Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1485 results about "Dentures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

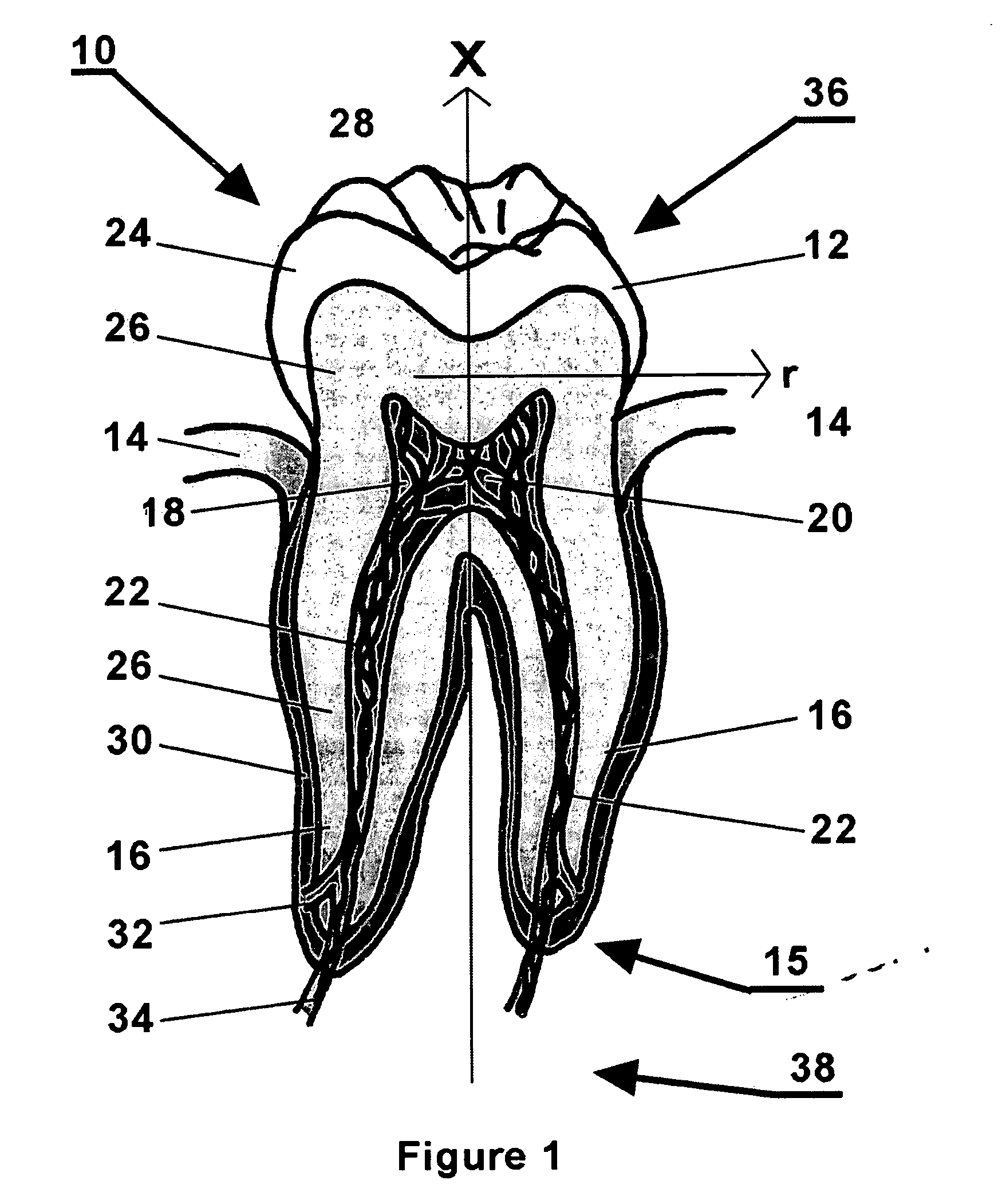

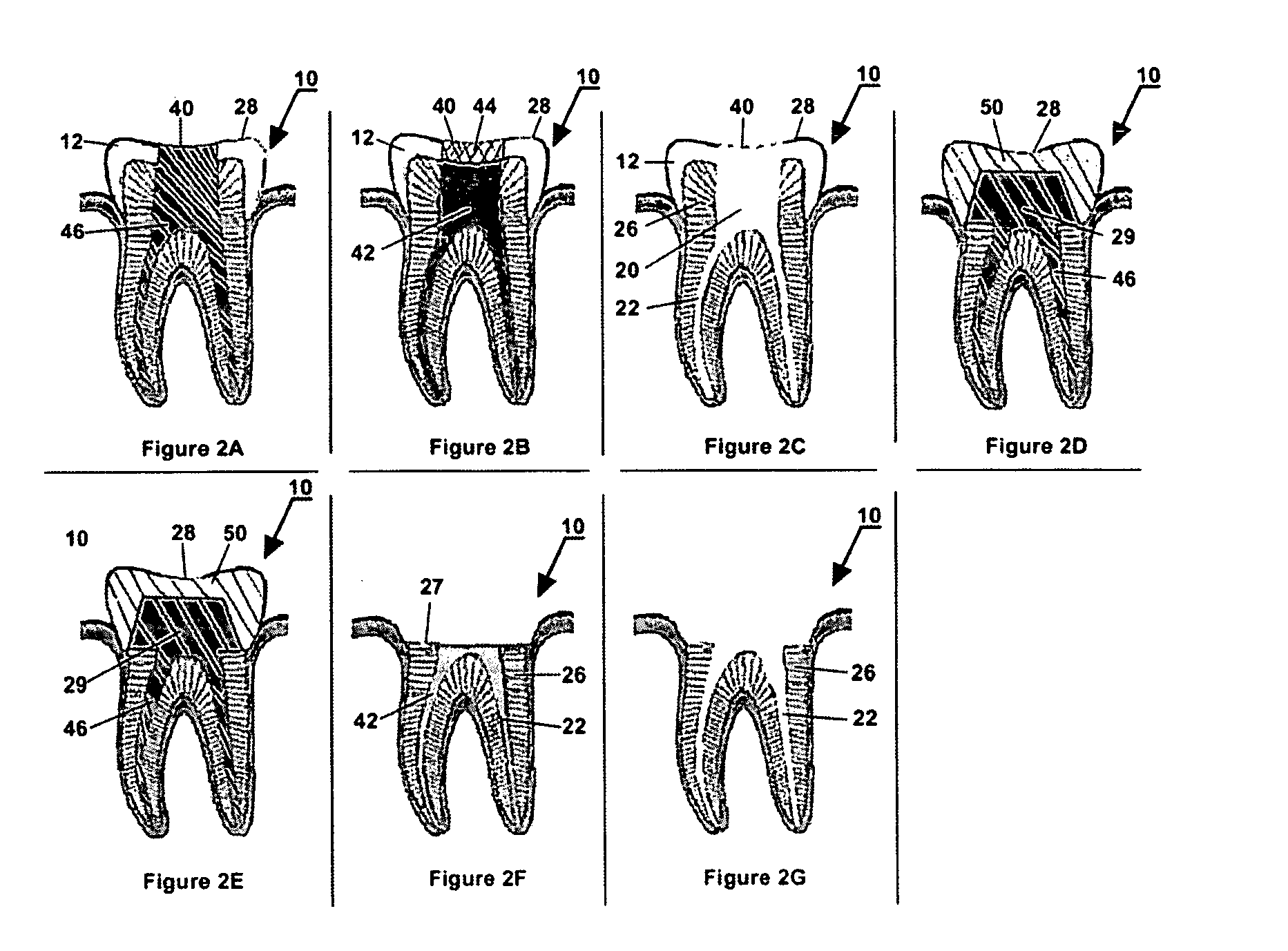

Dentures (also known as false teeth) are prosthetic devices constructed to replace missing teeth, and are supported by the surrounding soft and hard tissues of the oral cavity. Conventional dentures are removable (removable partial denture or complete denture). However, there are many denture designs, some which rely on bonding or clasping onto teeth or dental implants (fixed prosthodontics). There are two main categories of dentures, the distinction being whether they are used to replace missing teeth on the mandibular arch or on the maxillary arch.

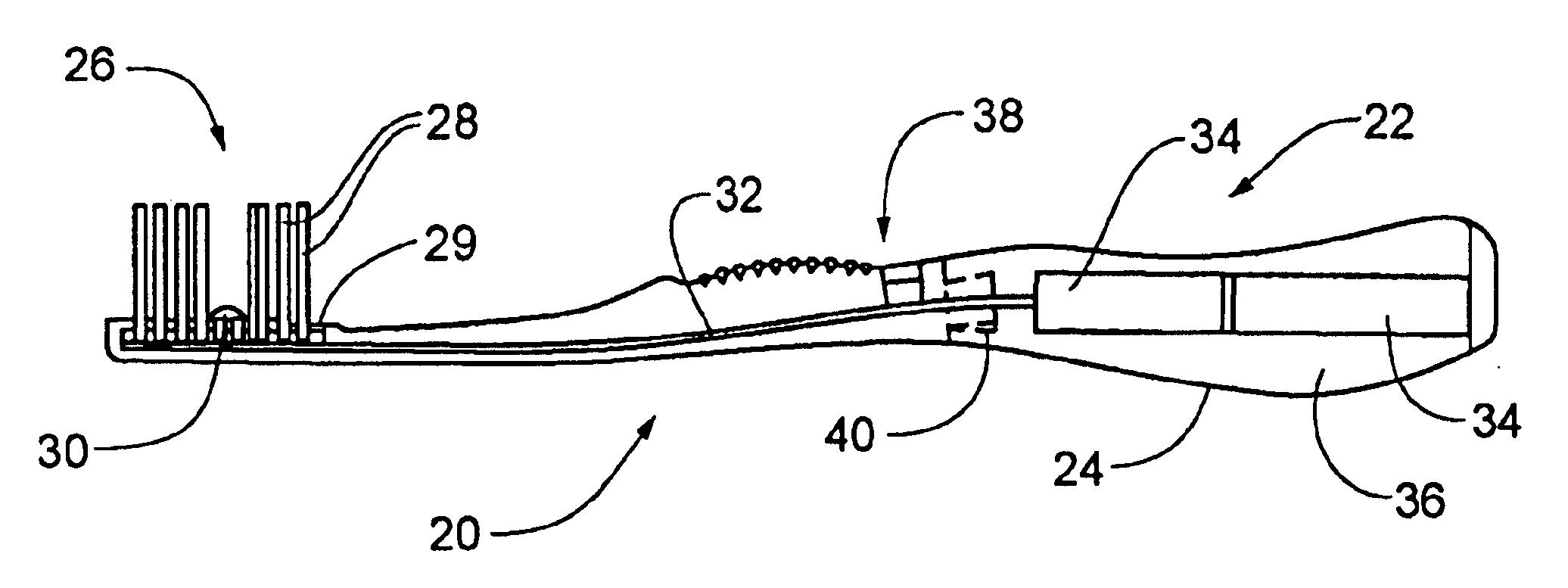

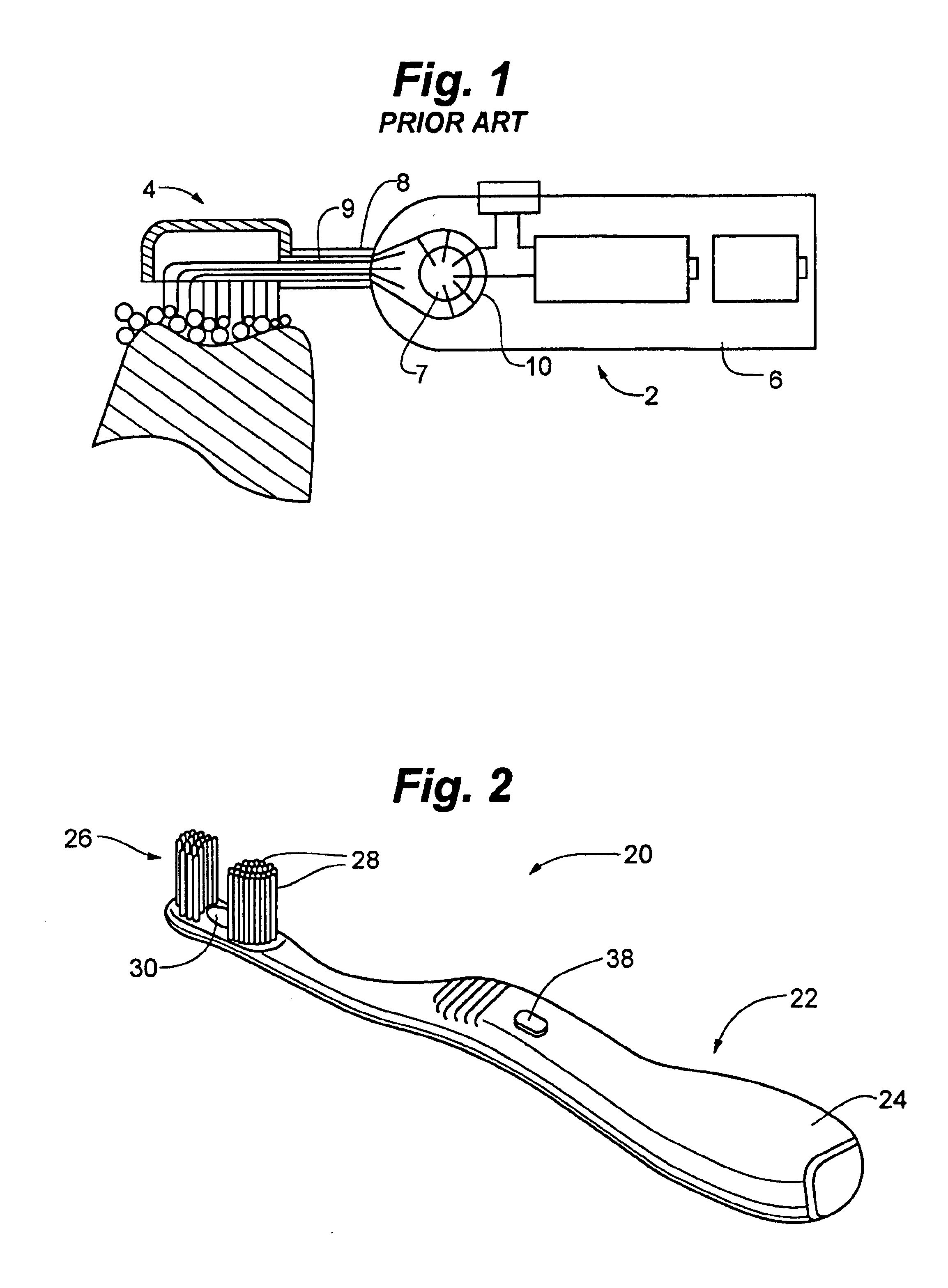

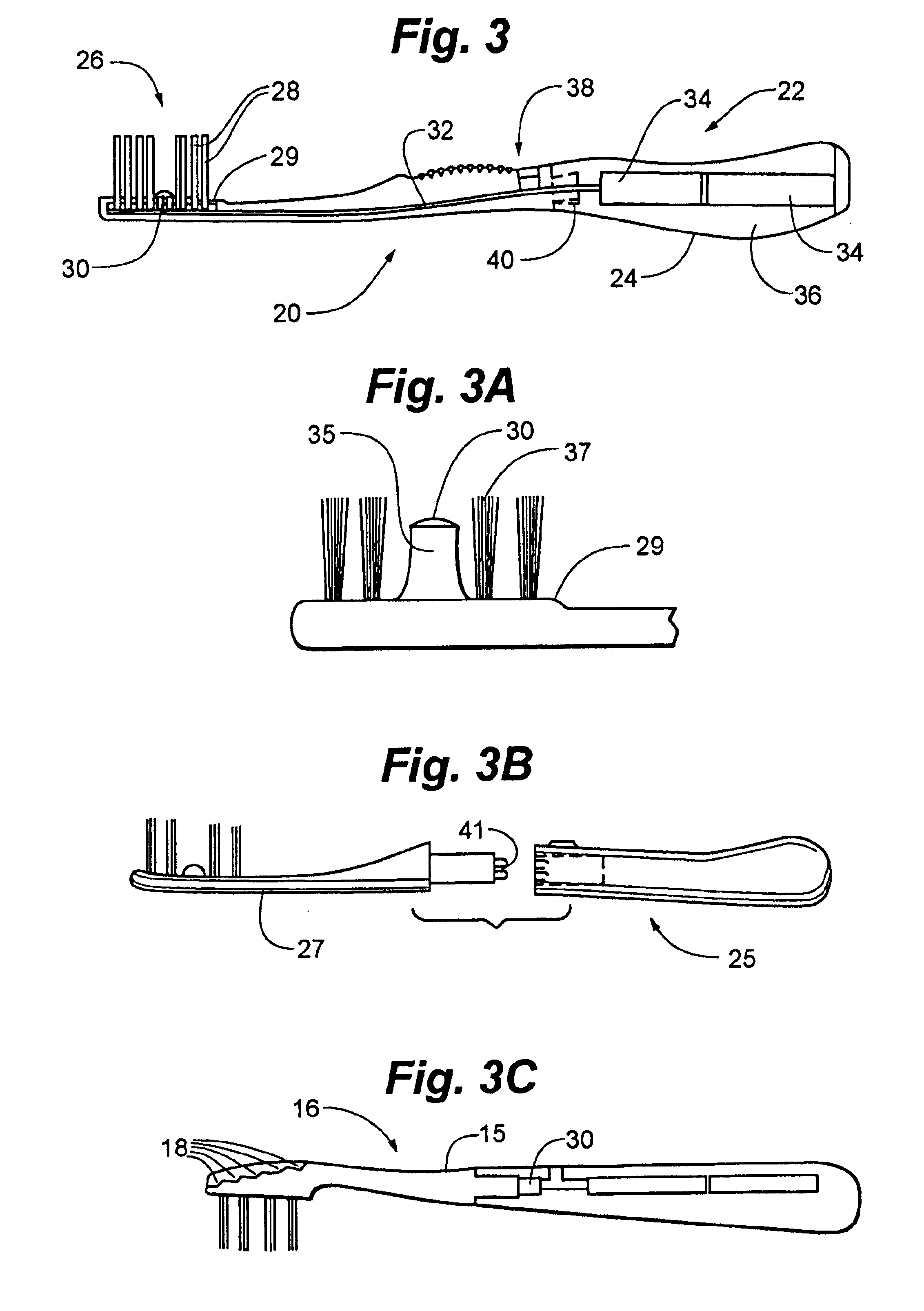

Enhanced dental hygiene system with direct UVA photoexcitation

A device and a method for delivering UVA light to the mouth in which a photocatalytic agent is distributed in the mouth and a UVA light source is located contiguously to the head of the device so that the photocatalytic agent distributed in the mouth is efficiently activated by UVA light produced by the device. The UVA light delivery device of the invention may be, inter alia, a toothbrush, a tongue scraper, an interdental toothbrush, a denture brush, a flossing device, a dental hand tool, or a wand adapted exclusively to applying UVA light to photocatalyst coated surfaces.

Owner:SUSR AMERICAS

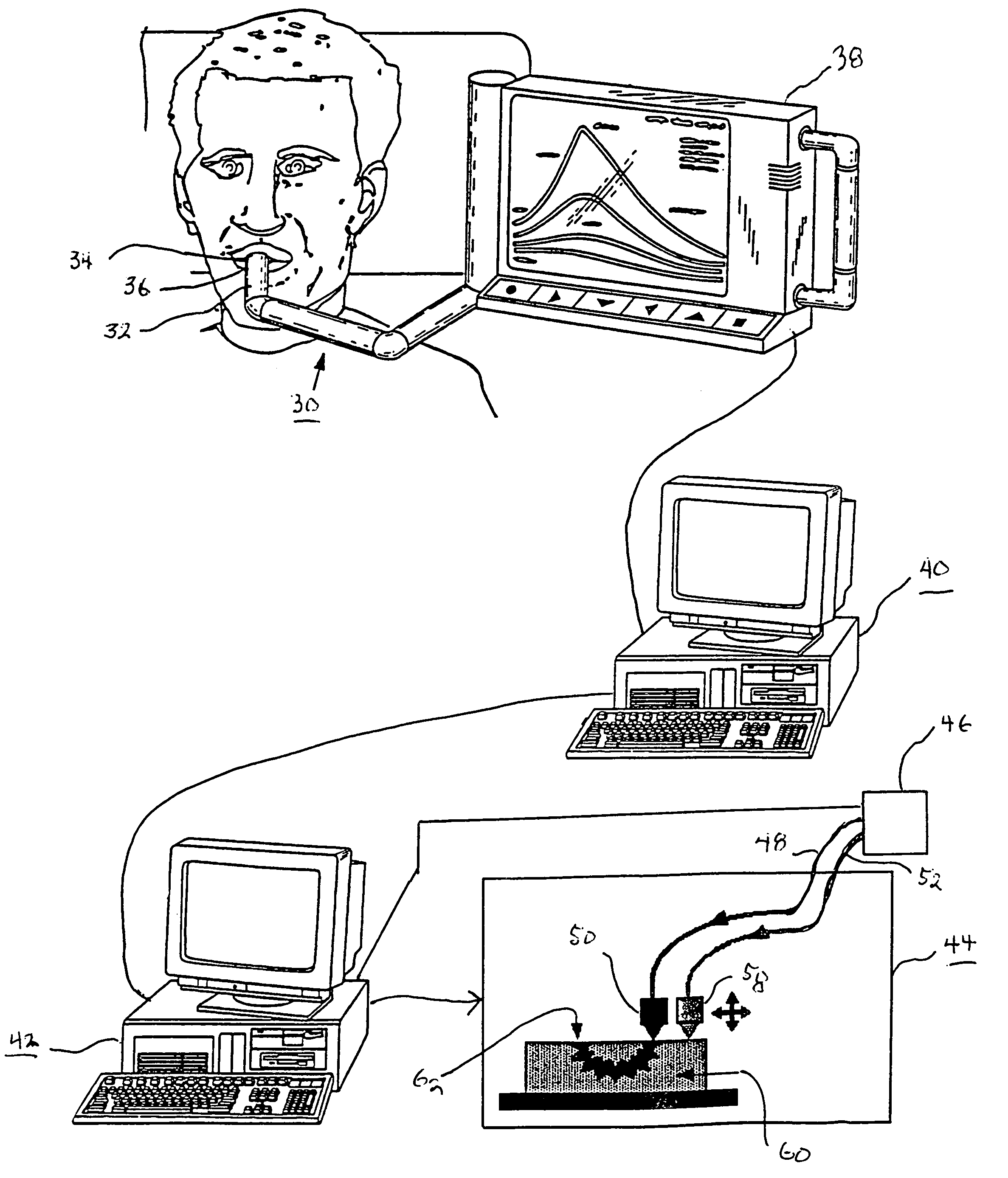

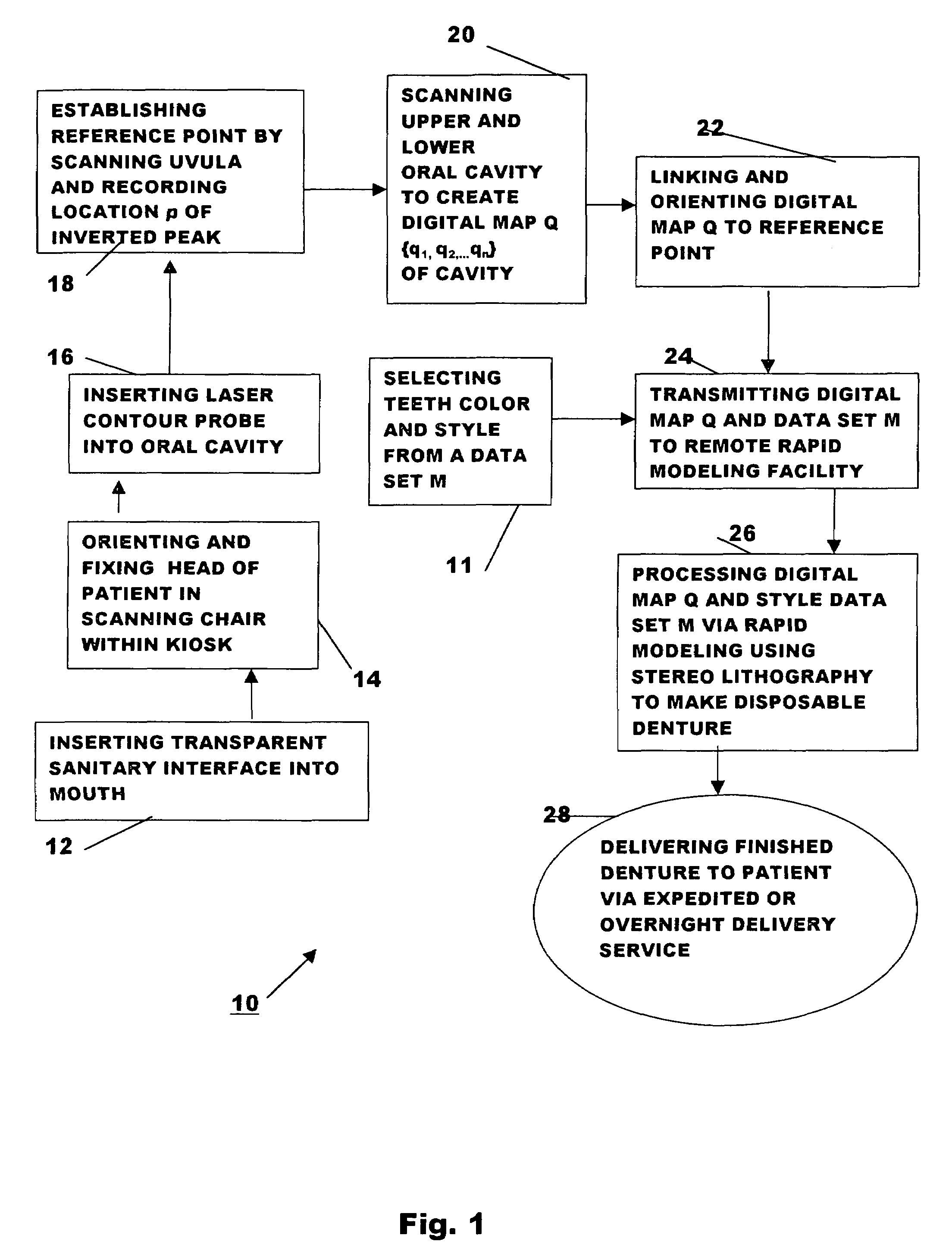

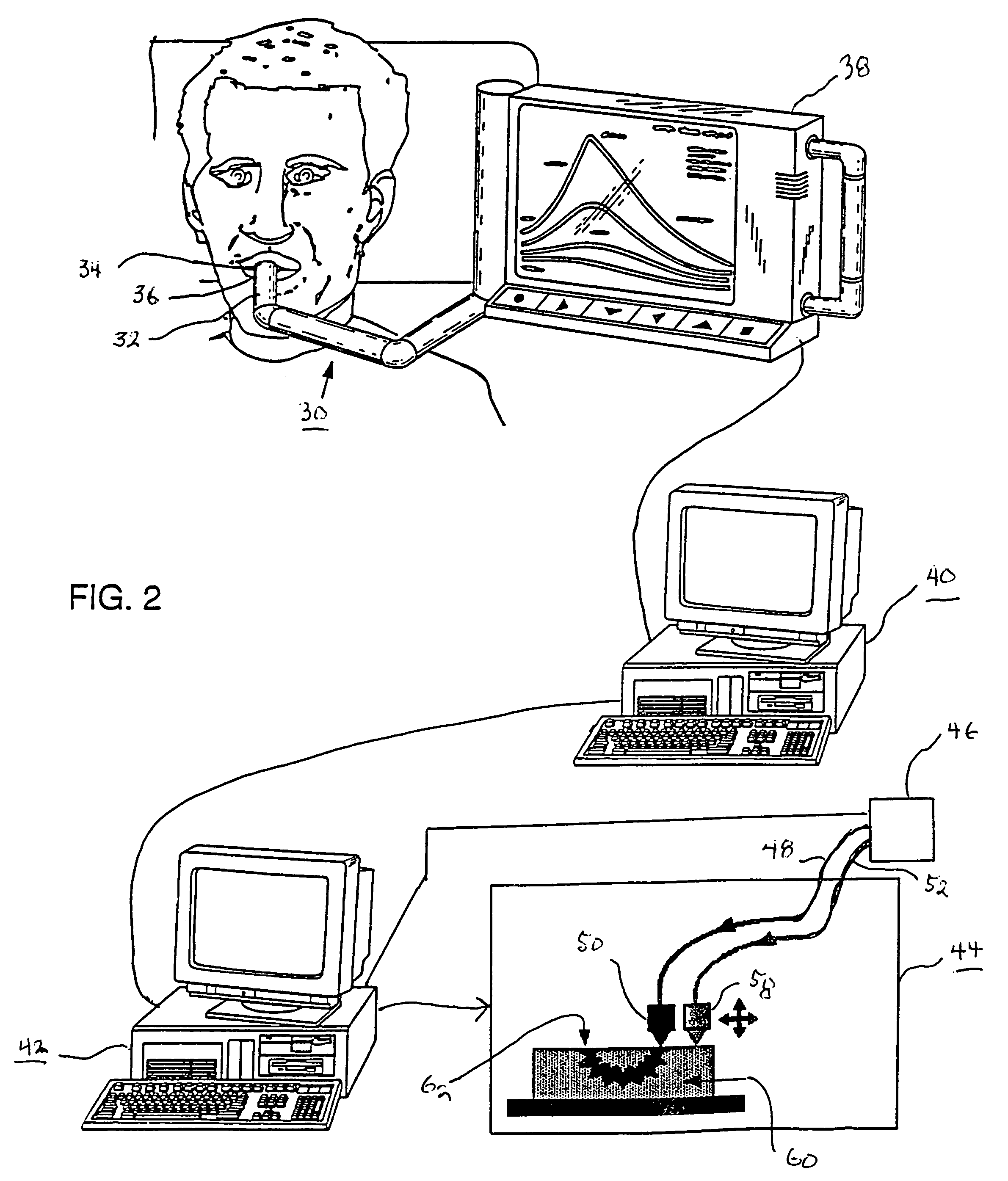

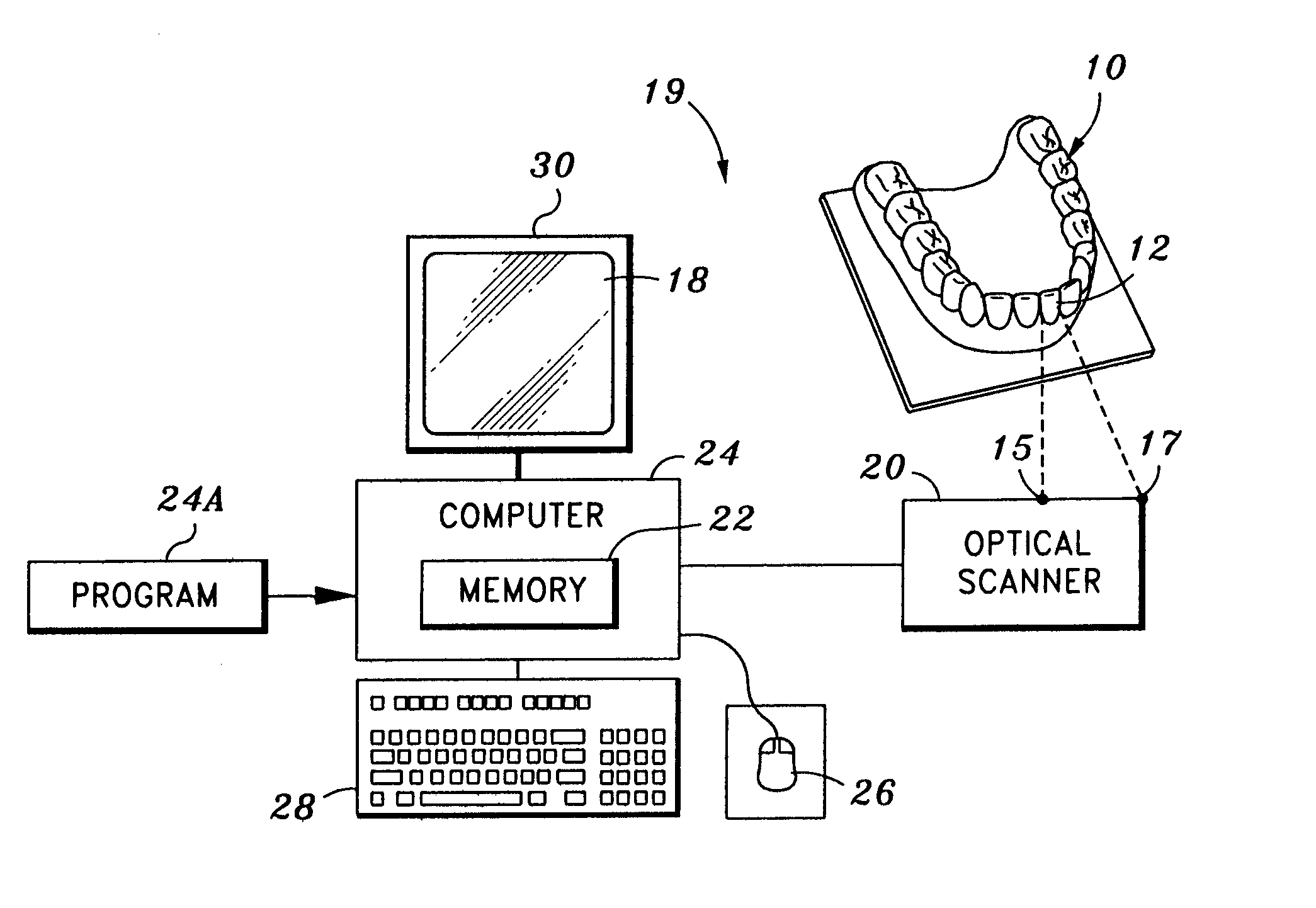

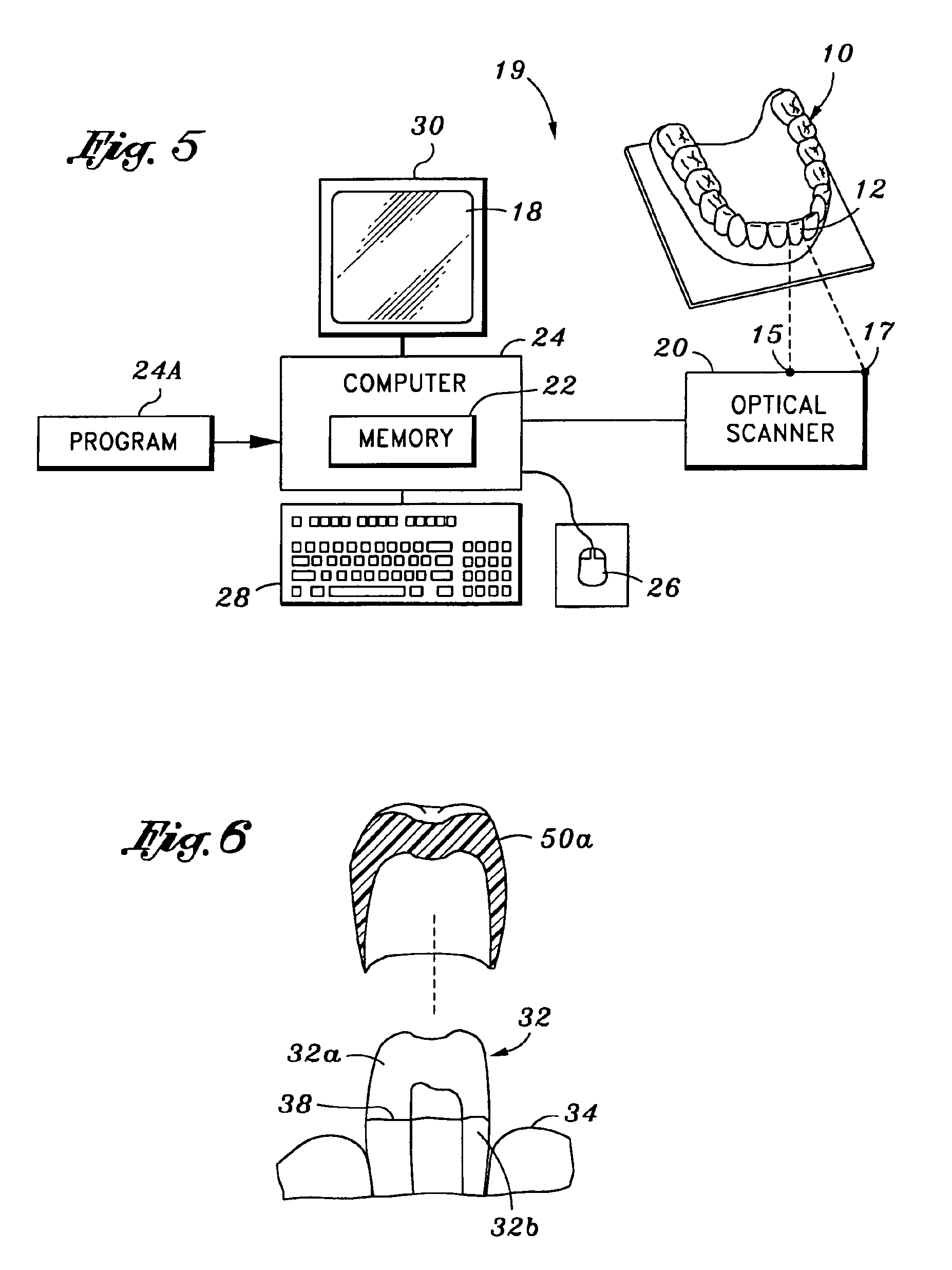

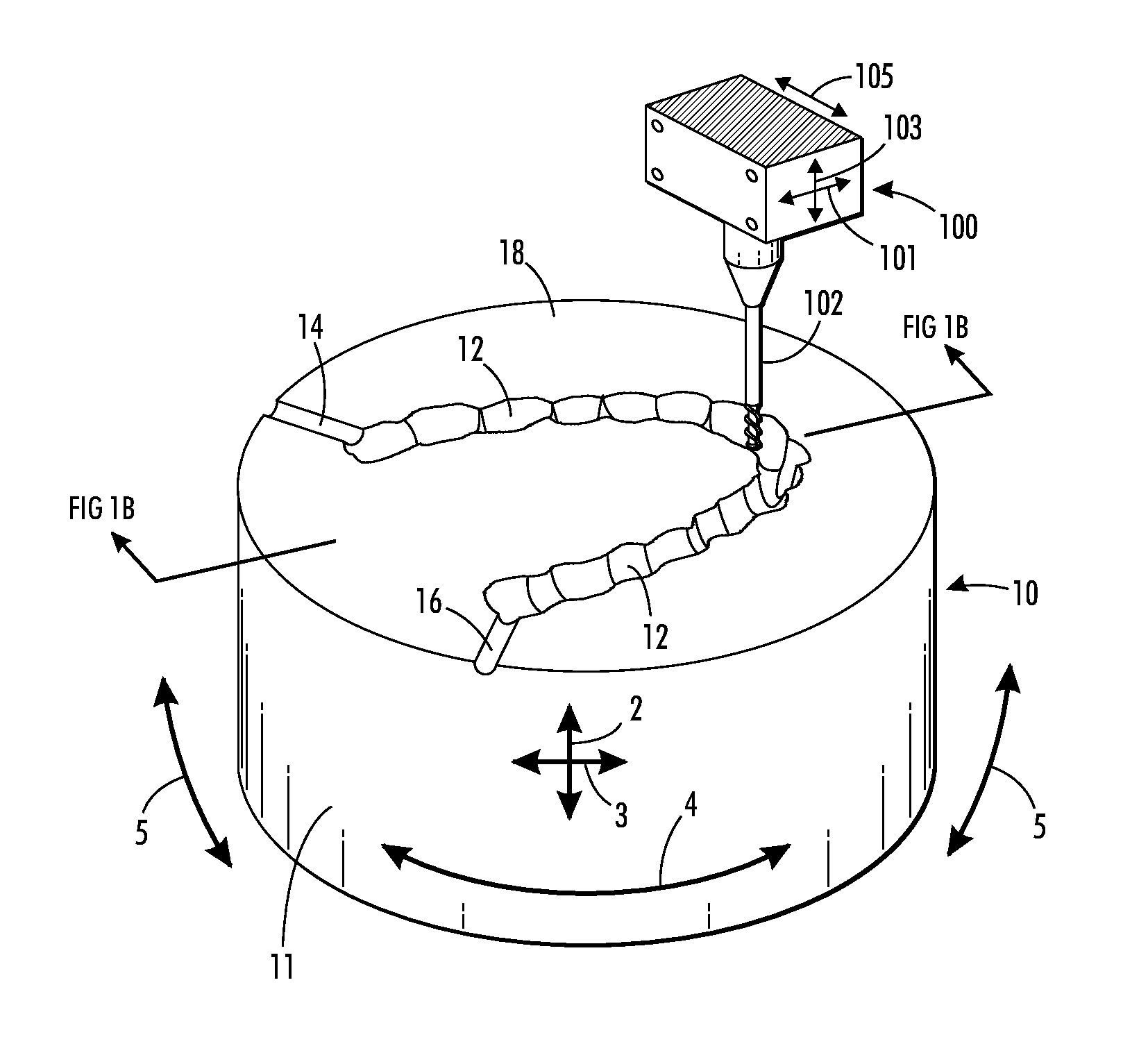

Method for automatically creating a denture using laser altimetry to create a digital 3-D oral cavity model and using a digital internet connection to a rapid stereolithographic modeling machine

InactiveUS7153135B1Low costFit closelyAdditive manufacturing apparatusImpression capsDenturesLaser scanning

A method is presented for rapidly making and delivering directly to a consumer a full upper and / or lower denture on the basis of contemporaneous digital image information laser scanned from the person's oral cavity after all respective upper and / or lower teeth have been removed, the delivery of the denture occurring substantially contemporaneously with the creation of the contemporaneous digital image information and optionally including and based on archived digital image information laser scanned from the person's oral cavity before all respective upper and / or lower teeth have been removed and digitally stored. According to which this contemporaneous digital image information and archival digital image information of the oral cavity is converted, by means of what is called the rapid prototyping technique and thus with a processing step (20) and a combination of an optional laser scanning step (18) solely for archiving the oral cavity when upper and / or lower teeth are present and a repetition of the laser scanning step (18) at a subsequent time when upper and / or lower teeth have been removed, a pre-selected block of plastic is used in a processing step (26) at a remote rapid modeling facility for receiving and processing digital information to form the block of plastic or like material into a denture of which at least a part is formed to substantially perfectly fit in juxtaposed relationship to the corresponding gums of the consumer. At least, pre-selected outer or non-juxtaposing is selected for manufacture of the denture using an arbitrary archived digital image not derived from the consumer's oral cavity image but selected by the consumer for its style, cosmetic characteristics, for example, color of teeth, size and variety of teeth, and / or perceived suitability.

Owner:THOMAS RICHARD J

Method of Manufacturing and Installing a Ceramic Dental Implant with an Aesthetic Implant Abutment

The present invention relates to a method for manufacturing a tooth prosthesis, for insertion in a jawbone, including an implant and an abutment on top of the implant. The method includes: defining a shape of the prosthesis and its location in the jawbone by using first data from a first CT scan image of the jawbone and second data from a second image of a gypsum cast, correlating first and second data by extracting from the first data first position reference data of a first reference in the first image, and from the second data second position reference data of a second reference in the second image, the second reference being identical to the first reference; performing a geometric transformation on the second data and / or the first data to have a coincidence of the second image with the first image and to combine the first and second data into composite scan data.

Owner:ORATIO

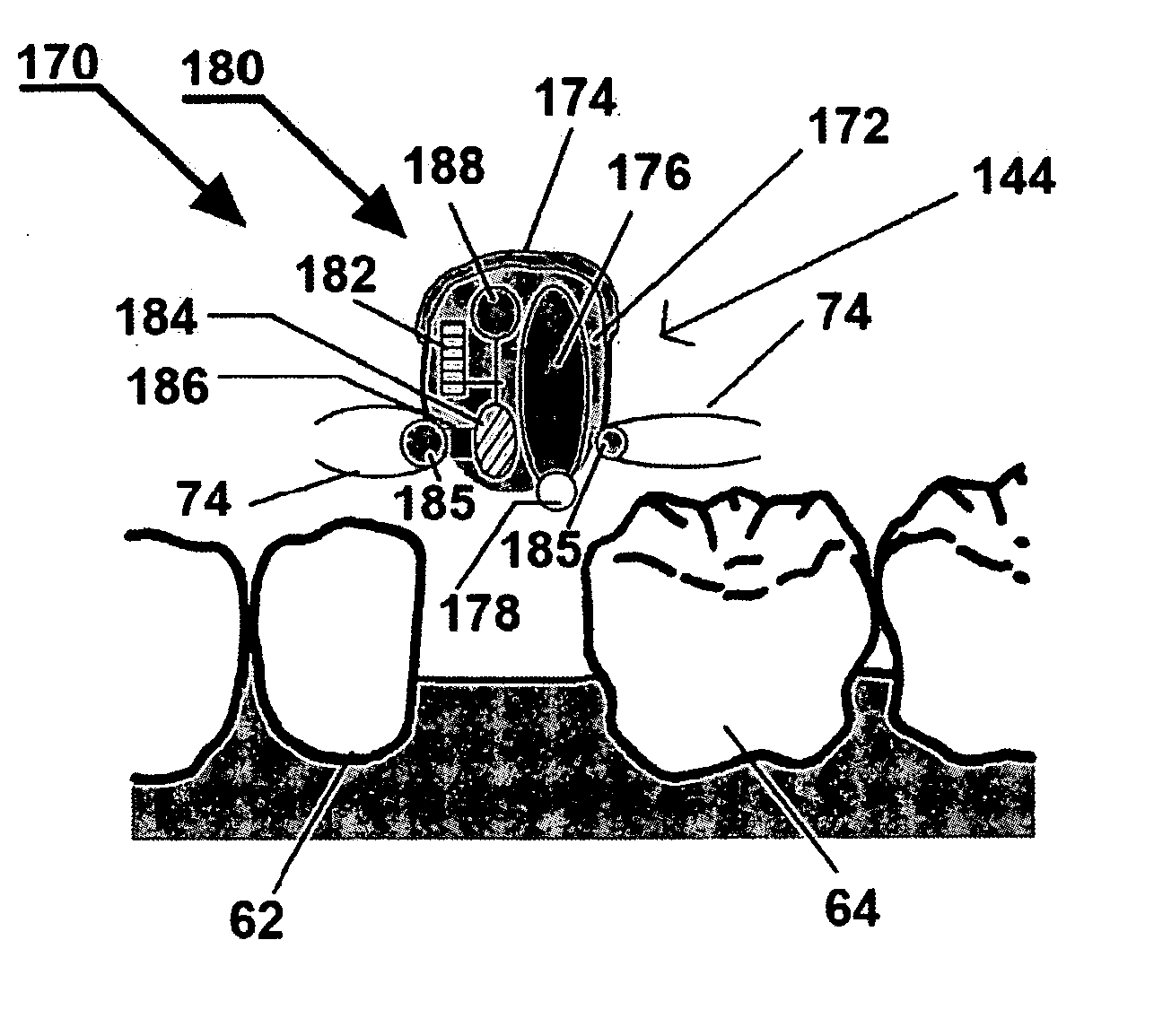

Intraoral apparatus for non-invasive blood and saliva monitoring & sensing

Controlled-specimen-sampling oral devices are described, implanted or inserted into an oral cavity, built onto a prosthetic tooth crown, a denture plate, braces, a dental implant, or the like. The devices are replaced as needed. The controlled specimen sampling may be passive, based on a dosage form, or electro-mechanically controlled, for a high-precision, intelligent, specimen sampling. Additionally, the controlled sampling may be any one of the following: sampling in accordance with a preprogrammed regimen, sampling at a controlled rate, delayed sampling, pulsatile sampling, chronotherapeutic sampling, closed-loop sampling, responsive to a sensor's input, sampling on demand from a personal extracorporeal system, sampling regimen specified by a personal extracorporeal system, sampling on demand from a monitoring center, via a personal extracorporeal system, and sampling regimen specified by a monitoring center, via a personal extracorporeal system. Specimen collection in the oral cavity may be assisted or induced by a transport mechanism, such as any one of, or a combination of iontophoresis, electroosmosis, electrophoresis, electroporation, sonophoresis, and ablation. The oral devices require replacement at relatively long intervals of weeks or months. The oral devices and methods for controlled specimen sampling apply to humans and animals.

Owner:BEISKI BEN ZION +1

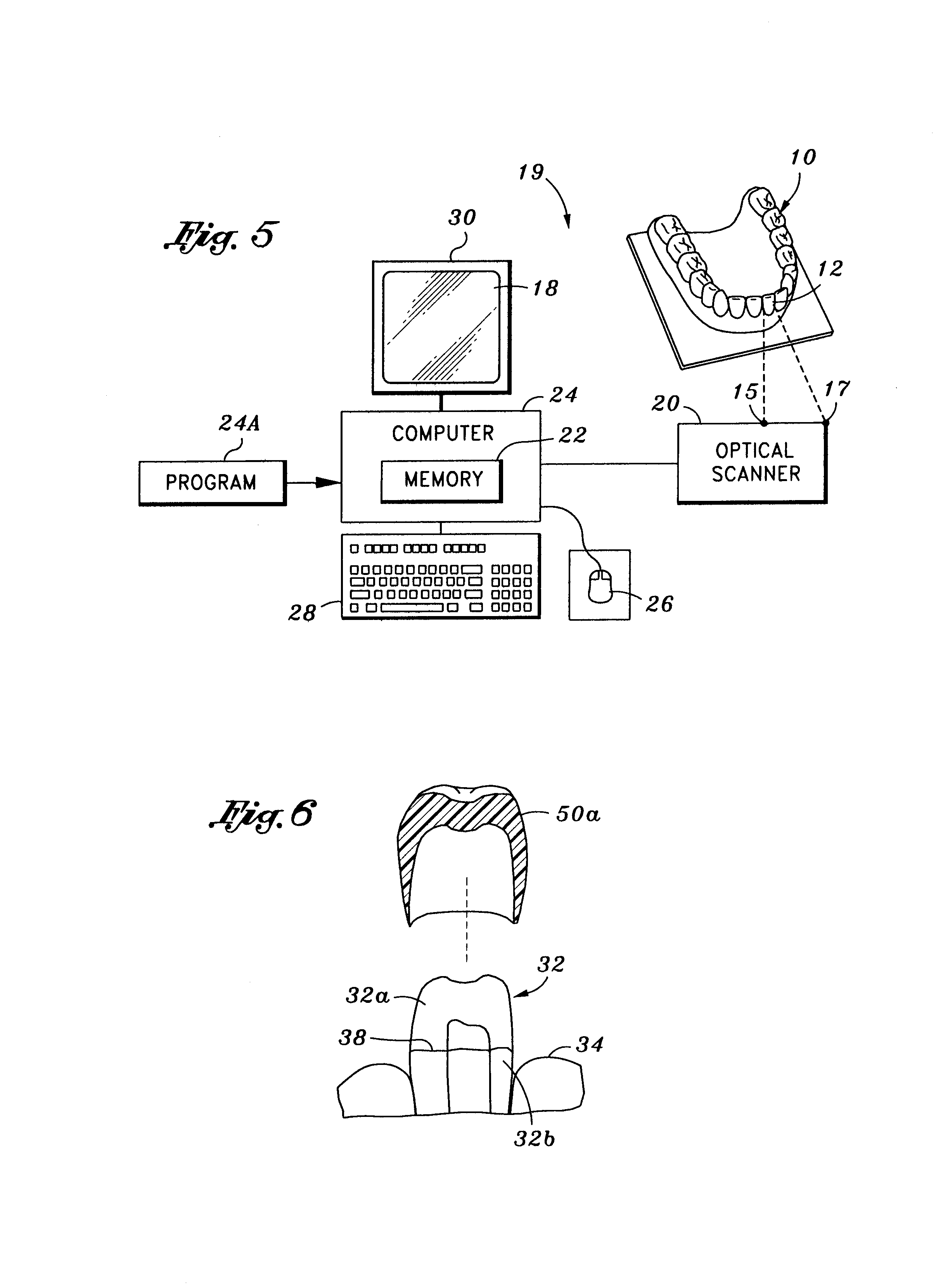

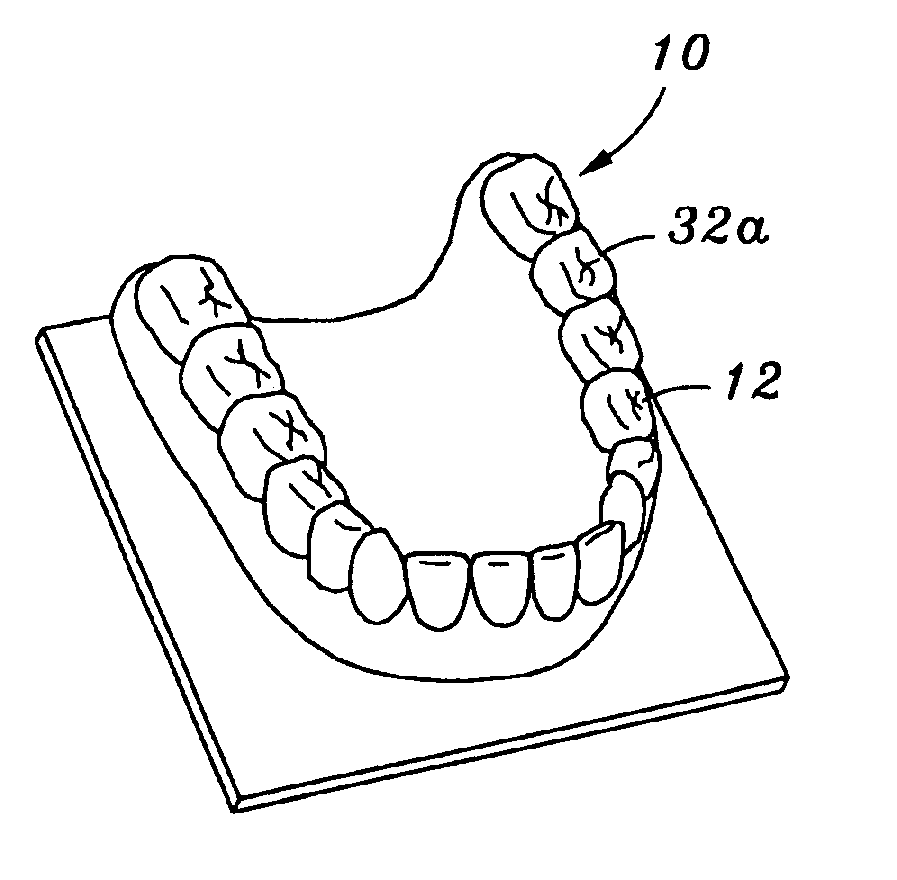

System and method for manufacturing full and partial dentures

There is provided a system for fabricating at least a portion of a denture. The system includes a three-dimensional scanning device for scanning a surface of a denture template, and a computer-readable medium including a computer program for receiving data from the scanning device, creating a 3-dimensional model of the surface, and optionally modifying the 3-dimensional model and / or adding features to the 3-dimensional model. The system also includes a fabricator for creating the at least the portion of the denture, from a selected material, based on the 3-dimensional model. The fabricator may be a device including a lathe, or a rapid prototyping machine. There is also provided a method for fabricating at least a portion of a denture.

Owner:SMITHKLINE BECKMAN CORP

Material for a dental prosthesis, method and device for determining the shape of a remaining tooth area to be provided with a dental prosthesis, method and arrangement for producing a dental prosthesis and use of the arrangement

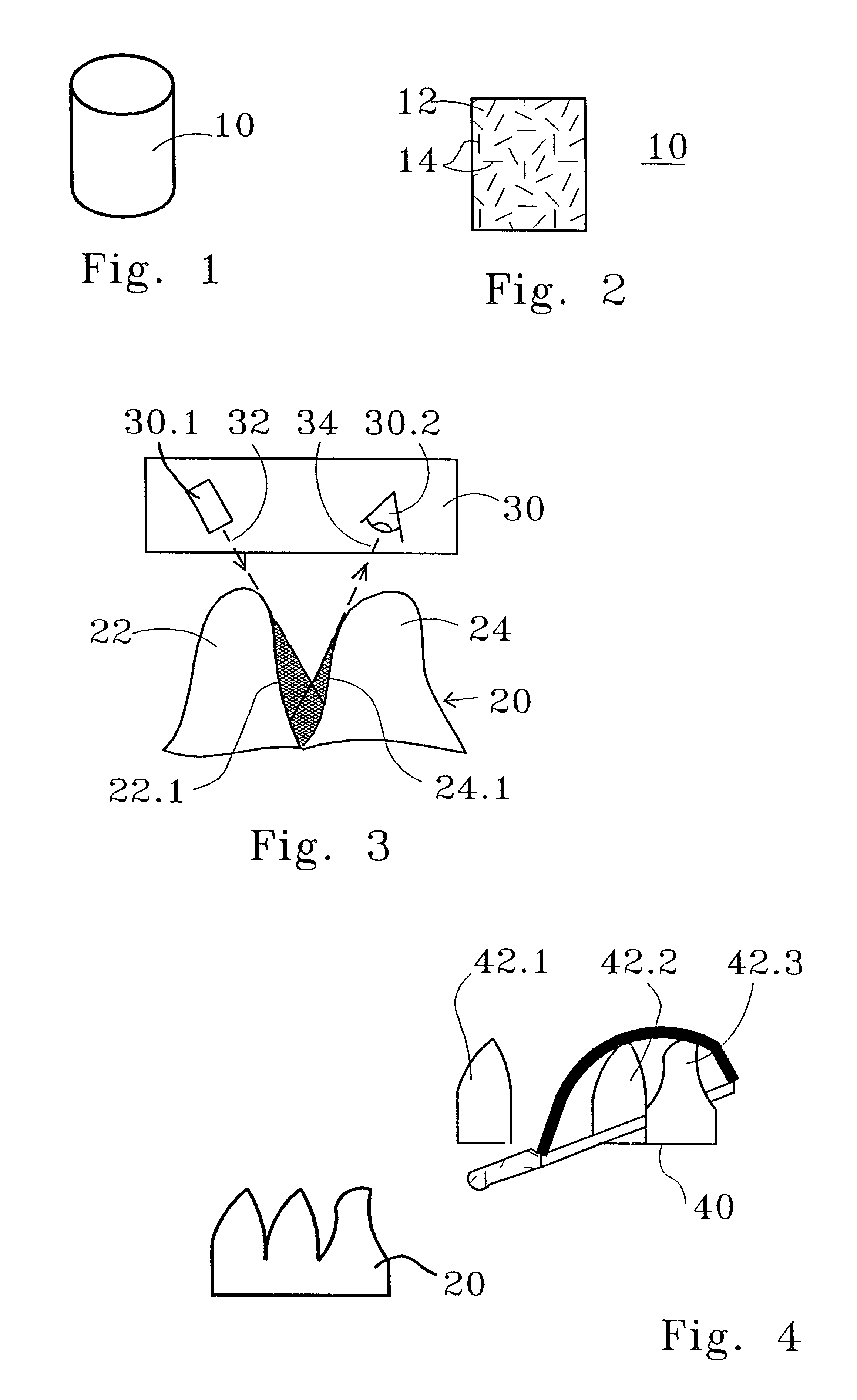

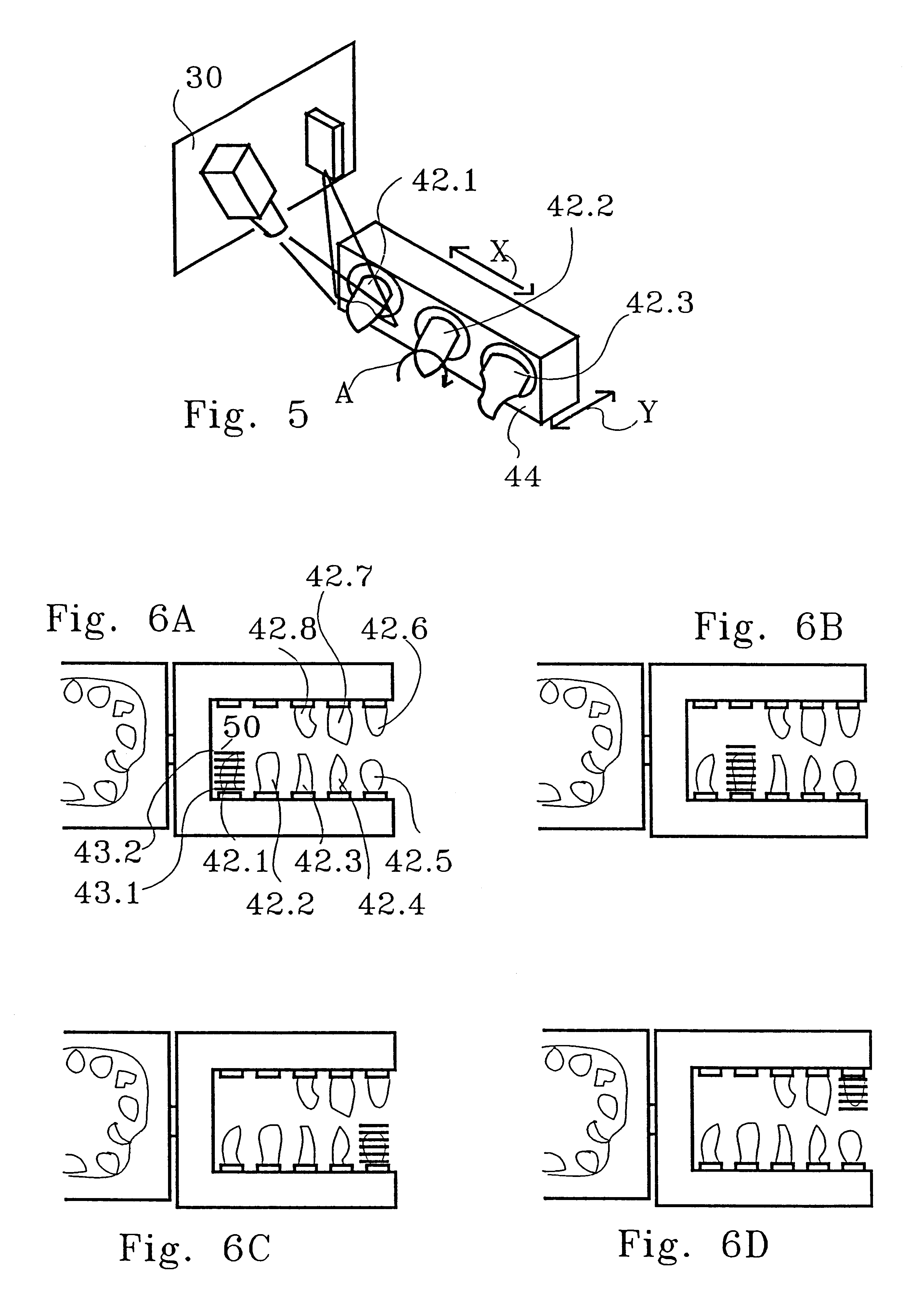

InactiveUS6287121B1Improve accuracySuitable for processingImpression capsTooth crownsDigital dataGlass fiber

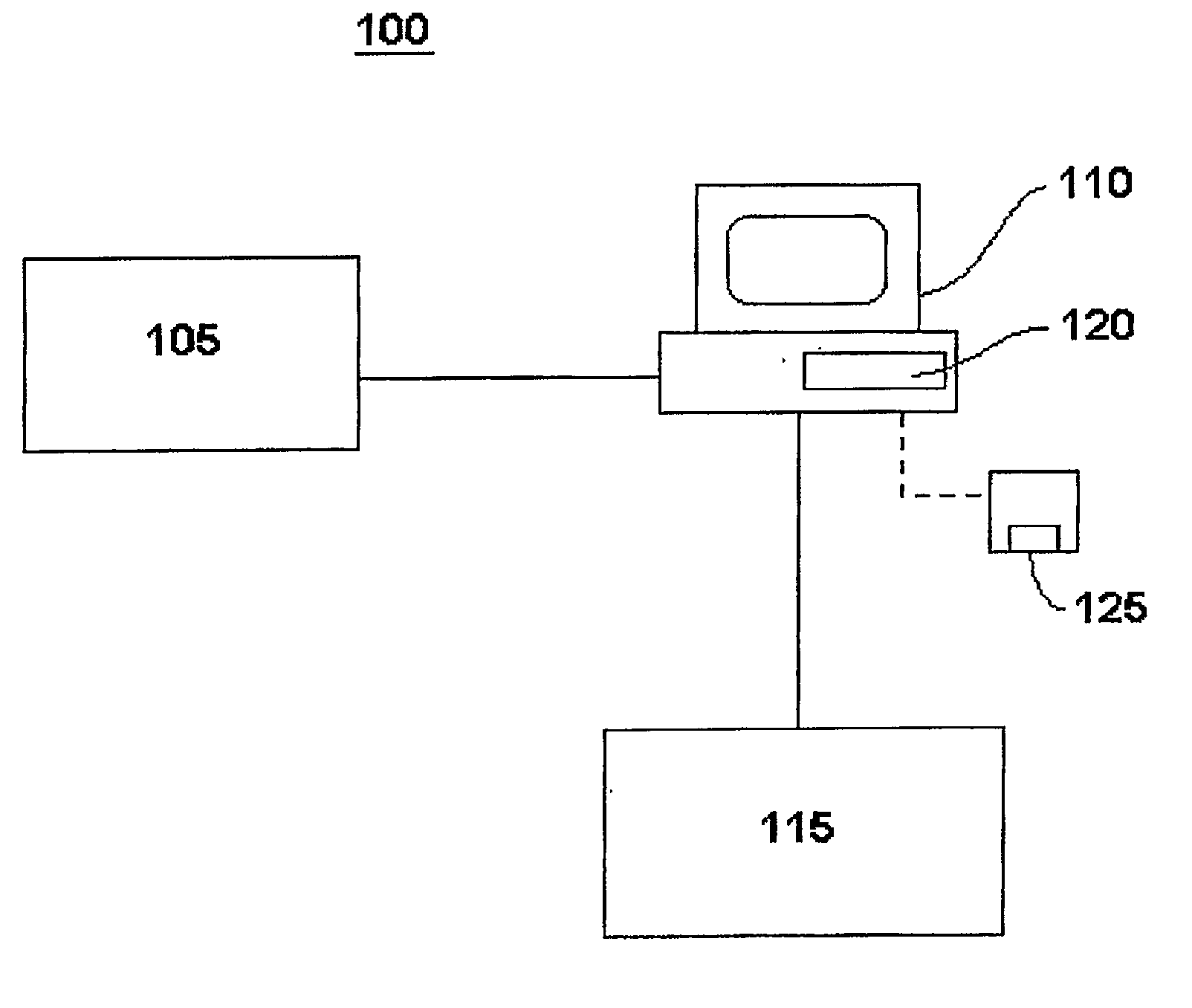

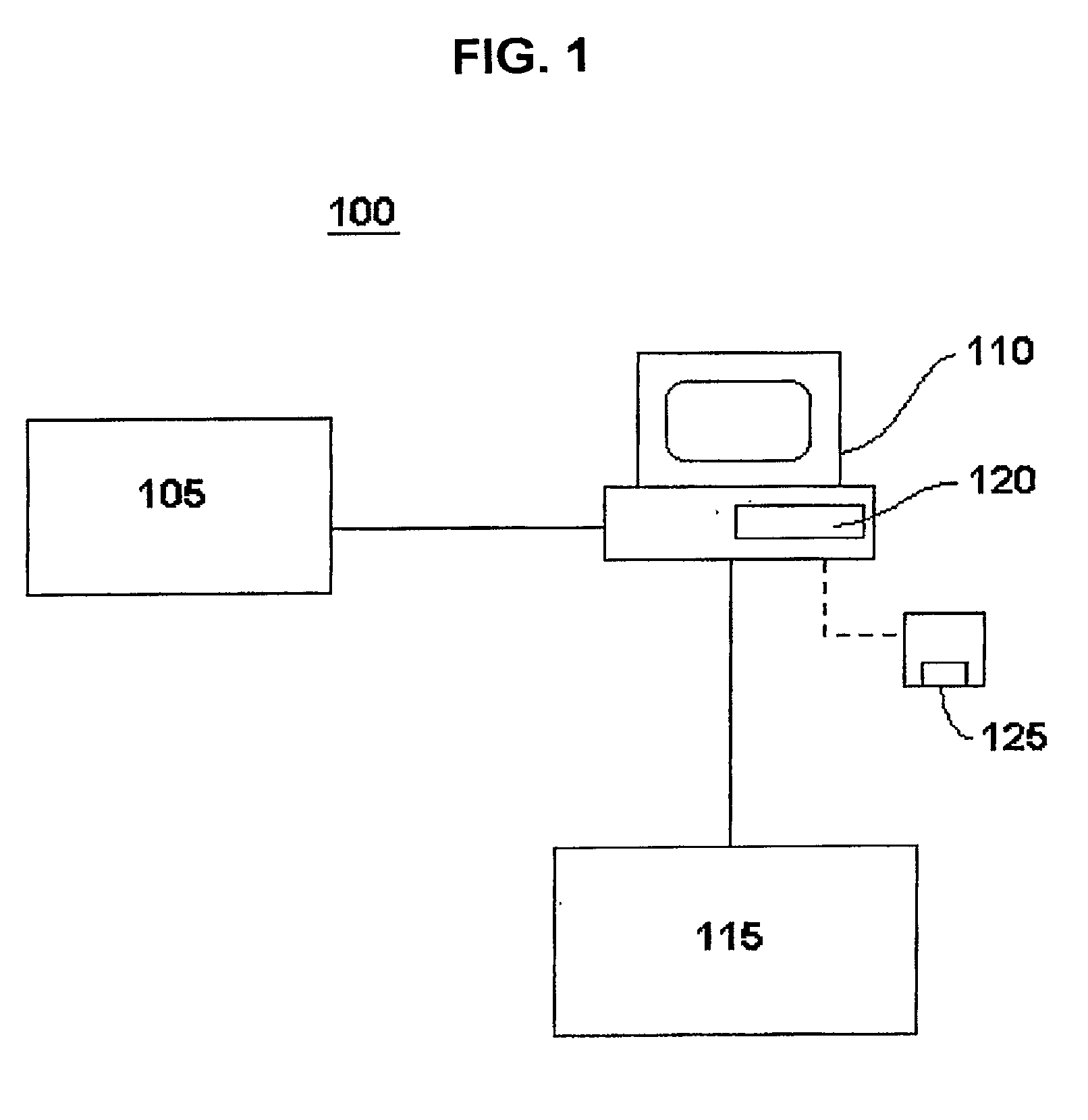

Material for a dental prosthesis consisting of fiber glass reinforced plastic. The material is used to produce a blank by means of a special injection-molding process, which can be worked by means of a machining process. A method and a device for determining the shape of a duplicate of a remaining tooth area to be provided with a dental prosthesis. The shape of the duplicate is determined, as is the shape of duplicate sections into which the duplicate has been divided, the determined data are stored and combined. A method and arrangement for producing a dental prosthesis. The shape of a duplicate (42) of a remaining tooth area to be provided with the dental prosthesis is determined by means of a shape determination device (110), the determined data are stored in the form of digital data (DD), and the dental prosthesis (143) is produced in a production machine (114), which is controlled by means of production data (FD). The shape determination device (110) and the production machine (114) are coupled by means of an EDP installation (118), which contains a memory unit for storing the digital data (DD) and performs the calculation of the production data (FD).

Owner:STRAUMANN HLDG AG +2

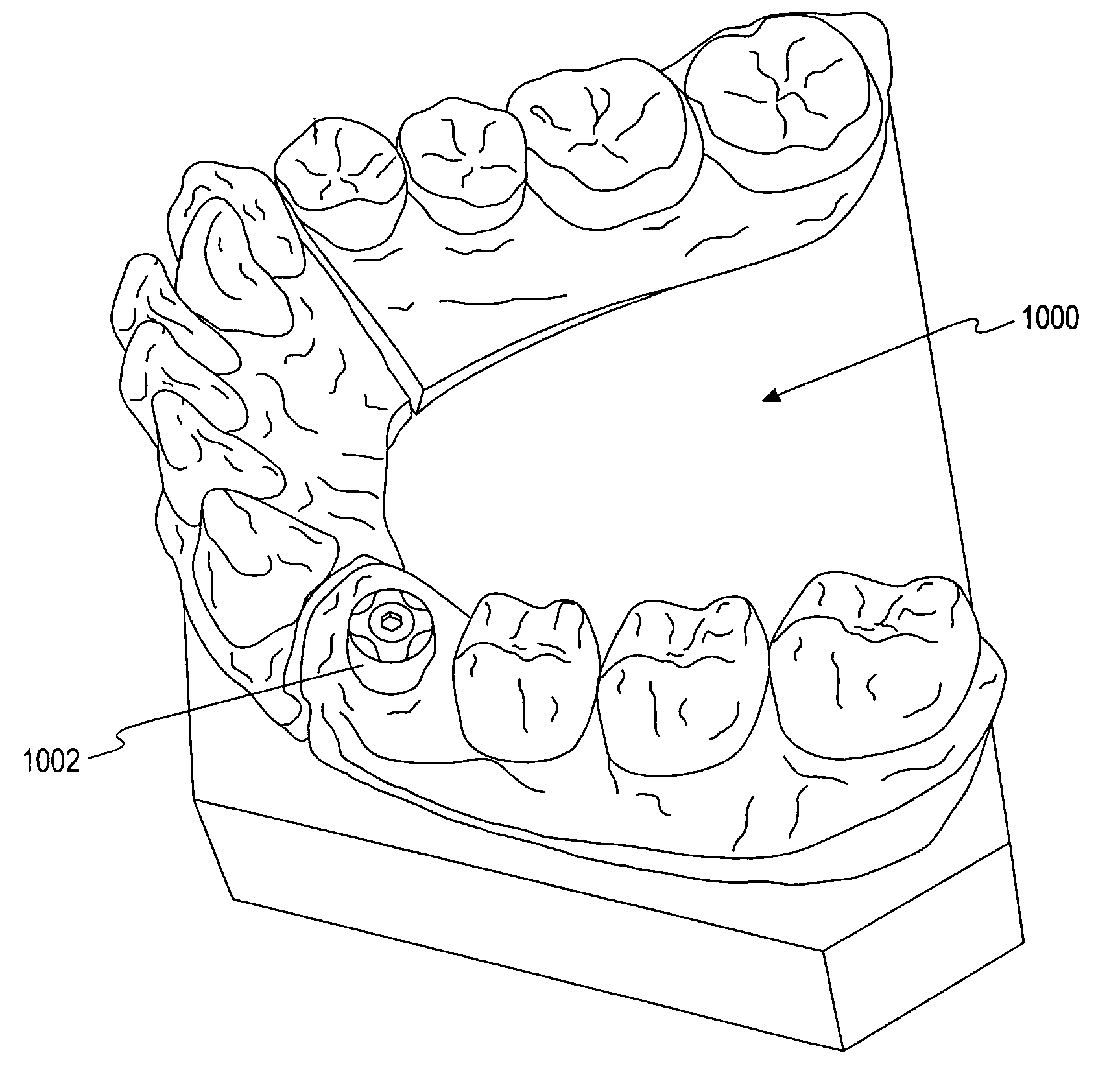

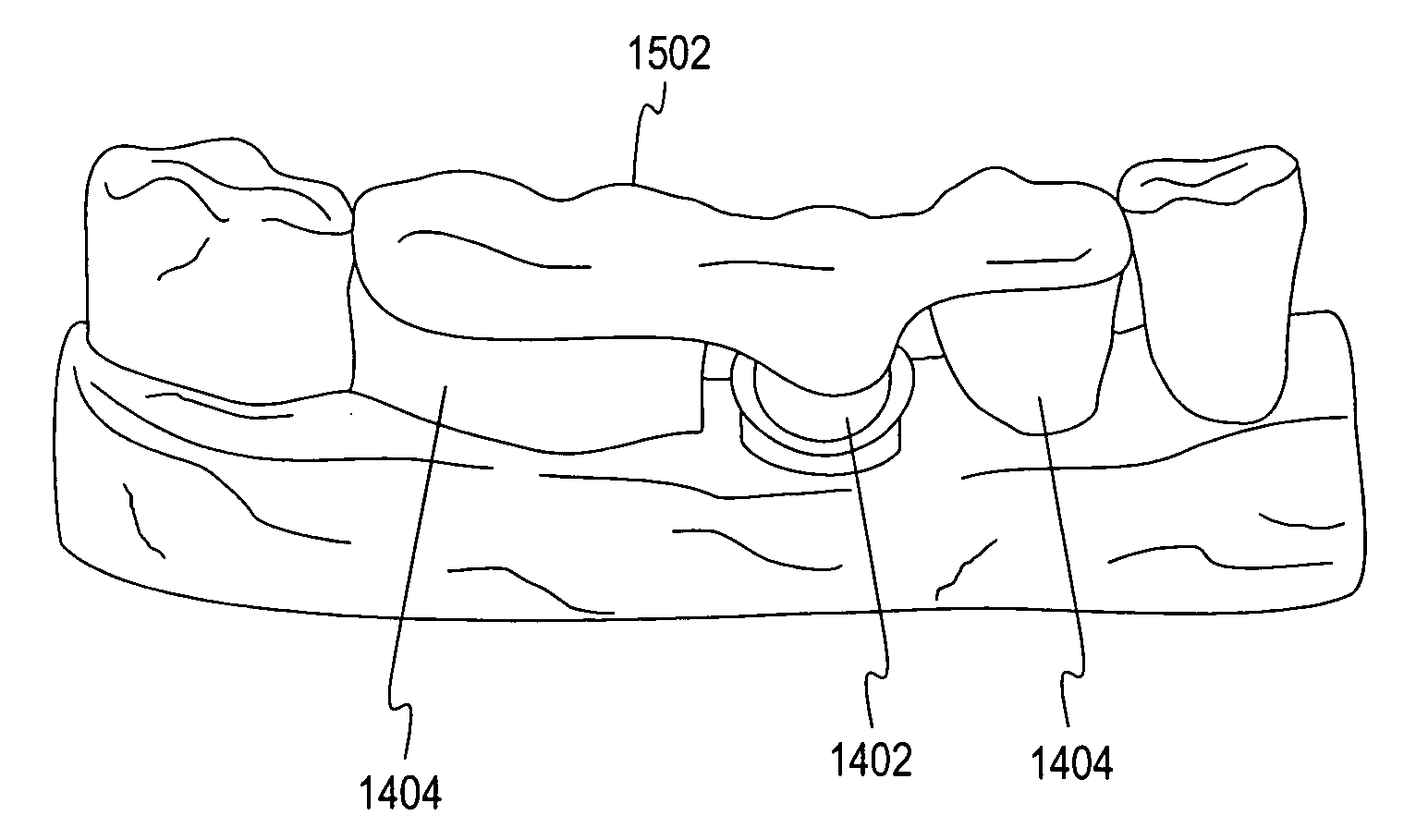

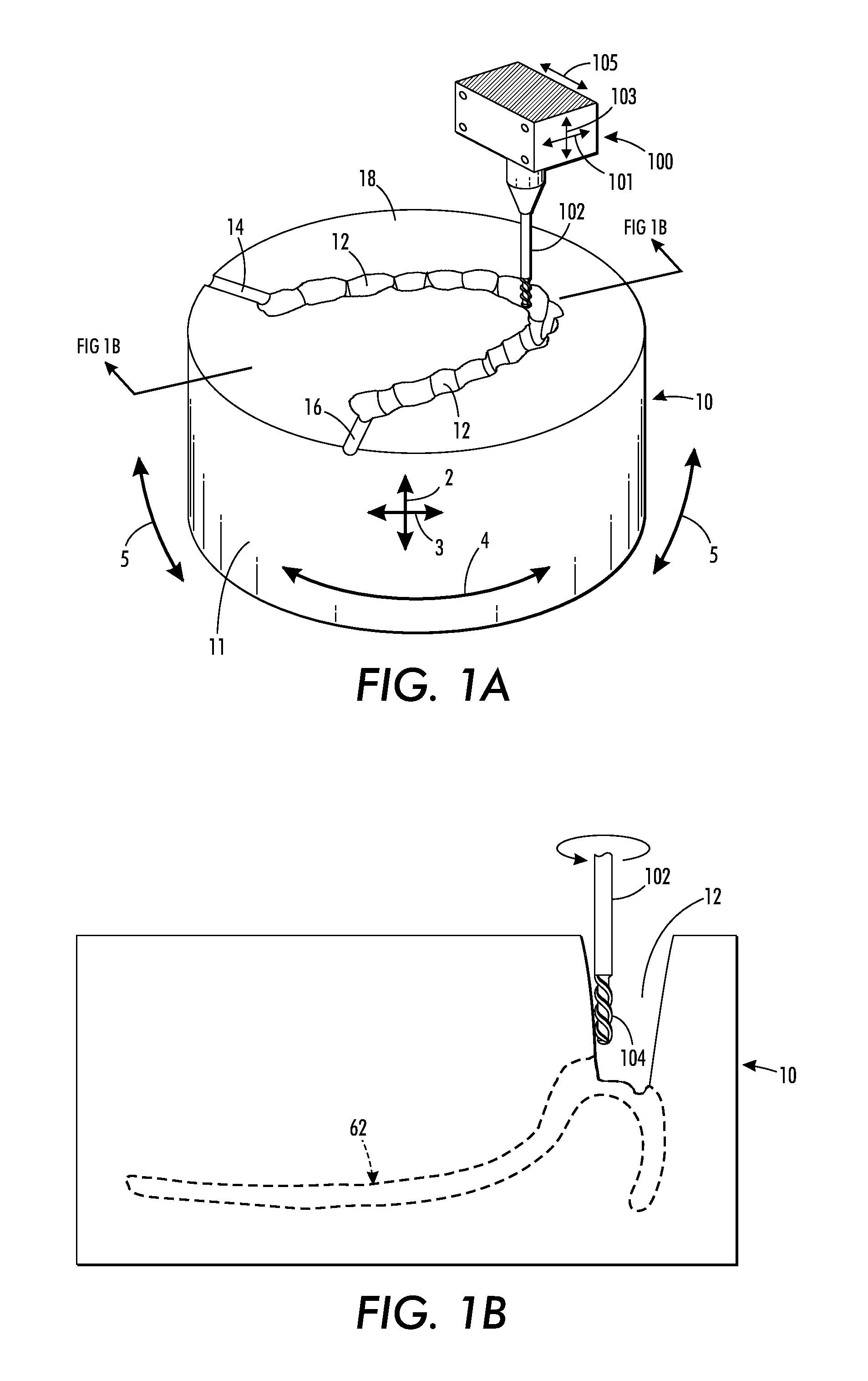

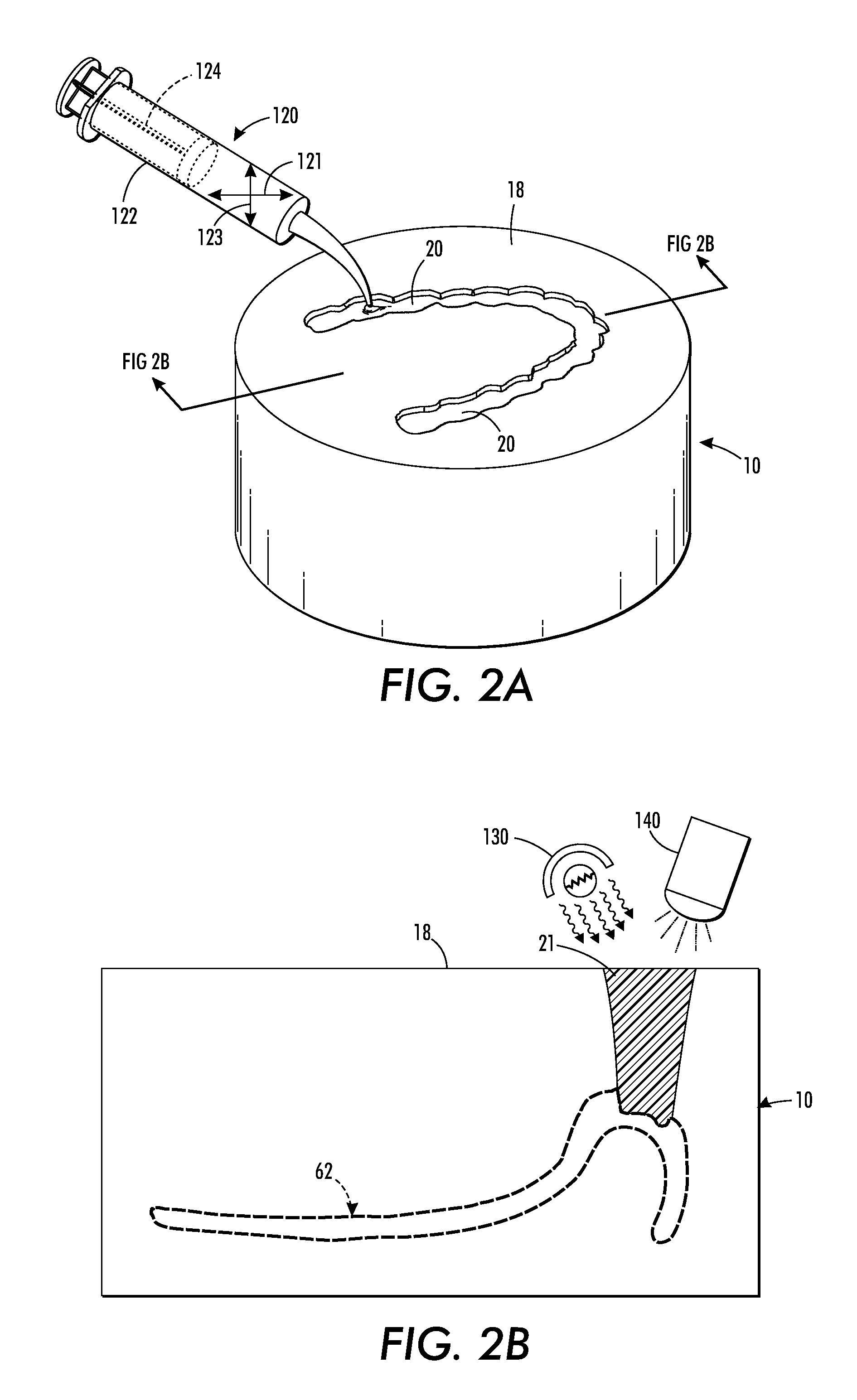

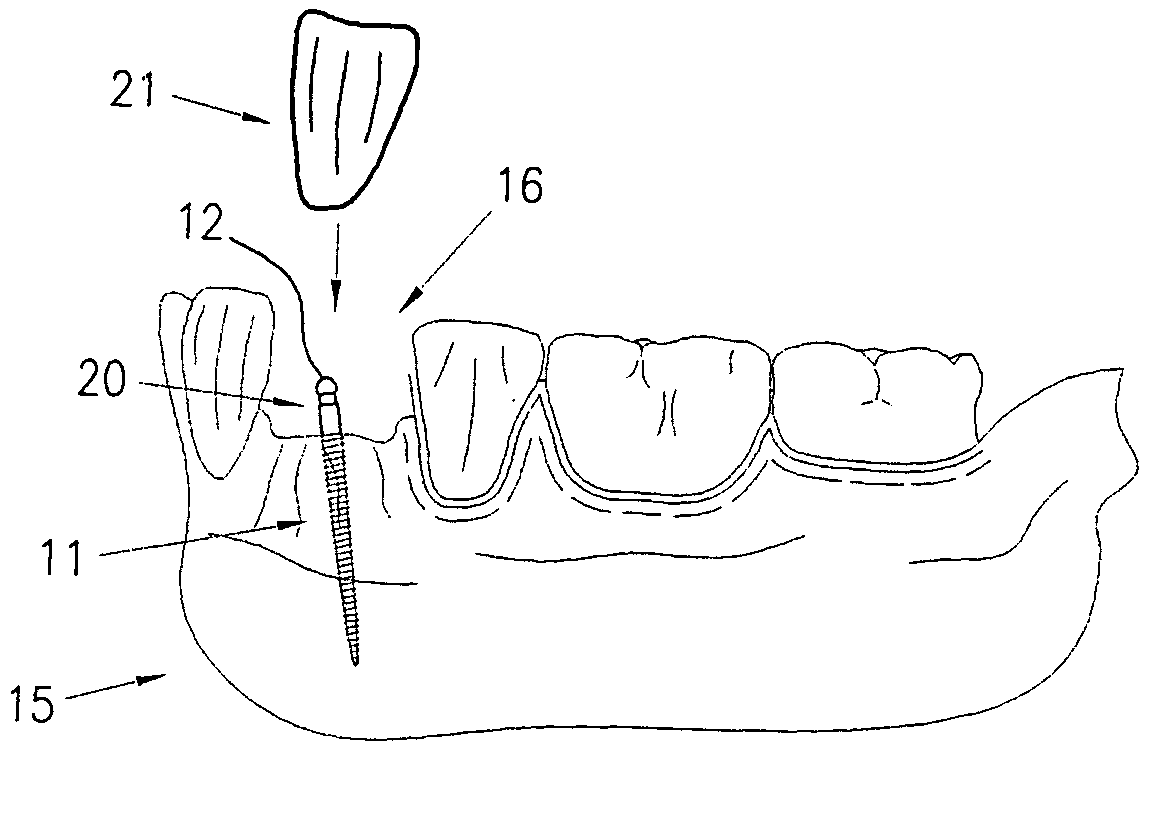

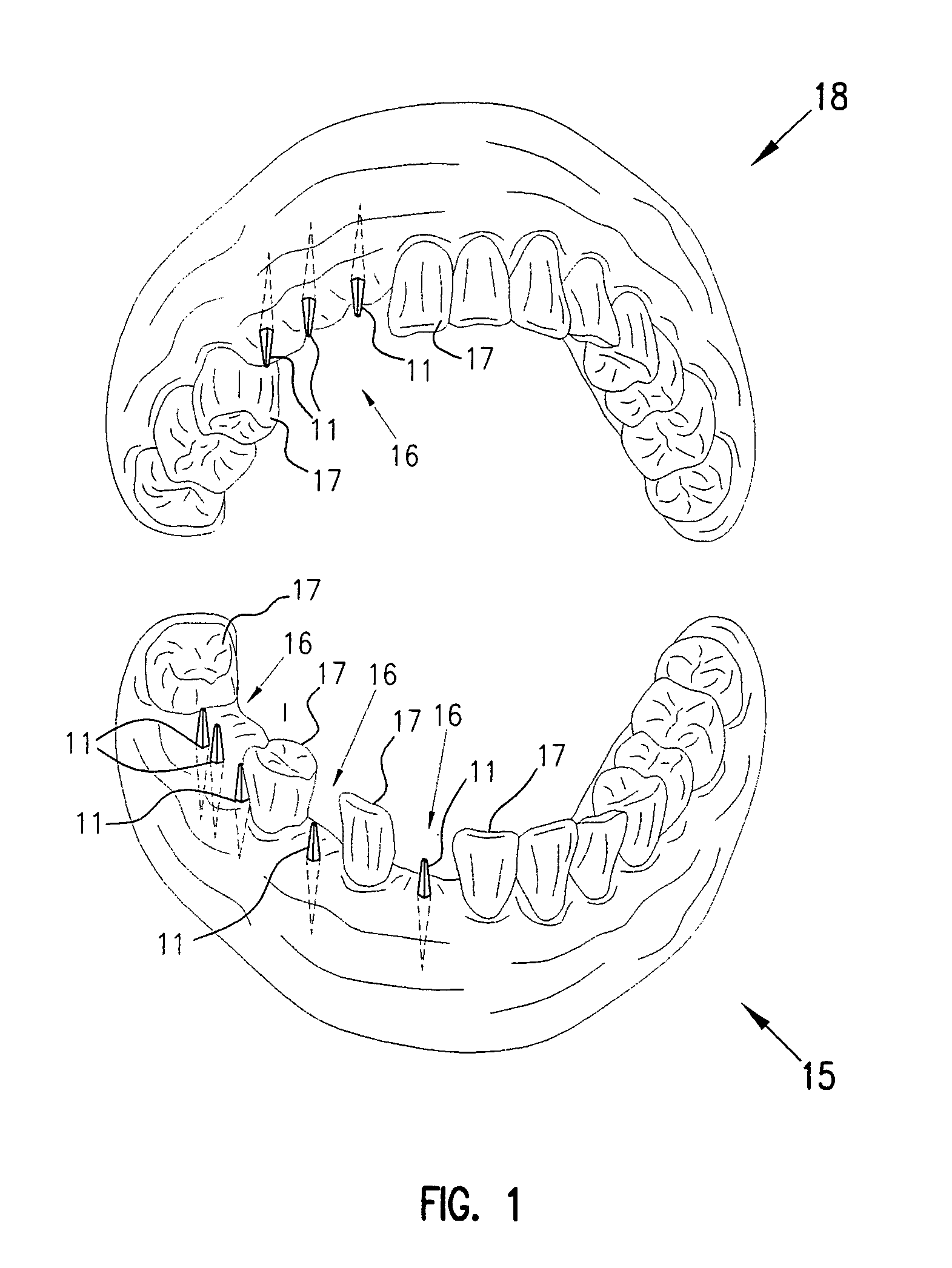

Methods for placing an implant analog in a physical model of the patient's mouth

A method of placing a dental implant analog in a physical model for use in creating a dental prosthesis is provided. The physical model, which is usually based on an impression of the patient's mouth or a scan of the patient's mouth, is prepared. The model is scanned. A three-dimensional computer model of the physical model is created and is used to develop the location of the dental implant. A robot then modifies the physical model to create an opening for the implant analog. The robot then places the implant analog within the opening at the location dictated by the three-dimensional computer model.

Owner:BIOMET 3I LLC

Methods for manufacturing dental implant components

A method of manufacturing a rapid prototype overmold for locating a dental implant analog in a modified stone model for use in creating a tooth prosthesis is provided. An impression of a mouth having a first installation site that has a dental implant and a gingival healing abutment with at least one informational marker installed is taken. A stone model based on the impression is prepared. The model is scanned. A three-dimensional computer model of the installation site on a CAD program using data from the scan is created. The at least one informational marker is determined to gather information about the location of the dental implant. Abutment dimensional information based on the three-dimensional image and the at least one informational marker is developed. Overmold rapid prototype dimensional information based on the three-dimensional image is developed. The overmold rapid prototype adapted to fit over the modified stone model is fabricated.

Owner:BIOMET 3I LLC

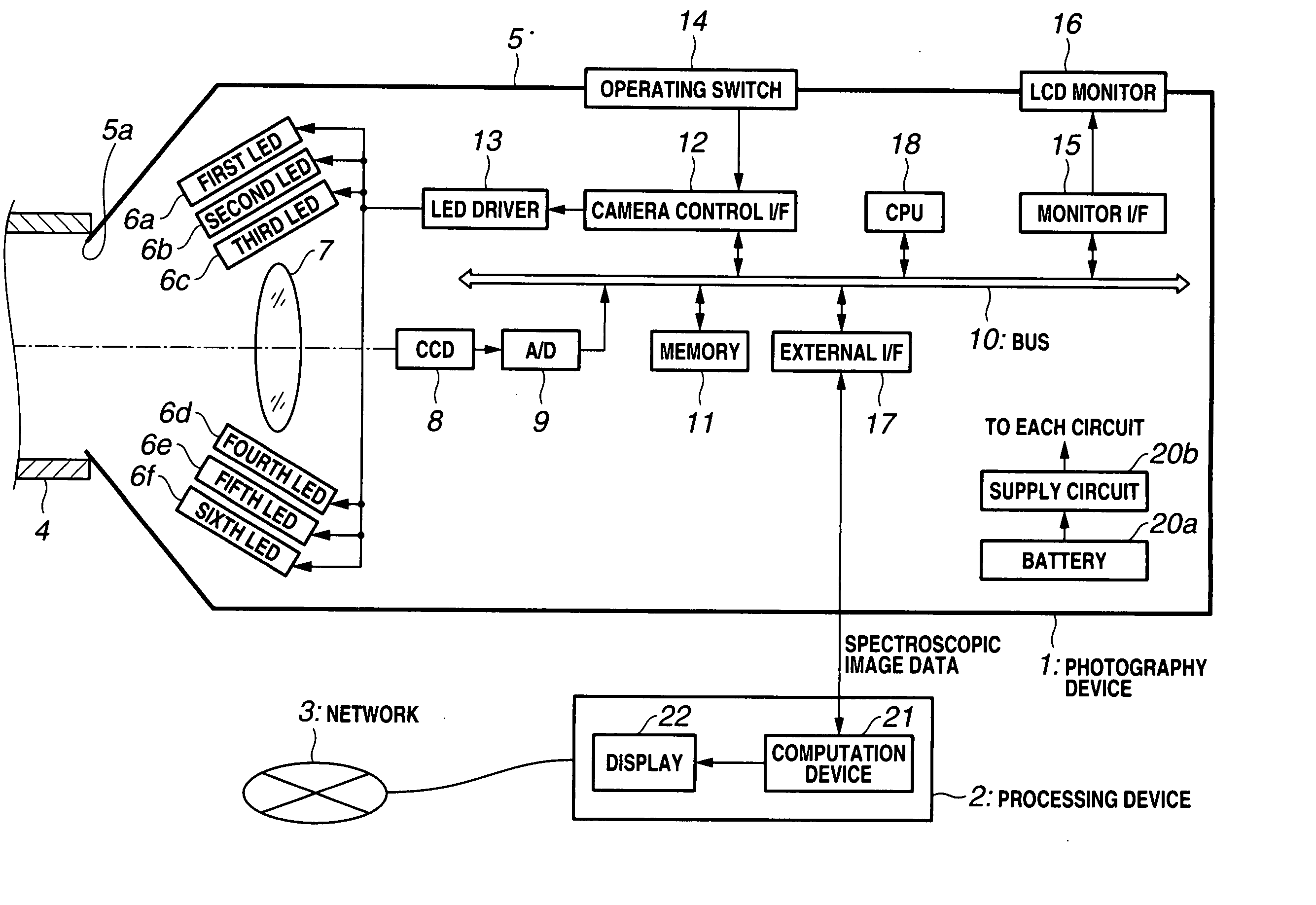

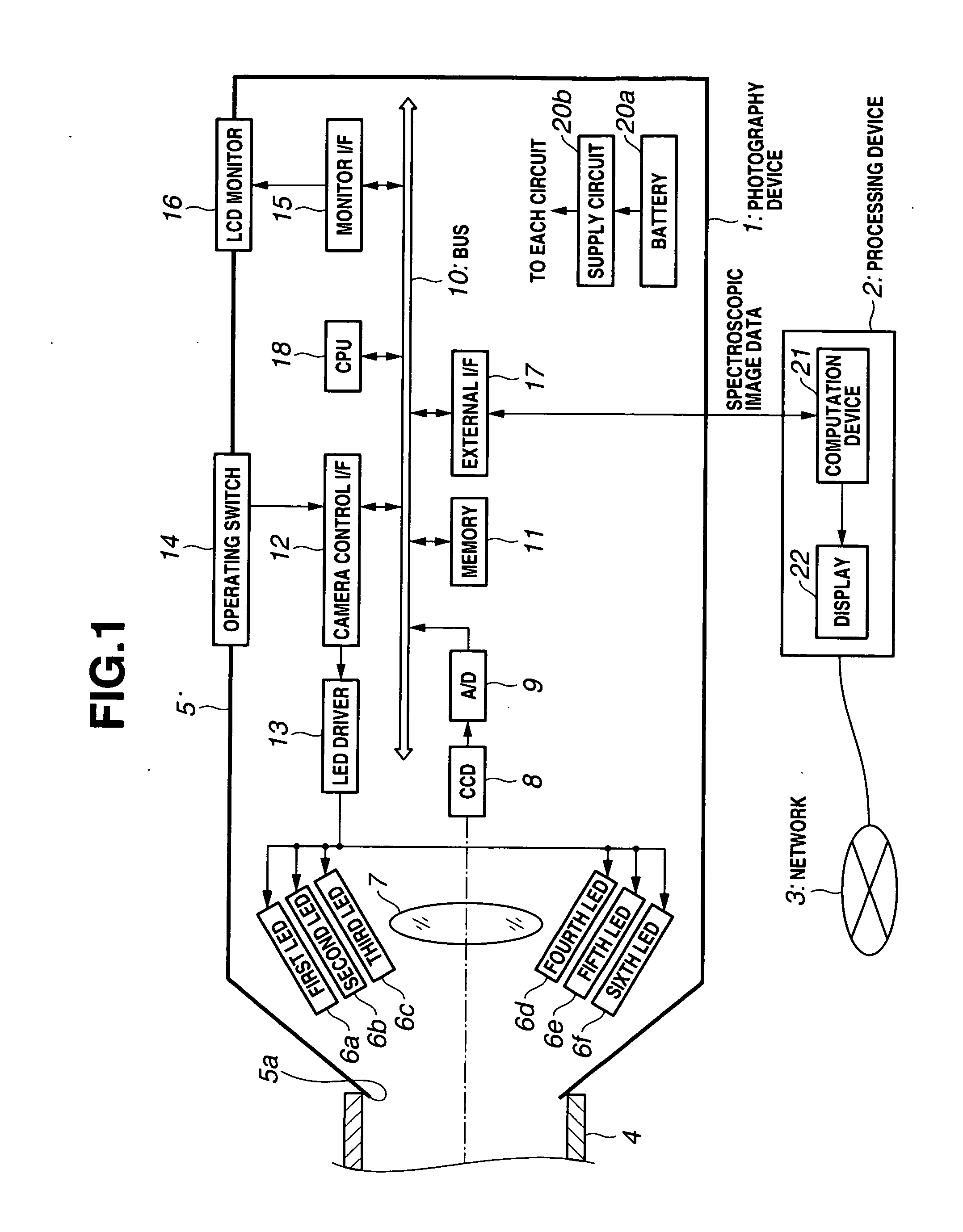

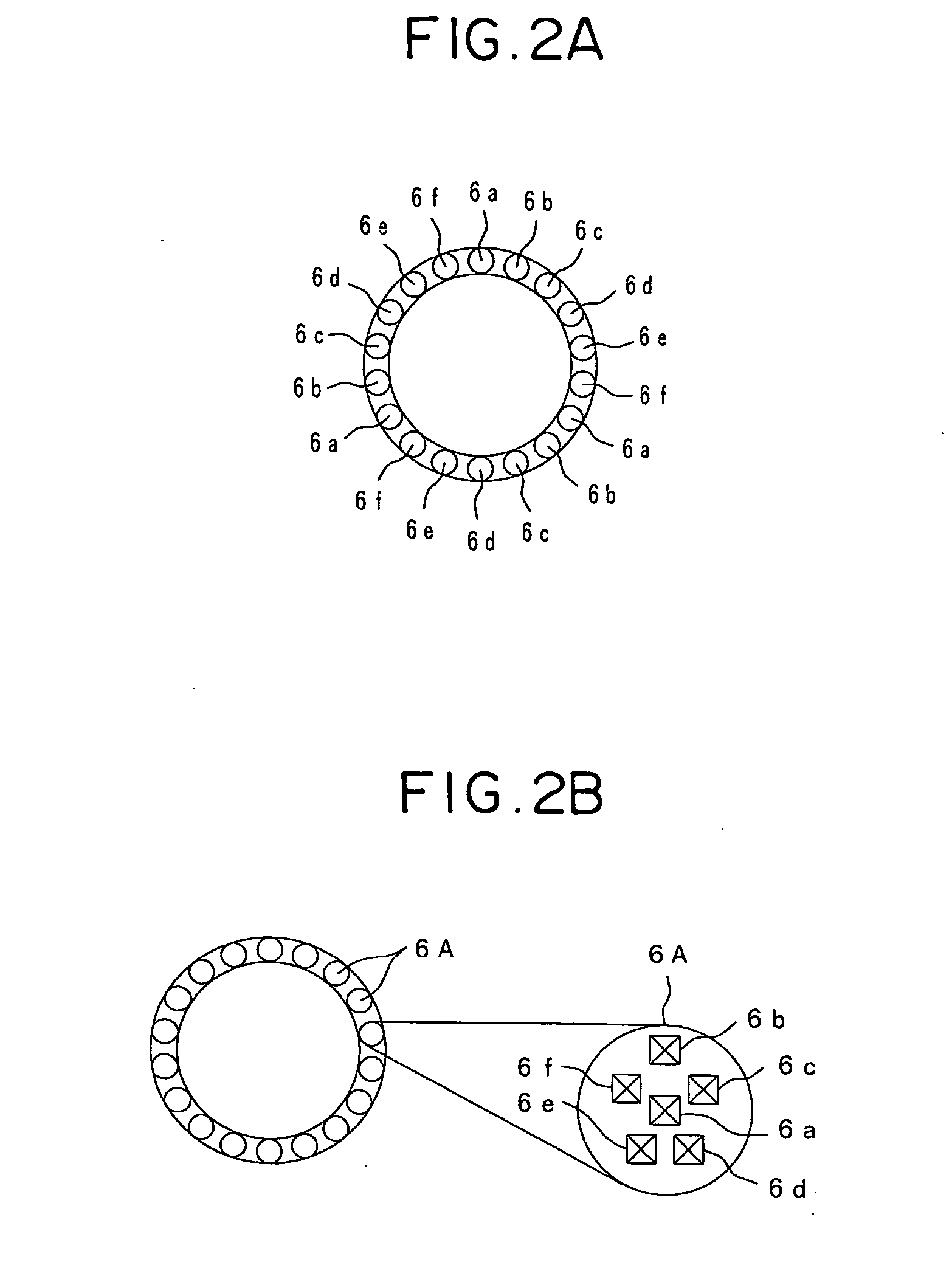

Image processing system and camera

The image processing system is applied to dentistry, for example, and performs photography of the teeth of a patient while causing a plurality of illumination light LEDs of different wavelengths to emit light by means of a photography device when producing a crown repair or denture of the patient, whereby image data are acquired. The image data are transmitted to a dental filing system constituting a processing device where color reproduction data are determined through computation. In addition, color reproduction data are transmitted to the dental technician's office via a public switched network. Therefore, a repair material compound ratio calculation database is searched and the compound data for a material that matches the hue of the patient's teeth are found, whereby a crown repair or denture or the like that very closely matches the color of the patient's teeth is produced.

Owner:OLYMPUS CORP

Oral care compositions comprising dicarboxy functionalized polyorganosiloxanes

InactiveUS7025950B2High retention ratePositive tooth feel benefitsCosmetic preparationsToilet preparationsPersonal careNatural tooth

Disclosed are compositions and methods for treating and modifying surfaces and for enhancing delivery of active agents to surfaces treated with the compositions, which comprise siloxane polymers functionalized with pendant moieties comprising anionic groups, specifically carboxylic acid groups. When applied to a suitable surface, the present composition comprising the carboxy functionalized siloxane polymers forms a substantially hydrophobic coating on the treated surface. These polymers effectively deposit on surfaces that have cationic sites, which are capable of forming bonds or linkages with the anionic groups of the polymer. The treated surface becomes hydrophobic due to the deposition of the carboxy functionalized siloxane polymer, which then imparts a variety of end use benefits to that surface such as ease of cleaning, stain removal and prevention, whitening, etc. The carboxy functionalized siloxane polymer further acts as a carrier to deposit active agents onto the surface and to improve retention and efficacy of said actives on the treated surface. The present compositions are useful in a variety of applications including oral care, hair and skin care, personal care, cosmetics, and fabric and hard surface cleaning and conditioning. Examples are oral compositions for use in cleaning and whitening of natural teeth and dental prosthesis; for preventing, reducing or removing plaque, calculus and surface deposited stains on teeth; and for providing shine, smoothness and positive feel benefits to teeth, the compositions comprising at least about 0.1% by weight of a dicarboxy functionalized siloxane polymer in a formulation that effectively deposits the polymer to teeth and other oral surfaces.

Owner:THE PROCTER & GAMBLE COMPANY

Method, blank, assortment of blanks, dental database and blank database comprising prefabricated partial end surfaces of partial dentures

ActiveUS20090181346A1Simple designSimple processMedical simulationDental implantsDenturesCentral region

The invention relates to a process, a blank, an assortment of blanks, a tooth database, and a database of blanks, for the production of a dental prosthetic item. The method comprises the provision of a 3D model of a dental prosthetic item and the selection of a suitable blank from a plurality of possible blanks. The provision of the 3D model of the dental prosthetic item comprises the determination of an esthetically relevant designed subregion of the 3D model of the dental prosthetic item as part of an exterior surface of said dental prosthetic item, and a blank is specified from a plurality of blanks having a prefabricated esthetically relevant terminal subsurface of a surface of the tooth, the terminal subsurface of said blank being such that it at least approximates the thus specified designed subregion. The 3D model of said dental prosthetic item is carved from the selected blank such that the prefabricated terminal subsurface of said blank remains unmachined in at least a central region thereof.

Owner:SIRONA DENTAL SYSTEMS

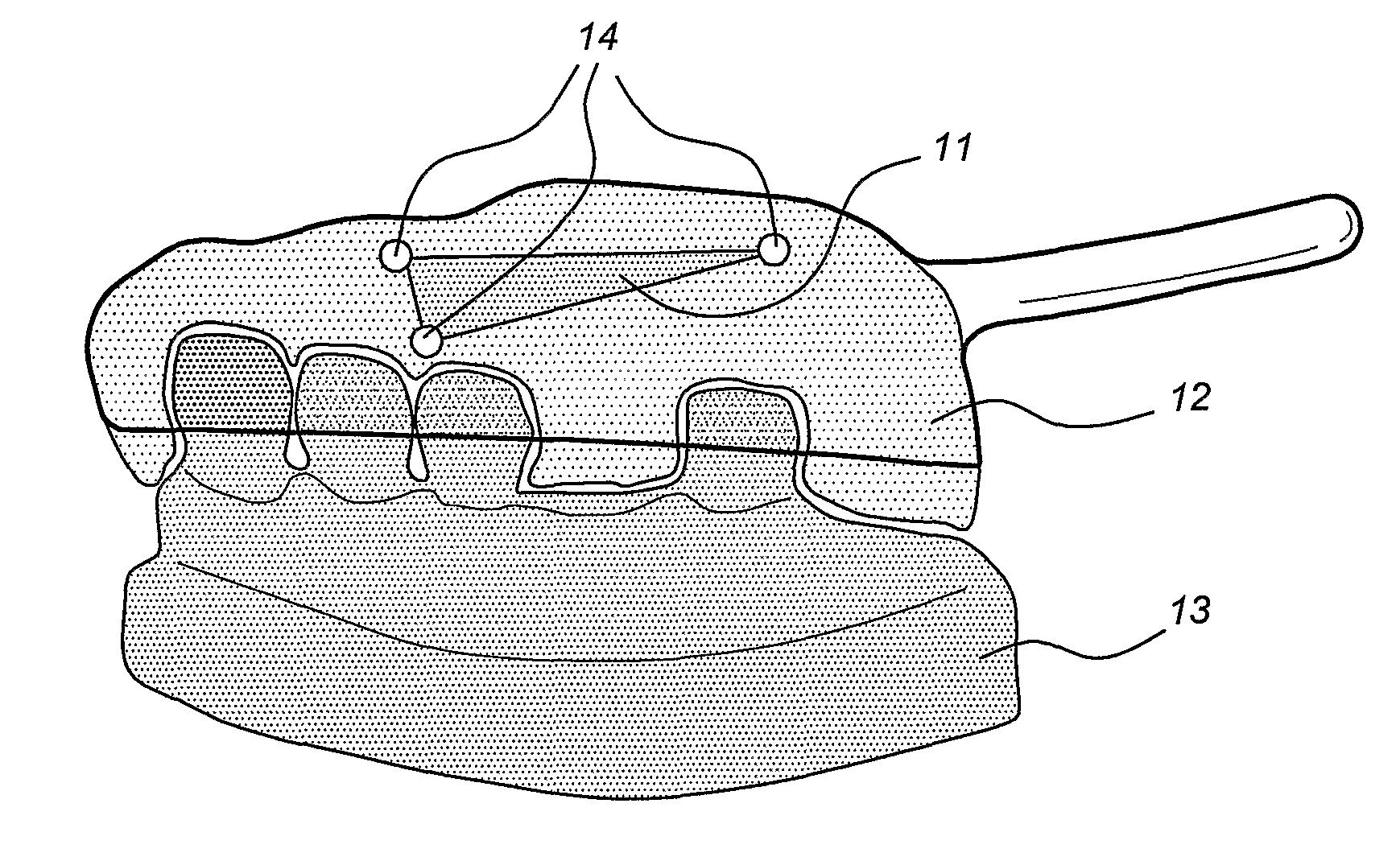

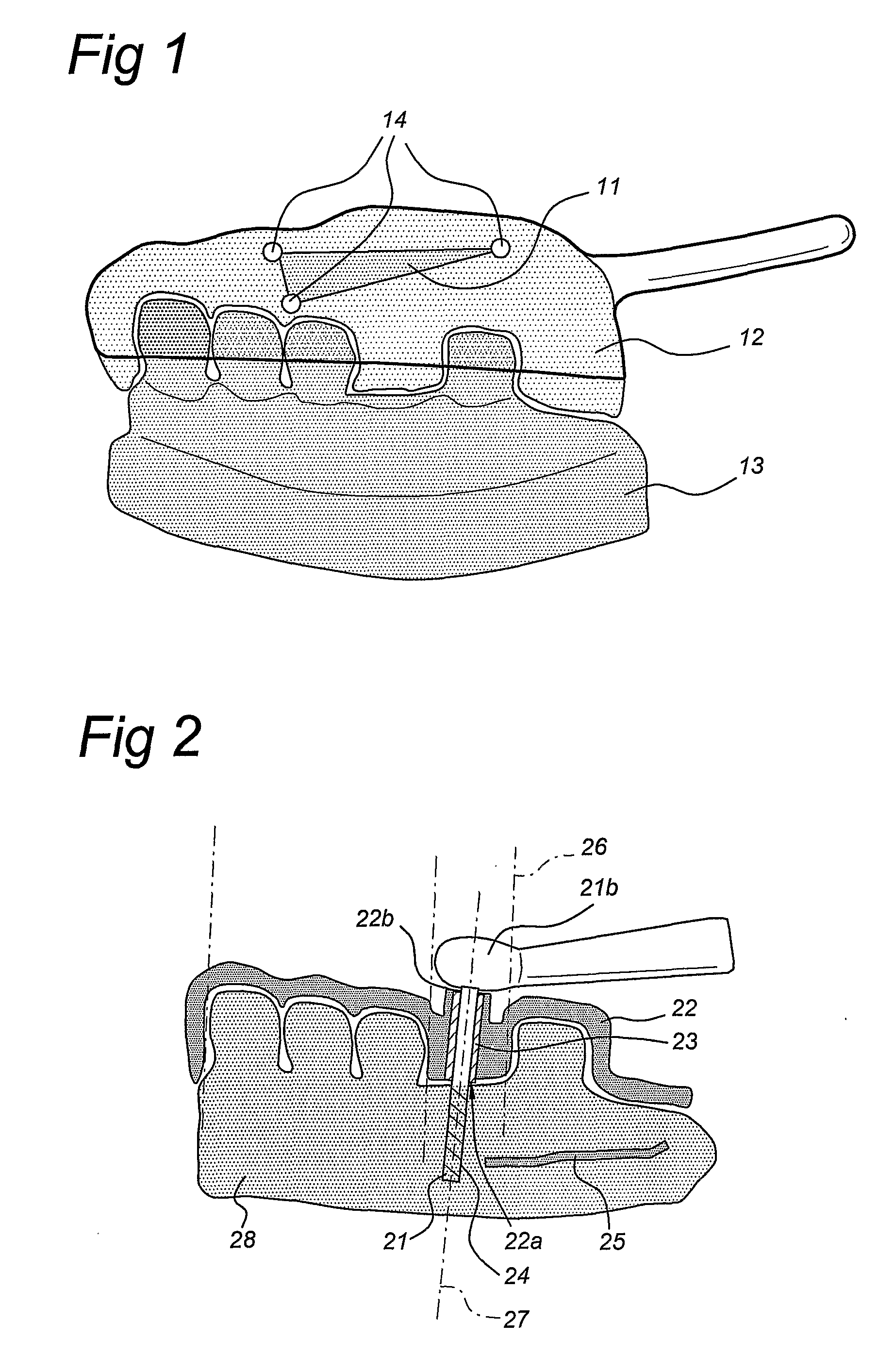

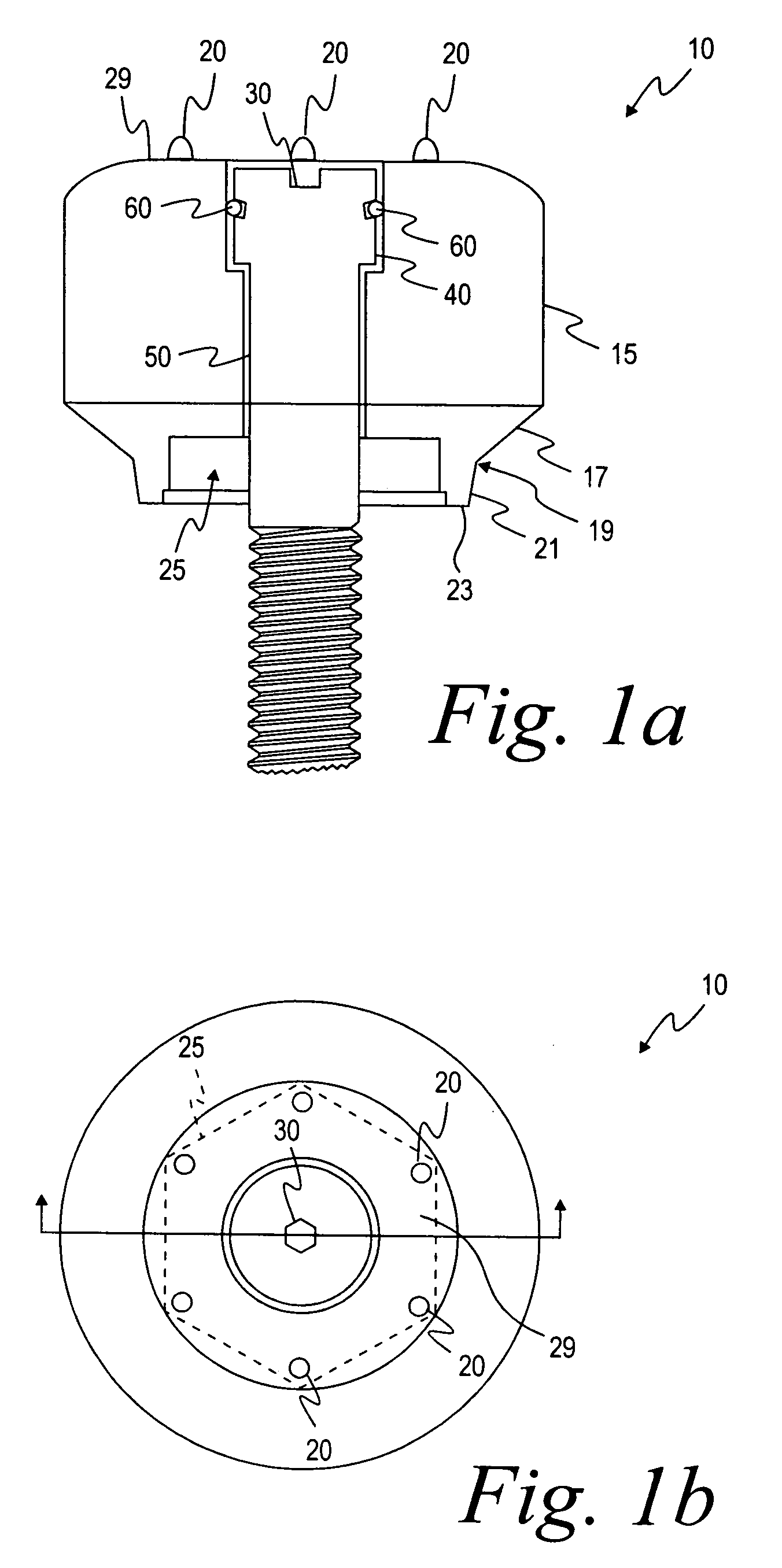

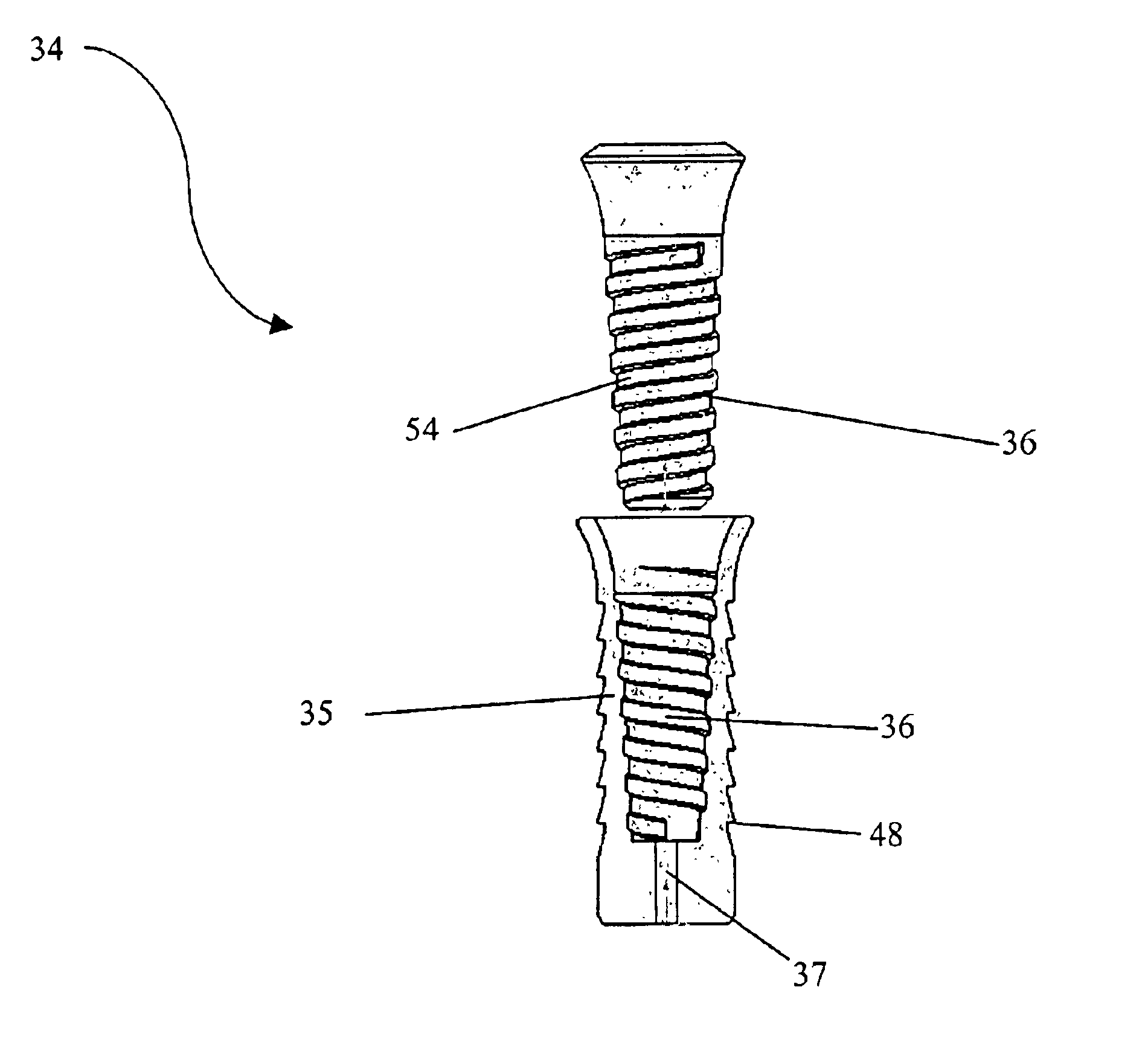

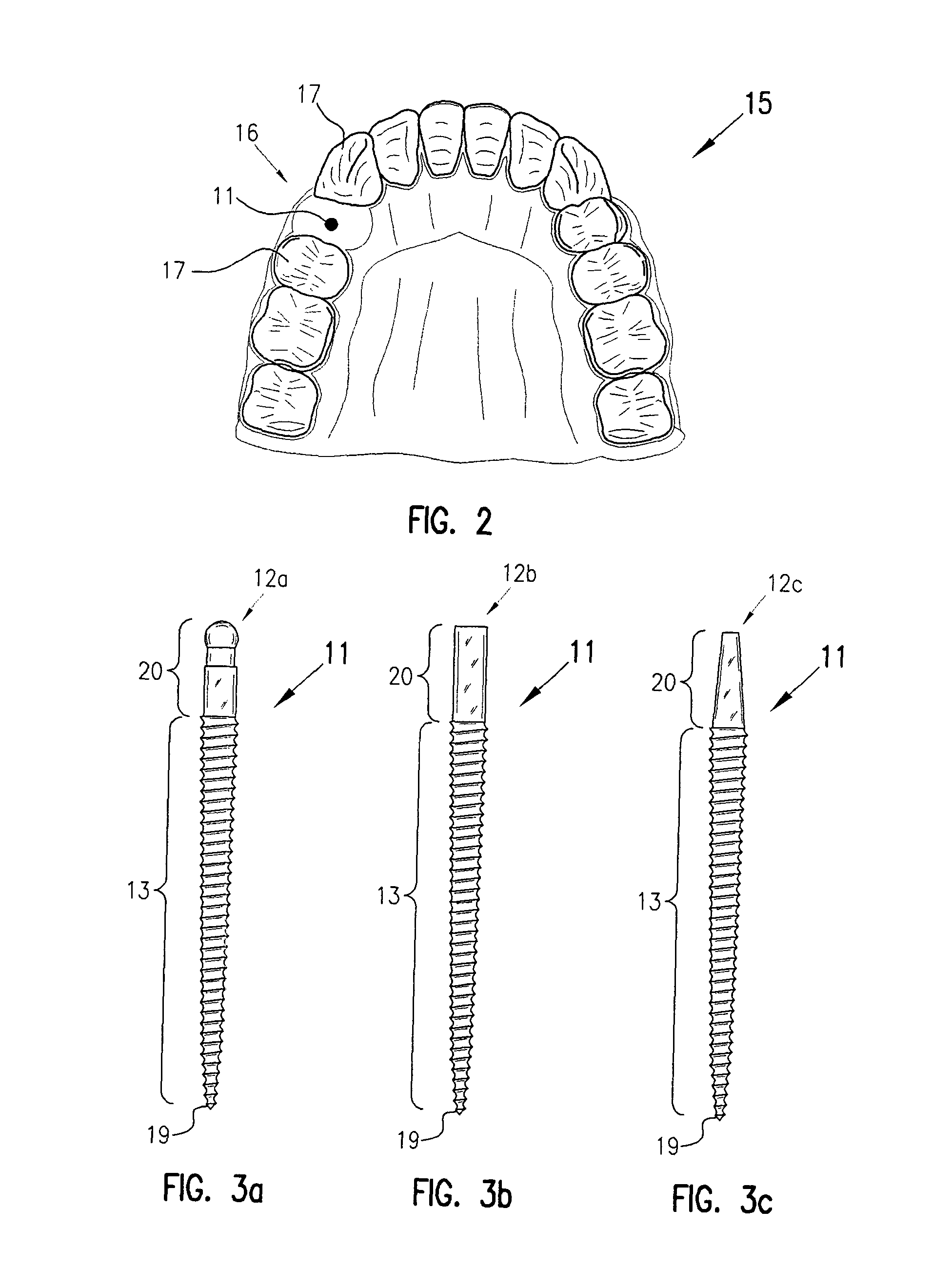

Support for sustaining and/or forming a dental prosthesis

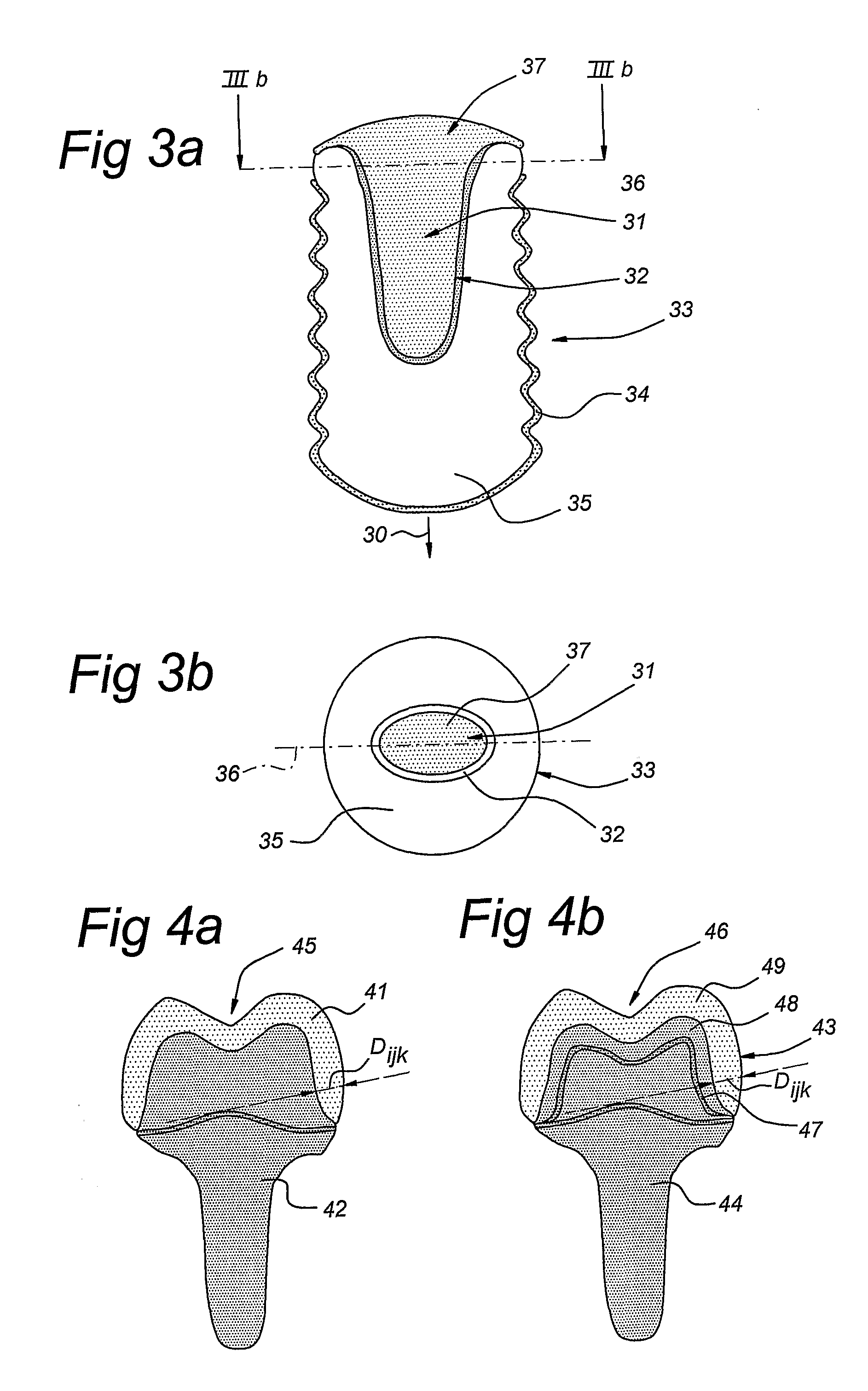

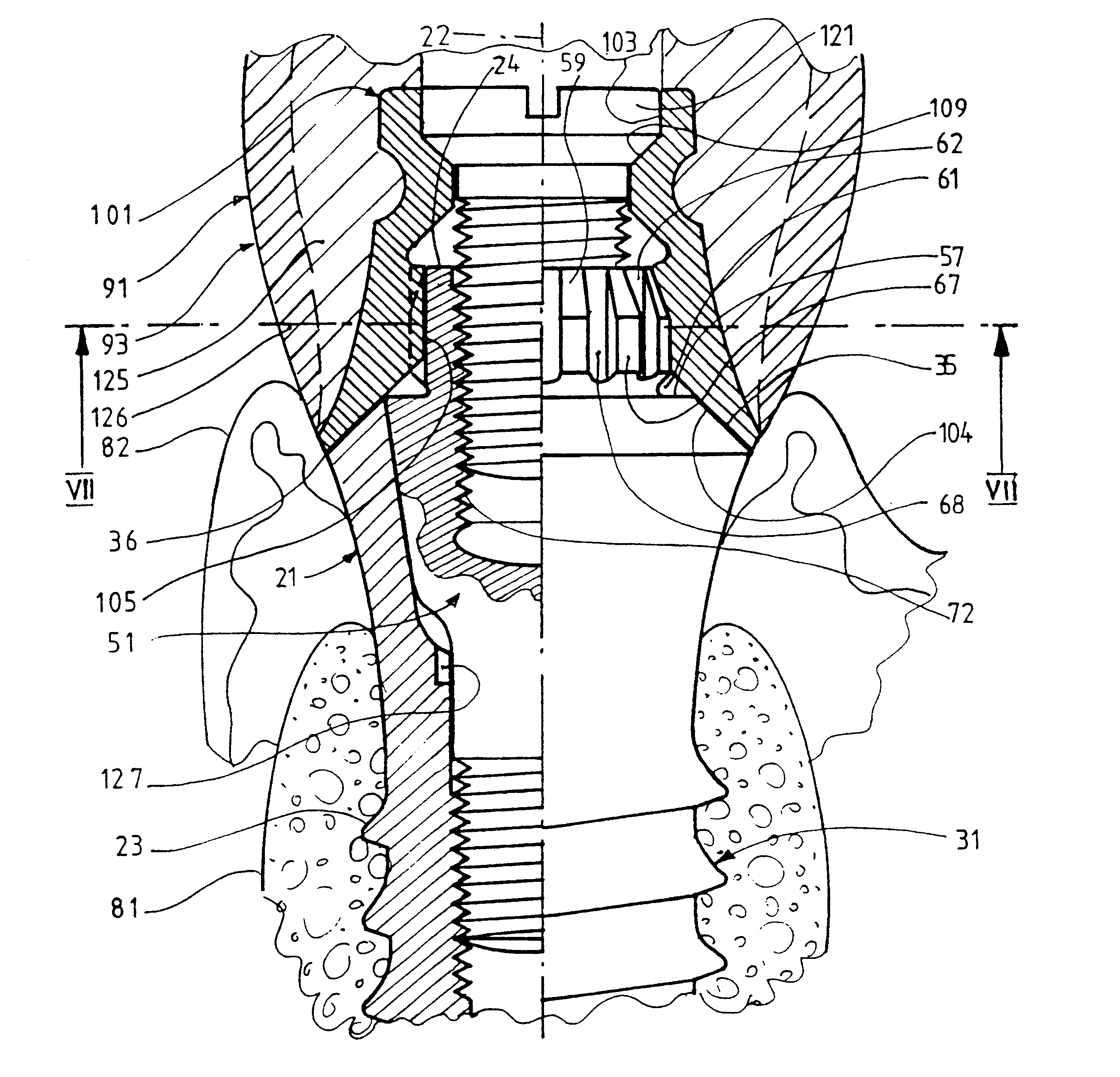

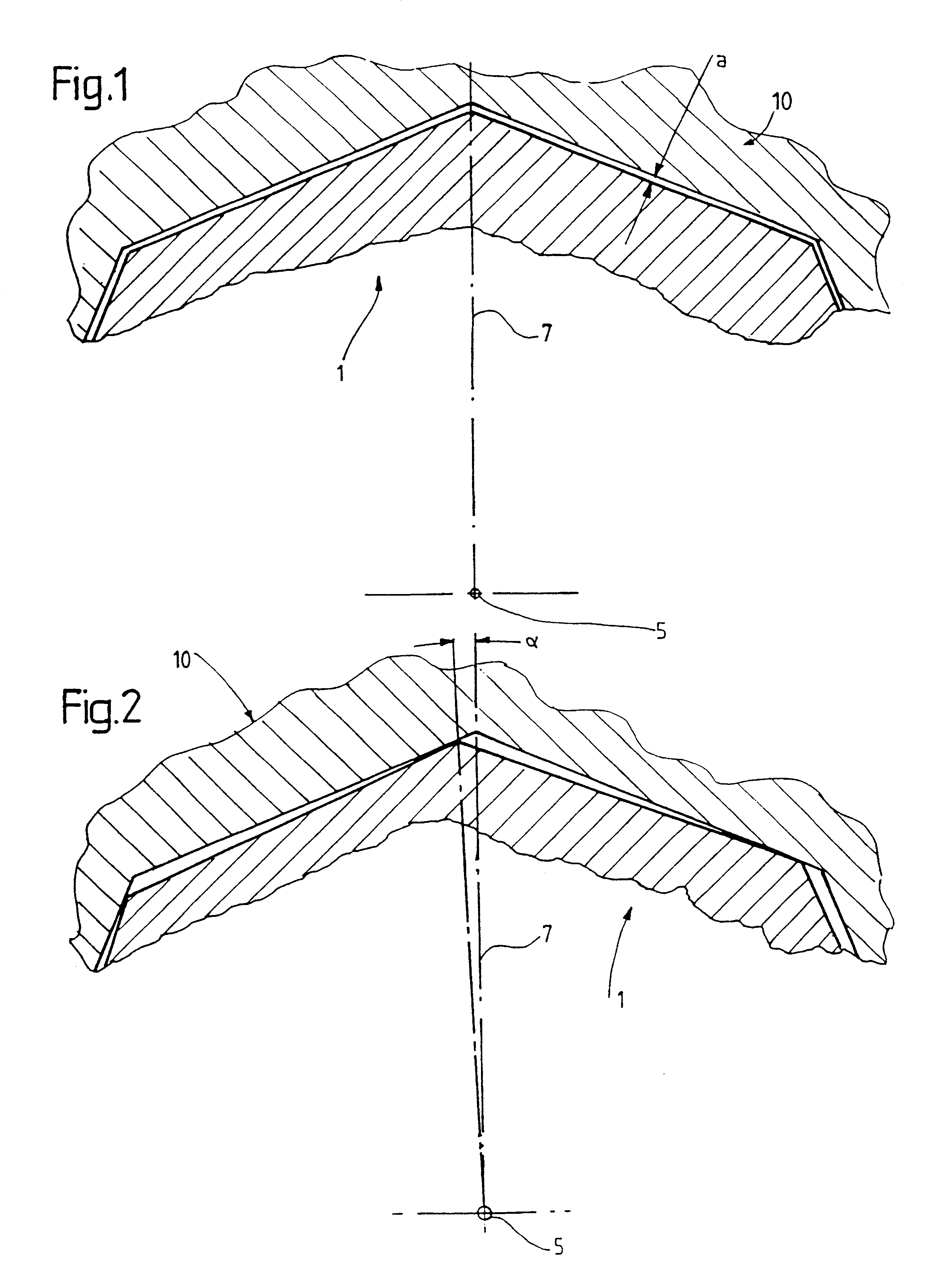

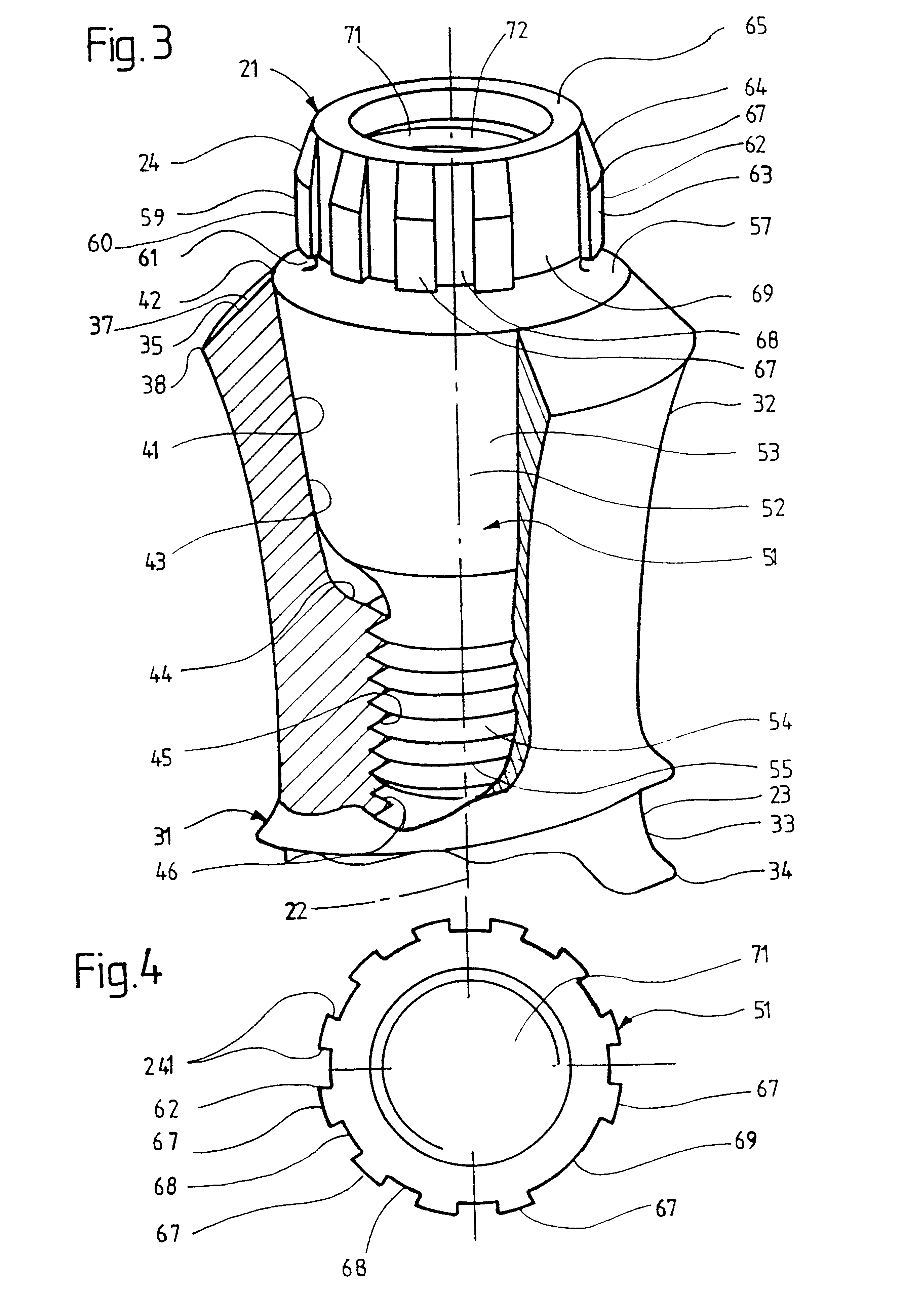

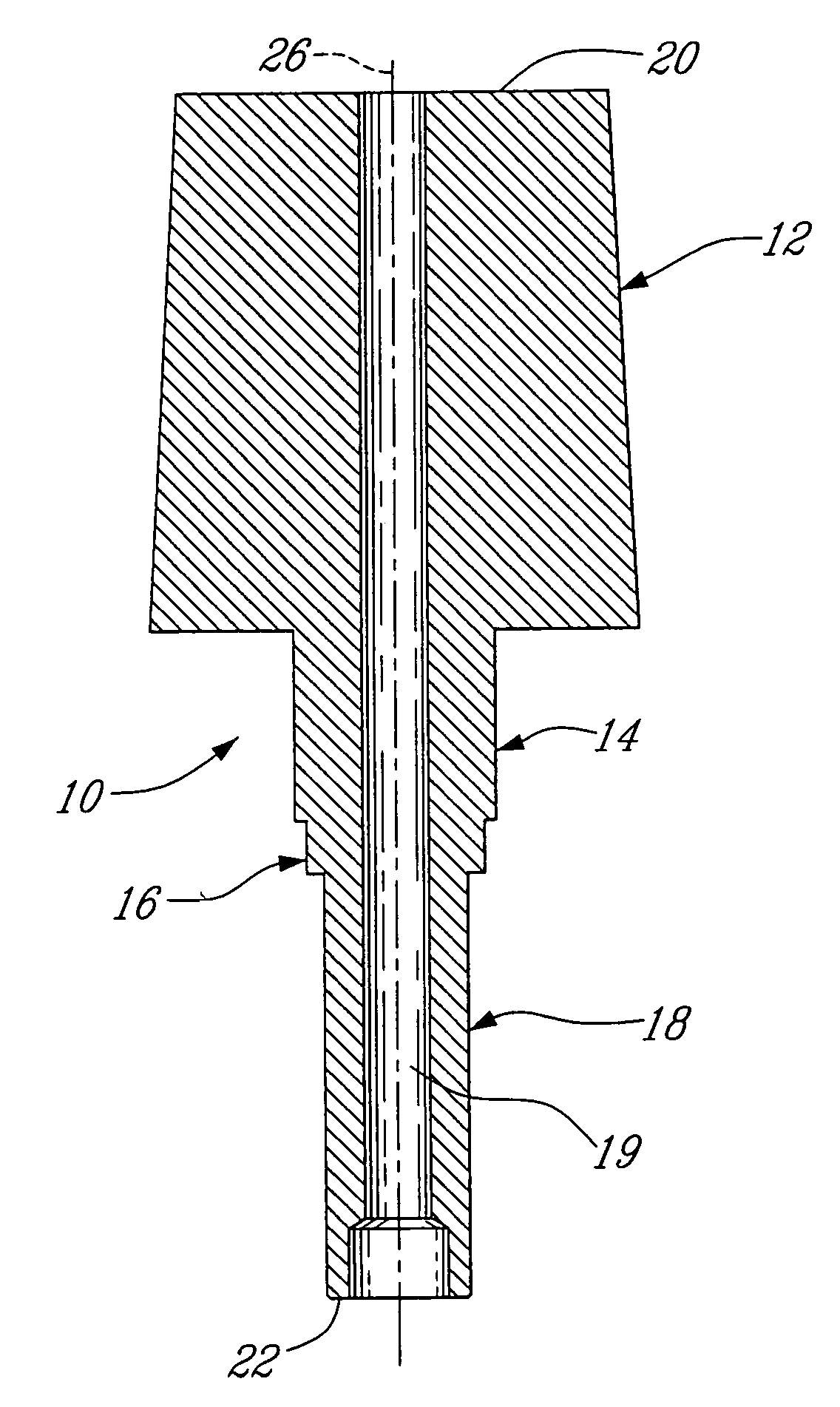

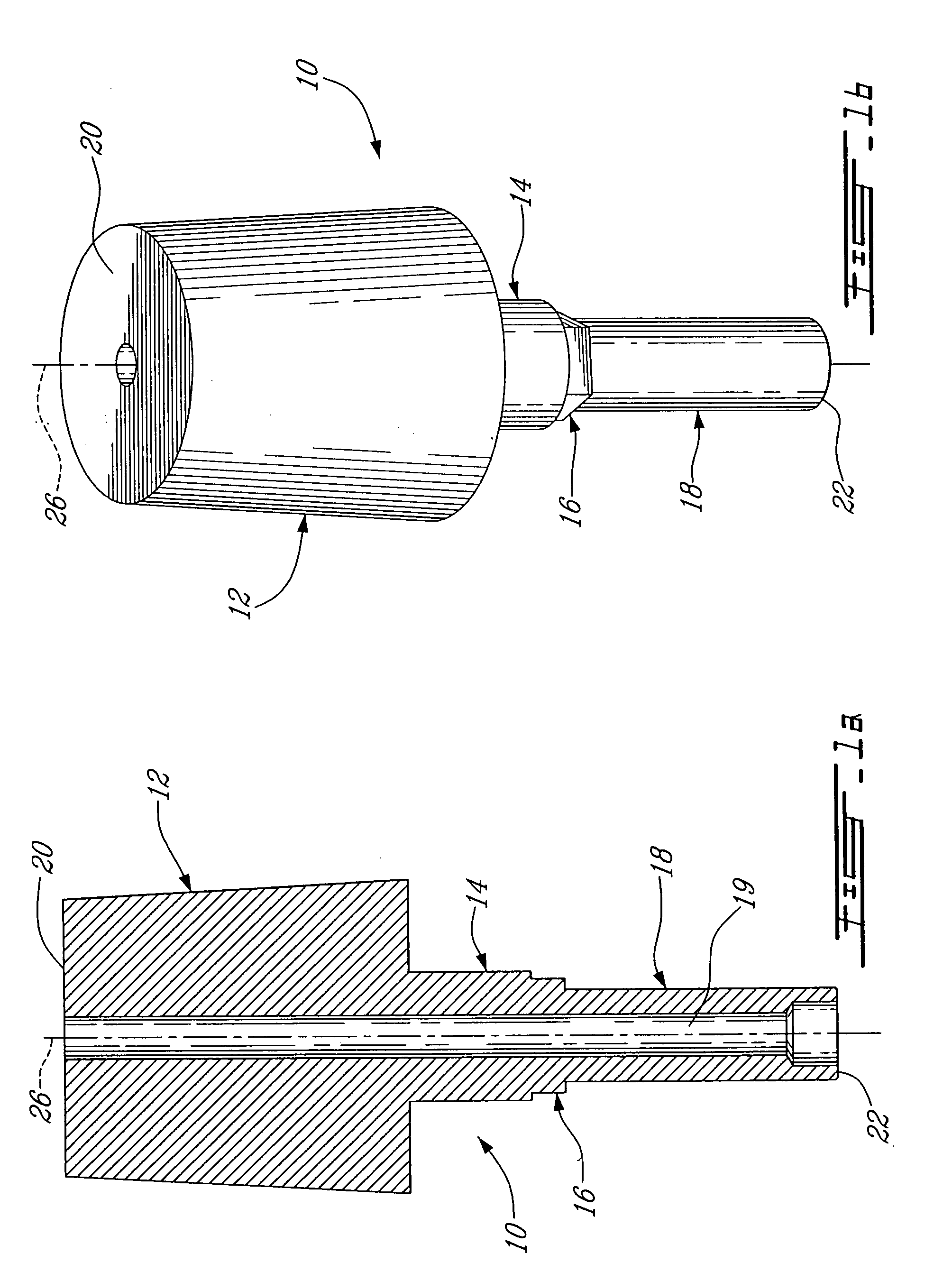

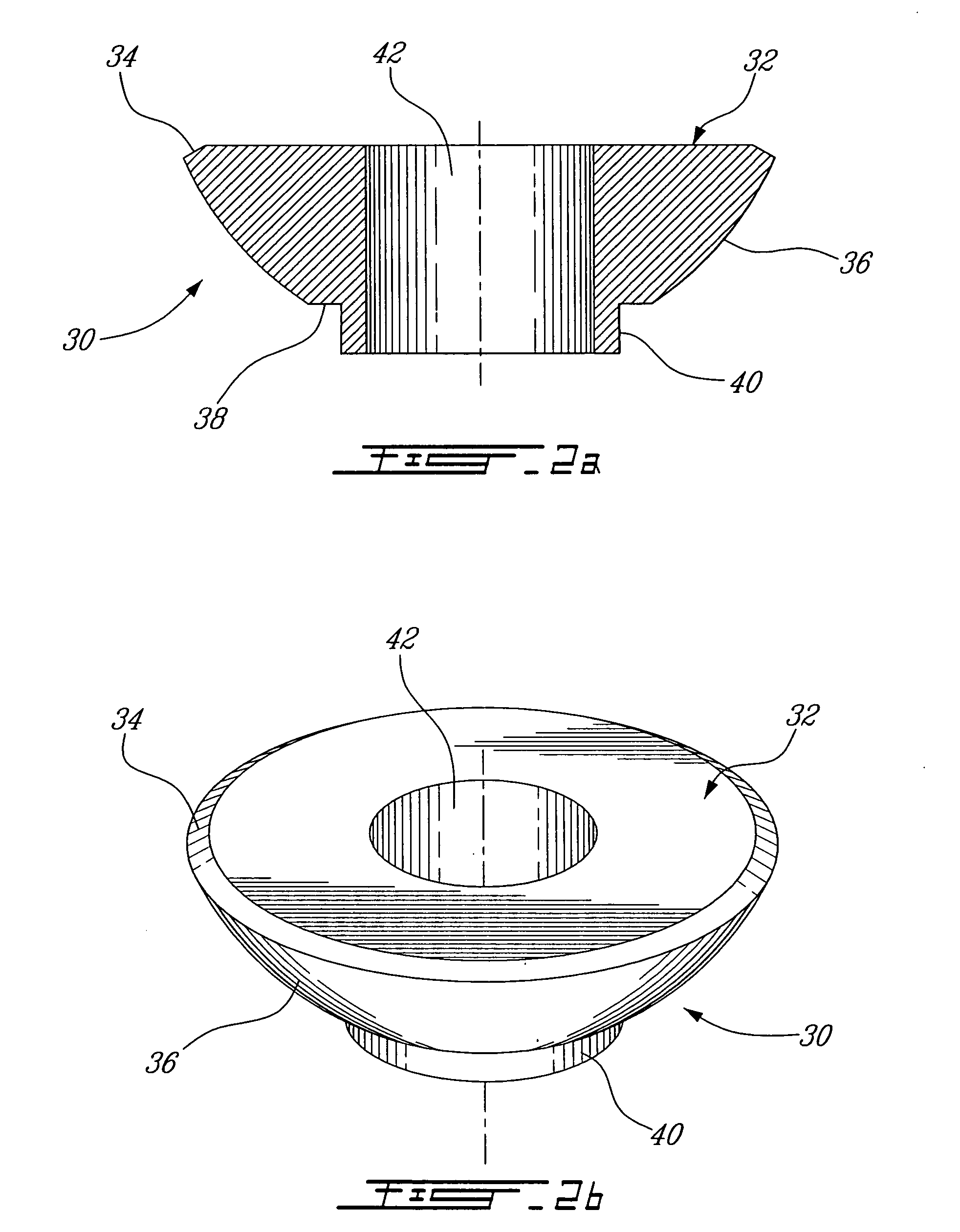

InactiveUS6726480B1Avoid disadvantagesPrecise positioningDental implantsDental prostheticsDenturesEngineering

A support for sustaining and / or forming a dental prosthesis, comprises an axle, an anchoring part which can be anchored in a bone or a master model, and a head part which protrudes out of said bone or master mode. The head part has intermediate spaces distributed around the axis, i.e., several first intermediate spaces forming a divided circle, and a second, wider and / or deeper intermediate space. A cap can be fixed to the support. The cap has at least one projecting part for engaging in an intermediate space and, optionally, can be configured for fixing in several different rotational positions or a single rotational position, the support allowing exact positioning. The cap can also be produced without a projecting part of the type mentioned. The same support can be used to form different types of dental prostheses.

Owner:STRAUMANN HLDG AG +1

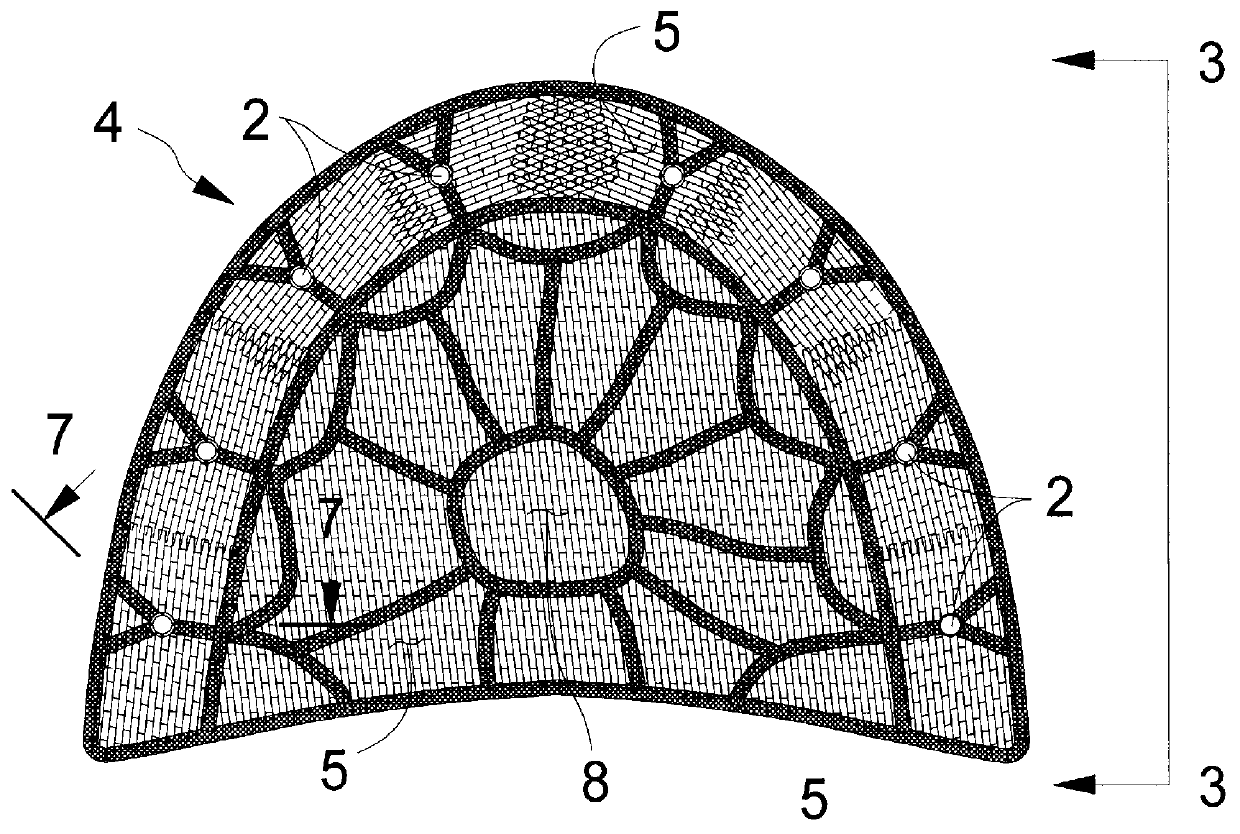

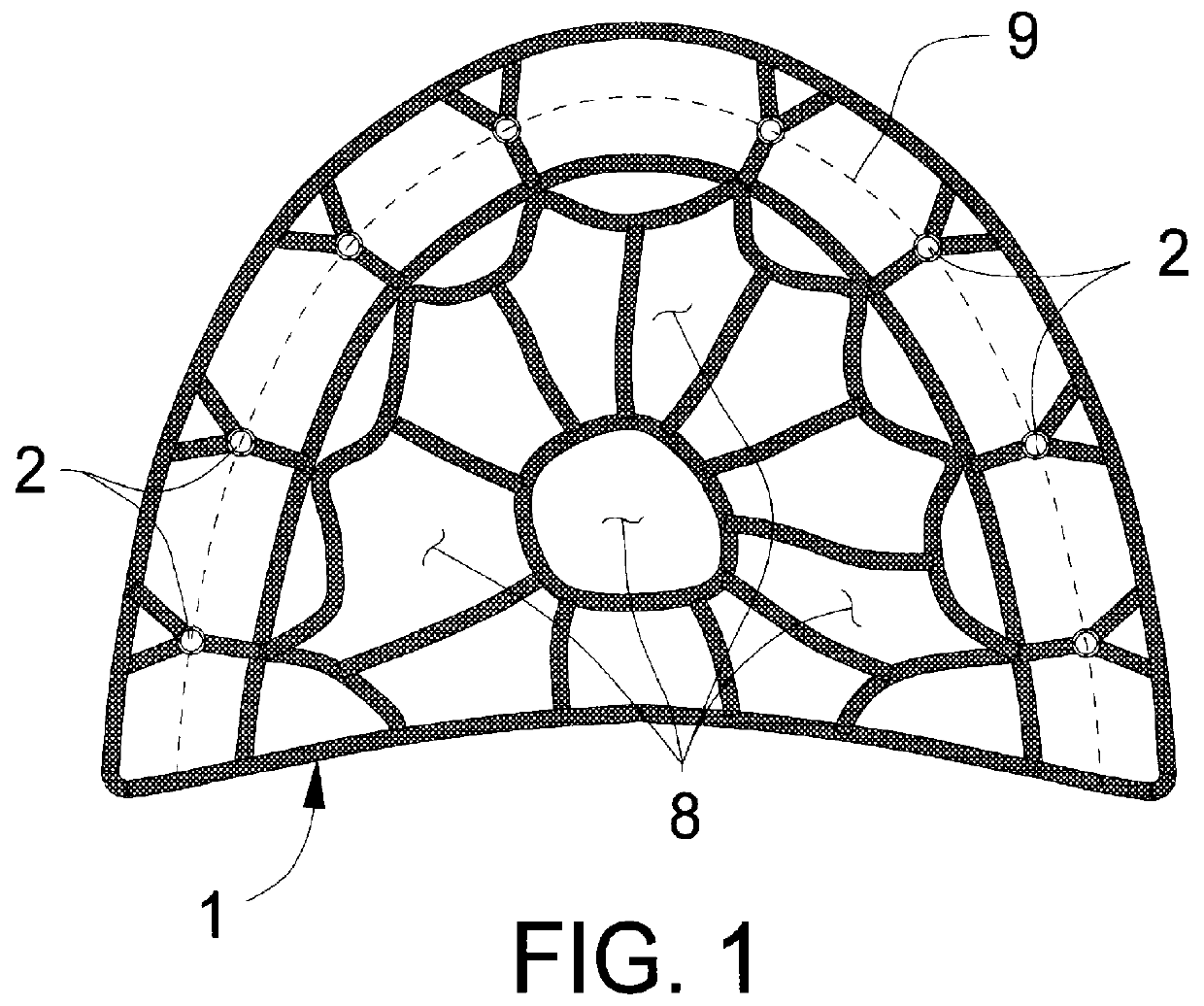

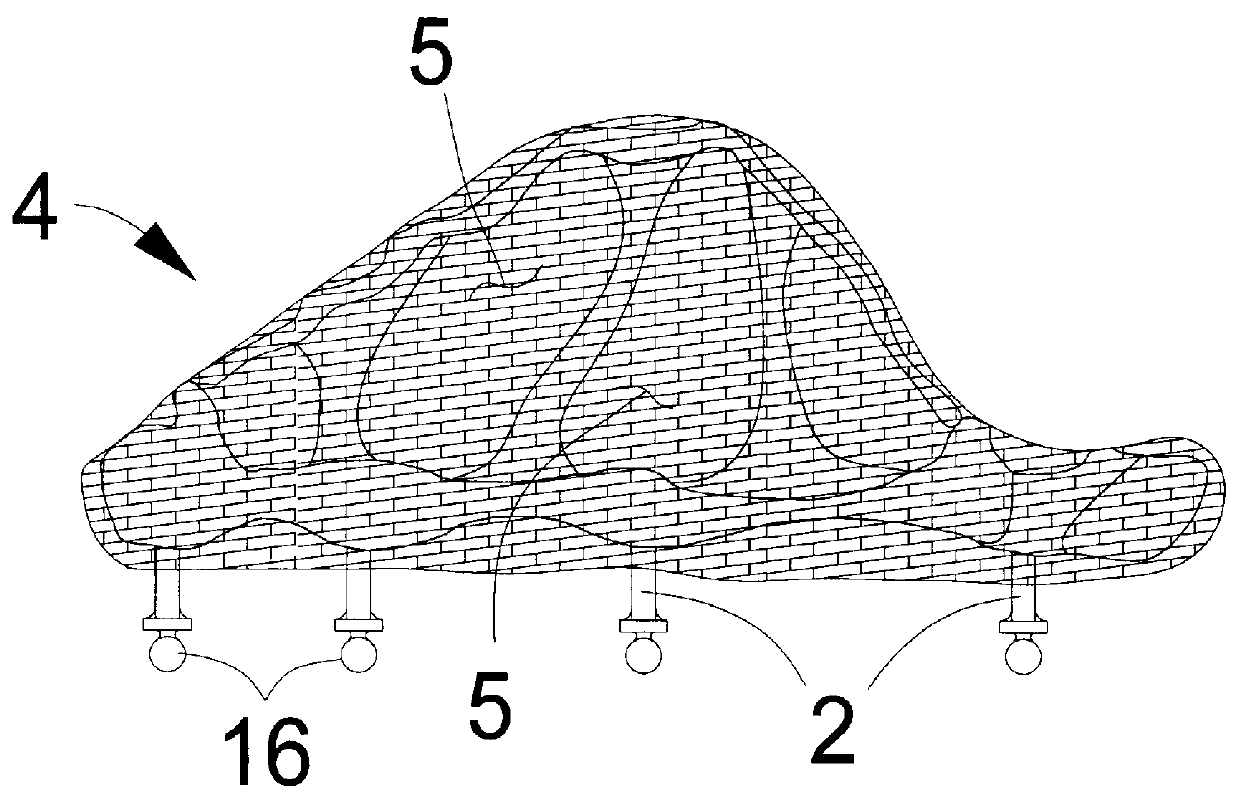

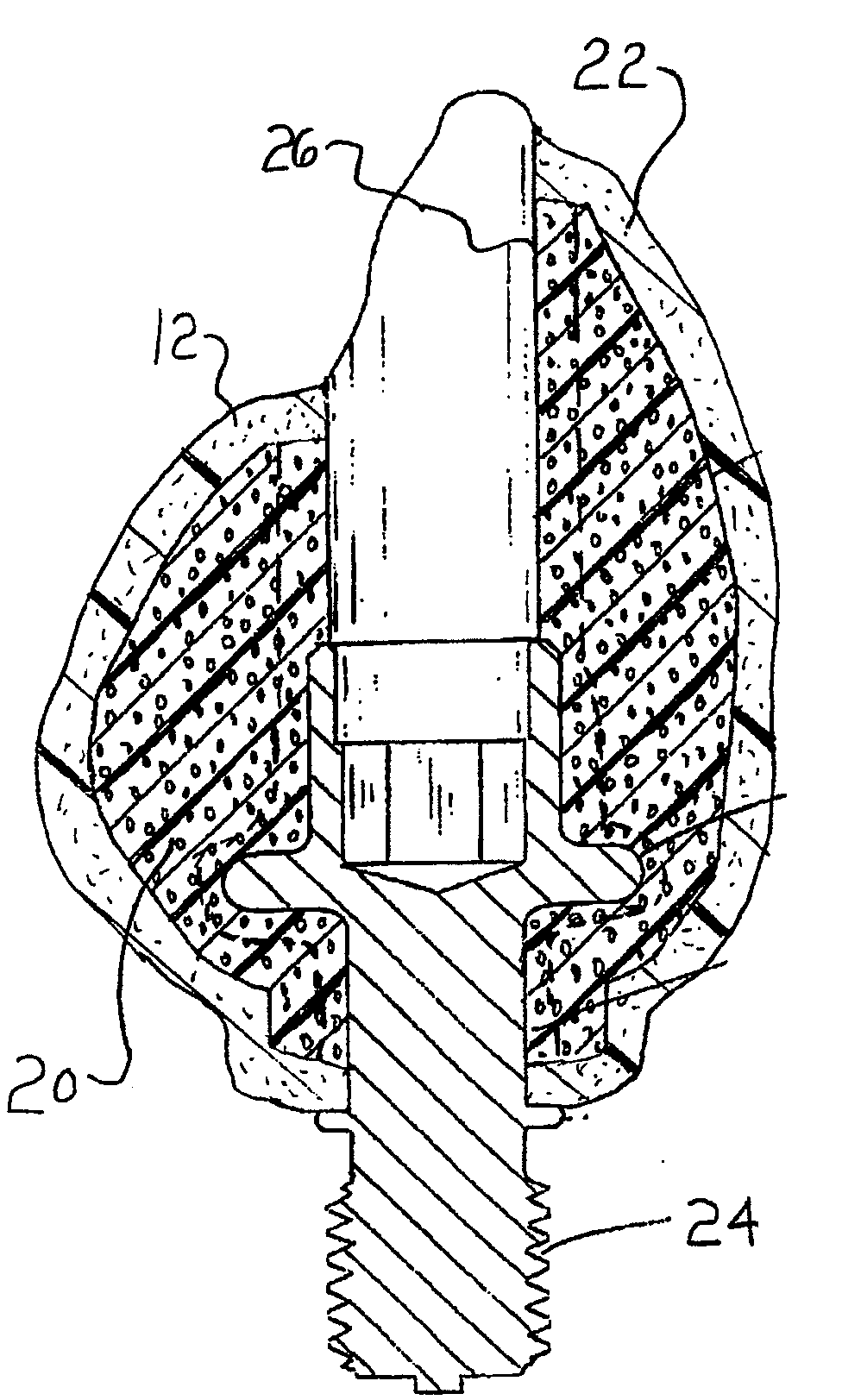

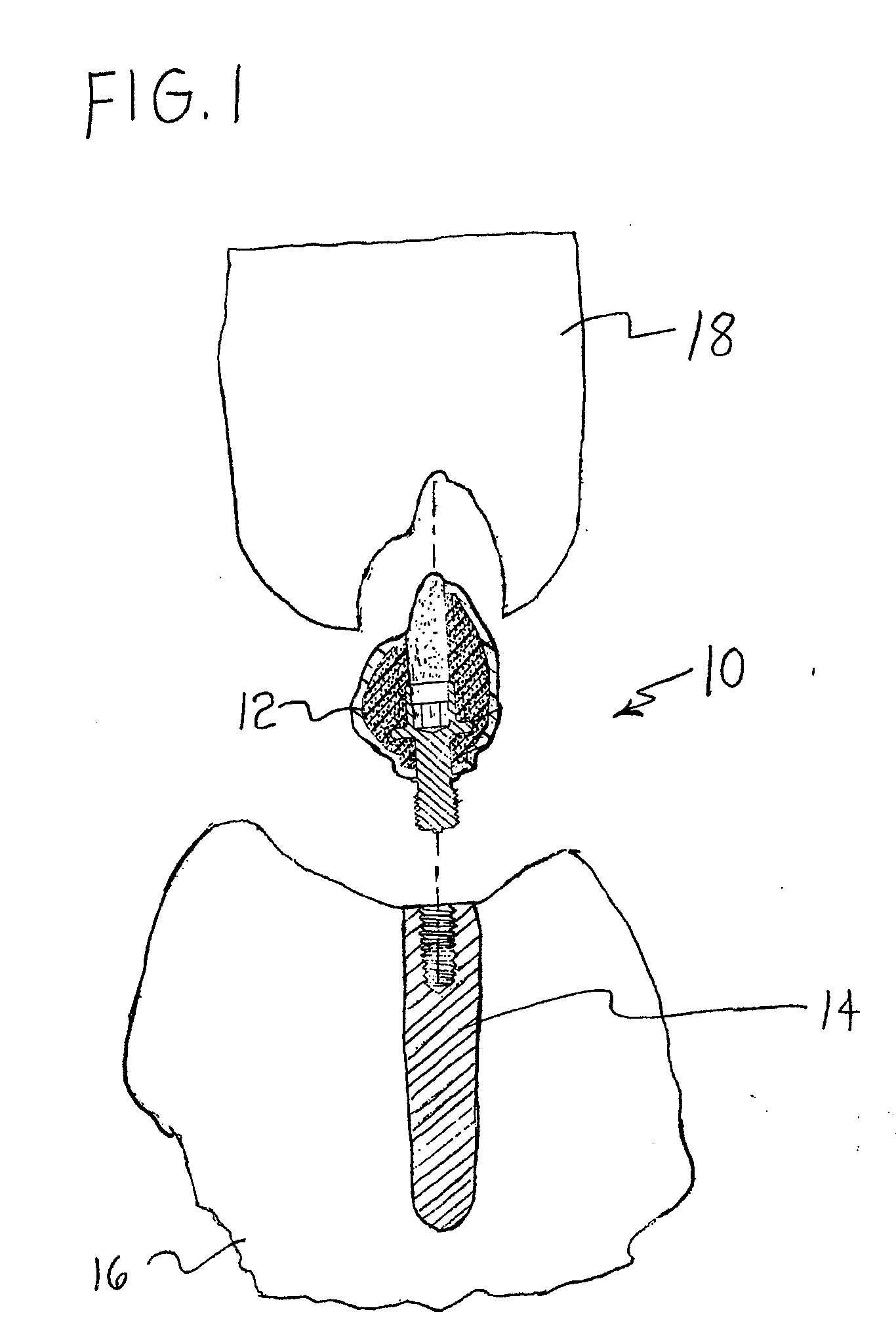

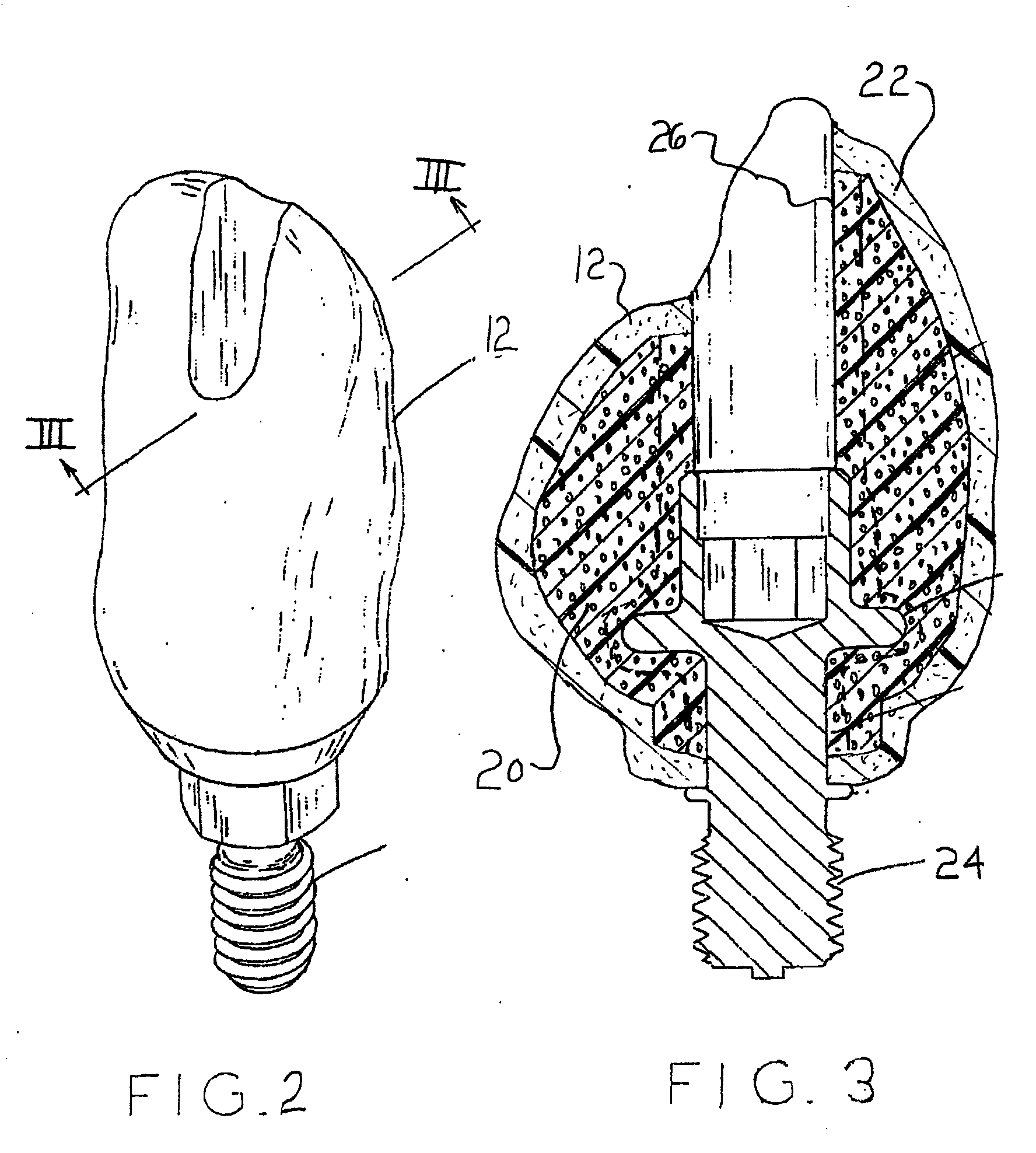

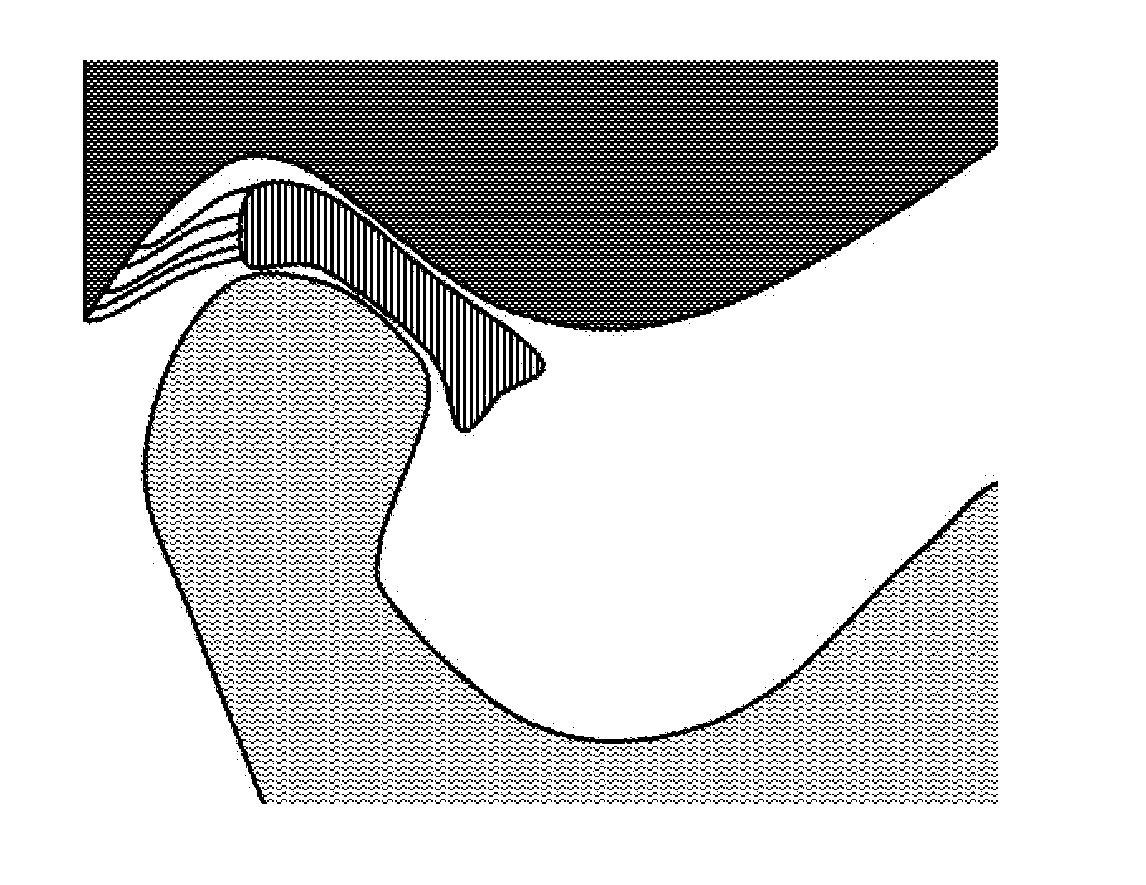

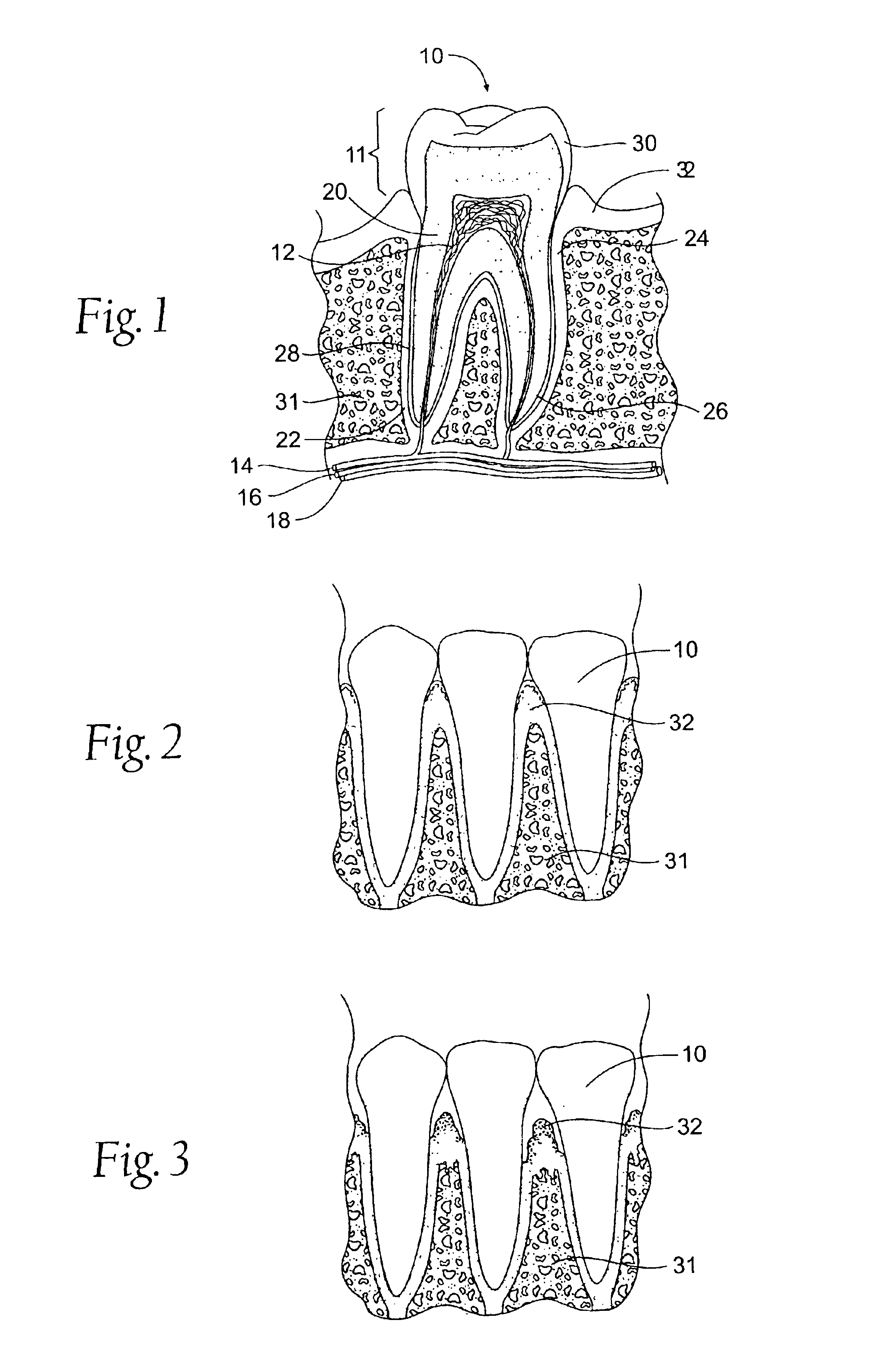

Osseo-integrated sub-periosteal implant

A sub-periosteally implantable prosthesis support structure for a fixed or detachable dental prosthesis includes a framework fitted to and generally conforming to the inner and outer contours of the bony ridge structures of a person. The framework is configured to provide a space extending generally normal to the bony ridge structure to an apex to provide space for subsequent bone growth. A plurality of denture support posts are distributed about the framework and depend outwardly from the apex in substantial alignment with the bony ridge structure. During the fabrication of the prosthesis support structure, a bio-compatible fine mesh screen is fixed to and spans, tent-like, the framework to substantially overlay the bone structure and the space provided for subsequent bone growth. After the support structure has been implanted, the growth of bone into the space and around the support structure is promoted to osseo-integrate the support structure with the person's bony ridge, thus providing a secure foundation for a denture or fixed dental prosthesis configured for detachable or fixed coupling with the denture support posts. The support structure may be made, partly or wholly, from either non-resorbable material, such as titanium stock and mesh, or from a resorbable material such as Vicryl TM .

Owner:ROBINSON DANE Q

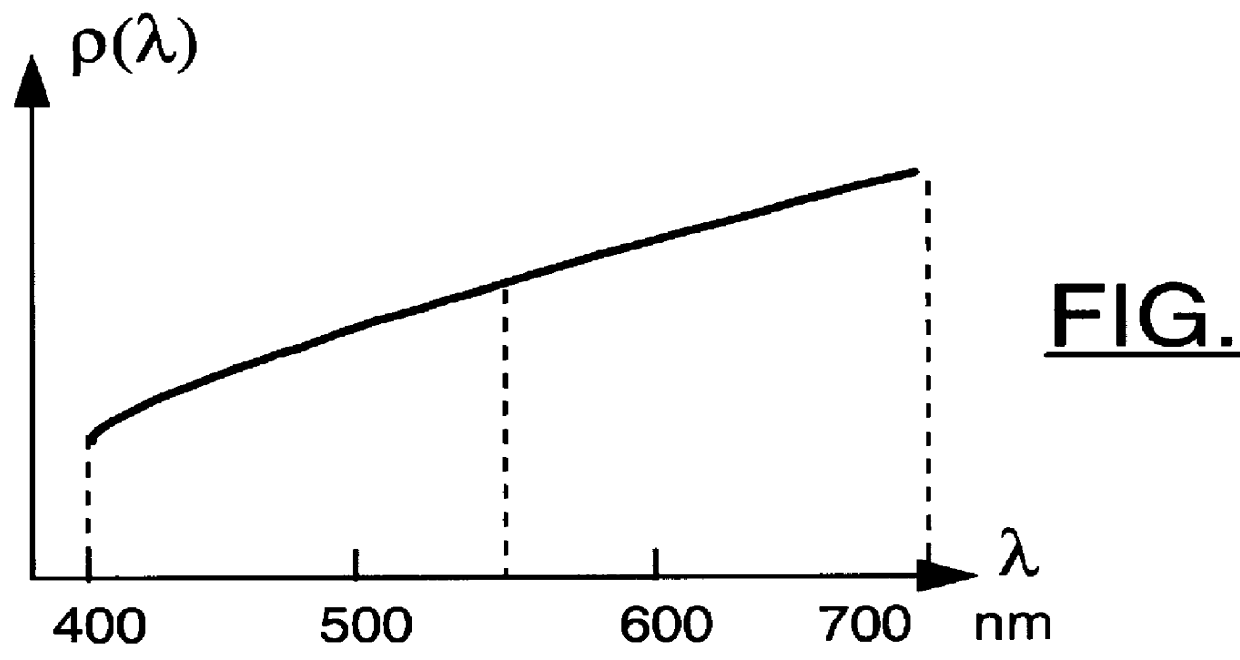

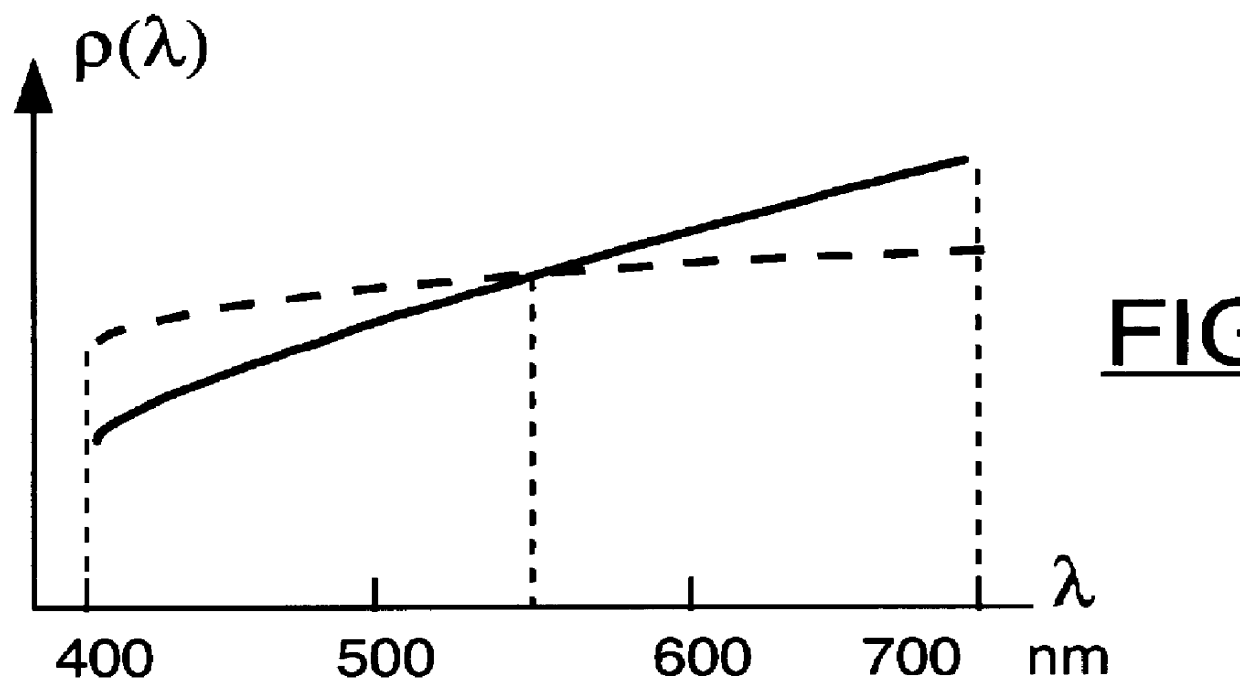

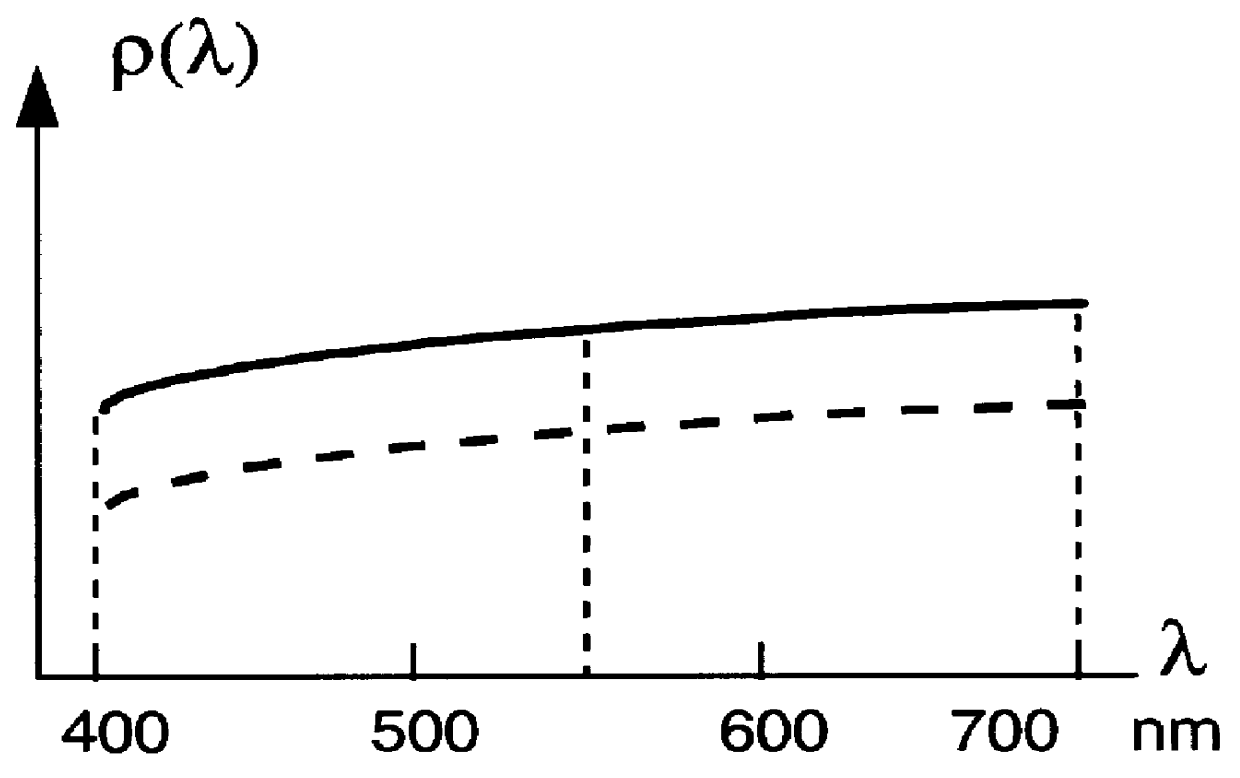

Method and apparatus for color matching of slightly colored translucent objects such as teeth and dental prosthesis, in particular

The invention relates to a method and apparatus for color matching of slightly colored objects which are transparent, diffusing an absorbent, by acuminating a small error of the objects with a first bunch of optical fibers. A second bunch of optical fibers is used to pick up the light back scattered from the area of the objects. The second fibers are located inside of the illuminating fibers. The light is measured at 3 wavelengths that correspond to blue, green and red colors and the pigmentation of the object is calculated as a difference between the red and blue spectrum components. Presentation of the brightness is calculated to be proportional to the green spectrum component. The pigmentation and brightness is then compared with the same perimeters of a standard shape pallet. The invention is particularly suitable for color matching the teeth in the mouth with dental prosthesis and dental restorative materials.

Owner:RAWICZ ANDREW +2

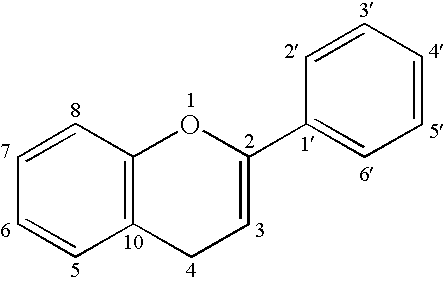

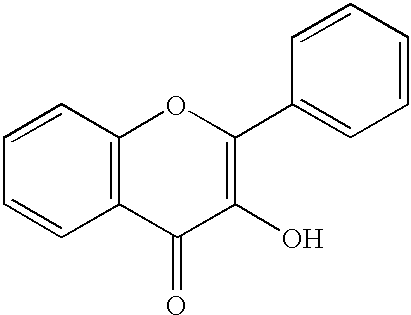

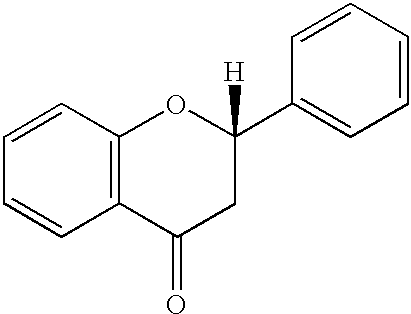

Oral compositions and use thereof

InactiveUS20040057908A1Cosmetic preparationsToilet preparationsAphthous ulcerationsDental plaque formation

The present invention relates to an oral composition which includes an organoleptically suitable carrier and an amount of a terpenoid and a flavonoid, dispersed in the carrier, which is effective to prevent or treat dental caries, dental plaque formation, gingivitis, candidiasis, dental stomatitis, aphthous ulceration, or fungal infection. The invention also relates to various uses of oral compositions, containing a terpenoid, a flavonoid, or both, such uses include: inhibiting the activity of surface-bound glusosyltransferase; treating or inhibiting dental caries, gingivitis, candidiasis, denture stomatitis; inhibiting the accumulation of microorganisms on an oral surface; and / or treating or inhibiting aphthous ulcerations on an oral surface.

Owner:UNIV ESTADUAL DE CAMPINAS UNICAMP +1

Polymer Core Prosthetic Dental Device with an Esthetic Surface

A prosthetic dental device has an inner portion formed of an inner material and an outer portion formed of an outer material that covers at least a part of the inner portion. The inner material is substantially different from the color of natural teeth while the outer material is substantially the same color as natural teeth. Both the inner material and the outer material comprise a polymer.

Owner:ZIMMER DENTAL INC

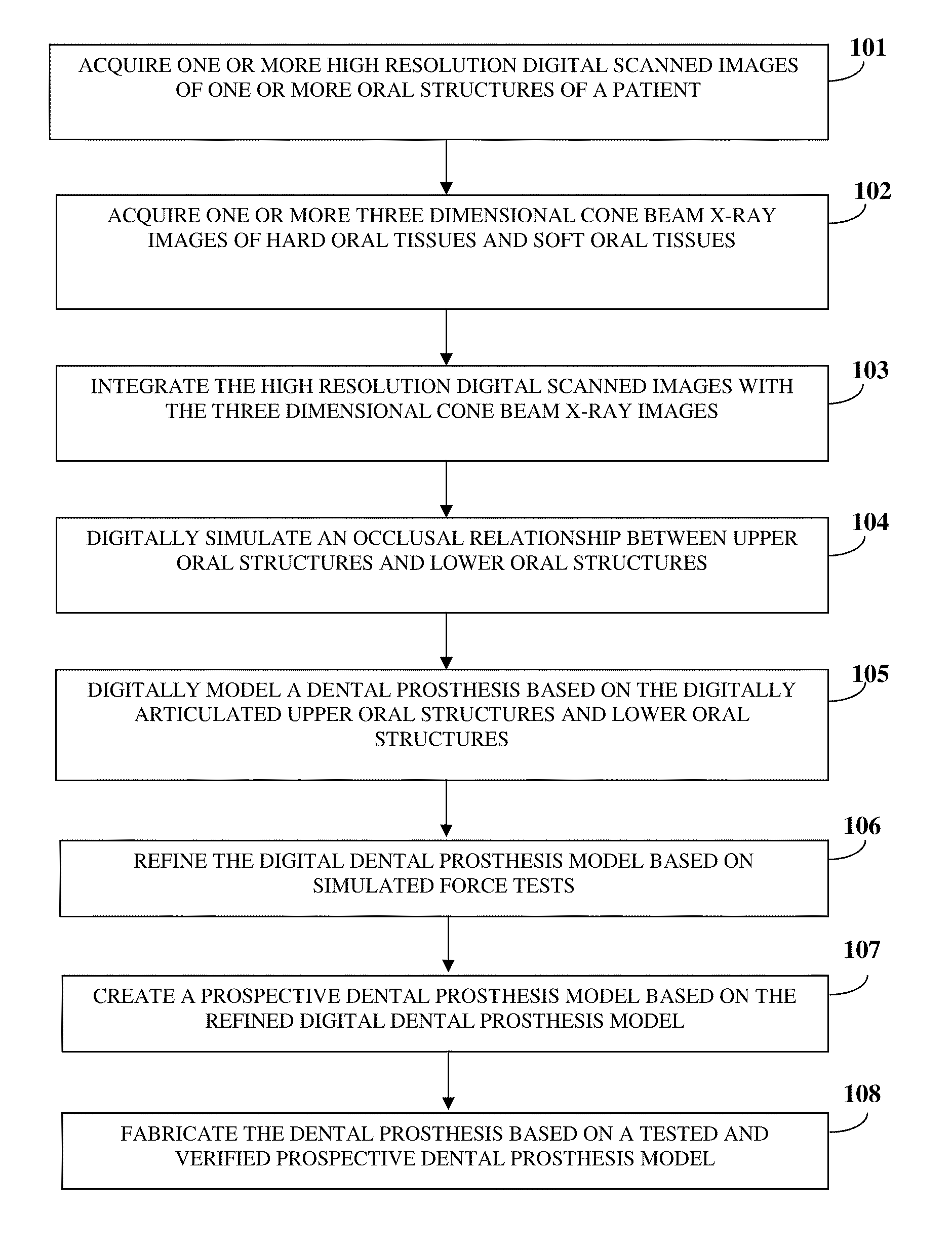

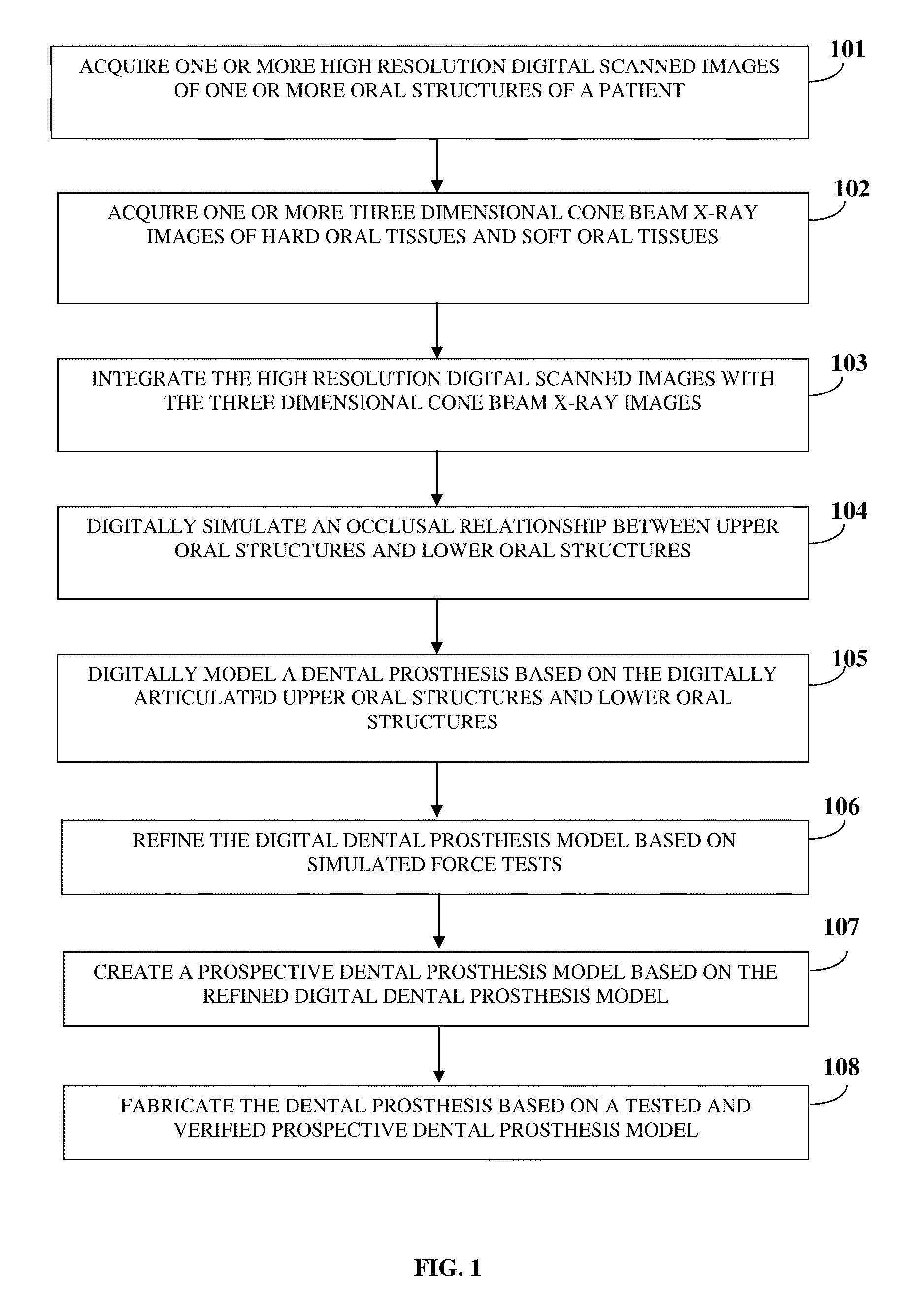

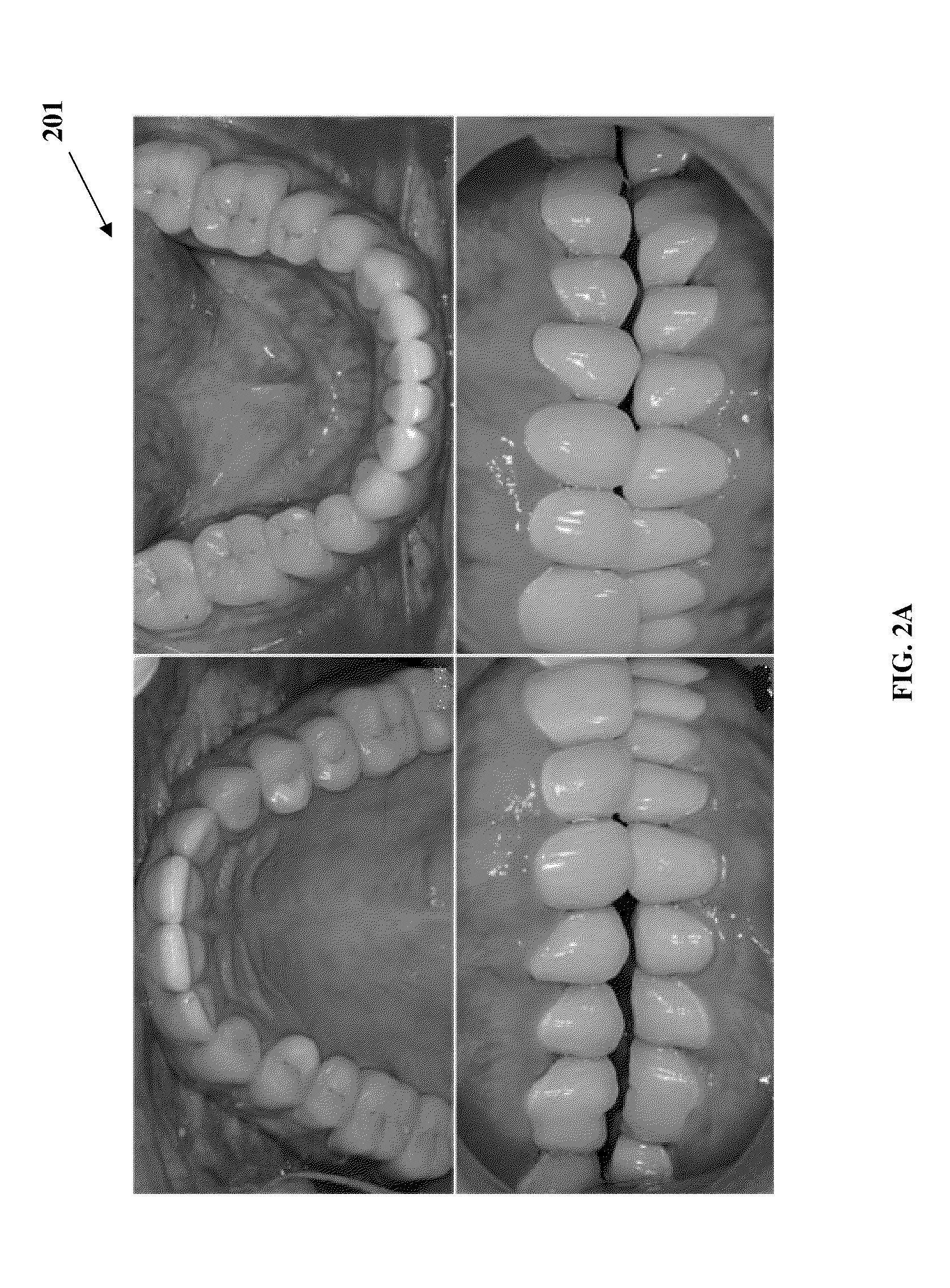

Computer-aided Fabrication Of A Removable Dental Prosthesis

InactiveUS20110276159A1Maximizing retention and functionHighly accurate model-lessAdditive manufacturing apparatusDental articulatorsX-rayComputer aid

A method and system for fabricating a dental prosthesis are provided. High resolution digital scanned images of a patient's oral structures are acquired. Three dimensional (3D) cone beam X-ray images of hard and soft oral tissues are acquired. The scanned images are integrated with the 3D cone beam X-ray images in a 3D space to obtain combined three dimensional images of the oral structures. The occlusal relationship between upper and lower oral structures are digitally simulated using the combined three dimensional images. The dental prosthesis is digitally modeled for planning intra-oral positioning and structure of the dental prosthesis. The digital dental prosthesis model is refined based on simulated force tests performed for assessing interference and retention of the digital dental prosthesis model. A prospective dental prosthesis model is created based on the refined digital dental prosthesis model. The dental prosthesis is fabricated based on a verified prospective dental prosthesis model.

Owner:HANKOOKIN

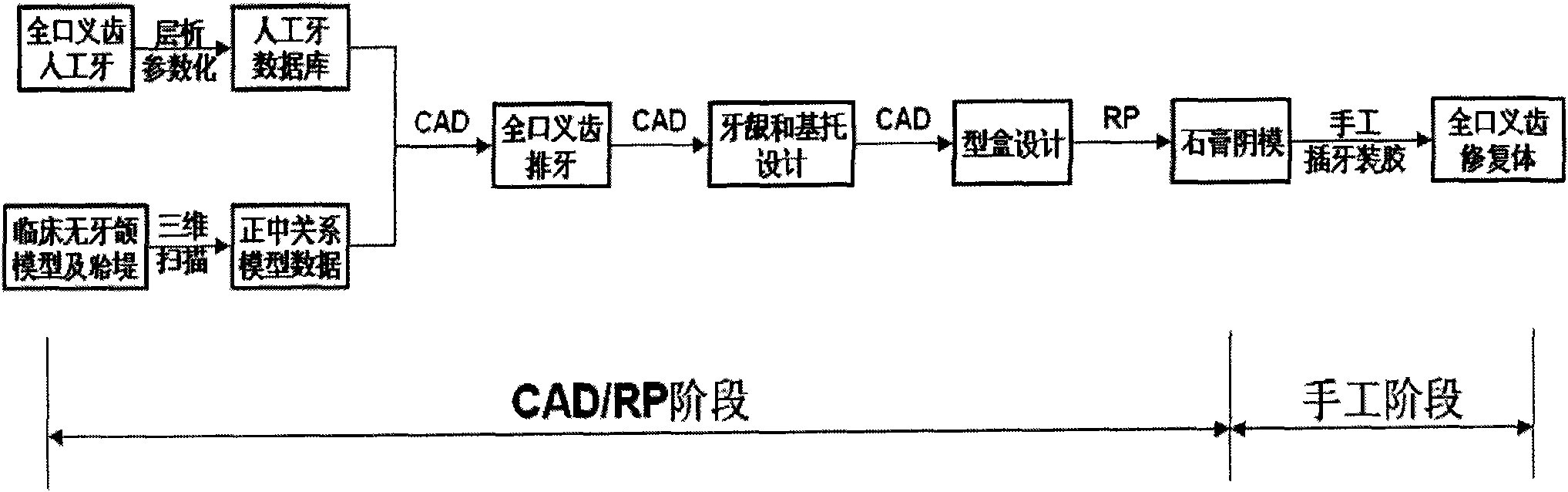

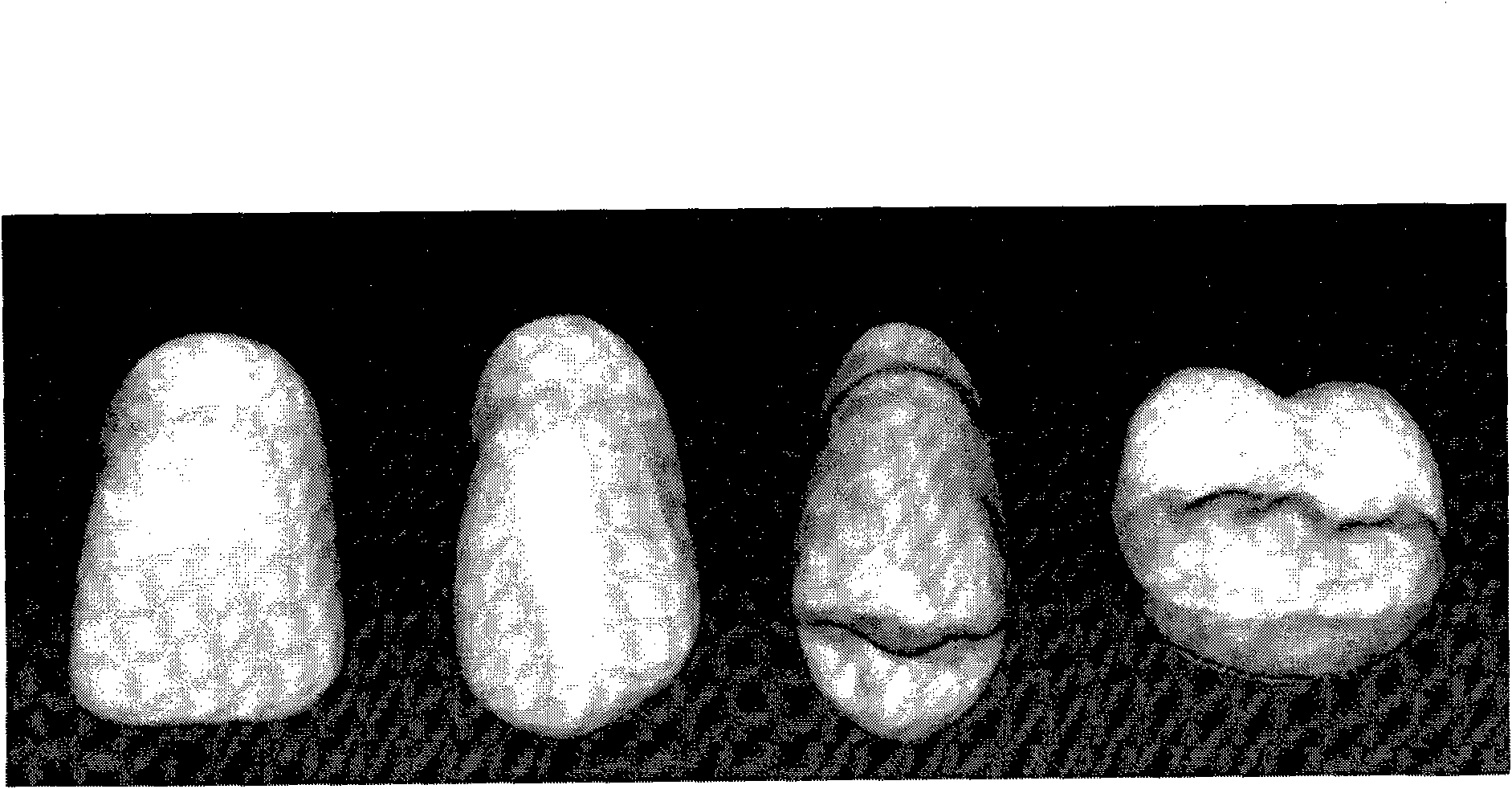

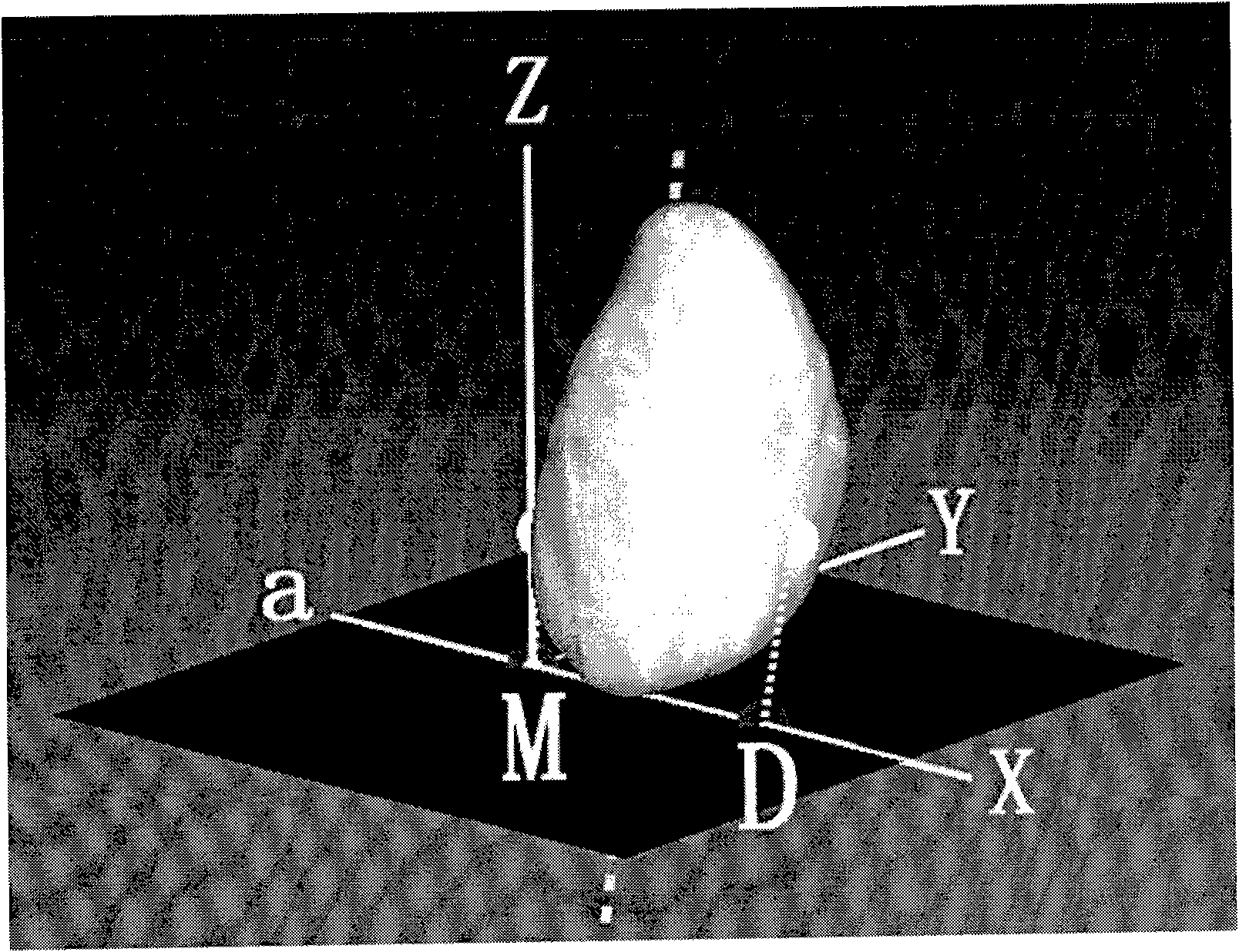

Complete denture designing and manufacturing method based on CAD/RP technology

InactiveCN101548911ARestore accuratelySimplify complicated proceduresDiagnostic recording/measuringSensorsWaxGraphics

The invention discloses a neutral zone complete denture manufacturing method based on a Computer Aided Design / RapidPrototyping (CAD / RP) technology. The method comprises the following steps: a complete denture artificial tooth three-dimensional image database is established on the basis of the parameterized positioning; the data of upper and lower edentulous jaws with centric relation and neutral zone jaw is collected on the basis of the three-dimensional laser scanning technology with spatial position relation; the complete denture artificial articulation conforming to the theory of neutral zone and complete denture balanced occlusion tooth arrangement is designed on the basis of reverse engineering software, the gum and the base conforming to the complete denture neutral zone theory and the aesthetic principle are designed on the basis of the reverse engineering software; a complete denture flask is designed and processed on the basis of the CAD / RP technology; and the complete denture restoration is finished through the manual tooth inserting and the adhesive applying. The invention creates the concept of a two-step method, finishes the manual tooth arrangement and the wax pattern preparation with the highest technical content and the most complex operation in the traditional fabrication by using the computer and rapid prototyping technology, can finish the full fabrication of the complete denture only by being finally aided with the simple manual step, i.e., the second step of the two-step method, greatly simplifies the complex working procedures of the traditional handwork process, improves the efficiency and the accuracy of restoration and realizes the transformation of the designing and manufacturing process of the complete denture from the manual mode to the digital mode.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

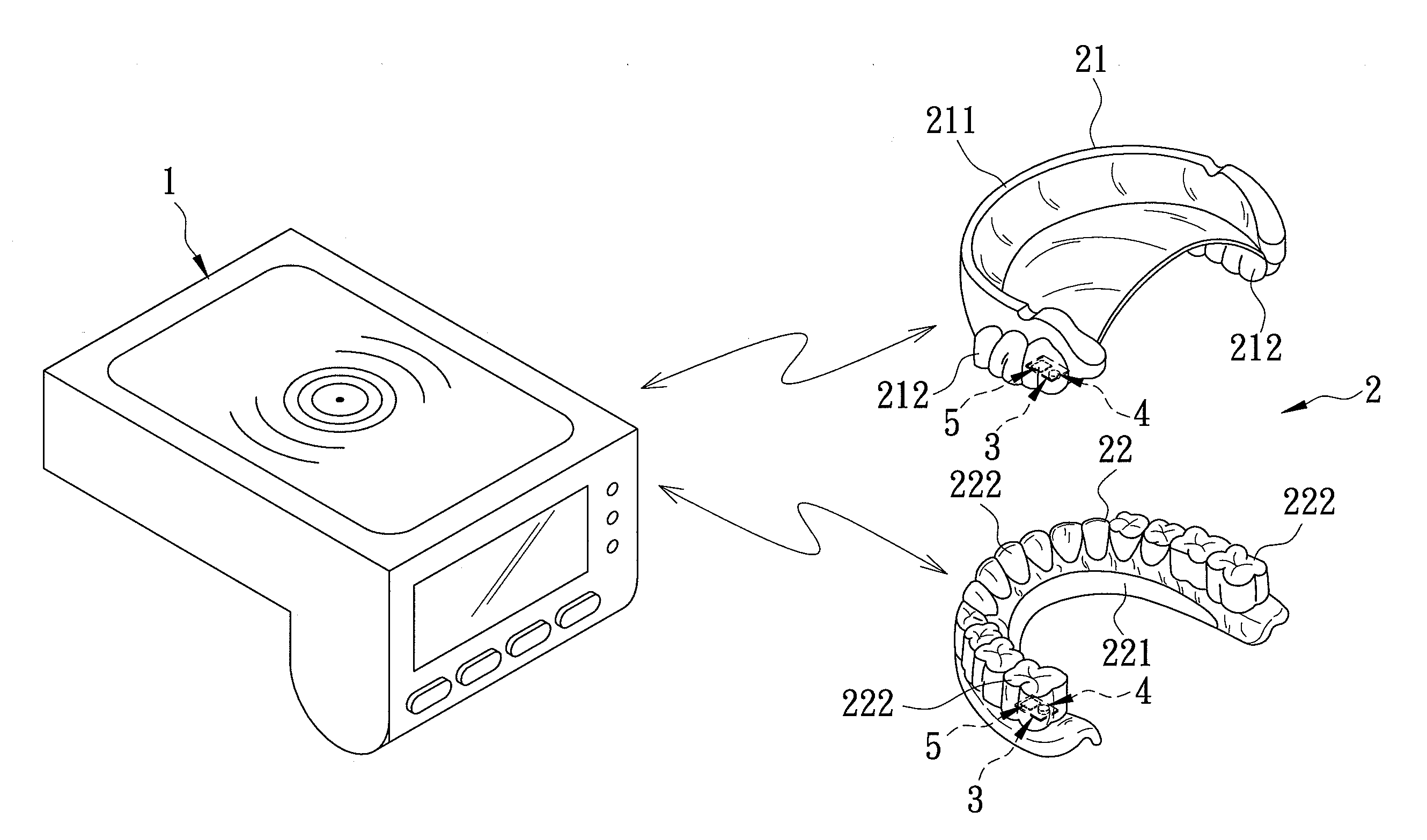

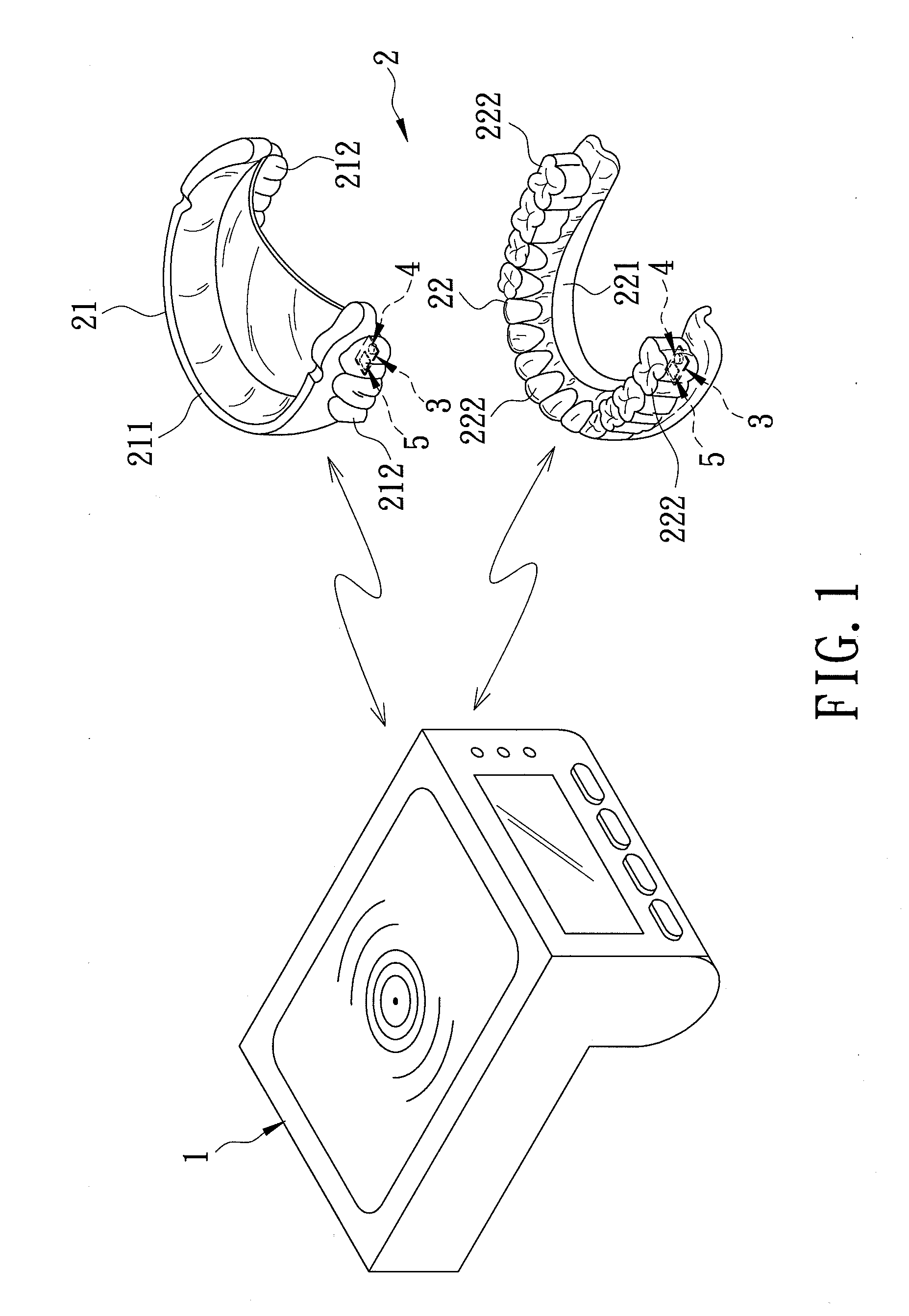

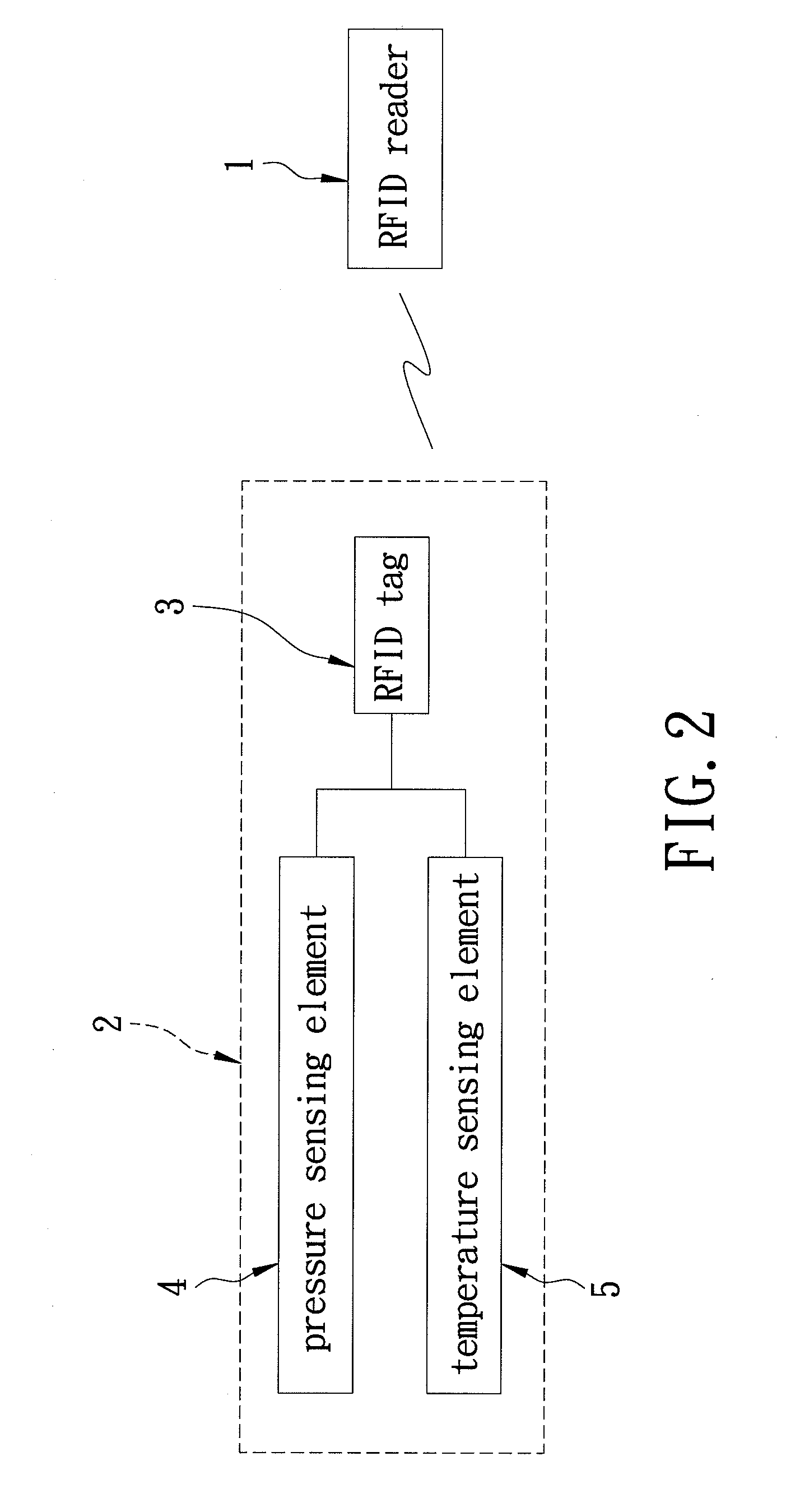

Denture

A denture is adapted to communicate with a radio frequency identification (RFID) reader. The denture includes a denture main body and at least one RFID tag embedded in the denture main body for storage of identification information of a user of the denture. The RFID tag transmits the information to the RFID reader by radio frequency wave.

Owner:CHINA MEDICAL UNIVERSITY(TW)

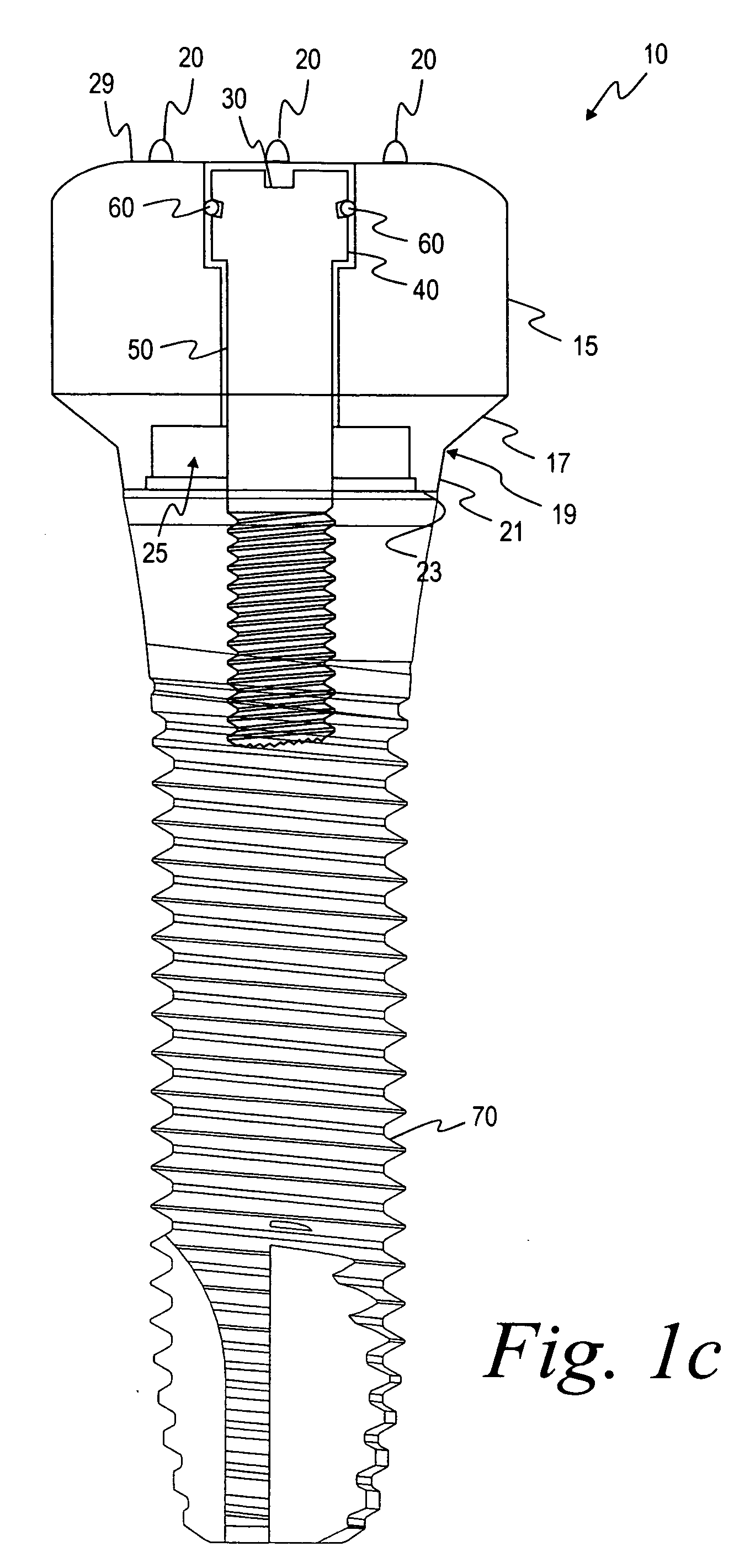

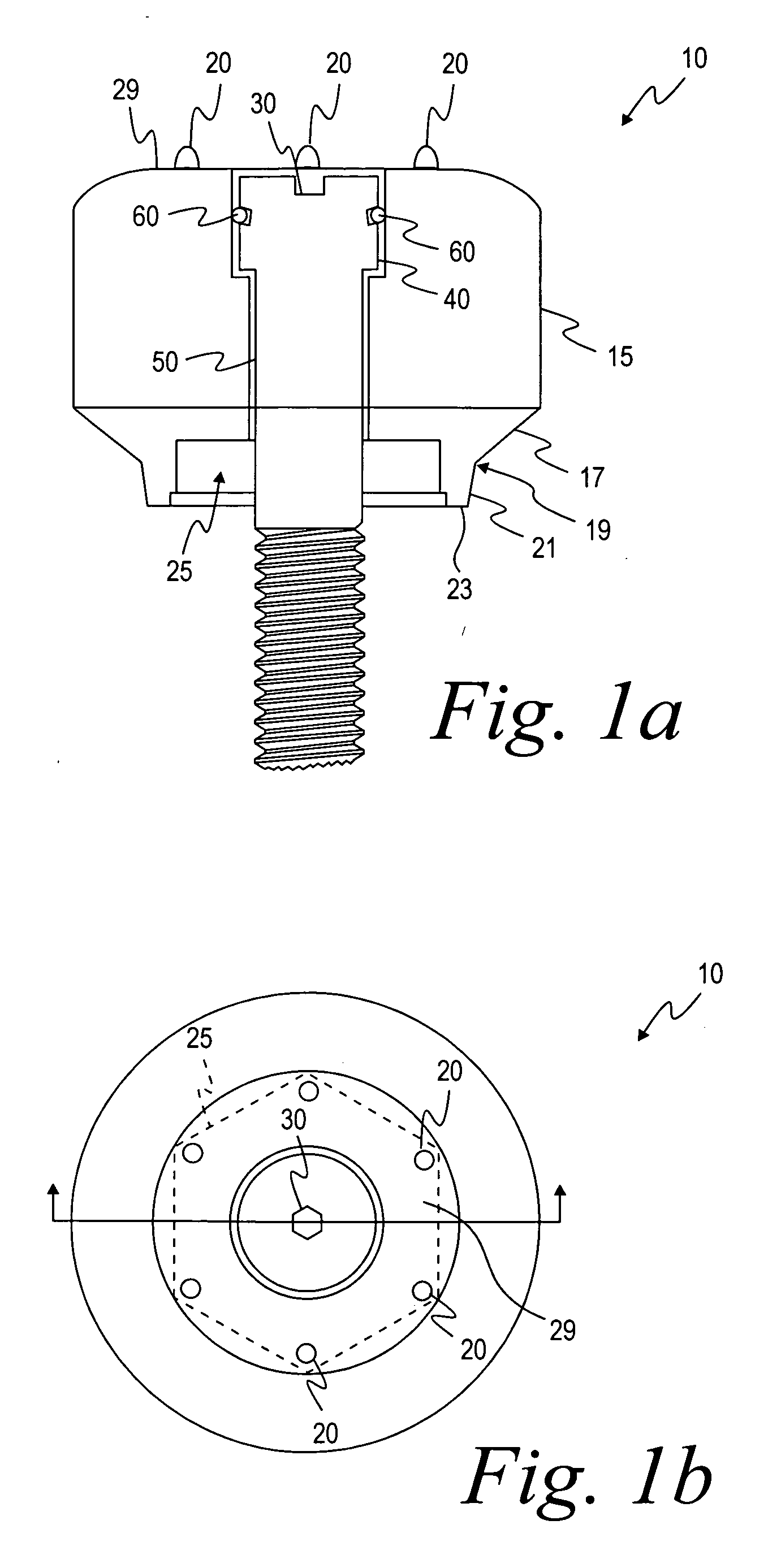

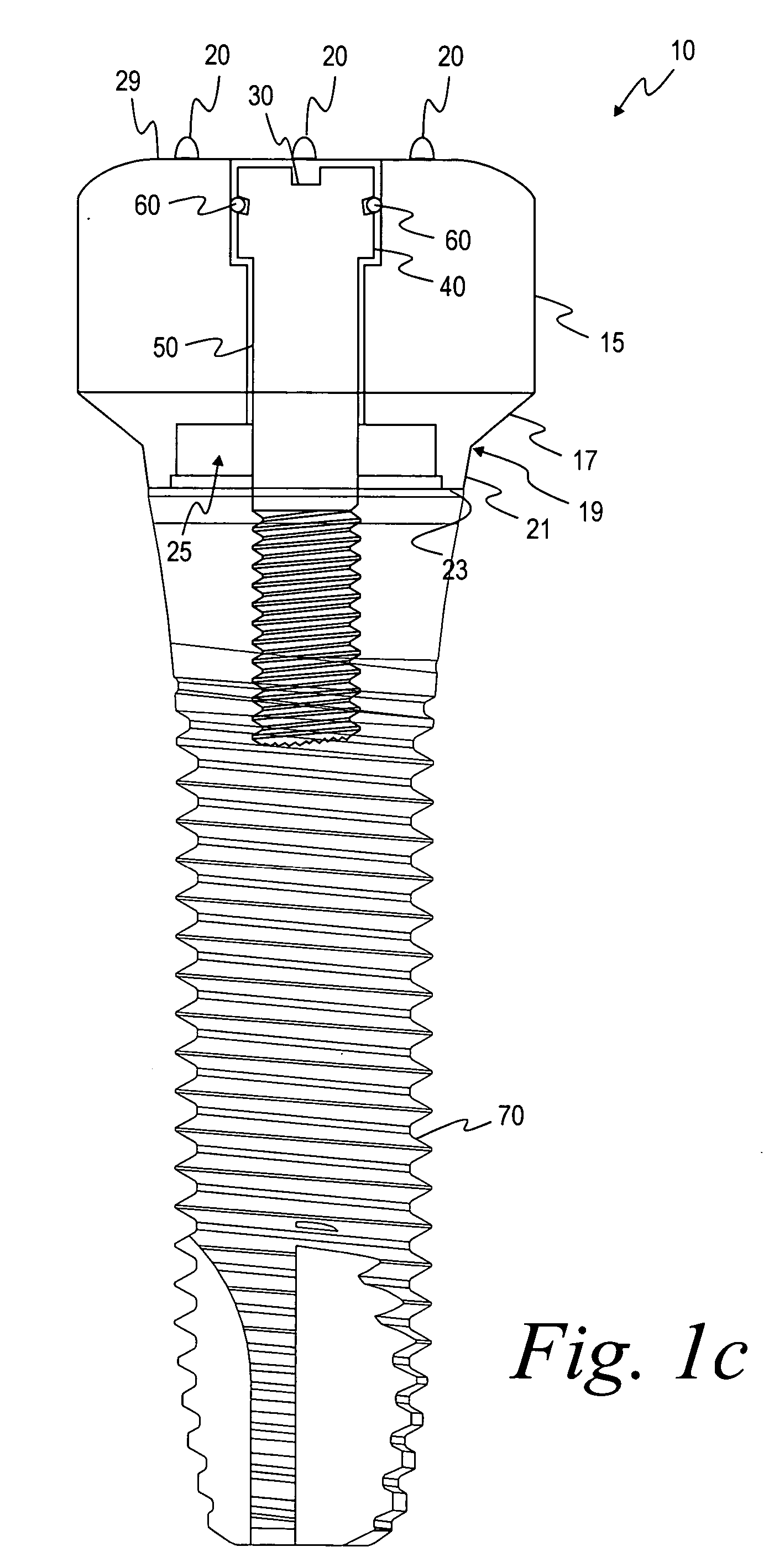

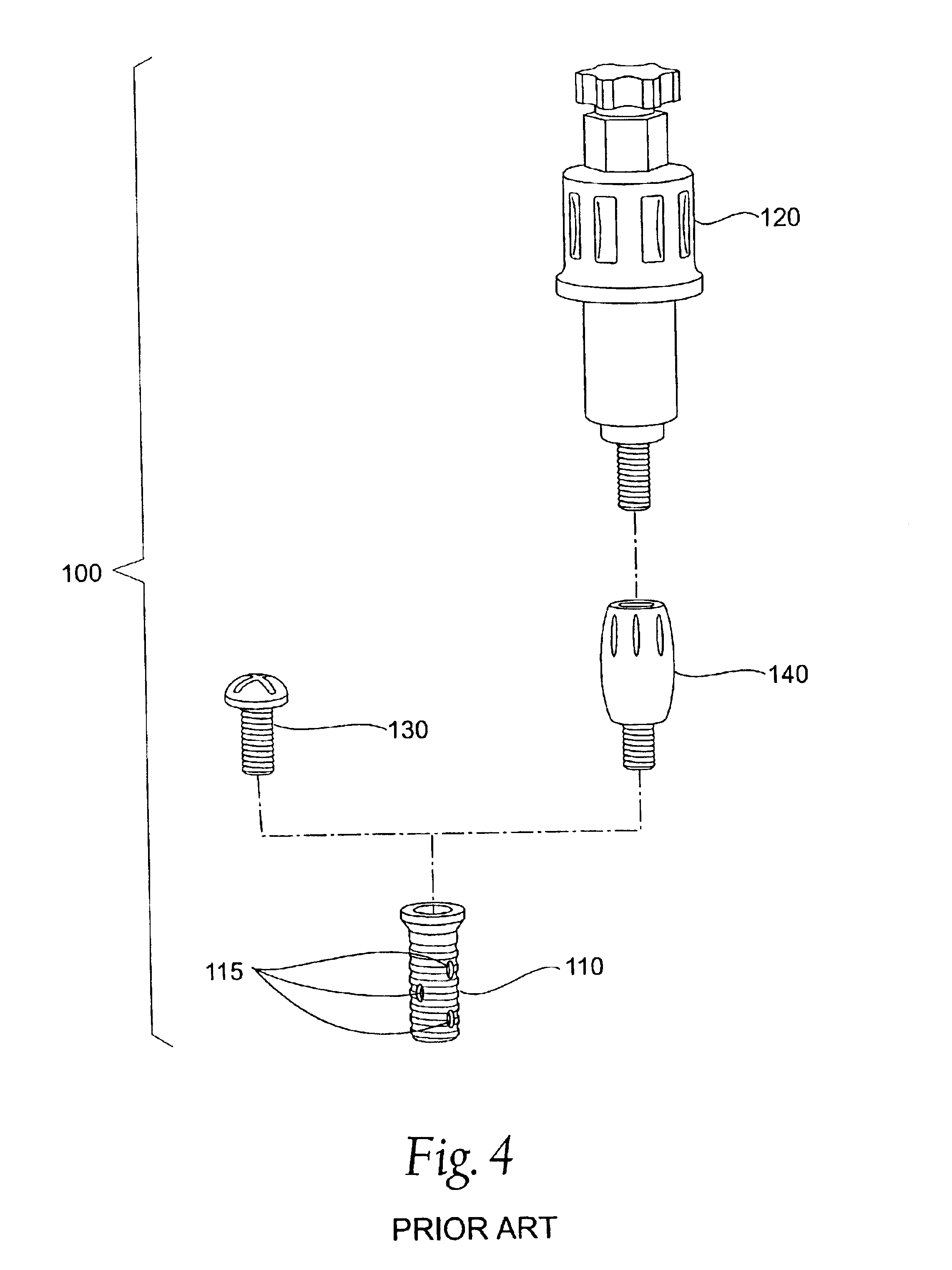

Implant system and method of installation thereof

The present invention provides an implant system of facilitated use and installation which comprise an implant and a prosthesis support and a method of installation thereof. The prosthesis support disclosed herein includes an abutment and a collar member. Prior art implant systems are mostly made of metallic parts which are assembled with a screw and are shaped to receive a tooth prosthesis. The design of the abutment allows it to be made from highly filled composite materials being of a better optical quality and being easily machinable and further allows its installation without the use of a screwing member. The design of the collar member allows minimization of bacteria growth and tartar formation. The optimization of the implant system proposed herein may reduce stress to the jaw bone and therefore minimize the risk of injury for the patient.

Owner:ENNAJIMI ELMEKKI +3

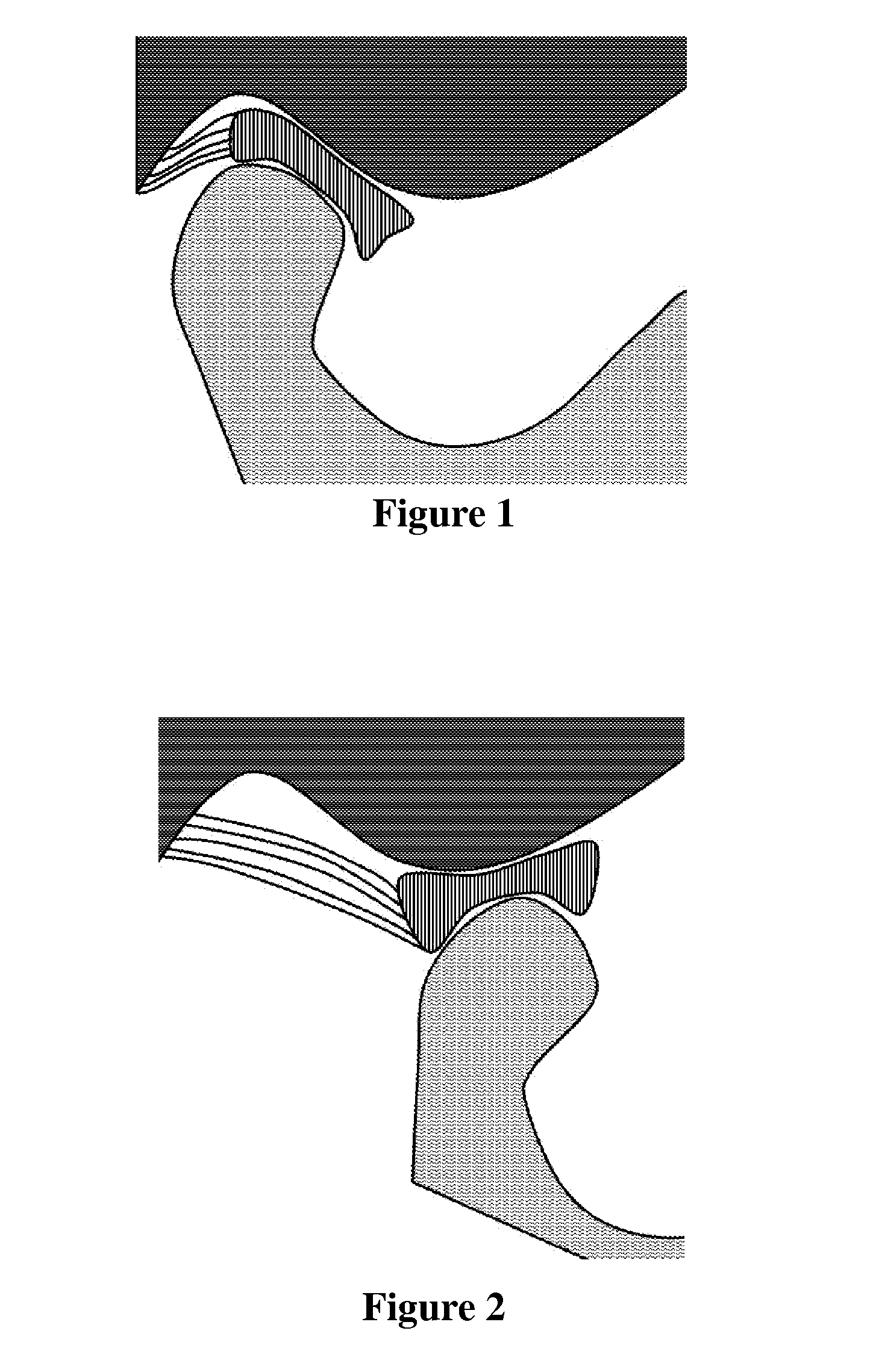

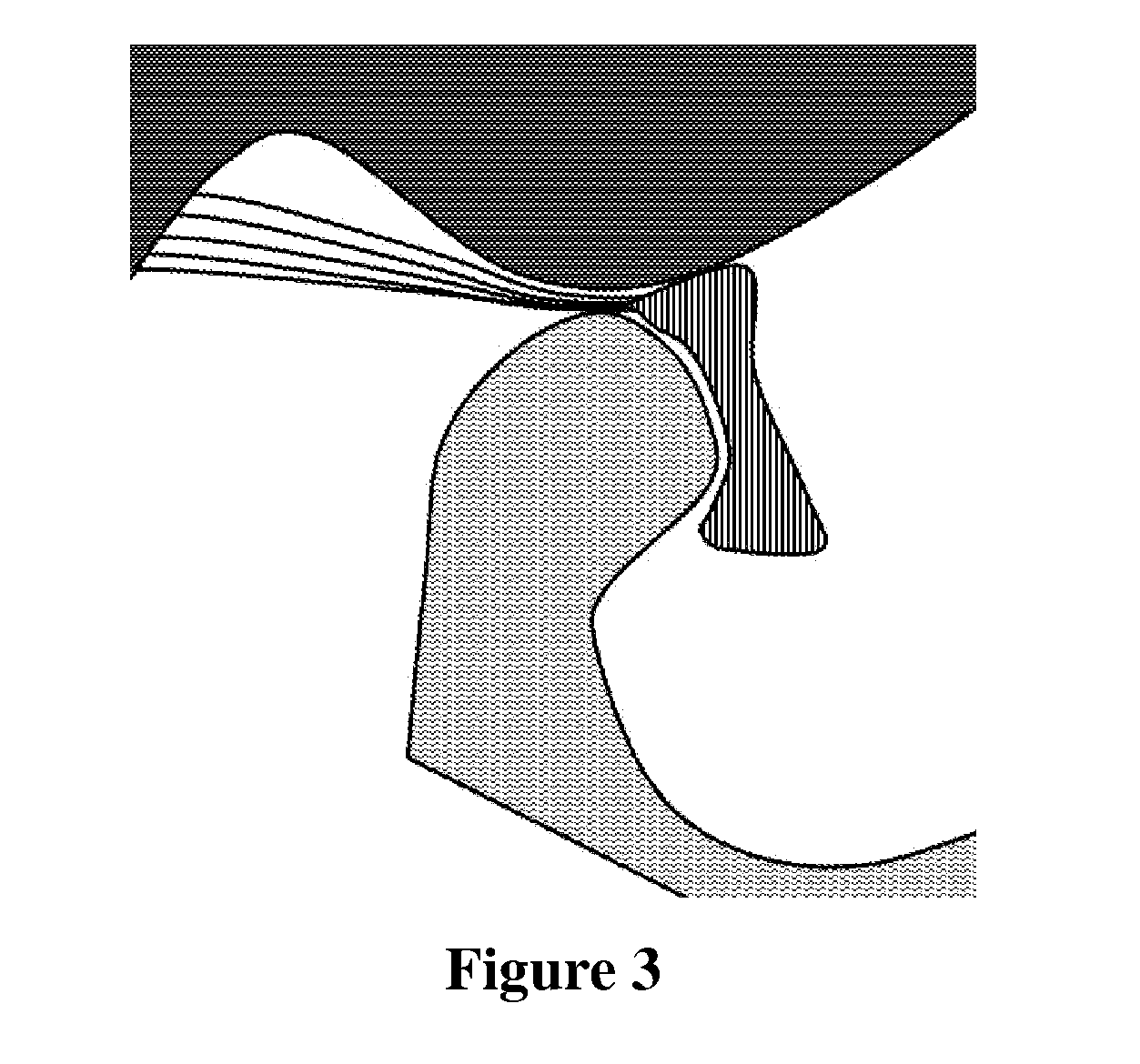

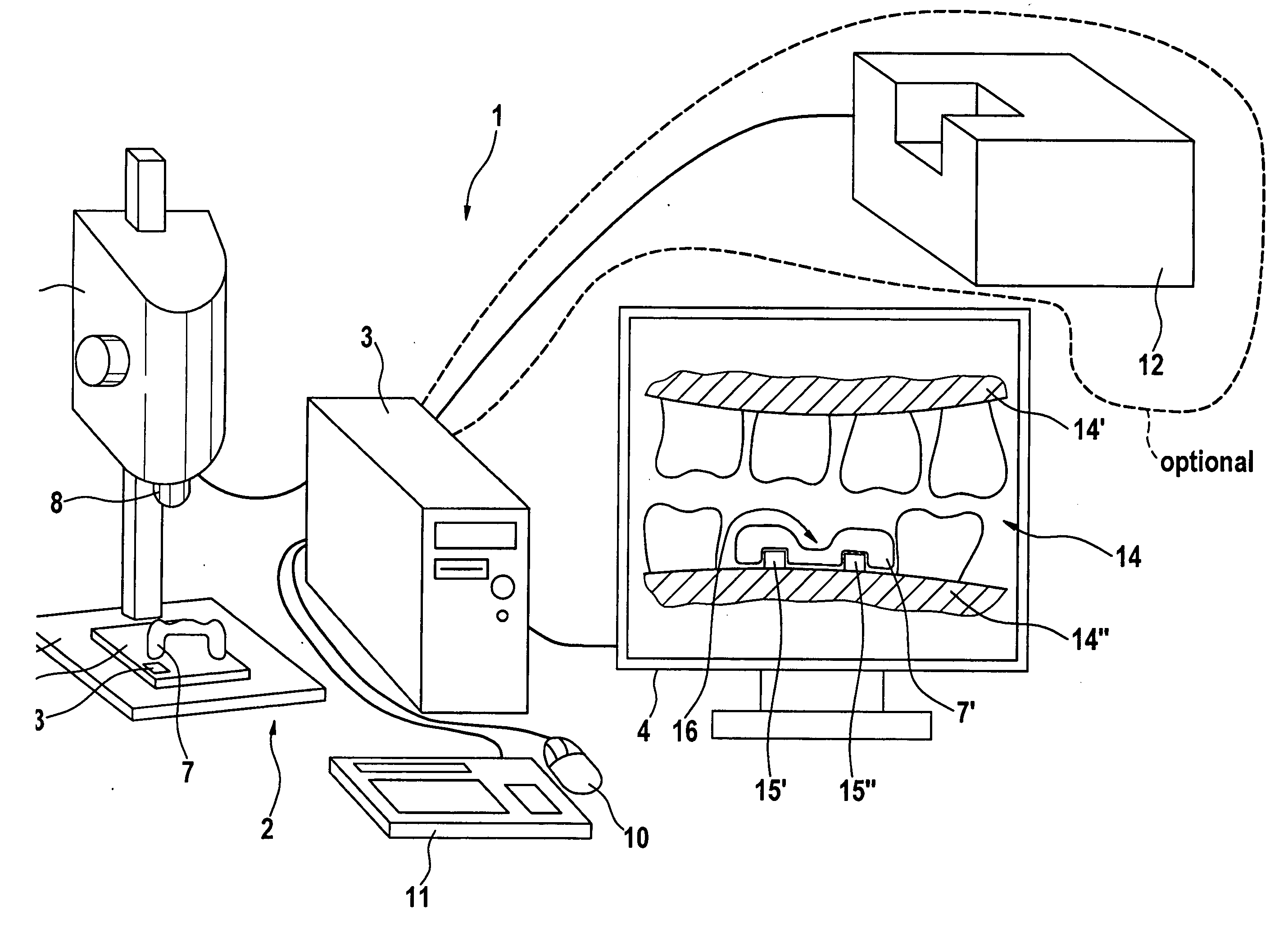

Method to determine the impact of a proposed dental modification on the temporomandibular joint

InactiveUS20110191081A1Information can be usedAnalogue computers for chemical processesDental articulatorsDistractionDental Articulators

Use of computer technology for image-assisted risk assessment / evaluation of proposed dental treatments is described, in particular a method and apparatus for determining the impact of a proposed dental modification on the temporomandibular joint(s), e.g. to obtain information relating to that impact. Use of a virtual articulator is described to determine the impact of a proposed dental modification on the temporomandibular joint(s). This dental modification includes, but is not limited to, the replacement of one or more teeth by artificial teeth, the replacement of one or more parts of a tooth by a prosthetic reconstruction such as a dental crown or veneer, the rearrangement of one or more existing teeth (orthodontic treatment), the distraction of one or both jaws in order to reposition the teeth (orthognatic treatment) and / or modifications of the occlusal surfaces of the teeth.

Owner:DENTSPLY IMPLANTS NV

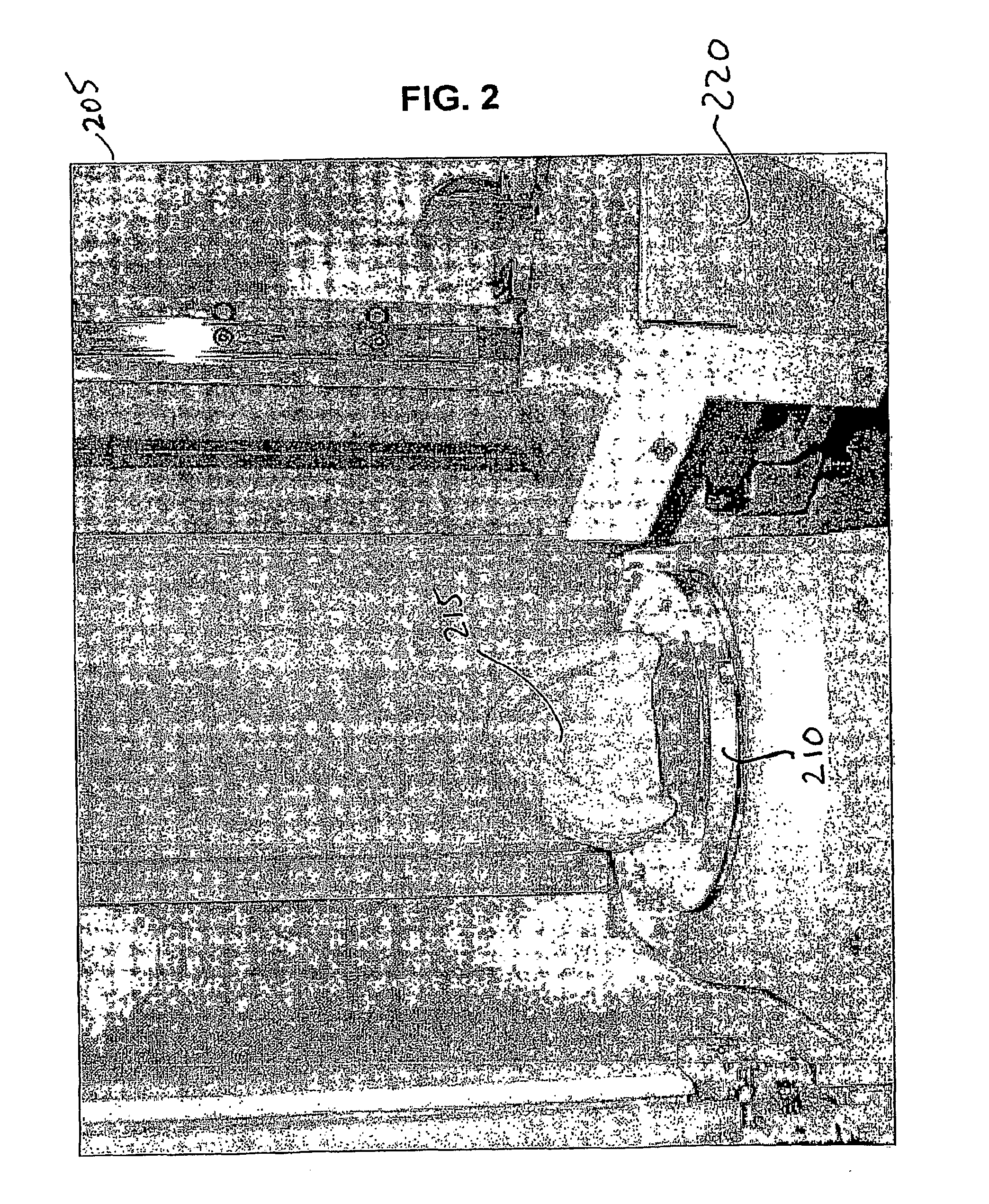

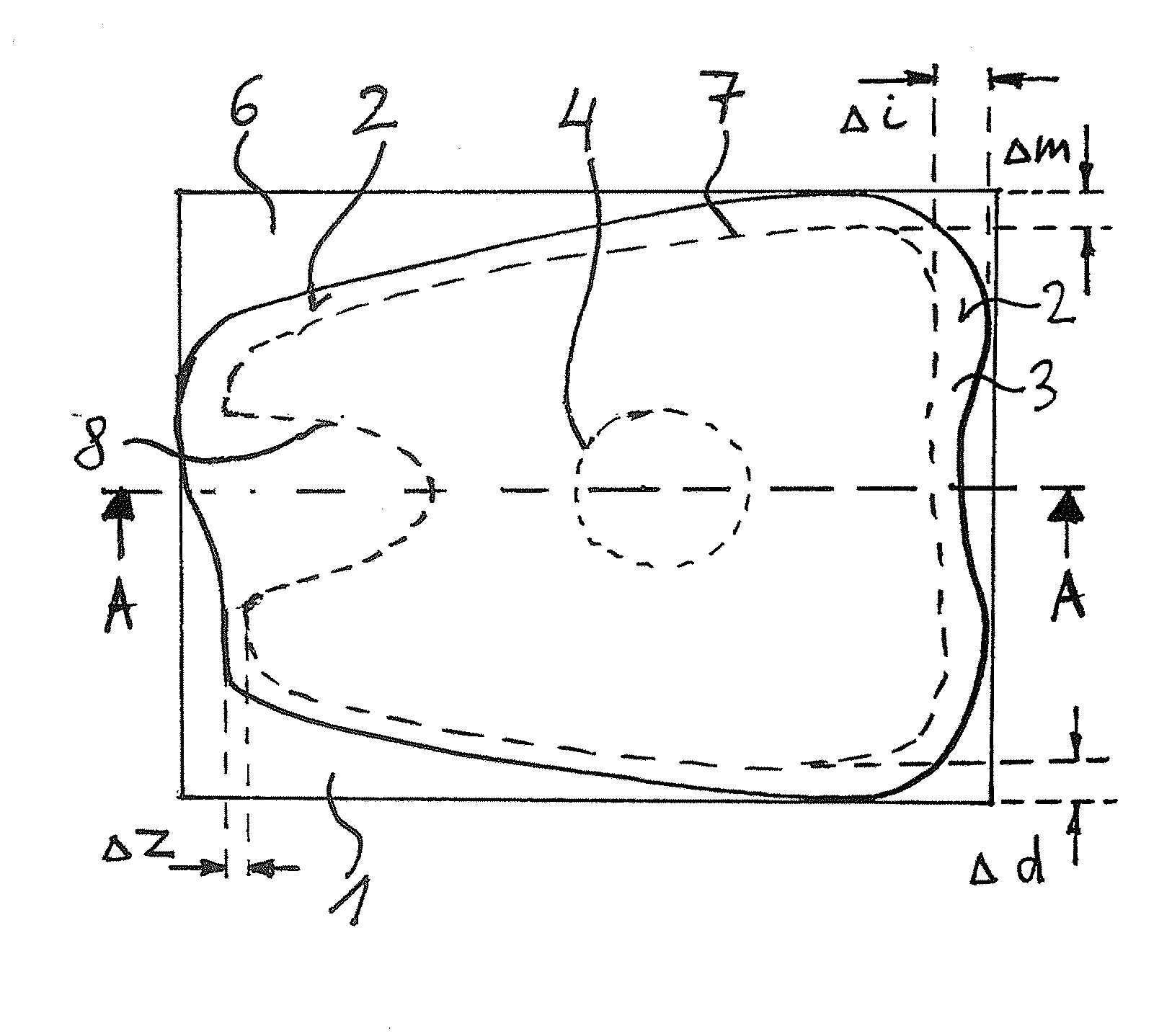

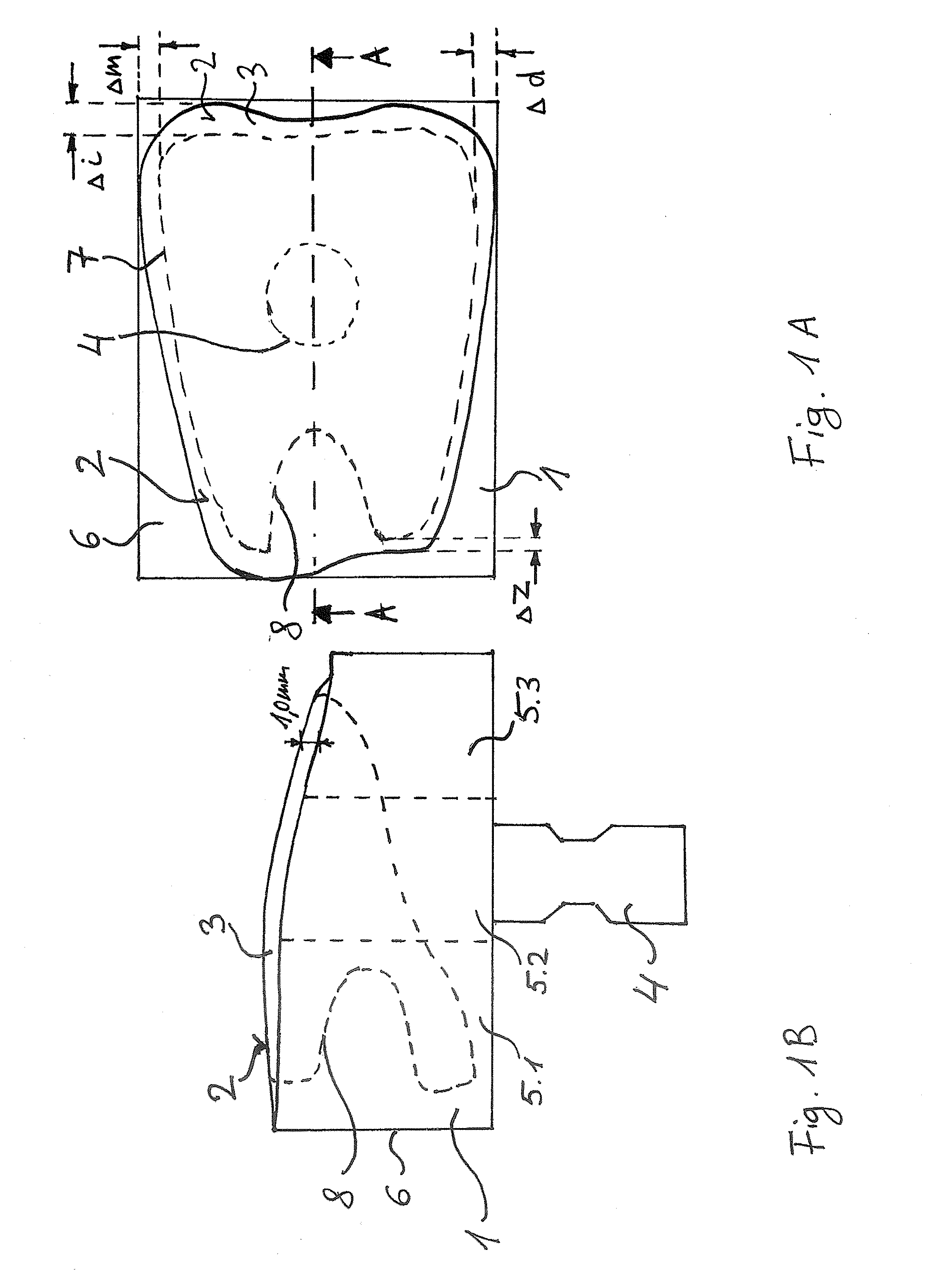

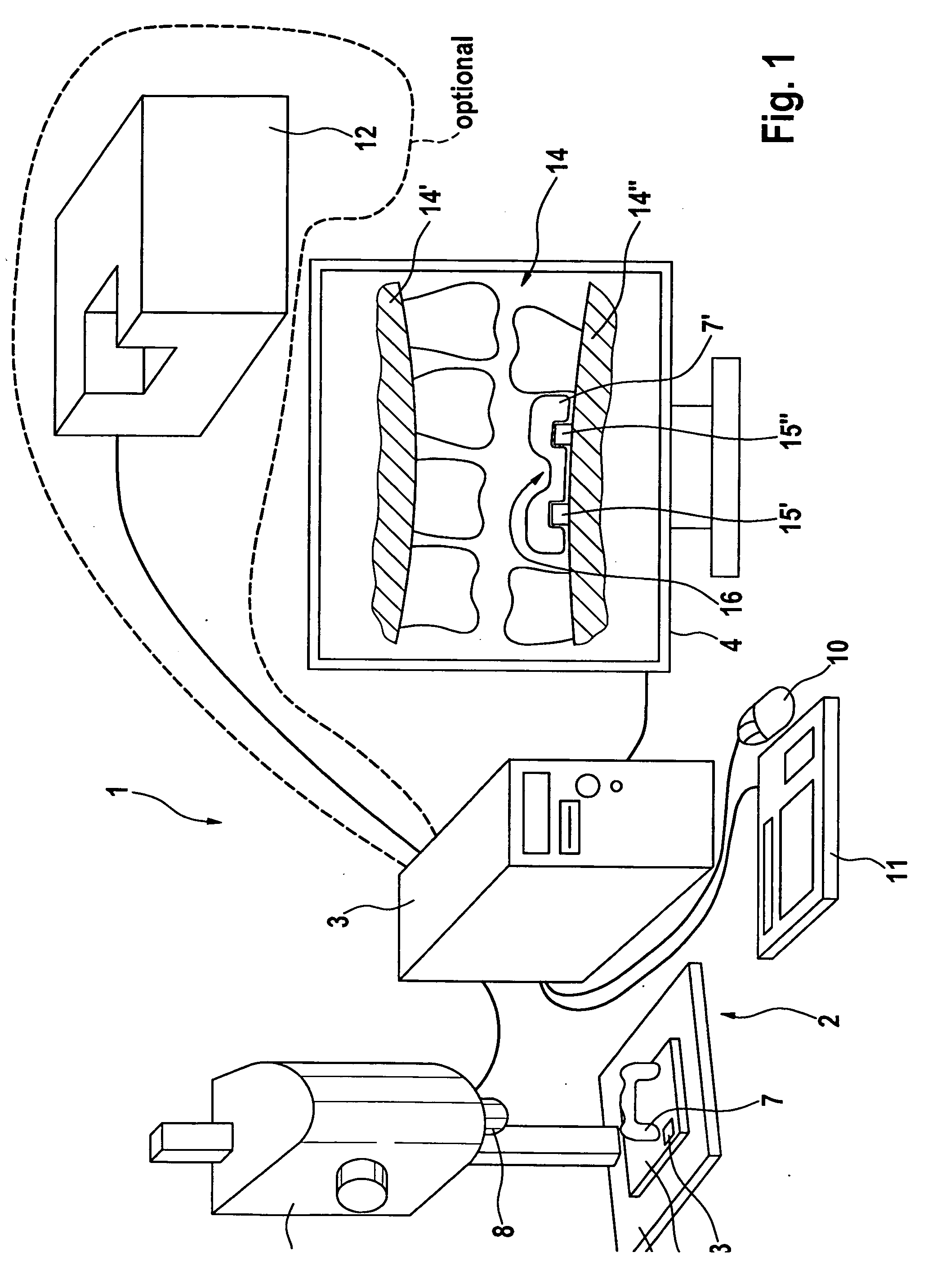

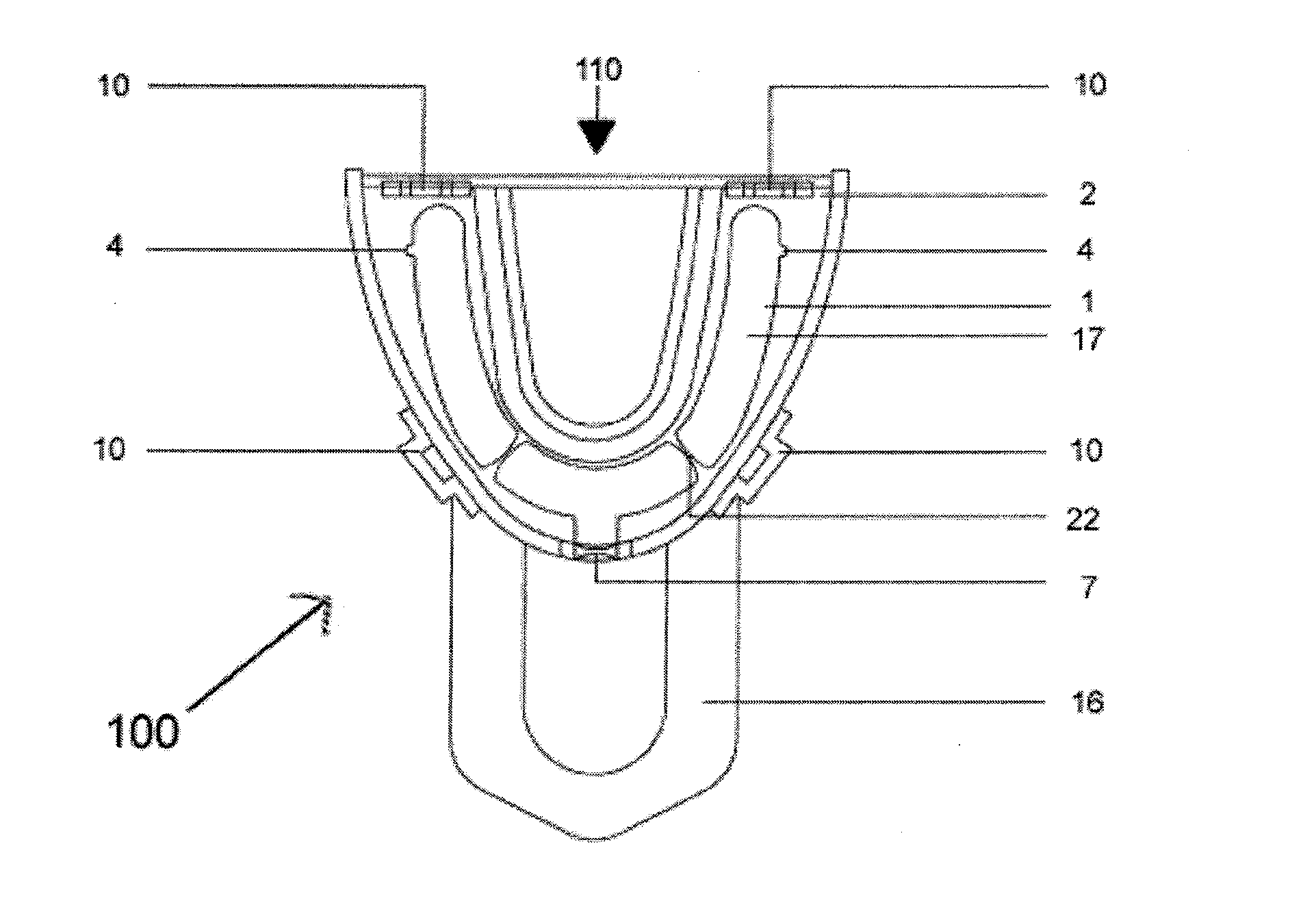

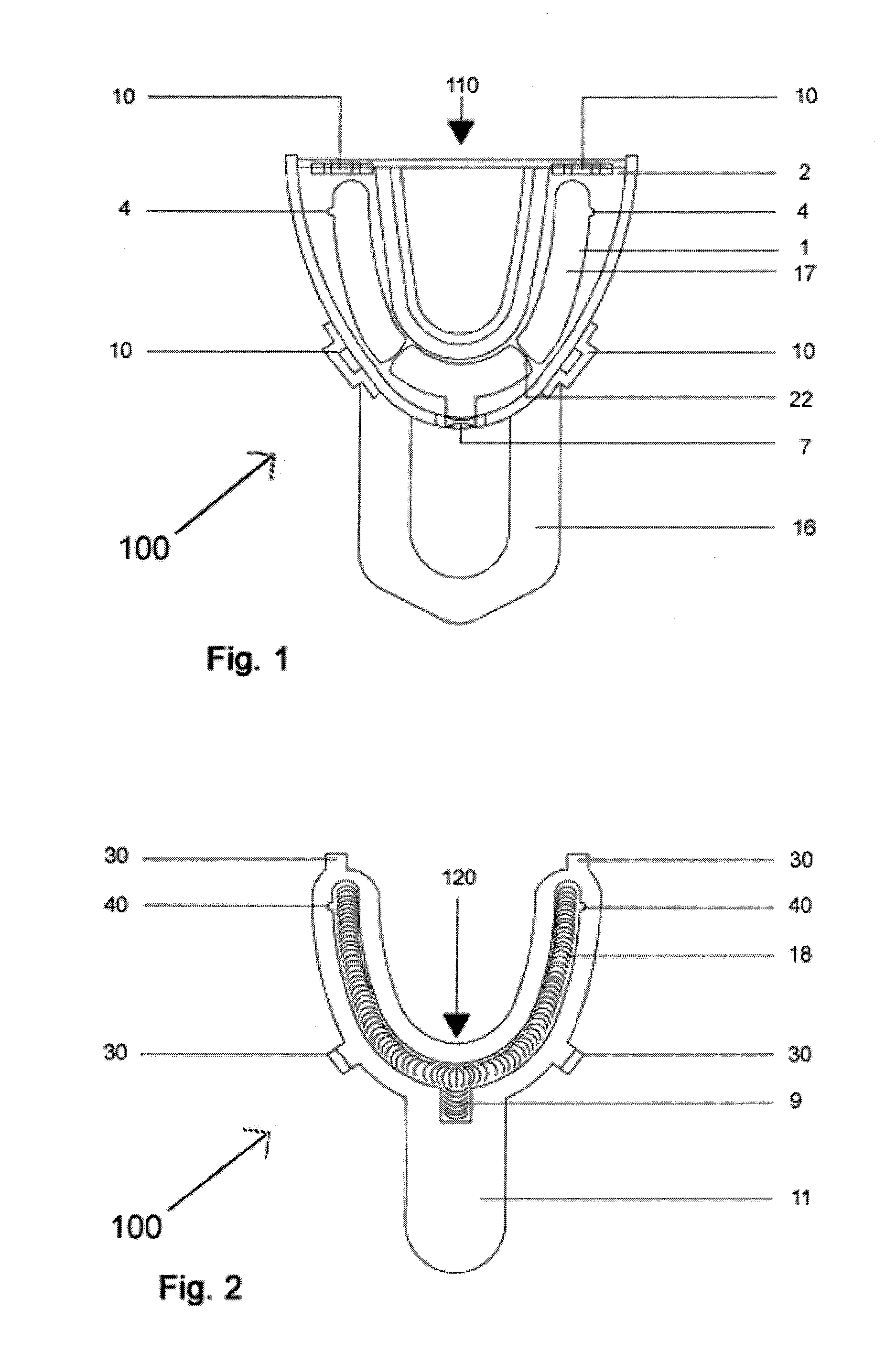

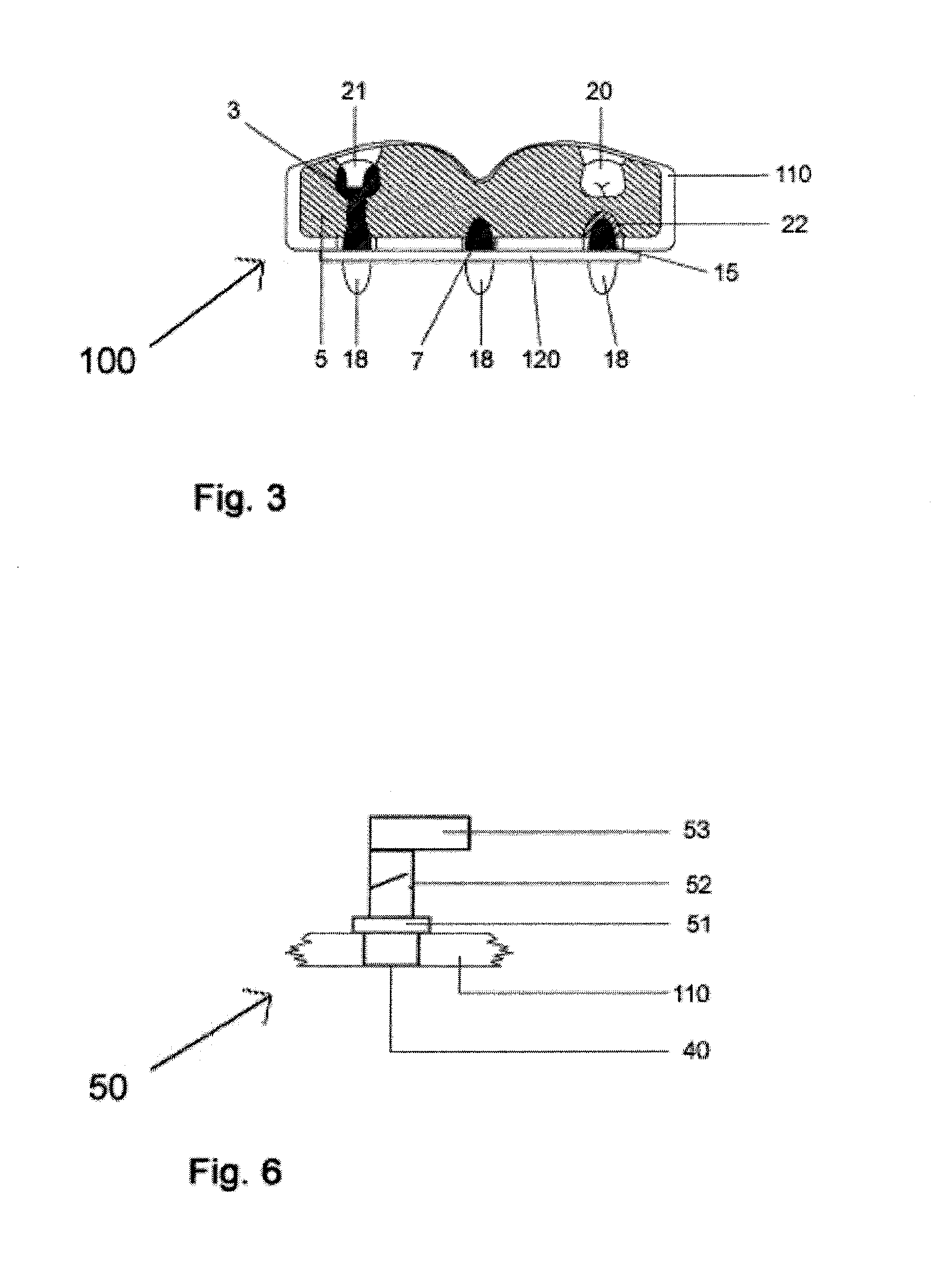

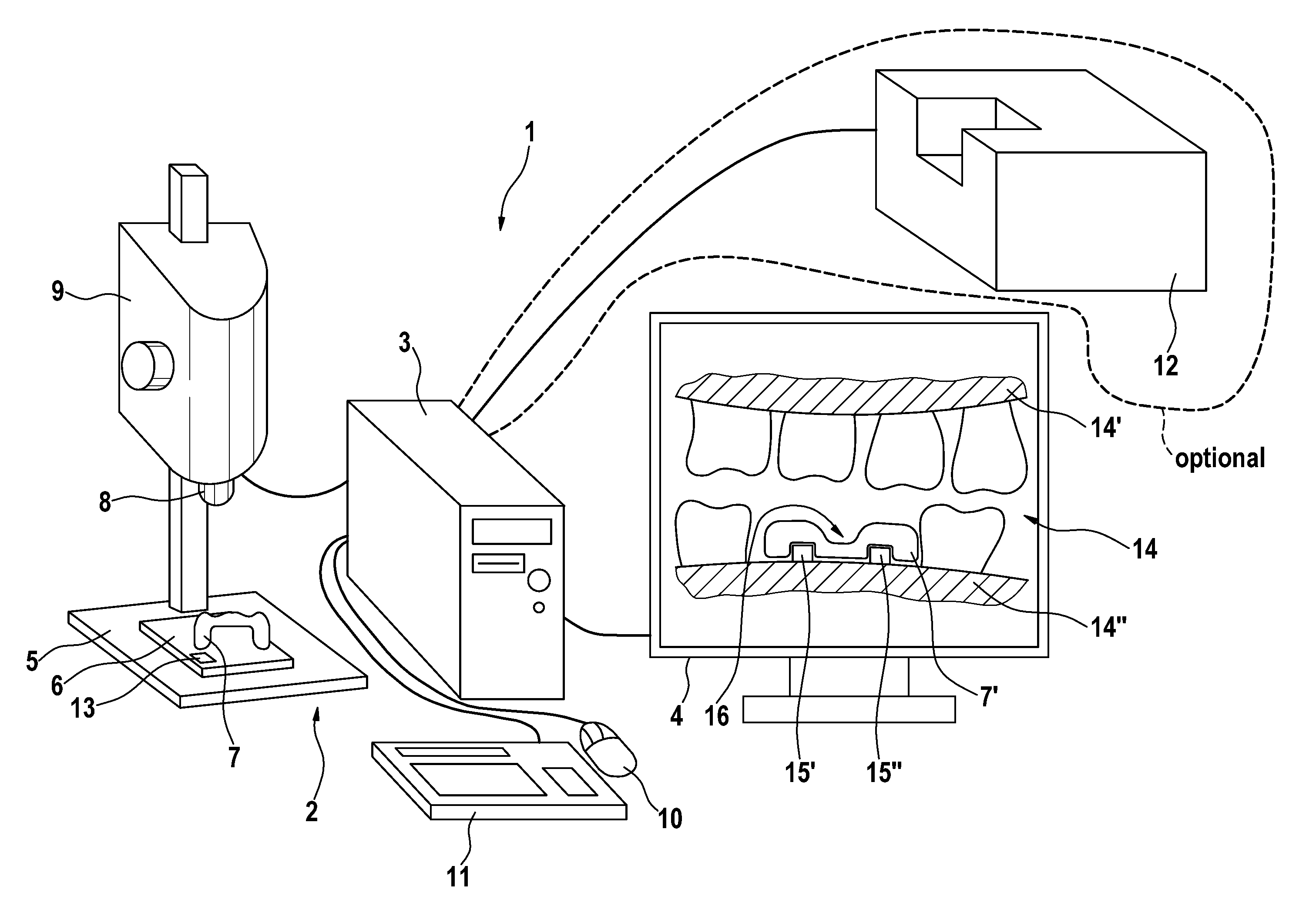

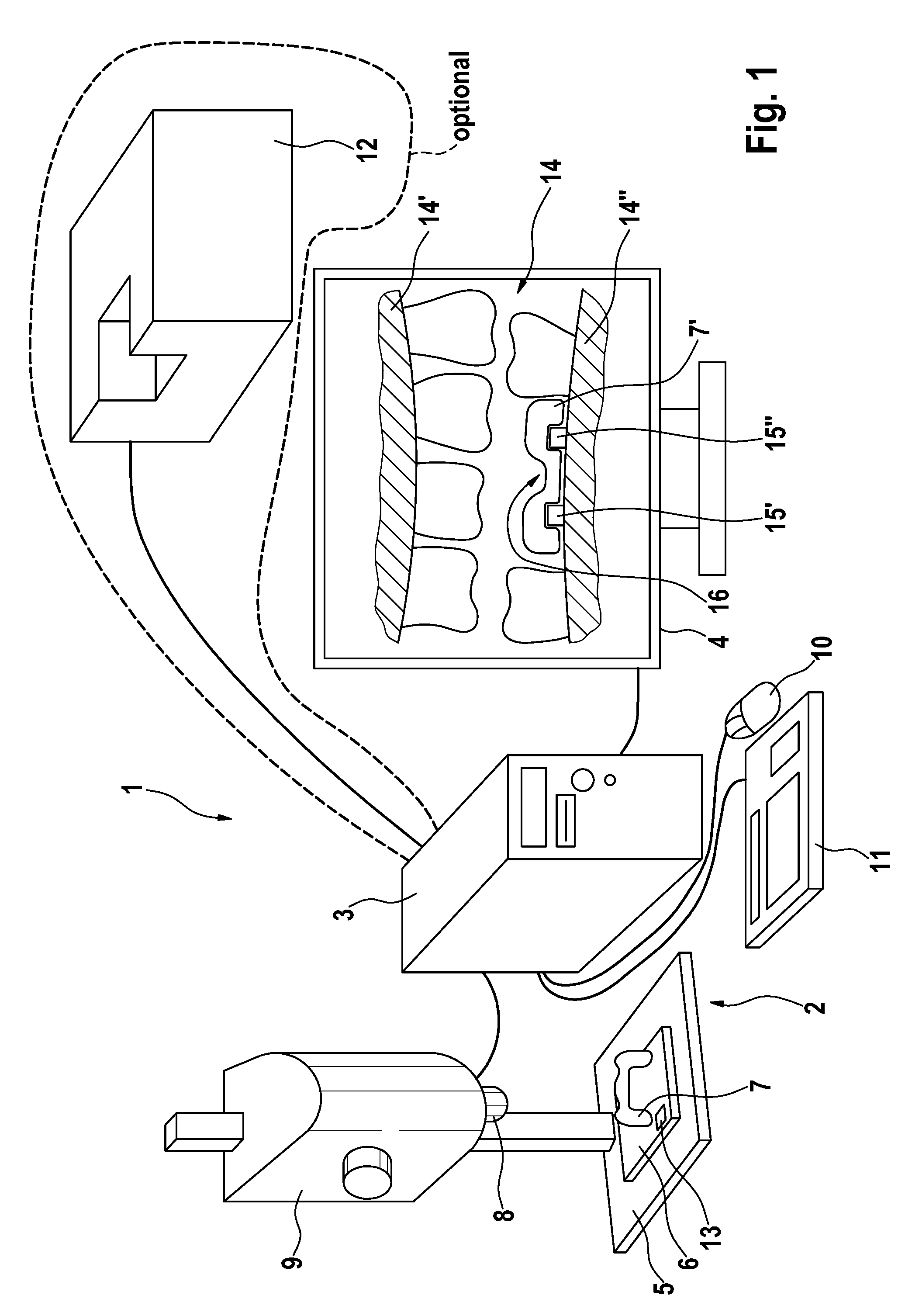

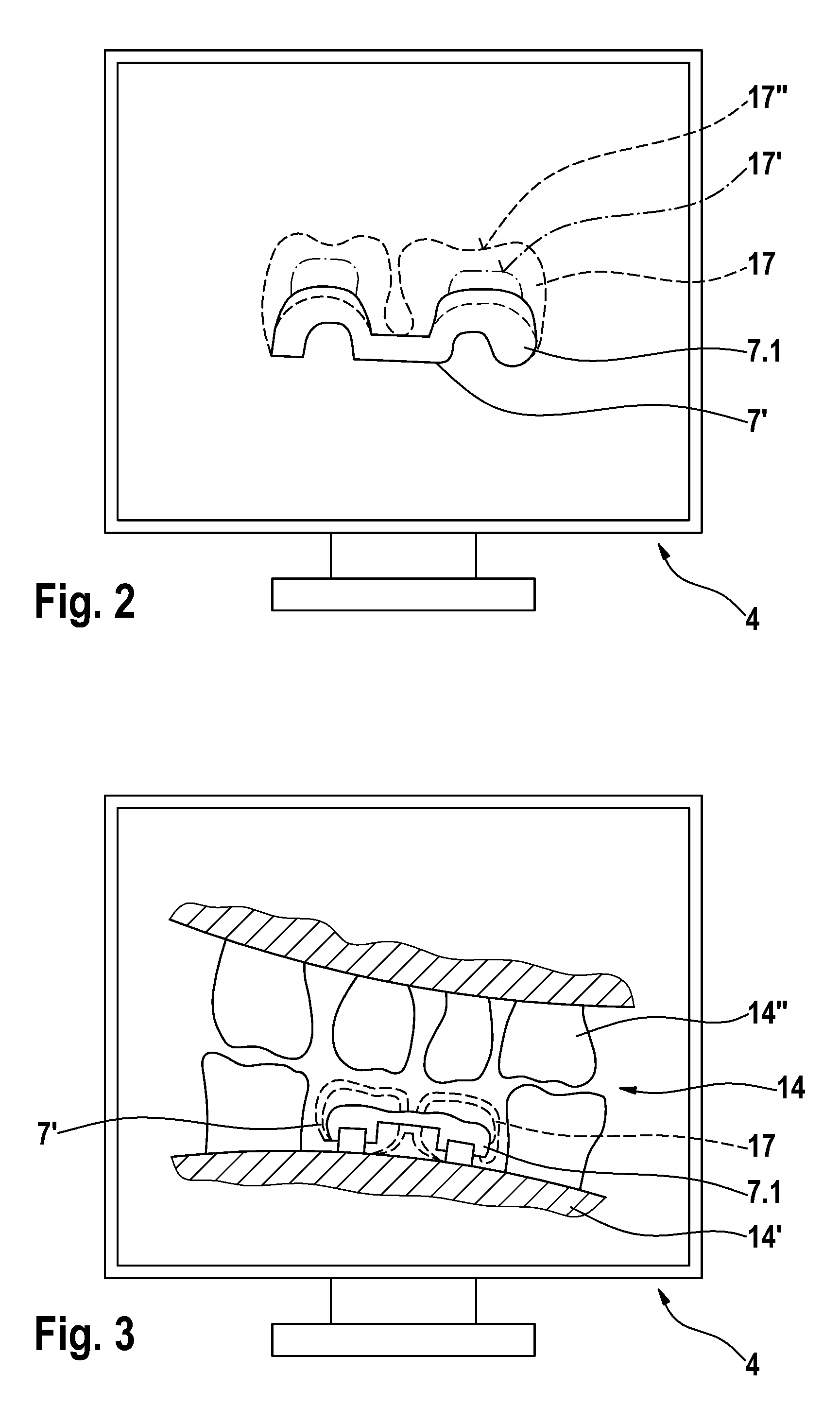

Method and Device for Producing Dental Prosthesis Elements

InactiveUS20090081616A1Easy to monitorAccurate fitDental implantsAdditive manufacturing apparatusDenturesProsthesis

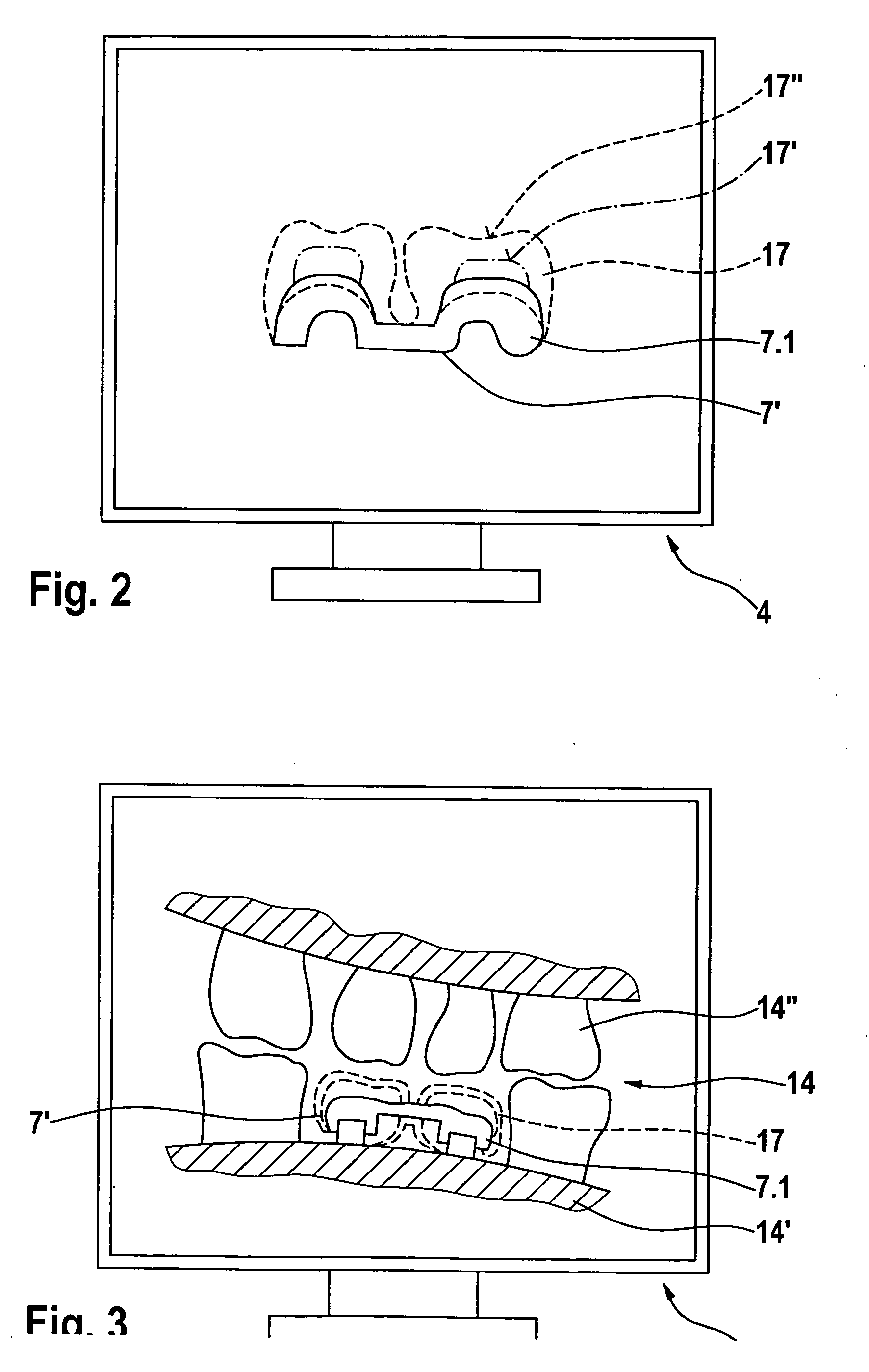

The invention relates to a method for producing a dental prosthesis element (7), according to which the dental prosthesis element (7) is manually reworked. Construction data (17, 17′, 17″) relating to the dental prosthesis element to be produced is recorded together with measurement data (7′) relating to the dental prosthesis element (7) to be produced and is reproduced on a display (4), the measurement data having been recorded by means of a three-dimensional measurement device (2). The invention also relates to one such method whereby a 3D data record of the tooth situation (14) is reproduced on the display (4) instead of the construction data. The invention further relates to a device for the partial manual treatment of the dental prosthesis element. Said device comprises a three-dimensional measurement device (2), a display (4), and a computer unit (3) comprising means for the correlation and comparison of two data records and for graphically presenting the data generated by the comparison.

Owner:SIRONA DENTAL SYSTEMS

Expandable polymer dental implant and method of use

Systems and methods for a dental implant system suitable for an endosteal implant into a jawbone are provided. The systems and methods make use of an tapered, expandable polymer sheath insertable into a jawbone, a tapered implant insertable into the sheath and causing expansion of the sheath upon insertion, and an abutment adapted to be coupled to the implant and permitting the attachment of a dental prosthesis.

Owner:DYNAMIC IMPLANTS

Apparatus for Producing Dental Impressions

Owner:NEUSCHAFER GERD

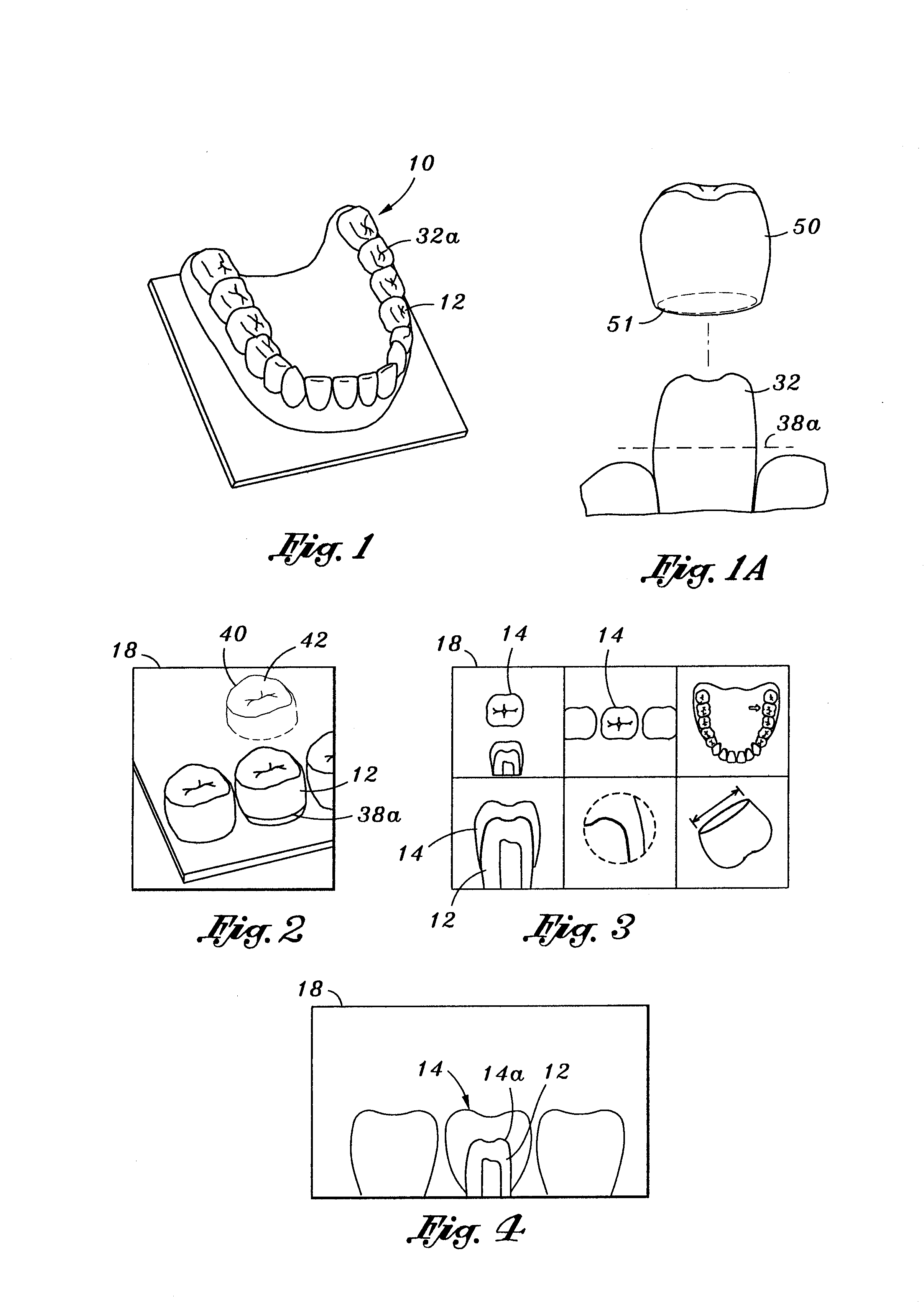

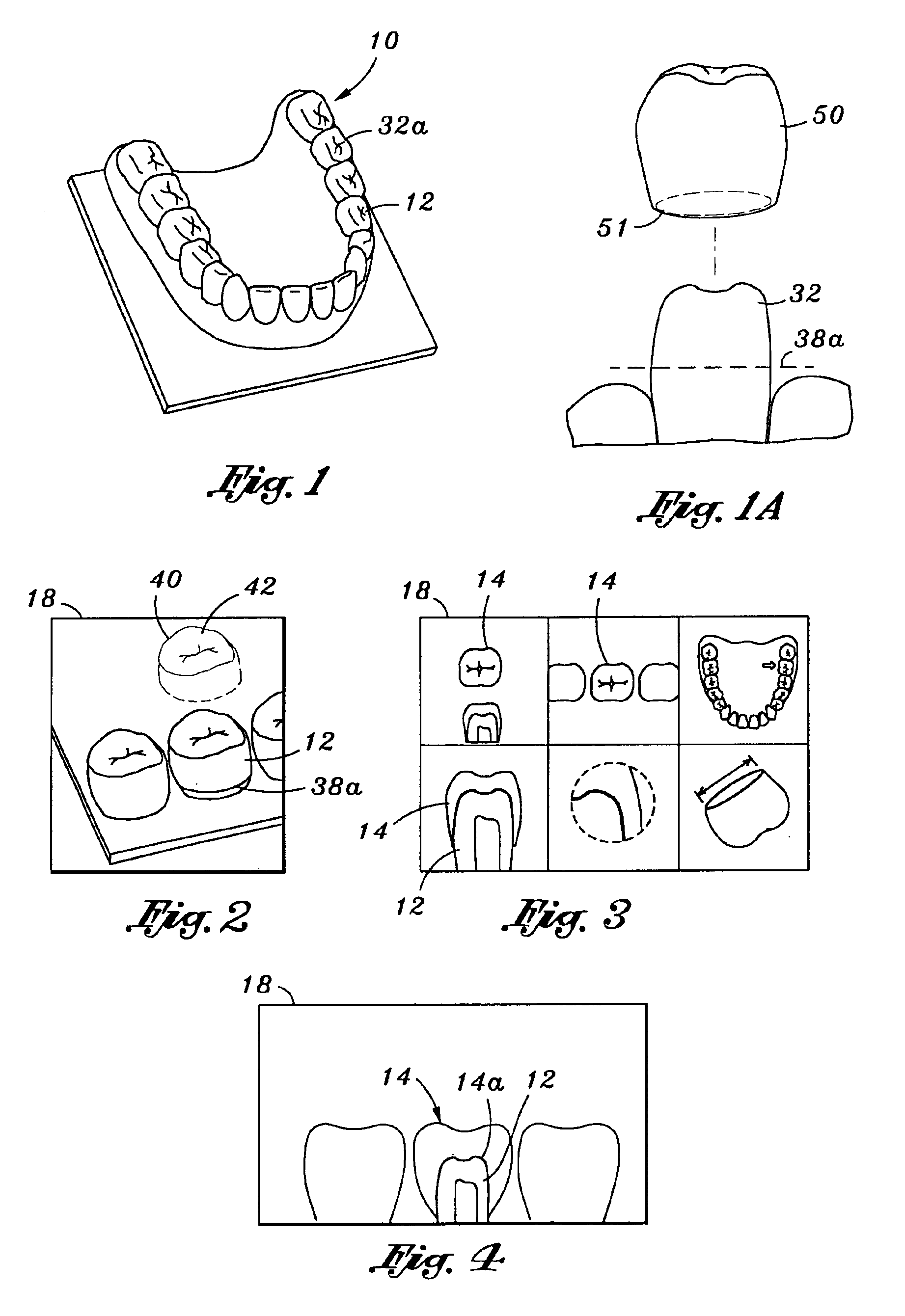

Dental prosthesis manufacturing process, dental prosthesis pattern @$amp; dental prosthesis made thereby

InactiveUS20020013636A1Improve accuracyShorten the timeSpecial data processing applicationsDental prostheticsDigital dataWax

<heading lvl="0">Abstract of Disclosure< / heading> A dental prosthesis is made by first forming a model of a patient's dentition. A three dimensional digital data corresponding to the surfaces of the model is then created. Based on this data, a three dimensional digital data file is then created substantially corresponding to the dental prosthesis to be manufactured. The three dimensional digital data of the dental prosthesis to be manufactured is next transmitted to automated prototyping equipment, and using the automated prototyping equipment, a wax pattern of the dental prosthesis is manufactured based upon this three dimensional digital data of the dental prosthesis. Finally, using this wax pattern in the lost wax investment casting process, the dental prosthesis is made. Prior to investment casting, marginal edges of the wax pattern are adjusted manually.

Owner:NAT DENTEX LLC

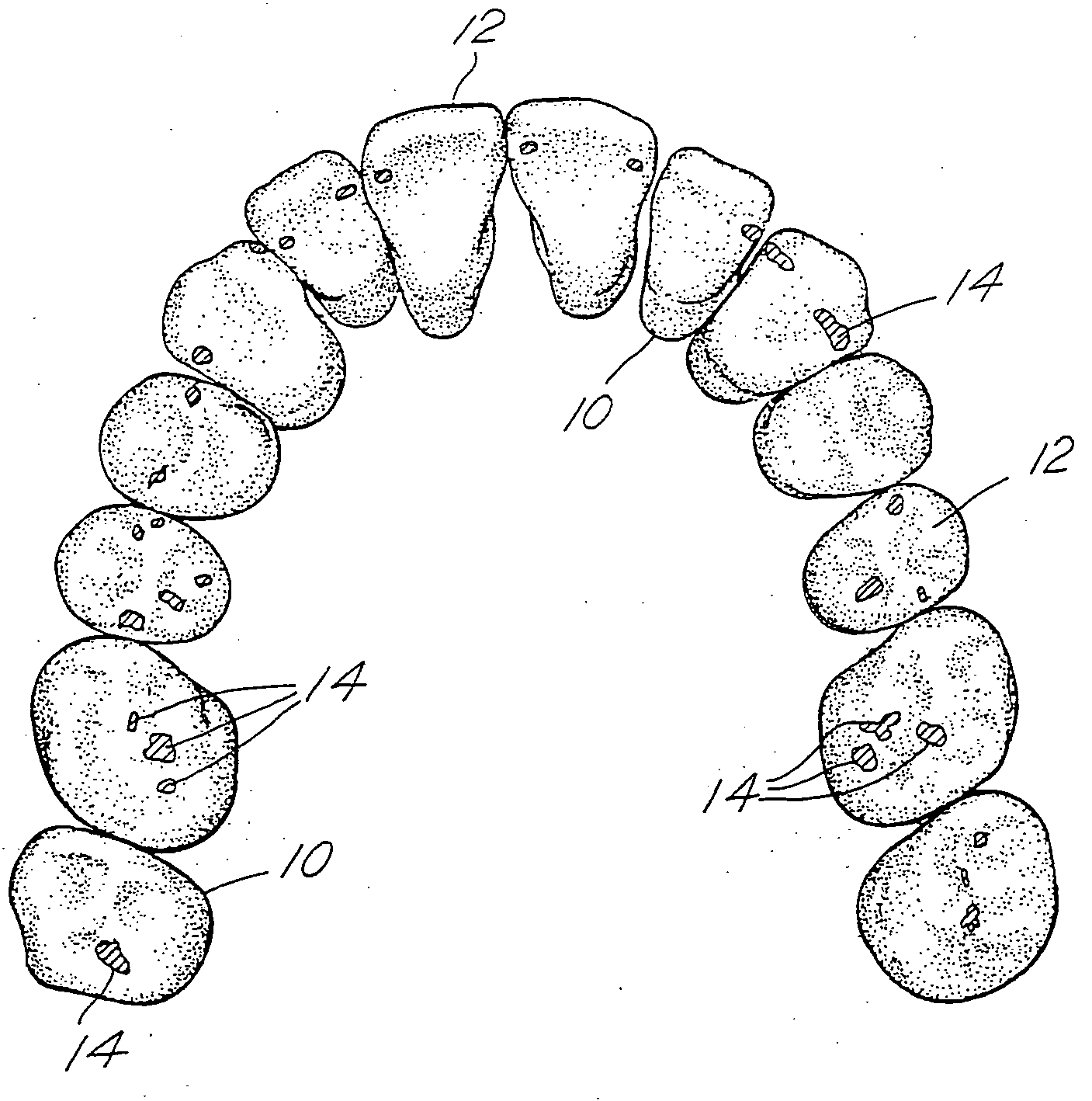

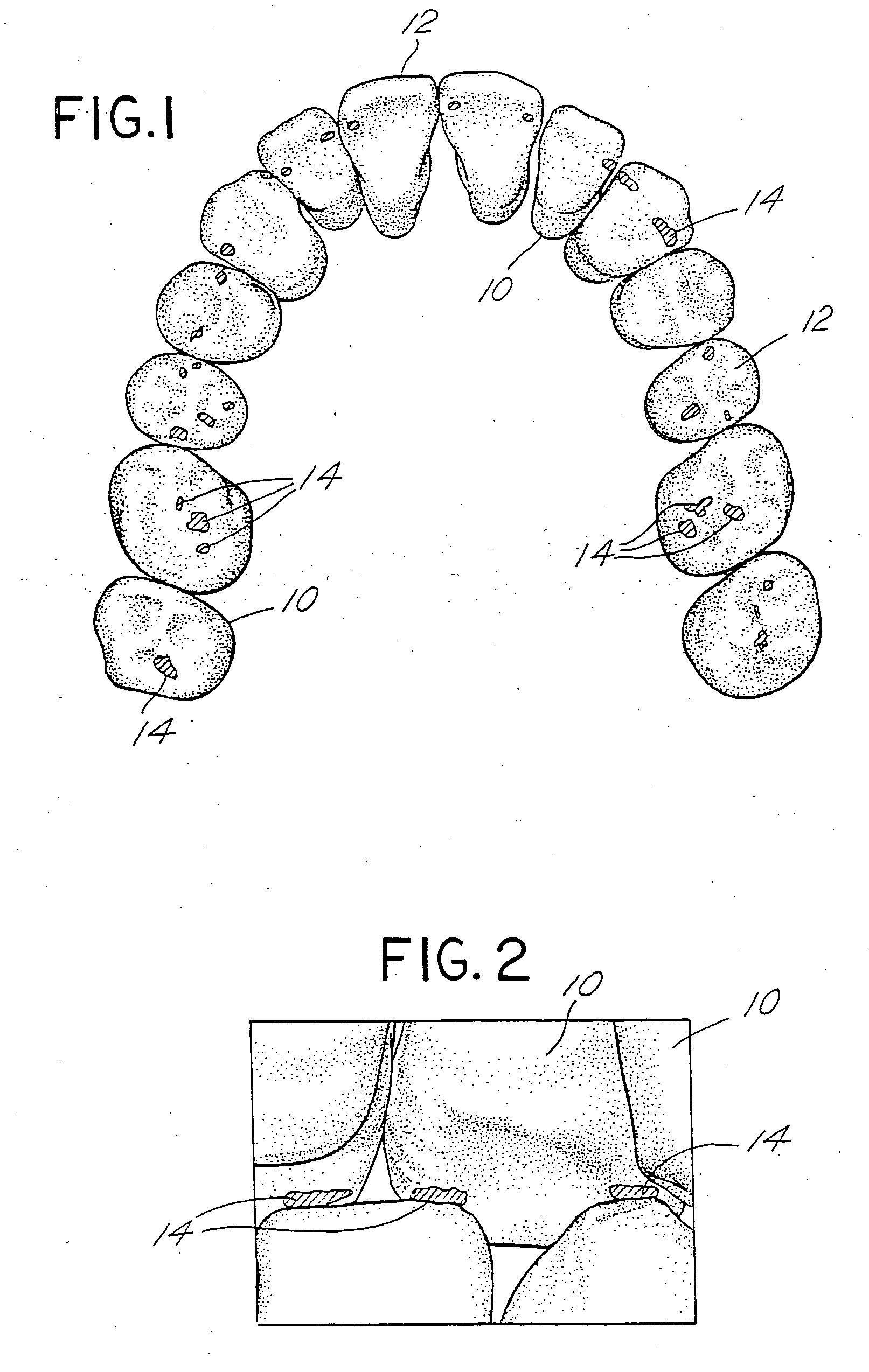

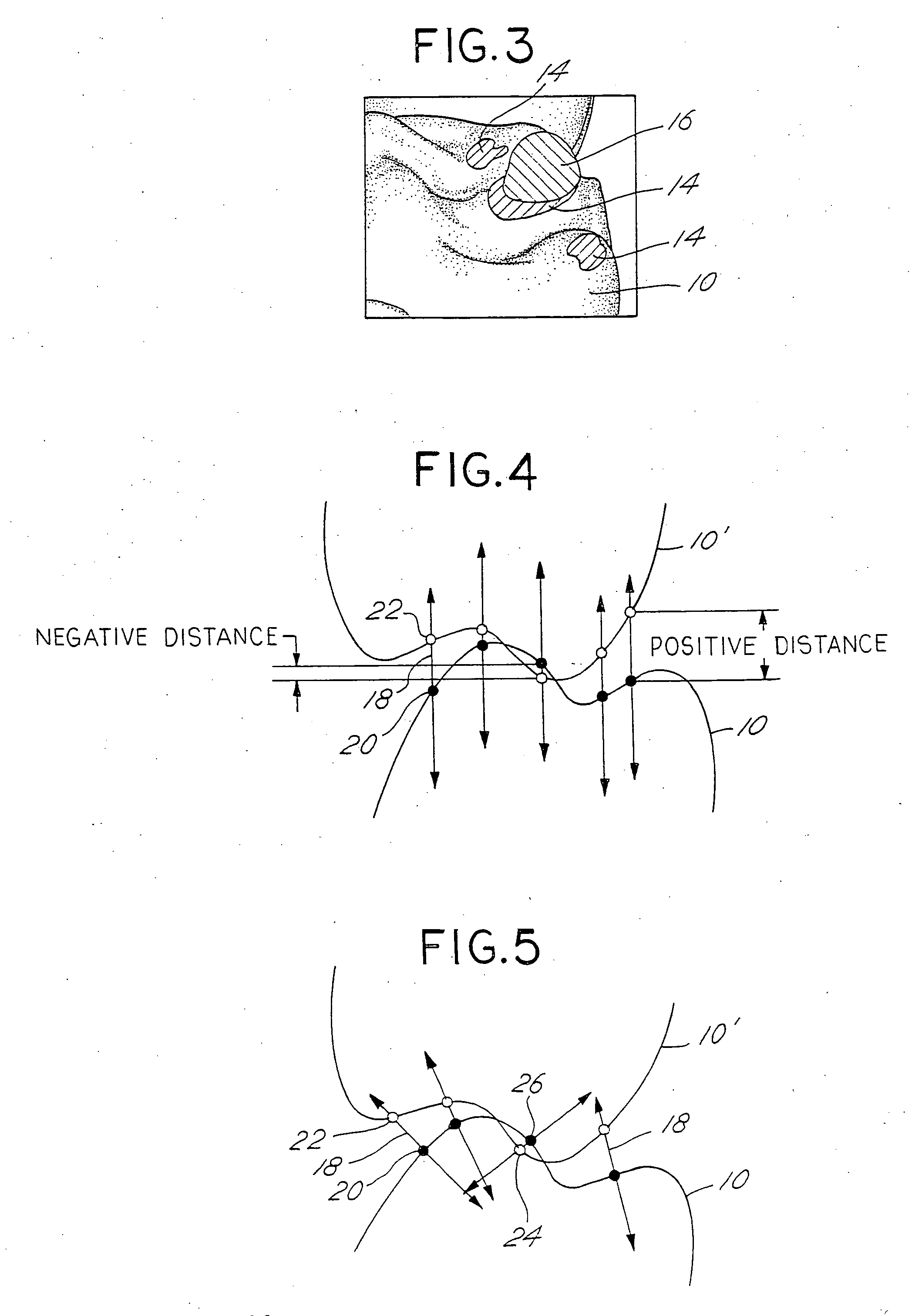

Three-dimensional occlusal and interproximal contact detection and display using virtual tooth models

InactiveUS20050095562A1Improve positionEasy to shapePhysical therapies and activitiesImpression capsPlan treatmentGeneral purpose

Occlusal contact between upper and lower virtual three-dimensional teeth of a patient when the upper and lower arches are in an occlused condition are determined and displayed to the user on a user interface of a general purpose computing device. Various techniques for determining occlusal contacts are described. The areas where occlusal contact occurs is displayed on the user interface in a readily perceptible manner, such as by showing the occlusal contacts in green. If the proposed set-up would result in a interpenetration of teeth in opposing arches, such locations of interpenetration are illustrated in a contrasting color or shading (e.g., red). The ability to calculate distances and display occlusal contacts in a proposed set-up assists the user in planning treatment for the patient. The process can be extended to interproximal contact detection as well. The concepts also apply to dental prosthetics, such as crowns, fillings and dentures.

Owner:ORAMETRIX

Method and device for producing dental prosthesis elements

InactiveUS7865261B2Accurate fitRetain controlDental implantsAdditive manufacturing apparatusGraphicsDentures

Owner:SIRONA DENTAL SYSTEMS

Dental prosthesis manufacturing process, dental prosthesis pattern & dental prosthesis made thereby

InactiveUS6915178B2Improved accuracy of the marginal edges of the dental prosthesisShorten the timeMedical simulationAdditive manufacturing apparatusDigital dataWax

A dental prosthesis is made by first forming a model of a patient's dentition. A three dimensional digital data corresponding to the surfaces of the model is then created. Based on this data, a three dimensional digital data file is then created substantially corresponding to the dental prosthesis to be manufactured. The three dimensional digital data of the dental prosthesis to be manufactured is next transmitted to automated prototyping equipment, and using the automated prototyping equipment, a wax pattern of the dental prosthesis is manufactured based upon this three dimensional digital data of the dental prosthesis. Finally, using this wax pattern in the lost wax investment casting process, the dental prosthesis is made. Prior to investment casting, marginal edges of the wax pattern are adjusted manually.

Owner:NAT DENTEX LLC

Denture and method and apparatus of making same

ActiveUS20130101962A1Optimize aestheticOptimize fitImpression capsAdditive manufacturing apparatusNatural toothBody of mandible

Owner:GLOBAL DENTAL SCI

System of dental restoration of single stage dental implants and loading with a preformed crown restoration

The present invention is prosthetic tooth replacement including a dental crown portion and a joining portion adapted to fixedly attach to a dental implant. Further, present invention also comprises the combination of a prosthetic tooth replacement and a dental implant. Additionally, the present includes a method for making an oral surgical guide stint by vacuum forming a thermoplastic material over a model of an implant target area. Finally, the present invention includes a method of inserting the combination of the prosthetic tooth replacement and implant into the jaw of a patient.

Owner:SHATKIN TODD E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com