Tyre crown rubber material and mixing method thereof

A technology of tire crown rubber and mixing, applied in special tires, tire parts, rolling resistance optimization and other directions, can solve the problems of high rolling resistance, non-conformity and poor wet skid resistance of tires, and achieve good comprehensive processing performance, low thermogenic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

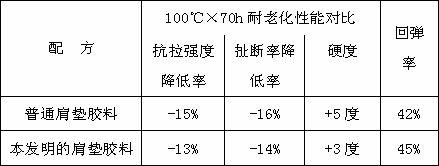

Image

Examples

Embodiment 1

[0040] A kind of all-steel radial truck tire crown compound. The raw materials are composed of natural rubber 60~80, butadiene rubber BR9000 30, peptizer a 0~0.4, medium super wear-resistant carbon black 10~30, white Carbon black 25~45, silane coupling agent 3~7, zinc oxide 3~5, stearic acid 1~4, antioxidant 6PPD1~3, antioxidant RD 0~2, microcrystalline paraffin wax 1~3, sulfur 1~ 3. Accelerator 1.5~2.5, fatty acid salt processing aid 4~6, anti-reversion agent 0~1, environmentally friendly aromatic oil TDAE 2~5, octyl phenolic tackifying resin 1~3, anti-scorching agent 0 ~ 0.3.

Embodiment 2

[0042] A kind of all-steel radial truck tire crown compound, the weight parts of which are composed of raw materials: natural rubber 70, butadiene rubber BR9000 30, peptizer a 0.3, medium super wear-resistant carbon black N234 20, high dispersibility white carbon black 25~45, silane coupling agent 5, zinc oxide 4, stearic acid 2, antioxidant 6PPD3, antioxidant RD 1, microcrystalline paraffin 3, sulfur 2, accelerator CBS 2, fatty acid salt processing aid 5, anti-aging agent Vulcanization reversion agent PK900 1, environmentally friendly aromatic oil TDAE 3, octyl phenolic tackifying resin 3, anti-scorching agent CTP 0.1.

[0043] The specific mixing process is as follows:

[0044] 1. One stage master mixing: mixing in an internal mixer, the internal mixer speed is 35-50 rpm, the mixing steps are:

[0045] (1) Add raw rubber and peptizer into the internal mixer and mix for 20-40 seconds;

[0046] (2) Mix 1 / 2 carbon black, 1 / 2 white carbon black, silane coupling agent, and processing ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com