Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

26832results about "Increasing energy efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

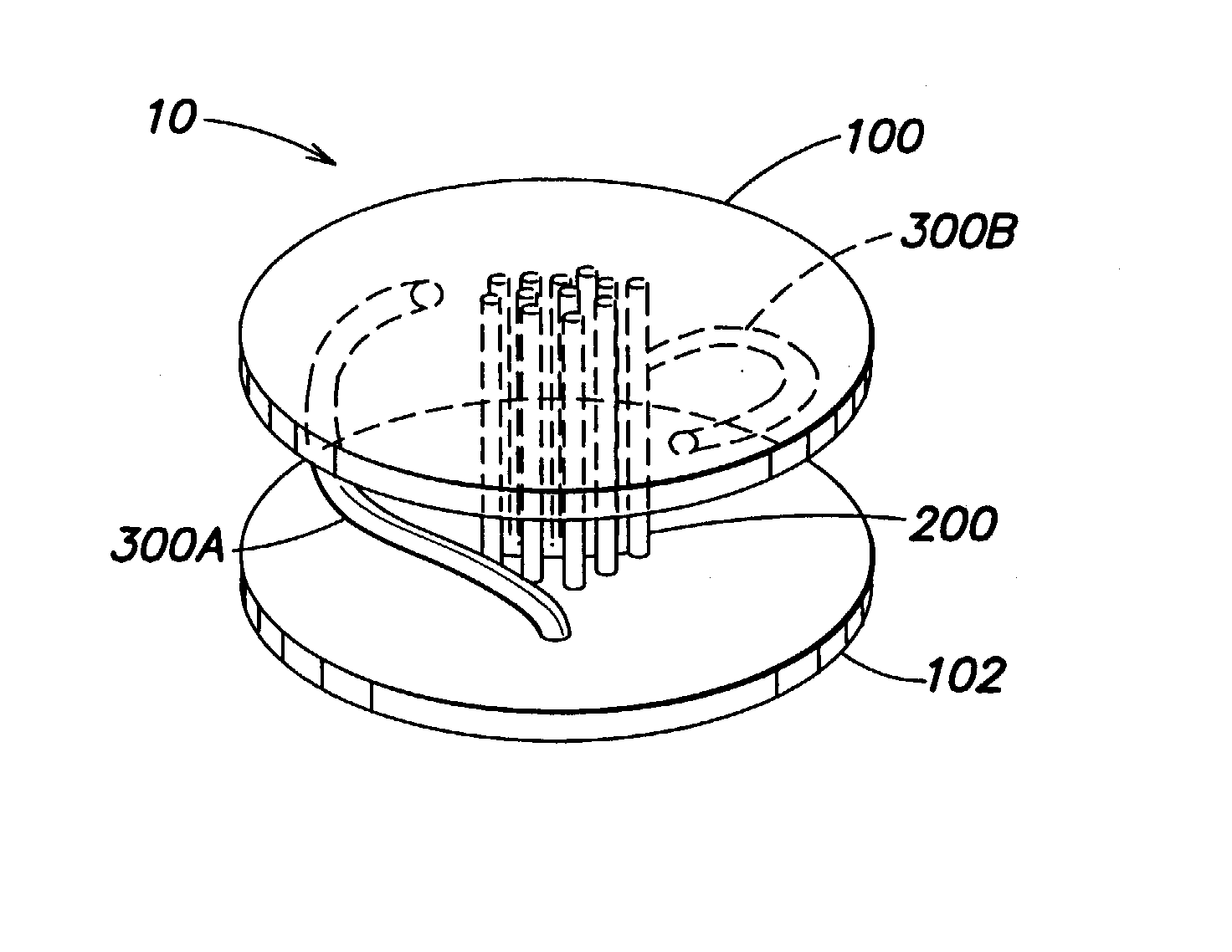

Orthopedic implant

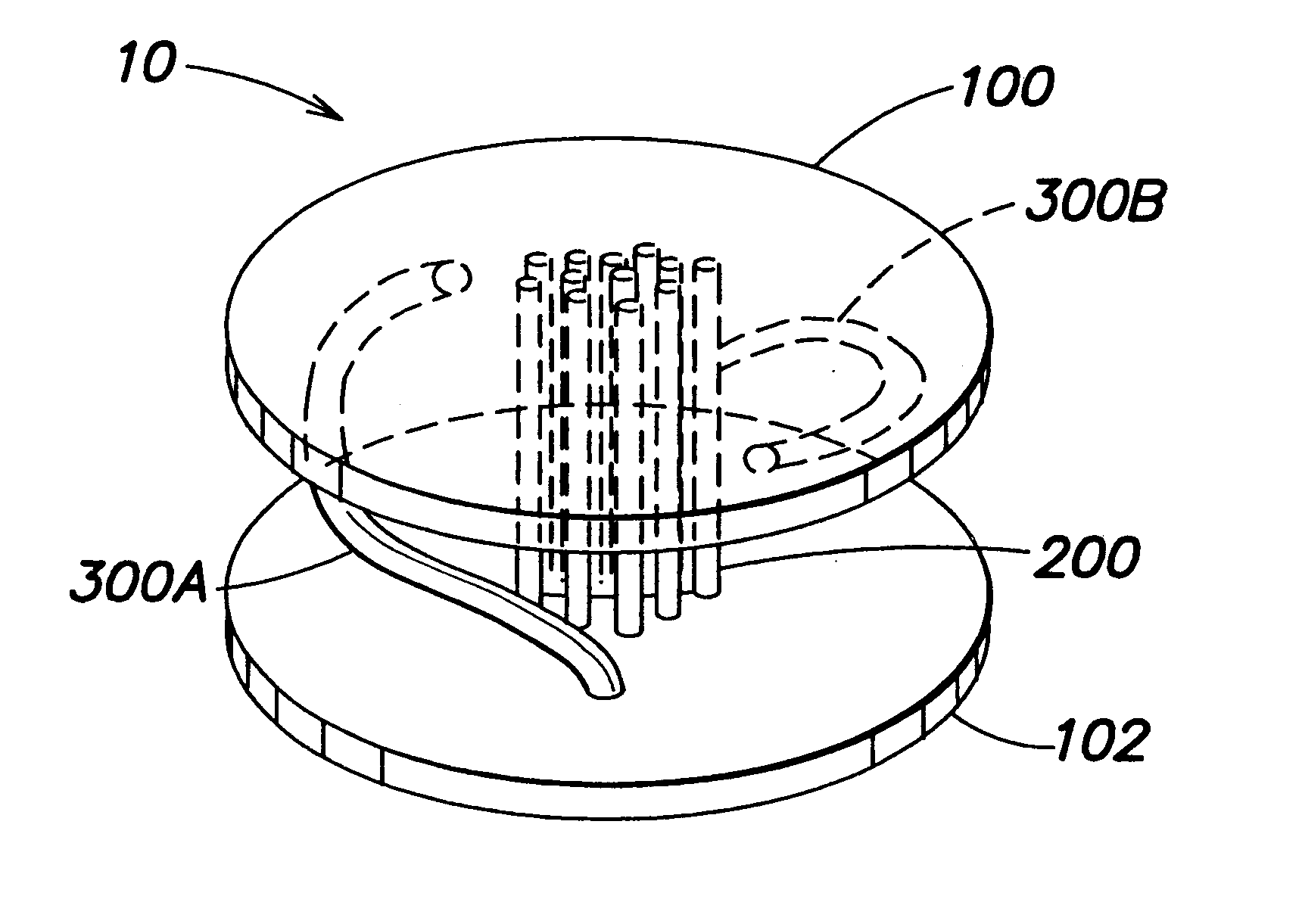

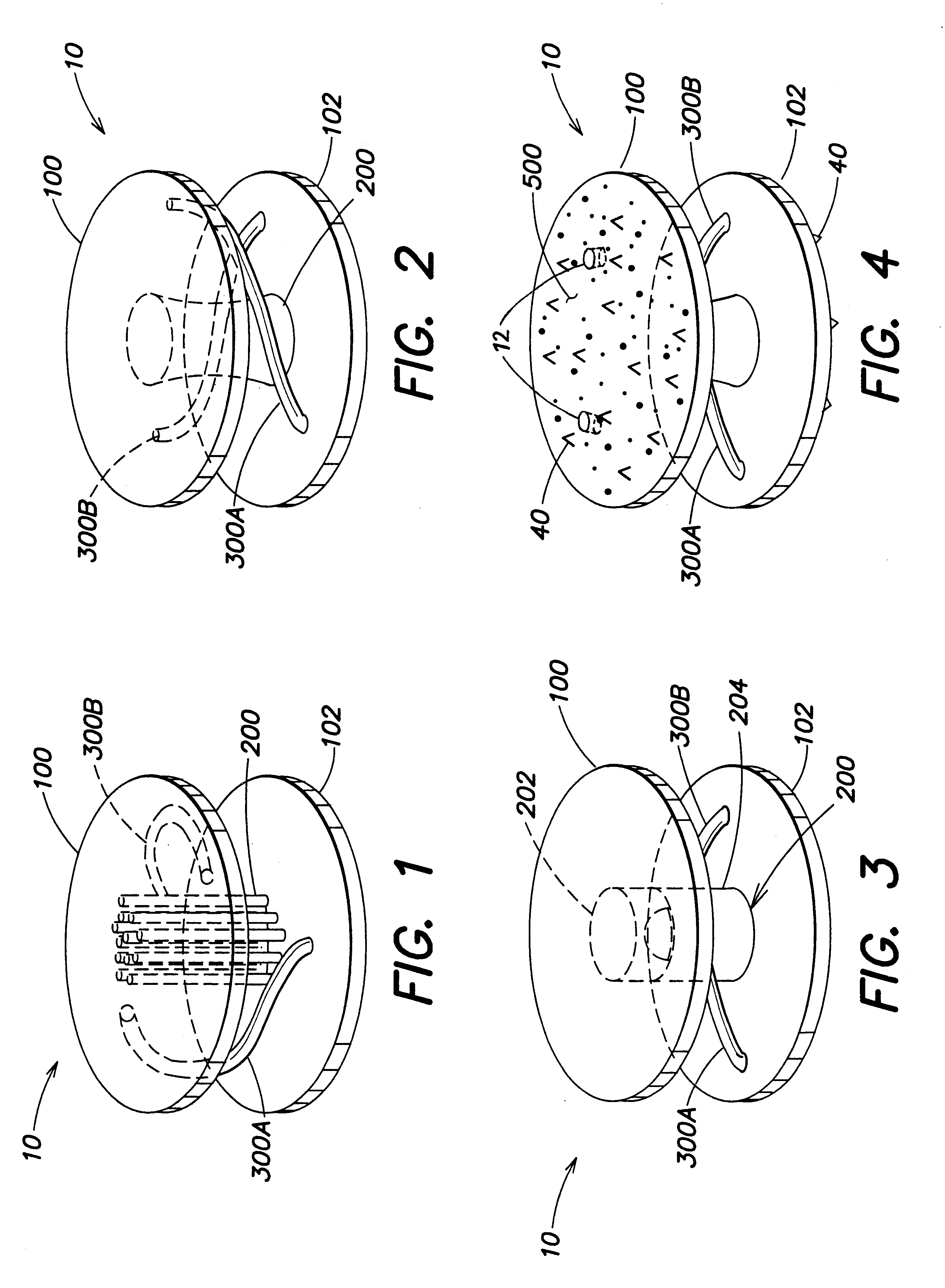

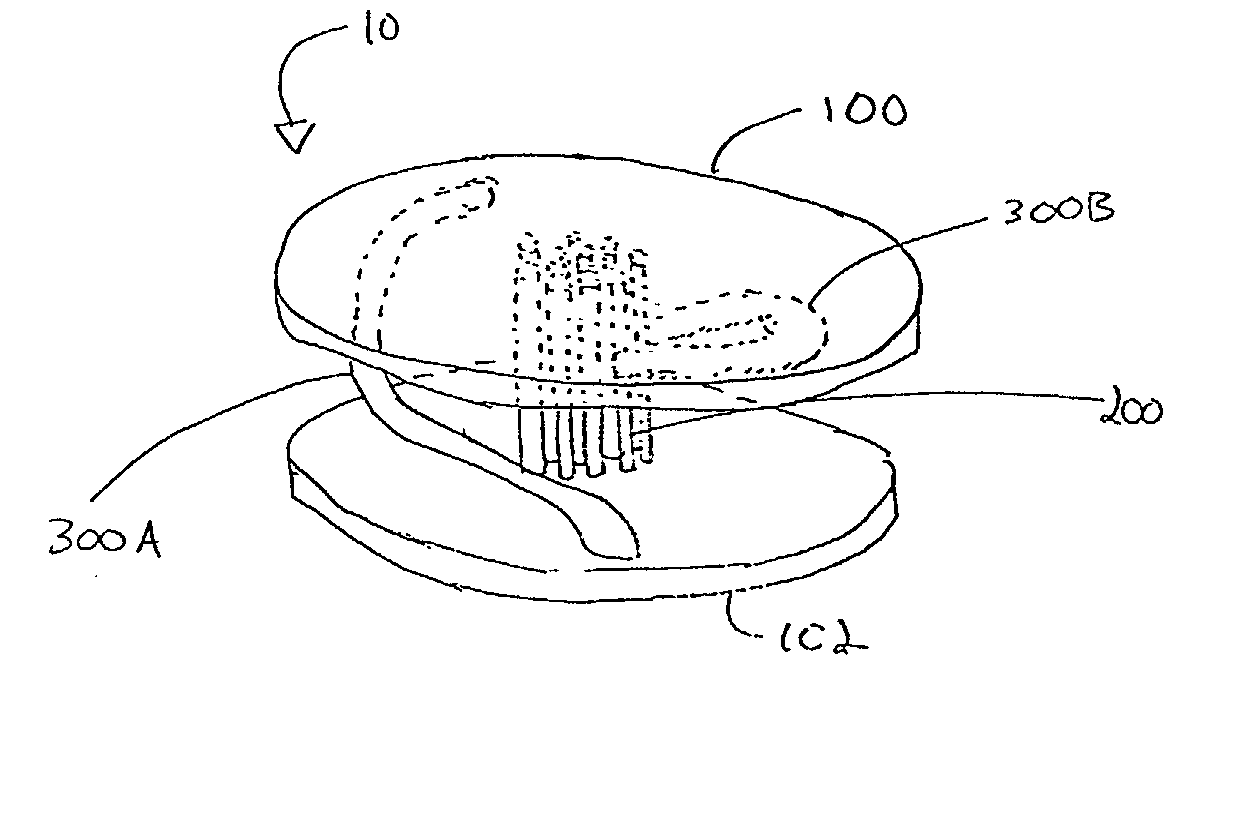

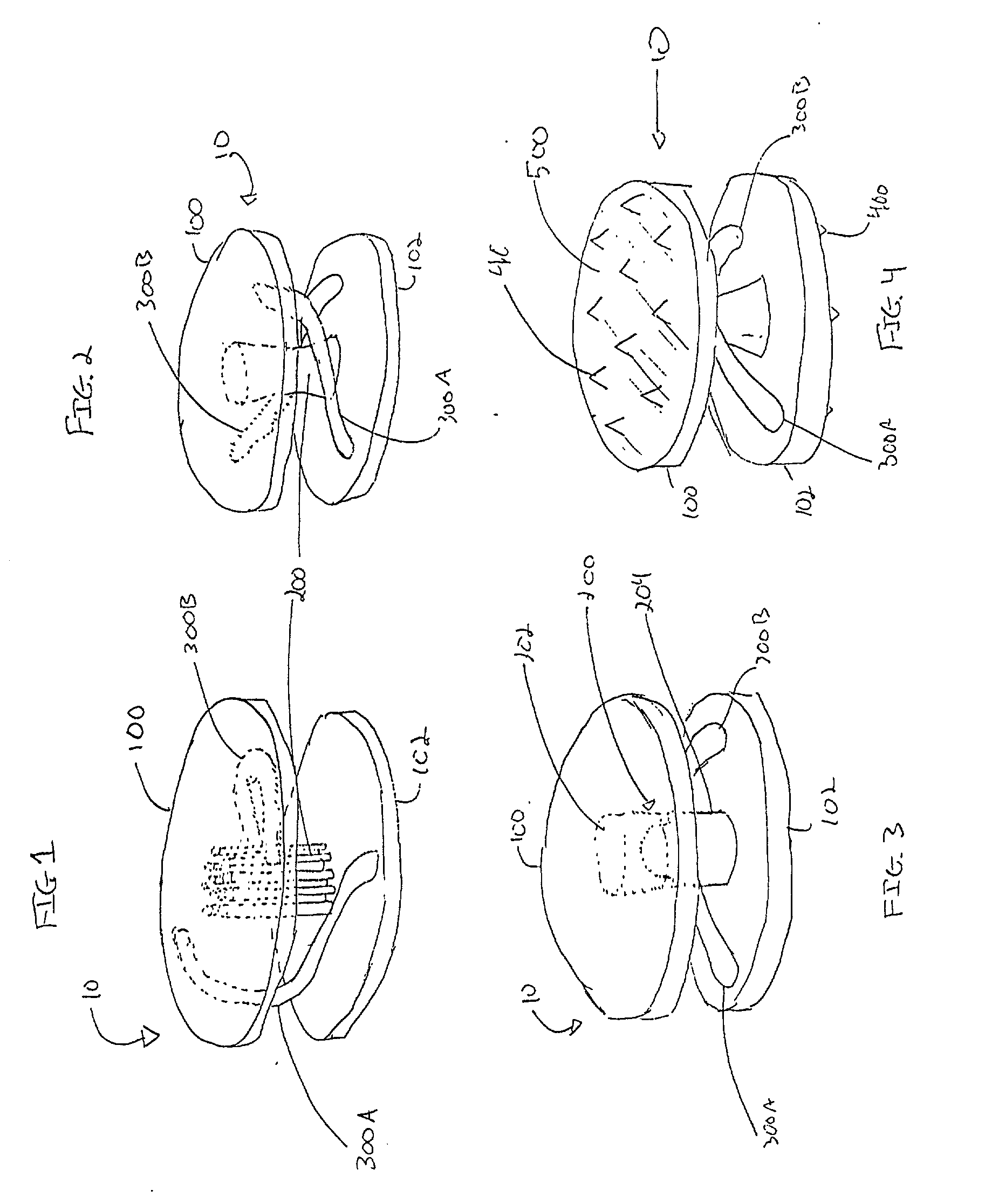

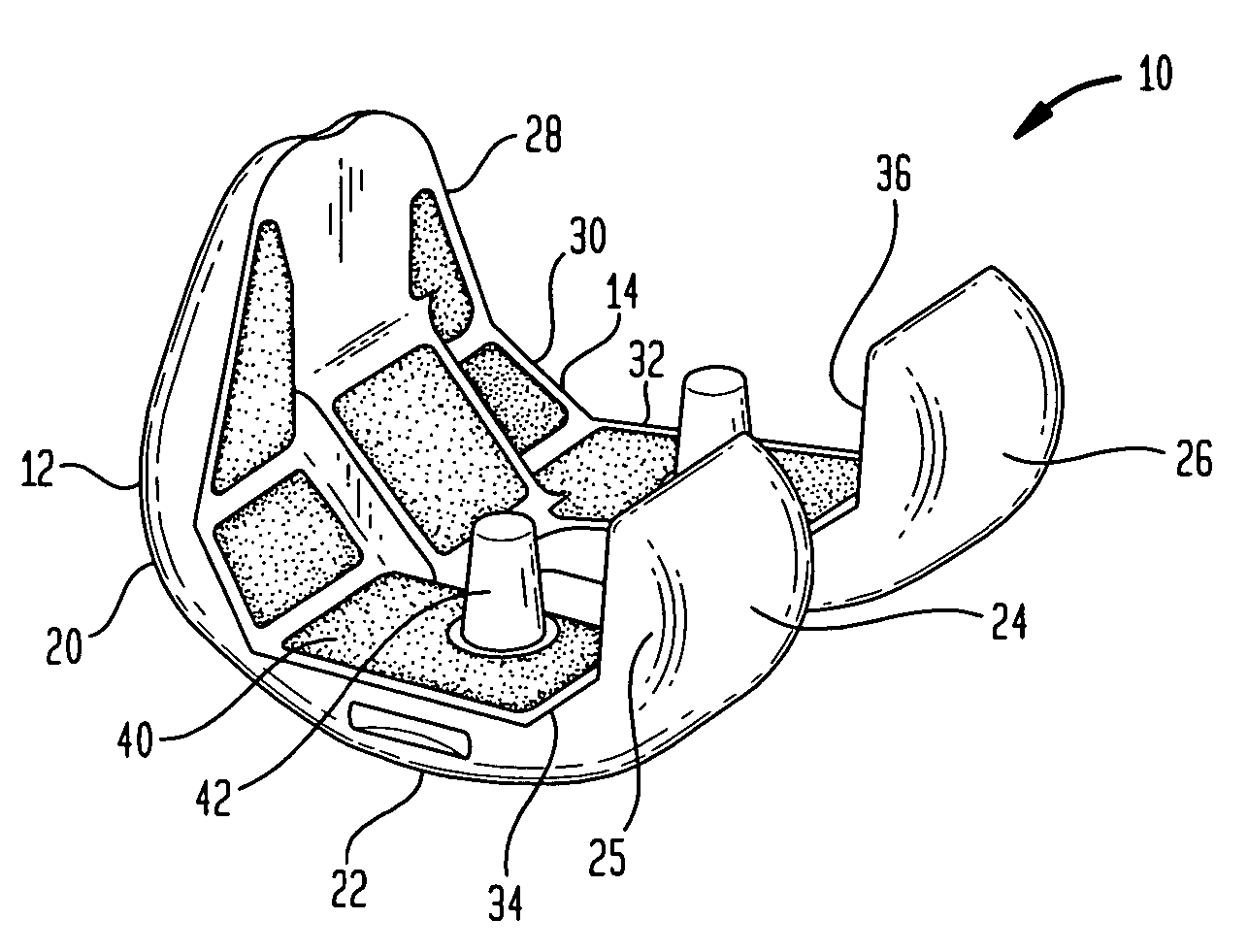

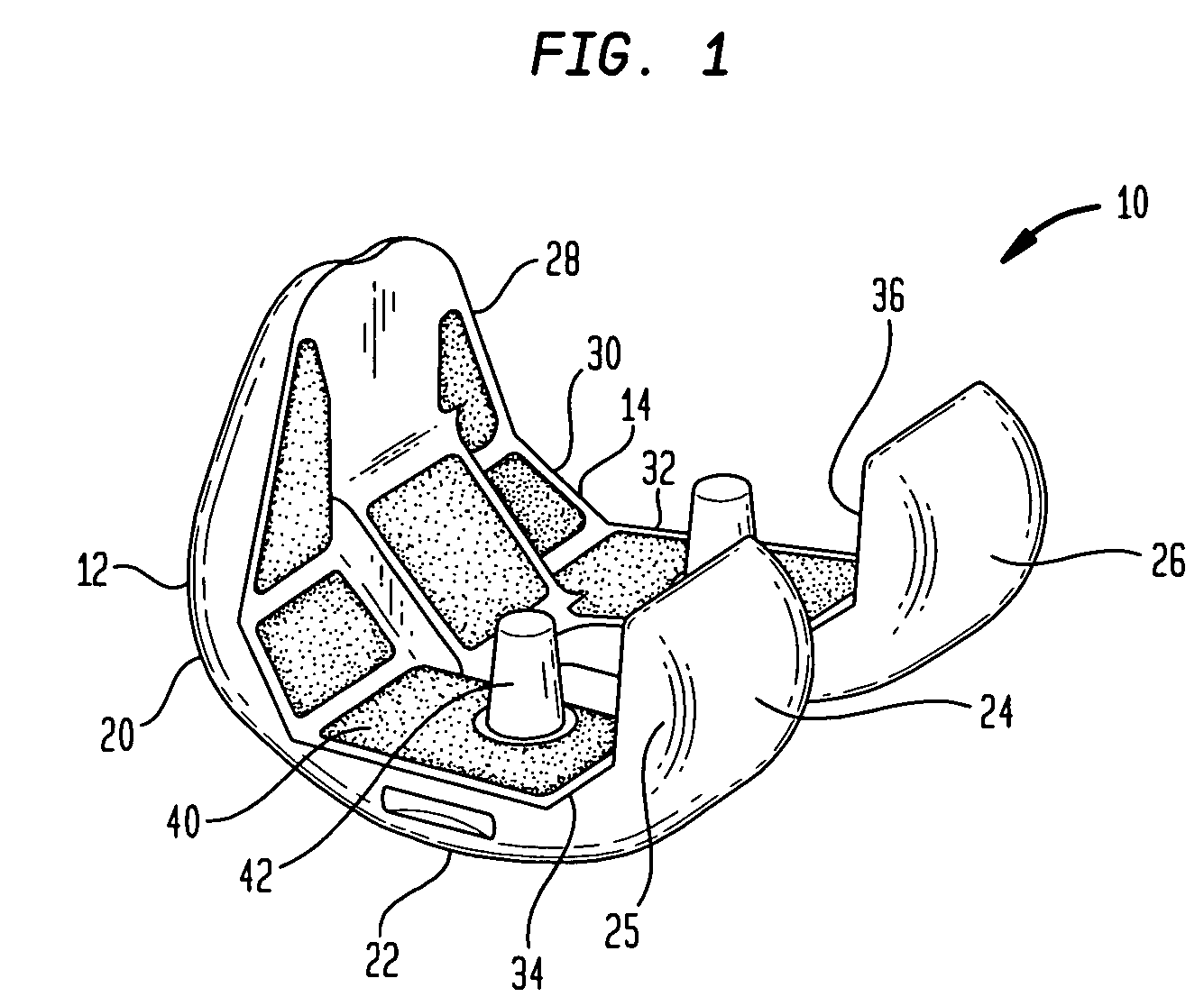

Disclosed is an orthopedic implant suitable for arthroplasty procedures. The orthopedic implant includes a first plate, a second plate, an axial support between the first plate and the second plate and one or more torsional supports connecting the first plate and the second plate. The axial support may be, for example, one or more flexible struts, such as cables, or a ball and socket joint. The torsional supports connect the first and second plates and may be, for example, curved around the axial support. The torsional supports may be integrally formed with the first and second plates as a single unitary device, by, for example, a Laser Engineered Net Shape (LENS) process.

Owner:DEPUY ACROMED INC

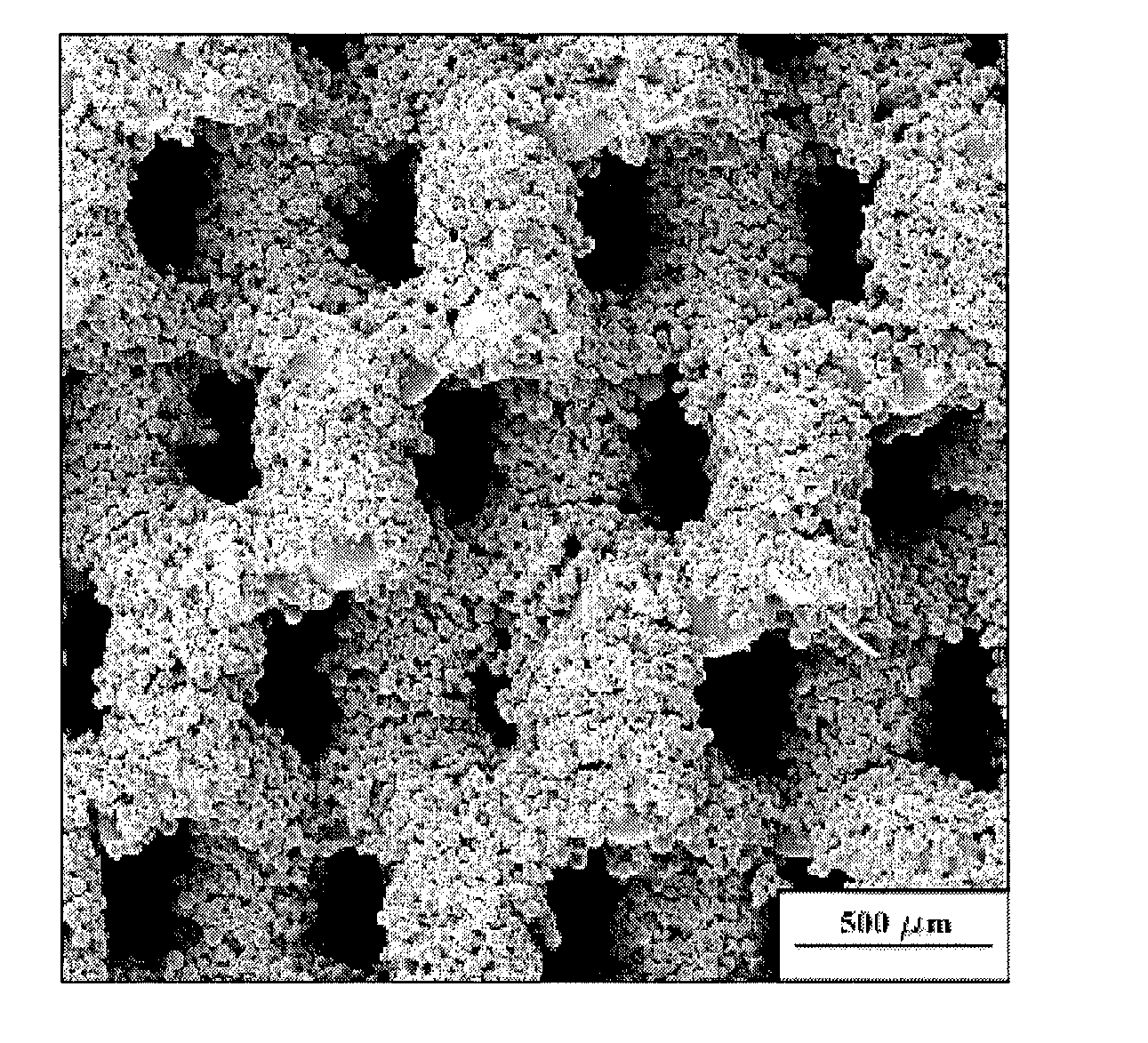

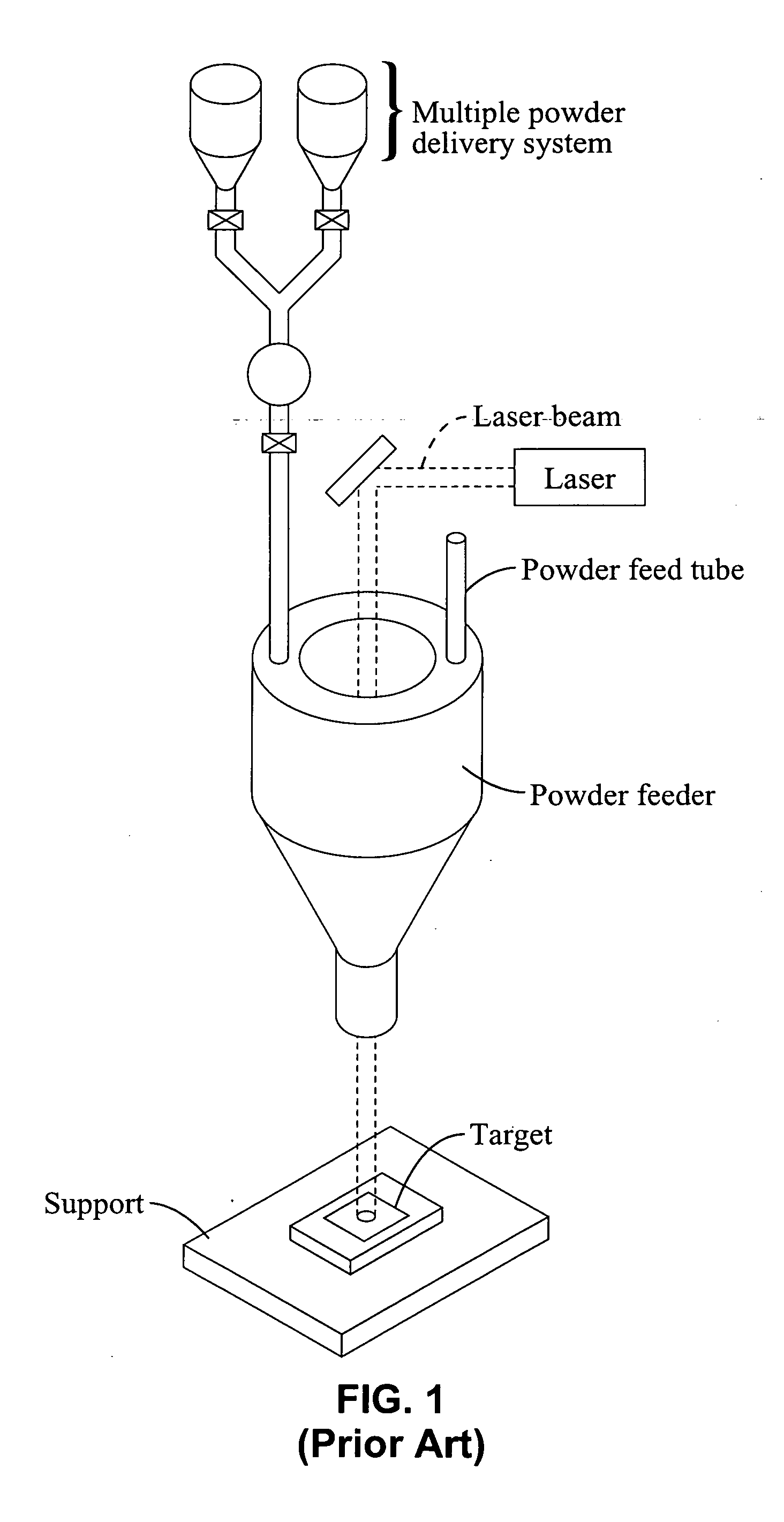

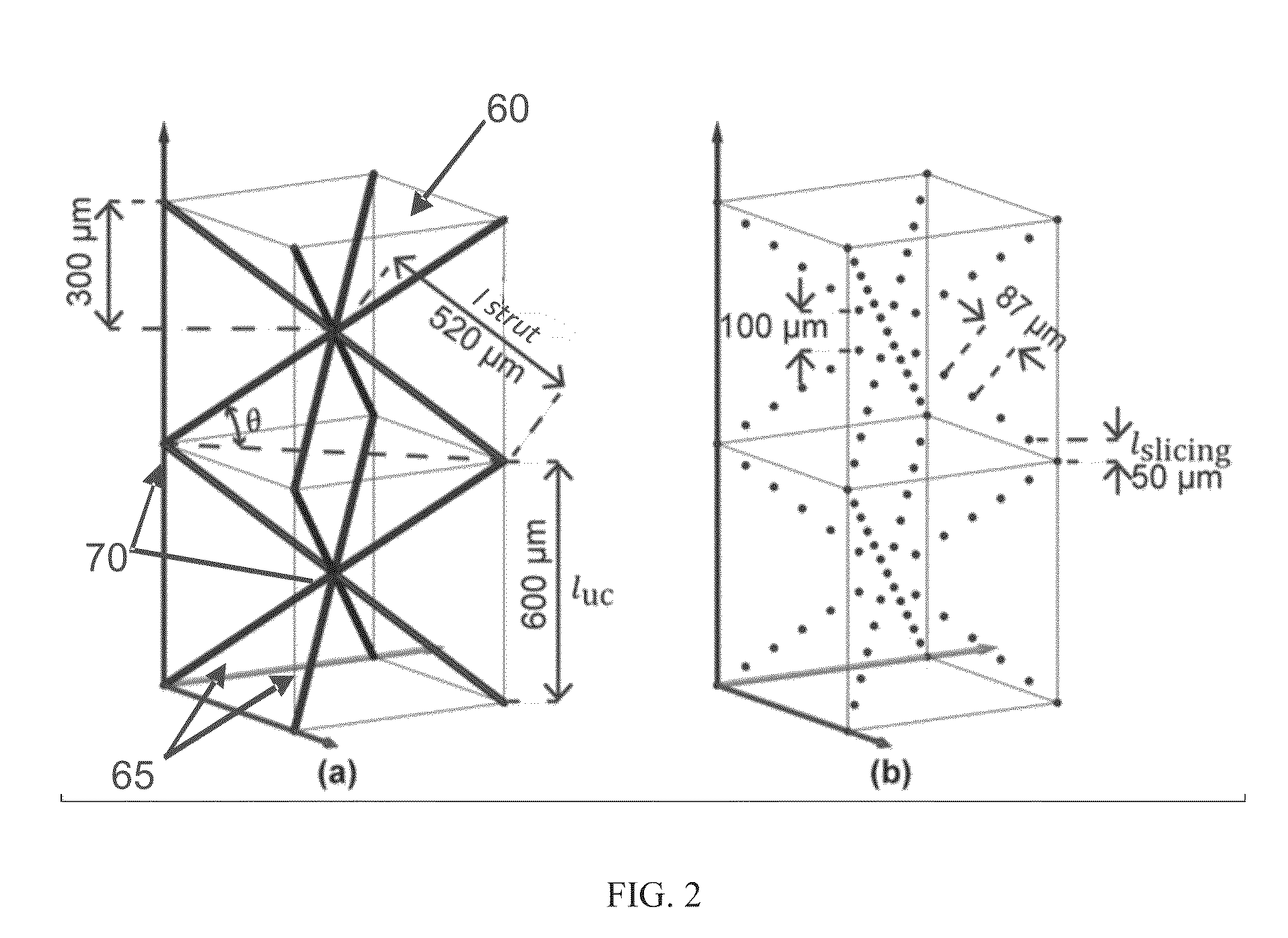

Laser-produced porous structure

The present invention disclosed a method of producing a three-dimensional porous tissue in-growth structure. The method includes the steps of depositing a first layer of metal powder and scanning the first layer of metal powder with a laser beam to form a portion of a plurality of predetermined unit cells. Depositing at least one additional layer of metal powder onto a previous layer and repeating the step of scanning a laser beam for at least one of the additional layers in order to continuing forming the predetermined unit cells. The method further includes continuing the depositing and scanning steps to form a medical implant.

Owner:UNIV OF LIVERPOOL +1

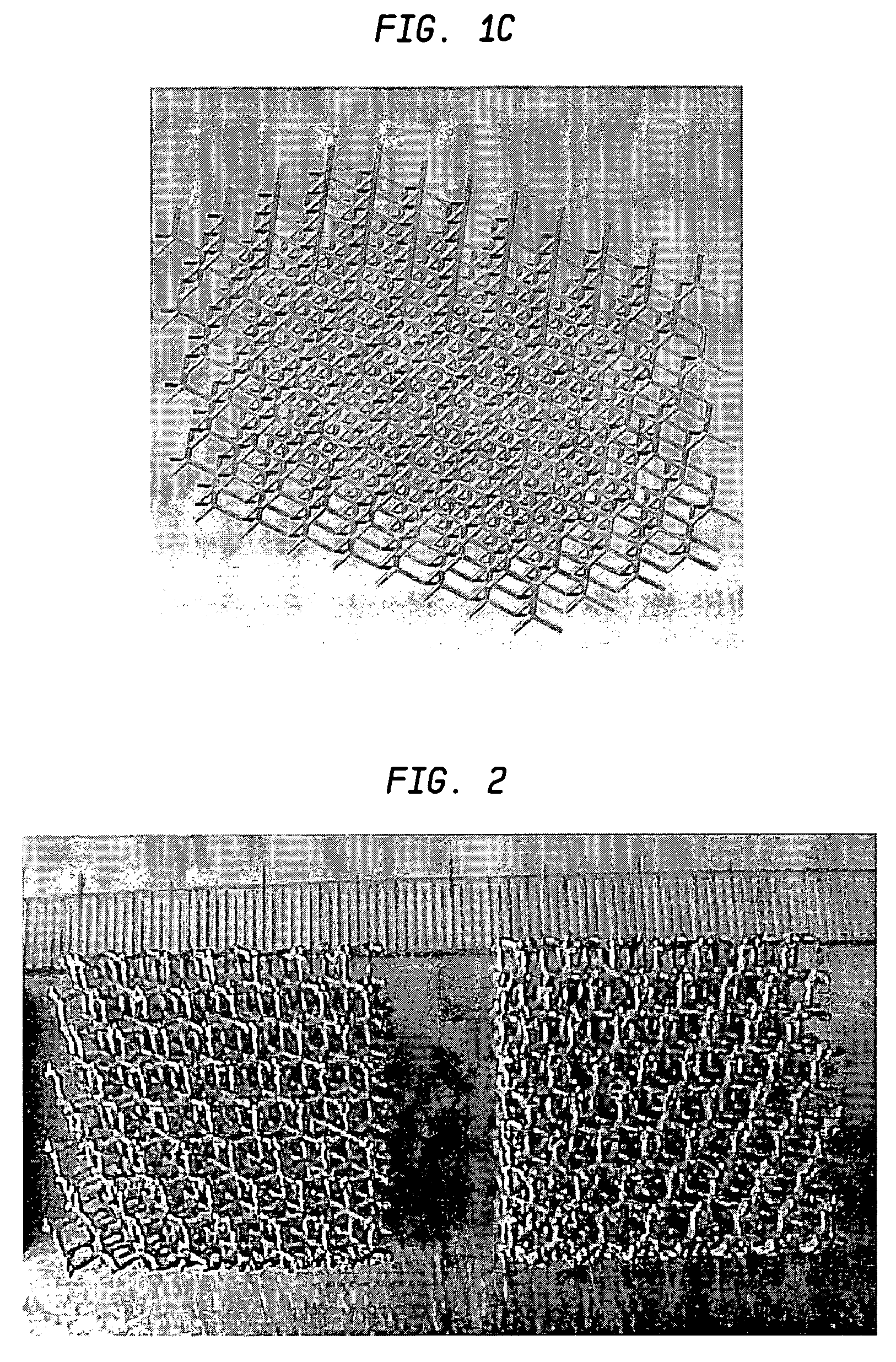

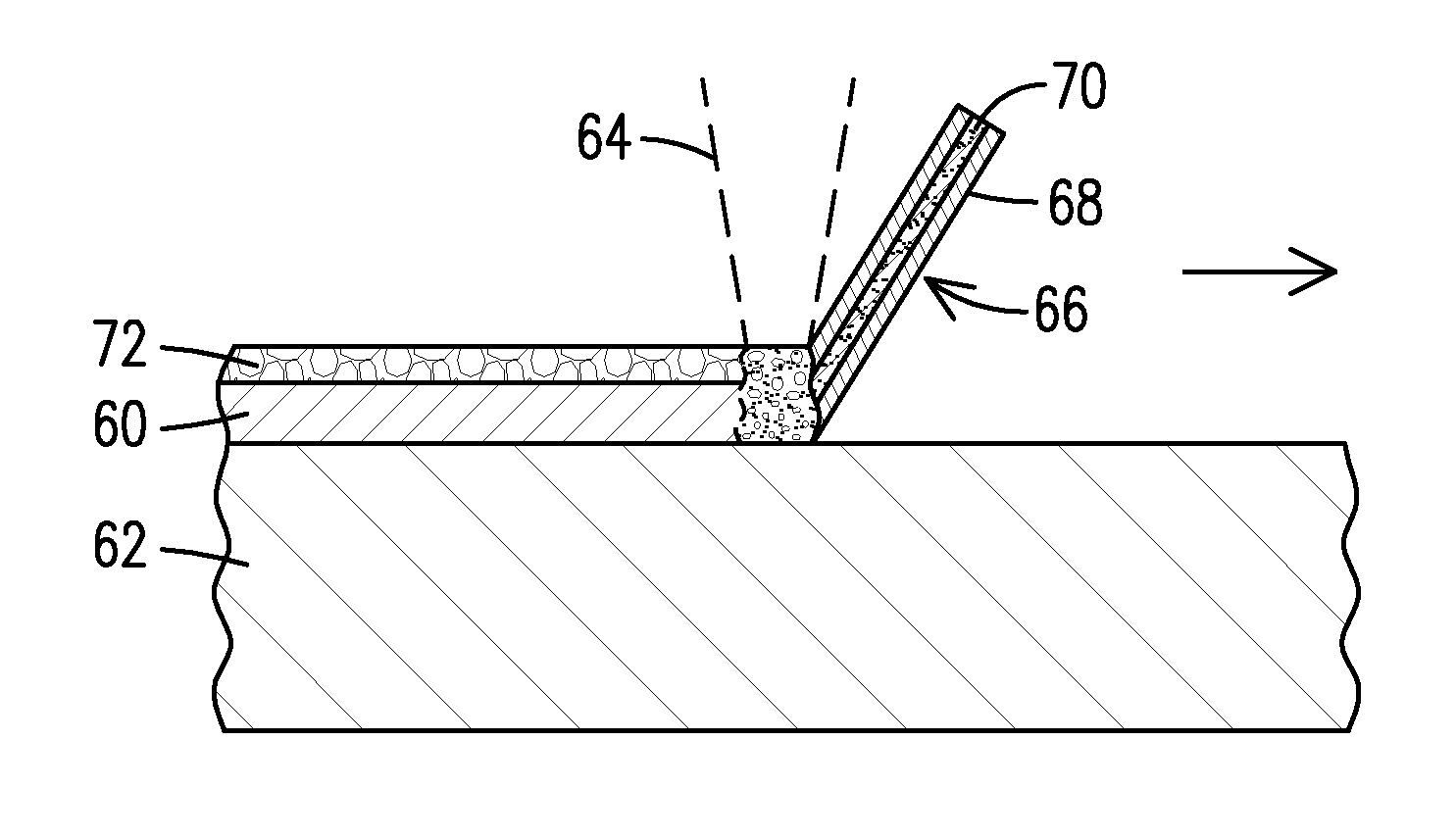

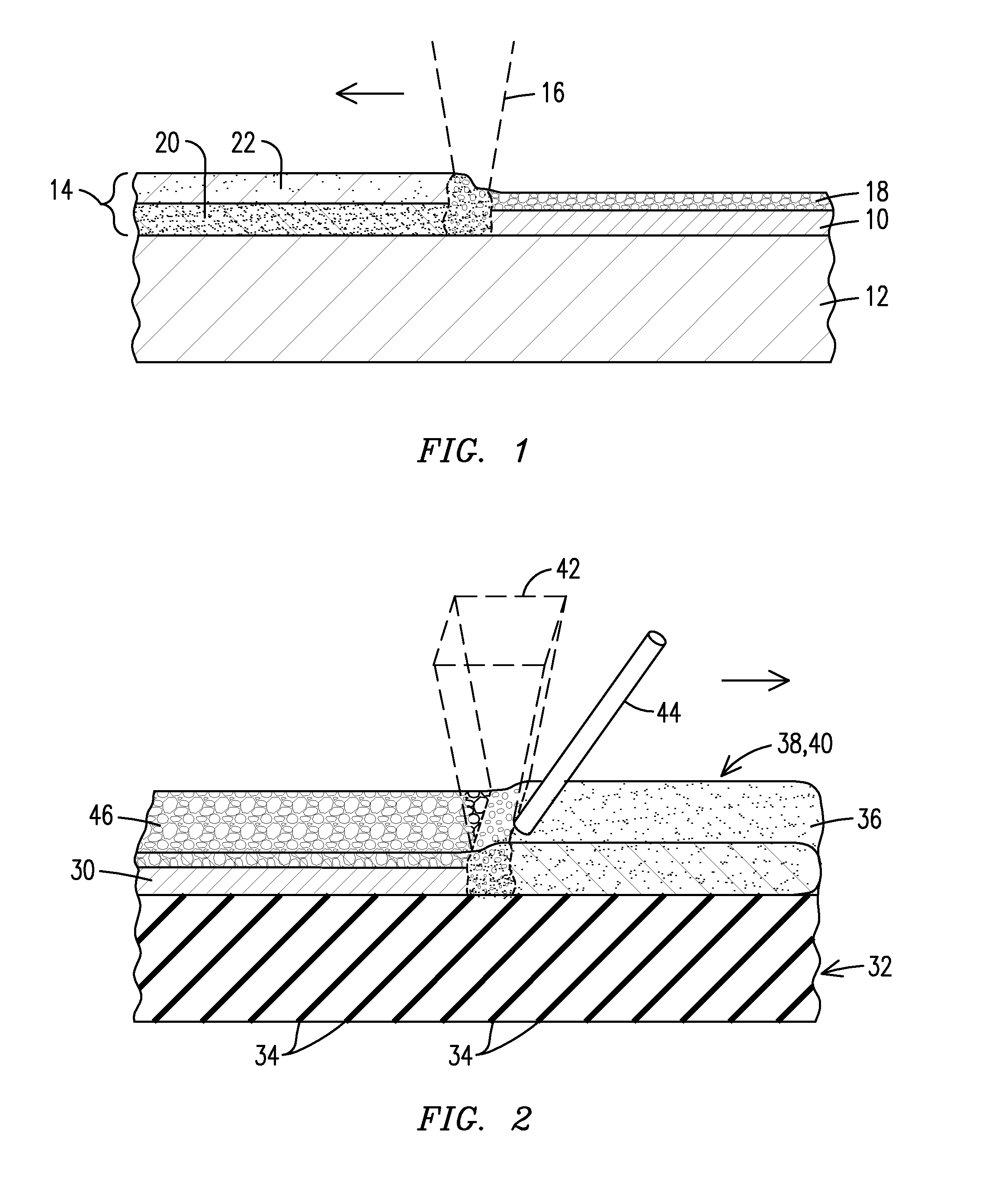

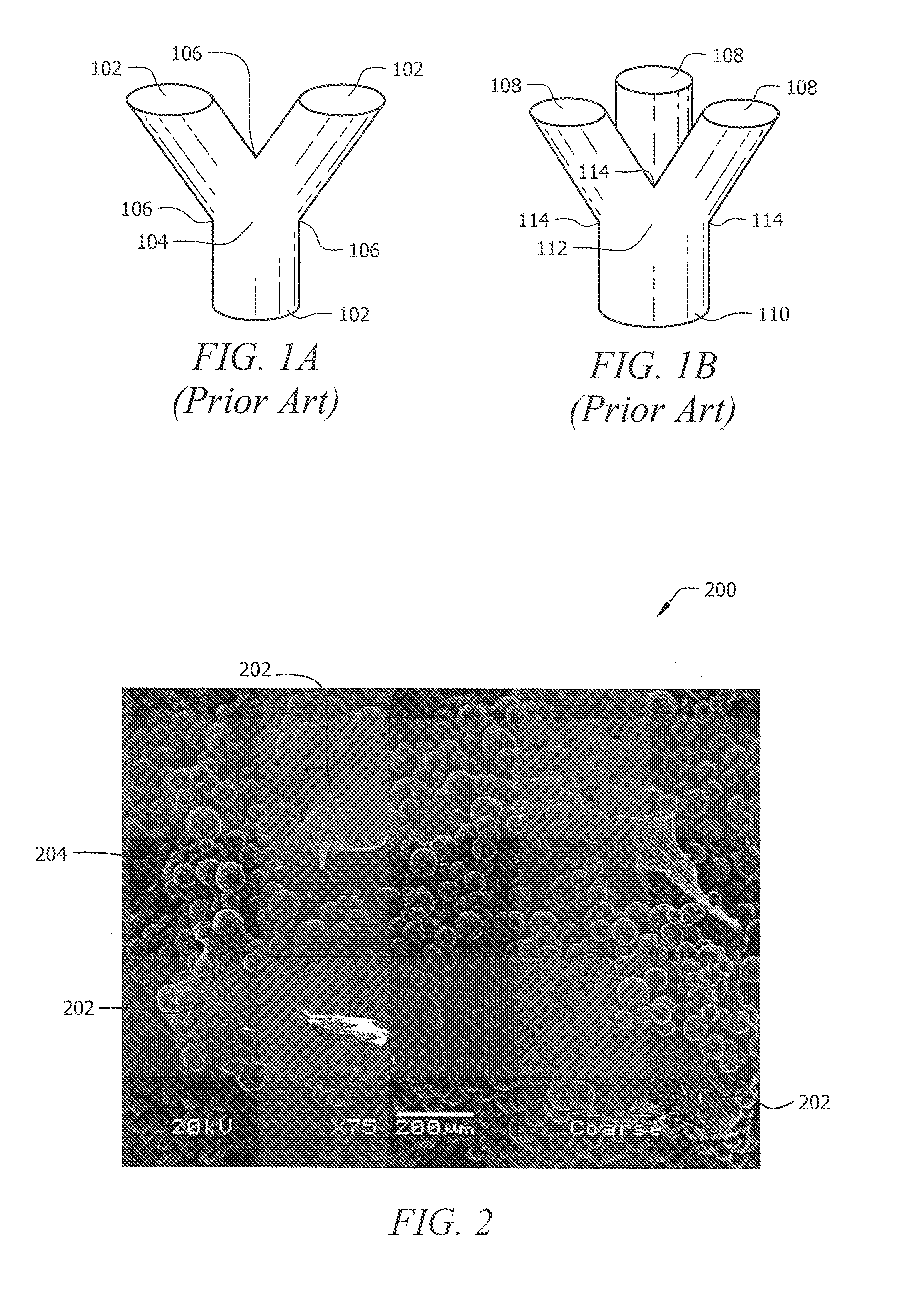

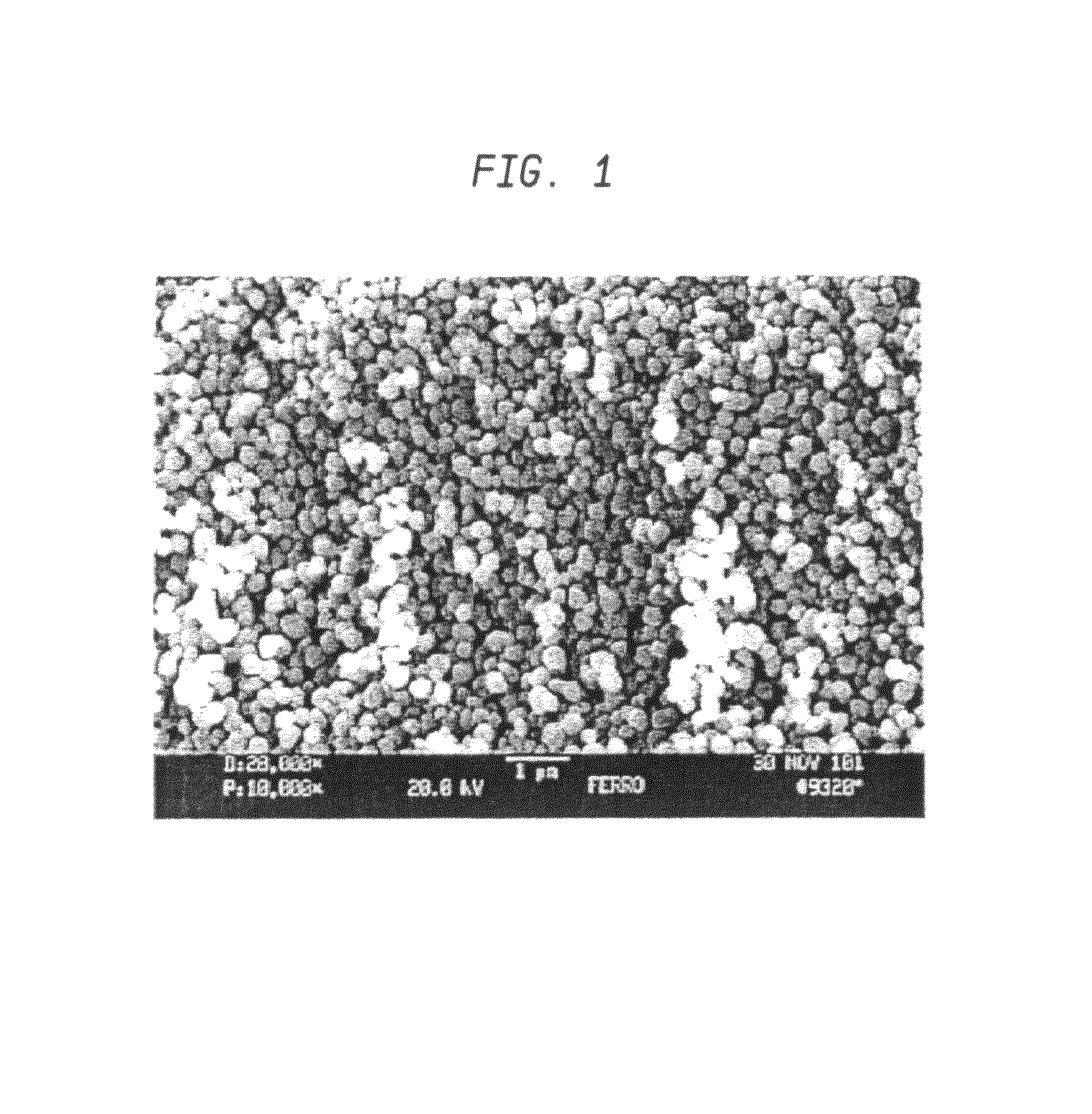

Laser-produced porous surface

ActiveUS20070142914A1Promote bone ingrowthGood stiffness characteristicsAdditive manufacturing apparatusMolten spray coatingLight beamMetal powder

A method of forming an implant having a porous tissue ingrowth structure and a bearing support structure. The method includes depositing a first layer of a metal powder onto a substrate, scanning a laser beam over the powder so as to sinter the metal powder at predetermined locations, depositing at least one layer of the metal powder onto the first layer and repeating the scanning of the laser beam.

Owner:UNIV OF LIVERPOOL +1

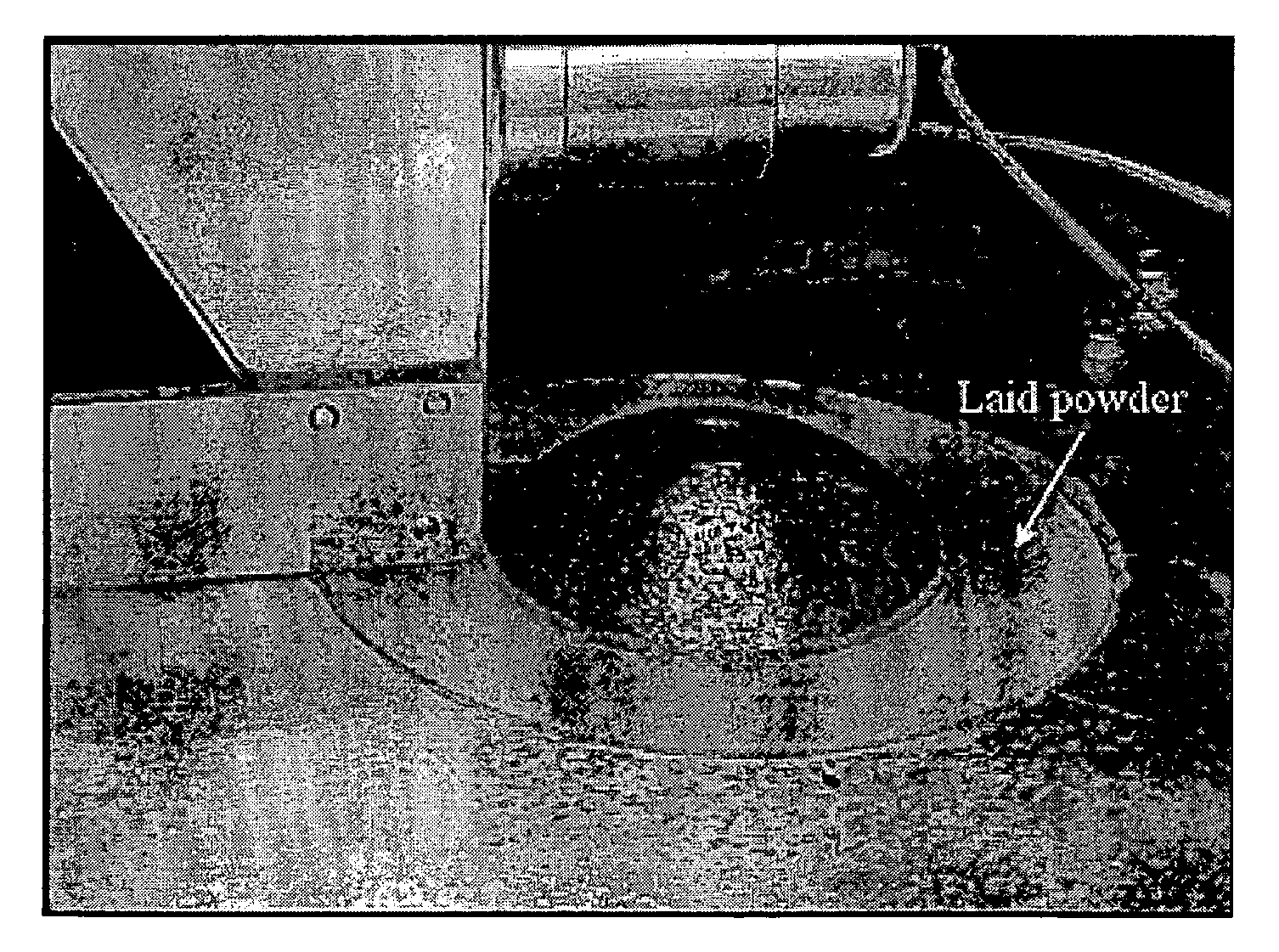

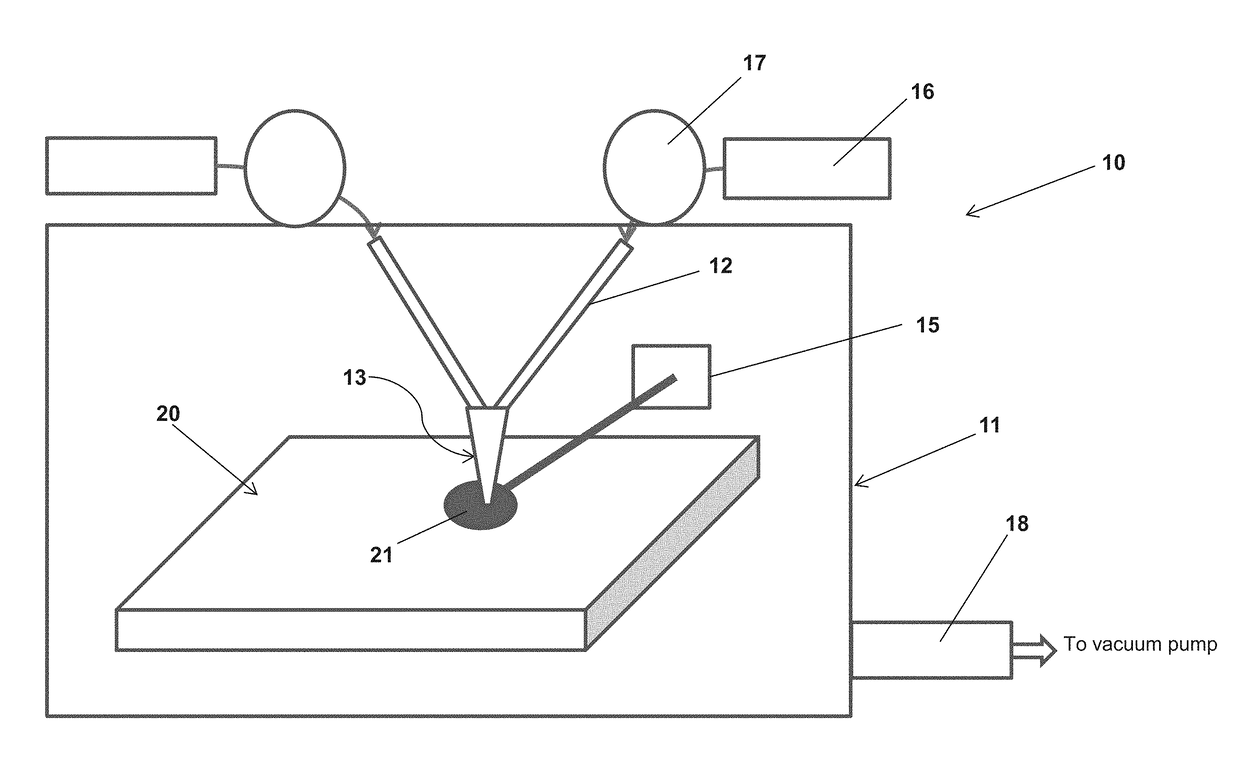

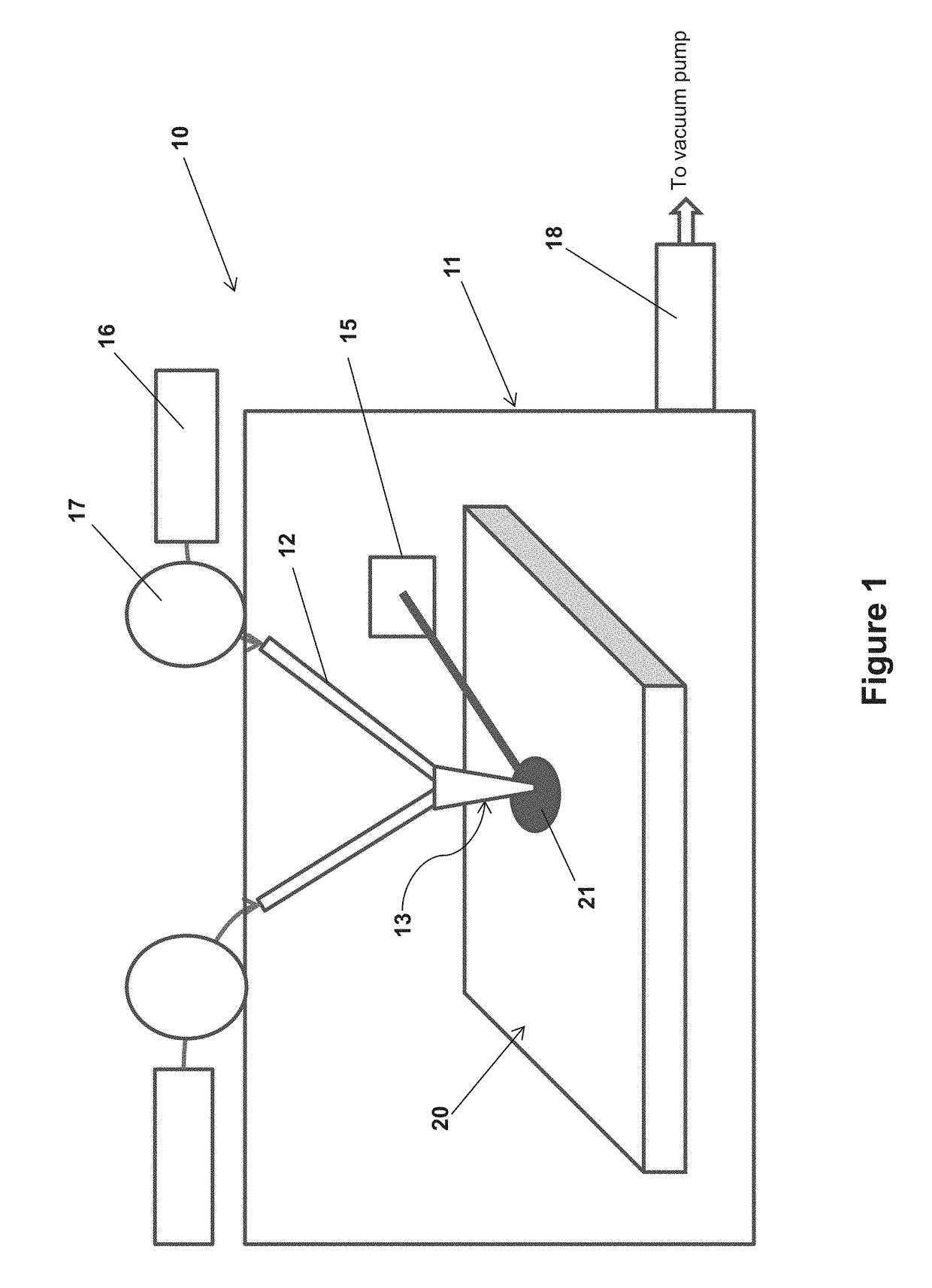

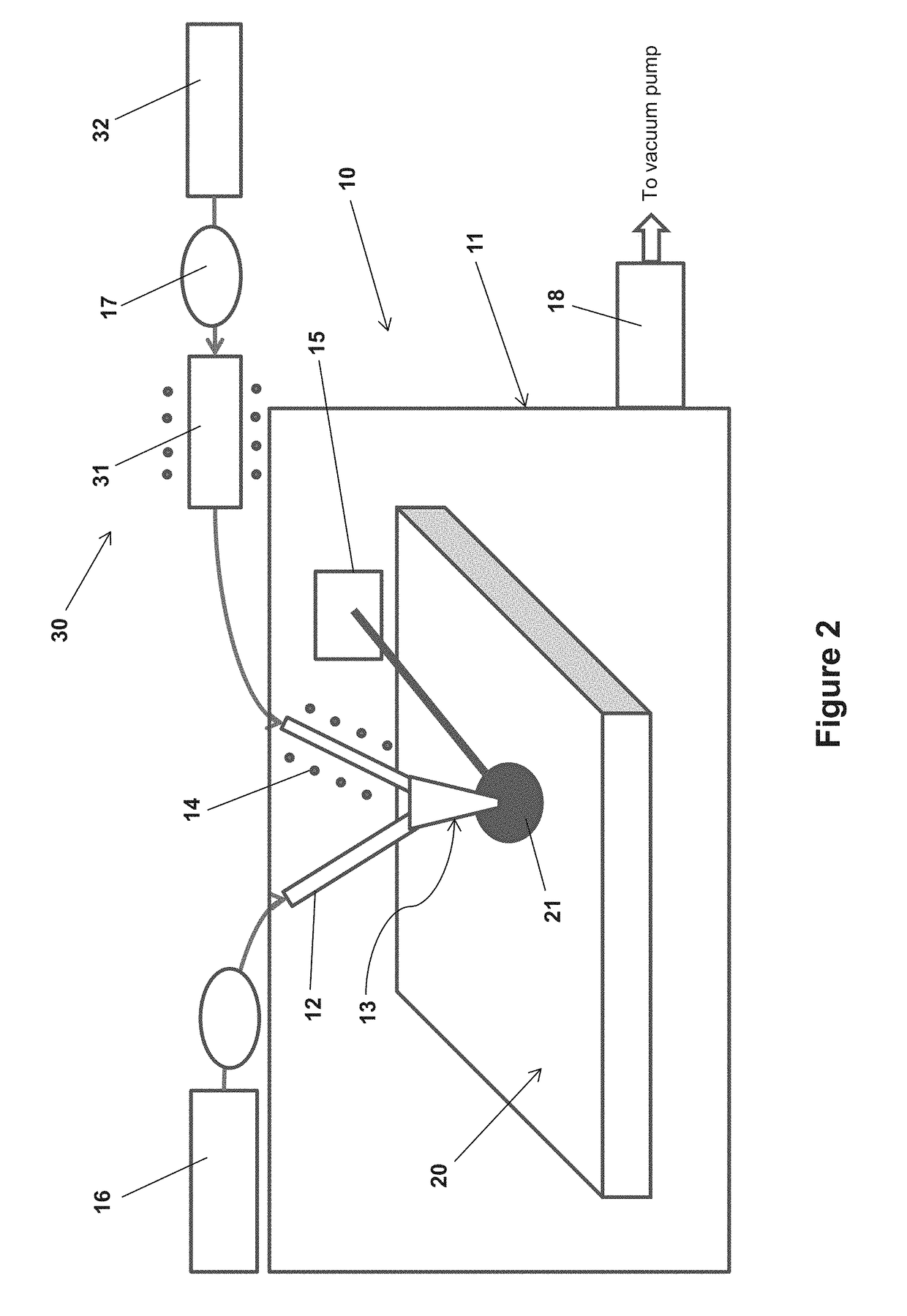

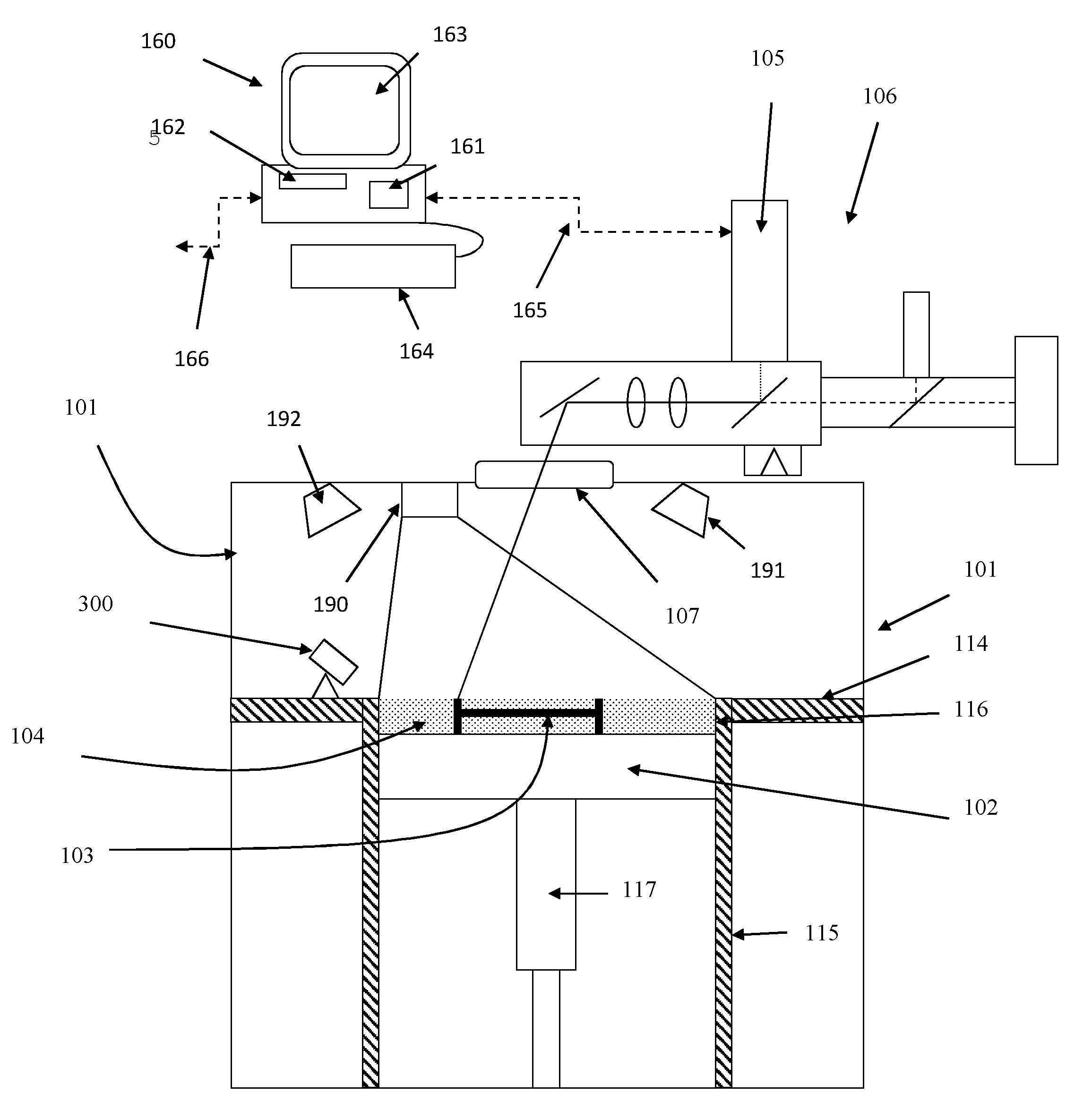

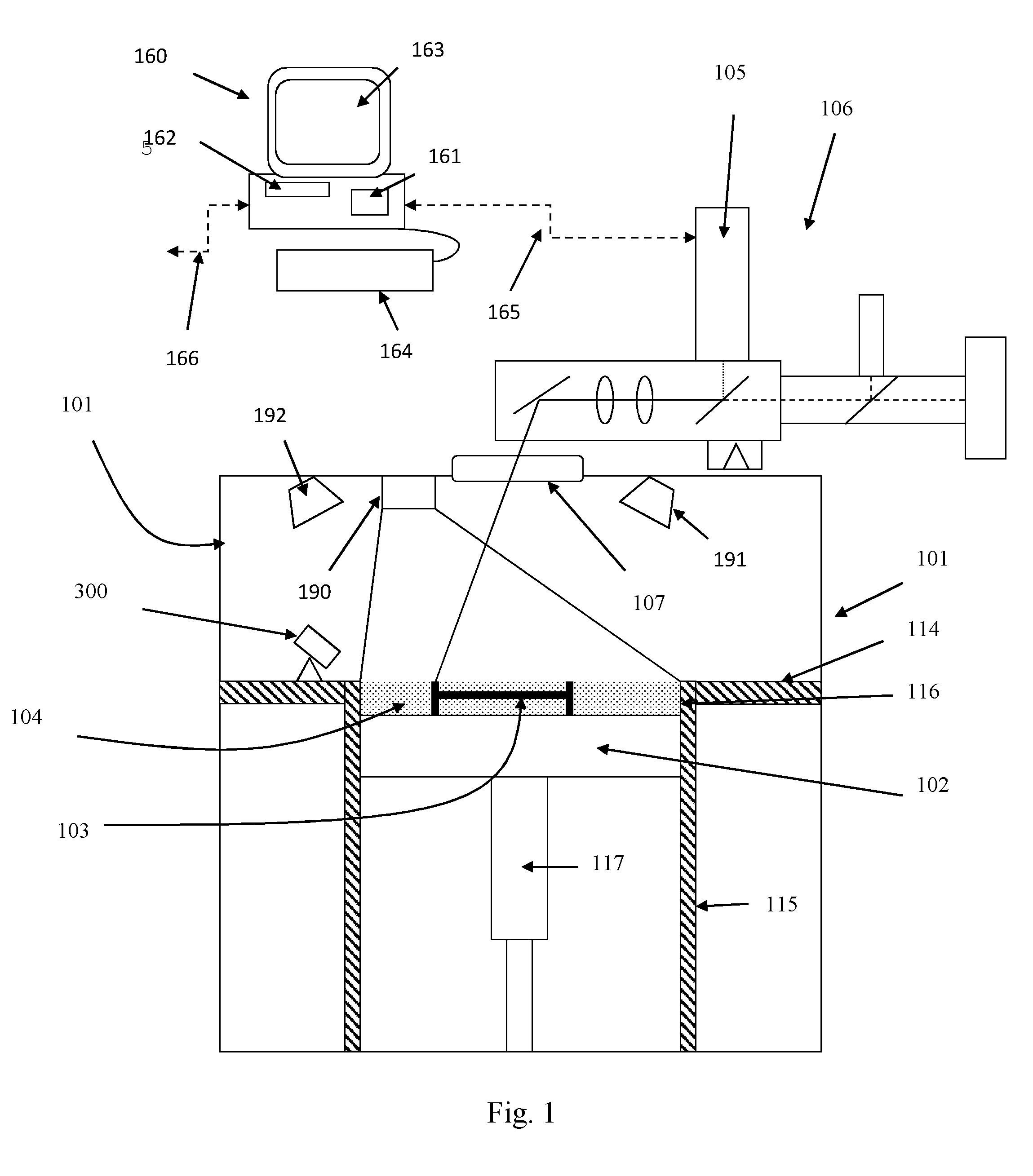

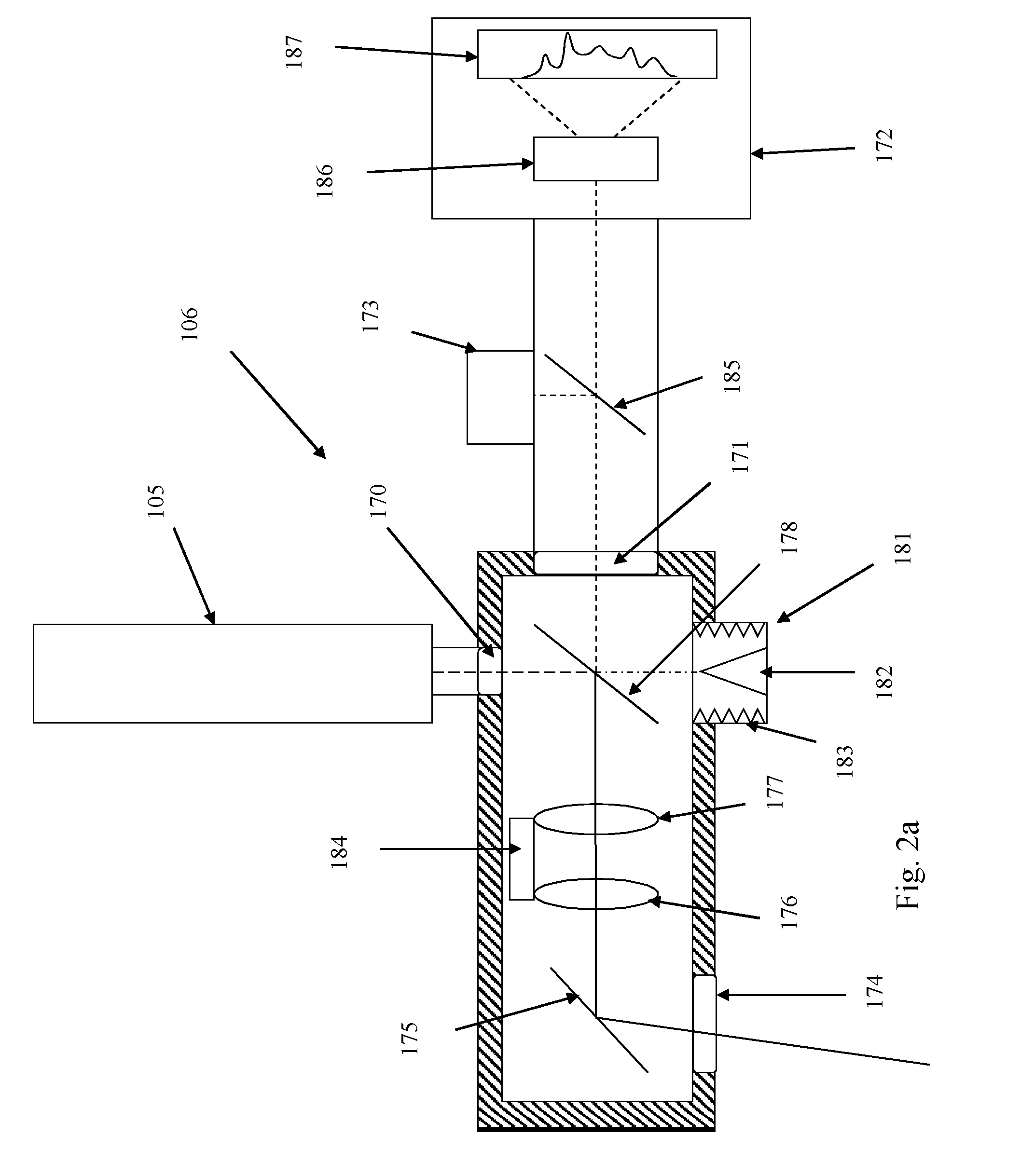

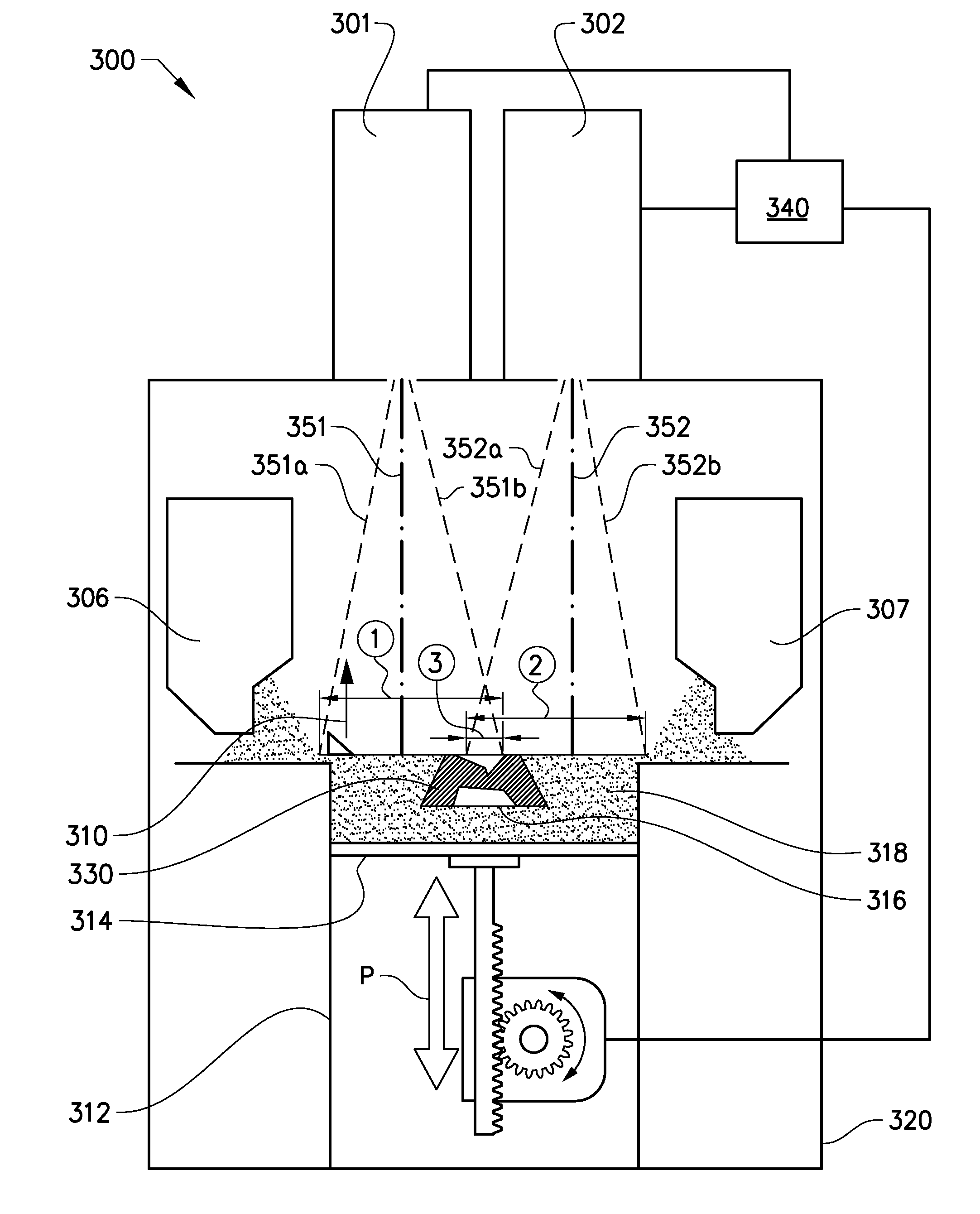

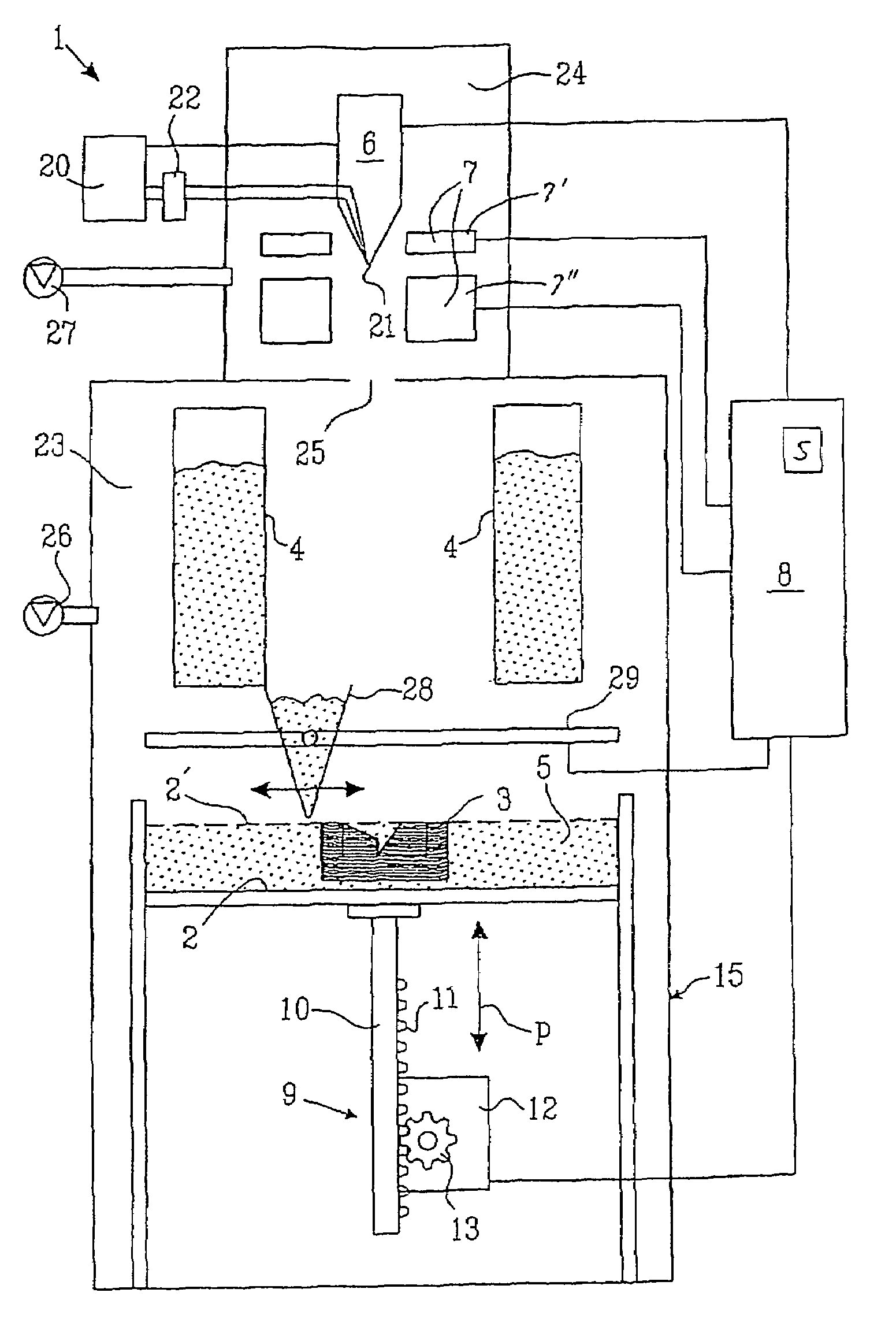

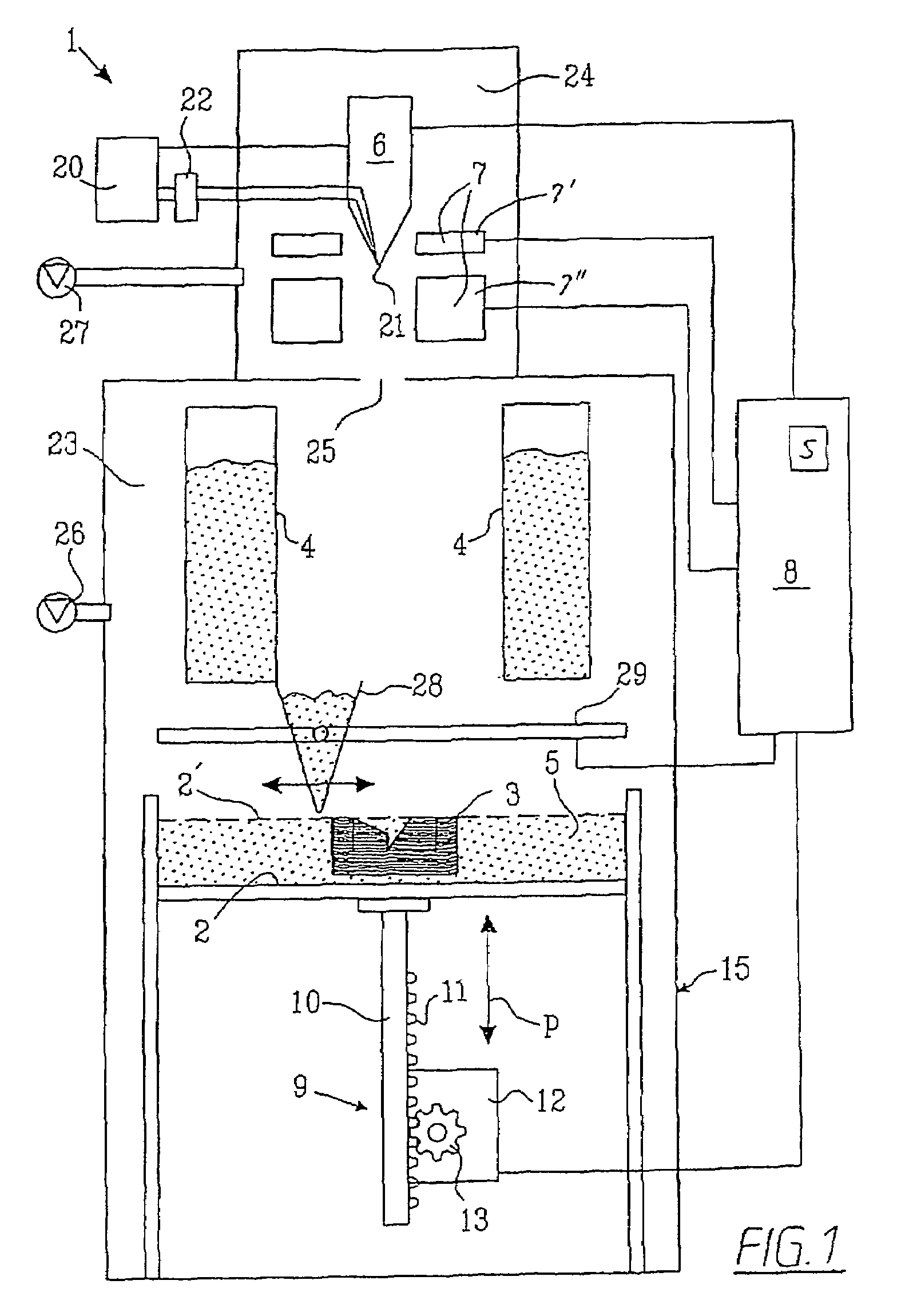

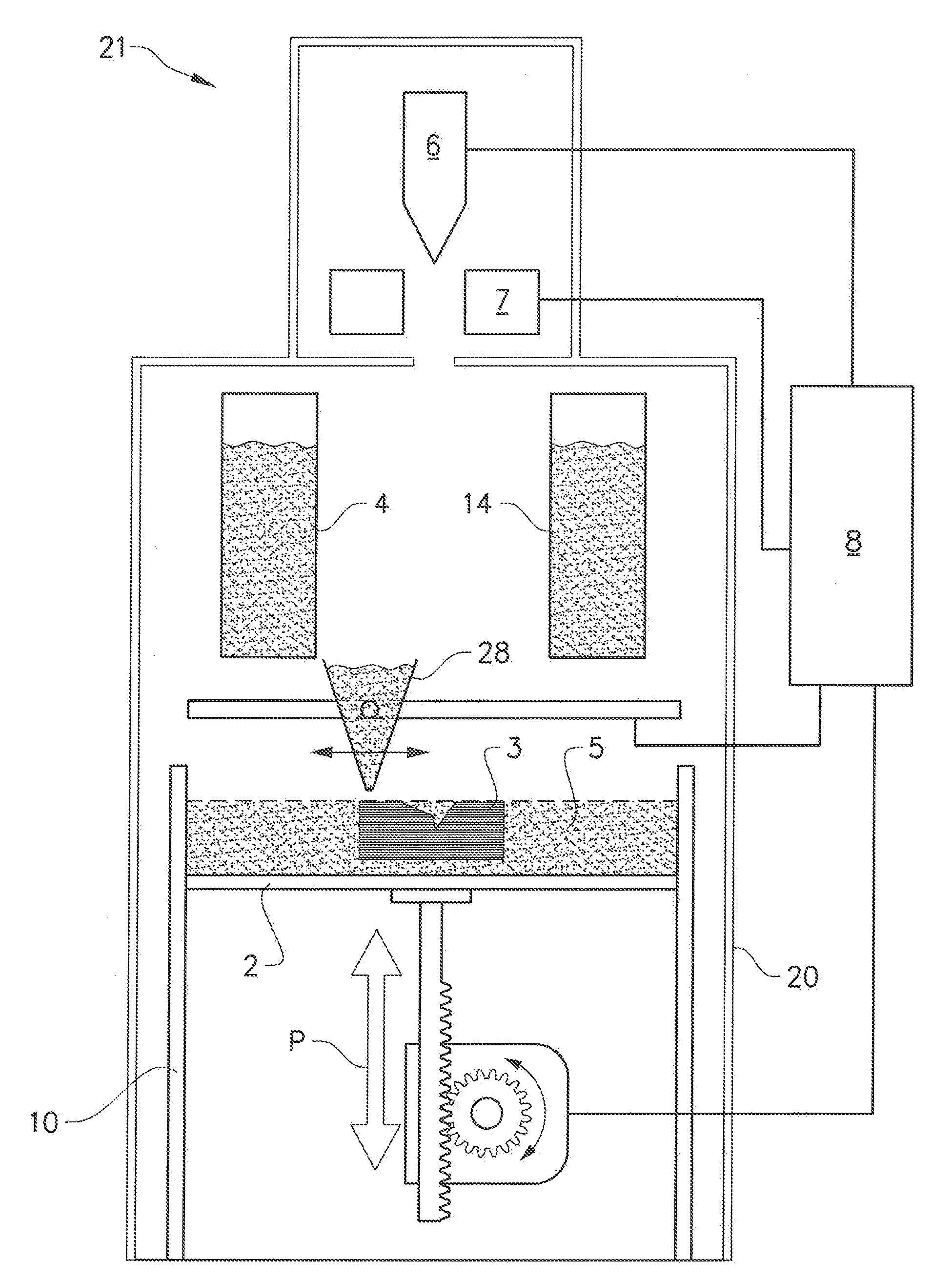

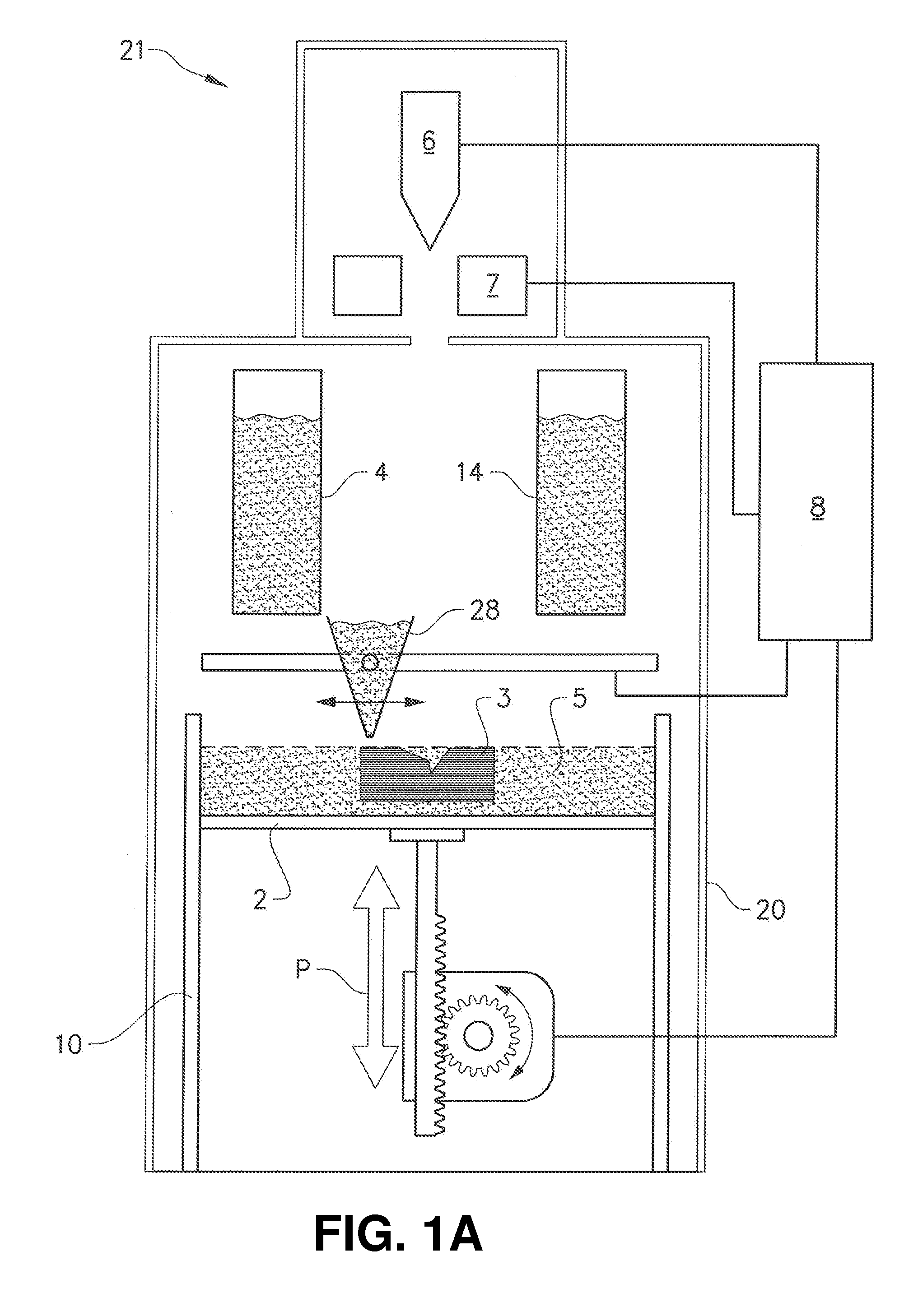

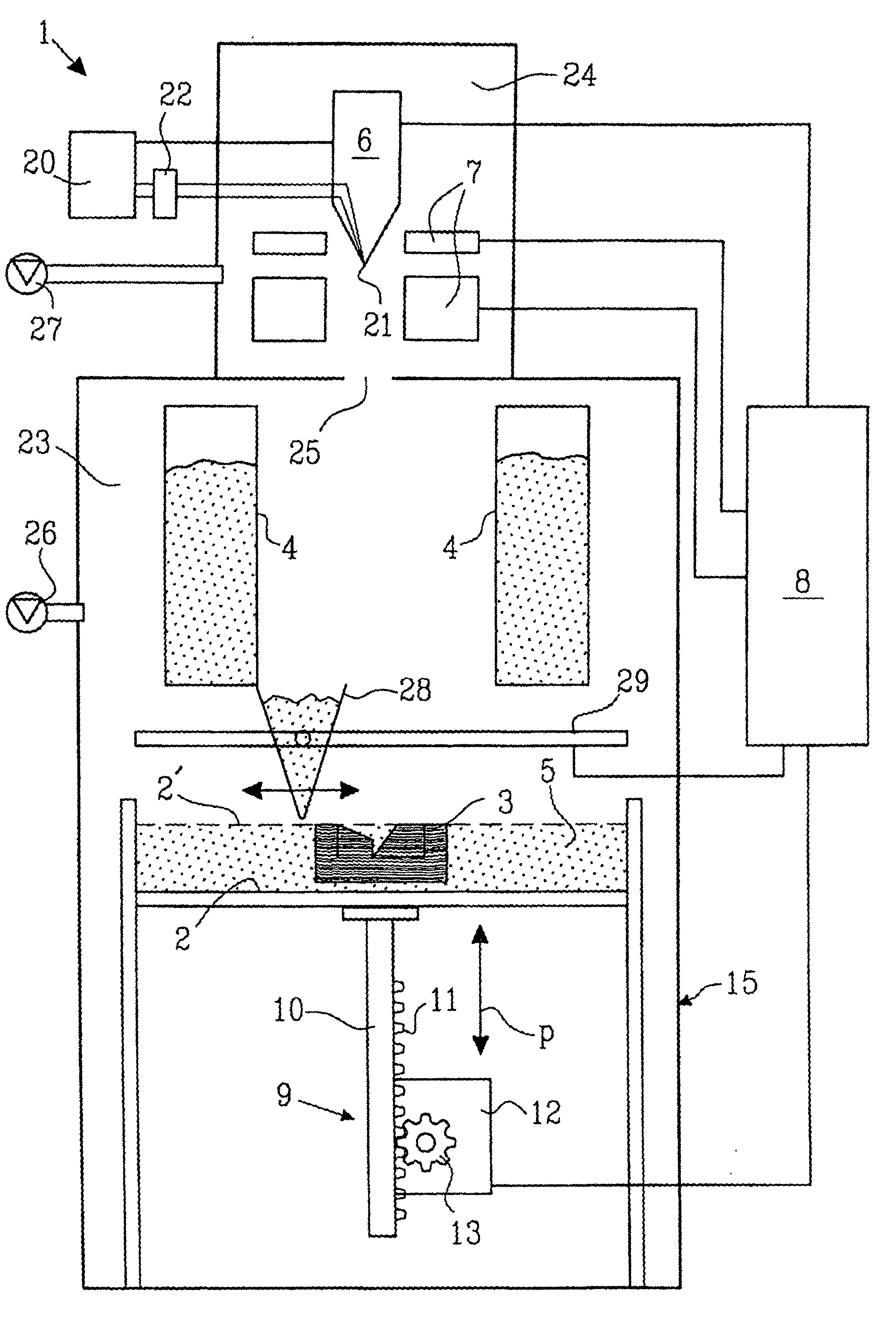

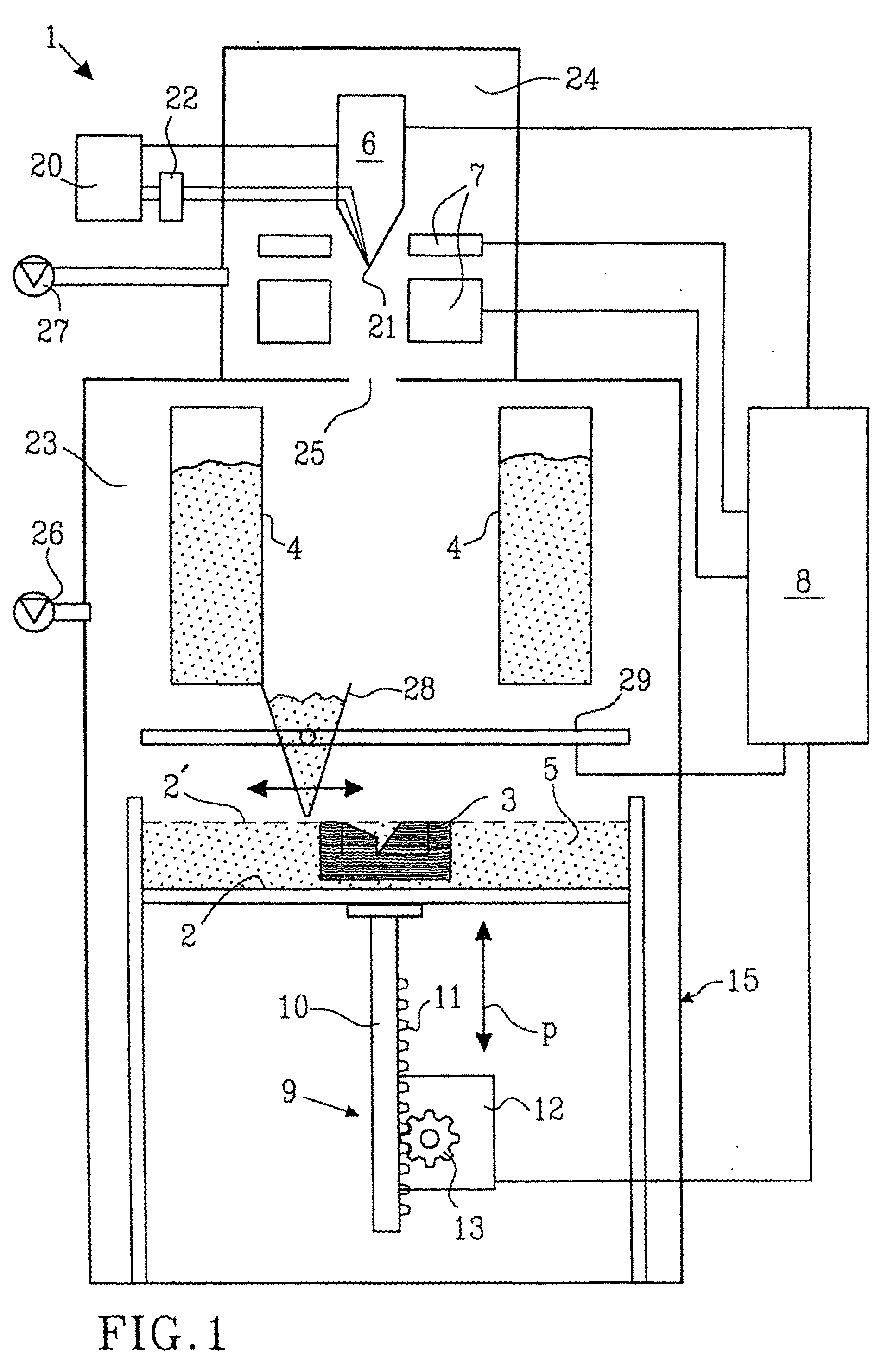

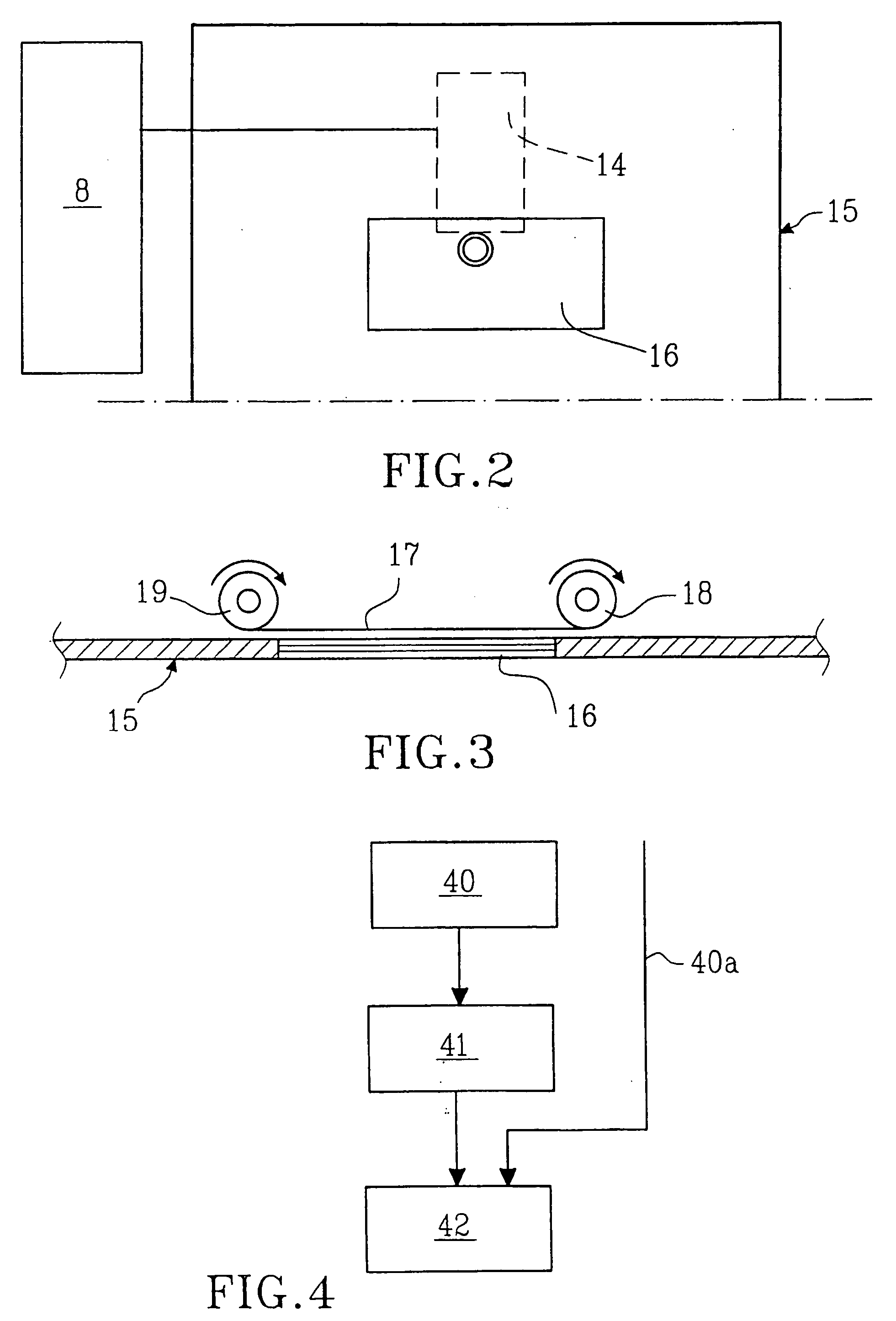

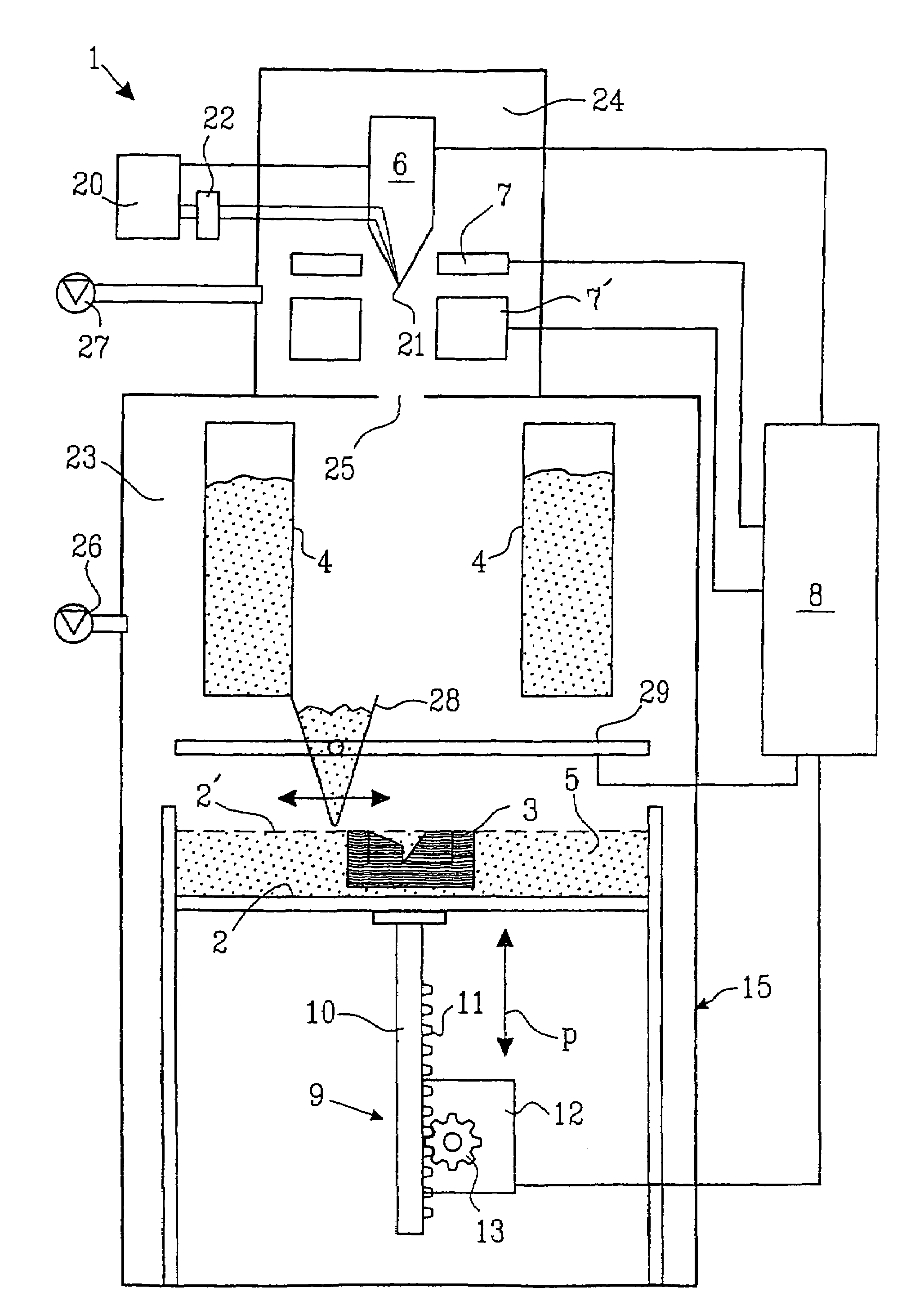

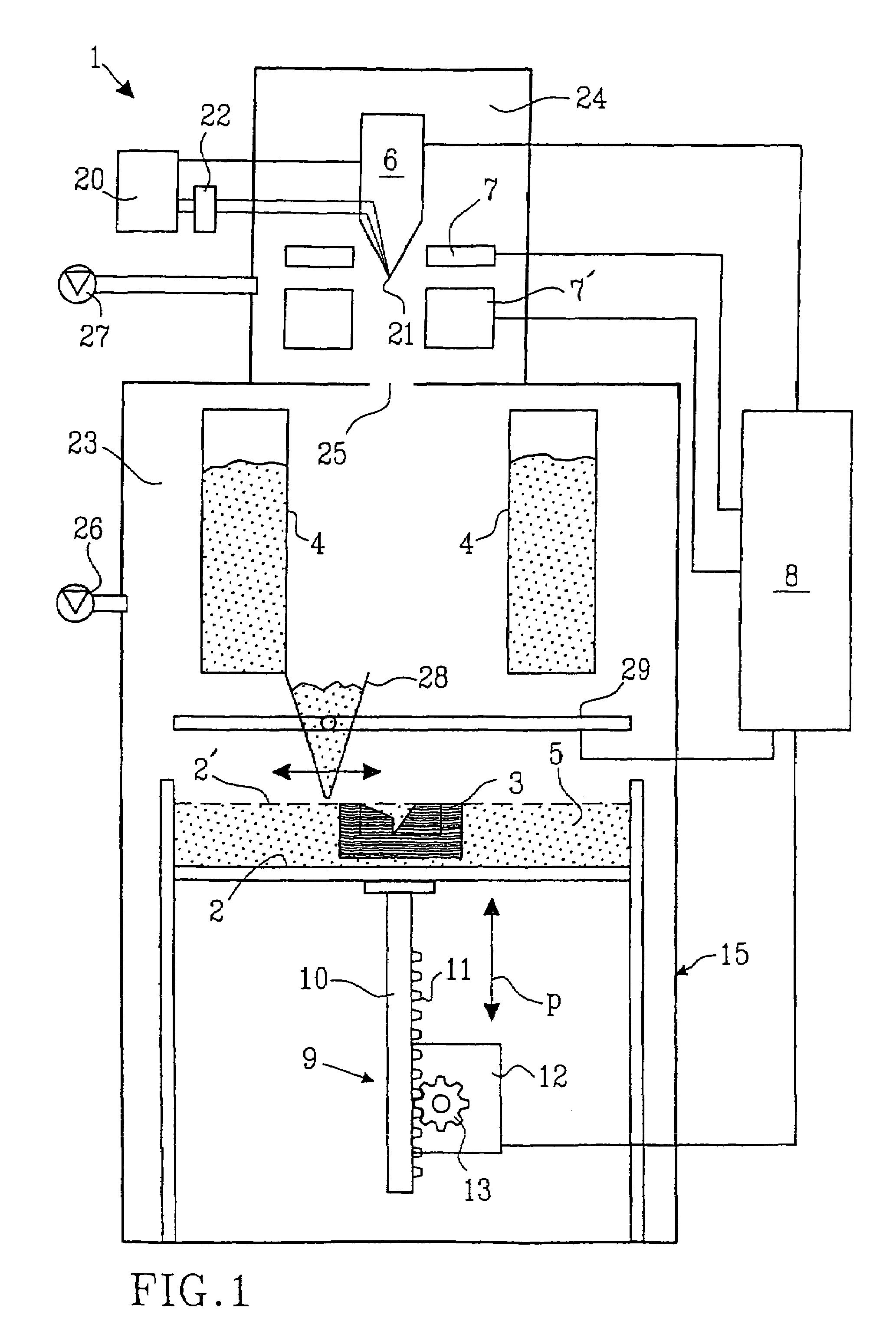

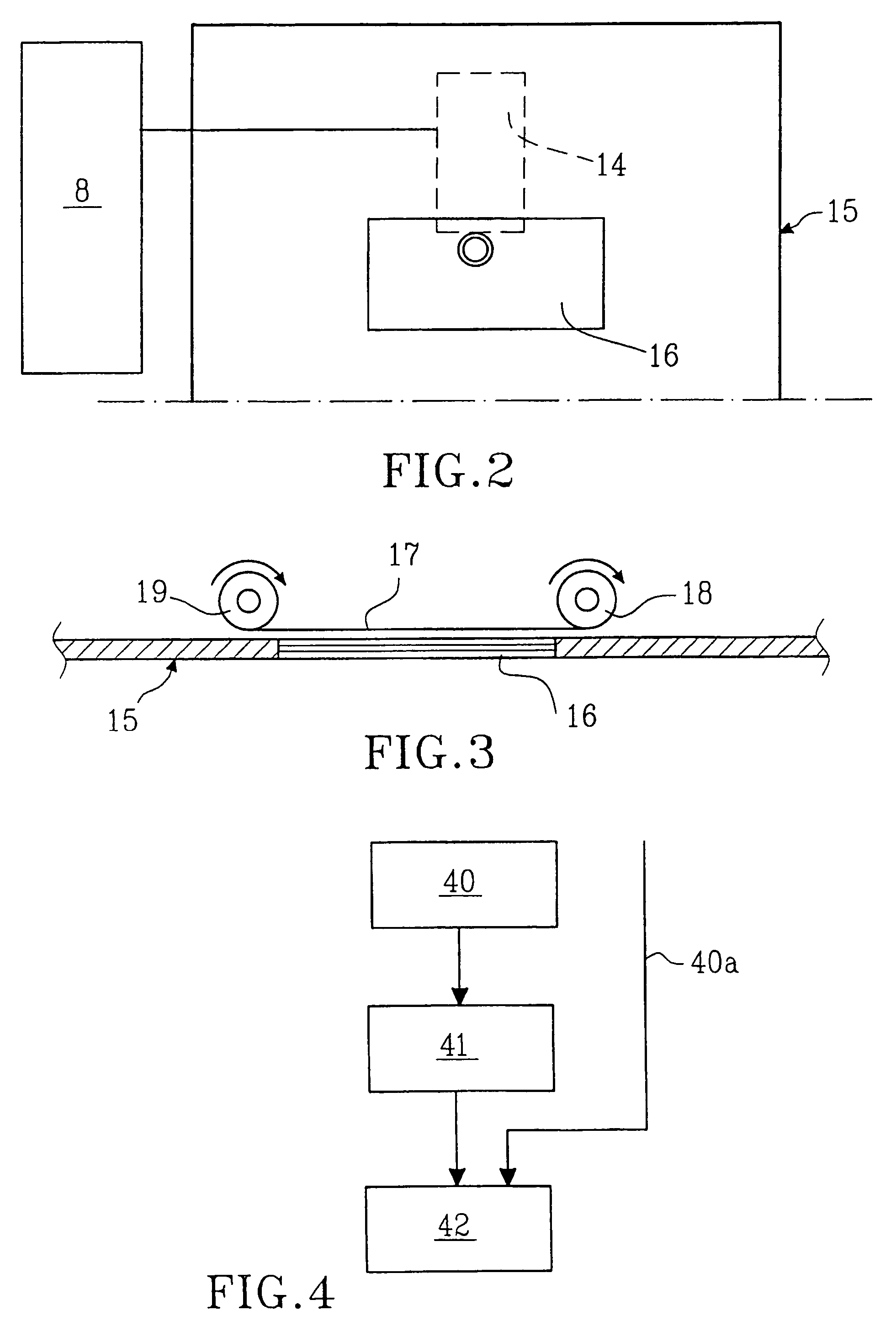

Procedure and apparatus for in-situ monitoring and feedback control of selective laser powder processing

InactiveUS20090206065A1Quality improvementReduce spectral distortionAdditive manufacturing apparatusIncreasing energy efficiencyControl systemFeedback controller

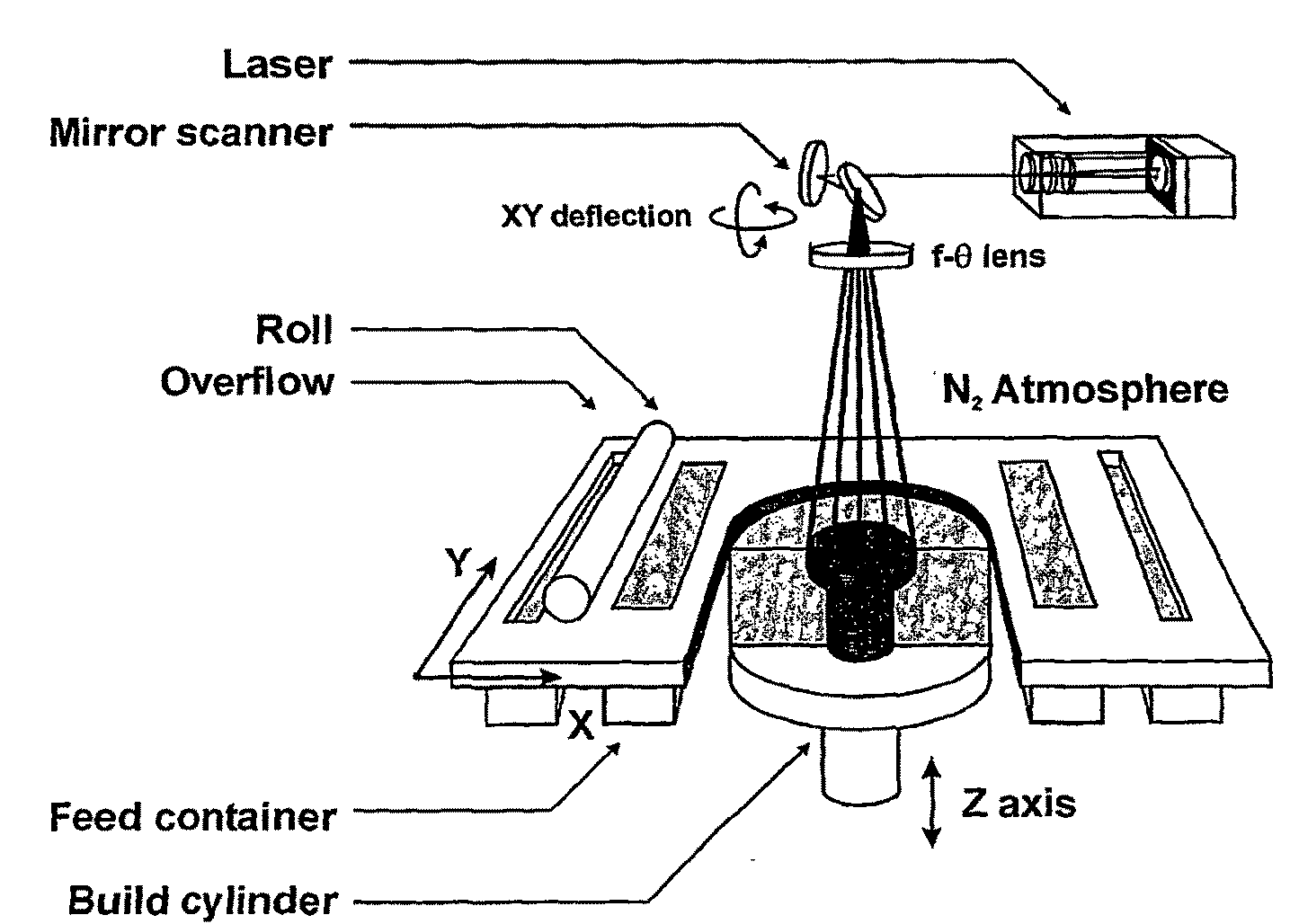

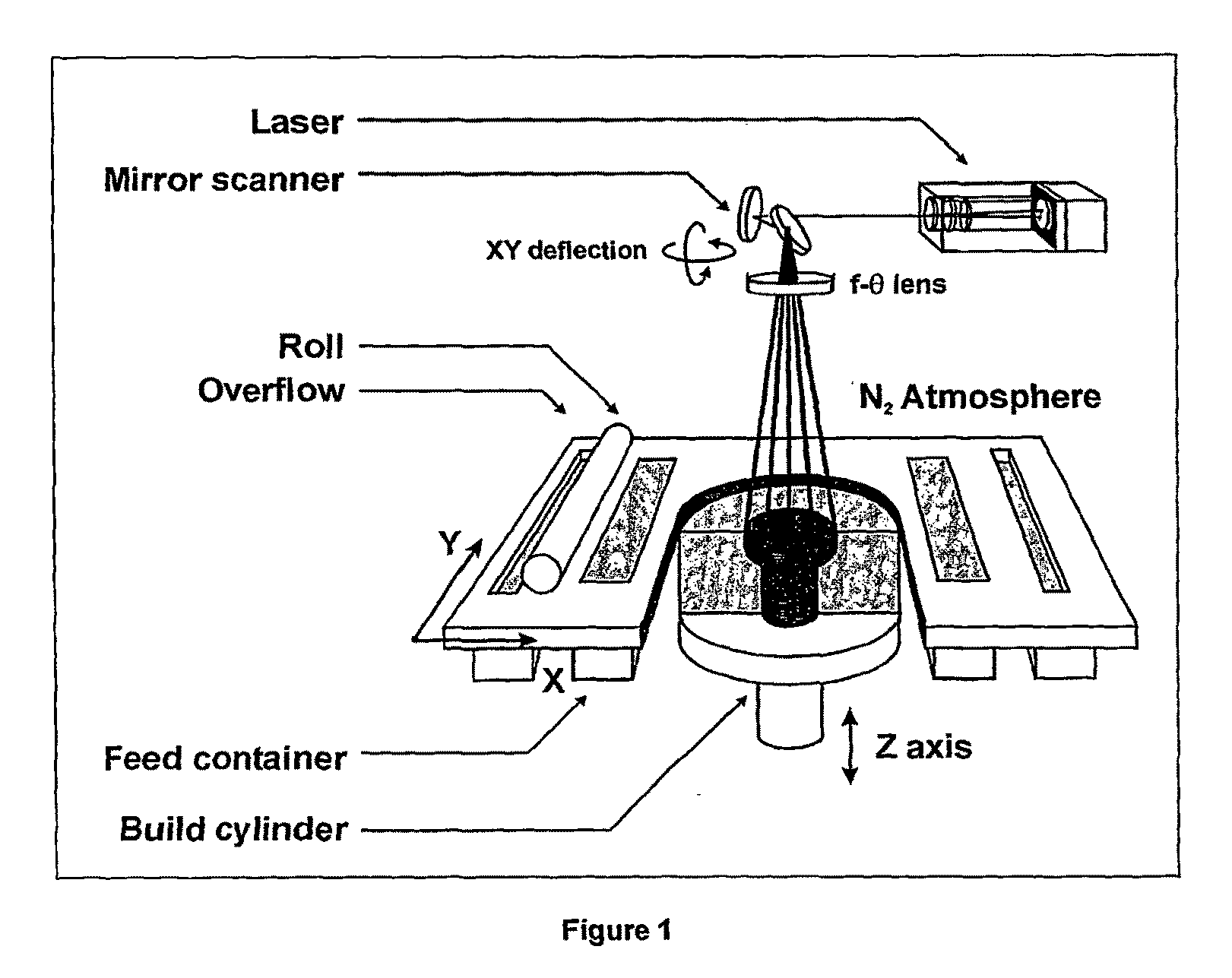

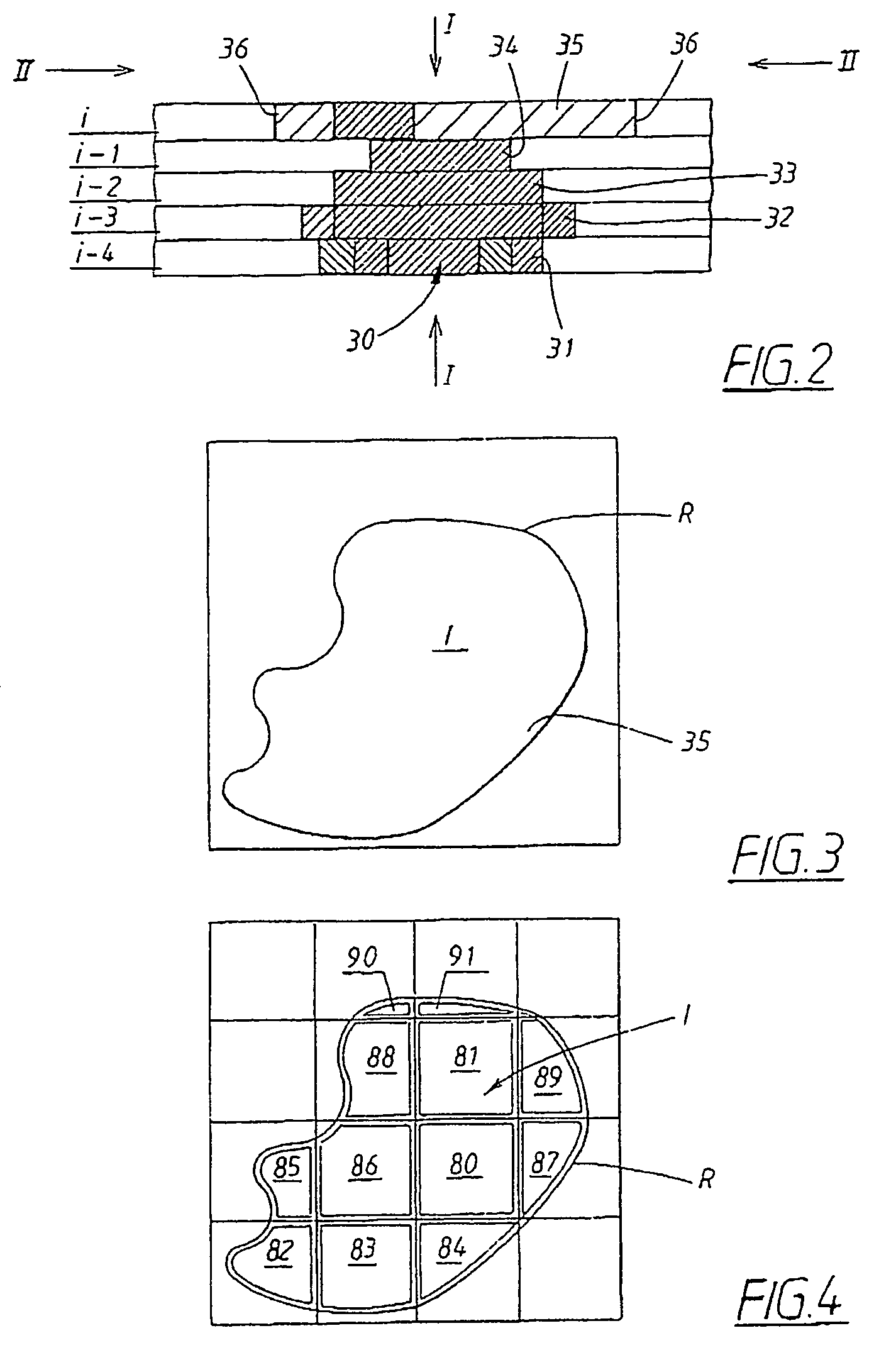

The present invention relates to a method and a device to monitor and control the Selective Laser Powder Processing. A Selective Laser Powder Processing device comprising a feedback controller to improve the stability of the Selective Laser Powder Processing process is presented. A signal reflecting a geometric quantity of the melt zone is used in the feedback controller to adjust the scanning parameters (e.g. laser power, laser spot size, scanning velocity, . . . ) of the laser beam (4) in order to maintain the geometric quantity of the melt zone at a constant level. The signal reflecting the geometric quantity of the melt zone can also be displayed in order to monitor the Selective Laser Powder Processing process. The present invention allows for the production of three-dimensional objects from powder material and improves the state of the art by compensating variations of the border conditions (e.g. local heat conduction rate) by a feedback control system based on a geometric quantity of the melt zone resulting in e.g. a lower amount of dross material when overhang planes are scanned.

Owner:KRUTH JEAN PIERRE +1

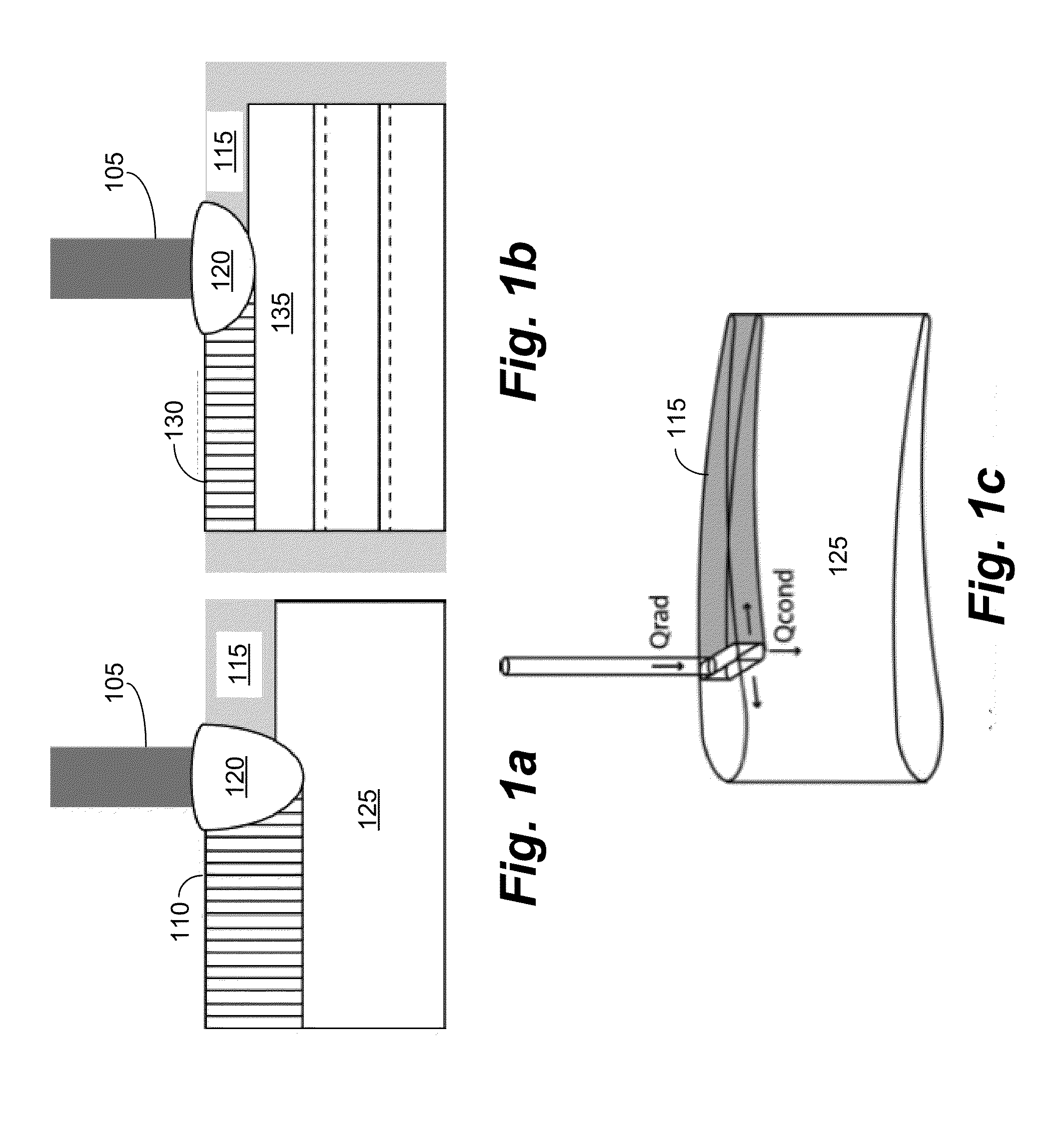

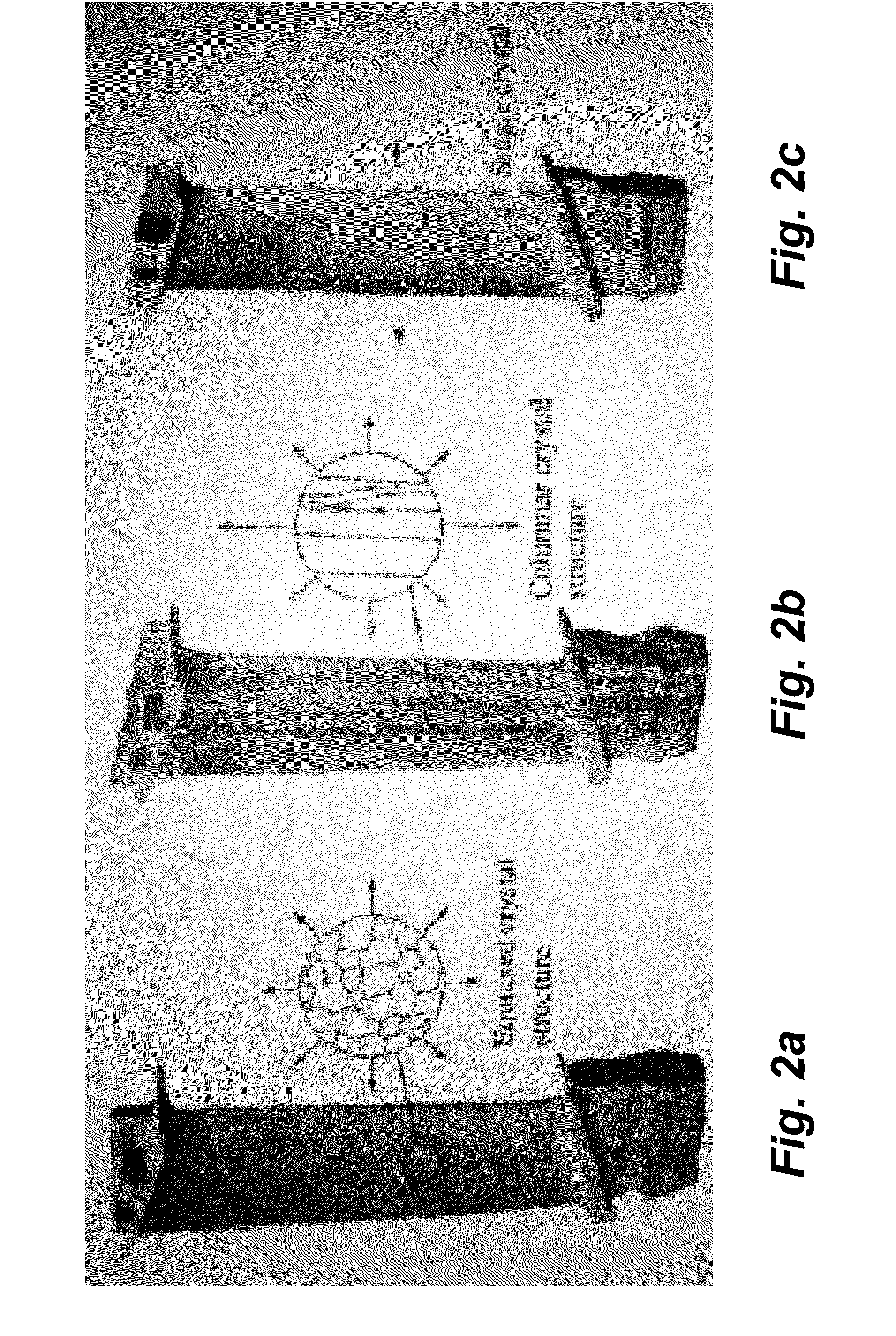

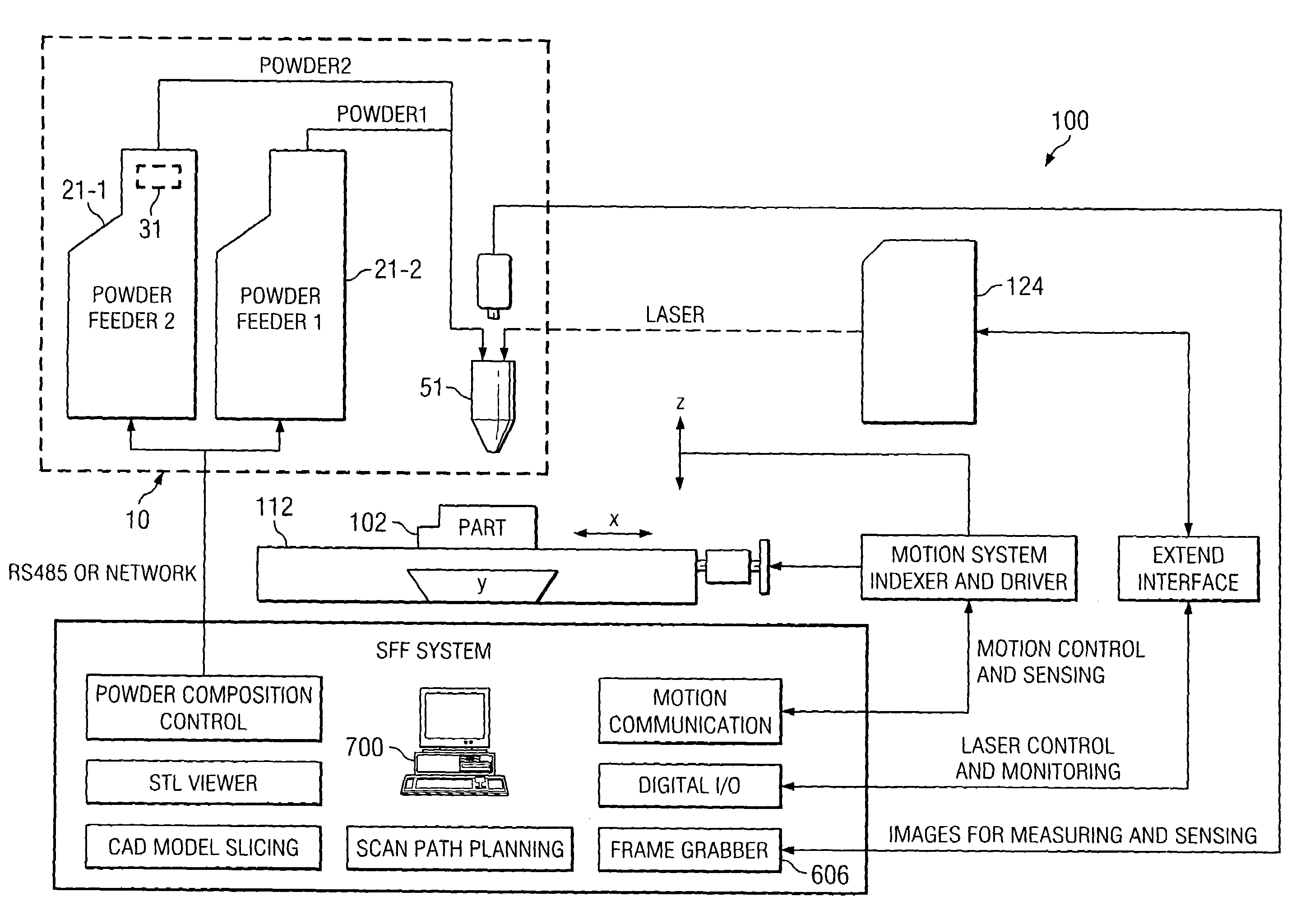

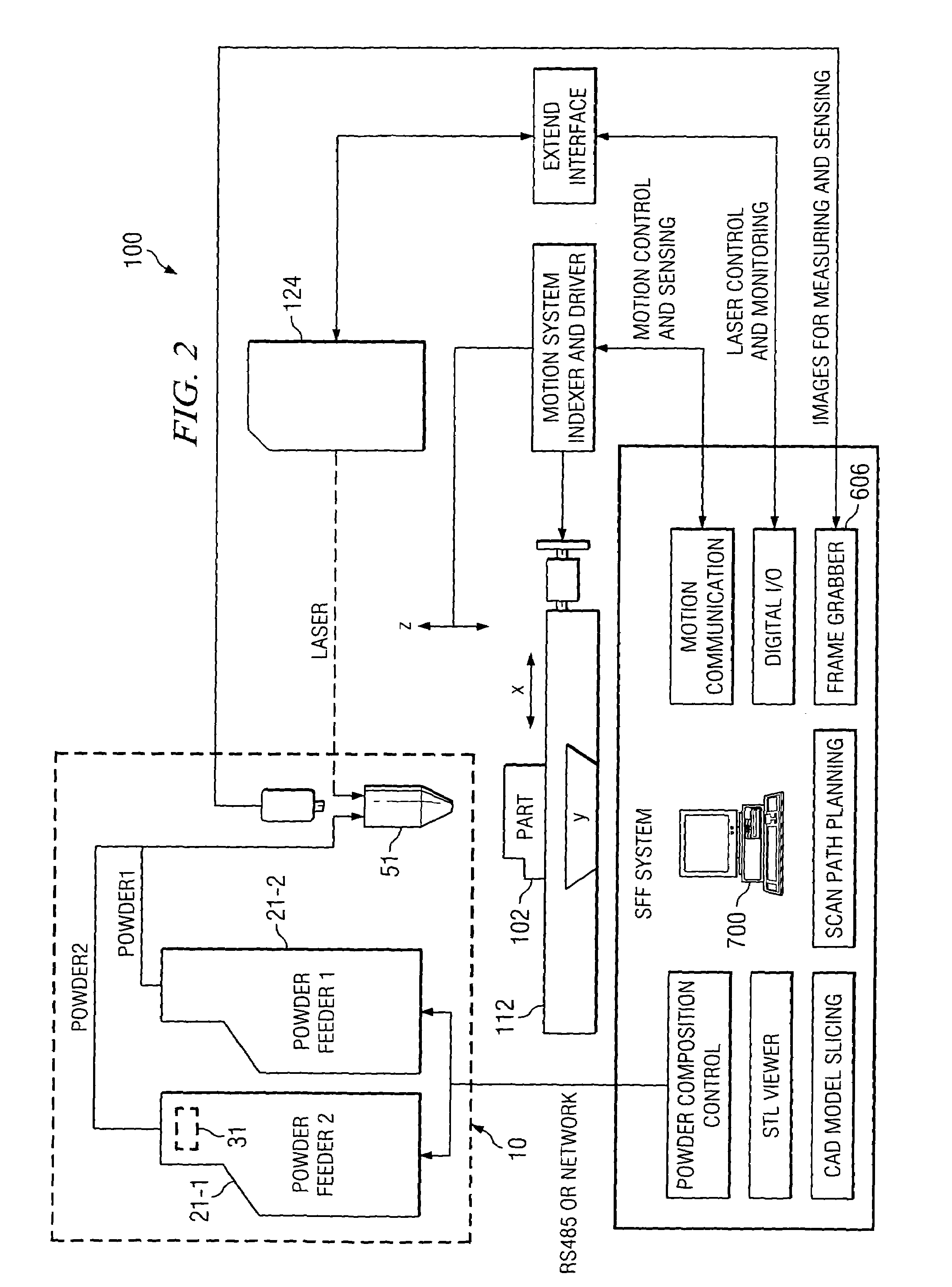

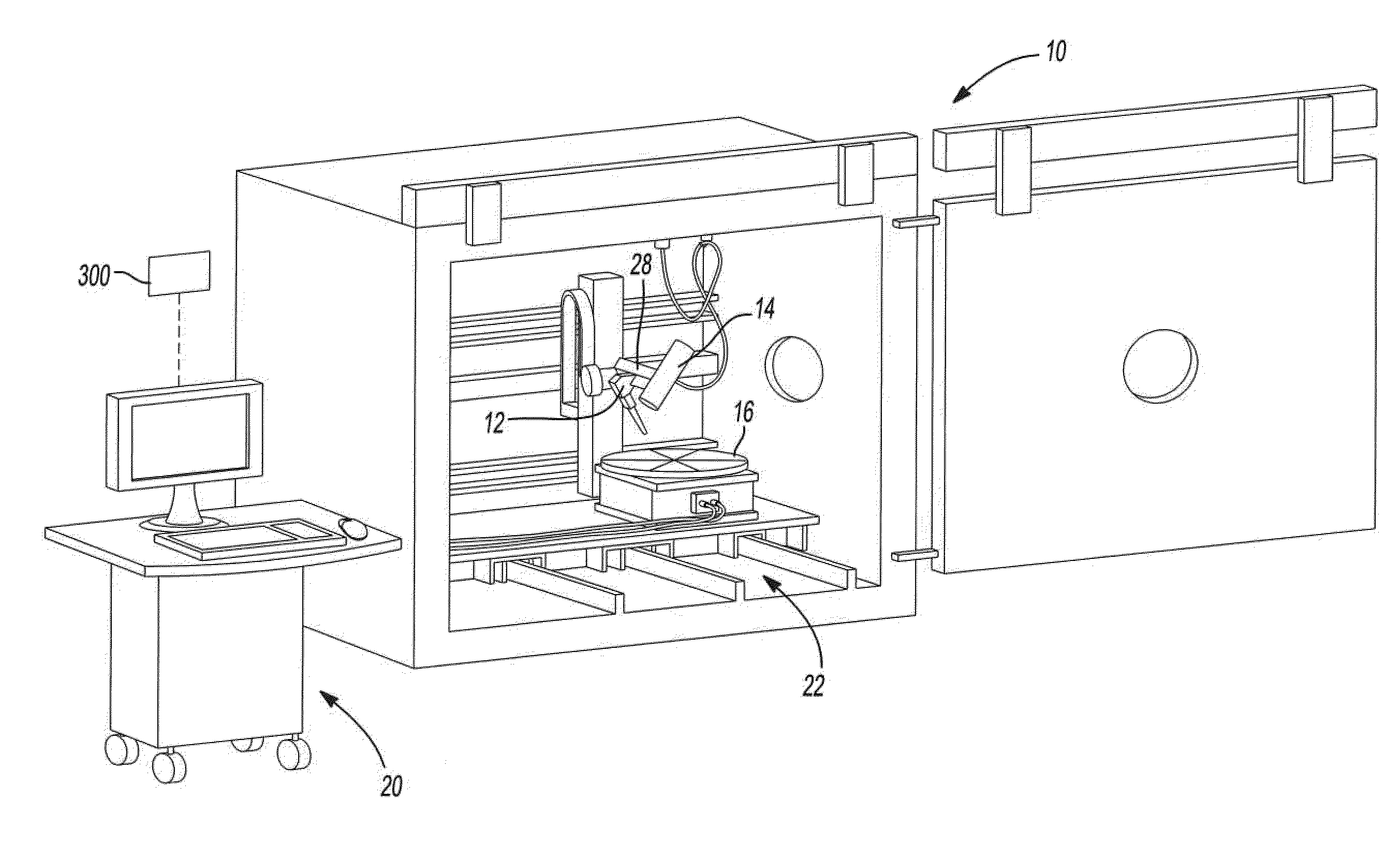

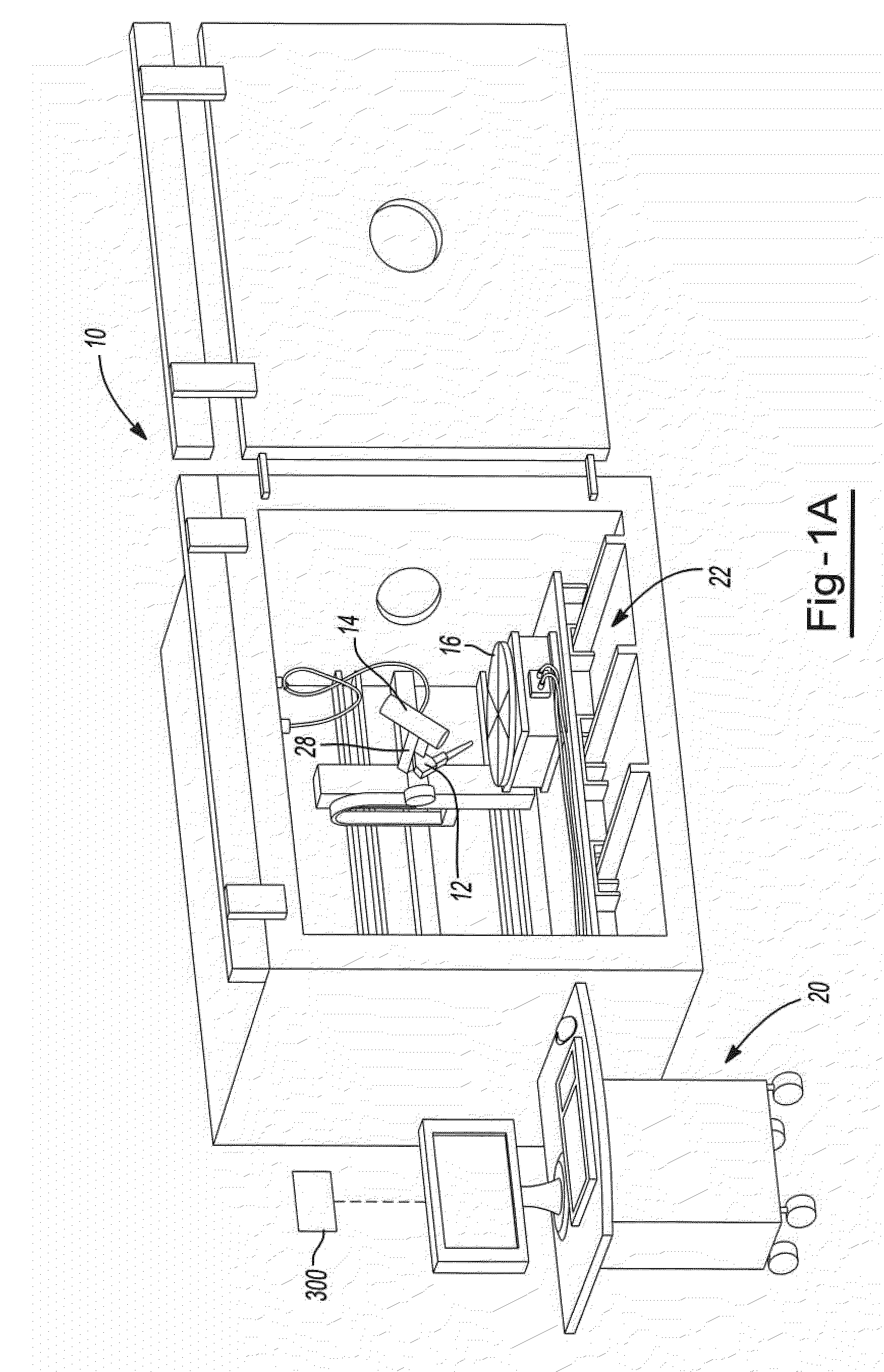

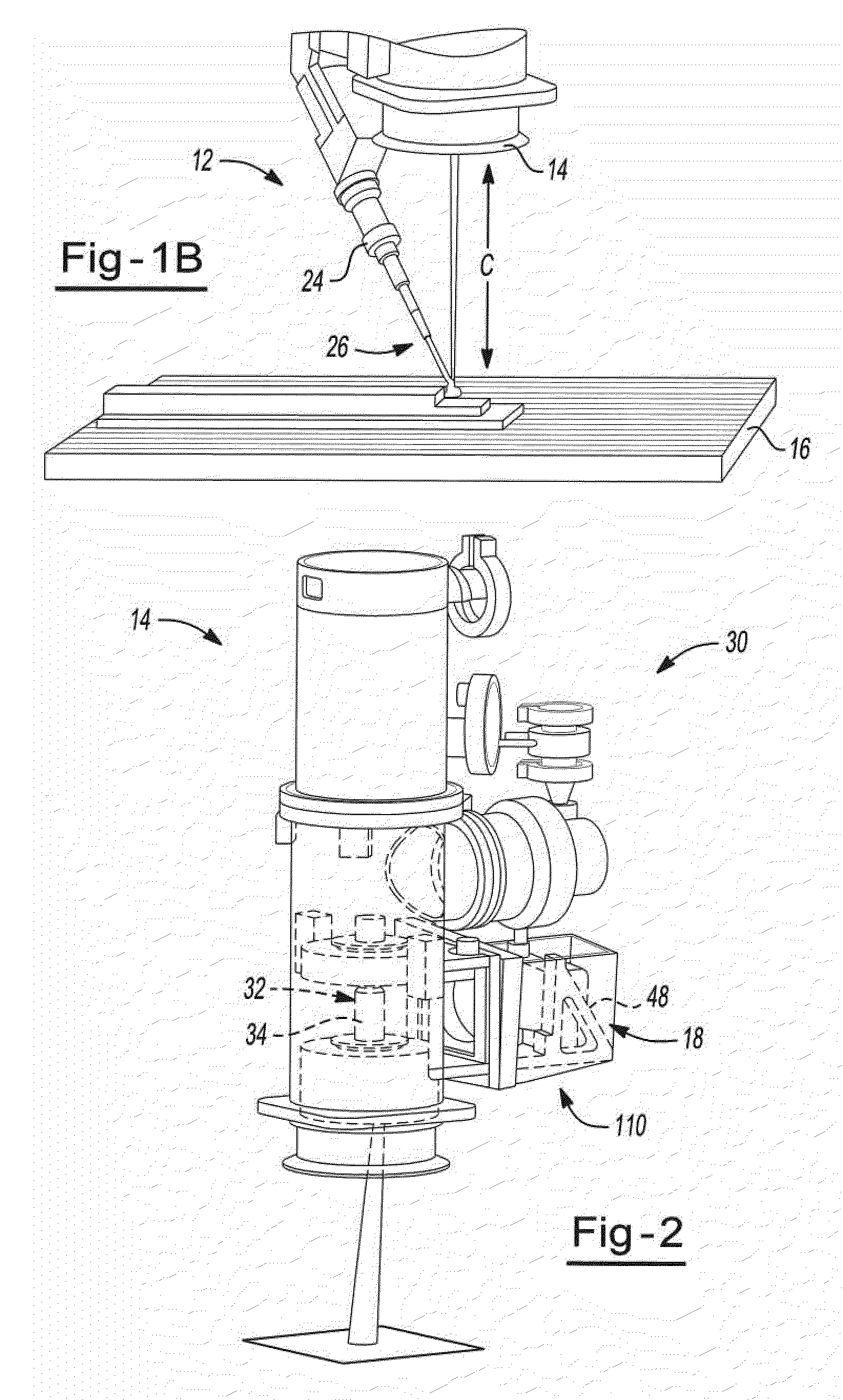

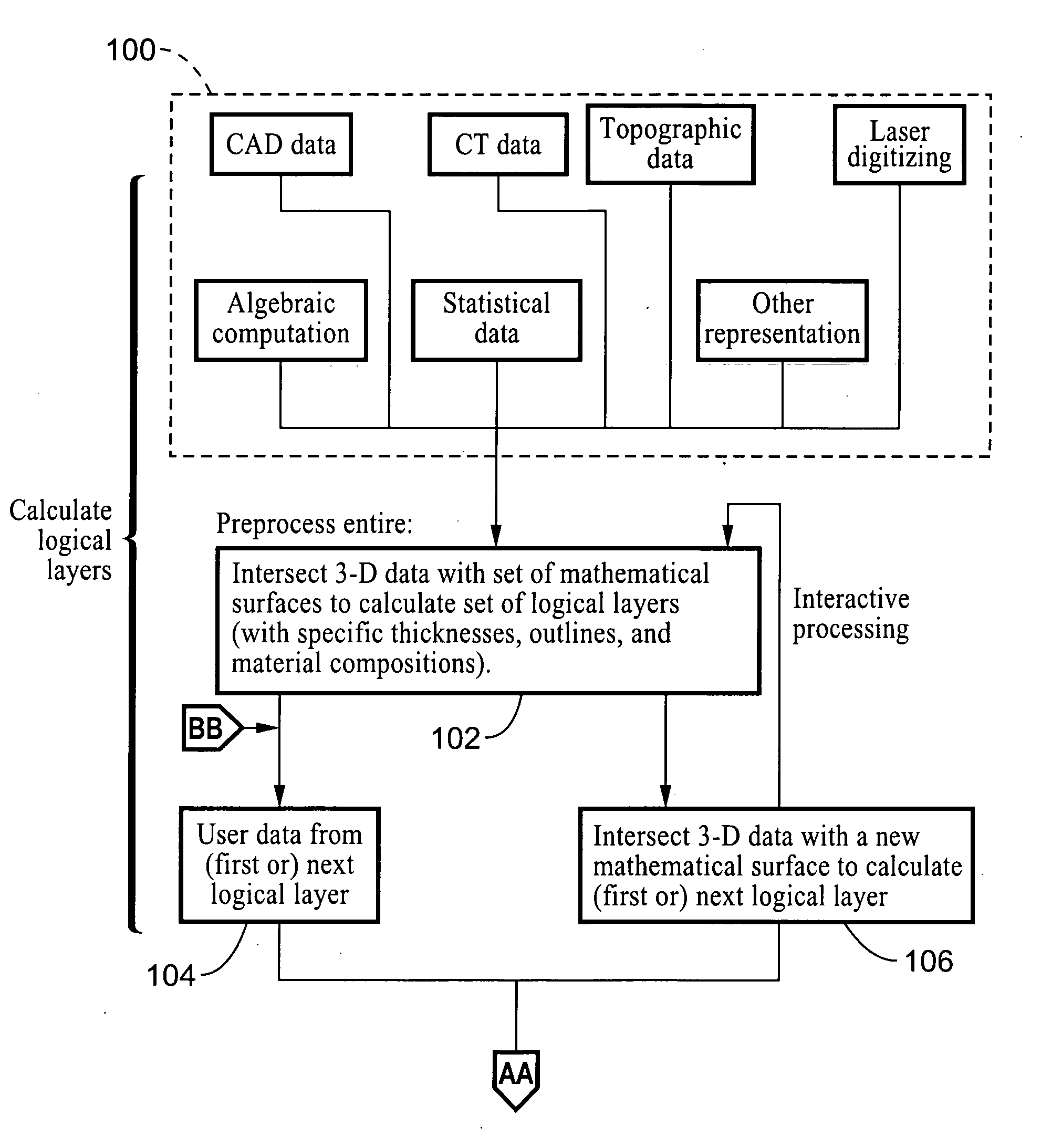

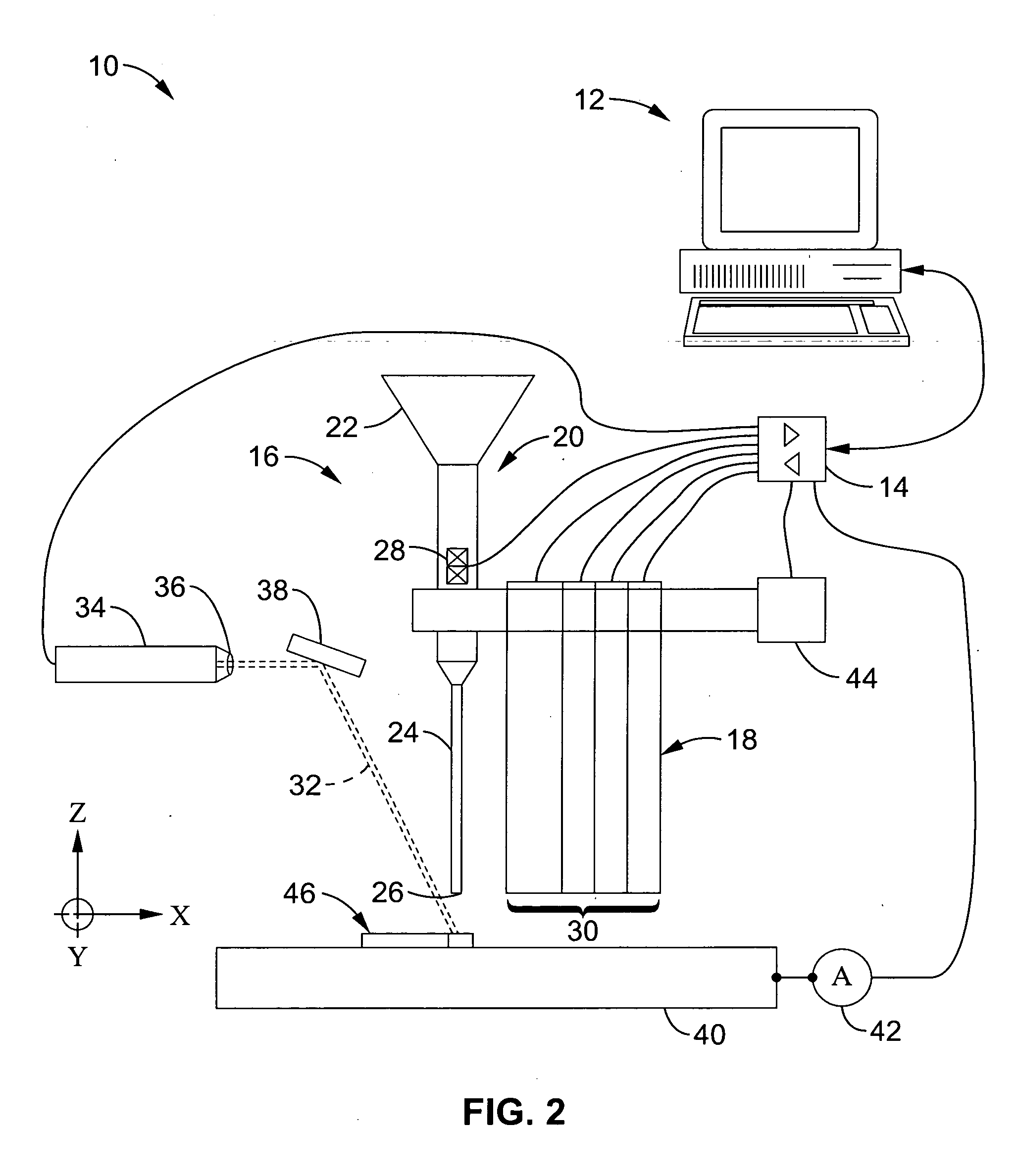

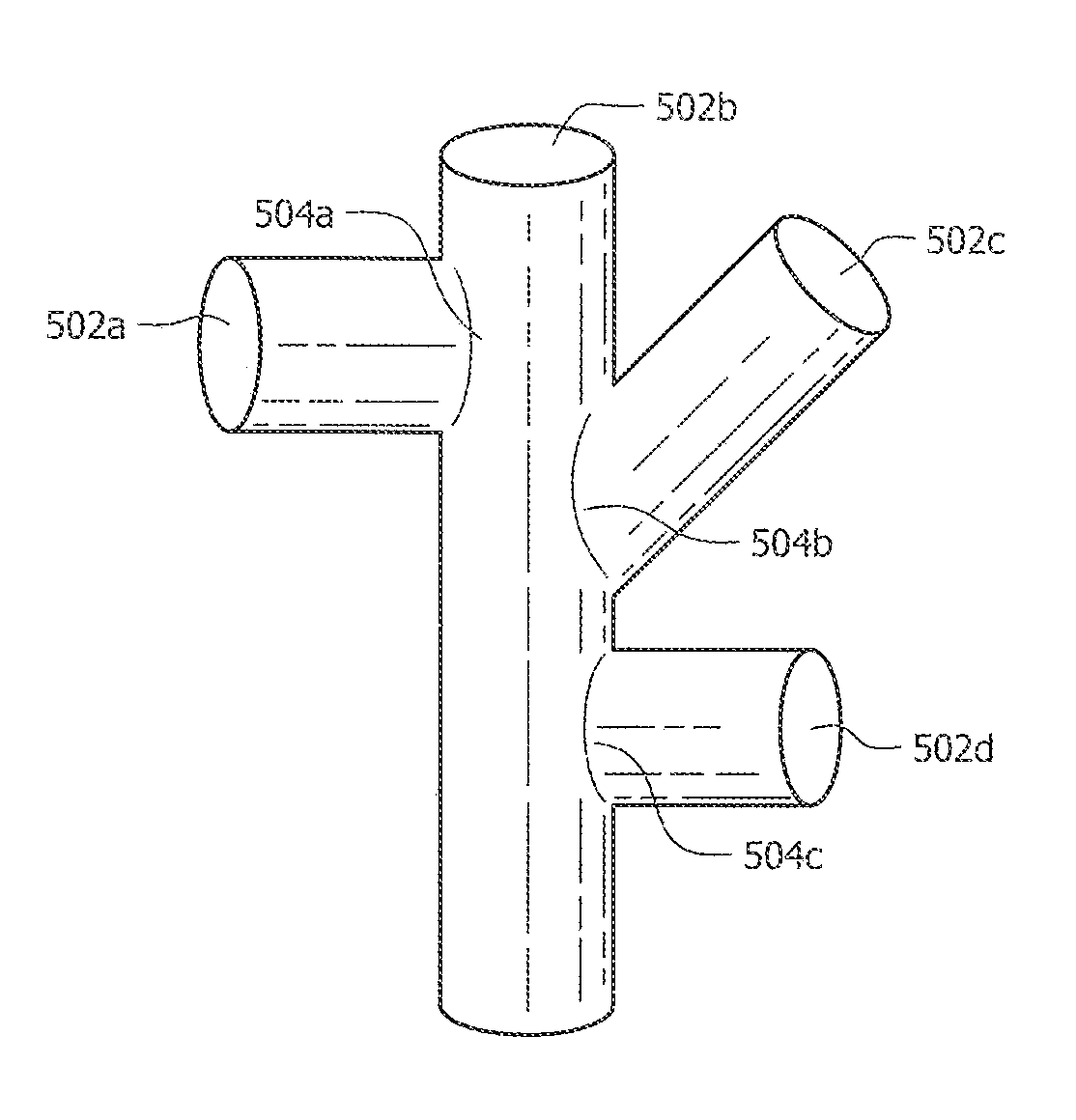

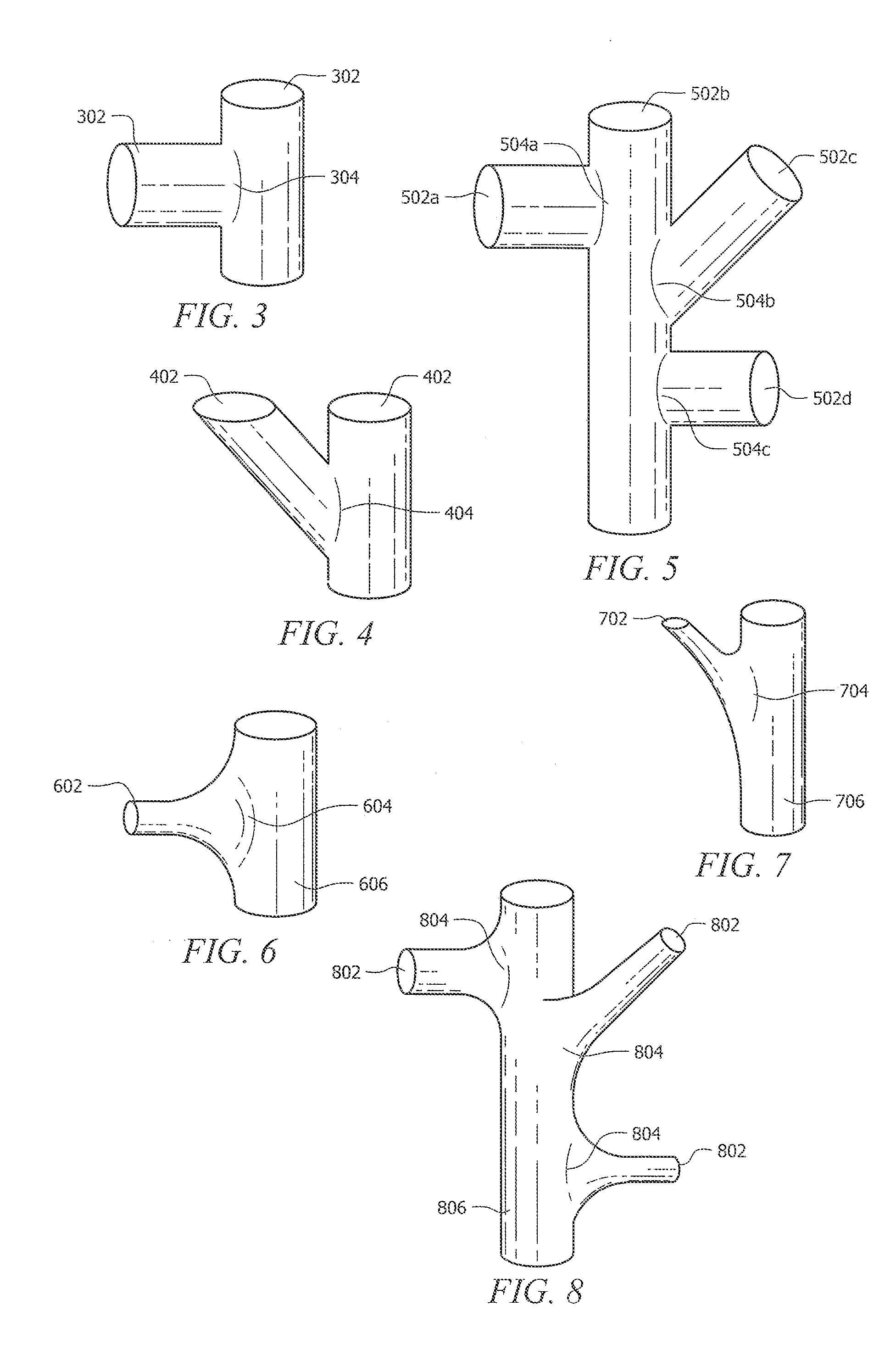

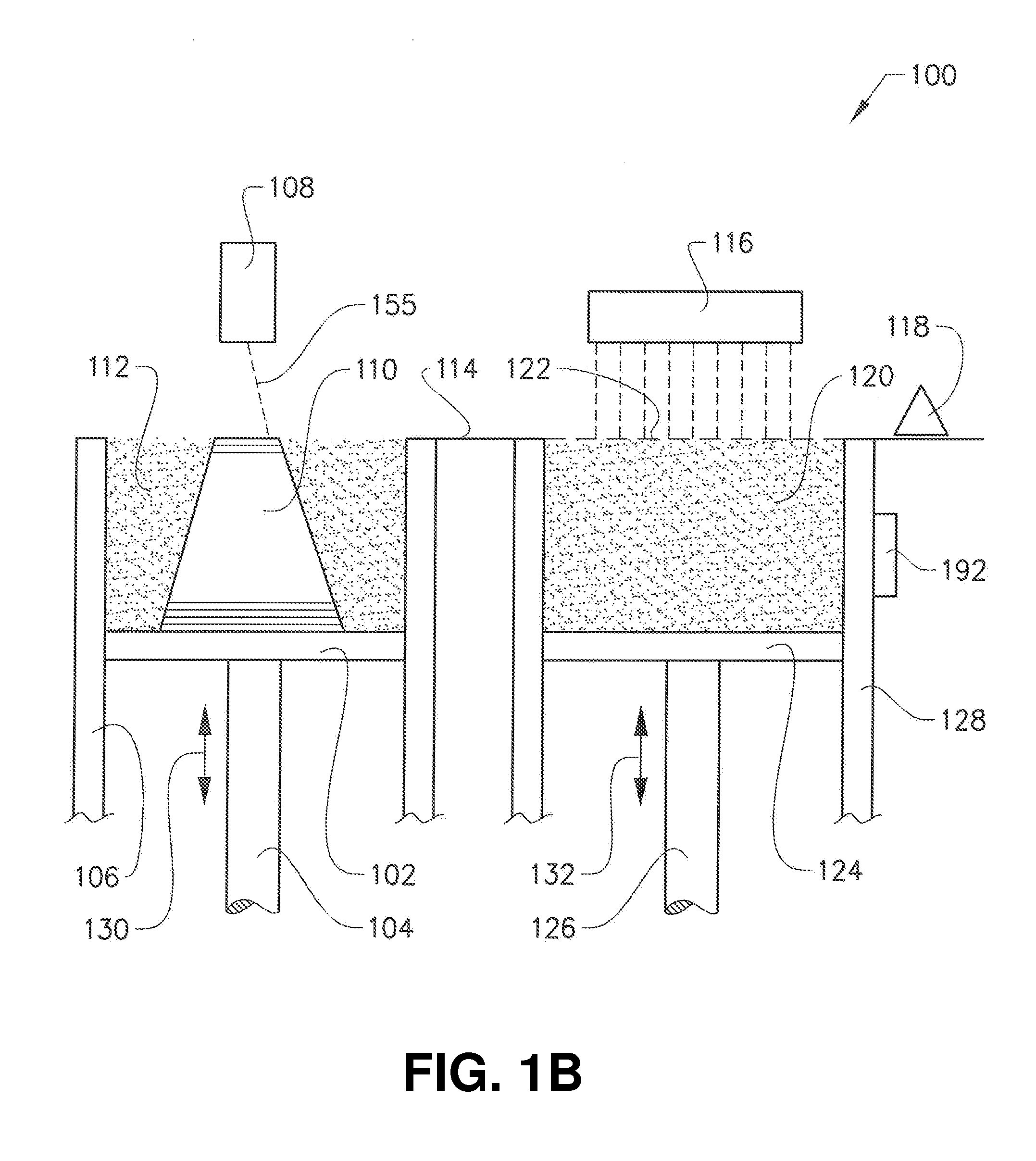

Systems and methods for additive manufacturing and repair of metal components

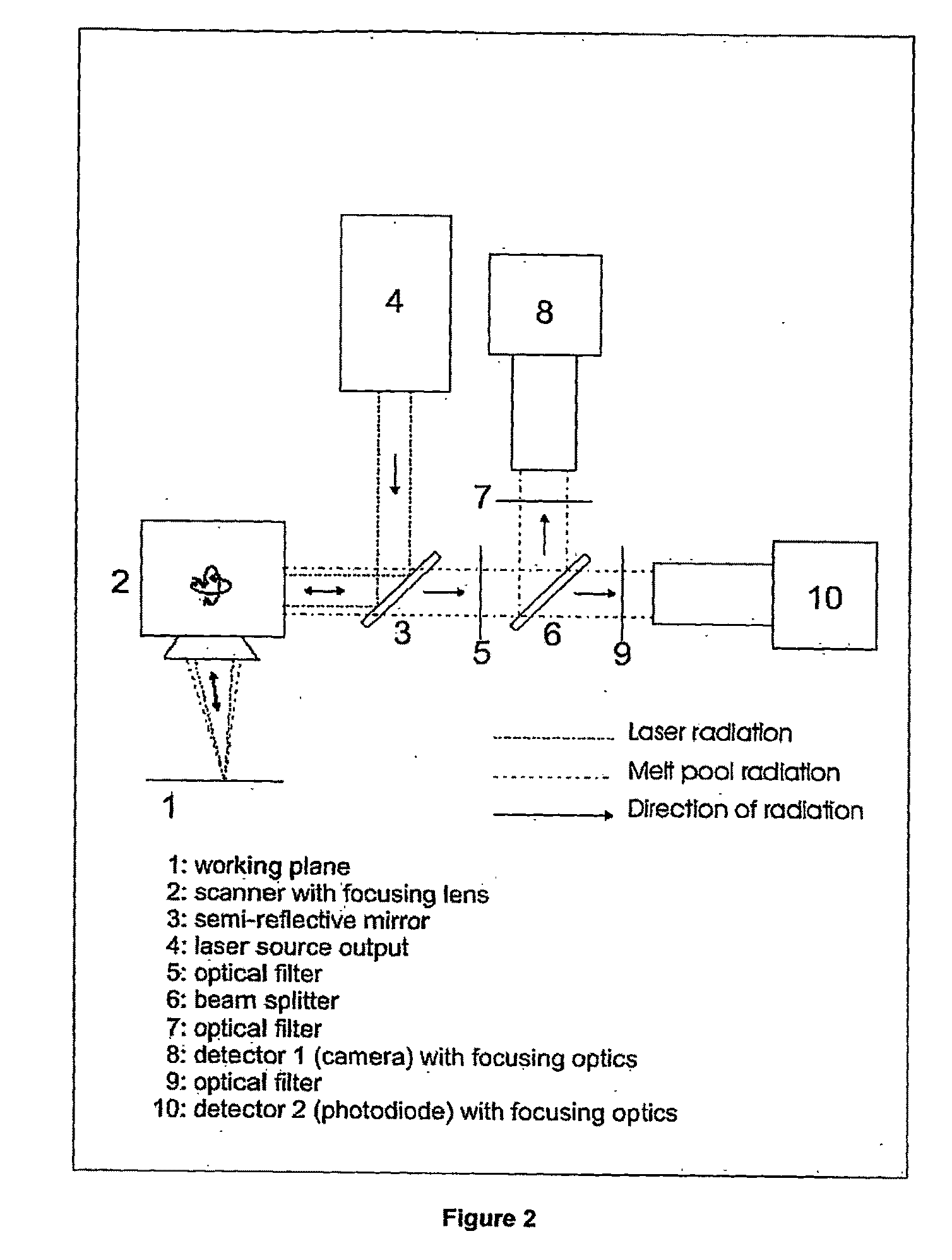

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

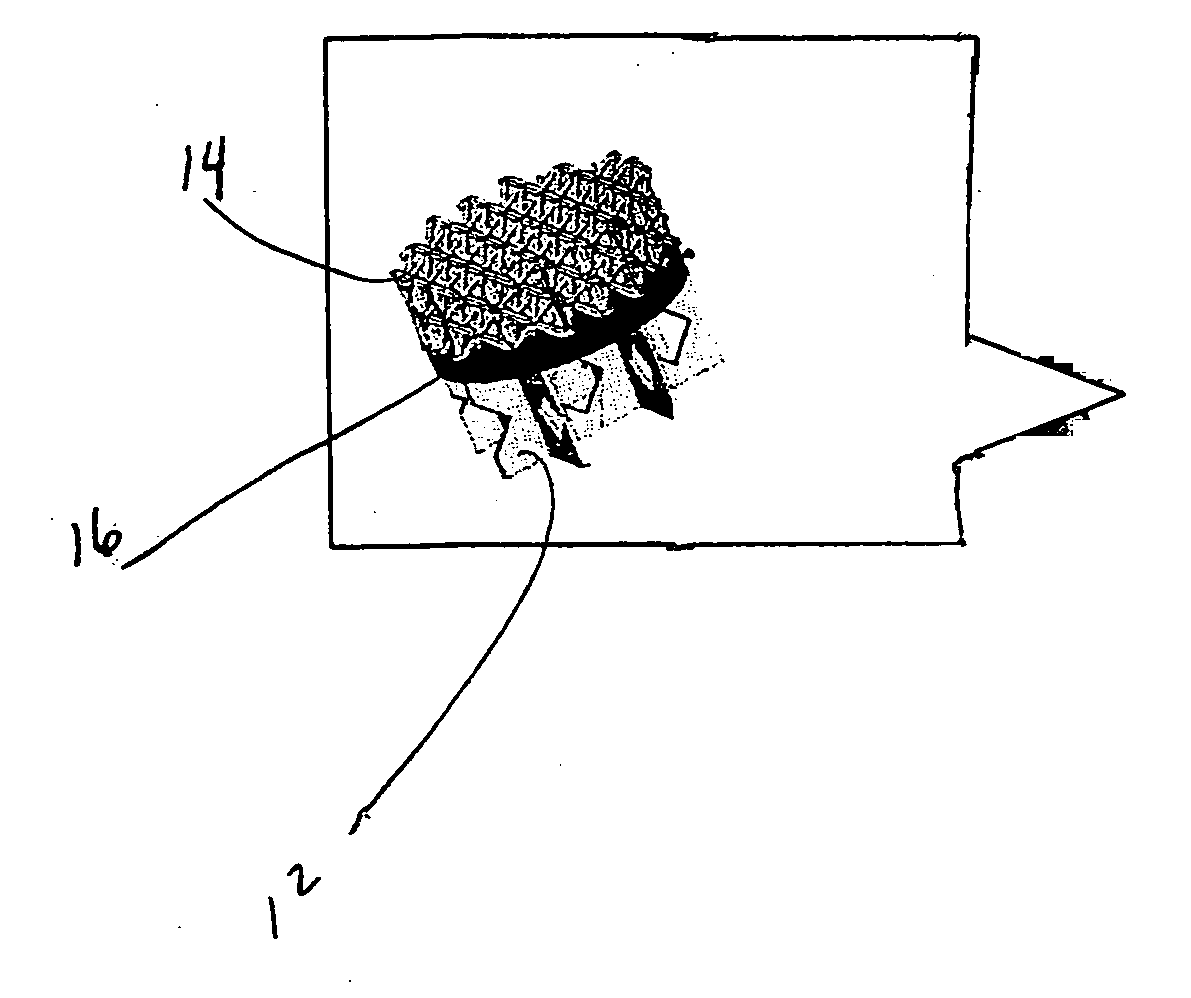

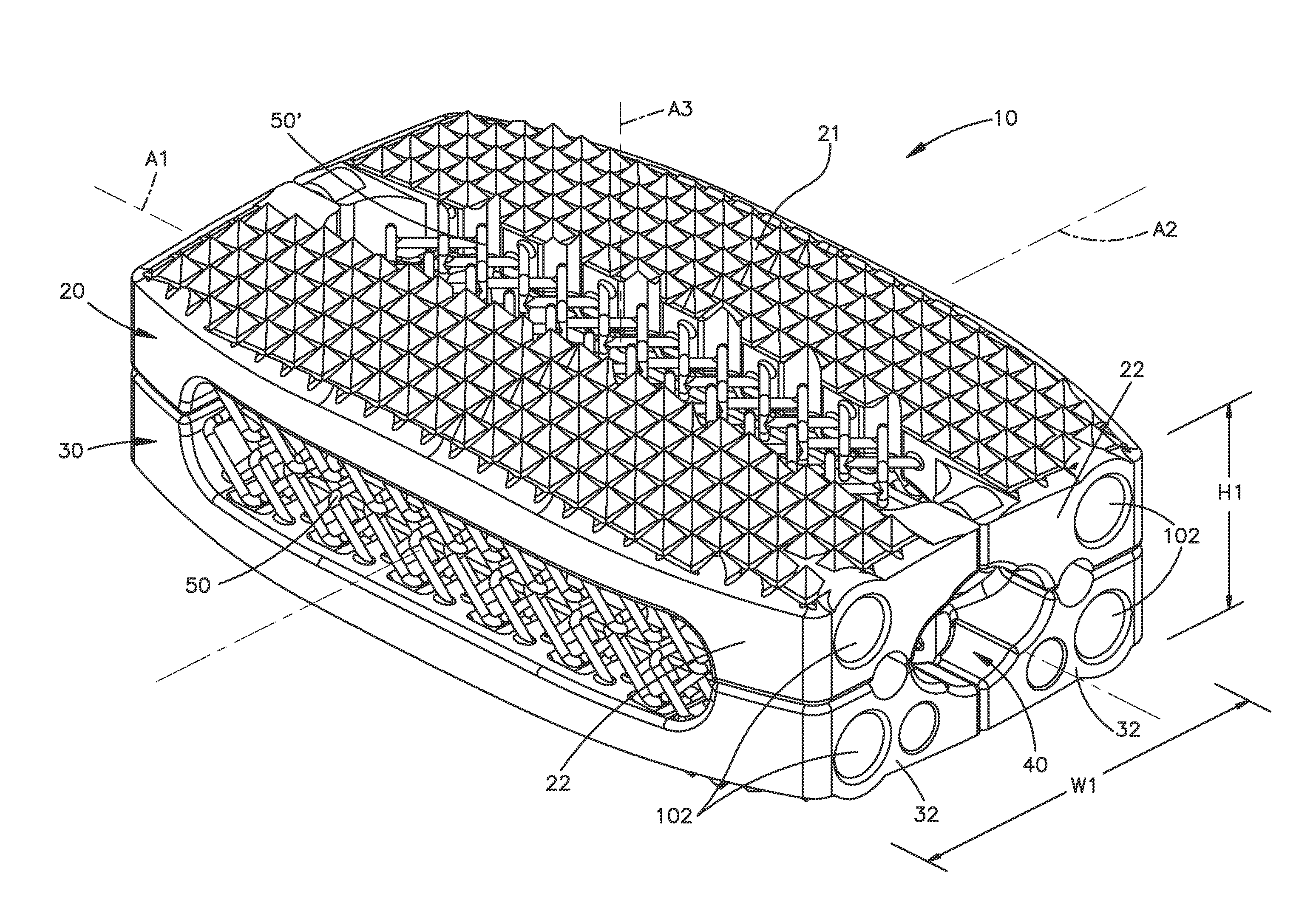

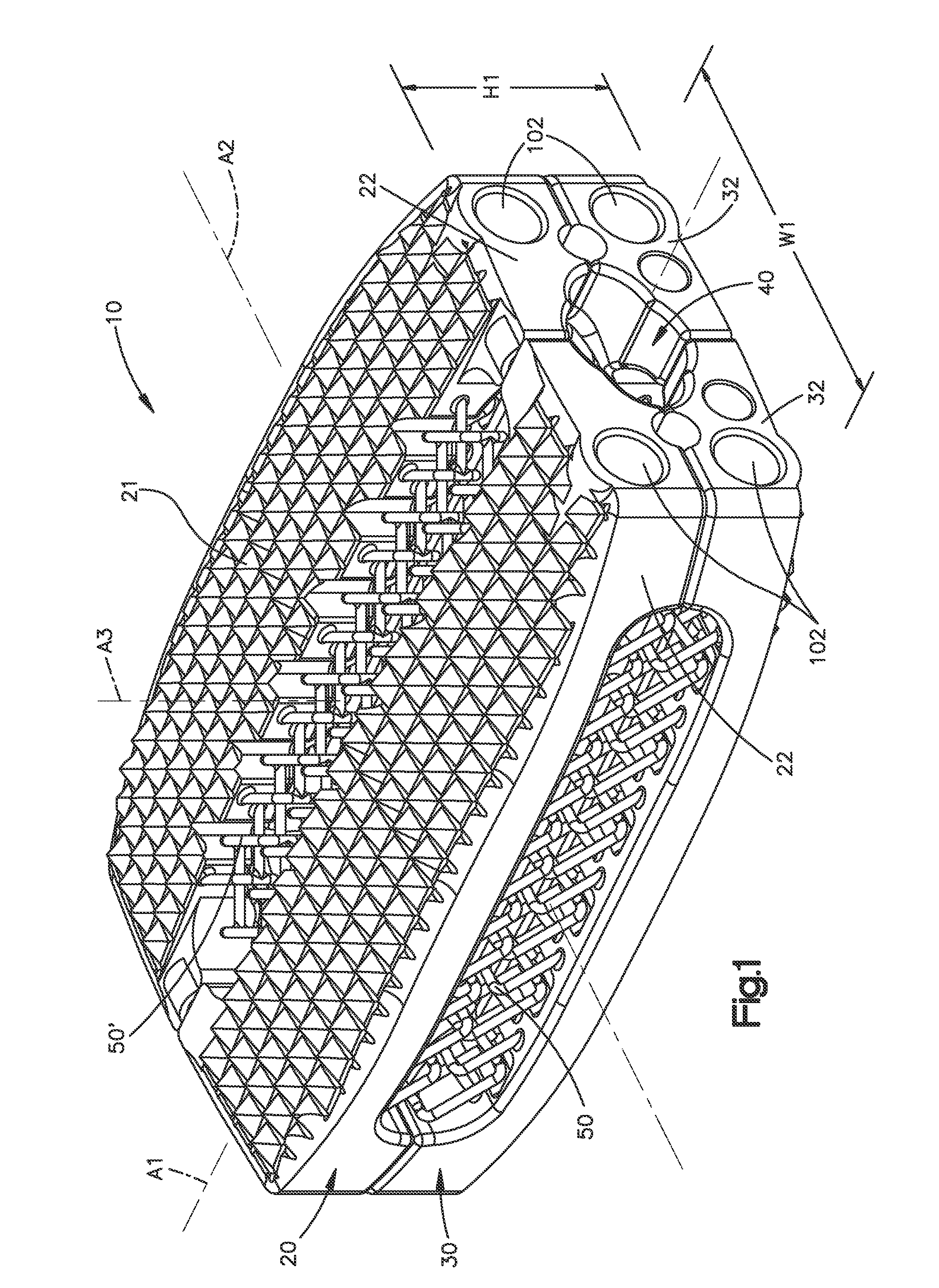

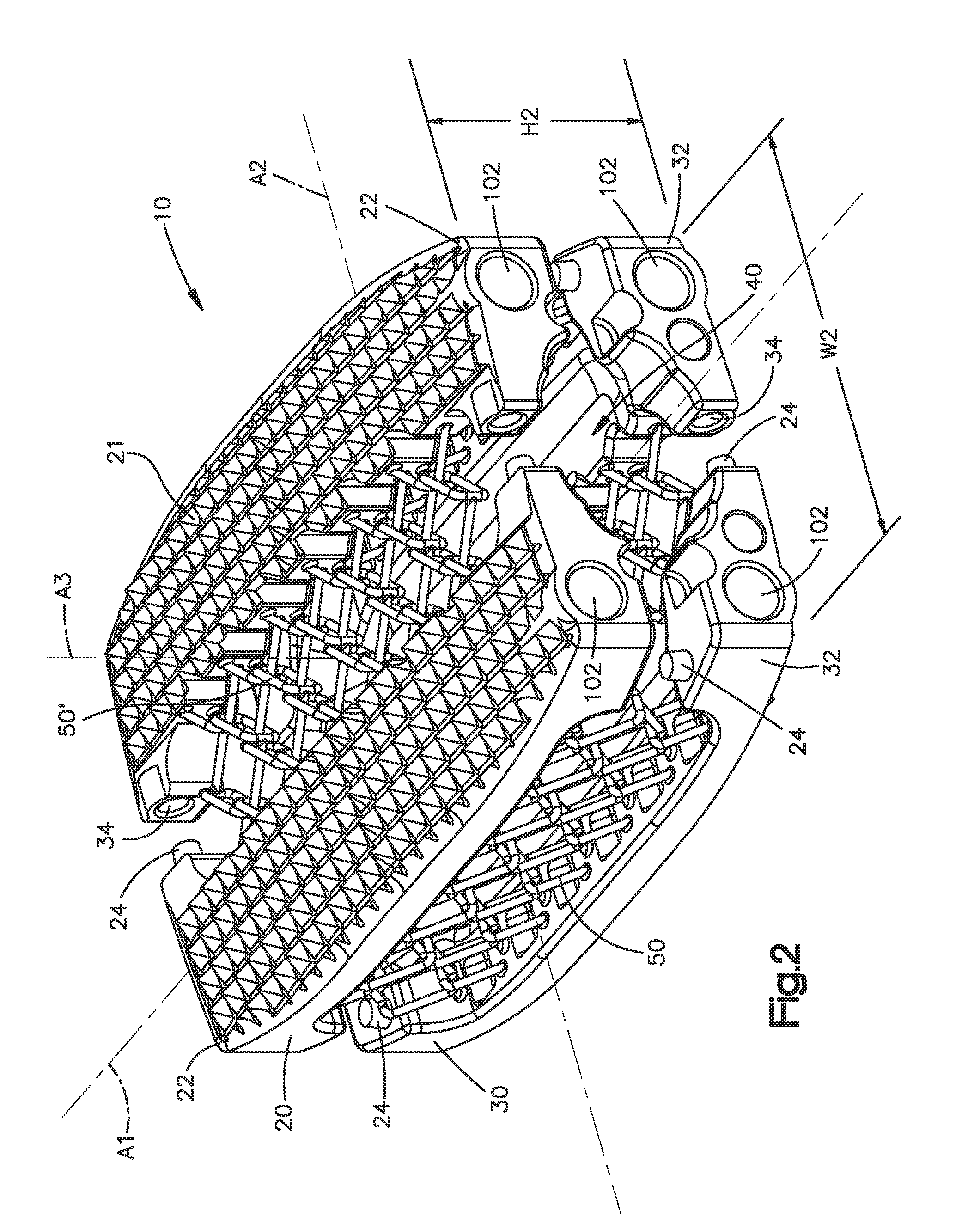

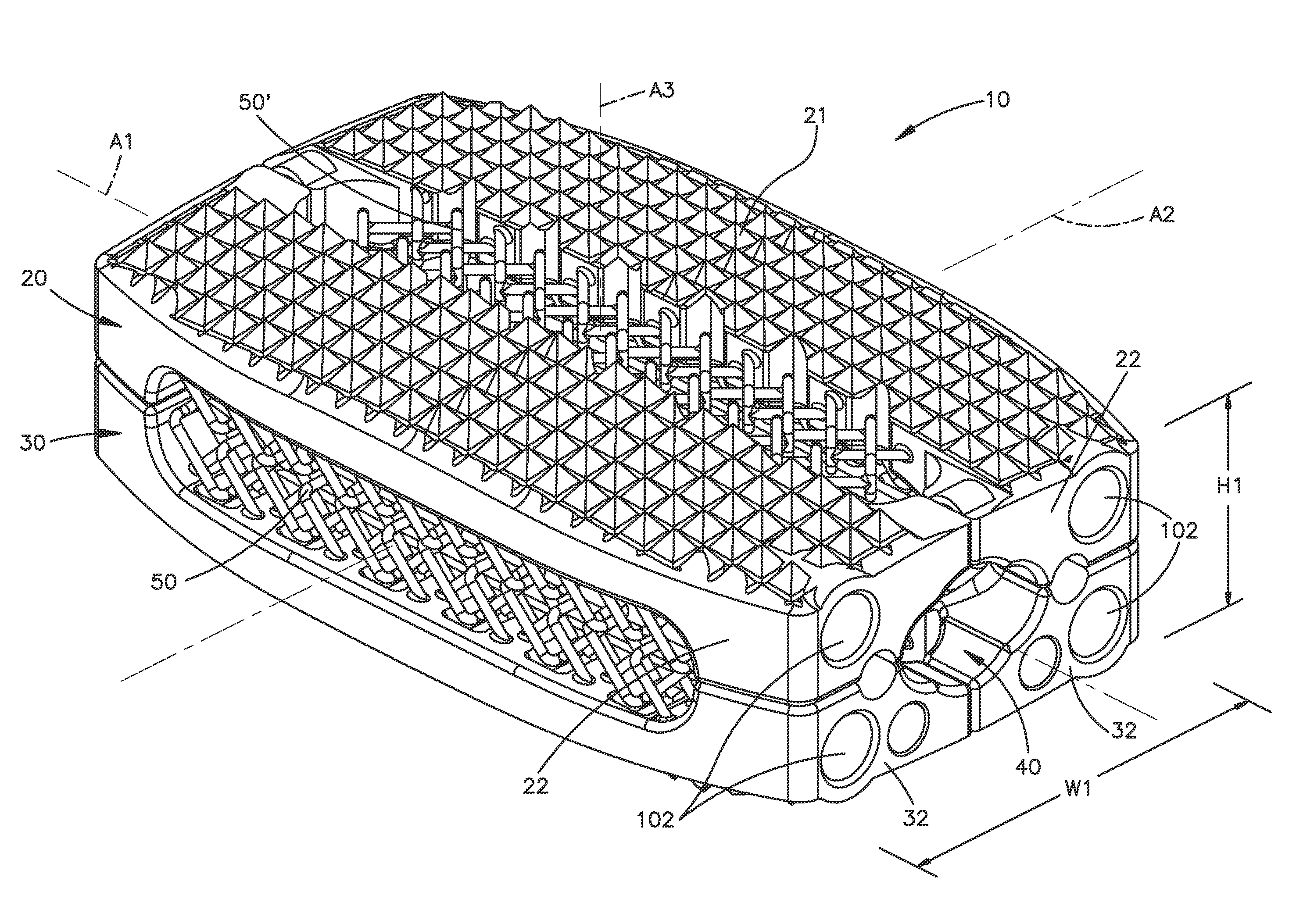

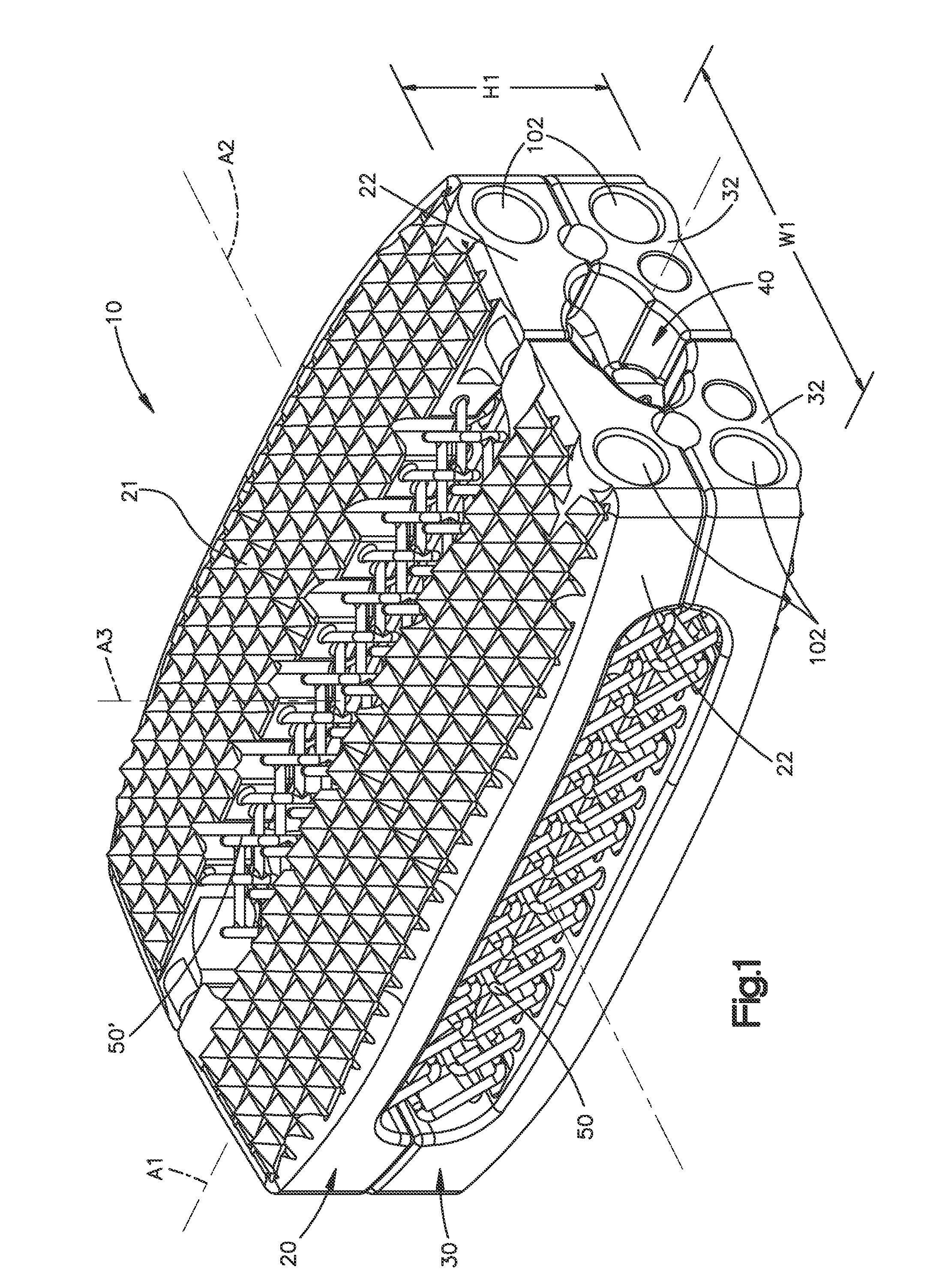

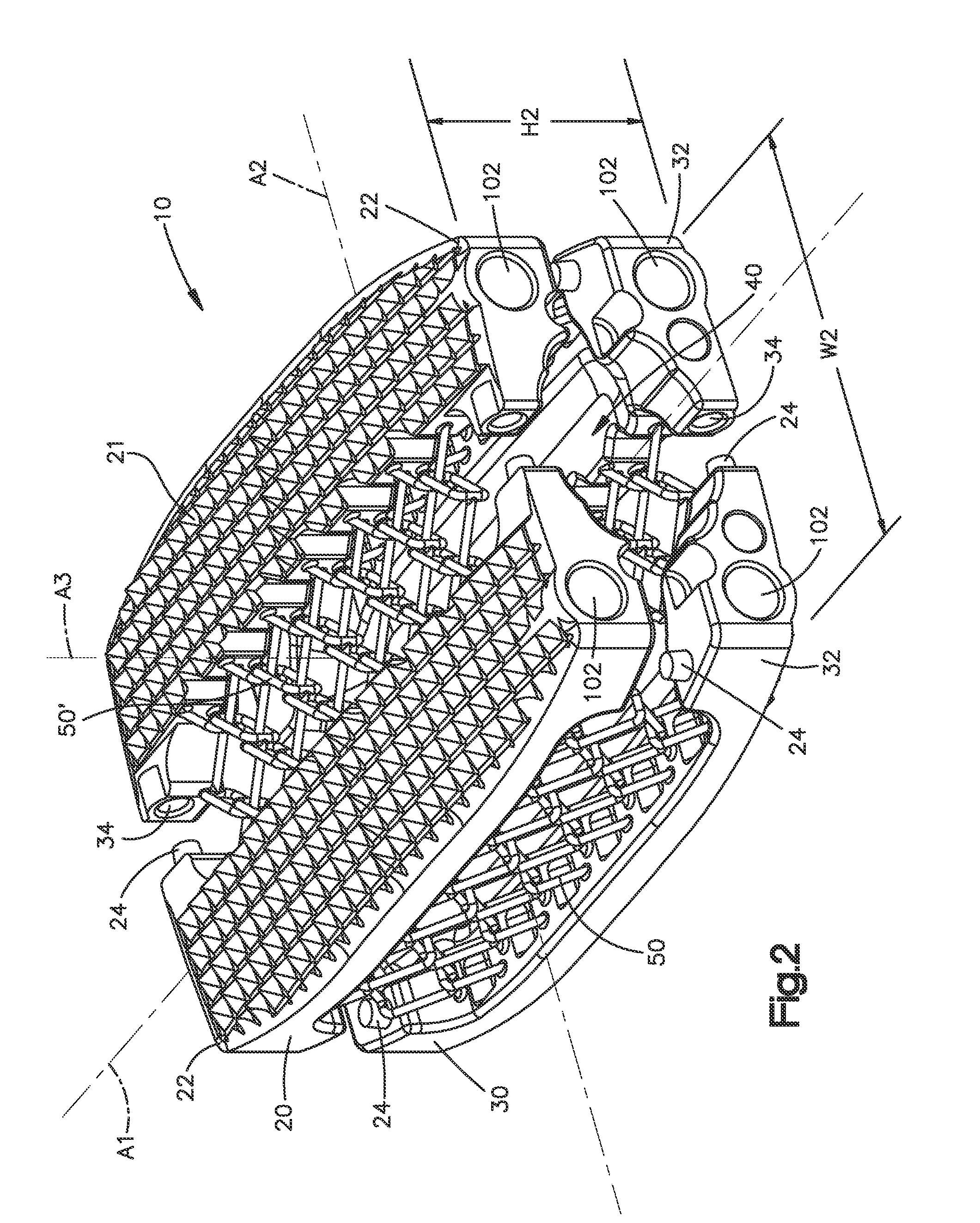

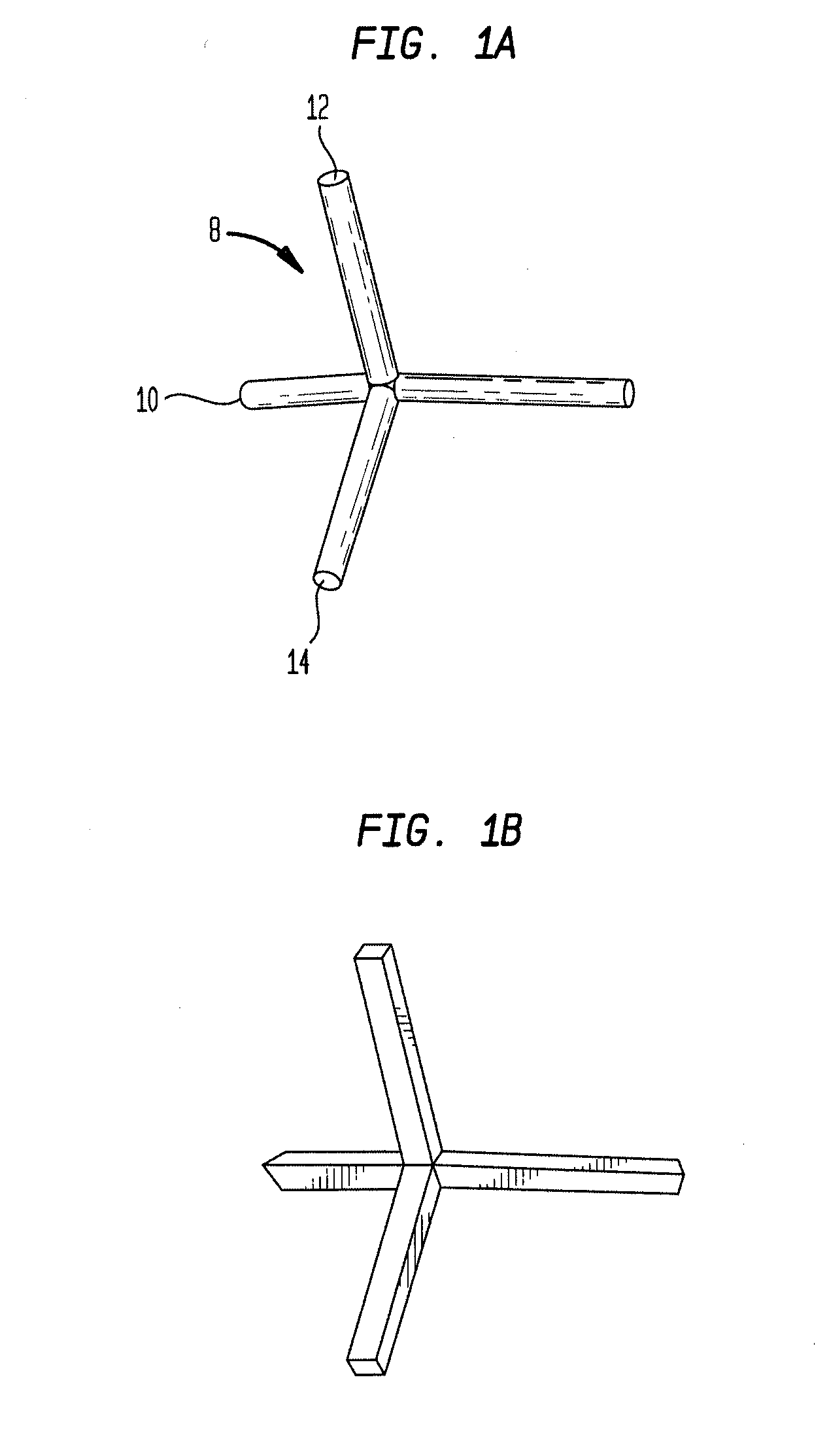

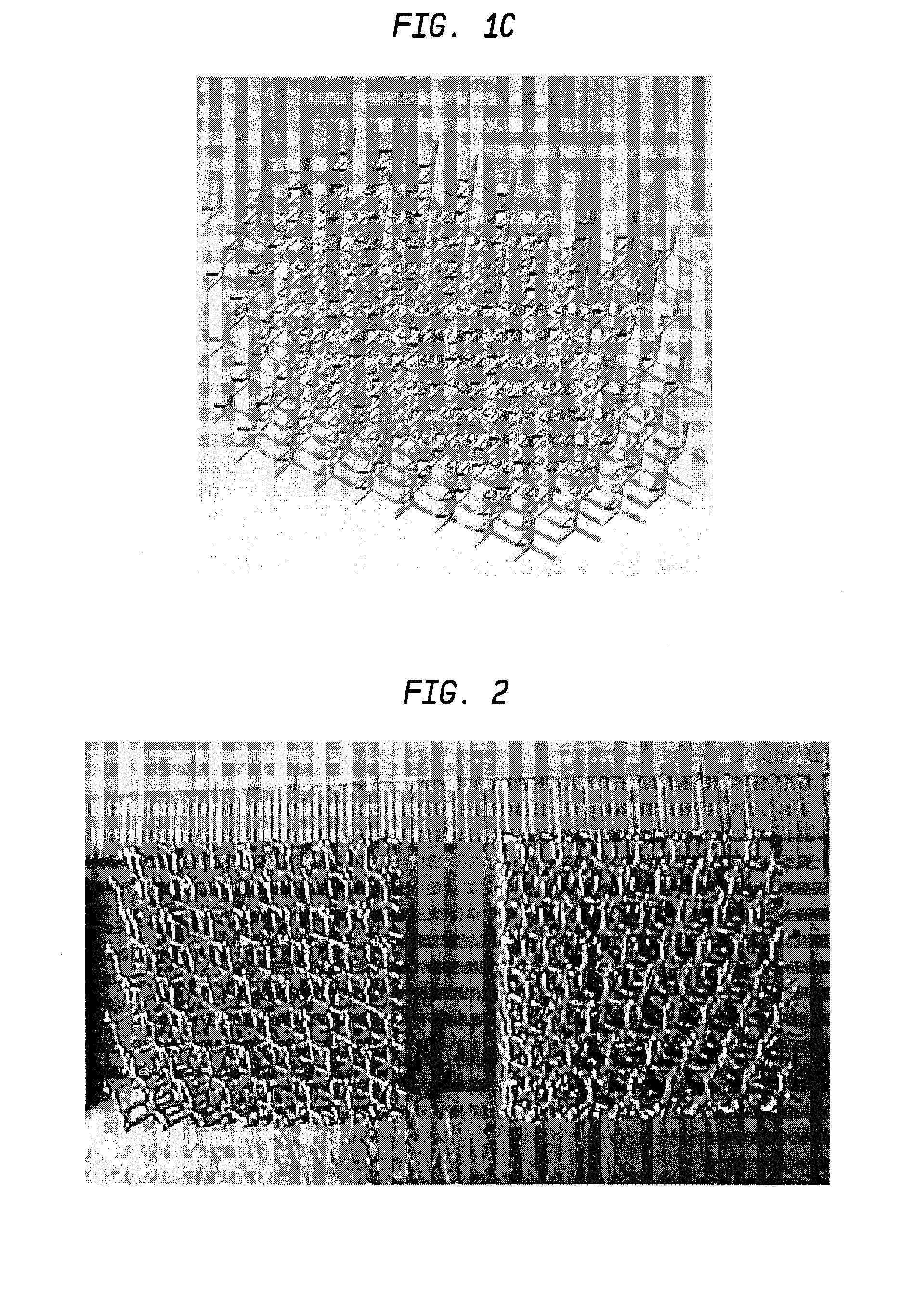

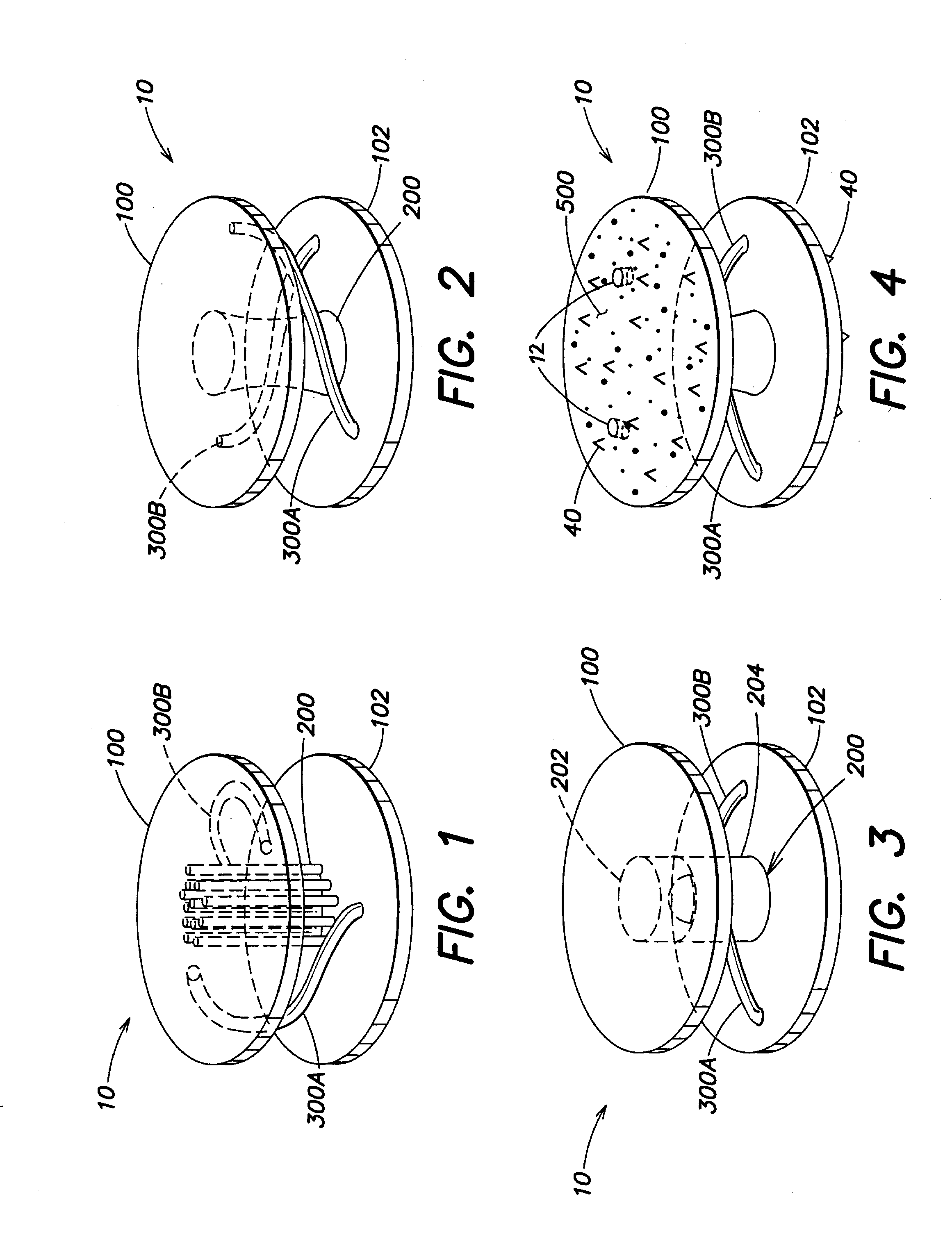

Expandable intervertebral implant and associated method of manufacturing the same

An expandable intervertebral implant (10) includes superior (20) and inferior (30) bone contacting members and at least one vertical wire netting (50) interconnecting the superior and inferior bone contacting members. The superior and inferior bone contacting members include at least two bone contacting components interconnected via one or more lateral wire nettings such that the implant is vertically and laterally expandable in situ from a first insertion configuration to a second expanded configuration. The vertical and lateral wire netting are preferably constructed of a plurality of individual link members. The present invention also preferably relates to an associated method of manufacturing the intervertebral implant such that the intervertebral implant can be manufactured as an integral component or part.

Owner:DEPUY SYNTHES PROD INC

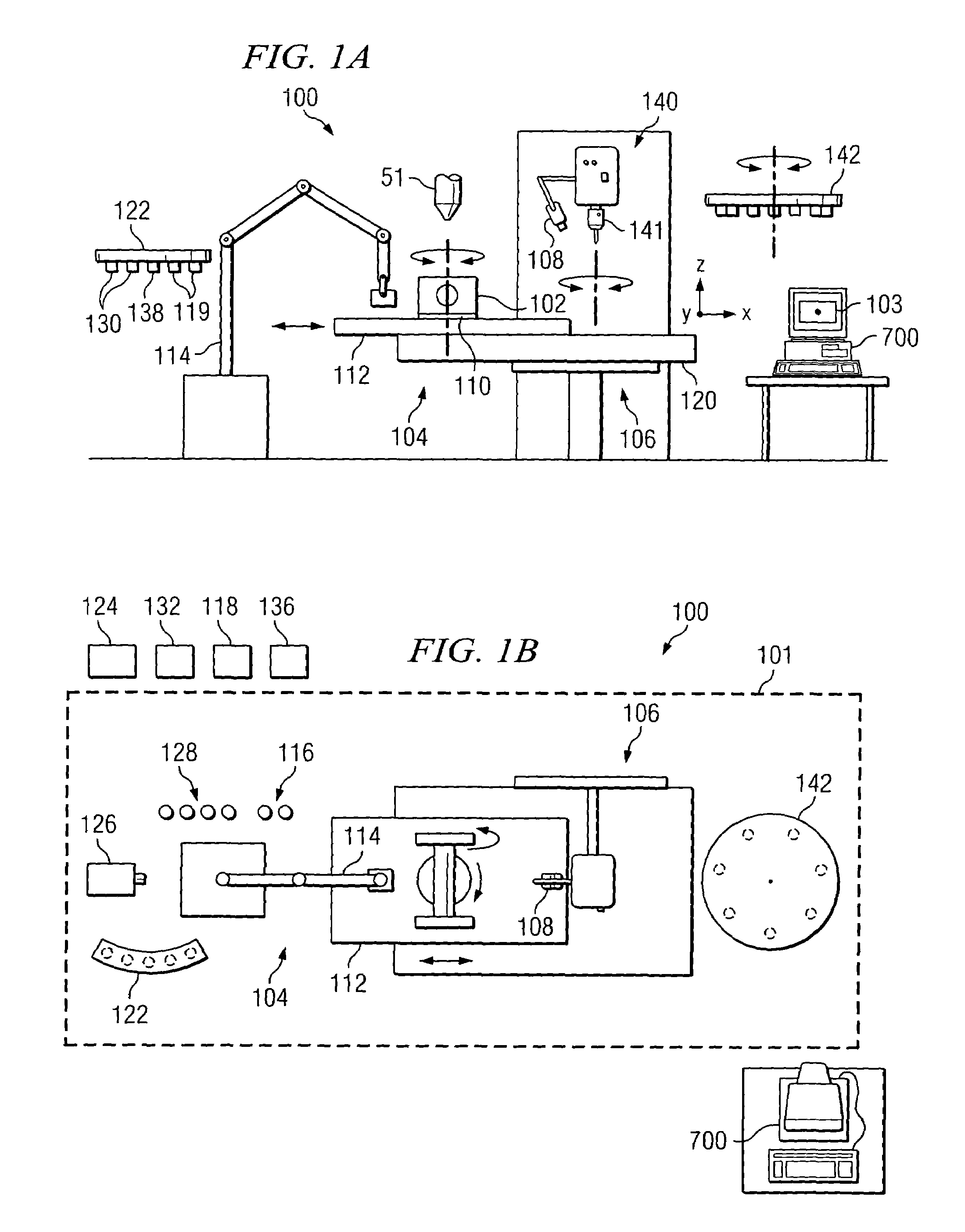

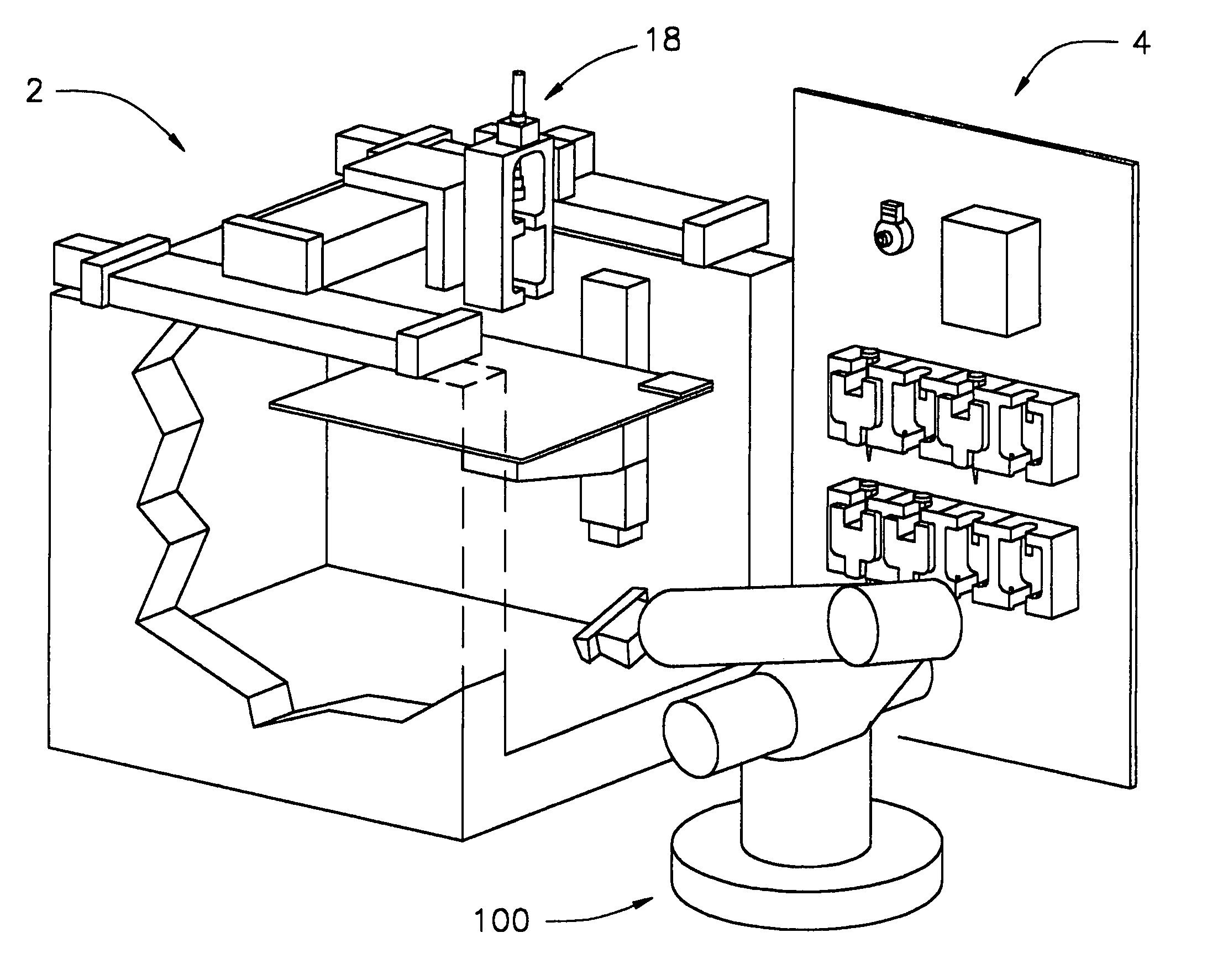

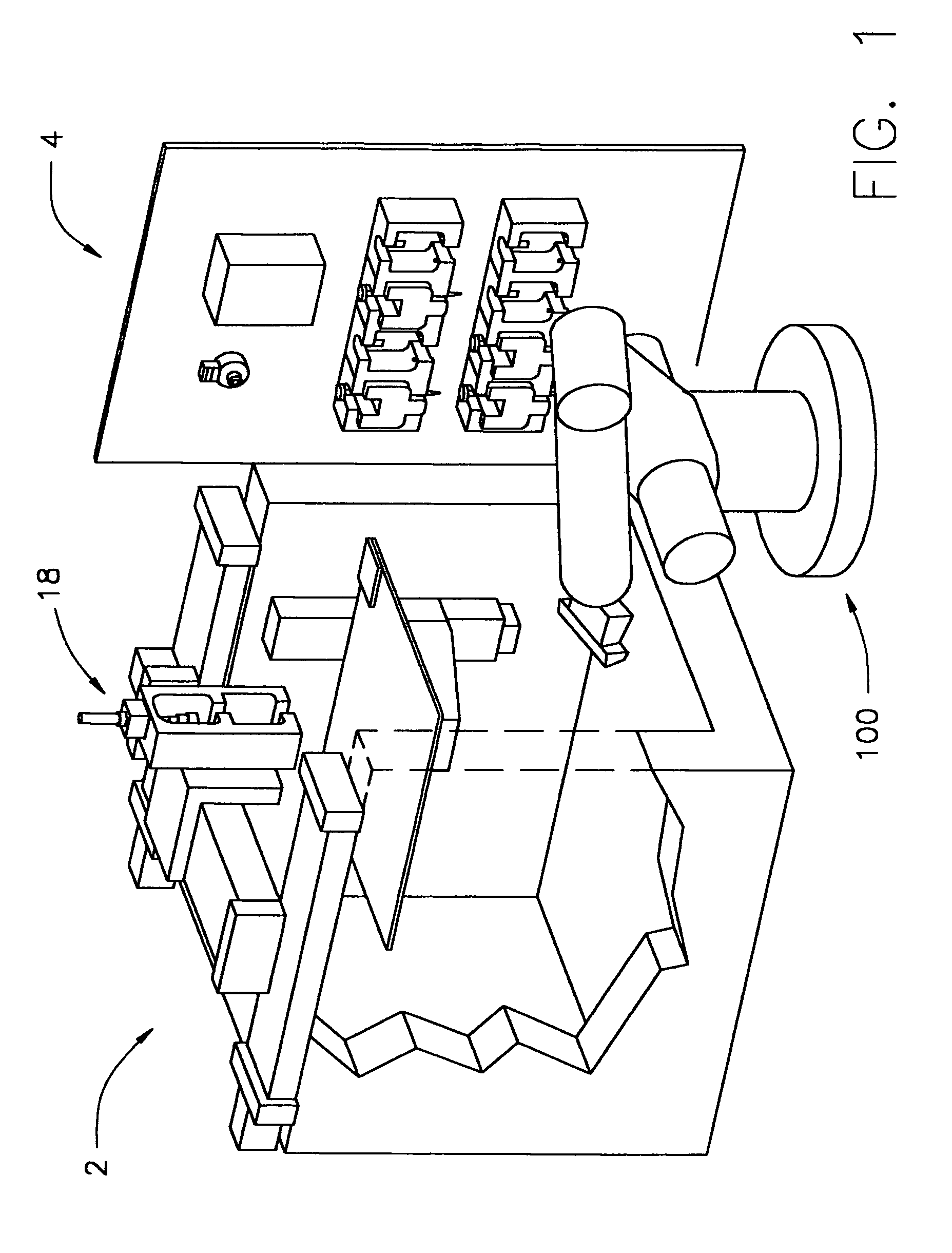

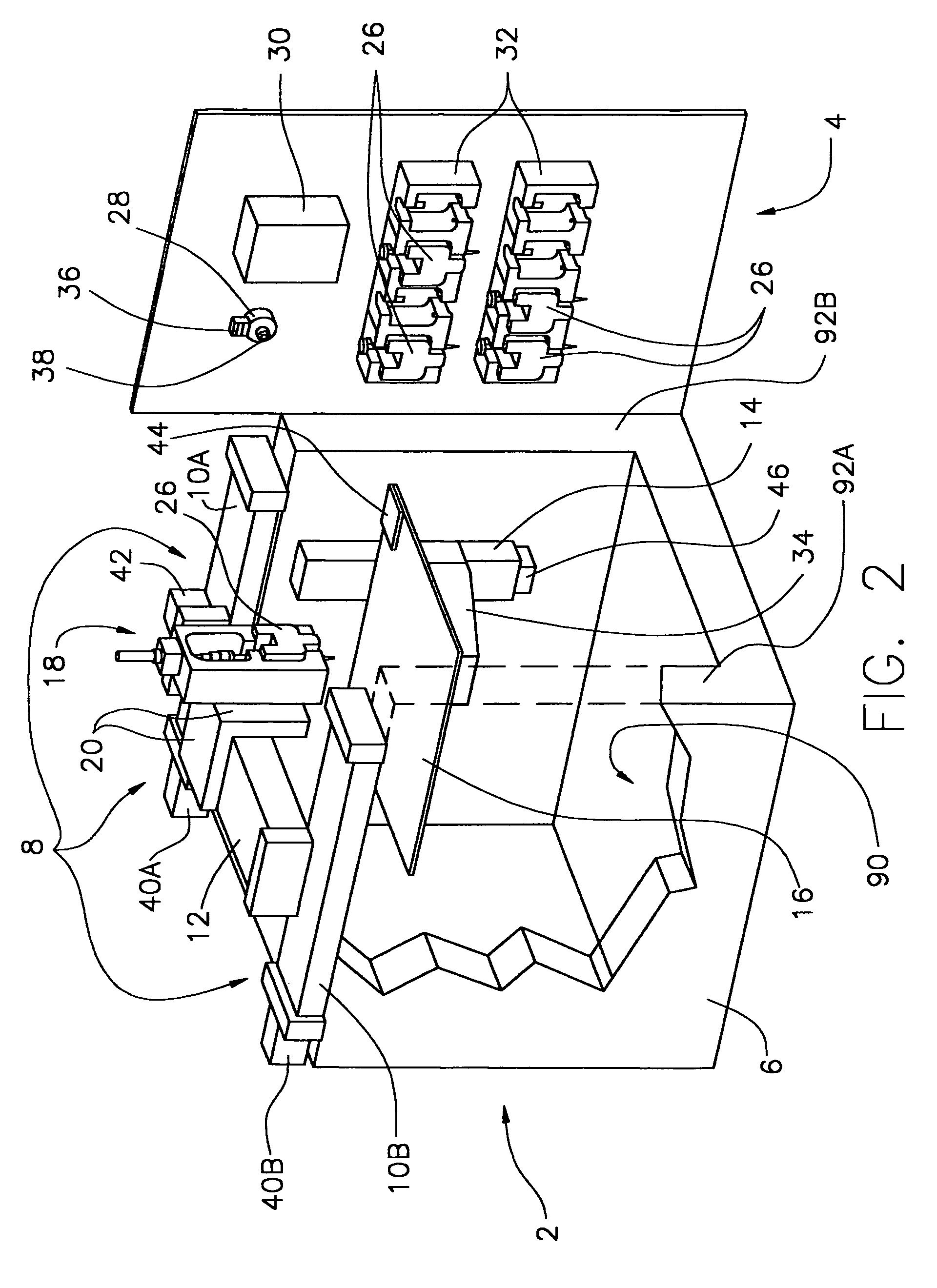

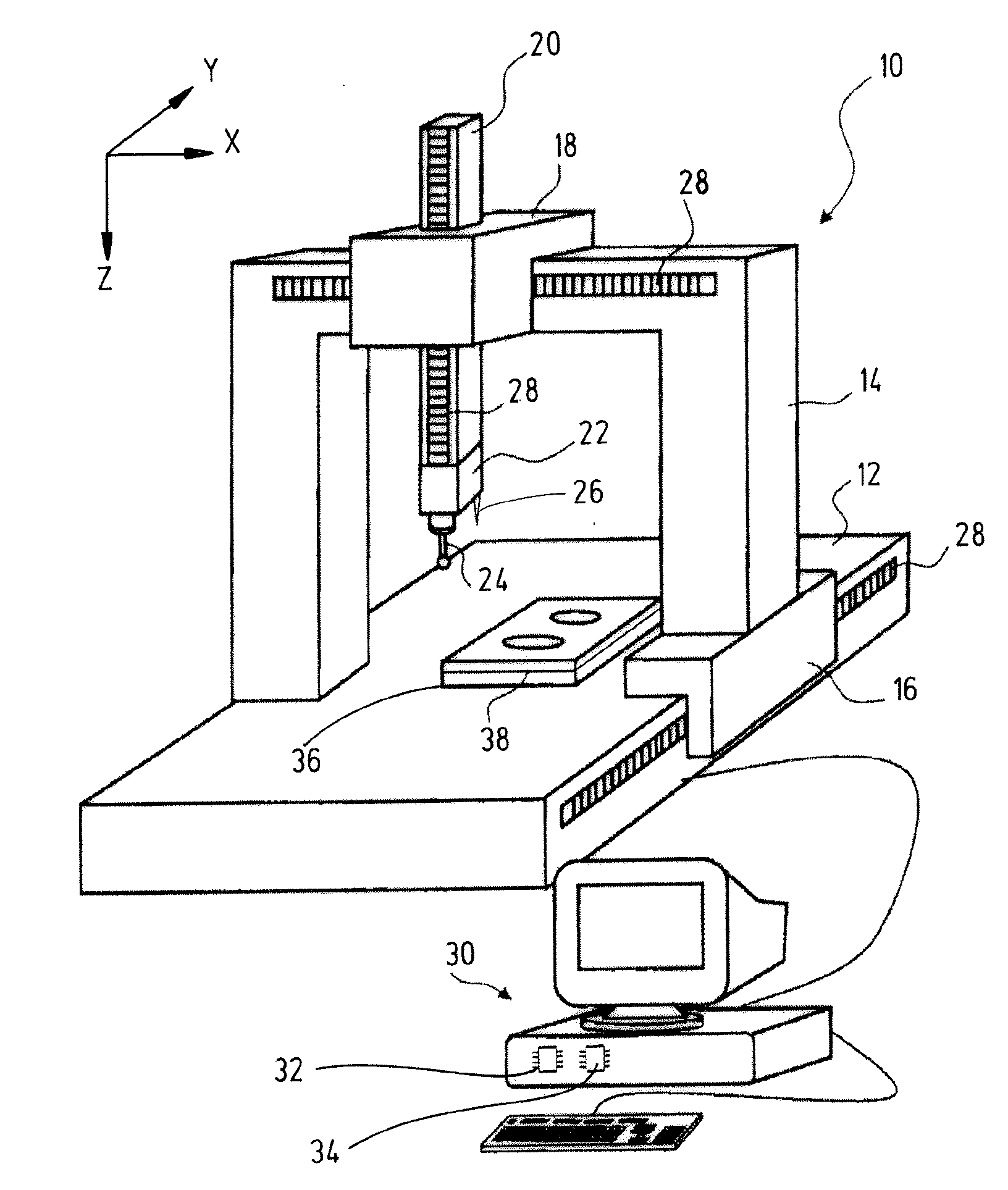

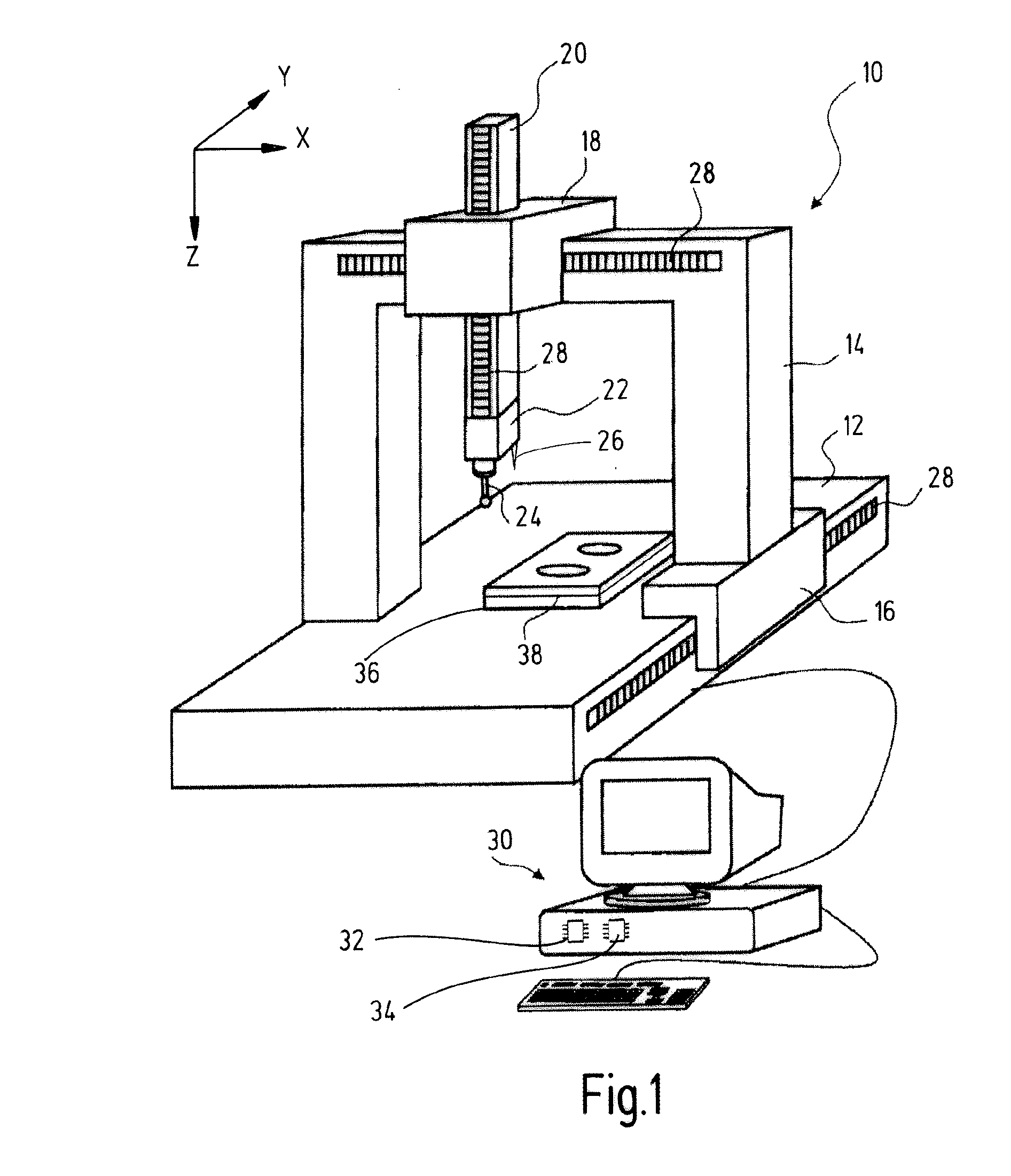

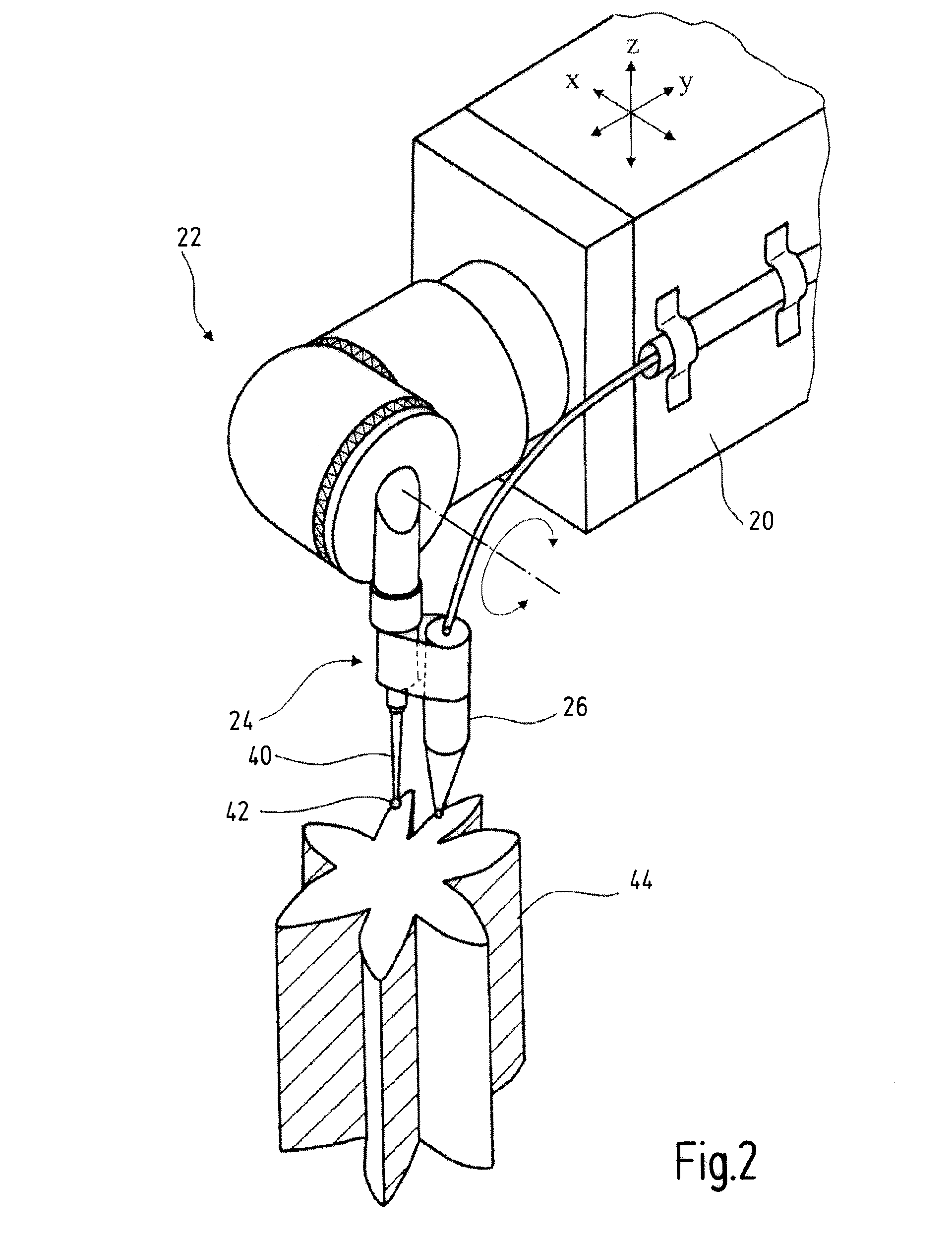

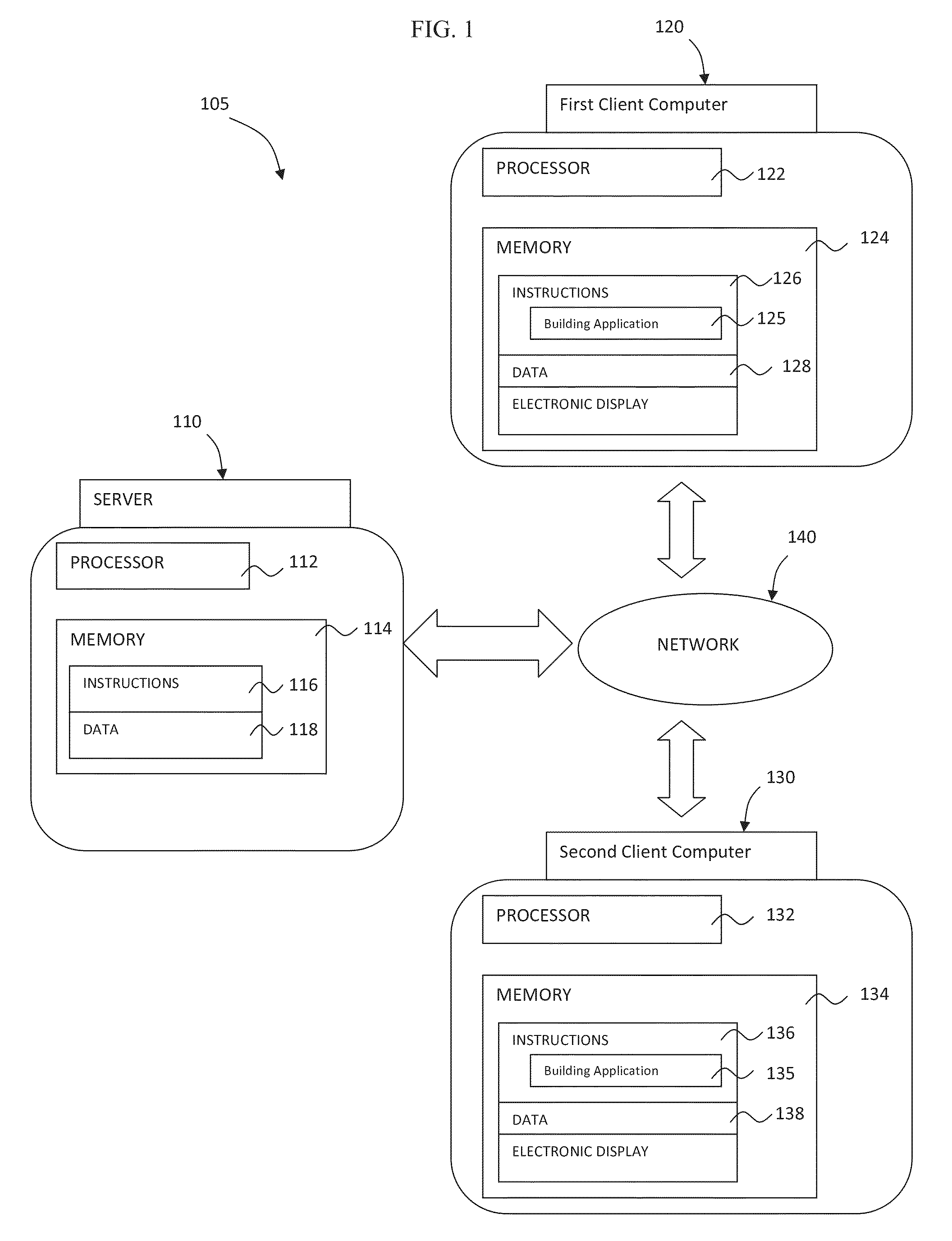

System and method for fabricating or repairing a part

InactiveUS7020539B1Improve accuracyHigh geometric accuracyAdditive manufacturing apparatusTool changing apparatusMulti axisMachining

According to one embodiment of the invention, a system for fabricating a part includes a computer operable to control the fabrication of a three-dimensional part using a solid CAD model, a deposition station operable to deposit successive two-dimensional layers of material to fabricate the three-dimensional part, and a machining station operable to remove at least a portion of one or more of the deposited two-dimensional layers of material. The deposition station includes a substrate on which to fabricate the three-dimensional part, a welding-based deposition system having a welding torch, a laser-based deposition system having a laser head, a plasma powder cladding system having a plasma torch, and a multi-axis robot operable to, when directed by the computer, utilize one of the welding-based deposition system, laser-based deposition system, and plasma powder cladding system to deposit any of the two-dimensional layers of material. The machining station includes a multi-axis milling machine and an automatic tool changer. The milling machine is operable to, when directed by the computer, select from a plurality of machining tools associated with the automatic tool changer for use in the milling machine.

Owner:SOUTHERN METHODIST UNIVERSITY

Methods and systems for the manufacture of layered three-dimensional forms

ActiveUS20050017394A1Lower potentialEasy to controlConfectionerySweetmeatsParticulatesBiological activation

New methods and systems for manufacturing a three-dimensional form, comprising steps of providing a plurality of particulates; contacting the particulates with an activation agent; contacting particulates having the activation agent with a binder material that is activatable by the activation agent; at least partially hardening the binder for forming a layer of the three-dimensional form; and repeating these steps to form the remainder of the three-dimensional form. Following sequential application of all required layers and binder material to make the form, the unbound particles are appropriately removed (and optionally re-used), to result in the desired three-dimensional form. The invention also contemplates a novel method for preparing a form, where unbound particulates free of binder material are re-claimed.

Owner:EXONE

Electron beam layer manufacturing

ActiveUS20110061591A1Obstruct passageProgramme controlAdditive manufacturing apparatusFree formClosed loop

A process and apparatus for free form fabrication of a three-dimensional work piece comprising (a) feeding raw material in a solid state to a first predetermined location; (b) depositing the raw material onto a substrate as a molten pool deposit under a first processing condition; (c) monitoring the molten pool deposit for a preselected condition; (d) comparing information about the preselected condition of the monitored molten pool deposit with a predetermined desired value for the preselected condition of the monitored molten pool deposit; (e) solidifying the molten pool deposit; (f) automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step (d); and repeating steps (a) through (f) at one or more second locations for building up layer by layer a three-dimensional work piece. The apparatus is characterized by a detector that monitors a preselected condition of the deposited material and a closed loop electronic control device for controlling operation of one or more components of the apparatus in response to a detected condition by the detector.

Owner:SCIAKY SA

Method and system for the localized deposit of metal on a surface

ActiveUS20170226636A1Desired patternPrecise patternPolycrystalline material growthSemiconductor/solid-state device manufacturingControl mannerCrystal growth

The present disclosure is directed to a method and system for the localized deposition of a metal layer on a surface. The method involves introducing at least two gaseous reactants to a substrate surface that is locally heated by a laser. The surface is heated to a temperature at which the gaseous reactants undergo a reaction that results in metal crystal growth on the substrate surface. The reaction is maintained for a desired period of time and under desired conditions to produce a localized deposit of a metal layer on the heated zone of the substrate. In some embodiments, the gas outlets and the laser may be moved in a controlled manner so that a metal layer may be deposited in a desired pattern on the substrate surface.

Owner:ILLINOIS TOOL WORKS INC

Expandable intervertebral implant and associated method of manufacturing the same

ActiveUS8551173B2Additive manufacturing apparatusInternal osteosythesisBiomedical engineeringWire mesh

An expandable intervertebral implant (10) includes superior (20) and inferior (30) bone contacting members and at least one vertical wire netting (50) interconnecting the superior and inferior bone contacting members. The superior and inferior bone contacting members include at least two bone contacting components interconnected via one or more lateral wire nettings such that the implant is vertically and laterally expandable in situ from a first insertion configuration to a second expanded configuration. The vertical and lateral wire netting are preferably constructed of a plurality of individual link members. The present invention also preferably relates to an associated method of manufacturing the intervertebral implant such that the intervertebral implant can be manufactured as an integral component or part.

Owner:DEPUY SYNTHES PROD INC

Additive manufacturing apparatus and method

ActiveUS20160236279A1Sufficient reflectivityAdditive manufacturing apparatusSpectrum investigationManufactured apparatusFeedback control

This invention concerns a laser solidification apparatus for building objects by layerwise solidification of powder material. The apparatus including a build chamber containing a build platform, a device for depositing layers of powder material on to the build platform, an optical unit for directing a laser beam to selectively solidify areas of each powder layer and a spectrometer for detecting characteristic radiation emitted by plasma formed during solidification of the powder by the laser beam. The invention also relates to a spectrometer for detecting characteristic radiation generated by interaction of the metal with the or a further laser beam. The spectra recorded using the spectrometer may be used for feedback control during the solidification process.

Owner:RENISHAW PLC

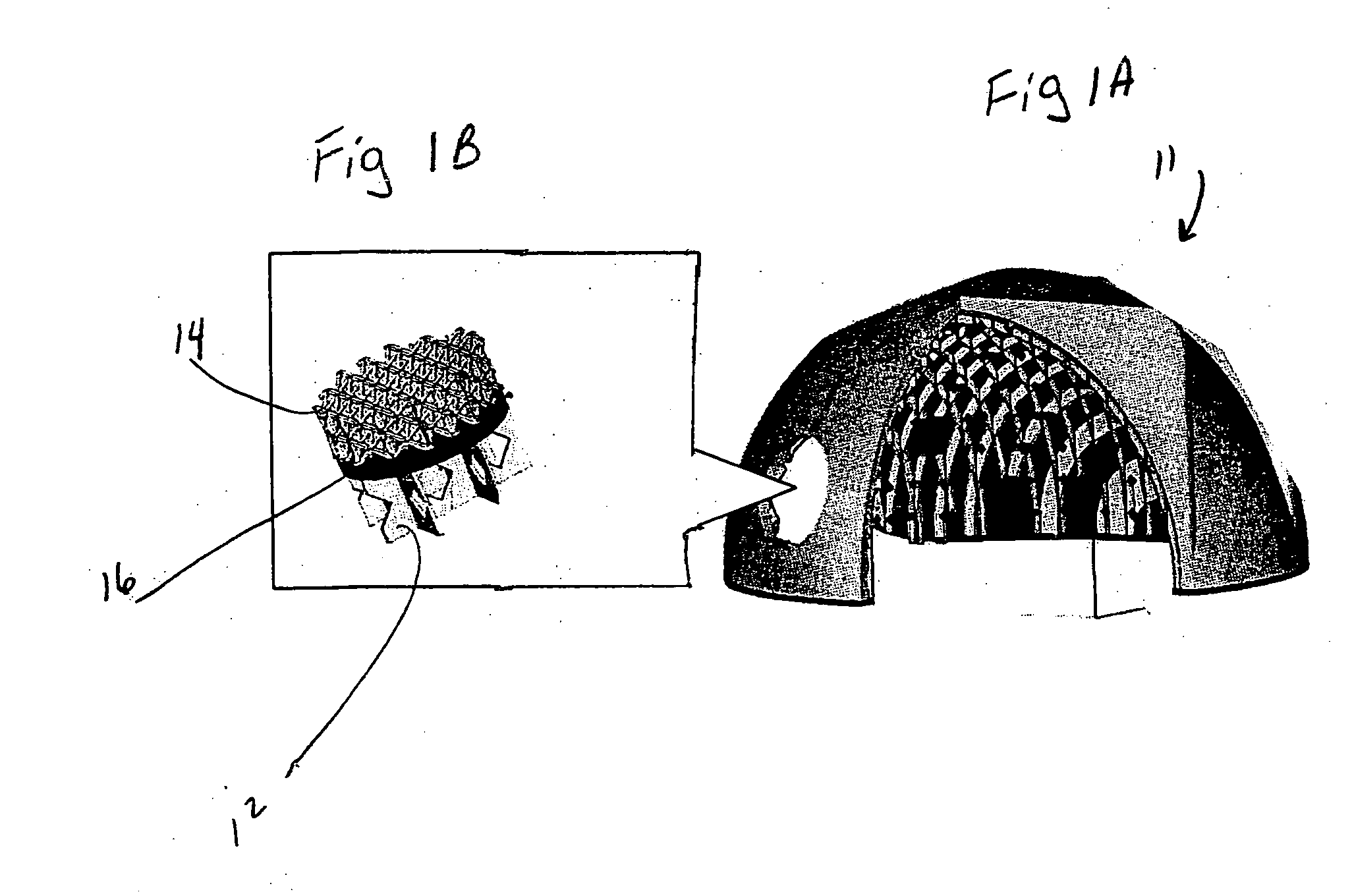

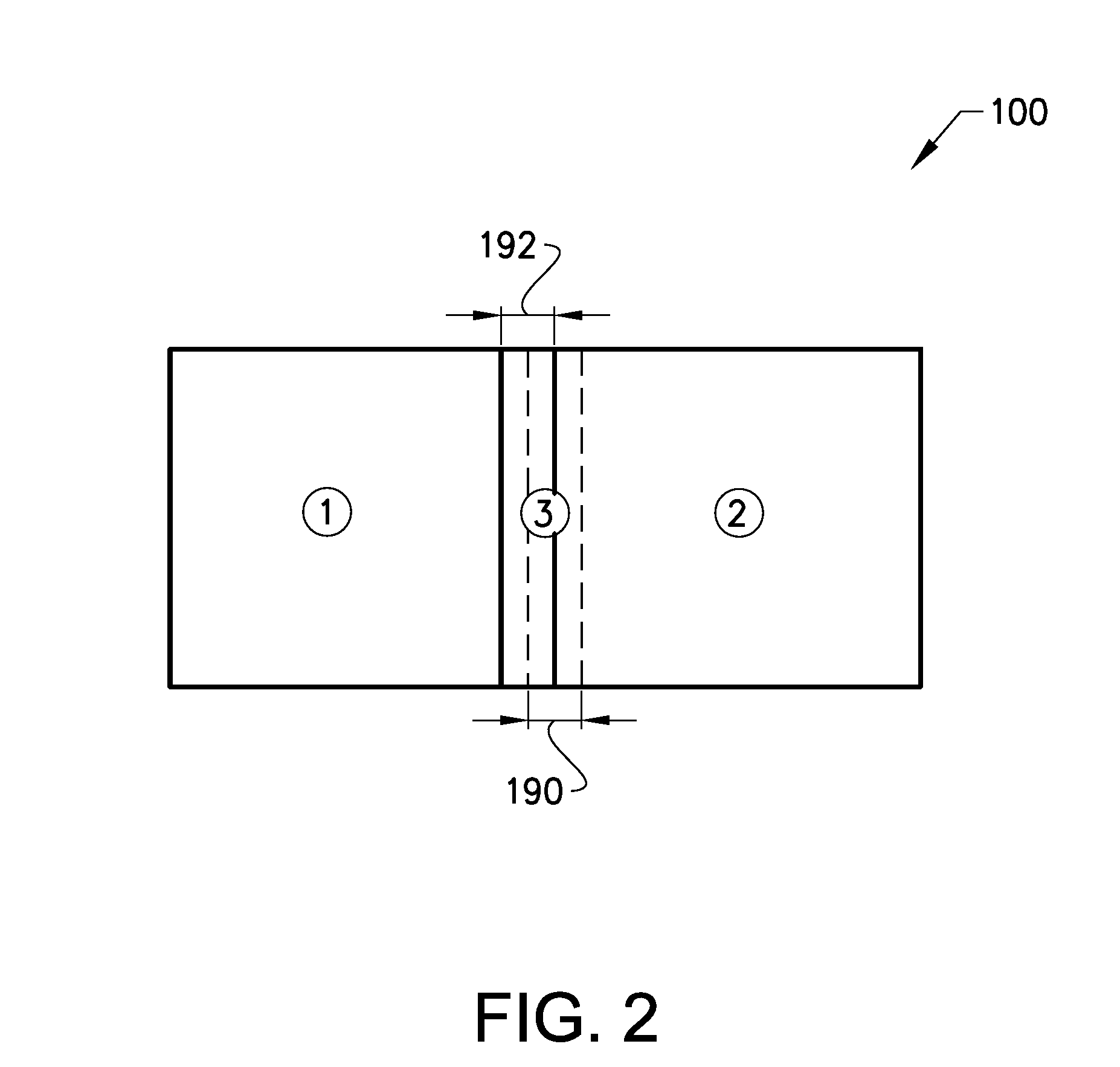

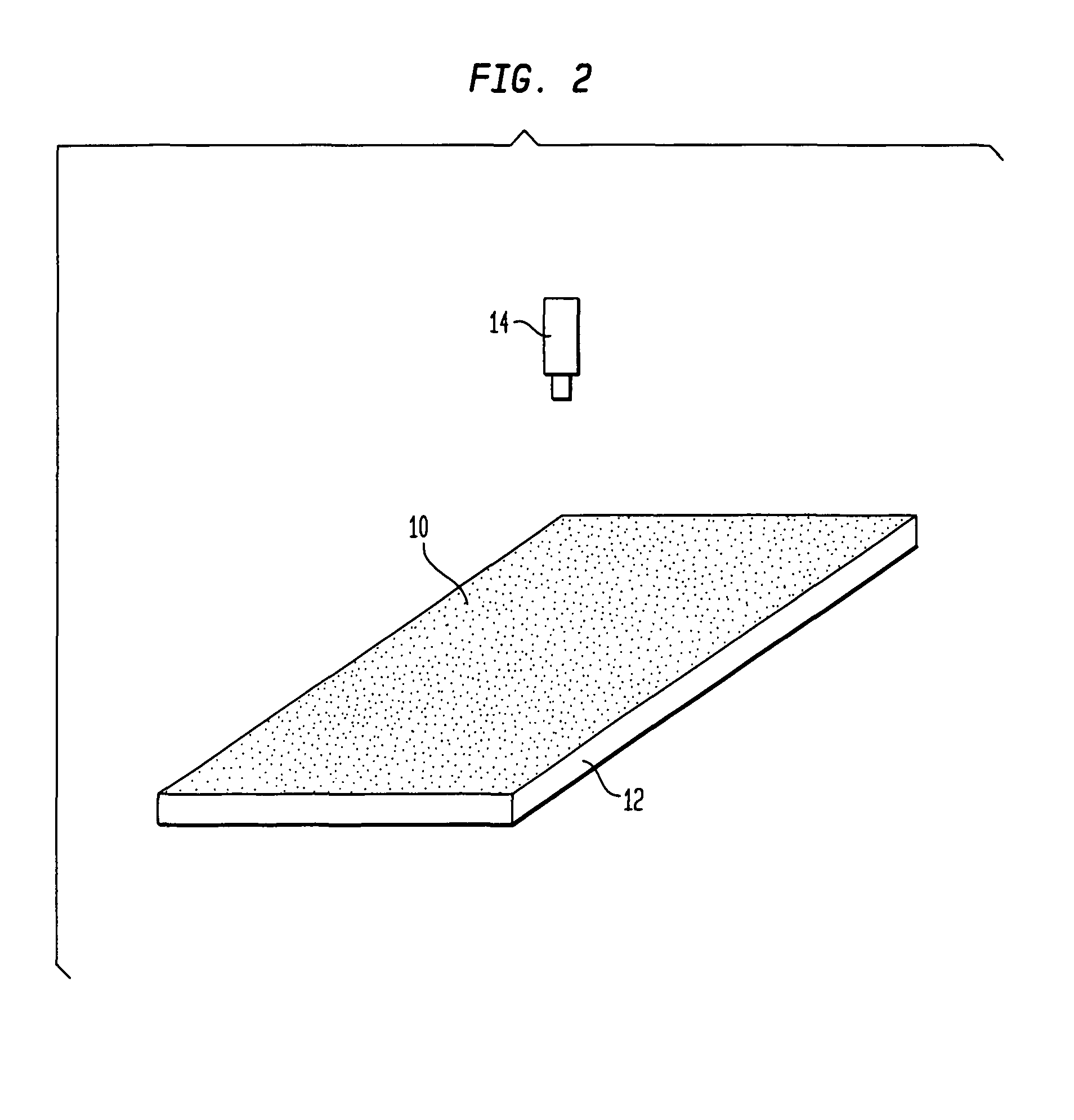

Orthopedic implant and method of making metal articles

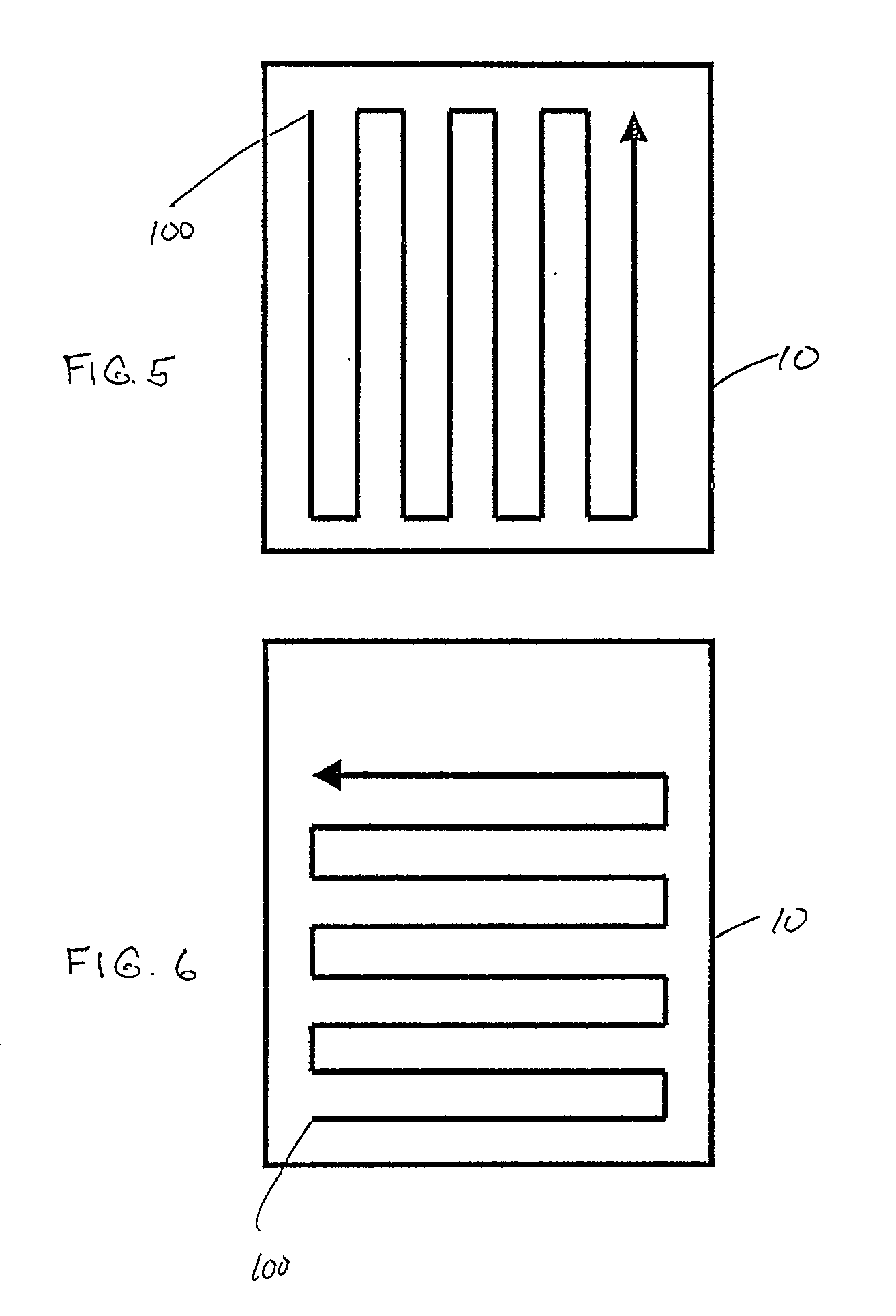

The present application is directed to an orthopedic implant. More specifically, the orthopedic implant is suitable for arthroplasty procedures where optimized multifunctional behavior of the implant is desired. In some embodiments the implant is suitable for the replacement of a spinal disc. In one embodiment, the present application is directed to an orthopedic implant including a first plate a second plate and a flexible support. The flexible support may have a single connection to the first plate and a single connection to the second plate and may vary in cross section. The first plate, the second plate and the flexible support may be unitarily formed. This application is also directed to methods of producing metal articles having microstructure for improved mechanical properties. Such methods may be suitable for the production of medical devices. In one embodiment, the method includes directing a stream including a particulate material in a pattern corresponding to at least a portion of a structure of an orthopedic implant and fusing at least a portion of the particulate material with a laser.

Owner:DEPUY ACROMED INC

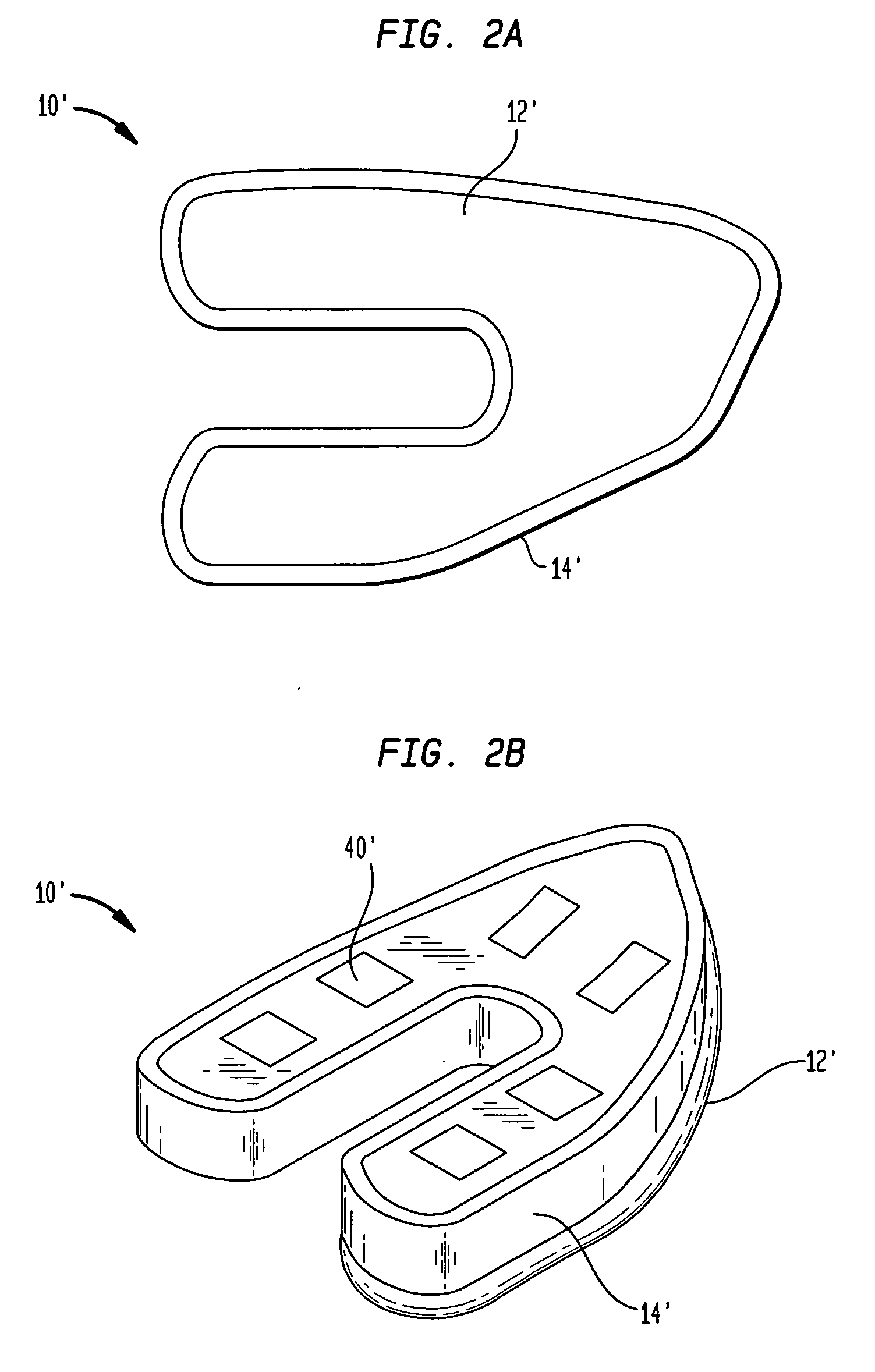

Laser-produced implants

A method of producing an orthopedic implant including the steps of building a flat open model of at least a portion of an implant. The flat open model may be built using a selective laser center process. The flat open model preferably includes at least one groove along either a first surface or a second surface of the model. Next a force may be applied to the flat open model at predetermined locations to thereby cause the model to bend and assume a shape similar to a desired result. The now bent model may be resurfaced by either applying additional material such that the bent flat open model assumes the shape of a desired implant or the bent open model may be snap fit to an additional element.

Owner:UNIV OF LIVERPOOL +2

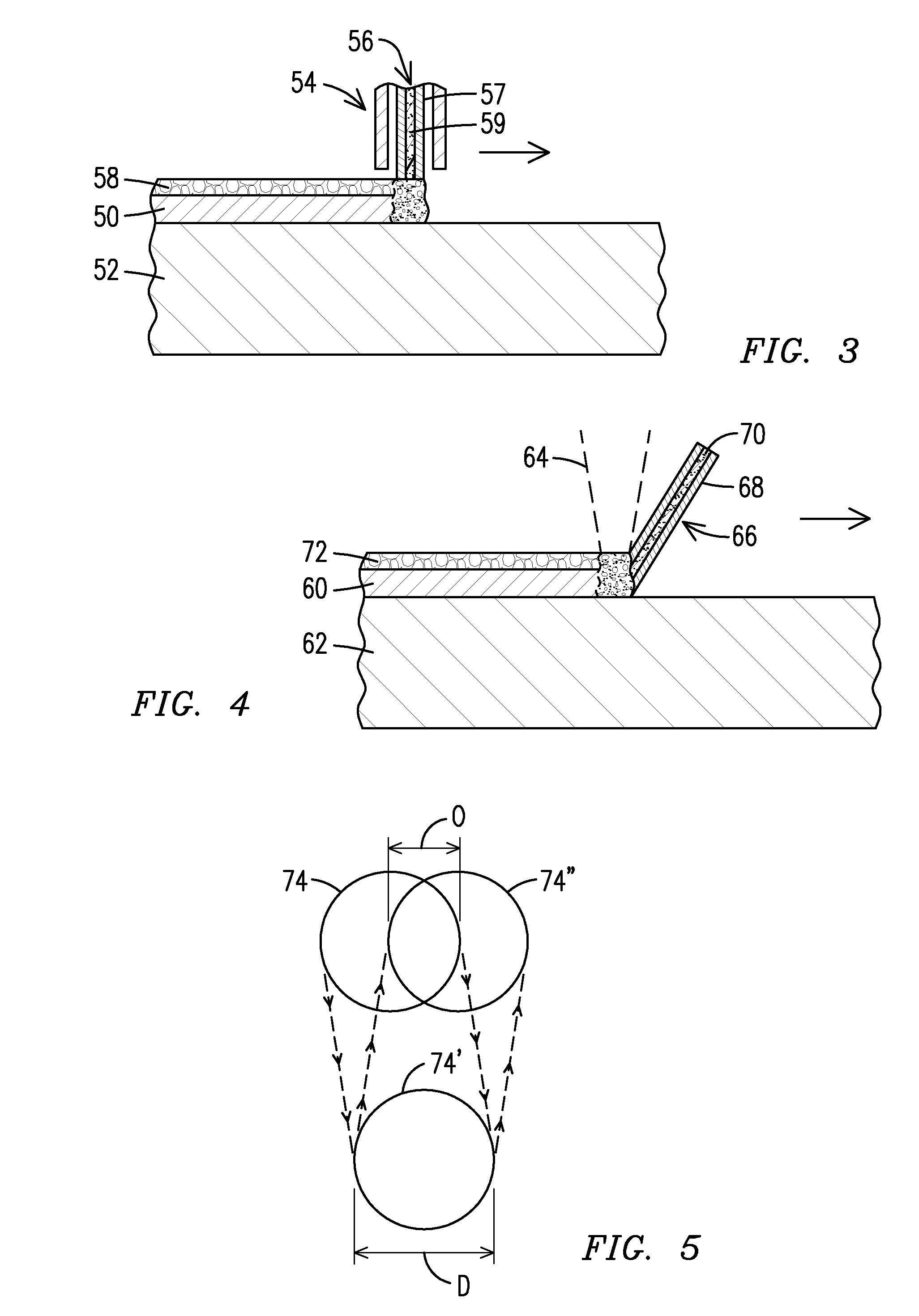

Method and apparatus for additive manufacturing

ActiveUS20140348691A1Large build volumeSacrificing qualityAdditive manufacturing apparatusAuxillary shaping apparatusBeam sourceEngineering

A method for forming a three-dimensional article through successive fusion of parts of a powder bed, which parts corresponds to successive cross sections of the three-dimensional article, said method comprising the steps of: providing a model of said three dimensional article, providing a first powder layer on a work table, directing a first energy beam from a first energy beam source over said work table causing said first powder layer to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article, directing a second energy beam from a second energy beam source over said work table causing said first powder layer to fuse in second selected locations according to said model to form the first cross section of said three-dimensional article, wherein said first and second locations of said first powder layer are at least partially overlapping each other.

Owner:ARCAM AB

Laser-produced porous structure

The present invention disclosed a method of producing a three-dimensional porous tissue in-growth structure. The method includes the steps of depositing a first layer of metal powder and scanning the first layer of metal powder with a laser beam to form a portion of a plurality of predetermined unit cells. Depositing at least one additional layer of metal powder onto a previous layer and repeating the step of scanning a laser beam for at least one of the additional layers in order to continuing forming the predetermined unit cells. The method further includes continuing the depositing and scanning steps to form a medical implant.

Owner:UNIV OF LIVERPOOL +1

Direct write and freeform fabrication apparatus and method

InactiveUS20050288813A1Improved part accuracyImprove accuracyAdditive manufacturing apparatusCeramic shaping apparatusTarget surfaceChemical reaction

A direct write or freeform fabrication apparatus and process for making a device or a three-dimensional object. By way of example the method comprises: (a) providing a target surface on an object-supporting platform; (b) operating a material deposition sub-system comprising a liquid deposition device for dispensing at least a liquid composition and a solid powder-dispensing device for dispensing solid powder particles to selected locations on the target surface; (c) operating a directed energy source for supplying energy to the dispensed liquid composition and the dispensed powder particles to induce a chemical reaction or physical transition thereof at the selected locations; and (d) moving the deposition sub-system and the object-supporting platform relative to one another in a plane defined by first and second directions to form the dispensed liquid composition and the dispensed powder particles into the device or object. An apparatus is also provided for carrying out this process.

Owner:NORTH DAKOTA STATE UNIVERSITY

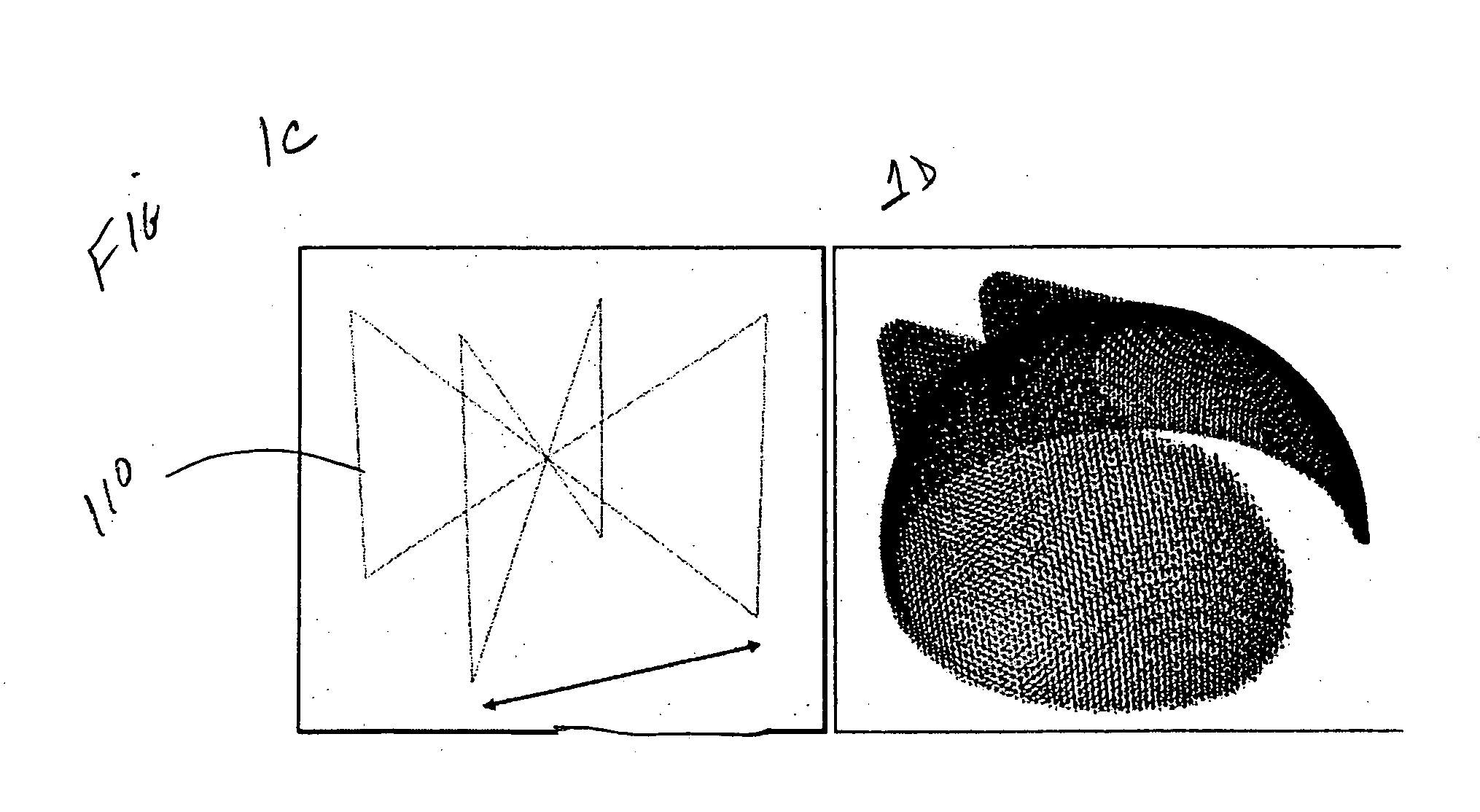

Selective laser melting / sintering using powdered flux

InactiveUS20130136868A1TurbinesRadiation applicationsSelective laser meltingSelective laser sintering

An additive manufacturing process (110) wherein a powder (116) including a superalloy material and flux is selectively melted in layers with a laser beam (124) to form a superalloy component (126). The flux performs a cleaning function to react with contaminants to float them to the surface of the melt to form a slag. The flux also provides a shielding function, thereby eliminating the need for an inert cover gas. The powder may be a mixture of alloy and flux particles, or it may be formed of composite alloy / flux particles.

Owner:SIEMENS ENERGY INC

Arrangement and method for producing a three-dimensional product

Arrangement for producing a three-dimensional product, which arrangement comprises a work table on which said three-dimensional product is to be built up, a powder dispenser which is arranged so as to distribute a thin layer of powder on the work table for forming a powder bed, a radiation gun for delivering energy to the powder, fusing together of the powder then taking place, means for guiding the beam emitted by the radiation gun over said powder bed for forming a cross section of said three-dimensional product by fusing together parts of said powder bed, and a control computer in which information about successive cross sections of the three-dimensional product is stored, which cross sections build up the three-dimensional product, where the control computer is intended to control said means for guiding the radiation gun over the powder bed according to an operating scheme forming a cross section of said three-dimensional body, said three-dimensional product being formed by successive fusing together of successively formed cross sections from by the powder dispenser, and method for producing three-dimensional product using such an arrangement.

Owner:ARCAM AB

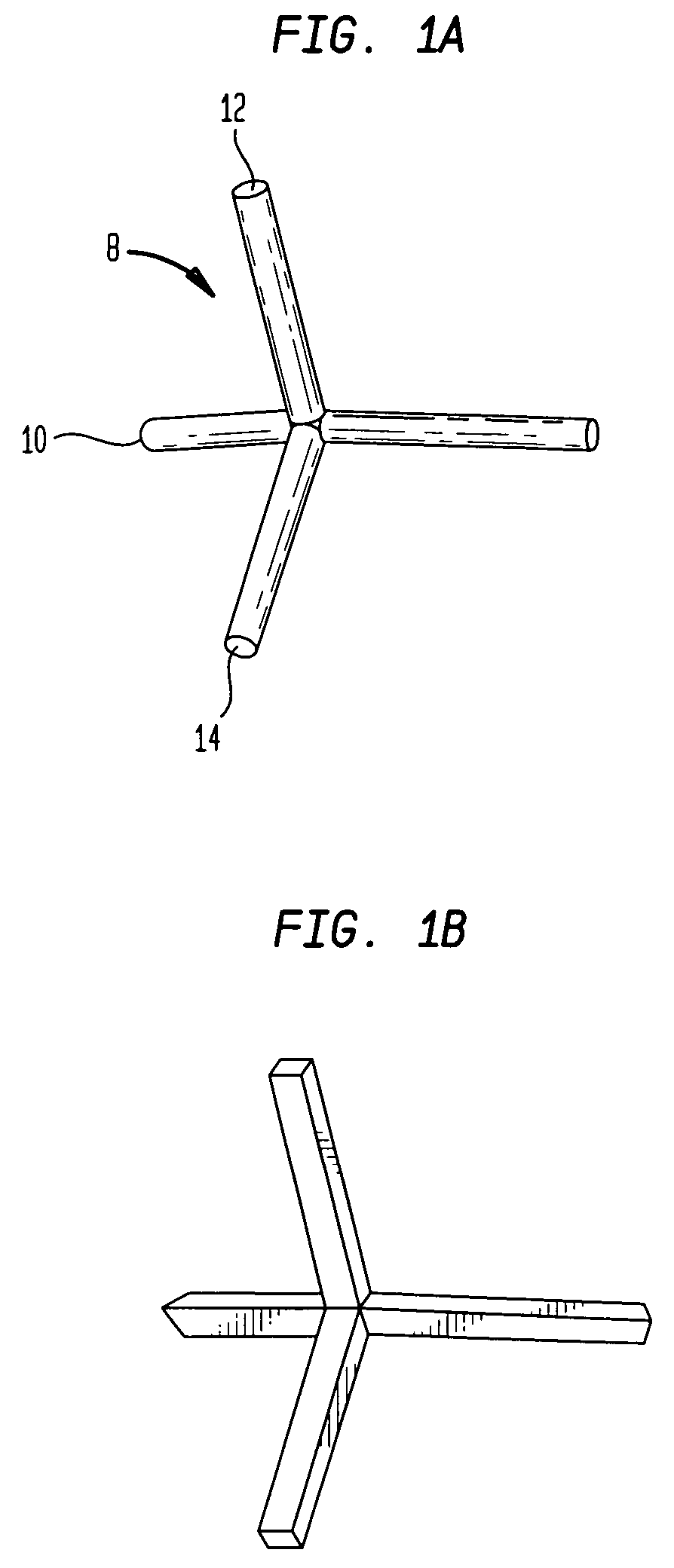

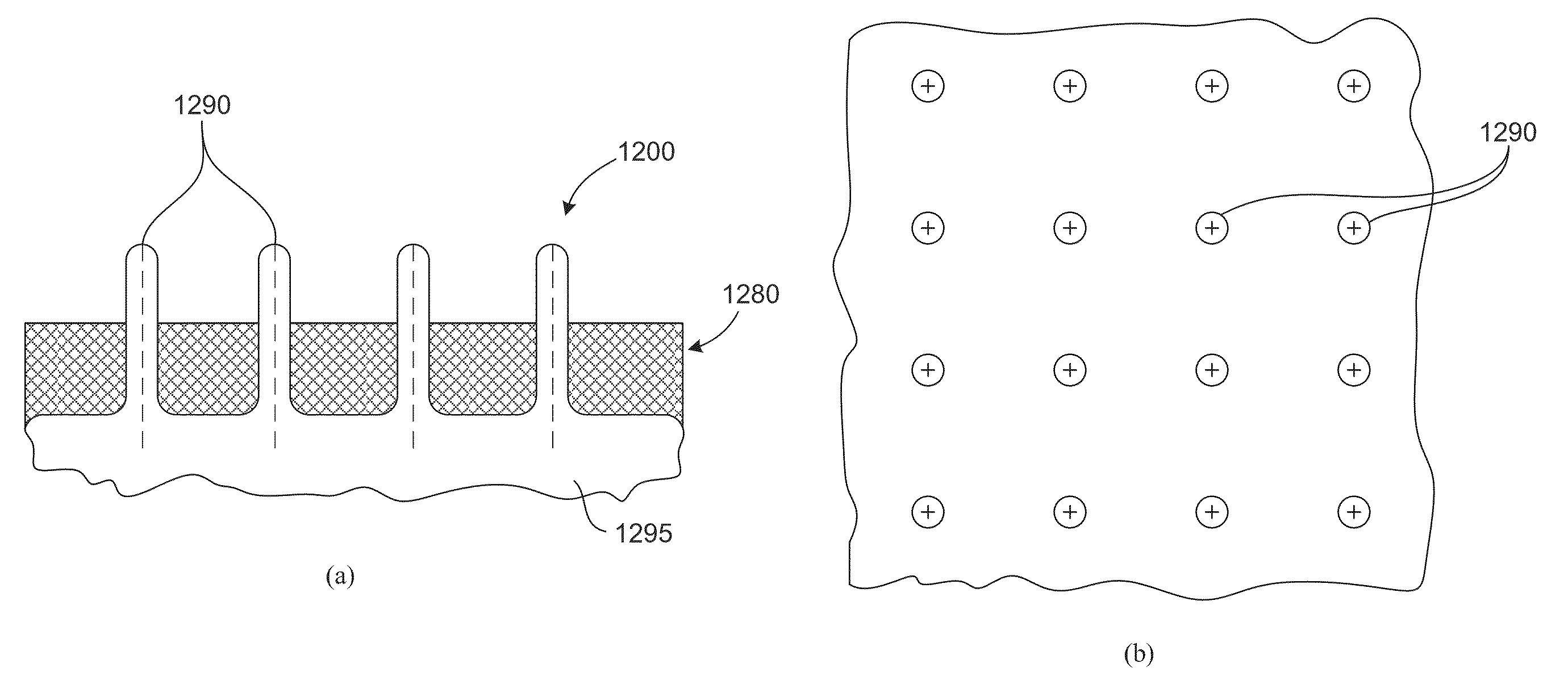

Porous implant structures

InactiveUS20120215310A1High porosityHigh strengthAdditive manufacturing apparatusSurgical adhesivesNODALManufacturing technology

Porous biocompatible structures suitable for use as medical implants and methods for fabricating such structures are disclosed. The disclosed structures may be fabricated using rapid manufacturing techniques. The disclosed porous structures has a plurality of struts and nodes where no more than two struts intersect one another to form a node. Further, the nodes can be straight, curved, portions that are curved and / or straight. The struts and nodes can form cells which can be fused or sintered to at least one other cell to form a continuous reticulated structure for improved strength while providing the porosity needed for tissue and cell in-growth.

Owner:SMITH & NEPHEW INC

Modular fabrication systems and methods

ActiveUS7625198B2Improve throughputAdapt to a wide rangeLiquid surface applicatorsConfectioneryEngineeringSystem controller

The present invention relates to an article fabrication system having a plurality of material deposition tools containing one or more materials useful in fabricating the article, and a material deposition device having a tool interface for receiving one of the material deposition tools. A system controller is operably connected to the material deposition device to control operation of the material deposition device. Also disclosed is a method of fabricating an article using the system of the invention and a method of fabricating a living three-dimensional structure.

Owner:CORNELL RES FOUNDATION INC

Method and apparatus for additive manufacturing

ActiveUS20140314964A1Improve conductivityReduce probabilityVacuum evaporation coatingPretreated surfacesMetallurgyElectron

Various embodiments provide a method and apparatus for forming a three-dimensional article through successive fusion of parts of at least one layer of a powder bed provided on a work table in an additive manufacturing machine, which parts corresponds to successive cross sections of the three-dimensional article. The method comprises the steps of: applying a layer of predetermined thickness of powder particles on the work table, applying a coating on at least a portion of the powder particles, which coating is at least partially covering the powder particles, and fusing the powder particles on the work table with an electron beam.

Owner:ARCAM AB

Orthopedic implant

Disclosed is an orthopedic implant suitable for arthroplasty procedures. The orthopedic implant includes a first plate, a second plate, an axial support between the first plate and the second plate and one or more torsional supports connecting the first plate and the second plate. The axial support may be, for example, one or more flexible struts, such as cables, or a ball and socket joint. The torsional supports connect the first and second plates and may be, for example, curved around the axial support. The torsional supports may be integrally formed with the first and second plates as a single unitary device, by, for example, a Laser Engineered Net Shape (LENS) process.

Owner:DEPUY ACROMED INC

Method and arrangement for producing a workpiece by using additive manufacturing techniques

ActiveUS20150061170A1Cost-efficient productionAdditive manufacturing apparatusAuxillary shaping apparatusManufacturing technologyProcess measurement

A method and an arrangement for producing a workpiece using additive manufacturing techniques involve in-process measurement in order to determine individual characteristics of one or more workpiece layers. In particular, dimensional and / or geometrical characteristics of a workpiece layer are measured before the next workpiece layer is produced. Advantageously, the measurement results are fed back into the production process in order to increase accuracy and precision of the production process.

Owner:CARL ZEISS IND MESSTECHN GMBH +1

Device and arrangement for producing a three-dimensional object

InactiveUS20040026807A1Reduced form requirementsSmall sizeConfectioneryWood working apparatusThin layerRunning time

A device for manufacturing a three-dimensional product, which device comprises a work table on which said three-dimensional product is to be built, a powder dispenser which is arranged to lay down a thin layer of powder on the work table for the formation of a powder bed, a ray gun for giving off energy to the powder whereby fusion of the powder takes place, members for controlling of the beam released by the ray gun across said powder bed for the formation of a cross section of said three-dimensional product through fusion of parts of said powder bed, and a controlling computer in which information about successive cross sections of the three-dimensional product is stored, which cross sections build the three-dimensional product, the controlling computer intended to control said members for guiding the ray gun across the powder bed according to a running schedule forming a cross section of said three-dimensional body, whereby said three-dimensional product is formed by successive fusion of successively formed cross sections from powder layers successively laid down by the powder dispenser.

Owner:ARCAM AB

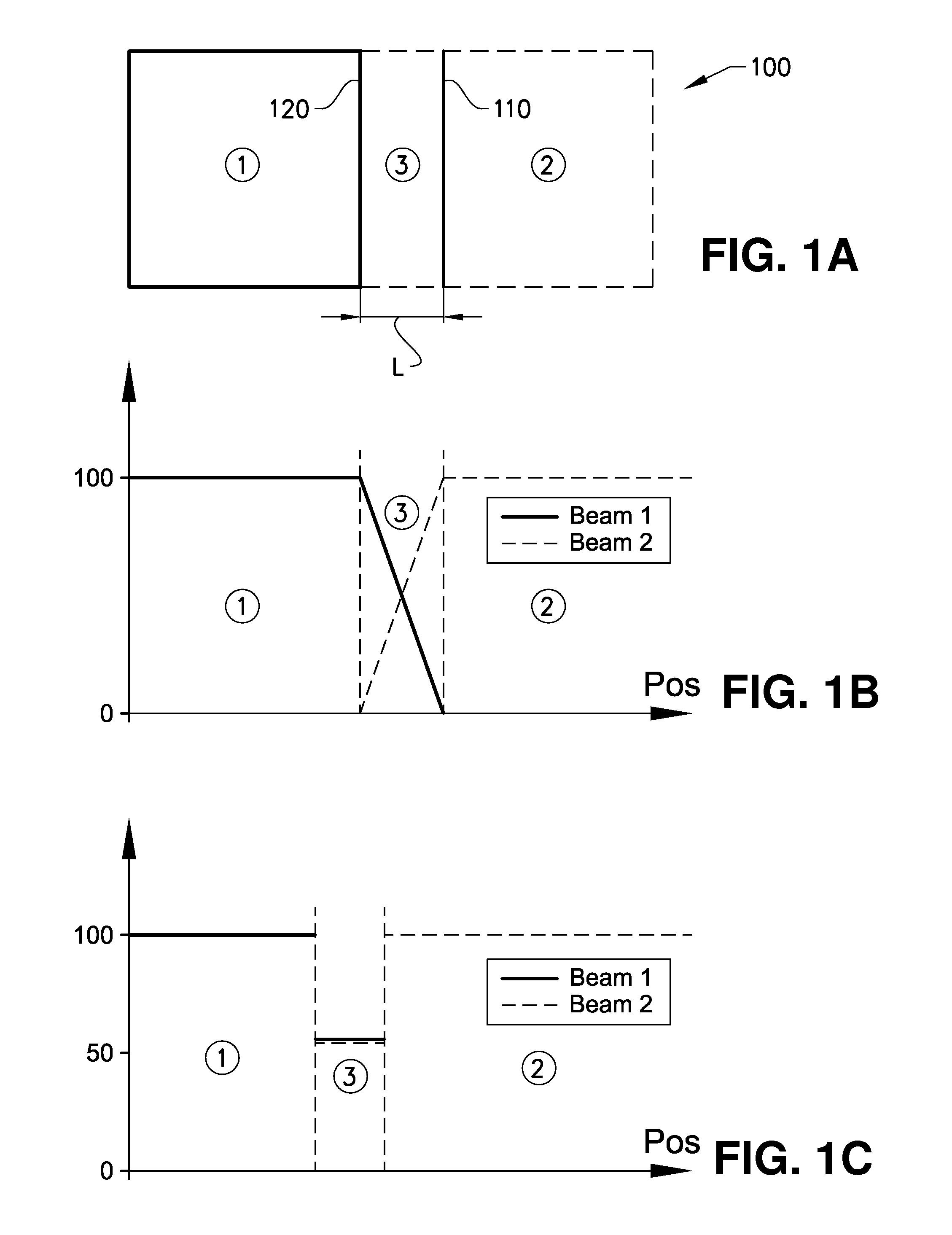

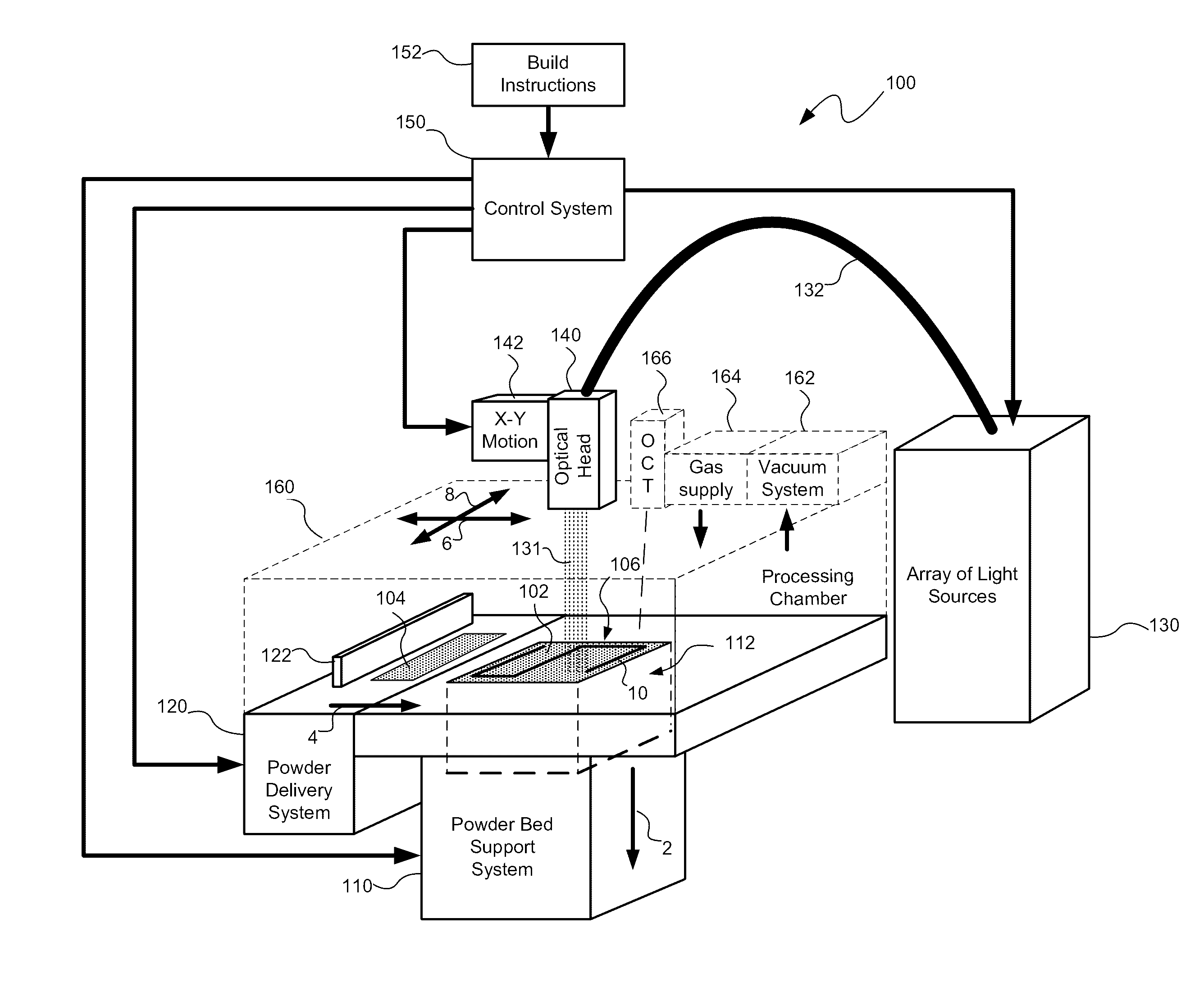

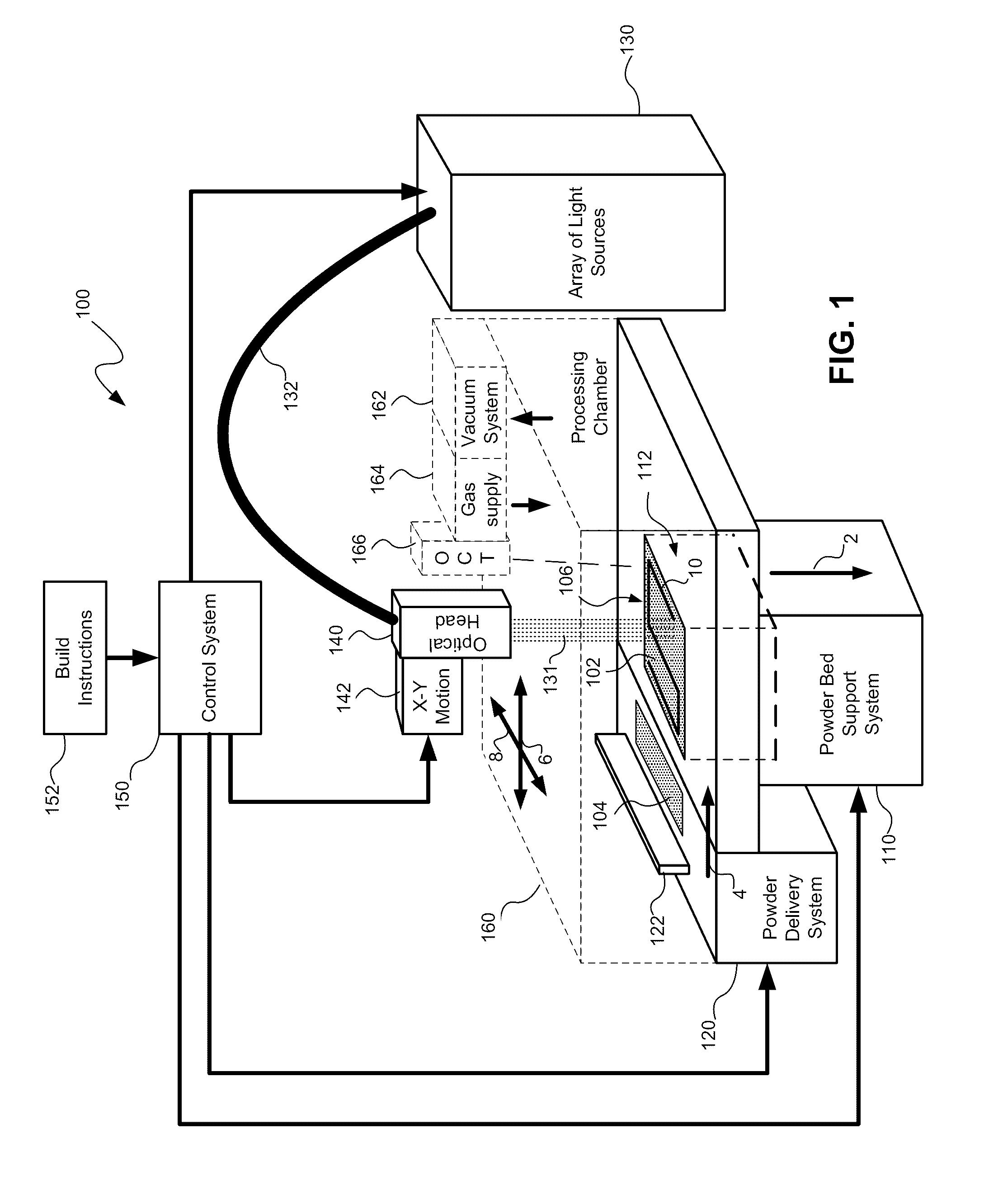

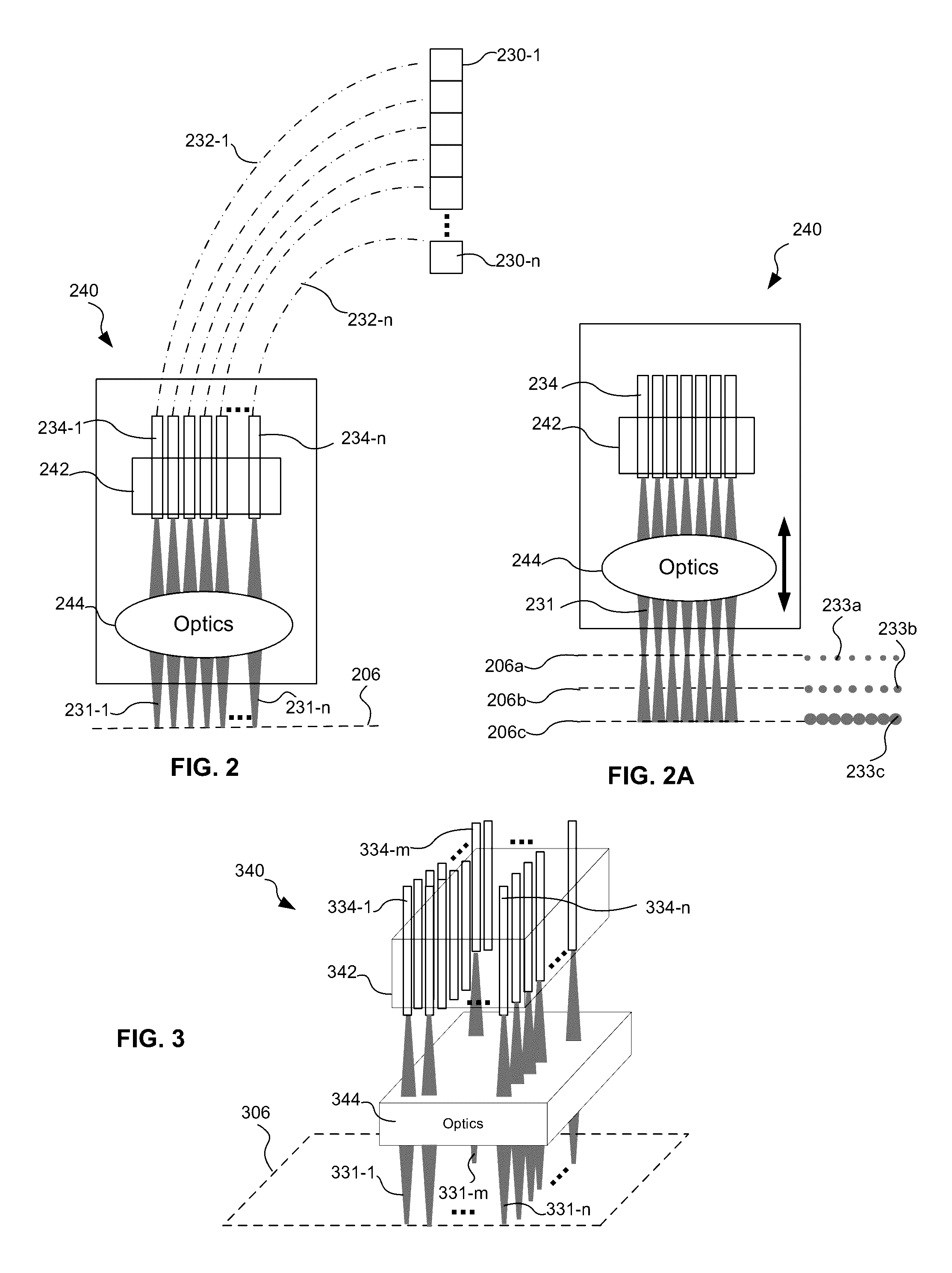

Multiple beam additive manufacturing

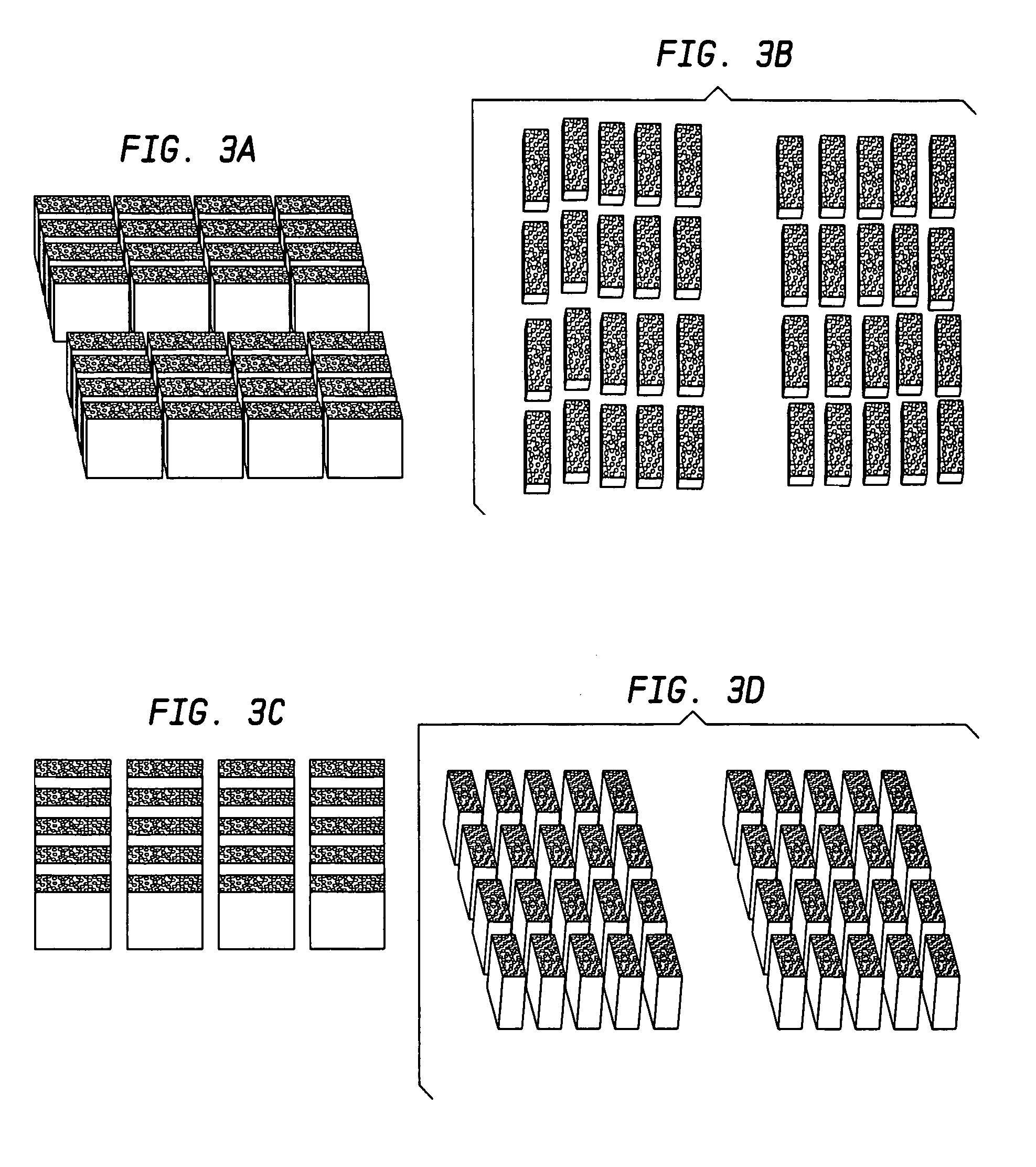

Systems and methods for multiple beam additive manufacturing use multiple beams of light (e.g., laser light) to expose layers of powder material in selected regions until the powder material fuses to form voxels, which form build layers of a three-dimensional structure. The light may be generated from selected light sources and coupled into an array of optical fibers having output ends arranged in an optical head in at least one line such that multiple beams are sequentially directed by the optical head to the same powder region providing multiple beam sequential exposures (e.g., with pre-heating, melting and controlled cool down) to fuse the powder region. The multiple sequential beams may be moved using various techniques (e.g., by moving the optical head) and according to various scan patterns such that a plurality of fused regions form each build layer.

Owner:IPG PHOTONICS CORP

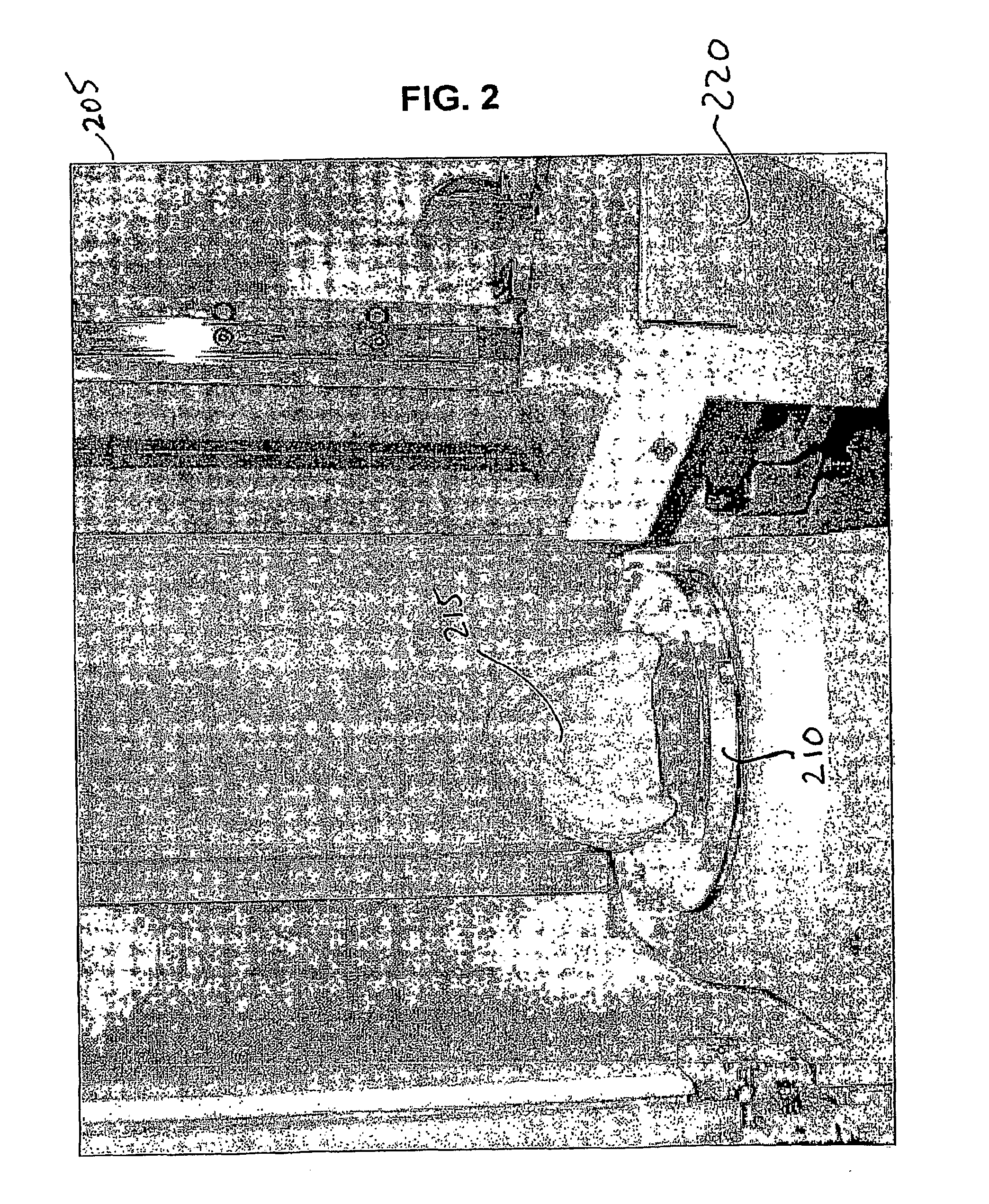

System and method for manufacturing full and partial dentures

There is provided a system for fabricating at least a portion of a denture. The system includes a three-dimensional scanning device for scanning a surface of a denture template, and a computer-readable medium including a computer program for receiving data from the scanning device, creating a 3-dimensional model of the surface, and optionally modifying the 3-dimensional model and / or adding features to the 3-dimensional model. The system also includes a fabricator for creating the at least the portion of the denture, from a selected material, based on the 3-dimensional model. The fabricator may be a device including a lathe, or a rapid prototyping machine. There is also provided a method for fabricating at least a portion of a denture.

Owner:SMITHKLINE BECKMAN CORP

Surface modified unit cell lattice structures for optimized secure freeform fabrication

Aspects of the present disclosure relate generally to preparing models of three-dimensional structures. In particular, a model of a three-dimensional structure constructed of porous geometries is prepared. A component file including a porous CAD volume having a boundary is prepared. A space including the porous CAD volume is populated with unit cells. The unit cells are populated with porous geometries having a plurality of struts having nodes on each end. The space is populated with at least one elongated fixation element extending beyond the boundary to produce an interlocking feature enabling assembly or engagement with a mating structure.

Owner:HOWMEDICA OSTEONICS CORP +1

Device and arrangement for producing a three-dimensional object

InactiveUS7537722B2Reduce biasReduce riskAdditive manufacturing apparatusAuxillary shaping apparatusThin layerRunning time

A device for manufacturing a three-dimensional product, which device comprises a work table on which said three-dimensional product is to be built, a powder dispenser which is arranged to lay down a thin layer of powder on the work table for the formation of a powder bed, a ray gun for giving off energy to the powder whereby fusion of the powder takes place, members for controlling of the beam released by the ray gun across said powder bed for the formation of a cross section of said three-dimensional product through fusion of parts of said powder bed, and a controlling computer in which information about successive cross sections of the three-dimensional product is stored, which cross sections build the three-dimensional product, the controlling computer intended to control said members for guiding the ray gun across the powder bed according to a running schedule forming a cross section of said three-dimensional body, whereby said three-dimensional product is formed by successive fusion of successively formed cross sections from powder layers successively laid down by the powder dispenser.

Owner:ARCAM AB

Antimicrobial implant

ActiveUS8147861B2Retention characteristicBiocideInorganic active ingredientsPlastic surgeryMaterials science

A method of building an orthopedic implant including the steps of mixing a powder having antimicrobial properties with a biocompatible powder to form a mixture. Next, the mixture is deposited on top of a substrate. The substrate may be part of the finished product or only a work platform. The mixture layer is then selectively melted.

Owner:UNIV OF LIVERPOOL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com