Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5255 results about "Melt extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot melt extrusion (HME) is the processing of polymeric materials above their glass transition temperature (Tg) in order to effect molecular level mixing of thermoplastic binders and/or polymers and active compounds. Used in several industries, HME is a combination of melting and mechanical energy to improve continuous...

Melt-extruded orally administrable opioid formulations

InactiveUS6261599B1Sustained effectSlow and control releaseBiocideOrganic active ingredientsMelt extrusionDosage form

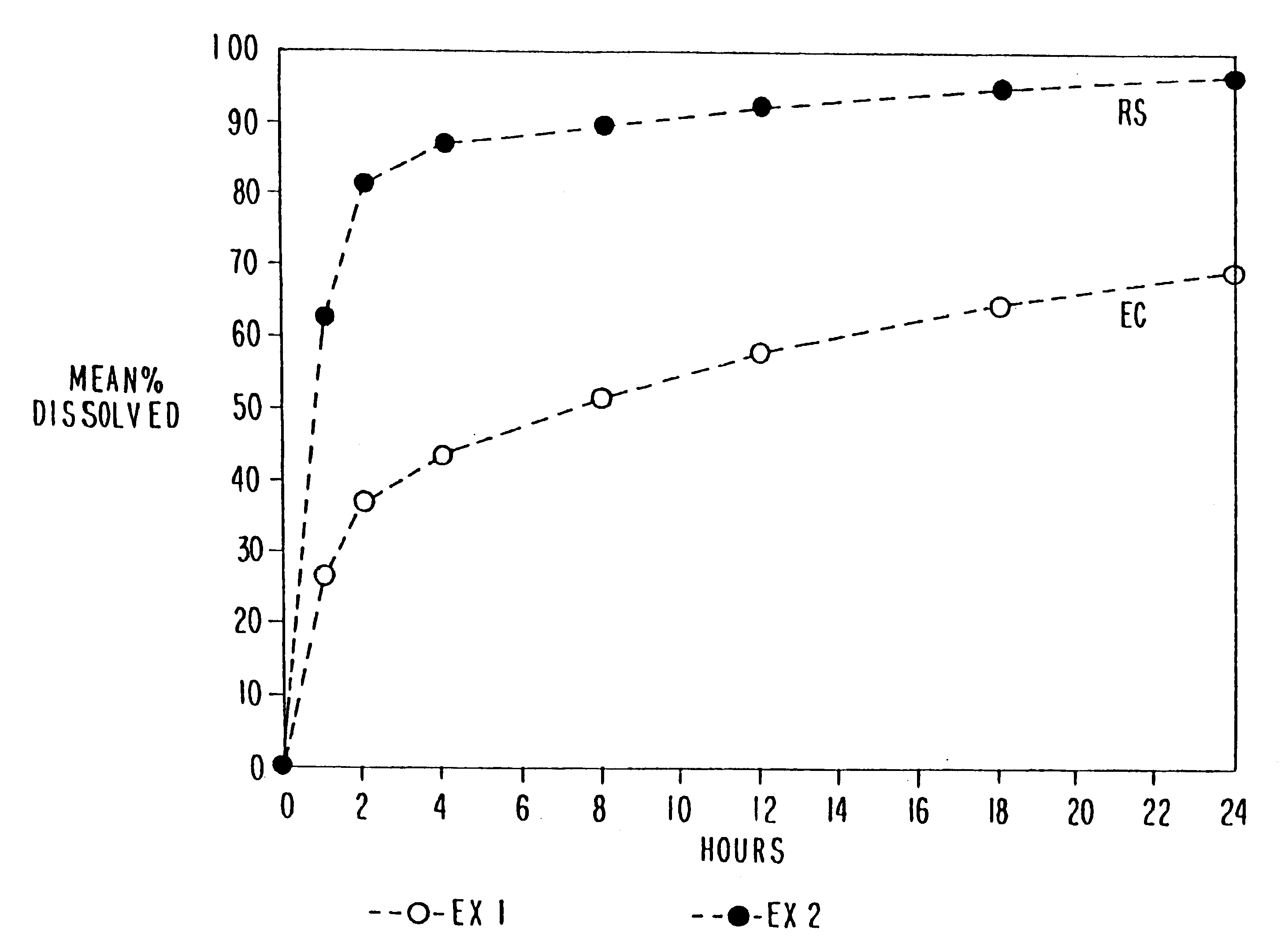

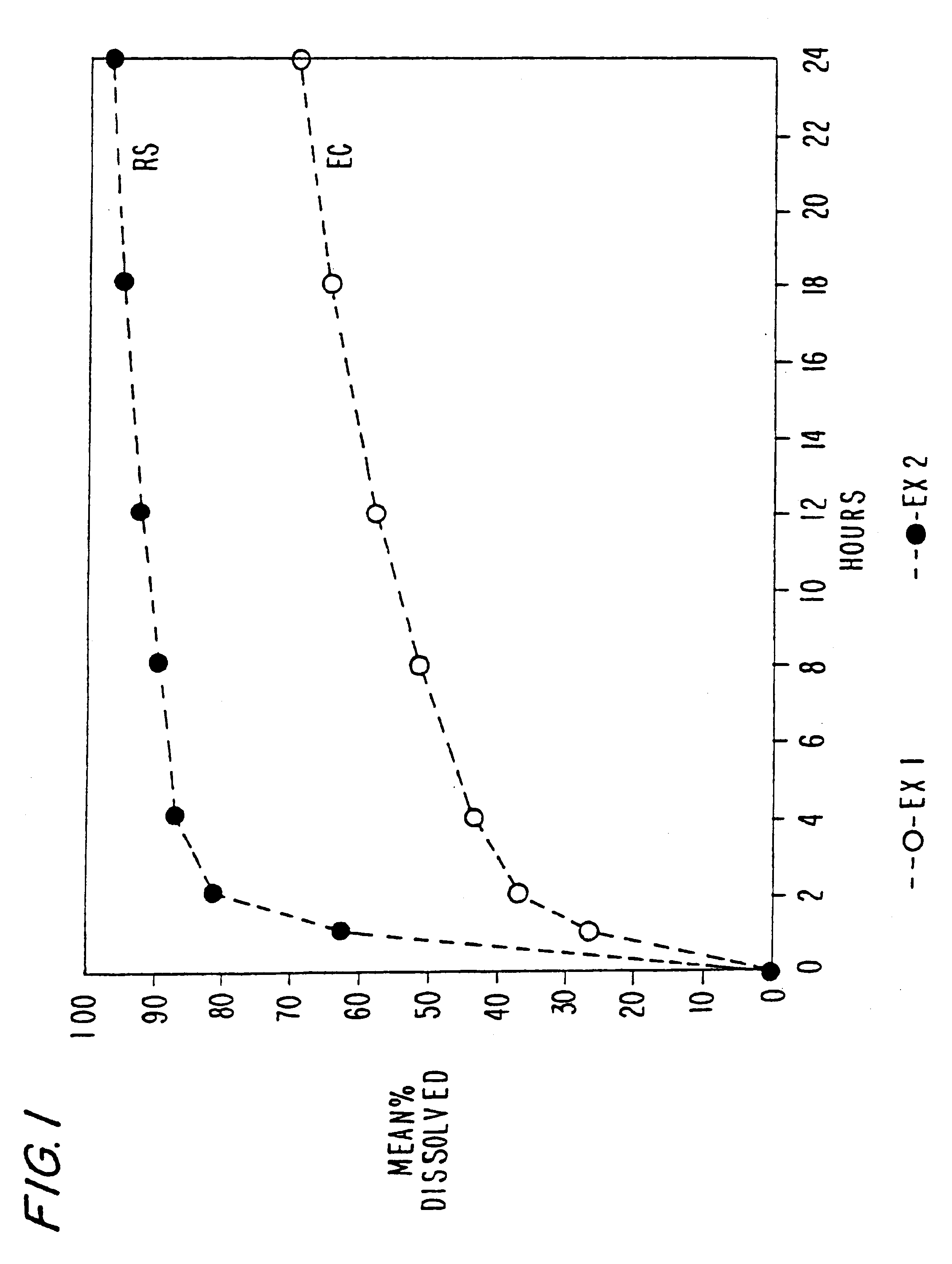

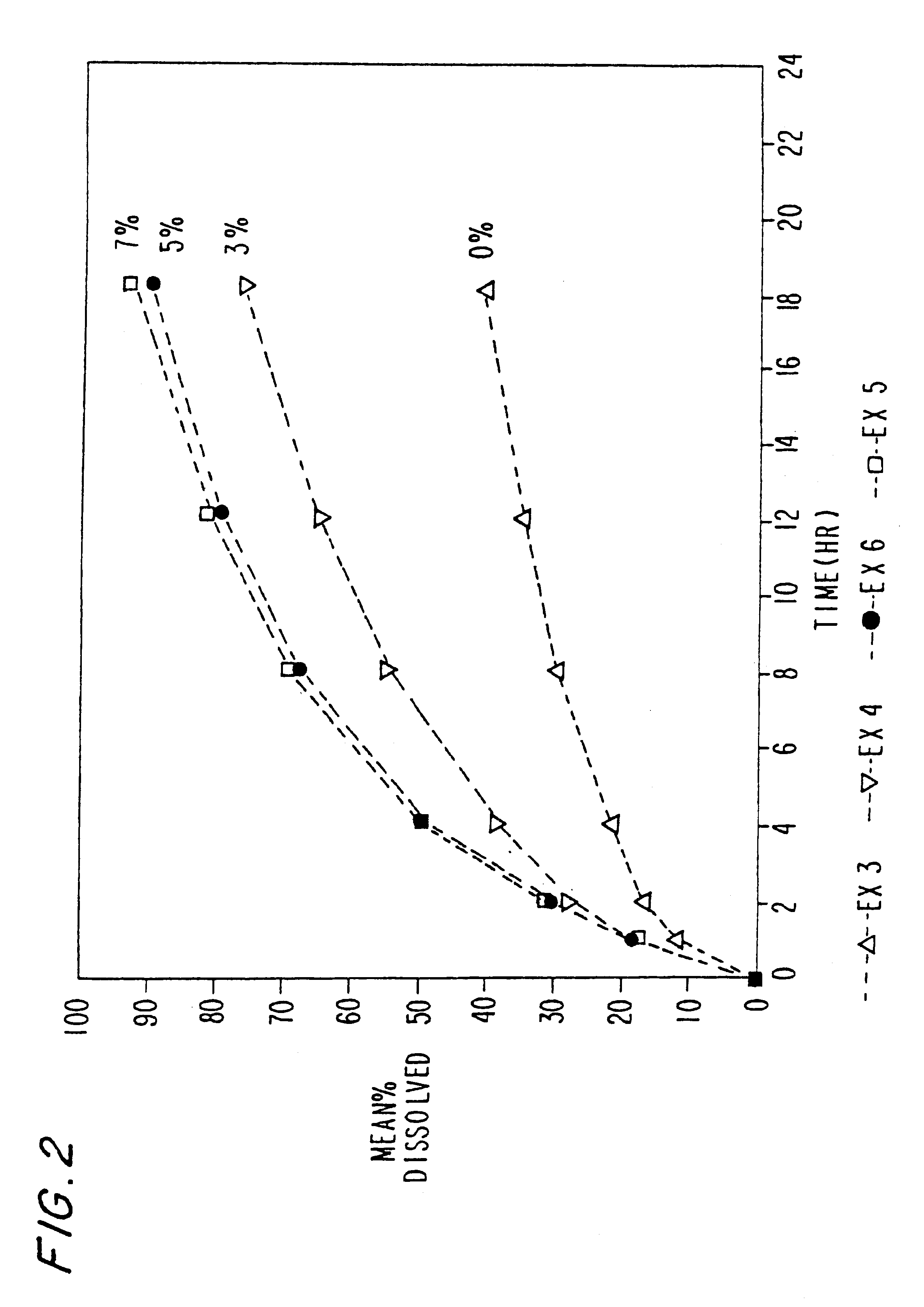

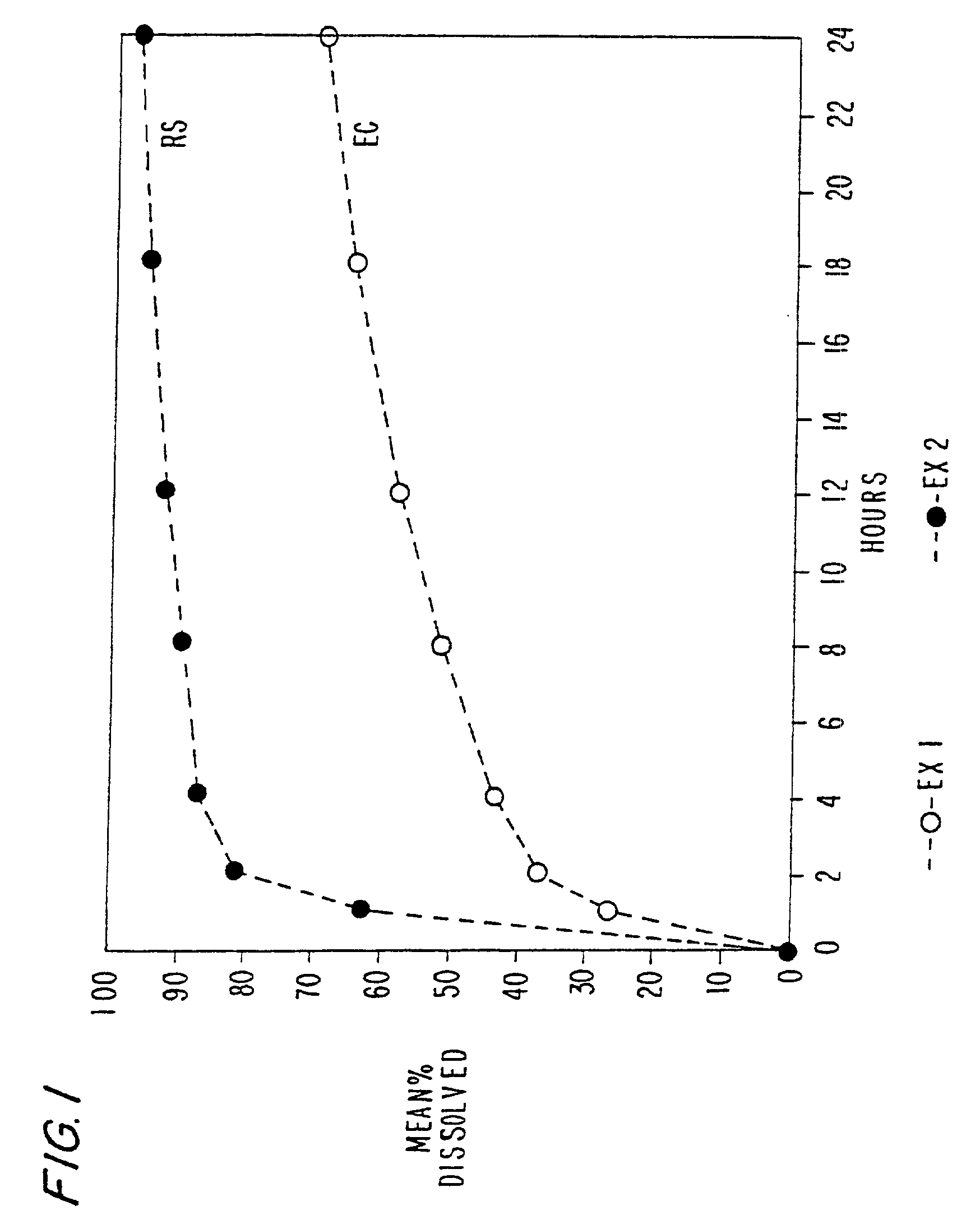

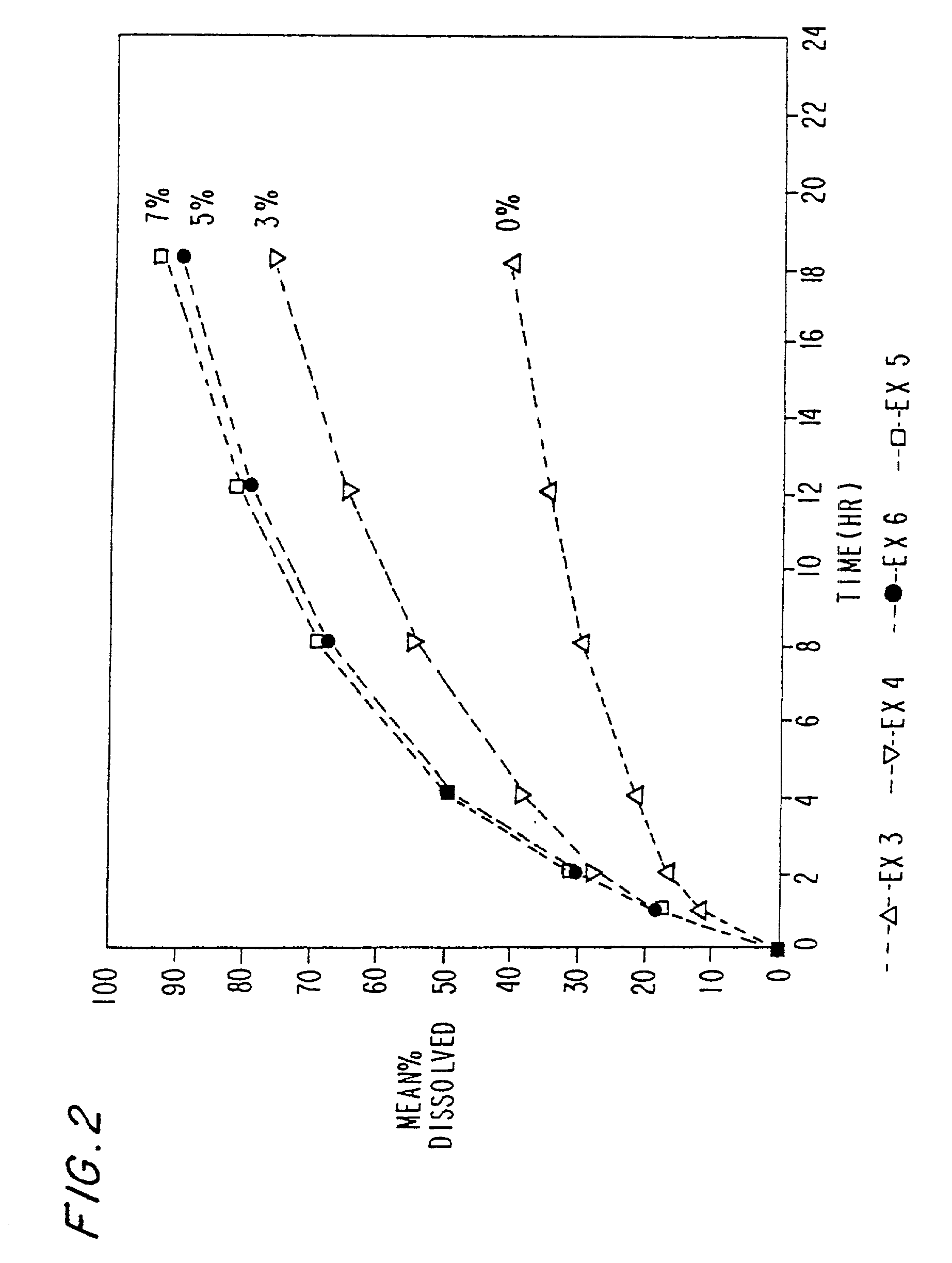

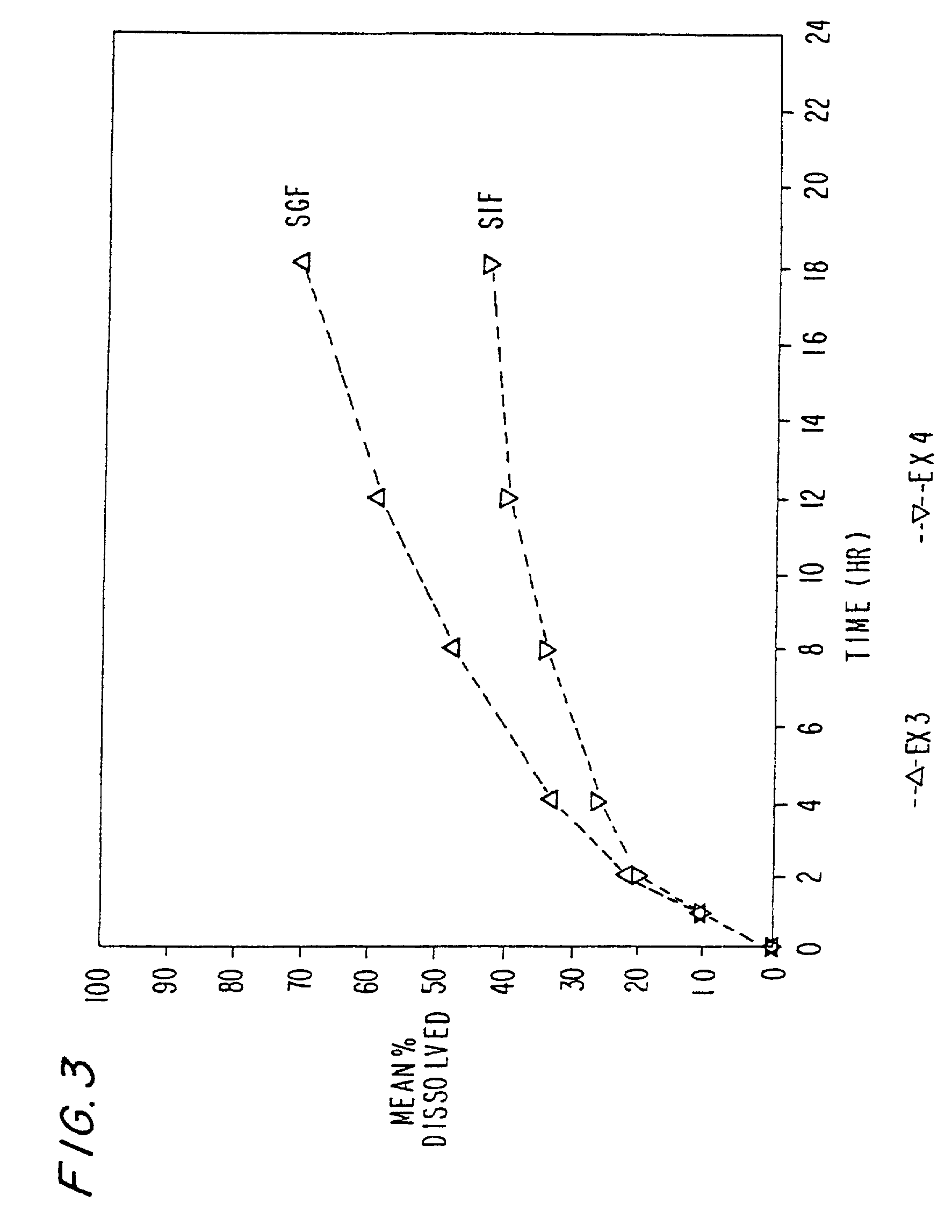

Bioavailable sustained release oral opioid analgesic dosage forms, comprising a plurality of multiparticulates produced via melt extrusion techniques disclosed.

Owner:PURDUE PHARMA LP

Preparation method of polymer/graphene composite material through in situ reduction

ActiveCN101864098AEvenly dispersedQuality improvementSpecial tyresNon-conductive material with dispersed conductive materialElectrical conductorVulcanization

The invention relates to a preparation method of a polymer / graphene composite material through in situ reduction, which is characterized by comprising the following steps: adopting ultrasonic wave or grinding to evenly disperse the graphite oxide prepared by a Hummers method into polymer dispersion; introducing reducing agent into the polymer dispersion for in situ reduction, enabling the graphite oxide to be reduced into the grapheme so as to obtain stable polymer / graphene composite emulsion; carrying out demulsification, agglomeration and drying to obtain the composite polymer / grapheme composite master batch; adding the dried polymer / grapheme composite master batch and various assistants into the polymeric matrix according to a certain ratio; and carrying out double-roller mixing, vulcanization, melt extrusion or injection molding to obtain the polymer / graphene composite material with excellent physical and mechanical properties.

Owner:成都创威新材料有限公司

Process for the production of an abuse-proofed solid dosage form

ActiveUS8114384B2Intense negative effectConsiderably complicatedNervous disorderPill deliveryBreaking strengthMedicine

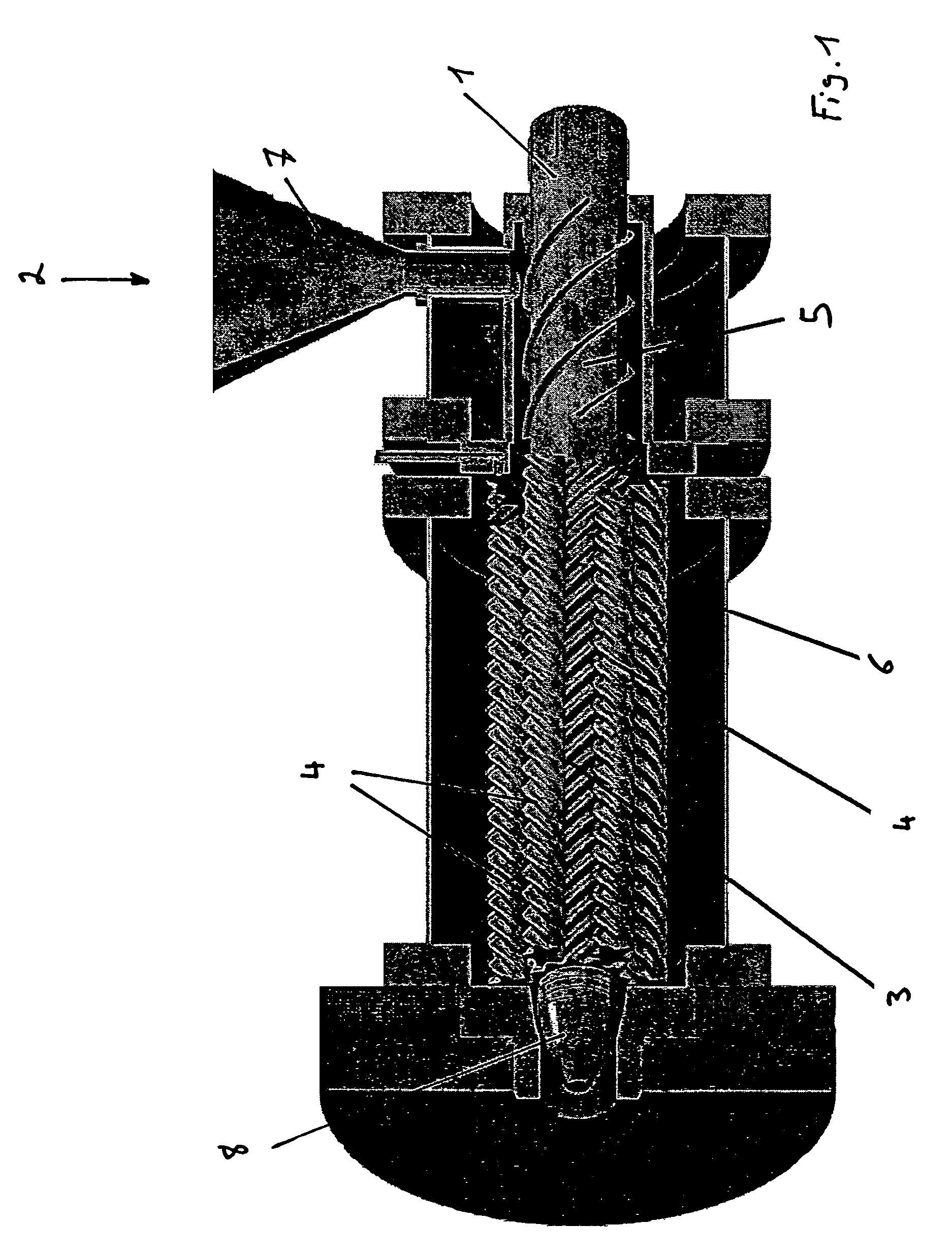

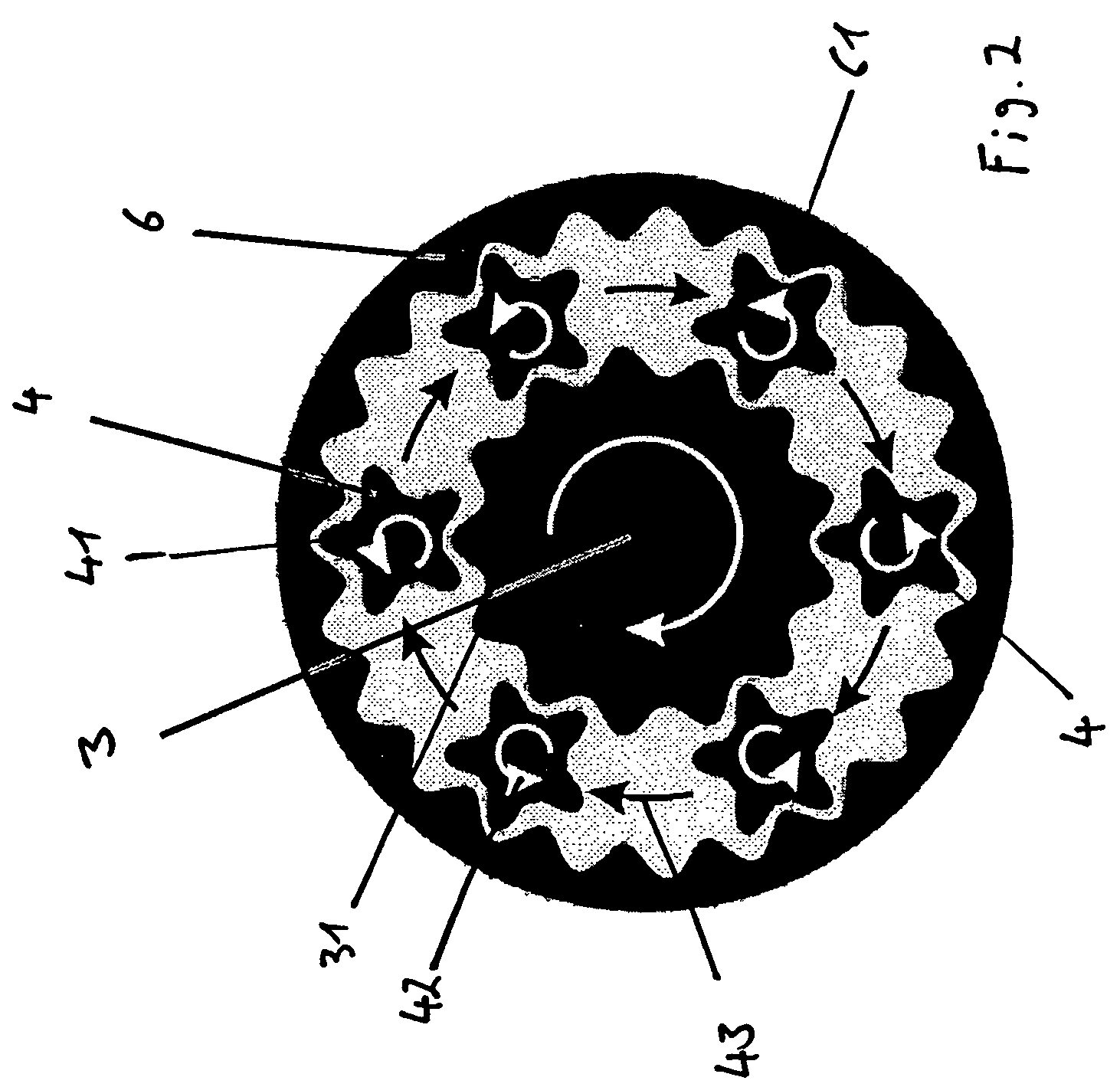

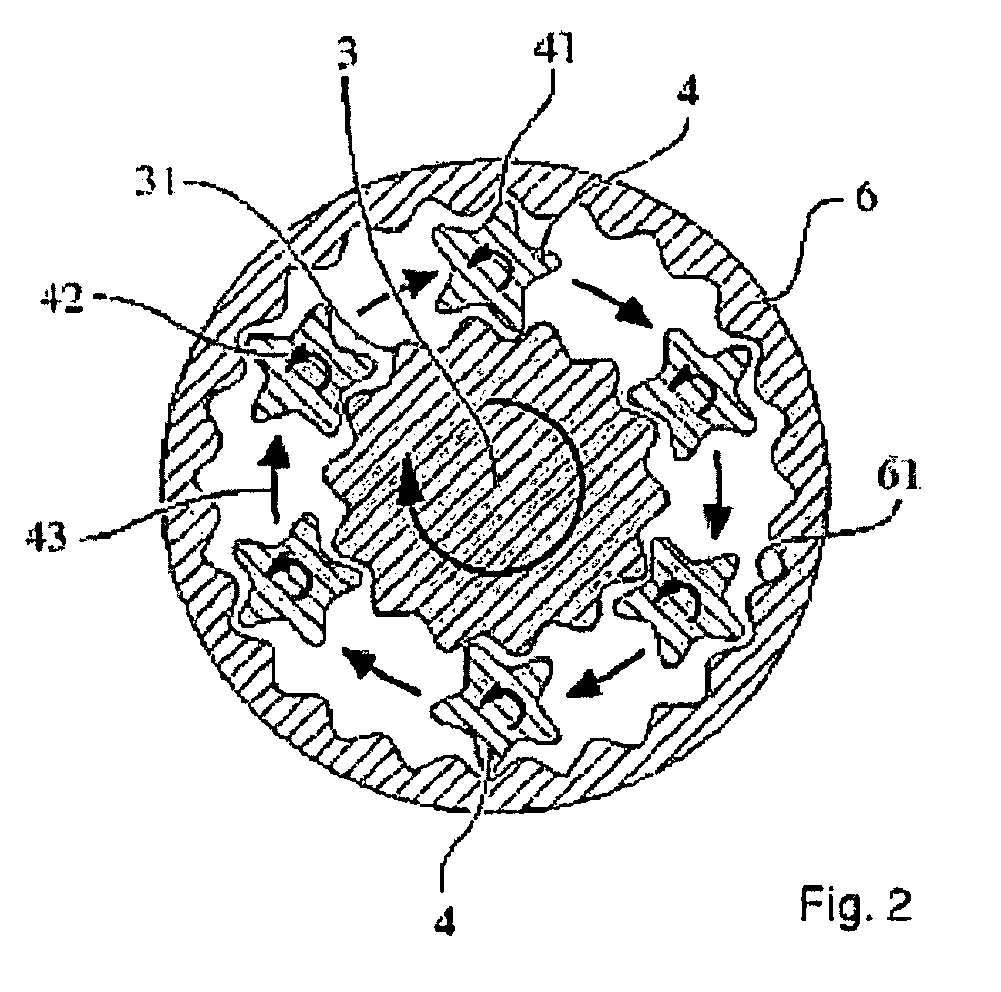

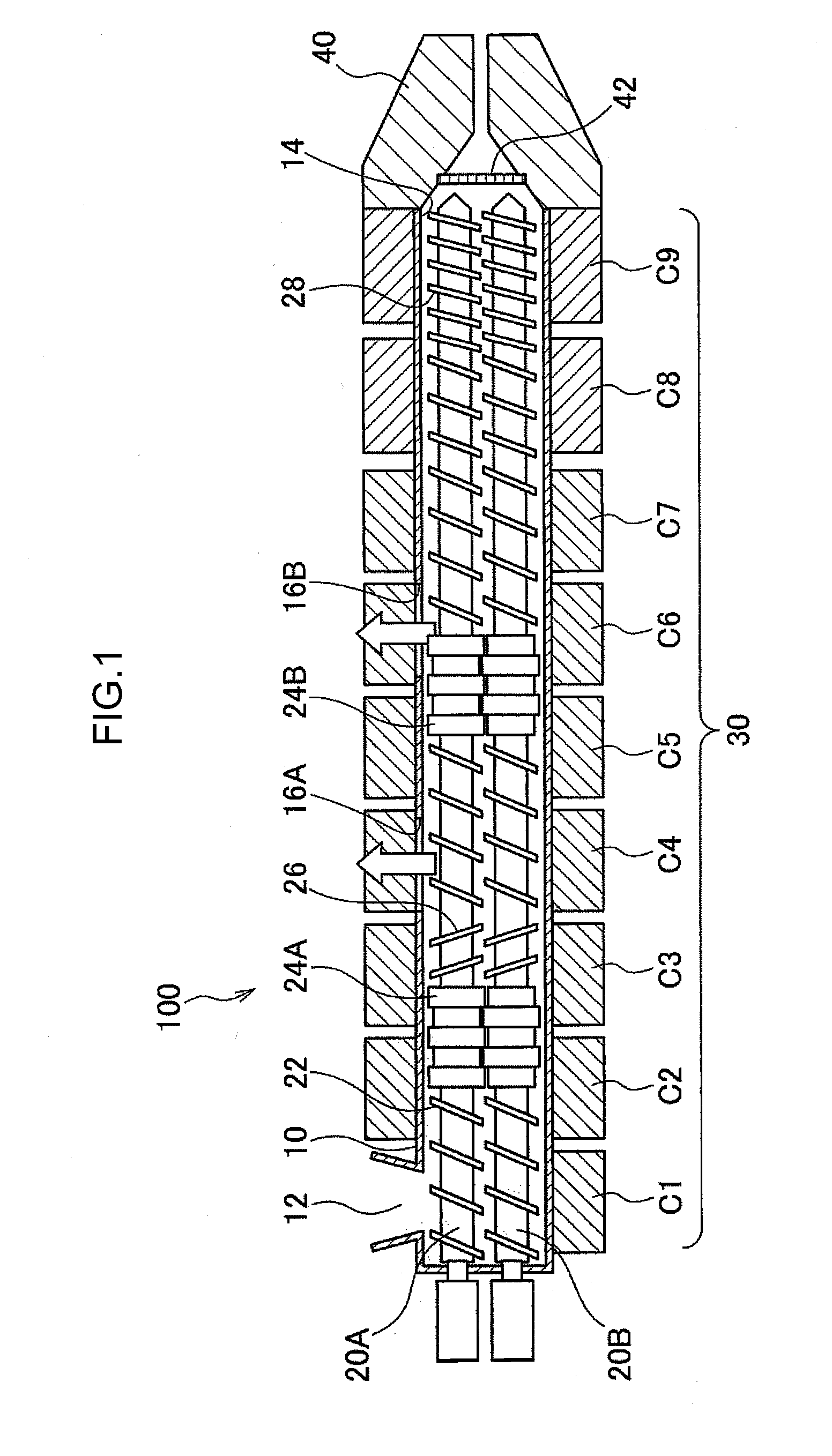

The present invention relates to a process for the production of an abuse-proofed solid dosage form containing at least one active ingredient with potential for abuse and a synthetic or natural polymer with a breaking strength of =500 N, characterized in that a corresponding mixture is processed by melt extrusion with the assistance of a planetary-gear extruder.

Owner:GRUNENTHAL GMBH

Melt-extruded orally administrable opioid formulations

Owner:PURDUE PHARMA LP

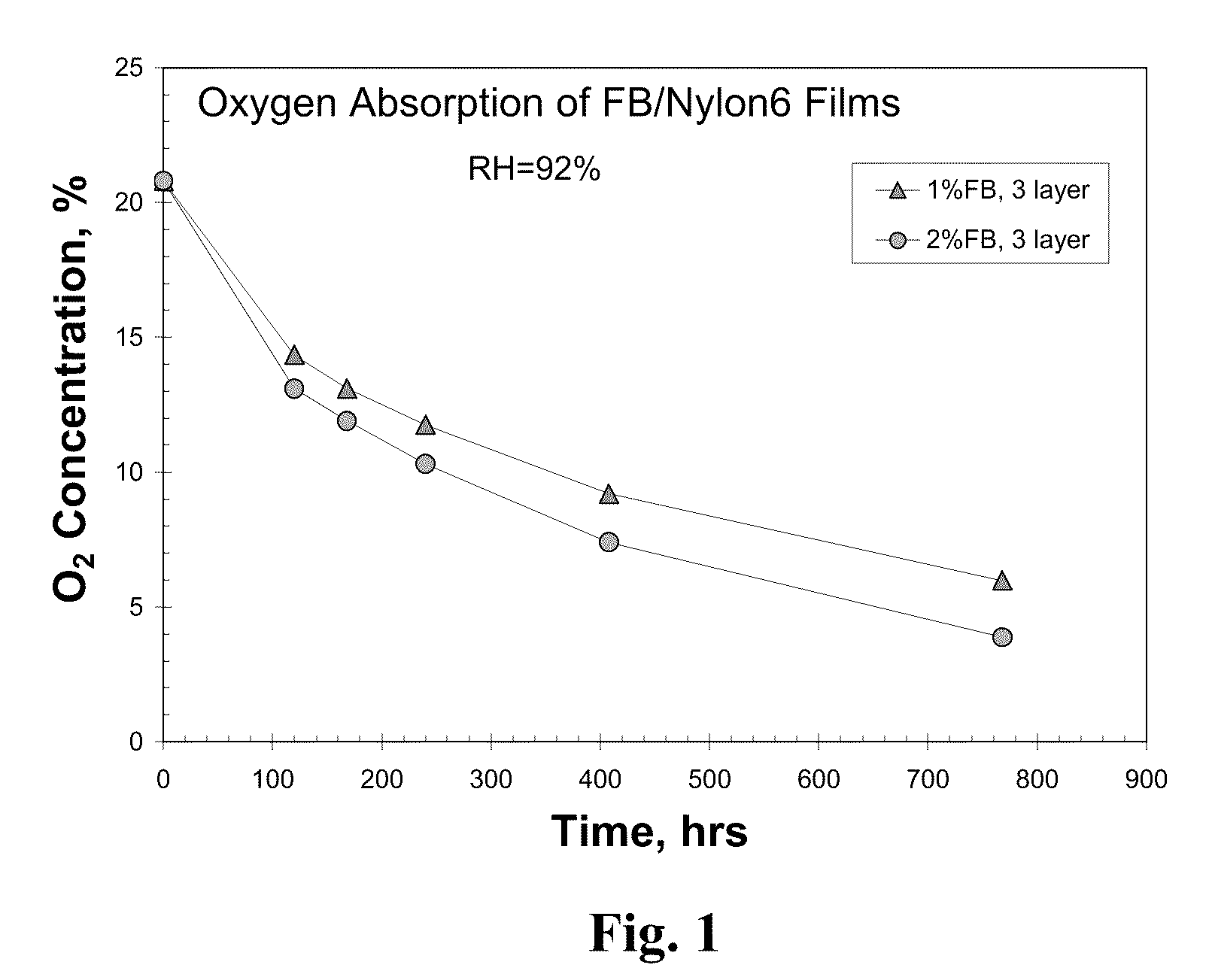

Oxygen scavenging films

InactiveUS20100255231A1Metal-working apparatusGlass/slag layered productsParticulatesAlkaline earth metal

A well dispersed oxygen scavenging particulate compounded in a polymer matrix. The oxygen scavenging formulation consists of iron powder with a mean particle sizes within 1-25 um and pre-coated with at least one or more activating and acidifying powdered compounds, usually in the form of solid organic and inorganic salts of alkaline and alkaline earth metals such as sodium chloride and sodium bisulfate. The pre-coated iron particulate is dispersed into a polymer resin by using a conventional melt processing method such as twin-screw extrusion. The oxygen scavenging compound is mixed with polymer pellets in the solid state prior to melting. The polymer resin pellets and the coated iron powder are preferably treated with a surfactant in the dry state to help dispersing the iron / salt powder with the resin pellets. The melt extruded compounds are pelletized and kept in the dry state to prevent premature activation.

Owner:MULTISORB TECH INC

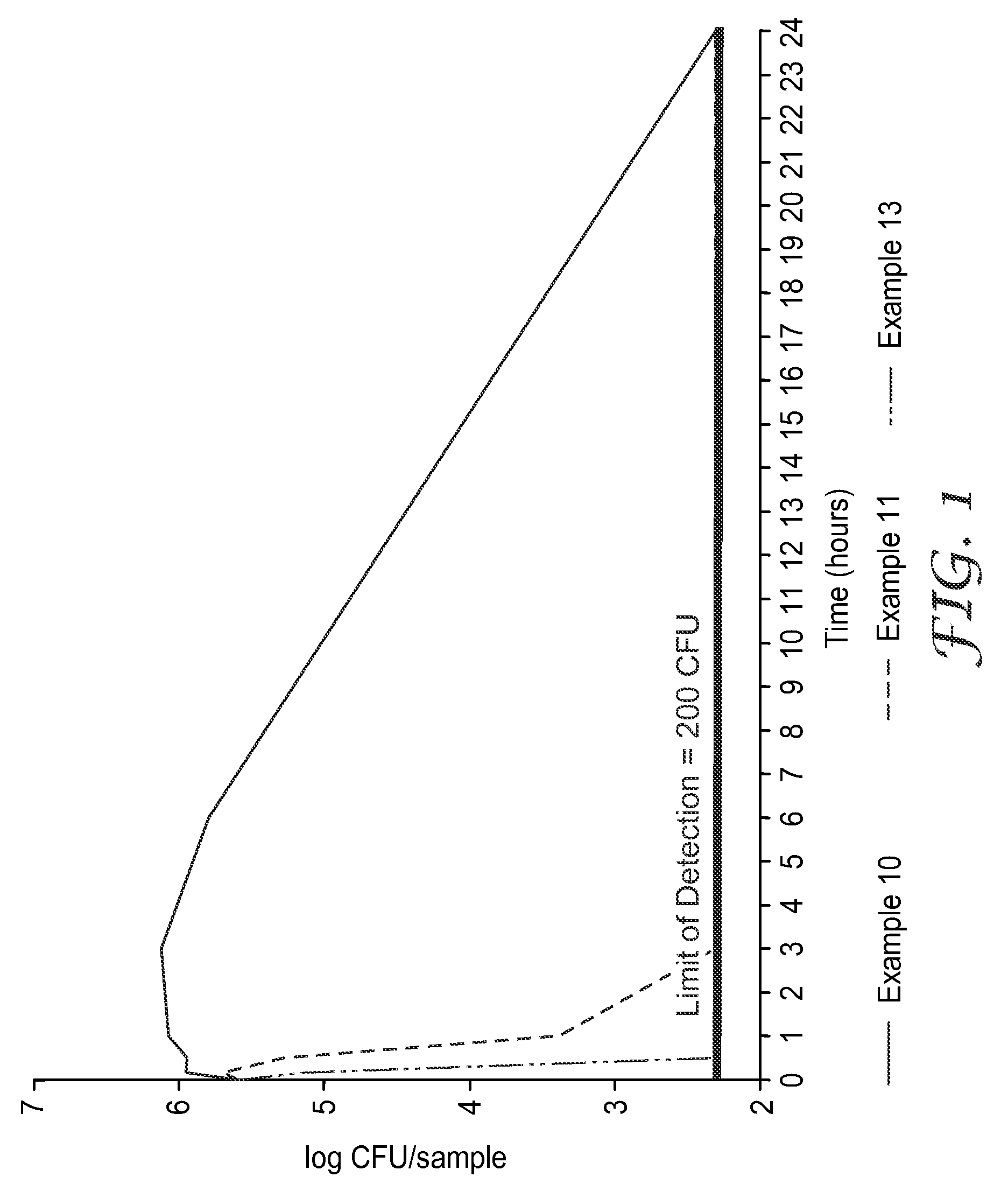

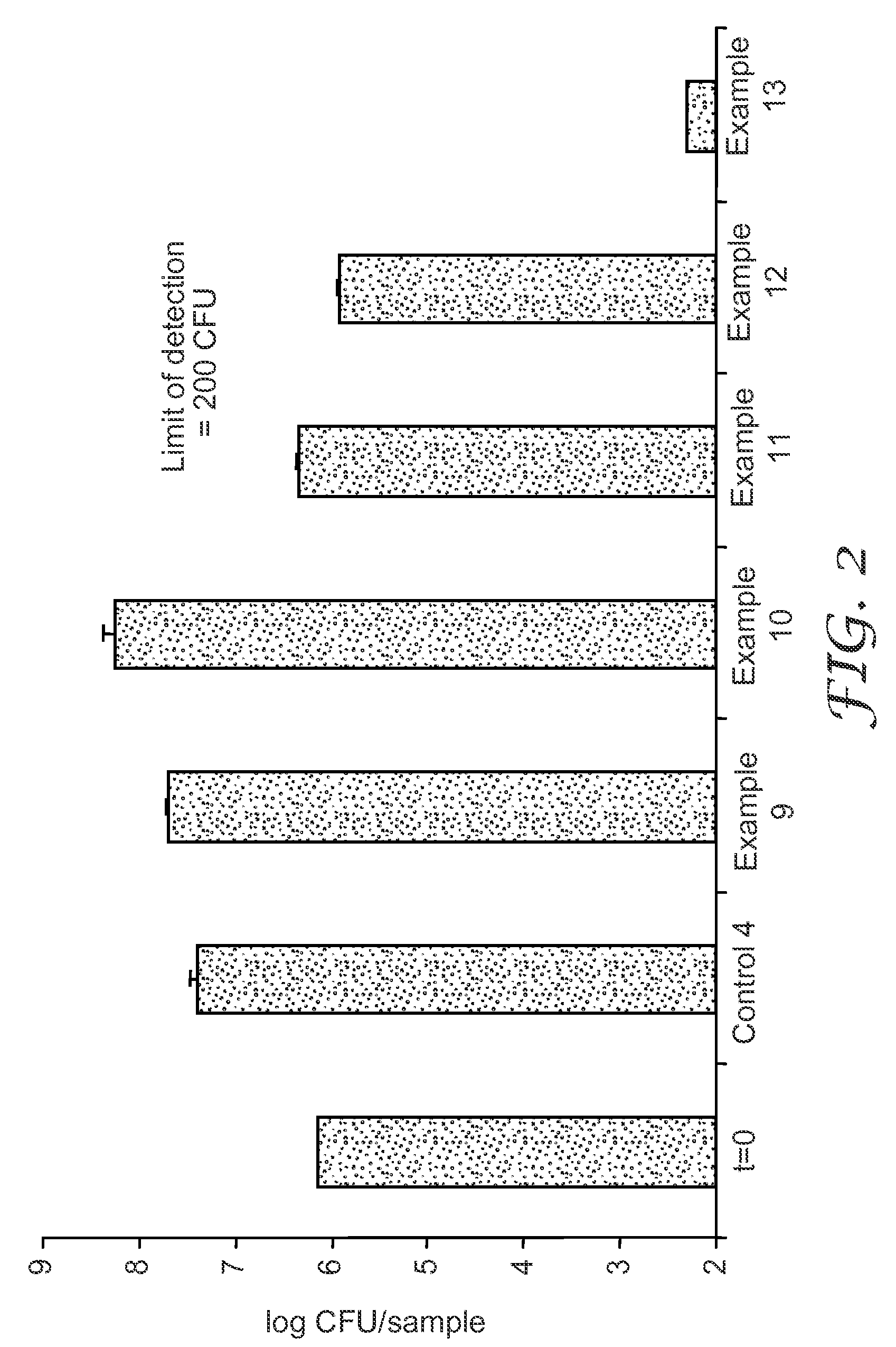

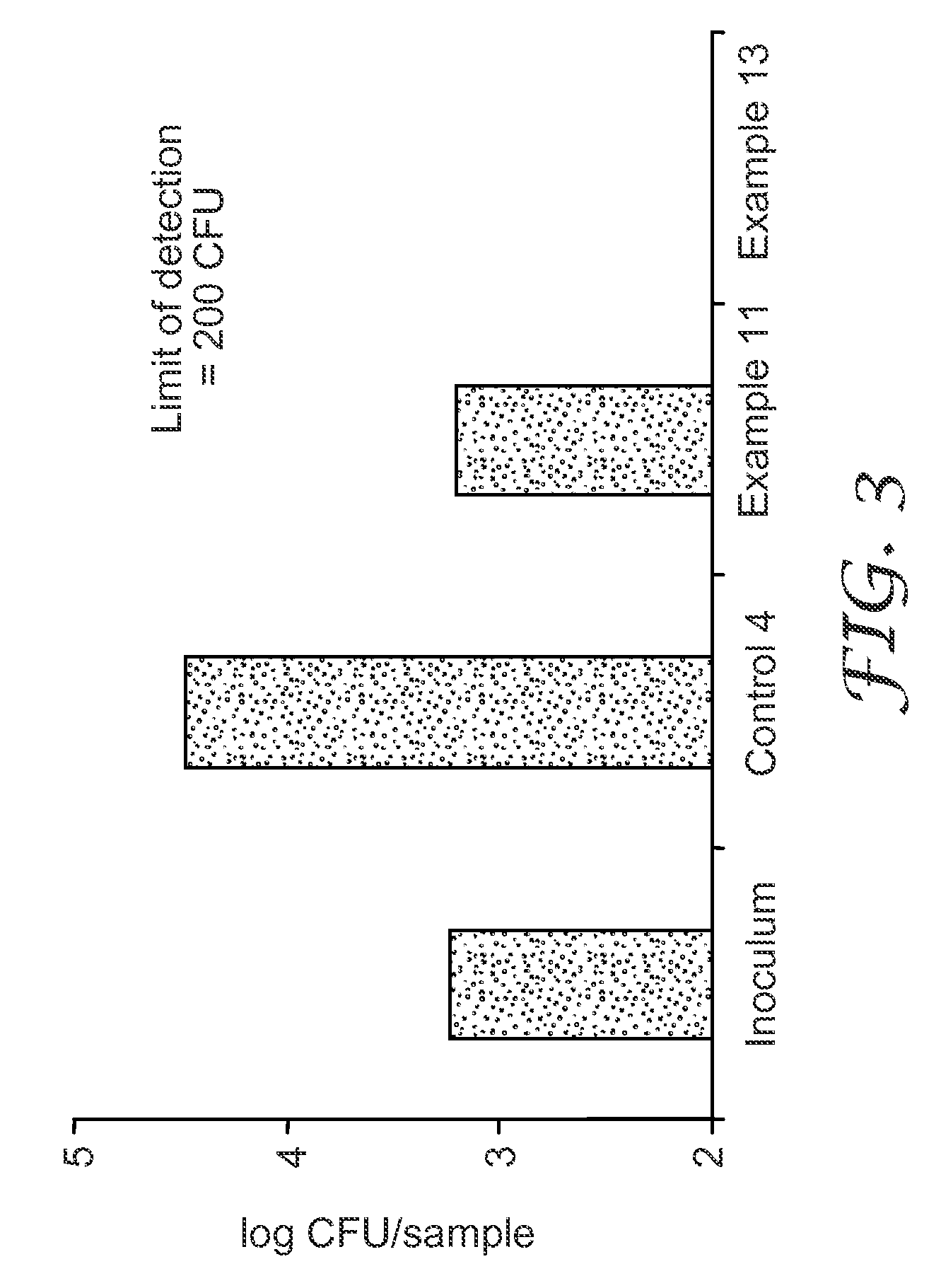

Antimicrobial disposable absorbent articles

InactiveUS20080200890A1Small amountImprove mechanical propertiesBiocideSurgeryPolyesterPersonal care

Disposable absorbent articles comprising an absorbent material and a degradable thermoplastic polymer composition comprising an aliphatic polyester and an antimicrobial composition. The antimicrobial composition includes an antimicrobial component and an enhancer component. The aliphatic polyester and antimicrobial composition are formed into webs by melt extrusion, such as nonwovens and films, that are incorporated into disposable absorbent articles, such as disposable infant diapers, adult incontinence articles, feminine hygiene articles such as sanitary napkins, panty liners and tampons, personal care wipes and household wipes to provide odor control, control of microbial growth, and control of microbial toxin production.

Owner:3M INNOVATIVE PROPERTIES CO

Water stable fibers and articles comprising starch, and methods of making the same

Water stable fibers and articles made therefrom are formed from a thermoplastic composition comprising destructured starch, polyhydric alcohol, triglyceride, and optionally acid. Processes for making water stable compositions may comprise melt extruding a mixture of destructured starch, polyhydric alcohol, triglyceride, and optionally acid, to form an extrudate, and heating the mixture, extrudate, or both to provide a water stable article.

Owner:THE PROCTER & GAMBLE COMPANY

Polypropylene composition useful for making solid state oriented film

Disclosed is a polypropylene composition useful for making solid state oriented film. The composition comprises two predominantly isotactic polypropylenes with the melting point temperature of one of the polypropylenes being substantially lower than the melting point temperature of the other. In one embodiment of the composition the higher melting point polypropylene is made by Ziegler-Natta catalysis, while the lower melting point polypropylene is made by metallocene catalysis. Compared to polypropylene with similar melt flow rate and made by Ziegler-Natta catalysis, and solid state oriented film thereof, the composition provides a better balance of elevated temperature draw characteristics and physical properties of oriented film made therefrom. Thus, at the same or lower elevated temperature yield stress, oriented film of the composition exhibits improved properties such as stiffness, elongation-at-break, dimensional stability, and oxygen barrier. Also disclosed is a method for the manufacture of oriented, flexible packaging film. In the method a cast sheet is melt extruded from the composition, and, after cooling until it is solid, the cast sheet is stretched to the desired extent of orientation at a temperature which the sheet does not break while being stretched, but below the Tm of the composition. The resulting film then is cooled to at least the crystallization temperature of the lower melting point polypropylene.

Owner:MONTELL TECH CO BV

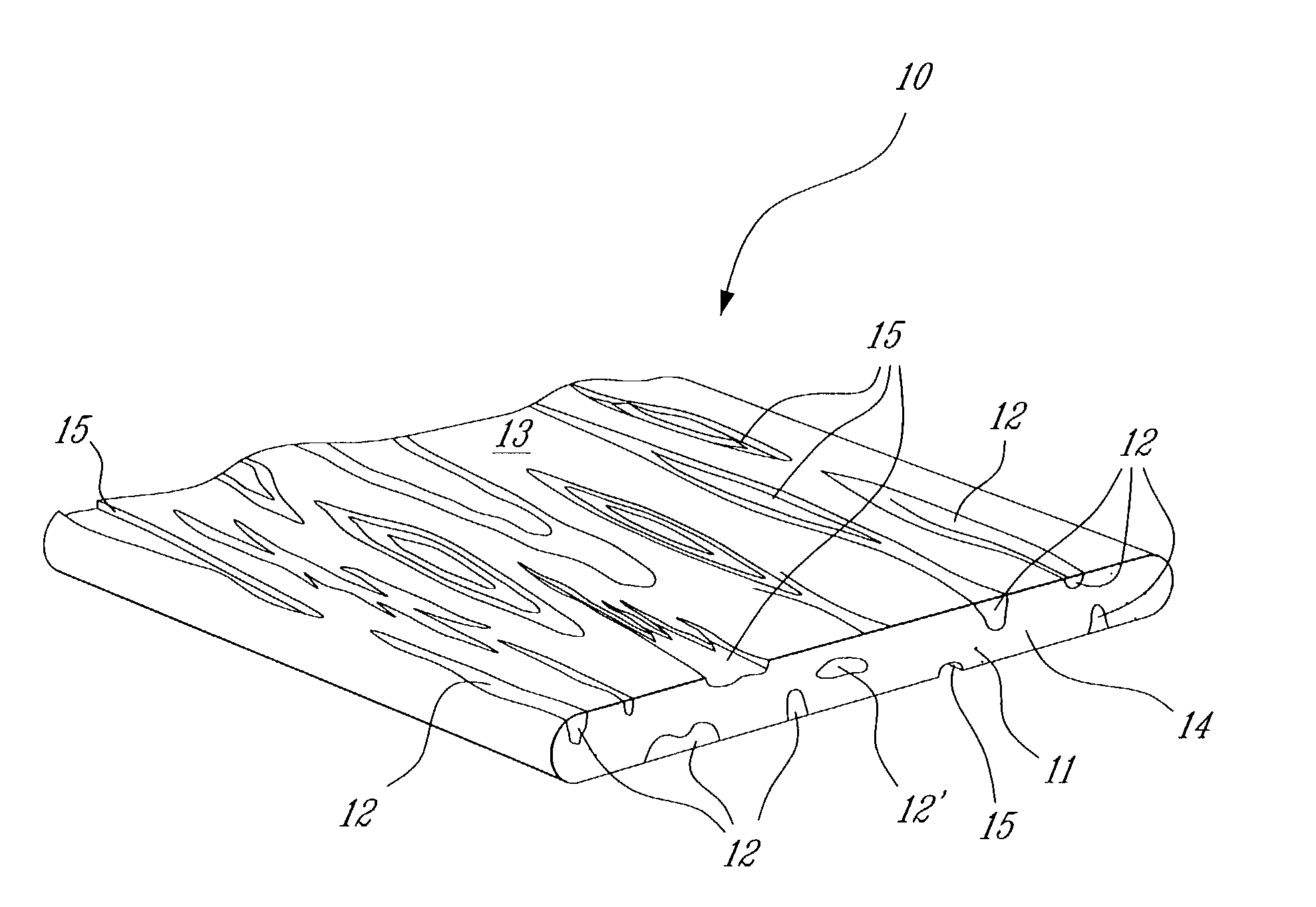

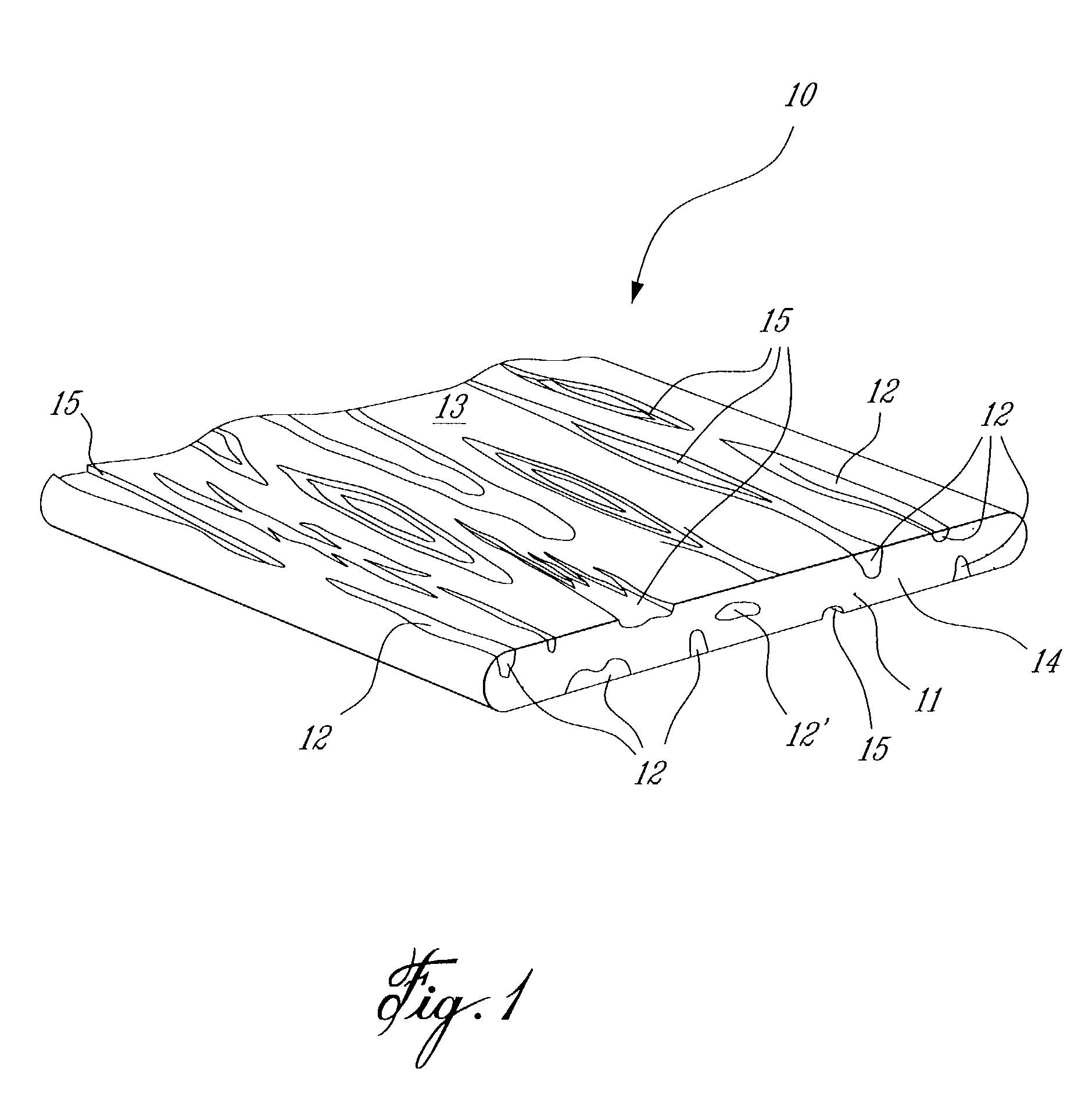

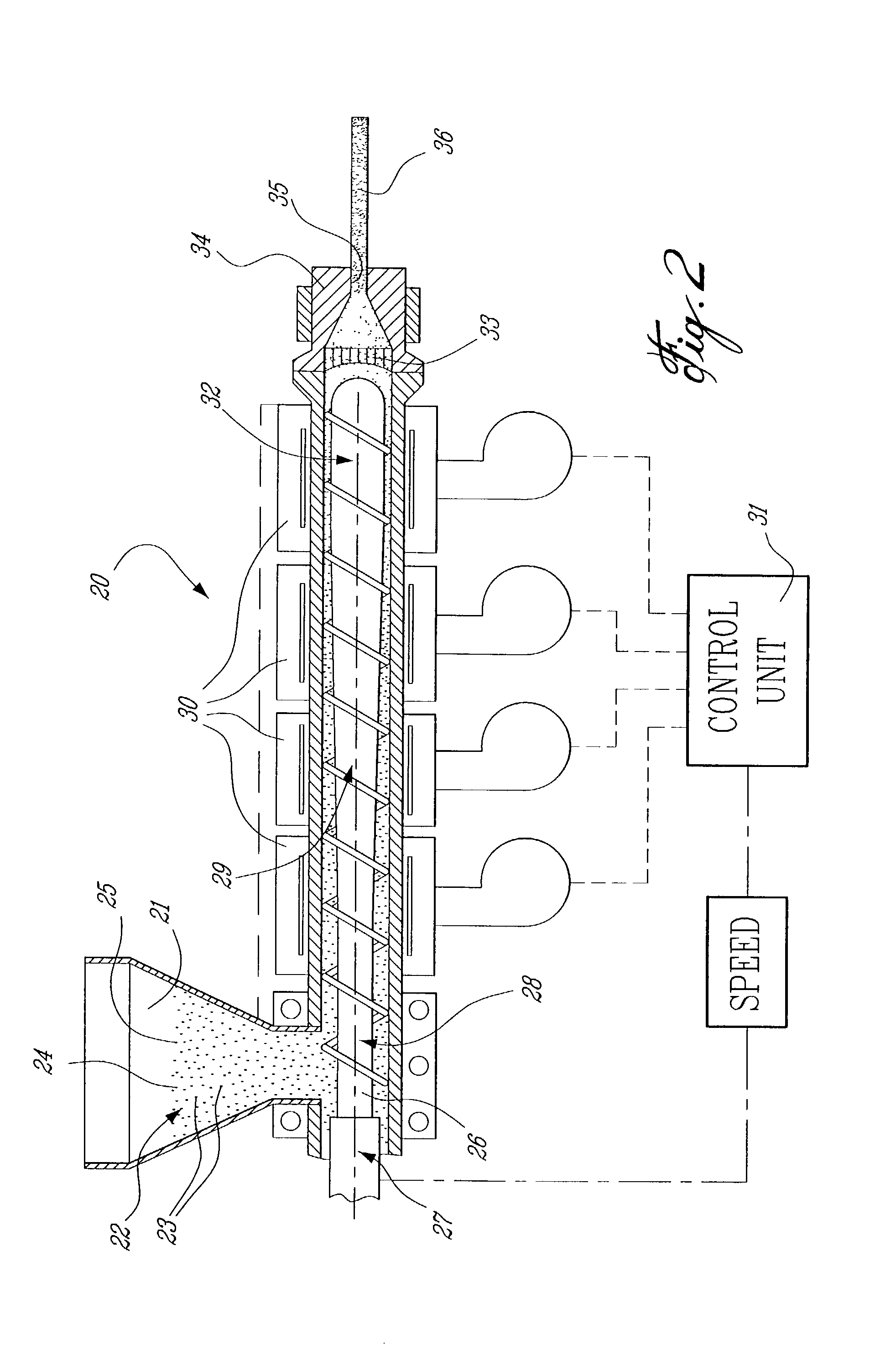

Extruded wood imitation component and process

An extruded wood imitation component and process is described. The component has a solid core containing coloured polymer material formed from a mix of coloured thermoplastic polymer with veins of contrasting coloured polymer throughout the core and on outer surfaces of the component simulating natural wood. In the extrusion process the mixture includes coloured polymer pellets of different colours and sizes which are mixed and melted in an extruder under controlled conditions to provide contrasting streaks of molten polymer throughout a molten extruded core and on outer surfaces of the core of the extrudate which exits the land of the die.

Owner:STAR PLAST HLDG

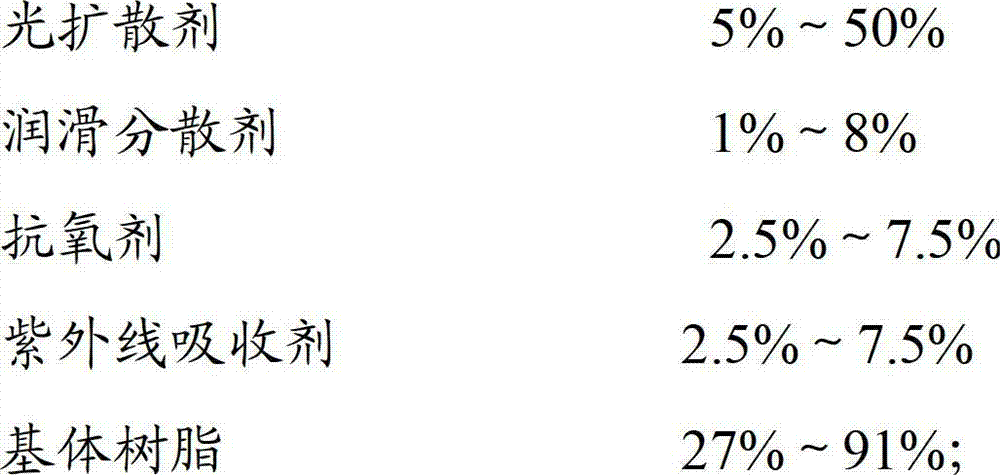

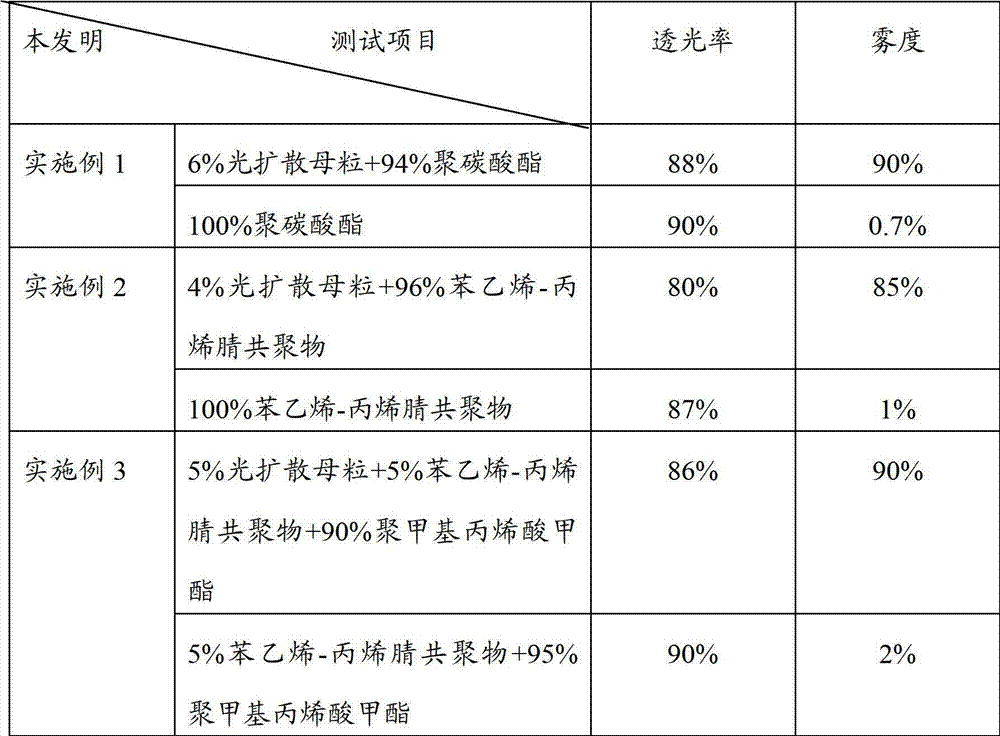

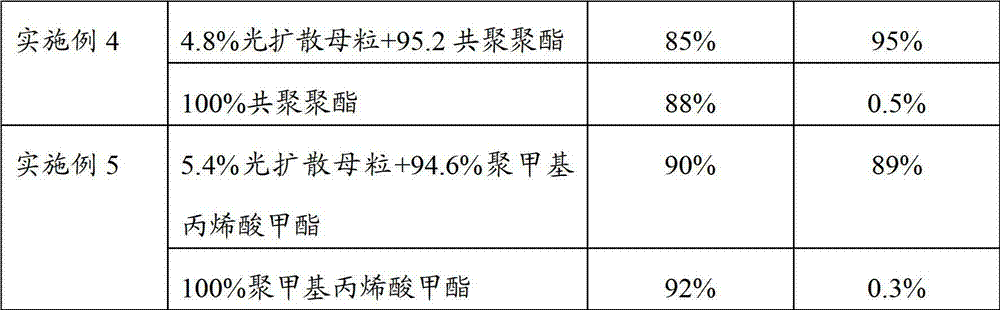

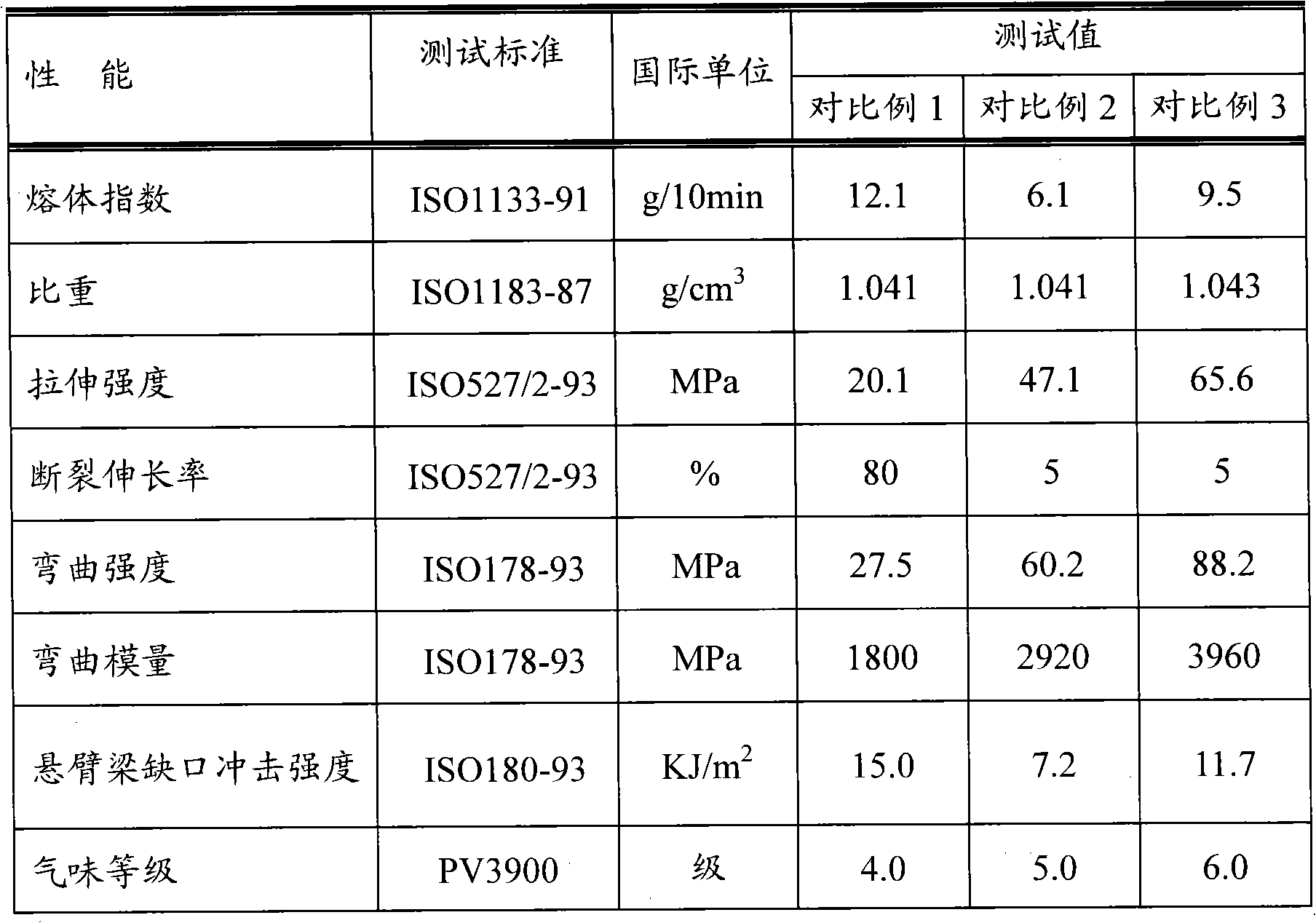

Light diffusion master batch for transparent plastics and preparation method thereof

ActiveCN103073867ASolve the problem of fragmentationAvoid the disadvantages of physical property degradationHigh concentrationAging resistance

The invention relates to the technical field of functional master batches, in particular to a light diffusion master batch for transparent plastics and a preparation method thereof. The light diffusion master batch comprises the following components in percentage by weight: 5-50% of light diffusant, 1-8% of lubrication dispersant, 2.5-7.5% of antioxidant, 2.5-7.5% of ultraviolet light absorber and 27-91% of matrix resin; after being mixed, the components are placed in an extruder for being molten and extruded; and the extruded materials are cooled, pelletized and dried to prepare the product of light diffusion master batch. The light diffusion master batch has stable properties, high transparency and high haze; and as the master batch contains a light stabilizing agent and a heat stabilizing agent with high concentrations, plastic products produced thereby have excellent ageing resistance, and are suitable for long-time use in locations of natural illumination or manual illumination.

Owner:东莞市普凯塑料科技有限公司

High thermal conducting composite material and preparation method thereof

InactiveCN101775213AImprove thermal conductivityEasy to processHeat-exchange elementsGlass fiberMixed materials

This invention relates to a high thermal conducting composite material for injecting or extrusion molding, which is prepared from the following components in parts by weight: 100 parts of plastic substrate, 30 to 100 parts of thermal conducting filler with a diameter between 50 to 300 microns, 0 to 50 parts of thermal conducting filler with a small diameter between 1 to 10 microns, 10 to 50 parts of fiberglass or silicon whisker, 0 to 5 parts of coupling agent and 0 to 8 parts of additive. The preparation of the high thermal conducting composite material comprises the following steps: adding the coupling agent to the thermal conducting filler with a small diameter and the thermal conducting filler with a big diameter respectively to do surface treatment for later use; putting the plastic substrate material, the processed thermal conducting filler with a big diameter and other additives to a super mixer to mix for 1 to 5 minutes; adding the processed thermal conducting filler with a small diameter into the super mixer to mix for 2 to 3 minutes; putting the mixed material into a feeding bucket of a twin screw extruder; adding the fiberglass into a glass fiber orifice; and pelleting after melting and extruding. The composite material prepared by the invention has good thermal conducting property and processing property.

Owner:黄晓峰

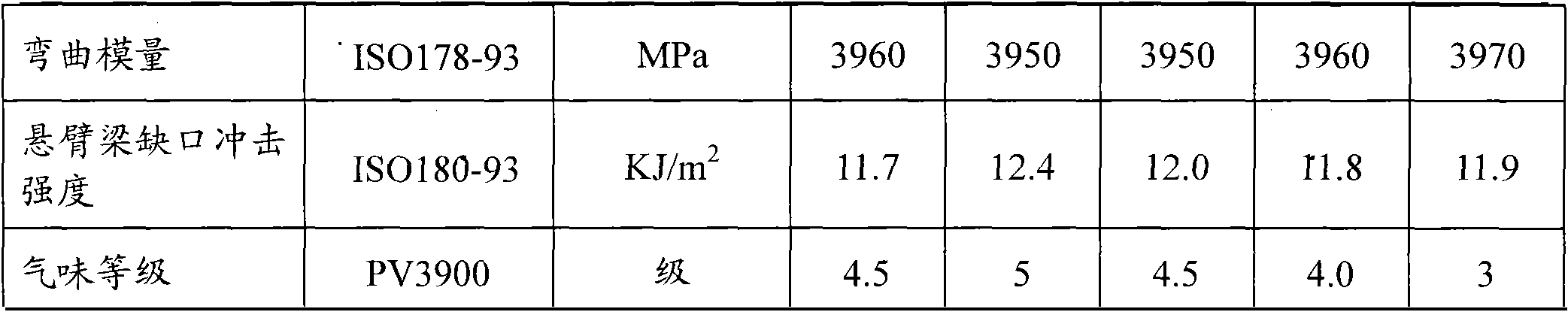

Glass fiber reinforced polypropylene composite material with low odor and preparation method thereof

The invention discloses a glass fiber reinforced polypropylene composite material with low odor and a preparation method thereof. The glass fiber reinforced polypropylene composite material comprises the following components: 32-91% of polypropylene resin, 5-50% of glass fiber, 2-8% of compatilizer, 1-6% of odor inhibitor and 1-4% of other auxiliary agent. The reinforced polypropylene material with low odor is prepared by fusing, extruding and granulating the components through a double screw extruder under the temperature control condition of 220-240 DEG C. The odor inhibitor comprises 30-50% of ricinoleic acid zinc, 20-40% of metal oxide and 10-30% of a clay mineral system. The odor of the glass fiber reinforced polypropylene composite material can be inhibited through combining a physical method and a chemical method. The glass fiber reinforced polypropylene composite material prepared by the method has excellent odor performance; the odor level can be reduced below level 3; the physical property of the glass fiber reinforced polypropylene composite material per se is not influenced after the odor inhibitor is added; and the application field of the glass fiber reinforced polypropylene material in vehicle interior trim parts and a part of home appliance parts can be widened.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +3

Composition for cushions, wound dressings and other skin-contacting products

A skin-contacting adhesive composition is described which has improved initial tack, long-term adhesion, water uptake and translucency characteristics and may be prepared by melt extrusion. Uses of these compositions are also described, for example, their use in wound dressings.

Owner:A V TOPCHIEV INST OF PETROCHEM +1

Talc powder filled polypropylene with high rigidity, high toughness and high scratch resistance and method for preparing same

The invention relates to high molecular processing field compound material, especially a high molecular organic sillicon elastomer filled with talcum powder agglomerate, with outstanding rigidity and resistance to heat and its preparing method, which can be applied in auto and toner field, such as pate of tenacity, door, plate of augxiliary tenacity, deconating stick and other polypropylene inside and outside automobile. The invention is comprised of high molecular organic sillicon elastomer and talcum powder agglomerate with high crystal and the percentages of each component are: high molecular organic sillicon elastomer 60-90, talcum powder agglomerate 10-40, scratch 3-10, dust 0.1-1.0, of talcum powder agglomerate 0.2-1.5, 0.05-1.0. The preparing method is: mix the high molecular organic sillicon elastomer, talcum powder agglomerate, dust, of talcum powder agglomerate and in, then place then into to form the particles. Its advantage is that, keeping the tenacity of polypropylene, the rigidity has also been increased, balancing its tenacity and rigidity, as well as its resistance to scratch, it can satisfy the requirements of elements in auto; besides, it also reduces dust, benefiting for protecting the work environment.

Owner:SHANGHAI PRET COMPOSITES

Nonwoven fabric for cylindrical bag filter, process for producing the same, and cylindrical bag filter therefrom

InactiveUS20100180558A1Excellent characteristicsImprove rigidityElectric discharge heatingDispersed particle filtrationEngineeringNonwoven fabric

The present invention provides a nonwoven fabric for cylindrical bag filter, wherein a long-fiber nonwoven fabric made of a synthetic fiber is used and the long-fiber nonwoven fabric is a long-fiber nonwoven fabric which is made of a thermoplastic continuous filament and is partially thermocompression-bonded. It is preferable that the circular arc flexural rigidity per basis weight is 0.050 to 1.000 ((cN / 2 cm) / (g / m2)) and the air permeation rate per basis weight is 0.010 to 0.500 ((cc / cm2 / sec) / (g / m2)). Further, there is provided a method for producing a nonwoven fabric for cylindrical bag filter including the steps of: melt-extruding a thermoplastic polymer through a spinneret; sucking and drawing the extrudate with an air sucker to form a thermoplastic continuous filament; allowing the filament to be subjected to electrification opening and to be piled on a moving collection surface to form a fiber web; and allowing the fiber web to be subjected to pressure welding treatment with a flat roll and partially thermocompression-bonding the fiber web with hot embossing rolls to form a long-fiber nonwoven fabric.

Owner:TORAY IND INC

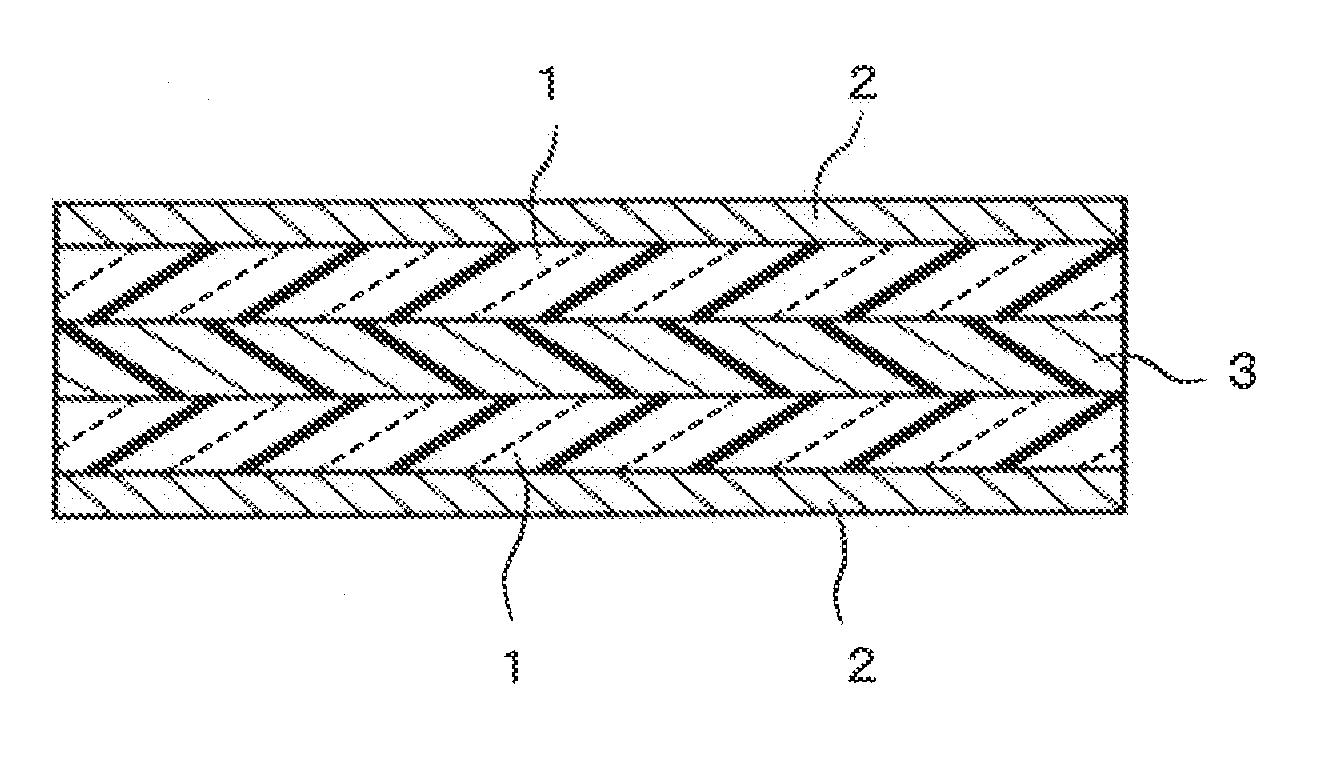

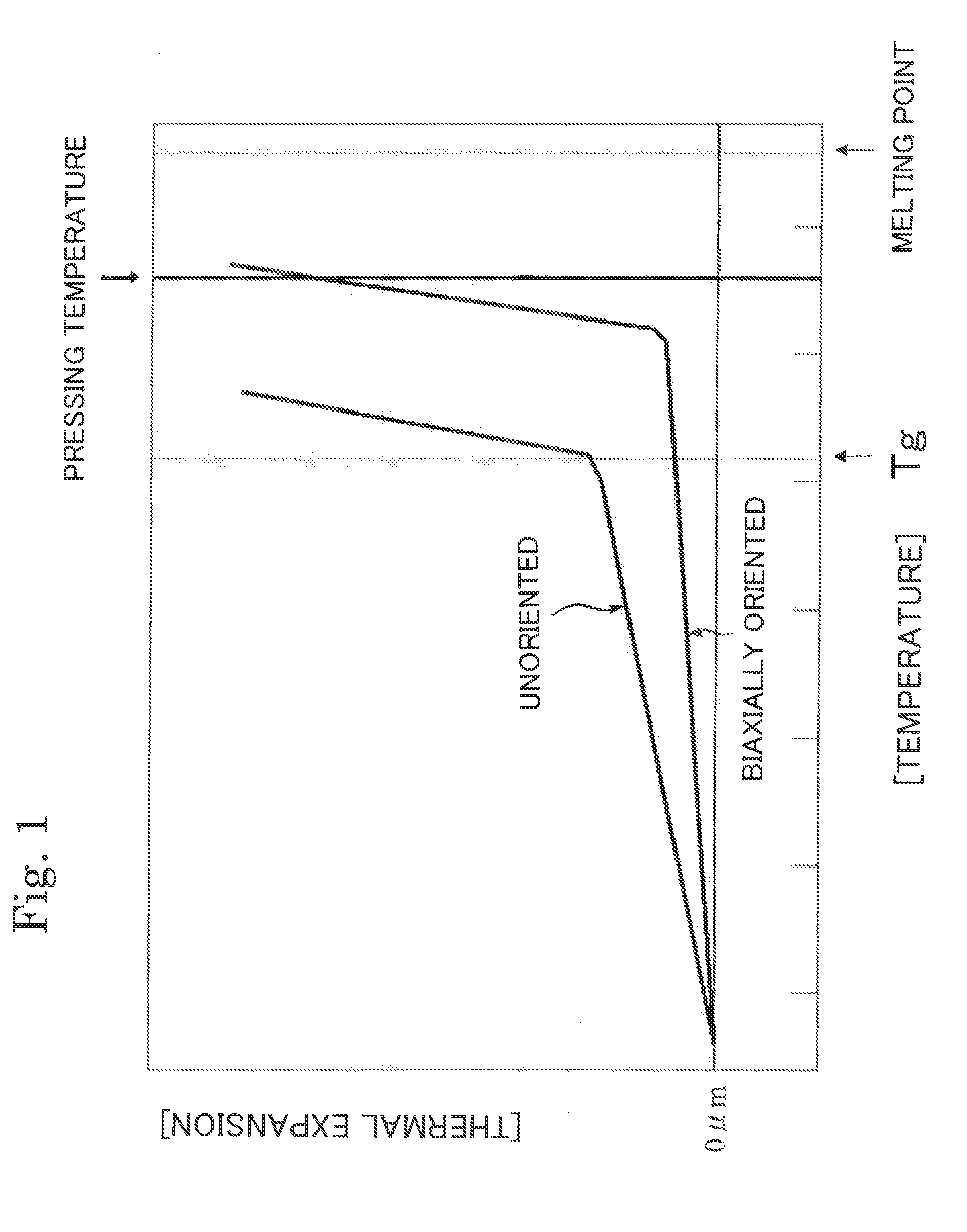

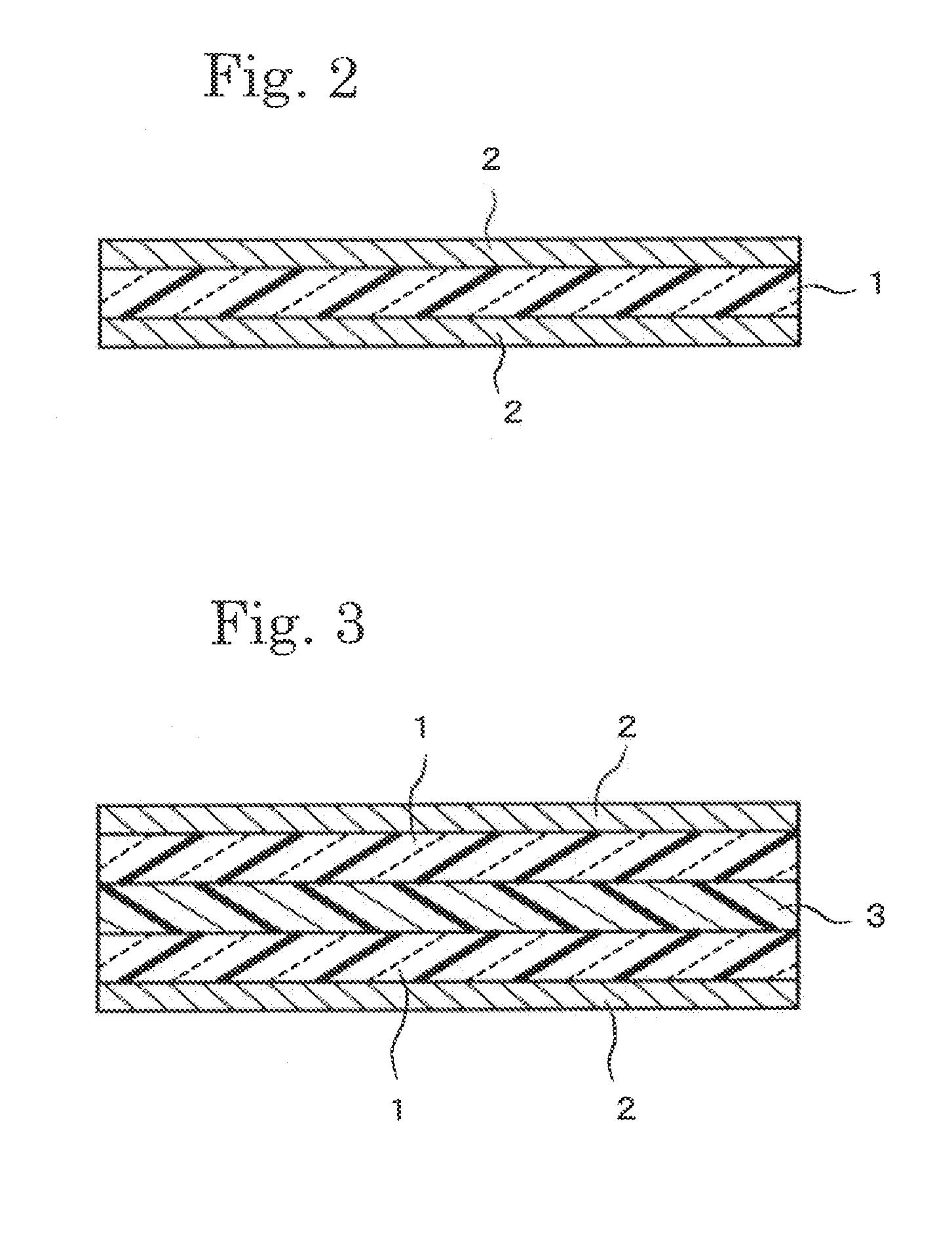

Flexible laminate having thermoplastic polyimide layer and method for manufacturing the same

InactiveUS20090035591A1Excellent heat resistance and electrical property and mechanical strengthEasy to manufactureSynthetic resin layered productsLaminationElectrical conductorHeat resistance

In a flexible laminate containing a metal foil layer / a thermoplastic polyimide layer or / and a conductor circuit layer / a thermoplastic polyimide layer, the metal foil layer or the conductor circuit layer is bonded to at least one side of the thermoplastic polyimide layer. The thermoplastic polyimide layer is formed from a thermoplastic polyimide resin film or sheet produced by melt extrusion of a thermoplastic polyimide resin. Alternatively, the thermoplastic polyimide layer is formed from a biaxially oriented thermoplastic polyimide resin film or sheet. Such a flexible laminate can be easily manufactured by a lamination method which comprises bonding a thermoplastic polyimide resin film (1) to a metal foil (2) or a conductive circuit layer (4) by heating under pressure, and has excellent heat resistance, electrical properties and mechanical strength inherent in a polyimide. When the biaxially oriented thermoplastic polyimide resin film or sheet is used, the flexible laminate can be improved in dimensional stability and resistance to soldering heat.

Owner:KURASHIKI BOSEKI KK +1

Low-odor low-VOC (volatile organic compound)-content styrene polymer composition and preparation method thereof

ActiveCN103044793AOvercome the shortcomings of not being able to directly add to raw materialsWon't overflowPolymer scienceAntioxidant

The invention discloses a low-odor low-VOC (volatile organic compound)-content styrene polymer composition and a preparation method thereof. The composition is prepared from the following components in percentage by weight: 70-99% of styrene polymer, 0.5-29% of strippant master batch and 0.01-1% of antioxidant. The preparation method comprises the following steps: preparing a strippant master batch, mixing the components in a high-speed mixer, adding the mixture into a screw extruder, carrying out melt extrusion, and granulating. The invention has the advantages of simple production technique and lower production cost, and effectively lowers the order and VOC content of the styrene polymer; and the prepared styrene polymer composition can be used in the field of materials with strict environmental requirements in packaging materials, daily necessities, home appliances, OA, toys, sports equipment, shoe materials, cables, instruments and meters, electronic components and equipment, construction materials and automobile materials.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +2

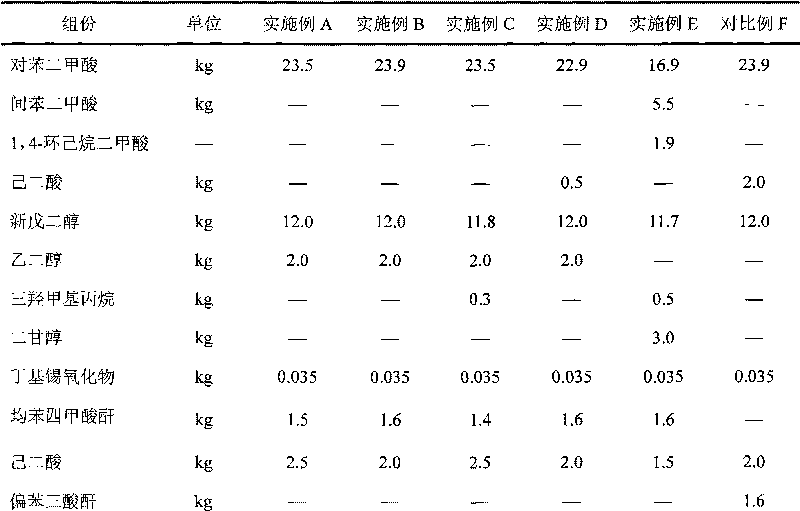

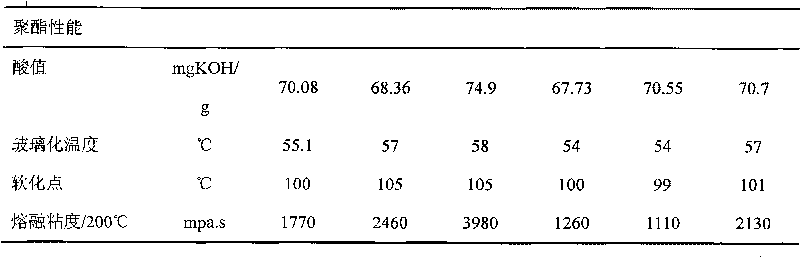

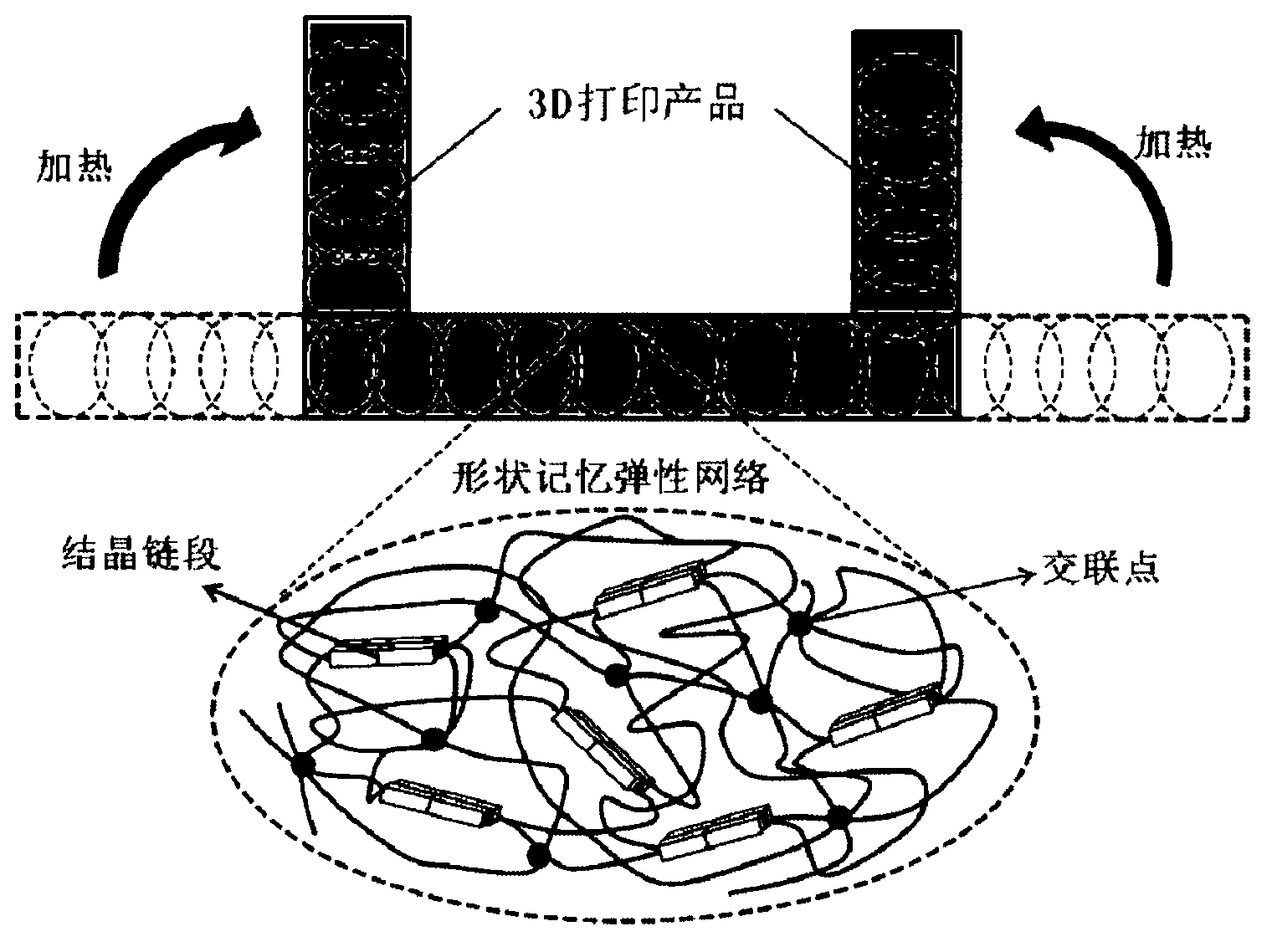

Low-temperature cured terminal carboxyl polyester resin for mixed powder coating and preparation method thereof

ActiveCN101735432ASuitable glass transition temperatureGood storage stabilityPowdery paintsEpoxy resin coatingsHybrid typeEpoxy

The invention discloses a low-temperature cured terminal carboxyl polyester resin for mixed powder coating. The polyester resin is prepared by performing melt polycondensation reaction on the following components in percentage by weight: 25 to 45 percent of polyalcohol, 35 to 65 percent of aromatic polyatomic acid, 0 to 10 percent of fat polyatomic acid, 0 to 2 percent of branching agent, 6 to 15 percent of acid hydrolysis agent, and 0.01 to 0.15 percent of esterification catalyst. The invention also discloses a method for preparing the low-temperature cured terminal carboxyl polyester resin. The prepared polyester resin has the characteristics of proper glass-transition temperature, softening point, good storage stability, and the like; the polyester resin, epoxy resin, filler and assistant in a certain proportion are mixed, and the mixture is prepared into powder through melt extrusion mixing, cooling, crushing and sieving; and the prepared powder can be cured at the temperature of 160 DEG C, and has the advantages of excellent leveling performance, good impact performance, and the like.

Owner:GUANGZHOU KINTE IND

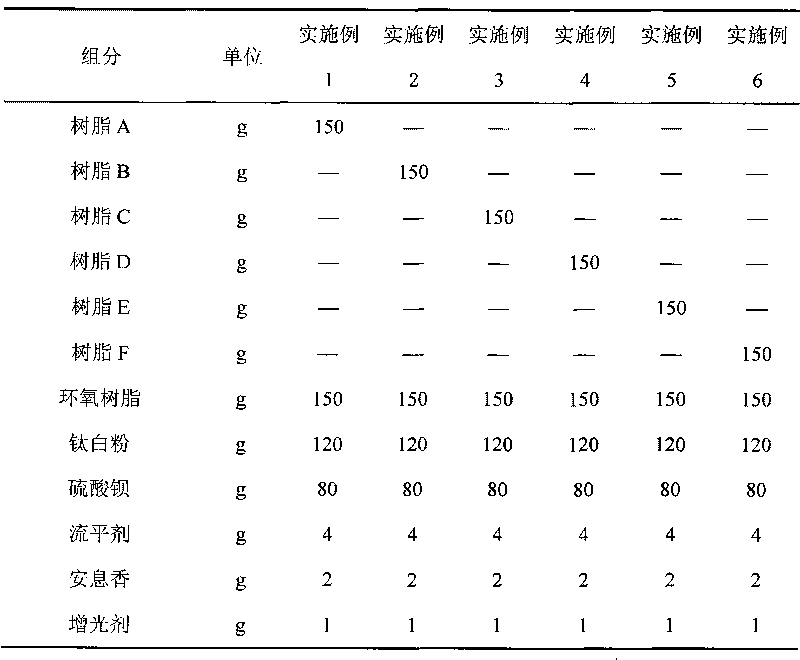

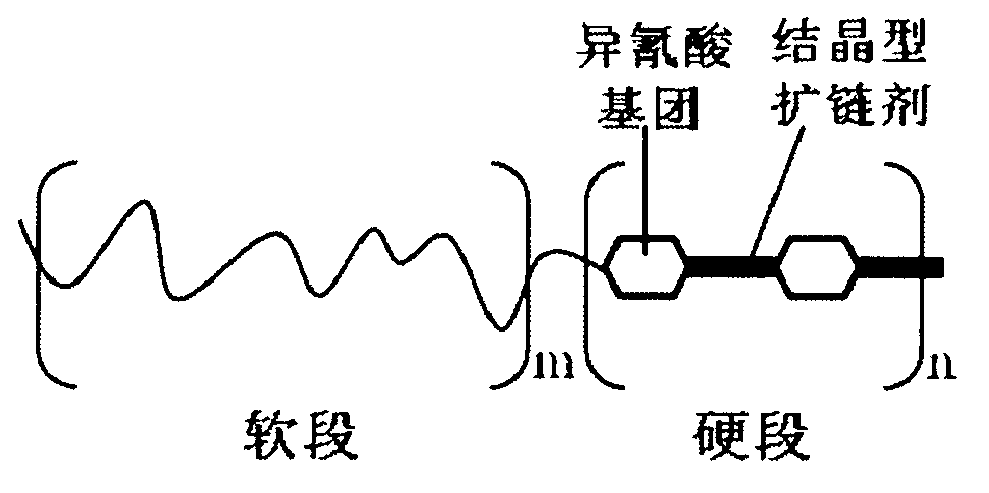

Rapid prototyping shape memory high polymer material and preparation method and application thereof

ActiveCN103160948AImprove cooling forming effectGuaranteed moldingMonocomponent synthetic polymer artificial filamentPolyesterCross-link

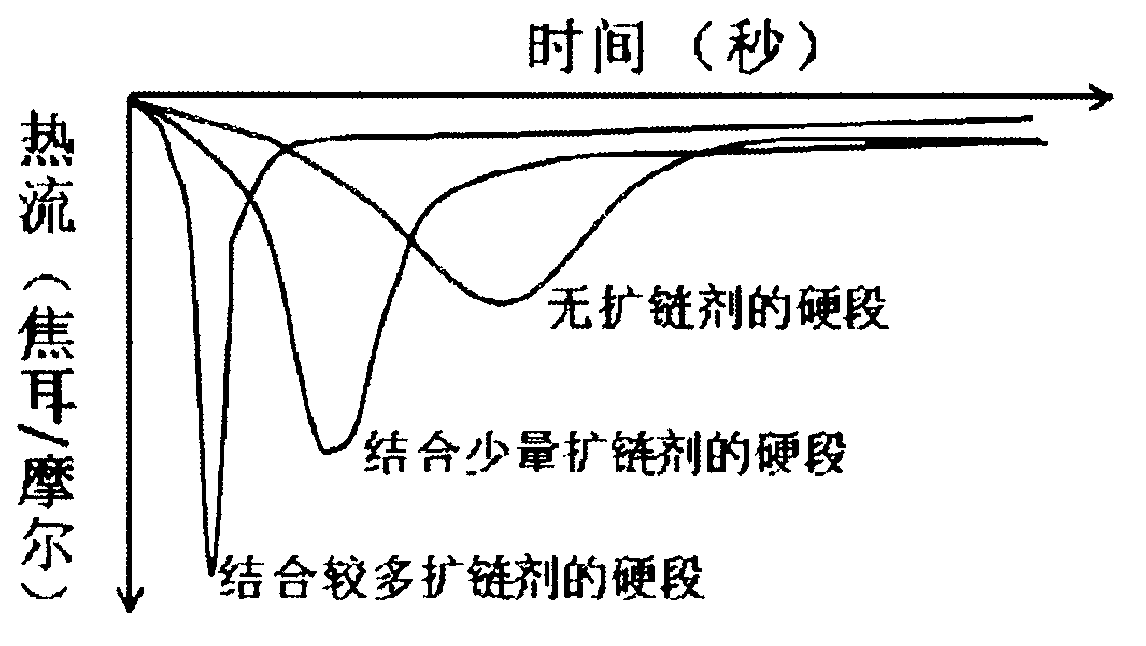

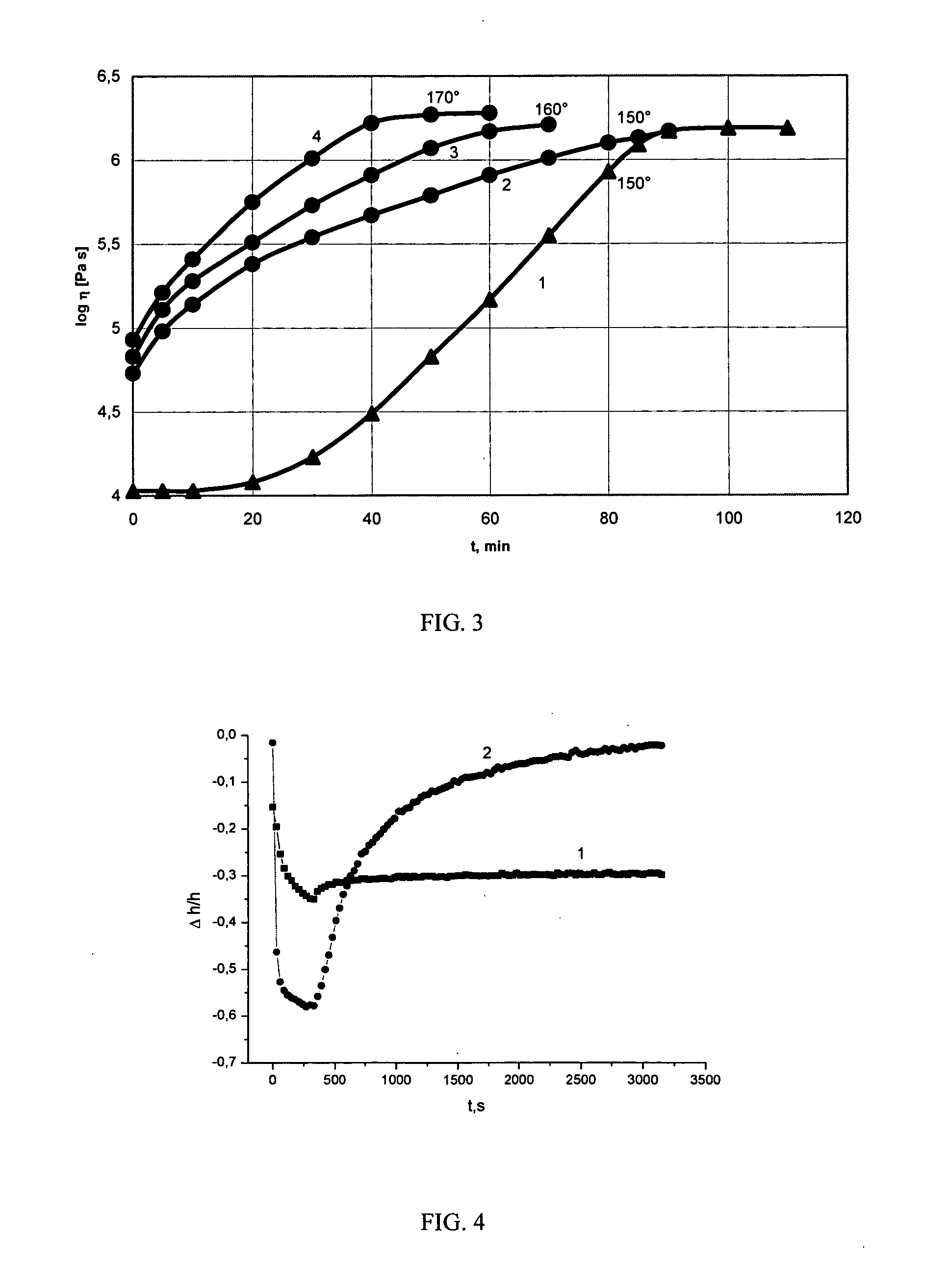

The invention discloses a rapid prototyping shape memory high polymer material and a preparation method and application thereof. The high polymer material comprises a physical cross-linking hard-segment structure which can be rapidly cooled and formed and a high polymer soft-segment structure which can be fixed and temporarily deformed, wherein the hard-segment structure is formed by combining diisocyanate and a crystallization type chain extender; the soft-segment structure is formed by combining polyester type or polyether type polyhydric alcohol with the crystallization type chain extender; and the molar ratio of hydroxyl in the polyhydric alcohol to diisocyanate group in the diisocyanate is 1:2-1:5. The material is functional, and the printed 3D product has the capability of self-deforming and restoring the time dimensionality; the material has good cooling forming performance, and the hard-segment part can rapidly form a physical cross-linking point in the temperature difference range of melt extrusion; the contained stationary phase and restoration phase double components are wide in material selection and low in price, a preparation process is simple, the defects that synthetic raw materials are expensive, the process is complex and the like in the prior art can be overcome, and the material is suitable for large-scale production.

Owner:JF POLYMERS (SUZHOU) CO LTD

Composition for cushions, wounds dressings and other skin-contacting products

A skin-contacting adhesive composition is described which has improved initial tack, long-term adhesion, water uptake and translucency characteristics and may be prepared by melt extrusion. Uses of these compositions are also described, for example, their use in wound dressings, adhesive cushions, and transdermal drug delivery devices.

Owner:CORIUM LLC

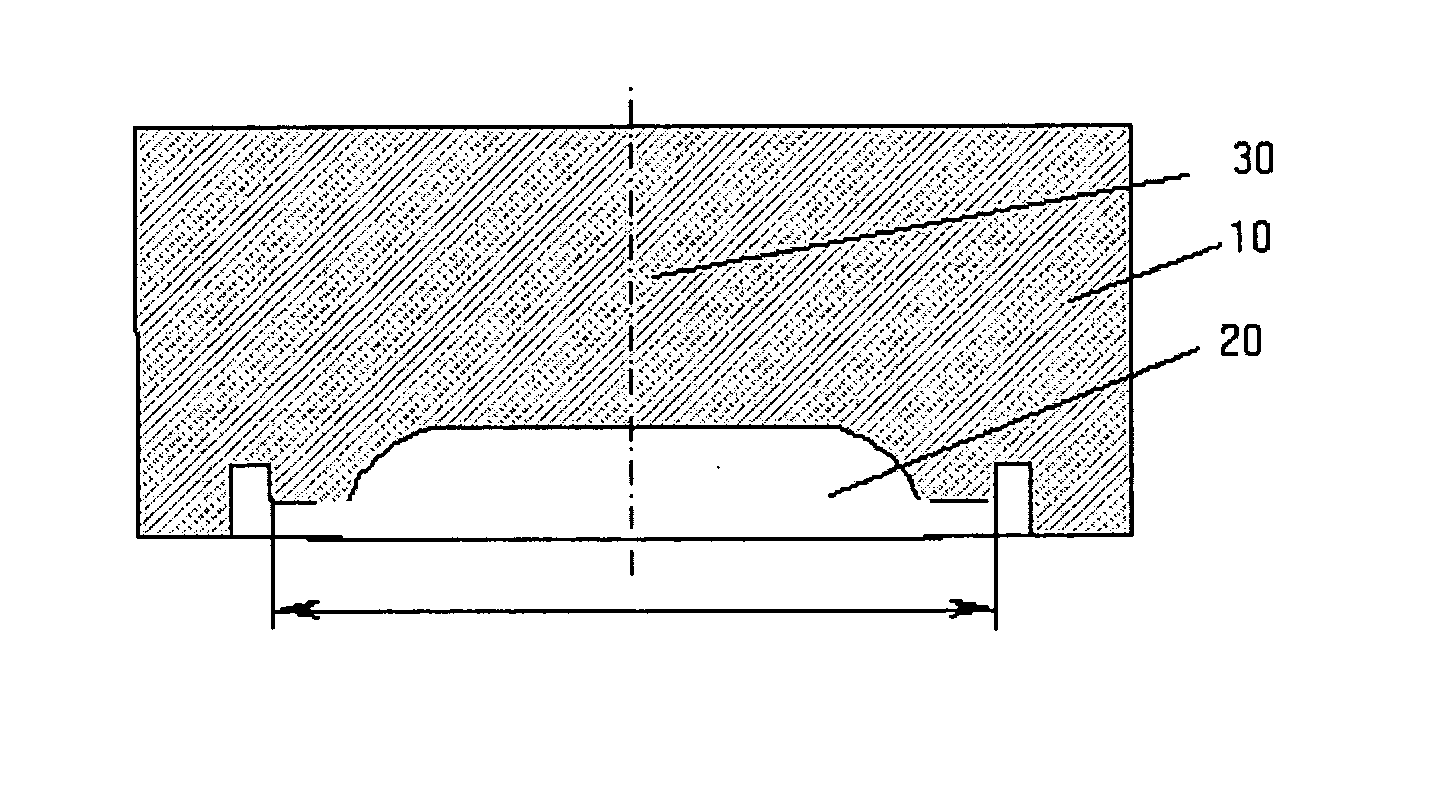

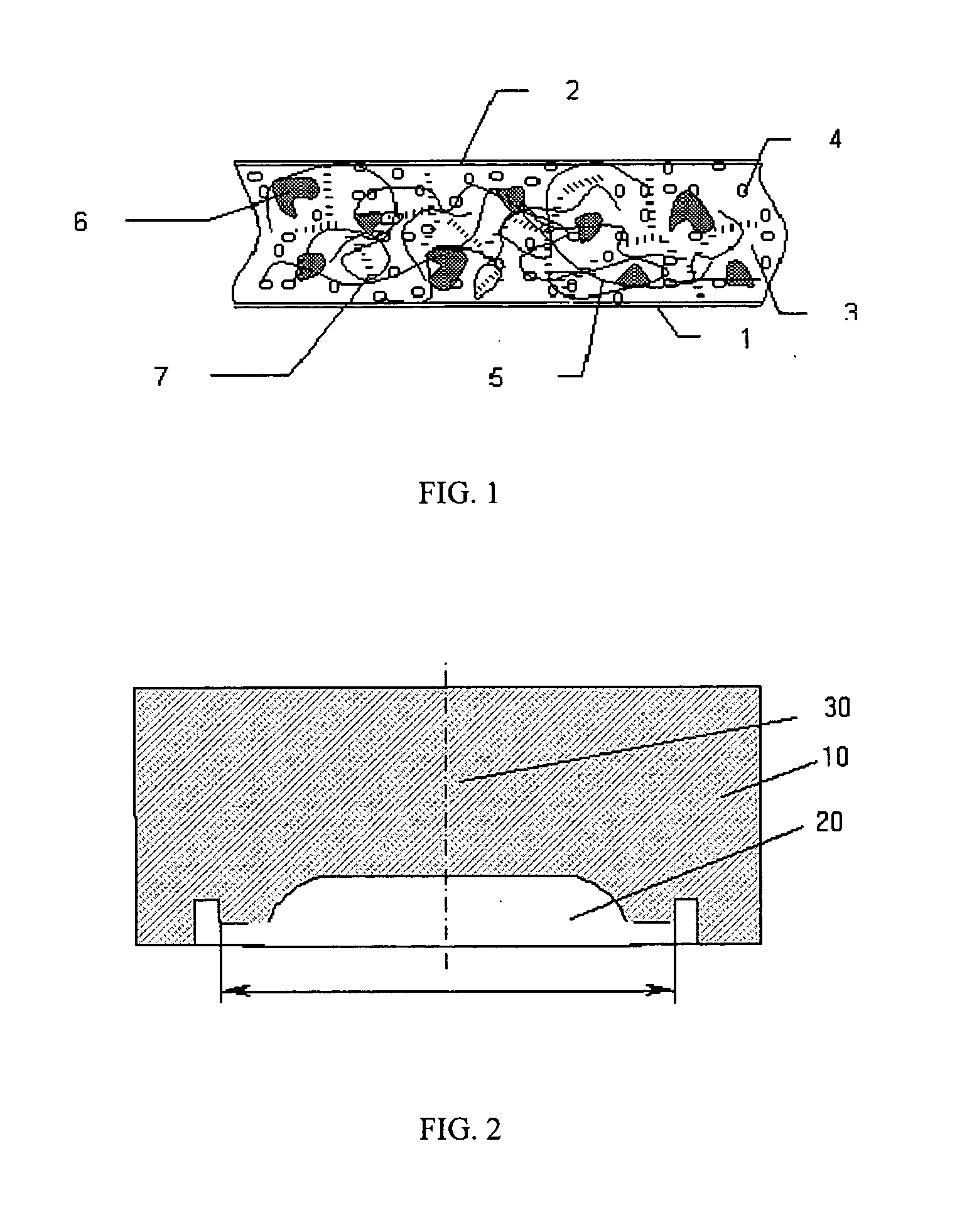

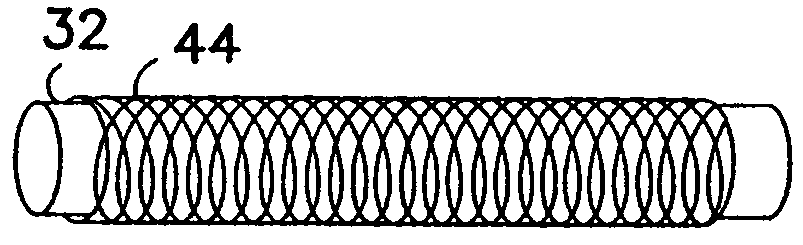

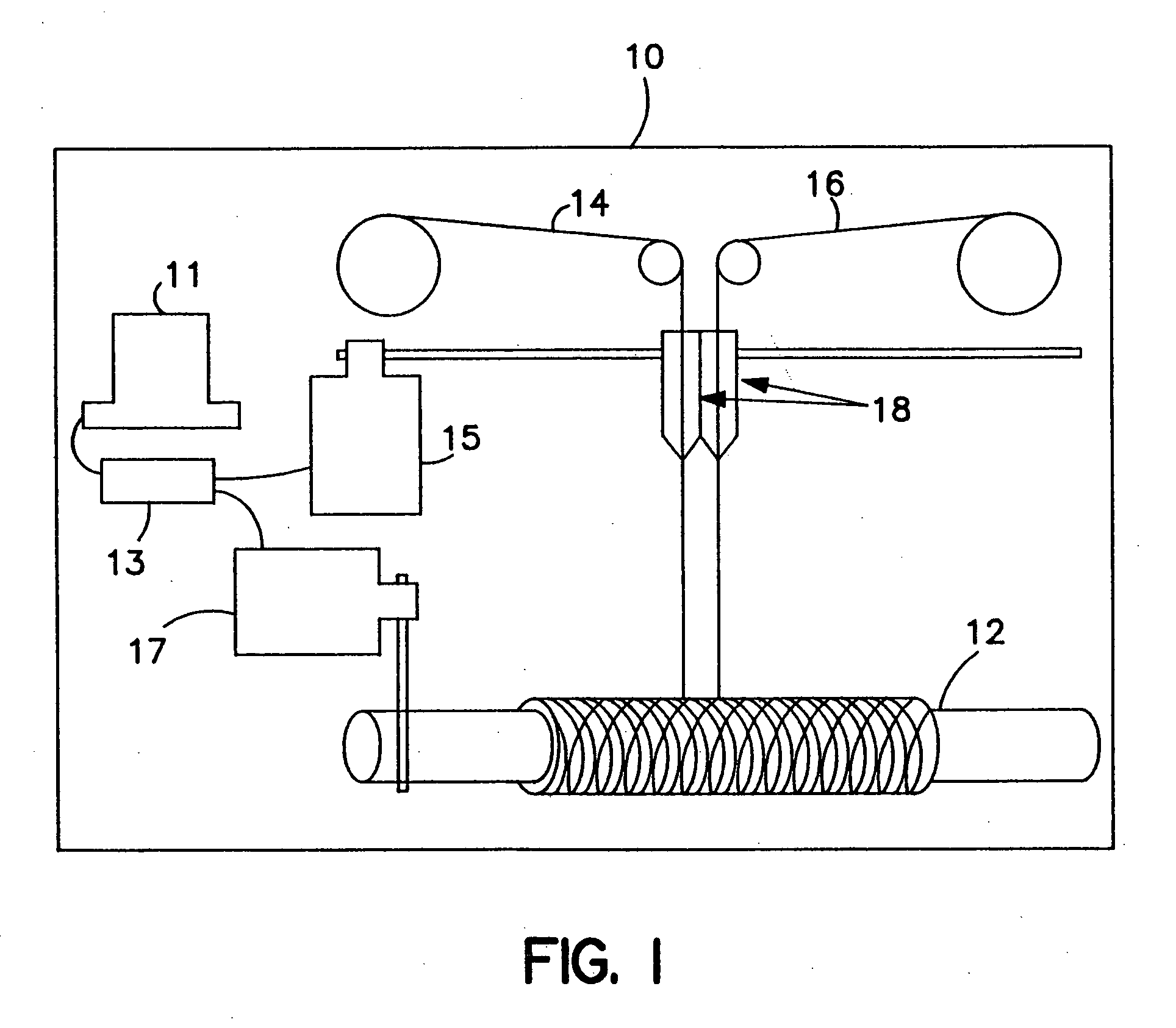

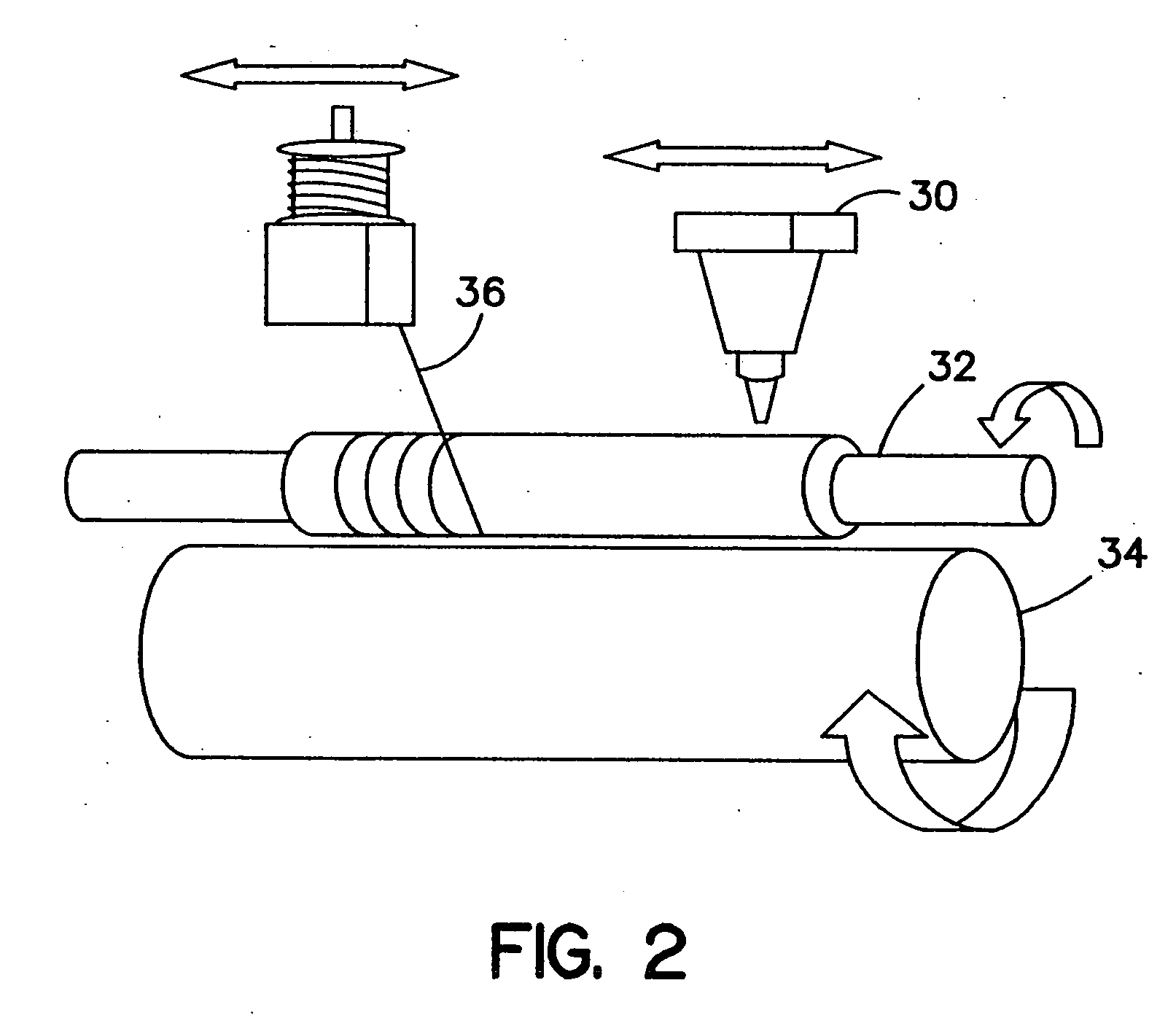

Porous synthetic vascular grafts with oriented ingrowth channels

Owner:MEDTRONIC INC

Ultraviolet crosslinked expansion type flame-retardant polyolefin cable insulation sheath material and preparation thereof

ActiveCN101481475AAdd lessHigh flame retardant efficiencyPlastic/resin/waxes insulatorsInsulated cablesPolyolefinProcedure Agents

The invention discloses an insulating and sheathing material of ultraviolet light crosslinking expanding type phosphorus nitrogen flaming resistance polyolefine cables and a preparation method thereof. The invention is characterized in that polyethylene / PEMA and / or ethylene vinyl acetate or maleic anhydride grafted ethylene vinyl acetate or acid amide grafted ethylene vinyl acetate copolymer are taken as base, added with expanding type phosphorus nitrogen halogen-free flame retardants, light trigger, polyfunctional group cross linker and chemical inhibitor and matched with flaming retardant synergistic agent, antismoke agent and processing aid, and then squeezed out and pelleted into photo-crosslinking flame retardant cable materials; and then the flame retardant cable materials are melted and extruded on a cable conductor wire core and clad into an insulating layer and a sheathing layer; hereupon the ultraviolet light irradiation crosslinking is carried on the insulating layer or the sheathing layer. Via detecting, the oxygen index of the insulating layer or the sheathing layer is larger than 30%, the vertical flaming experiment passes through UL-94 V0 level, the tensile strength is larger than 12Mpa, the elongation at break is larger than 350%, and the electric volume resistivity is larger than 8*10 omega.cm.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

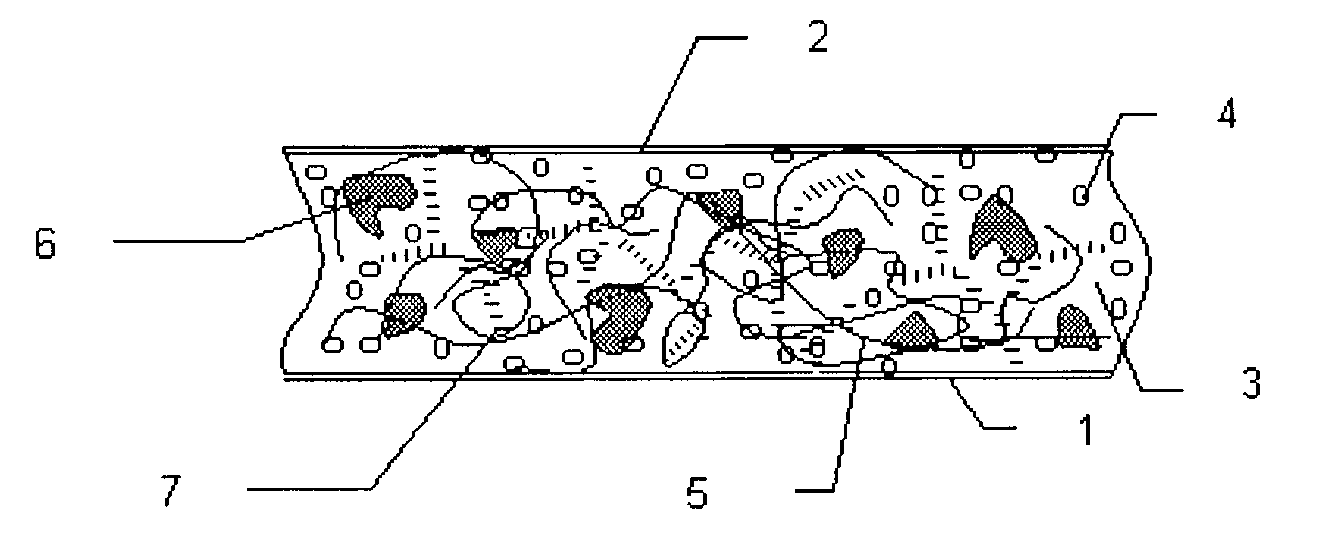

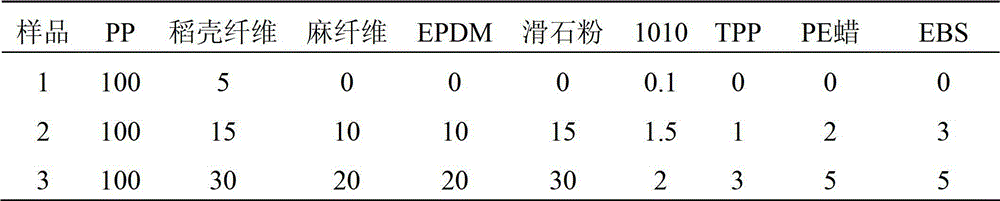

Injecting molding grade natural fiber composite material and preparation method thereof

The invention relates to a natural fiber composite material and a preparation method of the composite material. The composite material comprises the following components in parts by weight: 100 parts of thermoplastic resin, 5-50 parts of natural fiber, 0-20 parts of impact modifier, 0-30 parts of inorganic filler, 0.1-5 parts of anti-aging agent, and 0-10 parts of processing aid. The preparation method of the composite material comprises the steps of adding the natural fiber into an aqueous solution of a saline coupling agent to soak, then drying the natural fiber, mixing the natural fiber with the other processing aids, feeding the mixed material into a double-screw extruder to subject to the melting extrusion, and granulating to obtain the composite material. Compared with the prior art, the preparation method is simple in process and environment-friendly. More importantly, the problems that the composite material, into which a large amount of natural fiber is added, is poor in material mobility, low in intensity of parts, and poor in appearance quality, are solved. The current situation that the natural fiber composite material cannot adapt to the injection moldings of complex structures is changed.

Owner:CHERY AUTOMOBILE CO LTD

Multilayer structure including an active electrochemical material and ionic polymer in a electrochemical cell

InactiveUS6986967B2Minimize exposureElectrode manufacturing processesFinal product manufactureEngineeringLithium-ion battery

Multilayer articles, particularly multilayer articles having electrical or ionic conductivity, are made using an improved melt extrusion process. The process includes a combination step in which a macroscopically homogeneous mass is formed prior to introduction into an extruder. The multilayer article may include an electrode layer and a separator layer that are extruded onto a metal current collector. Such structures are particularly useful in lithium-ion batteries.

Owner:EI DU PONT DE NEMOURS & CO

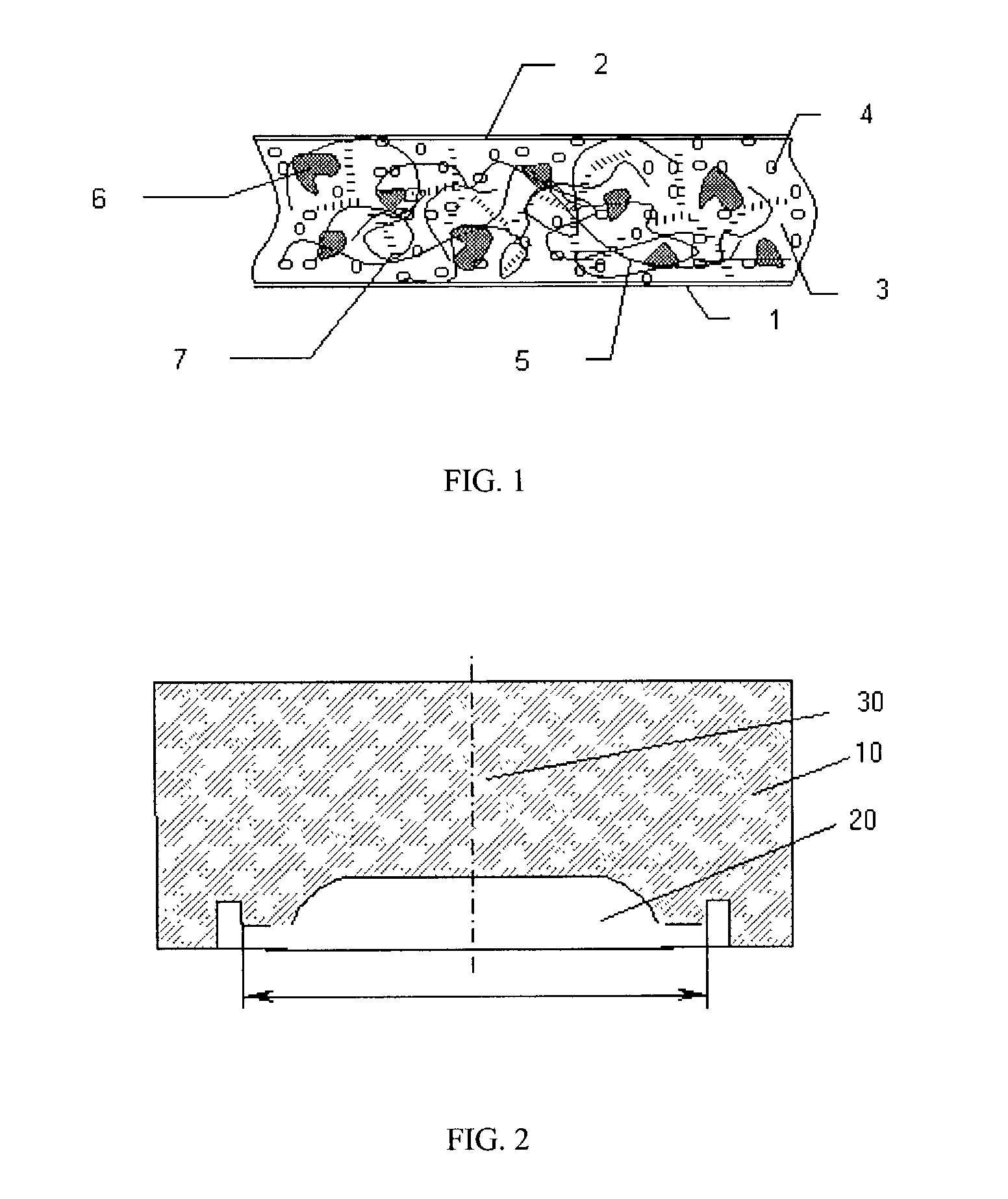

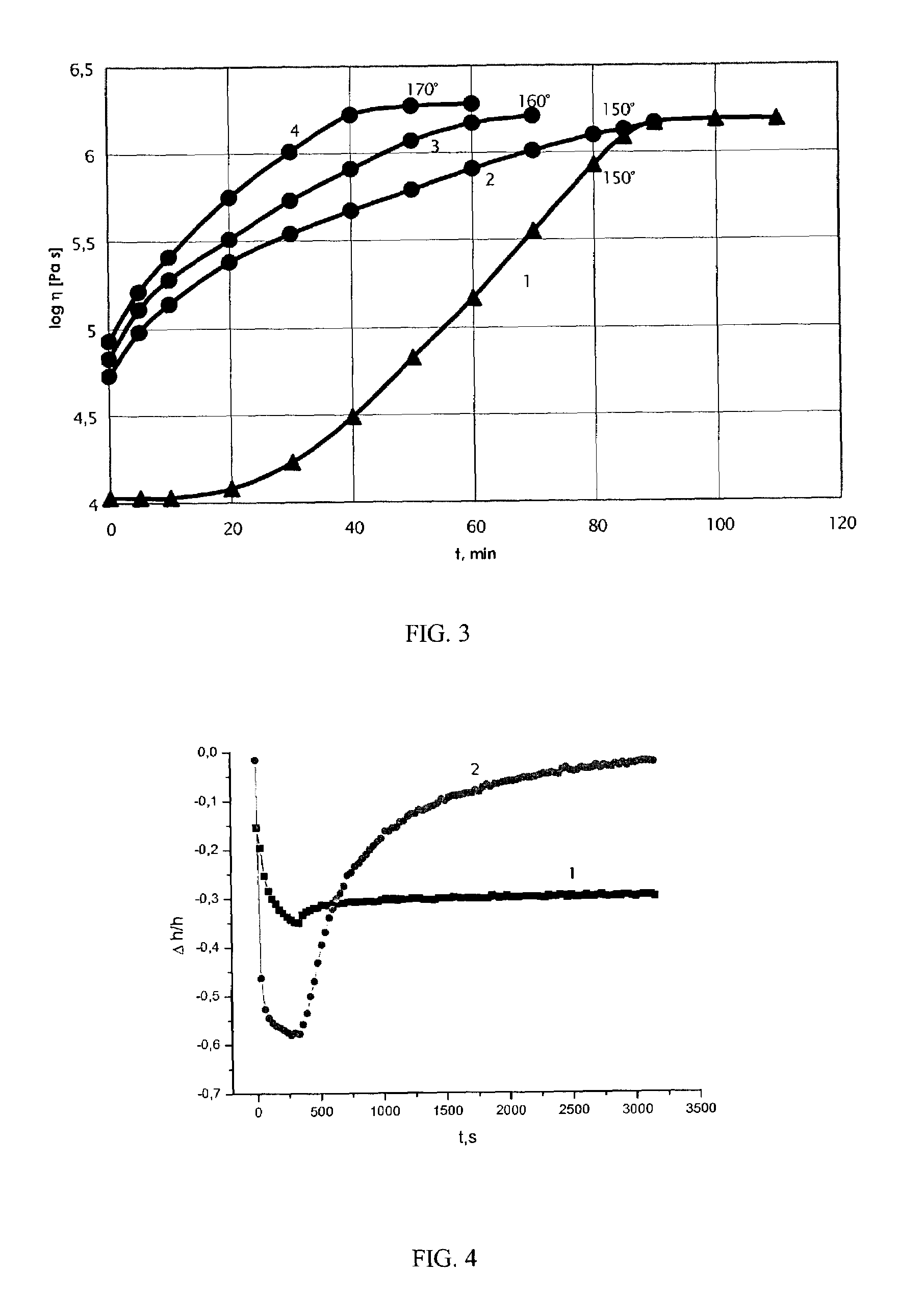

High-temperature resistant semi-aromatic nylon and its preparation method

ActiveCN102477219AOvercome the disadvantages of high viscosity, poor fluidity and difficult dischargeHigh viscosityPresent methodPolymer science

The invention relates to semi-aromatic high-temperature resistant nylon and its preparation method. The preparation method provided by the invention comprises the following steps of: by weight, adding 75-95 parts of nylon salt, 0.2-0.8 part of an end-capping reagent, 0.1-0.6 part of a catalyst, 0.5-1 part of an antioxidant, 0.1-0.5 part of a lubricant and 30-50 parts of deionized water into a stirred polymerization autoclave, synthesizing a high-temperature resistant nylon prepolymer in a high-pressure stirred tank reactor, and carrying out melting extrusion on the prepolymer through a double screw extruder twice. According to the invention, devolatilization efficiency is raised, tackifying time is shortened, and simultaneously the high-viscosity polymer in the reaction vessel can be smoothly discharged. By different extrusion temperatures, high-temperature degradation of the prepolymer is prevented. Intrinsic viscosity of the high-temperature resistant nylon prepared by the method is higher than that of a polymer prepared by a present method. Therefore, the obtained nylon in the invention has better mechanical properties.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Process for the production of an abuse-proofed solid dosage form

InactiveUS8323889B2Considerably complicatedAvoid formingBiocideNervous disorderEngineeringBULK ACTIVE INGREDIENT

The present invention relates to a process for the production of an abuse-proofed solid dosage form containing at least one active ingredient with potential for abuse and a synthetic or natural polymer with a breaking strength of =500 N, characterized in that a corresponding mixture is processed by melt extrusion with the assistance of a planetary-gear extruder.

Owner:GRUNENTHAL GMBH

Powder coating containing aerogel particles and preparing method thereof

InactiveCN101143981AImprove insulation performanceImprove sound insulationPolyurea/polyurethane coatingsPowdery paintsInsulation layerMixed materials

A powder coating containing aerogel particles and a method for preparing the same relates to a powder coating and a preparation method, which solves the problem that the existing heat insulating composite material containing aerogel is not suitable for making thinner heat insulation material and spraying insulation layer on the component surface, and the aqueous coating has high water content, long construction period and low heat insulation property. The coating of the invention is prepared by 5-80 percent of aerogel particles and 20-95 percent of powderedd resin by volume percentage, and the method includes the following steps: firstly, aerogel, resin and additive are mixed by volume percentage; secondly, the mixed materials are delivered into a melting-extruder melt and extrude; thirdly, the extrudate is pressed into thin sections; fourthly, the thin sections are ground into small pieces by roller machine; fifthly, the small pieces are conveyed into an air staged milling equipment to grind, so as to obtain the powder coating. The powder coating containing aerogel of the invention has advantages of environmental protection, clearness, economy, high efficiency, and good heat insulation property, sound insulation property and surface hydrophobicity.

Owner:HARBIN INST OF TECH

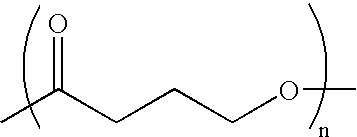

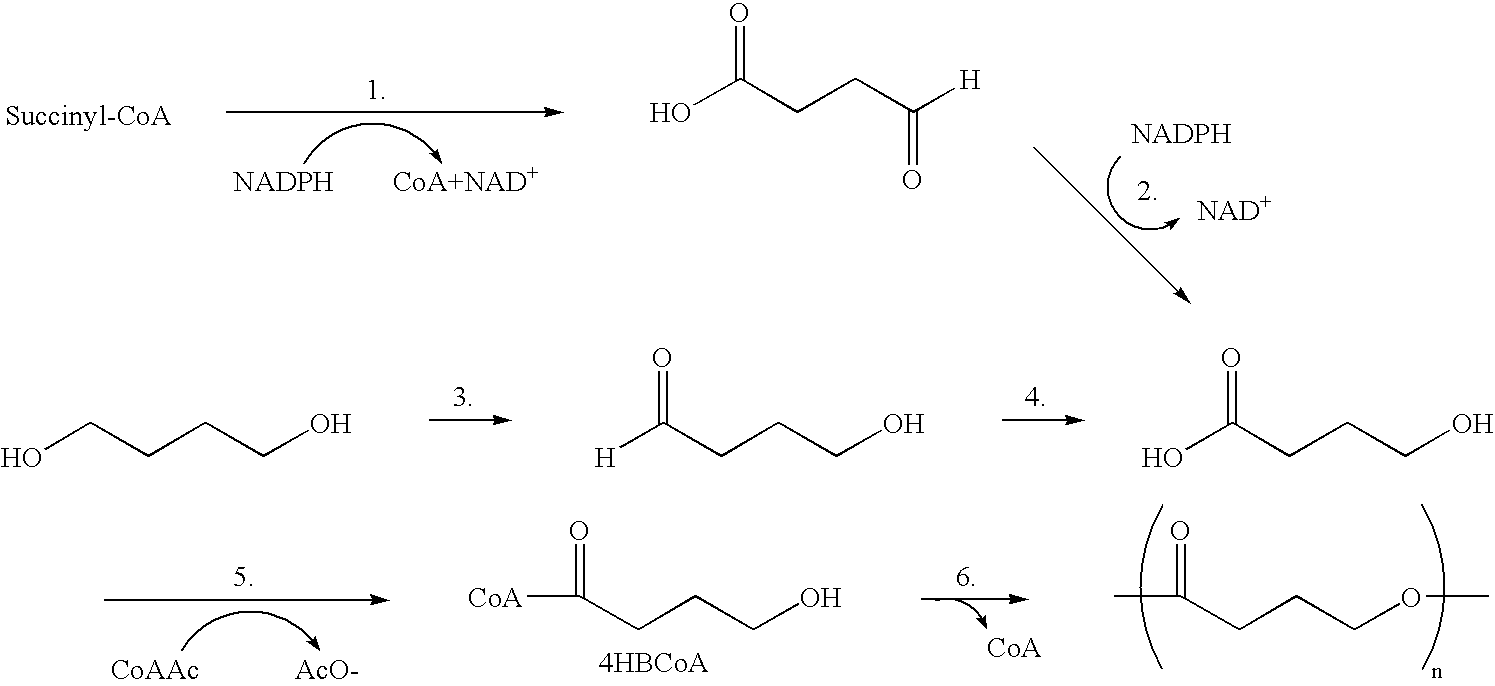

Medical devices containing oriented films of poly-4-hydroxybutyrate and copolymers

ActiveUS20080132602A1Improve toughnessLow modulusStentsImpression capsSolventUltimate tensile strength

Continuous processing methods for making absorbable polymeric films with one or more of the following properties: high toughness, low modulus, high tensile strength, and thickness less than 10 mm, more preferably less than 1 mm, and more preferably less than 100 μm, have been developed. In the preferred embodiment, the polymer is a polyhydroxyalkanoate, and in the most preferred embodiment, the polymer comprises 4-hydroxybutyrate. A particularly preferred embodiment is a film of poly-4-hydroxybutyrate or copolymer thereof, wherein the film has a tensile strength greater than 5.5 kgf / mm2, tensile modulus less than 181 kgf / mm2, and elongation at break from 10-500%, wherein the film is derived by a continuous process such as melt extrusion or solvent casting, followed by orientation to more than 25% of the film's original length in one or more directions. These can be used for a variety of purposes including fabrication of medical devices.

Owner:TEPHA INC

High temperature resistant economical electrostatic powder coating for electric room heater and preparation method thereof

InactiveCN101565587AImprove heat resistanceAvoid harmFireproof paintsPowdery paintsMetallurgyHigh pressure

The invention discloses a high temperature resistant economical electrostatic powder coating for an electric room heater and a preparation method thereof. The formulation of the powder coating comprises the following compositions in percentage by weight: 53 to 57 percent of thermosetting resin, 3 to 7 percent of curing agent, 1 to 30 percent of pigment, 5 to 34 percent of filler and 2 to 5 percent of auxiliary agent. The powder coating is produced by adopting the method of premixing, melt extrusion and mixing, tabletting, cooling and crushing, fine grinding and classification, sieving and separation, and product, wherein the average particle size of the powder coating is between 25 and 30 mu m, and the thickness requirement between 50 and 60 mu m of an economic coating is met. The powder coating is suitable for coating by a high voltage electrostatic powder coating method and simultaneously is suitable for coating by a frictional electrostatic powder coating method.

Owner:杨彬

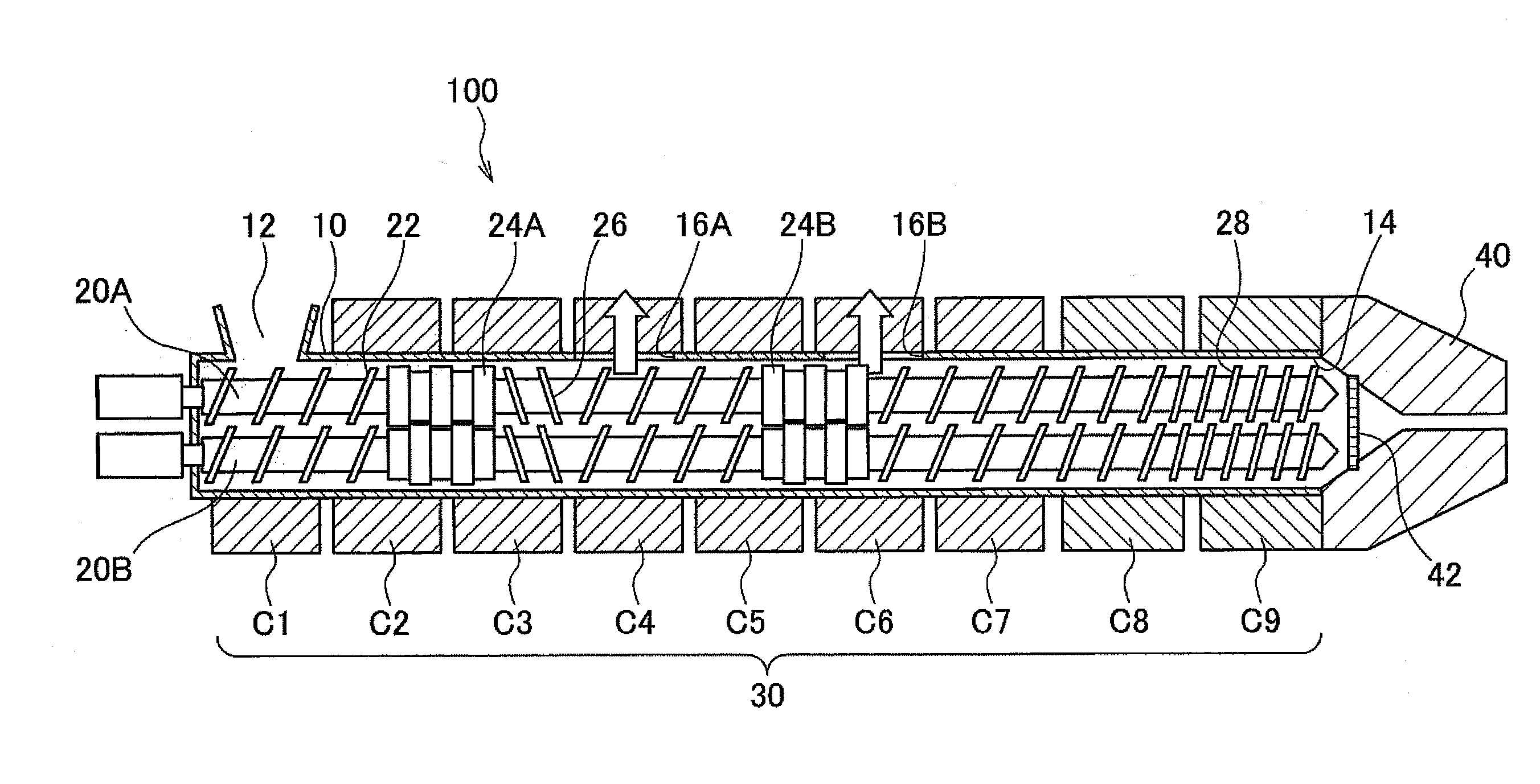

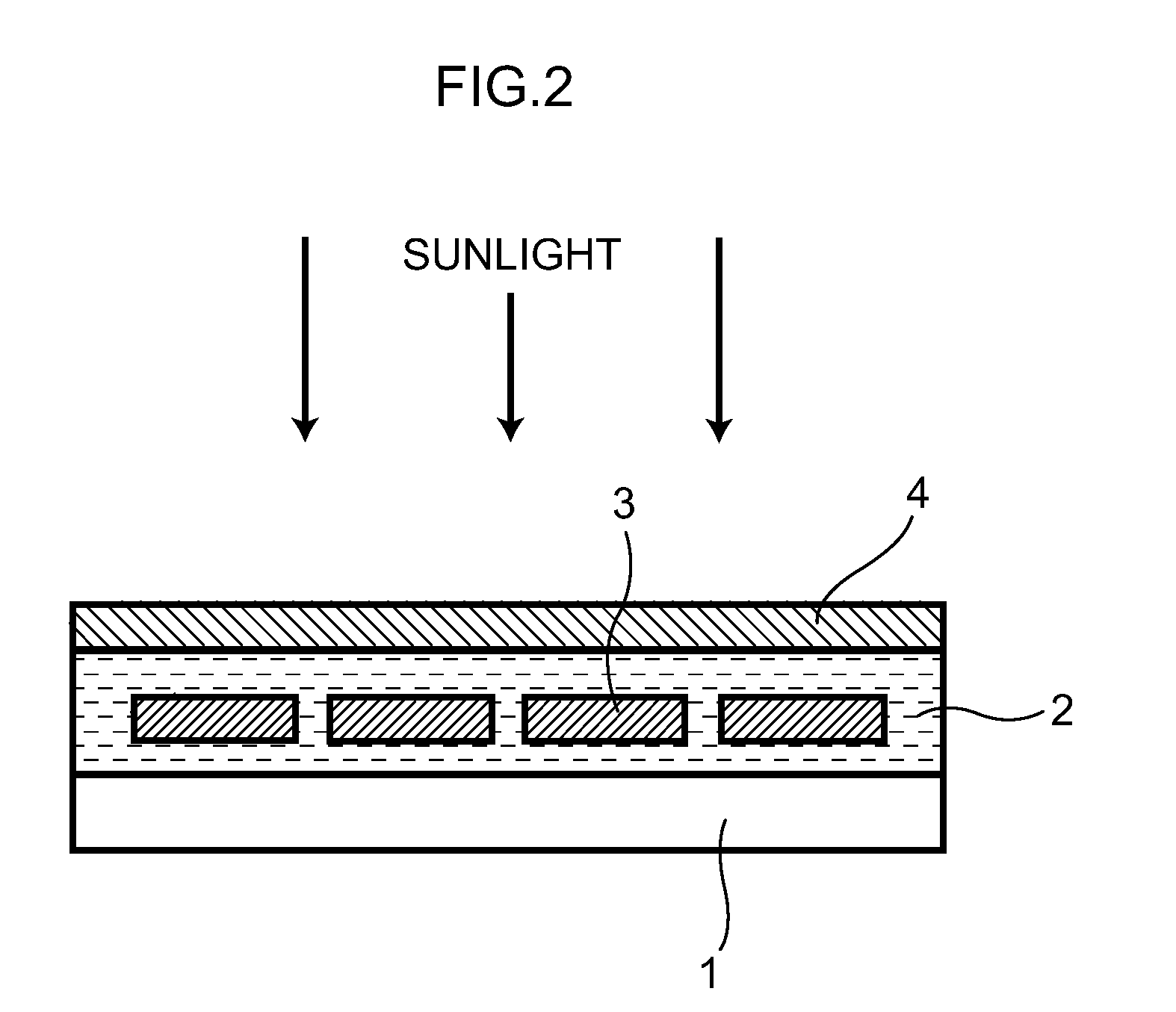

Polyester film, method for producing the same, back sheet for solar cells, and solar cell module

InactiveUS20120070615A1Not impairing effectImprove productivityLayered productsTraffic signalsShear rateEngineering

Provided is a method for producing a polyester film, including: subjecting a polyester raw material resin, which contains a titanium compound and has an intrinsic viscosity of from 0.71 to 1.00, to melt extrusion using a twin-screw extruder which includes a cylinder; two screws disposed inside the cylinder; and a kneading disk unit disposed in at least a portion of a region extending from a 10%-position to a 65%-position of screw length with respect to an upstream end of the screws in a resin extrusion direction as a starting point, at a maximum shear rate generated inside the twin-screw extruder of from 10 sec−1 to 2000 sec−1;forming an unstretched film by cooling and solidifying the melt extruded polyester resin on a cast roll; subjecting the unstretched film to biaxial stretching in a longitudinal direction and a lateral direction; and heat fixing the stretched film formed by biaxial stretching.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com