Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

544 results about "Jaw bone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for assessing the outcome of an orthodontic treatment

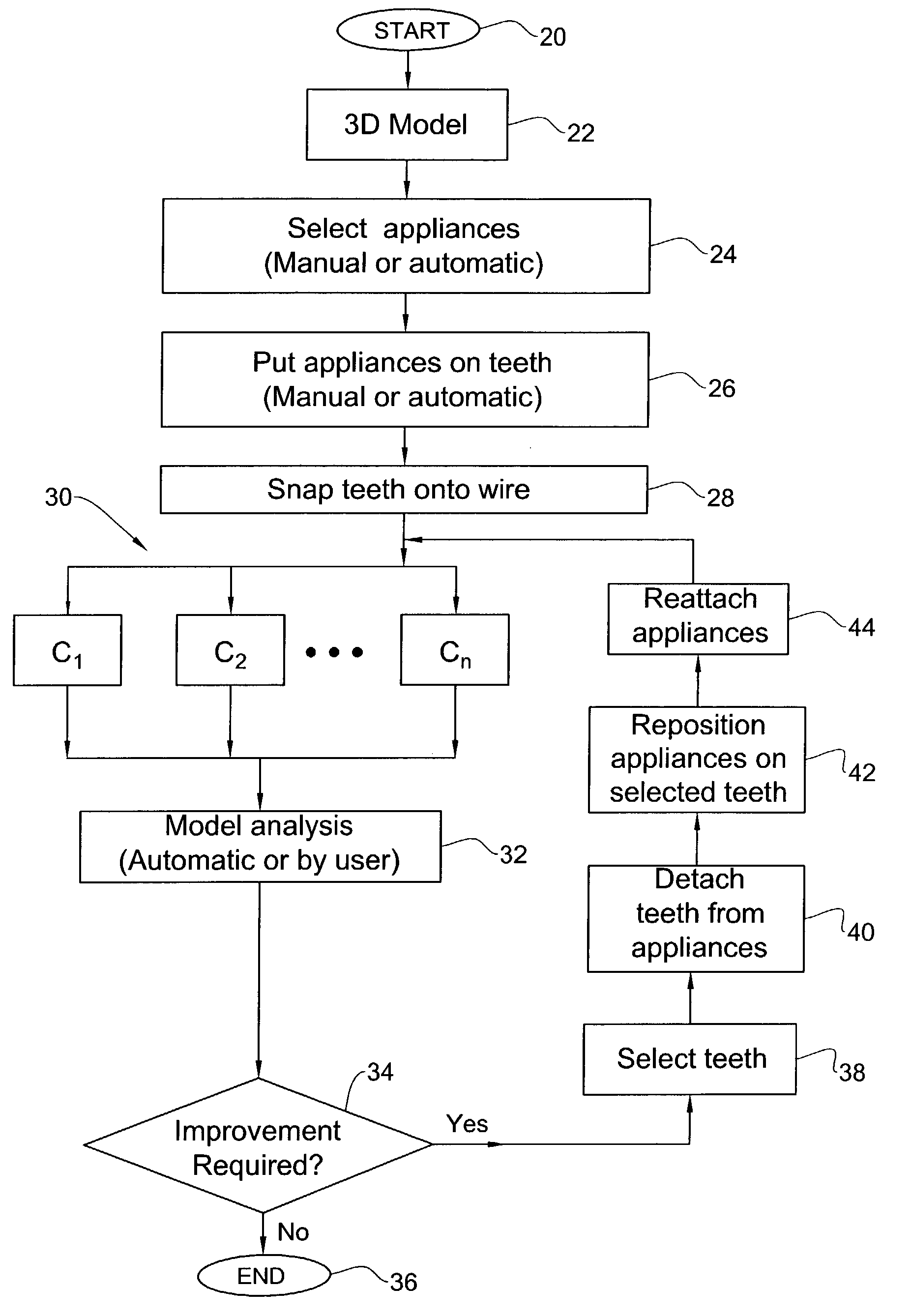

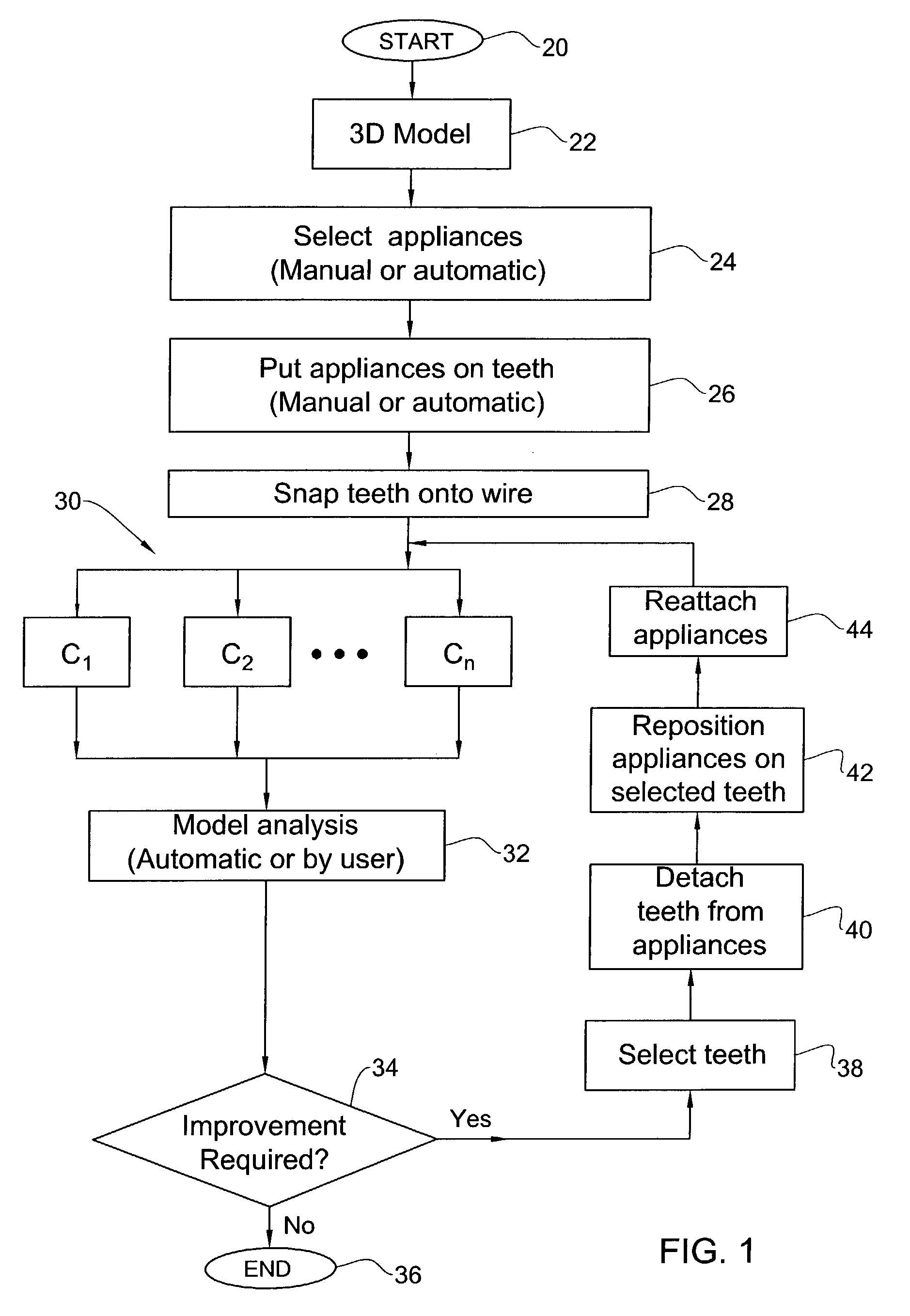

The present invention provides a virtual orthodontic treatment method, comprising, providing a virtual diagnostic setup model of teeth of at least one jaw of an individual, associating virtual orthodontic appliances with all teeth in the model to obtain a first composite model and repositioning teeth into an initial treatment state according to pre-defined appliances-dependent rules; in the initial treatment state, detaching one or more teeth from their corresponding one or more orthodontic appliances, repositioning one or more appliances, reassociating one or more appliances with the teeth, permitting the teeth to reposition according to the appliances-dependent rules to obtain an altered treatment state, yielding a better grade, according to one or more systems for grading an orthodontic model, as compared to the grade of initial treatment state.

Owner:ALIGN TECH

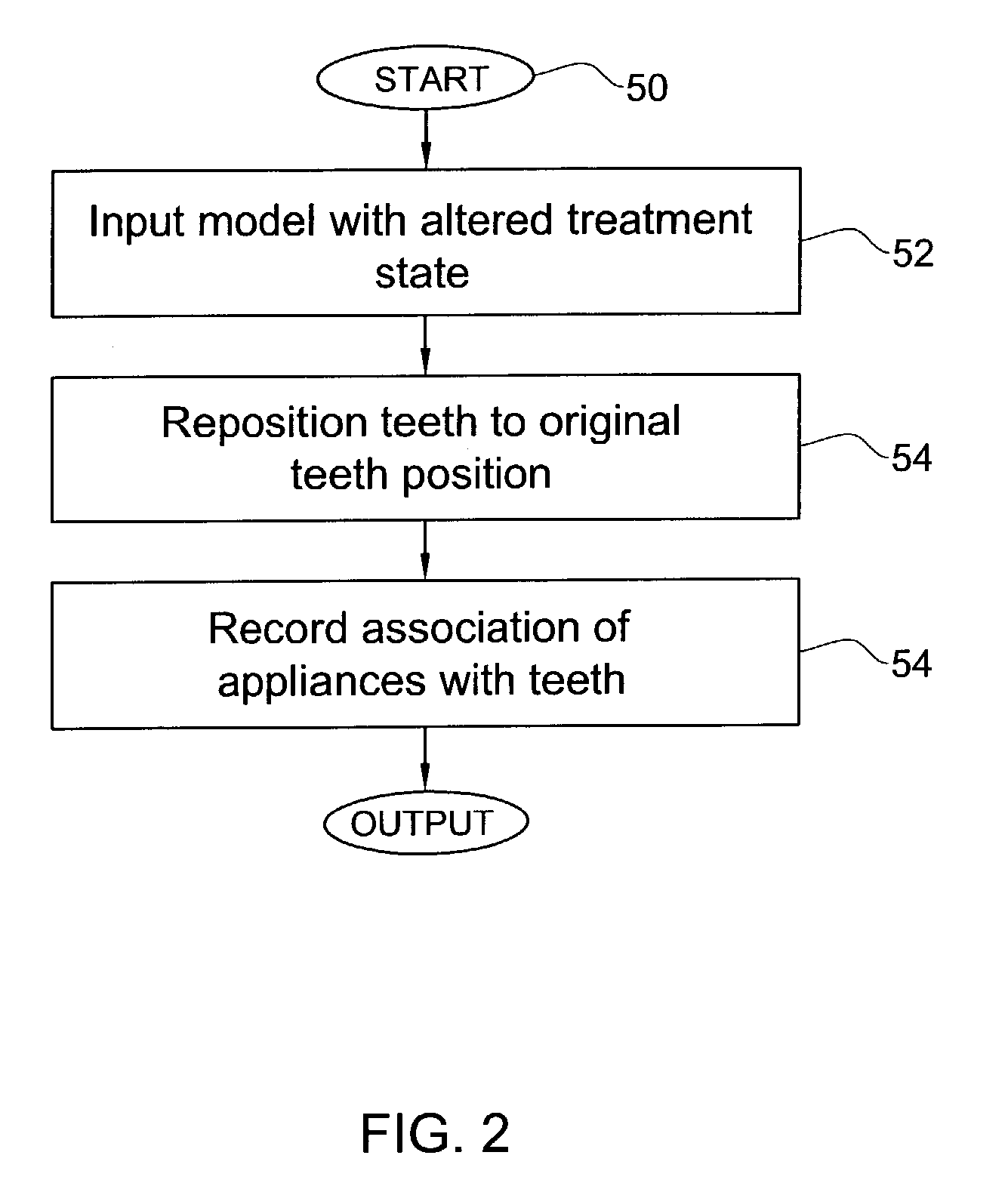

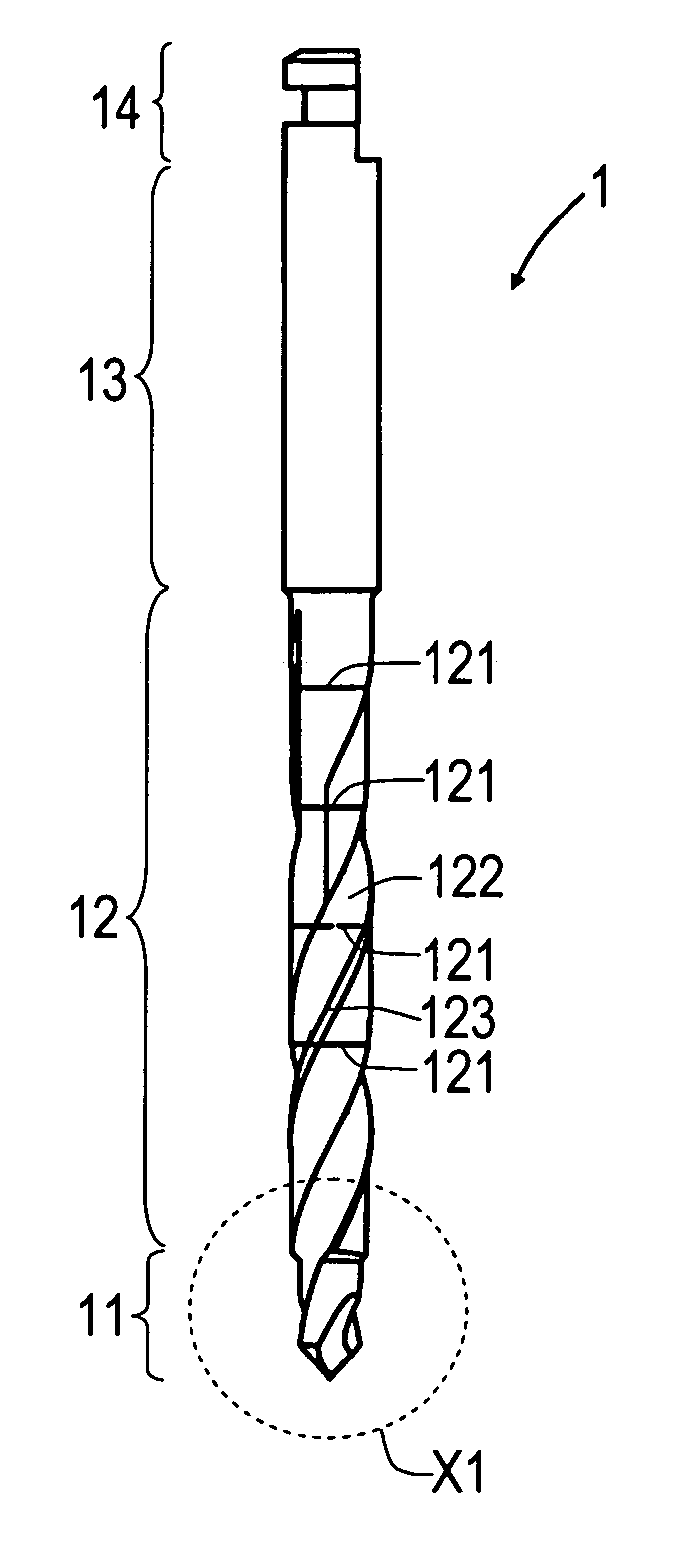

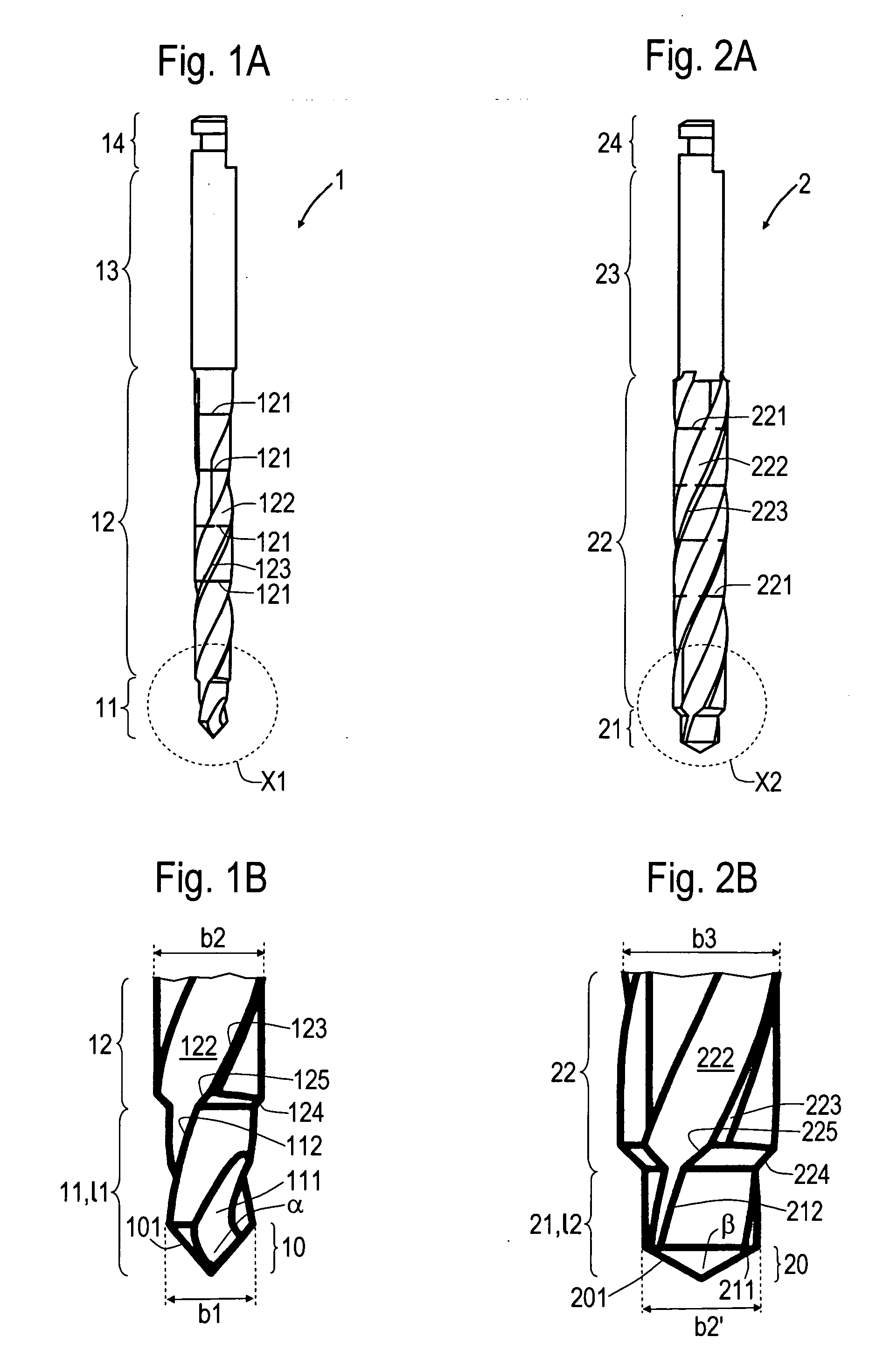

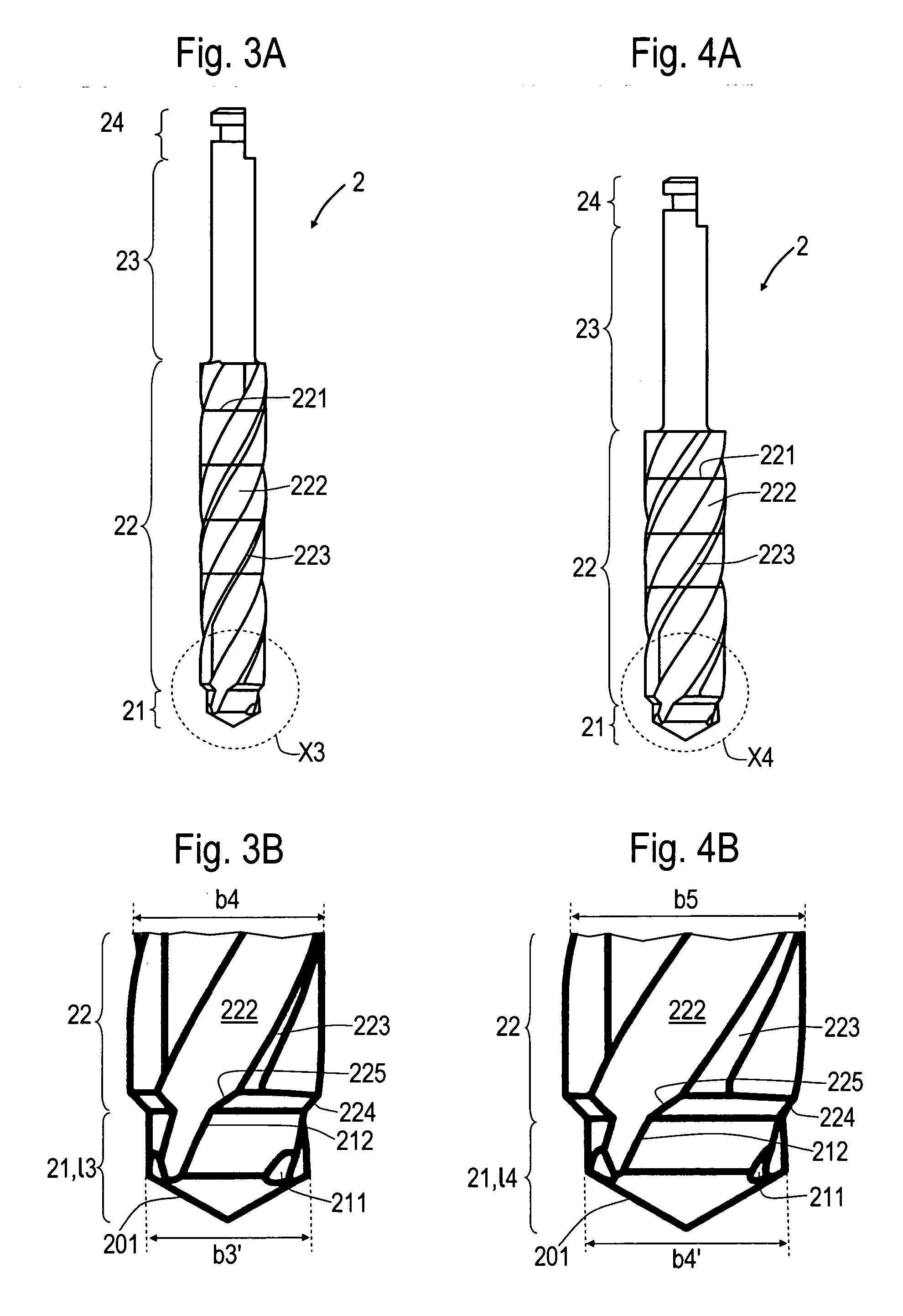

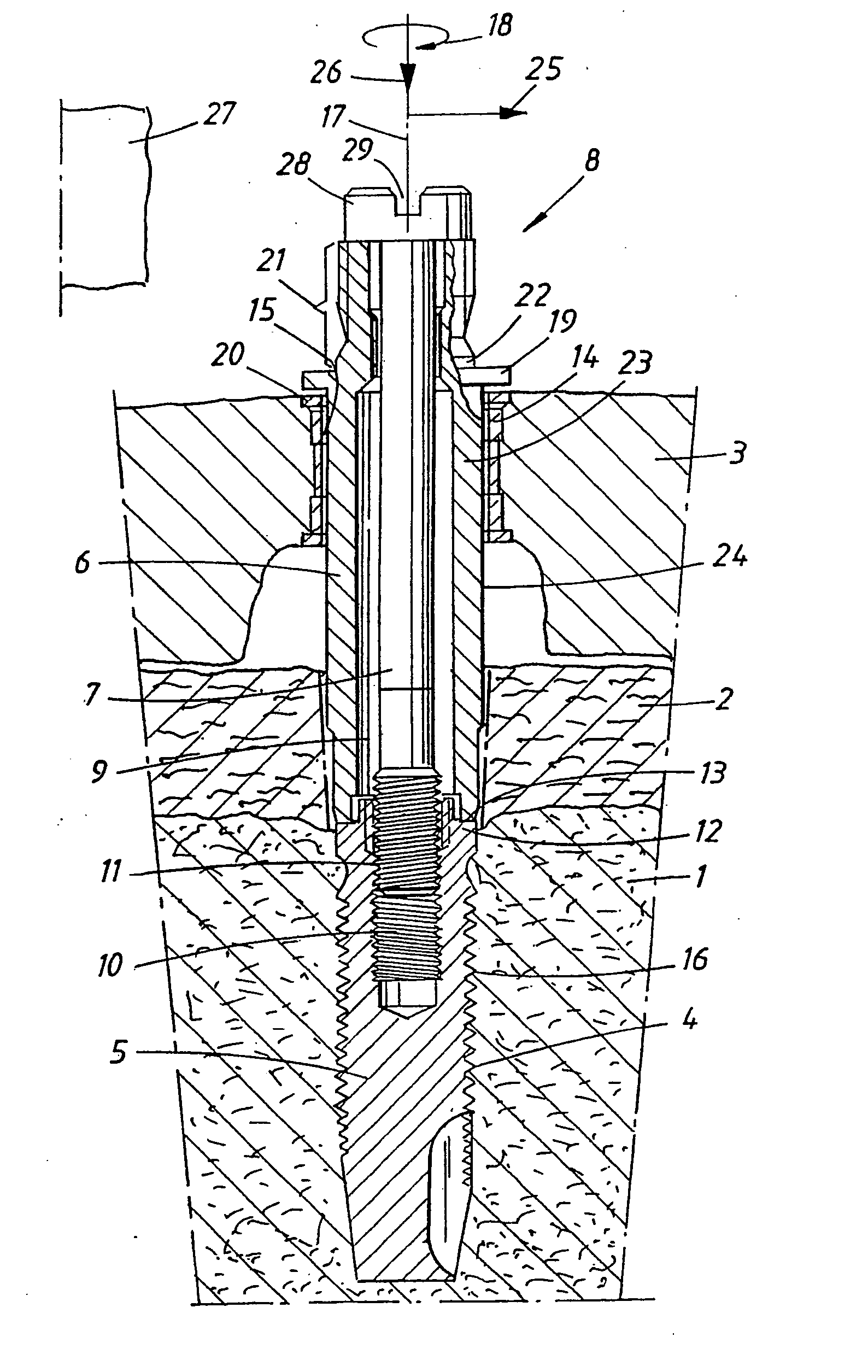

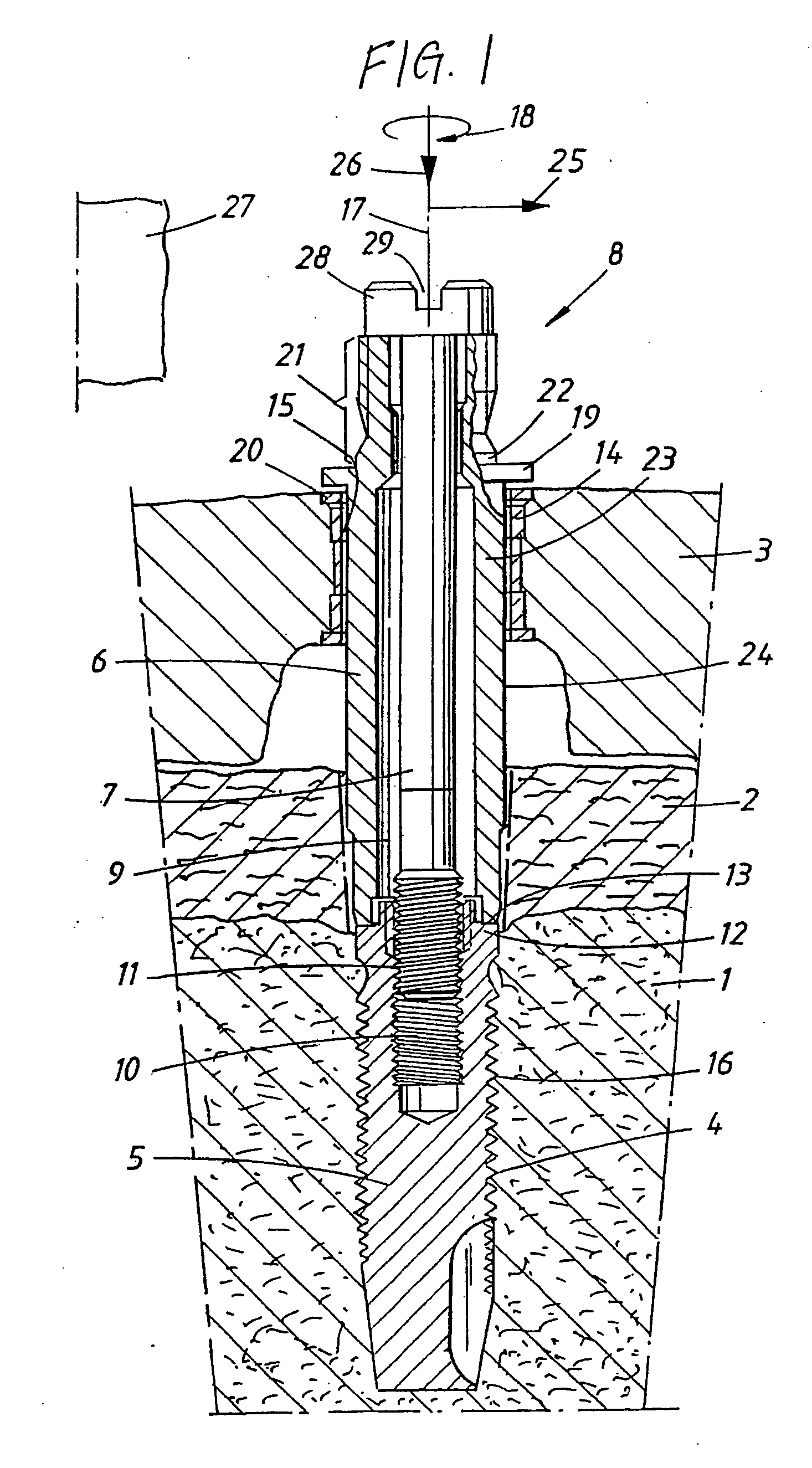

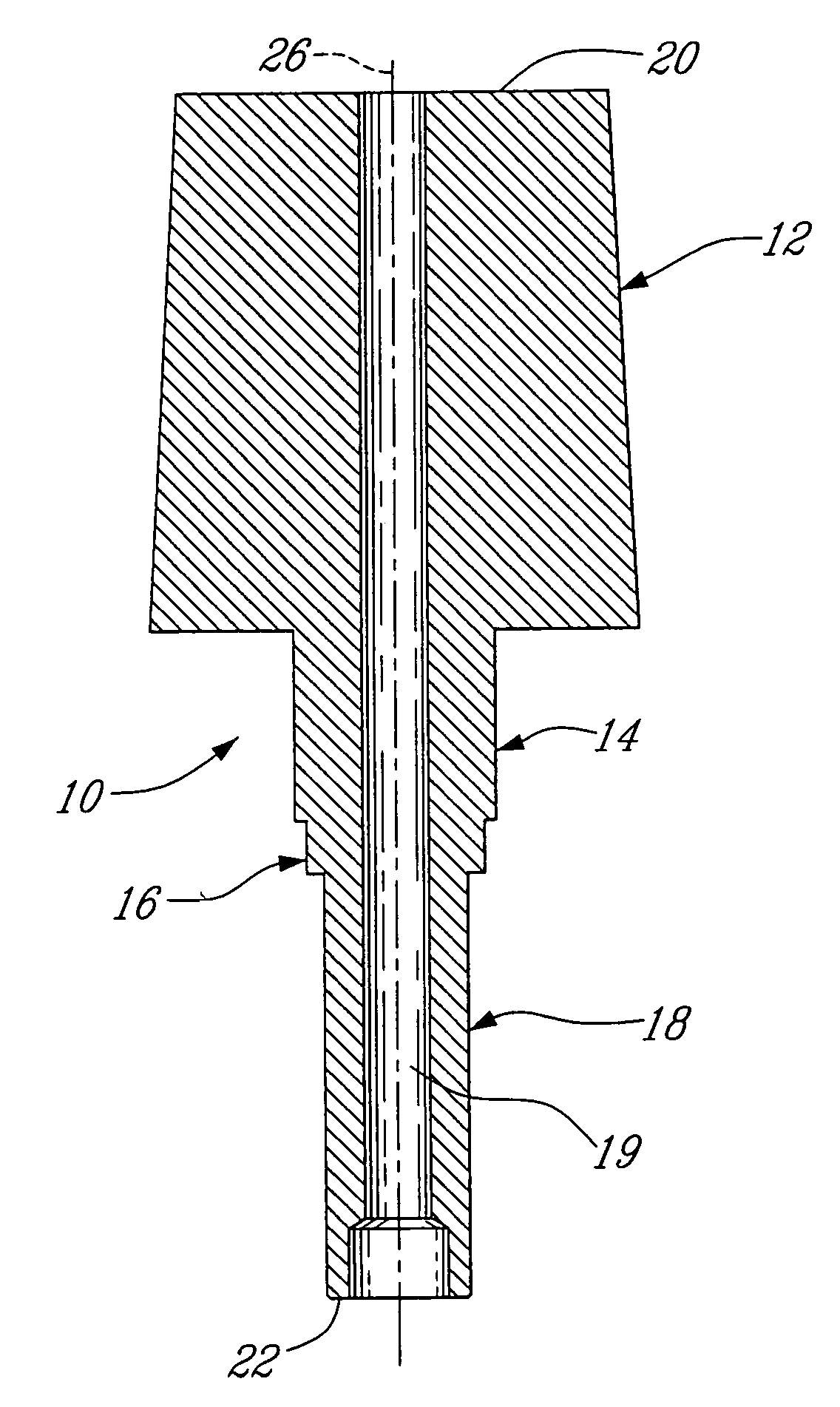

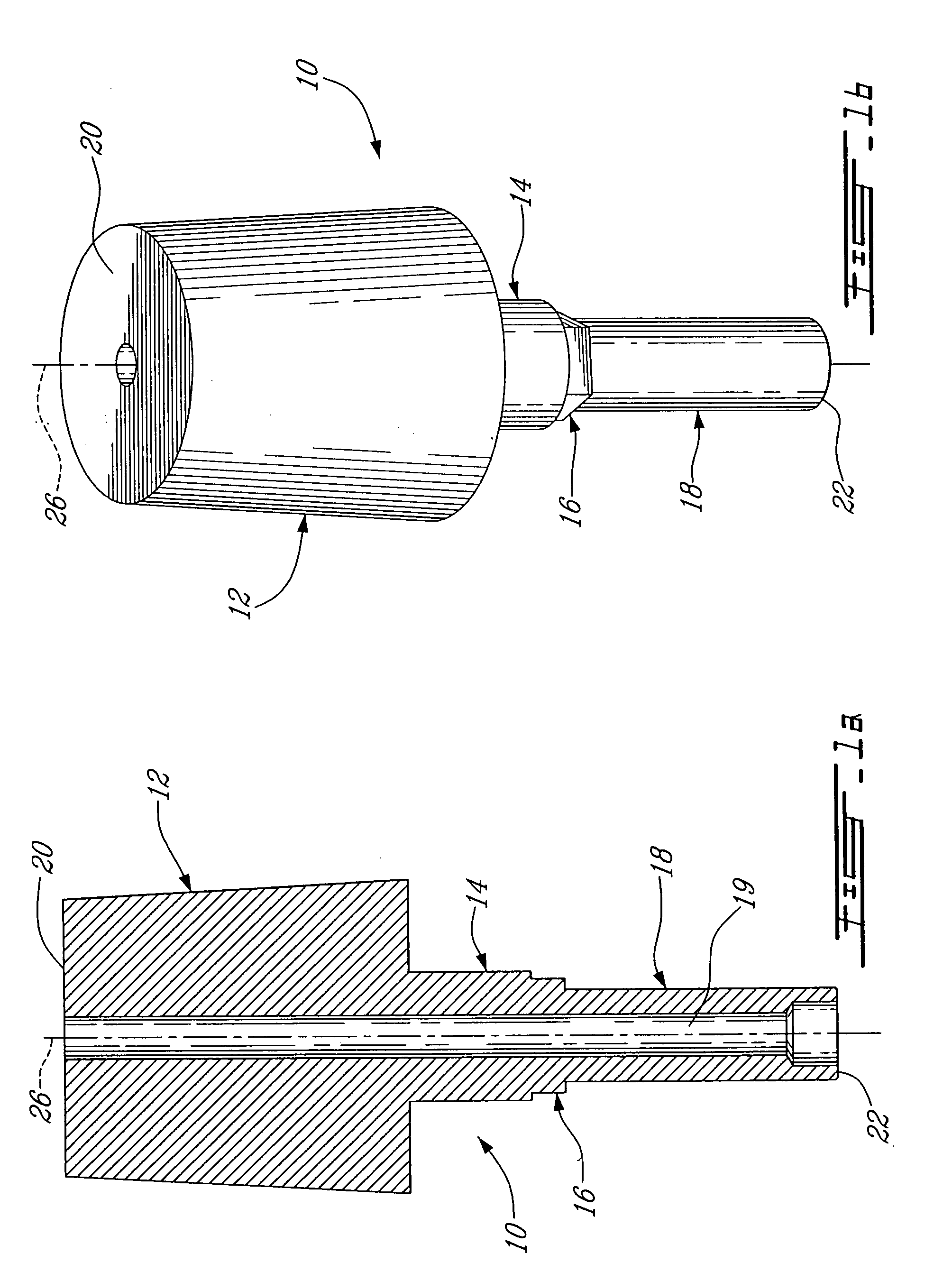

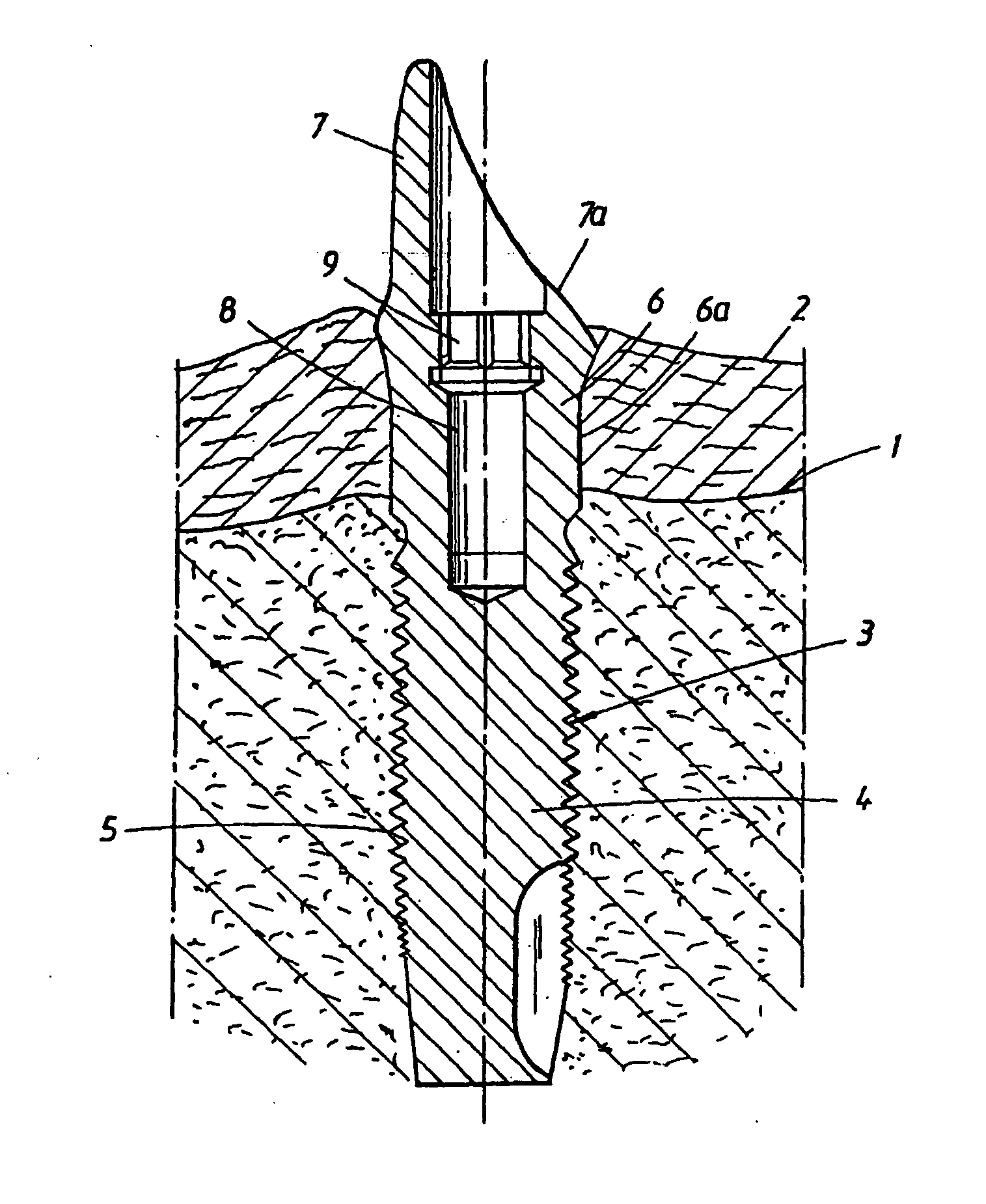

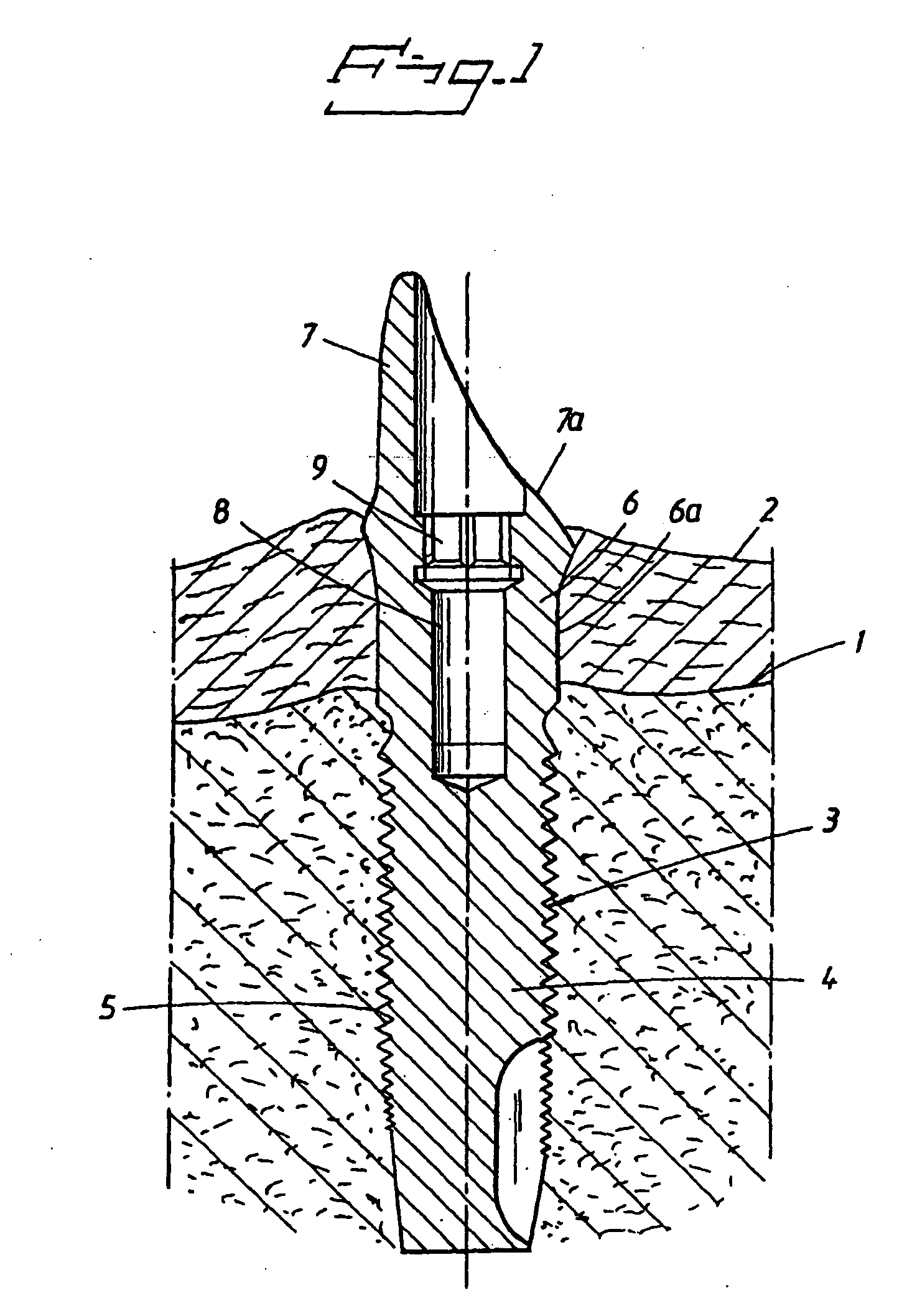

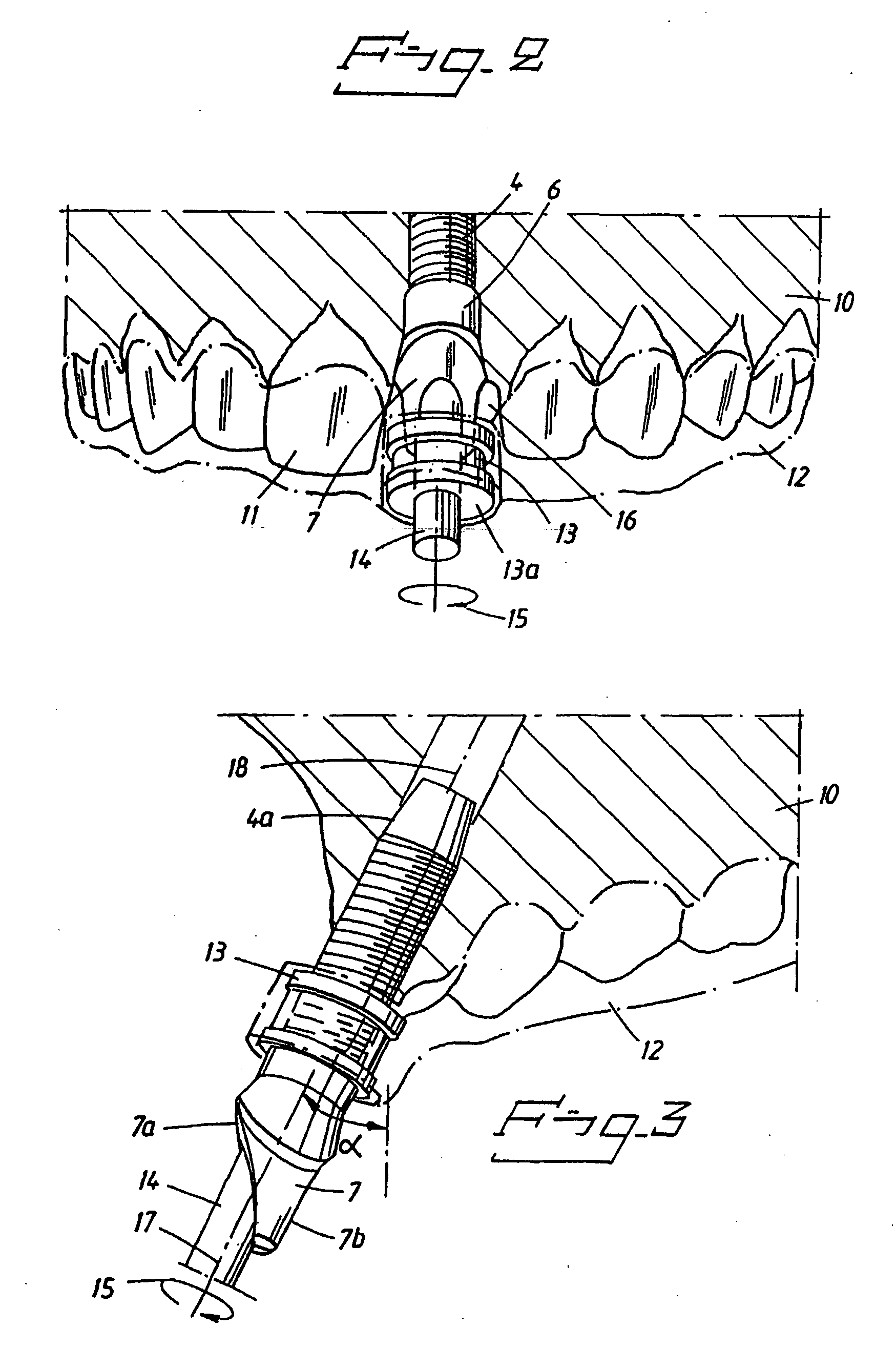

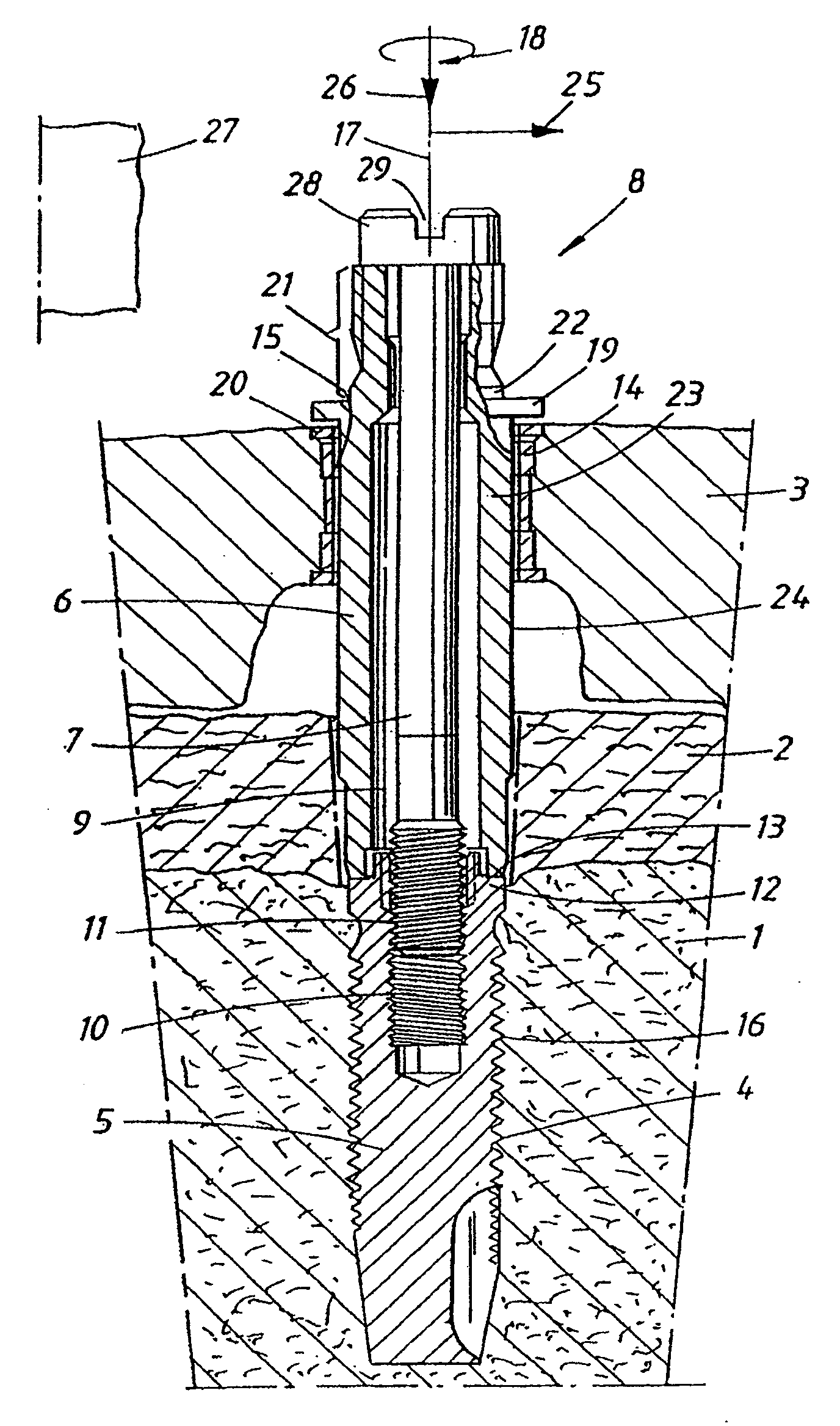

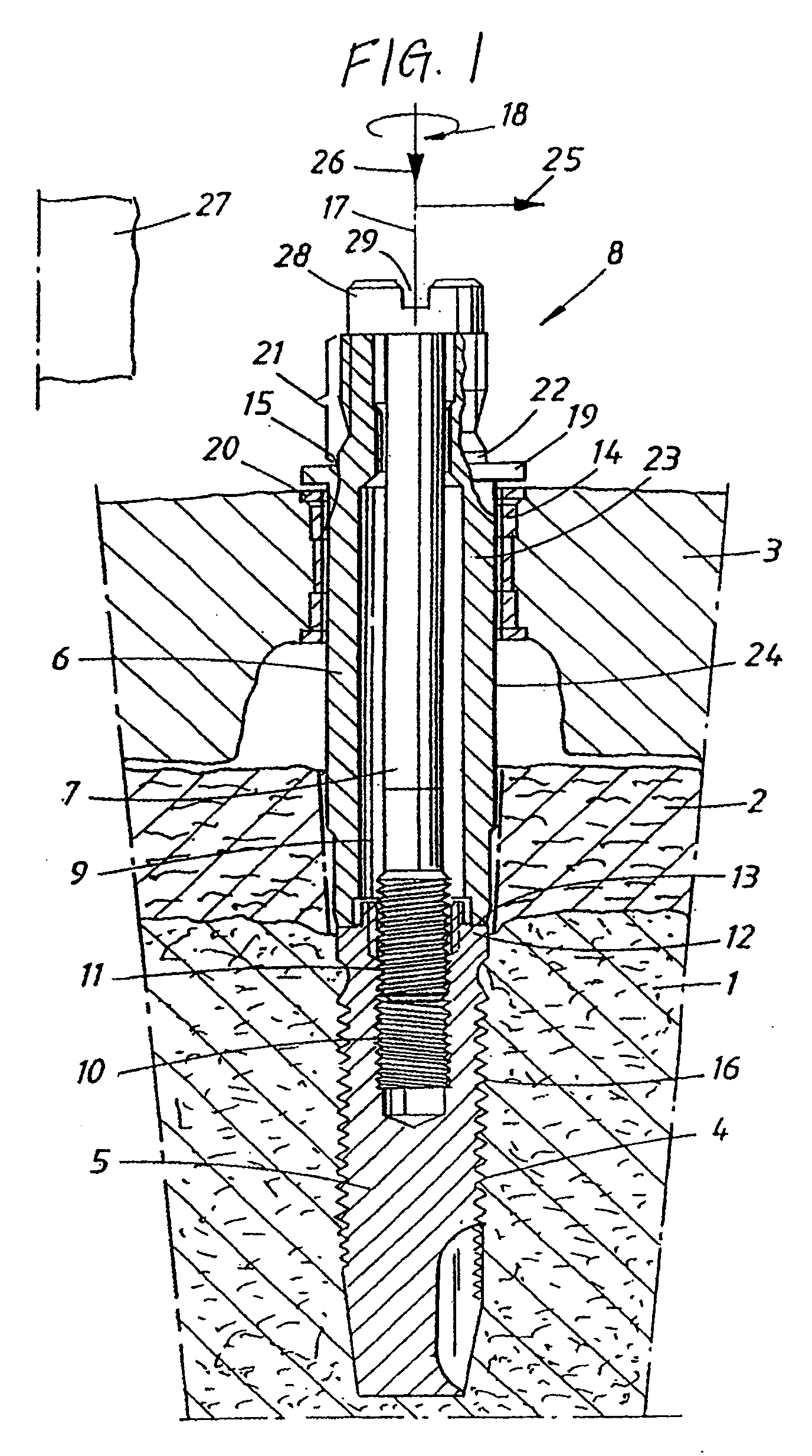

Pilot drill, step drill, and drill set for dental implant technology

The invention relates to a pilot drill (1) for producing a pilot bore in a human jaw bone in preparation for its enlargement into a step bore, achieved by means of a first step drill (2) or if the step bore is further enlarged, by means of second and third step drills (2). The prepared step bore is designed to receive a dental implant, preferably in screw form. The pilot drill (1) and the first step drill (2) form a drill set. The pilot guide (11) on the pilot drill (1), comprising a step (124) lying in the transition region leading to the drill neck (12), positions the drill at the commencement of drilling in the corticalis, whereby the drilling direction can be corrected prior to the continued drilling down to the maximum depth of the pilot bore. The pilot guide (11) has a drill diameter (b1), whereas the step (124) leads into an enlarged drill diameter (b2). The step guide (21) of the first step drill (2) has a drill diameter (b2′) that corresponds to the drill diameter (b2). The drill diameter (b3) at the drill neck (22) of the first step drill (2) corresponds to the drill diameter at the step guide (21) of the second step drill (2). The second step drill corresponds in a similar manner to the third step drill (2). The advantages of the invention are that it requires a reduced number of drilling tools, that the implant bed can be prepared in a precise, gentle manner and that the inserted implants achieve a primary stability.

Owner:THOMMEN MEDICAL

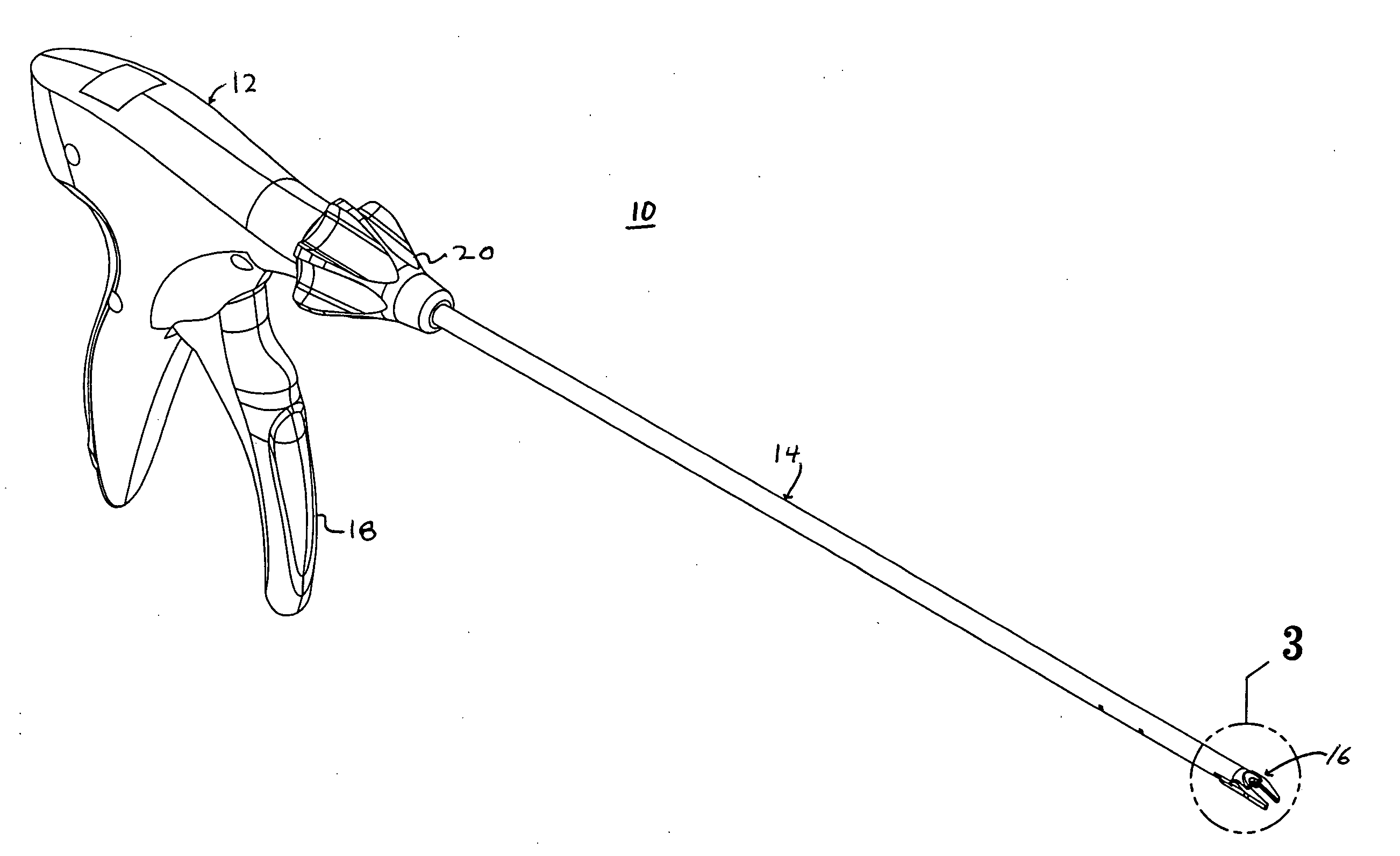

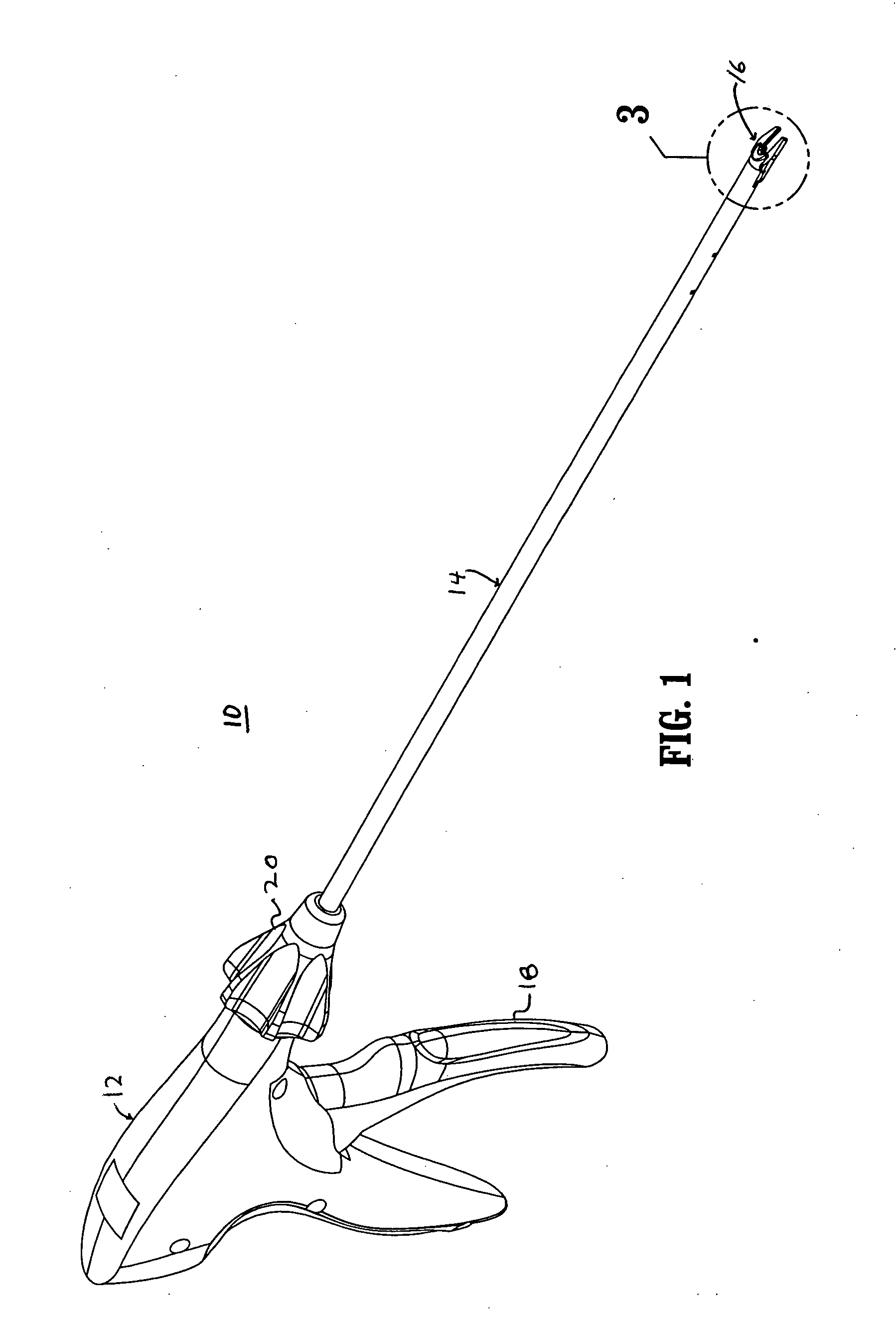

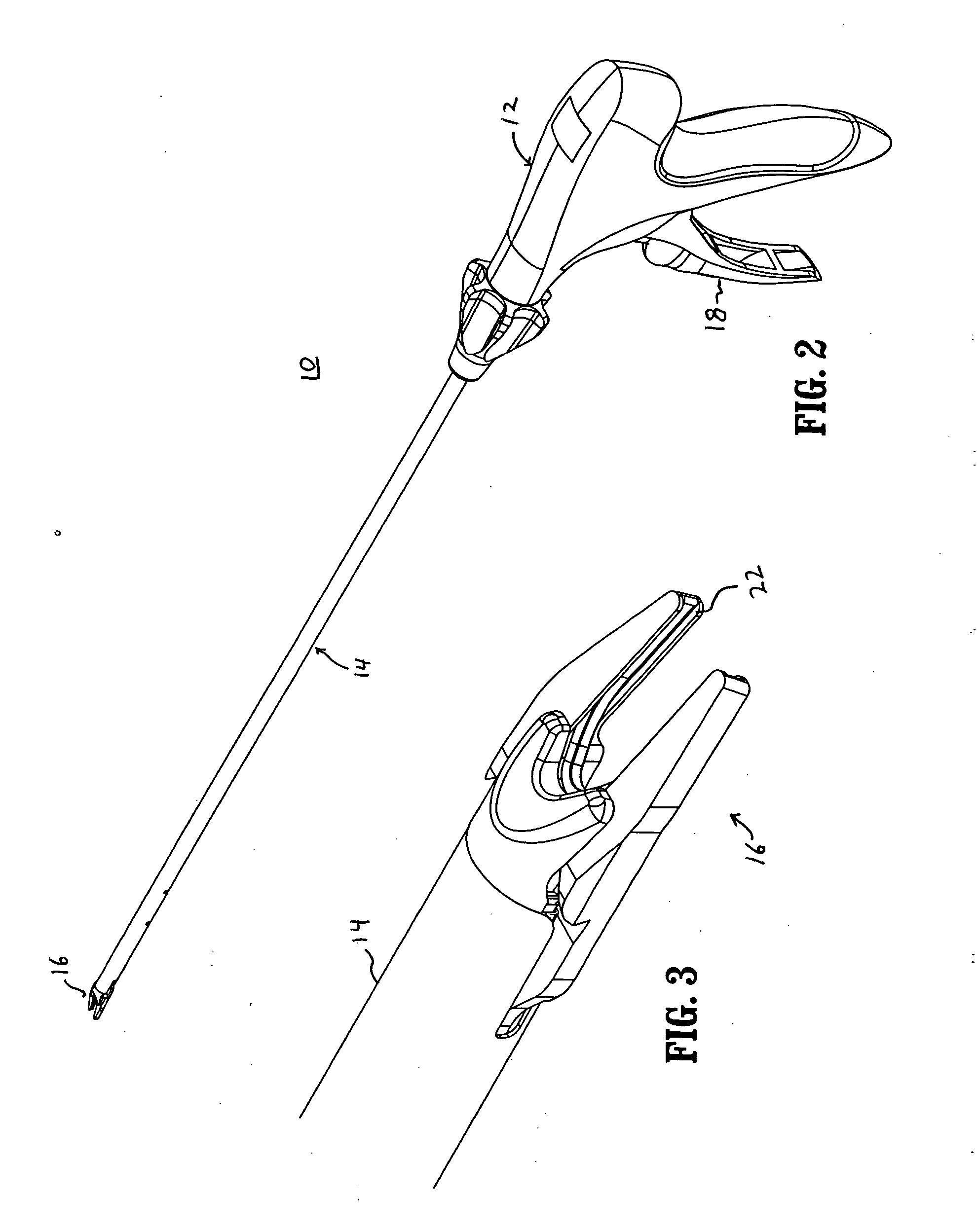

Endoscopic surgical clip applier

An apparatus for application of surgical clips to body tissue has a handle portion with a body extending distally from the handle portion defining a longitudinal axis and a plurality of surgical clips disposed within the body. The apparatus also has a jaw assembly mounted adjacent a distal end portion of the body with the jaw assembly including first and second jaw portions movable between a spaced-apart and an approximated position. The apparatus further has a wedge plate longitudinally movable between the first and the second jaw portions, and a clip pusher configured to individually distally advance a surgical clip to the jaw assembly while the jaw portions are in the spaced apart position with an actuator. The actuator is at least partially disposed within the body and longitudinally movable in response to actuation of the handle portion and has a cam link. The apparatus also has a jaw closure member positioned adjacent the first and second jaw portions to move the jaw portions to the approximated position. The cam link longitudinally moves wedge plate between the first and the second jaw portions.

Owner:TYCO HEALTHCARE GRP LP

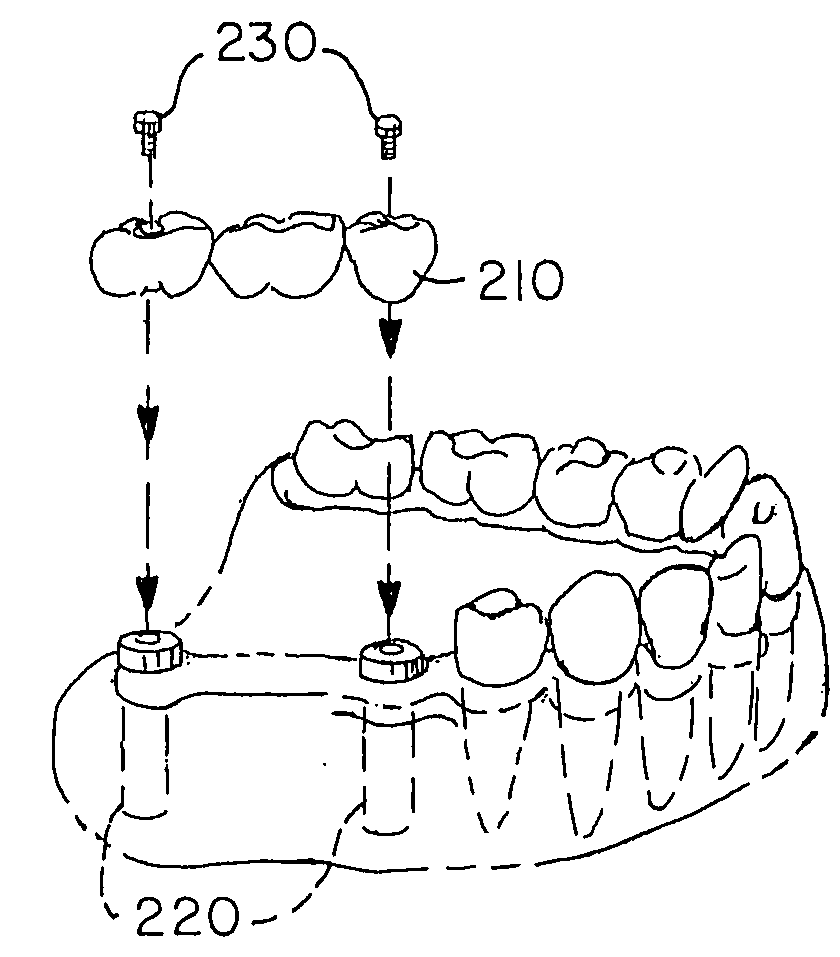

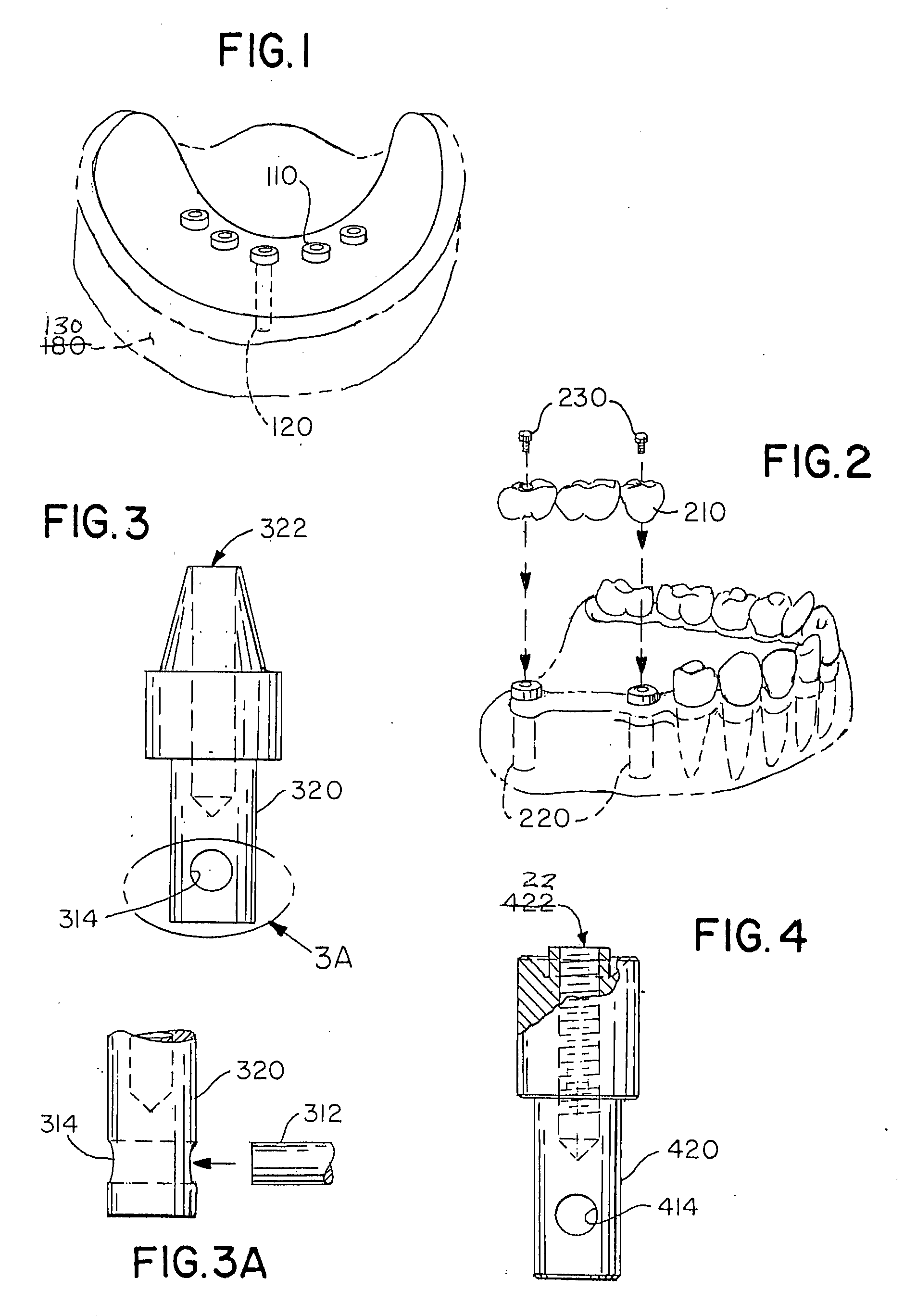

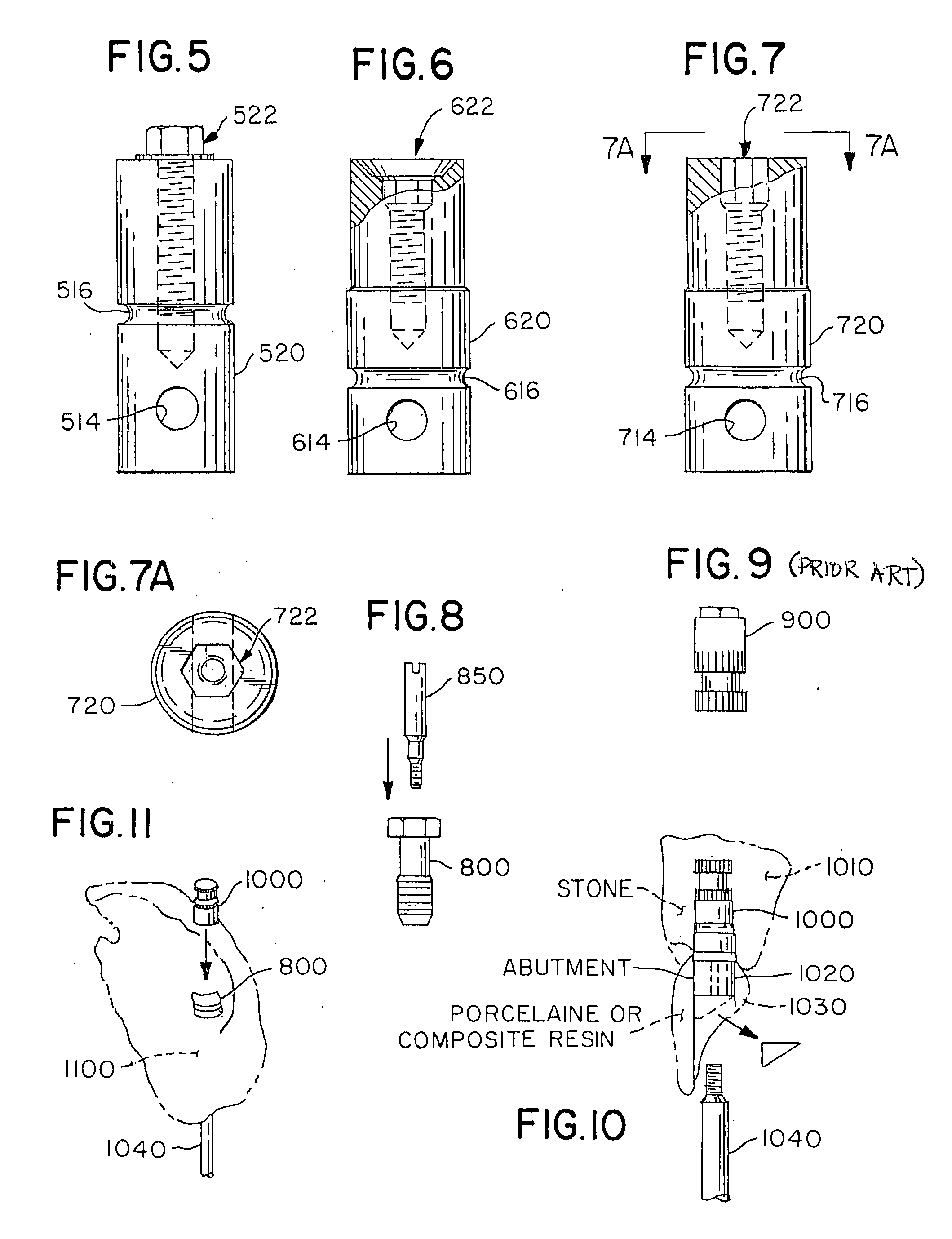

Accurate analogs for prostheses using computer generated anatomical models

ActiveUS20080124676A1Improve actionDental implantsAdditive manufacturing apparatusComputer generationEar prosthesis

Pre-surgical planning for cranial and facial reconstruction includes preparing a computer generated jaw or skull model for determining a locational position for a dental implant, a surgical bone implant to repair missing bone in the cranium, install ear prostheses, and / or install nose prostheses. The computer generated jaw or skull model is made from medical imagery and computer aided design. A surgical guide is prepared with oversize holes in registration with analogs for the dental or surgical bone implants to be inserted at the locational positions determined by a dentist or surgeon in the jaw or cranial skull model. The surgical guide is fitted atop each analog, and the surgical guide is bonded to the jaw or skull model at a predetermined angle of the analog in the jaw or skull. The surgical guide is removed from the model attached to the law or skull of a patient for accurate drilling during the dental or surgical procedure for insertion of the implants into the jaw or skull of the patient.

Owner:CLM ANALOGS LLC

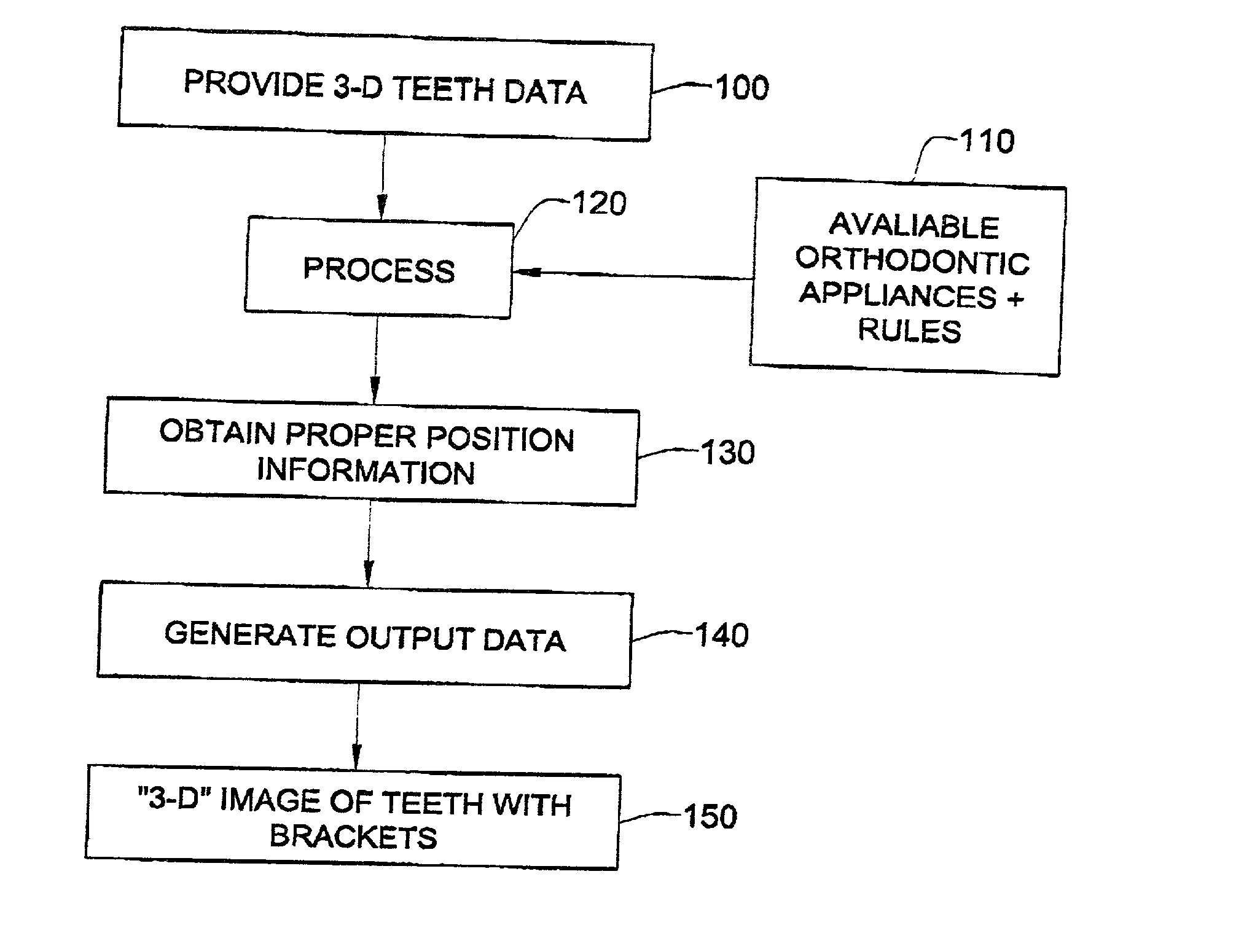

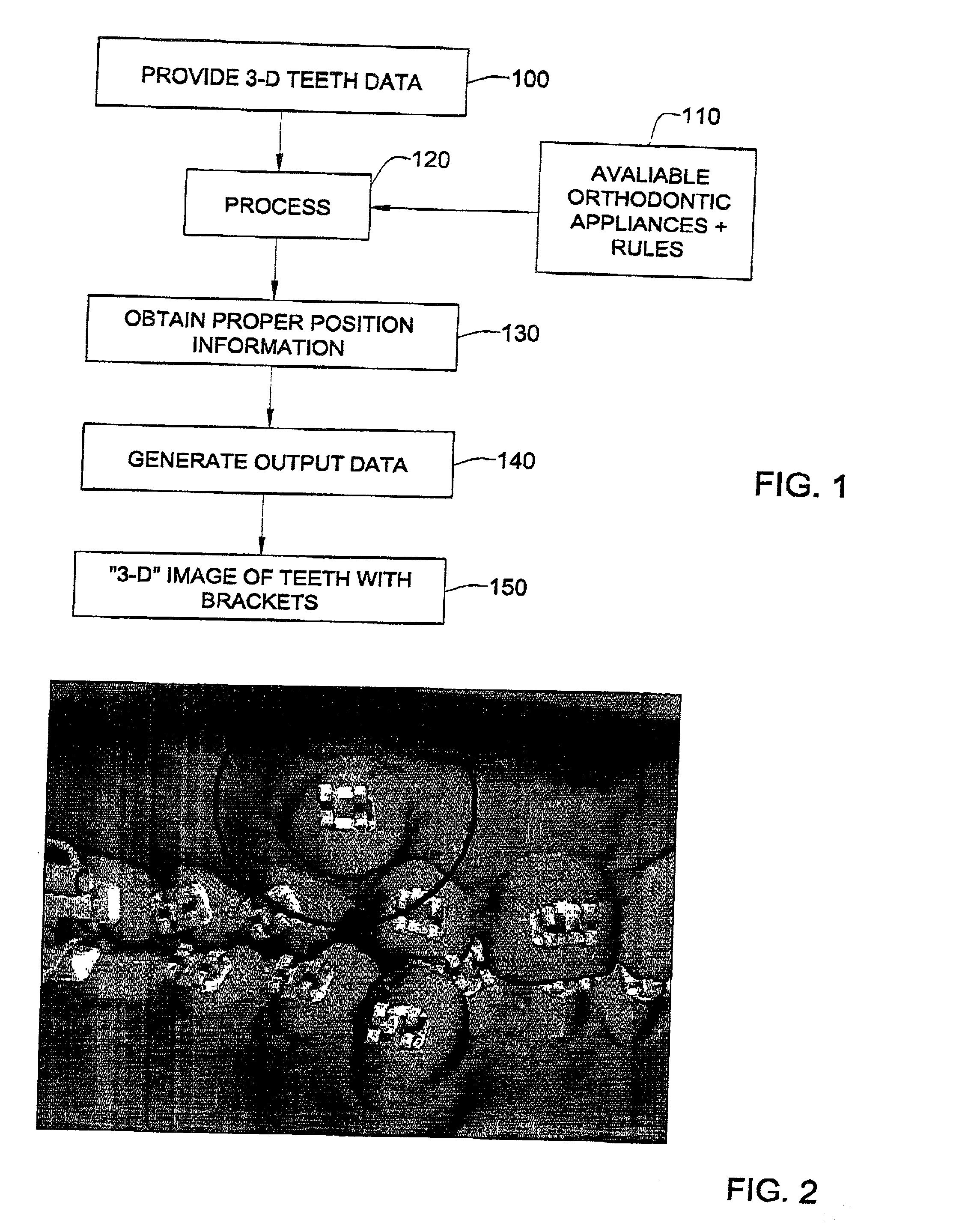

Method and system for assisting in applying an orthodontic treatment

A method and system for providing information for correct placement of one or more brackets on one or more corresponding teeth according to a predetermined treatment scheme. A virtual representation of a three-dimensional teeth arrangement of one or both jaws of the individual with brackets placed on said teeth is obtained, wherein the position and orientation of the brackets on said teeth being designed so as to achieve a desired treatment outcome. The virtual representation is processed to generate an output data, the output data driving a display, such as a computer monitor or a printed "hard-copy", to display an image of at least one tooth with a bracket thereon, the displayed image having three-dimensional qualities indicative of said at least one tooth as viewed from a defined viewpoint. The invention can be applied to the placement of brackets onto the buccal side of the teeth as well as onto the lingual side of the teeth.

Owner:ALIGN TECH

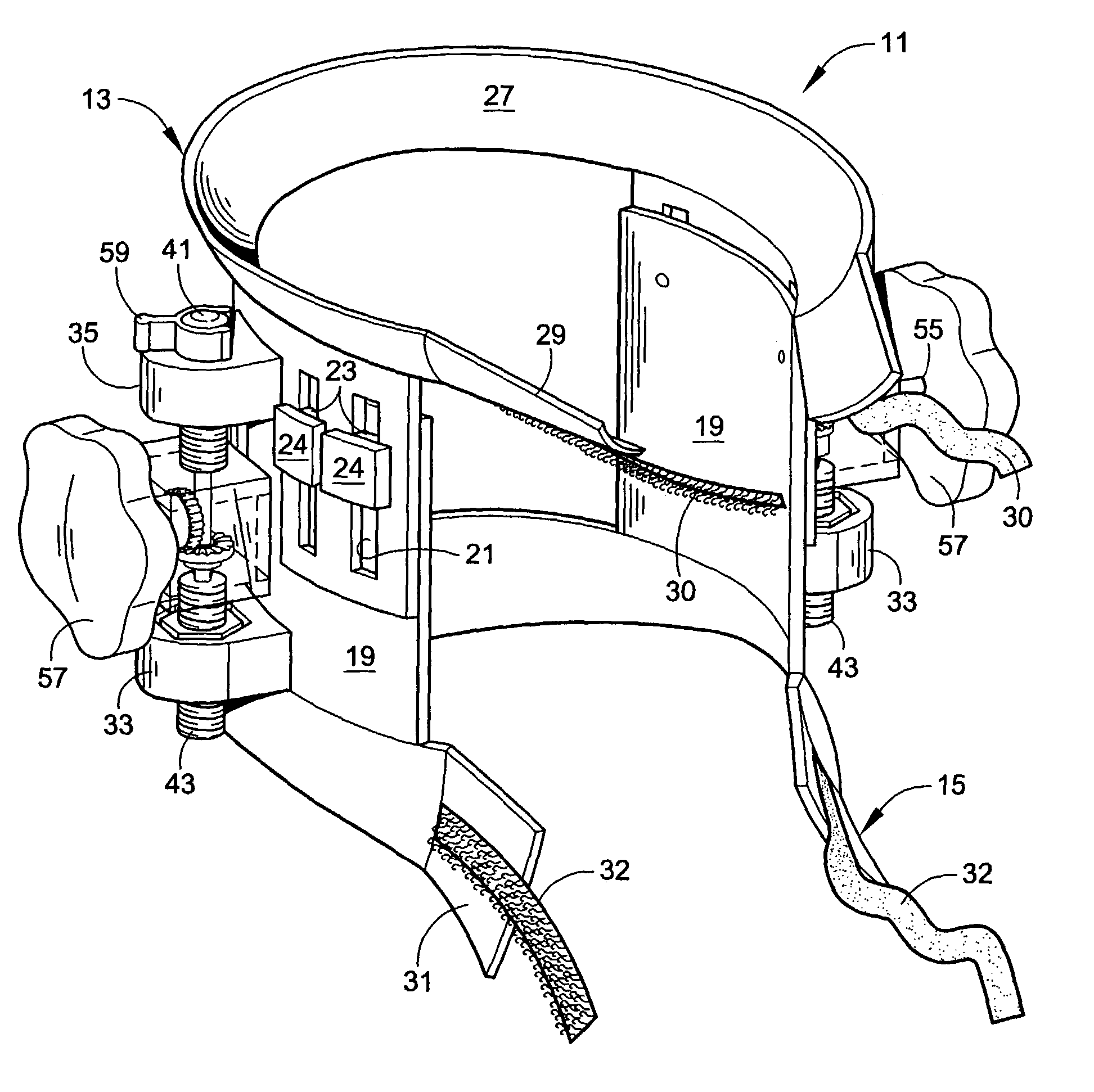

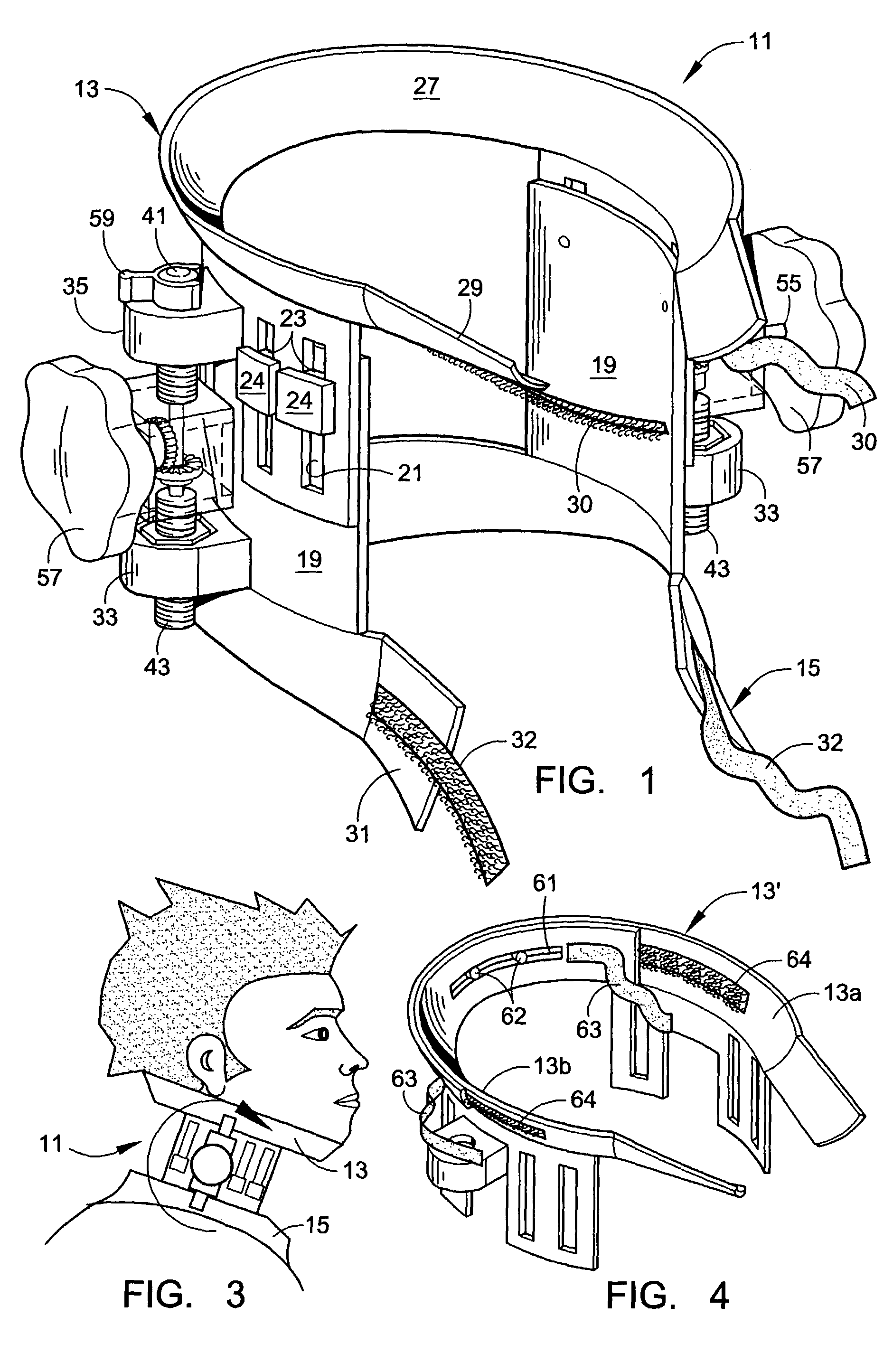

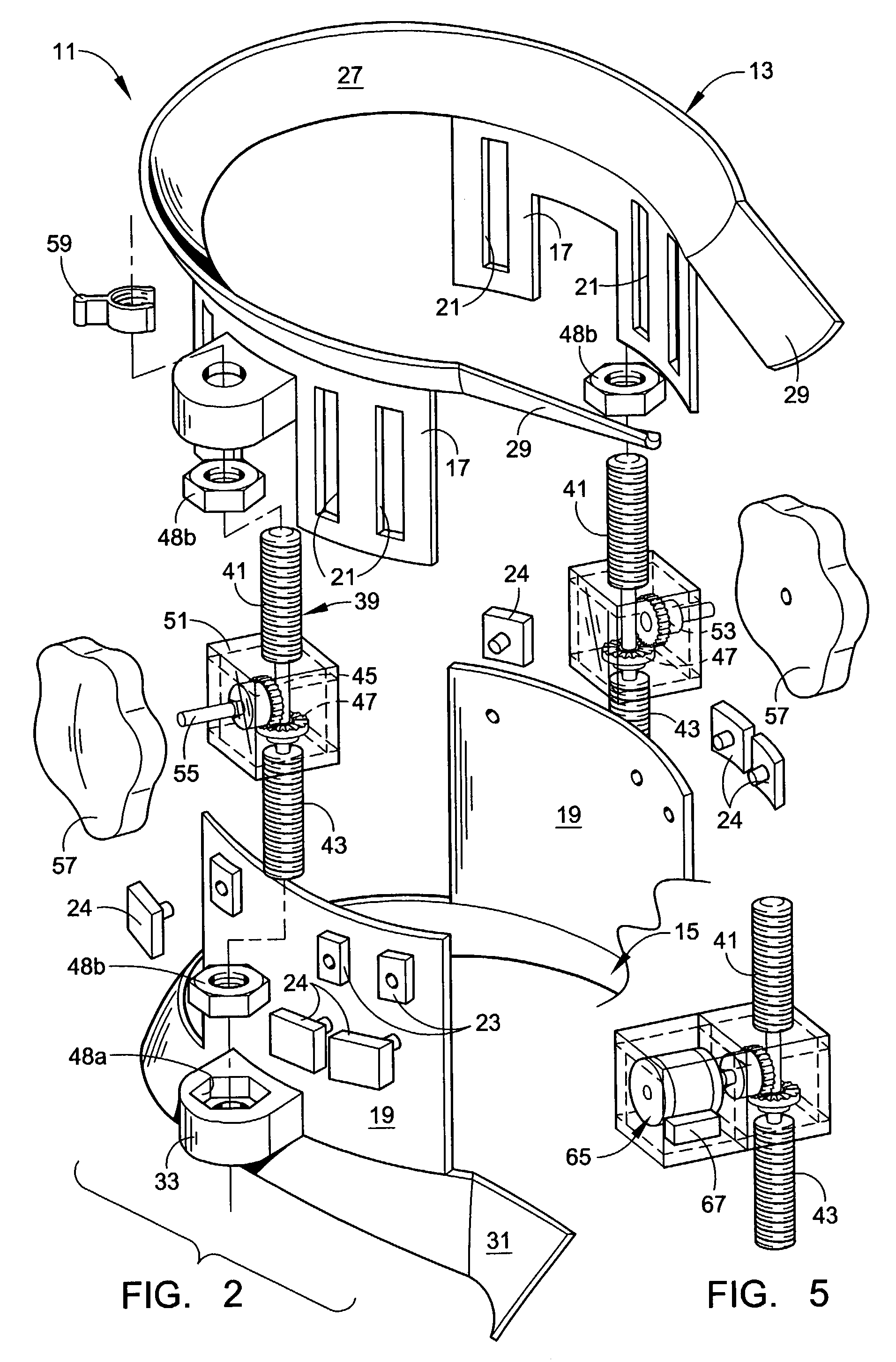

Cervical spine brace and traction device

A cervical spine brace and traction device incorporates a forwardly open head and jaw brace which is adjustably supported vertically above a forwardly collar member. The brace and the collar member have cooperating lateral wall sections having mating arcuate surfaces that are juxtaposed and which include interengaging means that assure they remain precisely angularly aligned with each other while the vertical spacing between them is being changed. Support of the brace and adjustment is by pairs of laterally extending brackets which interconnect with rotatable rod mechanisms that carry coaxial right-handed and left-handed lead screw surfaces. A miter gear affixed to each rod in a central location mates with a cooperative miter gear affixed to a horizontal shaft that carries a starwheel at one end which permits smooth and accurate patient adjustment.

Owner:DYNOTRAX

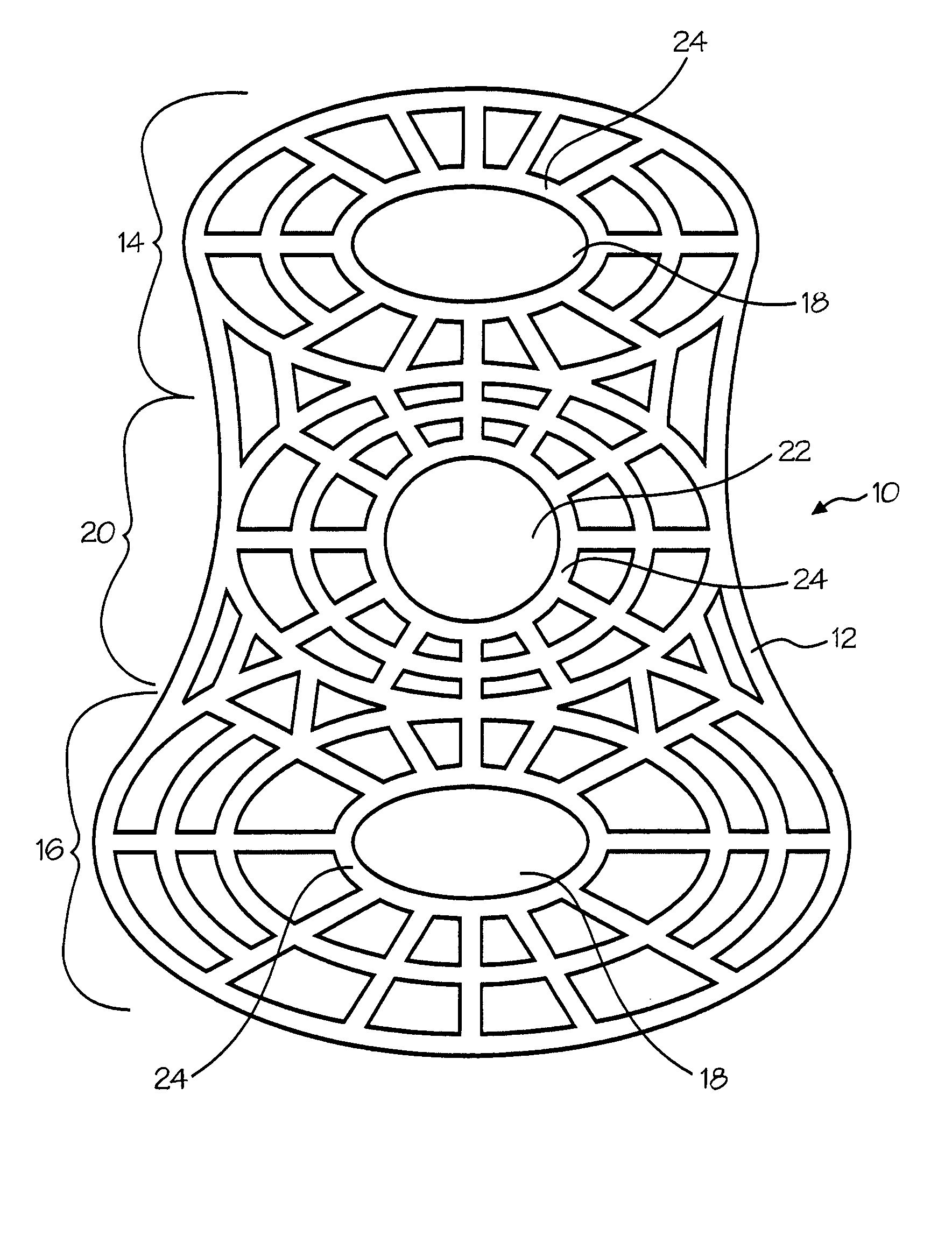

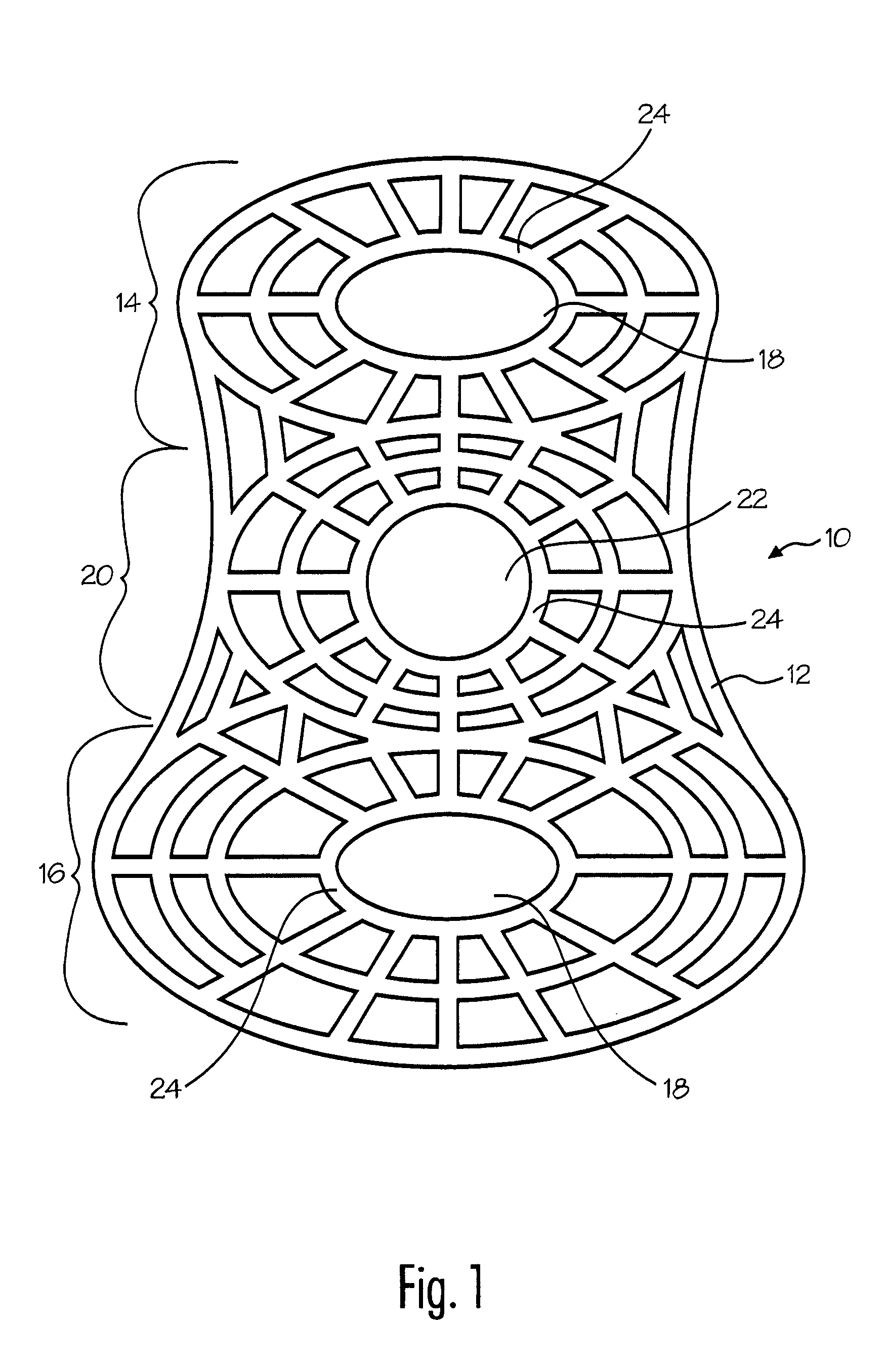

Device for use in stimulating bone growth

A method of growing jaw bone utilizing a device that can receive a sponge (or other material) that includes or is a substance that stimulates bone growth. The device positions the sponge next to the bone to be regenerated and is preferably a wire mesh partially surrounding the bone to be regenerated. The device defines a cavity having at least one or more openings through which the material may be inserted and thus received in the cavity.

Owner:ROBINSON DANE Q

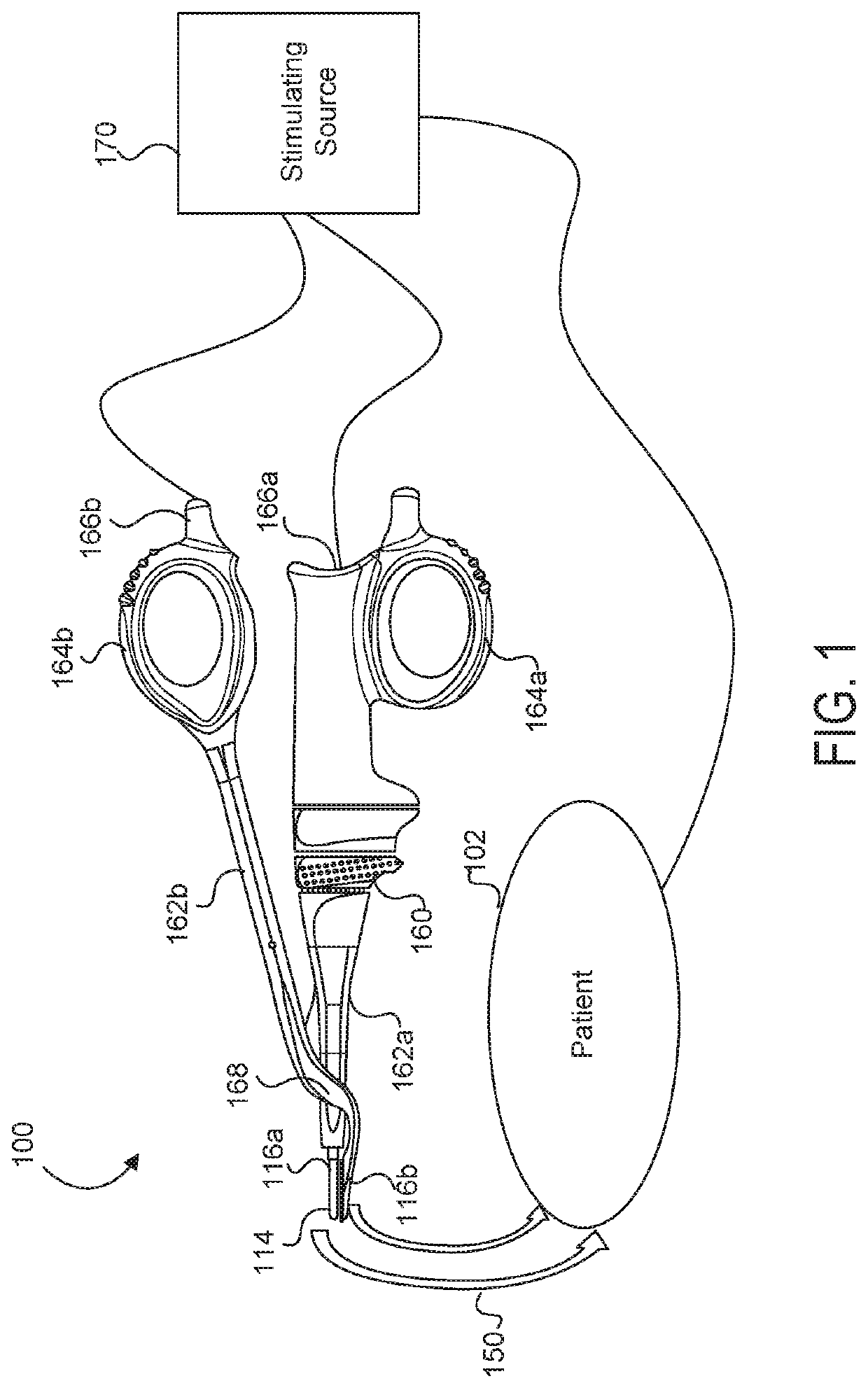

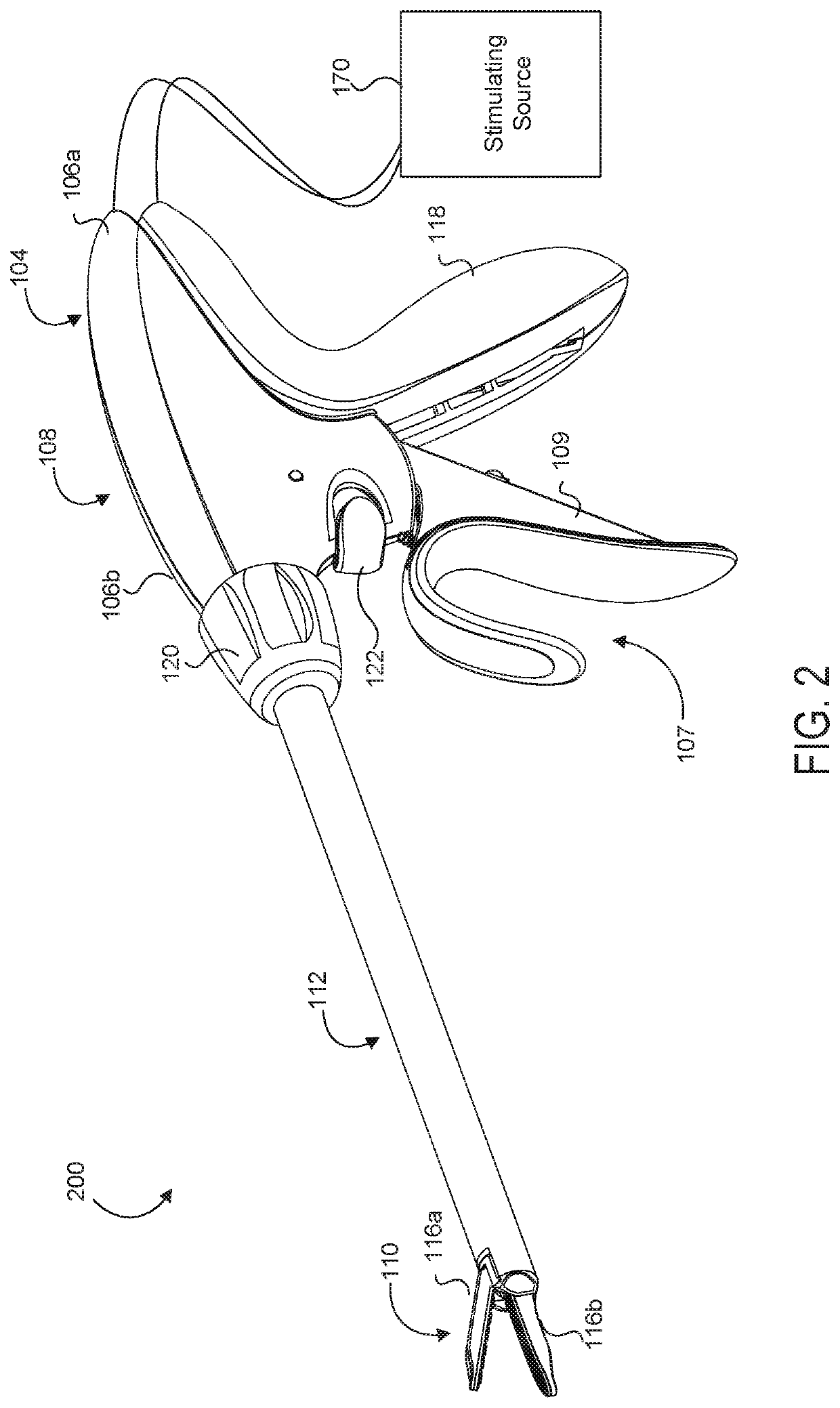

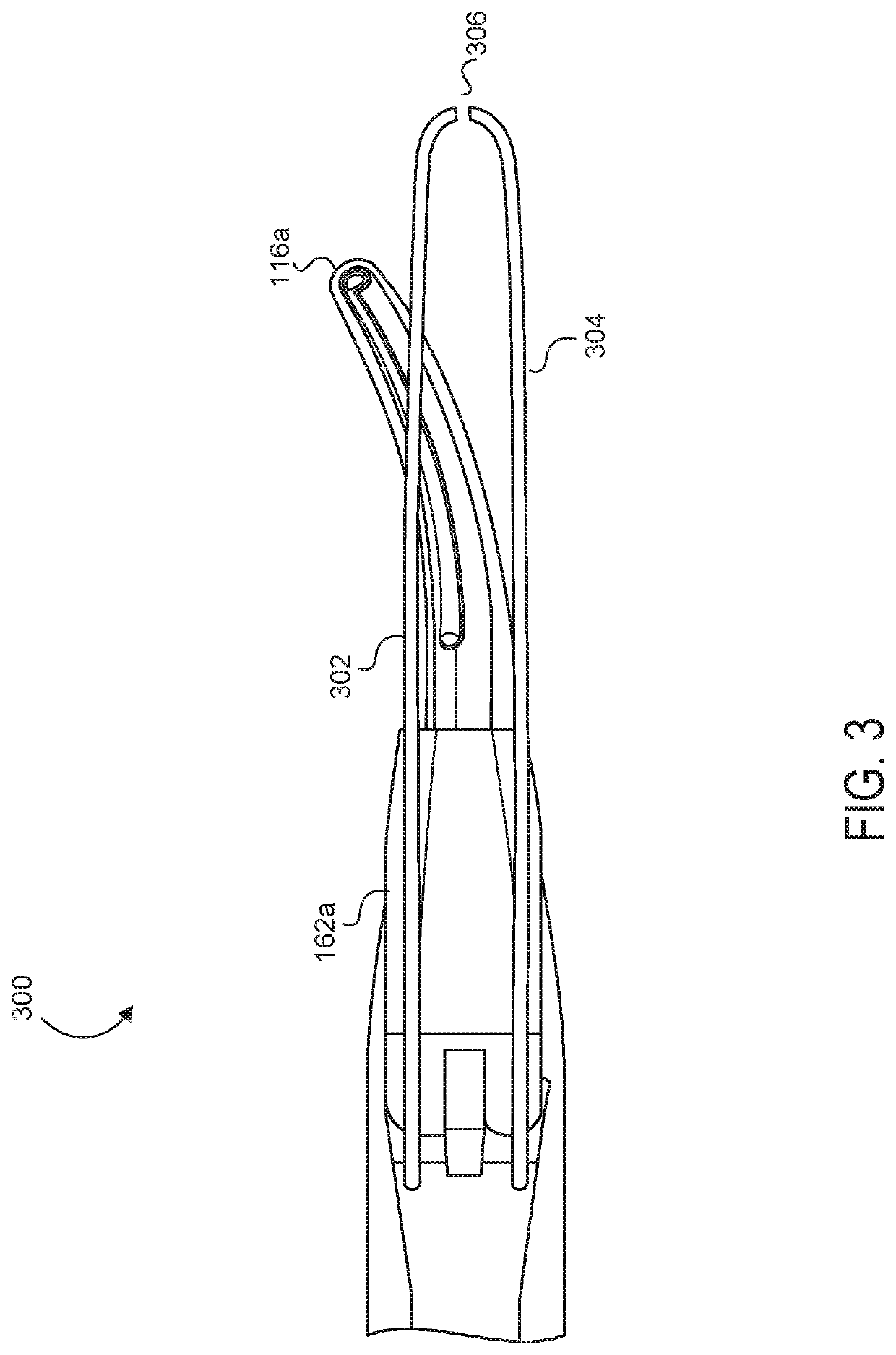

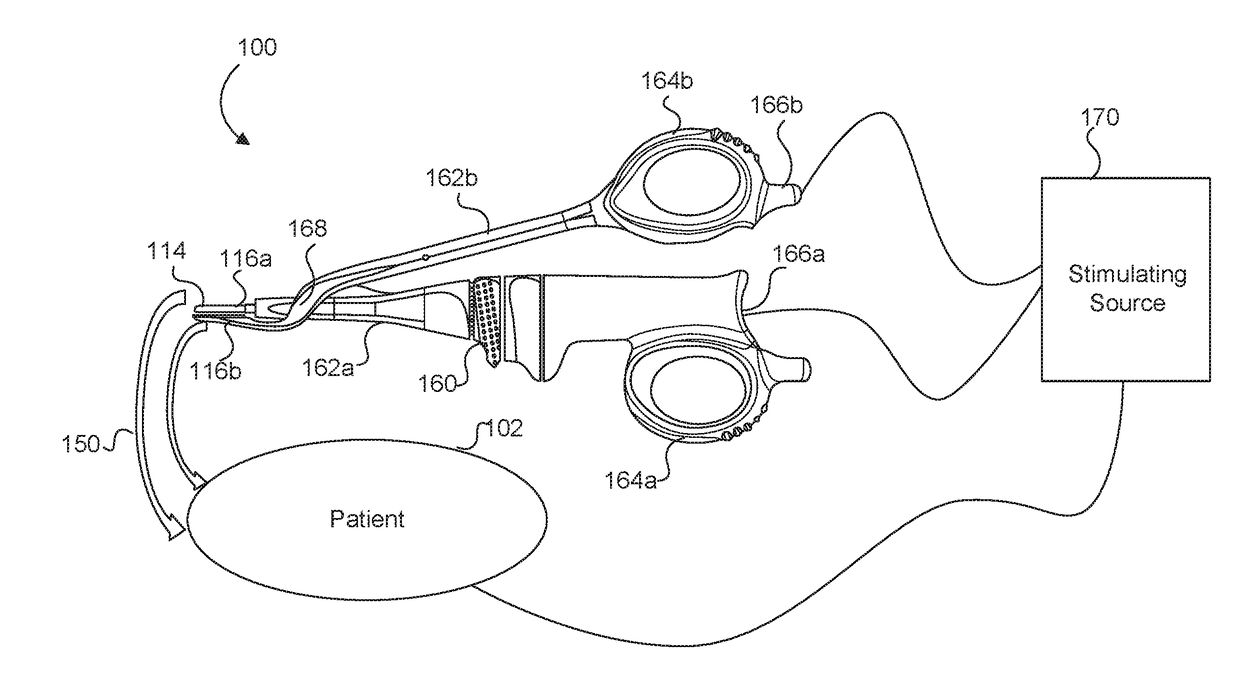

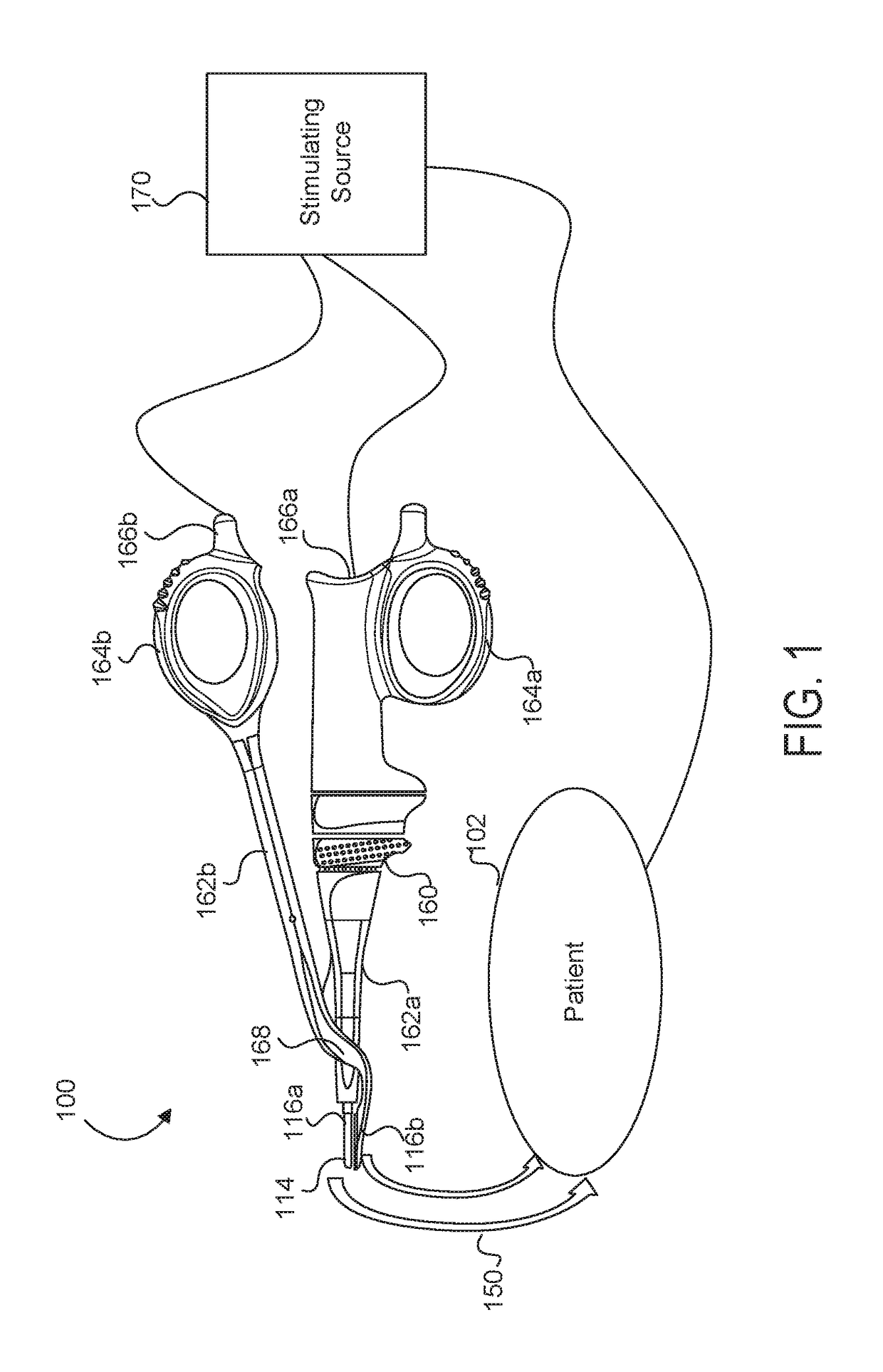

Medical device with a bilateral jaw configuration for nerve stimulation

ActiveUS20200078085A1Spinal electrodesImplantable neurostimulatorsSurgical operationNerve stimulation

Aspects of the present disclosure are presented for a single surgical instrument configured to grasp, seal, and / or cut tissue through application of therapeutic energy, and also detect nerves through application of non-therapeutic electrical energy. A medical device may include two jaws at an end effector, used to apply therapeutic energy and to perform surgical procedures. The therapeutic energy may be in the form of ultrasonic vibrations or higher voltage electrosurgical energy. One of the jaws may be configured to cut tissue through application of the blade. In addition, one or both of the two jaws may be configured to apply nontherapeutic energy for nerve stimulation probing. The application of therapeutic energy may be disabled while the nontherapeutic nerve stimulation energy is applied, and vice versa. The nontherapeutic nerve stimulation energy may be applied to the use of one or more probes positioned near one or both of the jaws.

Owner:CILAG GMBH INT

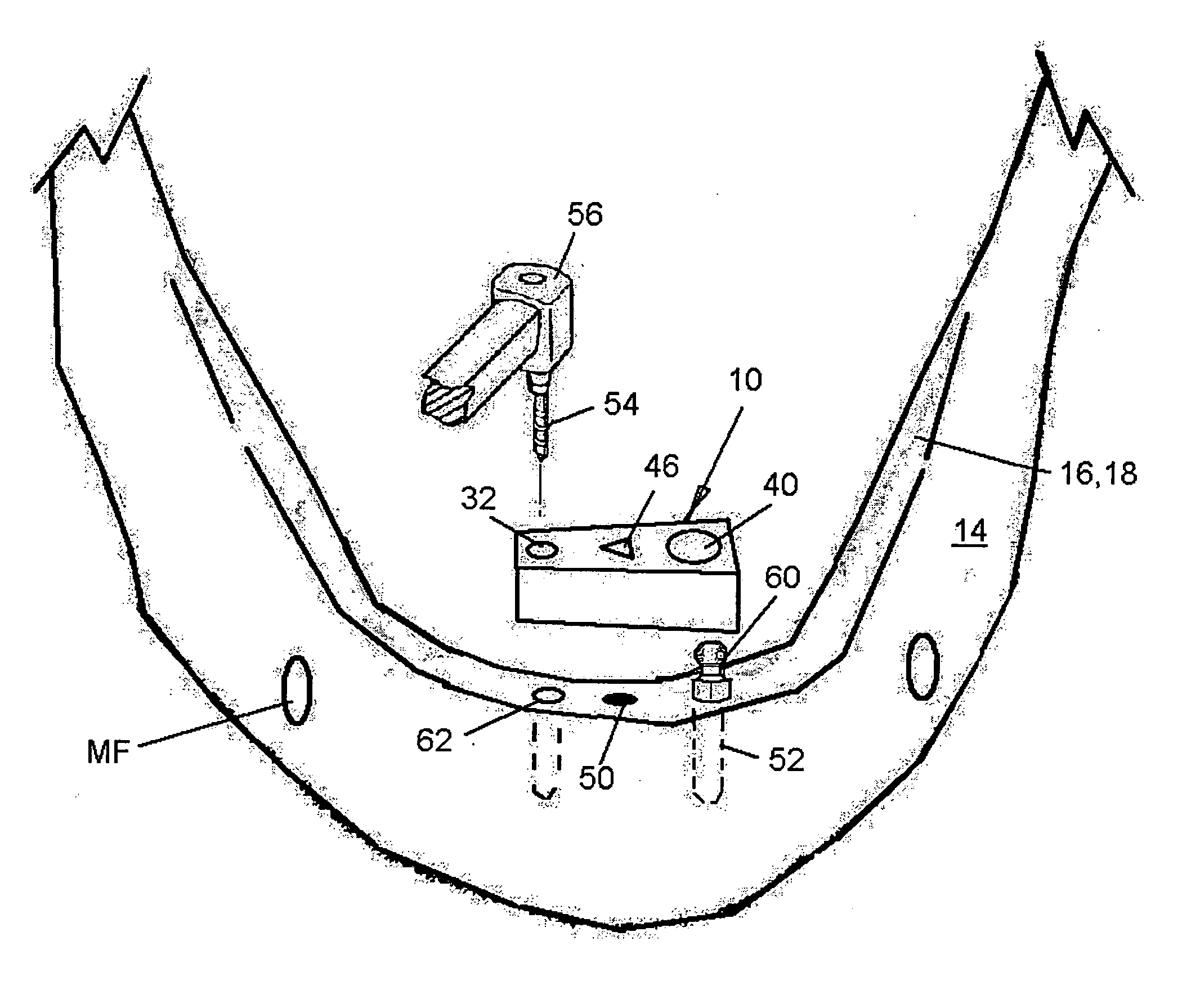

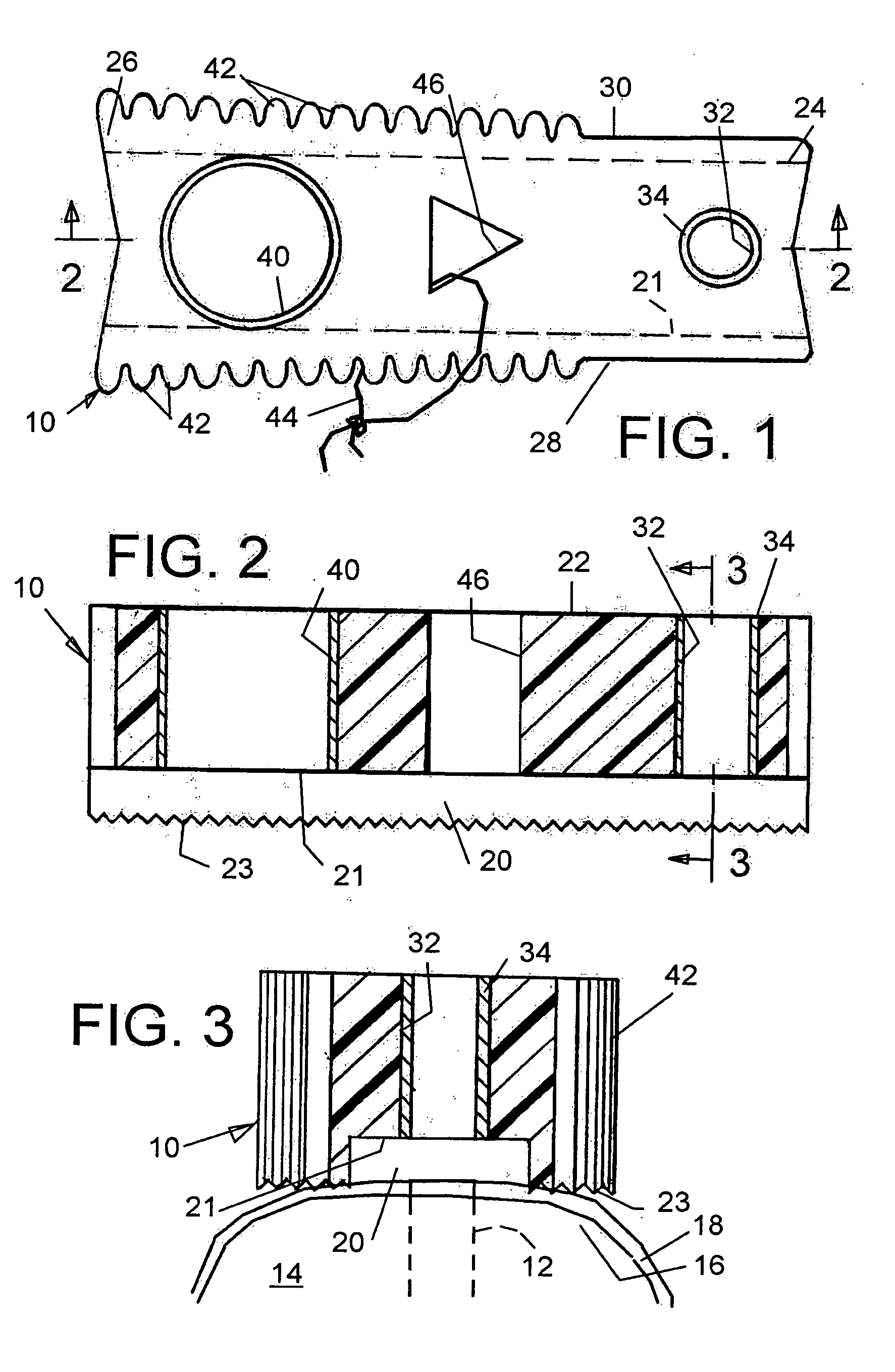

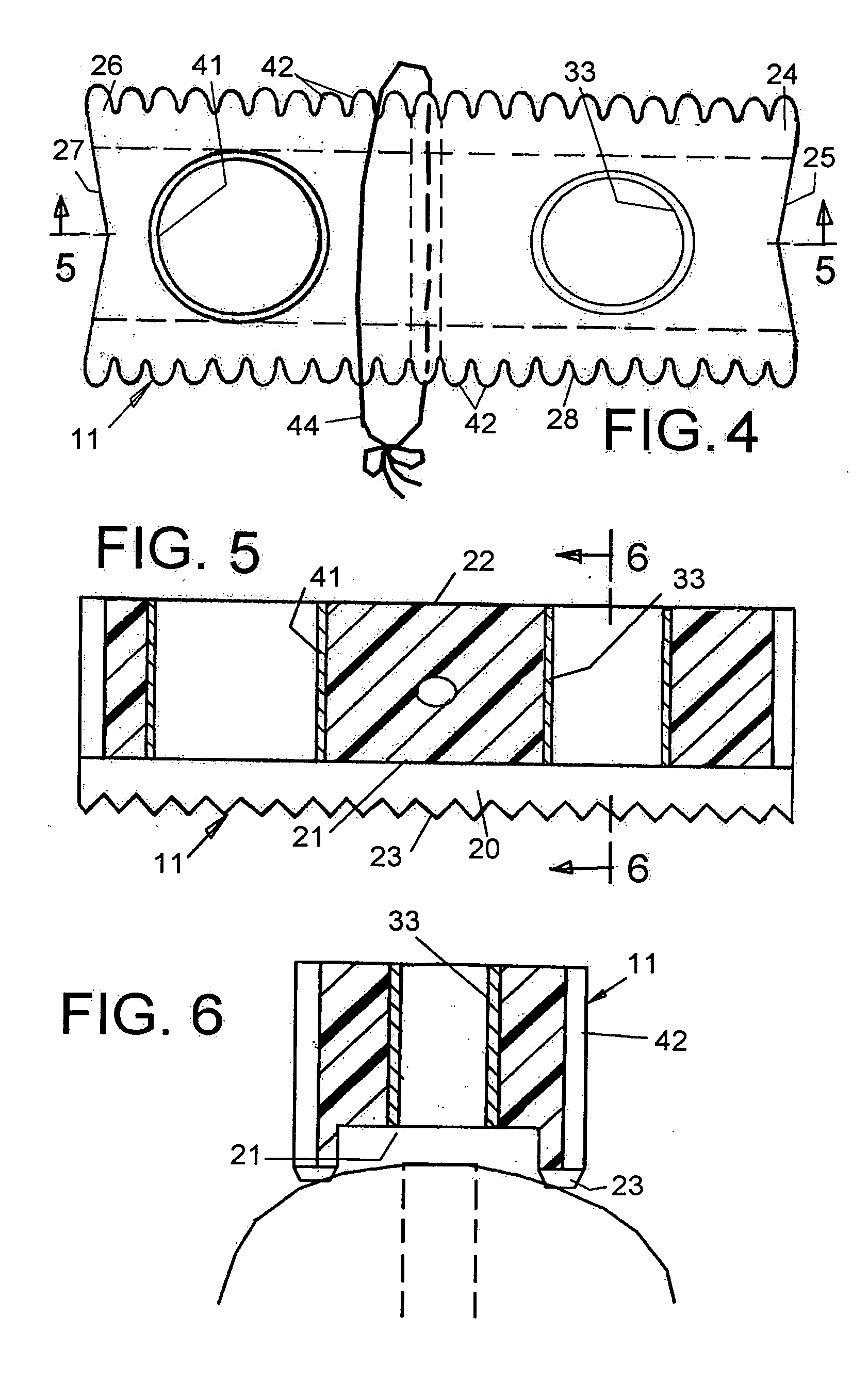

Hole guide for mini and standard dental implants

An implant hole guide is used for drilling a hole in jaw bone for a dental implant. A guide member of the guide has opposite ends and opposite surfaces, one being adapted to engage a jaw bone adjacent the site of a hole to be drilled. A guide bore extends in the guide member adjacent one end for guiding the drill. A second bore is spaced from the first bore in the guide member and either engages a previous implant to properly locate the first bore over a further hole site on the jaw, or for guiding the drilling of another implant hole in the jaw. The bores are parallel to each other and are spaced by a minimum center-to-center implant distance sufficient to maintain at least 3 mm of jaw bone between adjacent implant receiving holes in the jaw bone.

Owner:SUSSMAN HAROLD I +1

Device and arrangement for fixture installation

InactiveUS20060008763A1Avoid reconfigurationReduce extra costsDental implantsDental toolsJaw boneBiomedical engineering

A device and arrangement for installation of a fixture in a jaw bone comprises a fixture holder designed to cooperate with a guide member forming part of a template, via which guide member the fixture can be applied in its position in the jaw bone with the aid of the fixture holder. The arrangement is also provided with one or more elements which, with the aid of the guide member, ensure defined positions of the fixture in the vertical and transverse directions. The element or elements is or are arranged on the fixture holder.

Owner:NOBEL BIOCARE SERVICES AG

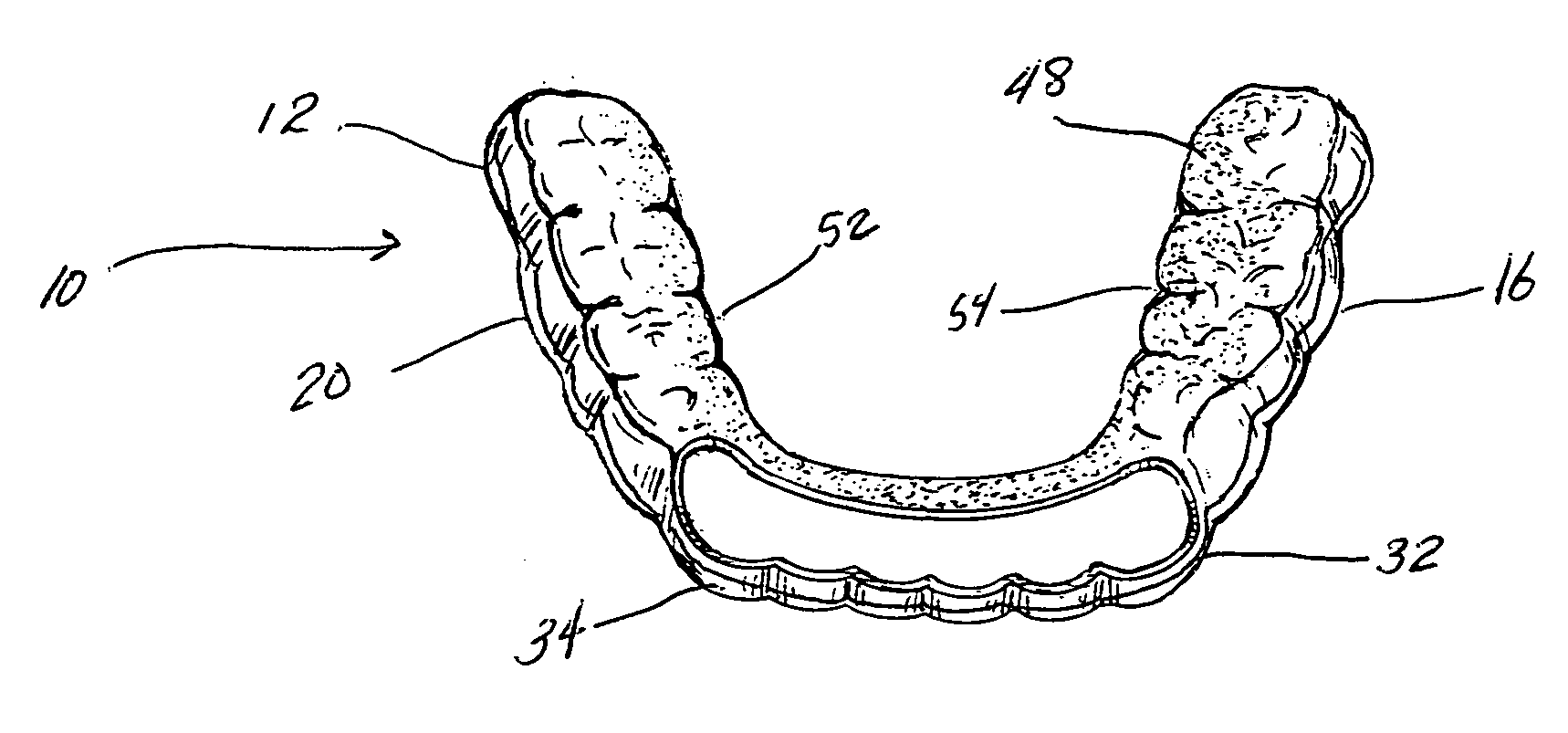

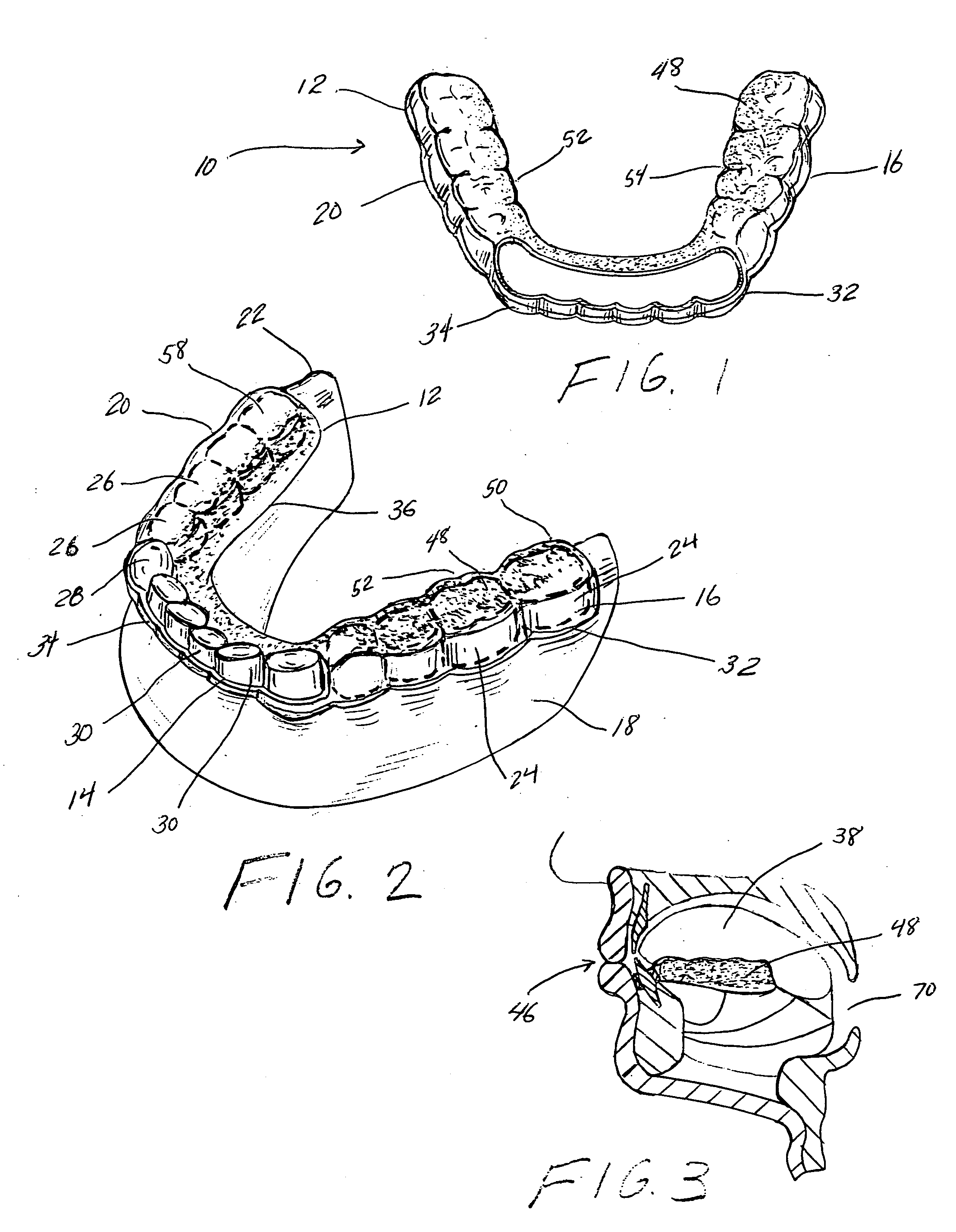

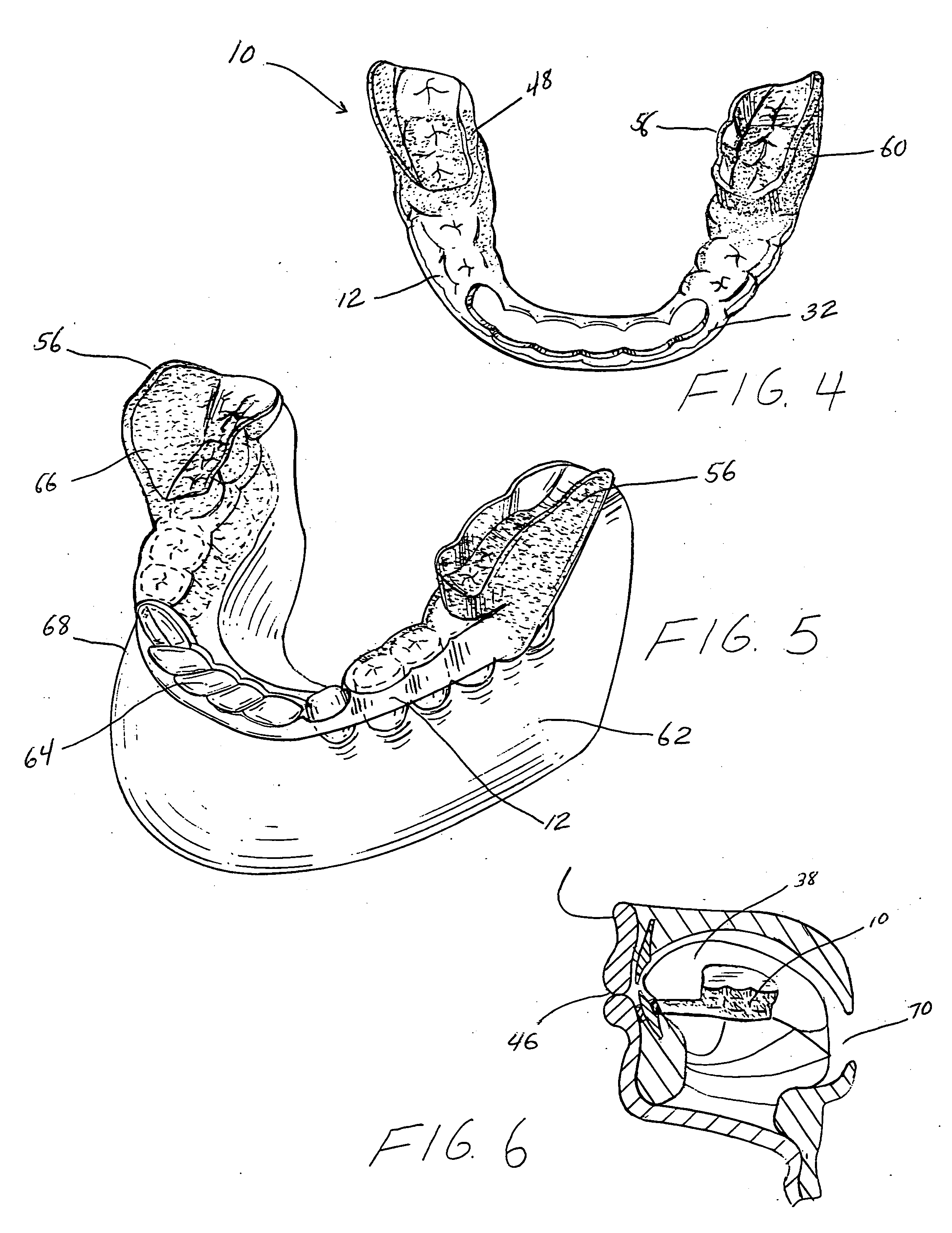

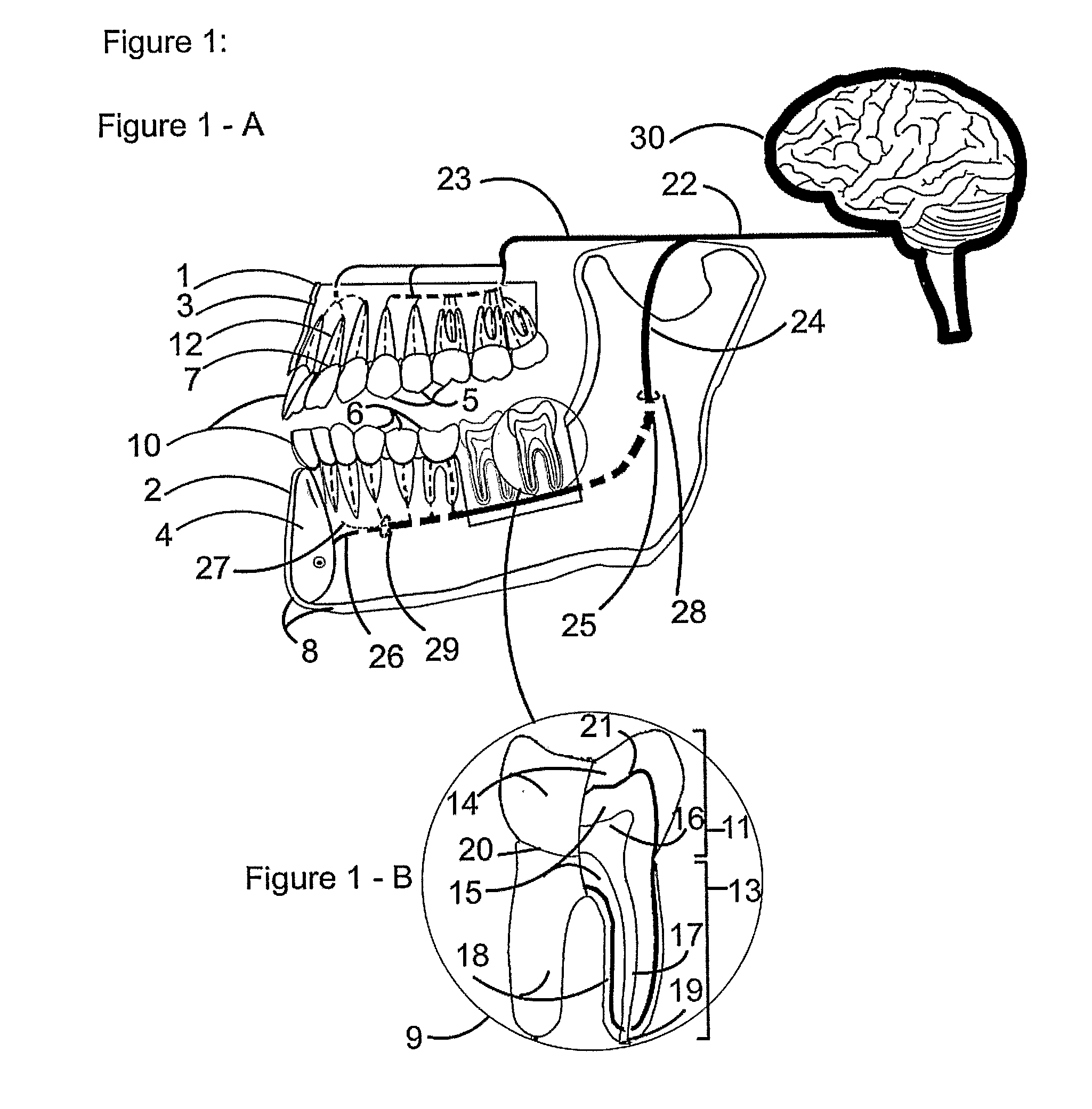

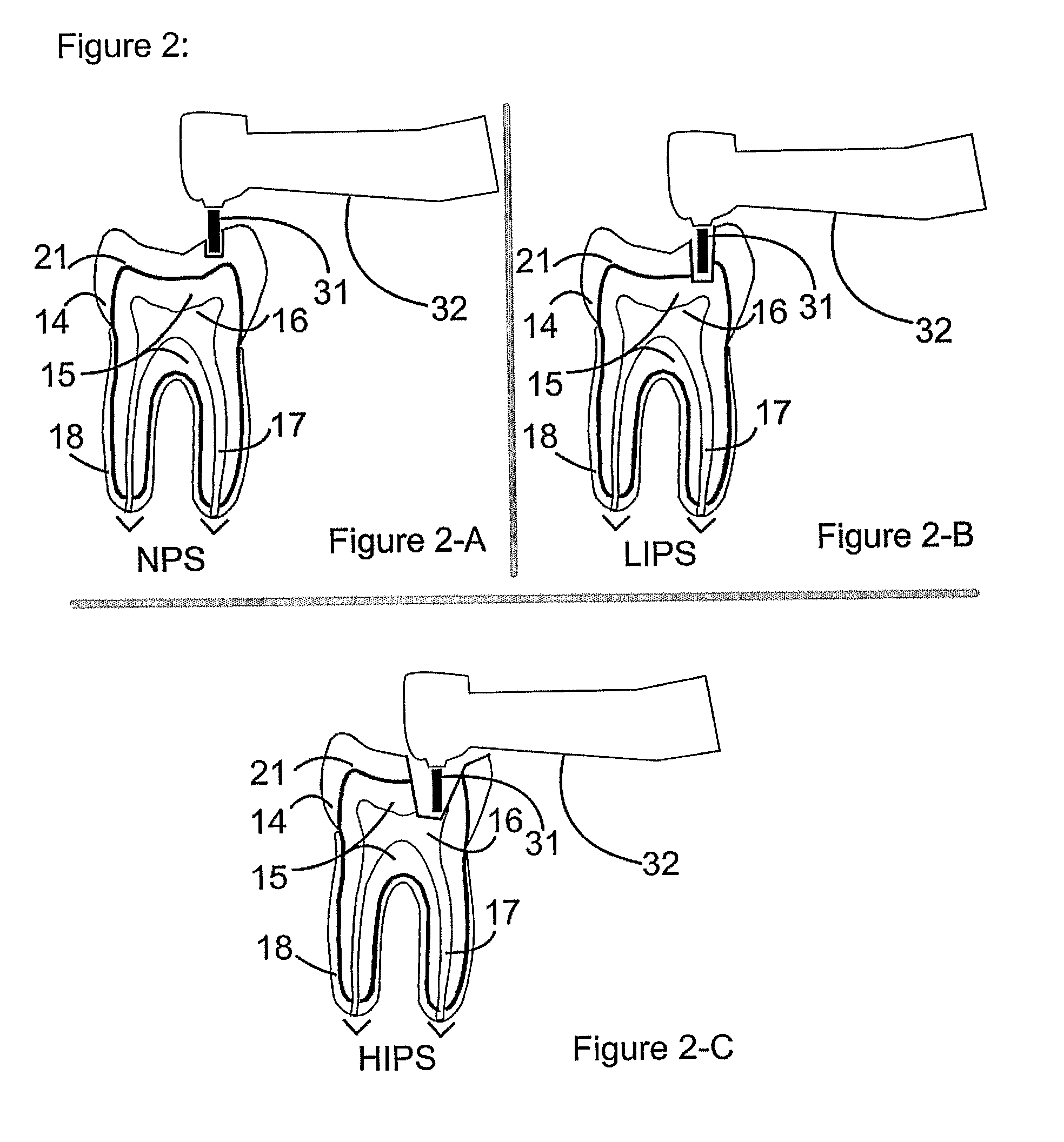

Dental orthotic for management of impaired oral functions

InactiveUS20060078840A1Effective treatmentImprove effectivenessOthrodonticsSnoring preventionThroatNervous system

An apparatus and method for addressing specific physiological symptoms through distinct combinations of jaw alignment, tongue and teeth interaction is described. A dental orthotic comprising a mandibular orthotic conforming to an user's mandibular dentition used for advancing a jaw of an user forward includes a plurality of contours for adjusting the tongue / teeth interaction, and may also include extensions for positioning the user's tongue. The plurality of contours are designed and applied to specific locations on the orthotic and extensions to promote a desired response for a specific physiological symptoms. The oral contours may include specific shapes such as protrusions, depressions, and grooves. The dental orthotic may also include a maxillary orthotic which is affixed to an upper surface of the mandibular orthotic. The contours change the shape of the mandibular orthotic as well as the dental shapes within the mouth, resulting in repositioning of the tongue and tissue of the throat, thereby improving the oral functions as well as relieving neuromuscular responses and autonomic nervous system dysfunctions.

Owner:ROBSON FARRAND C

Implant system and method of installation thereof

The present invention provides an implant system of facilitated use and installation which comprise an implant and a prosthesis support and a method of installation thereof. The prosthesis support disclosed herein includes an abutment and a collar member. Prior art implant systems are mostly made of metallic parts which are assembled with a screw and are shaped to receive a tooth prosthesis. The design of the abutment allows it to be made from highly filled composite materials being of a better optical quality and being easily machinable and further allows its installation without the use of a screwing member. The design of the collar member allows minimization of bacteria growth and tartar formation. The optimization of the implant system proposed herein may reduce stress to the jaw bone and therefore minimize the risk of injury for the patient.

Owner:ENNAJIMI ELMEKKI +3

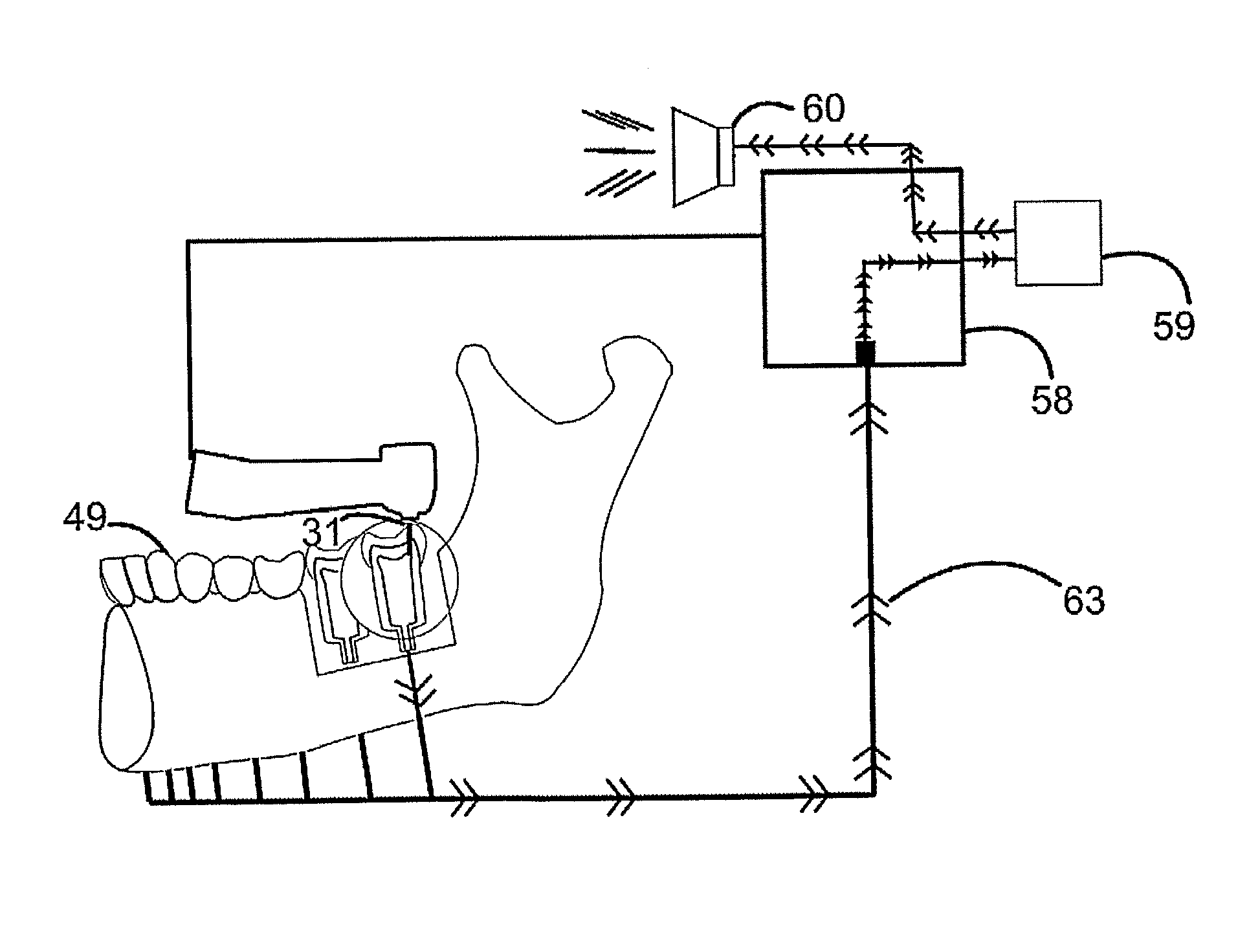

Method and a device for practicing dental treatments

A method, system, device and an artificial tooth is disclosed for simulating both pain and anesthesia in a model of jaws. The tooth is equipped with sensors and connected to a data processing unit, memory unit and audiovisual display unit. The system is for teaching and practicing in the field of dentistry according to which removing artificial tooth or artificial bone substances by a dental drill, generates signals of pseudo pain with different intensities. Signals are fed to the data processing unit which simulates perception of the simulated pain and accordingly to said audio-visual display unit which simulates reaction to the different intensities of generated pseudo pain signals by playing different sounds which are stored in said memory unit. Furthermore, the system is able to simulate anesthesia by generating block signals as a result of applying different anesthetic techniques by means of a dental syringe connected to the system.

Owner:DRSK DEV

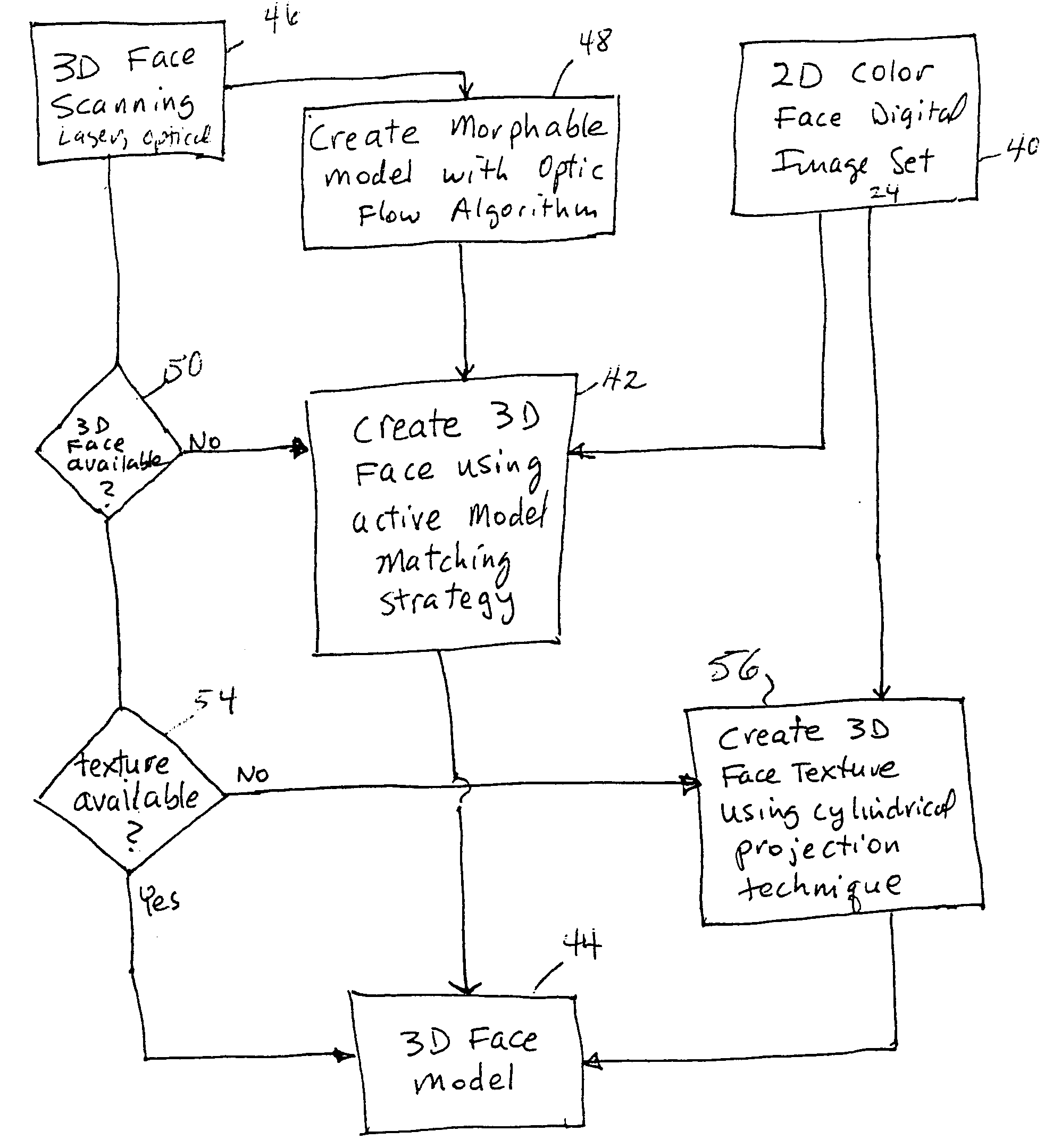

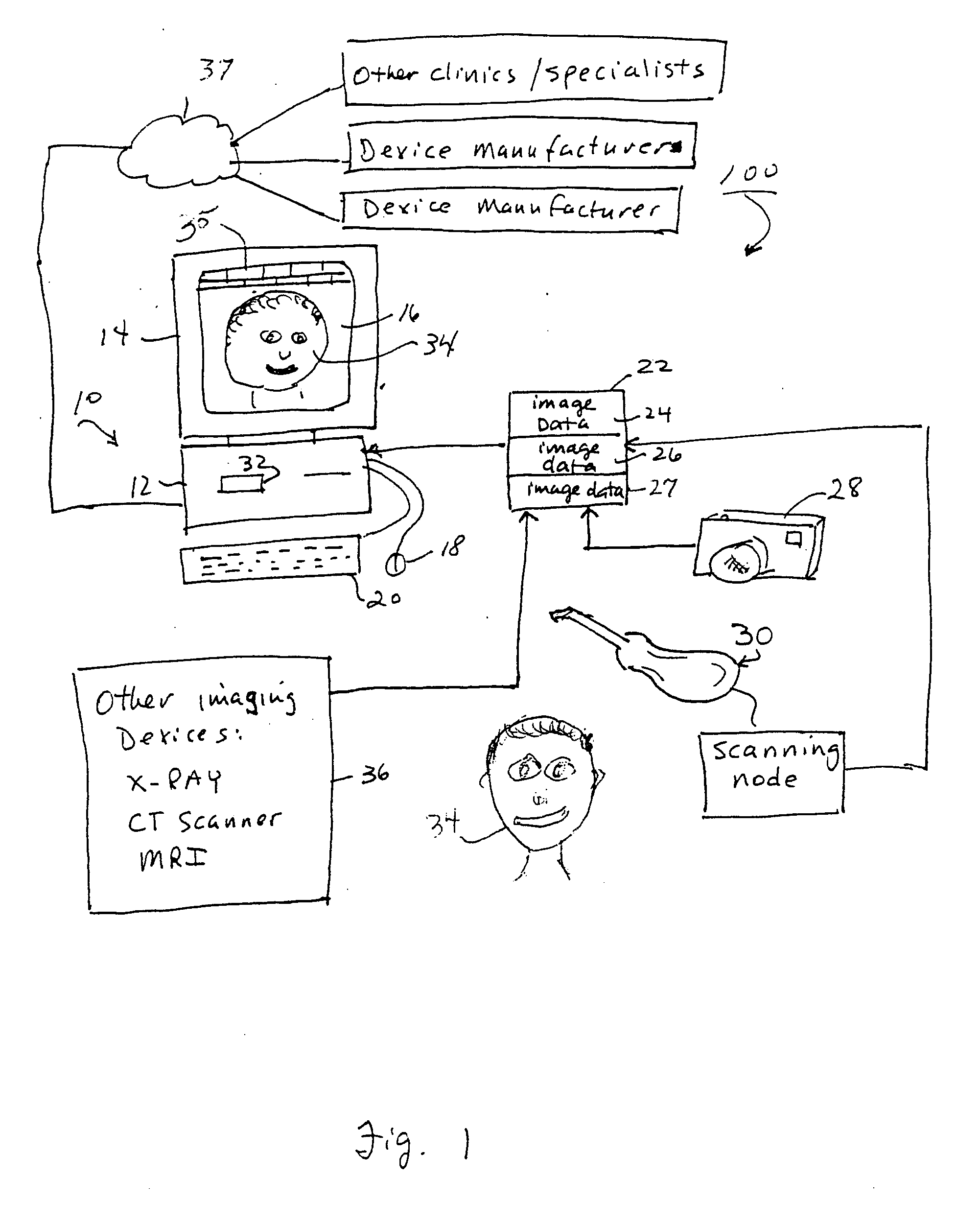

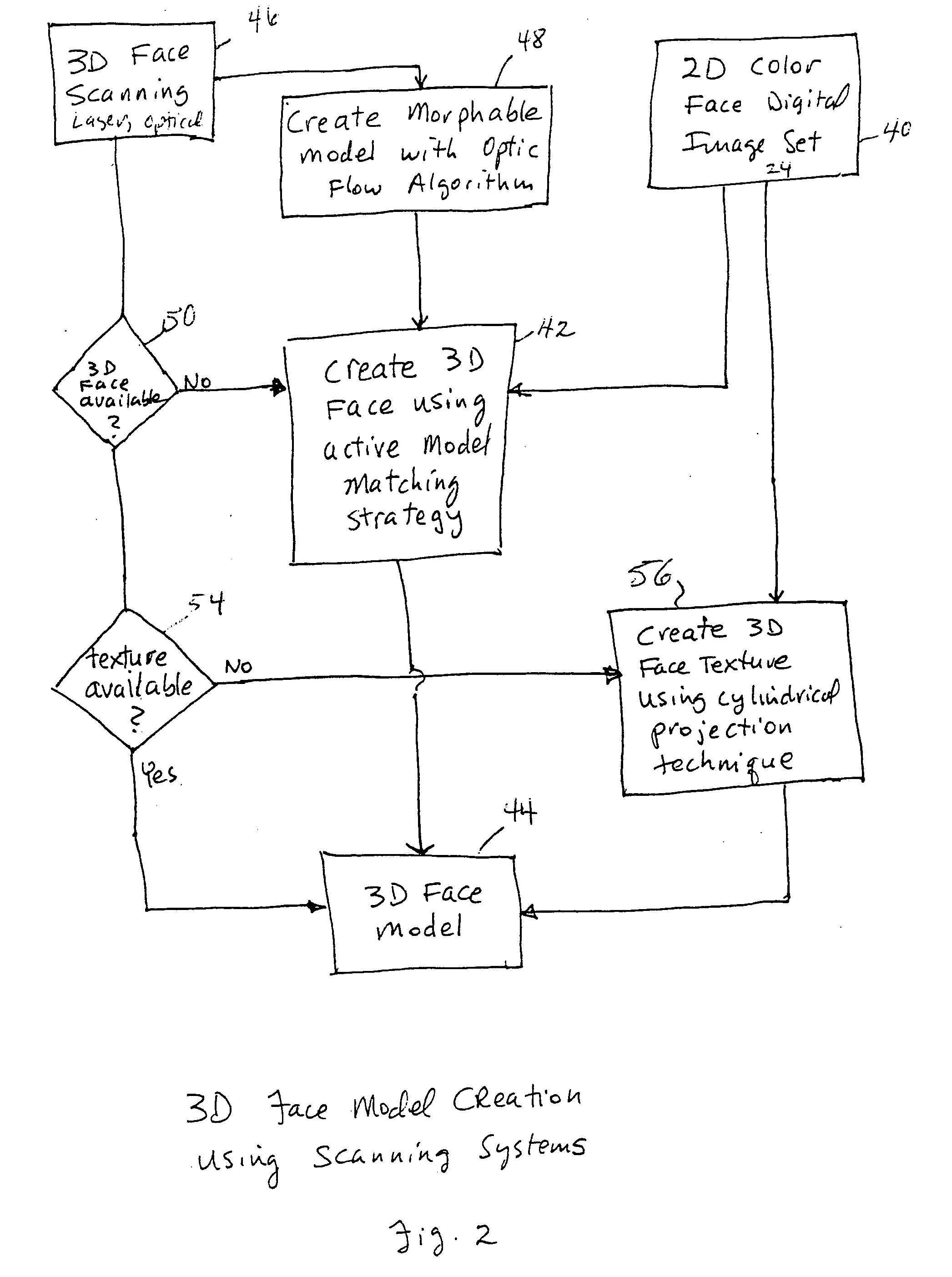

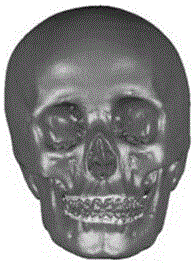

Unified workstation for virtual craniofacial diagnosis, treatment planning and therapeutics

An integrated system is described in which digital image data of a patient, obtained from a variety of image sources, including CT scanner, X-Ray, 2D or 3D scanners and color photographs, are combined into a common coordinate system to create a virtual three-dimensional patient model. Software tools are provided for manipulating the virtual patient model to simulation changes in position or orientation of craniofacial structures (e.g., jaw or teeth) and simulate their affect on the appearance of the patient. The simulation (which may be pure simulations or may be so-called “morphing” type simulations) enables a comprehensive approach to planning treatment for the patient. In one embodiment, the treatment may encompass orthodontic treatment. Similarly, surgical treatment plans can be created. Data is extracted from the virtual patient model or simulations thereof for purposes of manufacture of customized therapeutic devices for any component of the craniofacial structures, e.g., orthodontic appliances.

Owner:ORAMETRIX

Arrangement and device for using a template to form holes for implants in bone, preferably jaw bone

An apparatus includes a template which locates hole positions in a jawbone while the template is separated from the jawbone by gum tissue. The template follows a contour of the gum tissue surrounding the jawbone and has guide holes which receive a cutting tool. Anchoring elements attach the template to the jawbone. A system includes means for scanning an implantation site on a patient's jawbone, simulating the implantation site, and determining nerve-rich areas or nerve paths in the jawbone. A holed template is produced which is separated from the jawbone by at least gum tissue of the patient. Attachment hole positions in the jawbone are located so as to avoid nerve paths. A method of forming holes to attach a dental implant to a patient's jaw bone without surgical intervention in gum tissue of the patient to expose the jawbone is disclosed which avoids impingement on a nerve path.

Owner:NOBEL BIOCARE SERVICES AG

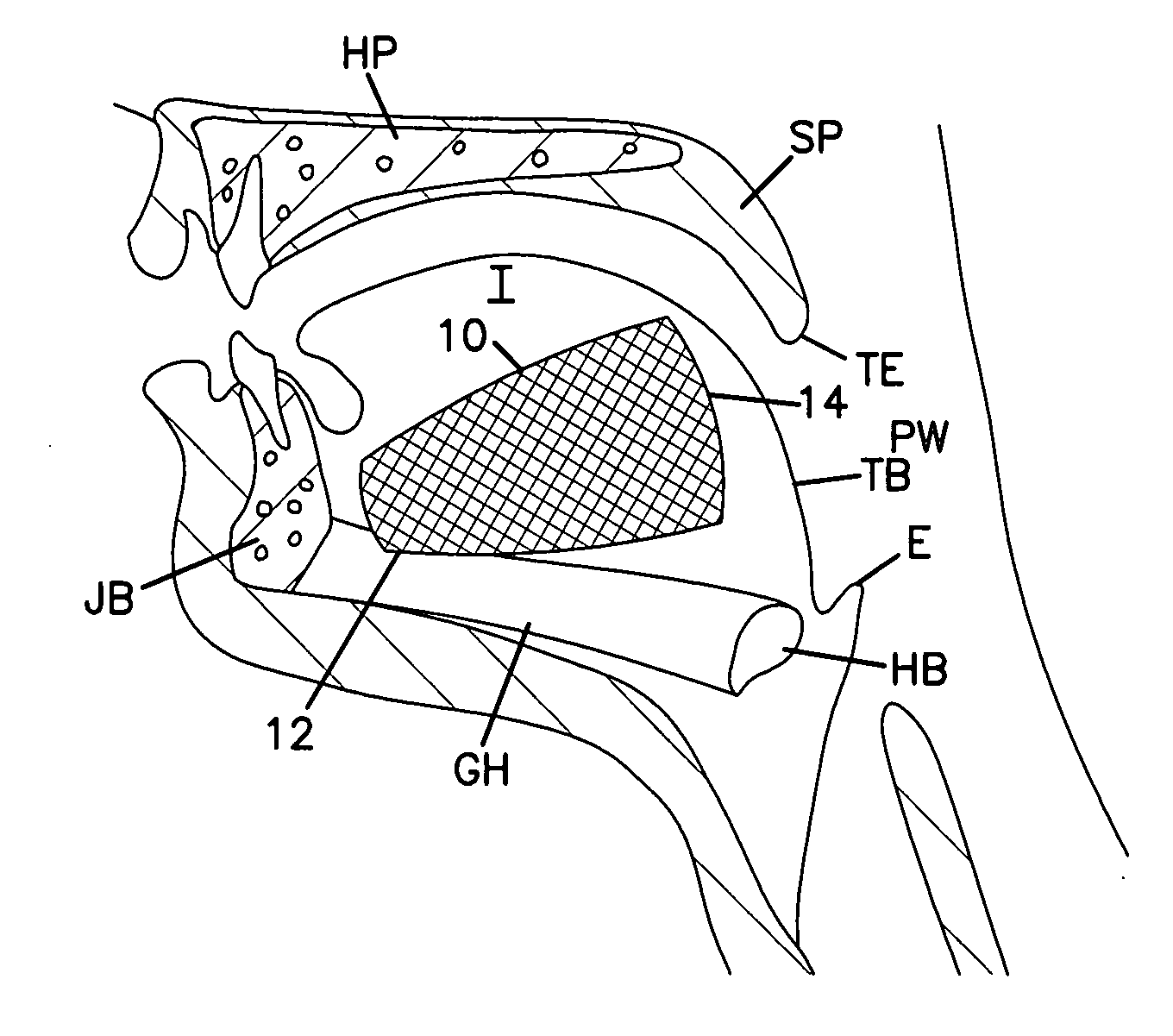

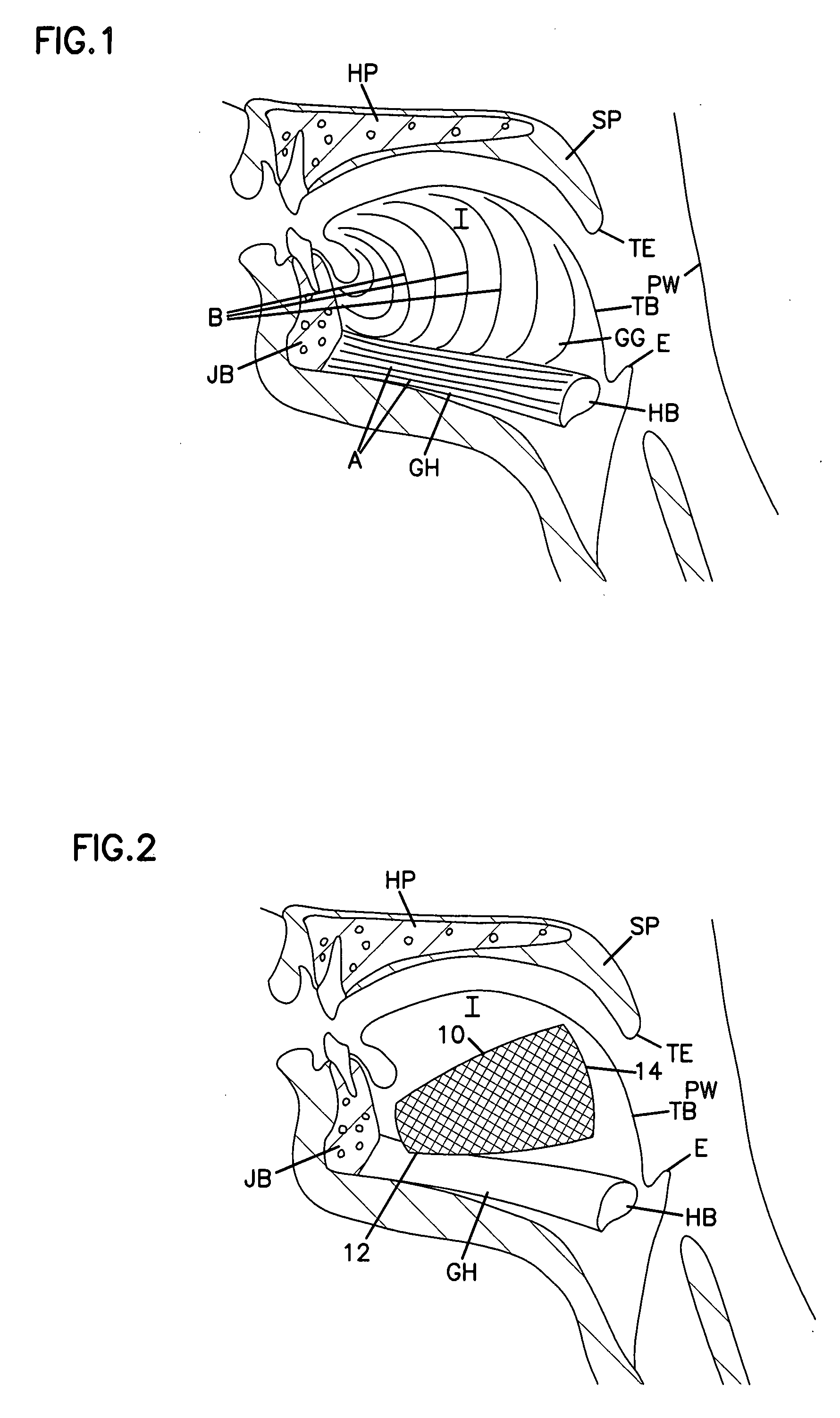

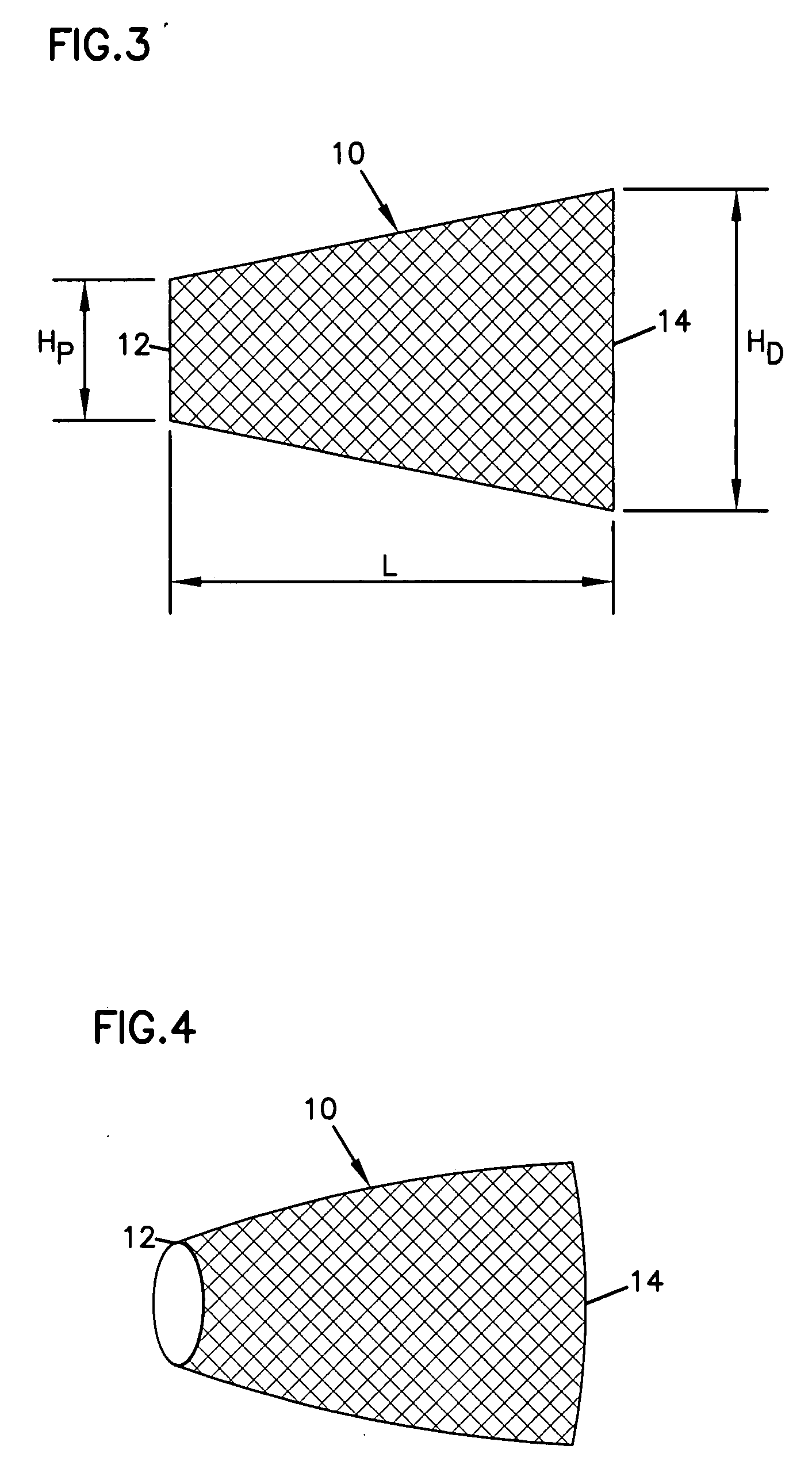

Tongue implant

A patient's obstructive sleep apnea is treated by identifying a patient with sleep apnea attributable at least in part to movement of a base of a tongue of the patient toward a pharyngeal wall of the patient. The tongue is stiffened by an implant sized to be placed within the tongue. A distal portion of the implant is sized to extend within the tongue from a first end near a mandibular-geniohyoid interface to a second end near a base of the tongue. A proximal portion is attached to the first end and adapted to be secured to a jaw bone of the patient following a period of healing after placement of the implant in the tongue.

Owner:RESTORE MEDICAL

Tooth implant arrangement

A tooth implant is used to replace a front tooth which has been lost or extracted. The implant comprises an anchoring part which is provided with an outer thread and which is applied in a recess formed in the jaw bone at the site of the lost or extracted tooth, a spacer sleeve part intended to extend through the gum of the jaw bone, and a prepared or preparable part which adjoins the spacer sleeve part and is intended to support a dental crown, for example. The anchoring part, the spacer sleeve part and the prepared or preparable part are arranged in one piece, the configuration and direction of the prepared or preparable part being substantially adapted or adaptable to the anatomy of the lost or extracted tooth, for example to the inner arc-shaped surface, and to the direction of said tooth. The one-piece implant affords a rapid and less traumatic replacement function compared to previously used three-part bridges.

Owner:NOBEL BIOCARE SERVICES AG

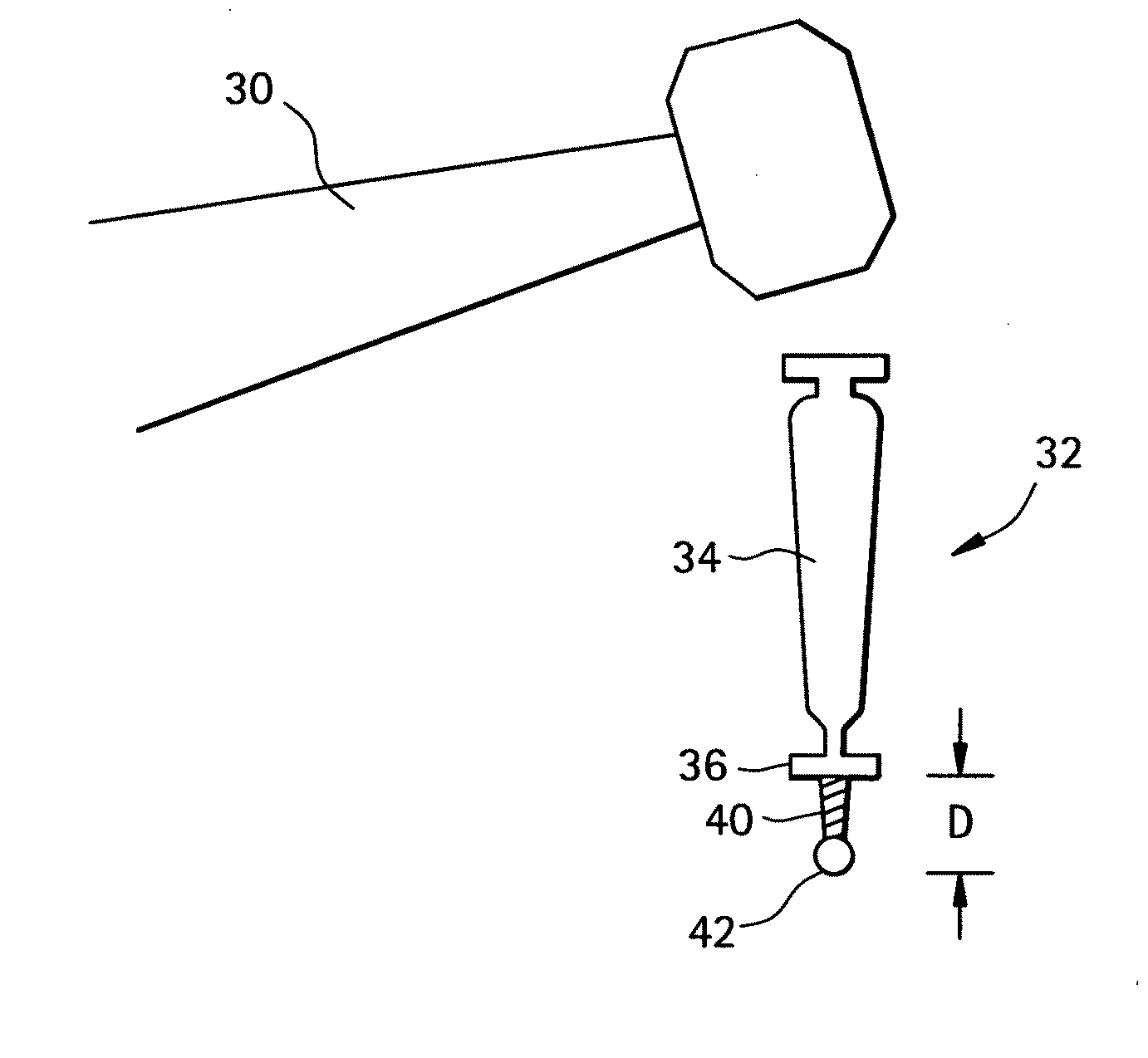

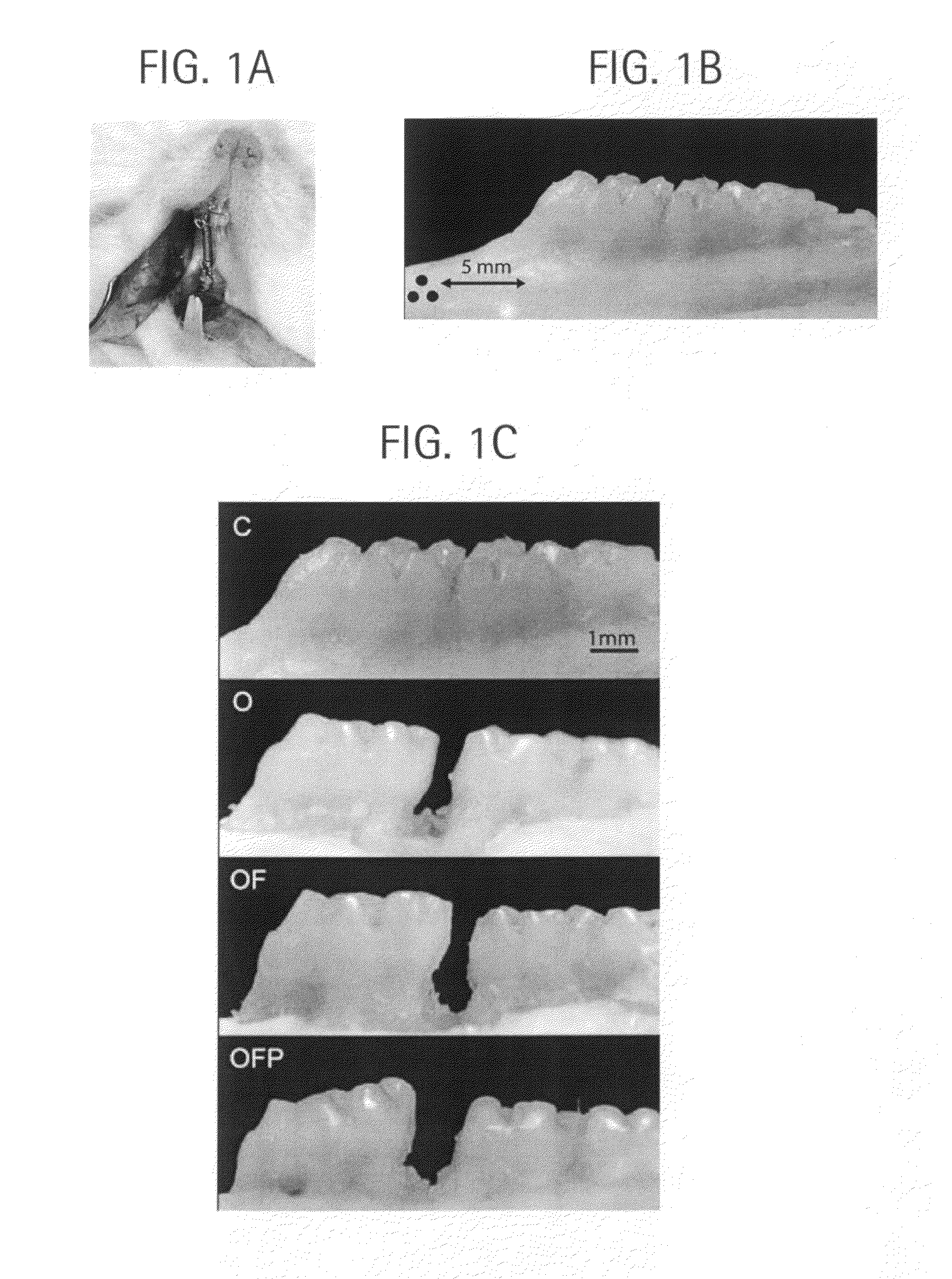

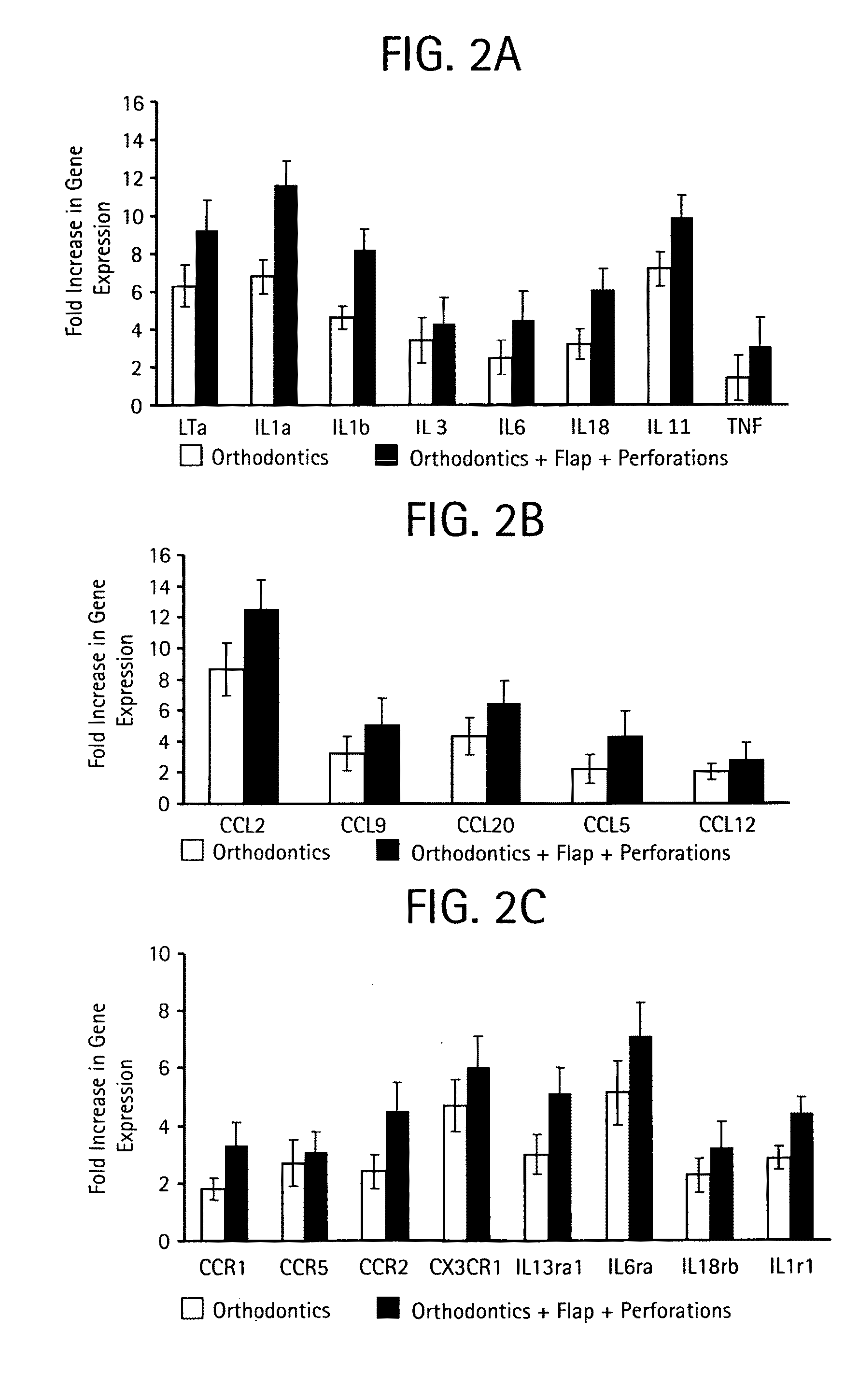

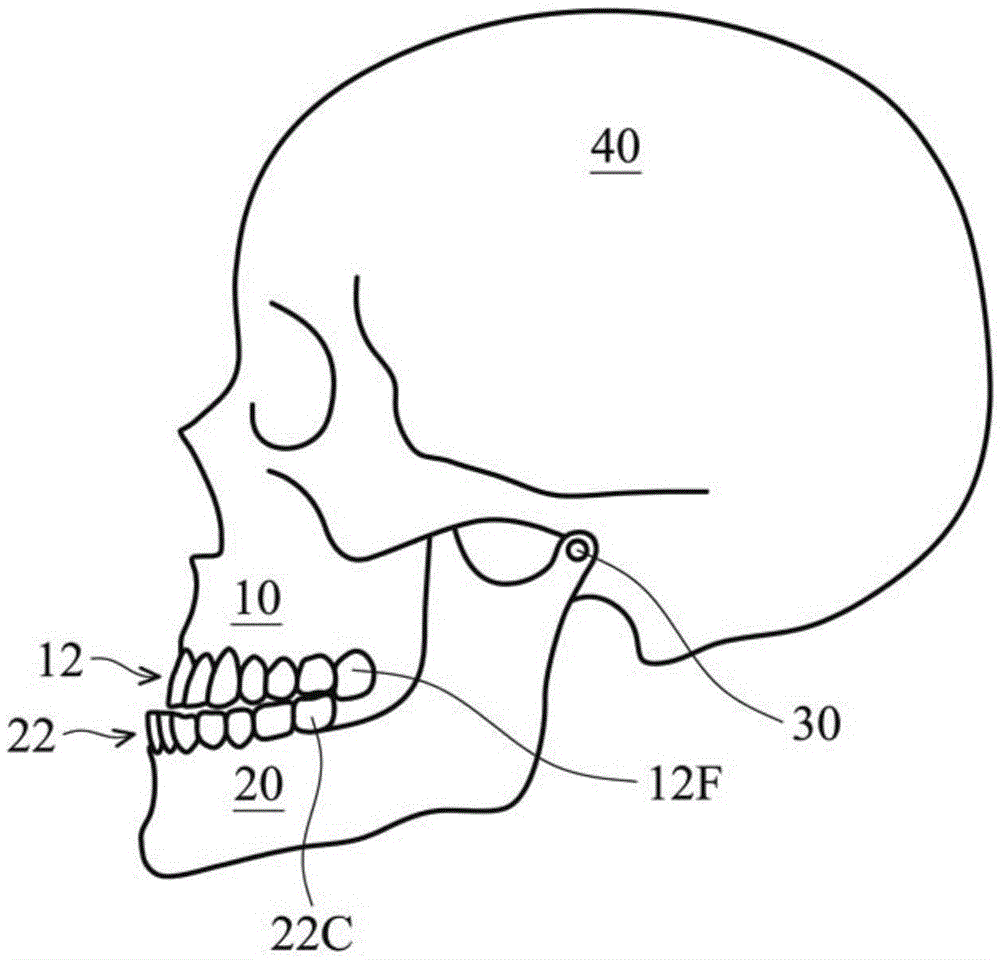

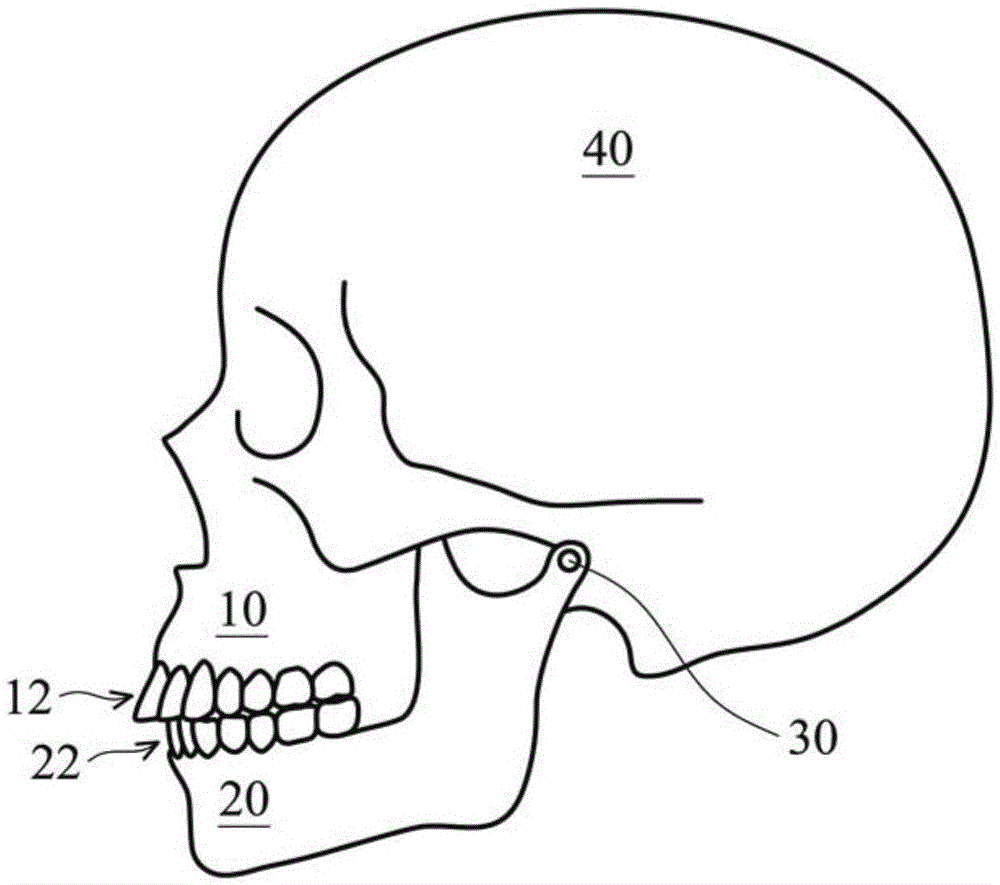

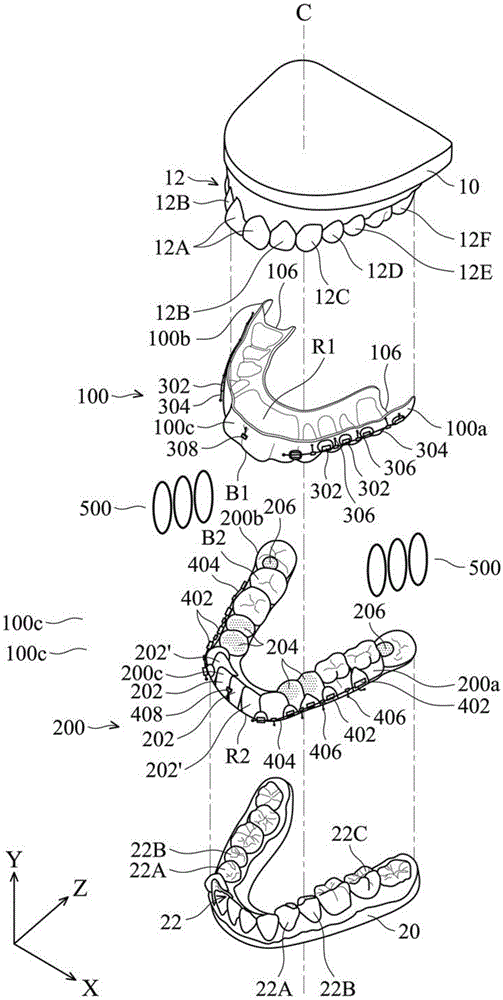

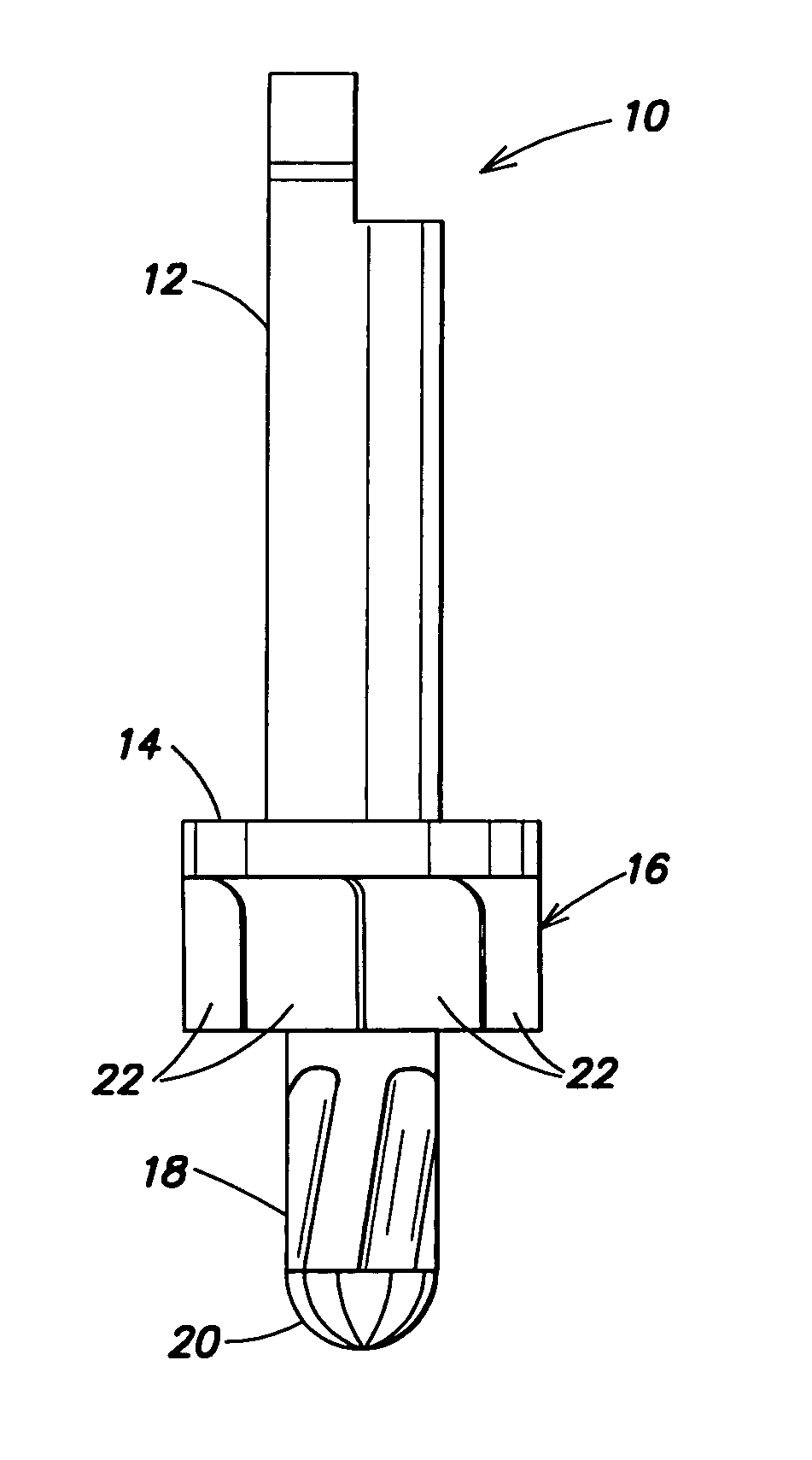

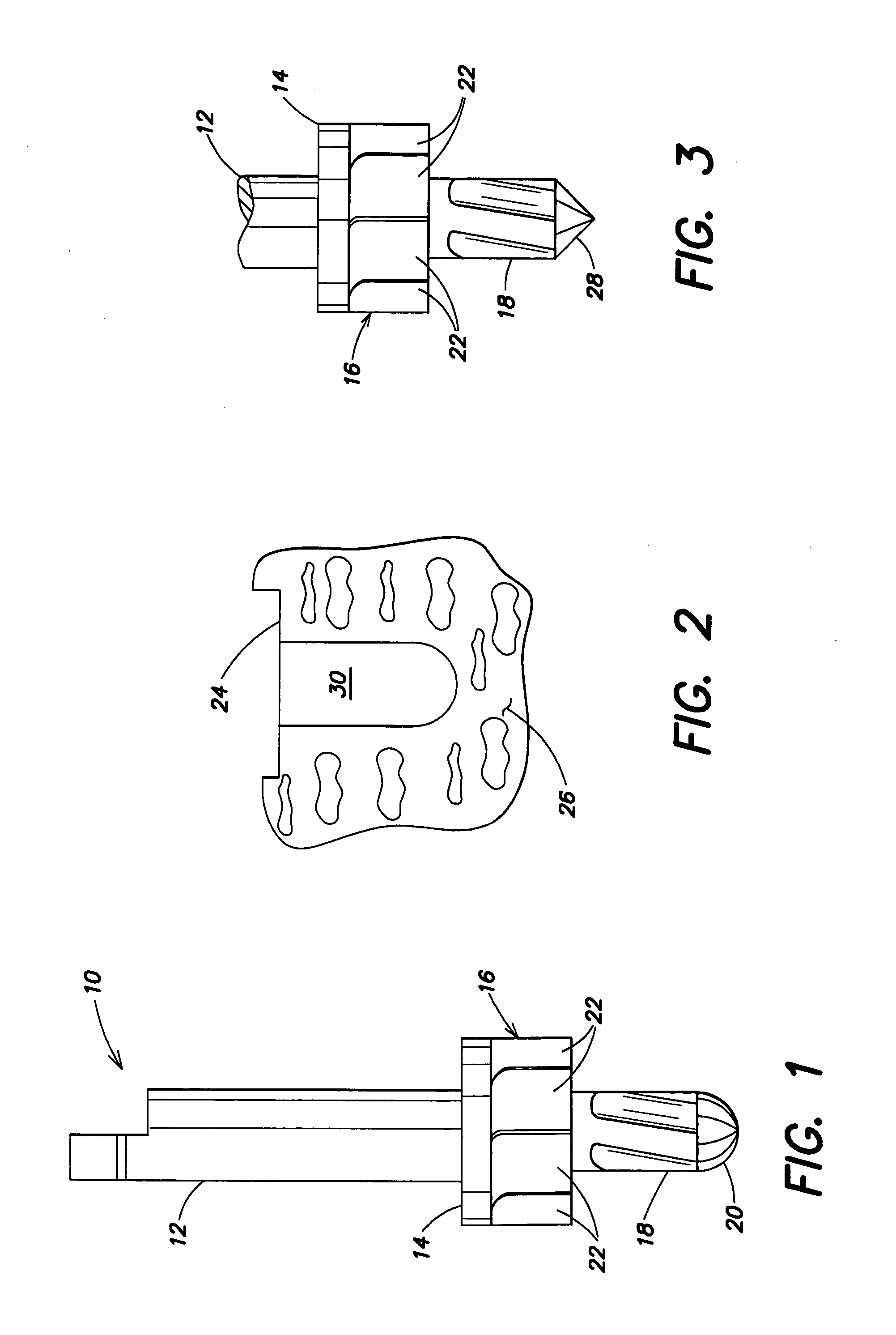

Orthodontic methods and devices

ActiveUS20110065060A1High expressionAccelerate bone remodeling processOthrodonticsTeeth fillingJaw boneHand held

The present invention provides methods for moving a tooth to a desired position within a patient's mouth using orthodontics including perforating tissue in the oral cavity sufficient to induce an inflammatory response. The perforations may be made in any area of the maxilla or mandible, and any number of perforations may be made that are preferably 0.5 to 1.5 mm diameter, and preferably 1 to 3 mm deep. The invention also provides a device that may be used in conjunction with slow-speed rotary instruments or with manual drivers for providing the perforations. The device has a drill that makes the perforations and a stop that prevents the drill from penetrating the jaw bone beyond a predetermined depth. The invention also provides a kit that supplies the professional with the necessary components in a sealed container to carry out the osteoperforations. The kit may include hand held and rotatory perforating devices, anesthetic, and a soft tissue punch.

Owner:NEW YORK UNIV

Tooth jaw orthotic device

The invention discloses a tooth jaw orthotic device which comprises a first positioner, a second positioner and at least two elastic pieces. The first positioner is detachably mounted on a dental arch of an upper jaw of an oral cavity and is provided with at least two first connecting parts which are fixed on a left cheek side face and a right cheek side face of the first positioner respectively. The second positioner is a detachably mounted on a dental arch of a lower jaw of the oral cavity and is provided with at least two second connecting parts which are fixed on a left cheek side face and a right cheek side face of the second positioner respectively. The elastic pieces are respectively connected with the first positioner and the second positioner which are fixed at the dental arch of the upper jaw and the dental arch of the lower jaw respectively, to be used for driving the second positioner to move relative to the first positioner, so as to adjust a relative position between a lower jaw bone of the second positioner and an upper jaw bone of the first positioner.

Owner:洪澄祥

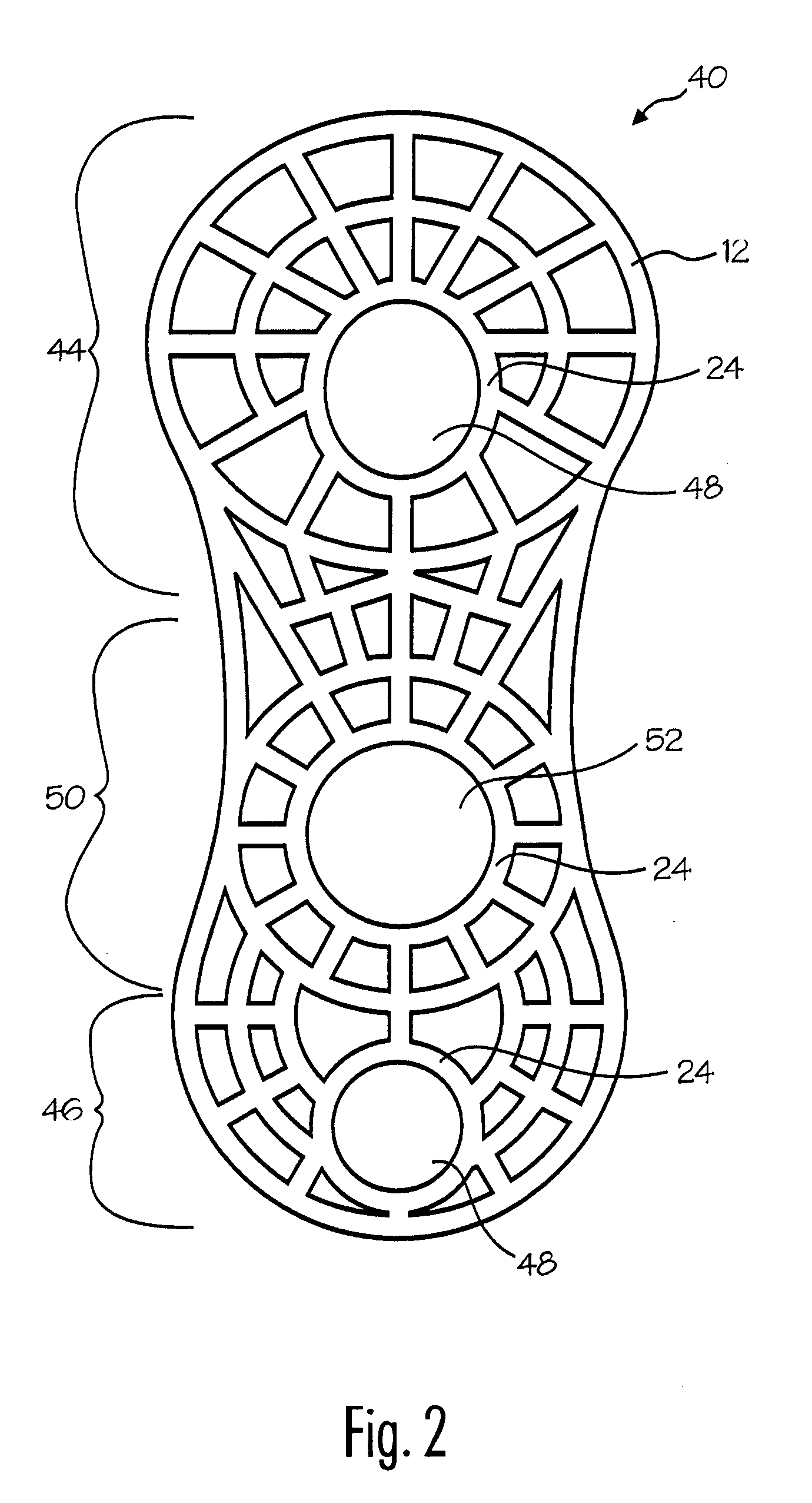

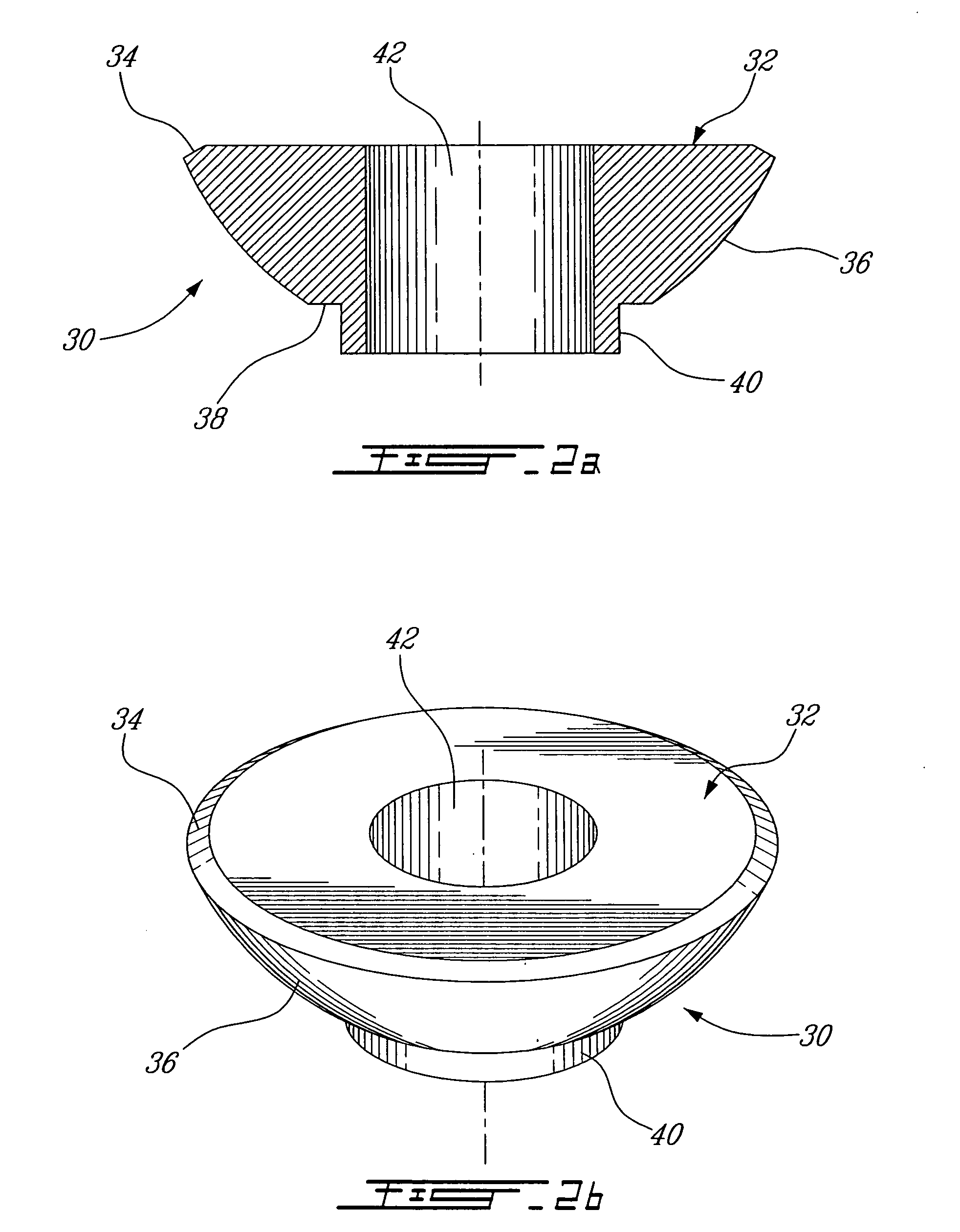

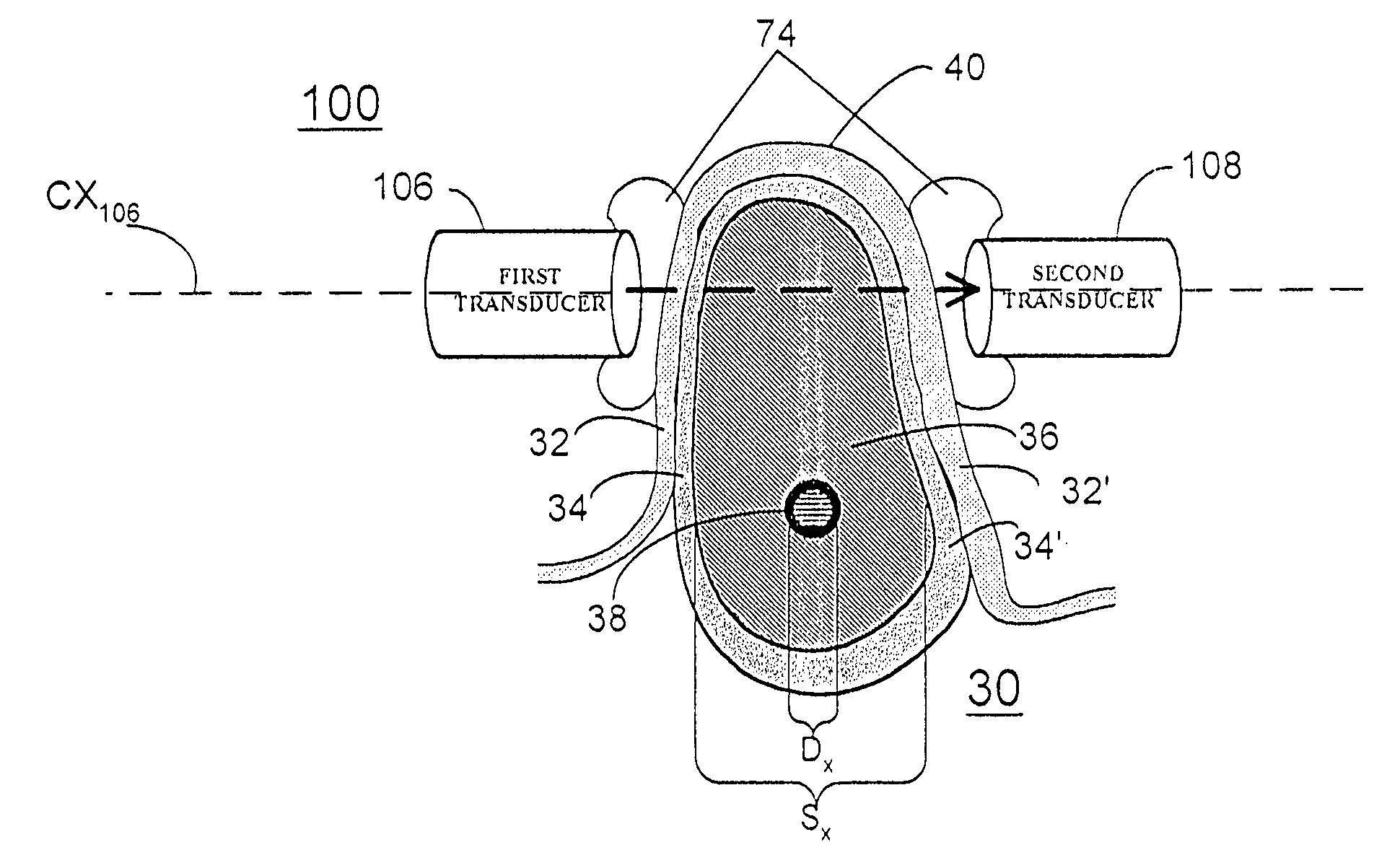

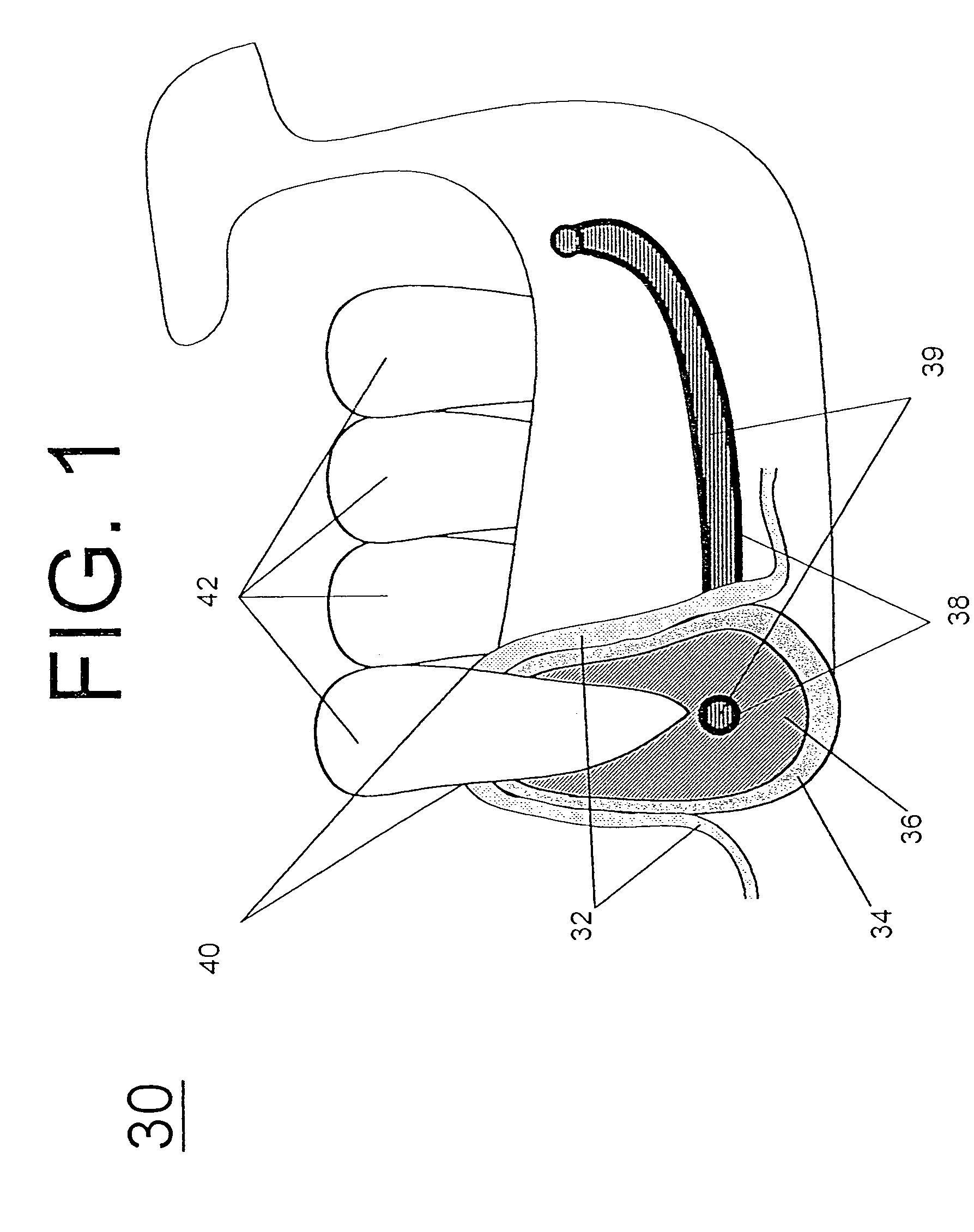

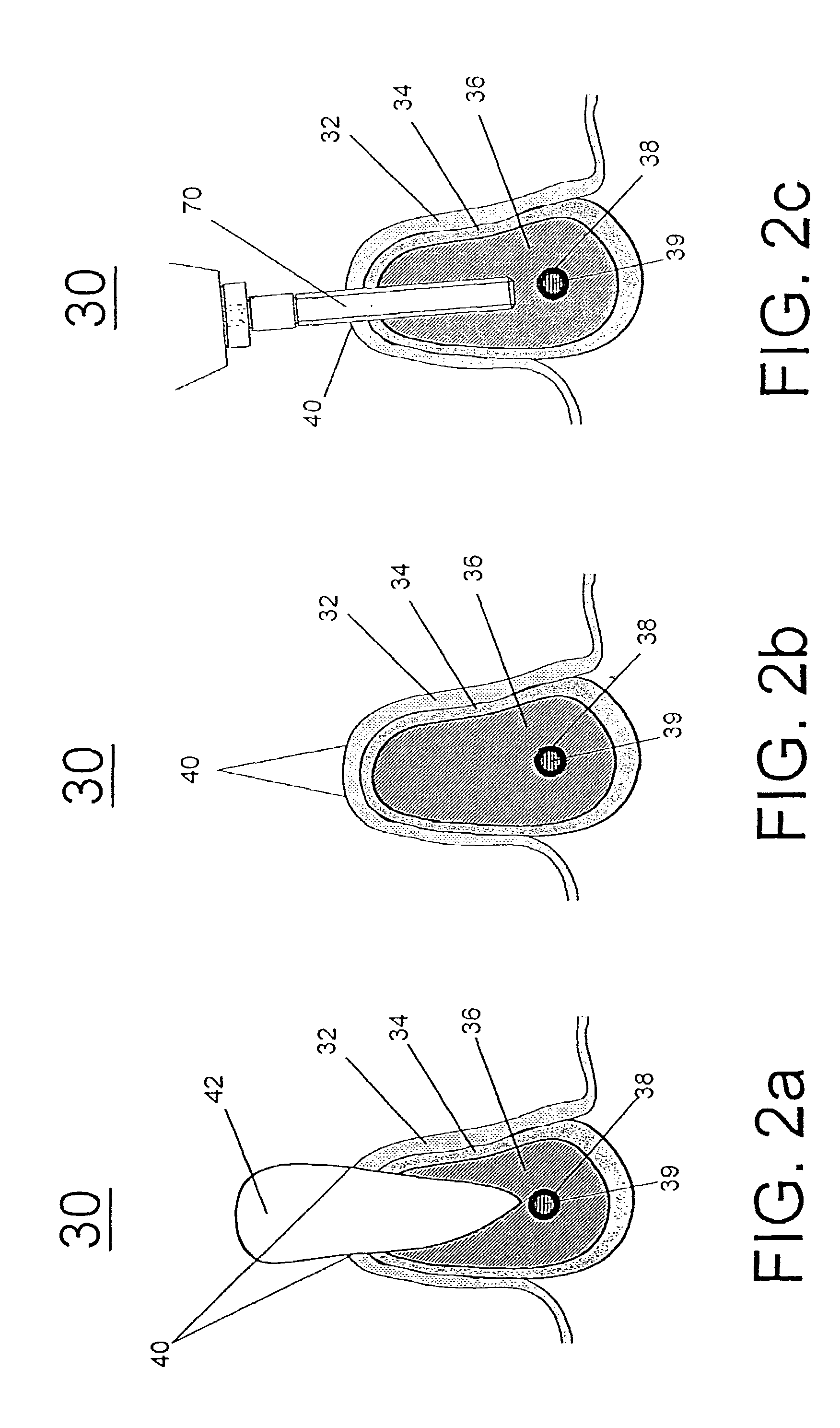

Systems for ultrasonic imaging of a jaw, methods of use thereof and coupling cushions suited for use in the mouth

InactiveUS7285093B2Enhance the imageTranslational motion is facilitatedAnalysing solids using sonic/ultrasonic/infrasonic wavesOrgan movement/changes detectionUltrasound imagingDigital data

Systems and methods for ultrasonic imaging of a jaw and coupling cushions suited for use in the mouth. The system includes a specially configured ultrasonic probe, a position locator module for defining a probe location and transmitting the definition to a central processing unit (CPU) and the CPU. The CPU is capable of receiving digital data from transducers in the probe and receiving the location of the probe and producing an image of at least a portion of a jaw. The method includes providing the ultrasonic probe, defining its location and communicating the location to a CPU and transmitting an signal from a transducer and receiving at least a portion of the signal at at least one of the transducers. The CPU receives transducer data and a location of the probe and produces an image of the at least a portion of the jaw. An ultrasonic coupling cushion is further disclosed.

Owner:IMADENT

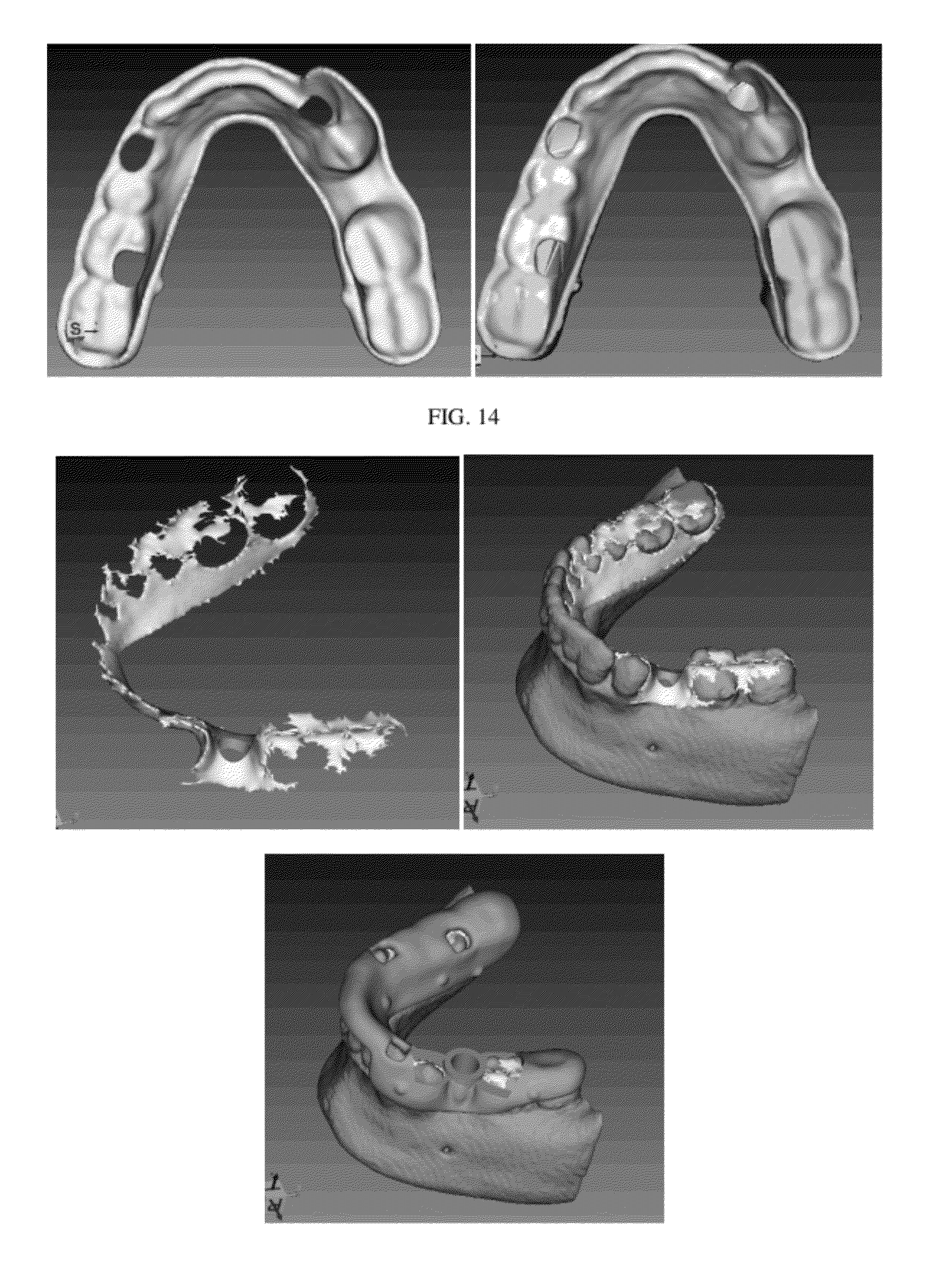

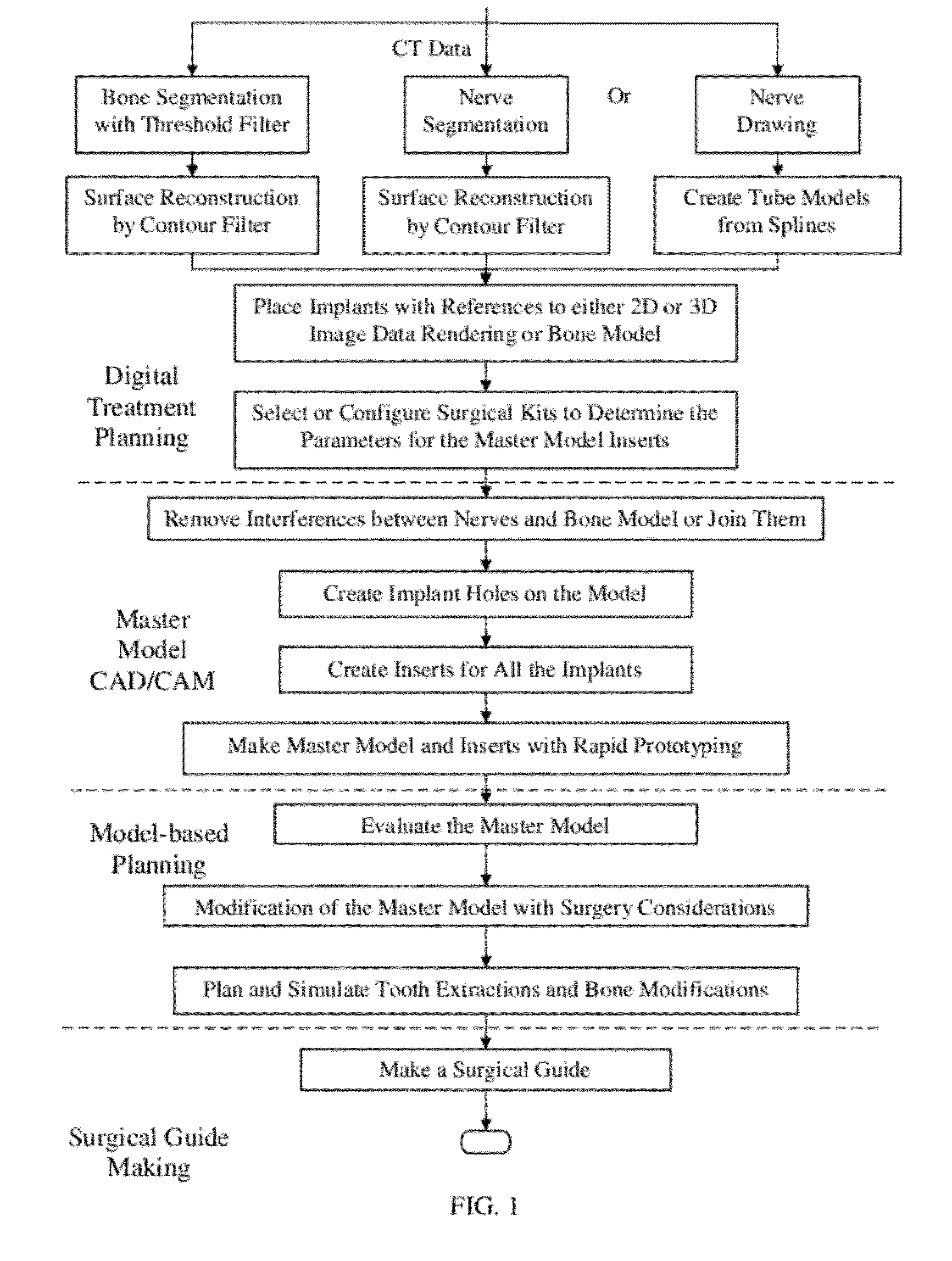

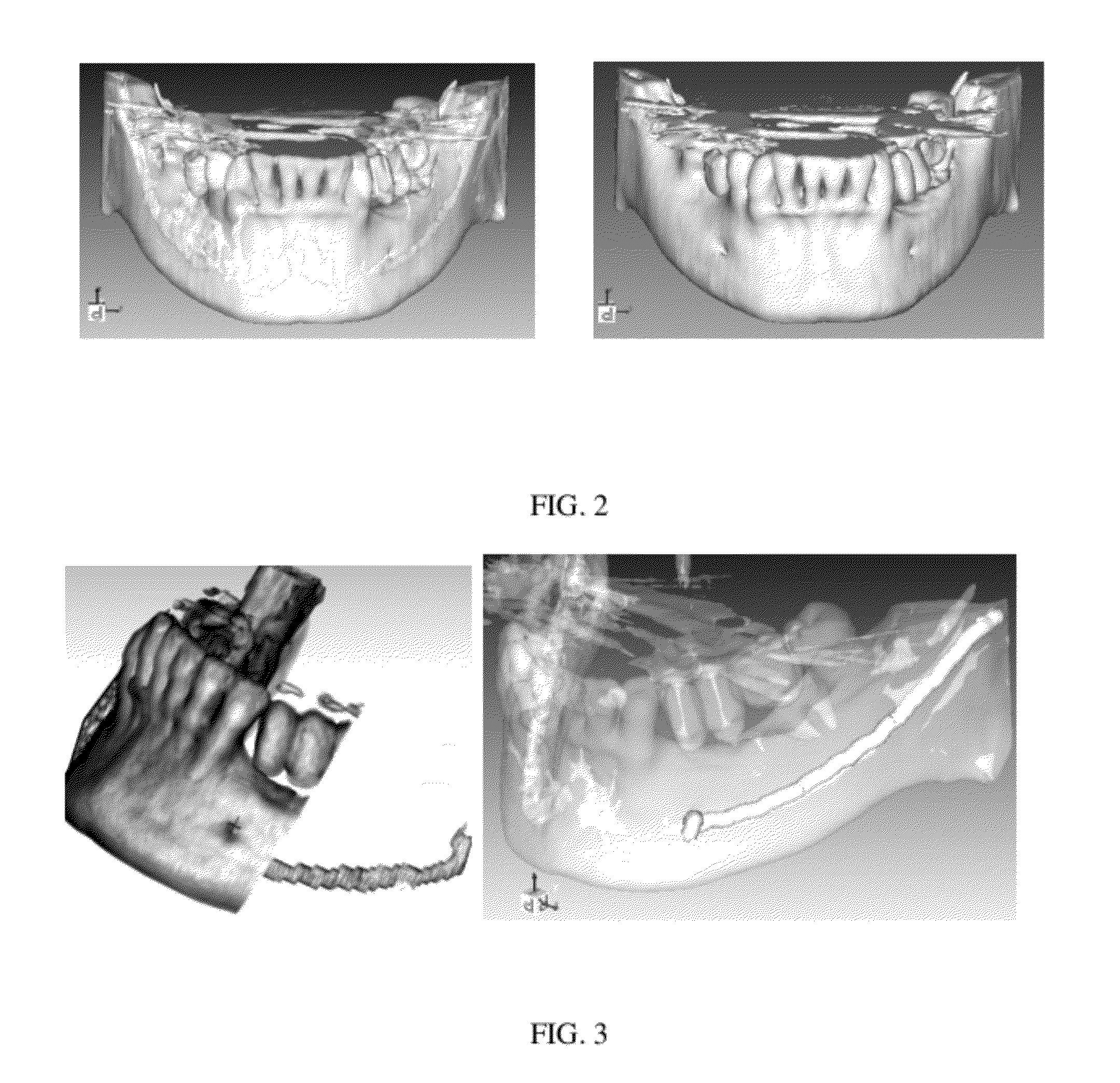

Hybrid method for dental implant treatment planning

InactiveUS20120046914A1Fast technologyDental implantsAdditive manufacturing apparatusSurgical operationAnatomical structures

A hybrid method for dental implant treatment planning and a corresponding approach to make a surgical guide. After digital treatment planning is performed with CT scan data, a master model is created, which embodies the patient anatomy and entire treatment plan. Jaw bone, tooth surfaces, soft tissues and nerves are all contained by the master model. The plan details including implant sizes and positions, surgical guide drill options, as well as the choice of a surgical kit, are all conveyed by the master model. Meanwhile, models of specially designed “implant inserts (or replicas)” are also generated, which have one end that fits into the implant holes on the master model and another end to make the surgical guide. The master model and inserts are manufactured with rapid prototyping technology. A surgical guide is later on made from them with conventional lab processes. A main characteristic of this approach is that the master model and the inserts are the physical embodiment of a virtual treatment plan. With them, the surgeons can continue the treatment planning for operations like tooth extractions and bone modifications before making the surgical guides. Therefore the treatment planning workflow is a combination of digital treatment planning and a physical model based planning, in other words, a hybrid approach. A differentiator in this invention is the generation of a closed solid model of the soft tissue, as part of the master model, from the scan data. This approach can be applied to create both bone-borne and tissue-borne surgical guides with low cost process, which is a big advantage over other approaches.

Owner:GAO FEI

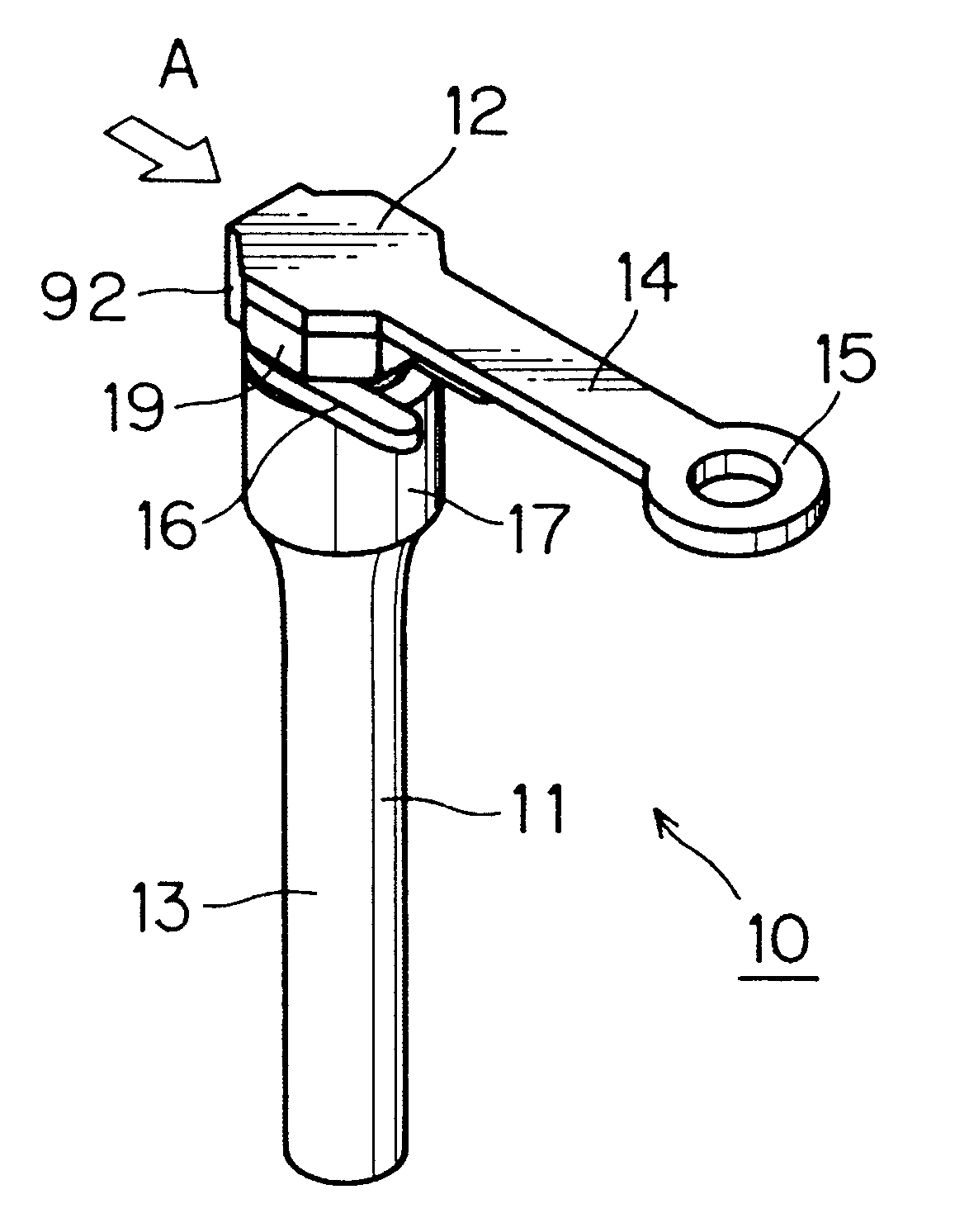

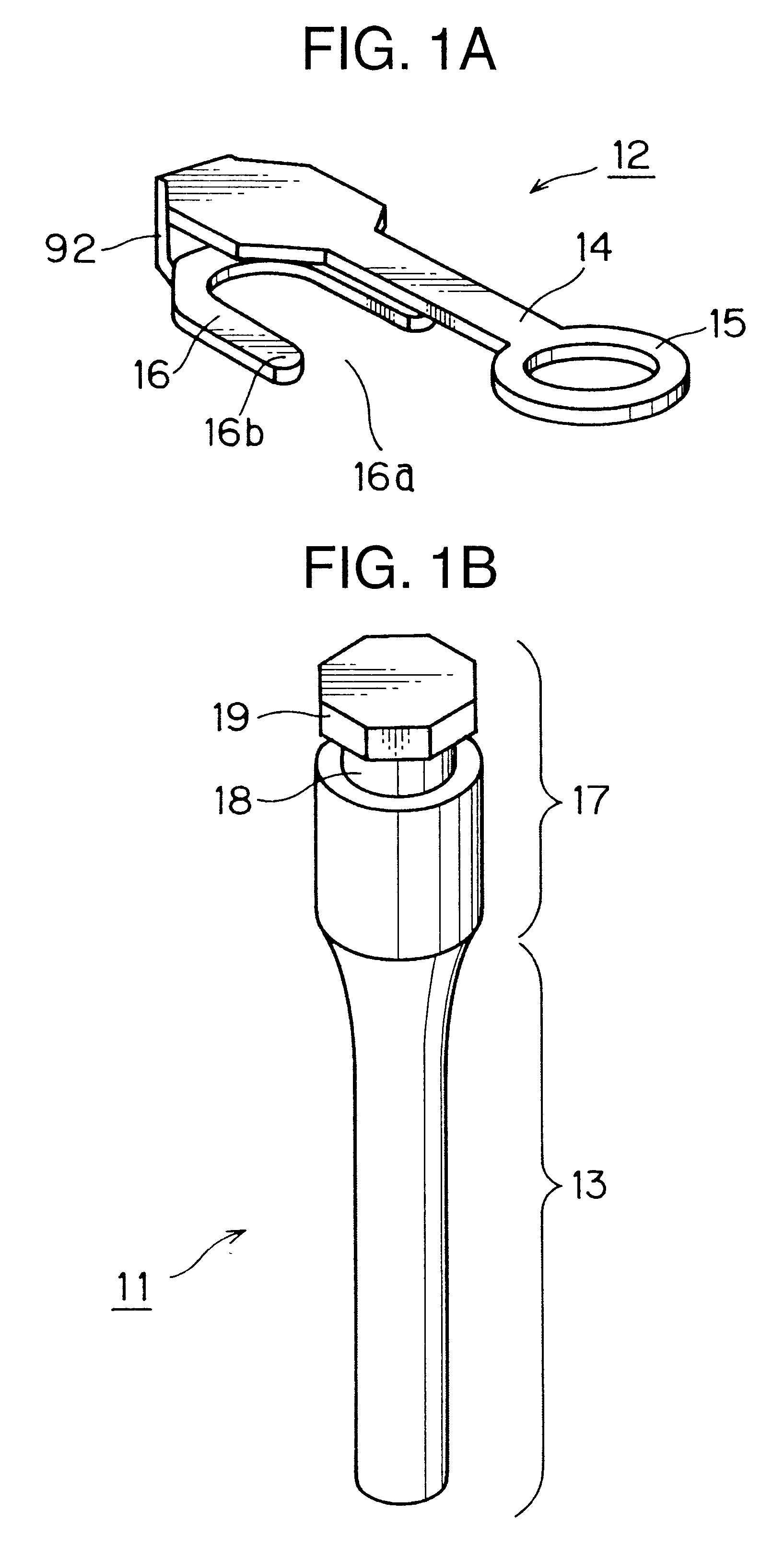

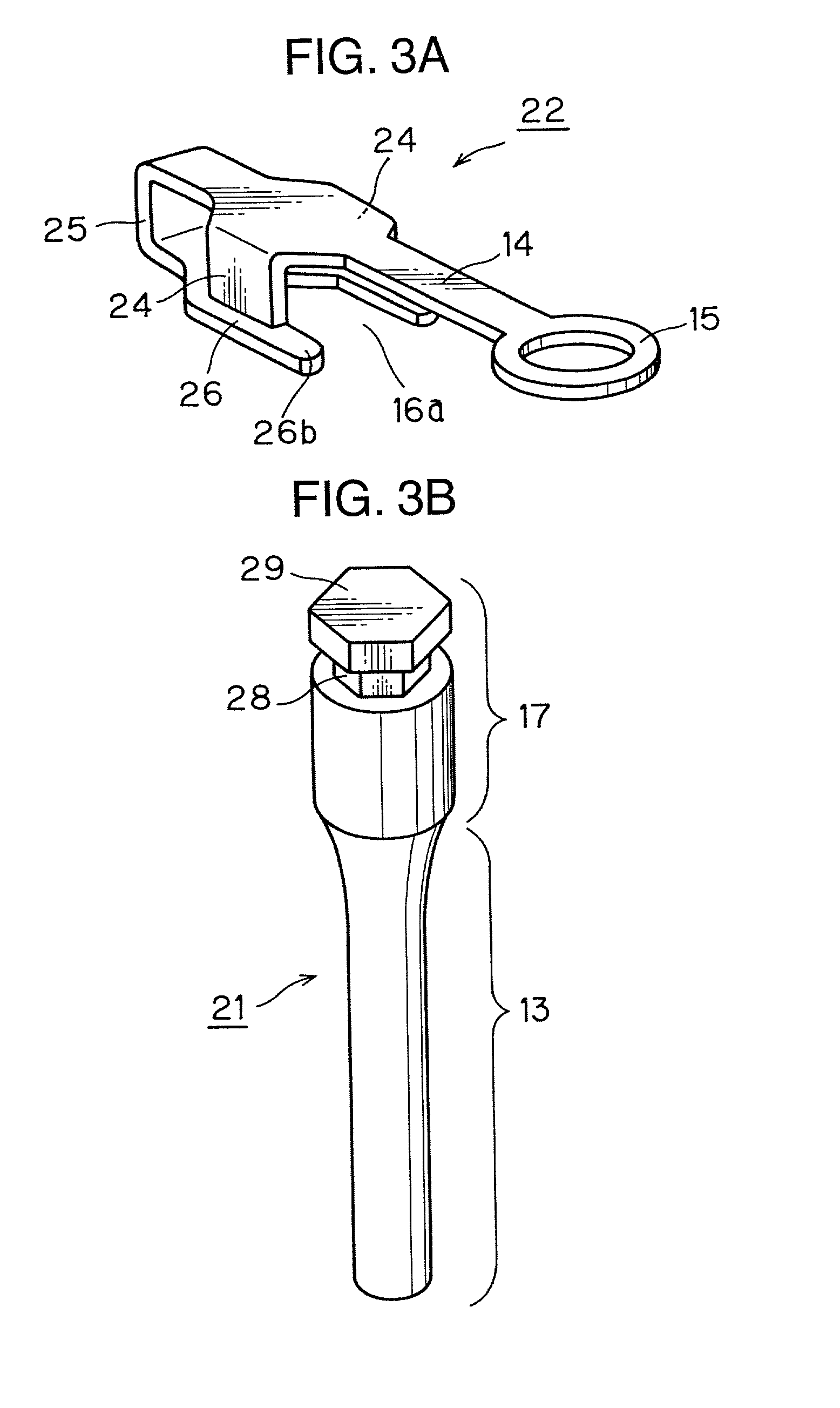

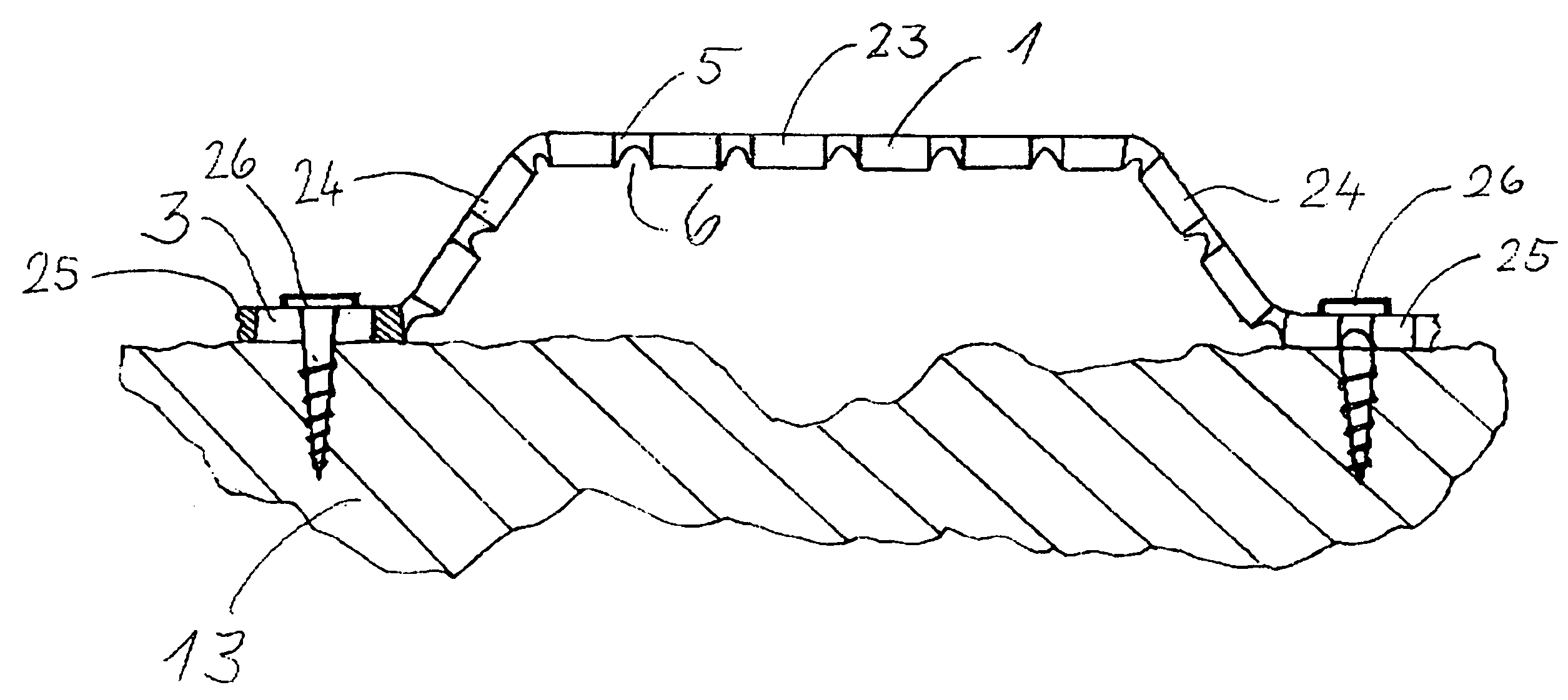

Orthodontic supporting structure

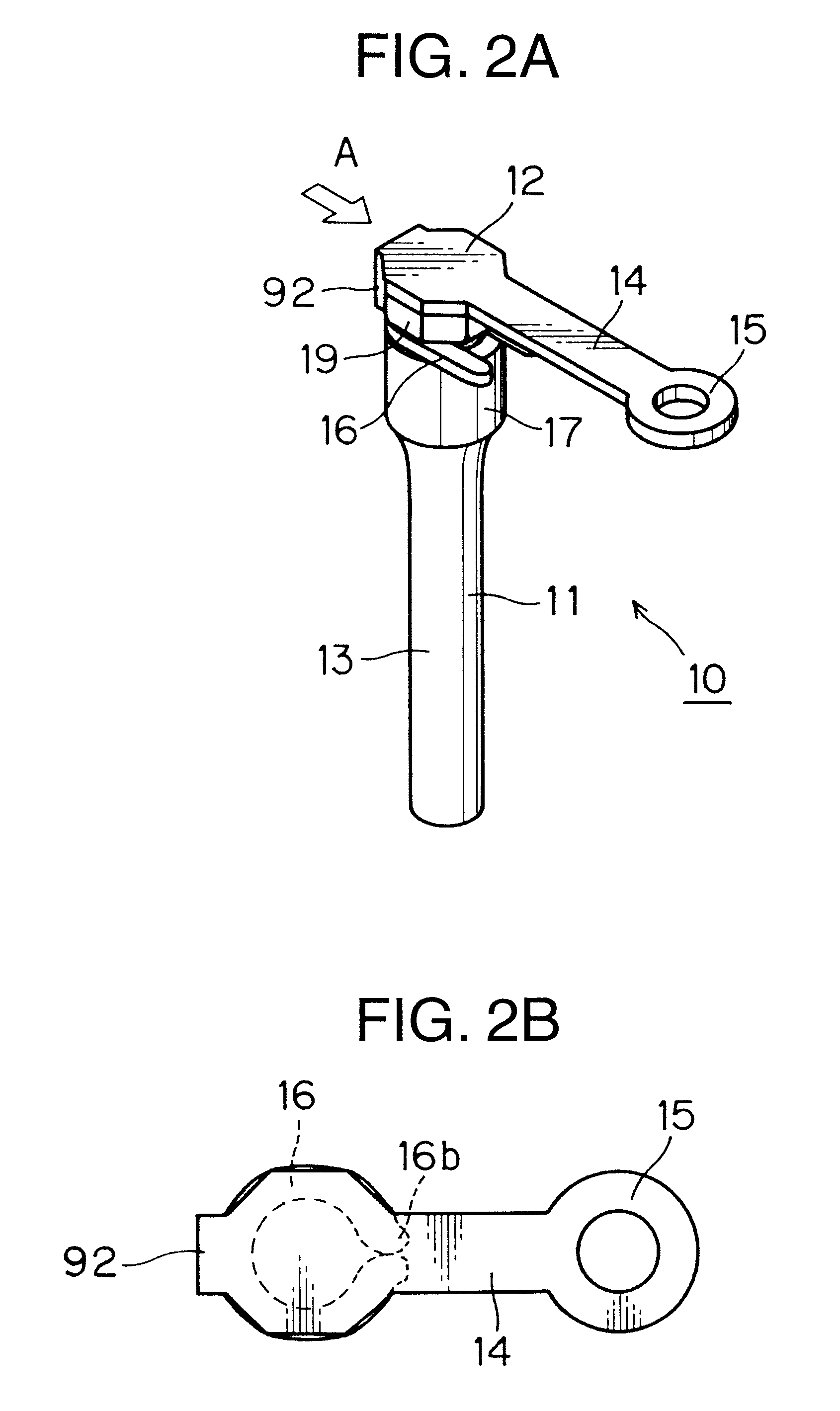

An orthodontic supporting structure of the present invention comprises an implant unit which is implantable in a jaw bone and a connecting unit which includes an arm part having a fastening portion. The implant unit has a narrow part in its upper portion. The connecting unit further includes an engaging part having an opening at one end. The engaging part fits on the narrow part of the implant unit. The connecting unit can be attached to the implant unit in a simple way by sliding the engaging part along the narrow part and then crimping far ends of the engaging part.

Owner:DENTSPLY SANKIN KK

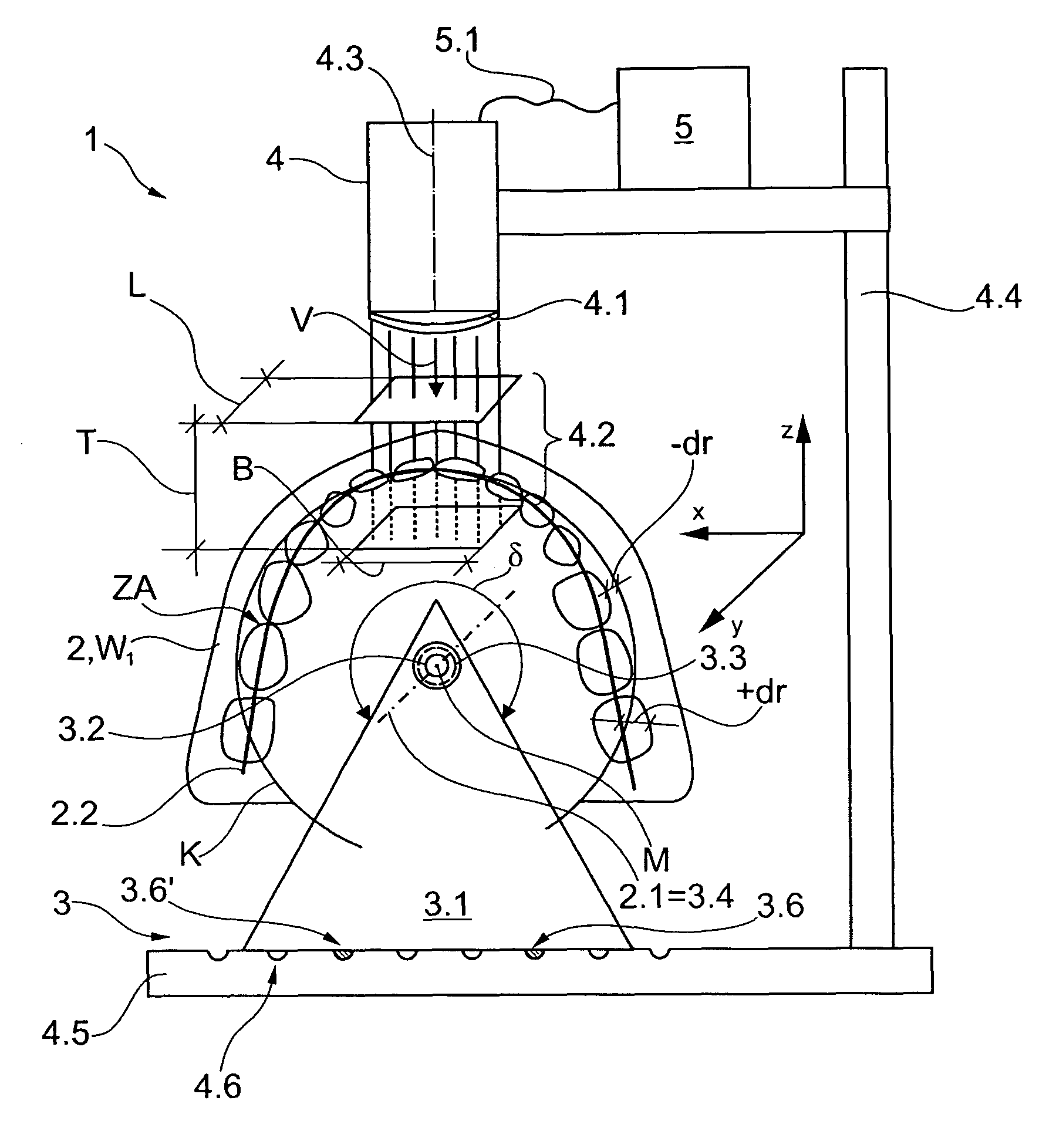

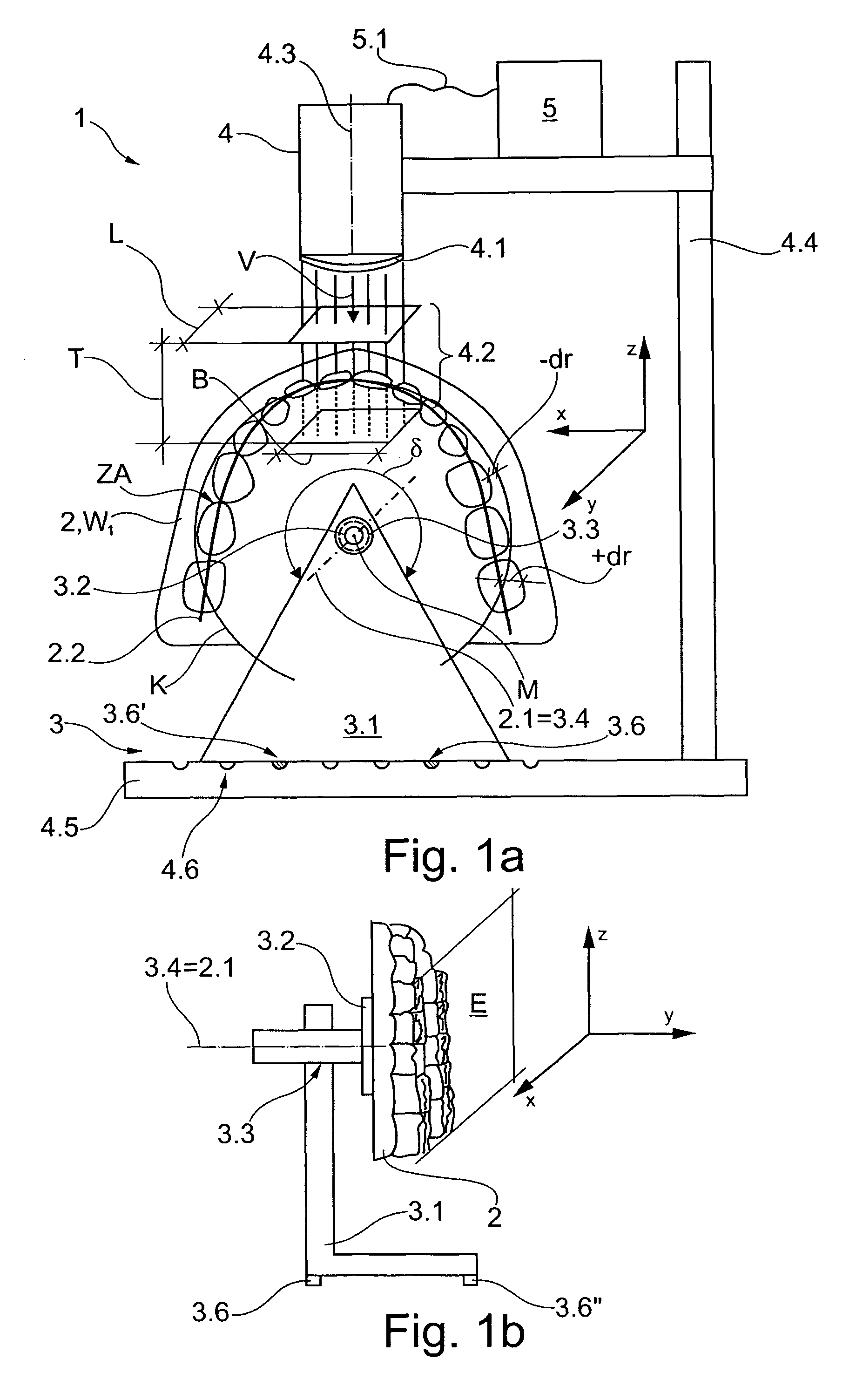

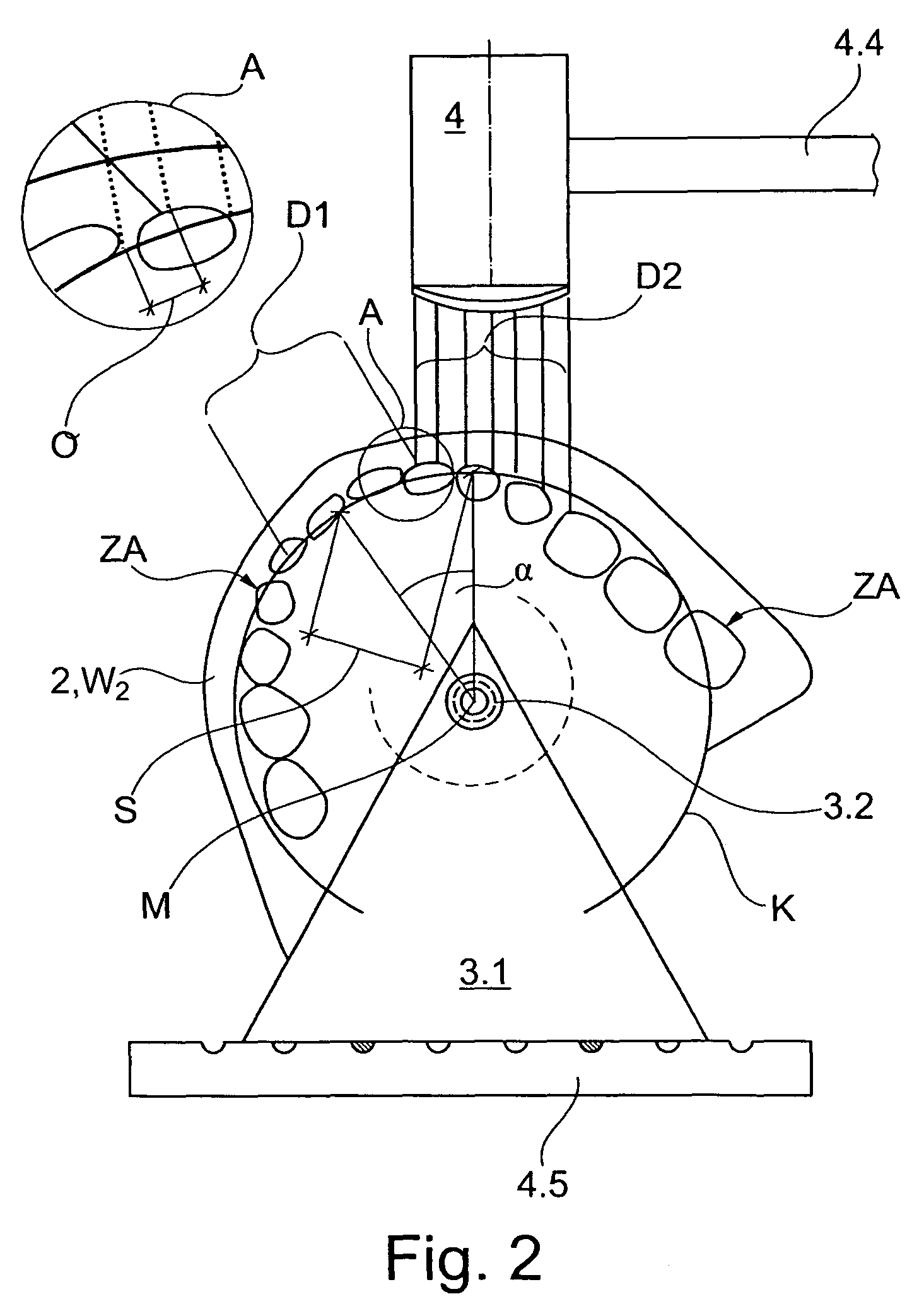

Measuring device and method for the 3D-measurement of dental models

InactiveUS7855354B2Impression capsBeam/ray focussing/reflecting arrangementsRotational axisMeasurement device

A scanning system for carrying out 3D scanning of dental models in a scanning direction V including a holding device for a whole jaw model which spans an occlusal plane E over a line-shaped mandibular arch, a base, a swivel bearing on a swivel axis normal to the scanning direction V and a stage mounted for rotation on the swivel bearing relatively to the base, on which the dental model to be scanned can be mounted. The stage can be rotated through an angular range δ of at least 150° about the swivel axis, and the whole jaw model can be mounted such that said occlusal plane E is aligned parallel to said scanning direction V. An evaluation unit receives data from a detector to generate a 3D data set.

Owner:SIRONA DENTAL SYSTEMS

Device and arrangement for fixture installation

InactiveUS20090253097A1Growth inhibitionExtra costDental implantsTeeth fillingJaw boneBiomedical engineering

A device and arrangement for installation of a fixture in a jaw bone comprises a fixture holder designed to cooperate with a guide member forming part of a template, via which guide member the fixture can be applied in its position in the jaw bone with the aid of the fixture holder. The arrangement is also provided with one or more elements which, with the aid of the guide member, ensure defined positions of the fixture in the vertical and transverse directions. The element or elements is or are arranged on the fixture holder.

Owner:NOBEL BIOCARE SERVICES AG

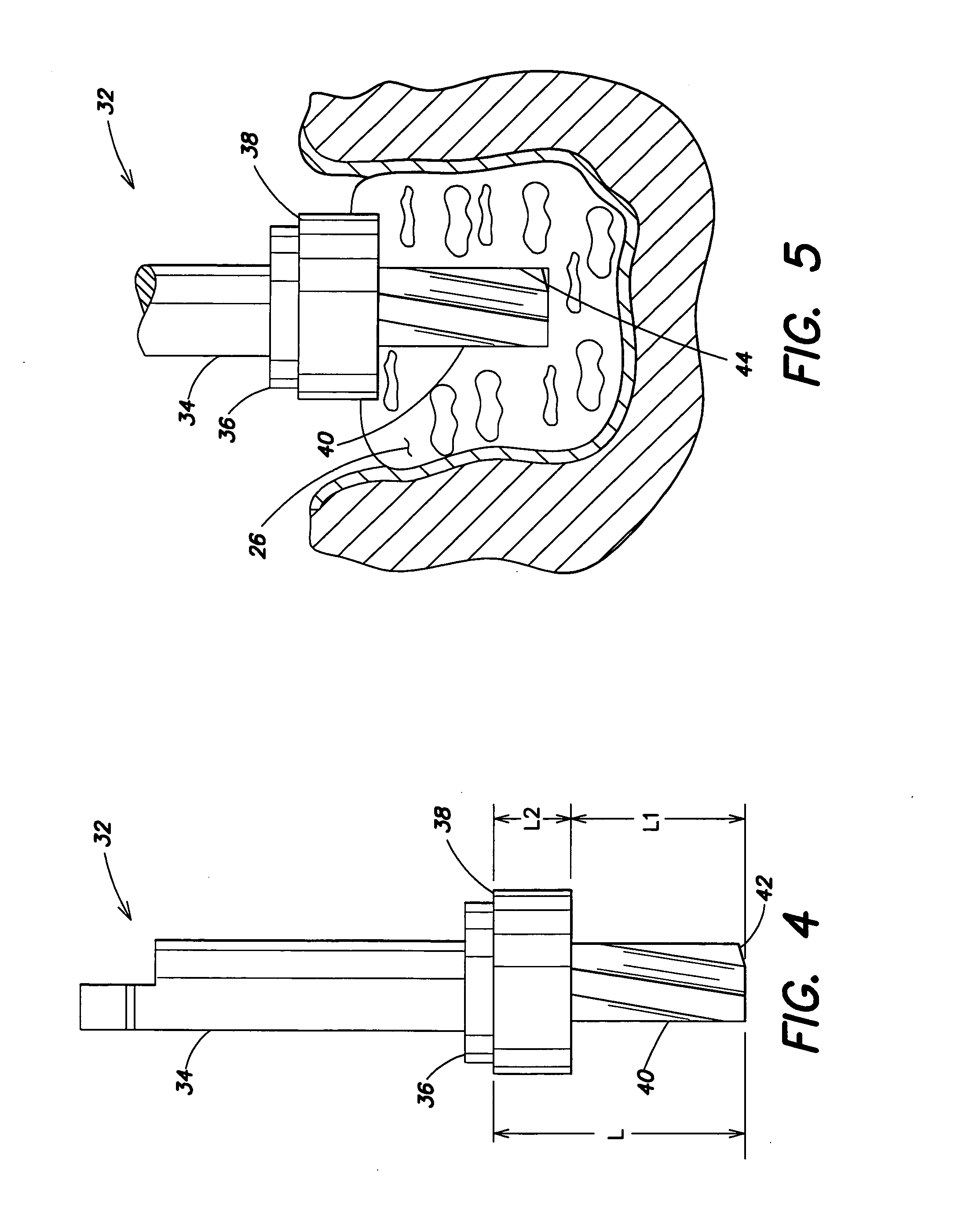

Drilling system and method for dental implants

InactiveUS20050003327A1Limited penetrationPrevent overdrillingDental implantsDiagnosticsJaw boneDrilling system

Method for drilling a hole for placement of an implant therein in which an initial hole is formed in the jaw bone having a diameter smaller than a desired diameter for placement of the implant and a depth smaller than a desired depth for placement of the implant. A flat ledge is formed in the bone around the initial hole by the same drill bit which forms the initial hole. The initial hole is then enlarged to the desired diameter and the desired depth using another drill bit which is designed to contact the ledge when the initial hole has been enlarged to exactly the desired depth. Penetration of the drill bit into the jaw bone once the hole has been enlarged to the desired depth is therefore prevented.

Owner:ELIAN NICOLAS +3

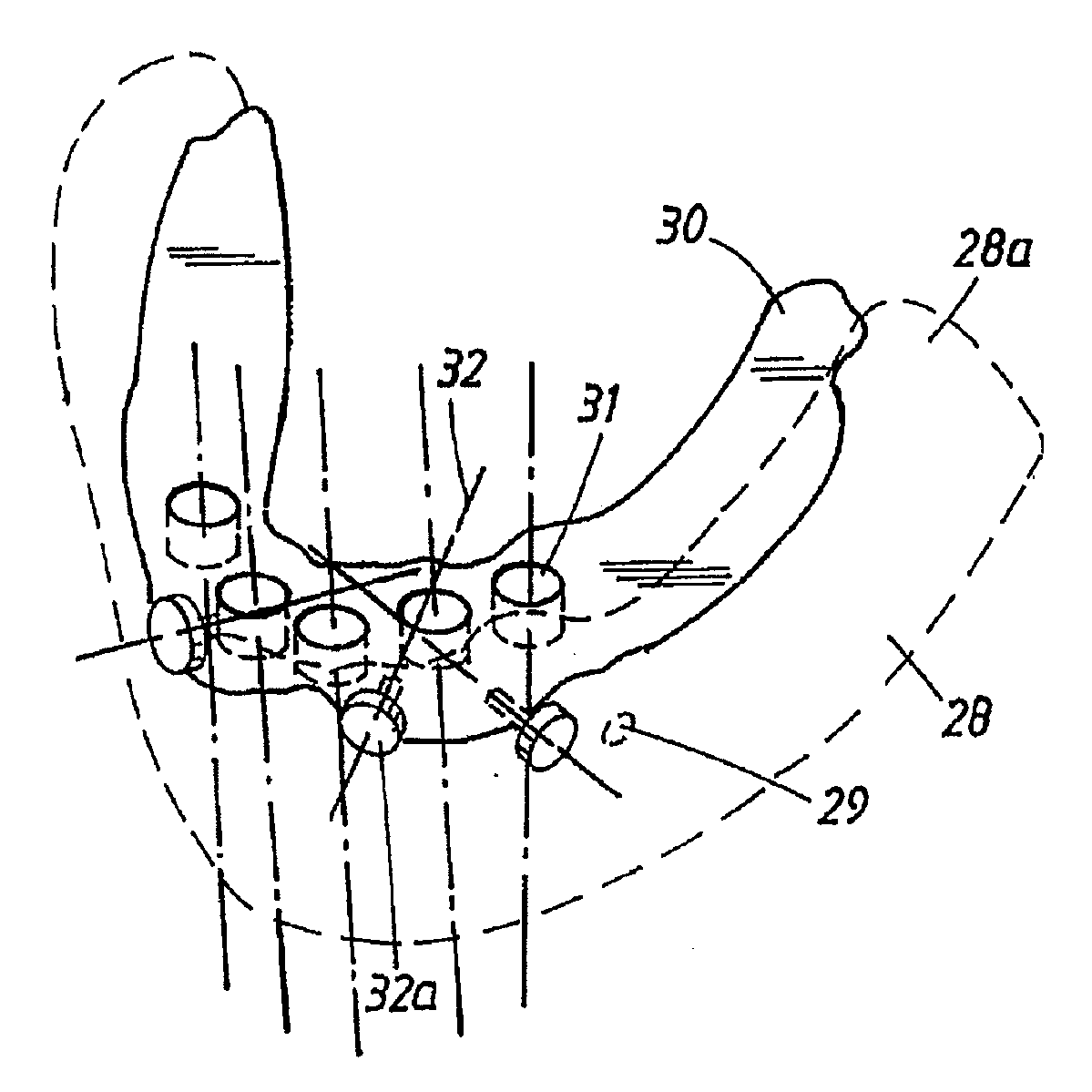

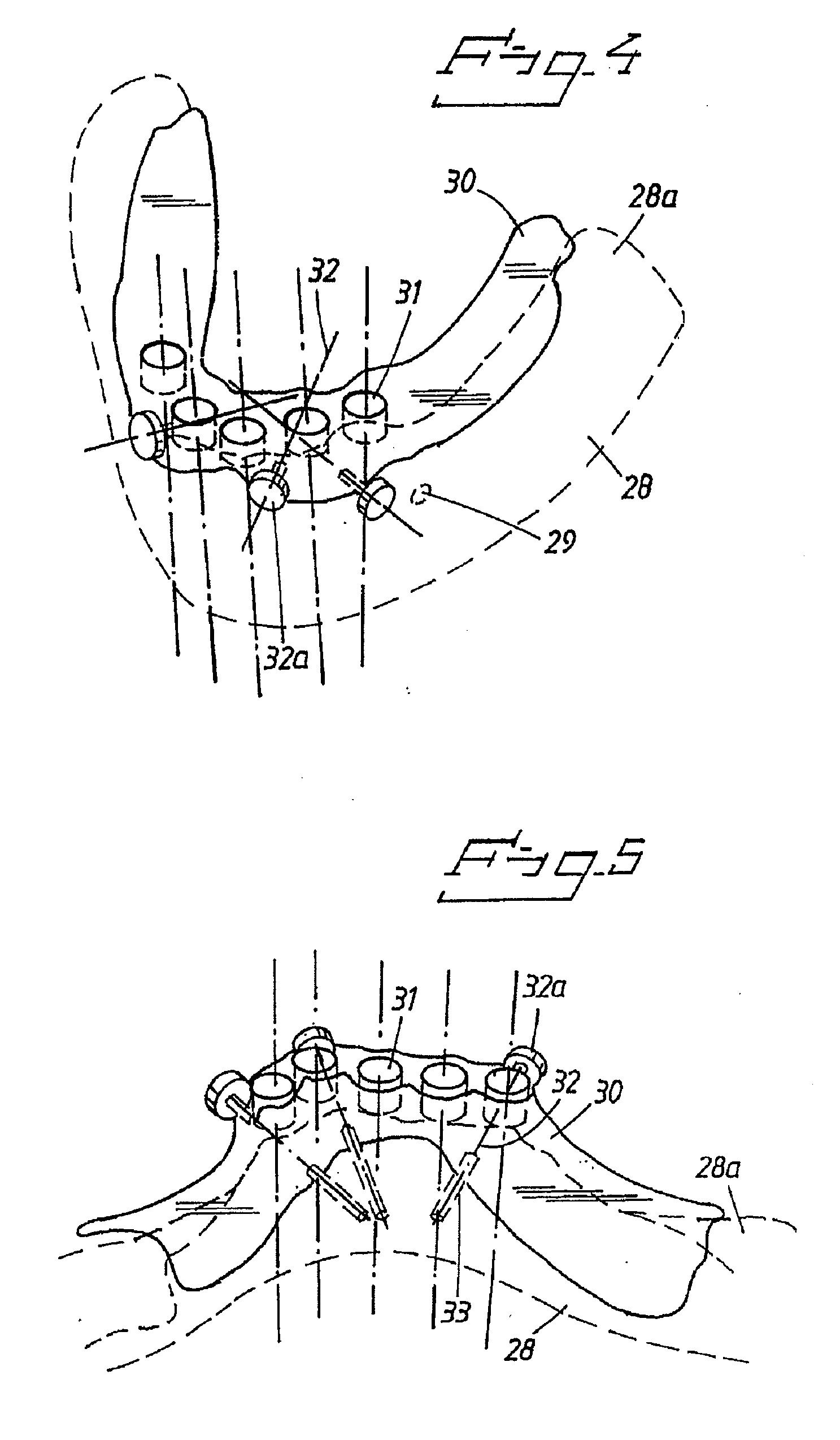

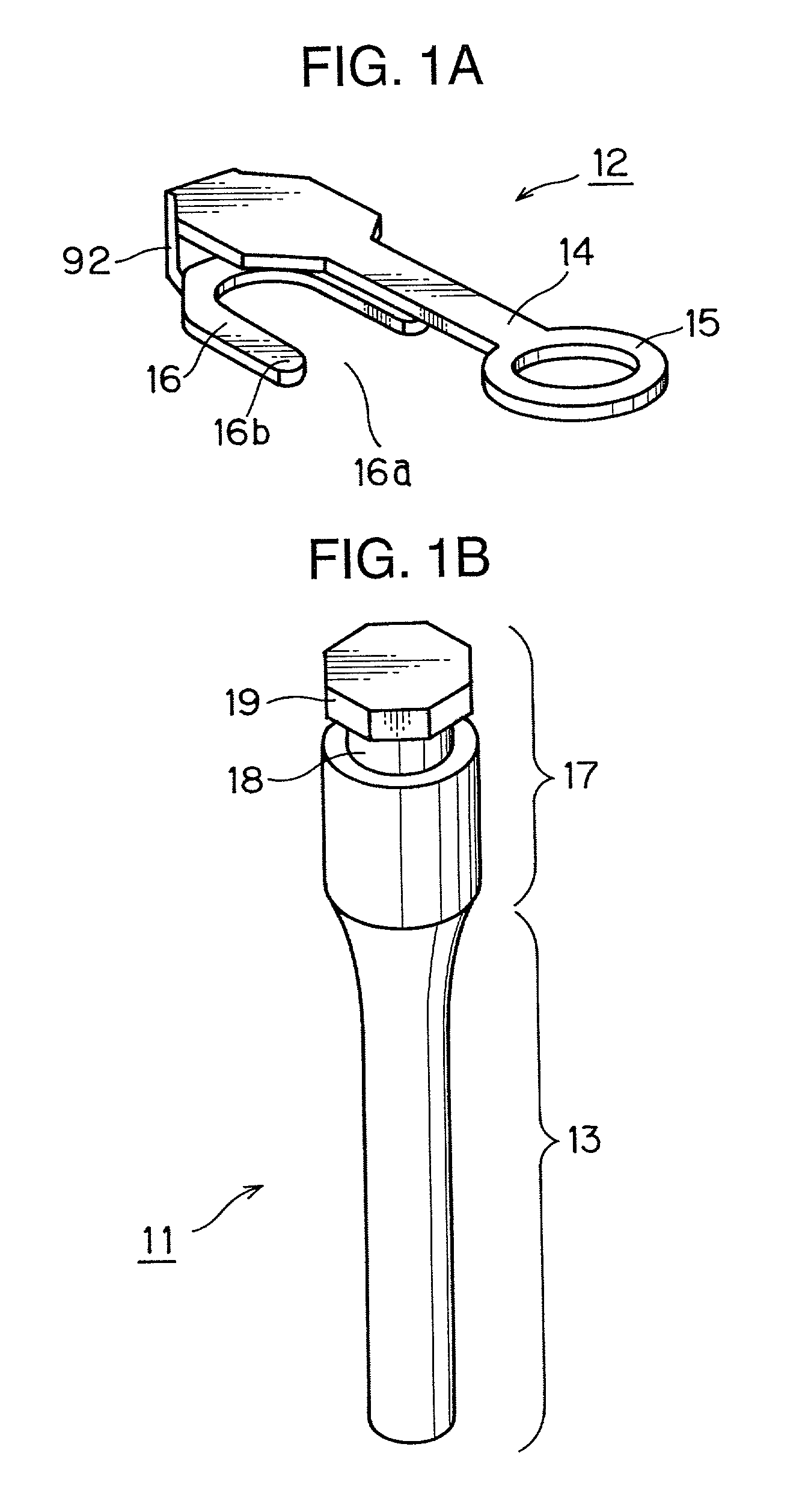

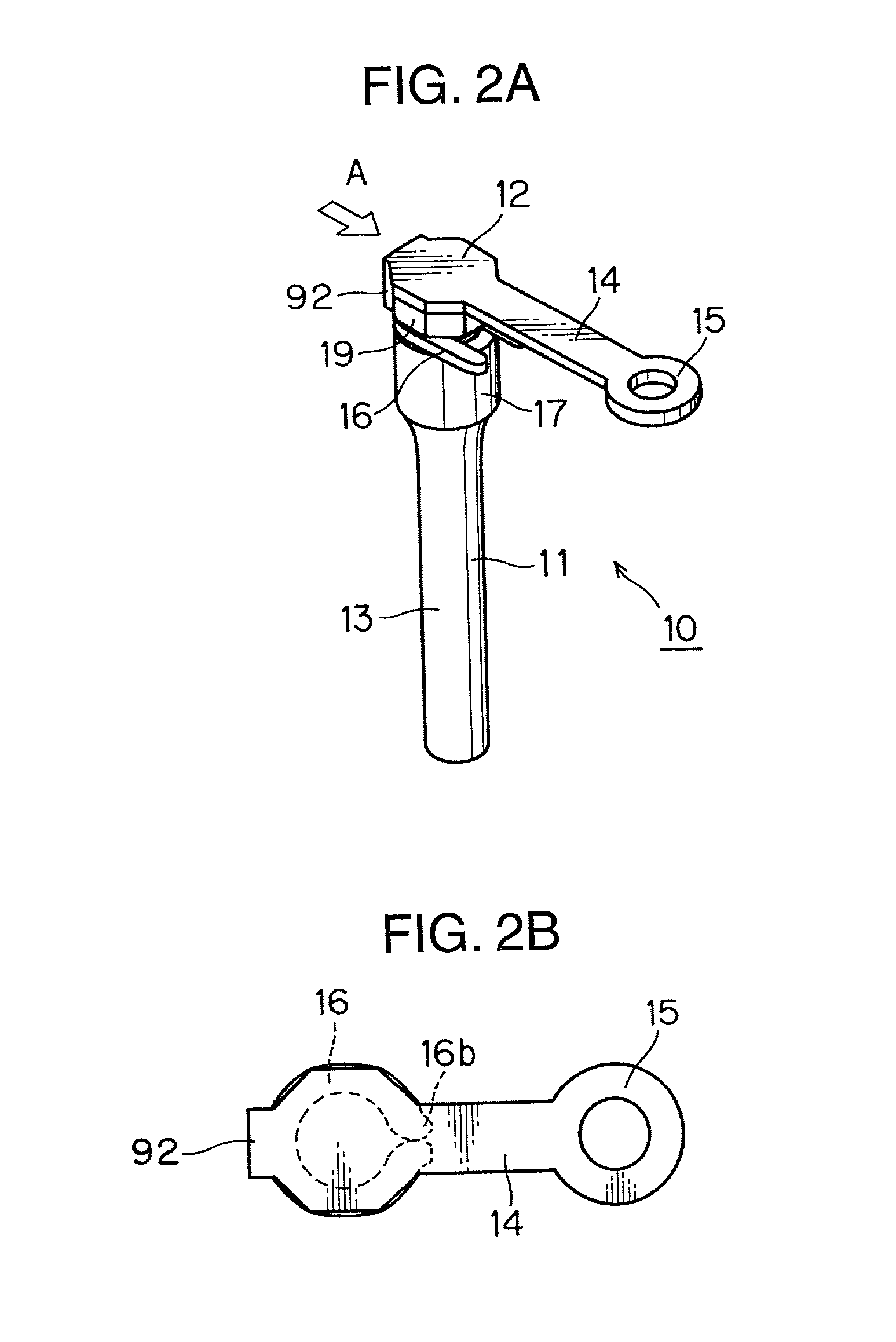

Orthodontic supporting structure

An orthodontic supporting structure of the present invention comprises an implant unit (21) which is implanted in a jaw bone and a connecting unit (22) which includes an arm part (14) having a fastening portion (15). The implant unit (21) has a narrow part (18) in its upper portion (17). The connecting unit (22) further includes an engaging part (26) having an opening (16a) at one end. The engaging part (26) can fit on the narrow part (18) of the implant unit (21). The connecting unit (22) can be attached to the implant unit (21) in a simple way by just sliding the engaging part (26) along the narrow part (18) and then crimping far ends (26b) of the engaging part (26).

Owner:DENTSPLY SANKIN KK

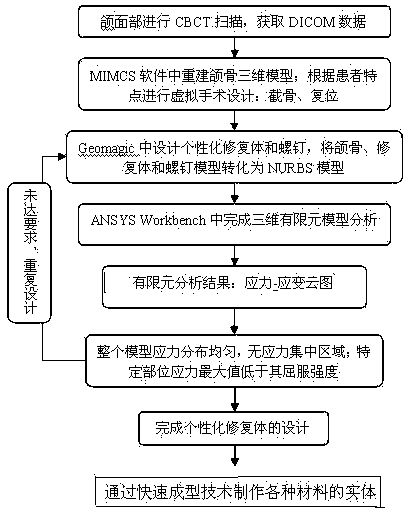

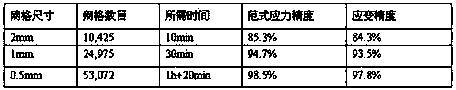

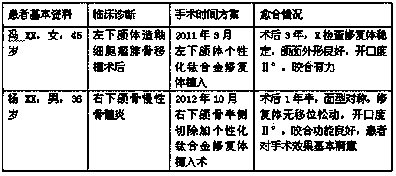

Manufacturing method for jaw defect individual restoration

ActiveCN103919631AHigh breaking strengthIncrease stressBone implantSurgeryBiomechanicsComputer-aided

The invention relates to the fields of computer-aided technology and maxillofacial plastic medical apparatus and instruments, in particular to an optimal design and manufacturing method for a jaw defect individual restoration. The optimal design and manufacturing method is characterized by comprising the following steps: conducting CBCT scanning on the maxillofacial part of a patient, obtaining DICOM data, guiding the data into three-dimensional modeling software-MIMICS (Materialise, Belgium) to reconstruct a jaw three-dimensional model, designing the individual restoration, designing models of a plurality of virtual screw according to the size of retention screws supposed to be adopted, then moving the models to the appropriate positions of the jaw to simulate the situation to the screw retention restoration, obtaining Von Mises stress and a strain nephogram, and manufacturing entities of various materials through the fast forming technology. The jaw defect individual restoration made through the manufacturing method for the jaw defect individual restoration has good performance in biomechanical properties including breaking strength, stress-strain distribution, the service life and the like. So far, a patient with upper and lower jaw defects accepting an implanting operation is observed for two years, and no bad complications of fracture, exposure and the like happen.

Owner:SICHUAN UNIV

Medical device with a bilateral jaw configuration for nerve stimulation

ActiveUS20170319265A1Increase energy levelDecreased energy levelSpinal electrodesImplantable neurostimulatorsMedicineSacral nerve stimulation

Aspects of the present disclosure are presented for a single surgical instrument configured to grasp, seal, and / or cut tissue through application of therapeutic energy, and also detect nerves through application of non-therapeutic electrical energy. A medical device may include two jaws at an end effector, used to apply therapeutic energy and to perform surgical procedures. The therapeutic energy may be in the form of ultrasonic vibrations or higher voltage electrosurgical energy. One of the jaws may be configured to cut tissue through application of the blade. In addition, one or both of the two jaws may be configured to apply nontherapeutic energy for nerve stimulation probing. The application of therapeutic energy may be disabled while the nontherapeutic nerve stimulation energy is applied, and vice versa. The nontherapeutic nerve stimulation energy may be applied to the use of one or more probes positioned near one or both of the jaws.

Owner:CILAG GMBH INT

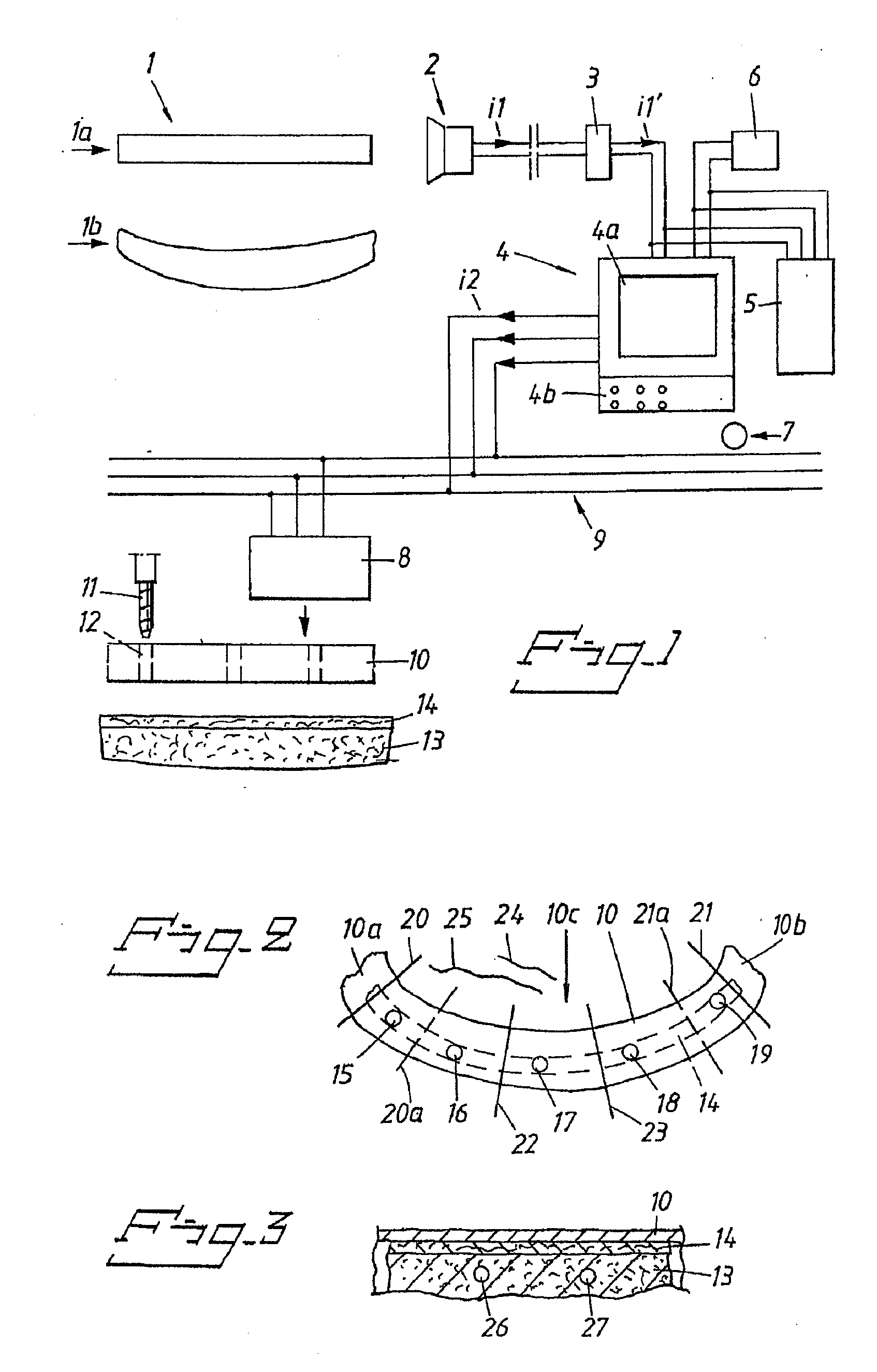

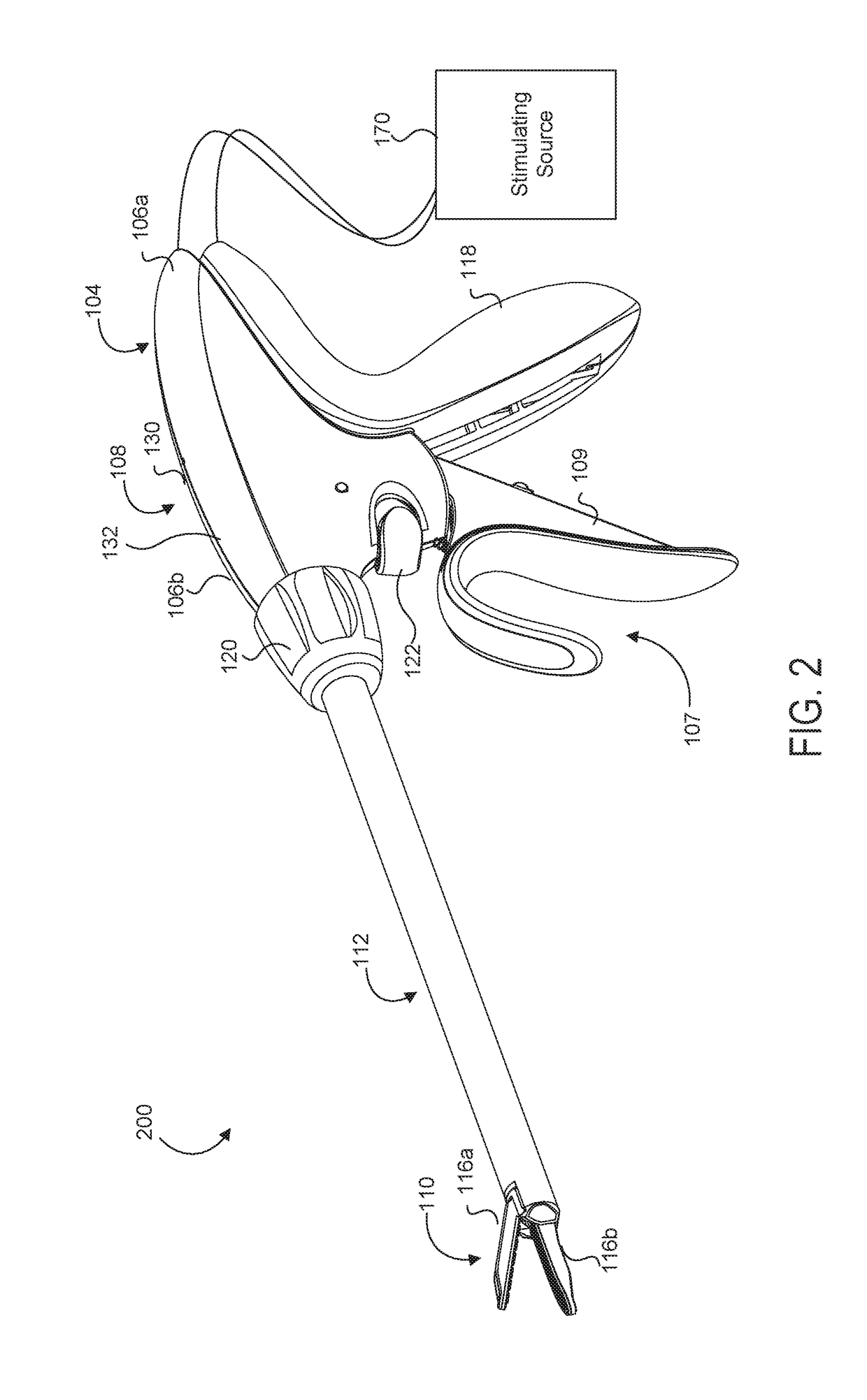

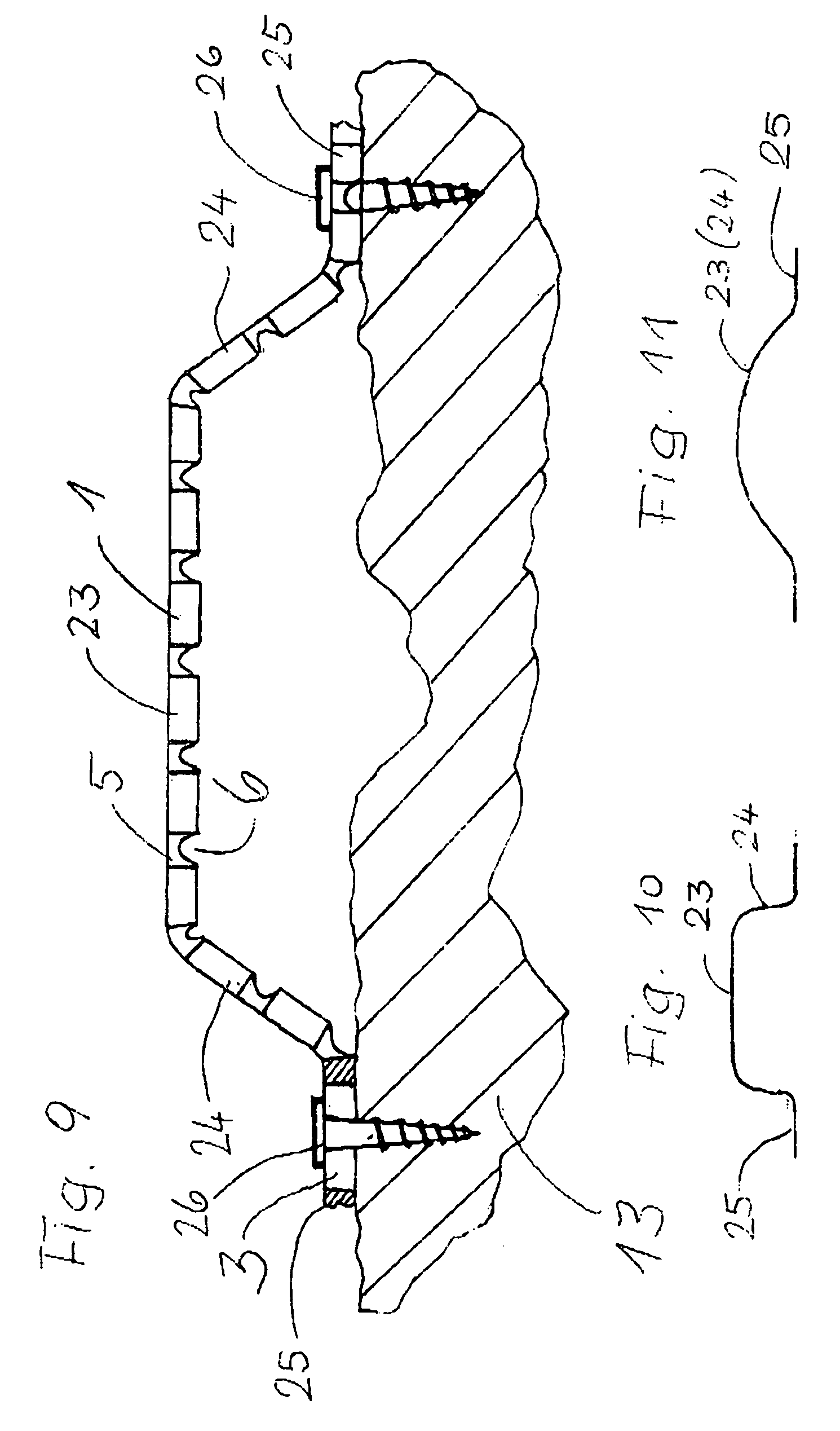

Device for regenerating, repairing, and modeling human and animal bone, especially the jaw area for dental applications

InactiveUS7172422B1Reduce stress loadStabilization and protectionDental implantsInternal osteosythesisTransverse grooveBone replacement

A device for reshaping human or animal bone with bone replacement material includes at least two spaced apart implants and a bar connected to the at least two spaced apart implants and bridging at least one reshaping location. The bar has notches at the longitudinal sides and transverse grooves at the underside. The bar has slotted holes extending in the longitudinal direction of the bar for receiving the implants, respectively, fasteners of the implants.

Owner:ESSIGER HOLGER K

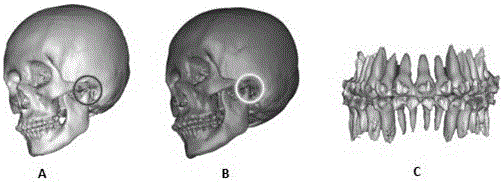

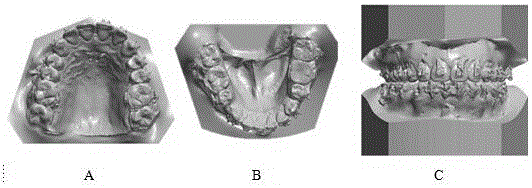

Method for building three-dimensional tooth-and-jaw fusion model

InactiveCN105919684AShorten the timeSave manpower and material resourcesDental articulatorsEducational modelsComputer Aided DesignLaser scanning

The invention discloses a method for building a three-dimensional tooth-and-jaw fusion model. The method includes the steps that data is collected in the occlusion state, and a skull CT image is rebuilt, laser scanning of a gypsum occlusion model is subjected to digital processing; picture processing and the image matching function are based on a reverse engineering software Geomagic Studio, a method based on point matching and the iterative algorithm are combined in the reverse engineering software, a gypsum dentition occlusion model and CT rebuilt dentitions are matched, indistinct CT rebuilt dentitions are replaced, and finally, the three-dimensional tooth-and-jaw fusion model matched in the occlusion state that a CT rebuilt jaw model and the gypsum dentition occlusion model are integrated is obtained. CT imaging artifacts caused by intraoral metal and the error, caused by upper-and-lower-jaw dentition overlapping in the occlusion state, between the occlusion relationship and the practical intraoral occlusion position in the fusion model are reduced, and therefore the accuracy of computer aided design and the treating effect are improved.

Owner:穆檬檬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com