Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4186 results about "Breaking strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Breaking strength is more commonly known as tensile strength. It is defined as the point at which certain materials will become deformed or break under a given load. The point at which the material comes to breaking strength is described as necking.

Copolymers of tetrafluoroethylene

ActiveUS7531611B2Synthetic resin layered productsThin material handlingBreaking strengthTetrafluoroethylene

A polymerization process for producing a tetrafluoroethylene copolymer, and the copolymer produced thereby, are provided. The copolymer is of the dispersion / fine powder type and contains polymerized tetrafluoroethylene monomer units and co-polymerized higher homologous comonomer units having the formula (CnF(2n+1))CH═CH2, wherein 6≦n<10, in which the primary particles are believed to have a core and shell structure and the polymerized comonomer units are present in an amount from 0.01 mol % to 0.3 mol %, based upon total copolymer composition. The copolymer has a raw dispersion primary particle size (RDPS) of less than 0.210 microns coupled with a standard specific gravity (SSG) of less than 2.143. Preferably the copolymer has comonomer units present in an amount from 0.05 mol % and 0.25 mol % and the RDPS is within the range between 0.178 microns and 0.200 microns, coupled with a SSG of less than 2.140. Copolymers produced according to the invention, (perfluorohexyl)ethylene (PFHE) and (perfluorooctyl)ethylene (PFOE), may be shaped into the form of 0.1 inch diameter expanded beading, which expanded beading can have a break strength of at least 10.0 lbs, and which may exceed 13.0 lbs.

Owner:WL GORE & ASSOC INC

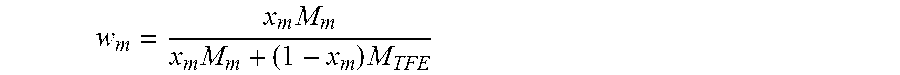

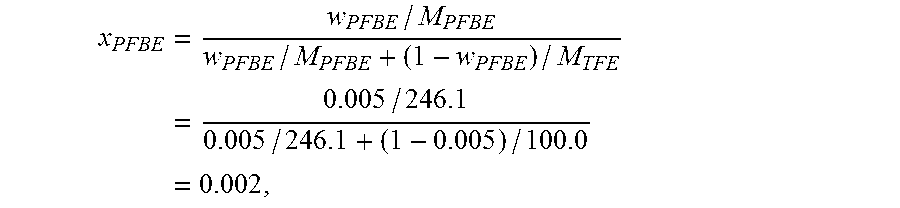

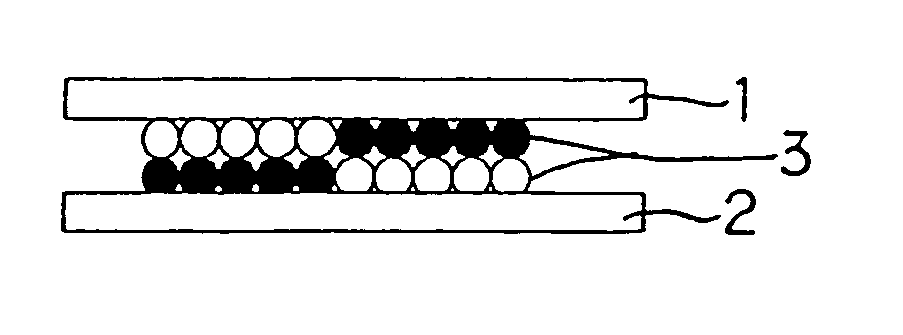

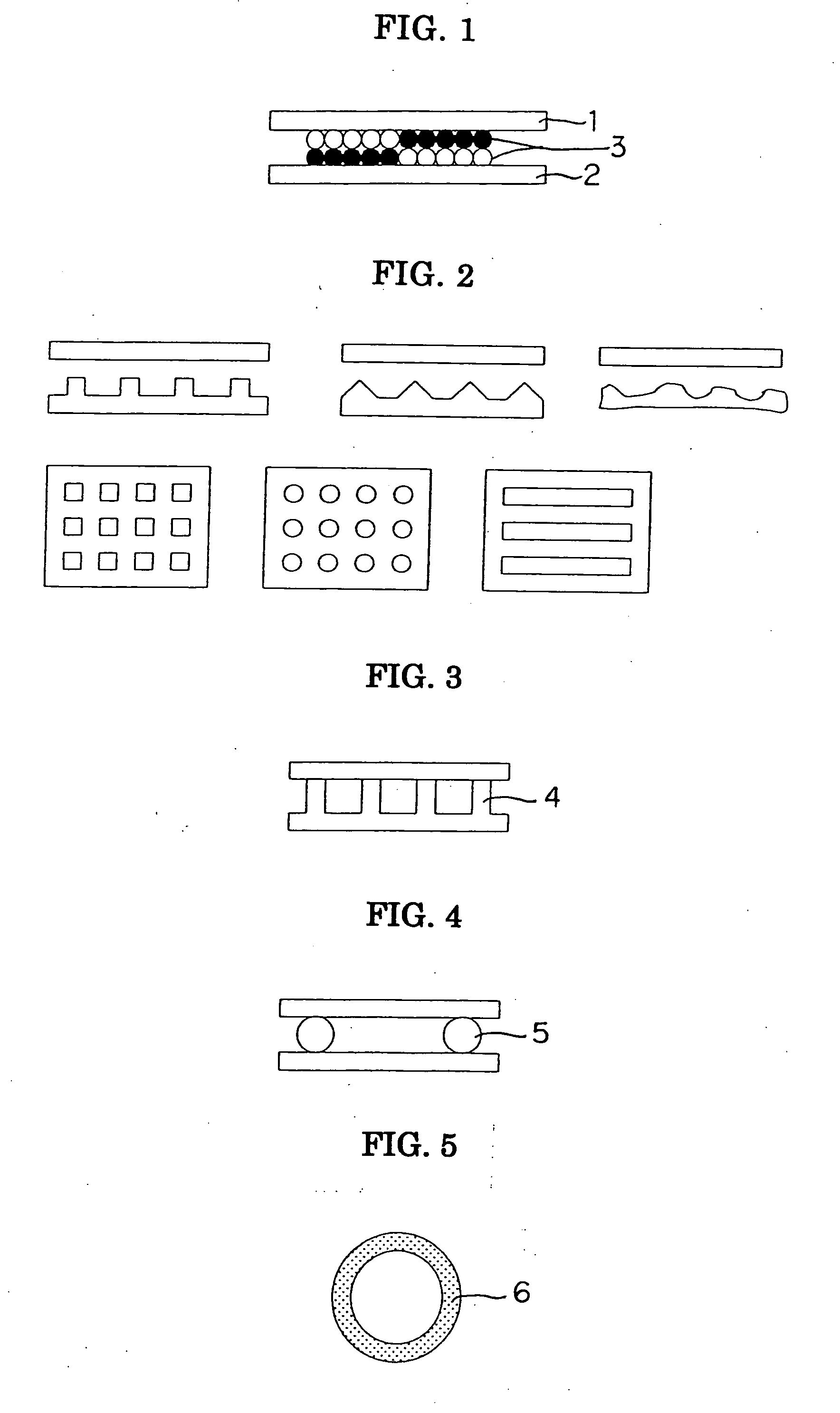

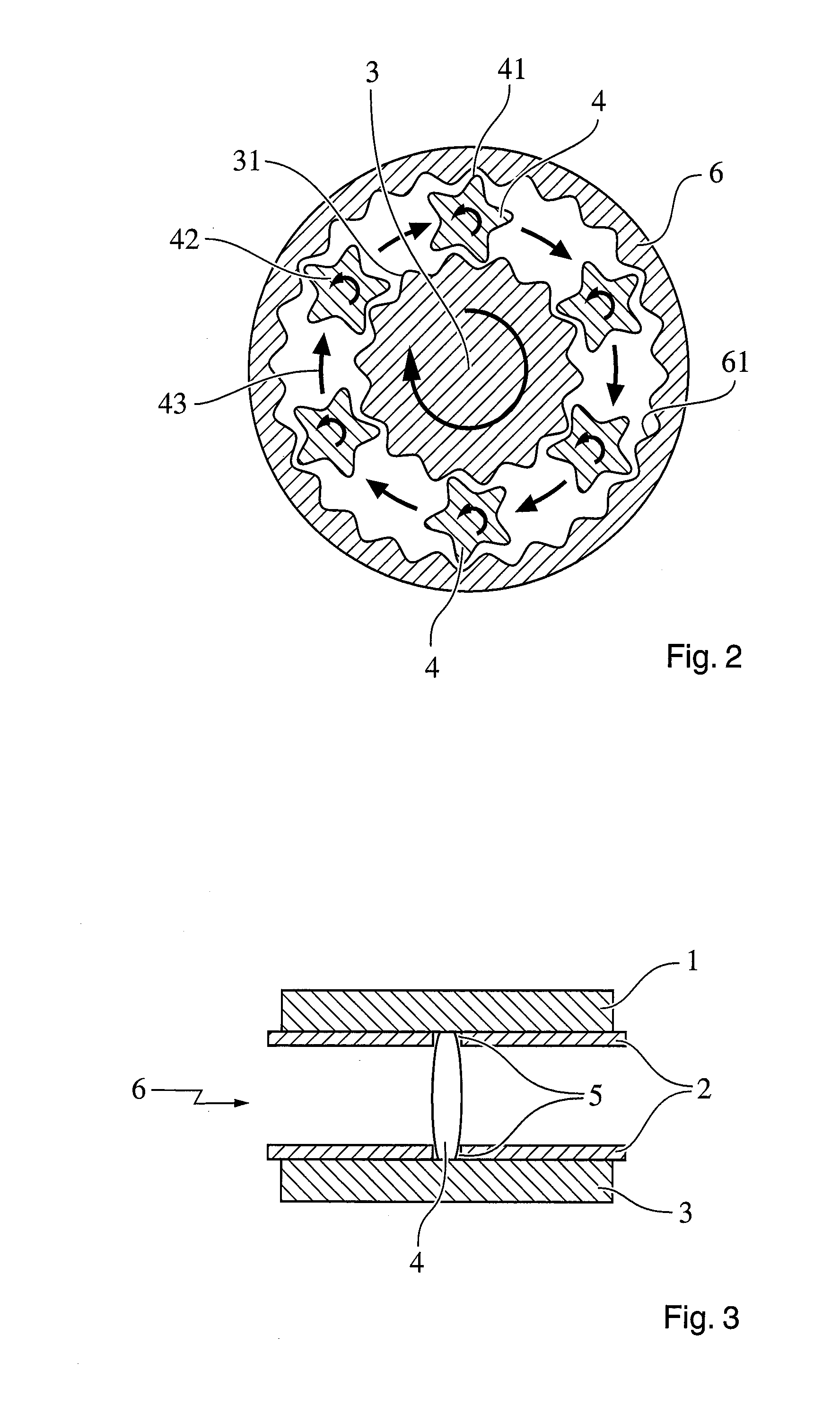

Particles and device for displaying image

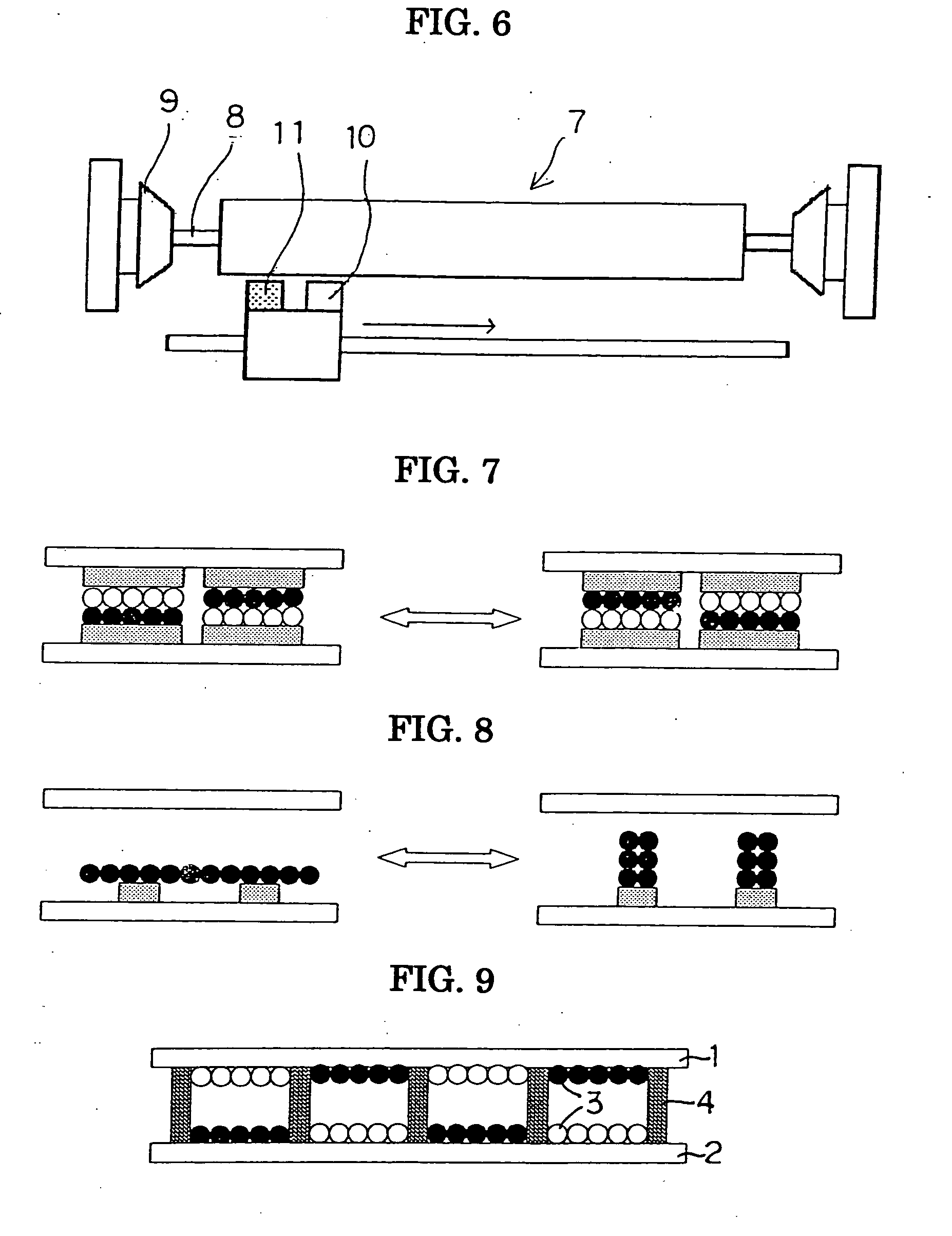

InactiveUS20050001810A1Improve stabilityEnhance the imageStatic indicating devicesNon-linear opticsBreaking strengthUltrasound attenuation

The present invention intends to provide particles for displaying images used in an image display device capable of displaying and eliminating repeatedly accompanied by flight and movement of particles utilizing Coulomb force, being superior in stability, particularly in repetition durability, memory characteristic stability, adaptability for temperature change, having capability of regulating charge amount, and accordingly, favorable images with sufficient contrast should be stably obtained. The present invention provides particles coated with a resin; specifying Span of particle diameter distribution, charge attenuation property, thermal change of the surface hardness, tensile break strength, Izod impact strength (with a notch), abrasion loss (Taber), tensile elastic modulus, flexural elastic modulus, or tear strength. The present invention also proposes about the structure of the particles.

Owner:BRIDGESTONE CORP

Abuse-proofed dosage form

ActiveUS8114383B2Pulverisation of the dosage form is considerably more difficultComplicating or preventing the subsequent abuseOrganic active ingredientsPowder deliveryBreaking strengthPhysiology

The present invention relates to an abuse-proofed, thermoformed dosage form containing, in addition to one or more active ingredients with abuse potential optionally together with physiologically acceptable auxiliary substances, at least one synthetic or natural polymer with a breaking strength of at least 500 N and to a process for the production thereof.

Owner:GRUNENTHAL GMBH

Abuse-proofed dosage form

InactiveUS20070048228A1Pulverization of the dosage form is considerably more difficultComplicating or preventing the subsequent abuseBiocidePill deliveryBreaking strengthUltimate tensile strength

The invention relates to a dosage form that is thermoformed without discoloration and is safeguarded from abuse, comprising at least one synthetic or natural polymer having a breaking strength of at least 500 N in addition to one or more active substances that could be subject to abuse. The invention also relates to a corresponding method for producing said dosage form.

Owner:GRUNENTHAL GMBH

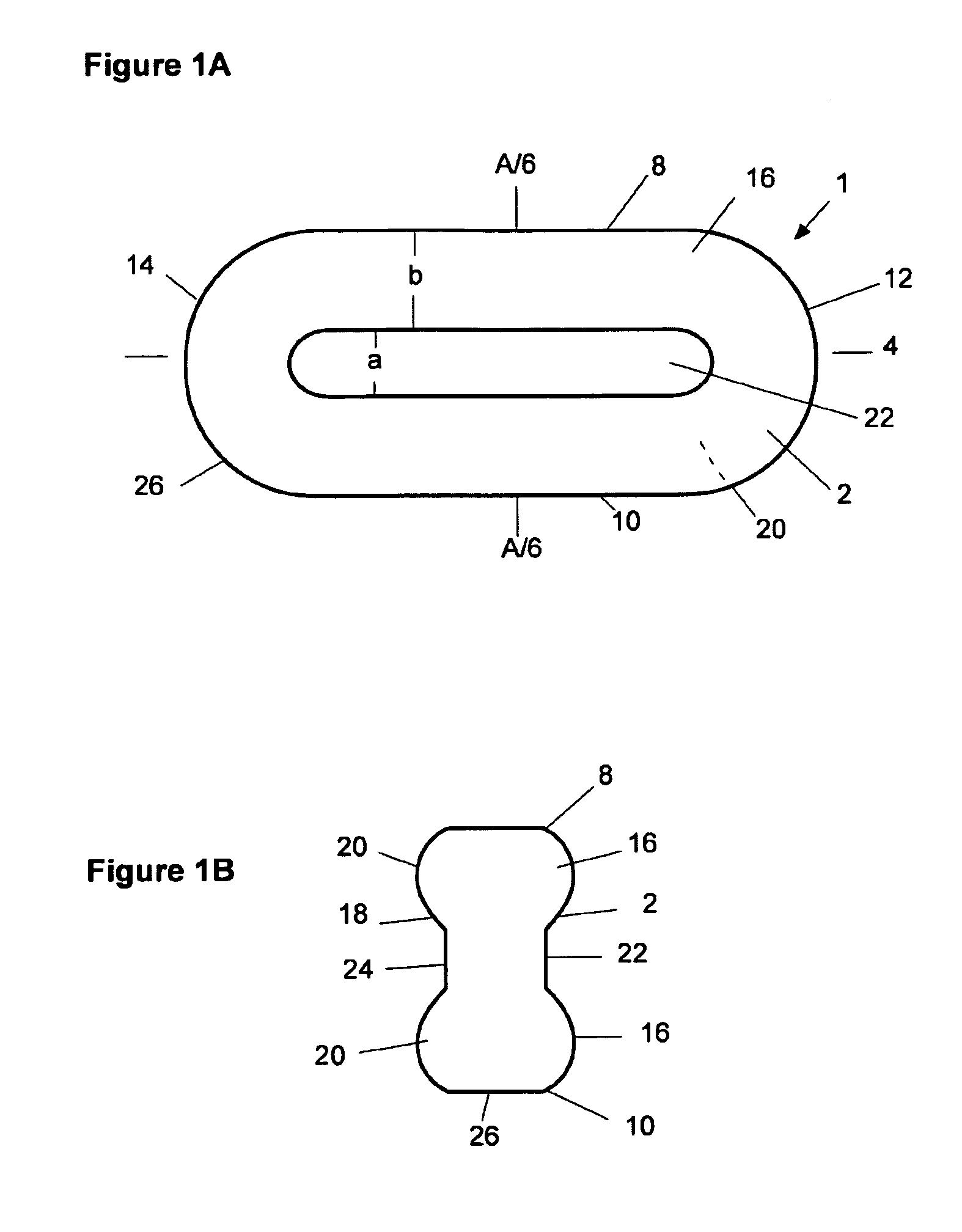

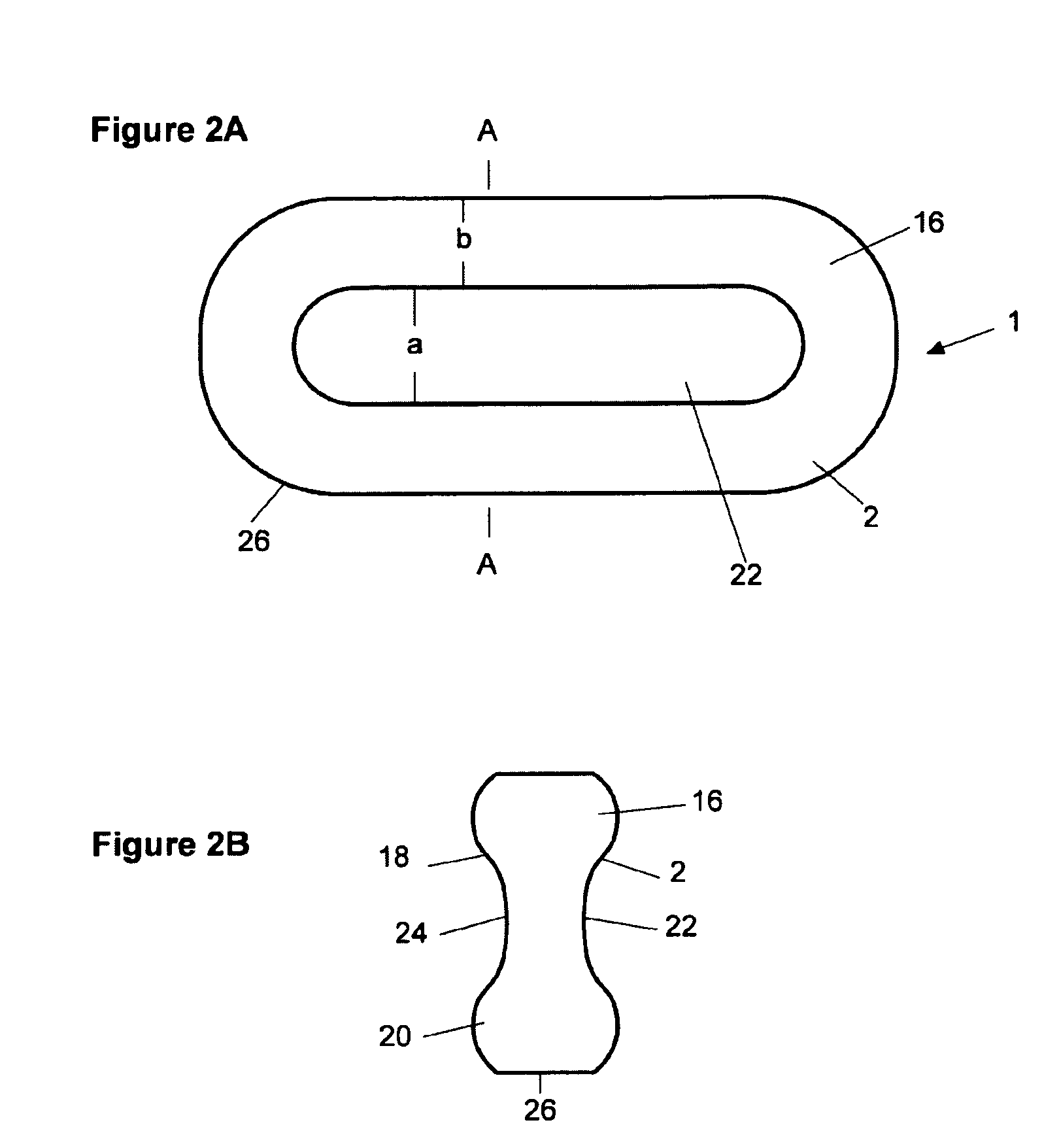

Pharmaceutical dosage form

ActiveUS20090202634A1Improved controlled releaseEasy to adjustBiocideOrganic active ingredientsControlled releaseBreaking strength

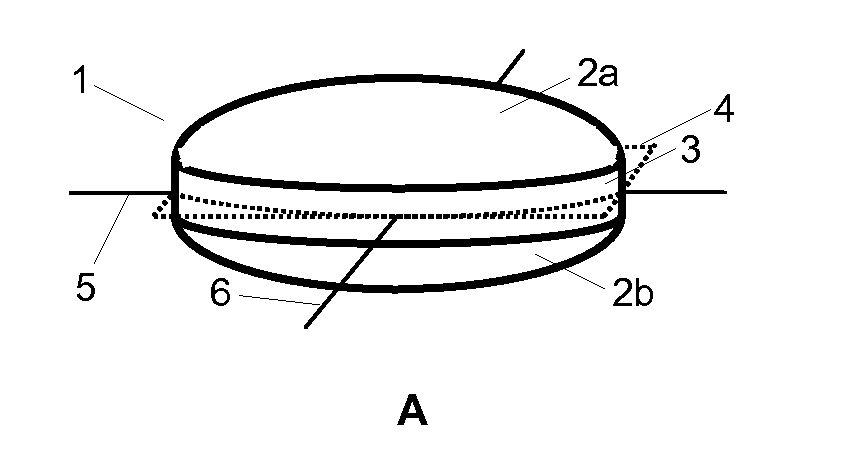

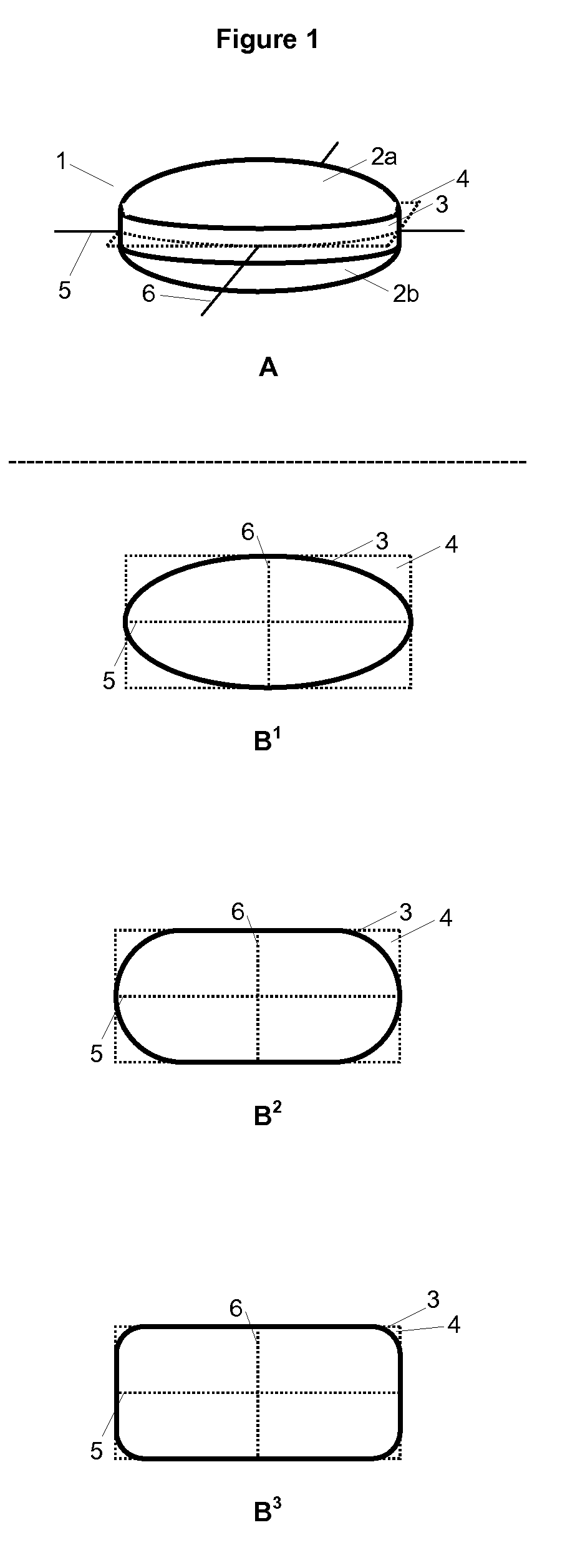

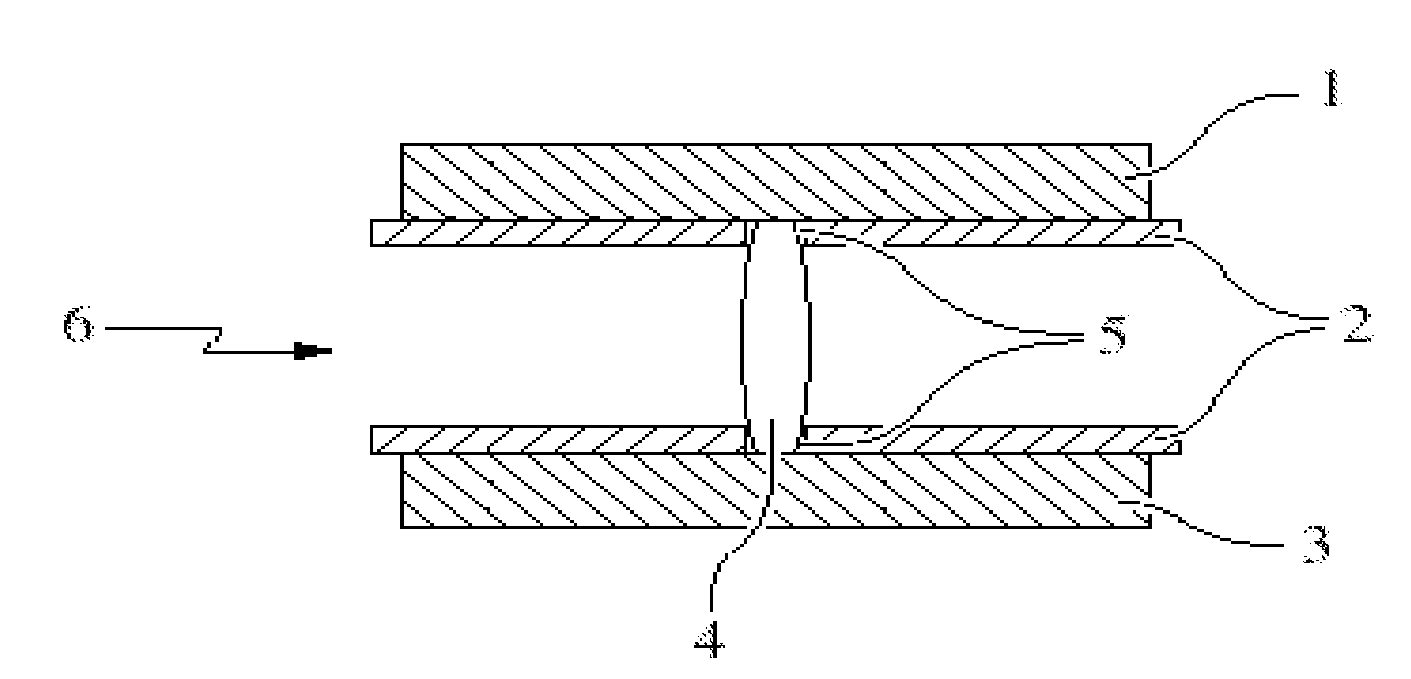

The invention relates to a pharmaceutical dosage form, preferably with controlled release of a pharmacologically active compound (A) contained therein, the pharmaceutical dosage form very preferably being tamper-resistant and most preferably having a breaking strength B1 of at least 500 N in direction of extension E1 and having a breaking strength B2 of less than 500 N in direction of extension E2.

Owner:GRUNENTHAL GMBH

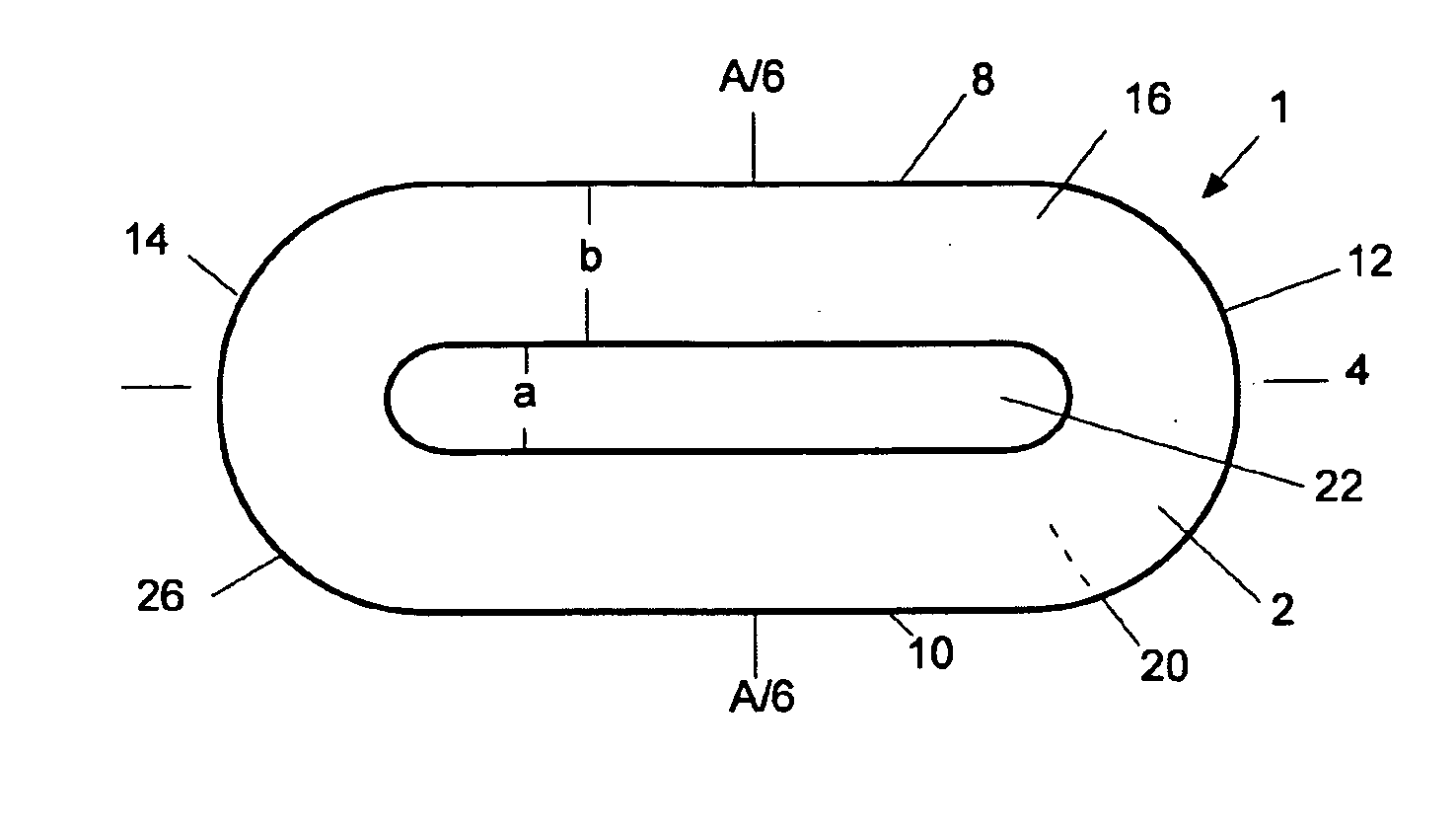

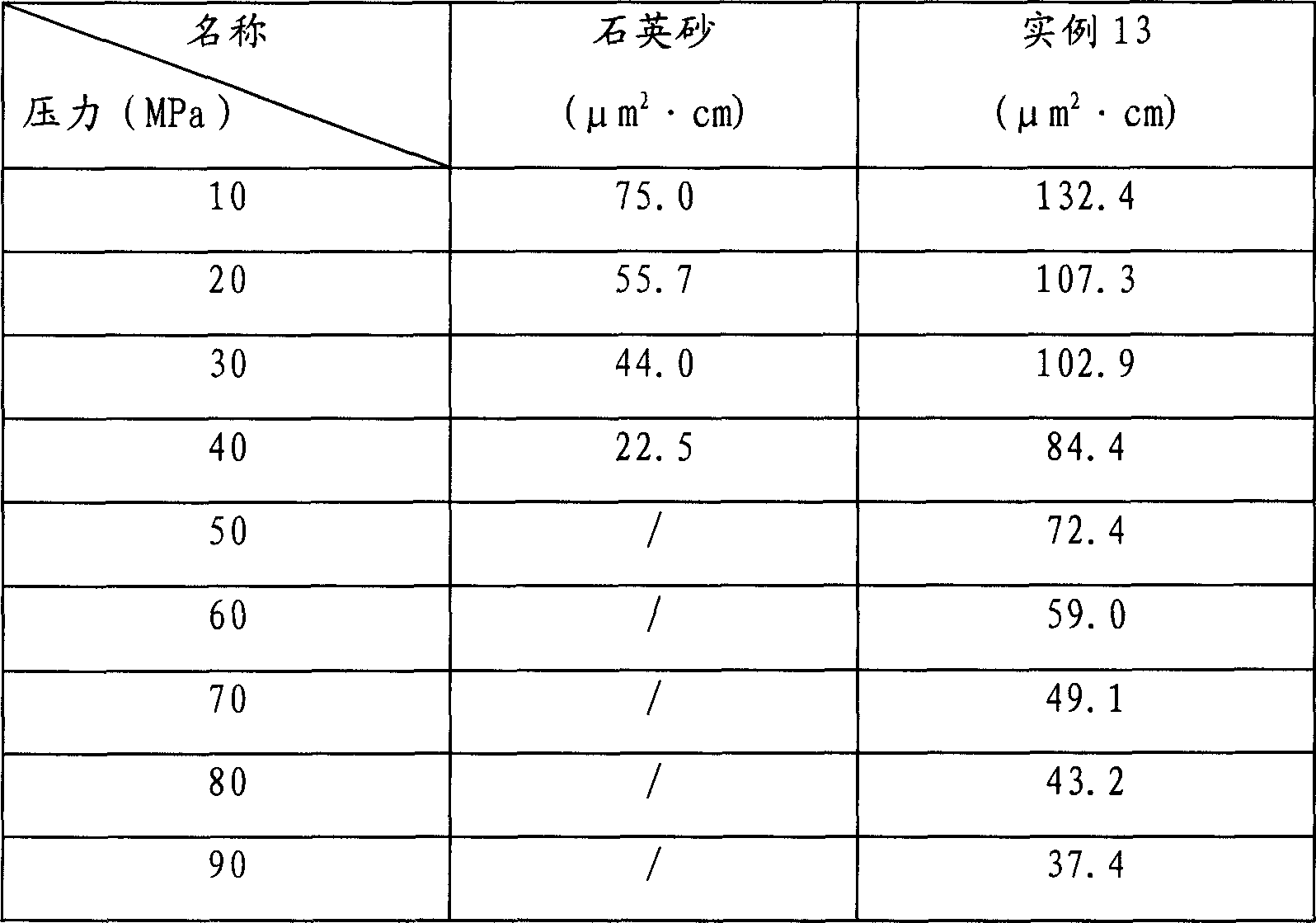

Hot-melt extruded pharmaceutical dosage form

ActiveUS20110038930A1Quick releaseRate of releaseBiocideNervous disorderBreaking strengthControlled release

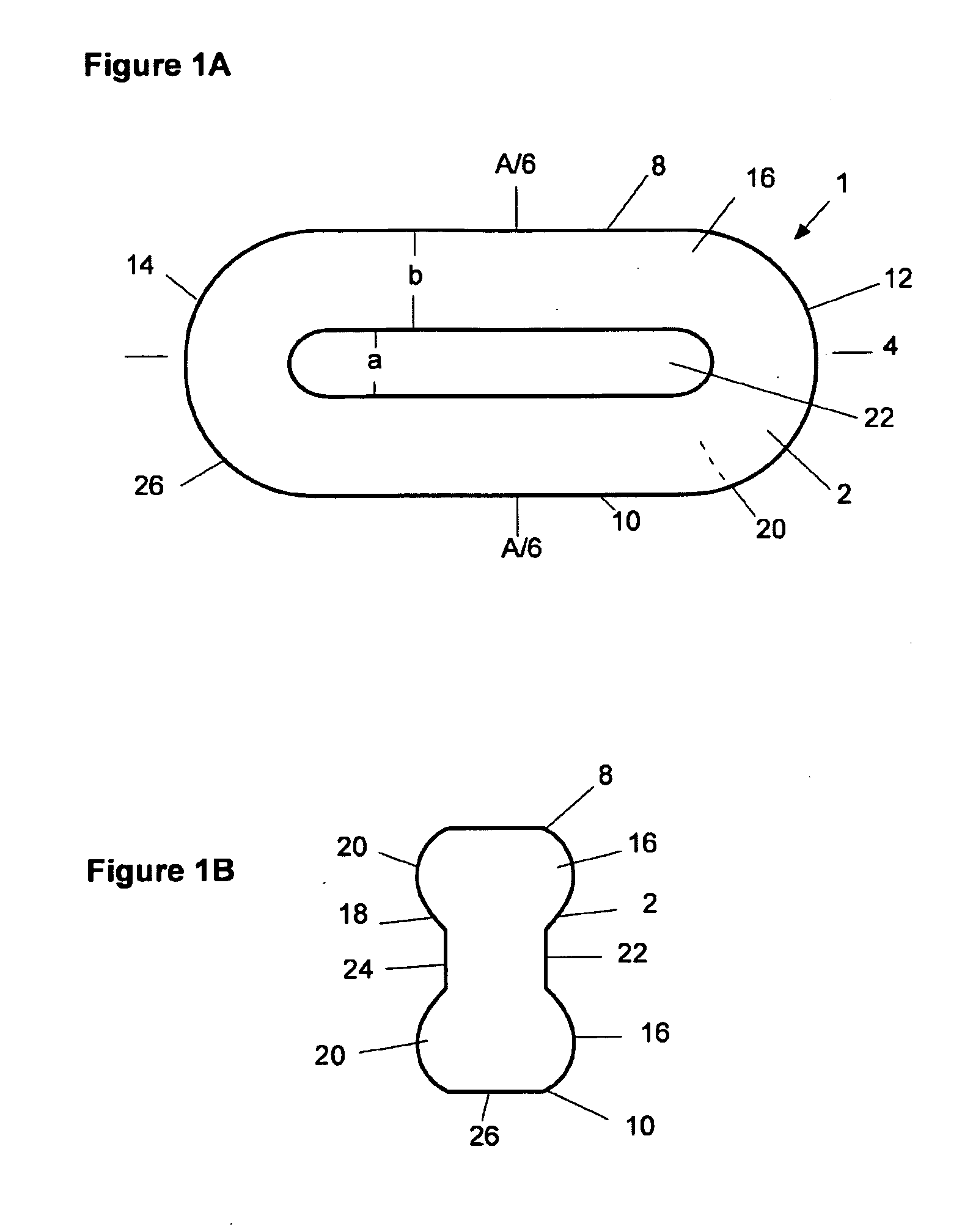

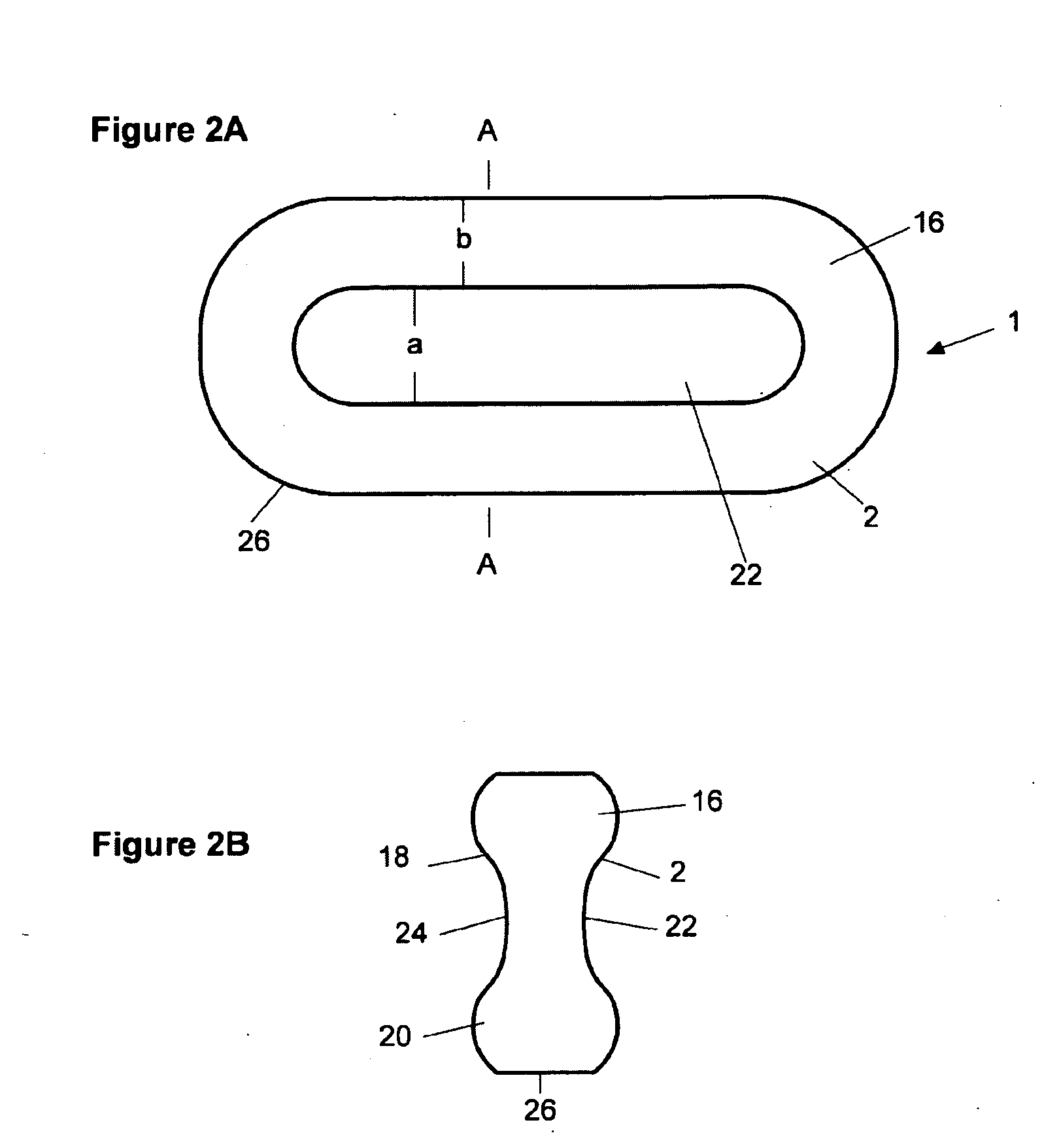

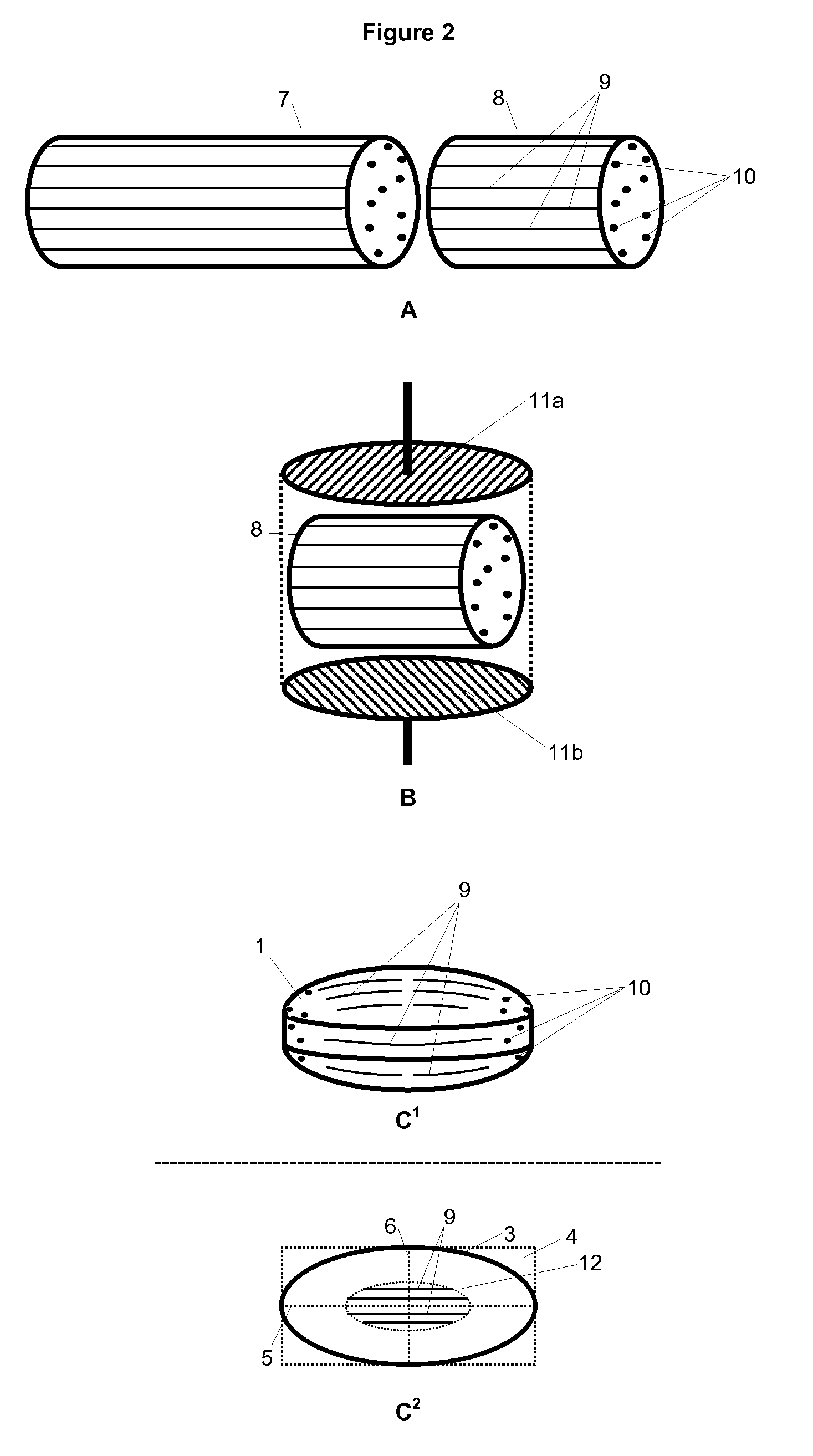

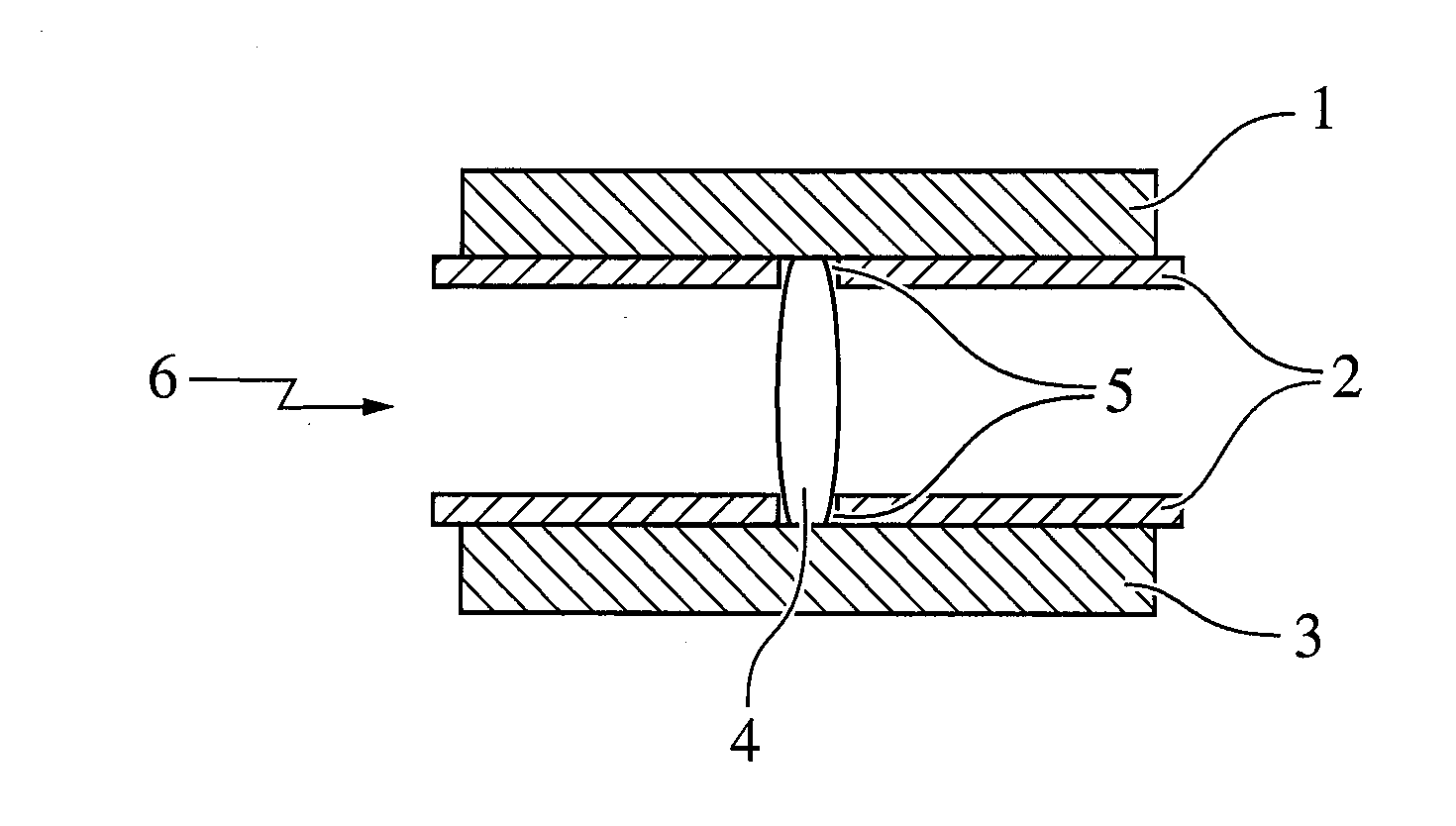

The invention relates to a hot-melt extruded pharmaceutical dosage form with controlled release of a pharmacologically active ingredient (A) embedded in a matrix comprising a polymer (C), the dosage form exhibiting a breaking strength of at least 300 N and having an oblong shape comprising a longitudinal direction of extension, a transversal direction of extension orthogonal to the longitudinal direction of extension, a front side, an opposite back side and a circumferential rim between said front and back side;whereinthe core of the pharmaceutical dosage form has a morphological orientation caused by hot-melt extrusion that is substantially orthogonal to the longitudinal direction of extension of the dosage form; and / orthe release per area of the pharmacologically active ingredient (A) through the front side and the opposite back side is faster than the release through the circumferential rim.

Owner:GRUNENTHAL GMBH

Process for the production of an abuse-proofed dosage form

InactiveUS20090005408A1Pulverisation of the dosage form is considerably more difficultComplicating or preventing the subsequent abuseBiocideNervous disorderBreaking strengthMedicine

The present invention relates to a process for the production of abuse-proofed, thermoformed dosage forms containing, apart from one or more active ingredients with potential for abuse and optionally physiologically acceptable auxiliary substances, at least one synthetic or natural polymer with a breaking strength of at least 500 N.

Owner:GRUNENTHAL GMBH

Process for the production of an abuse-proofed solid dosage form

ActiveUS8114384B2Intense negative effectConsiderably complicatedNervous disorderPill deliveryBreaking strengthMedicine

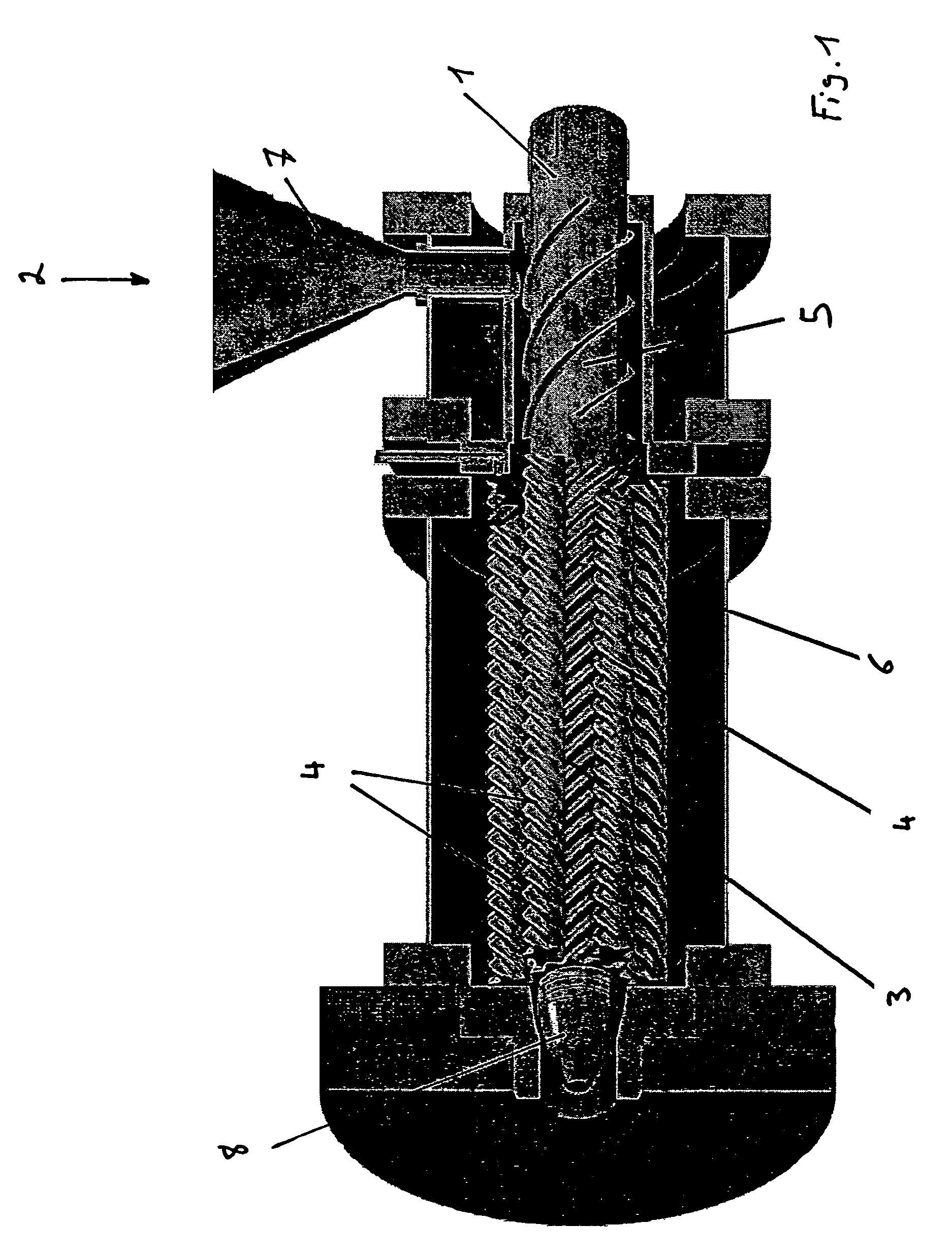

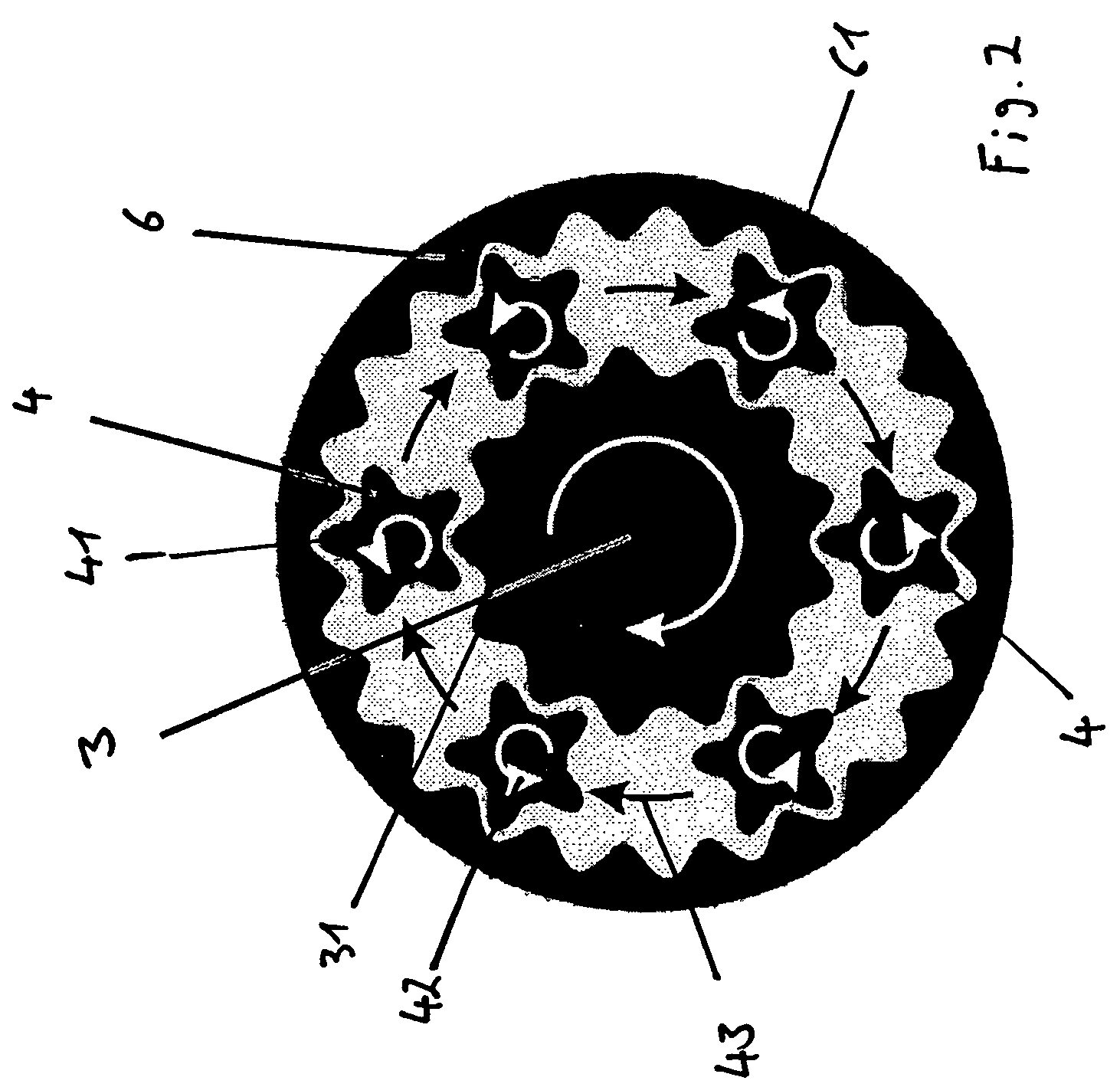

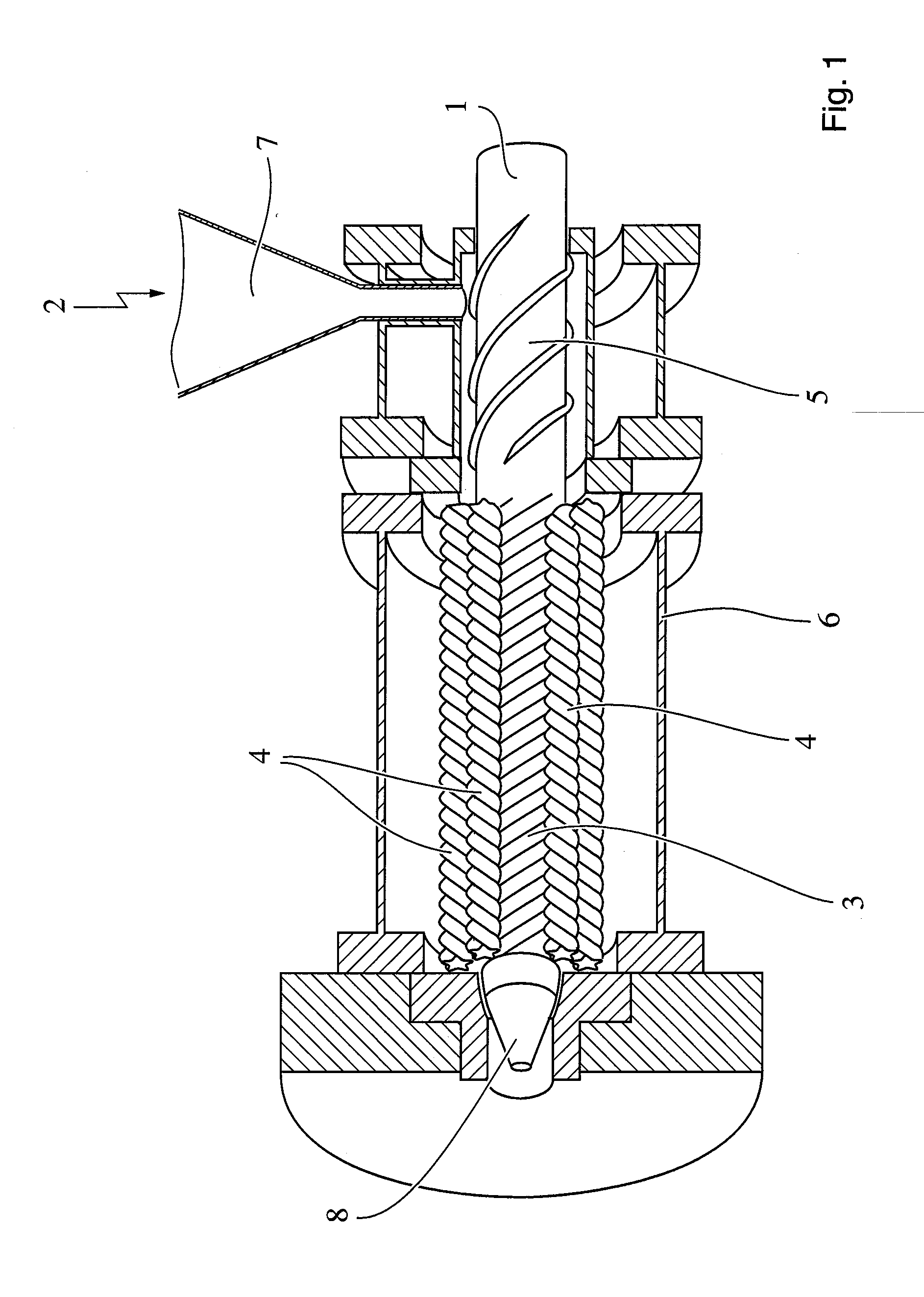

The present invention relates to a process for the production of an abuse-proofed solid dosage form containing at least one active ingredient with potential for abuse and a synthetic or natural polymer with a breaking strength of =500 N, characterized in that a corresponding mixture is processed by melt extrusion with the assistance of a planetary-gear extruder.

Owner:GRUNENTHAL GMBH

Dosage Form with Impeded Abuse

InactiveUS20090004267A1Prevent crushingPrevent the subsequent abuseOrganic active ingredientsPowder deliveryWaxBreaking strength

A multiparticulate dosage form formulated to make misuse more difficult containing least one active substance with potential for misuse (A), at least one synthetic or natural polymer (C), optionally at least one natural, semi-synthetic or synthetic wax (D), at least one disintegrant (E) and optionally one or more additional physiologically compatible excipients (B), wherein the individual particles of the dosage form display a breaking strength of at least 500 N and a release of active substance of at least 75% after 45 minutes measured according to Ph.Eur. in the paddle mixer with sinker in 600 ml of aqueous buffer solution with a pH value of 1.2 at 37° C. and 75 rpm.

Owner:GRUNENTHAL GMBH

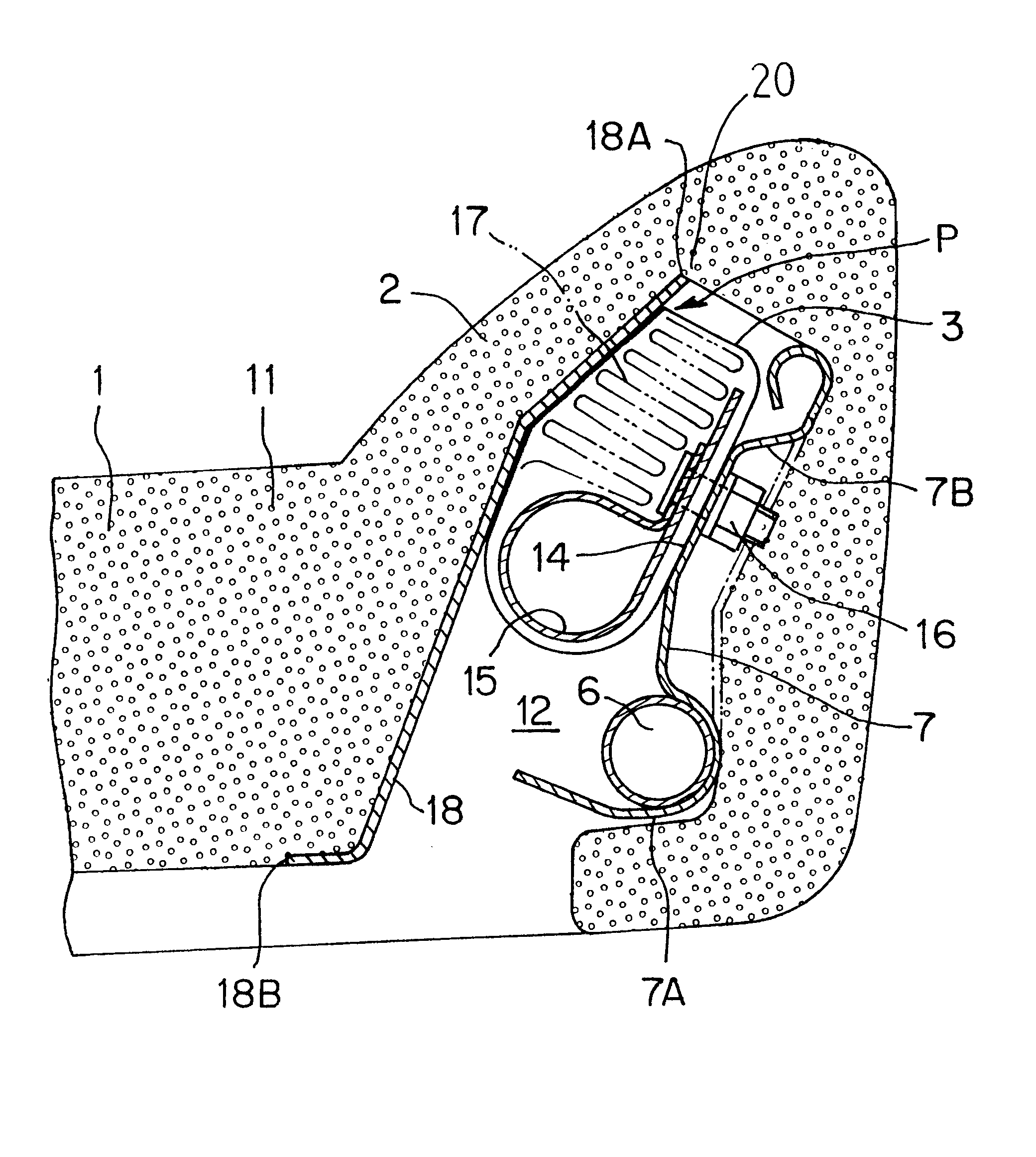

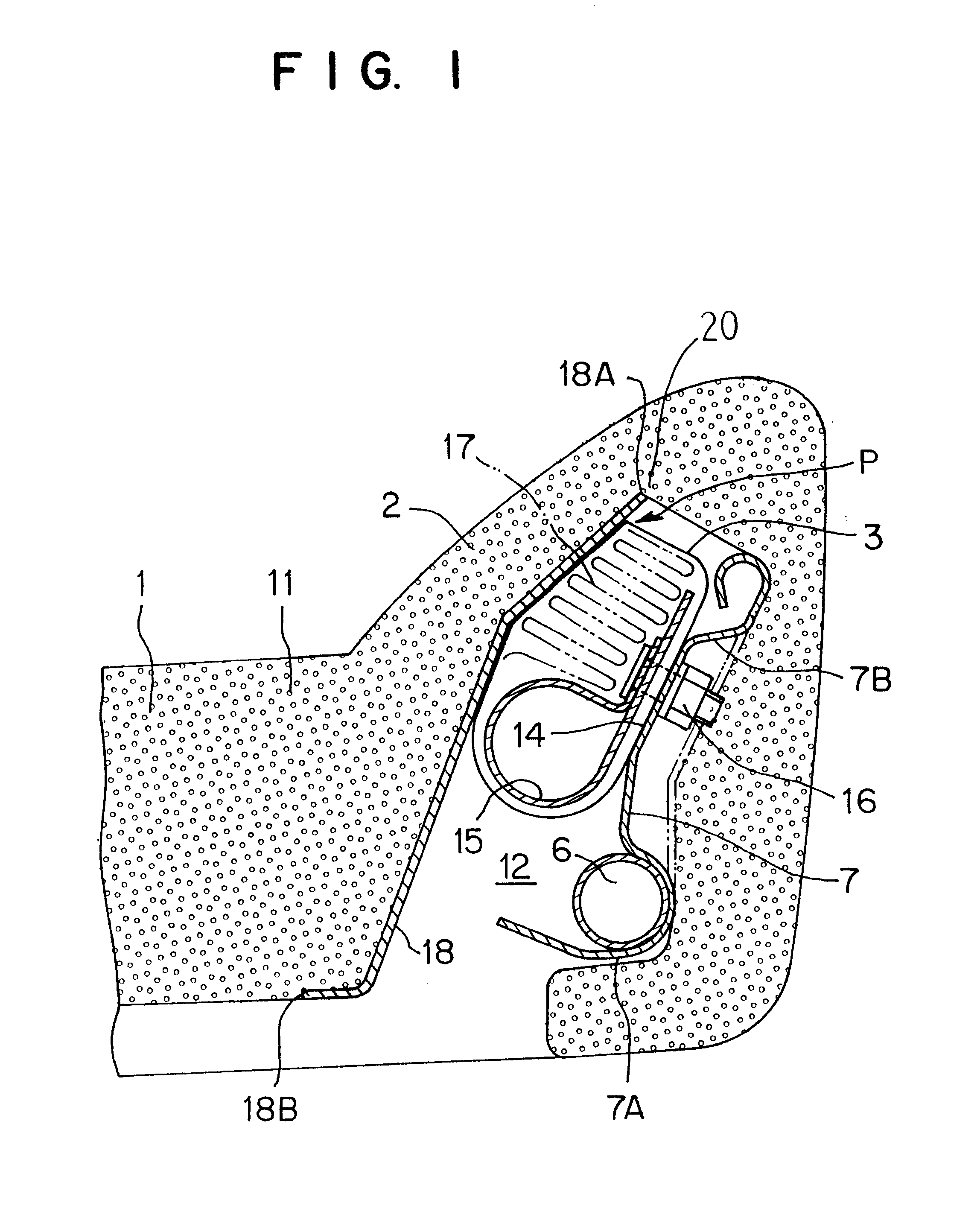

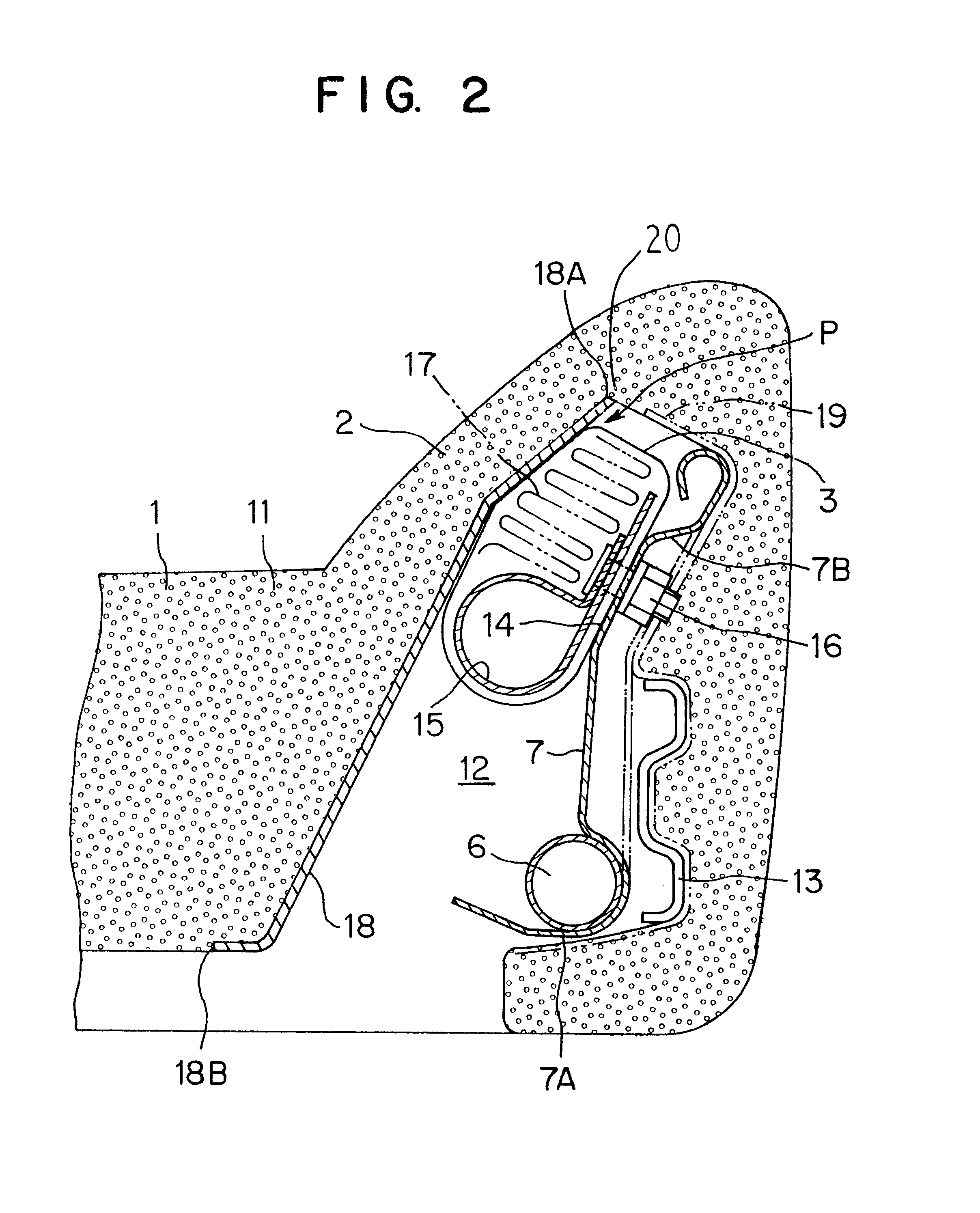

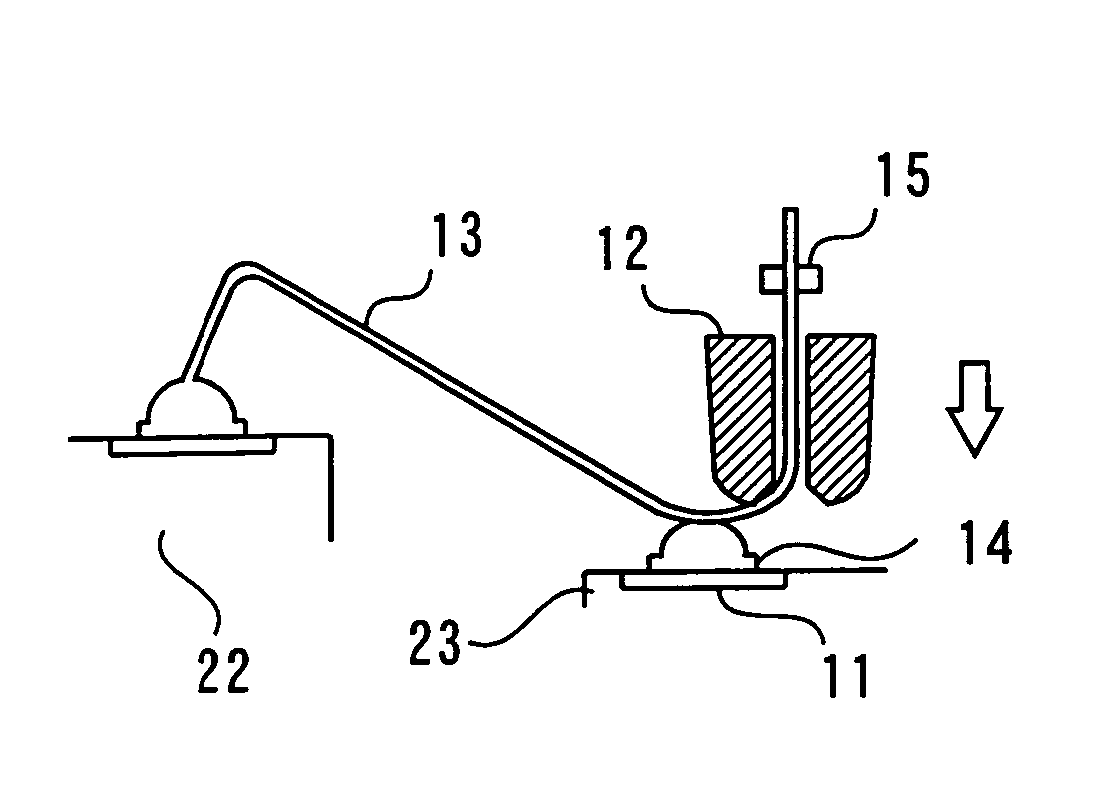

Automobile seat

InactiveUS6206466B1Stay attractiveGood effectPedestrian/occupant safety arrangementSeat framesBreaking strengthCar seat

An automobile seat is provided with a side impact air bag accommodated within a seat back. To permit prompt burst-out of the side impact air bag precisely at a predetermined position in a predetermined direction without the need for the arrangement of a member different in nature from a surface of the seat back on the surface of the seat back, an air bag module is arranged within a cushion pad of the seat back. Further, the cushion pad is provided, on a surface of a surrounding portion thereof with which the air bag is brought into contact upon spreading, with a guide member which increases breaking strength of the cushion pad and specifies the cushion pad to be broken at a break portion under inflating force of the air bag.

Owner:MITSUBISHI MOTORS CORP

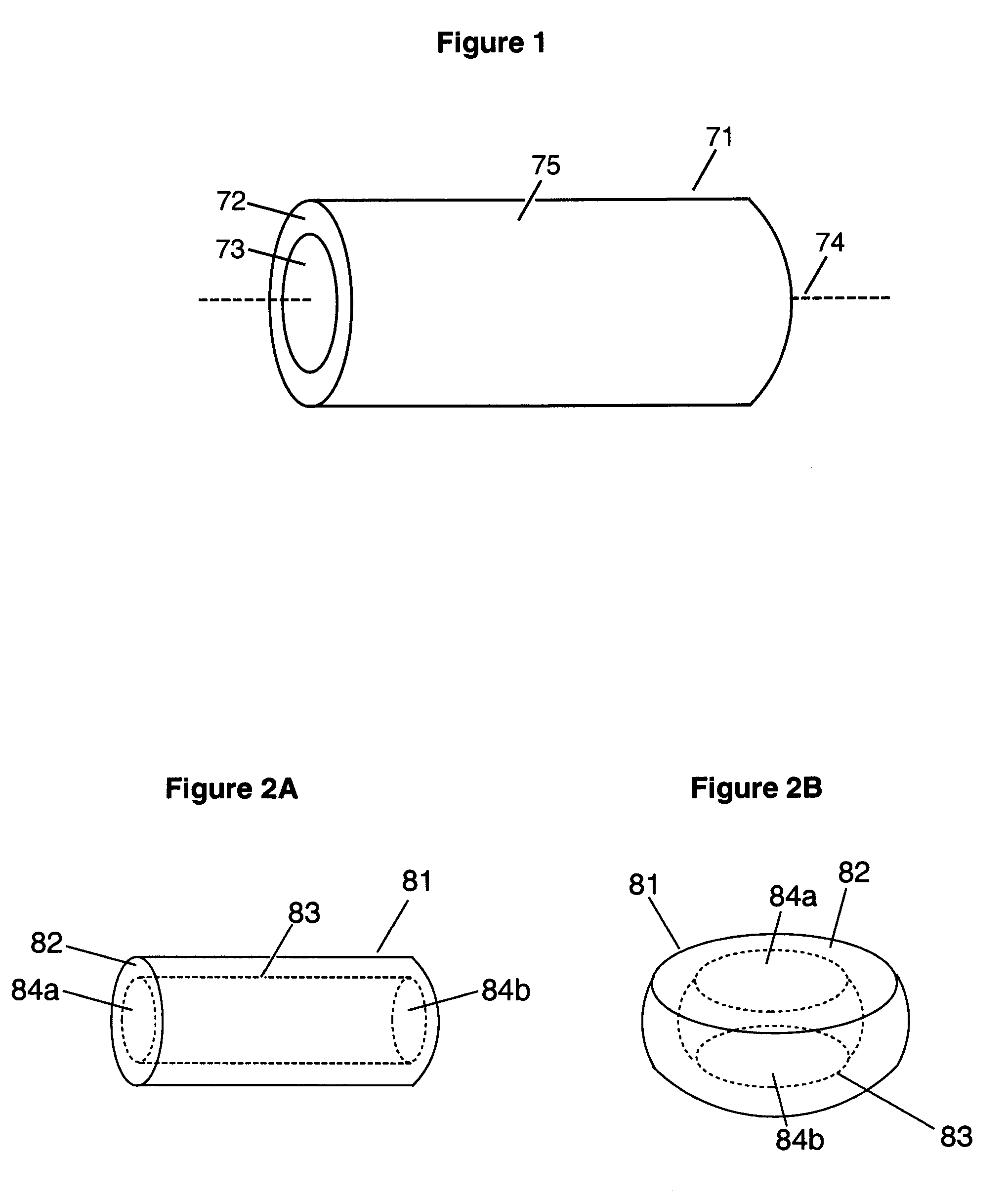

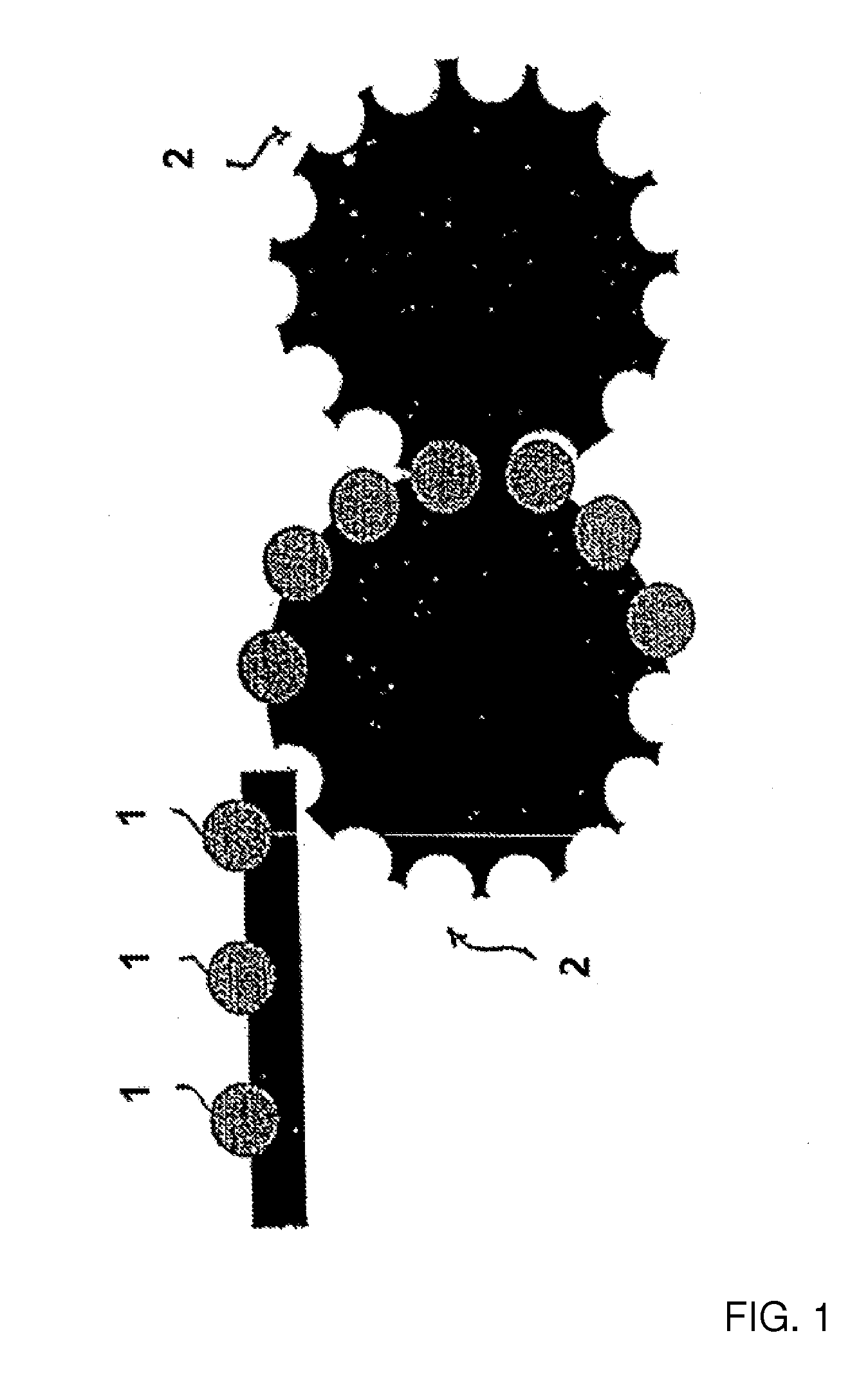

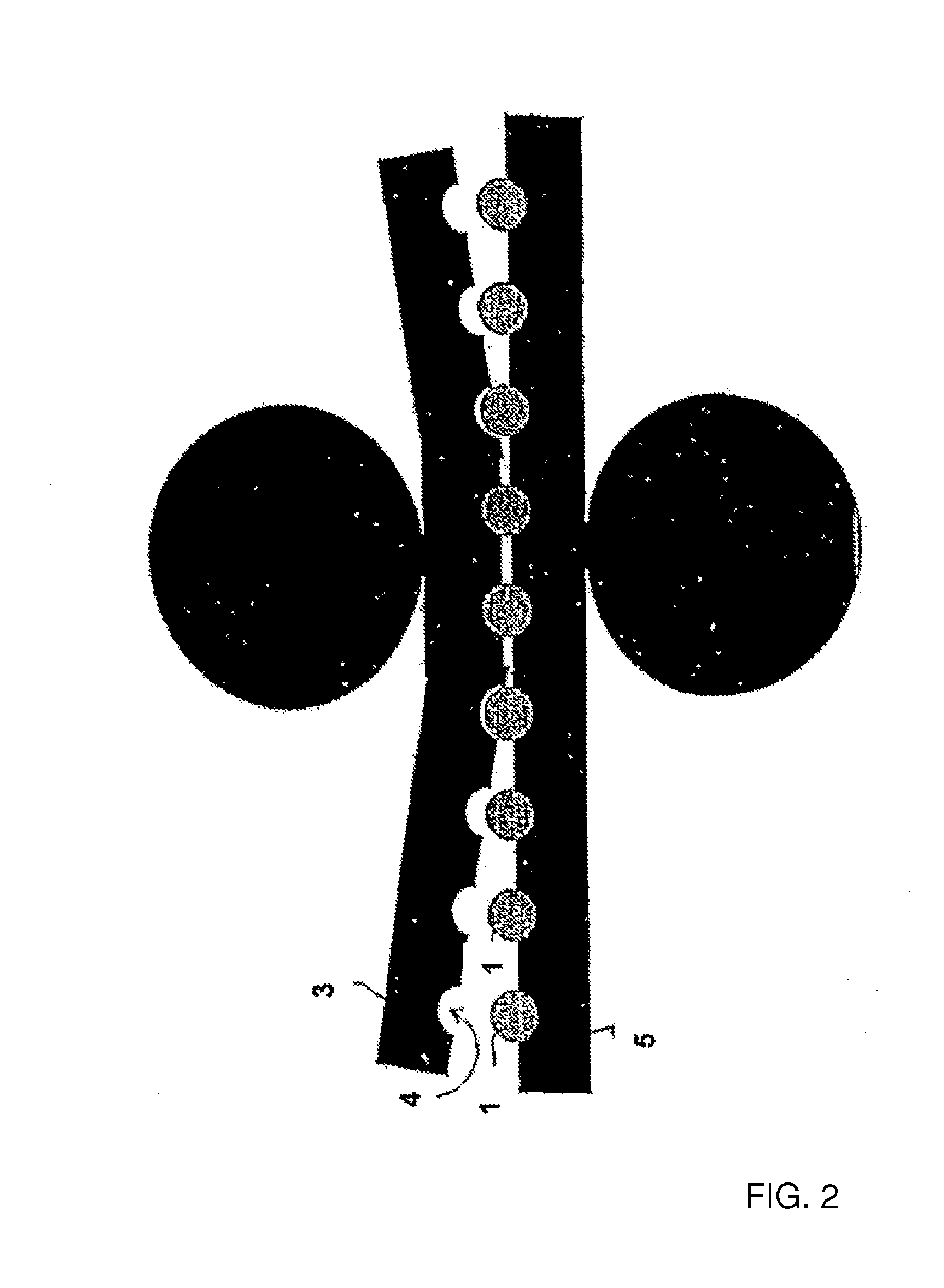

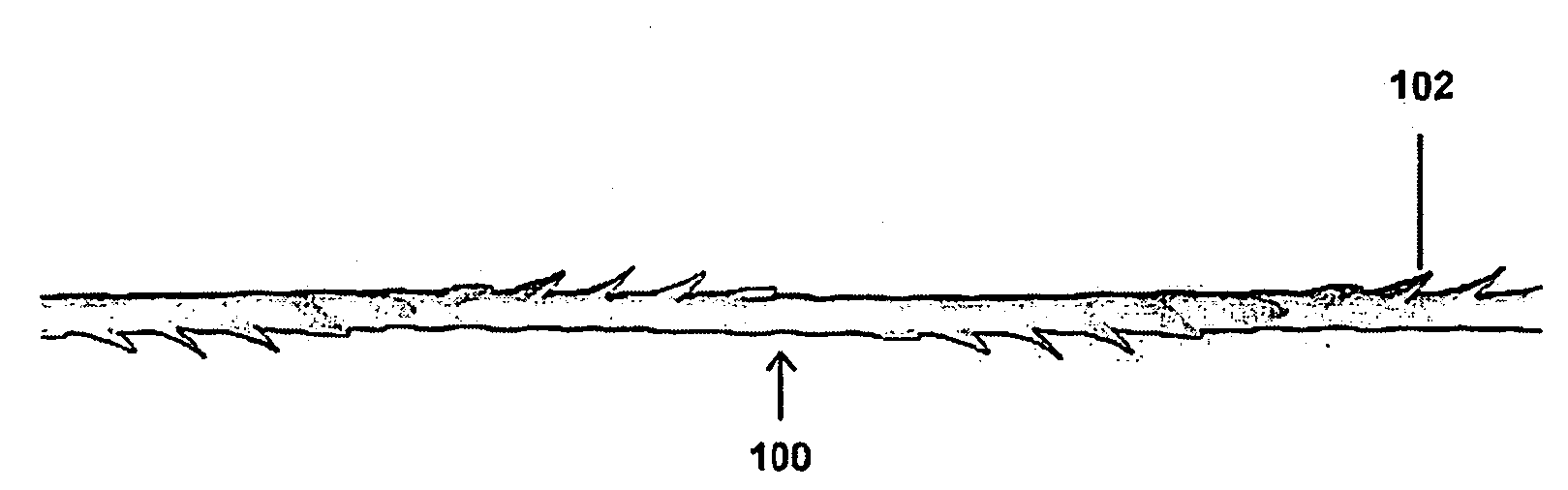

Recombinant expressed bioadsorbable polyhydroxyalkonate monofilament and multi-filaments self-retaining sutures

InactiveUS20090112259A1Suture equipmentsMonocomponent synthetic polymer artificial filamentMicroorganismBreaking strength

The present invention provides polymers made by genetically engineering microorganisms for making a self-retaining suture. In an embodiment of the present invention the genetically engineering microorganisms synthesize polyhydroxyalkanoate (PHA) polymers. In an alternate embodiment of the invention, the genetically engineering microorganisms synthesize polybetahydroxybutyrate (PHB) polymers. In an alternative embodiment of the invention, the self-retaining sutures can be made from a copolymer such as polyhydroxybutyratevalerate (PHBV), where the genetically engineering microorganisms produces PHA polymers as the monofilament base material and a different genetically engineering microorganisms produces polyhydroxybutyratevalerate (PHBV) polymers. In various embodiments of the invention, recombinant expressed self-retaining suture materials have a melting point in the range from between approximately 40° C. to approximately 180° C. In various embodiments of the invention, recombinant expressed self-retaining suture materials have extension-to-break strength of between approximately 8% and approximately 42%.

Owner:ETHICON INC

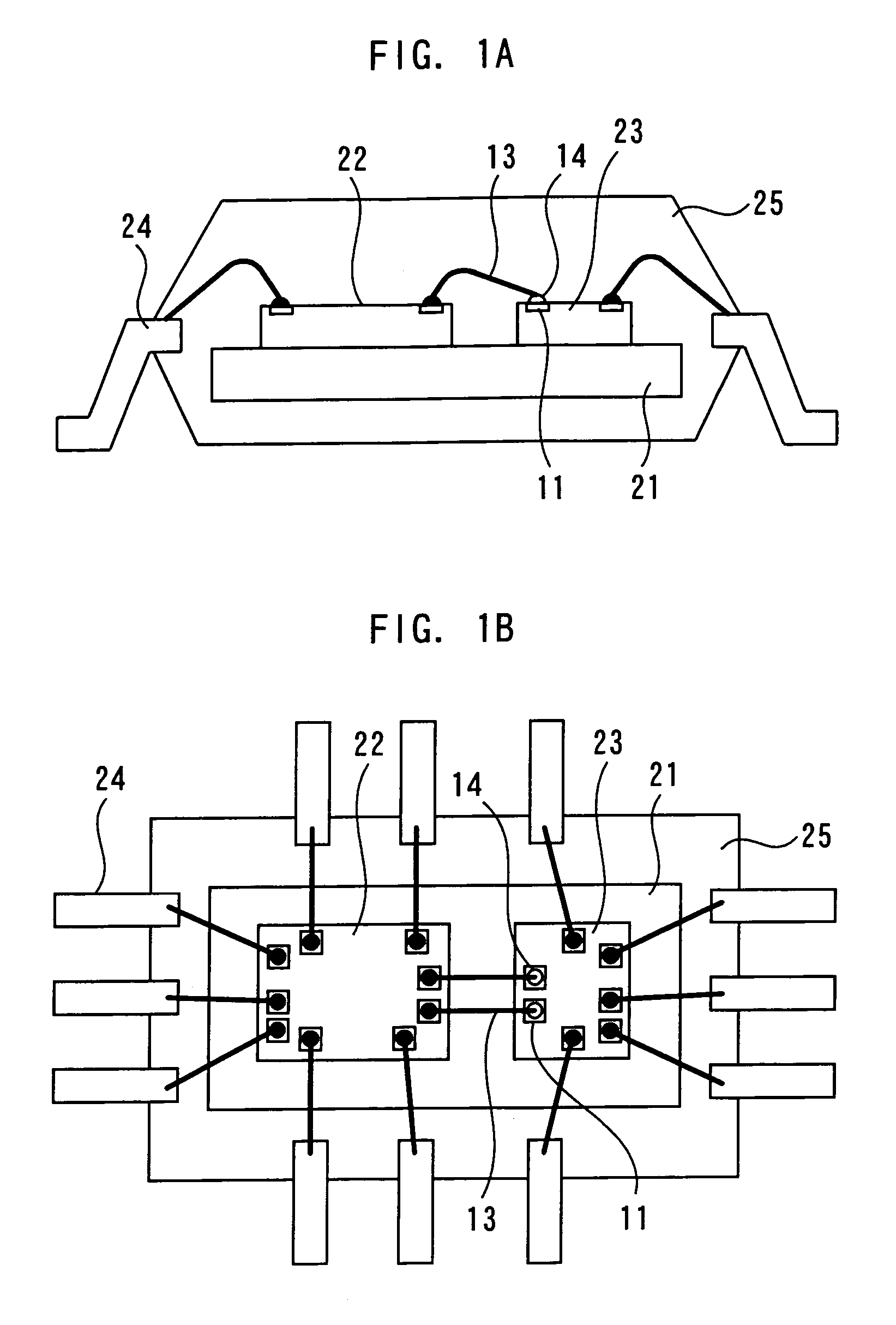

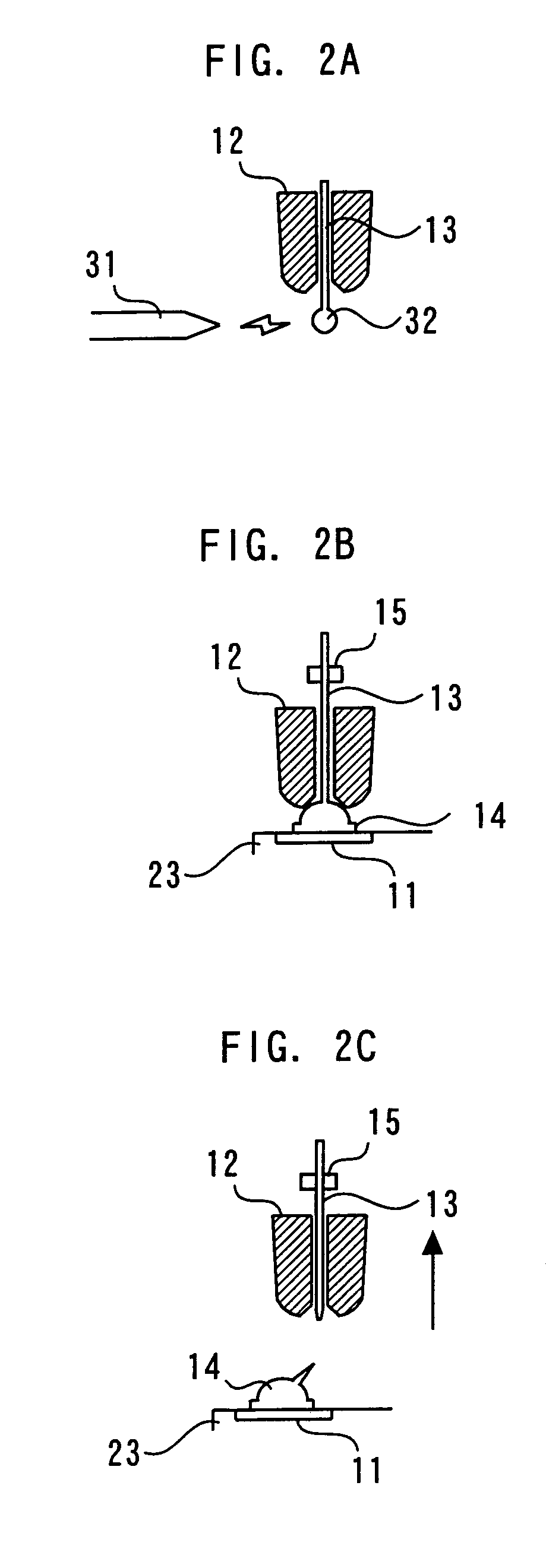

Semiconductor device and method of manufacturing the same

InactiveUS7456091B2Speed up preparationReduce loadSemiconductor/solid-state device detailsSolid-state devicesBreaking strengthUltimate tensile strength

A semiconductor device of the present invention includes a chip which has a pad; a bump electrode formed on the pad; and a wire whose stitch bonding is made on the bump electrode. The wire satisfies a condition: (modulus-of-elasticity / breaking strength per unit area) ≧400.

Owner:RENESAS ELECTRONICS CORP

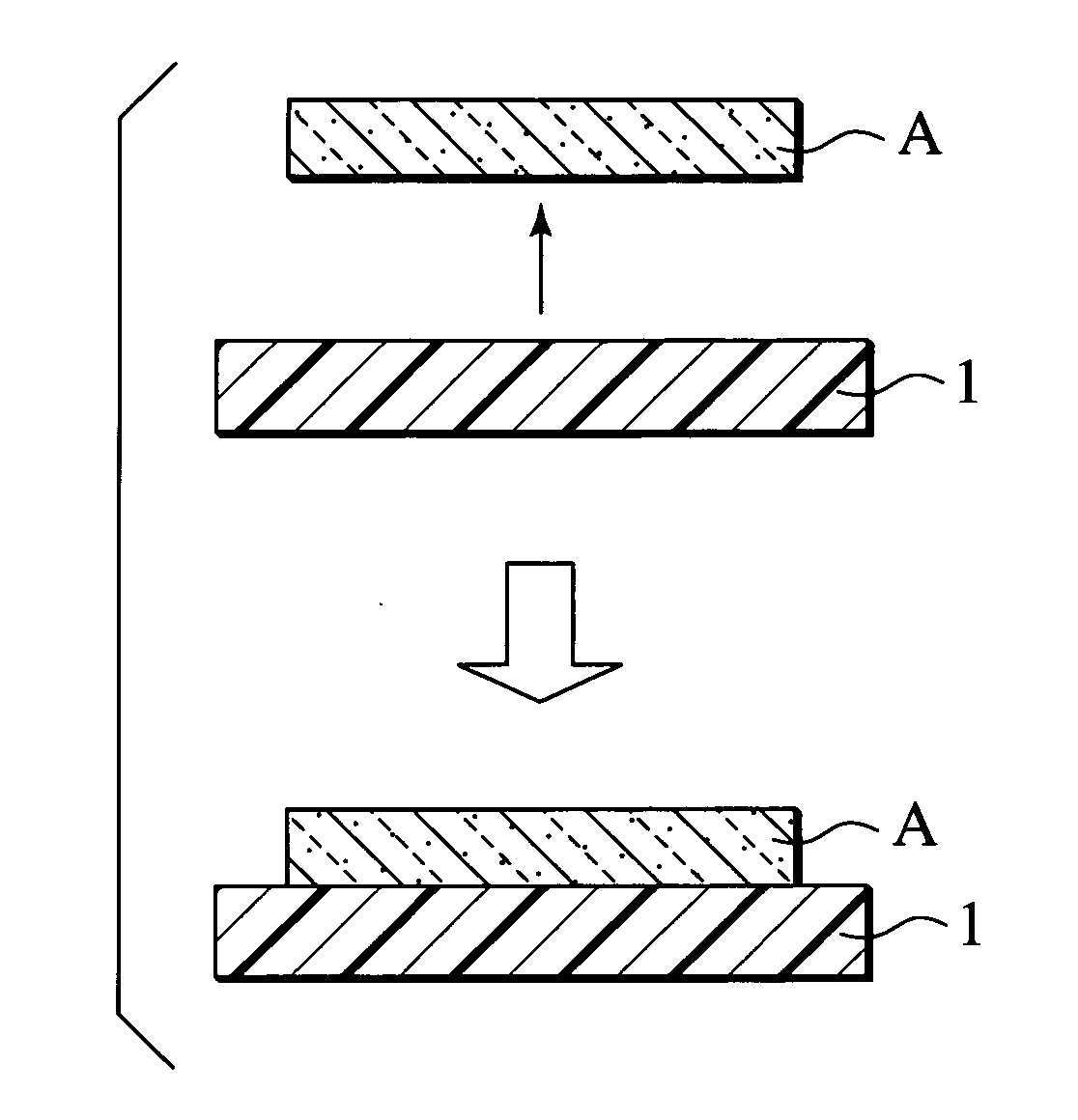

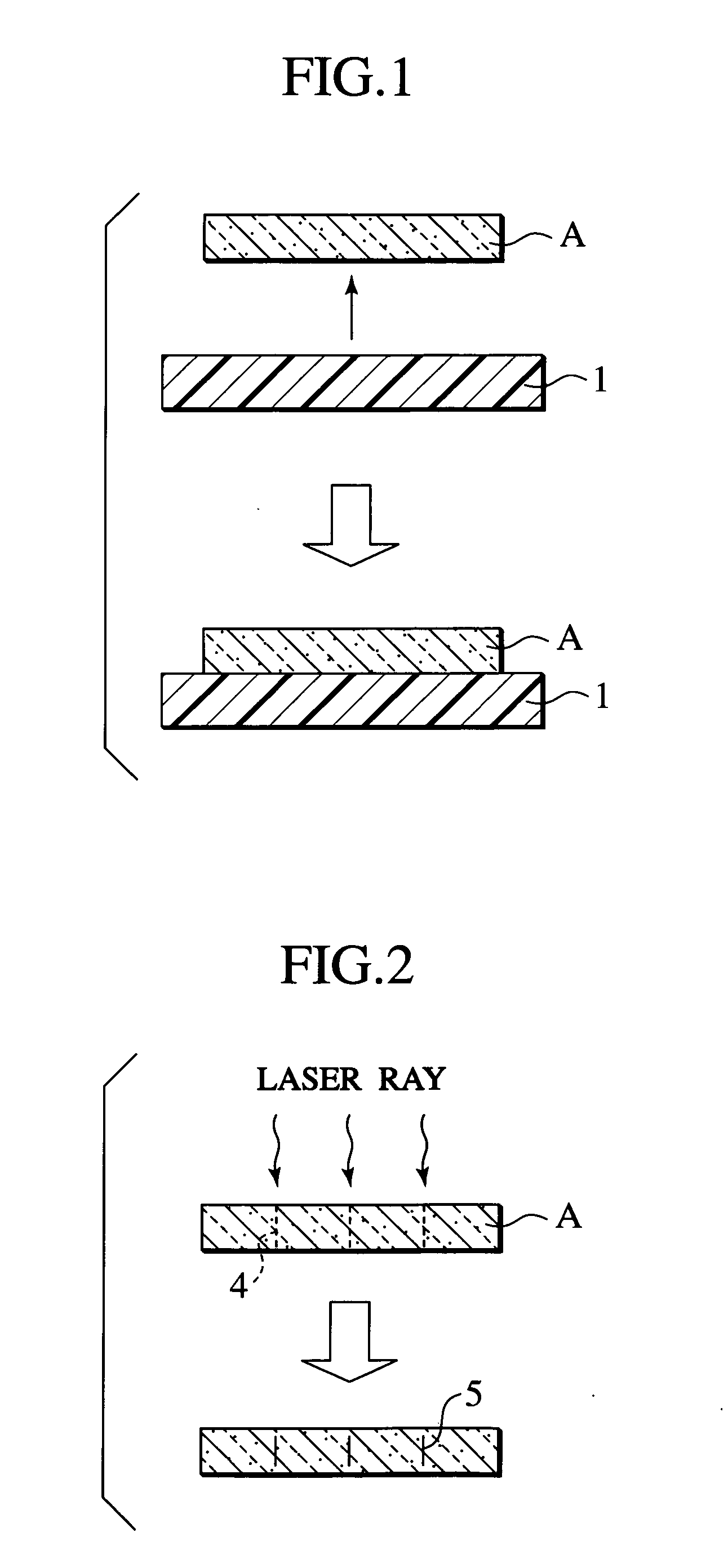

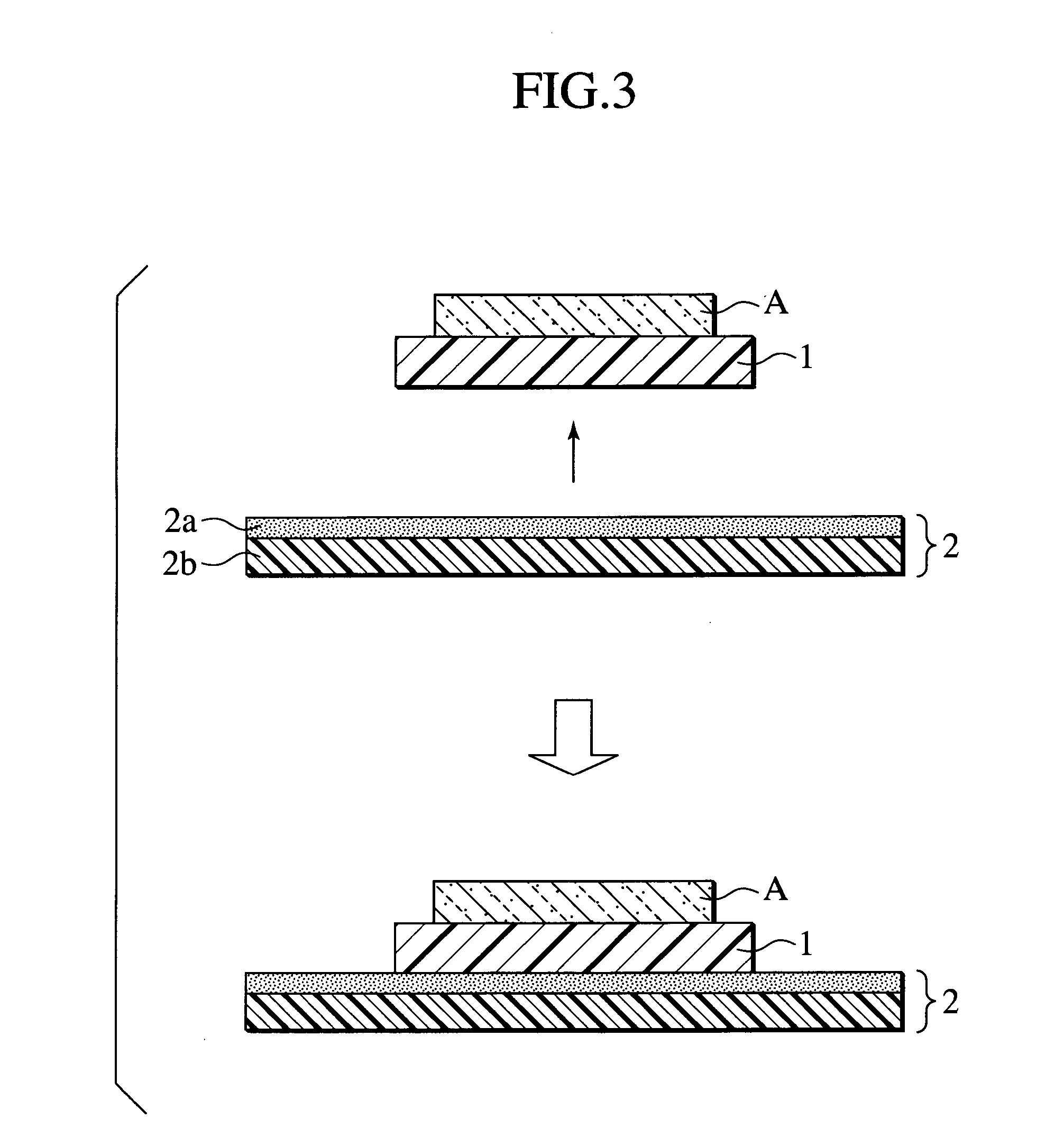

Adhesive sheet, dicing tape intergrated type adhesive sheet, and semiconductor device producing method

InactiveUS20060128065A1Efficient cuttingImprove bond reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeDevice material

The invention provides an adhesive sheet which can be stuck to a wafer at low temperatures of 100° C. or below, which is soft to the extent that it can be handled at room temperature, and which can be cut simultaneously with a wafer under usual cutting conditions; a dicing tape integrated type adhesive sheet formed by lamination of the adhesive sheet and a dicing tape; and a method of producing a semiconductor device using them. In order to achieve this object, the invention is characterized by specifying the breaking strength, breaking elongation, and elastic modulus of the adhesive sheet in particular numerical ranges.

Owner:HITACHI CHEM CO LTD

High-strength and high-toughness reactive powder concrete of carbon doped nano-tube and preparation method of high-strength and high-toughness reactive powder concrete

The invention provides high-strength and high-toughness reactive powder concrete of a carbon doped nano-tube. The high-strength and high-toughness reactive powder concrete is prepared by taking cement, a carbon nano-tube, silica fume, a water reducing agent, silica sand, coal ash, quartz powder, steel fiber and water as raw materials, wherein all the components in the mixture are calculated in parts by mass: 1000-1200 parts of cement, 250-350 parts of silica fume, 250-350 parts of slag powder, 40-50 parts of water reducing agent, 1200-1400 parts of silica sand, 180-230 parts of water, 190-230 parts of steel fiber, 180-250 parts of coal ash, 80-120 parts of quartz powder, 0.1-5 parts of carbon-nano-tube dispersing agent and 1-10 parts of carbon nano-tube powder. The invention also provides a preparation method of the high-strength and high-toughness reactive powder concrete. The reactive powder concrete obtained by the invention has the high compression strength of 250-300MPa and breaking strength of 45-60MPa, which are higher than the 200-level related performances of the traditional RPC (Reactive Powder Concrete). Meanwhile, the initial cracking strength of the reactive powder concrete material prepared by using the carbon nano-tube is greatly improved and is up to 10MPa in a direct stretching state, and the tensile strain corresponding to peak stress is up to more than 0.5%, so that the toughness and strength of the traditional RPC material are greatly improved.

Owner:浙江固邦新材料有限公司

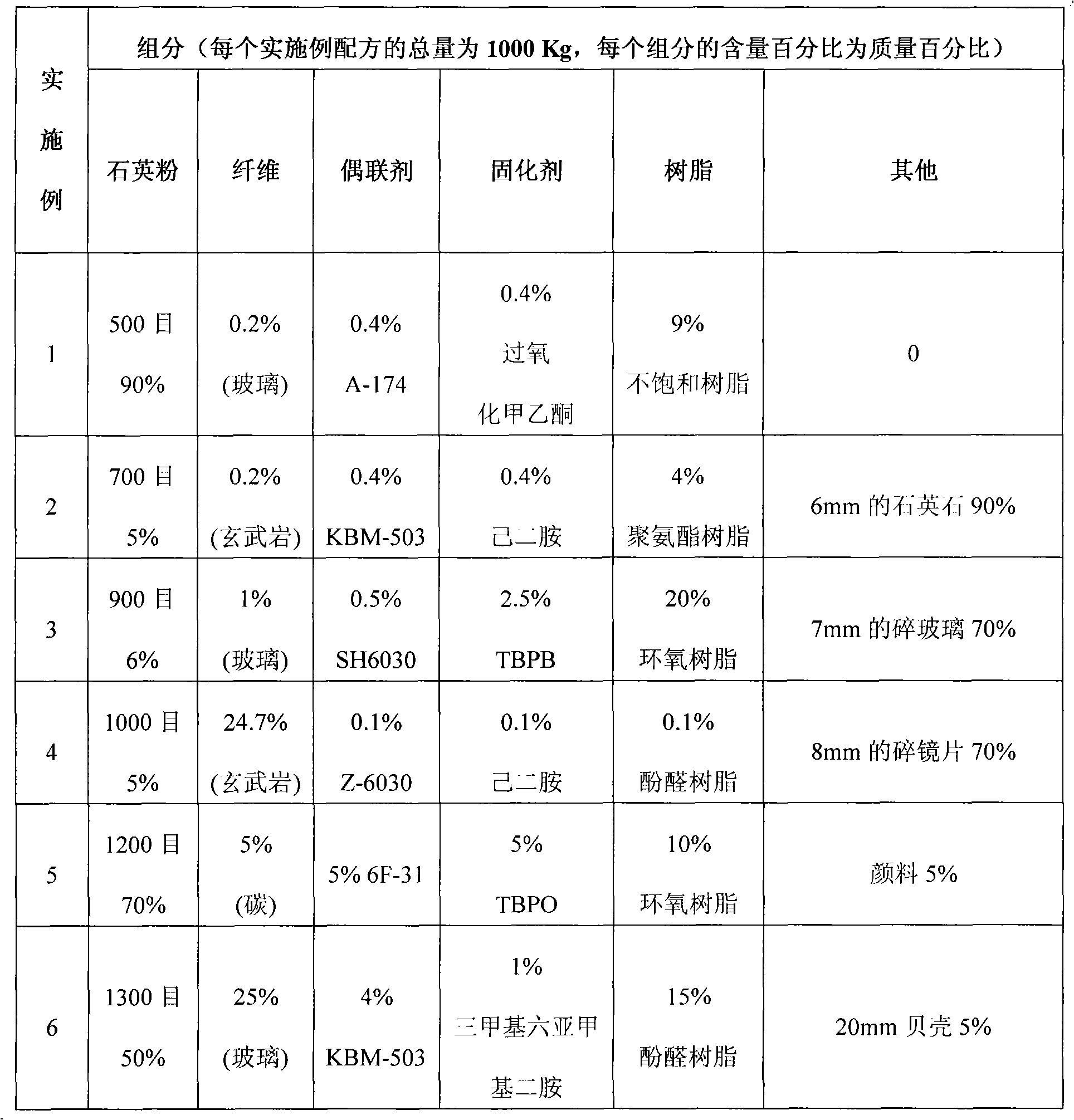

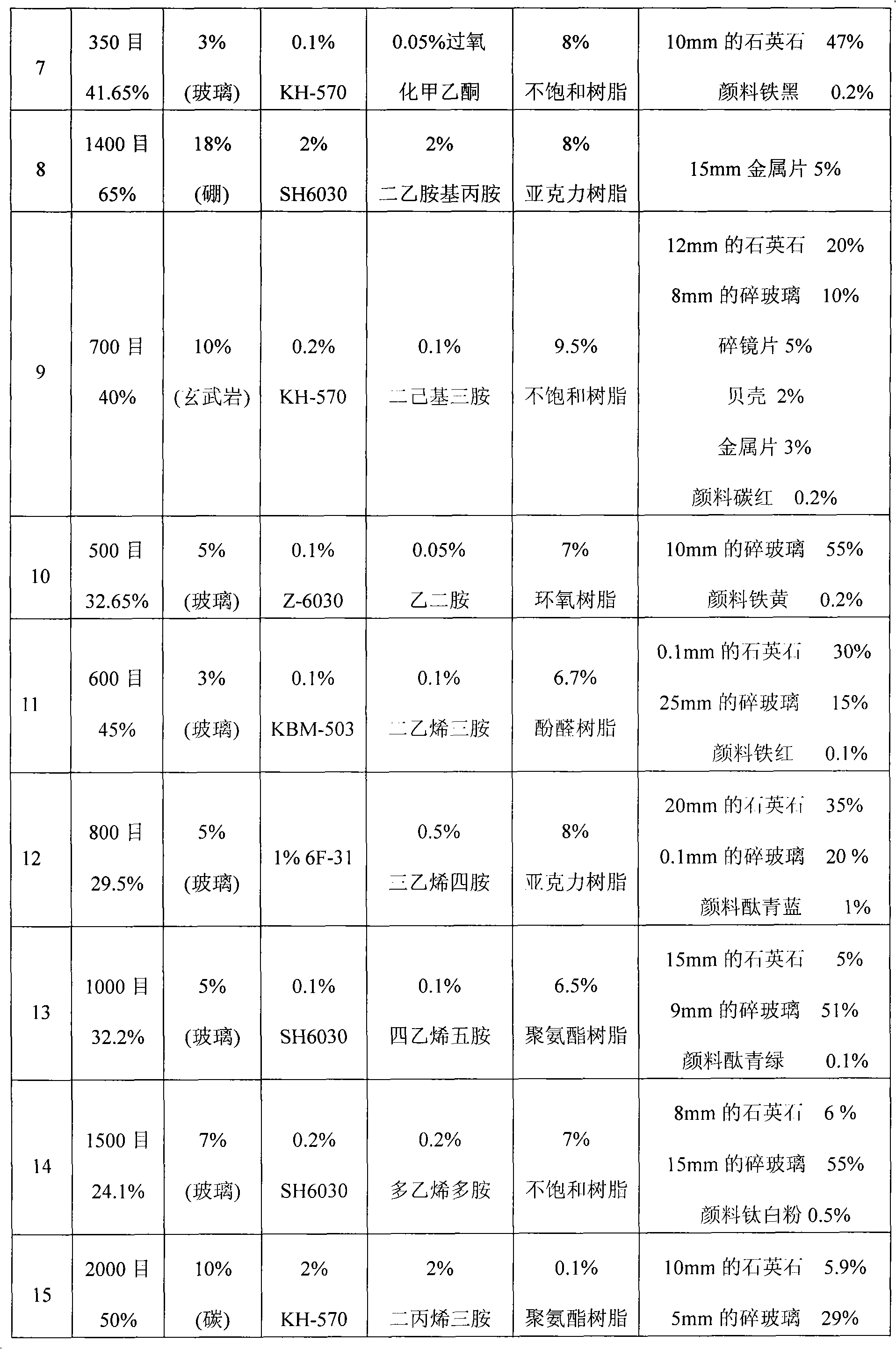

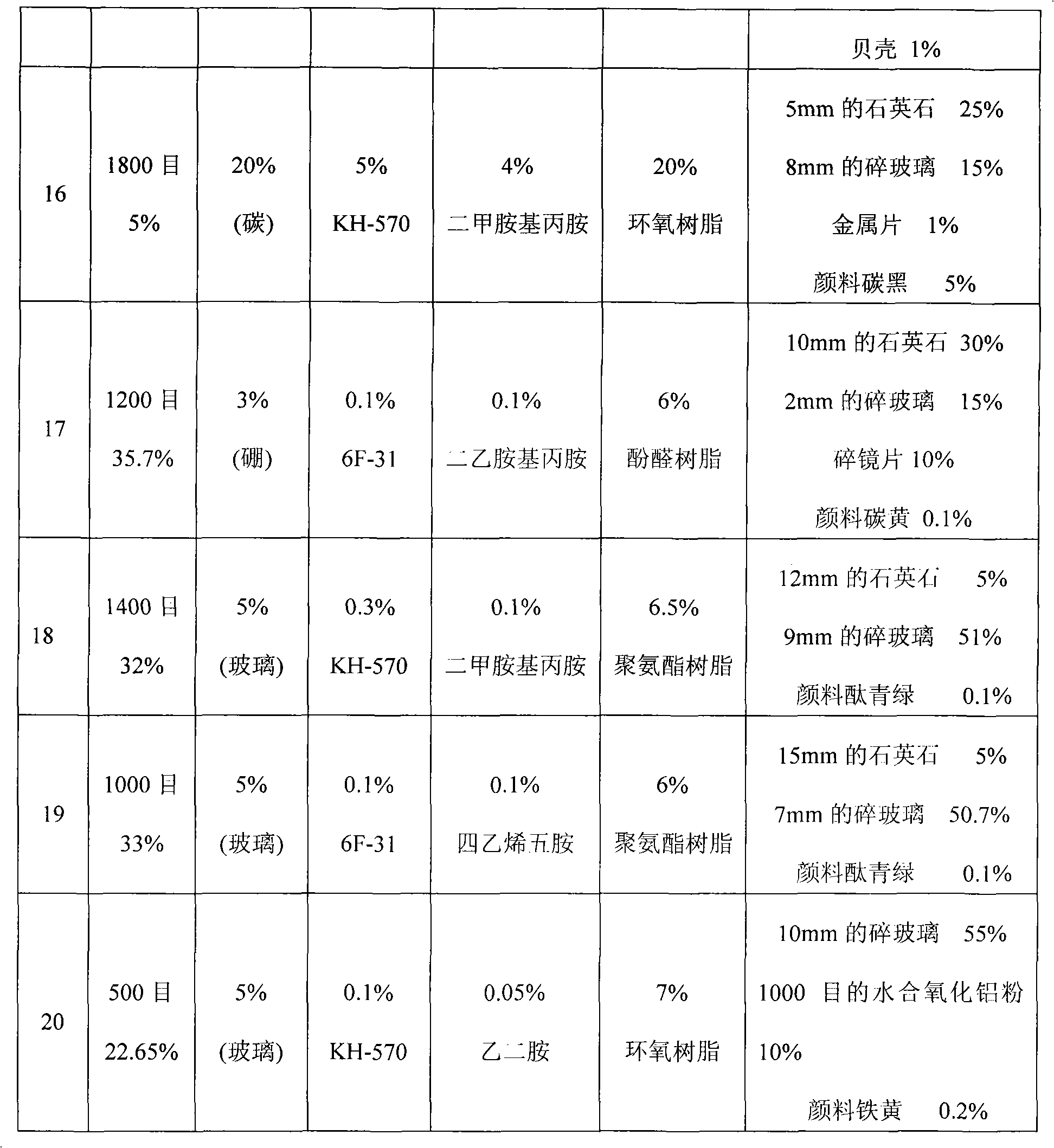

Artificial quartz in lump and fabrication technology thereof

The invention discloses a man-made quartz stone, which comprises 0 to 90 percent of quartz stone, 5 to 90 percent of silica flour, 1 to 25 percent of fiber, 0.1 to 20 percent of resin, 0.1 to 5 percent of a coupling agent, 0.1 to 5 percent of a curing agent, 0 to 70 percent of cullet, 0 to 70 percent of broken glass block, 0 to 5 percent of paint, 0 to 5 percent of shell, 0 to 5 percent of metal sheet by mass. The tear resistance, the compressive strength and the buckling strength of the man-made quartz stone are significantly improved compared with the prior man-made quartz stone. The invention further relates to a manufacturing process for a man-made quartz stone plate or block and vessel.

Owner:张璐 +1

Graphene blend regenerated cellulose fiber and preparation method thereof

ActiveCN103046151AImprove conductivityImprove thermal performanceArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentMoisture absorptionCellulose fiber

The invention relates to a graphene blend regenerated cellulose fiber. The graphene blend regenerated cellulose fiber is prepared by mixing an oxidized graphene solution and a regenerated cellulose solution, molding a mixture through a viscose wet spinning process and reducing the mixture; the dry breaking strength of the graphene blend regenerated cellulose fiber is not less than 1.8 cN / dtex, the wet breaking strength of the graphene blend regenerated cellulose fiber is not less than 0.9 cN / dtex, the dry breaking elongation of the graphene blend regenerated cellulose fiber is not less than 16%, the mass specific resistance of the fiber is 1-9X106 omega.g / cm2, and the thermal decomposition temperature of the fiber is not lower than 400 DEG C; and with the regenerated cellulose fiber as a matrix, the prepared graphene blend regenerated cellulose fiber has the advantages of good moisture absorption, good air permeability, soft handle and good dyeing performance and has the characteristics of ultrahigh strength, thermal conductivity, electric conductivity, antibacterial property and the like of the graphene; the conductive and thermal properties of the fiber are both improved by being compared with those of the traditional regenerated cellulose fiber; the antibacterial property of the fiber is additionally provided; and the graphene blend regenerated cellulose fiber provided by the invention has the advantages of simple production process, easiness in operation, and higher yield. People estimate that the developed graphene blend regenerated cellulose fiber can be widely applied to the field of costumes, industrial textiles and the like.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG +1

Thermal spray spherical particles, and sprayed components

InactiveUS6916534B2High densityImprove adhesionMolten spray coatingSynthetic resin layered productsBreaking strengthThermal spraying

Spherical particles of a rare earth (inclusive of yttrium)-containing compound and having a breaking strength of 10-300 MPa and an average particle diameter of 10-80 μm are suitable for plasma spraying.

Owner:SHIN ETSU CHEM IND CO LTD

Cladded quartz sand fracturing support agent for oil production

ActiveCN1640981AWith strengthReduce breakage rateFluid removalPigment treatment with macromolecular organic compoundsBreaking strengthOil production

The present invention relates to one kind of fracturing proppant for petroleum production and its production process. The proppant comprises quartzite grains and hardened thermoset resin film coating the surface of the quartzite grains. The proppant of the present invention has high breaking strength and low cost, and may be used to replace expensive haydite sand.

Owner:BEIJING RECHSAND SCI & TECH GRP

Pharmaceutical dosage form

ActiveUS8383152B2Improved controlled releaseEasy to adjustOrganic active ingredientsBiocideControlled releaseBreaking strength

The invention relates to a pharmaceutical dosage form, preferably with controlled release of a pharmacologically active compound (A) contained therein, the pharmaceutical dosage form very preferably being tamper-resistant and most preferably having a breaking strength B1 of at least 500 N in direction of extension E1 and having a breaking strength B2 of less than 500 N in direction of extension E2.

Owner:GRUNENTHAL GMBH

High-temperature resistant phenolic resin weak gel profile control plugging agent

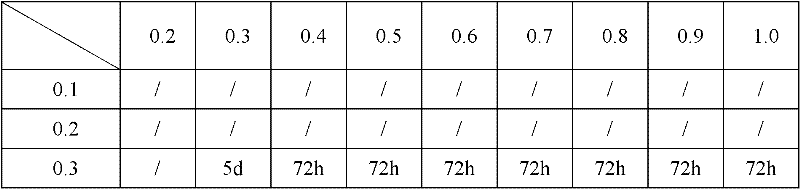

ActiveCN102559159AOvercoming the problem of poor selectivityHigh gel strengthDrilling compositionBreaking strengthCross-link

The invention relates to a high-temperature resistant phenolic resin weak gel profile control plugging agent, which is a profile control plugging agent formed by reacting partially-hydrolyzed polyacrylamide and a cross-linking agent by acylamino of the hydrolytic polyacrylamide. The profile control plugging agent comprises the following components in percentage by weight: 0.25 to 1.2 percent of partially-hydrolyzed polyacrylamide, 0.2 to 1 percent of cross-linking agent, 0.01 to 1 percent of additive and the balance of water. According to the high-temperature resistant phenolic resin weak gel profile control plugging agent, the water plugging rate is more than 80 percent, the oil plugging rate is less than 30 percent, the profile control plugging agent can be resistant to high temperature of over 90 DEG C, mineralization resistance is up to 85,000 mg / L (on the basis of 80,000 mg / L of sodium chloride and 5,000 mg / L of calcium chloride), the strength of gel is high, breaking strength is improved by 68 percent compared with the prior art, the gel-formation time is adjustable, the aims of plugging high-permeability layers in strata and adjusting water absorption profiles of water injection wells deeply can be fulfilled, the deep profile control of oil layers is realized, and the recovery ratio of petroleum is improved greatly.

Owner:PETROCHINA CO LTD

Recombinant expressed bioadsorbable polyhydroxyalkanoate monofilament and multi-filaments self-retaining sutures

InactiveUS20100057123A1Suture equipmentsMonocomponent synthetic polymer artificial filamentBreaking strengthMicroorganism

The present invention provides polymers made by genetically engineering microorganisms for making a self-retaining suture. In an embodiment of the present invention the genetically engineering microorganisms synthesize polyhydroxyalkanoate (PHA) polymers. In an alternate embodiment of the invention, the genetically engineering microorganisms synthesize polybetahydroxybutyrate (PHB) polymers. In an alternative embodiment of the invention, the self-retaining sutures can be made from a copolymer such as polyhydroxybutyratevalerate (PHBV), where the genetically engineering microorganisms produces PHA polymers as the monofilament base material and a different genetically engineering microorganisms produces polyhydroxybutyratevalerate (PHBV) polymers. In various embodiments of the invention, recombinant expressed self-retaining suture materials have a melting point in the range from between approximately 40° C. to approximately 180° C. In various embodiments of the invention, recombinant expressed self-retaining suture materials have extension-to-break strength of between approximately 8% and approximately 42%.

Owner:TEPHA INC

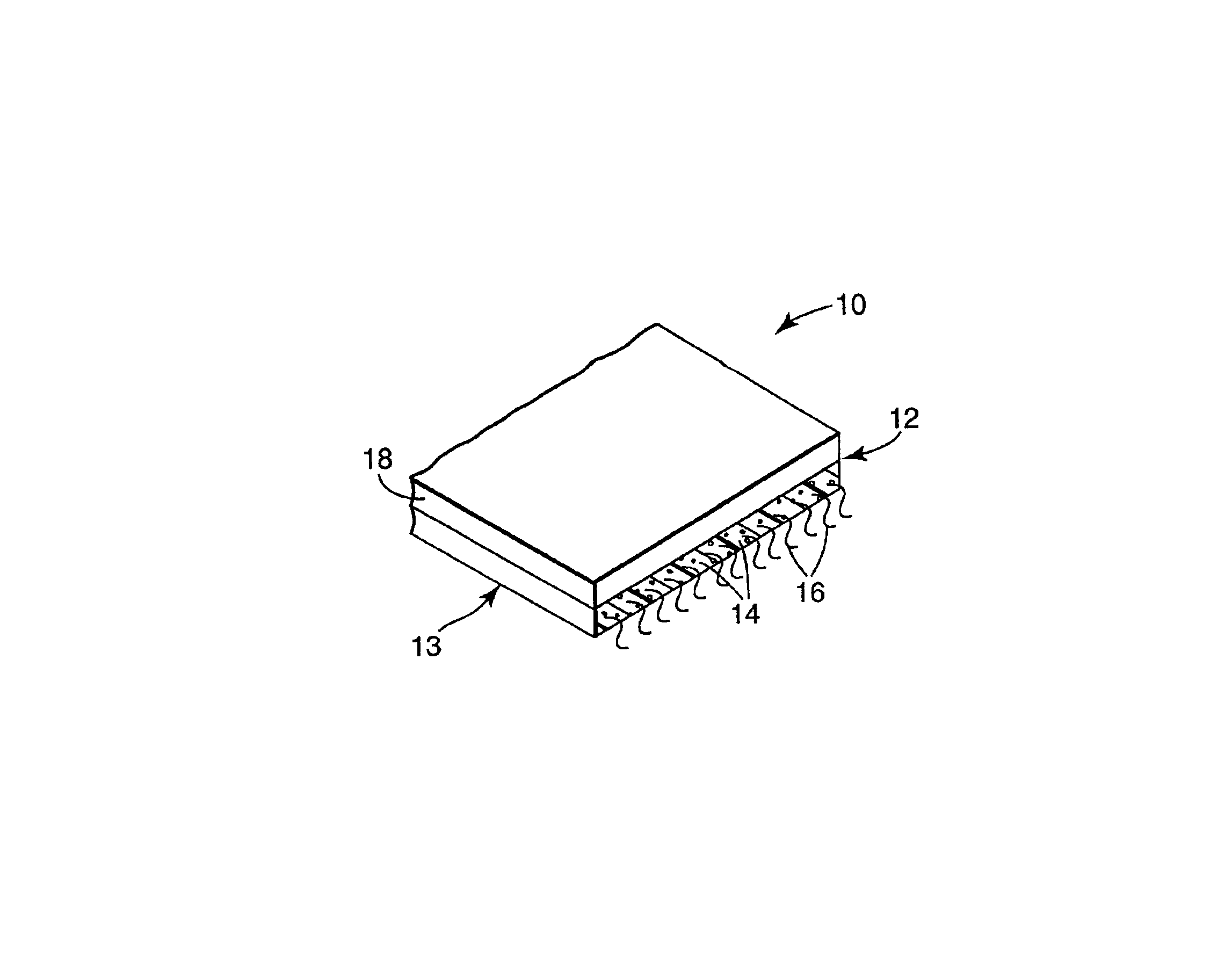

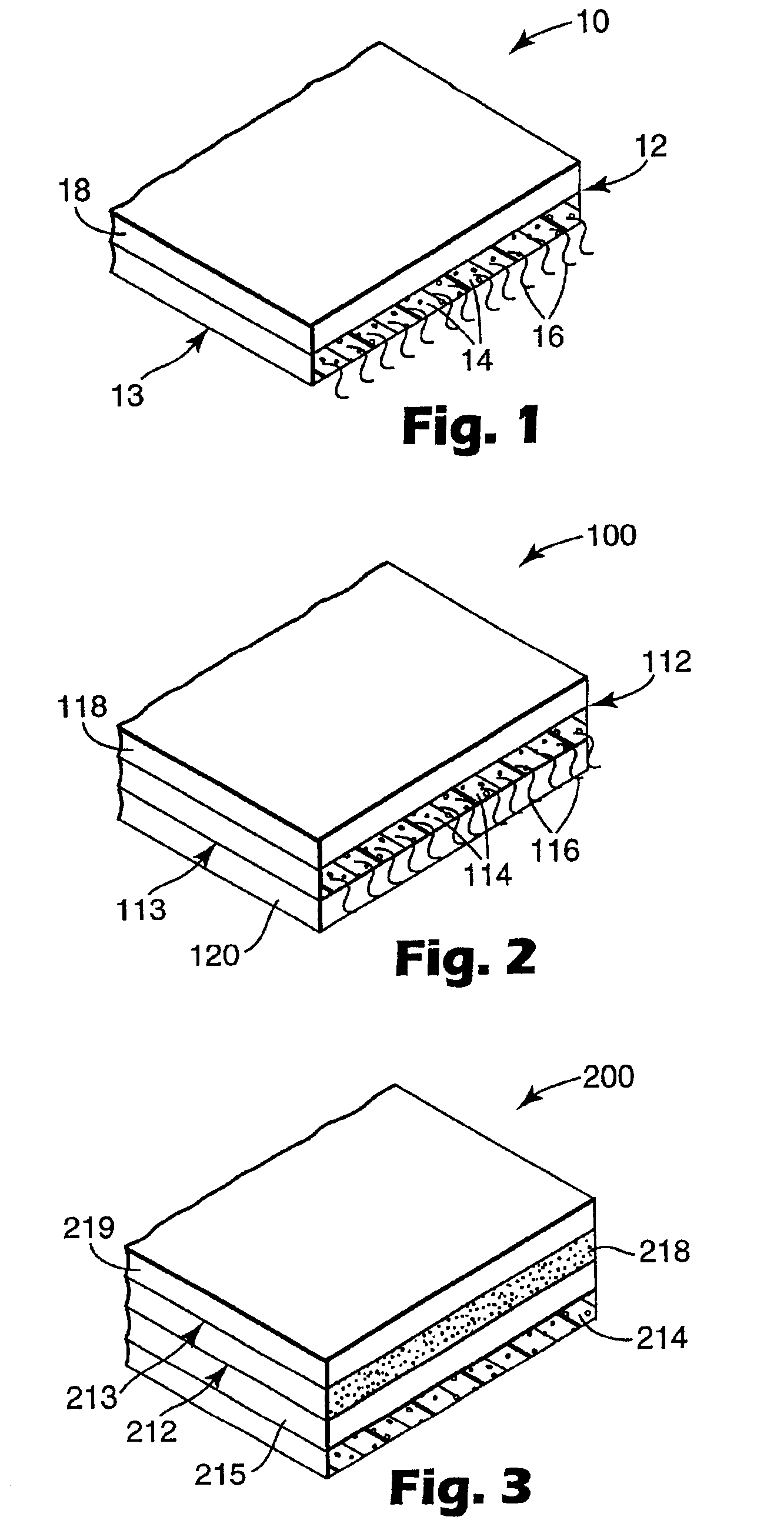

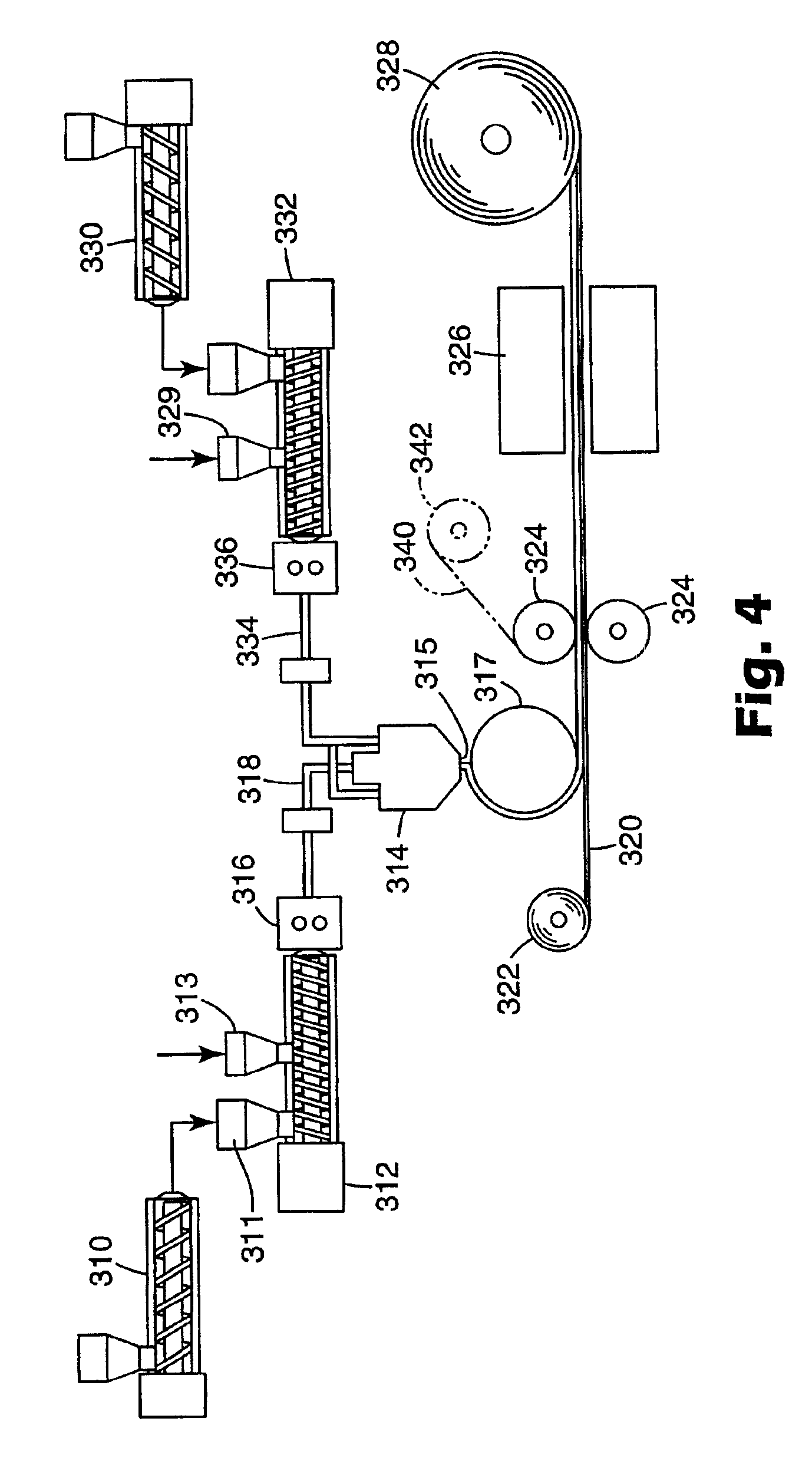

Cleanly removable tapes and methods for the manufacture thereof

InactiveUS6866928B2Reduces and eliminates tendencyReduce supplyPicture framesSynthetic resin layered productsBreaking strengthEngineering

The present invention provides a multi-layer tape, comprising: a first adhesive layer comprising a pressure sensitive adhesive; a core layer having an outer surface, the first adhesive layer adhered to at least a portion of the outer surface; and fibrous reinforcing material dispersed within the core layer, the fibrous reinforcing material imparting stretch release properties to the tape. The tape may comprise a second adhesive layer wherein the outer surface comprises a first major surface and a second major surface, the first adhesive layer being adhered to the first major surface, and the second adhesive layer being adhered to the second major surface. A fire retardant may be disposed in any of the first adhesive layer, the second adhesive layer, and the core layer. The tape may be cleanly removable. The fibrous reinforcing material typically comprises substantially continuous viscoelastic microfibers having a yield strength and a tensile break strength, and the tensile break strength is at least about 150% of the yield strength. In another aspect, the tapes of the invention may be formulated to be cleanly removable without including fibrous reinforcing material therein. The invention also provides a method for the manufacture of the foregoing tape as well as an assembly comprising: a substrate; a carpet overlying the substrate; and a tape according to the invention disposed between the carpet and the substrate and adhering the carpet to the substrate.

Owner:3M INNOVATIVE PROPERTIES CO

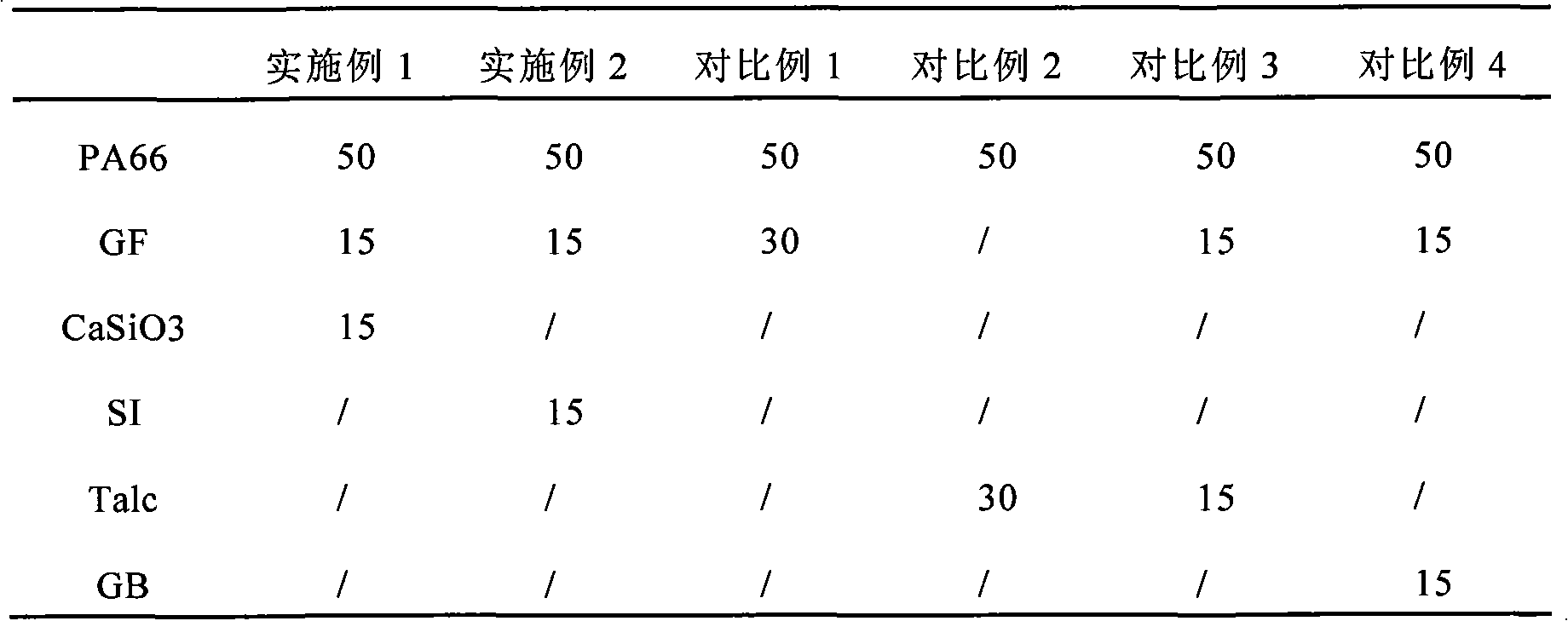

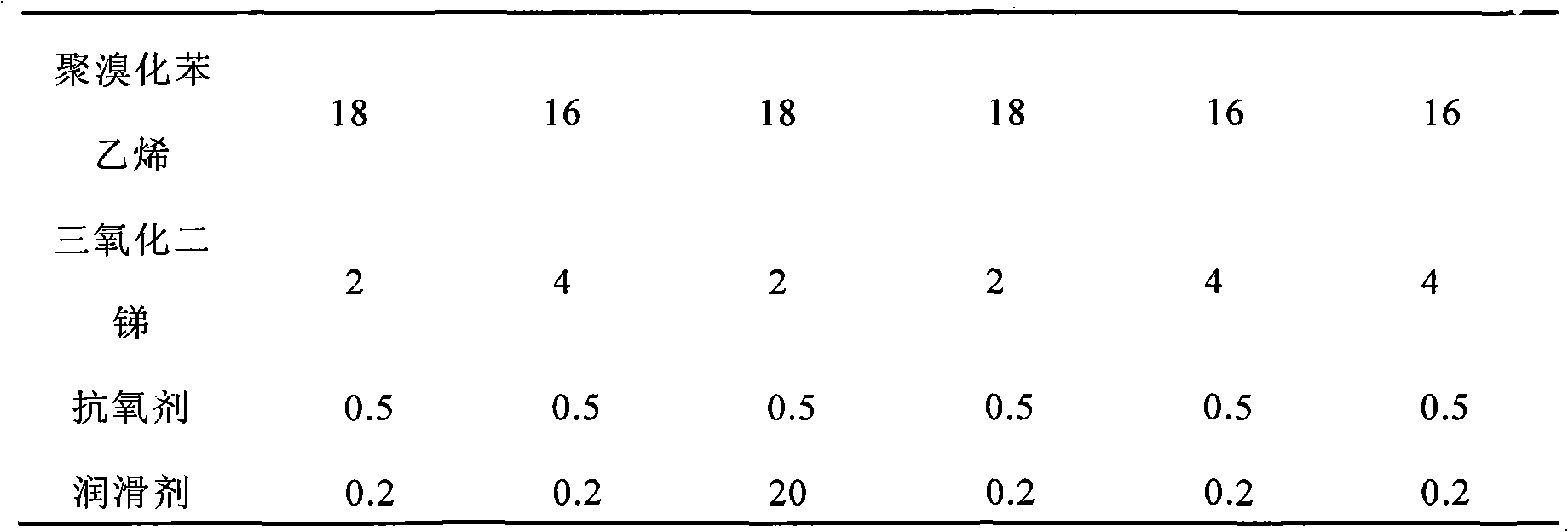

Plastic case material for breaker and preparation method thereof

ActiveCN102108204ASolve the problem of exposureHigh strengthProtective switch detailsBreaking strengthGlass fiber

The invention relates to a plastic case material for a breaker and a preparation method thereof. The material comprises the following components in parts by weight: 22-80 parts of nylon, 5-25 parts of glass fiber, 5-25 parts of needle-like filling material, 8-20 parts of fire retardant, 2-6 parts of auxiliary fire retardant and 0.1-2 parts of other auxiliaries. The preparation method comprises the following steps: evenly mixing the raw materials with a high-speed mixer at a high speed; and then bracing and pelleting the mixed materials with a screw extruder at the temperature of 220 DEG C-290DEG C to obtain the plastic case material. Compared with the prior art, the plastic case material has high breaking strength and elastic modulus, the strength of a compound material is barely influenced by a proper addition of the raw materials, and the obtained product has the advantages of no glass fiber rich surface, no buckling deformation, high strength and good heat resistance.

Owner:HEFEI GENIUS NEW MATERIALS

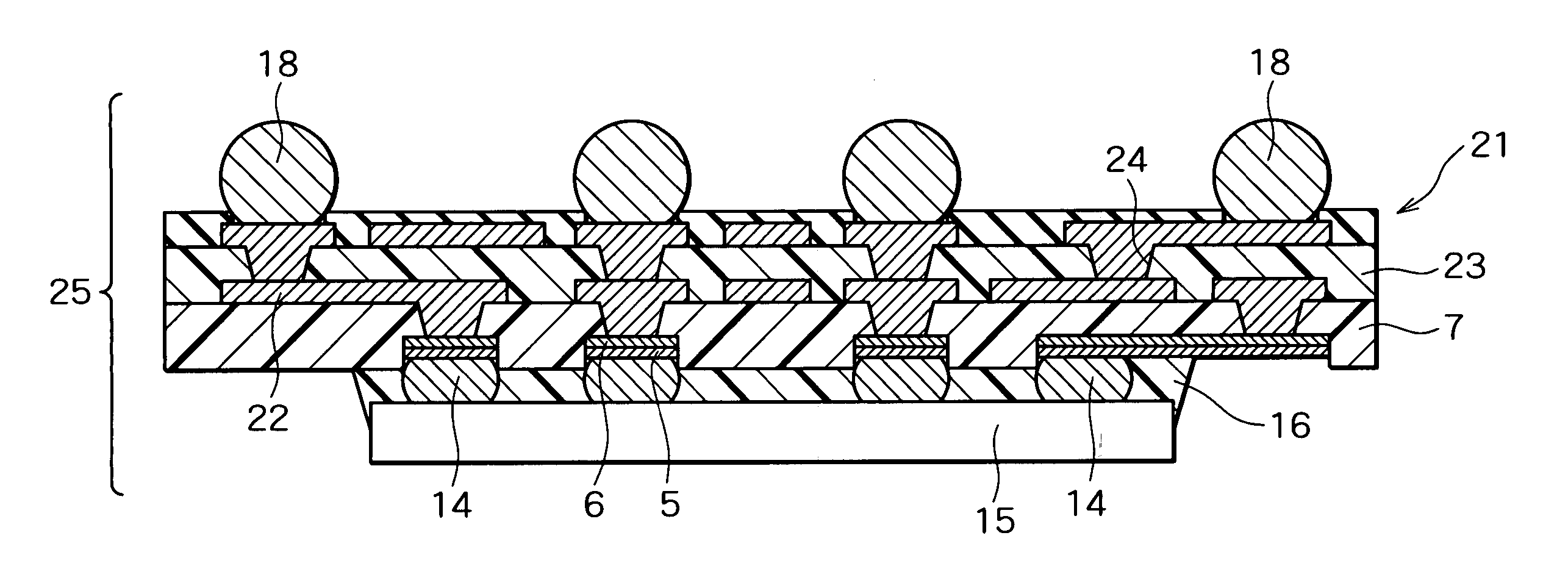

Wiring board and semiconductor package using the same

InactiveUS20050252682A1Easy to implementRelieve pressurePrinted electric component incorporationSemiconductor/solid-state device detailsBreaking strengthAramides

A wiring board has a base insulating film. The base insulating film has a thickness of 20 to 100 μm and is made of a heat-resistant resin which has a glass-transition temperature of 150° C. or higher and which contains reinforcing fibers made of glass or aramid. The base insulating film has the following physical properties (1) to (6) when an elastic modulus at a temperature of T° C. is given as DT (GPa) and a breaking strength at a temperature of T° C. is given as HT (MPa). (1) A coefficient of thermal expansion in the direction of thickness thereof is 90 ppm / K or less. (2) D23≧5 (3) D150≧2.5 (4) (D-65 / D150)≦3.0 (5) H23≧140 (6) (H-65 / H150)≦2.3

Owner:NEC CORP +1

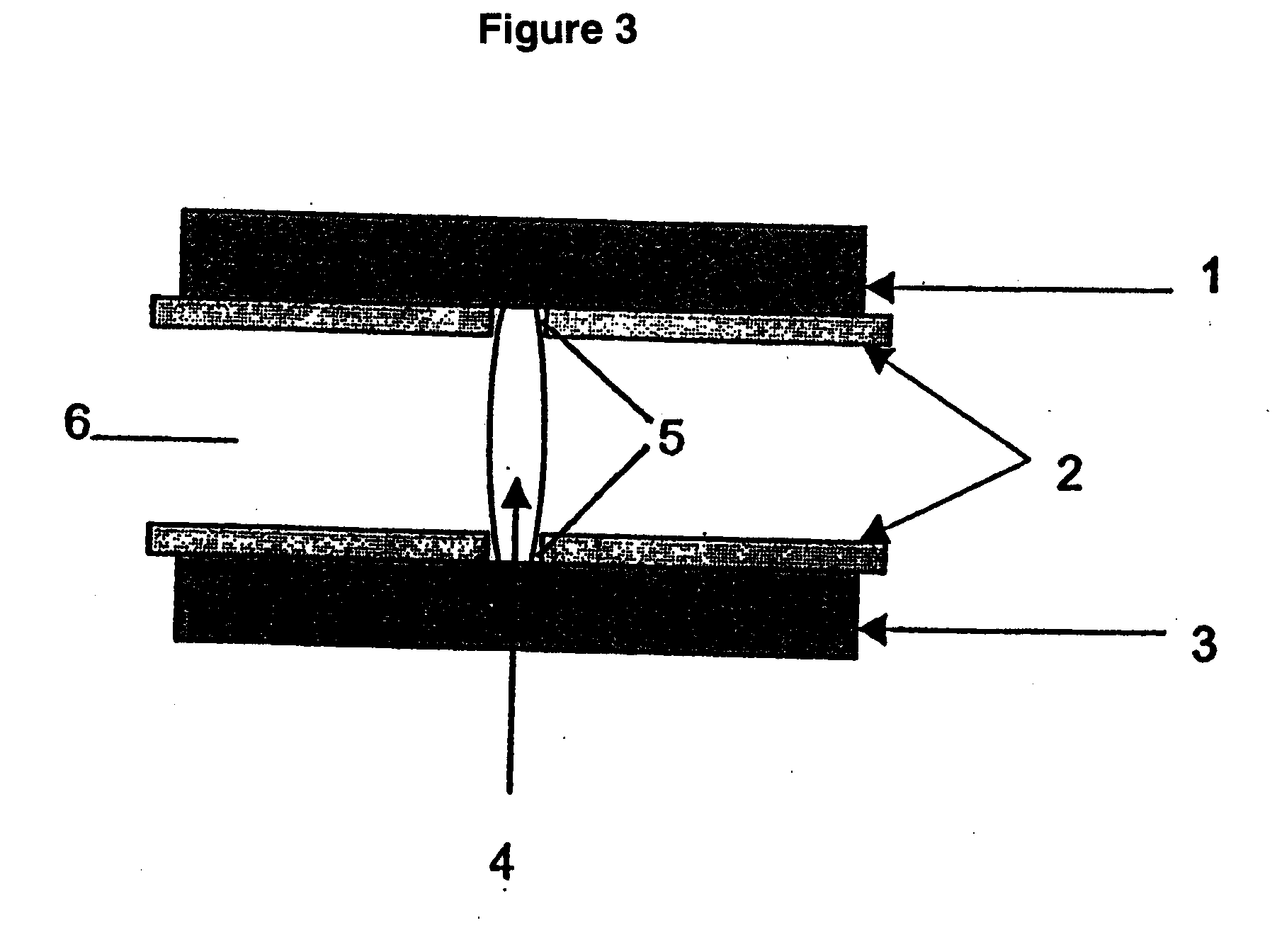

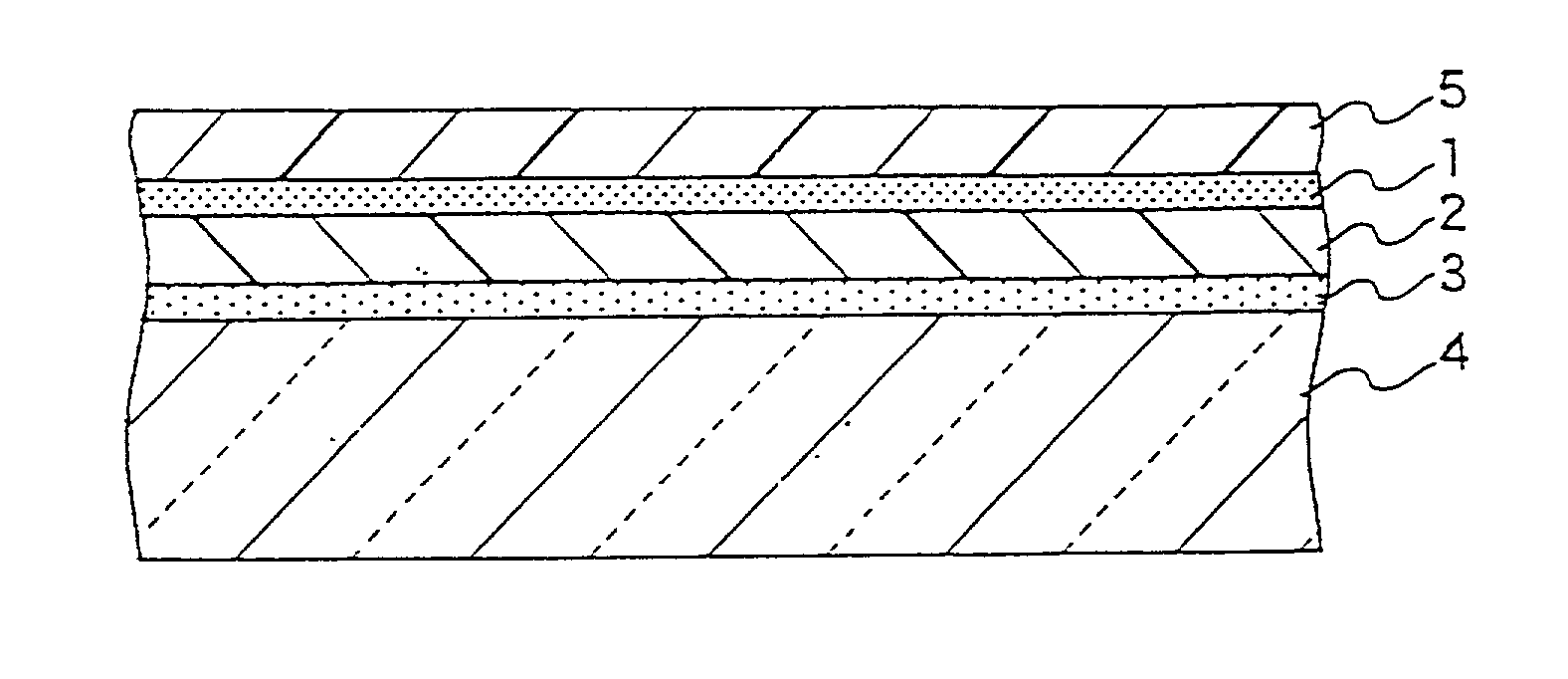

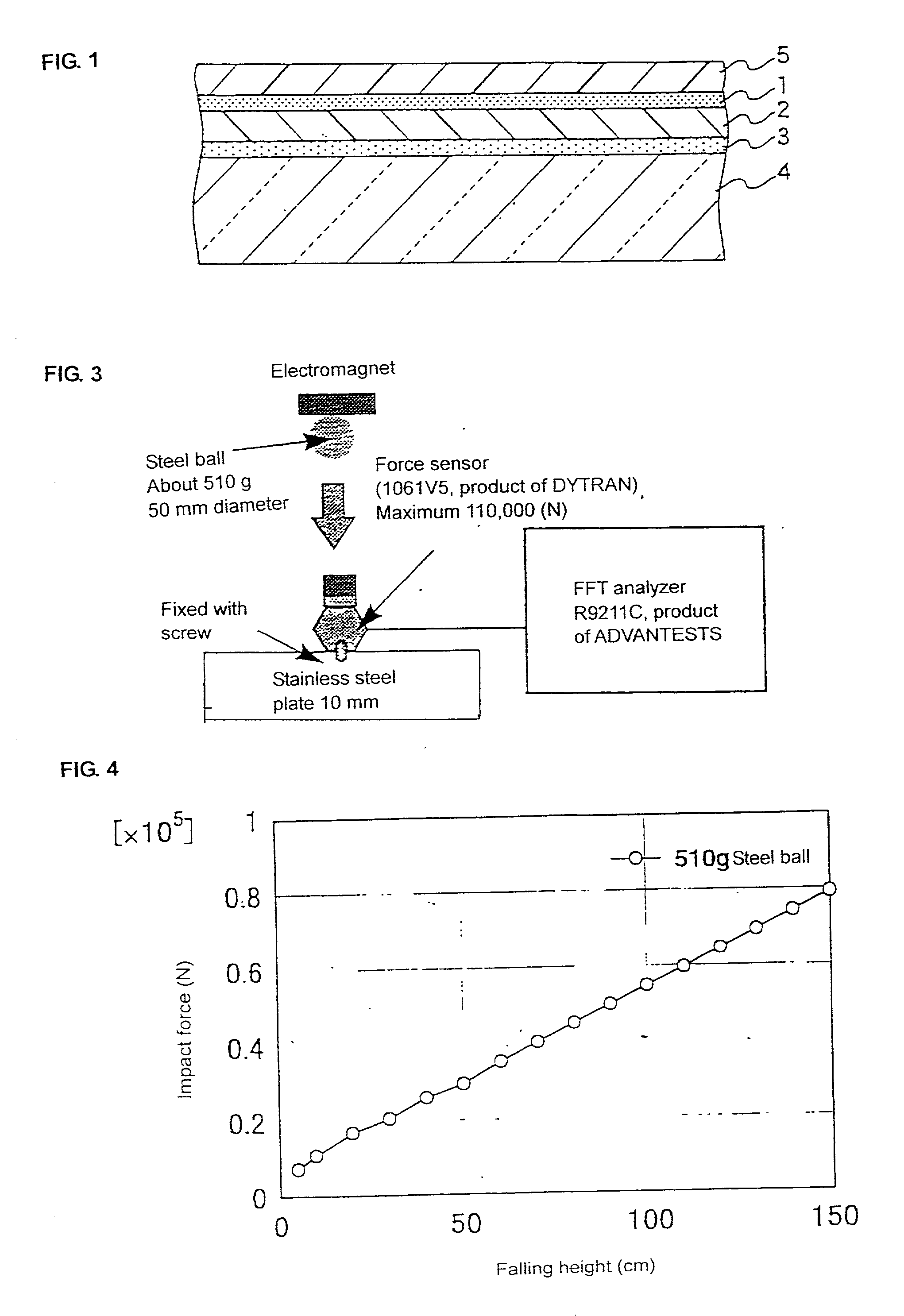

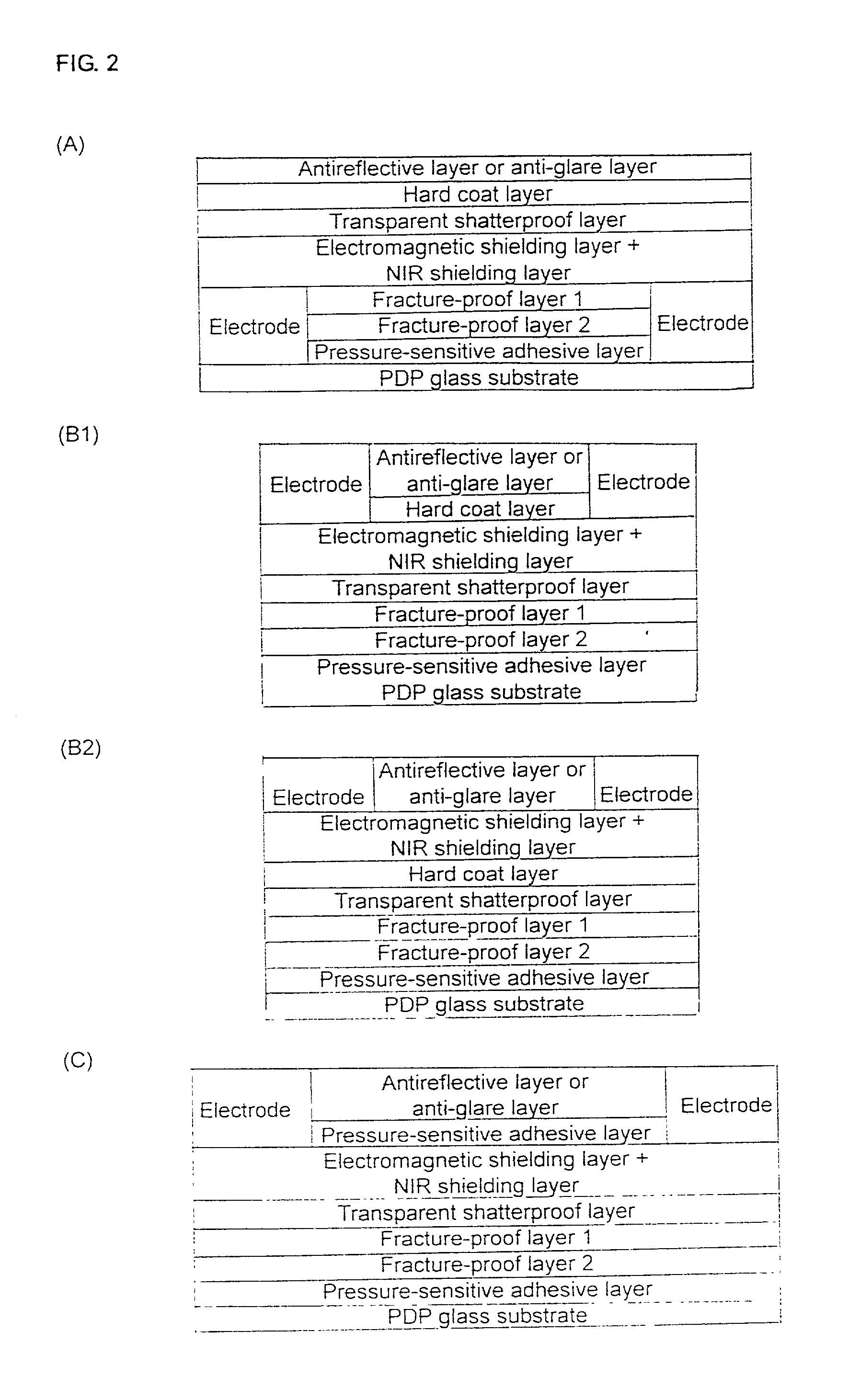

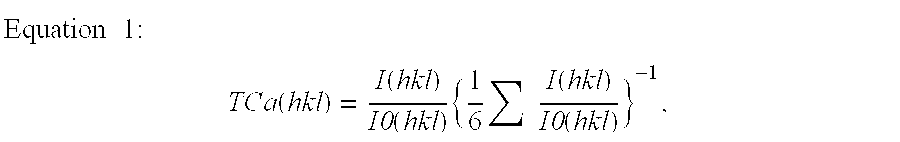

Transparent shock-absorbing laminate and flat panel display using the same

A transparent shock-absorbing laminate to be formed on a glass substrate for a display panel having a fracture strength such that it is fractured by a falling ball impact (drop height: 1.5 m; ball weight: 510 g) corresponding to 79,000 N, the transparent shock-absorbing laminate comprising a shatterproof layer having a shearing modulus of 2x108 Pa or more, at least two fracture-proof layers having a shearing modulus ranging from 1x104 to 2x108 Pa, each having different modulus, and a transparent pressure-sensitive adhesive layer.

Owner:NITTO DENKO CORP

Epoxy emulsion modified quick repair mortar for concrete roads and bridges and preparation method for mortar

The invention discloses epoxy emulsion modified quick repair mortar for concrete roads and bridges and a preparation method for the mortar, and belongs to the technical field of chemical construction materials. The prepared epoxy emulsion modified quick repair mortar for the concrete roads and bridges is good in construction performance, high in early strength and stable in later strength, does not shrink, and can be formed by selecting a proper formula according to different engineering requirements; the early strength is increased quickly, the repair speed is high, the traffic can be openedin 4 hours, the 4H compressive strength is more than 25MPa, and the 4H breaking strength is more than 3.5MPa; and the mortar is highly bonded to an old concrete base layer, and the positive pulling bonding strength in 28 days is more than 2.5MPa; and the mortar is good in freezing resistance and impermeability. The mortar mainly solves the problems of long traffic opening time, low bonding strength with the old concrete base material, poor durability and the like of the conventional quick repair mortar for the concrete roads and bridges.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

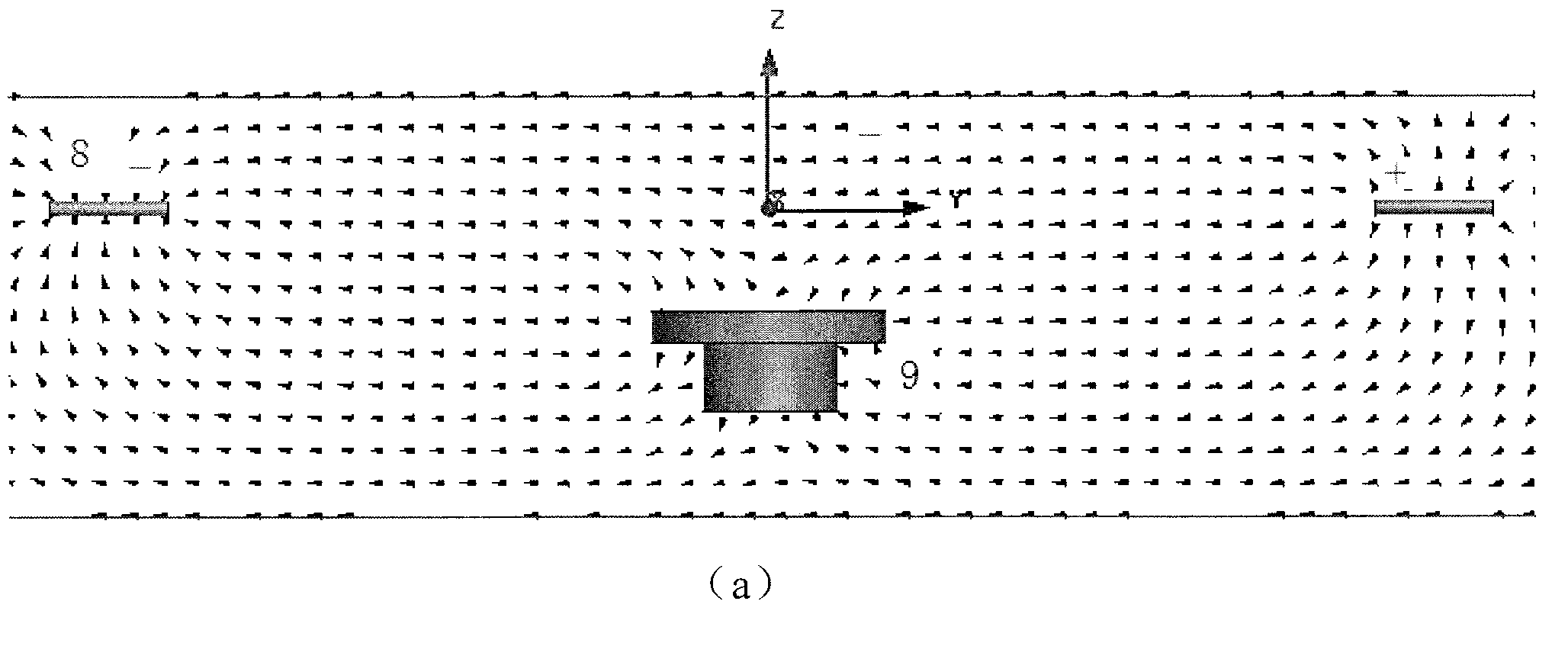

Coated cemented carbide cutting tool

InactiveUS6293739B1Extended service lifeImproving flaking resistance of coating layerLayered productsTurning toolsCrystal structureAlloy

The invention is to prolong the life time of tools dramatically by (1) considerably improving the flaking resistance of the coating layer at the time of cutting, (2) increasing the wear resistance and crater resistance of the coating layer itself, and (3) enhancing the breakage strength of the coating layer in comparison with the conventional coating cutting tools. In order to achieve the object, the coated cemented carbide of the invention has the following structure in the coating layer on the surface of the cemented carbides: The outer layer has an Al2O3 layer practically having an alpha-type crystal structure. The Al2O3 layer has a region where alpha-type and kappa-type crystal grains coexist in the first row of the crystal grains that grow on the inner layer. In addition to that, the crystal grains of alpha-Al2O3 in the region include no pores.

Owner:SUMITOMO ELECTRIC IND LTD

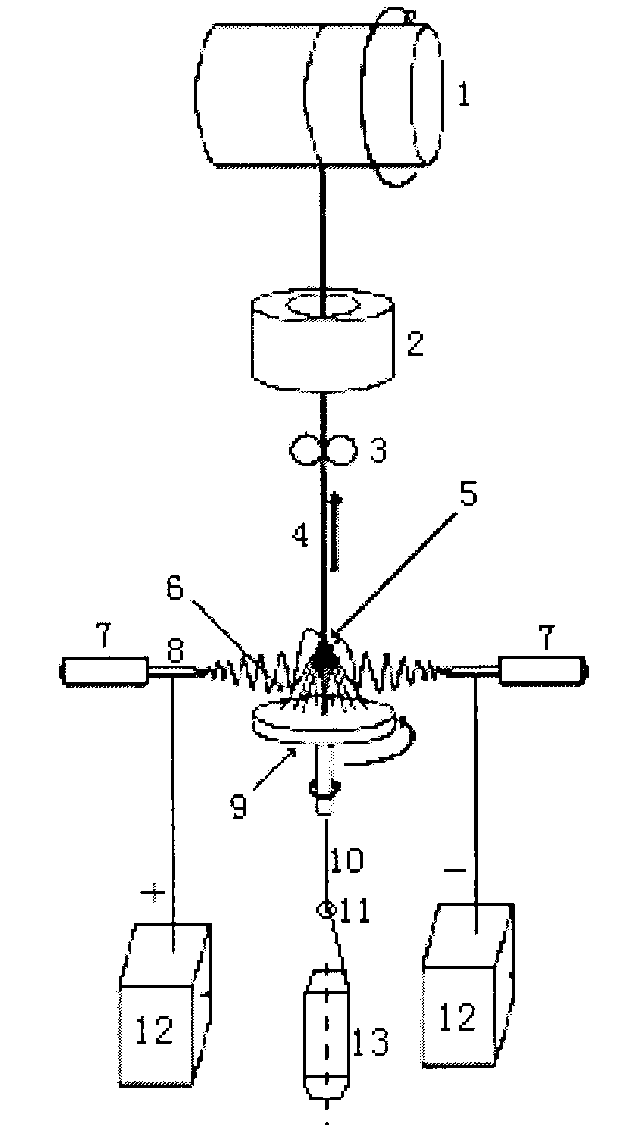

Orientation electro-spinning nanometer fiber spinning method and device thereof

InactiveCN103132194AHigh degree of axial orientationSuppress spinning instabilityDrafting machinesFilament/thread formingBobbinEngineering

The invention discloses an orientation electro-spinning nanometer fiber spinning method and a device thereof. A metal shower nozzle which exerts positive and negative high pressure is adopted to spin two strands of nanometer fibers with opposite charges, an electric field line of a spinning electric field, relative to a common spinning electric field, is straight, stability of spinning is effectively restrained, and the spinning nanometer fibers are straight. Two strands of the fibers surround the yarn tail and form a cone-shaped twisting trigonum on the upper portion of a metal twisting machine, and enable the nanometer fibers to be further oriented and twisted to form yarn through electric field force, tractive force of the yarn and acting force of the metal twisting force. The spinning nanometer fiber yarn is conducted heat shaping through a heat processing device under certain tensile force, degree of orientation of the nanometer fibers along the axial direction of the yarn, breaking force and yarn levelness are further improved, and the yarn after shaped is collected by a winding bobbin. The device can achieve the aim that orientation nanometer fiber yarn can be continuously prepared, is simple in device, convenient to operate, and good in resultant yarn continuity, yarn breaking strength and yarn levelness, and not only can spin pure nanometer fiber yarn, but also can spin nanometer fibers / filament core composite yarn. The orientation nanometer fiber spinning method and the device thereof have important application value in the fields, such as a biomedical field and a sensor field.

Owner:杨恩龙 +1

Wiring board and semiconductor package using the same

InactiveUS7397000B2Easy to implementRelieve pressurePrinted electric component incorporationSemiconductor/solid-state device detailsVitrificationBreaking strength

A wiring board has a base insulating film. The base insulating film has a thickness of 20 to 100 μm and is made of a heat-resistant resin which has a glass-transition temperature of 150° C. or higher and which contains reinforcing fibers made of glass or aramid. The base insulating film has the following physical properties (1) to (6) when an elastic modulus at a temperature of T° C. is given as DT (GPa) and a breaking strength at a temperature of T° C. is given as HT (MPa).(1) A coefficient of thermal expansion in the direction of thickness thereof is 90 ppm / K or less(2) D23≧5(3) D150≧2.5(4) (D−65 / D150)≦3.0(5) H23≧140(6) (H−65 / H150)≦2.3.

Owner:NEC CORP +1

Polyvinylidene fluoride microporous film and preparation method

InactiveCN101632903AWith nanoscale dimensionsImprove hydrophobicitySemi-permeable membranesDistillationFatty alcohol

The invention provides a polyvinylidene fluoride microporous film and a preparation method; the polyvinylidene fluoride microporous film is prepared by using polyvinylidene fluoride, fatty alcohol (non solvent) and polar organic solvent as raw materials, the proportioning of which is as follows: the mass content of polyvinylidene fluoride is 10%-15%, and the content of non solvent is 6-12%; the specific steps are as follows: polyvinylidene fluoride, polar organic solvent and non solvent are mixed, dissolved and filtered, set aside and are deaerated to obtain clear casting film liquid which is struck on a coarse structure template substrate and placed in air; gel forms film in a coagulating bath, is processed by hot water, and then soaked in water and absolute ethyl alcohol to obtain high hydrophobic polyvinylidene fluoride microporous film; the contact angle between the surface of high hydrophobic polyvinylidene fluoride microporous film and water reaches 130 degrees to 140 degrees, air flux of the film reaches 6.0m<3> / (m<2>-h-kPa) under 60kPa, the maximum bore diameter is less than 0.5 mum, tensile strength reaches breaking strength which is larger than 5Mpa, and the elongation at break is larger than 50%. The invention is the polyvinylidene fluoride microporous film with high hydrophobicity, high flux and good mechanical strength and the preparation method, which is mainly applied to the film distillation and associated film process.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com