Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Uniform hole formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing hollow fiber film

InactiveCN1899678AImprove throughputUniform hole formationSemi-permeable membranesHollow fibre membraneNon solvent

The melt spinning process of producing hollow fiber membrane includes the first mixing inorganic particle, polymer pore creating agent, surfactant and non-solvent to constitute spinning composition, heating the composition to temperature higher than the smelting point of the polymer, the subsequent extruding the melt through spinning head and cooling to form hollow fiber, and final eliminating the inorganic particle, polymer pore creating agent, surfactant and non-solvent to produce the hollow fiber membrane. The spinning composition consists of polymer 20-90 wt%, inorganic pore creating agent 5-50 wt%, polymer pore creating agent 1-30 wt%, surfactant 0.05-20 wt%, and organic non-solvent 1-60 wt%.

Owner:TIANJIN POLYTECHNIC UNIV

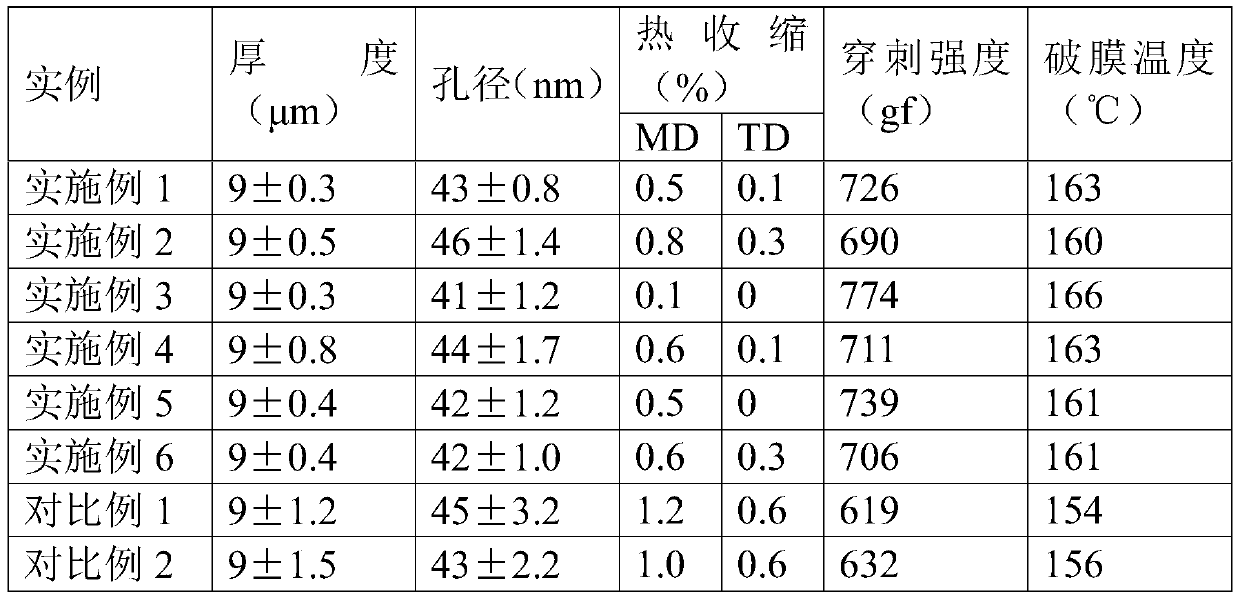

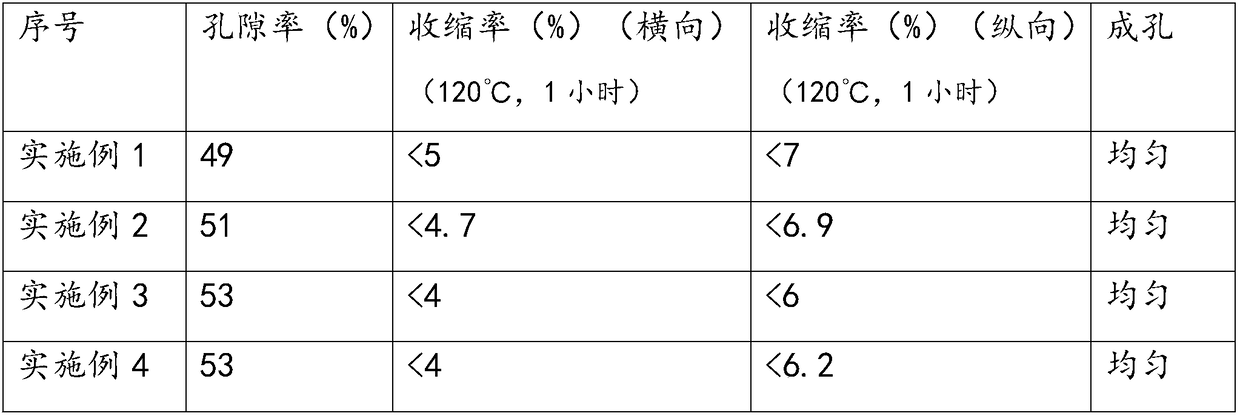

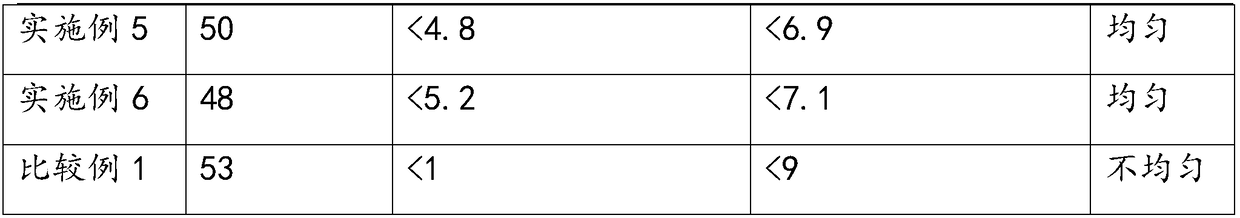

Polyolefin microporous diaphragm and preparation method thereof

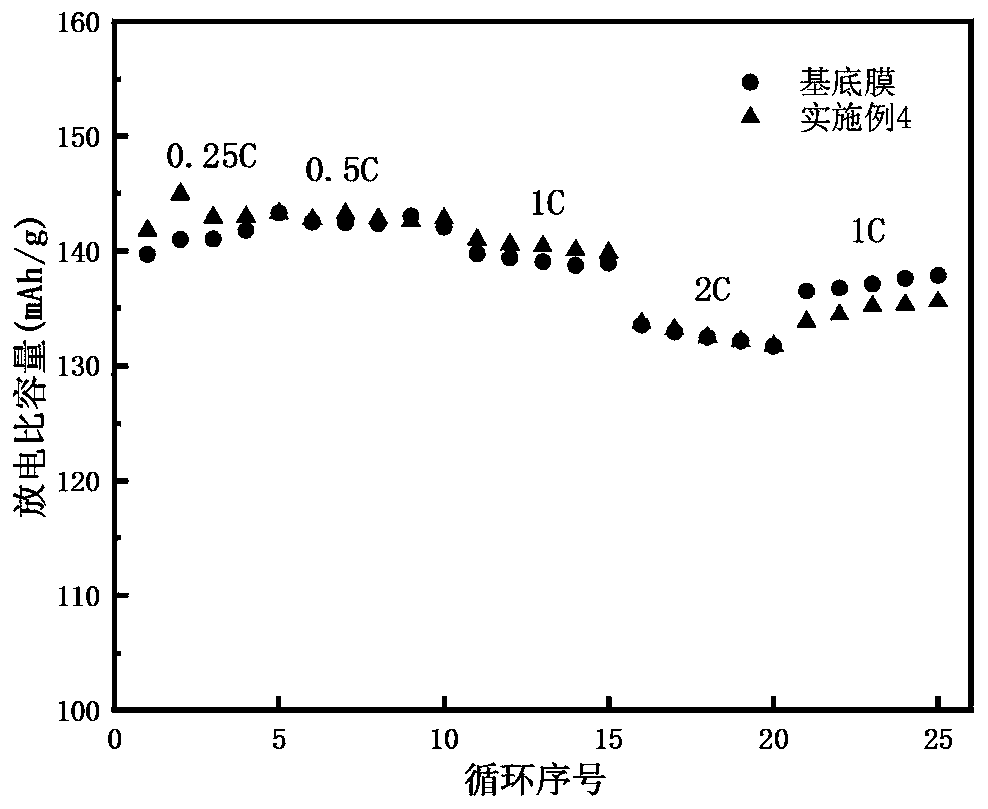

ActiveCN102148346AEasy to form holesUniform hole formationCell component detailsPorosityPower battery

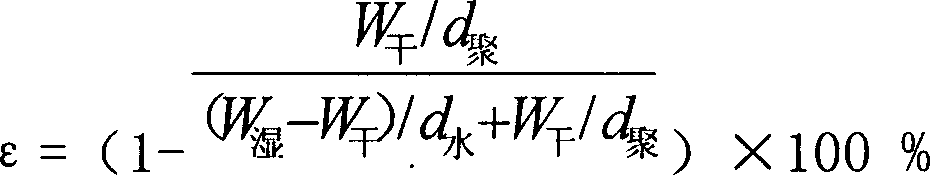

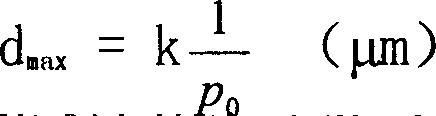

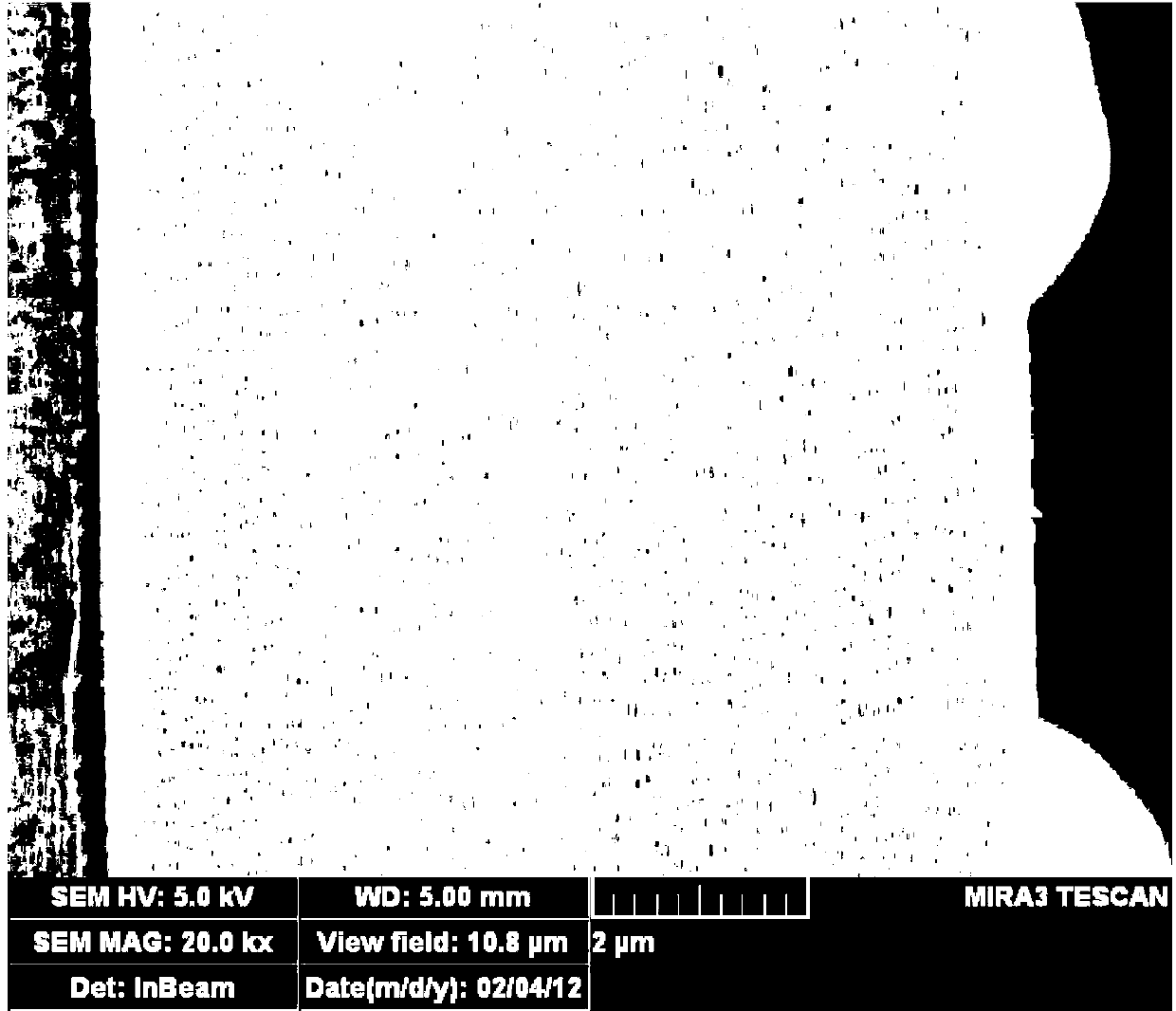

The invention belongs to the technical field of preparation of lithium batteries and in particular relates to a polyolefin microporous diaphragm for a lithium ion power battery and a preparation method thereof. The polyolefin microporous diaphragm is formed by adding a beta crystal type nucleating agent and an antioxidant into polyolefin resin, wherein the weight percent of the content of the beta crystal type nucleating agent to the polyolefin resin is 0.001-5.0%, and the weight percent of the antioxidant to the polyolefin resin is 0.001-1%. By adopting the polyolefin resin after modification for preparing the porous diaphragm, the diaphragm is easy to form holes; furthermore, the formed holes are uniform, the aperture is small (the average aperture is 0.01-0.1 mu m), the porosity is high (35%-80%), the air permeability is good, and the strength of the diaphragm is high.

Owner:河南天工膜材新能源科技有限公司

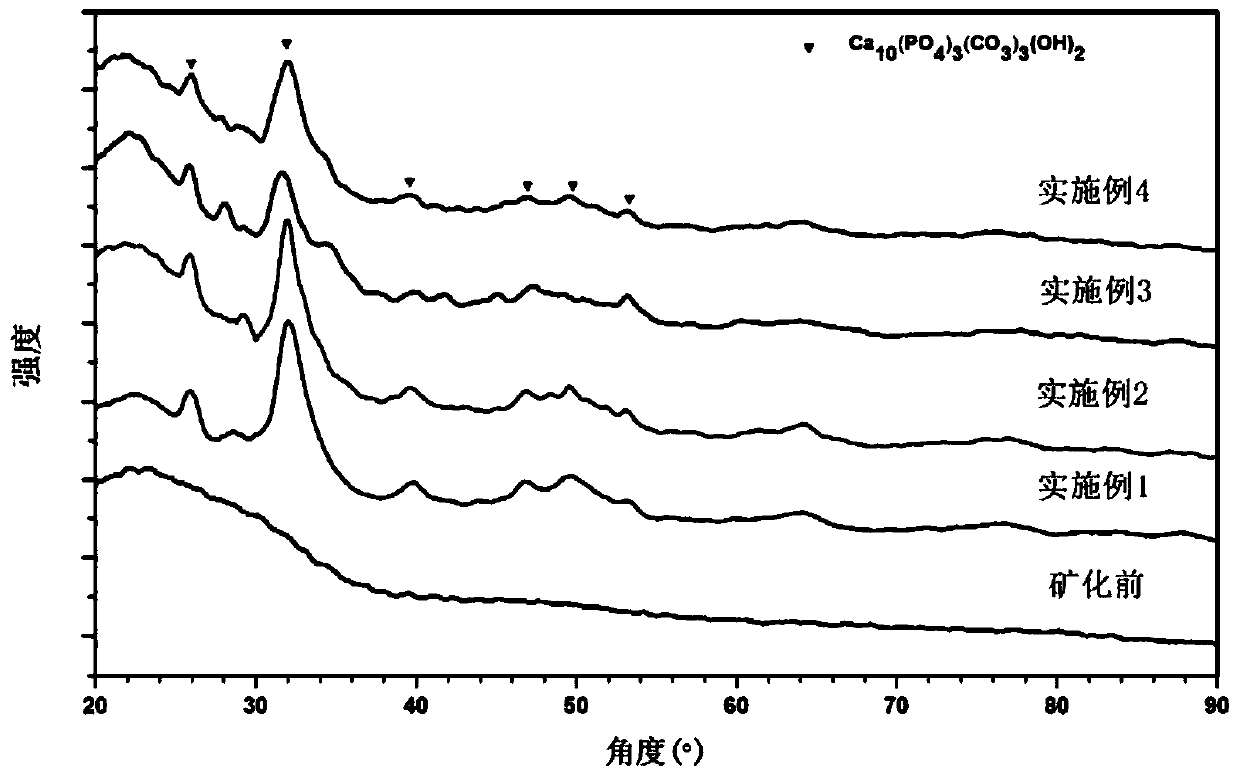

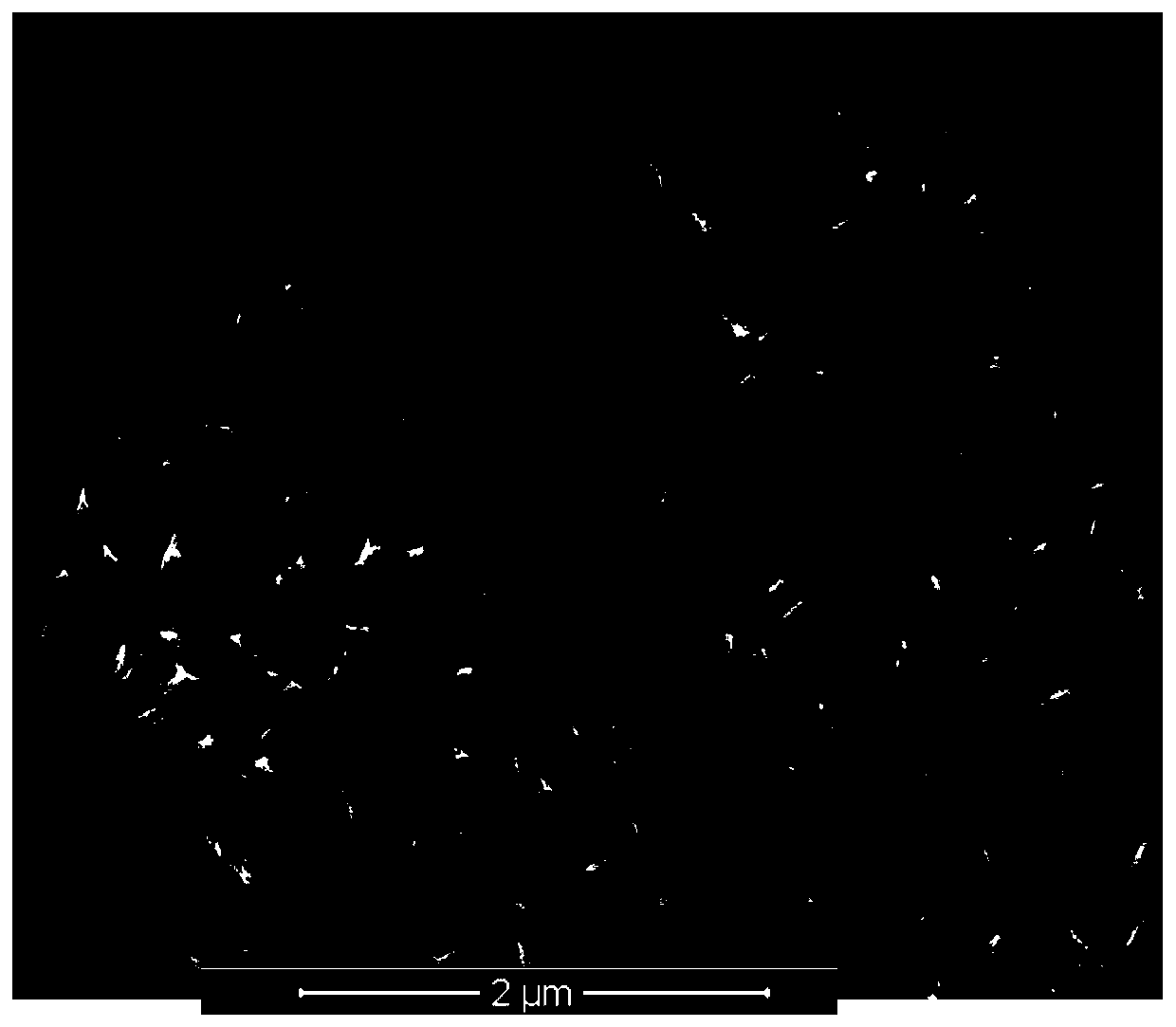

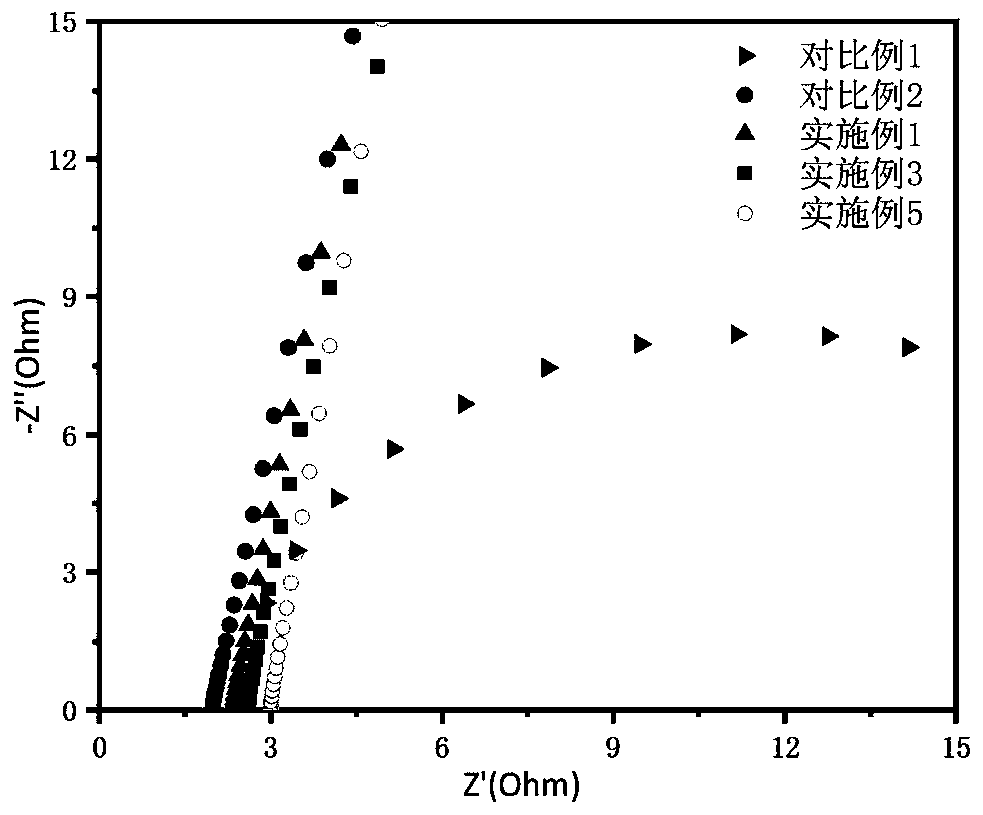

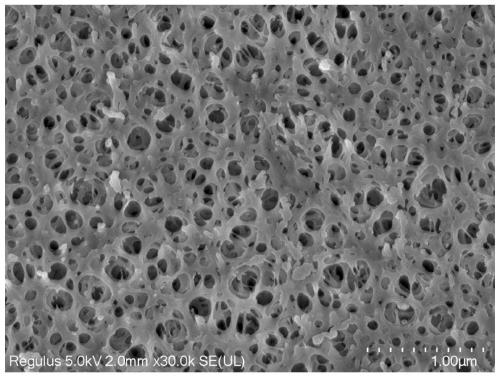

Degradable regenerative medical material for promoting tissue in-situ regeneration and preparation method of medical material

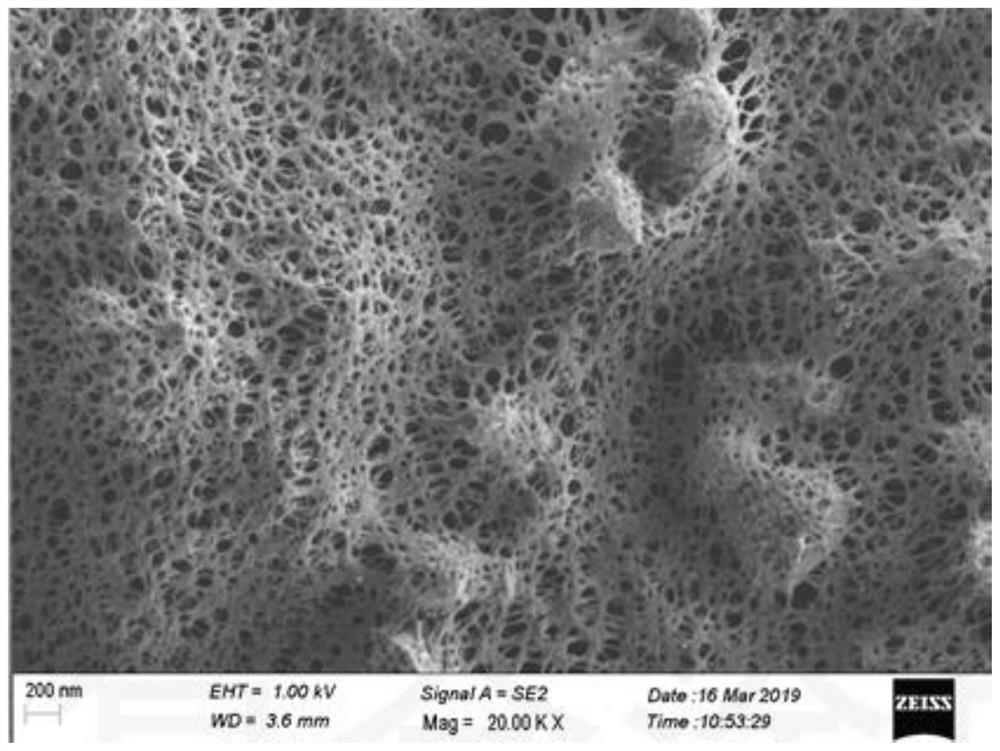

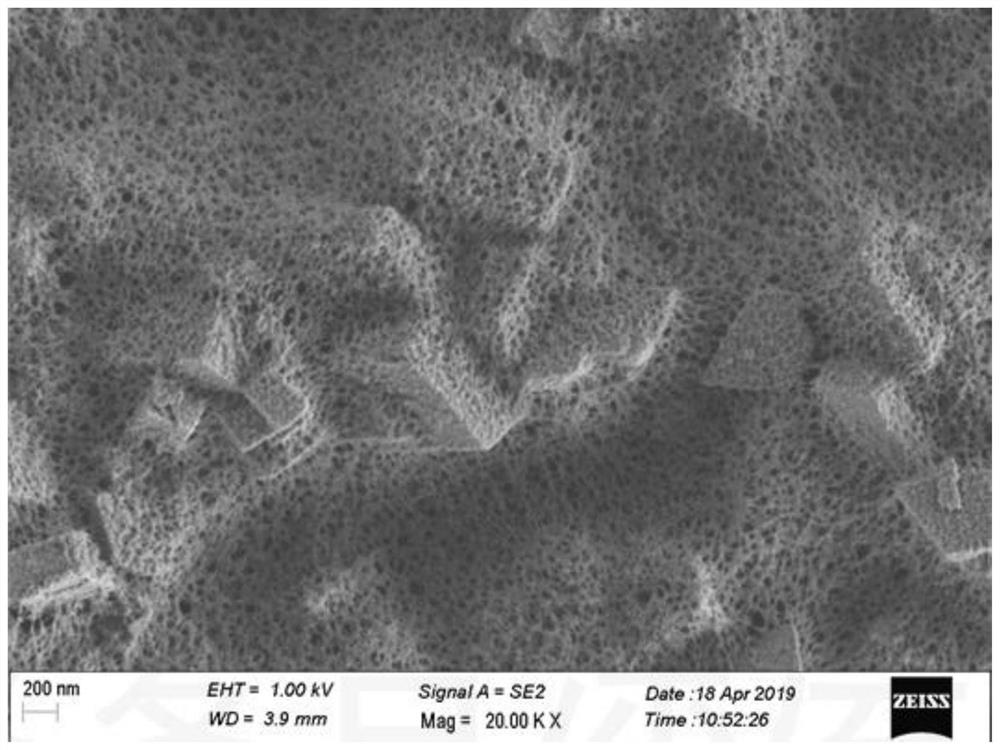

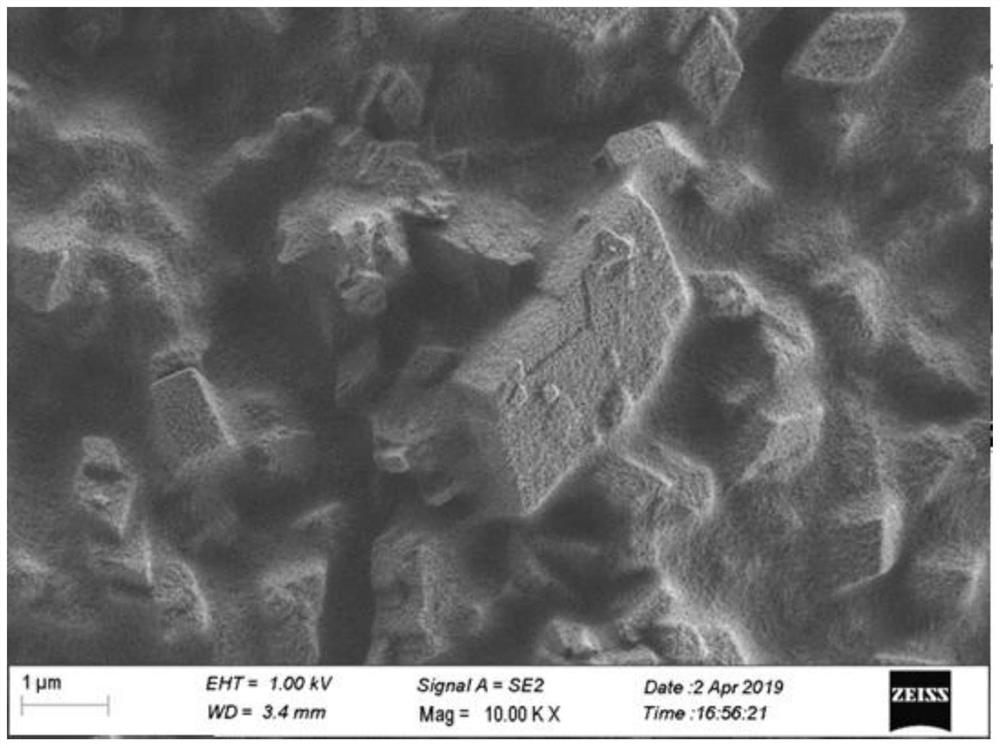

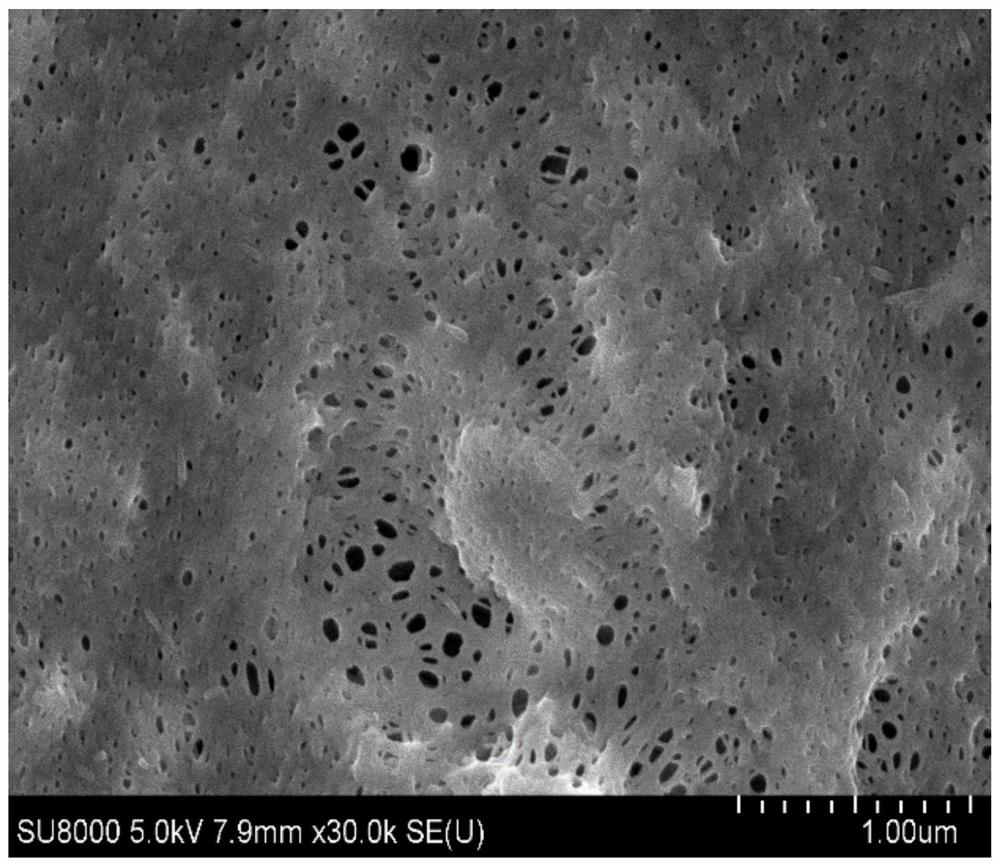

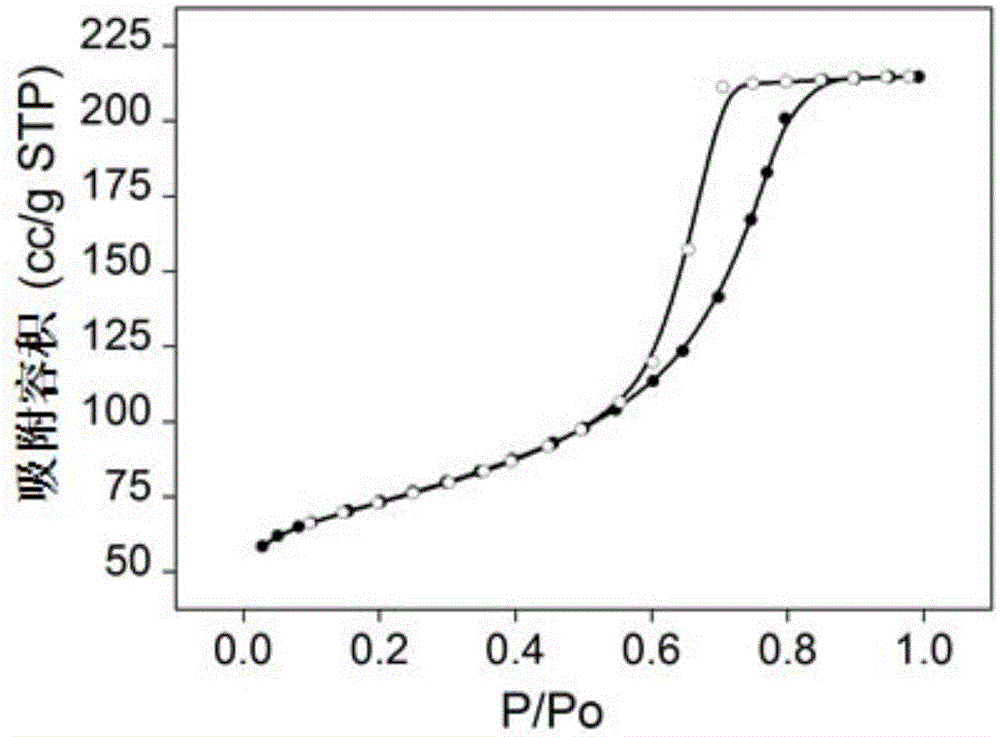

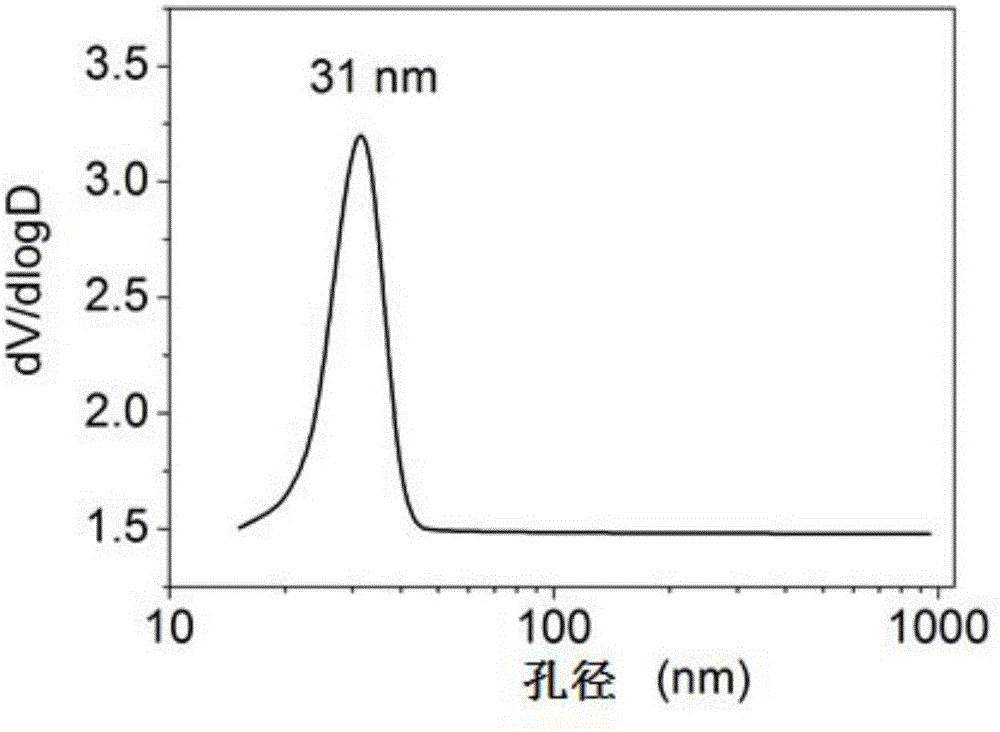

The invention discloses a degradable regenerative medical material for promoting tissue in-situ regeneration and a preparation method of the medical material. The degradable regenerative medical material is formed by Si, P, O, and metallic elements containing calcium through chemical bonding, and is of a regular three-dimensional net structure formed by taking a material with a nano-scale mesoporous structure as a framework, and pores and micron-scale macropores communicated with the pores are uniformly formed in the regular three-dimensional net structure. The preparation method of the degradable regenerative medical material comprises the steps of preparation of mixed gel, foaming and curing and calcination. The regenerative medical material has a huge specific surface area, powerful biological activity, high biological safety, has an effect of promoting cell proliferation, can induce rapid regeneration of own cells of injury tissue, and achieve an in-situ tissue repair function.

Owner:BEIJING BEST LIFE REGENERATIVE MEDICINE TECH CO LTD

Aramid fiber phase-inversion coating lithium ion battery diaphragm and preparation method thereof

InactiveCN111370625AImprove thermal stabilityUniform hole formationSecondary cellsCell component detailsInterface impedancePhysical chemistry

The invention relates to a preparation method of an aramid fiber phase-inversion coating lithium ion battery diaphragm, which is characterized by comprising the following steps: (1) dissolving aramidfiber, a cosolvent, an oily assistant and a pore-forming agent in a first solvent at 60-100 DEG C to prepare a uniformly mixed coating solution; (2) coating one side or two sides of a diaphragm base material with the coating liquid, immersing the mixture into a coagulating bath consisting of a second solvent and water for phase inversion for 1-3 minutes, then immersing the mixture into pure waterto remove the redundant solvent, and drying to obtain a finished product of the lithium ion battery diaphragm; the surface of the diaphragm is coated with the high-temperature-resistant polymer, so that the thermal stability and the mechanical strength of the diaphragm are improved; a water-soluble pore-forming agent is used in the coating liquid, and pores are uniformly formed after phase inversion of a coating layer; and the used oily auxiliary agent reduces the interface impedance on the basis of maintaining the main body skeleton structure of the aramid fiber, improves the conductivity oflithium ions, and improves the hole plugging effect caused by oily coating.

Owner:SOUTH CHINA UNIV OF TECH

Supported high-porosity porous metal oxide material, and preparation method and application thereof

PendingCN110143608AReduce manufacturing costLarge specific surface areaMaterial nanotechnologyZinc oxides/hydroxidesEvaporationSilicon oxide

The invention discloses a supported high-porosity porous metal oxide material, and a preparation method and application thereof, and belongs to the technical fields of advanced functional materials and nano materials. The method comprises the following steps: firstly, adding a pre-hydrolyzed silicon oxide oligomer solution into a mixed solution of a metal salt and a load, uniformly carrying out stirring, and then removing the solvent by evaporation to obtain a metal hydroxyl oxide solid uniformly doped with a silicon oxide oligomer; and further calcining the solid to crystallize the metal oxide, and then removing silicon oxide by etching through an alkaline solution to form pores, so that the high-porosity supported porous metal oxide material is obtained. The material has a crystallized metal oxide skeleton, high specific surface area and porosity and a three-dimensional communicated multi-stage pore channel, so that diffusion and mass transfer of gas and liquid in the material are facilitated, and then the material has excellent performance in the fields of gas sensing, heterogeneous catalysis and the like. The method disclosed by the invention is simple to operate, has easily available raw materials, and is suitable for large-scale industrial production.

Owner:上海复感科技有限公司

Preparation method of high-heat-resistance vinylidene fluoride polymer mixed coating diaphragm

ActiveCN110635090AGood heat shrinkabilityImprove adhesionSecondary cellsCell component detailsPolymer scienceHeat resistance

The invention relates to a preparation method of a high-heat-resistance vinylidene fluoride polymer mixed coating diaphragm, the high-heat-resistance vinylidene fluoride polymer mixed coating diaphragm prepared by the method and a lithium battery comprising the high-heat-resistance vinylidene fluoride polymer mixed coating diaphragm. The prepared high-heat-resistance vinylidene fluoride polymer mixed coating diaphragm has good heat resistance and air permeability and is formed by one-time coating with simple process. The vinylidene fluoride polymer improves the adhesion between the coating andthe diaphragm and between the coating and the pole pieces, increases the liquid storage capacity of the electrolyte and improves the cycle performance of the lithium battery. The heat-resistant additive forms a heat-resistant network layer with ceramics to improve the heat shrinkage performance of the diaphragm.

Owner:NINGDE ZHUOGAO NEW MATERIAL TECH CO LTD

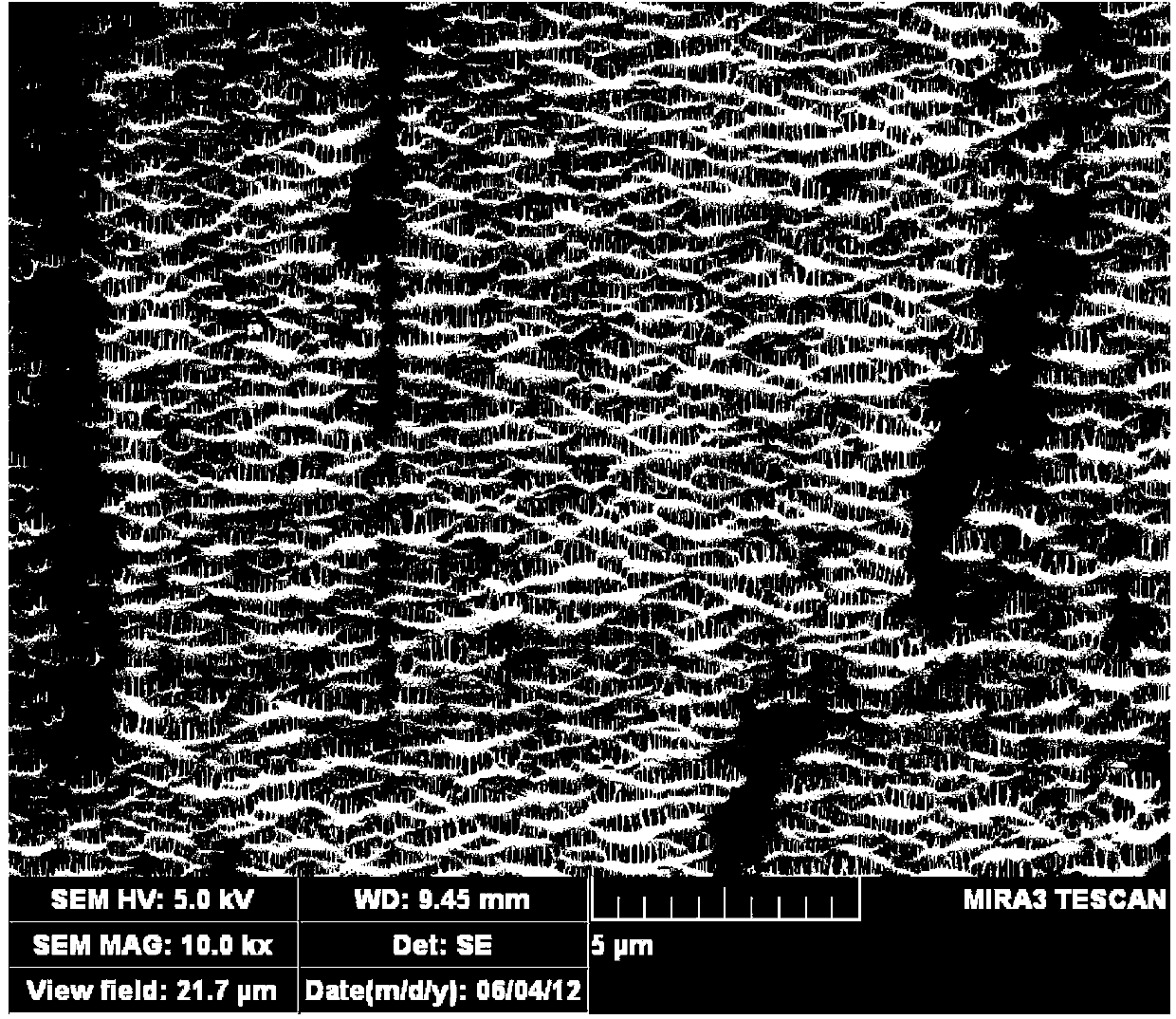

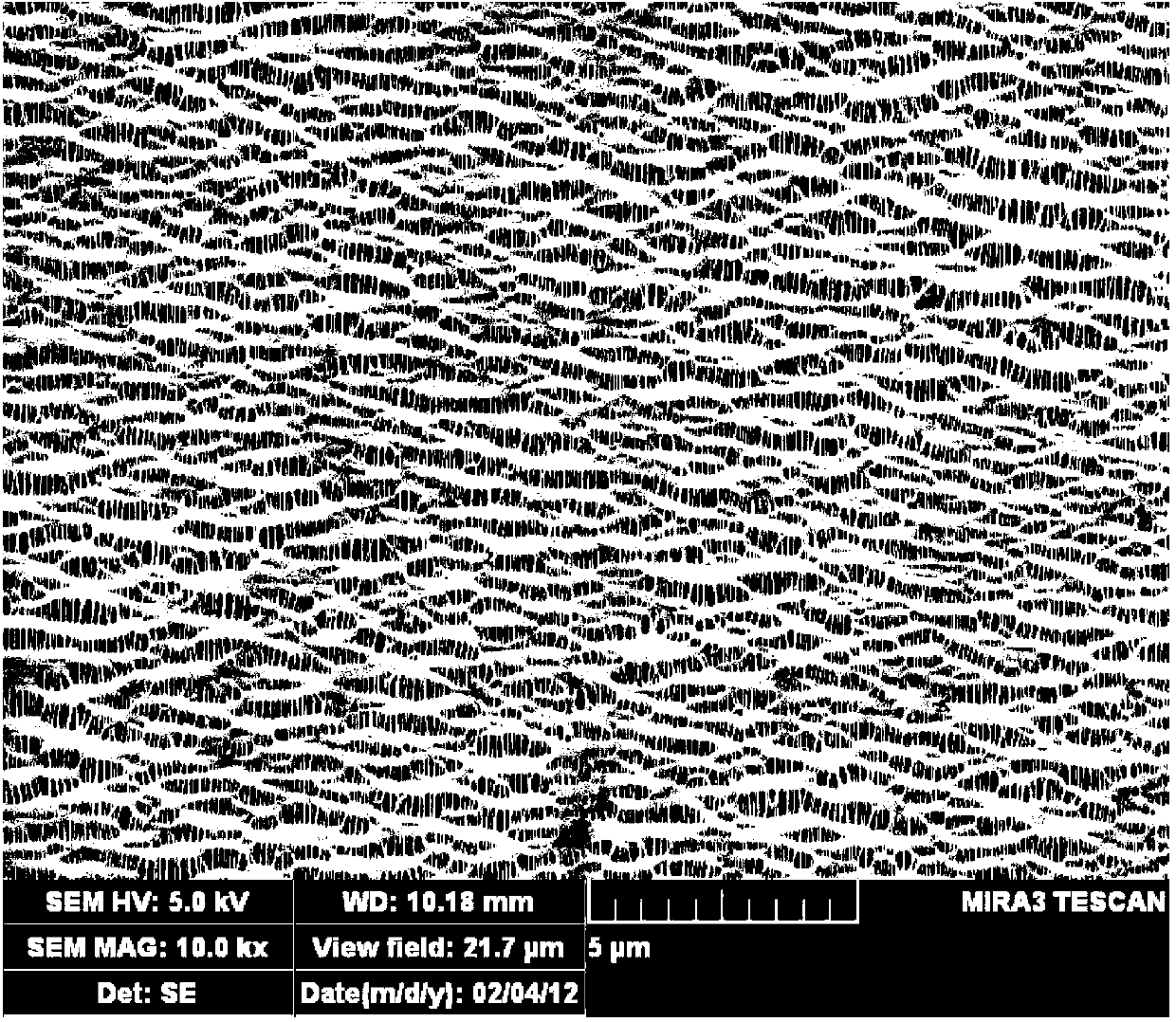

Preparation method for ultrathin polyolefin microporous membrane, and polyolefin microporous membrane prepared by same

ActiveCN103273654AUniform hole formationSolve for uniformityFlat articlesCoatingsPolymer sciencePolyolefin

The invention discloses a preparation method for an ultrathin polyolefin microporous membrane, and a polyolefin microporous membrane prepared by the same. The preparation method comprises the steps of tape casting a polyolefin melt into a substrate, annealing the substrate, stretching at a drawing ratio of 1.0-2.5, and performing thermosetting treatment to prepare the polyolefin microporous membrane. The stretching step includes cold stretching and stepwise hot stretching, wherein the conditions for the stepwise hot drawing stretching are as follows: a number of stretching points is 10-30; a stretching rate per stretching point is smaller than or equal to 200% / min; and a stretching temperature at each stretching point is from Tm-90 DEG C to Tm-15 DEGC, wherein Tm represents a melting point of the polyolefin. The method is characterized in that the prepared polyolefin microporous membrane has the characteristic of very uniform pore structure by stepwise hot stretching at relatively low stretching rate through a plurality of stretching points. Besides, the method is very suitable for making the ultrathin polyolefin microporous membrane with the thickness of 6-14 [mu]m. The polyolefin microporous membrane can meet applications having relatively high requirements for pore-forming homogeneity of the microporous membrane and the thickness of the membrane, and is particularly suitable for the fields of battery diaphragms.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

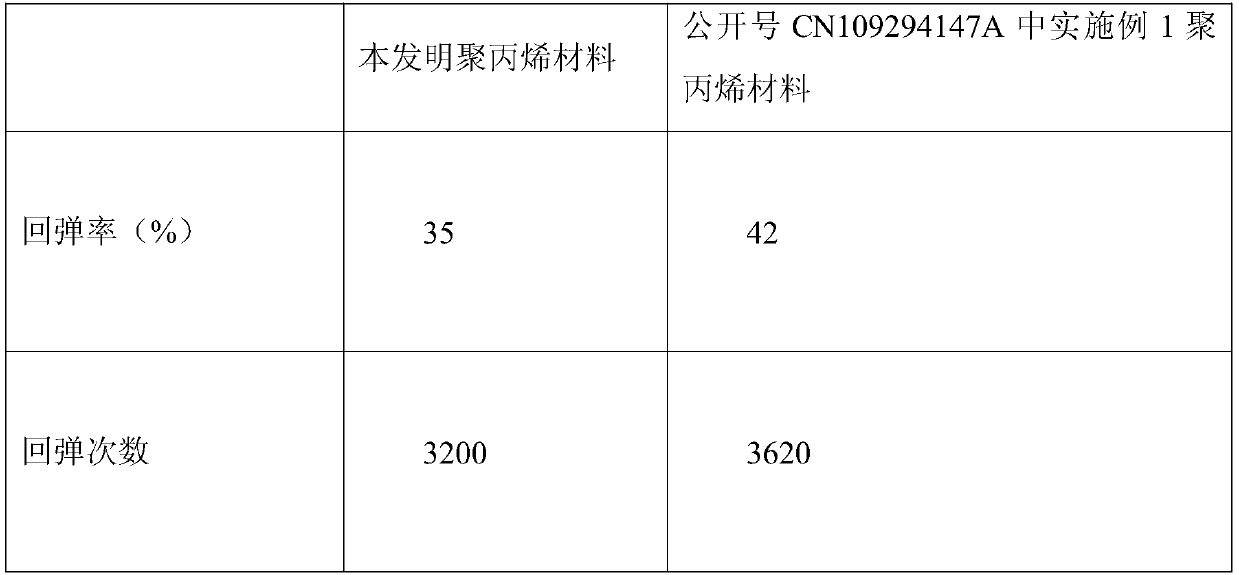

Preparation method of polypropylene type brush filaments

The invention discloses a preparation method of polypropylene type brush filaments, the method comprises the following steps: step 1, preparation of a polypropylene matrix material, to be more specific, polypropylene is soaked for 1-2h by using an activation elasticizing liquid at a soaking temperature of 65-75 DEG C, then dried at room temperature, and subjected to silane activation treatment. According to the invention, the surface activity of the polypropylene is improved by rare earth lanthanum chloride, and then the surface is dispersed and modified by a flexible medium so as to improve the surface tissue structure and achieve a flexible elasticization effect; by combination of the effects of the activation elasticizing liquid and the electric field, the flexible medium can be bettercontacted with a polypropylene material to improve the treatment effect; and then coupling treatment is adopted to improve the surface activity energy and enhance the adhesive force between the polypropylene and other materials to compound a prepared polypropylene matrix with nitrile rubber and a high-rebound polymer polyol, and then an adhesive reinforcing solution is adopted to improve the adhesive force among raw materials and improve the overall resilience.

Owner:安徽省恒昌刷业有限公司

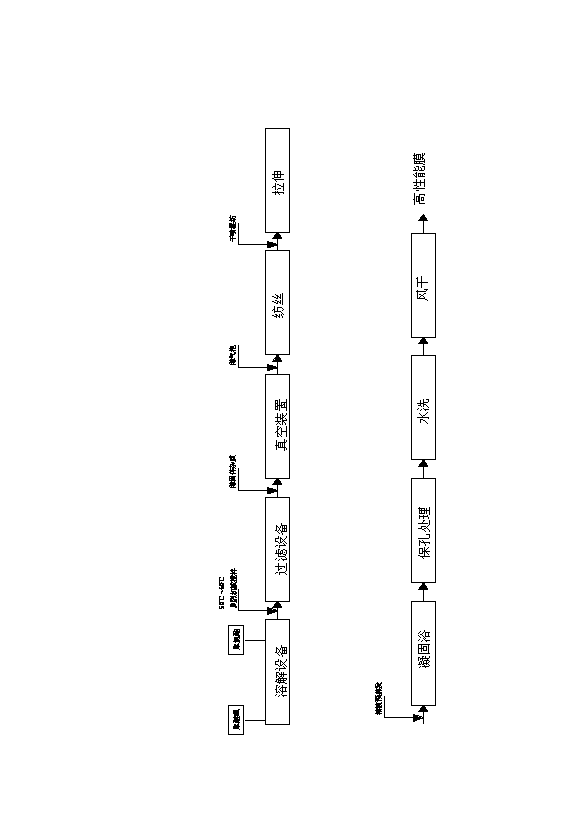

Melt-spinning preparation method of polyvinylidene fluoride hollow fiber filter membrane

ActiveCN108977903AGood dispersionEvenly dispersedSemi-permeable membranesHollow filament manufactureInorganic particleOrganic solvent

A melt-spinning preparation method of a polyvinylidene fluoride hollow fiber filter membrane includes steps: S1, subjecting, by weight, 18-35 parts of polyvinylidene fluoride, 10-30 parts of a solvent, 40-60 parts of inorganic particles, 1-3 parts of a coupling agent and 2-6 parts of a hydrophilic polymer to high-speed mixing at the room temperature to obtain uniform mixed powder; extruding the mixed powder at 170-220 DEG C through a double-screw extruder to obtain uniform particles. The method has advantages that an inorganic filler material, the organic solvent, the coupling agent and a macromolecular pore-forming agent are highly mixed and blended through the double-screw extruder to form the uniform particles; then an annular spinneret plate of a single-screw extruder is adopted for making the uniform particles into fibers; the fibers are subjected to stretching, acid soaking and washing to obtain the hollow fiber filter membrane. In addition, member fibers produced according to the method has advantages of simple production process, low cost, high flux and uniformity in pore forming.

Owner:HUBEI MEICHEN ENVIRONMENTAL PROTECTION CO LTD

Optical glass polishing disk and manufacturing method thereof

InactiveCN108068025AReduce dosageTough and durableFlexible-parts wheelsGrinding devicesCross-linkManufacturing cost reduction

The invention discloses an optical glass polishing disk and a manufacturing method thereof. A polishing disc raw material comprises the following components in percentage by weight: 30-45% of polishing powder, 6-18% of resin, 10-22% a pore forming substance, 0.2-20% of aminolipin, 8-18% of a curing agent and 8-18% of a catalyst. By improving the formula of the polishing disc, the dosage of the polishing powder is reduced directly, the manufacturing cost is lowered, the environmental pollution is reduced, and damage on human body can be also reduced. The added aminolipin organic high-molecularpolymer in cross-linking reaction with resin is high in adhesive force and good in toughness. The polishing powder after coordinated bonding is high in Moh's hardness, and the grinding force of the optical glass polishing disk is enhanced; finally, the polishing disc is high in light out-coupling efficiency, good in polishing effect and durable. 300-400 tons of rare earth polishing powder can be saved by only one county of Pujiang every year.

Owner:王佳佳

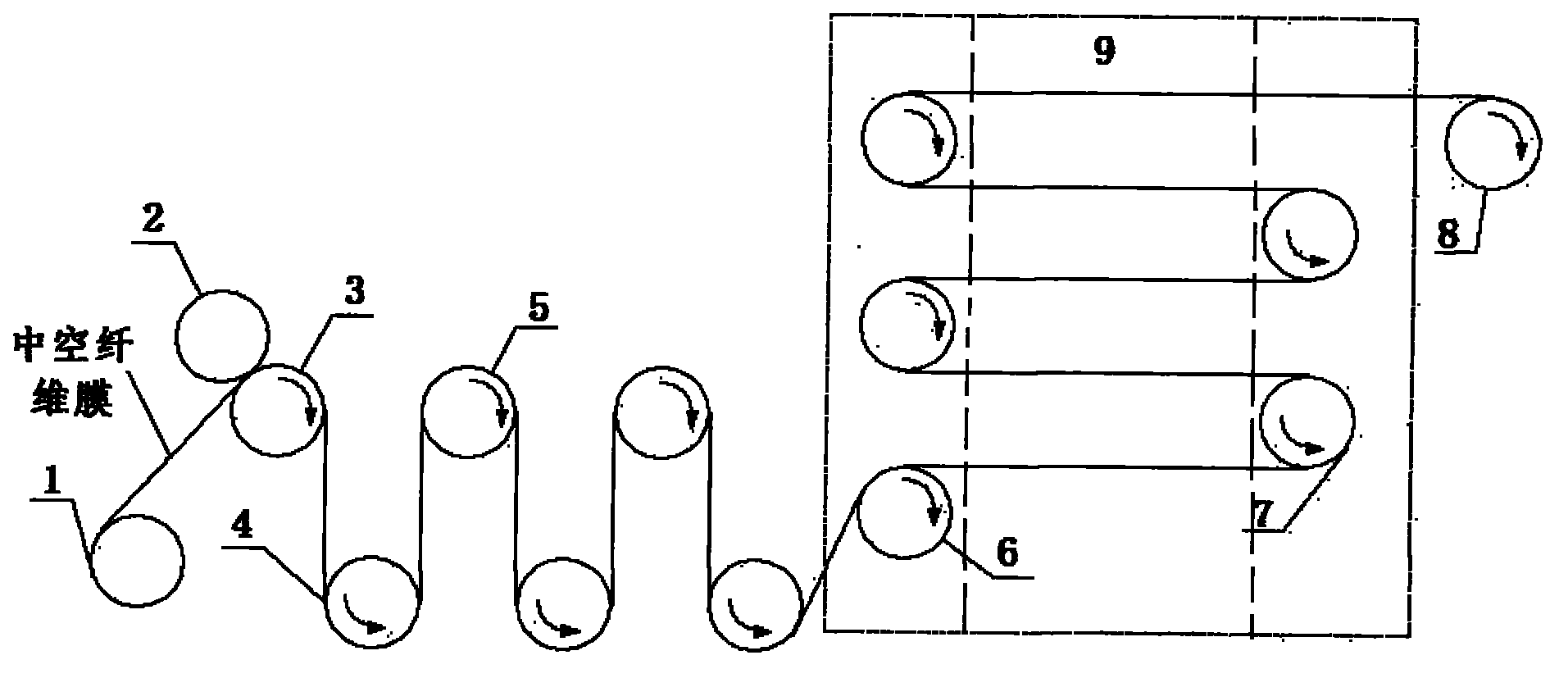

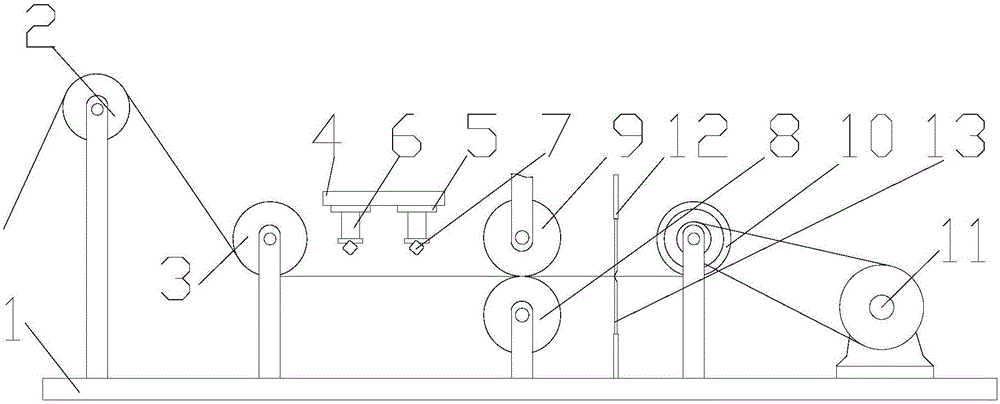

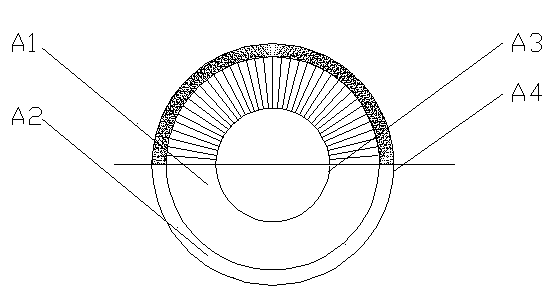

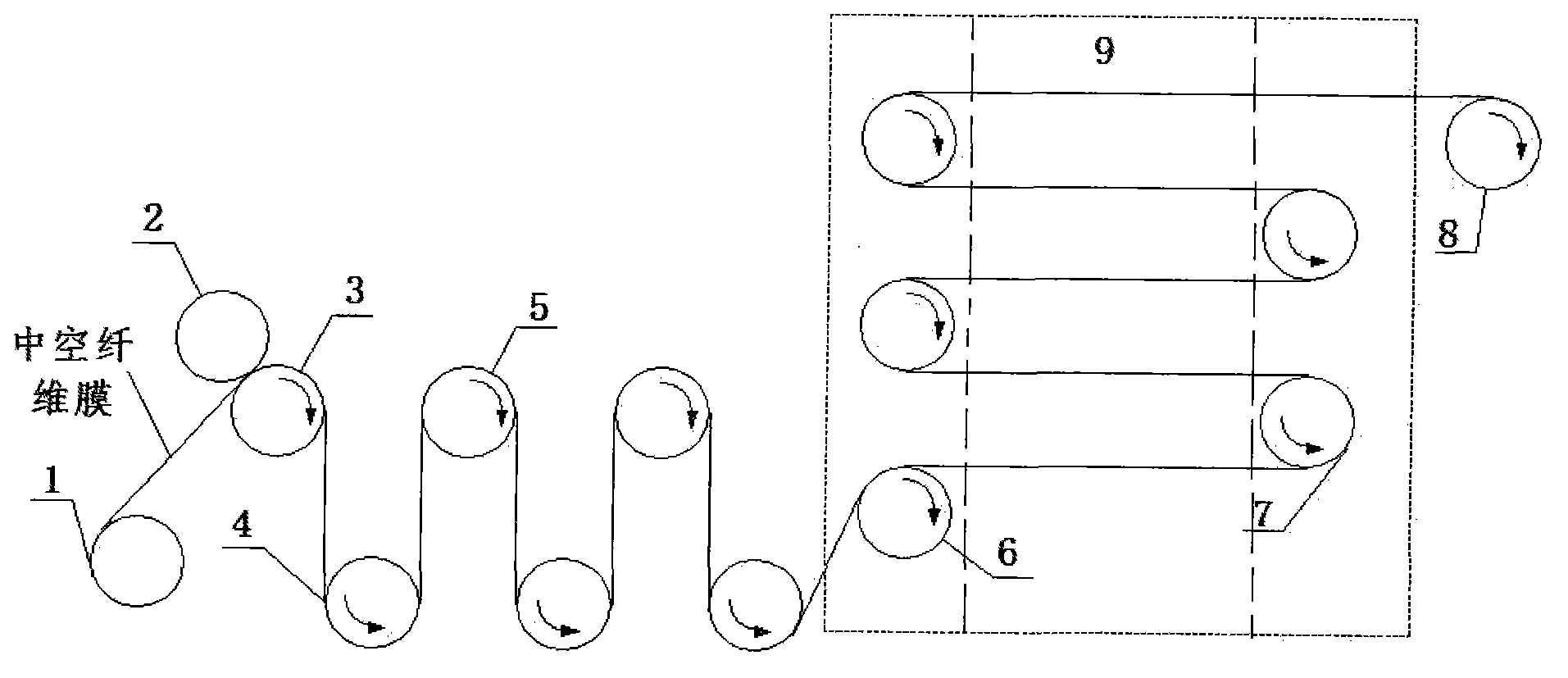

Hollow fiber membrane stretching device

ActiveCN103055708AConsistent speedConsistent tensionSemi-permeable membranesYarnHollow fiber membrane

The invention discloses a hollow fiber membrane stretching device which comprises a tension roller group, a setting component, a yarn unreeling roller, a rolling roller and a pressing roller, wherein the tension roller group comprises an upper roller and a lower roller; a hollow fiber membrane is wound between the upper roller and the lower roller in an S shape; the setting component comprises a setting device used for heating the hollow fiber membrane; at least two tension roller groups are arranged on the setting component; the upper roller and the lower roller are arranged on two sides of the setting component opposite to each other and are vertically arranged; the wire uncoiling roller is arranged at the front end of the tension roller group; the rolling roller is arranged at the rear end of the tension roller group; the rolling speed is consistent with that of the tension roller in a setting area; a gap used for allowing the hollow fiber membrane to pass is formed between the pressing roller and the upper roller; multiple tension groups are arranged, a speed ratio is formed, and the aim of stretching the fiber membrane to form a hole is fulfilled; and the passing speed of the fiber membrane is consistent with that of the last stretched roller in the setting area, and the stressed tension is kept consistent during passing. Therefore, the efficiency and the product quality are improved.

Owner:ZHEJIANG CREATION ENVIRONMENT TECH

Preparation method for filamentous vinylidene fluoride polymer composite coated diaphragm

ActiveCN110600657AUniform coatingHigh porositySecondary cellsCell component detailsPorosityPolymer science

The invention relates to a preparation method for a filamentous vinylidene fluoride polymer composite coated diaphragm, a filamentous vinylidene fluoride polymer composite coated diaphragm prepared bythe method and a lithium battery comprising the filamentous vinylidene fluoride polymer composite coated diaphragm. The prepared filamentous vinylidene fluoride polymer composite diaphragm is uniformin vinylidene fluoride polymer coating, large in porosity and good in air permeability, the air permeability of a coated film cannot be increased, the binding power between the diaphragm and a pole piece is improved, the electrolyte storage capacity is improved, and the cycle performance of a lithium battery is improved.

Owner:NINGDE ZHUOGAO NEW MATERIAL TECH CO LTD

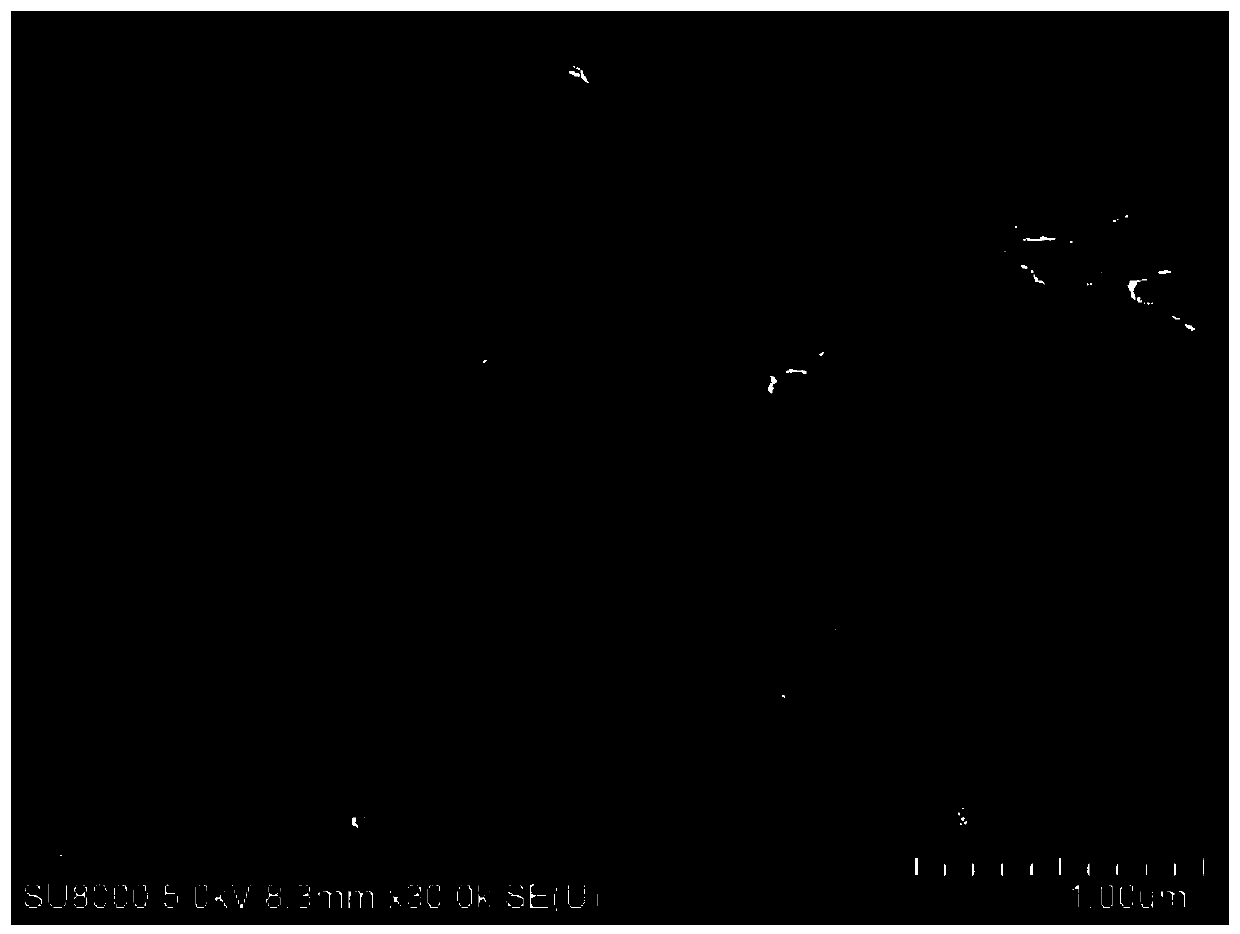

Aramid fiber slurry and preparation method thereof, and diaphragm based on aramid fiber slurry

ActiveCN110416473AUniform hole formationPlay an extraction effectCell component detailsPolyamide coatingsNon solventAlcohol

The invention discloses aramid fiber slurry and a preparation method thereof, and a diaphragm based on the aramid fiber slurry; the preparation method of the aramid fiber slurry comprises the following steps of preparing a first solution and a second solution, mixing the first solution with dimethylacetamide, stirring to be uniform, adding water, stirring until uniform, adding isopropyl alcohol, stirring until the mixture is uniform, adding dimethyl carbonate, stirring until the mixture is uniform, adding the second solution, and uniformly stirring to obtain the aramid fiber slurry. The aramidfiber slurry contains alcohol, water and ester, and the three non-solvents (alcohol, water and ester) are creatively adjusted, enabling alcohol, water and ester to occupy the position of the aramid fiber slurry under the combined action of alcohol, water and ester; and after the aramid fiber is cured by pure water, the non-solvent is uniformly dissolved in water, so that the extraction effect isachieved, and uniform pore forming of the aramid fiber is realized.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

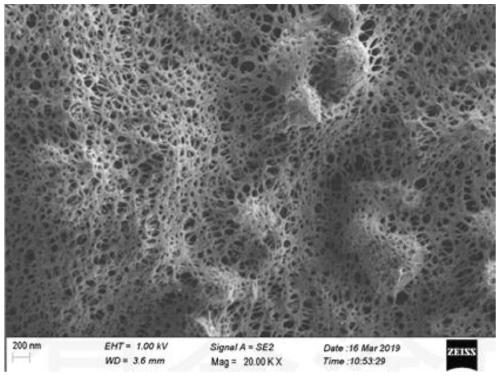

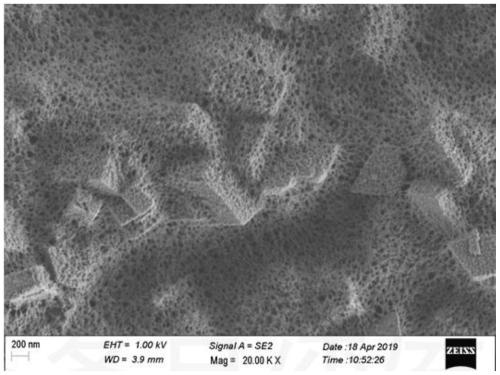

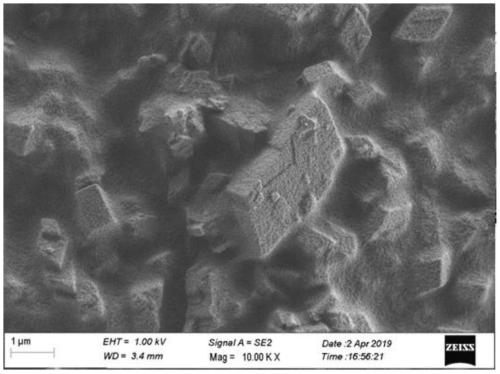

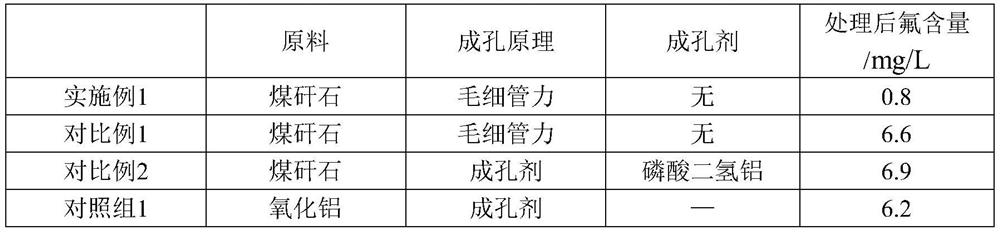

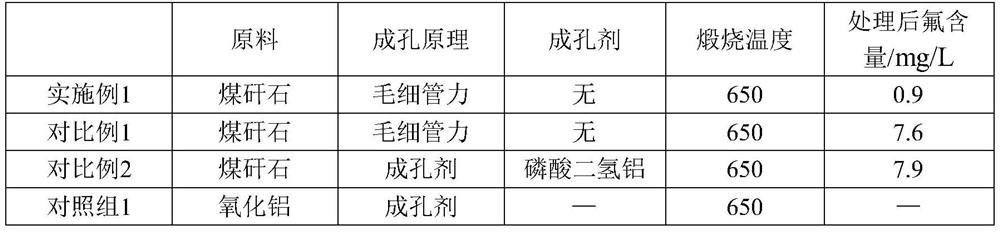

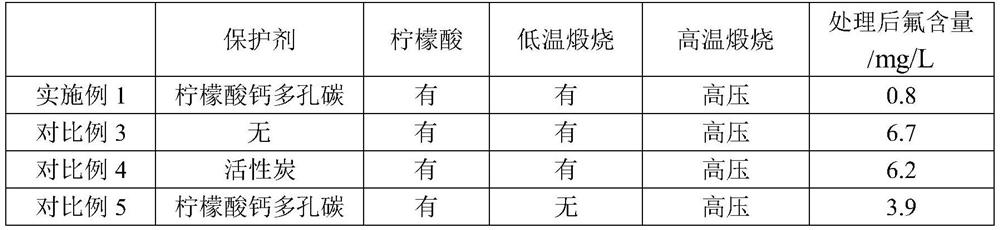

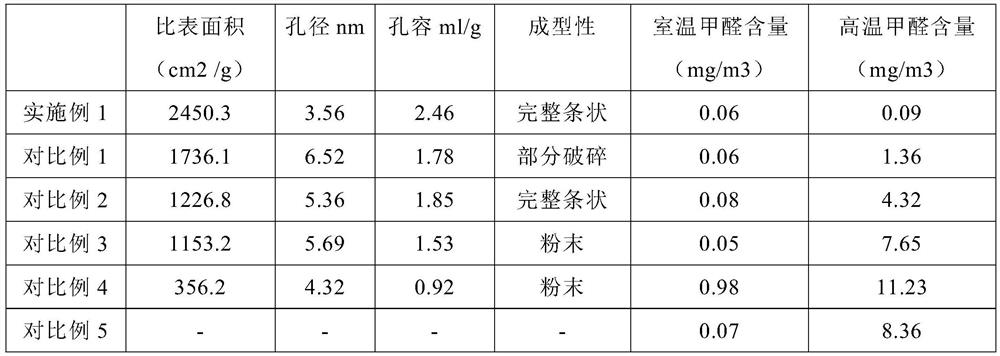

Method for preparing porous ceramic from coal gangue

ActiveCN111763097AUniform hole formationStable structureCeramic materials productionCeramicwareCoal gangueParaffin oils

The invention discloses a method for preparing porous ceramic from coal gangue. The method is characterized by comprising the following steps of: carrying out acid reaction pretreatment on coal gangue, carrying out melting pretreatment on the coal gangue, adding citric acid and a protective agent, carrying out mixing, stirring until the materials are molten, carrying out mixing, drying to obtain coal gangue powder, screening the coal gangue powder, adding a proper amount of paraffin oil, carrying out aging, carrying out injection molding, carrying out degreasing, carrying out low-temperature calcination, and carrying out pressurized high-temperature calcination to obtain porous ceramic, wherein the protective agent is calcium citrate porous carbon. The method has the beneficial effects that pore forming is completed in a biscuit forming stage by utilizing capillary force formed between raw material solid particles and two liquid phases; and alumina of coal gangue and a citric acid principle are utilized, calcium citrate porous carbon is creatively added, high-pressure calcination is carried out, generated molten aluminum chloride is protected, pore forming is completed by utilizingcapillary force formed between raw material solid particles and two liquid phases, silicon and aluminum oxides of coal gangue are fully utilized, and the porous ceramic with catalytic activity is generated by adopting a one-step method.

Owner:淄博钛金窑炉科技有限公司

Preparation method of high-permeability vinylidene fluoride polymer mixed coating diaphragm

ActiveCN110635089AImprove breathabilityGood heat shrinkabilityLi-accumulatorsCell component detailsPorosityPolymer science

The invention relates to a preparation method of a high-permeability vinylidene fluoride polymer mixed coating diaphragm, the high-permeability vinylidene fluoride polymer mixed coating diaphragm prepared by the method and a lithium battery comprising the high-permeability vinylidene fluoride polymer mixed coating diaphragm. According to the method, the vinylidene fluoride polymer mixed coating diaphragm is formed by one-time coating, the process is simple, and the prepared mixed coating diaphragm has higher porosity and pore-making uniformity, increases the liquid storage capacity of the electrolyte and improves the cycle performance of the lithium battery.

Owner:NINGDE ZHUOGAO NEW MATERIAL TECH CO LTD

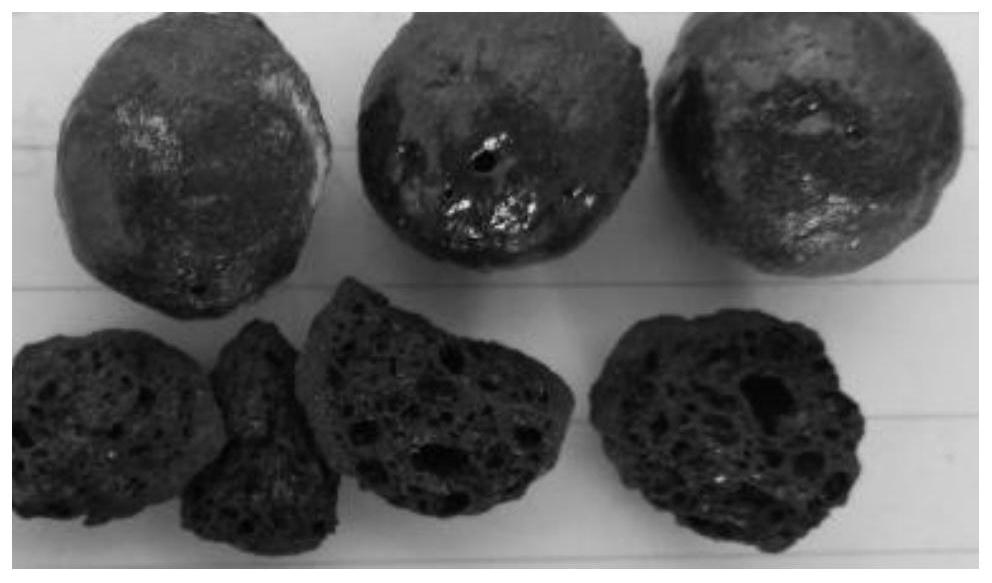

Composite glass fiber reinforced plastic waste lightweight high-strength ceramsite and preparation method thereof

ActiveCN108440015AEasy to operateCalcination temperature is lowCeramic materials productionCeramicwareGlass fiberPlastic waste

The invention provides a composite glass fiber reinforced plastic waste lightweight high-strength ceramsite and a preparation method thereof. The composite glass fiber reinforced plastic waste lightweight high-strength ceramsite is mainly prepared from the following raw materials in percentages by mass: 36-42% of glass fiber reinforced plastic wastes, 32-40% of flyash, 0-8% of alkali residues and18-24% of sandy soil, wherein water is added according to the water-solid ratio (taking the masses of all solids as a reference) being 0.2-0.3. The preparation method comprises the following steps: accurately weighing the glass fiber reinforced plastic wastes, the flyash, the alkali residues, the sandy soil and the water according to the proportion of the raw materials and uniformly mixing the rawmaterials to form a uniform basic admixture; and carrying out pelleting and forming by an artificial method to obtain ceramsite raw meal nodules, and firing the ceramisite raw meal nodules to obtainthe composite glass fiber reinforced plastic waste lightweight high-strength ceramsite. The lightweight high-strength ceramsite is prepared by taking the glass fiber reinforced plastic wastes as a main gas forming agent, and is applied to the fields of lightweight concrete wall materials, lightweight concrete tube materials and the like, glass fiber reinforced plastic waste resources can be reutilized, furthermore, environmental pollution can be relieved, and the economic benefit and the environment benefit are remarkable.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +2

Preparation method of lithium ion battery diaphragm

ActiveCN111129398AUniform plasticizationEvenly dispersedSecondary cellsCell component detailsPlasticulturePhysical chemistry

The invention relates to a preparation method of a lithium ion battery diaphragm. The preparation method comprises the following steps: mixing ultrahigh molecular weight polyethylene and a solvent, and heating and stirring for the first time to obtain a pre-swelling mixed solution; grinding the pre-swelling mixed solution, then adding a fluorine-containing polymer, and heating and stirring for thesecond time to obtain a dispersion solution; carrying out melt extrusion on the dispersion liquid to obtain a plasticized melt film; and carrying out post-treatment on the plasticized melt film. According to the preparation method disclosed by the invention, the ultra-high molecular weight polyethylene can be uniformly plasticized, the formed diaphragm is uniform in thickness distribution, and the method has the advantage of being uniform in micropore size and distribution, small in high-temperature thermal shrinkage, high in puncture strength and high in diaphragm breaking temperature.

Owner:FOSHAN JINHUI HIGH TECH OPTOELECTRONICS MATERIAL

Punching assembly of plastic film production system

InactiveCN106346144AEasy to operateUniform hole formationLaser beam welding apparatusPunchingEngineering

The invention provides a punching assembly of a plastic film production system. A frame is provided with a discharging roller, and the discharge side of the discharging roller is provided with a laser punching mechanism. The laser punching mechanism comprises a hanging mechanism, at least two sets of drilling assemblies are provided on the hanging mechanism, and the drilling assemblies include a slider, a supporting rod and a laser puncher. The slider can be horizontally and slidingly disposed on the hanging mechanism, and a first driving device drives the slider to move left and right. The supporting rod is slidingly disposed on the slider, and a second driving device drives the supporting rod to move back and forth. According to the laser drilling device for the plastic film production system, the operation is simple, holes are formed uniformly, and the size, shape and separation distance and number of rows of the holes can be adjusted according to the requirements of production; labor intensity is low, work efficiency is high, and the laser drilling device for the plastic film production system is suitable for continuous production in enterprises.

Owner:ANQING XINGFENG IND & TRADE

Preparation method of high-reinforcing titanium dioxide for water-based coating

ActiveCN108774414AMake up for deficienciesGood dispersionCoatingsPigment physical treatmentWater basedCrack resistance

The invention relates to a preparation method of high-reinforcing titanium dioxide for a water-based coating, and belongs to the technical field of the preparation of titanium dioxide functional materials. The preparation method comprises the following steps: A) preparation of paste: mixing titanium dioxide and inorganic mineral powder in distilled water, adding a dispersant, stirring to prepare mixed paste of the inorganic mineral powder and titanium dioxide; B) preparation of slurry: adding a pore forming agent into the mixed paste of step A, and high-speed stirring to prepare the slurry; C)preparation of a pore-forming composite: performing spray drying on the slurry prepared in step B in a spray dryer to prepare a composite of pore-forming titanium dioxide and inorganic minerals; andD) preparation of high-reinforcing titanium dioxide: enabling the pore-forming composite prepared in step C to be subjected to airflow pulverization in an airflow pulverizer, and performing organic coating treatment during the airflow pulverization to prepare the high-reinforcing titanium dioxide. The high-reinforcing titanium dioxide prepared by the method is used in the water-based coating to improve the weather resistance, bonding strength, crack resistance, color change resistance and the like of a coating layer.

Owner:HEBEI MILSON TITANIUM DIOXIDE

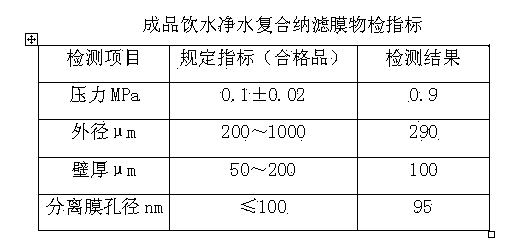

Drinking water purification composite nano-filtration membrane and preparation process thereof

InactiveCN103962019AWith wear resistanceAging resistanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiltration membraneHazardous substance

The present invention relates to the technical field of polymer material membranes, particularly to a novel drinking purification composite nano-filtration membrane. According to the method, polyether sulfone and polyurethane are adopted as main materials, and other pore forming solvents are adopted to blend, wherein through blending of polyether sulfone with polyurethane, the prepared drinking purification composite nano-filtration membrane is provided withcharacteristics of a certain complementarity, high temperature resistance, good acid resistance, good alkali resistance, good hydrophobicity, good oil resistance, toughness, wear resistance, aging resistance, high flux, uniform pore size, and nano-scale size. According to the present invention, after deep well water or municipal tap water is purified through the drinking water purification composite nano-filtration membrane, bacteria, viruses, rust, colloid, chlorine residue, ammonia, nitrogen, organic polymer compounds and other harmful substances in water can be removed, the obtained water can be directly and safely drunk, minerals, trace elements, dissolved oxygen and other beneficial substances in water are not destroyed and lost, the purified water is weakly alkaline so as to provide benefits for human body health, and the required minerals are not required to be additionally supplemented so as to provide the low production cost.

Owner:SHANGHAI HEALTHY WATER TECH DEV

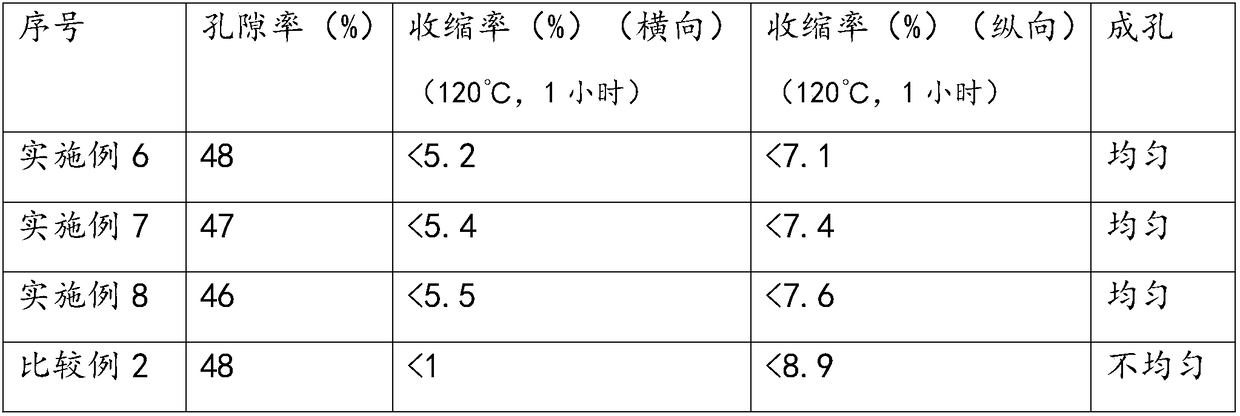

Composition for manufacturing diaphragm of lithium battery

InactiveCN109326761AReduce typesHigh porosityCell seperators/membranes/diaphragms/spacersState of artPorosity

The invention relates to a composition for manufacturing a diaphragm of a lithium battery, which mainly solves the problem of failure in simultaneous obtaining of high porosity, high shrinkage rate and uniform pore forming in the prior art. The composition for manufacturing the diaphragm of the lithium battery adopts the technical scheme that the composition consists of polyethylene powder and paraffin oil, wherein the polyethylene powder comprises polyethylene particles, an antioxidant a and an antioxidant b; the mixing ratio of the polyethylene powder to the paraffin oil is 1:1 to 1:5.5; themasses of antioxidant a and antioxidant b respectively account for 0.1% to 1% of the mass of the polyethylene powder, so as to well solve the problem of failure in simultaneous obtaining of high porosity, high shrinkage rate and uniform pore forming in the prior art.

Owner:泰州衡川新能源材料科技有限公司

Method for producing hollow fiber film

Owner:TIANJIN POLYTECHNIC UNIV

Aramid pulp, preparation method thereof, and separator based on the aramid pulp

ActiveCN110416473BUniform hole formationPlay an extraction effectCell component detailsPolyamide coatingsNon solventPolymer science

The invention discloses an aramid fiber slurry, a preparation method thereof, and a diaphragm based on the aramid fiber slurry. The preparation method of the aramid fiber slurry includes the following steps: preparing a first solution and a second solution, and dissolving the first solution Mix with dimethylacetamide, stir until uniform, add water, stir until uniform, add isopropanol, stir until uniform, then add dimethyl carbonate, stir until uniform, add the second solution, stir until uniform, Obtain the aramid fiber slurry, the aramid fiber slurry of the present invention contains alcohol, water and ester, adjust the ratio of three kinds of non-solvents (alcohol, water and ester) creatively, let alcohol, water and ester three kinds of non-solvents jointly Under the action, it occupies the position of the aramid fiber slurry, and after the aramid fiber is solidified with pure water, the non-solvent is evenly dissolved into the water, which has an extraction effect and makes the aramid fiber evenly form pores.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

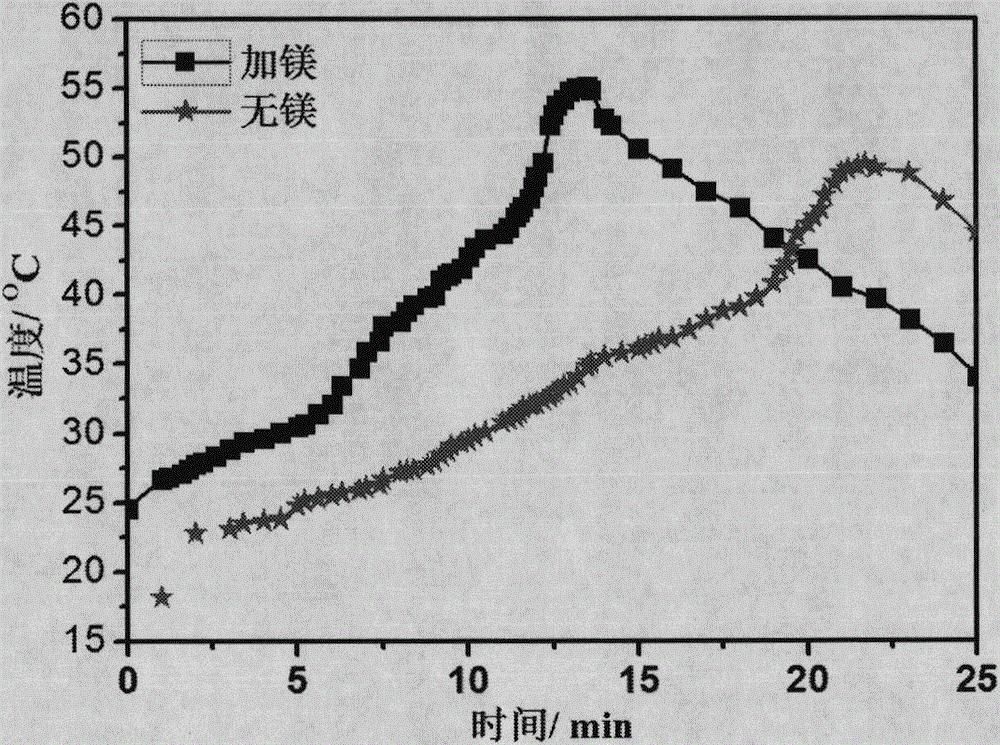

A kind of bone cement and preparation method thereof

The invention relates to novel bone cement and a preparation method thereof. The novel bone cement consists of the following components in percentage by weight: 47-78wt% of magnesium oxide, 20-50wt% of ammonium phosphate, 0.5-10wt% of retarder, 0.01-10wt% of magnesium powder and a solidifying liquid, wherein the liquid-solid ratio of the solidifying liquid to the mixture of the materials is 0.06-1.0ml / g. According to the novel bone cement and the preparation method thereof disclosed by the invention, the system is accelerated to generate ammonia gas to form pores by adding the magnesium powder into the system of ammonium phosphate and magnesium oxide. The preparation process provided by the invention is simple and convenient. According to the porous structure obtained by the method, the pore size is uniform and the porosity is great, so that cell adsorption and climbing are facilitated, thereby promoting the growth of bone cells. The novel bone cement provided by the invention has good mechanical properties, biocompatibility and biocompatibility and can be widely applied to the field of medical materials.

Owner:NINGBO HICREN BIOTECH

Preparation method of highly air-permeable vinylidene fluoride polymer mixed-coated separator

ActiveCN110635089BImprove breathabilityGood heat shrinkabilityLi-accumulatorsCell component detailsElectrolytic agentPhysical chemistry

The invention relates to a preparation method for a highly air-permeable vinylidene fluoride polymer mixed-coated diaphragm, a highly air-permeable vinylidene fluoride polymer mixed-coated diaphragm prepared by the method and a membrane comprising the highly air-permeable vinylidene fluoride polymer mixed-coated diaphragm lithium battery. According to the method of the present invention, a vinylidene fluoride polymer mixed-coated diaphragm is formed by one-time coating, and the process is simple. The prepared mixed-coated diaphragm has greater porosity and pore-forming uniformity, increases the electrolyte storage capacity, and improves the performance of the lithium battery. cycle performance.

Owner:NINGDE ZHUOGAO NEW MATERIAL TECH CO LTD

Diaphragm used for lithium-ion storage battery and manufacturing method thereof

The invention discloses a diaphragm used for a lithium-ion storage battery and a manufacturing method thereof. The porosity of the diaphragm is 50%-70%, the average pore size of the diaphragm is 0.1-0.3um, and the largest pore size to the average pore size of the diaphragm is 1.10-1.25. The preparing method of the invention has simple process, and the porosity and the pore size of the diaphragm are controlled through the synergistic effect of plasma discharging processing technology and a nucleating agent, thereby solving the problem that troubles are brought for mixing of melt and uniformityof pore forming as the vast scale of inorganic fillers are added into the diaphragm for increasing the pore size and porosity.

Owner:乐凯胶片股份有限公司

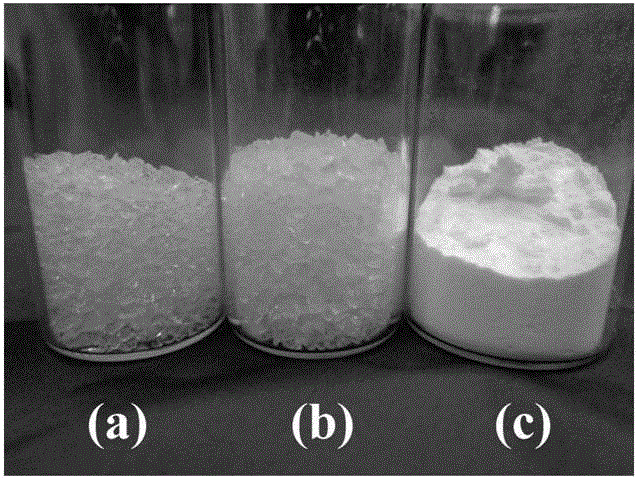

A kind of synthesis method of nanometer magnesium fluoride of high specific surface area

ActiveCN103482661BShort processEasy to controlMagnesium fluoridesMaterial nanotechnologyFiltrationMagnesium salt

The invention discloses a synthetic method of nanometer magnesium fluoride with a high specific surface area. The method comprises the steps as follows: 1), magnesium salt is fully dissolved in deionized water, so that a reaction liquid A is obtained, wherein the magnesium salt adopts one or a combination of any of magnesium acetate, magnesium chloride and magnesium nitrate; and ammonium salt is dissolved in deionized water, so that a reaction liquid B is obtained, wherein the ammonium salt adopts ammonium fluoride or a combination of the ammonium fluoride and ammonium acetate; 2), the reaction liquid A and the reaction liquid B are mixed under stirring, and reaction is performed; 3), after reaction, stirring is stopped, and the mixture is stood for aging; 4), after aging, filtration or centrifugal separation is performed, and the mixture is dried; and 5), a dried sample is roasted, so that the nanometer magnesium fluoride is obtained. The nanometer magnesium fluoride prepared with the method has the high specific surface area, the synthetic method is simple, the production cost is low, the preparation period is short, operation and control are easy, and small corrosiveness is caused to a device.

Owner:ZHEJIANG UNIV OF TECH

Hollow fiber membrane stretching device

The invention discloses a hollow fiber membrane stretching device which comprises a tension roller group, a setting component, a yarn unreeling roller, a rolling roller and a pressing roller, wherein the tension roller group comprises an upper roller and a lower roller; a hollow fiber membrane is wound between the upper roller and the lower roller in an S shape; the setting component comprises a setting device used for heating the hollow fiber membrane; at least two tension roller groups are arranged on the setting component; the upper roller and the lower roller are arranged on two sides of the setting component opposite to each other and are vertically arranged; the wire uncoiling roller is arranged at the front end of the tension roller group; the rolling roller is arranged at the rear end of the tension roller group; the rolling speed is consistent with that of the tension roller in a setting area; a gap used for allowing the hollow fiber membrane to pass is formed between the pressing roller and the upper roller; multiple tension groups are arranged, a speed ratio is formed, and the aim of stretching the fiber membrane to form a hole is fulfilled; and the passing speed of the fiber membrane is consistent with that of the last stretched roller in the setting area, and the stressed tension is kept consistent during passing. Therefore, the efficiency and the product quality are improved.

Owner:ZHEJIANG CREATION ENVIRONMENT TECH

Preparation method of air purification activated carbon adsorption material

ActiveCN113620290AFull dehydration pre-carbonizationUniform hole formationCarbon compoundsOther chemical processesActivated carbonPhysical chemistry

The invention discloses a preparation method of an air purification activated carbon adsorption material, which comprises the following steps of: well mixing sorghum flour and zinc chloride, adding the mixture into cold water, uniformly pulping, heating to 90-100 DEG C in a stirring state, adding sodium hydroxide, carrying out open heat preservation for 2-4 hours, stopping stirring, heating to 150-160 DEG C, carrying out heat preservation for 2-4 hours, solidifying, cooling, cutting the solidified material into parts with the same size, putting the material into a high-temperature furnace, calcining in a nitrogen atmosphere, putting the calcined material into 10% hydrochloric acid water, heating to 60 DEG C, slowly oscillating and washing, then rinsing the material with clear water until the material is neutral, and drying the material.

Owner:桐源(上海)网络技术有限公司

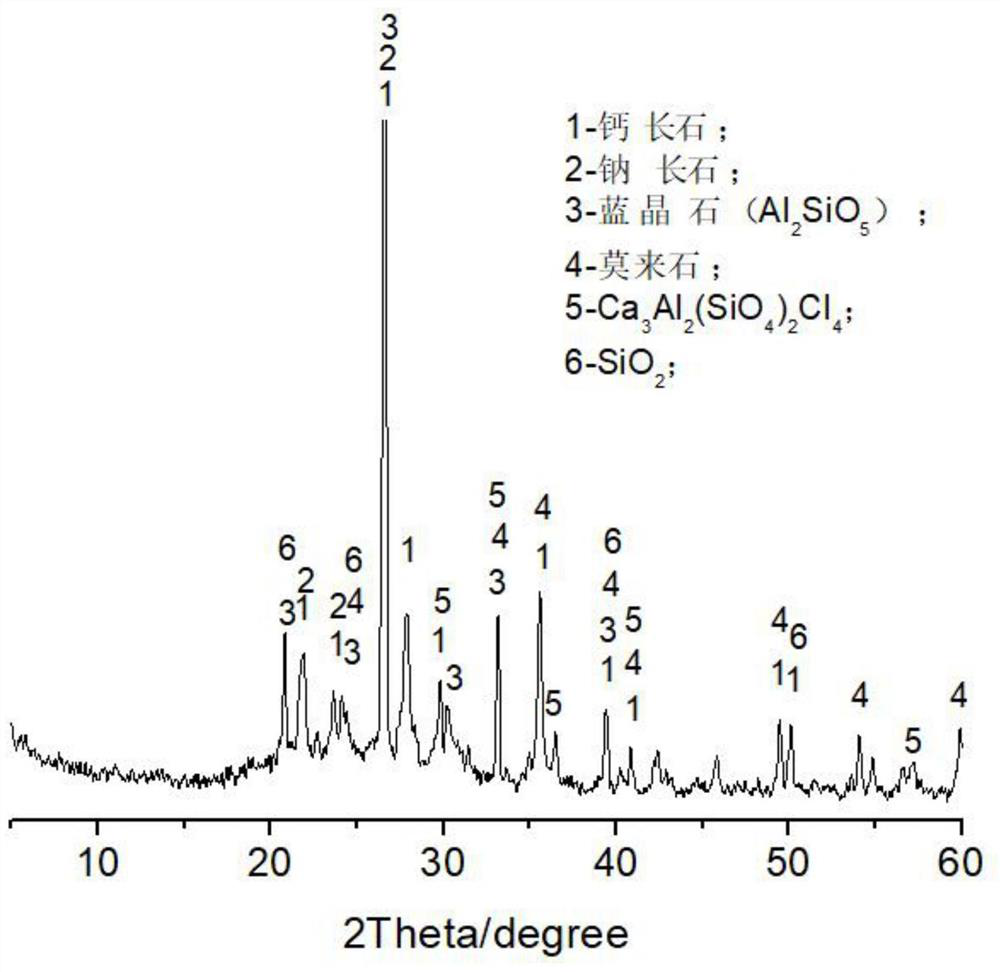

Core-shell structure ceramsite based on iron tailings and alkali slag and its preparation method

ActiveCN110615667BLower firing temperatureReduce generationCeramic materials productionClaywaresSlagMullite

The invention discloses a preparation method of core-shell structure ceramsite based on iron tailings and alkali slag, which comprises the following steps: weighing iron tailings powder, fly ash and alkali slag according to the proportion and mixing them uniformly to obtain the core Batch material A, put the core batch material A into the ball machine and add water to get the core raw meal ball; weigh the iron tailings powder, fly ash and flux in proportion and mix them evenly to get the shell layer batch material B; Put the core raw meal balls into the shell batch material B and roll to obtain the ceramsite raw meal balls; raise the obtained ceramsite raw meal balls from room temperature to 1100~1260°C and keep it warm for 30~100min, then cool naturally to At room temperature, the core-shell structure ceramsite was obtained. The present invention mainly provides Al from fly ash 2 o 3 and SiO 2 composition, iron tailings provide SiO 2 Composition, the alkali metal ions in the alkali slag can reduce the firing temperature of the core, reduce the viscosity of the liquid phase, increase the production of mullite, kyanite, anorthite and glass phases during the calcination process, and increase the ceramsite core. Part of the mechanical properties.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com