Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

723 results about "Ball and socket joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The ball and socket joint (or spheroid joint) is a type of synovial joint in which the ball-shaped surface of one rounded bone fits into the cup-like depression of another bone. The distal bone is capable of motion around an indefinite number of axes, which have one common center. It enables the bone to move in many places (nearly all directions).

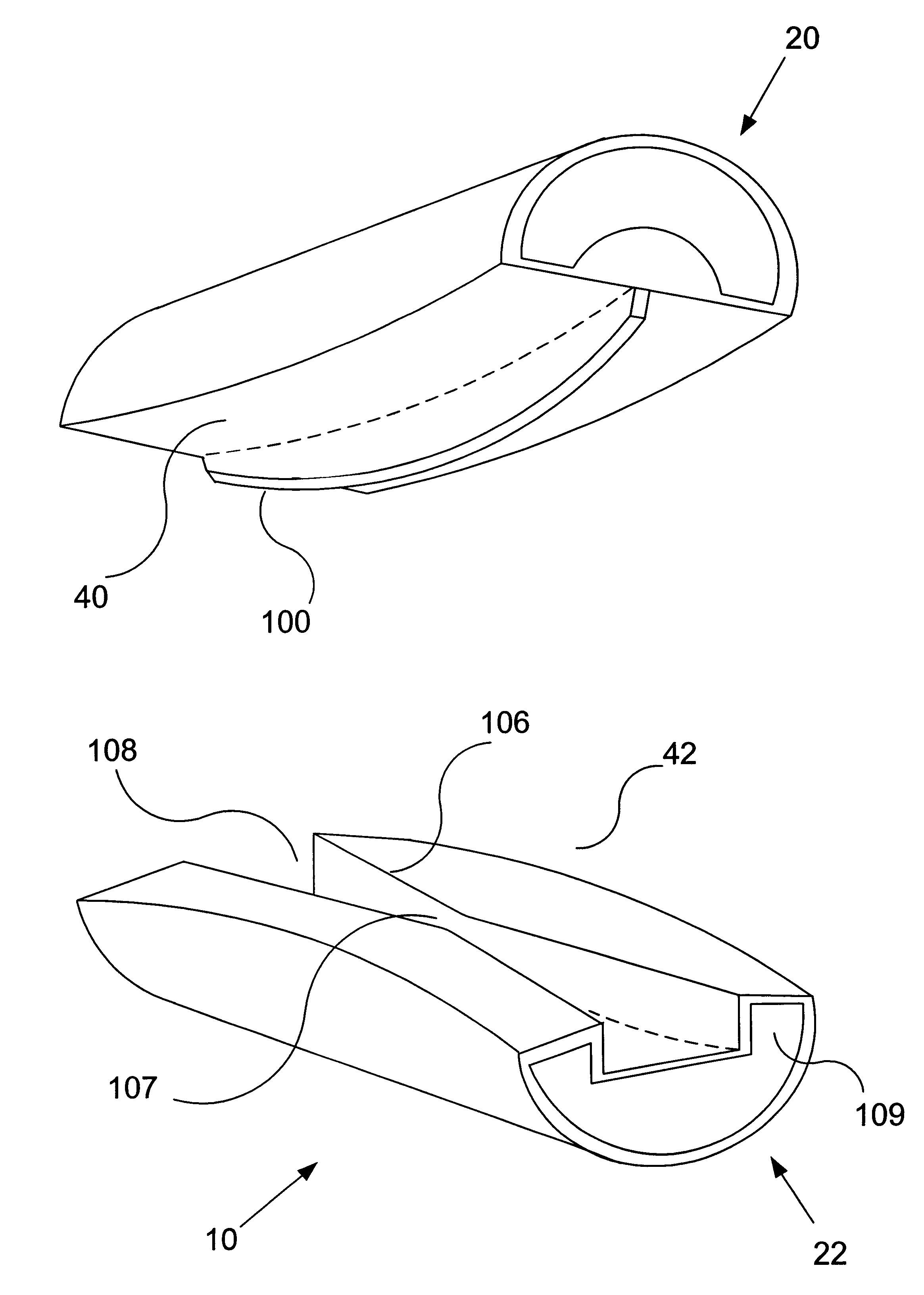

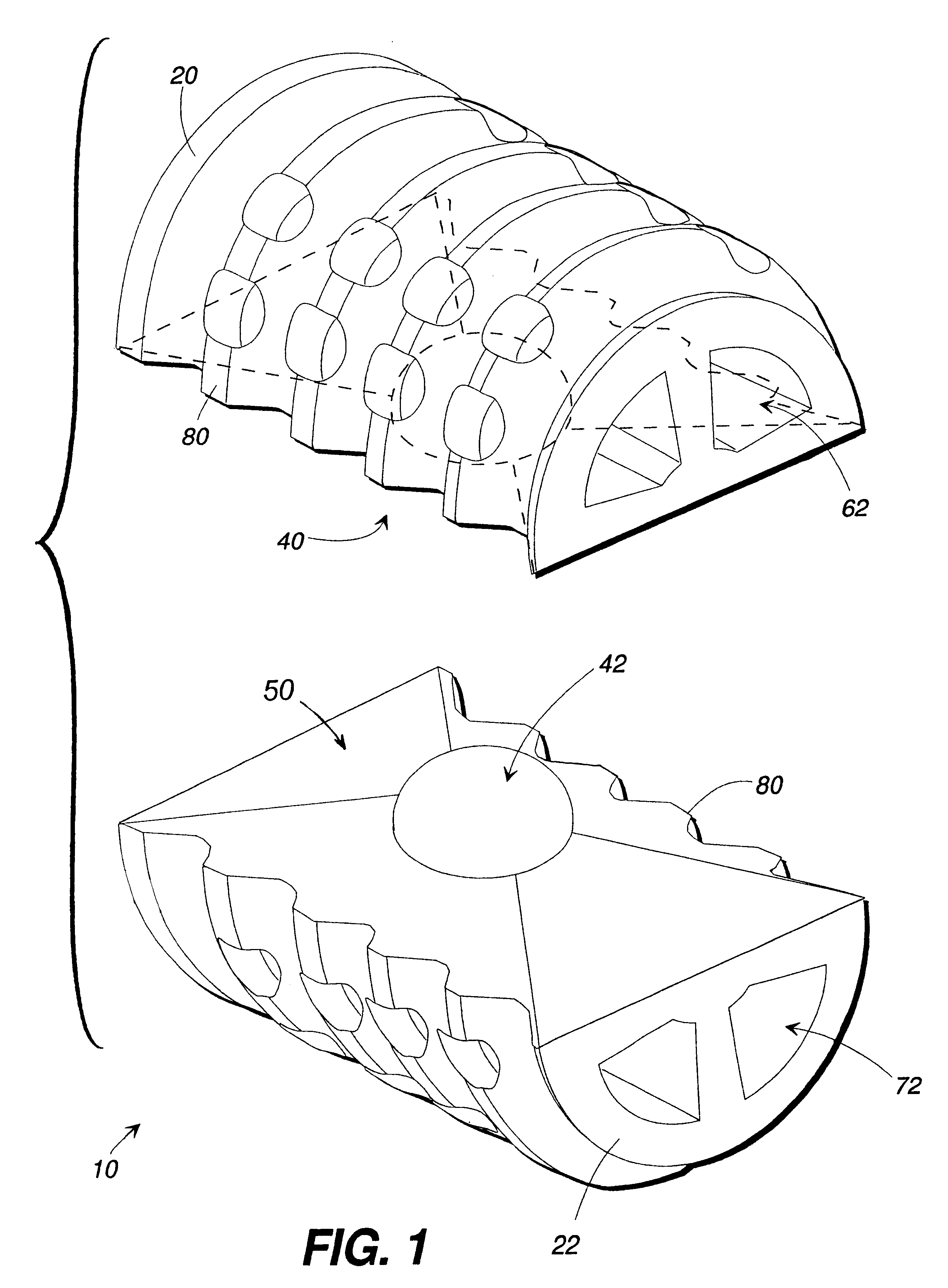

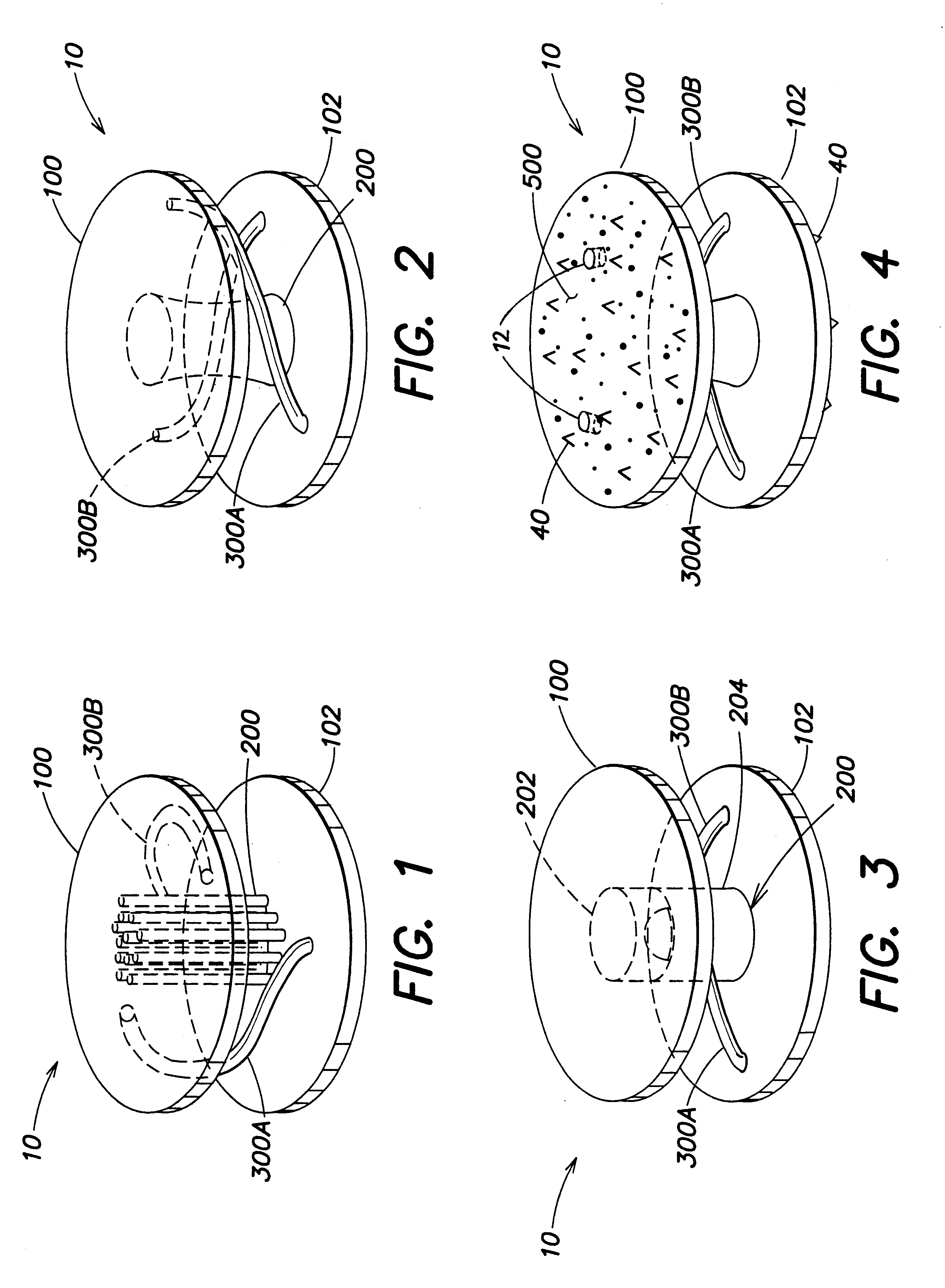

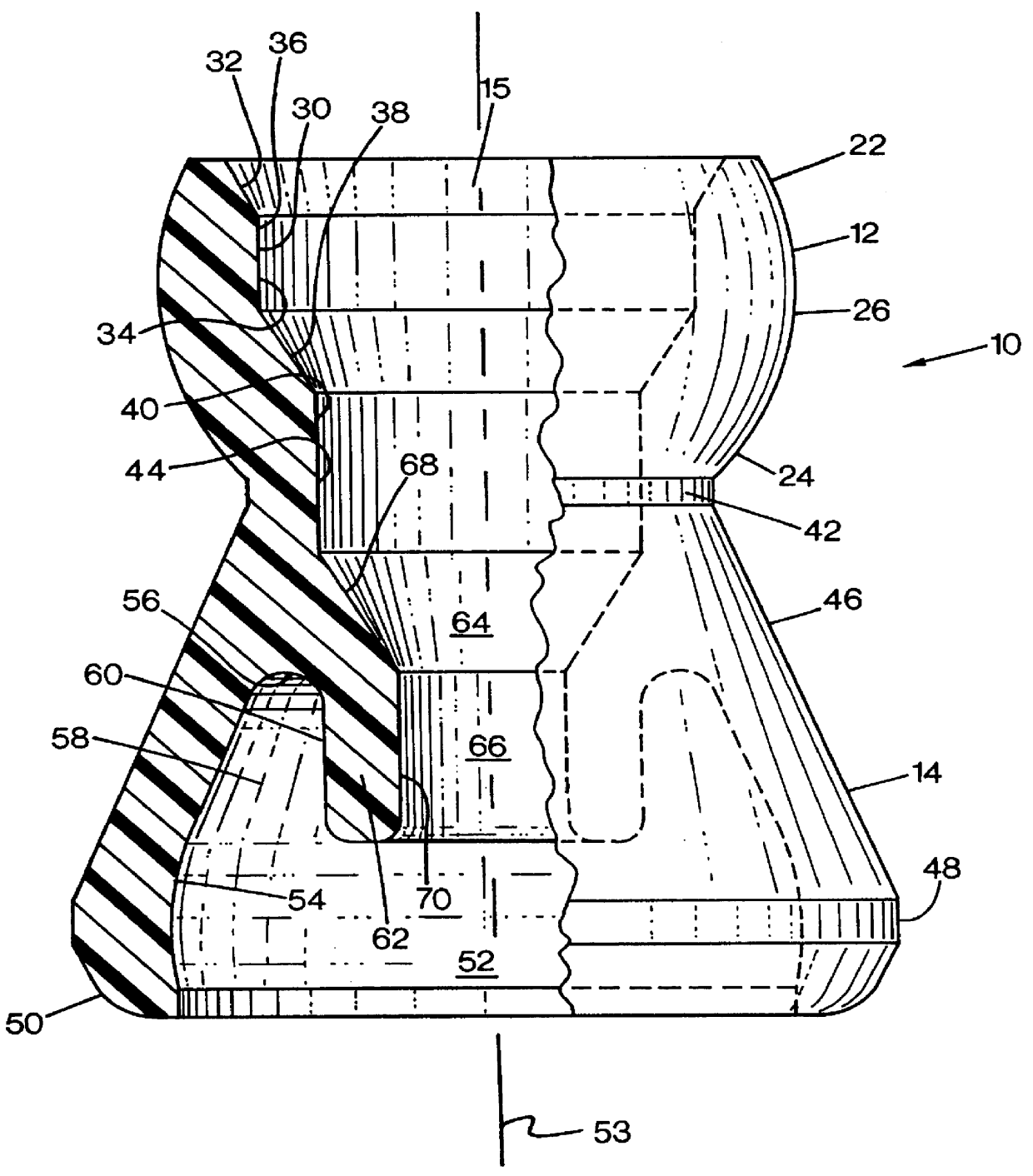

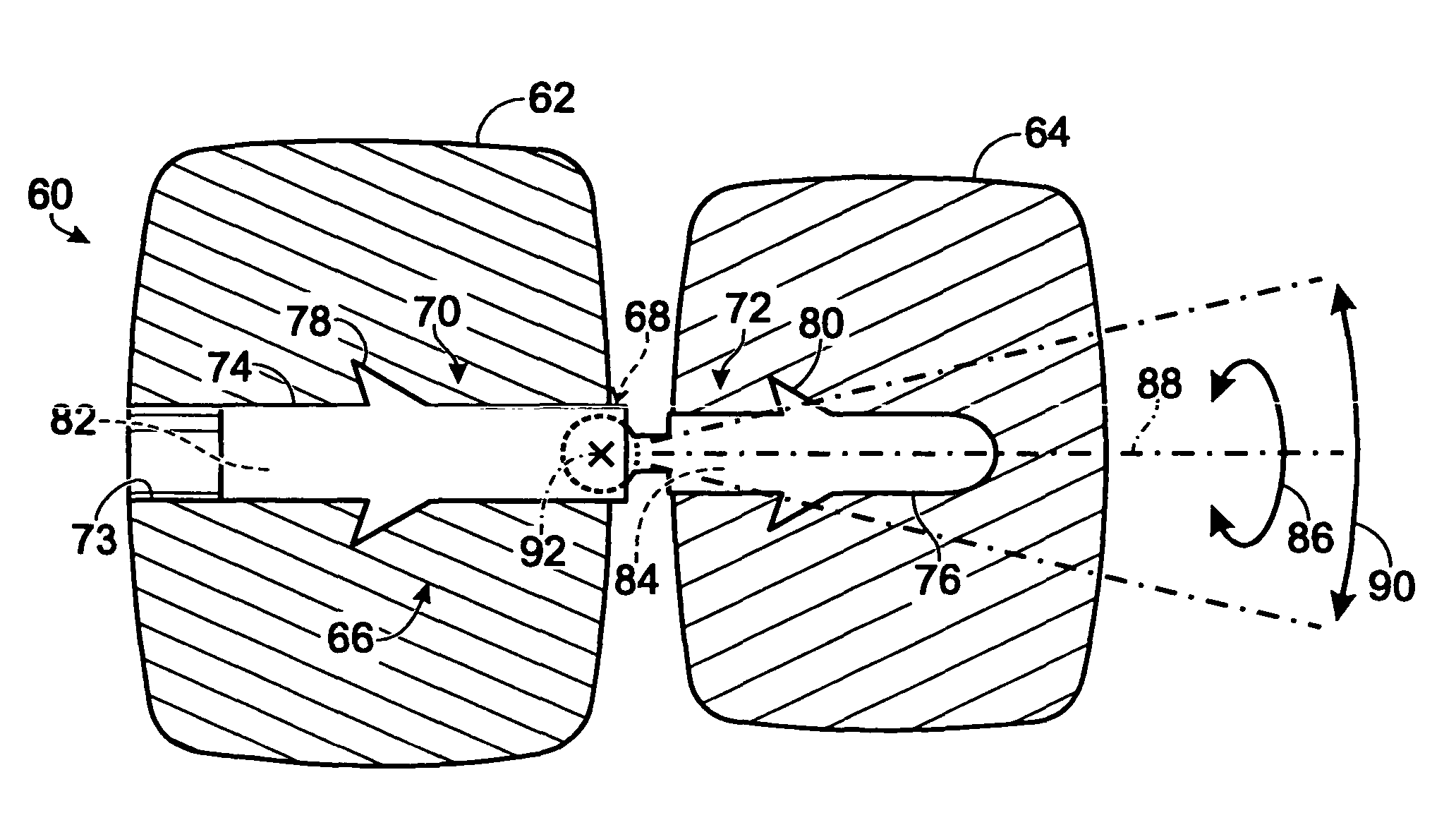

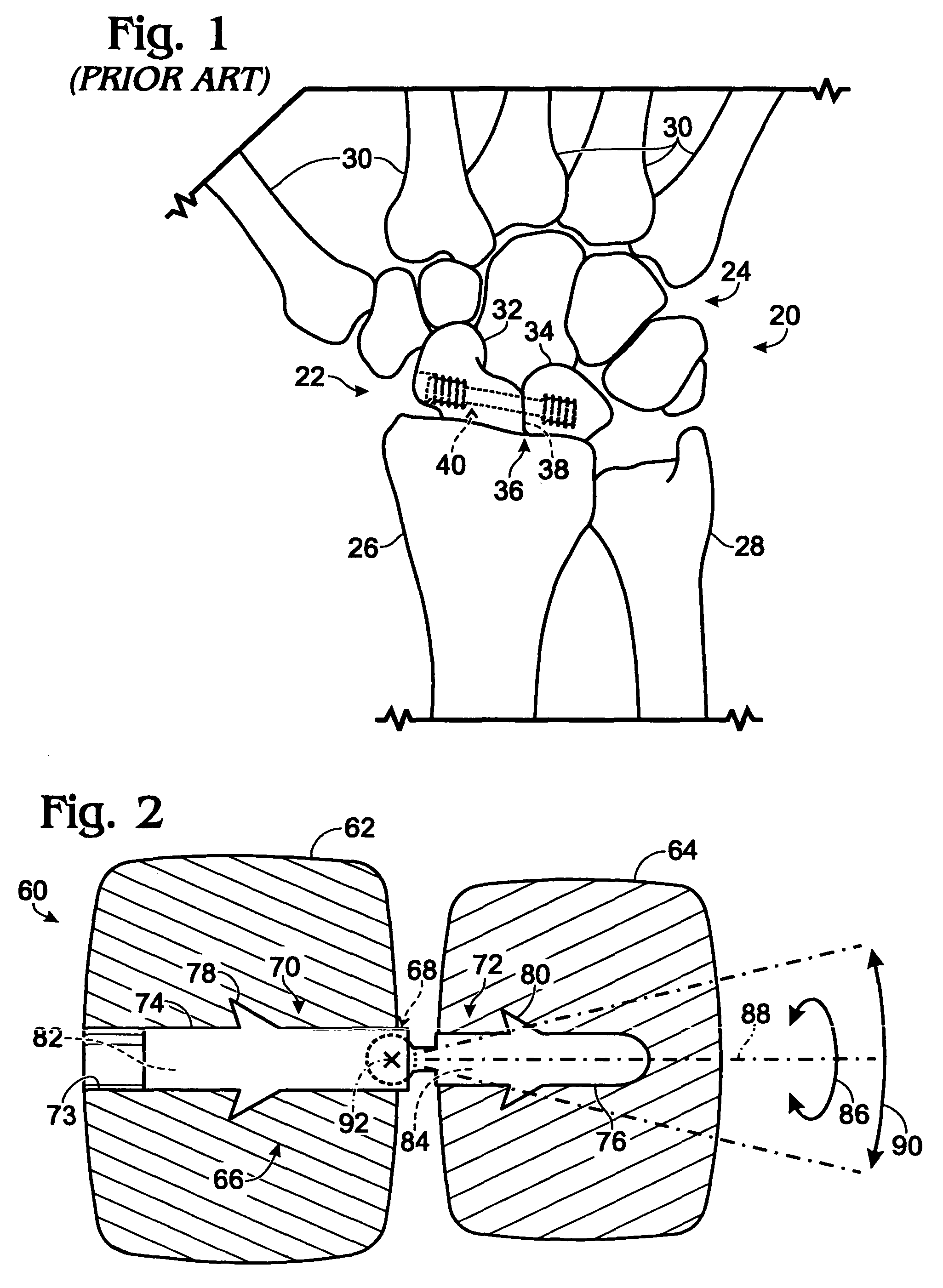

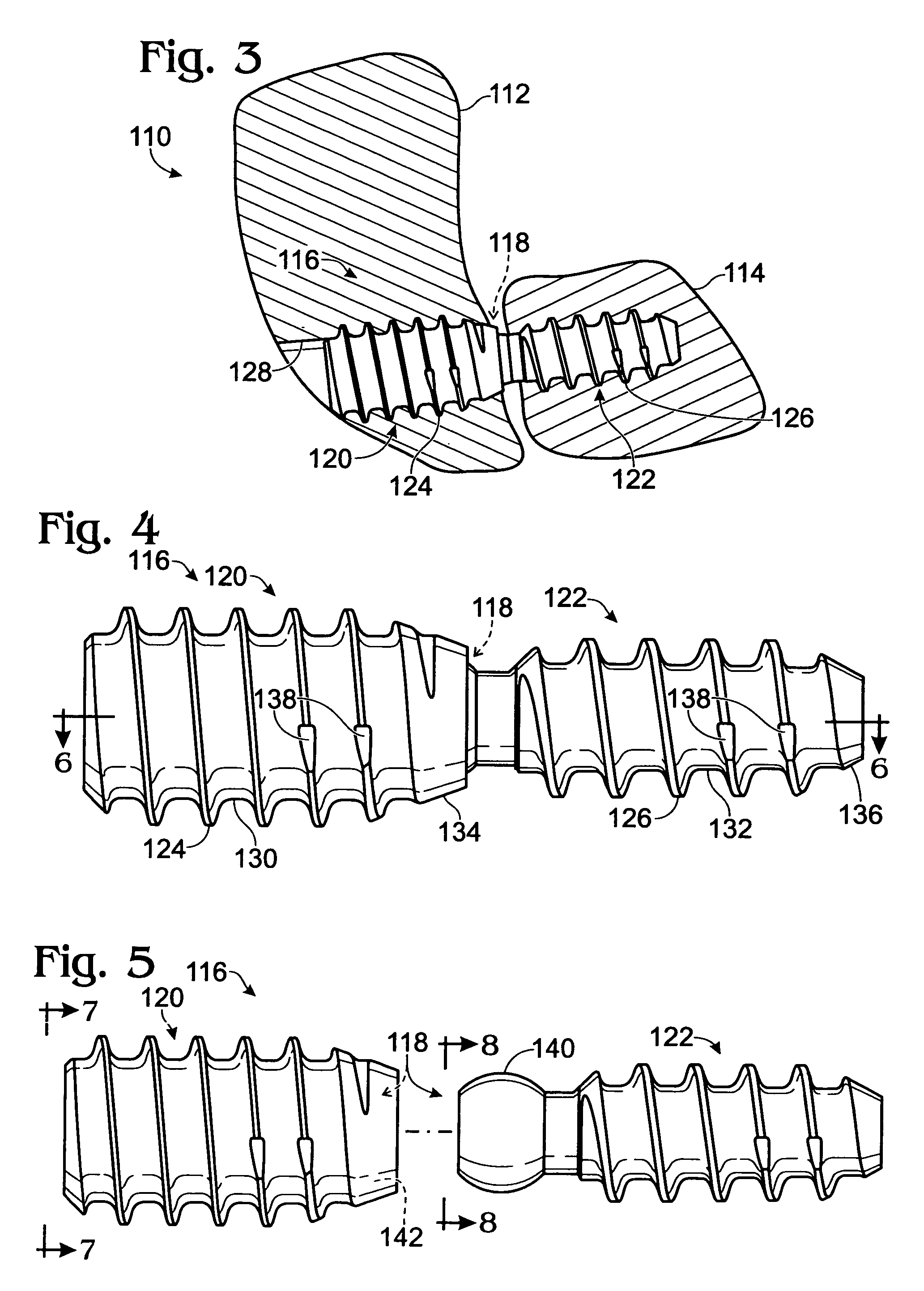

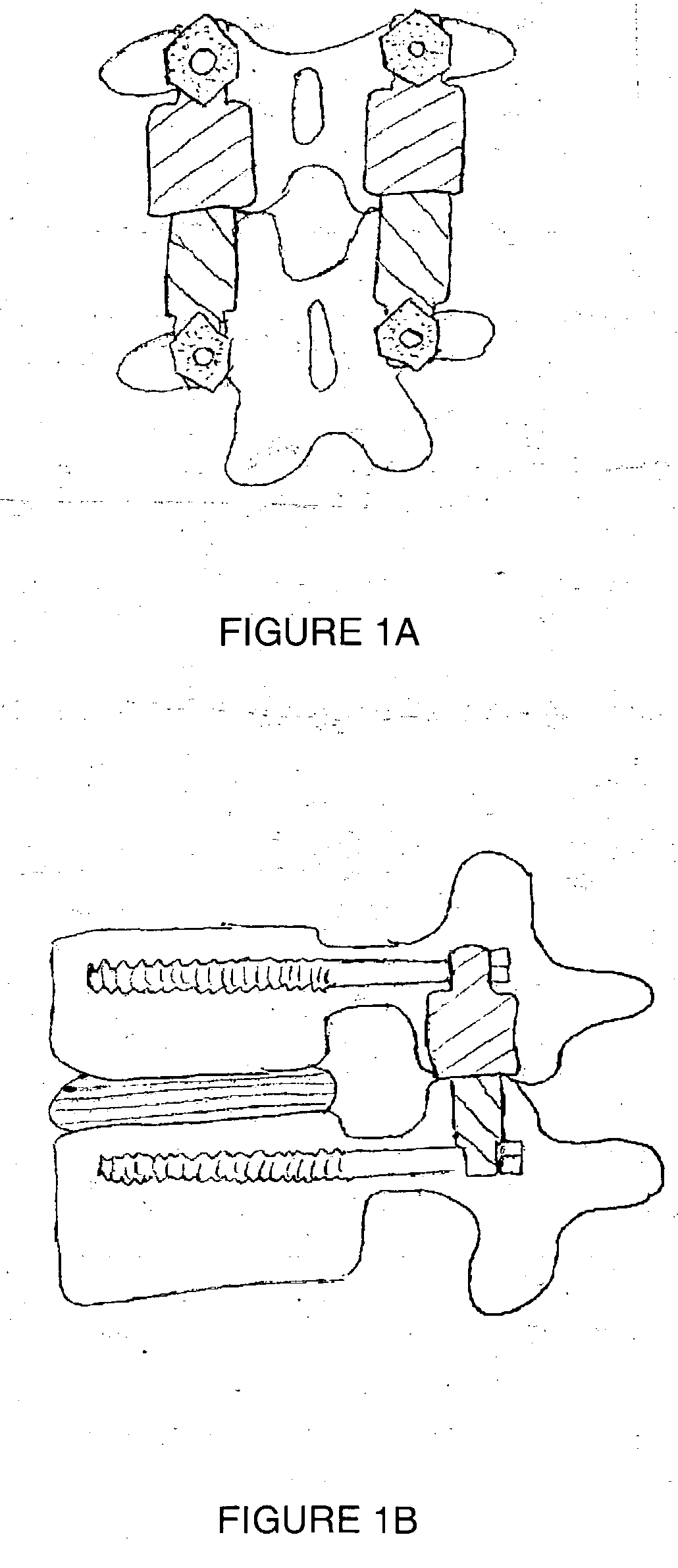

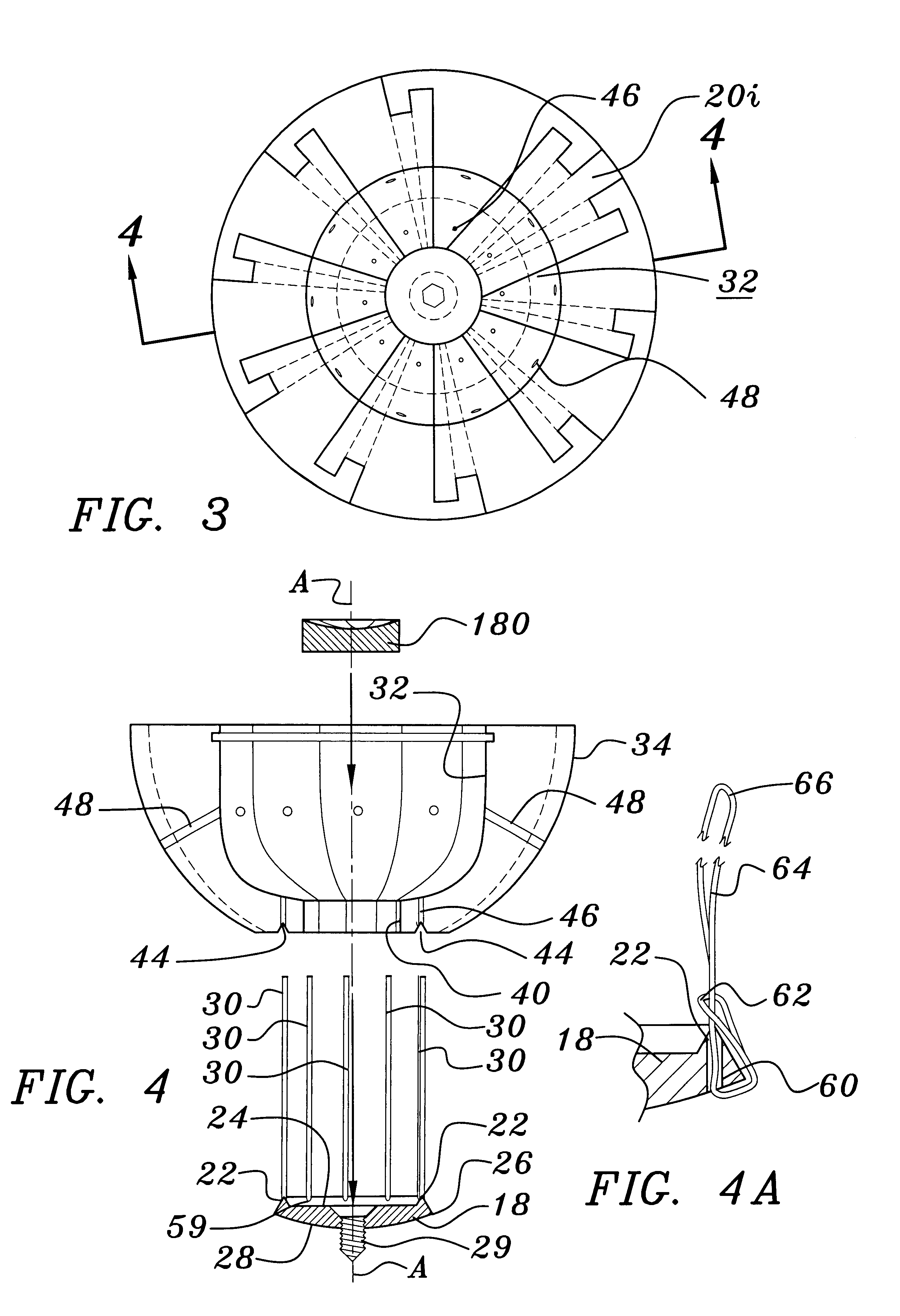

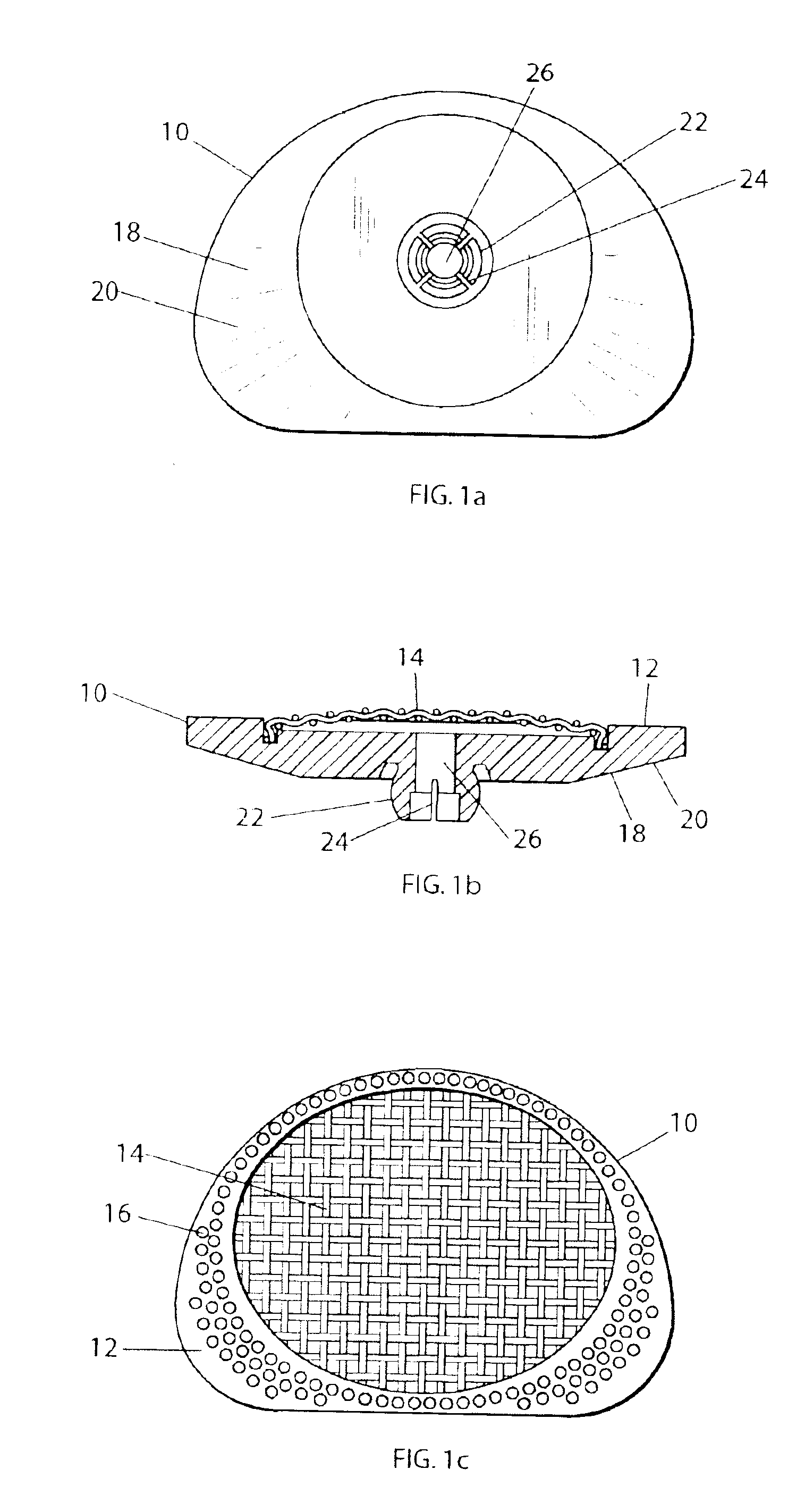

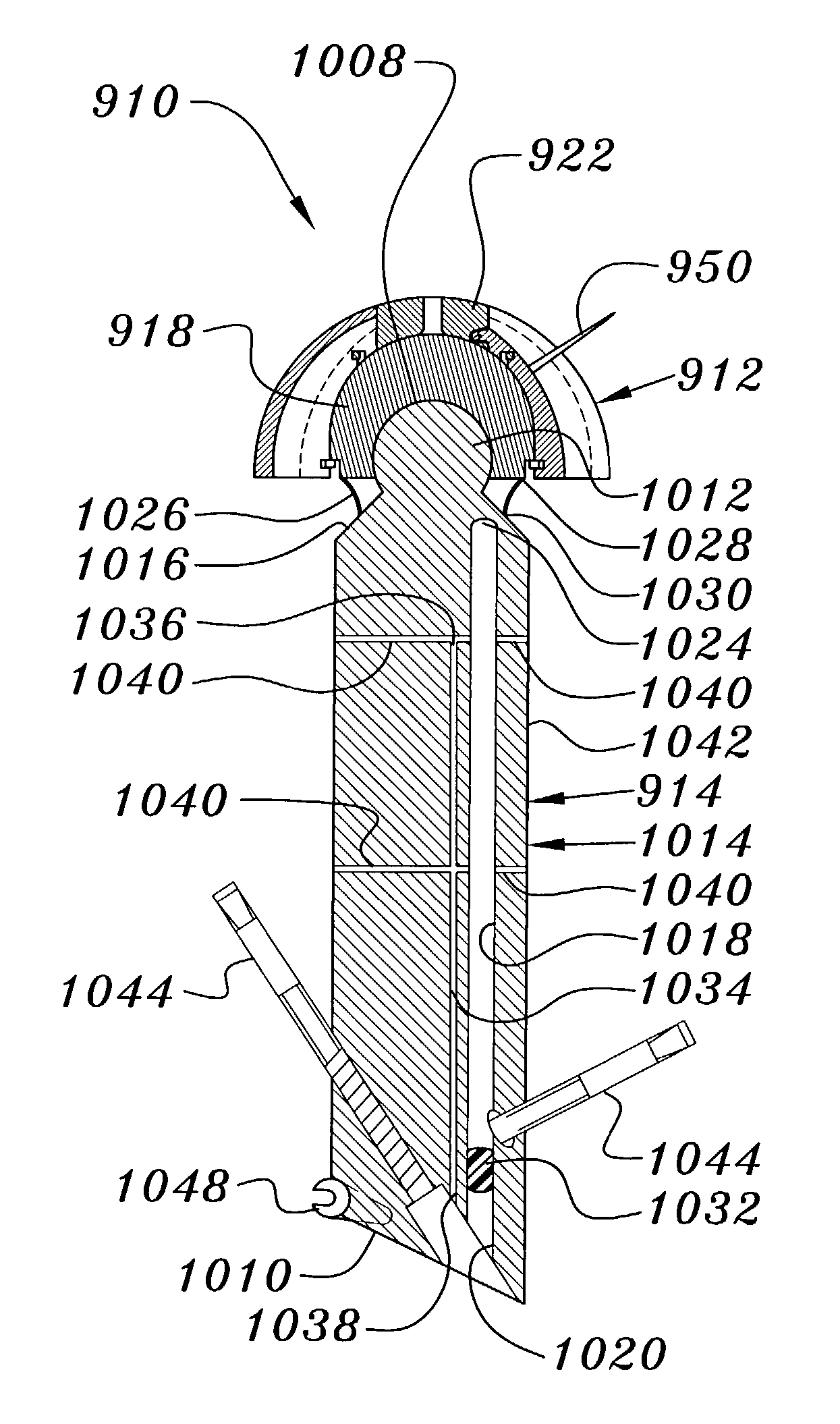

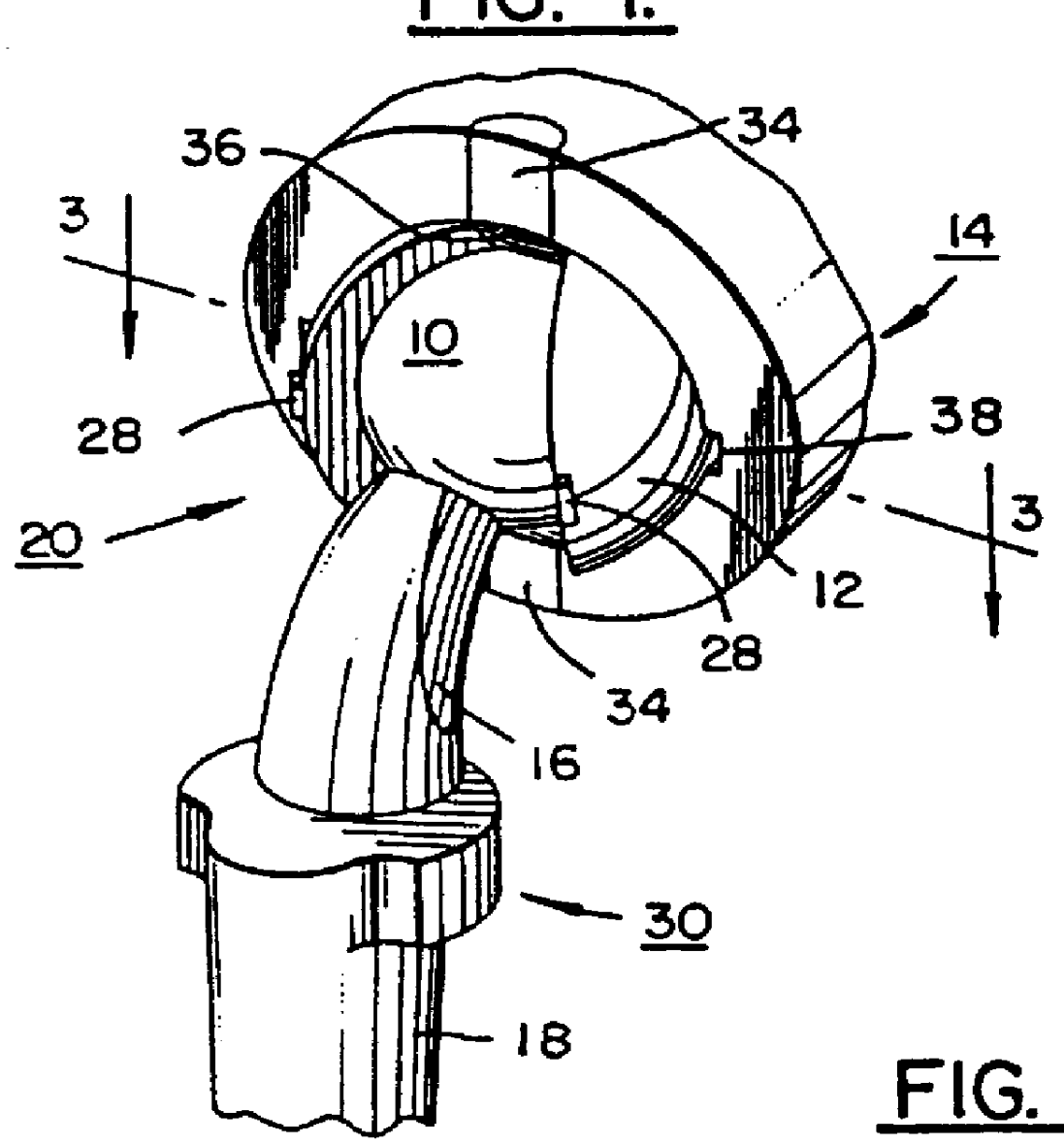

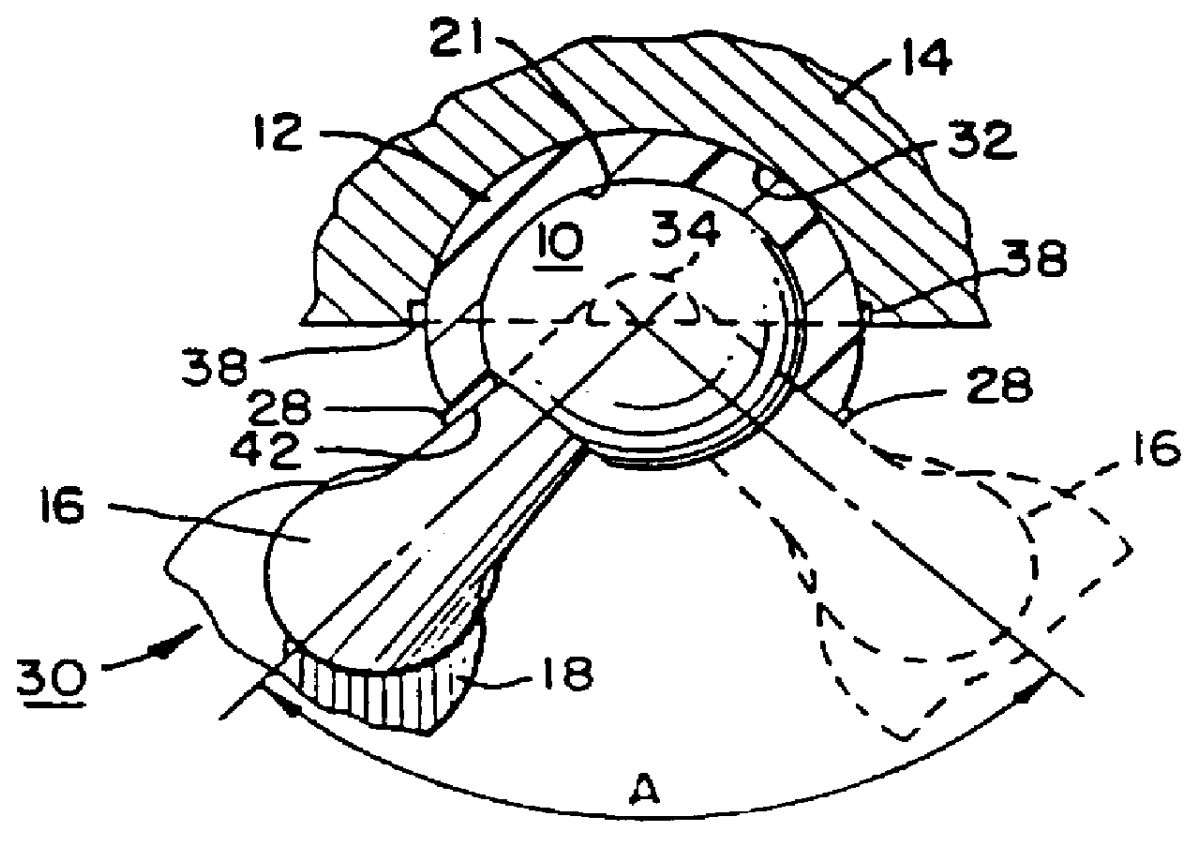

Articulating spinal implant

A spinal implant for intervertebral disc replacement. The implant is formed from two hemicylindrical elements, each engaging one of an adjacent pair of vertebrae. An articulating ball-and-socket joint between the two elements resists compression and lateral movement between the vertebra, but allows pivotal movement, thereby preserving mobility. Fusion chambers are provided for allowing bone ingrowth to fuse the elements to the vertebrae. Biocompatible, bioreabsorbable struts, shims, fillers and / or end caps are provided for temporary stabilization of the first and second hemicylindrical elements. Bone chips removed from the vertebrae during implantation or bone growth stimulators can be inserted into the fusion chamber or otherwise applied to the implant to enhance bone ingrowth.

Owner:WARSAW ORTHOPEDIC INC

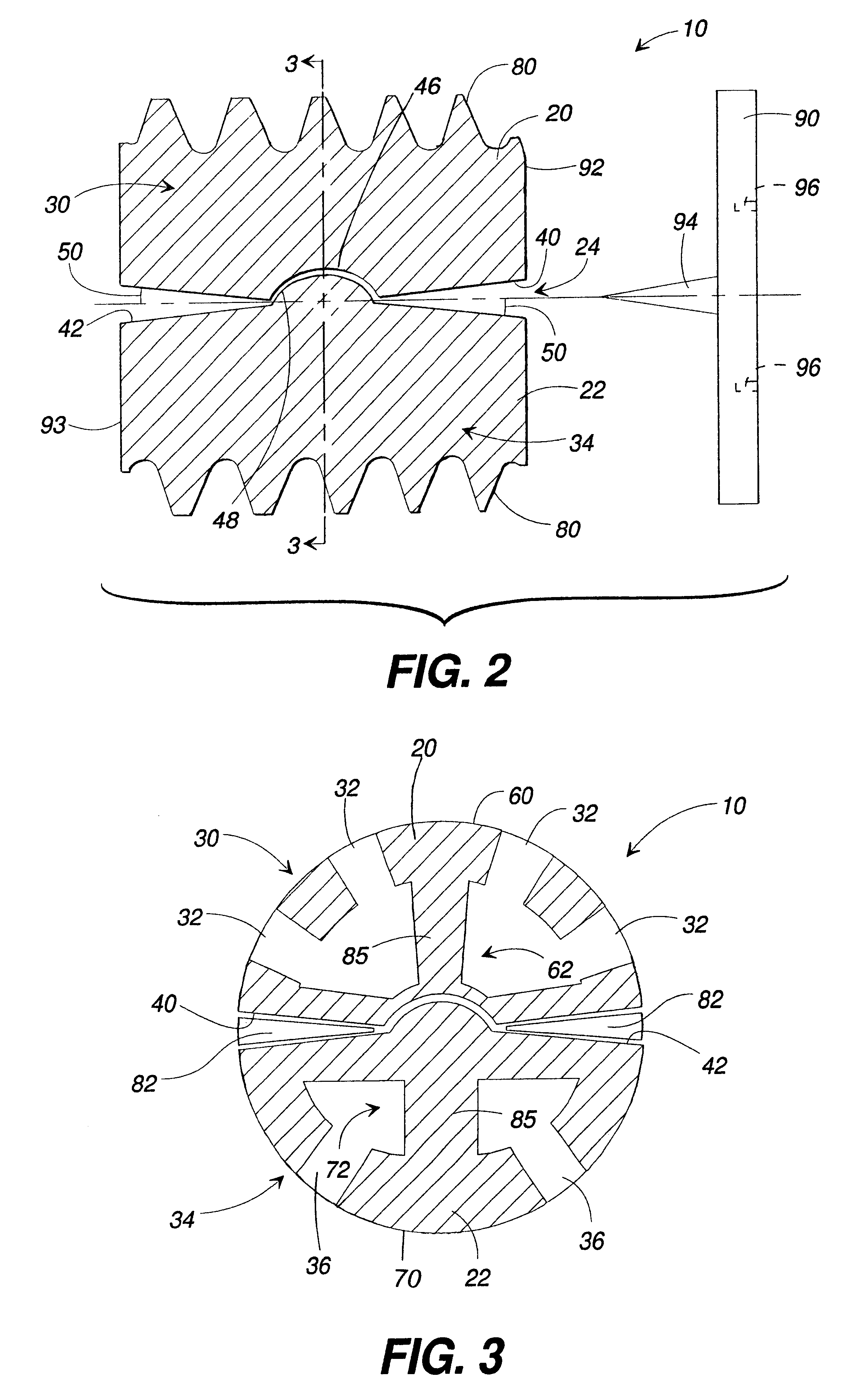

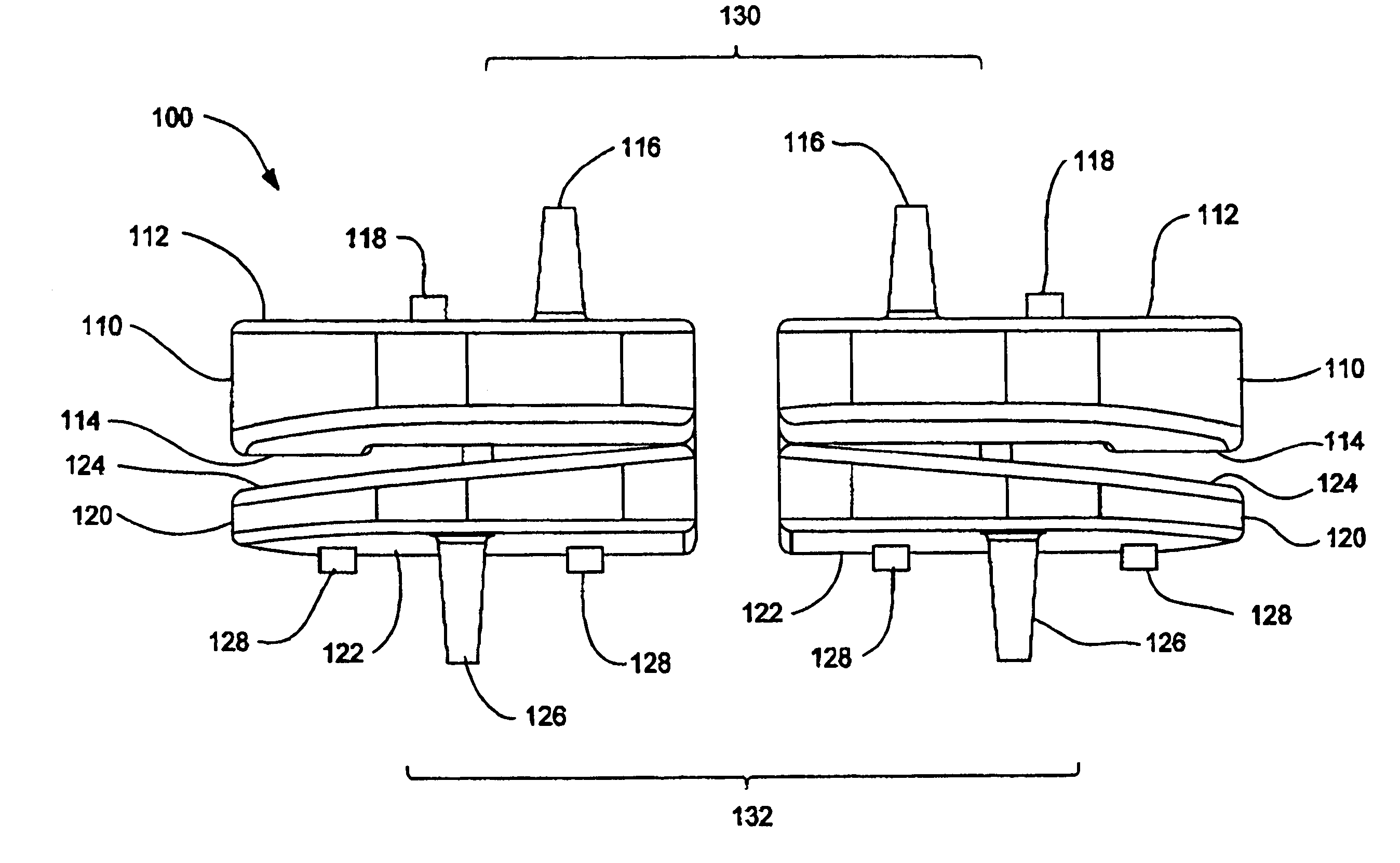

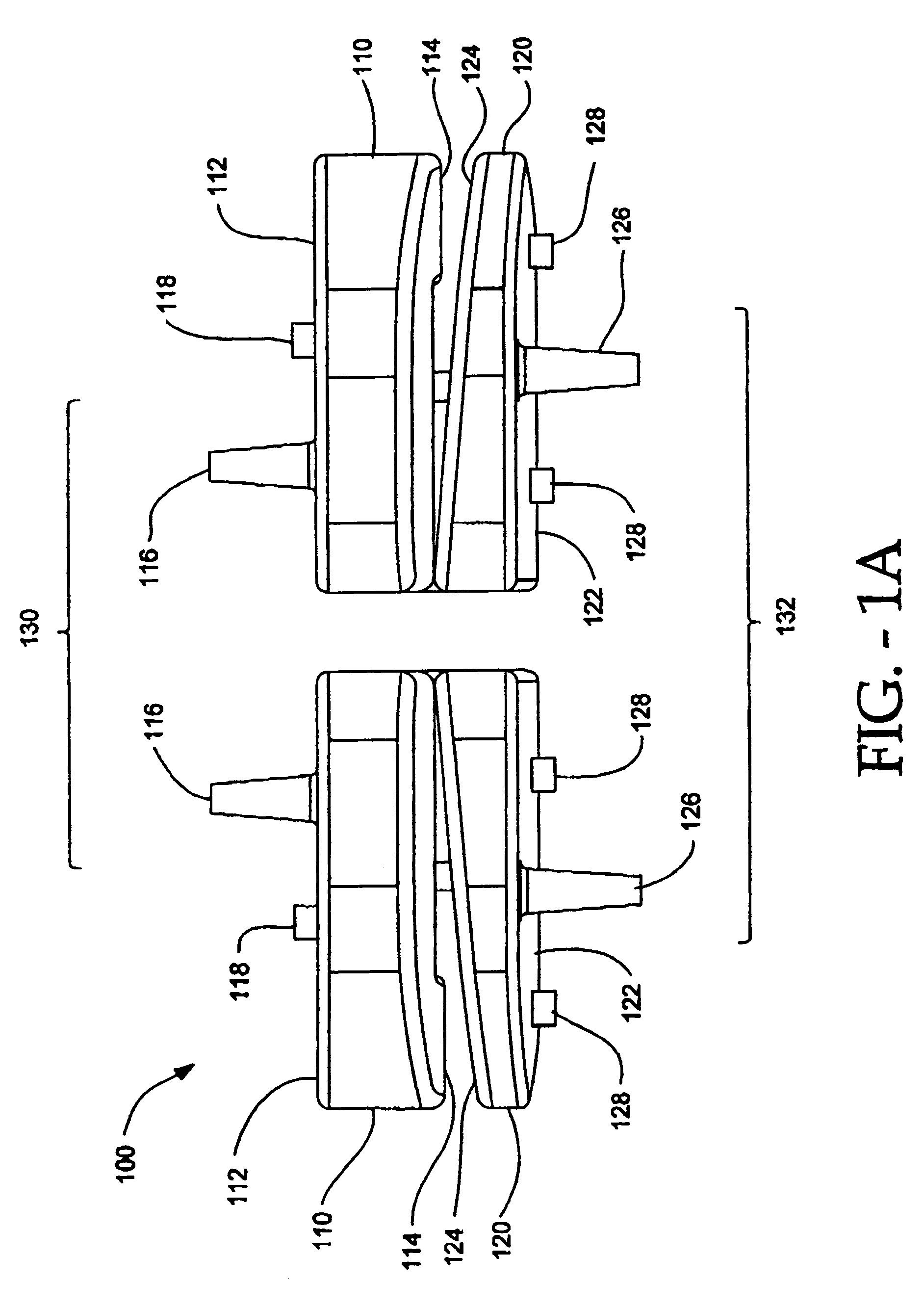

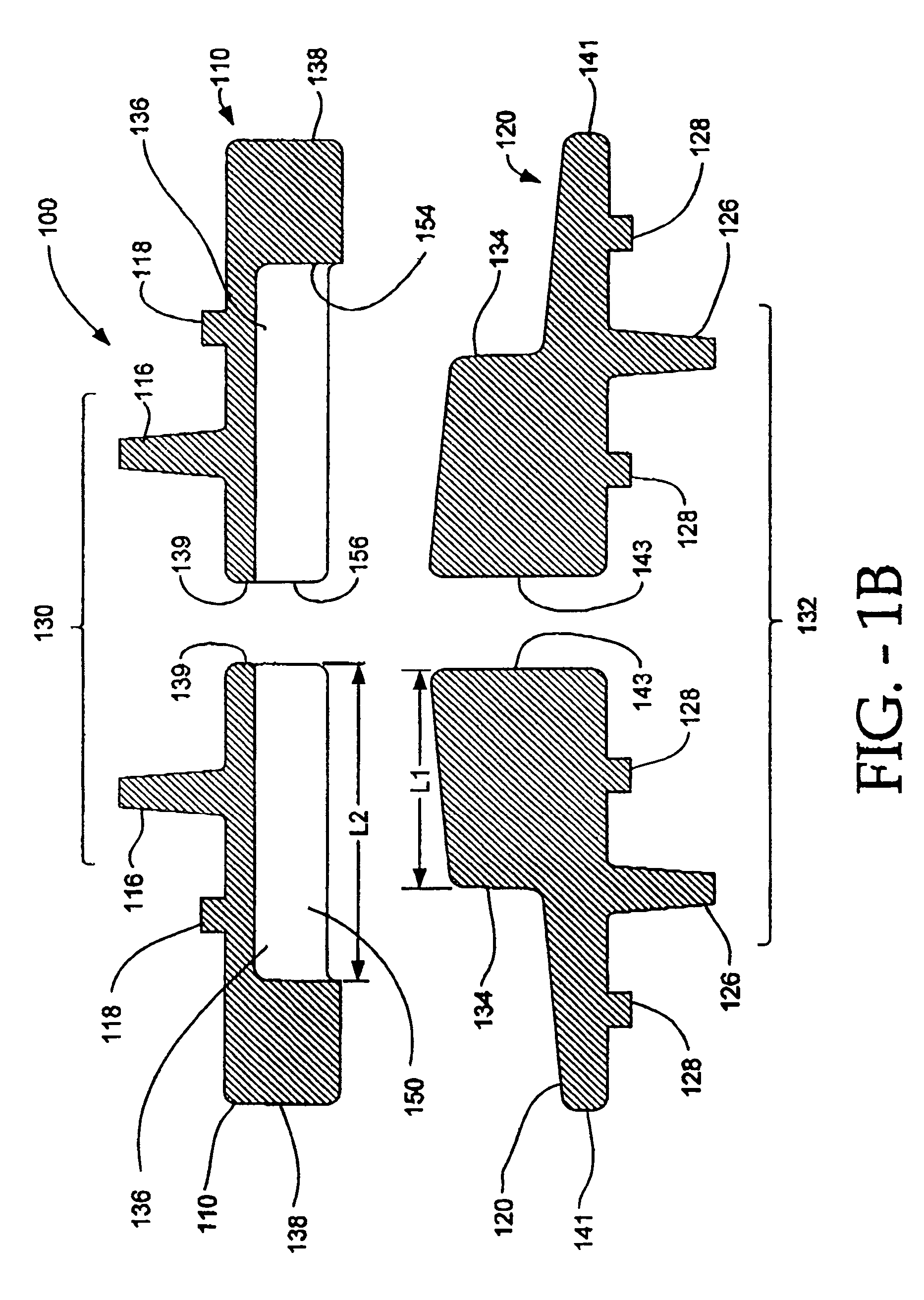

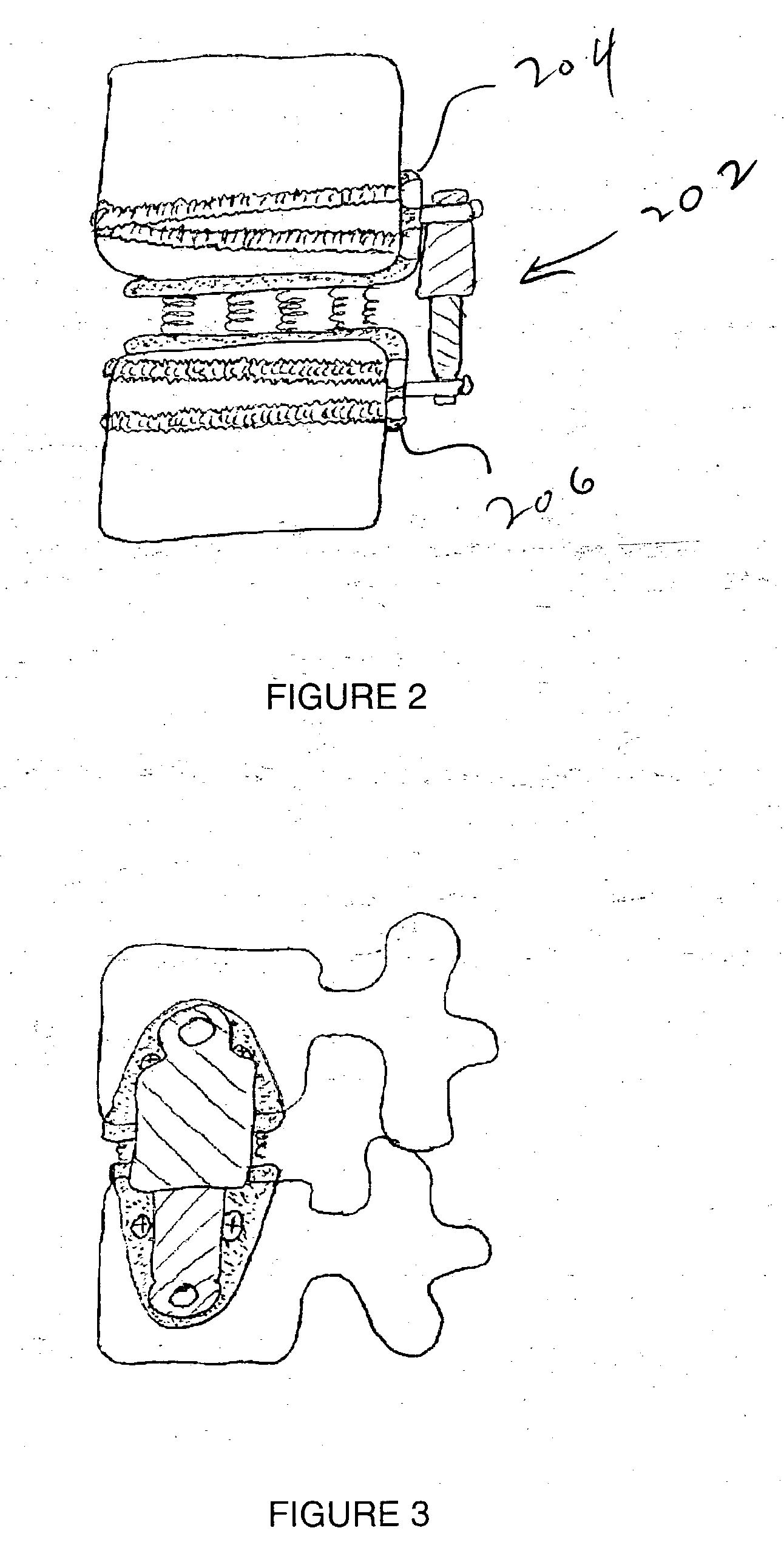

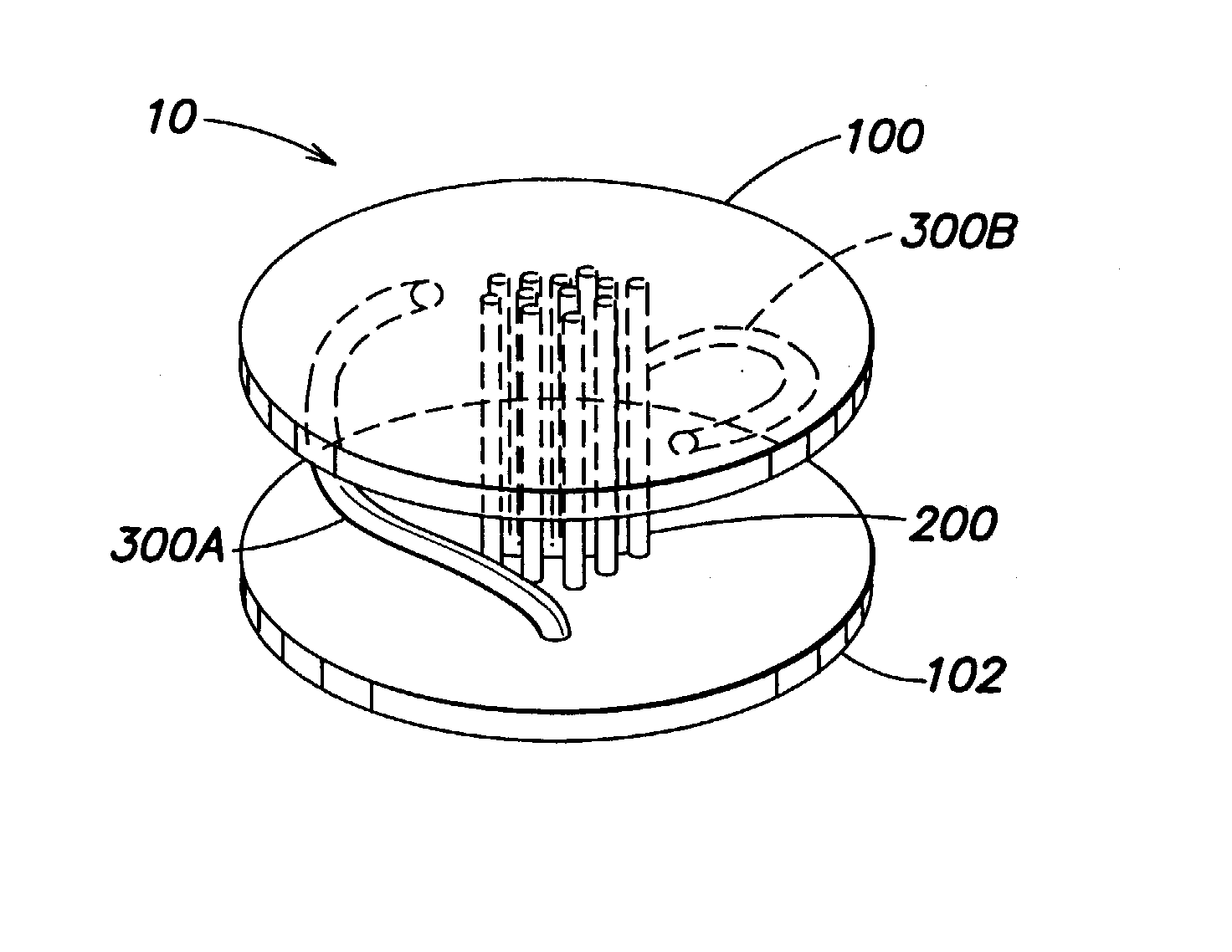

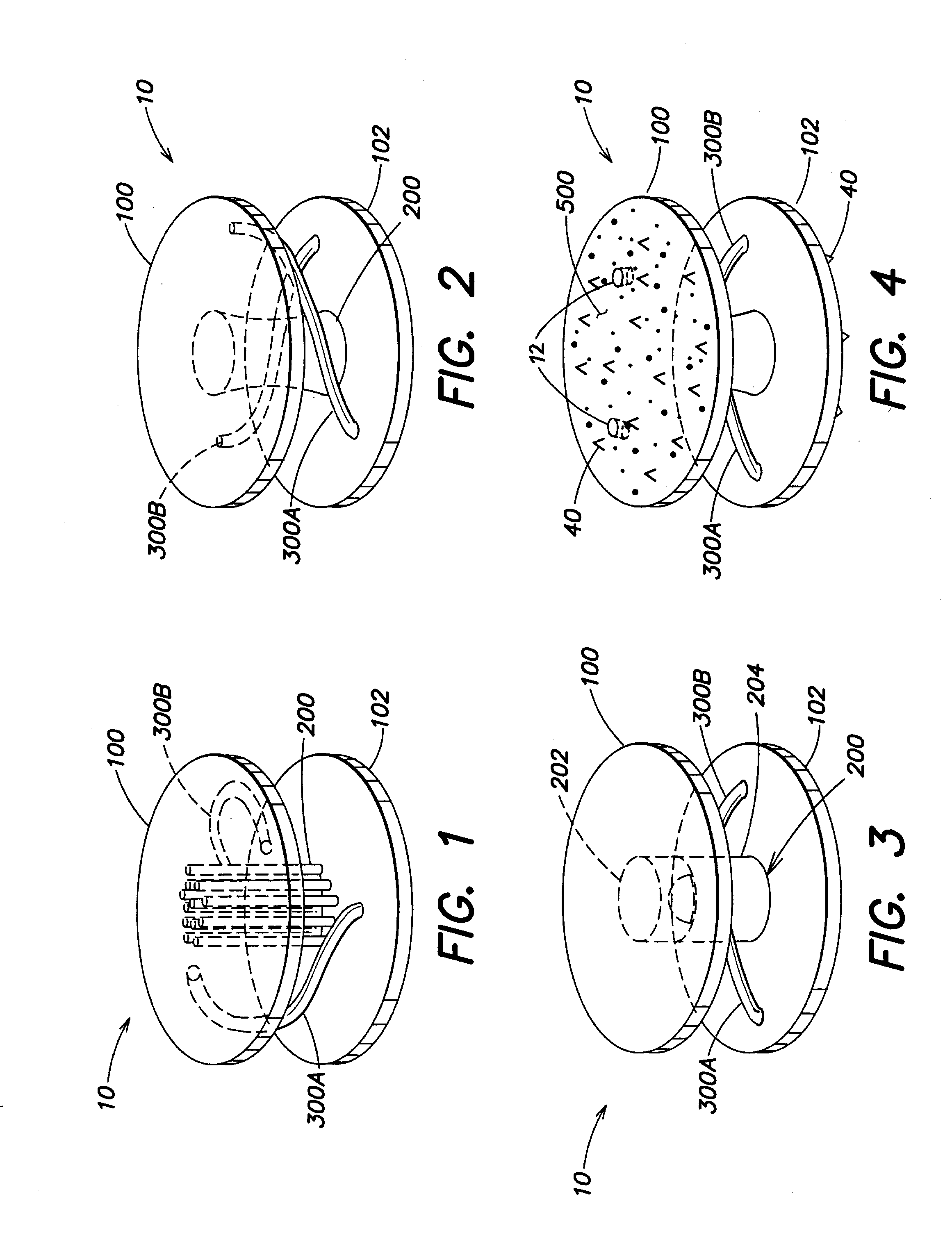

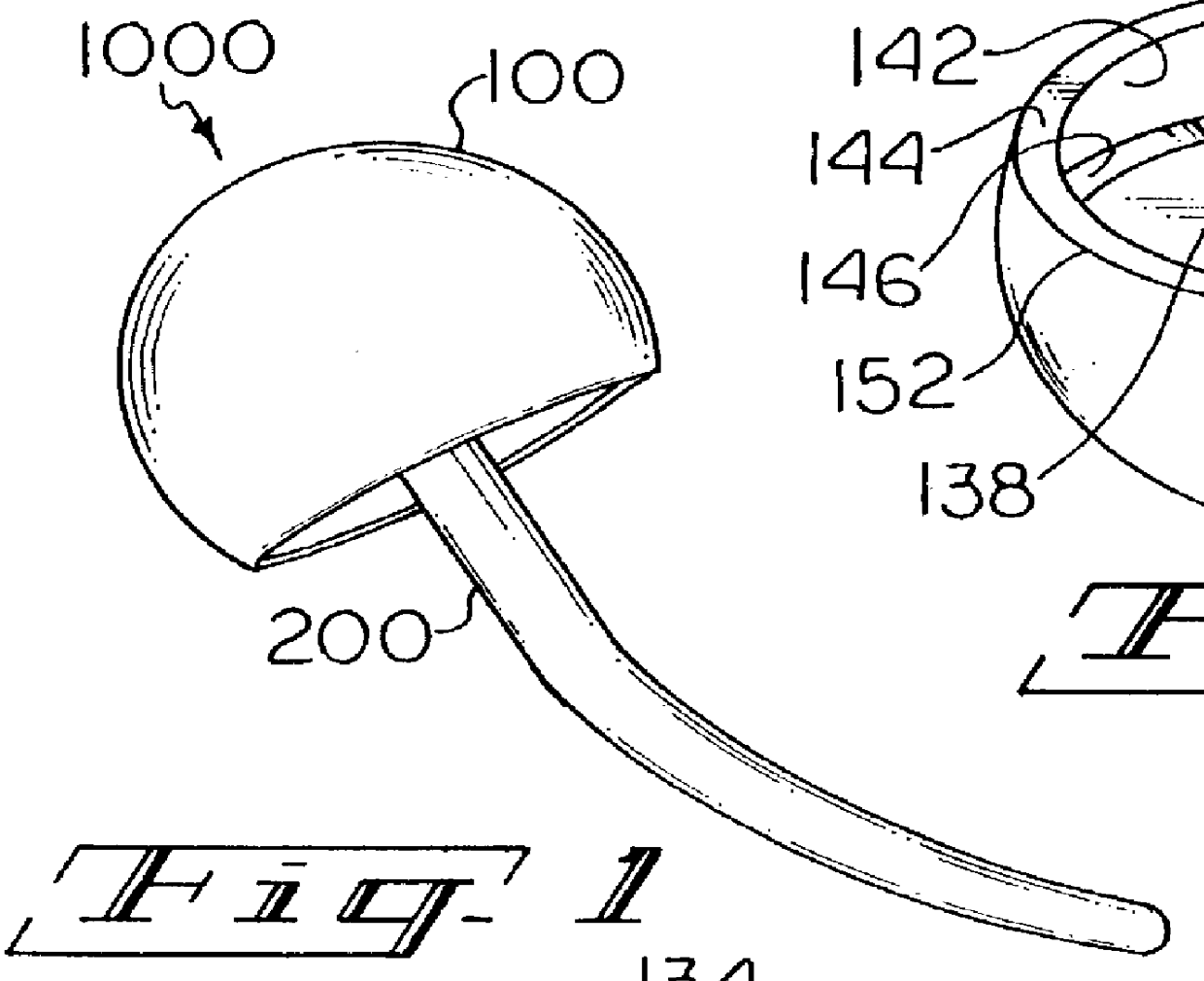

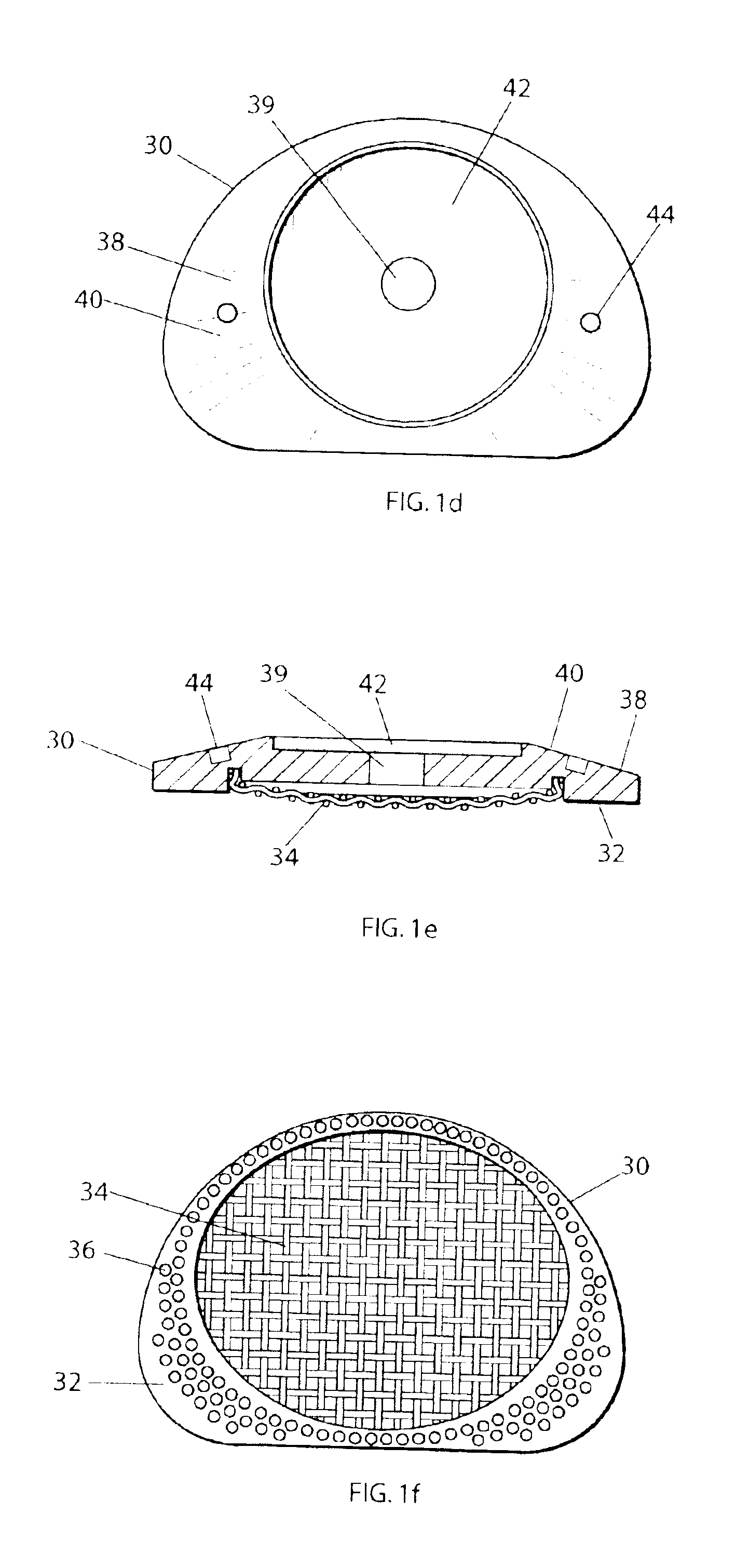

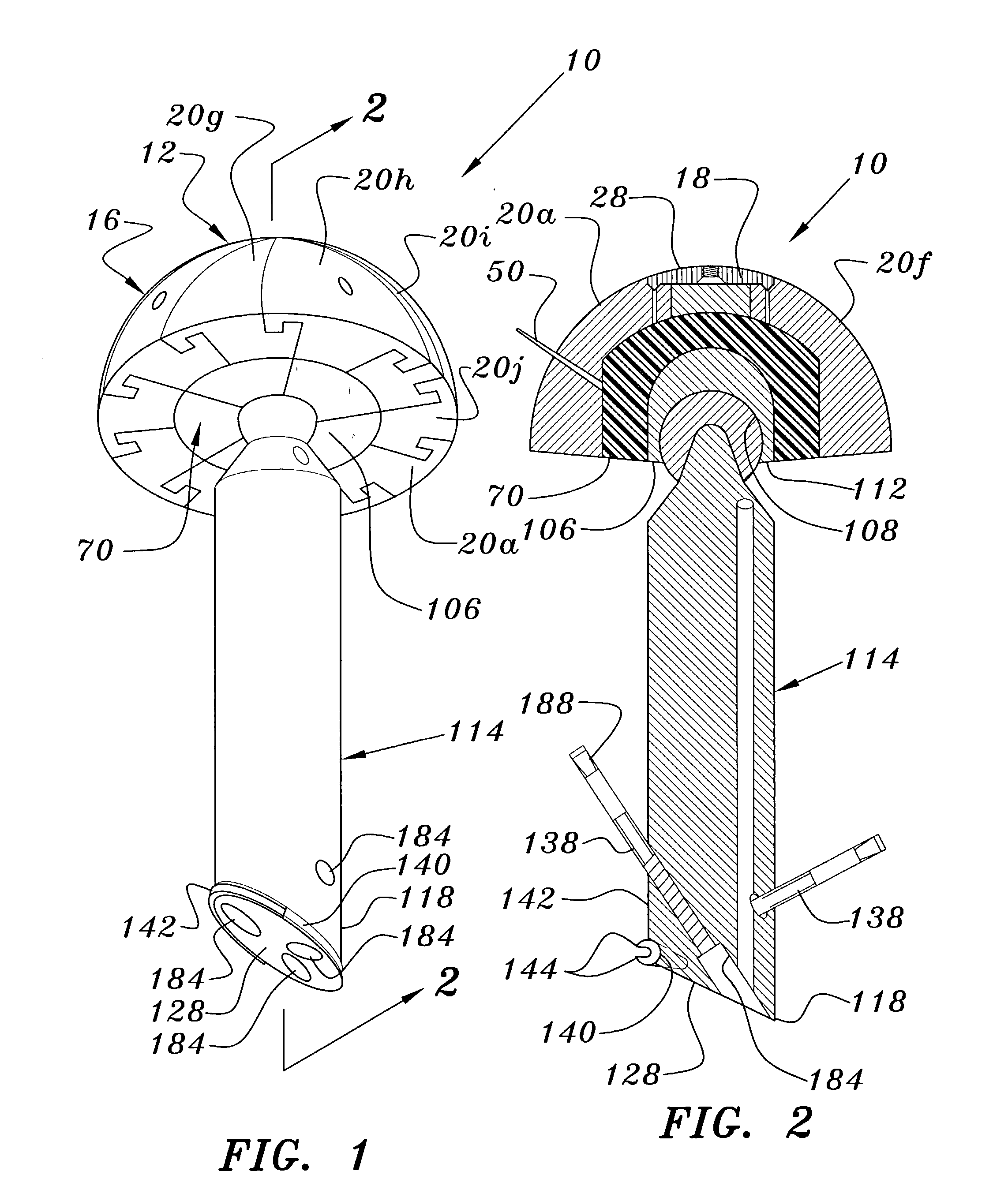

Orthopedic implant

Disclosed is an orthopedic implant suitable for arthroplasty procedures. The orthopedic implant includes a first plate, a second plate, an axial support between the first plate and the second plate and one or more torsional supports connecting the first plate and the second plate. The axial support may be, for example, one or more flexible struts, such as cables, or a ball and socket joint. The torsional supports connect the first and second plates and may be, for example, curved around the axial support. The torsional supports may be integrally formed with the first and second plates as a single unitary device, by, for example, a Laser Engineered Net Shape (LENS) process.

Owner:DEPUY ACROMED INC

Articulating spinal implant

A spinal implant for intervertebral disc replacement. The implant is formed from two hemicylindrical elements, each engaging one of an adjacent pair of vertebrae. An articulating ball-and-socket joint and / or rocker and channel between the two elements resists compression and lateral movement between the vertebra, but allows pivotal movement, thereby preserving mobility. Fusion chambers are provided for allowing bone ingrowth to fuse the elements to the vertebrae. Biocompatible, bioreabsorbable struts, shims, fillers and / or end caps are provided for temporary stabilization of the first and second hemicylindrical elements. Bone chips removed from the vertebrae during implantation or bone growth stimulators can be inserted into the fusion chamber or otherwise applied to the implant to enhance bone ingrowth.

Owner:WARSAW ORTHOPEDIC INC

Artificial vertebral disk replacement implant with translating pivot point

An artificial vertebral disk replacement implant is disclosed along with its method of operation and a method of implanting. The implant has first and second plates that each mate with a vertebral body. Each plate has one side for mating with a vertebral body. The first plate has a socket on one side, and the second plate has an elongated ball on one side. The ball of the first plate and the socket of the second plate form a ball-and-socket joint when the two plates are in contact with each other. The implant achieves a range of motion equivalent to a natural range of motion.

Owner:KYPHON

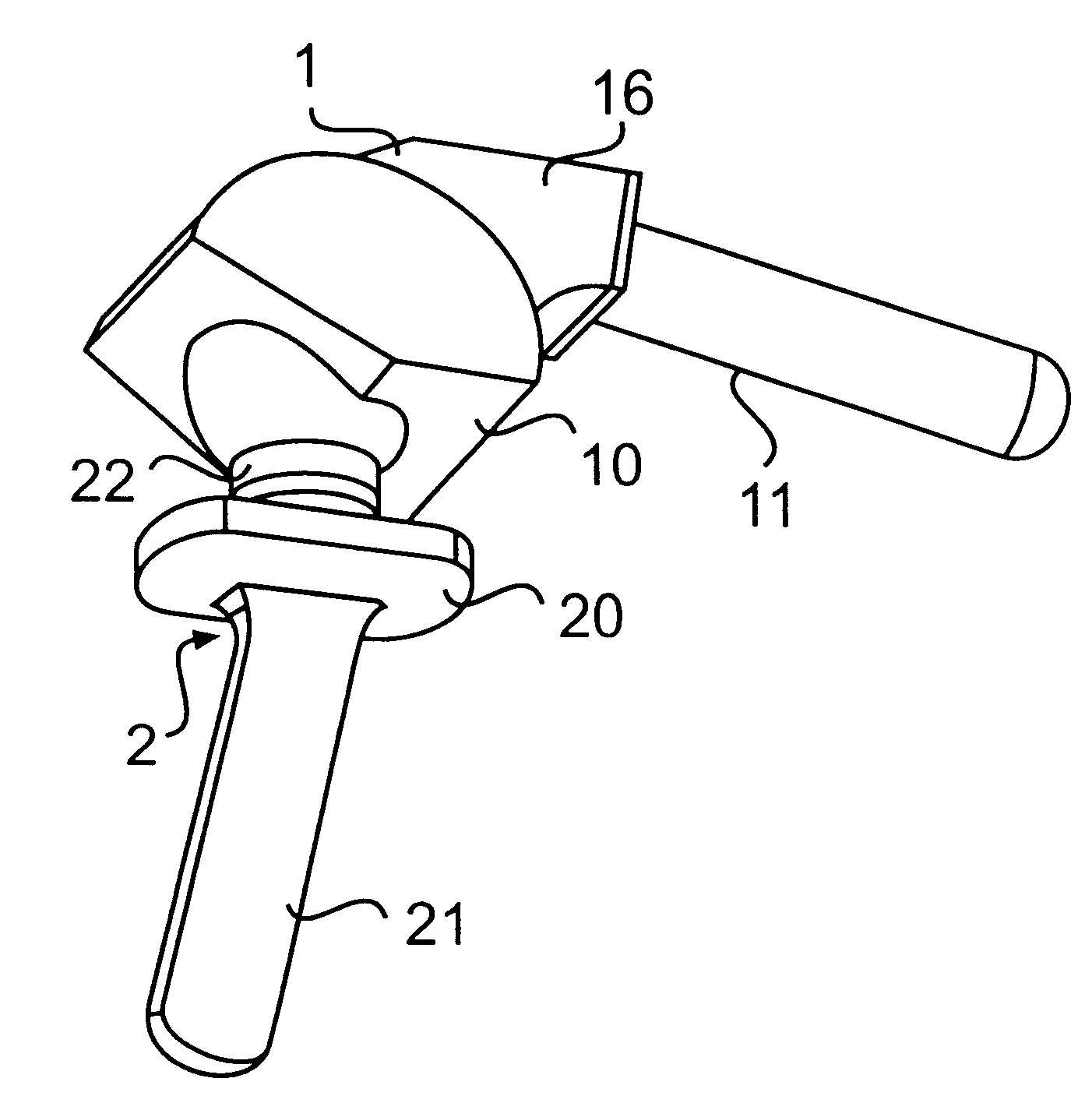

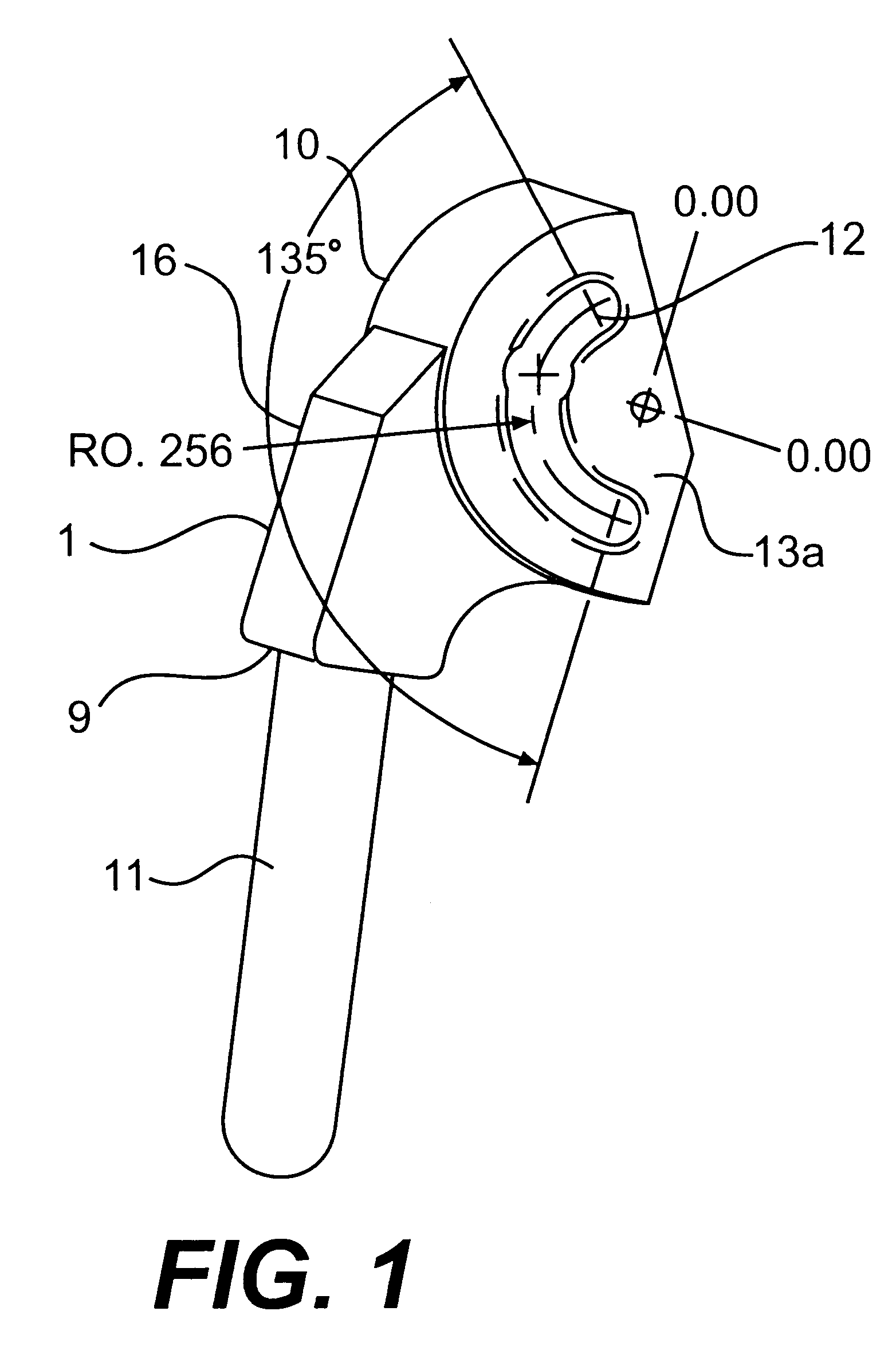

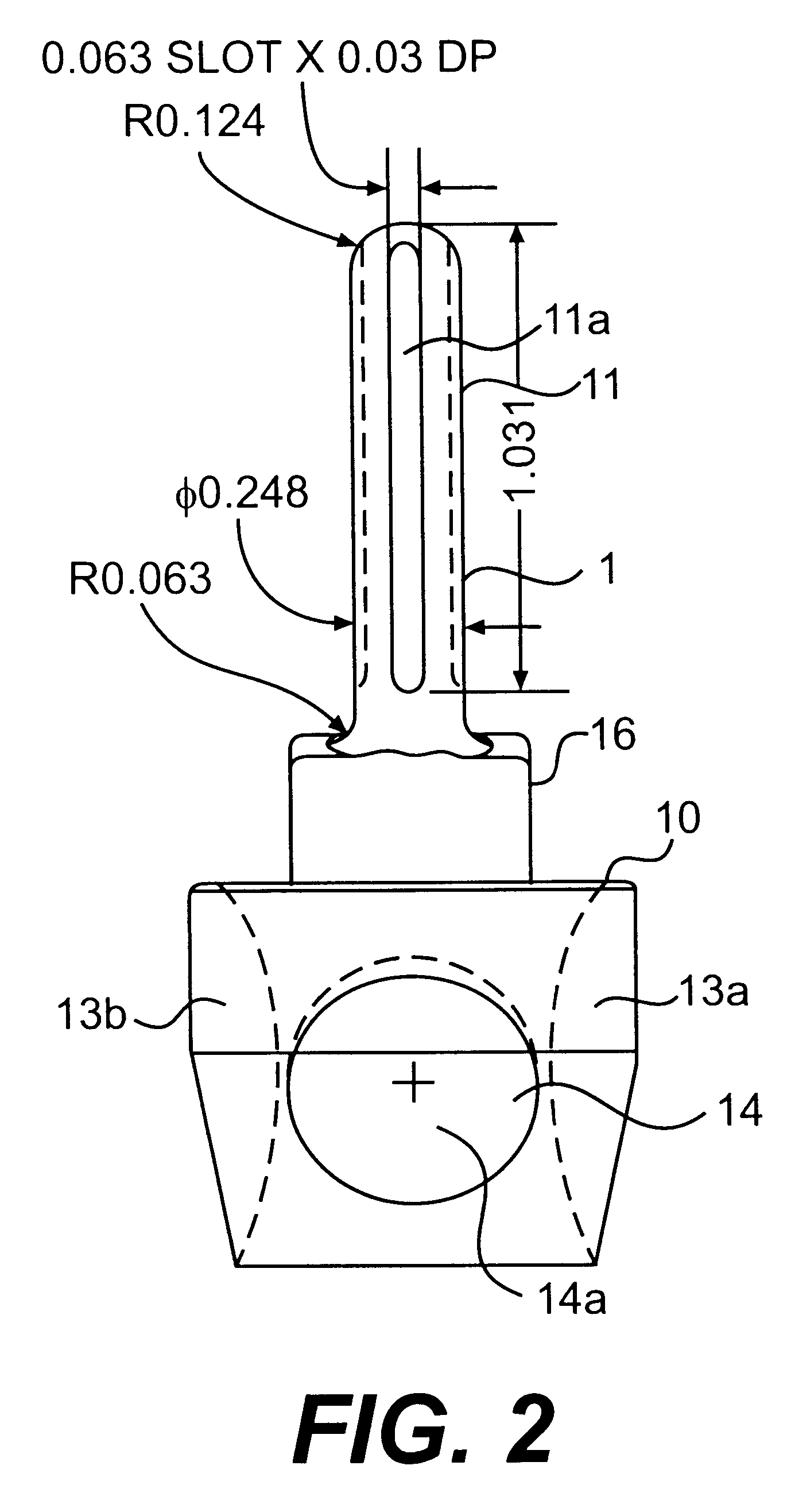

Ball and socket joint with internal stop

A first connector includes opposite ball and socket elements having a passageway formed therethrough. The socket element has a cavity formed therein for receiving a ball element of a second hose connector to form a hose assembly. A ring is disposed within the cavity for limiting pivotal movement of a ball element inserted therein to minimize the risk that the connectors, and thereby the hose assembly, will separate.

Owner:LOCKWOOD PROD

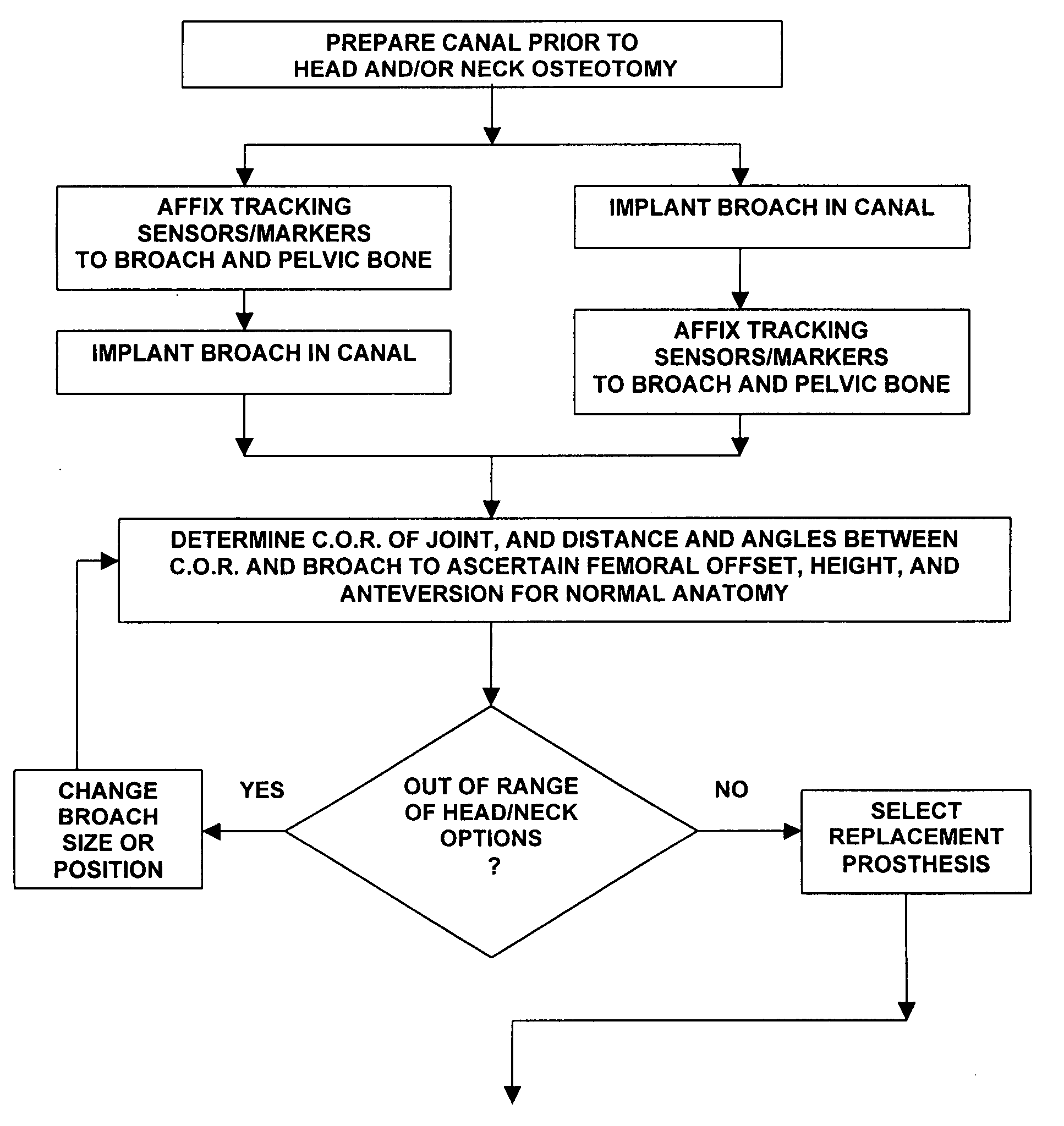

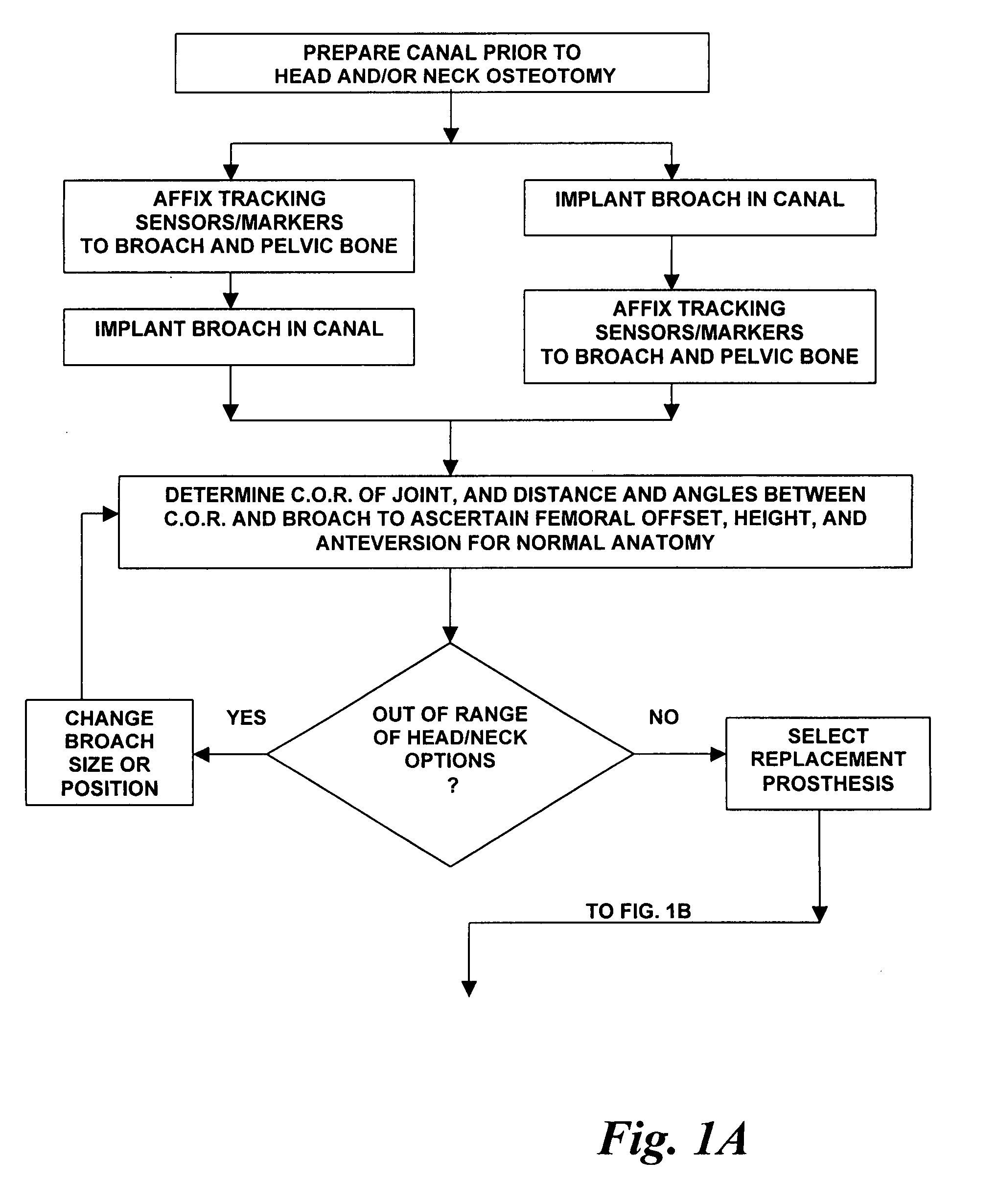

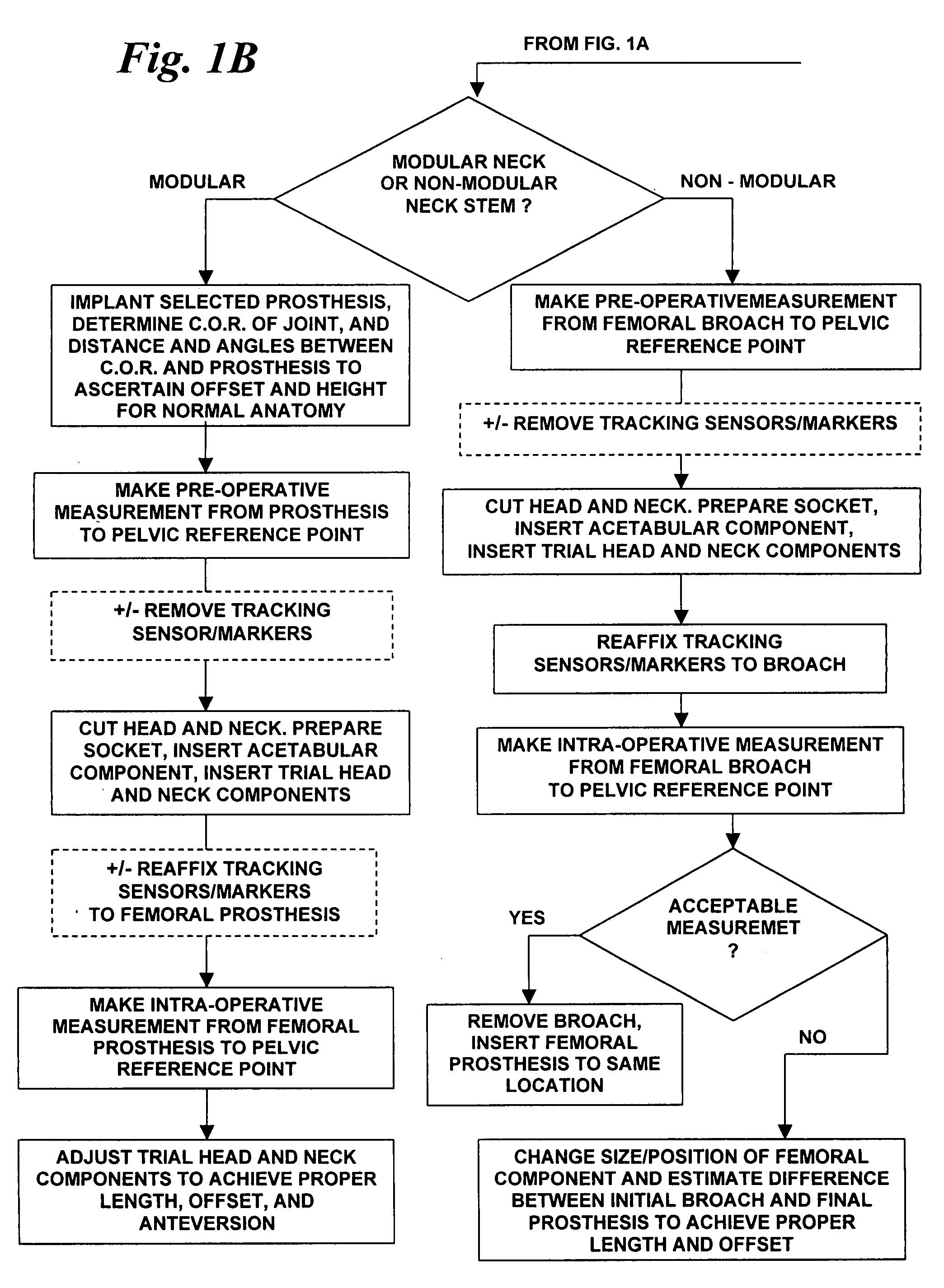

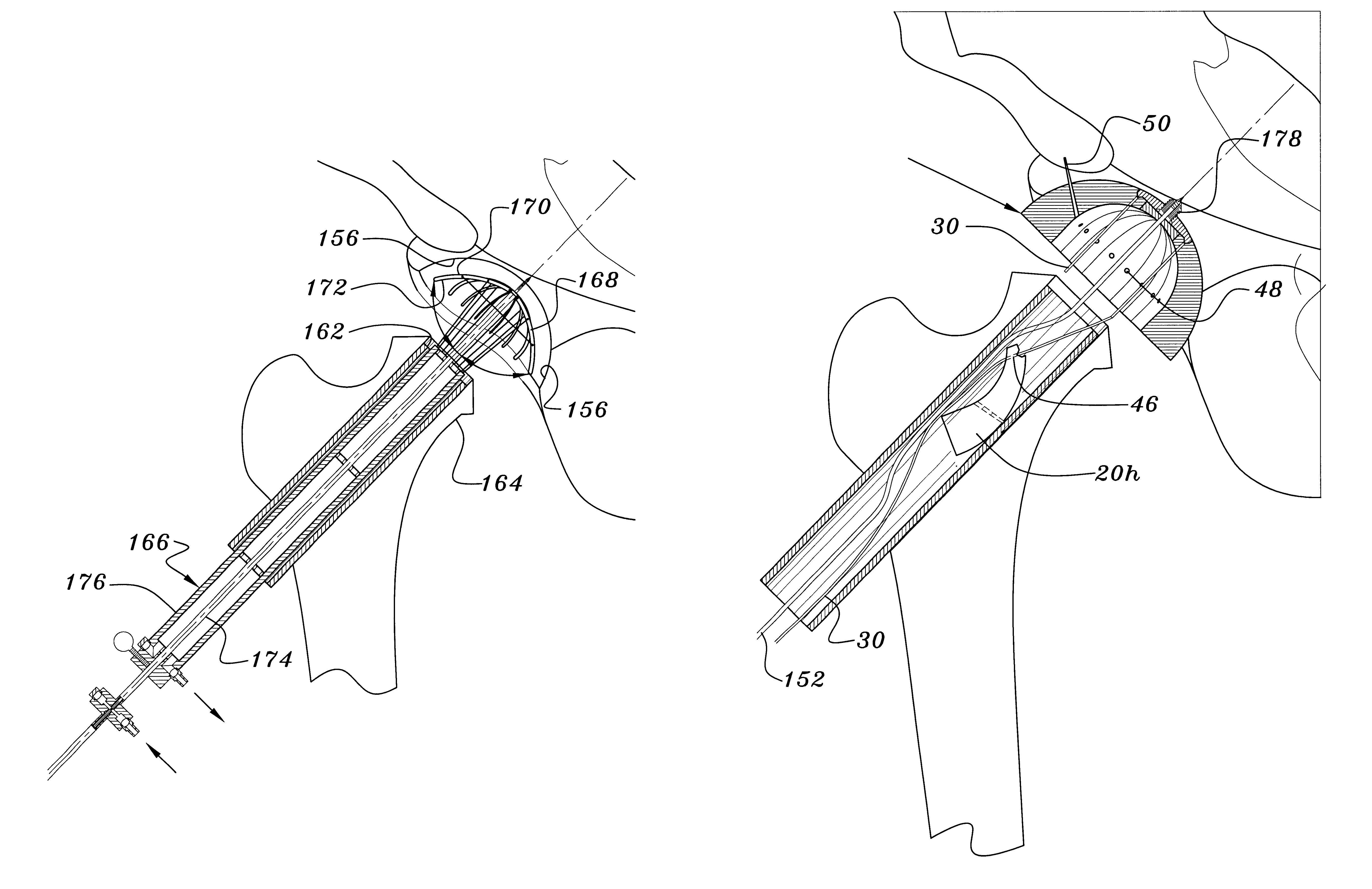

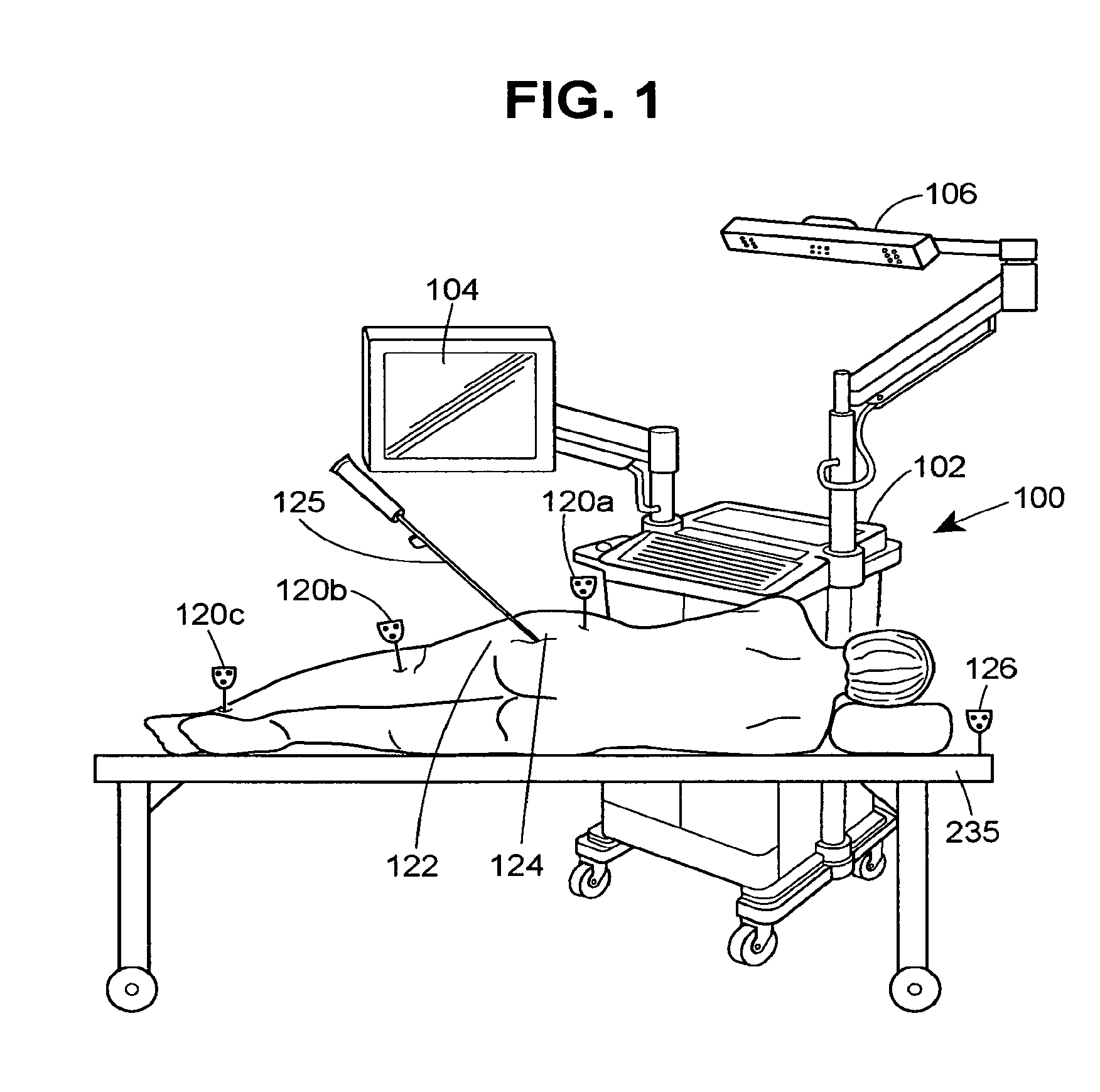

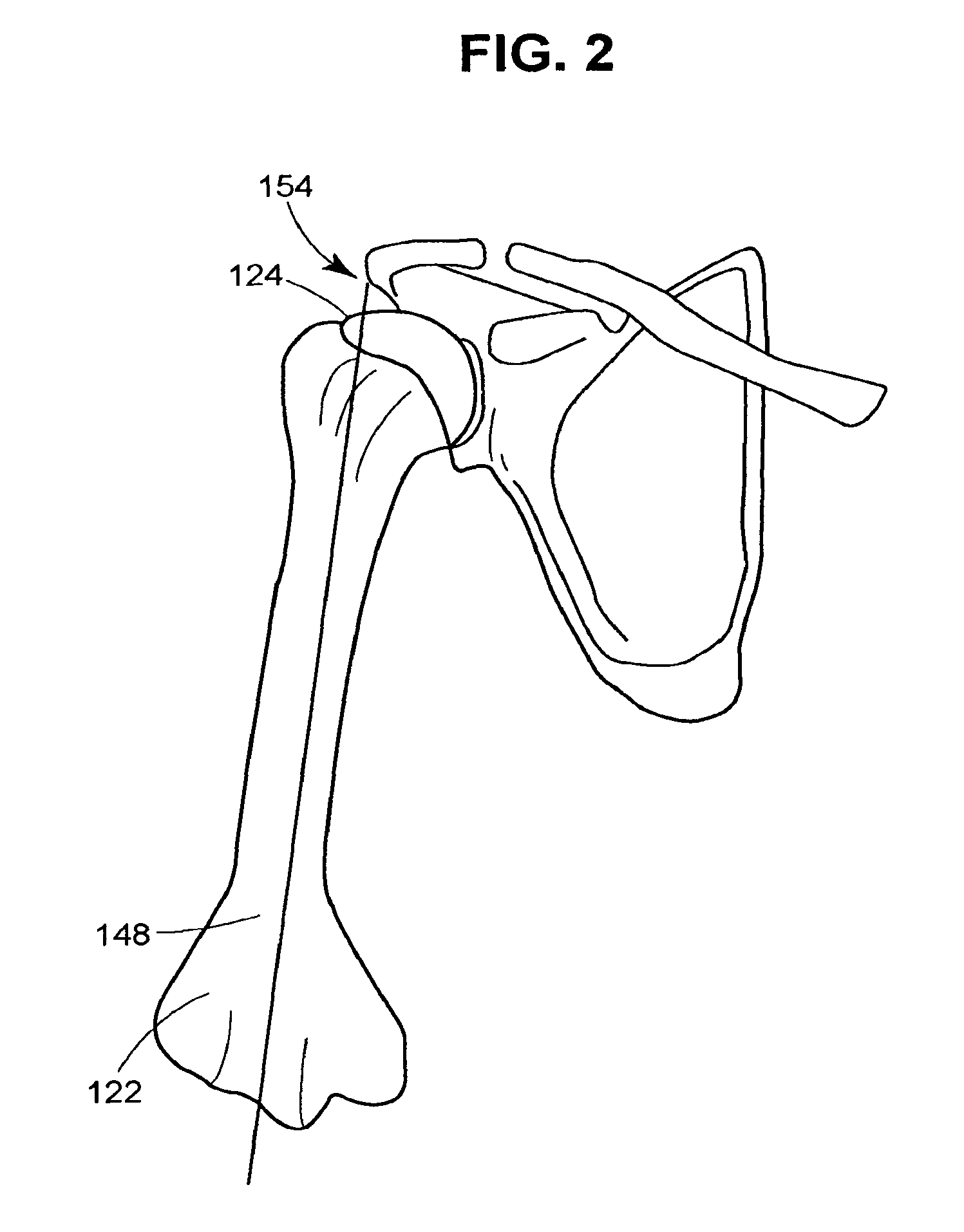

Total joint replacement component positioning as predetermined distance from center of rotation of the joint using pinless navigation

InactiveUS20080146969A1Precise positioningAccurate measurementSurgical navigation systemsPerson identificationArticular surfacesArticular surface

A system and method used in total joint arthroplasty of a ball and socket joint such as hip and shoulder replacements for accurate positioning of a prosthesis through pinless surgical navigation during replacement surgery according to a predetermined distance from the center of rotation of the replaced joint and / or articular surface to obtain the proper length, offset, and biomechanics of the replaced joint.

Owner:KURTZ WILLIAM B

Bone connector with pivotable joint

System, including methods, apparatus, and kits, for connecting bones and / or bone portions using a bone connector with a pivotable ball and socket joint.

Owner:ACUMED

Vertebral shock absorbers

InactiveUS20050261682A1Extended range of motionFacilitate lateral applicationInternal osteosythesisJoint implantsElastic componentLamina terminalis

A vertebral shock absorber in the form of an elongated compressible member having two ends, one fastened to an upper vertebra, and the other fastened to a lower vertebra. The elongated member may be fastened using pedicle screws or by way of ball-and-socket joints for enhanced range of motion. In the preferred embodiment, the elongated compressible member is constructed using telescoping sleeves to create a cavity wherein there is disposed a compressible, resilient component such as a spring, elastomeric material, liquid, gel, hydrogel, or other suitable substance. The shock absorber may be combined with an intradiscal component and / or one or more plates that extends at least partially onto a vertebral endplate to facilitate lateral application.

Owner:FERREE BRET A

Joint prosthesis and method for placement

A prosthesis for replacement of a ball and socket joint in the human body. The prosthetic components comprise a plurality of separate parts which may be inserted through a hole in the femur of the patient and assembled and attached to the prepared acetabulum of the hip bone to form a cup-shaped first shell. A cup is also passed through the hole in the femur and attached to the first shell to form the socket portion of the joint. A shaft having a first end with a ball formed thereon is inserted in the hole through the femur so that the ball engages the cup for movement therein.

Owner:TARABISHY IMAD ED

Orthopedic implant

Disclosed is an orthopedic implant suitable for arthroplasty procedures. The orthopedic implant includes a first plate, a second plate, an axial support between the first plate and the second plate and one or more torsional supports connecting the first plate and the second plate. The axial support may be, for example, one or more flexible struts, such as cables, or a ball and socket joint. The torsional supports connect the first and second plates and may be, for example, curved around the axial support. The torsional supports may be integrally formed with the first and second plates as a single unitary device, by, for example, a Laser Engineered Net Shape (LENS) process.

Owner:DEPUY ACROMED INC

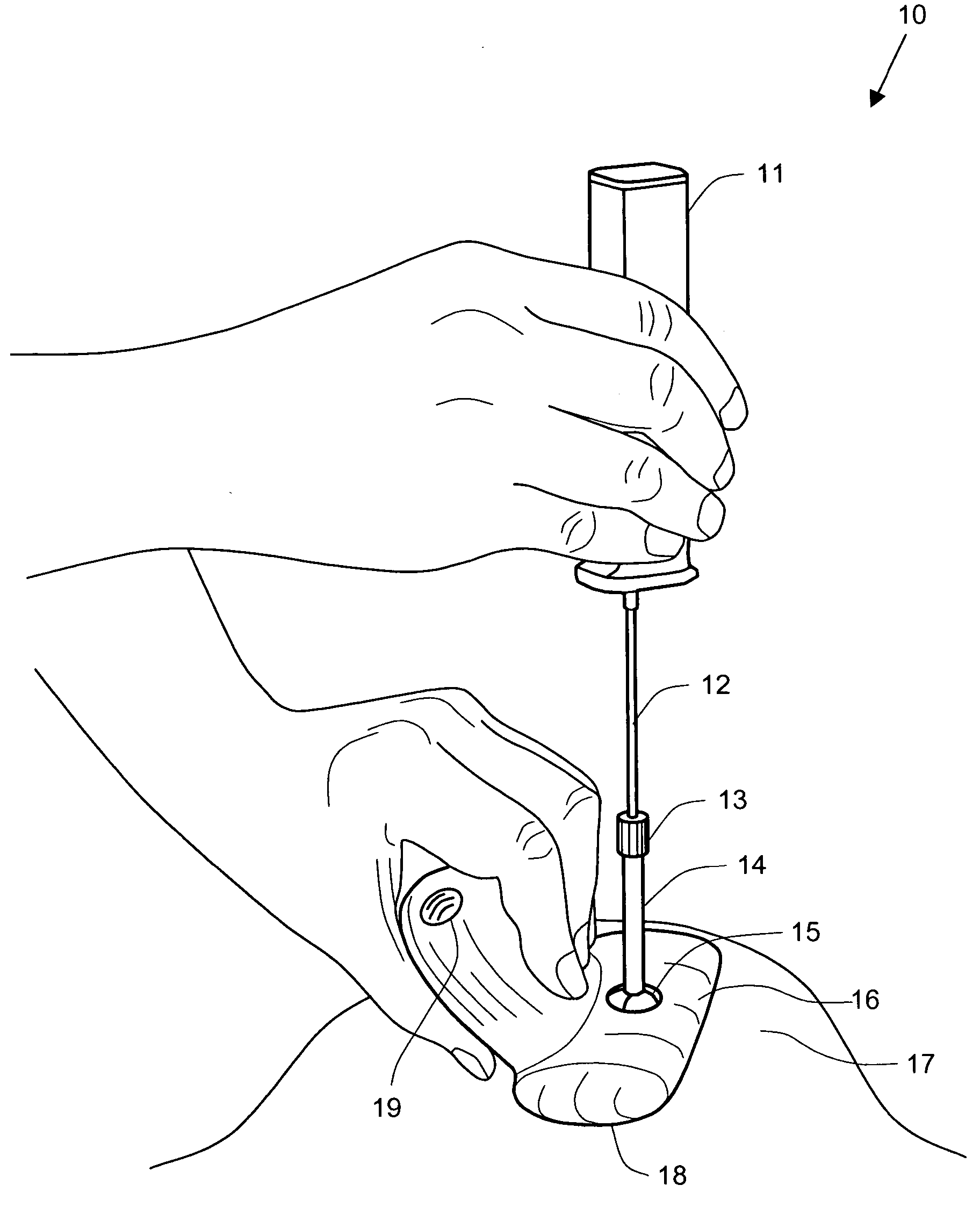

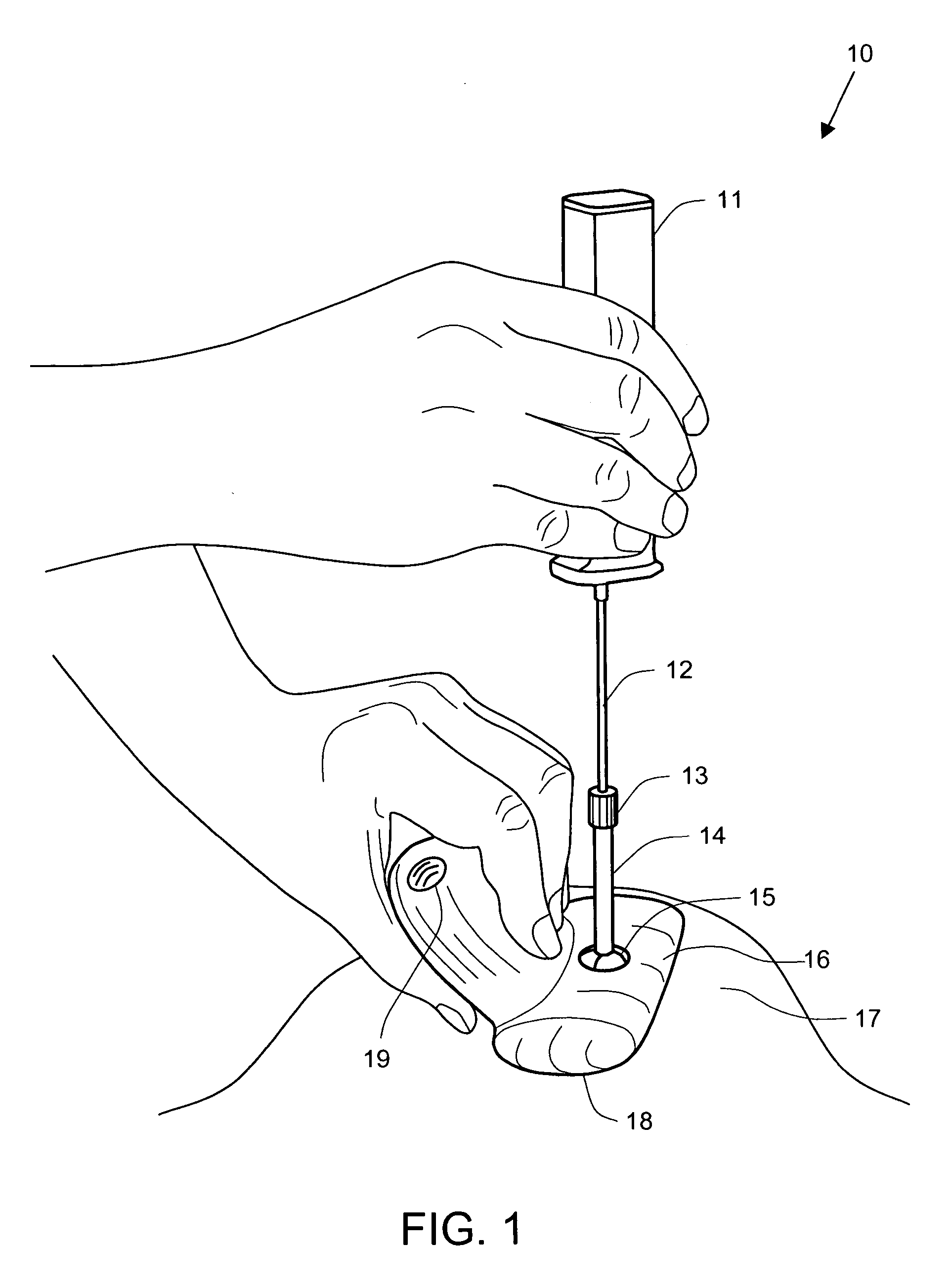

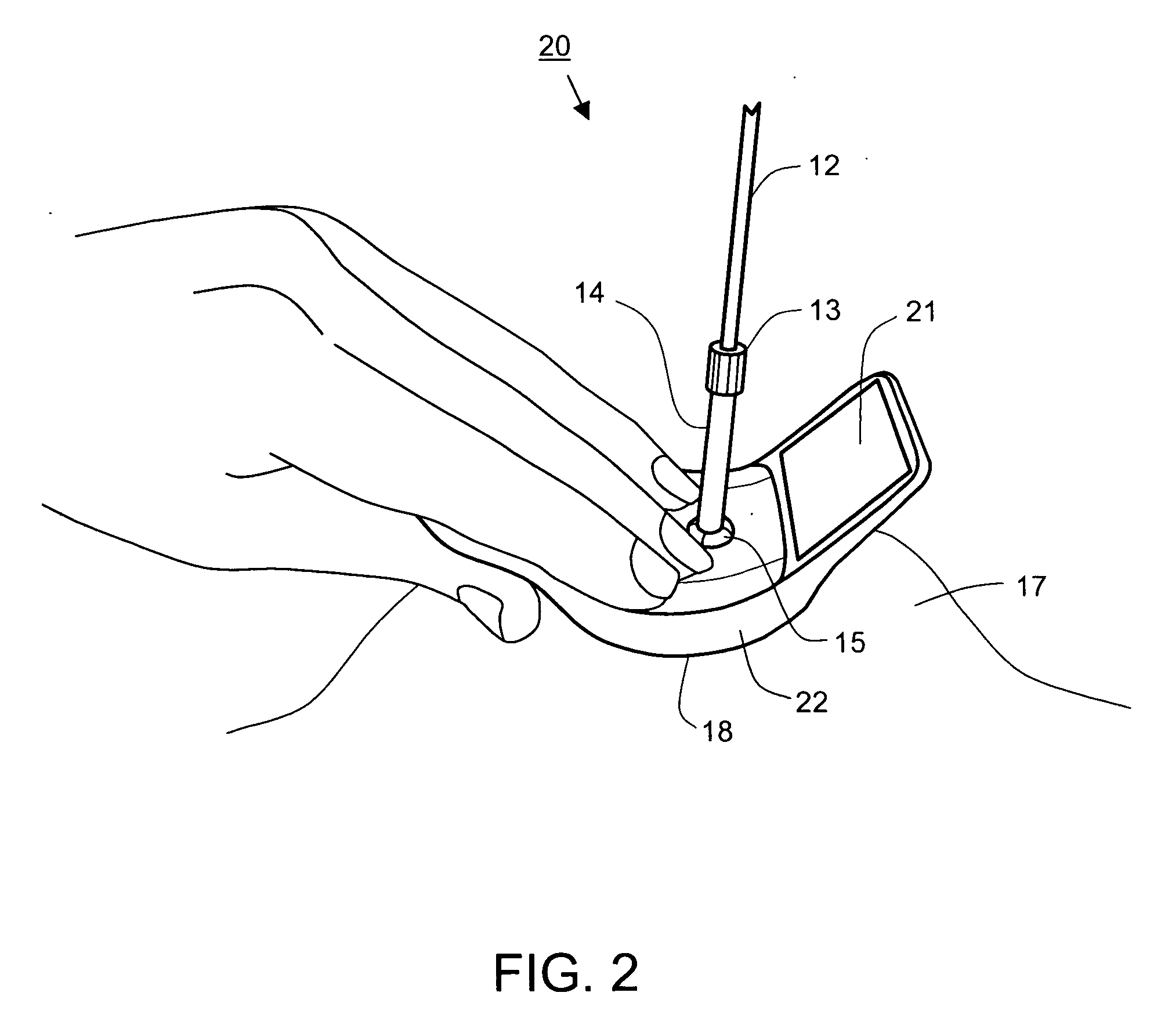

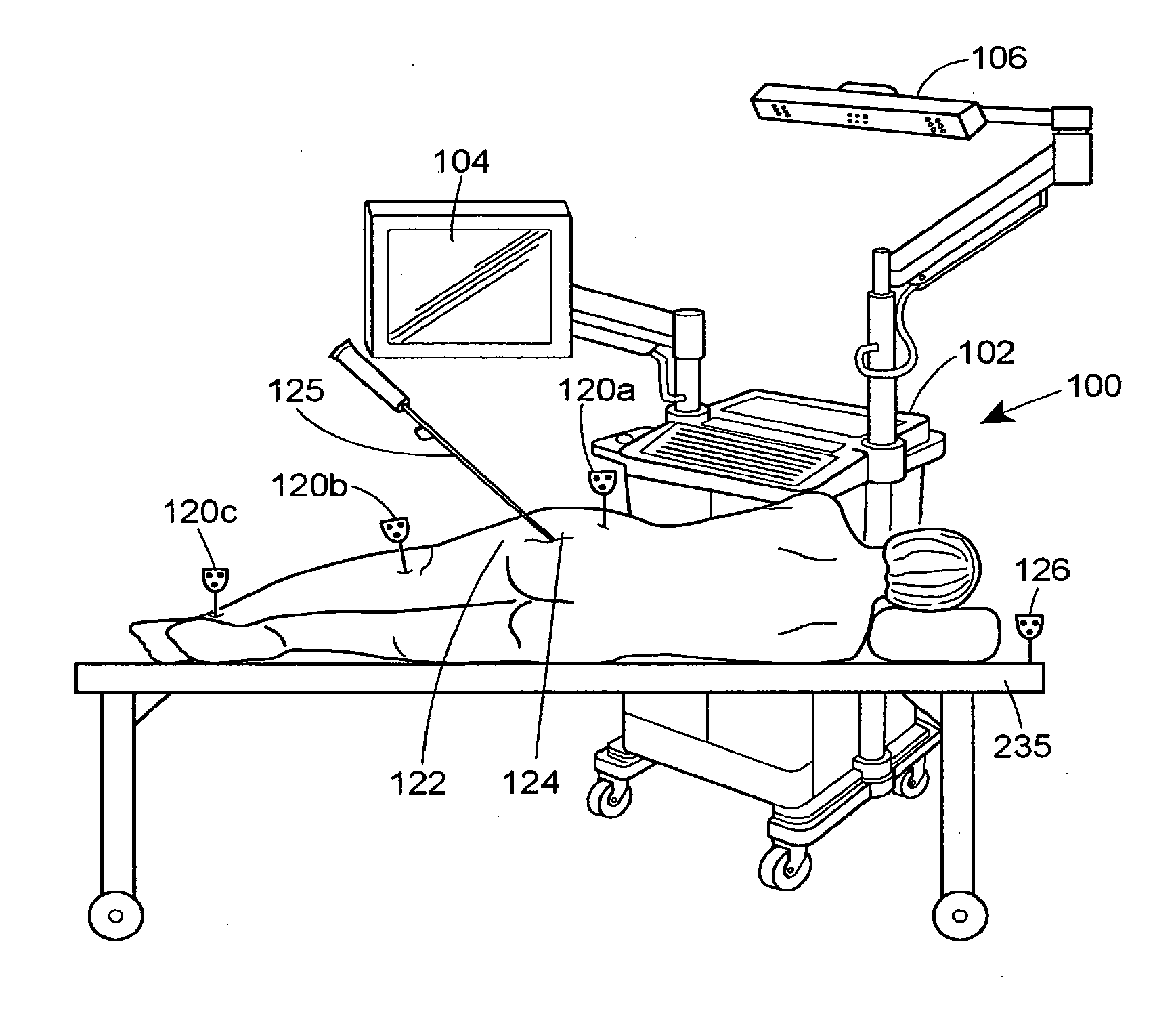

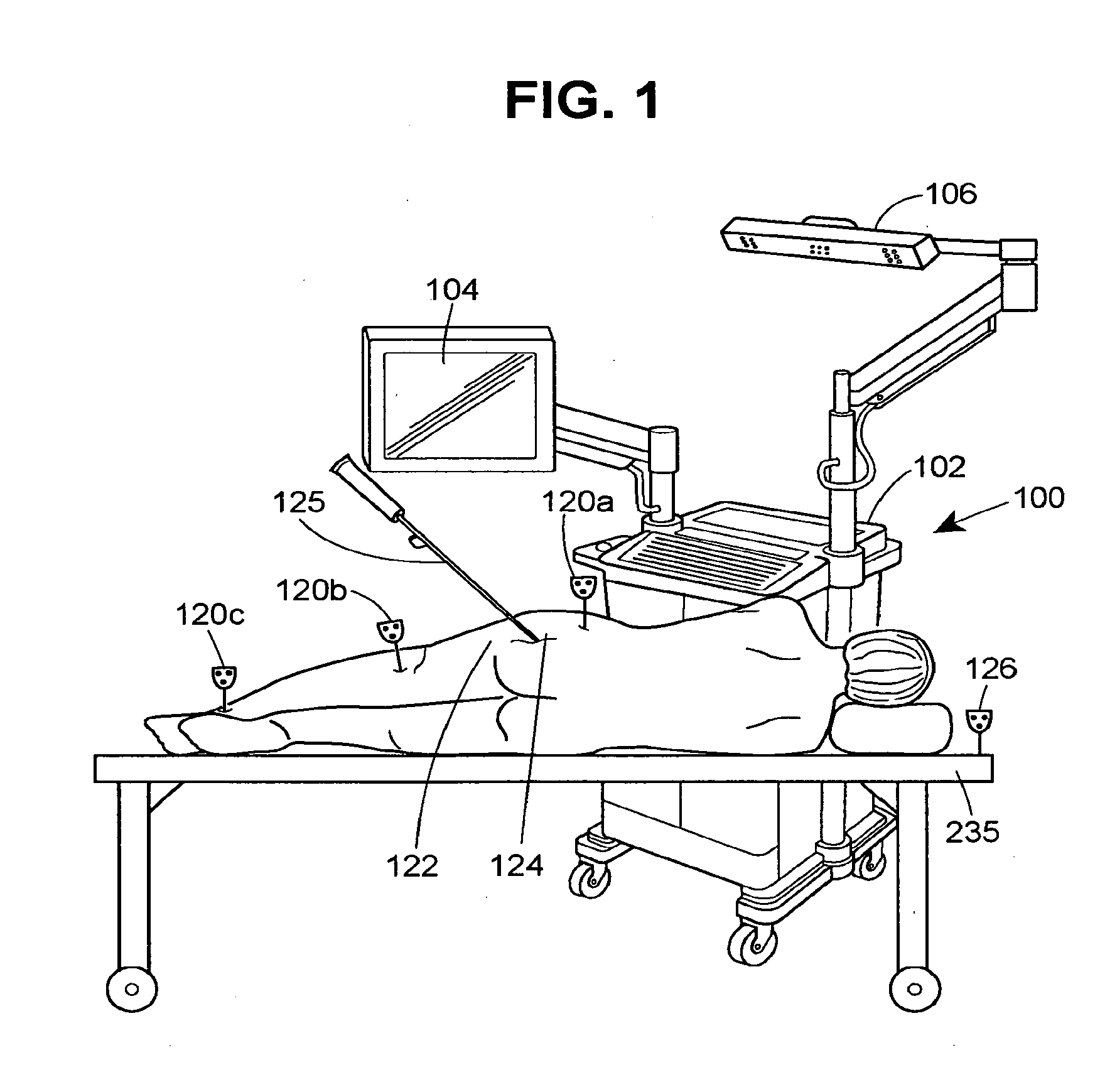

Device and method for biopsy guidance using a tactile breast imager

InactiveUS20040267121A1Provide real-timeIncreased sensitivity and repeatability and accuracyUltrasonic/sonic/infrasonic diagnosticsSurgical needlesBiopsy procedurePressure sense

A biopsy guidance device is enclosed based on a tactile imaging probe adapted to accept a biopsy gun. The tactile imaging probe includes a pressure sensing surface providing real-time 2-D images of the underlying tissue structures allowing to detect a lesion. A cannula is provided supported at a center point by a ball and socket joint. The joint is equipped with linear and angular sensors and supports the cannula with the ability to rotate thereof about the center point. The position, linear and angular displacement and direction of the needle tip of a biopsy needle placed inside the cannula is therefore known at all times and provided as a feedback signal to a physician. Also provided to a physician is a position of the target site at a lesion, as well as a linear and angular deviation of the needle tip away from the target site. Such audio, light, or visual feedback allows the physician to correct the insertion angle and depth to confidently reach the target site to perform a biopsy. Method is also disclosed to guide the biopsy procedure.

Owner:ARTANN LAB

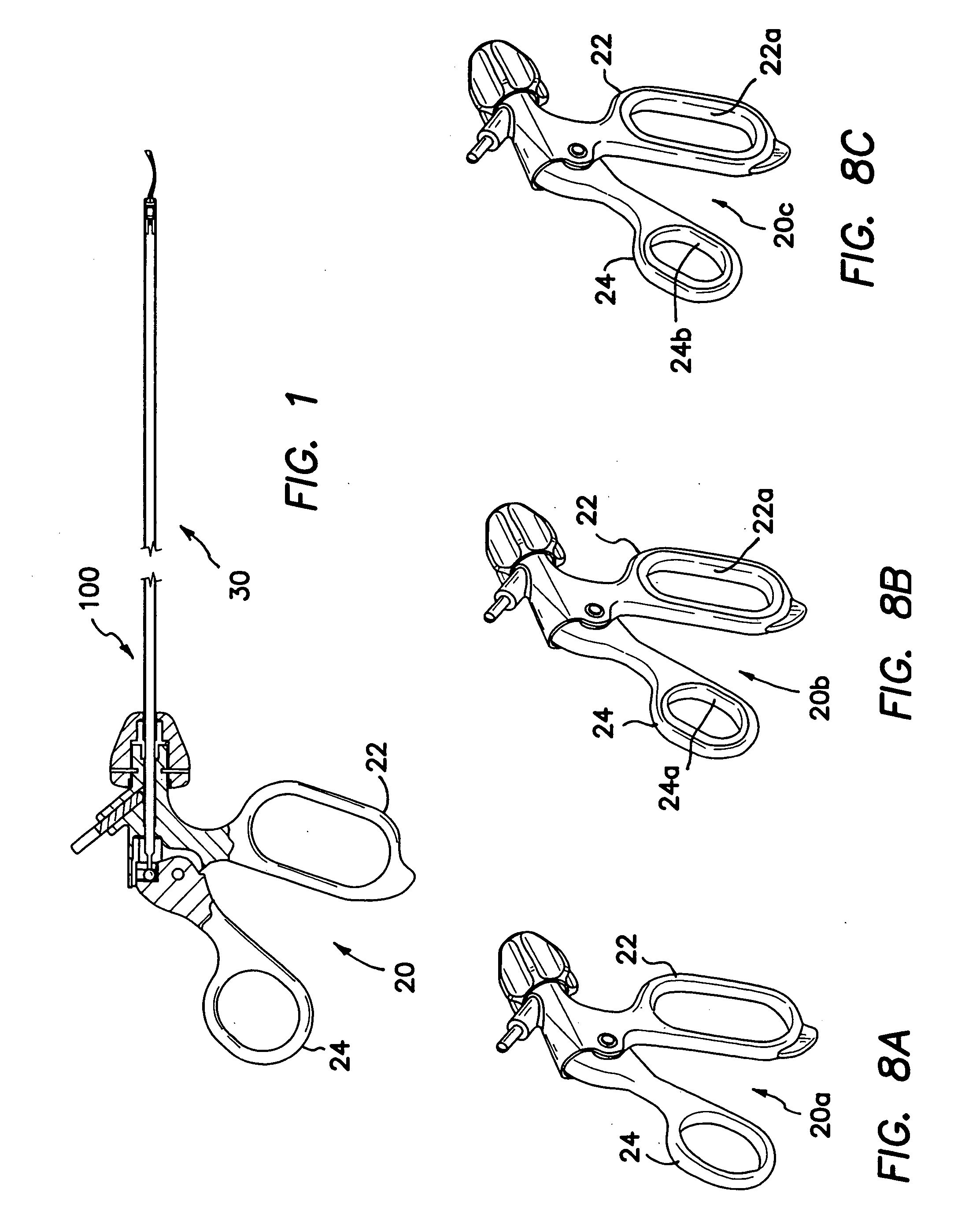

Disposable laparoscopic instrument

InactiveUS20060161190A1Maintain relatively stableReduce rotational frictionSurgical scissorsVaccination/ovulation diagnosticsEngineeringSurgical instrument

The invention is directed to a surgical instrument including a handle assembly and a shaft assembly. The handle assembly further includes a fixed handle and a pivoting handle. The shaft assembly extends from the handle assembly and further includes an outer tube and an inner actuation rod that slides coaxially with the outer tube. The shaft assembly includes a rotatable knob to provide 360° rotation. The actuation rod has a proximal end and a distal end; the proximal end has a ball end that couples with the pivoting handle to form a rotatable ball-and-socket joint. The outer tube is formed of plastic and fits over the actuation rod to function as an electrical insulator.

Owner:APPL MEDICAL RESOURCES CORP

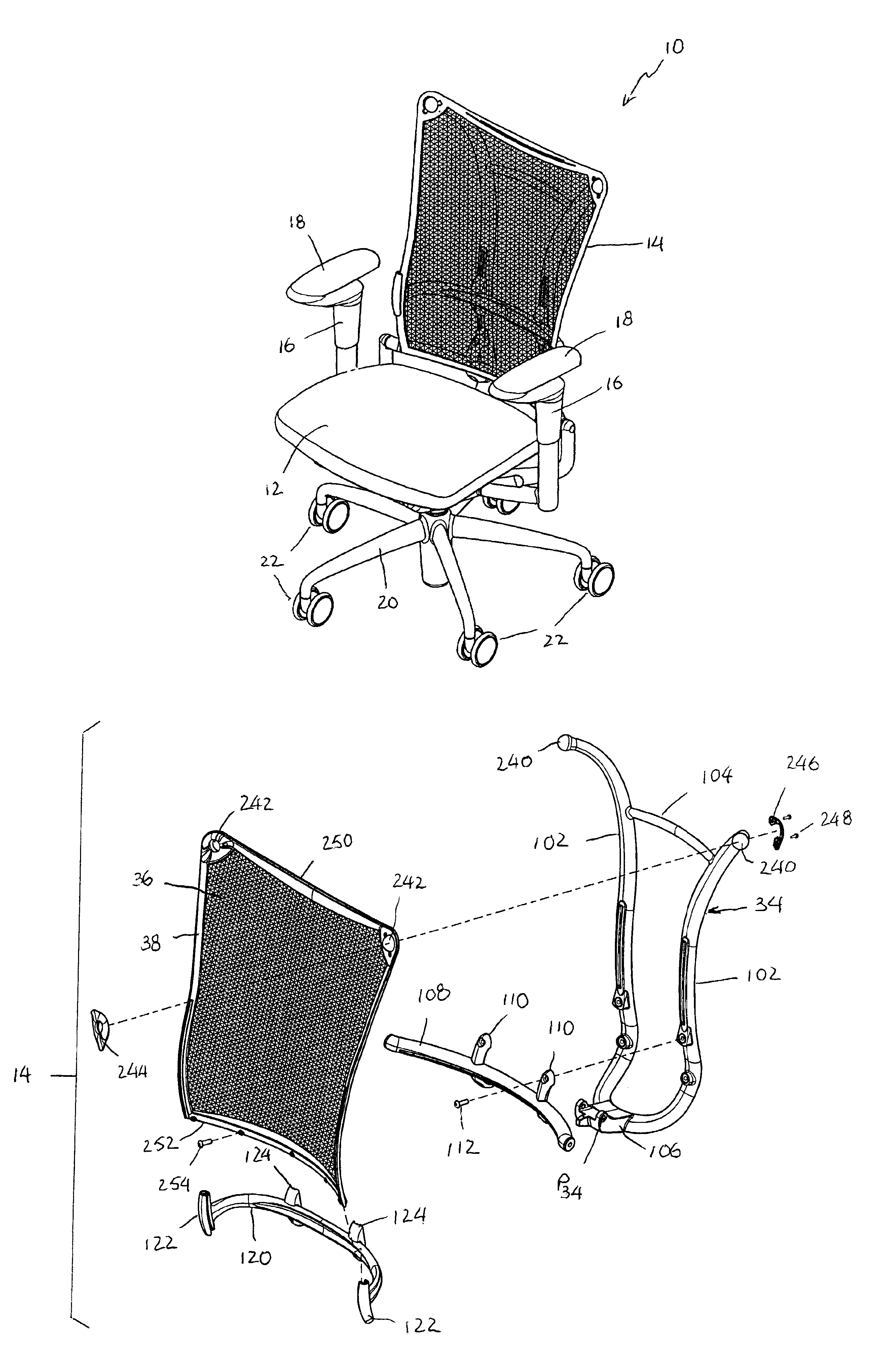

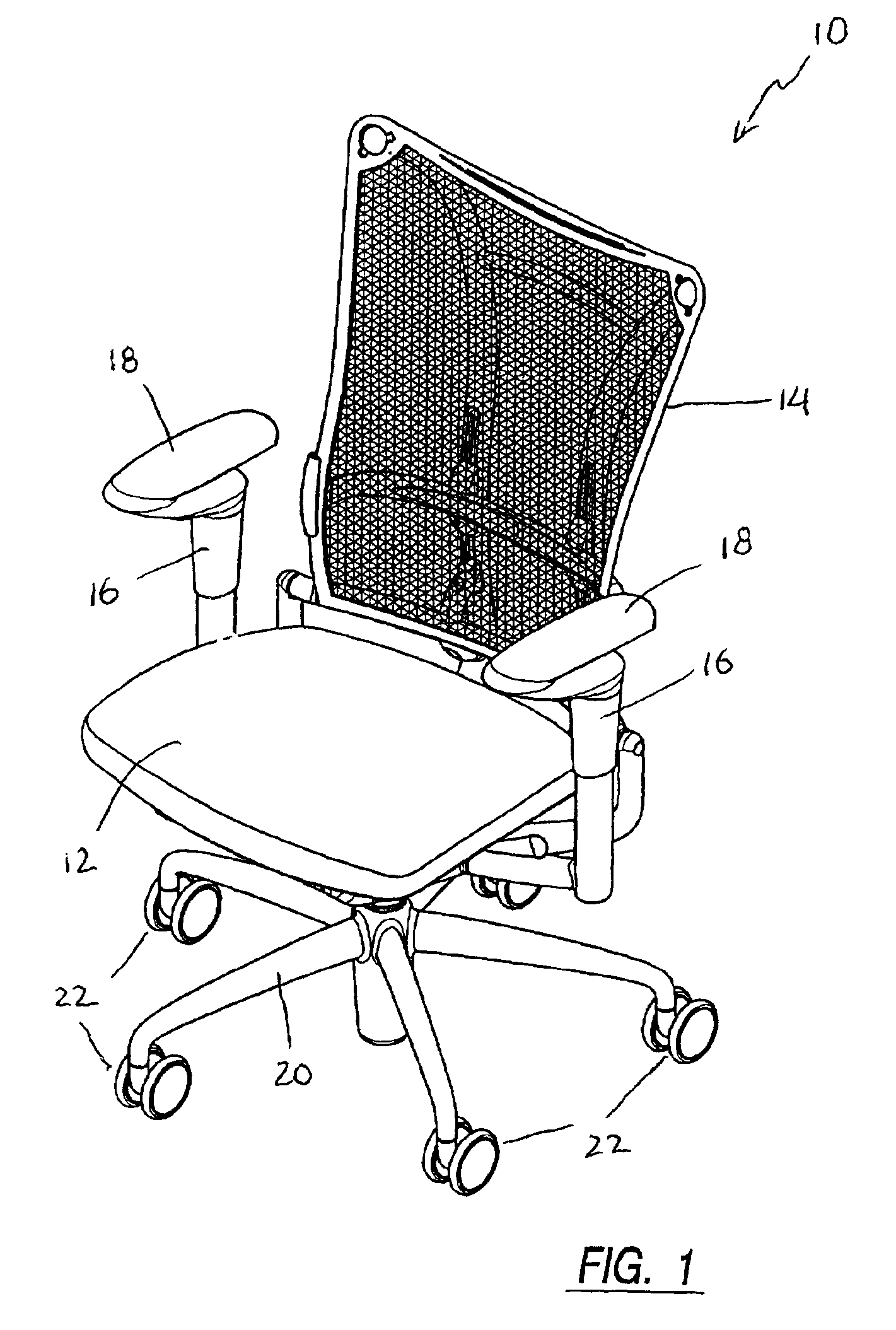

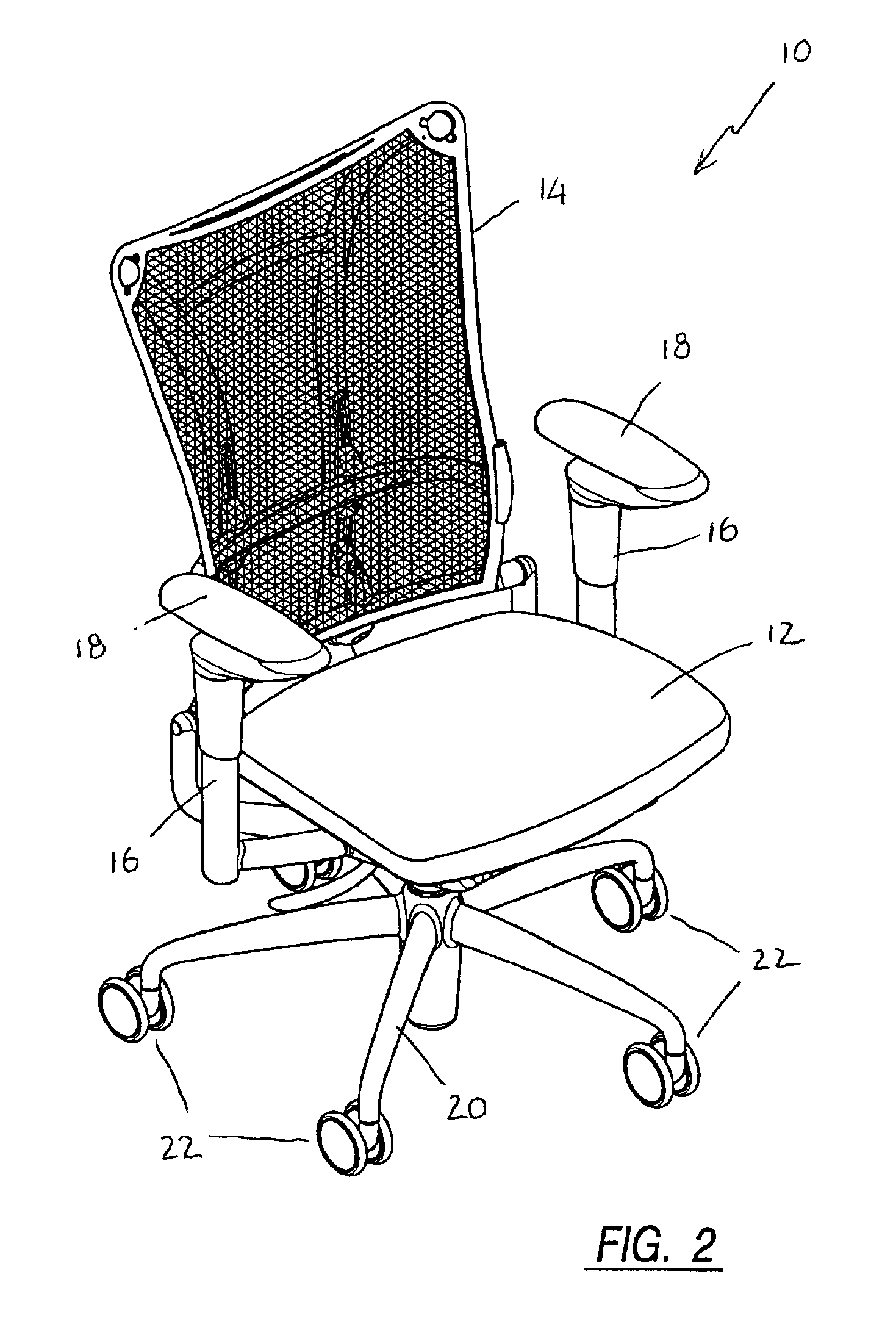

Chair back construction

InactiveUS7014269B2Easy height adjustmentLimited degreeStoolsReclining chairsEngineeringBall and socket joint

A back for a chair includes fabric panel with a flexible carrier attached to the panel around its periphery. The carrier is configured to be secured along a bottom edge to a bottom portion of a chair back frame member. The carrier is also secured to two vertical frame supports at its two upper corners. Preferably, the upper carrier and frame connections are ball and socket joints. A lumbar support is provided that is easily height adjustable, by providing tension to the back frame and requires no screws or adjustment knobs in its adjustment mechanism.

Owner:HNI TECH INC

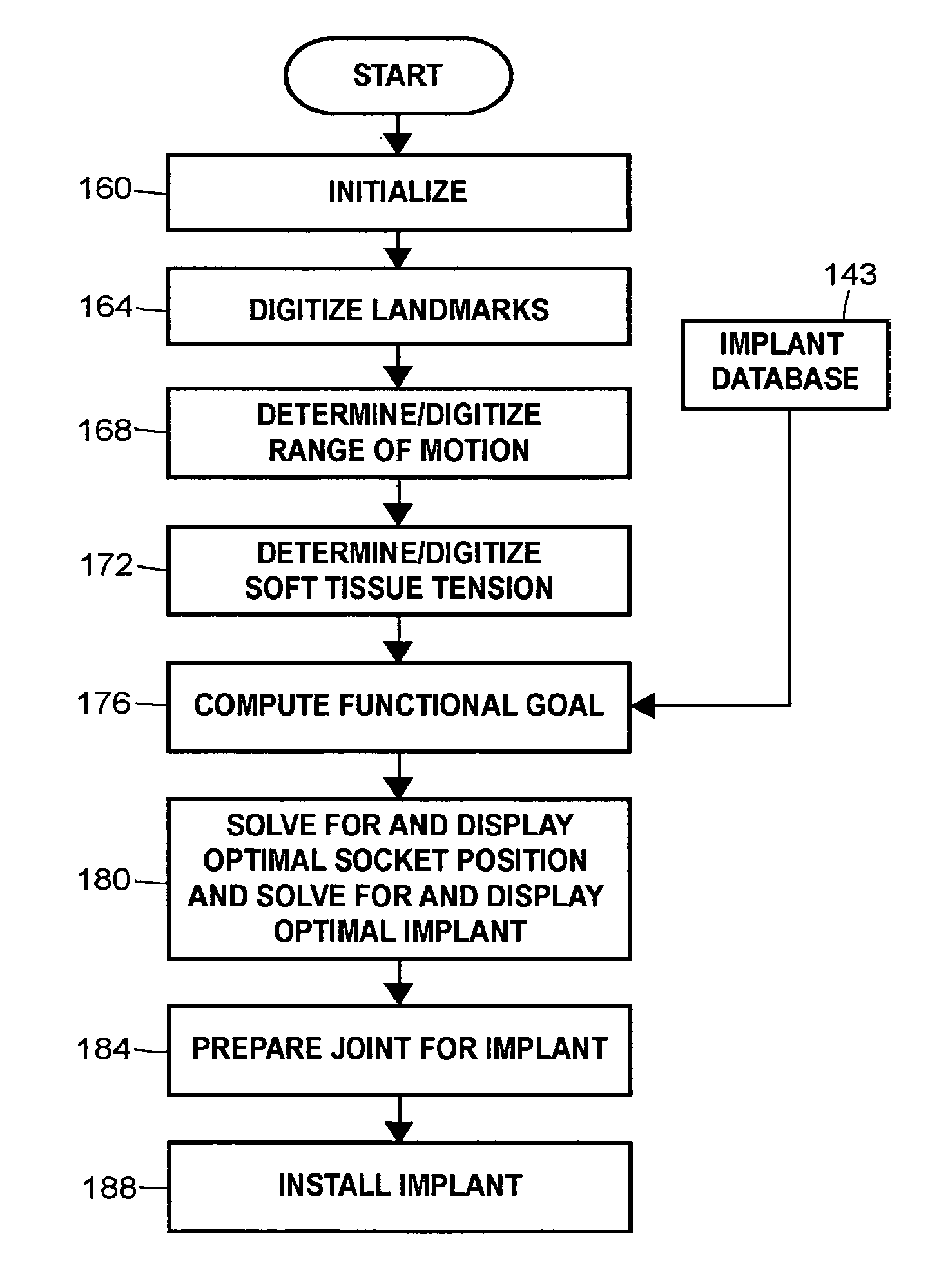

System and method for performing arthroplasty of a joint and tracking a plumb line plane

ActiveUS20060095047A1Improve stabilityMinimal potential for impingementSurgical navigation systemsPerson identificationRange of motionNavigation system

A method of performing an arthroplasty of a ball and socket joint with a surgical navigation system includes the step of digitizing landmarks to provide geometrical parameters of the joint and a limb depending there from, including digitizing aspects of a socket region of the ball and socket joint. A range of motion parameter is determined. A soft tissue tension parameter is determined. A functional goal is computed based on landmark data, the range of motion parameter, the soft tissue tension parameter, and a database of potential implants. An optimal socket position is solved for to minimize impingement of potential implants. An implant is chosen based on the optimal socket position and the functional goal. The joint is prepared to receive the chosen implant. The chosen implant is installed into the joint.

Owner:STRYKER EURO OPERATIONS HLDG LLC

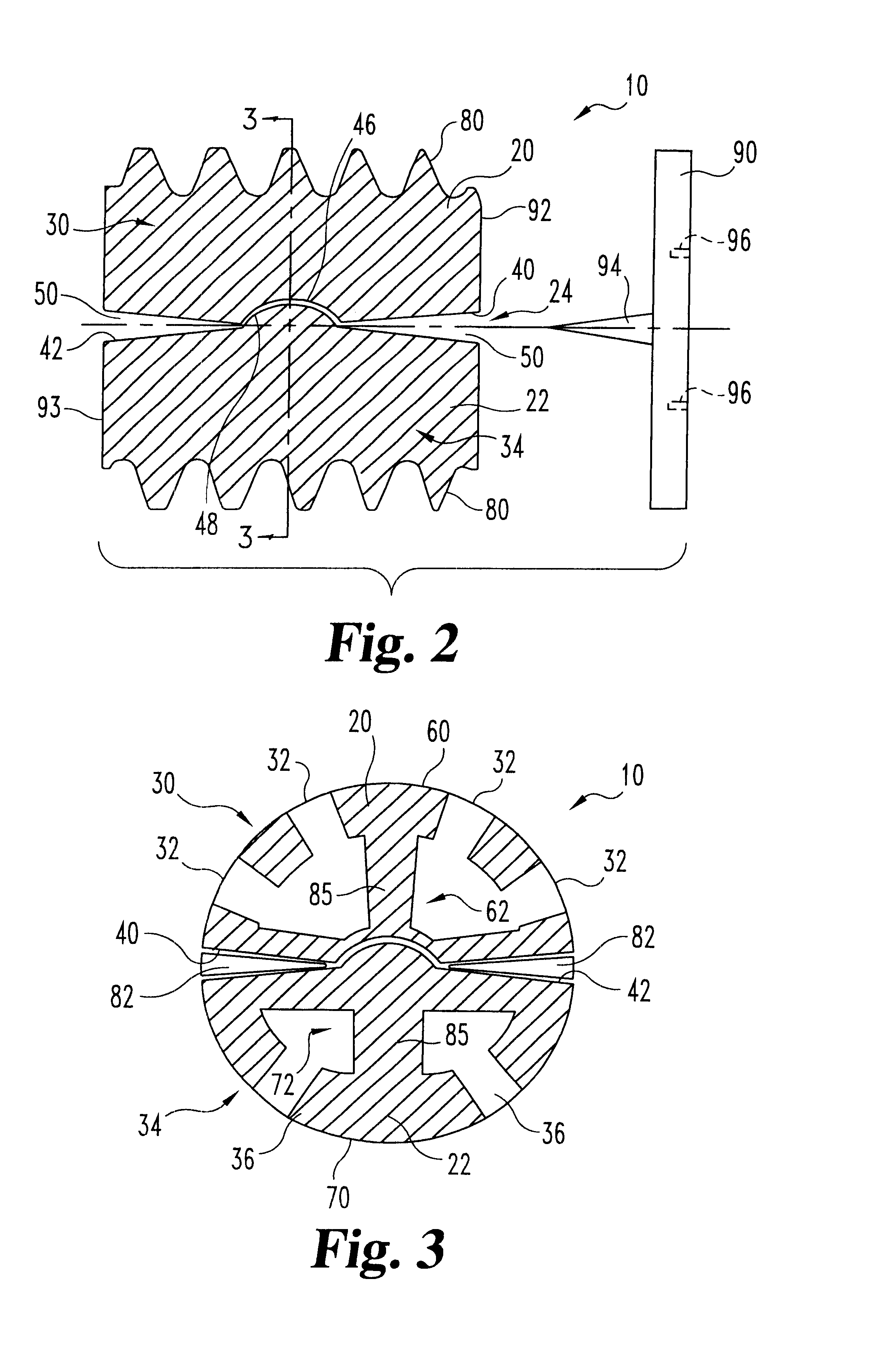

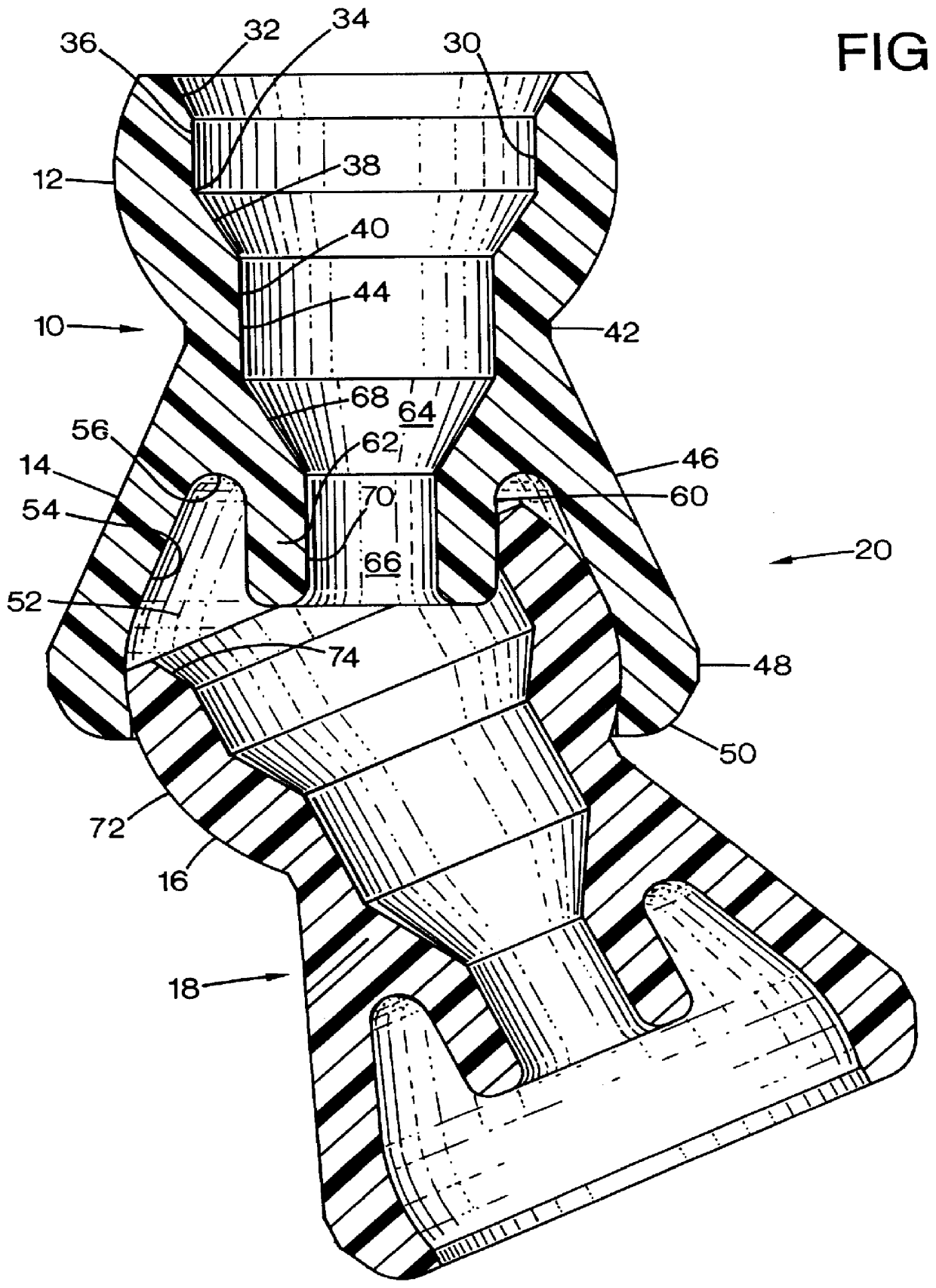

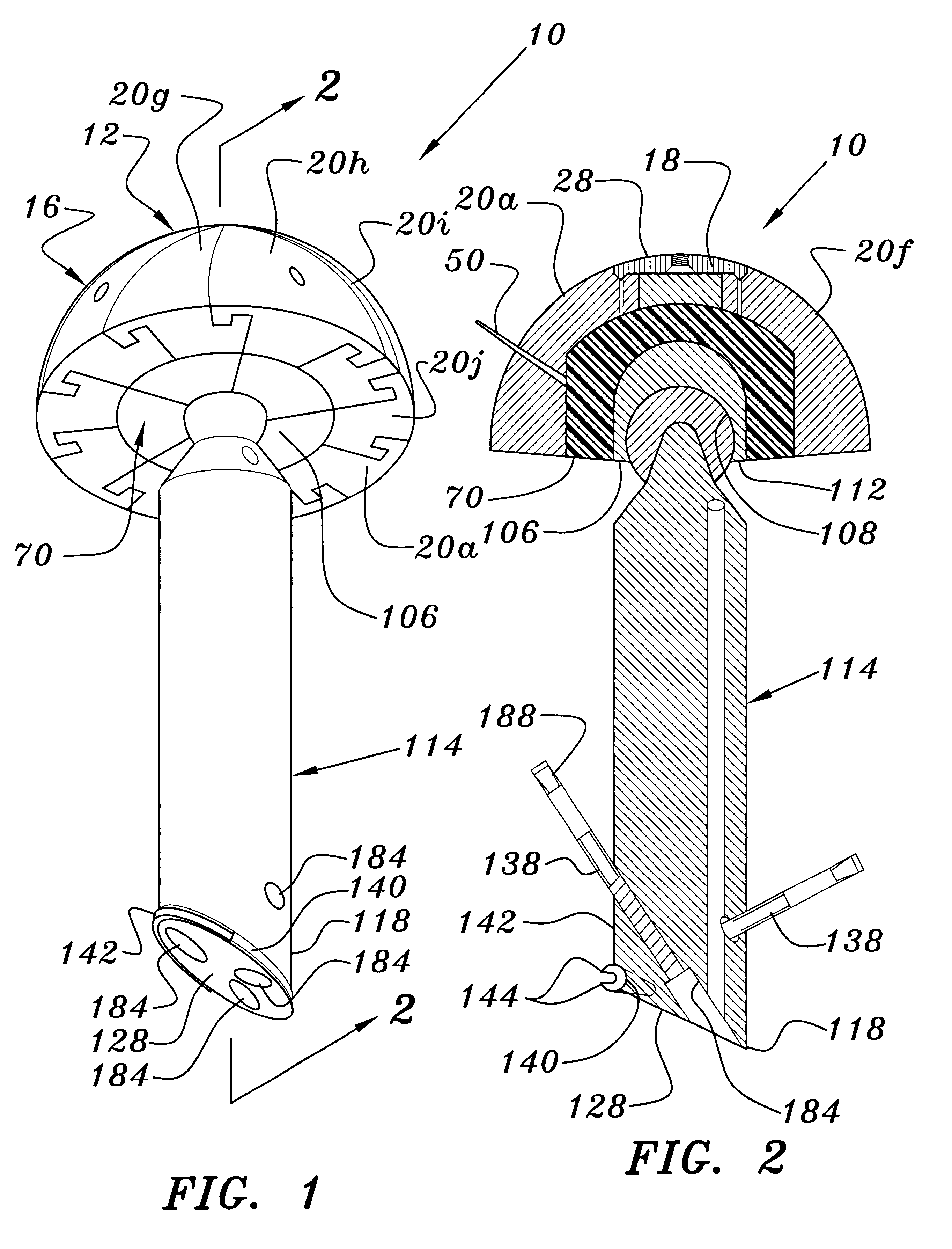

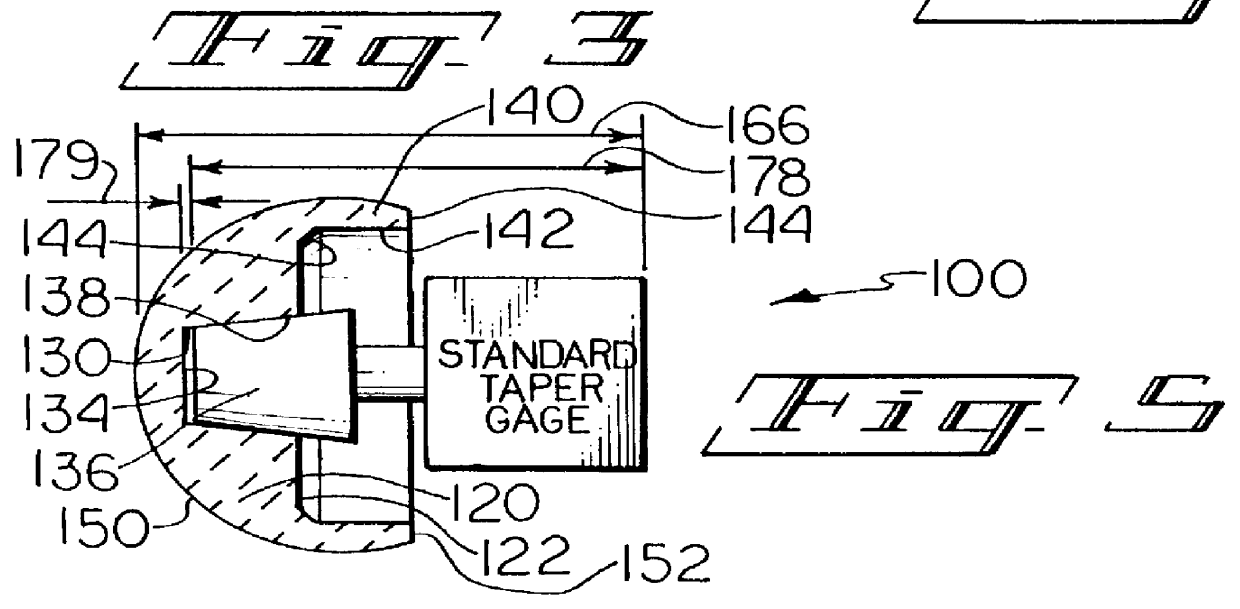

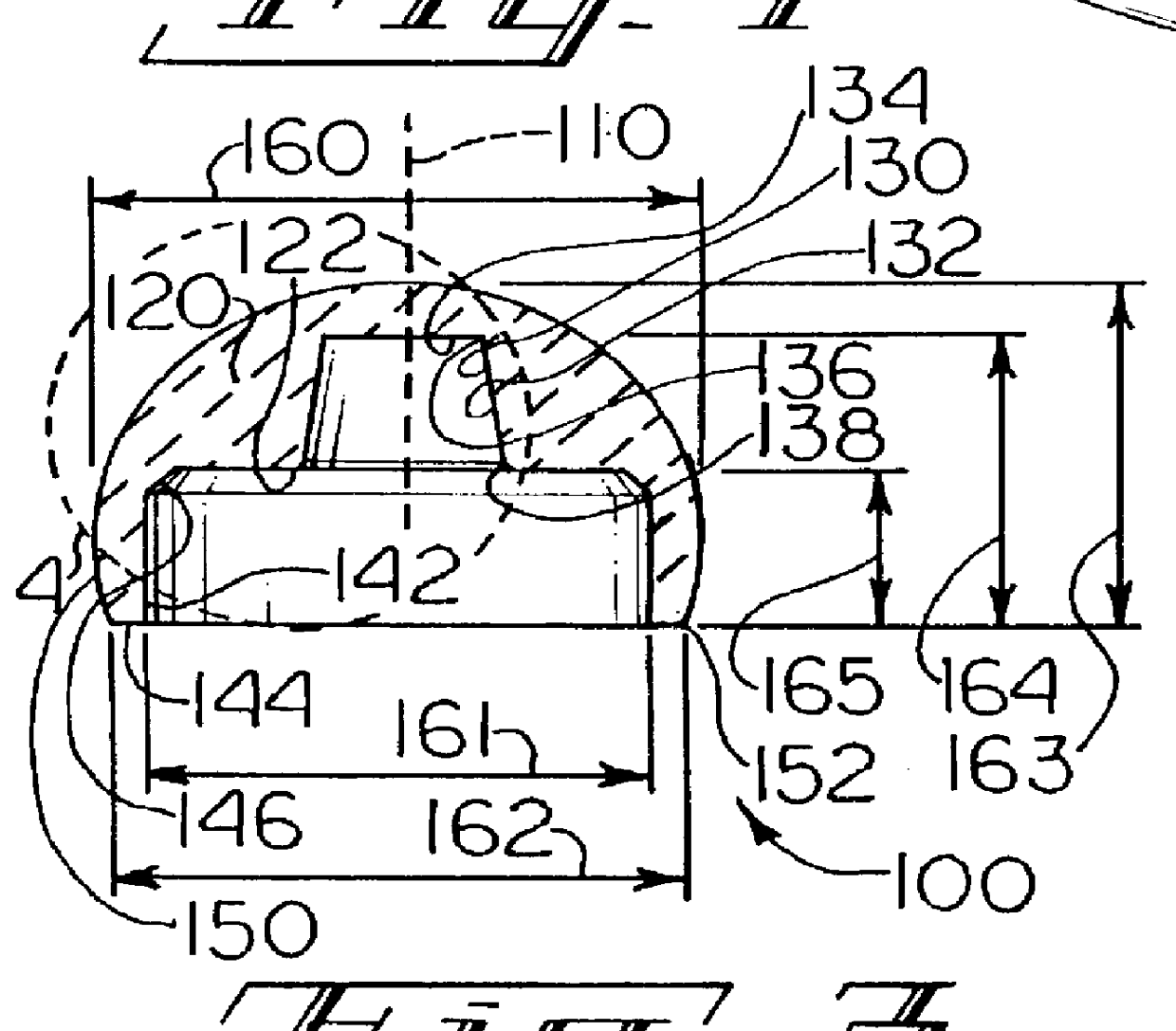

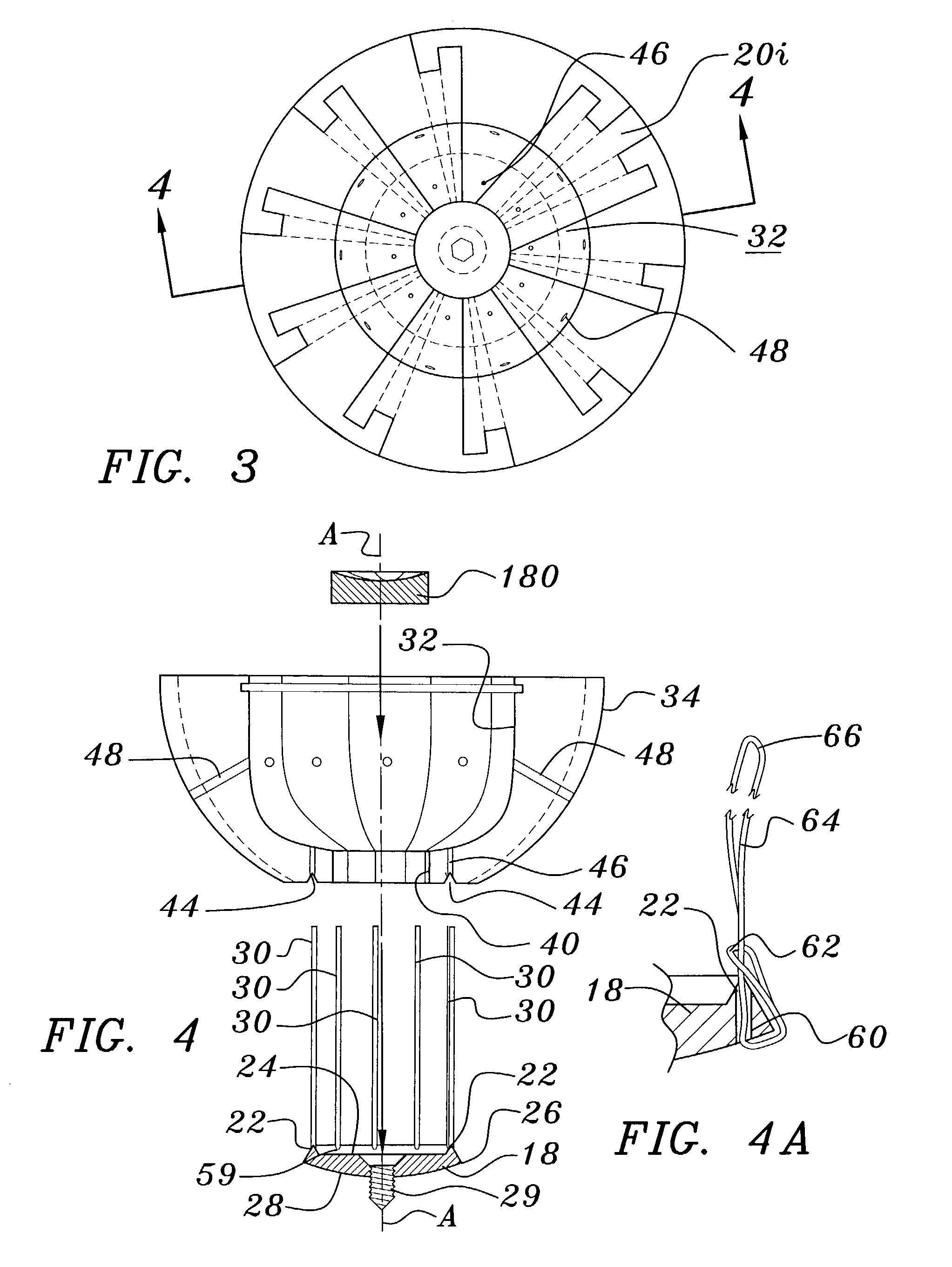

Modular ball and socket joint preferably with a ceramic head ball

InactiveUS6096084AIncrease surgical versatilityImprove proficiencyJoint implantsFemoral headsArticular surfacesArticular surface

Modular ball and socket joint has 1) a cupped ball head, preferably of ceramic, having a support body with an inferior, deep, distally facing, preferably generally planar, surface having a substantially circular outer boundary thereto; a distally opening stem receiving bore preferably centrally located in the support body; a cup wall, extending distally from the support body and having a preferably substantially cylindrical inner surface which extends from said outer boundary of said distally facing surface; and a superficially facing, generally semispherical, smooth external surface, preferably and optimally of a low friction coefficient, encapsulating the support body and cup wall; and 2) an interchangable and modular stem, preferably of metal or metal alloy, having a distally directed spike, and a superior stem cap which is insertable into the bore of the head; optionally with 3) a head-receiving articular cup having an inner articular surface and a mountable back surface, the articular surface of which, when the head-receiving cup is suitably mounted in suitable receiving stock, mates in articulating contact with said smooth external surface of said head when said head and stem are suitably mounted in suitable receiving stock. The head and stem modularity allows for noticeably increased versatility and efficiency in surgical procedures, and the ceramic material is beneficially adapted for employment in the fabrication of femoral resurfacing implants for conservative arthroplasty.

Owner:BIOPRO

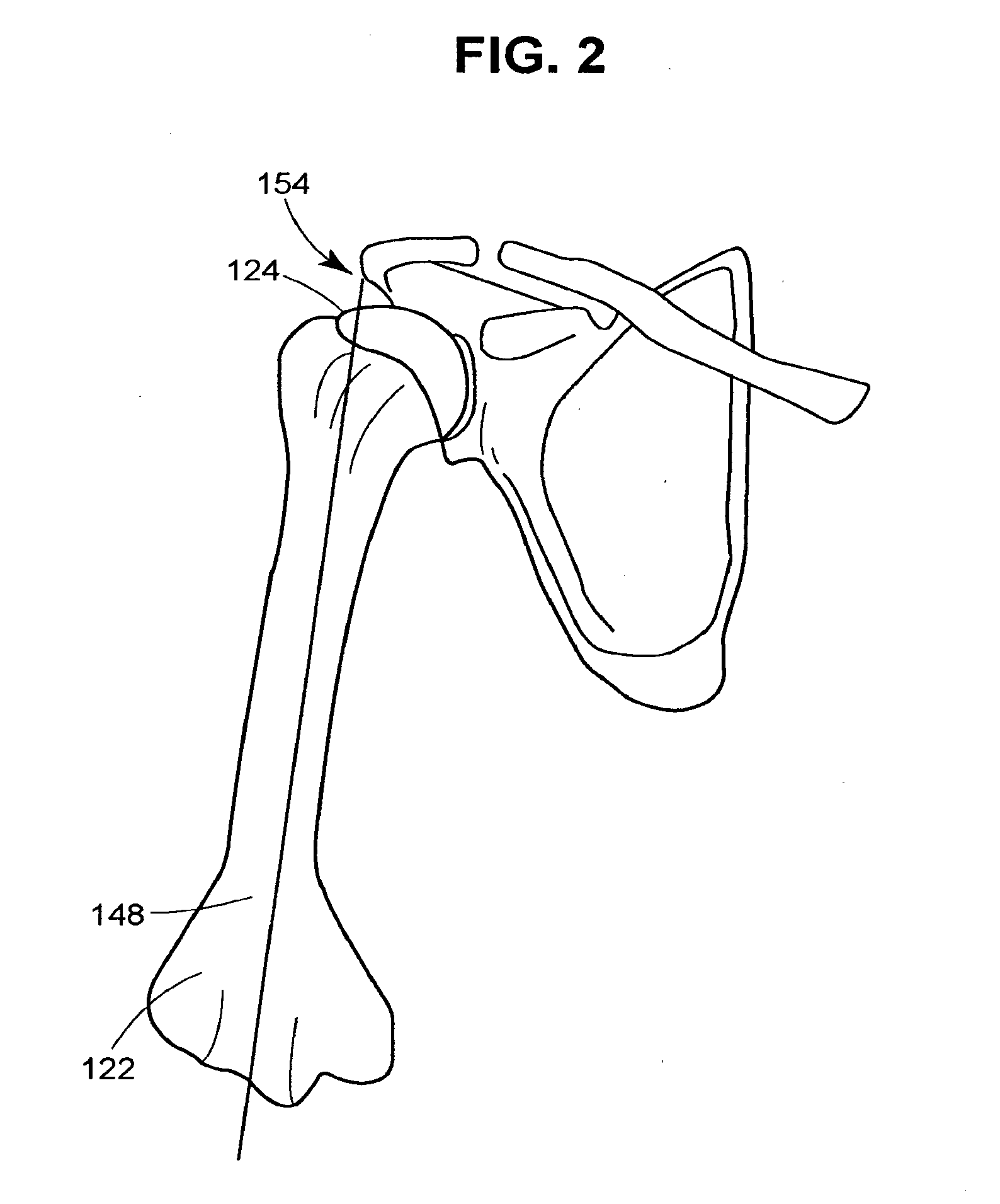

Total elbow arthroplasty system

A total elbow arthroplasty system, incorporating a humeral component, a radial component and a ball component, may be used as a total elbow replacement in the canine, as well as in other species. The implant of the present invention has an isometric humeral component and an isometric radial component. An isometric ball component having an isometric articular surface is mounted on the radial component. The humeral and radial components have stems for mounting in the medullary canals of the respective bones, which are angled so as to approximate the configuration of the original humerus and radius. The components work together to form a nonconstrained ball and socket joint. The invention is also directed to methods for implanting the novel endoprosthesis of the present invention in a canine elbow joint. The apparatus and methods of the present invention are useful in the treatment of elbow osteoarthritis in canines, as well as in other species, including other quadrupeds and humans.

Owner:IOWA STATE UNIV RES FOUND

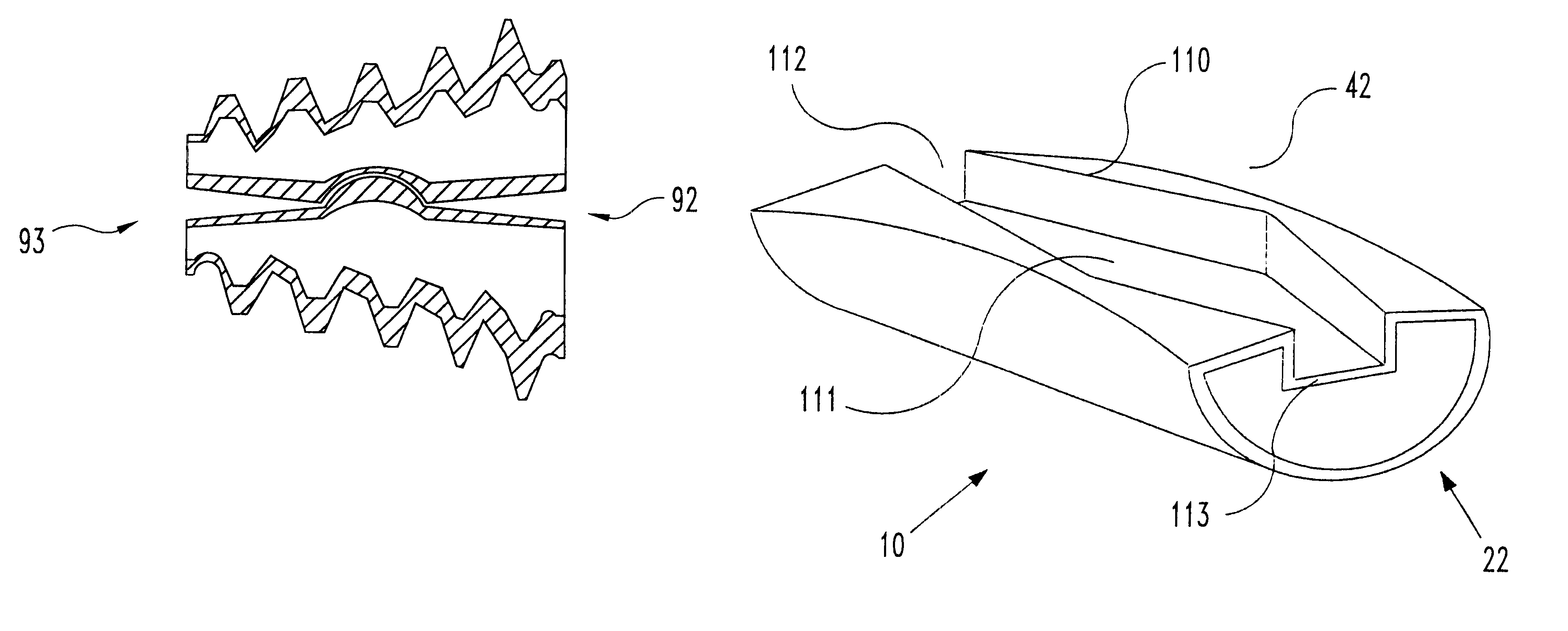

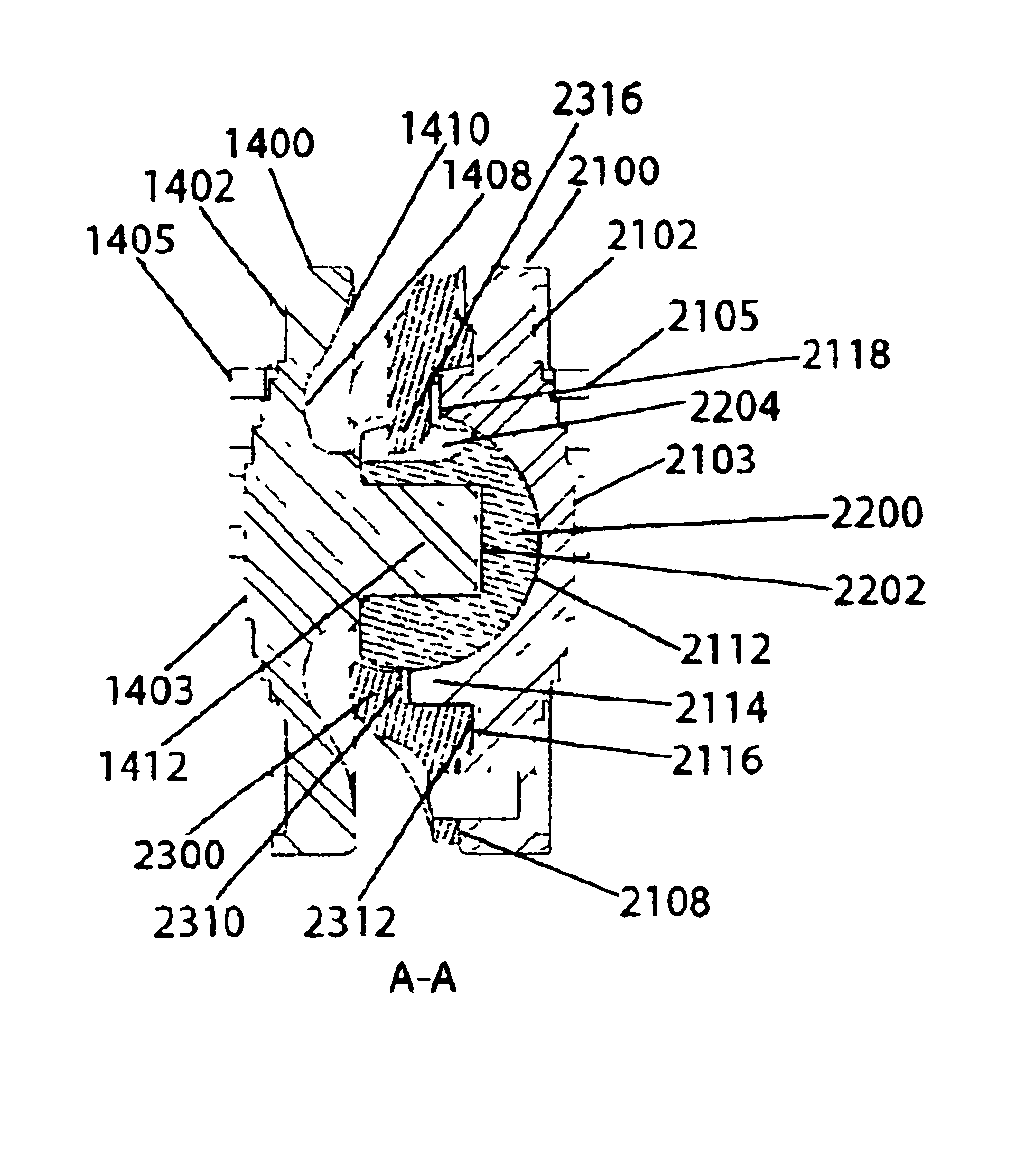

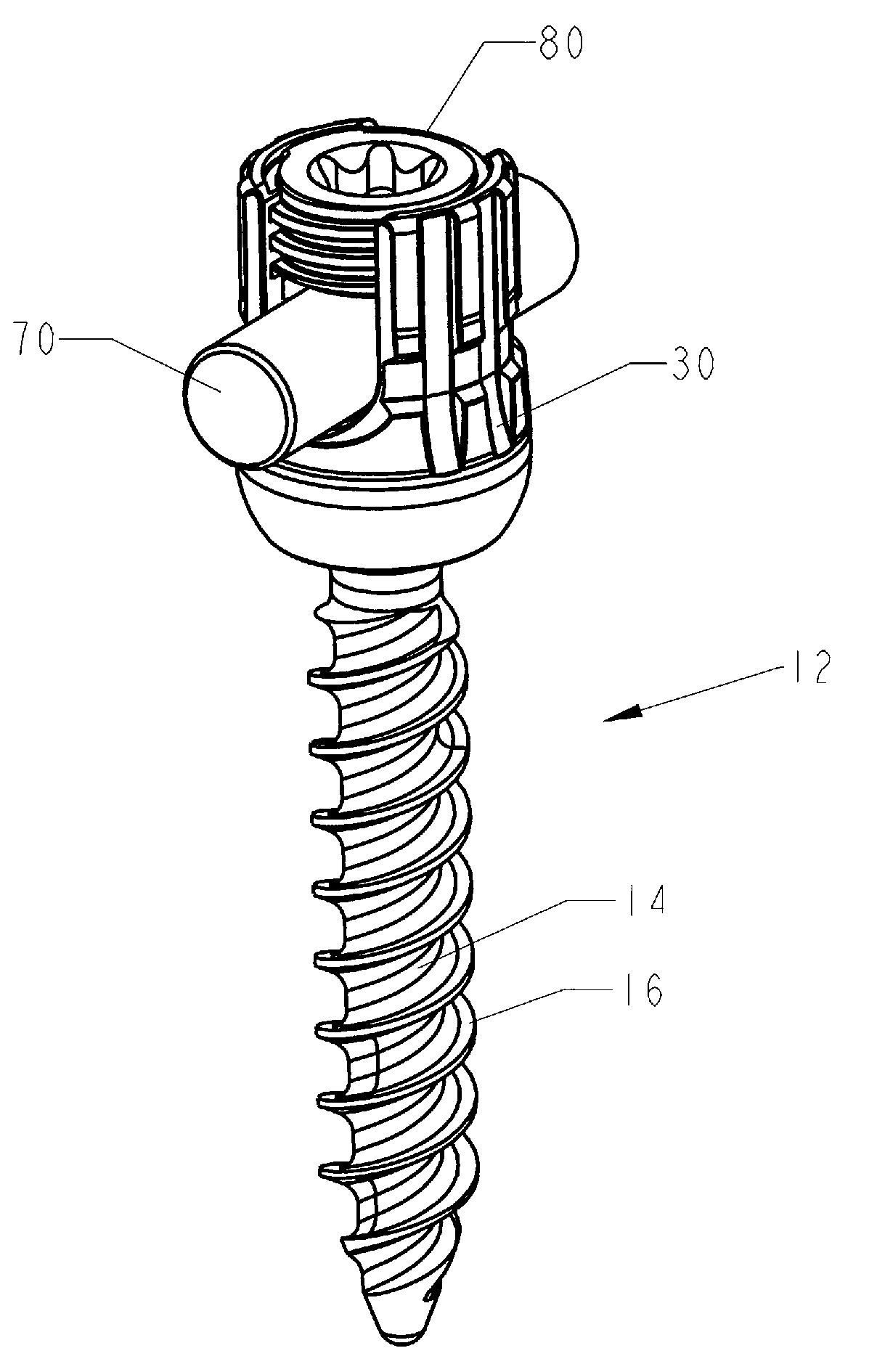

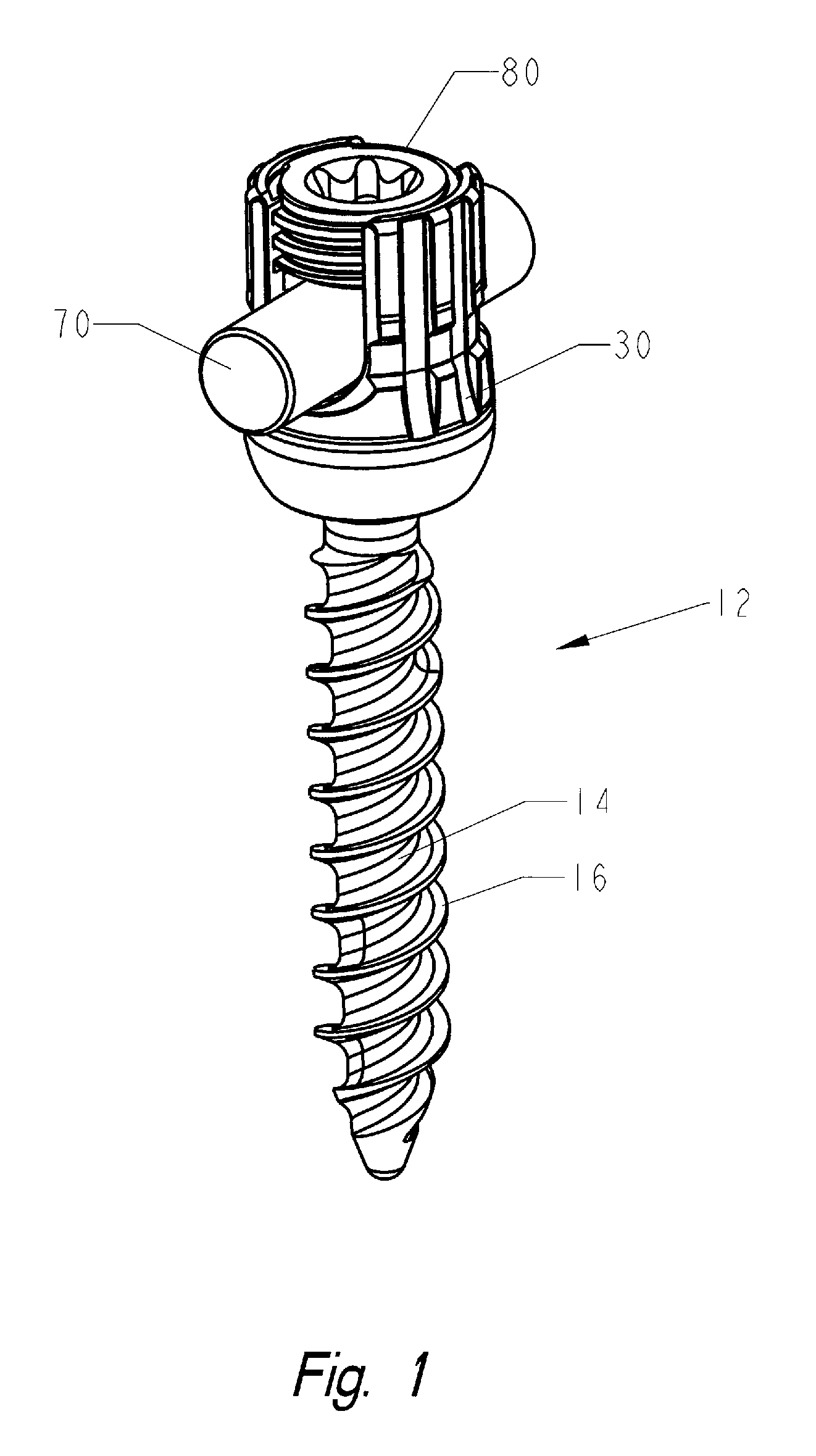

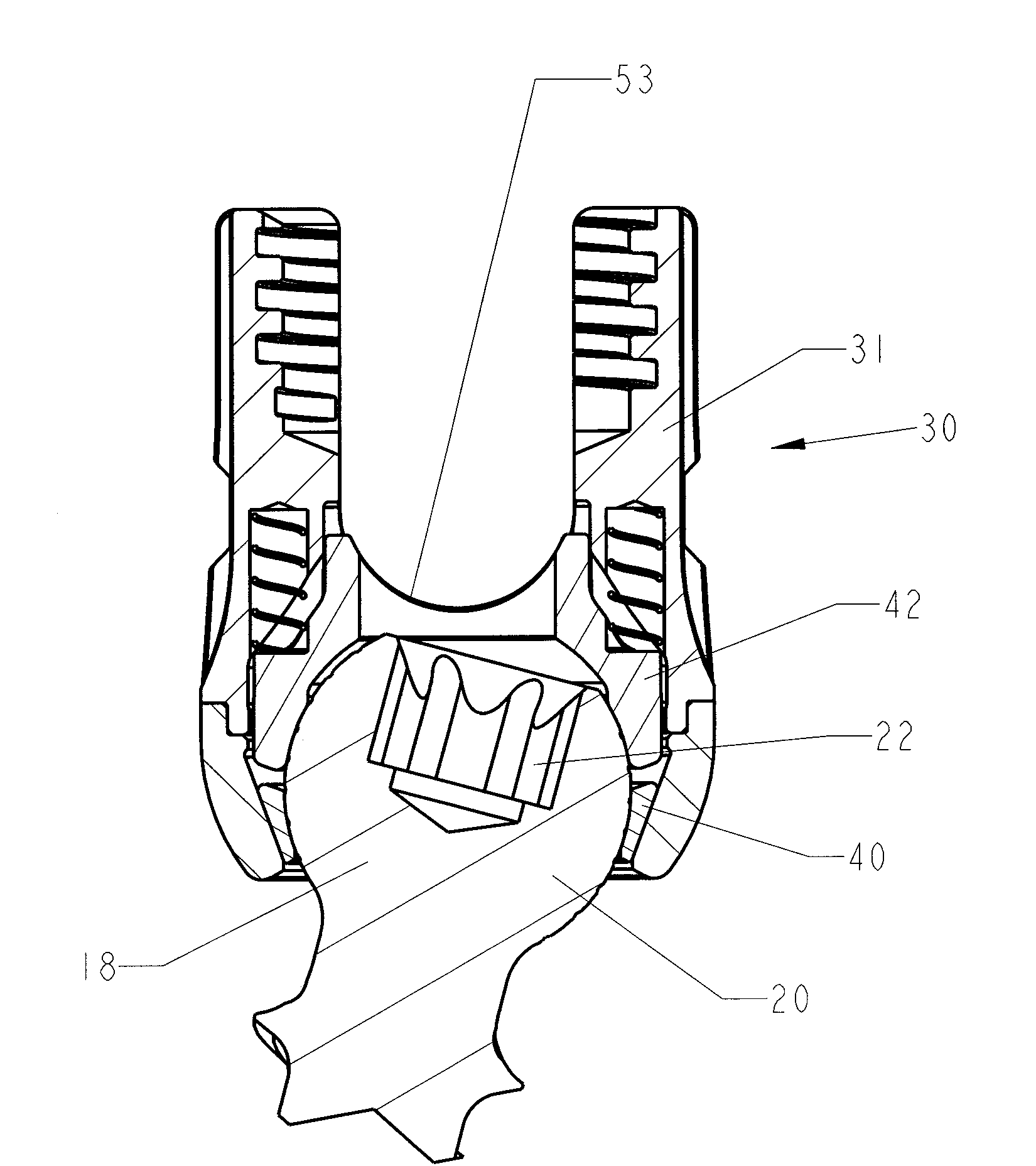

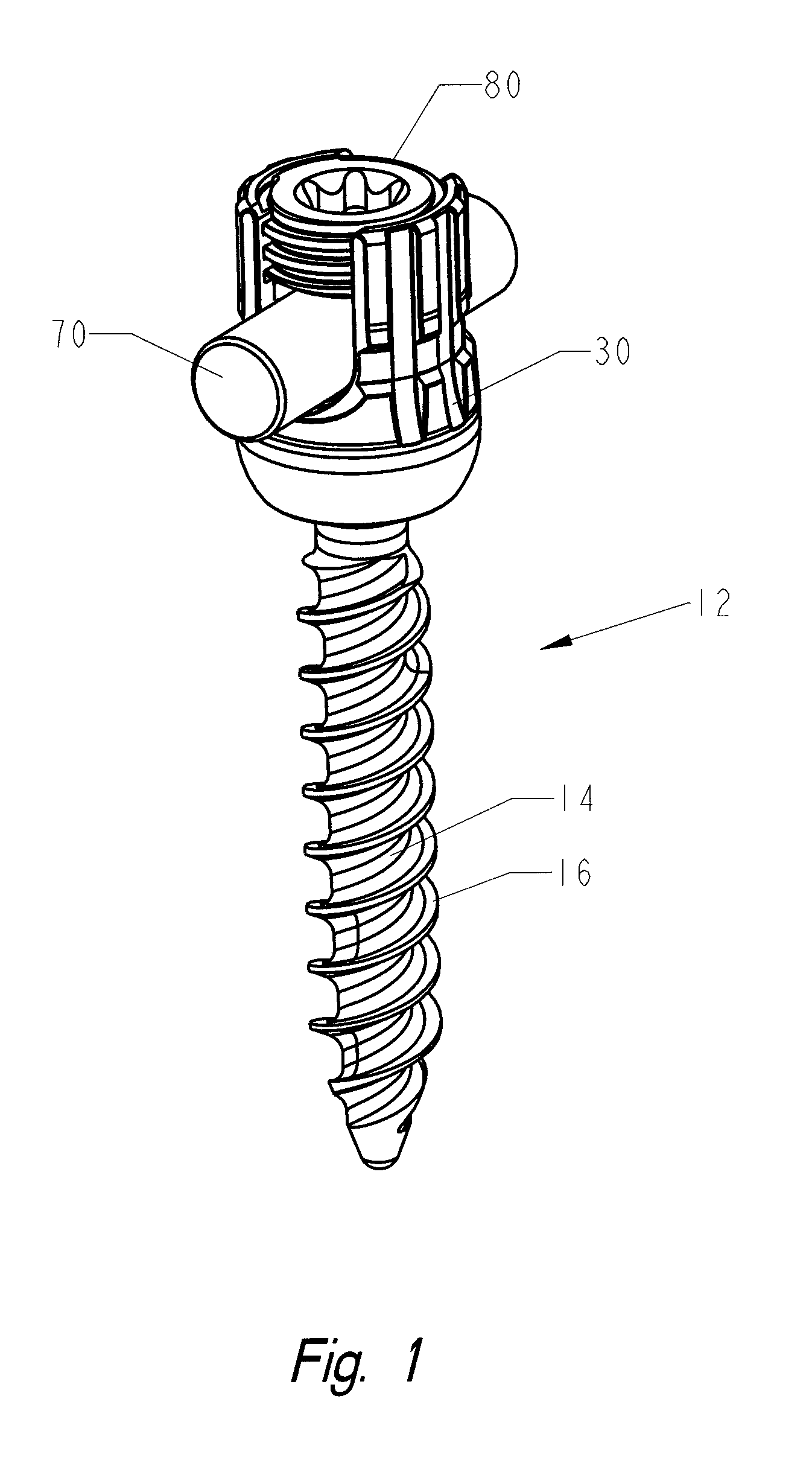

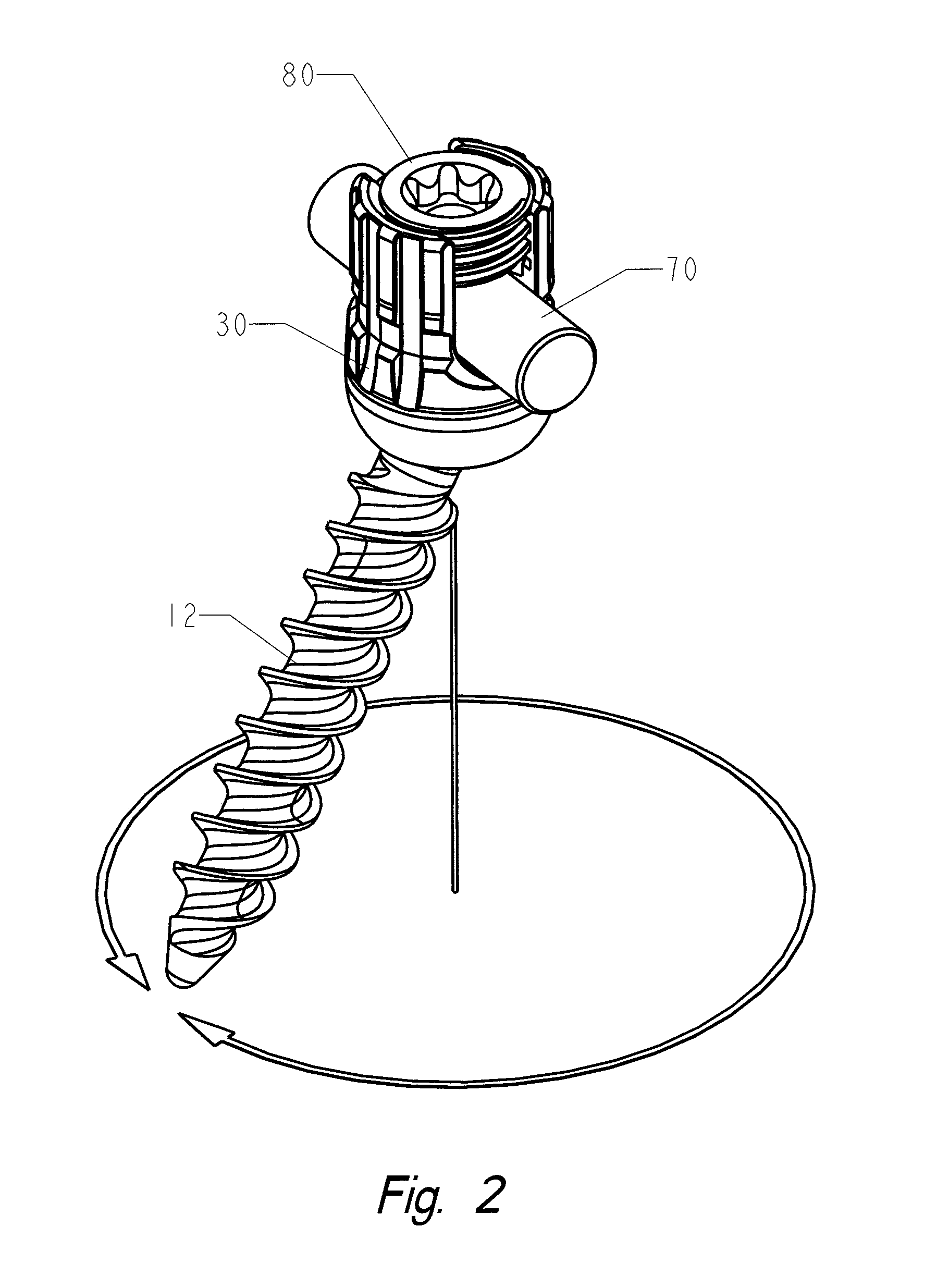

Locking Polyaxial Ball And Socket Fastener

ActiveUS20100125302A1Reduce the amount requiredCorrected satisfactorilySuture equipmentsInternal osteosythesisEngineeringScrew thread

A polyaxial ball and socket joint that can be locked into a fixed position. The fastening system consists of the polyaxial ball and socket joint used in conjunction with a bone screw having threads on one end for use in anchoring to the spine and a spherical connector on the other end operating as a pivot point about which a connecting assembly moves in a polyaxial fashion. A substantially U-shaped connecting assembly has a lower receptacle that operates as a socket for housing an upper retainer ring and a lower split retaining ring. The socket is receptive to the spherical connector which is inserted through the lower split retainer ring causing a momentary displacement thereof which allows for the positioning of the spherical connector between the upper and lower retainer rings.

Owner:ORTHO INNOVATIONS

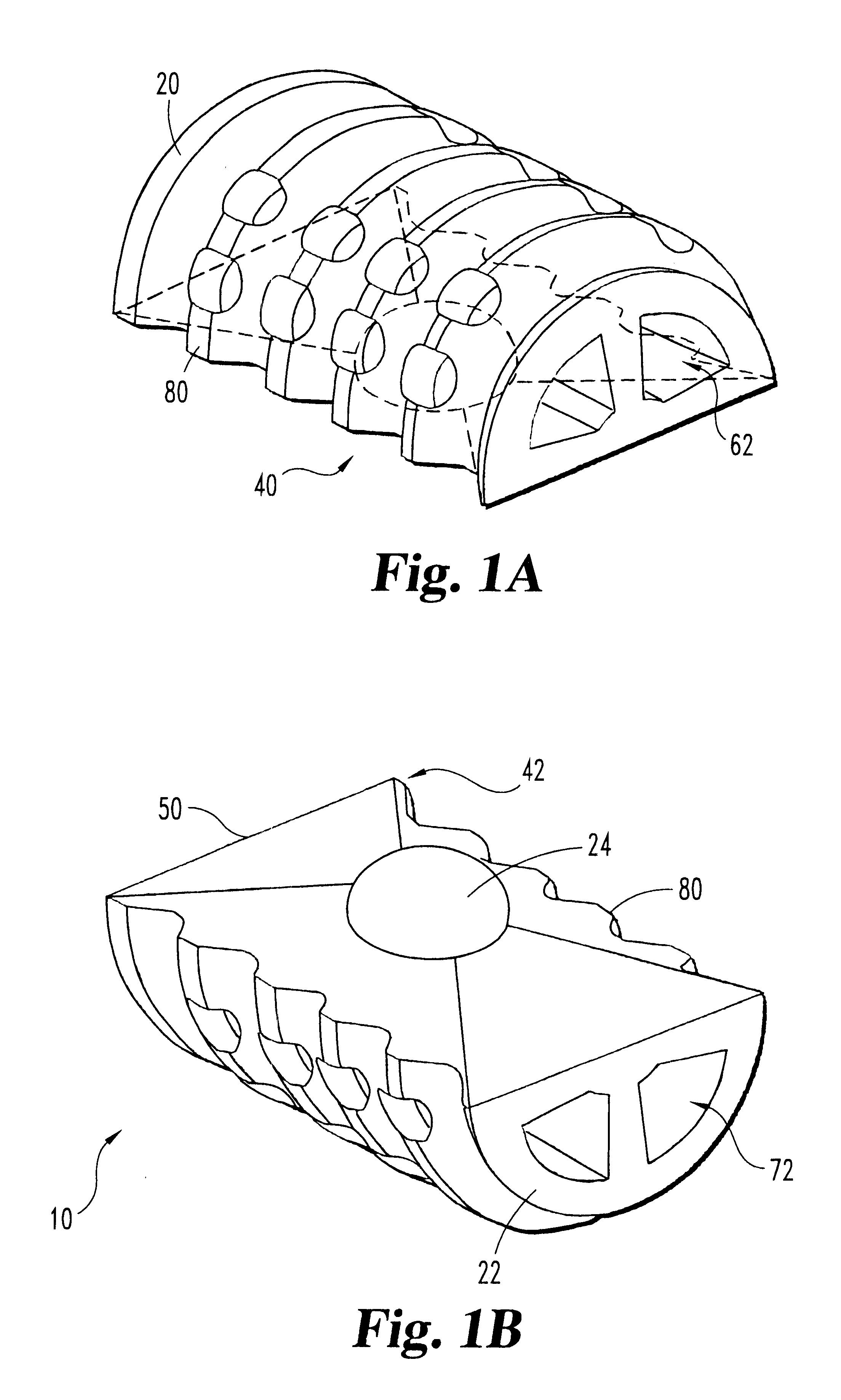

Artificial intervertebral disc

InactiveUS6989032B2Inhibition of translationAvoid separationJoint implantsSpinal implantsConvex structureVertebral bone

An artificial disc having a pair of opposing baseplates, for seating against opposing vertebral bone surfaces, separated by a ball and socket joint that includes a ball compression locked to a post extending from one of the baseplates. The ball is captured within a curvate socket formed in a peak of a convex structure attached to the other of the baseplates. The socket is formed by opposing curvate surfaces, one on the convex structure and one on the other of the baseplates. While the ball angulates freely in the socket, the rotation of the ball in the socket has a limited range due to interference between a protrusion on the convex structure that extends into the socket and a curvate recess on the ball. The ball and socket joint therefore permits the baseplates to rotate relative to one another through a limited range and also angulate relative to one another.

Owner:HOWMEDICA OSTEONICS CORP

Locking polyaxial ball and socket fastener

ActiveUS7947065B2Reduce manufacturing costFacilitates the receipt of the spherical connectorSuture equipmentsInternal osteosythesisEngineeringScrew thread

Owner:ORTHO INNOVATIONS

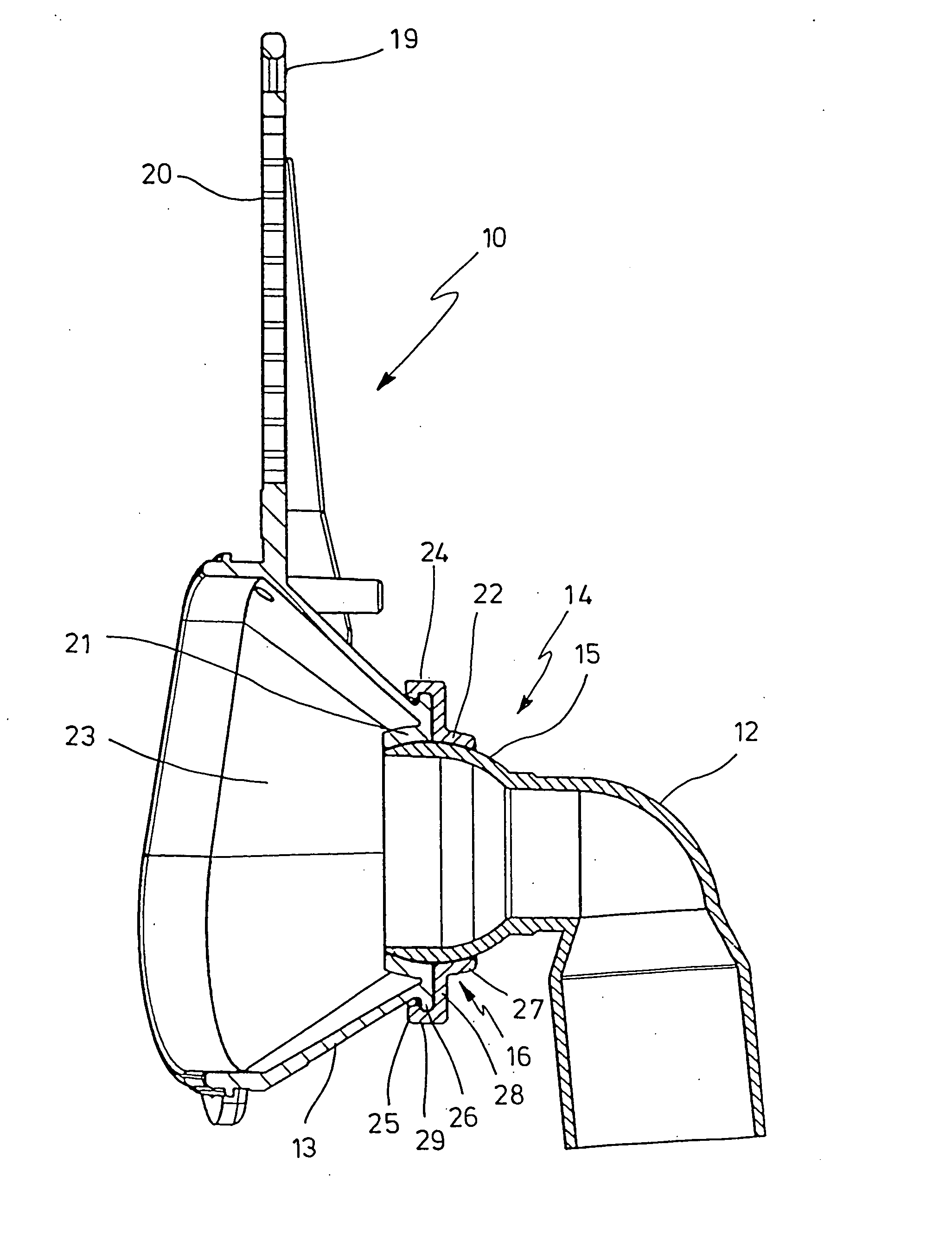

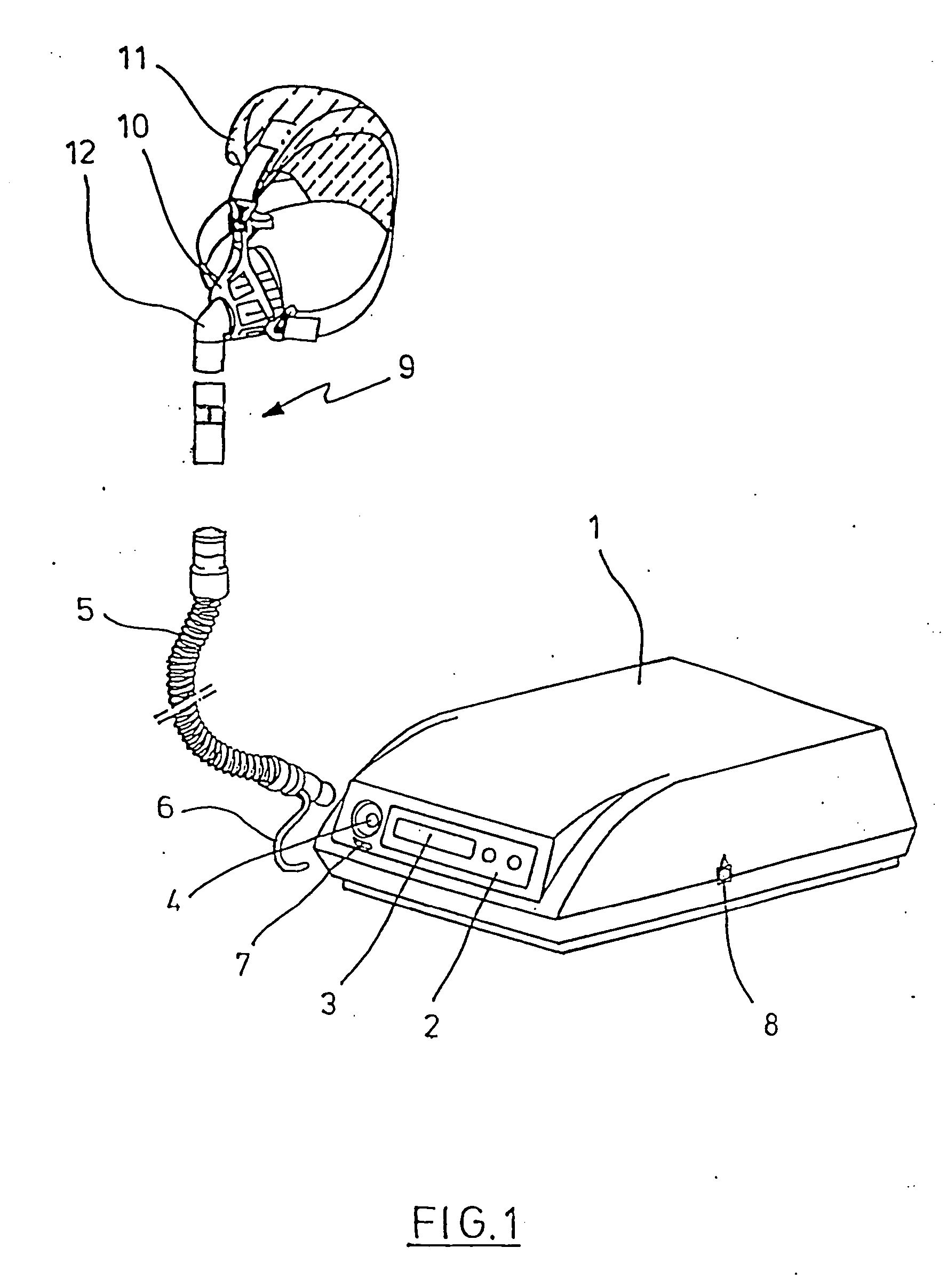

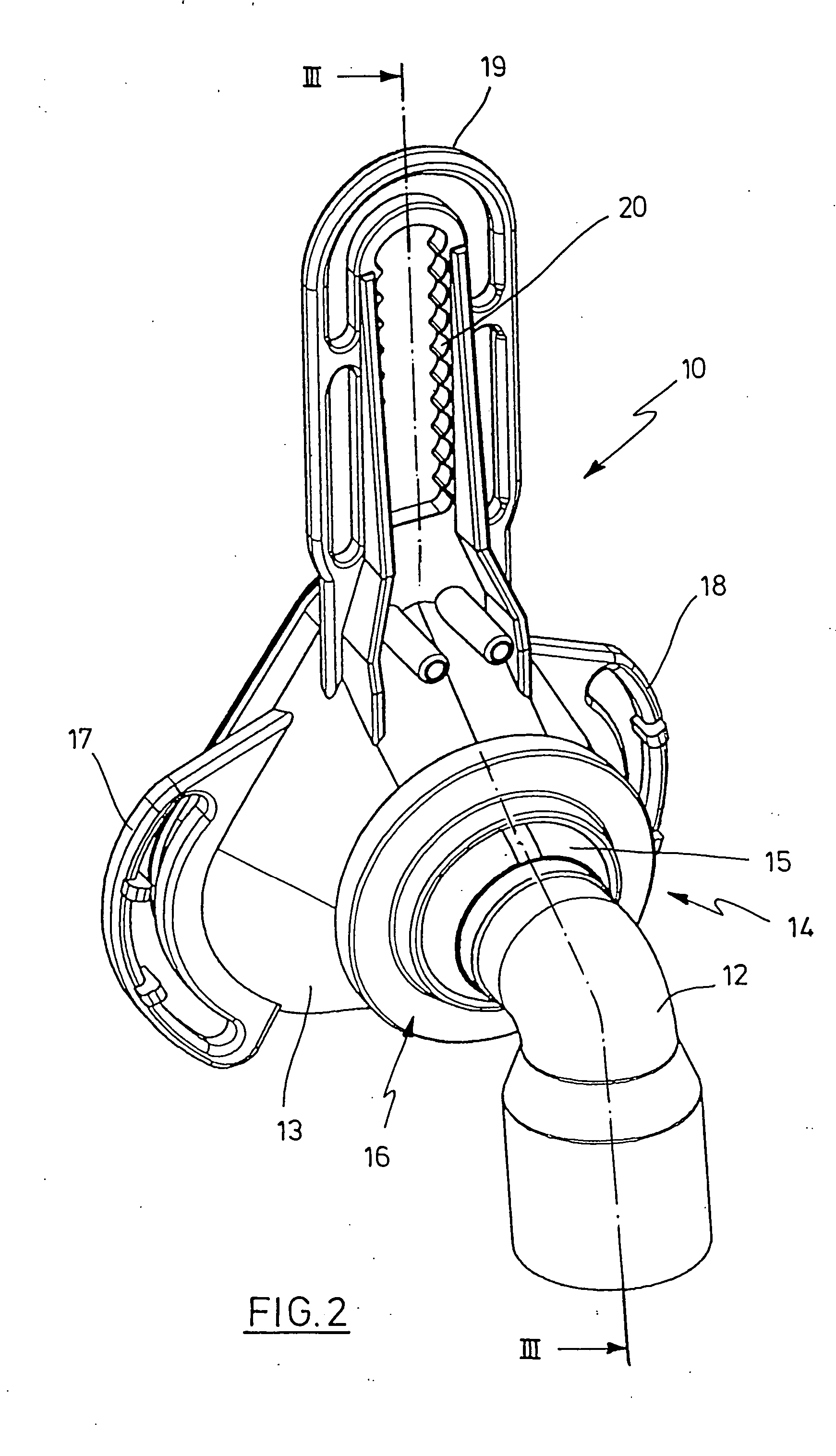

Ventilation device

InactiveUS20050150497A1Improve mechanical stabilityEasy to assembleRespiratory masksBreathing masksBreathing gasEngineering

A device used for ventilation includes a ventilation mask that can be connected to a respiratory gas hose. The ventilation mask has a respiratory gas hose coupling that is movably connected by a joint with the base of the ventilation mask. The joint is a ball-and-socket joint, which has an inner part that is shaped like a spherical segment and an outer shell for guiding the inner part. The outer shell is constructed from at least two shell segments that can be connected with each other.

Owner:WEINMANN GERATE FUR MEDIZIN

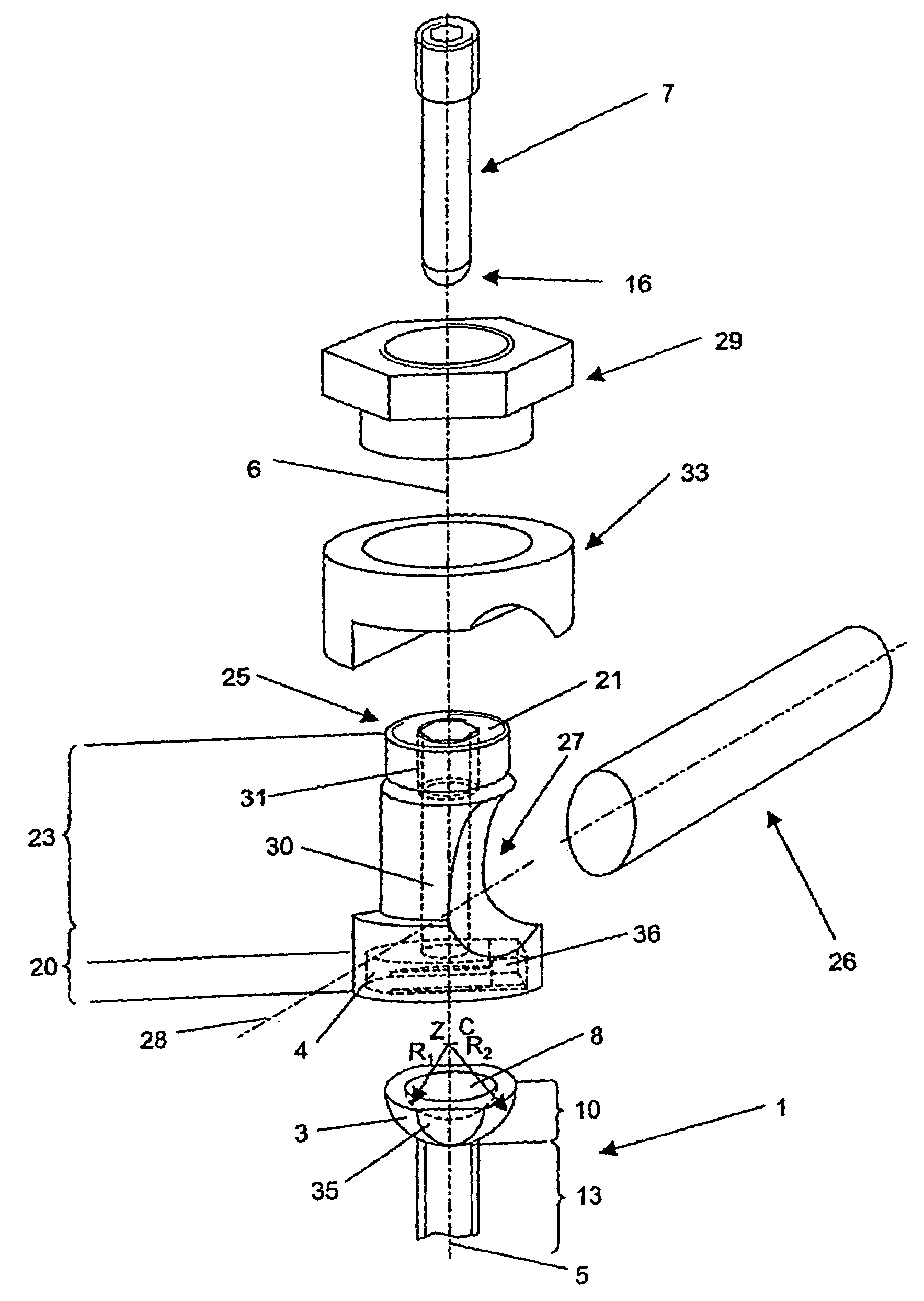

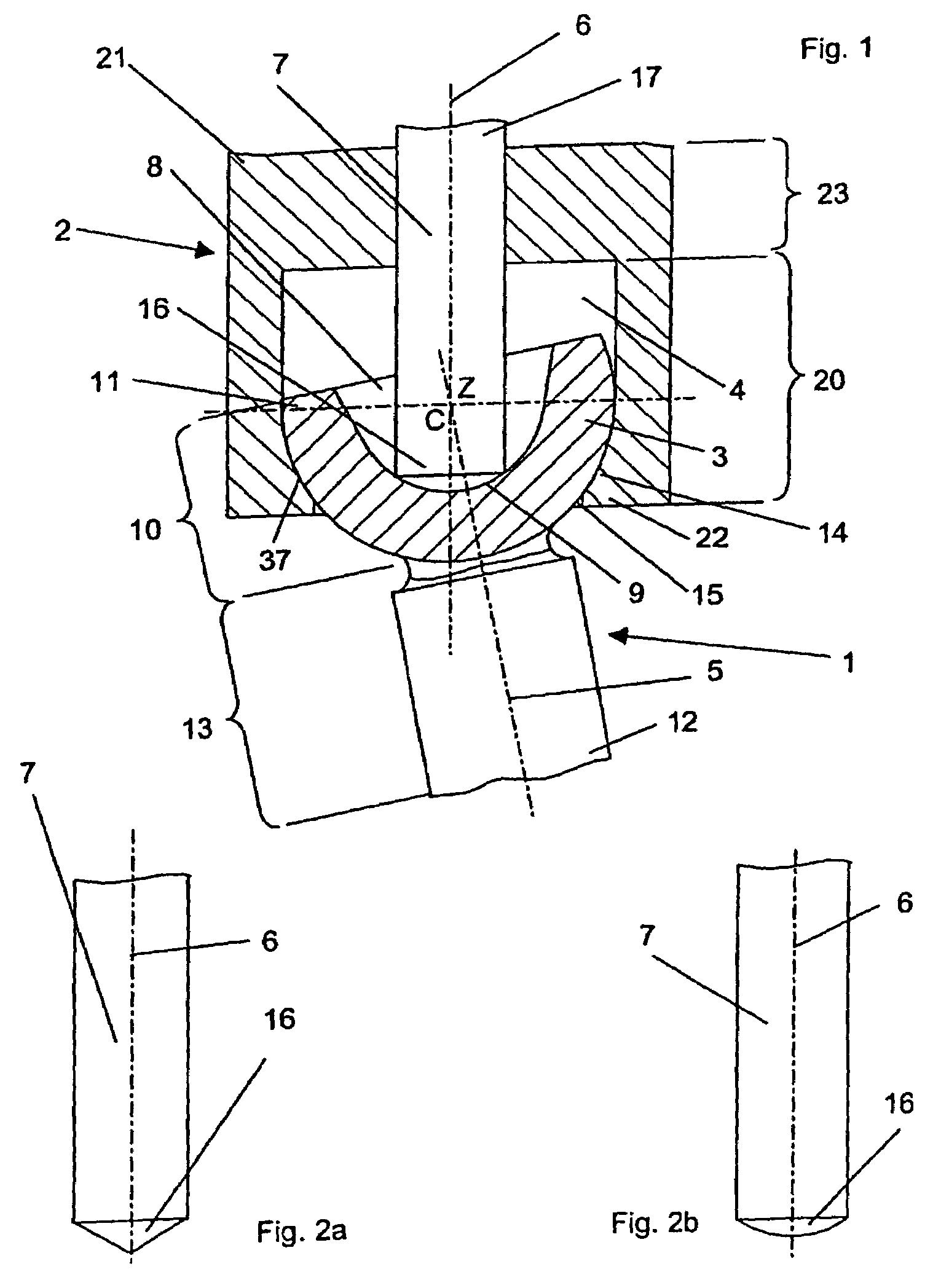

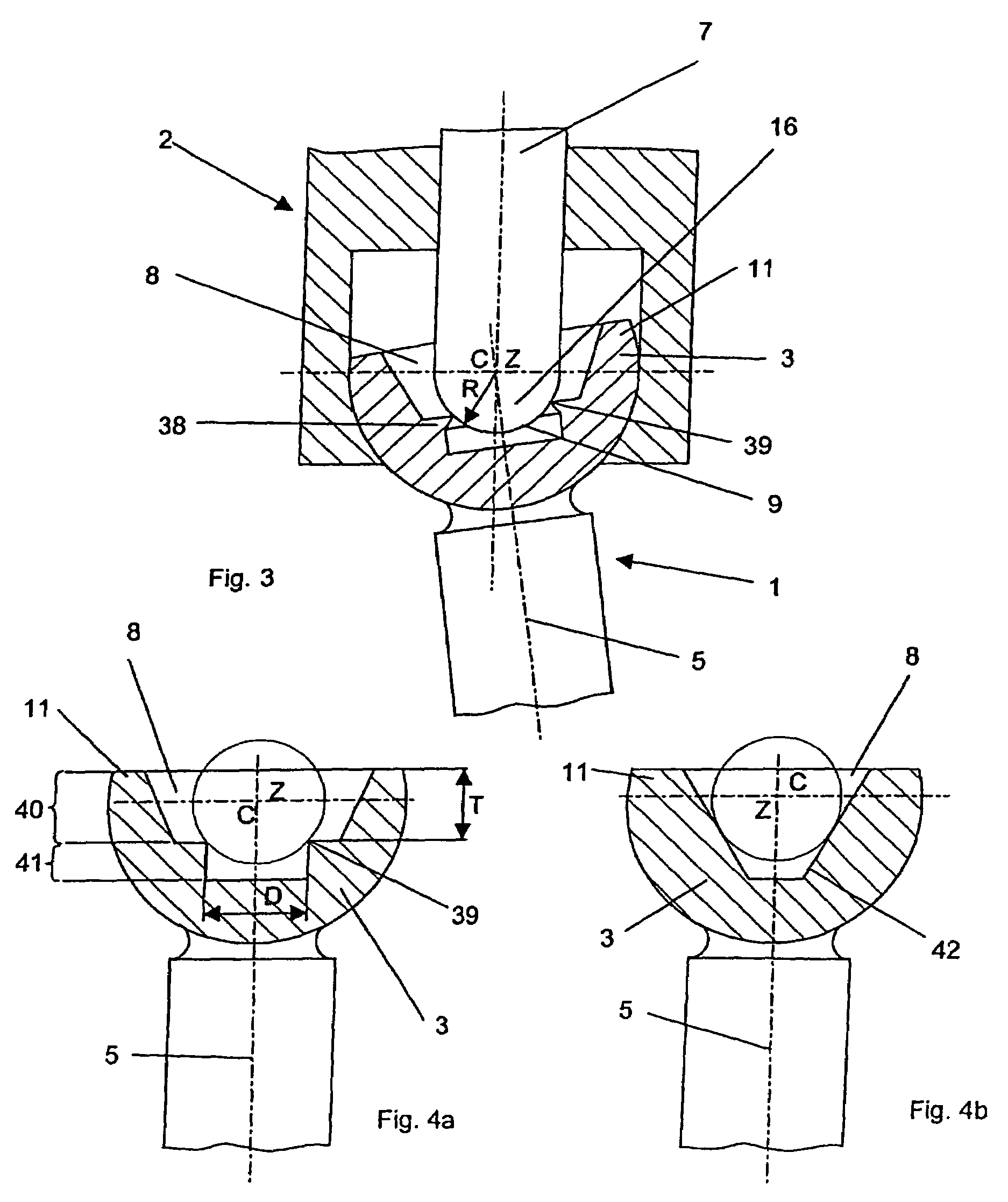

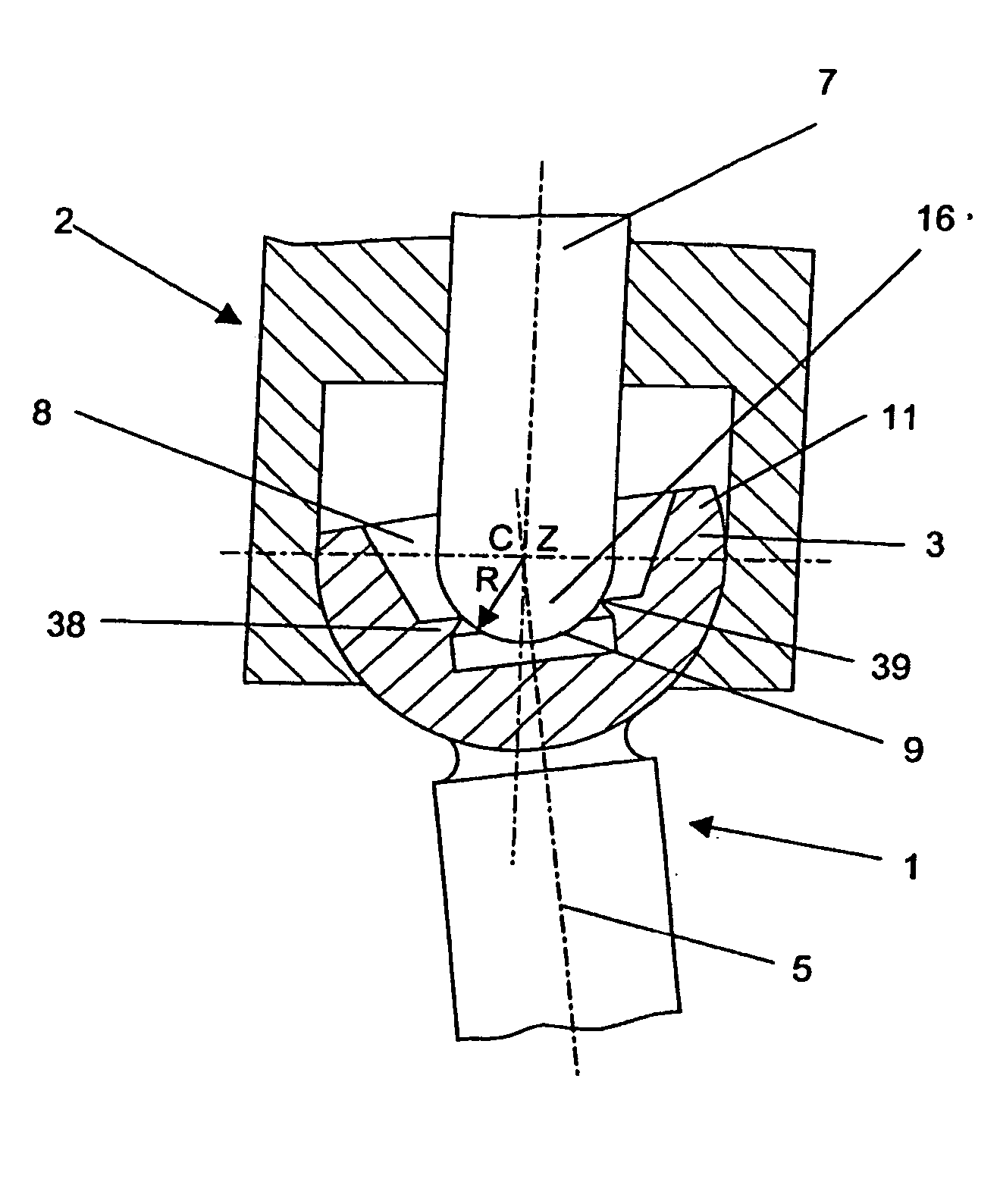

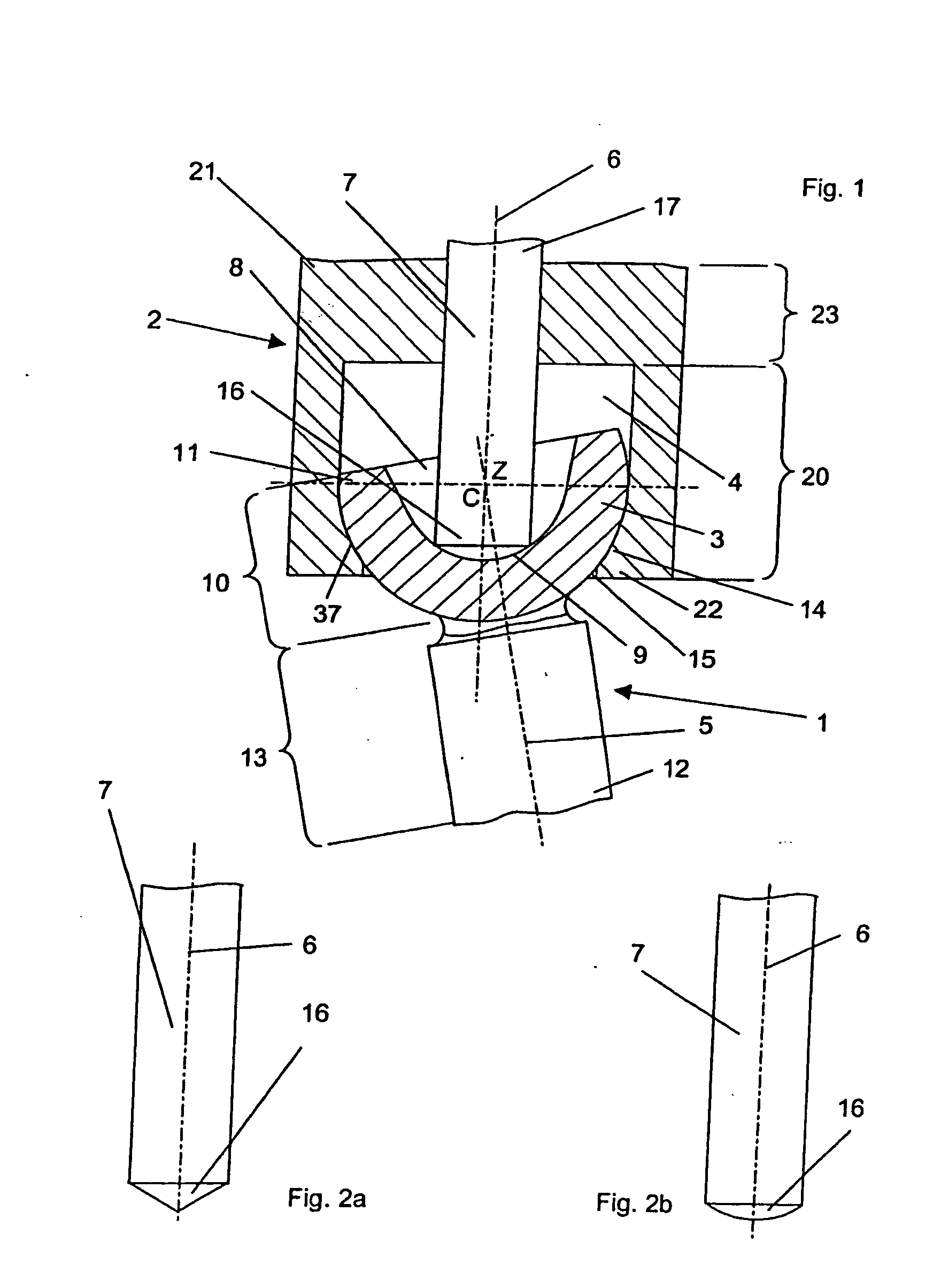

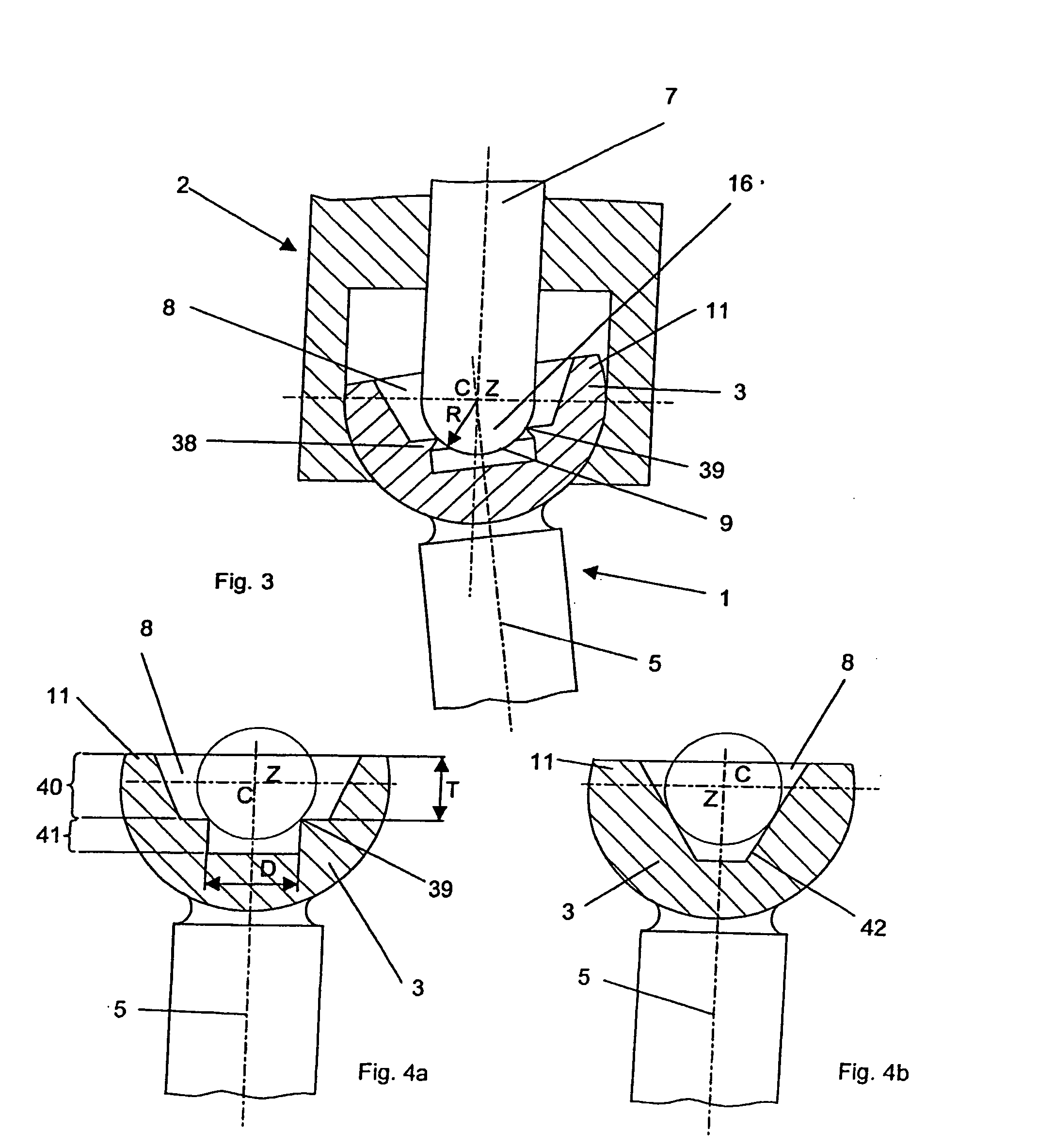

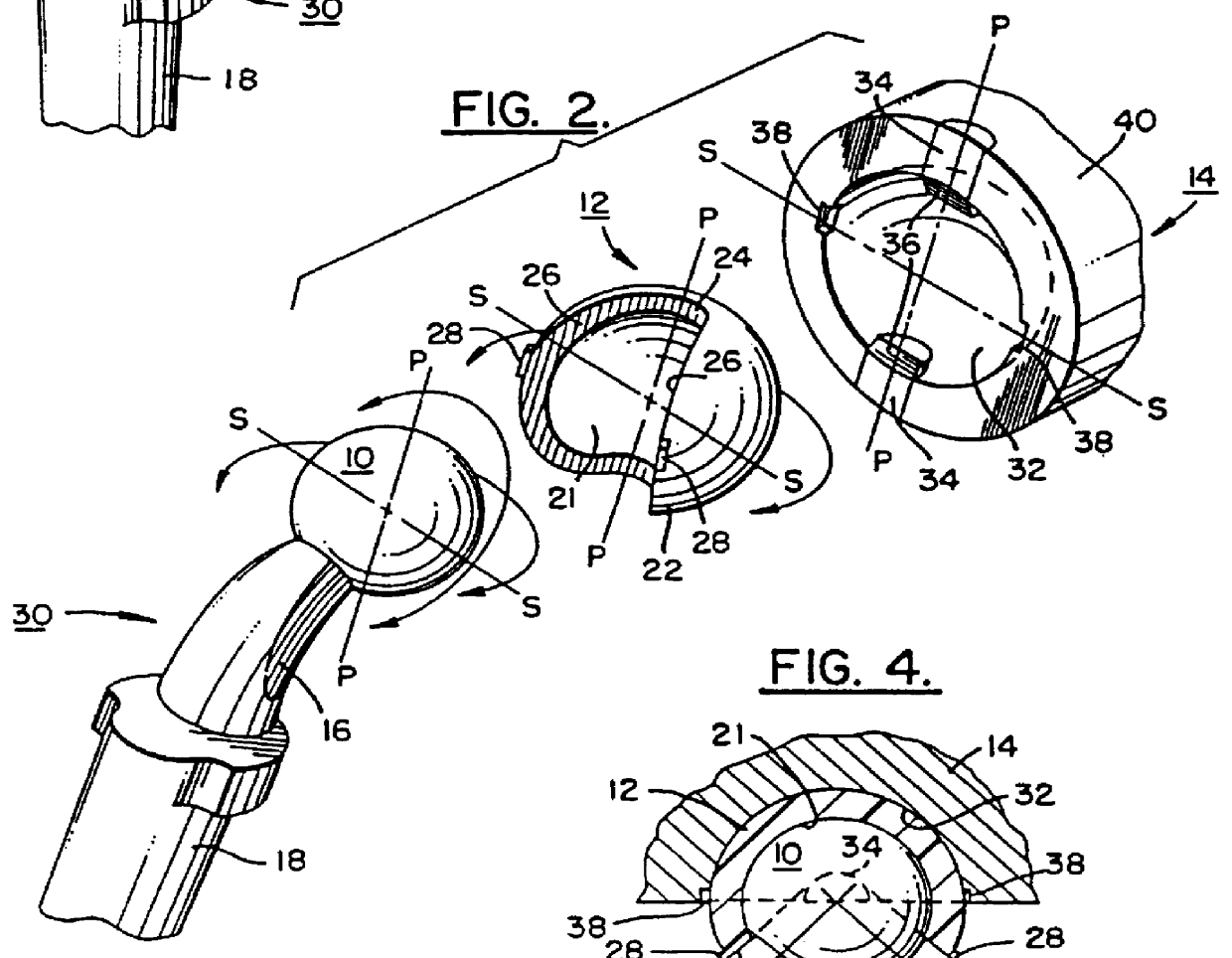

Device for a ball-and-socket joint type connection of two members

InactiveUS7121755B2Small dimensionReduce the overall heightSuture equipmentsScaffold connectionsEngineeringSpherical form

A device for a ball-and-socket-type connection of two members includes a first member having a head and a second member having a cavity that receives the head. The cross-sectional surface of the cavity is tapered at the lower end of the second member as a result of a constriction. The head and / or cavity is configured spherically with a center of articulation (Z). The ball-and-socket-type connection between the two members can be detachably fixed by a clamping element that can be connected to the second member. The head has a recess in which the front end of the clamping element can rest. The recess and / or the front end has an at least partially spherical surface with a centre (C). In the clamped position of the device, the center of articulation (Z) and the centre (C) are identical.

Owner:SYNTHES USA

Locking polyaxial ball and socket fastener

ActiveUS8075603B2Sufficient forceEasy to installSuture equipmentsInternal osteosythesisEngineeringScrew thread

The fastening system consists of the polyaxial ball and socket joint used in conjunction with a bone screw having threads on one end for use in anchoring to the spine and a spherical connector on the other end operating as a pivot point about which a connecting assembly moves in a polyaxial fashion. A substantially U-shaped connecting assembly has a lower receptacle that operates as a socket for housing an upper retainer ring and a lower split retaining ring. The socket is receptive to the spherical connector which is inserted through the lower split retainer ring causing a momentary displacement thereof which allows for the positioning of the spherical connector between the upper and lower retainer rings. A resilient component positioned between the upper retainer ring and the connecting assembly permits relative predetermined placement and retention of the spherical connector relative to the connector assembly due to the force generated by the resilient component and frictional engagement between the surfaces of spherical connector, the upper and lower retainer rings and the connector assembly. The polyaxial ball and socket can be locked into a fixed position.

Owner:ORTHO INNOVATIONS

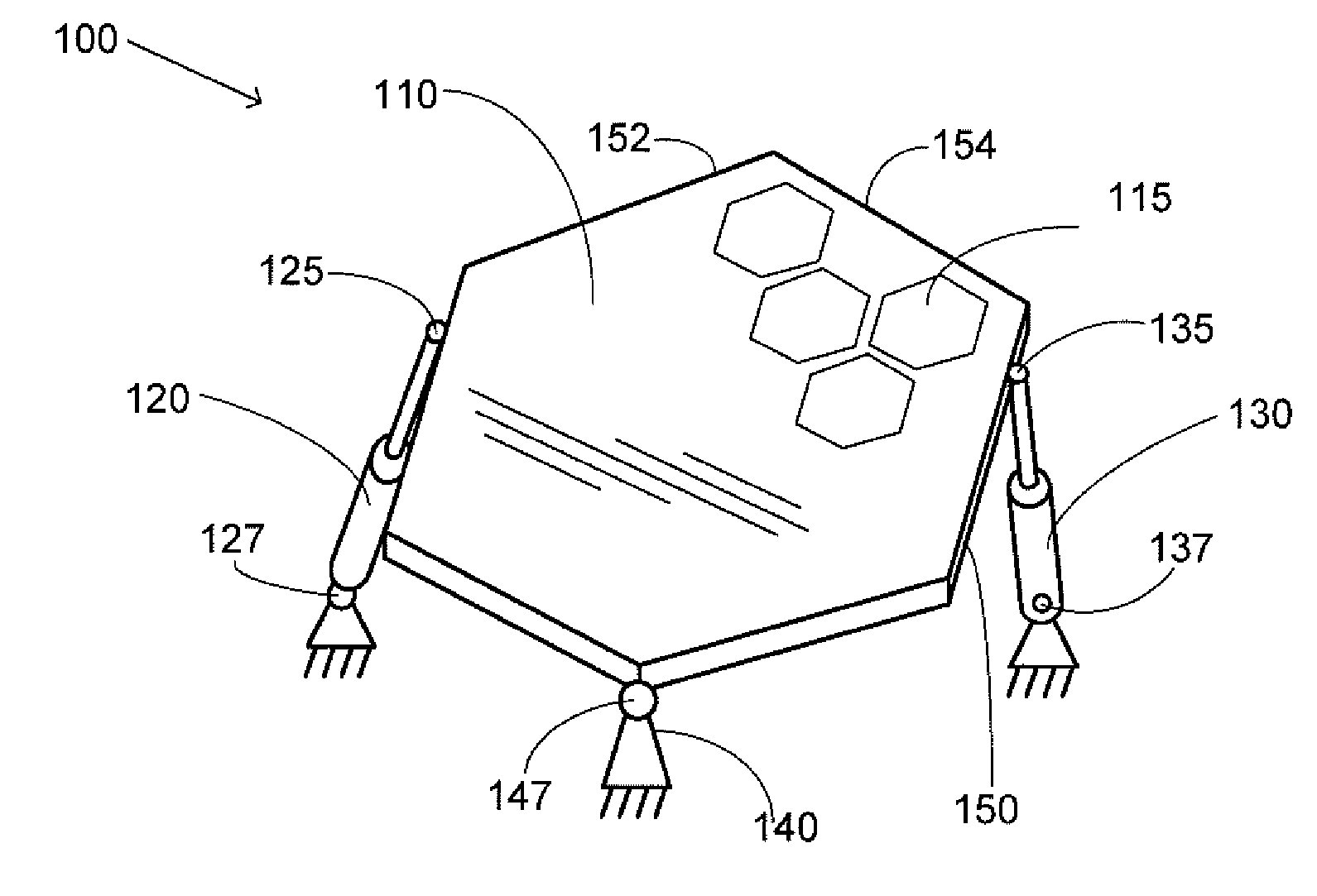

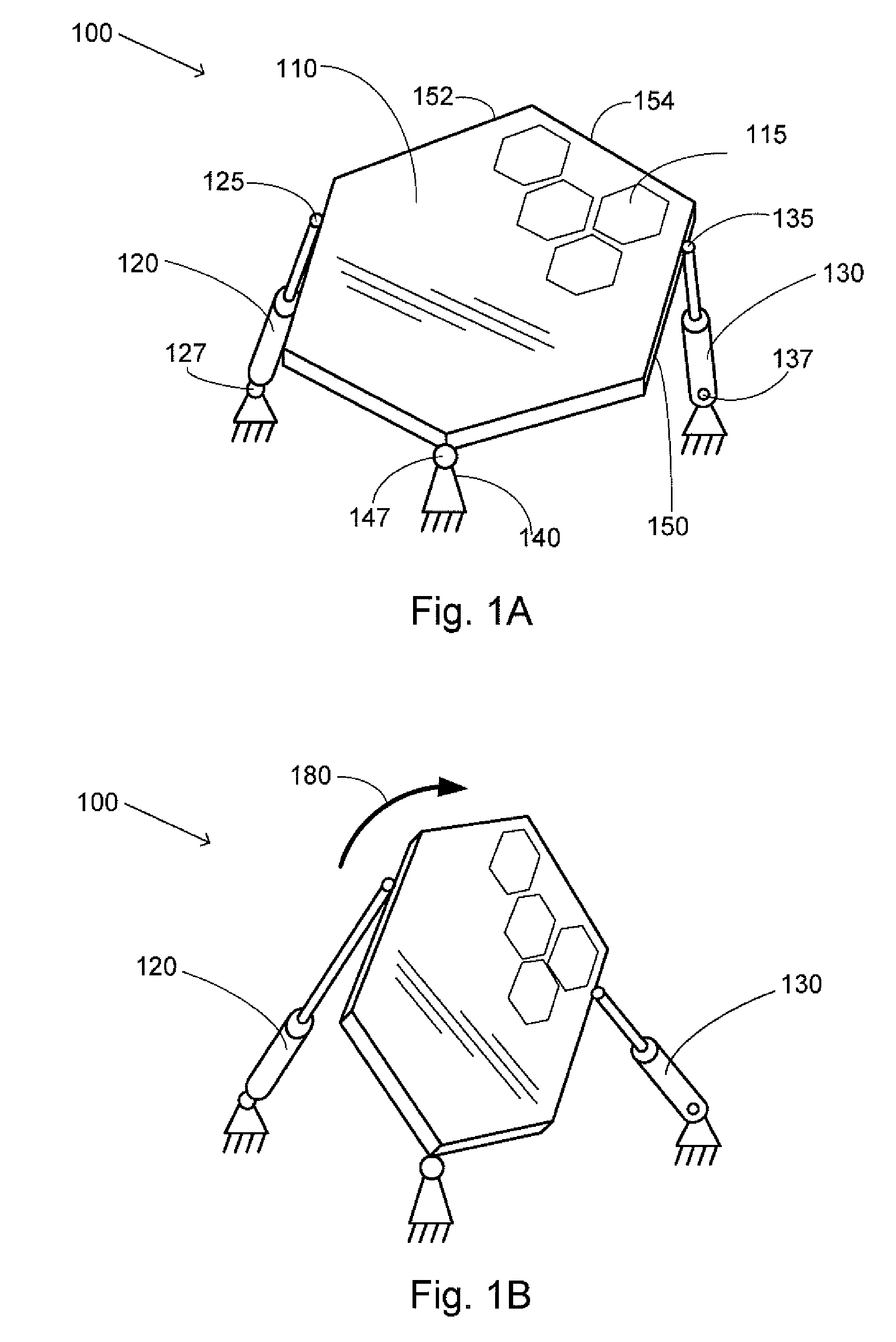

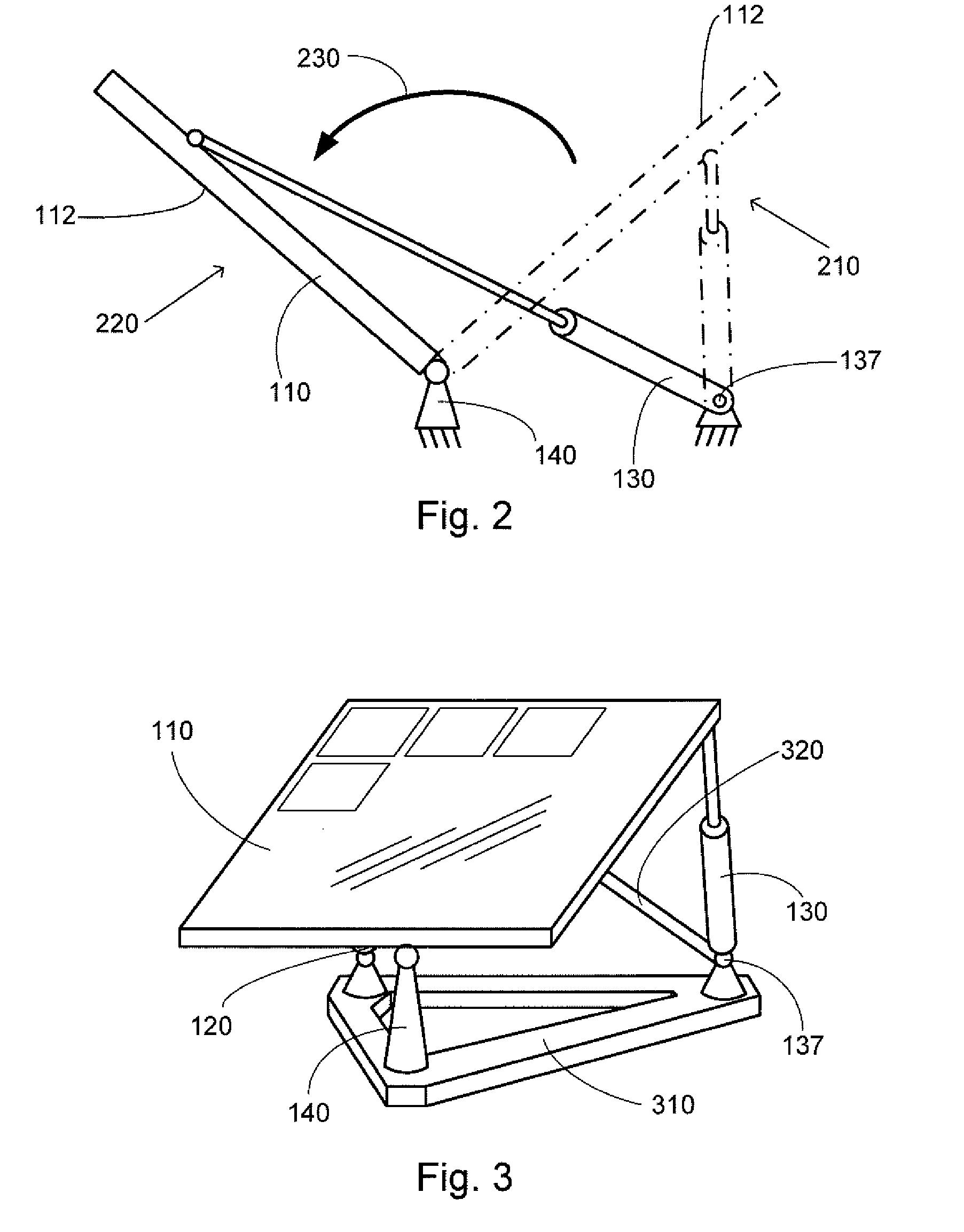

System and Method for Solar Tracking

InactiveUS20090050191A1Easy to installStable and cost-effective designSolar heating energyPhotometry using reference valueRange of motionComputer module

Owner:SOLFOCUS

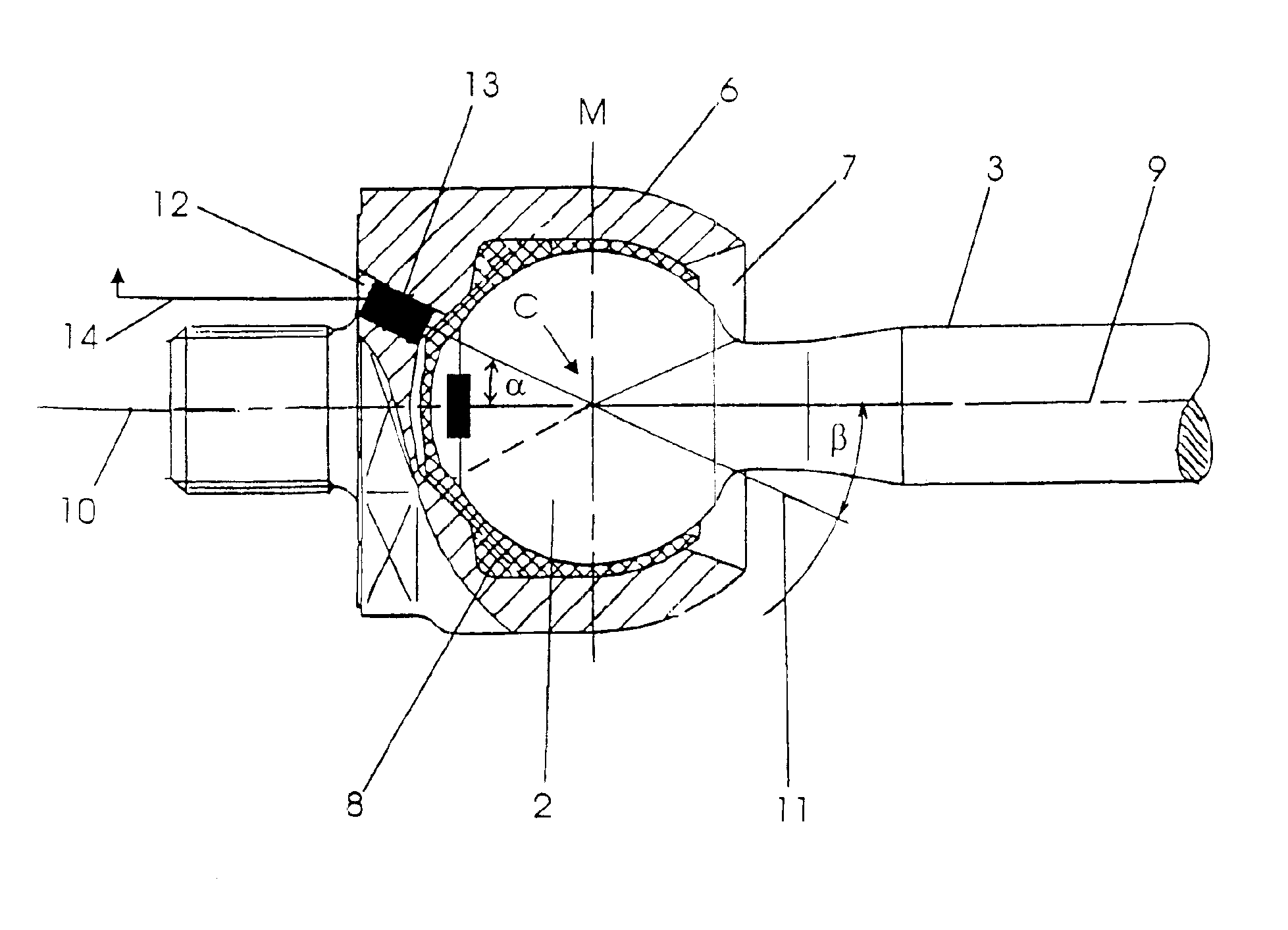

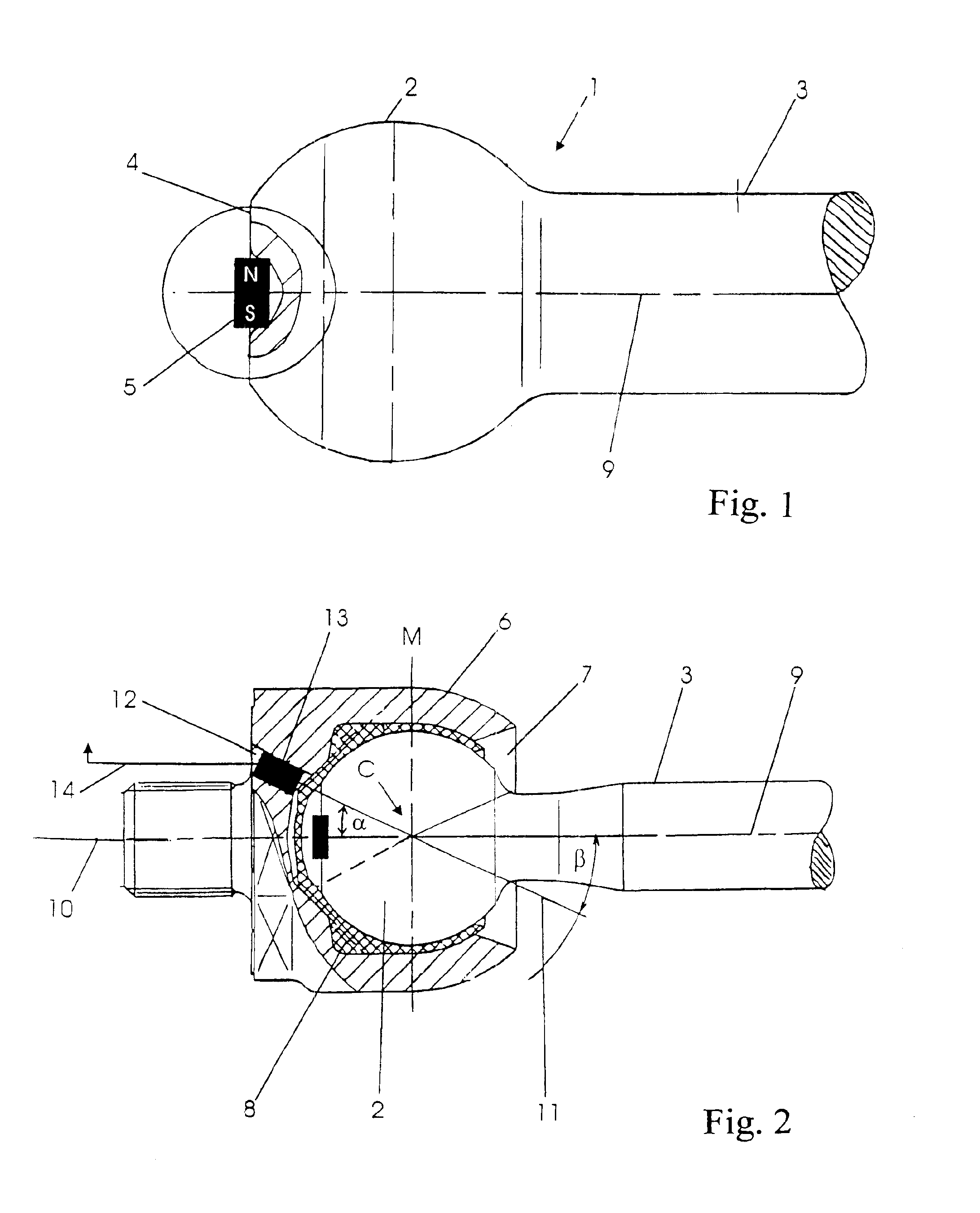

Ball joint with integrated angle sensor

InactiveUS6879240B2Improve accuracyDetect any spatial positionBearing assemblyShaftsTransducerEngineering

A ball-and-socket joint with integrated angle sensor for a motor vehicle, especially for the chassis of the motor vehicle is created. The ball-and-socket joint has a ball-and-socket joint housing (6) provided with a joint opening (7), a ball pivot (1) having a joint ball (2) and a pin (3), which is mounted, with its joint ball (2), rotatably and pivotably in a hollow-ball-shaped bearing surface in the ball-and-socket joint housing (6), and projects, with its pin (3), through the joint opening (7) out of the ball-and-socket joint housing (6). A two-pole field transducer (5) is provided at the end of the joint ball (2) facing away from the pin (3). The poles of the field transducer (5) are arranged on the ball surface. In this case, at least two field sensors (13) are arranged at a distance from one another with respect to the meridian plane defined by the large circle on the hollow-ball-shaped bearing surface running at right angles to the bearing longitudinal axis in the area or on the ball-and-socket joint housing (6) facing away from the joint opening, and interact with the field produced by the field transducer (5).

Owner:ZF LEMFOERDER METALLWAREN AG

Device for a ball-and-socket joint type connection of two members

InactiveUS20050033436A1Reduce the overall heightSuture equipmentsScaffold connectionsSpherical formBiomedical engineering

The invention relates to a device for a ball-and-socket-type connection of two members. Said device including a first member and a second member, which are interconnected by a ball-and-socket-type articulation; the first articulation segment is configured on the first member as an articulation head and the second articulation segment is configured on the second member as a cavity that receives the articulation head; the cross-sectional surface of the cavity being tapered at the lower end of the second member as a result of a constriction; at least one of the articulation segments in the contact area of the latter is configured spherically with a center of articulation Z; the ball-and-socket-type connection between the two articulation segments can be detachably fixed by means of a clamping element that can be connected to the second articulation segment; the articulation head has a recess, in which the front end of the clamping element can rest; the recess and / or the front end of the clamping element has an at least partially spherical surface with a centre C; and in the clamped position of the device, the center of articulation Z and the centre C are identical.

Owner:SYNTHES USA

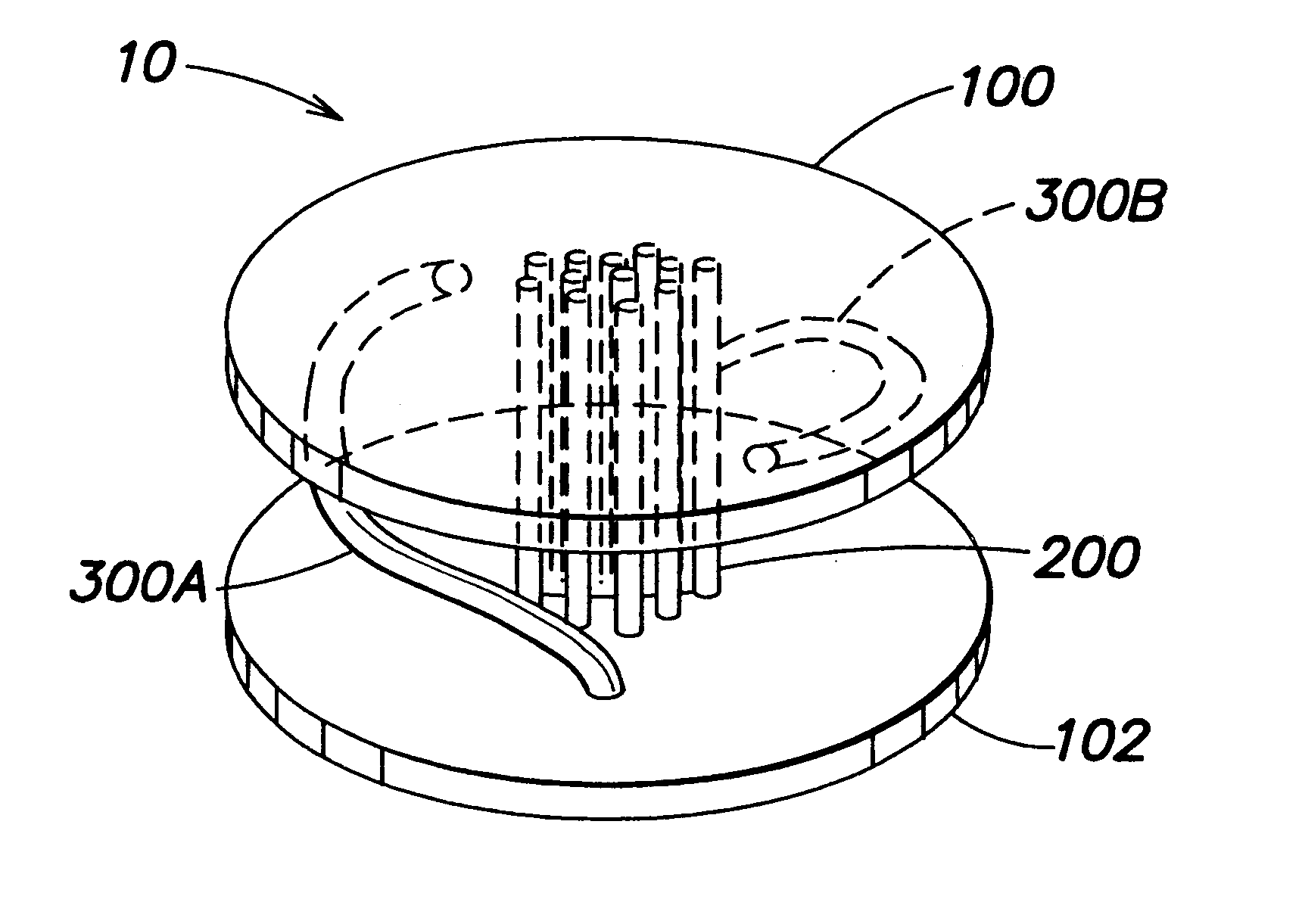

System and method for dynamic vertebral stabilization

An intervertebral stabilization device and method is disclosed. The device preferably includes a planar spring enclosed within a housing. The housing is joined to an articulation component at either end, and the articulation components have couplings connectable to anchoring components which are securable to adjacent vertebrae. The planar spring can flex and retract providing relative motion between the adjacent vertebrae. The articulation components are ball and socket joints which allow the entire assembly to flexibly follow the curvature of the spine. A fusion rod with articulation components and couplings at either end may be substituted for the spring device. The couplings enable interchangeability between a fusion rod assembly and spring assembly, so that dynamic stabilization can occur at one vertebral level and fusion at the adjacent vertebral level. An overhung spring assembly with a sideways displaced housing which allows for a shorter pedicle to pedicle displacement is also disclosed.

Owner:STRYKER EURO OPERATIONS HLDG LLC

System and method for performing arthroplasty of a joint and tracking a plumb line plane

ActiveUS8007448B2Improve functional propertiesImprove stabilitySurgical navigation systemsPerson identificationRange of motionMotion parameter

A method of performing an arthroplasty of a ball and socket joint with a surgical navigation system includes the step of digitizing landmarks to provide geometrical parameters of the joint and a limb depending there from, including digitizing aspects of a socket region of the ball and socket joint. A range of motion parameter is determined. A soft tissue tension parameter is determined. A functional goal is computed based on landmark data, the range of motion parameter, the soft tissue tension parameter, and a database of potential implants. An optimal socket position is solved for to minimize impingement of potential implants. An implant is chosen based on the optimal socket position and the functional goal. The joint is prepared to receive the chosen implant. The chosen implant is installed into the joint.

Owner:STRYKER EURO OPERATIONS HLDG LLC

Joint prosthesis and method for implantation

A prosthesis for replacement of a ball and socket joint in the human body. The prosthetic components comprise a plurality of separate parts which may be inserted through a hole in the femur of the patient and assembled and attached to the prepared acetabulum of the hip bone to form a cup-shaped first shell. A cup is also passed through the hole in the femur and attached to the first shell to form the socket portion of the joint. A shaft having a first end with a ball formed thereon is inserted in the hole through the femur so that the ball engages the cup for movement therein.

Owner:TARABISHY IMAD ED

Mounting apparatus using ball and socket joints with gripping features

The present invention is directed towards ball and socket joint connectors which, when interconnected, form a flexible assembly. In some embodiments, the ball and socket joint connectors are designed and constructed such that the interference fit of the ball and socket causes creep in the material resulting in more even frictions in the various ball and socket joints. In some embodiments, the ball and socket joint connectors utilize an over-molded strip around the outside of the connector to facilitate in their use for gripping. In an exemplary embodiment utilizing the aforementioned ball and socket joint connectors, a tripod apparatus uses legs comprising the ball and socket joint connectors for support and for gripping objects.

Owner:VIDENDUM MEDIA SOLUTIONS SPA

Ball and socket bearing for artificial joint

InactiveUS6042611ALarge range of motionRestrains the ball within the socketJoint implantsFemoral headsArtificial jointsSacroiliac joint

A ball and socket joint for implanting in the body is provided wherein the sooket portion of the joint can have various orientations with respect to the patient's anatomy, and the orientation used for a particular patient can be selected and / or changed in situ, that is, during or after implantation of the joint. In addition, the configuration of the joint, e.g., constrained versus semi-constrained, as well as the materials making up the socket portion of the joint, e.g., plastic versus metal, can be selected and / or changed in situ.

Owner:JOINT MEDICAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com