Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1118 results about "Non solvent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non polar solvents contain bonds between atoms with similar electronegativities, such as carbon and hydrogen (think hydrocarbons, such as gasoline) Examples of non-polar solvents: carbon tetrachloride (CCl4), benzene (C6H6), and diethyl ether ( CH3CH2OCH2CH3), hexane (CH3(CH2)4CH3), methylene chloride (CH2Cl2).

Lyophilization process and products obtained thereby

ActiveUS20070116729A1Dissolve fastSuitable for useBiocidePowder deliveryHigh concentrationFreeze-drying

A lyophilization process which comprises dissolving a material in one or more solvents for said material to form a solution; forcing said material at least partially out of solution by combining the solution and a non-solvent for the material, which non-solvent is miscible with the solvent or solvents used and wherein said non-solvent is volatilizable under freeze-drying conditions. In addition, for hydrophobic and / or lipophilic materials, the anti-solvent can be omitted, and the solution of the material in the solvent can be subjected directly to freeze drying. The lyophilizates can then be reconstituted with typical aqueous diluent in the case of hydrophilic materials. Hydrophobic and or lipophilic materials can be initially reconstituted with propylene glycol and / or polyethyleneglycol to form a high concentration solution therein and this is further diluted for use with a diluent of Intralipid, plasma, serum, or even whole blood.

Owner:SCIDOSE PHARMA +1

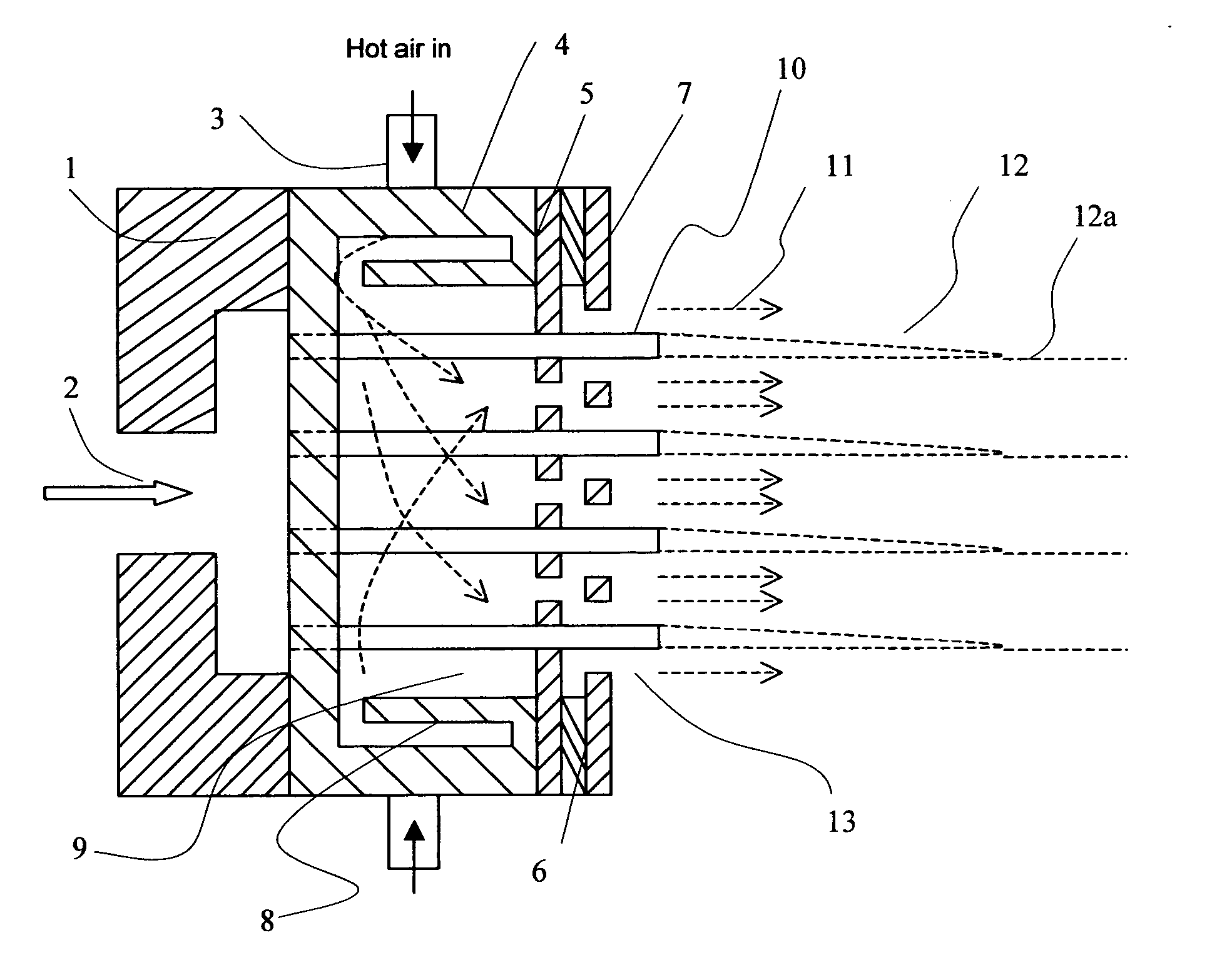

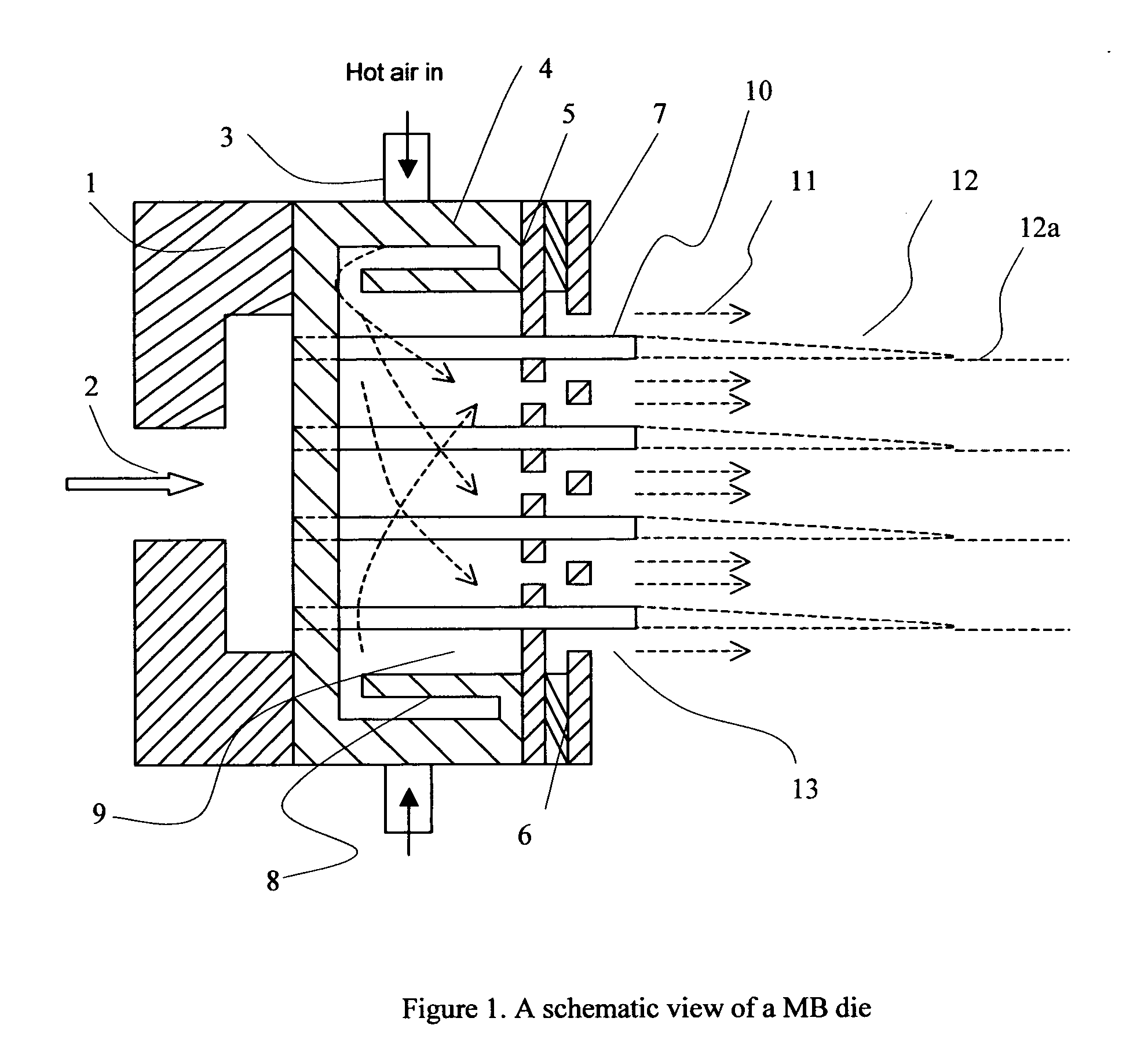

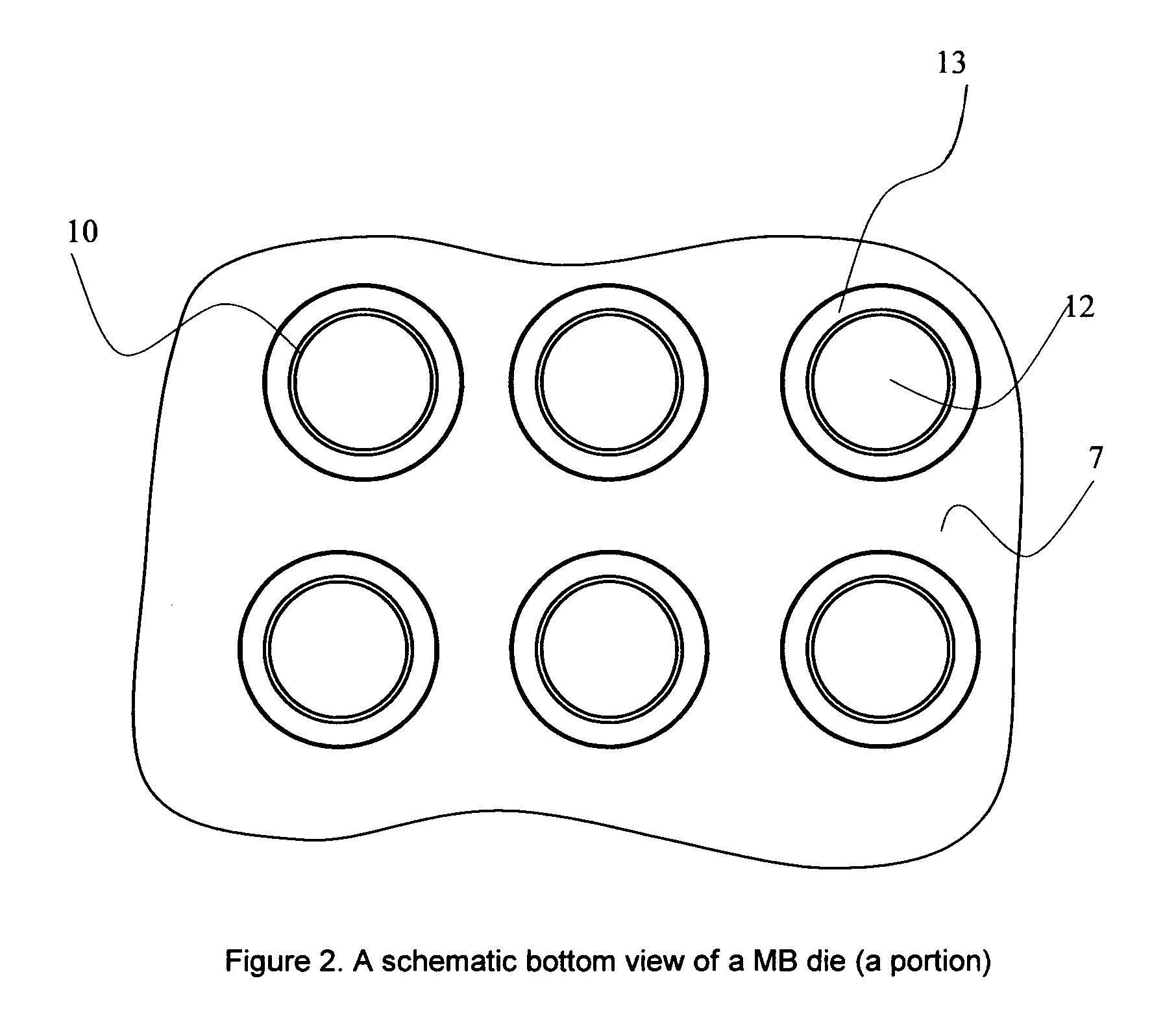

Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

InactiveUS20050056956A1Artificial filament washing/dryingLoose filtering material filtersNon solventEngineering

This invention relates to a process of melt blowing a cellulose solution through a concentric melt blown die with multiple rows of spinning nozzles to form cellulosic microfiber webs with different web structures. The process comprises the steps of (a) extruding a cellulose solution (dope) through a melt blown spinneret with multiple rows of spinning nozzles; (b) drawing each individual extrudate filament to fine fiber diameter by its own air jet; (c) coagulating and entangling the fine fibers with a series of pressured hydro needling jets of recycling solution of the mixture of cellulose solvent and non-solvent in the spin-line; (d) collecting the stream of microfibers, air and needling jets on a moving collecting surface to form cellulosic fiber web; (e) hydro-entangling the said pre-bonded web downstream with at least one set of hydro needling jets of recycling solvent / non-solvent solution for forming well bonded nonwoven web; (f) regenerating the fine fibers in at least one bath for at least 5 seconds; (g) further regenerating and washing the fine fibers in another bath for at least 5 seconds; (h) pinching the well bonded melt blown cellulosic nonwoven with pressure rollers to remove major portions of the non-solvent; (i) drying the nonwoven web by heat, or vacuum or both, and (j) winding the nonwoven web into rolls.

Owner:BIAX FIBERFILM CORP

Composite natural polymer gel material

ActiveCN105837861ALarge specific surface areaImprove mechanical propertiesAerogel preparationColloidal chemistry detailsNon solventWater based

The invention discloses a composite natural polymer gel material with a cross-linking agent. The material comprises hydrogel, organogel, aerogel and bioplastics and mainly overcomes the problem of low mechanical strength of conventional natural polymer gel materials. According to the invention, a certain amount of the cross-linking agent is added into a natural polymer water-based solution or dispersion liquid, then stirring is carried out, the obtained mixture is placed in a non-solvent for physical cross-linking, and then washing is carried out so as to obtain composite natural polymer hydrogel; water in the composite natural polymer hydrogel is replaced with an organic solution so as to prepare composite natural polymer organogel; the composite natural polymer hydrogel or organogel is dried so as to prepare composite natural polymer aerogel; the composite natural polymer aerogel is subjected to hydrophobic treatment so as to obtain hydrophobic aerogel; the composite natural polymer aerogel is subjected to heat treatment so as to obtain carbon aerogel; and one or more selected from the above-mentioned gel materials are subjected to high-temperature pressing so as to prepare composite natural polymer bioplastics. The composite natural polymer gel material prepared in the invention has the advantages of excellent mechanical properties, a high specific surface area, high elongation at break, etc., and can be easily processed into molded products of a plurality of forms.

Owner:浙江绍兴万德福生物技术有限公司 +1

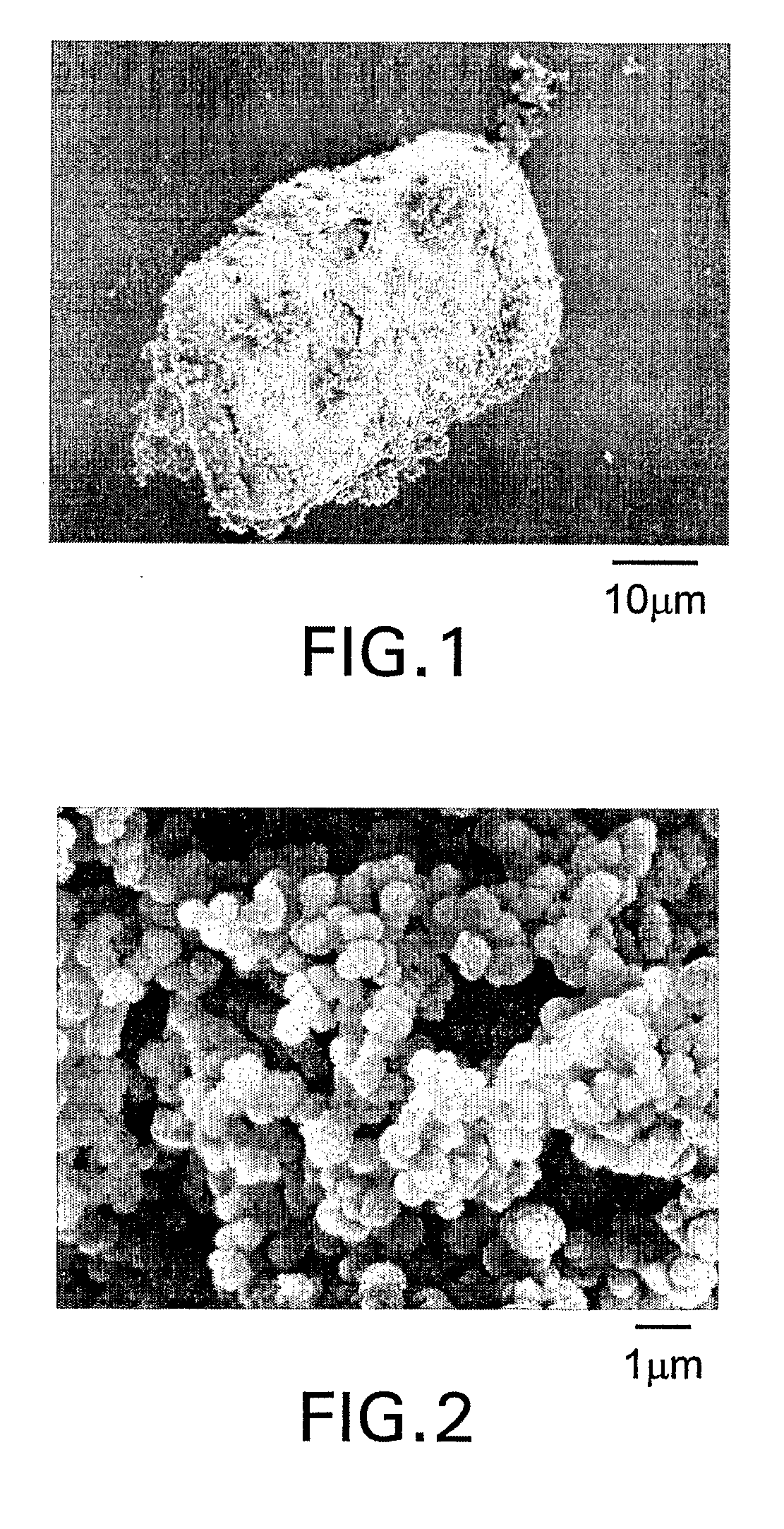

Thermally stable polycrystalline diamond constructions

InactiveUS20110036643A1Improve thermal characteristicsReduces and eliminates crack formationPigmenting treatmentDrill bitsNon solventSized small

Thermally stable polycrystalline constructions comprise a diamond body joined with a substrate, and may have a nonplanar interface. The construction may include an interlayer interposed between the diamond body and substrate. The diamond body preferably has a thickness greater than about 1.5 mm, and comprises a matrix phase of bonded together diamond crystals and interstitial regions disposed therebetween that are substantially free of a catalyst material used to sinter the diamond body. A replacement material is disposed within the interstitial regions. A population of the interstitial regions may include non-solvent catalyst material and / or an infiltrant aid disposed therein. The diamond body comprises two regions; namely, a first region comprising diamond grains that may be sized smaller than diamond grains in a second region, and / or the first region may comprise a diamond volume that is greater than that in the second region.

Owner:SMITH INT INC

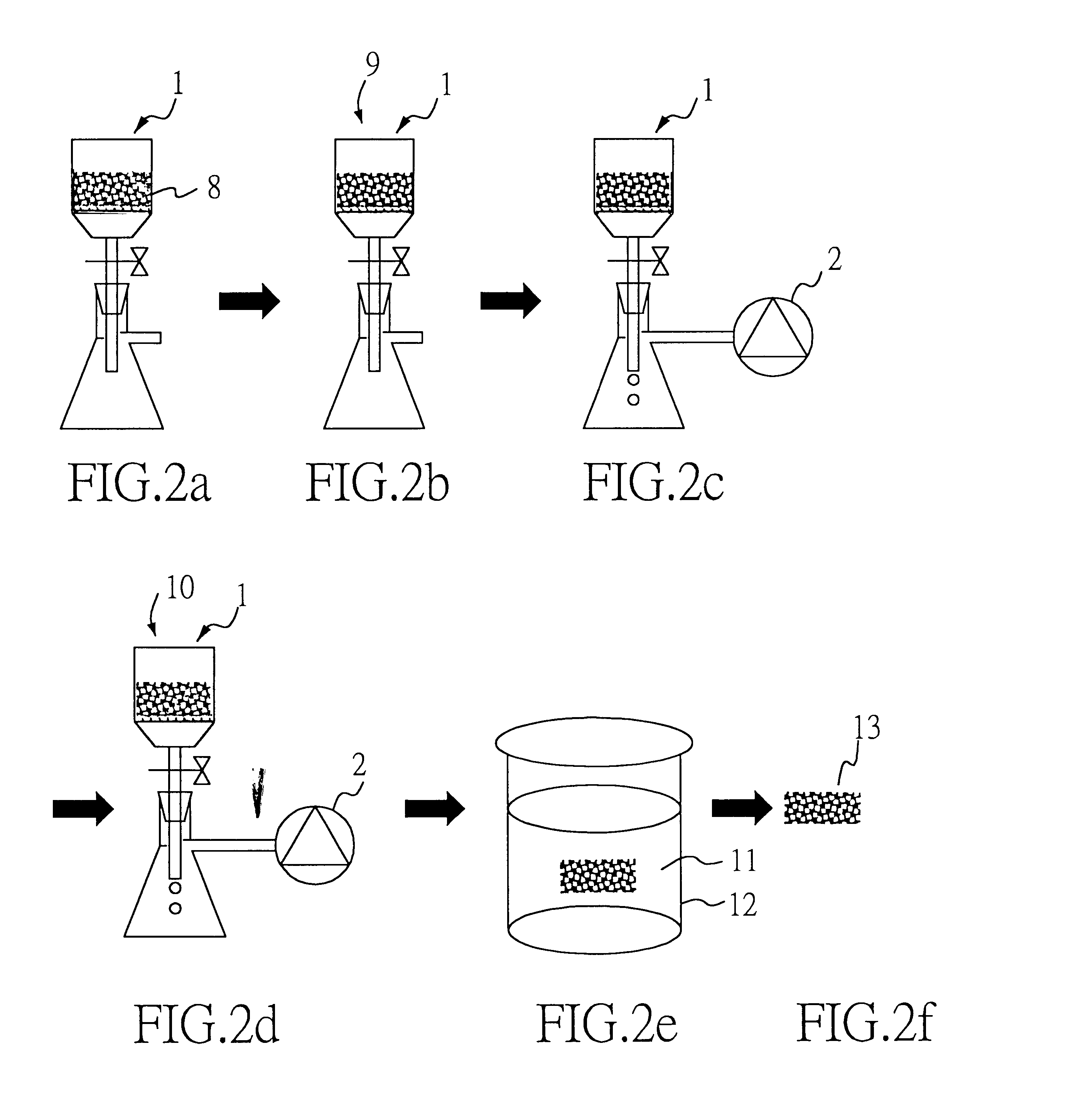

Composite thermotropic phase separation film-making method

The invention relates to a composite thermotropic phase isolated membrane preparation method which is characterized in that used composite diluent is the mixture of water-soluble good solvent and water-soluble additive of polymers. The membrane forming separation is a composite process which mainly takes the thermotropic membrane phase separation as the dominant role and non-solvent induced phaseseparation as the subsidiary role. The membrane prepared through the method has the advantages of high abruption strength, high abruption elongation and high water flux. The method is applicable to the preparation of membranes which are made of a plurality of polymers, including polyvinylidene fluoride, polysulfone, polyether sulfone, polyvinyl chloride and polyacrylonitrile. The performances of the membranes are improved greatly. Thus, the membranes can be widely applied to the fields of drinking water advanced treatment, pretreatment before reverse permeation, membrane bioreactor wastewatertreatment, reclaimed water reuse, etc.

Owner:湖南坎普尔环保技术有限公司

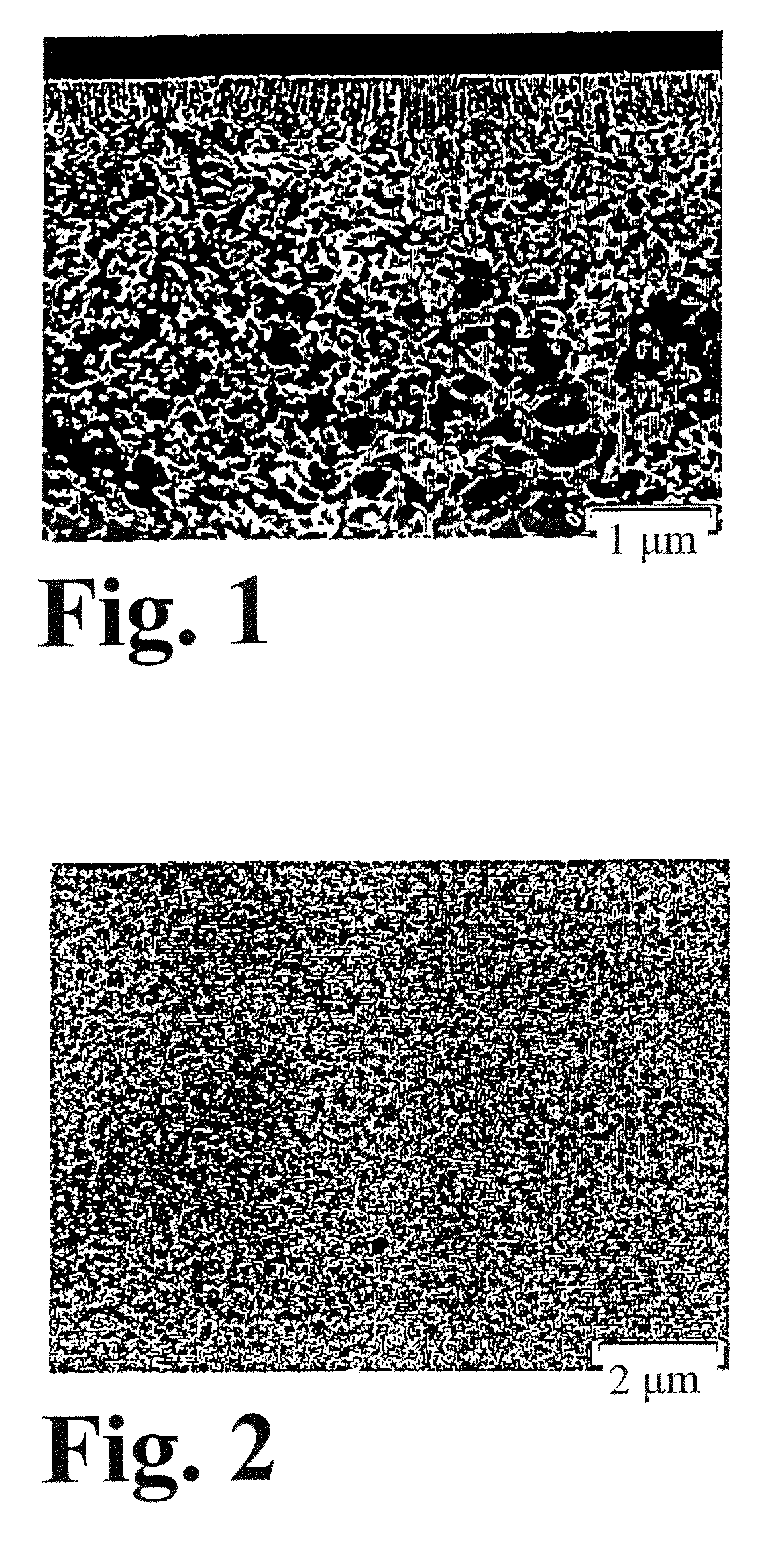

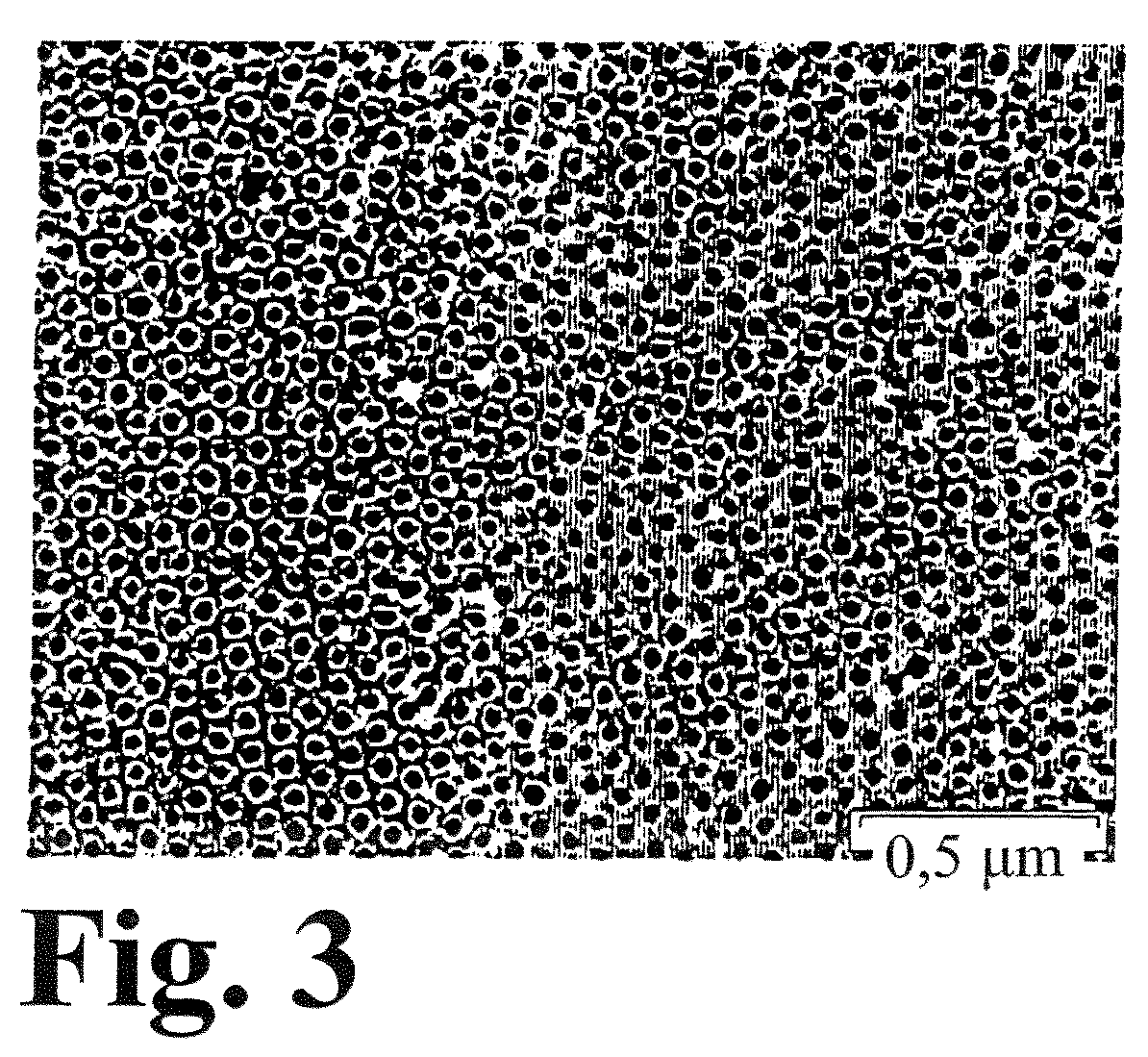

Isoporous membrane and method of production thereof

A membrane is produced by dissolving one or more polymers, at least one of which is a block copolymer, in a liquid which includes a solvent, to produce a casting solution. The casting solution is formed into film, and the film is immersed into a precipitation bath which contains at least one non-solvent for the block copolymer so that the film forms a membrane. The membrane is used for filtering a fluid that contains colloidal particles or proteins, and / or for ultrafiltration or nanofiltration, by flowing the fluid through the membrane.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

Asymmetric Gas Separation Membranes with Superior Capabilities for Gas Separation

InactiveUS20080143014A1Excellent permeation fluxHigh selectivityMembranesSemi-permeable membranesCellulose diacetatePolymer science

This invention relates to a method of making flat sheet asymmetric membranes, including cellulose diacetate / cellulose triacetate blended membranes, polyimide membranes, and polyimide / polyethersulfone blended membranes by formulating the polymer or the blended polymers dopes in a dual solvent mixture containing 1,3 dioxolane and a second solvent, such as N,N′-methylpyrrolidinone (NMP). The dopes are tailored to be closed to the point of phase separation with or without suitable non-solvent additives such as methanol, acetone, decane or a mixture of these non-solvents. The flat sheet asymmetric membranes are cast by the phase inversion processes using water as the coagulation bath and annealing bath. The dried membranes are coated with UV curable silicone rubber. The resulting asymmetric membranes exhibit excellent permeability and selectivity compared to the intrinsic dense film performances.

Owner:UOP LLC

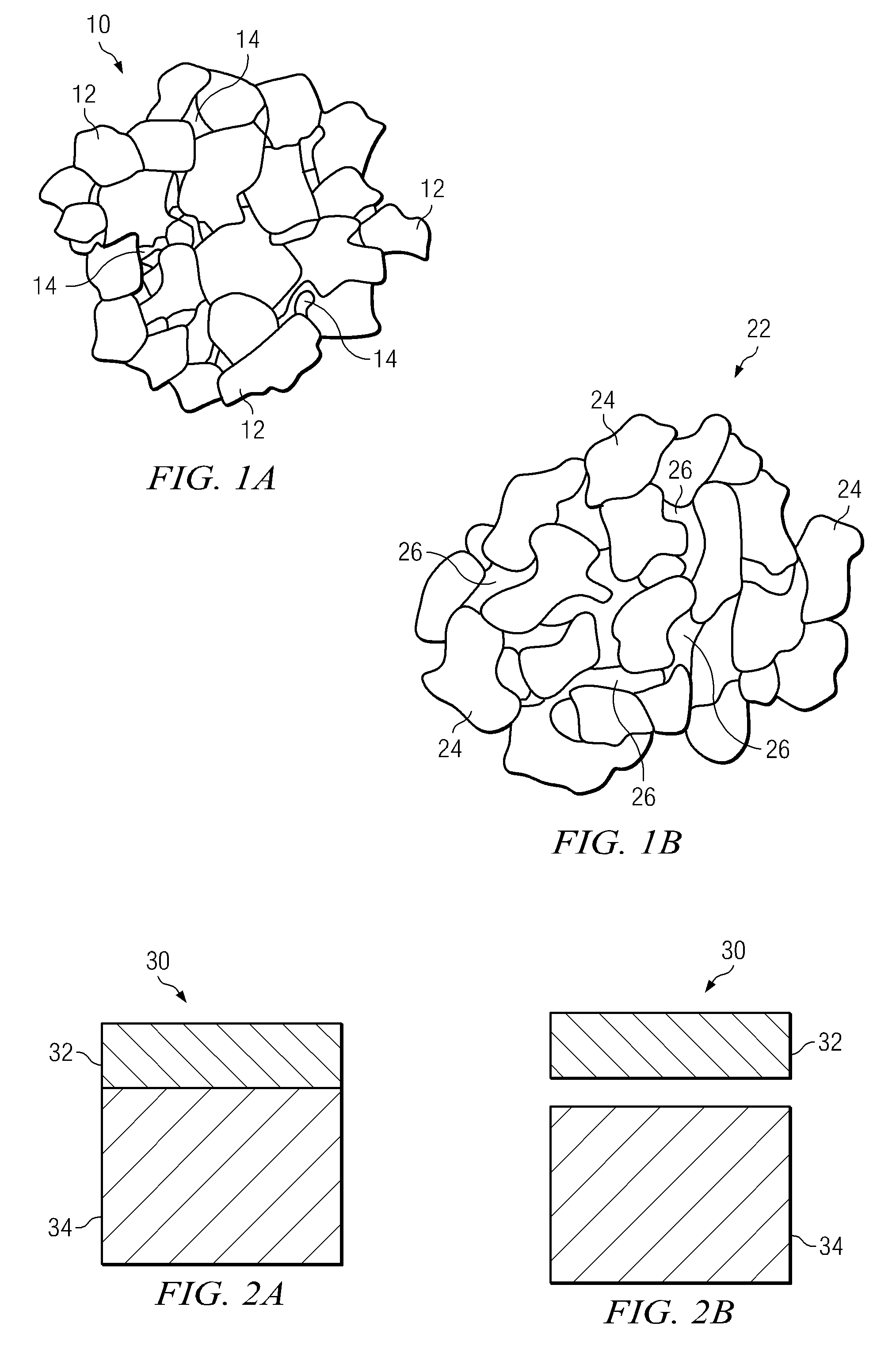

Polymeric drug formulations

InactiveUS7101840B2Improve performanceTrend downPowder deliverySaccharide peptide ingredientsNon solventWater insoluble

A method of forming a polymeric drug formulation in which a water-soluble drug is blended with a water-insoluble tissue-compatible polymer that is miscible in the solid phase with the drug, and with a poly(alkylene oxide), in a solvent system capable of forming a homogeneous solution of the drug, the tissue-compatible polymer and the poly(alkylene oxide), after which the solution is added to a non-solvent for the drug, the tissue-compatible polymer and the poly(alkylene oxide), so that a microdomain-separated solid co-precipitate of the drug, the tissue-compatible polymer and the poly(alkylene oxide) is formed, wherein the poly(alkylene oxide) is blended in an amount effective to form phase-separated microdomains in said co-precipitate.

Owner:EMORY UNIVERSITY +1

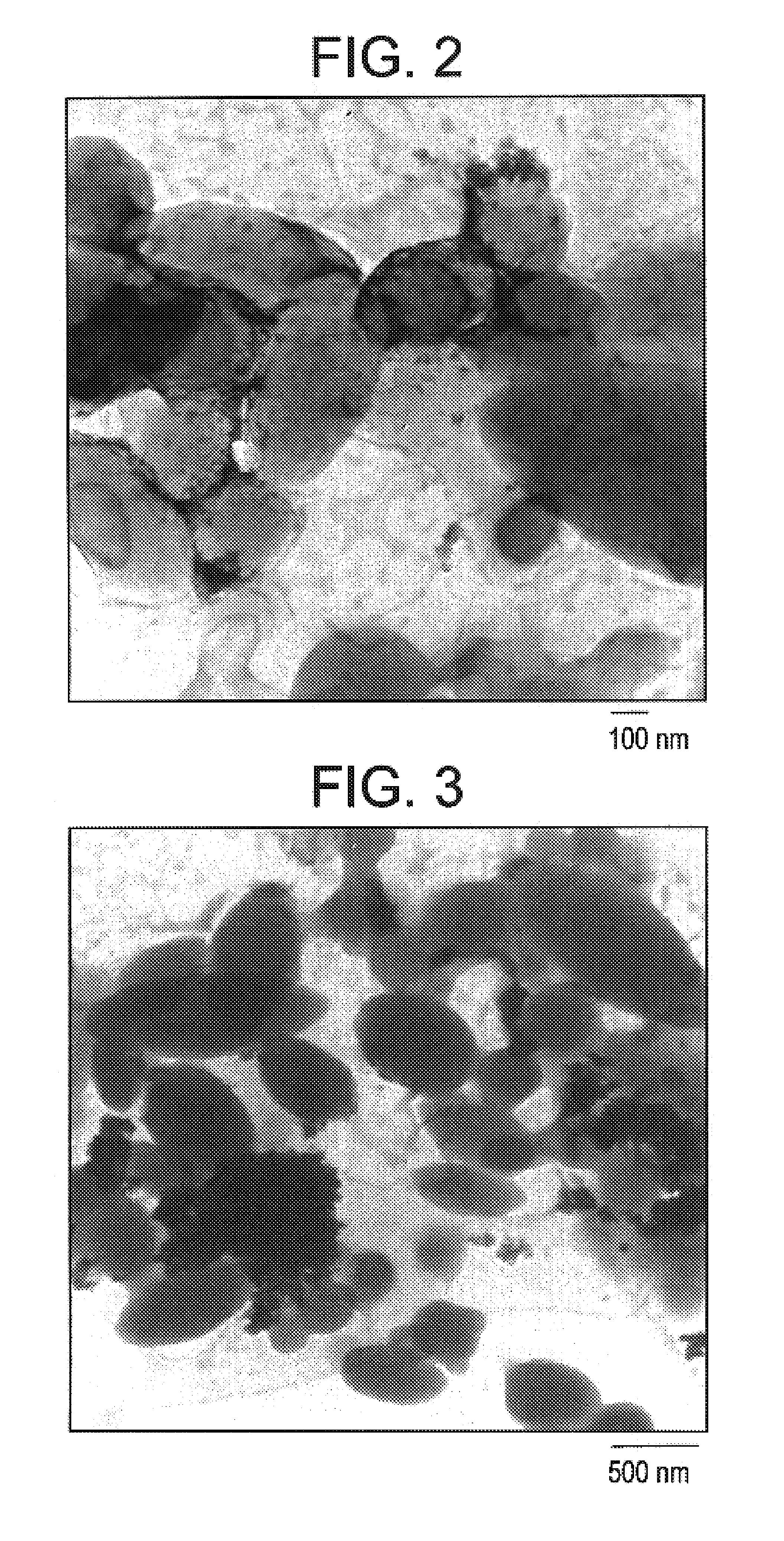

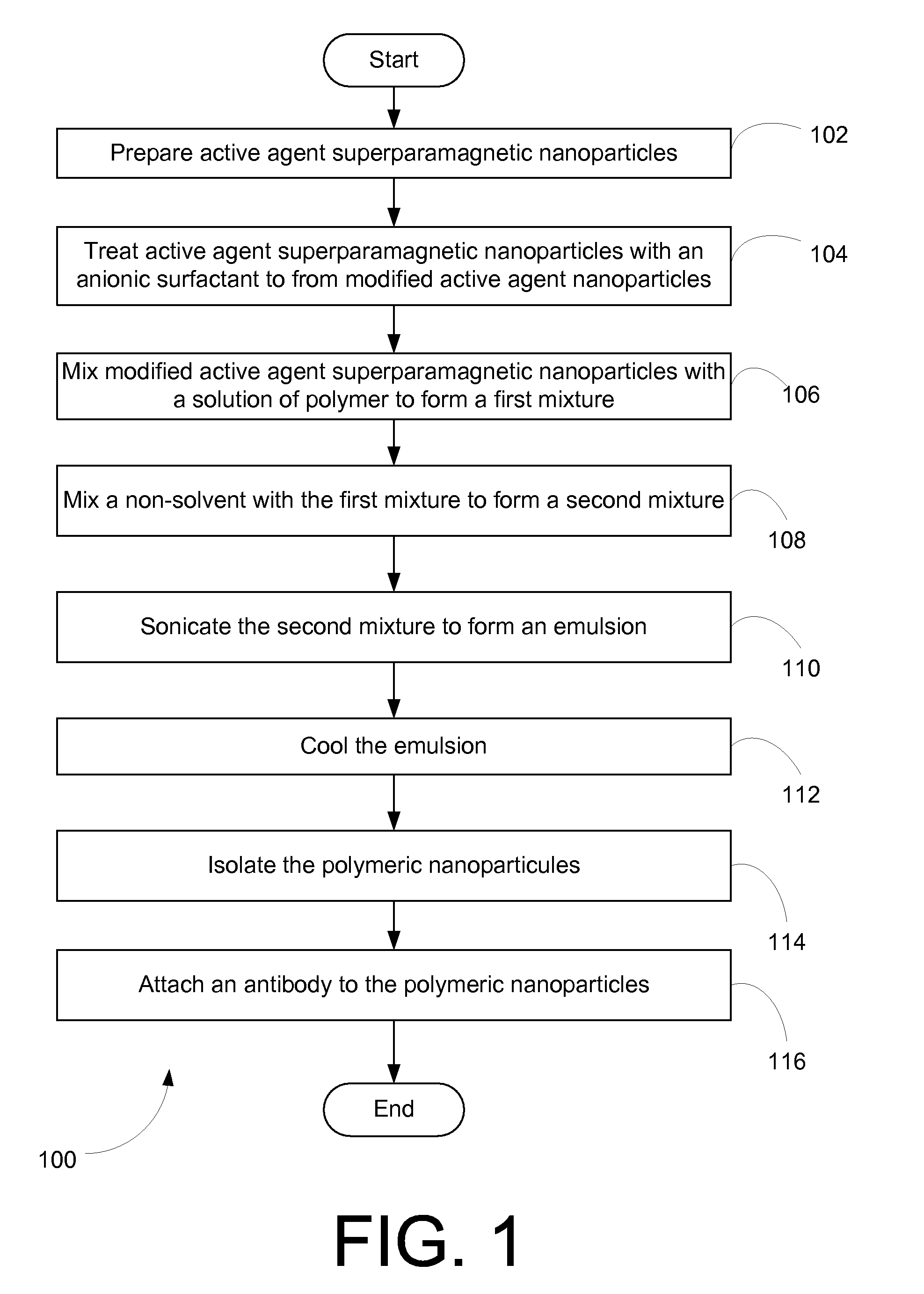

Polymeric encapsulation of nanoparticles

Polymeric nanoencapsulation methods, which combine sonication and nonsolvent temperature induced crystallization, are provided. The steps include (a) providing active agent nanoparticles having an average diameter between about 5 and about 100 nm; (b) treating said active agent nanoparticles (e.g., a superparamagnetic material) with an anionic surfactant to form modified active agent nanoparticles; (c) mixing the modified active agent nanoparticles with a solution of a polymer in a solvent at a first temperature, which is greater than the melting temperature of the polymer and less than the boiling point of the solvent to form a first mixture, said mixing comprising the use of sonication; (d) mixing a non-solvent with the first mixture to form a second mixture, the non-solvent being a non-solvent for the solvent and for the polymer and having a boiling point greater than the melting temperature of the polymer; (e) sonicating the second mixture to form an emulsion; and (f) cooling the emulsion to a second temperature and at a rate effective to precipitate polymeric nanoparticles comprising the polymer with the modified active agent nanoparticles dispersed therein.

Owner:SUTHERLAND ASBILL BRENNAN LLP +2

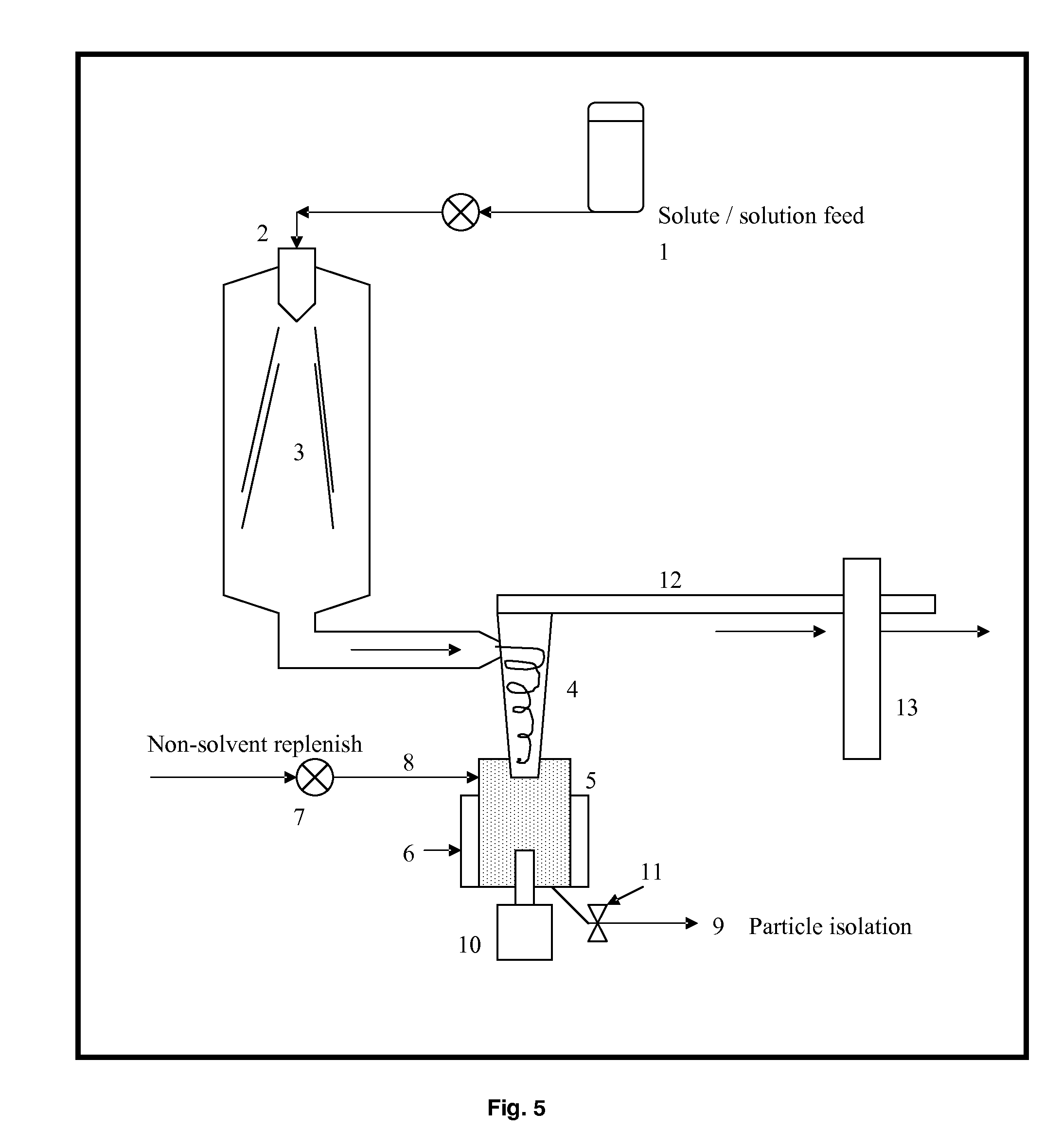

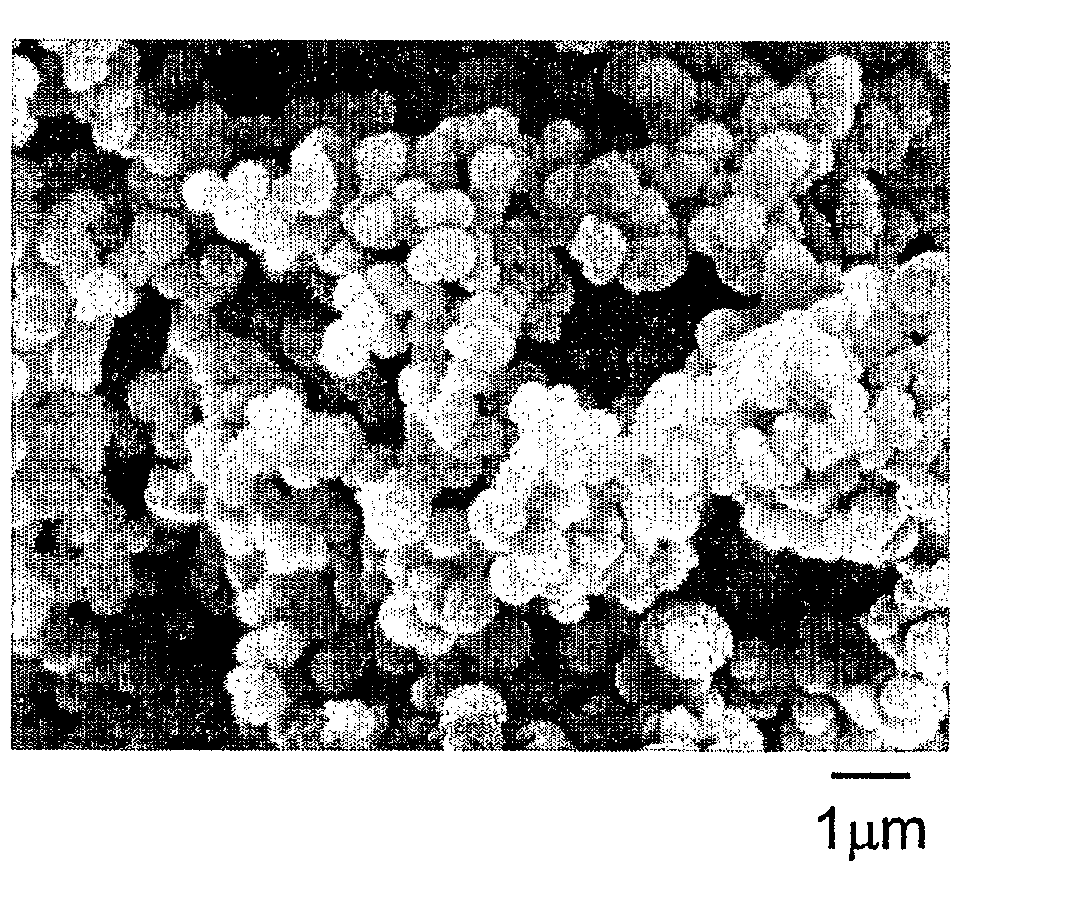

Process for improving crystallinity

ActiveUS20110146678A1High crystallinityPrevent leakageOrganic active ingredientsPowder deliveryNon solventCrystallinity

This invention provides a process for increasing the crystallinity of at least one solid material which is less than 100% crystalline, comprising contacting said solid material with solvent in which the solid material is insoluble or poorly soluble (a non-solvent); and applying ultrasound to the solid material when in contact with said non-solvent.

Owner:CIRCASSIA

Lyophilization process and products obtained thereby

A lyophilization process which comprises dissolving a material in one or more solvents for said material to form a solution; forcing said material at least partially out of solution by combining the solution and a non-solvent for the material, which non-solvent is miscible with the solvent or solvents used and wherein said non-solvent is volatilizable under freeze-drying conditions. In addition, for hydrophobic and / or lipophilic materials, the anti-solvent can be omitted, and the solution of the material in the solvent can be subjected directly to freeze drying. The lyophilizates can then be reconstituted with typical aqueous diluent in the case of hydrophilic materials. Hydrophobic and or lipophilic materials can be initially reconstituted with propylene glycol and / or polyethyleneglycol to form a high concentration solution therein and this is further diluted for use with a diluent of Intralipid, plasma, serum, or even whole blood.

Owner:SCIDOSE PHARMA +1

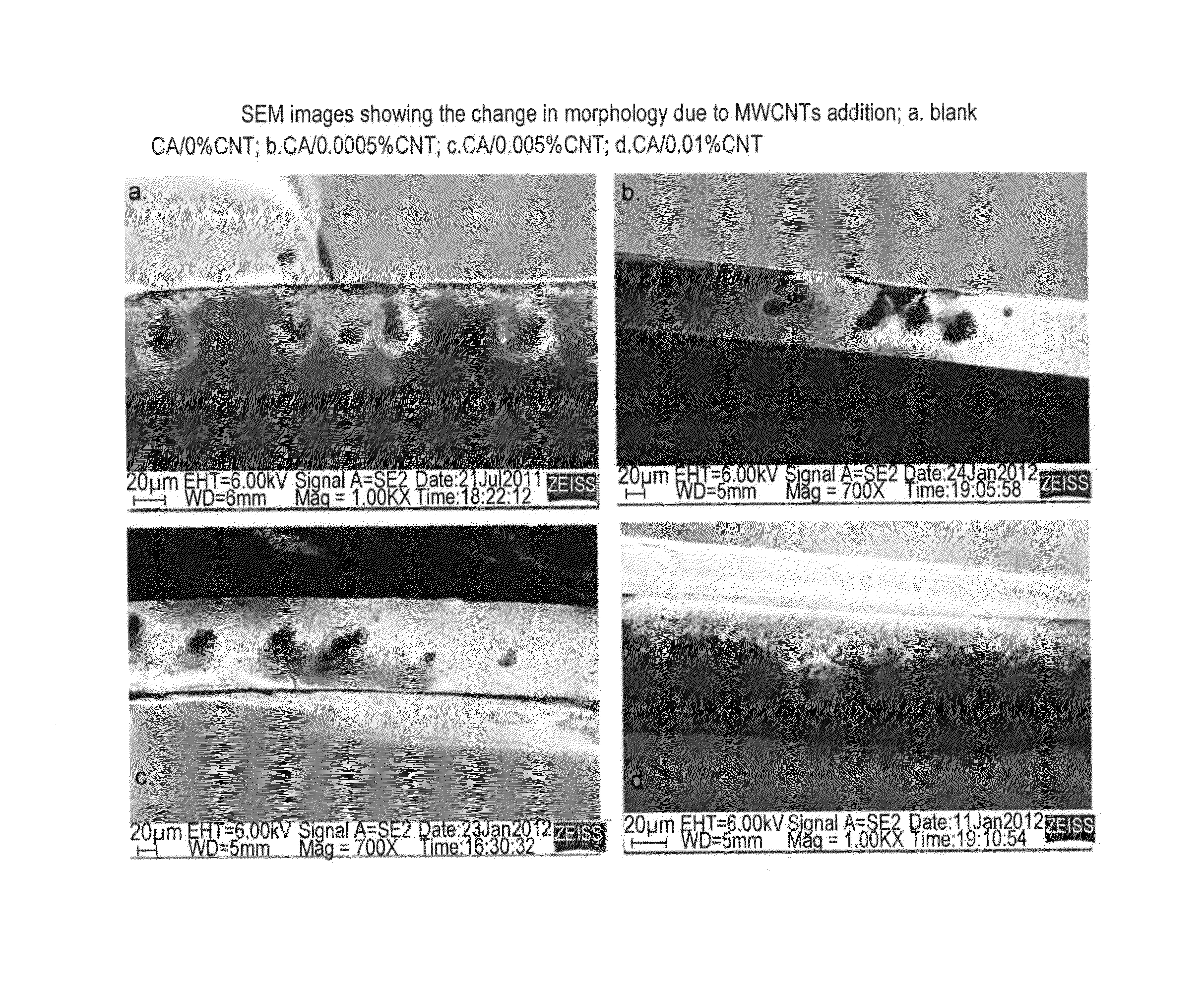

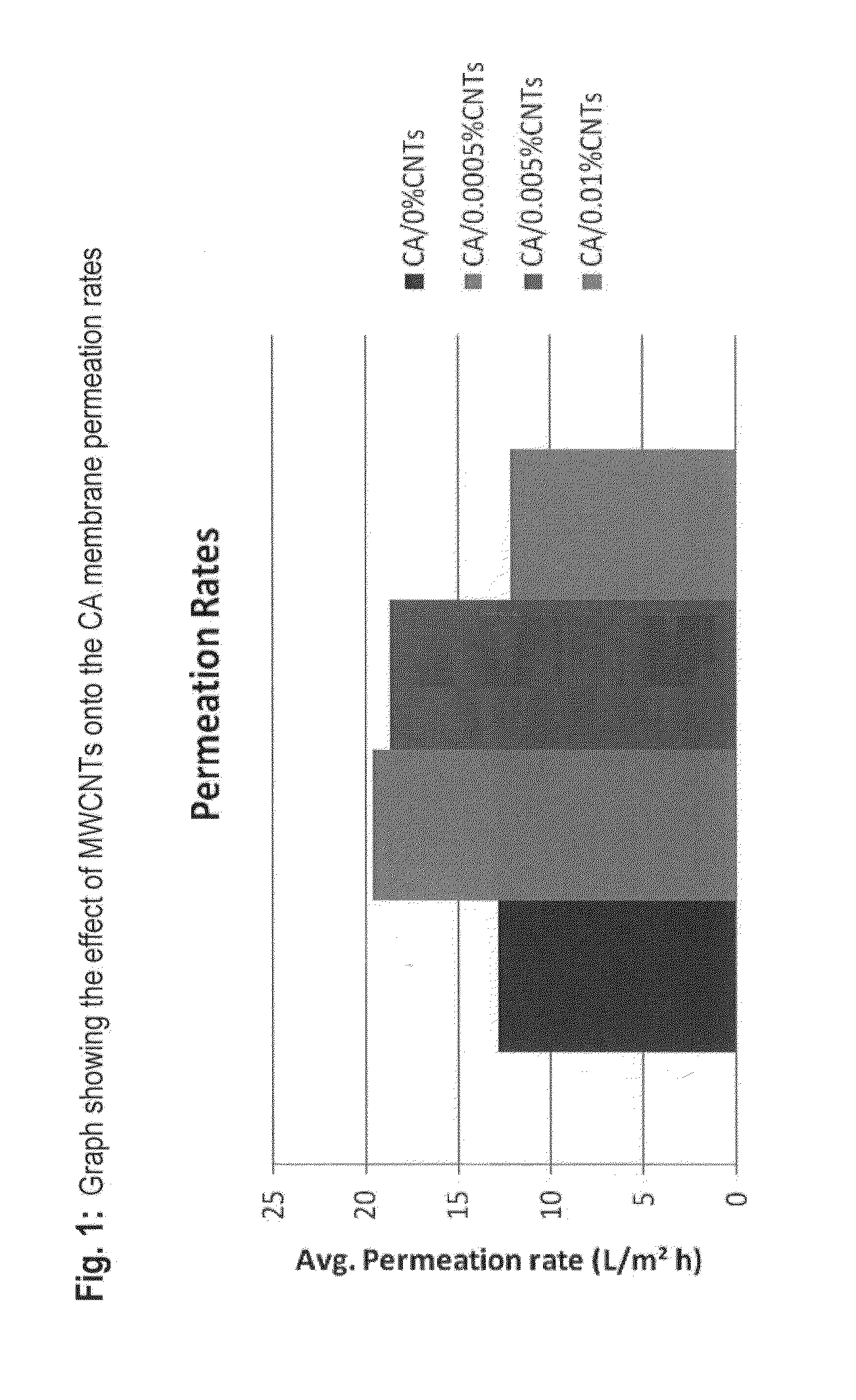

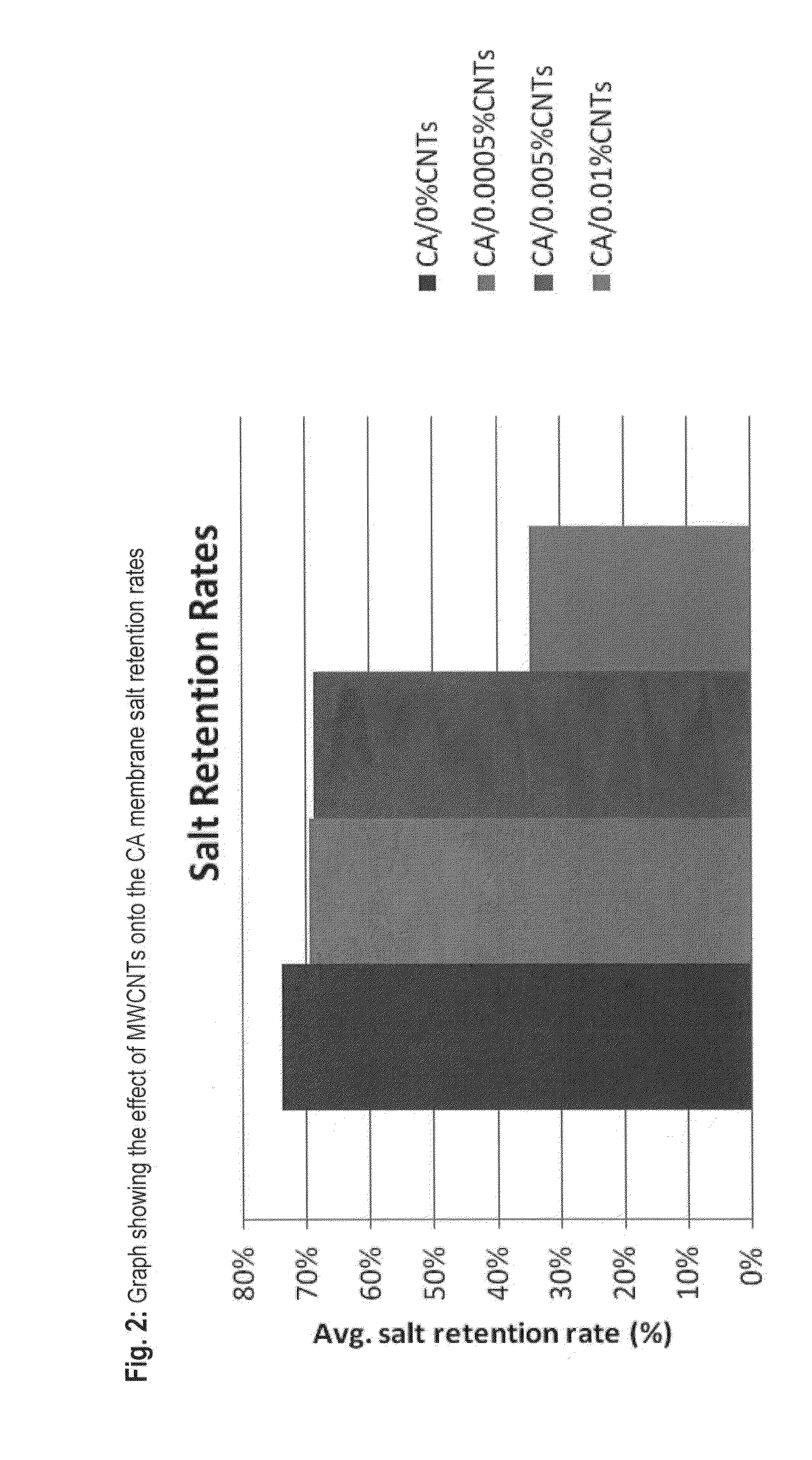

Polymer-carbon nanotube nanocomposite porous membranes

This invention relates to an asymmetric composite membrane containing a polymeric matrix and carbon nanotubes within a single membrane layer, where the carbon nanotubes are randomly oriented within the polymeric matrix and the composite membrane is formed by phase inversion. This invention also relates to a method for producing the composite membrane which includes: coating a surface with a film of a polymer solution containing a polymeric matrix and carbon nanotubes dissolved in at least one solvent; immersing the coated surface in a non-solvent to affect solvent / non-solvent demixing resulting in phase inversion to form a carbon nanotube-containing membrane; and optionally, removing the carbon nanotube-containing membrane from the surface. The invention also relates to a desalination method using the composite membrane.

Owner:AMERICAN UNIV OF CAIRO AUC

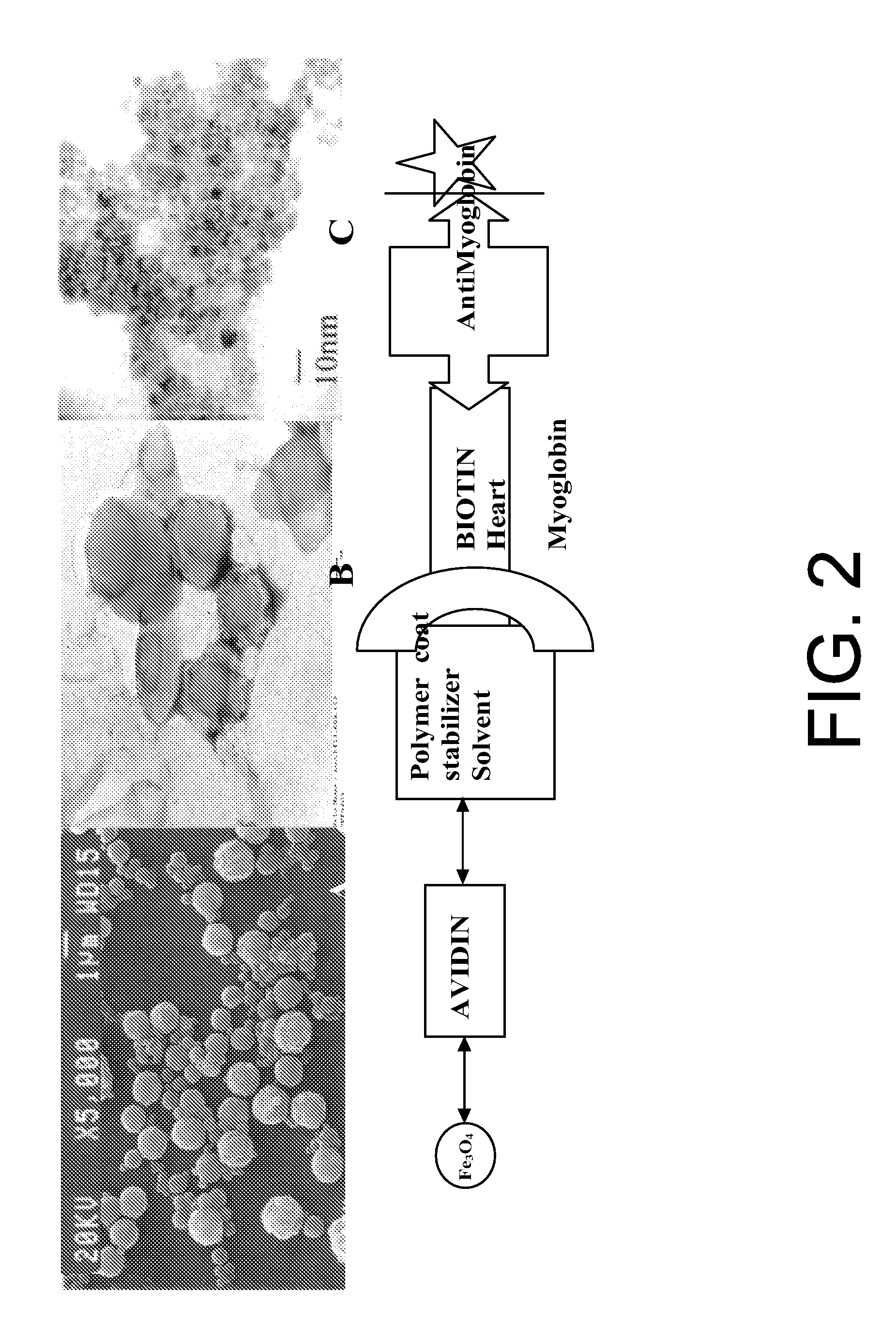

Nanoparticles that facilitate imaging of biological tissue and methods of forming the same

InactiveUS20090220434A1Enhance the imageGood adhesionPharmaceutical containersPretreated surfacesNon solventAntiendomysial antibodies

Nanoparticles that facilitate imaging of biological tissue and methods for formulating the nanoparticles are provided. In order to form suitable nanoparticles for imaging, an anionic surfactant may be applied to superparamagnetic nanoparticles to form modified nanoparticles. The modified nanoparticles may be mixed with a polymer in a solvent to form a first mixture, and a non-solvent may be mixed with the first mixture to form a second mixture. An emulsion may be formed from the second mixture and the polymeric nanoparticles may be isolated from the emulsion. In certain embodiments of the invention, an antibody may be attached to the polymeric nanoparticles to facilitate attachment of the nanoparticles to biological tissue.

Owner:FLORIDA STATE UNIV RES FOUND INC

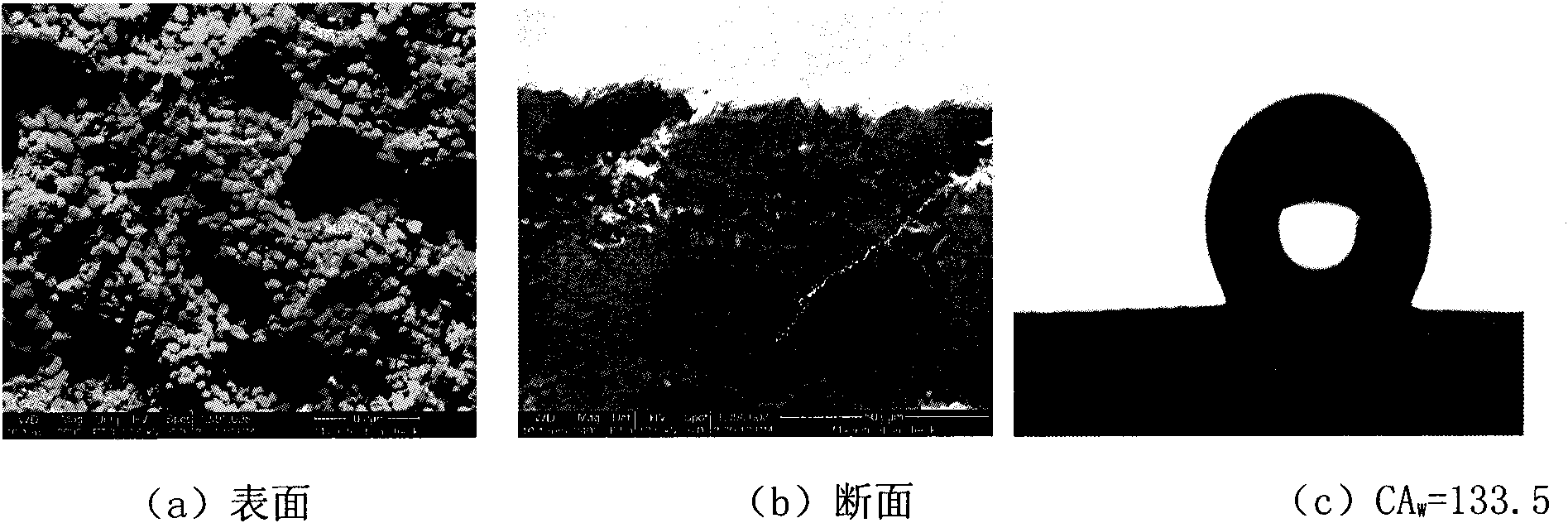

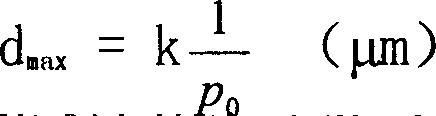

Polyvinylidene fluoride microporous film and preparation method

InactiveCN101632903AWith nanoscale dimensionsImprove hydrophobicitySemi-permeable membranesDistillationFatty alcohol

The invention provides a polyvinylidene fluoride microporous film and a preparation method; the polyvinylidene fluoride microporous film is prepared by using polyvinylidene fluoride, fatty alcohol (non solvent) and polar organic solvent as raw materials, the proportioning of which is as follows: the mass content of polyvinylidene fluoride is 10%-15%, and the content of non solvent is 6-12%; the specific steps are as follows: polyvinylidene fluoride, polar organic solvent and non solvent are mixed, dissolved and filtered, set aside and are deaerated to obtain clear casting film liquid which is struck on a coarse structure template substrate and placed in air; gel forms film in a coagulating bath, is processed by hot water, and then soaked in water and absolute ethyl alcohol to obtain high hydrophobic polyvinylidene fluoride microporous film; the contact angle between the surface of high hydrophobic polyvinylidene fluoride microporous film and water reaches 130 degrees to 140 degrees, air flux of the film reaches 6.0m<3> / (m<2>-h-kPa) under 60kPa, the maximum bore diameter is less than 0.5 mum, tensile strength reaches breaking strength which is larger than 5Mpa, and the elongation at break is larger than 50%. The invention is the polyvinylidene fluoride microporous film with high hydrophobicity, high flux and good mechanical strength and the preparation method, which is mainly applied to the film distillation and associated film process.

Owner:HEBEI UNIV OF TECH

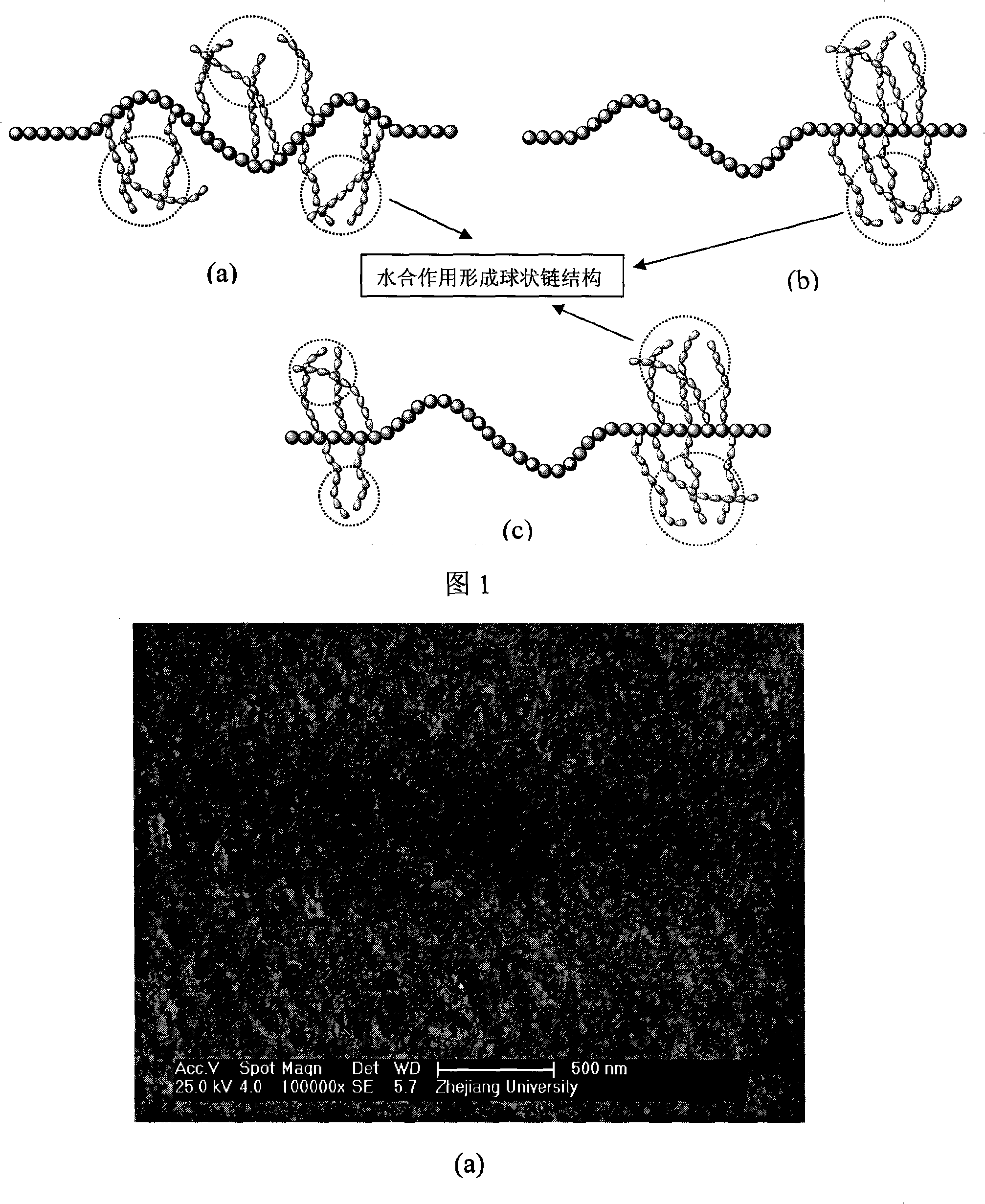

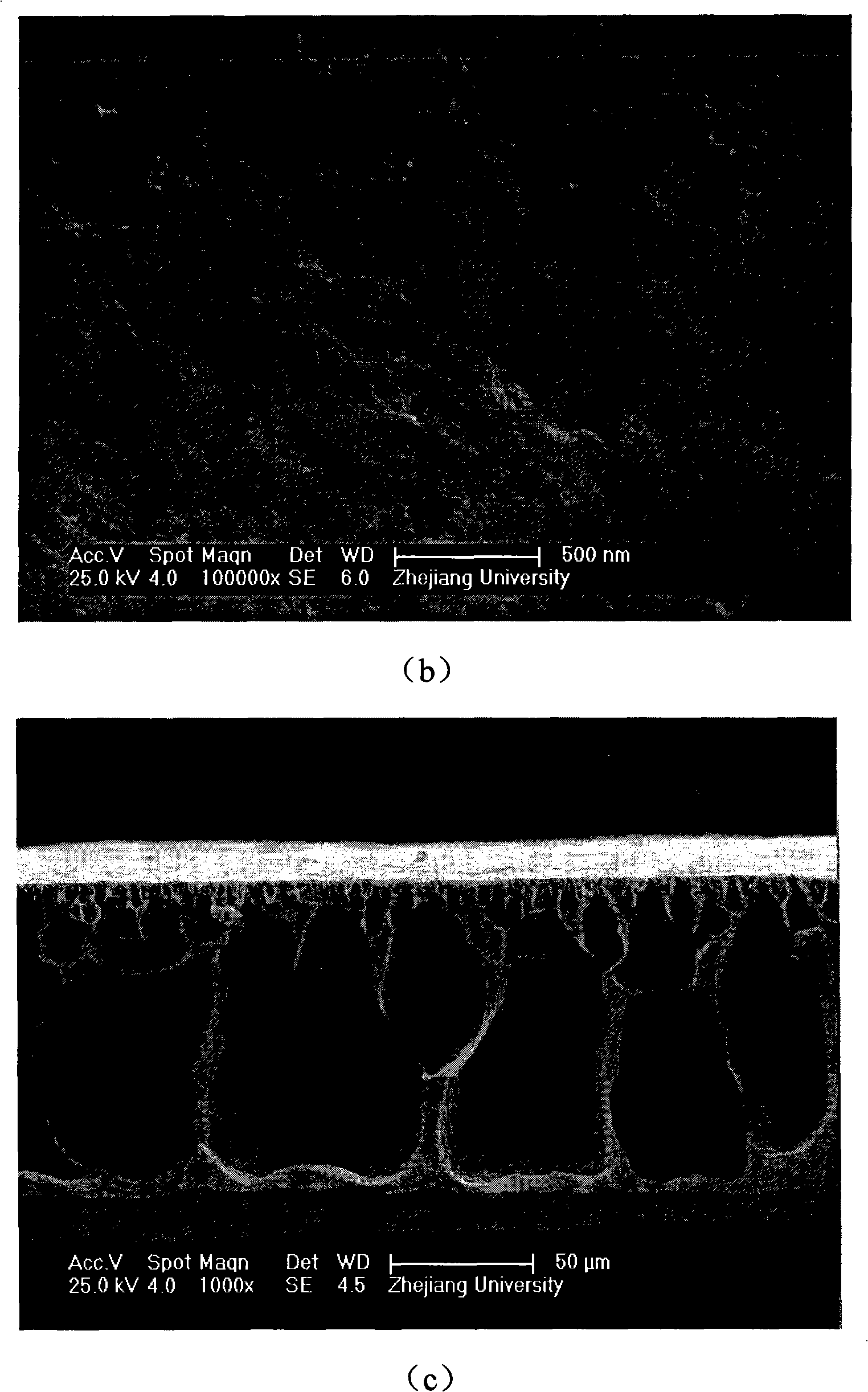

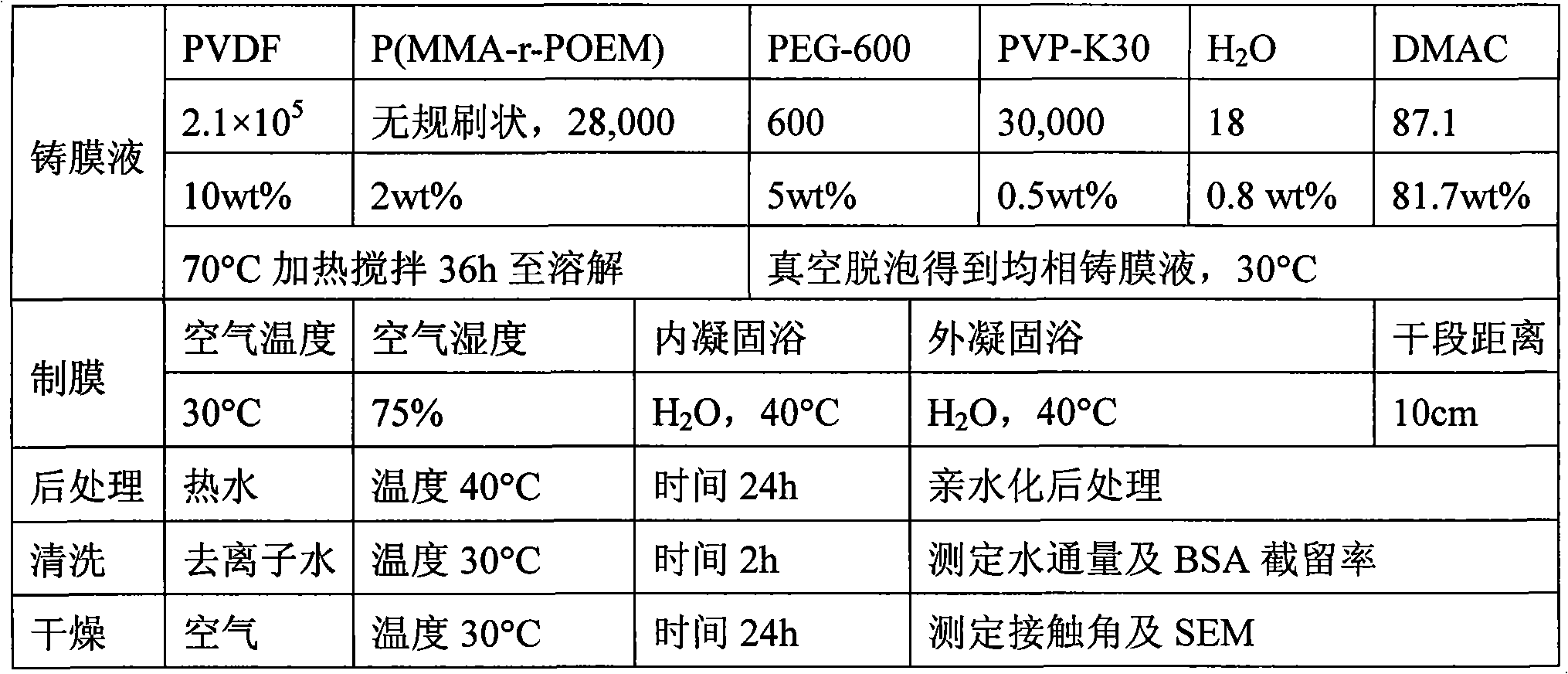

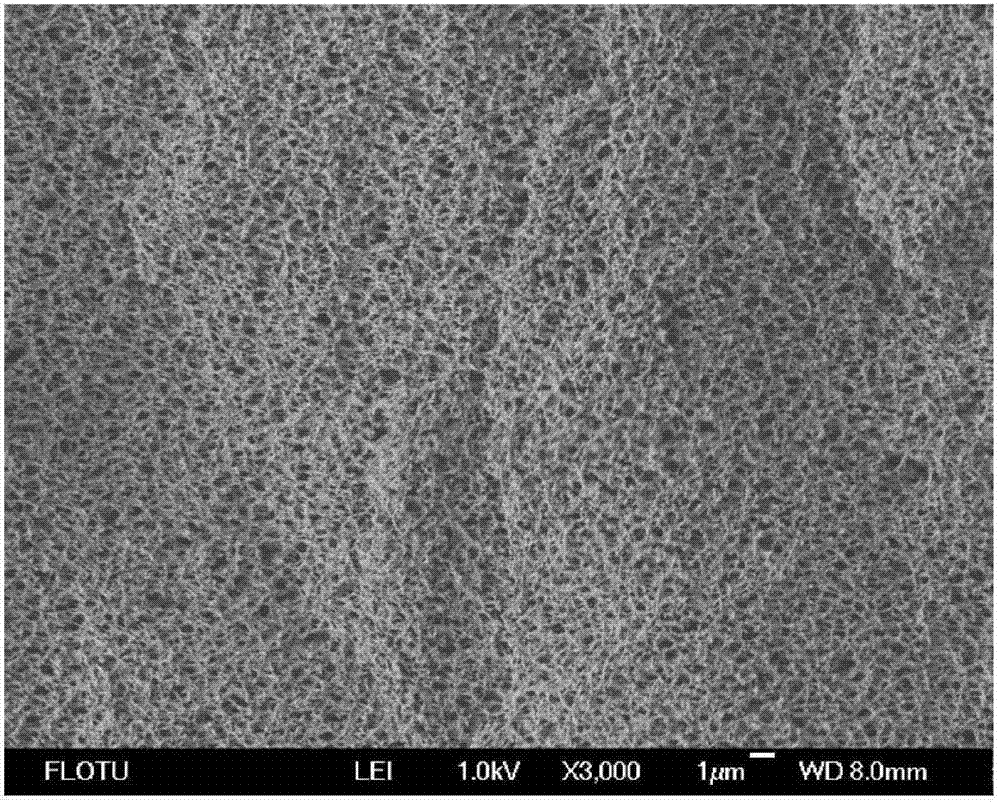

Method for modifying polyvinylidene fluoride ultrafiltration membrane by amphiphilic co-polymer

InactiveCN101264428AImprove hydrophilicityReduce energy consumptionSemi-permeable membranesUltrafiltrationDumbbell shaped

The invention discloses a method of producing the hyperfiltration membrane of amphiphilic copolymer modified polyvinylidene fluoride, comprising the following steps: 1) mixing polyvinylidene fluoride, poly (methyl methacrylate - monomethyl ether polyoxyethylene methyl methacrylate), additives, non-solvent and solvent to form the casting film solution; 2) making the casting film solution into the polyvinylidene fluoride membrane by using the film forming machine and then soaking in the coagulation bath; 3) conducting the posttreatment of hydrophilicity; 4)obtaining the hydrophilic polyvinylidene fluoride ultrafiltration membrane after cleaning and drying. The method is characterized in that the brush shape, chain ball shape or dumbbell shape amphiphilic copolymer are mixed with the polyvinylidene fluoride to produce the polyvinylidene fluoride hyperfiltration membrane with hydrophilicity, anti-pollution, large flux and high retention rate by adopting the solution phase conversion method. The method has the advantages that the obtained membrane is provided with dozens to hundreds nanometer of particular densified hydrogel surface layers, the contact angle of the membrane surface can be reduced below 60 degrees and can be lowered to 0 degree within tens of seconds, the water flux can reach 1000L / m<2> / h (0.1Mpa) or above, the retention rate of BSA can reach 90% or more and the recovery rate of water cleaning flux can reach 90% or higher.

Owner:ZHEJIANG UNIV

Preparation method for biodegradable polymeric microspheres using solvent extraction and preparation method for microspheres for treating local inflammation using the same

InactiveUS6149944ALow efficiencyEfficient curingLayered productsPharmaceutical non-active ingredientsDiseaseNon solvent

PCT No. PCT / KR97 / 00055 Sec. 371 Date Aug. 2, 1999 Sec. 102(e) Date Aug. 2, 1999 PCT Filed Apr. 1, 1997 PCT Pub. No. WO97 / 36949 PCT Pub. Date Oct. 9, 1997A preparation method for biodegradable polymeric microspheres using a solvent extraction method for biodegradable polymeric microspheres for treating a local inflammation disease using the same which are capable of effectively curing ozena such as sinusitis and a middle ear infection. Since a non-solvent of polymer is added into an outer aqueous phase in advance, the solidification of the polymer is implemented in a short time which, in turn, improves encapsulation of the therapeutic agent used.

Owner:AMOREPACIFIC CORP

Method of preparing high orientation nanoparticle-containing sheets or films using ionic liquids, and the sheets or films produced thereby

InactiveUS7550520B2High magnetic anisotropyImprove signal-to-noise ratioNanostructure manufactureConductive materialNon solventMagnetite Nanoparticles

A method is provided for the preparation of nanomaterials, which involves the dissolution and / or suspension of a combination of (a) one or more resin substrate materials and (b) one or more magnetic nanoparticulate substances, in a medium made from one or more ionic liquids, to provide a mixture, and recovering the solid nanomaterial by combining the mixture with a non-solvent (solvent for the ionic liquids but not the other components), while also applying an electromagnetic field to the mixture during the recovering step to align the magnetic nanoparticulate substances, along with the use of the resulting nanomaterials to provide unique information storage media, particularly in the form of sheets or films.

Owner:UNIVERSITY OF ALABAMA +1

Developer solvent for photopolymer printing plates and method

InactiveUS6248502B1Improved relief depthImproved sidewall structurePhotosensitive material processingOriginals for photomechanical treatmentNon solventOrganic solvent

Flexographic printing plates crosslinkable by photopolymerization are produced by exposing the plates to a light source and washing out (developing) with a solvent the non-crosslinked areas that are masked out during the exposure process. The invention provides terpene ester-based solvents suitable for use in the development of photopolymer printing plates. The solvents, which include terpene esters alone or terpene esters mixed with organic solvents and / or non-solvents, are effective in developing a a large number of different photopolymer printing plates and can produce images superior to those obtained with commercially available solvents currently used in such applications.

Owner:EASTMAN KODAK CO

High-water-flux forward-osmosis composite membrane and preparation method thereof

ActiveCN103977718AHigh selectivityImprove hydrophilicitySemi-permeable membranesConcentration polarizationPolysulfone membrane

The invention relates to a high-water-flux forward-osmosis composite membrane and a preparation method thereof. The forward-osmosis composite membrane is a polysulfone-sulfonated polysulfone-inorganic filler blended / polyamide composite membrane. A traditional osmosis membrane is generally applied to a reverse-osmosis system, and if the traditional osmosis membrane is used in a forward-osmosis process, the water flux of osmosis is far lower than a theoretical value since the traditional osmosis composite membrane is large in thickness, the hydrophilicity of a supporting layer of a polyamide layer is poor so as to cause serious inner concentration polarization. The preparation method comprises the following steps: blending a polymer with a modifier to form film casting liquid; after scraping or leveling, performing non-solvent coagulating bath with water; by a phase-inversion method, preparing a polysulfone ultrafiltration membrane with good hydrophilicity, high porosity, uniform surface pore structure and narrow pore diameter distribution; and in a clean environment and at room temperature, airing the polysulfone membrane till the surface is dry, and growing a polyamide active layer on the surface of the polysulfone membrane by an interfacial polymerization method, thereby obtaining the forward-osmosis composite membrane with good hydrophilicity, high porosity, low thickness and high mechanical strength. The high-water-flux forward-osmosis composite membrane disclosed by the invention has the advantages that not only the osmosis flux is high, but also the reverse leakage of an extraction medium is low, and the selective permeability is good.

Owner:UNIV OF SCI & TECH OF CHINA

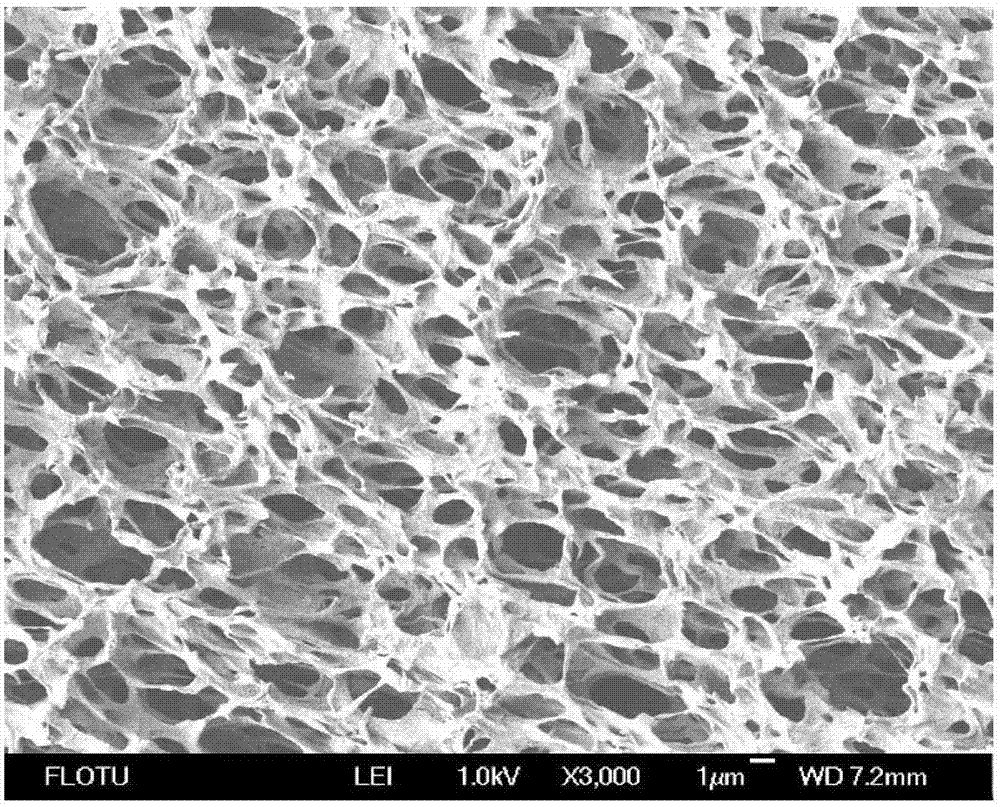

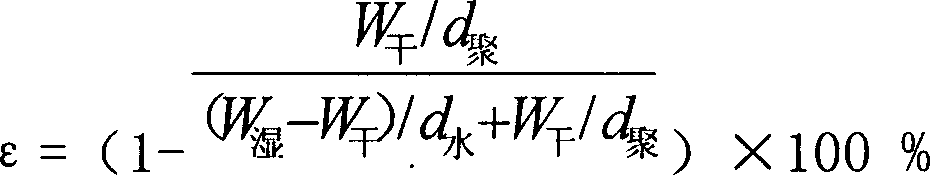

Method for preparing polyvinylidene fluoride ultra-filtration membranes

The invention discloses a method for preparing polyvinylidene fluoride ultra-filtration membranes. The method includes the steps of mixing the polyvinylidene fluoride with diluents, and heating the mixture to form a homogeneous phase solution, wherein the diluents are a mixture of a solvent and a non-solvent of the polyvinylidene fluoride, and at least one of the solvent and the non-solvent of the polyvinylidene fluoride can be dissolved in water; subjecting the homogeneous phase solution to knife coating on a supporting screen to form a plate-shaped membrane casting solution or to be spinned into a membrane casting solution in a hollow fiber shape by a spinneret, submerging the membrane casting solution into a cooling liquid to be cooled, subjecting the membrane casting solution to phase separation and solidifying into membranes; extracting the diluents in the membranes through an extracting agent to obtain the polyvinylidene fluoride membranes. Sections of the polyvinylidene fluoride membranes are in a homogeneous spongeous structure with bore diameters in a range of 0.02 to 4 microns, and the membranes have surface layers with surface bore diameters ranging from 2 nanometers to 100 nanometers. Simultaneously, the polyvinylidene fluoride ultra-filtration membranes have the advantages of high strength, porosity, flux and separation accuracy.

Owner:TSINGHUA UNIV

Process for homogenizing polyolefin drag reducing agents

ActiveUS6894088B2Accelerated dissipationImprove solubilityOther chemical processesRefining by heating/coolingPolyolefinKetone

A process for producing polymer drag reducing agent (DRA) slurries without cryogenic temperatures or conventional grinding is described. The homogenizing or size reduction of polymer, such as poly(alpha-olefins), may be achieved by the use of granulated polymer and at least one liquid, non-solvent for the polymer DRA. In one non-limiting embodiment of the invention, the homogenizing is conducted at ambient temperature. Examples of suitable non-solvents include water and non-aqueous non-solvents including, but not necessarily limited to, alcohols, glycols, glycol ethers, ketones, and esters; having from 2-6 carbon atoms, and combinations thereof. The polymeric DRA may be homogenized to an average particle size of about 600 microns or less.

Owner:BAKER HUGHES INC

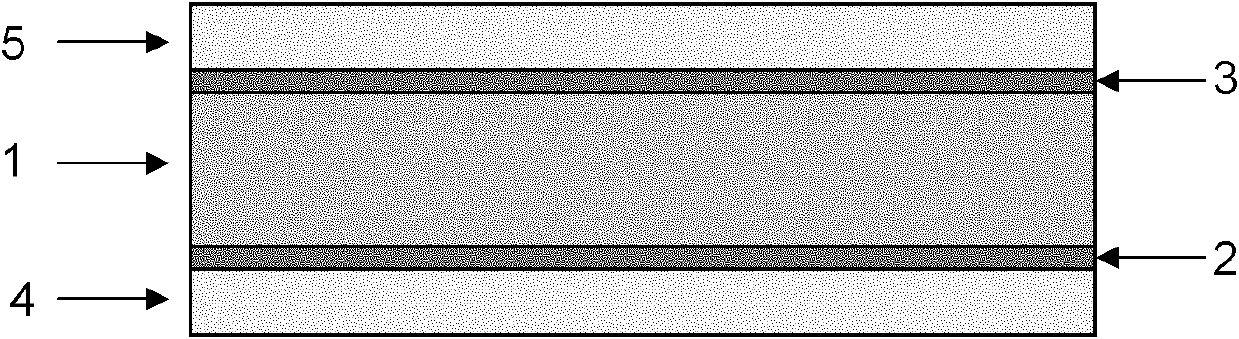

Solar module back veneer comprising non-solvent bonding layers and manufacturing method thereof

ActiveCN102569451AAvoid pollutionImprove performanceFinal product manufacturePhotovoltaic energy generationPolymer scienceAcrylic resin

The invention provides a solar module back veneer comprising non-solvent bonding layers. The solar module back veneer comprises: a base film layer, the bonding layers on two sides of the base film layer, a fourth thin layer and a fifth thin layer which are on another two sides of the bonding layers. The materials of the bonding layers are selected from one or more of the following components: polyethylene and a vinyl copolymer, polypropylene and modified polypropylene, thermoplastic polyurethane, acrylic resin and ABS series resin. The invention also provides a manufacturing method of the back veneer. According to the invention, a solvent adhesive can be completely avoided to be used. By using the method of the invention, pollution generated through volatilization and emission of the solvent to environment during a traditional back veneer manufacturing process can be avoided. Simultaneously, adhesive strength, ageing resistance, barrier performance and a long-term service ability can be increased. By using the non-solvent bonding layers, a fusion extrusion technology can be used during manufacturing the solar module back veneer, which substantially reduces production cost.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

Method for producing hollow fiber film

InactiveCN1899678AImprove throughputUniform hole formationSemi-permeable membranesHollow fibre membraneNon solvent

The melt spinning process of producing hollow fiber membrane includes the first mixing inorganic particle, polymer pore creating agent, surfactant and non-solvent to constitute spinning composition, heating the composition to temperature higher than the smelting point of the polymer, the subsequent extruding the melt through spinning head and cooling to form hollow fiber, and final eliminating the inorganic particle, polymer pore creating agent, surfactant and non-solvent to produce the hollow fiber membrane. The spinning composition consists of polymer 20-90 wt%, inorganic pore creating agent 5-50 wt%, polymer pore creating agent 1-30 wt%, surfactant 0.05-20 wt%, and organic non-solvent 1-60 wt%.

Owner:TIANJIN POLYTECHNIC UNIV

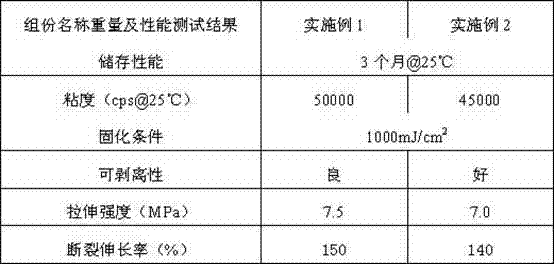

UV-cured peelable blue gel for temporary protection of touch screen and preparation method thereof

InactiveCN103031053AFast curing and film formationIncrease productivityPolyurea/polyurethane coatingsPolyether coatingsNon solventUV curing

The invention provides a UV-cured peelable blue gel for temporary protection of a touch screen and a preparation method thereof. The UV-cured peelable blue gel comprises the following components of 50-70 parts of modified acrylate resin, 20-30 parts of acrylate monomer, 1.0-5.0 parts of light curing agent, 0.1-1.0 part of thixotropic agent, 0.1-5.0 parts of auxiliary and 0.1-1.0 part of pigment; and the preparation method comprises the following steps of: accurately weighing various raw materials according to a formula ratio; firstly adding the modified acrylate resin, the acrylate monomer, the light curing agent, the auxiliary and the pigment to a reaction kettle in sequence and then stirring these materials in the reaction kettle; after these materials are uniformly stirred, adding the thixotropic agent to these materials; and uniformly dispersing an obtained mixture to discharge out a material. The UV-cured peelable blue gel provided by the invention is a non-solvent and a system containing no phthalate substance and is much safer and more environment-friendly. Through the adoption of a UV curing system, the film curing and forming speed is high and the production efficiency of the touch screen is greatly increased.

Owner:TONSAN ADHESIVES INC

Polymer Particles And Encapsulated Compositions Using Organoborane Amine Complexes

A polymerized product is obtained from a mixture containing (i) a free radical polymerizable monomer, oligomer or polymer; (ii) an organoborane amine complex, (iii) a poor or non-solvent for the polymerized product of (i); and (iv) an amine reactive compound. The mixture may include (v) an active ingredient to be encapsulated by the polymerized product, and (vi) an optional component(s). Polymer particles are obtained by (A) forming a composition containing components (i)-(iv); (B) agitating components (i)-(iv) in the presence of oxygen to initiate polymerization, at a rate and for a time sufficient to provide a uniform dispersion and reaction of the components; (C) allowing the reaction to proceed to completion at room temperature; and (D) recovering the polymer particles by removing component (iii). The composition may include (v) the active ingredient to be encapsulated by the polymer particles.

Owner:DOW SILICONES CORP

Process for producing porous polymer materials

InactiveUS6436426B1Rapidly and massively producingHigh porosityPowder deliveryProsthesisNon solventPorosity

The present invention provides a process for producing porous polymer materials. In the present invention, a polymer material and a soluble material are mixed in their solid states. The surface of the polymer material is partially dissolved and fused by introducing a solvent. The present invention makes use of a pressure difference while introducing a non-solvent into the polymer material to solidify and resolve the solved polymer material. Then, a substantial amount of water is used to wash the inside soluble material out. Therefore, the porous polymer materials with high porosity and interconnecting pores inside the materials are produced massively and rapidly.

Owner:IND TECH RES INST

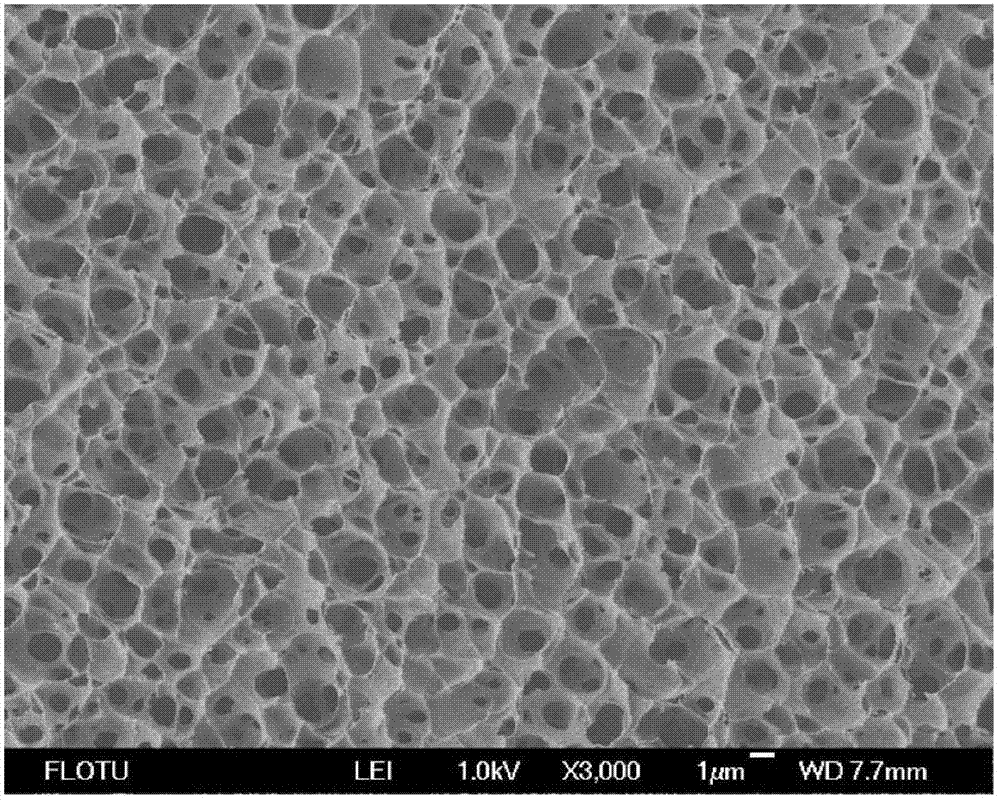

Polyvinylidene fluoride hollow fiber membrane and preparation method thereof

InactiveCN102266728AHigh porosityImprove throughputSemi-permeable membranesBreaking strengthNon solvent

The invention relates to a polyvinylidene fluoride hollow fiber membrane and a preparation method thereof. The hollow fiber membrane uses polyvinylidene fluoride as the membrane material, and adds polymer pore-forming agents, surfactants, inorganic additives and solvents to make the casting liquid, and uses dry-wet method, that is, non-solvent-induced phase separation method to spin Process to prepare polyvinylidene fluoride hollow fiber membranes. The prepared polyvinylidene fluoride hollow fiber membrane has good flexibility and high strength at the same time, the tensile breaking strength is 3.5-6MPa; it has good hydrophilicity, and the pure water at a pressure of 0.1MPa and a temperature of 25°C The flux is 300~3200L / m2·H.

Owner:HUIZHOU QIXIN MEMBRANE PURIFICATION & ENVIRONMENTPROTECTION

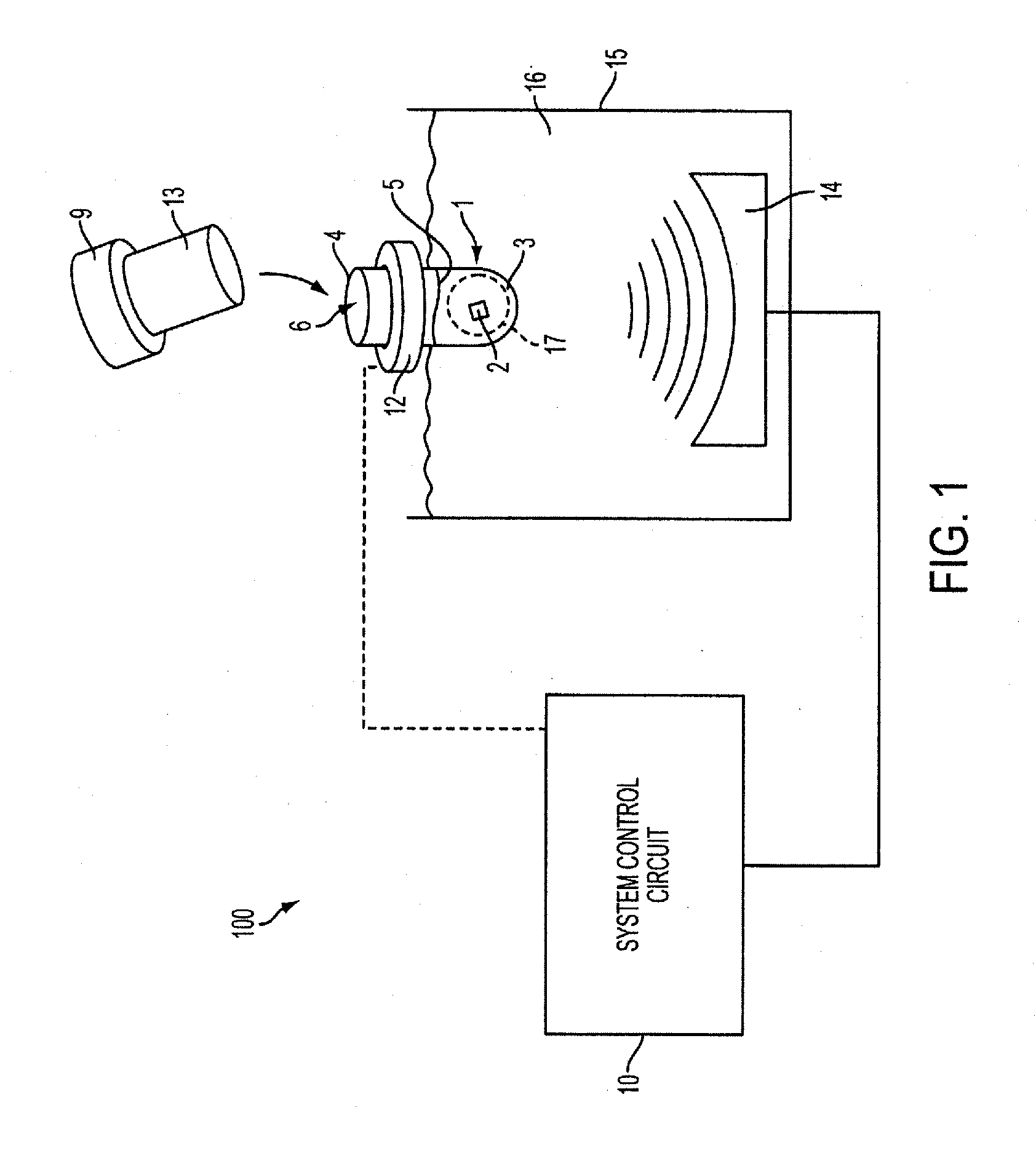

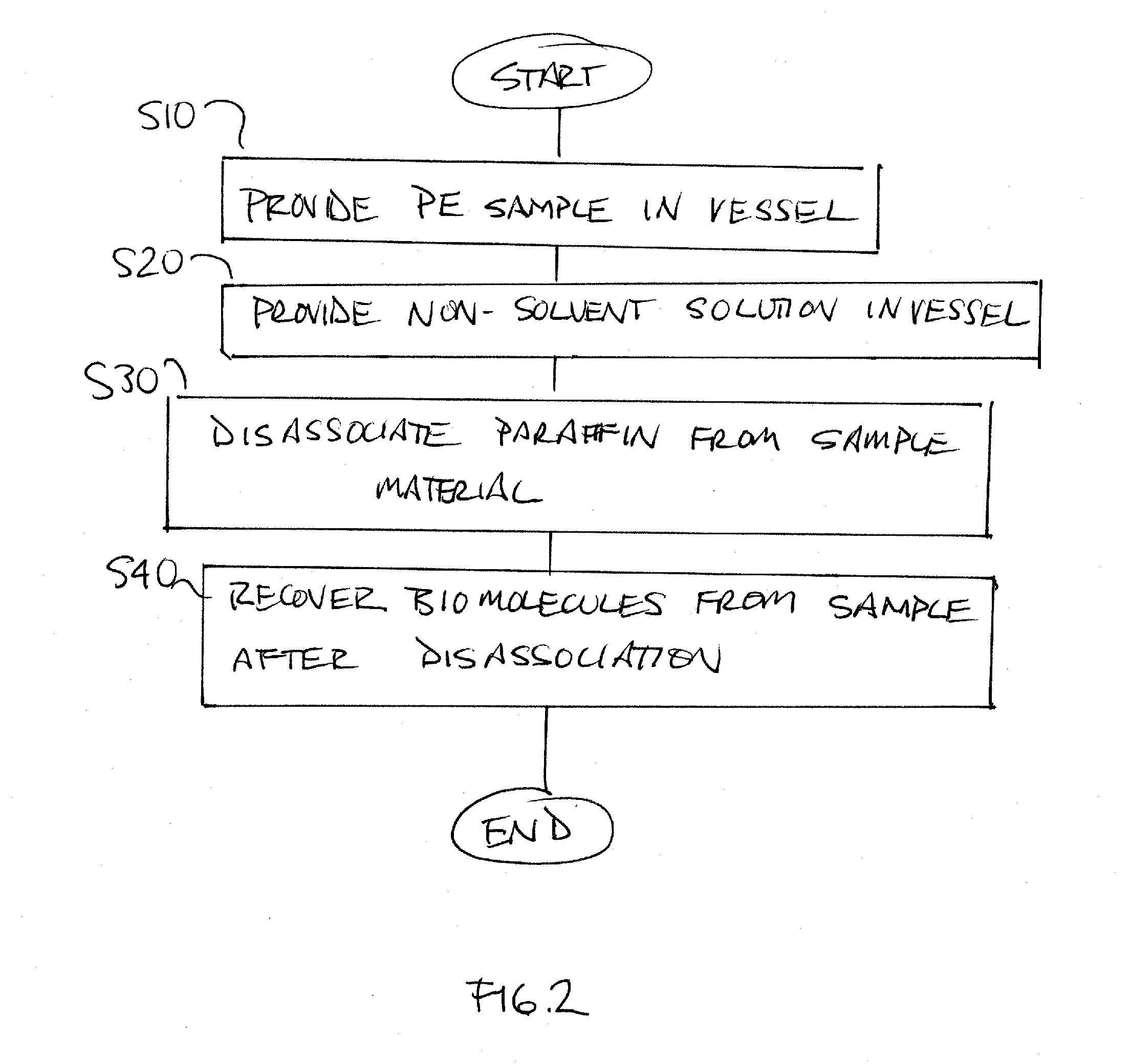

System and method for processing paraffin embedded samples

ActiveUS20140141413A1Reduce yieldIncrease nucleic acid material yieldMicrobiological testing/measurementSurgeryNon solventAcoustic energy

Method and apparatus for processing paraffin embedded samples, e.g., to disassociate paraffin from tissue components and / or other biomolecules from the paraffin. The sample may be exposed to focused acoustic energy while held in a vessel containing a non-solvent, aqueous solution. Disassociated paraffin may be emulsified into the liquid or otherwise separated from the sample.

Owner:COVARIS INC

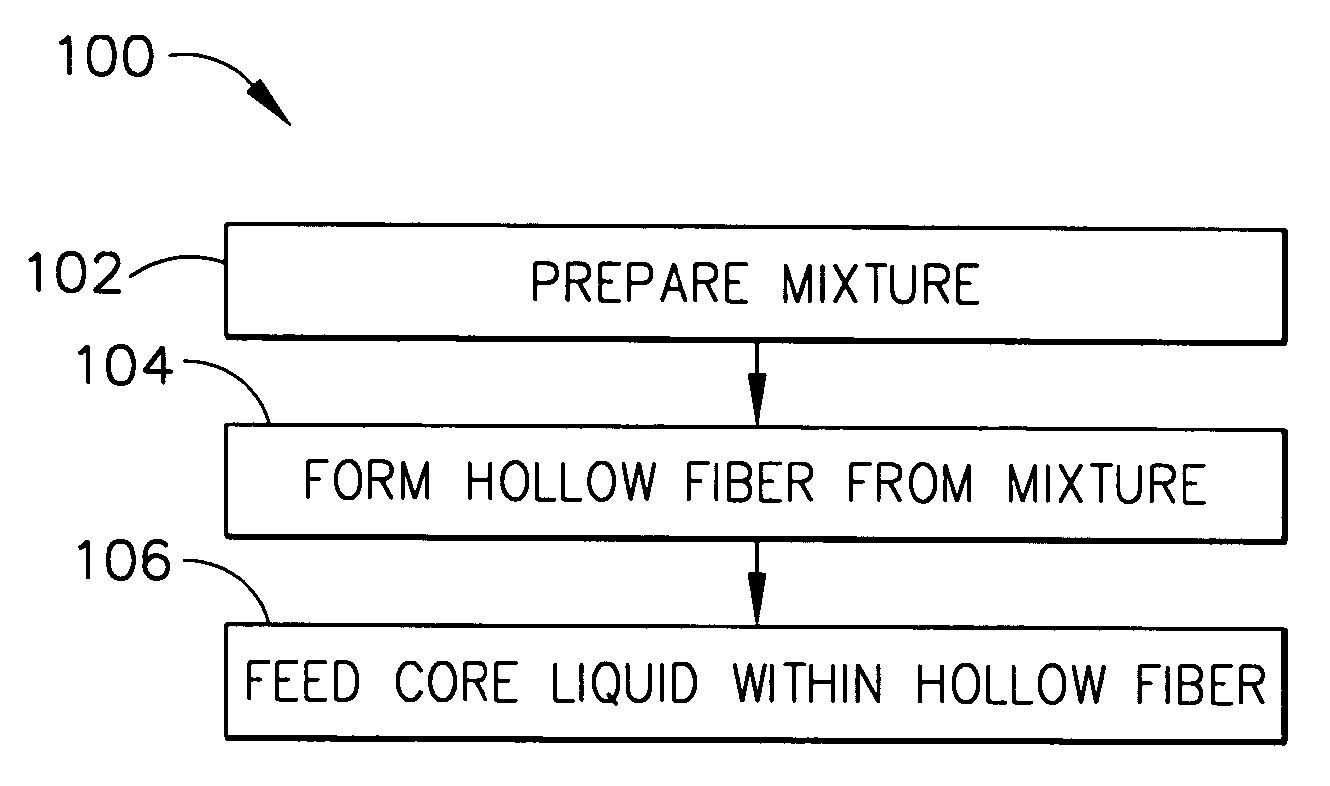

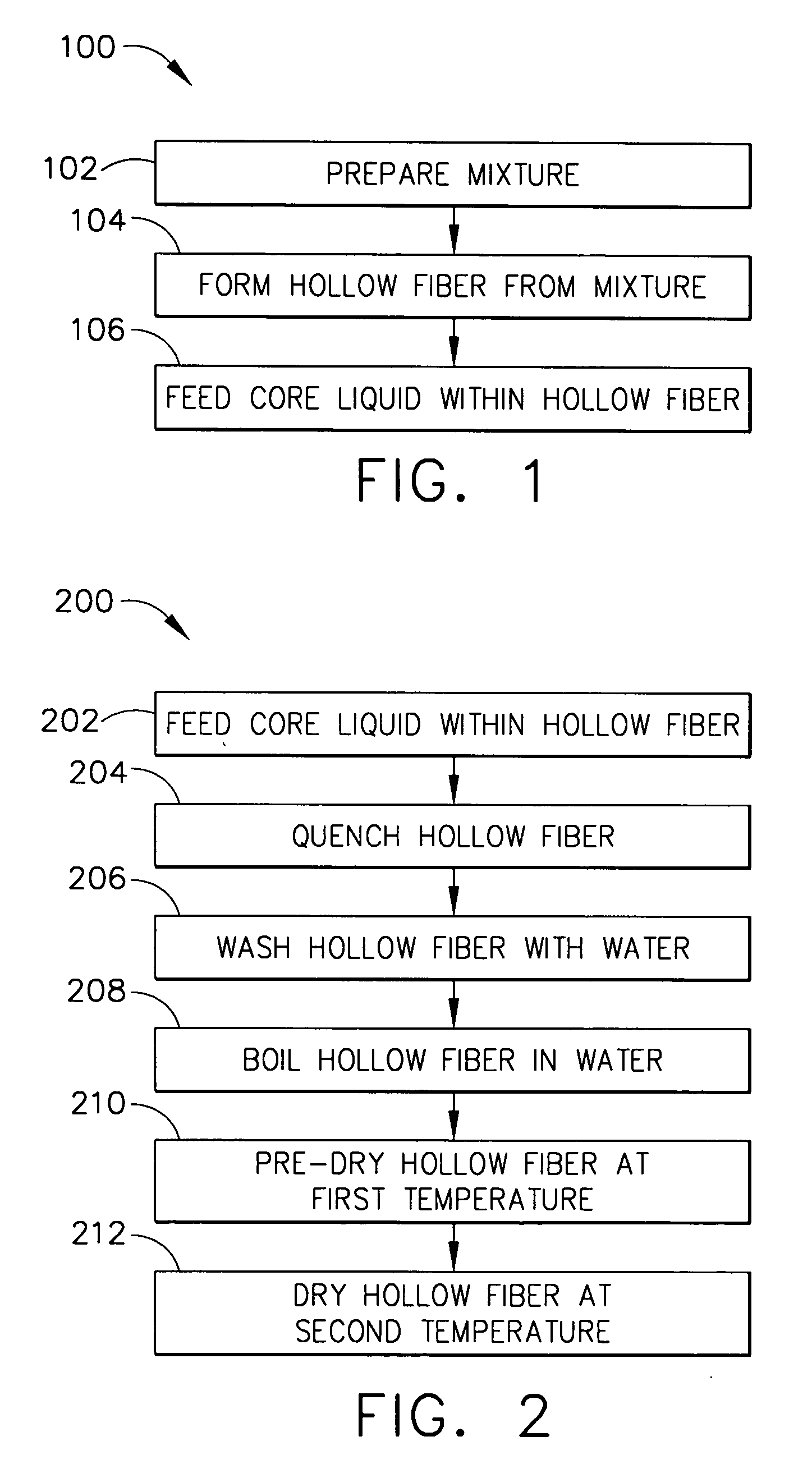

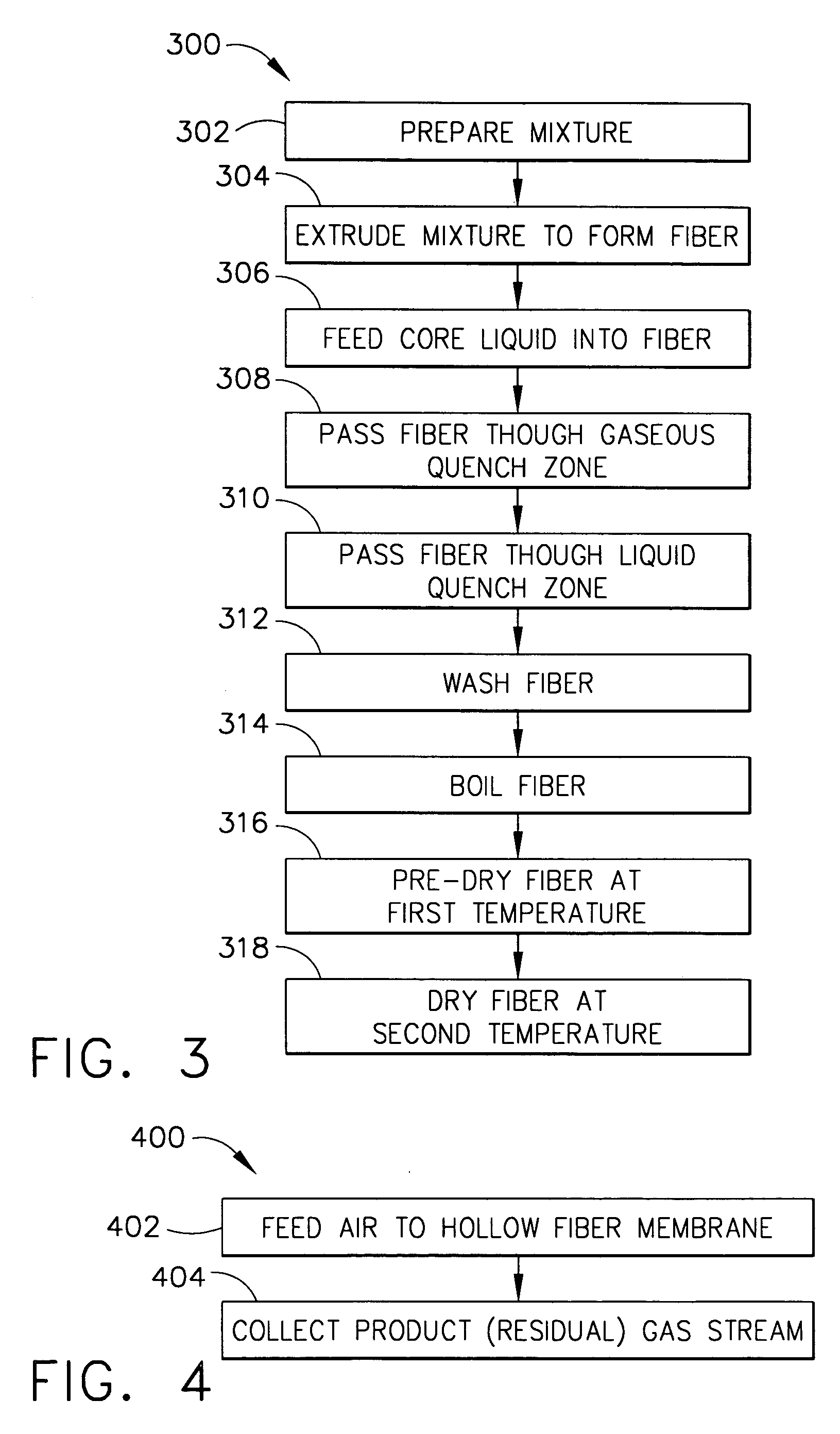

High temperature gas separation membrane suitable for OBIGGS applications

Gas separation membranes and methods for preparing such membranes. The gas separation membranes of the instant invention can separate oxygen and nitrogen in air to provide nitrogen enriched air (NEA), and are stable during exposure to temperatures of at least about 160° C. The gas separation membranes of the instant invention may be formed from polyetherimide by extruding a hollow fiber using a core liquid, quenching the extruded fiber in dry air to promote loss of solvent and non-solvent, and drying the fiber. Methods for separating bleed air fed directly from an aircraft precooler to a high temperature gas separation hollow fiber membrane, to provide NEA, are also disclosed.

Owner:HONEYWELL INT INC

Cation water polyurethane/acrylic ester composite emulsion and preparation method thereof

The invention relates to cationic water-based polyurethane / acrylic ester composite emulsion and the preparation process, belonging to the chemical product and preparation technology field. Raw materials comprise diisocyanate mixture, polyhydric alcohol, organotin catalyst, chain extender, thinner, neutralizing agent and initiating agent. The preparation process comprises adding polyhydric alcohol into a reactor to dehydrate in vacuum, adding into diisocyanate mixture and organotin catalyst, conducting prepolymerization reaction to synthesize prepolymer with isocyanate-termi-nated, coldly adding thinner to dilute and to condense and reflow, adding chain extender to obtain mixture through chain extending reaction, cooling down, adding neutralizing agent to finish salt-forming reaction, regulating pH value, adding deionized water to conduct dispersed emulsification to obtain cationic water-based polyurethane elusion, and heating up and adding initiating agent to initiate free radical polymerization reaction to prepare composite elusion. The cationic water-based polyurethane / acrylic ester composite emulsion is synthesized through adopting non solvent process with low pollution and environment-friendly, increases solvent resistance, water resistance and tensile strength of glue film through introducing micro-cross-linked structure, increases hydrolytic stability of the glue film through introducing carbodiimide structure, and increases elongation at break and elasticity property through of glue film through introducing 2, 4-MDI.

Owner:WANHUA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com