Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

579 results about "Thermoplastic polyimide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic Polyimide (PI) Thermoplastic PI is a thermoplastic, further classified an an imide plastic. It can have a moderately high tensile strength among the thermoplastics in the database. The properties of thermoplastic PI include three common variations. This page shows summary ranges across all of them.

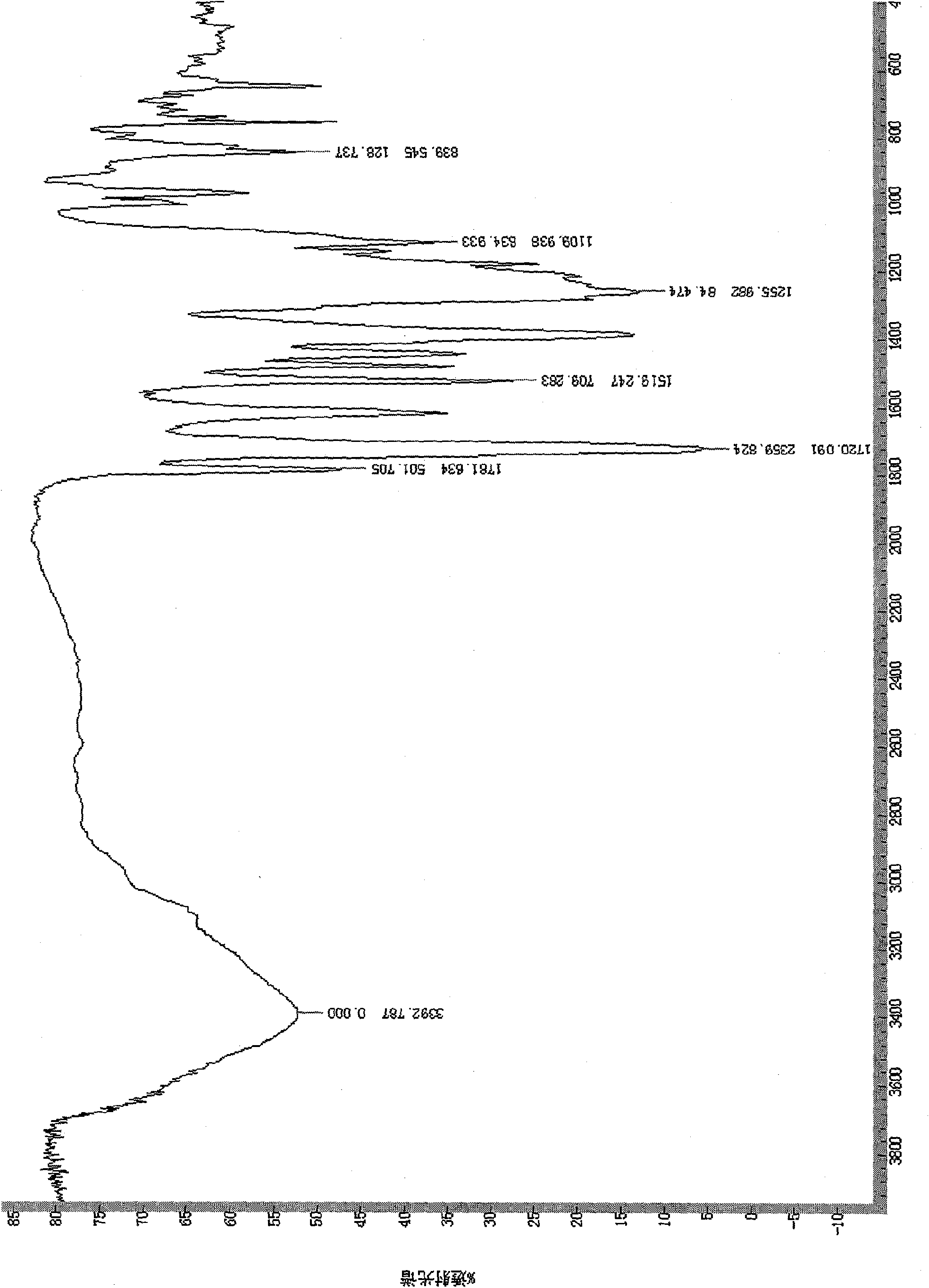

Preparation method of high temperature resistant single-component solventless epoxy adhesive

InactiveCN101649174AConvenient sourceSimple preparation processEpoxy resin adhesivesSolventThermoplastic polyimide

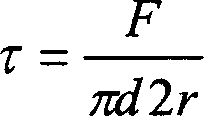

The invention relates to a preparation method of high temperature resistant single-component solventless epoxy adhesive. The method comprises the following steps: adding aromatic binary primary amine and strongly polar non-proton organic solvent in a reaction tank, stirring at room temperature to dissolve, adding aromatic binary acid anhydride to perform refluxing and water-segregating reaction at 120-150 DEG C for 6-12h, cooling, adding the reaction solution in a stamp tank with precipitant to precipitate solid powder, namely white thermoplastic polyimide powder, adding white thermoplastic polyimide powder and tertiary amine compound or imidazole compound in epoxy resin to react for 1-2h, adding active diluent and latent curing agent to stir evenly and obtaining the product. The production process is easy and the cost is low so as to realize industrialized production; the tensile shear intensions of the epoxy adhesive at room temperature and 120 DEG C are respectively up to 28Mpa and26Mpa and the epoxy adhesive has broad application prospect in fields such as electronics and microelectronics, electrical motors, aviation and aerospace and the like.

Owner:DONGHUA UNIV

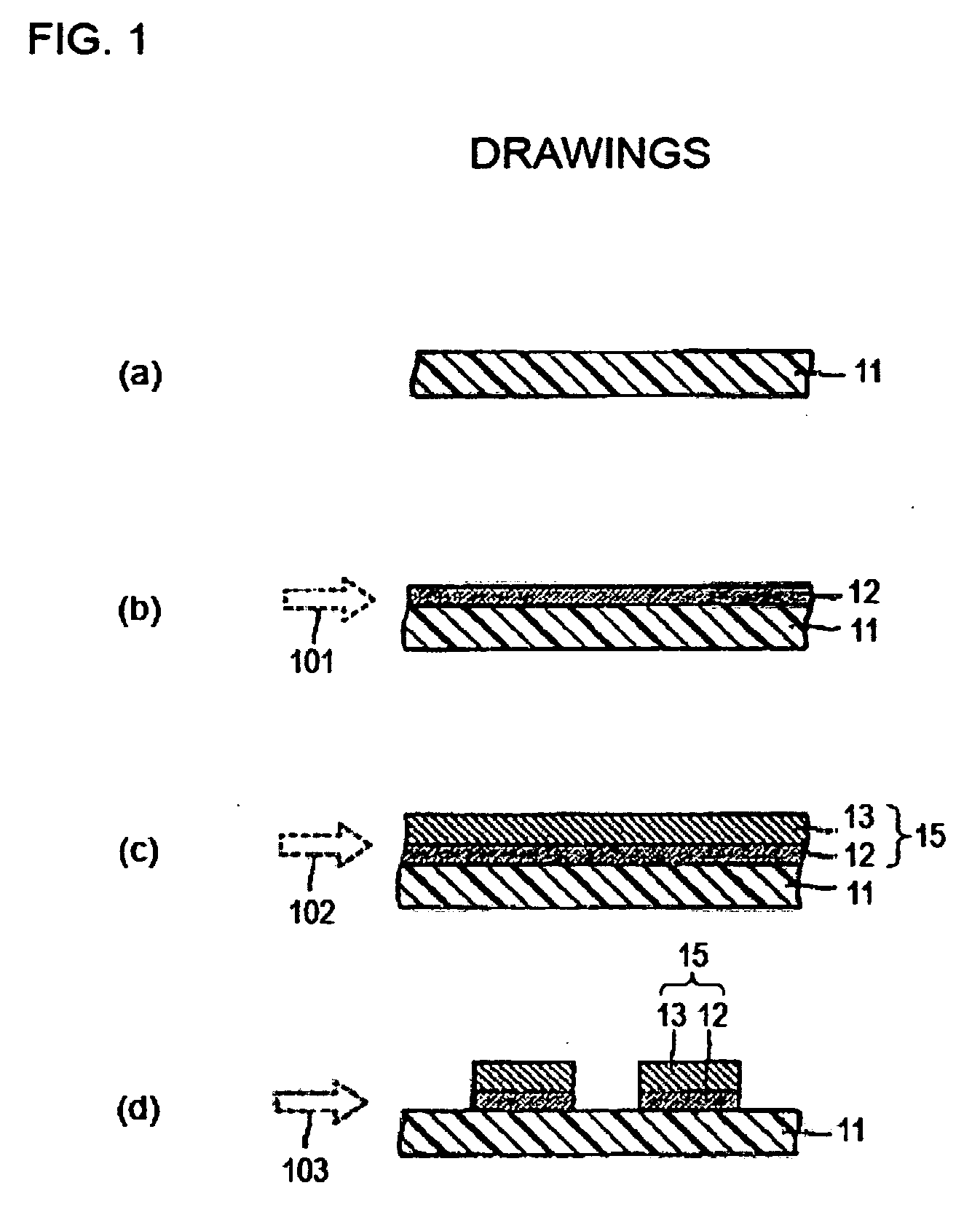

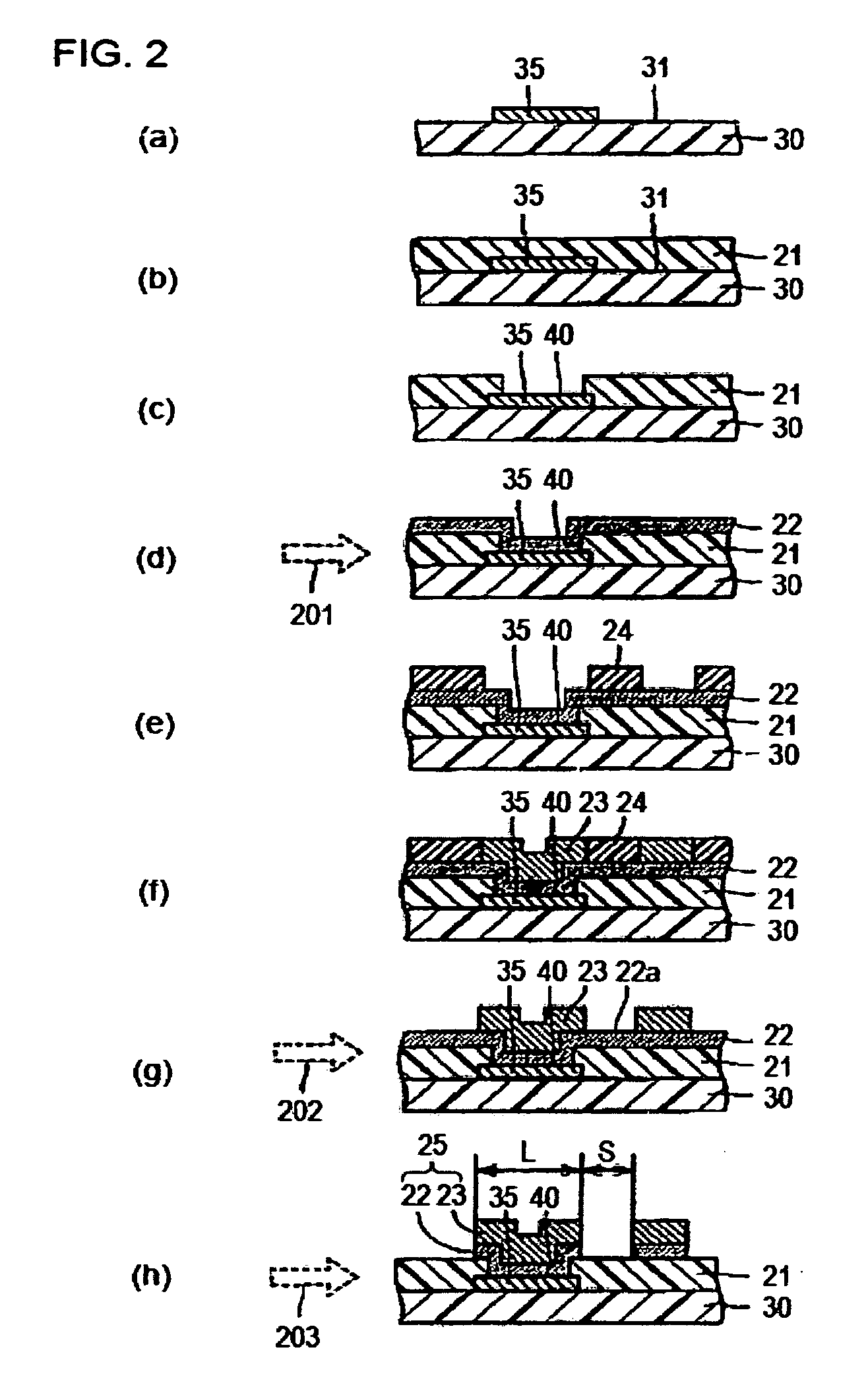

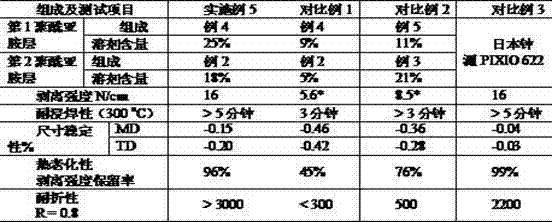

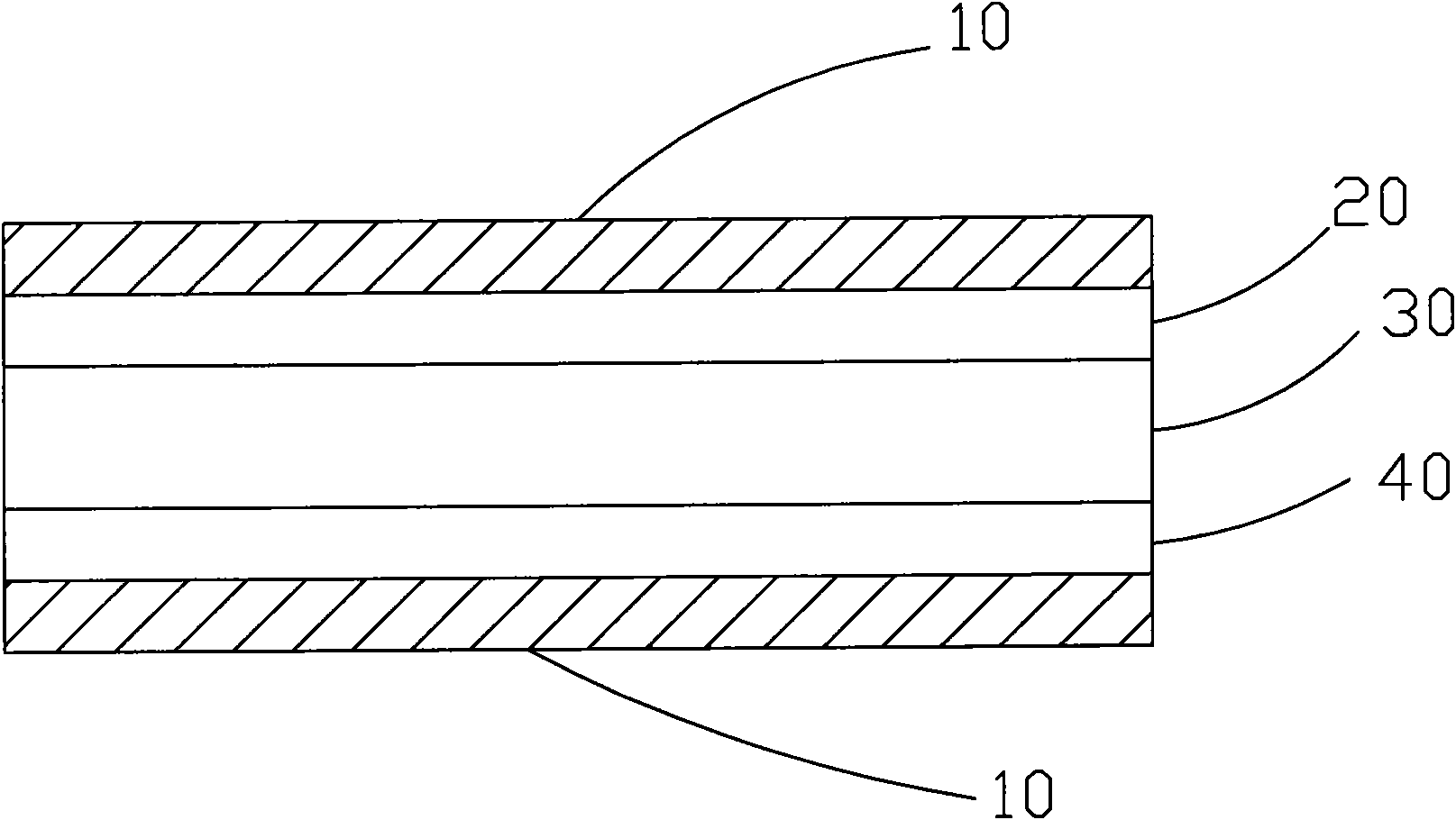

Thermoplastic polyimide resin film, multilayer body and method for manufacturing printed wiring board composed of same

ActiveUS20060115670A1Maintain good propertiesHigh bonding strengthPrinted circuit assemblingSynthetic resin layered productsPrinted circuit boardThermoplastic polyimide

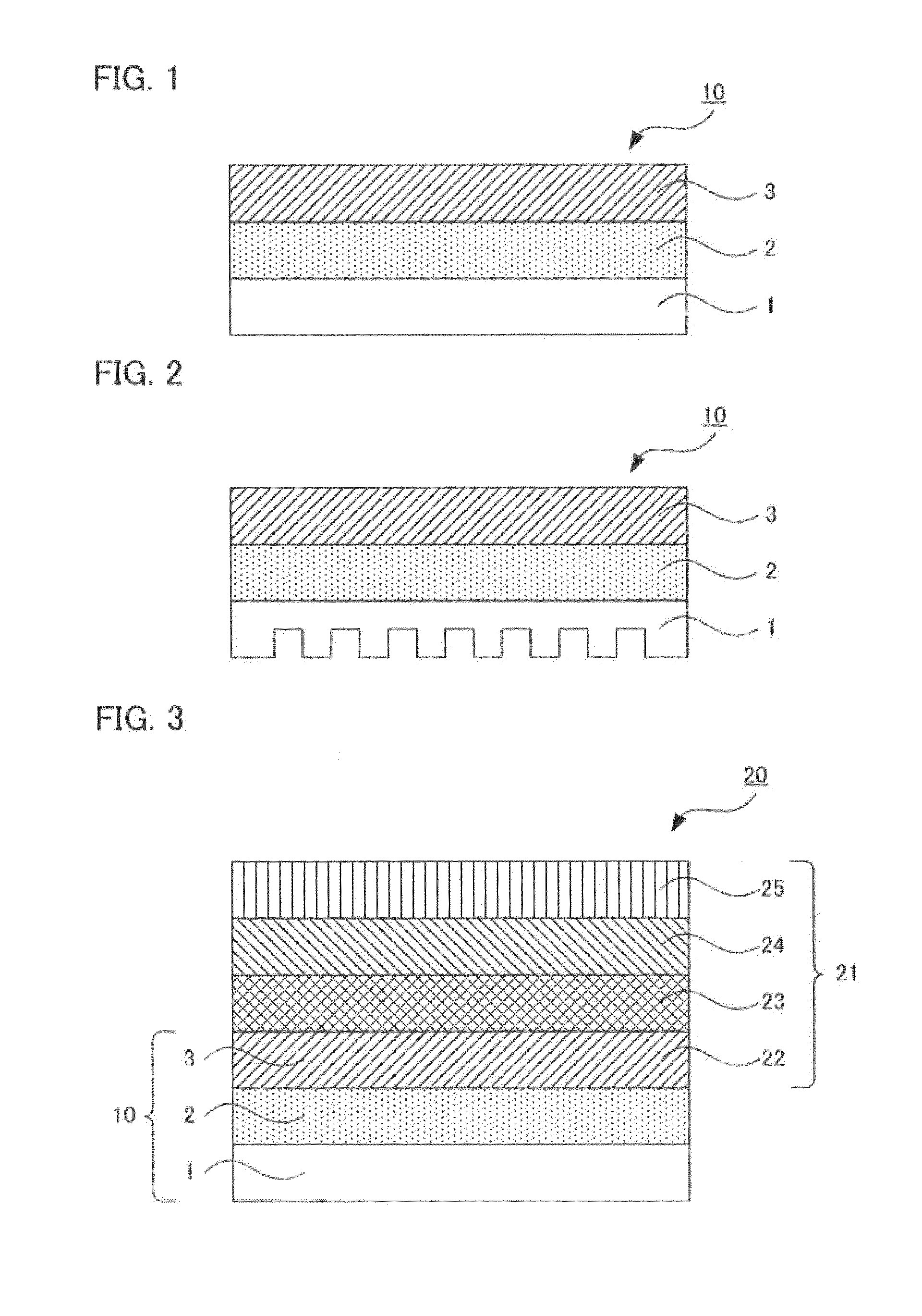

The present invention provides a laminate having a two-layer or three-layer structure including a non-thermoplastic polyimide film and a thermoplastic polyimide layer provided on one or both of the surfaces thereof, the surface of the thermoplastic polyimide layer being surface-treated; a laminate including a polymer film and a layer provided on one or both of the surfaces thereof, the layer including a polyimide resin composition comprising a polyimide resin with a specified structure and a thermosetting component; and a resin film and a laminate including the same which provided one, at least, of surface having a Ra1 value of arithmetic mean roughness of 0.05 μm to 1 μm measured with a cutoff value of 0.002 mm, and a Ra1 / Ra2 ratio of 0.4 to 1, Ra2 being a value measured with a cutoff value of 0.1 mm. These laminates can provide a printed circuit board with excellent adhesiveness, on which a micro-wiring circuit can be formed.

Owner:KANEKA CORP

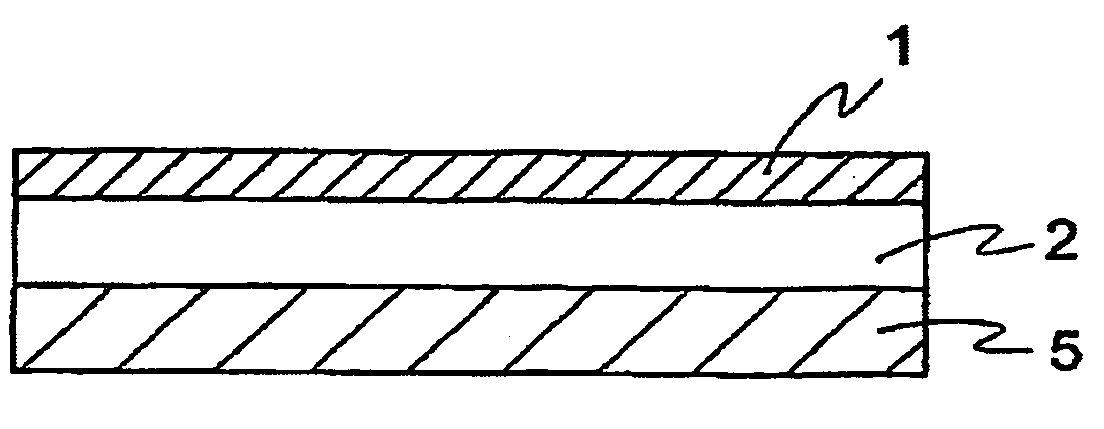

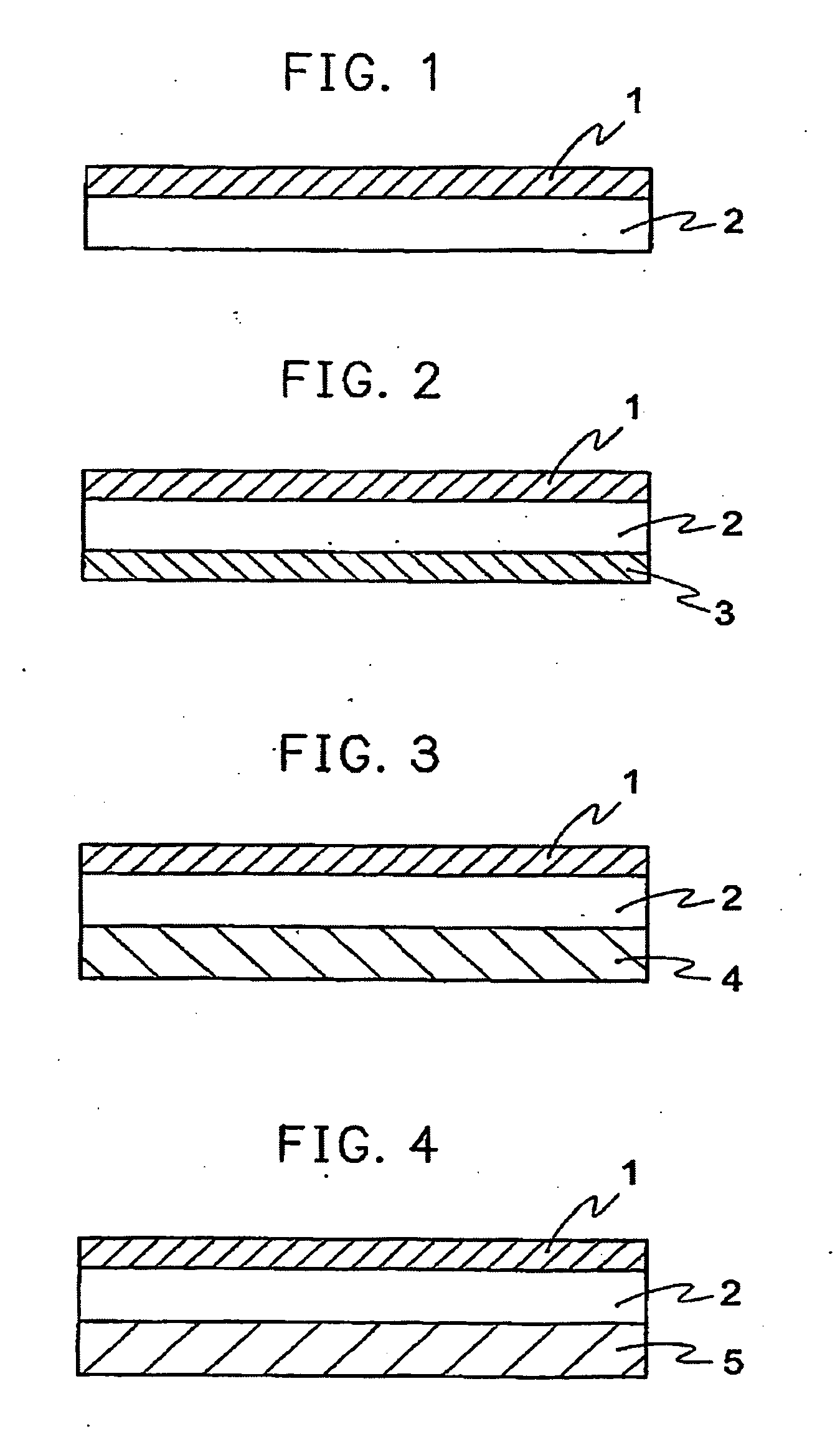

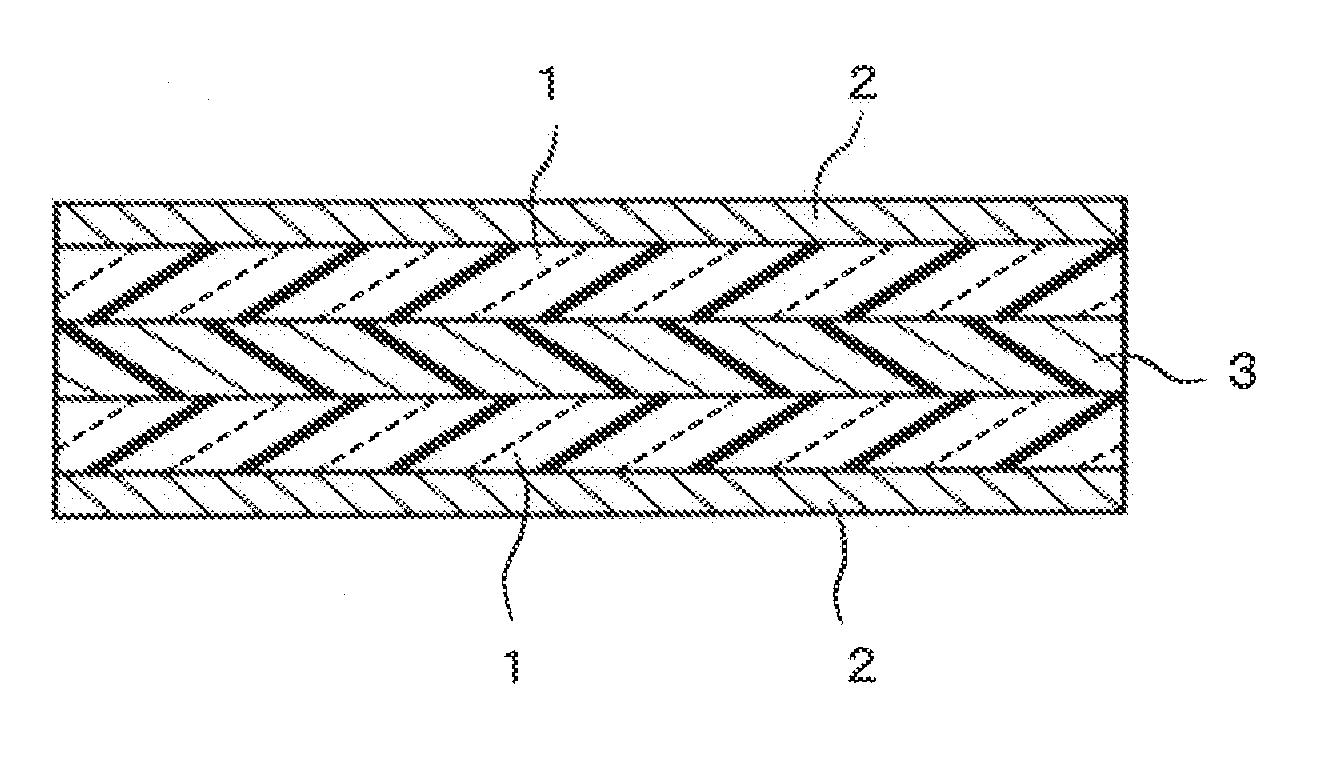

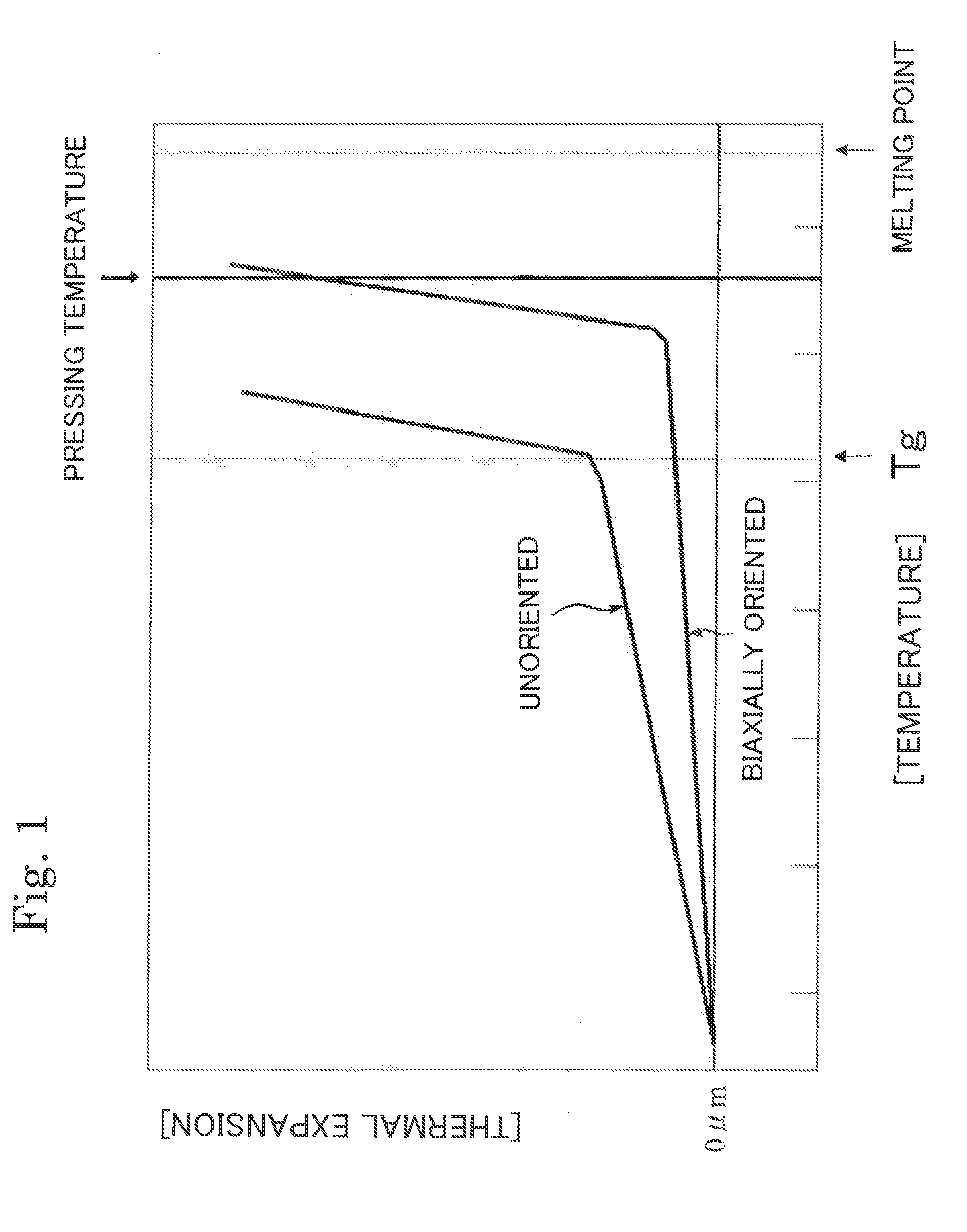

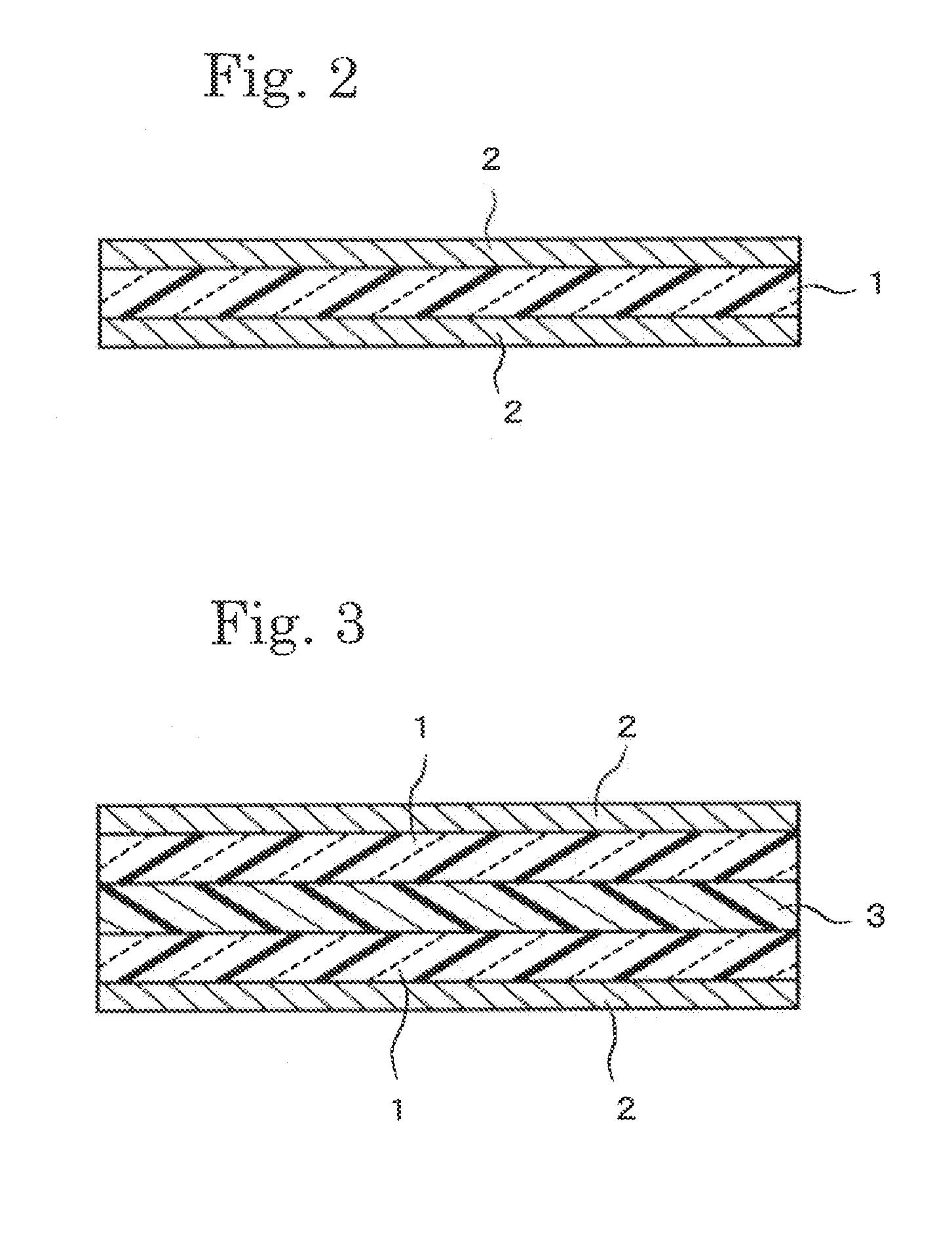

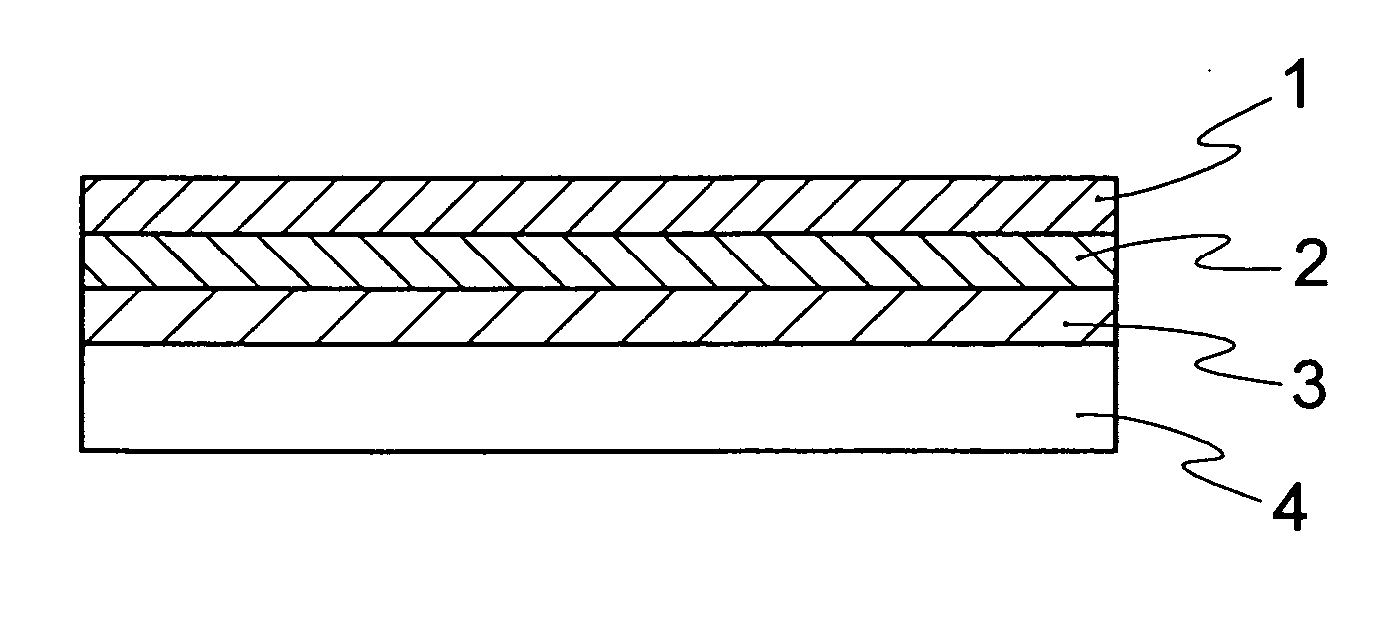

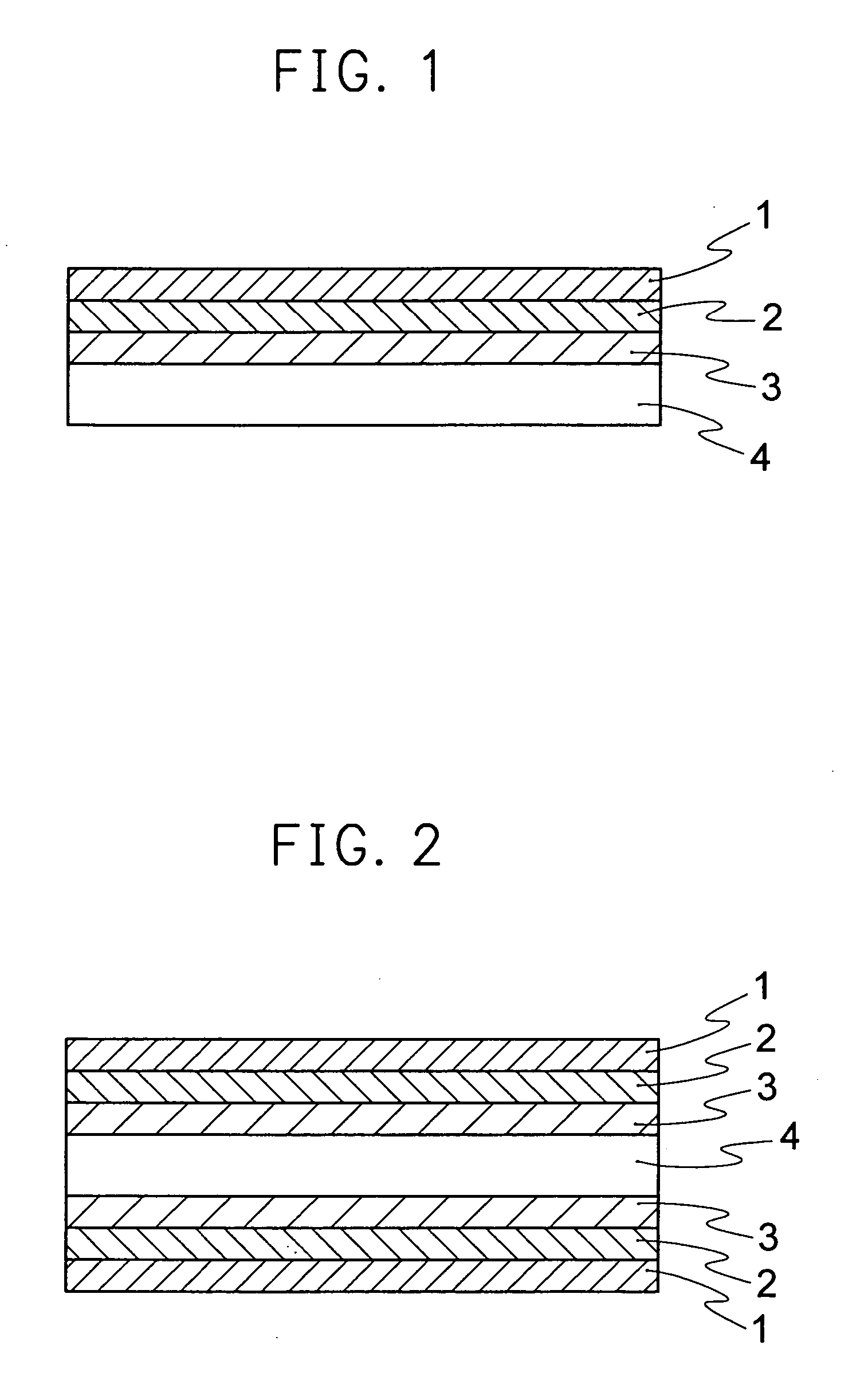

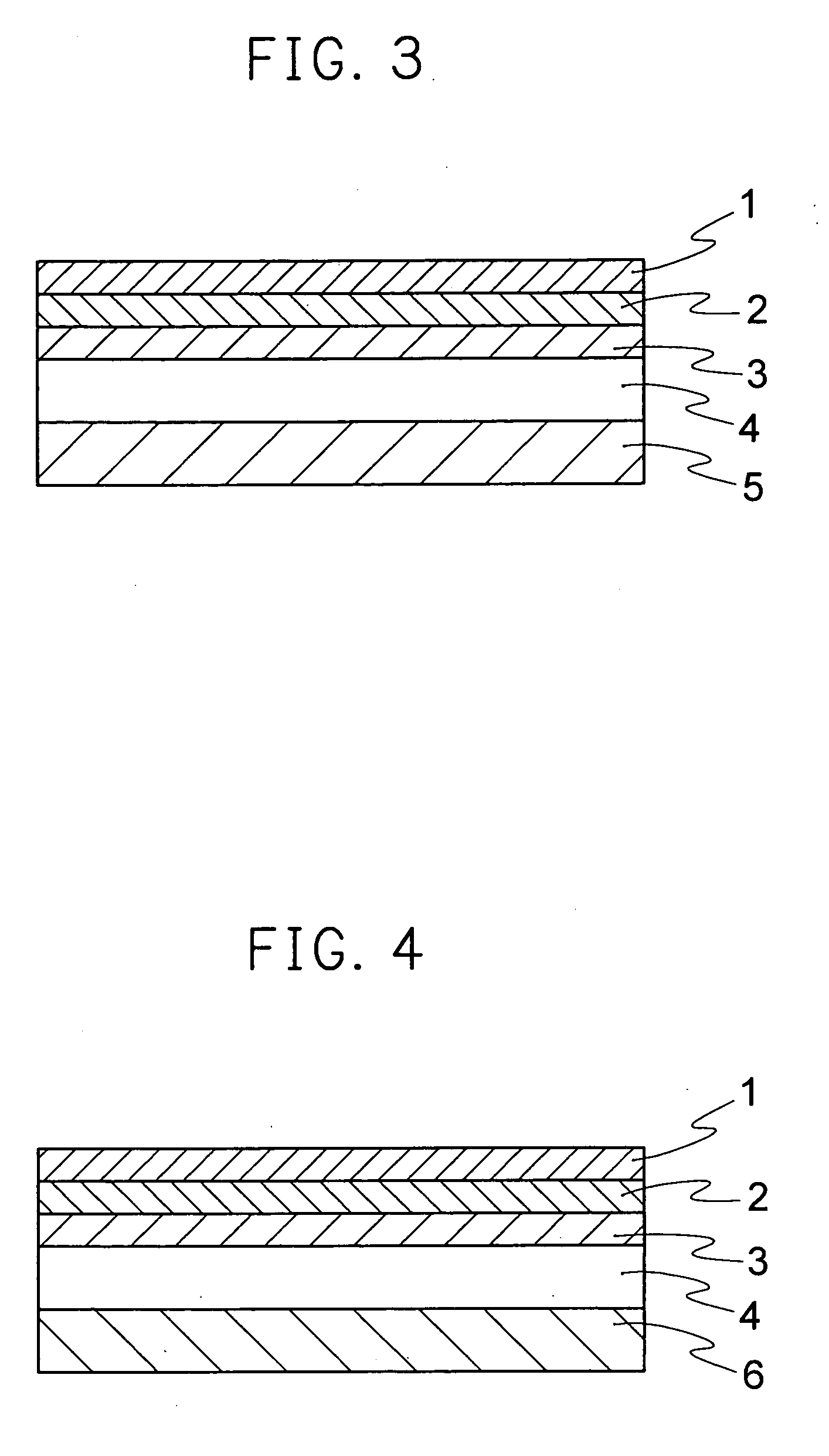

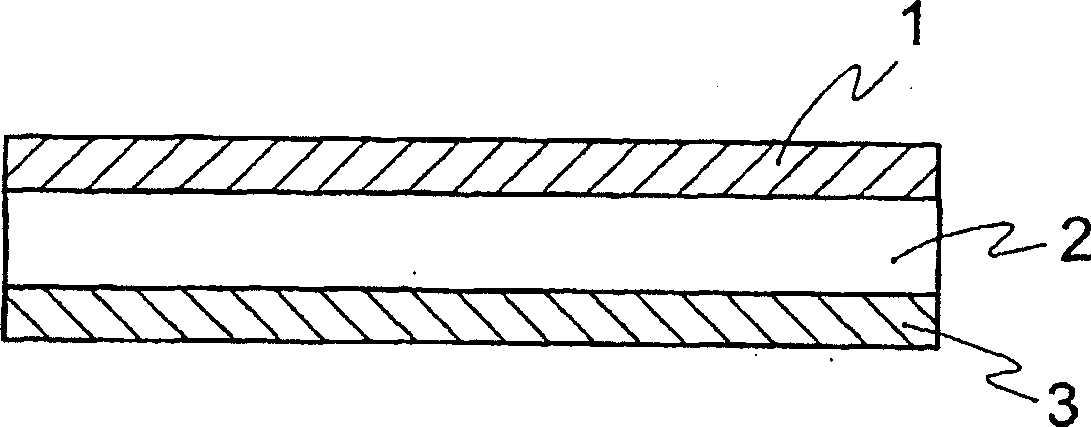

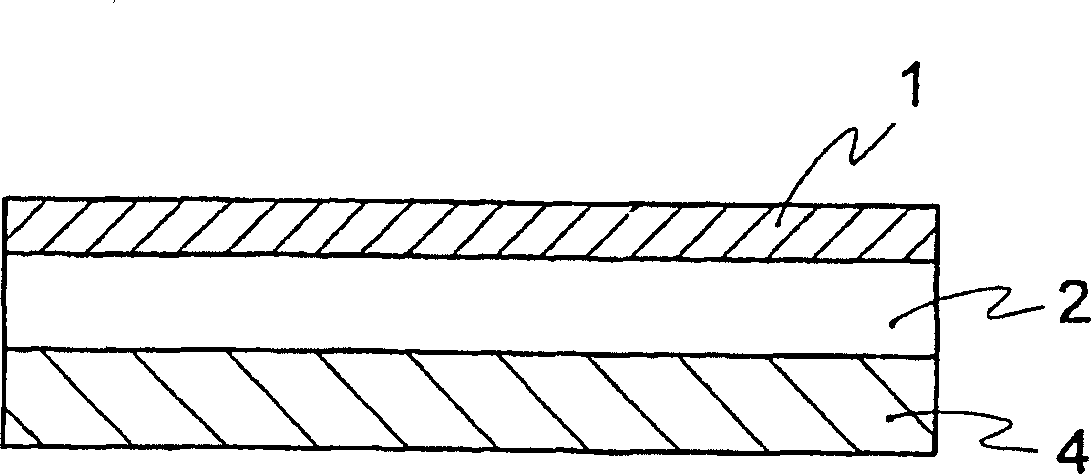

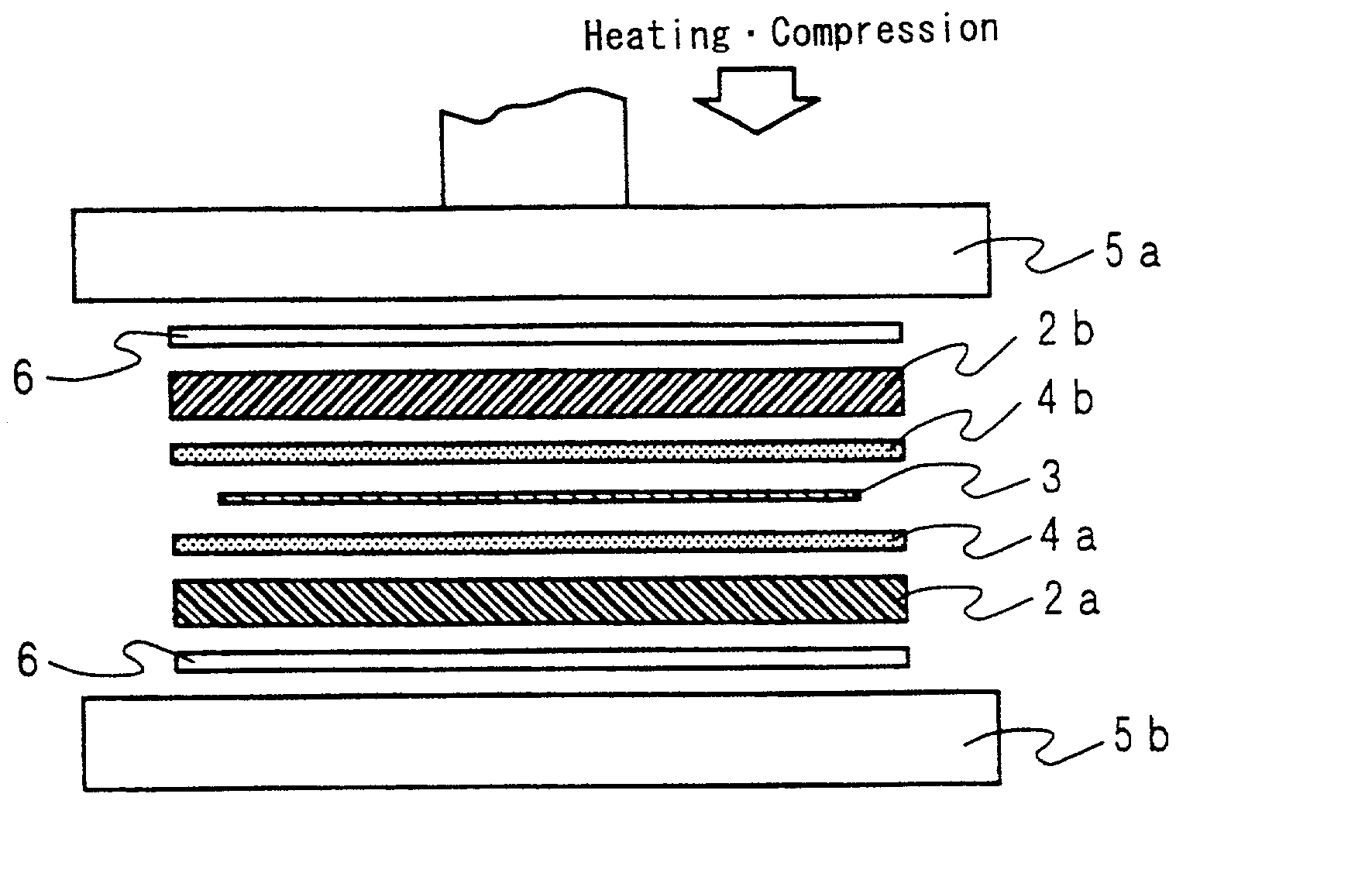

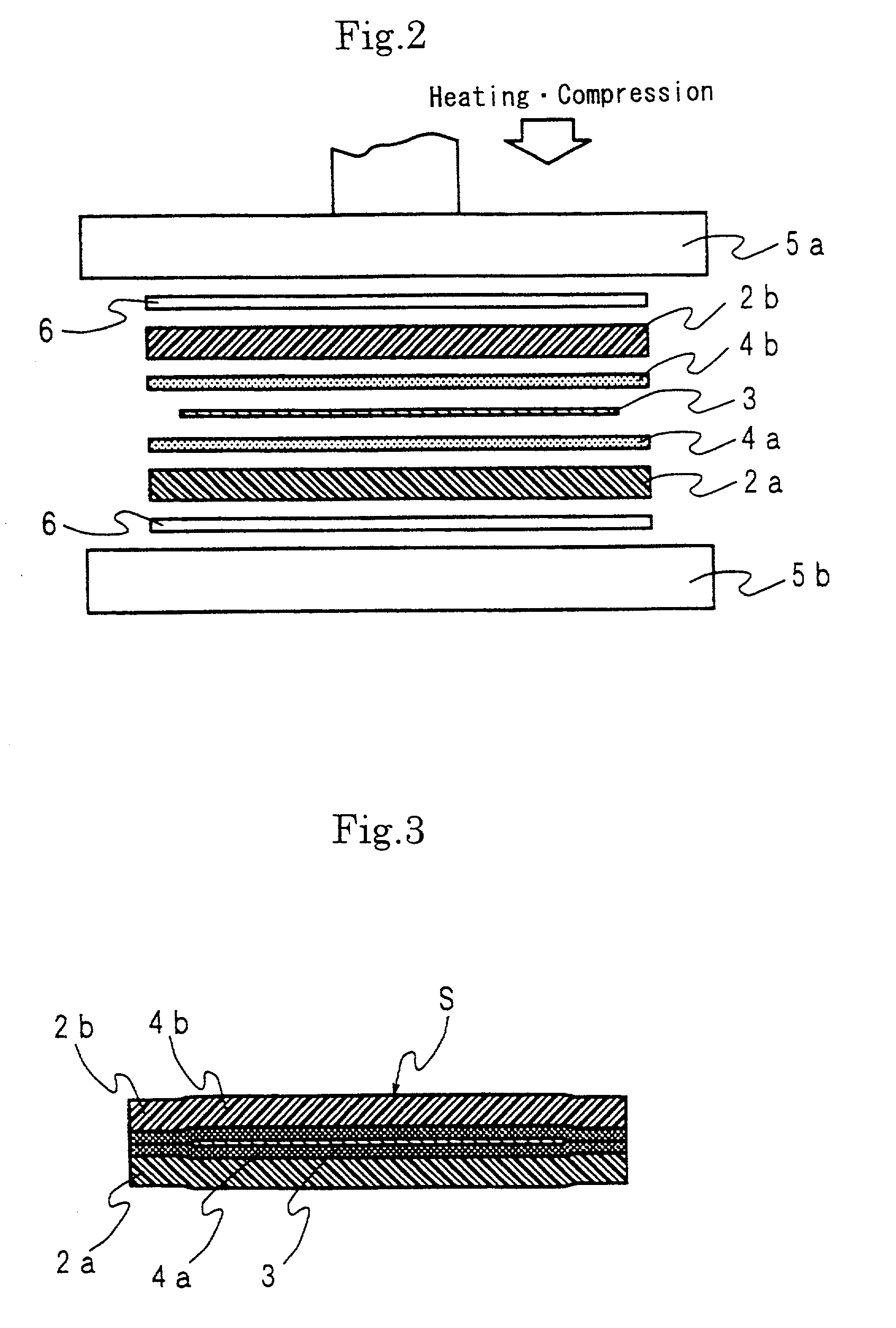

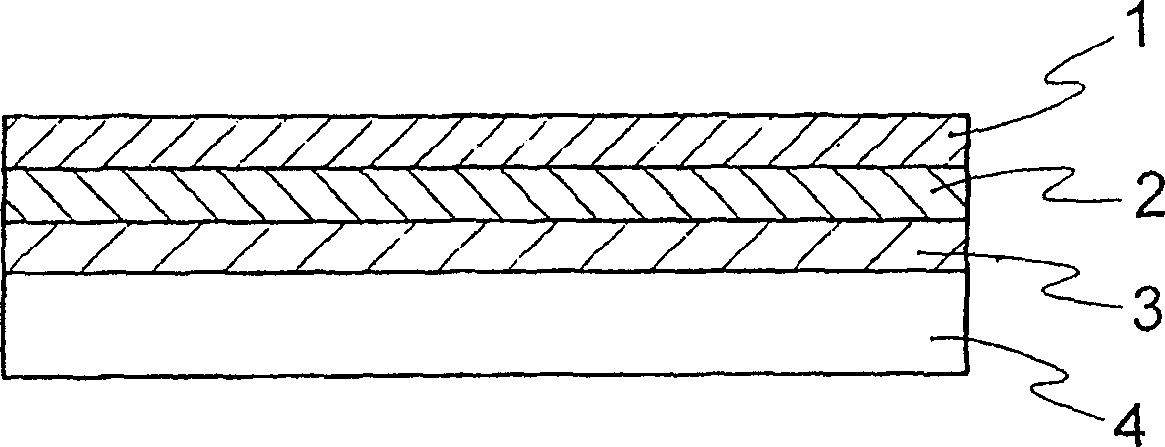

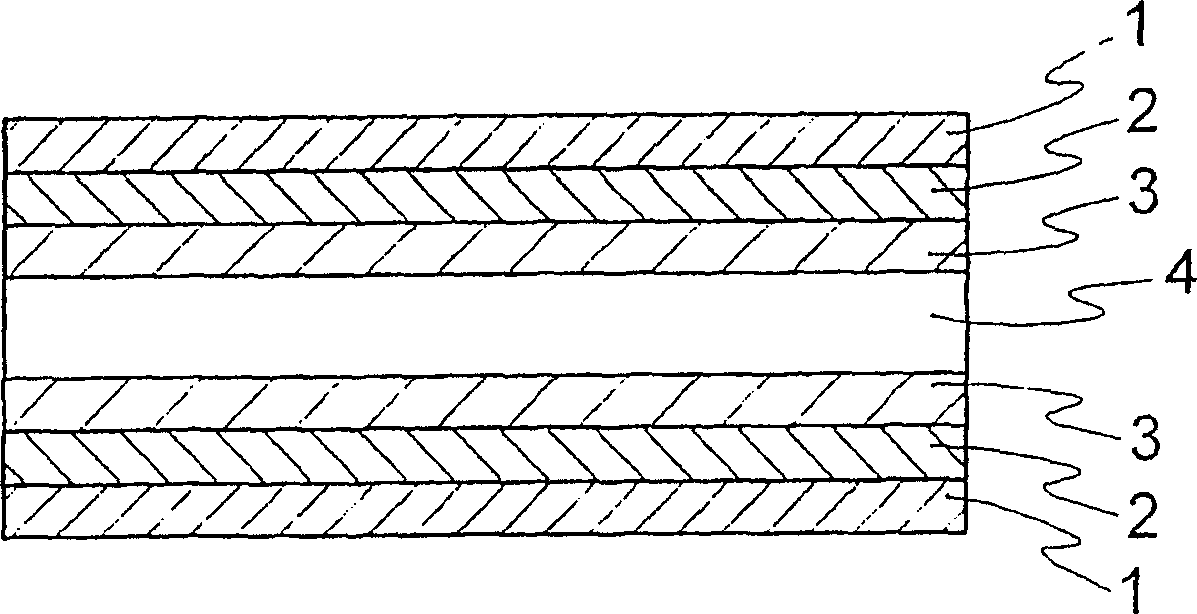

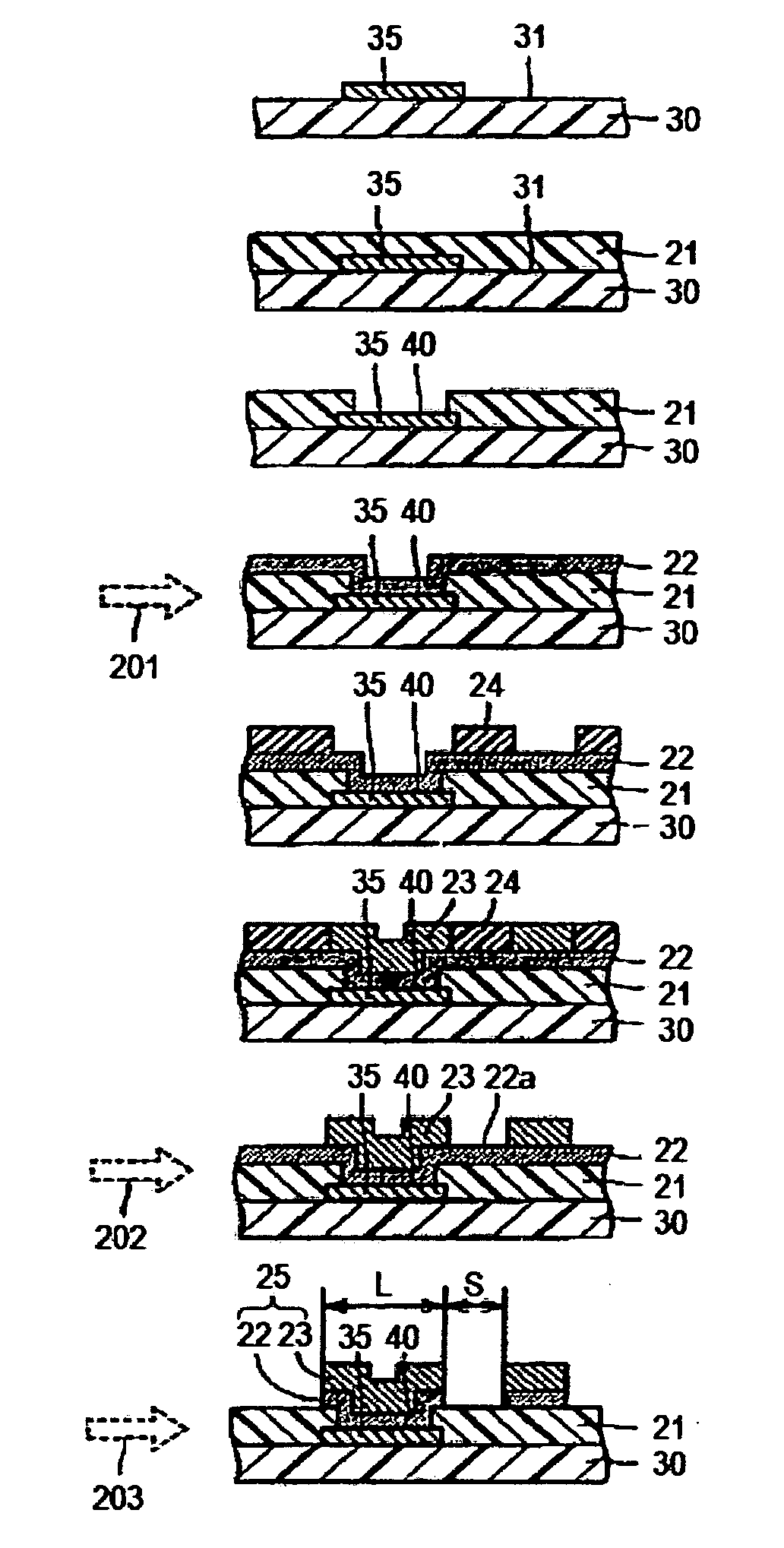

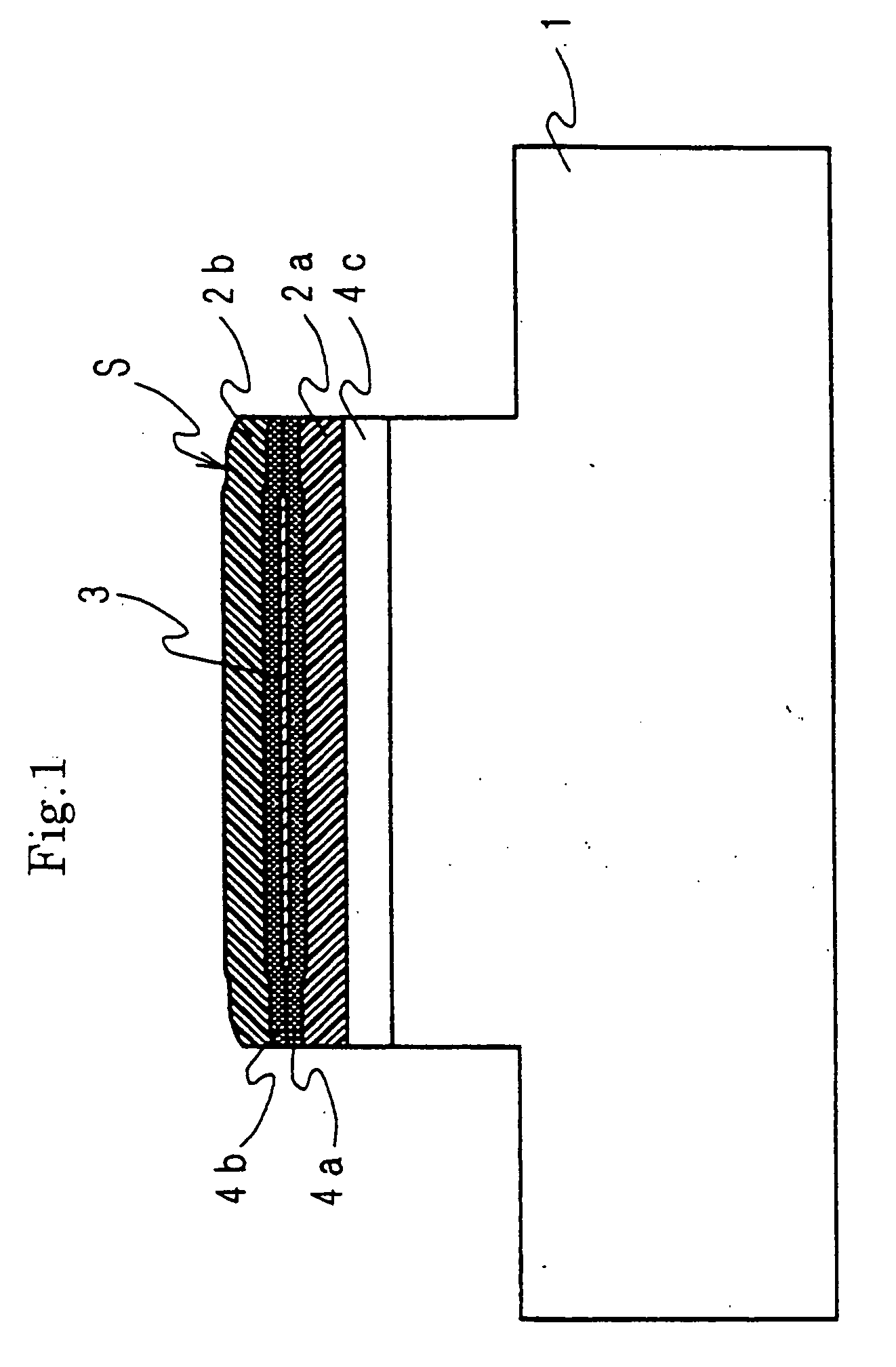

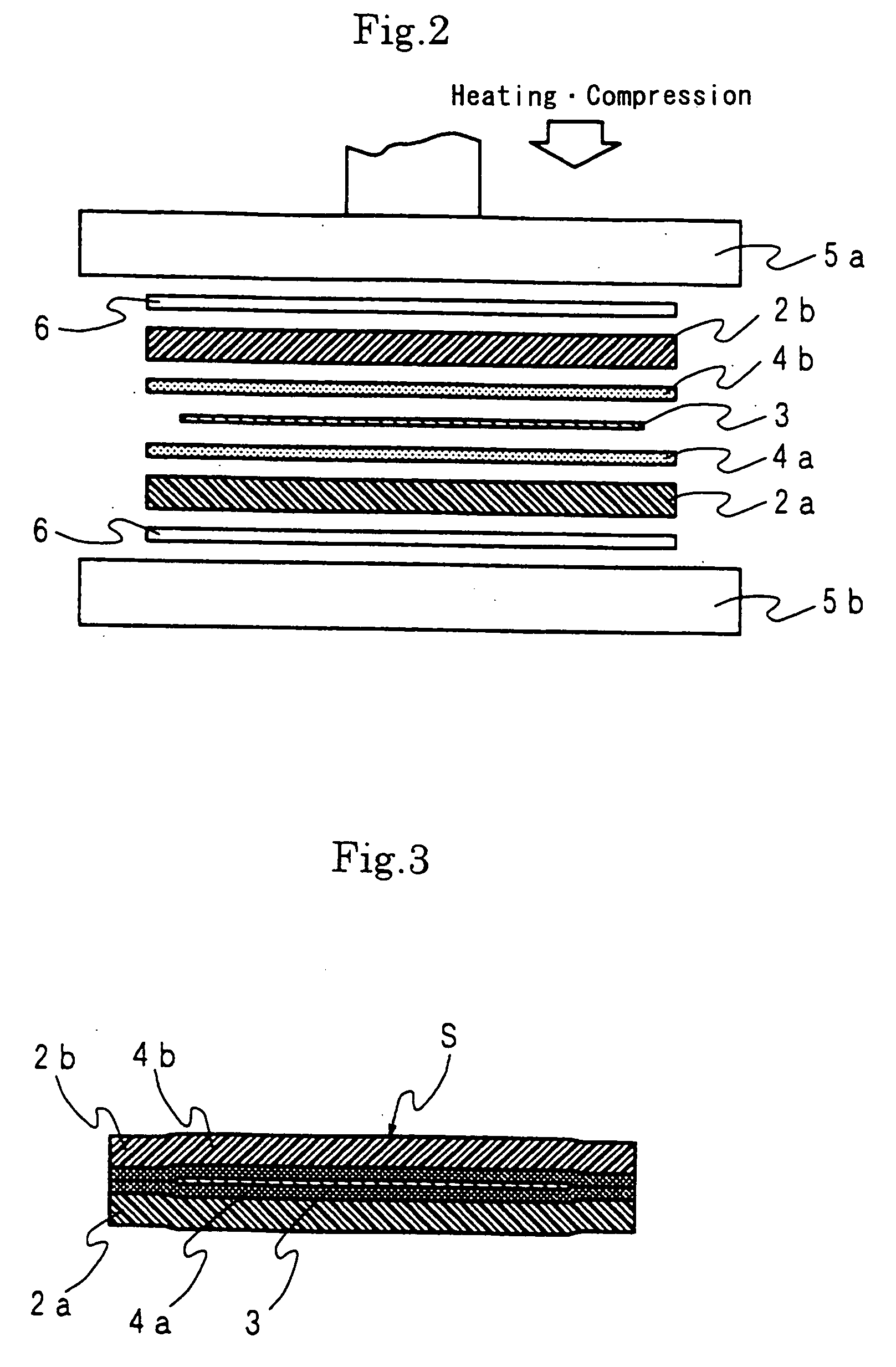

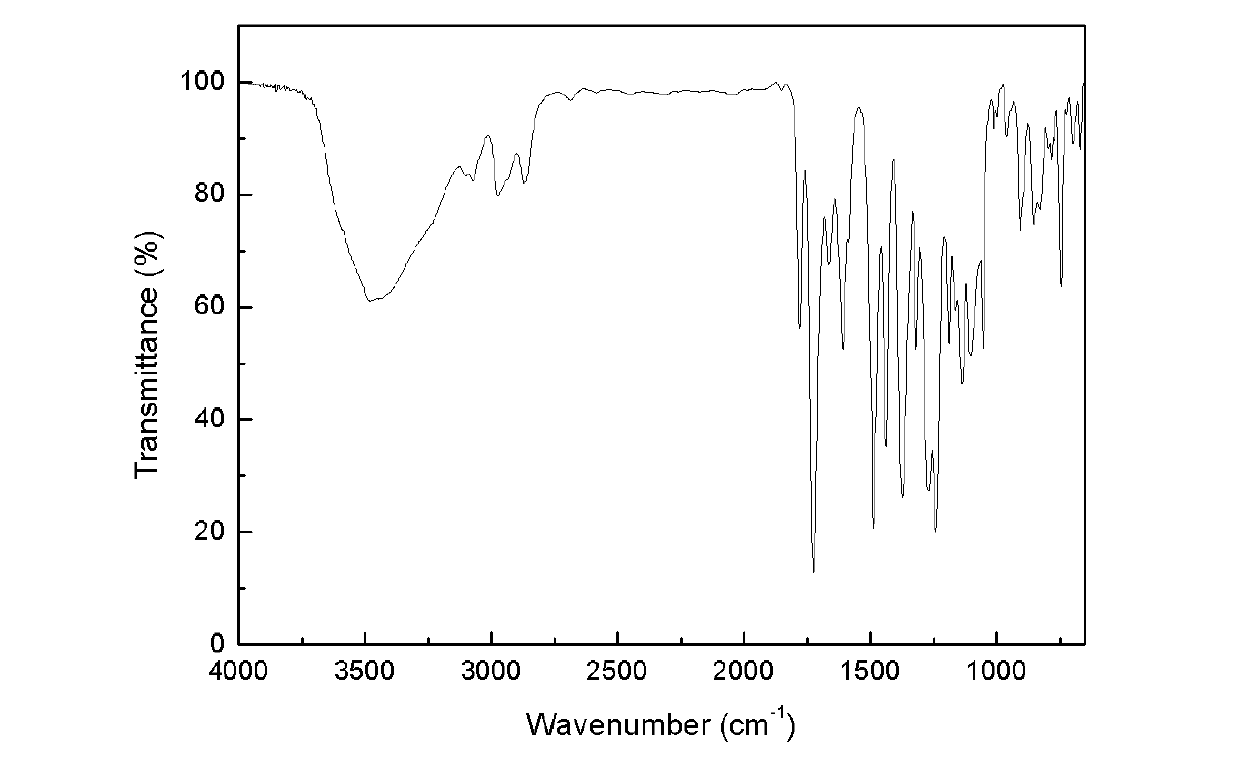

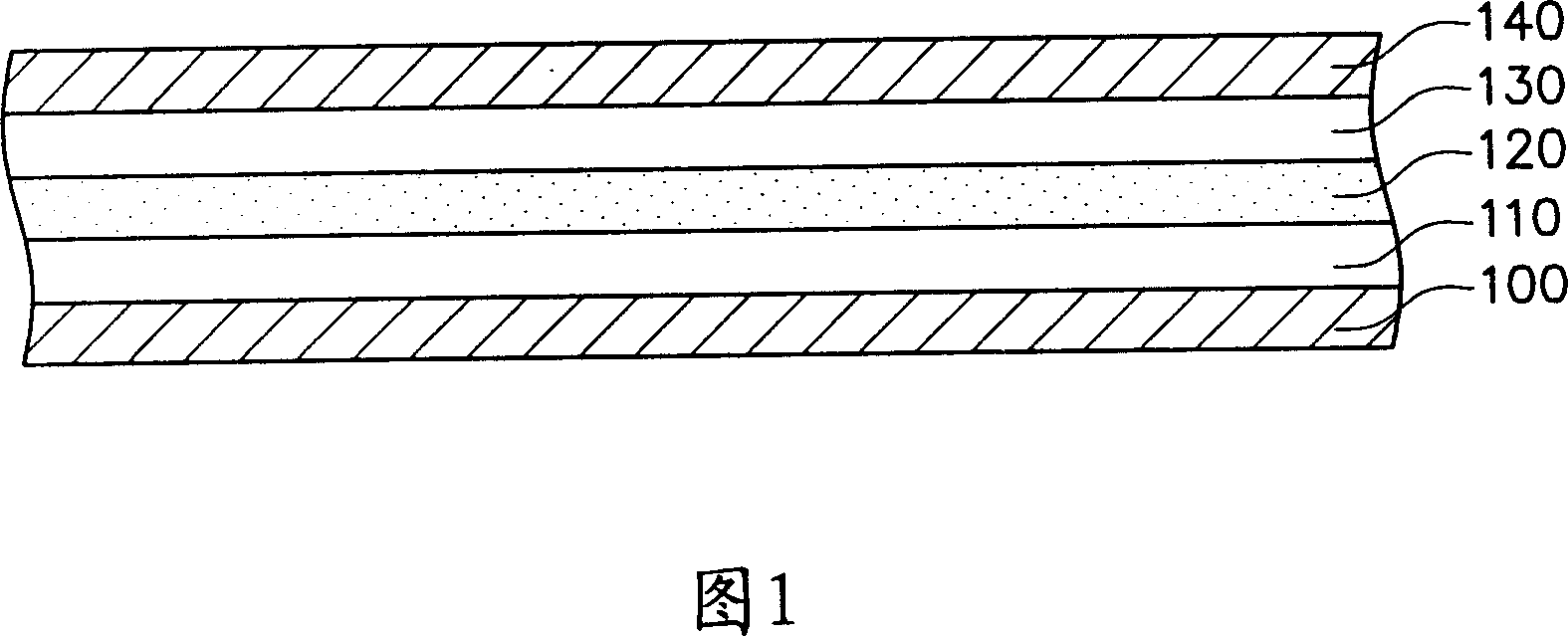

Flexible laminate having thermoplastic polyimide layer and method for manufacturing the same

InactiveUS20090035591A1Excellent heat resistance and electrical property and mechanical strengthEasy to manufactureSynthetic resin layered productsLaminationElectrical conductorHeat resistance

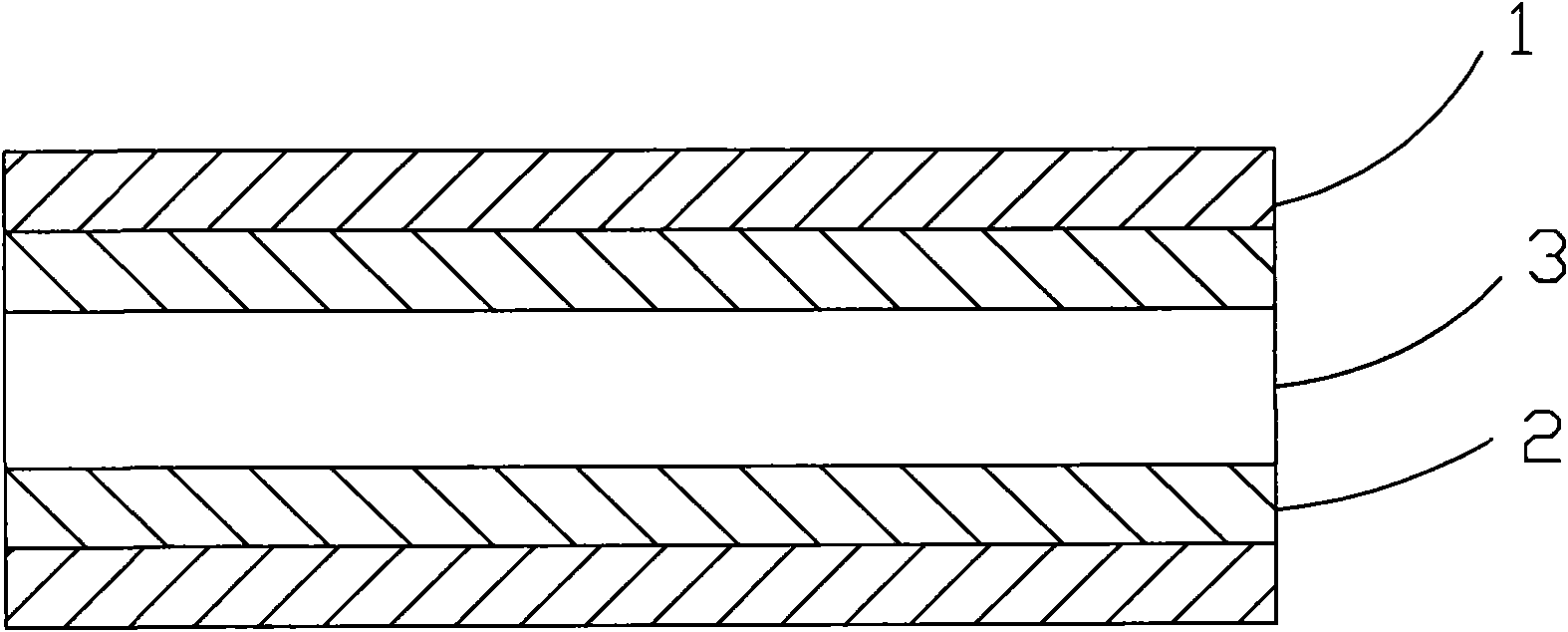

In a flexible laminate containing a metal foil layer / a thermoplastic polyimide layer or / and a conductor circuit layer / a thermoplastic polyimide layer, the metal foil layer or the conductor circuit layer is bonded to at least one side of the thermoplastic polyimide layer. The thermoplastic polyimide layer is formed from a thermoplastic polyimide resin film or sheet produced by melt extrusion of a thermoplastic polyimide resin. Alternatively, the thermoplastic polyimide layer is formed from a biaxially oriented thermoplastic polyimide resin film or sheet. Such a flexible laminate can be easily manufactured by a lamination method which comprises bonding a thermoplastic polyimide resin film (1) to a metal foil (2) or a conductive circuit layer (4) by heating under pressure, and has excellent heat resistance, electrical properties and mechanical strength inherent in a polyimide. When the biaxially oriented thermoplastic polyimide resin film or sheet is used, the flexible laminate can be improved in dimensional stability and resistance to soldering heat.

Owner:KURASHIKI BOSEKI KK +1

Laminate, printed circuit board, and preparing method thereof

InactiveUS20060048963A1Improve adhesion stabilityAchieve adhesion propertyInsulating substrate metal adhesion improvementMagnetic/electric field screeningHigh densityPrinted circuit board

A laminate which comprises a thermoplastic polyimide layer and a metal layer, or comprises a non-thermoplastic polyimide film layer and, formed on one or both surfaces, a thermoplastic polyimide layer and a metal layer; and a printed wiring board comprising the laminate. The laminate can be used for forming a high density circuit thereon, exhibits good resistance to further processing such as desmearing and excellent adhesion, and is excellent in adhesion reliability in a high temperature atmosphere.

Owner:KANEKA CORP

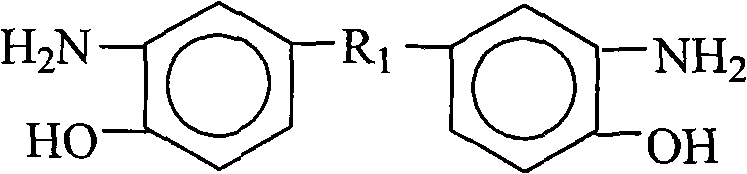

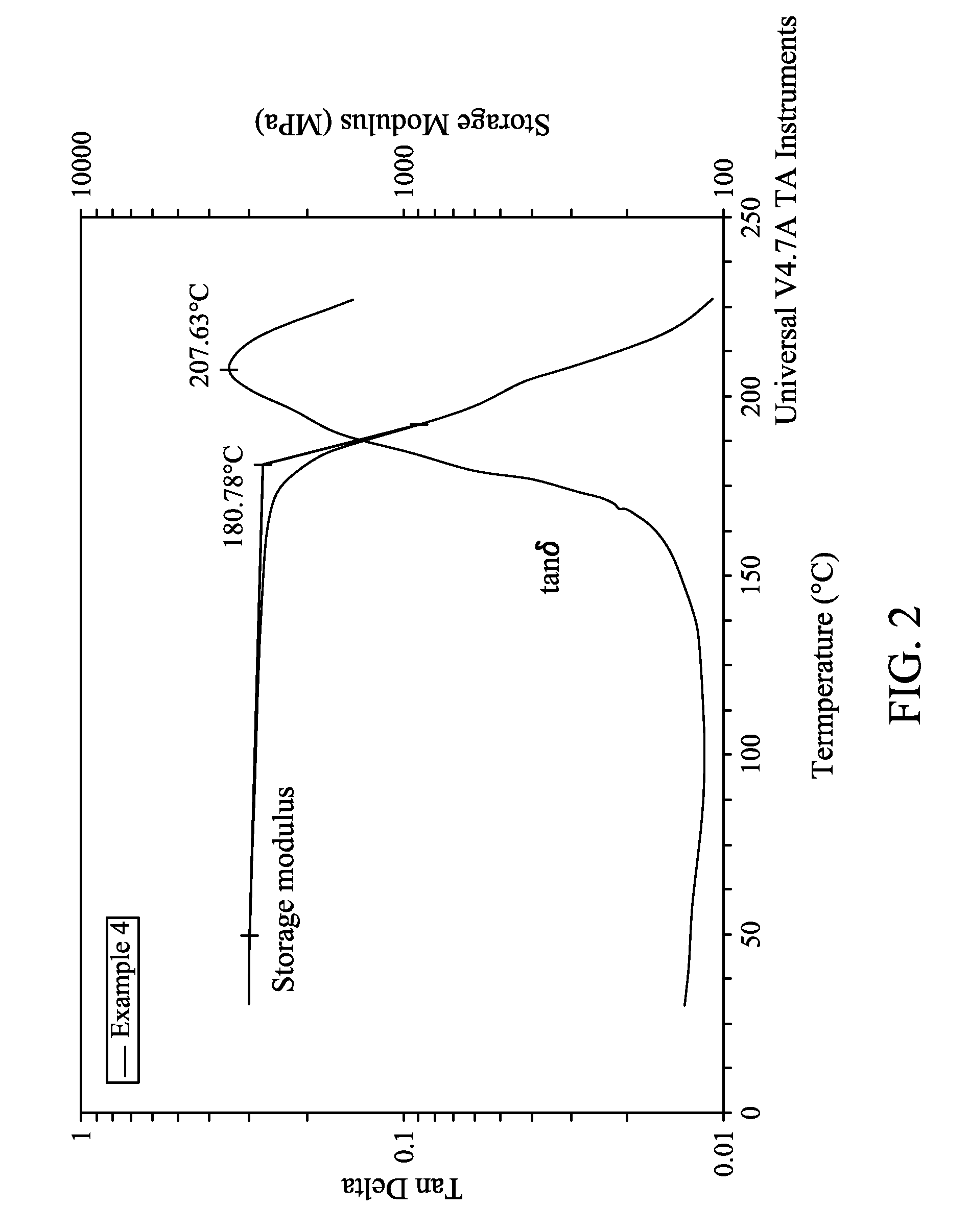

Aromatic diamines and polyimides based on 4,4'-bis-(4-aminophenoxy)-2,2' or 2,2',6,6'-substituted biphenyl

This invention relates the novel diamines, the polyimide oligomers and the polyimides derived therefrom and to the method of preparing the diamines, oligomers and the polyimides. The thermoplastic polyimides derived from the aromatic diamines of this invention are characterized as having a high glass transition temperature, good mechanical properties and improved processability in the manufacture of adhesives, electronic and composite materials for use in the automotive and aerospace industry. The distinction of the novel aromatic diamines of this invention is the 2,2',6,6'-substituted biphenyl radicals which exhibit noncoplanar conformation that enhances the solubility of the diamine as well as the processability of the polyimides, while retaining a relatively high glass transition temperature and improved mechanical properties at useful temperature ranges.

Owner:UNITED STATES OF AMERICA

Temp, resisting type carbon fibre emulsion sizing agent and its preparation process and application

The heat resisting emulsion sizing agent for carbon fiber consists of main sizing agent and assistant in 1-5 wt% of the main sizing agent. The main sizing agent is mixture of thermoplastic polyimide resin and glycidol ether type epoxy resin in the weight ratio of 50-90 to 10-50; and the assistant includes emulsifier, wetting agent and defoaming agent in the weight ratio of 10-80 to 10-80 to 10. The present invention has the advantages of low cost, stable performance, convenient use and no environmental pollution.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

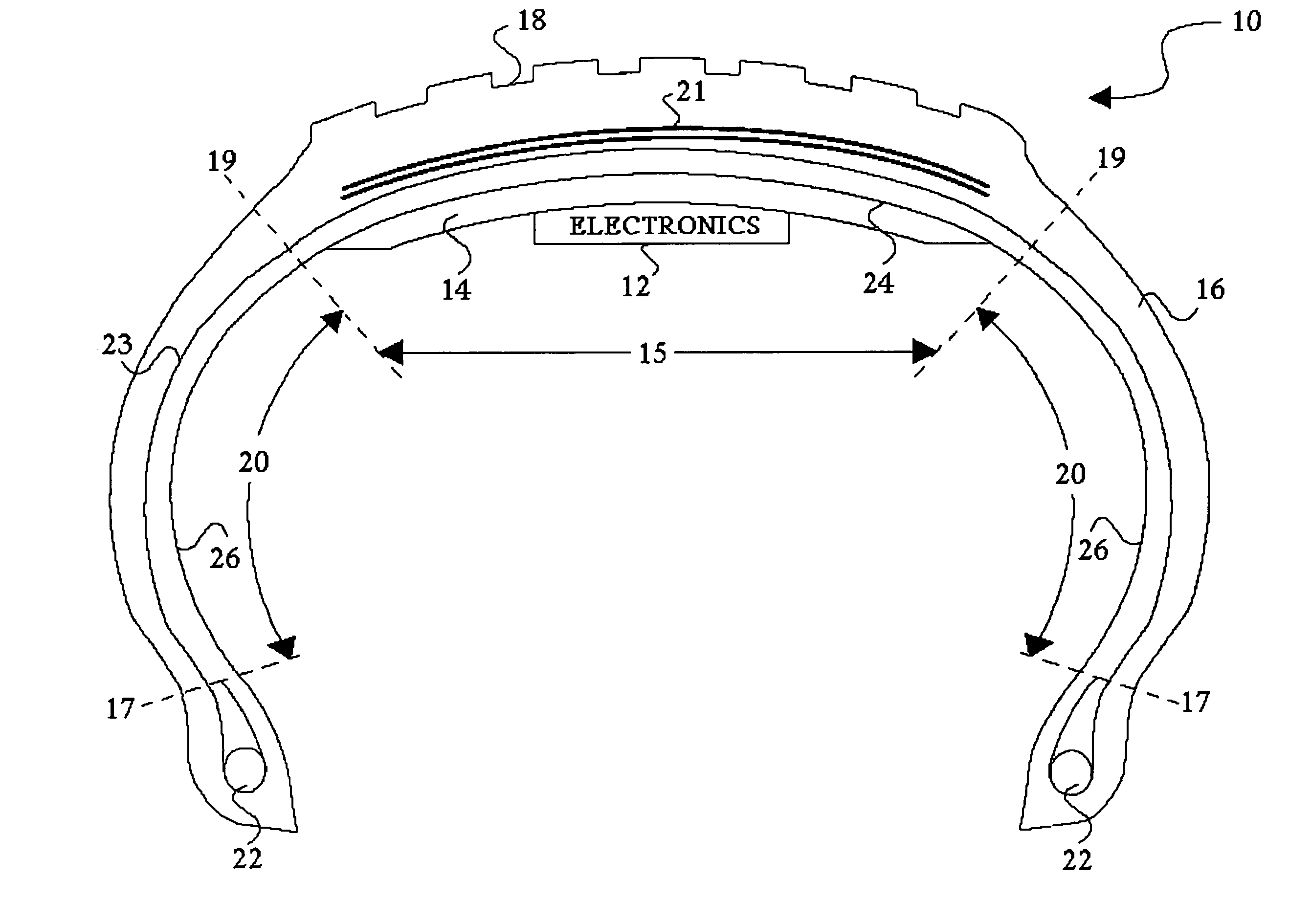

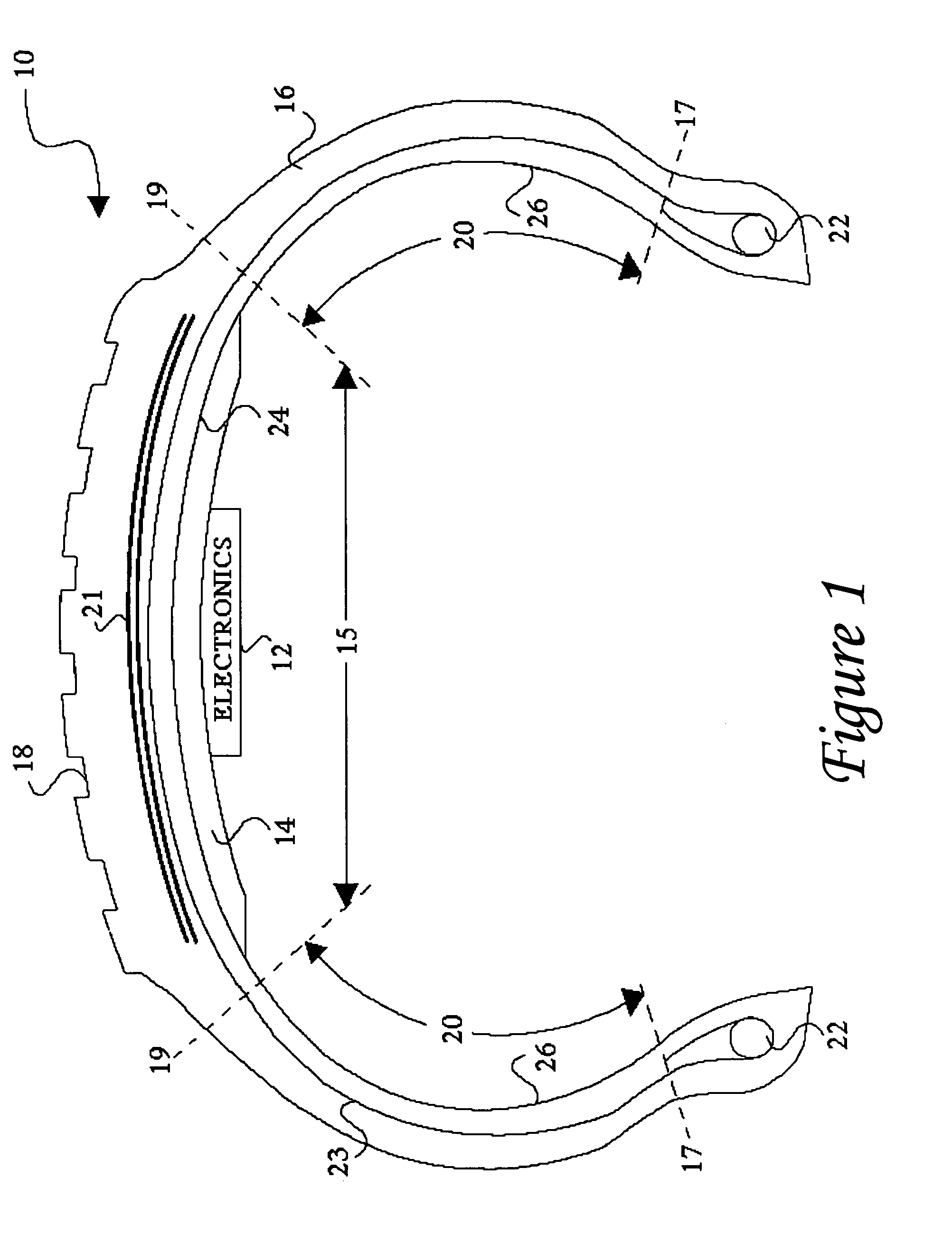

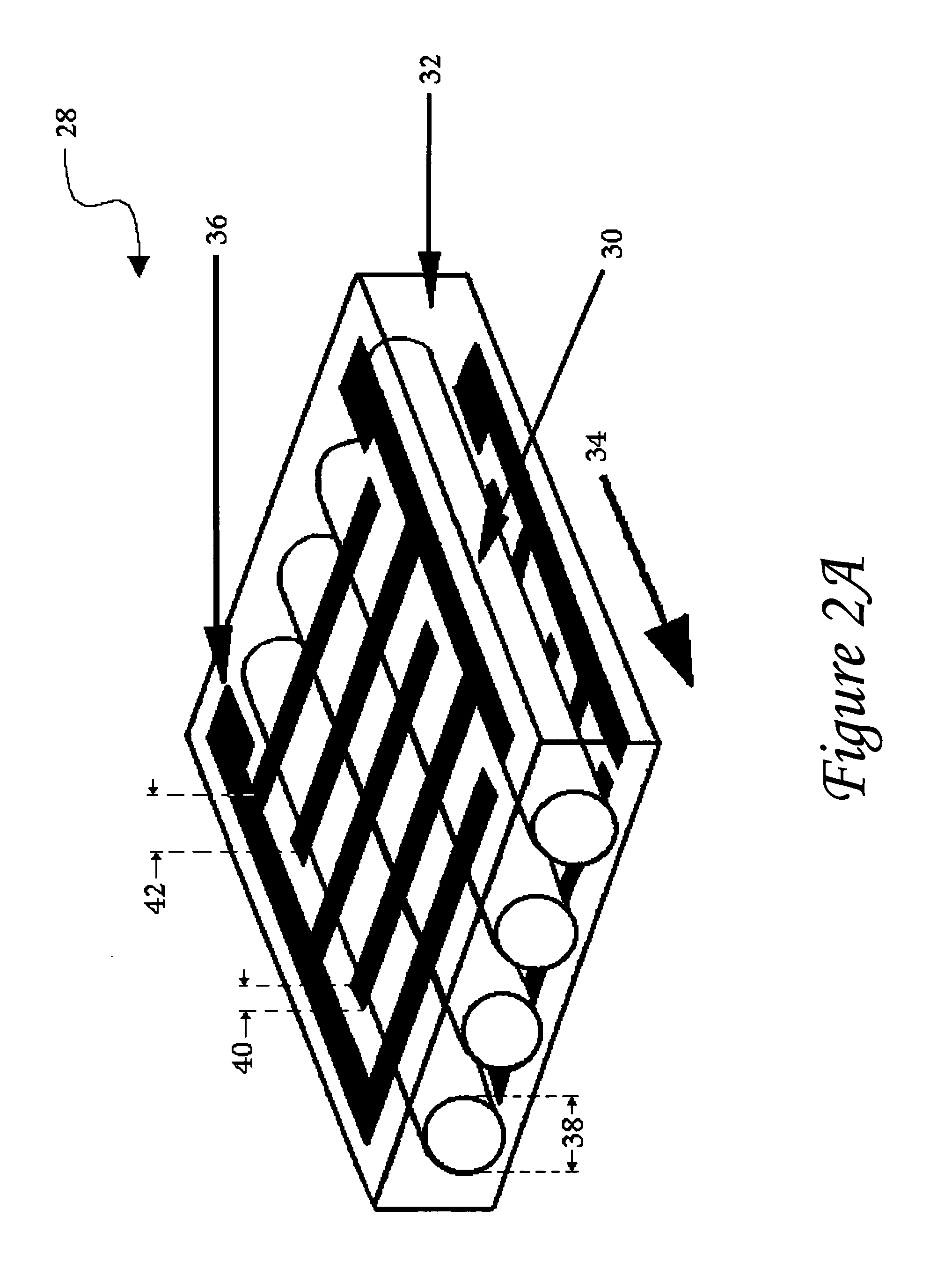

System and method for generating electric power from a rotating tire's mechanical energy

InactiveUS7096727B2Reduce amountFunction increaseAuxillary drivesBatteries circuit arrangementsElectric power systemMechanical energy

A tire assembly with integrated power generation features includes one or more piezoelectric devices and power conditioning modules. Piezoelectric devices may include a plurality of piezoelectric fibers embedded in a generally unidirectional fashion within an epoxy matrix, a piezoceramic wafer provided on a substrate and substantially surrounded by a protective casing, or a piezoceramic unimorph structure adhered with a thermoplastic polyimide to respective top and bottom conductive layers. Each piezoelectric device may include multiple piezoelectric elements connected in series and / or parallel arrangements, configured with respective poling directions in opposing or in-phase arrangements and / or configured in d33 or d31 displacement modes. Piezoelectric devices are preferably mounted within a tire or wheel assembly such that electric charge is generated therein as the wheel assembly moves along a ground surface and is subsequently stored in one or more energy storage devices. Stored energy may then be used to power electronics such as a tire monitoring system that wirelessly transmits such information as tire pressure, temperature and identification variables to a remote receiver location.

Owner:MICHELIN RECH & TECH SA

Thermoplastic polyimide resin film, multilayer body and method for manufacturing printed wiring board composed of same

InactiveCN1726259AHigh bonding strengthGood adhesionSynthetic resin layered productsLiquid/solution decomposition chemical coatingEngineeringThermoplastic polyimide

The present invention provides a circuit wiring board that has micro wiring circuits and excellent adhesive performance. The board is formed through the following steps: (1) a thermoplastic polyimide layer is formed on one side or both sides of a non-thermoplastic polyimide film so as to form a two-layer or three-layer structure; then Venus treatment is done on the thermoplastic polyimide layer so as to prepare a laminated body; (2) a polymer film is arranged; a layer of the combination of polyimide resin that has a specific structure and polyimide resin that contains thermoset component is arranged on one side or two sides of the film; and (3) at least one side is provided with a resin film and a laminated body thereof; wherein, the resin film has a surface shape, in which Ra1 is 0.05 Mu m to 1 Mu m when the critical value of arithmetic average roughness is 0.002mm and the ratio between Ra1 and Ra2 is 0.4 to 1 when the critical value is 0.1mm.

Owner:KANEKA CORP

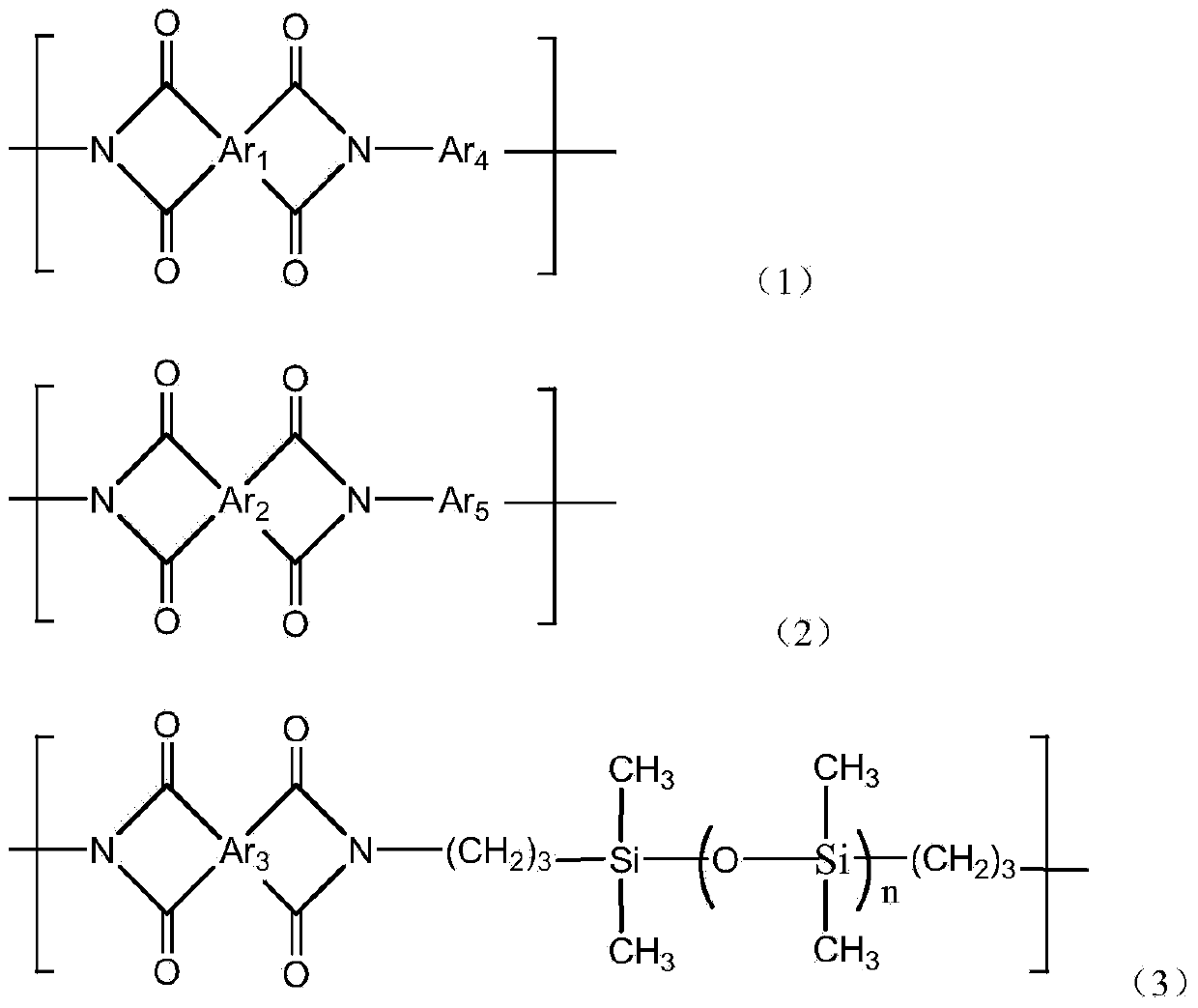

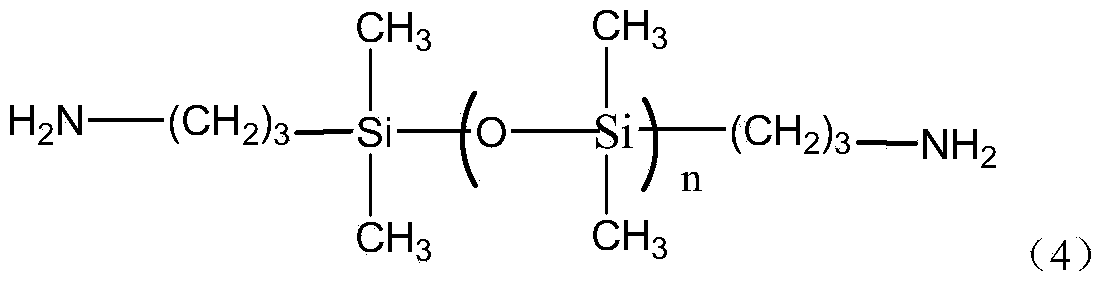

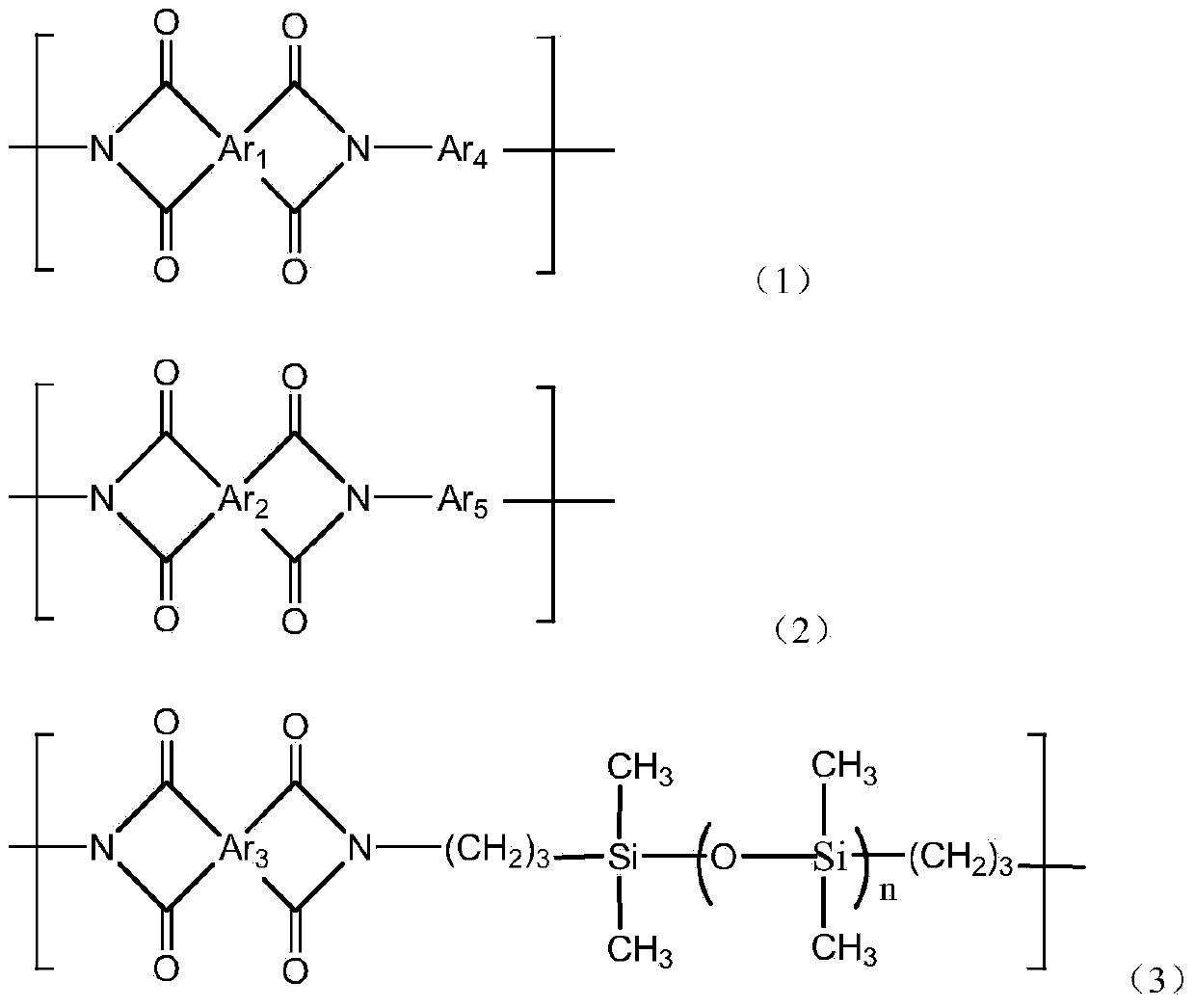

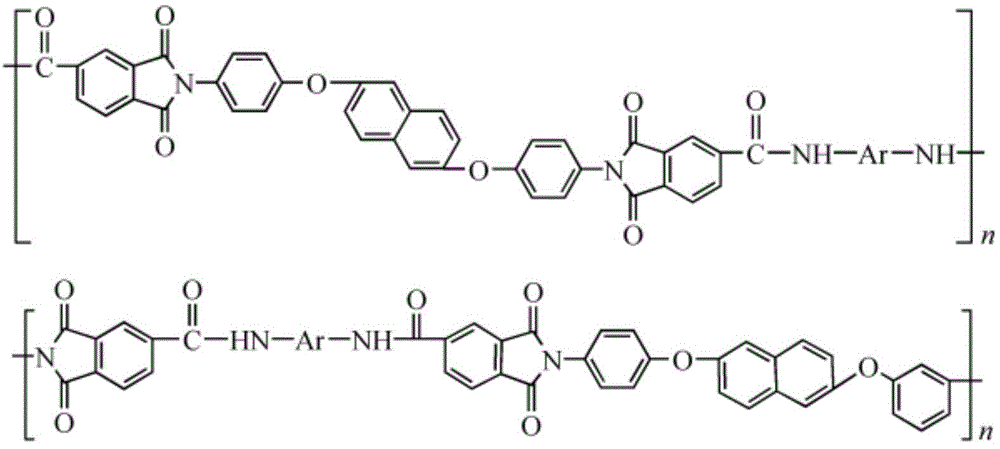

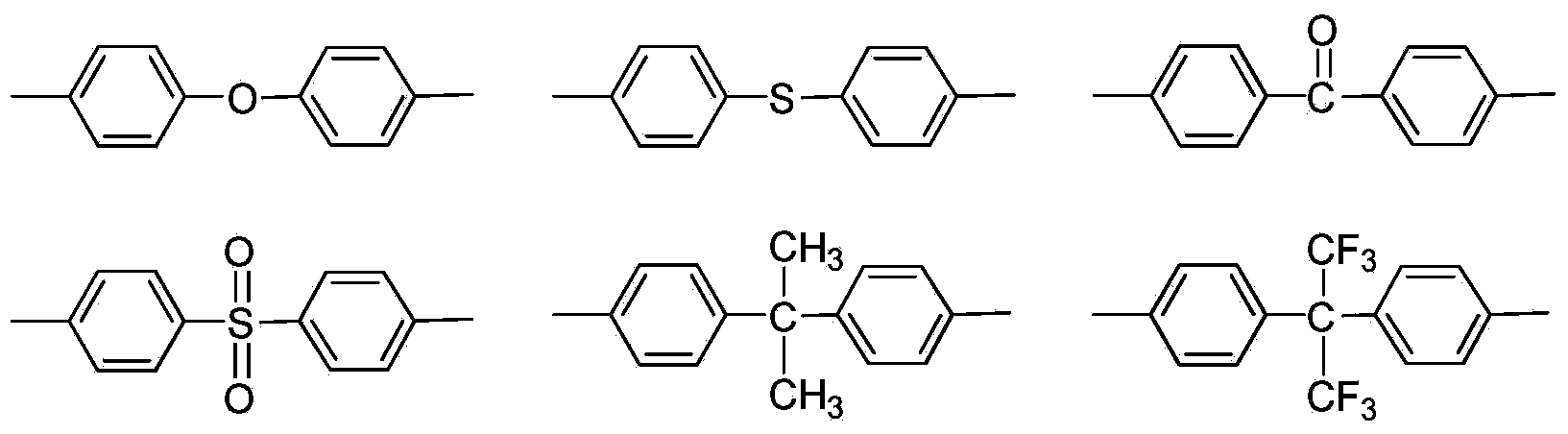

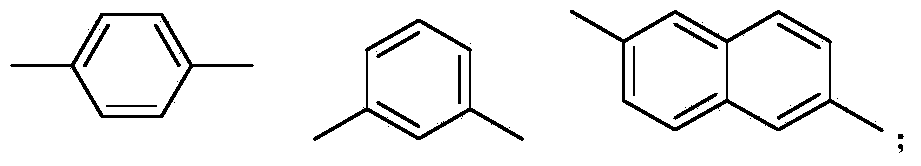

Thermoplastic polyimide and method for preparing flexible copper-clad plate from thermoplastic polyimide

ActiveCN103739842AGood adhesionImprove heat resistanceSynthetic resin layered productsMetal layered productsCopperStructural unit

The invention provides a thermoplastic polyimide which is prepared by polymerizing a diamine monomer and a dianhydride monomer. The thermoplastic polyimide is characterized by comprising at least one of structural units expressed by a general formula (1), a general formula (2) and a general formula (3) as shown in specification, wherein the proportion of the structural unit expressed by the general formula (1) is more than 30mol%, the proportion of the structural unit expressed by the general formula (2) is more than 10mol%, the proportion of the structural unit expressed by the general formula (3) is more than 10mol%, and n in the general formula (3) is an positive integer greater than 1; Ar1, Ar2 and Ar3 are quadrivalent aromatic groups, Ar4 is a bivalent aromatic group containing hetero atoms, and Ar5 is a bivalent aromatic group without hetero atoms. The thermoplastic polyimide is mainly terminated with the anhydride group, and can be applied to the production of a no-adhesive flexible copper-clad plate by a two layer method.

Owner:RAYITEK HI TECH FILM CO LTD

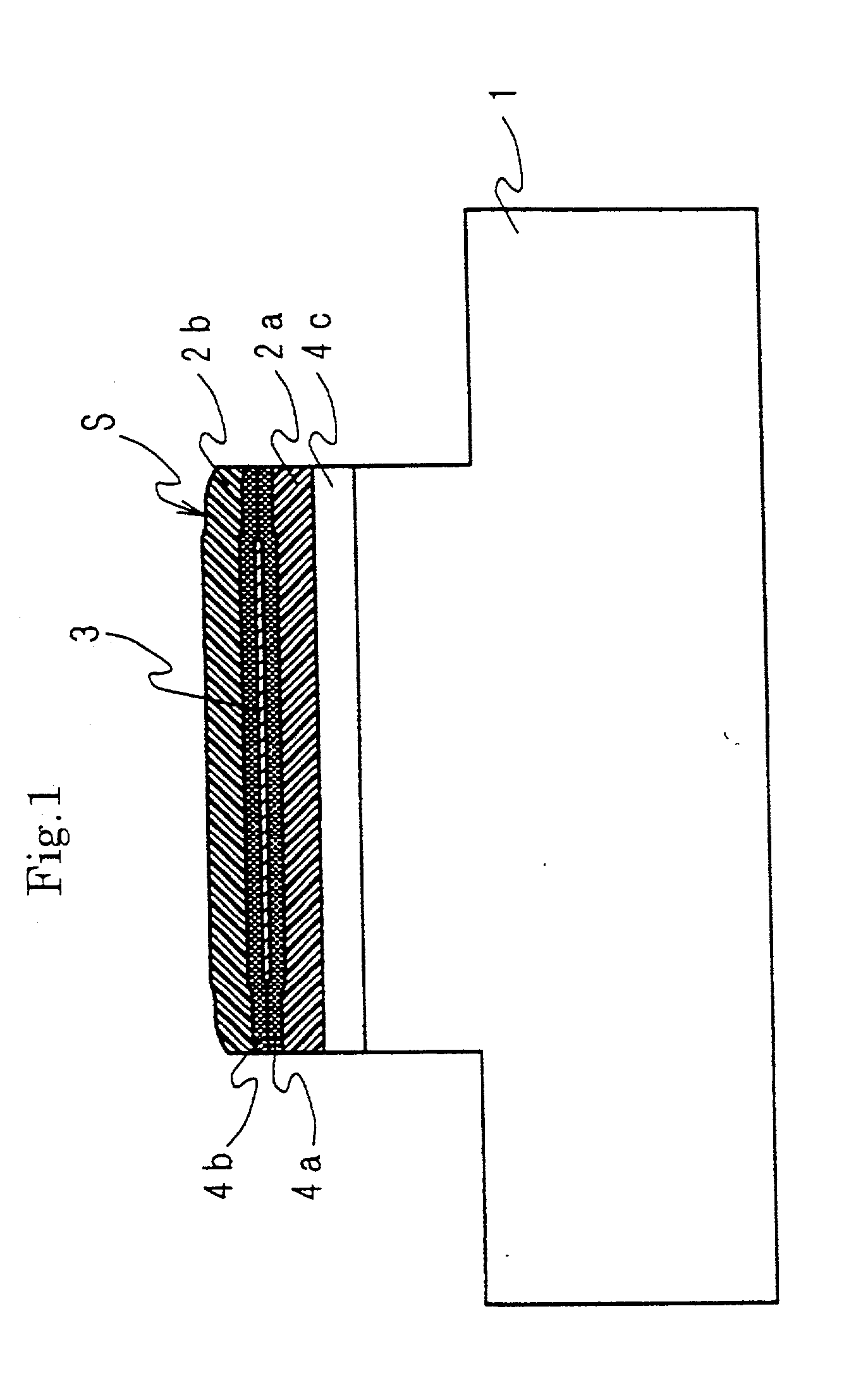

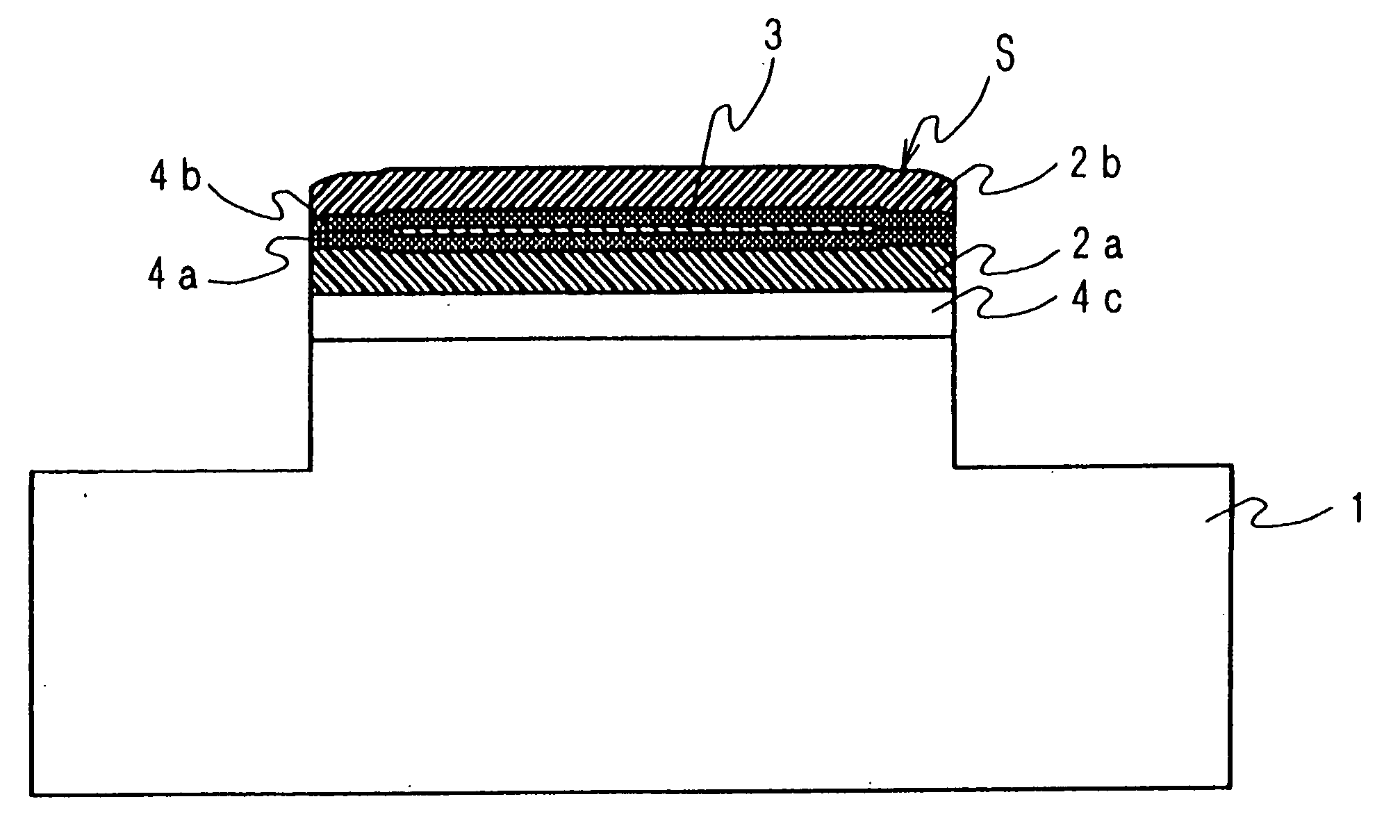

Electrostatic chucking device and manufacturing method thereof

InactiveUS20020021545A1Improve abilitiesIncreased durabilitySleeve/socket jointsSemiconductor/solid-state device manufacturingInsulation layerHeat resistance

The present invention discloses an electrostatic chucking device having a laminated structure which is formed by sequentially laminating a first insulation layer, an electrode layer and a second insulation layer on metal substrate, wherein the first insulation layer and the second insulation layer are constituted of polyimide films, and at least the adhesion between the metal substrate and the first insulation layer, and, preferably, further, the adhesions including the adhesion between the first insulation layer and the electrode layer and the adhesion between the electrode layer and the second insulation layer are performed by using thermoplastic polyimide-based adhesive films having a film thickness of 5 to 50 mum. Further, to manufacture the electrostatic chucking devices having such a constitution, the present invention also discloses an electrostatic chucking device manufacturing method which performs the low-temperature compression bonding processing under pressure at a temperature of 100 to 250° C. between the metal substrate and the first insulation layer, between the first insulation layer and the electrode layer, and between the electrode layer and the second insulation layer using thermoplasticpolyimide-based adhesion films. According to the present invention, the electrostatic chucking device can exhibit the excellent attraction performance over a long period while ensuring the excellent durability and the excellent heat resistance. Further, the method can manufacture the electrostatic chucking devices which do not contaminate a periphery of the device and a wafer.

Owner:CREATIVE TECH CORP

Low-melt-viscosity thermoplastic polyimide material and 3D printing moulding method thereof

ActiveCN103980489AOutstanding performanceHighlight application valueSolventUltimate tensile strength

The invention discloses a low-melt-viscosity thermoplastic polyimide material which is used for 3D printing. Molecular structure of the thermoplastic polyimide material is subjected to a modification process (such as introducing a special flexibility structure unit, a large side group or solvophilic group, a twisted and non-coplaner structure, characteristic atoms such as a heterocycle and a fluorine silicon and the like, and carrying out a main chain copolymerization reaction) to enable the polyimide material to be meltable and thus to have good processability a well processing performance. The polyimide material, after being mixed with a heat stabilizer and a reinforcing agent, is manufactured into a high-performance polyimide product in a manner of melting 3D printing technology. The polyimide material widens a selectable range of present 3D printing materials. With the high-performance and low-melt-viscosity thermoplastic polyimide as a 3D printing material, the high-performance polyimide product prepared from the polyimide material has excellent high temperature resistance performance, corrosion resistance performance and mechanical strength.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Laminate, printed wiring board and method for manufacturing them

InactiveCN1720136AImproves bond stabilityImprove bond reliabilityPrinted circuit manufactureMetal layered productsHigh densityEngineering

The invention provides a laminate which can be used for forming a high density circuit thereon, with good resistance to further processing such as decontamination and excellent adhesion, and excellent adhesion reliability in a high temperature atmosphere, as well as a print circuit wiring board, that is, the invention relates to a laminate and a print circuit wiring board, comprising a thermoplastic polyimide film layer and a metal layer which are formed on one side or two sides thereof or a non-thermoplastic polyimide film layer.

Owner:KANEKA CORP

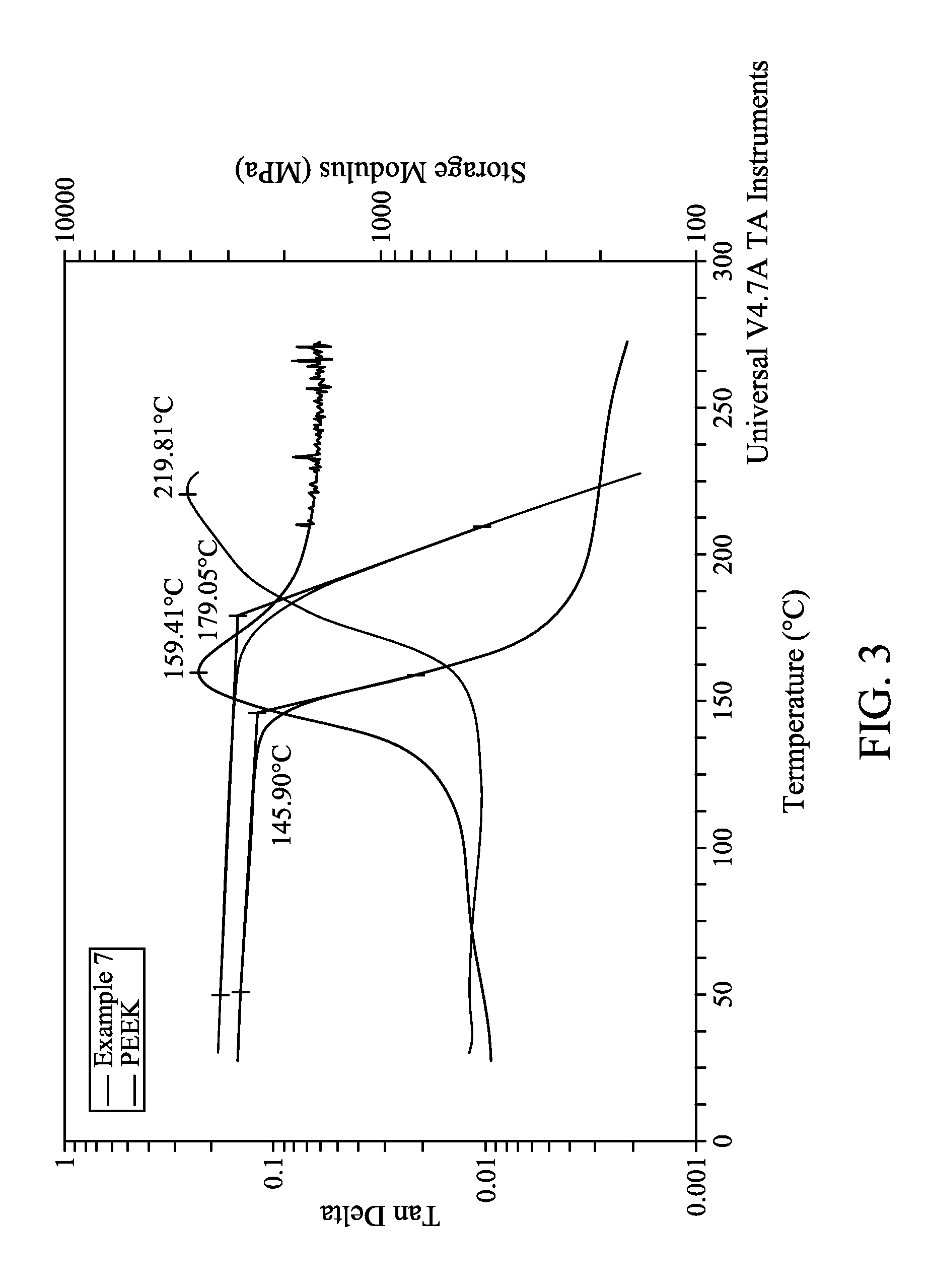

High temperature polymer blends of poly(aryl ether ketone phthalazinone)

The present invention provides high temperature compositions comprising blends of a first polymer, poly(aryl ether ketone phthalazinone)s, and a second polymer, selected from poly(aryl ether ketone)s, poly(aryl ketone)s, poly(ether ether ketone)s, poly(ether ketone ketone)s, or polybenzimidazoles, thermoplastic polyimides, polyetherimides, poly(aryl ether sulfone)s, poly(phenylene sulfide)s, and mixtures thereof. The compositions have improved high temperature characteristics, e.g., improved high temperature load capability and improved high temperature melt processibility.

Owner:POLYMER INSTR & CONSULTING SERVICES LTD

Preparation of low thermal expansion coefficient thermoplastic polyimide film

The invention relates to a preparation method of a thermoplastic polyimide film with low coefficient of thermal expansion, which obtains an objective product by copolymerization, sol-gel process and condensation. Two different diamine and dianhydride are added into copolyreaction to generate polyreaction. A sol-gel in situ method is adopted, the reaction process is easy to control, the purity of the product is good and the uniformity is good; and the obtained solution is heated step by step in a vacuum oven and carries out condensation. The preparation technique is simple and is easy to control; the obtained product has better heat resistance; and the invention is suitable for being used by flexible copper clad laminate and has higher application value in the industry.

Owner:NANJING UNIV OF TECH

Polyimide Resin Composition, Polymer Film Containing Polymide Resin and Laminate Using the Same, and Method for Manufacturing Printed Wiring Board

InactiveUS20070269665A1High heating temperatureImprove featuresInsulating substrate metal adhesion improvementSynthetic resin layered productsHigh humidityThiol

The present invention relates to a polyimide resin composition including an organic thiol compound and a thermoplastic polyimide resin, a polymeric film containing the polyimide resin, a laminate including the same, and a printed circuit board. By using the polyimide resin composition, it is possible to form an electroless plating film having high adhesive strength even under high-temperature, high-humidity conditions in spite of the fact that the surface roughness of the insulating layer is extremely low. Furthermore, by using the polymeric film and a laminate including the polymeric film and a metal layer, it is possible to obtain a printed circuit board capable of forming high-density circuit and having excellent adhesiveness, and excellent adhesion reliability in a high-temperature, high-humidity environment.

Owner:KANEKA CORP

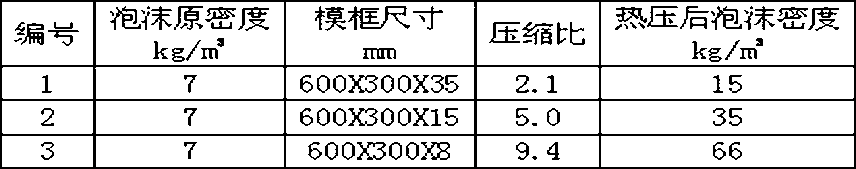

Novel mould-pressing polyimide foamed plastic and preparation method thereof

The invention discloses a novel mould-pressing polyimide foamed plastic and a preparation method thereof. The foamed plastic comprises the following chemical components based on 100 mass parts of aromatic dianhydride: 100 parts of aromatic dianhydride, 60-70 parts of solvent, 60-65 parts of aromatic diamine, 100-130 parts of fatty alcohol, 1-5 parts of a foam stabilizing agent, 0.5-1 part of a catalyst and 20-30 parts of a foaming agent. The preparation method comprises the following steps of: (1) esterifying the aromatic dianhydride and the fatty alcohol to prepare diacid diester; (2) reacting the diacid diester with the aromatic dianhydride to prepare a precursor solution; (3) preparing a surfactant and a catalyst removal solvent by the precursor solution, drying and grinding into powder; (4) preparing a melt by taking the water as a foaming agent; (5) by a microwave foaming process, preparing a thermoplastic polyimide foam body; and (6) cutting the foam body and carrying out mould-pressing to prepare polyimide foam boards differing in density. The novel mould-pressing polyimide foamed plastic disclosed by the invention is simple in preparation process, dense and uniform in foam bubbles, low in preparation cost and easy in industrial production.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

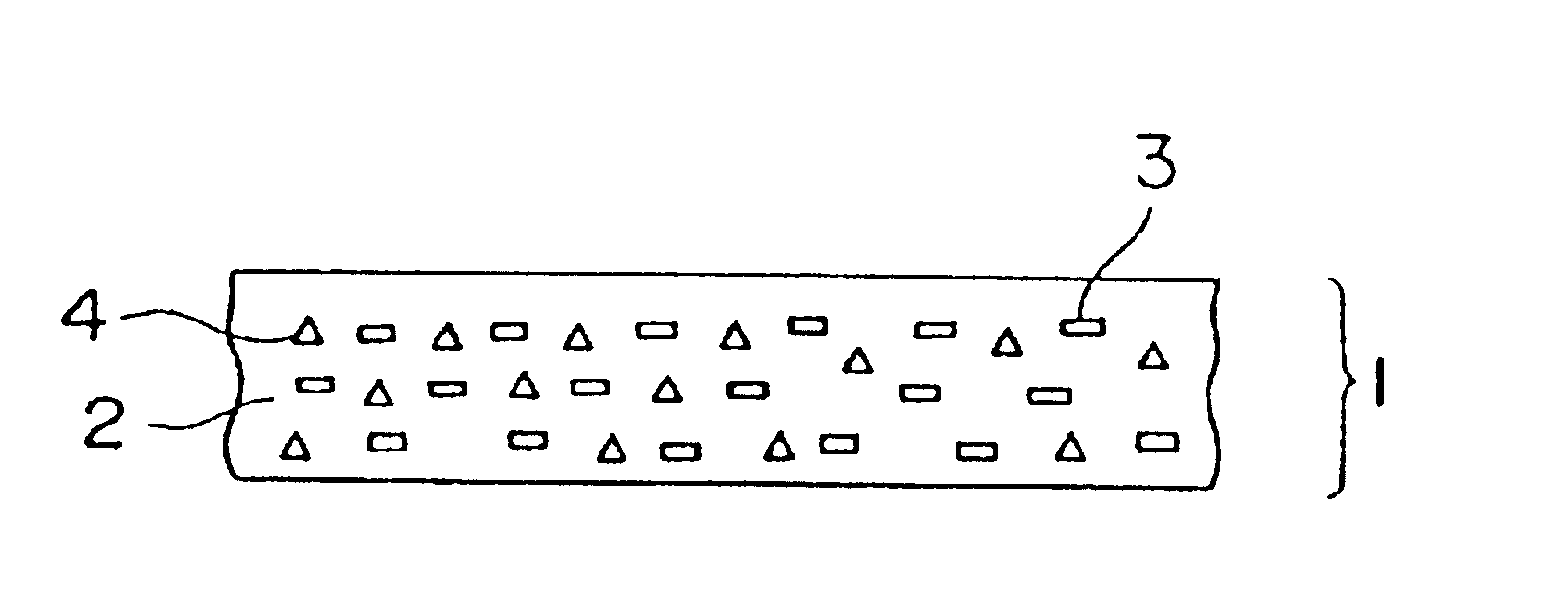

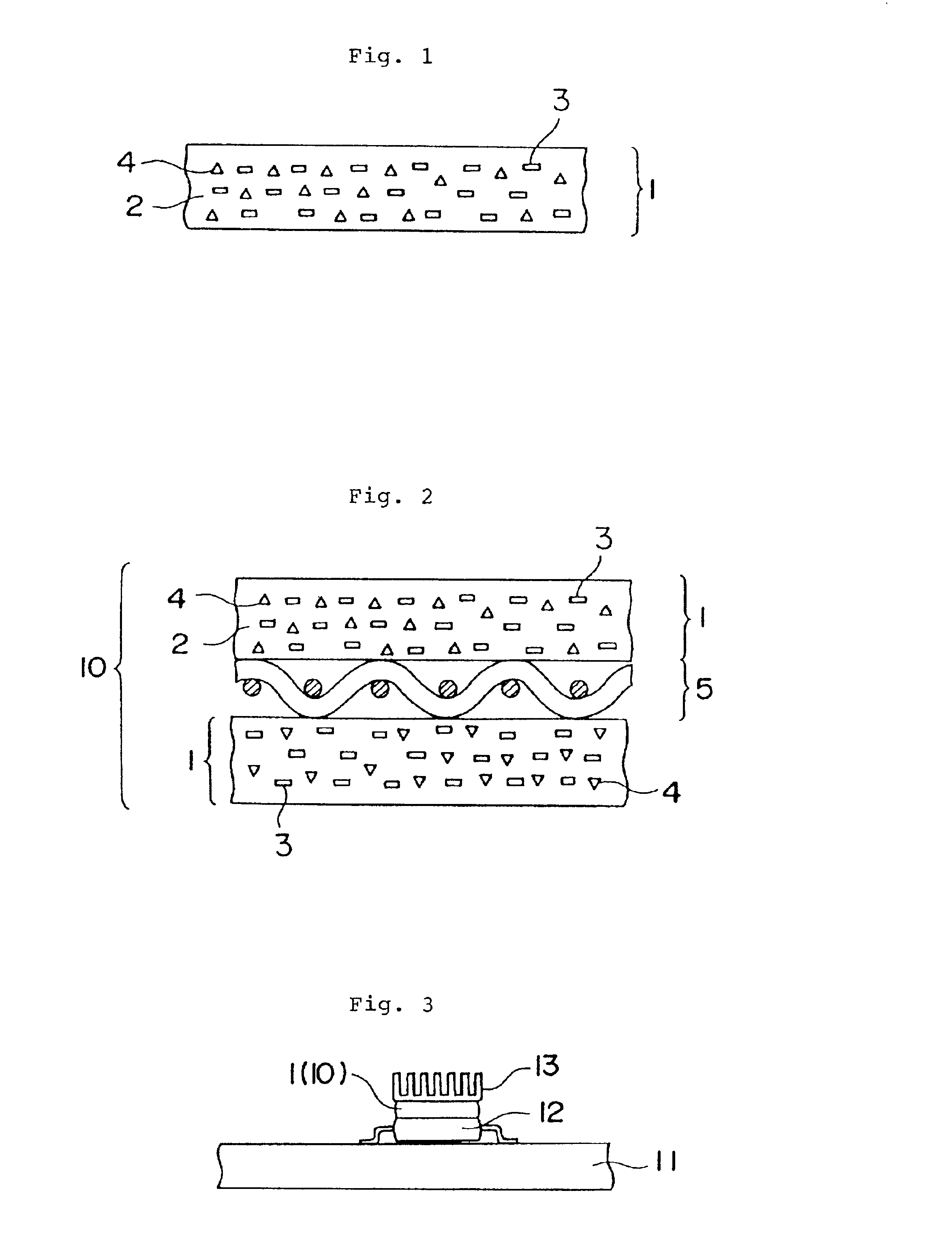

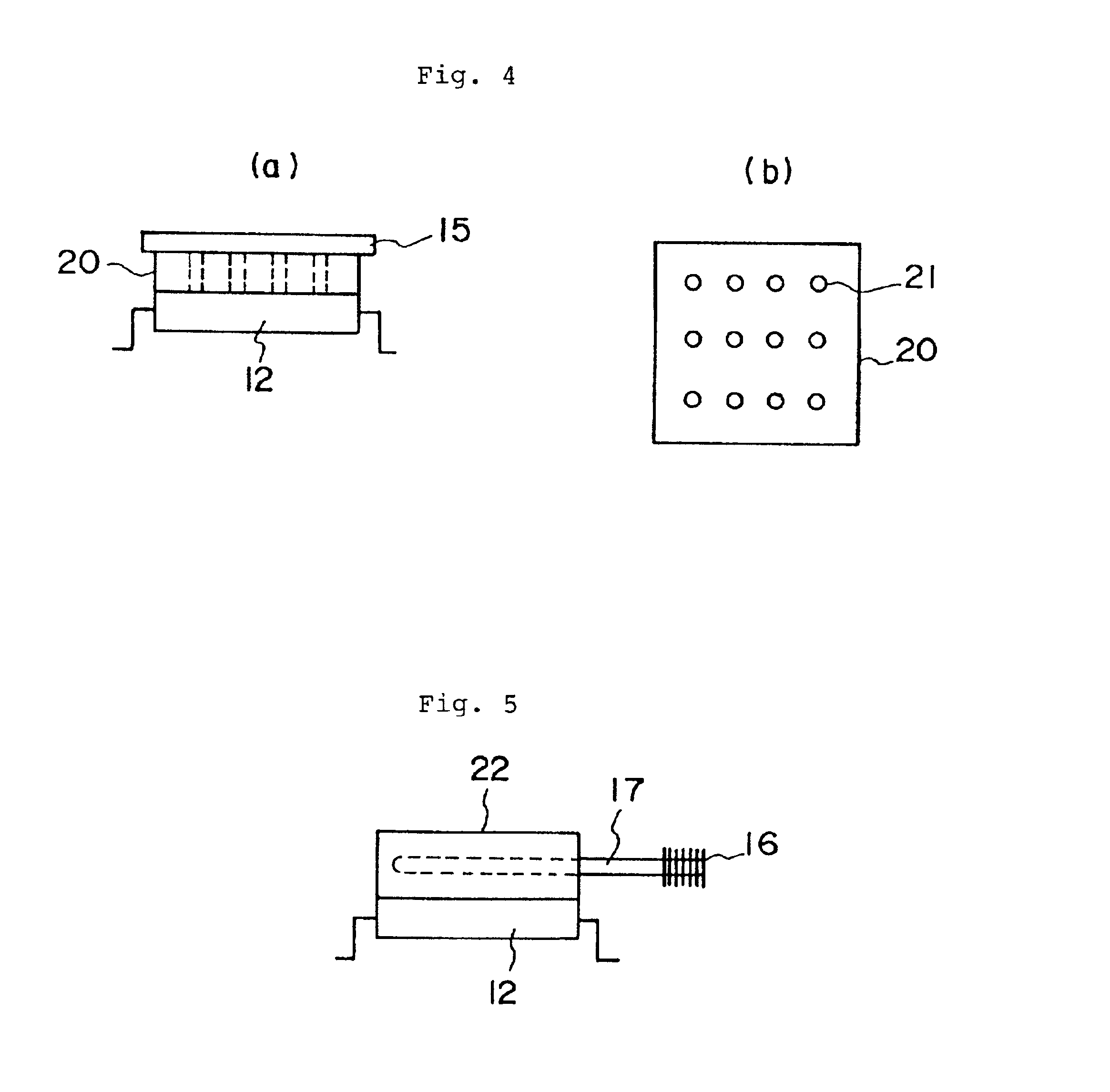

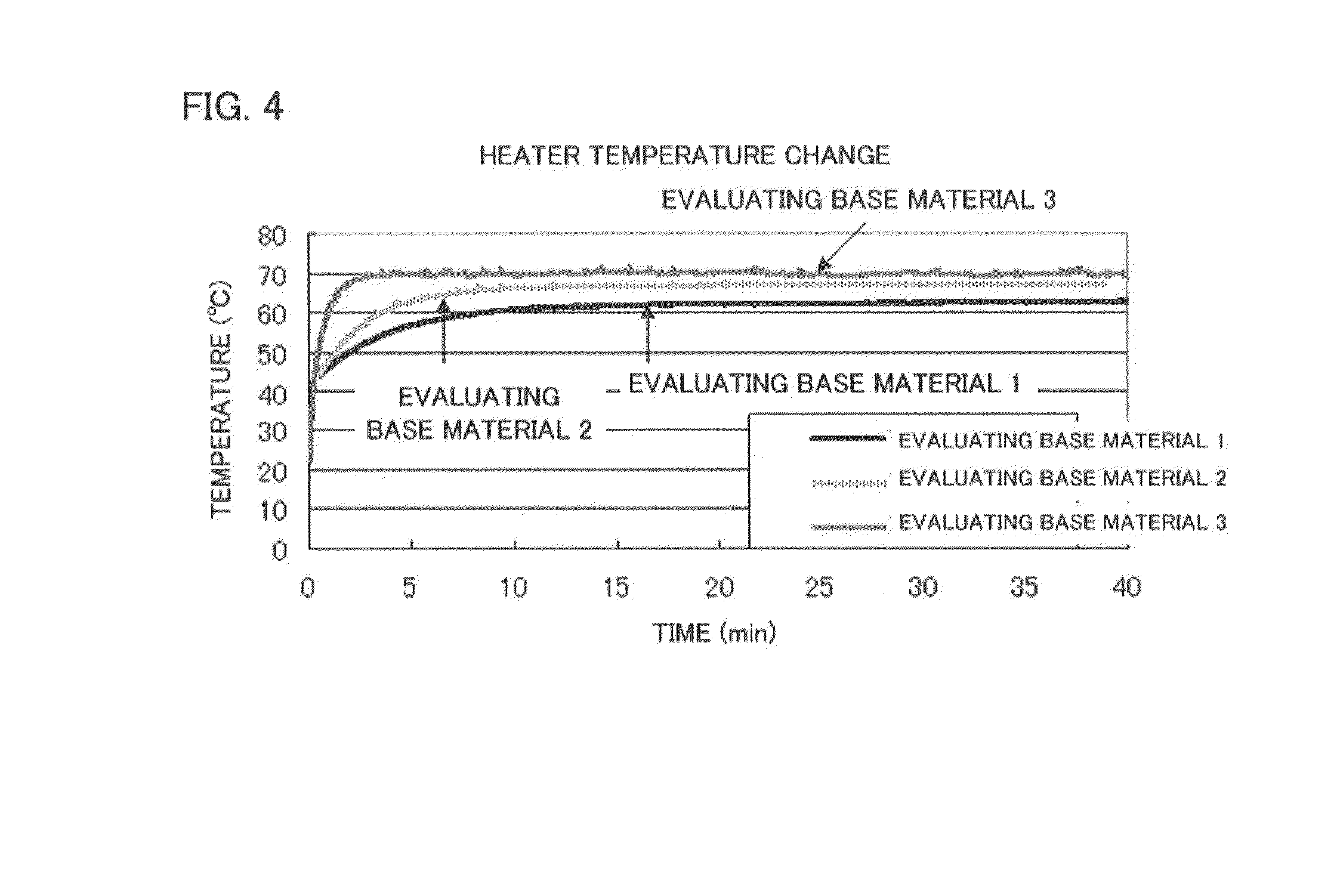

Highly heat-conductive composite magnetic material

InactiveUS6962753B1Improve thermal conductivityMagnetic/electric field screeningSemiconductor/solid-state device detailsElectromagnetic interferenceThermoplastic polyimide

In a composite magnetic body comprising soft magnetic powder dispersed in an organic binding agent and having an electromagnetic interference suppressing effect, powder excellent in thermal conductivity is further dispersed into the organic binding agent so as to provide a composite magnetic body excellent in thermal conductivity. This composite magnetic body may also be used as a heat dissipation sheet for an electronic device. Further, it may also constitute a heat sink having an electromagnetic interference suppressing effect. As the organic binding agent, thermoplastic polyimide or liquid crystal polymer can be cited. As the powder excellent in thermal conductivity, Al2O3, AlN, cubic BN, insulating SiC or a heat conductive reinforcement (capton) can be cited.

Owner:TOKIN CORP

Electrostatic chucking device and manufacturing method thereof

InactiveUS20040160021A1Improve abilitiesIncreased durabilitySleeve/socket jointsSynthetic resin layered productsInsulation layerEngineering

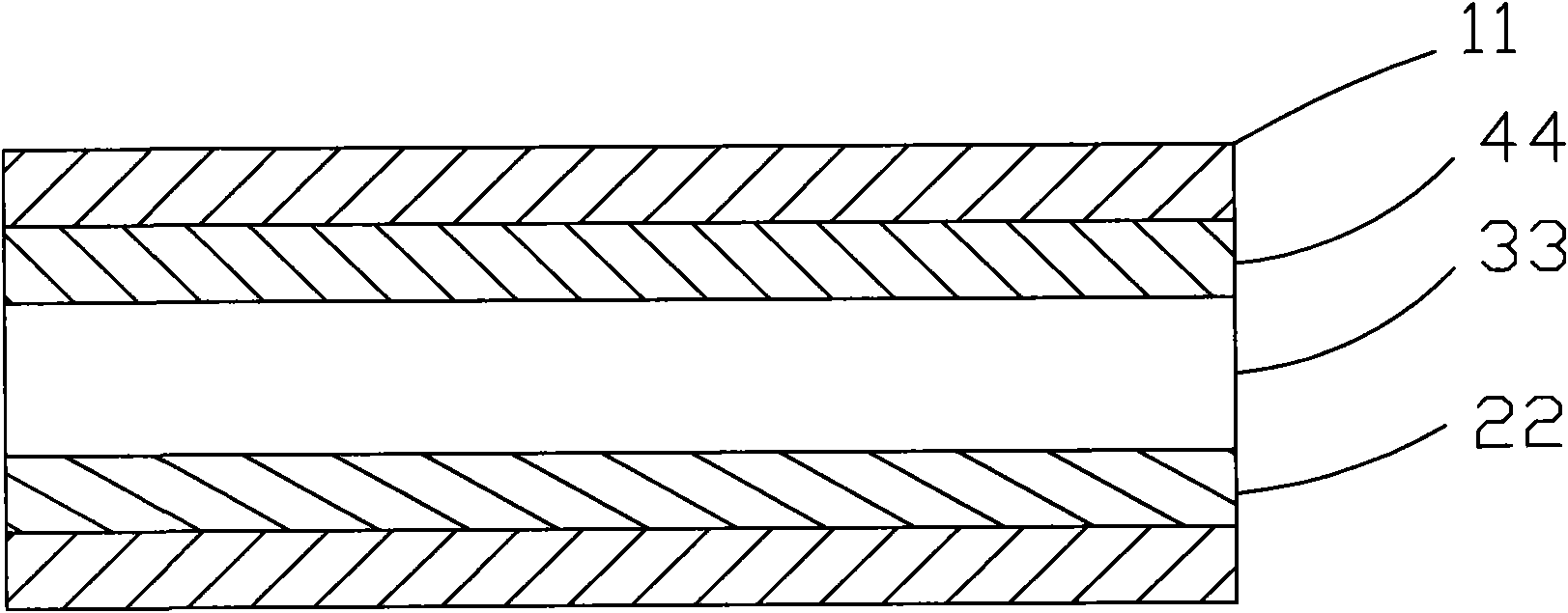

An electrostatic chucking device having a laminated structure formed by sequentially laminating a first insulation layer, an electrode layer, and a second insulation layer on a metal substrate. The first and second insulation layers are formed from polyimide films. At least one adhesion layer is provided between the metal substrate and the first insulation layer, and is a thermoplastic polyimide-based adhesive film having a film thickness of 5 to 50 mum.

Owner:CREATIVE TECH CORP

Process for producing adhesive film

ActiveUS20070158869A1Control expansionGood dimensional stabilitySynthetic resin layered productsElectrical equipmentHeat resistanceThermoplastic polyimide

A process for producing an adhesive film includes laminating an adhesive layer containing thermoplastic polyimide onto at least one surface of a highly heat-resistant polyimide layer by coextrusion casting method, wherein a chemical dehydrator and a catalyst are contained in a precursor solution of the highly heat-resistant polyimide and / or a solution containing either the thermoplastic polyimide or a precursor of the thermoplastic polyimide.

Owner:KANEKA CORP

Preparation method of dual-layer glue-free type double-face flexible copper-clad plate

ActiveCN104325774AImprove heat resistanceGood dimensional stabilityLaminationLamination apparatusCopper foilThermoplastic polyimide

The invention discloses a preparation method of a dual-layer glue-free type double-face flexible copper-clad plate. The plate is composed of a thermosetting polyimide layer, a thermoplastic polyimide layer, and two copper foil layers. The preparation method comprises the following steps: painting a thermosetting polyimide precursor solution on a copper foil to form a non-imidized precursor dry membrane; then painting a thermoplastic polyimide precursor solution on the copper foil to form a thermoplastic polyimide precursor dry membrane; then subjecting the polyimide precursor dry membranes to high-temperature imidization, covering a copper foil on the membrane-covered copper foil, and pressing. In the provided preparation method, only one high-temperature heat treatment is required during the production process, and thus the production cost is reduced. Moreover, the problem that layering easily appears between the multiple polyimide layers of the double-face flexible copper-clad plate is also solved by the preparation method, and the obtained polyimide layers are tightly bonded, so the performance of the copper-clad plate is more excellent, and the copper-clad plate is more practical.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Preparation method of 3D printing rapid-prototyping precoated sand

InactiveCN105195667AStable in natureHigh surface glossFoundry mouldsFoundry coresStearic acidAmmonium bromide

The invention discloses a preparation method of 3D printing rapid-prototyping precoated sand. The method is characterized by comprising the steps that 1, fused ceramite is washed with water, soaked in a water solution with hexadecyl trimethyl ammonium bromide mass percentage concentration being 1-2%, filtered, washed with water to be neutral and dried to obtain pretreated fused ceramite; 2, by mass, 89-94% of pretreated fused ceramite, 2-5% of thermoplastic polyimide, 2-5% of phenolic resin, 0.4-1.0% of bisphenol A type dianhydride, 0.4-1.0% of glyceryl monostearate and acetone are added into a stirring machine, a grinding machine is started to rotate by 120 turns per minute, the mixture is ground for 30 min and then dried, and therefore the 3D printing rapid-prototyping precoated sand is obtained. The precoated sand can be directly molded under laser sintering, and has the advantages that the preparation process is simple, the conditions are easy to control, the production cost is low, and industrial production is easy to achieve.

Owner:UNIV OF JINAN

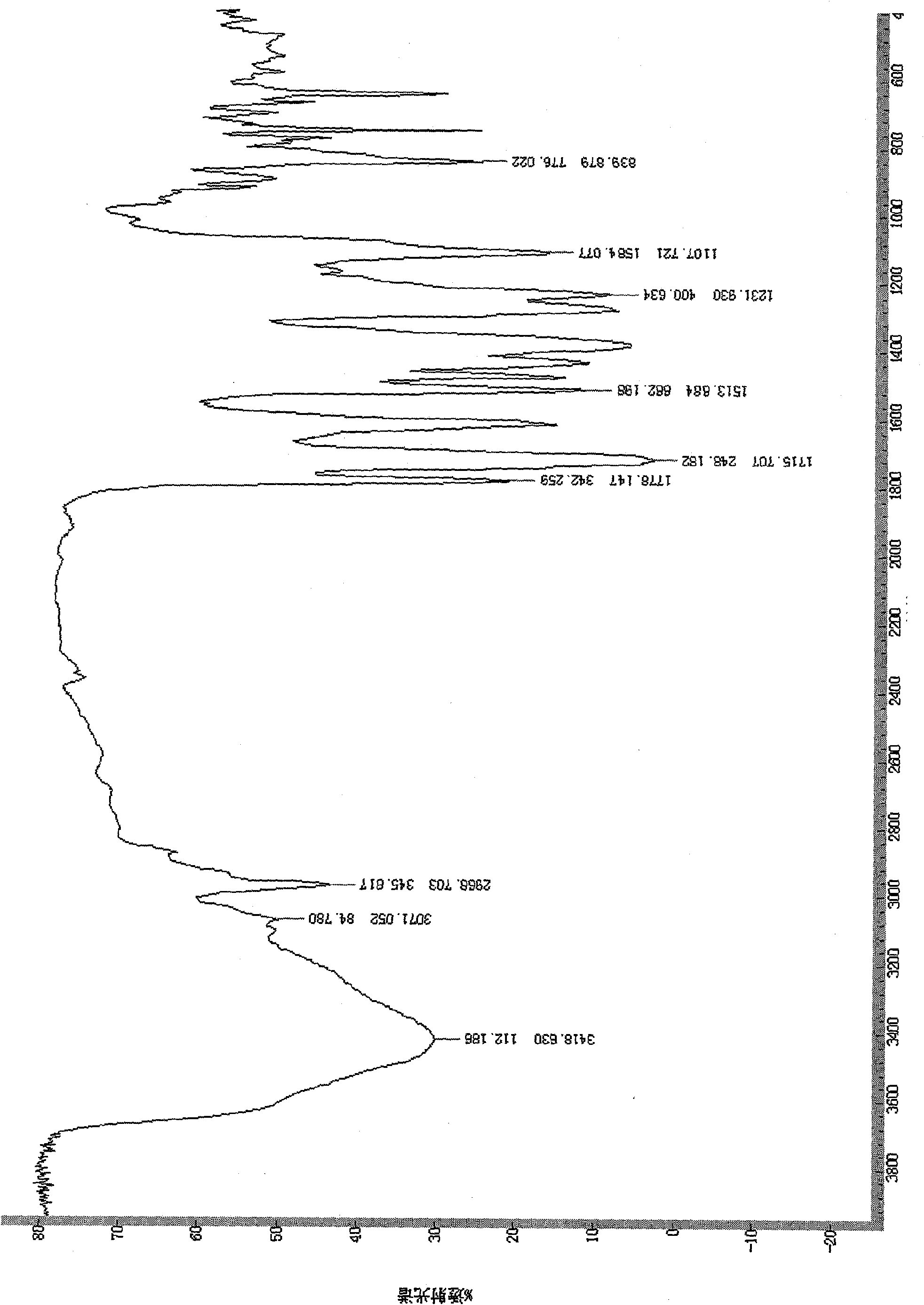

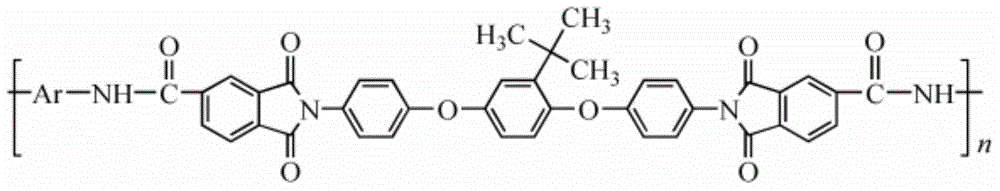

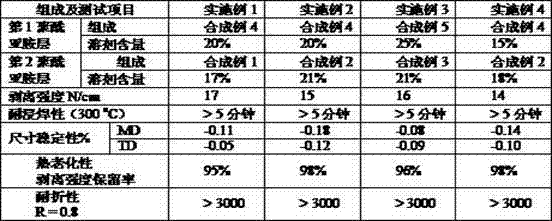

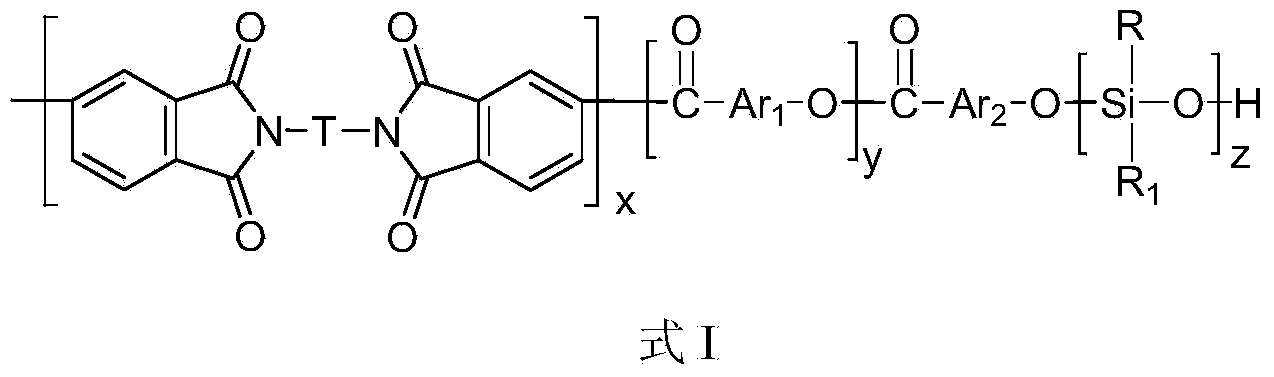

Thermoplastic polyimide adhesive film as well as preparation method and application thereof

The invention discloses a thermoplastic polyimide adhesive film as well as a preparation method and application thereof. A structural formula of a polymer for manufacturing the adhesive film is as shown in a formula I in the specification. The preparation method comprises the following steps of: (1) uniformly mixing aromatic diamine, aromatic tetracid dianhydride and a blocking agent in an organic solvent to obtain a homogeneous solution, then adding methylbenzene and isoquinoline to be mixed uniformly, heating to 170-190 DEG C and reacting for 10-24 hours to evaporate the methylbenzene, stopping heating after heating a reaction system to above 200 DEG C, precipitating after cooling to 80-120 DEG C; and (2) dissolving the obtained polymer in an organic solvent to obtain a glue solution of polyimide, coating the glue solution of polyimide on a baseplate, and drying to obtain the polyimide adhesive film. The adhesive film has excellent room-temperature and high-temperature splicing performance when being used for splicing metal materials, resin composite materials and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Heat dissipating substrate, and element equipped with same

ActiveUS20140085830A1Improve performanceSemiconductor/solid-state device detailsPrinted circuits stress/warp reductionPolymer scienceEngineering

A main object of the invention is to provide a heat dissipating substrate which is excellent in heat dissipating performance, and undergoes neither peel therein nor short circuit. The invention attains this objet by providing a heat dissipating substrate comprising a support base material, an insulating layer formed directly on the support base material, and a wiring layer formed directly on the insulating layer, wherein the insulating layer is formed by non-thermoplastic polyimide resin, and has a thickness in the range of 1 μm to 20 μm.

Owner:DAI NIPPON PRINTING CO LTD

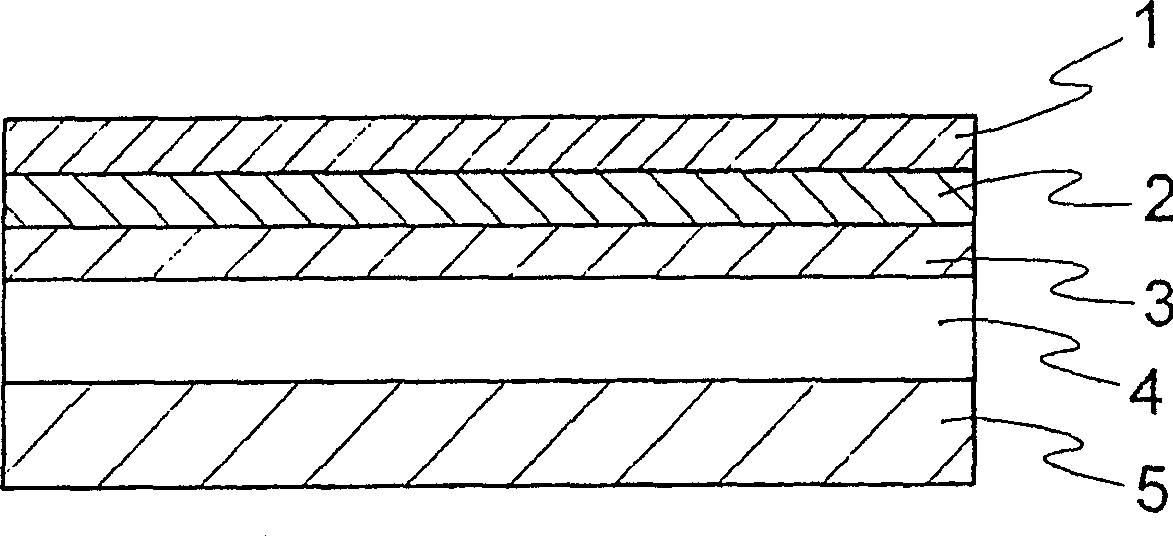

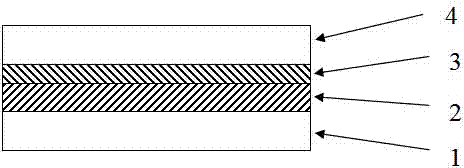

Two-layer-process double-sided flexible copper-clad laminate (CCL) and manufacture method thereof

ActiveCN101786354AImprove heat resistanceImprove moisture resistanceLaminationLamination apparatusHeat resistanceThermal expansion

The invention relates to a two-layer-process double-sided flexible copper-clad laminate (CCL) and a manufacture method thereof. The two-layer-process double-sided flexible CCL comprises an upper copper foil, a lower copper foil and three polyimide resin layers sequentially clamped between the two copper foils, i.e. a thermoplastic polyimide resin layer with a thermal expansion coefficient larger than 40 ppm / DEG C, a thermoset polyimide resin layer with a low thermal expansion coefficient of 0-20 ppm / DEG C and a thermoset polyimide resin layer with a high thermal expansion coefficient of 20-40 ppm / DEG C. The two-layer-process double-sided flexible provided by the invention has higher thermal stability and high moisture fastness and can still have excellent high thermal stability, favorable size stability and high stripping strength under the harsh environment of high temperature, high moisture, and the like, thereby having favorable industrial prosperities. The double-sided flexible CCL manufactured by the invention has practically improved size stability under the condition of heavy moisture. When being applied to the environment of high temperature, high moisture, and the like, the double-sided flexible CCL and printing circuits made by the same have excellent thermal stability, high temperature reliability and moisture fastness stability.

Owner:GUANGDONG SHENGYI SCI TECH

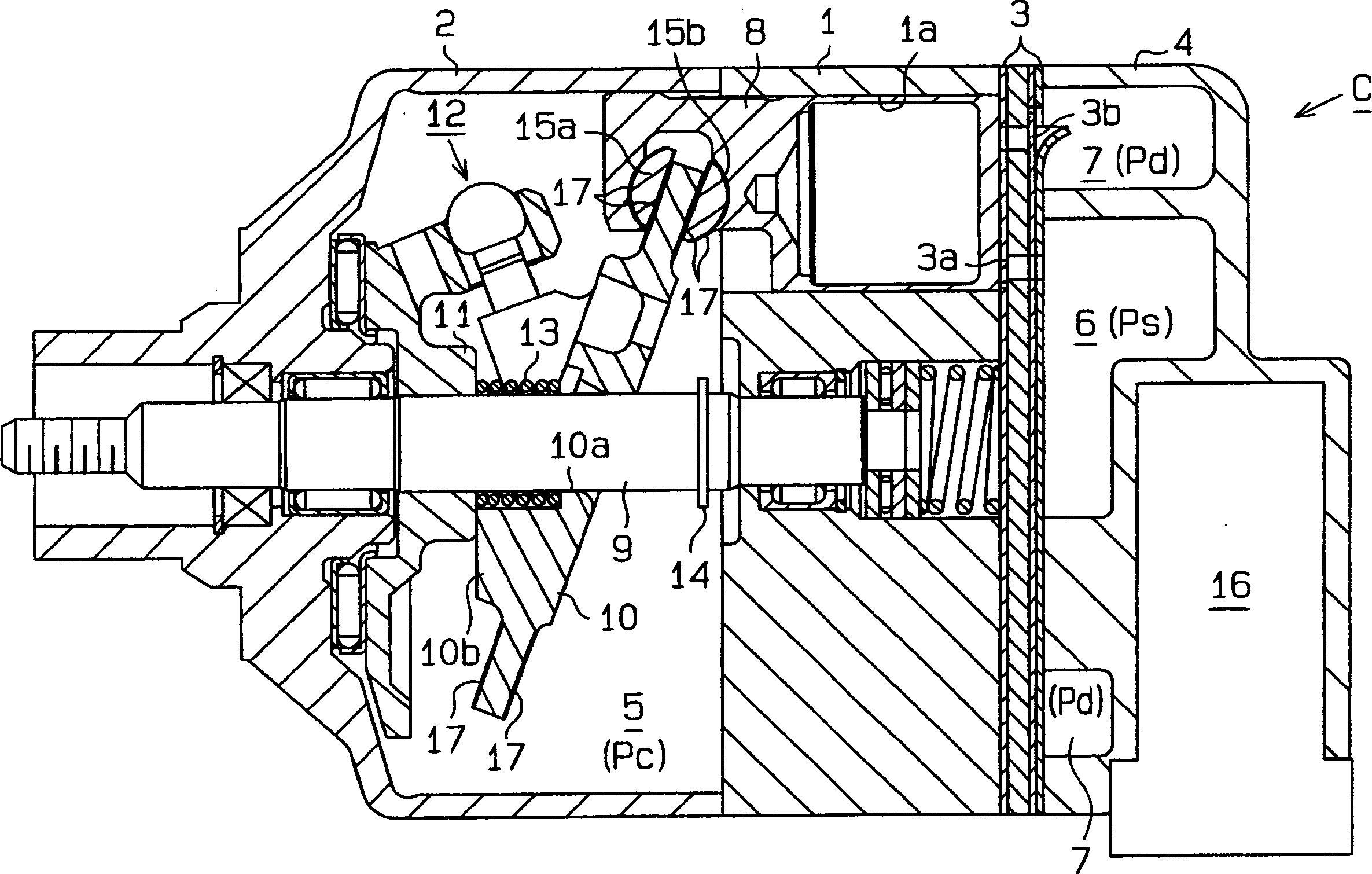

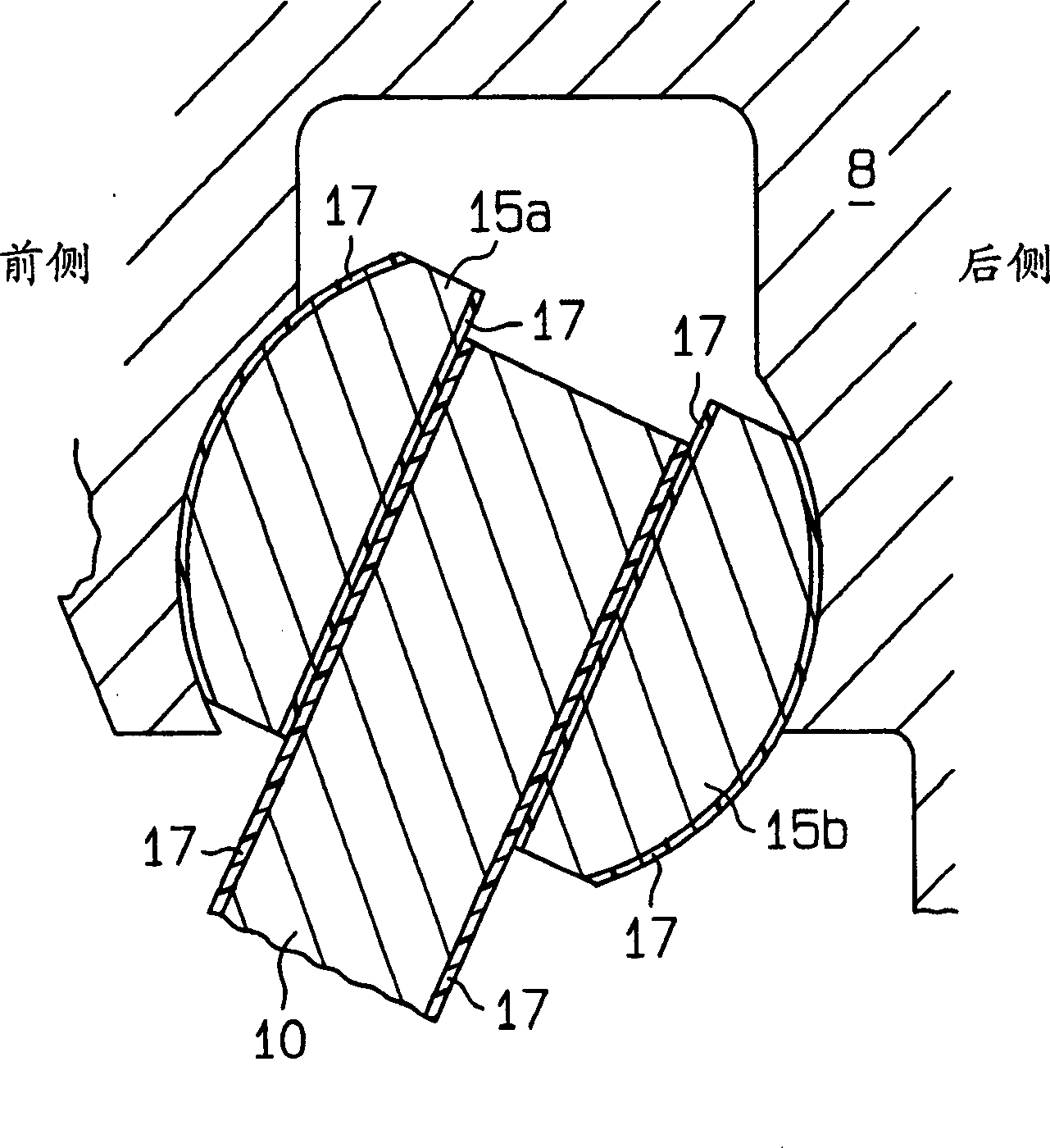

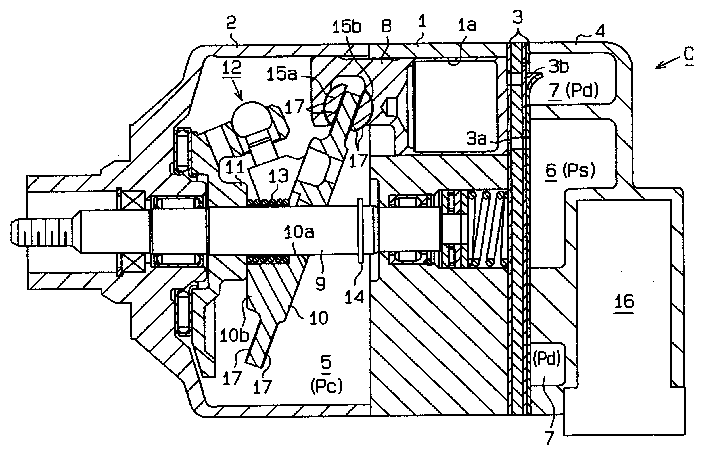

Sliding component and compressor

InactiveCN1401898AGood sliding propertiesEasy to manufacturePositive displacement pump componentsBearing componentsReciprocating motionDrive shaft

Owner:TOYOTA IND CORP

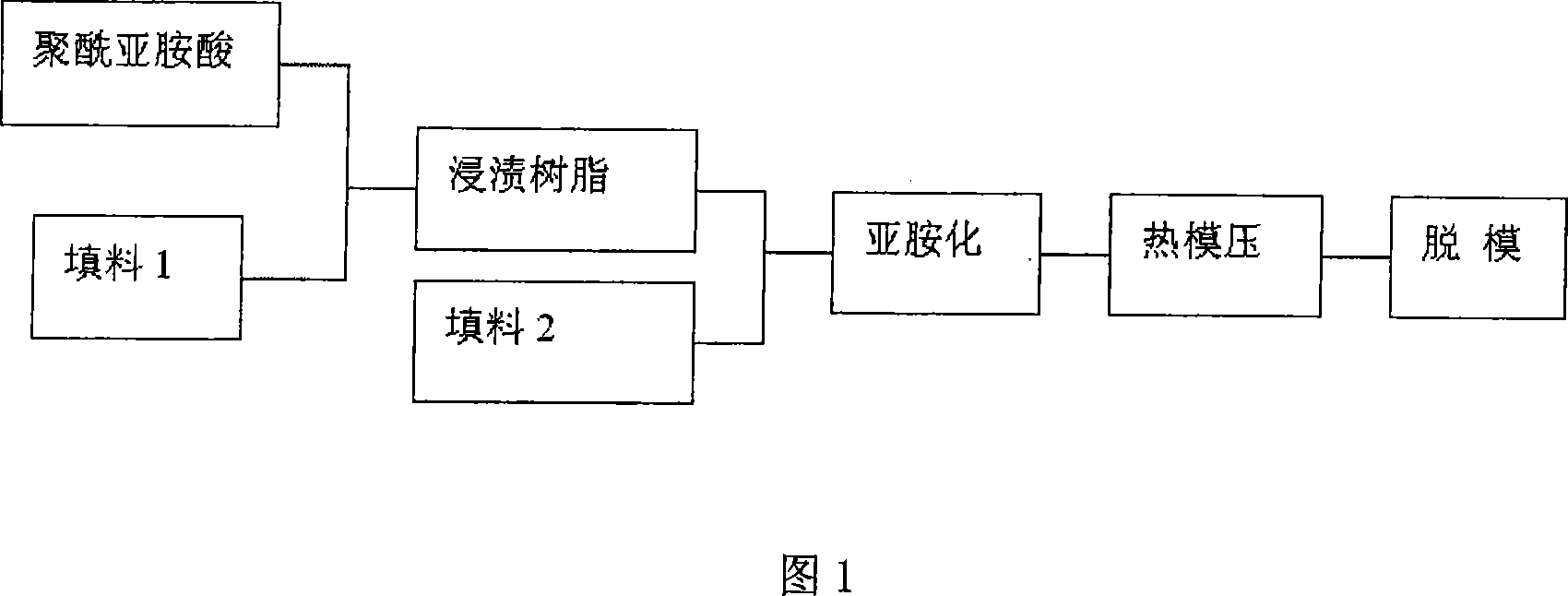

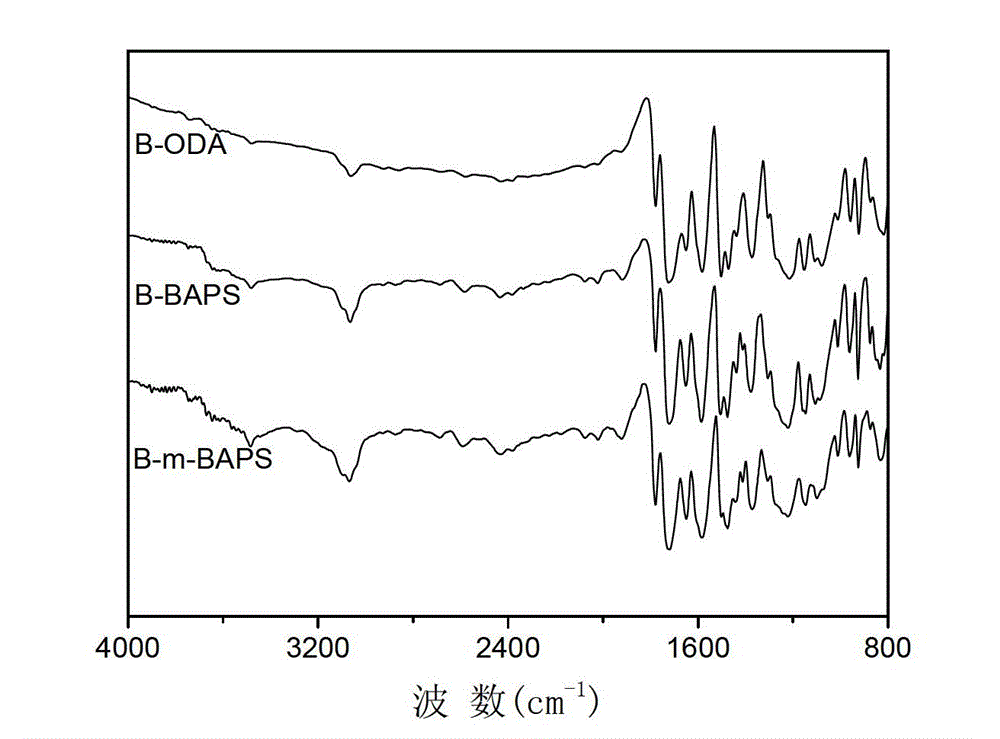

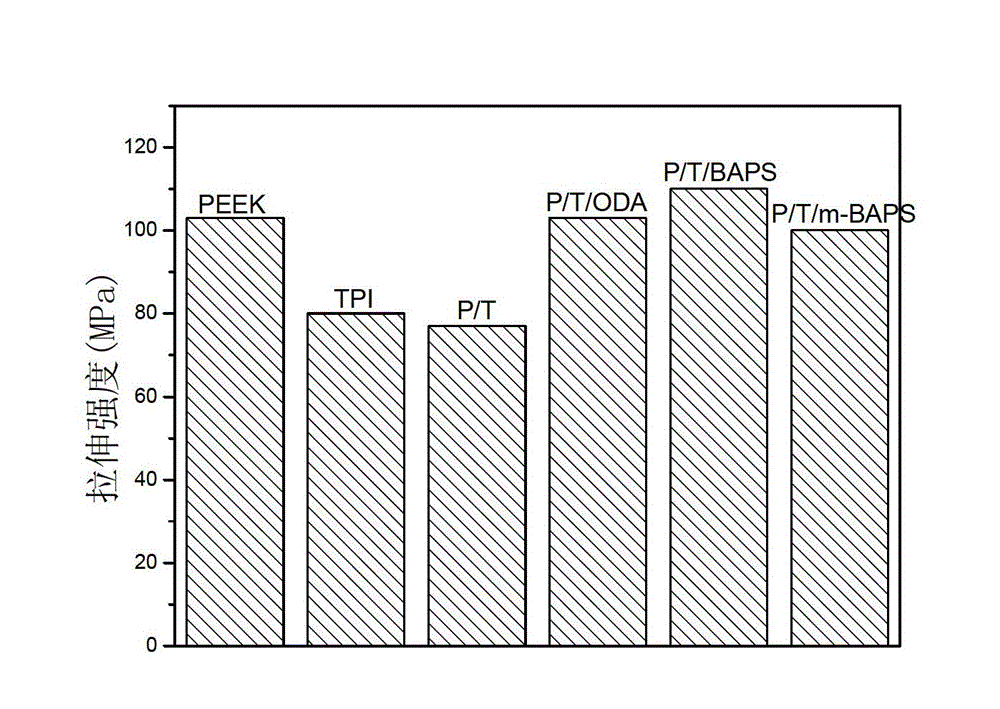

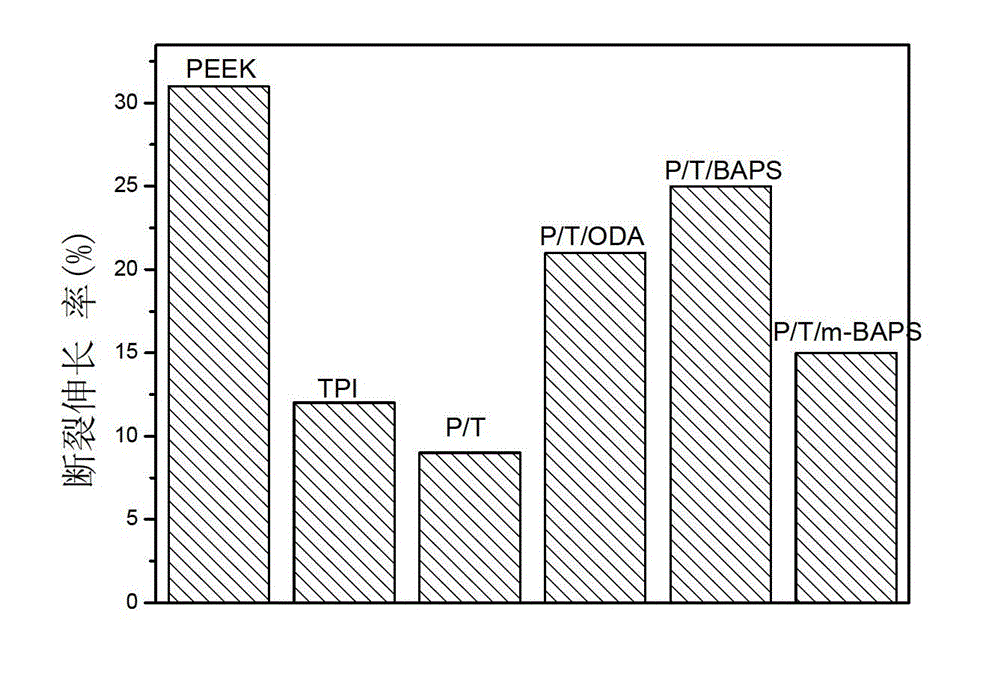

Thermoplastic polyimide composite material and its production

A thermoplastic polyimide composite material with high-thermal conductivity and its production are disclosed. The raw materials consist of thermoplastic polyamide acid, thermal-conducting filler 1 and thermal-conducting filler 2. The process is carried out by adding thermal-conducting 1 into thermoplastic polyamide acid solution proportionally, high-speed agitating to obtain polyamide solvent impregnated resin containing thermal-conducting filler, dip-coating onto thermal-conducting filler 2, dip coating fiber cloth, putting into baker, imine treating to obtain polyimide composite embryo-cloth. It's simple and convenient, has excellent comprehensive performances and higher thermal-conducting coefficient.

Owner:NANJING UNIV OF TECH

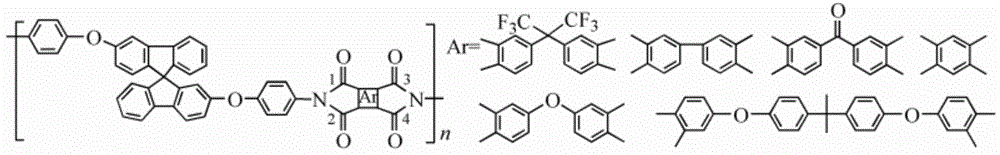

Aromatic polyetheretherketone-polyimide block polymer, and preparation method and application thereof

InactiveCN102875819AGood compatibilityImprove mechanical propertiesPolymer sciencePoly ether ether ketone

The invention relates to an aromatic block polymer, and a preparation method and application thereof as a compatibilizer. Amino-terminated polyetheretherketone oligomer and acid-anhydride-terminated polyimide oligomer are subjected to nucleophilic polycondensation reaction in an organic solvent to obtain the polyetheretherketone-polyimide block polymer. The polymerization degree of the two oligomers can be regulated to prepare the block polymer, so that the number-average molecular weight of the prepared polyetheretherketone block and polyimide block is 1000-6000, and the number-average molecular weight of the block polymer is 20000-40000. When being adding into a polyetheretherketone-thermoplastic polyimide blend system as a compatibilizer, the block polymer is beneficial to improving the compatibility of the blend system, thereby preparing the high-polymer alloy material with excellent comprehensive properties, such as mechanical properties, working properties, thermal properties and the like.

Owner:JILIN UNIV

Polyimide copper foil laminates and method for manufacturing same

InactiveCN1929716AEasy to controlThe production process is simpleLiquid surface applicatorsPrinted circuit secondary treatmentPolyamide-imidePolyamide

This invention relates to one polyamide-imides foil deposition layer to process flexible print circuit board, which comprises copper foil, heat fixing polyamide layers, heating plastic polyamide layers and copper foil. This invention method comprises the following steps: coating heated fix polyamide copper foil structure; then using plastic polyamide adhesive structure for heat fix polyamide layers; finally binding and pressing to the invention product.

Owner:THINFLEX CORP

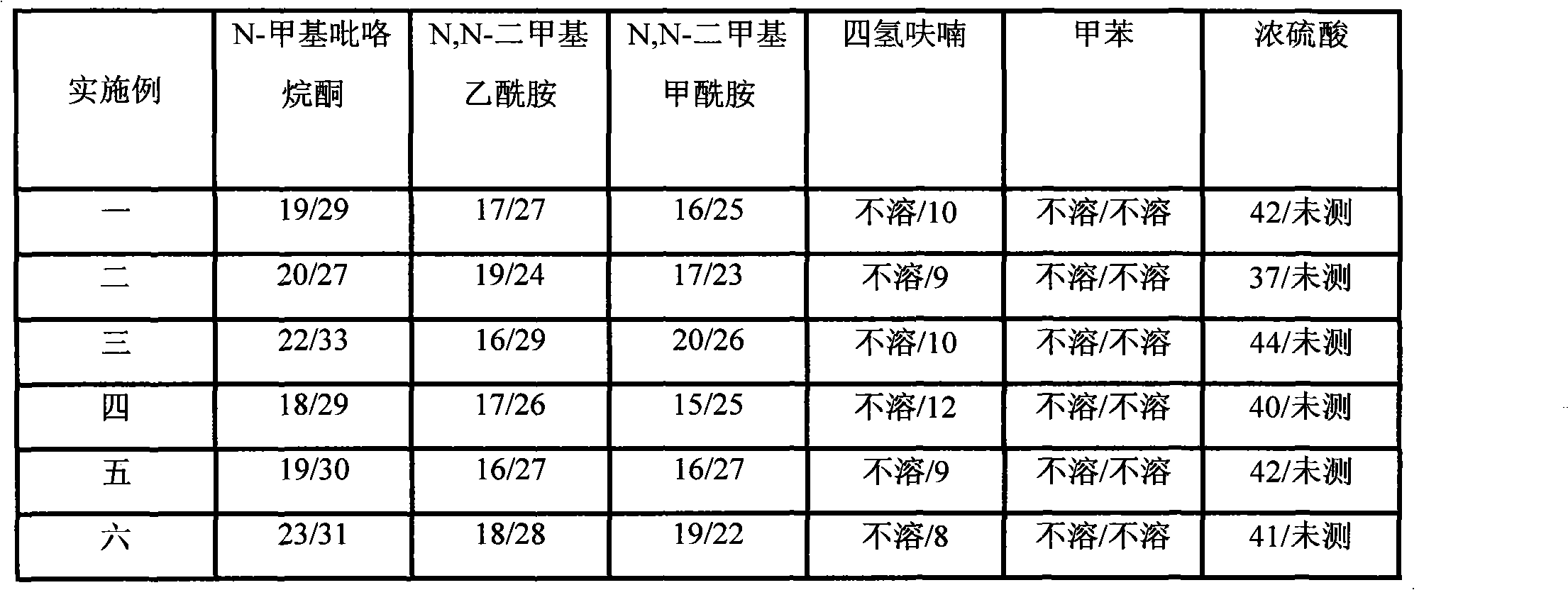

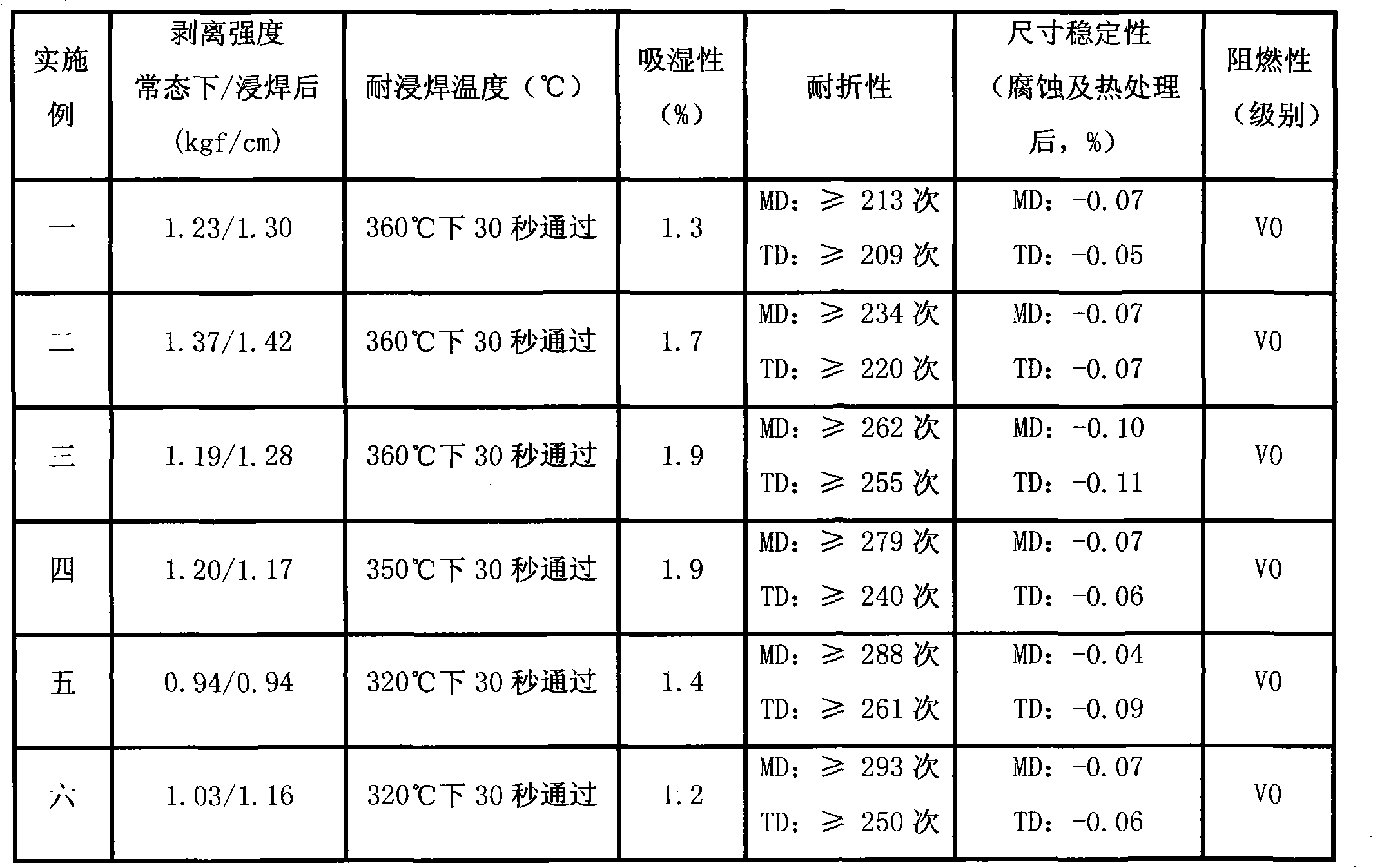

Thermoplastic polyimide material and method for preparing flexible copper clad laminate through using material

The invention relates to a thermoplastic polyimide (TPI) material used for preparing a two-layer flexible copper clad laminate (2L-FCCL). The excellent dissolvability TPI material is obtained through generating a polyamide acid copolymer by using main reaction components 4-ethoxydiphenol-3,5-diaminobenzoate and 2,2-bis(4-aminophenyl)hexafluoropropane according to a specific molar ratio, a corresponding diamine and a corresponding acid anhydride, and processing the copolymer by utilizing a chemical imidization process. The 2L-FCCL with good comprehensive performances of dimensional stability, dip soldering resistance, peeling performance and the like can be obtained through dissolving powder of the TPI material and compositing the TPI material with a thermosetting polyimide film and copper foil.

Owner:南通今朝机床有限公司

Method for preparing flame-retardant thermoplastic polyimide resin

The invention discloses a flame-retardant thermoplastic polyimide resin. The method comprises the following steps: (1) introducing a monomer which has a flame-retardant effect and contains a DOPO and siloxane structure and synthesizing thermotropic liquid crystal polyester-imide PEtI-TLCP which has flame retardant property and liquid crystal characteristics and has a chemical structure similar to thermoplastic polyimide; and (2) performing in-situ synthesis on the prepared PEtI-TLCP and the thermoplastic polyimide (TPI), thus obtaining the flame-retardant thermoplastic polyimide resin. The method can be suitable for a process for producing a high-performance flame-retardant thermoplastic polyimide resin in a severe environment. The prepared flame-retardant thermoplastic polyimide resin has excellent mechanical property, thermal performance, processability, flame-retardant property and resistance to heat and humidity, can be used for preparing high-temperature protective textiles and special electrical insulation films and has extremely high commercial value.

Owner:宏威高新材料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com