Powder atomic layer deposition device and deposition method and application for same

An atomic layer deposition, powder technology, applied in coating, metal material coating process, gaseous chemical plating and other directions, can solve the problems of high powder loss rate, single growth form, high cost, improve utilization efficiency, equipment manufacturing Simple, low-cost coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

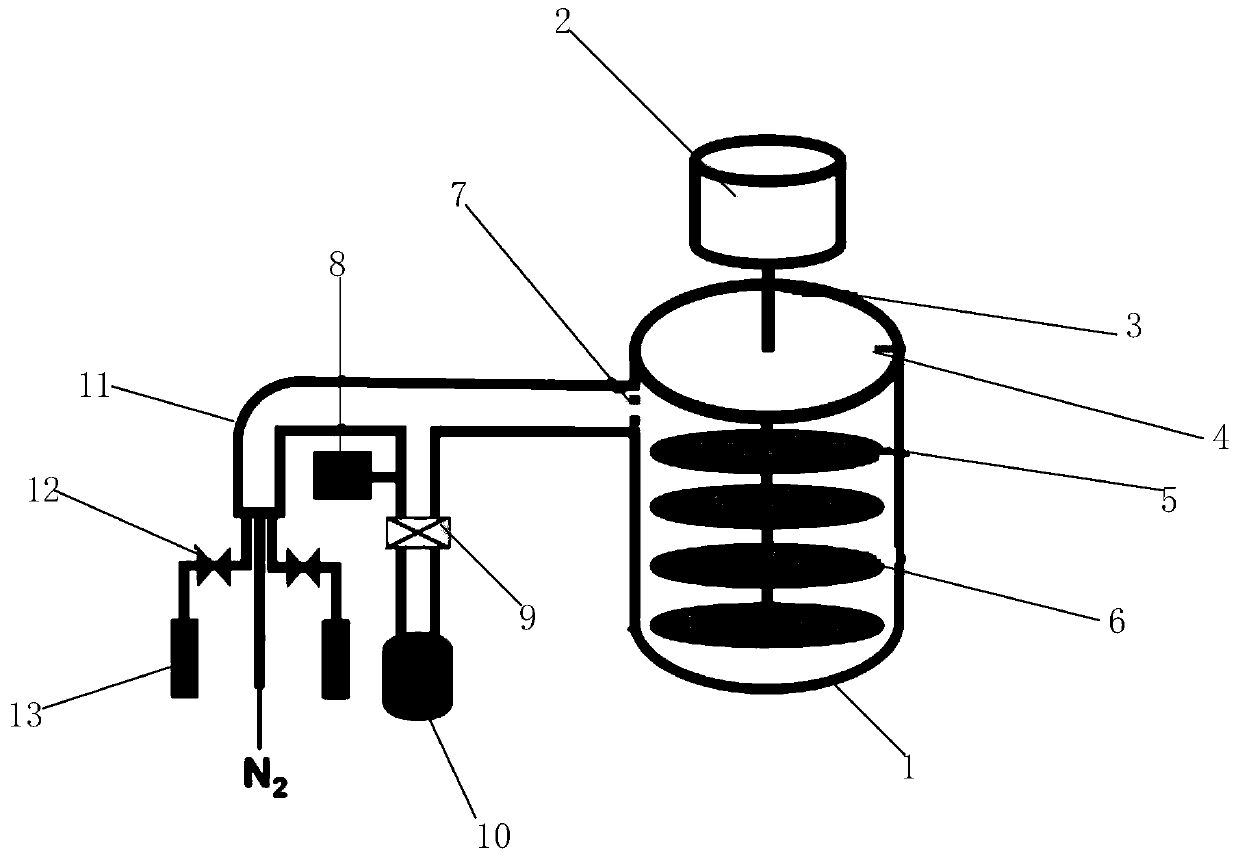

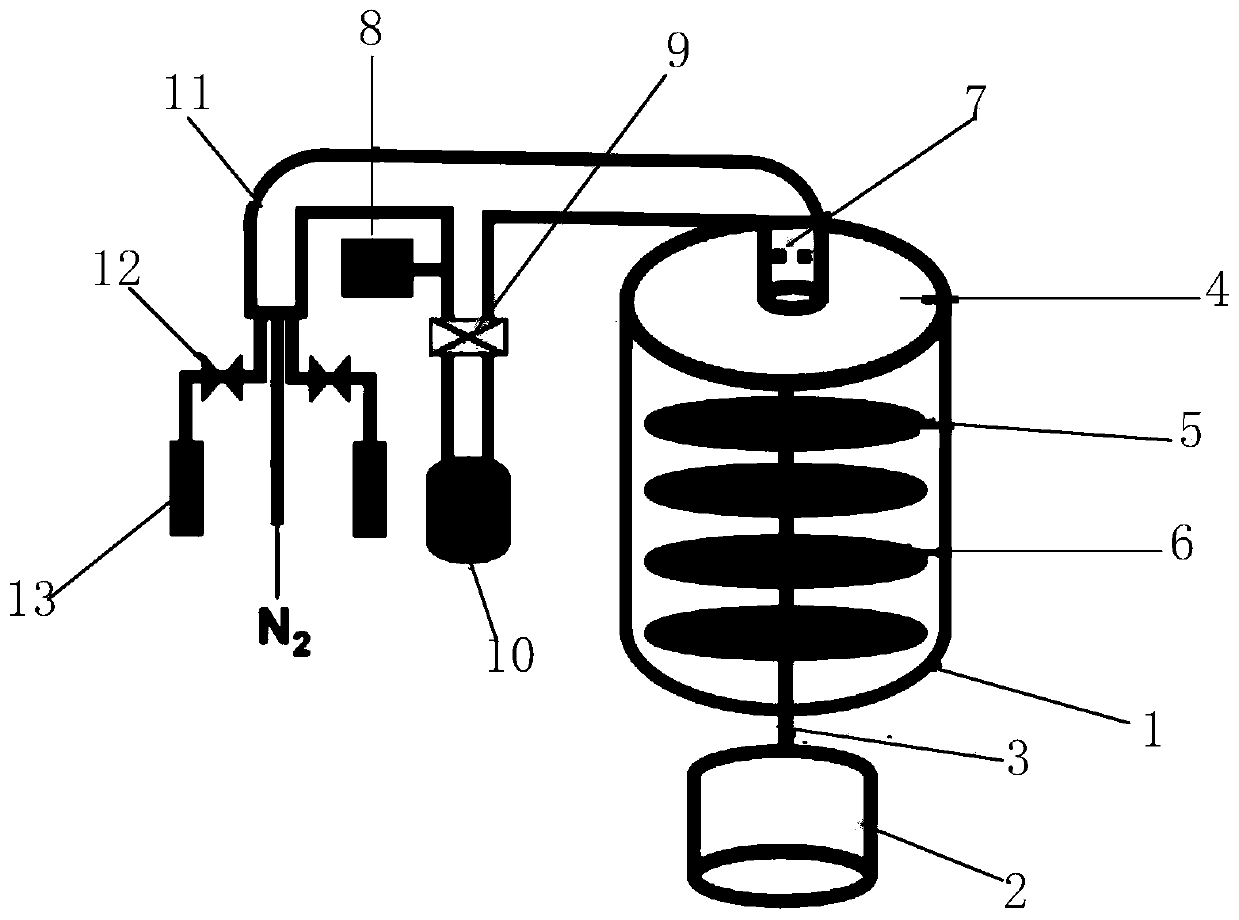

[0086] like figure 1 As shown, the powder atomic layer deposition equipment provided by the embodiment of the present invention is provided with a heatable main chamber 1; the heatable main chamber 1 is fixed with a mechanical transmission shaft 3 through a bearing, and a powder growth chamber is clamped on the mechanical transmission shaft 3. Bed 5, powder growth bed 5 is covered with powder sample 6, and the upper end of mechanical transmission shaft 3 is provided with vibration rotator 2.

[0087] The left end of the heatable main cavity 1 is fixed with a heatable gas pipeline 11 through a flange, and a powder filter 7 is arranged at the connection between the heatable gas pipeline 11 and the heatable main cavity 1 .

[0088] The heatable gas pipeline 11 is connected to the solenoid valve 9 through a ferrule, the solenoid valve 9 is connected to the vacuum pump 10 through the heatable gas pipeline 11 , and a residual gas analyzer 8 is arranged on the upper end of the soleno...

Embodiment 2

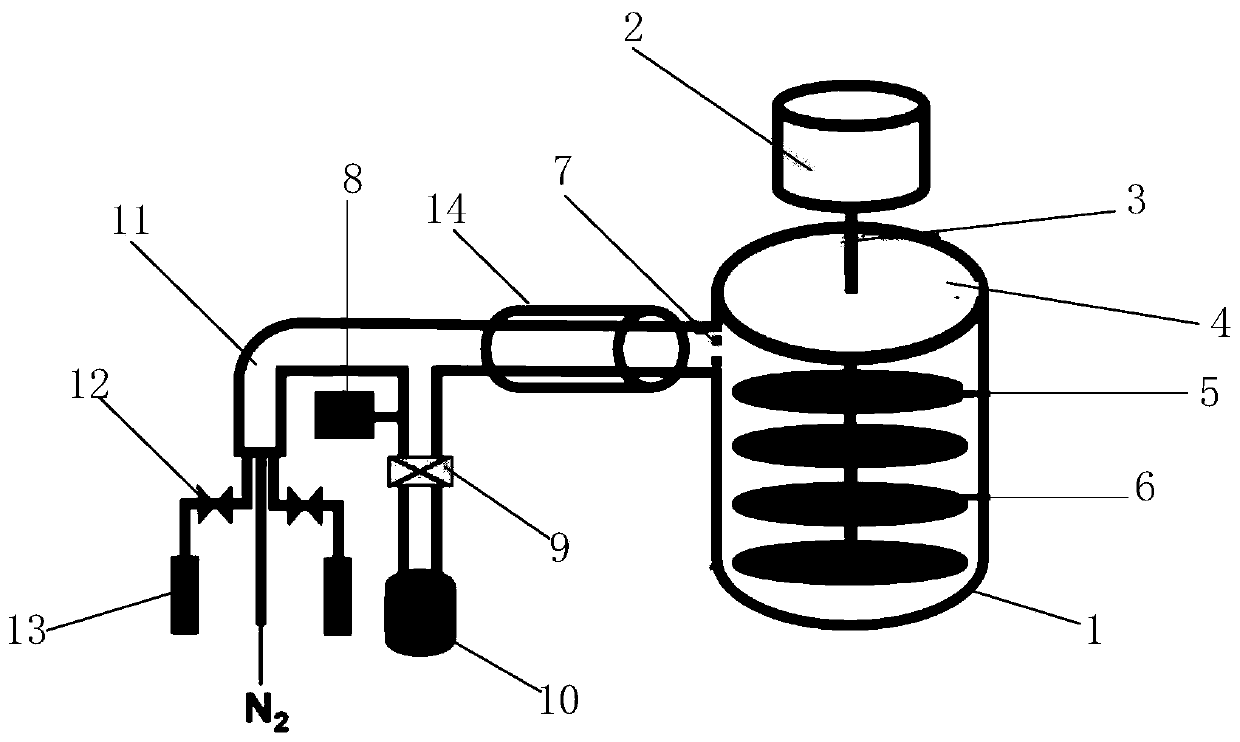

[0094] like figure 2 As shown, the preparation of the aluminum nitride thin film provided by the embodiment of the present invention is provided with: a heatable main cavity 1 .

[0095] The heatable main cavity 1 is fixed with a mechanical transmission shaft 3 through bearings, and the mechanical transmission shaft 3 is clamped with a powder growth bed 5, and the powder growth bed 5 is covered with powder samples 6, and the upper end of the mechanical transmission shaft 3 is provided with a vibrating rotator 2 .

[0096] The left end of the heatable main chamber 1 is fixed with a heatable gas pipeline 11 through a flange, a powder filter 7 is arranged at the connection between the heatable gas pipeline 11 and the heatable main chamber 1, and the left end of the powder filter 7 is provided with a Plasma generator 14.

[0097] The plasma generator 14 is connected with the residual gas analyzer 8 through the heatable gas pipeline 11, the plasma generator 14 is connected with ...

Embodiment 3

[0102] Based on the device of Example 2, the present invention provides a method of using the aluminum nitride film preparation device to prepare the aluminum nitride film, the method of the aluminum nitride film comprising:

[0103] The first step is to determine the growth temperature of the powder sample and keep the heatable main cavity at the corresponding growth temperature;

[0104] In the second step, the precursor 1 introduced into the growth film is adsorbed on the surface of the powder in the form of chemical adsorption;

[0105] The third step is to extract excess precursor 1, the plasma generator works, and then feed precursor 2 to make precursor 2 react with precursor 1 chemically adsorbed on the surface of the powder;

[0106] In the fourth step, the plasma stops working, and the excess precursor 2 is extracted to complete the two-phase compound growth process.

[0107] Another object of the present invention is to provide a deposited aluminum nitride film util...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com