Thermoplastic polyimide adhesive film as well as preparation method and application thereof

A technology of polyimide film and polyimide, which is applied in the direction of adhesives, film/sheet adhesives, etc., and can solve the problem of easy generation of pores on the bonding surface, high bonding temperature, and hot-melt temperature of the film. Advanced problems, to achieve excellent room temperature and high temperature bonding performance, simple process, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

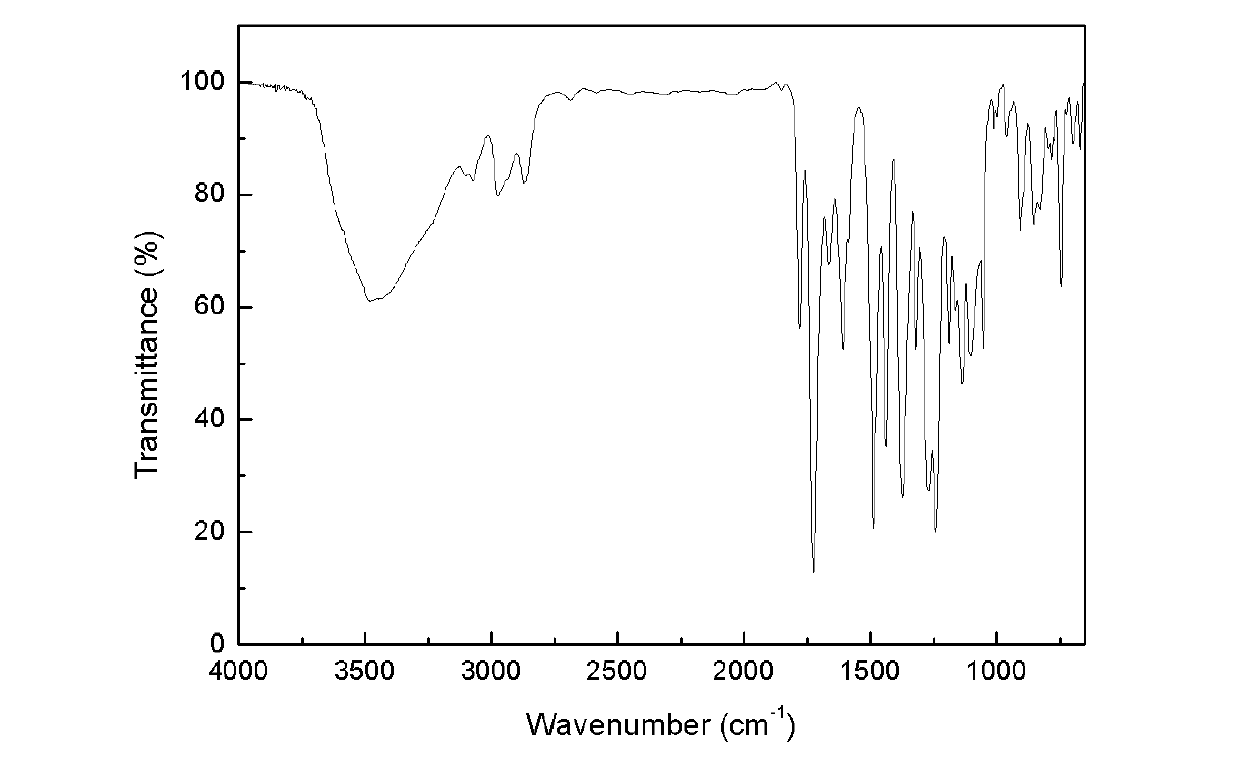

Image

Examples

Embodiment 1

[0039] Embodiment 1, prepare polyimide adhesive film

[0040] In a three-neck round bottom flask equipped with mechanical stirring, nitrogen inlet and thermometer, 42 parts of 1,4-bis(4'-amino-2'-trifluoromethylphenoxy)benzene (6FAPB) and 24 parts 4,4'-sulfonyl diphenylamine (4,4'-DADPS) was added to 550 parts of m-cresol, and stirred for 0.5 hours. Add 60 parts of 3,3',4,4'-diphenylmethyl ether tetra-acid dianhydride (ODPA) and 1.2 parts of end-capping agent phthalic anhydride (PA) to 550 parts of m-cresol, and stir for 0.5 hours . The above solutions were mixed and stirred to obtain a homogeneous solution.

[0041] Add 50 parts of toluene and 8 parts of isoquinoline to the above homogeneous solution, raise the temperature to 180°C and react for 12 hours, then distill off the toluene, and stop heating when the temperature of the reaction system reaches 220°C.

[0042] Cool the reaction solution to 80°C and pour it into ethanol, collect the precipitated solid, wash repeated...

Embodiment 2

[0053] Embodiment 2, prepare polyimide adhesive film

[0054] In a three-necked round bottom flask equipped with mechanical stirring, nitrogen inlet and thermometer, 135 parts of 1,4-bis(4'-amino-2'-trifluoromethylphenoxy)benzene (6FAPB) and 40 parts 3,3'-sulfonyldiphenylamine (3,3'-DADPS) was added to 1400 parts of N,N-dimethylformamide (DMF), and stirred for 0.5 hours. Add 150 parts of 3,3',4,4'-diphenylmethyl ether tetra-acid dianhydride (ODPA) and 3 parts of end-capping agent phthalic anhydride (PA) to 1400 parts of N-methylpyrrolidone (NMP) , stirred for 0.5 hours. The above solutions were mixed and stirred to obtain a homogeneous solution.

[0055] Add 125 parts of toluene and 20 parts of isoquinoline to the above homogeneous solution, heat up to 170°C and react for 10 hours, then distill off the toluene, and stop heating when the temperature of the reaction system rises to 210°C.

[0056] Cool the reaction solution to 80°C and pour it into methanol, collect the preci...

Embodiment 3

[0062] Embodiment 3, prepare polyimide film

[0063]In a three-neck round bottom flask equipped with mechanical stirring, nitrogen inlet and thermometer, 54 parts of 1,4-bis(4'-amino-2'-trifluoromethylphenoxy)benzene (6FAPB) and 27 parts 3,3'-Diaminobenzophenone (3,3'-DABP) was added to 650 parts of N-methylpyrrolidone (NMP), and stirred for 0.5 hour. Add 75 parts of 3,3',4,4'-diphenylmethyl ether tetra-acid dianhydride (ODPA) and 0.6 parts of end-capping agent phthalic anhydride (PA) to 650 parts of N-methylpyrrolidone (NMP) , stirred for 0.5 hours. The above solutions were mixed and stirred to obtain a homogeneous solution.

[0064] Add 60 parts of toluene and 10 parts of isoquinoline to the above homogeneous solution, raise the temperature to 190°C and react for 10 hours, then distill off the toluene, and stop heating when the temperature of the reaction system reaches 210°C.

[0065] The reaction solution was cooled to 80° C. and then poured into water. The precipitated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com