Thermoplastic polyimide adhesive film as well as preparation method and application thereof

A polyimide film, polyimide technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problem of high bonding temperature, high hot-melt temperature of the film, and easy generation of adhesive surfaces. Air holes and other problems, to achieve the effect of simple process, easy operation, excellent room temperature and high temperature bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

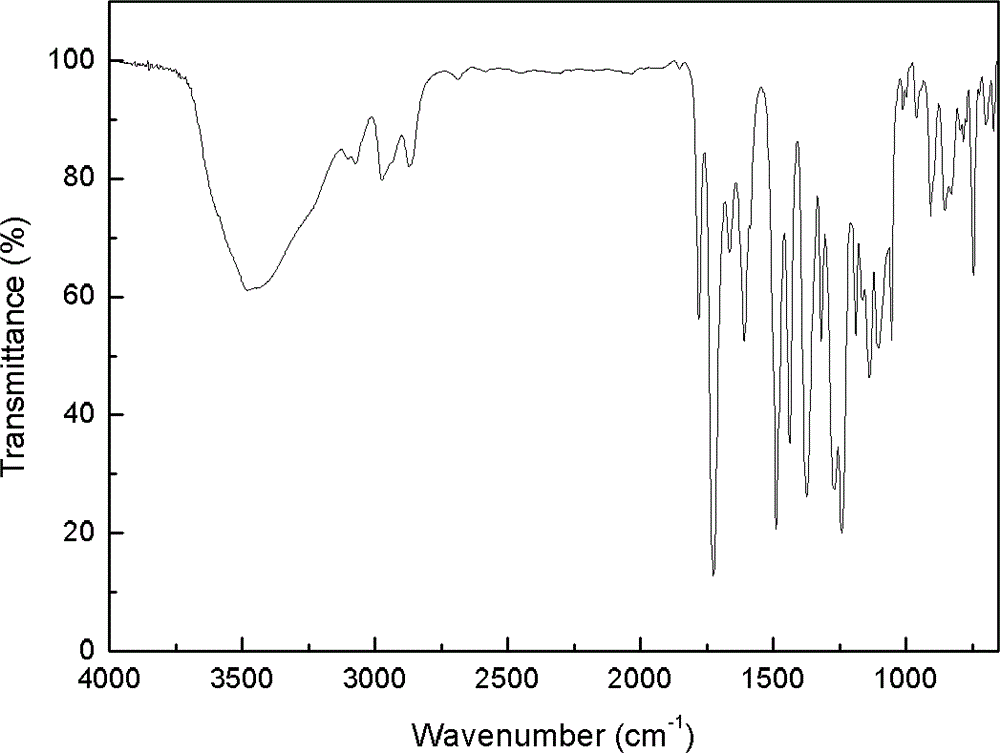

Image

Examples

Embodiment 1

[0039] Embodiment 1, prepare polyimide adhesive film

[0040] In a three-neck round bottom flask equipped with mechanical stirring, nitrogen inlet and thermometer, 42 parts of 1,4-bis(4'-amino-2'-trifluoromethylphenoxy)benzene (6FAPB) and 24 parts 4,4'-sulfonyl diphenylamine (4,4'-DADPS) was added to 550 parts of m-cresol, and stirred for 0.5 hours. Add 60 parts of 3,3',4,4'-diphenylmethyl ether tetra-acid dianhydride (ODPA) and 1.2 parts of end-capping agent phthalic anhydride (PA) to 550 parts of m-cresol, and stir for 0.5 hours . The above solutions were mixed and stirred to obtain a homogeneous solution.

[0041] Add 50 parts of toluene and 8 parts of isoquinoline to the above homogeneous solution, raise the temperature to 180°C and react for 12 hours, then distill off the toluene, and stop heating when the temperature of the reaction system reaches 220°C.

[0042] Cool the reaction solution to 80°C and pour it into ethanol, collect the precipitated solid, wash repeated...

Embodiment 2

[0052] Embodiment 2, prepare polyimide adhesive film

[0053] In a three-necked round bottom flask equipped with mechanical stirring, nitrogen inlet and thermometer, 135 parts of 1,4-bis(4'-amino-2'-trifluoromethylphenoxy)benzene (6FAPB) and 40 parts 3,3'-sulfonyldiphenylamine (3,3'-DADPS) was added to 1400 parts of N,N-dimethylformamide (DMF), and stirred for 0.5 hours. Add 150 parts of 3,3',4,4'-diphenylmethyl ether tetra-acid dianhydride (ODPA) and 3 parts of end-capping agent phthalic anhydride (PA) to 1400 parts of N-methylpyrrolidone (NMP) , stirred for 0.5 hours. The above solutions were mixed and stirred to obtain a homogeneous solution.

[0054] Add 125 parts of toluene and 20 parts of isoquinoline to the above homogeneous solution, heat up to 170°C and react for 10 hours, then distill off the toluene, and stop heating when the temperature of the reaction system rises to 210°C.

[0055] Cool the reaction solution to 80°C and pour it into methanol, collect the preci...

Embodiment 3

[0061] Embodiment 3, prepare polyimide film

[0062]In a three-neck round bottom flask equipped with mechanical stirring, nitrogen inlet and thermometer, 54 parts of 1,4-bis(4'-amino-2'-trifluoromethylphenoxy)benzene (6FAPB) and 27 parts 3,3'-Diaminobenzophenone (3,3'-DABP) was added to 650 parts of N-methylpyrrolidone (NMP), and stirred for 0.5 hours. Add 75 parts of 3,3',4,4'-diphenylmethyl ether tetra-acid dianhydride (ODPA) and 0.6 parts of end-capping agent phthalic anhydride (PA) to 650 parts of N-methylpyrrolidone (NMP) , stirred for 0.5 hours. The above solutions were mixed and stirred to obtain a homogeneous solution.

[0063] Add 60 parts of toluene and 10 parts of isoquinoline to the above homogeneous solution, raise the temperature to 190°C and react for 10 hours, then distill off the toluene, and stop heating when the temperature of the reaction system reaches 210°C.

[0064] The reaction solution was cooled to 80° C. and then poured into water. The precipitate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com