Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13882 results about "Powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A powder is a dry, bulk solid composed of many very fine particles that may flow freely when shaken or tilted. Powders are a special sub-class of granular materials, although the terms powder and granular are sometimes used to distinguish separate classes of material. In particular, powders refer to those granular materials that have the finer grain sizes, and that therefore have a greater tendency to form clumps when flowing. Granulars refers to the coarser granular materials that do not tend to form clumps except when wet.

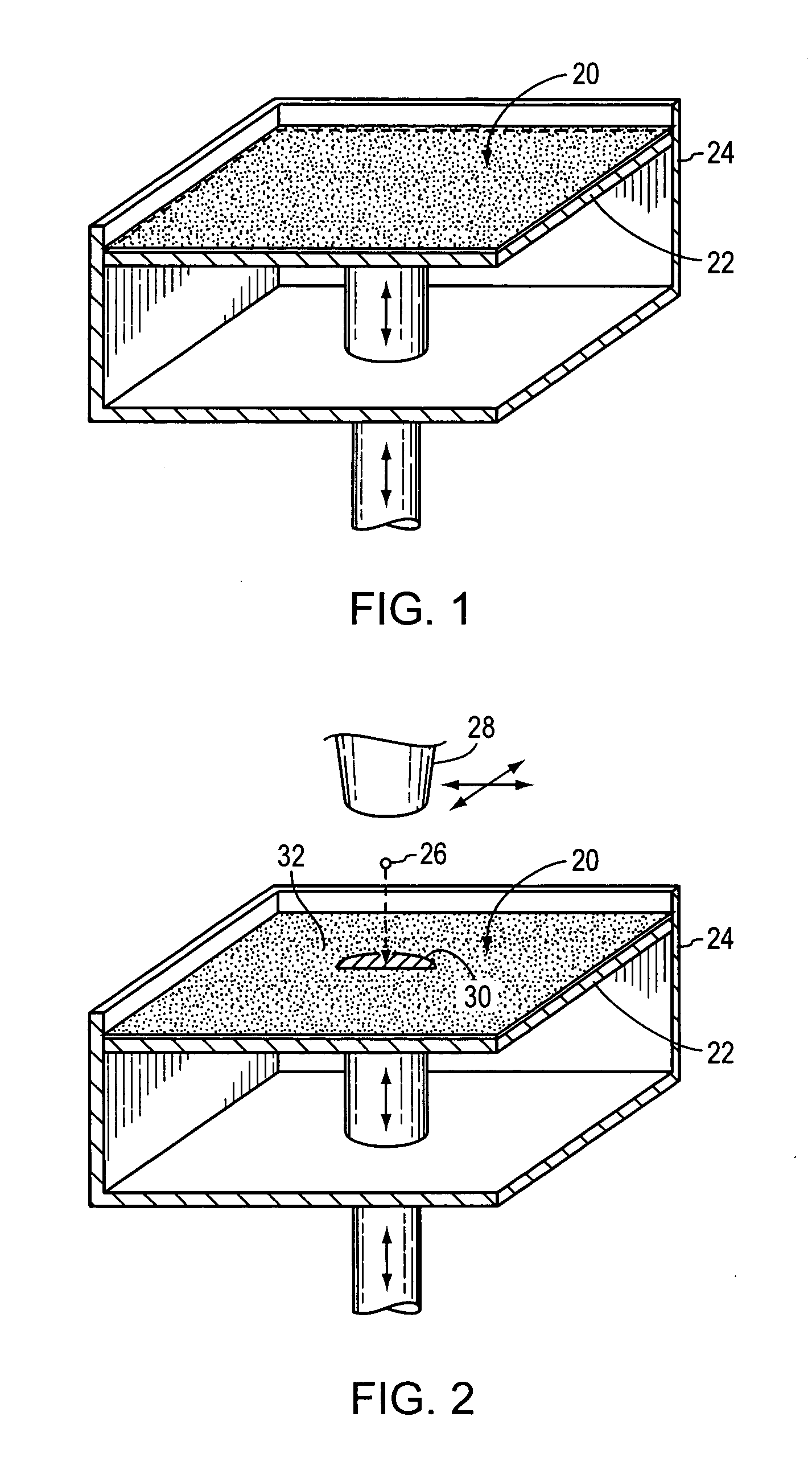

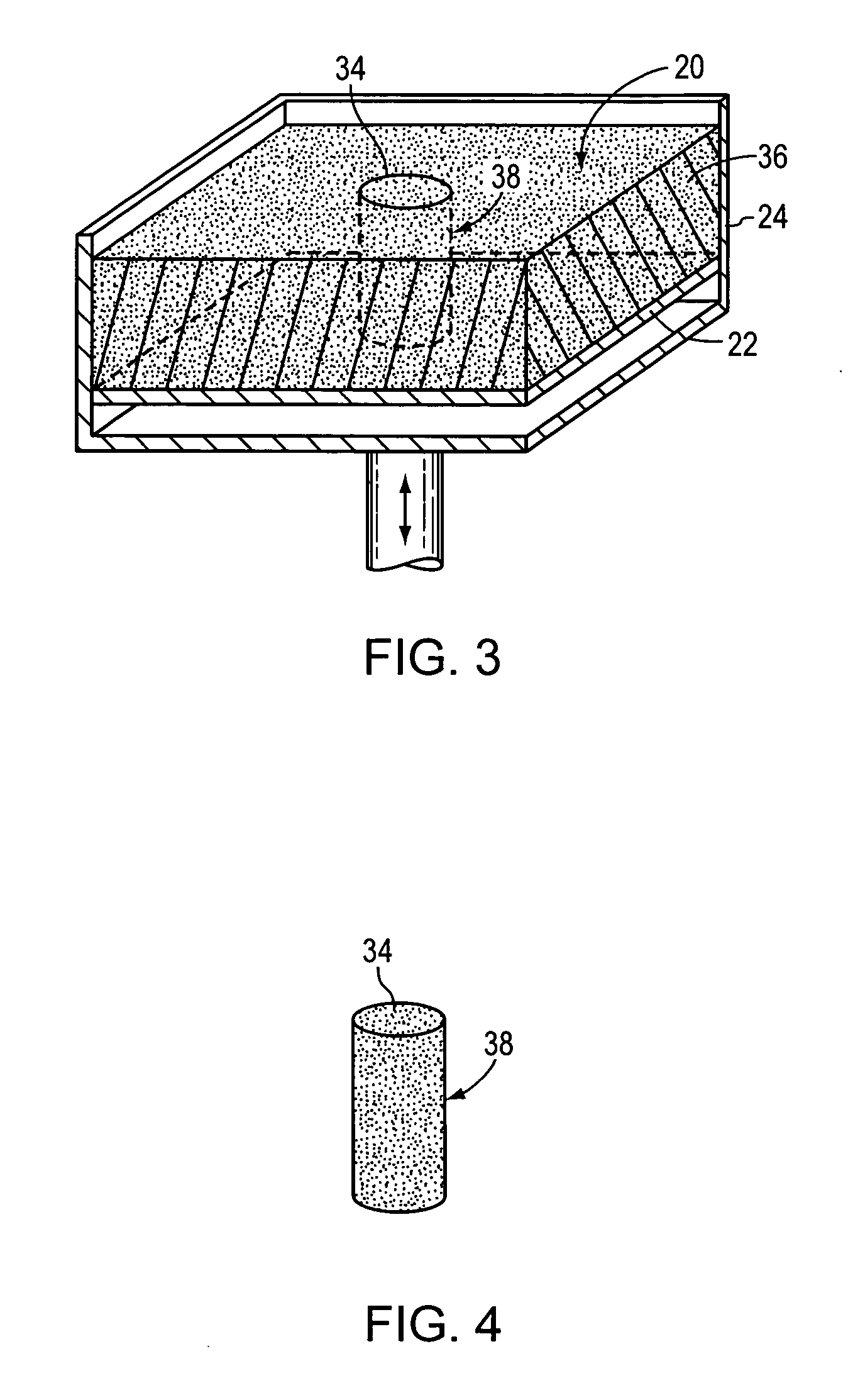

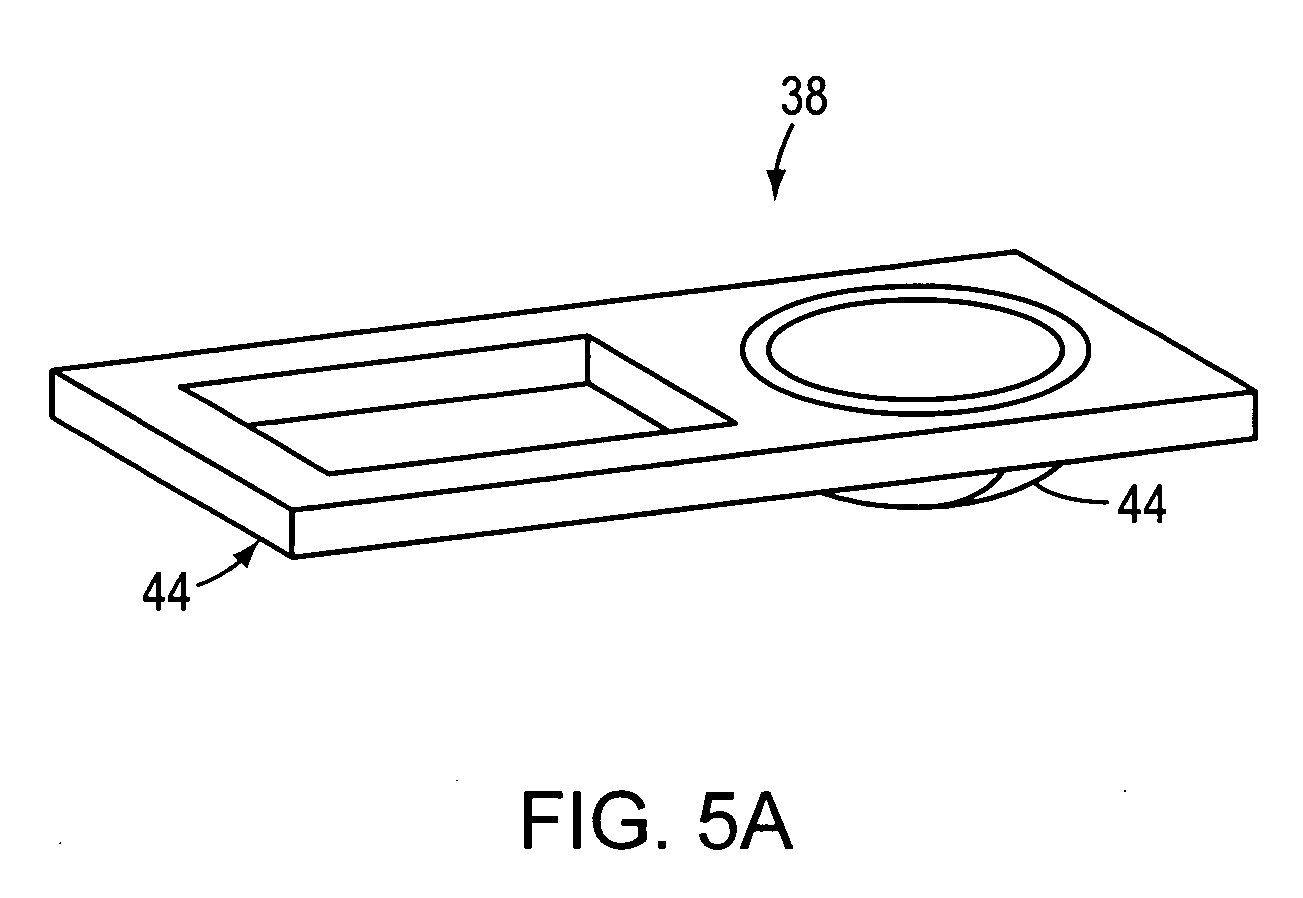

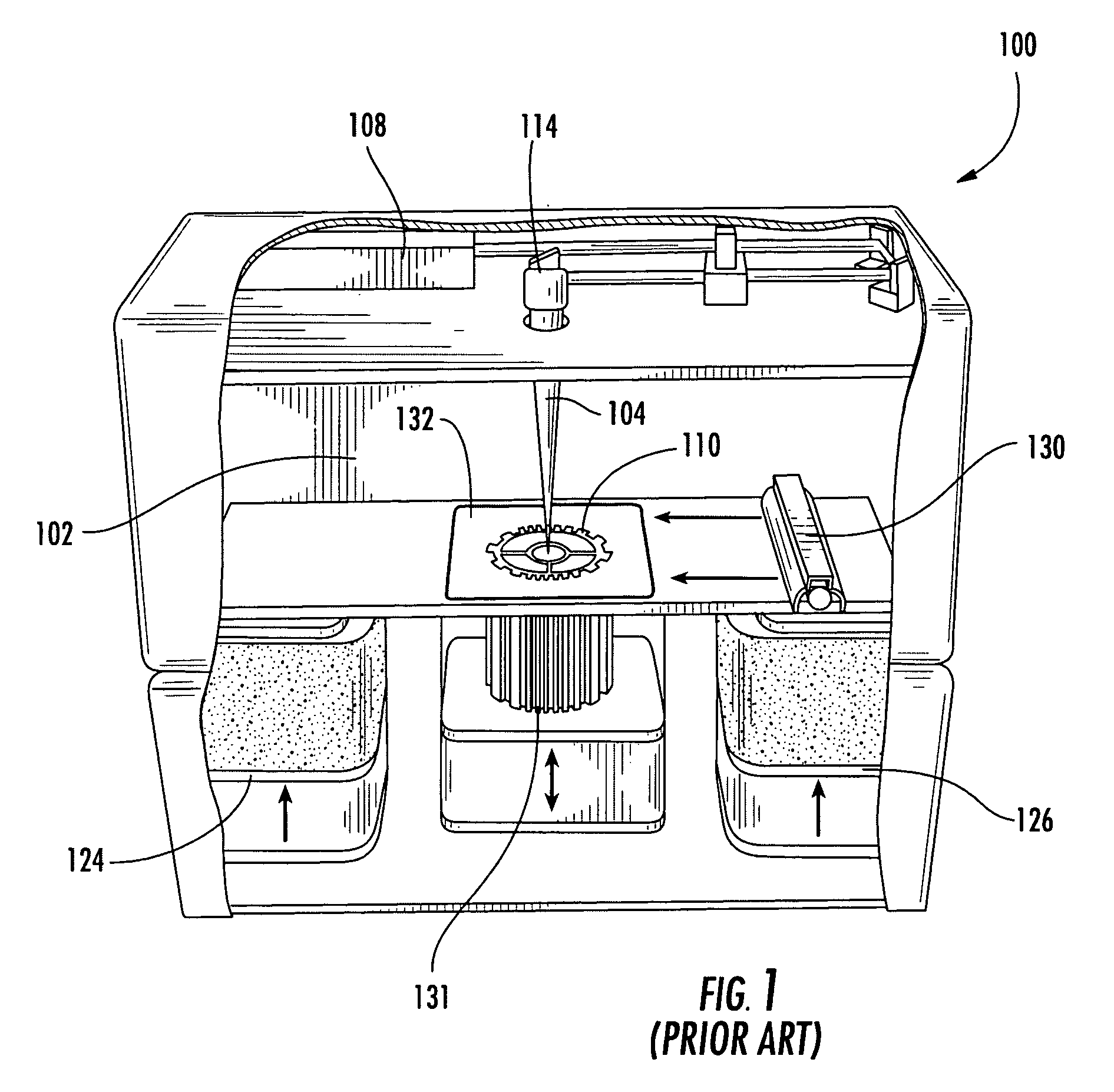

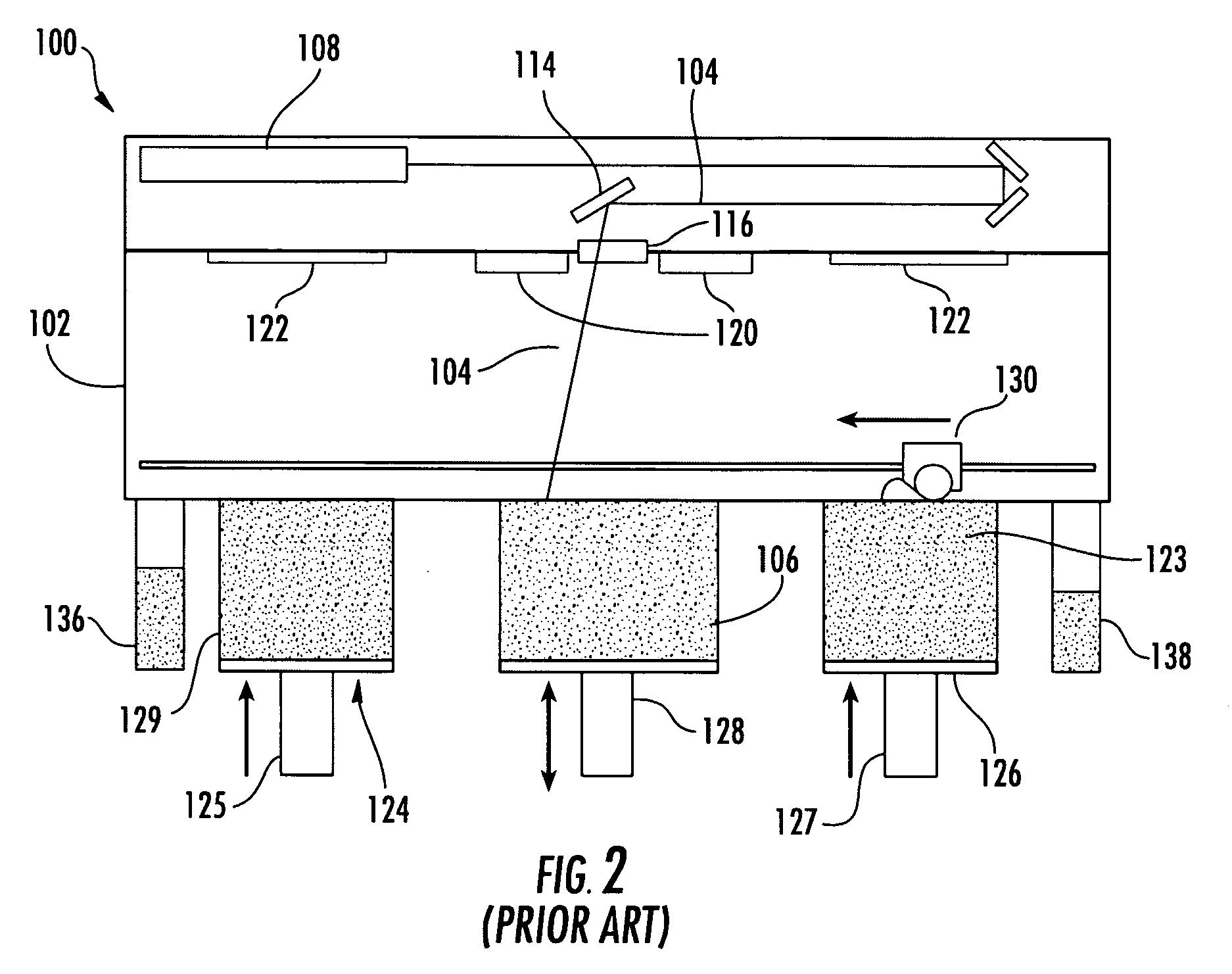

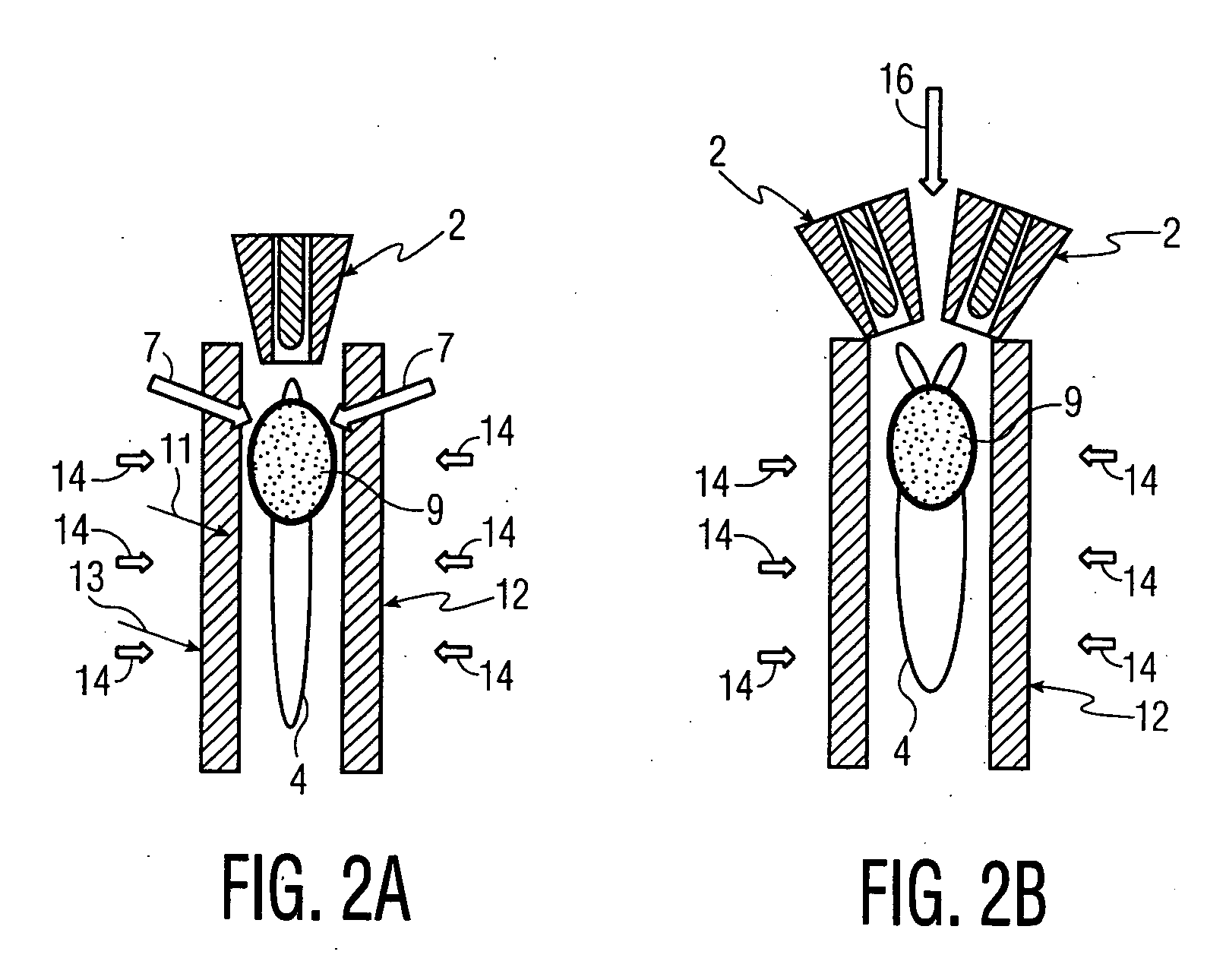

Absorbent fillers for three-dimensional printing

InactiveUS20050059757A1Quick and reliable and safe and inexpensiveSmooth surface finishPigmenting treatmentAdditive manufacturing apparatusParticulatesEngineering

A materials system and methods are provided to enable the formation of articles by three-dimensional printing. The materials system includes an absorbent particulate filler that facilitates absorption of infiltrants, thereby allowing the accurate definition of articles with enhanced mechanical and structural characteristics. The methods include the use of phase-change materials to bind a powder, as well as the formation of support structures to improve the control of the shape of the articles.

Owner:Z CORPORATION

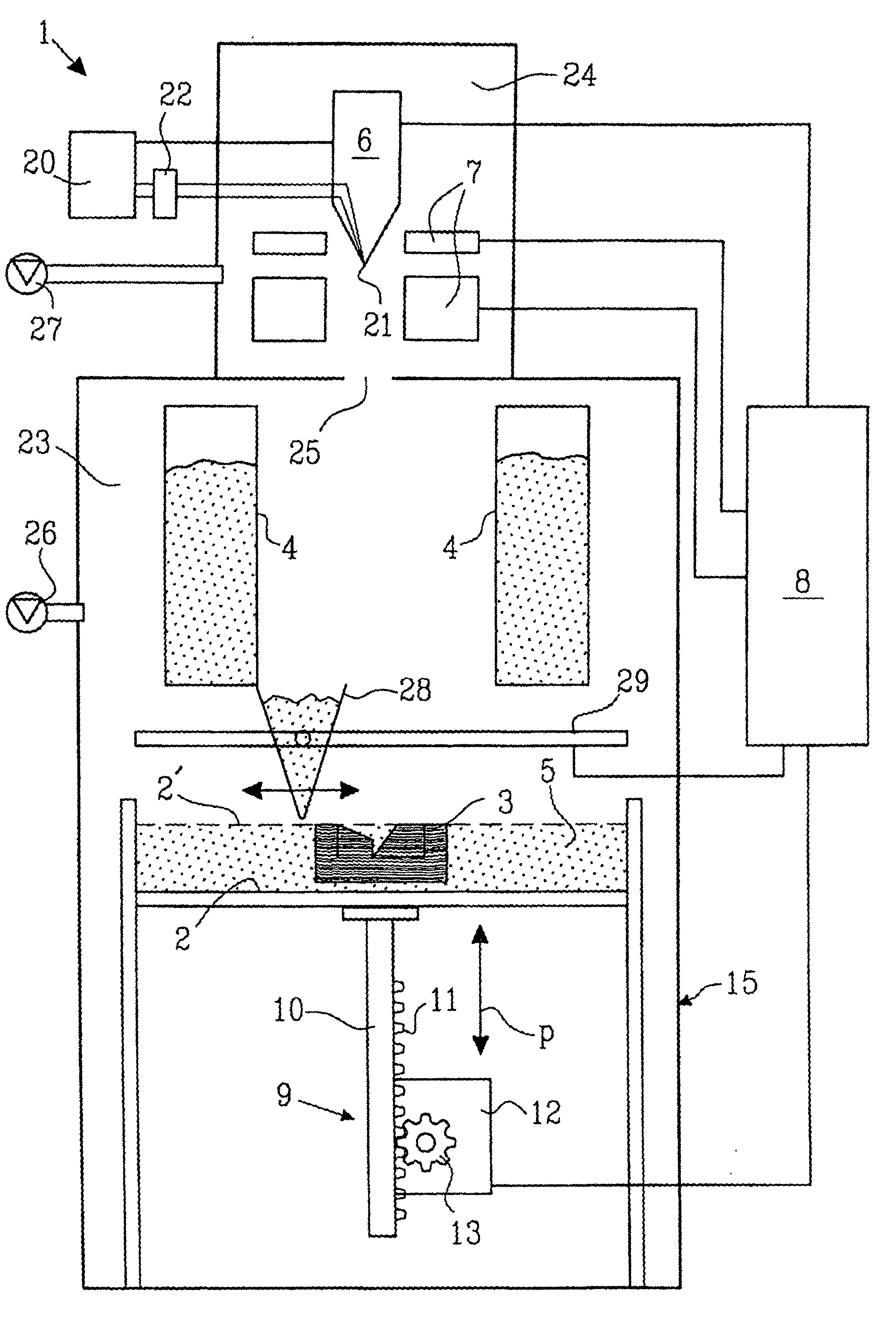

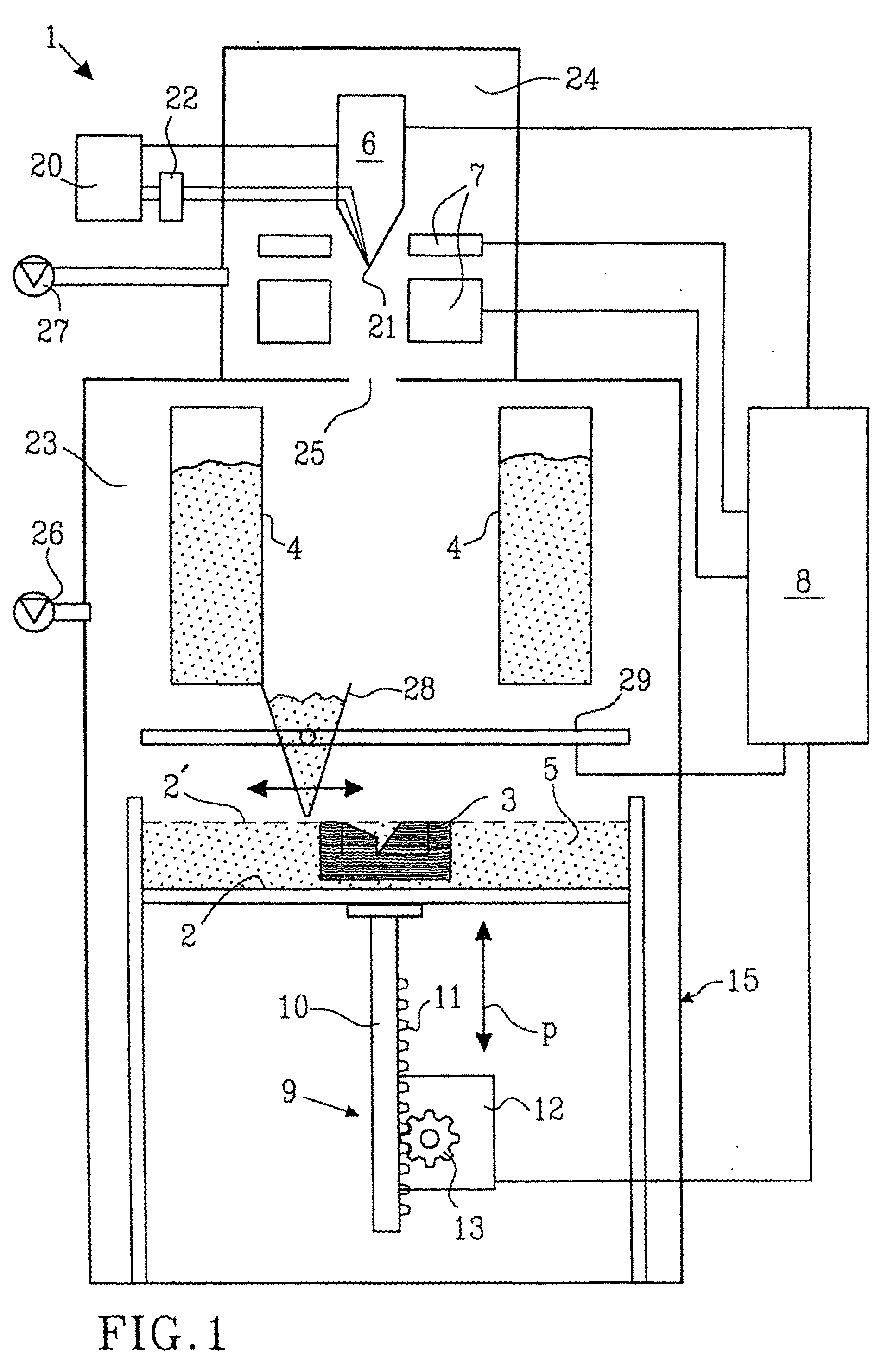

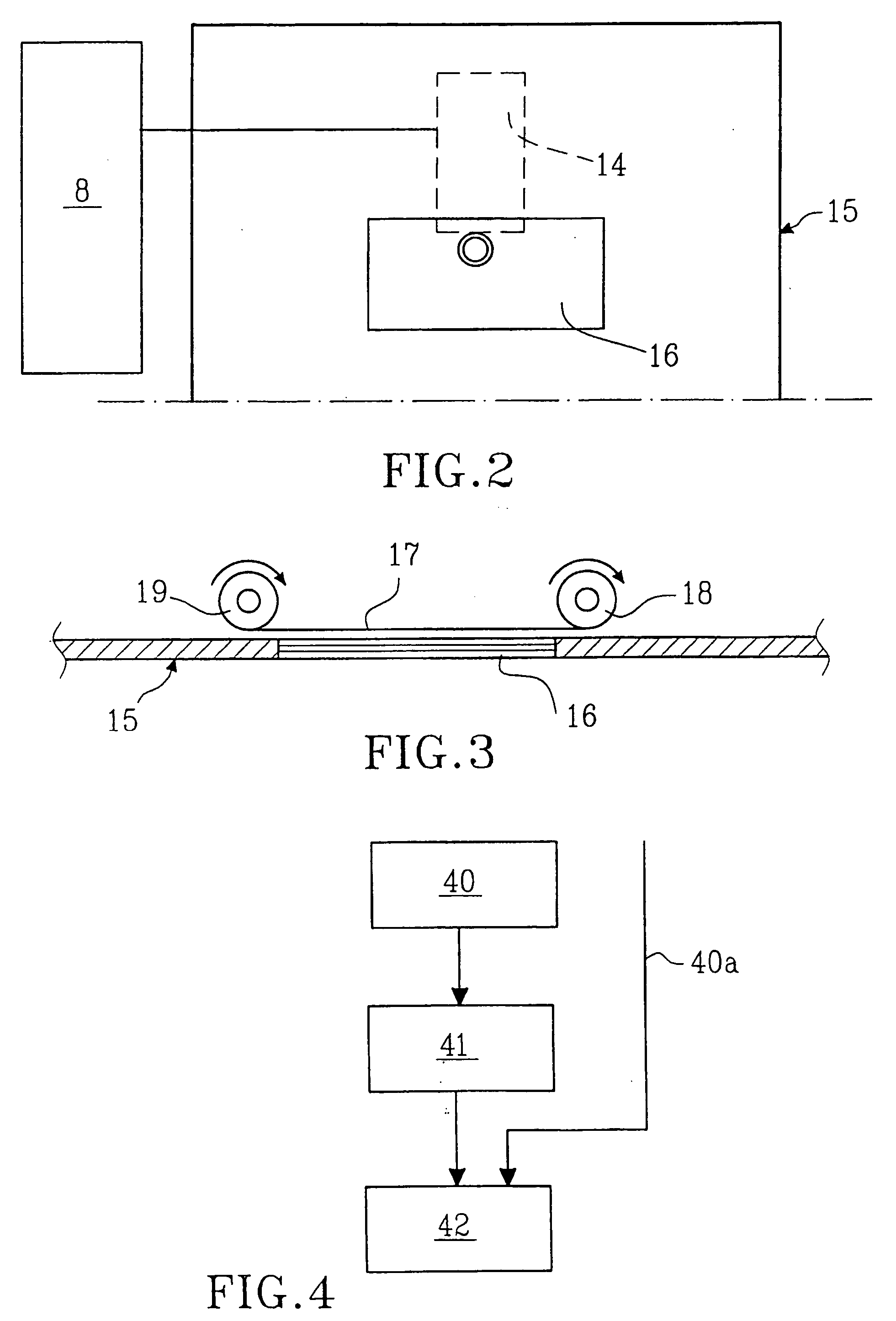

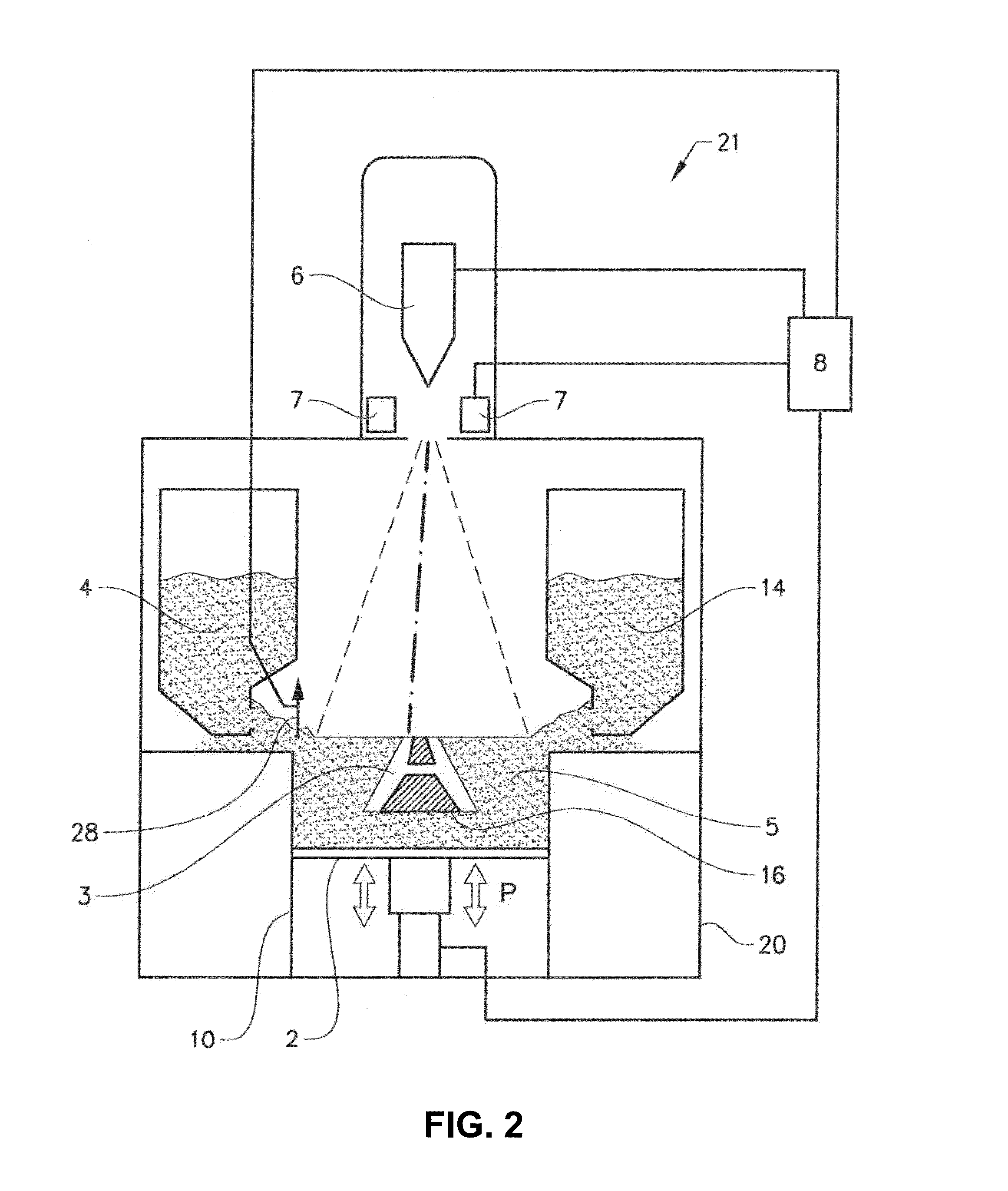

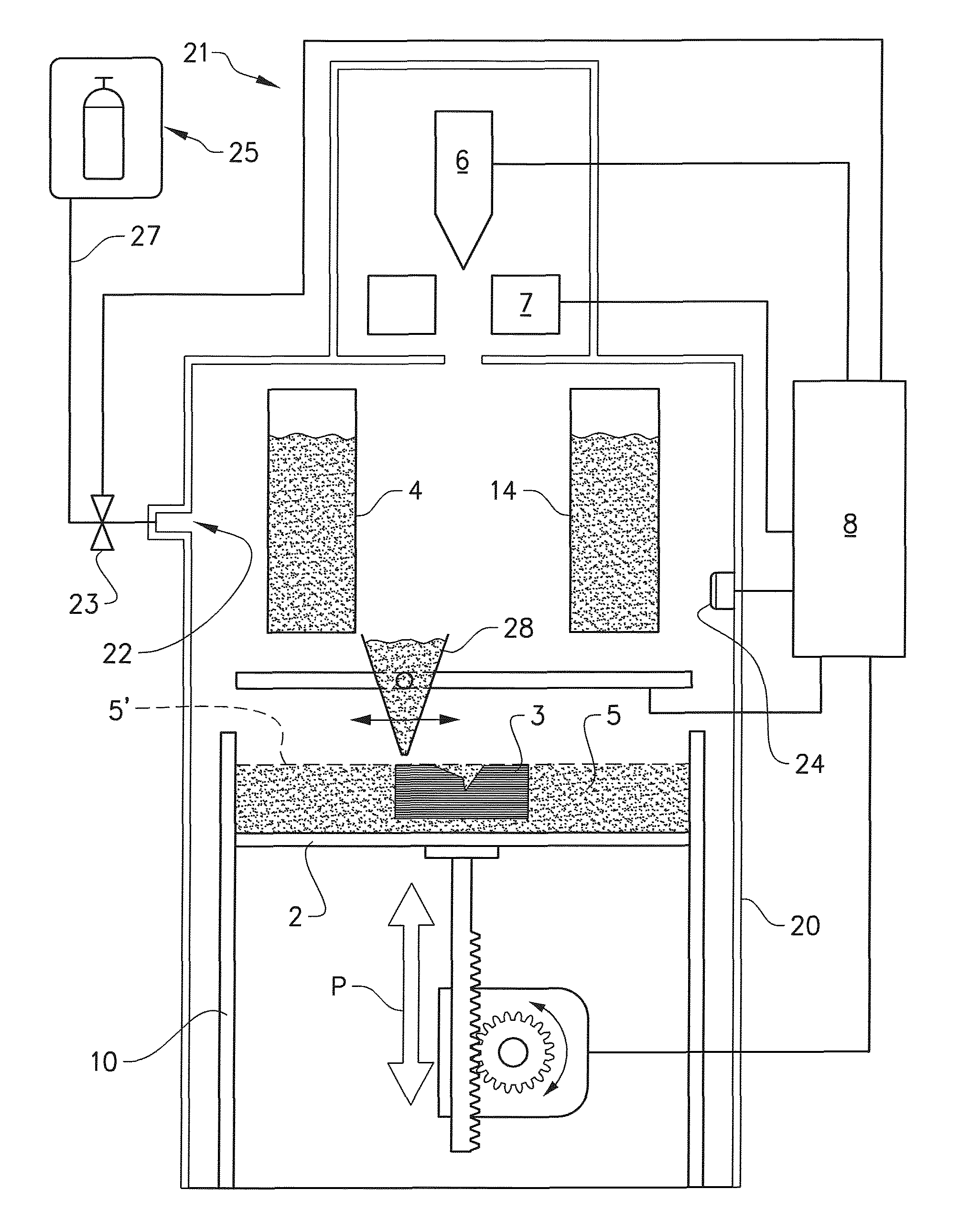

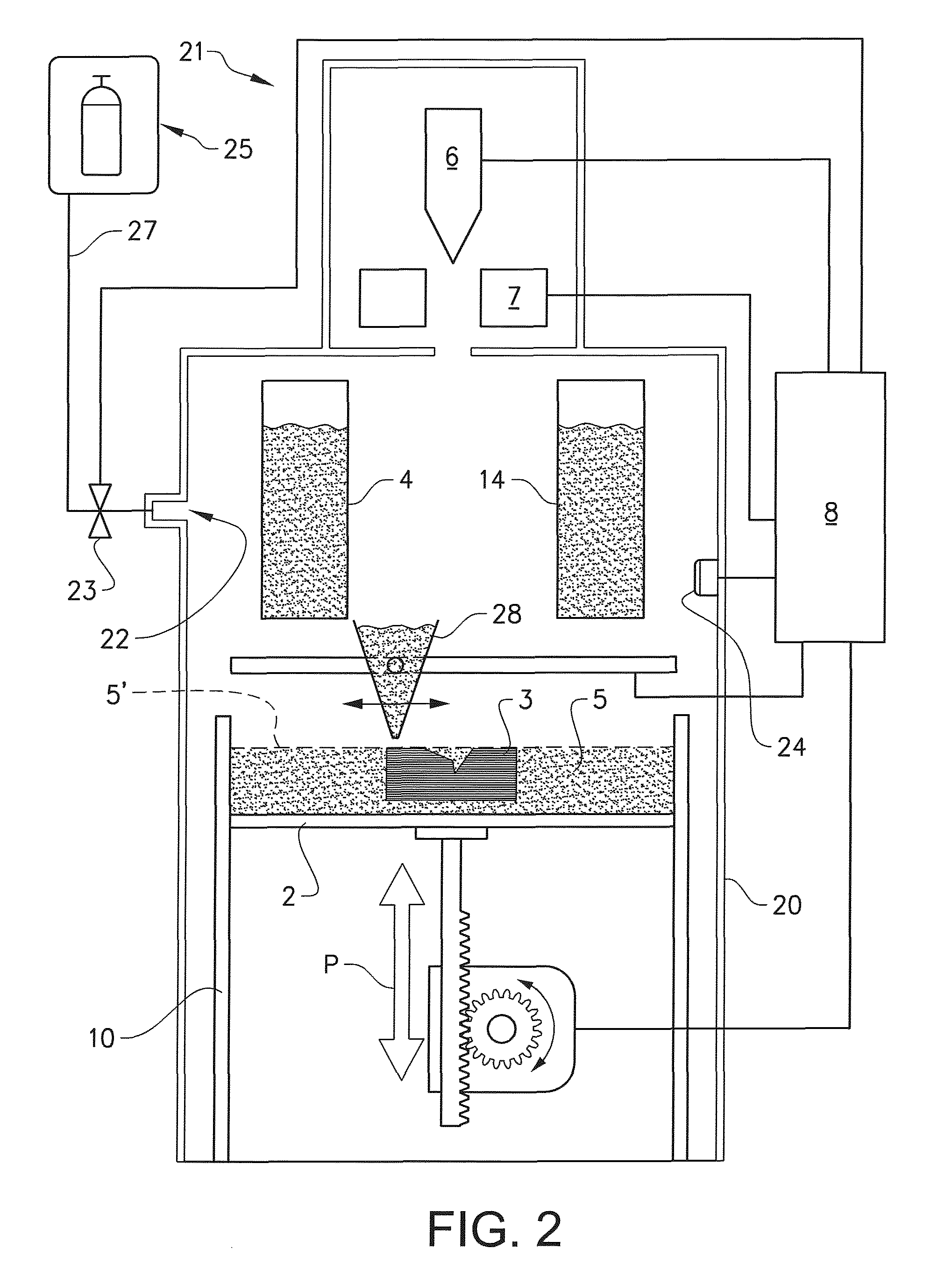

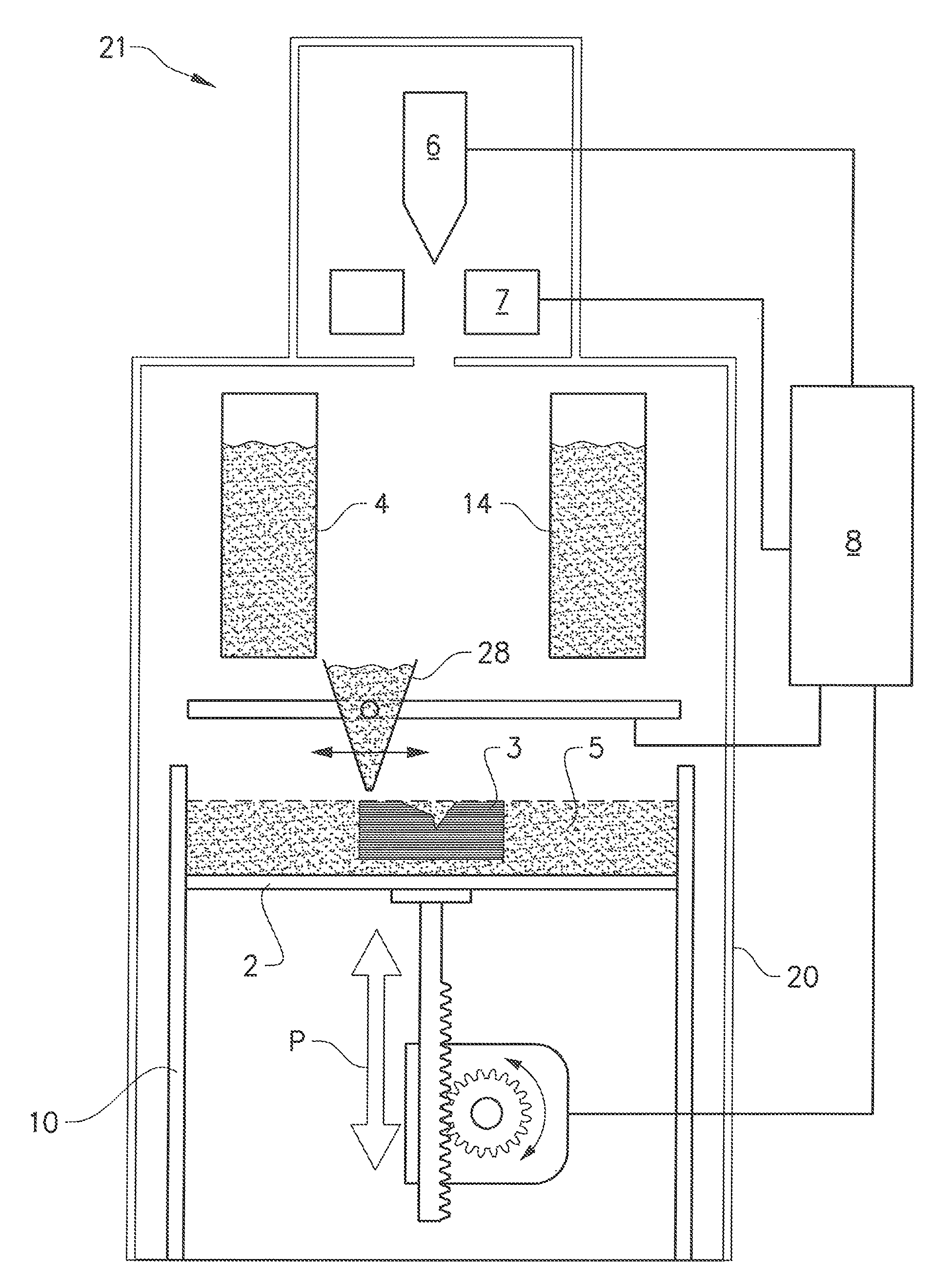

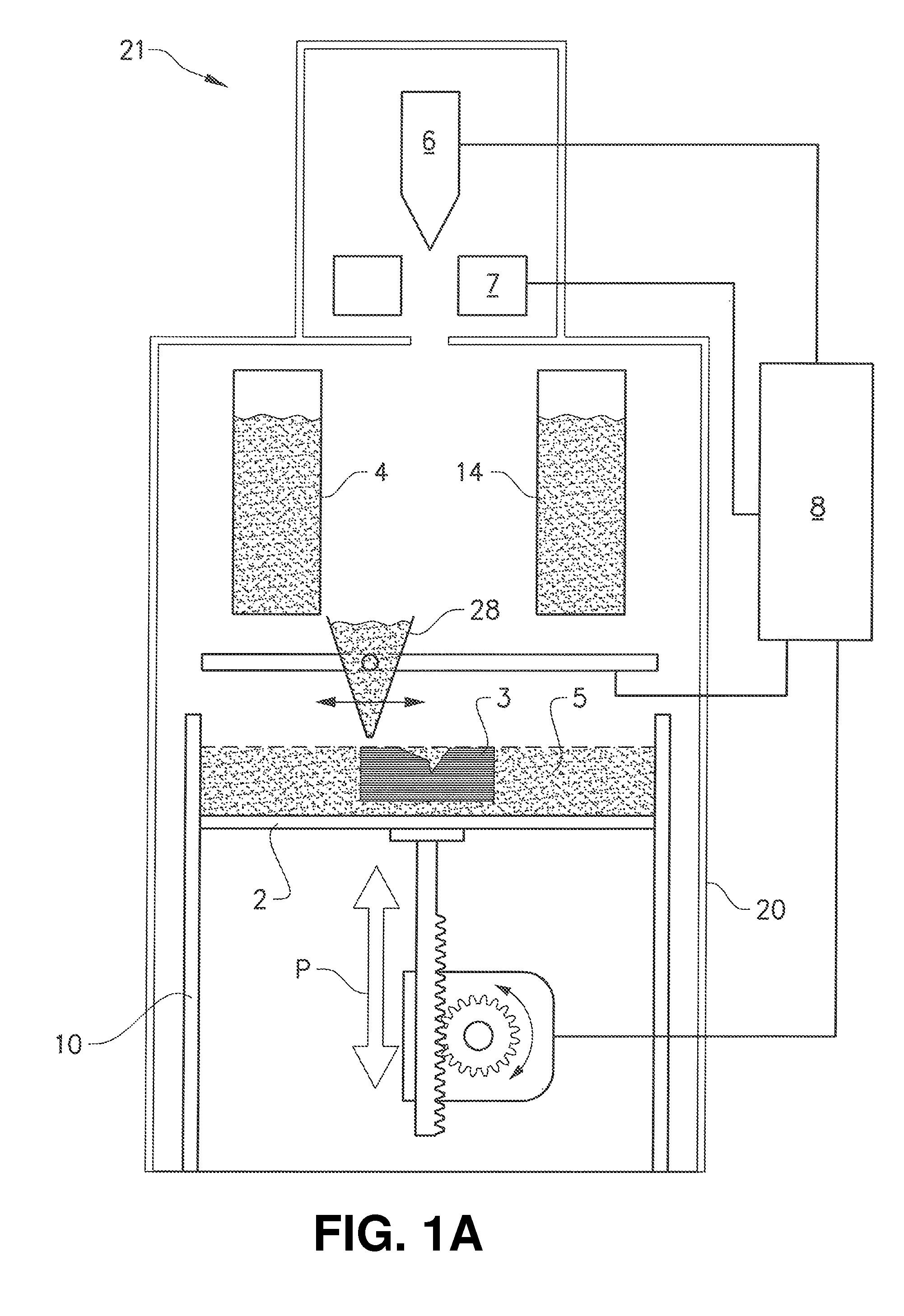

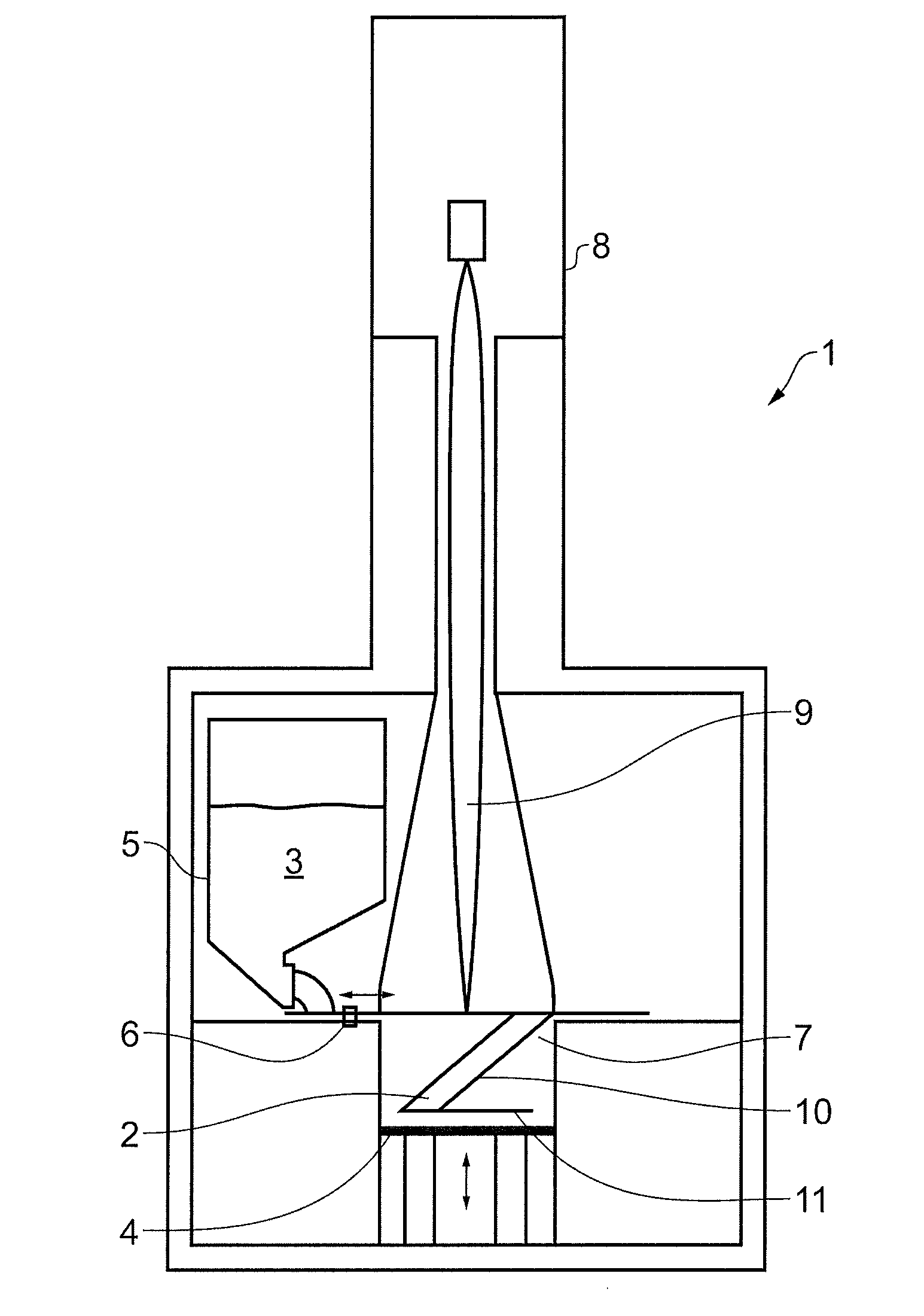

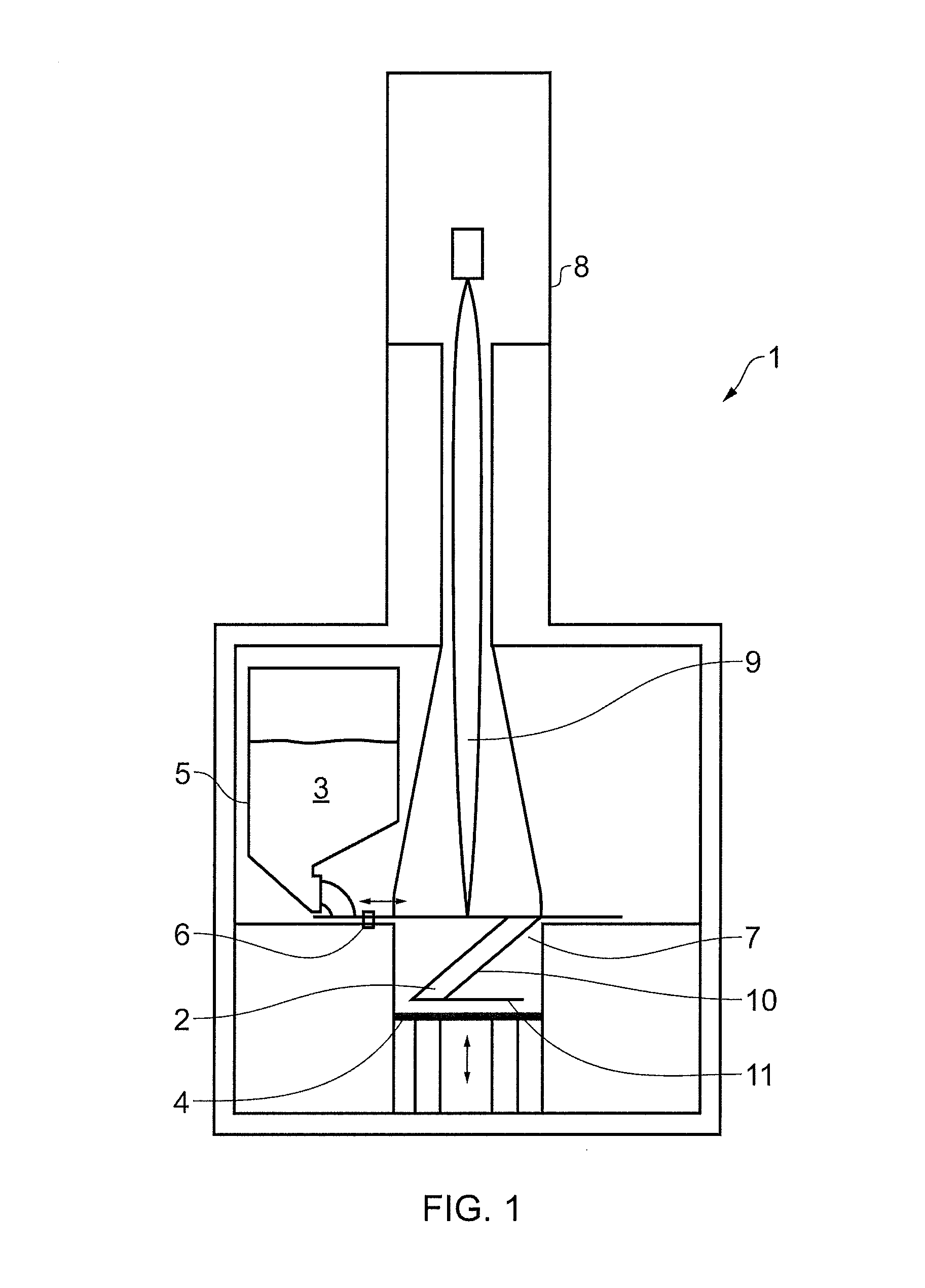

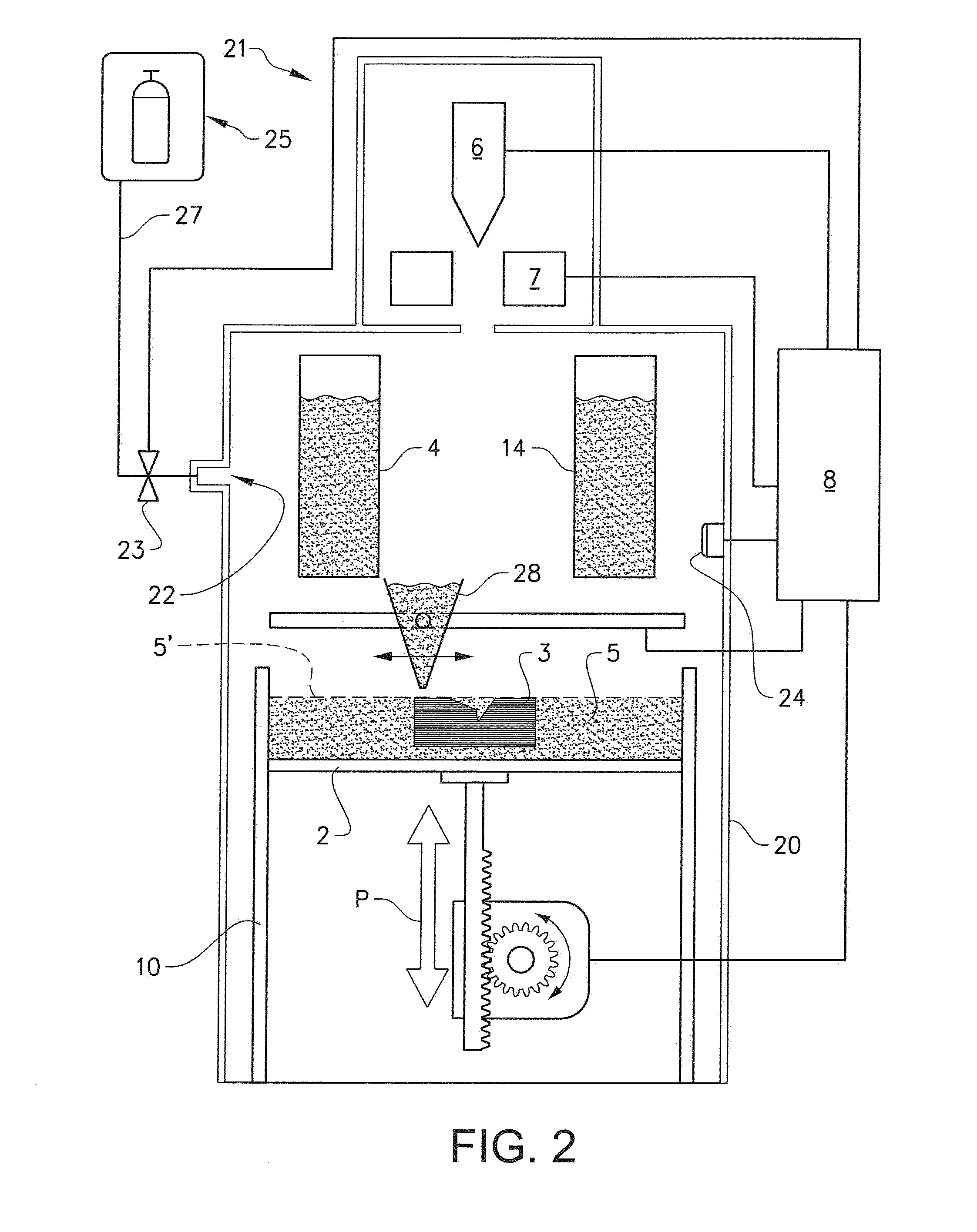

Device and arrangement for producing a three-dimensional object

InactiveUS20040026807A1Reduced form requirementsSmall sizeConfectioneryWood working apparatusThin layerRunning time

A device for manufacturing a three-dimensional product, which device comprises a work table on which said three-dimensional product is to be built, a powder dispenser which is arranged to lay down a thin layer of powder on the work table for the formation of a powder bed, a ray gun for giving off energy to the powder whereby fusion of the powder takes place, members for controlling of the beam released by the ray gun across said powder bed for the formation of a cross section of said three-dimensional product through fusion of parts of said powder bed, and a controlling computer in which information about successive cross sections of the three-dimensional product is stored, which cross sections build the three-dimensional product, the controlling computer intended to control said members for guiding the ray gun across the powder bed according to a running schedule forming a cross section of said three-dimensional body, whereby said three-dimensional product is formed by successive fusion of successively formed cross sections from powder layers successively laid down by the powder dispenser.

Owner:ARCAM AB

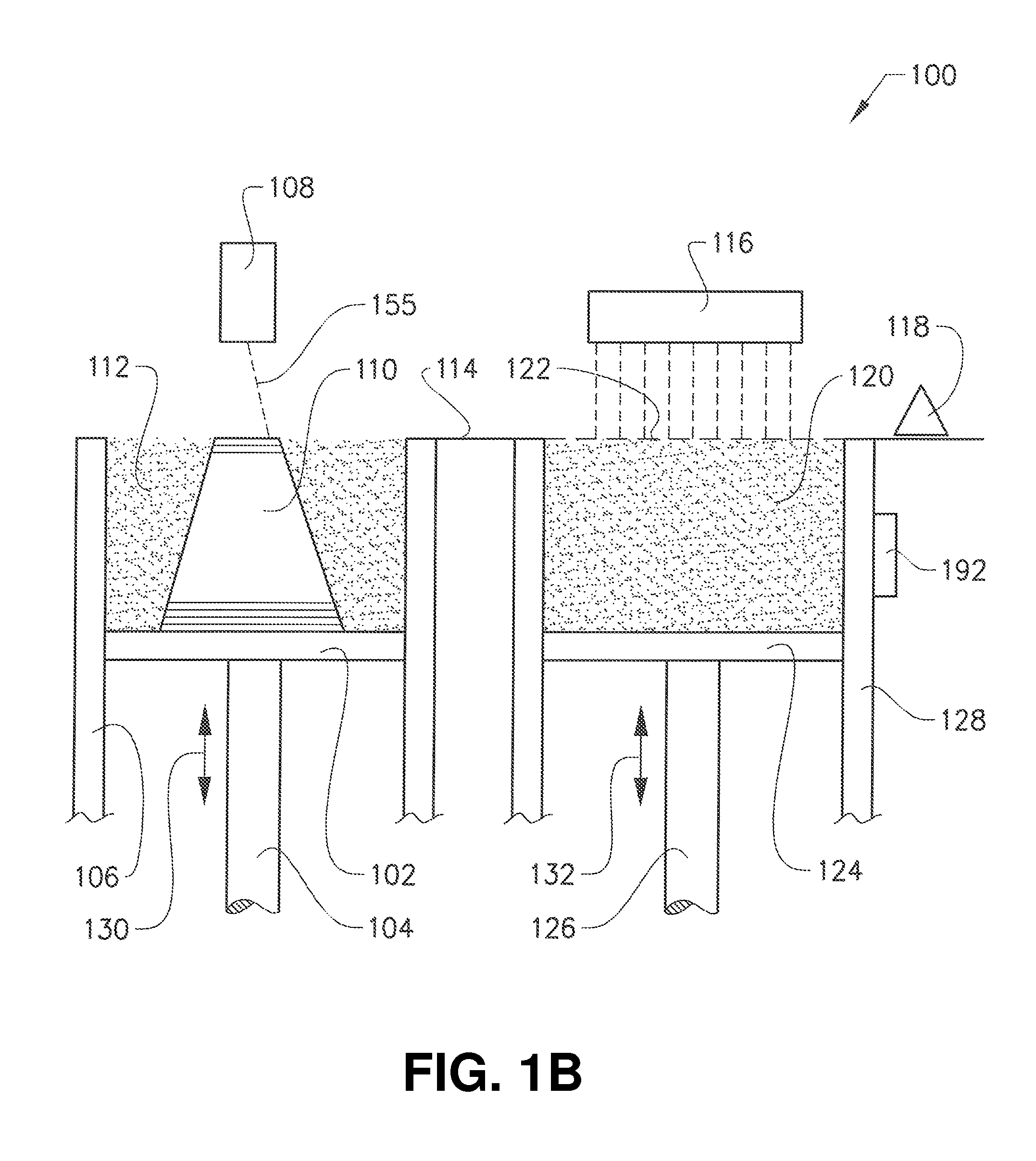

Additive manufacturing of three-dimensional articles

ActiveUS20150165525A1Improve material characteristicImprove material propertiesAdditive manufacturing apparatusArc welding apparatusBeam sourcePower flow

The present invention relates to a method for forming a three-dimensional article through successively depositing individual layers of powder material that are fused together so as to form the article, said method comprising the steps of: providing at least one electron beam source emitting an electron beam for heating and / or fusing said powder material. Controlling the electron beam source in a first mode when said formation of said three dimensional article is in a first process step. Controlling said electron beam in a second mode when said formation of said three dimensional article is in a second process step, wherein in said first mode an electron beam current from said electron beam source is controlled in a feed-forward mode and in said second mode said electron beam current is controlled in a feed-back mode.

Owner:ARCAM AB

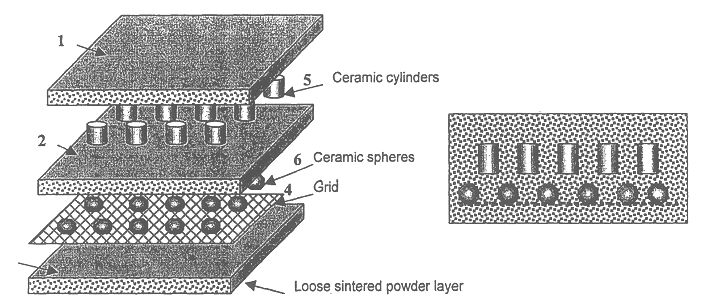

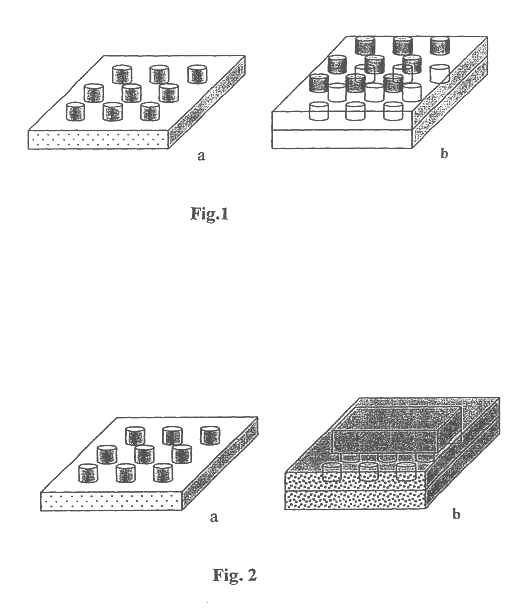

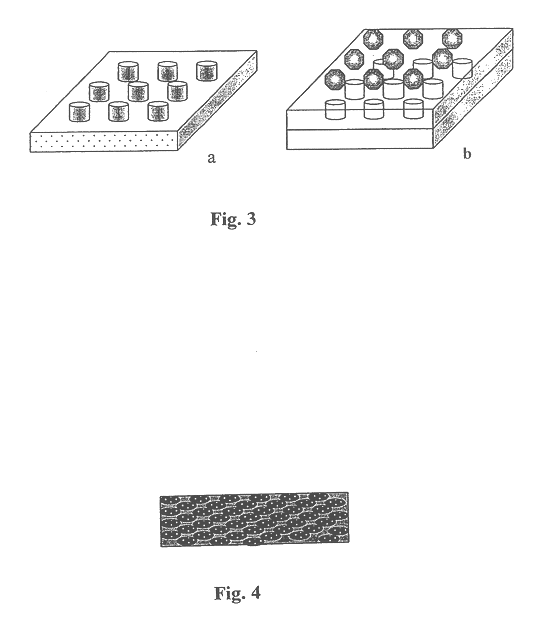

Bulletproof lightweight metal matrix macrocomposites with controlled structure and manufacture the same

InactiveUS6635357B2Stop crack propagation after bullet orPromote reproductionMilitary adjustmentWelding/cutting media/materialsPorosityMetal insert

The lightweight bulletproof metal matrix macrocomposites (MMMC) contain (a) 10-99 vol. % of permeable skeleton structure of titanium, titanium aluminide, Ti-based alloys, and / or mixtures thereof infiltrated with low-melting metal selected from Al, Mg, or their alloys, and (b) 1-90 vol. % of ceramic and / or metal inserts positioned within said skeleton, whereby a normal projection area of each of said inserts is equal to or larger than the cross-section area of a bullet or a projectile body. The MMMC are manufactured as flat or solid-shaped, double-layer, or multi-layer articles containing the same inserts or different inserts in each layer, whereby insert projections of each layer cover spaces between inserts of the underlying layer. The infiltrated metal contains 1-70 wt. % of Al and Mg in the balance, optionally, alloyed with Ti, Si, Zr, Nb, V, as well as with 0-3 wt. % of TiB2, SiC, or Si3N4 sub-micron powders, to promote infiltrating and wetting by Al-containing alloys. The manufacture includes (a) forming the permeable metal powder and inserts into the skeleton-structured preform by positioning inserts in the powder followed by loose sintering in vacuum to provide the average porosity of 20-70%, (b) heating and infiltrating the porous preform with molten infiltrating metal for 10-40 min at 450-750° C., (c) hot isostatic pressing of the infiltrated composite, and (d) re-sintering or diffusion annealing.

Owner:ADVANCED MATERIALS PRODS

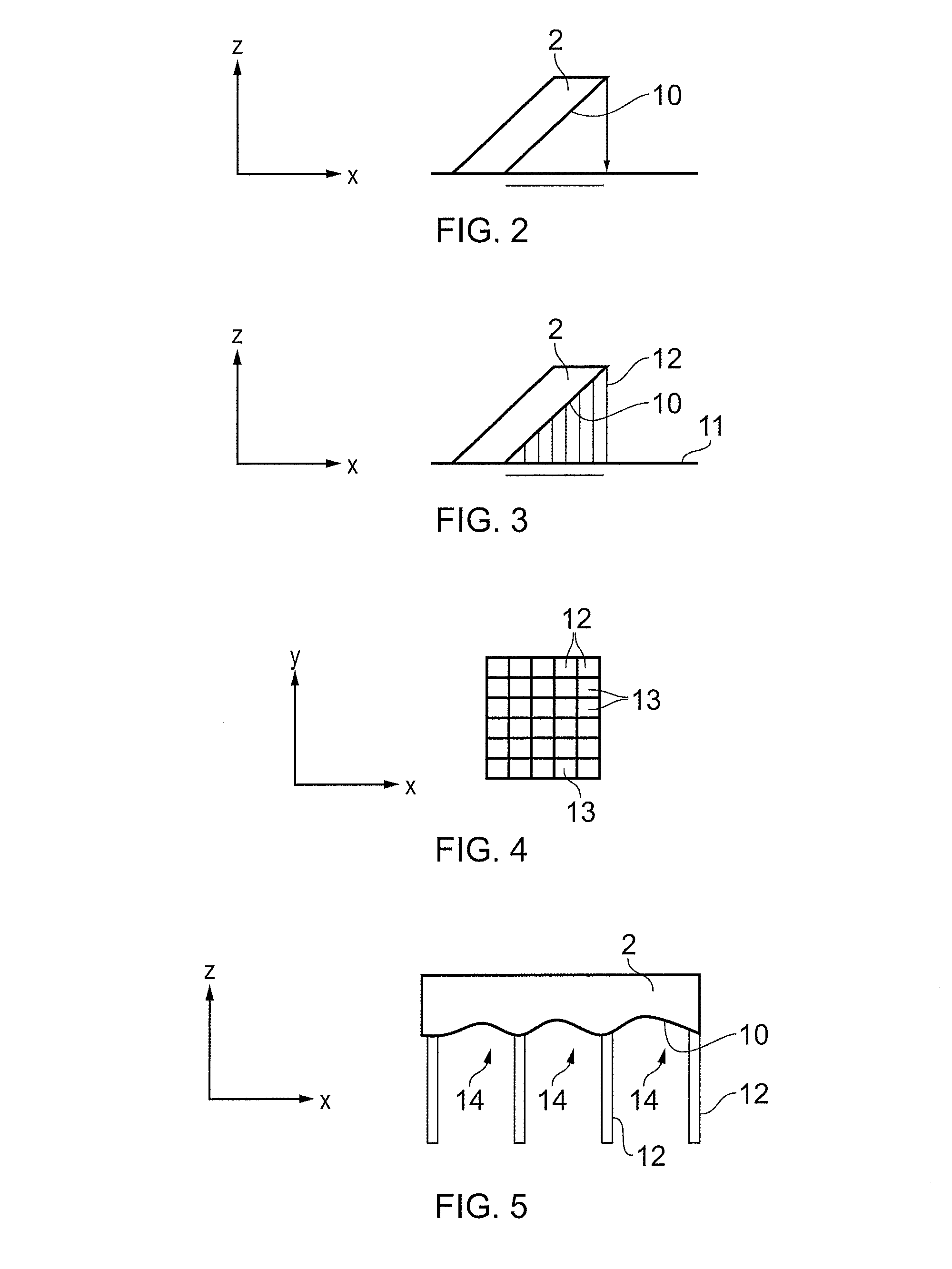

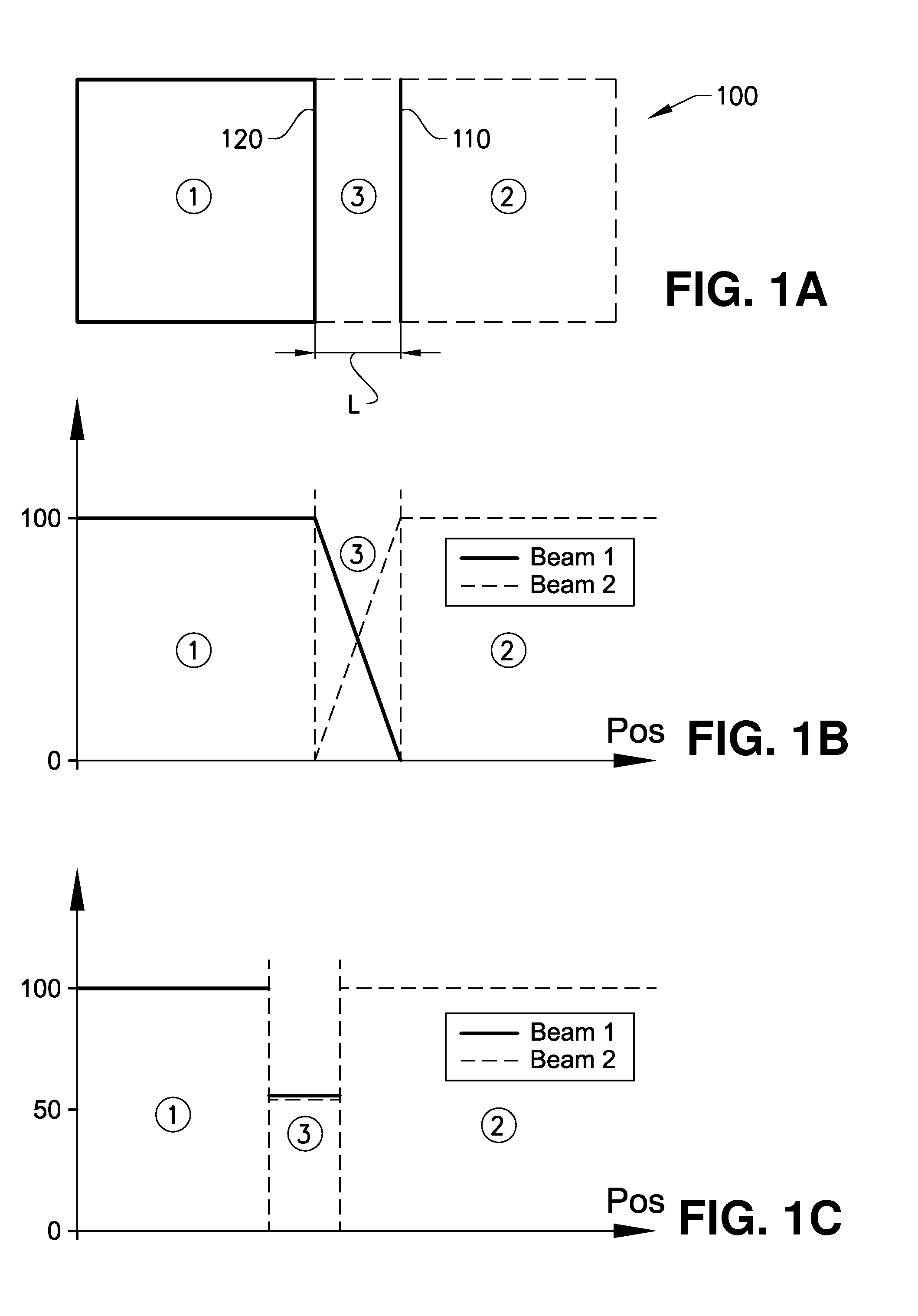

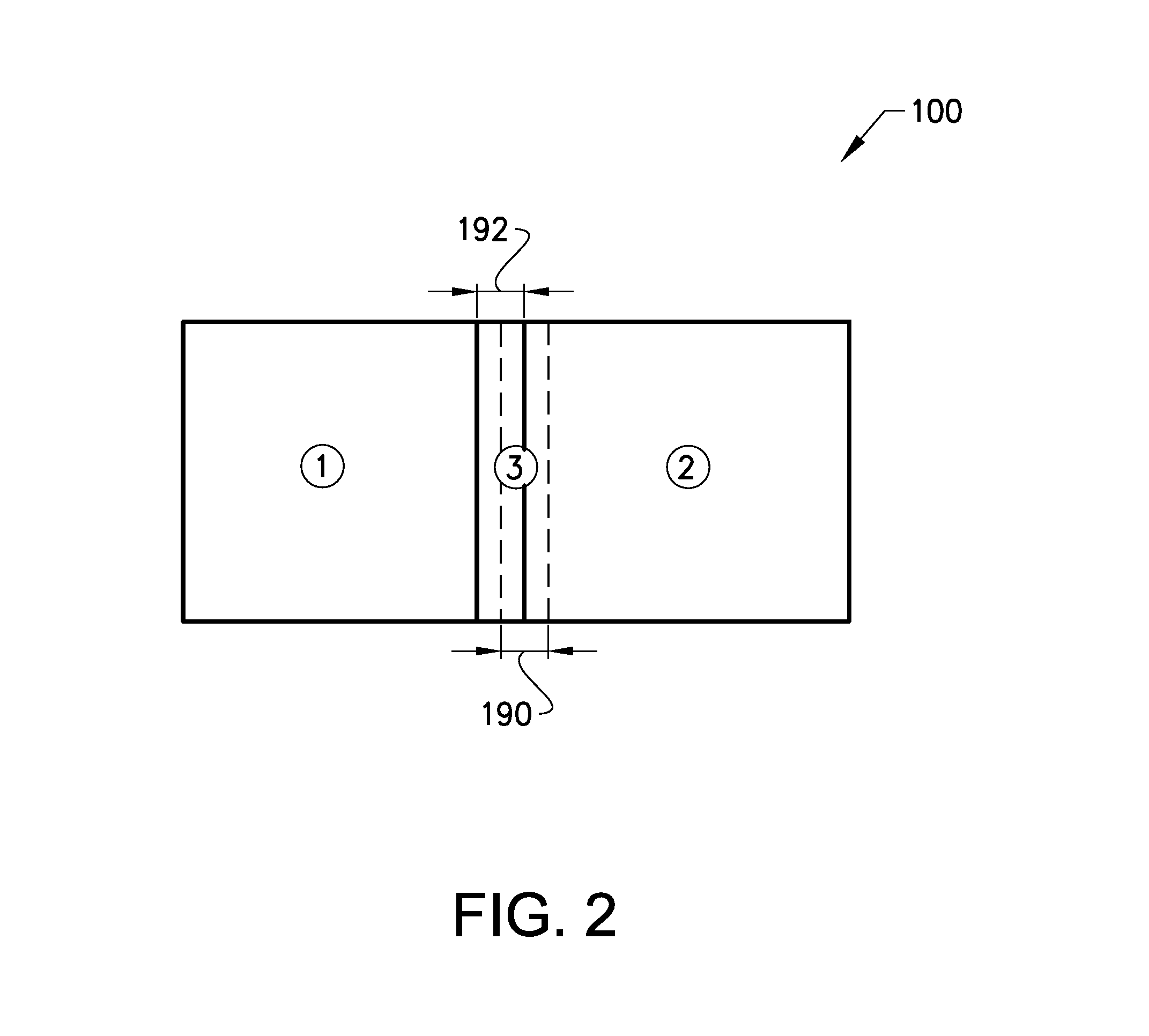

Method and apparatus for increasing the resolution in additively manufactured three-dimensional articles

ActiveUS9079248B2High resolutionHigh pressure levelAdditive manufacturing apparatusIncreasing energy efficiencyPowder bedImage resolution

Owner:ARCAM AB

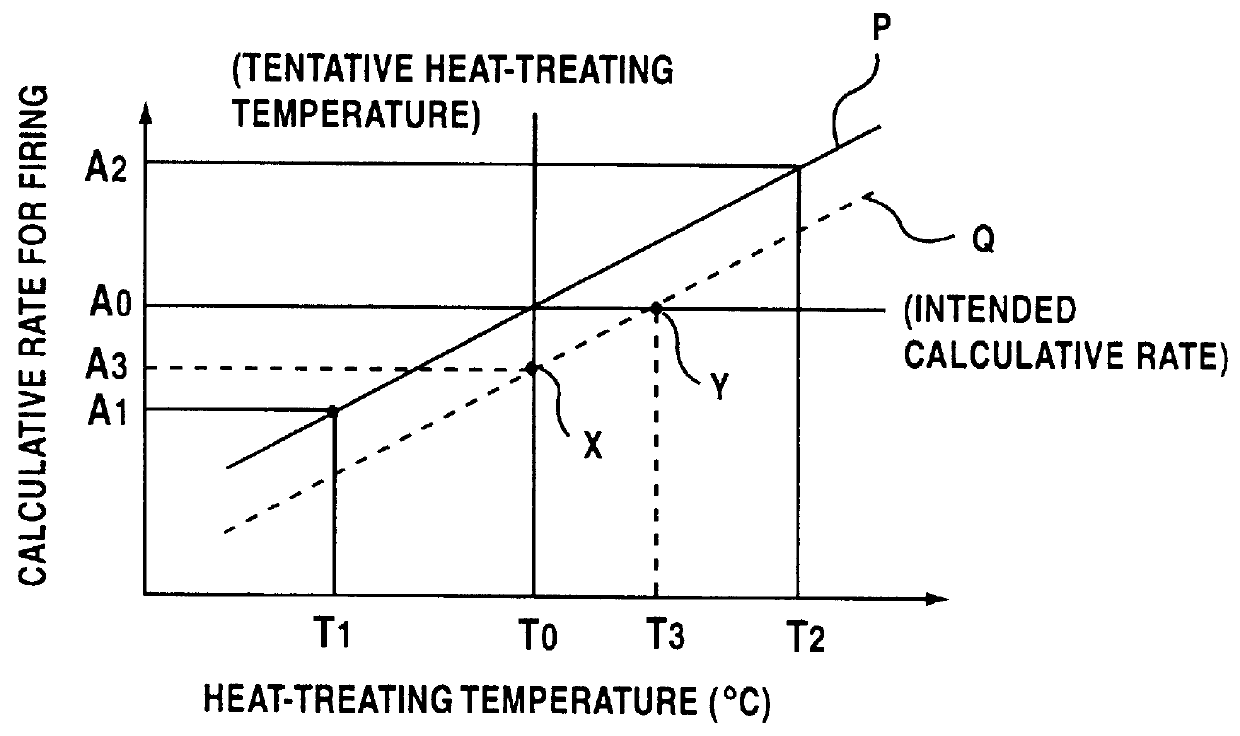

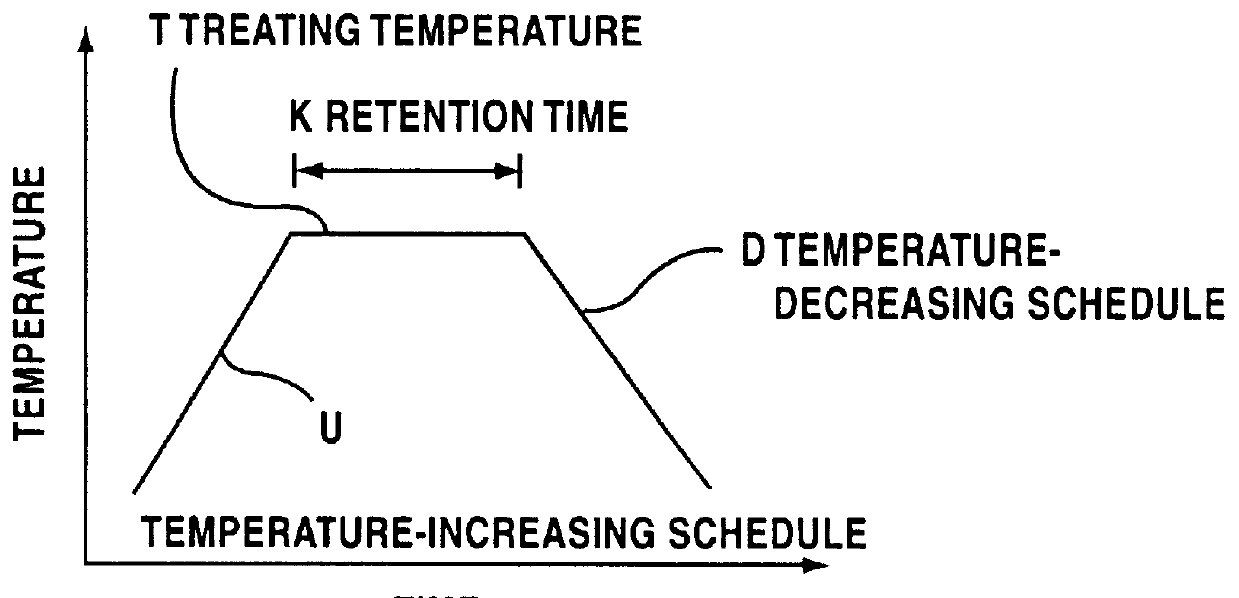

Method for controlling firing shrinkage of ceramic green body

A method of controlling the amount of firing shrinkage of a ceramic green body prepared by molding a ceramic powder (A) to a desired value A1 by heat treating the powder at a temperature T1 that provides the firing shrinkage A1 at a predetermined firing temperature. The temperature T1 is determined based on an established correlation between an amount of firing shrinkage at the predetermined firing temperature and a heat-treatment temperature of a powder (B) having a composition similar to that of the powder (A) in such an extent that a total amount of a greatest common content of an individual component common between the powders (A) and (B) in terms of percent is 90% by weight or more, and satisfying such a relation that the spherical diameter of powder (A) is within a range of + / - 30% relative to the spherical diameter (Rs) of the powder (B) and that its average degree of aggregation (+E,uns x+EE ) is within the range from +E,fra 1 / 2+EE fold to 2 fold relative to the average degree of aggregation (+E,uns x+EE ) of the powder (B).

Owner:NGK INSULATORS LTD

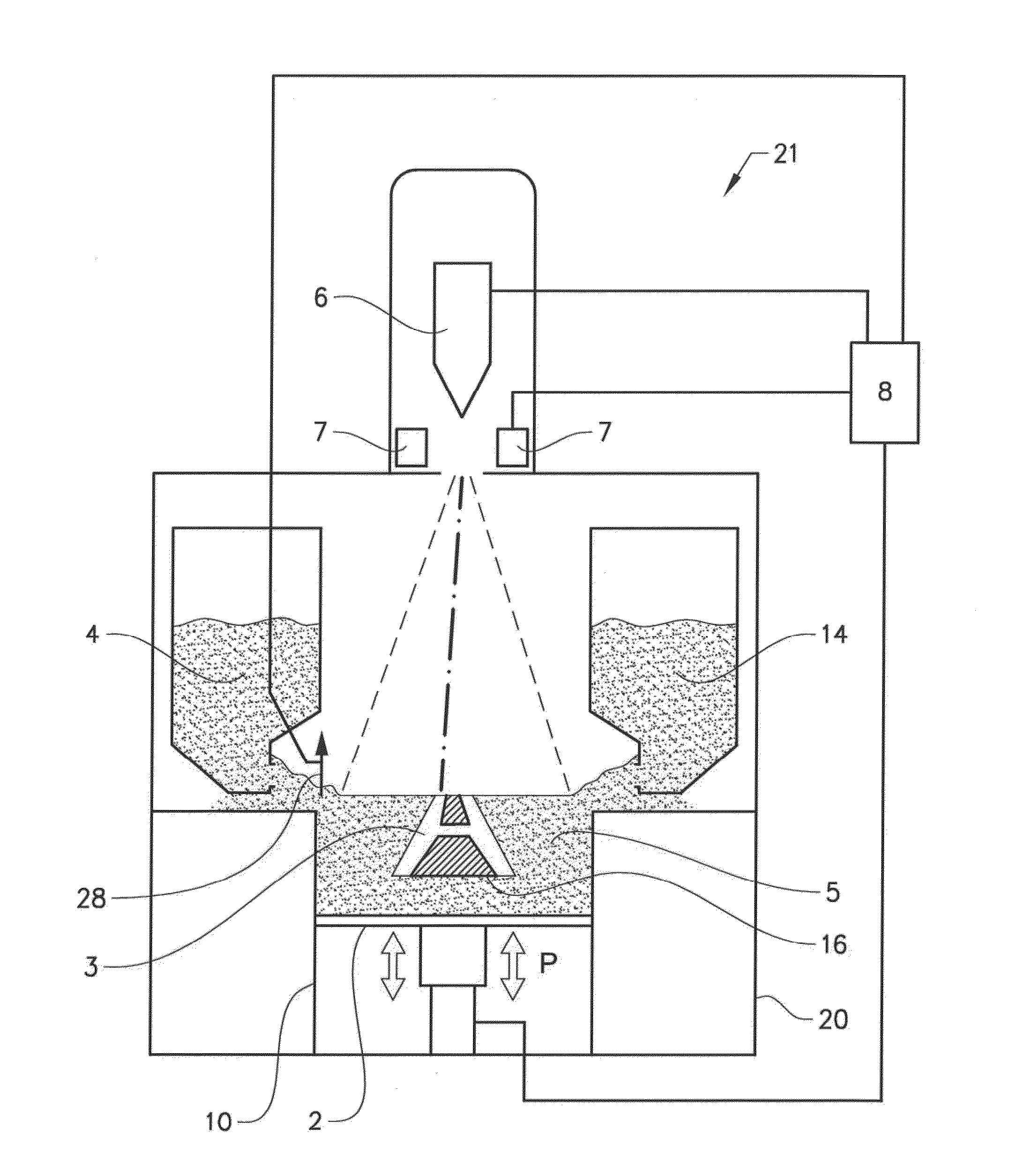

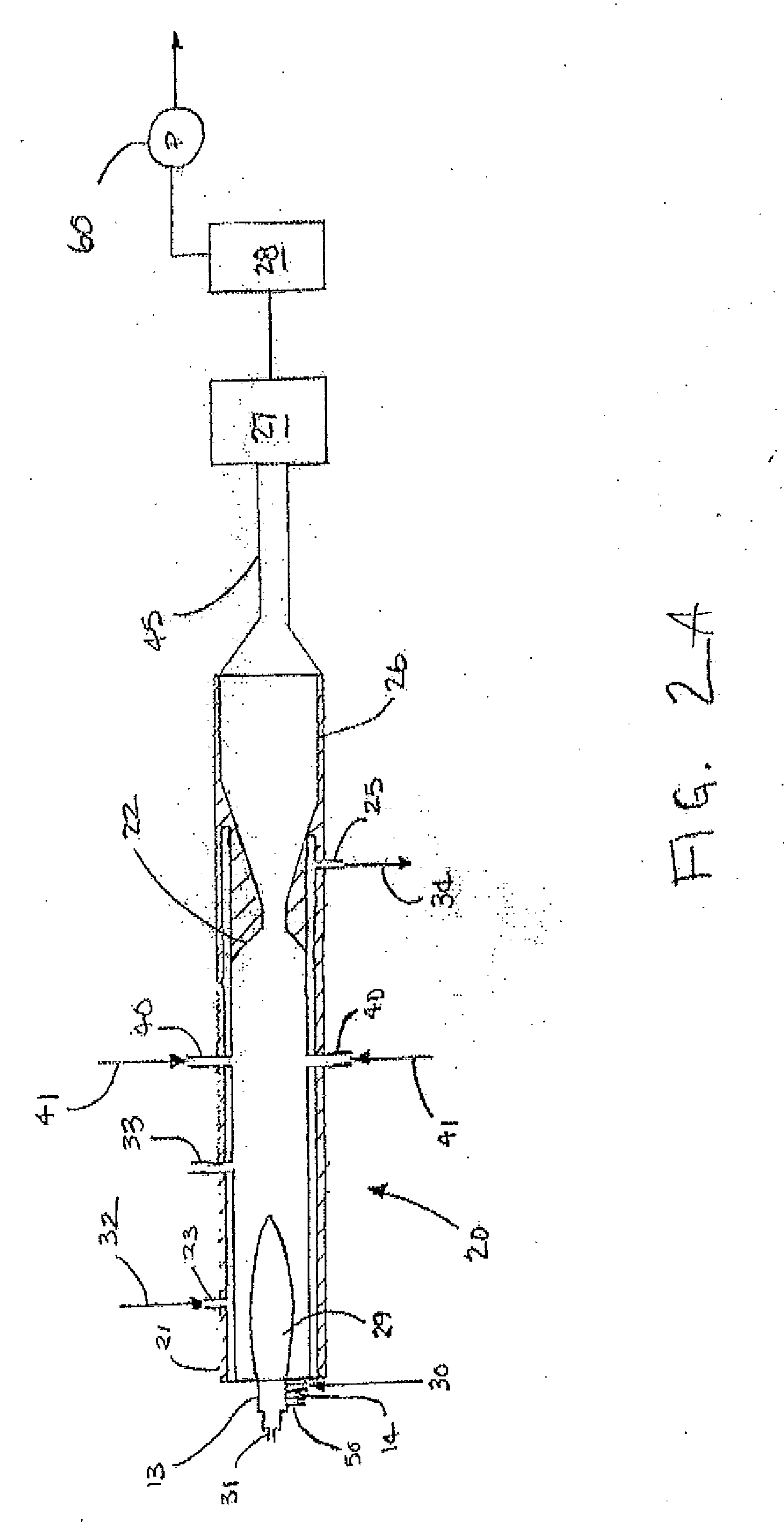

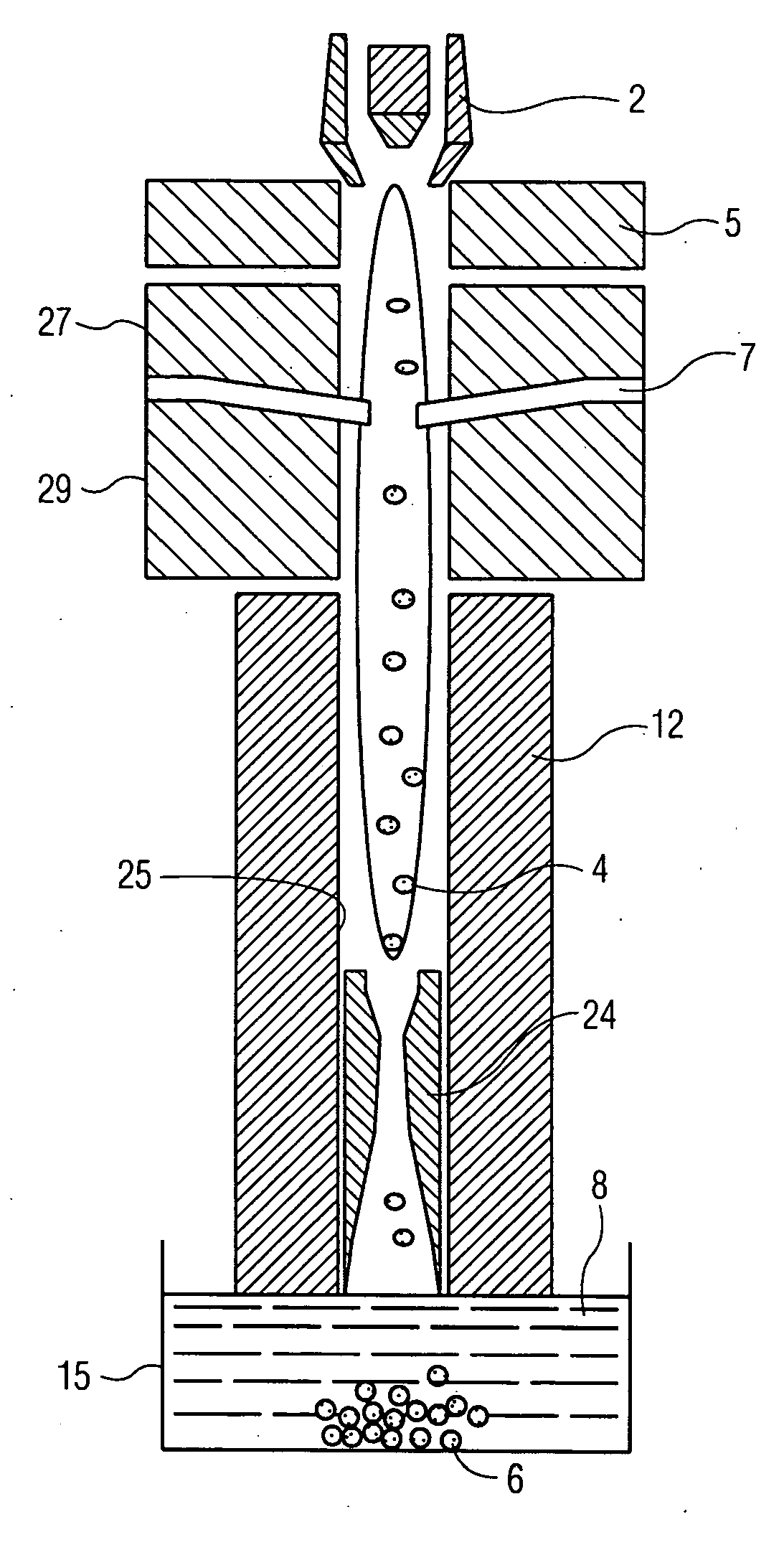

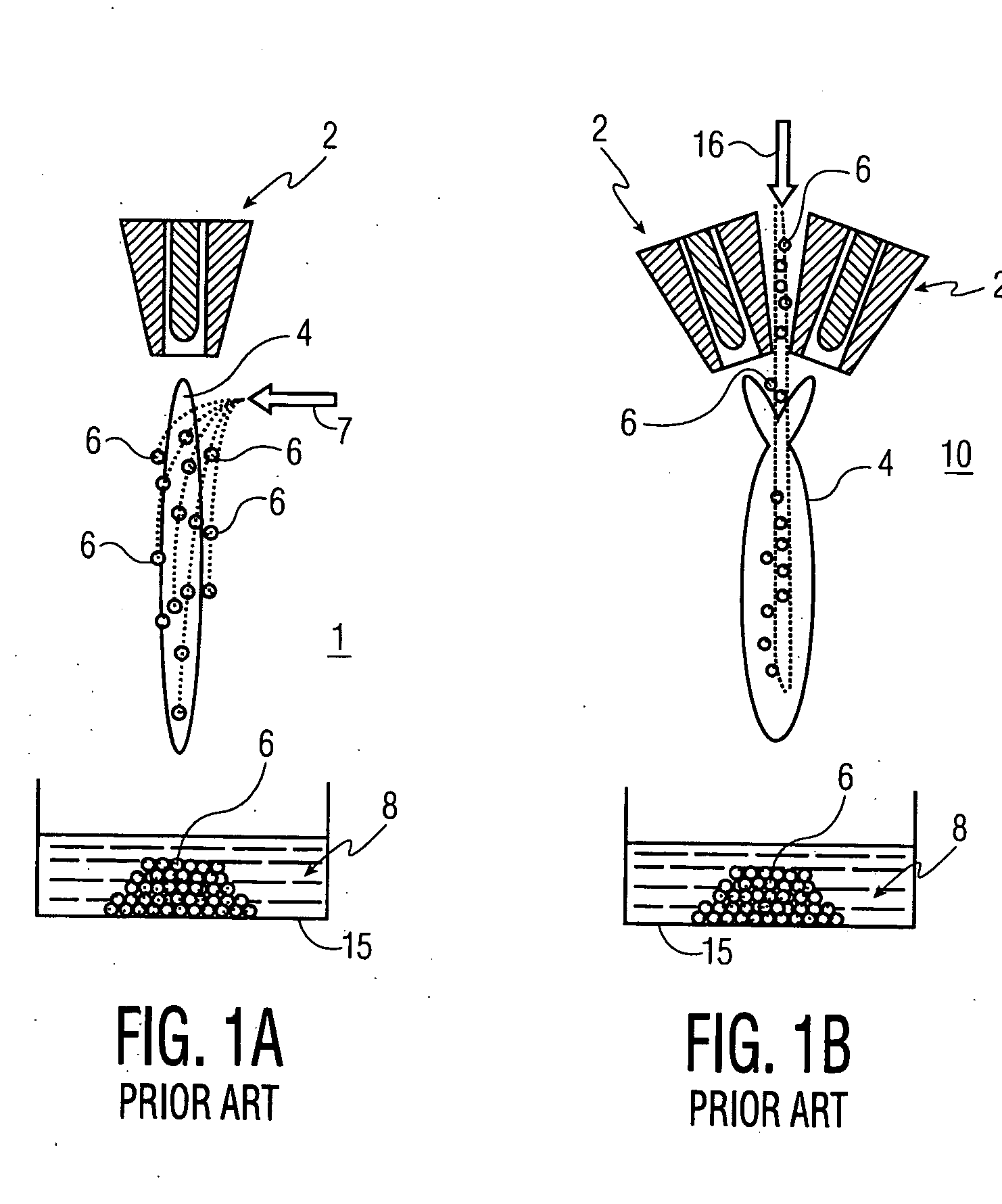

Method and apparatus for producing three-dimensional objects

ActiveUS20160303687A1Equally distributedAdditive manufacturing apparatusIncreasing energy efficiencyLight beamMechanical engineering

Owner:ARCAM AB

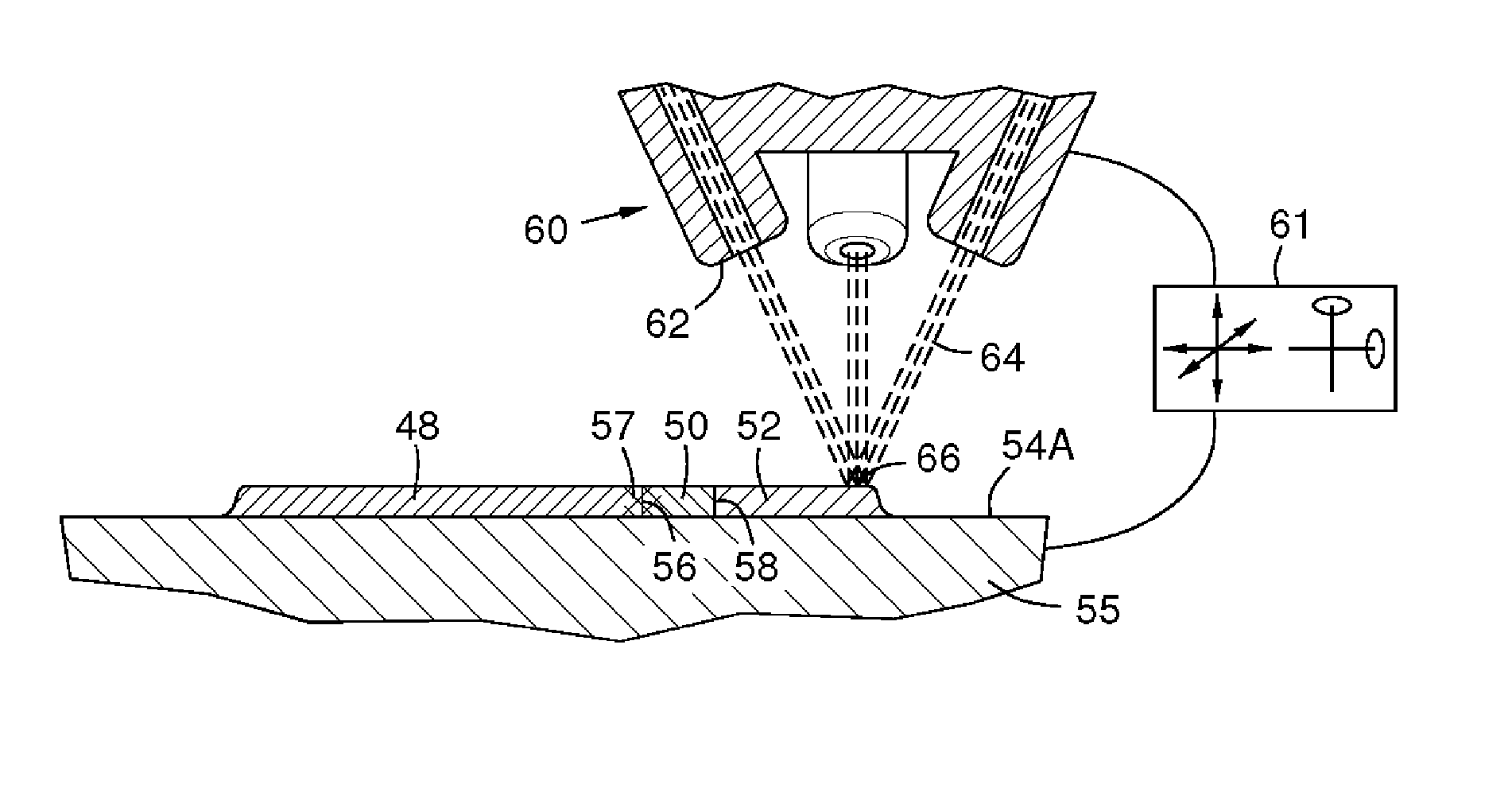

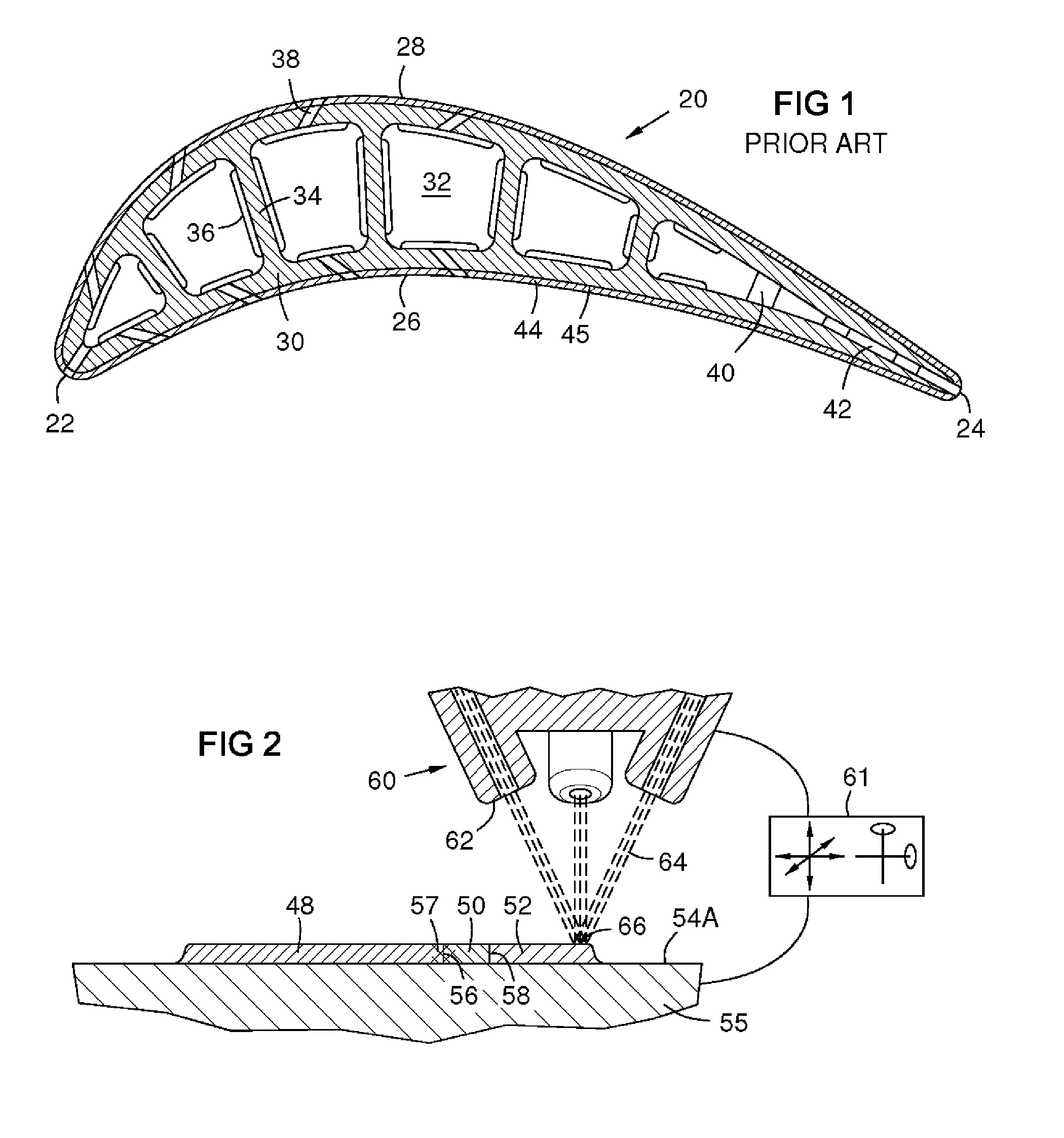

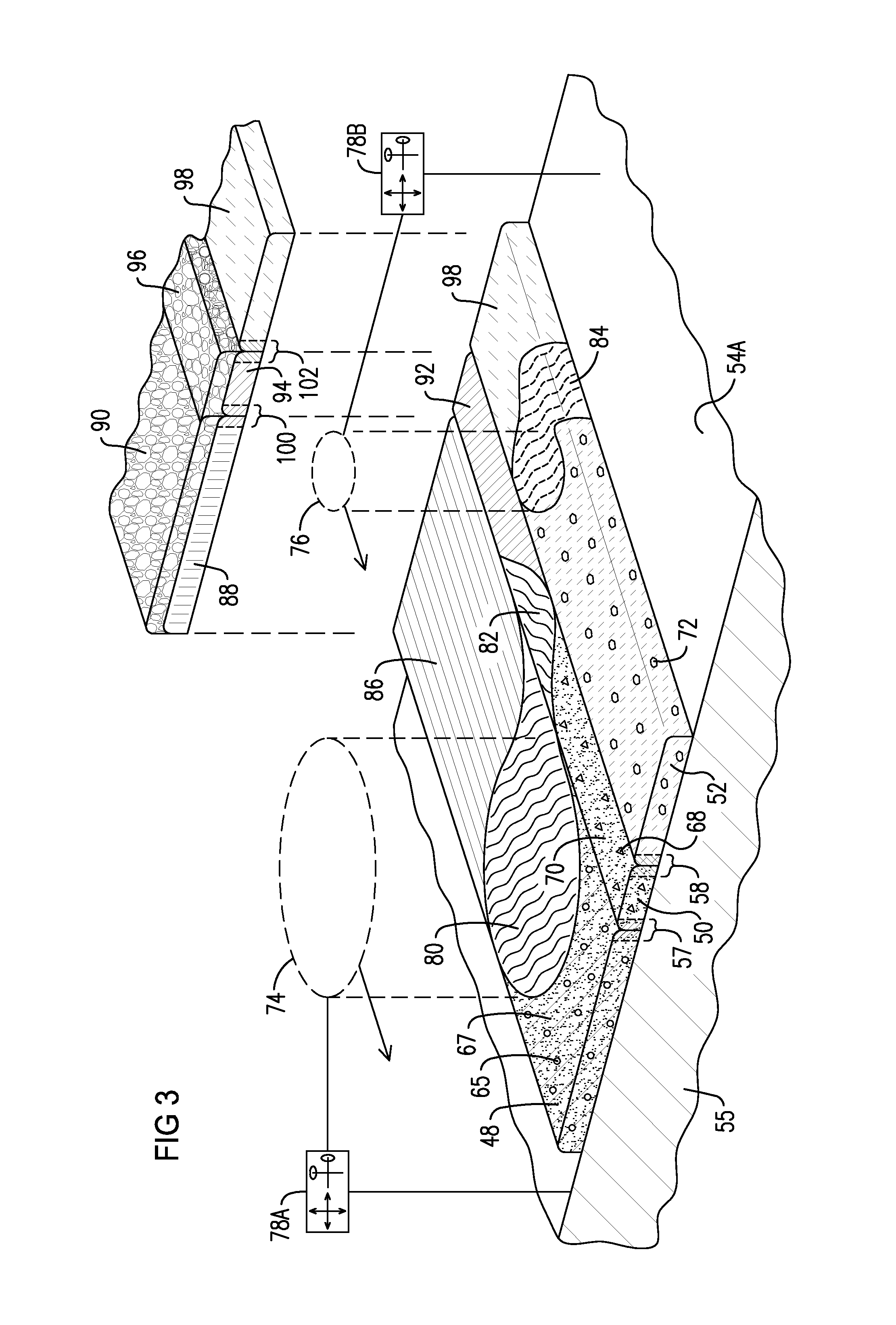

Laser additive manufacture of three-dimensional components containing multiple materials formed as integrated systems

Methods for laser additive manufacture are disclosed in which a plurality of powder layers (48, 50 and 52) are delivered onto a working surface (54A) to form a multi-powder deposit containing at least two adjacent powders layers in contact, and then applying a first laser energy (74) to a first powder layer (48) and a second laser energy (76) to a second powder layer (52) to form a section plane of a multi-material component. The multi-powder deposit may include a flux composition that provides at least one protective feature. The shapes, intensities and trajectories of the first and second laser energies may be independently controlled such that their widths are less than or equal to widths of the first and second powder layers, their intensities are tailored to the compositions of the powder layers, and their scan paths define the final shape of the multi-material component.

Owner:SIEMENS ENERGY INC

Method and apparatus for additive manufacturing

ActiveUS9550207B2Improve conductivityReduce probabilityAdditive manufacturing apparatusTransportation and packagingPowder bedEngineering

Various embodiments provide a method and apparatus for forming a three-dimensional article through successive fusion of parts of at least one layer of a powder bed provided on a work table in an additive manufacturing machine, which parts corresponds to successive cross sections of the three-dimensional article. The method comprises the steps of: applying a layer of predetermined thickness of powder particles on the work table, applying a coating on at least a portion of the powder particles, which coating is at least partially covering the powder particles, and fusing the powder particles on the work table with an electron beam.

Owner:ARCAM AB

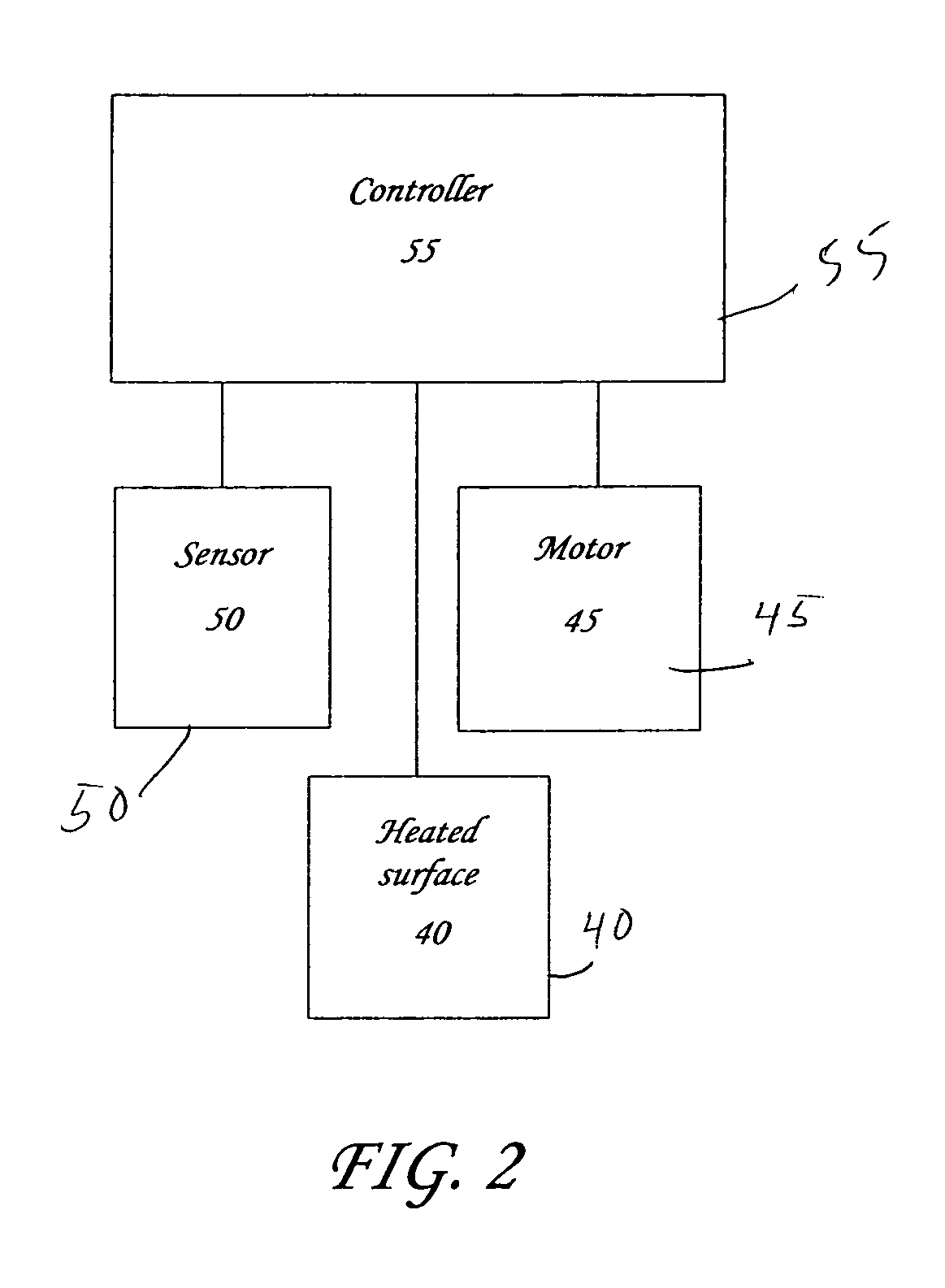

Controllably feeding organic material in making OLEDs

ActiveUS20060177576A1Effective waySolid-state devicesVacuum evaporation coatingOLEDMaterials science

A method for metering powdered or granular material onto a heated surface to vaporize such material, includes providing a container with powdered or granular material having at least one component; providing a rotatable auger disposed in material receiving relationship with the container for receiving powdered or granular material from the container and as the auger rotates, such rotating auger translates such powdered or granular material along a feed path to a feeding location; and providing at least one opening at the feeding location such that the pressure produced by the rotating auger at the feeding location causes the powdered or granular material to be forced through the opening onto the heated surface in a controllable manner.

Owner:GLOBAL OLED TECH

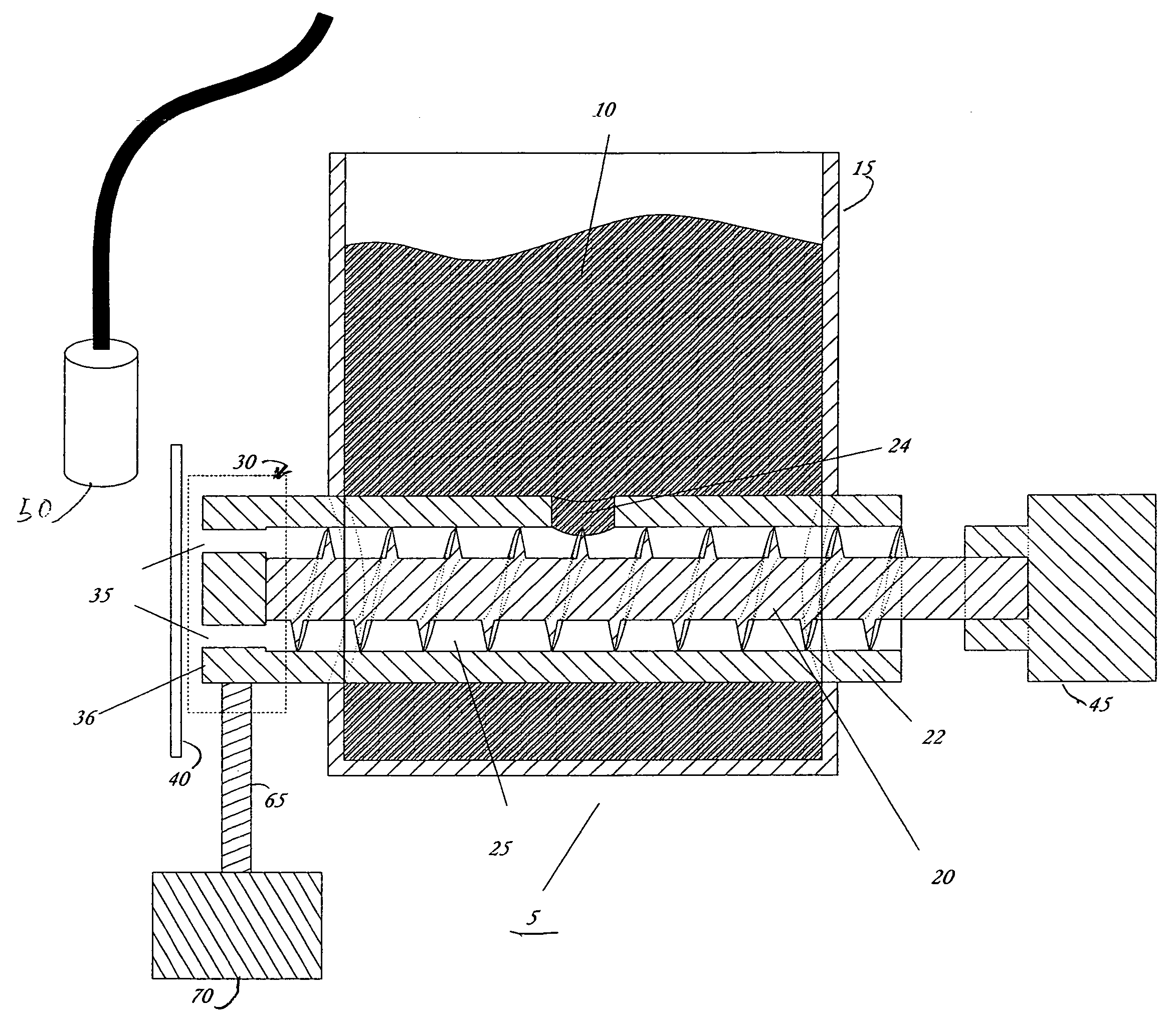

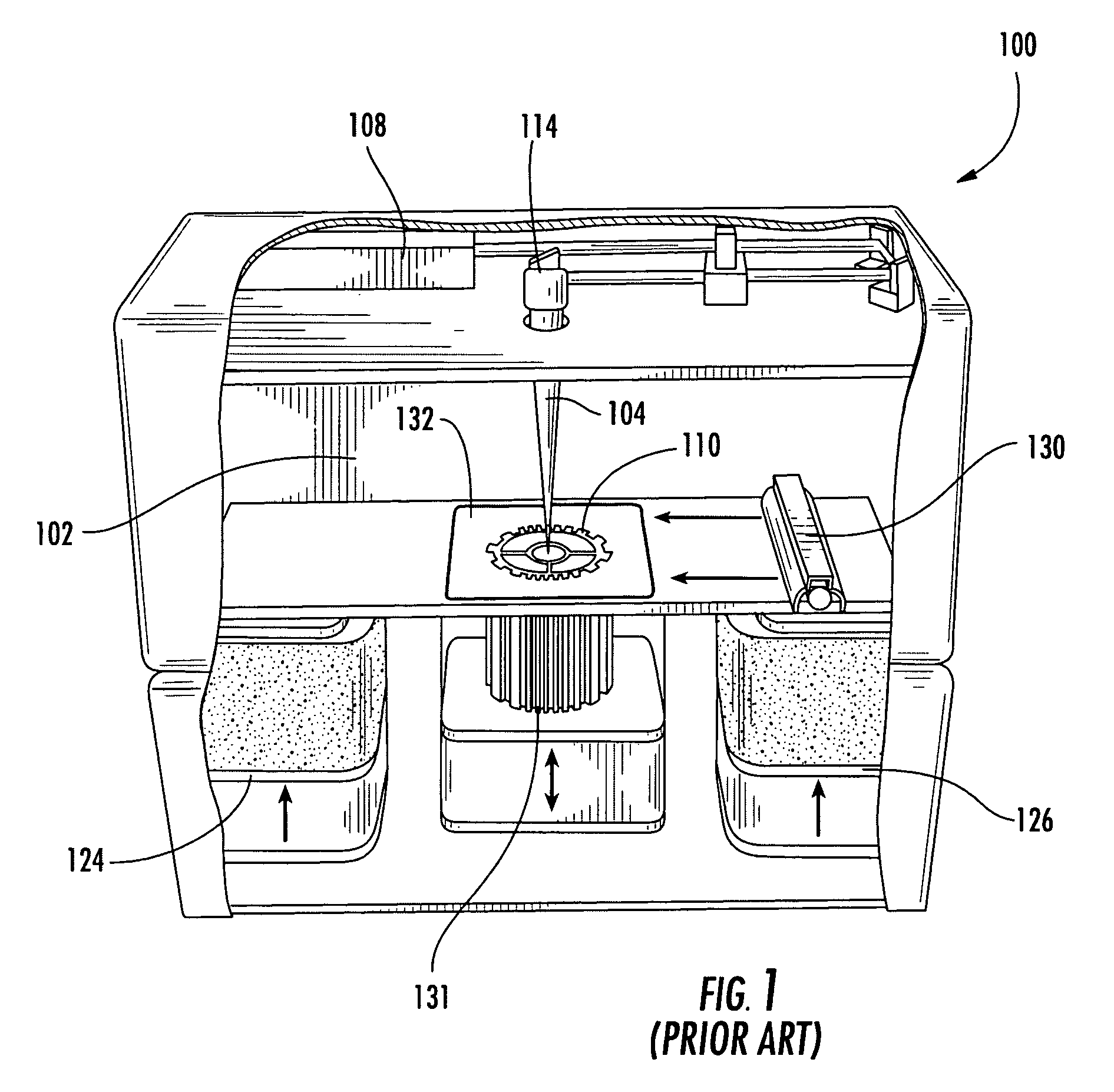

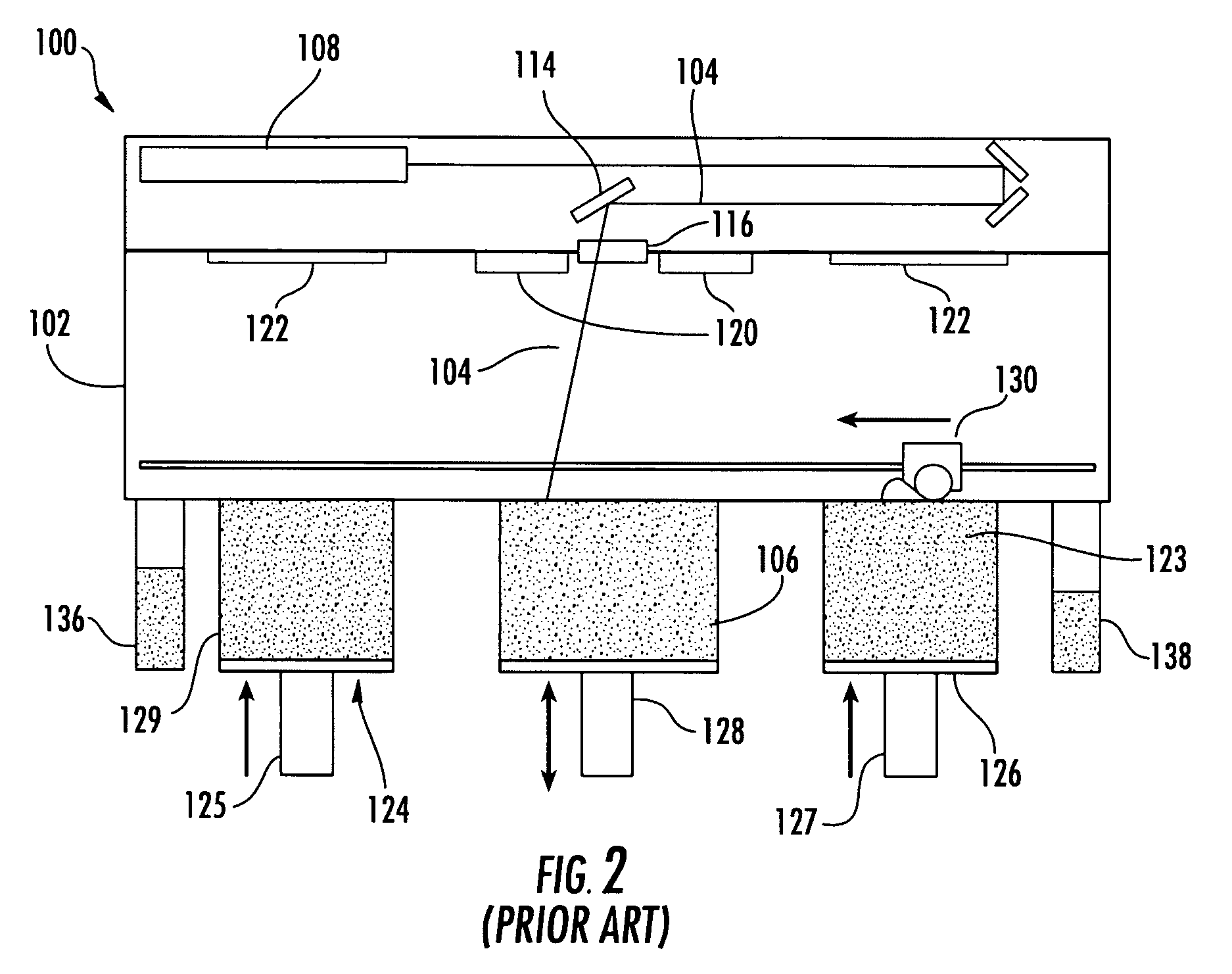

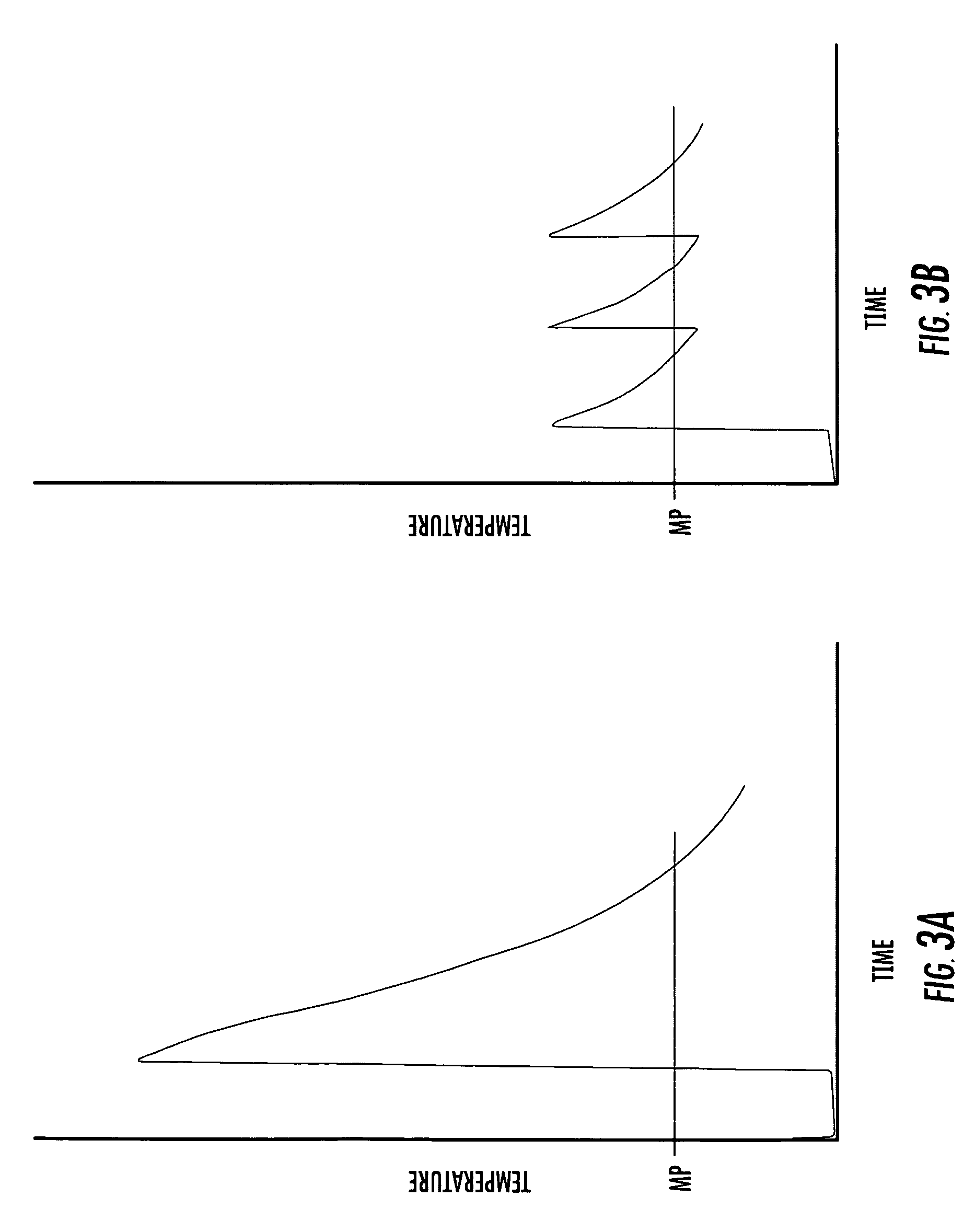

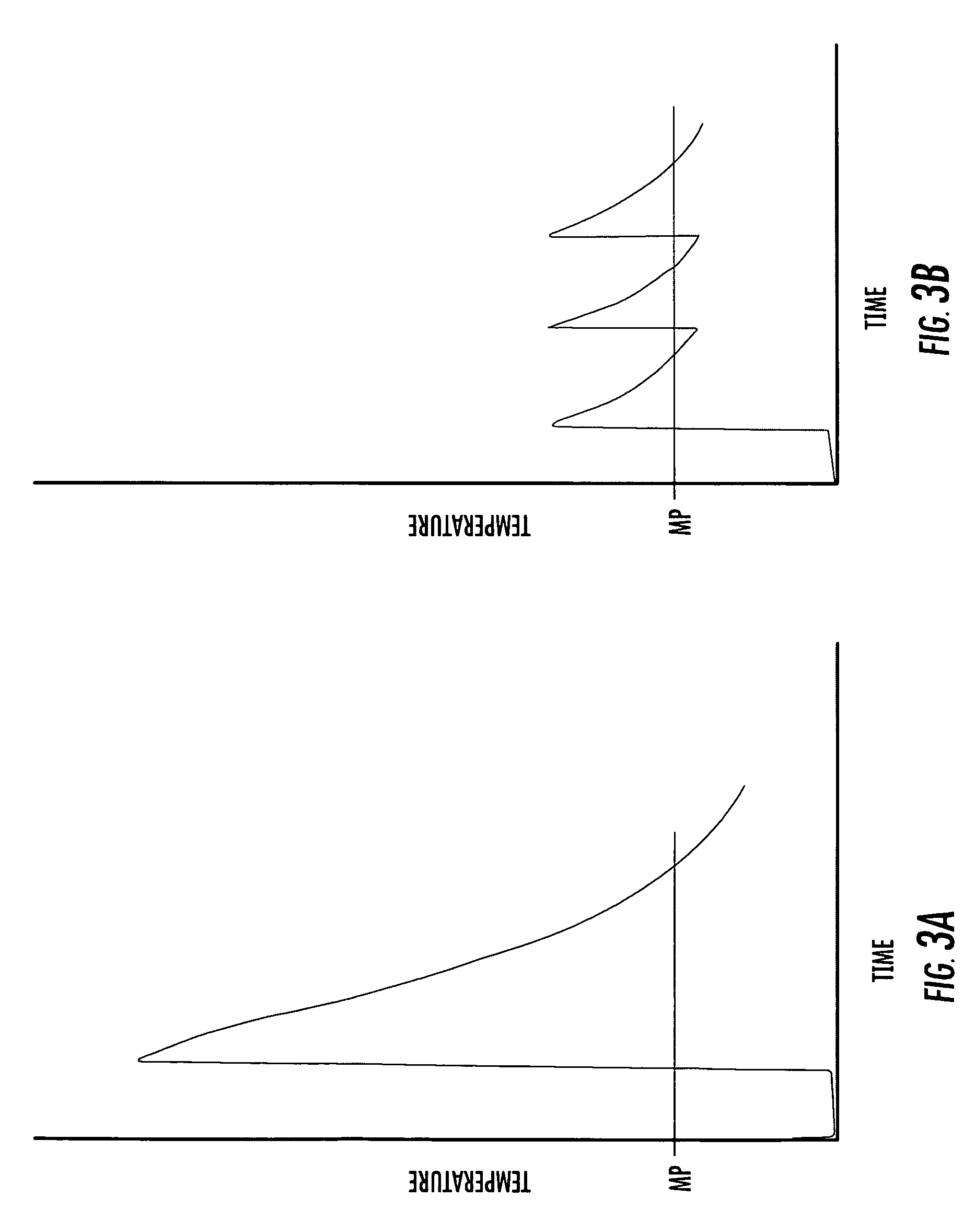

Controlled densification of fusible powders in laser sintering

ActiveUS7569174B2Heat dissipationSimple methodAdditive manufacturing apparatusAuxillary shaping apparatusHigh energyTime segment

The invention relates to a method producing parts using laser sintering wherein a fusible powder is exposed to a plurality of laser scans at controlled energy levels and for time periods to melt and densify the powder and in the substantial absence of particle bonding outside the fusion boundary. Strength is improved up to 100% compared to previous methods. An example includes a relatively high energy initial scan to melt the powder followed by lower energy scans controlled to densify the melt and separated in time to dissipate heat to the surrounding part cake. The rate and extent to which the powder particles are fused together can be controlled so that each successive scan can be used to fuse the particles together in discreet incremental steps. As a result, the final dimensions of the part and its density and mechanical properties can be improved compared to conventional methods and part growth avoided.

Owner:3D SYST INC

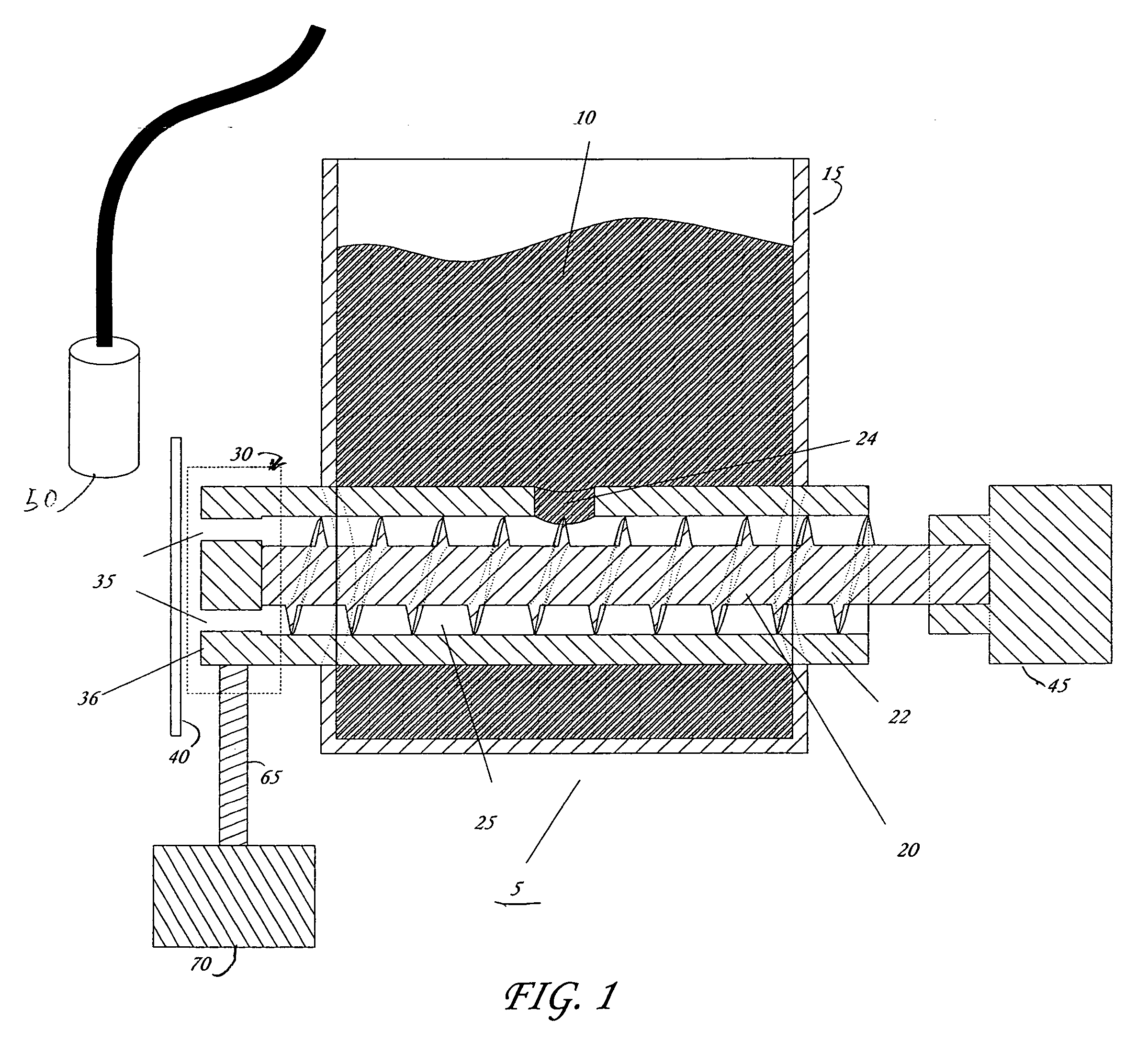

Controlled densification of fusible powders in laser sintering

ActiveUS20060119012A1Heat dissipationSimple methodAdditive manufacturing apparatusAuxillary shaping apparatusHigh energyLaser scanning

The invention relates to a method producing parts using laser sintering wherein a fusible powder is exposed to a plurality of laser scans at controlled energy levels and for time periods to melt and densify the powder and in the substantial absence of particle bonding outside the fusion boundary. Strength is improved up to 100% compared to previous methods. An example includes a relatively high energy initial scan to melt the powder followed by lower energy scans controlled to densify the melt and separated in time to dissipate heat to the surrounding part cake. The rate and extent to which the powder particles are fused together can be controlled so that each successive scan can be used to fuse the particles together in discreet incremental steps. As a result, the final dimensions of the part and its density and mechanical properties can be improved compared to conventional methods and part growth avoided.

Owner:3D SYST INC

Monolithic honeycomb structure made of porous ceramic and use as a particle filter

InactiveUS6582796B1Prevent the evaporation of the waterEasy curingInternal combustion piston enginesSilencing apparatusSodium BentoniteOxygen

A monolithic honeycomb-type structure useful in particular as a particle filter for exhaust gases from diesel engines has a number of passages that empty into the end faces of said monolith, but are alternately open and sealed. The monolith consists of a porous refractory material that comprises: 70 to 97% by mass of alpha and / or beta crystallographic-type silicon carbide that has at least one particle size and preferably at least two particle sizes, and 3 to 30% by mass of at least one bonding ceramic phase in the form of a micronic powder or particles that are obtained by atomization, comprising at least one simple oxide, for example, B2O3, Al2O3, SiO2, MgO, K2O, Li2O, Na2O, CaO, BaO, TiO, ZrO2 and Fe2O3 and / or at least one mixed oxide, for example, the alkaline aluminosilicates (of Li, Na, or K) or alkaline-earth aluminosilicates (of Mg, Ca, Sr or Ba), clays, bentonite, feldspars or other natural silico-aluminous materials. The production of the monolith comprises a calcination stage under an oxygen-containing atmosphere at a temperature up to 1650° C., but less than 1550° C.

Owner:INST FR DU PETROLE

Additive layer manufacturing method

An additive layer manufacturing method includes the steps of: a) laying down powder layer on powder bed, and b) focussing energy on an area of powder layer to fuse area of powder layer and thereby form a cross-section of the product; wherein steps a) and b) are repeated to form successive cross-sections of product, and wherein at least one of said steps b) involves focussing energy on an area of respective powder layer which is unsupported by a previously formed cross-section of product to thereby form a downwardly facing surface of product. Method is at least some of said successive steps b) involve focussing energy on a support area of respective powder layer, to fuse support area and thereby form successive cross-sections of a support pin within powder bed, support pin extending outwardly from downwardly facing surface of product when it is formed, so as to support downwardly facing surface.

Owner:ROLLS ROYCE PLC

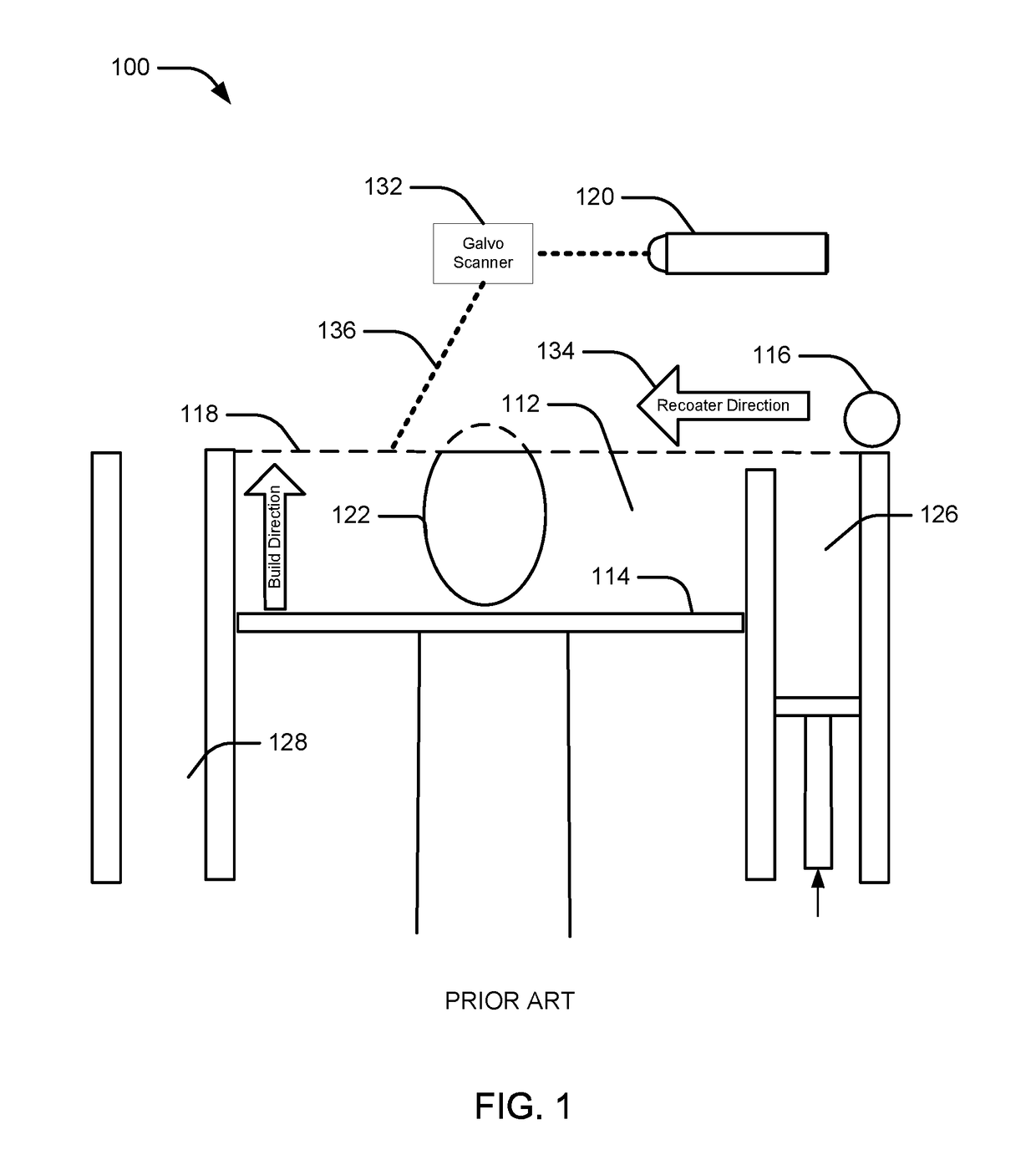

Method and apparatus for increasing the resolution in additively manufactured three-dimensional articles

ActiveUS20140370323A1High pressure levelHigh beam qualityAdditive manufacturing apparatusIncreasing energy efficiencyImage resolutionVacuum chamber

A method for increasing the resolution when forming a three-dimensional article through successive fusion of parts of a powder bed, said method comprising providing a vacuum chamber, providing an electron gun, providing a first powder layer on a work table inside said vacuum chamber, directing an electron beam from said electron gun over said work table causing the powder layer to fuse in selected locations to form a first cross section of said three-dimensional article, providing a second powder layer on said work table, directing the electron beam over said work table causing said second powder layer to fuse in selected locations to form a second cross section of said three-dimensional article, reducing the pressure in the vacuum chamber from a first pressure level to a second pressure level between the providing of said first powder layer and said second powder layer.

Owner:ARCAM AB

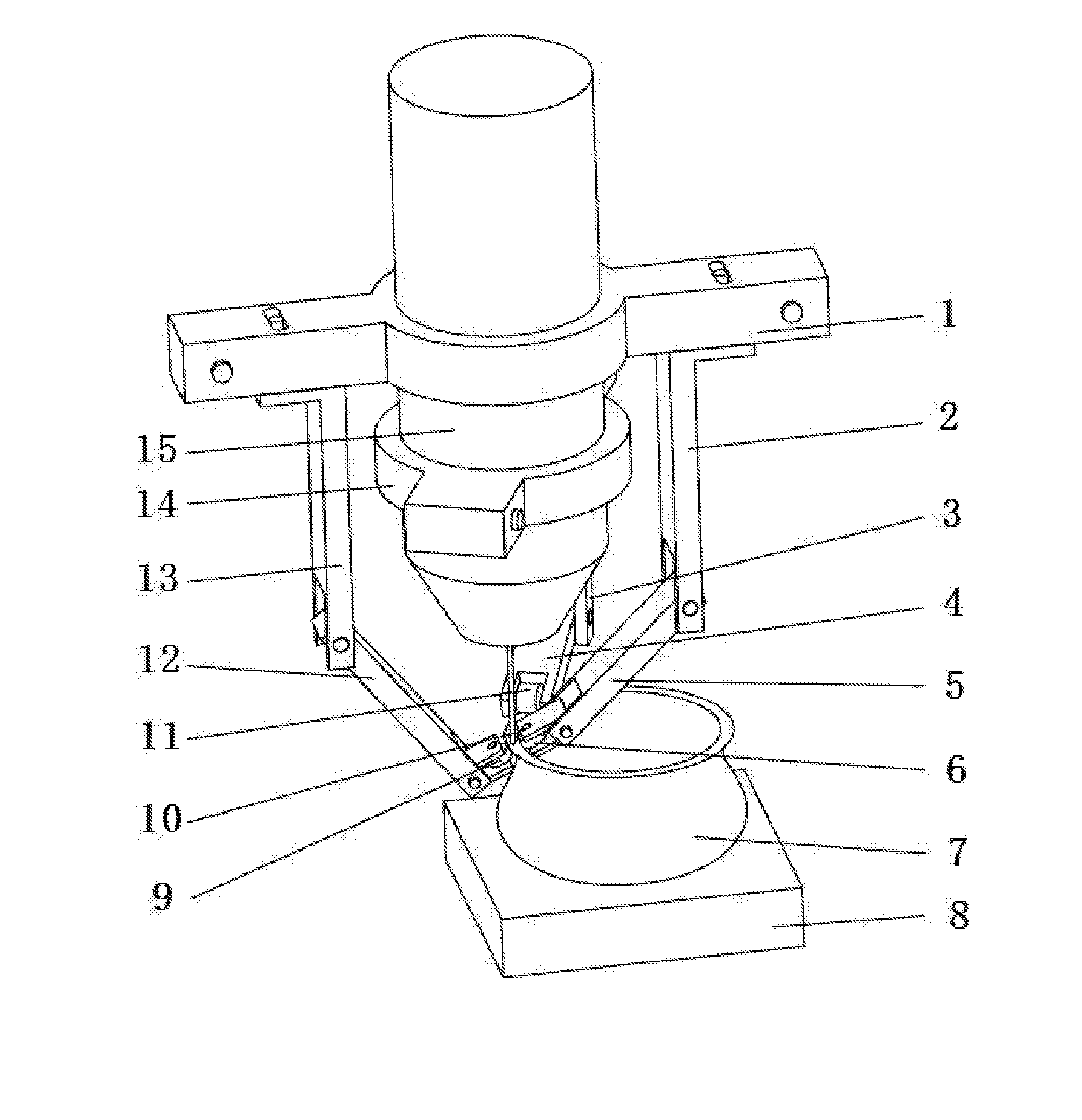

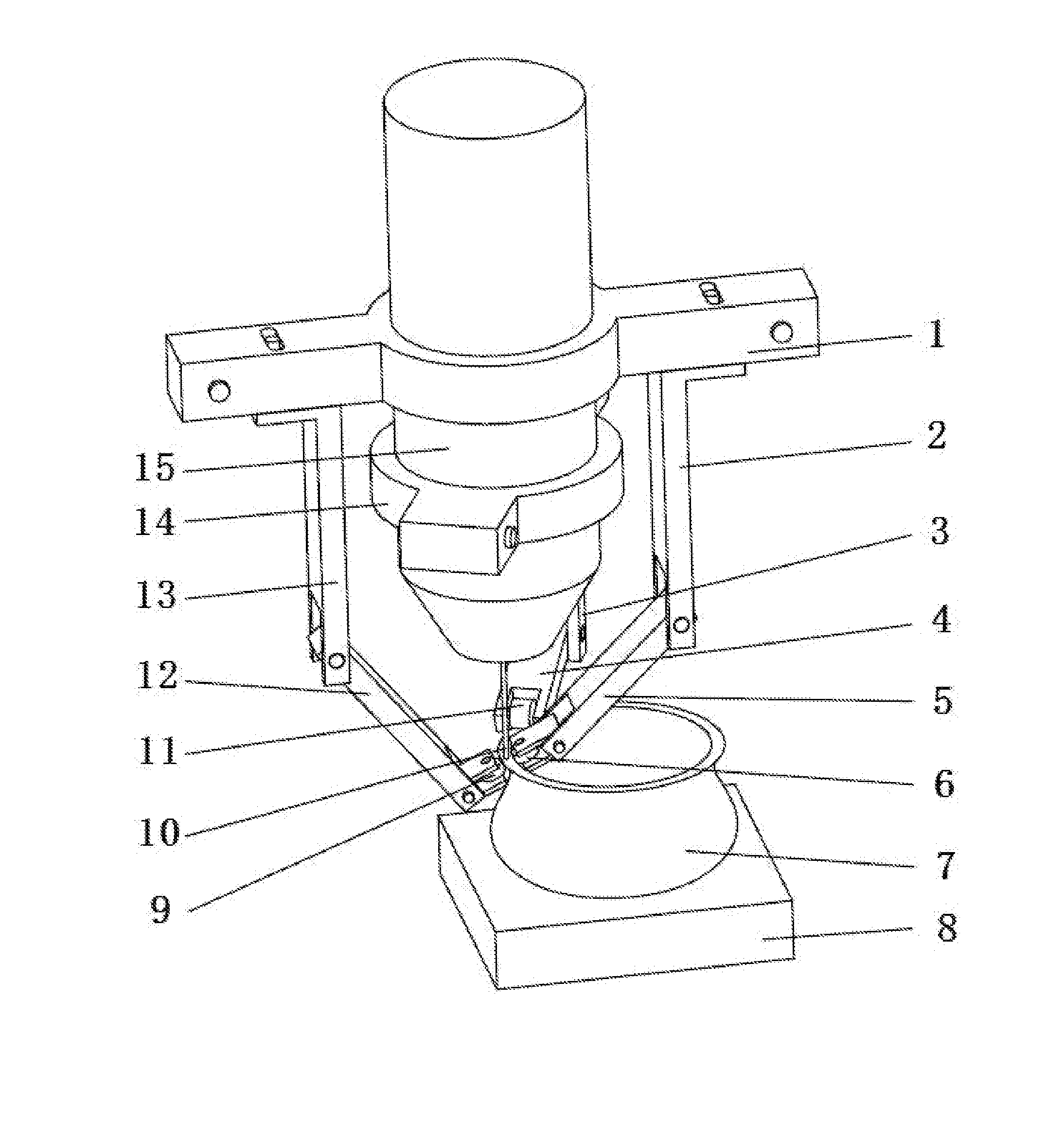

Method for manufacturing metal parts and molds and micro-roller used therefor

ActiveUS20130197683A1Formability of complexImprove accuracyArc welding apparatusAdditive manufacturing with liquidsNumerical controlWire rod

A method for manufacturing parts and molds by: 1) slicing a three-dimensional CAD model of a part or mold; 2) planning a modeling path according to slicing data of the three-dimensional CAD model, whereby generating numerical control codes for modeling processing; and 3) performing fused deposition modeling of powders or wire material of metal, intermetallic compounds, ceramic and composite functional gradient materials by layer using a welding gun on a substrate layer via a numerical control gas shielded welding beam or laser beam according to a track specified by the numerical control code for each layer. A micro-roller or a micro-extrusion unit is installed at a contact area between melted and softened areas. The micro-roller or the micro-extrusion unit synchronously moves along with fused deposition area, which results in compressing and processing of the fused deposition area during the fused deposition modeling.

Owner:HUAZHONG UNIV OF SCI & TECH

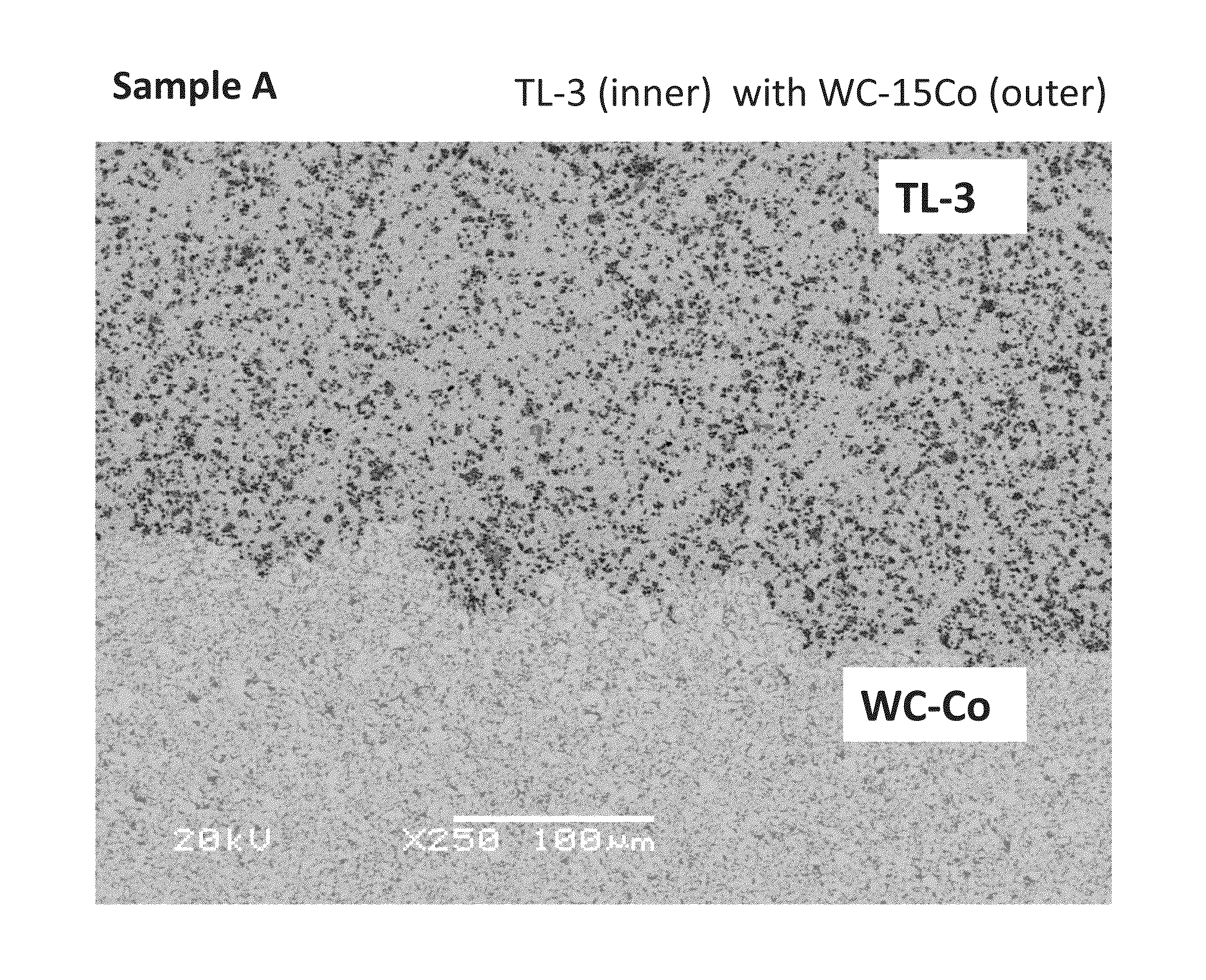

Methods of forming a metallic or ceramic article having a novel composition of functionally graded material and articles containing the same

ActiveUS20140087210A1Improve fracture toughnessLow costAdditive manufacturing apparatusLayered productsCarbideFunctionally graded material

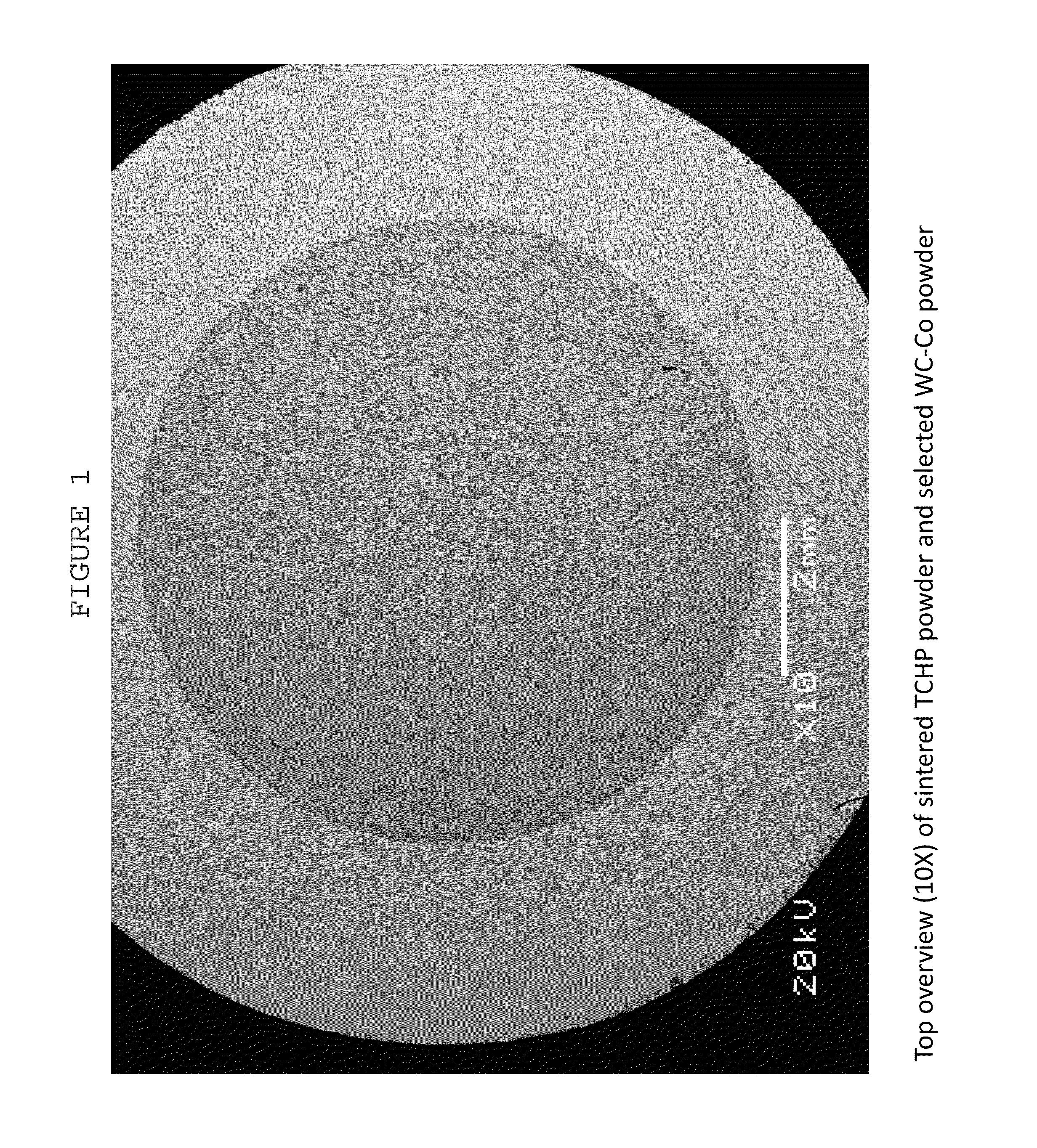

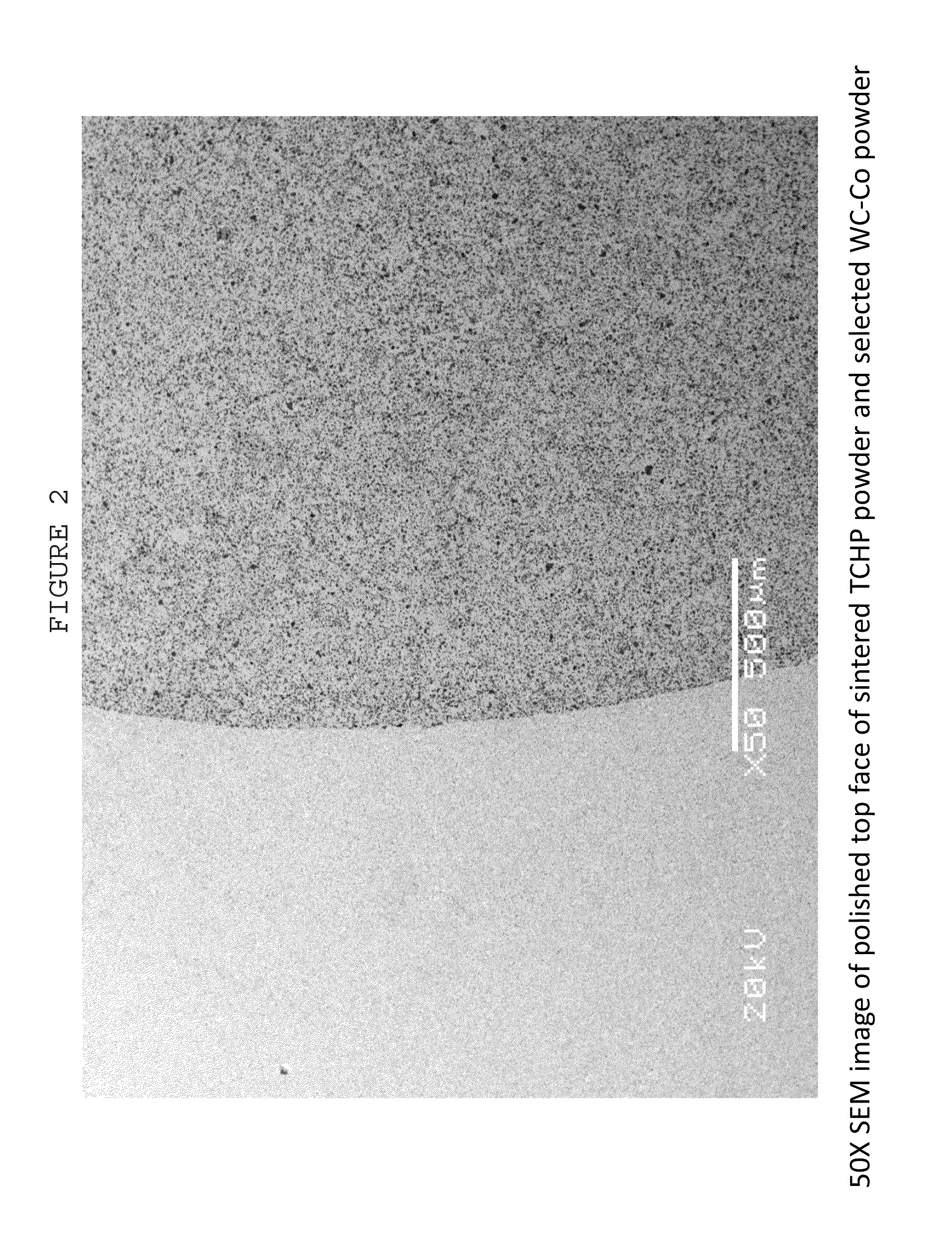

There is disclosed a method of making a metallic or ceramic component, such as a cutting or forming tool, from at least two distinct powder precursors. In one embodiment, the method comprising forming a first mixture comprised of a plurality of coated particles, such as Tough-Coated Hard Powder (TCHP) composite particles created by encapsulating extremely hard core particles with very tough binder and structural materials, and at least one support powder, such as a carbide, typically WC—Co. The mixture is formed into a green body and sintered to form a functionally graded or multicomponent article. Non-limiting examples of the articles made from the disclosed methods are also disclosed and include drills, mills, cutting tools, forming tools, wires dies and mechanical components.

Owner:ETERNALOY HLDG GMBH

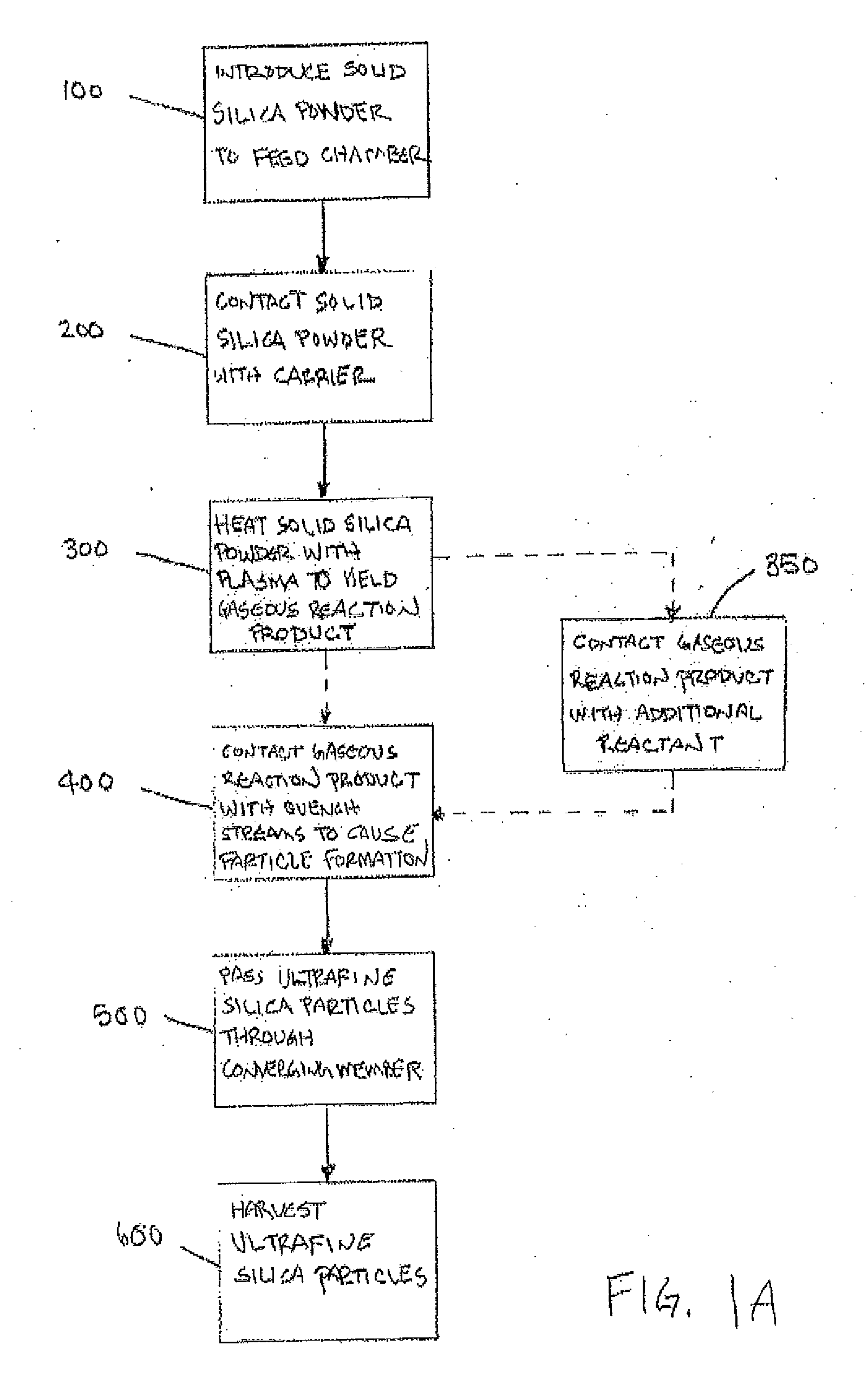

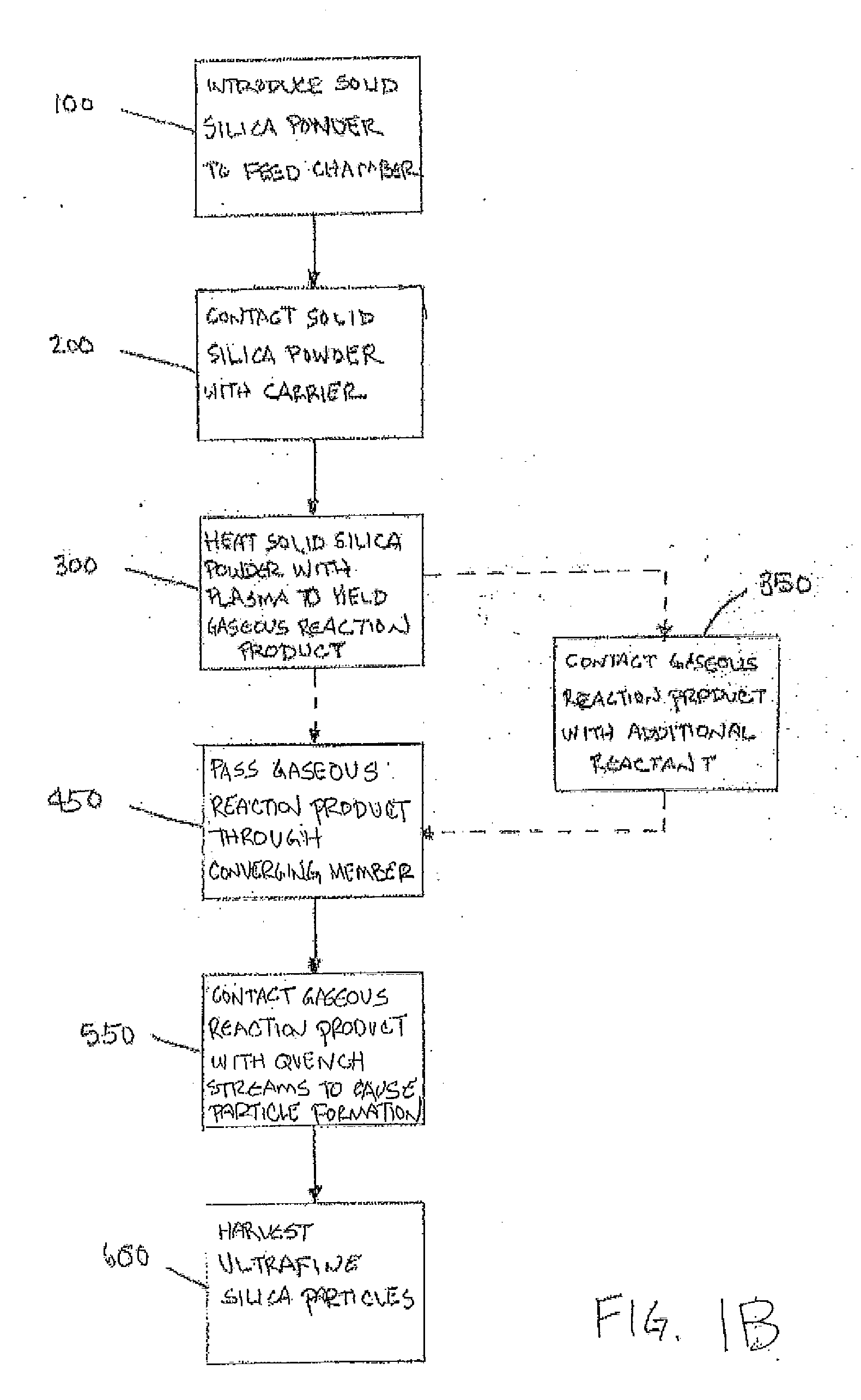

Method and apparatus for the production of ultrafine silica particles from solid silica powder and related coating compositions

Owner:PPG IND OHIO INC

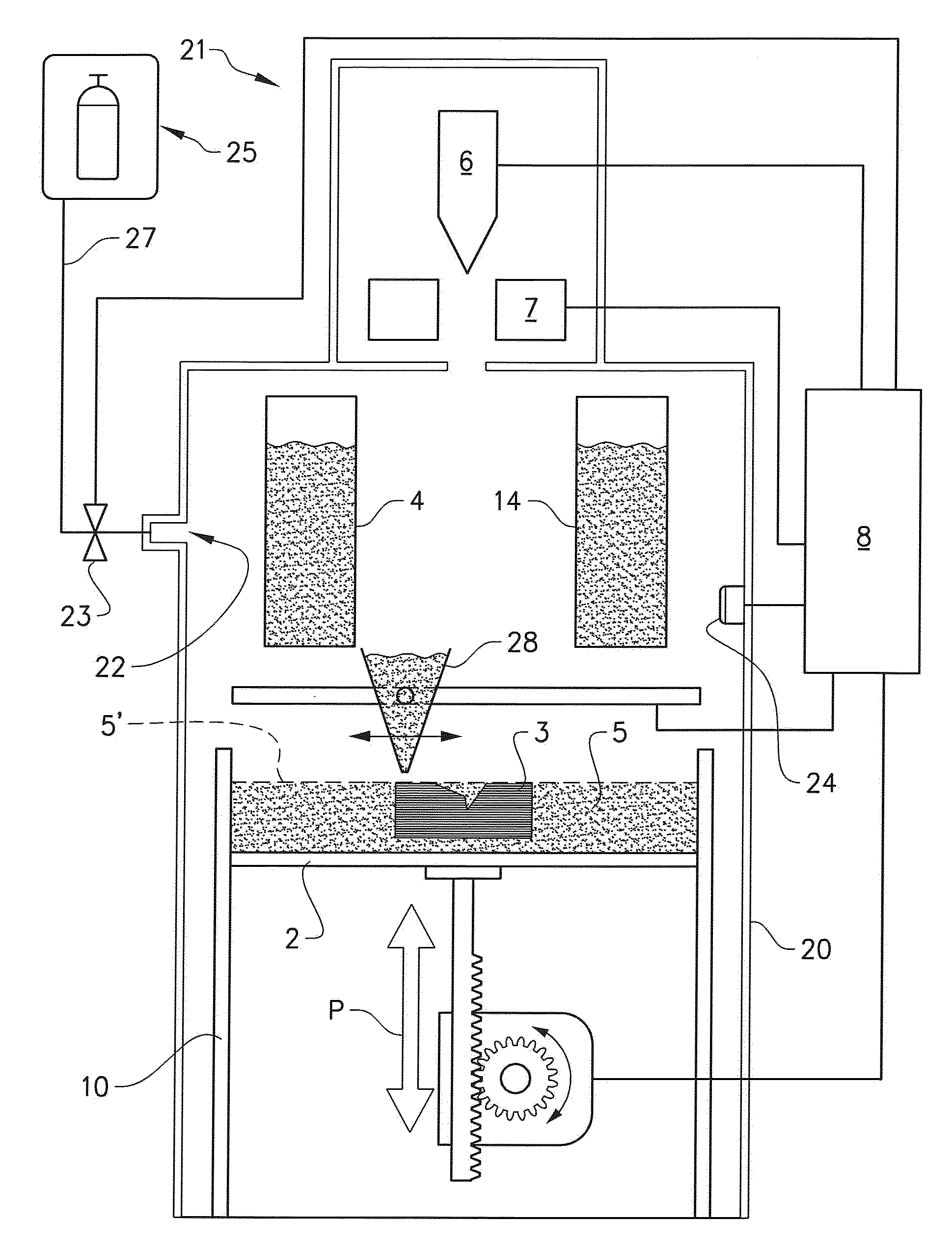

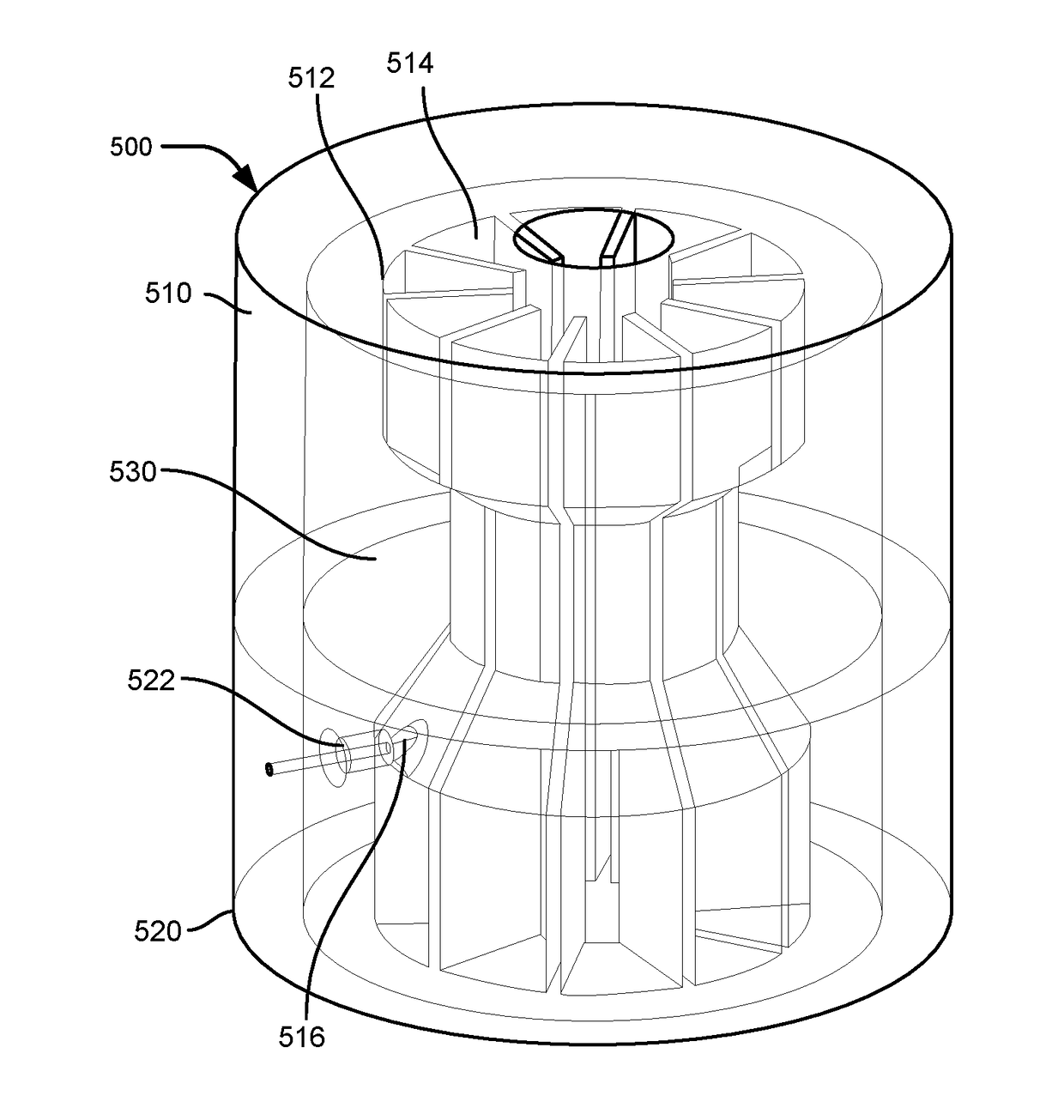

Method and apparatus for additive manufacturing

ActiveUS9505172B2Easy to manufactureBuilding time is minimumManufacturing driving meansManufacturing heating elementsRotational axisAdditive layer manufacturing

The present invention relates to a method for forming a three-dimensional article through successive fusion of applied powder. Said method comprising the steps of: providing at least one powder hopper comprising powder to be used for forming said three-dimensional article, providing a predetermined amount of powder at a build support, directing an energy beam over said build support causing at least a portion of said powder to sinter and causing at least a portion of said powder to bond to said build support, directing an energy beam over said build support causing said powder to fuse in selected locations according to a model to form a first portion of said three-dimensional article, rotating said build support around an axis of rotation for creating said three-dimensional article, which three-dimensional article is build up layer by layer in a radial direction with respect to said axis of rotation.

Owner:ARCAM AB

Method for preparing B4C-Al composite material

ActiveCN102094132ALower requirementEasy to processAluminium alloyMechanical properties of carbon nanotubes

The invention relates to a method for preparing a B4C-Al composite material, which is characterized by comprising the following steps of: 1, uniformly mixing a certain proportion of raw material boron carbide powder with aluminum alloy powder in a high-energy ball milling way; 2, compressing the uniformly-mixed power for molding; 3, sintering compression-molded compact in the step 2 at certain temperatures; 4, extruding sintered compact sintered in the step 3 at certain temperatures; and 5, conducting multiple-time hot rolling for the extruding-molded material in the step 4 at certain temperatures to obtain B4C-Al composite boards. By adopting the preparation method in the invention, the ball milling efficiency is high, the preparation process almost has no material loss, and the prepared B4C-Al composite boards have the characteristics of uniform distribution of boron carbide and good mechanical property and can be applied to neutron absorption / shielding.

Owner:ANHUI YINGLIU JIUYUAN NUCLEAR ENERGY NEW MATERIAL TECH CO LTD

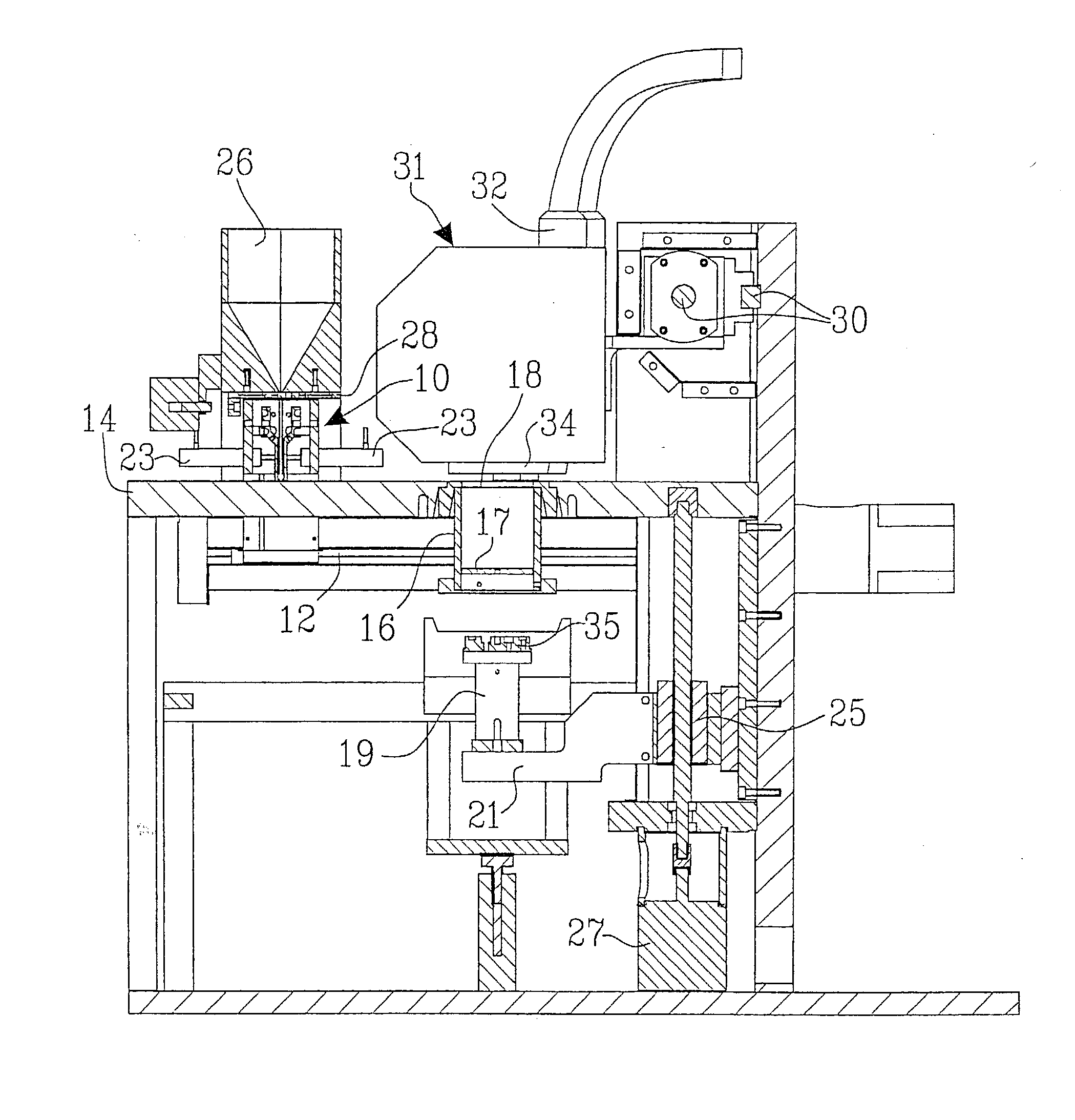

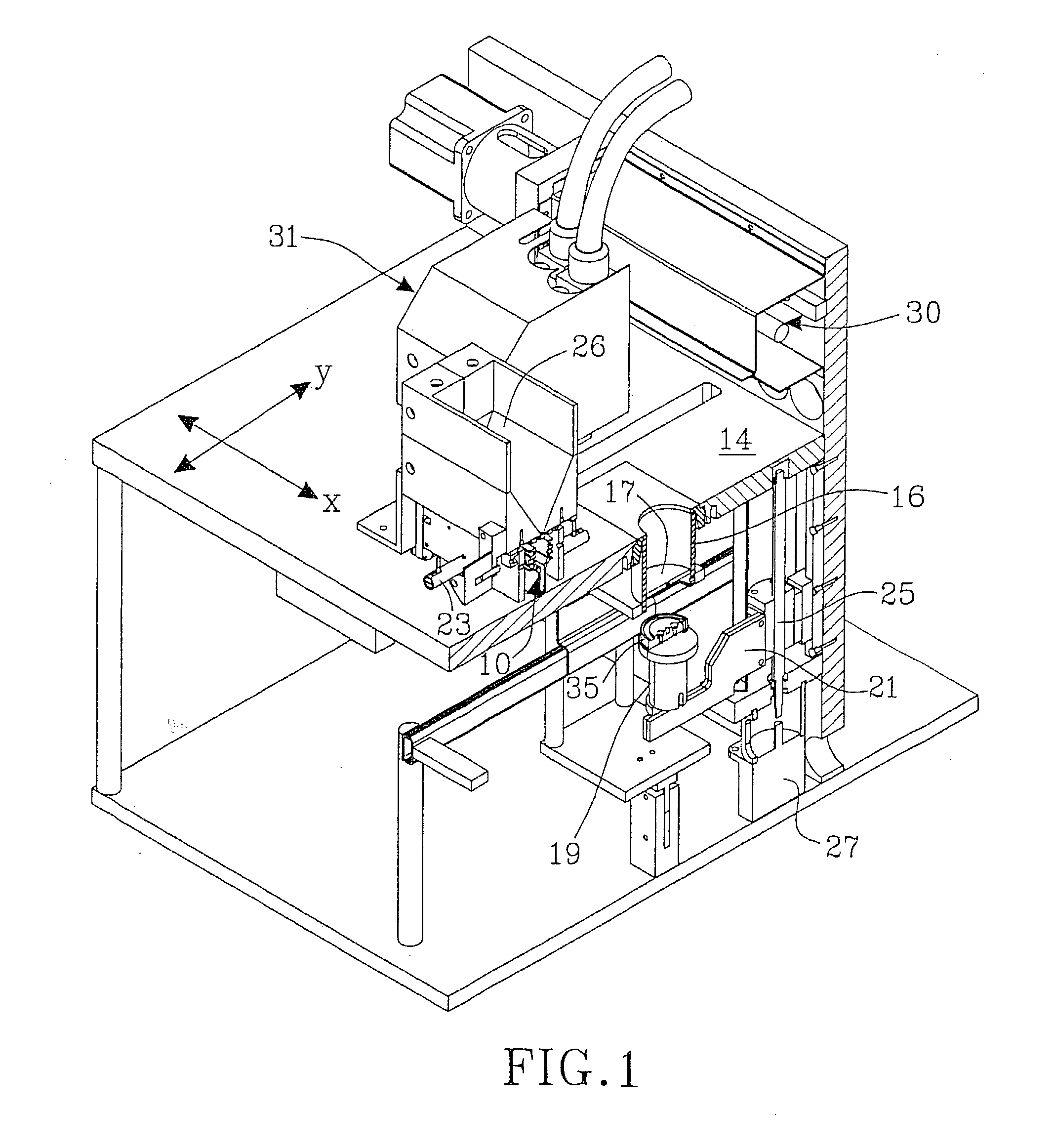

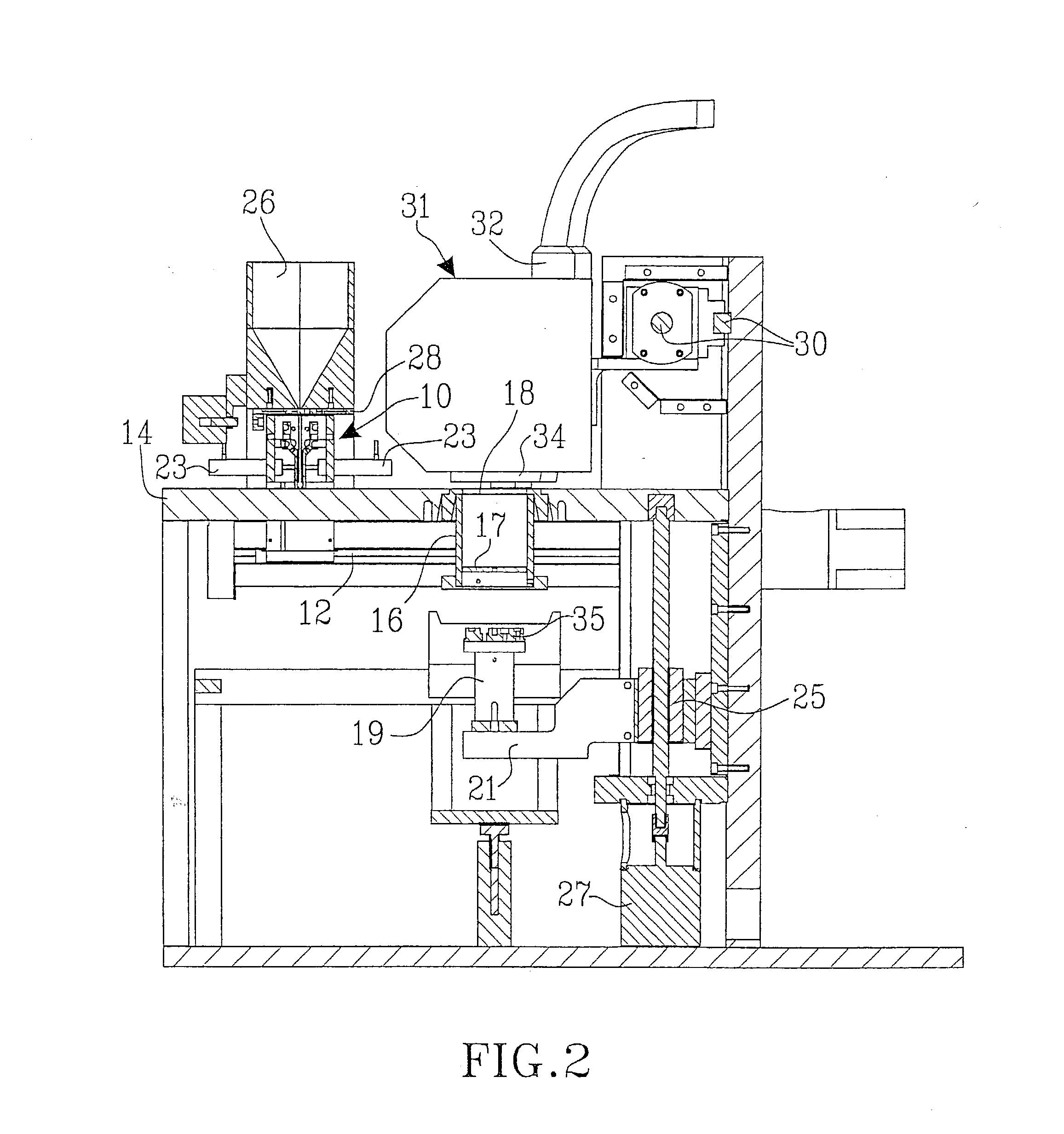

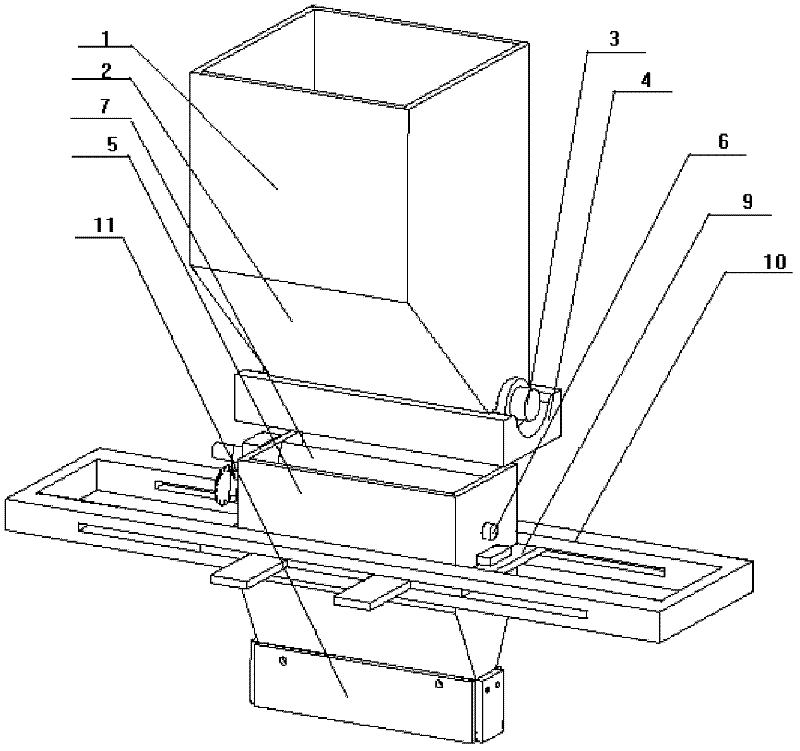

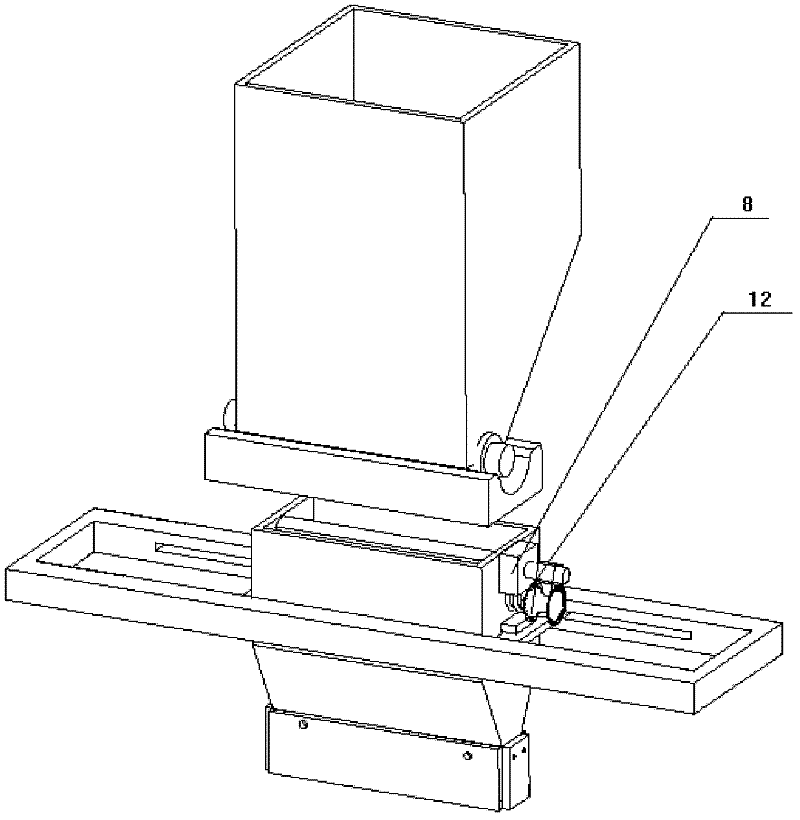

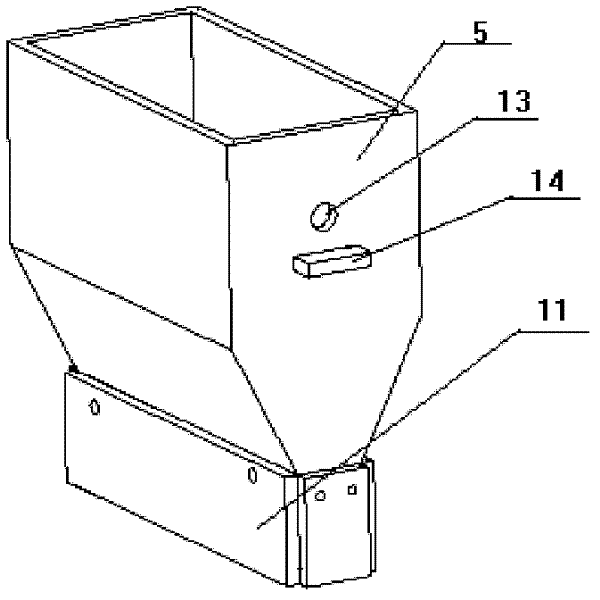

Movable-arm-type powder bed powder spreading device

The invention discloses a powder spreading device for rapid forming equipment. The device mainly comprises a quantitative powder conveying device, a movable silo, a movable arm, a movable frame and the like. The quantitative powder conveying device is used for supplying powder to the movable silo. Whether the powder falls down or not is controlled through a rotating sheet. According to the section of parts, the movable silo does regular translational motion within a working plane under the drive of the movable arm and the movable frame, and a scraper on the silo can realize dynamic powder spreading. By combining the movable arm and the movable silo with the movable frame, defining the powder within the area of the parts and adjusting the magnitude and the position of spread powder according to the change of the section of the parts, not only can the amount of the used powder is greatly saved, but also the powder spreading speed is high; and the structural design of the powder spreading device is simple, the powder spreading device is convenient to disassemble and assemble, the realization is easy, the cost is lower and the powder spreading device has an important application value to the improvement of the overall technical level of a powder bed quick forming technology.

Owner:HUAZHONG UNIV OF SCI & TECH

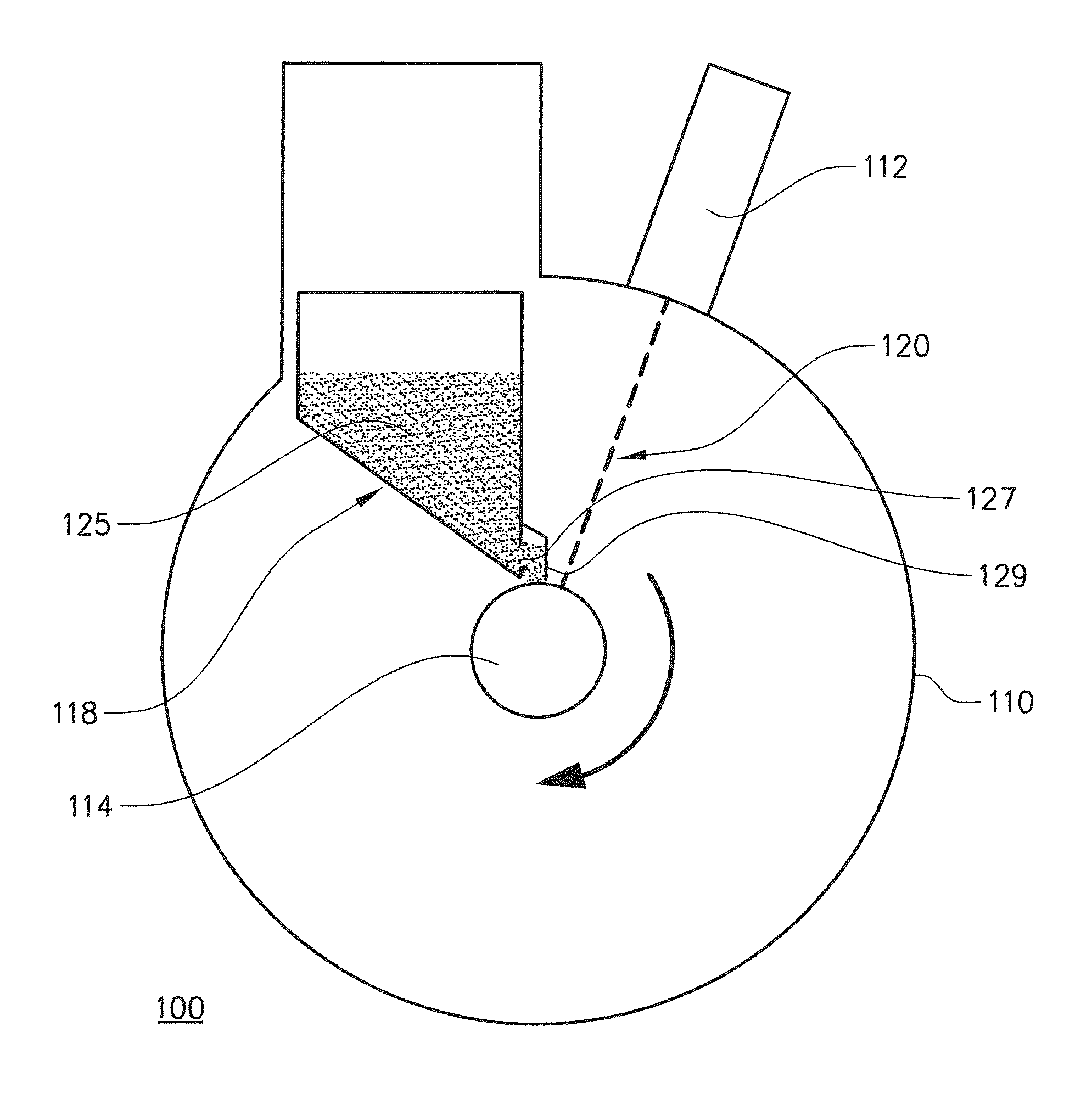

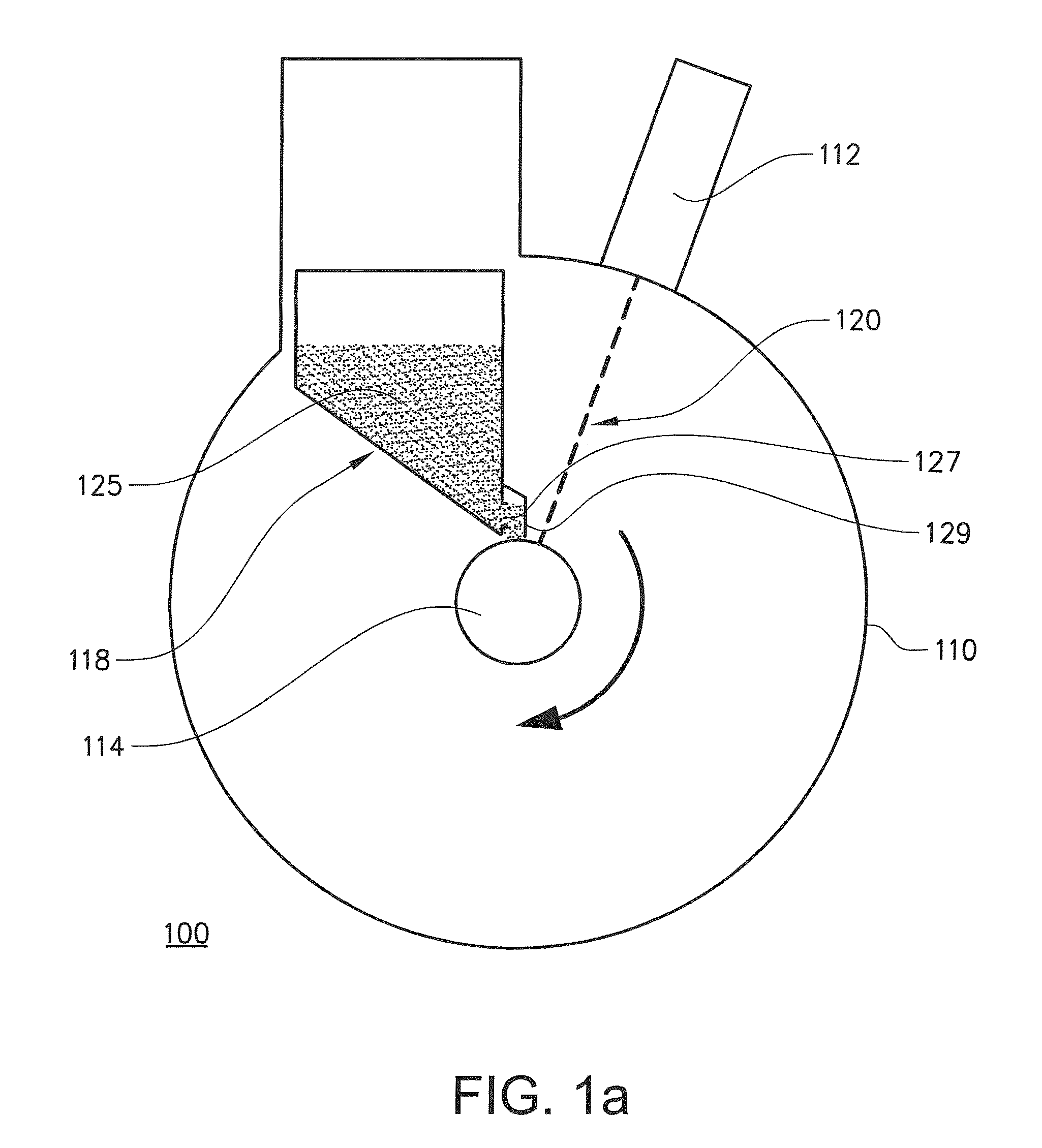

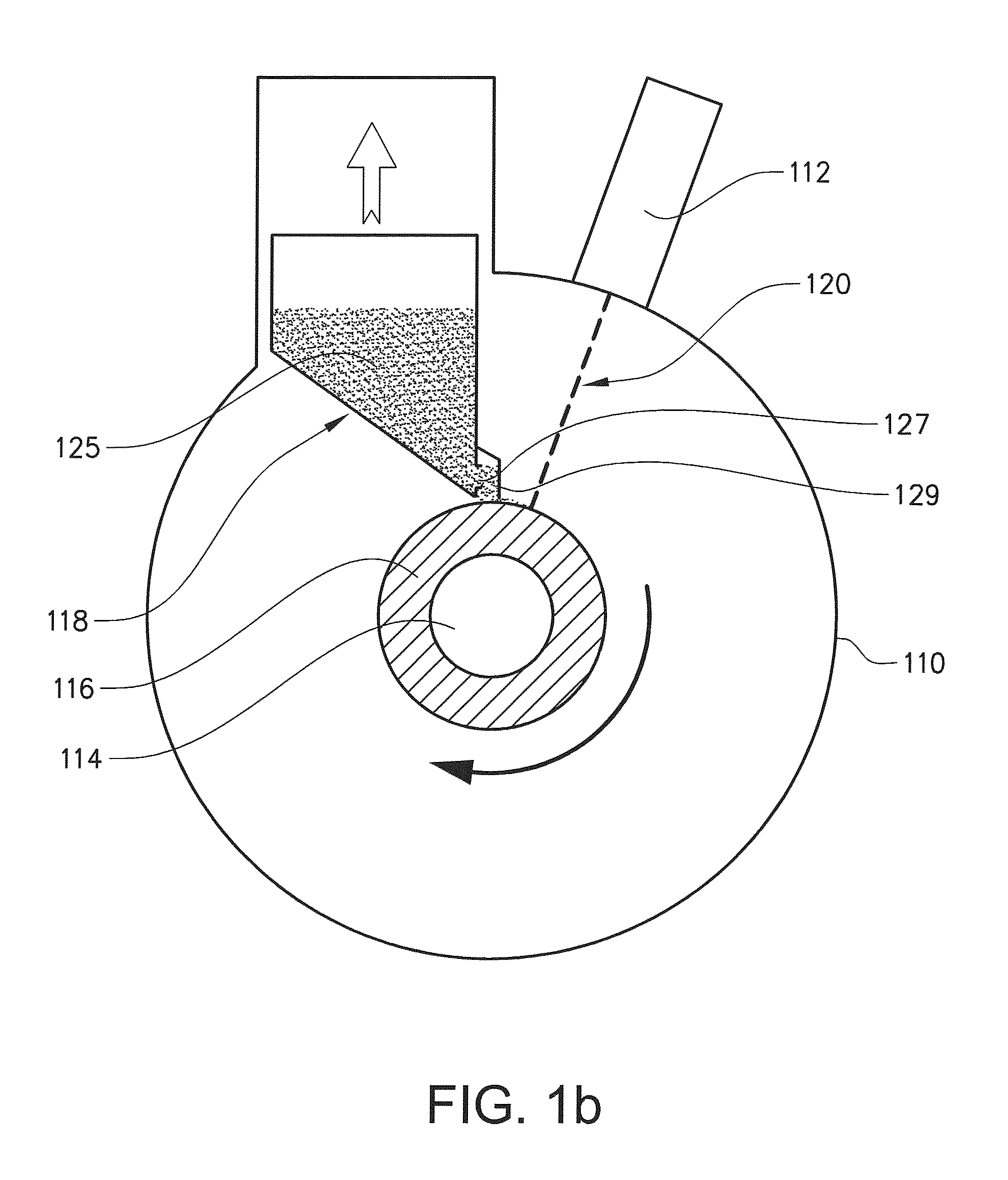

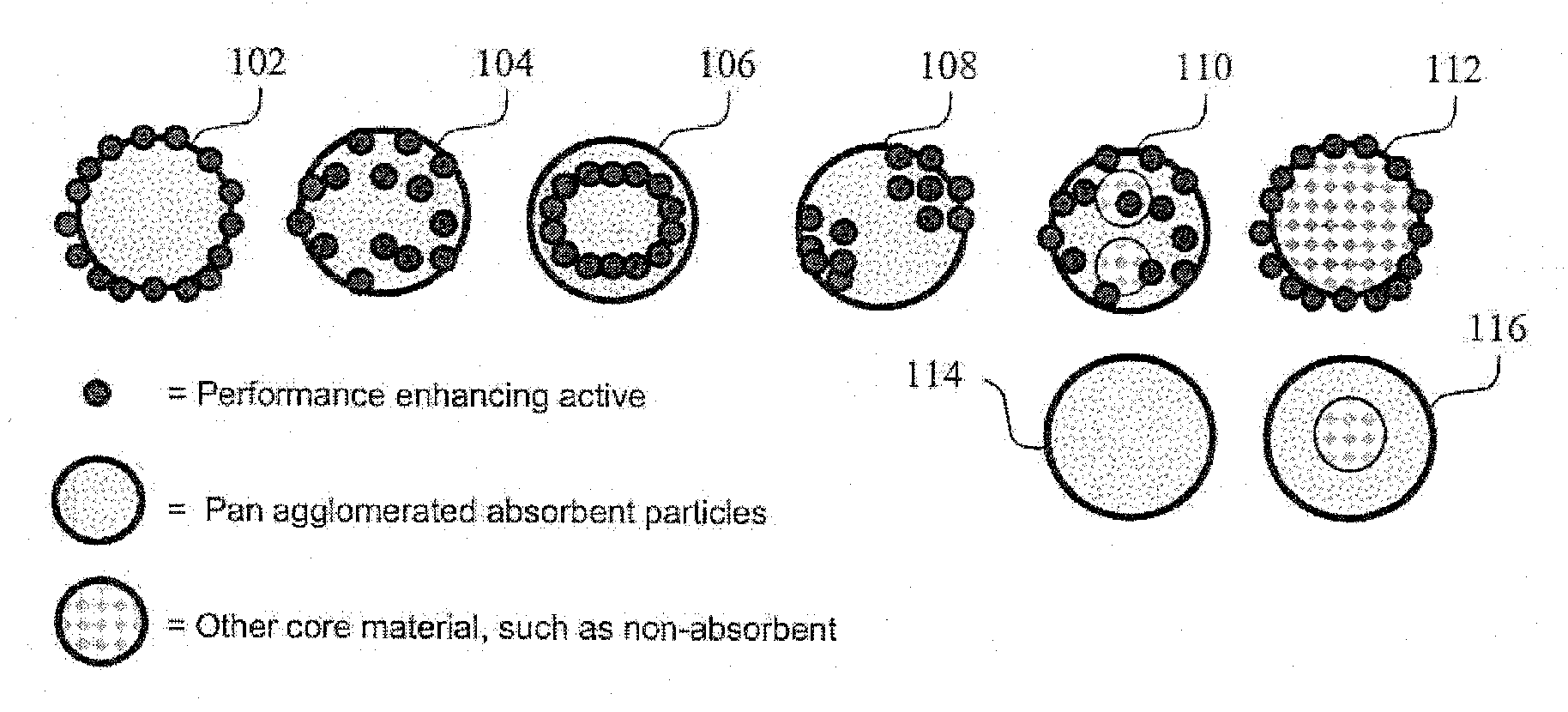

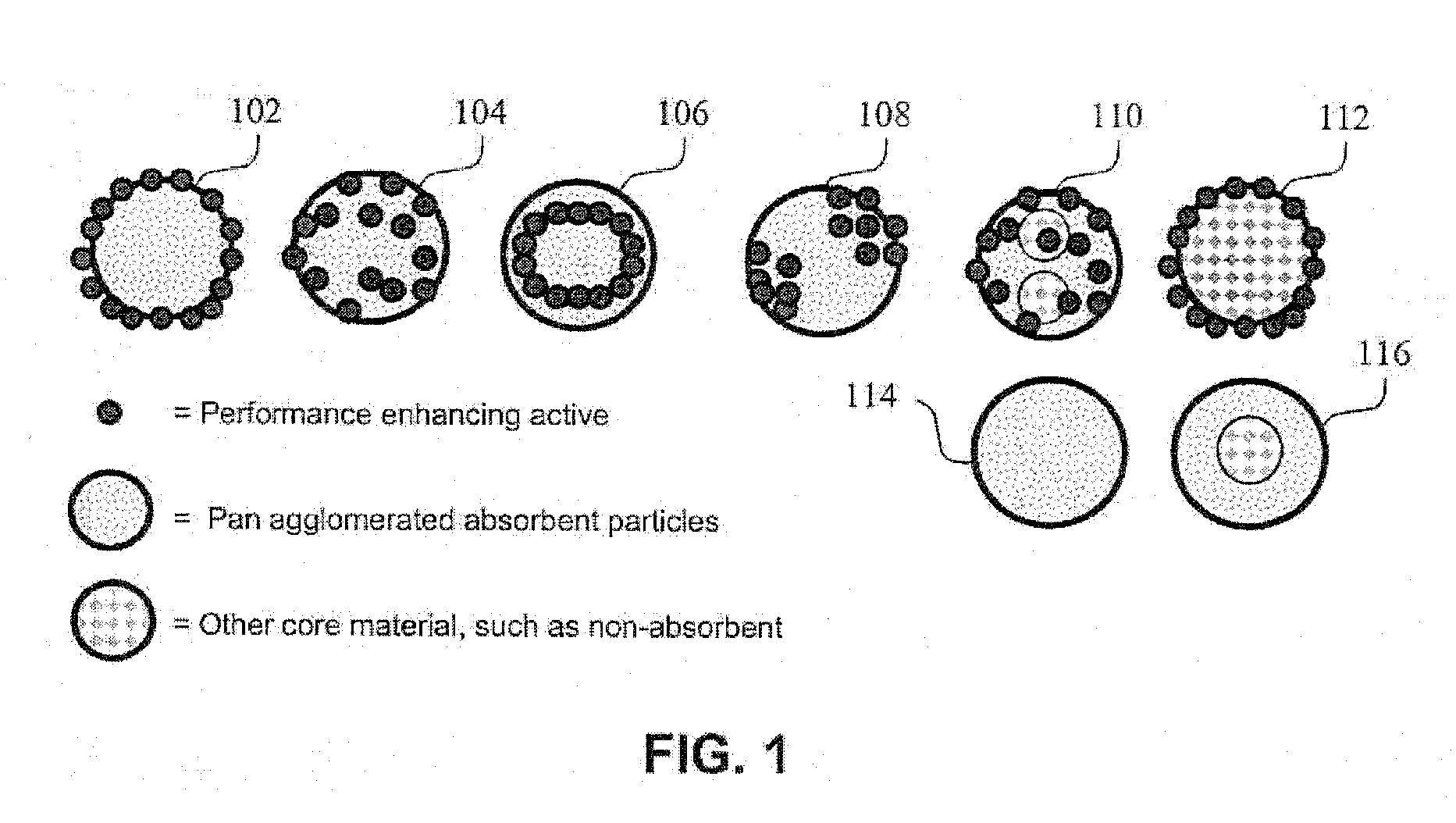

Dry Bed Agglomeration Process and Product Formed Thereby

A method for creating a particle from a powder according to one embodiment includes applying a droplet of a liquid to a bed of powder, wherein a particle is formed at about a point of contact of the droplet with the bed. A composite particle according to one embodiment includes a liquid-absorbing material and a liquid-induced binding agent substantially homogeneously dispersed in the particle. A composite particle according to yet another embodiment includes a liquid-absorbing material and a byproduct of a liquid-induced gas forming agent substantially homogeneously dispersed in the particle. A composite particle suitable for use as an animal litter according to an embodiment includes a liquid-absorbing material, where the particle has at least one of the following properties: hollow, cupped, and generally bagel shaped. A composite particle in yet another embodiment includes a material formed in a shape substantially defined by a droplet of liquid.

Owner:THE CLOROX CO

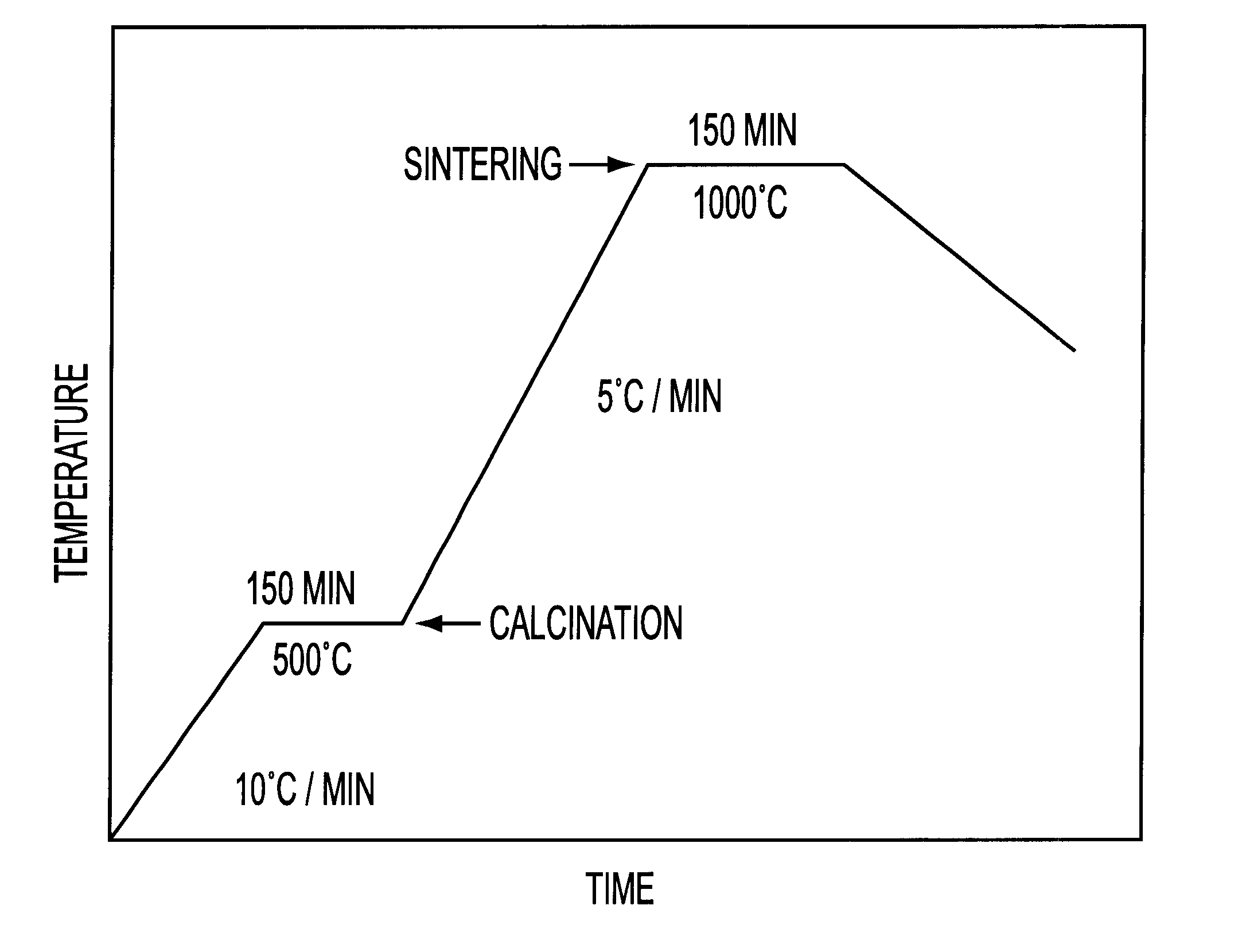

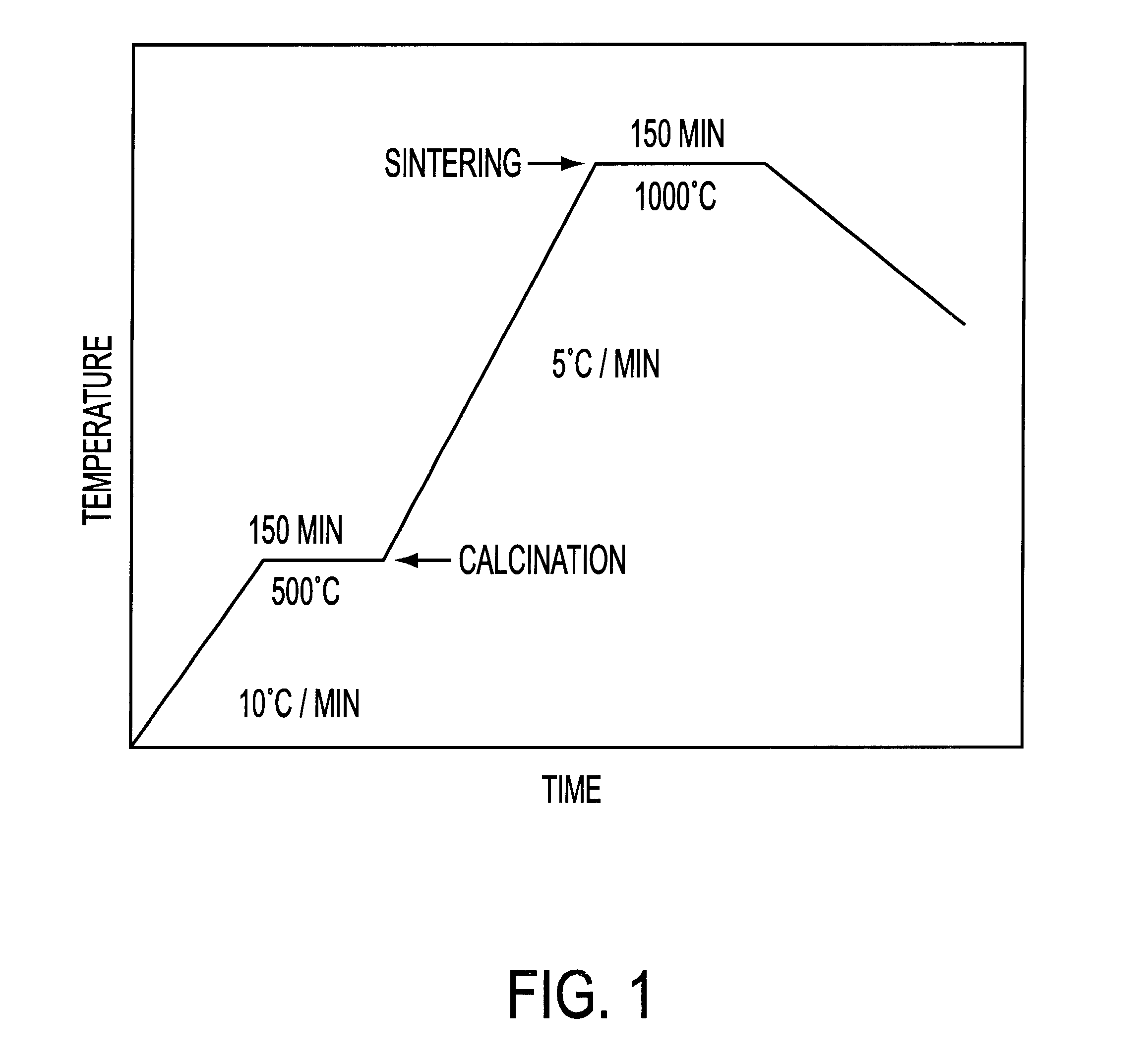

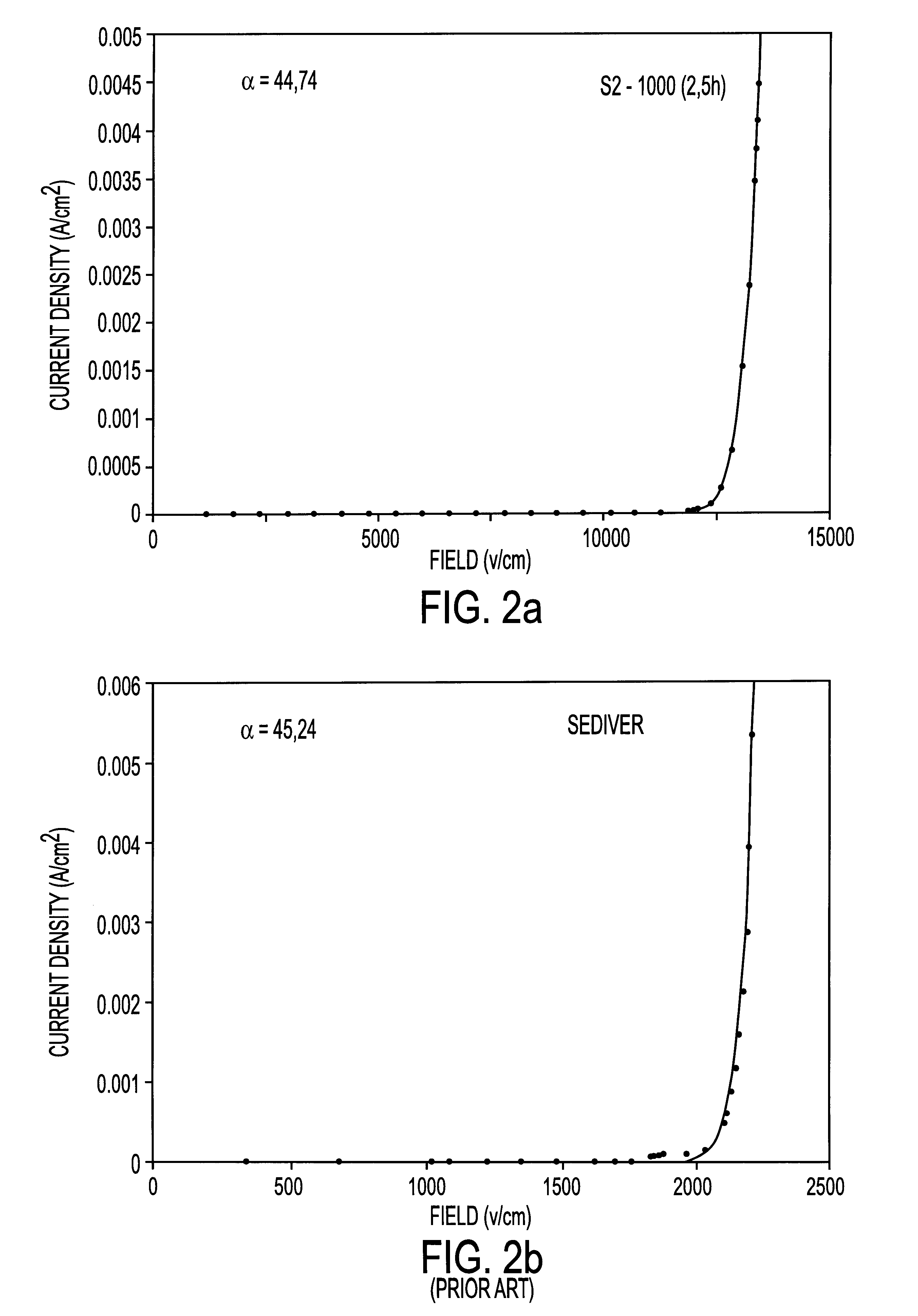

Varistors based on nanocrystalline powders produced by mechanical grinding

InactiveUS6620346B1Lower breakdown voltageImprove breakdown voltageMaterial nanotechnologyConductive materialGrain boundaryBreakdown voltage

The invention concerns novel varistors based on zinc oxide and a method for making same, which consists in using as base products nanocrystalline powders obtained by high-intensity mechanical grinding and in subjecting the mixture resulting from said nanocrystalline powders a consolidating treatment such as sintering, in suitably selected temperature and time conditions so as to retain the smallest possible grain size of ZnO. The resulting varistors have a very fine homogeneous microstructure and an average grain size characteristically not more than 3pm, i.e. five times smaller than standard materials. Said novel varistors have a larger number of grain boundaries per unit length unit and therefore a much higher breakdown voltage. Said voltage is characteristically higher than 10 kV / cm and can reach 17 kV / cm which is almost one order of magnitude above the breakdown voltage of standard varistors. The non-linearity coefficient of the current-voltage curve is also improved, and is greater than 20 and can reach values as high as 60. Moreover, the leakage currents below the breakdown voltage of said varistors, are much lower.

Owner:HYDRO QUEBEC CORP

Shrouded-plasma process and apparatus for the production of metastable nanostructured materials

InactiveUS20070044513A1Improve compactnessImprove sintering performanceMaterial nanotechnologyNitrogen compoundsLiquid jetShort range order

A method and apparatus for producing metastable nanostructured materials employing a ceramic shroud surrounding a plasma flame having a steady state reaction zone into which an aerosol or liquid jet of solution precursor or powder material is fed, causing the material to be pyrolyzed, melted, or vaporized, followed by quenching to form a metastable nanosized powder that has an amorphous (short-range ordered), or metastable microsized powder that has a crystalline (long-range ordered) structure, respectively.

Owner:RUTGERS THE STATE UNIV

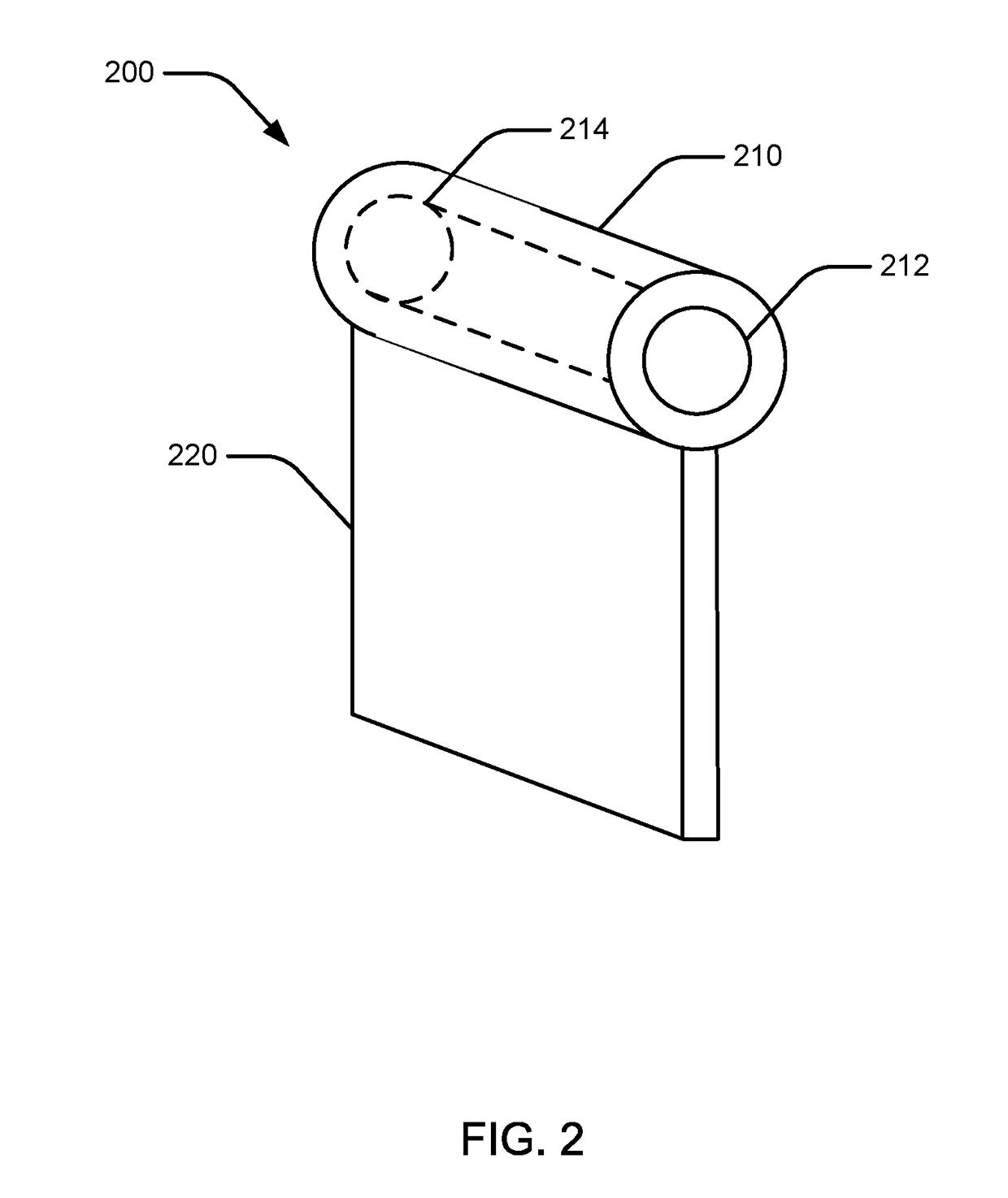

Method and supports with powder removal ports for additive manufacturing

ActiveUS20170232670A1Additive manufacturing apparatusIncreasing energy efficiencyStructural engineeringMechanical engineering

The present disclosure generally relates to methods for additive manufacturing (AM) that utilize powder removal ports in the process of building objects, as well as novel support structures including powder removal ports to be used within these AM processes. The objects include walls defining regions of unfused powder. The powder removal ports include at least one tube aligned with an opening in the walls to allow removal of the powder. The methods include removing unfused powder from the enclosed space via the at least one tube.

Owner:GENERAL ELECTRIC CO

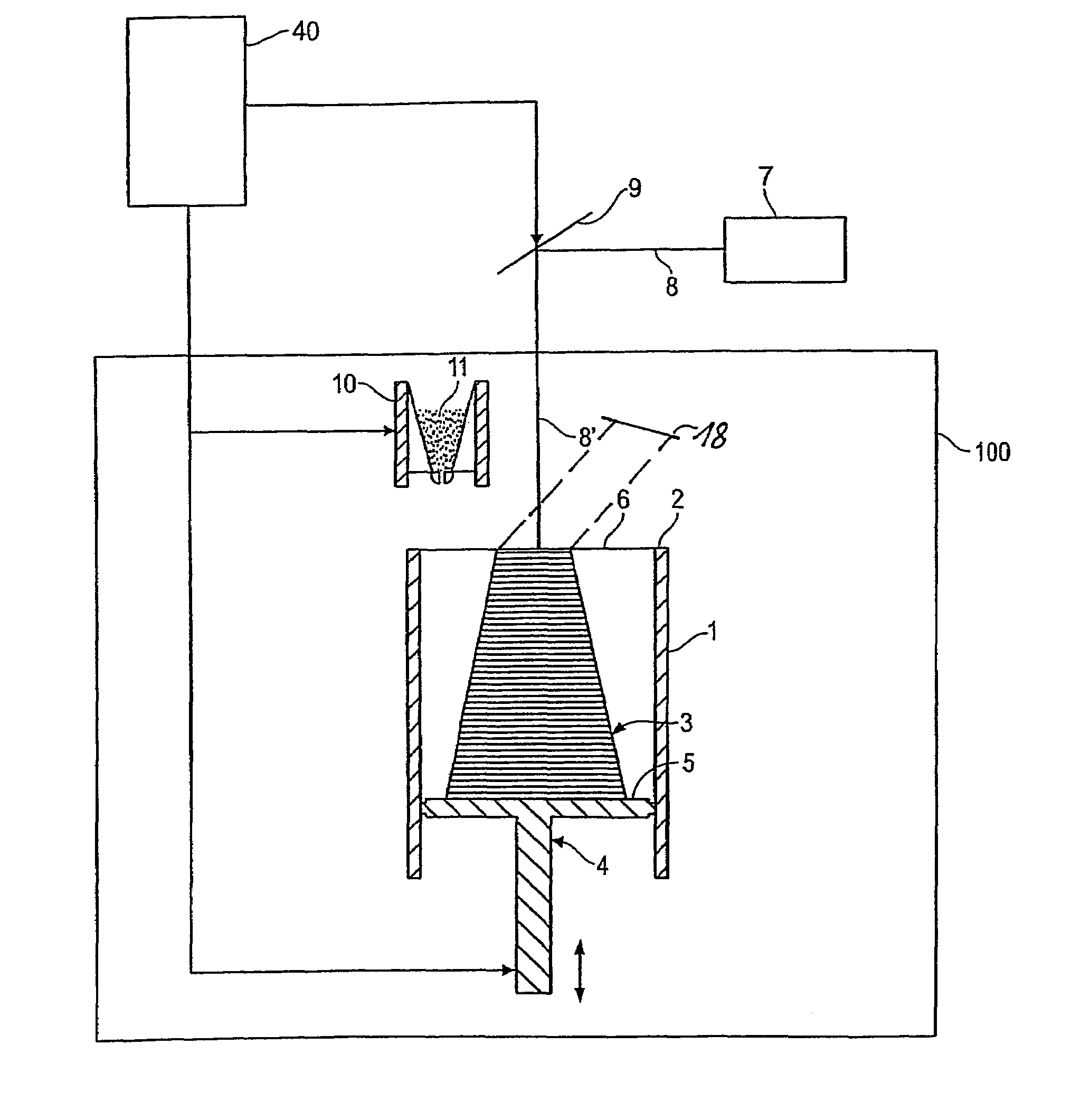

Method for a layer-wise manufacturing of a three-dimensional object

ActiveUS9011982B2Shorten the durationShorten the timeAdditive manufacturing apparatusPretreated surfacesParticle beamElectromagnetic radiation

A method for a layer-wise manufacturing of a three-dimensional object has a first step of providing a layer of a material in powder form or a liquid material on a support or a layer that has already been solidified at selected positions previously and a second step of directing a focussed photon or particle beam (8′) selectively at selected positions of the layer. In the second step, the photon or particle beam is selected such that it brings about a change of the absorption of the material when hitting the layer. After the termination of the second step, a third step is carried out, in which the layer is irradiated by means of electromagnetic radiation (18′) such that the material is homogenously solidified at those positions of the layer that correspond to the cross-section of the object to be formed.

Owner:EOS ELECTRO OPTICAL SYST

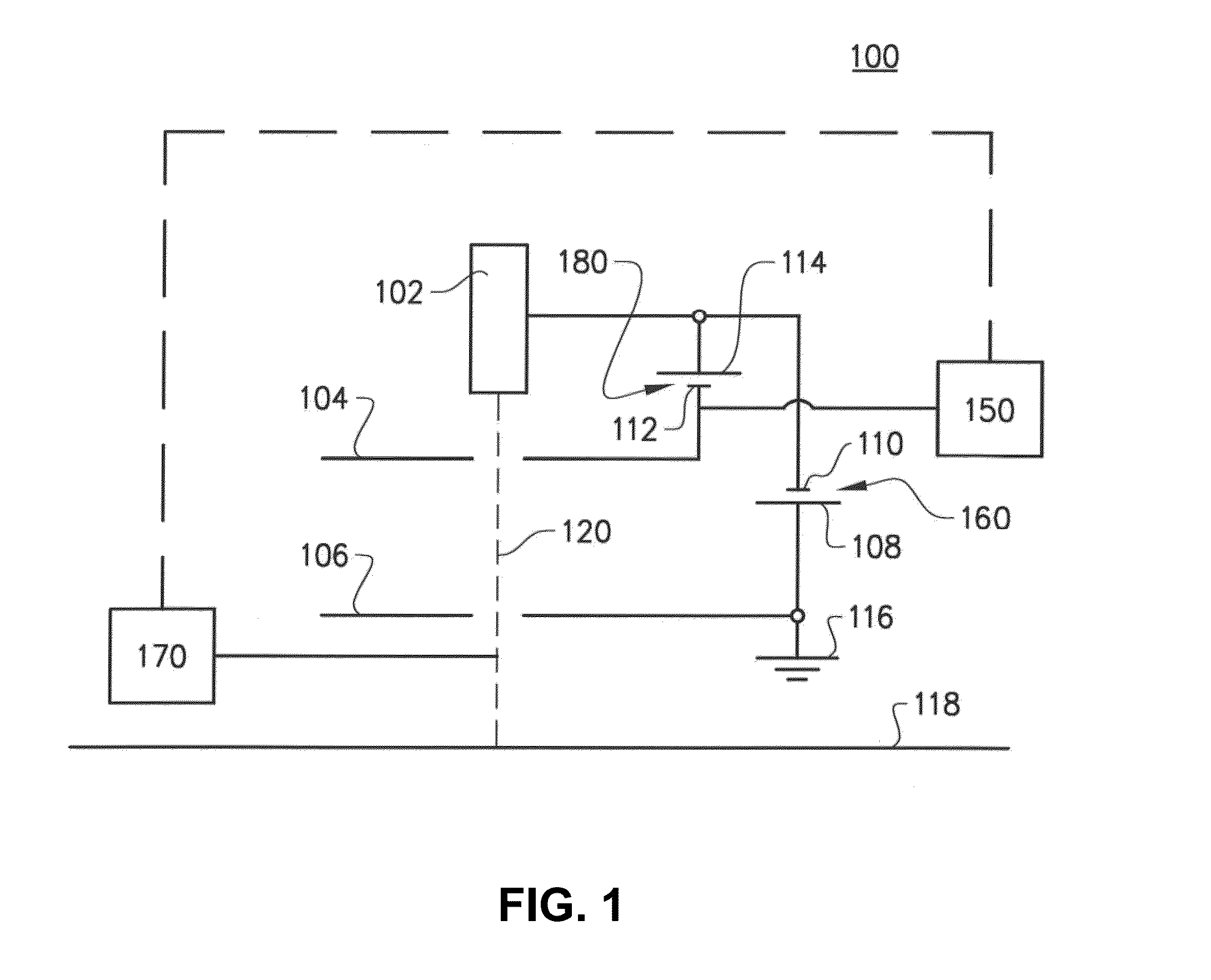

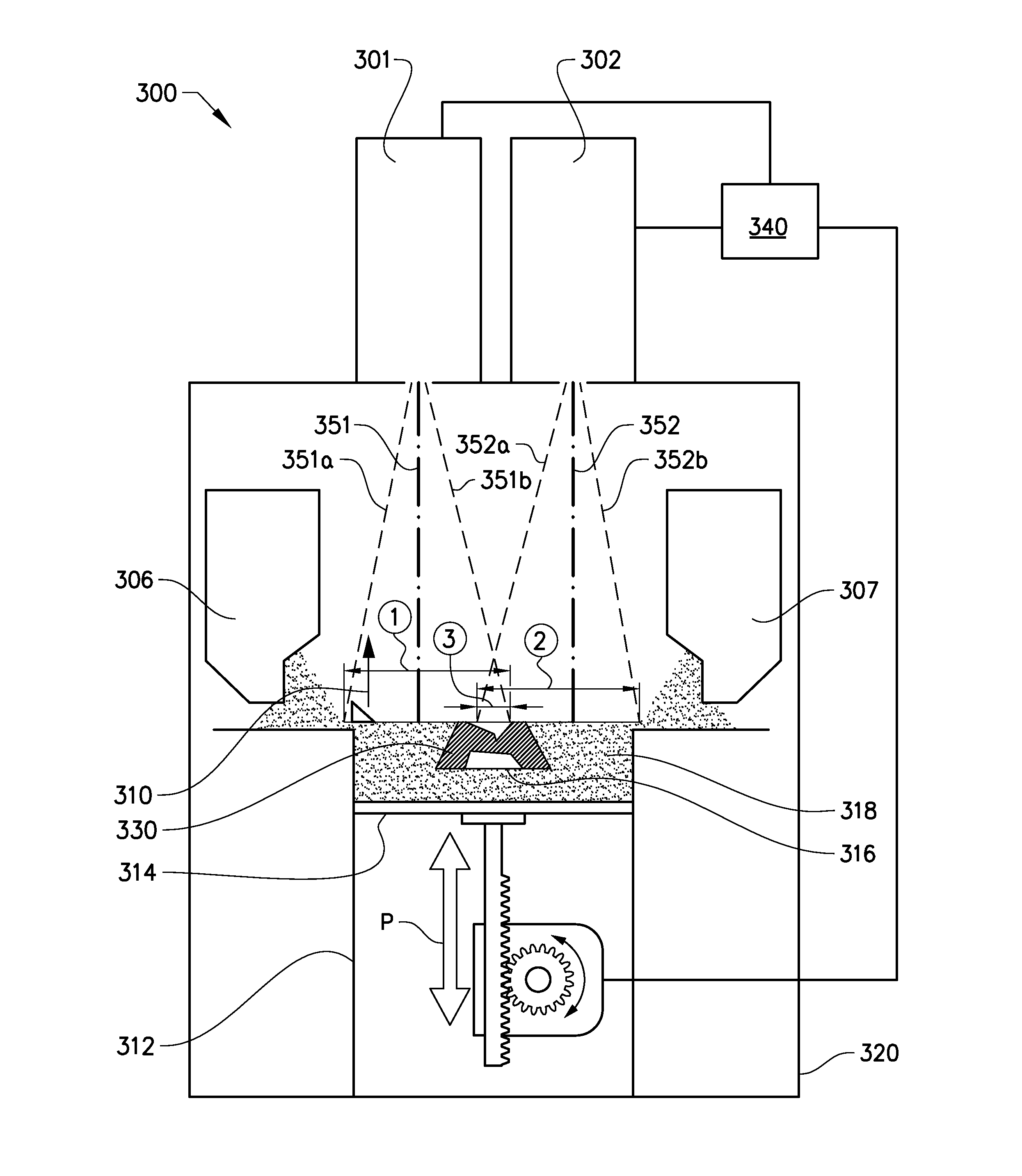

Method and apparatus for additive manufacturing

ActiveUS9415443B2Large build volumeSacrificing qualityAdditive manufacturing apparatusIncreasing energy efficiencyPowder bedBeam source

A method for forming a three-dimensional article through successive fusion of parts of a powder bed, which parts corresponds to successive cross sections of the three-dimensional article, said method comprising the steps of: providing a model of said three dimensional article, providing a first powder layer on a work table, directing a first energy beam from a first energy beam source over said work table causing said first powder layer to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article, directing a second energy beam from a second energy beam source over said work table causing said first powder layer to fuse in second selected locations according to said model to form the first cross section of said three-dimensional article, wherein said first and second locations of said first powder layer are at least partially overlapping each other.

Owner:ARCAM AB

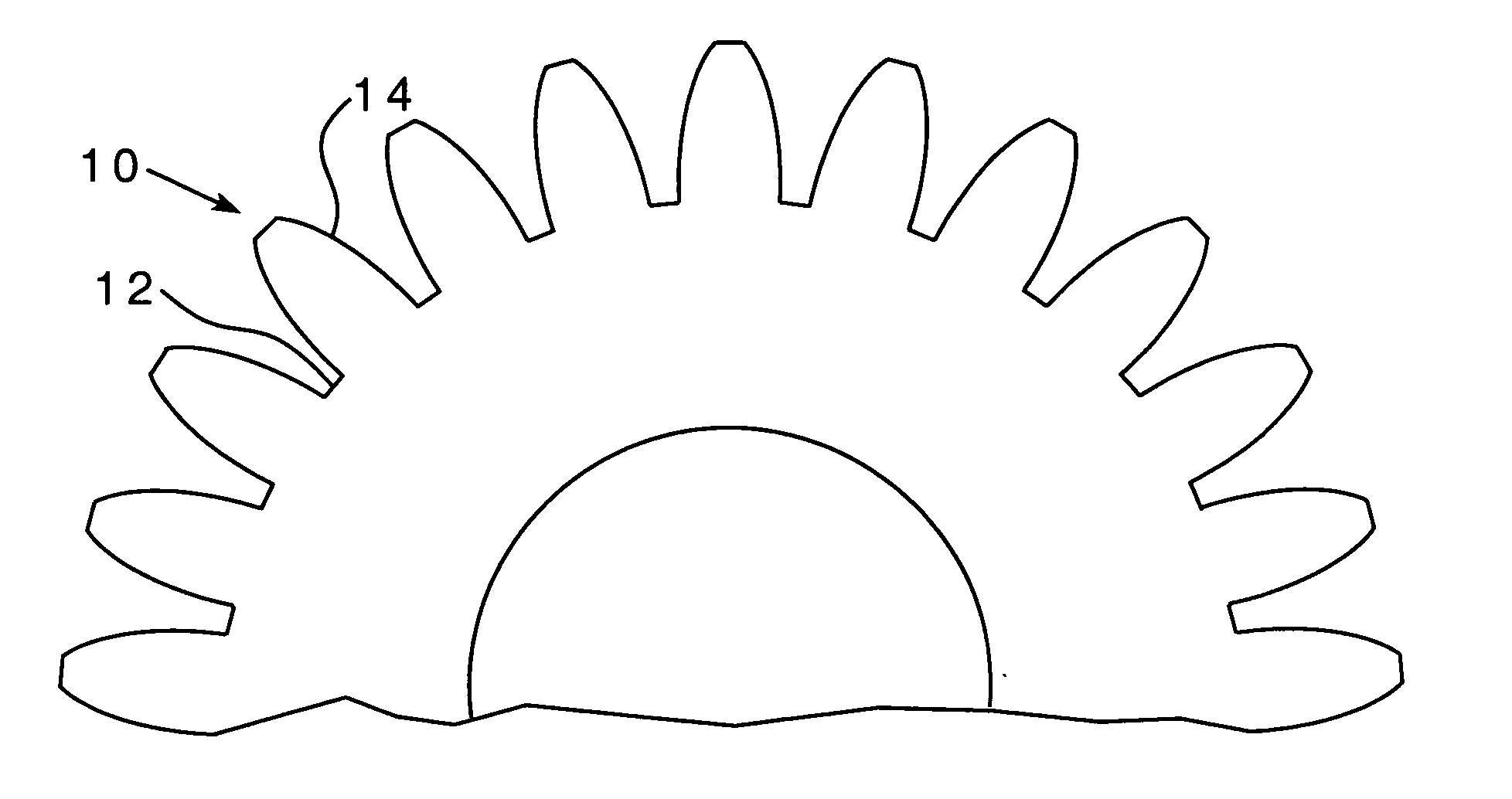

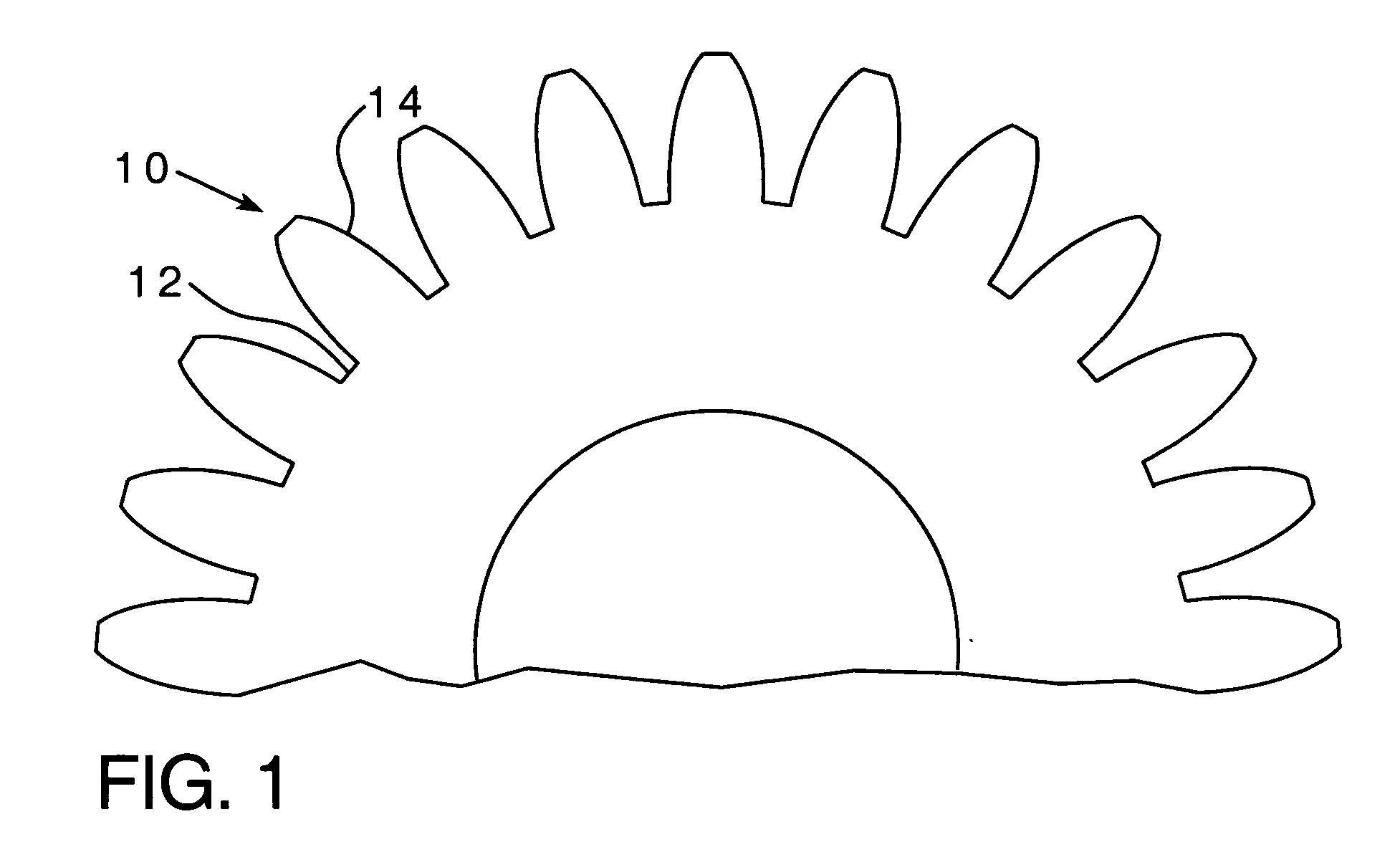

Powder metal materials and parts and methods of making the same

Embodiments of the present invention relate to methods of forming powder metals materials and parts. More specifically, certain embodiments of the present invention relate to methods of forming powder metals materials and parts by densifying at least a portion of a surface of the materials and / or parts after sintering and prior to densifying one or more core regions of the materials and / or parts. Other embodiment provide powder metal parts, such as gears and sprockets, having surface regions that are uniformly densified to full density to depth ranging from 0.001 inches to 0.040 inches, and core regions that can have at least 92 percent theoretical density and further can have essentially full density, or full density. Still other embodiments relate to brazed, welded, plated and gas-tight powder metal parts and components that can be made in accordance with the various non-limiting methods disclosed herein.

Owner:KEYSTONE INVESTMENT CORP

Composite agglomeration technology of iron powdered ore

The invention discloses a ferric powder composite block preparing technology, which is characterized by the following: separating fine ferric ore individually; preparing ball; blending rough particle with ferric powder and other raw materials; paving on the traditional sintering machine; inserting high-alkaline sintering ore of acid ball ore.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com