Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61 results about "Residual gas analyzer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

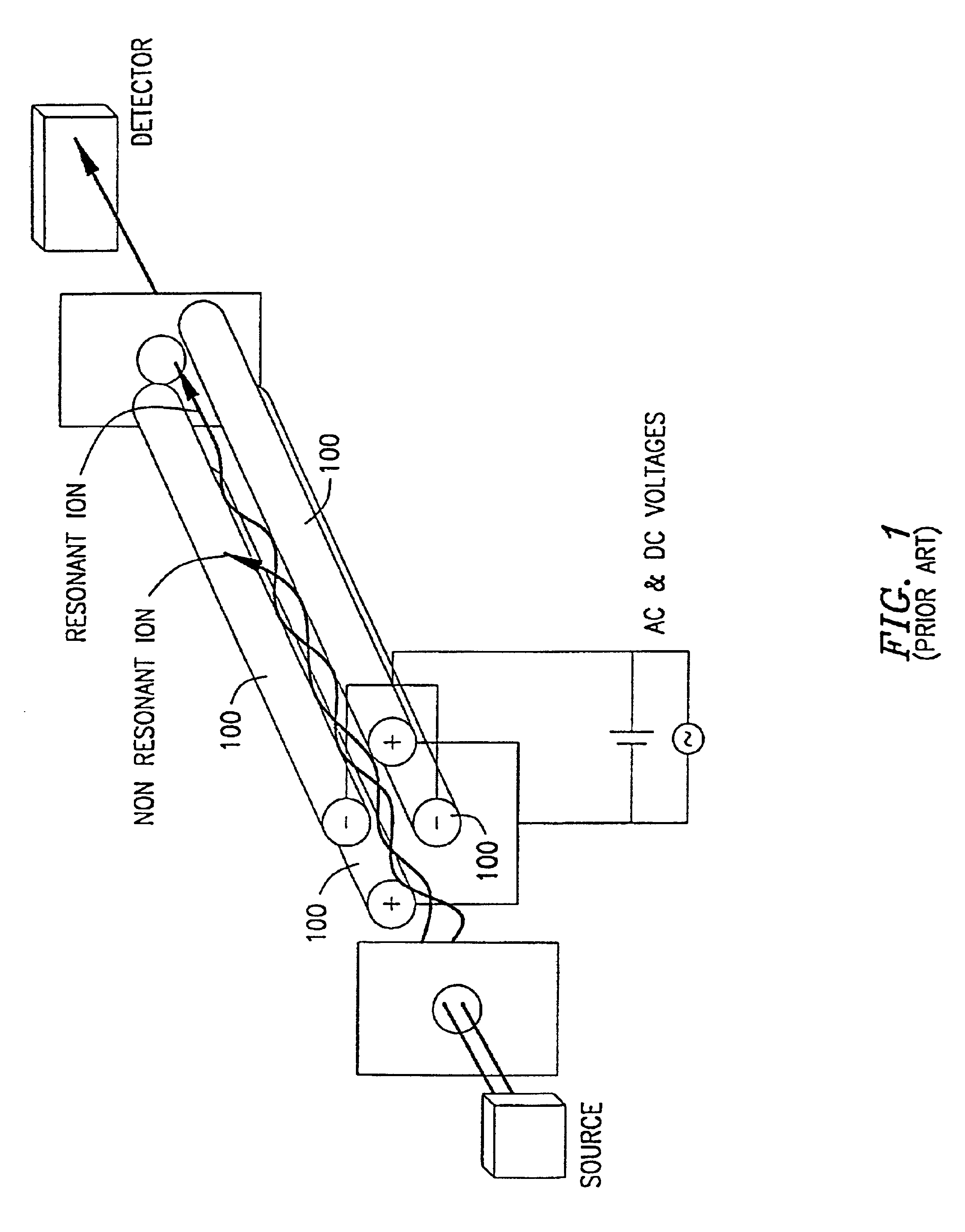

A residual gas analyzer (RGA) is a small and usually rugged mass spectrometer, typically designed for process control and contamination monitoring in vacuum systems. Utilizing quadrupole technology, there exists two implementations, utilizing either an open ion source (OIS) or a closed ion source (CIS). RGAs may be found in high vacuum applications such as research chambers, surface science setups, accelerators, scanning microscopes, etc.

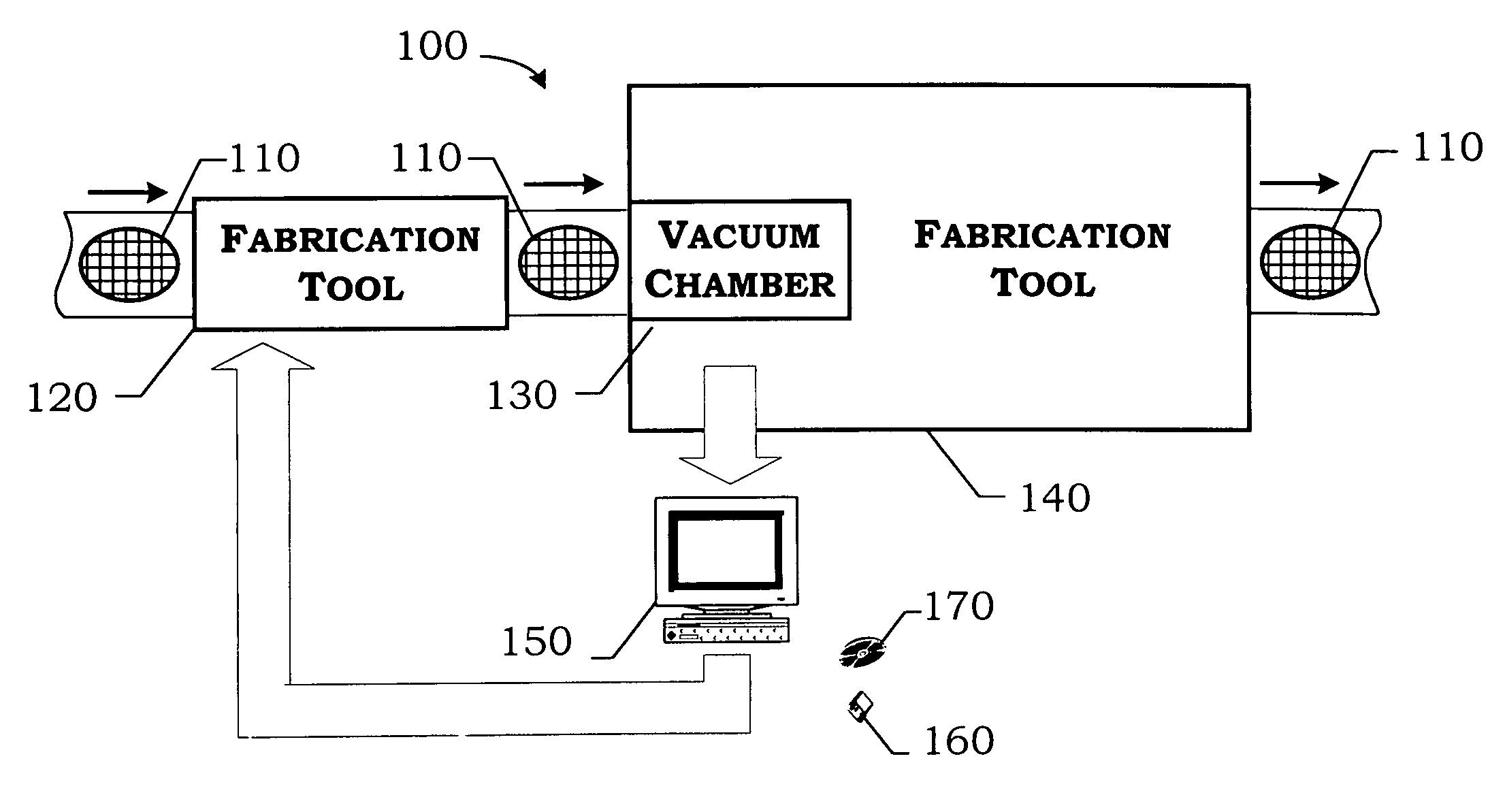

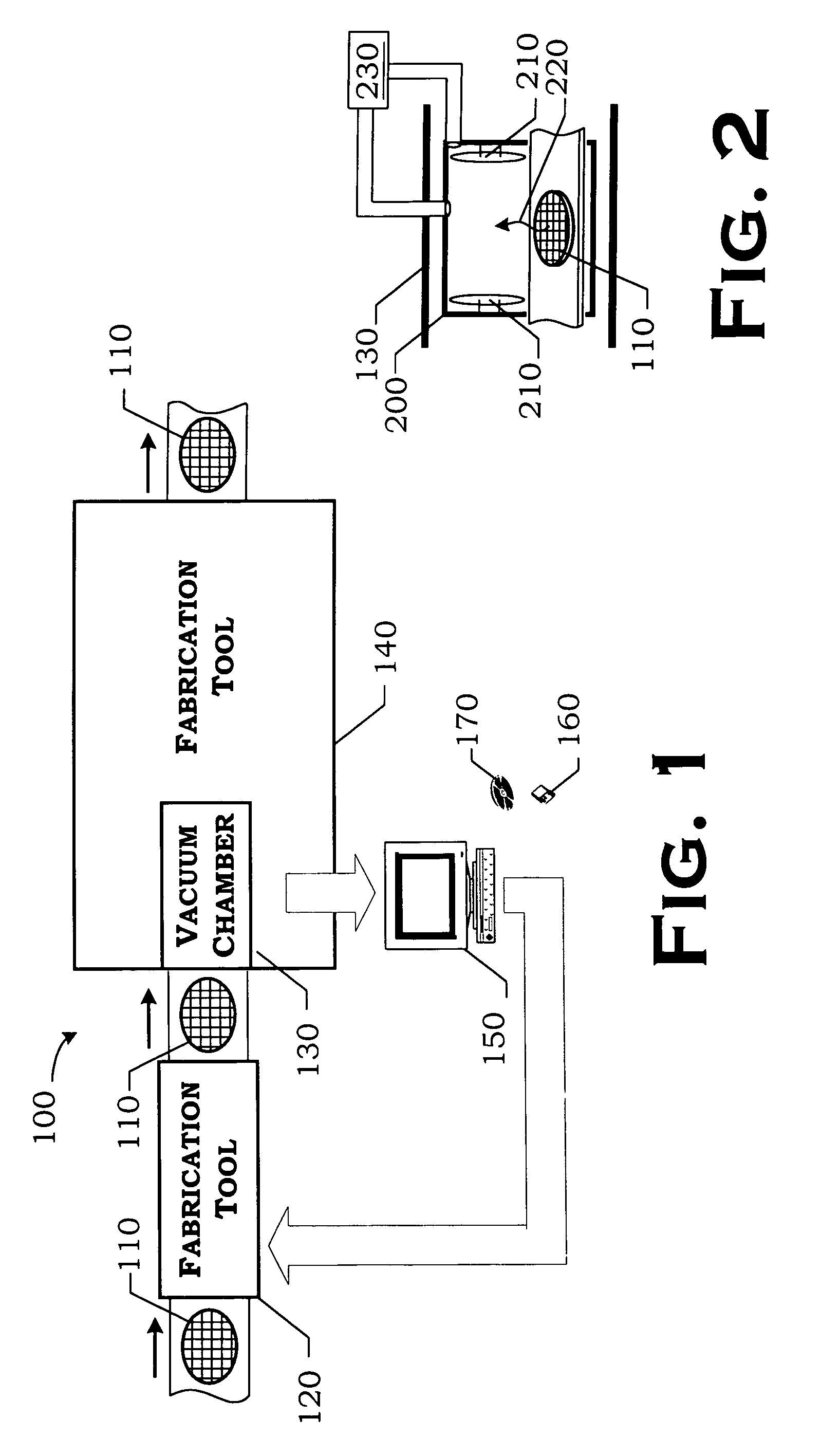

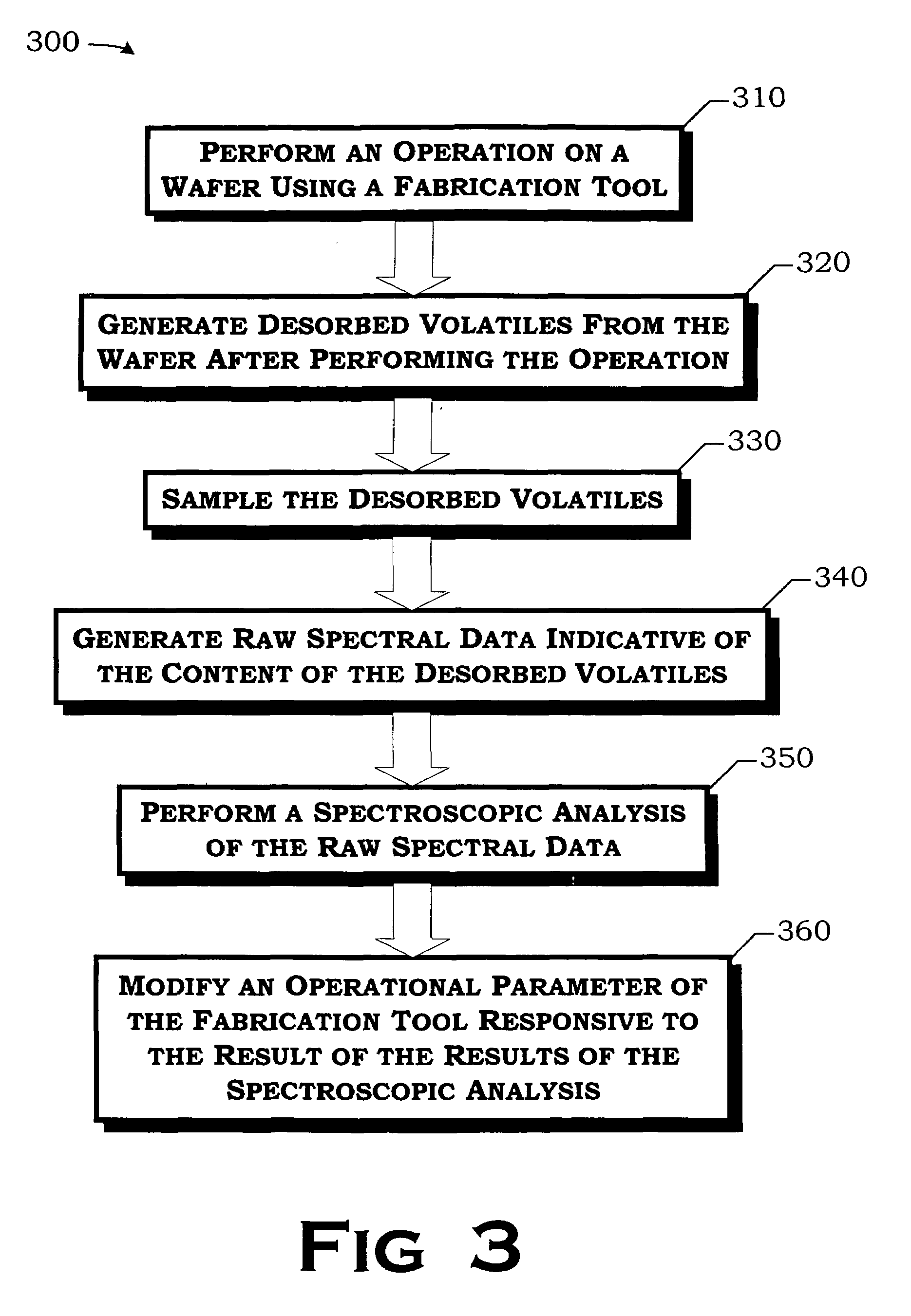

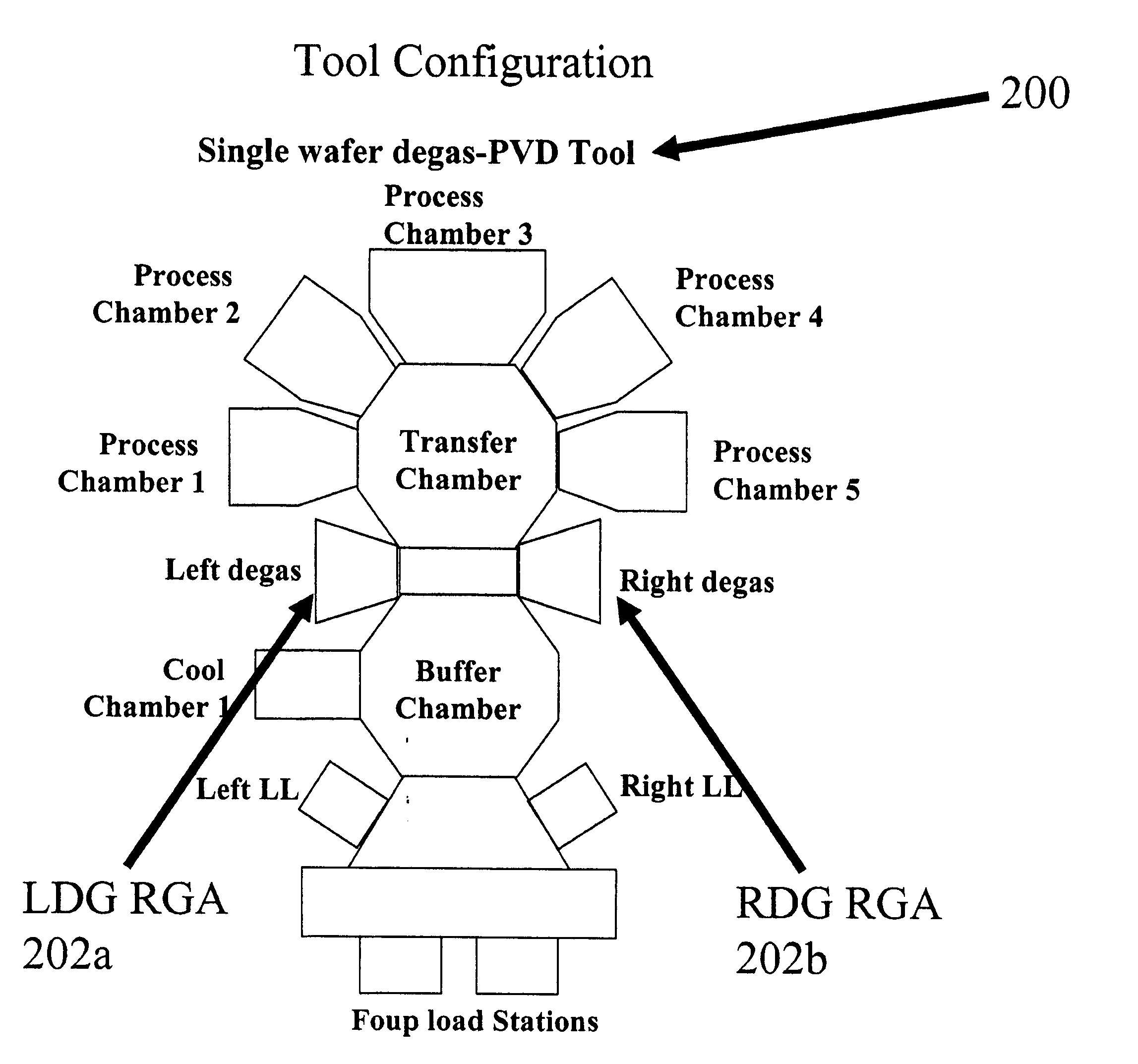

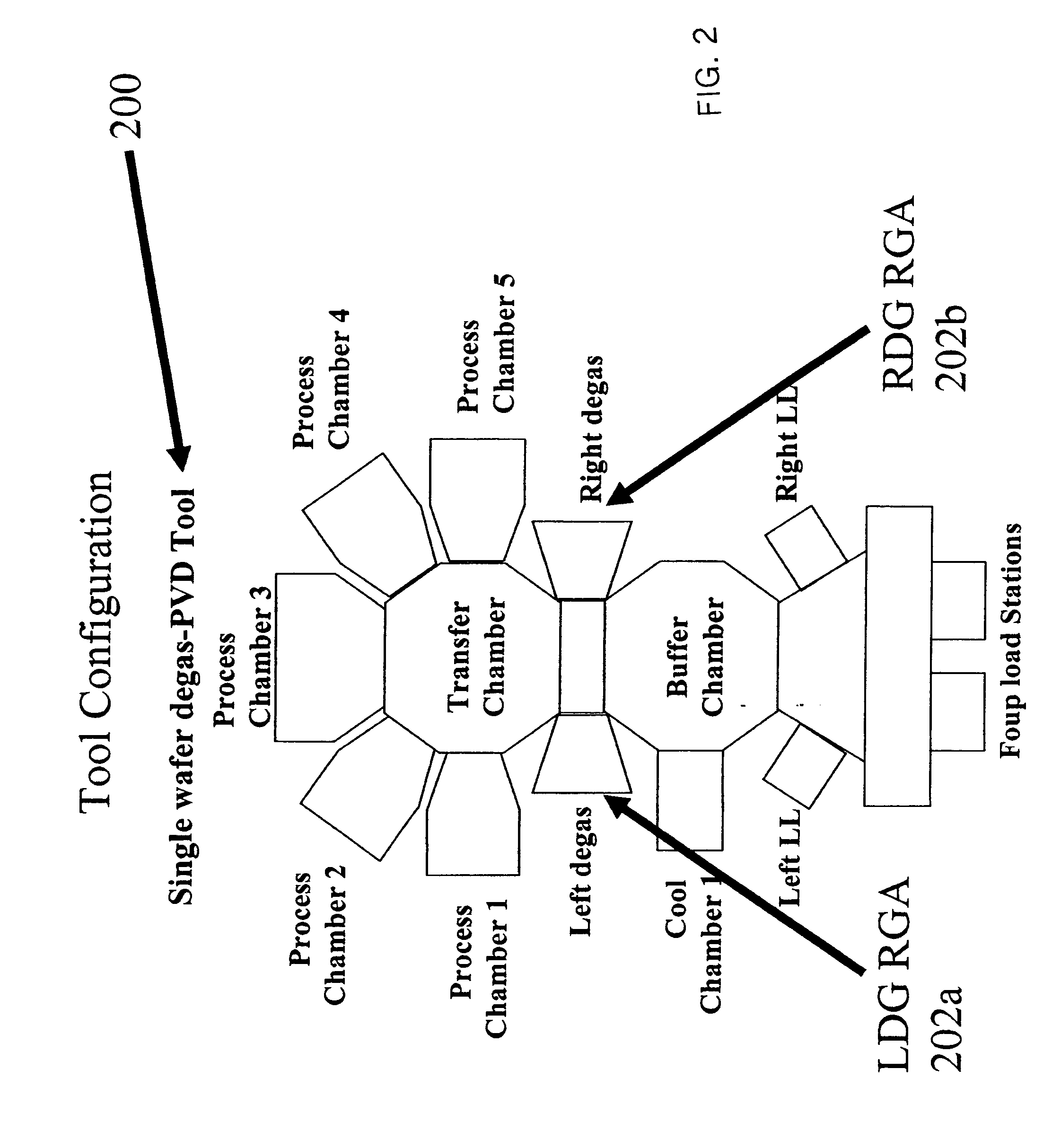

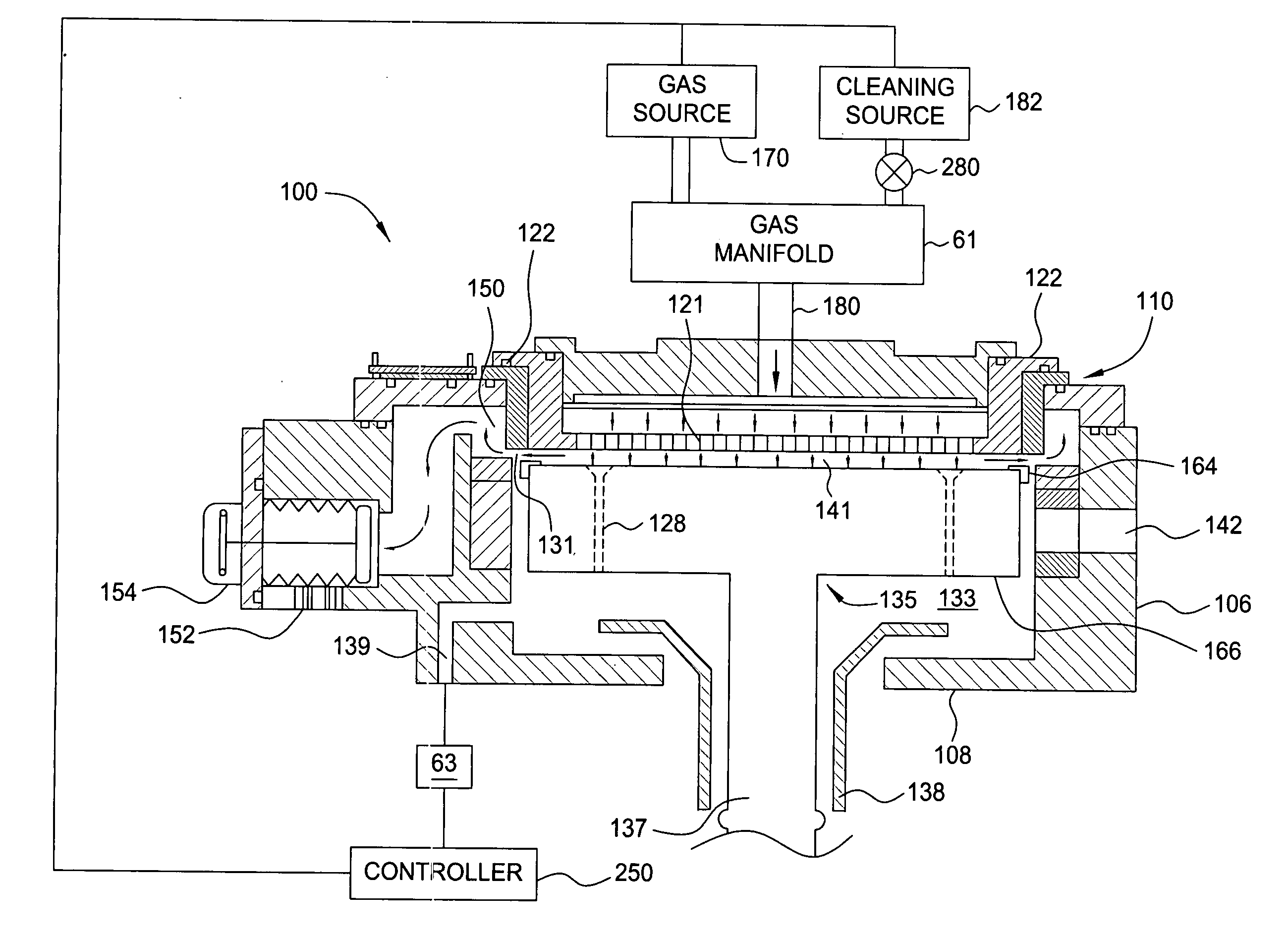

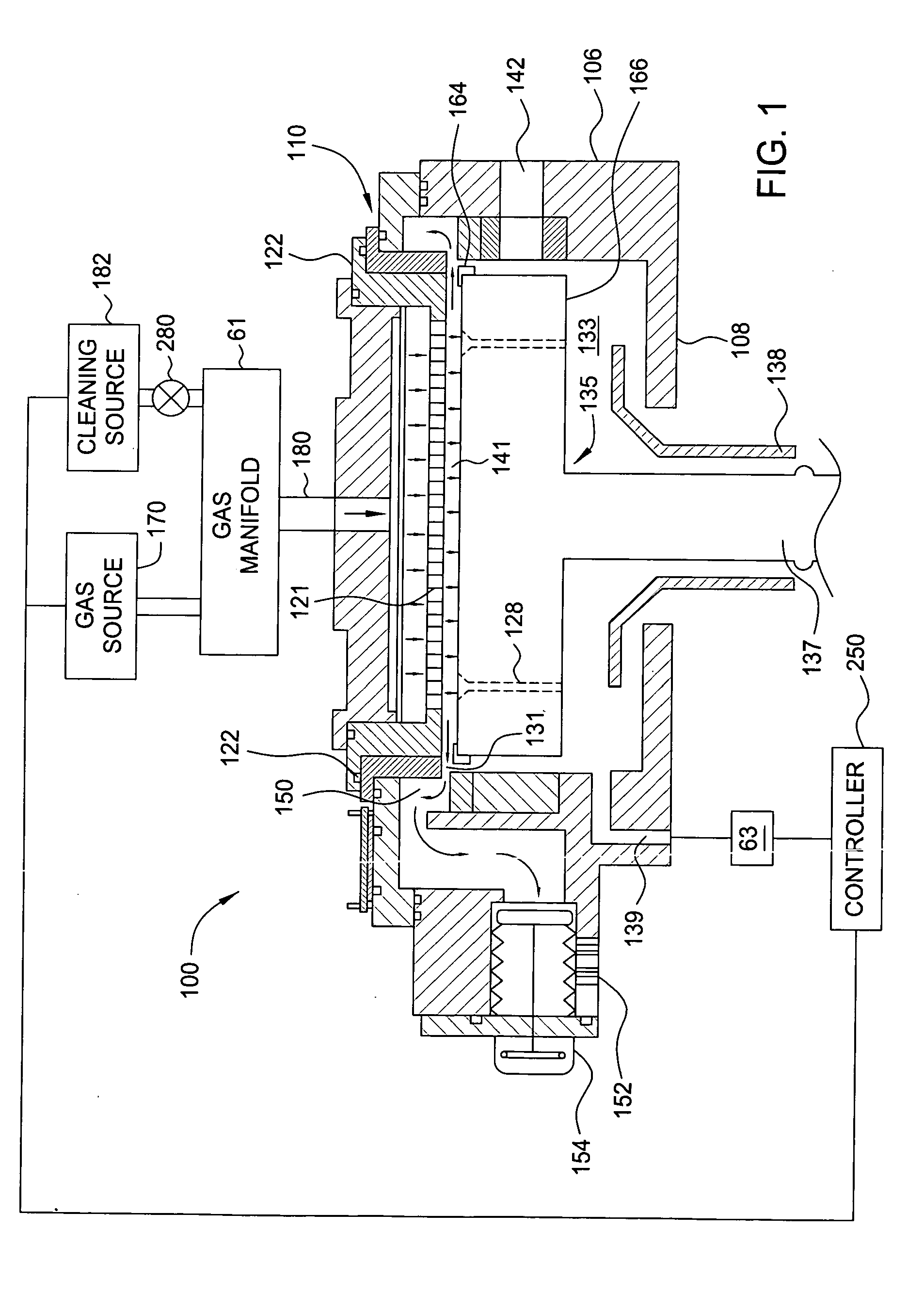

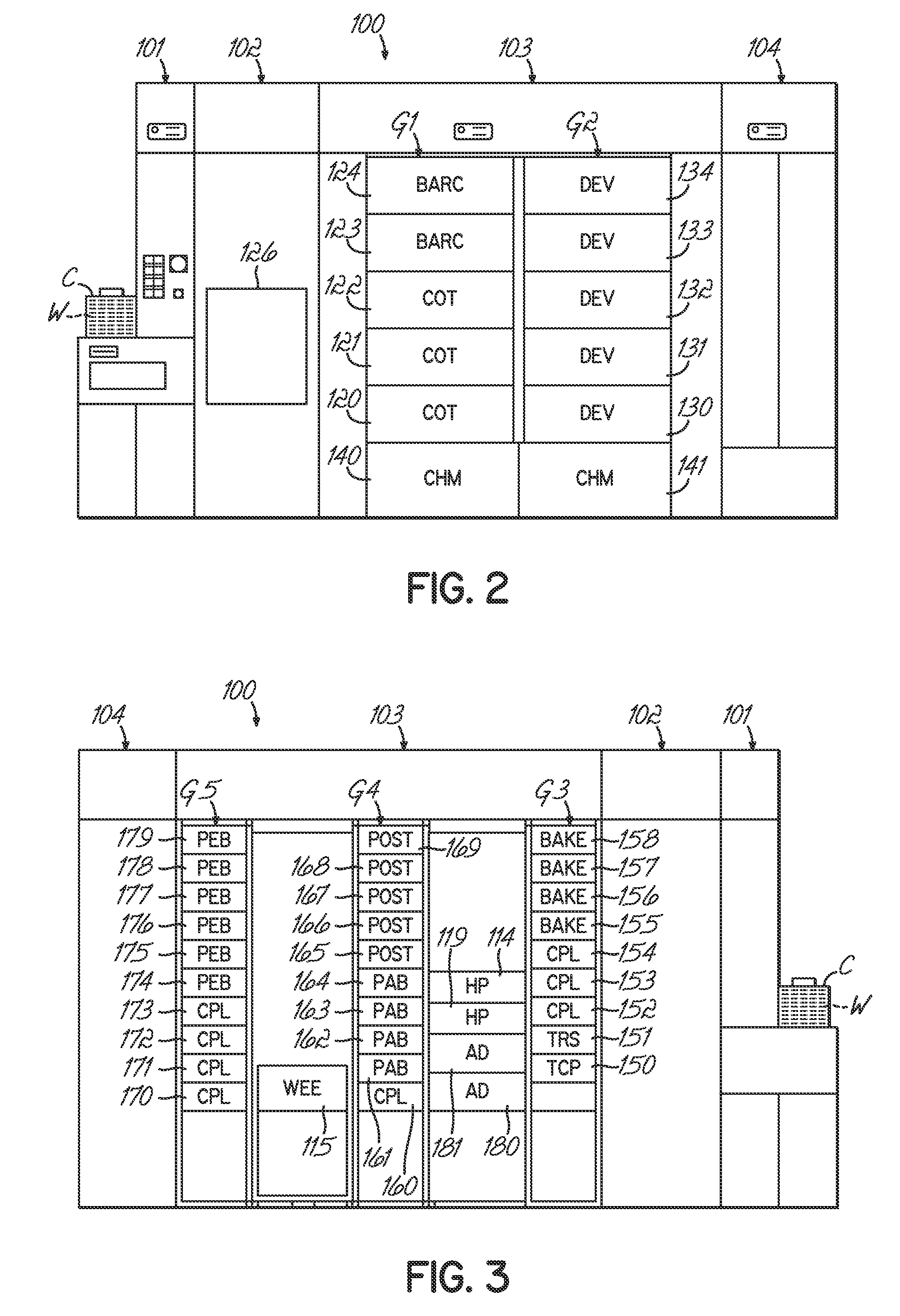

Closed loop residual gas analyzer process control technique

InactiveUS6955928B1Reduce the amount requiredSemiconductor/solid-state device testing/measurementSolid-state devicesResidual gas analyzerClosed loop

A technique for use in fabricating an integrated circuit are disclosed. The method generally begins by performing an operation on a wafer using a fabrication tool. Next, volatiles are desorbed from the wafer. The desorbed volatiles are sampled and raw spectral data indicating the content of the desorbed volatiles is generated. The raw spectral data is subjected to a spectroscopic analysis. An operational parameter of the fabrication tool is then modified responsive to the result of the results of the spectroscopic analysis. In one particular aspect of the invention, a controller receives the raw spectral data and processes the raw spectral data to determine the presence of a residual material on the wafer. The controller then controls the process flow operation to reduce the amount of the residual material on the wafer responsive to the results of processing the raw spectral data. Other aspects of the invention include the apparatus implementing the process flow and the controller itself.

Owner:TAIWAN SEMICON MFG CO LTD

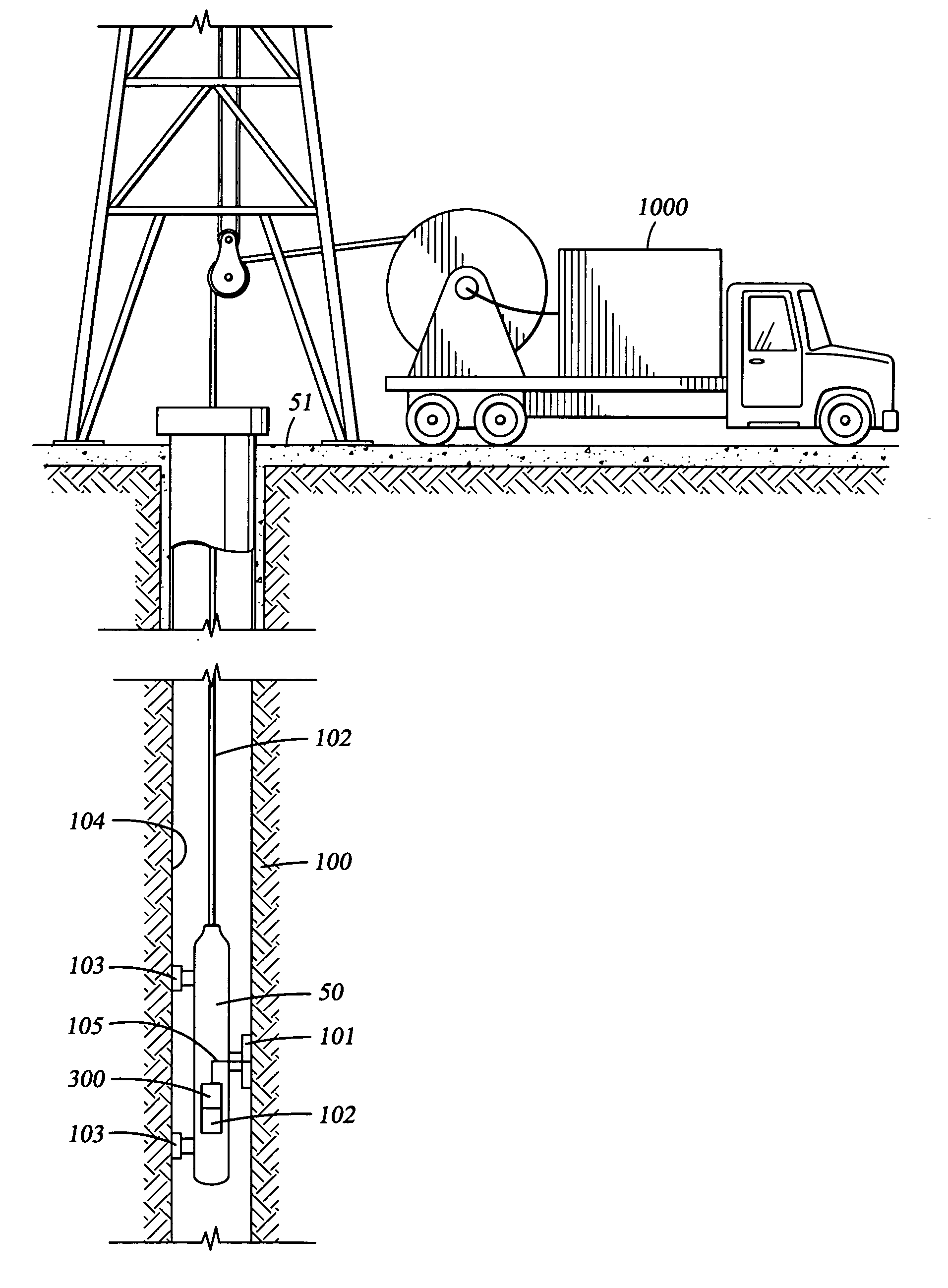

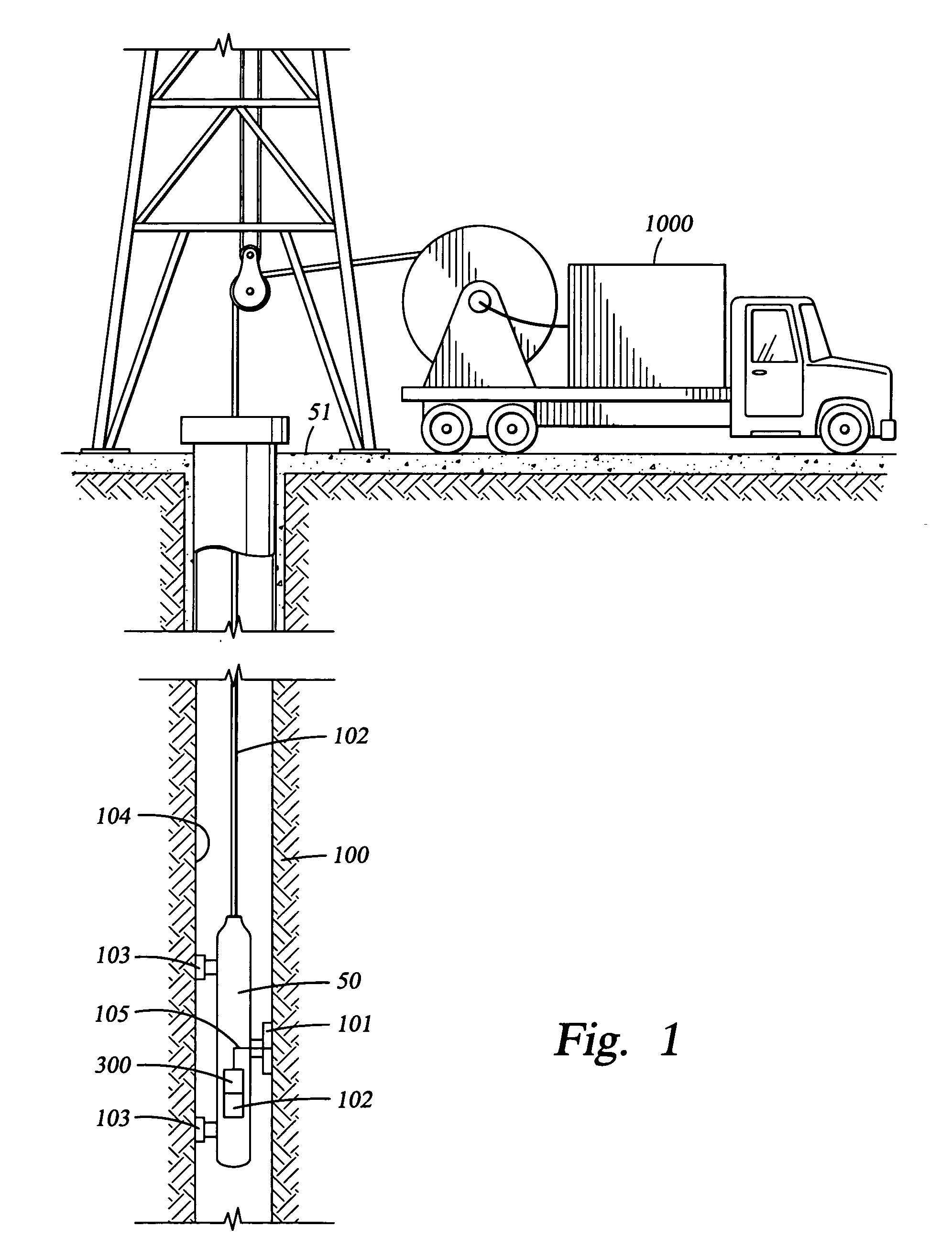

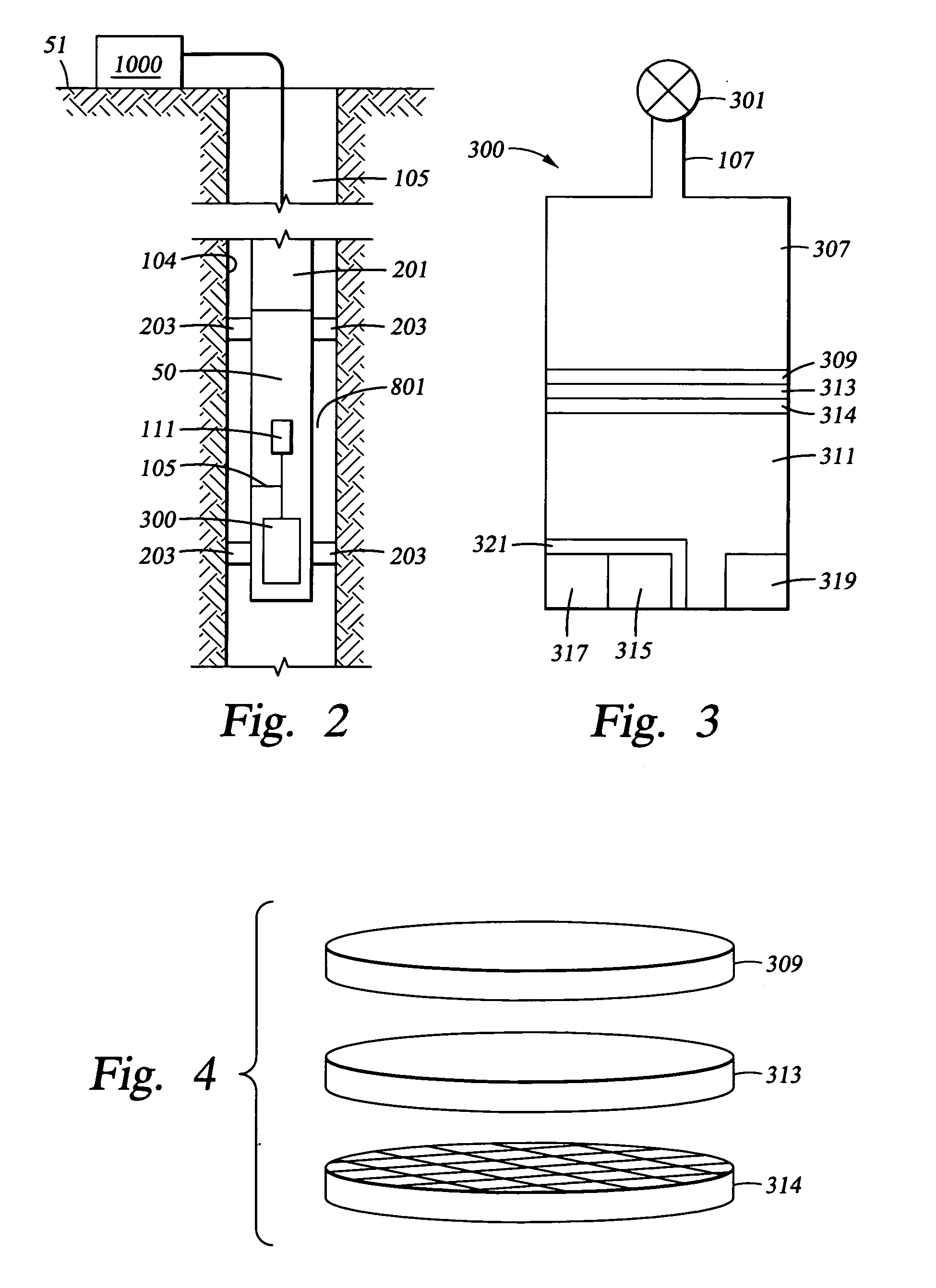

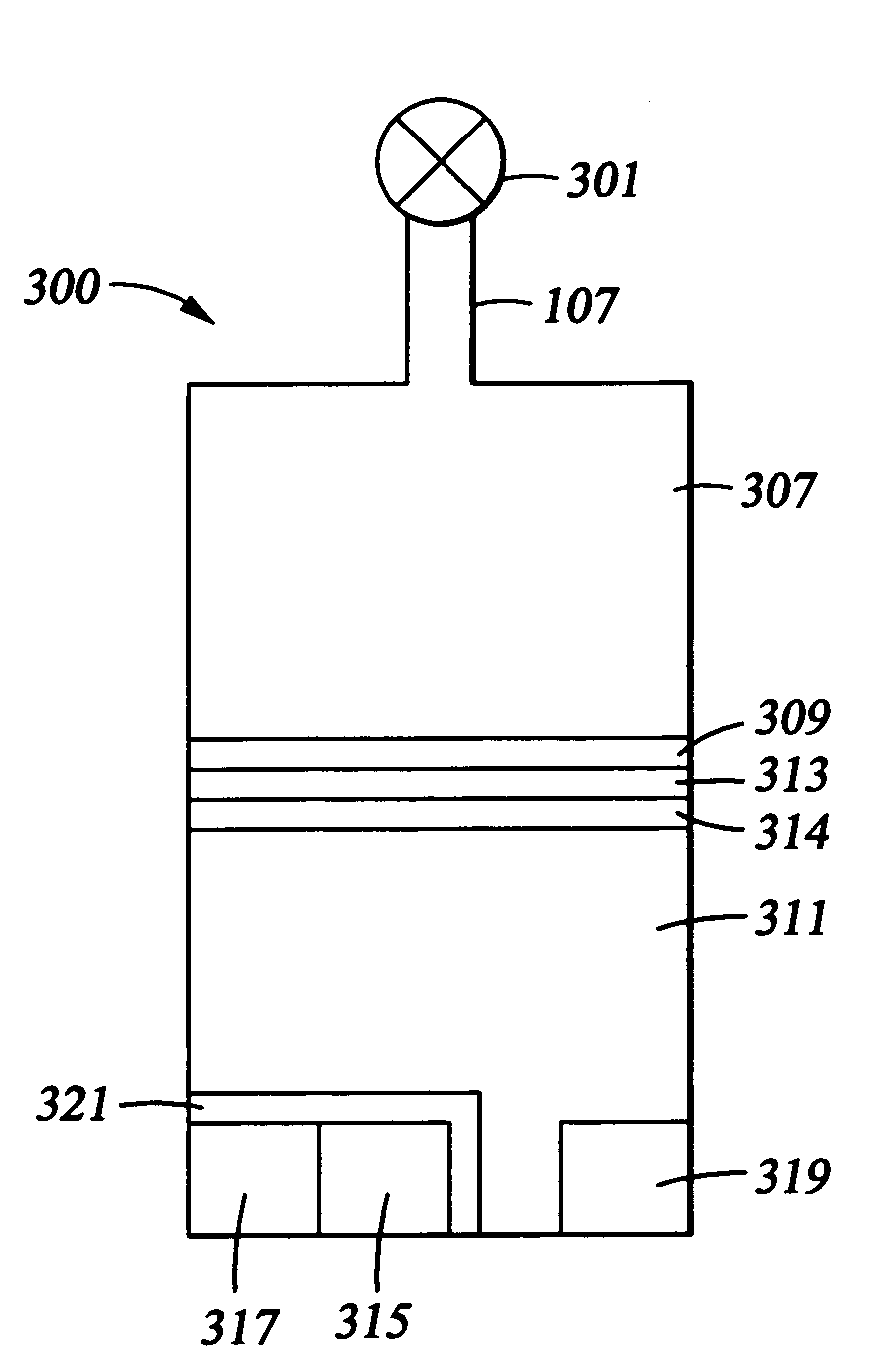

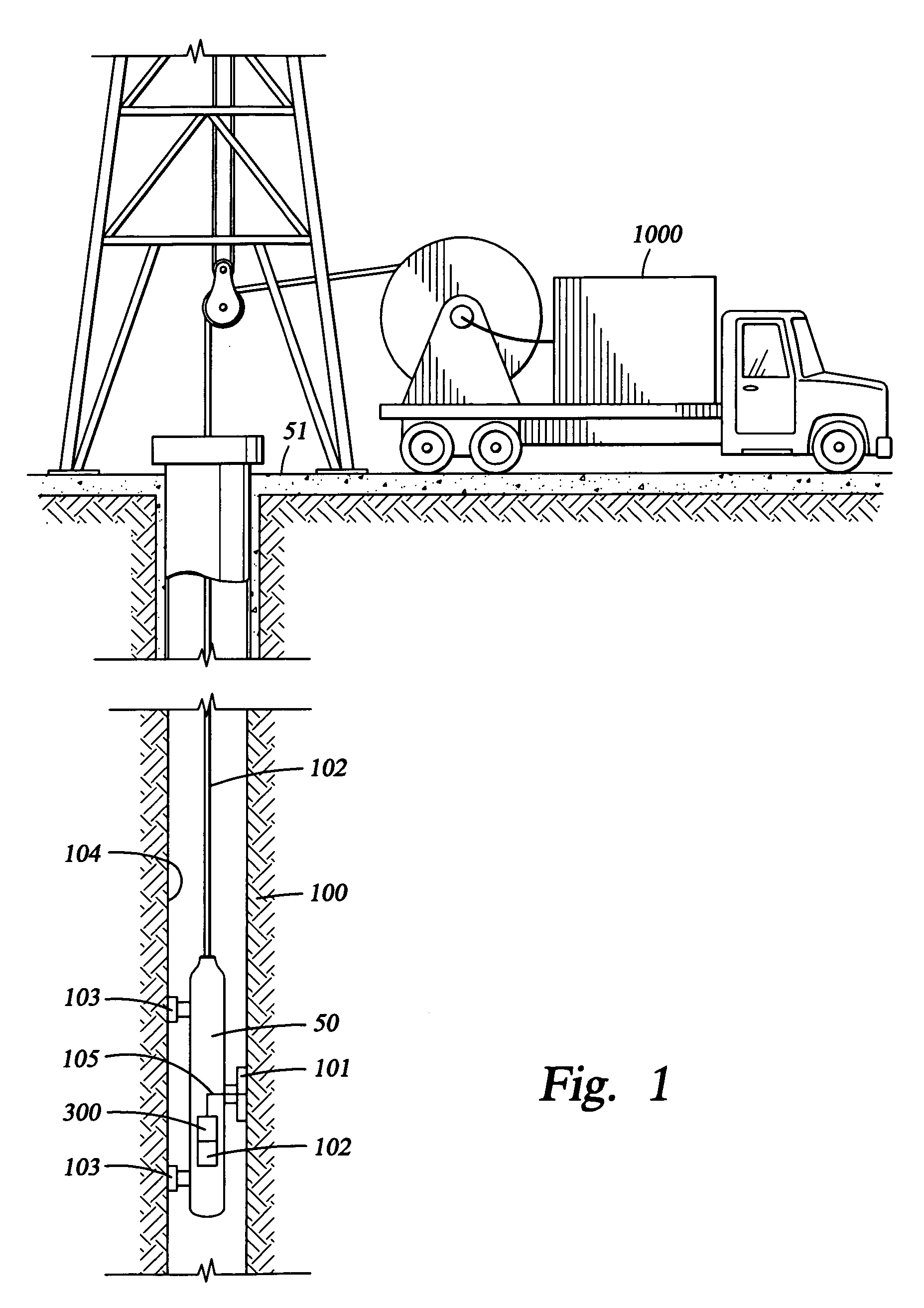

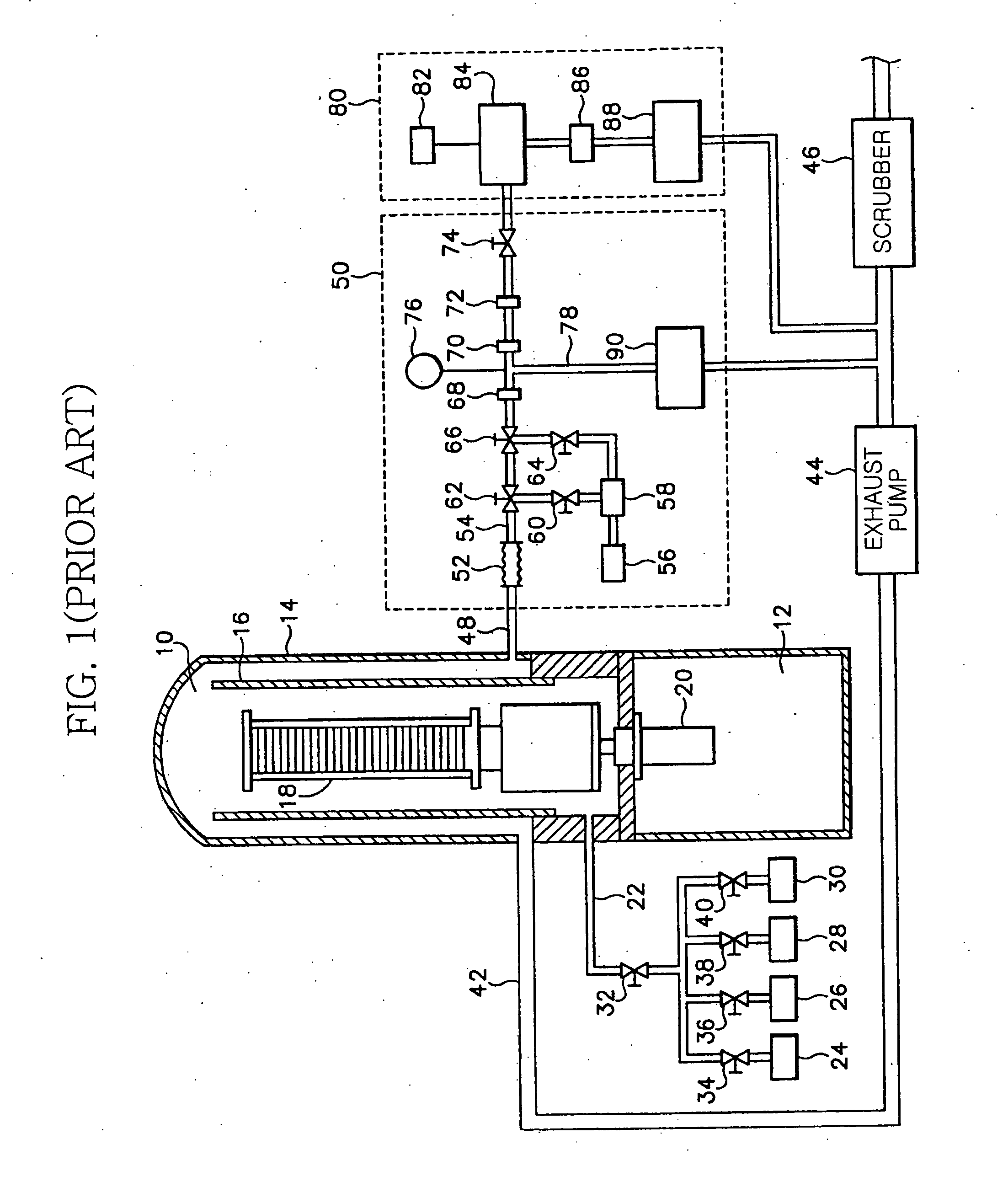

Method and apparatus for downhole fluid analysis for reservoir fluid characterization

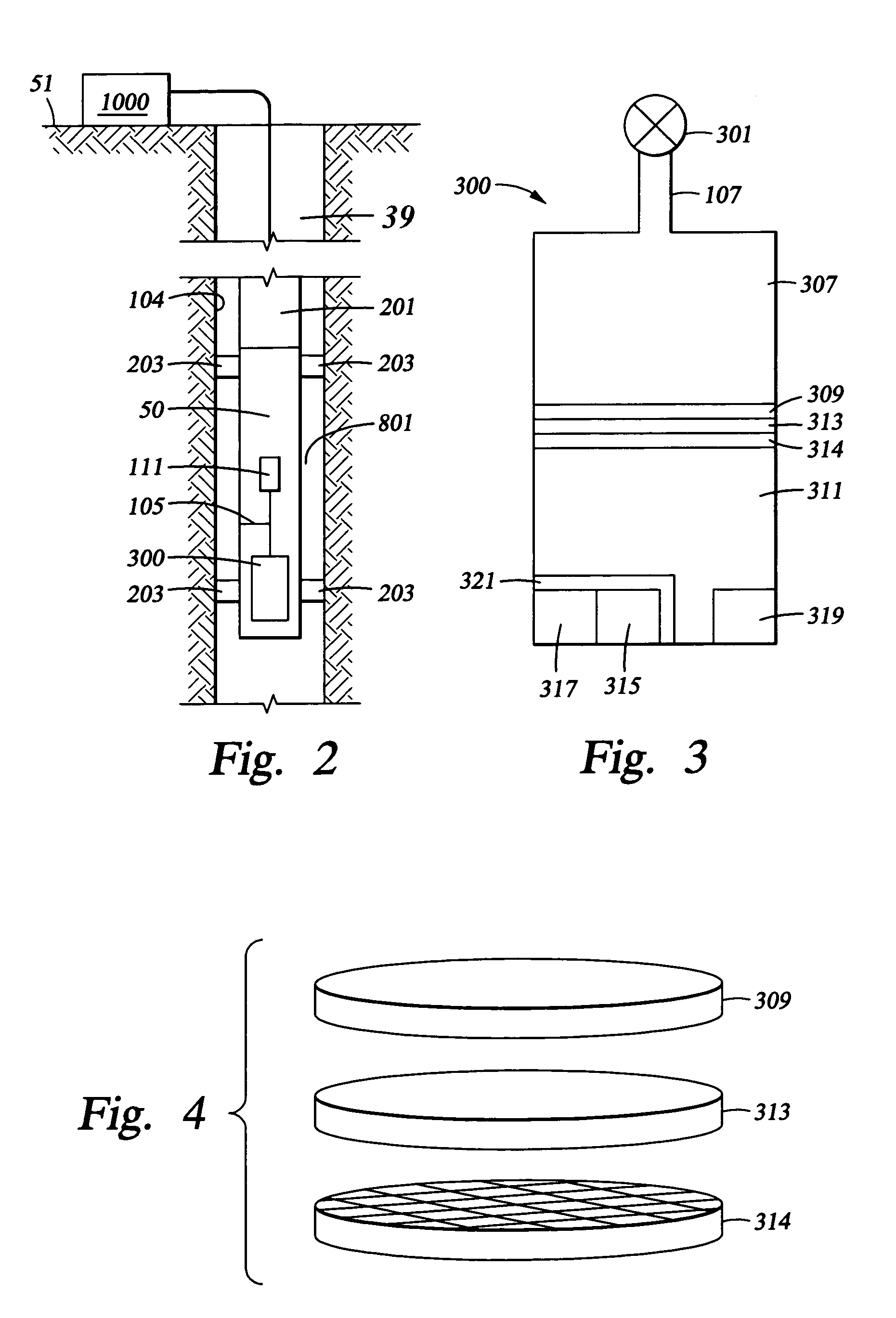

InactiveUS20050205256A1Interfere with measurementSurveyParticle separator tubesResidual gas analyzerSorbent

A formation fluid sample is exposed to a rigidly-supported semi-permeable membrane such as silicone rubber to permit diffusion of gases and vapors from the formation fluid into a vacuum chamber, while at the same time, blocking the passage of any liquids. The membrane-transmitted gas is analyzed in the vacuum chamber by a residual gas analyzer. An ion pump or sorbent is associated with the evacuated chamber to maintain the vacuum. The ion pump or sorbent removes gases and vapors from the chamber that diffuse into the chamber from the reservoir sample that is on the opposite side of the semi-permeable membrane.

Owner:BAKER HUGHES INC

Method and apparatus for downhole fluid analysis for reservoir fluid characterization

InactiveUS7219541B2Interfere with measurementSurveyParticle separator tubesResidual gas analyzerSorbent

A formation fluid sample is exposed to a rigidly-supported semi-permeable membrane such as silicone rubber to permit diffusion of gases and vapors from the formation fluid into a vacuum chamber, while at the same time, blocking the passage of any liquids. The membrane-transmitted gas is analyzed in the vacuum chamber by a residual gas analyzer. An ion pump or sorbent is associated with the evacuated chamber to maintain the vacuum. The ion pump or sorbent removes gases and vapors from the chamber that diffuse into the chamber from the reservoir sample that is on the opposite side of the semi-permeable membrane.

Owner:BAKER HUGHES INC

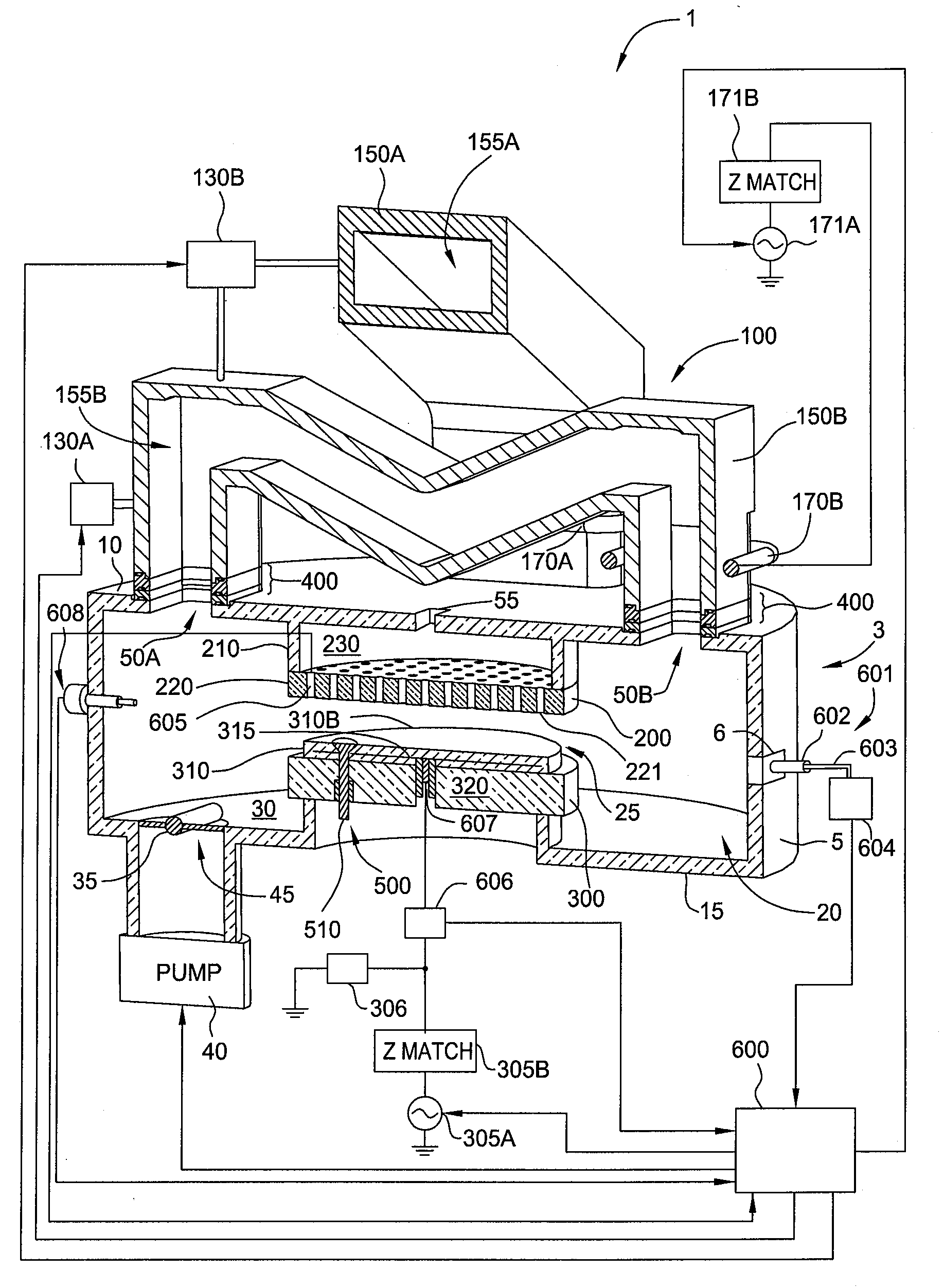

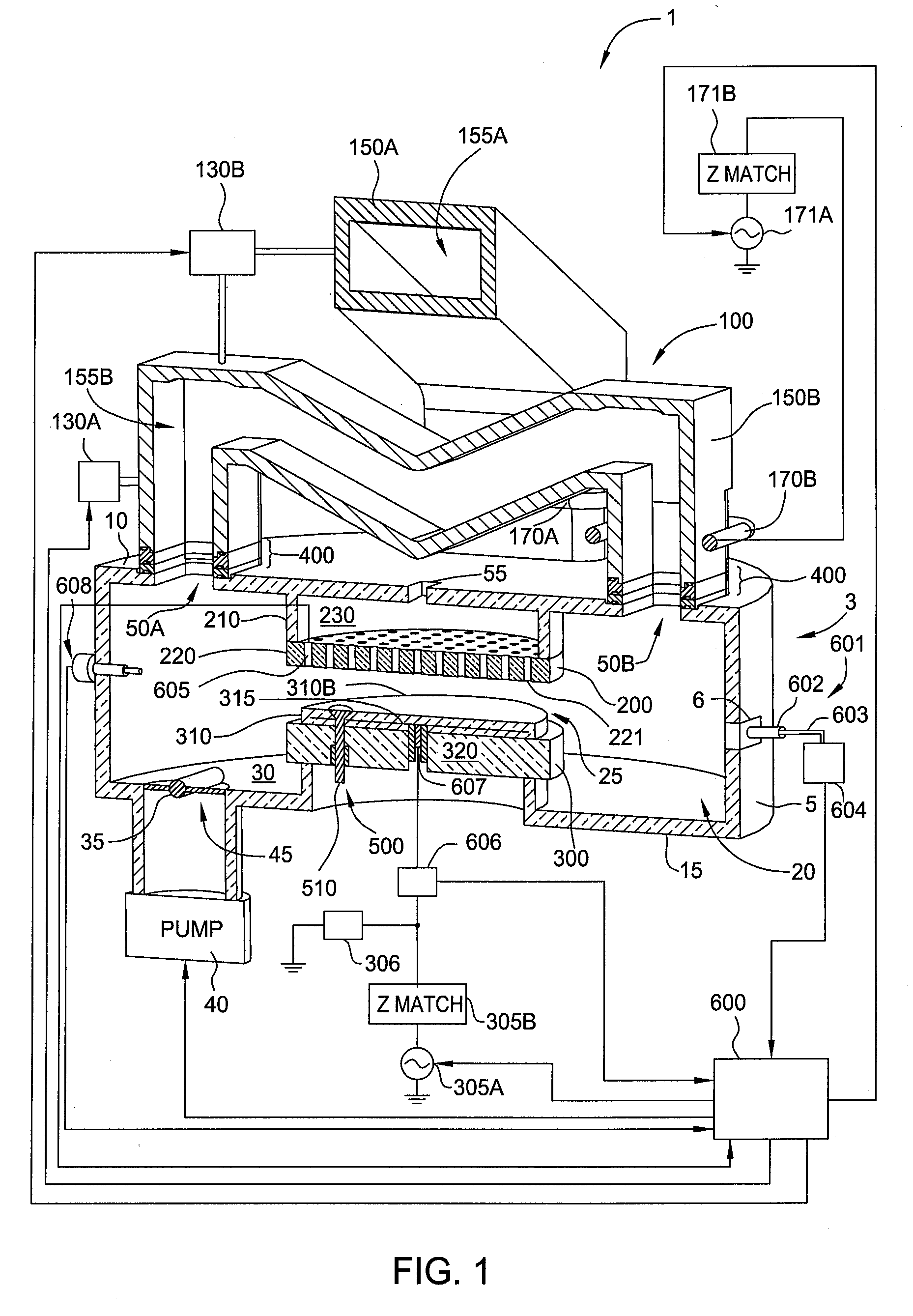

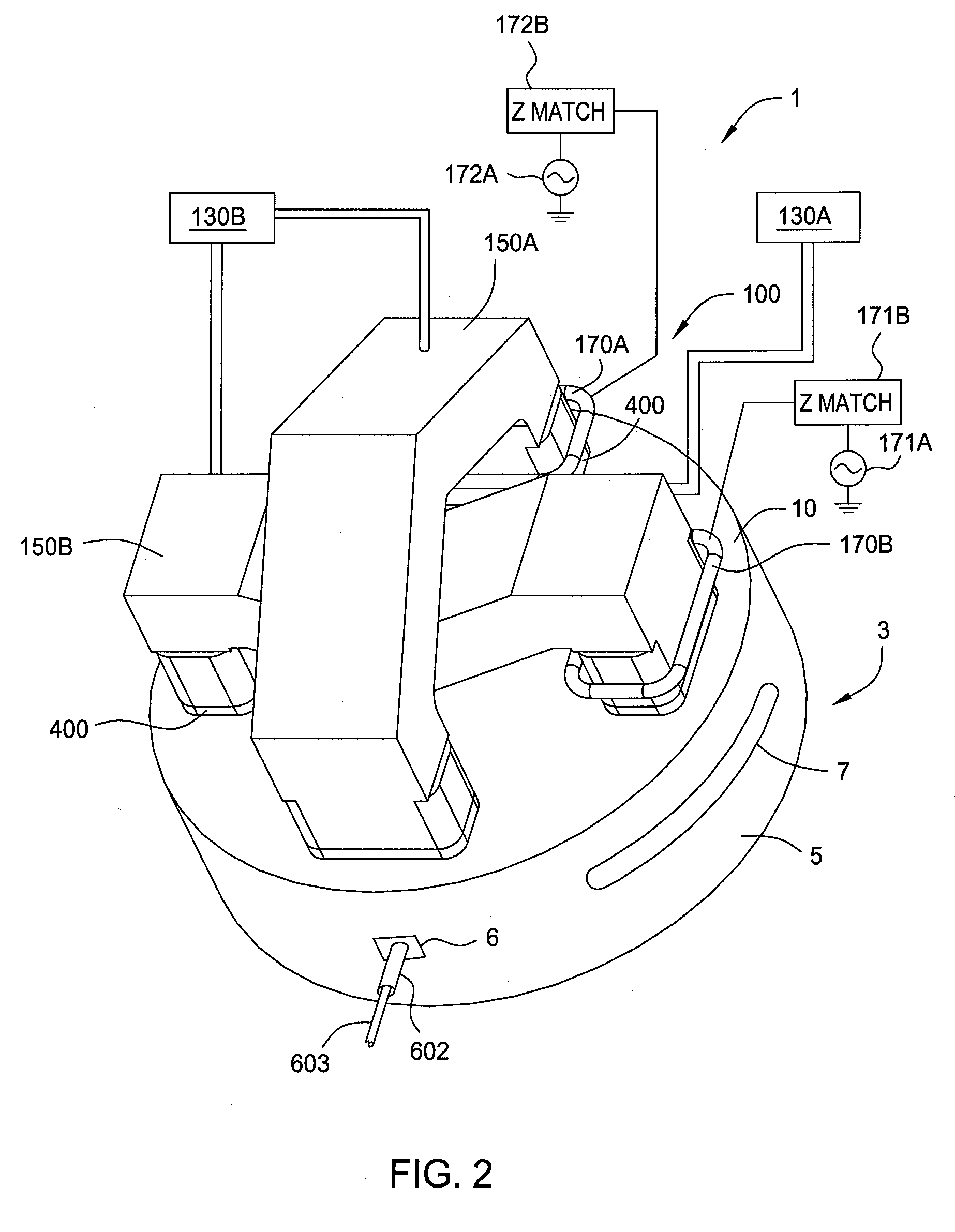

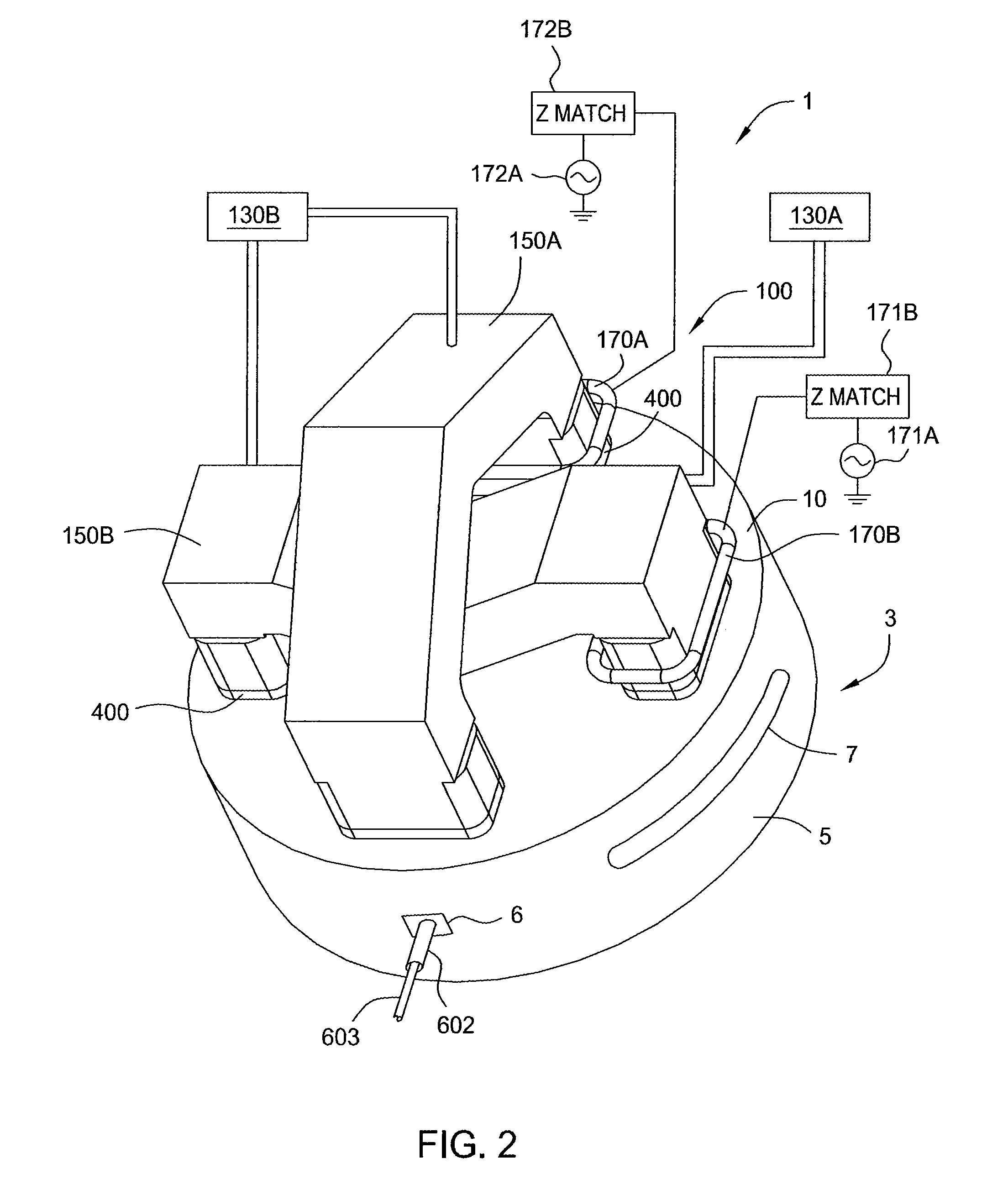

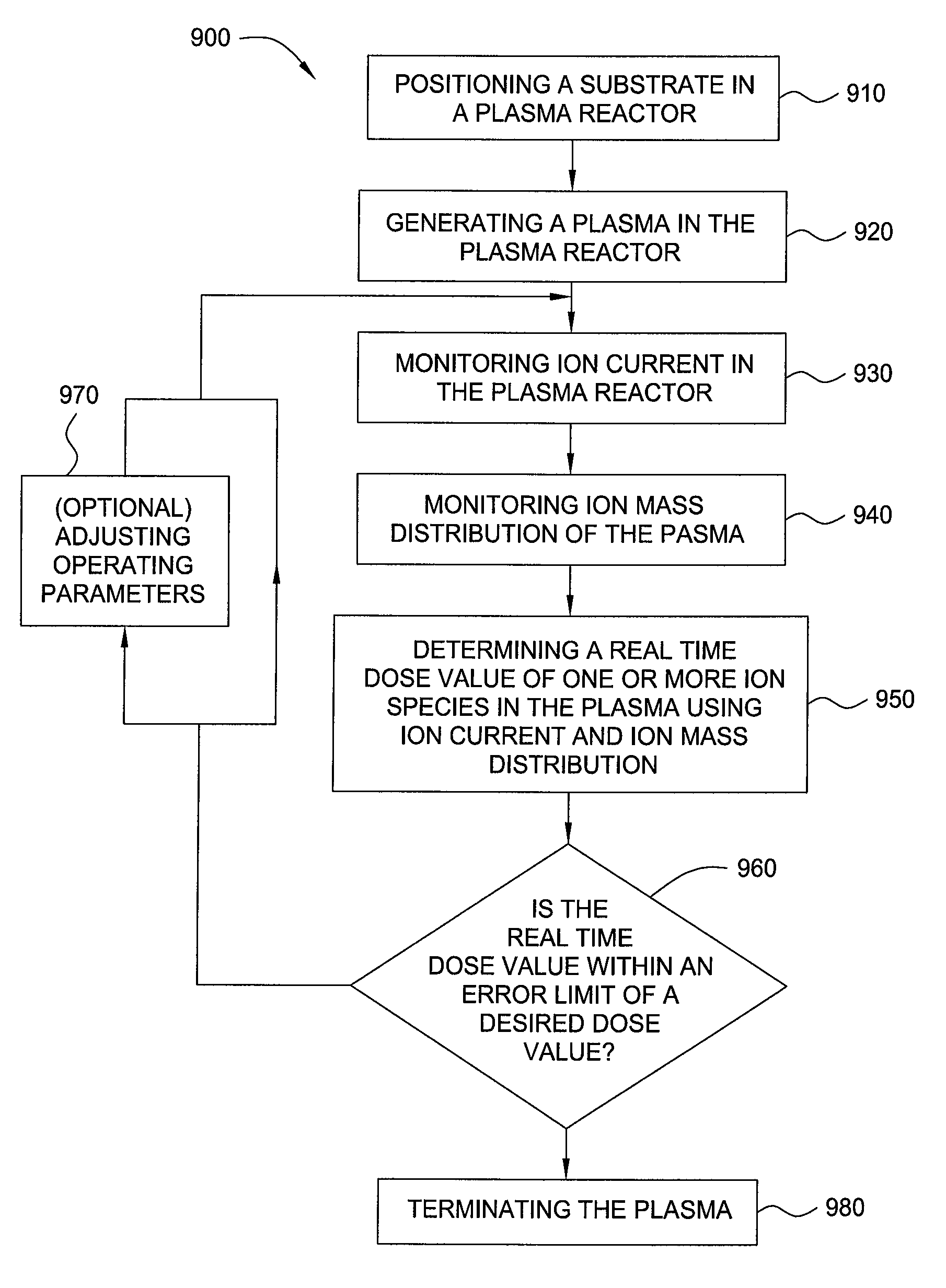

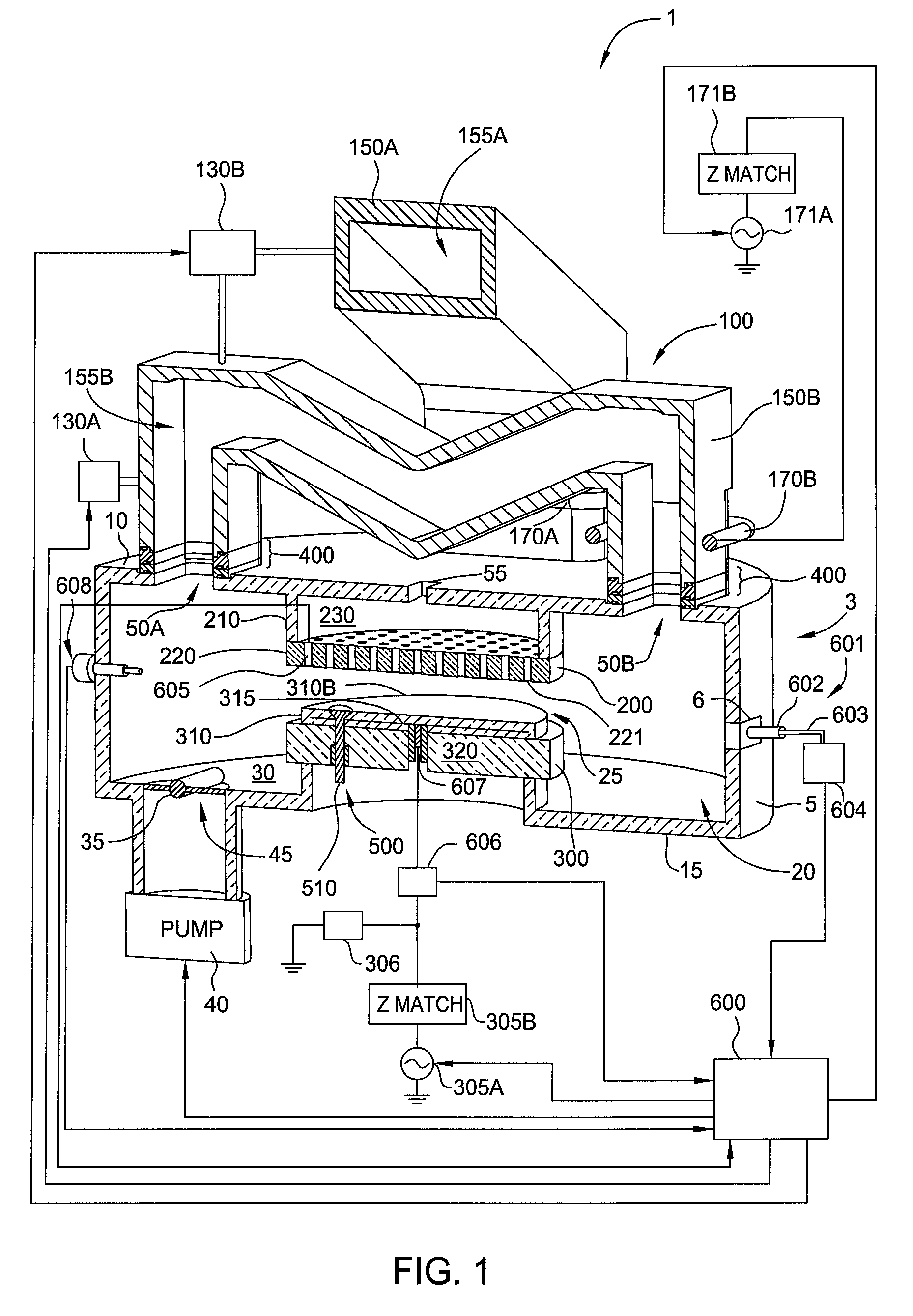

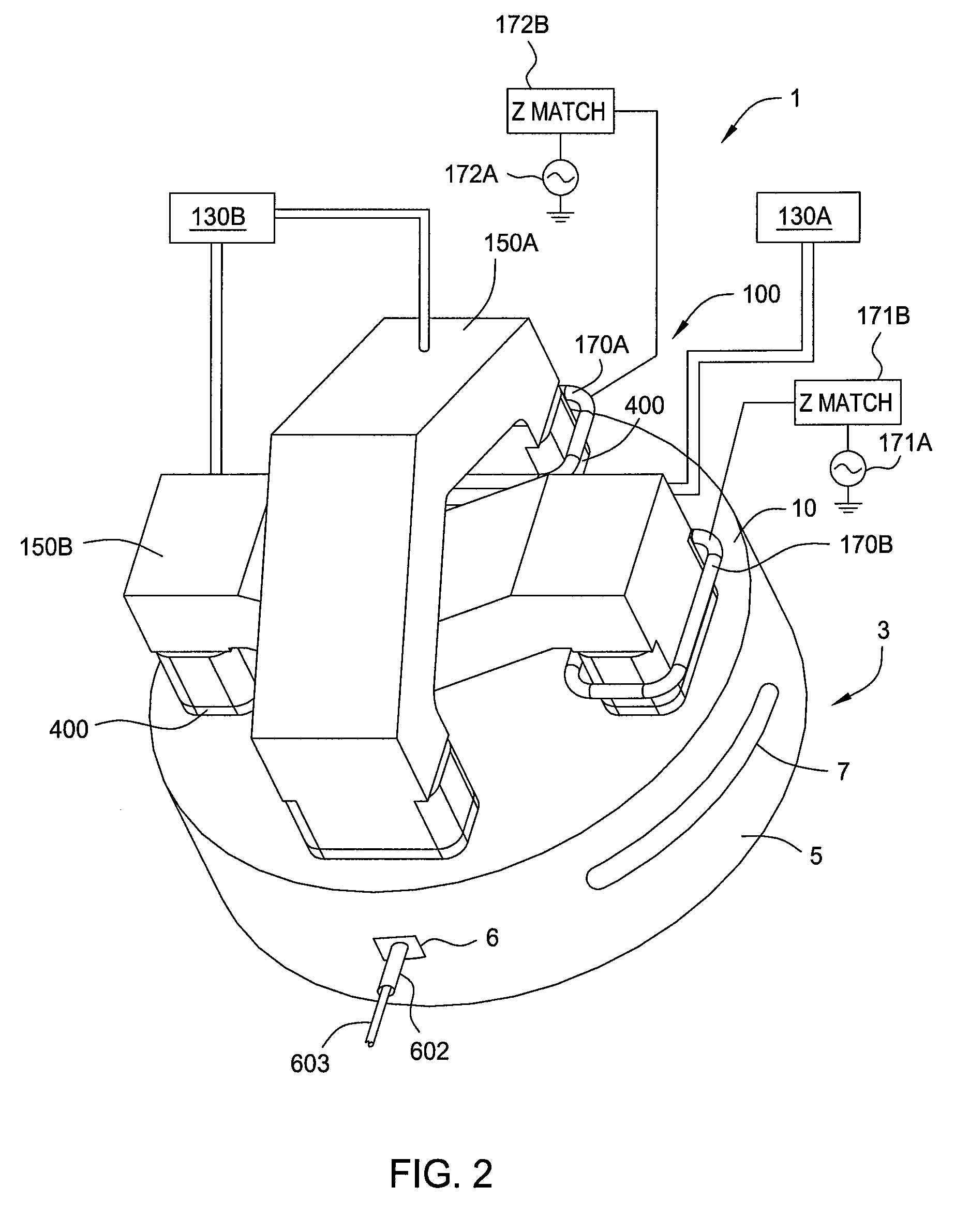

Dosimetry using optical emission spectroscopy/residual gas analyzer in conjuntion with ion current

ActiveUS20080075834A1Liquid surface applicatorsMaterial analysis using wave/particle radiationDosimetry radiationOptical emission spectrometry

The present invention generally provides methods and apparatus for controlling ion dosage in real time during plasma processes. In one embodiment, ion dosages may be controlled using in-situ measurement of the plasma from a mass distribution sensor combined with in-situ measurement from an RF probe.

Owner:APPLIED MATERIALS INC

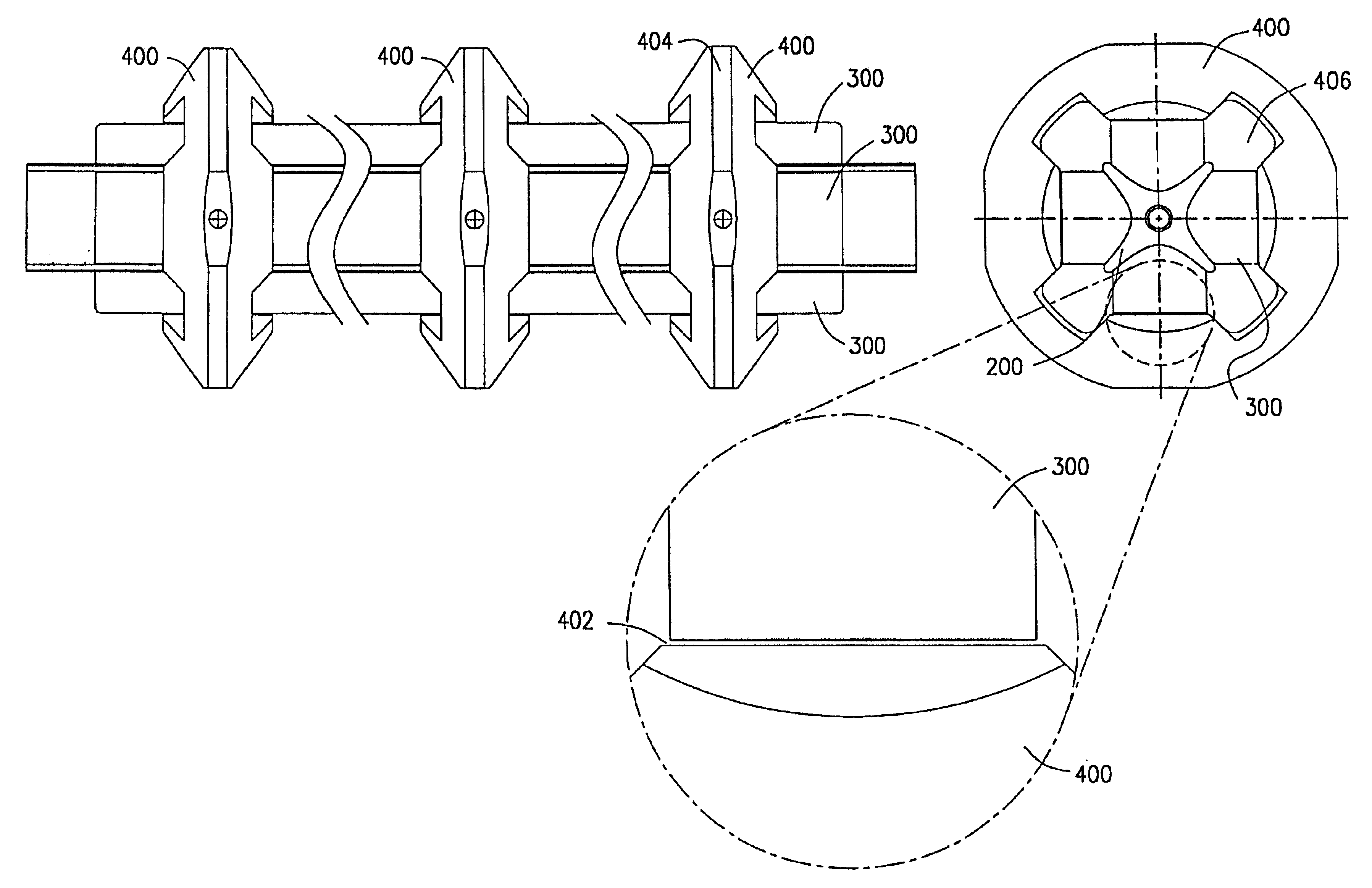

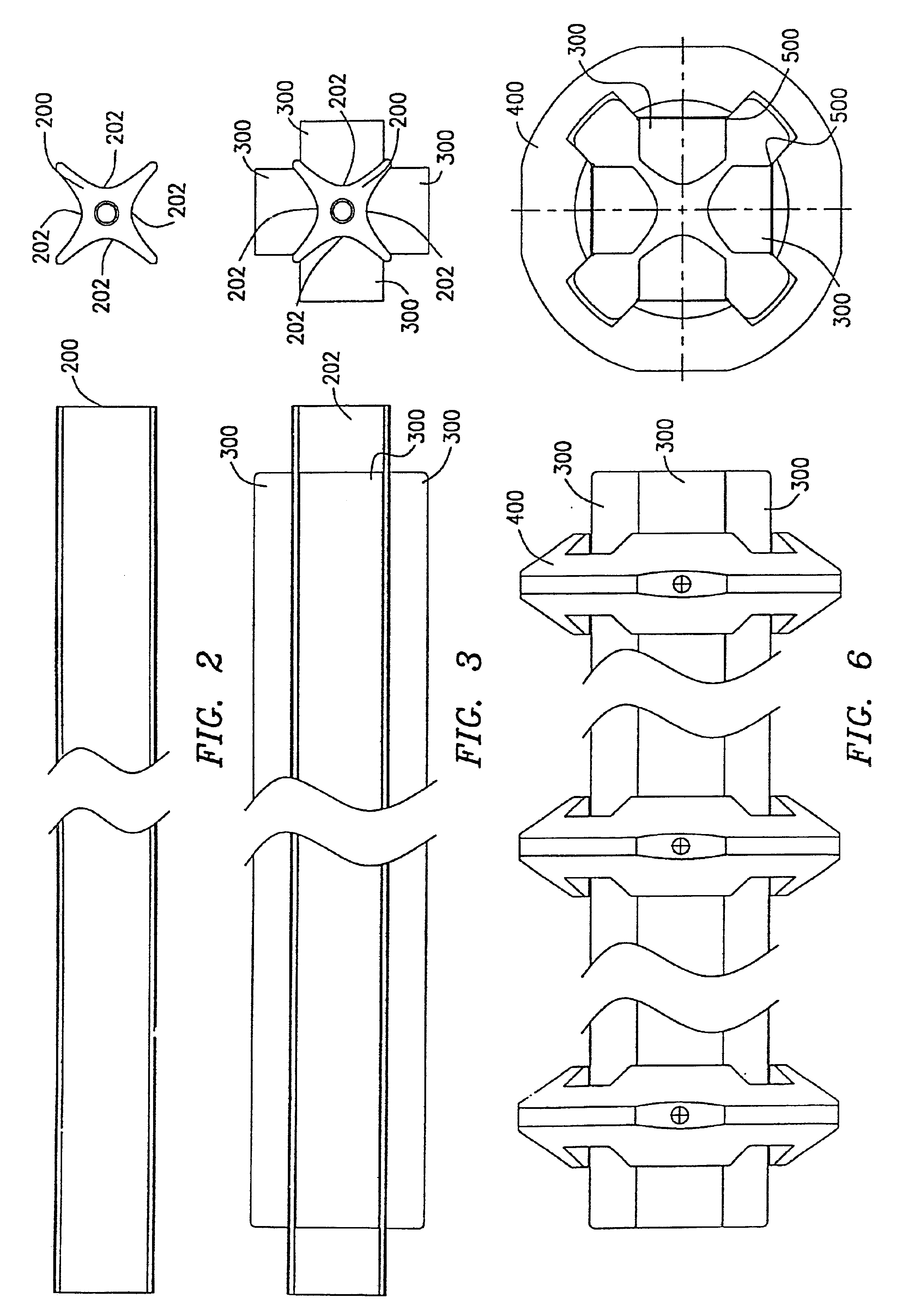

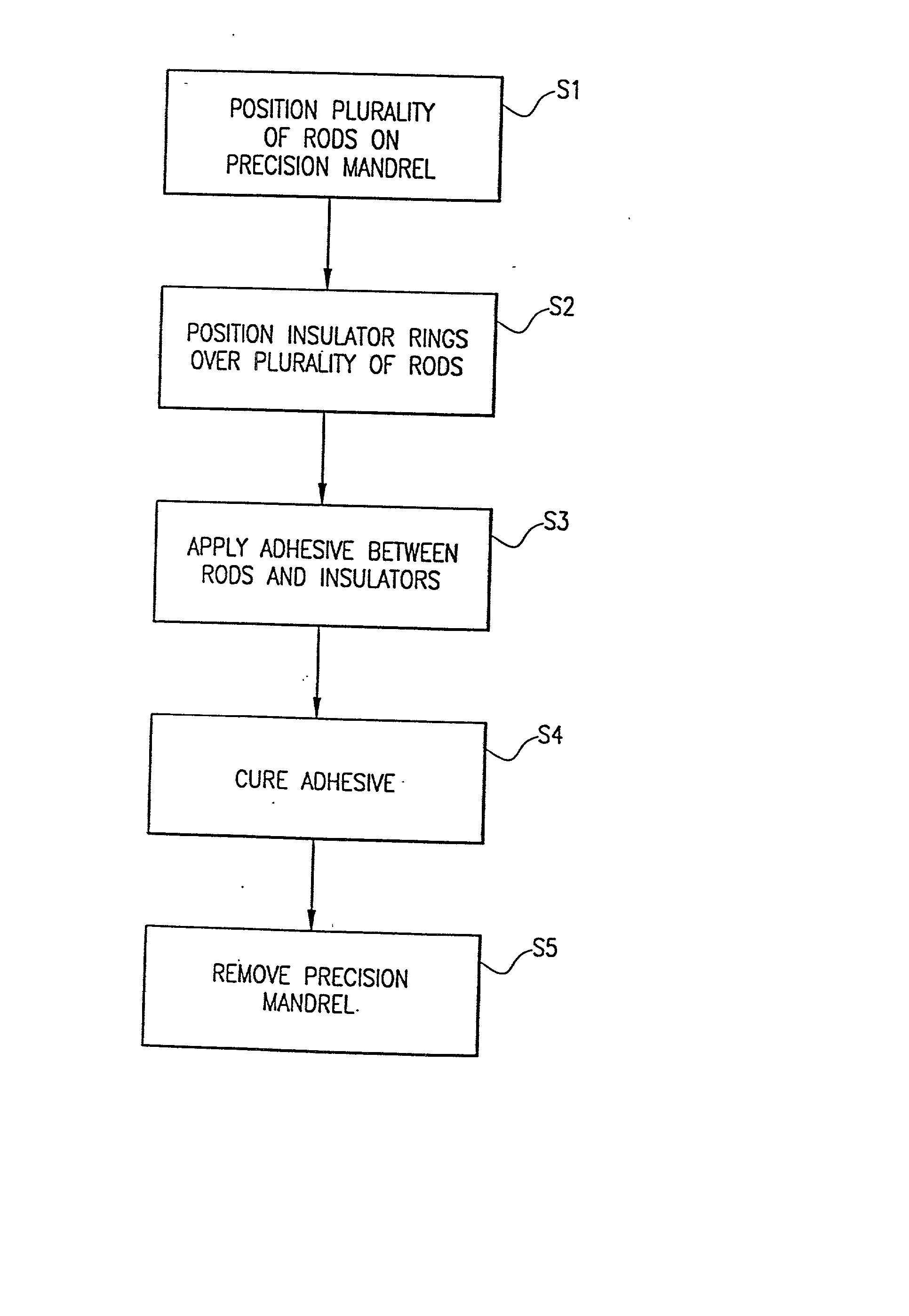

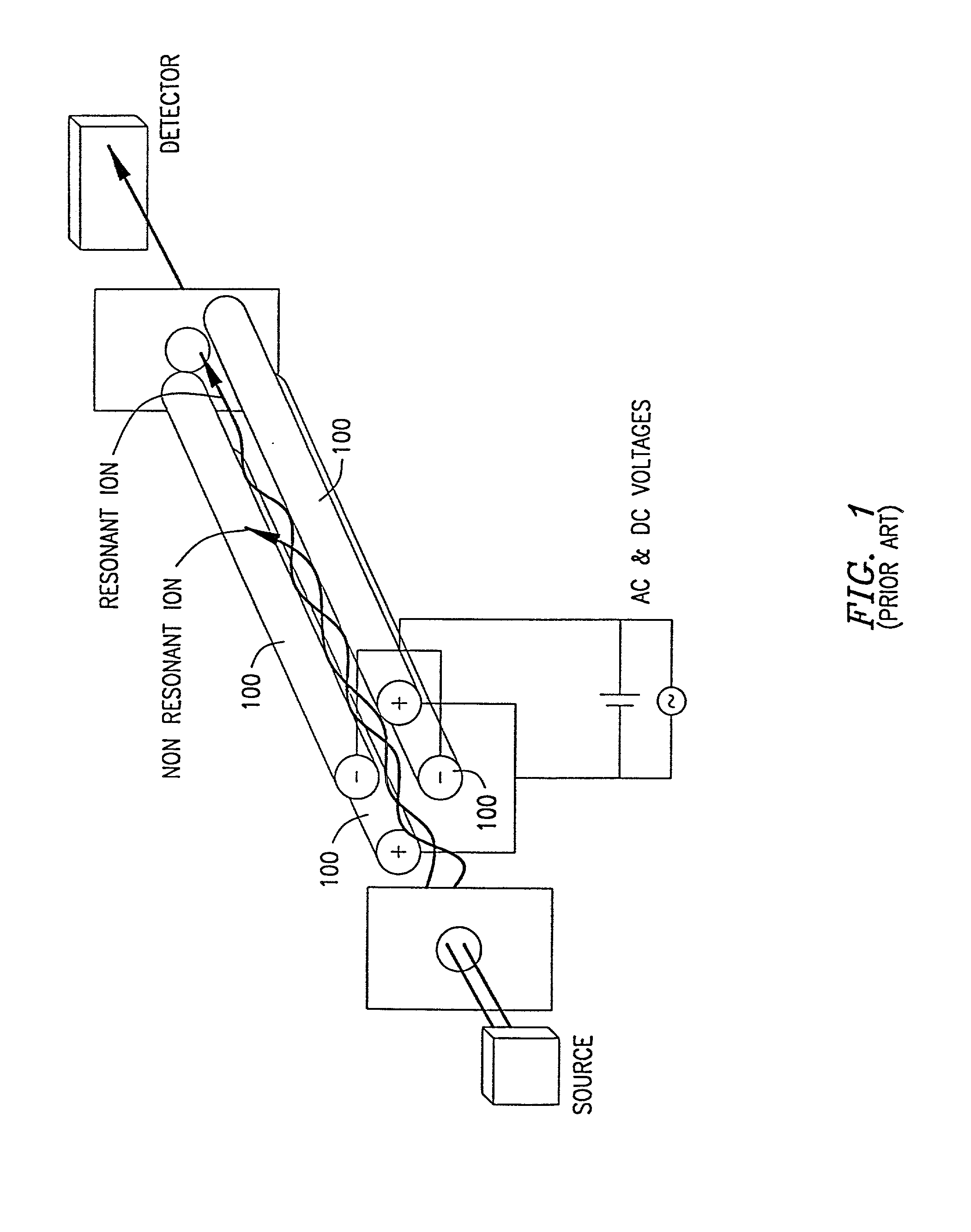

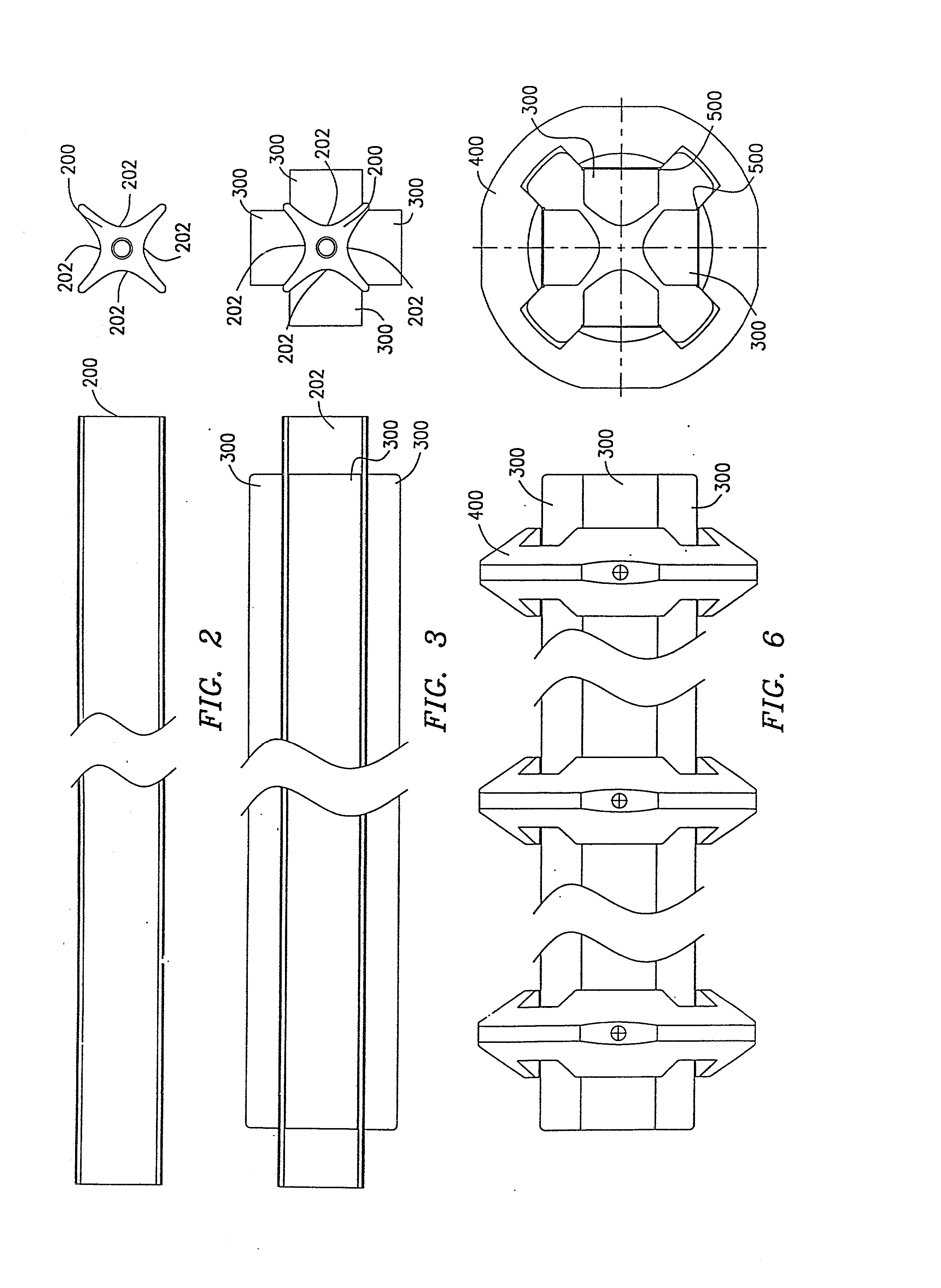

Manufacturing precision multipole guides and filters

InactiveUS6926783B2Precise positioningImprove accuracyAdhesive processesStability-of-path spectrometersResidual gas analyzerParticle beam

A method for manufacturing a multipole assembly for use in mass spectrometers, residual gas analyzers, mass filters, ion containment apparatus and particle beam accelerators. A precision mandrel tool is utilized for positioning a plurality of electrode rods in position during the manufacturing process. The electrode rods are placed on the mandrel. At least one insulator is positioned about the mandrel-rod assembly such that the mandrel-rod assembly psses through the insulator. The rods are tightly clamped to the mandrel and adhesive is placed in a gap established between each rod and the insulator. The adhesive is cured such that it acts both as a rigid bond between the insulator and each rod, as well as a precision spacer for positioning each rod in a precision position after the mandrel is removed from the assembly.

Owner:AGILENT TECH INC

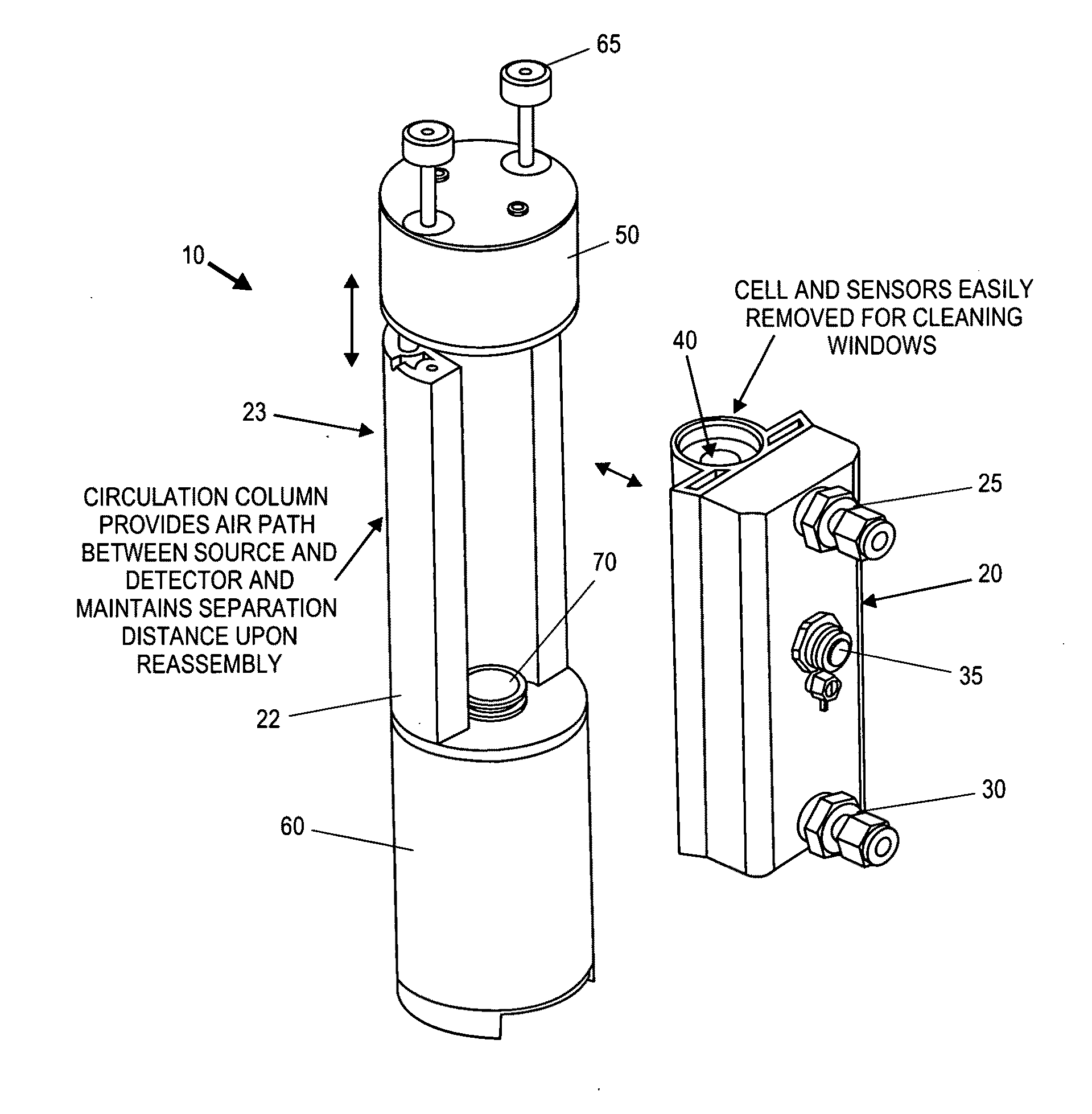

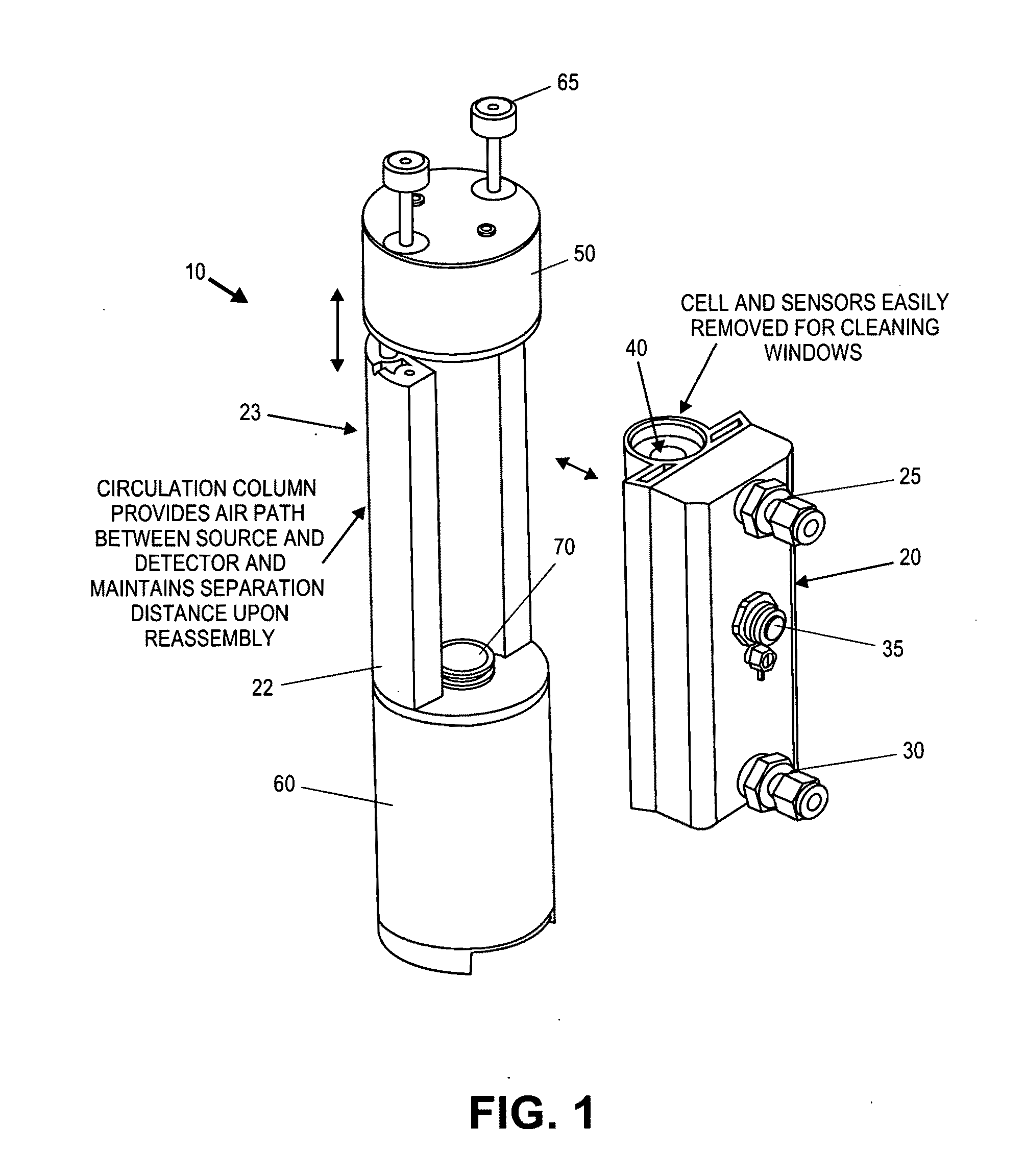

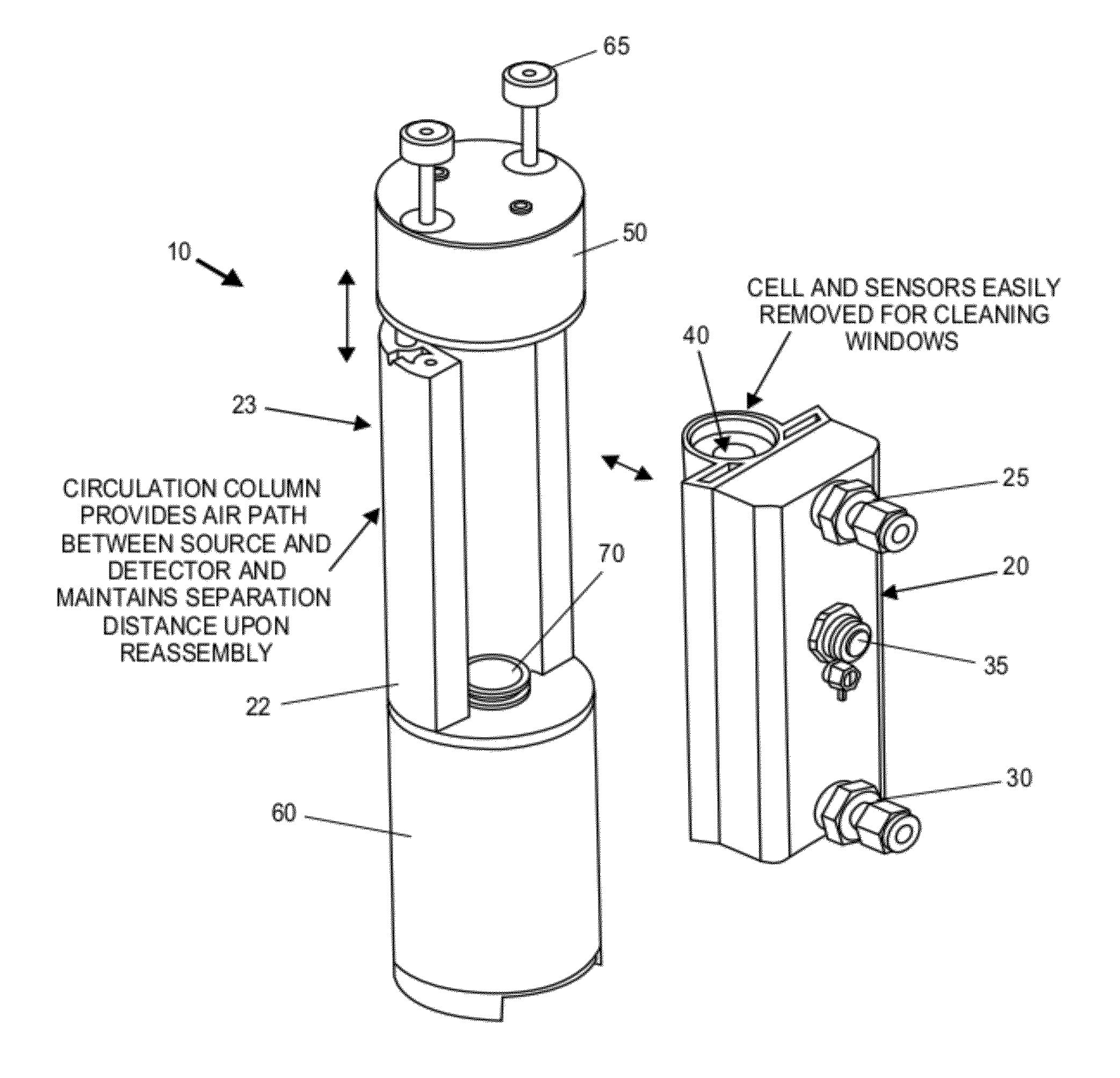

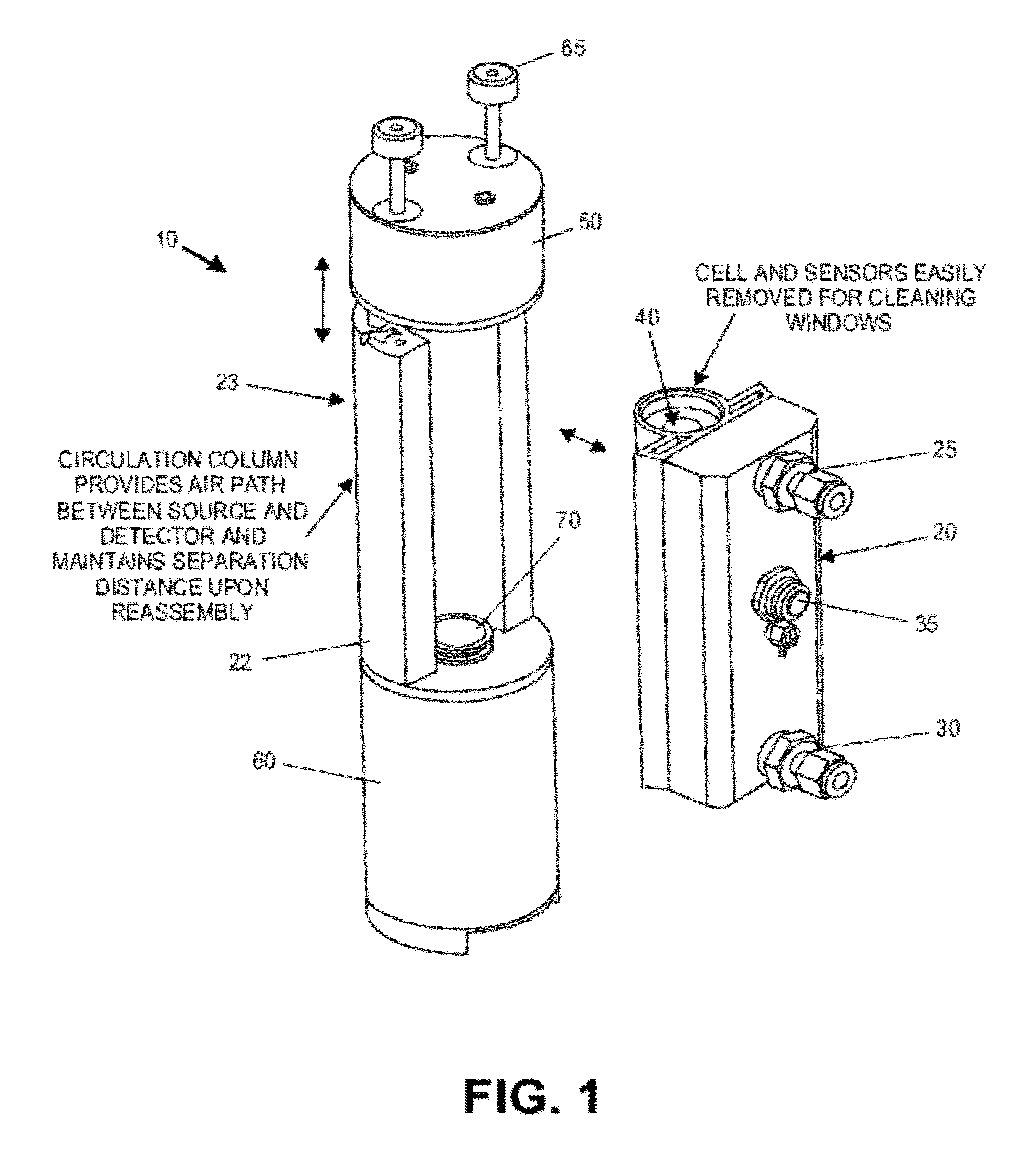

Hybrid gas analyzer

ActiveUS20100110438A1Quick measurementShort intake tubeTransmissivity measurementsResidual gas analyzerFast measurement

Gas analyzer systems and methods for measuring concentrations of gasses and in particular dry mole fraction of components of a gas. The systems and method allow for rapid measurement of the gas density and / or dry mole fraction of gases for a number of environmental monitoring applications, including high speed flux measurements. A novel coupling design allows for tool-free removal of a cell enclosing a flow path to enable in field cleaning of optical components and to enable re-configuration between open- and closed-path analyzer configurations.

Owner:LI COR

Real time alarm classification and method of use

InactiveUS20080238699A1Testing/monitoring control systemsFire alarm smoke/gas actuationResidual gas analyzerRoot cause

A real time alarm classification system and method of use and, more particularly, to a residual gas analyzer configured to identify specific root causes of an abnormal condition such as, for example, contamination, undesirable process variability and equipment malfunction in wafer processing. The real-time alarm classification system comprises a computer infrastructure operable to: generate top contributors associated with an alarm triggered by sensed abnormal conditions; compare the top contributors to contributors of historic RGA (residual gas analyzer) alarms of known root causes that were generated by a validated model; and provide a probable root cause of the sensed abnormal conditions when a match is found between the top contributors and the contributors associated with the historic RGA alarms of known root causes. A method and computer readable medium is also contemplated to provide the processes.

Owner:IBM CORP

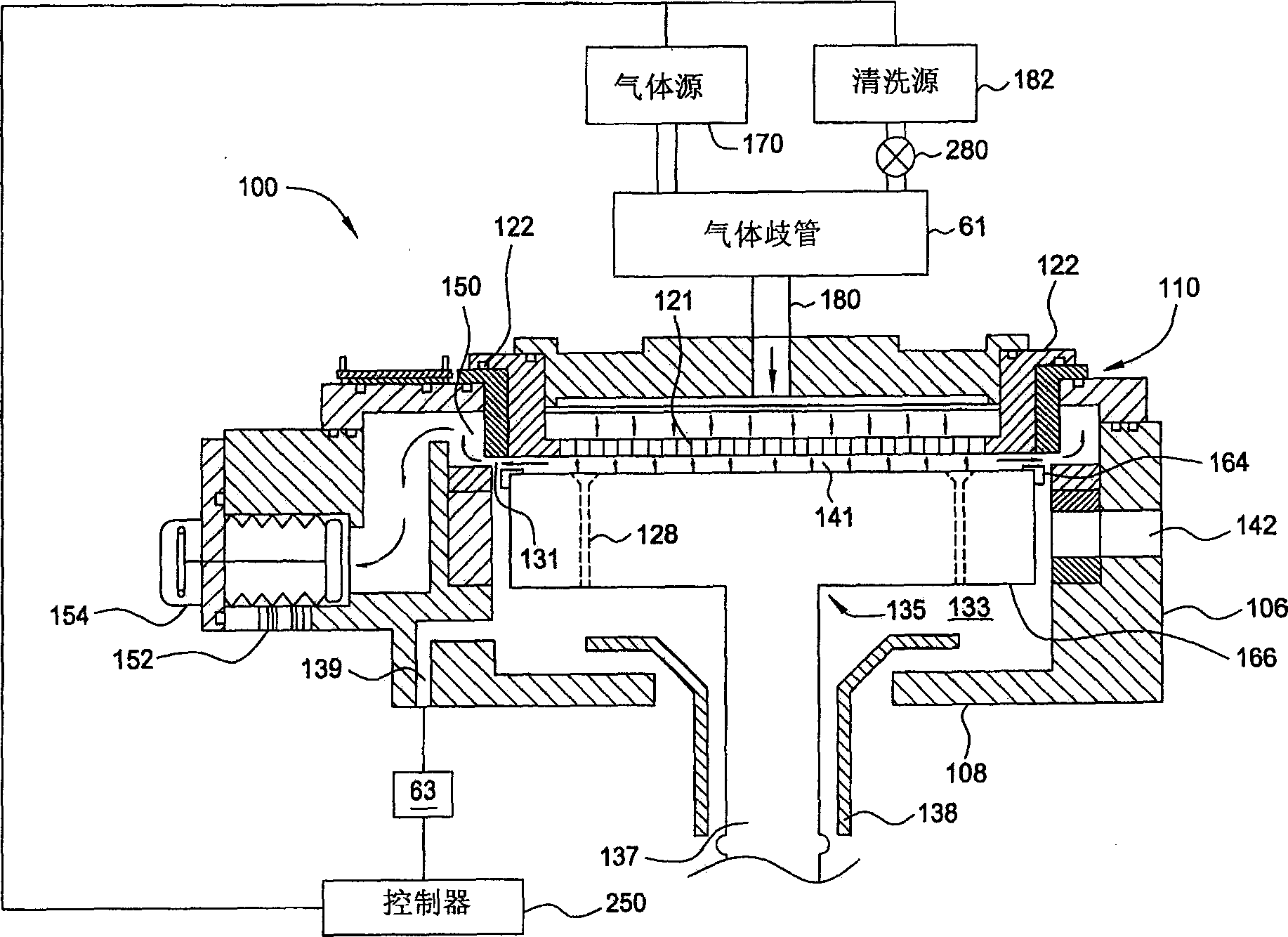

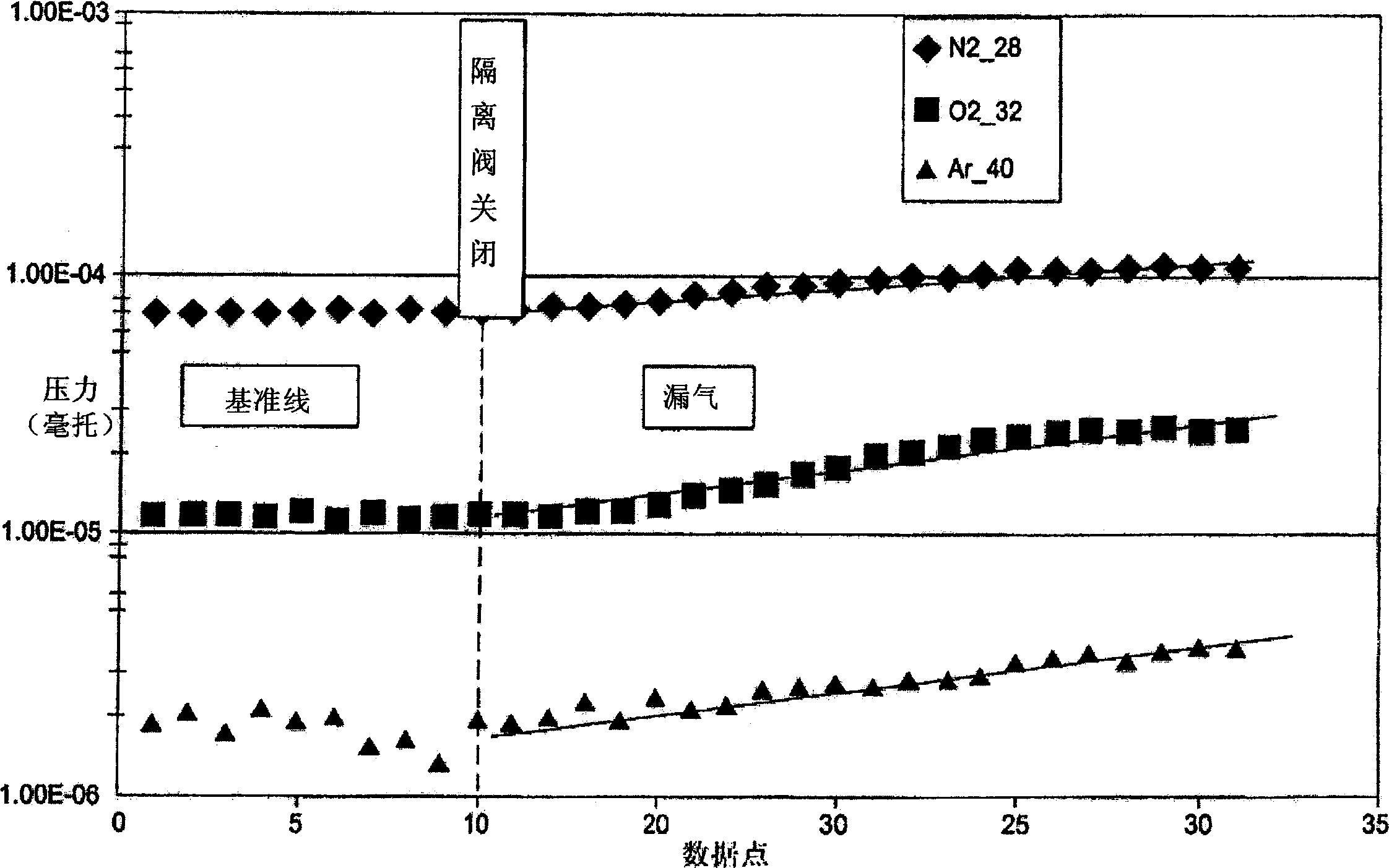

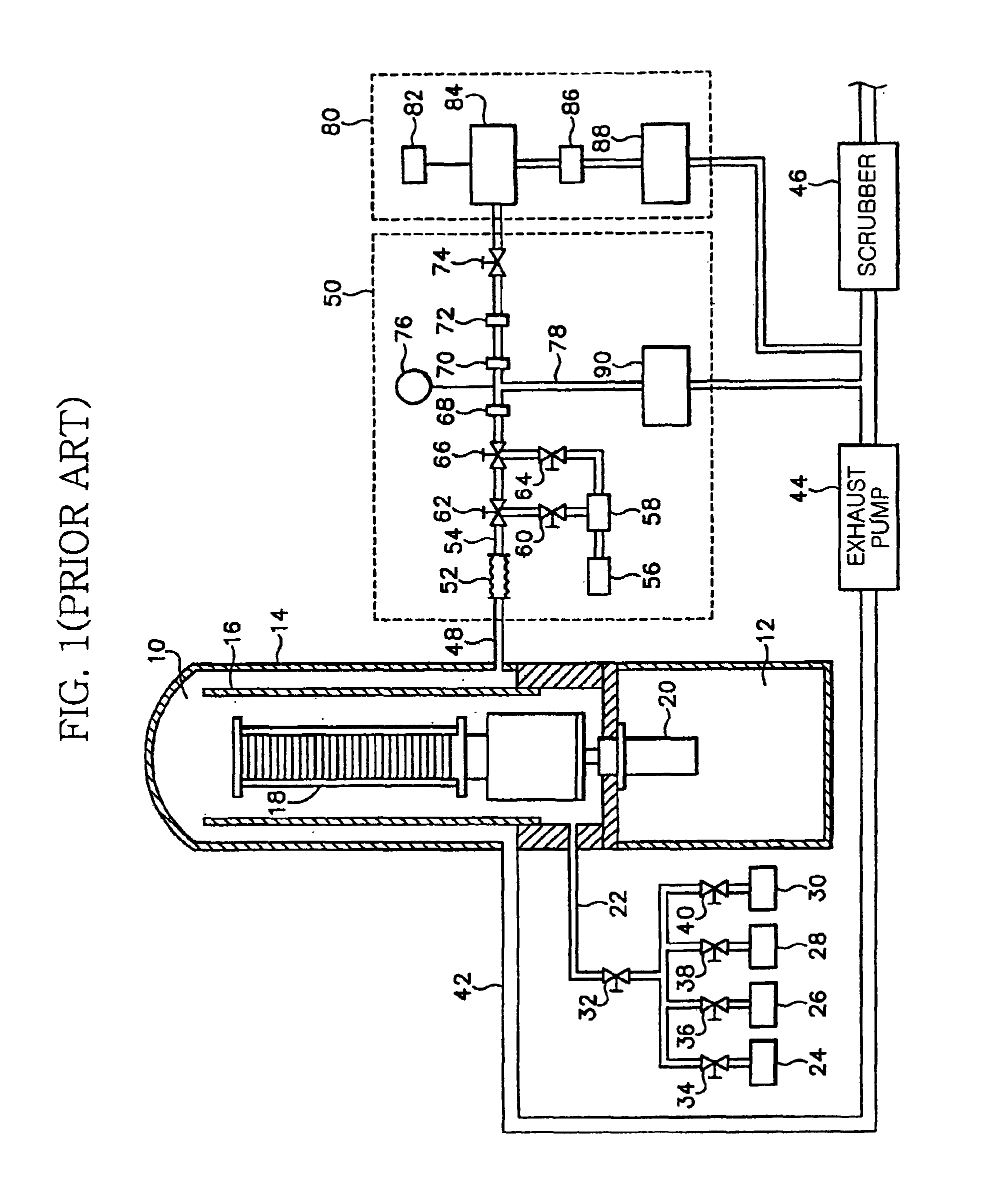

Leak detector and process gas monitor

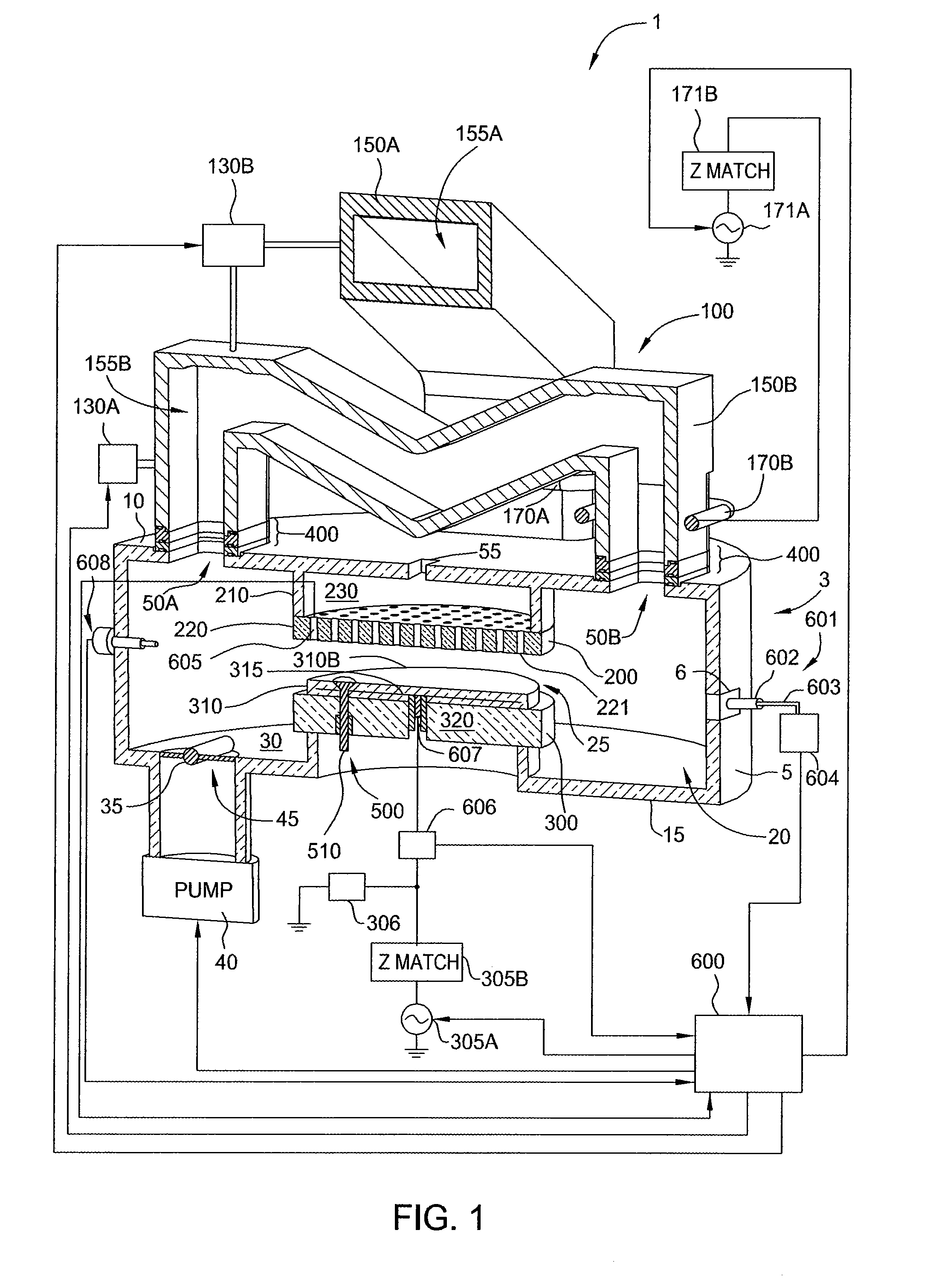

InactiveUS20060075968A1Electric discharge tubesPretreated surfacesResidual gas analyzerTime function

A method and apparatus for a plasma enhanced chemical vapor deposition system for processing one or more flat panel display substrates comprising a vacuum deposition process chamber configured to contain gas, a residual gas analyzer configured to analyze the gas within the process chamber and to provide feedback, and a controller to monitor feedback from the gas analyzer. Also, a method for identifying a process upset within a plasma enhanced chemical vapor deposition system configured to process flat panel display substrates comprising determining a historical slope of a line for partial pressure as a function of time, calculating a new slope of a line based on partial pressure measurements by a residual gas analyzer, comparing the historical and new slopes, and sending a signal to an operator.

Owner:APPLIED MATERIALS INC

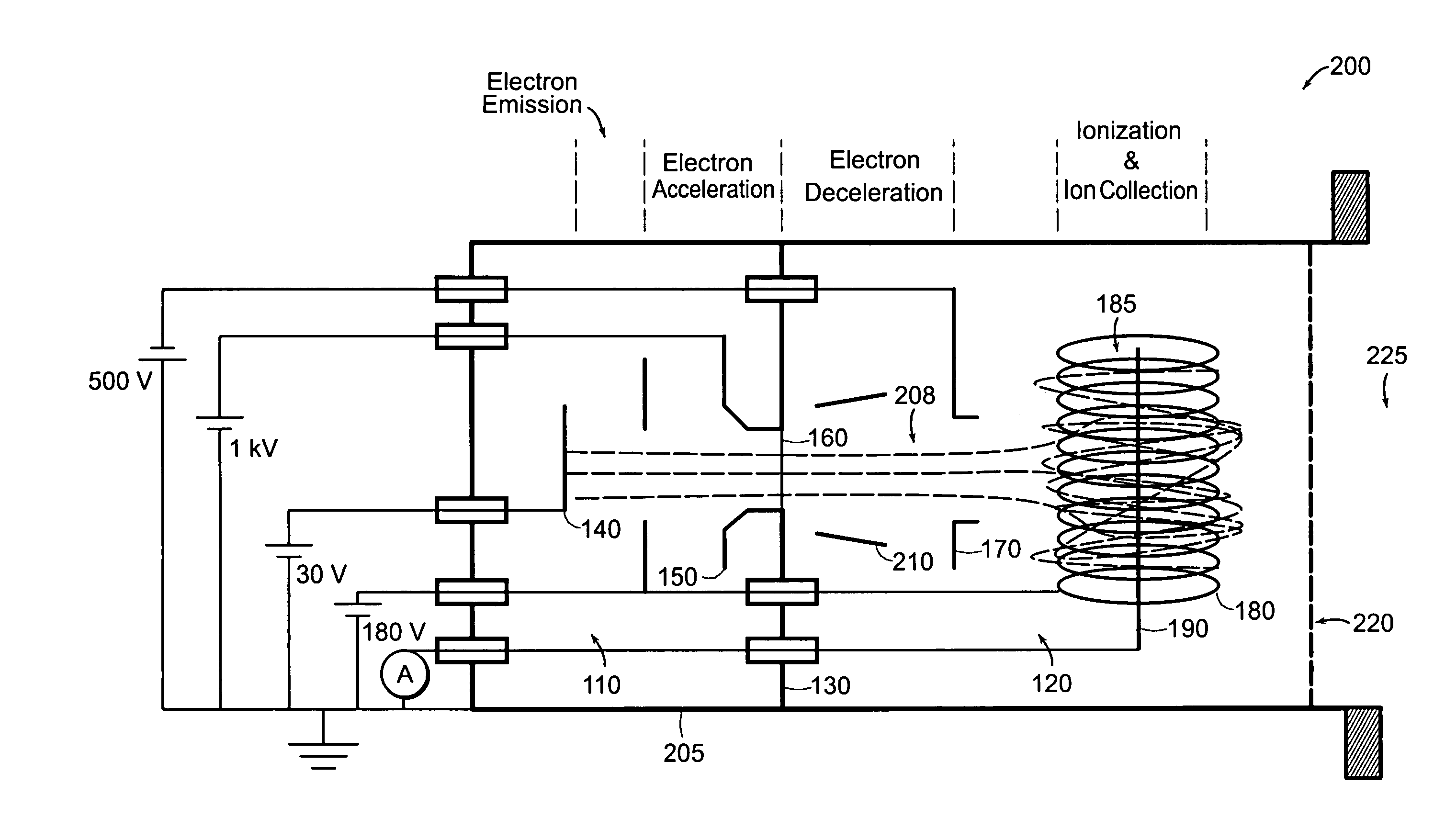

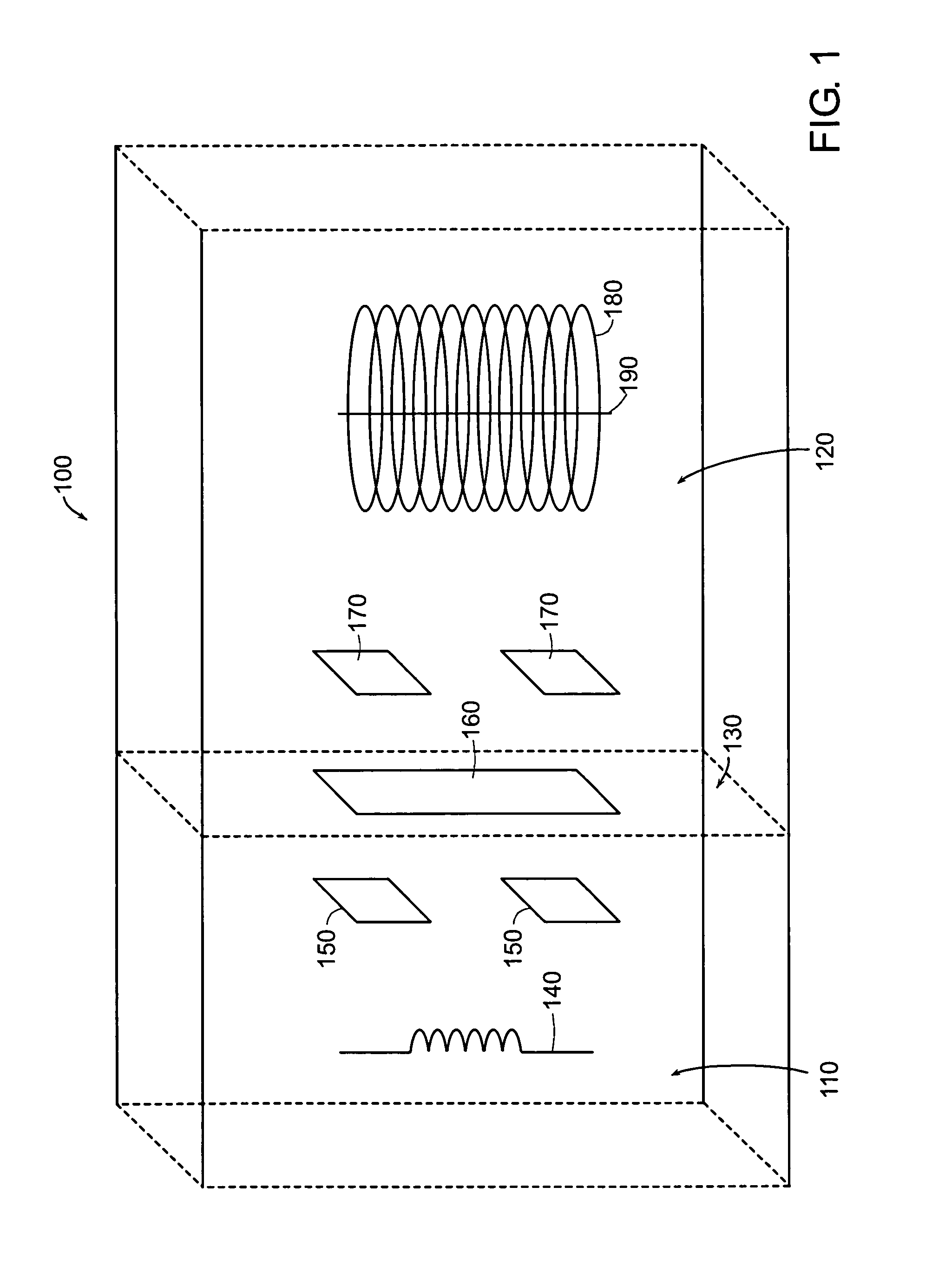

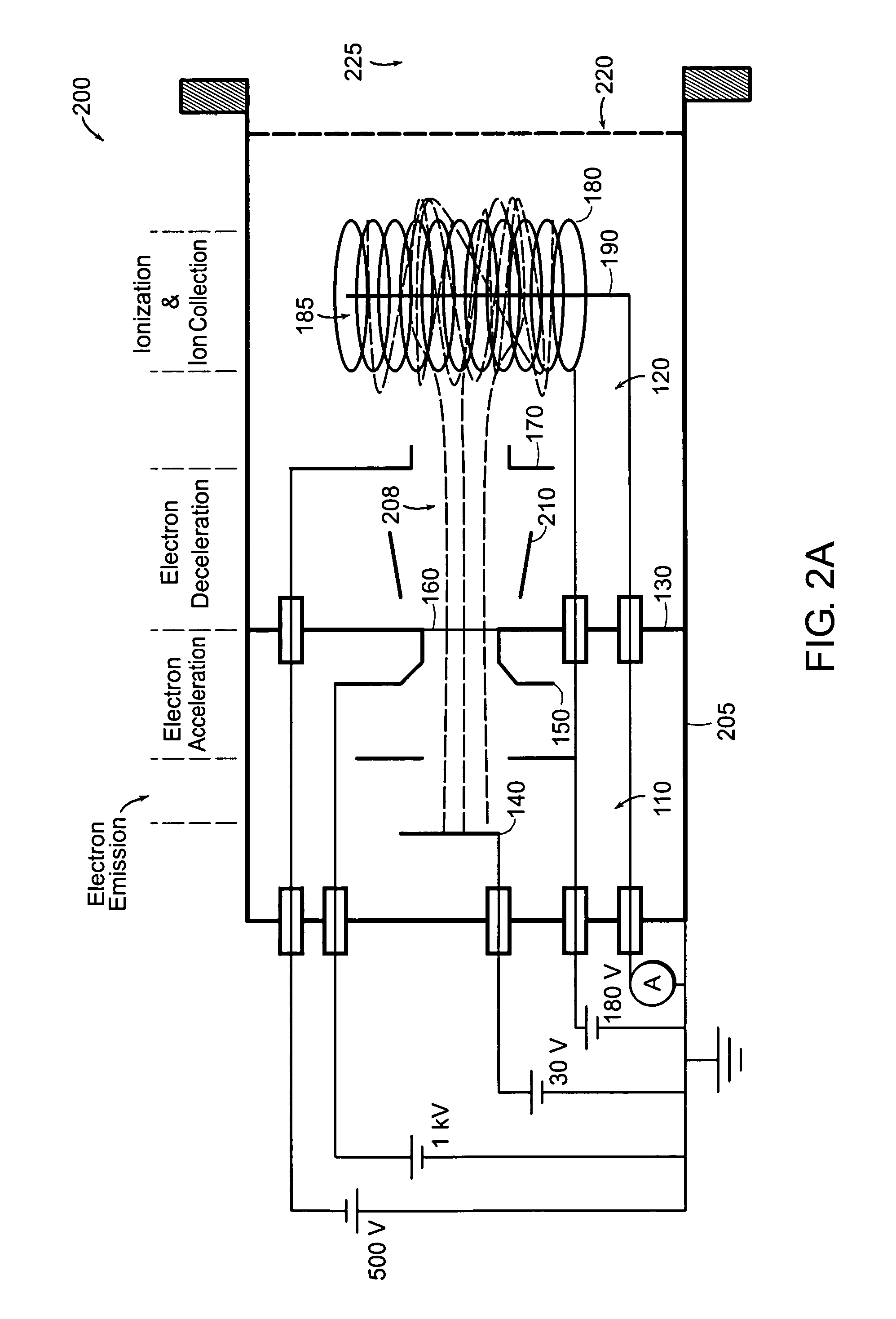

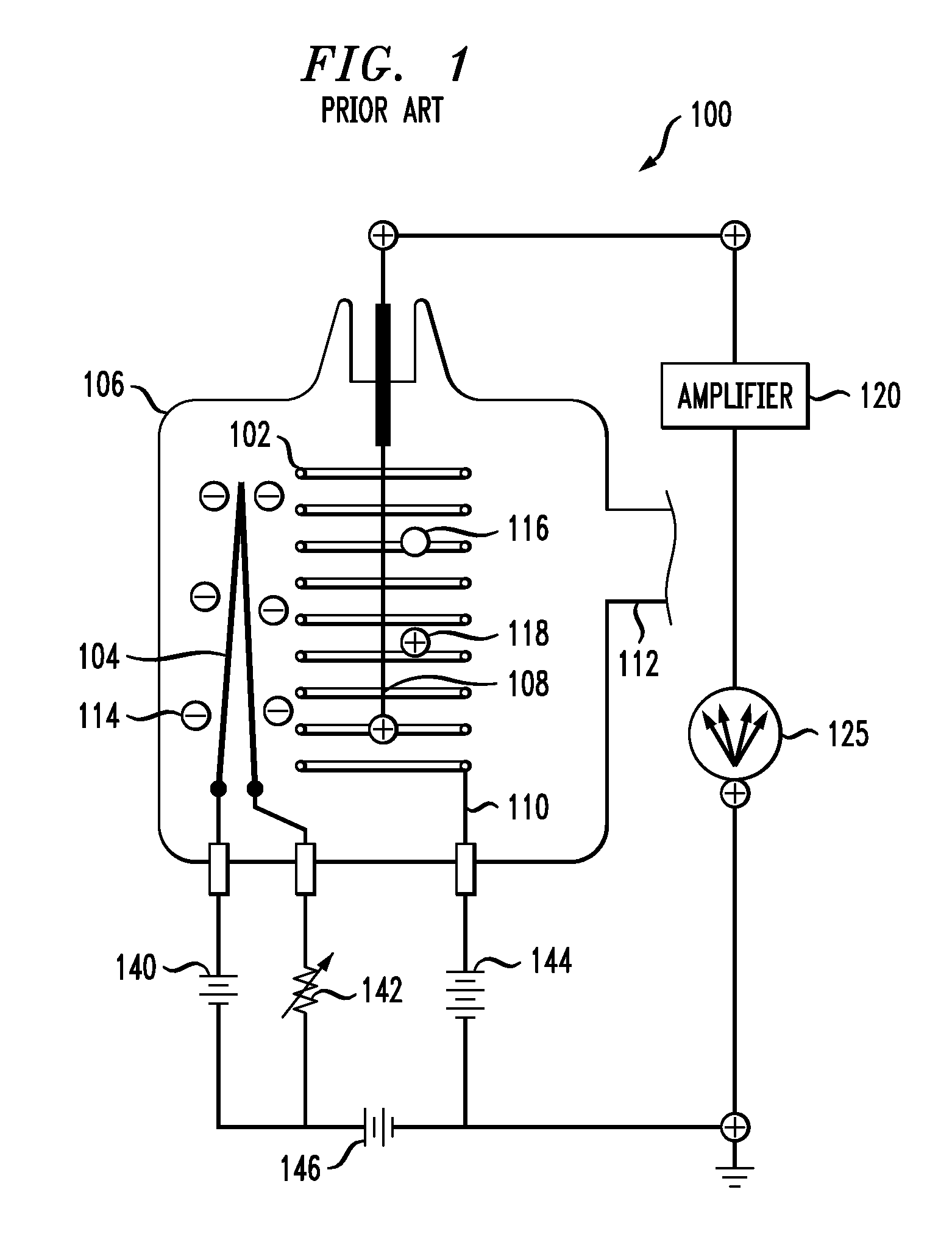

Ionization gauge

ActiveUS20050184735A1Decreased operational lifetimeReduce in quantityVacuum gauge using ionisation effectsMaterial analysis by electric/magnetic meansResidual gas analyzerElectron source

Owner:MKS INSTR INC

Ionization gauge

ActiveUS7030619B2Reduce in quantityReduce stepsVacuum gauge using ionisation effectsMaterial analysis by electric/magnetic meansResidual gas analyzerElectron source

Owner:MKS INSTR INC

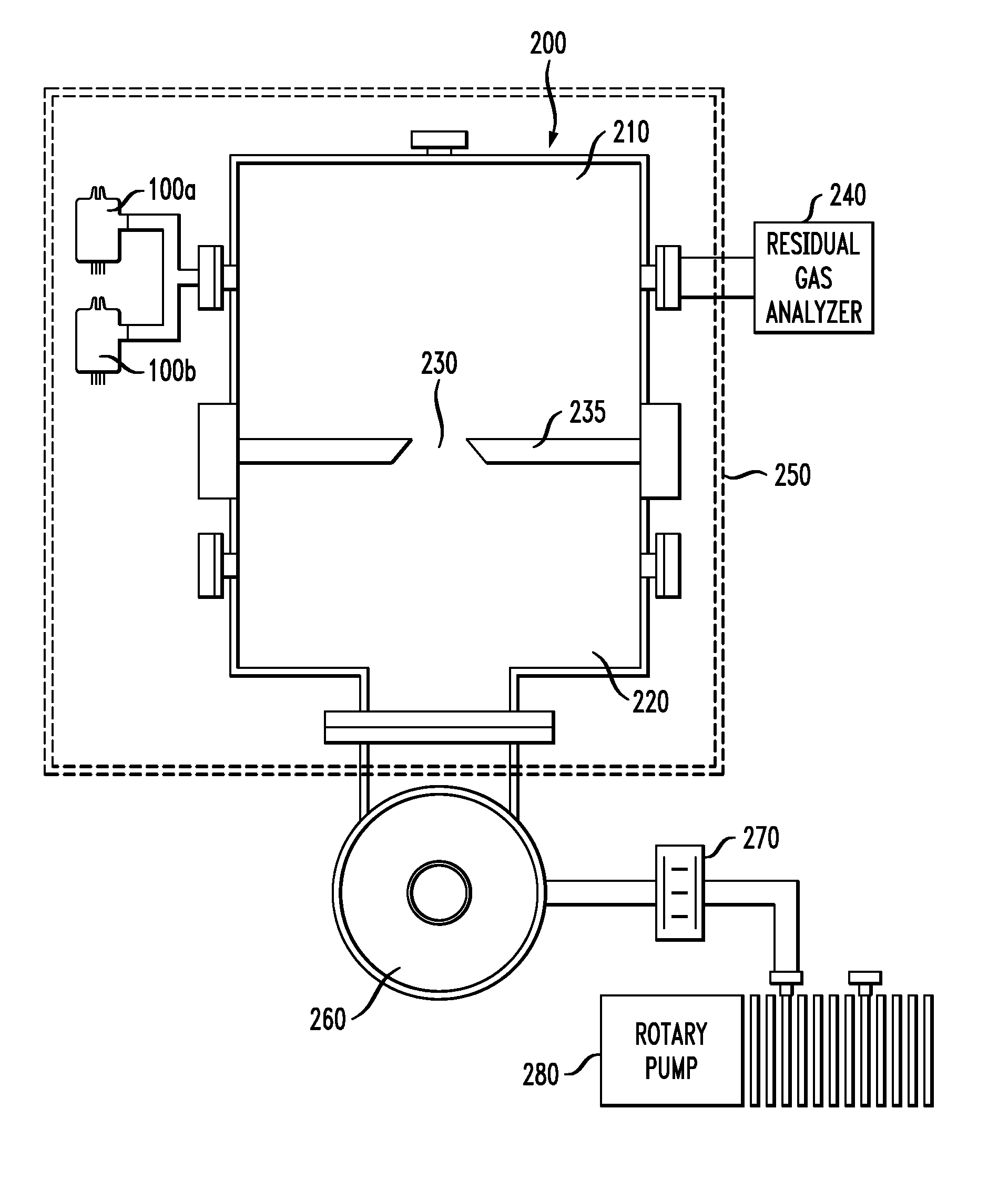

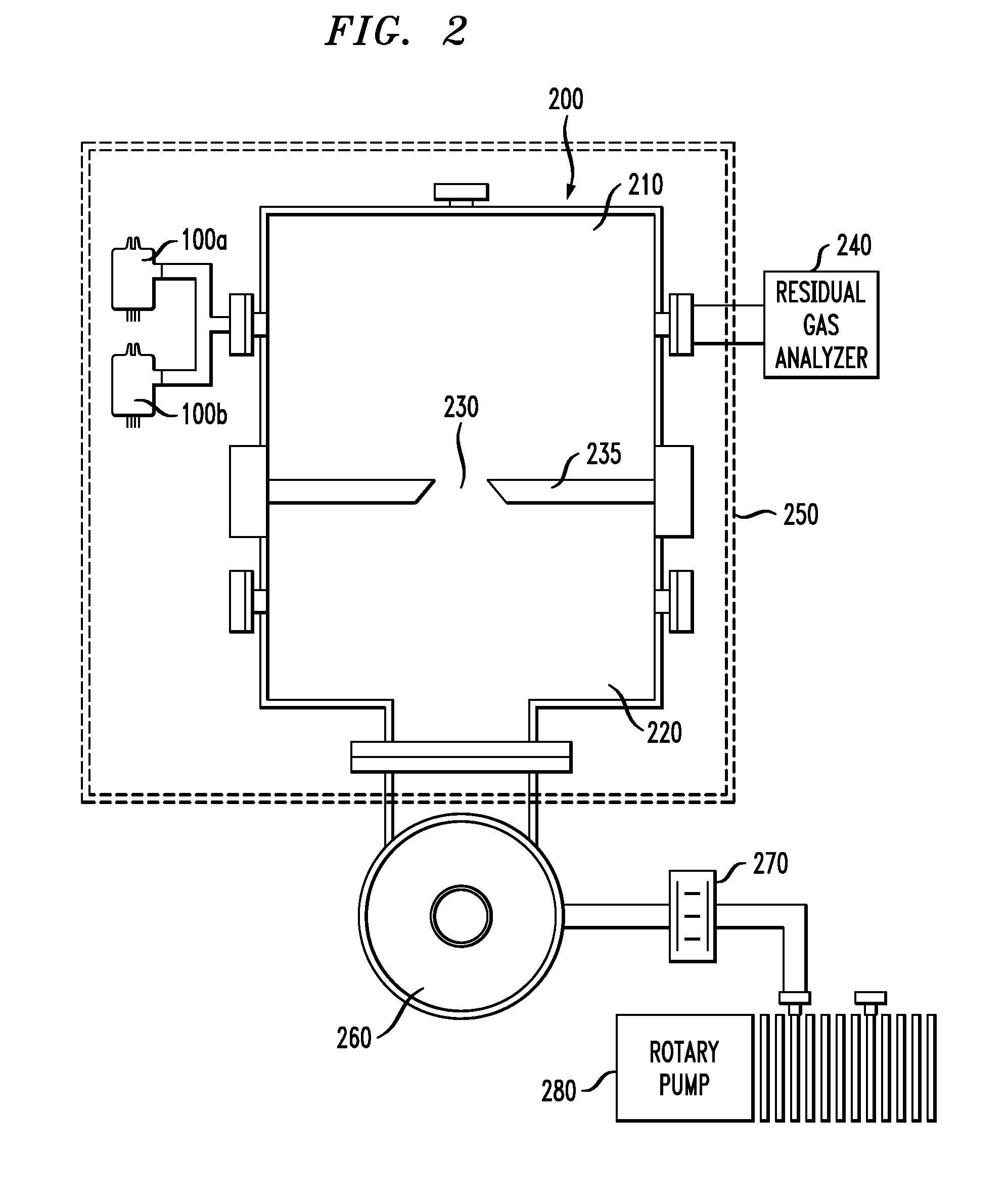

Apparatus for and method of measuring composition and pressure of the discharged gas from ion gauge using residual gas analyzer

InactiveUS20080048663A1Quality improvementAvoid chemical reactionsVacuum gauge using ionisation effectsFluid pressure measurement by electric/magnetic elementsResidual gas analyzerProduct gas

Disclosed herein are an apparatus for and method of measuring the composition and the pressure of the discharged gas from an ion gauge by using a residual gas analyzer. In this regard, there are provided a vacuum container 200 divided into a pressure container 210 and a discharge container 220 by means of a partition 235 having an orifice 230 formed thereon; an ion gauge 100 mounted at the pressure container 210 side of the vacuum container 200 for discharging the gas at the time of vacuum formation; a residual gas analyzer 240 mounted at the pressure container 210 side of the vacuum container 200 for measuring the composition and the pressure of the residual gas; pump means disposed at one side of the discharge container 220 of the vacuum container 200 for discharging the inside gas; and heating means disposed at the vacuum container 200 for heating the vacuum container 200 to a predetermined temperature.

Owner:KOREA RES INST OF STANDARDS & SCI

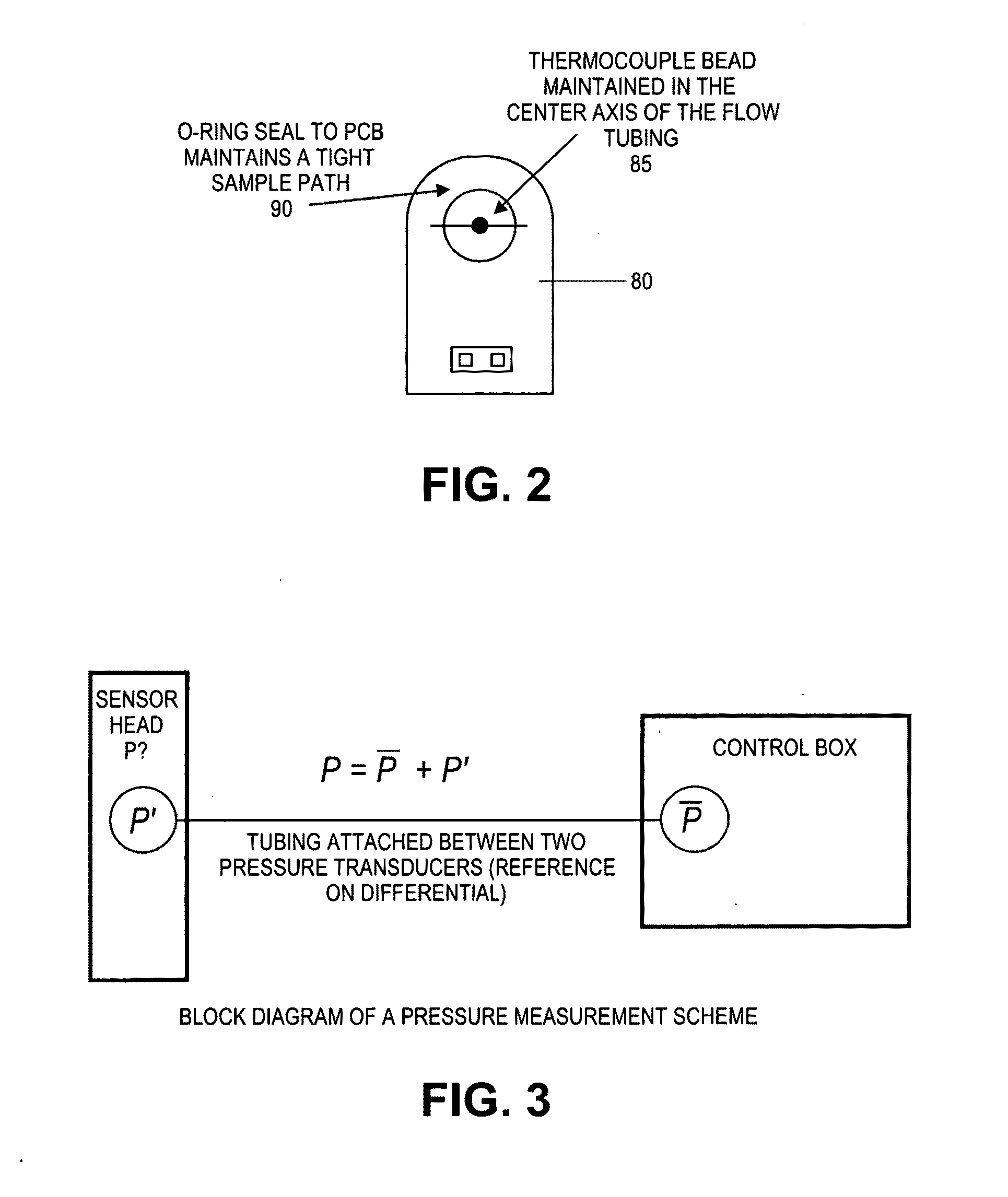

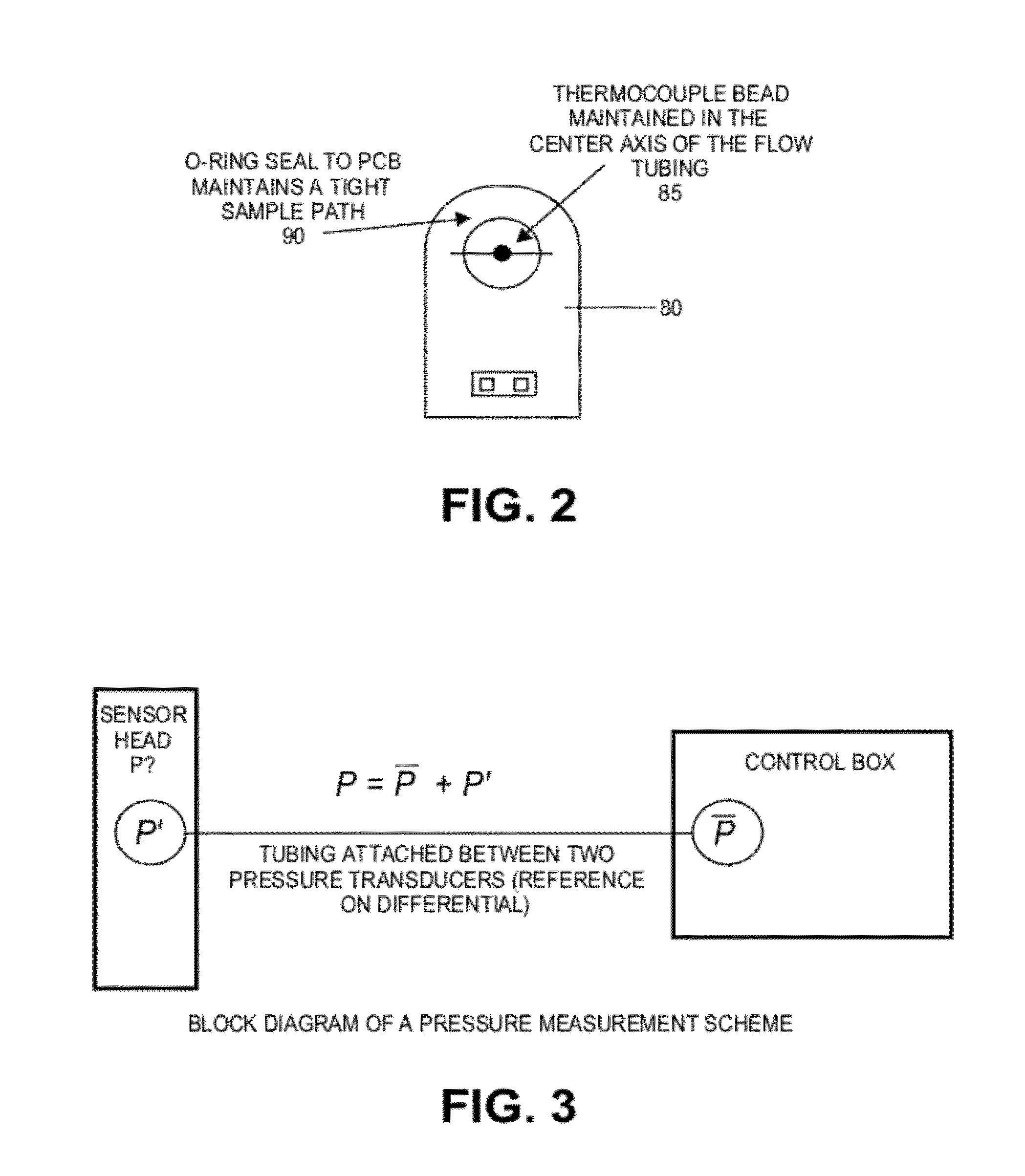

Hybrid gas analyzer with thermally insulated flow cell

ActiveUS20120120397A1Quick measurementShort intake tubeWithdrawing sample devicesTransmissivity measurementsThermal isolationResidual gas analyzer

Gas analyzer systems and methods for measuring concentrations of gases and in particular dry mole fraction of components of a gas. The systems and methods allow for rapid measurement of the gas density and / or dry mole fraction of gases for a number of environmental monitoring applications, including high speed flux measurements. A novel coupling design allows for tool-free removal of a cell enclosing a flow path to enable infield cleaning of optical components and to enable re-configuration between open- and closed-path analyzer configurations. In closed path configurations, the sample flow path is thermally isolated from the remainder of the gas analyzer to provide more accurate temperature measurements. Composite plastic / metal sample cells are presented with achieve this thermal isolation without compromising analyzer performance.

Owner:LI COR

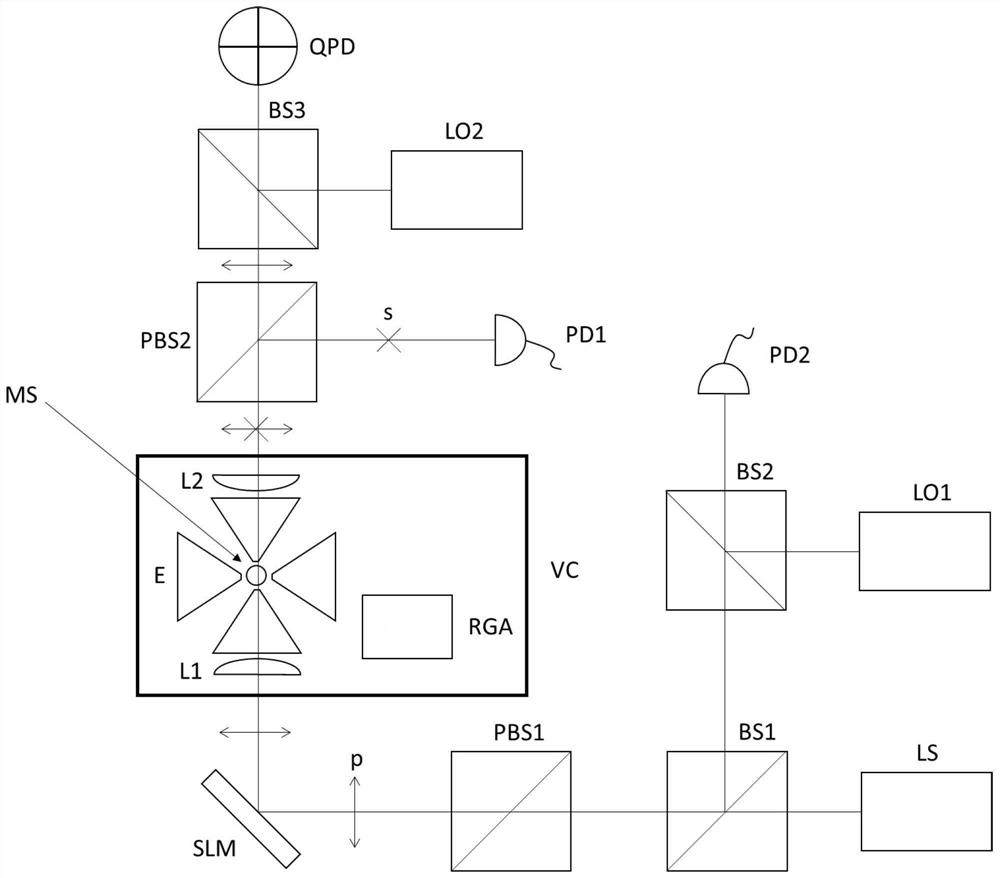

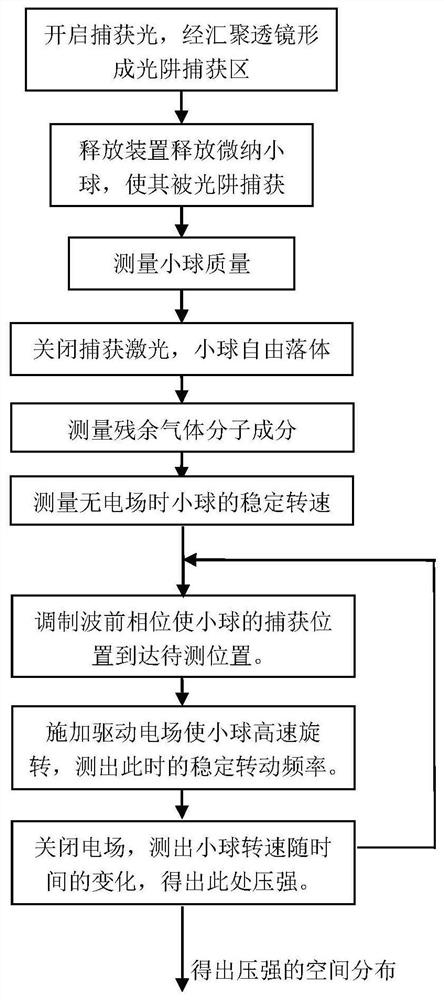

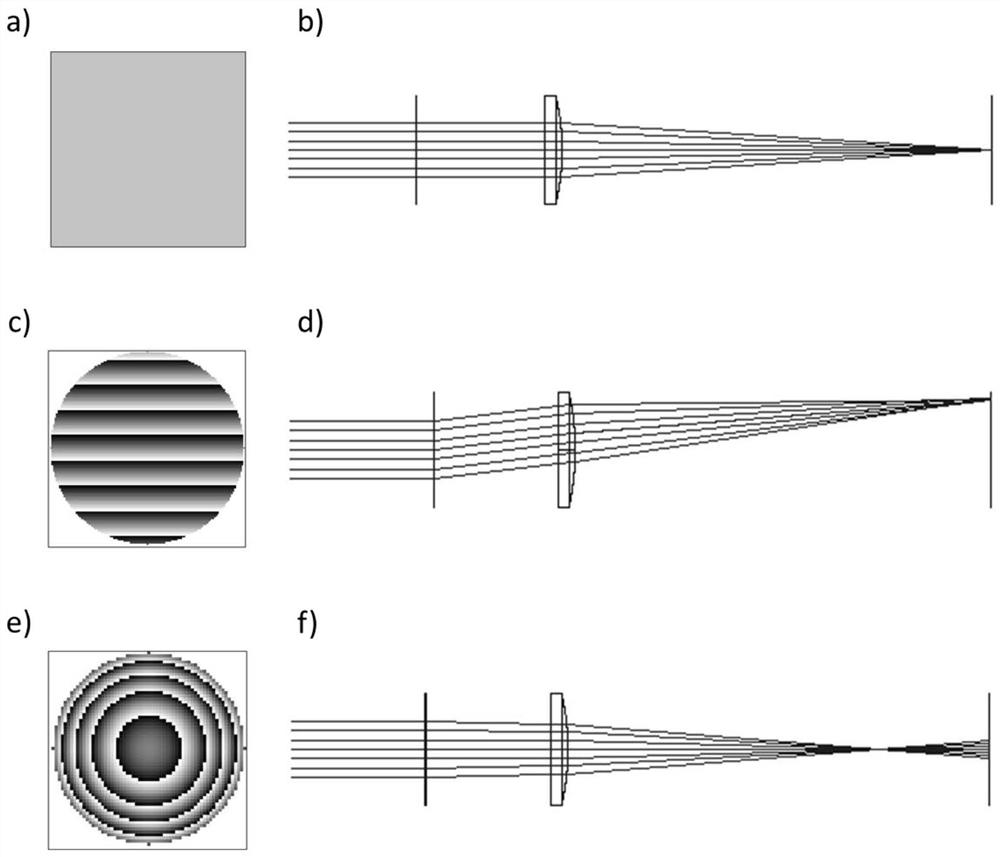

Spatial resolution pressure intensity measurement system and method based on vacuum holographic optical tweezers

ActiveCN112880912AEliminate distractionsChange capture positionVacuum gaugesBeam splitterSpatial light modulator

The invention discloses a spatial resolution pressure measurement system and method based on vacuum holographic optical tweezers. The system comprises a vacuum cavity, micro-nano particles, an optical tweezers device, a feedback cooling device, a driving electric field device, a spatial light modulator, a polarization control and detection device and a residual gas analyzer, laser is emitted from a laser source, enters a first polarizing beam splitter through the first beam splitter to be transmitted, is reflected and modulated by the spatial light modulator and is transmitted and converged by a first convex lens to form captured light, and captured light irradiates the micro-nano particles to form a light trap capturing area; the captured light passes through the micro-nano particles, is transmitted and converged by a second convex lens and then enters a second polarizing beam splitter to be reflected and transmitted, and a light beam reflected by the second polarizing beam splitter enters a first photodiode; and six electrodes are arranged around the light trap capture region. According to the invention, the control flexibility of the holographic optical tweezers is utilized, and the local detection means of the micro-nano particles is combined, so that the pressure distribution measurement of the micro-nano scale spatial resolution under high vacuum can be realized.

Owner:ZHEJIANG UNIV +1

Leak detector and process gas monitor

InactiveCN1766162AElectric discharge tubesSemiconductor/solid-state device manufacturingGas phaseDisplay device

A method and apparatus for a plasma-enhanced chemical vapor deposition system for processing one or more flat panel display substrates, the apparatus comprising a vacuum deposition chamber for containing gas, a chamber for analyzing the gas in the reaction chamber and providing A feedback residual gas analyzer and a controller for monitoring feedback from the gas analyzer. A method for identifying process disturbances in a plasma-enhanced chemical vapor deposition system for processing one or more flat panel display substrates, the method comprising: determining the past slope of a partial pressure curve as a function of time; calculating a new slope of the curve from partial pressure measurements taken by the residual gas analyzer; comparing the past slope to the new slope; and sending a signal to an operator.

Owner:APPLIED MATERIALS INC

Apparatus and methods for curing a layer by monitoring gas species evolved during baking

InactiveUS20080241354A1Semiconductor/solid-state device manufacturingPretreated surfacesElectricityResidual gas analyzer

A heat treatment apparatus and method for curing a layer of a processable material on a substrate. The apparatus includes a residual gas analyzer that communicates with a process space in which the layer is heated to cure the processable material. A controller, which is electrically connected to the residual gas analyzer, is operable to adjust a bake time for the layer in relation to a concentration of a gas species evolved from the processable material.

Owner:TOKYO ELECTRON LTD

Manufacturing precision multipole guides and filters

InactiveUS20020117247A1Adhesive processesStability-of-path spectrometersResidual gas analyzerParticle beam

A method for manufacturing a multipole assembly for use in mass spectrometers, residual gas analyzers, mass filters, ion containment apparatus and particle beam accelerators. A precision mandrel tool is utilized for positioning a plurality of electrode rods in position during the manufacturing process. The electrode rods are placed on the mandrel. At least one insulator is positioned about the mandrel-rod assembly such that the mandrel-rod assembly psses through the insulator. The rods are tightly clamped to the mandrel and adhesive is placed in a gap established between each rod and the insulator. The adhesive is cured such that it acts both as a rigid bond between the insulator and each rod, as well as a precision spacer for positioning each rod in a precision position after the mandrel is removed from the assembly.

Owner:AGILENT TECH INC

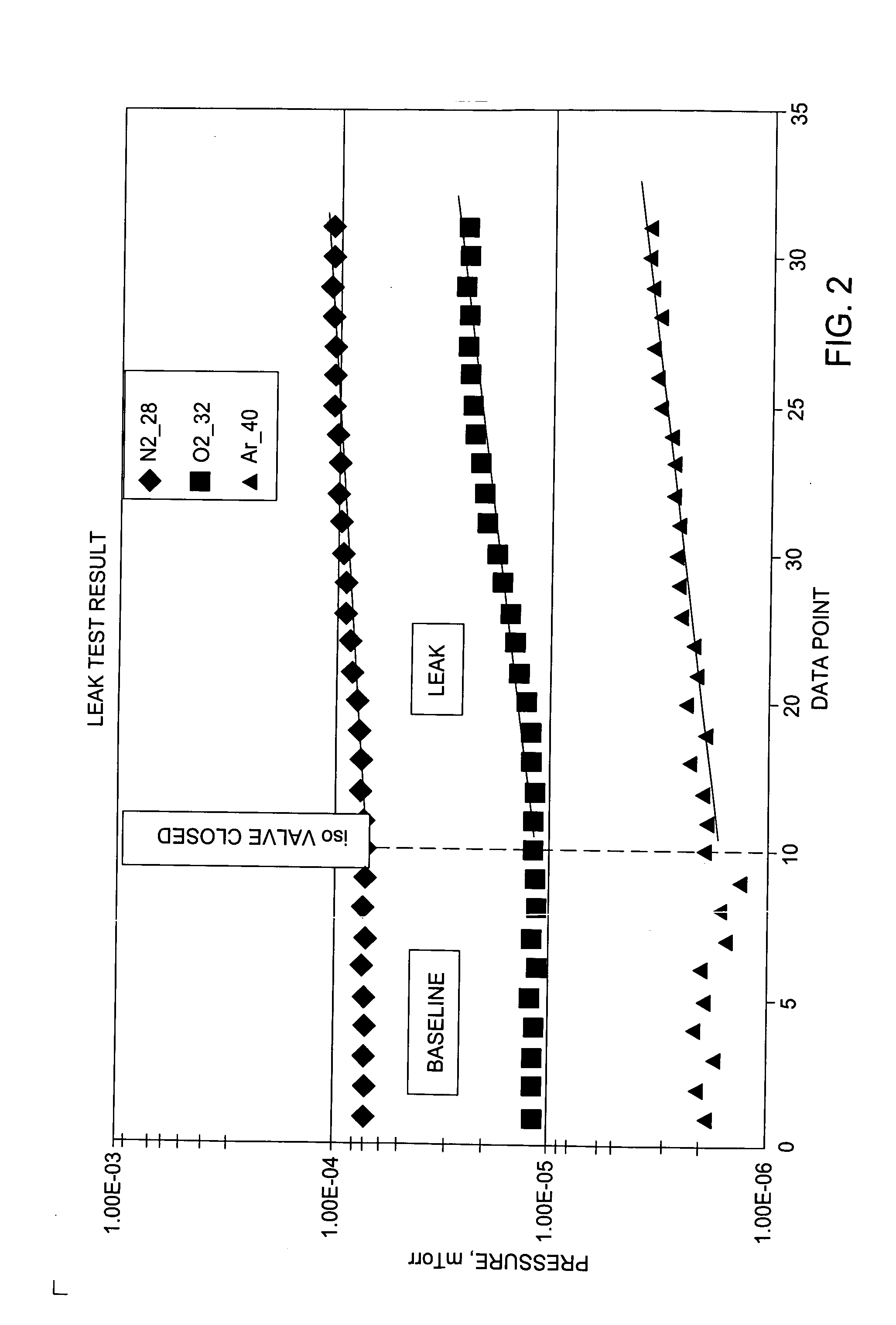

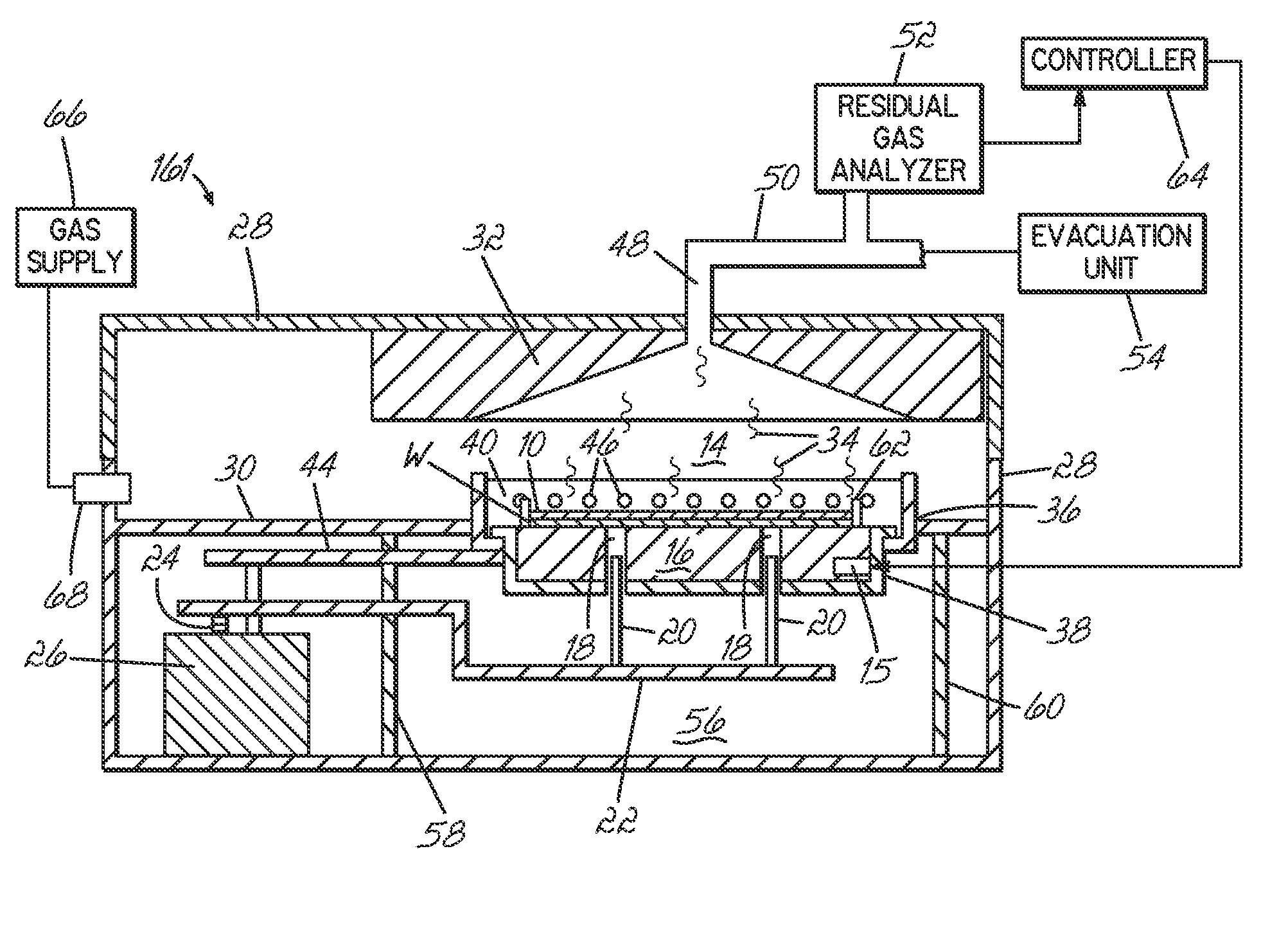

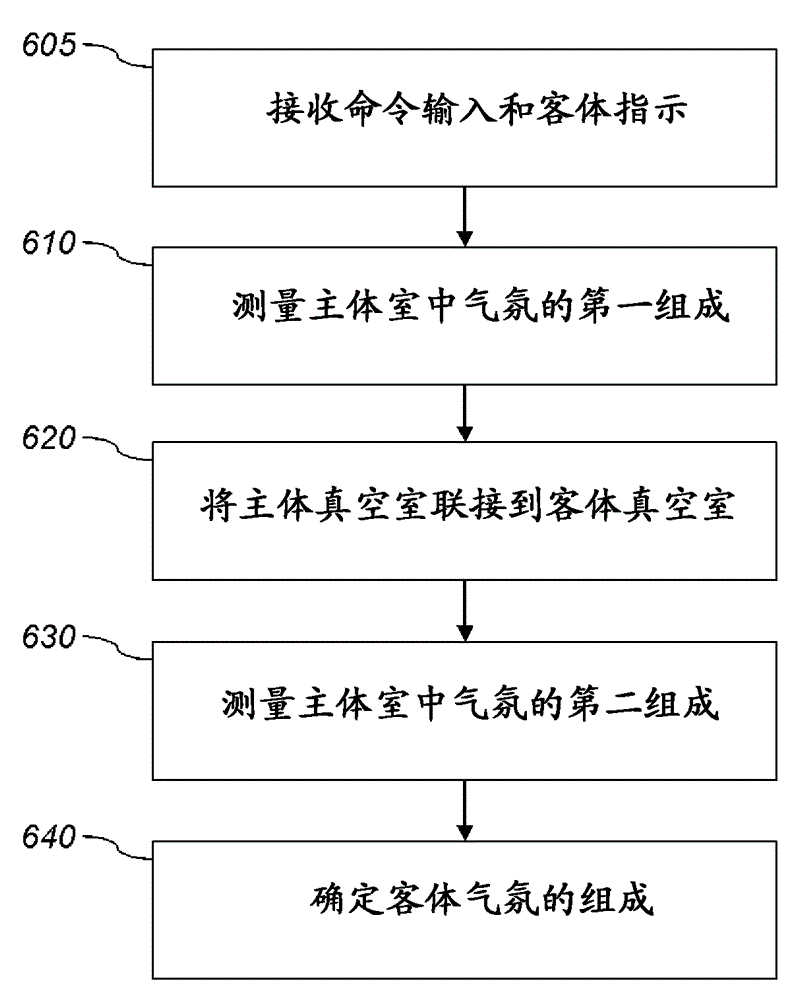

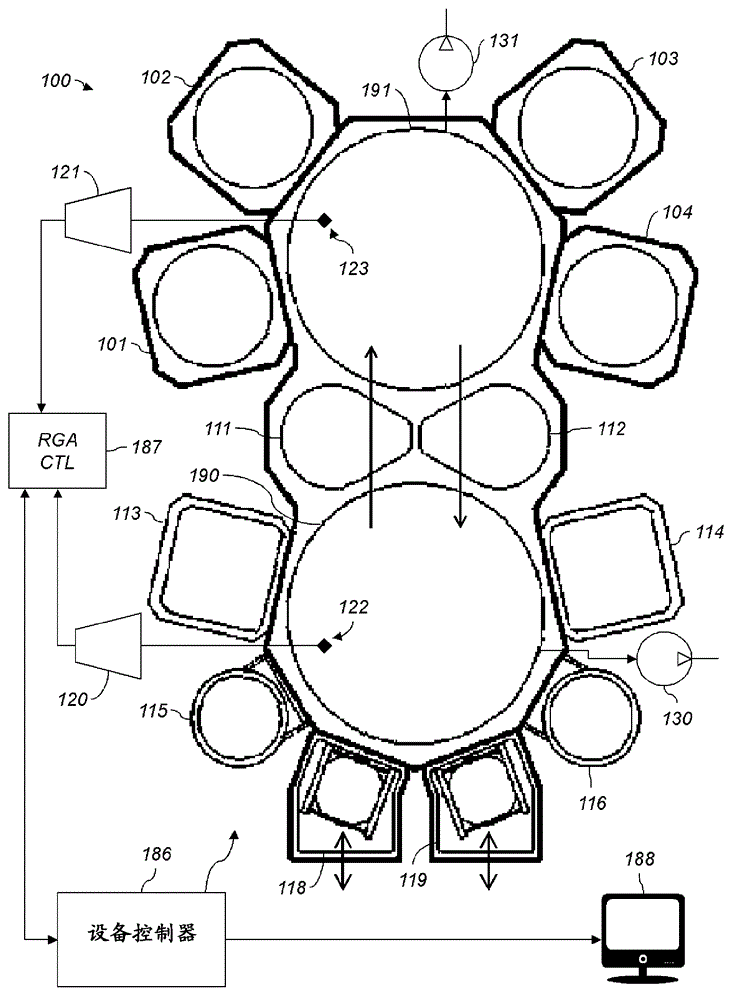

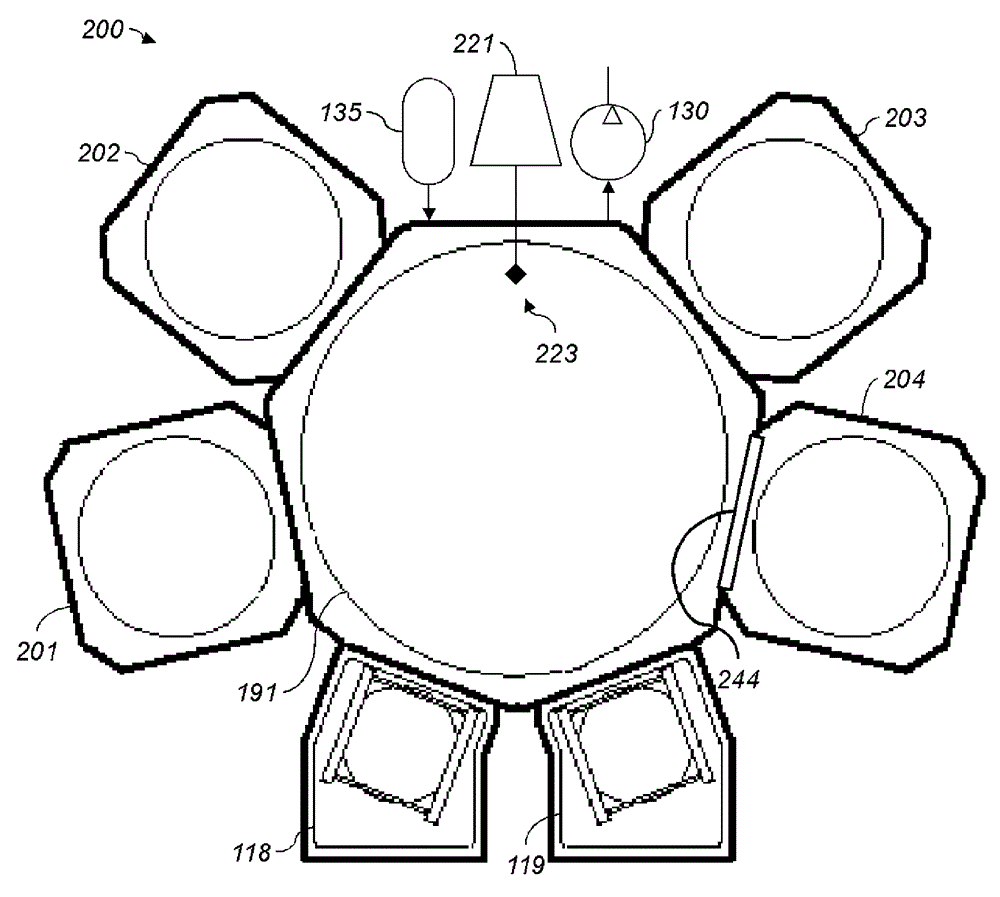

Vacuum chamber measurement using residual gas analyzer

ActiveCN103855048ALow costReduce complexitySemiconductor/solid-state device testing/measurementGas analyser construction detailsResidual gas analyzerEngineering

The present invention relates to vacuum chamber measurement using a residual gas analyzer. A method of measuring an atmosphere in a guest vacuum chamber of a vacuum tool includes measuring a first composition of the atmosphere in the host vacuum chamber using a residual gas analyzer (RGA). The host and guest vacuum chambers are not coupled during the measuring of the first composition. The host vacuum chamber is coupled to the guest vacuum chamber, so the atmospheres in each can mix in the host vacuum chamber. A second composition of the atmosphere in the host vacuum chamber is measured using the RGA after the chambers are coupled. Using a processor, a composition of the guest atmosphere is automatically determined using the measured first and second compositions. A vacuum tool can include the host and guest chambers, the valve, the RGA, and a processor configured to control the valve to carry out this or other methods.

Owner:INFICON INC

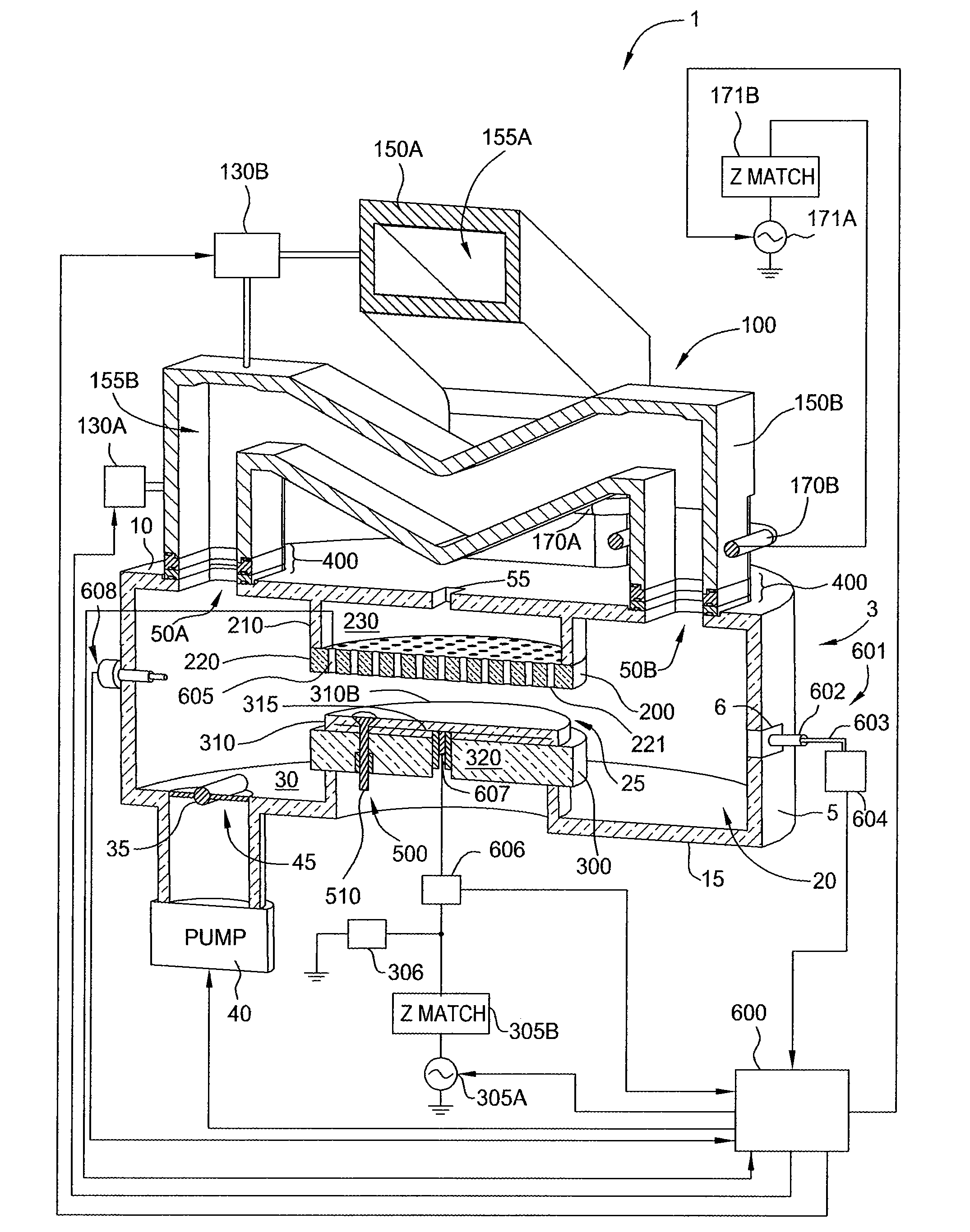

Dosimetry using optical emission spectroscopy/residual gas analyzer in conjunction with ion current

InactiveUS20090195777A1Radiation pyrometryLiquid surface applicatorsResidual gas analyzerDosimetry radiation

The present invention generally provides methods and apparatus for controlling ion dosage in real time during plasma processes. In one embodiment, ion dosages may be controlled using in-situ measurement of the plasma from a mass distribution sensor combined with in-situ measurement from an RF probe.

Owner:APPLIED MATERIALS INC

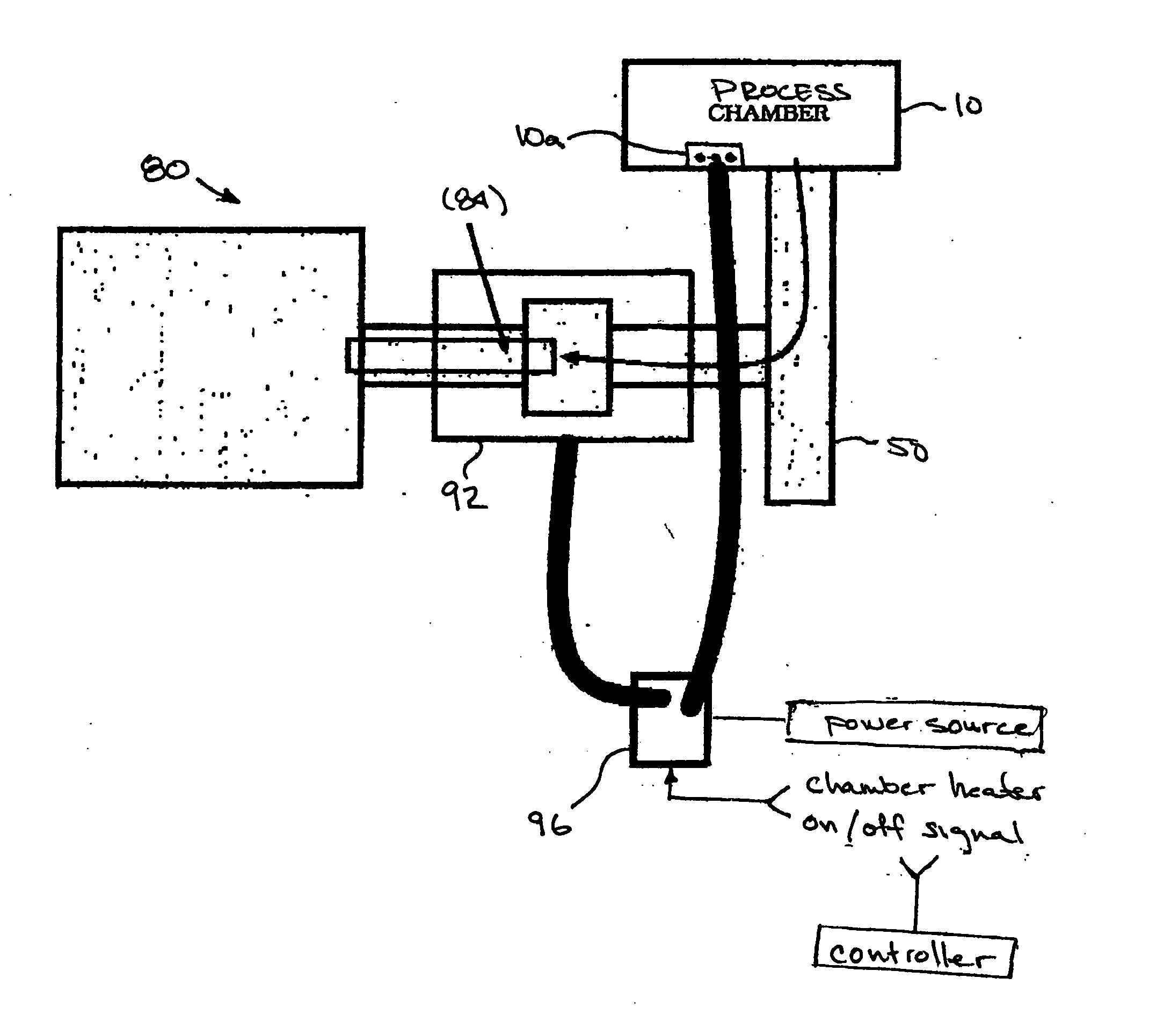

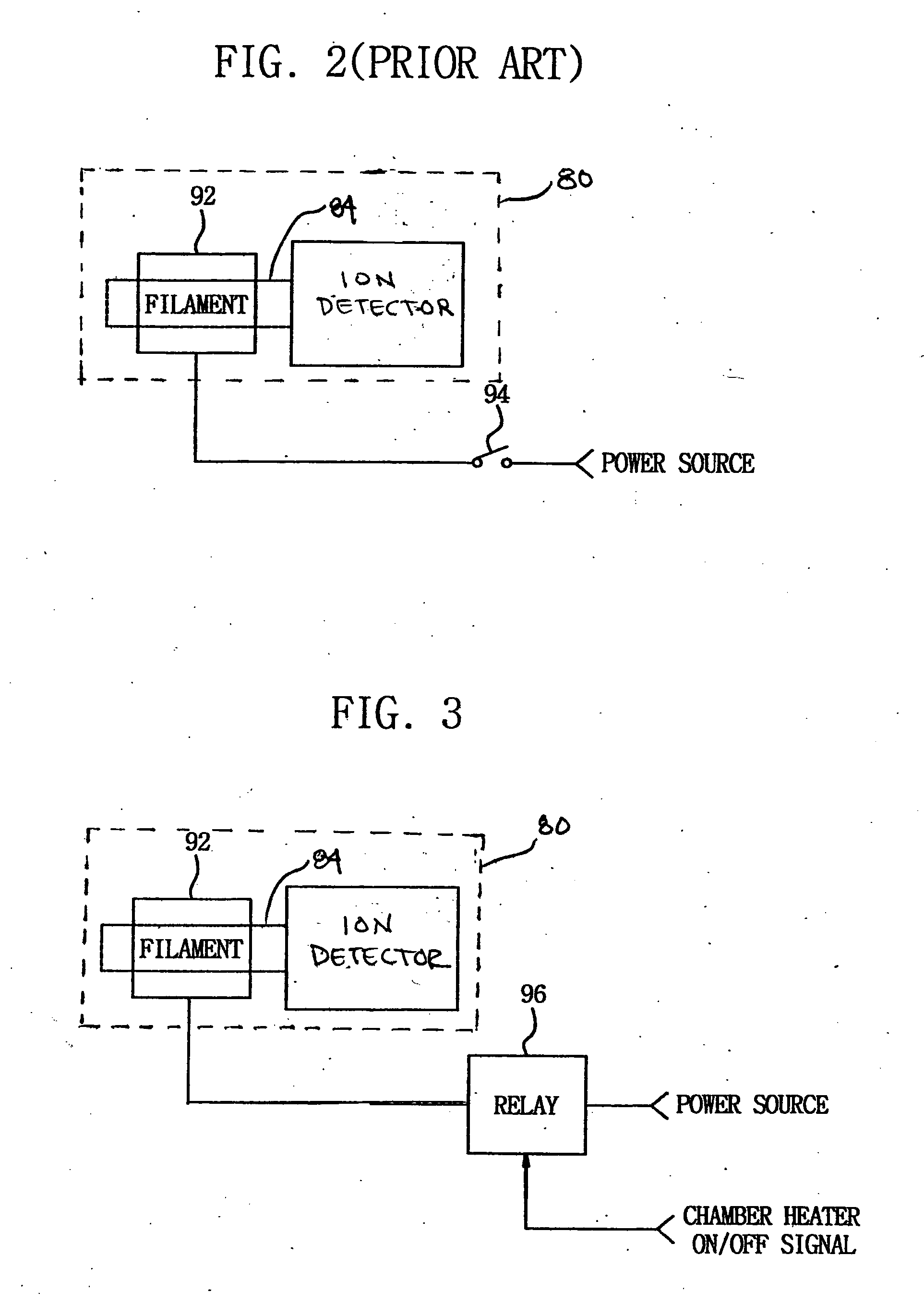

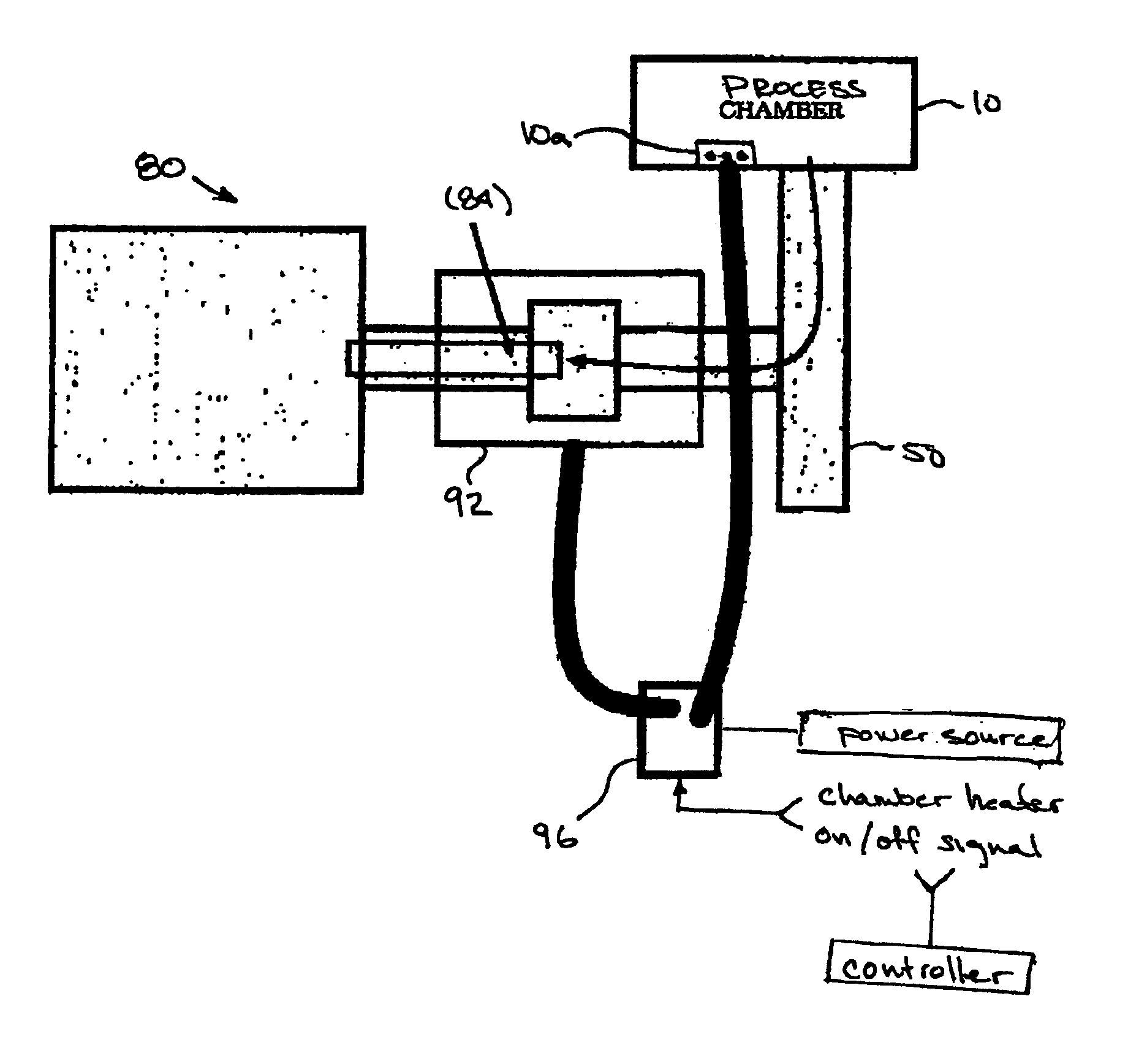

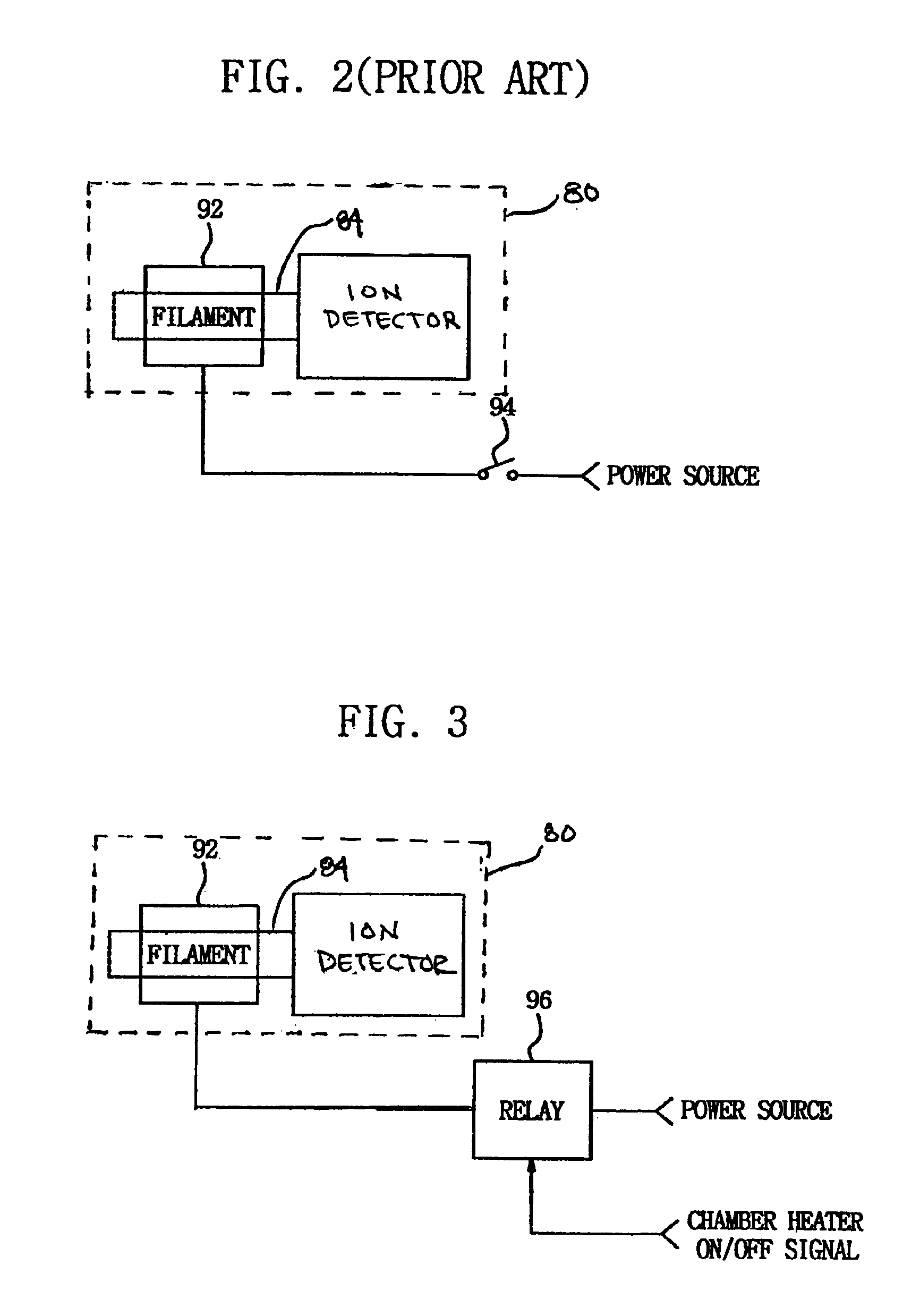

Residual gas analyzer of semiconductor device manufacturing equipment

InactiveUS20050017168A1Accurate detectionAvoid defectsDetection of fluid at leakage pointSamples introduction/extractionResidual gas analyzerProcess engineering

In semiconductor manufacturing equipment having a residual gas analyzing apparatus for analyzing the composition of residual gas in a process chamber of the equipment, a heater of the residual gas analyzer is interlocked with a heater of the process chamber. The residual gas analyzer includes an ion detector, and the heater of the residual gas analyzer has a filament and a heating jacket surrounding a portion of the ion detector. A relay connects a power source of the heater for the process chamber to the heater of the residual gas analyzer. Power is supplied to and cut off from the heater of the residual gas analyzer in response to heater on / off signals used for controlling the operation for the heater for the process chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

Residual gas analyzer of semiconductor device manufacturing equipment

InactiveUS6881952B2Accurate detectionDefects in the products being processed in the process chamber can be preventedDetection of fluid at leakage pointSamples introduction/extractionResidual gas analyzerProcess engineering

In semiconductor manufacturing equipment having a residual gas analyzing apparatus for analyzing the composition of residual gas in a process chamber of the equipment a heater of the residual gas analyzer is interlocked with a heater of the process chamber. The residual gas analyzer includes an ion detector, and the heater of the residual gas analyzer has a filament and a heating jacket surrounding a portion of the ion detector. A relay connects a power source of the heater for the process chamber to the heater of the residual gas analyzer. Power is supplied to and cut off from the heater of the residual gas analyzer in response to heater on / off signals used for controlling the operation for the heater for the process chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

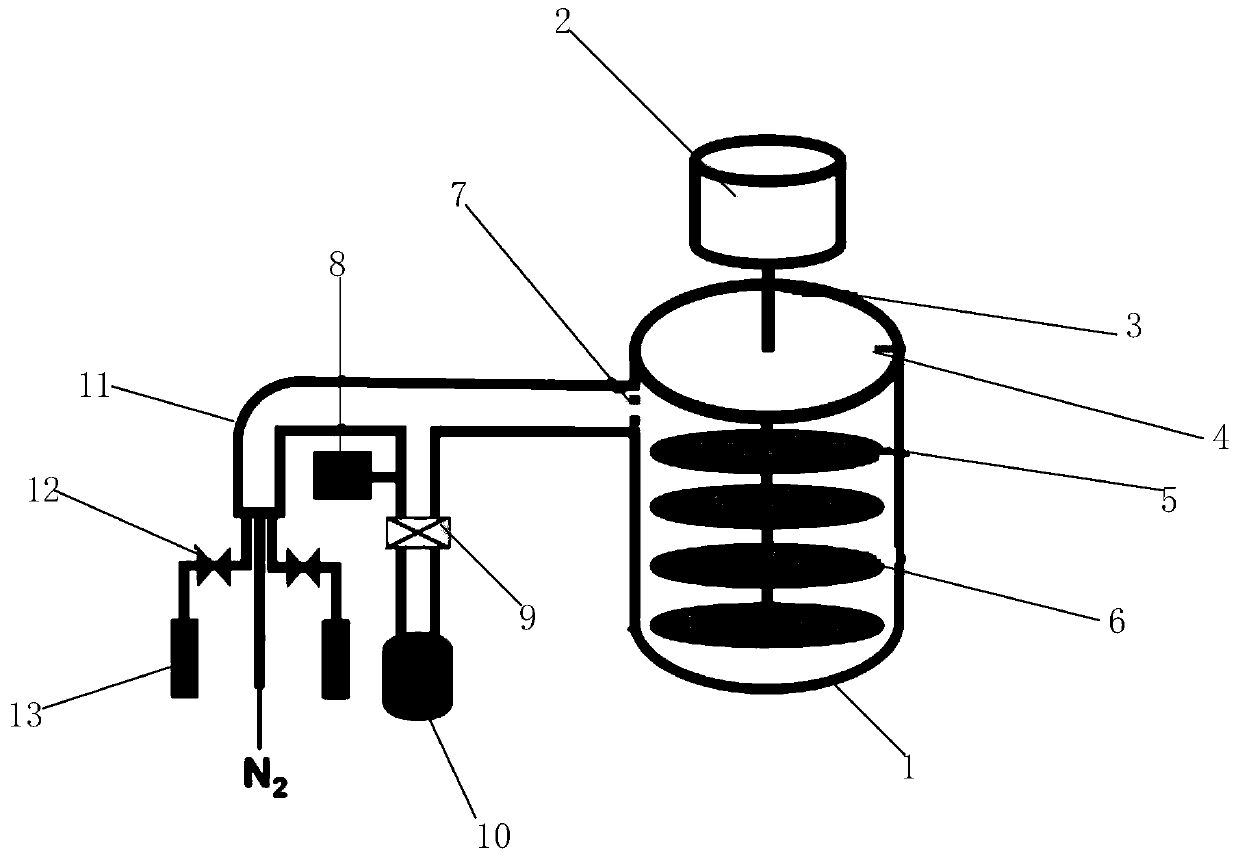

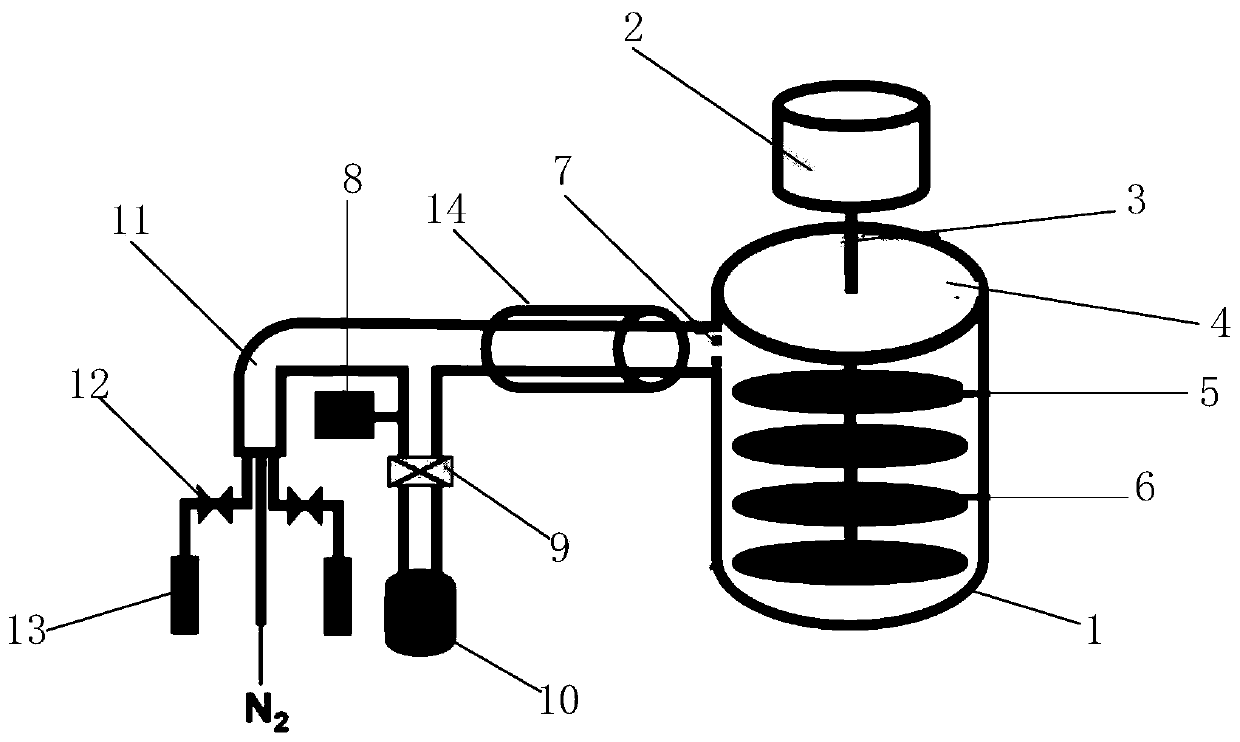

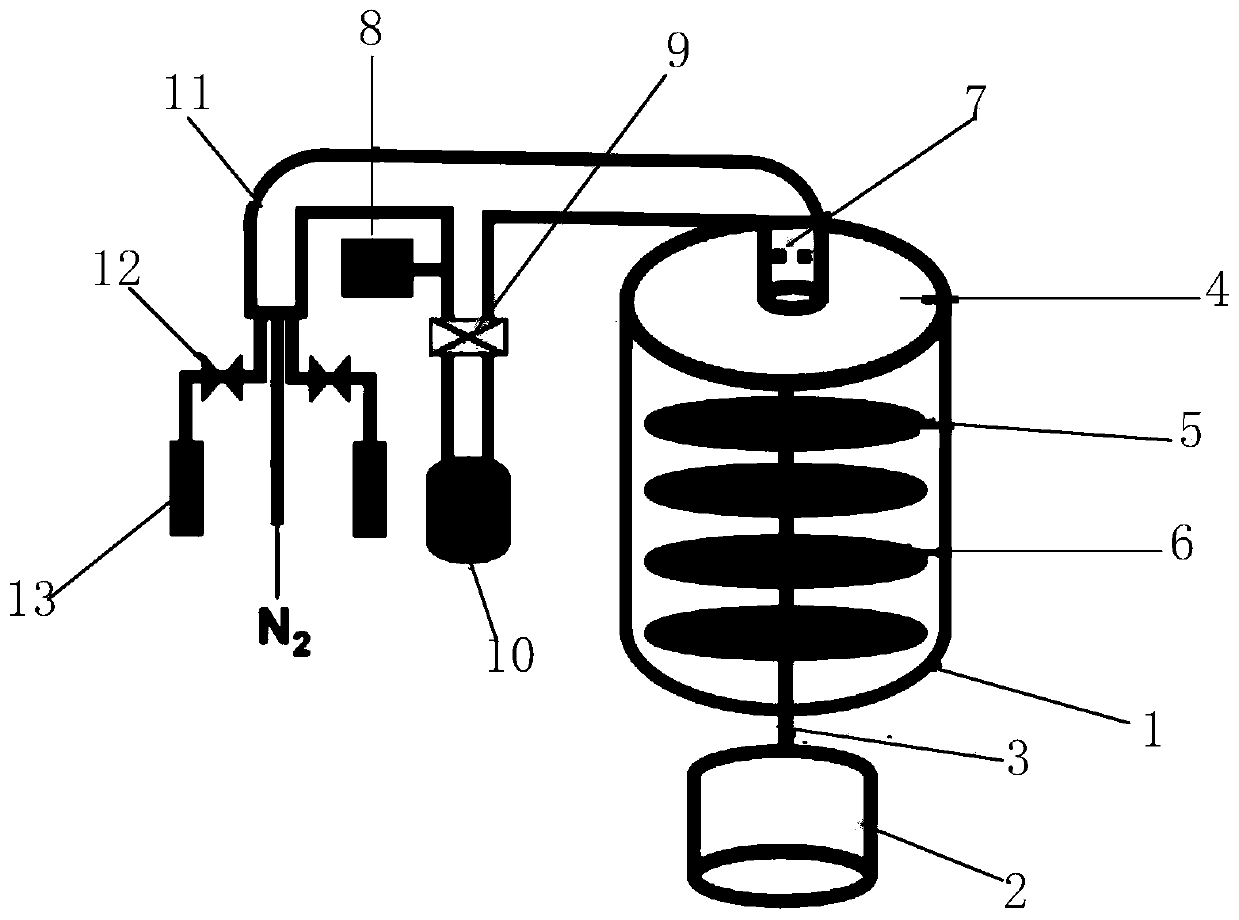

Powder atomic layer deposition device and deposition method and application for same

ActiveCN110055513ATake full advantage of diffusion propertiesImprove utilization efficiencyChemical vapor deposition coatingResidual gas analyzerClamp connection

The invention belongs to the field of atomic layer deposition and discloses a powder atomic layer deposition device and a deposition method and application for the same. A heatable main cavity of thepowder atomic layer deposition device is fixed with a mechanical transmission shaft by a bearing, a powder growth bed is in clamped connection to the mechanical transmission shaft, a powder sample ispaved on the powder growth bed, and a vibrating rotation device is disposed on the upper end of the mechanical transmission shaft; a heatable gas pipeline is fixed on the left end of the heatable maincavity by a flange, and a powder filter is disposed at a joint between the heatable gas pipeline and the heatable main cavity; and the heatable gas pipeline is connected to an electromagnetic valve by a clamping sleeve, the electromagnetic valve is connected to a vacuum pump by the heatable gas pipeline, and a residual gas analyzer is disposed on the upper end of the electromagnetic valve. The device disclosed by the invention has the beneficial effects that an inlet source and air suction are configured on the same end; thin film growth efficiency is high, growth of different thin film materials is realized, and stability of the grown thin film materials is high; and overall device manufacture is simple, and utilization efficiency of a precursor source is increased.

Owner:NANKAI UNIV

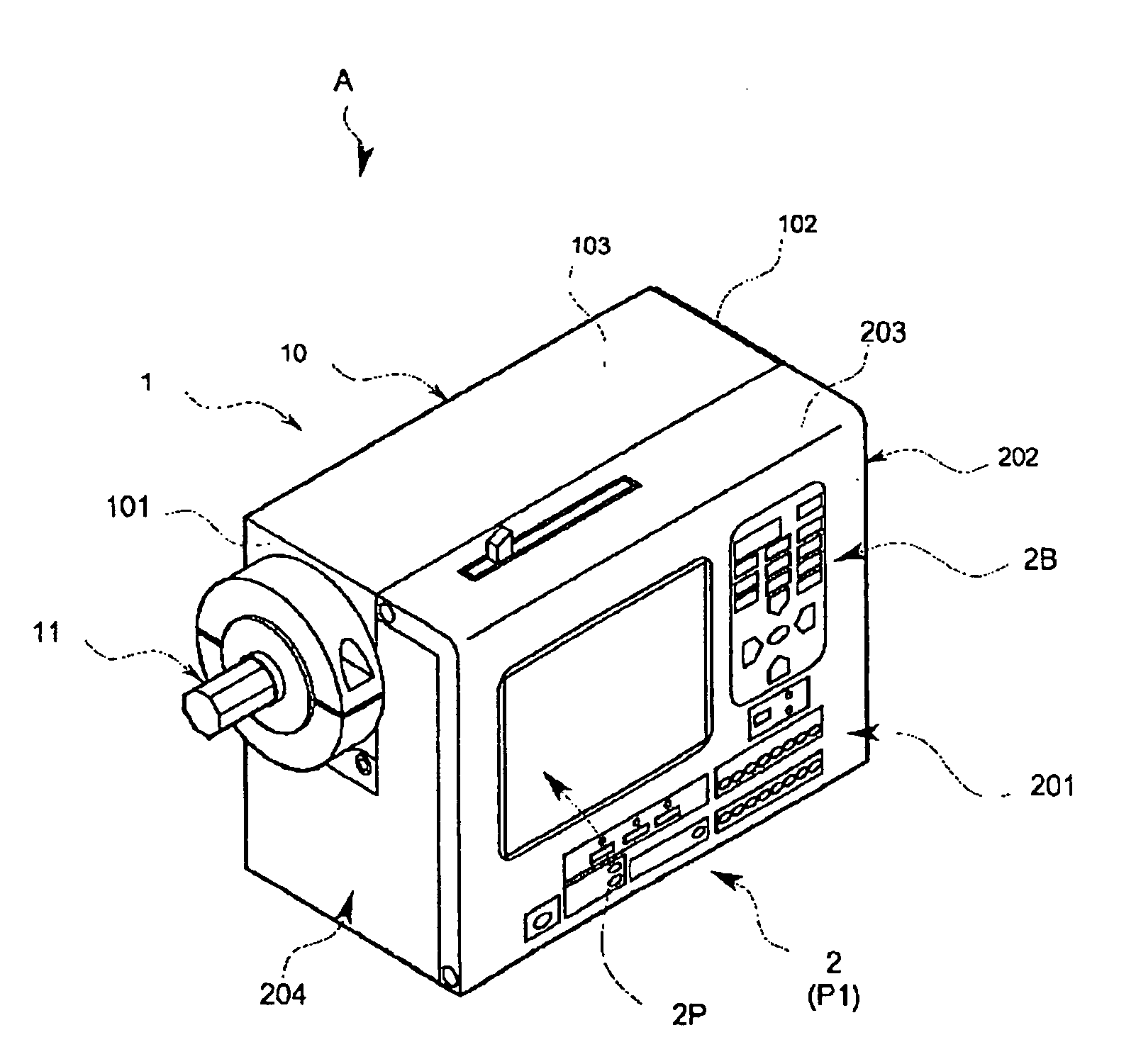

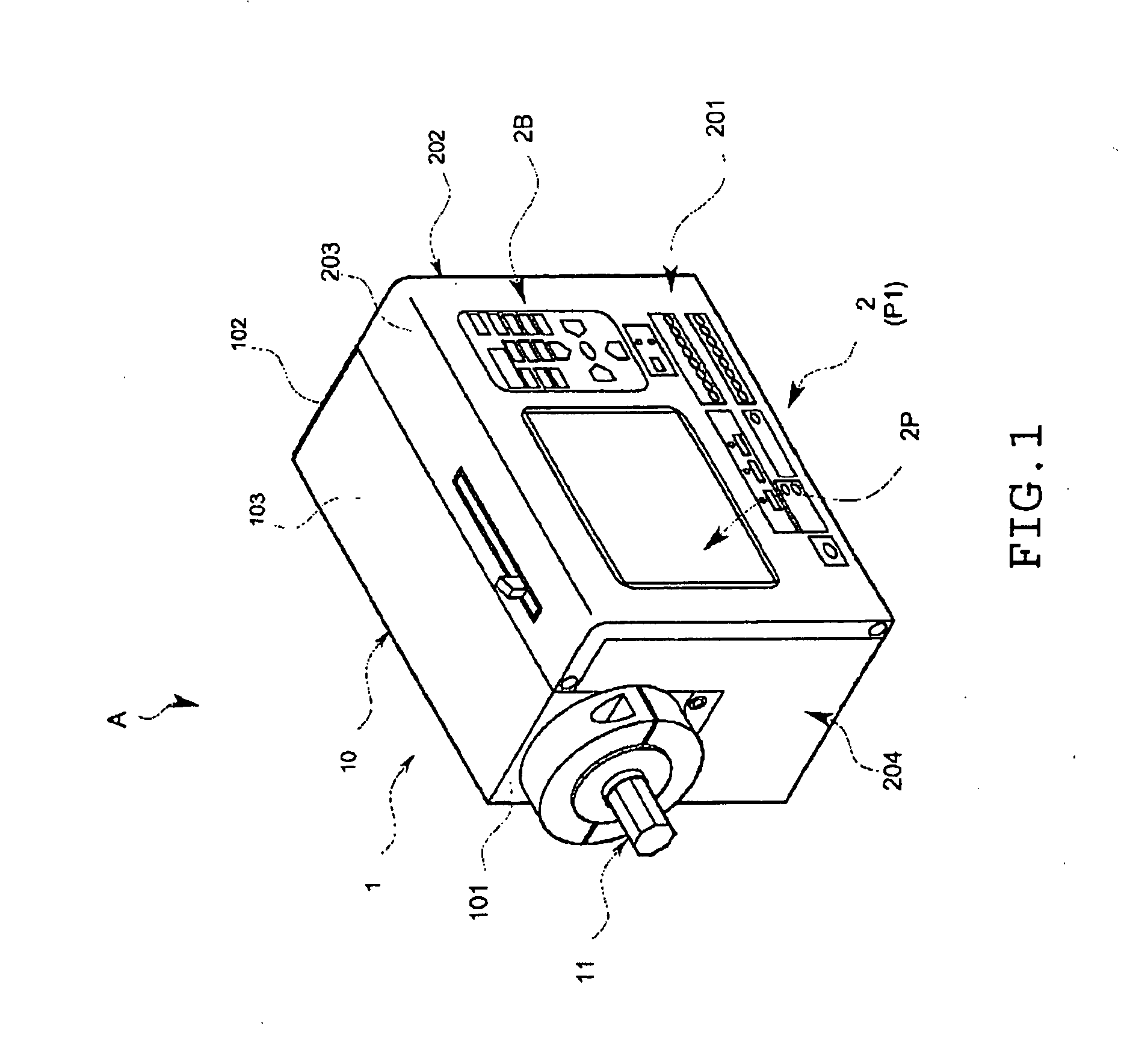

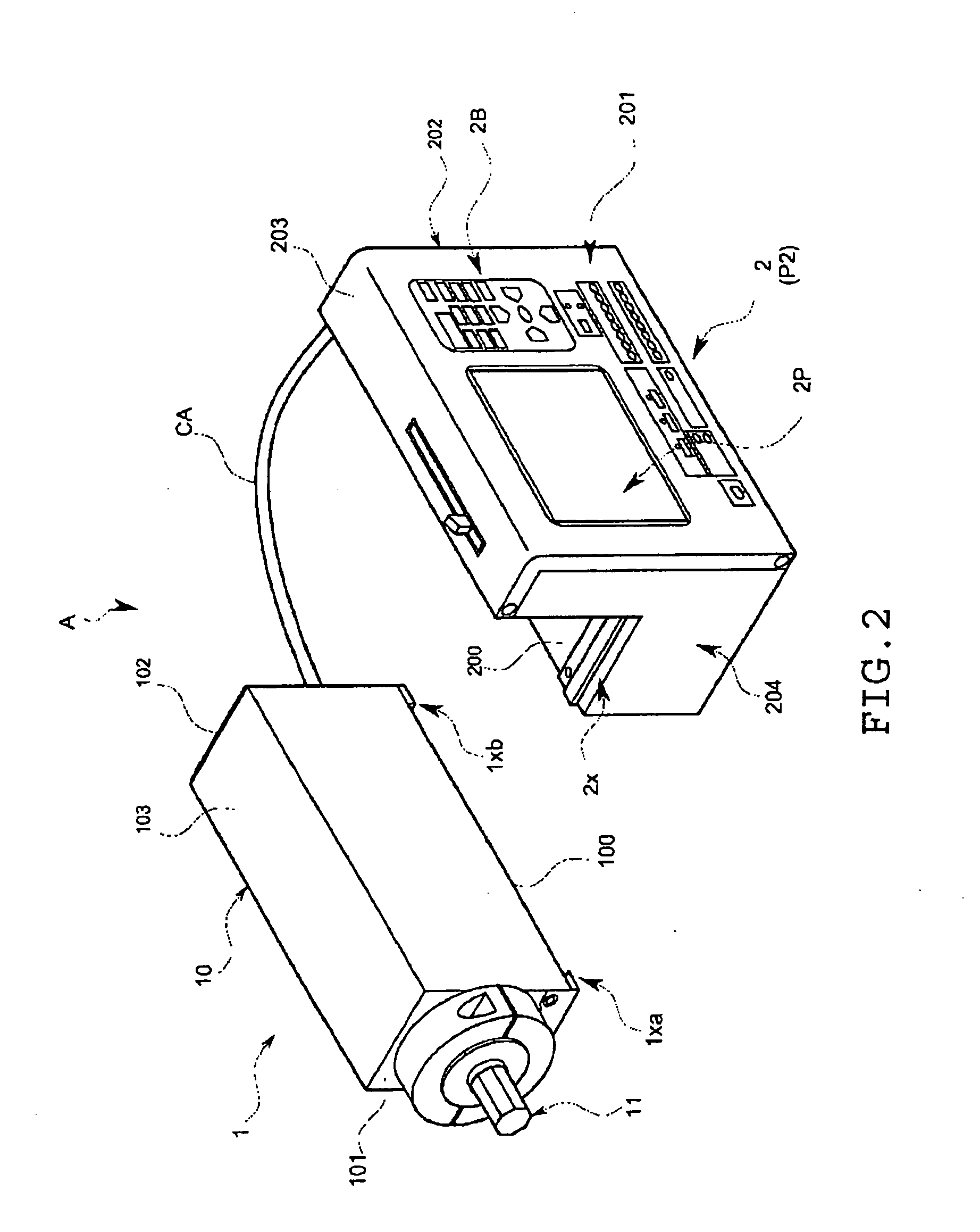

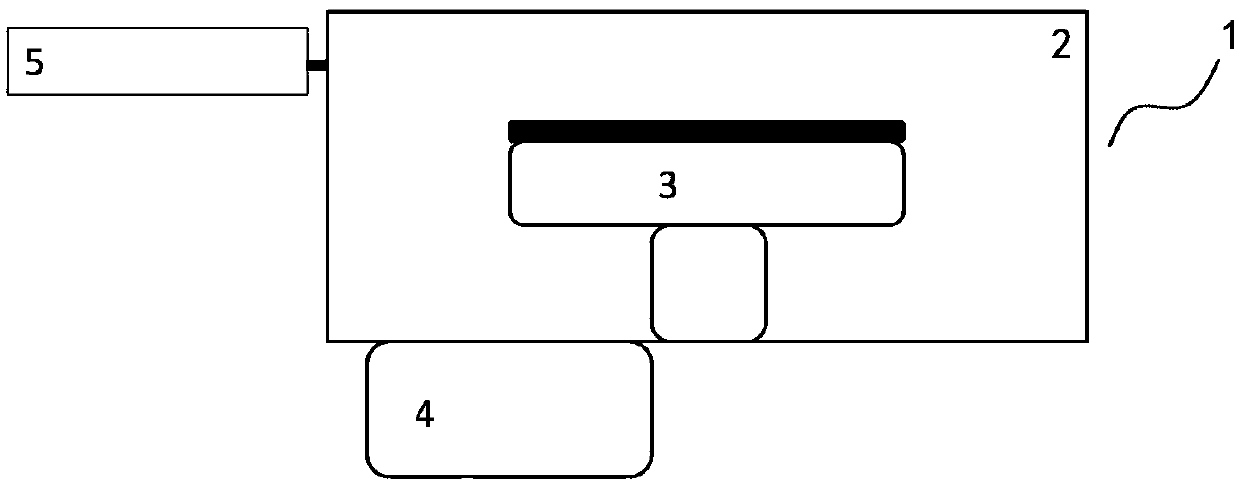

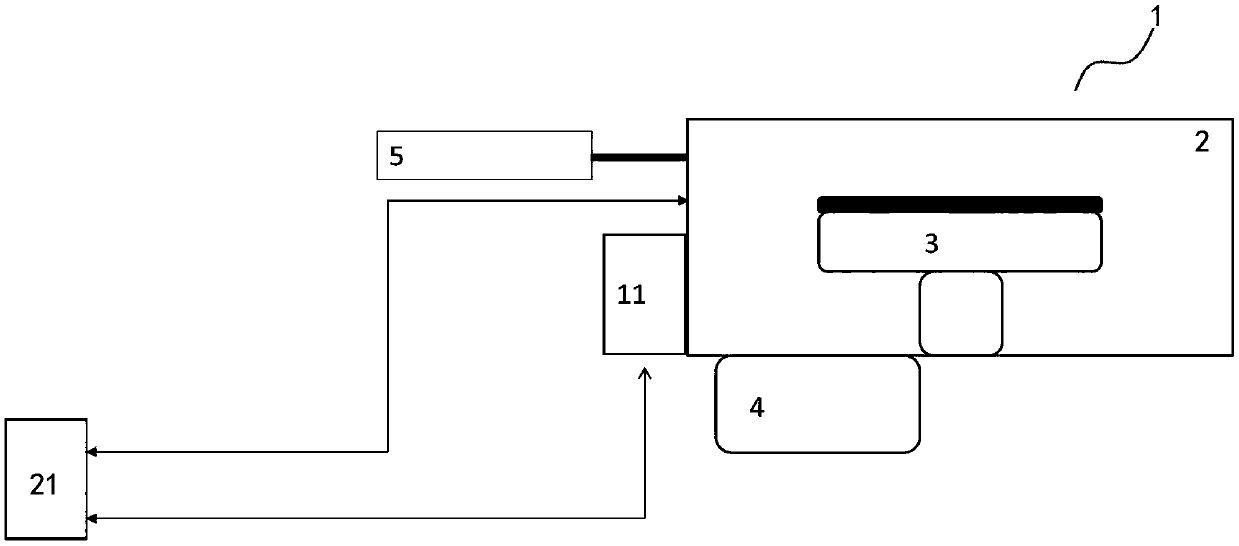

Residual gas analyzer

InactiveUS20100134116A1Easy to handleMaterial analysis by electric/magnetic meansMass spectrometersResidual gas analyzerGas analysis

Provided is an excellent residual gas analyzer, which can perform measurement by being suitably arranged even in small areas, such as those in semiconductor equipments, and can perform measurement to display of measurement results without an external personal computer. The analyzer is provided with a sensor unit (1) having a sensor section (11) for detecting a residual gas; an operating section for receiving operation for controlling the sensor section (11); a residual gas analysis processing section for processing analysis of the residual gas based on the output from the sensor section (11); and an analysis processing result screen display section for displaying on a screen the analysis processing results obtained from the residual gas analysis processing section. The analyzer is also provided with a device main body (2) which can be in a mounted status (P1) wherein the sensor unit (1) is mounted or in a removed status (P2) wherein the sensor unit is removed.

Owner:HORIBA STEC CO LTD

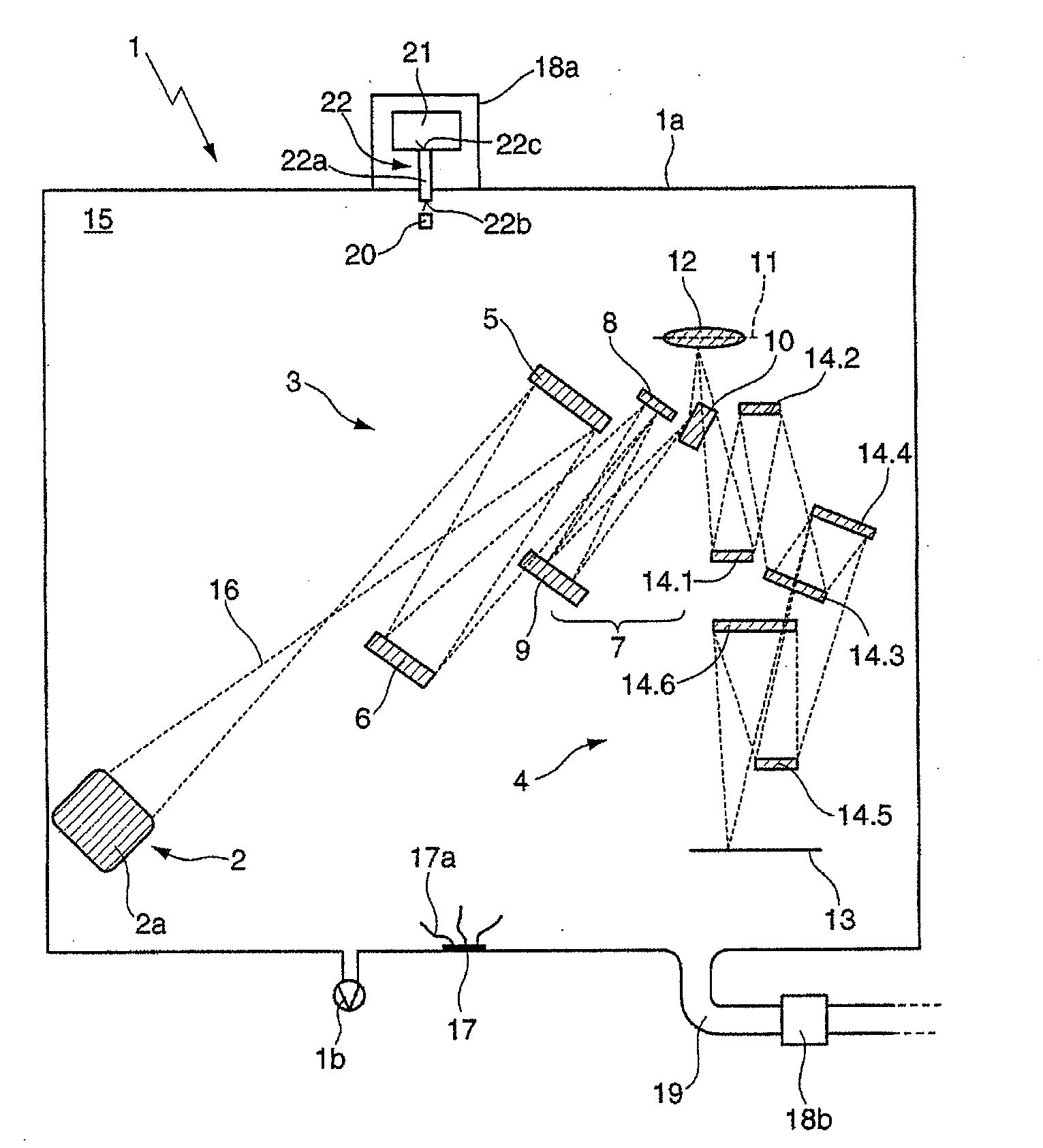

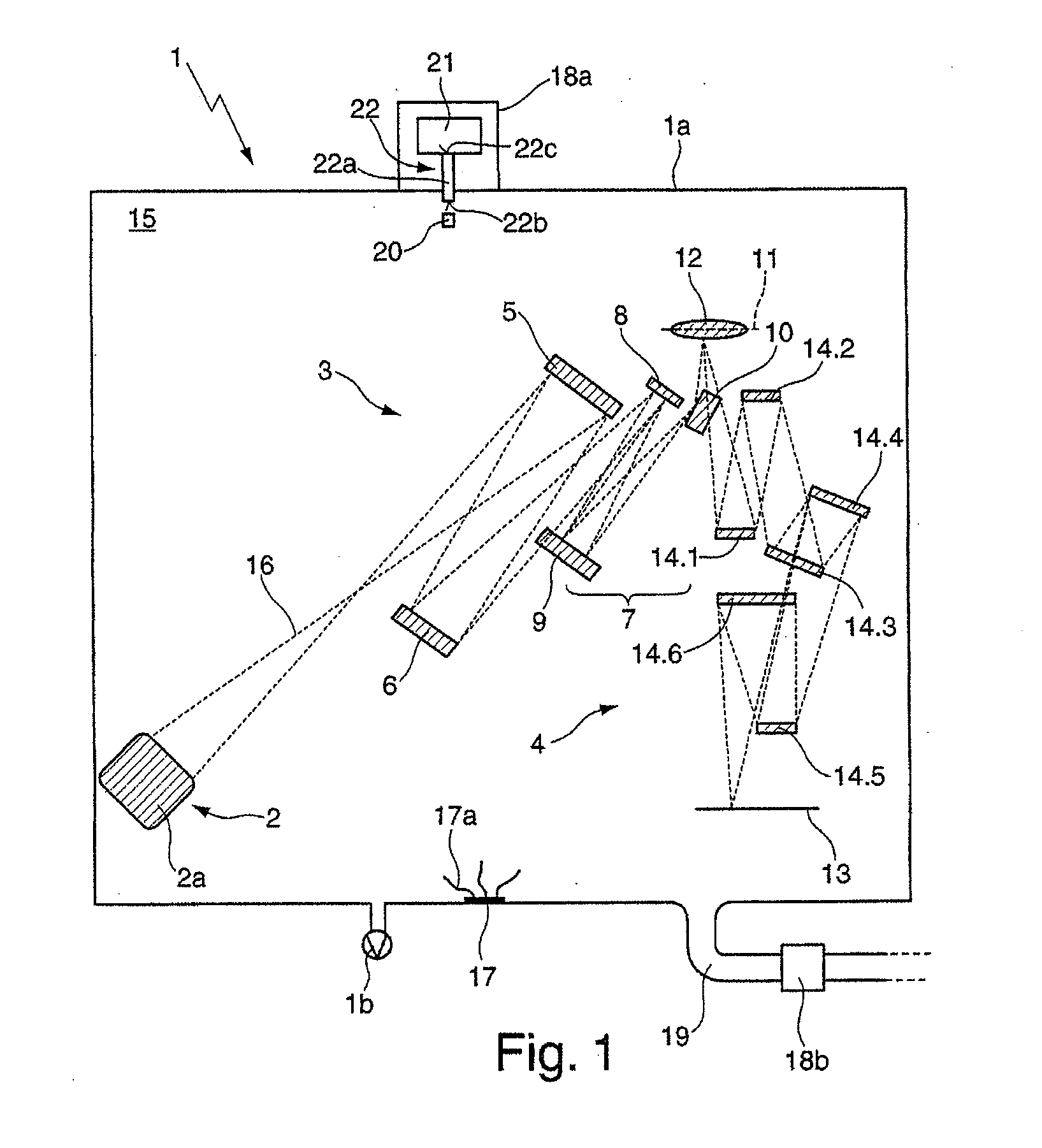

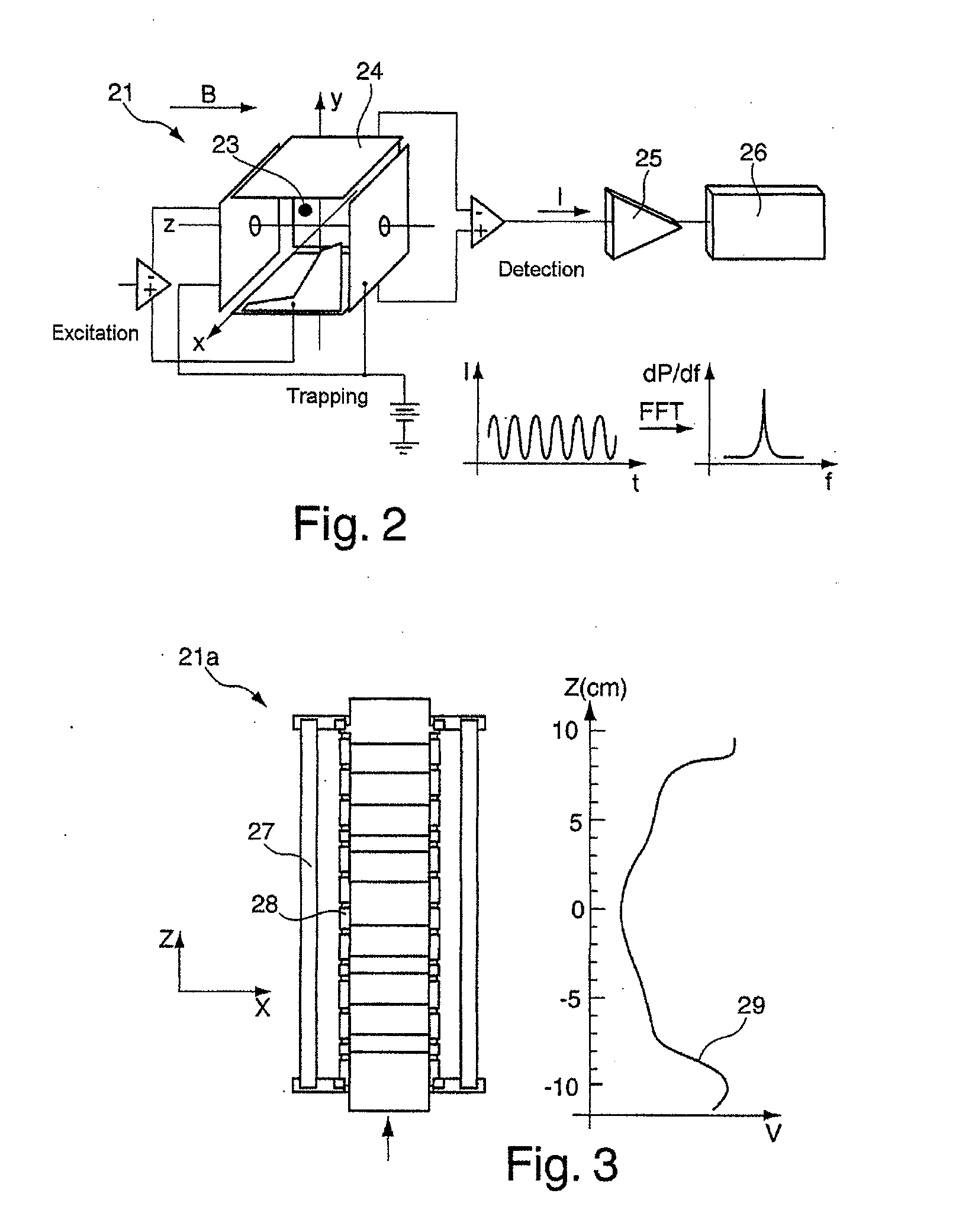

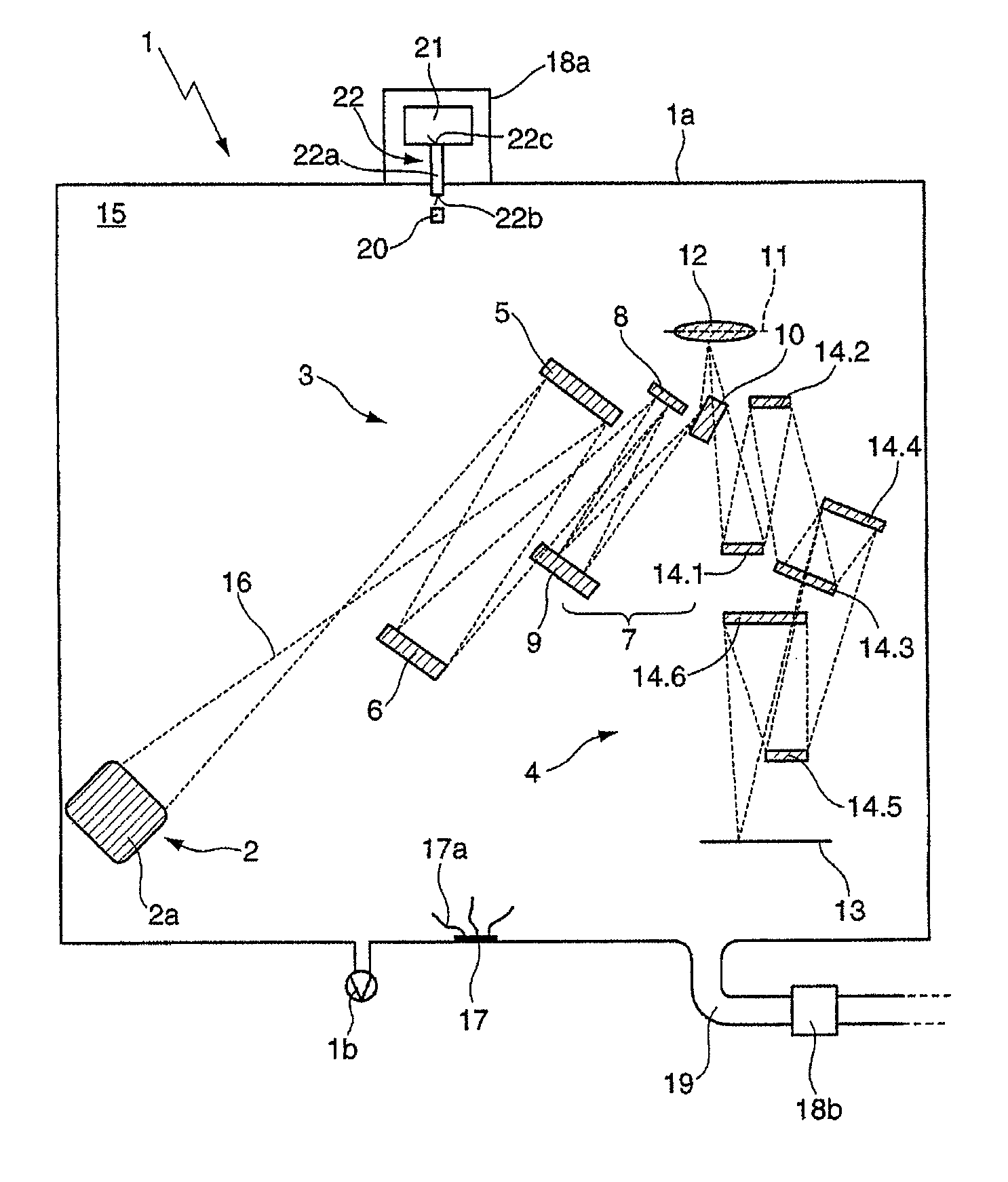

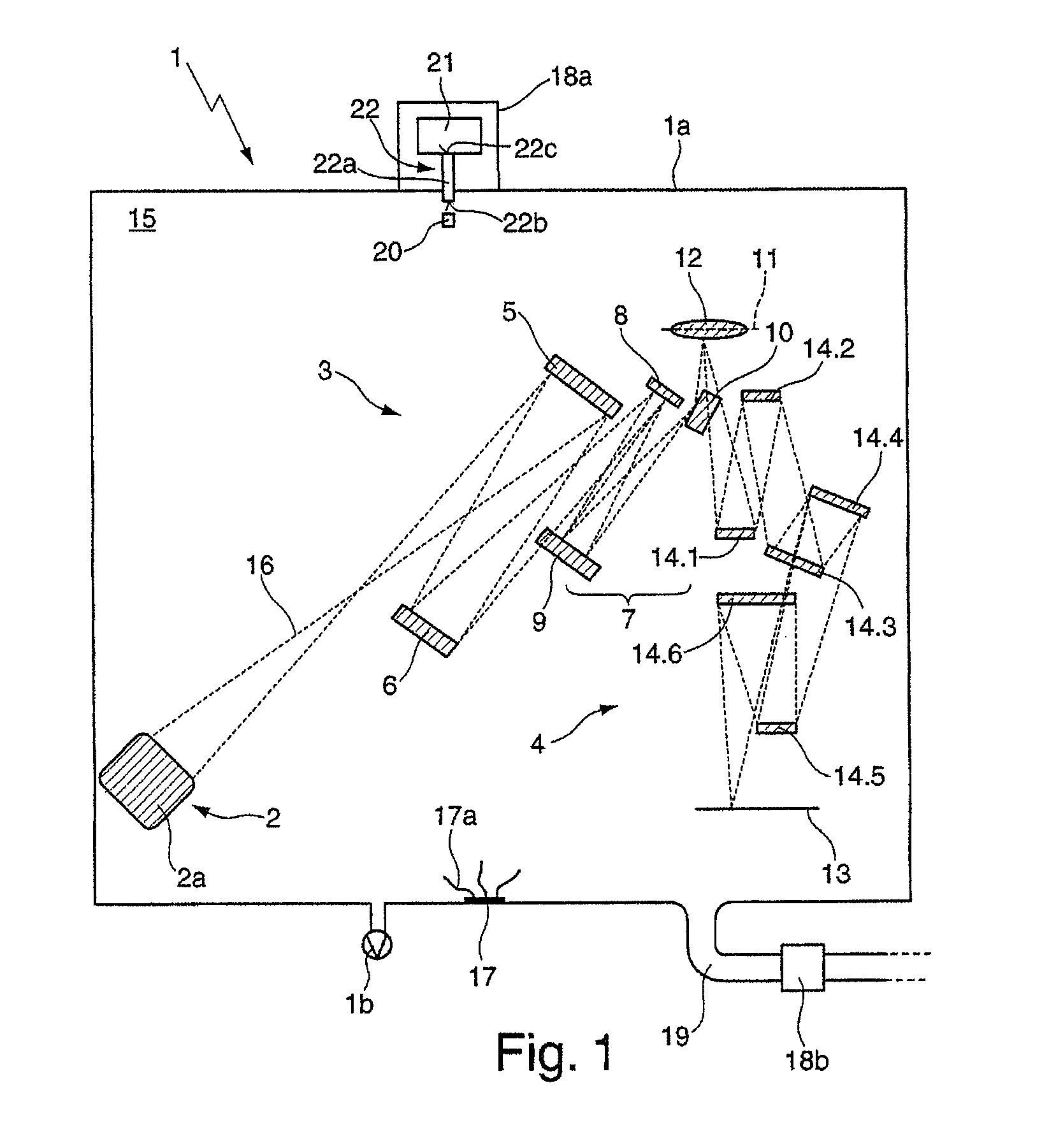

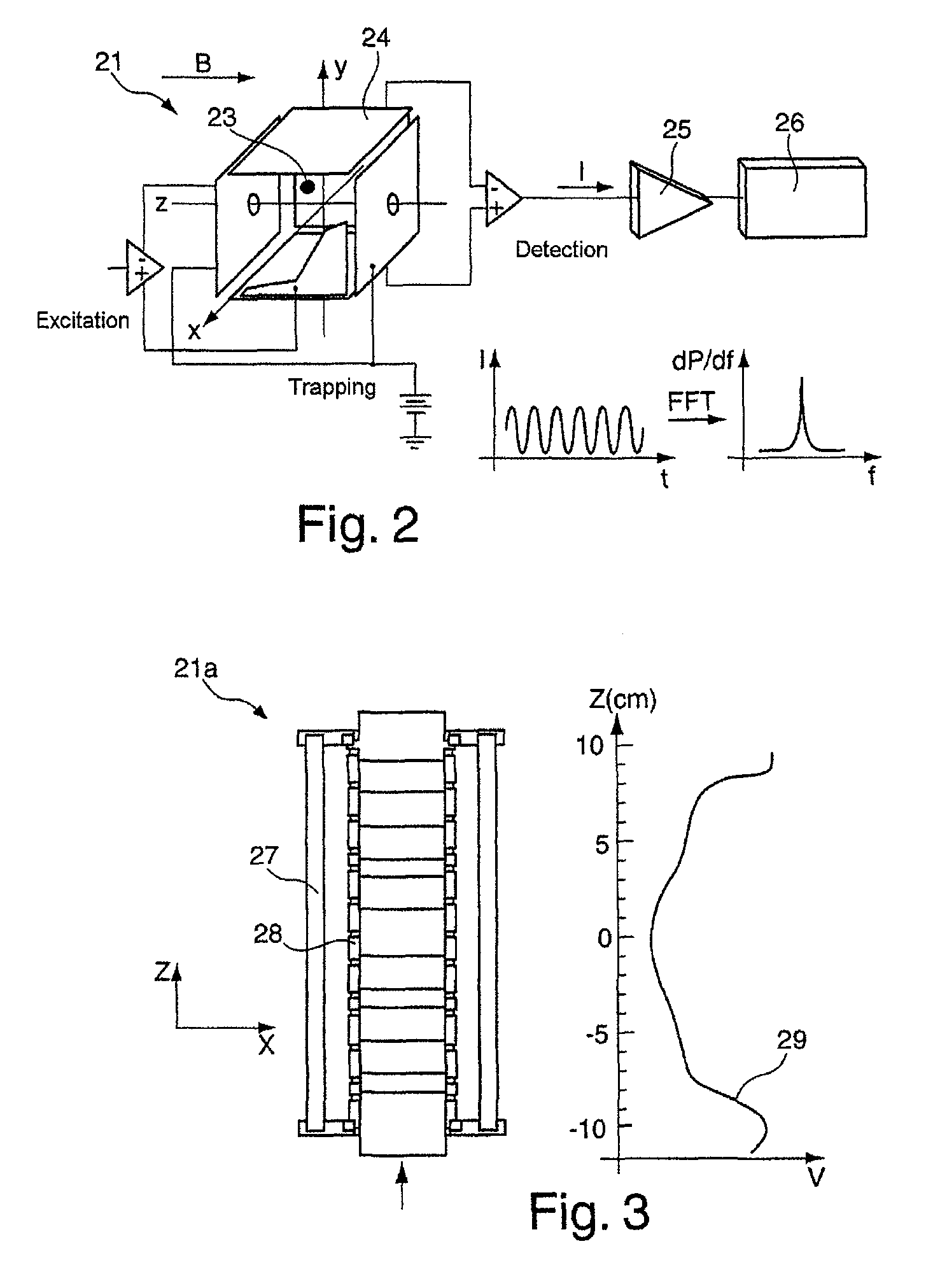

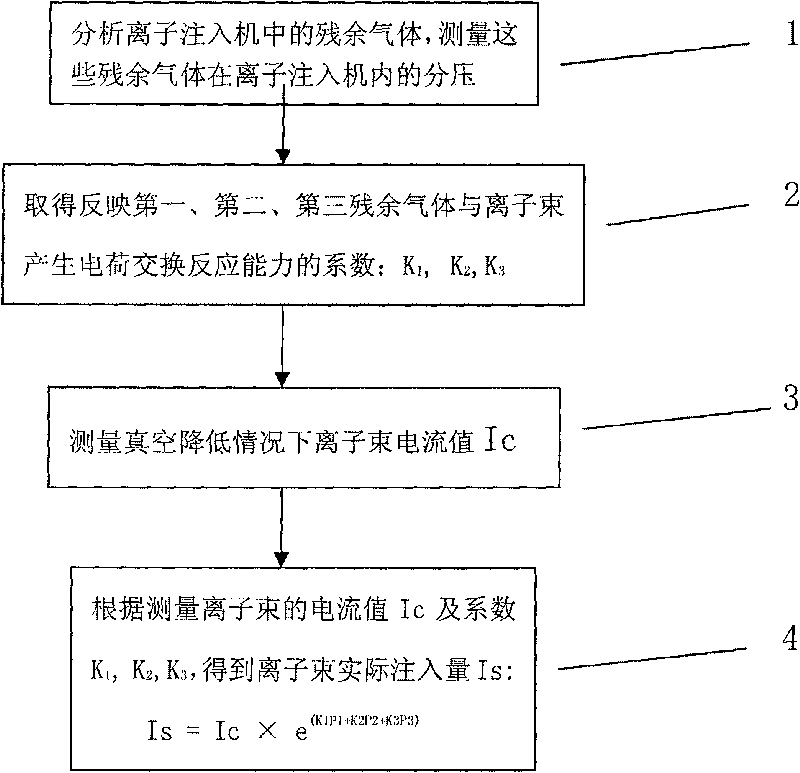

Detection of contaminating substances in an EUV lithography apparatus

ActiveUS20110211179A1Avoid large quantitiesHigh detection sensitivityParticle separator tubesPhotomechanical exposure apparatusResidual gas analyzerGas analysis

An EUV (extreme ultraviolet) lithography apparatus (1) including: a housing (1a) enclosing an interior (15), at least one reflective optical element (5, 6, 8, 9, 10, 14.1 to 14.6) arranged in the interior (15), a vacuum generating unit (1b) generating a residual gas atmosphere in the interior (15), and a residual gas analyzer (18a, 18b) detecting at least one contaminating substance (17a) in the residual gas atmosphere. The residual gas analyzer (18a) has a storage device (21) having an ion trap for storing the contaminating substance (17a). Additionally, a method for detecting at least one contaminating substance by residual gas analysis of a residual gas atmosphere of an EUV lithography apparatus (1) having a housing (1a) having an interior (15), in which at least one reflective optical element (5, 6, 8, 9, 10, 14.1 to 14.6), is arranged, wherein the contaminating substance (17a) is stored in a storage device (21) in order to carry out the residual gas analysis.

Owner:CARL ZEISS SMT GMBH

Dosimetry using optical emission spectroscopy/residual gas analyzer in conjunction with ion current

ActiveUS7531469B2Liquid surface applicatorsMaterial analysis using wave/particle radiationDosimetry radiationOptical emission spectrometry

The present invention generally provides methods and apparatus for controlling ion dosage in real time during plasma processes. In one embodiment, ion dosages may be controlled using in-situ measurement of the plasma from a mass distribution sensor combined with in-situ measurement from an RF probe.

Owner:APPLIED MATERIALS INC

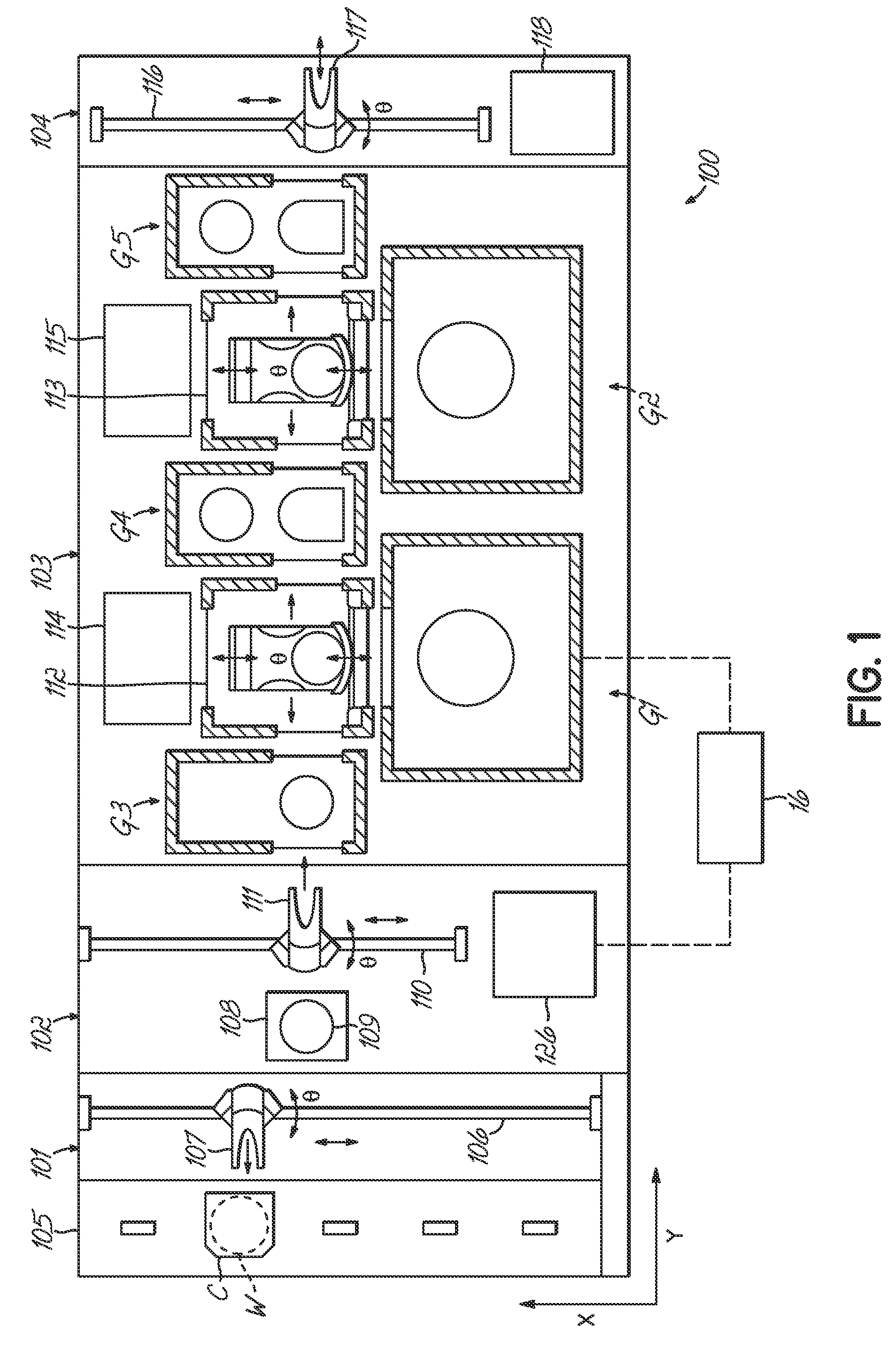

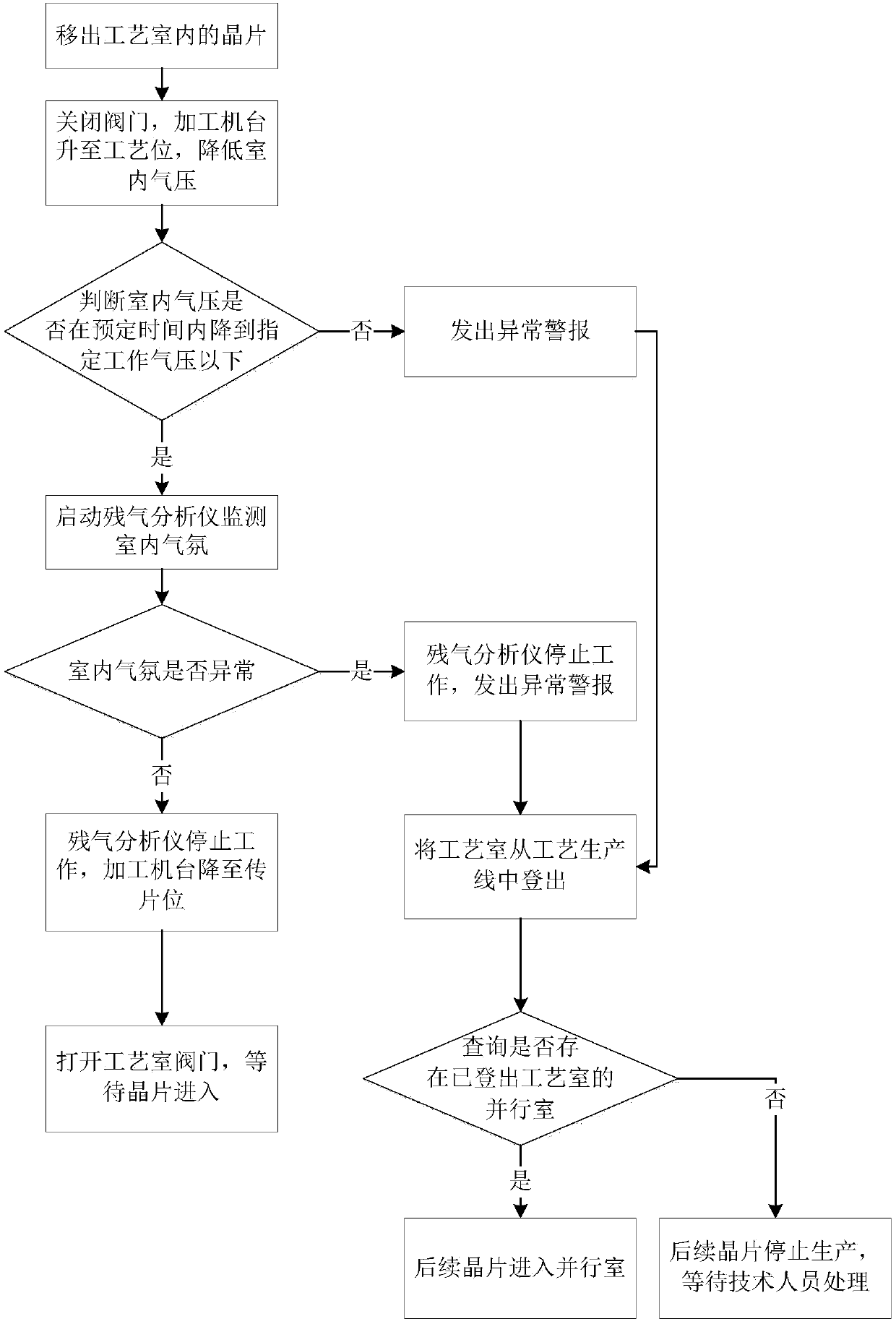

Method for detecting atmosphere of technological chamber, and wafer processing equipment

ActiveCN107591344ADoes not affect workflowLow costSemiconductor/solid-state device manufacturingResidual gas analyzerStopped work

The invention discloses a method for detecting the atmosphere of a technological chamber, and wafer processing equipment. The method comprises the steps: removing a wafer in the technological chamber;closing a valve of the technological chamber, and reducing the indoor air pressure till the indoor air pressure is lower than specific working pressure; starting a residual gas analyzer for detectingthe indoor atmosphere; enabling the residual gas analyzer to stop working if the indoor atmosphere is normal, and opening the valve of the technological chamber to wait for the entry of the wafer; enabling the residual gas analyzer to stop working if the indoor atmosphere is abnormal, and giving an abnormality alarm. The method reduces the processing cost of the wafer.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

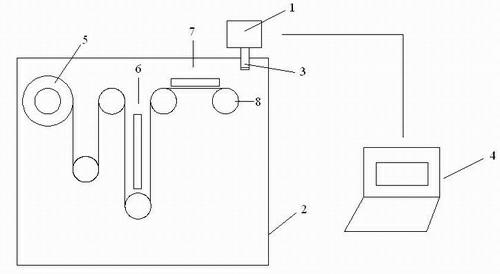

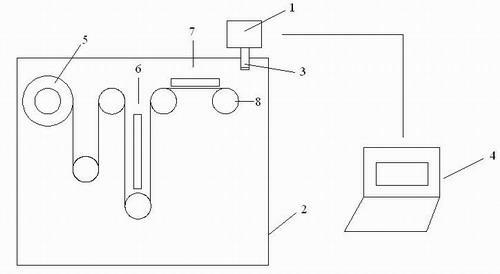

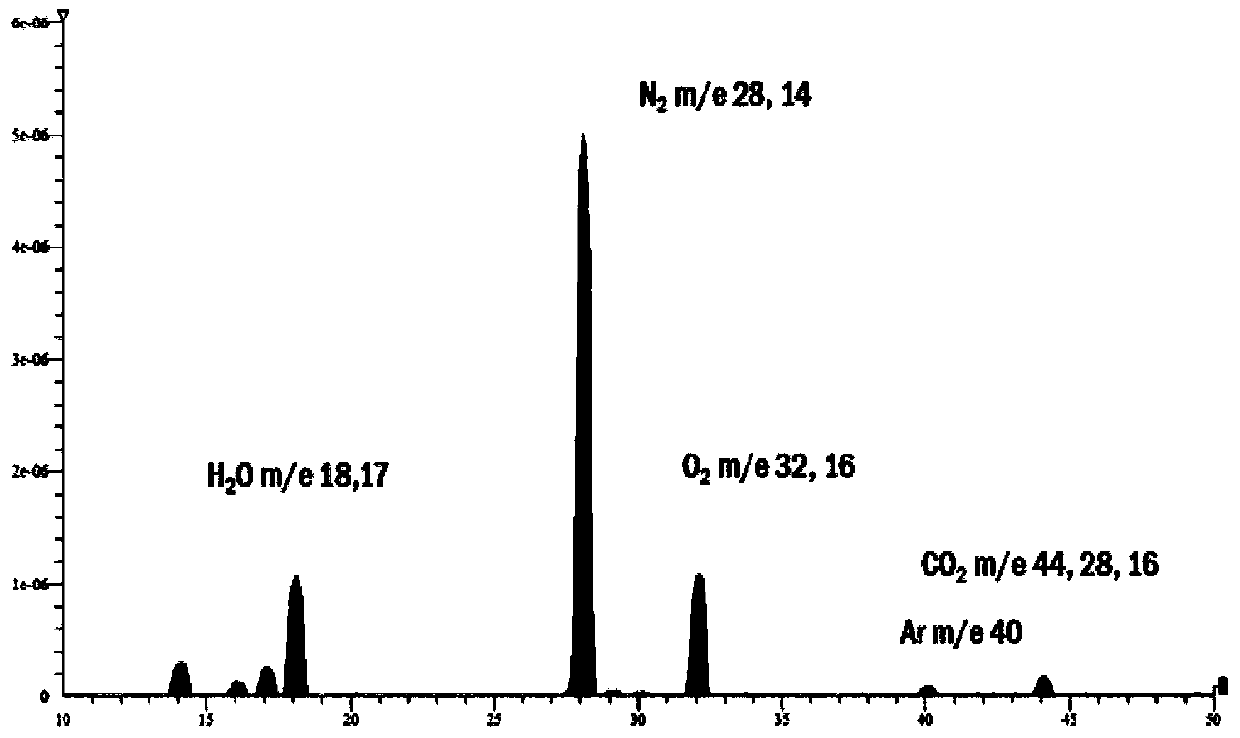

Method for on-line monitoring of residual gas on coiling coating machine

InactiveCN102304695AFast integrationVacuum evaporation coatingSputtering coatingGas analysisResidual gas analyzer

The invention discloses a method for on-line quick monitoring of a residual gas on a coiling coating machine and relates to the fields of vacuum coating and gas analysis. The method comprises the following steps: A) connecting a residual gas analyzer on the coiling coating machine with an inductive probe and a computer; B) inserting the inductive probe in the step A) into an uncoiling vacuum chamber of the coiling coating machine, and timely collecting the gas generated after pretreating a PET (Polyethylene Terephthalate) coiled material which can quickly move after unfolding, wherein the uncoiling vacuum chamber comprises a substrate coiled material, an infrared heater, a plasma etching device and a tension isolation drum; and C) displaying a mass spectrogram of the gas to be detected by passing the gas collected in the step B through the residual gas analyzer, and comparing the mass spectrogram with a standard gas bank, so that the components and content of the gas can be determined.

Owner:NANCHANG O FILM TECH CO LTD

Detection of contaminating substances in an EUV lithography apparatus

ActiveUS8953145B2Avoid large quantitiesHigh detection sensitivityParticle separator tubesPhotomechanical exposure apparatusResidual gas analyzerGas analysis

An EUV (extreme ultraviolet) lithography apparatus (1) including: a housing (1a) enclosing an interior (15), at least one reflective optical element (5, 6, 8, 9, 10, 14.1 to 14.6) arranged in the interior (15), a vacuum generating unit (1b) generating a residual gas atmosphere in the interior (15), and a residual gas analyzer (18a, 18b) detecting at least one contaminating substance (17a) in the residual gas atmosphere. The residual gas analyzer (18a) has a storage device (21) having an ion trap for storing the contaminating substance (17a). Additionally, a method for detecting at least one contaminating substance by residual gas analysis of a residual gas atmosphere of an EUV lithography apparatus (1) having a housing (1a) having an interior (15), in which at least one reflective optical element (5, 6, 8, 9, 10, 14.1 to 14.6), is arranged, wherein the contaminating substance (17a) is stored in a storage device (21) in order to carry out the residual gas analysis.

Owner:CARL ZEISS SMT GMBH

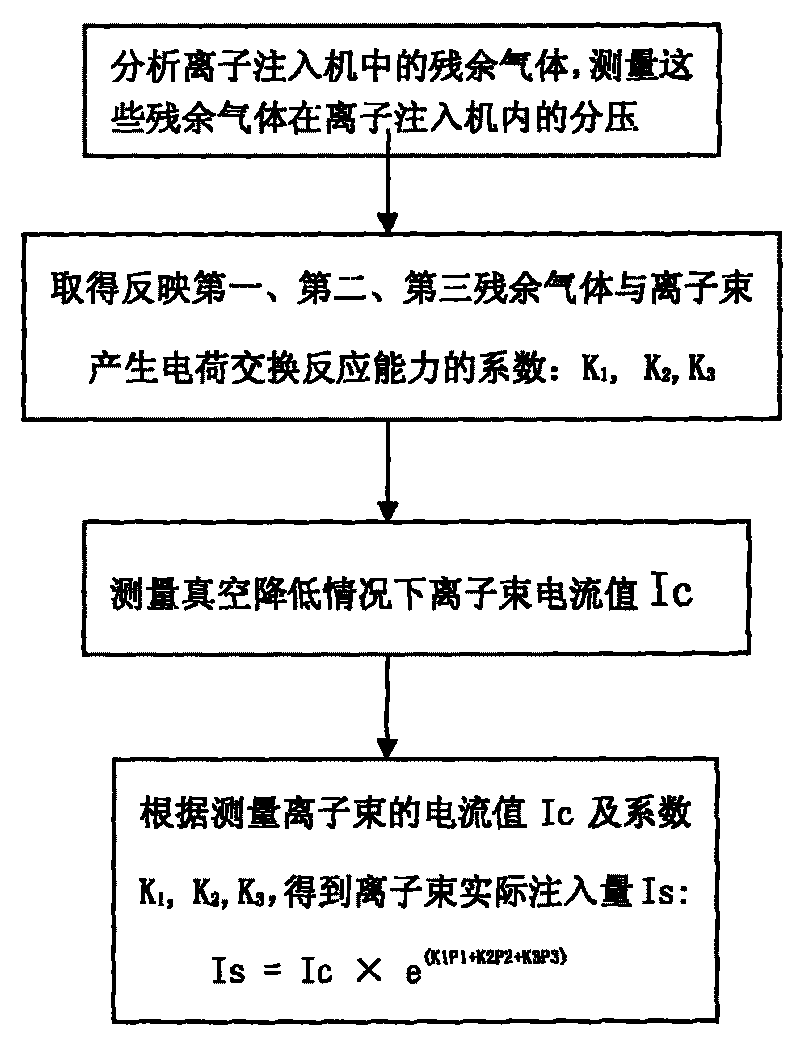

Novel reduced-vacuum implantation dose compensation method for ion implantation apparatus

The invention discloses an ion implantation dose accurate control method for ion implantation apparatus. The novel reduced-vacuum implantation dose compensation method for the ion implantation apparatus comprises the following four steps: (1) analyzing residual gases in the ion implantation apparatus by using a residual gas analyzer to obtain the kinds of the residual gases in the ion implantation apparatus, and measuring the partial pressure value of the residual gases in the ion implantation apparatus; (2) finding out the constant K of each residual gas according to the analyzed kinds of the residual gases, wherein the constant K stands for the capacity of the residual gas to carry out the charge exchange reaction with a ion beam; (3) measuring the current value Ic of the ion beam under the condition of reduced vacuum; (4) and according to the current value Ic of the ion beam, the coefficients K1, K2 and K3, and the following formula, calculating to obtain the actual implantation dose of the ion beam, Is:Is=Ic*e(K1P1+K2P2+K3P3). Thus, the theoretical implantation dose compensation method can avoid the problem of adding vacuum pumps to the implantation apparatus in order to increase the vacuum pumping speed as well as the related problems, thereby reducing the cost of the ion implantation apparatus; and meanwhile, the method can be flexibly applied according to actual conditions.

Owner:BEIJING ZHONGKEXIN ELECTRONICS EQUIP

Monitoring system and monitoring method for semiconductor manufacturing device

PendingCN111199896AReduce the burden onInstant detection of air leaksSemiconductor/solid-state device manufacturingGas analyser construction detailsGas analysisResidual gas analyzer

The invention provides a monitoring system and a monitoring method for a semiconductor manufacturing device. The monitoring system comprises a semiconductor manufacturing device and a residual gas analyzer, wherein the semiconductor manufacturing device is provided with a reaction chamber for depositing a semiconductor; and the residual gas analyzer is arranged in the reaction chamber and is provided with a detection unit for detecting the state information in the reaction chamber in real time to obtain the real-time state information. The preparation process in the reaction chamber can be monitored in real time, so that the defects of air leakage, source deterioration, pollution, exhaust and the like can be found in time, a large number of bad products are prevented from being produced, and the production cost is greatly reduced. In addition, as manual monitoring is not needed in the preparation process, not only is the product defect caused by misoperation of operators avoided, but also the burden of the operators is greatly reduced.

Owner:CHANGXIN MEMORY TECH INC

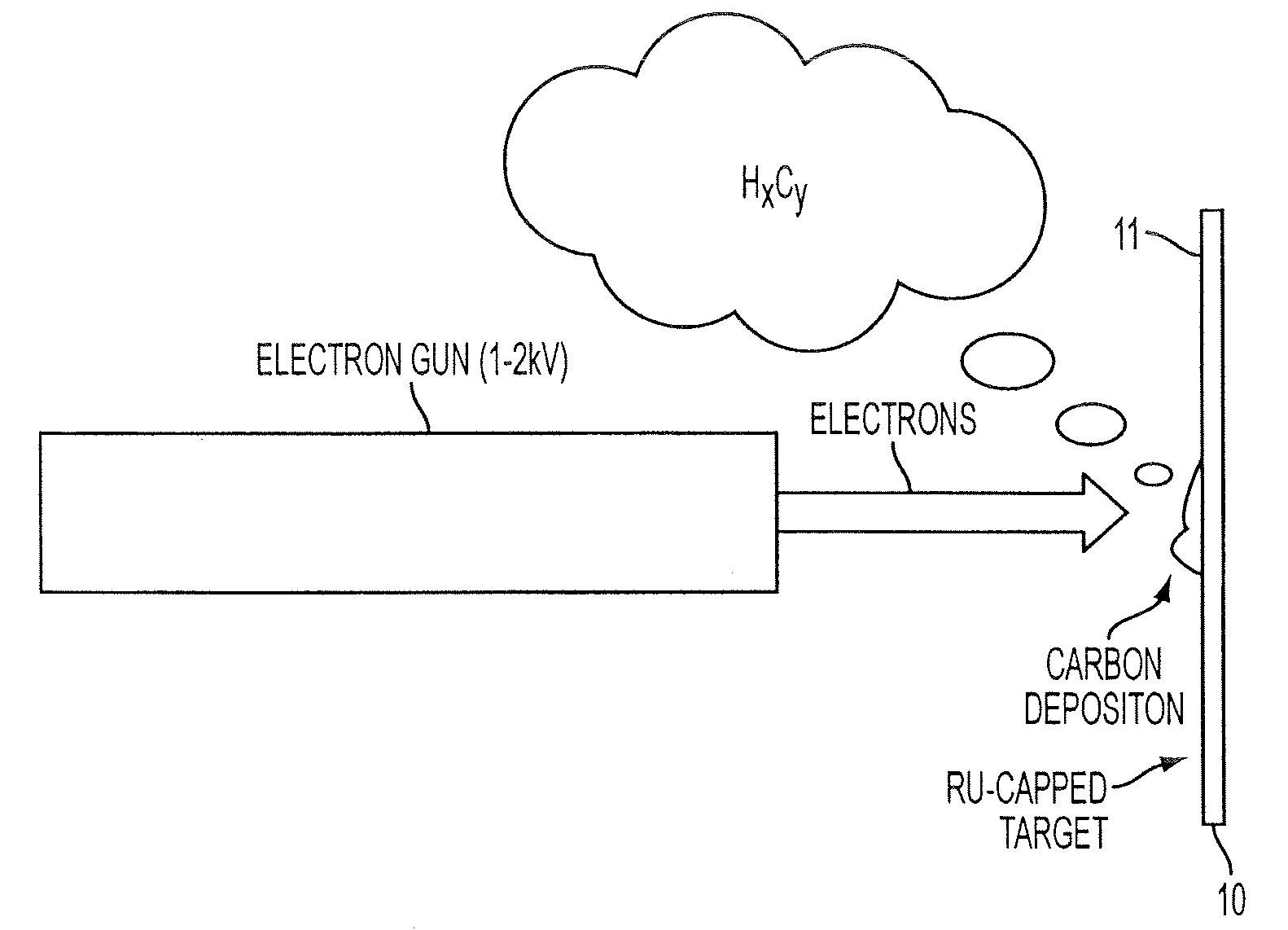

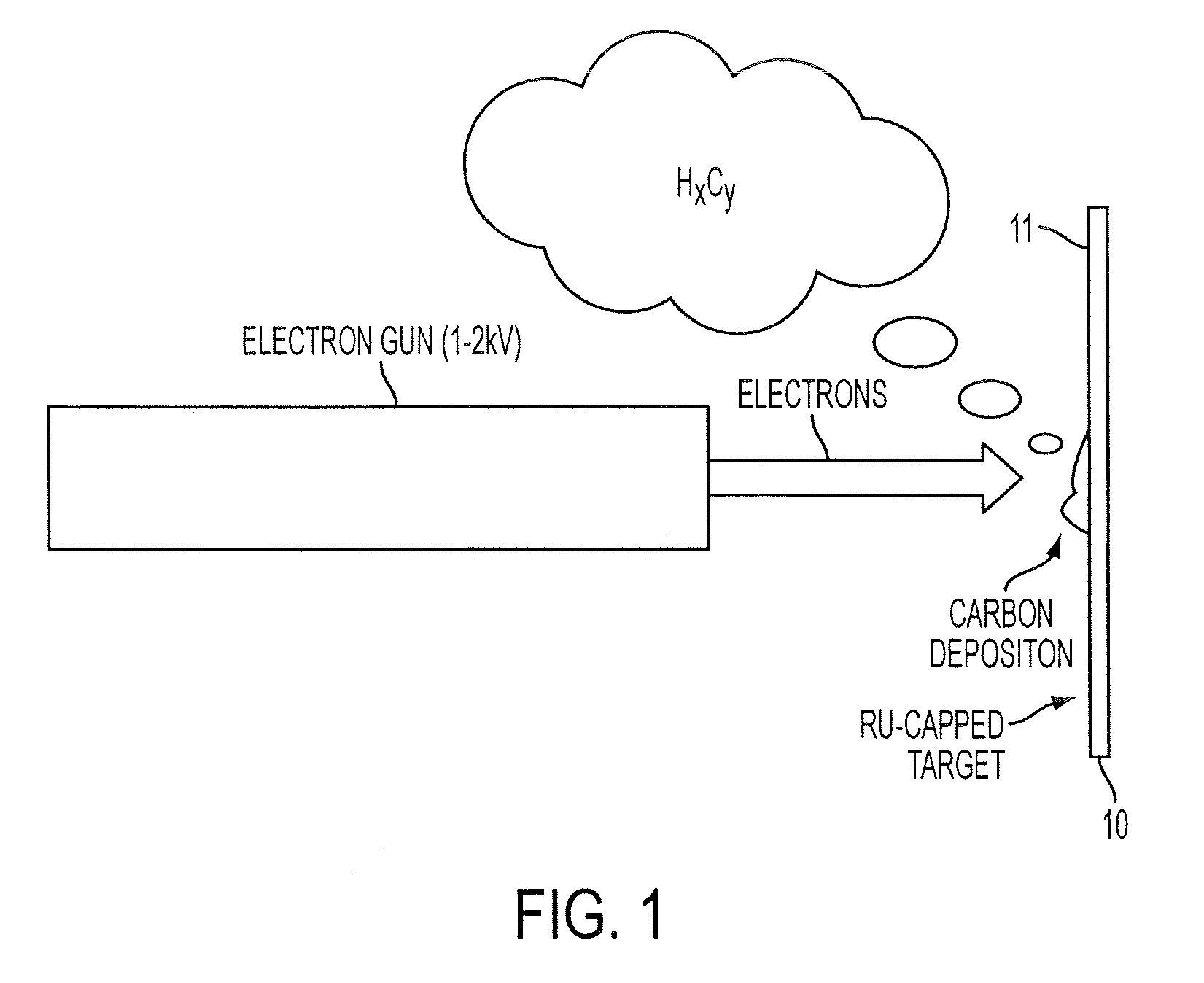

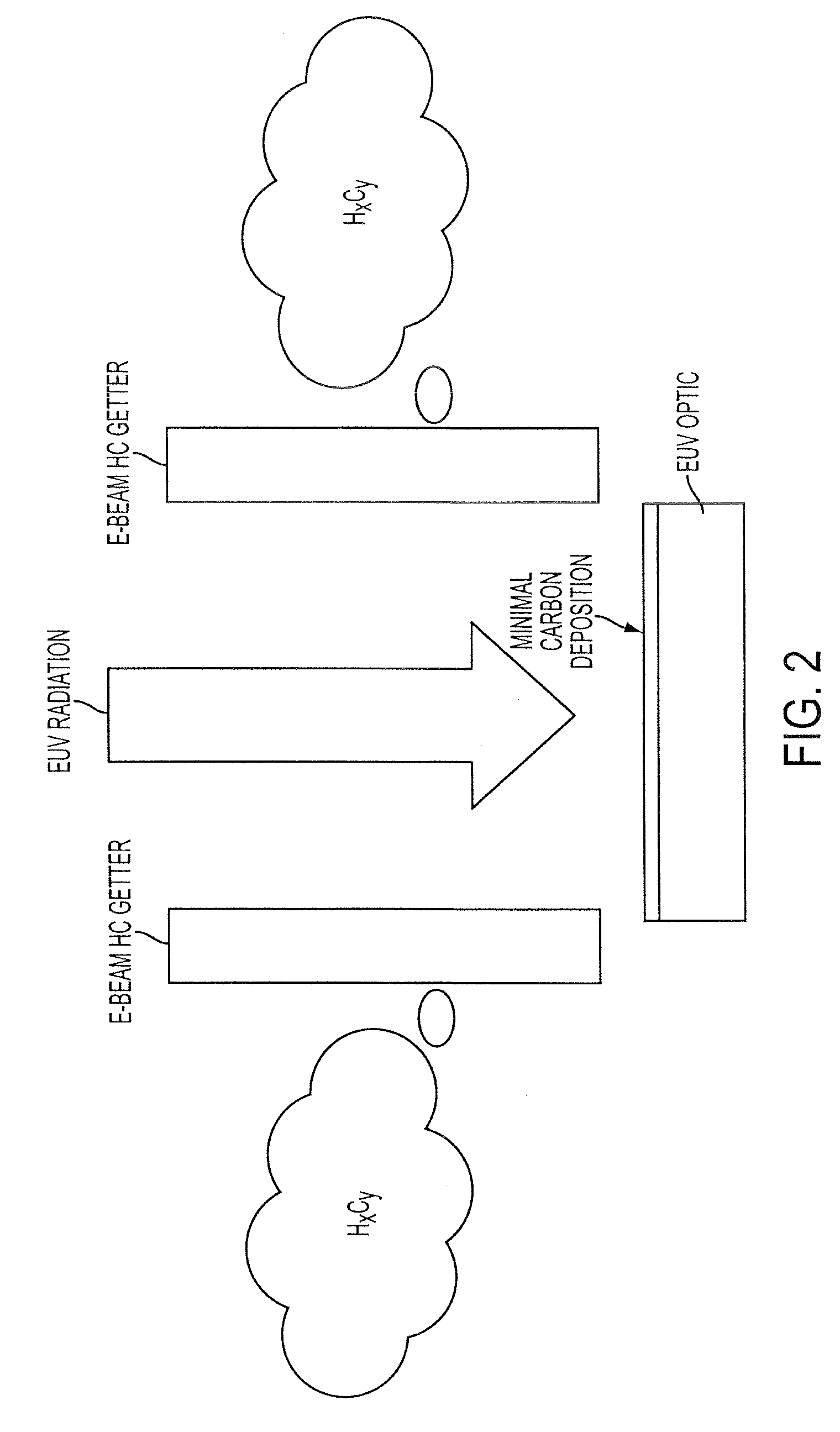

Hydrocarbon getter for lithographic exposure tools

ActiveUS20090002647A1Reduce carbon depositionAvoid adverse of adverse carbon depositionPhotomechanical apparatusSemiconductor/solid-state device manufacturingHigh energyGetter

Carbon contamination of optical elements in an exposure tool is minimized by incorporating a hydrocarbon getter. Embodiments include EUV lithography tools provided with at least one hydrocarbon getter comprising a substrate and a high energy source, such as an electron gun or separate EUV source, positioned to direct an energy beam, having sufficient energy to crack heavy hydrocarbons and form carbon, on the substrate. Embodiments also include exposure tools equipped with a hydrocarbon getter comprising an energy source positioned to impinge a beam of energy on a quartz crystal thickness monitor, a residual gas analyzer, and a controller to control the electron-current and maintain the amount of hydrocarbons in the system at a predetermined low level.

Owner:ADVANCED MICRO DEVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com