Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2870results about How to "Good physical and mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ophthalmic devices, methods of use and methods of fabrication

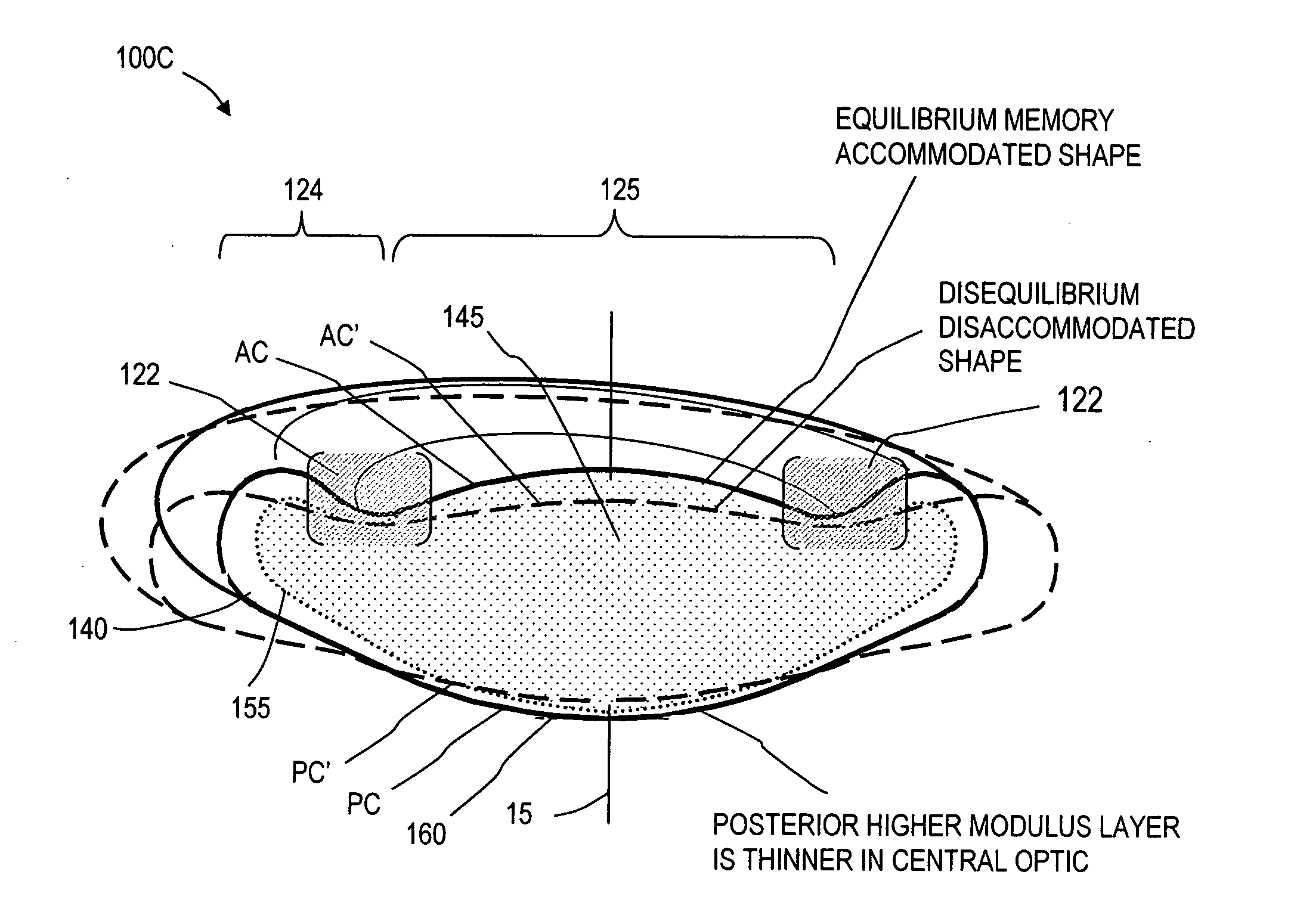

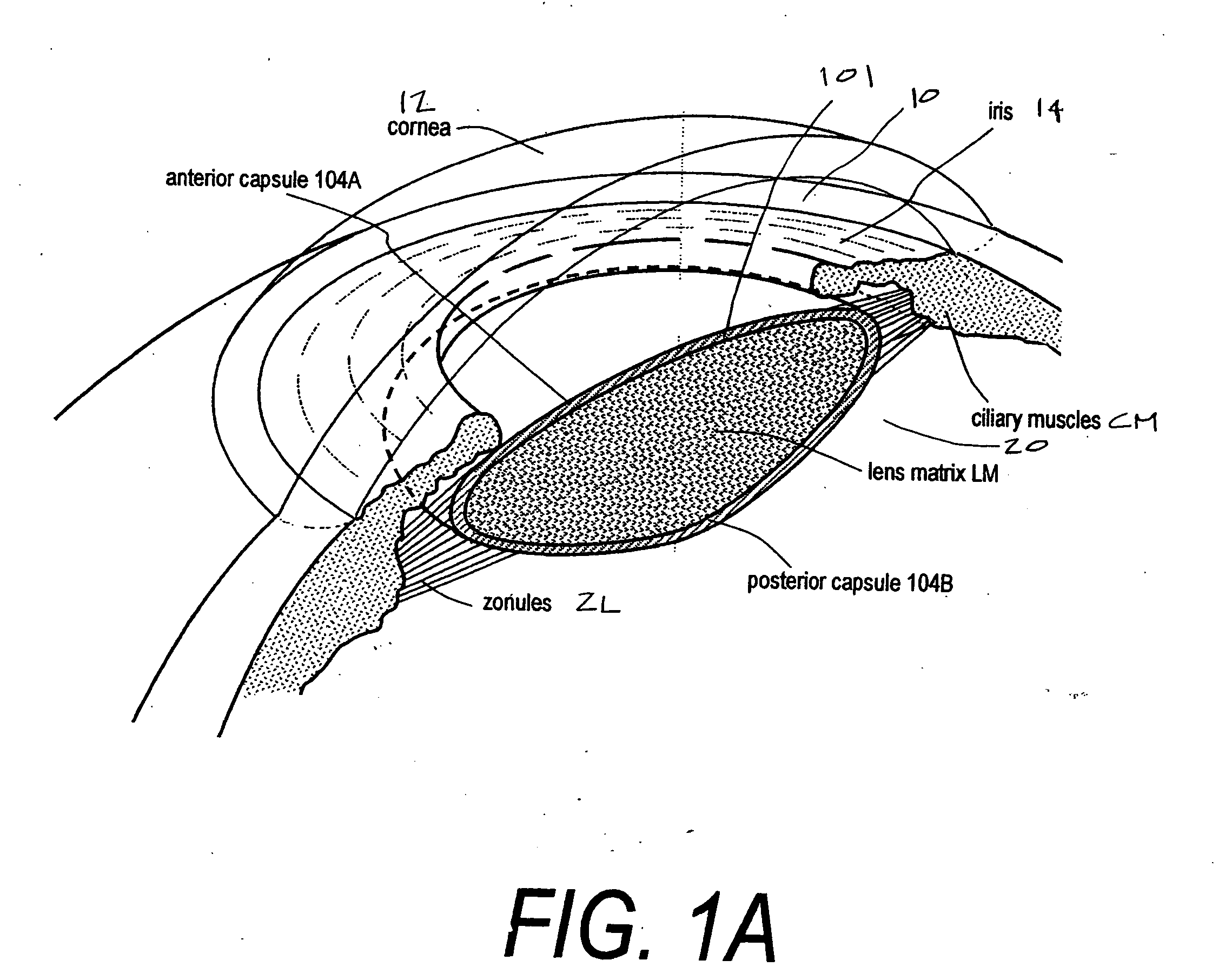

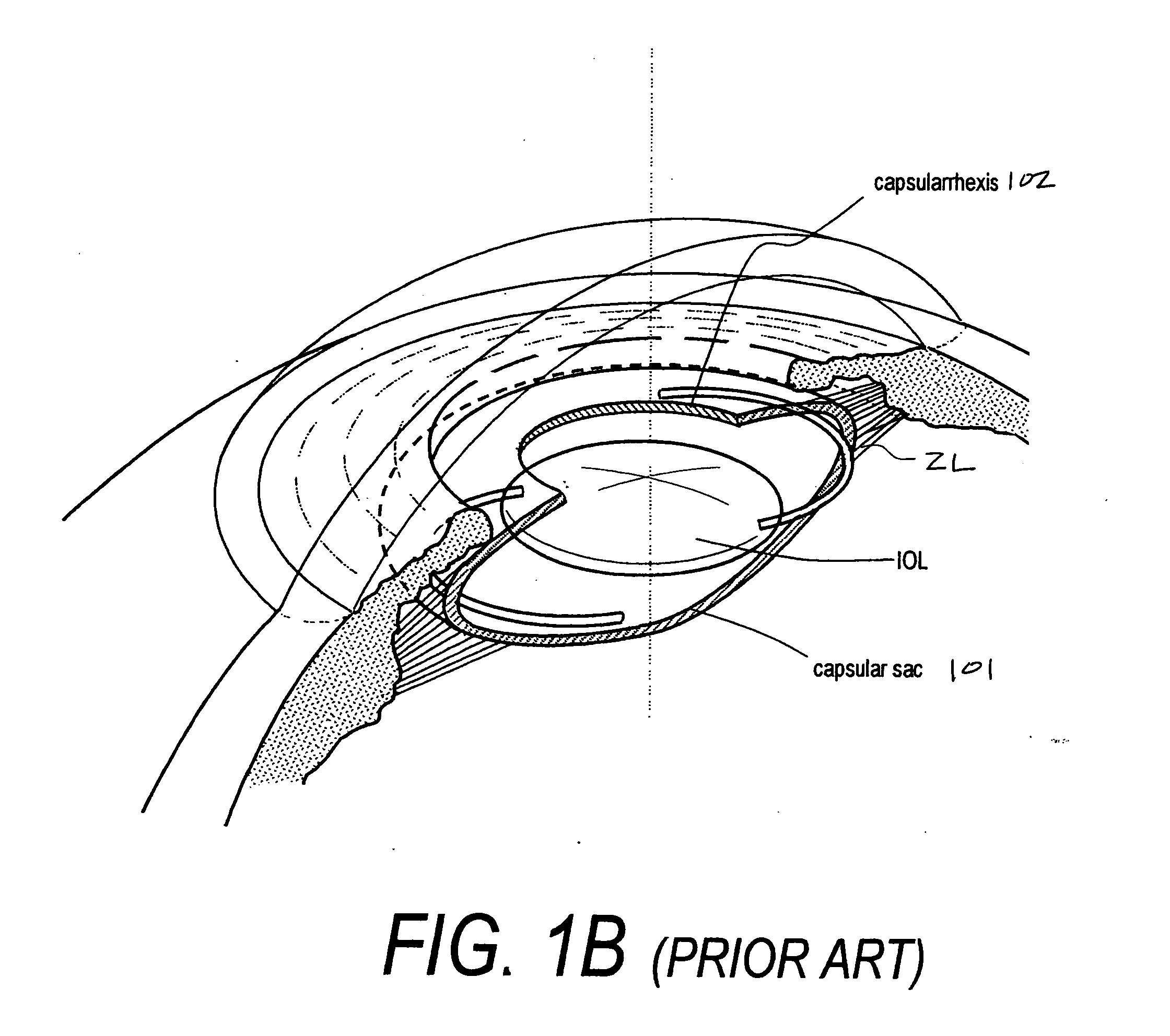

InactiveUS20050021139A1Increase the adjustment rangeImproved force transmissionIntraocular lensElastomerYoung's modulus

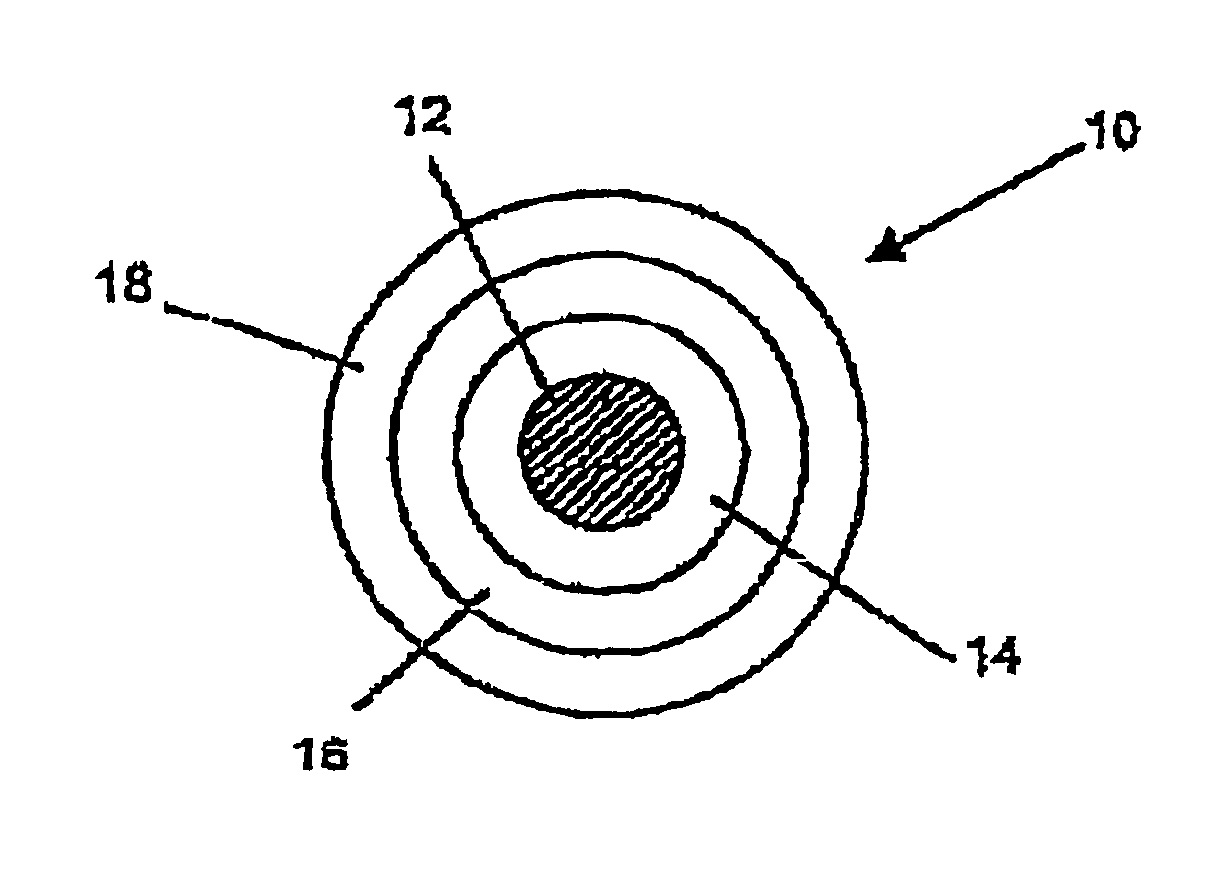

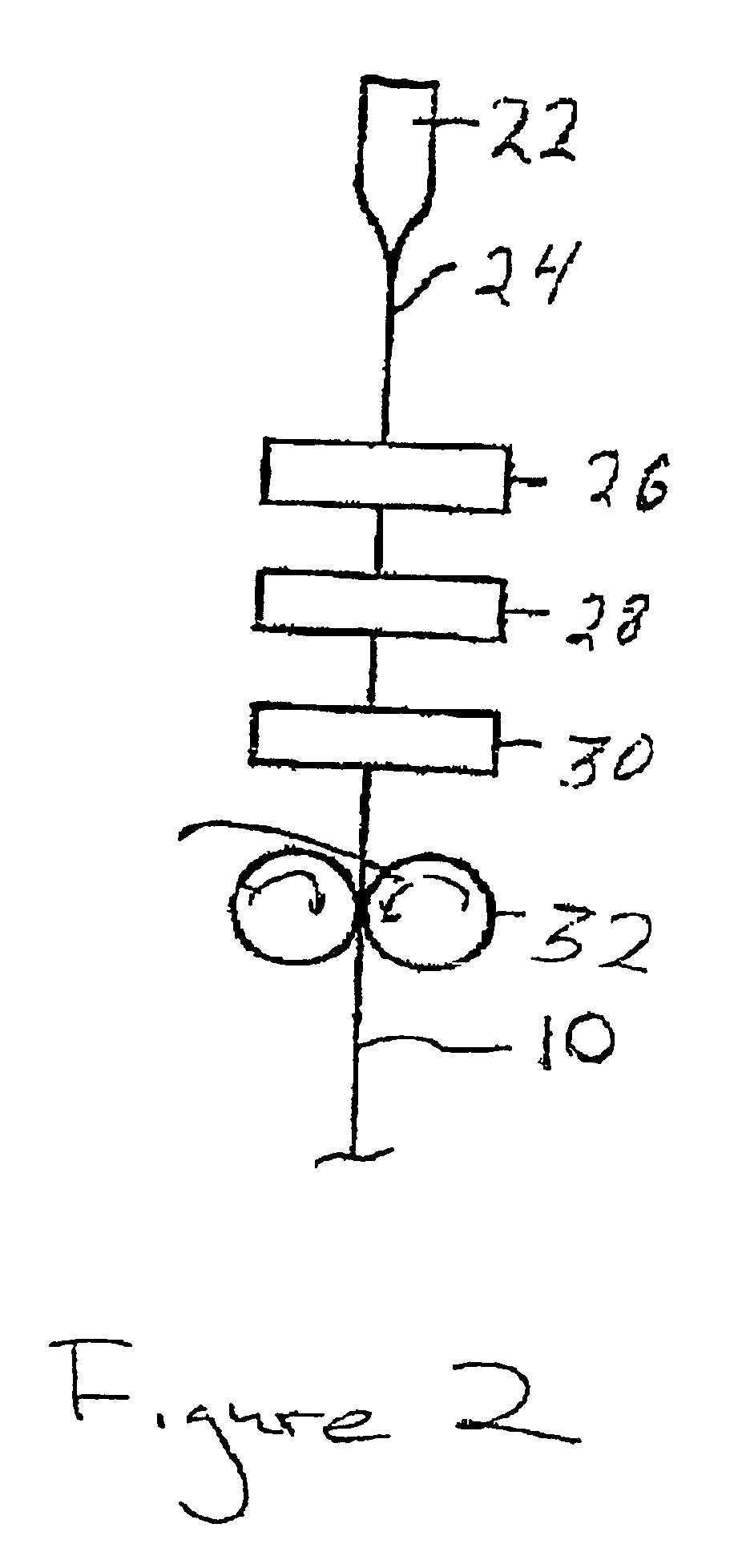

An adaptive optic for refractive lens exchange or cataract patients. The intracapsular implant comprises an elastomeric monolith with an equilibrium memory shape that imparts to the capsular sac's periphery the natural shape of the capsule in an accommodated state. In one embodiment, the monolith carries a recessed deformable central lens portion having an ultralow modulus that allows for high accommodative amplitude in response to equatorial tensioning. In a preferred embodiment, the adaptive optic defines an anisotropic modulus with a plurality of on-axis, rotationally symmetric elastomer block portions each having a different Young's modulus. The invention further provides composite materials for enhancing deformation of lens curvature, including the use of auxetic polymeric materials and negative stiffness materials. In preferred embodiments, at least a portion of the lens is fabricated of a shape memory polymer that provides a memory shape and a temporary shape with a reduced cross-sectional shape for introduction into the patient's eye.

Owner:POWERVISION

Thermally conductive thermoplastic

InactiveUS6162849AImprove thermal conductivityImprove mechanical propertiesPlastic/resin/waxes insulatorsMixingThermoplasticPolymer science

This invention relates to a thermally conductive moldable polymer blend comprising a thermoplastic polymer having a tensile at yield of at least 10,000 psi; at least 60% by weight of a mixture of boron nitride powders having an average particle size of at least 50 microns; and a coupling agent. The composition displays a thermal conductivity of at least about 15 W / m DEG K and it is capable of being molded using high speed molding techniques such as injection molding.

Owner:FERRO CORP

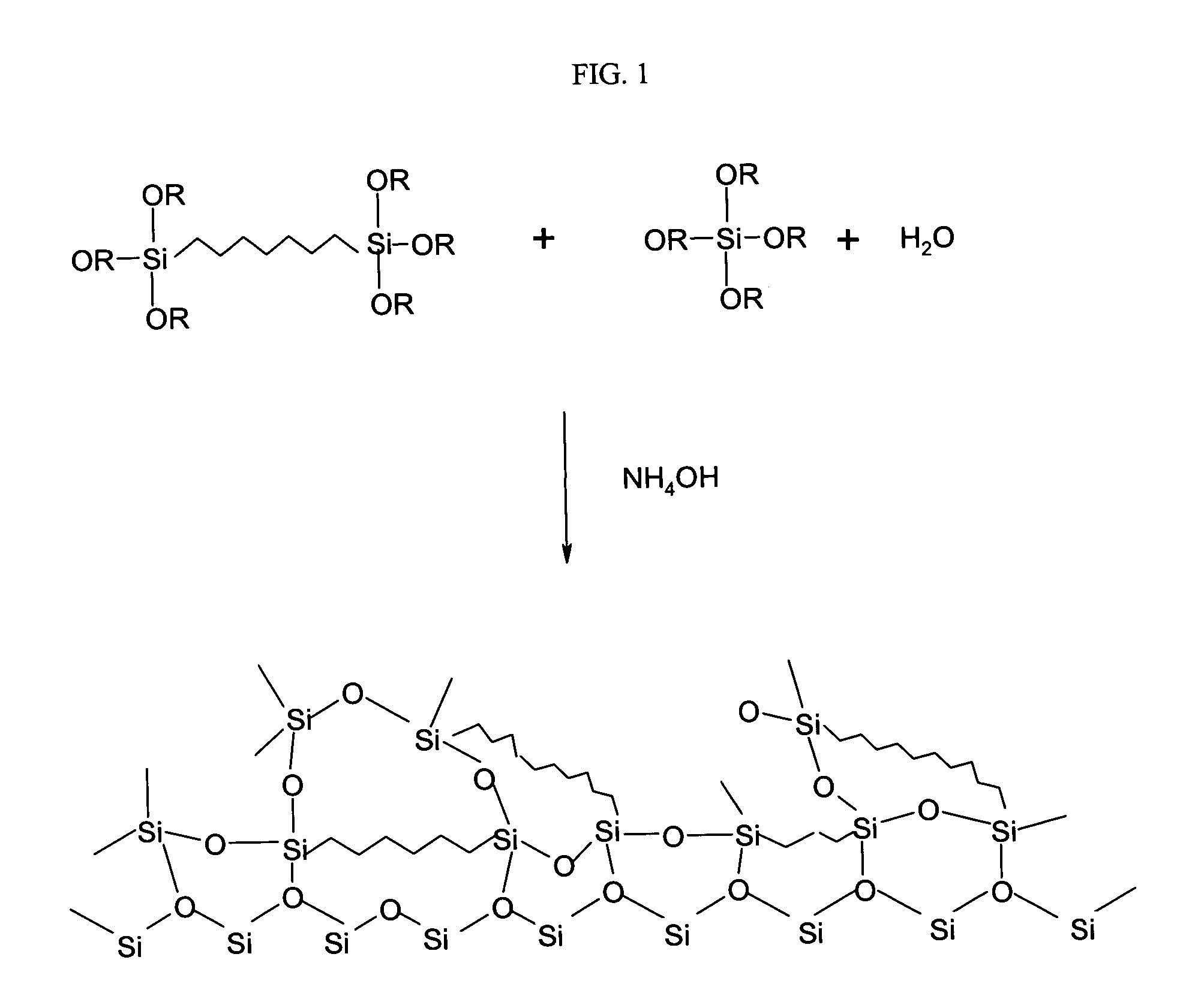

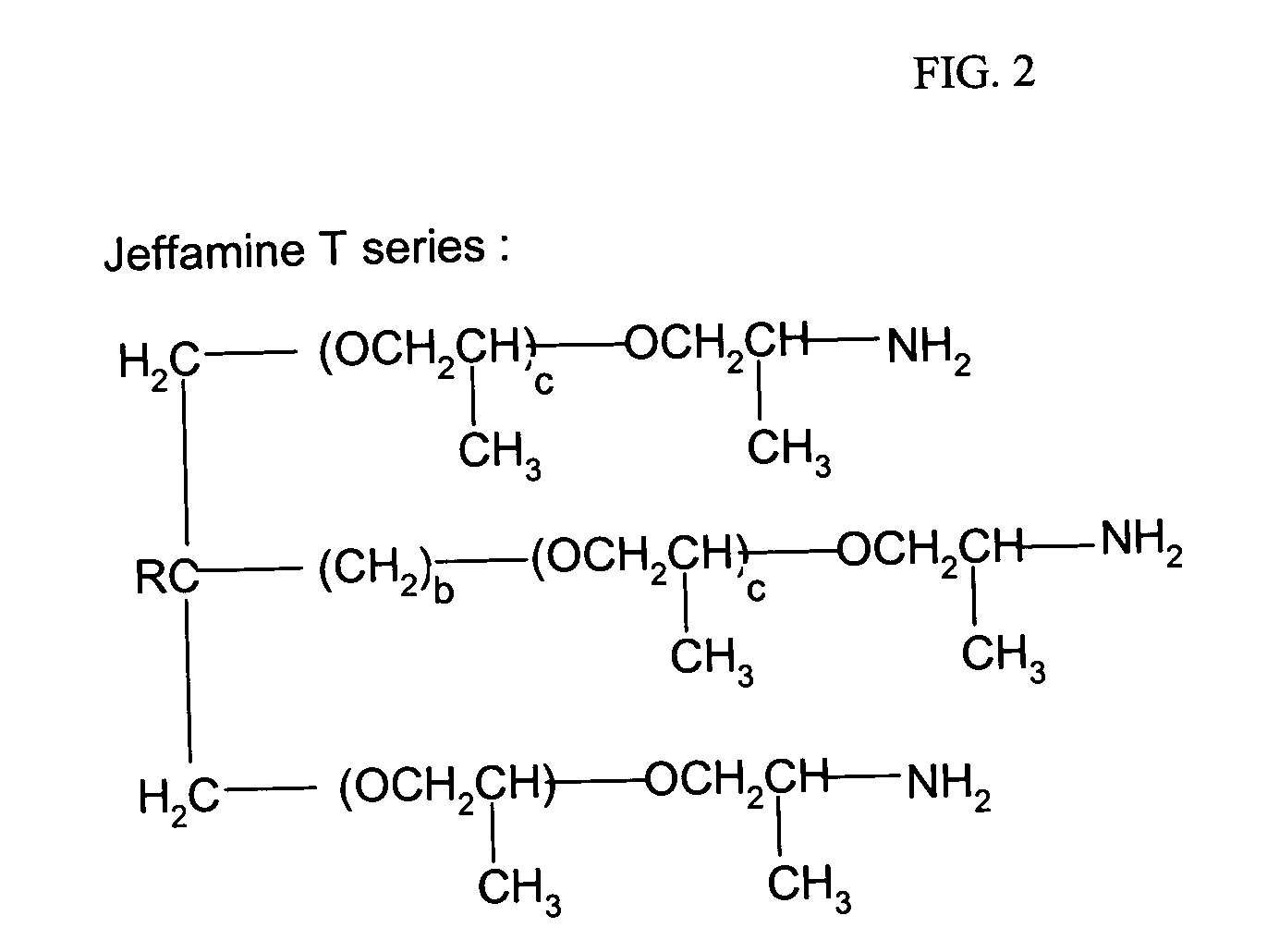

Ormosil aerogels containing silicon bonded linear polymers

ActiveUS20050192367A1Good physical and mechanical propertiesSynthetic resin layered productsWoven fabricsFiber-reinforced compositeSilicon

Owner:ASPEN AEROGELS INC

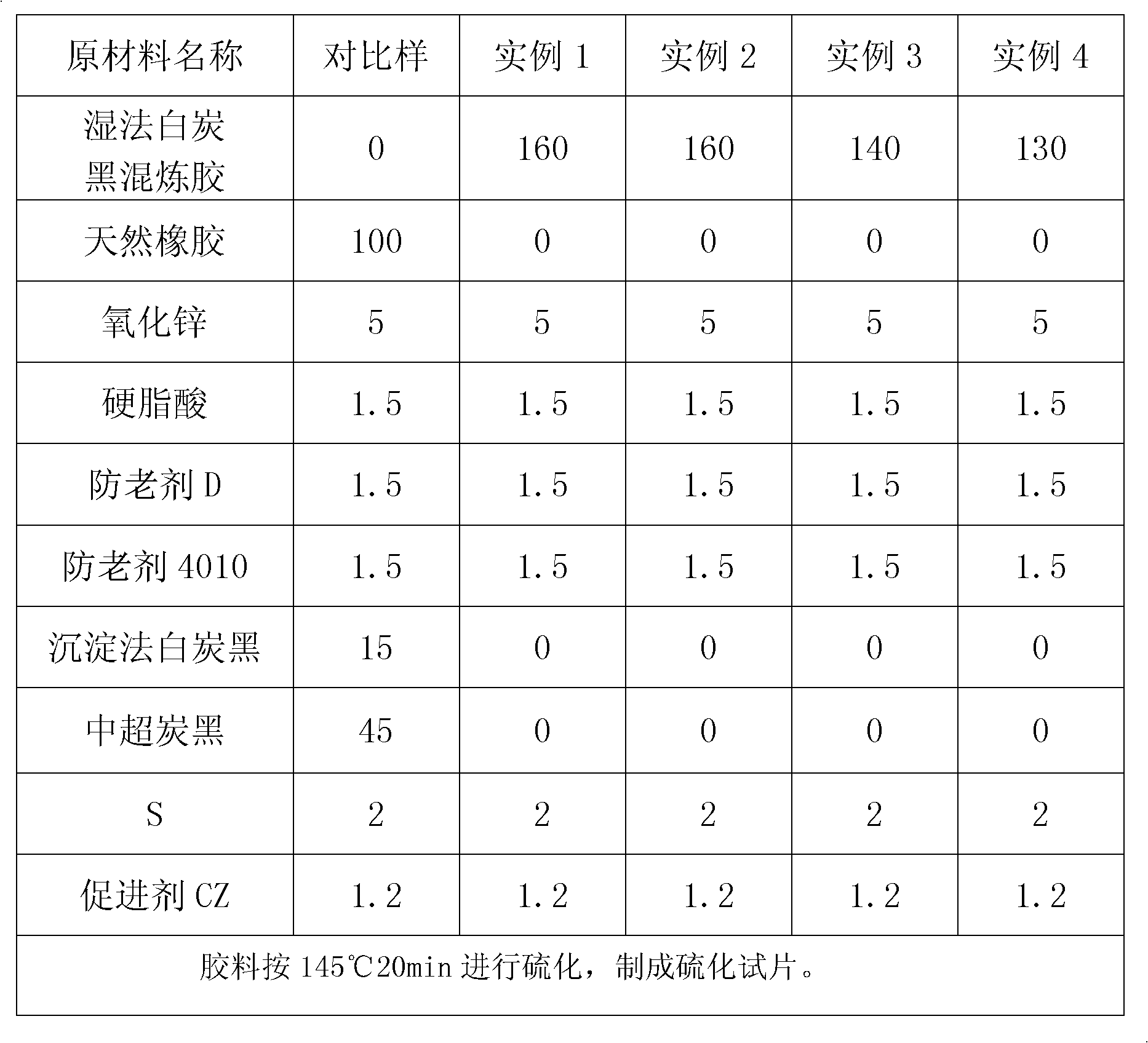

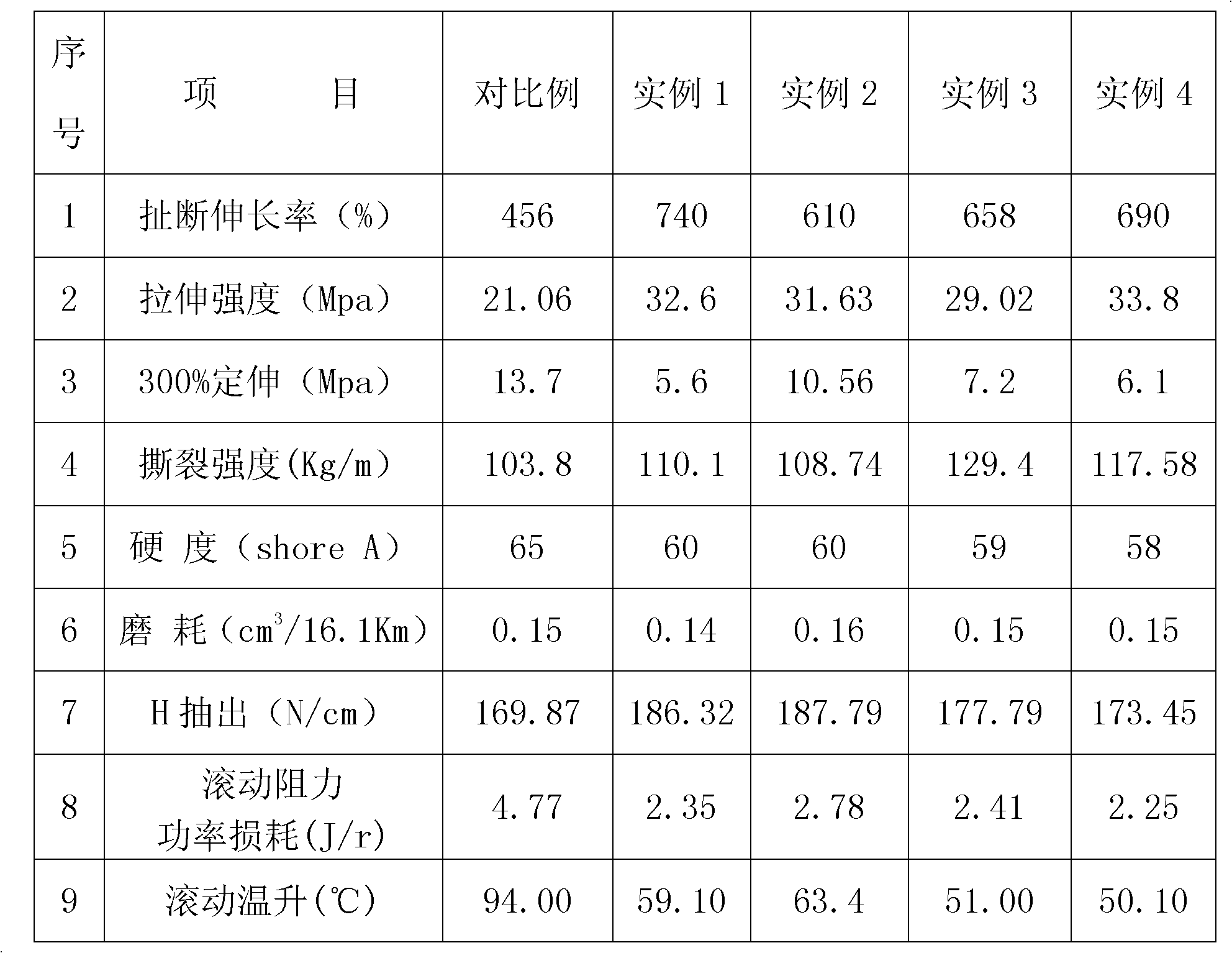

Preparation method of wet process mixed natural rubber material

ActiveCN102153792AGood dispersionImprove uniformityRolling resistance optimizationRubber materialPolymer science

The invention relates to a preparation method of a wet process mixed natural rubber material. The method comprises the following steps of: preparing slurry and soaking 15-40 percent of dry white carbon black in 60-85 percent of deionized water; adding a coupling agent and a surfactant, uniformly mixing, grinding, preparing latex mixed liquor, extracting natural latex and adding white carbon black water dispersoid into the latex; stirring and mixing to obtain a latex mixed liquor, flocculating and adding acetic acid into the mixed liquor; performing rubber washing and dehydration by using a rubber washing machine and feeding to a rubber pelletizer for pelletizing; and feeding rubber particles into a box drying cabinet for drying. The preparation method has the advantages of simple machining process, small equipment investment, realization of various ideal performances with the most ordinary white carbon black, low dust pollution in the entire production process and energy saving. A tire manufactured with the method has small rolling resistance, low heat generation, high tensile strength, high tearing strength and high rubber material ageing resistance. Mixing of the white carbon black is performed in a liquid phase, so that the dispersivity and uniformity are enhanced.

Owner:ZHUZHOU ANBAOLINFENG NEW MATERIALS

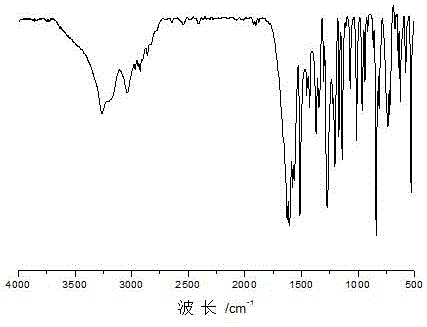

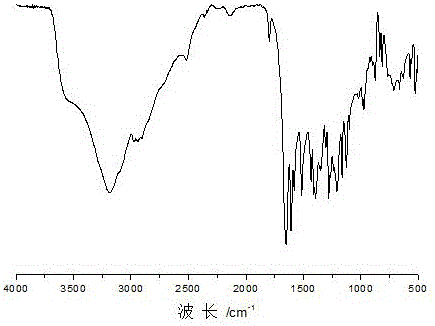

Blend of fluorubber and silastic, and preparation thereof

InactiveCN101412835ASmall compression setThe preparation method is simple and feasibleTemperature resistancePolymer blend

The invention relates to a blend of fluorine rubber and silicone rubber, as well as a preparation method thereof. The composition in weight percentage of the blend of fluorine rubber and silicone rubber is as follows: 12 to 50 percent of fluorine rubber, 12 to 50 percent of silicone rubber, 2.5 to 10 percent of compatibilizer, 2.5 to 10 percent of acid-acceptor, 12 to 35 percent of reinforcing filler, 0.5 to 7 percent of constitution controller, 0.5 to 3 percent of vulcanizing agent and 0.5 to 4 percent of crosslinking additive. The blend of fluorine rubber and silicone rubber is prepared by a mechanical blending method and is vulcanized by use of peroxides. Vulcanized rubber has good mechanical properties, heat resistance, low-temperature resistance, oil resistance and low-compression permanent deformation performance, and can be used for producing and manufacturing high-performance rubber tubes, adhesive tapes, sealing elements, rubber linings and the like needed in automobile, mechanical, chemical, aerospace and other industries.

Owner:SOUTH CHINA UNIV OF TECH

Heat conduction nylon composite material and preparation method thereof

The invention provides a heat conduction nylon composite material and a preparation method thereof. The heat conduction nylon composite material comprises the following components by mass: 20-60 percent of nylon, 3-10 percent of a compatilizer, 5-10 percent of high thermal conductivity fiber, 30-50 percent of a high thermal conductivity filling material and 0.5-16 percent of assistants. The heat conduction nylon composite material has the advantages as follows: through the addition proportion control of a branching agent and a chain extendor, the effect that slight crosslinking occurs in the modification process of the material and deep crosslinking is conducted in the processing process of injection moulding in a later period is achieved, so that the material is directly changed from a thermoplastic material into a thermoset product, and the physical and mechanical properties of the product are greatly improved, so as to solve the problem of over large impact on the physical properties of the product caused by high filling amount of heat conduction ingredients.

Owner:辰东意普万新材料(广东)有限公司

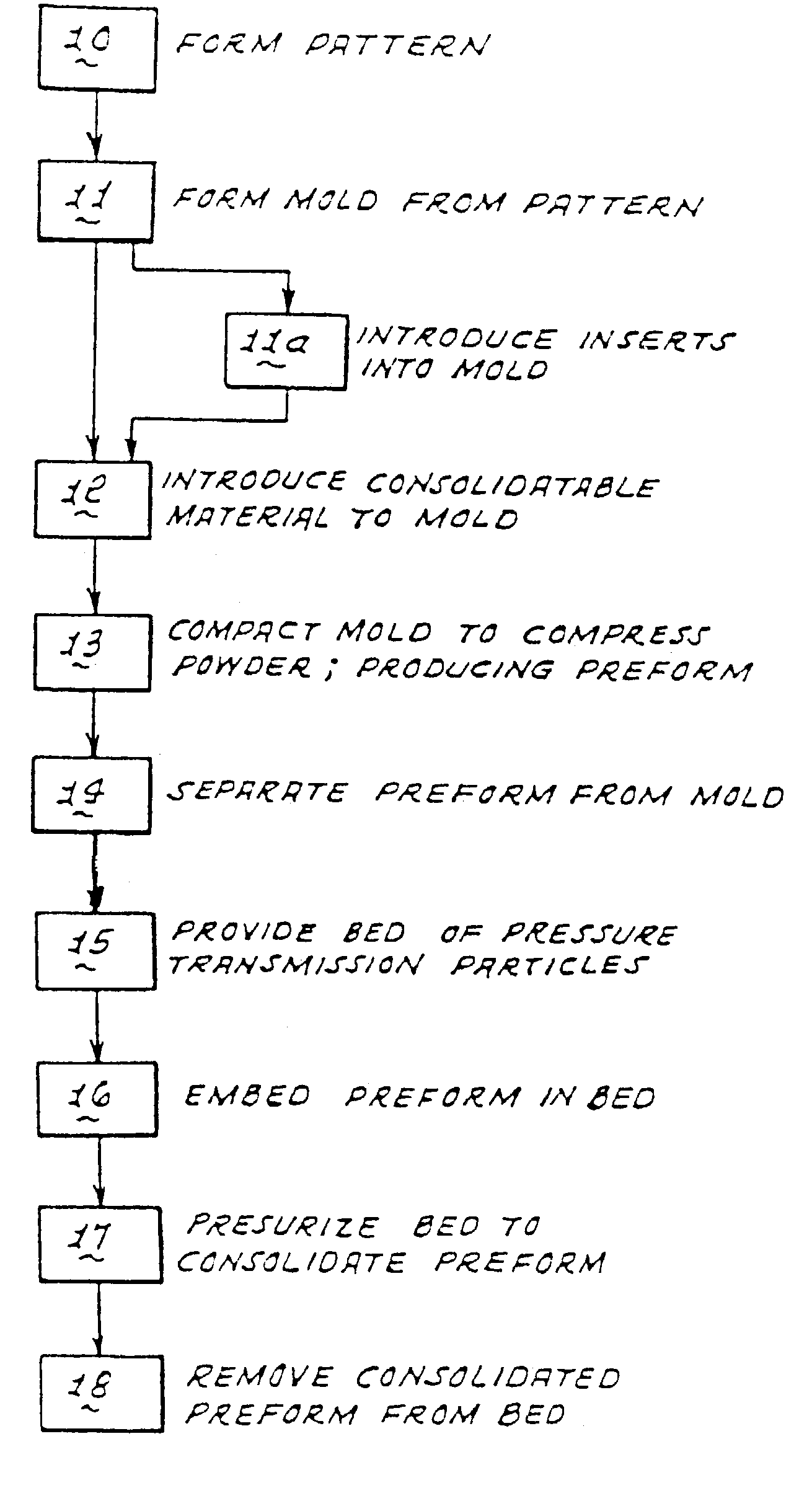

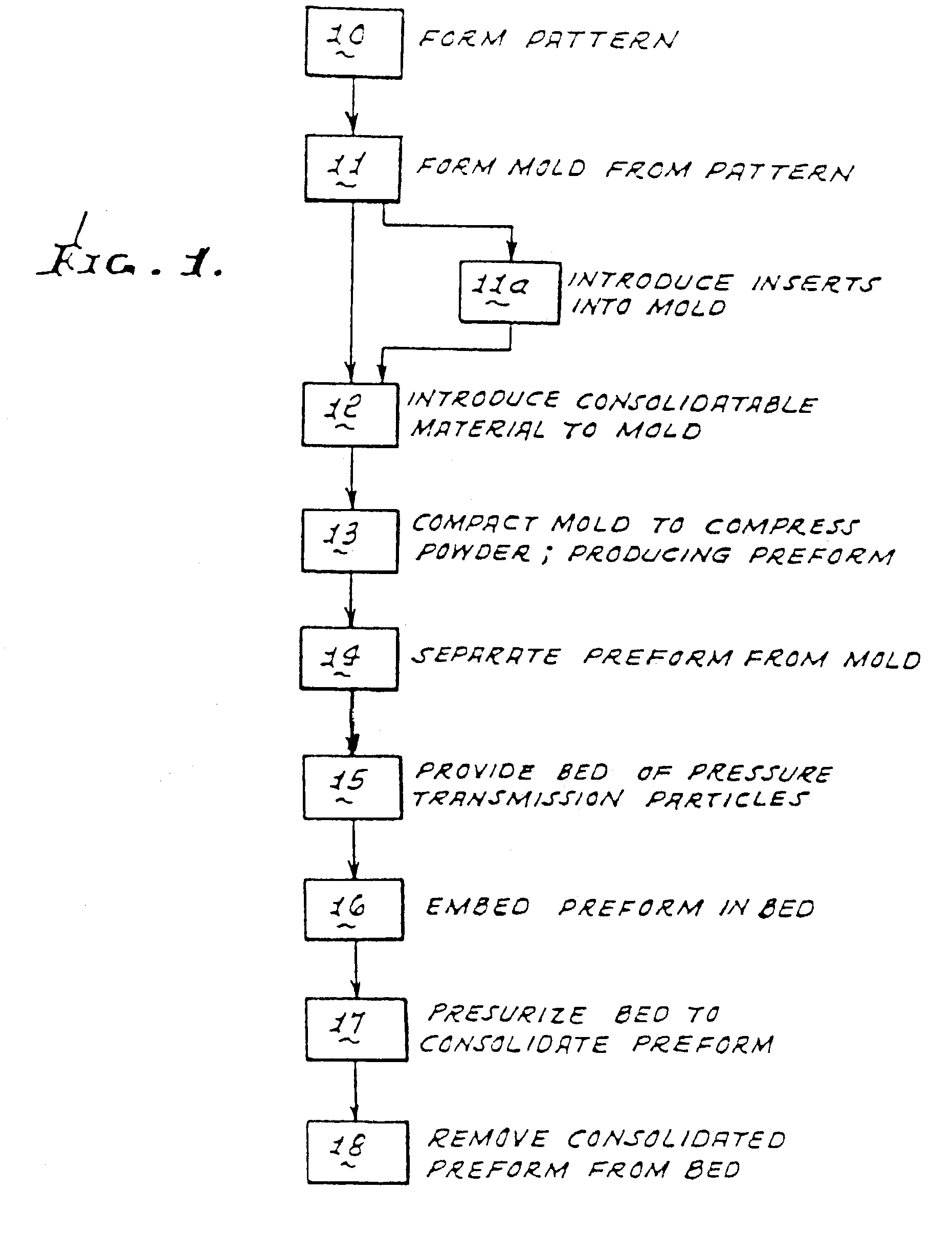

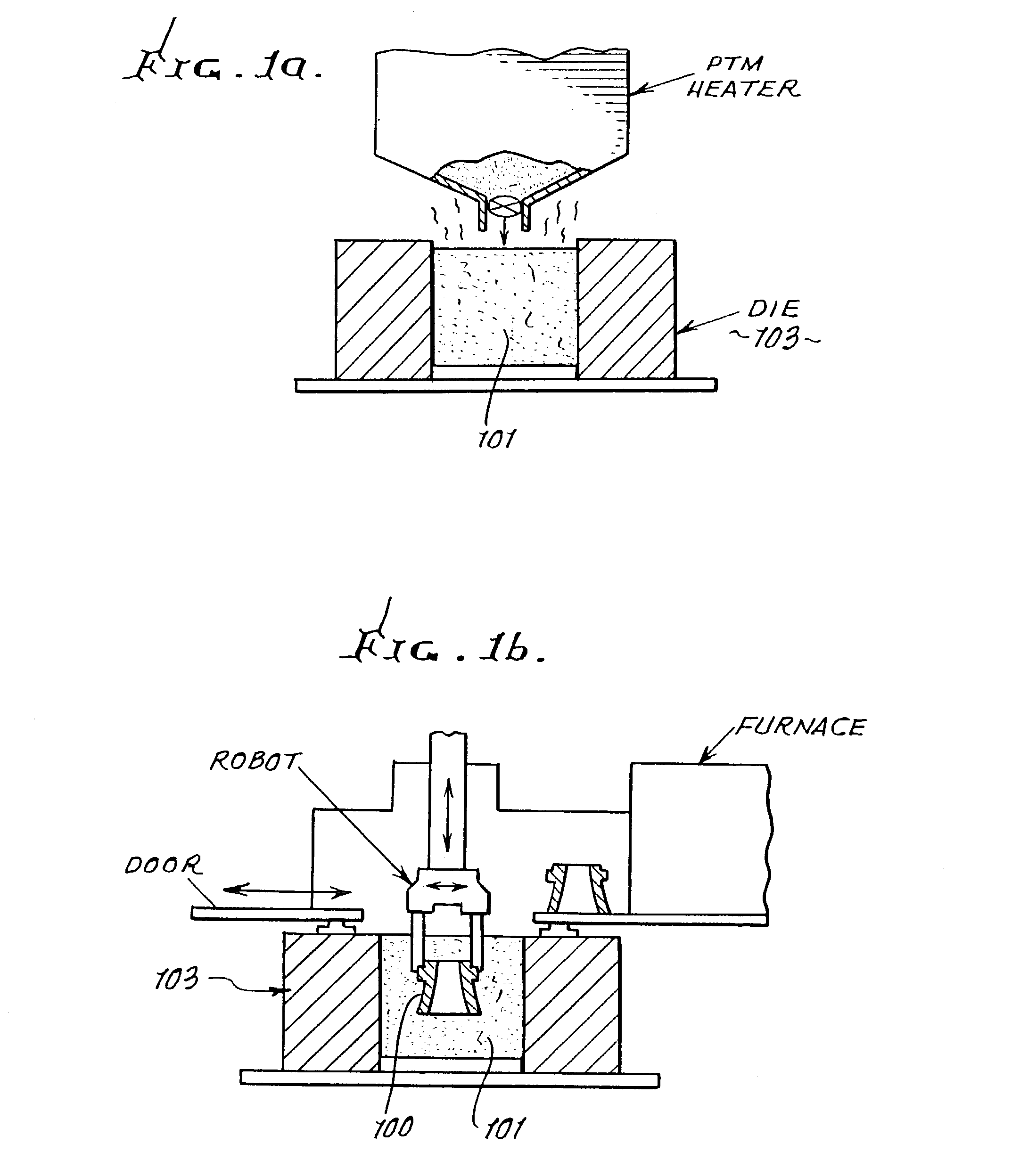

Nanocrystalline aluminum alloy metal matrix composites, and production methods

InactiveUS7097807B1Increase in flexure in flexure strengthIncrease modulusTransportation and packagingMetal-working apparatusParticulatesMetal matrix composite

Owner:CERACON

Composite material of polypropylene in low smell and preparation method

InactiveCN1727390AGood physical and mechanical propertiesSimple preparation processMolecular sieveChemistry

A polypropene composition with low odor is proportionally prepared from polypropene, talc powder, molecular sieve (powdered silicoaluminate of alkali-metal), toughening agent poe, and thermal stabilizer.

Owner:SHANGHAI PRET COMPOSITES

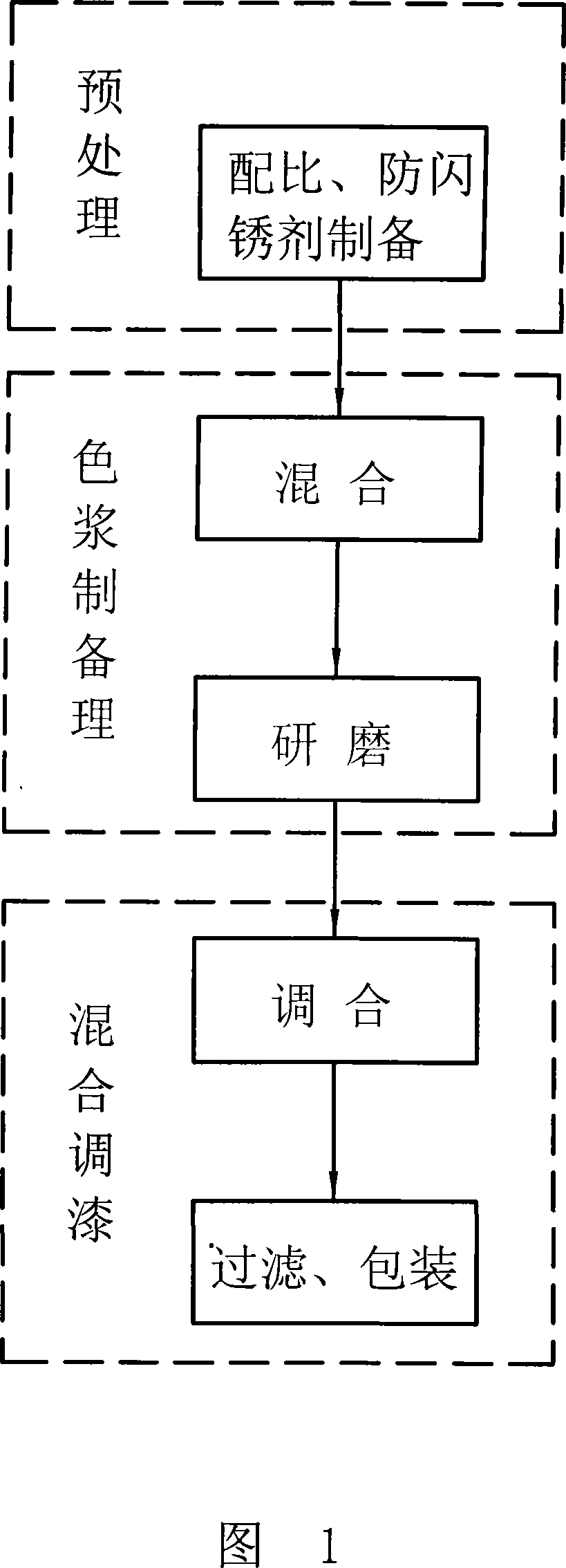

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

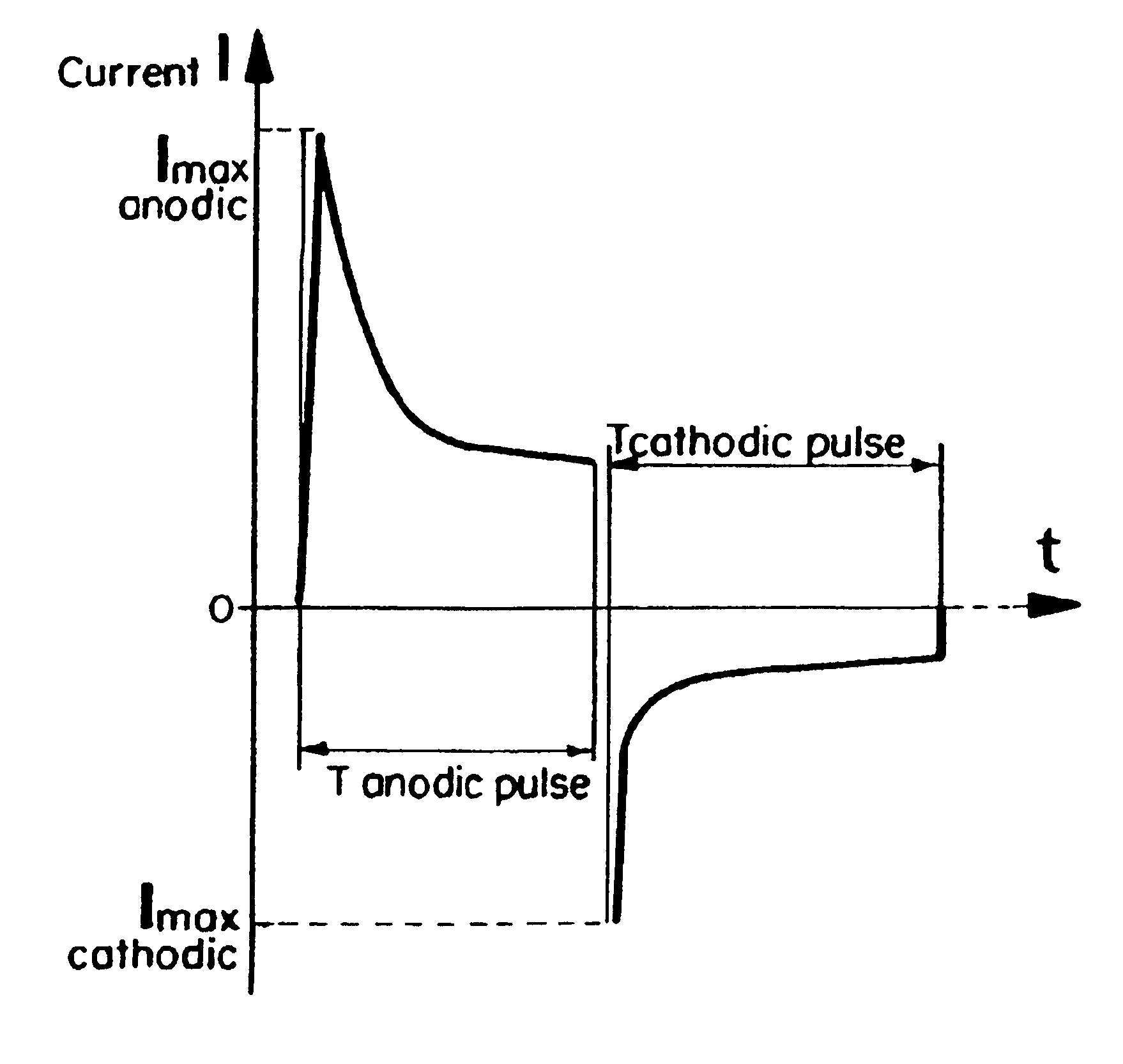

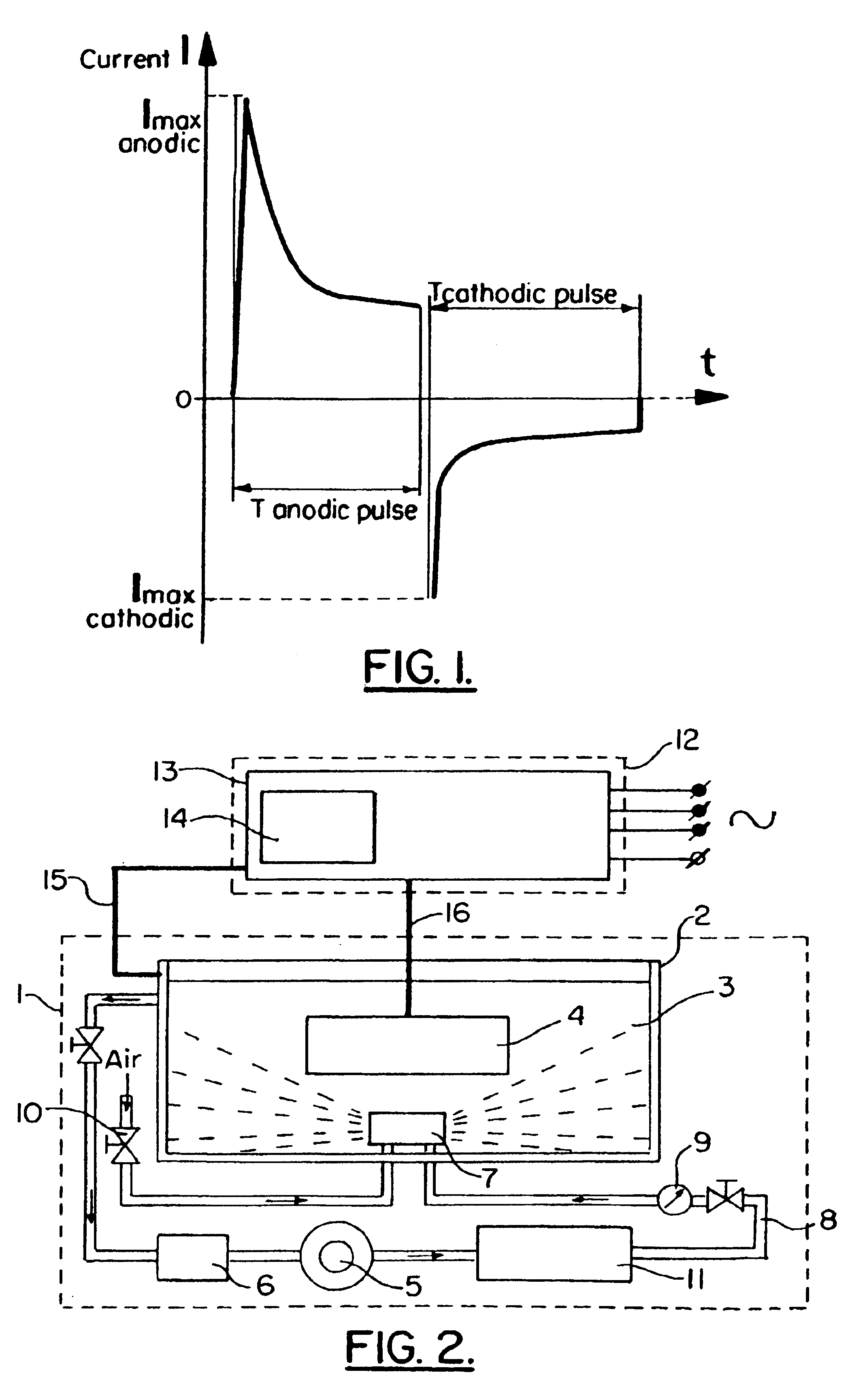

Process and device for forming ceramic coatings on metals and alloys, and coatings produced by this process

InactiveUS6896785B2Increase usageImprove adhesionAnodisationCellsPlasma electrolytic oxidationCeramic coating

Owner:KERONITE INT LTD

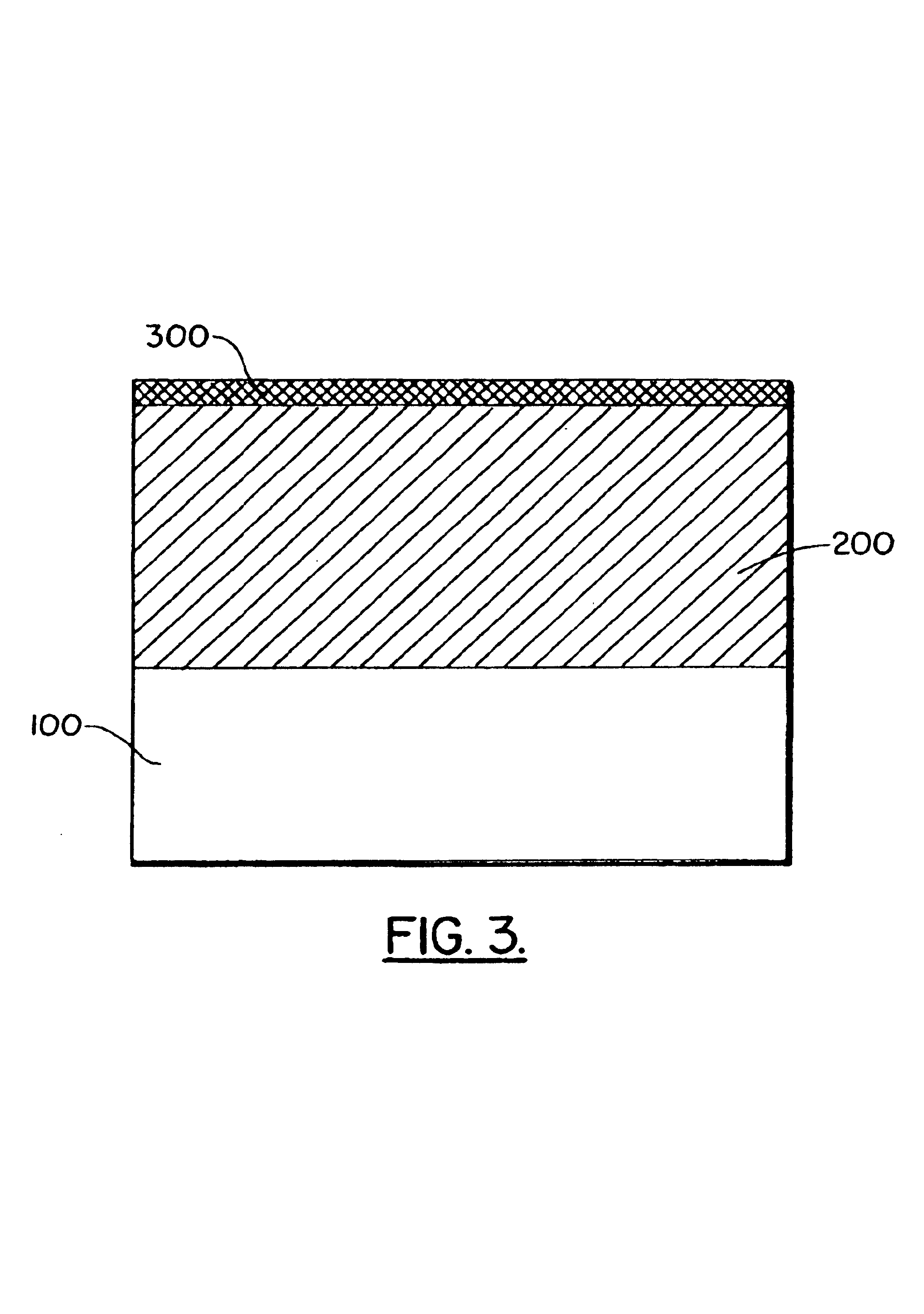

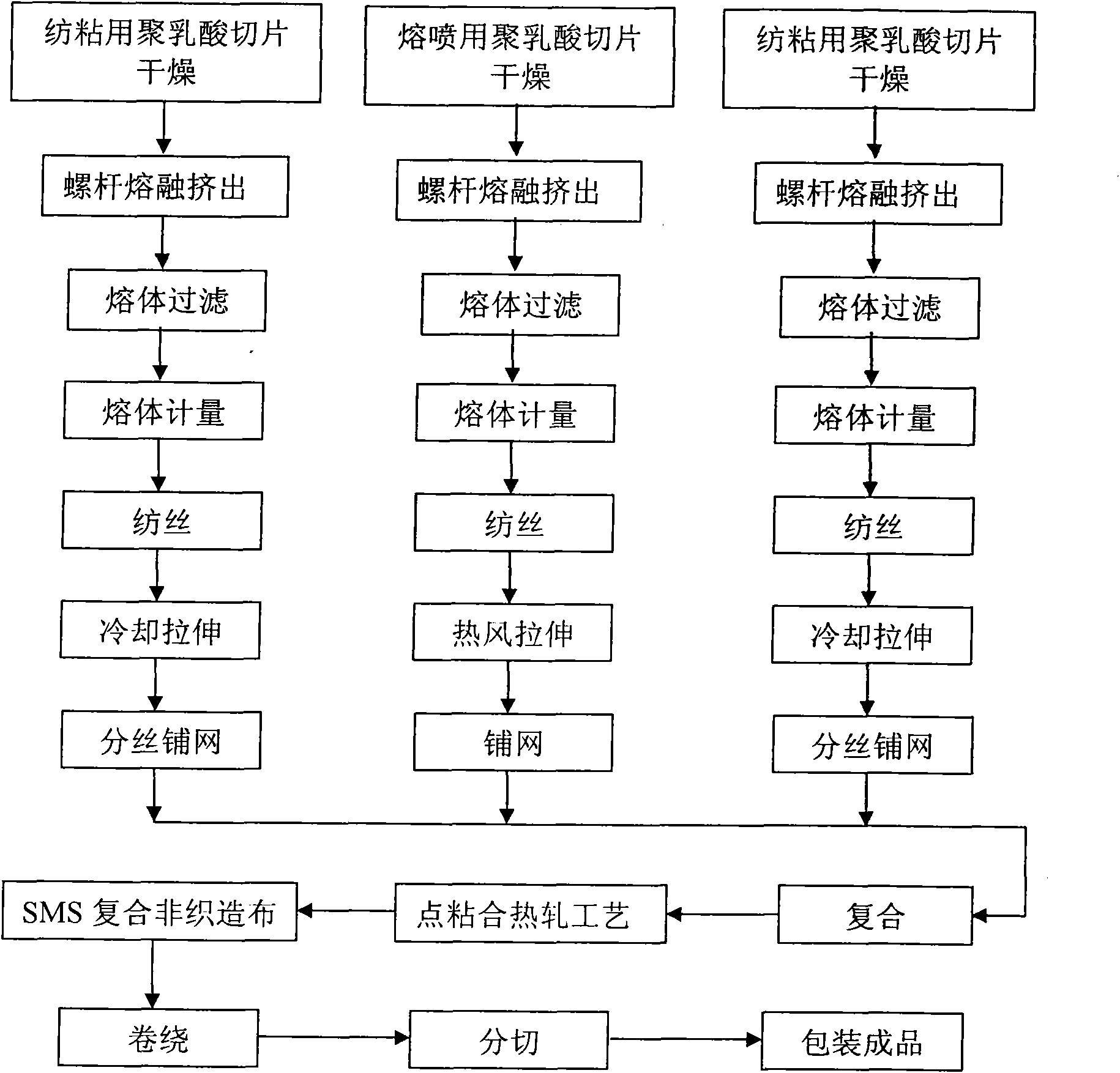

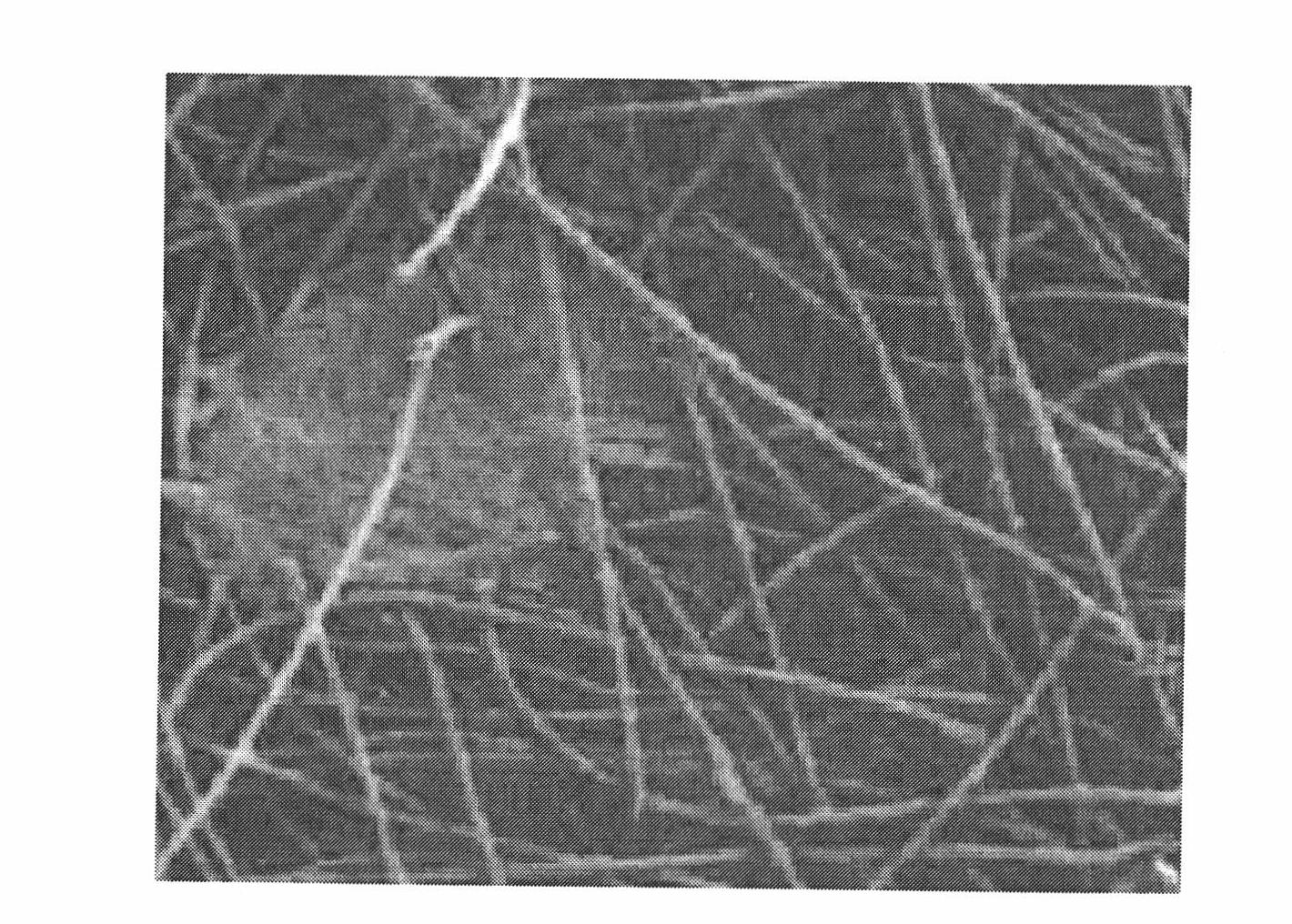

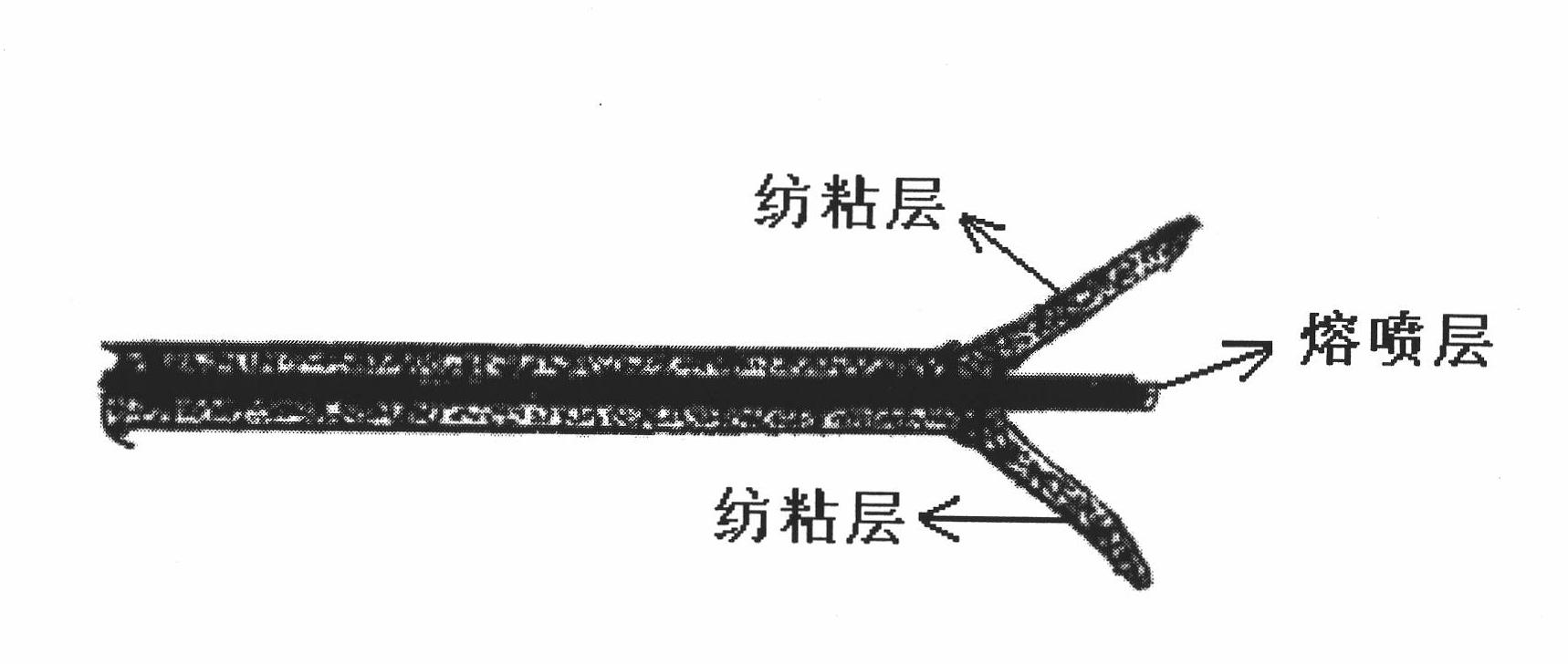

Fully-degradable polylactic acid fiber SMS compound non-woven and manufacturing method thereof

InactiveCN101851830APromote growthCapable of biocompostingSpinning head liquid feederMelt spinning methodsNonwoven fabricPhysical property

The invention discloses a fully-degradable polylactic acid fiber SMS compound non-woven and a manufacturing method thereof. The non-woven is compounded by three layers of non-woven by self-bonding or hot rolling, wherein the middle layer is polylactic acid meltblown non-woven, and the upper layer and the lower layer of the middle layer are both polylactic acid spunbonded non-woven. The SMS non-woven is even and has stable quality and excellent physical property, filtering property and shielding property. A thin SMS product has favourable waterproof permeability and is especially suitable for the fields of hygienic materials, packaging materials and the like; an SMS product with medium thickness is suitable for the disposable products of the field of medical treatments, and a thick SMS product is suitable for the field of industrial filtering. The production technology of the invention is easy to operate and control, has favorable stability and can carry out industrial production.

Owner:豆丁乐园(南京)婴儿用品有限公司

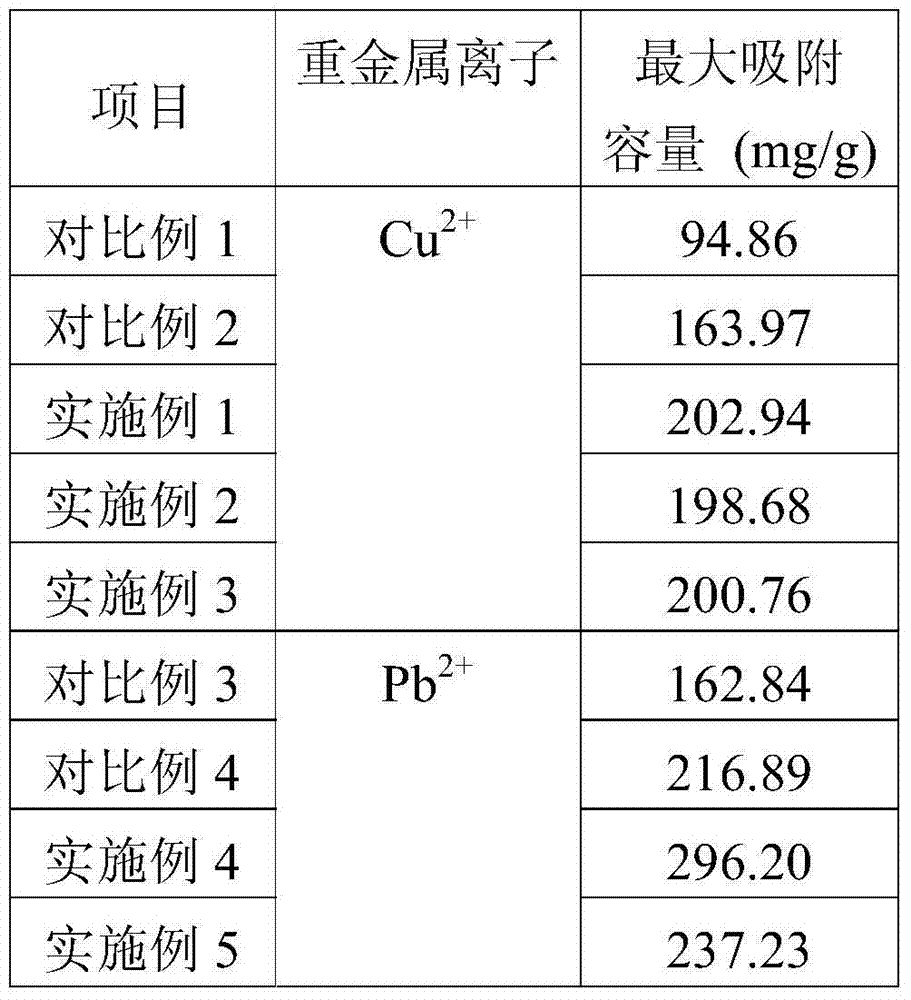

Composite hydrogel for adsorption of heavy metal ions and preparation method thereof

ActiveCN104226281ASimple preparation processGood biocompatibilityOther chemical processesAlkali metal oxides/hydroxidesIonHeavy metals

The invention discloses composite hydrogel for adsorption of metal ions and a preparation method thereof. The hydrogel comprises, by weight, 5-95 parts of polyvinyl alcohol, 5-95 parts of chitosan, 0.1-20 parts of modified graphene oxide and 2-6 parts of sodium alginate, the weight ratio between the polyvinyl alcohol and the chitosan is (5: 95)-(95: 5), modified graphite oxide includes modified graphene oxide modified by dopamine and / or modified graphene oxide modified by ferroferric oxide, all components are uniformly mixed in a certain sequence, and the composite hydrogel is obtained under special conditions. The composite hydrogel for adsorption of the heavy metal ions and the preparation method thereof have the advantages that high speed, high efficiency, high adsorption capacity and high selectivity are achieved, the adsorption effect on the heavy metal ions is remarkable, meanwhile, the preparation process is simple, and the operability is high.

Owner:JIANGNAN UNIV

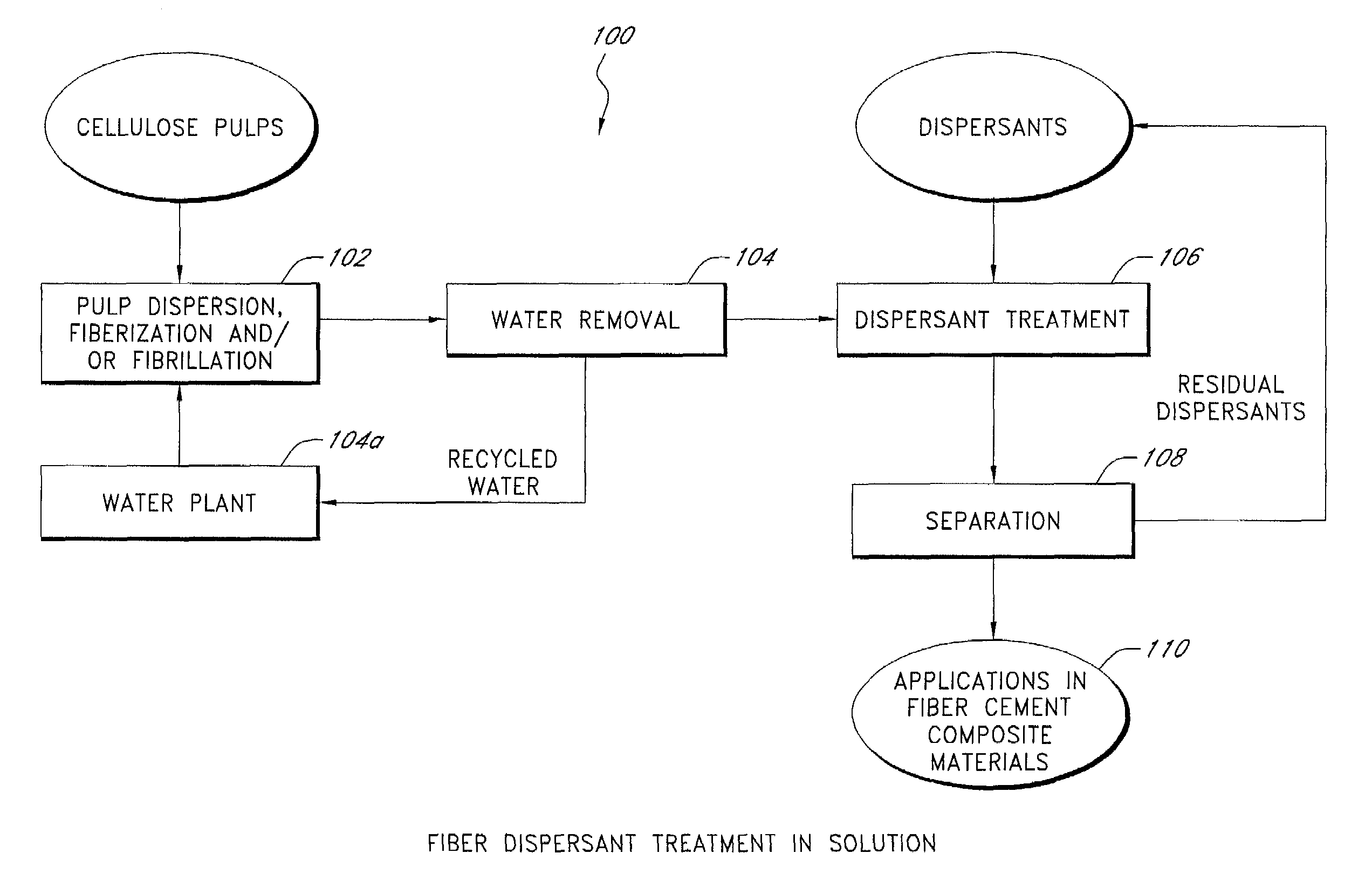

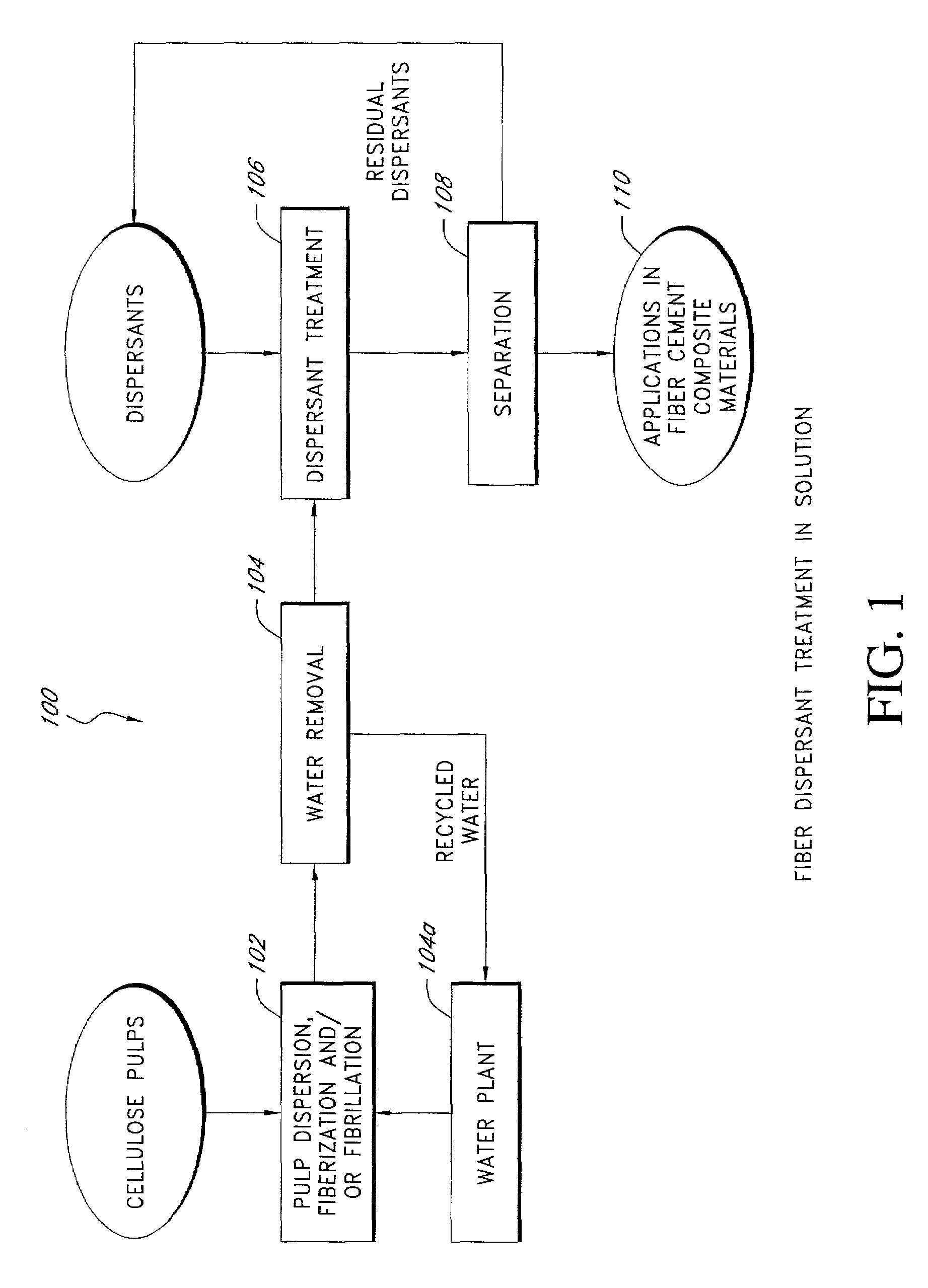

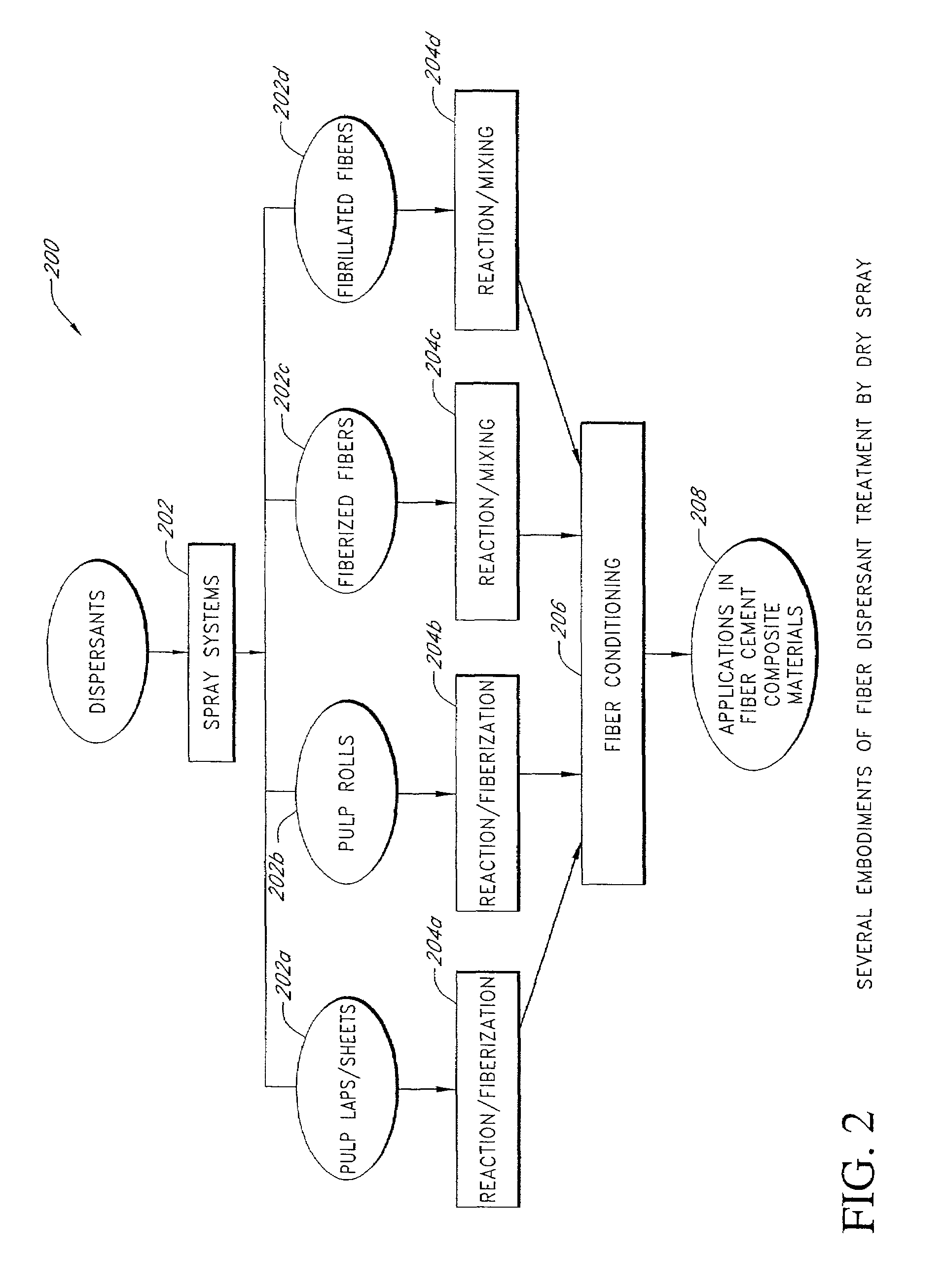

Fiber reinforced cement composite materials using chemically treated fibers with improved dispersibility

InactiveUS7344593B2Improve material propertyIncrease modulusPulp properties modificationSolid waste managementBuilding materialFibre reinforcement

A fiber-reinforced building material in one embodiment incorporates cellulose fibers that are chemically treated with a dispersant to impart improved dispersibility to the fibers. The fibers are treated with a dispersant which deactivates the hydroxyl sites of the fiber surfaces and in some cases, making the fiber surface more hydrophobic. The dispersant inhibits the hydroxyl groups on the cellulose fiber surface from bonding with hydroxyl groups of other fibers and from bonding with hydroxyl groups of the same fiber, thereby significantly reducing inter-fiber and intra-fiber hydrogen bonding. The treated fibers can be readily dispersed and uniformly distributed throughout a mixture without re-clustering or reclumping once the mechanical mixing action stops. The chemically treated fibers with improved dispersibility improve the fiber distribution and reinforcing efficiency, which in turn improves key physical and mechanical properties of the material such as the modulus of rupture, z-direction tensile strength, and toughness, and surface finishes. With improved fiber reinforcing efficiency, less dosage of fiber is needed to achieve the required physical and mechanical properties.

Owner:JAMES HARDIE TECH

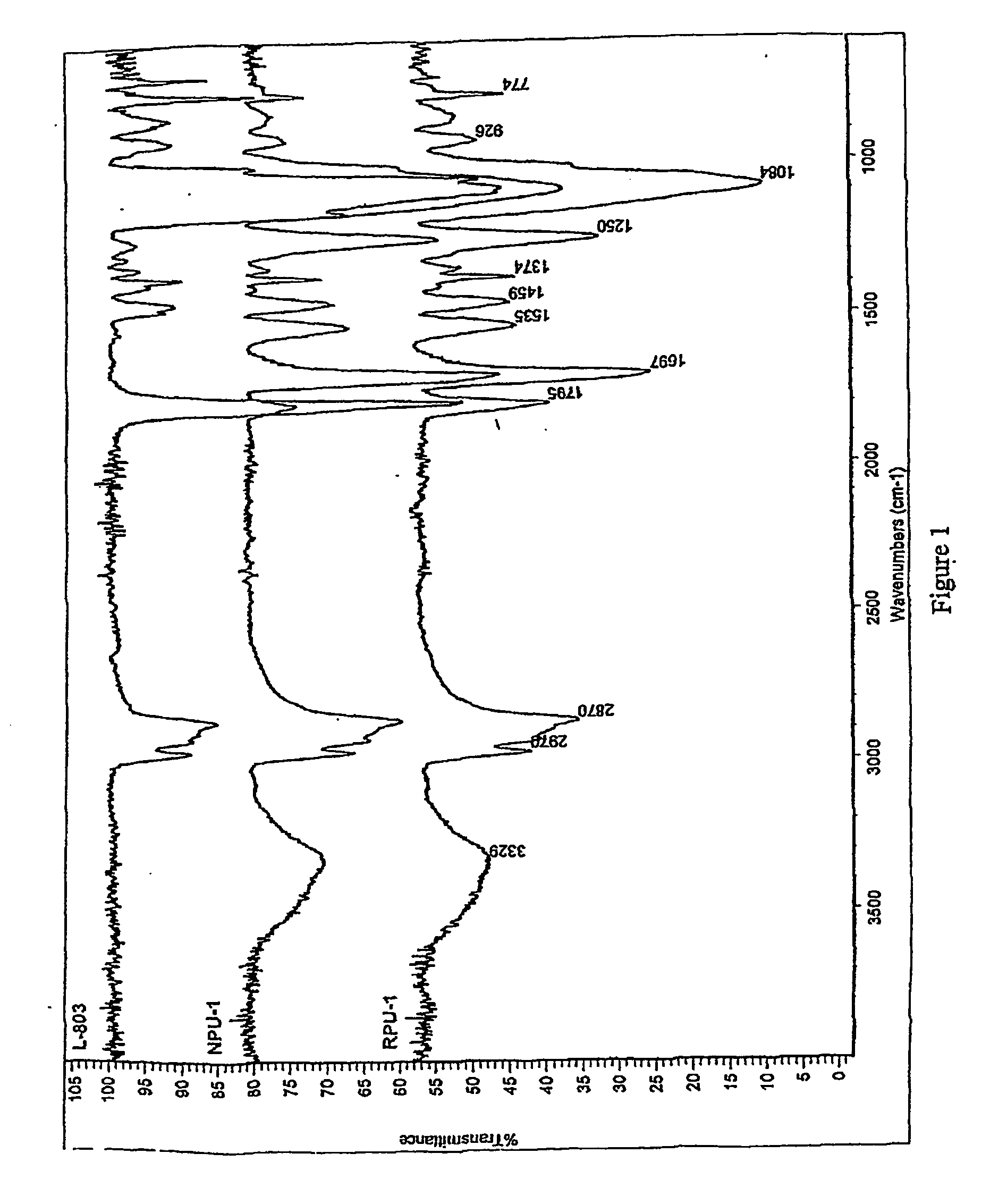

Optical fiber with an improved primary coating composition

InactiveUS6849333B2Improve mechanical propertiesGood physical propertiesLayered productsOptical fibre with multilayer core/claddingOligomerPolyol

The present invention is directed to a radiation curable primary coating composition and an optical fiber with said coating. The primary coating preferably results in excellent mechanical and physical properties, and when coated on optical fibers in a reduction in micro-bending transmission losses over optical fibers with conventional coatings. In one embodiment of this invention, it relates to a coated optical fiber comprising an optical fiber and a radiation cured primary coating wherein the radiation cured primary coating on the optical fiber comprises an oligomer and wherein the oligomer is formed from a reaction comprising a polyol having “m” hydroxyl functional groups, wherein “n” hydroxyl groups of said polyol are terminated in forming the oligomer and “m” is greater than “n”.

Owner:CORNING INC

Inorganic matrix composition and composites incorporating the matrix composition

InactiveUS6969422B2Good physical and mechanical propertiesIncrease loadAlkali metal silicate coatingsCement productionSlurryOragene

A modified alkali silicate composition for forming an inorganic network matrix. The modified alkali silicate matrix is made by reacting an alkali silicate (or its precursors such as an alkali hydroxide, a SiO2 source and water), an acidic inorganic composition, such as a reactive glass, water and optional fillers, additives and processing aids. An inorganic matrix composite can be prepared by applying a slurry of the modified aqueous alkali silicate composition to a reinforcing medium and applying the temperature and pressure necessary to consolidate the desired form. The composite can be shaped by compression molding as well as other known fabrication methods. A notable aspect of the invention is that, although composite and neat resin components prepared from the invention can exhibit excellent dimensional stability to 1000° C. and higher, they can be prepared at the lower temperatures and pressures typical to organic polymer processing.

Owner:THE BF GOODRICH CO

Nanocomposites based on polyurethane or polyurethane-epoxy hybrid resins prepared avoiding isocyanates

ActiveUS20070135588A1Beneficial physicochemical and mechanical propertyAvoid damageMaterial nanotechnologySynthetic resin layered productsNanometreAspect ratio

A fast curable non-isocyanate-based polyurethane- and polyurethane-epoxy network nanocomposite polymeric compositions are derived upon crosslinking a mixture comprising of natural or modified nano-clay [ionic phyllosilicate] with platelet thickness in the scale of A (˜1 nm) and aspect ratio (length / thickness) higher than 10 (nm)] preferably natural or modified montmorillonite with either a monomer(s) or oligomer(s) bearing at least one cyclocarbonate group or a mixture of the latter with an epoxy resin, with a hardener, which is a monomer or oligomer or mixtures therefrom, bearing primary and / or secondary amino groups. The use of the nanoclays reduces the gel time and increases the adhesion of the cured polyurethane and polyurethane / epoxy hybrid and also reduces its water absorption.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC

Composite phase-change energy storage material for microcapsule and preparation method thereof

InactiveCN101824307ANo leaksPlay the role of self-control temperature controlHeat-exchange elementsMicroballoon preparationCrack resistanceSolvent

The invention discloses a composite phase-change energy storage material for microcapsules and a preparation method thereof. The coating of the microcapsule is made of silicon dioxide, and the core of the microcapsule is made of a phase-change energy storage material, wherein the phase-change energy storage material is a paraffin organic solid-liquid phase-change energy storage material. 0.2 to 0.5 wt.% of dispersed emulsifier, 52.5 to 62.5 wt.% of solvent water, 18.75 to 31.5 wt.% of phase-change energy storage material and 15.5 to 18.75 wt.% of inorganic silica source are matched and put into a reactor for stirring for 5 to 8 hours; the mixture is uniformly dispersed and emulsified at the temperature 3 to 8 DEG C higher than that for solid-liquid phase change; hydrochloric acid aqueous solution catalyst with the pH value of 0.93 to 4.07 or sodium hydroxide aqueous solution catalyst with the pH value of 8.0 to 12.0 is added into the emulsion; the reacting solution is naturally cooled to room temperature and precipitation solution is obtained; the precipitate is washed with the combination of water and petroleum ether, wherein the mass percent of the petroleum ether is 30 wt.%; then the precipitate is washed with deionized water and is filtered, and the product is naturally aired. The invention improves the technology of phase-change energy storage and conservation, and has the function of automatic temperature regulation, favorable physical and chemical stability, crack resistance, flame retardancy, wear resistance and high thermal conductivity.

Owner:BEIJING UNIV OF CHEM TECH

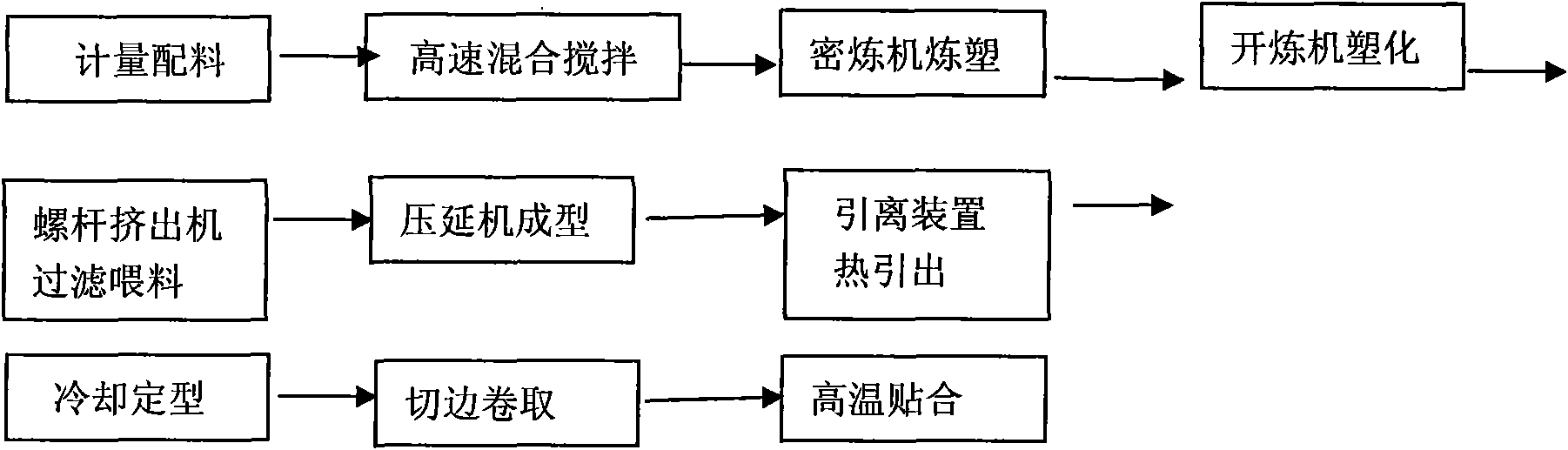

High-elastic wearproof athletic floor material and preparation method thereof

ActiveCN101538393AIncrease elasticityGood surface wear resistanceResiliently-mounted floorsPlasticizerPolyresin

The invention discloses a high-elastic wearproof athletic floor material, which is prepared by raw materials with the following proportioning by weight: 100 portions of PVC high-polymerization degree resin, 40-60 portions of plasticizer, 5-10 portions of TPU polyurethane elastomer, 2.5-4.0 portions of composite heat stabilizer, 0.05-0.1 portion of mildew inhibitor, and 30-50 portions of filler modifier. The method adopts the technology of laminating high-strength ultralow-shrinkage fibre glass mesh cloth in the high-performance rolling embryonic membrane, and the athletic floor produced by the method completely meets the service performance requirements, and simultaneously has high elasticity, good surface abrasion resistance and small shrinkage factor of product size.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Inorganic matrix compositions and composites incorporating the matrix composition

InactiveUS20050022698A1Maintain good propertiesExcellent thermalAlkali metal silicate coatingsCement productionCompression moldingInorganic composition

A modified alkali silicate composition for forming an inorganic network matrix. The modified alkali silicate matrix is made by reacting an alkali silicate (or its precursors such as an alkali hydroxide, a SiO2 source and water), an acidic inorganic composition, such as a reactive glass, water and optional fillers, additives and processing aids. An inorganic matrix composite can be prepared by applying a slurry of the modified aqueous alkali silicate composition to a reinforcing medium and applying the temperature and pressure necessary to consolidate the desired form. The composite can be shaped by compression molding as well as other known fabrication methods. A notable aspect of the invention is that, although composite and neat resin components prepared from the invention can exhibit excellent dimensional stability to 1000° C. and higher, they can be prepared at the lower temperatures and pressures typical to organic polymer processing.

Owner:THE BF GOODRICH CO

Ventilated polyurethane plastic race-track surface layer cementing material

ActiveCN103666233AGuaranteed bonding strengthGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMass ratioEnd-group

The invention discloses a ventilated polyurethane plastic race-track surface layer cementing material, and belongs to the technical field of race-track construction. The ventilated polyurethane plastic race-track surface layer cementing material consists of a component I and a component II at the mass ratio of 1:(3-4), wherein the component I is prepolymer containing isocyanate end group prepared from environment-friendly polyisocyanate, polyether glycol and an addition agent by reacting in a reaction kettle for 3 to 4 hours at the temperature of 70 to 80 DEG C, and the component II comprises polyether glycol with three functionalities, inorganic filler, pigment, a plasticizing agent, a curing agent, an antioxygen, an ultraviolet light absorber and the like. The obtained plastic race-track has the advantages that surface particles are not easy to fall out, the surface is smooth, the quality of the plastic race-track is improved, the service life of the plastic race-track is prolonged, the qualification rate of the plastic race-track is increased to more than 95% as compared with the conventional 82%, the production cost and the use cost are reduced. Moreover all of the used raw materials are environmental protection materials, and belongs to environment friendly materials, the environmental pollution is avoided, and security is provided for the health safety of sporters.

Owner:金华市一家建设工程有限公司

Phase-change energy-storage fibre and method for making same

ActiveCN101041911AHigh phase change enthalpyFunction increaseConjugated cellulose/protein artificial filamentsMelt spinning methodsCelluloseWax

The invention discloses a phase-variable energy-storage fiber and relative production, which comprises that using cellulose slurry to prepare cellulose adhesive solution, to be mixed with phase-variable wax fused solution to prepare spinning dope to obtain the phase-variable energy-saving adhesive fiber. The functional fiber is mainly formed by cellulose and wax, while the wax content is 10-40% (relative to the cellulose content). And the inventive production has simple process, significantly reduced phase-variable material loss in the process, improve the phase-variable material content and improve the phase-variable energy-saving function and mechanical function.

Owner:潍坊欣龙生物材料有限公司

Dihydric alcohol containing acylhydrazone bond, dihydric alcohol containing acylhydrazone bond and disulfide bond, self-repairing polyurethane elastomer and preparation method thereof

ActiveCN106117486AAchieve self-healingGood physical and mechanical propertiesHydrazone preparationHydropoly/poly sulfide preparationPolyesterMechanical property

The invention provides dihydric alcohol containing an acylhydrazone bond, dihydric alcohol containing an acylhydrazone bond and a disulfide bond, a self-repairing polyurethane elastomer and a preparation method thereof. The polyurethane elastomer is prepared from the dihydric alcohol containing the acylhydrazone bond or the dihydric alcohol containing the acylhydrazone bond and the disulfide bond and a polyurethane prepolymer. The dihydric alcohol containing the acylhydrazone bond is prepared from a dihydrazide monomer and hydroxy aldehyde. The dihydric alcohol containing the acylhydrazone bond and the disulfide bond is prepared from a dithio lipid monomer, hydrazine hydrate and hydroxy aldehyde. The polyurethane prepolymer is prepared from a polyester or polyether polyol monomer and diisocyanate. After the self-repairing polyurethane elastomer is mechanically damaged, the acylhydrazone bond or the disulfide bond on a crosslinked polymer molecular chain achieves material self-repairing through dynamic exchange reaction. The self-repairing crosslinked polyurethane elastomer material is simple in preparation, can achieve self repairing at room temperature, is high in repairing capability, short in repairing time and capable achieving many times of self repairing and has better mechanical properties.

Owner:QINGDAO UNIV OF SCI & TECH +1

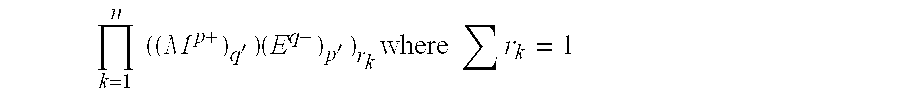

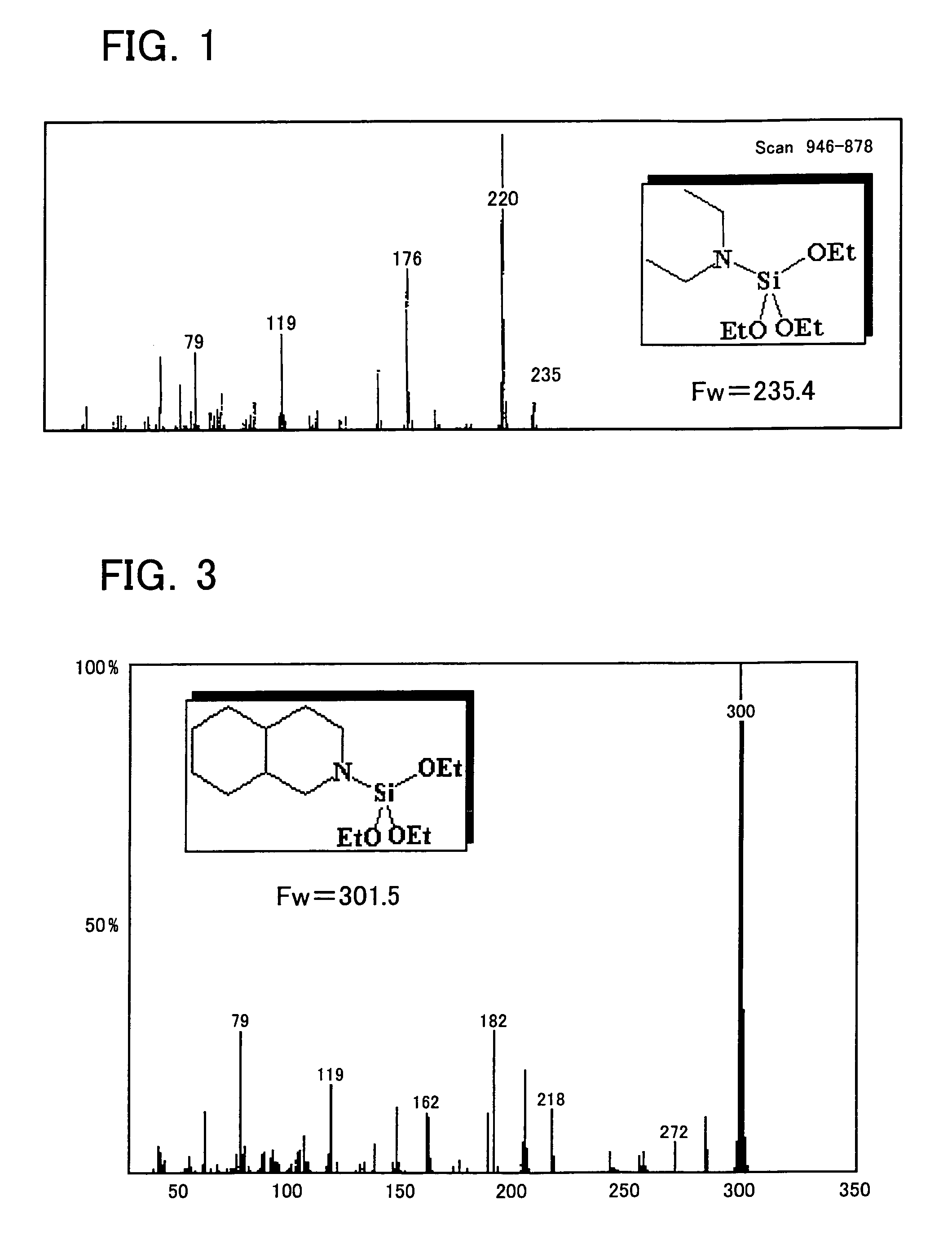

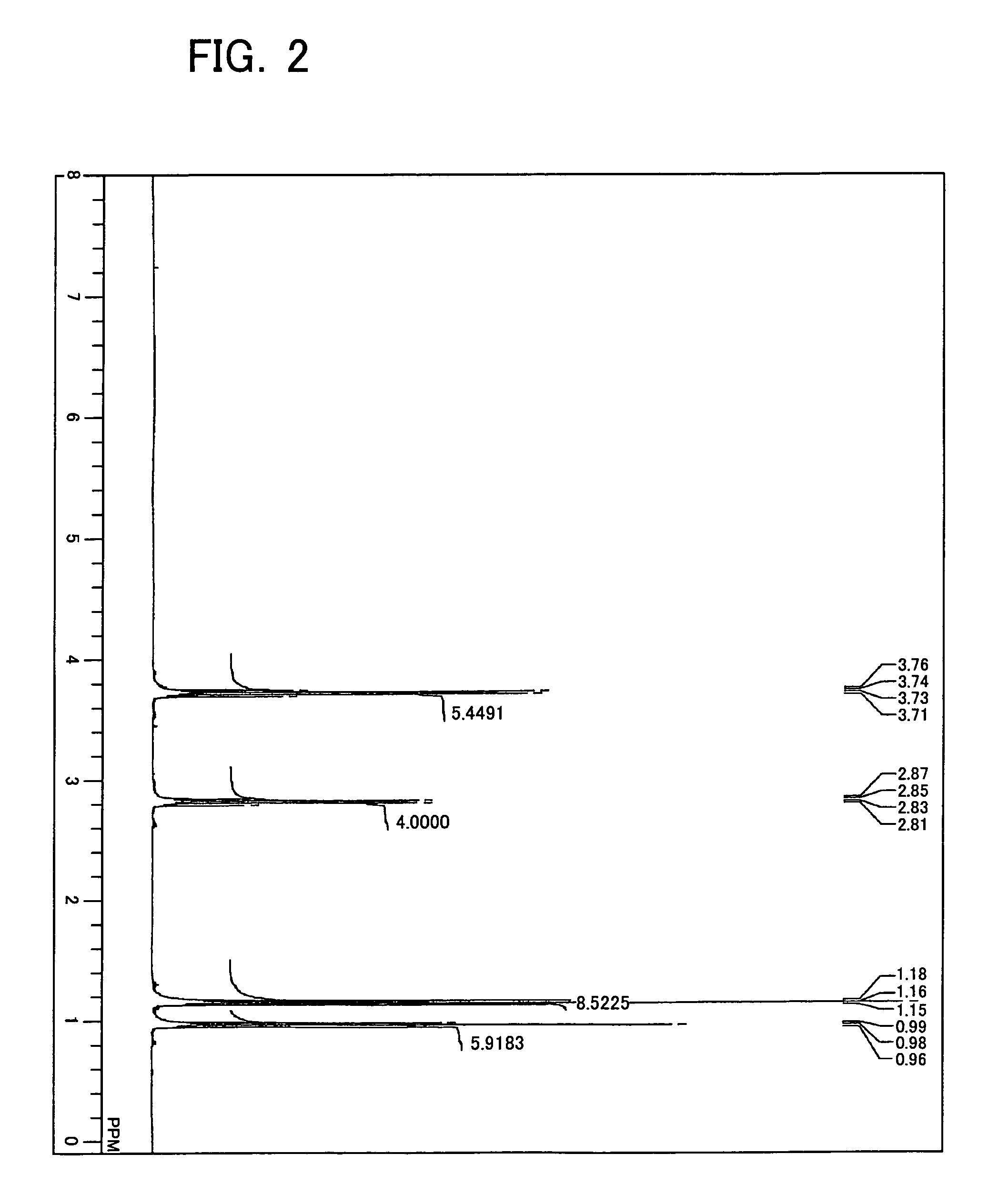

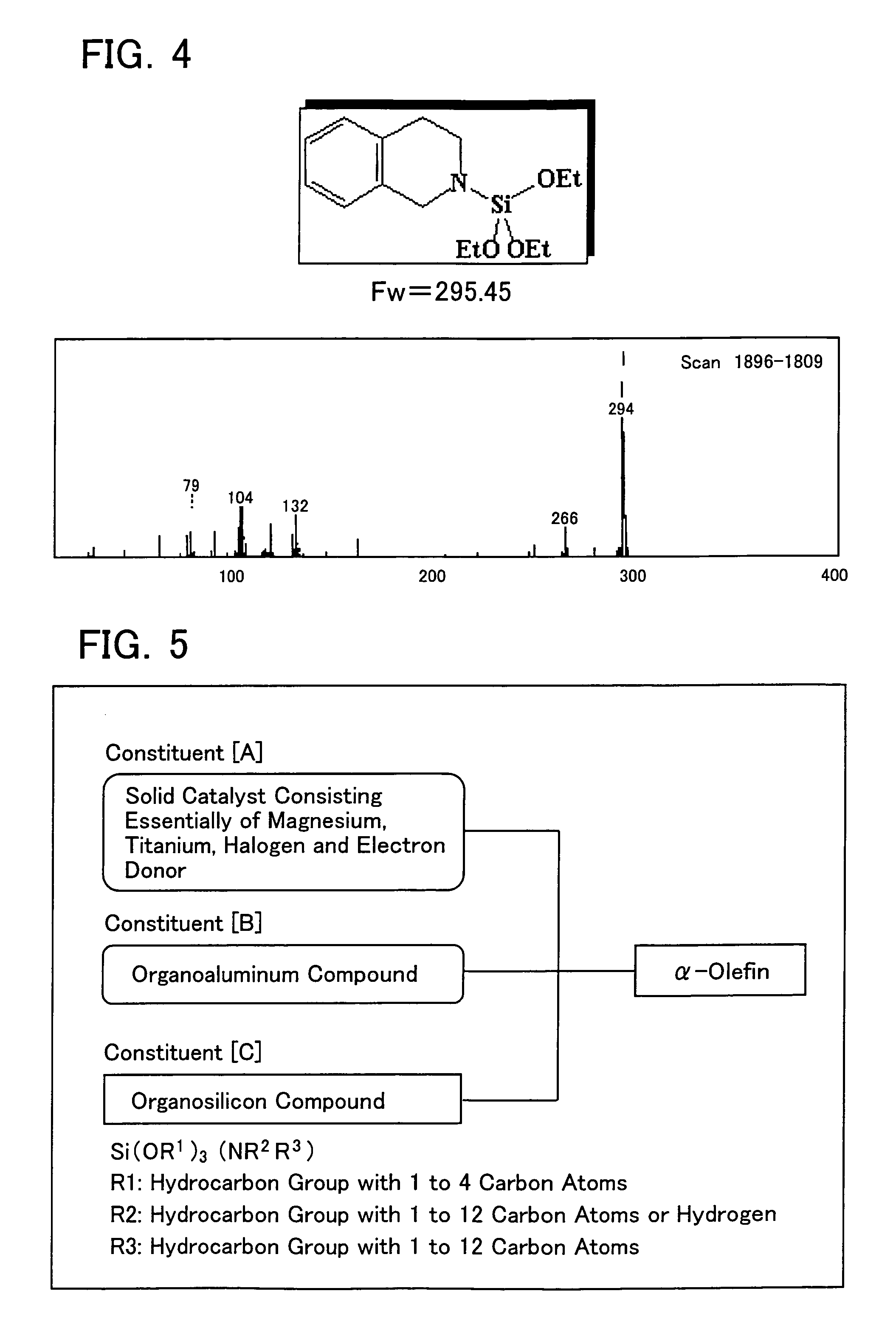

Catalysts for polymerization or copolymerization of α-olefins, catalyst components thereof, and processes for polymerization of α-olefins with the catalysts

InactiveUS7238758B2Improve responseIncrease the rate of polymerizationSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenReaction rate

The invention has an object to provide a catalyst for polymerizing or copolymerizing an α-olefin, catalyst constituent thereof, and method of polymerizing α-olefins with the catalyst, for production of α-olefin polymers or copolymers with high hydrogen response, high polymarization reaction rate, high stereoregularity and excellent melt fluidity. The invention discloses a catalyst constituent of the catalyst for polymerizing or copolymerizing an α-olefin, represented by Formula 37 or 38:Si(OR1)3(NR2R3)Formula 37(where in Formula 37, R1 is a hydrocarbon group with 1 to 6 carbon atoms; R2 is a hydrocarbon group with 1 to 12 carbon atoms or hydrogen; and R3 is a hydrocarbon group with 1 to 12 carbon atoms)RNSi(OR1)3Formula 38(where in Formula 38, R1 is a hydrocarbon group with 1 to 6 carbon atoms; and RN is a cyclicl amino group).

Owner:TOHO TITANIUM CO LTD

Glass reinforced nylon blend with improved knitline strength

The present invention provides a polymer alloy including from about 40% to about 75% by weight of at least one polyamide, from about 10% to about 50% by weight polypropylene, from about 0.01% to about 1.0% by weight of at least one block copolymer including a vinyl aromatic monomer and a conjugated diene, and also includes an unsaturated dicarboxylic reagent, from about 0.1% to about 5.0% by weight of at least one block copolymer or terpolymer, wherein the terpolymer may have an unsaturated dicarboxylic reagent grafted thereto, from about 0.01% to about 7.5% of a compatibilizing agent, and from about 5% to about 50% by weight of a filler. The alloy of the present invention exhibits improved knitline strength and improved drop impact results compared with prior art fiberglass-reinforced nylon blends.

Owner:LYONDELLBASELL ADVANCED POLYMERS INC

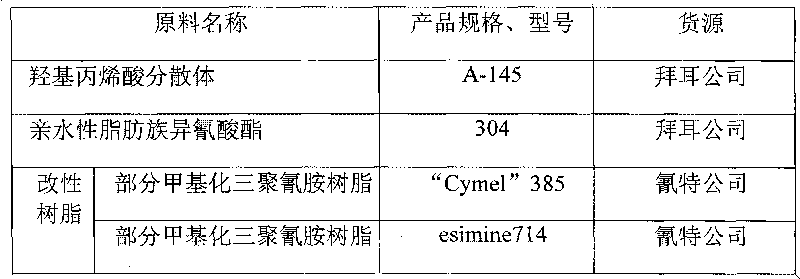

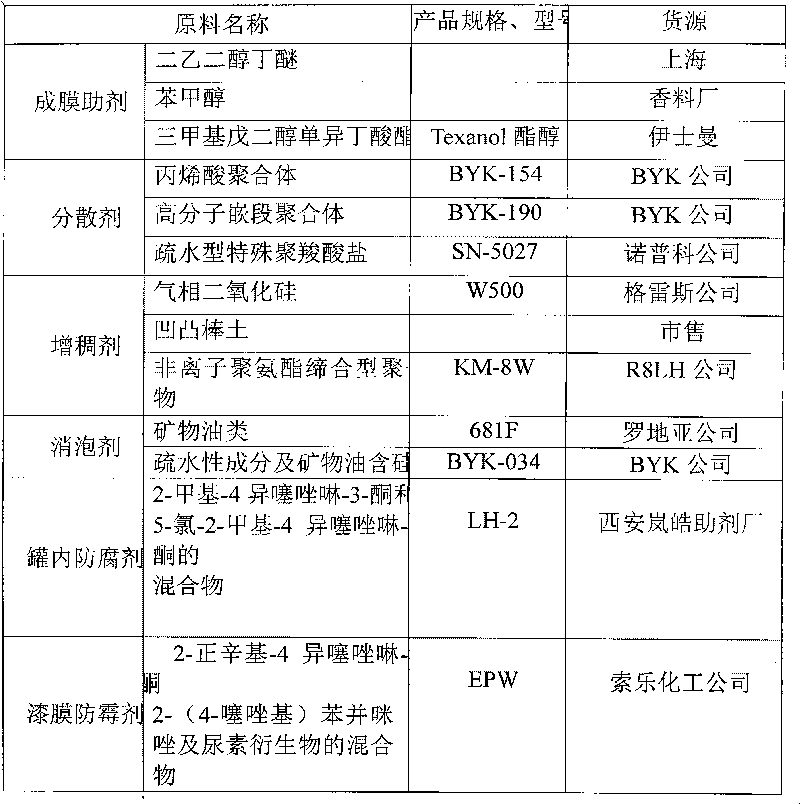

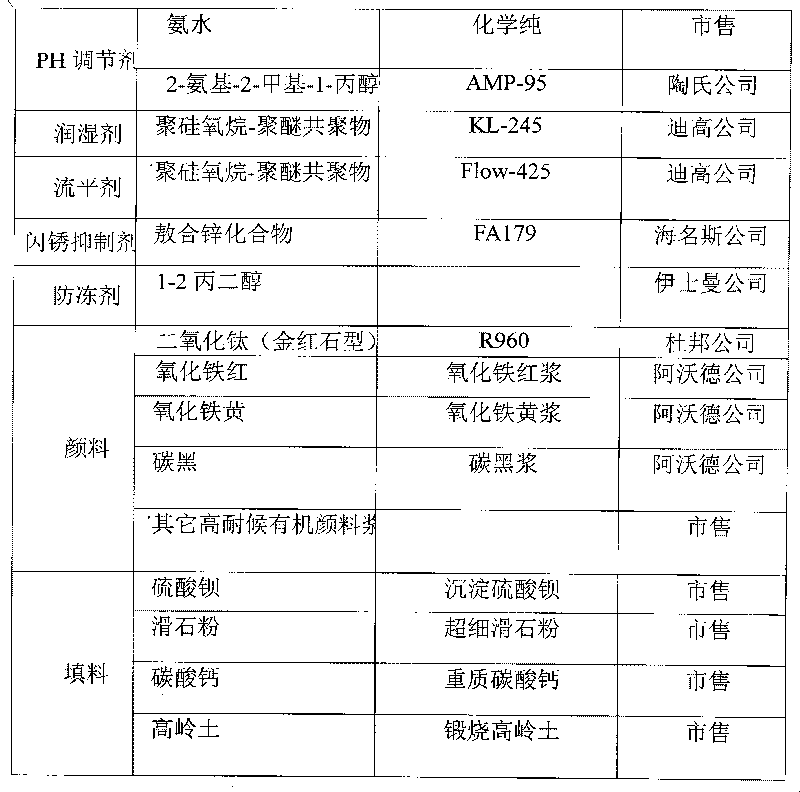

Water-based two-pack polyurethane preservative coating and preparation method thereof

ActiveCN101701128AHigh glossGood chemical resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedDipropylene glycol monomethyl ether acetate

The invention relates to the preservative coating technology, in particular to a water-based two-pack polyurethane preservative coating and a preparation method thereof. The water-based two-pack polyurethane preservative coating comprises two parts, namely paint vehicle and curing agent, wherein the paint vehicle is prepared from water-based hydroxylated acrylic dispersion, modified resin, pigment, filler, additive and water, the curing agent part comprises hydrophilic aliphatic isocyanate, dodecyl ester and propylene glycol methyl ether acetate. When using the coating of the invention, the weight ratio of the paint vehicle to the curing agent is 74-85:15-26 and the coating can solve the defects of the existing preservative coating.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

Anticorrossion antiwear ceramic paint

InactiveCN1325931AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGlass fiber

An anticorrosion and antiwear ceramic paint is prepared from epoxy resin (28.5-35 wt.portions), dibutyl phthalate (3.75-6), mixed solvent of xyrene and n-butyl ester (20-24), gas-phase SiO2 (0.5-1) and ceramic powder (38-45) which contains TiO2 (3-6.3), Al2O3 (11.7-20) and Si3N4 (16-20.45). The weight ratio of main component to slidifying agent is (14.5-17):1. It can be directly applied to the surfaces of metal, glass fibre, plastic, or concrete with the advantages of high antiwear performance and adhesion, and thin and compact coated layer.

Owner:BEIJING UNIV OF CHEM TECH

Composite of modified road asphalt by microwave radiating old rubber powder and its preparation process

InactiveCN1597782AGood dispersionGood physical and mechanical propertiesBuilding insulationsWaxMicrowave

The invention relates to a microwave-irradiated waste-rubber powder modified pitch combination and its preparing method, using higher-wax content pitch as a substrate, adding in powdery butadiene-styrene rubber and microwave-irradiated waste rubber powder, and making high-speed cutting and uniform commixing to make the modified pitch. The modified pitch has the characters of high-temperature stability, obviously increased low-temperature extensibility, good antiaging property, etc, has road performance synthetically improved and can act as high-grade road pitch for use.

Owner:NORTHWEST NORMAL UNIVERSITY

Industrial lignin reinforcing rubber and preparation method of industrial lignin reinforcing rubber

The invention relates to industrial lignin reinforcing rubber and a preparation method of the industrial lignin reinforcing rubber. The industrial lignin reinforcing rubber is characterized in that 1, the industrial lignin reinforcing rubber comprises lignin dispersoid, rubber latex, a small number of plasticizers and operation oil or comprises multi-component lignin dispersoid, rubber latex, a small number of plasticizers and operation oil; 2, the lignin dispersoid is suspension of lignin in water, the weight part of the lignin is 5 to 30 percent, the multi-component lignin dispersoid is suspension of the lignin and inorganic fillers in water, and the weight proportion of the lignin to the water is (5-30):(95-70); and 3, in the lignin dispersoid and the multi-component lignin dispersoid, the lignin is hydroxymethylation modified dispersoid. The preparation method comprises the steps of 1. lignin preparation, 2, lignin dispersoid preparation, 3, rubber latex preparation, 4, cosedimentation and solidification and 5, industrial lignin reinforcing rubber obtaining. The industrial lignin reinforcing rubber and the preparation method have the advantages that the physical and mechanical properties of the rubber are not reduced, meanwhile, the drying processes in the lignin and rubber production process are combined, and the motive power consumption of rubber mixing is reduced.

Owner:广西合山林格高分子材料科技有限公司

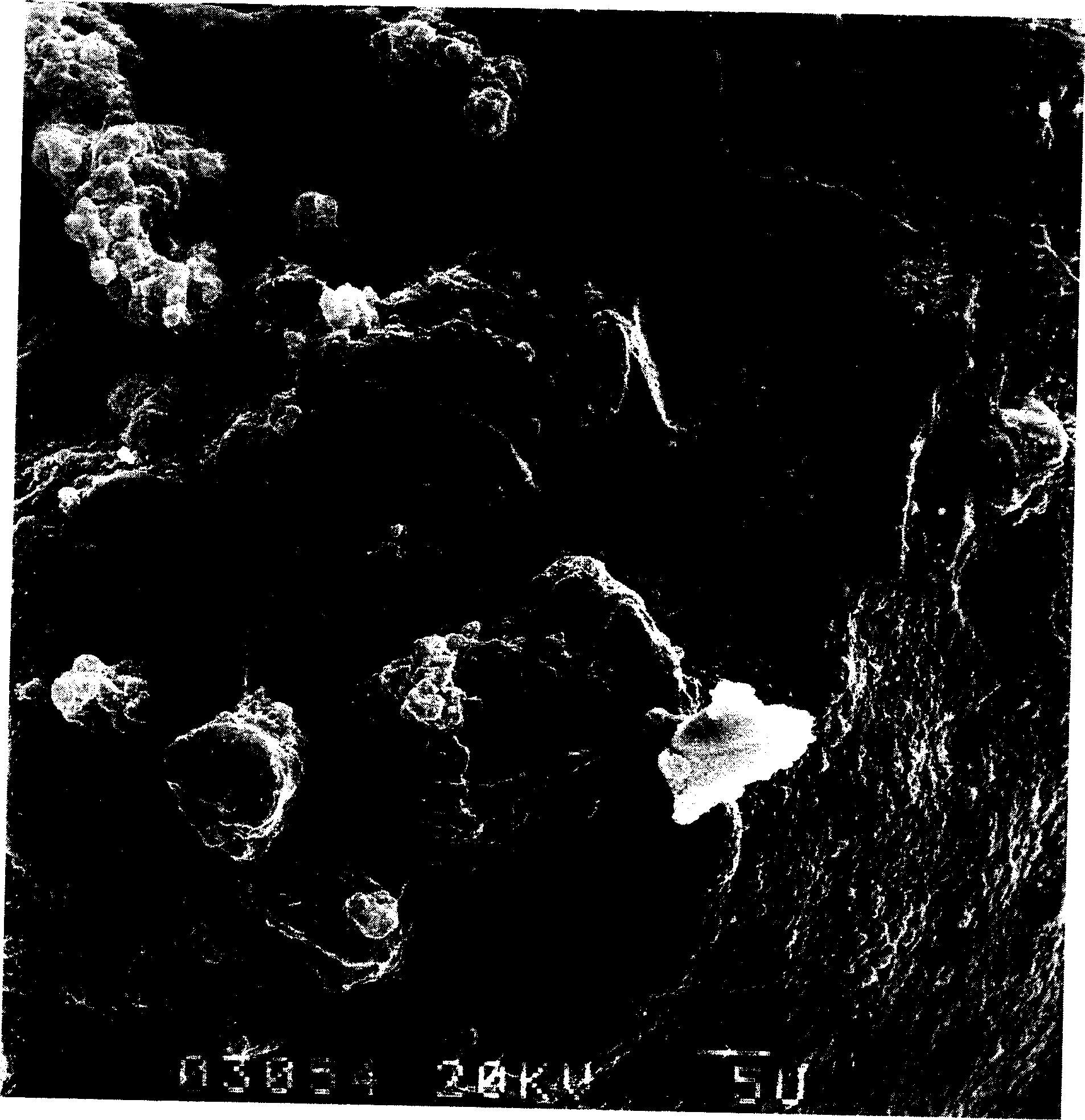

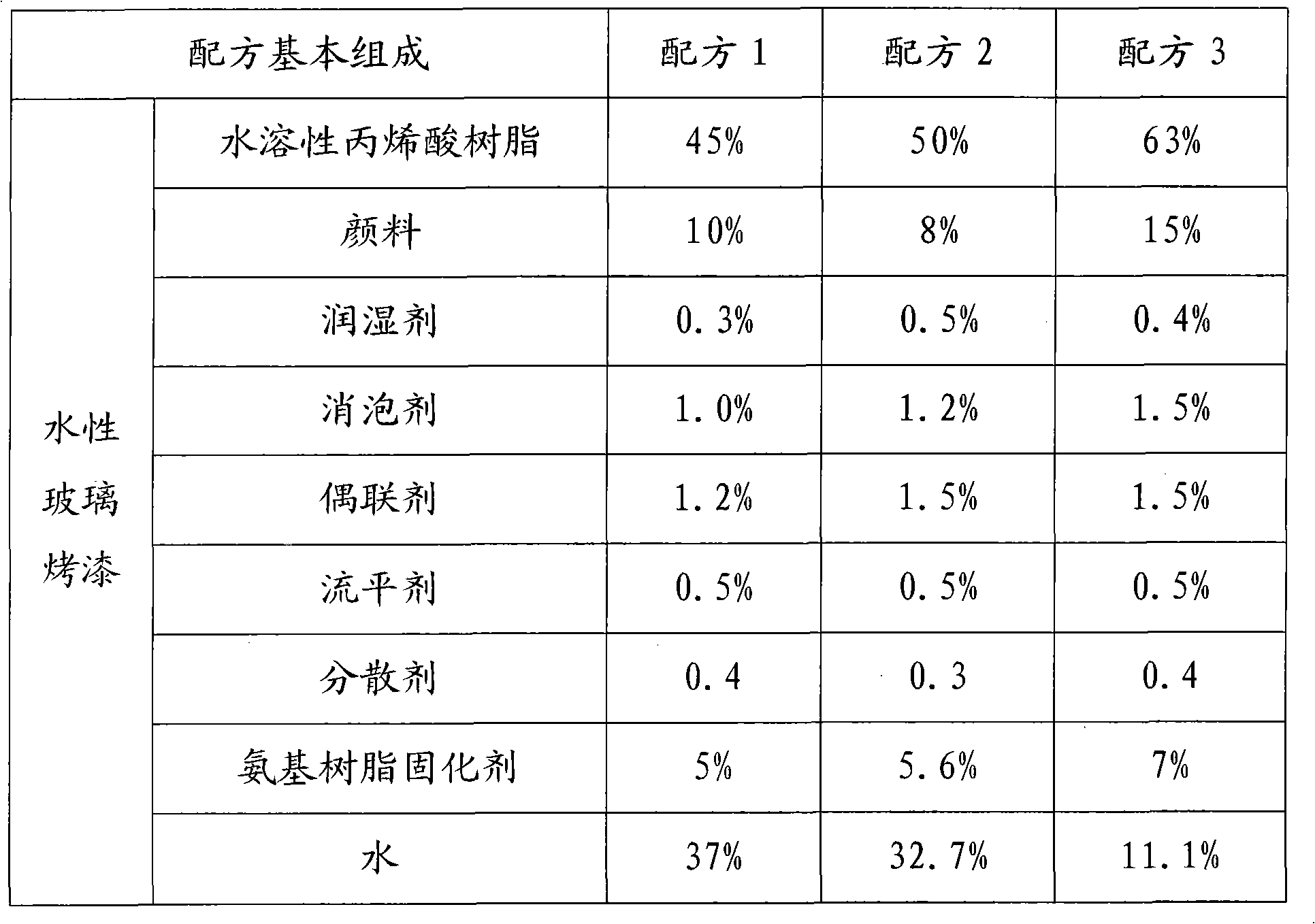

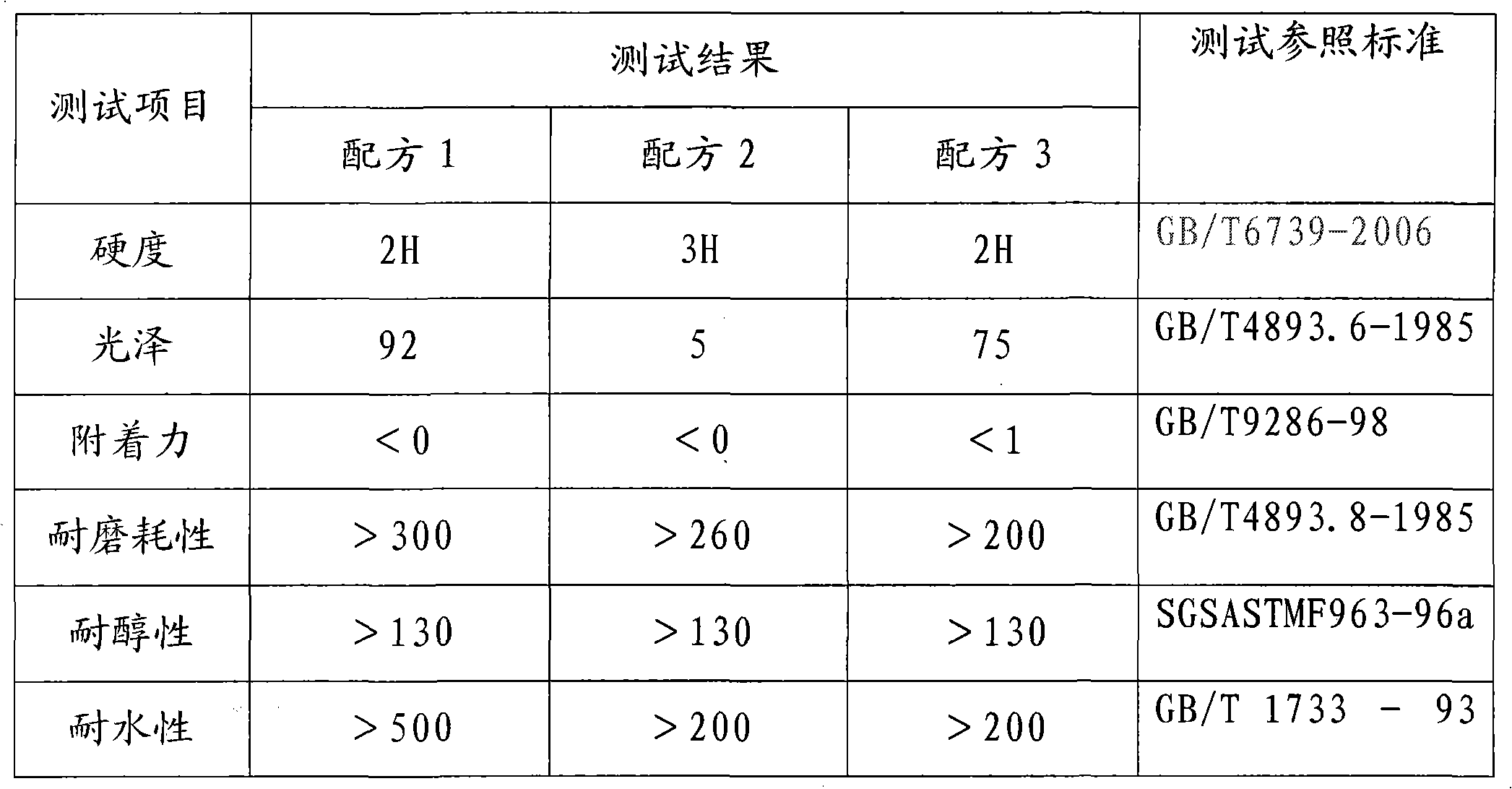

Water-based baking paint for glass substrate and preparation and use methods thereof

InactiveCN101845255ASimplify the construction processMeet the use requirementsCoatingsPolymer scienceAcrylic resin

The invention discloses a water-based baking paint for a glass substrate and a preparation method and the application thereof; the formula of the water-based glass baking paint comprises the following components in parts by weight: 45 to 63 percent of water-soluble acrylic resin, 5 to 7 percent of methylated amino resin, 5 to 15 percent of water-based paste, 1.2 to 1.5 percent of coupling agent, 2 to 5 percent of additive and 25 to 30 percent of deionized water. When the baking paint is prepared, first the water-soluble acrylic resin, defoamer, wetting agent, leveling agent, dispersant and some water are sequentially added into a stirring tank to be stirred, is added with the water-based slurry and the like to be stirred and dispersed at high speed; and finally the methylated amino resin, the coupling agent and the rest water are sequentially added in to be stirred into a uniform coating system. The invention also provides a use method of the glass baking paint. When being applied to ground glass, hard glass and other substrates, the coating has the advantages of simple preparation process, convenient construction, strong coating adhesion, high hardness, water resistance, good heat resistance and the like.

Owner:FUJIAN HANSEN PAINT

Environment-friendly low-temperature curing pure polyester powder paint and preparation method thereof

InactiveCN101985538AGood physical and mechanical propertiesLow curing temperaturePowdery paintsPolyester coatingsChemistryLow toxicity

The invention discloses an environment-friendly low-temperature curing pure polyester powder paint, comprising the following components in parts by weight: 100-200 parts of hydroxyl polyester resin, 1-20 parts of HAA curing agent, 0-30 parts of auxiliaries, 0-16 parts of inorganic filler and 0-30 parts of pigment. The invention also discloses a preparation method of the powder paint. The environment-friendly low-temperature curing pure polyester powder paint provided by the invention has simple formula, low toxicity, environment protection and low curing temperature, and contains no TGIC in the raw material components by adopting the novel carboxyl-terminated polyester resin to be combined with beta-hydroxyalkylamides, and the cured coating has the characteristics of excellent physical and mechanical properties, chemical resistance, outdoor weather fastness and the like; in addition, the powder paint provided by the invention can be used in outdoor appliances and is a real energy-saving environment-friendly paint product.

Owner:CHINA NAT ELECTRIC APP RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com