering. The filtered light is processed by general purpose digital-signal processors. Image subtraction methods are used to detect wafer defects, which are reported to a main computer to aid in statistical process control, particularly for manufacturing equipment.

Owner:KLA TENCOR CORP

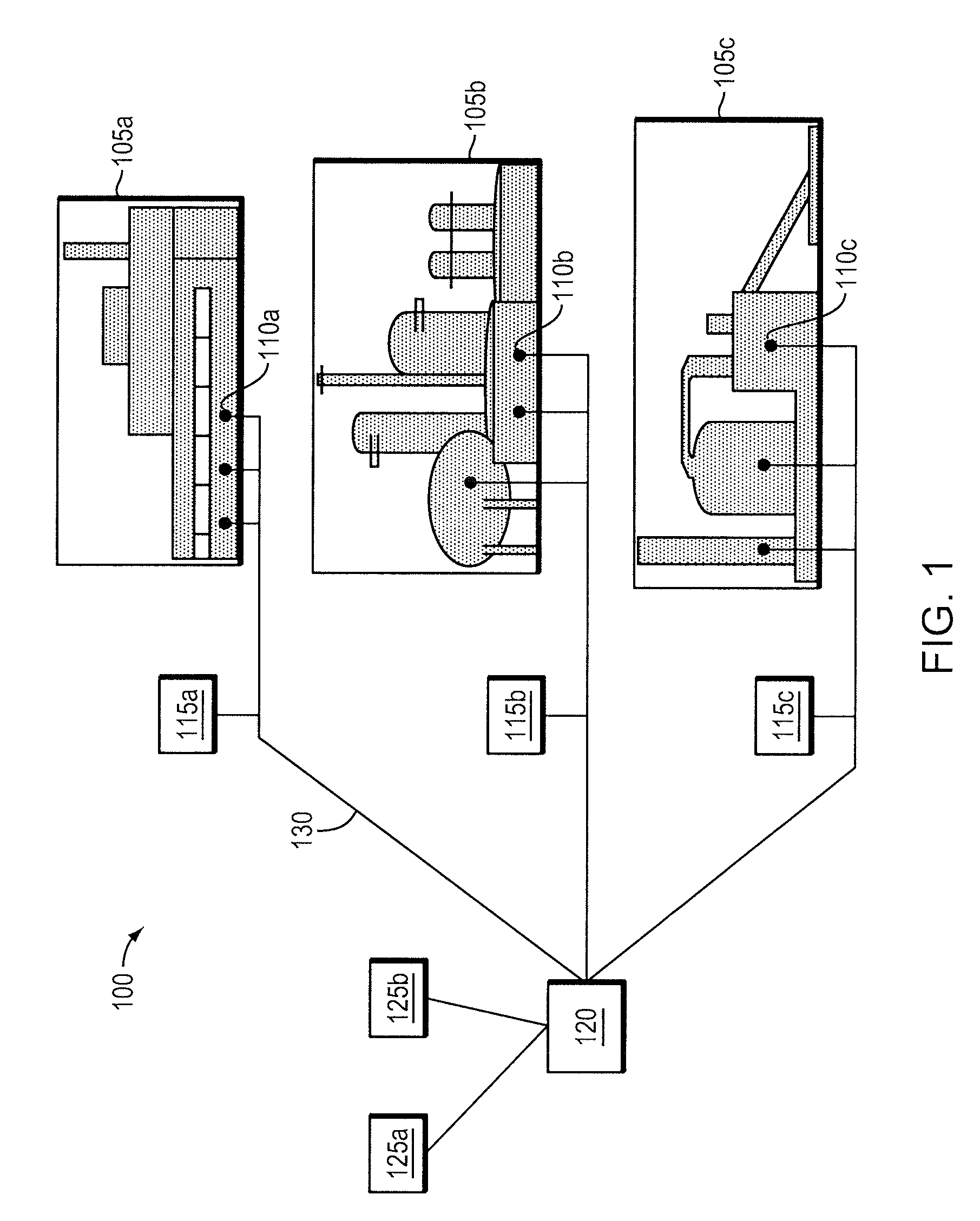

Visualization of process control data

ActiveUS20090210814A1Easy to demonstrateOptimizationComputer controlError detection/correctionGraphicsData mining

Graphical representations of operational process control data associated with monitored processes is displayed within the context of the geographical locations at which the processes operate, and in a manner as to model individual components of the processes.

Owner:IONICS INC

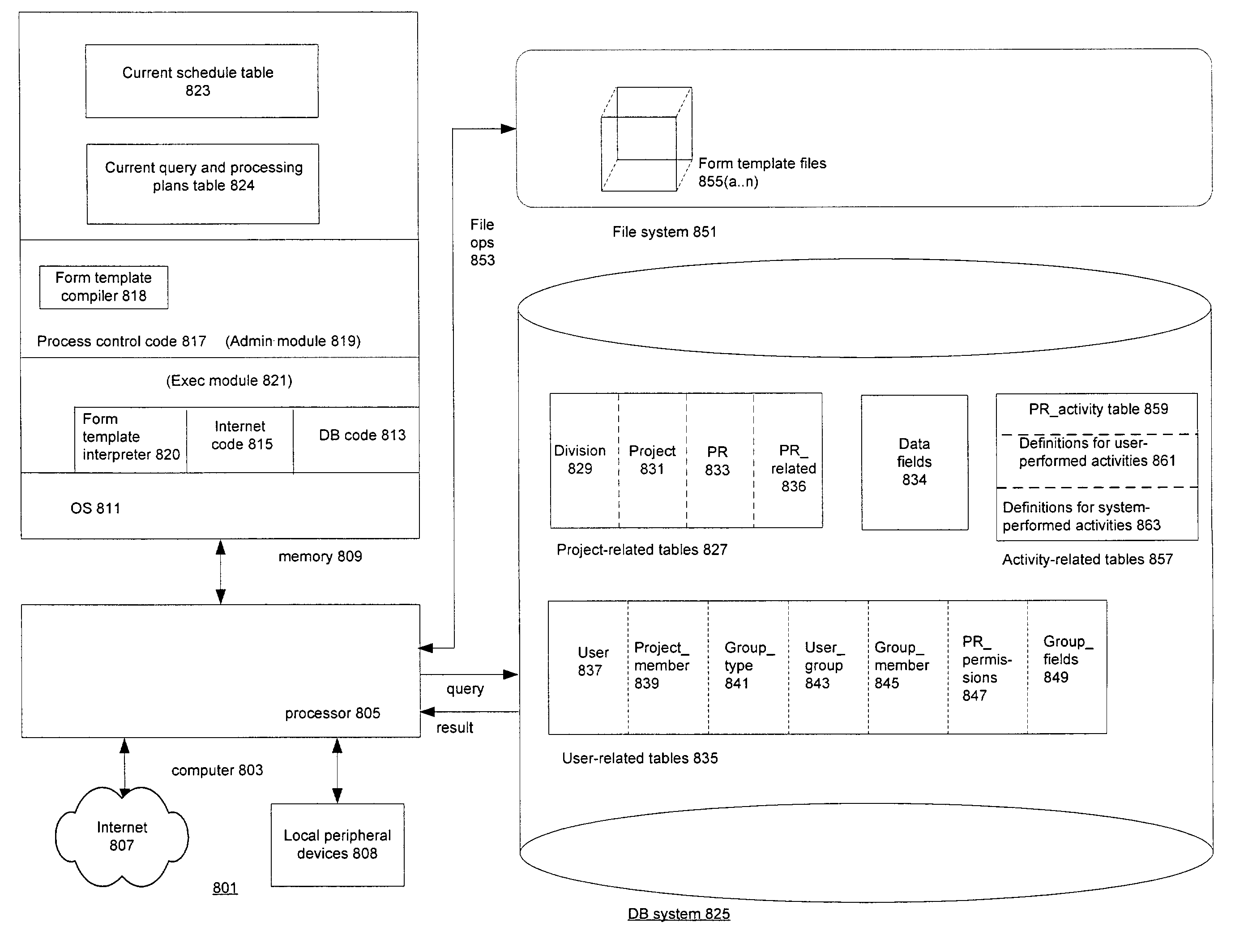

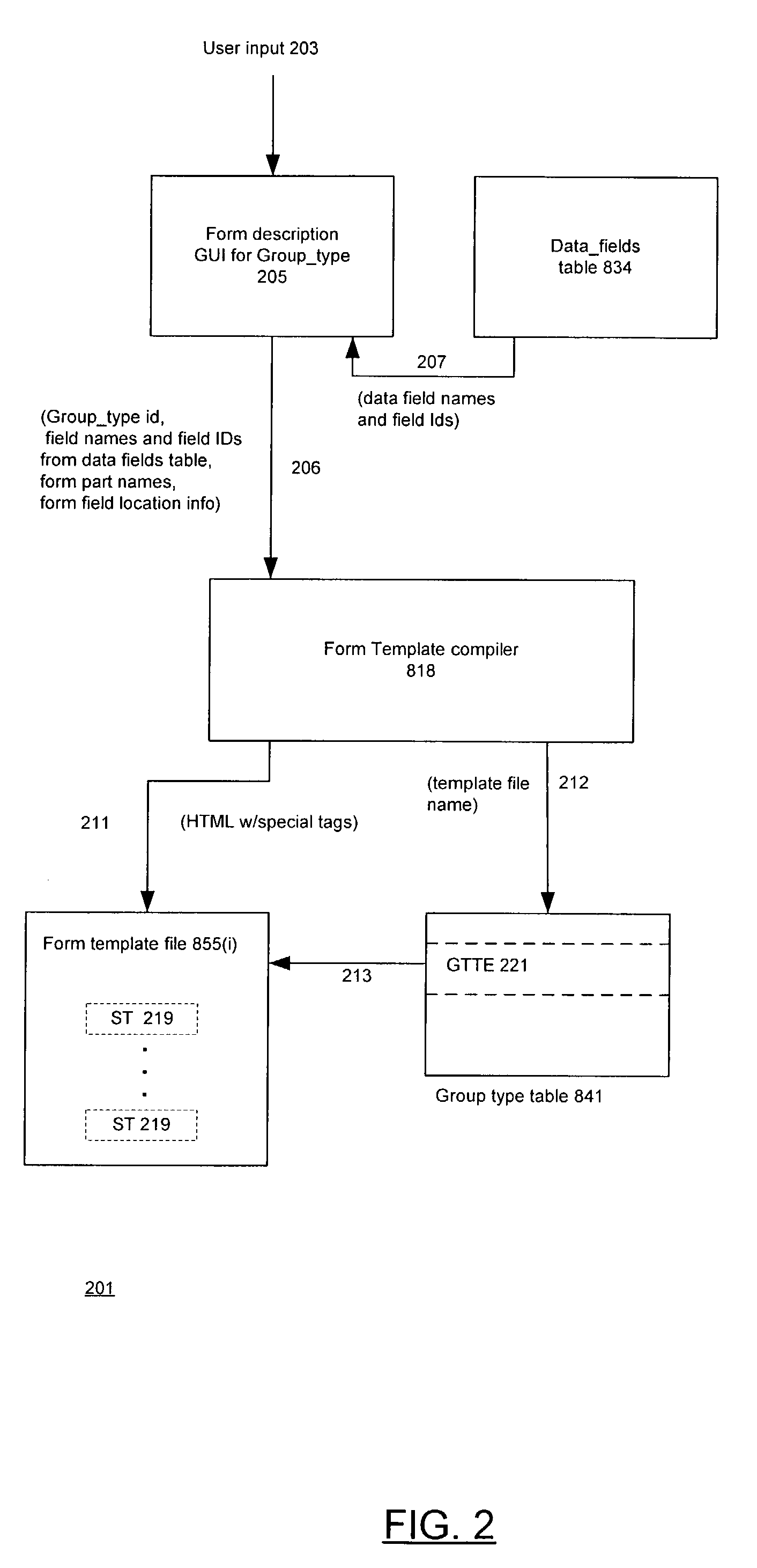

Defining user access in highly-configurable systems

ActiveUS7703021B1Computer security arrangementsInput/output processes for data processingConfigurable systemsDatabase

A highly-configurable process control system that uses process records in a database system to track a process. The database system relates process records, users, and projects. User permissions to view the process records include permissions for all process records related to a project to which the user is related, all such records that the user has created, all such records that a group the user belongs to have created, all such records that have been assigned to the user, and all such records that belong to an entity to which the user is related.The process records further include user-configurable fields. User permissions for the fields are provided according to group types which are related to groups to which the users belong. Included are permissions for inserting and deleting values in the user-configurable fields which are separate from the permission to edit the values.

Owner:SPARTA SYST INC

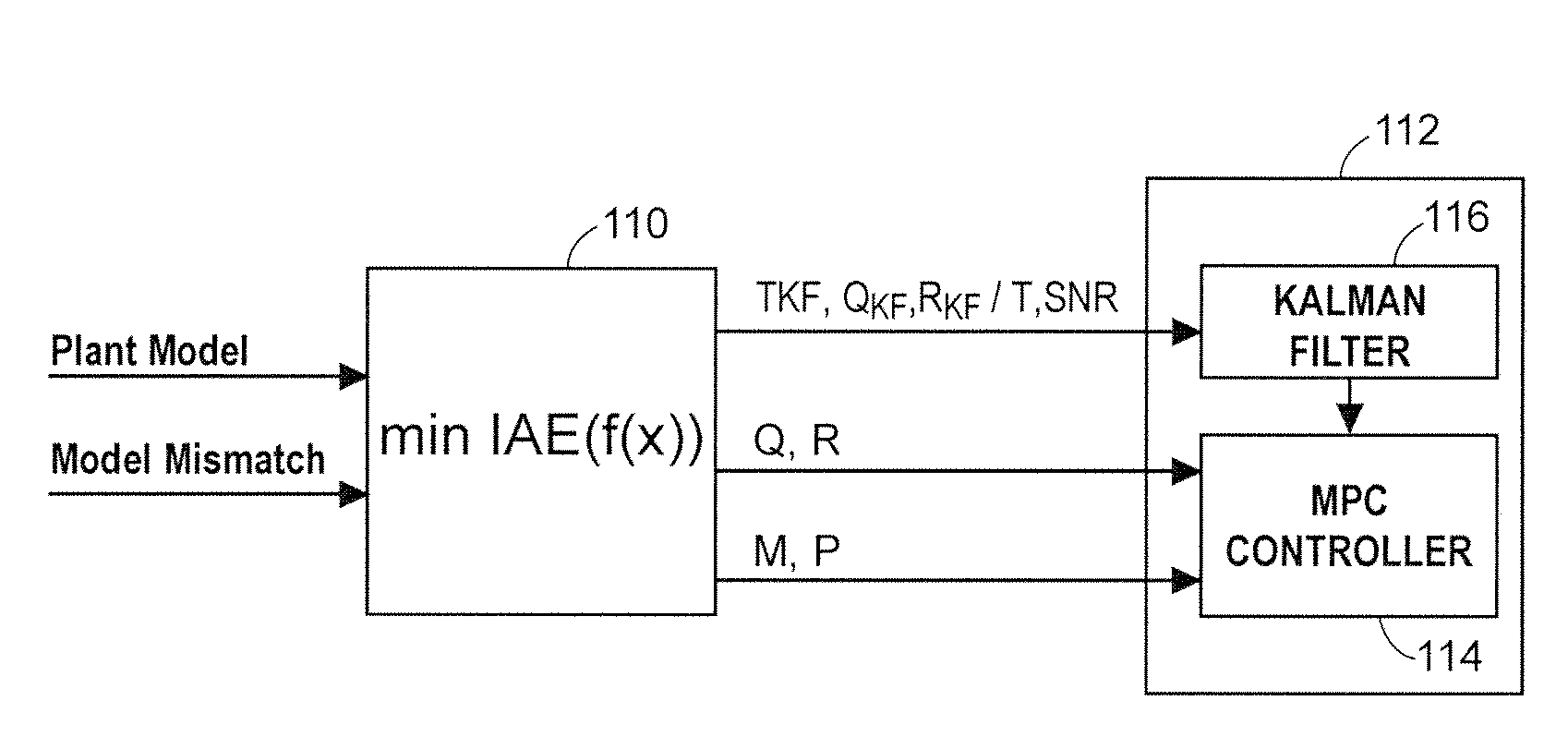

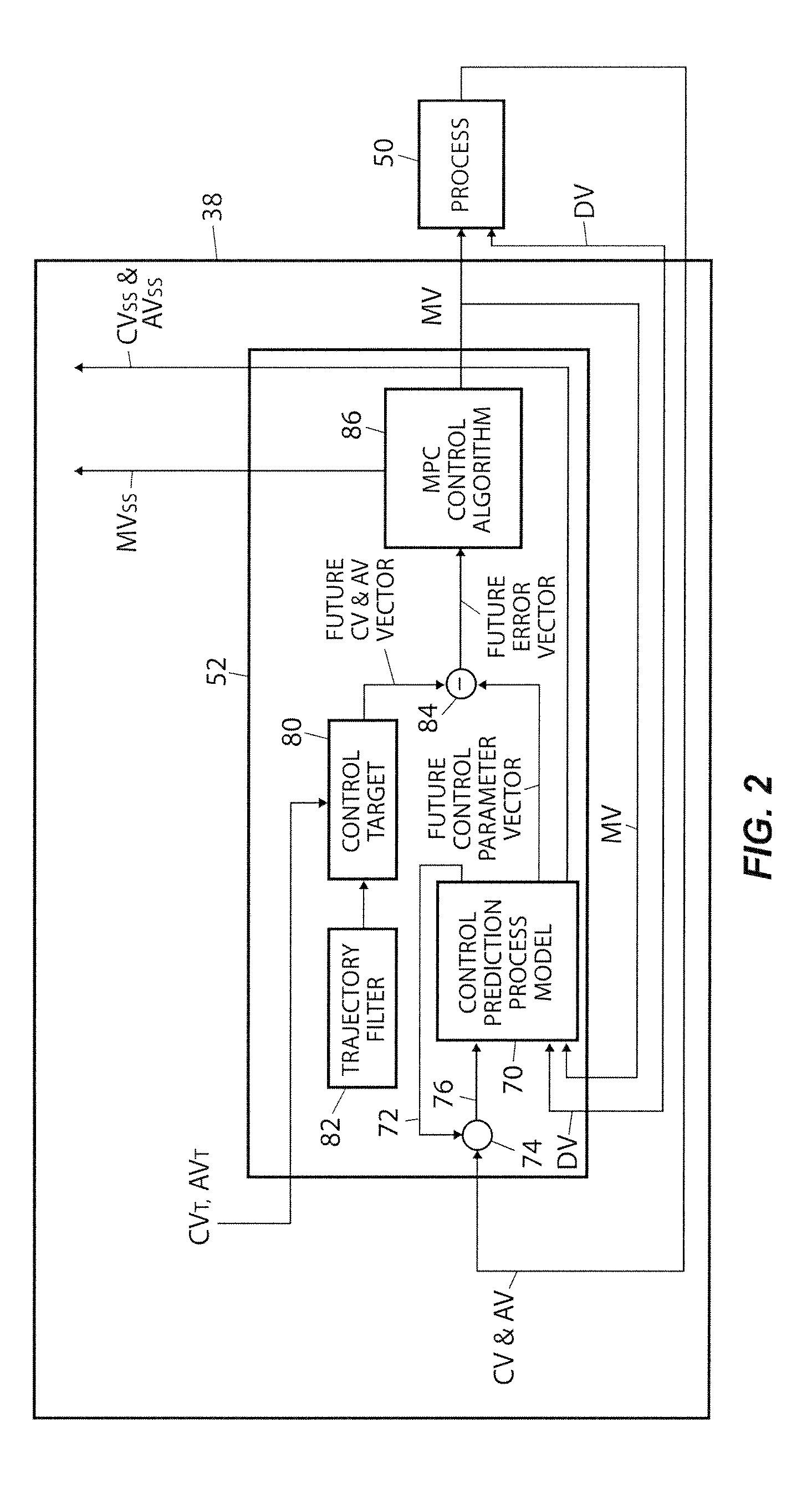

Robust adaptive model predictive controller with tuning to compensate for model mismatch

ActiveUS20090198350A1Improve immunityImprove performanceComputer controlSimulator controlClosed loopPredictive controller

An MPC adaptation and tuning technique integrates feedback control performance better than methods commonly used today in MPC type controllers, resulting in an MPC adaptation / tuning technique that performs better than traditional MPC techniques in the presence of process model mismatch. The MPC controller performance is enhanced by adding a controller adaptation / tuning unit to an MPC controller, which adaptation / tuning unit implements an optimization routine to determine the best or most optimal set of controller design and / or tuning parameters to use within the MPC controller during on-line process control in the presence of a specific amount of model mismatch or a range of model mismatch. The adaptation / tuning unit determines one or more MPC controller tuning and design parameters, including for example, an MPC form, penalty factors for either or both of an MPC controller and an observer and a controller model for use in the MPC controller, based on a previously determined process model and either a known or an expected process model mismatch or process model mismatch range. A closed loop adaptation cycle may be implemented by performing an autocorrelation analysis on the prediction error or the control error to determine when significant process model mismatch exists or to determine an increase or a decrease in process model mismatch over time.

Owner:FISHER-ROSEMOUNT SYST INC

Method and system of monitoring, sensor validation and predictive fault analysis

InactiveUS20050210337A1Simplicity of implementationEasy maintenanceError detection/correctionElectric testing/monitoringLinear correlationPredictive failure analysis

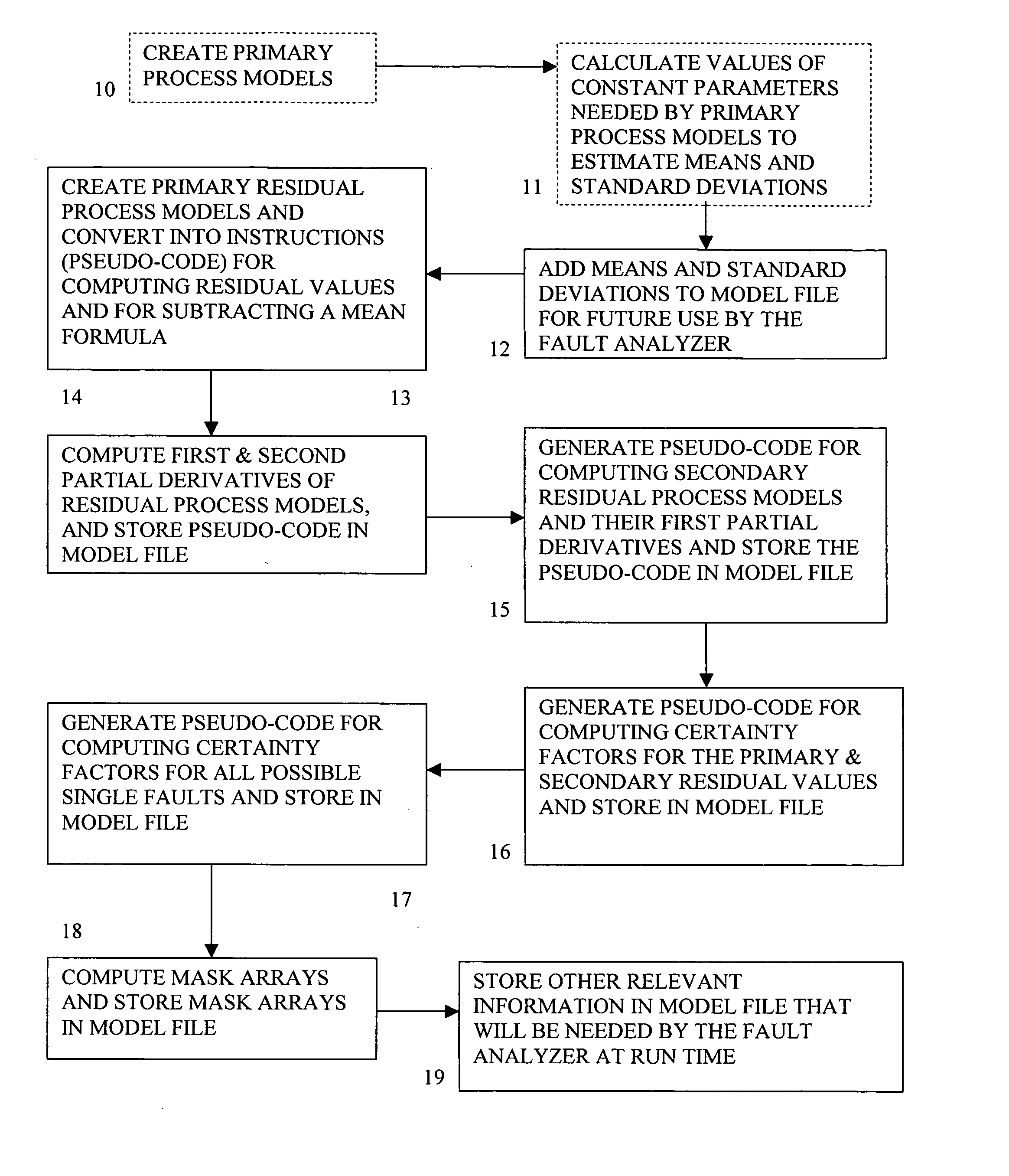

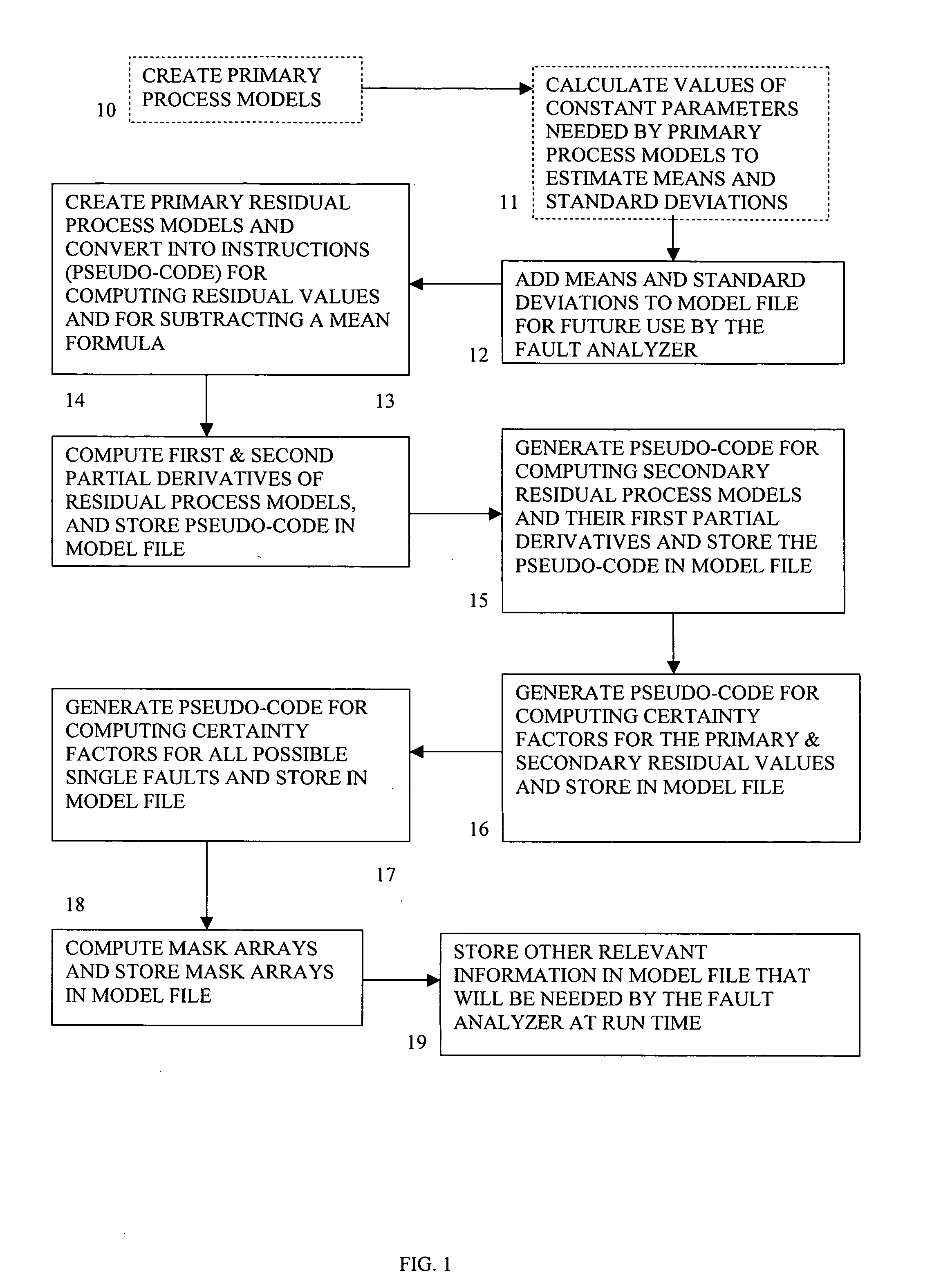

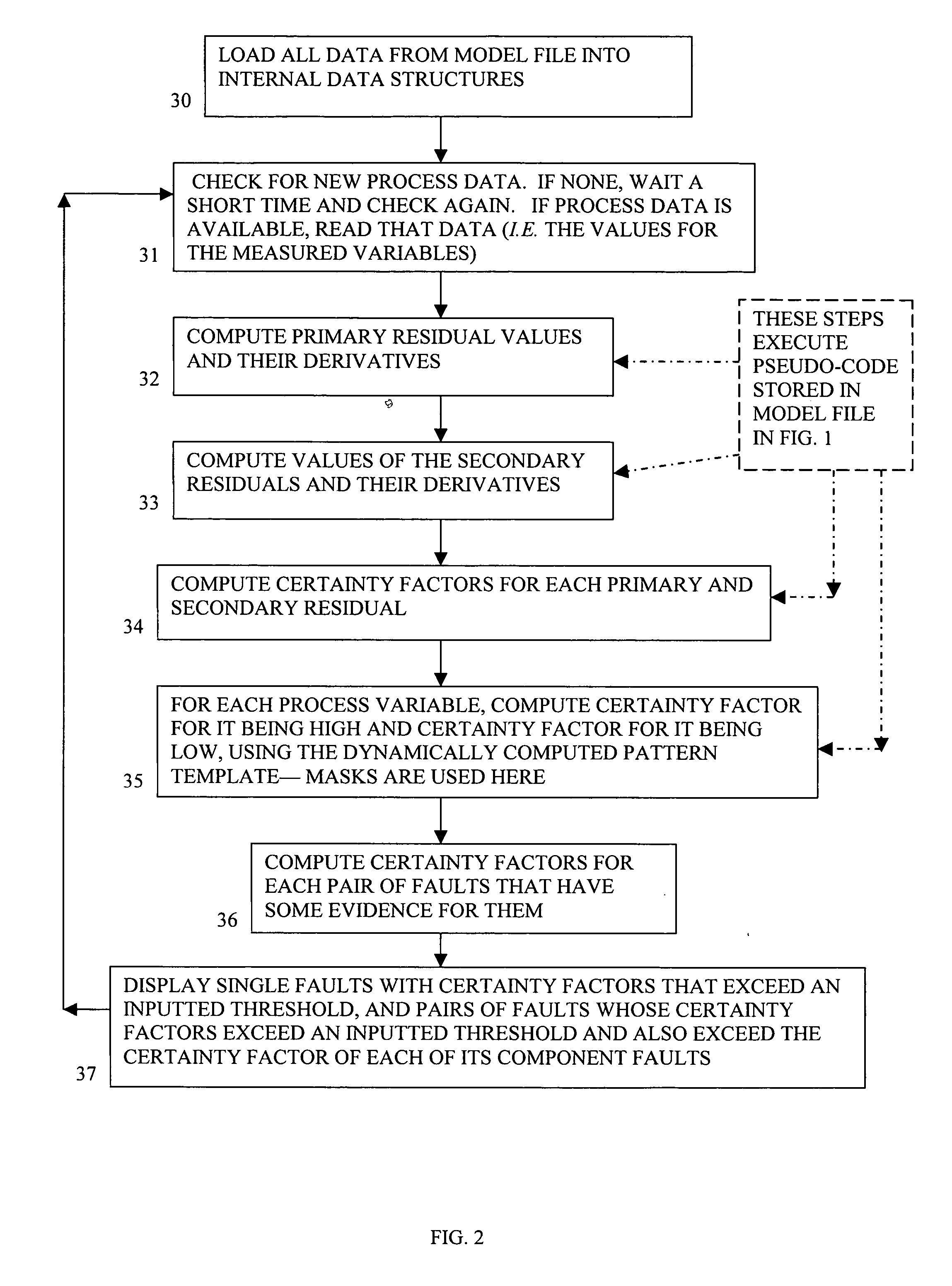

The present invention provides an improved method and system for real-time monitoring, validation, optimization and predictive fault analysis in a process control system. The invention monitors process operations by continuously analyzing sensor measurements and providing predictive alarms using models of normal process operation and statistical parameters corresponding to normal process data, and generating secondary residual process models. The invention allows for the creation of a fault analyzer directly from linearly independent models of normal process operation, and provides for automatic generation from such process models of linearly dependent process models. Fuzzy logic is used in various fault situations to compute certainty factors to identify faults and / or validate underlying assumptions. In one aspect, the invention includes a real-time sensor data communications bridge module; a state transition logic module; a sensor validation and predictive fault analysis module; and a statistical process control module; wherein each of the modules operates simultaneously.

Owner:FALCONEER TECH

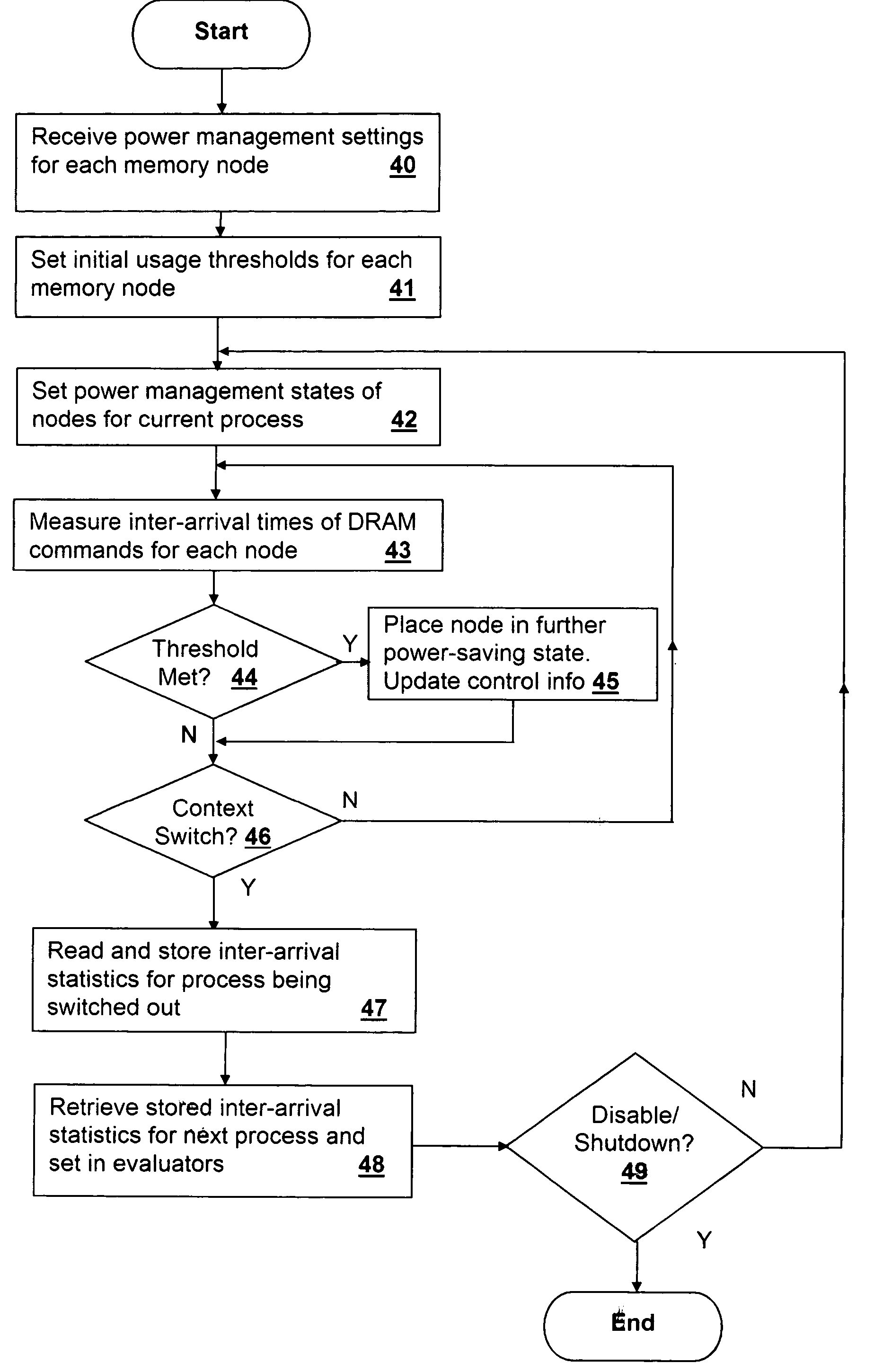

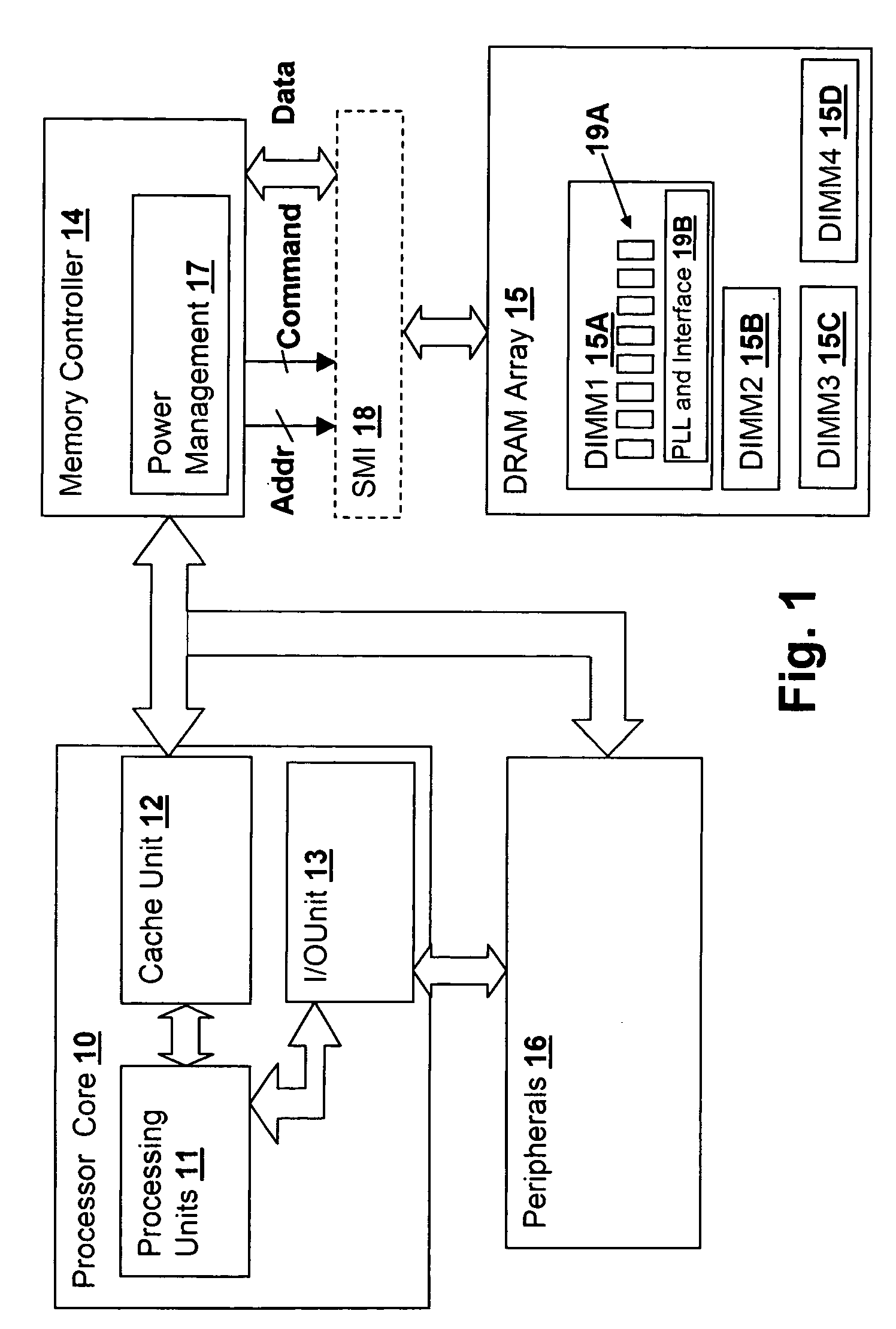

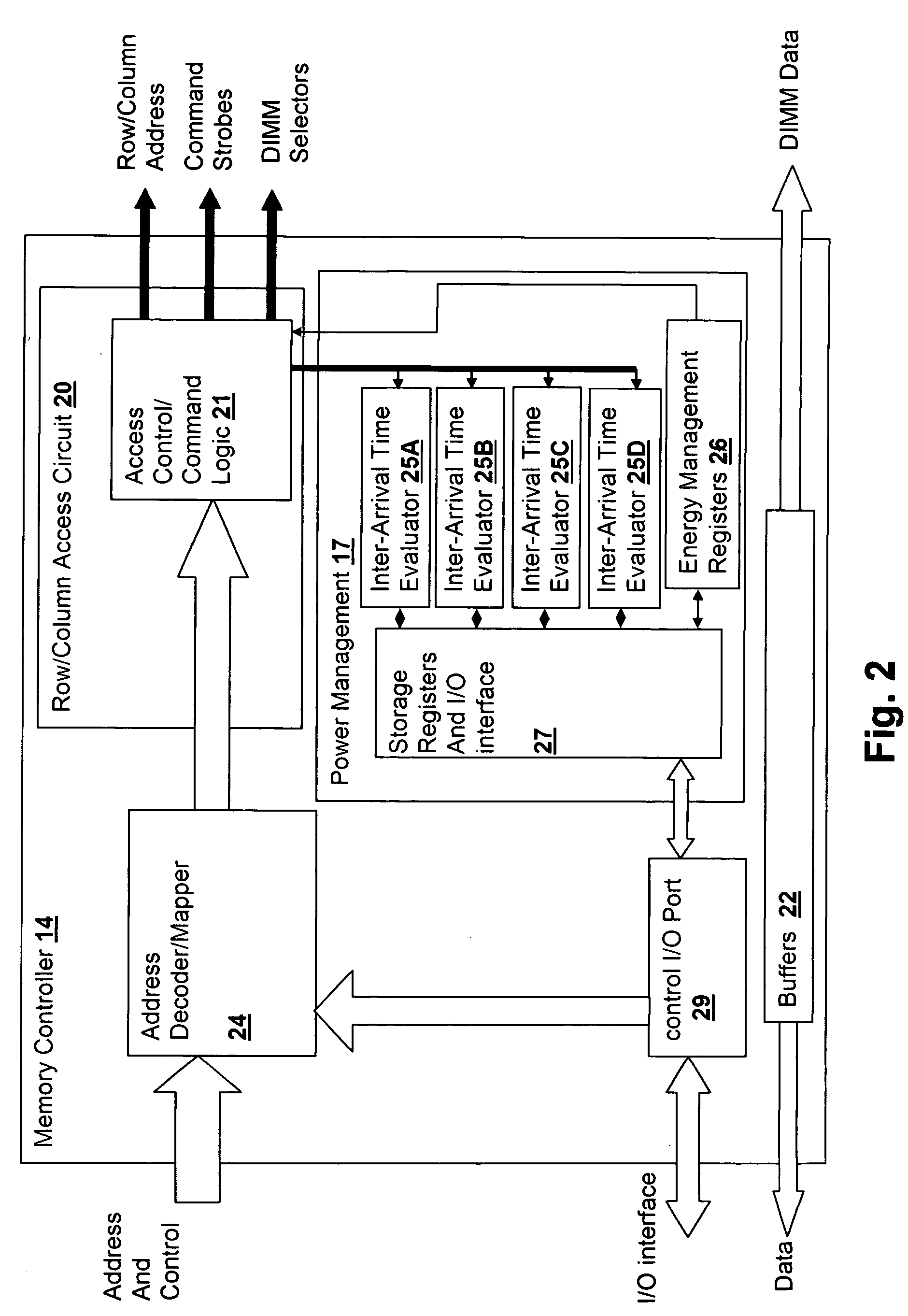

Method and system for power management including device controller-based device use evaluation and power-state control

InactiveUS20050125702A1Lower latencyReduce power consumptionEnergy efficient ICTVolume/mass flow measurementOperational systemDevice Usage

A method and system for power management including device controller-based device use evaluation and power-state control provides improved performance in a power-managed processing system. Per-device usage information is measured and evaluated during process execution and is retrieved from the device controller upon a context switch, so that upon reactivation of the process, the previous usage evaluation state can be restored. The device controller can then provide for per-process control of attached device power management states without intervention by the processor and without losing the historical evaluation state when a process is switched out. The device controller can control power-saving states of connected devices in conformity with the usage evaluation without processor intervention and across multiple process execution slices. The device controller may be a memory controller and the controlled devices memory modules or banks within modules if individual banks can be power-managed. Local thresholds provide the decision-making mechanism for each controlled device. The thresholds may be history-based, fixed or adaptive and are generally set initially by the operating system and may be updated by the memory controller adaptively or using historical collected usage evaluation counts or alternatively by the operating system via a system processor.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com