Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10411 results about "Rubber material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

NR, or Natural Rubber sometimes called “india rubber” is a visco-elastic material consisting of a natural organic compound called polyisopreme as well as, others organic compounds including water. This material is an elastic polymer or elastomer derived from natural latex from certain plants and trees.

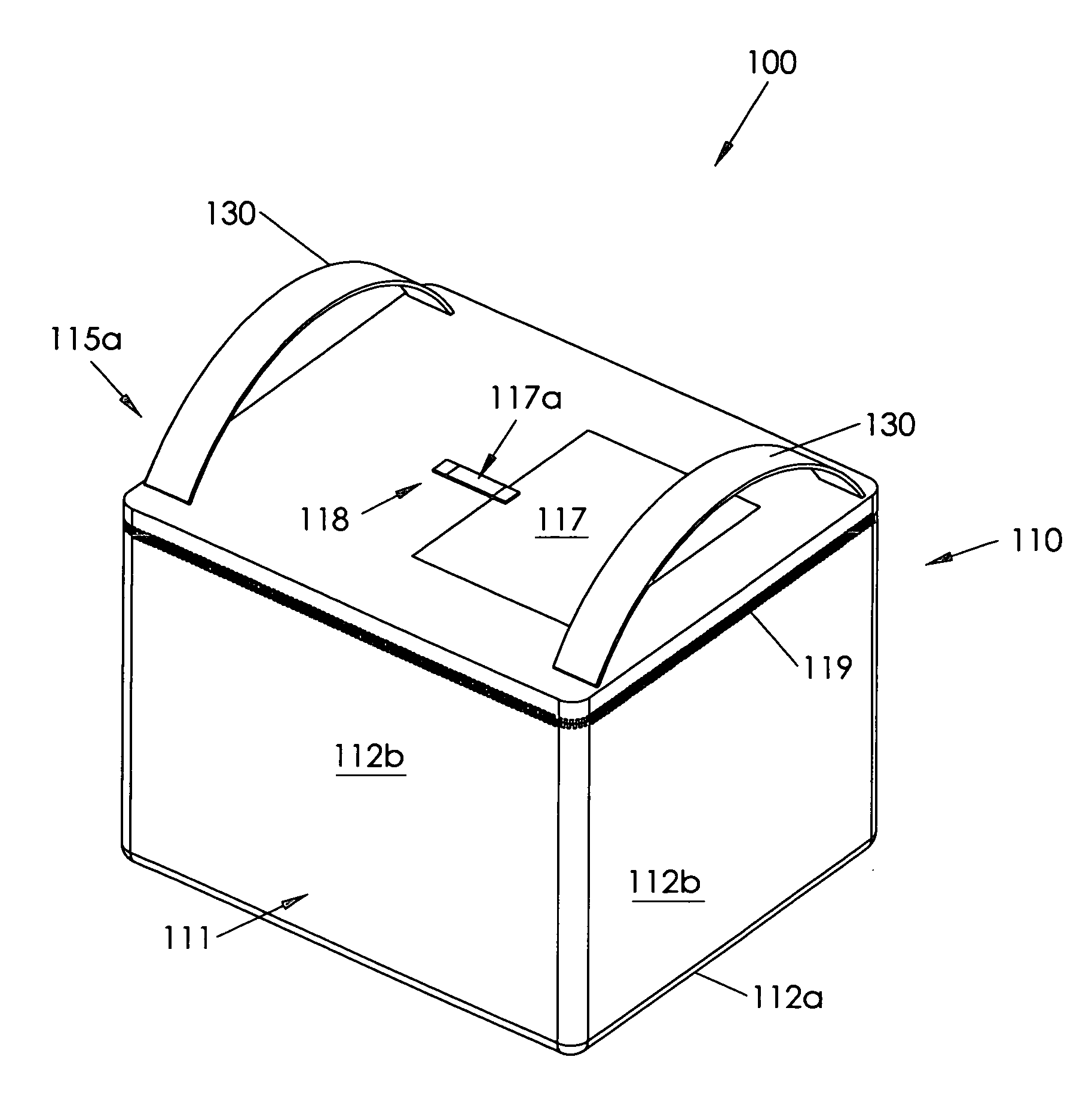

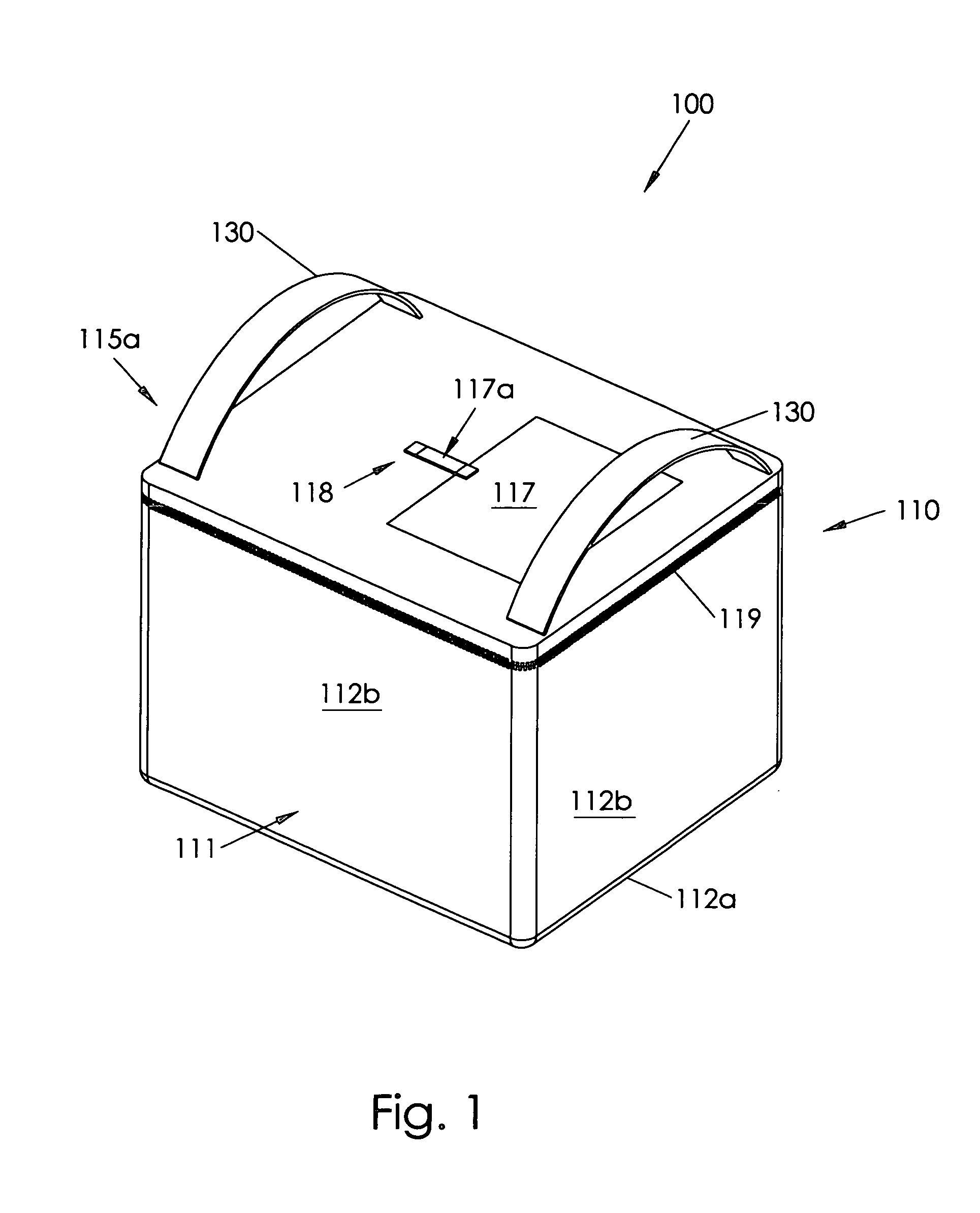

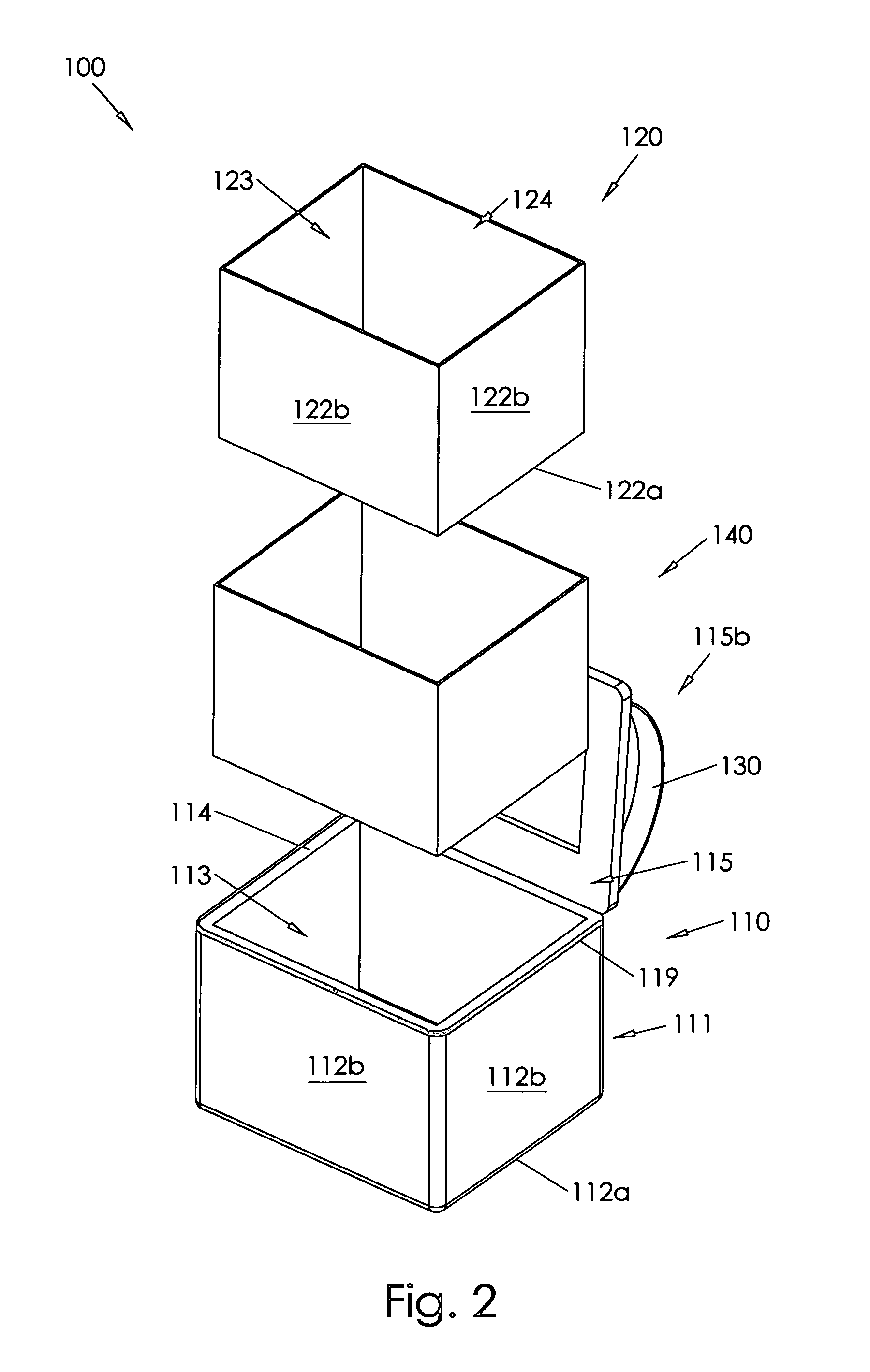

Insulating container

InactiveUS7677406B2Easy constructionEasy accessDomestic cooling apparatusClosuresRubber materialAuxiliary memory

Owner:MAXSON FLOYD S

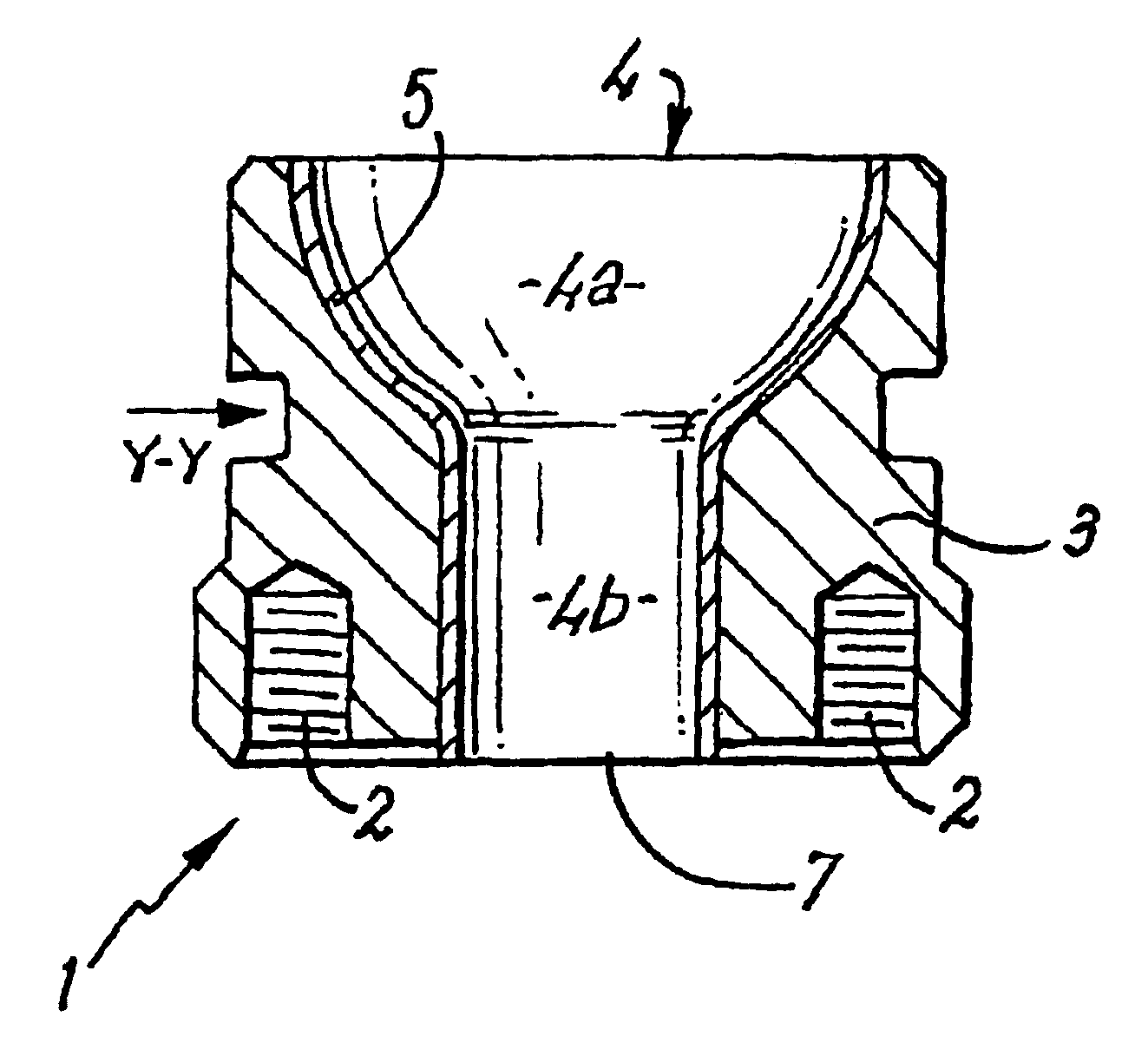

Drillable drill bit nozzle

InactiveUS6848517B2Thin structureImprove corrosion resistanceDrill bitsDrilling rodsHigh resistanceRubber material

A drill bit nozzle providing a through bore for the passage of drilling fluid through a drill bit. The nozzle is made of a material or materials which can be drilled through by standard well bore drilling equipment. The material(s) are selected to provide a surface to the through bore which has a relatively high resistance to erosion to withstand the abrasive and corrosive impact of jetted drilling fluid. Embodiments are described using a hard chrome / copper combination and a single rubber material.

Owner:WEATHERFORD TECH HLDG LLC

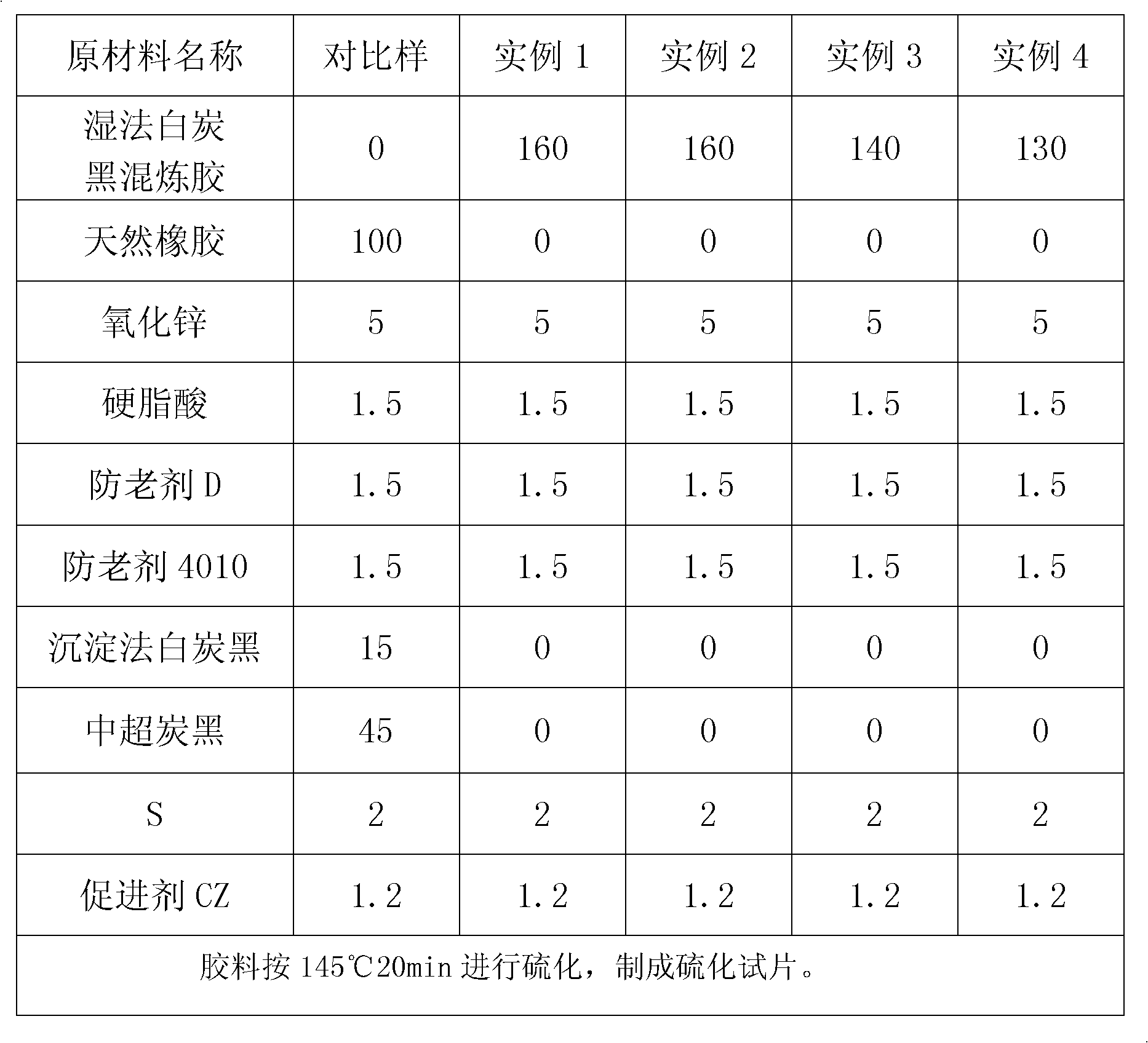

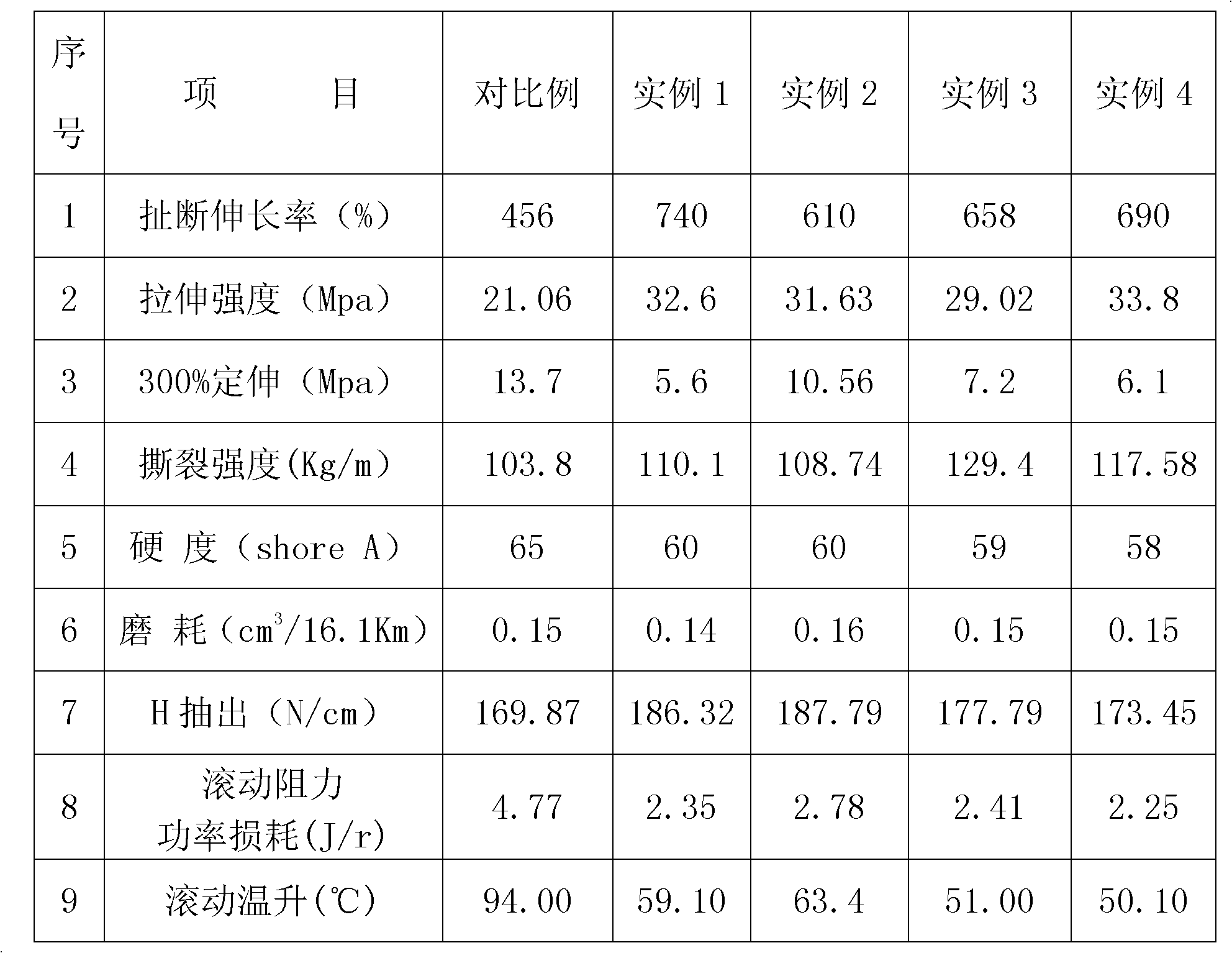

Preparation method of wet process mixed natural rubber material

ActiveCN102153792AGood dispersionImprove uniformityRolling resistance optimizationRubber materialPolymer science

The invention relates to a preparation method of a wet process mixed natural rubber material. The method comprises the following steps of: preparing slurry and soaking 15-40 percent of dry white carbon black in 60-85 percent of deionized water; adding a coupling agent and a surfactant, uniformly mixing, grinding, preparing latex mixed liquor, extracting natural latex and adding white carbon black water dispersoid into the latex; stirring and mixing to obtain a latex mixed liquor, flocculating and adding acetic acid into the mixed liquor; performing rubber washing and dehydration by using a rubber washing machine and feeding to a rubber pelletizer for pelletizing; and feeding rubber particles into a box drying cabinet for drying. The preparation method has the advantages of simple machining process, small equipment investment, realization of various ideal performances with the most ordinary white carbon black, low dust pollution in the entire production process and energy saving. A tire manufactured with the method has small rolling resistance, low heat generation, high tensile strength, high tearing strength and high rubber material ageing resistance. Mixing of the white carbon black is performed in a liquid phase, so that the dispersivity and uniformity are enhanced.

Owner:ZHUZHOU ANBAOLINFENG NEW MATERIALS

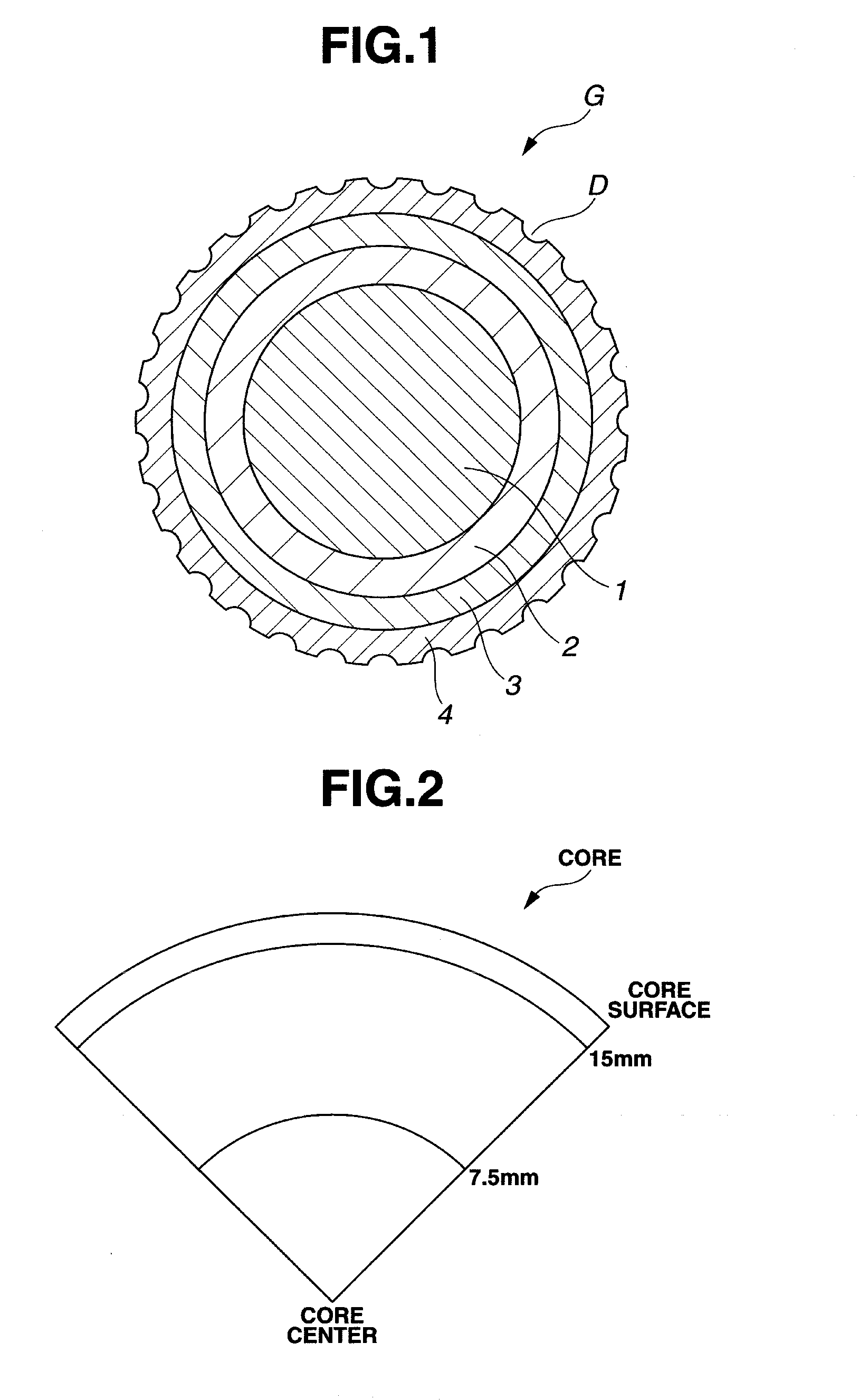

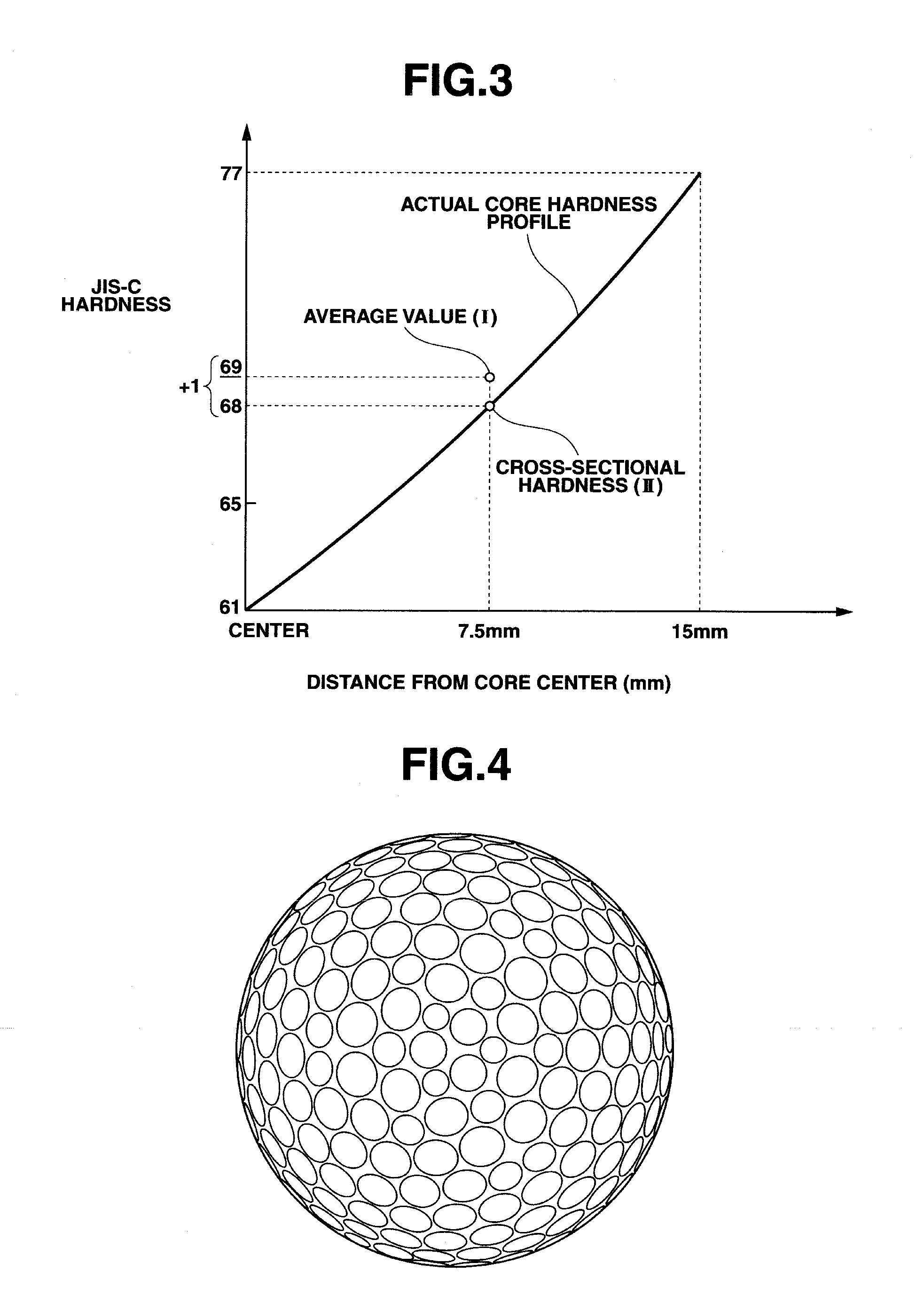

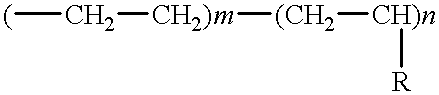

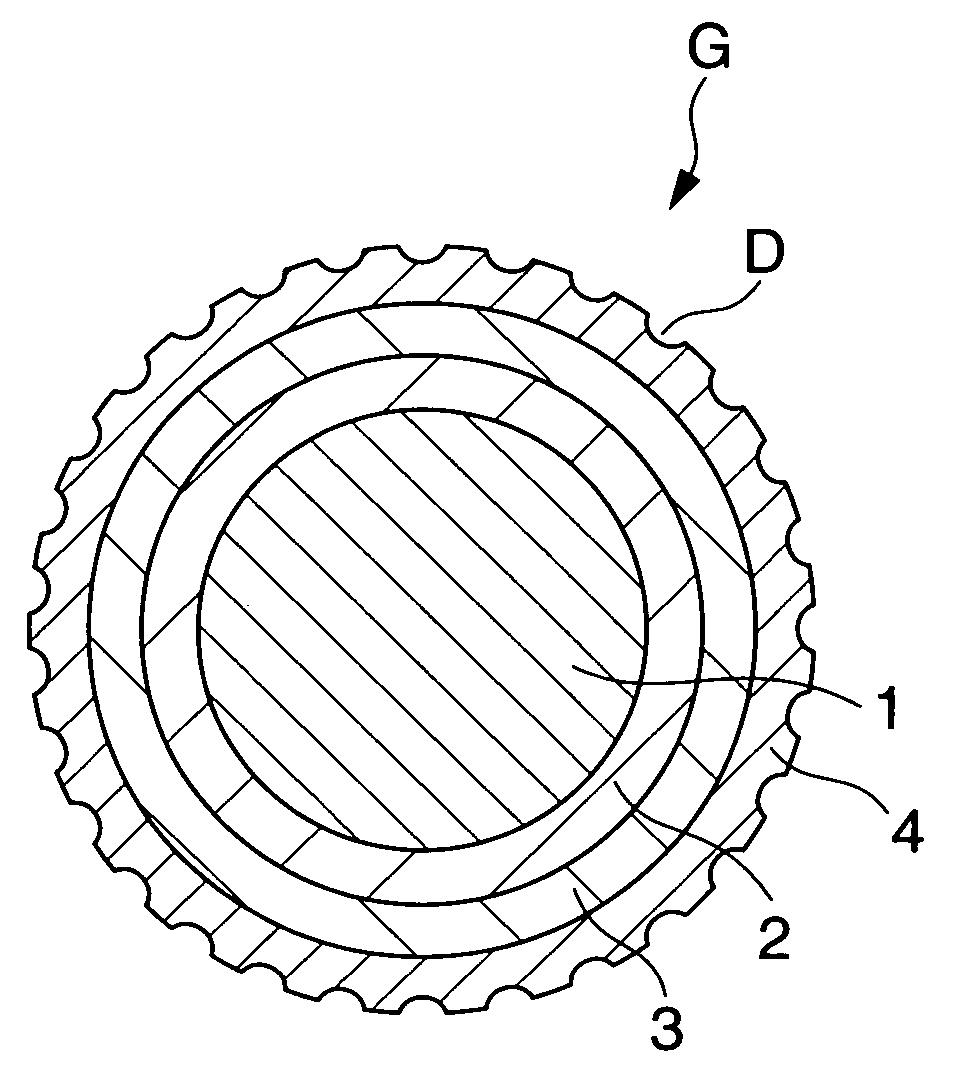

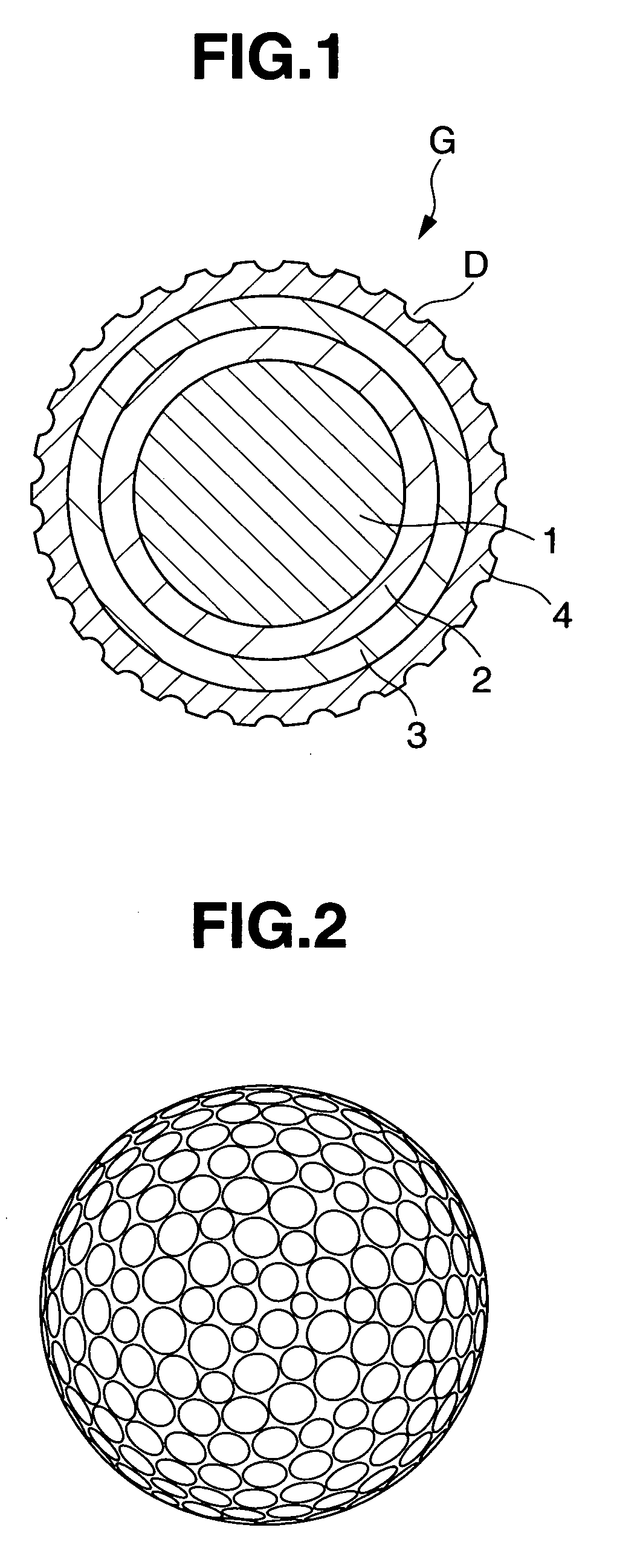

Multi-piece solid golf ball

ActiveUS20100273575A1Reduce speedImprove wear resistanceGolf ballsSolid ballsRubber materialInter layer

The present invention provides a multi-piece solid golf ball having a core, an envelope layer encasing the core, an intermediate layer encasing the envelope layer, and a cover which encases the intermediate layer and has formed on a surface thereof a plurality of dimples. The core is formed primarily of a rubber material and has a hardness which gradually increases from a center to a surface thereof, the hardness difference in JIS-C hardness units between the core center and the core surface being at least 15 and, letting (I) be the average value for cross-sectional hardnesses at a position about 15 mm from the core center and at the core center and letting (II) be the cross-sectional hardness at a position about 7.5 mm from the core center, the hardness difference (I)−(II) in JIS-C units being not more than ±2. The envelope layer, intermediate layer and cover have hardnesses which satisfy the condition:cover hardness>intermediate layer hardness>envelope layer hardness.The golf ball of the invention has an improved distance, and also has an excellent durability to cracking on repeated impact and an excellent scuff resistance.

Owner:BRIDGESTONE SPORTS

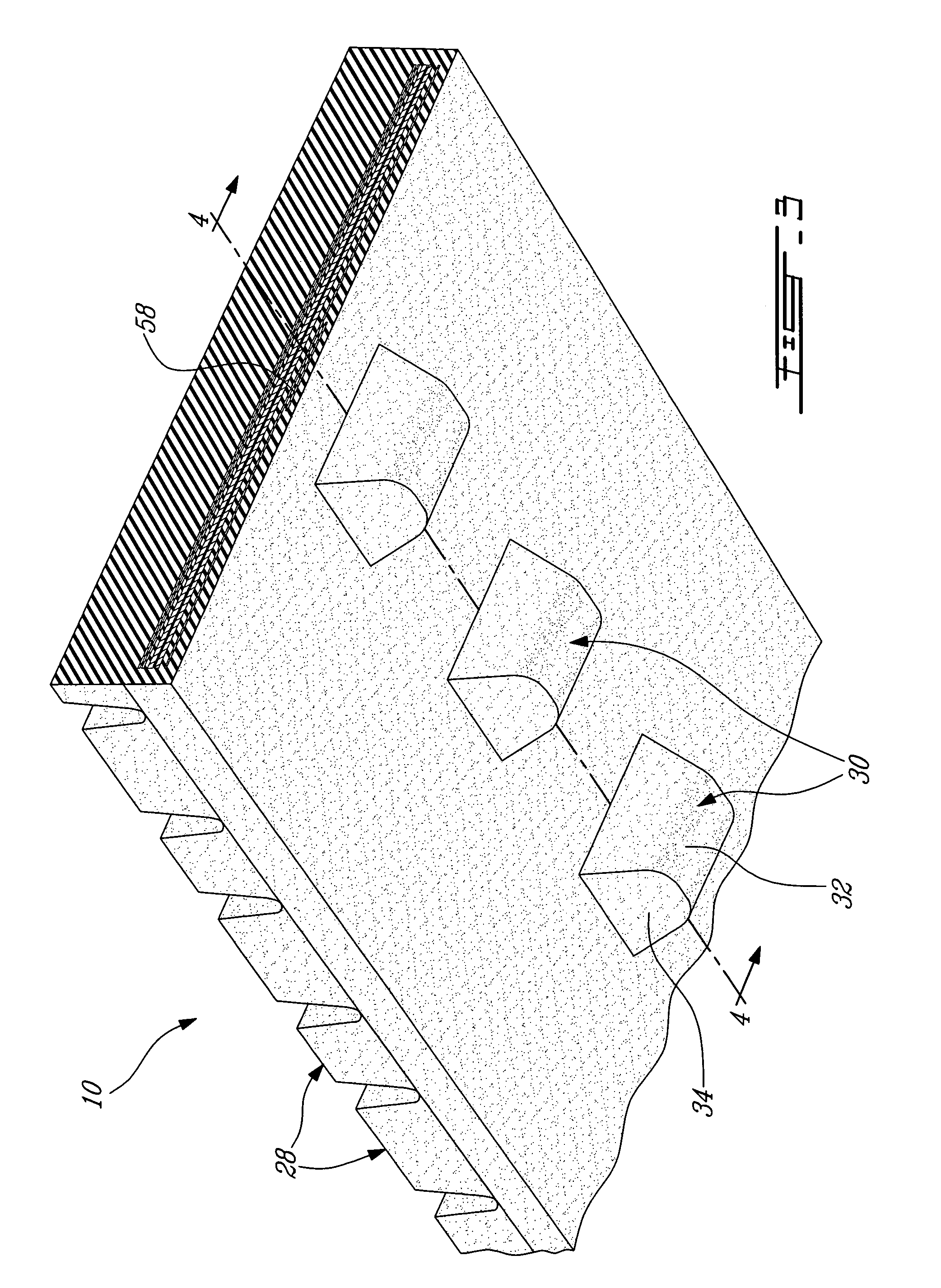

Products useful as roof shingles and a process for making such products

InactiveUS6194519B1ExpensePromote degradationRoof covering using tiles/slatesOther chemical processesElastomerRubber material

The present invention relates to low-cost, efficiently-manufactured, polymer-based products useful as roofing shingles and similar products. The inventive shingles are weatherproof, inexpensive to manufacture and durable, particularly as contrasted with conventional shingles in areas of the country subject to hail damage. The invention also includes a method of making such shingle products. In a preferred embodiment, products of this invention use rubber material as the polymer base in combination with specific types of polyolefins. The rubber material can be most efficiently provided by the use of crumb rubber particles from spent automobile tires and other recycled rubber debris which are readily available and of very low cost. The products will have an average life far greater than that of current commercial roofing shingles, which are made using fiberglass or asphalt.The products of the instant invention are produced by extrusion as a mixture of materials, which product and its materials can be summarized as follows as a roofing shingle product which comprises:a. one or more side-branched polyolefins as an elastomer;b. optionally a blend of additional synthetic polymers, such as ethylene and propylene, as a second elastomer; andc. a rubber fraction, preferably obtained in part from recycled spent automotive or truck tires, and similar sources of waste rubber (sometimes known as "crumb rubber"), ground or recycled into particles having a mesh size of from 10 to 30 (i.e., approximately from about 500 to about 1000 microns).

Owner:MONTY MCWILLIAMS +3

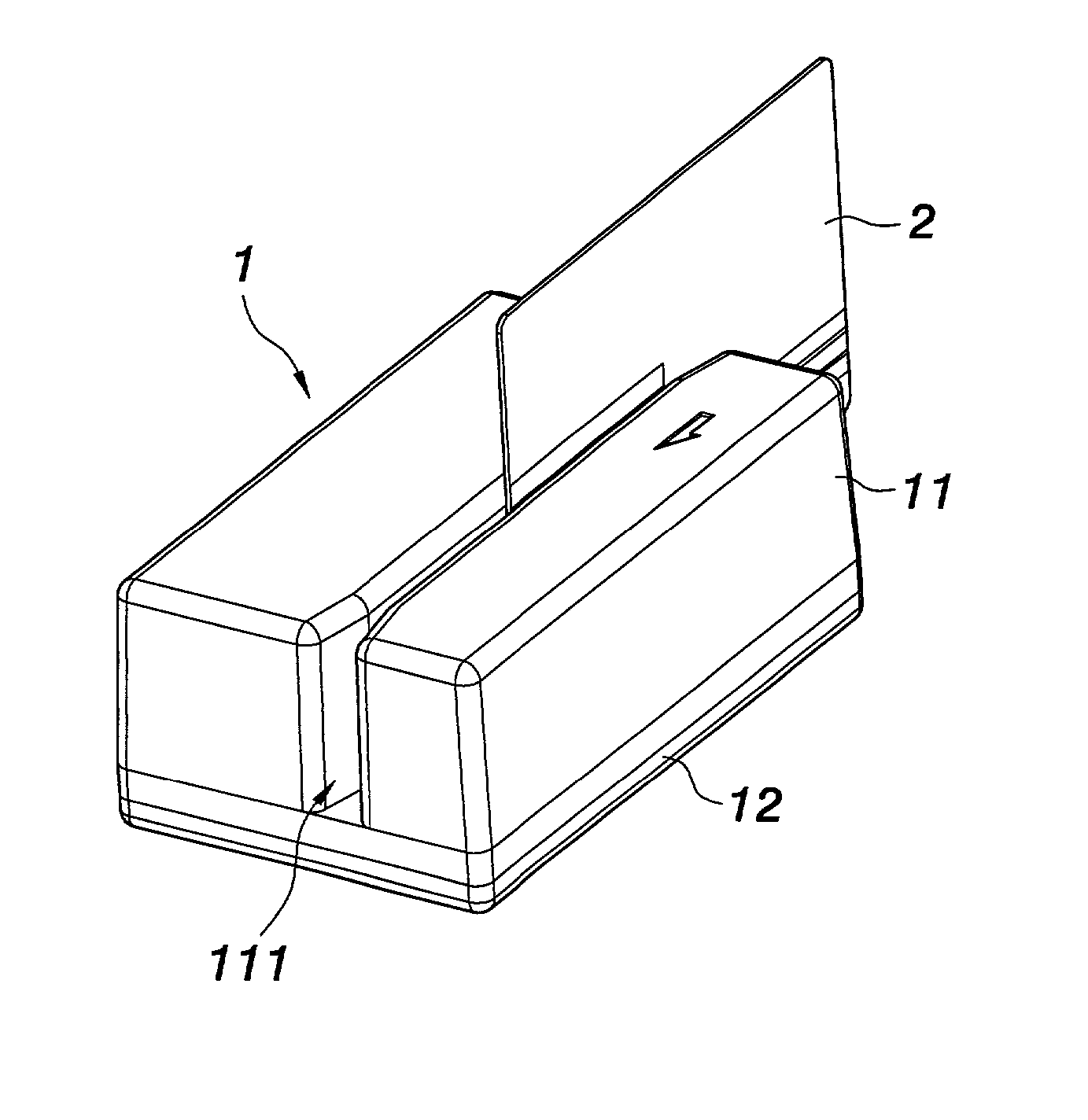

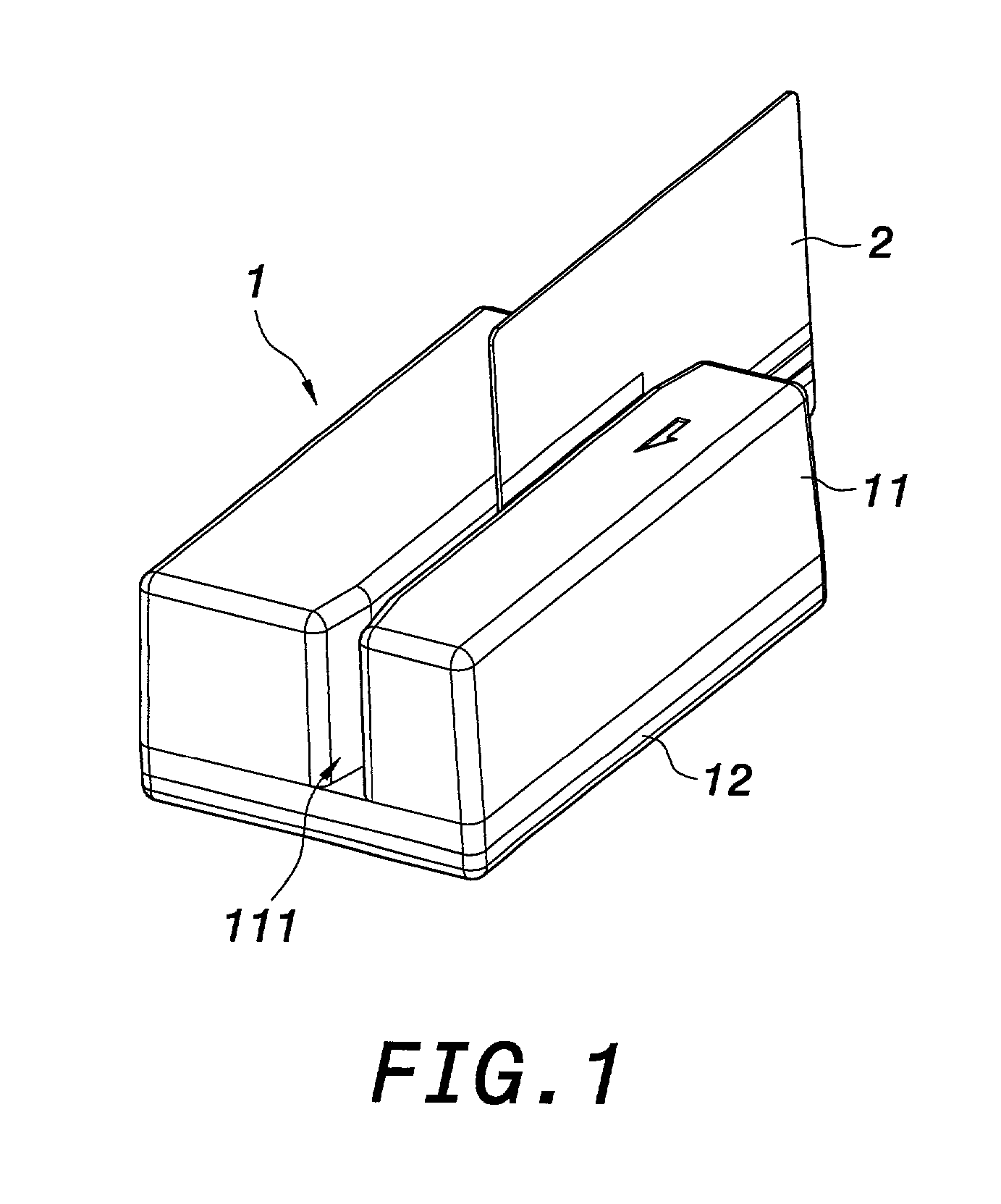

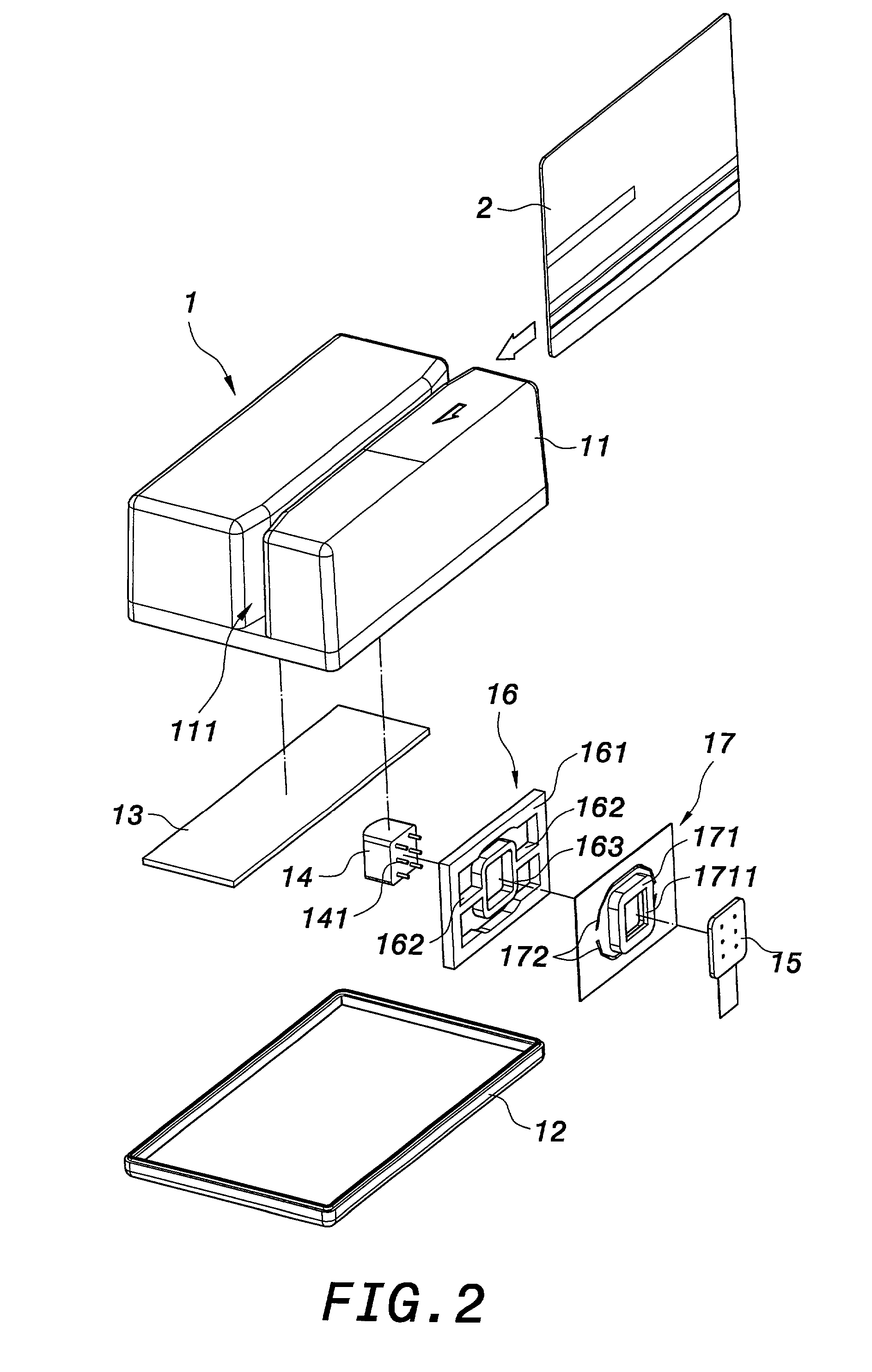

Waterproof structure for card machine

A waterproof structure installed in card machine includes a rigid support and a flexible support. The rigid support, formed of plastics, includes a frame that internally extends into two transversal bars. The transversal bars oppositely connect a receptacle frame located between the transversal bars so that a magnetic head of the card machine can be tightly arranged in the receptacle frame. The flexible support, formed of rubber material, includes a central region where a fixation slot is defined. The fixation slot matches with the receptacle frame to fixedly fasten the magnetic head. An opening is defined in the fixation slot, whereby the magnetic head can connect into a flexible circuit carrier. On upper and lower sides of the fixation slot, a clamping member composed of semi-ringed flanges is arranged around the fixation slot to tightly clamp the transversal bars of the rigid support.

Owner:UNITECH ELECTRONICS

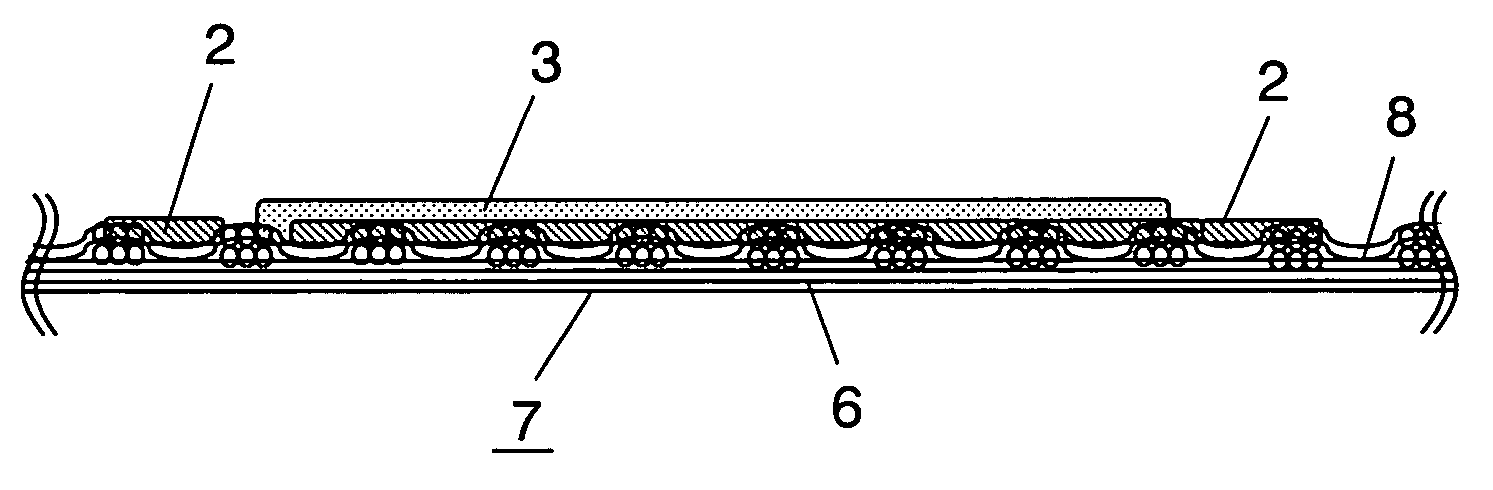

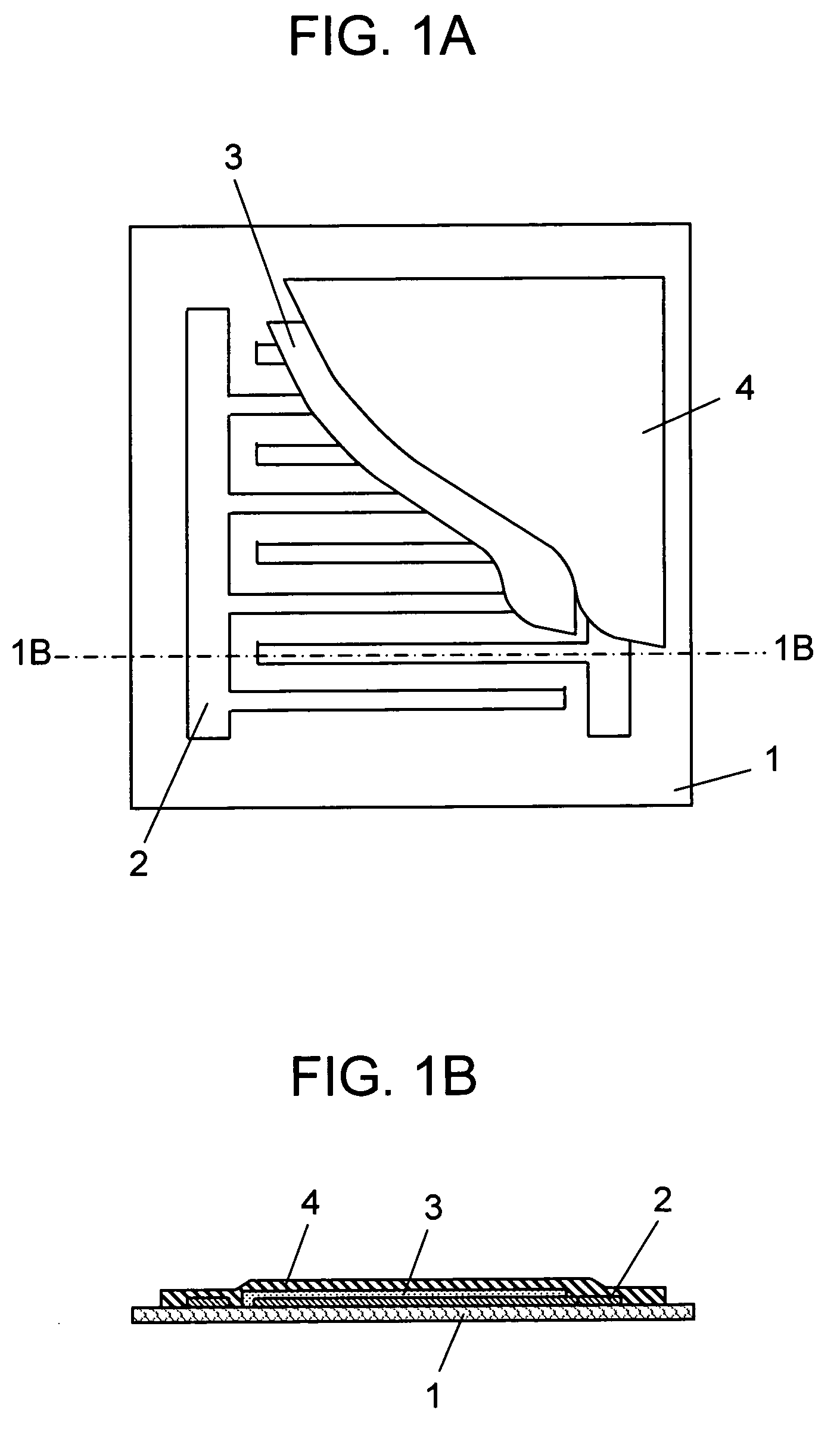

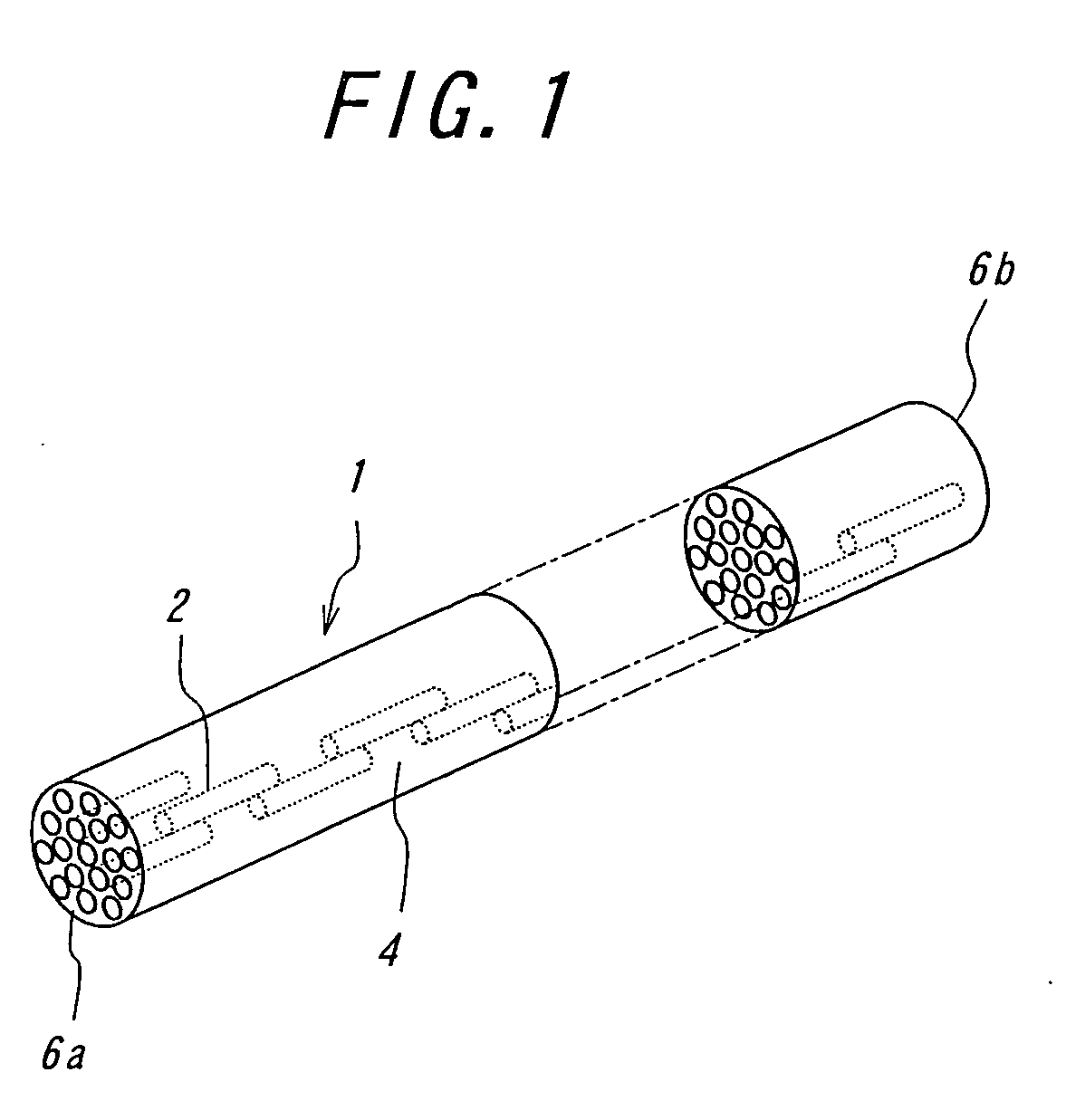

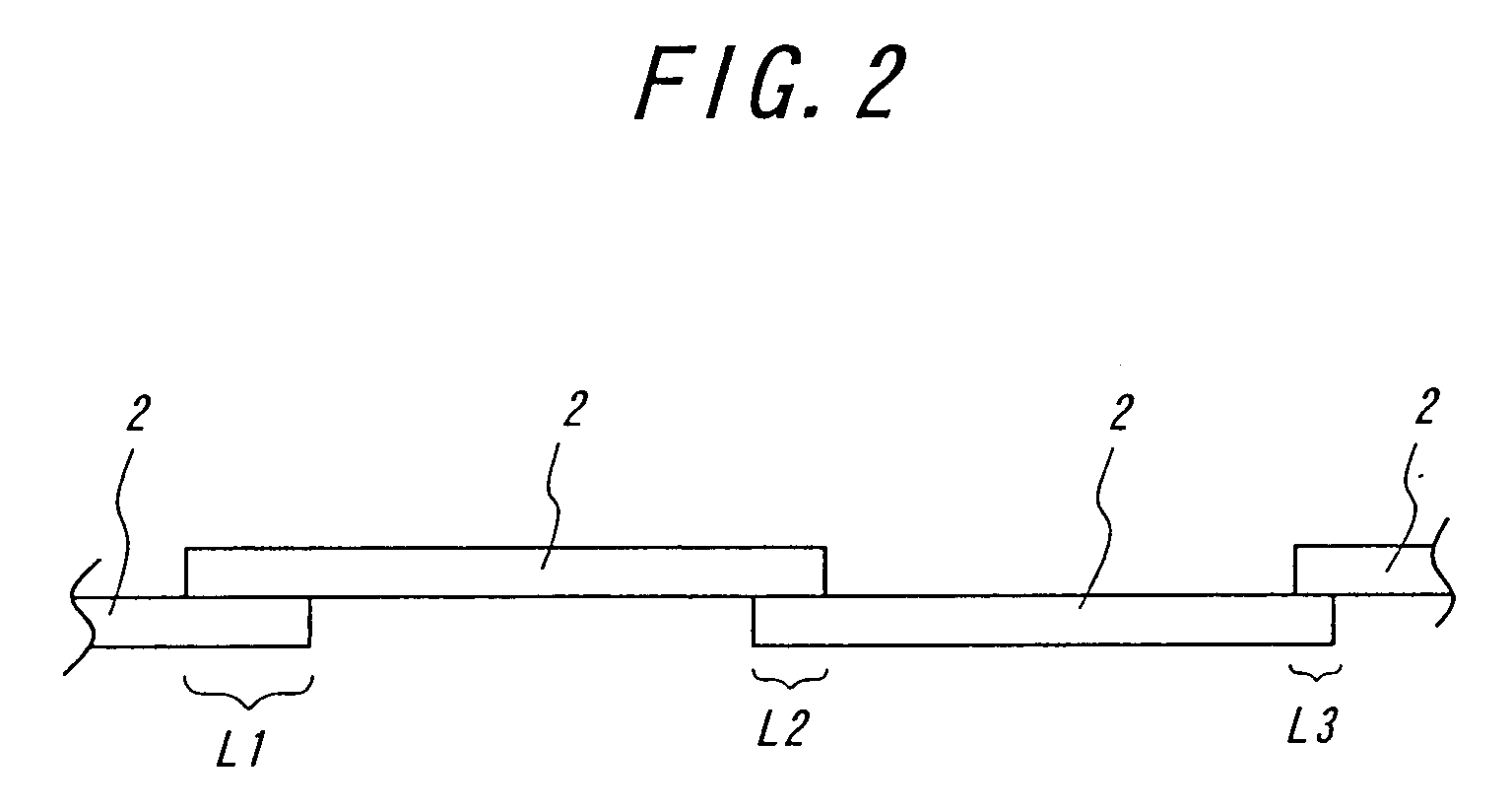

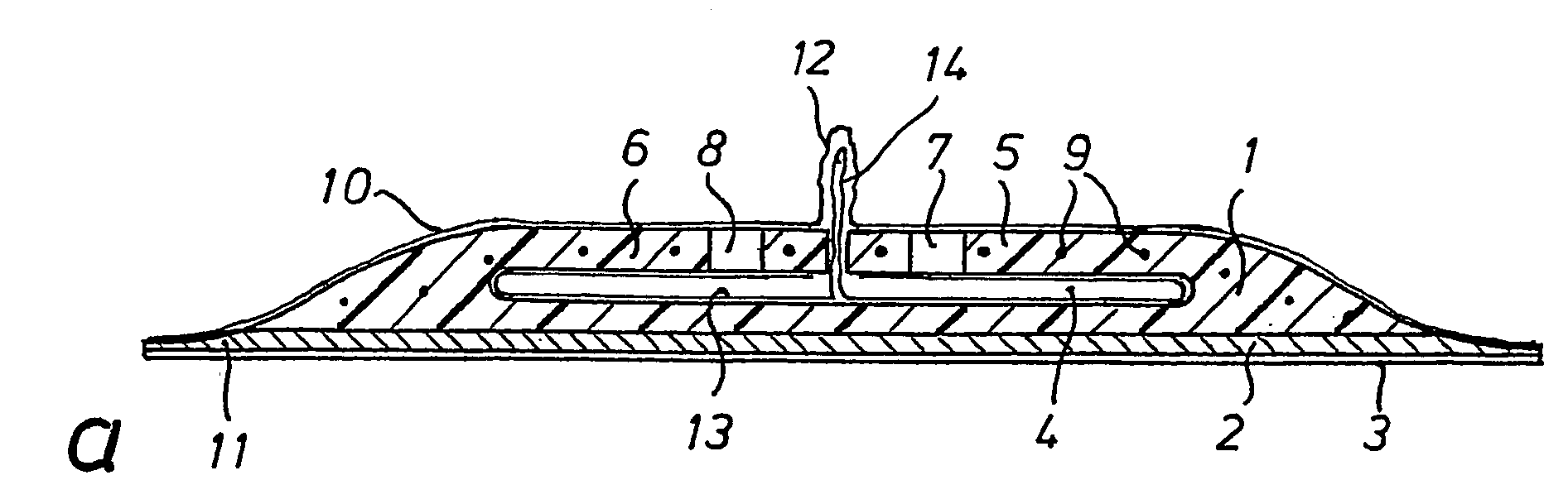

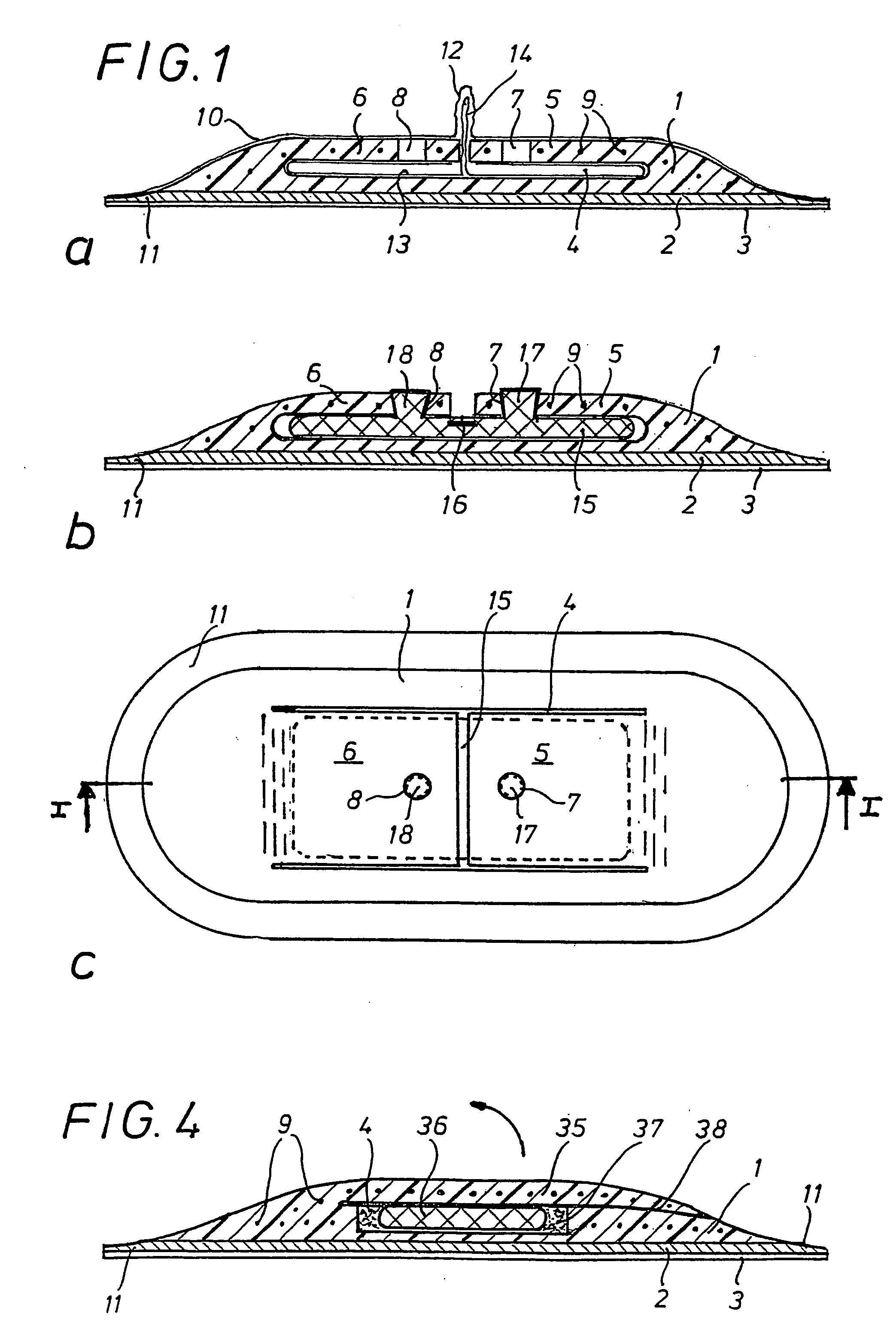

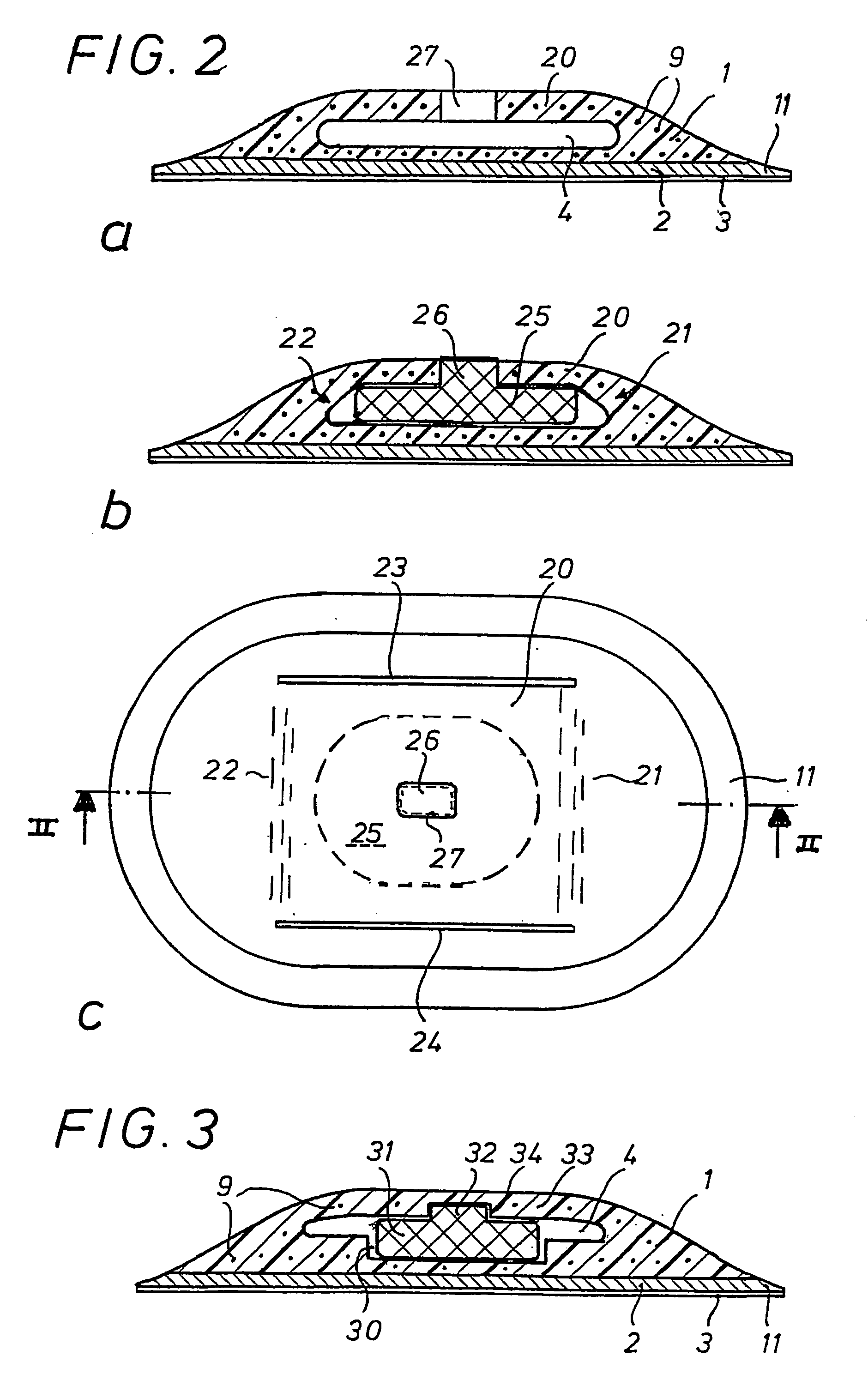

Flexible PTC heating element and method of manufacturing the heating element

InactiveUS7049559B2Resistor terminals/electrodesResistor mounting/supportingRubber materialEngineering

The flexible PTC heating element according to the invention has one of the following constitutions. A portion of an electrodes and a PTC resistor is impregnated into a flexible substrate. A flexible substrate is made of resin foam or rubber material having a concave / convex shape formed on the surface. The flexible PTC heating element has an elongation deformation portion disposed to at least one of an electrode and a PTC resistor. A flexible substrate has adhesiveness and either a flexible substrate or a flexible cover material has an elongation control portion. Therefore, the flexible PTC heating element is highly flexible and excellent in vibration durability.

Owner:PANASONIC CORP

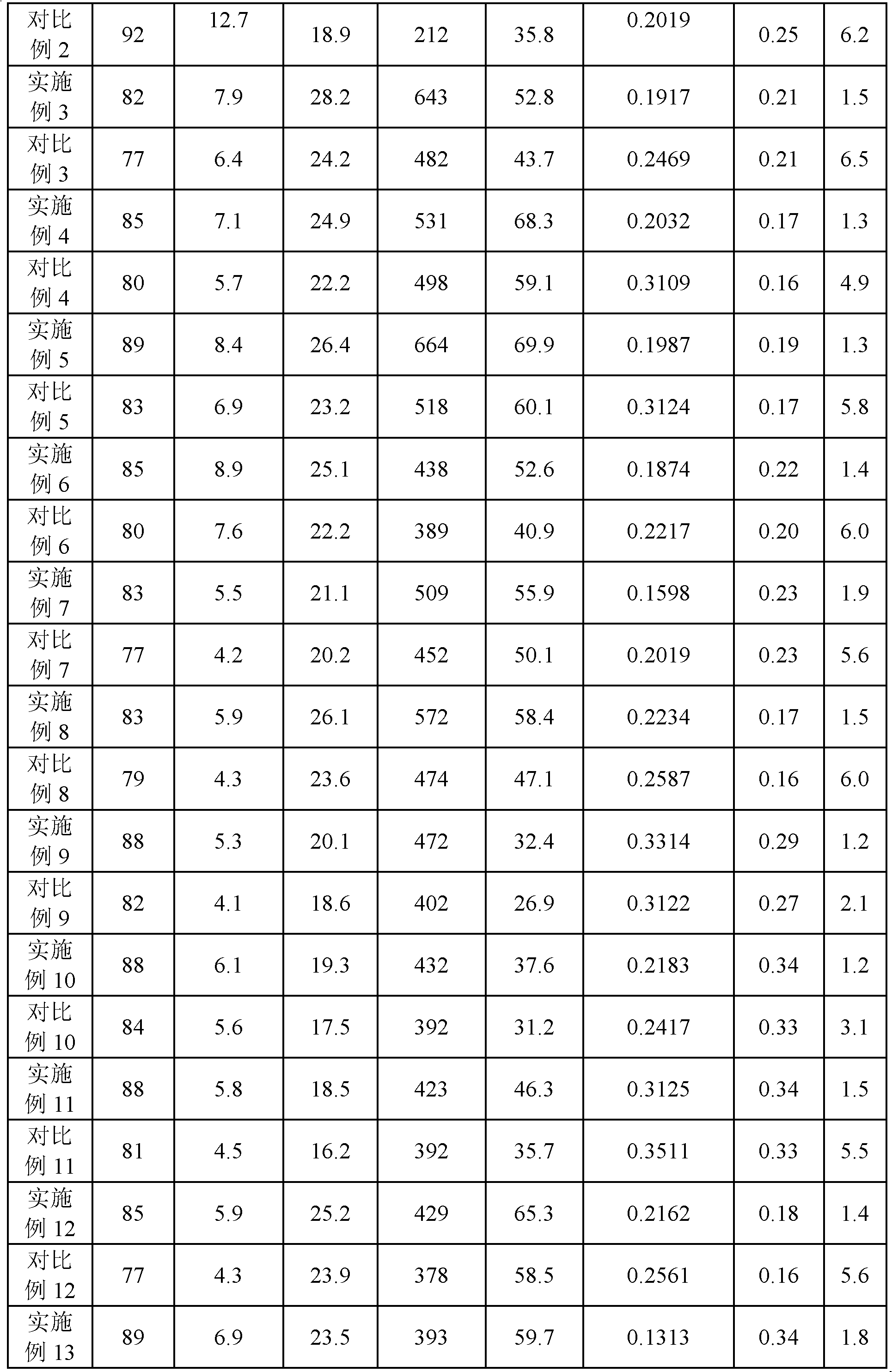

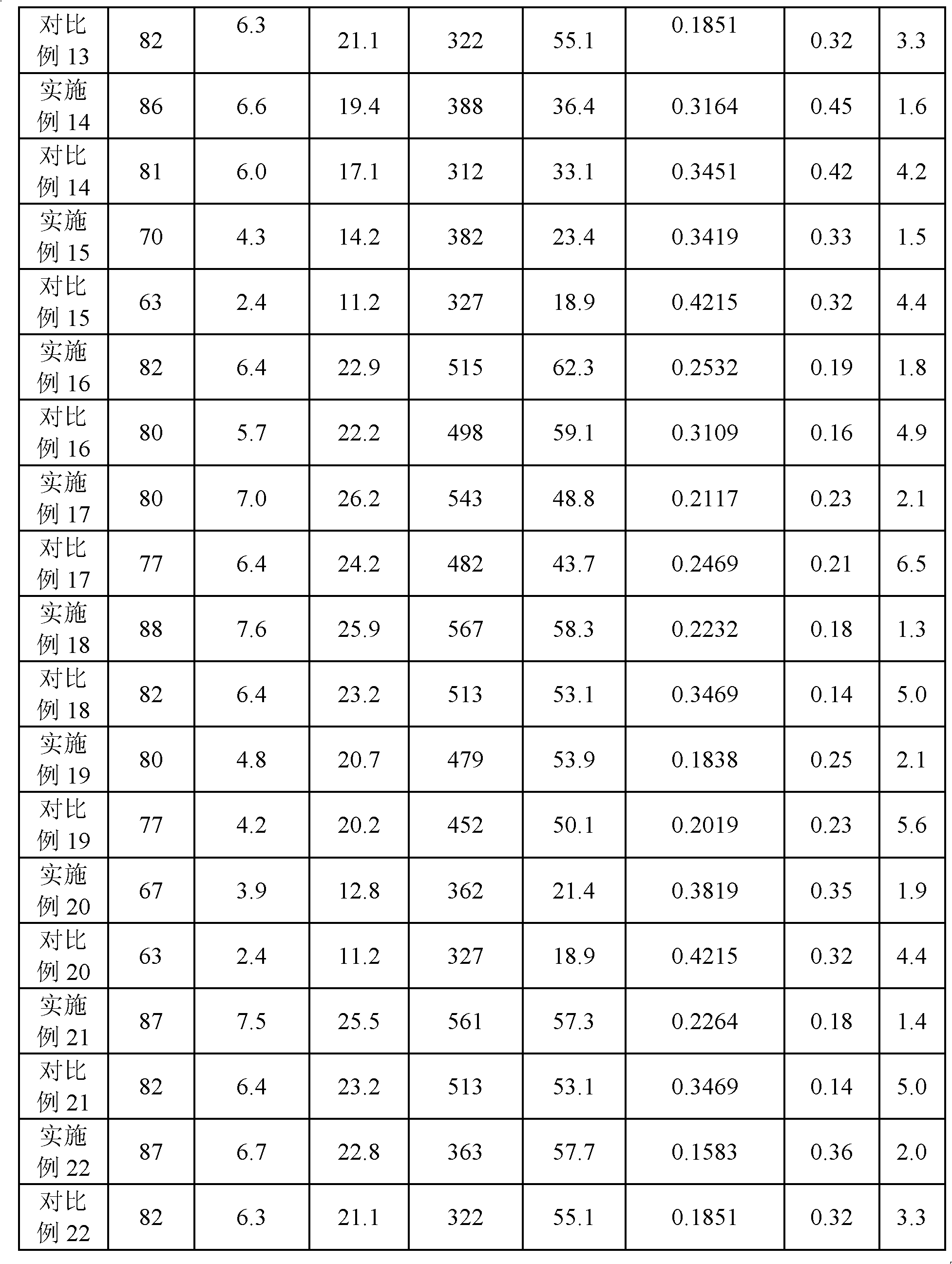

Method for preparing graphene oxide/white carbon black/rubber nanocomposite

The invention relates to a method for preparing a graphene oxide / white carbon black / rubber nanocomposite, which adopts a solution blending method or a mechanical blending method. In the graphene oxide / white carbon black / rubber nanocomposite prepared by the method provided by the invention, graphene and white carbon black are inserted with each other to effectively effective the aggregation of the two fillers, so as to obtain a highly-dispersed highly-stripped nano-sized composite. Not only the composite has high modulus and low rolling resistance, but also the wear resistance of a rubber material is greatly improved, and the modulus and tear resistance of the composite are further improved; in addition, due to the lamellar structure and good self-recovery capability of graphene oxide, the rubber material is also endued with good gas barrier performance and self-recovery capability, and the nanocomposite has the advantages that cannot be matched by any traditional filler. The method provided by the invention is simple and feasible, and suitable for industrial production, and has low cost, wide application range and good economic and social benefits.

Owner:BEIJING UNIV OF CHEM TECH

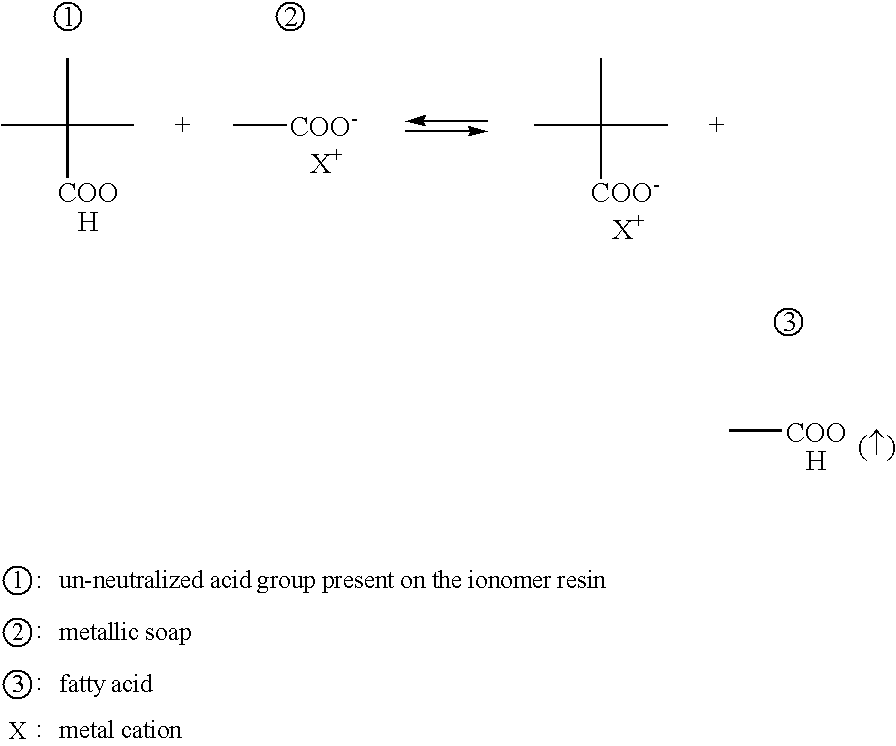

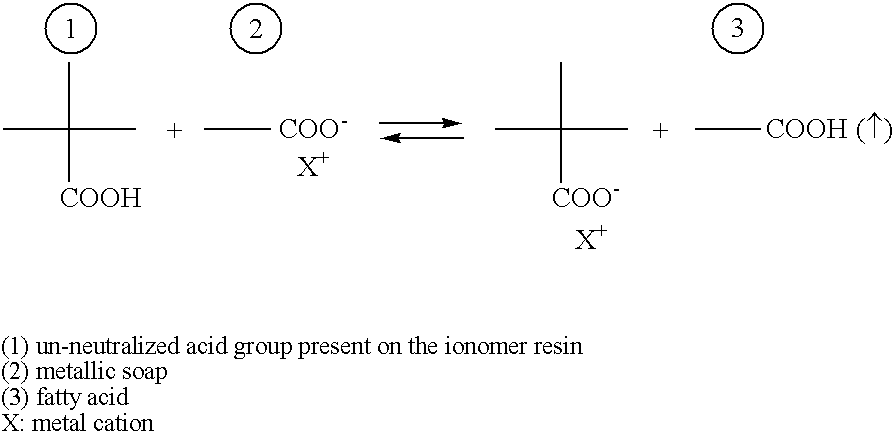

Method of manufacturing a golf ball

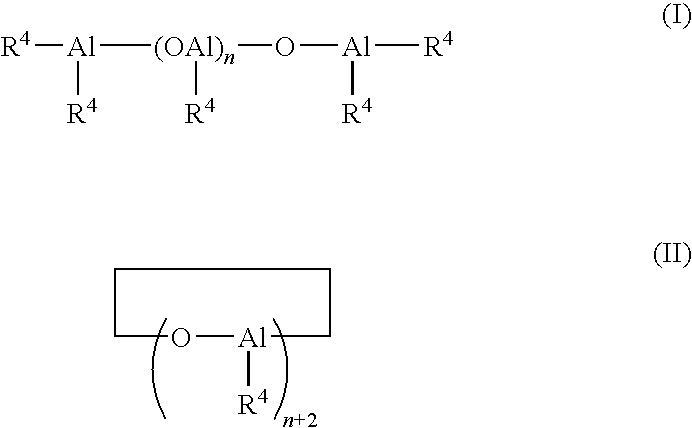

The present invention relates to an industrially beneficial method of manufacturing golf balls which includes the steps of pre-preparing a masterbatch of an unsaturated carboxylic acid and / or a metal salt thereof by mixing an unsaturated carboxylic acid and / or a metal salt thereof with a rubber material, preparing a rubber composition that contains the rubber material by using the masterbatch, and employing a material obtained by molding the rubber composition under heat as a golf ball component. The masterbatch is composed of:(A) from 20 to 100 wt % of a modified polybutadiene obtained by a modification reaction wherein a polybutadiene having a vinyl content of from 0 to 2%, a cis-1,4 bond content of at least 80% and an active end is modified at the active end with at least one type of alkoxysilane compound, and(B) from 80 to 0 wt % of a diene rubber other than Ingredient A.such that ingredients A and B are included in a combined amount of 100 wt %, and(C) an unsaturated carboxylic acid and / or a metal salt thereof.

Owner:BRIDGESTONE SPORTS

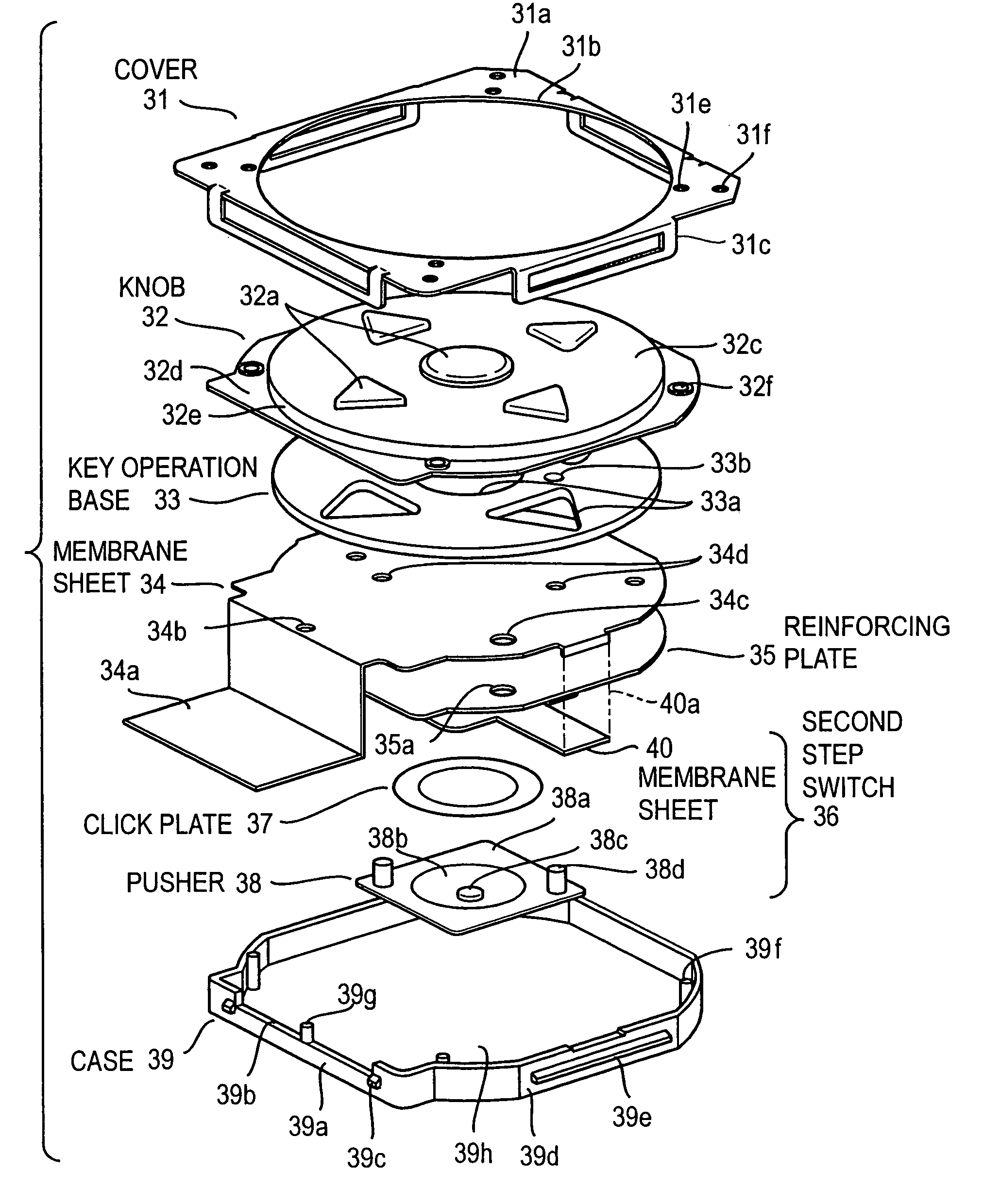

Depression responsive switch unit

InactiveUS7019225B2Reliably turnedExtended service lifeEmergency actuatorsContact operating partsRubber materialThermoplastic elastomer

A pusher formed of a rubber material, a click plate, a membrane switch which serves as a second step switch, a reinforcing plate, a membrane sheet on which a plurality of first step switches are formed, a key operation base and a knob are sequentially assembled into a case. The knob includes a plurality of depressing pieces having on its internal surface a projection which moves into contact with each membrane switch and also includes a marginal portion which is supported by the top surface of the case. The knob is thin-walled except for the depressing piece, and the thin-walled portion comprises a thermoplastic elastomer or silicone rubber. The knob, the key operation base and the reinforcing plate are secured together. As the depressing piece is depressed, the thin-walled portion which is located therearound becomes flexed, whereby the membrane switch is depressed by the projection to turn the switch on. When the depressing piece is further depressed, the reinforcing plate moves and the click plate reverses, turning the switch on.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

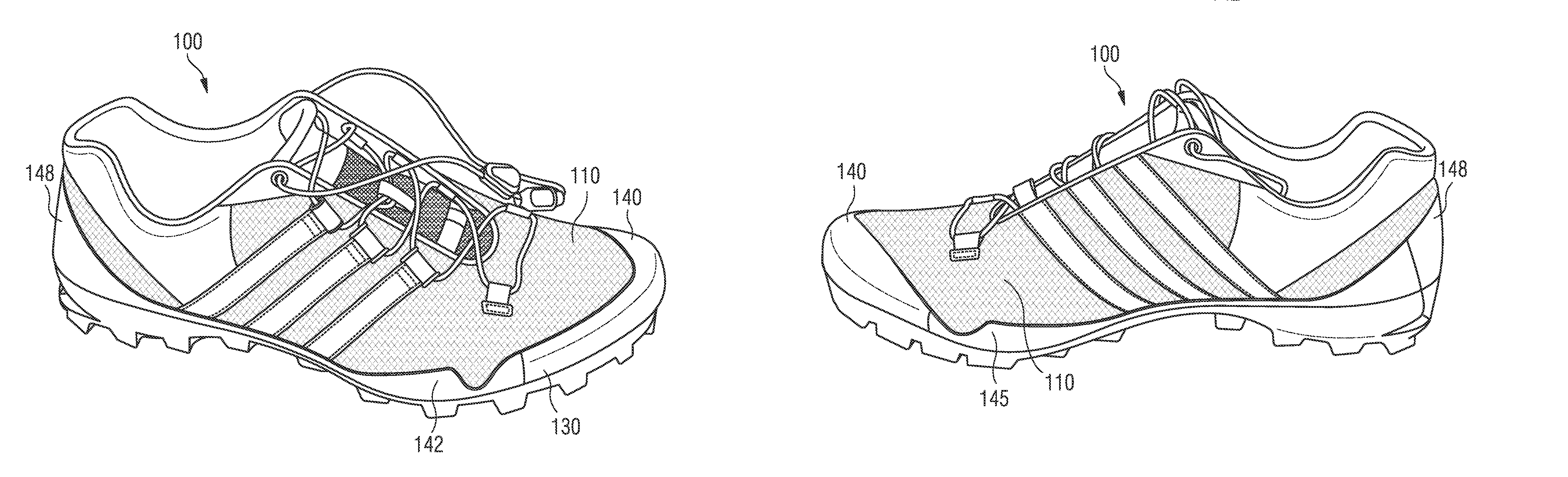

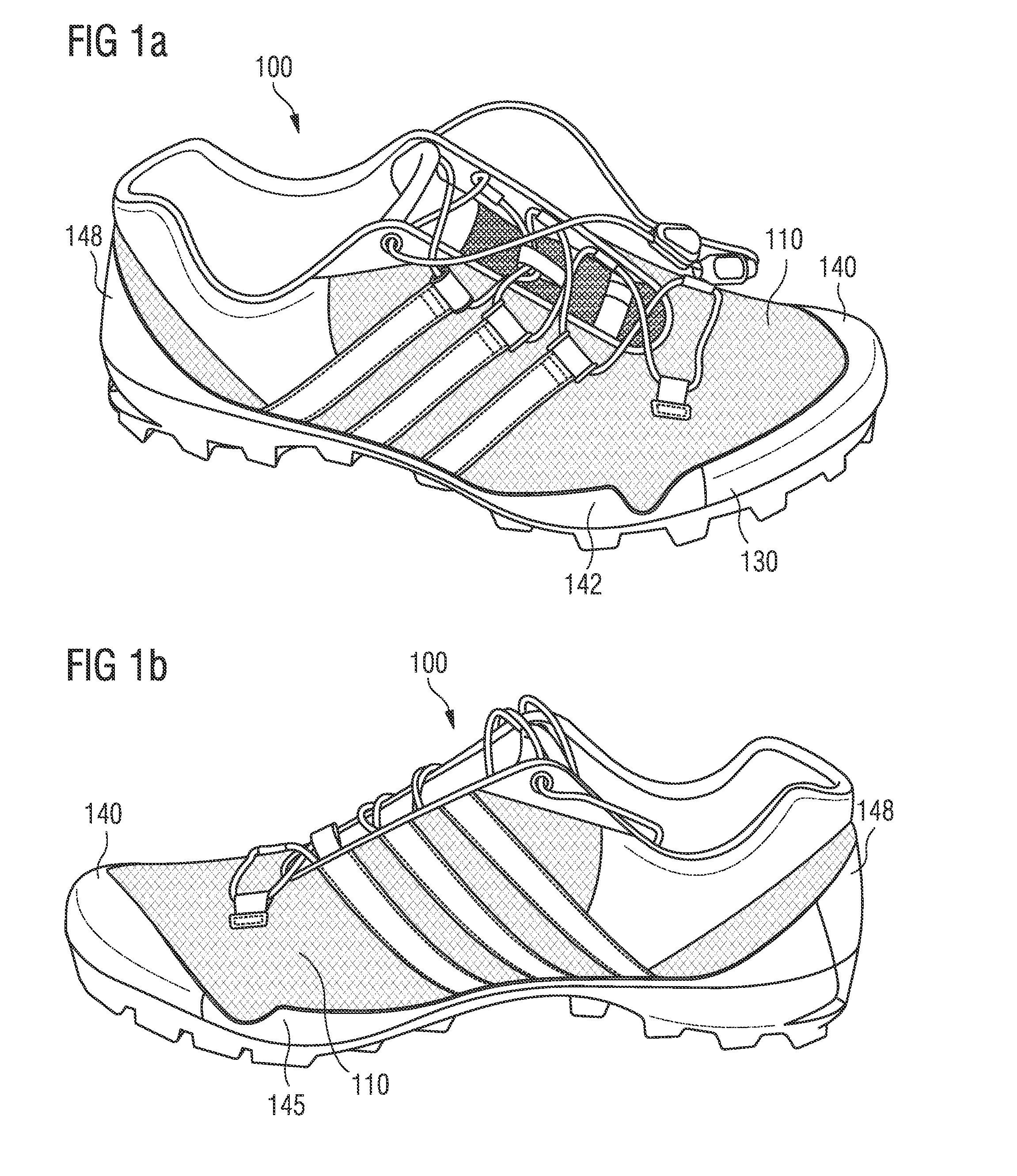

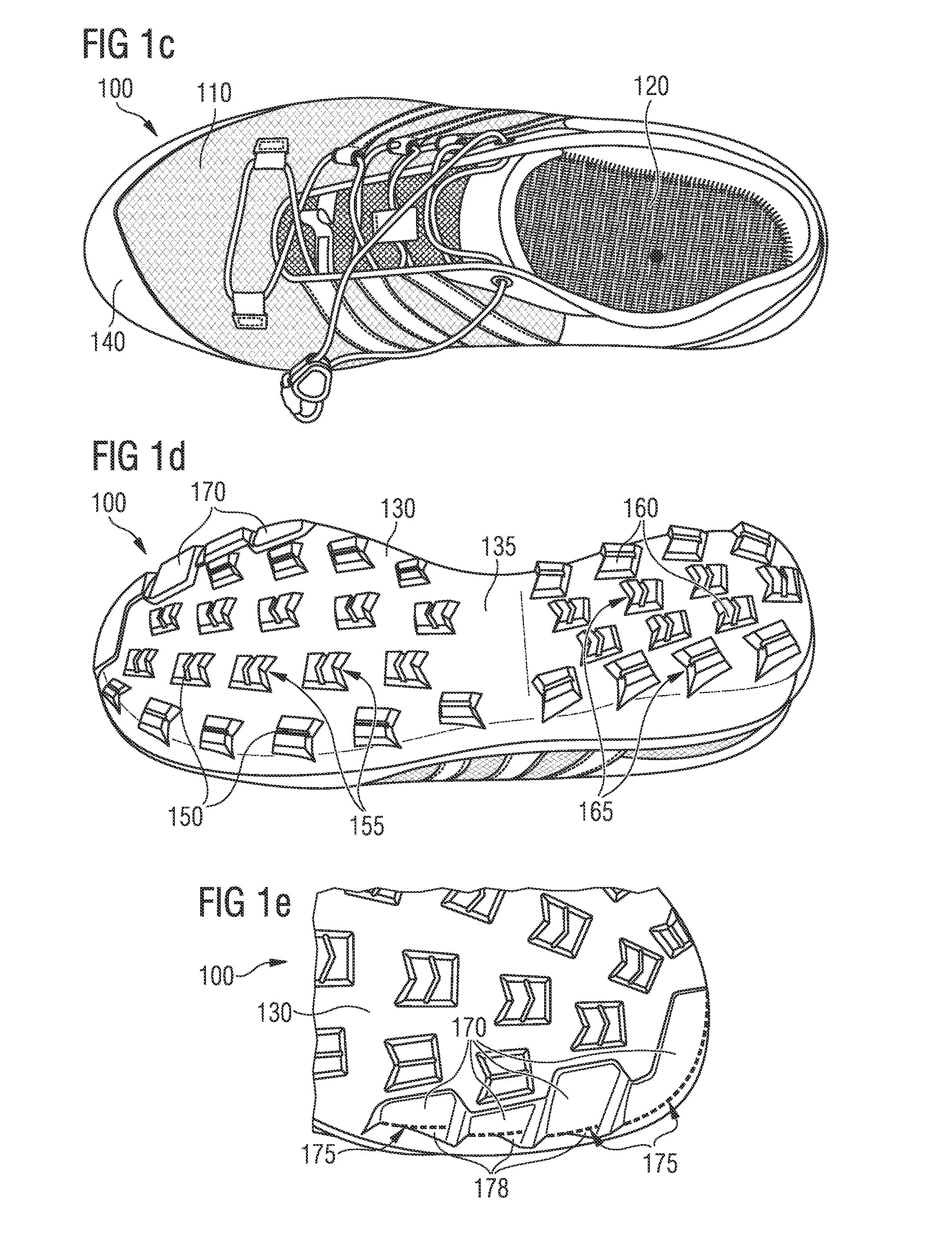

Multifunctional outdoor shoe

Described are shoes, in particular mountain shoes, mountain running shoes, trail running shoes and climbing shoes, as well as methods for their manufacture. The shoe may include a shoe upper, a textile two-dimensional region connected to the shoe upper, which extends beneath a foot of a user of the shoe when worn, and an outsole unit with a rubber material. The textile two-dimensional region is connected to the rubber material of the outsole unit without a bonding agent.

Owner:ADIDAS

High-heat-conductivity rubber composite material and preparation method thereof

InactiveCN102504358AImprove thermal conductivitySimple preparation processRubber materialVulcanization

The invention discloses a high-heat-conductivity rubber composite material and a preparation method of the high-heat-conductivity rubber composite material. The high-heat-conductivity rubber composite material consists of the following ingredients in parts by mass: 100 of rubber, 4 to 6 of zinc oxide, 1 to 3 of stearic acid, 1 to 2 of anti-aging agents, 40 to 60 of carbon black, 1 to 1.5 of promoters, 1 to 3 of sulphur and 50 to 170 of heat conducting agents. The manufacture method comprises the following process steps that: the rubber is added into an open mill, the zinc oxide, the stearic acid, the anti-aging agents, the promoters, the carbon black and the heat conducting agents are sequentially added after the roll recovering, and finally, the sulphur is added. After rubber materials are uniformly mixed, the thin conduction is carried out, triangle bag packing and rolling are respectively carried out for five times, and the roll distance is regulated to 1.5mm for sheet output. The material sheets are placed into a mold, the vulcanization is carried out on a flat plate vulcanization machine, the vulcanization time is 15 to 20 minutes, the vulcanization temperature is 160 to 165 DEG C, and the vulcanization pressure is 10 to 12MPa. The material disclosed by the invention has an excellent physical and mechanical property and a high heat conduction factor.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

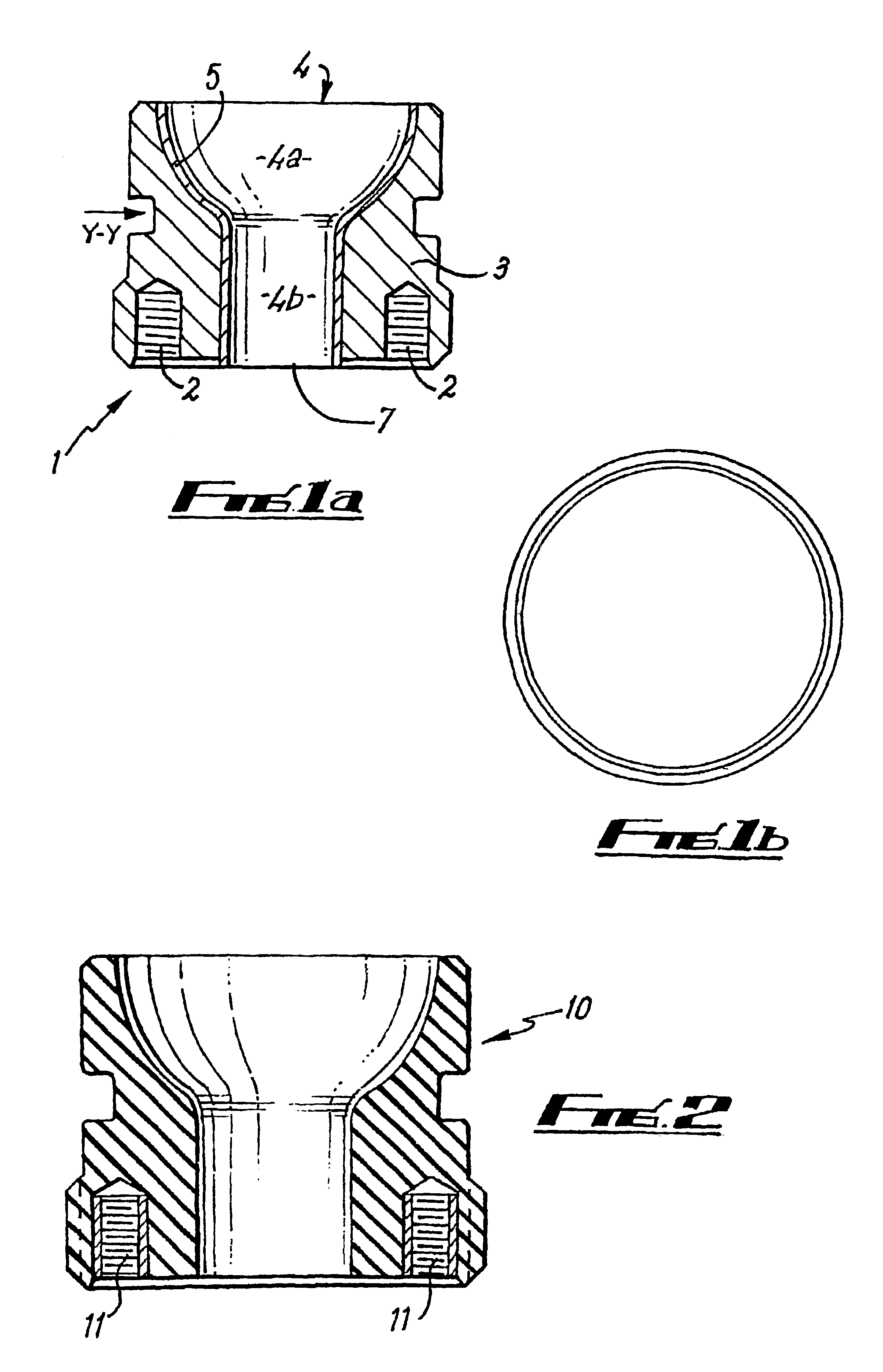

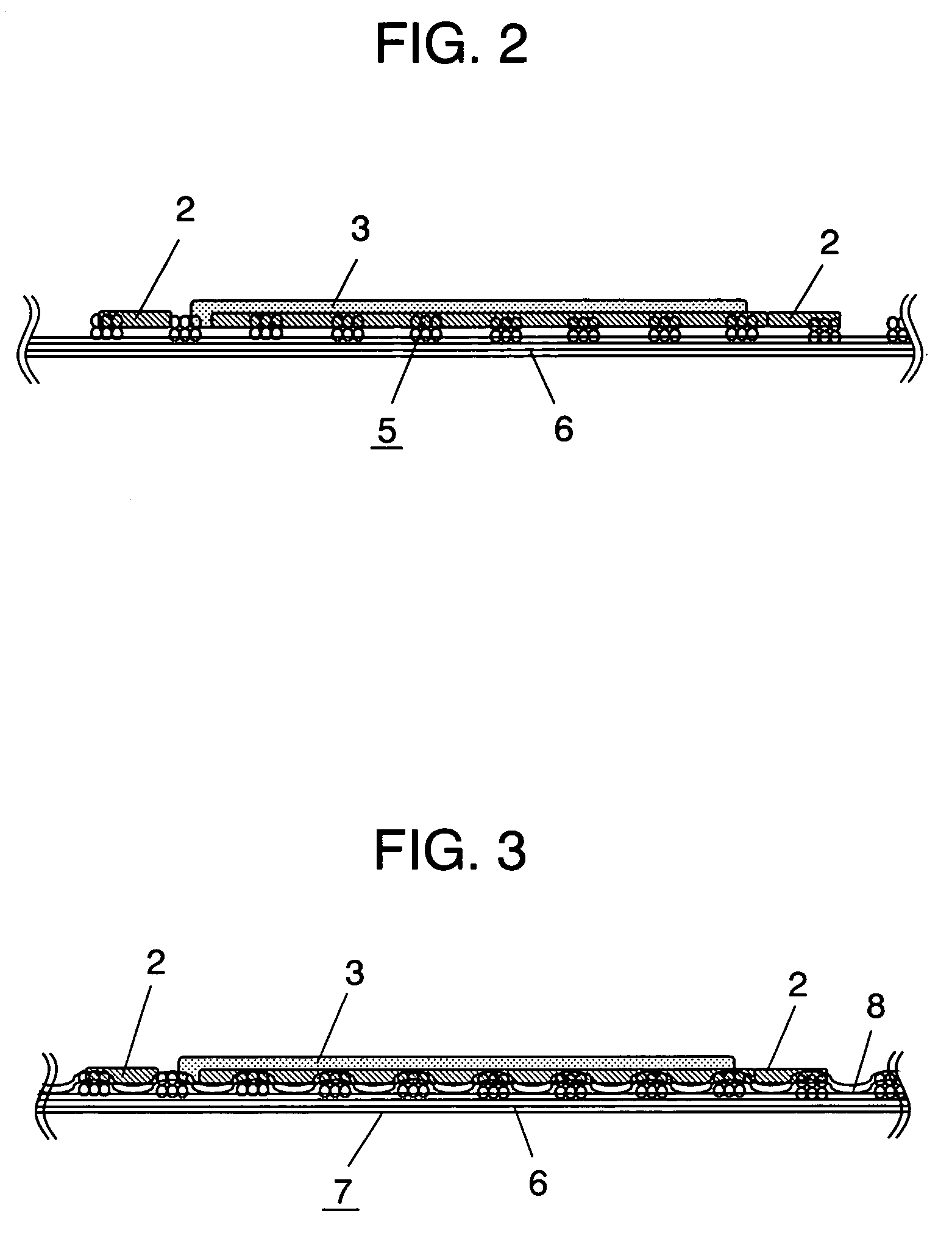

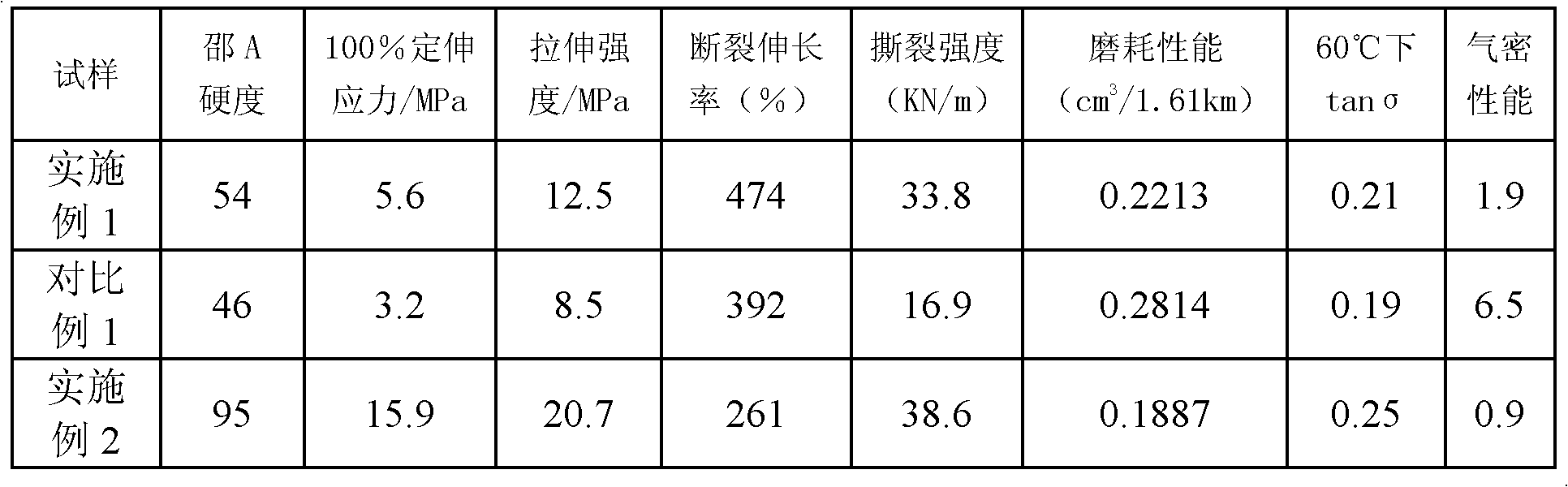

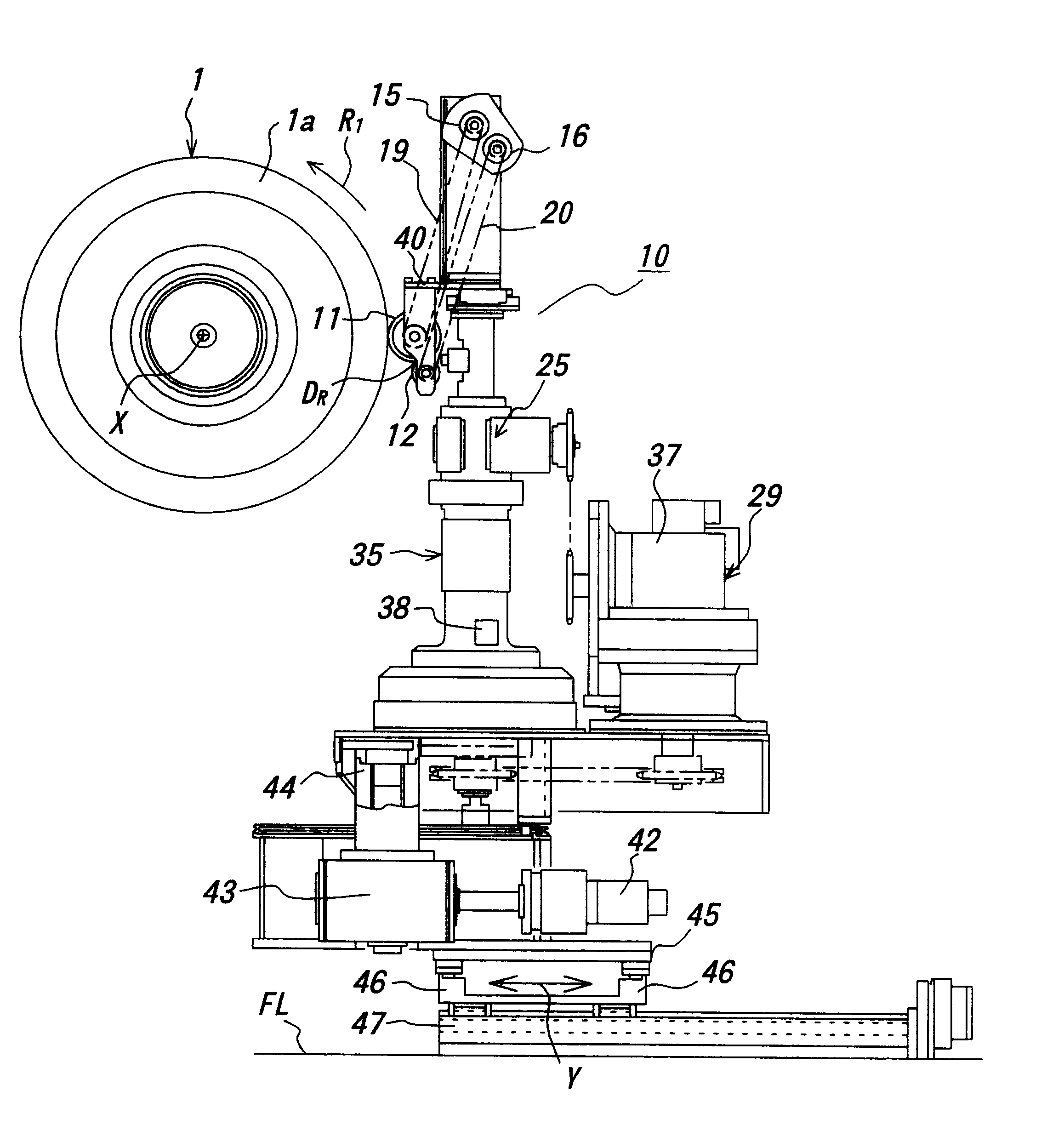

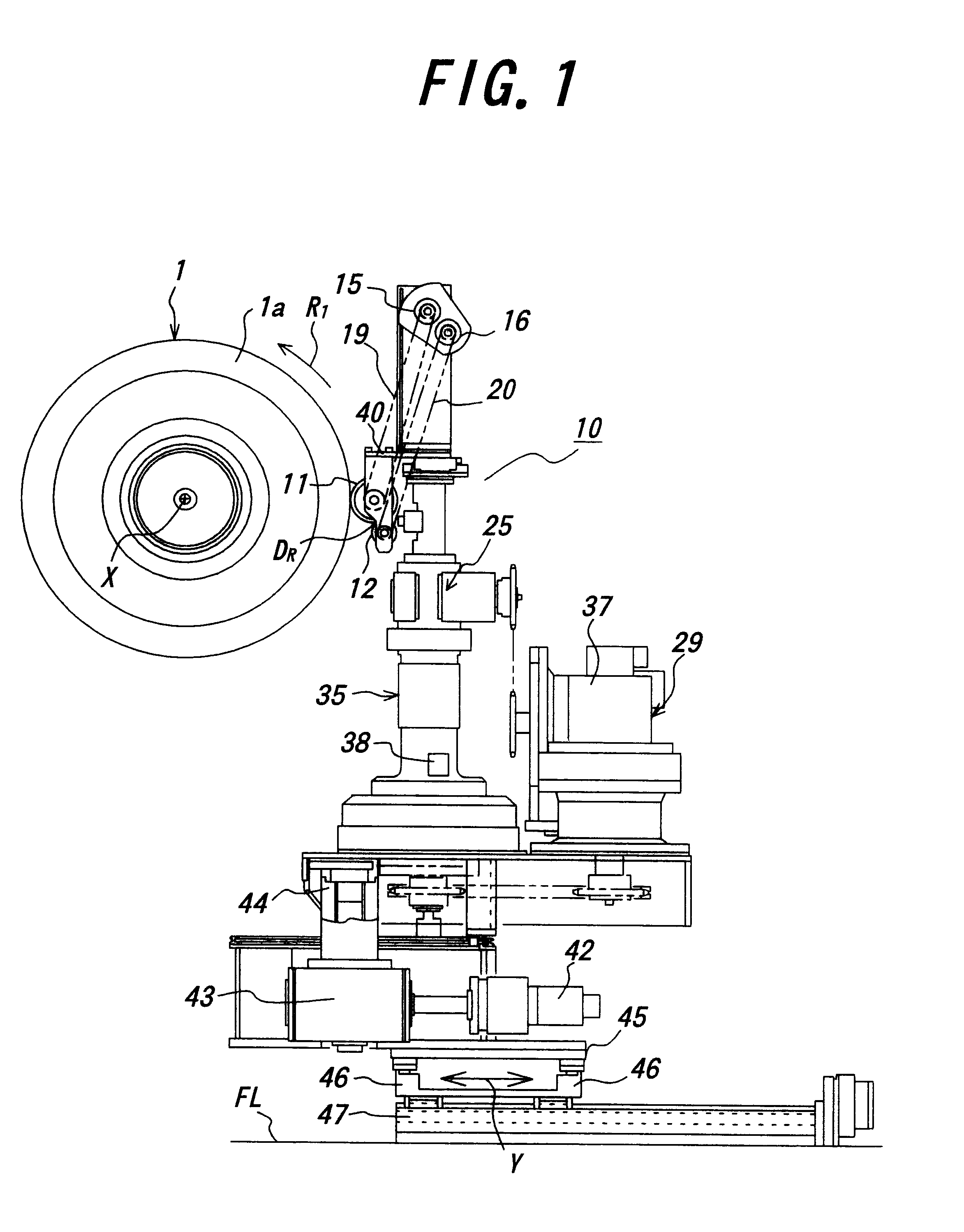

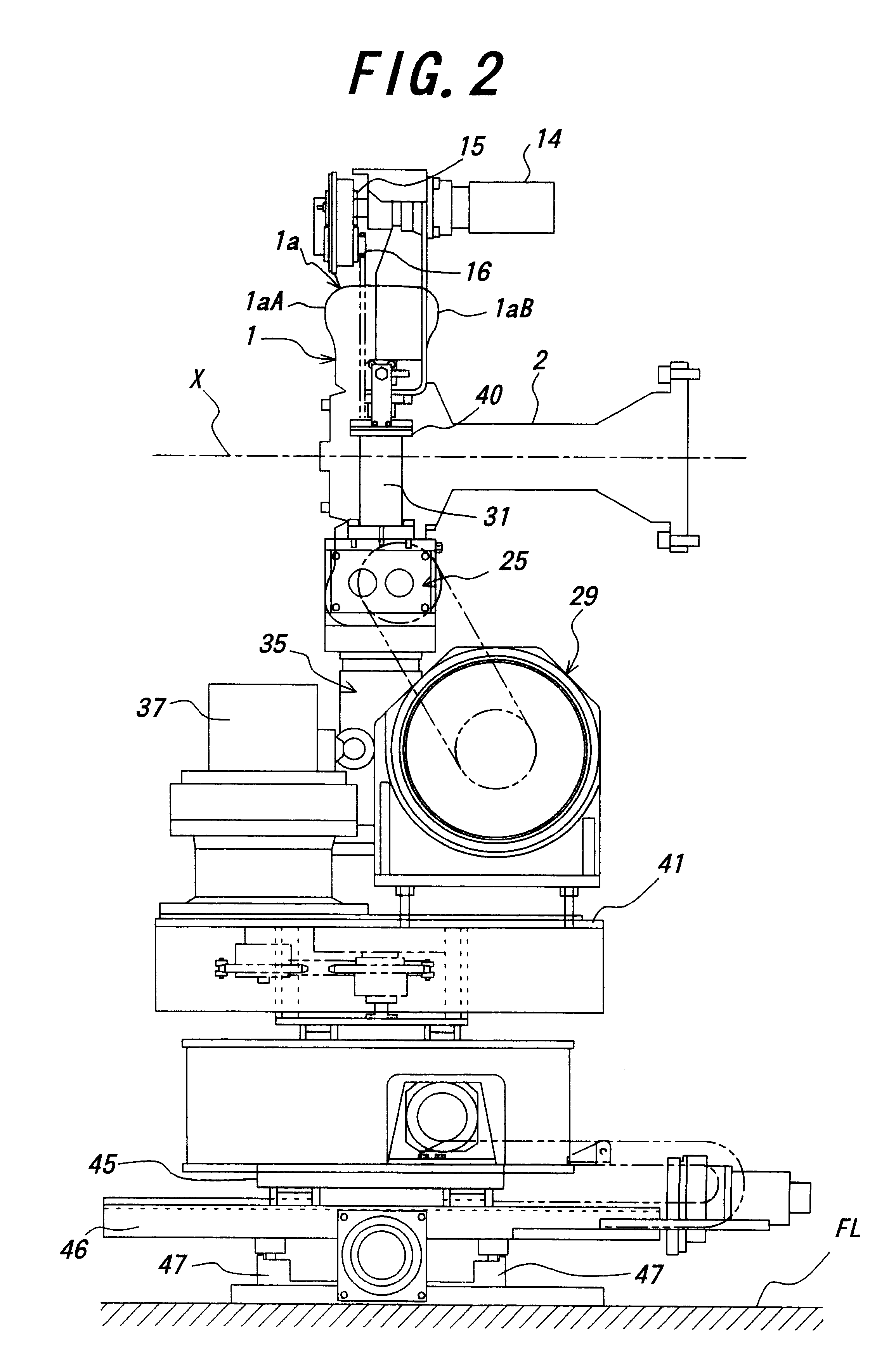

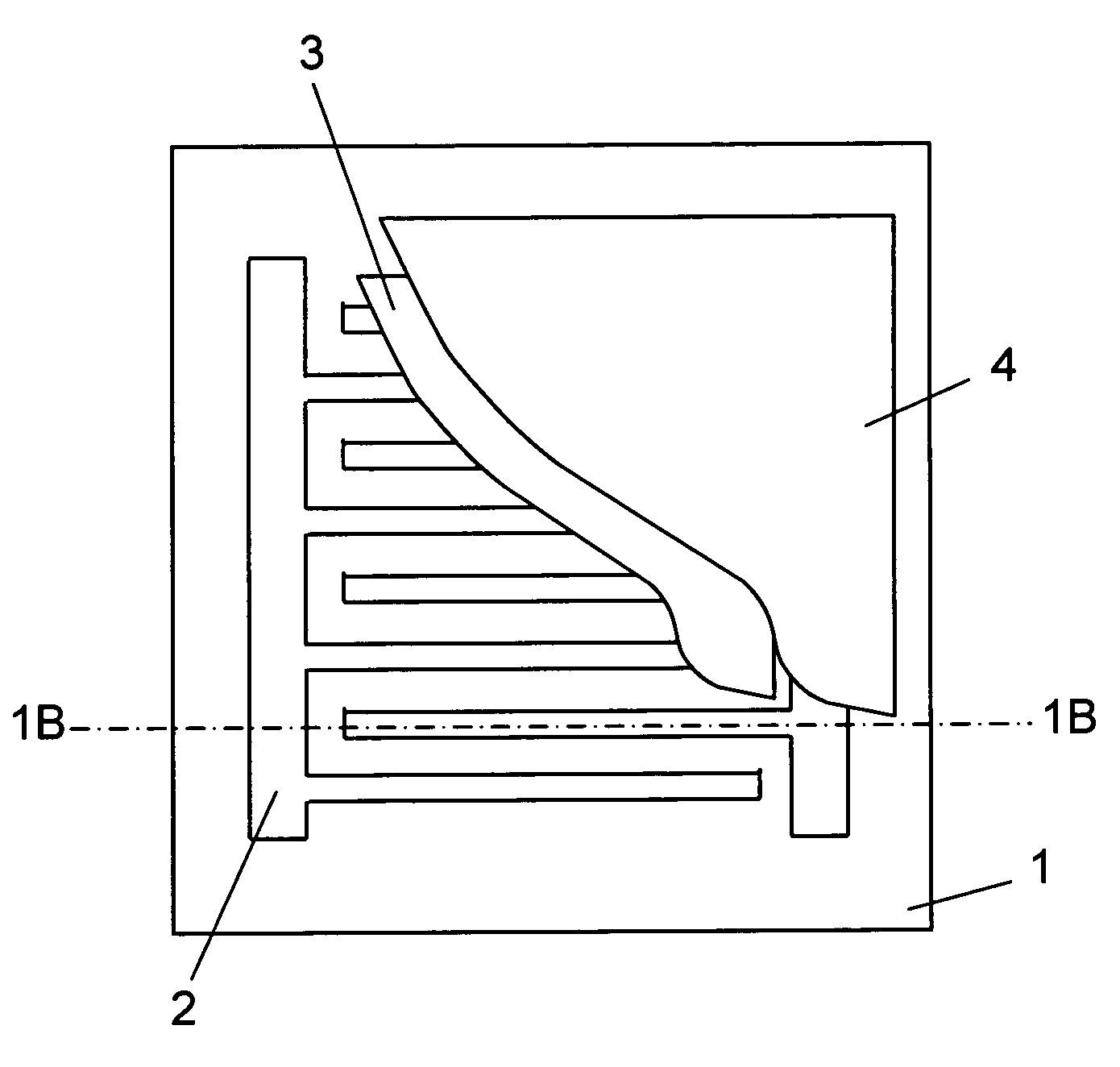

Process and apparatus for laying rubber materials for tire-constitutional members

A rubber material for tire-constitutional member is laid on a rotating support at a high efficiency and a high accuracy by arranging a pair of rollers rotating in opposite directions in the vicinity of a radially outer surface portion of the support and utilizing a gap defined between the rollers as a roller die.

Owner:BRIDGESTONE CORP

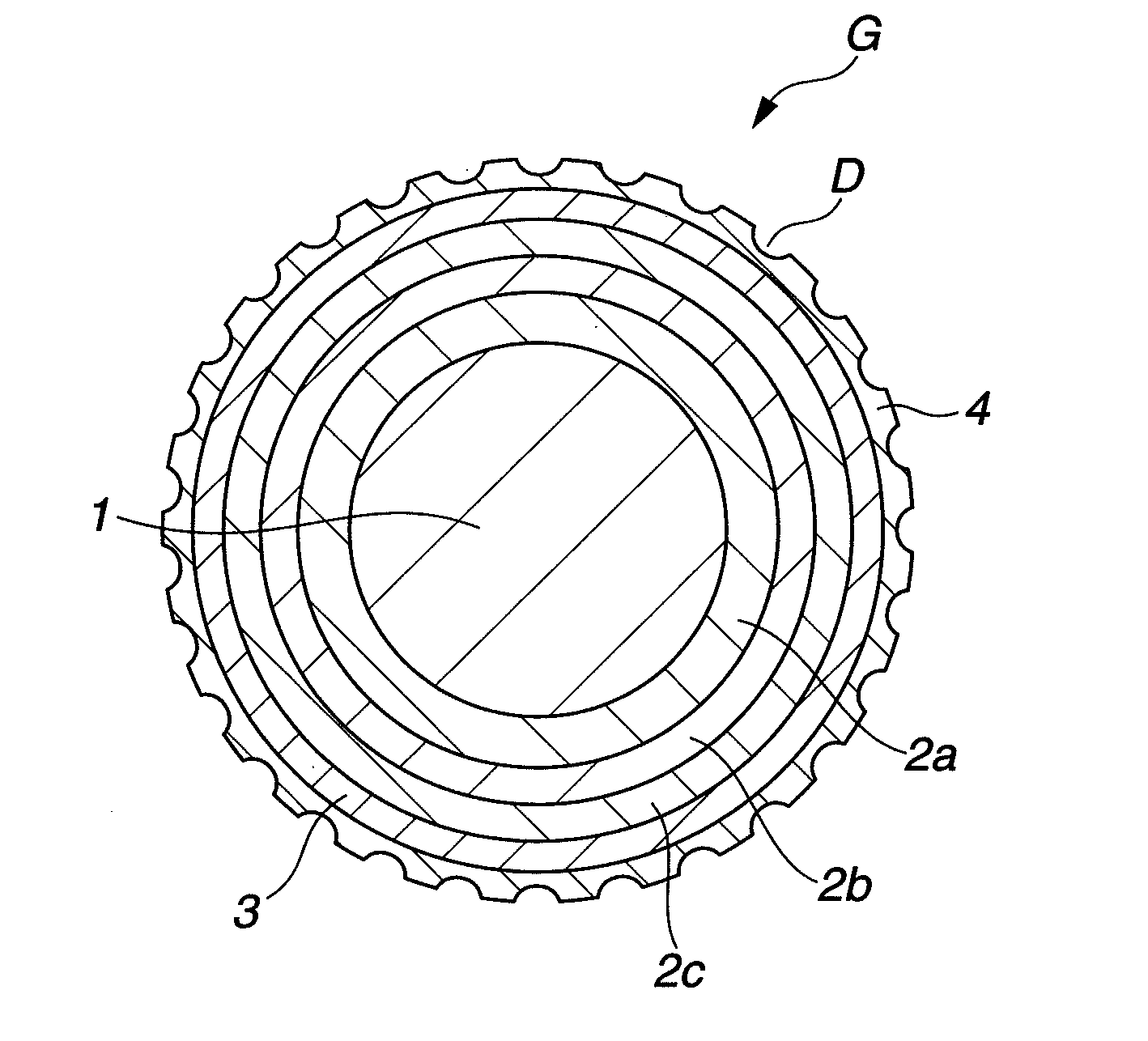

Multi-piece solid golf ball

ActiveUS20070281801A1Improve wear resistanceFlight performance and controllabilityGolf ballsSolid ballsRubber materialEngineering

The invention provides a multi-piece solid golf ball having a core, an envelope layer enclosing the core, an intermediate layer enclosing the envelope layer, and a cover which encloses the intermediate layer and has formed on a surface thereof a plurality of dimples. The core is formed primarily of a rubber material and has a diameter of at least 31 mm, the envelope layer and the intermediate layer are each formed primarily of the same or different resin materials, and the cover is formed primarily of polyurethane. The envelope layer, intermediate layer and cover have thicknesses which satisfy the relationship cover thickness<intermediate layer thickness<envelope layer thickness; and the envelope layer, intermediate layer and cover have surface hardnesses (Durometer D hardness) which satisfy the relationship core surface hardness≦envelope layer surface hardness<intermediate layer surface hardness>cover surface hardness. The golf ball has an excellent flight performance and controllability that are acceptable to professionals and other skilled golfers, while also having an excellent durability to cracking on repeated impact and an excellent scuff resistance.

Owner:BRIDGESTONE SPORTS

Composite rubber material

InactiveCN103627330ALow costReduce manufacturing costPolyureas/polyurethane adhesivesInorganic adhesivesRubber materialPolymer science

The invention relates to a bonding rubber material, especially provides a binder or a thermosetting molding rubber cement for bonding and reinforcement of door cores of a fireproof door an antitheft door and bonding and production of building and decoration materials, and aims to provide a composite rubber material, with low cost, good bonding strength and rapid surface dry, which can be cured at room temperature. The composite rubber material is characterized in that the composite rubber material is composed of a water-based A material and a polyurethane prepolymer-containing B material, the ratio (weight ratio) of the A material to the B material is 0.5-1:0.5-1, the A material comprises 30-70% of water and / or water glass and / or silica sol, 19.5-48% of organic modifiers, and 12-55% of additives, the B material comprises polyurethane prepolymers with a content of being more than 30%, 8-24% of -NCO group, and 0-30% of synergists, The synergists are one or combination of more than one selected from a polymerization inhibitor, a blocking agent, a water glass curing agent and a diluting agent. The composite rubber material is advantaged by good bonding strength, flame retardance, thermal insulation, low price and environmental protection.

Owner:CHONGQING LIERDA SCI & TECH DEV +1

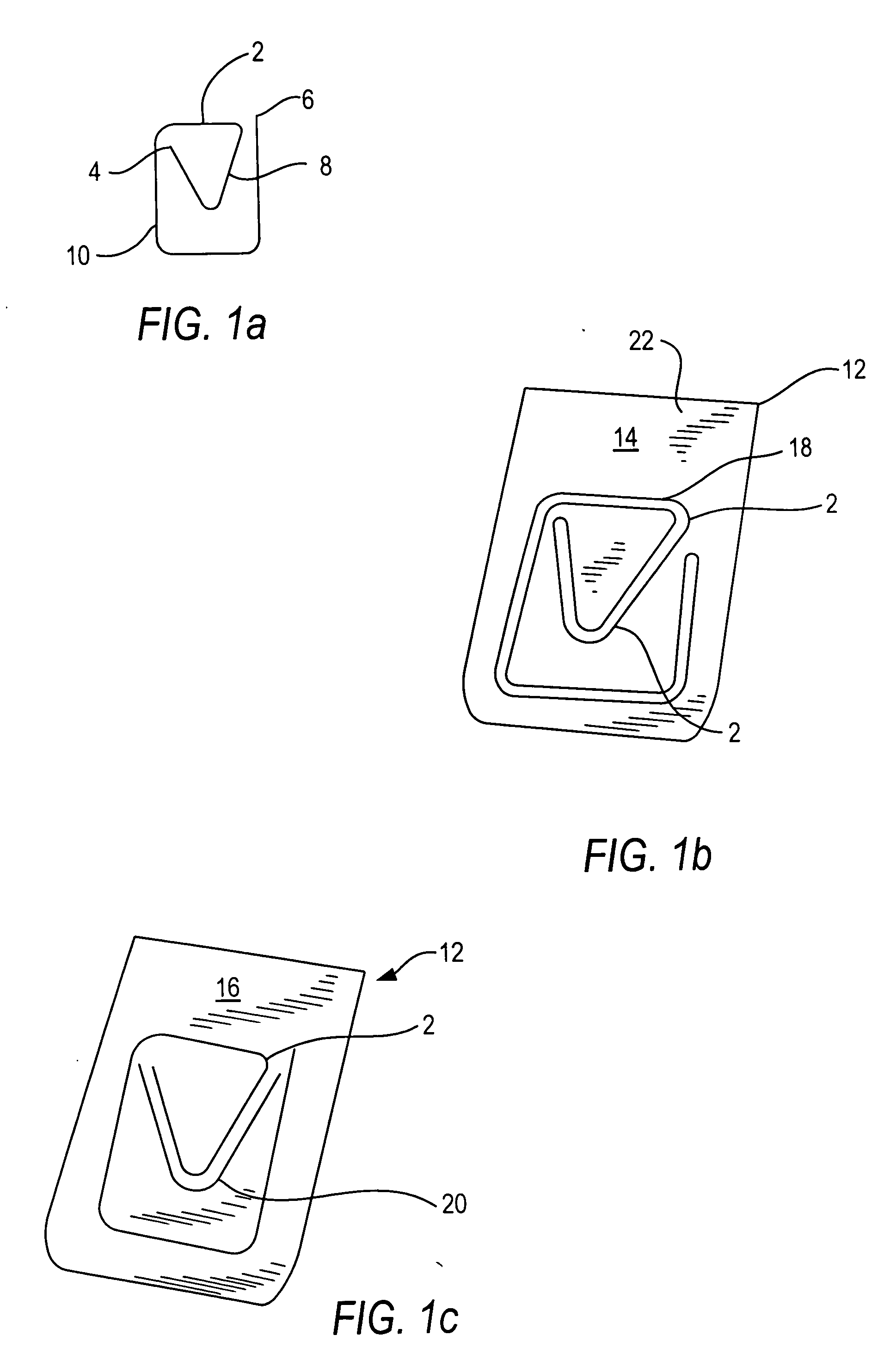

Clip

A clip is described that includes a clipping part for clipping to an object, and a tab part arranged to extend from the clipping part. The tab part includes a first plastics material and a second rubber material. This allows the tab part to be marked with ink from a conventional pen.

Owner:LSC COMM US LLC +1

Modified rubber powder and its prepn and use

InactiveCN1974621ALow costReduce noiseNon-macromolecular adhesive additivesOther chemical processesRubber materialChemical reaction

The present invention relates to modified rubber powder and its preparation process and use. Structurally, the modified rubber powder has alkyl group, alkenyl group, hydroxyl group, carboxyl group, nitrile group or amino group in the side chain or has side chain connected via double bond reaction to butadiene, polystyrene, vinyl acetate, acrylate, acrylonitrile or other compound. The modified rubber powder has the structural features of rubber retained and thus excellent mechanical performance, physical and chemical performance and machining performance. The introduction of functional group to the side chain results in obviously raised compatibility with other rubber material, plastic and other polymer material, easy grafting reaction and functional group chemical reaction for further modification. In addition, the performances may be regulated via altering the sort and amount of the introduced functional groups.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

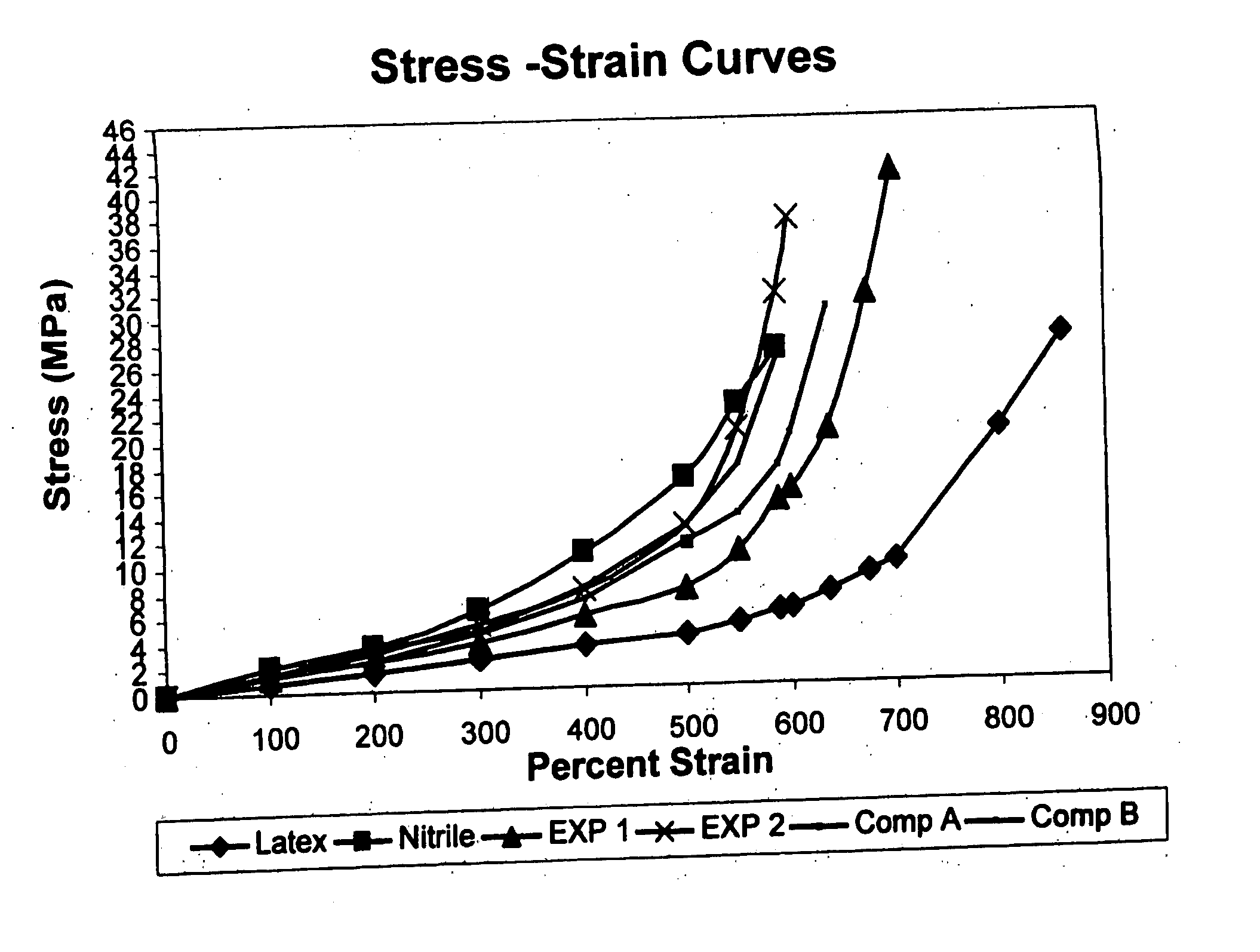

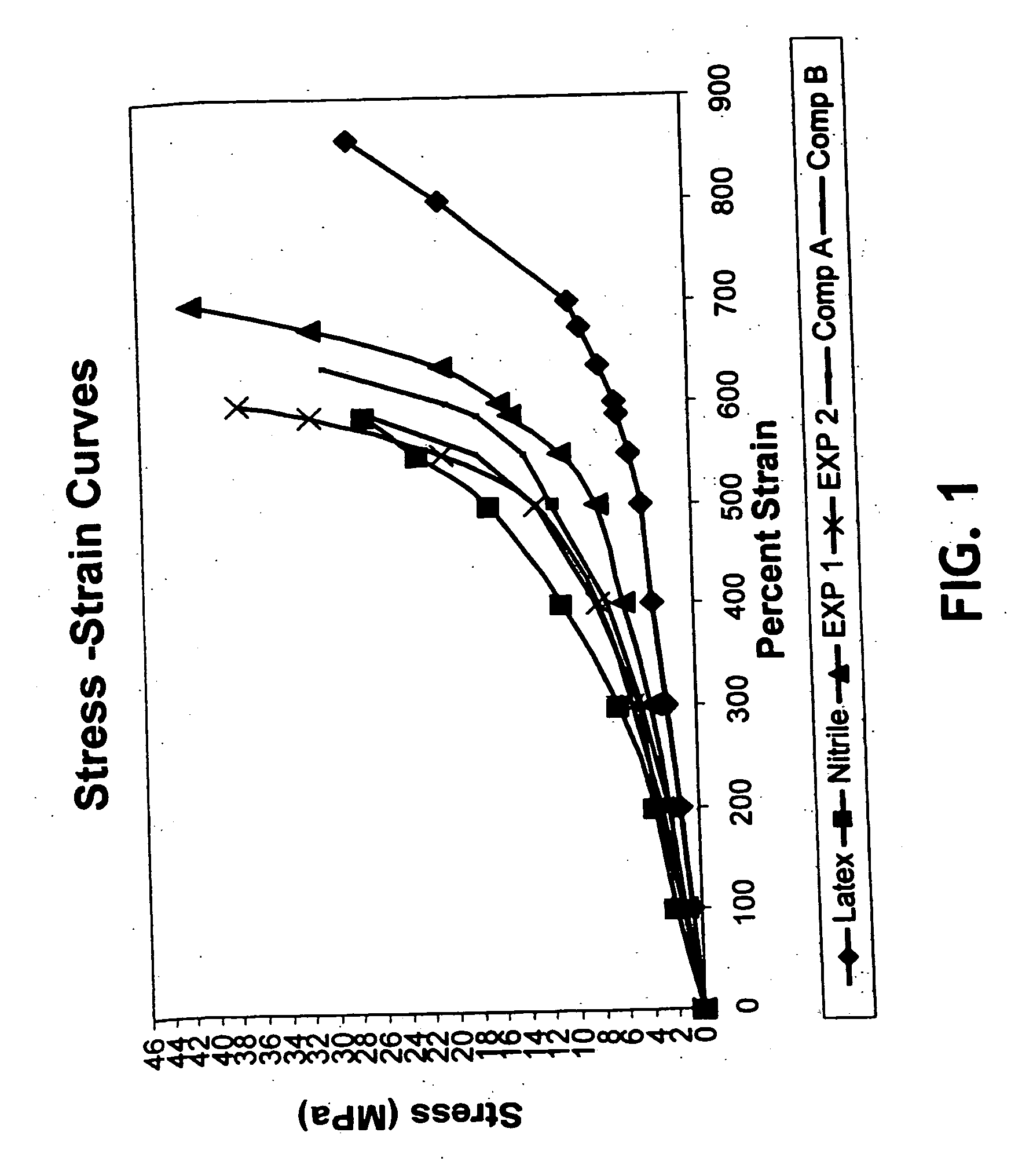

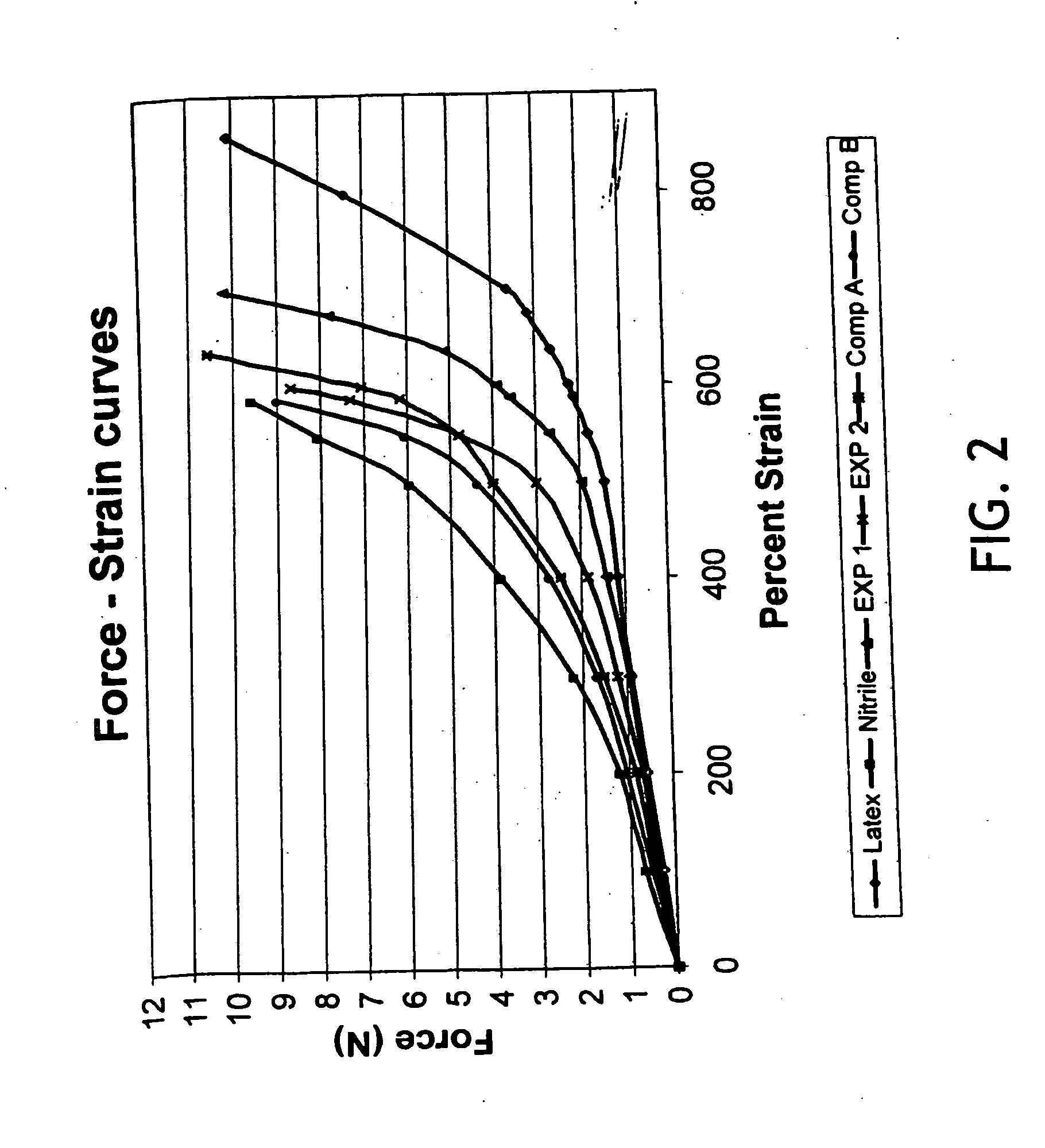

Exterior-coated nitrile rubber article having natural rubber characteristics

ActiveUS20060257674A1Maximize material strengthMinimize forceCosmetic preparationsBiocideRubber materialPolymer science

A material for making elastomeric nitrile rubber articles is disclosed. In particular, the process and material formulation can produce nitrile rubber based articles, which exhibit force-strain characteristics that are comparable to those of natural rubber latex articles, while maintaining the tensile strength properties of nitrile rubber. The process includes an accelerator composition at the pre-cure stage having a dithiocarbamate, a thiazole, and a guanidine compound. The invention also includes an elastomeric nitrile rubber product made by the process, such as examination, surgical, or work gloves, which can have an exterior coating over naked rubber selected from either a silicone emulsion or oil, glycerin solution, a combined mixture of silicone and glycerin / glycerol, a fluorocarbon release agent, or a natural or synthetic hydrocarbon-based oil in amounts that do not degrade said substrate rubber material.

Owner:O&M HALYARD INC

Modified hydrogenated nitrile-butadiene rubber and its preparing method

The present invention relates to the preparing technology of composite rubber material. Carbon nanotube via surface treatment and liquid rubber are ultrasonically mixed and added into partial hydrogenated nitrile-butadiene rubber to prepare mother rubber; the mother rubber is mixed with the rest hydrogenated nitrile-butadiene rubber, carbon black, zinc oxide and sulfurizing agent, and the mixture is mixed in a rolling mixer or a Banbury mixer and sulfurized to obtain the carbon nanotube modified hydrogenated nitrile-butadiene rubber. The present invention has the beneficial effects of raised heat performance, antiwear performance, mechanical strength, antiageing performance, etc. raised use performance and expanded application range.

Owner:SINOPEC OILFIELD EQUIP CORP

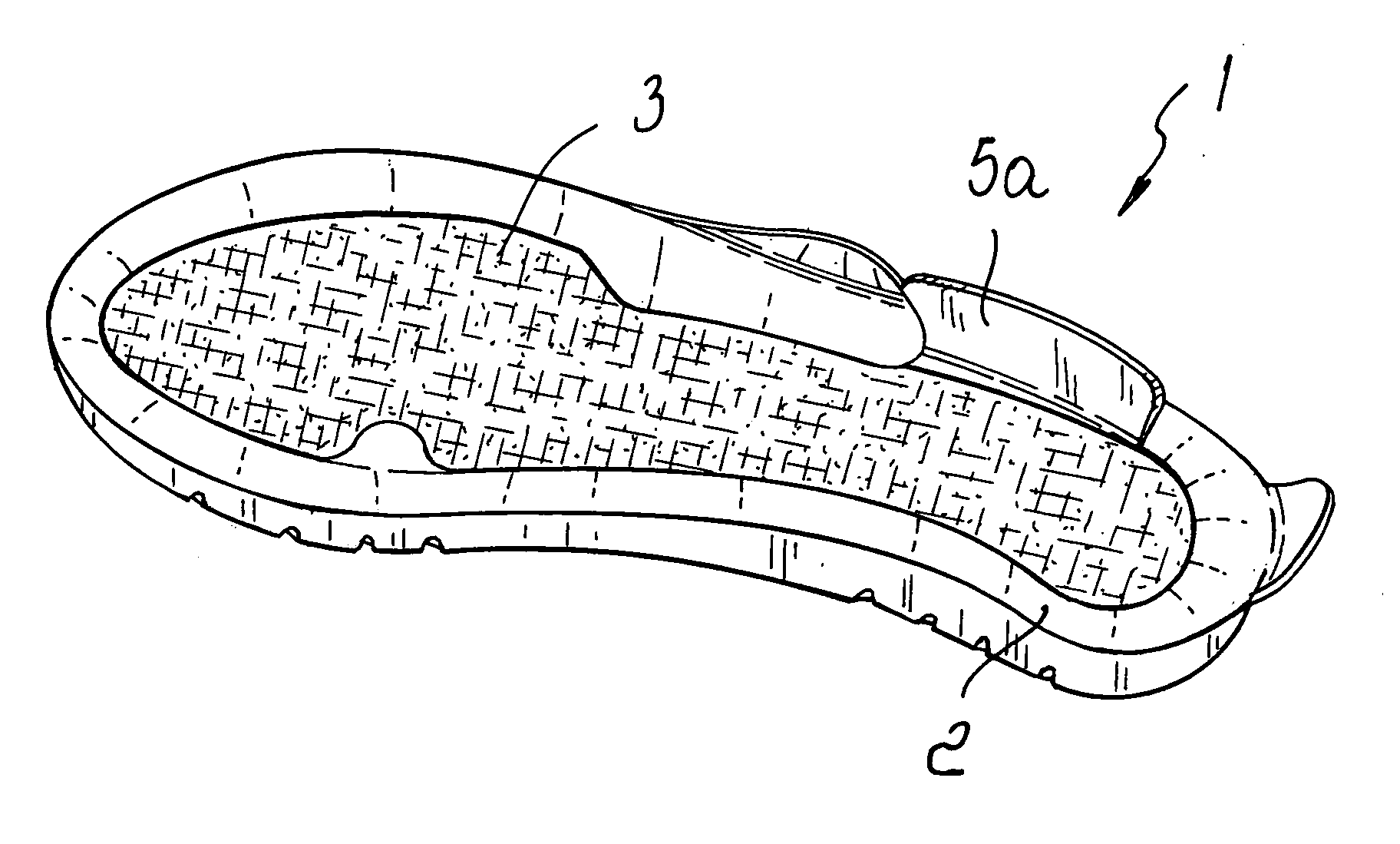

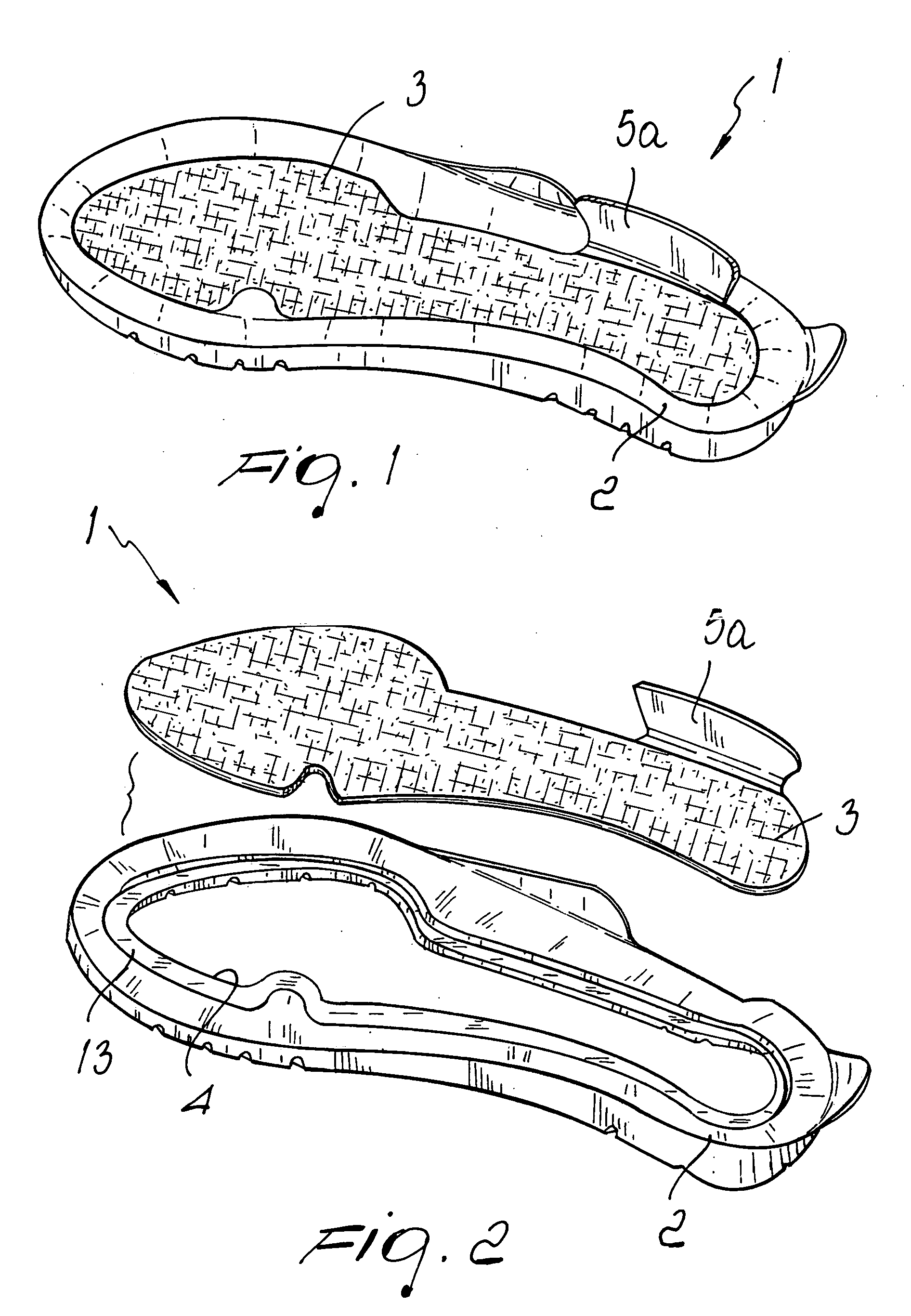

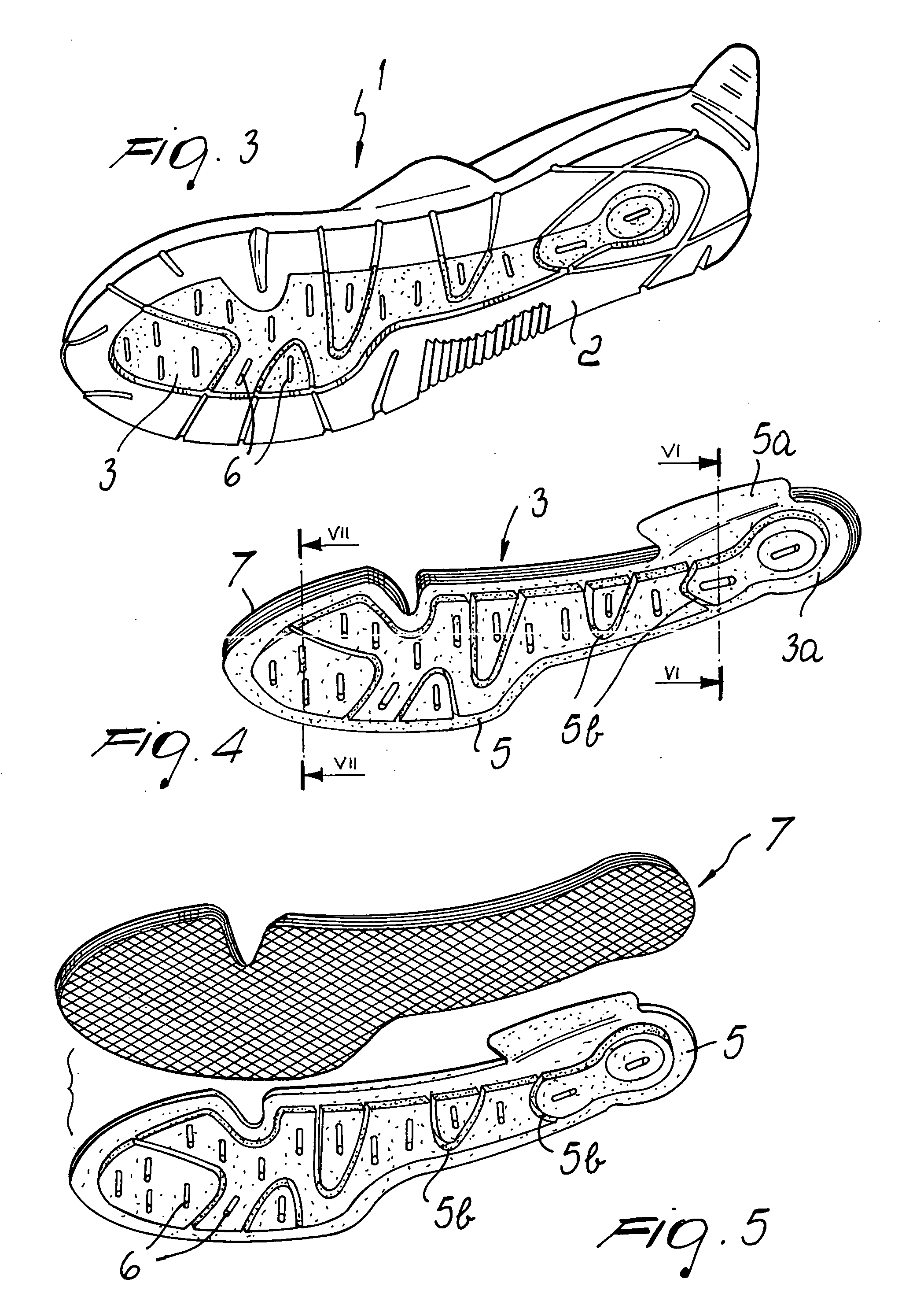

Sole for shoes

InactiveUS20050229431A1Easy and comfortable walkingMore elasticSolesDomestic footwearRubber materialBiomedical engineering

A sole for shoes comprising a sole base body, the sole base body having at least one cutout that is closed at least partially by at least one multilayer sheet insert; the insert has, in its lower part intended to be directed toward the ground, a layer made of rubber material, which is molded directly by direct microinjection onto the remaining part of the multilayer sheet insert.

Owner:CALZATURIFICIO MONTEROSA

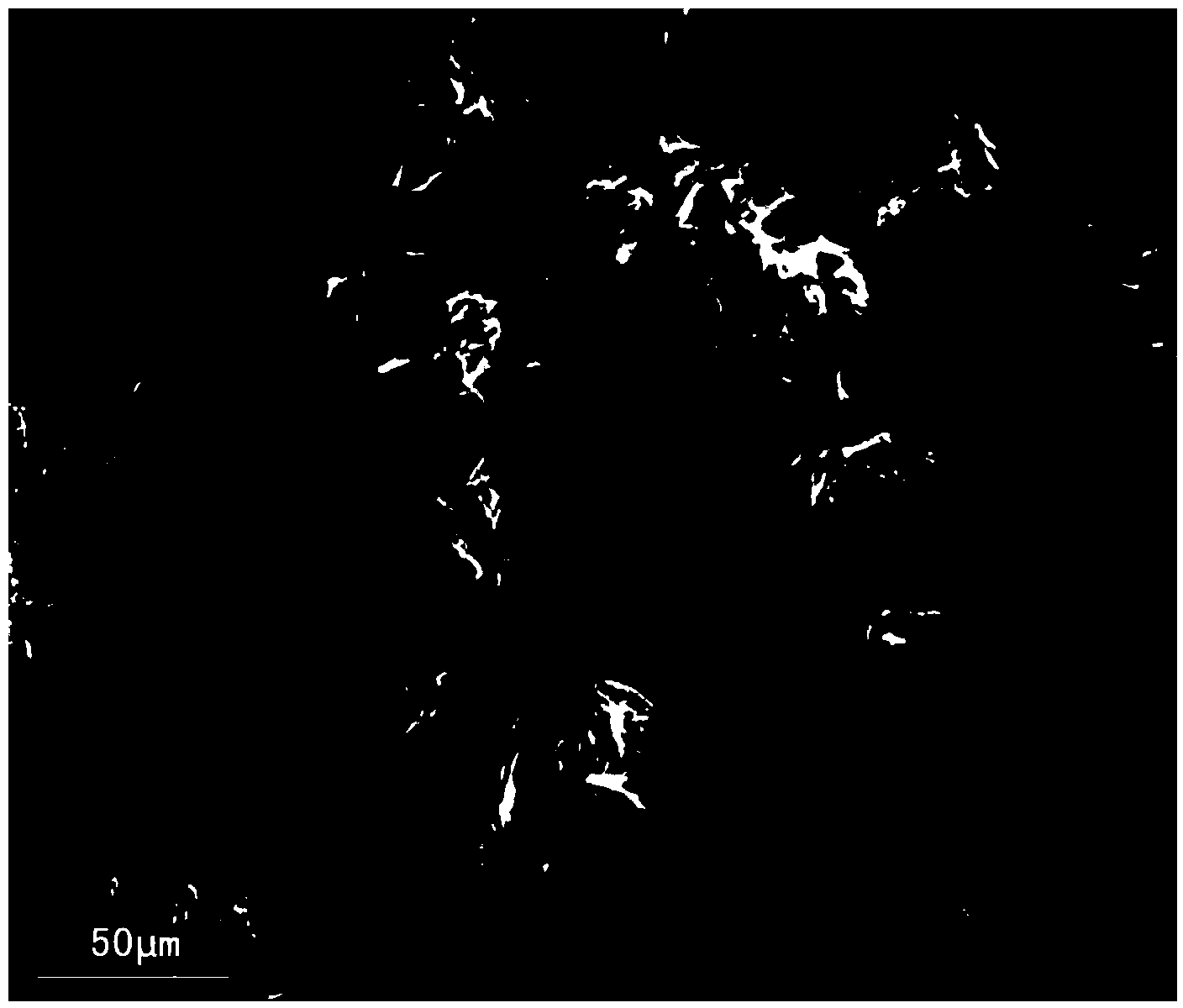

Orientated carbon nanotube composite, process for producing orientated carbon nanotube, and, produced using orientated carbon nanotube composite, pneumatic tire, wheel for vehicle, tire wheel assembly and disk brake

InactiveUS20060061011A1Improve efficiencyImprove conductivityMaterial nanotechnologyBraking discsRubber materialCarbon nanotube

A carbon nanotube orientated composite formed by orientating carbon nanotubes in a given direction in a matrix having a heat conductivity lower than that of carbon nanotube, in which at least a part of carbon nanotubes are contacted with each other to be continuous from one end to the other end between both ends in the orientated direction, is provided as a material having a heat conductivity considerably higher than that of copper, aluminum or the like or a material to be disposed in rubber material having a low heat releasing characteristic to considerably improve the heat conduction, and also there are provided a method of producing the same as well as a pneumatic tire, a wheel for a vehicle, a tire-wheel assembly and a disc brake using this material.

Owner:BRIDGESTONE CORP

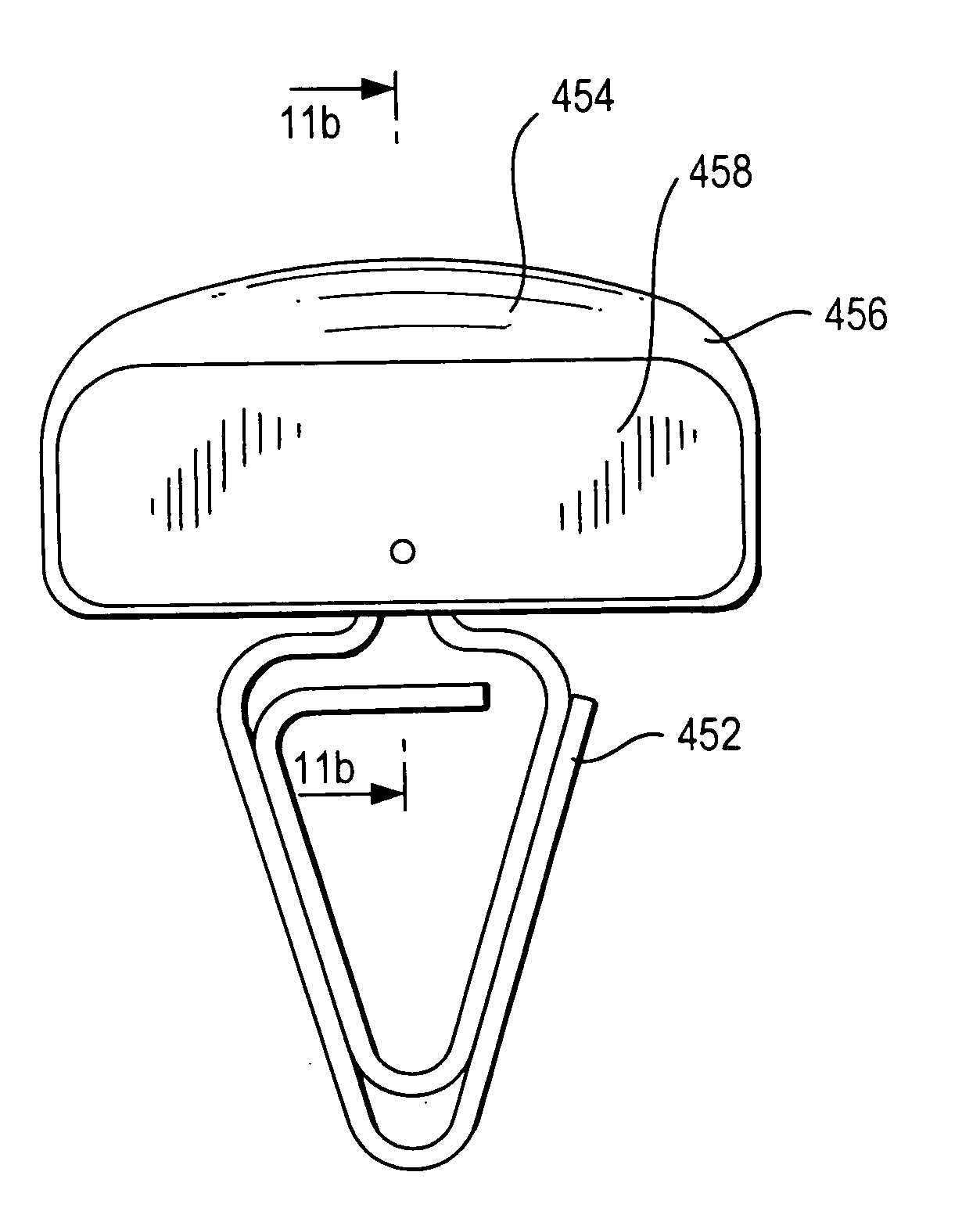

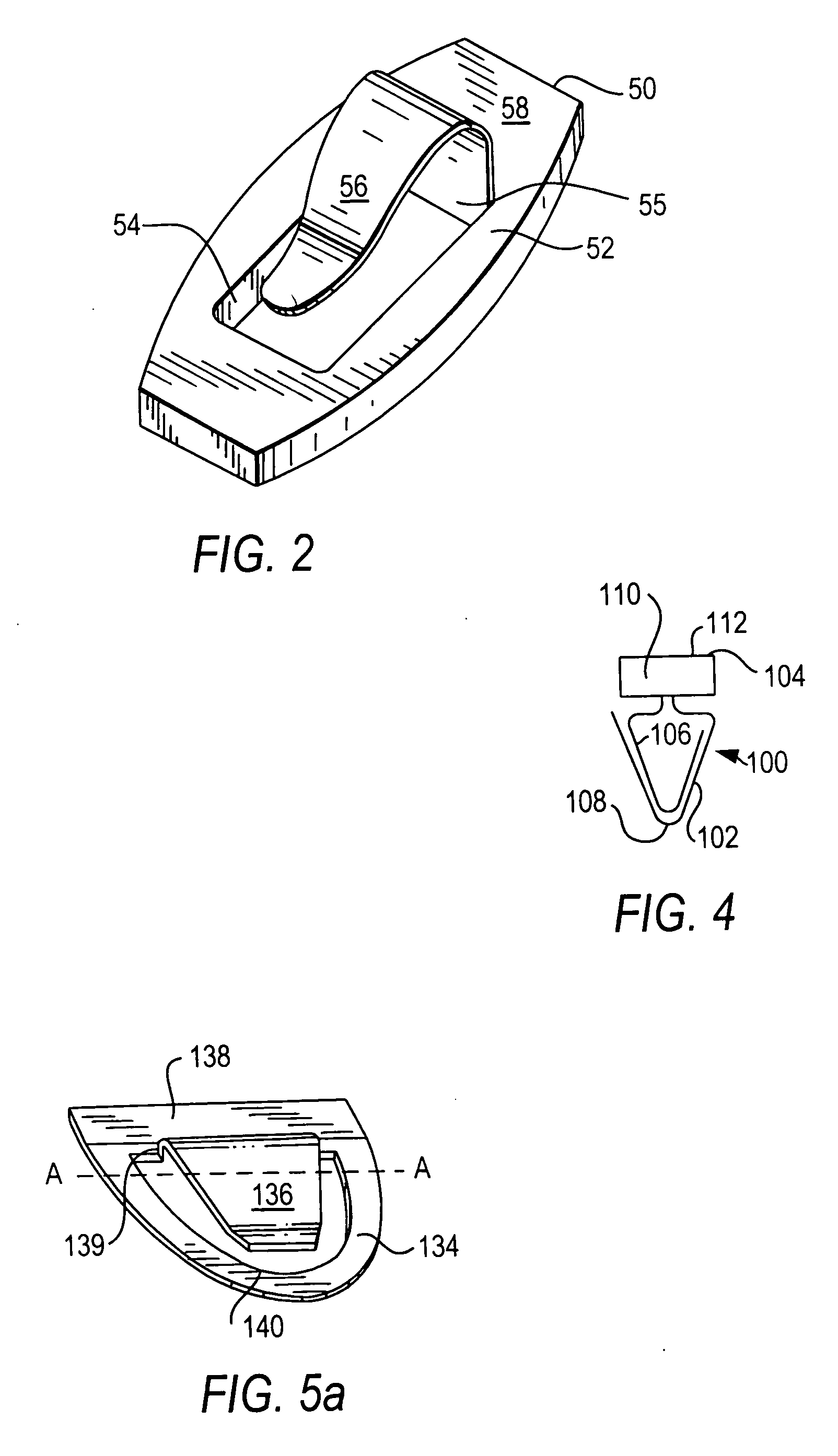

Mount for attaching an electronic component to a rubber article

InactiveUS20060220816A1Permanent attachmentSmall loadSolid-state devicesTyre measurementsRubber materialTectorial membrane

A main body for attaching an electronic component, for example, a transponder, on a rubber article, such as a tire, a conveyor belt, or the like. The mount has a connecting layer made, in one embodiment, of uncured, curable rubber material which is covered by an adhering protection film prior to use. A main body made of cured or uncured rubber material is permanently connected with this connecting layer and has a recess for accommodating the electronic component. A cover preferably made of the main body material, serves for fixing the electronic component in the recess in the main body.

Owner:STAHLGRUBER OTTO GRUBER

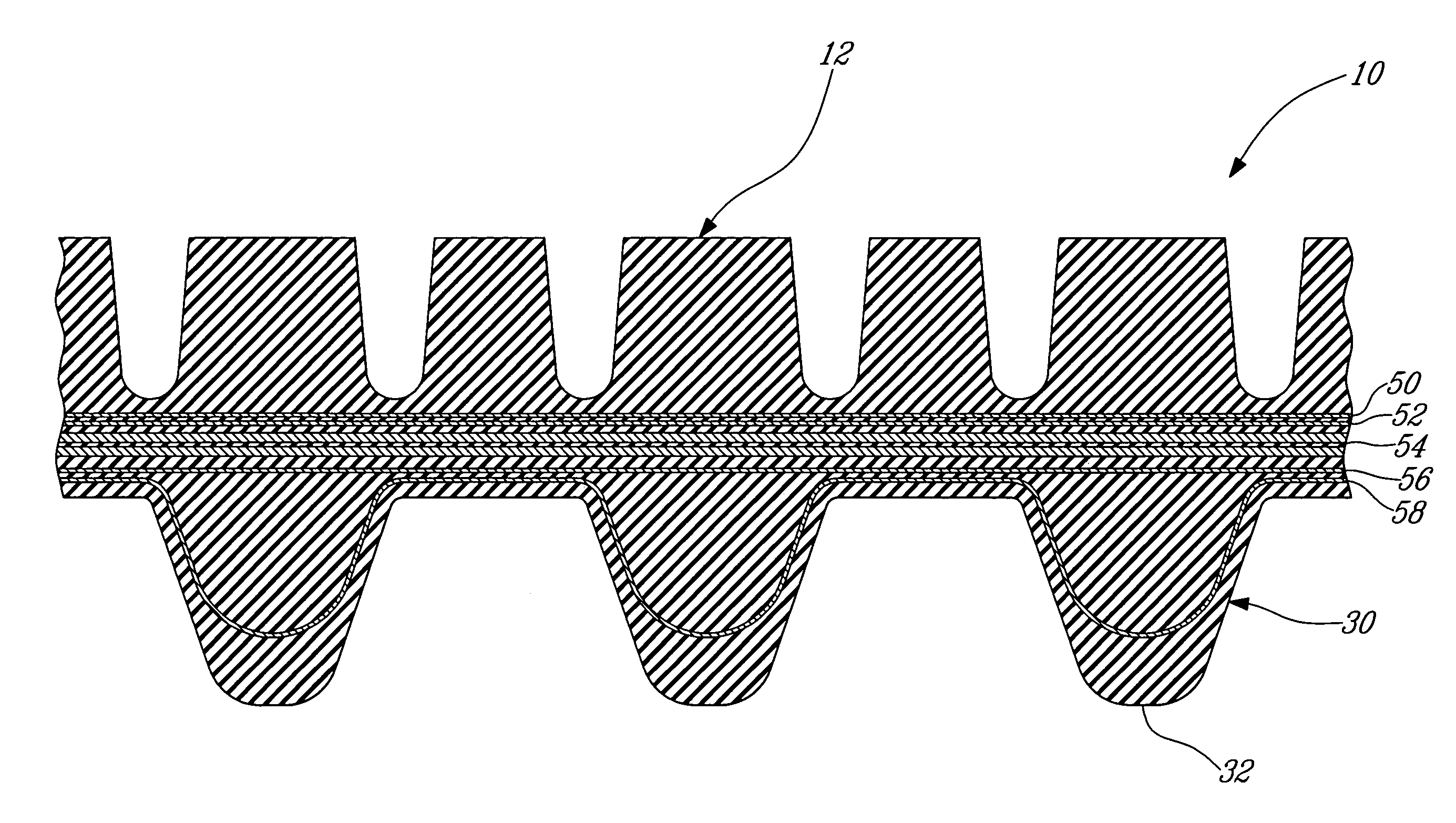

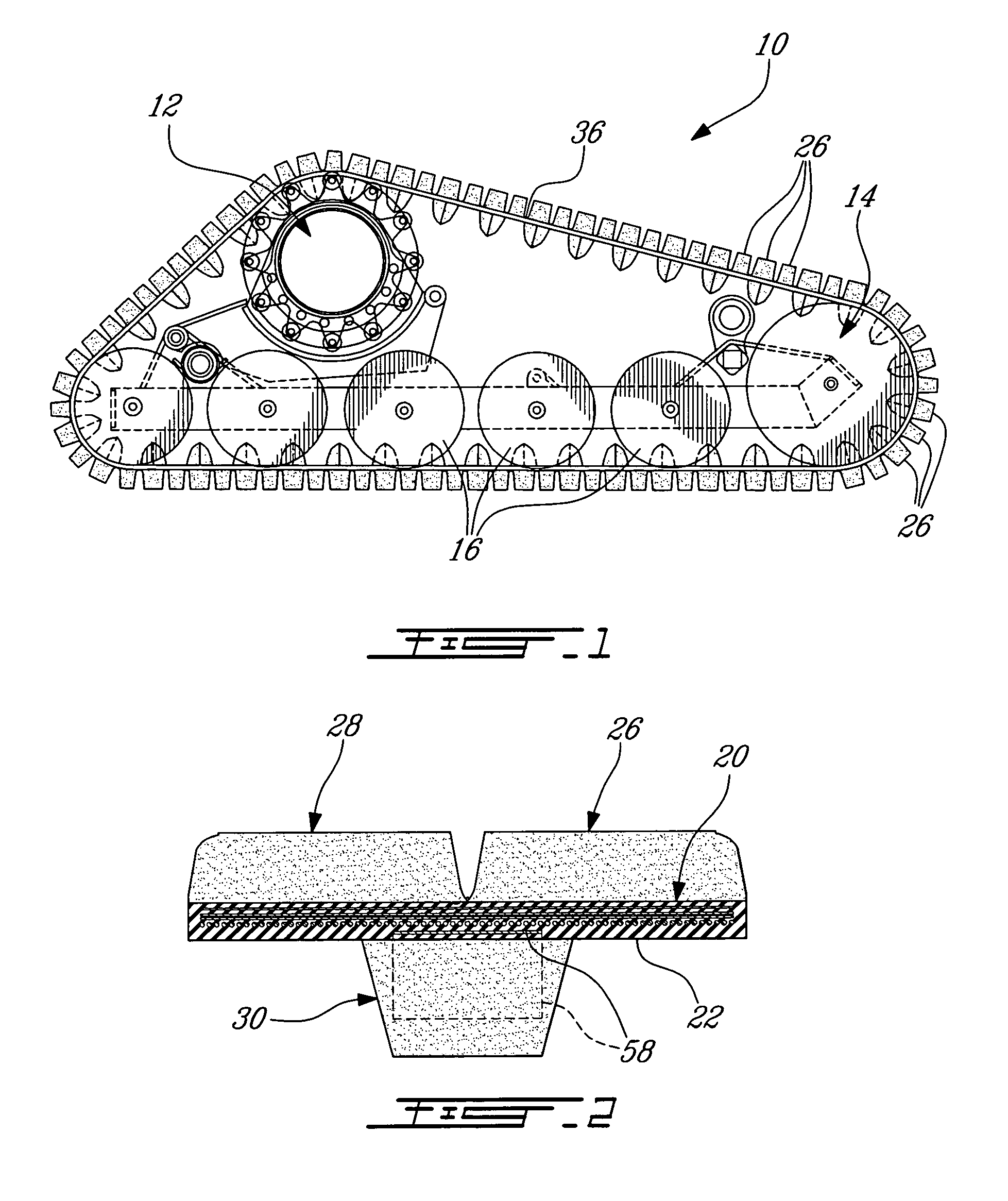

Endless track for industrial or agricultural vehicles

Described is an endless track for an industrial or agricultural vehicle consisting of a body formed of a rubber material having an outer surface displaying a series of ground engaging profiles longitudinally spaced along the surface and an inner surface displaying a series of longitudinally spaced drive lugs adapted to be engaged by drive sprockets on the vehicle driving assembly. The body of the endless track is fabric reinforced. One layer of fabric longitudinally extends at a distance from the inner surface of the track and has a width slightly less than the width of the drive lugs so that the fabric may extend inside the drive lugs to increase their rigidity.

Owner:CAMOPLASY INC

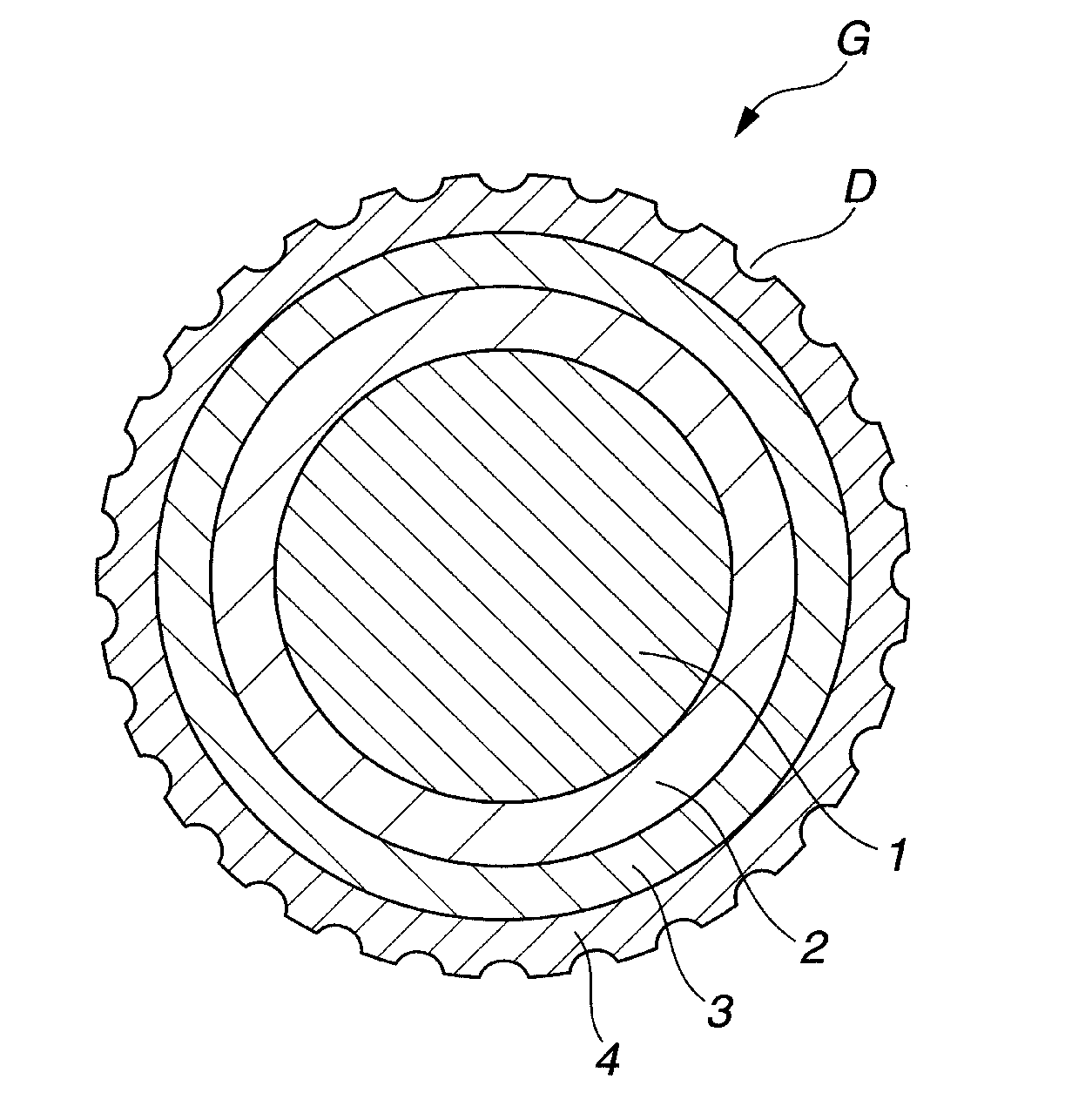

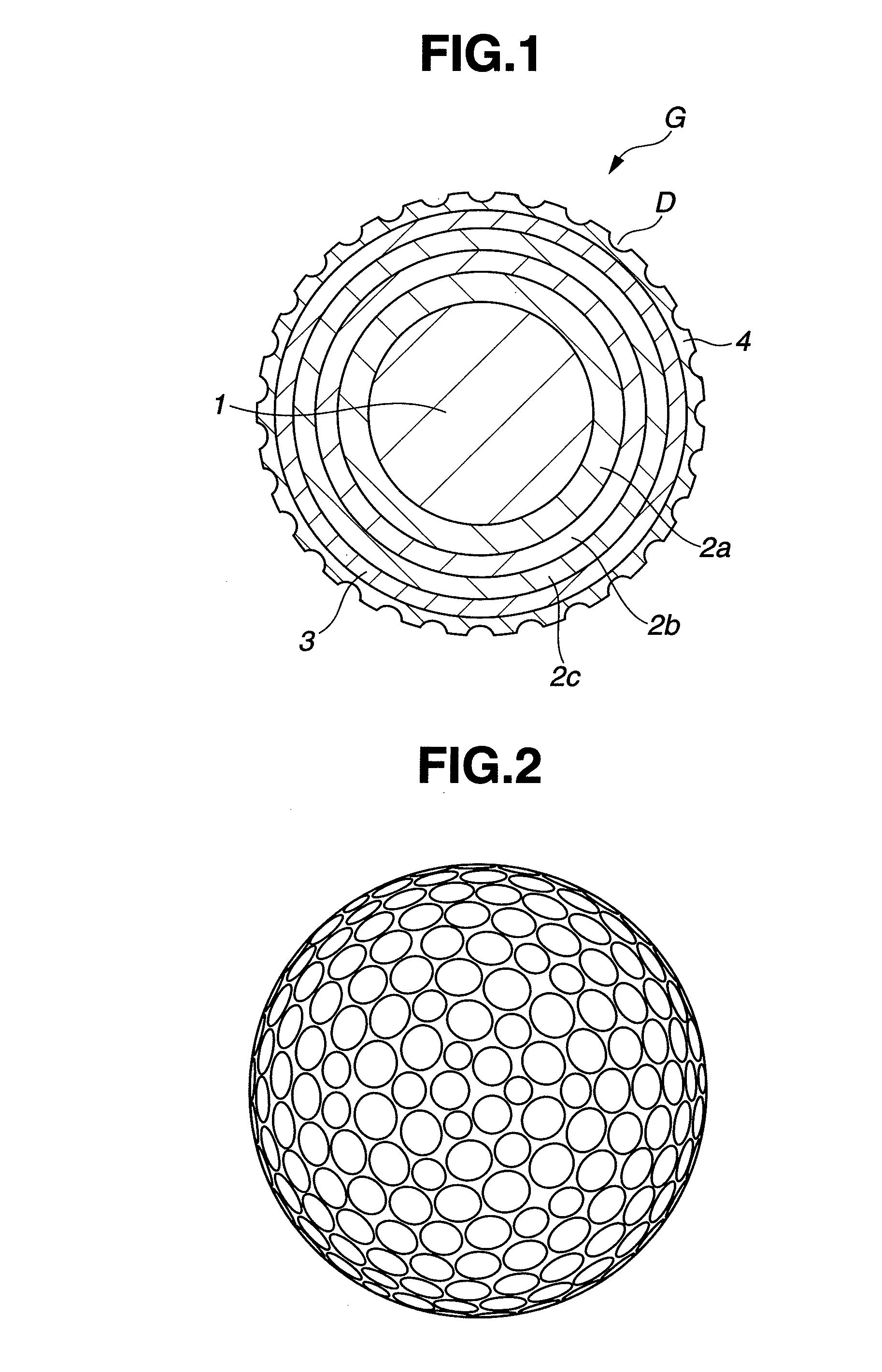

Multi-piece solid golf ball

ActiveUS20090111611A1Satisfactory controllabilitySatisfactory flight performanceGolf ballsSolid ballsRubber materialInter layer

The present invention provides a multi-piece solid golf ball having a core, an envelope encasing the core, an intermediate layer encasing the envelope, and a cover which encases the intermediate layer and has formed on a surface thereof a plurality of dimples. The envelope is composed of at least two layers. The core is formed primarily of a rubber material. The envelope, intermediate layer and cover are each formed primarily of the same or different resin materials. The envelope layers and the intermediate layer have a combined thickness which is at least 5.0 times thicker than the cover. An optimized surface hardness relationship exists between the core, a Sphere I composed of the core encased by the envelope layers, a Sphere II composed of the core encased by the envelope layers and the intermediate layer, and a Sphere III composed of the core encased by the envelope layers, the intermediate layer and the cover. The golf ball has an outstanding flight performance and controllability which are acceptable to professionals and other skilled players, in addition to which it has an excellent durability to cracking under repeated impact and an excellent scuff resistance.

Owner:BRIDGESTONE SPORTS

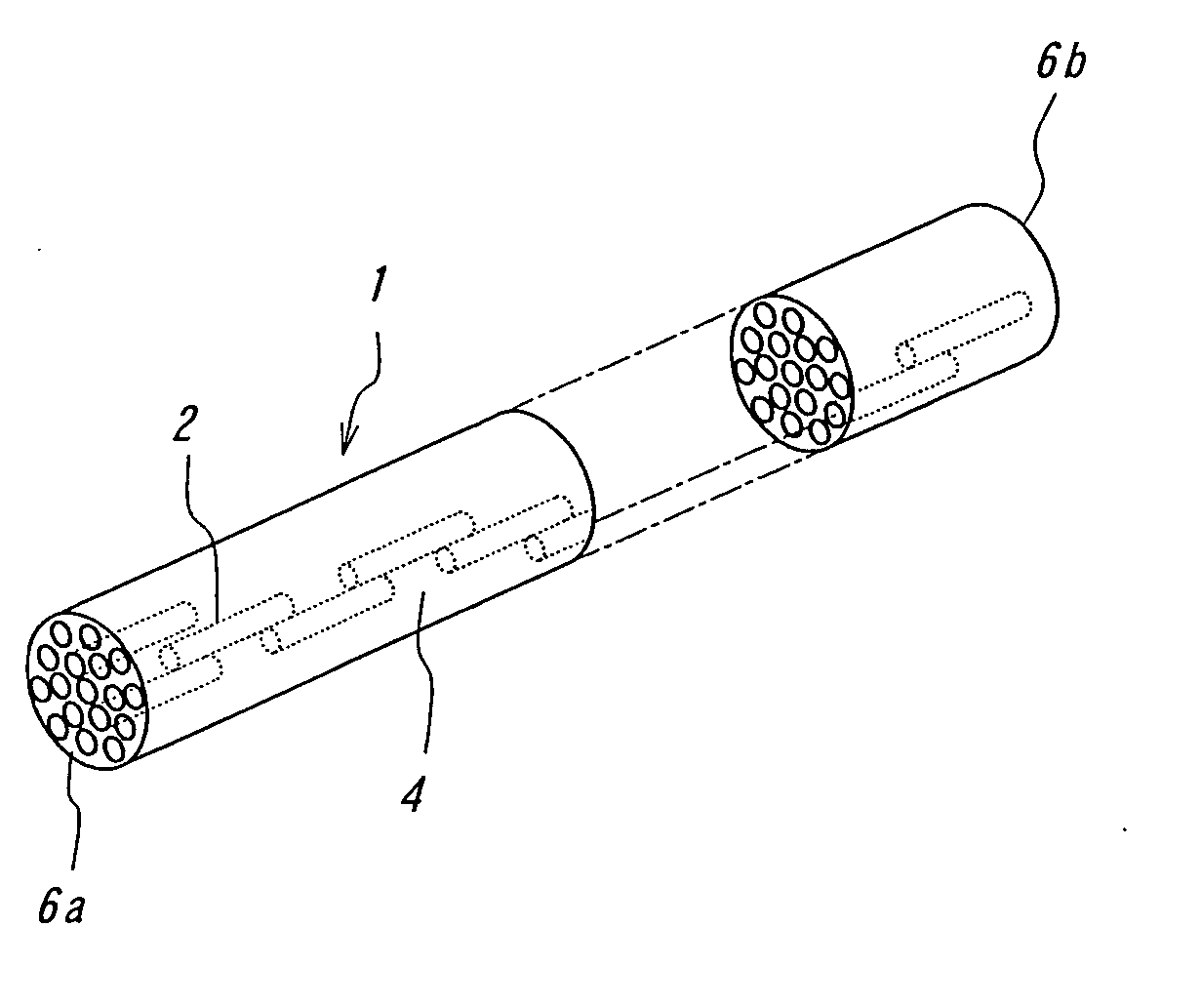

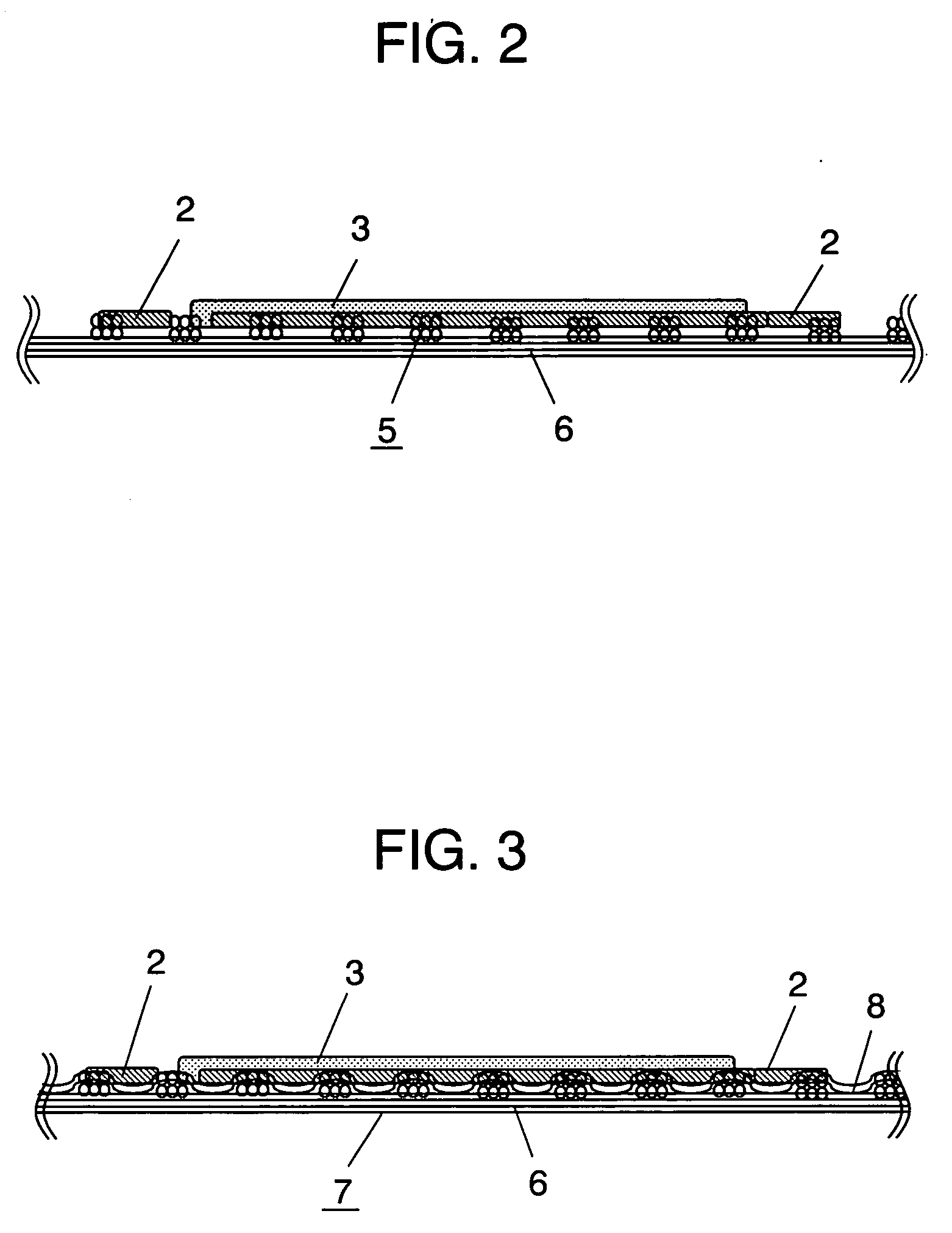

Flexible ptc heating element and method of manufacturing the heating element

InactiveUS20050173414A1Resistor terminals/electrodesResistor mounting/supportingRubber materialEngineering

The flexible PTC heating element according to the invention has one of the following constitutions. A portion of an electrodes and a PTC resistor is impregnated into a flexible substrate. A flexible substrate is made of resin foam or rubber material having a concave / convex shape formed on the surface. The flexible PTC heating element has an elongation deformation portion disposed to at least one of an electrode and a PTC resistor. A flexible substrate has adhesiveness and either a flexible substrate or a flexible cover material has an elongation control portion. Therefore, the flexible PTC heating element is highly flexible and excellent in vibration durability.

Owner:PANASONIC CORP

Composite wear-resisting shoe sole

A composite wear-resisting shoe sole is prepared from, by weight, 60-100 parts of natural rubber, 10-50 parts of styrene butadiene rubber, 5-20 parts of polar rubber, 10-60 parts of modified white carbon black, 1-10 parts of zinc oxide, 1-4 parts of accelerant, 0.1-0.5 part of antioxidant, 2.5-4.5 parts of active agent, 5-20 parts of filler and 1-10 parts of sulfur .The filler is tetrapod-like zinc oxide whiskers .According to the composite wear-resisting shoe sole, the natural rubber and a small amount of polar rubber are jointly used as main rubber materials, the white carbon black subjected to toluene diisocyanate graft modification is added to serve as a reinforcing material, the tetrapod-like zinc oxide whiskers of a highly regular structure are used as a filling frame, the accelerant, the composite antioxidant and the active agent are added in sequence, and the composite wear-resisting shoe sole with high slippery resistance and tear strength and a remarkably improved frictional coefficient is prepared.

Owner:宁波市富罗迷鞋业有限公司

Graphene-containing silicone rubber composite material with high thermal conductivity and preparation method thereof

InactiveCN103627179AImprove thermal conductivityUnique two-dimensional sheet structureHeat-exchange elementsRubber materialVulcanization

The invention belongs to the field of a heat conducting polymer-based composite, and particularly relates to a graphene-containing silicone rubber composite material with the high thermal conductivity and a preparation method thereof. The composite material comprises a matrix, a heat conducting filler and a vulcanizing agent. The preparation method comprises the following steps: mixing at a room temperature so as to obtain a mixed rubber material; and carrying out hot press molding and one-stage vulcanization on the mixed rubber material by using a flat vulcanizing machine, and putting in a drying oven, carrying out two-stage vulcanization, thus obtaining the silicone rubber composite material with the high thermal conductivity. As graphene is high in thermal conductivity and has a unique two-dimensional lamellar structure, an interconnected heat conducting network is easy to form in the composite material, and the thermal conductivity of the silicon rubber composite material is obviously increased; and the thermal conductivity of the graphene-containing silicone rubber composite material is 0.3W / m.K-1.5W / m.K, and the hardness of the silicone rubber composite material can be reduced. The graphene-containing silicone rubber composite material with the high thermal conductivity is simple in preparation technology, high in production efficiency and easy for the realization of industrialization mass production, and meanwhile, a direction is pointed out for the batch application of graphene.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

All-steel giant-scale engineering tyre side glue and all-steel giant-scale engineering tyre using the same

The present invention relates to a tyre side rubber with perfect ozone resistance, thermo-oxidative ageing resistance and flex crack resistance, applying ethylene -propylene-diene rubber in single-layer huge full steel engineering tyre; the invention also relates to the full steel huge engineering tyre using the tyre side rubber. The full steel huge engineering tyre using the tyre side rubber of the present invention comprises usable sulfur and / or sulfur rubber mixture, the rubber mixture comprises: a. 10-30 parts by weight of ethylene -propylene-diene rubber; b. 50-90 parts by weight of caoutchouc; c. 0-20 parts by weight of butadiene rubber and / or styrene butadiene rubber; and the total content of the ethylene -propylene-diene rubber, caoutchouc, butadiene rubber and / or styrene butadiene rubber is 100 parts by weight compositions. The tyre side rubber produced according to the formula has perfect ozone resistance, thermo-oxidative ageing resistance and flex crack resistance, the rigidity of the rubber material of the tyre side rubber is 55-70 Shore A, the tension intensity is 15-25 Mpa, the flex crack resistance grade is less than or equal to 6 grade / 300000 times.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

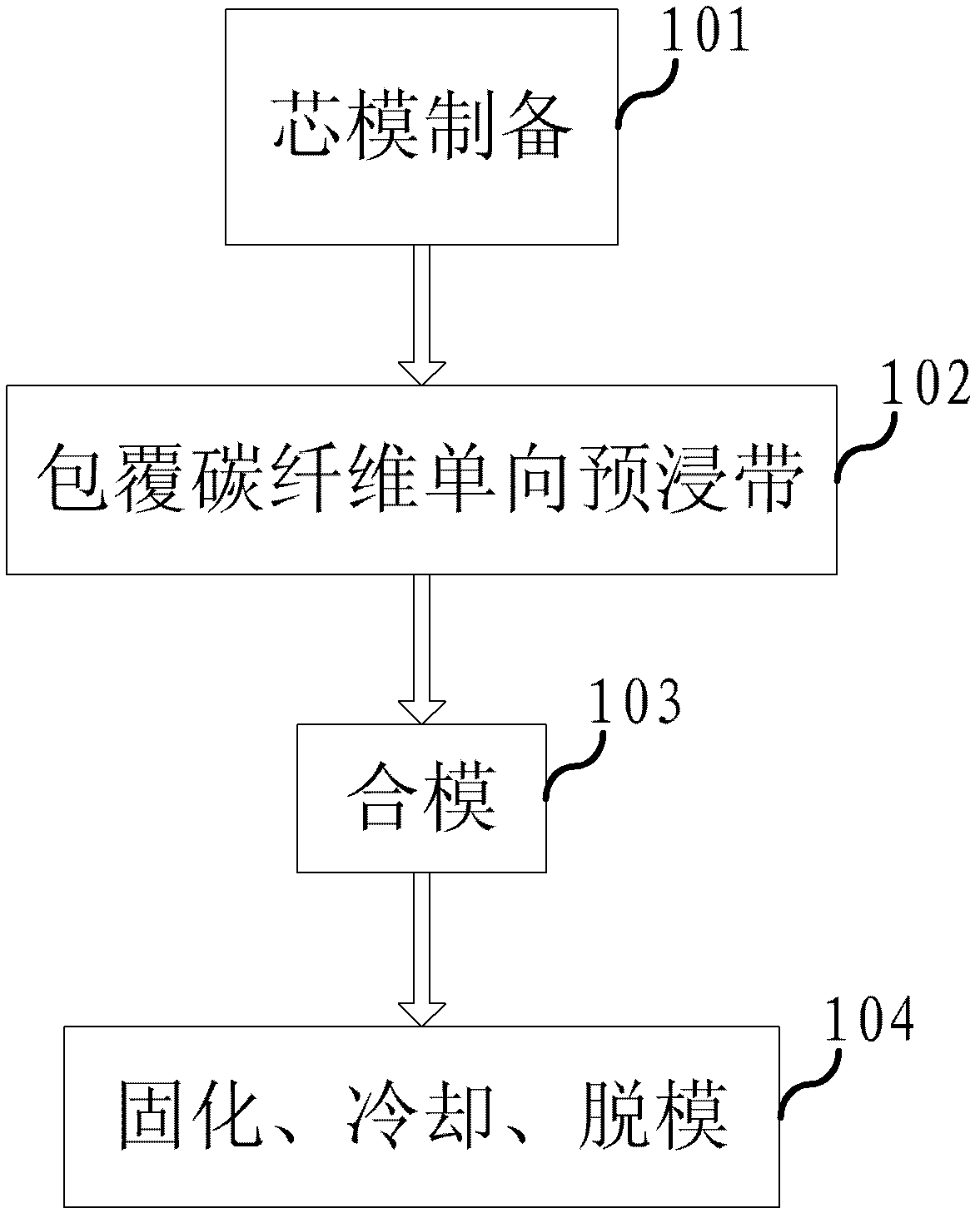

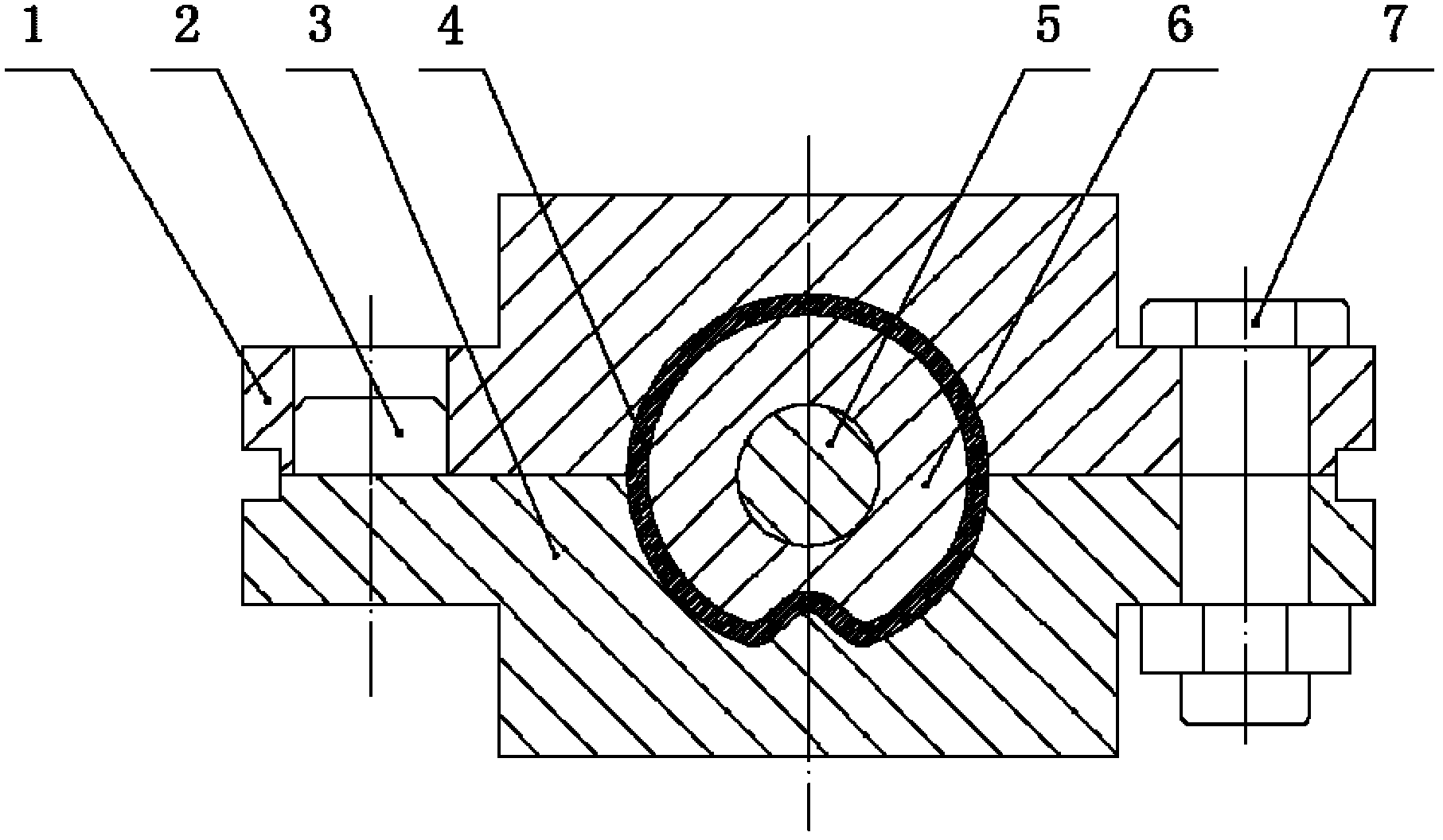

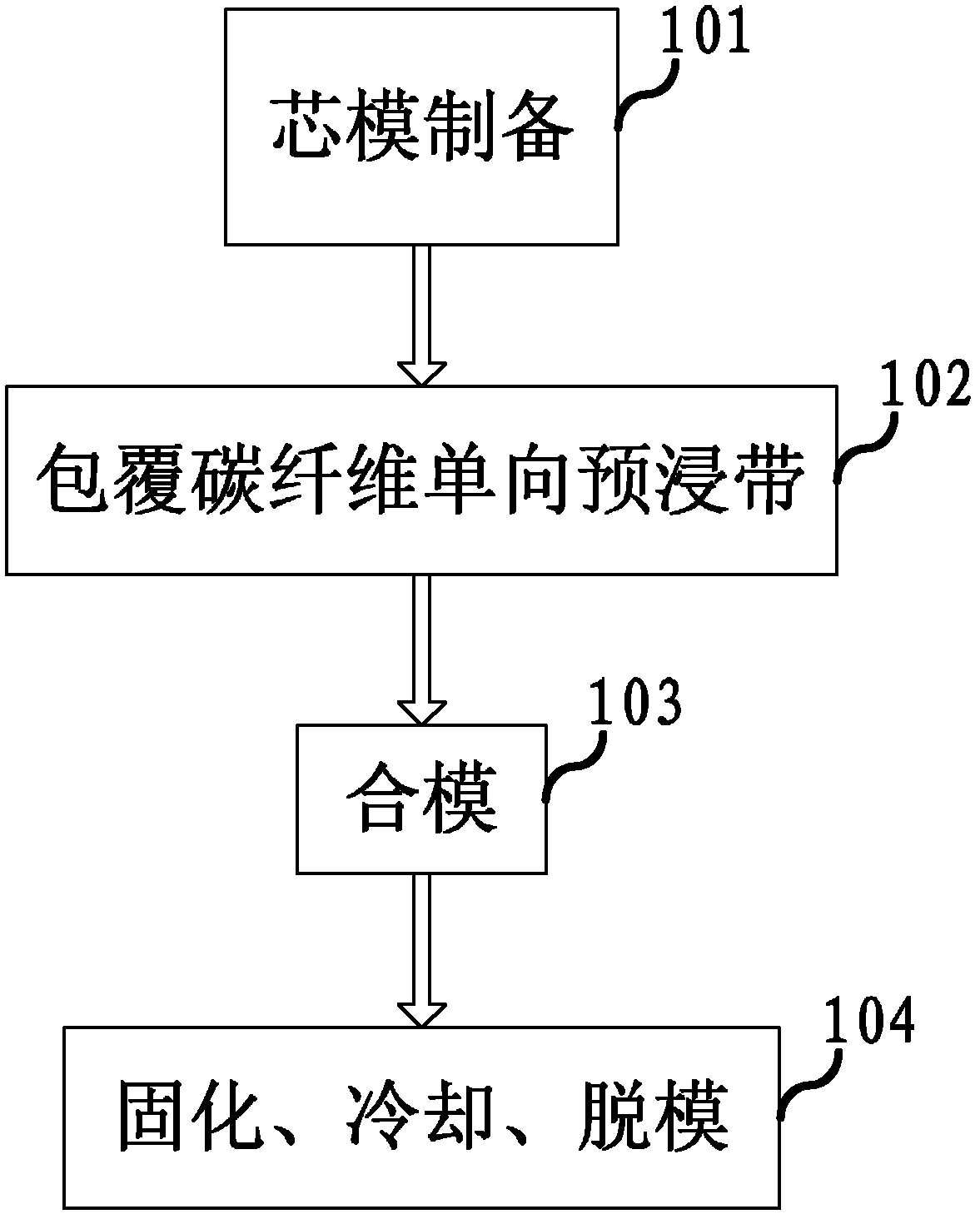

Method for forming carbon fiber pipe and die thereof

The invention discloses the technical field of carbon fiber composite materials, and discloses a method for forming a carbon fiber pipe. The method comprises the following steps of: preparing a core mould, namely preparing the core mould for wrapping carbon fiber one-way preimpregnation belts, wherein the core mould comprises a metal core rod and a rubber material wrapping the metal core rod; paving and coating the carbon fiber one-way preimpregnation belts, namely after coating a release agent on the surface of the core mould, paving and coating a plurality of layers of carbon fiber one-way preimpregnation belts according to different angles; closing the die, namely positioning the core mould in which the carbon fiber one-way preimpregnation belts are paved and coated and putting into a female die, closing the die, and fastening; and curing, cooling and demoulding, namely putting the die which is closed into a drying oven, curing, cooling with a furnace, and demoulding to form the required finished piece. The method for forming the carbon fiber pipe has the advantages of simple process, high production efficiency, low manufacturing cost, uniform wall thickness of the product, high quality and stability and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Tyre crown rubber material and mixing method thereof

InactiveCN102604170AGood physical and mechanical propertiesIncrease elasticitySpecial tyresRolling resistance optimizationRubber materialPolymer science

The invention discloses a tyre crown rubber material. The tyre crown rubber material comprises the following raw materials in parts by weight: 60-80 of natural rubber, 20-40 of butadiene rubber BR9000, 0-0.4 of peptizer, 10-30 of intermediate super abrasion furnace black, 25-45 of white carbon black, 3-7 of silane coupling agent, 3-5 of zinc oxide, 1-4 of stearic acid, 1-3 of antiager 6PPD, 0-2 of antiager RD, 1-3 of microcrystalline paraffin, 1-3 of sulfur, 1.5-2.5 of accelerator, 4-6 of fatty acid salt processing agent, 0-1 of anti-reversion agent, 2-5 of environment-friendly arene oil TDAE (Treated Distillate Aromatic Extract), 1-3 of octyl phenolic aldehyde tackifying resin and 0-0.3 of scorch retarder. When mixing is carried out in three sections, partial formula raw materials are subjected to rubber material mixing, and then other formula materials are added for rubber material mixing. The tyre crown rubber material produced by using the tyre crown rubber material formula is good in comprehensive processing property, has the characteristics of low thermogenesis, ageing resistance and tearing resistance and is environment-friendly and can be used for producing green full-steel radial tyre crown.

Owner:安徽大瑞橡胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com