Method for forming composite material pipe mold element by pressurizing air bags with assistance of resin film transfer

A composite material and resin film technology, which is applied in the field of manufacturing engineering, can solve the problems of rare reports of tubular composite material parts and the difficulty of getting rid of the difficulty in demoulding tubular male mold tooling, and achieves the expansion of the scope of application of the process, product quality and manufacturing process. The effect of optimizing and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

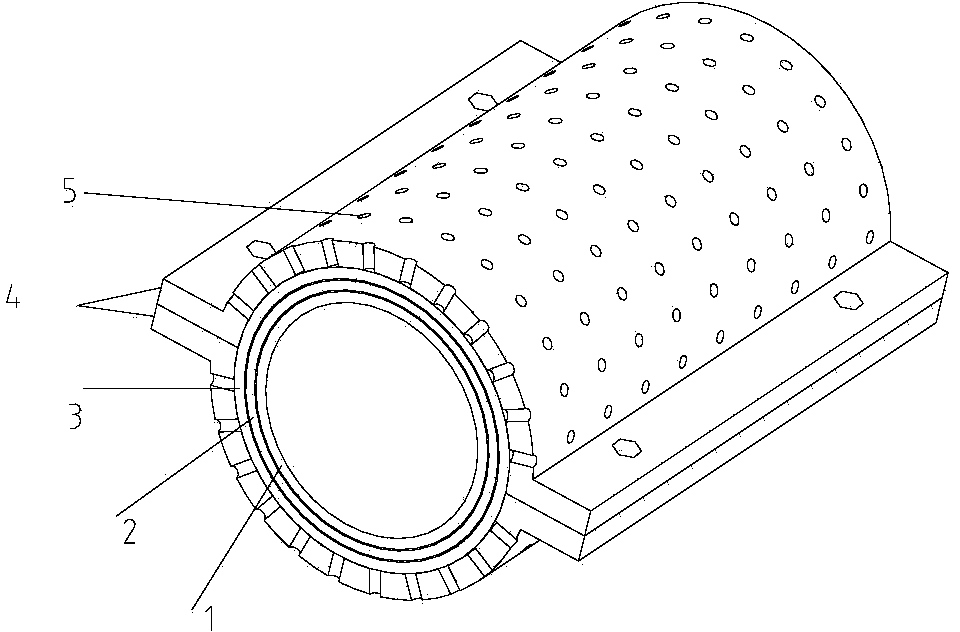

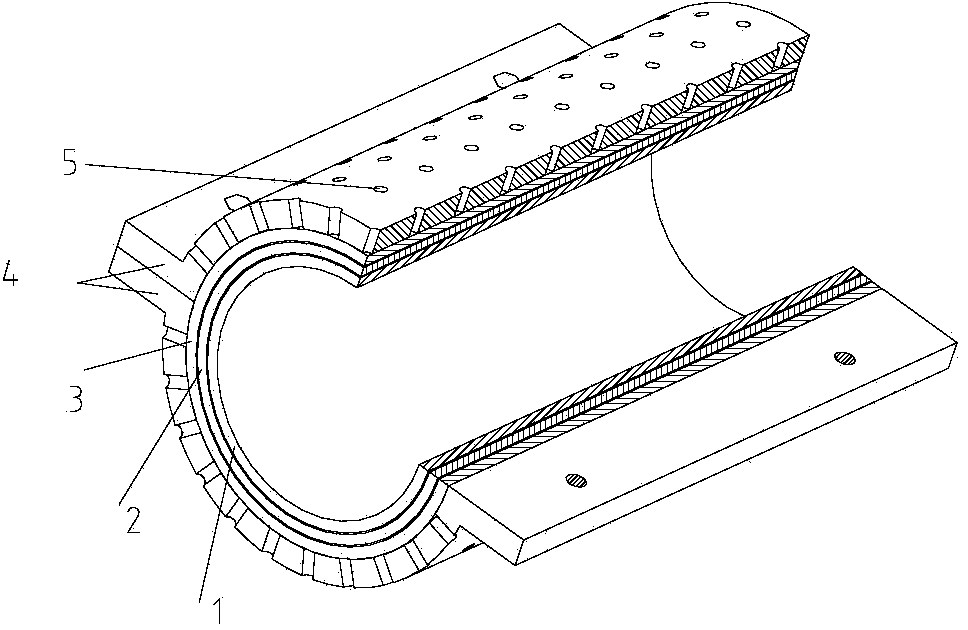

[0024]In the manufacture of a straight carbon fiber circular tube with a diameter of Φ50mm, a wall thickness of 2.0mm, and a length of 600mm, the steel combined female mold is composed of an upper and lower mold, and the diameter of the uniformly distributed pores is Φ0.5mm, and the spacing is 5mm; The inner core soft mold is made of rubber material, with a wall thickness of about 1.5mm and a diameter of Φ40mm; the adhesive film adopts a medium-temperature 125°C curing epoxy resin system, and the surface density of the adhesive film is 100g / m 2 ;The reinforcing fiber is plain weave cloth woven with 3K carbon fiber, and the surface density of the carbon fiber cloth is 193g / m 2 , according to the direction of ± 45 ° sewing into about Φ42mm or so carbon fiber sleeve.

[0025] During operation, the soft mold of the inner core of the airbag is filled with a certain air pressure to a diameter of about Φ42mm, covered with 15 layers of epoxy resin film, and then covered with 10 layers...

Embodiment 2

[0028] In the manufacture of a linear carbon fiber oval tube with a diameter of Φ65mm, a wall thickness of 1.5mm, and a length of 1500mm, the steel shape mold is composed of an upper and lower mold, and the diameter of the uniformly distributed pores is Φ3mm, and the spacing is 50mm; the inner core of the airbag is soft The mold is made of rubber material, the wall thickness is about 3mm, and the diameter is Φ60mm; the adhesive film adopts a high temperature 180°C curing epoxy resin system, and the surface density of the adhesive film is 75g / m 2 ; The reinforced fiber is U3160 unidirectional T300 carbon fiber fabric, and the surface density of the carbon fiber cloth is 160g / m 2 .

[0029] During operation, the inner core soft mold is filled with a certain air pressure to a diameter of about Φ63mm, covered with 9 layers of epoxy resin film, and then covered with 9 layers of carbon fiber sleeves on the film. After the paving is completed, it is moved to the shape mold, and then...

Embodiment 3

[0031] In the manufacture of an "S"-shaped carbon fiber oval tube with a diameter of Φ150mm, a wall thickness of 2.5mm, and a length of 1500mm, the steel shape mold is composed of three 1 / 3 modules, and the diameter of the uniformly distributed pores is Φ1.0mm , the spacing is 30mm; the inner core soft mold is made of silicon-containing heat-resistant rubber material, the wall thickness is about 3.0mm, and the diameter is Φ135mm; the adhesive film is made of low-temperature 100℃ polyurethane resin system, and the surface density of the adhesive film is 350g / m 2 ;The reinforced fiber is made of 6K carbon fiber braided pipe sleeve, which is woven by industrialized machines. The fiber weaving is mainly in the direction of 0° / 90°.

[0032] During operation, add a self-made oblong rod-shaped inflatable airbag rod in the inner cavity of the airbag inner core soft mold, inflate it until the diameter of the airbag inner soft mold is about Φ140mm, and cover with 6 layers of modified bis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com