Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4480 results about "Resin adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bi-component epoxide-resin adhesive and preparation method thereof

InactiveCN101397486AImprove heat resistanceImproved tensile shear strengthEpoxynovolac adhesivesEpoxyBenzene

The invention relates to a two-component epoxy resin adhesive, including the following components: novolac epoxy resin, lipid ring type epoxy resin and terminal carboxylic acrylonitrile butadiene rubber in component A, and 1, 4-di-benzene (2, 4-diaminobenzene oxygen) in component B, wherein, the mass percentage of the lipid ring type epoxy resin is 20-35 percent of the novolac epoxy resin, the mass percentage of the terminal carboxylic acrylonitrile butadiene rubber CTBN is 12 percent of the novolac epoxy resin and the mass percentage of the 1, 4-di-benzene (2, 4-diaminobenzene oxygen) is 15-20 percent of the novolac epoxy resin; and the preparation of the two-component epoxy resin adhesive includes the step of evenly mixing the component A and the component B for use. The two-component epoxy resin adhesive used for conductive adhesive has good heat resistance, average stretching and shearing strength of 21.28MPa, simple preparation process and operation without solvent, and plays the role of protecting environment.

Owner:DONGHUA UNIV +1

Epoxy Enhanced Polymer Membrane to Increase Durability of Biosensors

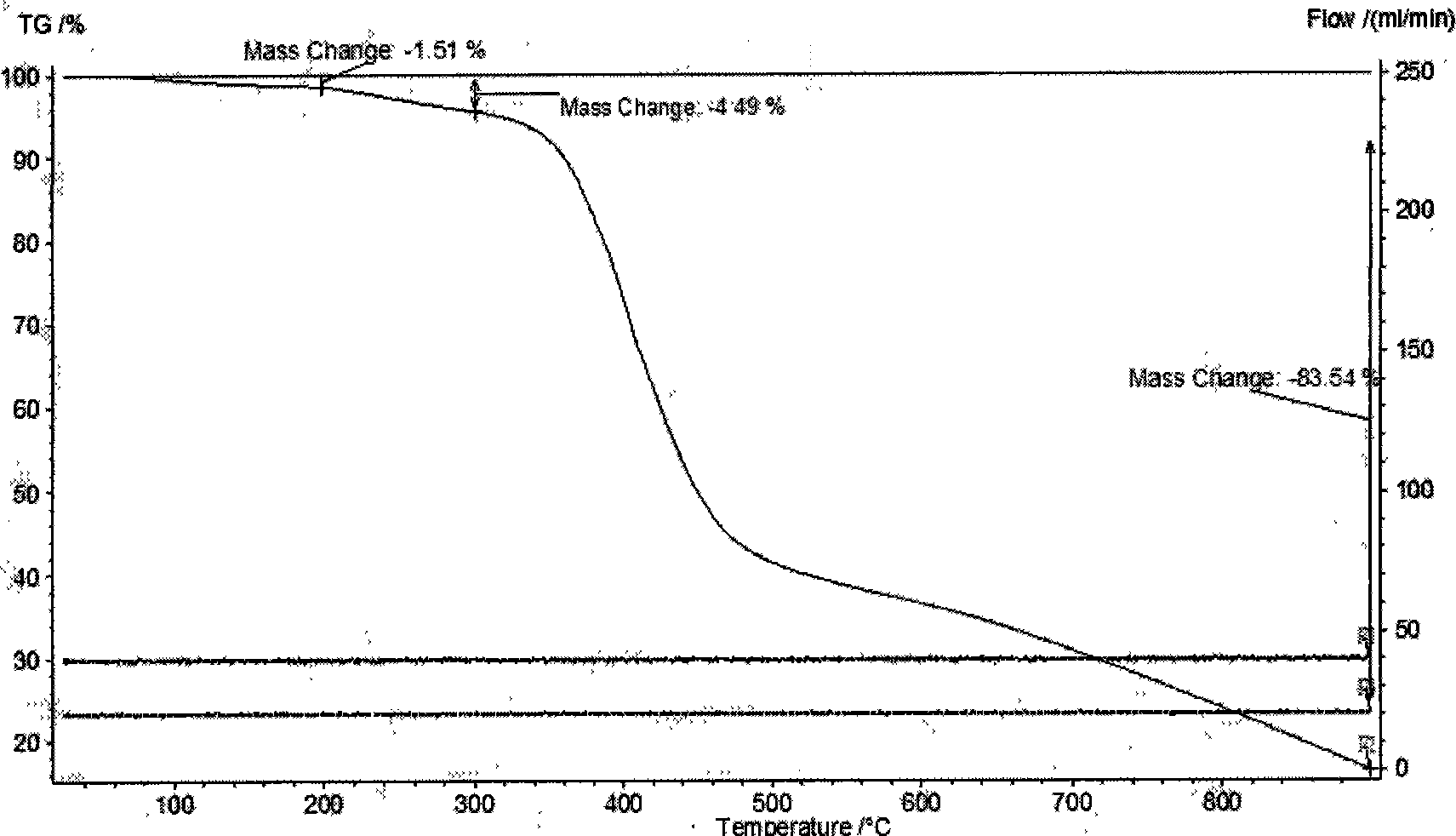

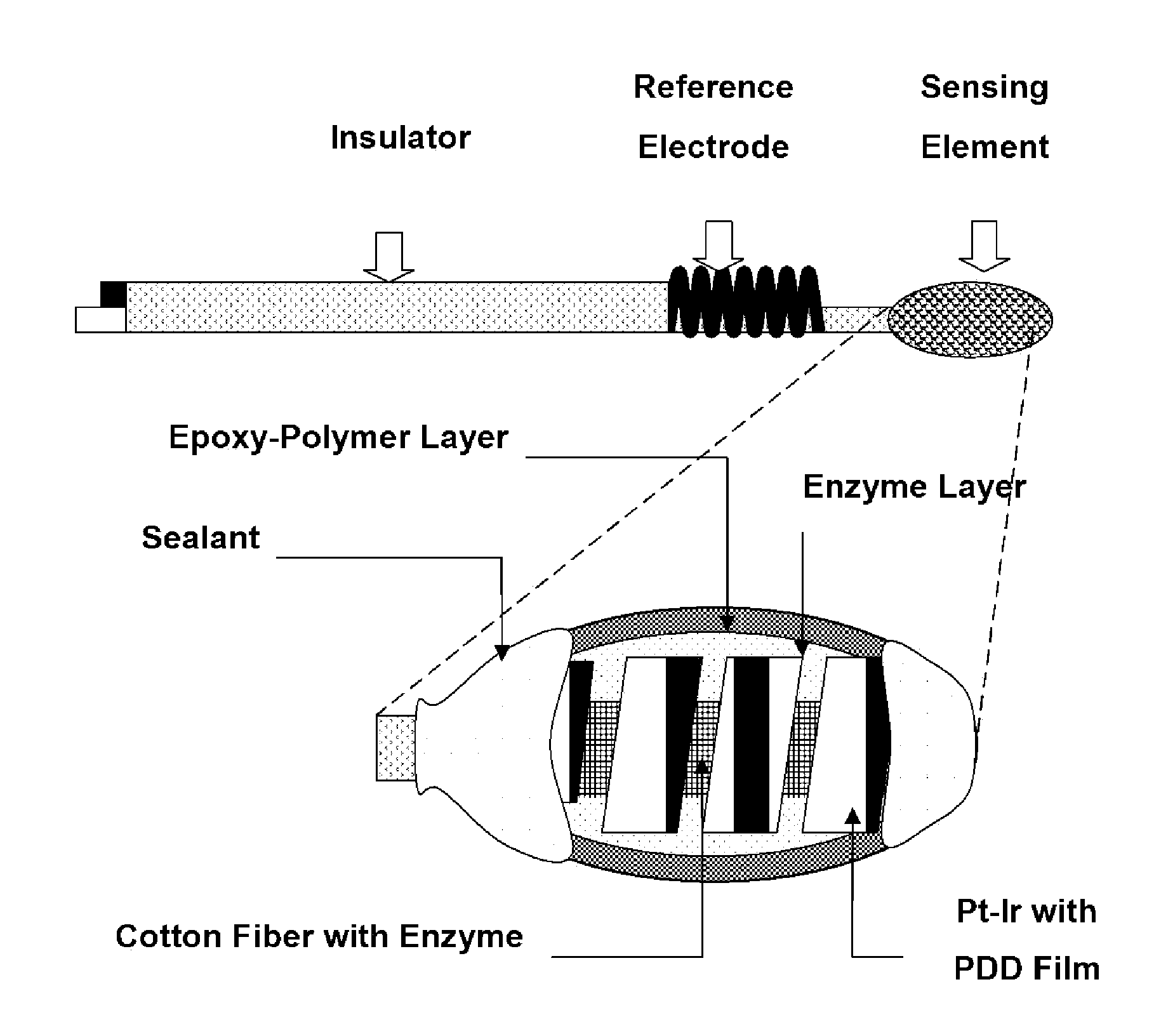

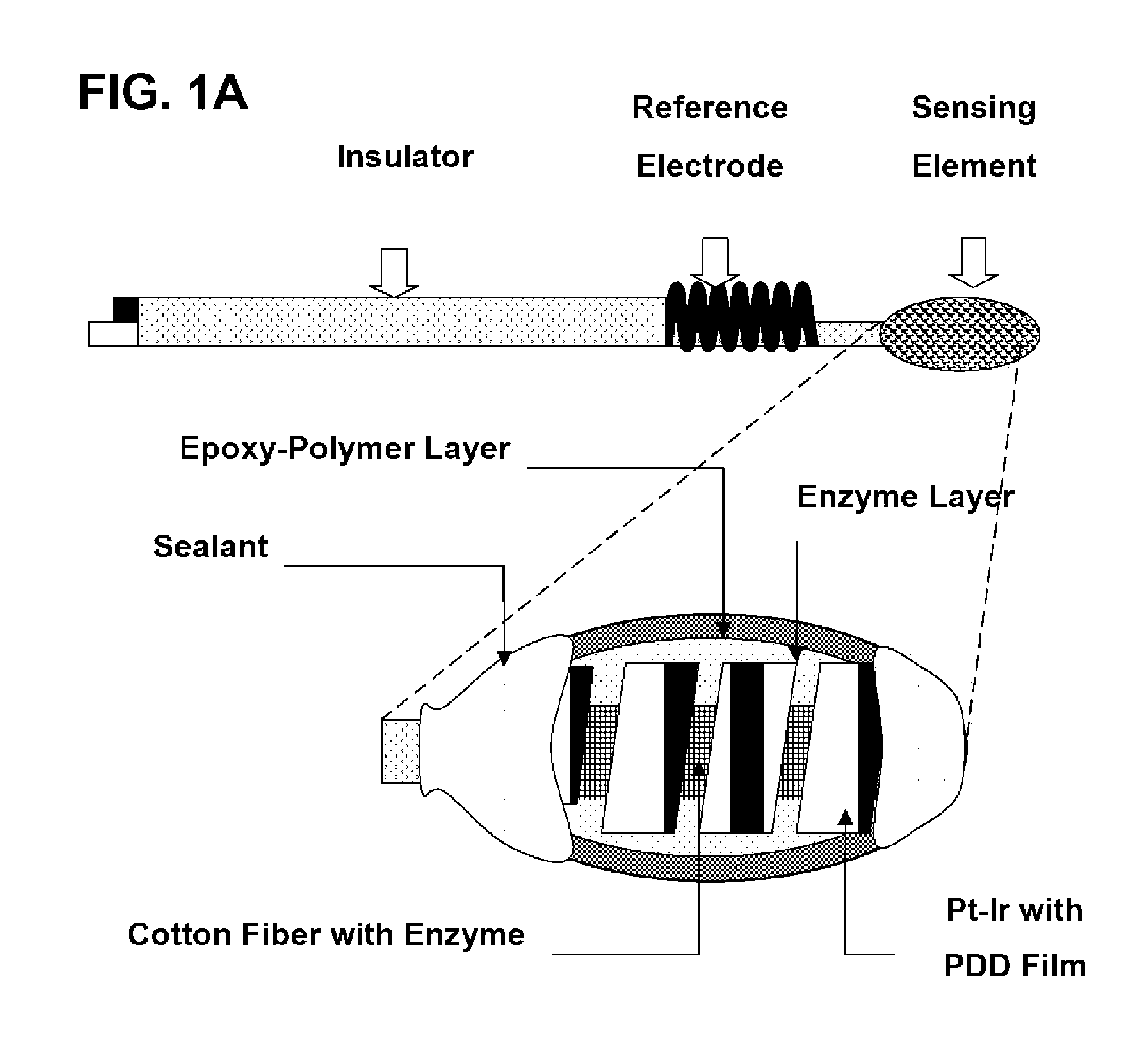

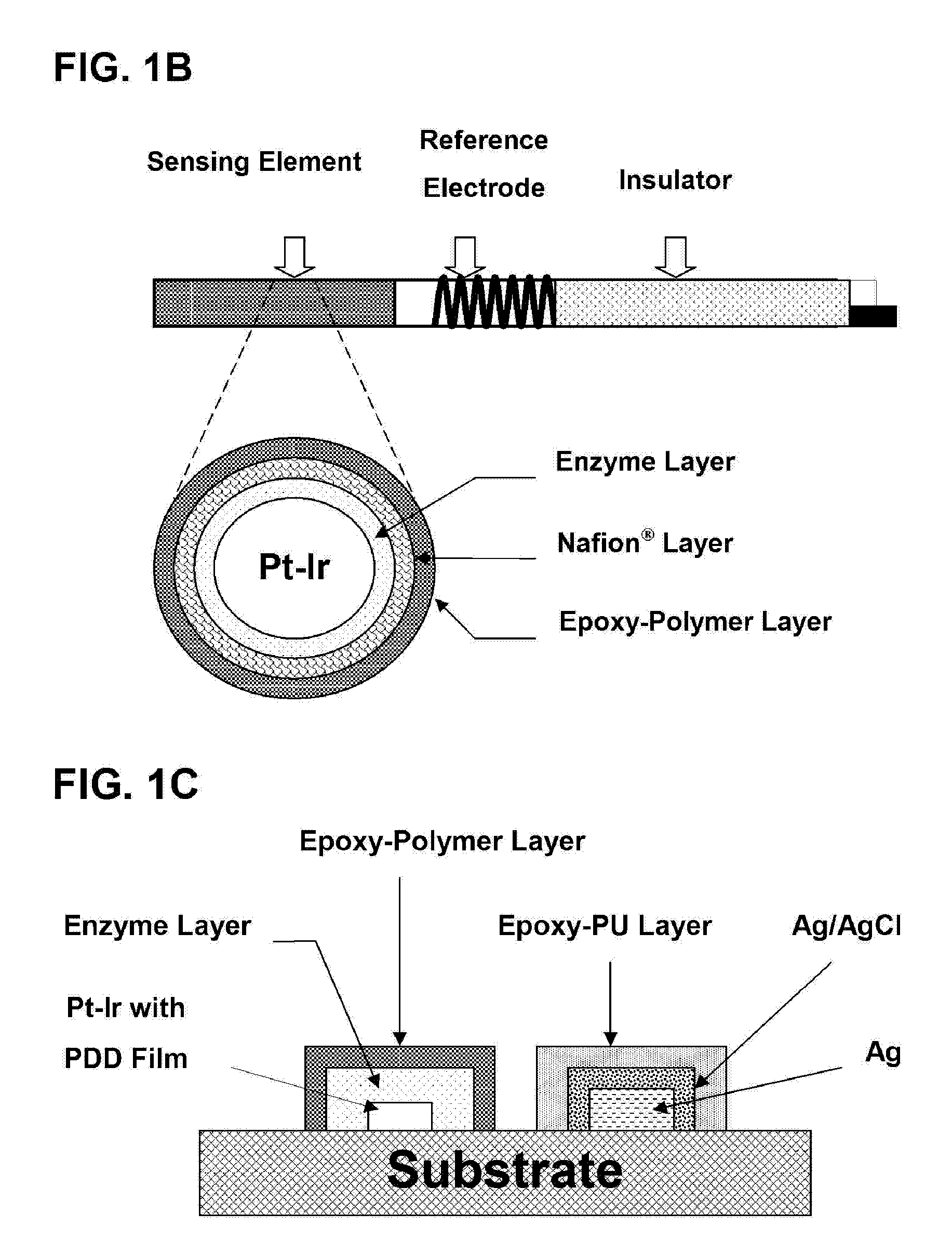

ActiveUS20060289307A1Increasing in vivo durabilityImprove long-term stabilityImmobilised enzymesBioreactor/fermenter combinationsEpoxyPolyethylene oxide

The present invention provides a polymer membrane enhanced with cured epoxy resin for use as the outer membrane of biosensors. The membrane includes approximately 30-80% epoxy resin adhesives, 10-60% polymer such as poly(vinyl chloride), polycarbonate and polyurethane and 0-30% plasticizers and 5-15% surface modifier reagent such as polyethylene oxide-containing block copolymers. Utilizing the polymer membrane of the present invention, a three-layered sensing element has been developed. This sensing element will be particularly useful for miniaturized biosensors used for in vitro blood measurements or for continuous in vivo monitoring such as implantable biosensors. This element includes an enzyme layer, an interference-eliminating layer and the novel polymer member of the present invention as the outer polymer layer. This novel sensing element shows excellent response characteristics in solutions and has an extremely long lifetime. This technology is particularly useful for improving the lifetime of implantable biosensors.

Owner:UNIV OF SOUTH FLORIDA

Epoxy resin adhesive for manufacturing blades of wind driven generator and preparation method thereof

ActiveCN101851481AHigh strengthHigh modulusNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyWind driven

The invention discloses an epoxy resin adhesive for manufacturing blades of a wind driven generator and a preparation method thereof. The epoxy resin adhesive is prepared by combining a resin part and a curing agent part, wherein the resin part comprises epoxy resin, a dilutent, filler, a thixotropic agent and an auxiliary agent; the curing agent part comprises an amine curing agent, filler and athixotropic agent; and the filler comprises a powdery filler part and a fibrous filler part. The epoxy resin adhesive prepared by using the general epoxy resin has high strength, particularly furtherimproves the strength of materials by adding the fibrous filler, improves the anti-cracking performance of the materials, meets the special requirements of the blades of wind driven generators with megawatt or more on the materials and has low material cost and high economy.

Owner:四川东树新材料有限公司

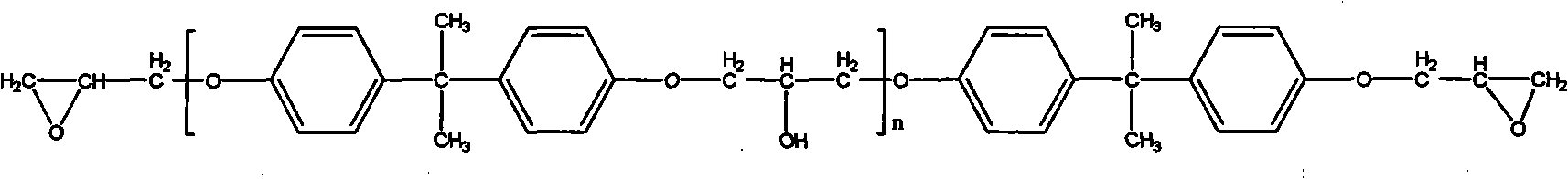

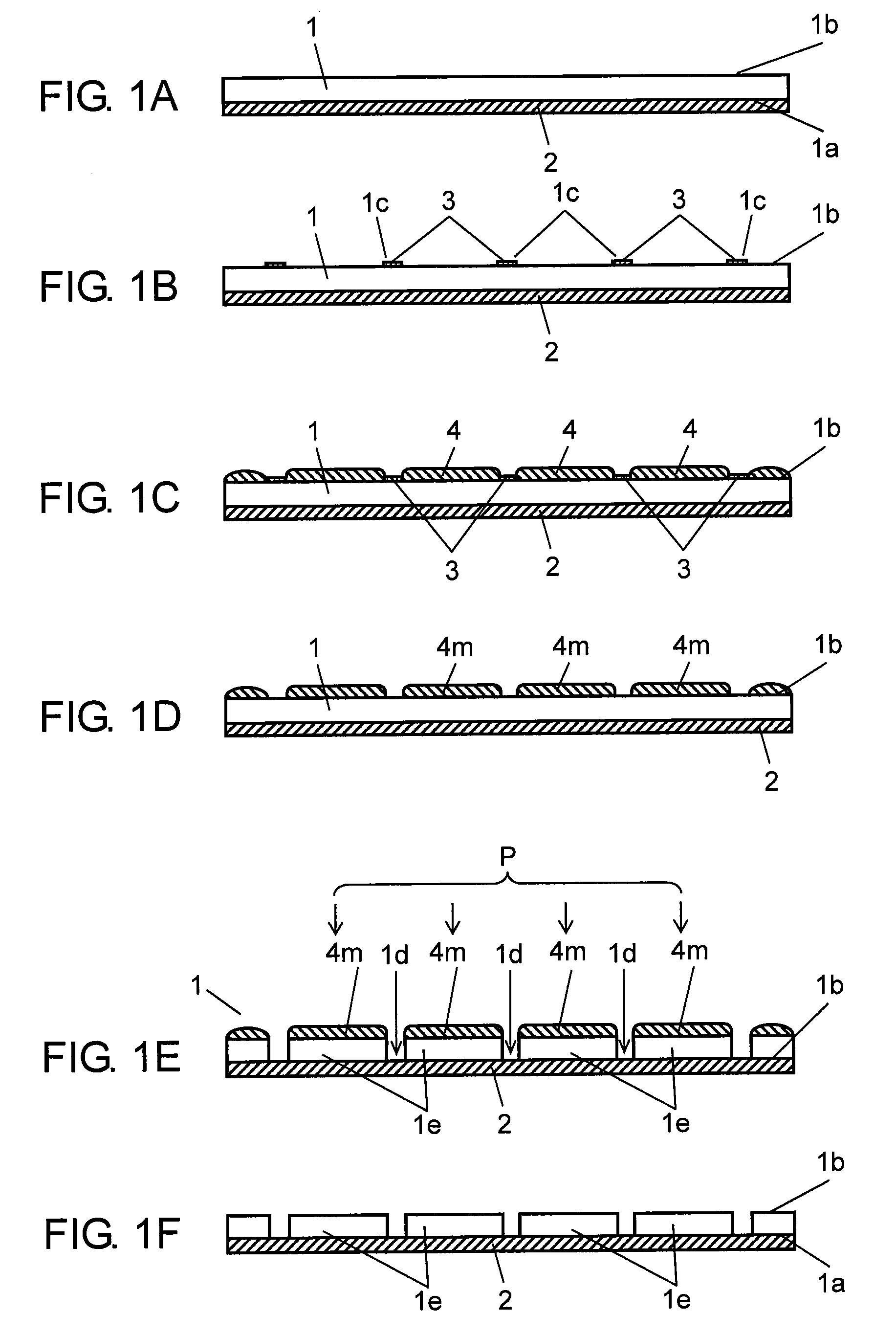

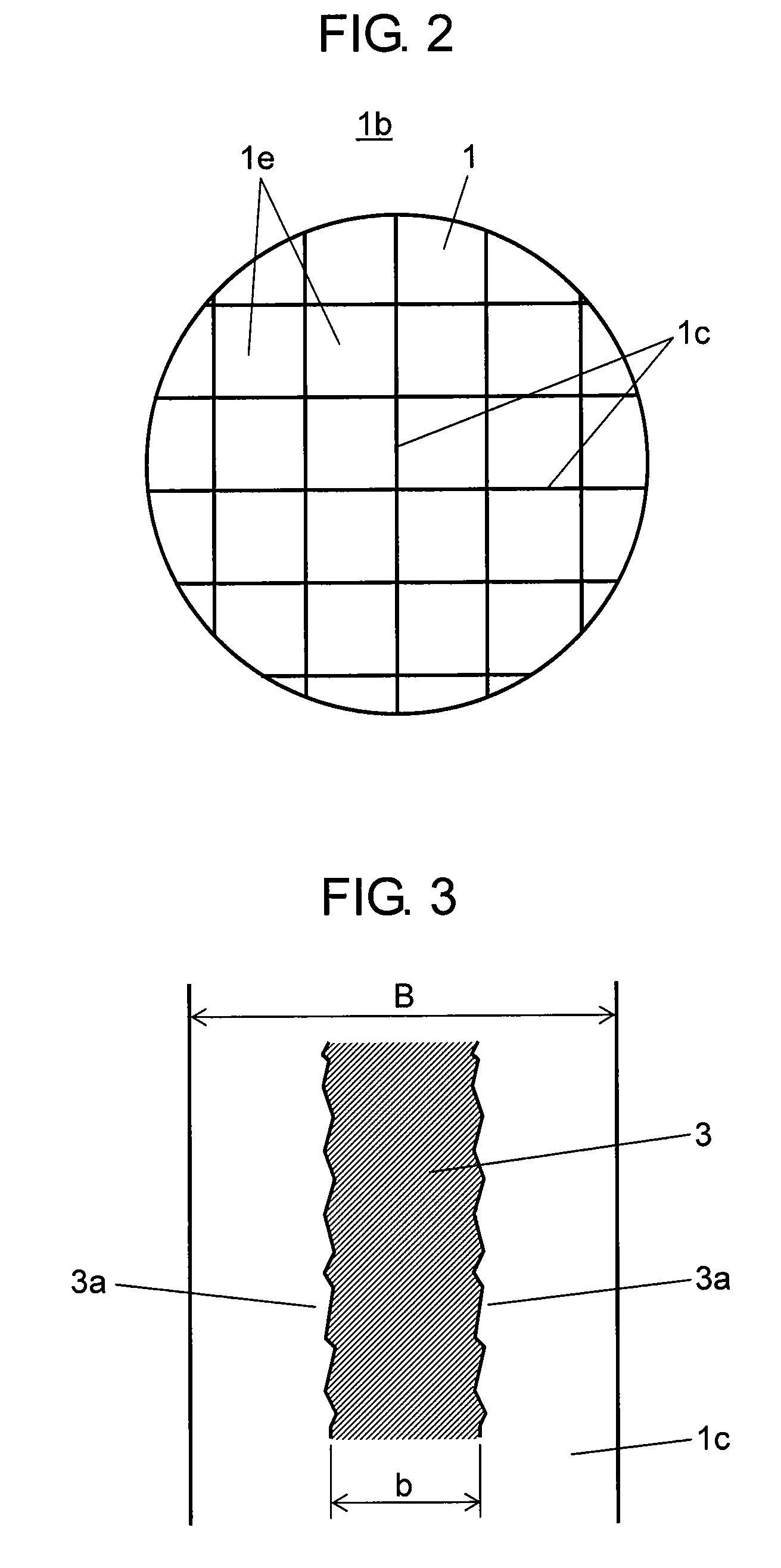

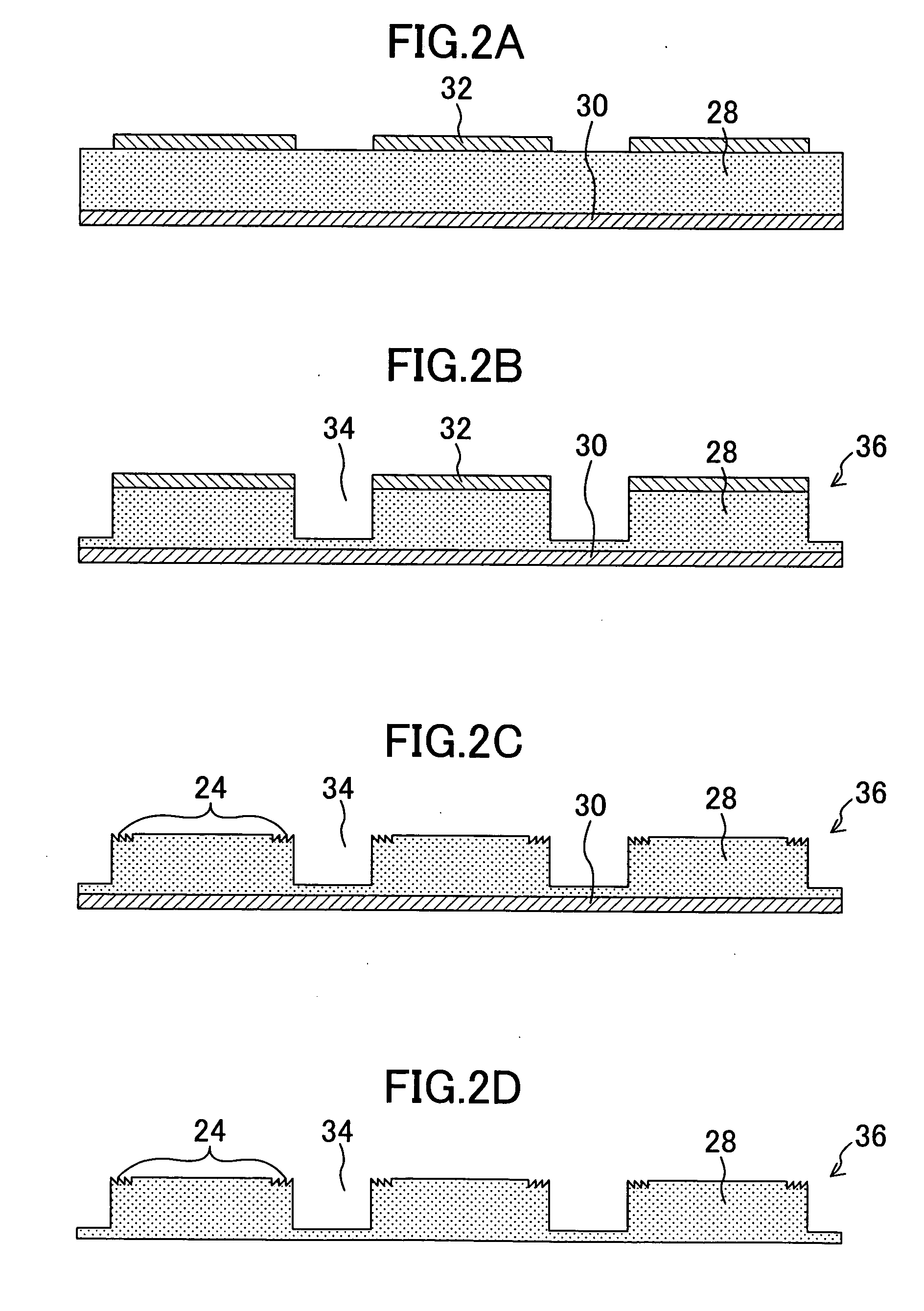

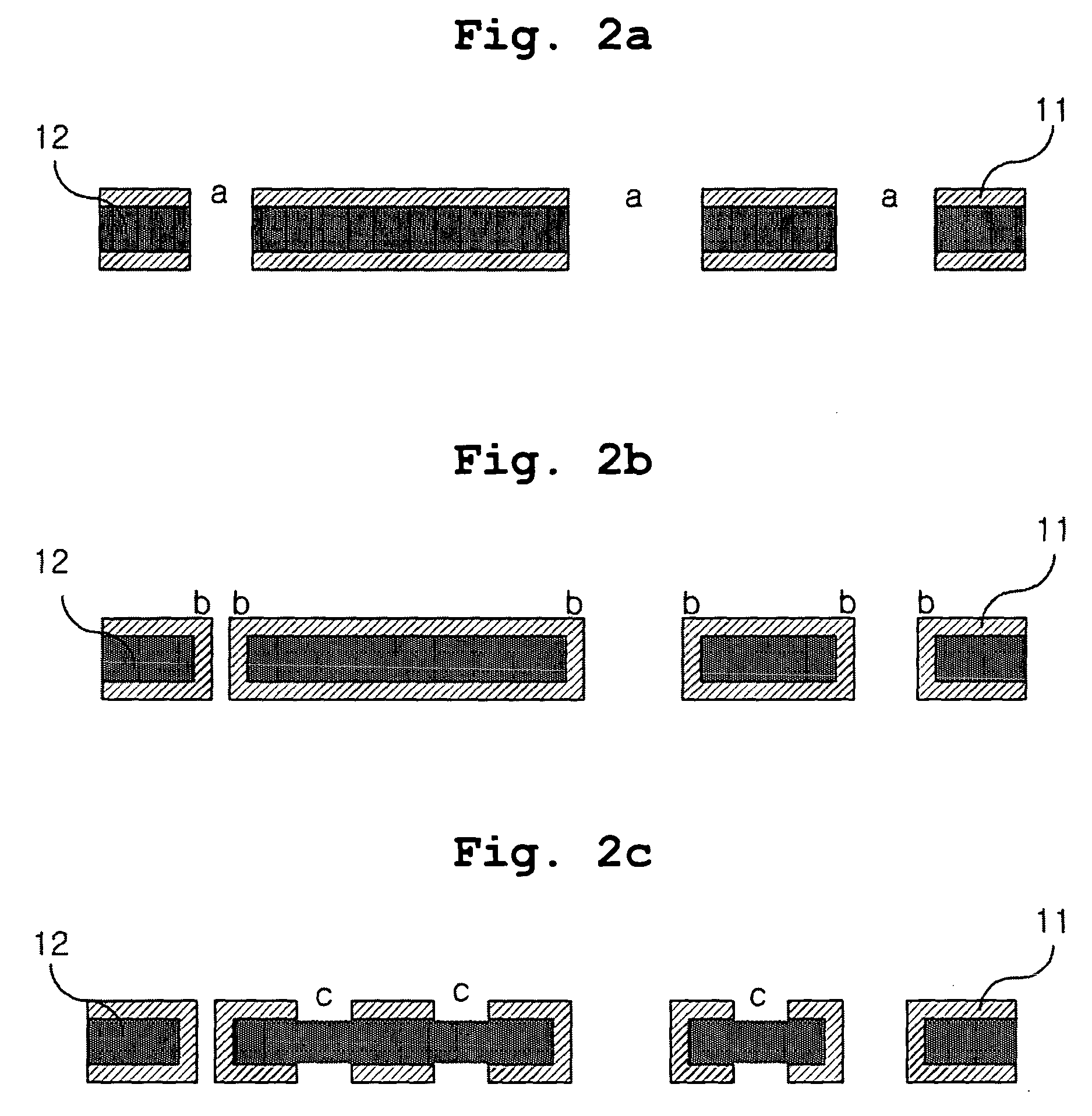

Method for processing a substrate, method for manufacturing a semiconductor chip, and method for manufacturing a semiconductor chip having a resin adhesive layer

ActiveUS20110014777A1Low costLow cost manufacturingSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

A mask used when a semiconductor wafer is diced into individual semiconductor chips by plasma etching is formed as follows. First, a pattern of a liquid-repellent film is formed by printing a liquid-repellent liquid on the area to be etched on the rear surface of the semiconductor wafer. Next, a resin film thicker than the liquid-repellent film is formed in the area not having the liquid-repellent film by supplying a liquid resin to the rear surface on which the liquid-repellent pattern has been formed. Then, the resin film is cured to form the mask covering the area other than the area to be removed by the etching. This method allows the formation of an etching mask without using a high-cost method such as photolithography.

Owner:PANASONIC CORP

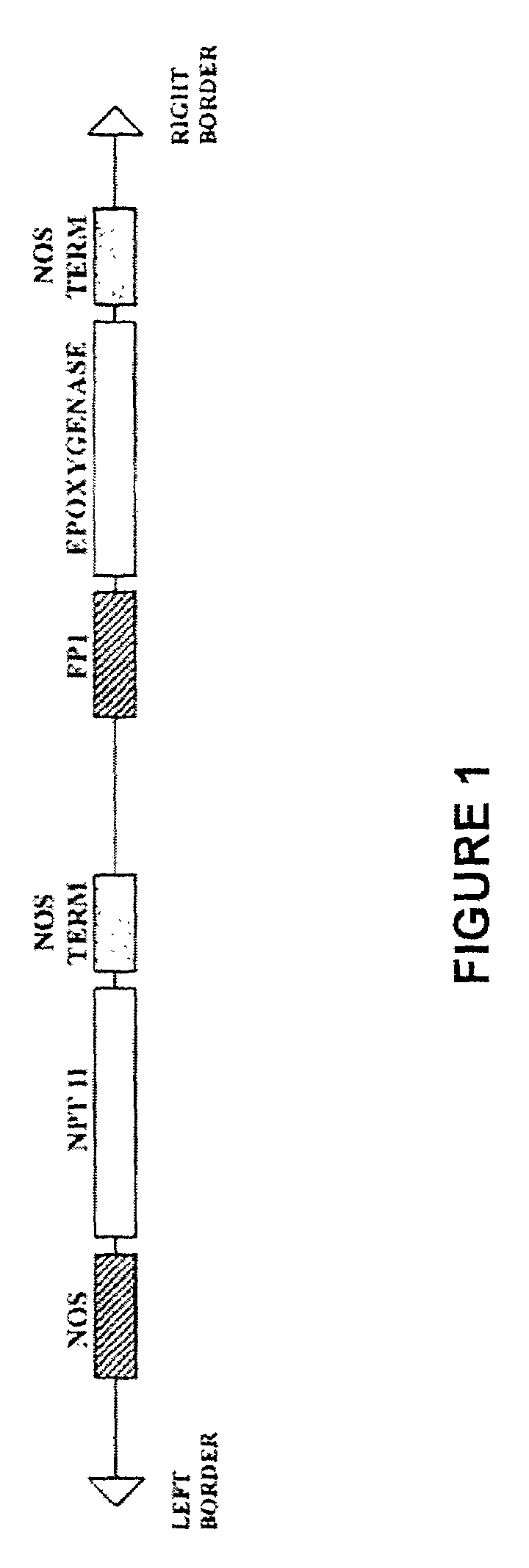

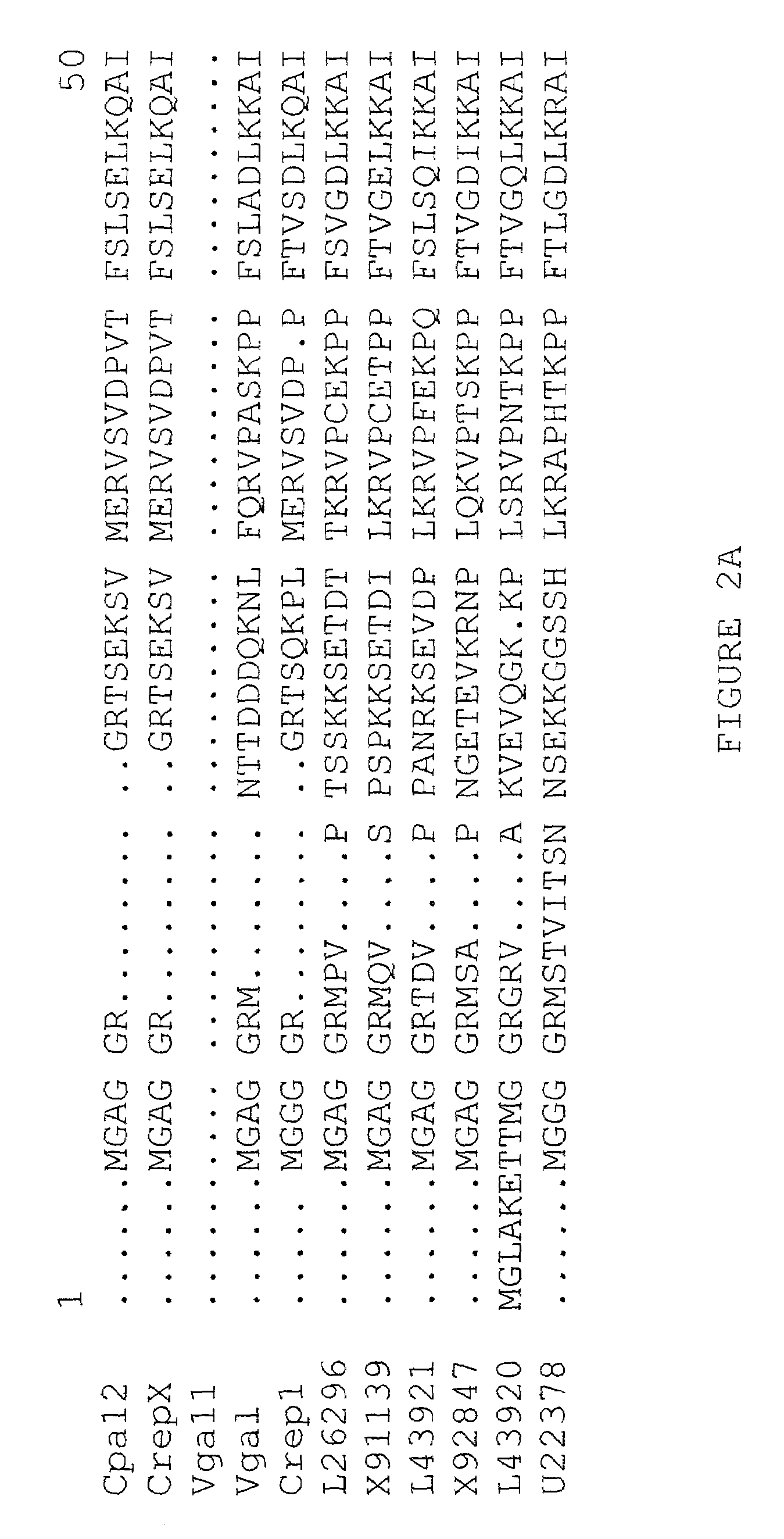

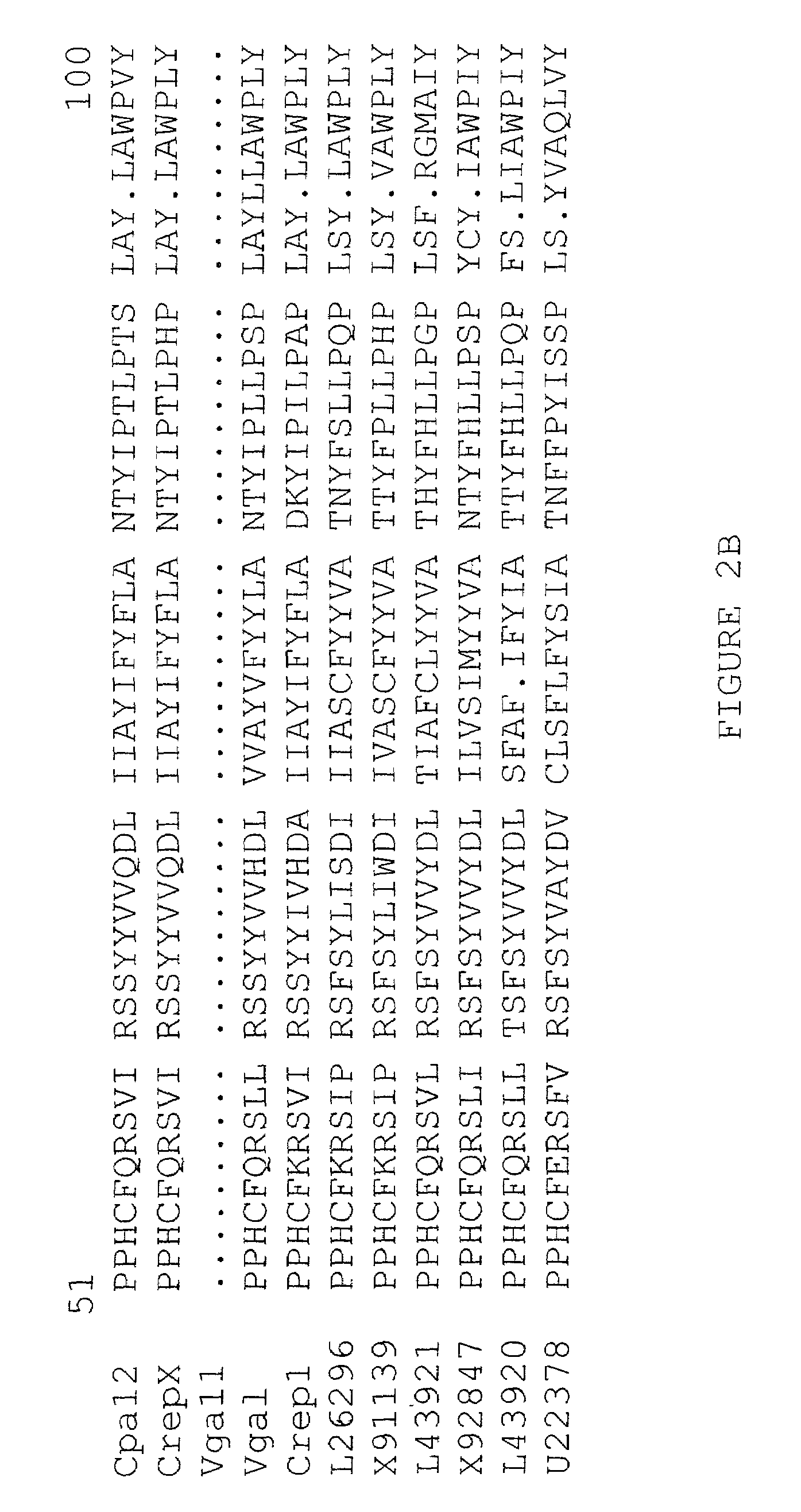

Fatty acid epoxygenase genes from plants and uses therefor in modifying fatty acid metabolism

The present invention relates generally to novel genetic sequences that encode fatty acid epoxygenase enzymes, in particular fatty acid Δ12-epoxygenase enzymes from plants that are mixed function monooxygenase enzymes. More particularly, the present invention exemplifies cDNA sequences from Crepis spp. and Vernonia galamensis that encode fatty acid Δ12-epoxygenases. The genetic sequences of the present invention provide the means by which fatty acid metabolism may be altered or manipulated in organisms, such as, for example, yeasts, moulds, bacteria, insects, birds, mammals and plants, and more particularly in plants. The invention also extends to genetically modified oil-accumulating organisms transformed with the subject genetic sequences and to the oils derived therefrom. The oils thus produced provide the means for the cost-effective raw materials for use in the efficient production of coatings, resins, glues, plastics, surfactants and lubricants.

Owner:COMMONWEALTH SCI & IND RES ORG

Making process of E1/E0 level green artificial plate

InactiveCN1526528AThe effect of free formaldehyde content is obviousGuarantee market supplyWood veneer joiningFlat articlesFiberHigh density

The present invention discloses one kind of making process of E1 / E0 level environment protection artificial plate. After plain plate with free formaldehyde releasing amount greater than or equal to E2 level is made with common urea resin adhesive, the plain plate is processed through ammonia vacuum process to lower the free formaldehyde releasing amount to E1 / E0 level. According to the density and initial formaldehyde releasing amount of the plain plate, the ammonia consumption and formaldehyde lowering time are regulated to control the processing effect. The said process has stable product quality and low cost, and is suitable for various artificial plates, including plywood, medium density fiber plate, high density fiber plate and shaving board.

Owner:NANJING FORESTRY UNIV

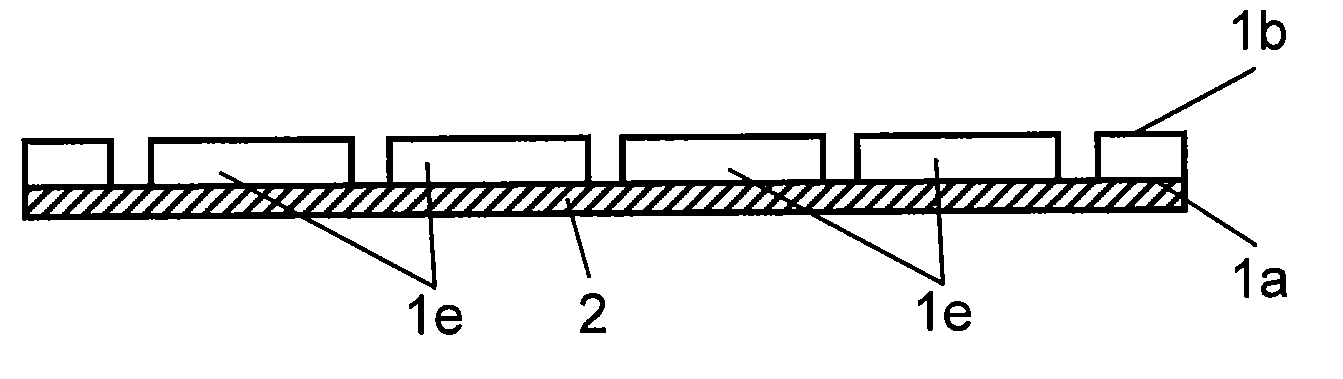

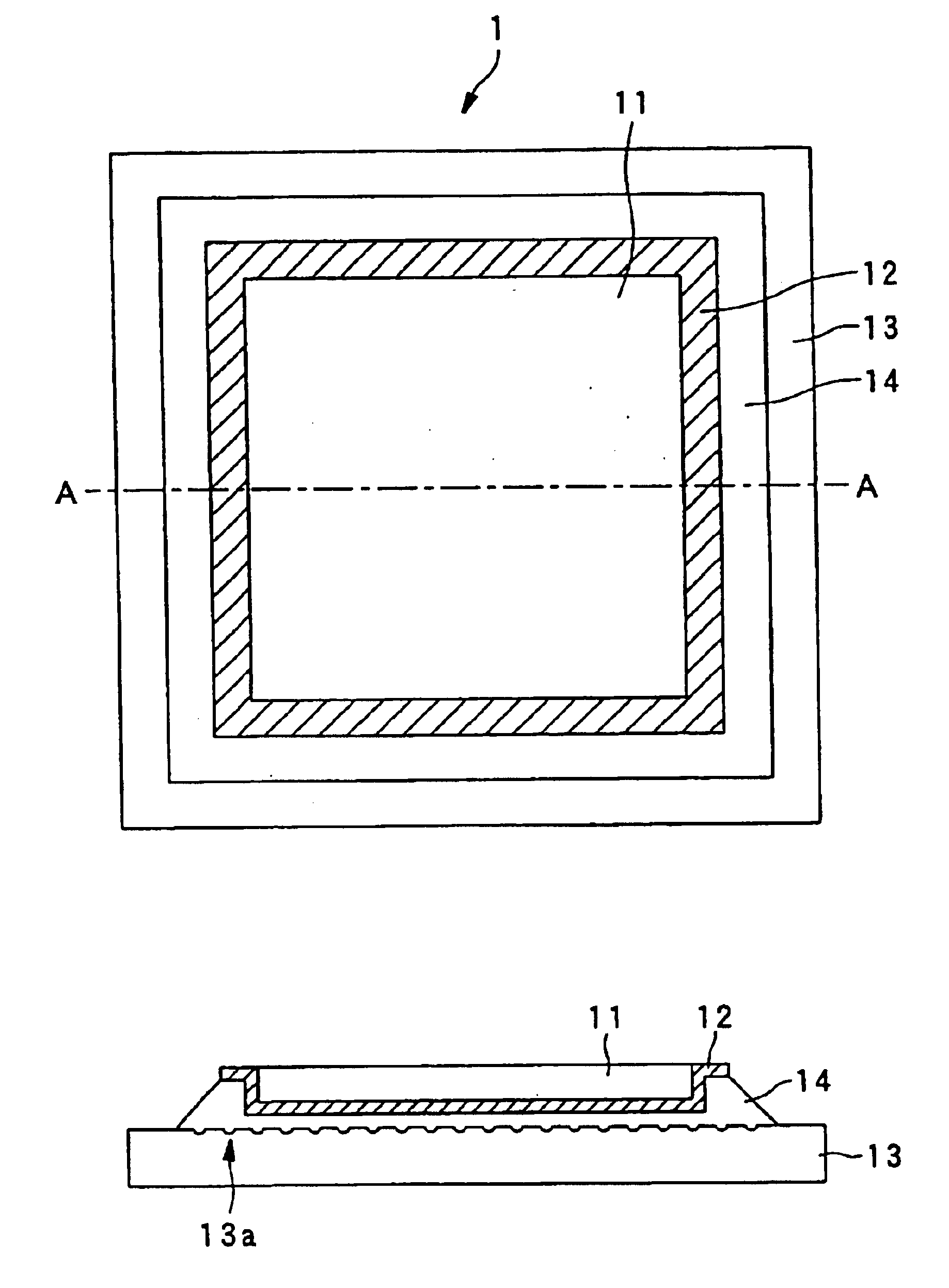

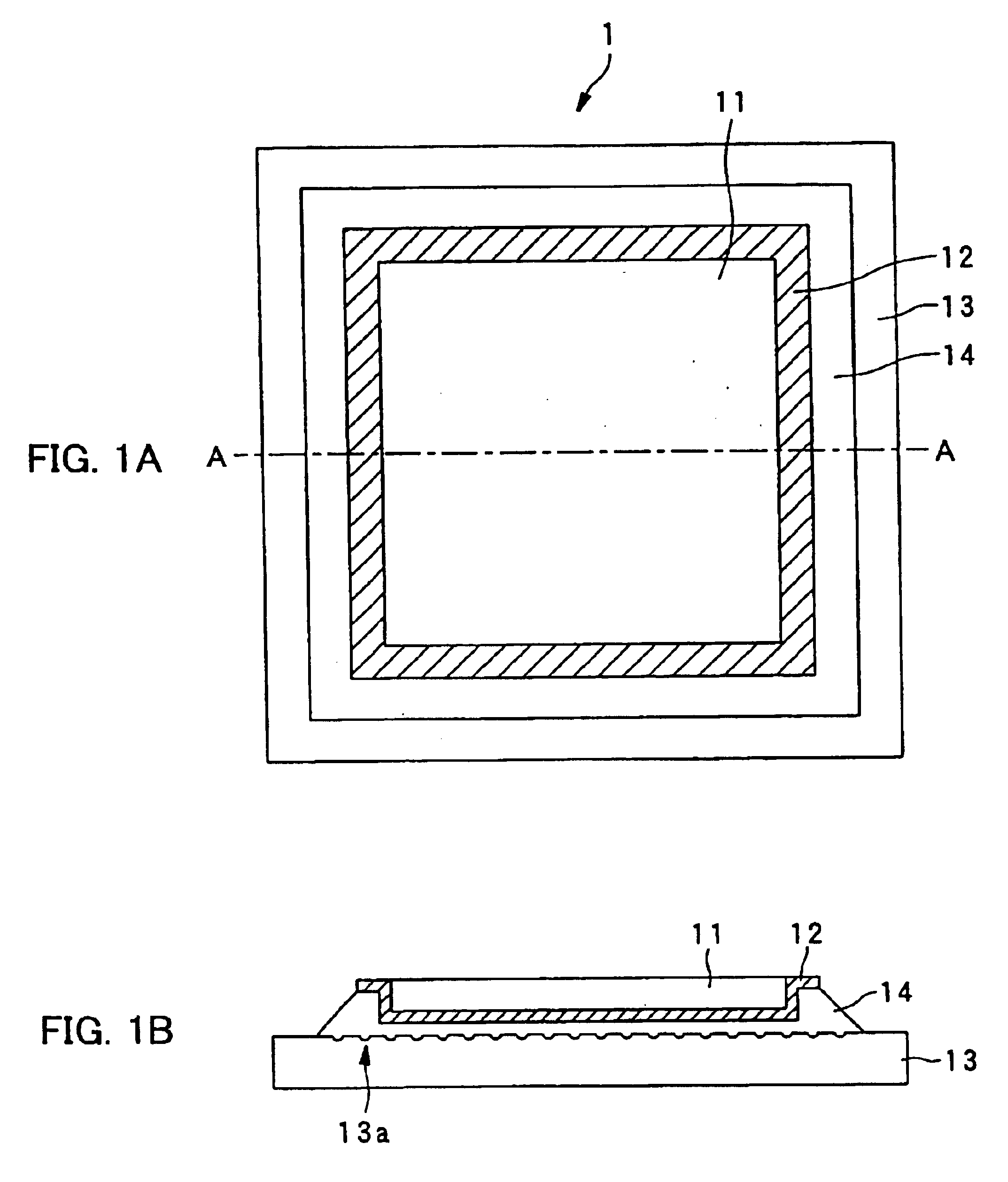

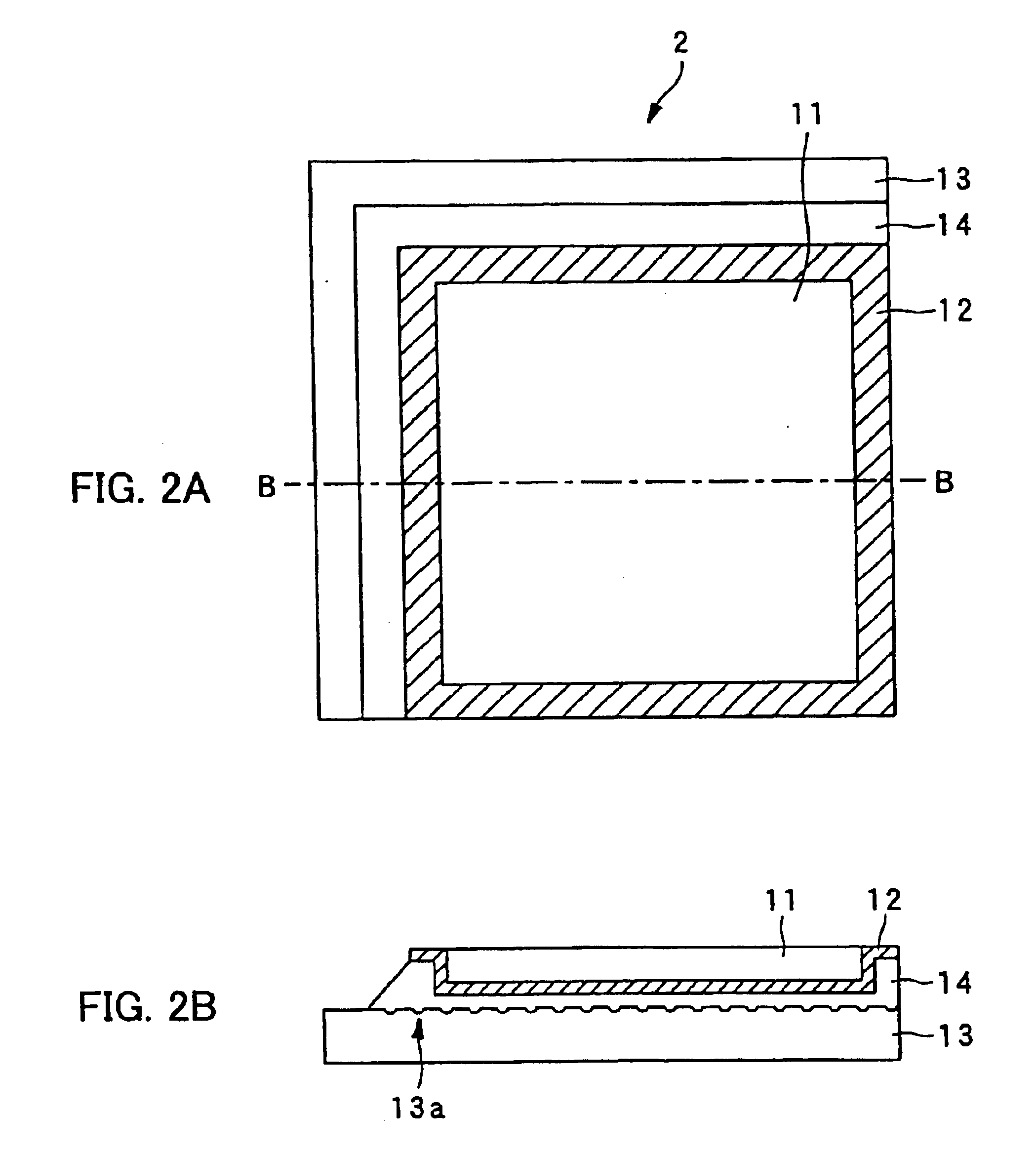

Dielectric recording medium, and method of and apparatus for producing the same

InactiveUS6841220B2Remove electric charge on the recording surface rapidlyImprove abilitiesNanoinformaticsFerroelectric carrier recordingSingle crystalOptoelectronics

The dielectric recording medium is provided with a dielectric material, a conductive thin film, and a substrate. The conductive thin film and the substrate are bonded by a resin adhesive. The dielectric material is constructed of a ferroelectric single crystal having a uniform thickness, and its one surface is used for a recording and / or reproducing surface, on the order of mm on a side and about 5000 Å thick. The conductive thin film, about 1000 to 2000 Å thick, is placed on a surrounding portion and a back surface of the recording and / or reproducing surface of the dielectric material. The substrate is intended to preserve the thin dielectric material and maintain the planarity, and concave portions are formed on the adhesive surface. The concave portions absorb excessive resin adhesive when the dielectric material is bonded onto the substrate, which makes the adhesive surface uniform and flat.

Owner:PIONEER CORP +1

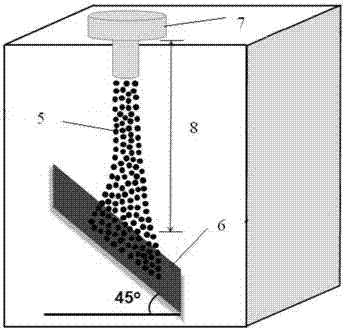

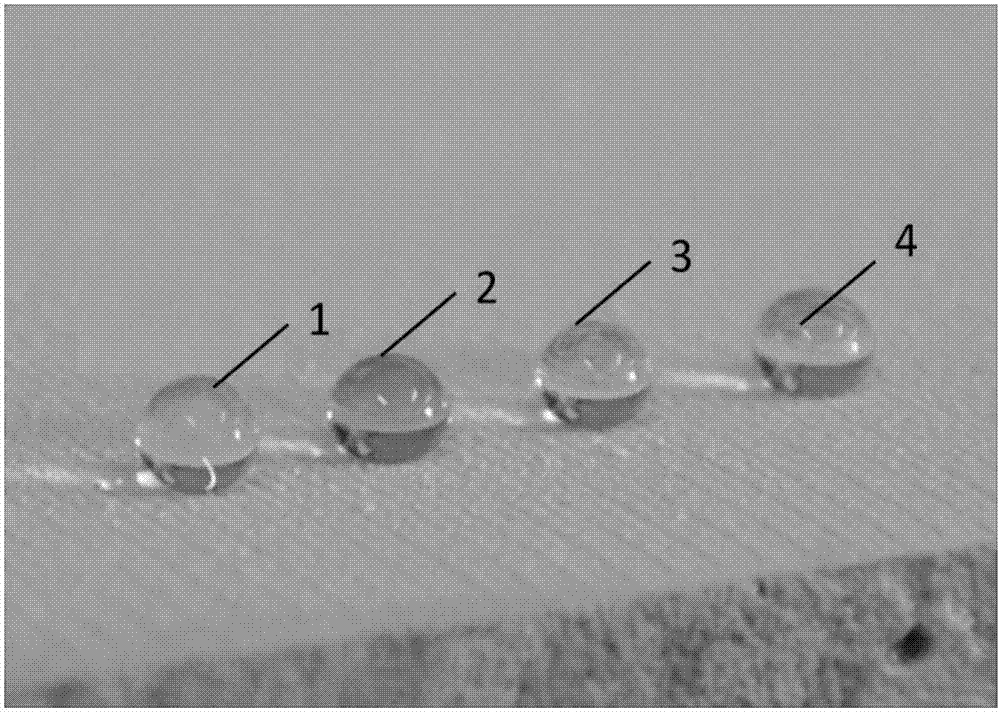

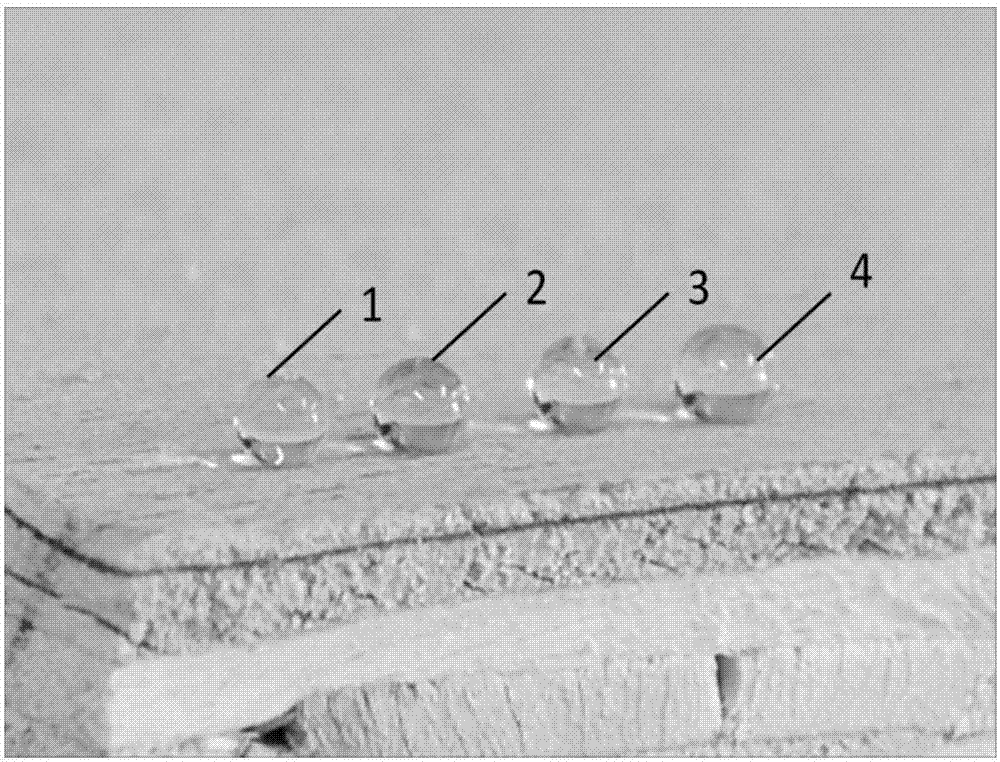

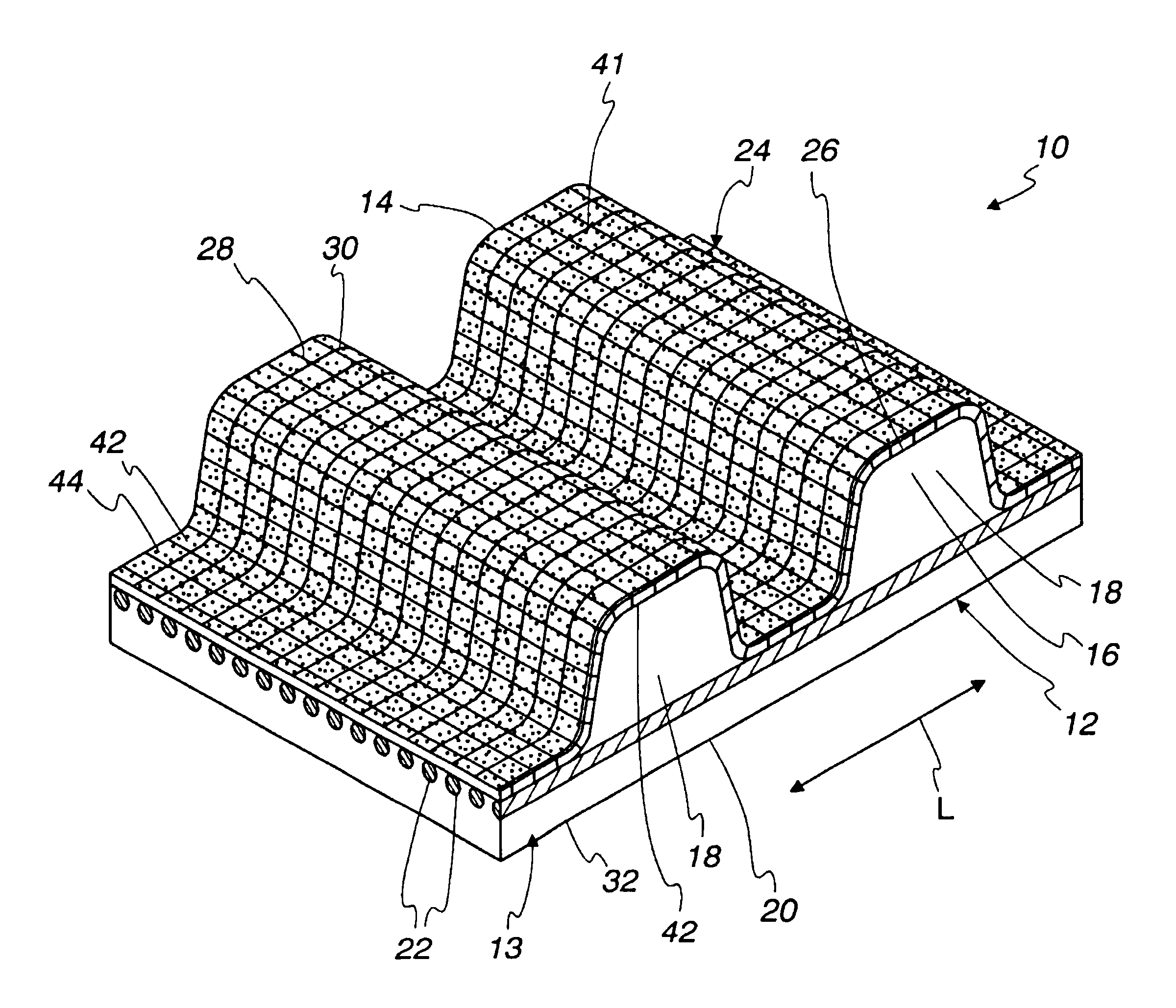

Method for preparing durable super-amphiphobic coatings capable of being sprayed

ActiveCN106893454AIncrease roughnessHigh bonding strengthAnti-corrosive paintsPolyurea/polyurethane coatingsAnti freezingSand blasting

The invention belongs to the field of super-hydrophobic or super-amphiphobic coating preparation, and particularly relates to a method for preparing durable super-amphiphobic coatings capable of being sprayed. The method particularly includes steps of 1, carrying out cleaning and sand blasting roughening treatment on the surfaces of base materials; 2, preparing resin solution; 3, preparing particle composite suspension; 4, spraying the resin solution obtained at the step 2 on the surfaces, treated at the step 1, of the base materials, drying the base materials and carrying out semi-solidification on resin adhesive; 5, spraying the particle composite suspension obtained at the step 3 on the surfaces of the base materials obtained at the step 4, and drying the base materials to completely solidify the base materials; 6, washing the surfaces of the base materials obtained at the step 5 to obtain the durable super-amphiphobic coatings capable of being sprayed. The method has the advantage that the durable super-amphiphobic coatings with excellent durability and firmness can be prepared on the surfaces of the various base materials by the aid of spraying technologies and have persistent anti-freezing performance.

Owner:哈尔滨毓干科技有限公司

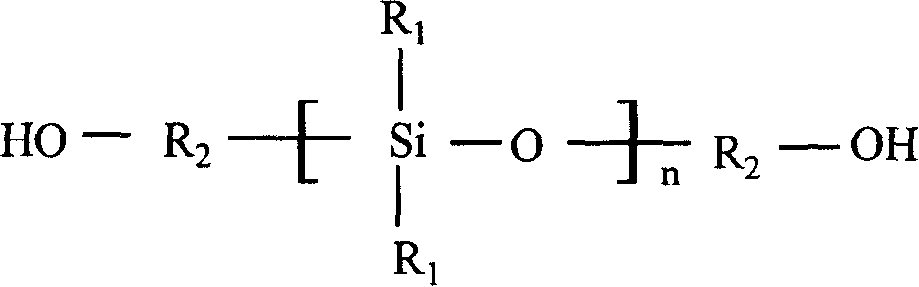

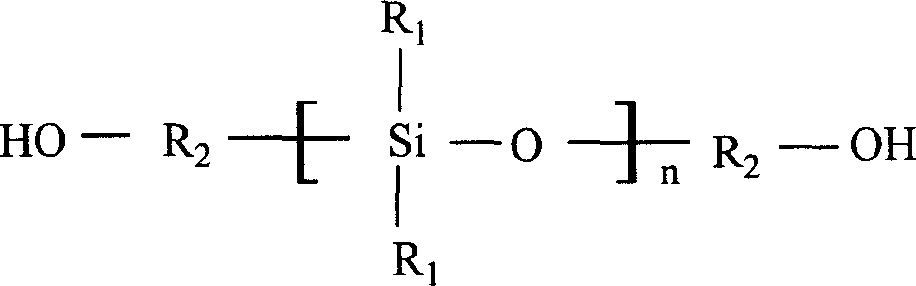

Modified epoxy resin adhesive and its preparation process

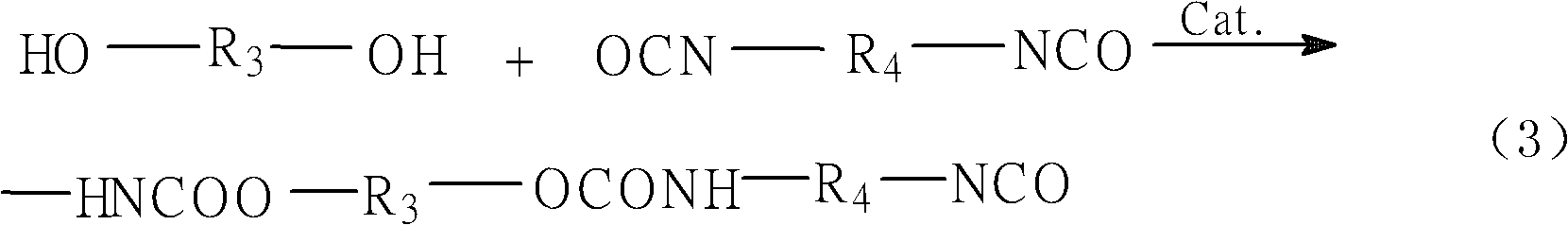

The invention relates to a modified epoxide resin adhesive agent and its preparation process to overcome the disadvantage such as brittleness and bad temperature resistance of common epoxide resin adhesive agents, which comprises: mixing the epoxide resin (component A) modified by polyurethane prepolymer and curing agent (component B) produced by author in the proportion of between 10:1 to 1:1 to prepare the curing system of fire resistant, good toughness and large reaction, wherein the polyurethane prepolymer is polysiloxane polyurethane prepolymer capped by isocyanate groups which are produced by the reaction of hydroxy-terminated polysiloxane and diisocyanate in a definite proportion, then using the said polyurethane prepolymer to modified treat epoxide resin. The said curing agent produced by author is made of diamine, imidazolinium compounds, silane coupling agents, mineral filler and catalyst. The said modified epoxide resin adhesive agent can be cured in room temperature and has the good characteristics of oil resistant, water resistant, acid and alkali resistant and resistance to organic solvent, also can adhere to the damp face, oil face, metal, plastic, ceramic, hard rubber and wood and so on.

Owner:李洁华

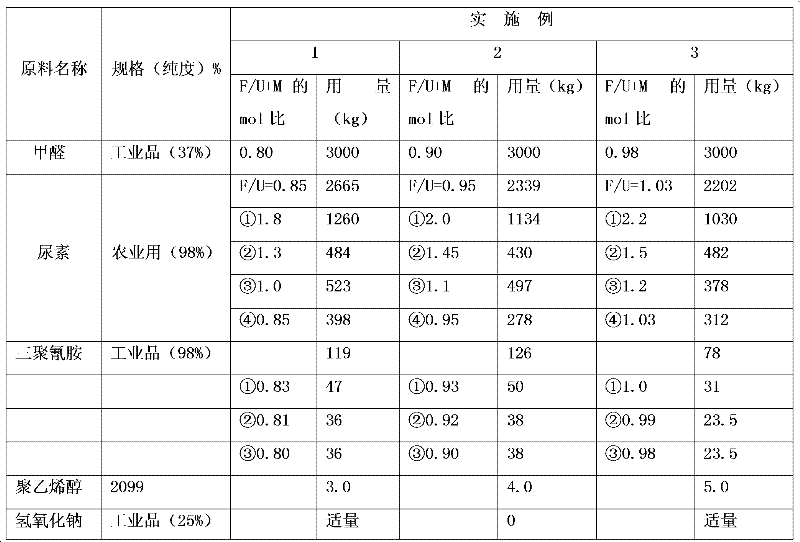

E0-grade melamine modified urea-formaldehyde resin adhesive, and preparation method and application thereof

InactiveCN102604573AImprove stabilityLow costAldehyde/ketone condensation polymer adhesivesMelamineResin adhesive

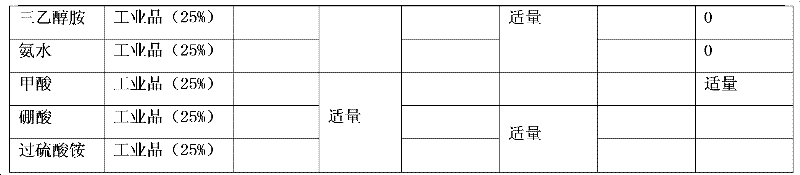

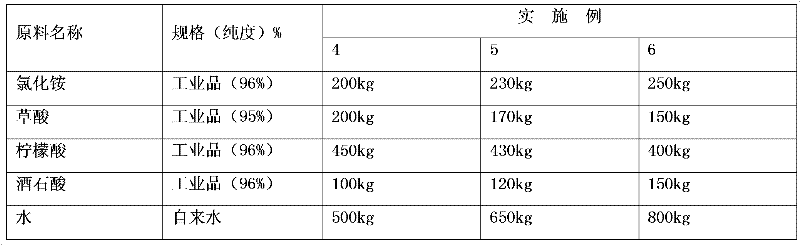

The invention relates to an E0-grade melamine modified urea-formaldehyde resin adhesive, and a preparation method and application thereof. The E0-grade melamine modified urea-formaldehyde resin adhesive is characterized by comprising an E0-grade melamine modified urea-formaldehyde resin, a composite curing agent and a composite filler, wherein the E0-grade melamine modified urea-formaldehyde resin is prepared from the following raw materials in parts by mass: 100 parts of formaldehyde, 0.1-0.5 part of polyvinyl alcohol, 100-200ml of basic catalyst and 200-400ml of acidic catalyst; the mol ratio of the formaldehyde to the urea+melamine (F / (U+M)) is equal to 0.80-0.98; the composite curing agent is prepared from the following raw materials in parts by mass: 200-250 parts of ammonium chloride, 150-200 parts of oxalic acid, 400-450 parts of citric acid, 100-150 parts of tartaric acid and 500-800 parts of water; and the composite filler is prepared from the following raw materials in parts by mass: 60 parts of industrial flour, 20 parts of 800-mesh light calcium carbonate and 20 parts of 800-mesh wood meal. The E0-grade melamine modified urea-formaldehyde resin adhesive is used for gluing plates. The E0-grade melamine modified urea-formaldehyde resin adhesive has the advantages of low free formaldehyde content, low cost, favorable precompression performance, good gluing performance and the like.

Owner:BEIHUA UNIV

Phenolic resin/phosphate hybrid adhesive and preparation method thereof

InactiveCN101875830AEasy to prepareImprove thermal stabilityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPhosphateWorking temperature

The invention provides a phenolic resin / phosphate hybrid adhesive and a preparation method thereof, relating to an adhesive and a preparation method thereof. The invention solves the problems of low working temperature, rigorous curing process and low adhesion strength of the conventional high-temperature resisting phenolic resin adhesive. The adhesive is prepared from phenolic resin, heat-resistant reinforced resin, a coupling agent, a toughening agent, phosphate, a curing agent, a framework material, fillers and a dispersing agent. The preparation method comprises the following steps of: mixing the phenolic resin, the heat-resistant reinforced resin, the coupling agent and the toughening agent and then evenly stirring to obtain a phenolic resin component; then mixing the phosphate, the curing agent, the framework material and the fillers and then evenly stirring to obtain a phosphate component; and then adding the phosphate component and the dispersing agent into the phenolic resin component and evenly stirring. The adhesive can be applied in aerospace, military and machining industries with the working temperature above 800 DEG C.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Method for preparing phenolic aldehyde adhesive based on lignin phenolized liquid and application thereof

InactiveCN101260283AImprove liquidityGood storage stabilityAldehyde/ketone condensation polymer adhesivesThermal insulationResin adhesive

The invention provides a preparation method for phenolic adhesive based on lignin phenolization liquid and application thereof. Under the condition of normal pressure heating or thermalcatalysis, phenol is taken as liquefaction reagent, lignin is added, the temperature is raised to 90 to 150 DEG C, the thermal insulation liquefaction reaction is made to cool to obtain a lignin liquefaction product; basic catalyst and formaldehyde are directly added into the liquefaction liquid, the temperature is raised to 70 to 97 DEG C under normal pressure to react for 1 to 3 hours, the reaction is terminated when the viscosity is measured to meet the preset requirement, and low-free formaldehyde environmental protection type phenolic adhesive based on lignin phenolization liquid is obtained. The adhesive obtained by the invention has lower cost and lower content of free formaldehyde than the prior phenolic resin adhesive. The plywood pressed by using the adhesive obtained by the invention has good bonding performance.

Owner:HUANGSHAN UNIV

Cyanurotriamide modified urea resin and prepn. process

InactiveCN1834186AImprove boiling water resistanceHigh activityAldehyde/ketone condensation polymer adhesivesCyanurotriamideAmmonium hydroxide

This invention provides a method for manufacturing melamine-modified urea-formaldehyde resin adhesive used on wood cement templates. The method adopts formaldehyde and urea at a molar ratio of 1.2-1.4 as the raw materials, and urea is added into formaldehyde in four times. Before the first time of urea addition, formaldehyde is activated at 50 minus or plus 5 deg.C for 15-25 min. in the third time of urea addition, melamine 3-20 wt. % of total urea is also added. After the fourth time of urea addition, ammonia solution is added for post treatment so that the content of free formaldehyde in the modified urea-formaldehyde resin adhesive is below 0.2 wt. %. at the same time the boiling water-resistance of the urea-formaldehyde resin adhesive can be improved. This invention can be used as a substitute for expensive phenol-formaldehyde resin adhesive; therefore the cost is reduced while the performance of wood cement templates can be guaranteed.

Owner:EVERFIRST WISEFUND TECH BEIJING +1

Preparation method of stable superhydrophobic hot liquid coating

ActiveCN105440888AFix performance issuesPolyurea/polyurethane coatingsEpoxy resin coatingsCatalytic effectHydrolysis

The invention discloses a preparation method of a stable superhydrophobic hot liquid coating, and belongs to the technical field of surface coating preparation. According to the preparation method, in an acetone-water mixed system, in the catalytic effect of acid or base, organic silane and nano particles carry out hydrolysis and condensation reactions to obtain organic silane polymer / nano particle compound suspension; then organic resin adhesive is added into the compound suspension, the mixture is evenly mixed and evenly sprayed on the surface of a substrate material, and finally a thermal curing treatment is performed to obtain the stable superhydrophobic hot liquid coating. The prepared coating has an excellent superhydrophobic hot liquid performance, has the advantages of good mechanical stability, chemical stability, and environmental stability, and thus has a good application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

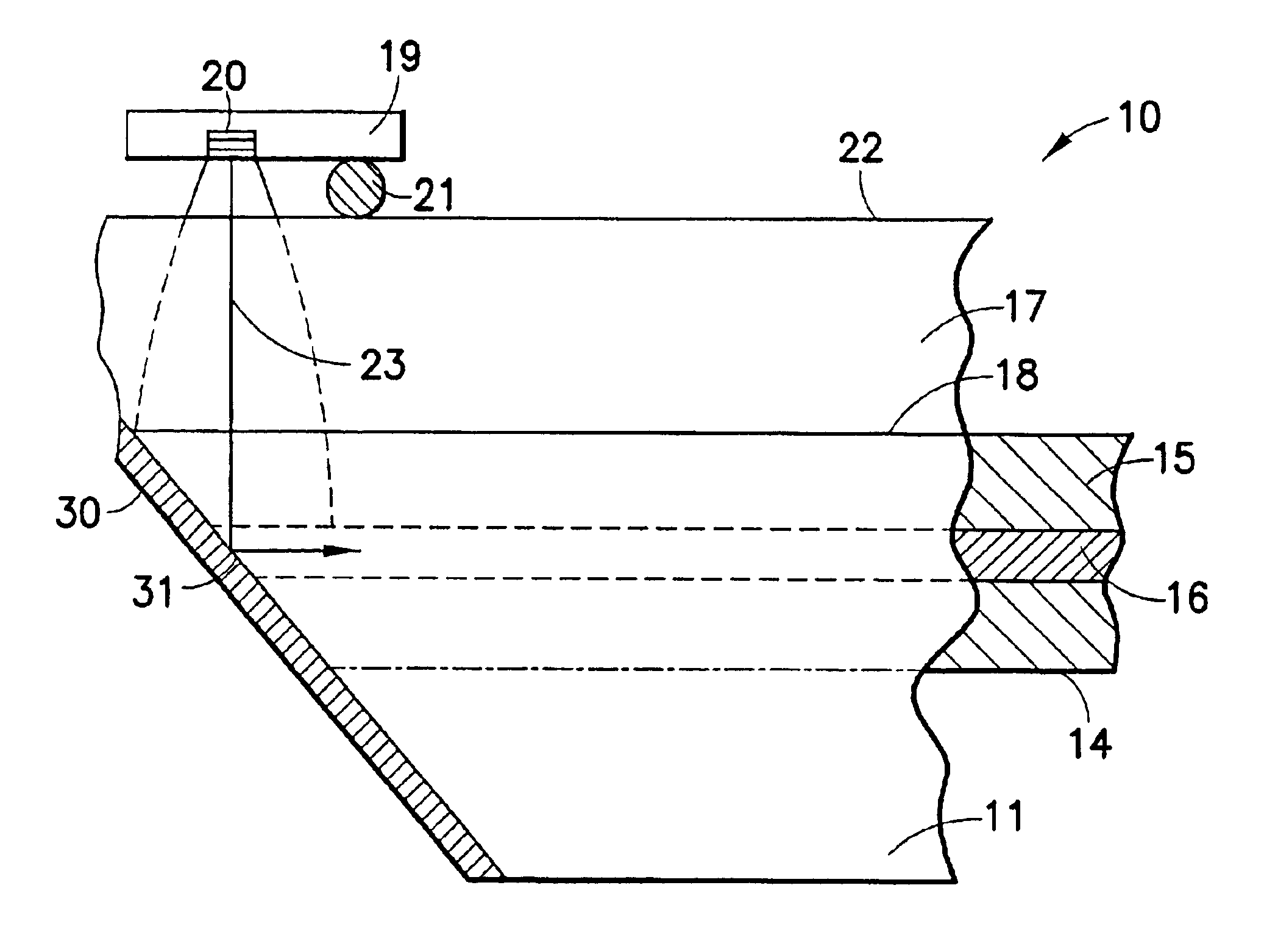

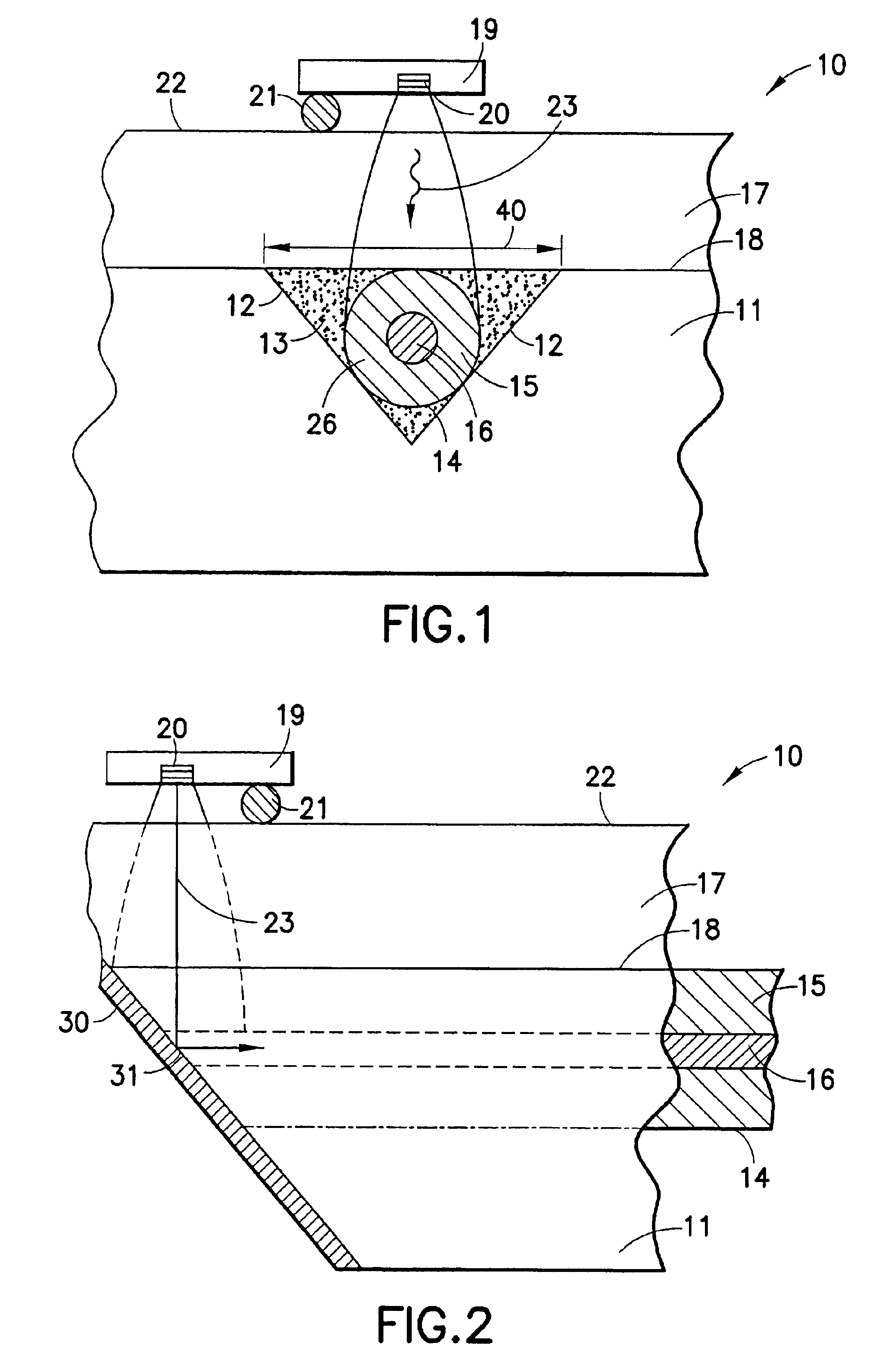

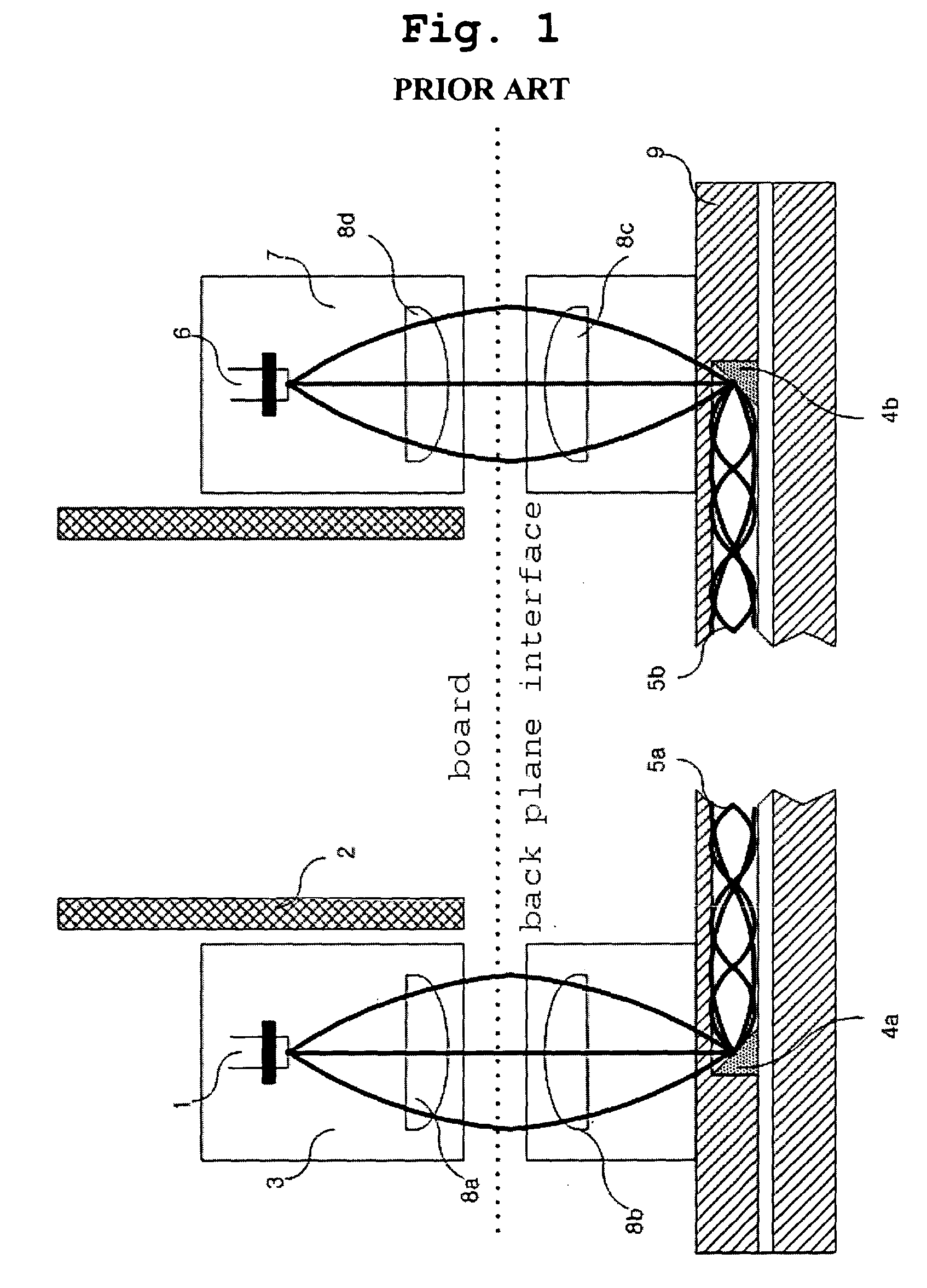

Coupled optical and optoelectronic devices, and method of making the same

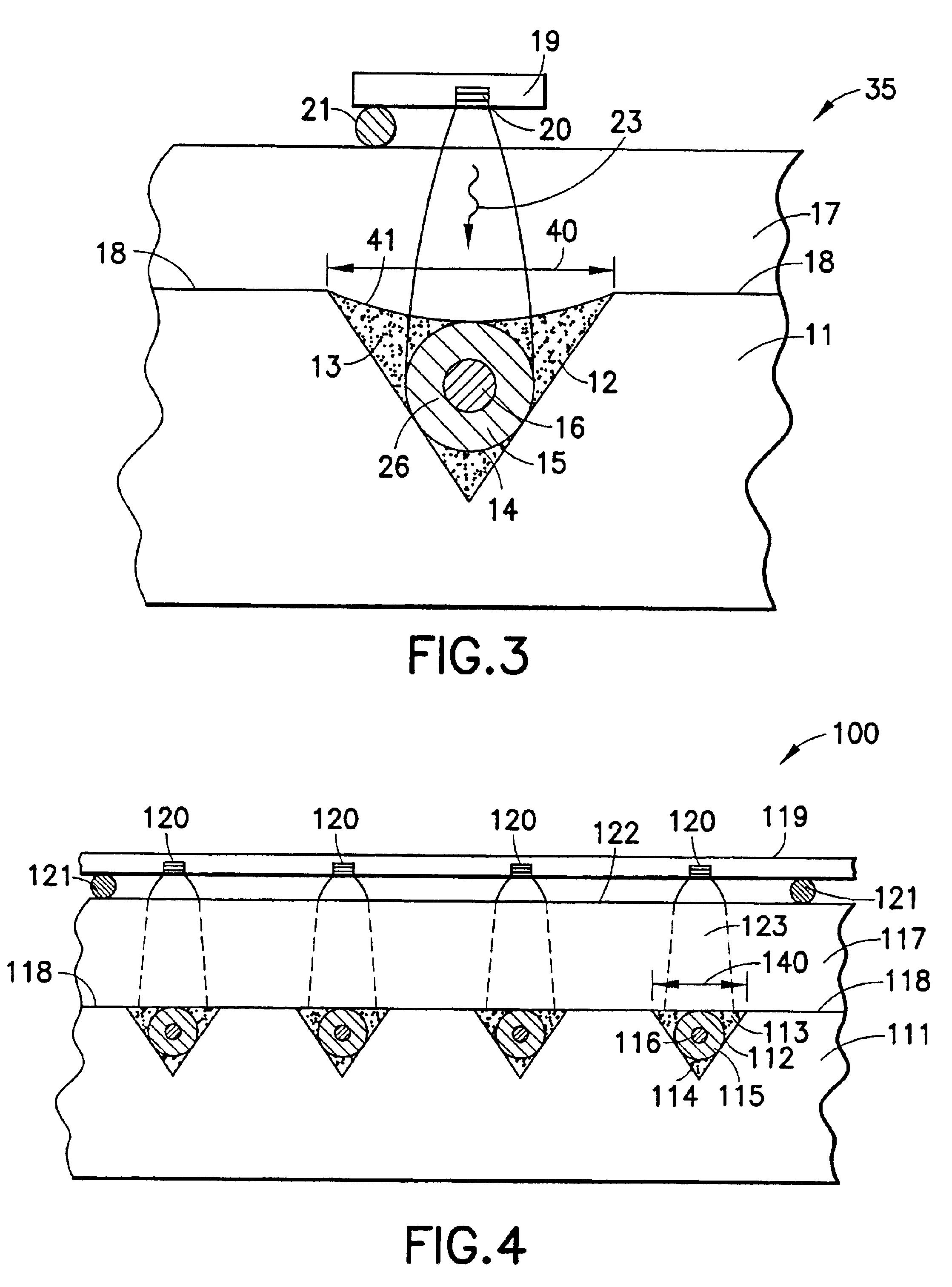

InactiveUS6869229B2Easy to manufactureSacrifice power performanceSolid-state devicesCoupling light guidesCouplingRefractive index

An optical-optoelectronic coupling structure comprising a flip-chip optoelectronic / ultrathin silicon-on-sapphire device mounted on a V-groove, optical-fiber-bearing carrier substrate, including light-reflective structures for launching light into the optical fiber core or transmitting light emitted by the optical fiber core to the optoelectronic device. The optical fiber may be immobilized in the V-groove using a curable resin adhesive characterized by a refractive index substantially similar to the refractive index of the optical fiber.

Owner:PSEMI CORP

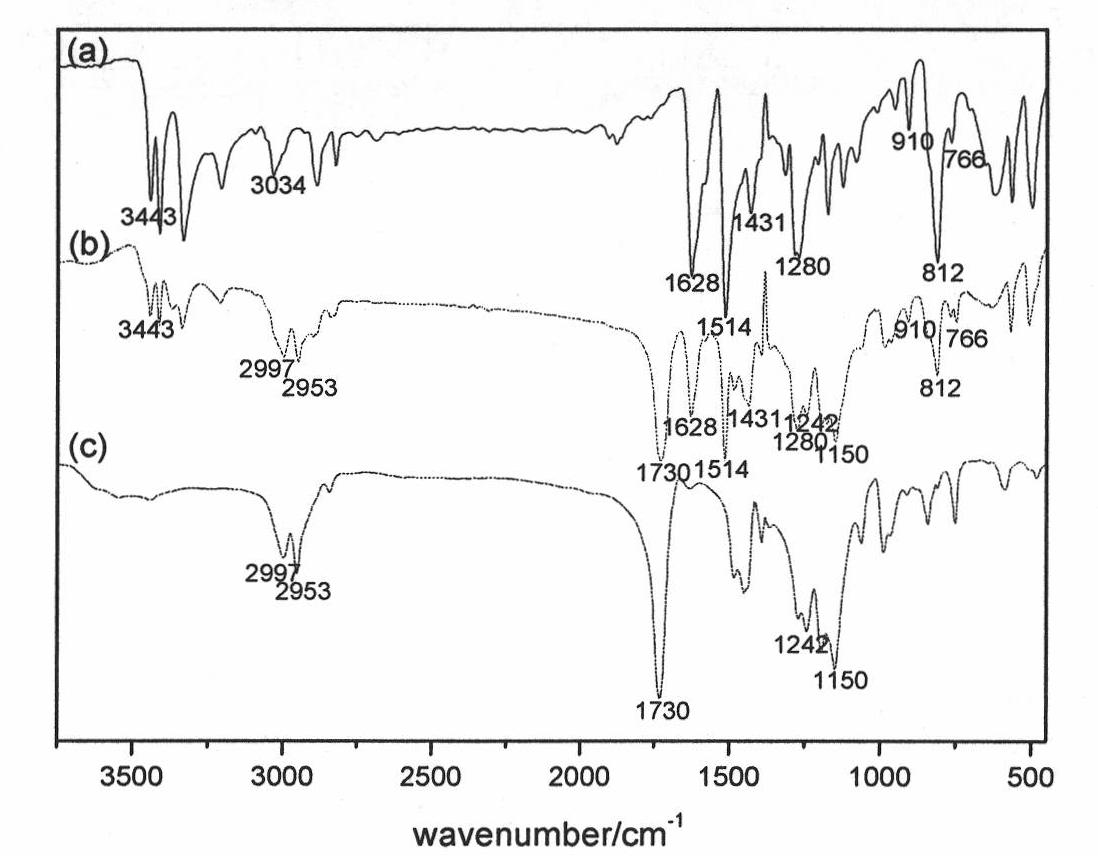

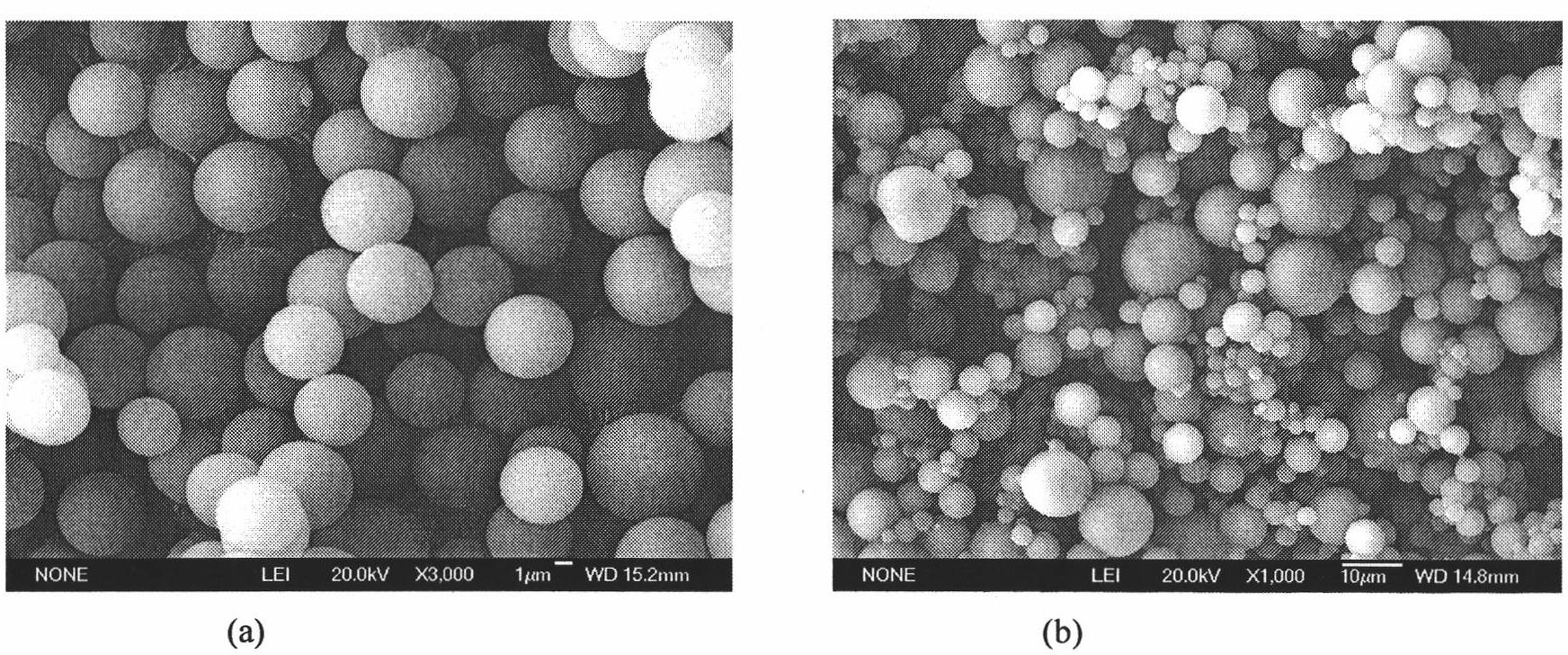

Latent microcapsule curing agent initiating thermosetting epoxy resin curing at medium temperature and preparation method of adhesive thereof

InactiveCN102423673AHigh core contentFlat surfaceMicroballoon preparationMicrocapsule preparationEpoxyMicrosphere

The invention relates to a latent microcapsule curing agent initiating thermosetting epoxy resin curing at medium temperature and a preparation method of an adhesive thereof. The latent microcapsule curing agent is technically characterized in that the high-activity medium temperature curing agent is taken as a core material, thermoplastic high polymer microspheres are taken as a wall material, the solvent evaporation technology is adopted for preparing the latent microcapsule curing agent with better curing performance and latent performance, and the latent microcapsule curing agent can be applied to an epoxy resin system for preparing the single-component medium temperature curing epoxy resin adhesive. Microcapsules prepared by the method are high in capsule core content, smooth in surfaces, narrow in particle size distribution and good in compatibility with matrix epoxy resin and can be better dispersed in the epoxy resin; and the prepared single component adhesive can realize curing at the medium temperature, the storage period at room temperature is longer and the tensile shear strength performance can be further improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

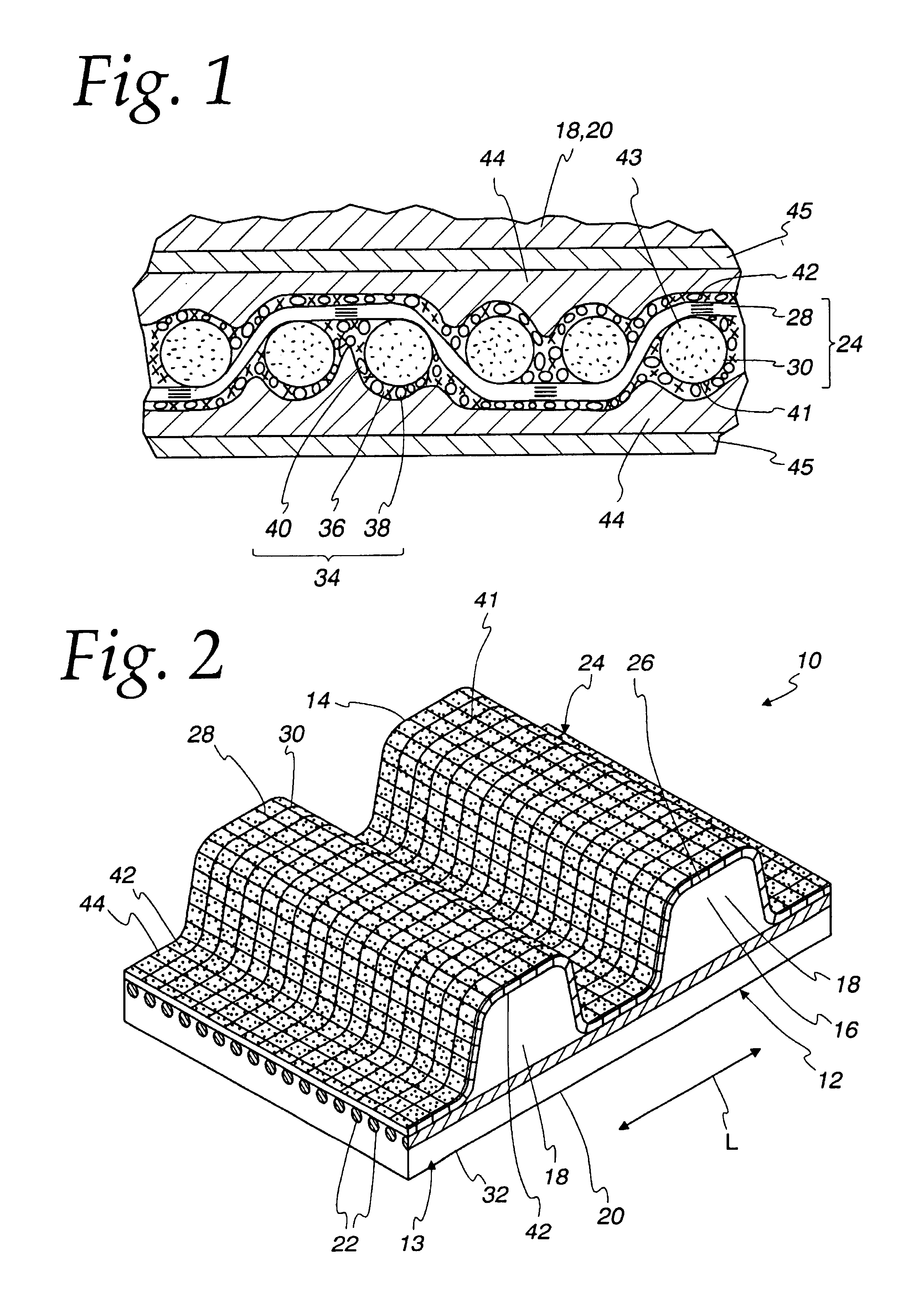

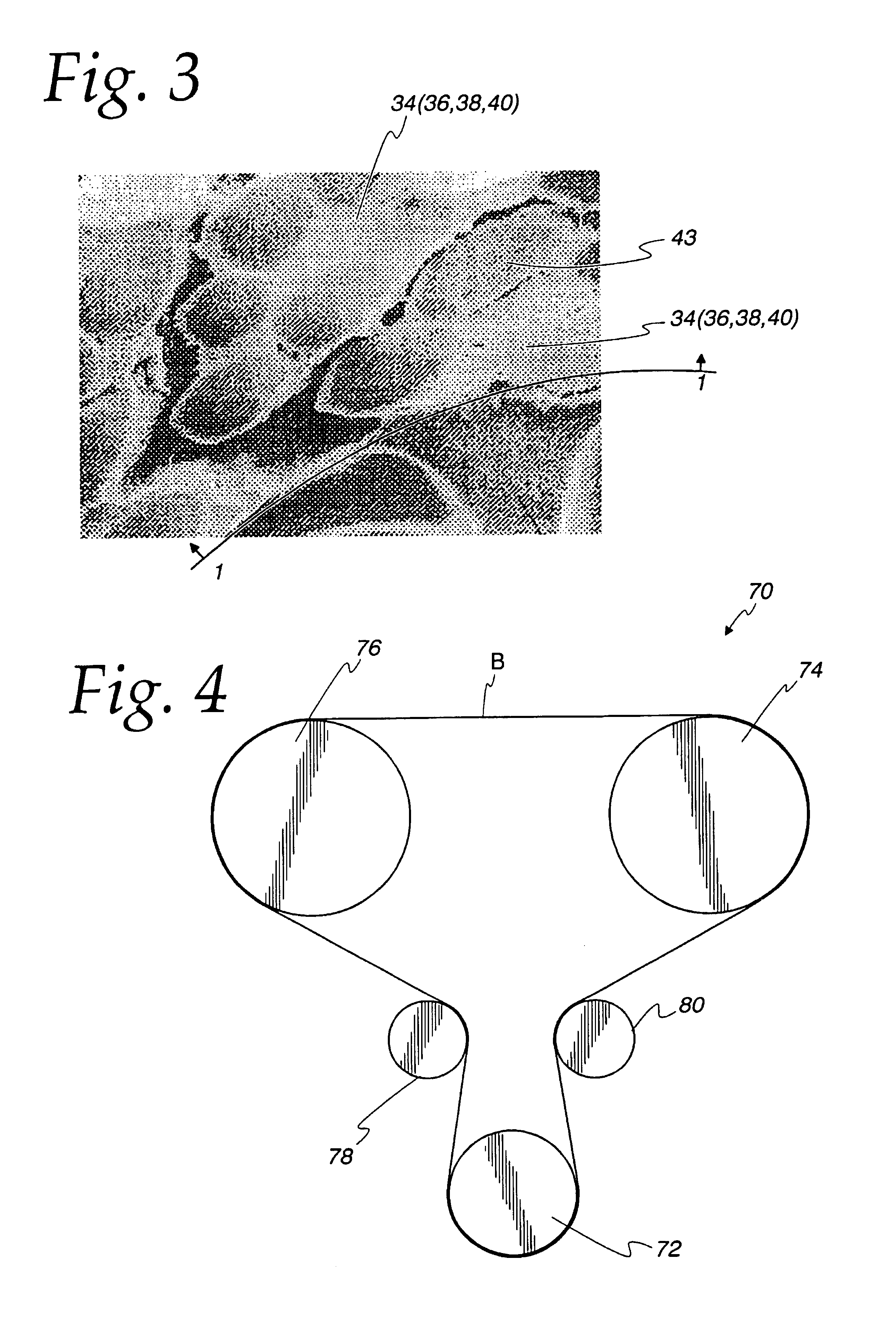

Power transmission belt and method of manufacturing the power transmission belt

A power transmission belt having a body defined by rubber and having an exposed outer surface, a fiber layer on at least a part of the exposed outer surface of the body, and a mixture including a resin adhesive ingredient, a rubber ingredient, and a lubricant that is a fluorine resin powder that is applied to the fiber layer.

Owner:MITSUBOSHI BELTING LTD

Synthesis and application of light-cured polyurethane-acrylic acid-epoxy resin adhesive

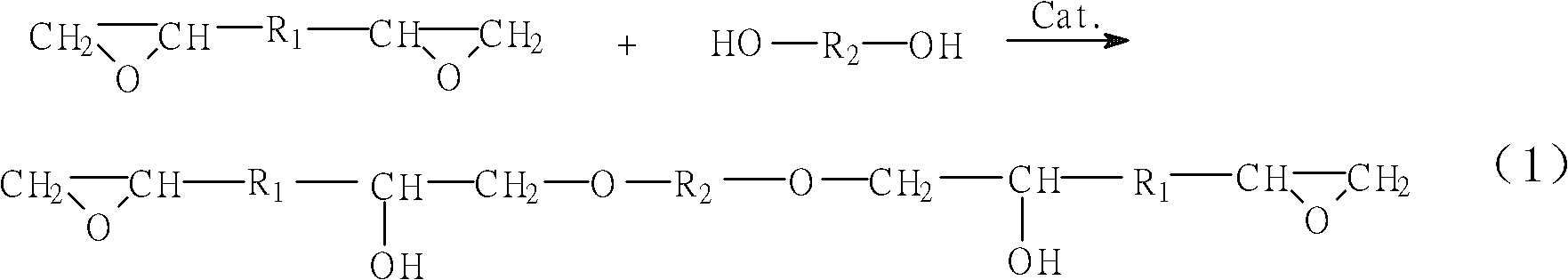

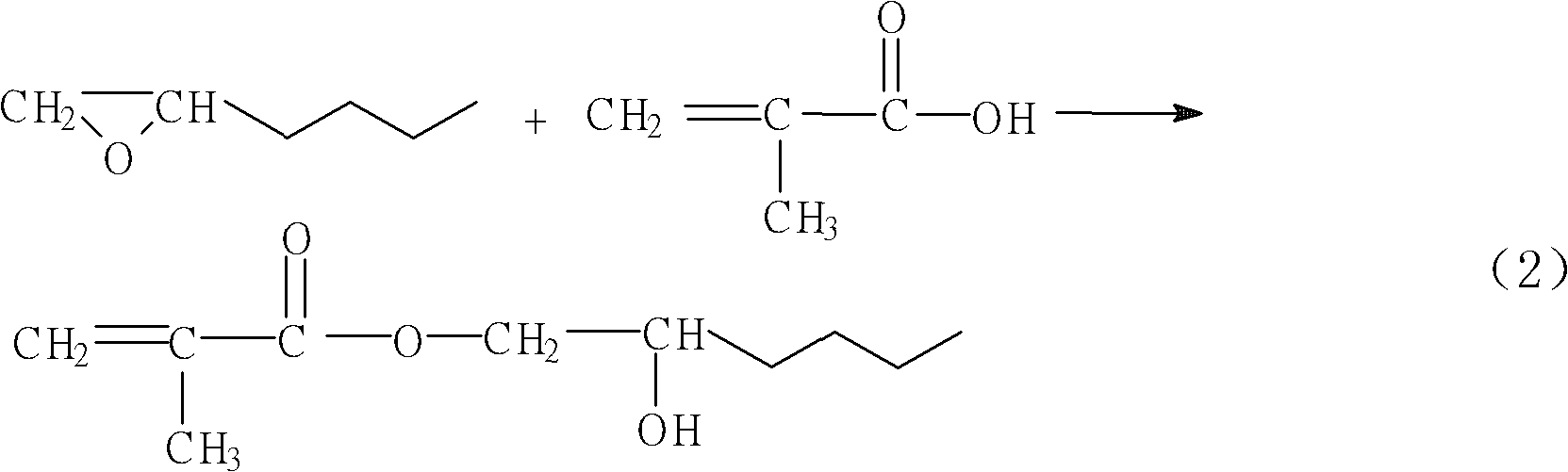

The invention relates to a novel polyurethane-acrylic acid-epoxy resin photosensitive pre-polymer, a synthesis method of the pre-polymer, a high-performance ultraviolet (UV) cured polyurethane modified acrylic acid epoxy resin adhesive prepared from the pre-polymer and application of the UV cured adhesive to bonding of a nylon membrane material and a polyurethane or modified polyurethane elastic body. A method for preparing the photosensitive pre-polymer comprises the following steps of: 1, synthesizing a lower-viscosity epoxy acrylic ester pre-polymer; 2, preparing a pre-polymer of urethane acrylate resin; and 3, mixing or reacting the two pre-polymers in a certain ratio so as to obtain the polyurethane-acrylic acid-epoxy resin photosensitive pre-polymer. A polyurethane-acrylic acid-epoxy resin UV cured adhesive is further prepared by adding a photoinitiator, a photosensitive diluent, a light curing crosslinking agent, other necessary aids and the like.

Owner:BEIHANG UNIV

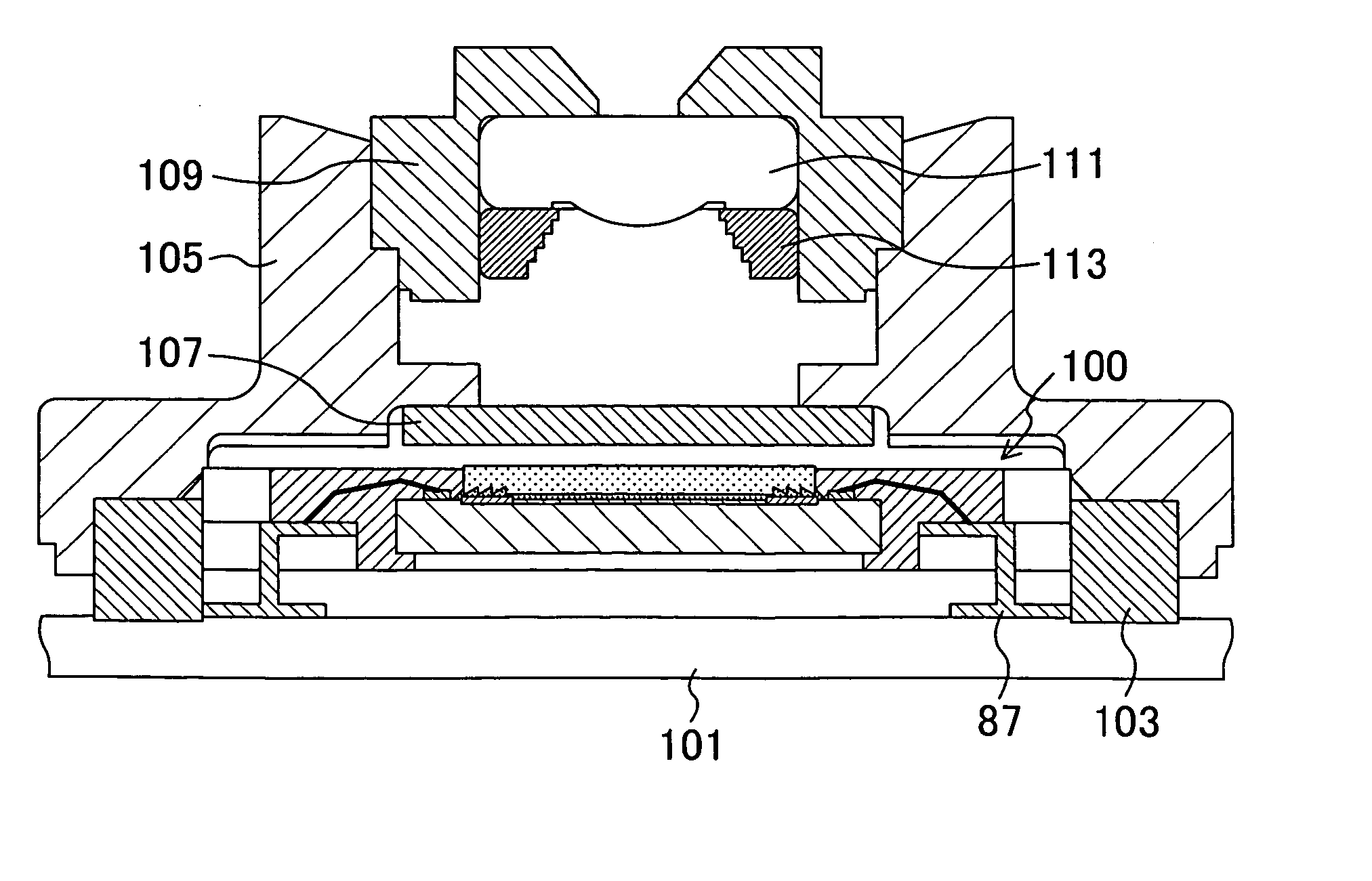

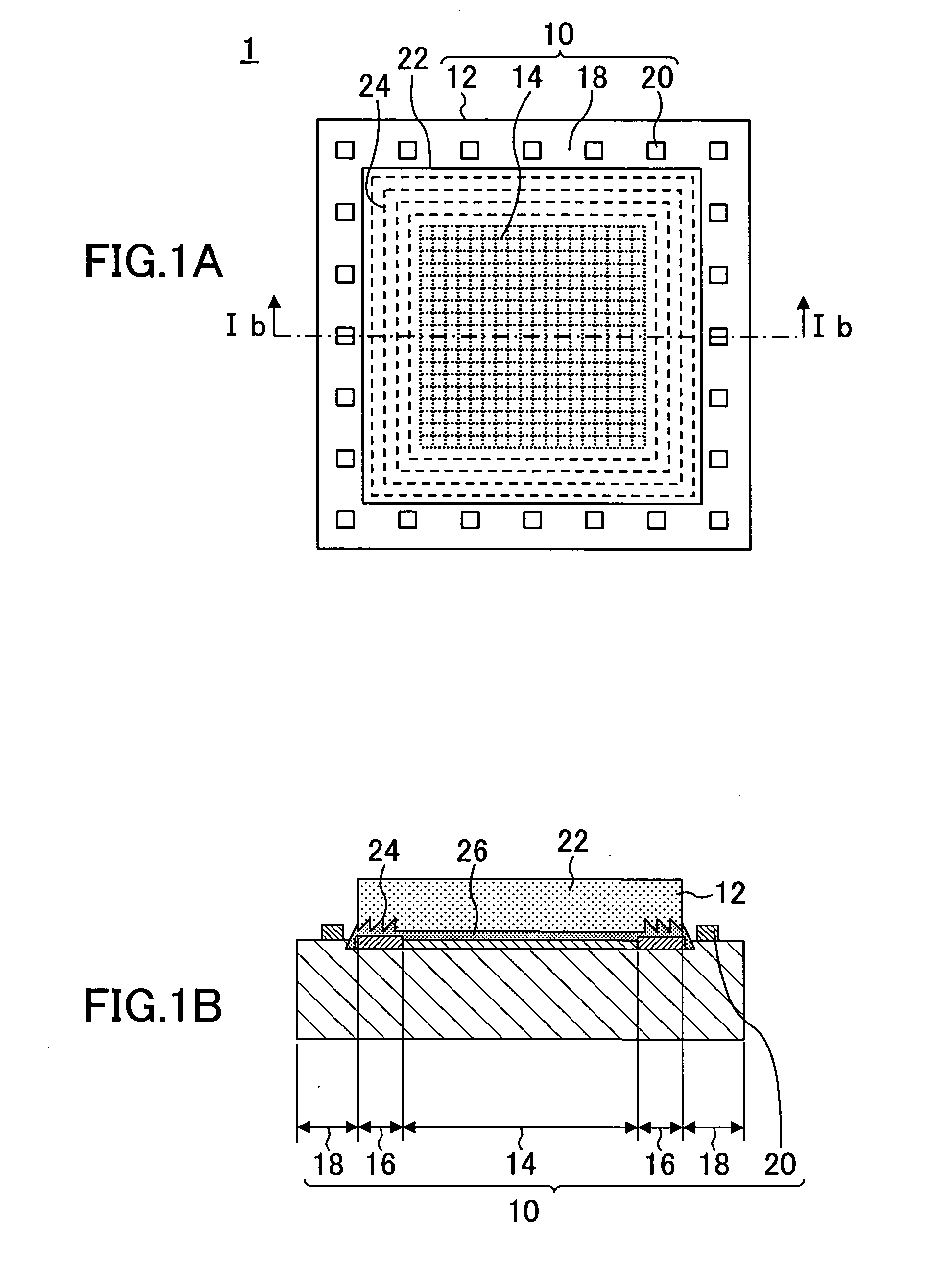

Optical device, optical device apparatus, camera module, and optical device manufacturing method

ActiveUS20070019101A1Reduce thicknessSmall sizeTelevision system detailsSolid-state devicesCamera moduleResin adhesive

An optical device includes an optical element, a transparent member arranged on the optical element, and a transparent resin adhesive for causing the transparent member to adhere and be fixed onto a circuit formation face of the optical element. The optical device includes a light detecting region having a plurality of micro lenses, a peripheral circuit region formed in the outer peripheral part of the light detecting region, and an electrode region formed at the outer peripheral part of the peripheral circuit region. A roughed region in a saw-toothed shape in section is formed in part of a face of the transparent member which adheres to the optical element, the part being overlapped with the outer peripheral part of the light detecting region as viewed in plan.

Owner:PANNOVA SEMIC

Wood composites bonded with protein-modified urea-formaldehyde resin adhesive

InactiveUS20050070635A1Aldehyde/ketone condensation polymer adhesivesResin adhesiveUrea-formaldehyde

An adhesive binder composition containing a urea-formaldehyde resin modified with a protein, preferably with a source of soy protein and the use of the binder for preparing wood composites, especially particleboard.

Owner:GEORGIA PACIFIC RESINS INC

Modified urea-formaldehyde resin adhesive and production method thereof

ActiveCN103450832AHigh viscosityViscosity increases relatively gentlyNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer sciencePhosphoric acid

The invention provides a modified urea-formaldehyde resin adhesive low in formaldehyde residue and a production method thereof. The modified urea-formaldehyde resin adhesive is characterized by being prepared from the following raw materials in parts by weight: 100 parts of modified urea-formaldehyde resin, 20-25 parts of reinforcing agent and 0.1-0.2 part of defoamer, wherein the reinforcing agent is any one or a composition of several of white carbon black, titanium dioxide, calcium carbonate and kaolin having the particle size greater than 300 meshes; the defoamer is polydimethylsiloxane or tributyl phosphate. The formaldehyde residue of the modified urea-formaldehyde resin adhesive provided by the invention is less than 0.1 mg / L; the modified urea-formaldehyde resin adhesive is used as an adhesive for an artificial board; as the modified urea-formaldehyde resin adhesive is low in release amount of formaldehyde, the health of customers is protected.

Owner:广西横州丽冠环保材料有限公司

Composite modification method for phenolic resin adhesive

ActiveCN102108275ASimple processEasy to controlAldehyde/ketone condensation polymer adhesivesPolymer scienceResin adhesive

The invention provides a composite modification method for a phenolic resin adhesive. A mixture of organic silicon and (or) a polyhydric compound serves as a modifier in a synthetic process of phenolic resin. The composite modification method is technically characterized in that: the modifier is added in a prepolymerization reaction process or after the prepolymerization reaction; formaldehyde is added at one time under an alkaline condition; dehydration is not performed in the later period of the reaction; the whole process flow is simple and is easy to operate; the product has stable performance and does not pollute environment; and the content of free formaldehyde is low.

Owner:江苏泰尔新材料股份有限公司 +1

Modified epoxy resin adhesive and preparation method thereof

ActiveCN101654605AGood flexibilityHigh peel strengthInsulating substrate metal adhesion improvementCarboxyl rubber adhesivesEpoxyPliability

The invention discloses a modified epoxy resin adhesive, which comprises the following components in portion by weight: 10 to 50 portions of epoxy resin, 20 to 80 portions of toughening agent, 0.2 to 5 portions of curing agent, 0 to 2 portions of curing accelerant, 0 to 1 portion of assistant, 2 to 15 portions of inorganic filler and 20 to 80 portions of solvent. In order to overcome the defects in the prior art, the invention provides the modified epoxy resin adhesive with strong flexibility, high peeling strength, good flexure property, good size stability, strong chemical corrosion resistance and excellent electric performance, and a method for producing the modified epoxy resin adhesive.

Owner:ZHONGSHAN DONGYI HIGH TECH MATERIAL

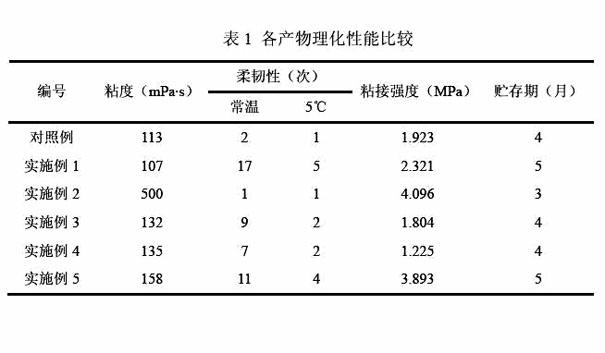

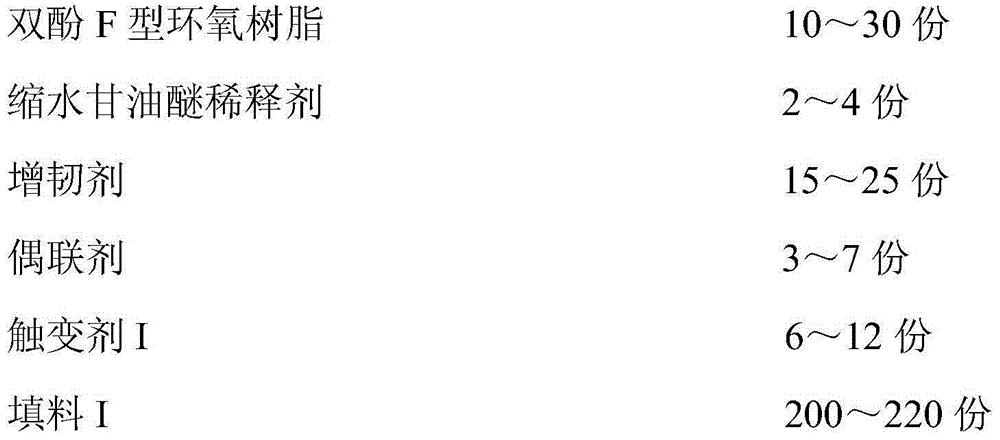

Double-component high-strength building epoxy structural adhesive and preparing method thereof

ActiveCN105062396AStir wellImprove toughnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberGlycidyl ethers

The invention provides double-component high-strength building epoxy structural adhesive and a preparing method thereof. The structural adhesive is mainly formed by mixing a component A and a component B at the weight ratio of 1.8-2.5:1. The component A is mainly composed of bisphenol A type epoxy resin, bisphenol F type epoxy resin, glycidyl ether diluent, a flexibilizer, a coupling agent, a thixotropic agent I and filler I. The component B is mainly composed of a complex-amine curing agent, an accelerator, hixotropic agent II and filler II. The epoxy structural adhesive is used for reinforcing construction of carbon fiber plates, and the carbon fiber plates are light in mass, convenient to bond in construction (the structural adhesive does not flow) and high in strength. Compared with a steel bonding construction method, the procedures of welding, polishing, pressurizing and the like are not needed in the method. The complex-amine curing agent is adopted in the developed component B, and the curing object is high in bonding strength, good in water resistance and good in toughness. The epoxy resin adhesive component A is free of crystallization, easy to smear and convenient to construct.

Owner:CARBON TECH CO LTD

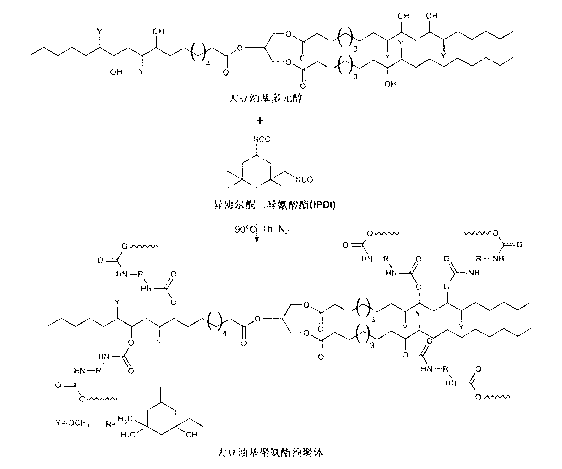

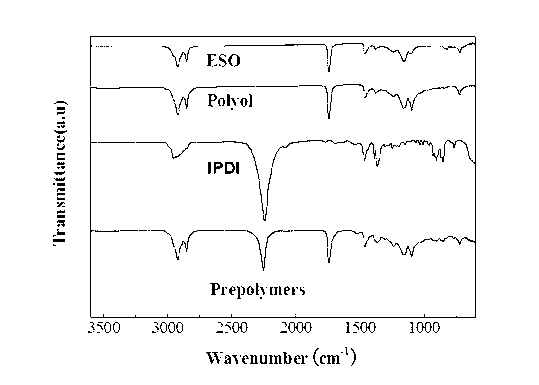

High-performance thermosetting epoxy resin adhesive for roads and bridges and preparation method thereof

InactiveCN103160234AIncreased durabilityFast curing reactionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyBridge deck

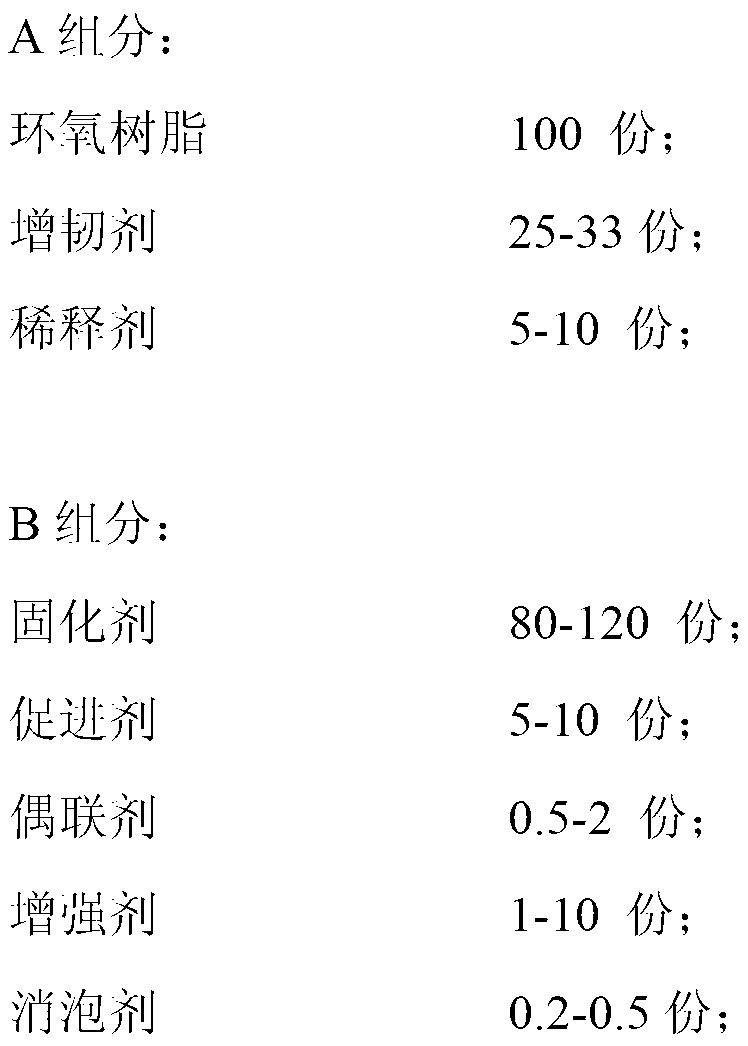

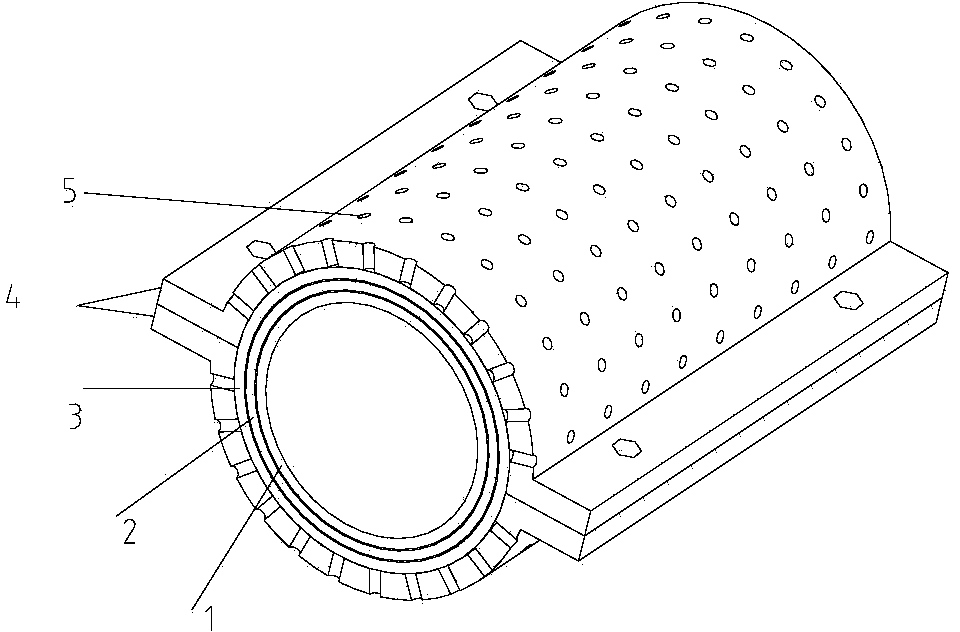

The invention provides a high-performance thermosetting epoxy resin adhesive for roads and bridges. The adhesive comprises a component A and a component B, wherein, the component A comprises the following components in parts by mass: 100 parts of epoxy resin, 25 to 33 parts of flexibilizer, and 5 to 10 parts of diluent; the component B comprises the following components in parts by mass: 80 to 120 parts of curing agent, 5 to 10 parts of accelerant, 0.5 to 2 parts of coupling agent, 1 to 10 parts of reinforcing agent, and 0.2 to 0.5 part of antifoaming agent; and the ratio of the component A to the component B is 100:100-100:120. According to the adhesive, a flexible long-chain aliphatic amine serving as the curing agent has a curing reaction with the epoxy resin to form a solid crosslinking structure, so that the epoxy resin adhesive is high in adhesion capability and water resistance; The toughness of the epoxy asphalt adhesive is improved by adopting the soybean oil-based polyurethane to be adapted to the flexibility of a steel plate, and the soybean oil-based polyurethane containing massive hydroxyl has good compatibility with the epoxy resin. The adhesive is applicable to adhesion and waterproofing of steel bridge decks, viaducts, cement concrete bridge decks, tunnels, expressways and other decks. The invention discloses a preparation method of the high-performance thermosetting epoxy resin adhesive.

Owner:NANJING UNIV

Uv-curable optical resin adhesive composition

InactiveUS20120115976A1Increased durabilityImprove reliabilityEster polymer adhesivesOrganic non-macromolecular adhesiveMeth-Side chain

A UV-curable optical resin adhesive composition is provided, which is excellent in transparency, adhesive reliability and durability and suitable for rework (repair) without an adverse influence on the brightness, the contrast and the Quality of a display image. The UV-curable optical resin adhesive composition is used for filling a gap between an image display panel and a protective cover plate, and comprises: (A) an acryl polymer having a (meth)acryloyl group at its side chain; and (B) a photopolymerization initiator.

Owner:NITTO DENKO CORP

Method for preparing post-crosslinking modified urea-formaldehyde resin adhesive

The invention relates to a preparation method for post-crosslinking modified urea-formaldehyde resin, which is characterized in that under low molar ratio of formaldehyde / carbamide, a cross linker is added in the addition stage or the condensation stage. The method of the invention guarantees the excellent bonding strength of the resin under low free formaldehyde content and low formaldehyde release amount. By detecting, the modified urea-formaldehyde resin prepared by the invention has less than 0.1 percent of free formaldehyde content, less than 1mg / L of formaldehyde release amount of plywood and larger than 2.8MPa of bonding strength and the comprehensive performance is obviously better than the existing urea-formaldehyde resin adhesive.

Owner:BEIJING UNIV OF CHEM TECH

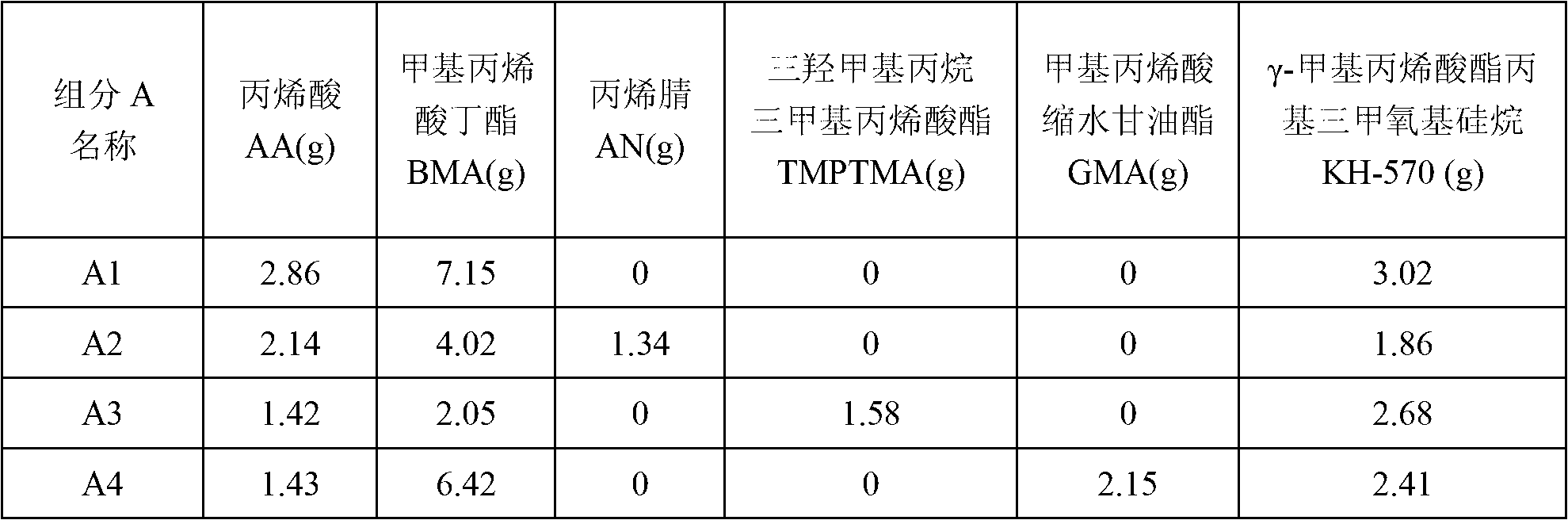

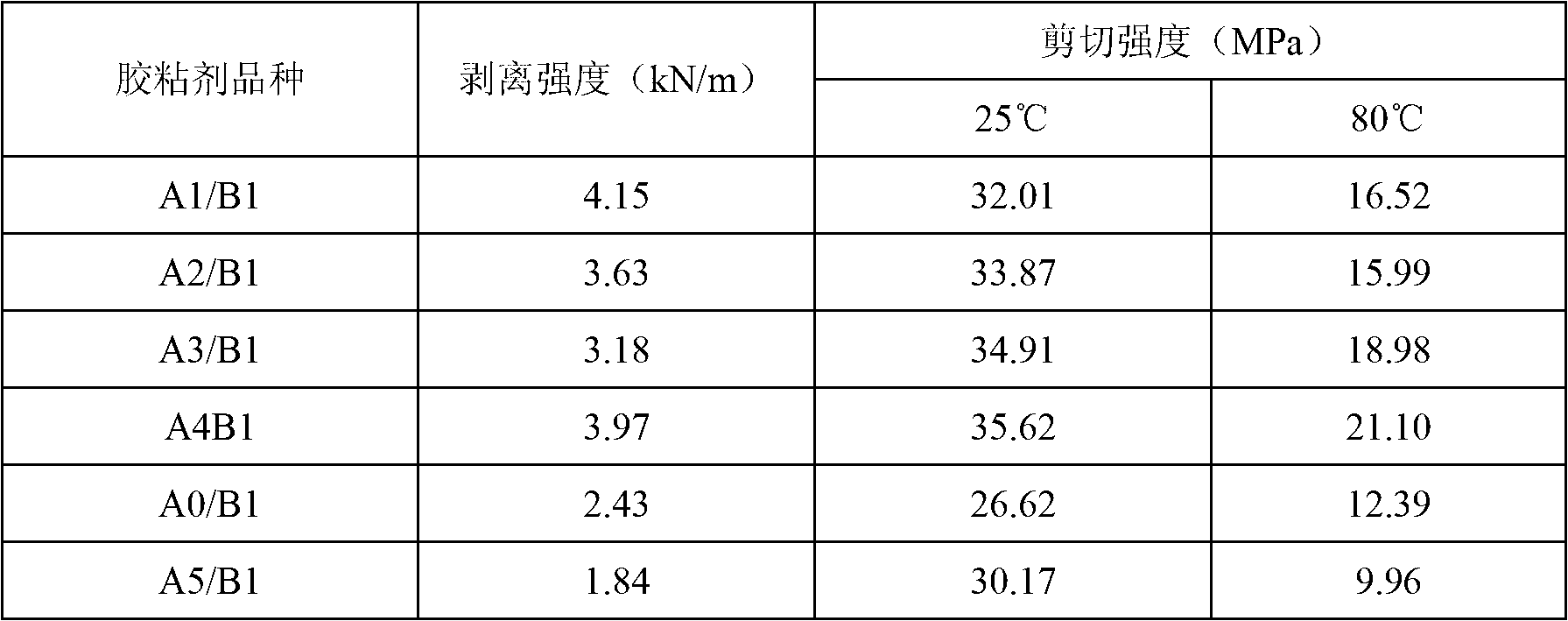

Preparation method of nano silicon dioxide/polyacrylate modified epoxy resin adhesive

InactiveCN102703009AHigh peel strengthGood adhesionNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyNanoparticle

The invention relates to a preparation method of an epoxy resin adhesive, particularly a preparation method of a nano silicon dioxide / polyacrylate modified epoxy resin adhesive. The invention solves the problems of unsatisfactory high-temperature properties and peel strength in the existing nano silicon dioxide modified epoxy resin adhesive. The method comprises the following steps: 1. preparing polyacrylate-modified nano silicon dioxide compound particles; 2. preparing the nano silicon dioxide / polyacrylate modified epoxy resin; and 3. preparing the nano silicon dioxide / polyacrylate modified epoxy resin adhesive. The invention has the characteristics of smaller addition amount of modified nanoparticles, obvious toughening effect and high high-temperature strength; and the peel strength and the shear strength of the nano silicon dioxide / polyacrylate modified epoxy resin adhesive are obviously enhanced.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

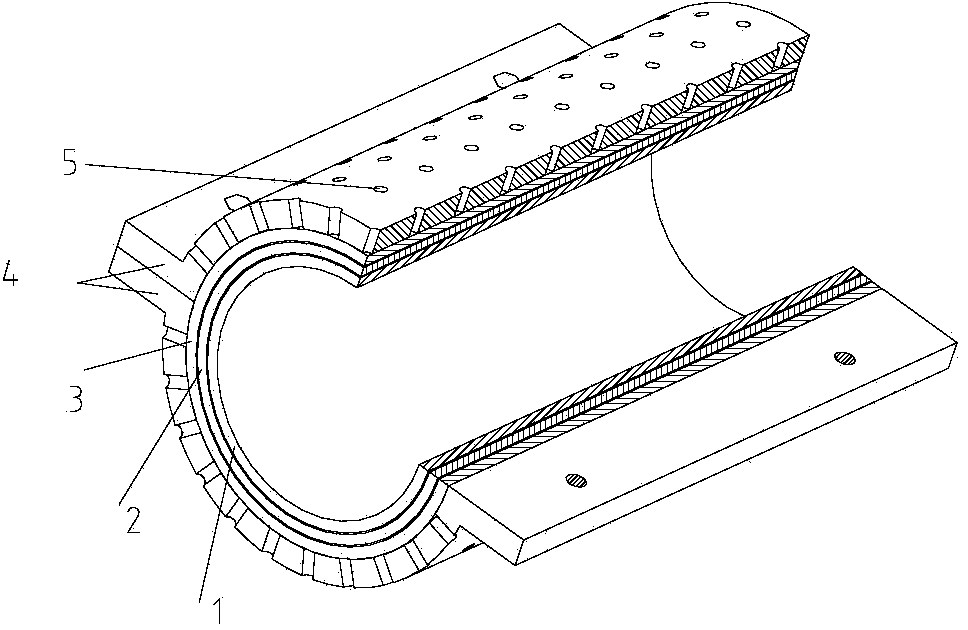

Method for forming composite material pipe mold element by pressurizing air bags with assistance of resin film transfer

InactiveCN104070687AGet rid of usingReduce manufacturing costTubular articlesManufacturing cost reductionManufacturing technology

The invention belongs to the technical field of manufacture engineering, relates to a manufacture technology method of a high-performance composite material pipe mold element, and particularly relates to a method for forming a composite material pipe mold element by pressurizing air bags with assistance of resin film transfer. According to the invention, a dry state fiber fabric and a thermoset resin adhesive film act as a base of a material, so that the method has the multiple advantages of reducing the manufacture cost obviously, improving the production efficiency effectively, expanding the application range of the manufacture technology extremely and the like. Compared with the traditional prepreg-autoclave technology, the fiber / adhesive film pre-dipping process is saved, so that on one hand, the using of a pre-dipping machine is prevented, and the cost of production equipment is reduced obviously, and on the other hand, the reduction of manufacture links improves the production efficiency effectively; additionally, most importantly, as for manufacture of pipe mold elements with the dry state fiber structure incapable of being treated by the pre-dipping mode, such as fiber 2.5D / 3D braided structure, the technology provided by the invention can also be used, and the technology application range is expanded extremely.

Owner:AVIC COMPOSITES

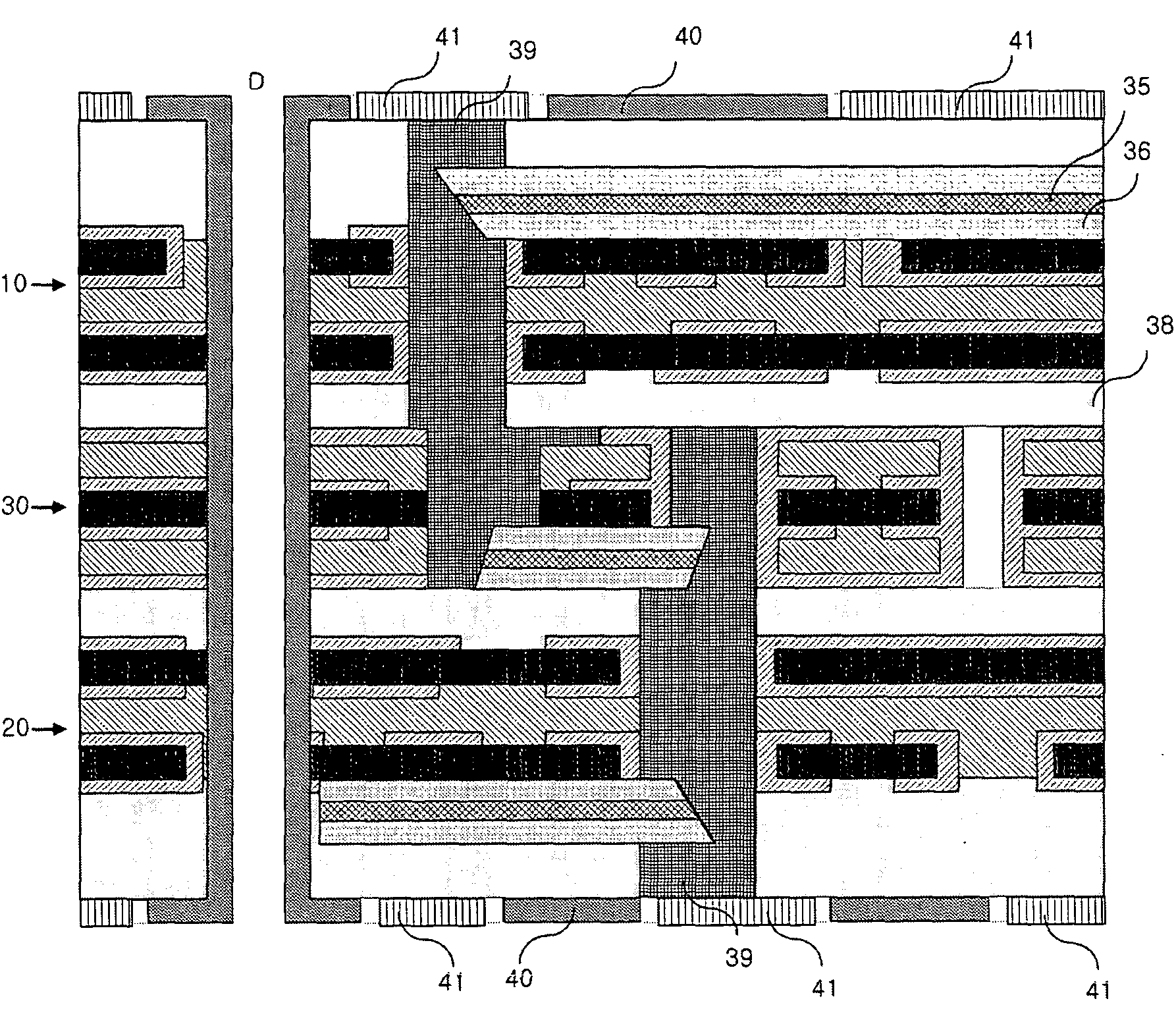

Printed circuit board with opto-via holes and process of forming the opto-via holes

InactiveUS6996305B2Minimize damageThe transmission signal is stableInsulating substrate metal adhesion improvementCircuit optical detailsEngineeringCopper

Disclosed is a printed circuit board with opto-via holes for transmitting an optical signal to an optical waveguide in the PCB, and a process of forming the opto-via holes. The process comprises forming a plurality of via holes on a plurality of copper clad laminates using a drill, plating an inner wall of each via hole, exposing and etching the plated portions of an upper and lower side of each copper clad laminate to form a circuit pattern on the upper and lower side of the copper clad laminate, layering the patterned copper clad laminates on each other using an insulating resin adhesive, and removing the insulating resin adhesive in the predetermined via holes to form opto-via holes. Therefore, the process is advantageous in that the optical signal is stably transmitted to the optical waveguide in the PCB without damage to the optical waveguide directly exposed to an external environment, and the optical waveguide suitable to physical properties of the material constituting the PCB is easily inserted between the inner layer and the outer layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com