Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33331results about "Non-macromolecular adhesive additives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

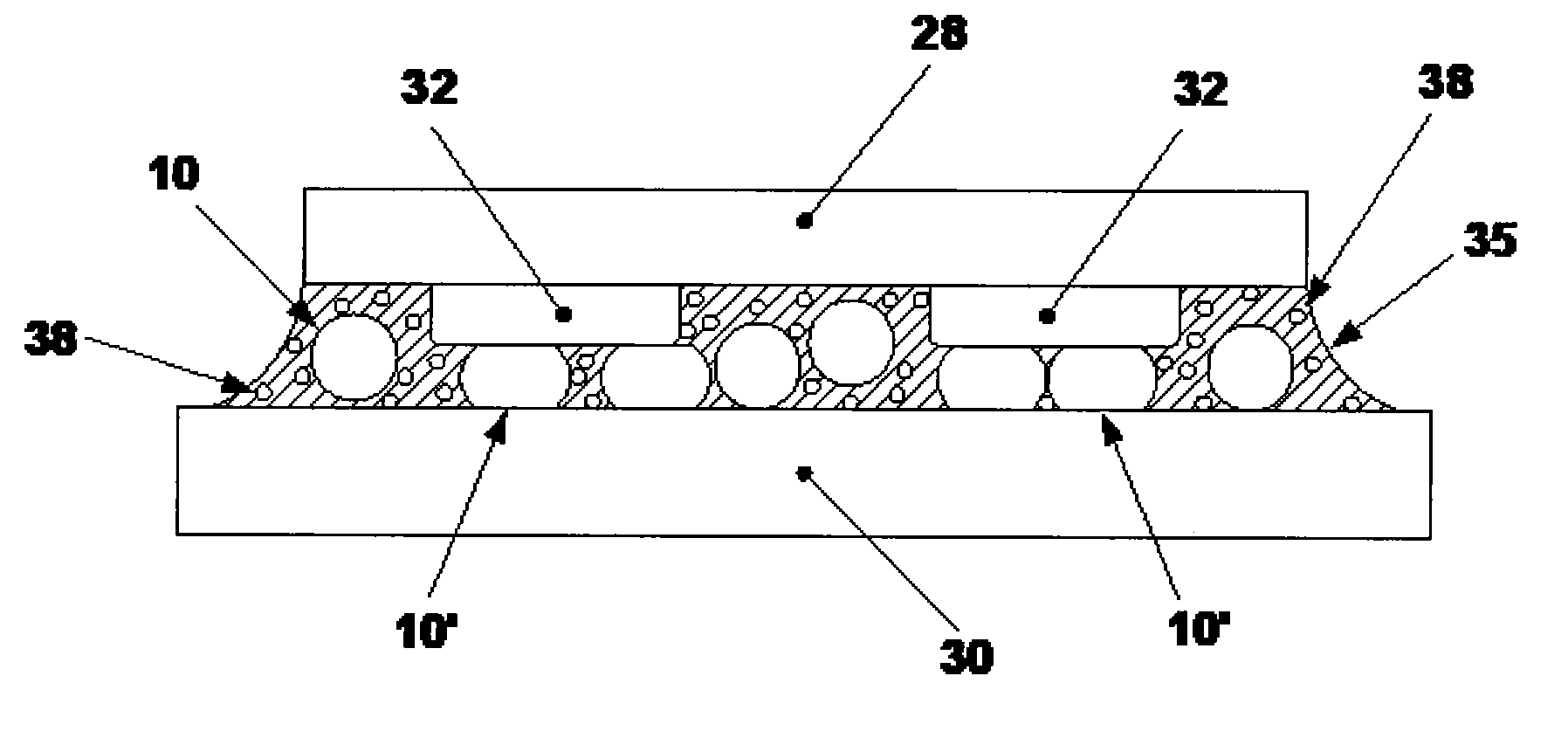

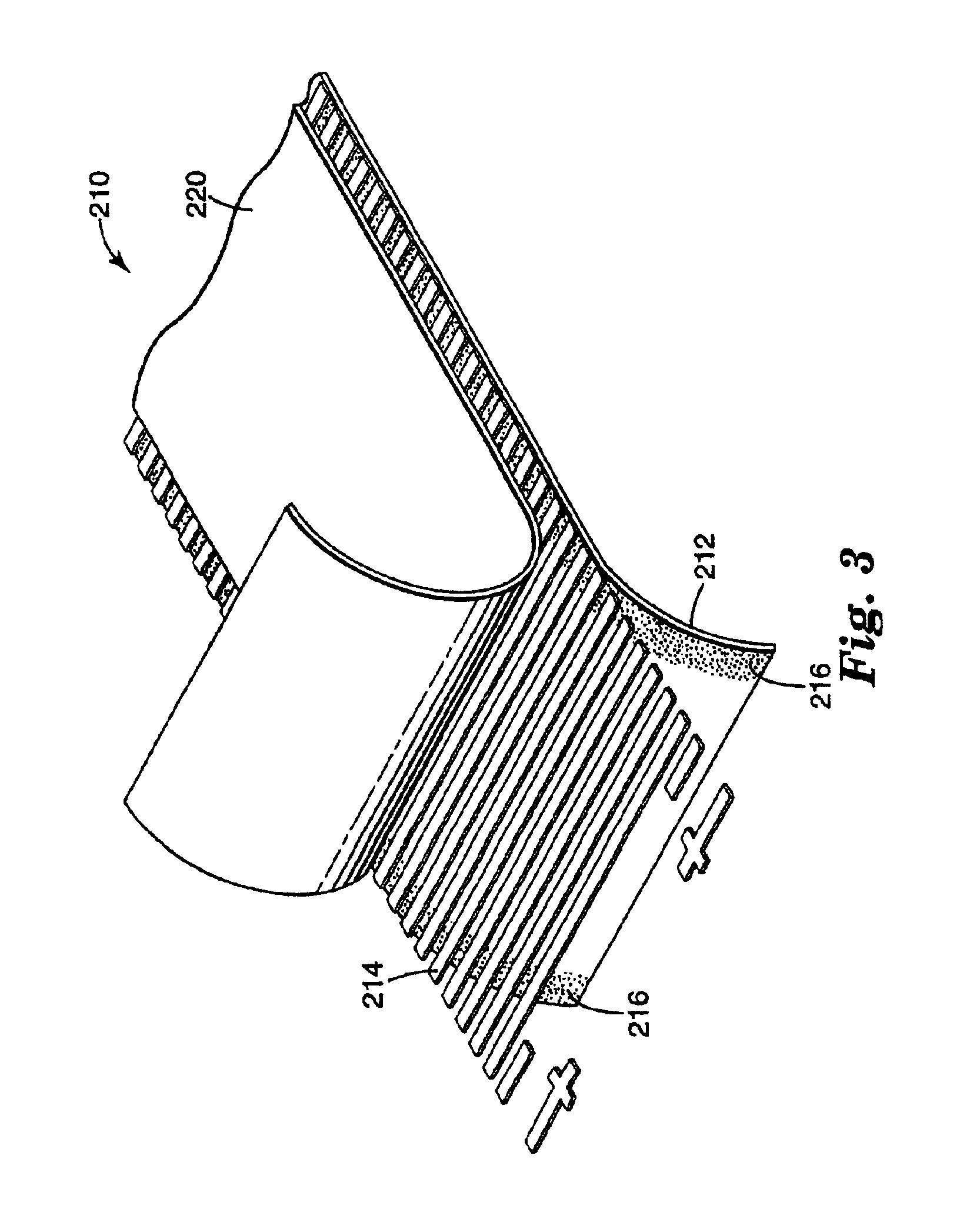

Electro-optic display and materials for use therein

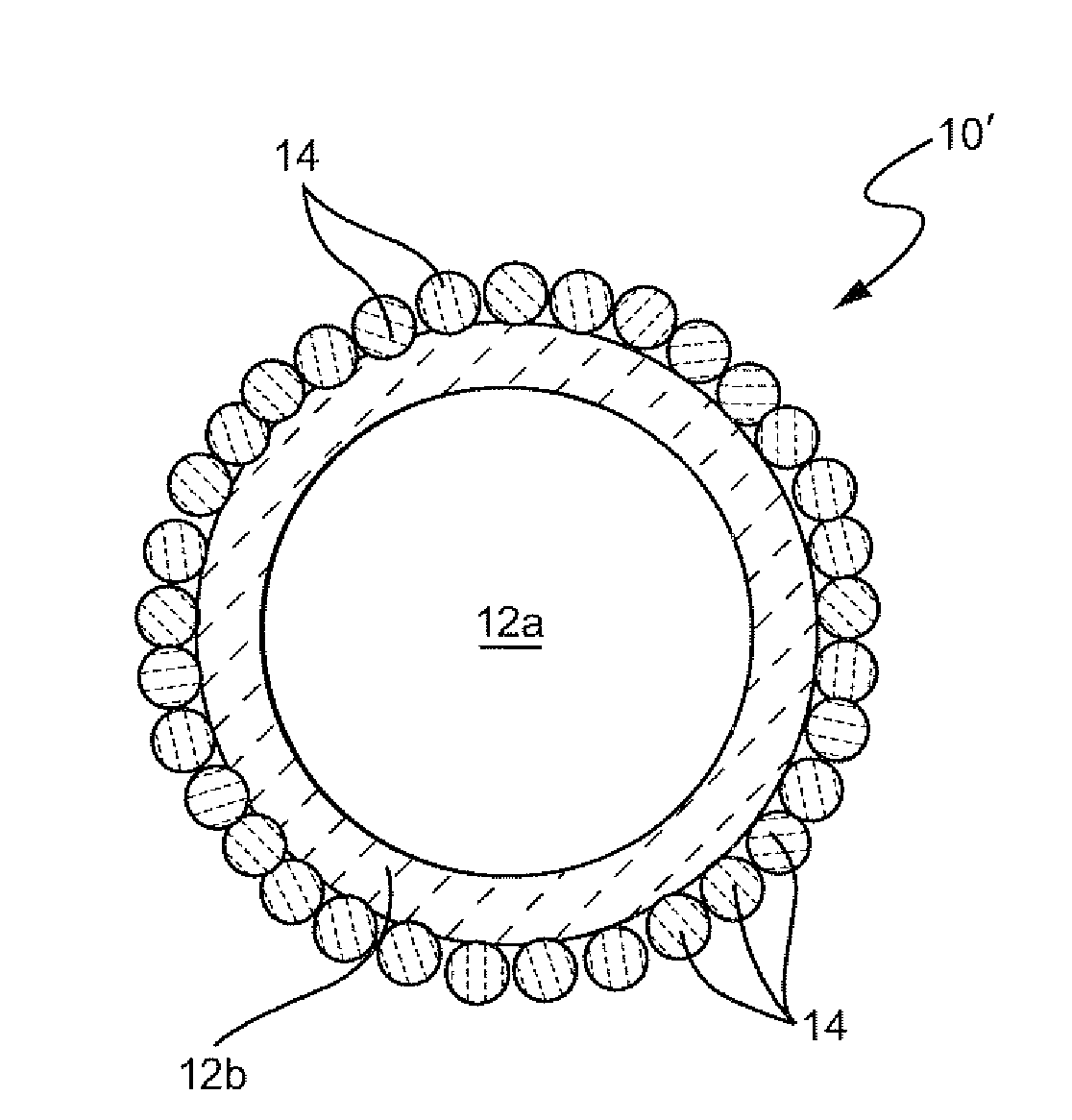

InactiveUS7535624B2High viscosityImprove conductivityNon-macromolecular adhesive additivesStatic indicating devicesAdhesiveDisplay device

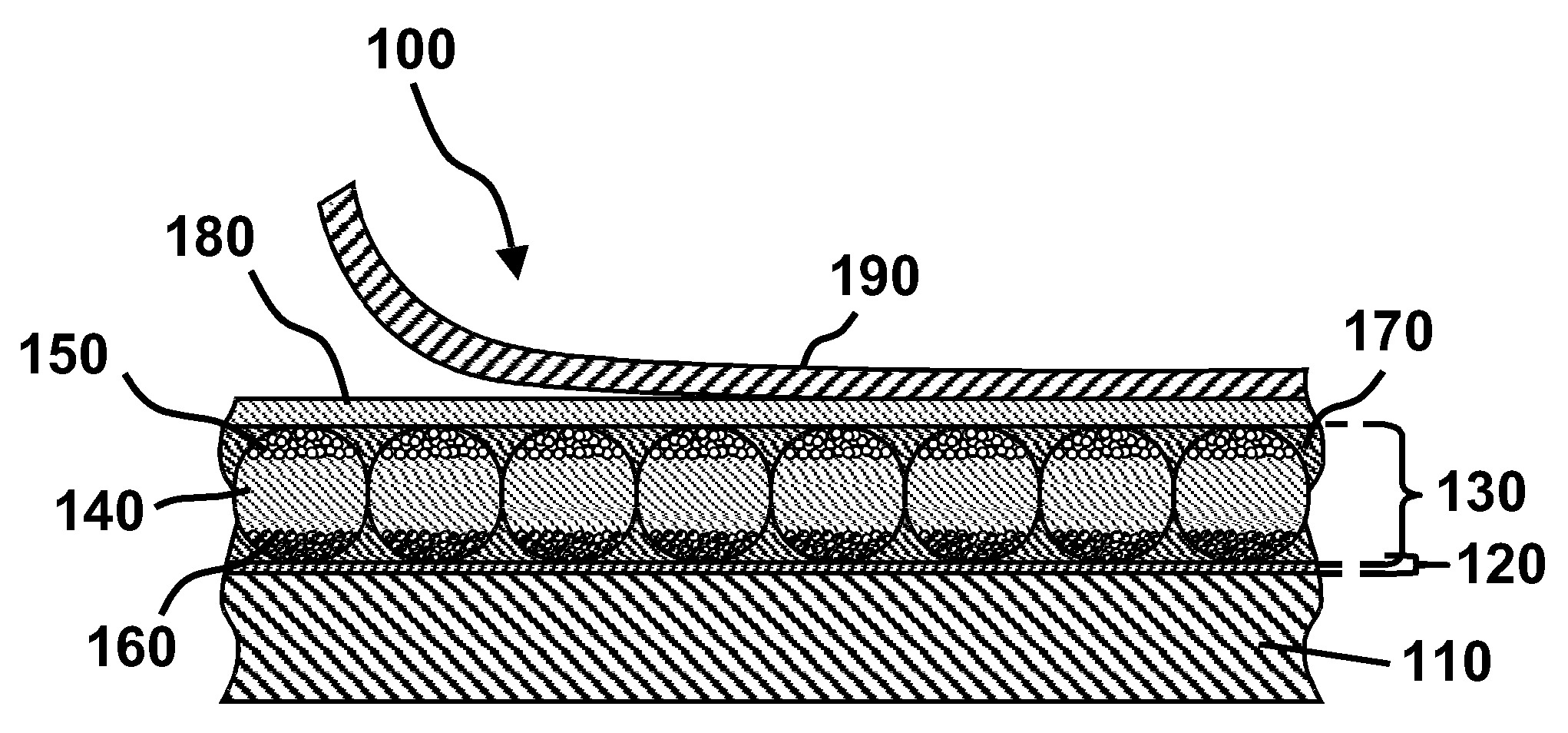

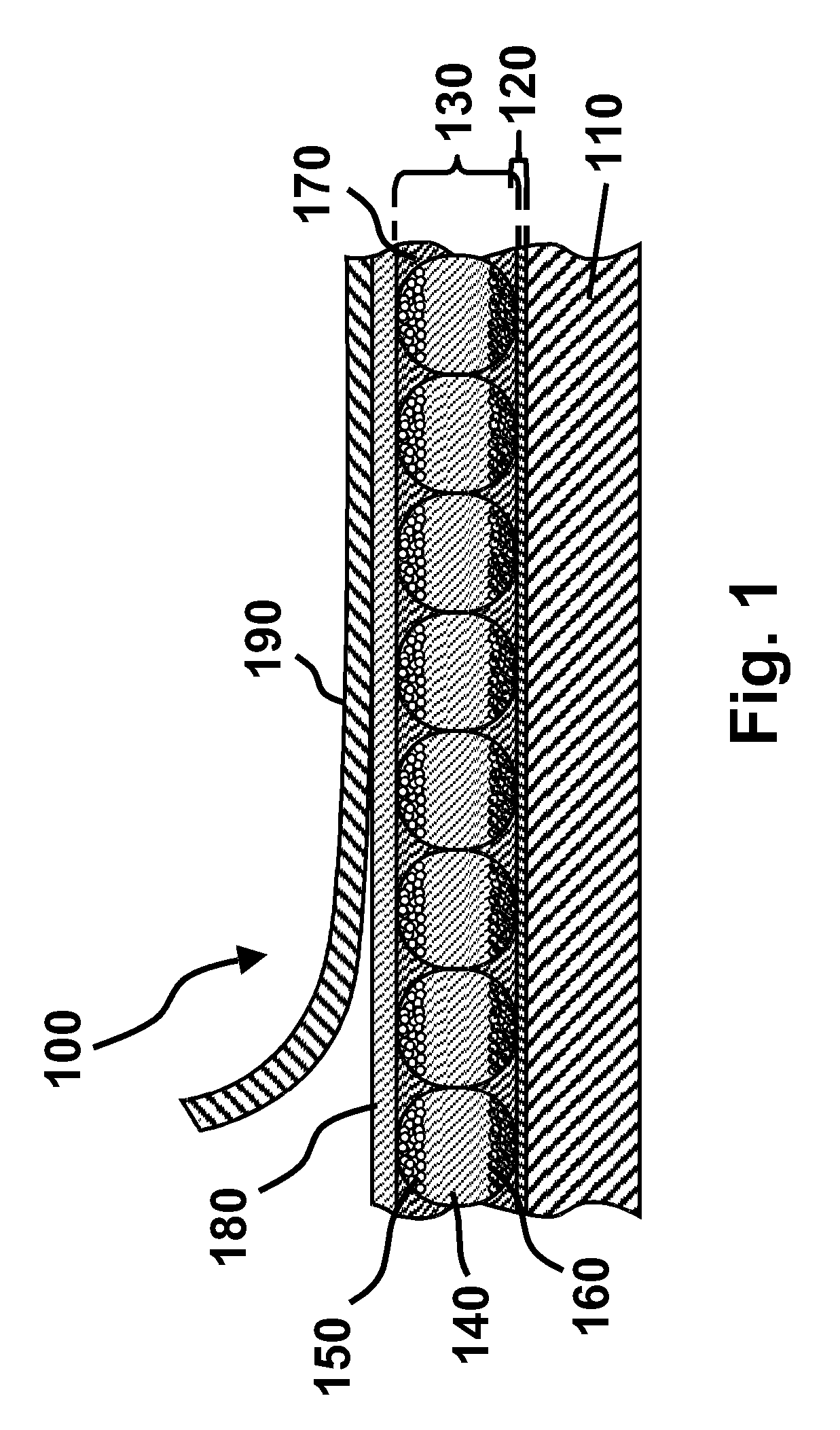

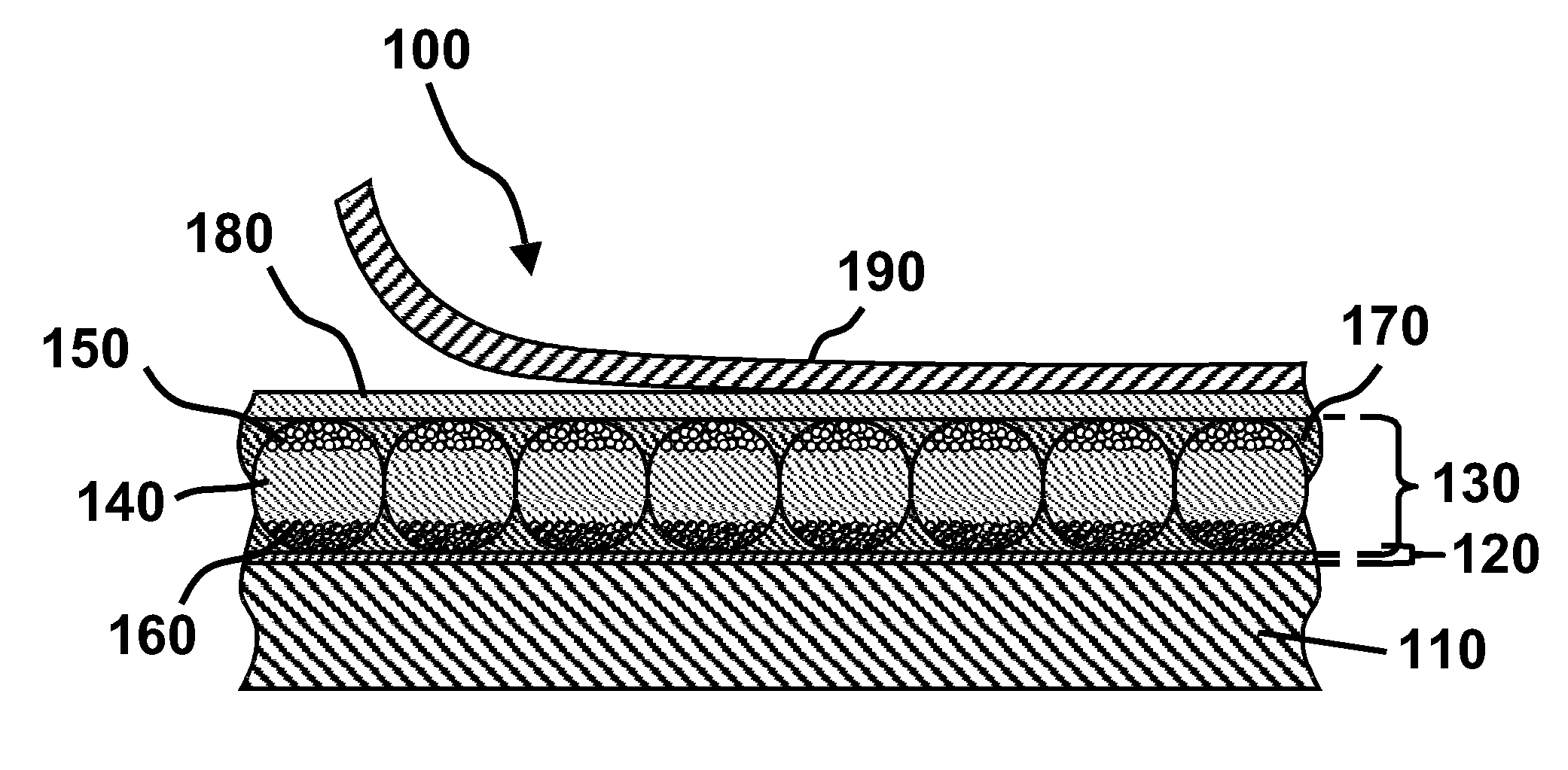

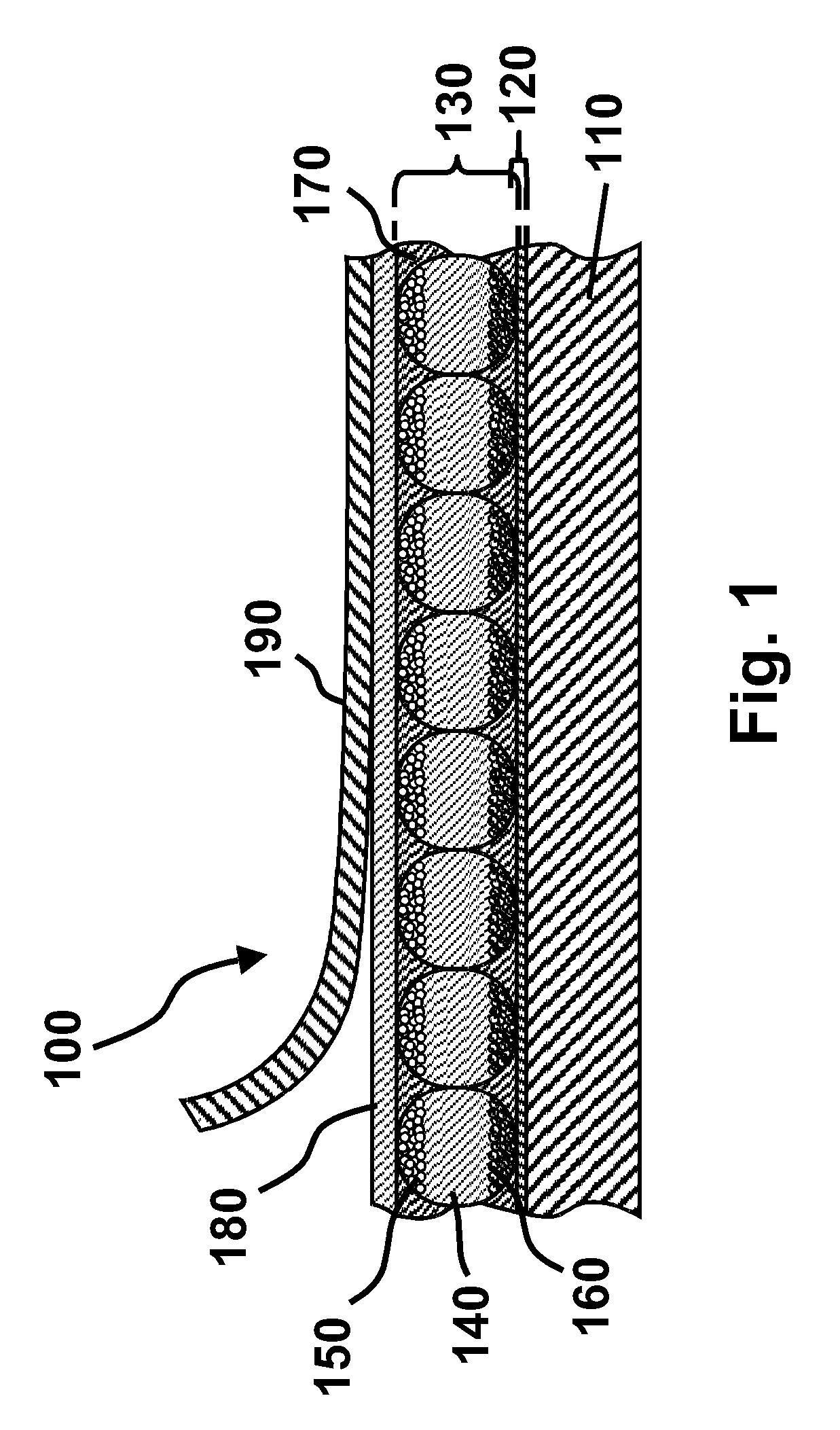

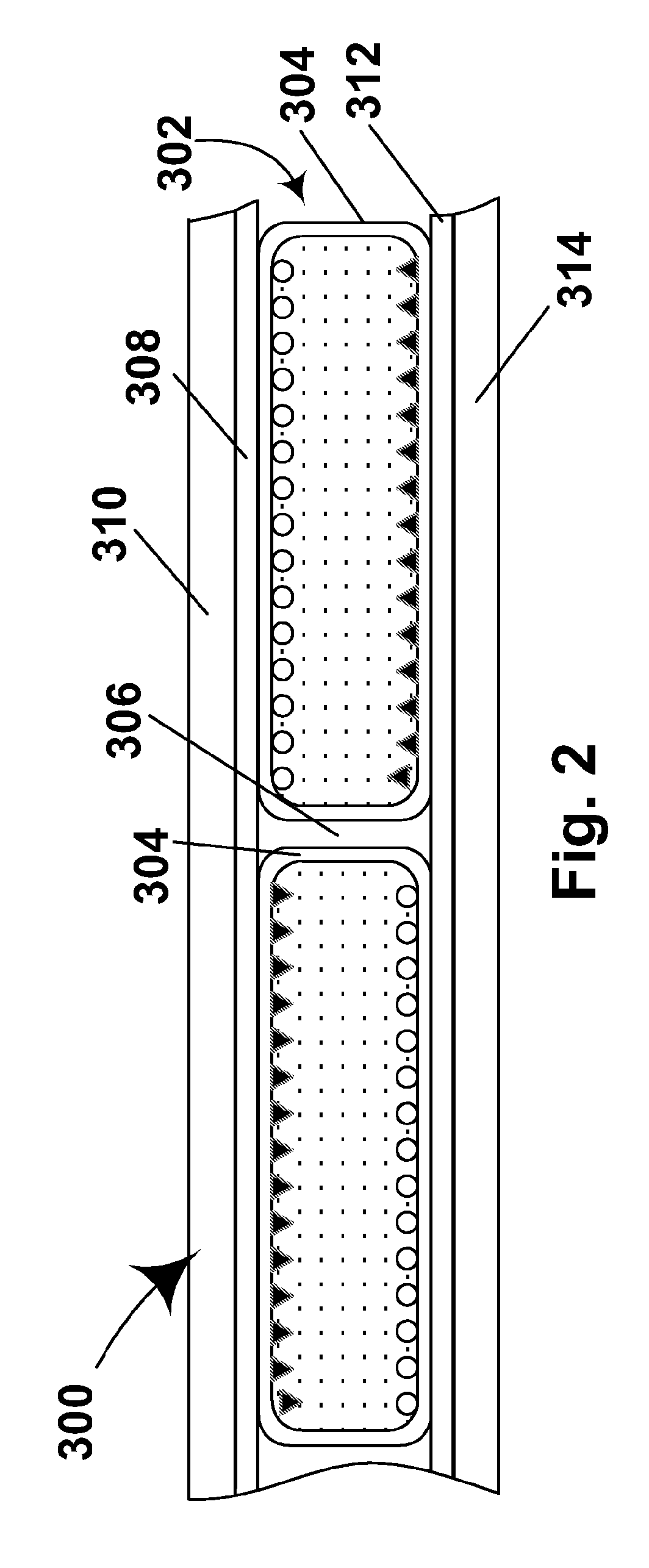

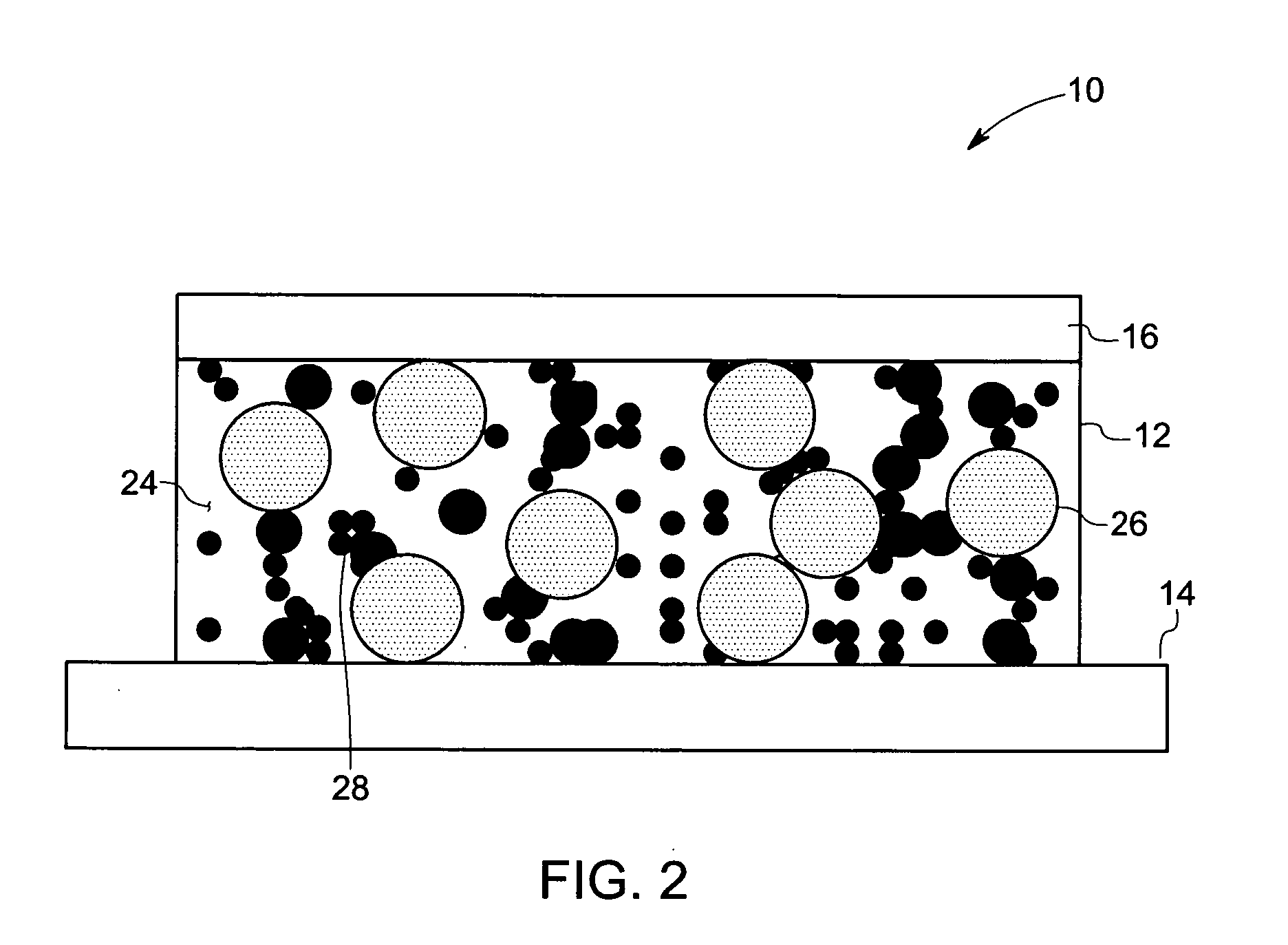

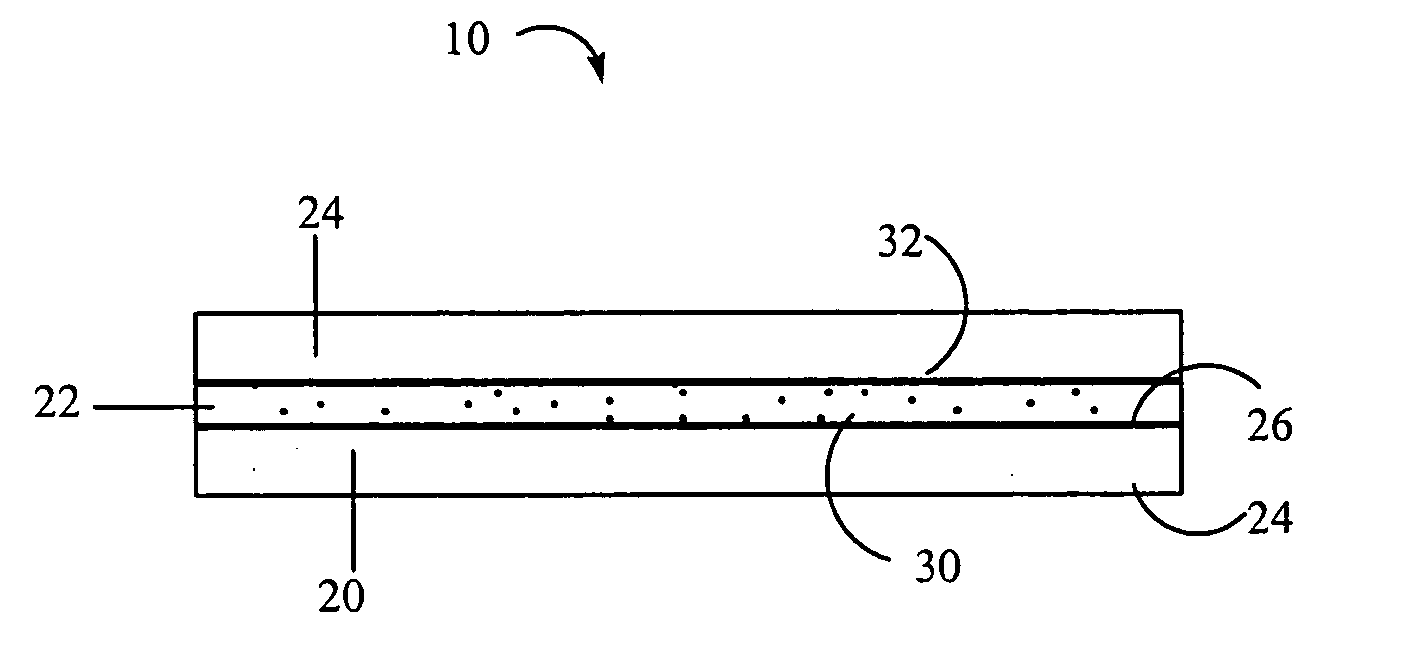

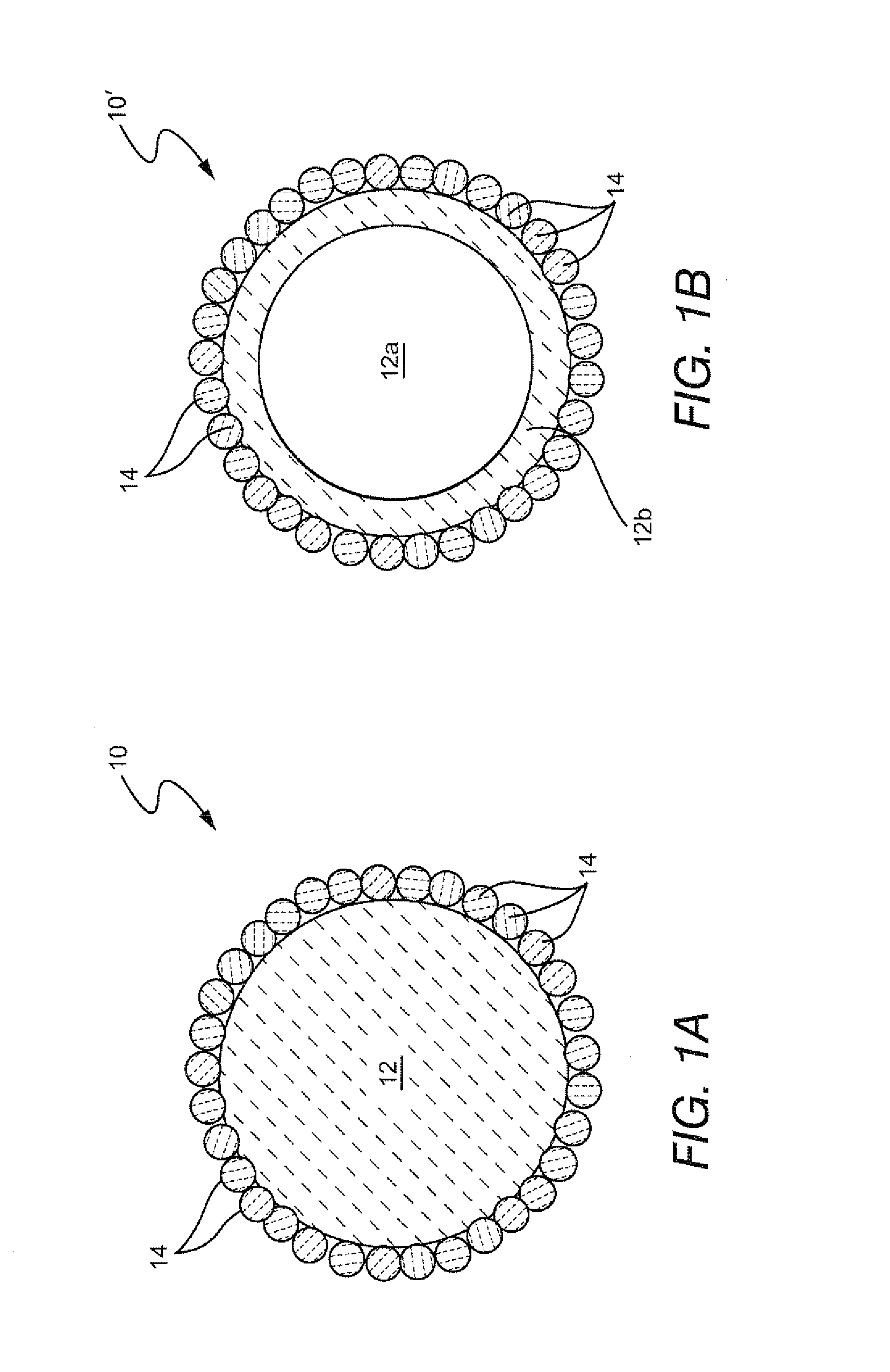

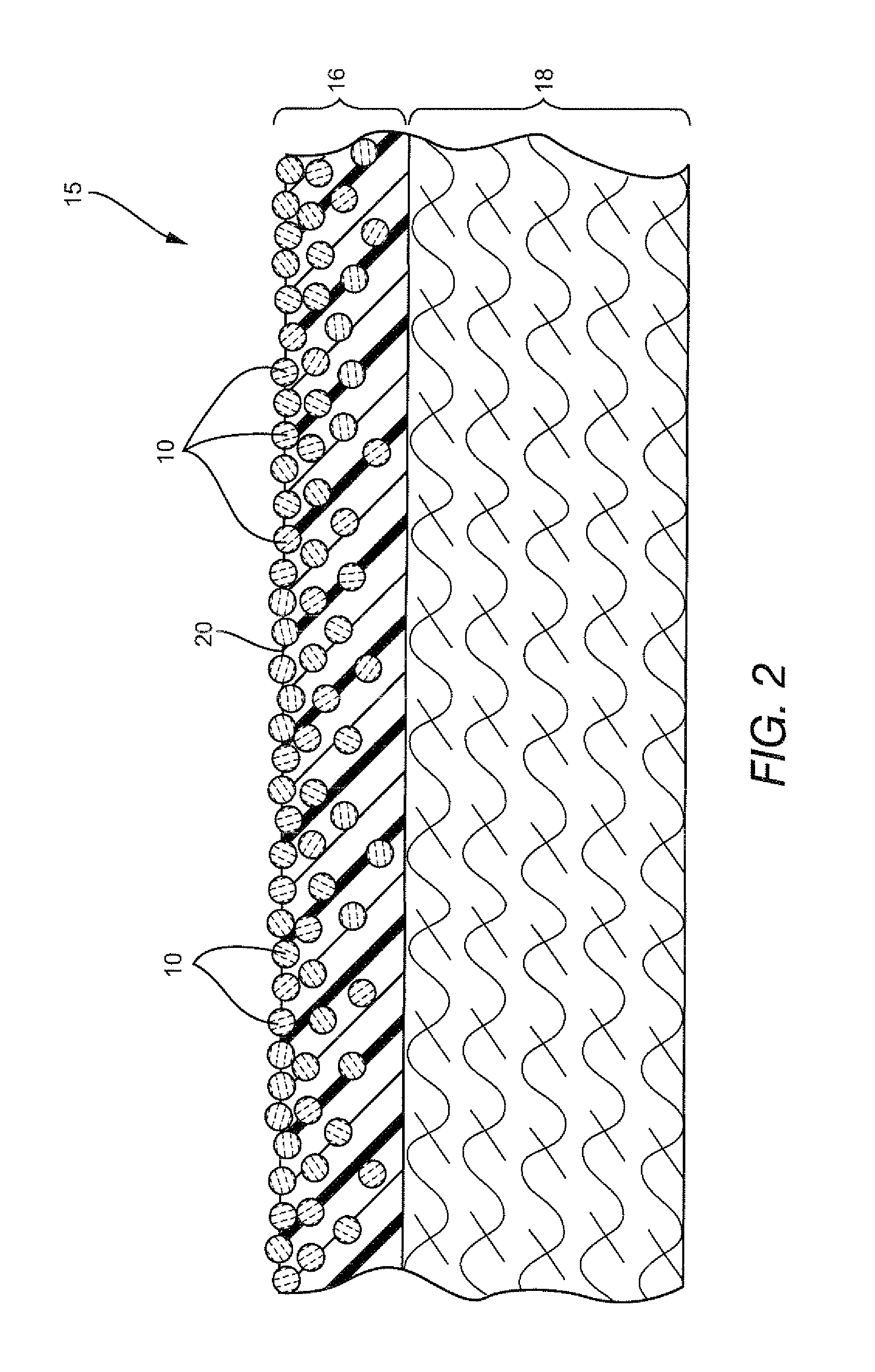

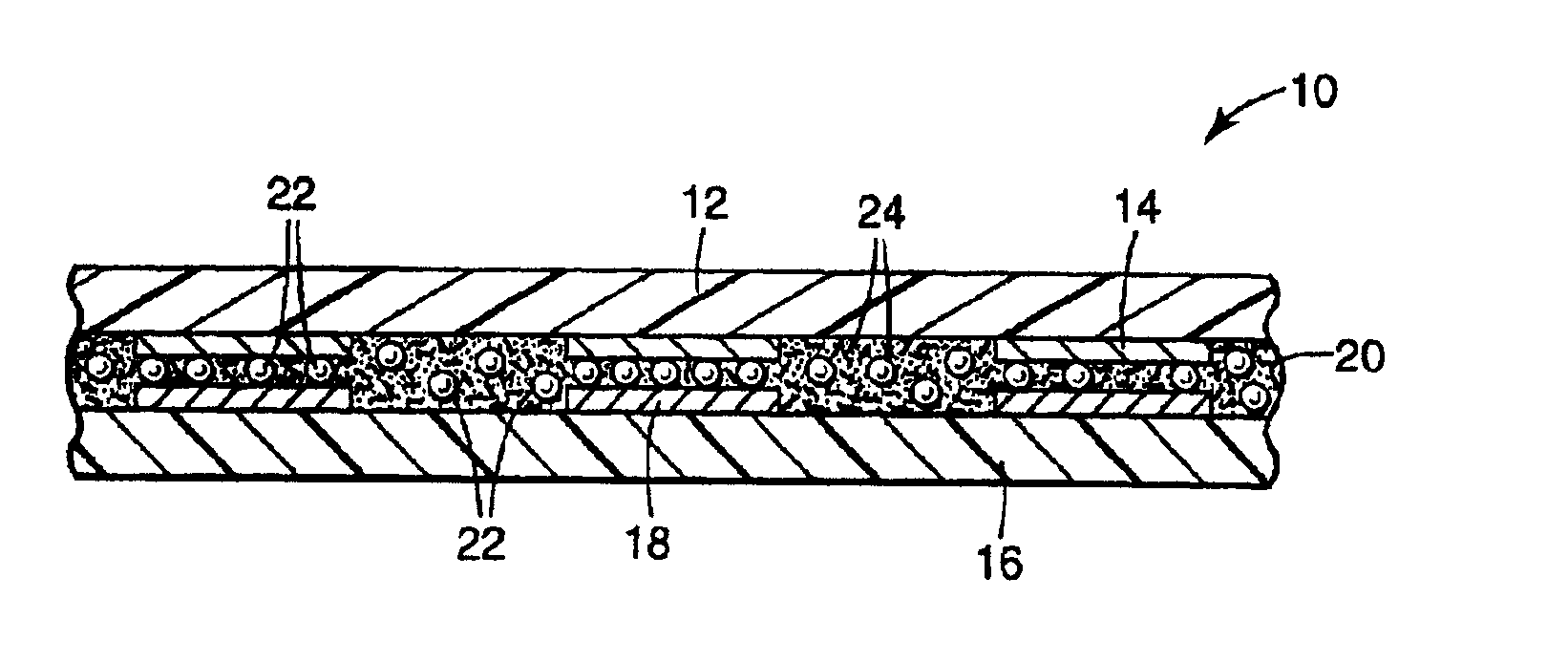

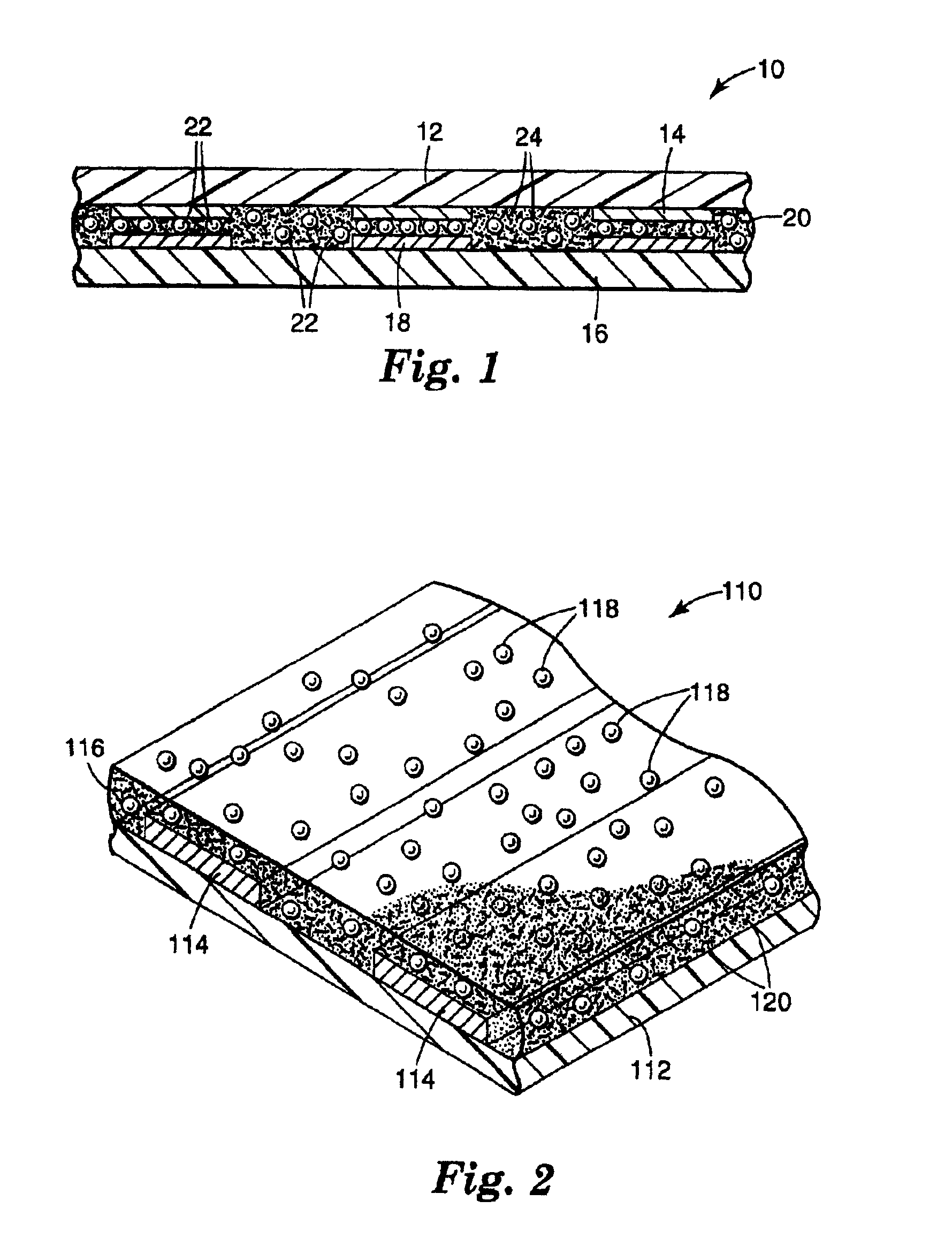

An electro-optic display comprises a layer (130) of a solid electro-optic material, at least one electrode disposed adjacent the layer (130) of electro-optic material, and a layer (180) of a lamination adhesive interposed between the layer (130) of electro-optic material and the electrode, the lamination adhesive (180) having a higher electrical conductivity in a direction perpendicular to the layer of lamination adhesive than in the plane of the layer.

Owner:E INK CORPORATION

Electro-optic display and adhesive composition for use therein

InactiveUS6657772B2Non-macromolecular adhesive additivesStatic indicating devicesDisplay deviceElectric resistivity

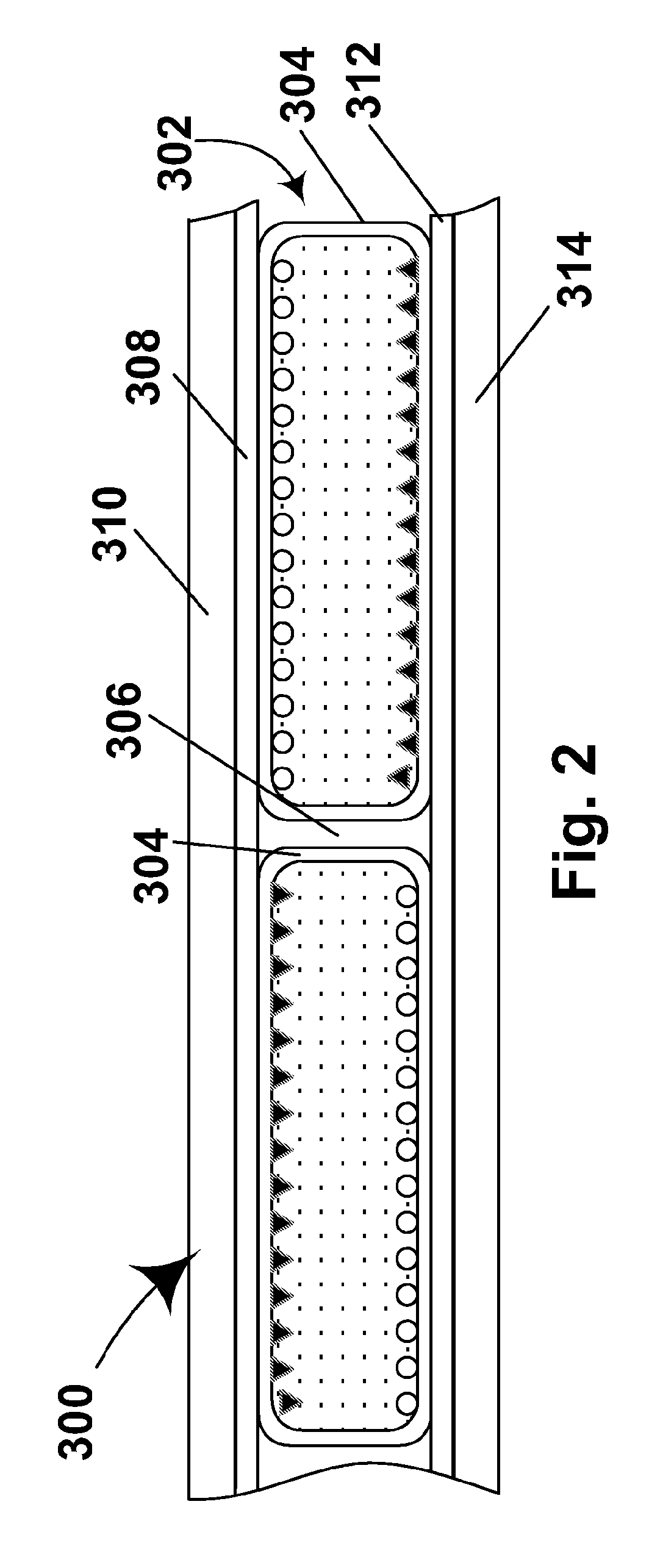

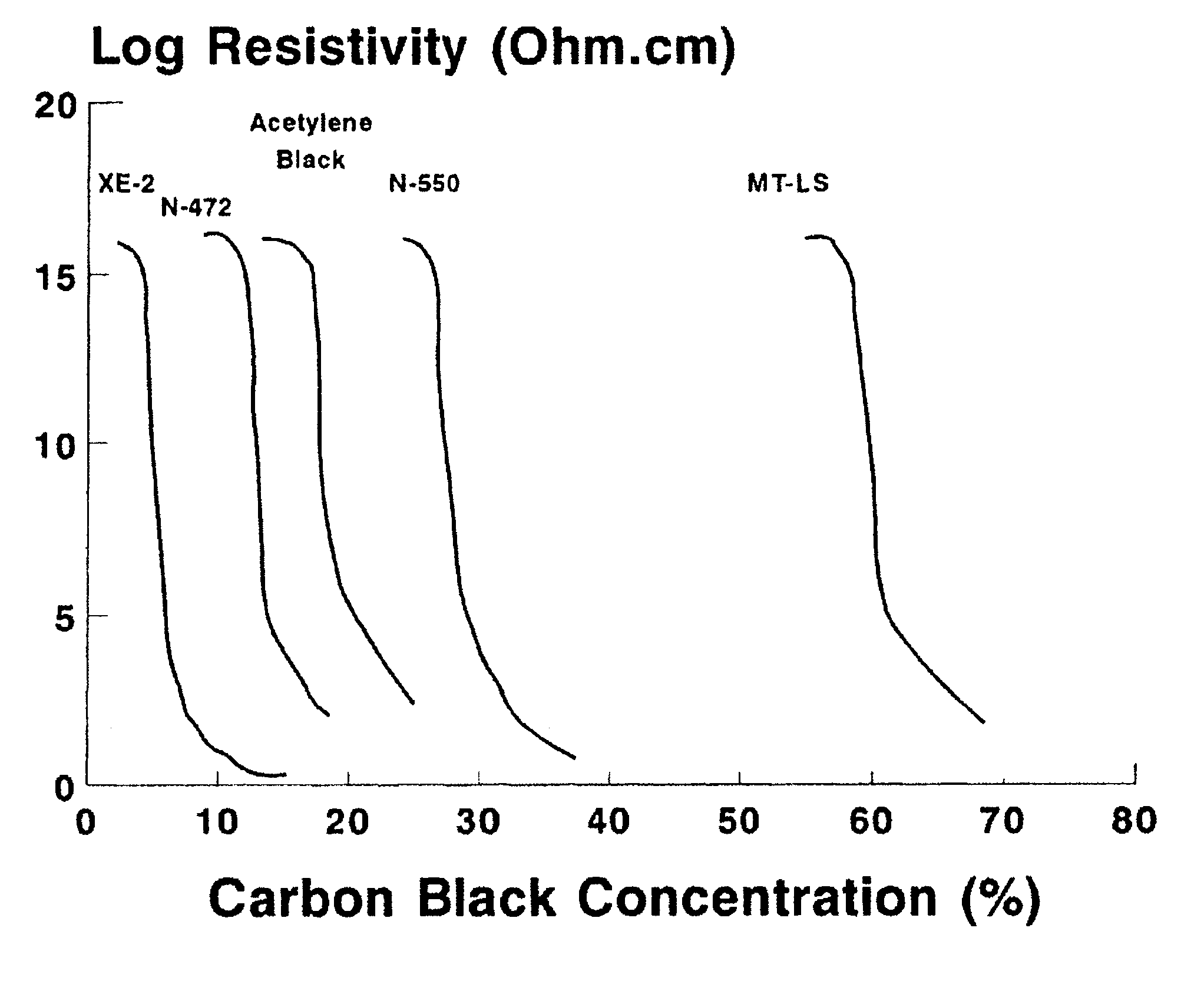

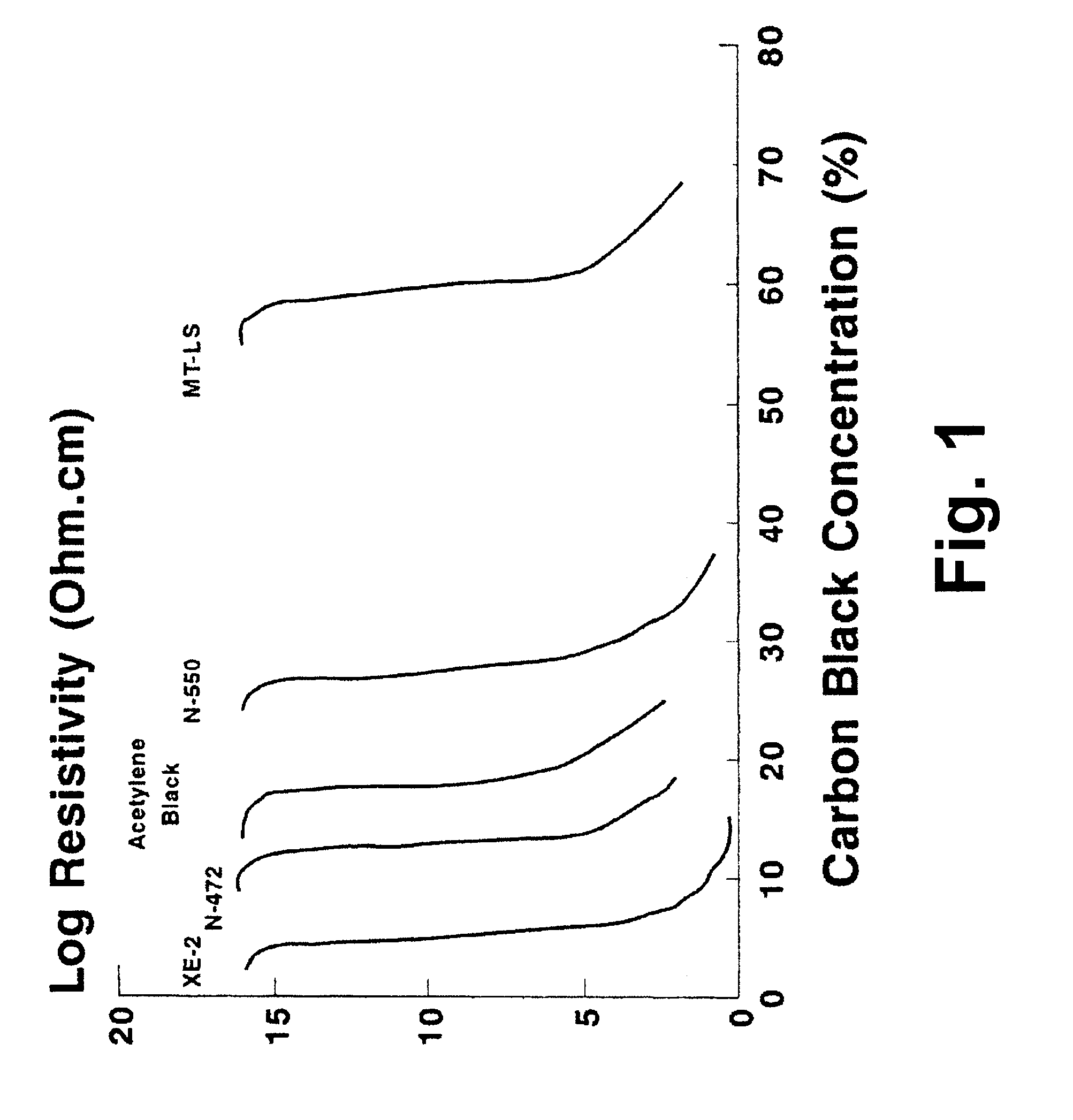

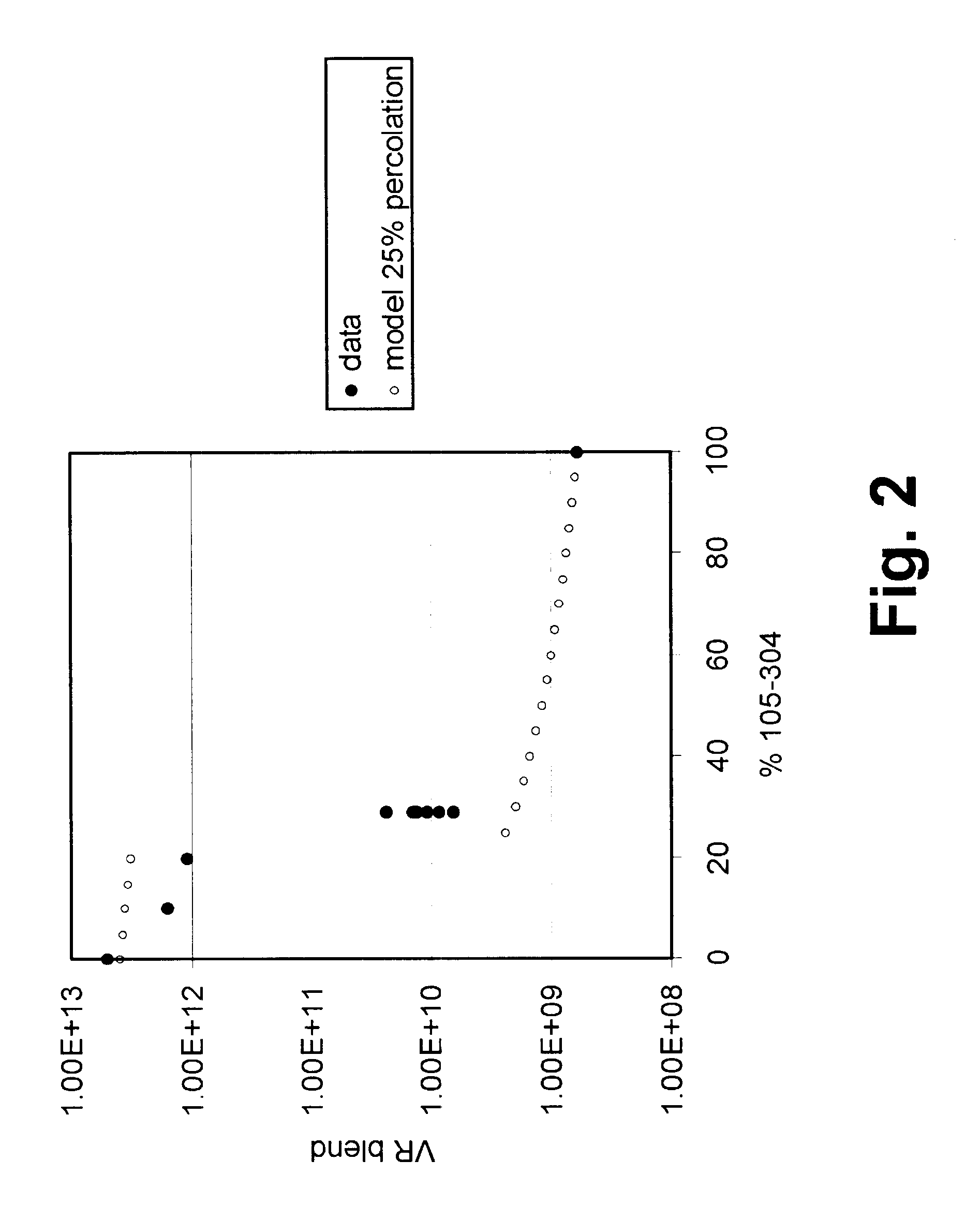

An electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates. The adhesive layer has a volume resistivity in the range of about 10<9 >to about 10<11 >ohm cm and comprises a mixture of an adhesive material having a volume resistivity of at least about 5x10<11 >ohm cm and a filler having a volume resistivity not less than about 10<7 >ohm cm, the filler being present in the mixture in a proportion above its percolation threshold in the adhesive material.

Owner:E INK CORPORATION

Electro-optic display and materials for use therein

InactiveUS20070035808A1Improve conductivityHigh viscosityNon-macromolecular adhesive additivesFilm/foil adhesives without carriersAdhesiveDisplay device

An electro-optic display comprises a layer (130) of a solid electro-optic material, at least one electrode disposed adjacent the layer (130) of electro-optic material, and a layer (180) of a lamination adhesive interposed between the layer (130) of electro-optic material and the electrode, the lamination adhesive (180) having a higher electrical conductivity in a direction perpendicular to the layer of lamination adhesive than in the plane of the layer.

Owner:E INK CORPORATION

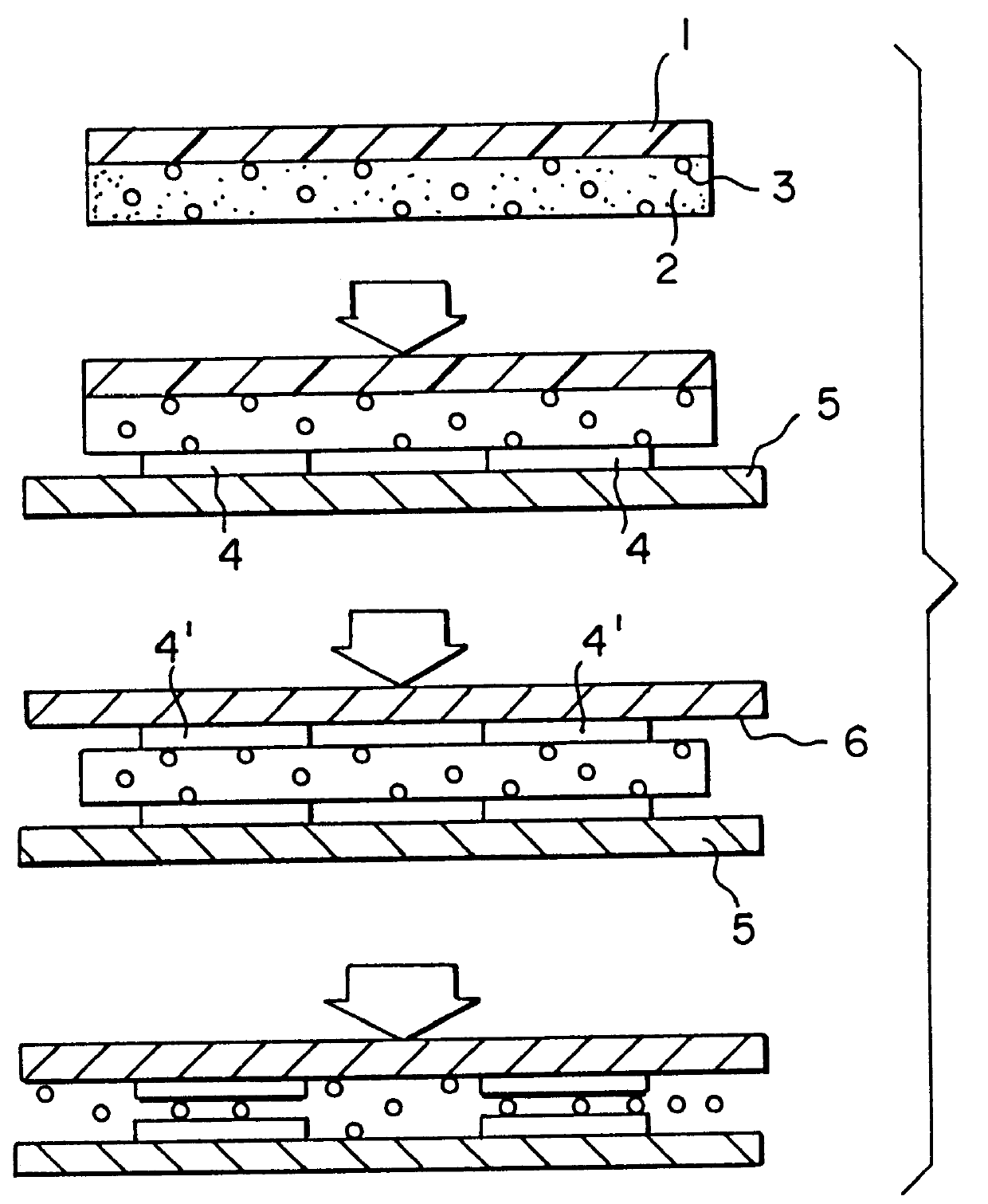

Adhesion method and electronic component

InactiveUS20010004131A1Efficiently dissipatedEnhanced radiationAdhesive processesLamination ancillary operationsAdhesiveBoron nitride

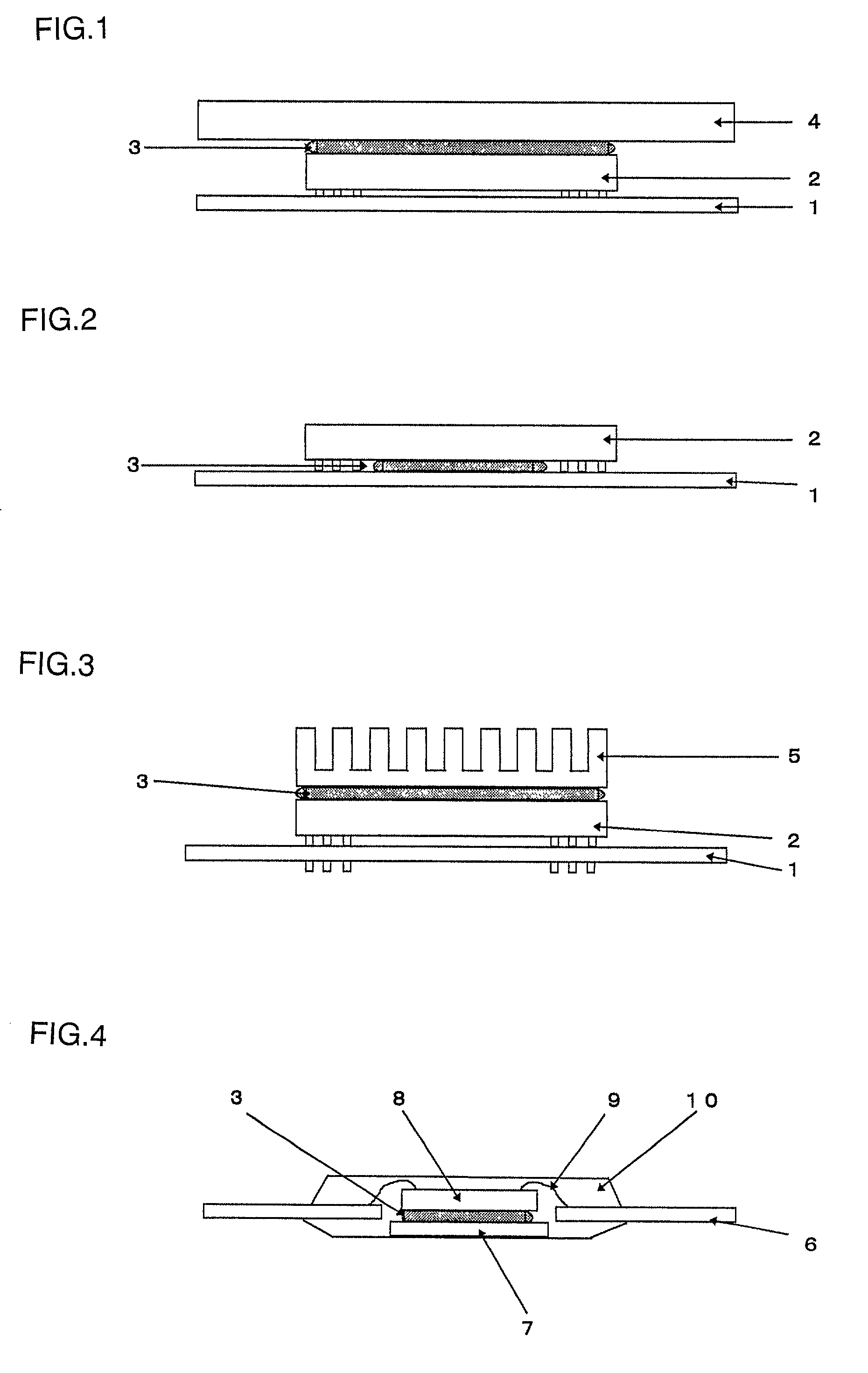

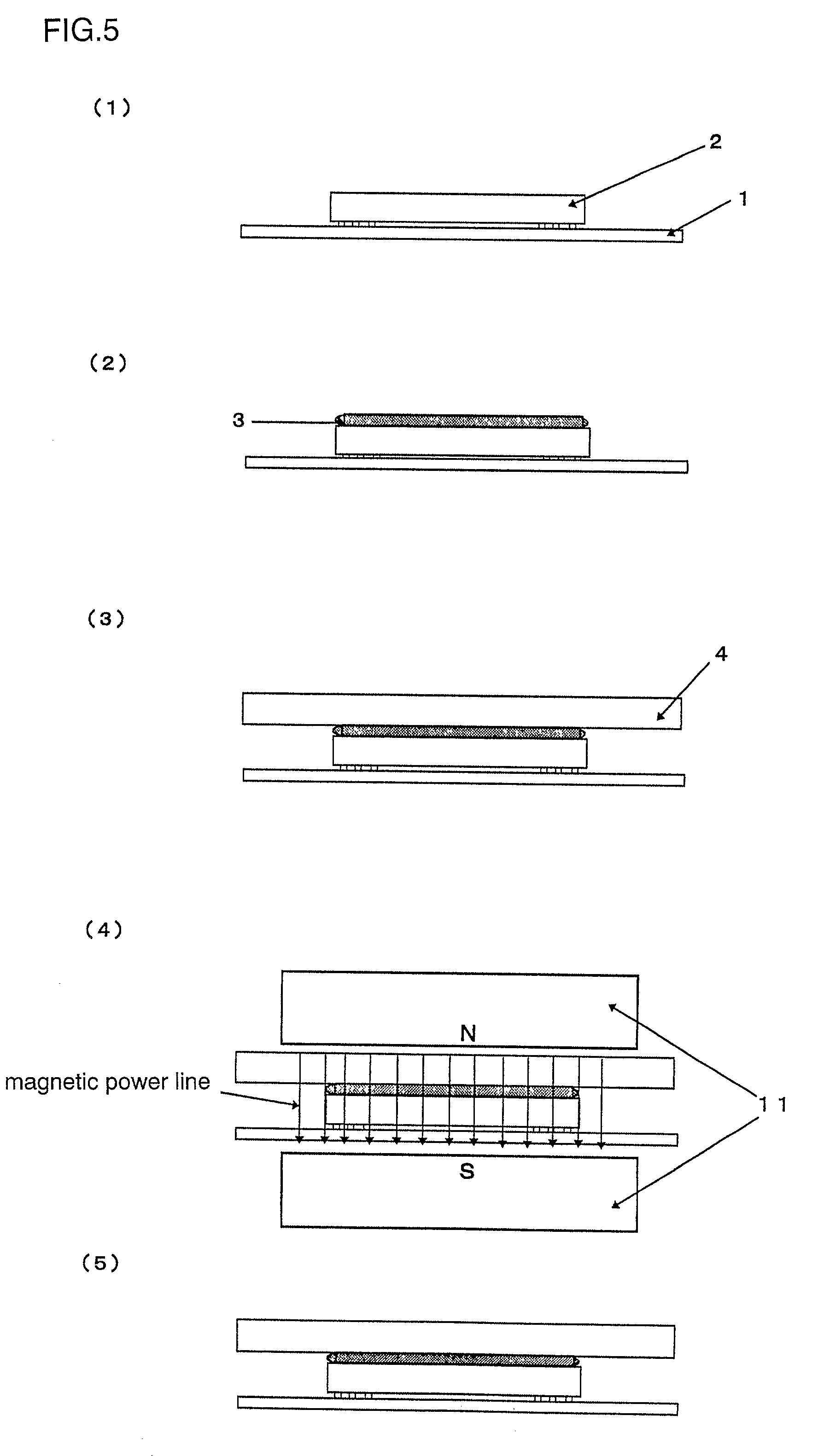

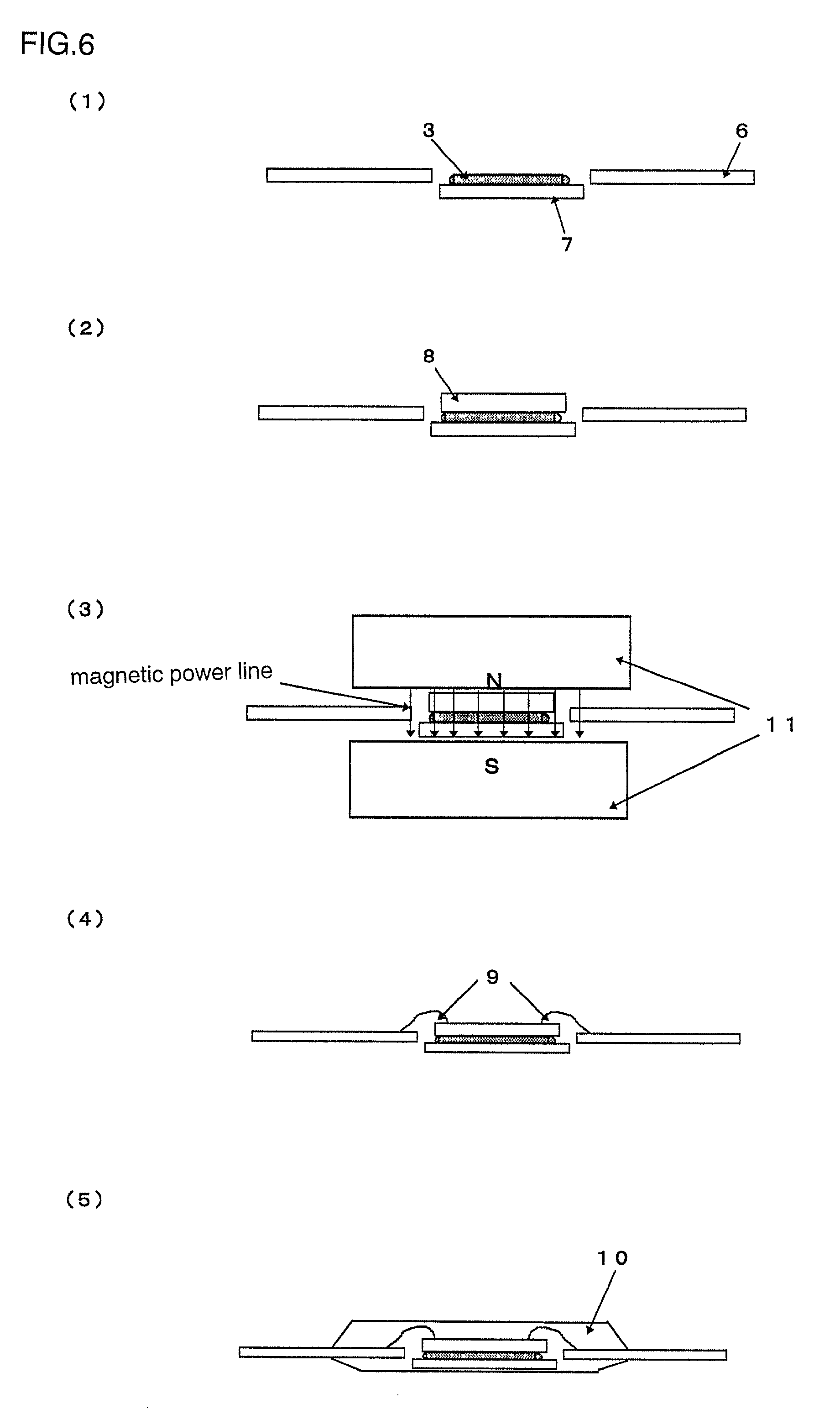

The present invention provides an adhesion method of improving the heat conduction in a fixed direction by using a heat conductive adhesive made by blending boron nitride powder and adhesive polymer and adhering by orienting boron nitride powder in the heat conductive adhesive to the fixed direction under the magnetic atmosphere and an electronic component for effectively dissipating heat generated from semiconductor device 2, power source 4, light source or other components used for the electric products, and an electronic component excellent in radiation.

Owner:POLYMATECH CO LTD

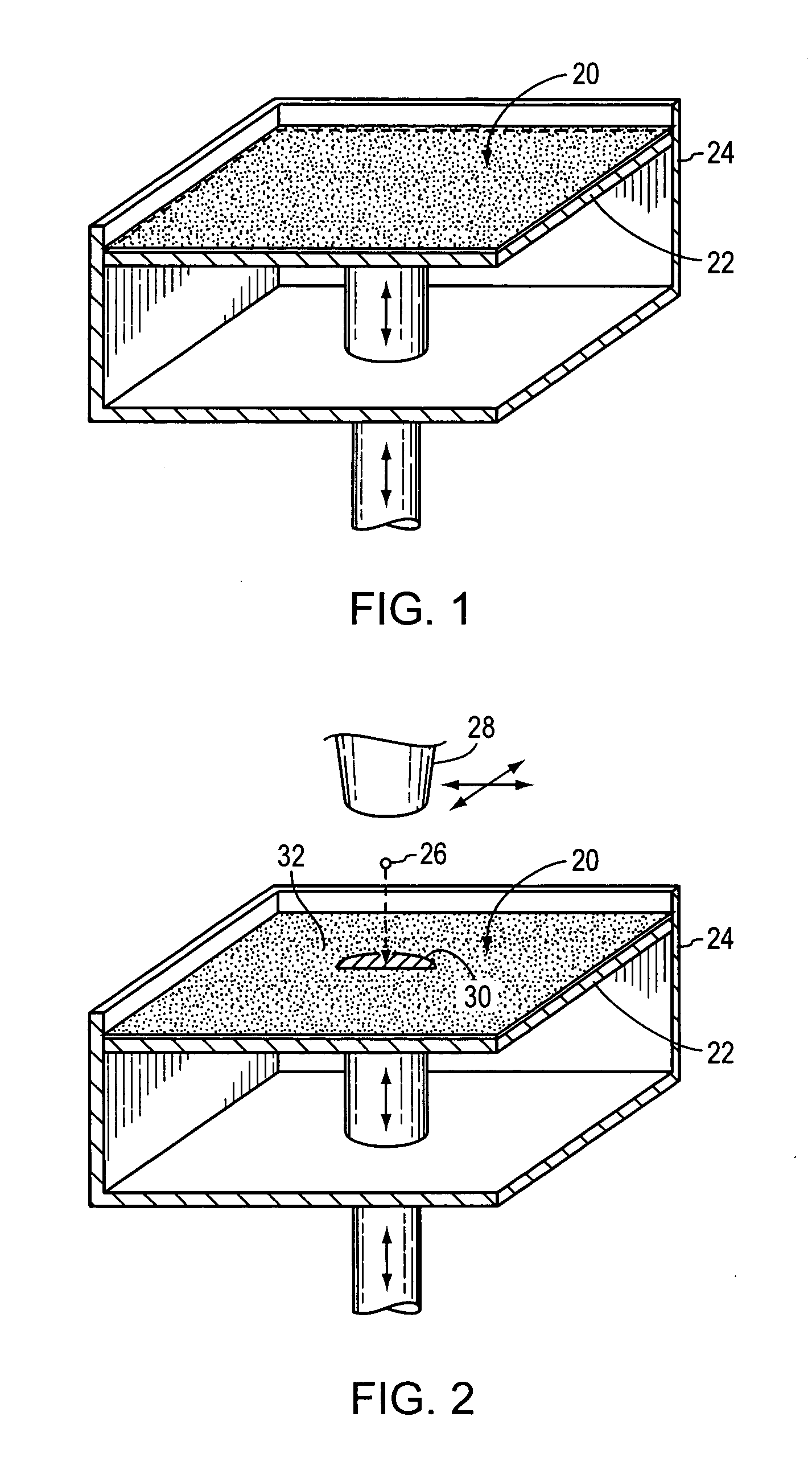

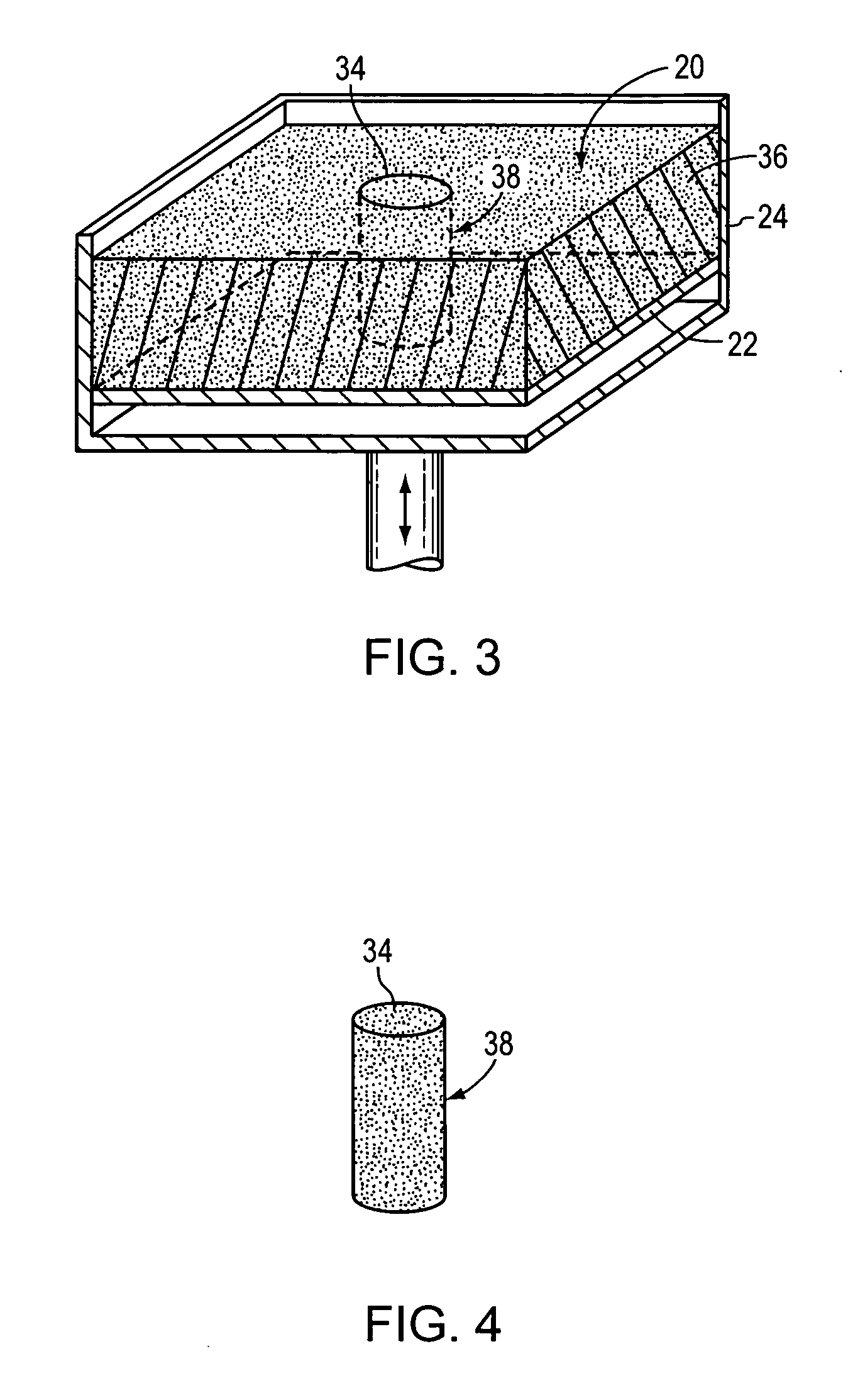

Absorbent fillers for three-dimensional printing

InactiveUS20050059757A1Quick and reliable and safe and inexpensiveSmooth surface finishPigmenting treatmentAdditive manufacturing apparatusParticulatesEngineering

A materials system and methods are provided to enable the formation of articles by three-dimensional printing. The materials system includes an absorbent particulate filler that facilitates absorption of infiltrants, thereby allowing the accurate definition of articles with enhanced mechanical and structural characteristics. The methods include the use of phase-change materials to bind a powder, as well as the formation of support structures to improve the control of the shape of the articles.

Owner:Z CORPORATION

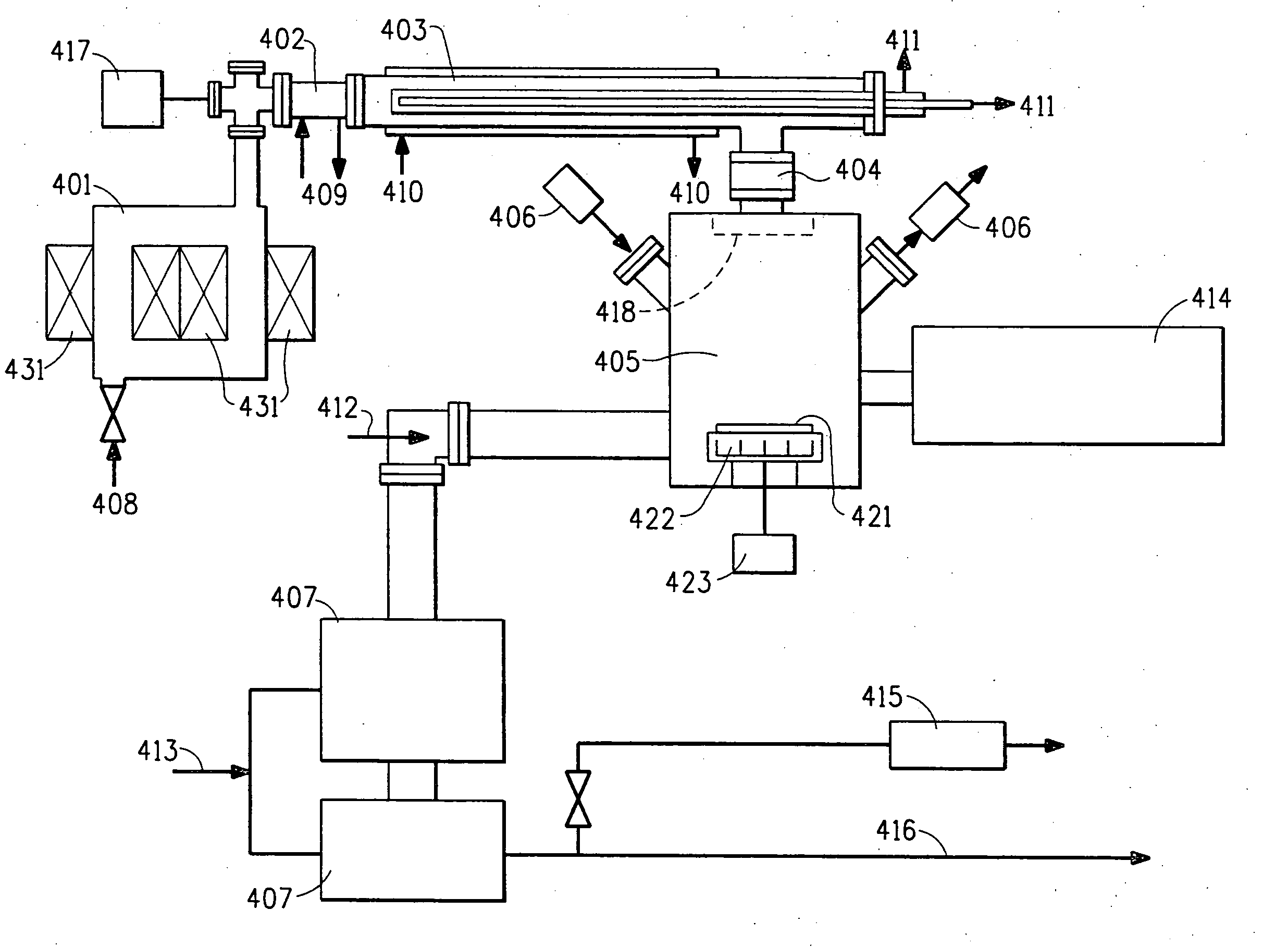

Method for removing surface deposits in the interior of a chemical vapor deposition reactor

InactiveUS20080087642A1Non-macromolecular adhesive additivesElectric discharge tubesEngineeringBiological activation

Disclosed is a deposition apparatus assembly comprising a deposition chamber, a remote chamber outside the deposition chamber for producing a reactive species from a precursor gas mixture, an activation source adapted to deliver energy into said remote chamber, a conduit for flowing the reactive species from said remote chamber to said deposition chamber and a flow restricting device interposed between said conduit and said remote chamber wherein said flow restricting device is cooled by an external source.

Owner:MASSACHUSETTS INST OF TECH

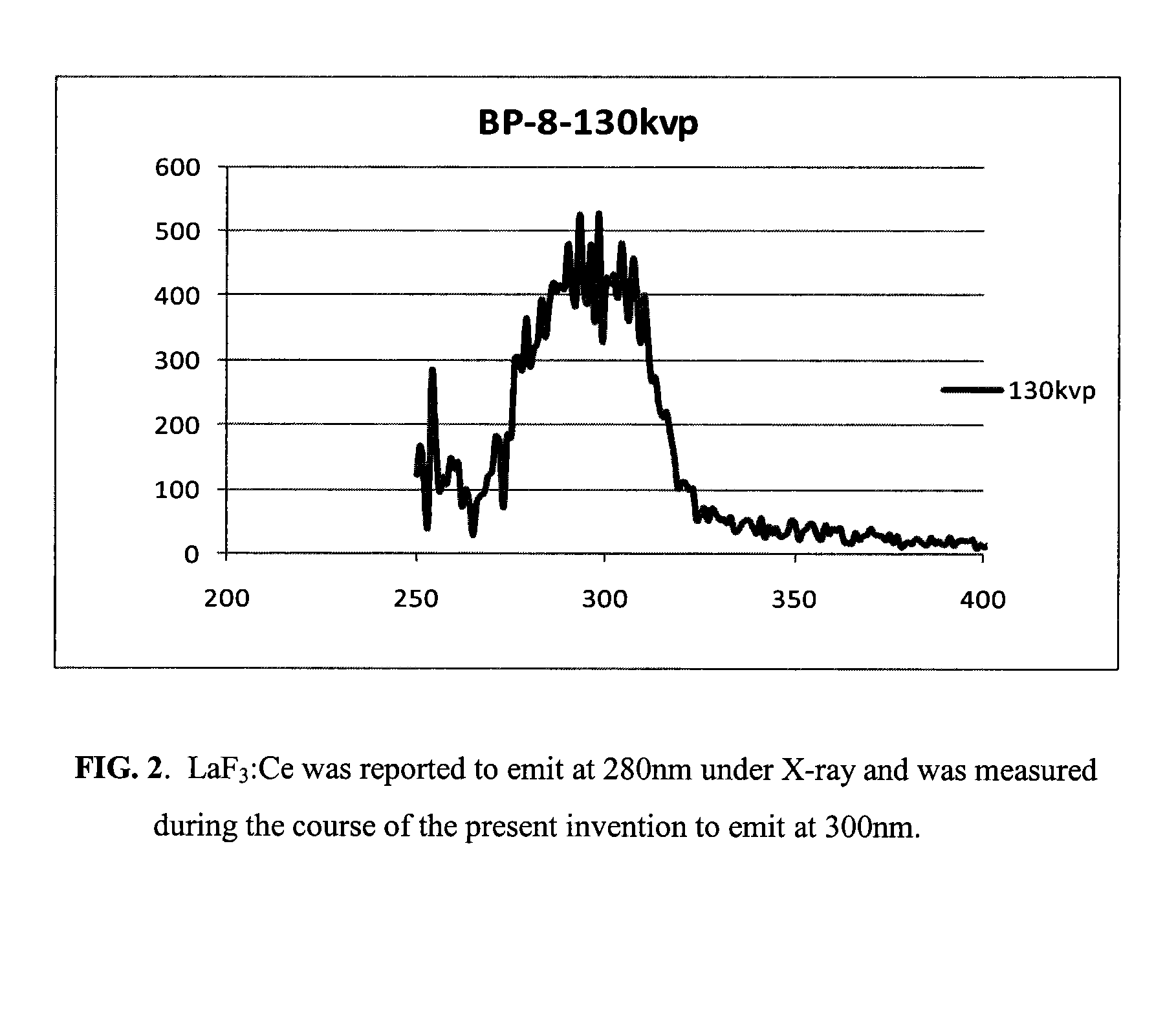

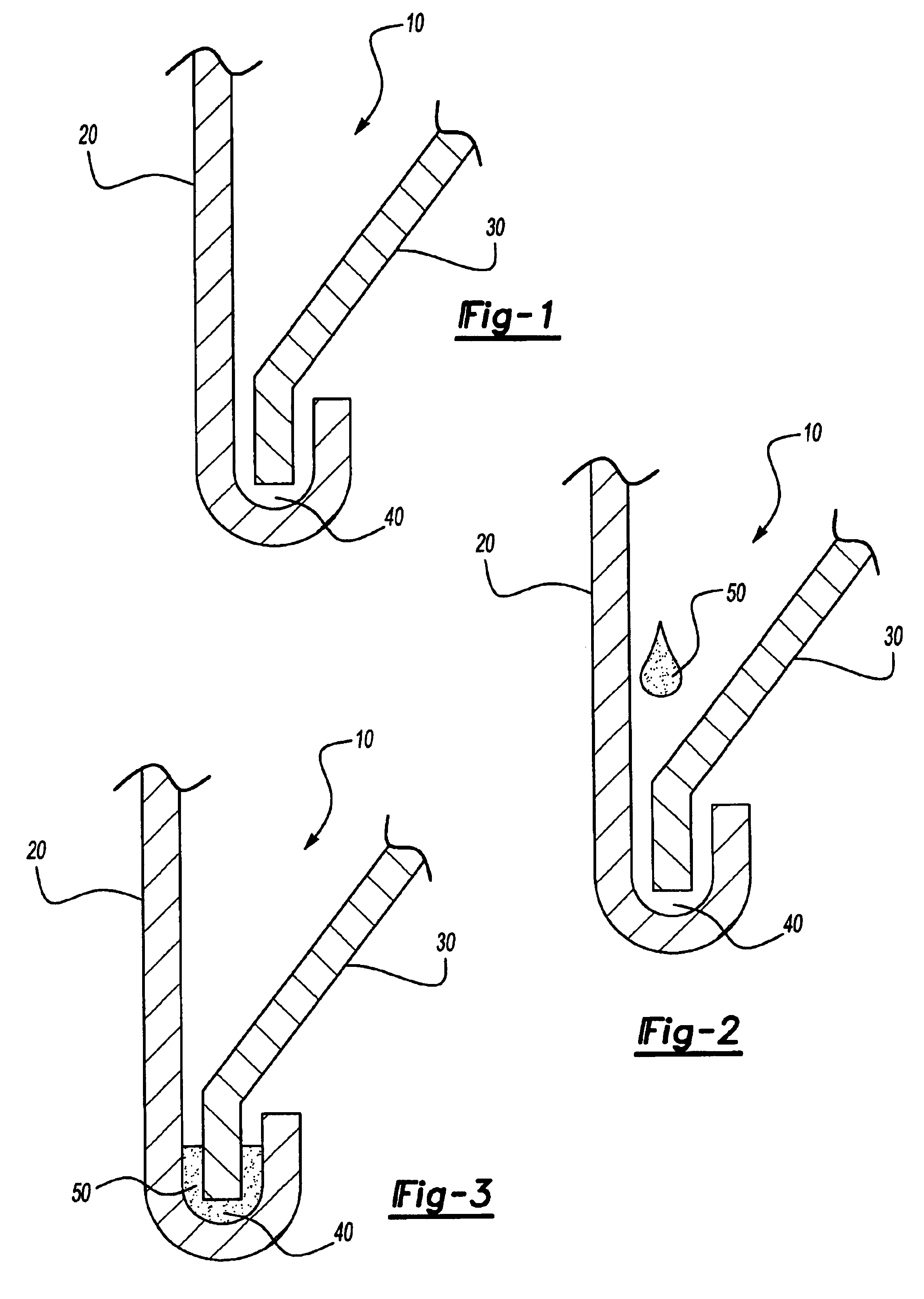

Adhesive bonding composition and method of use

A polymerizable composition includes at least one monomer, a photoinitiator capable of initiating polymerization of the monomer when exposed to light, and a phosphor capable of producing light when exposed to radiation (typically X-rays). The material is particularly suitable for bonding components at ambient temperature in situations where the bond joint is not accessible to an external light source. An associated method includes: placing a polymerizable adhesive composition, including a photoinitiator and energy converting material, such as a down-converting phosphor, in contact with at least two components to be bonded to form an assembly; and, irradiating the assembly with radiation at a first wavelength, capable of conversion (down-conversion by the phosphor) to a second wavelength capable of activating the photoinitiator, to prepare items such as inkjet cartridges, wafer-to-wafer assemblies, semiconductors, integrated circuits, and the like.

Owner:IMMUNOLIGTHT LLC +1

Electrically conductive adhesives

InactiveUS20070131912A1Material nanotechnologyNon-macromolecular adhesive additivesElastomerMetal particle

The present invention provides an electrically conductive adhesive composition having cured low modulus elastomer and metallurgically-bonded micron-sized metal particles and nano-sized metal particles. The low modulus elastomer provides the mechanical robustness and reliability by relieving the stresses generated; and the metallurgically-bonded micron-sized metal particles and nano-sized metal particles provide a continuous conducting path with minimized interface resistance. Addition of nano-sized metal particles lowers the fusion temperature and allows the metallurgical-bonding to occur at manageable temperatures.

Owner:GENERAL ELECTRIC CO

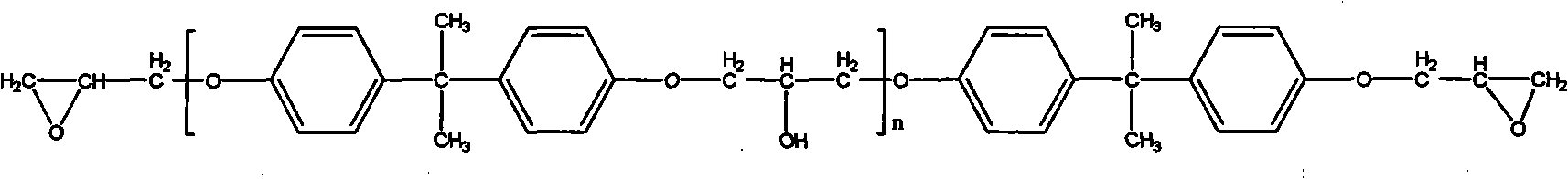

Anisotropic conductive adhesive and method for preparation thereof and an electronic apparatus using said adhesive

InactiveUS6039896AReduce weightEasy to manufactureNon-macromolecular adhesive additivesDigital data processing detailsEpoxyPhosphoric Acid Esters

An anisotropic conductive adhesive contains conductive particles dispersed in a resin composition, wherein the resin composition includes a radical polymerization resin (A), an organic peroxide (B), a thermoplastic elastomer (C) and a phosphoric ester (D). The resin composition can further contain an epoxy silane coupling agent (E) represented by formula (2) or (3). The resin composition is mixed with other components after the radical polymerization resin (A), the thermoplastic elastomer (C), the phosphoric ester (D) and the epoxy silane coupling agent (E) are reacted. It is also possible to preliminarily react only the phosphoric ester (D) and the epoxy silane coupling agent (E) and to react the product of the preliminary reaction with the radical polymerization resin (A) and the thermoplastic elastomer (C), and then to add other components. The anisotropic conductive adhesive of the present invention can be used for electrical joining of electronic or electric parts of electrical apparatus.

Owner:SUMITOMO BAKELITE CO LTD

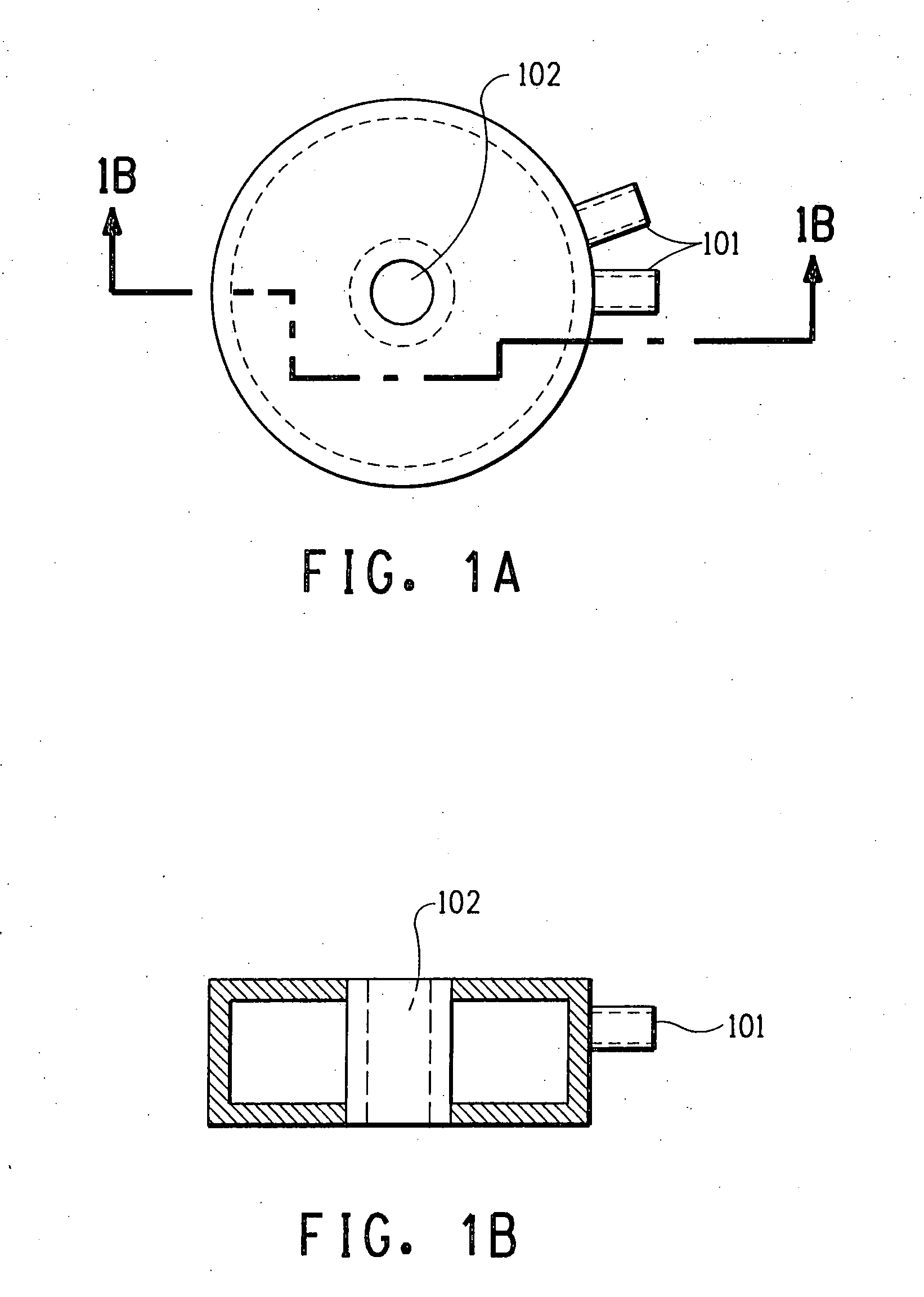

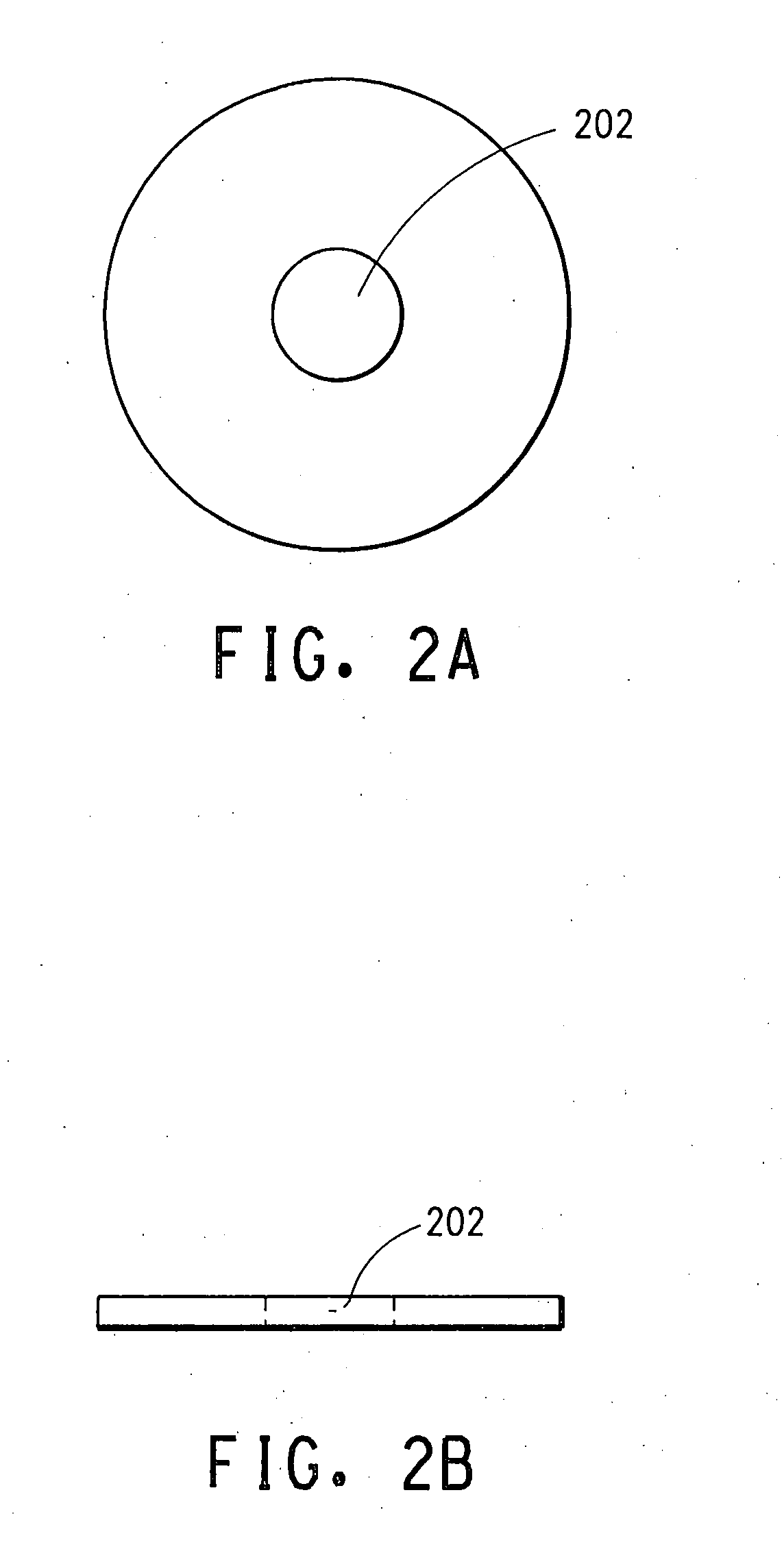

Cationic and hybrid radiation curable pressure sensitive adhesives for bonding of optical discs

InactiveUS6180200B1Improve adhesionImprove adhesion qualityTelevision system detailsNon-macromolecular adhesive additivesAdhesive bondingPressure sensitive

Cationic and hybrid radiation-curable pressure sensitive adhesive compositions for digital versatile discs and other substrates, a method for bonding versatile digital disc layers together with a cationic or hybrid radiation-curable pressure sensitive adhesive, and a digital versatile disc bonded by cationic or hybrid radiation-curable pressure sensitive adhesive.

Owner:DSM IP ASSETS BV

Electrically conductive pressure sensitive adhesives, method of manufacture, and use thereof

InactiveUS20050062024A1Material nanotechnologyNon-macromolecular adhesive additivesCarbon nanotubePressure sensitive

An adhesive, comprising a pressure-sensitive adhesive composition; and carbon nanotubes in an amount effective to render the pressure-sensitive adhesive composition electrically conductive. Such adhesives are of particular use with gasketing materials.

Owner:WORLD PROPERTIES

Carbon Fibrous Conjunct and Composite Material Using Thereof

InactiveUS20080254296A1High strengthImprove abilitiesMaterial nanotechnologyNon-macromolecular adhesive additivesFiberCarbon fibers

Carbon fibrous conjunct is provided by adding to carbon fibrous structures, which each comprises a three dimensional network of carbon fibers each having an outside diameter of 15-100 nm, wherein the carbon fibrous structure further comprises a granular part with which the carbon fibers are bound in the state that the carbon fibers extend outwardly from the granular part, a binder for binding the carbon fibrous structures. The fine carbon fibrous structures having such unique configuration and also bearing physical properties suitable for a filler for a composite material can be provided with a good handleability by this carbon fibrous conjunct. Composite material is prepared by adding to the matrix the carbon fibrous conjuncts, at an amount of 0.1 to 30% by weight based on the total weight of the composite material.

Owner:HODOGOYA CHEMICAL CO LTD

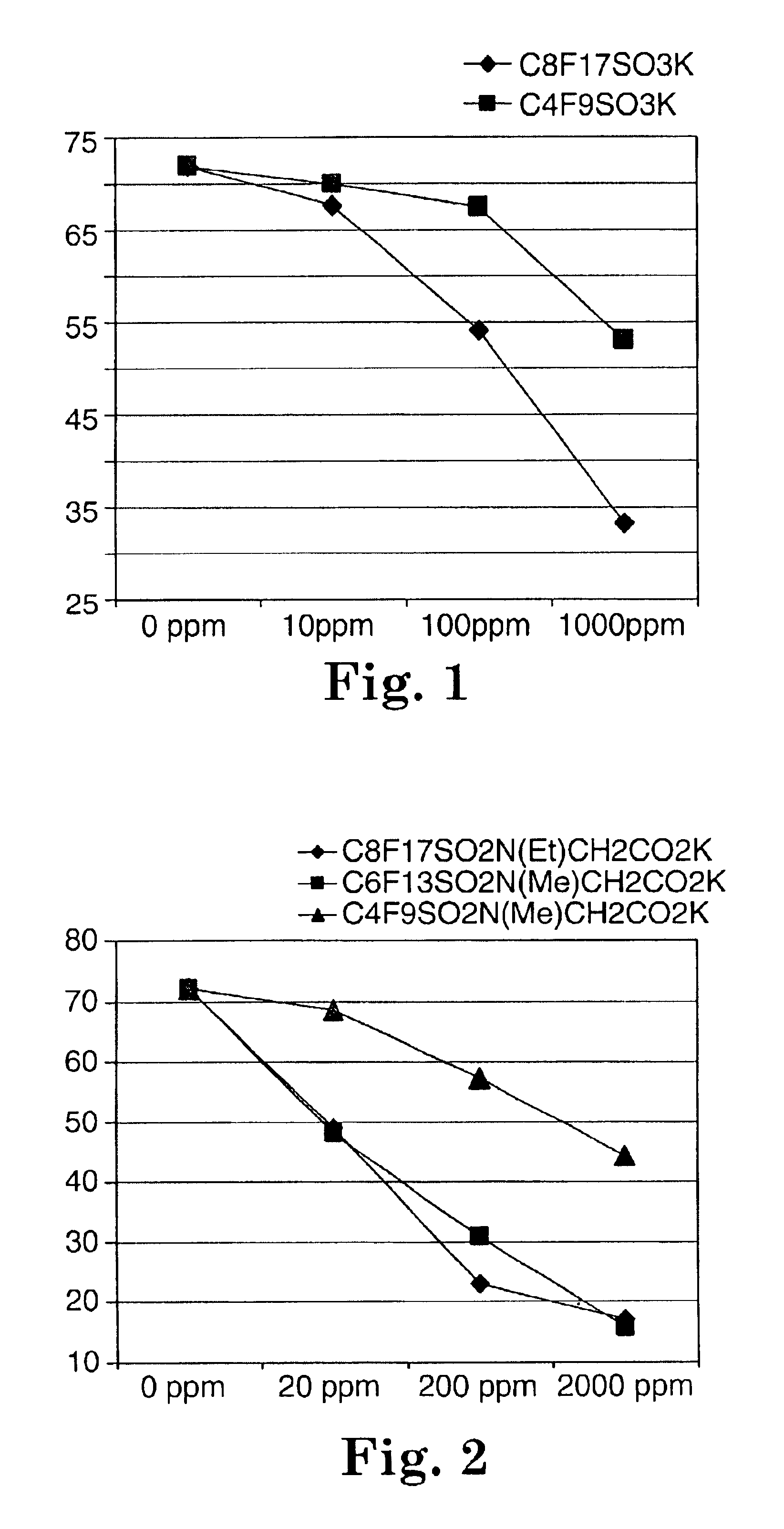

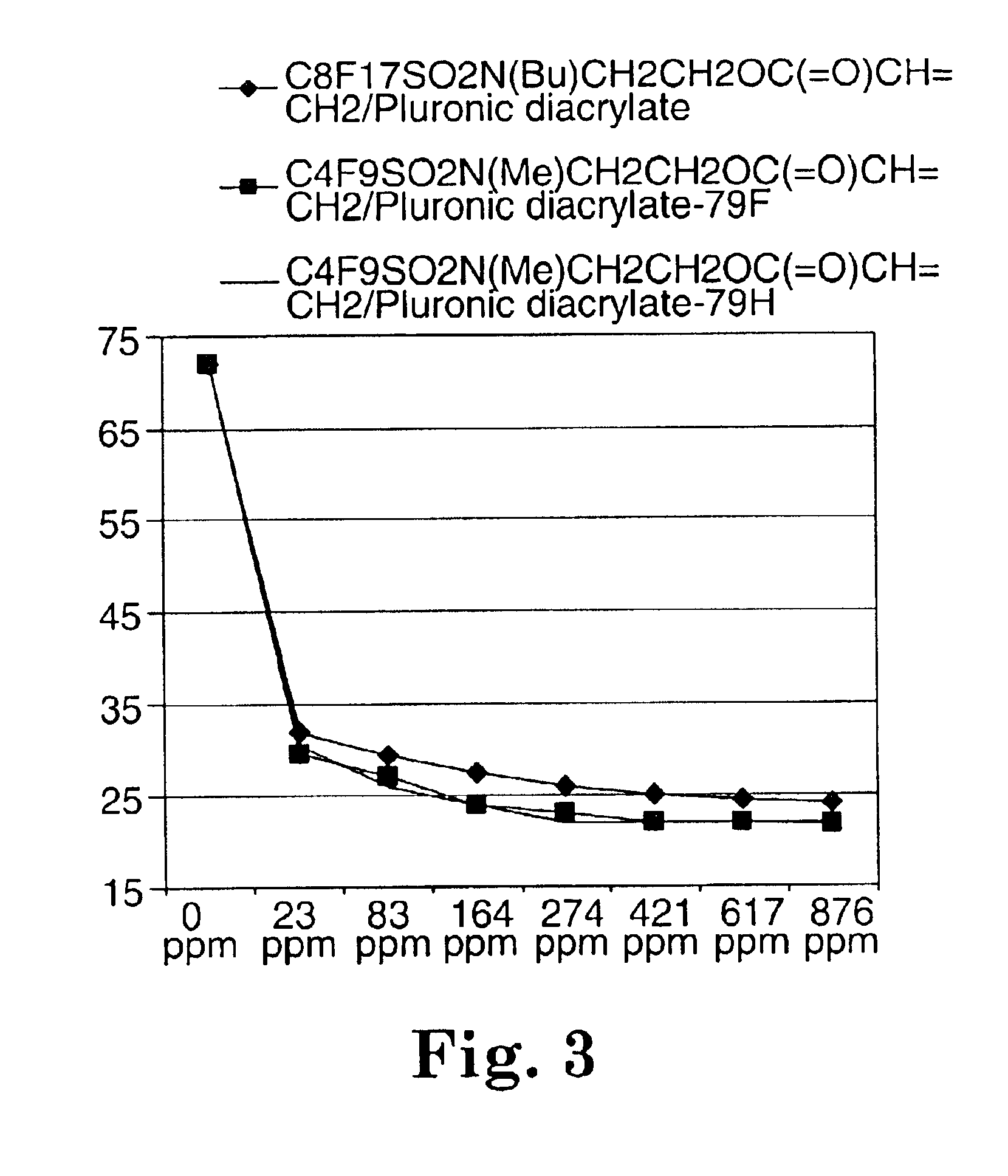

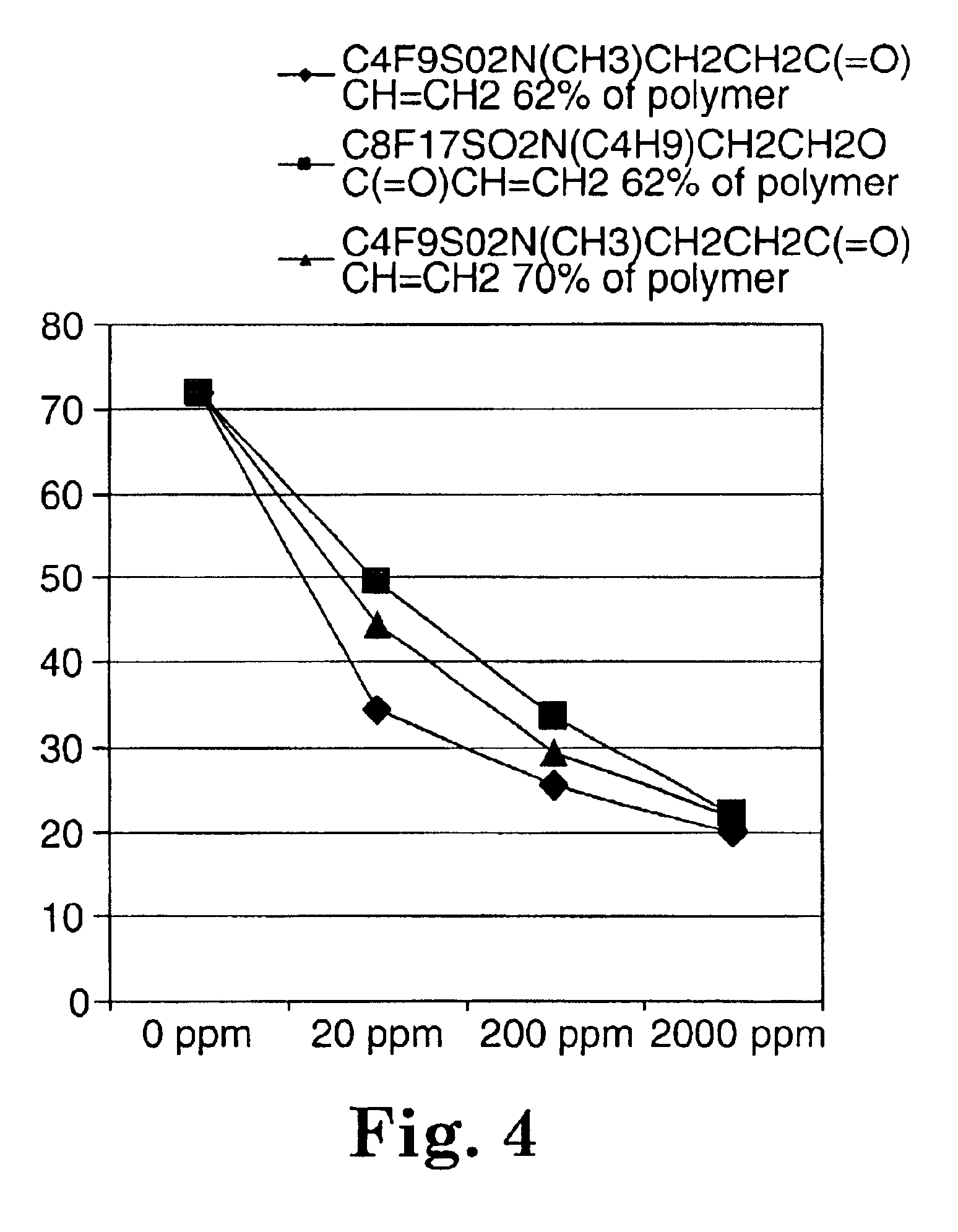

Fluorochemical sulfonamide surfactants

InactiveUS6852781B2High yieldLow costNon-macromolecular adhesive additivesPhotosensitive materialsSide chainSulfonyl fluoride

Described are fluorochemical surfactants derived from nonafluorobutanesulfonyl fluoride that contain polyalkyleneoxy side chains and may be copolymerized with acrylic acid or methacrylic acid to form polyacrylates or polymethacrylates. The surfactants surprisingly lower the surface tension of water and other liquids in the same or similar low values achieved by premier surfactants such as those derived from perfluorooctane sulfonyl fluoride.

Owner:3M INNOVATIVE PROPERTIES CO

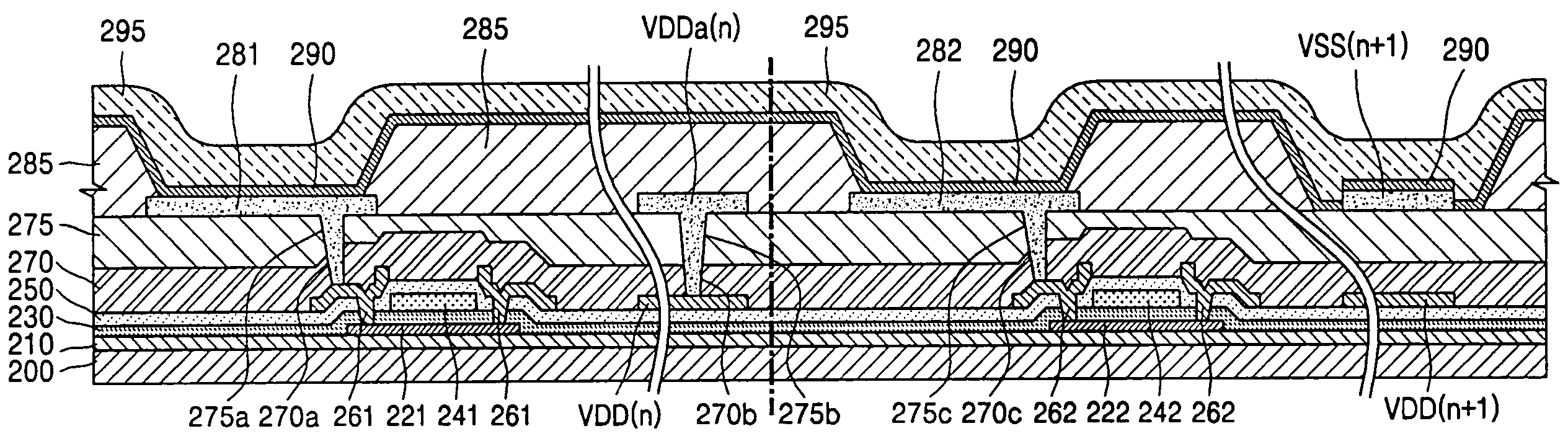

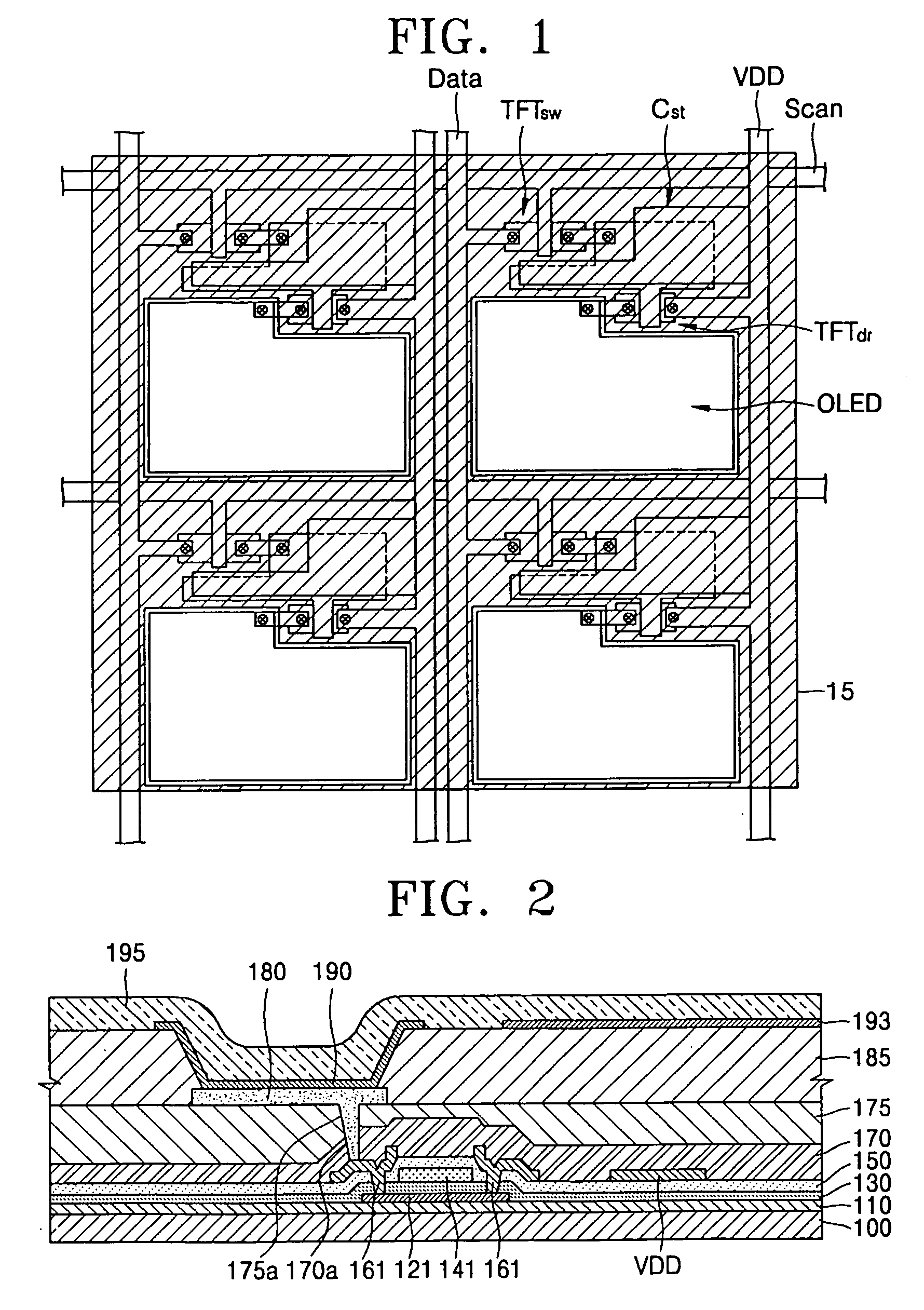

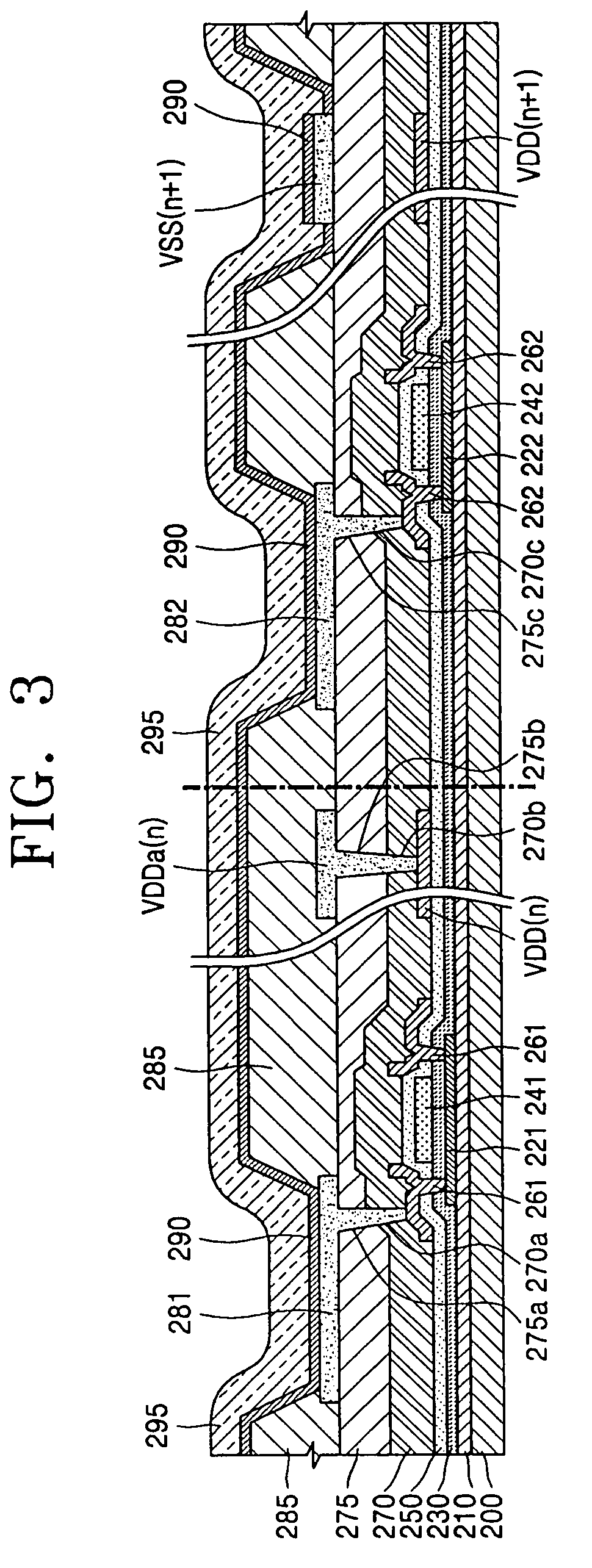

Organic electro-luminescent display device and method of manufacturing the same

ActiveUS20050179374A1Improving imaging characteristicsIncrease brightnessDischarge tube luminescnet screensNon-macromolecular adhesive additivesOrganic filmDisplay device

An organic electroluminescence device which includes a power line formed on the same layer as source and drain electrodes of a thin film transistor (TFT) and formed on a substrate on which the TFT is formed, a first insulating layer formed on the TFT, a lower electrode that electrically connected to one of the source and drain electrodes of the TFT and disposed on the first insulating layer, a first auxiliary power line and a second auxiliary power line formed on the same layer as the lower electrode in the second insulating layer, a second insulating layer formed on an edge portion of the lower electrode and not formed on the second auxiliary power line, wherein an opening that exposes a portion of the lower electrode is formed, an organic film formed on a substrate; and an upper electrode formed on the substrate.

Owner:SAMSUNG DISPLAY CO LTD

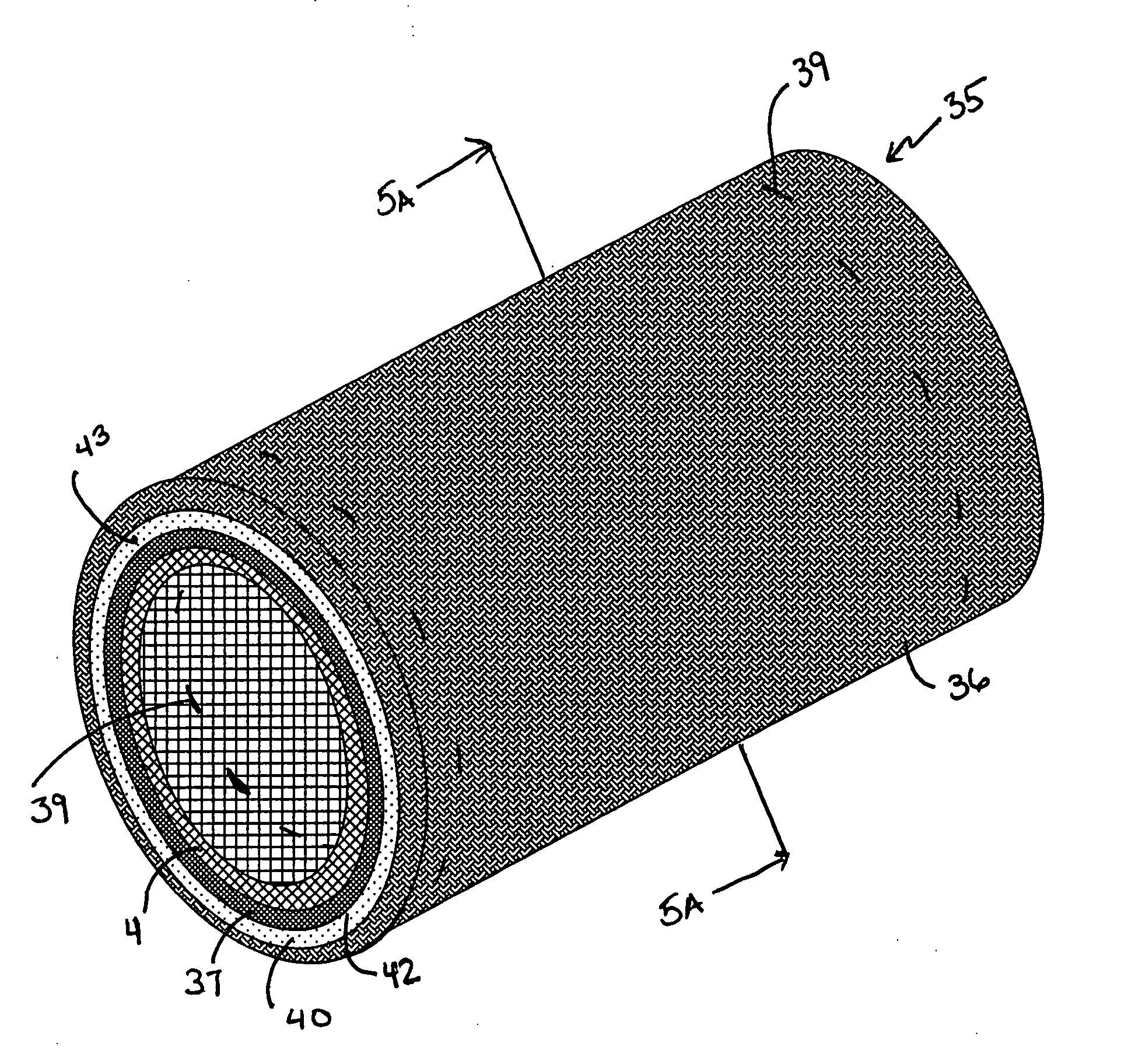

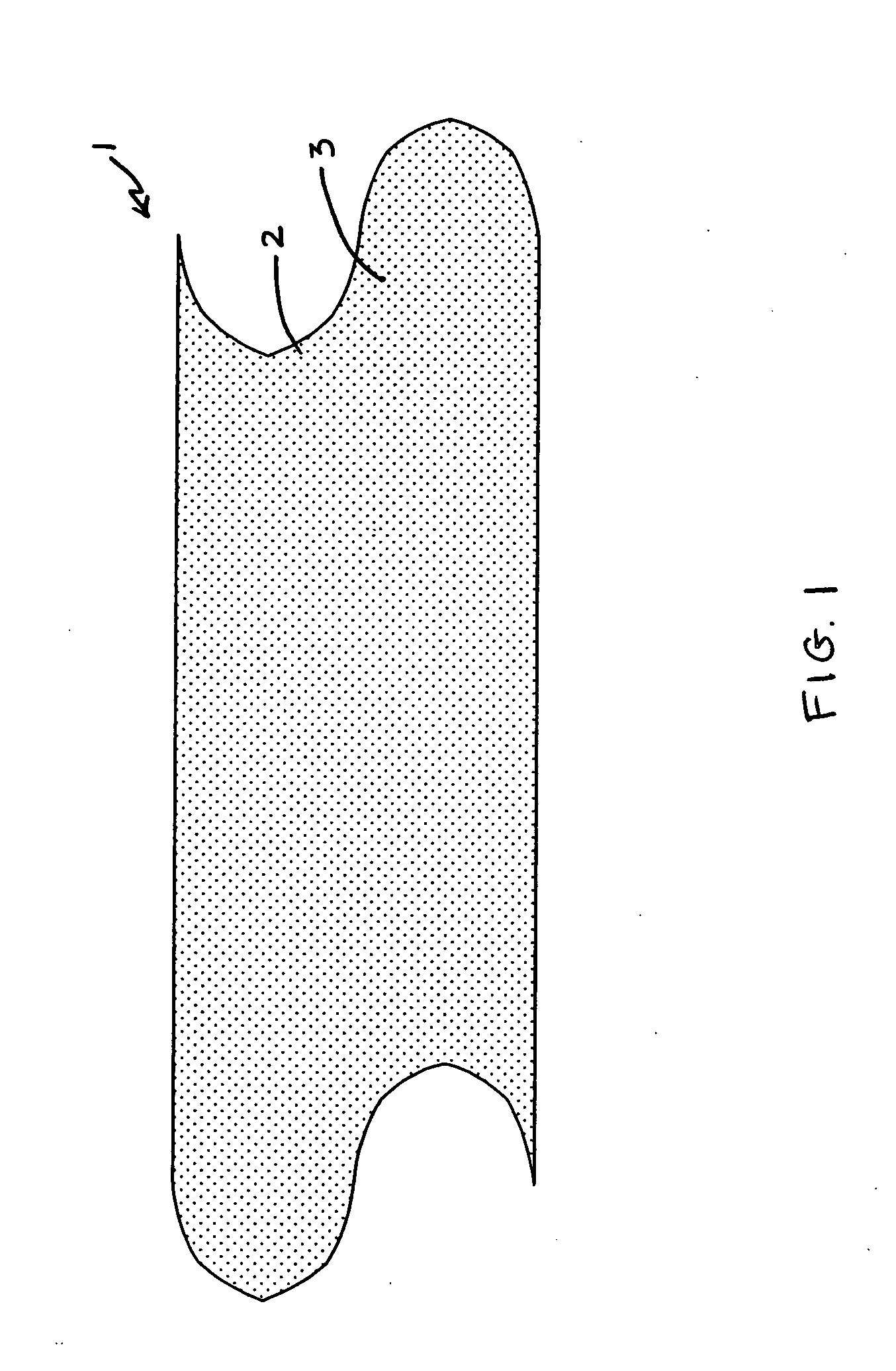

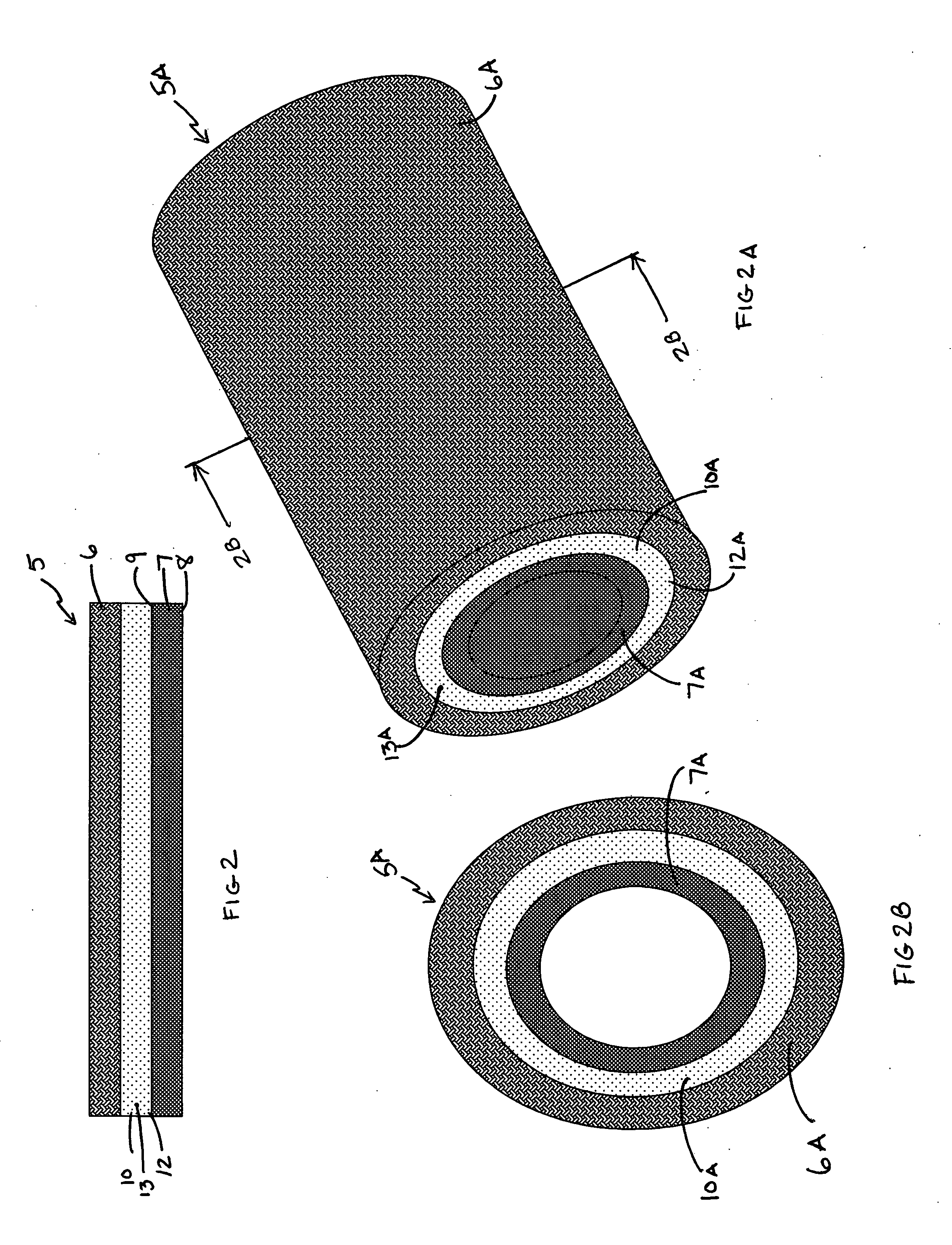

Elastomeric radiopaque adhesive composite and prosthesis

InactiveUS20060058867A1Enhanced tissue ingrowthHigh suture retention strengthStentsSurgical adhesivesElastomerAdhesive

An elastomeric radiopaque adhesive composition which includes a biocompatible elastomeric matrix and a radiopaque material distributed therein in sufficient amounts to produce a radiopaque image. Further, a hybrid vascular prosthesis including a PTFE structure, a textile structure and a cured elastomeric bonding agent adhesively secures the PTFE to the textile. The elastomeric agent having radiopaque material impregnated therein in sufficient amounts to produce a radiopaque image.

Owner:LIFESHIELD SCI

Structural hot melt material and methods

InactiveUS6887914B2Reduce and eliminate stepAvoid corrosionAdhesive processesNon-macromolecular adhesive additivesEpoxyHot melt

The present invention relates to a material, method, and application for reinforcement of structural members, especially joints such as a hem flange joint of an automobile. The method and material of the present invention comprises of combining, in parts by weight: less than about twenty percent (<20%) ethylene copolymer, less than about forty percent (<40%) epoxy, less than about thirty percent (<45%) epoxy-based resin, less than about two percent (<2%) blowing agent and from about one percent (1%) to about five percent (5%) curing agent (and optionally add any of the following components: less than about two percent (<2%) curing agent accelerator, from about twenty-five percent (25%) to fifty-five percent (55%) filler, and less than about one percent (<1%) of coloring agent). The application of the present invention comprises of: (1) providing a structural member having two substrates forming a space to be joined; (2) placing the material of the present invention in proximity of the space to be joined; (3) exposing the material to a heat source causing it to flow, fill, and cure in the defined area or space to be joined.

Owner:ZEPHYROS INC

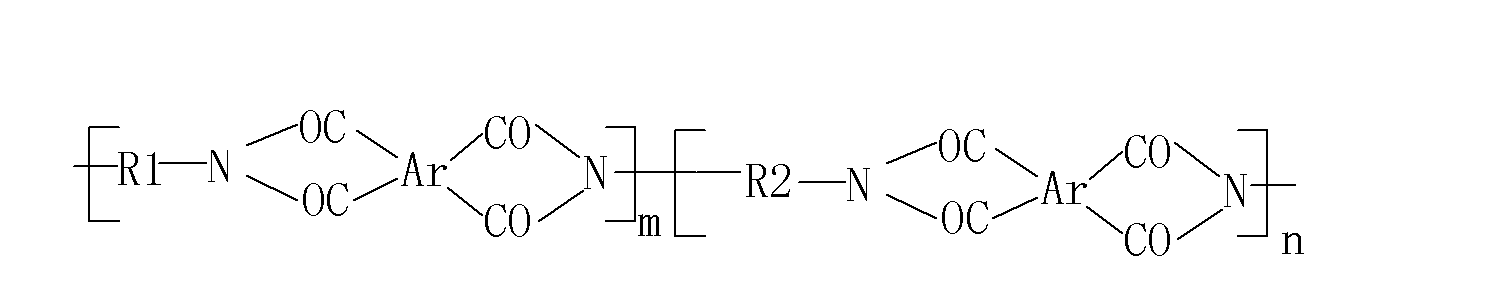

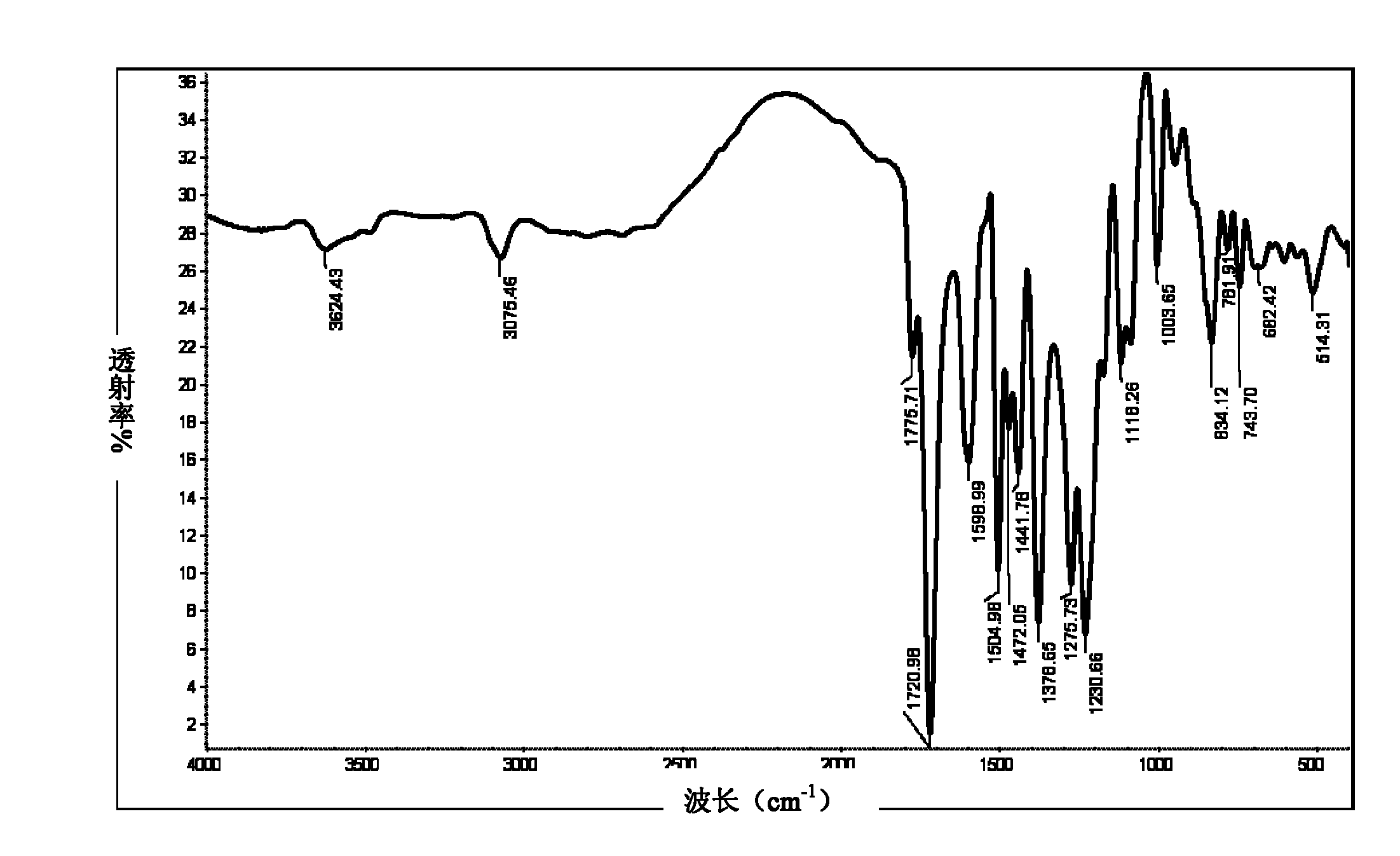

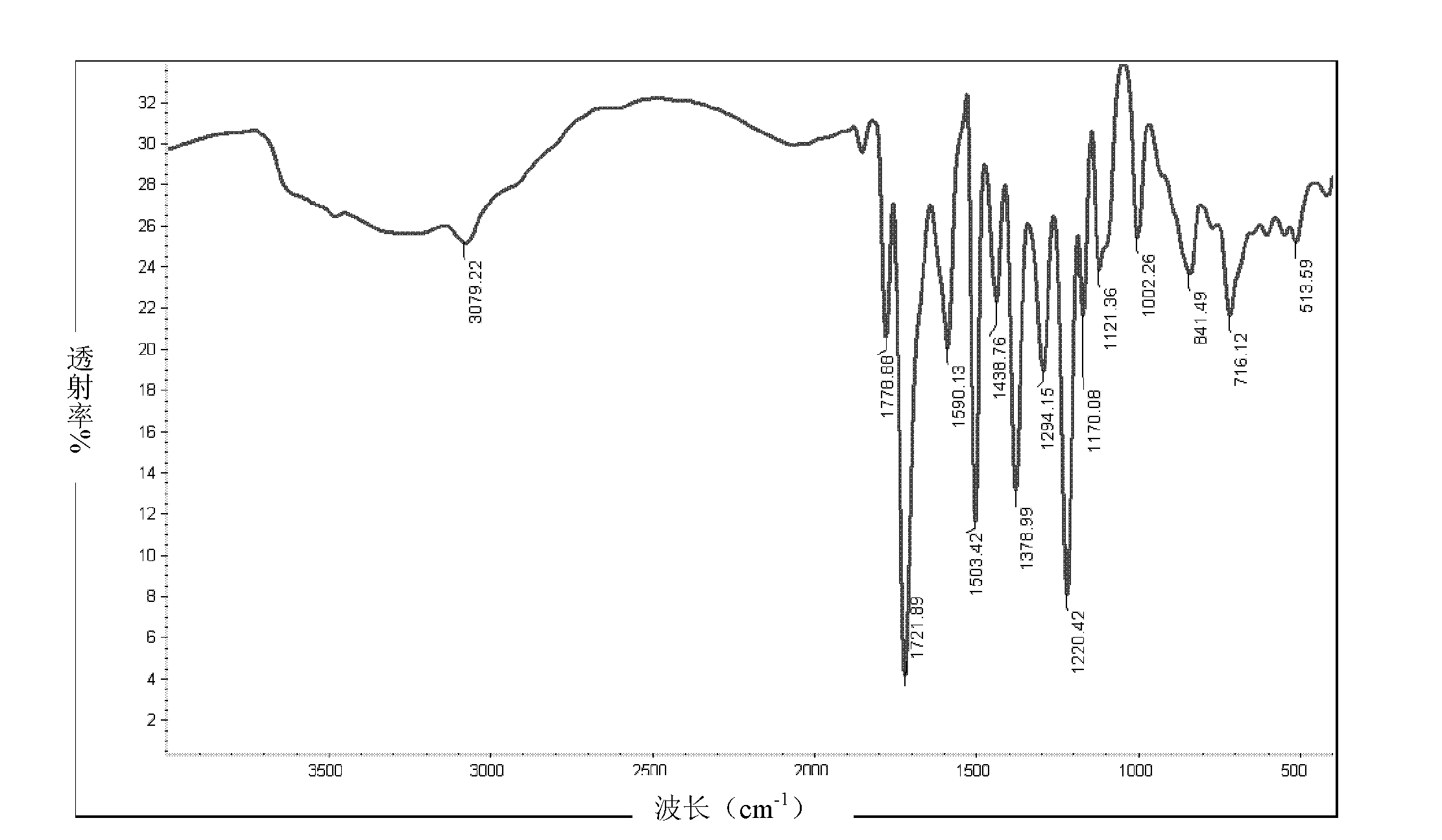

High-temperature resisting adhesive and preparation method thereof

InactiveCN102220102AConvenient sourceLow costNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyOrganic solvent

The invention relates to a high-temperature resisting adhesive and a preparation method thereof; the adhesive is formed by the following ingredients: carboxyl contained polyimide resin powder, epoxide resin, curing agent and organic solvent with weight ratio of 1:10-20:0.1-2:20-30. The preparation method of the high-temperature resisting adhesive comprises the following steps: adding the carboxylcontained polyimide resin powder, the epoxide resin and the curing agent into a reaction kettle, heating the reaction kettle to 80-90 DEG C for carrying out stirring reaction for 0.5-1.5 hours, and then adding the organic solvent continuously, and stirring the mixture uniformly at room temperature, thus obtaining the high-temperature resisting adhesive. The preparation method has simple process and low cost and is environment-friendly, the preparation process can be carried out in a general device, thereby being suitable for industrial production.

Owner:DONGHUA UNIV +1

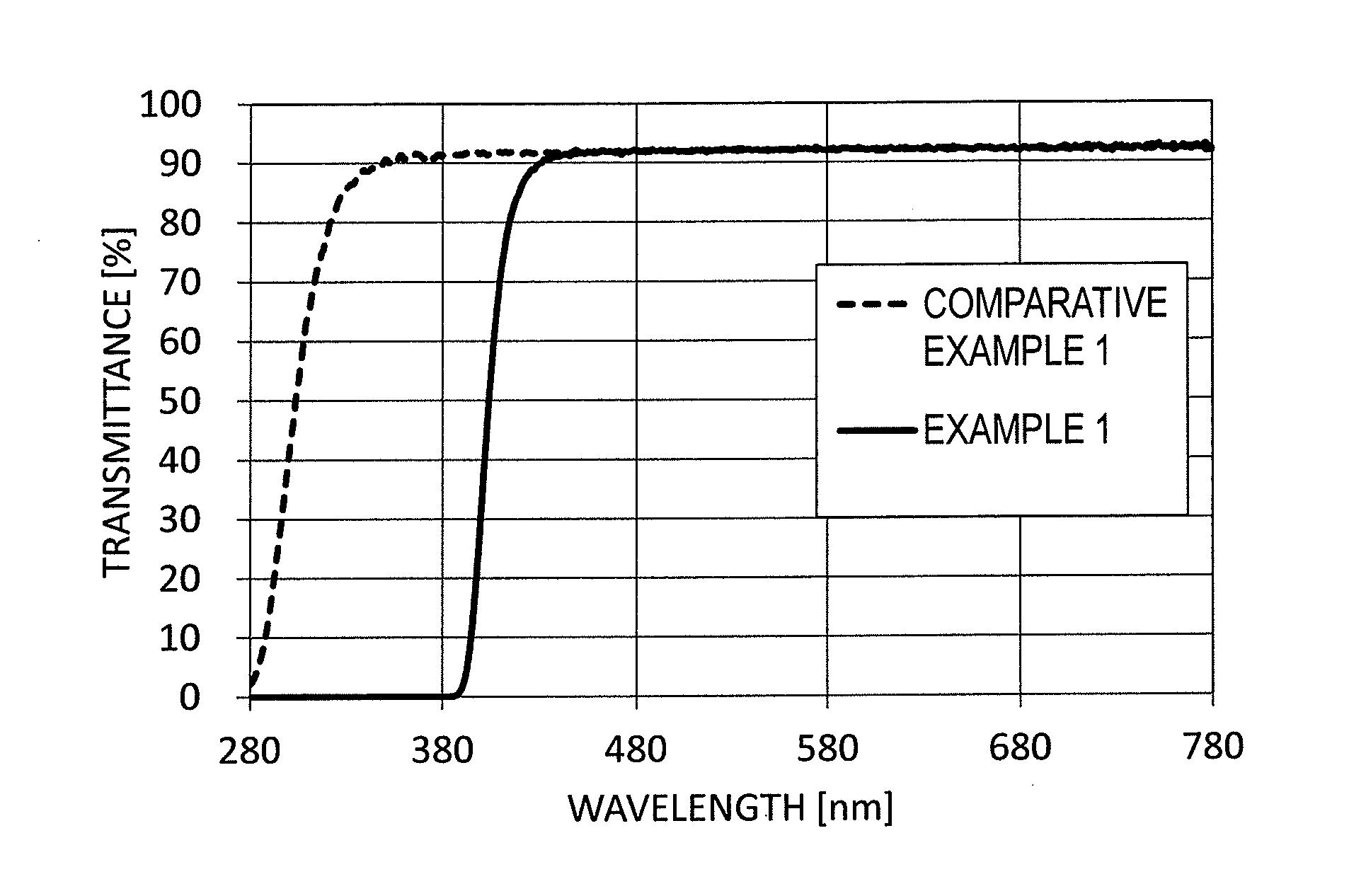

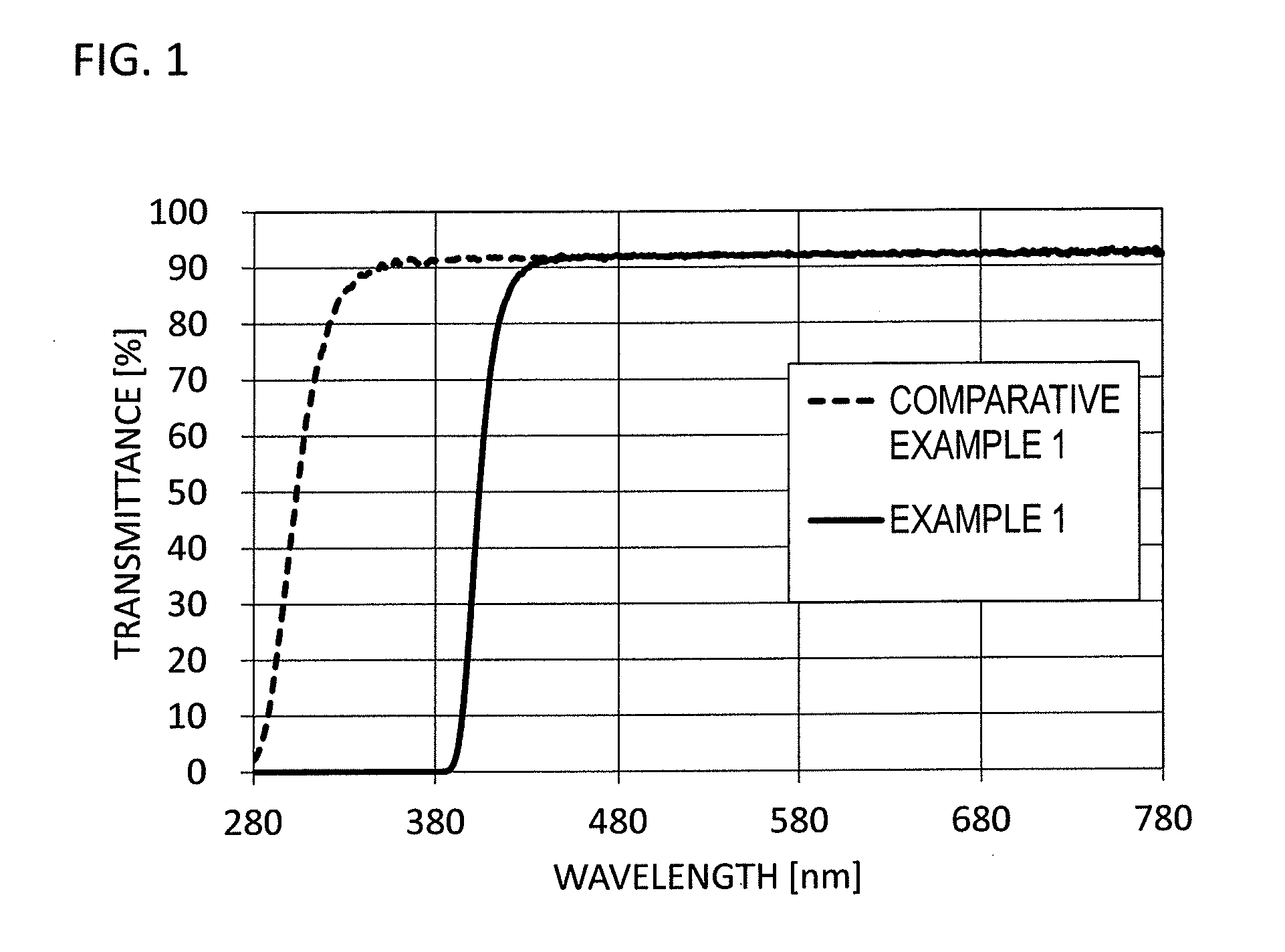

Pressure-sensitive adhesive sheet

ActiveUS20130085215A1Improves UV protectionRetaining optical characteristicNon-macromolecular adhesive additivesEster polymer adhesivesDisplay deviceEngineering

The present invention realizes a display device or input device having excellent ultraviolet protection property for the touch panel, display element or the like, while retaining optical characteristics, even when a small amount of or no optical film is used. The pressure-sensitive adhesive sheet of the present invention has a total light transmittance of 85% or more, a light transmittance at a wavelength of 380 nm of 5% or less, and a haze of 3% or less. The pressure-sensitive adhesive sheet preferably includes a pressure-sensitive adhesive layer containing an acrylic polymer and a triazine-based ultraviolet absorber.

Owner:NITTO DENKO CORP

Acrylic emulsion as well as preparation method and application thereof

ActiveCN102060954AIncrease elasticityGood dispersionNon-macromolecular adhesive additivesEster polymer adhesivesCross-linkEmulsion

The invention discloses an acrylic emulsion as well as a preparation method and an application thereof. The preparation method of the acrylic emulsion comprises the following steps: (1) mixing all monomers, 1 / 4-1 / 3 of deionized water and 2 / 3-3 / 4 of anionic emulsifier in raw materials, and emulsifying the mixture for 10-30 minutes to obtain a pre-emulsion; adding the left deionized water, the leftanionic emulsifier and 1 / 20-1 / 5 of pre-emulsion to a reactor, heating the reactor to 75-85 DEG C, adding an initiator, and making the mixture react for 0.5-1 hour; and (2) dropwise adding the left pre-emulsion for 2-4 hours, preserving heat for 2 hours at 75-85 DEG C, decreasing the temperature to 60 DEG C, adding a non-ionic emulsifier, stirring for 20 minutes, cooling the mixture to 20-30 DEG C, adjusting the pH value of the mixture to 7-8, adding a cross-linking agent, stirring and discharging. The acrylic emulsion has good rebound elasticity and good batch stability, can well disperse inorganic powder and overcomes a series of defects of the existing acrylic emulsion, and the preparation process of the acrylic emulsion is simple and is easy to realize industrial production.

Owner:GUANGZHOU HUMAN CHEM

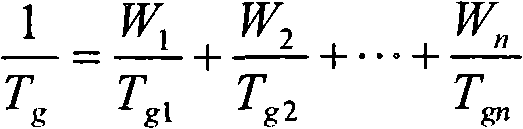

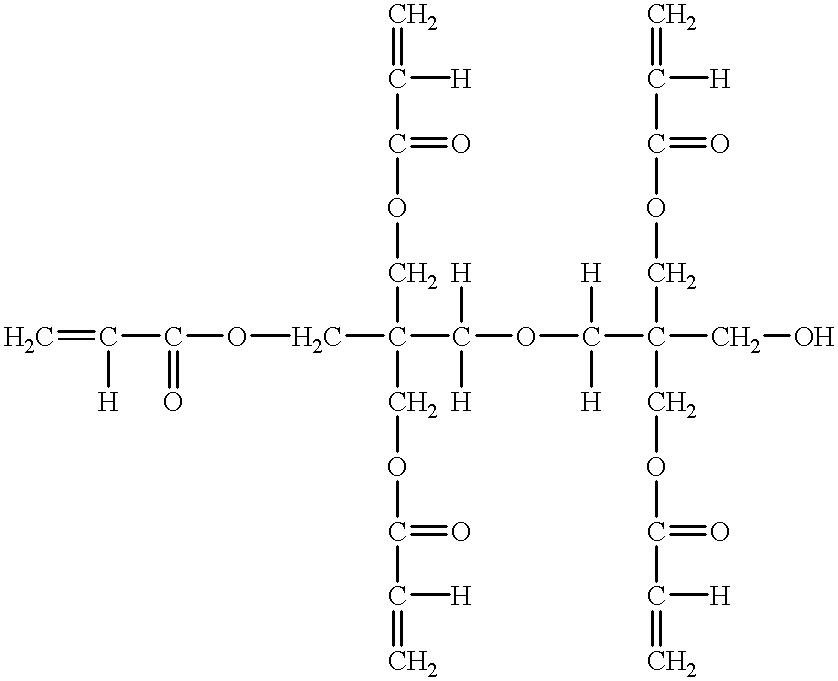

Self-lubricating bearing and coating

InactiveUS6180574B1Improve wear resistanceEasy bearing maintenanceNon-macromolecular adhesive additivesPretreated surfacesPentaerythritolAramides

A self-lubricating coating is provided which includes a mixture of a curable acrylate composition including a dipentaerythritol pentaacylate and a solid lubricant, such as polytetraflourethylenr. The curable acrylate composition may also include triethylene glycol dimethacrylate. An aramid pulp may also be added to the coating mixture. Also disclosed is a method of manufacturing the coating, and a self-lubricating bearing having the coating disposed on its surface.

Owner:REXNORD CORP

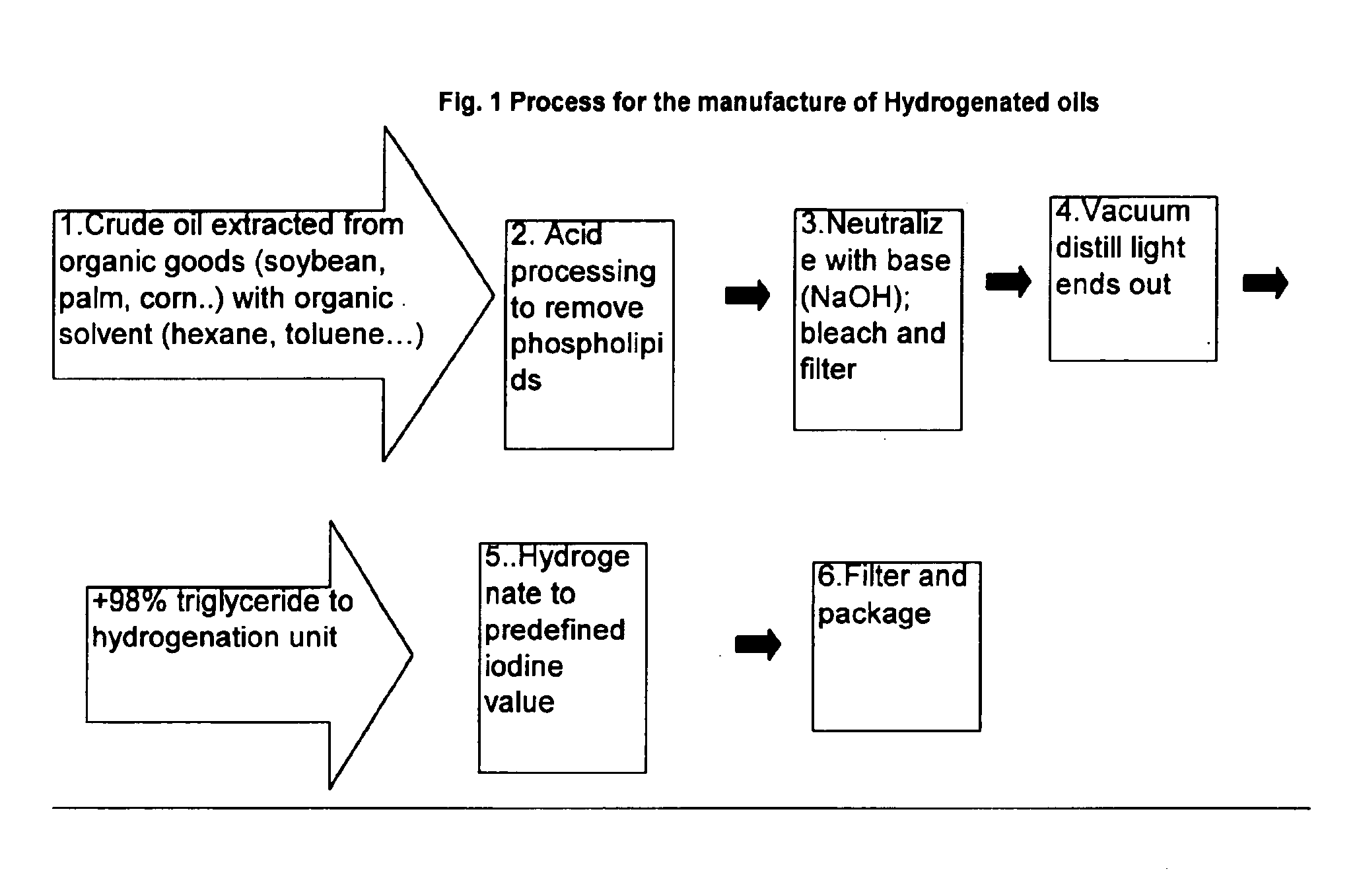

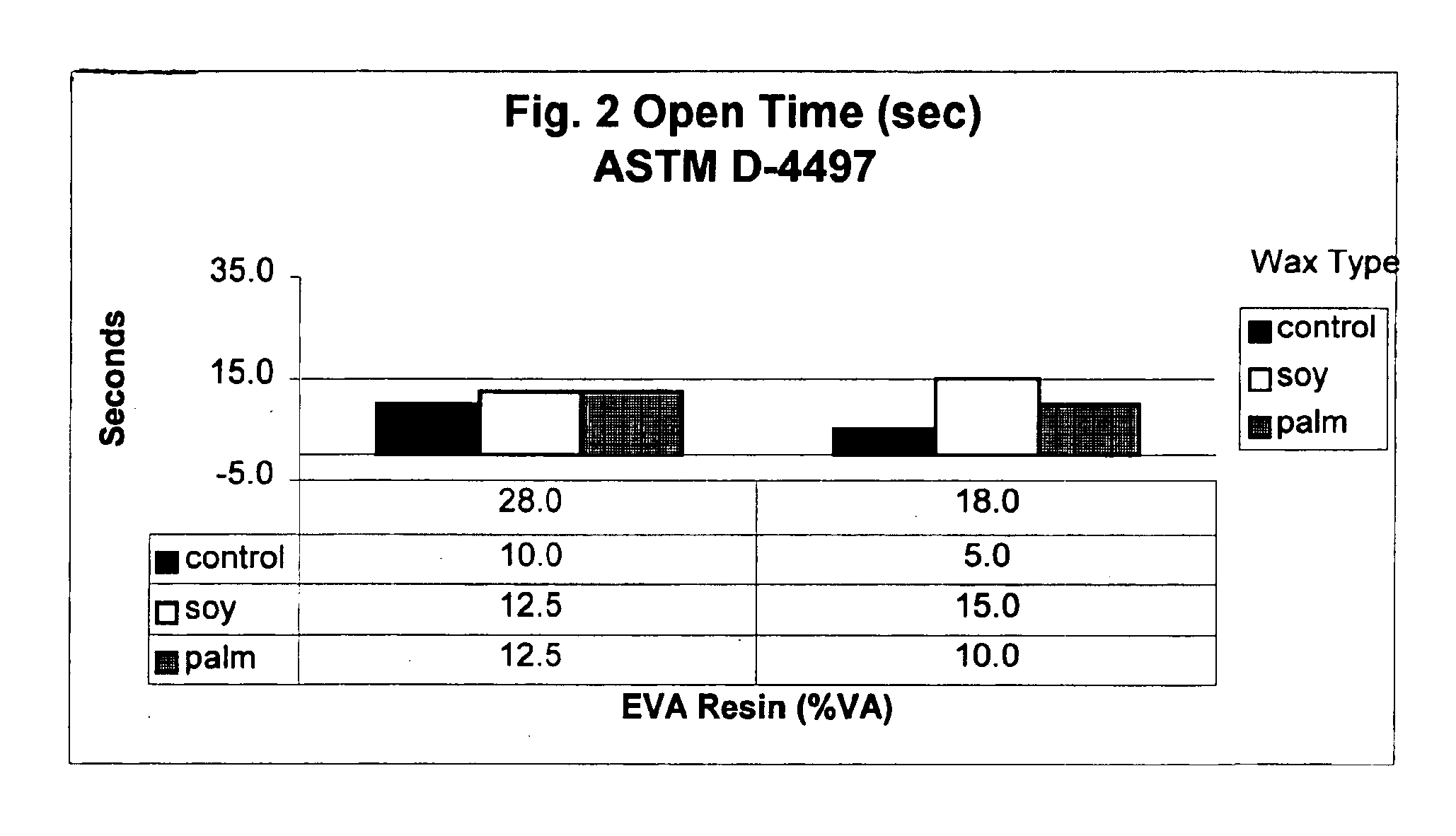

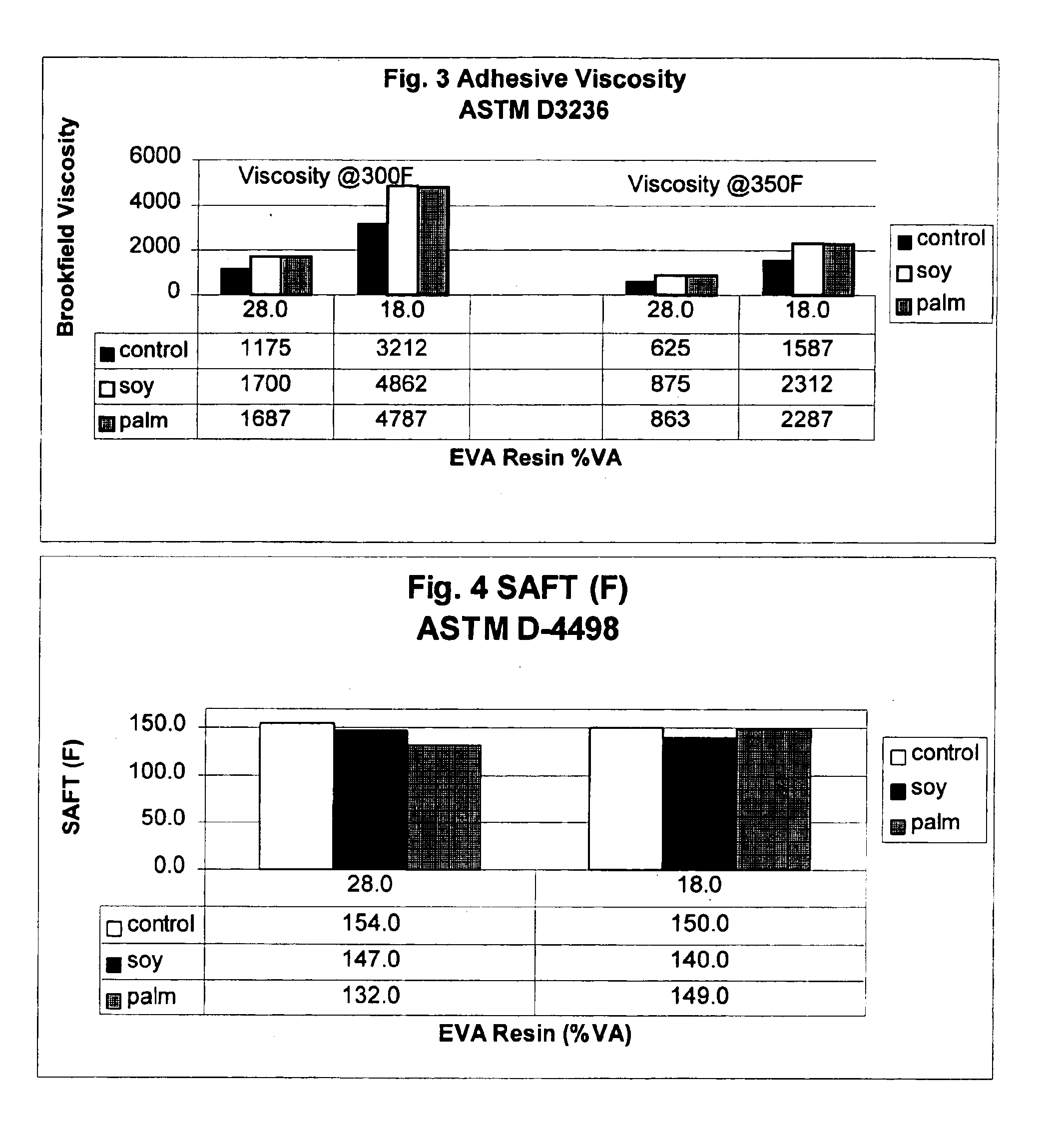

Wax for hot melt adhesive applications

InactiveUS6890982B2Produced economicallyProperty securityNon-macromolecular adhesive additivesFilm/foil adhesivesTG - TriglycerideStearic acid

Waxes prepared from hydrogenated plant oils, such as palm and soybean, are used as substitutes for petroleum derived waxes in hot-melt adhesive compositions. Unlike petroleum-derived or synthetic waxes, adhesive compositions comprising these waxes, which are obtained from naturally derived, renewable resources, achieve adhesion performance similar to conventional adhesives containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-165 degrees F. (Mettler Drop Point). These waxes comprise a triglyceride whose fatty acids are predominantly stearic acid (C18). The naturally derived waxes are used as an alternative to petroleum and synthetically derived waxes in the manufacture of adhesives used to bond paper, wood, glass, plastic and metal in a variety of manufacturing operations.

Owner:MARCUS OIL & CHEM

Micron nano material composite modified water-based adhesive

InactiveCN101210157ALow shrinkageImprove performanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesMicro nanoExtensibility

The invention relates to an aqueous binder which is compounded and modified by micro nano material. The modified aqueous binder of the invention adopts emulsion adhesive as matrix and micro-size and nano-size inorganic powder as modifier to prepare the compound and modified aqueous binder. The method of the invention can not only enhance the interface binding force of the aqueous binder, but also greatly improve the properties of water resistance, toughness and extensibility, leading comprehensive performance of the aqueous binder to be improved.

Owner:郑旷宇

Additive particles having superhydrophobic characteristics and coatings and methods of making and using the same

InactiveUS20090298369A1Non-macromolecular adhesive additivesLiquid repellent fibresCoating systemSilanes

Additive particles may be employed in sufficient amounts to impart superhydrophobicity to a coating system in which the additive particles are incorporated. The additive particles include carrier microparticles and a dense plurality of nanoparticles adhered to the surfaces of the carrier microparticles (e.g., preferably by electrostatic deposition or covalent bonding). The additive particles are advantageously incorporated into a coating material (e.g., a polymeric material) in amounts sufficient to render a substrate surface superhydrophobic when coated with the coating material. The substrate may be rigid (e.g., glass, ceramic or metal) or flexible (e.g., a polymeric film or sheet or a fabric). In some preferred embodiments, both the microparticle and nanoparticles are formed of silica and are surface treated with a hydrophobic treatment so as to impart superhydrophobic properties thereto. Especially preferred are particles treated with silicone fluid comprised of a polysiloxane and / or a perfluoro silane having between 1 and 40 carbon atoms.

Owner:LUNA INNOVATIONS

Devices, compositions, and methods incorporating adhesives whose performance is enhanced by organophilic clay constituents

InactiveUS6884833B2Faster build-upImprove adhesionPrinted circuit assemblingNon-insulated conductorsOrganoclayHot melt

Incorporating organophilic clay into hot melt adhesive compositions, particularly those comprising semi-crystalline, thermoplastic polymers, greatly improves the adhesive properties in many respects. Some of these improvements are particularly beneficial to the specific use of hot melt adhesives filled with electrically conductive particles for use as electrically conductive adhesives.

Owner:3M INNOVATIVE PROPERTIES CO

Epoxy resin adhesive for manufacturing blades of wind driven generator and preparation method thereof

ActiveCN101851481AHigh strengthHigh modulusNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyWind driven

The invention discloses an epoxy resin adhesive for manufacturing blades of a wind driven generator and a preparation method thereof. The epoxy resin adhesive is prepared by combining a resin part and a curing agent part, wherein the resin part comprises epoxy resin, a dilutent, filler, a thixotropic agent and an auxiliary agent; the curing agent part comprises an amine curing agent, filler and athixotropic agent; and the filler comprises a powdery filler part and a fibrous filler part. The epoxy resin adhesive prepared by using the general epoxy resin has high strength, particularly furtherimproves the strength of materials by adding the fibrous filler, improves the anti-cracking performance of the materials, meets the special requirements of the blades of wind driven generators with megawatt or more on the materials and has low material cost and high economy.

Owner:四川东树新材料有限公司

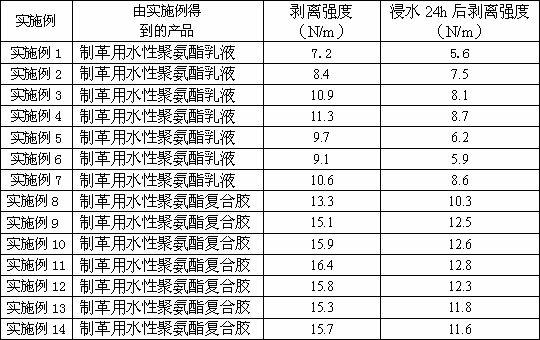

Water-based polyurethane composite adhesive for tanning and preparation method and application of composite adhesive

InactiveCN102618202ATroubleshoot MigrationOvercome the problem that the performance cannot fully meet the requirements of useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention discloses water-based polyurethane composite adhesive for tanning and a preparation method and application of the composite adhesive, belongs to the technical field of water-based polyurethane composite adhesive preparation methods, and in particular relates to a method for preparing composite adhesive in the fields of artificial leather and synthetic leather. The method for preparing the water-based polyurethane composite adhesive for tanning is characterized by comprising the following steps of: reacting polyol polymer and isocyanate, adding chain extender, hydrophilic chain extender, cross linker, catalyst and solvent, reacting, cooling and emulsifying, to obtain emulsion; and mixing the emulsion, curing agent, wetting agent, tackifier, adsorbent and thickening agent uniformly, and thus obtaining the hot-melt adhesive for artificial leather adhesive layers. The water-based polyurethane composite adhesive for tanning is used for compounding polyvinyl chloride (PVC) / cloth for artificial leather of luggage and clothes. The prepared water-based polyurethane composite adhesive for tanning has high adhesive fastness and good water and solvent resistance, and can be applied to processes of knife coating, roll coating and the like of binding materials of middle layers of artificial leather and synthetic leather in the fields of textiles, leather processing and the like.

Owner:江阴市诺科生物新材料科技有限公司

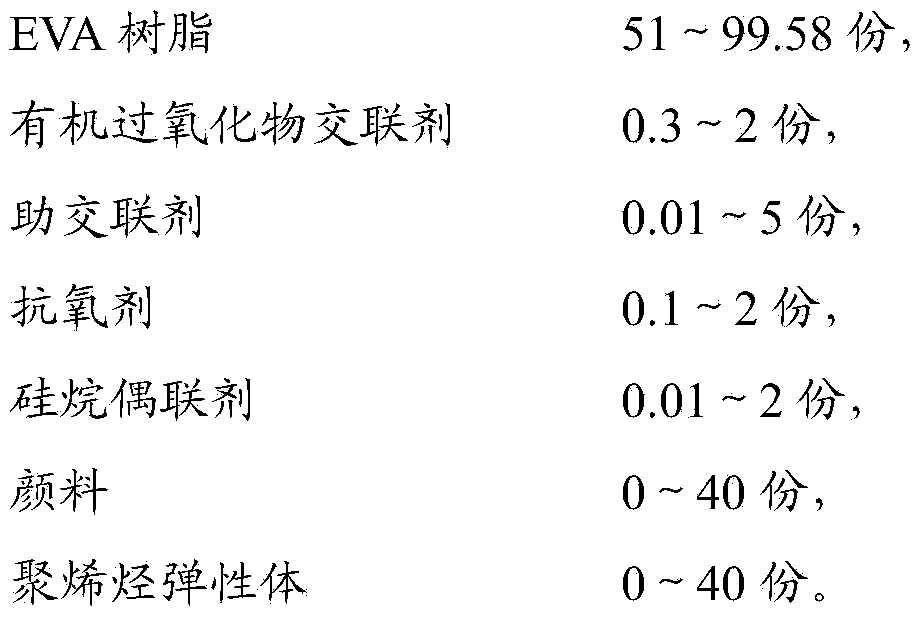

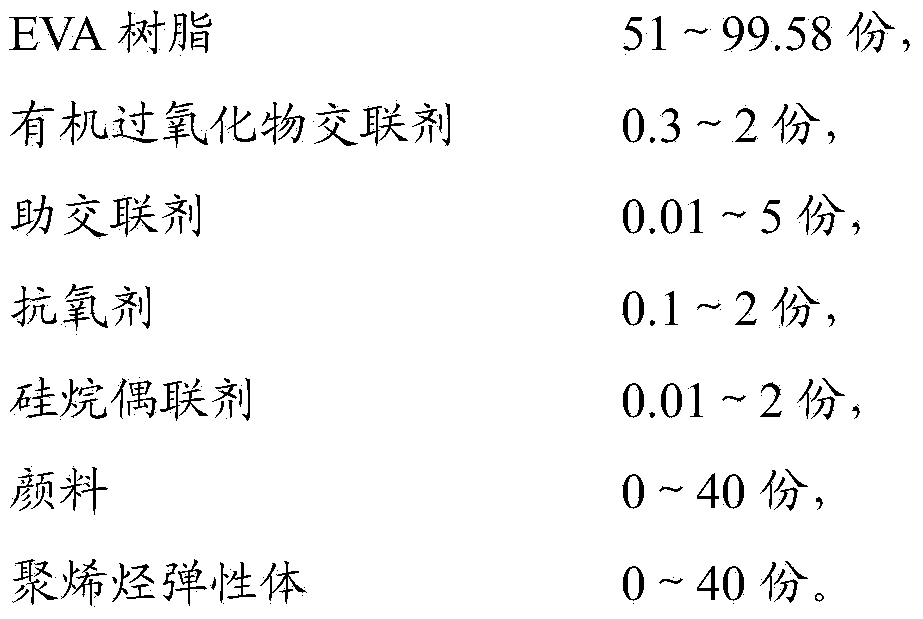

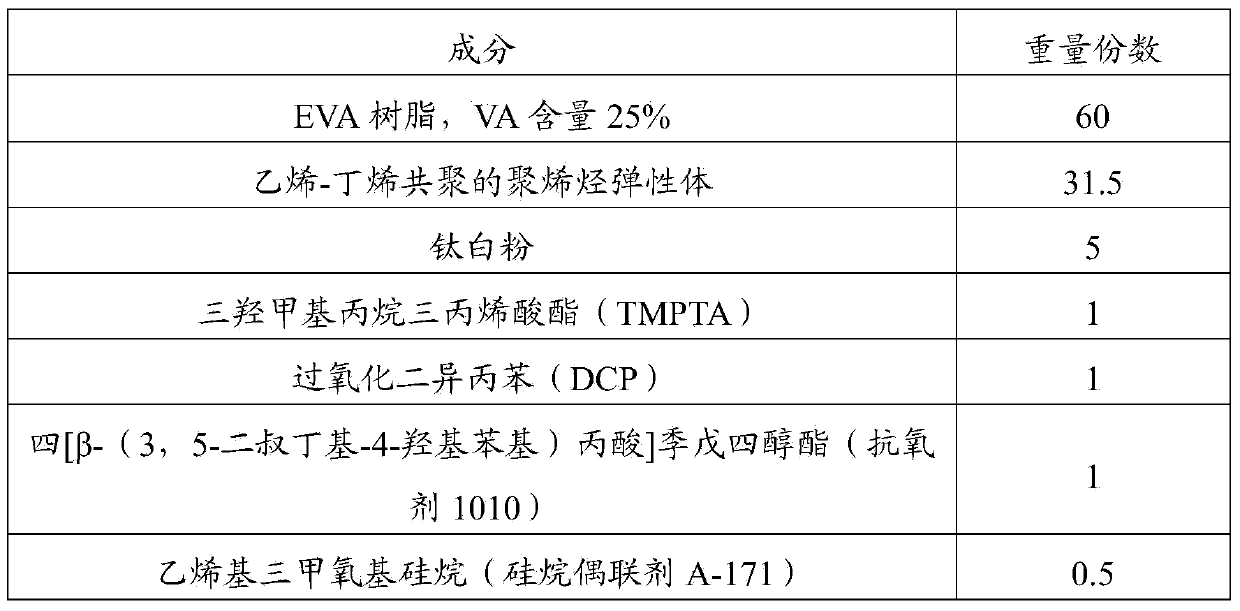

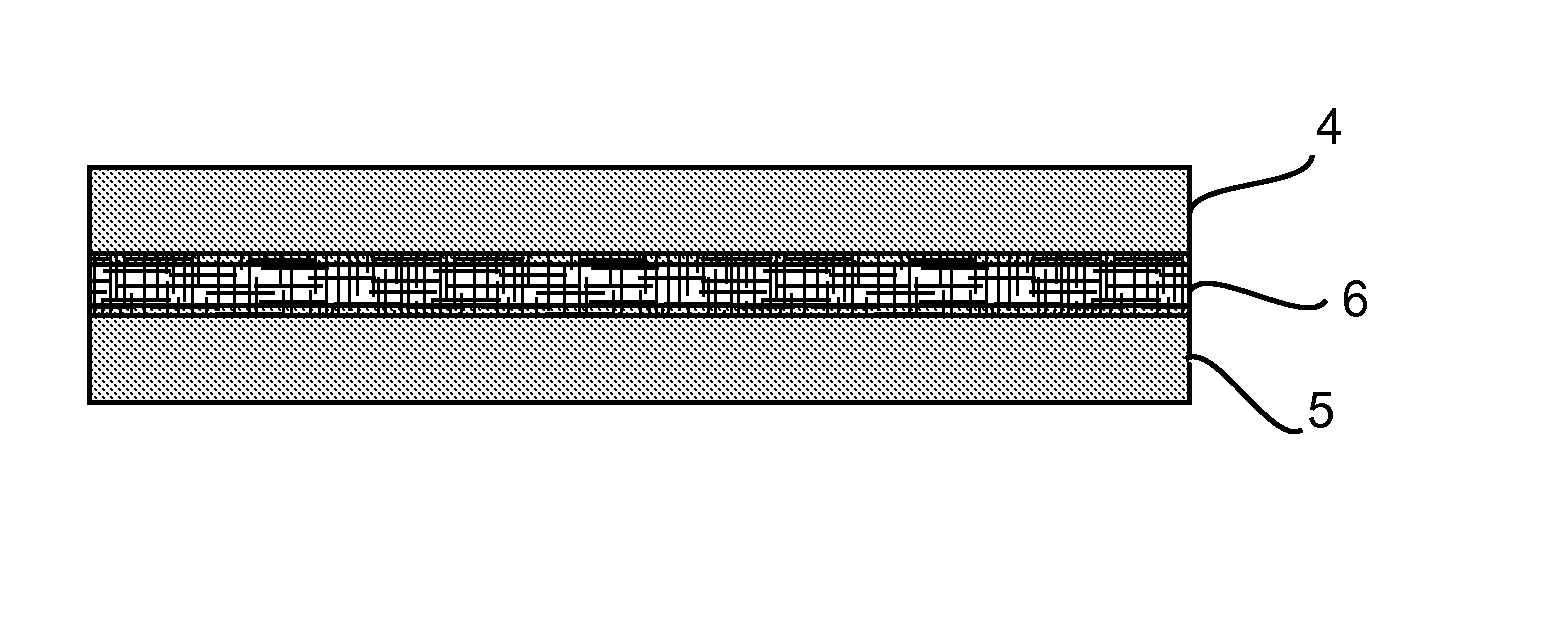

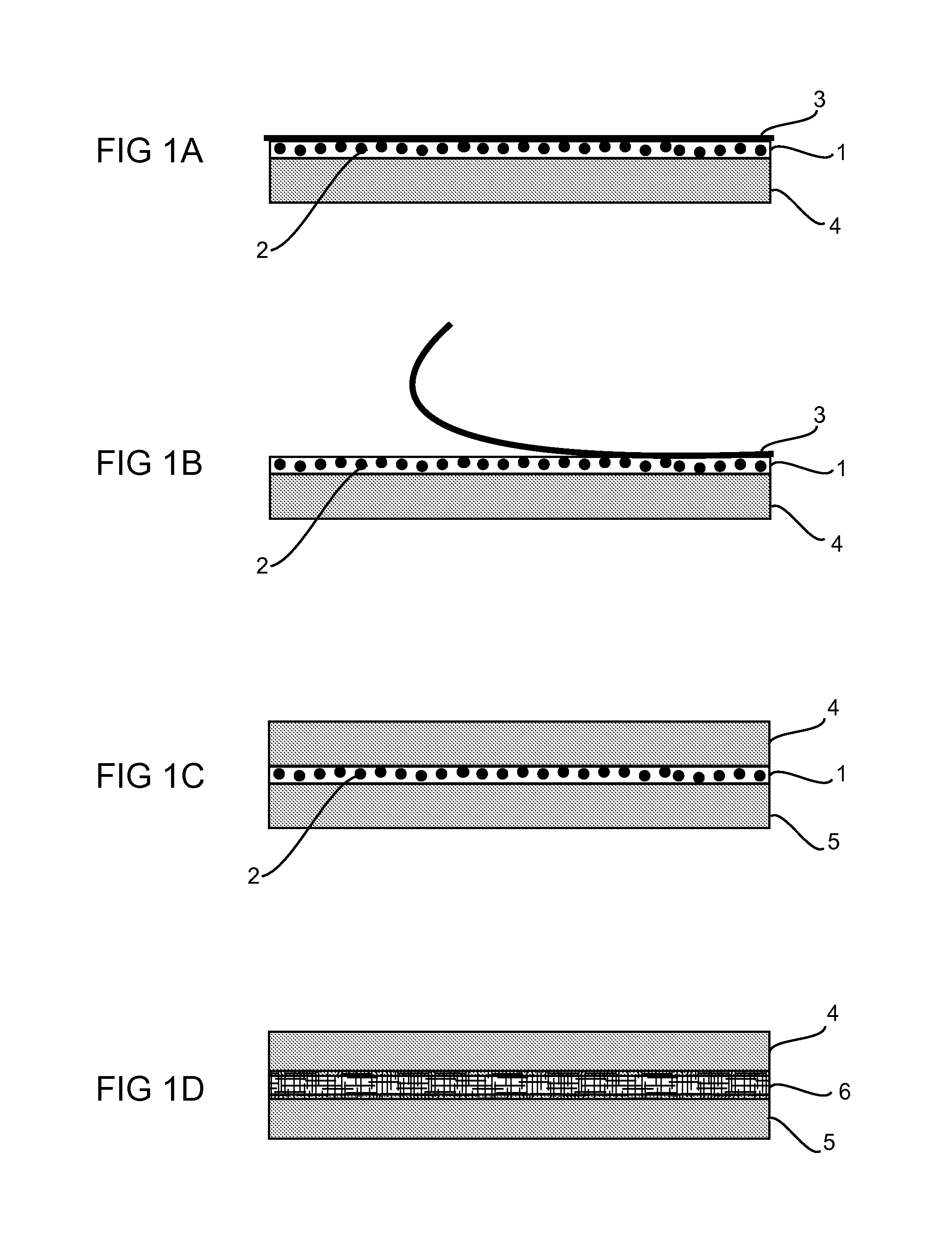

Radiation pre-crosslinked ethylene-vinyl acetate (EVA) resin film and preparation method thereof

ActiveCN103804774AGood dimensional stabilityImprove heat resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolyolefin

The invention discloses a radiation pre-crosslinked ethylene-vinyl acetate (EVA) resin film which comprises the following components in parts by weight: 51-99.58 parts of EVA resin, 0.3-2 parts of organic peroxide crosslinking agent, 0.01-5 parts of assistant crosslinking agent, 0.1-2 parts of antioxidant, 0.01-2 parts of silane coupling agent, 0-40 parts of pigment and 0-40 parts of polyolefin elastomer. The invention also discloses a preparation method of the radiation pre-crosslinked EVA resin film, which comprises the steps of sufficiently mixing 51-99.58 parts of EVA resin, 0.3-2 parts of organic peroxide crosslinking agent, 0.01-5 parts of assistant crosslinking agent, 0.1-2 parts of antioxidant, 0.01-2 parts of silane coupling agent, 0-40 parts of pigment and 0-40 parts of polyolefin elastomer, and adding into an extruder; extruding and forming a film through a T-shaped flat mould; rolling and radiating to obtain the radiation pre-crosslinked EVA resin film. Since the film is partially crosslinked before use, the dimensional stability and heat resistance of the film are remarkably improved, thus the film is suitable for large-scale popularization and application.

Owner:SHANGHAI HIUV NEW MATERIALS

Conductive film adhesive

InactiveUS20140120356A1Evenly distributedNon-macromolecular adhesive additivesConductive materialHeat resistanceMaterials science

An inventive composition and process for formation of a conductive bonding film are disclosed. The invention combines adhesive bonding sheet technologies (e.g. die attach films, or DAFs) with the electrical and thermal conductivity performance of transient liquid phase sintered paste compositions. The invention films are characterized by high bulk thermal and electrical conductivity within the film as well as low and stable thermal and electrical resistance at the interfaces between the inventive film and metallized adherends.

Owner:ORMET CIRCUITS

Adhesives & sealants nanotechnology

ActiveUS20060035087A1Increase volumeLow costNon-macromolecular adhesive additivesOther chemical processesAdhesiveSealant

Adhesives and sealants comprising submicron particles and nanomaterials, methods of making such adhesives and sealants, and methods of using such adhesives and sealants are provided.

Owner:PPG IND OHIO INC

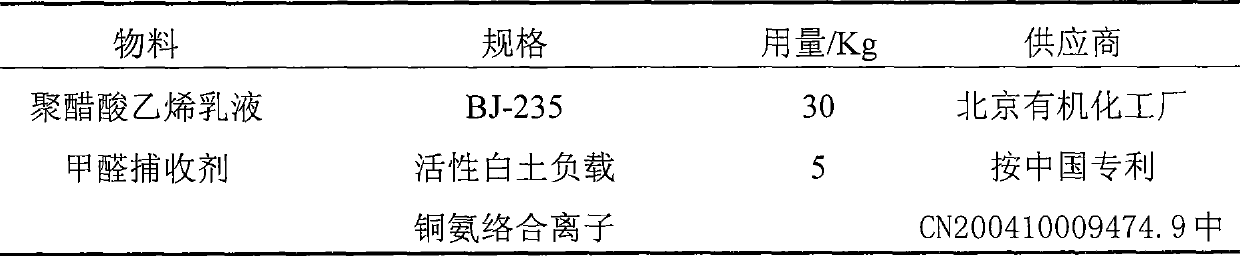

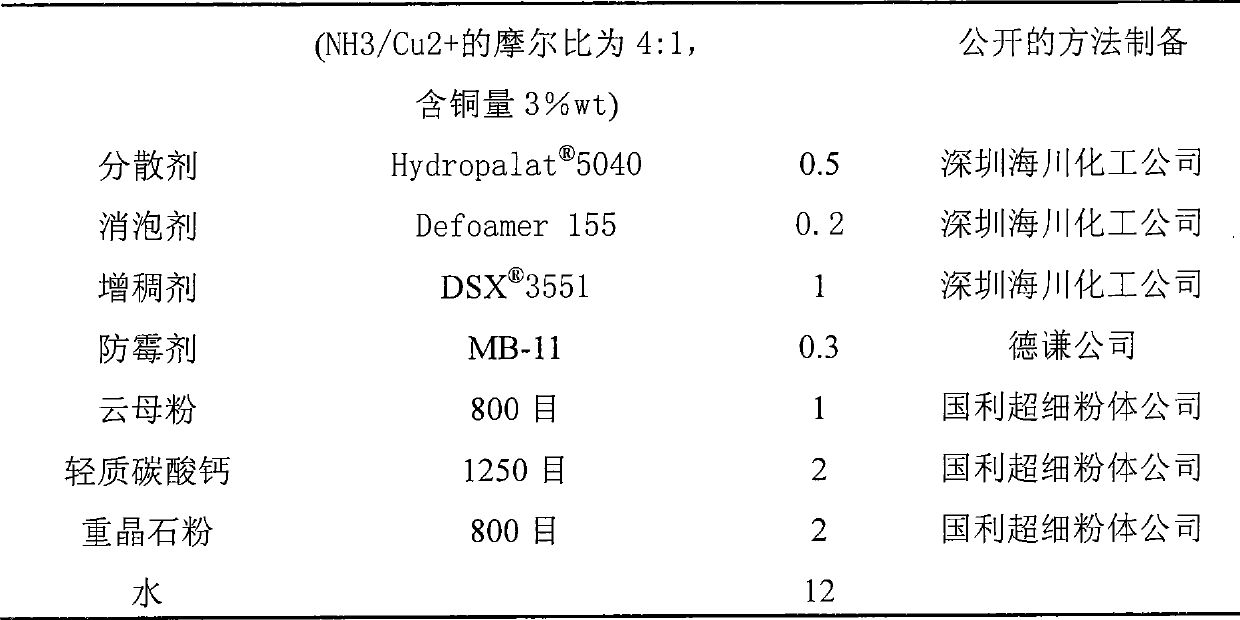

Coating for collecting formaldehyde

InactiveCN101475767AEffective absorptionAdhesive strength effectNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesActive componentAdhesive

The invention relates to adhesive for collecting formaldehyde and paint for collecting the formaldehyde, both of which use formaldehyde collecting agent as a composition of active components. The adhesive is used for adhesion of the outmost layer in a man-made board or adhesion and edge sealing at a kerf of the man-made board, can effectively absorb formaldehyde released by the man-made board, does not cause influence on the adhesive strength of the board, and is comparatively cheap. The paint is used for painting indoor walls, absorbs the formaldehyde in the indoor air, can also be used for painting the surface of the man-made board, seals and absorbs formaldehyde gas, and reduces the release amount of the formaldehyde. Compared with the prior art, the adhesive and the paint for collecting the formaldehyde have the advantages that the adhesive and the paint are cheap, can efficiently adsorb the formaldehyde and generate stable compounds, and do not re-decompose and release the formaldehyde, so the adhesive and the paint cannot generate other secondary pollutants.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com