Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3530 results about "Ceramic coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

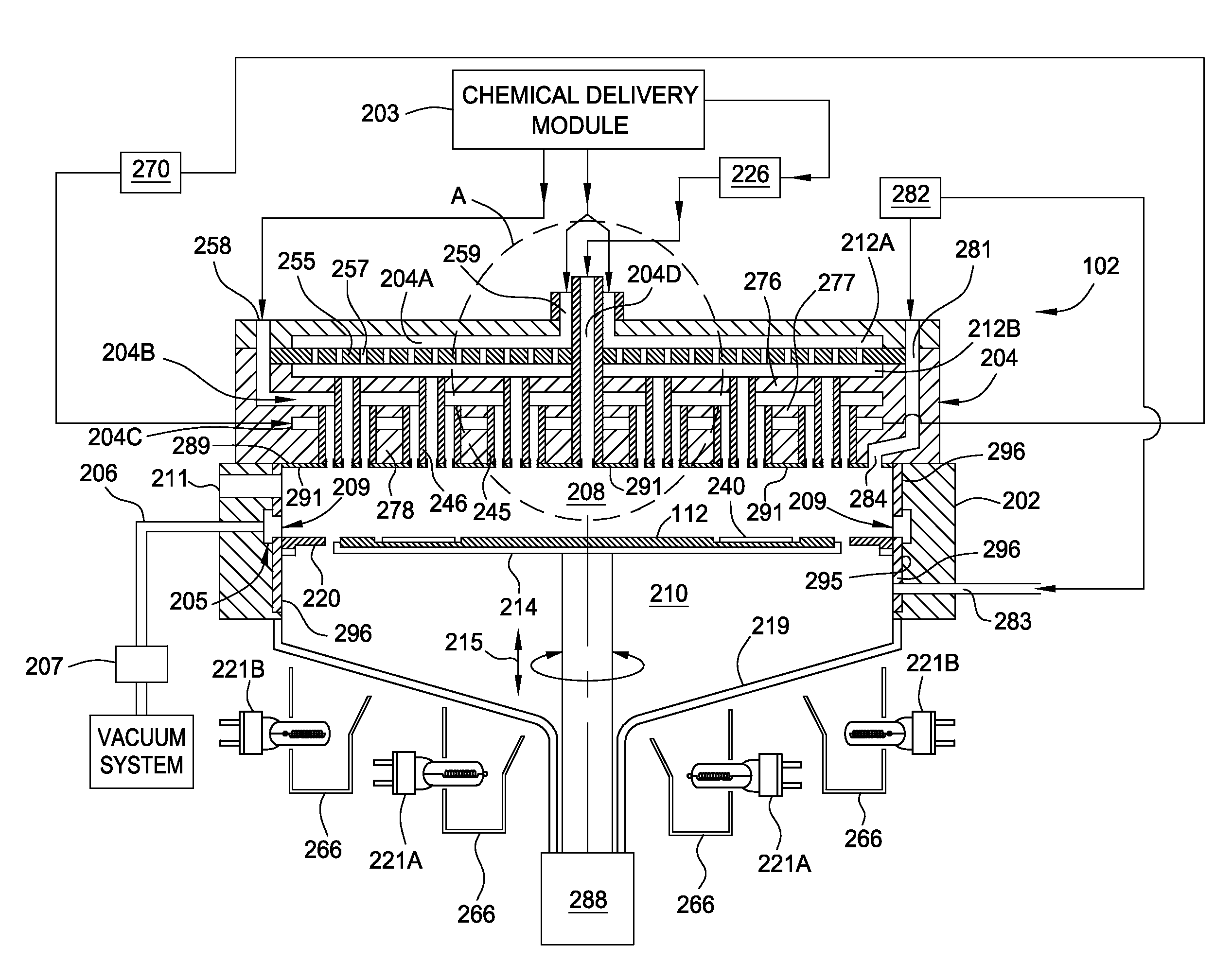

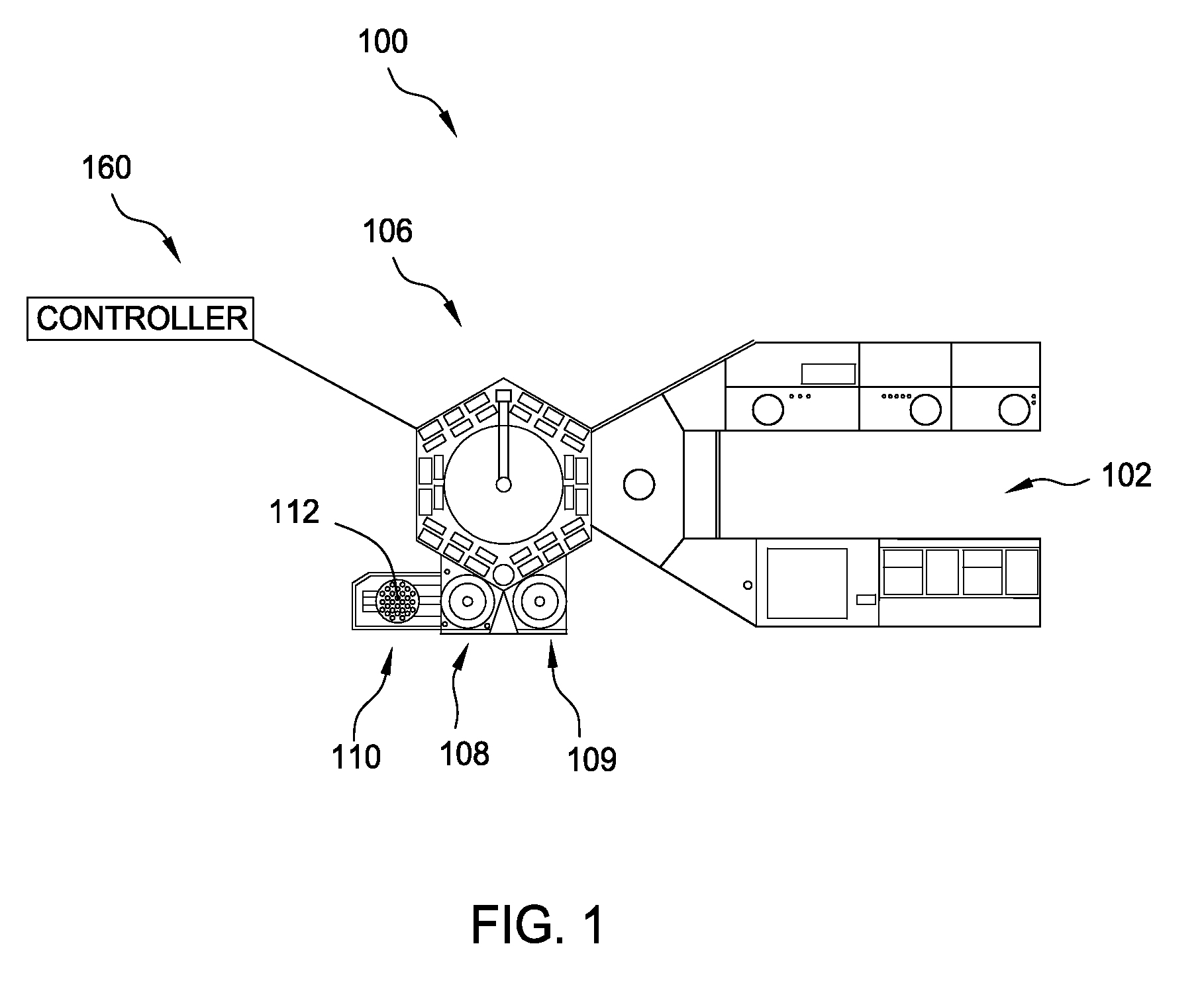

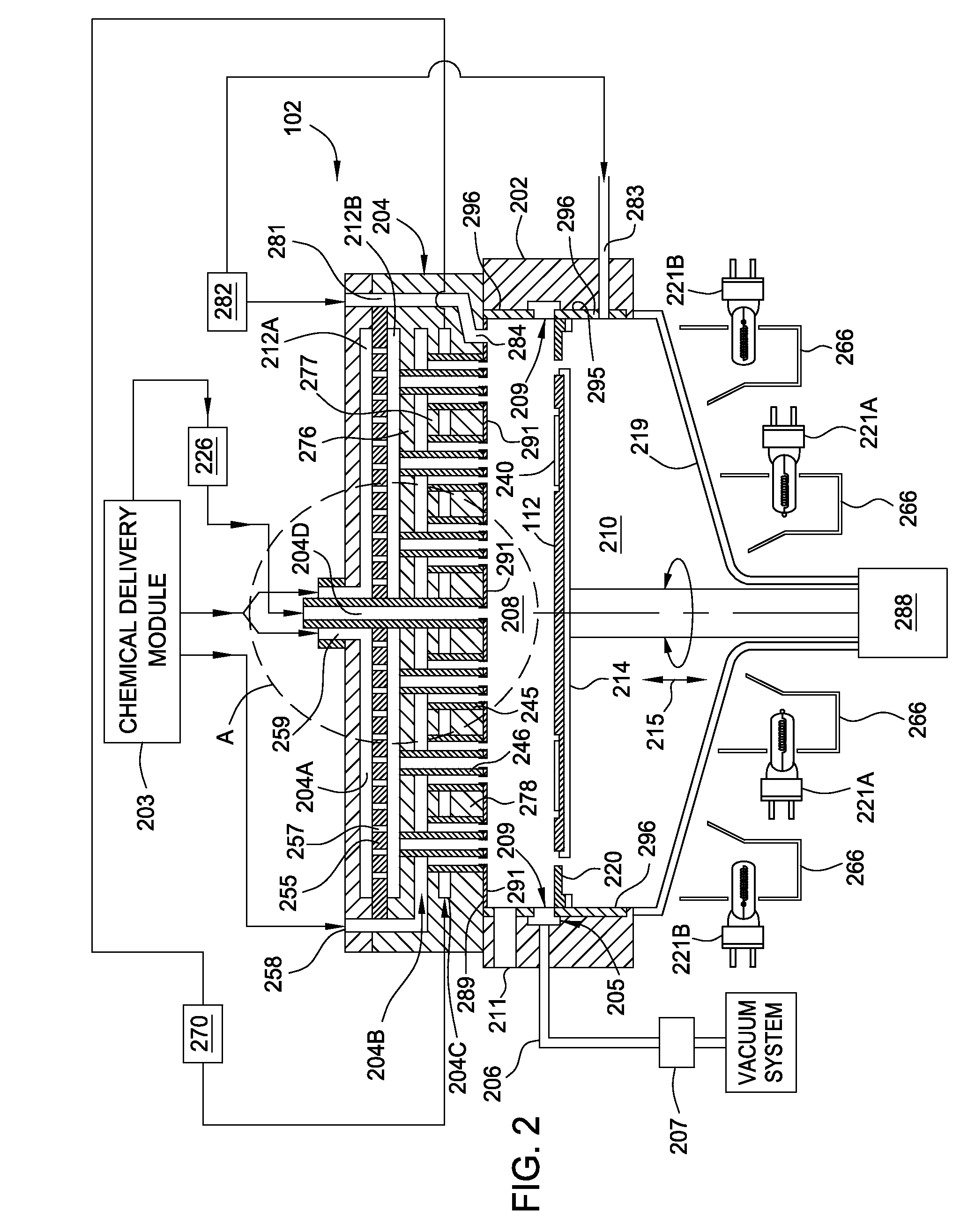

Gas distribution showerhead and method of cleaning

During a deposition process, material may deposit not only on the substrate, but also on other chamber components. In a MOCVD chamber, one of those components is the gas distribution showerhead. The showerhead may be cleaned by bombarding the showerhead with radicals generated by a plasma that includes an inert gas and chlorine. In order to generate the plasma, the showerhead may be negatively biased or floating relative to the substrate support. The showerhead may comprise stainless steel and be coated with a ceramic coating.

Owner:APPLIED MATERIALS INC

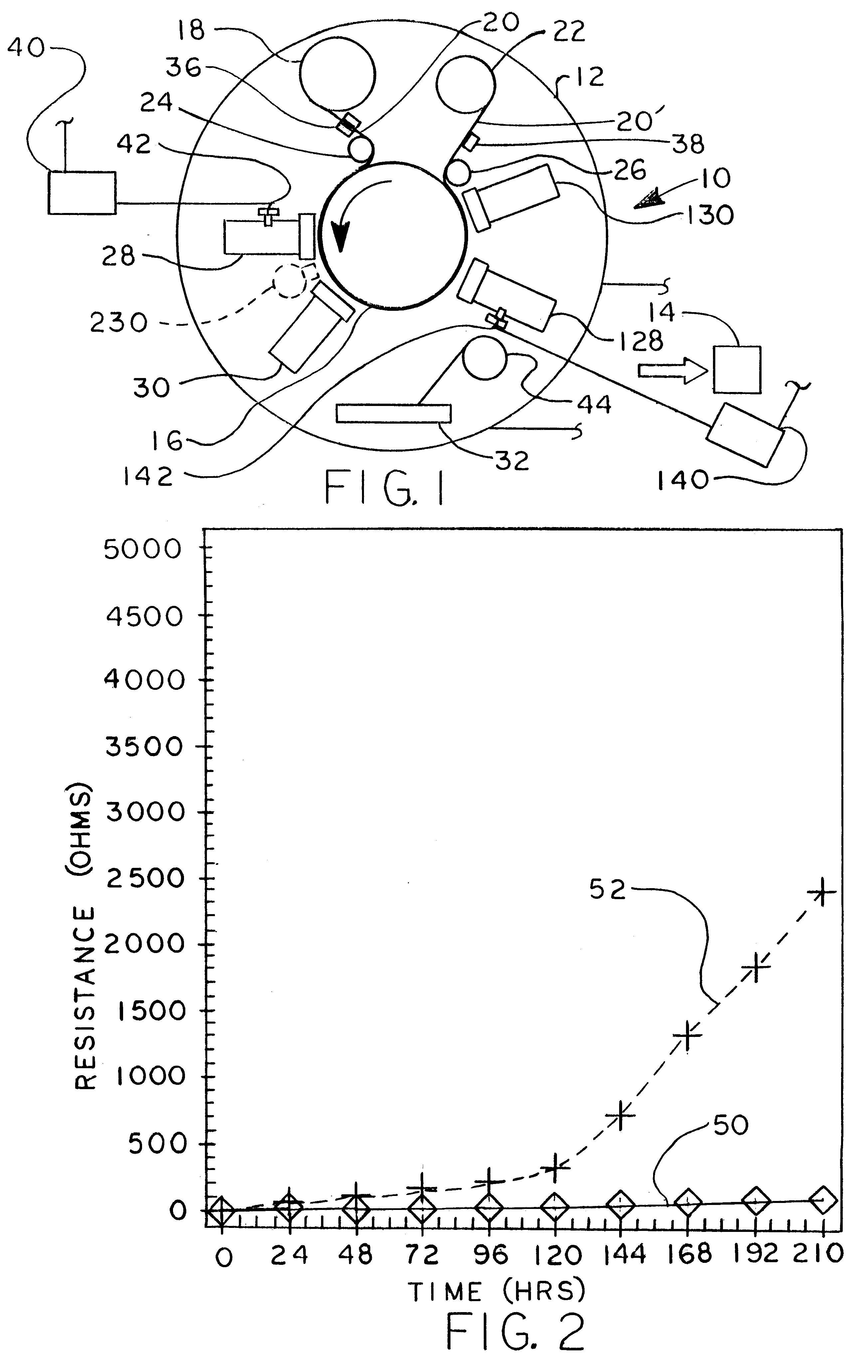

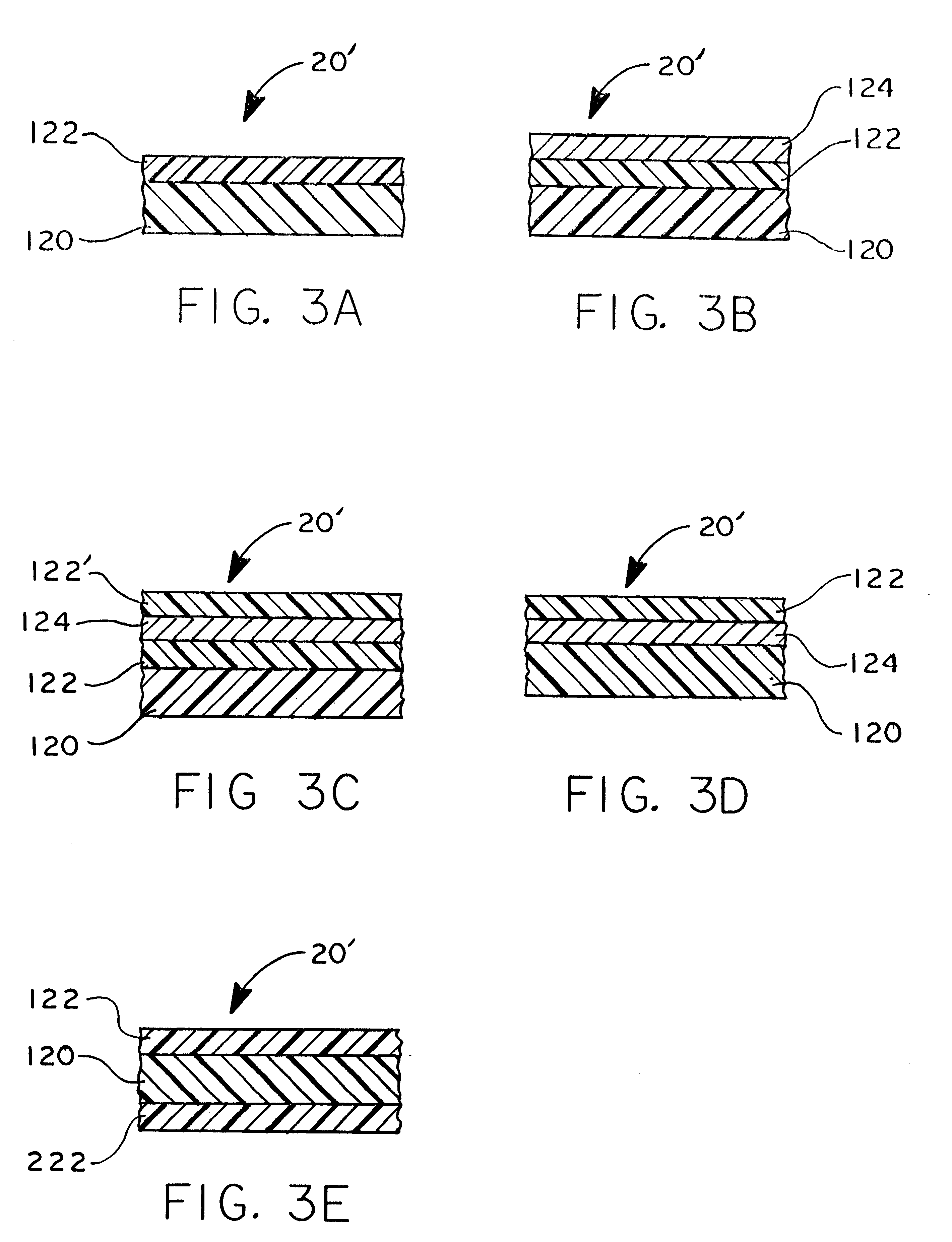

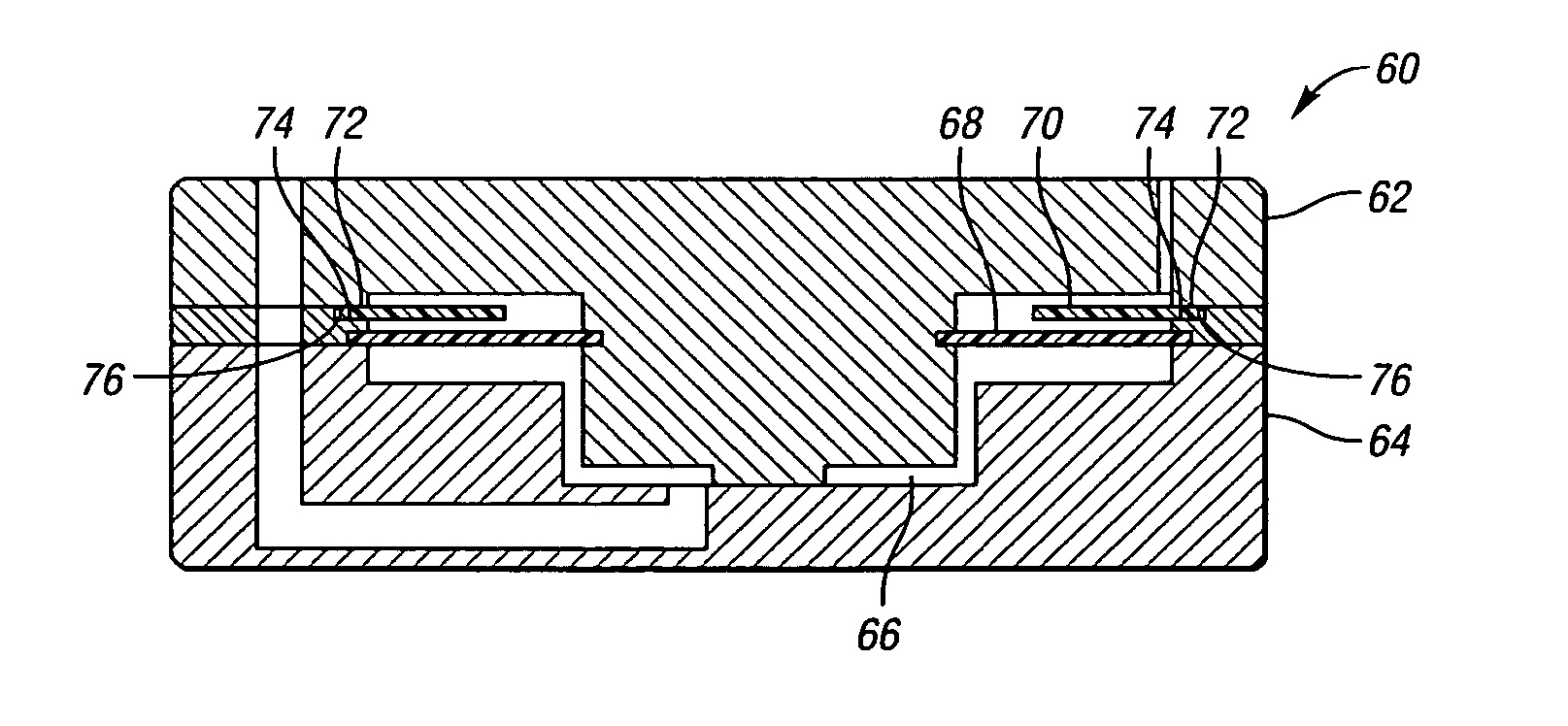

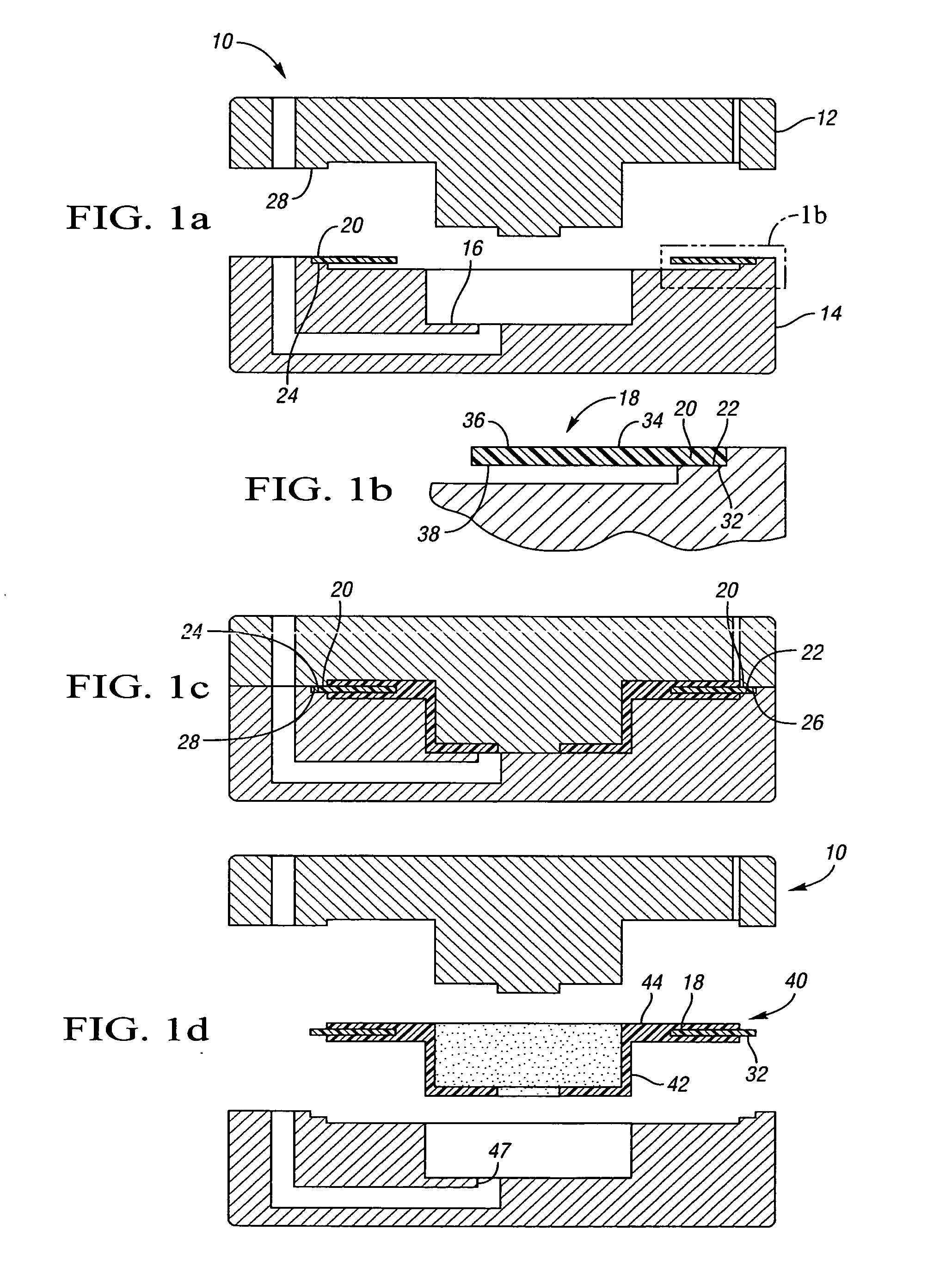

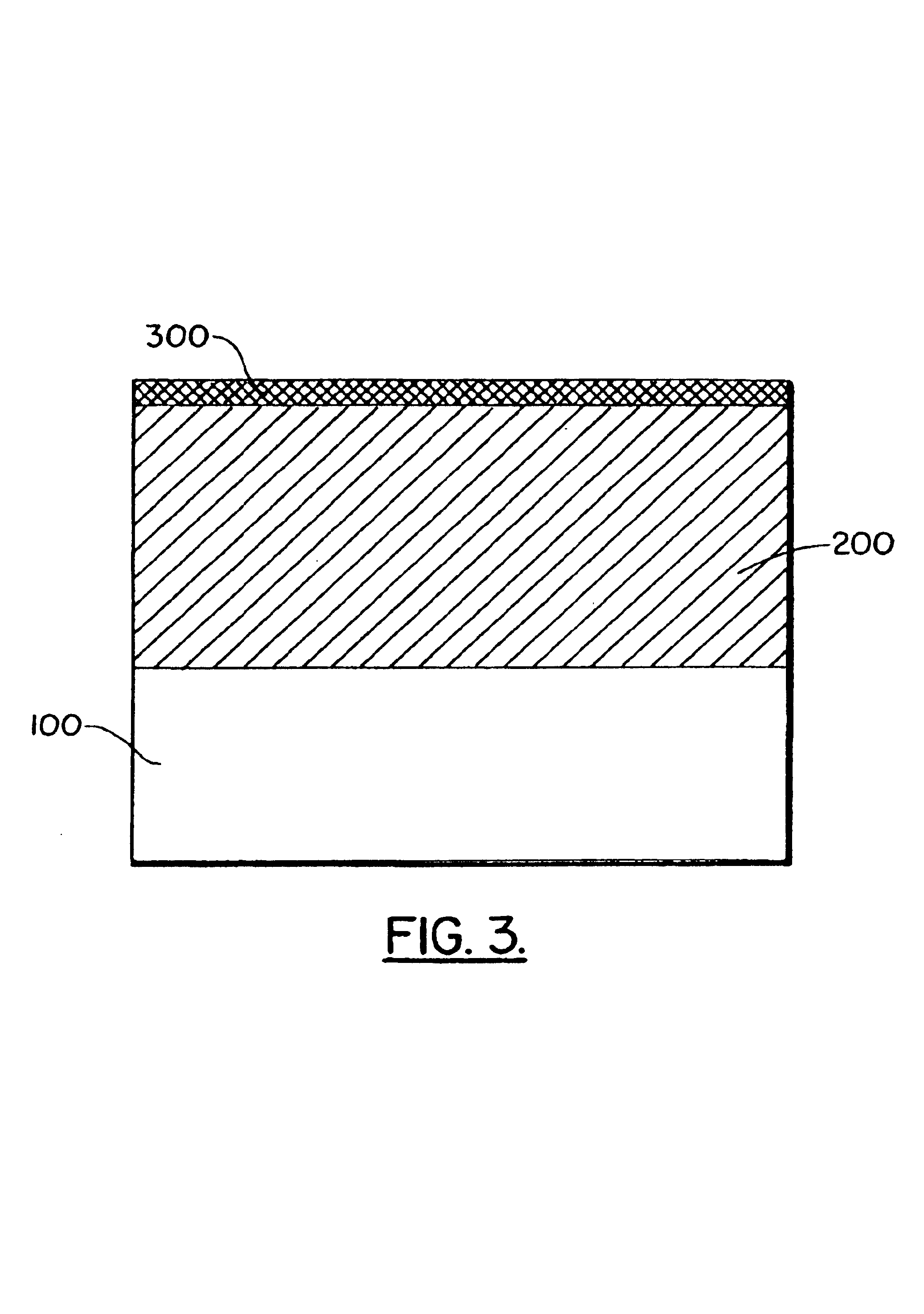

Method of forming a hybrid polymer film

InactiveUS6214422B1Fine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

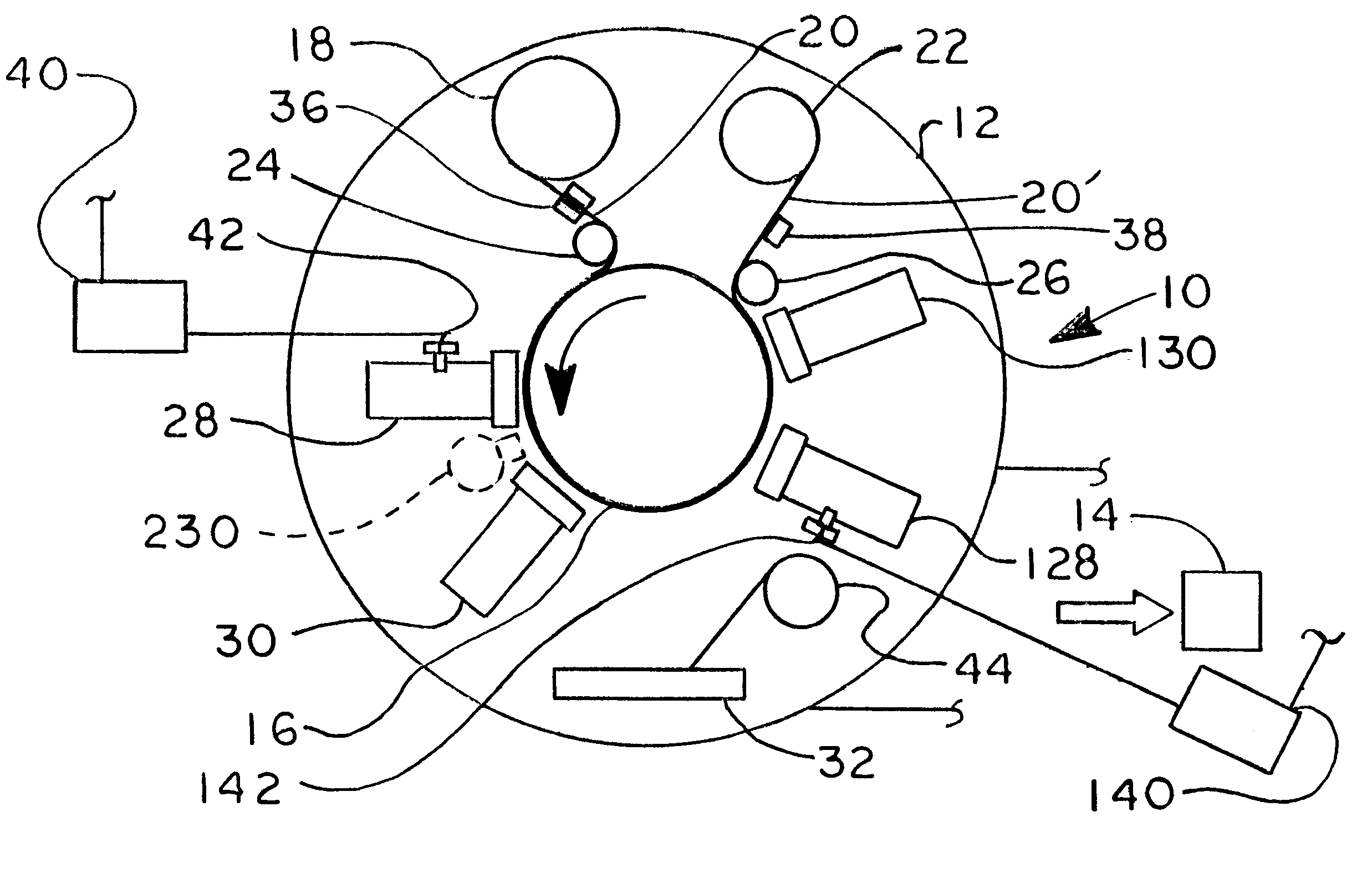

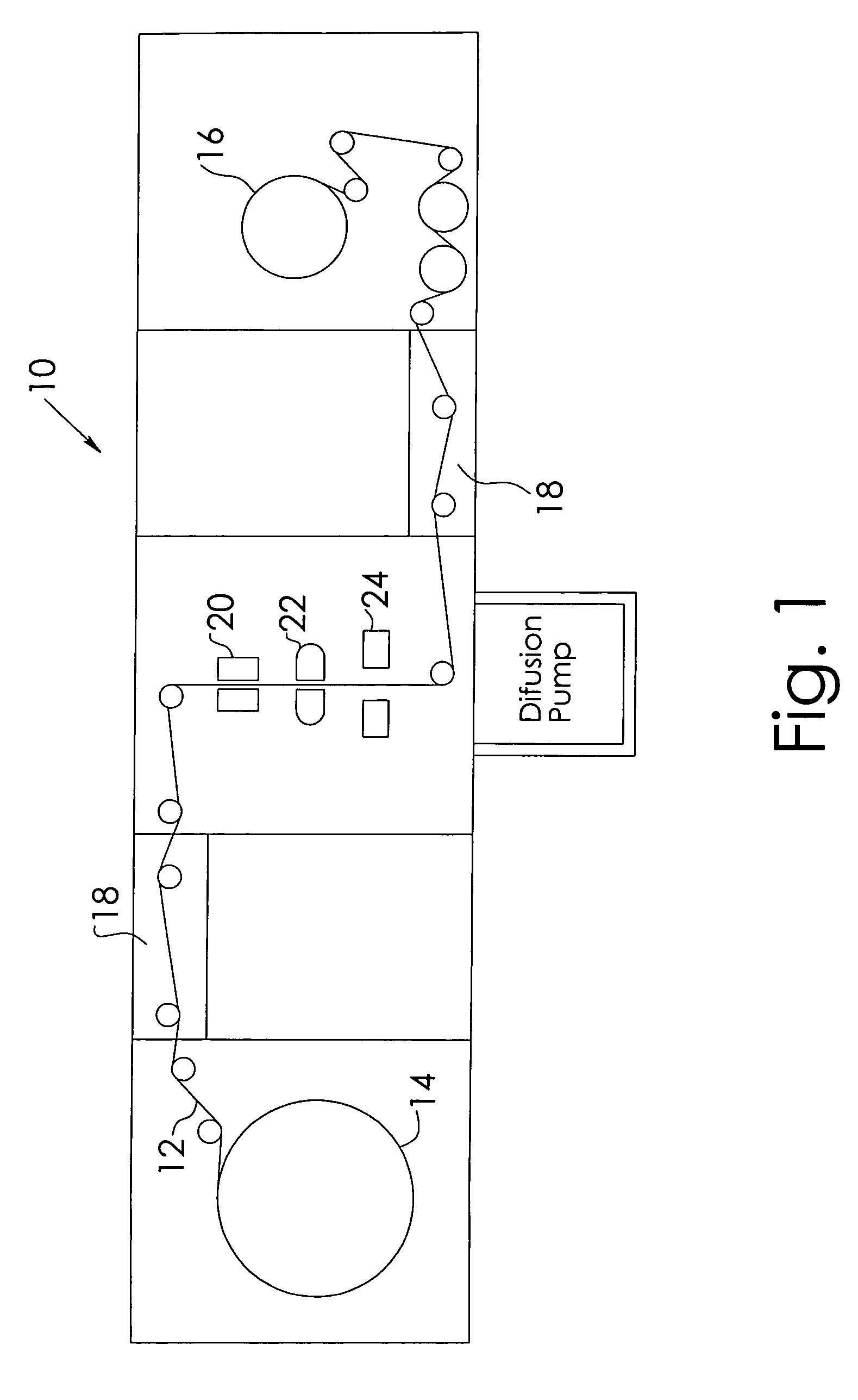

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-liked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

Hybrid polymer film

InactiveUS6083628AFine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer. A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-linked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

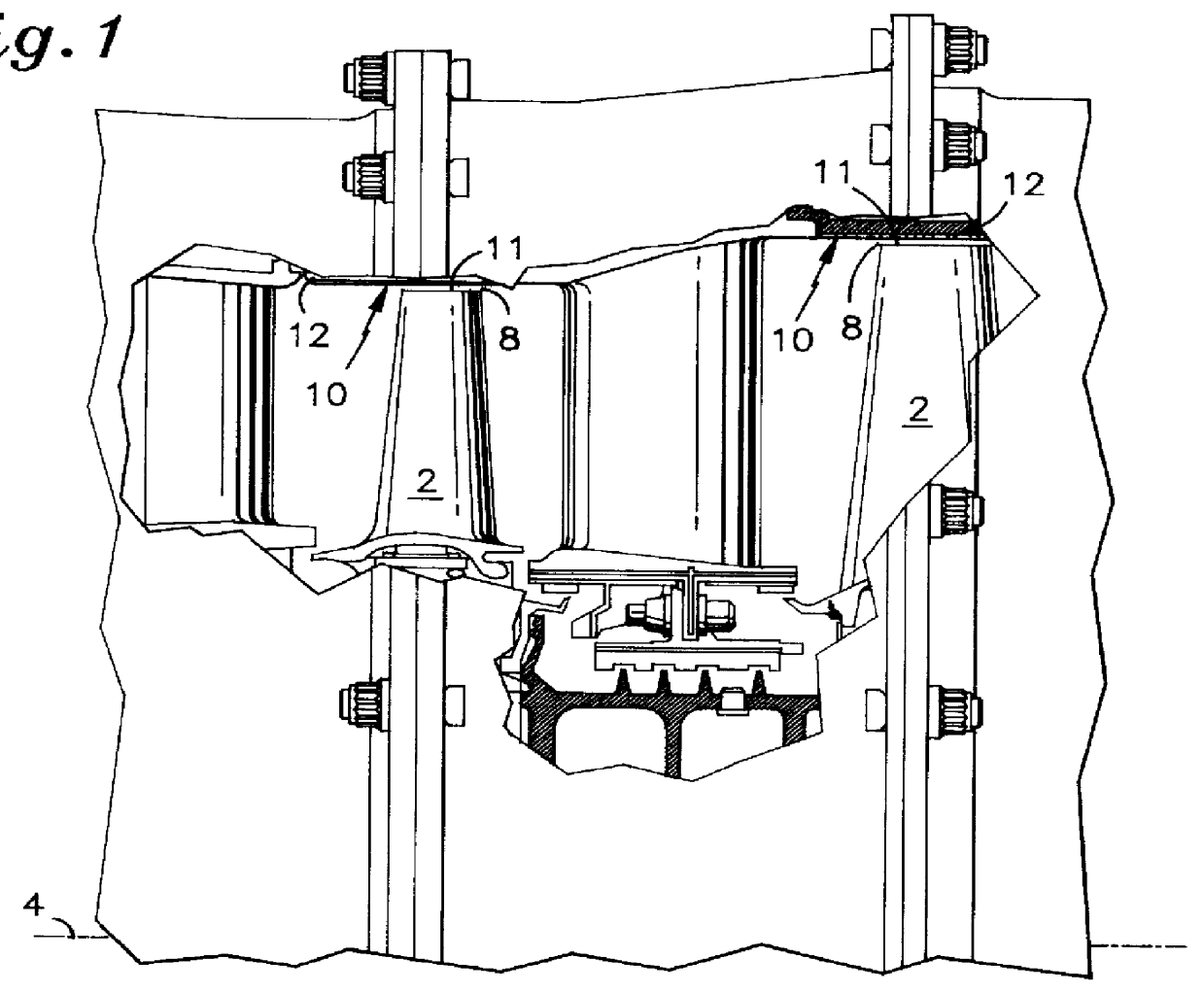

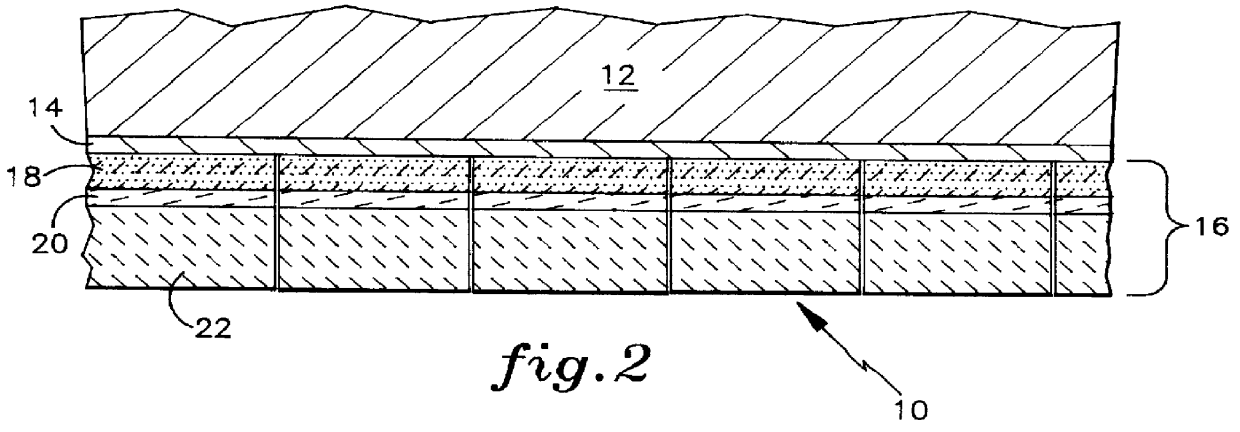

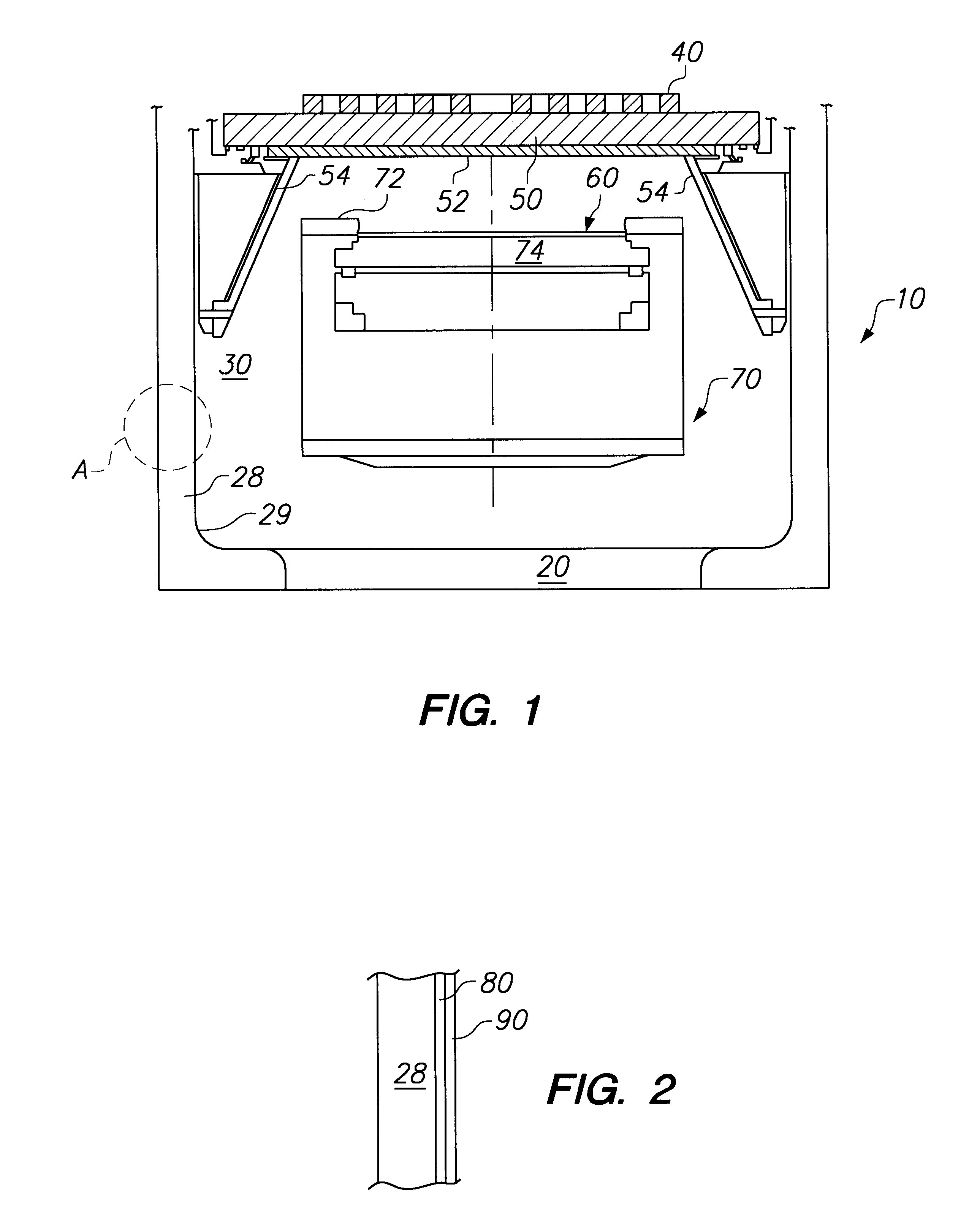

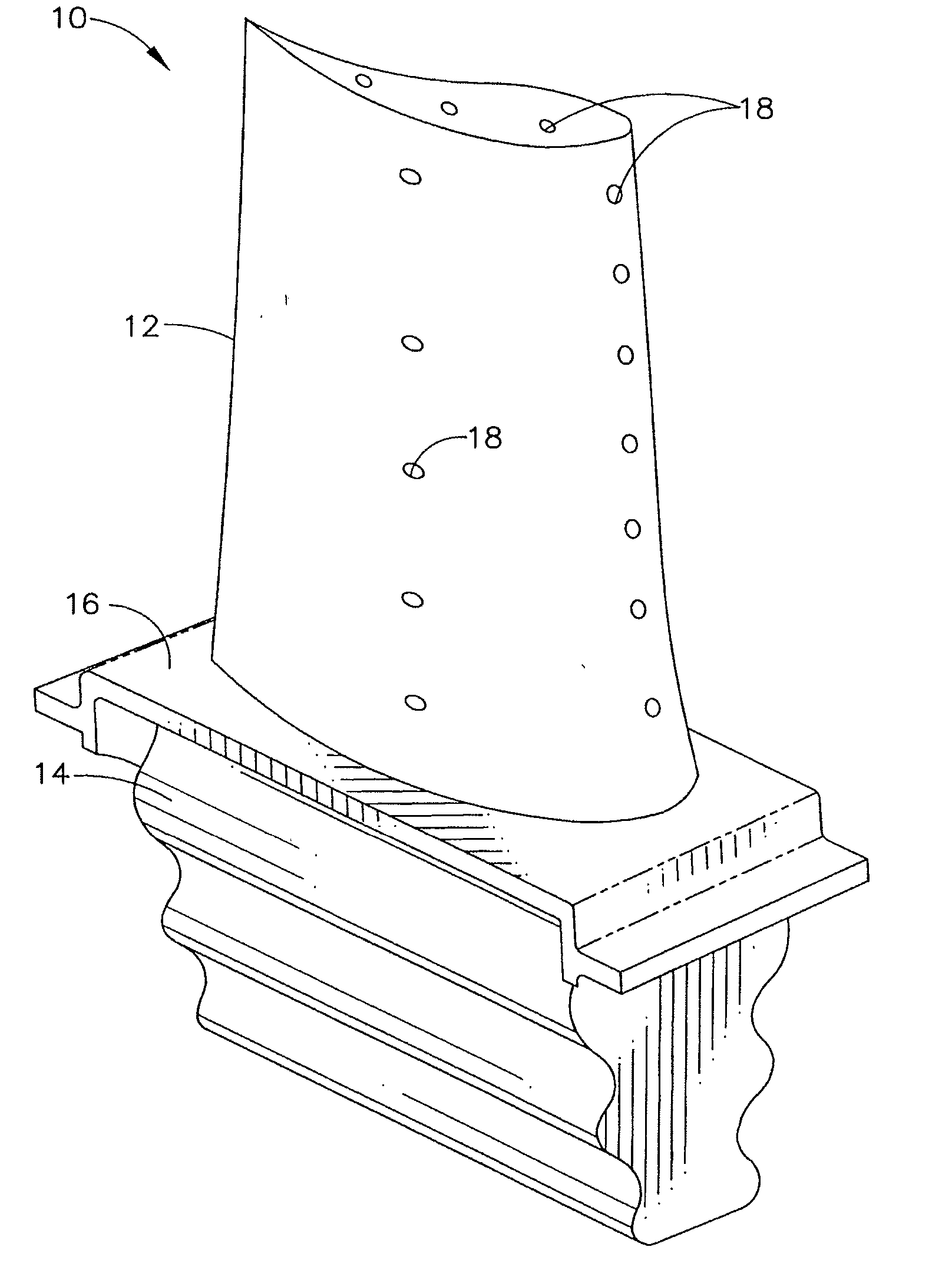

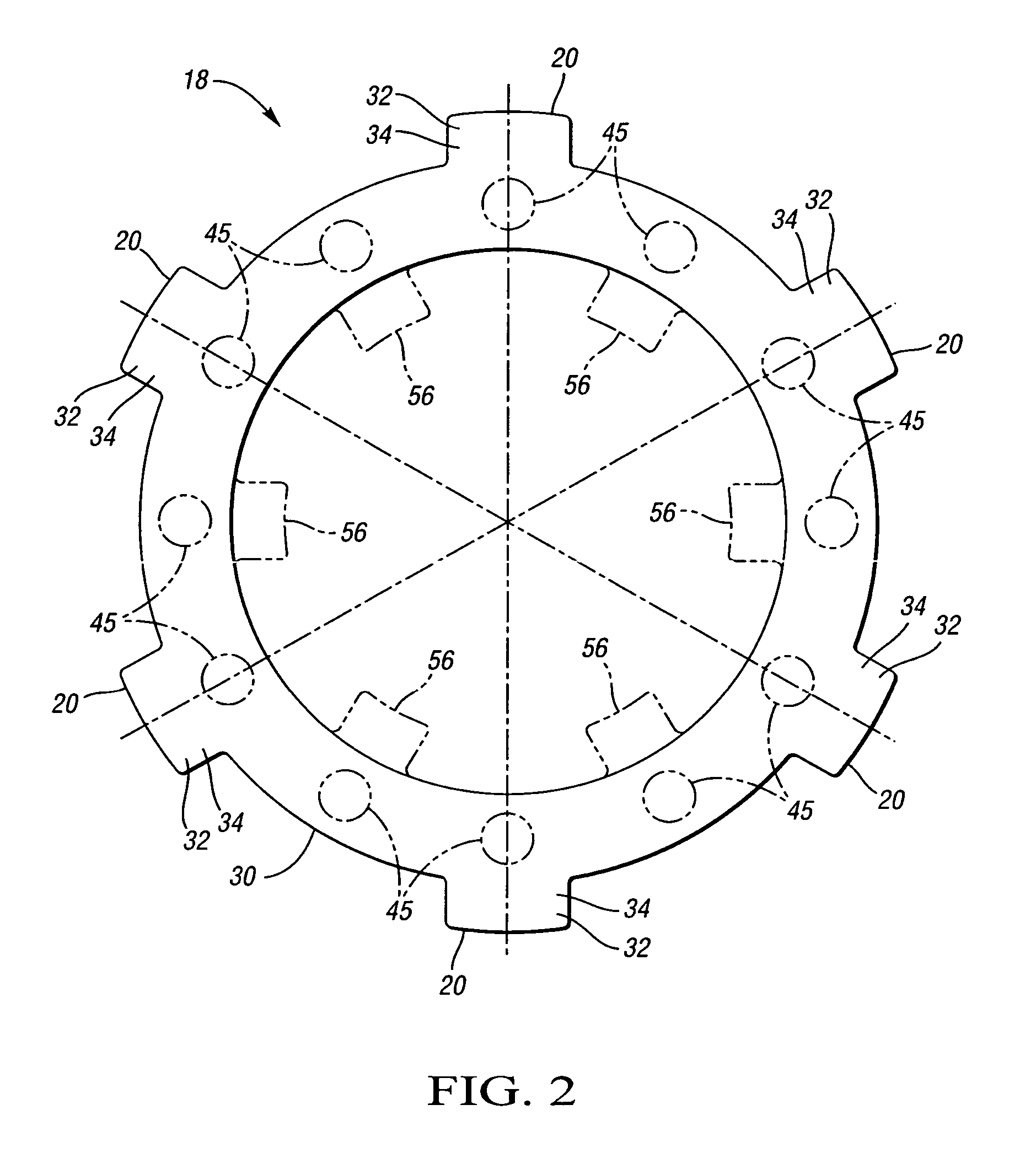

Segmented abradable ceramic coating

InactiveUS6102656AImprove wear resistanceSufficient resistanceMolten spray coatingPump componentsCeramic coatingWear resistance

A segmented abradable ceramic coating system having superior abradability and erosion resistance is disclosed. The system includes a duct segment having a metallic substrate, a MCrAlY bond coat on the substrate and a segmented abradable ceramic coating on the bond coat. The segmented abradable ceramic coating includes a base coat foundation layer, a graded interlayer and an abradable top layer for an overall thickness of preferably about 50 mils (1.270 mm). The coating is characterized by a plurality of vertical microcracks. By precisely controlling the deposition parameters, composition of the layers and layer particle morphology, segmentation is achieved, as well as superior abradability and erosion resistance.

Owner:UNITED TECH CORP

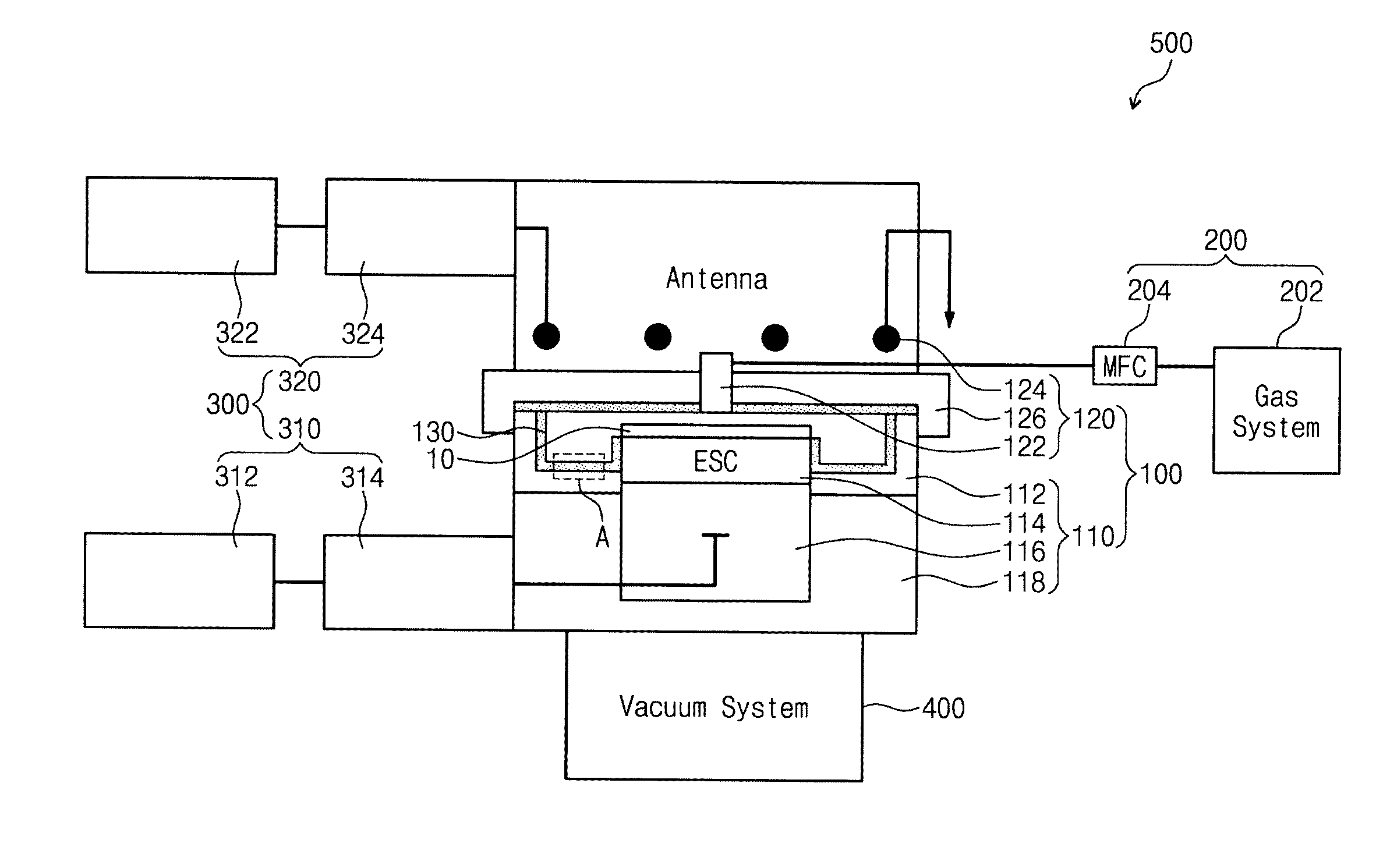

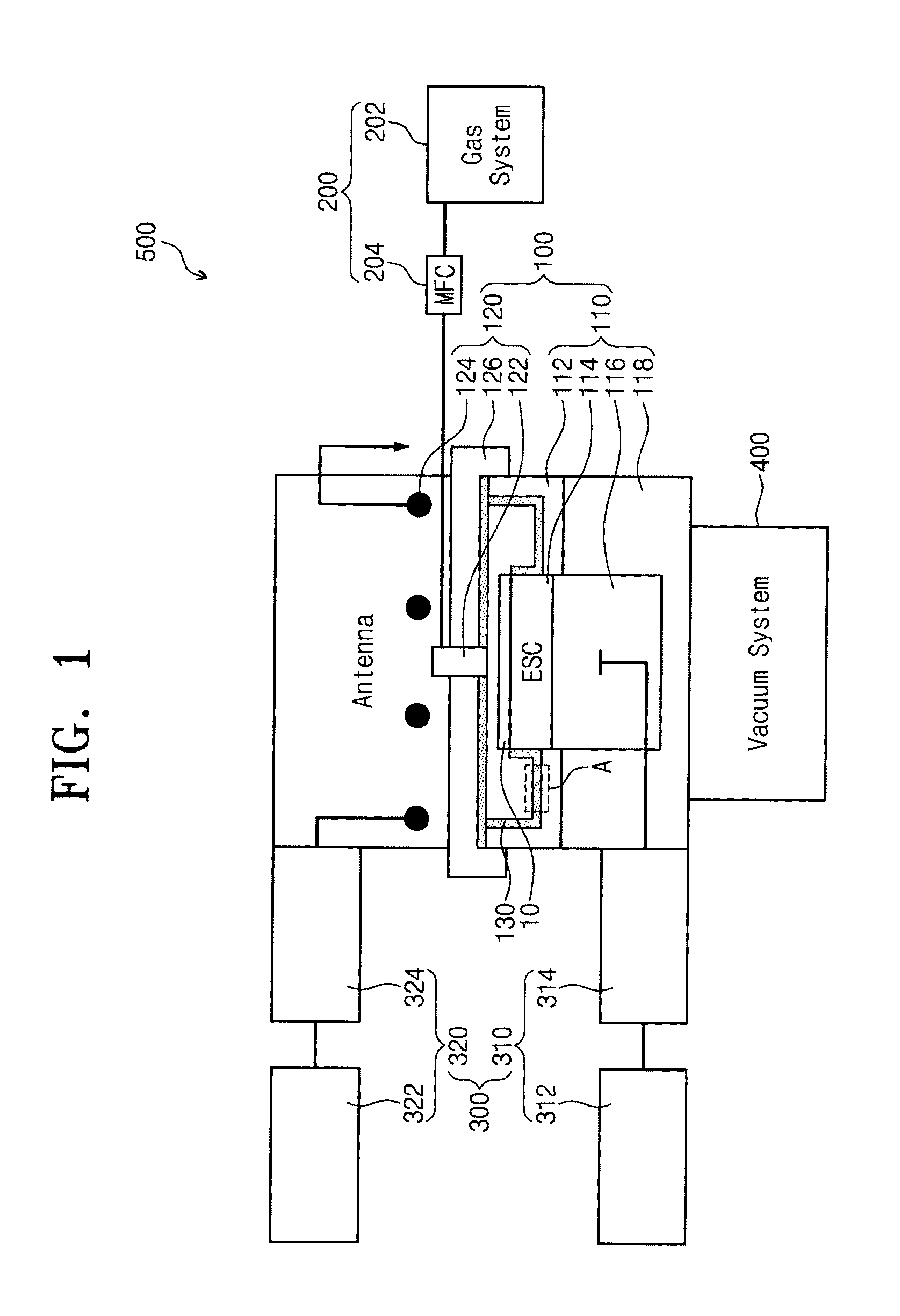

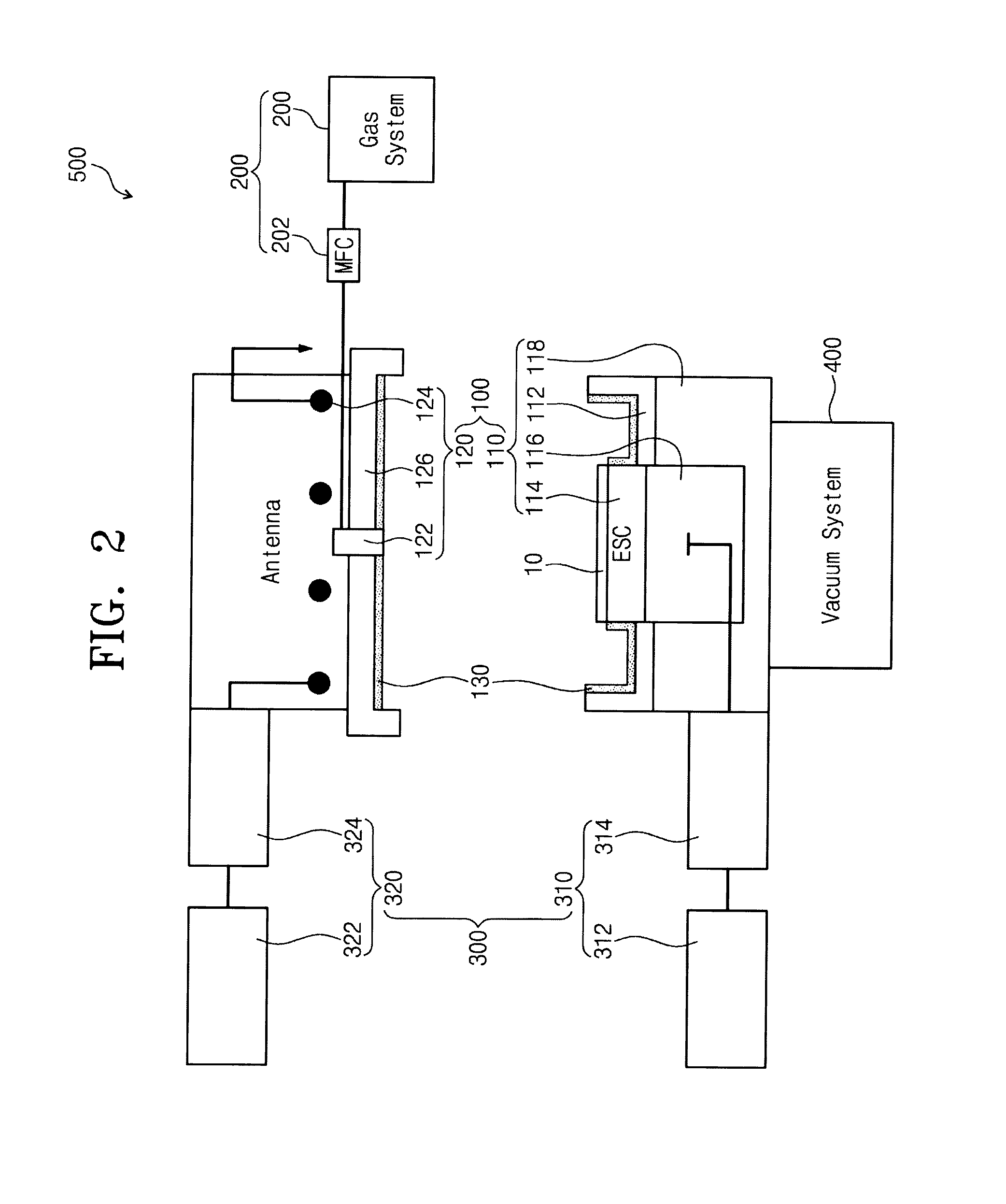

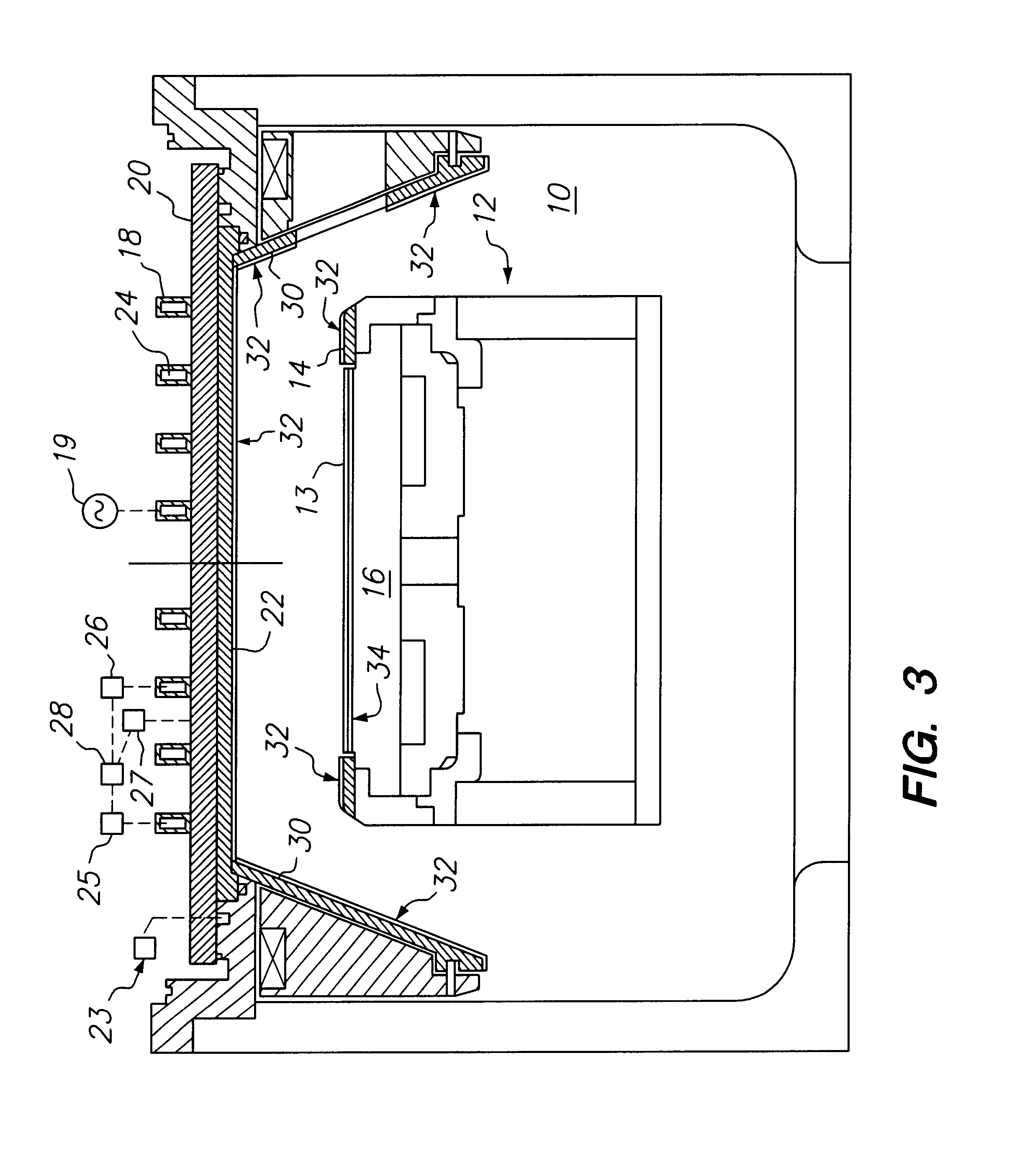

Substrate Processing System and Ceramic Coating Method Therefor

InactiveUS20160307740A1Reduce failureElectric discharge tubesSemiconductor/solid-state device manufacturingMetallurgyCeramic coating

Owner:SAMSUNG ELECTRONICS CO LTD

Corrosion resistant component of semiconductor processing equipment and method of manufacturing thereof

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a metal surface such as aluminum or aluminum alloy, stainless steel, or refractory metal coated with a phosphorus nickel plating and an outer ceramic coating such as alumina, silicon carbide, silicon nitride, boron carbide or aluminum nitride. The phosphorus nickel plating can be deposited by electroless plating and the ceramic coating can be deposited by thermal spraying. To promote adhesion of the ceramic coating, the phosphorus nickel plating can be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

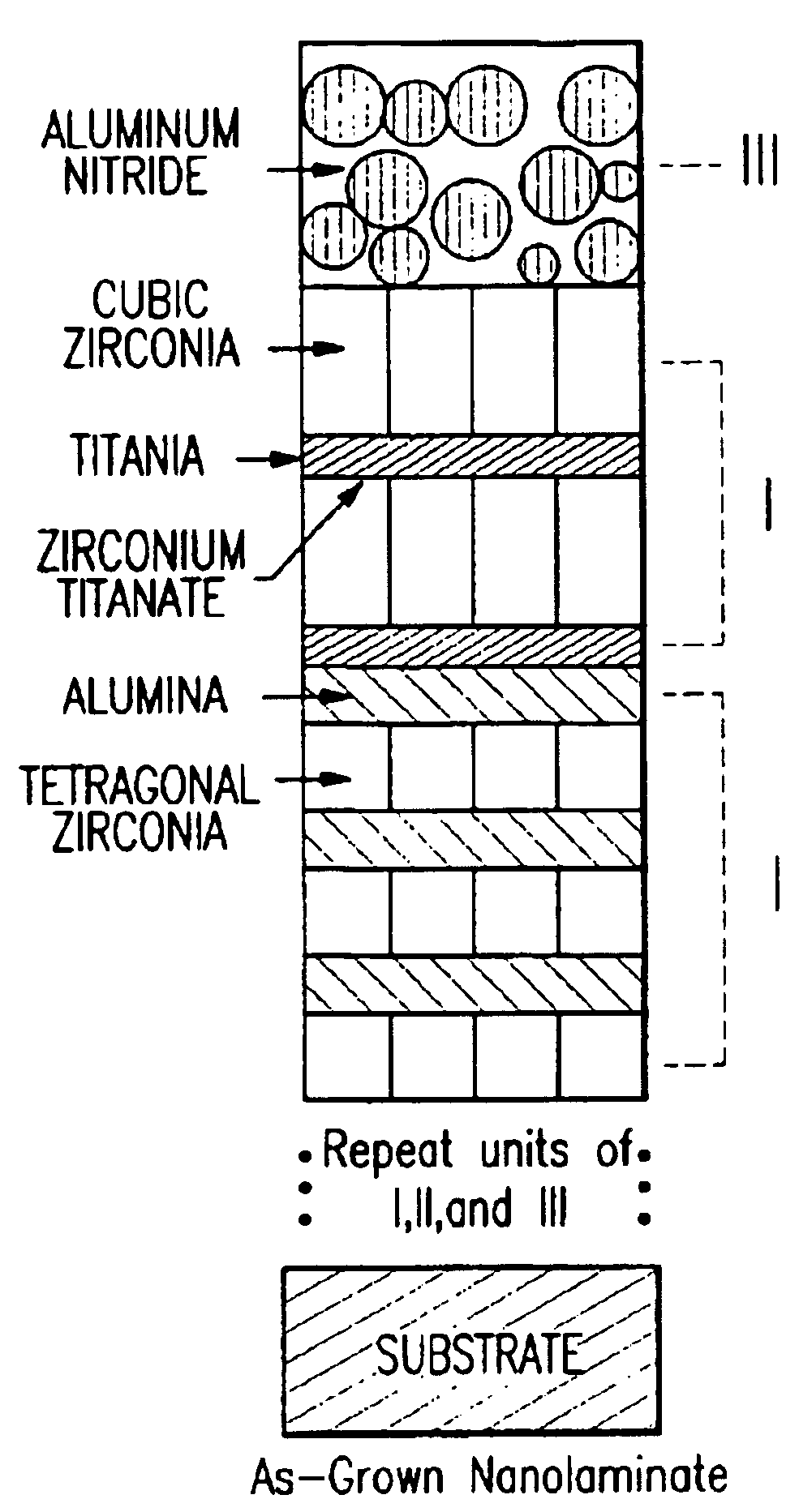

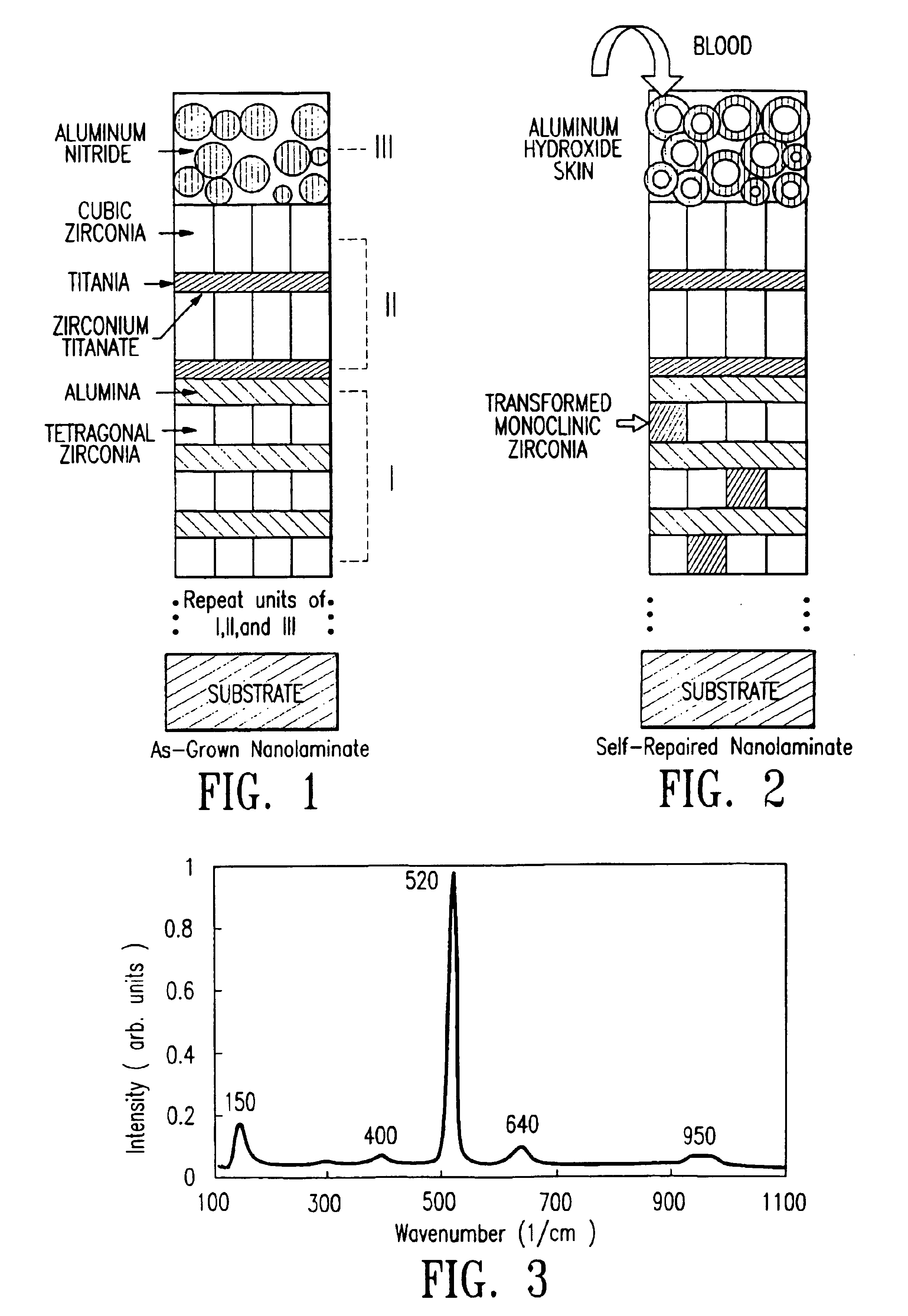

Self-repairing ceramic coatings

A protective coating for a substrate is disclosed having an outer component or module formed of a swellable material and an inner module formed of a plurality of layer or bilayers formed of ceramic material. The coating comprising a plurality of modules comprising a first module comprising a number (m) of bilayers comprising zirconia and alumina wherein (m) is a number greater than 1. The coating further comprises a second module disposed on the first module comprising a number (n) of bilayers comprising zirconia and titania wherein (n) is a number greater than 1. The coating further comprises a third module disposed on the second module comprising a third-module compound capable of forming a hydrate or hydroxide compound upon contact with an oxygen containing environment.

Owner:AITA CAROLYN

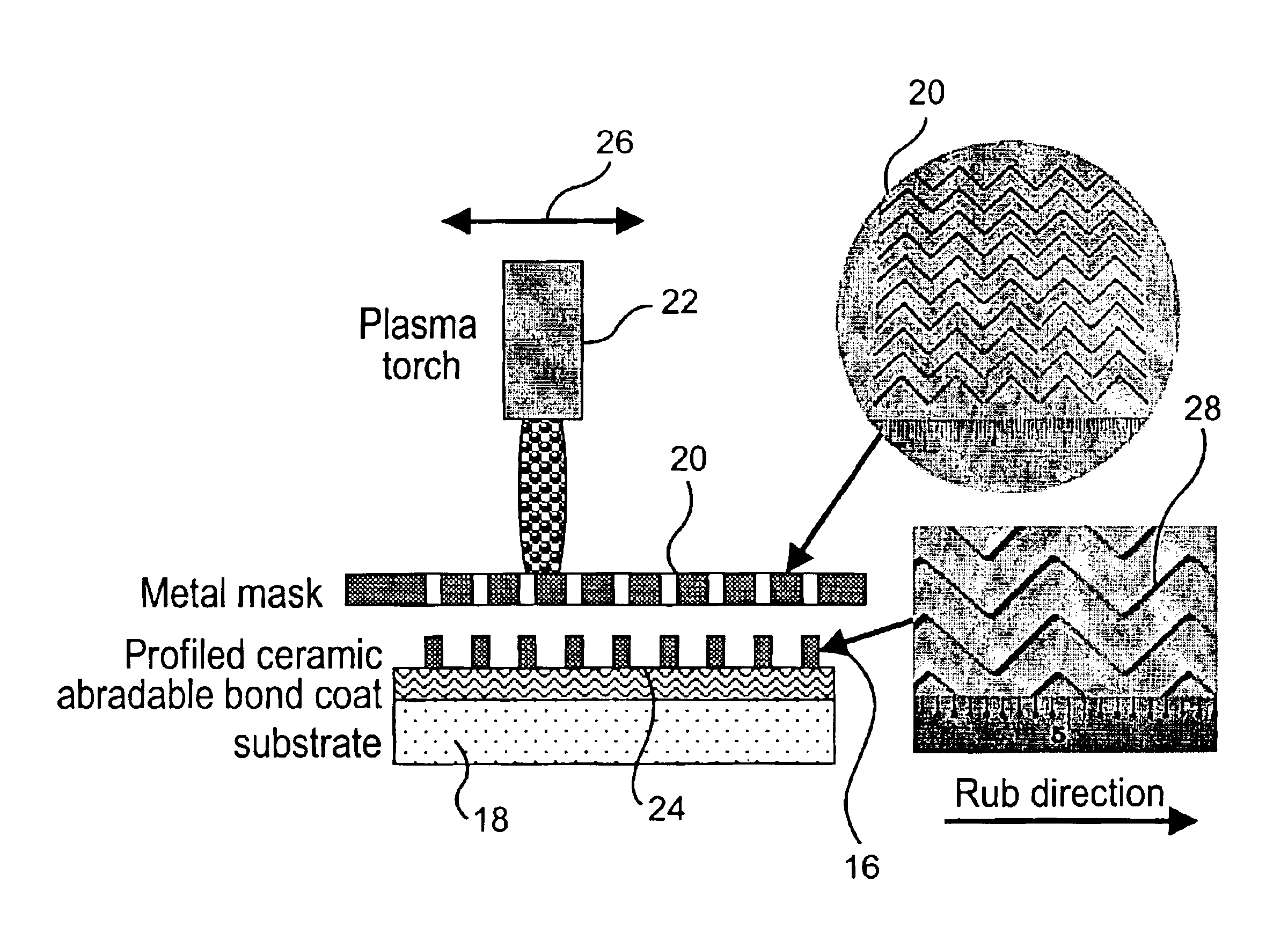

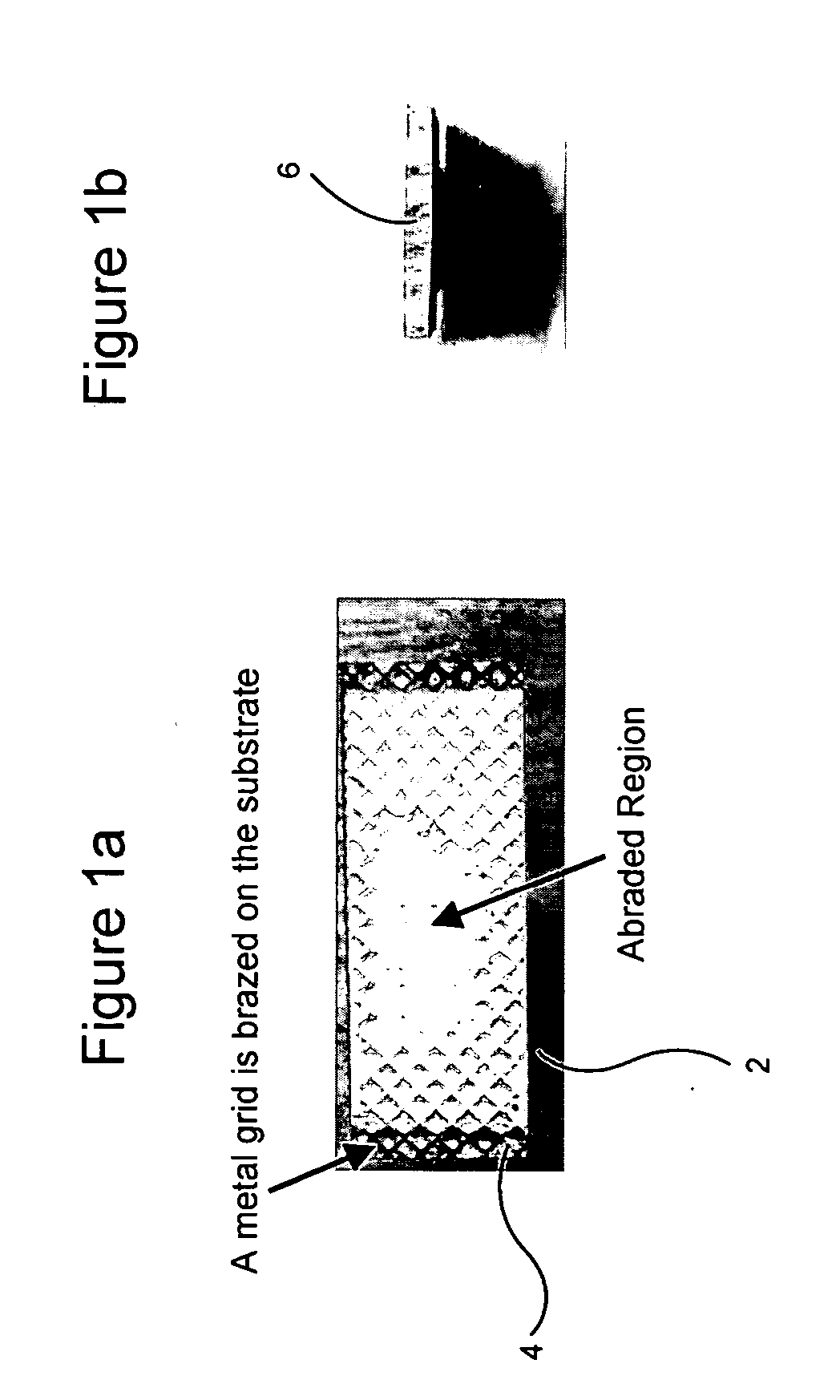

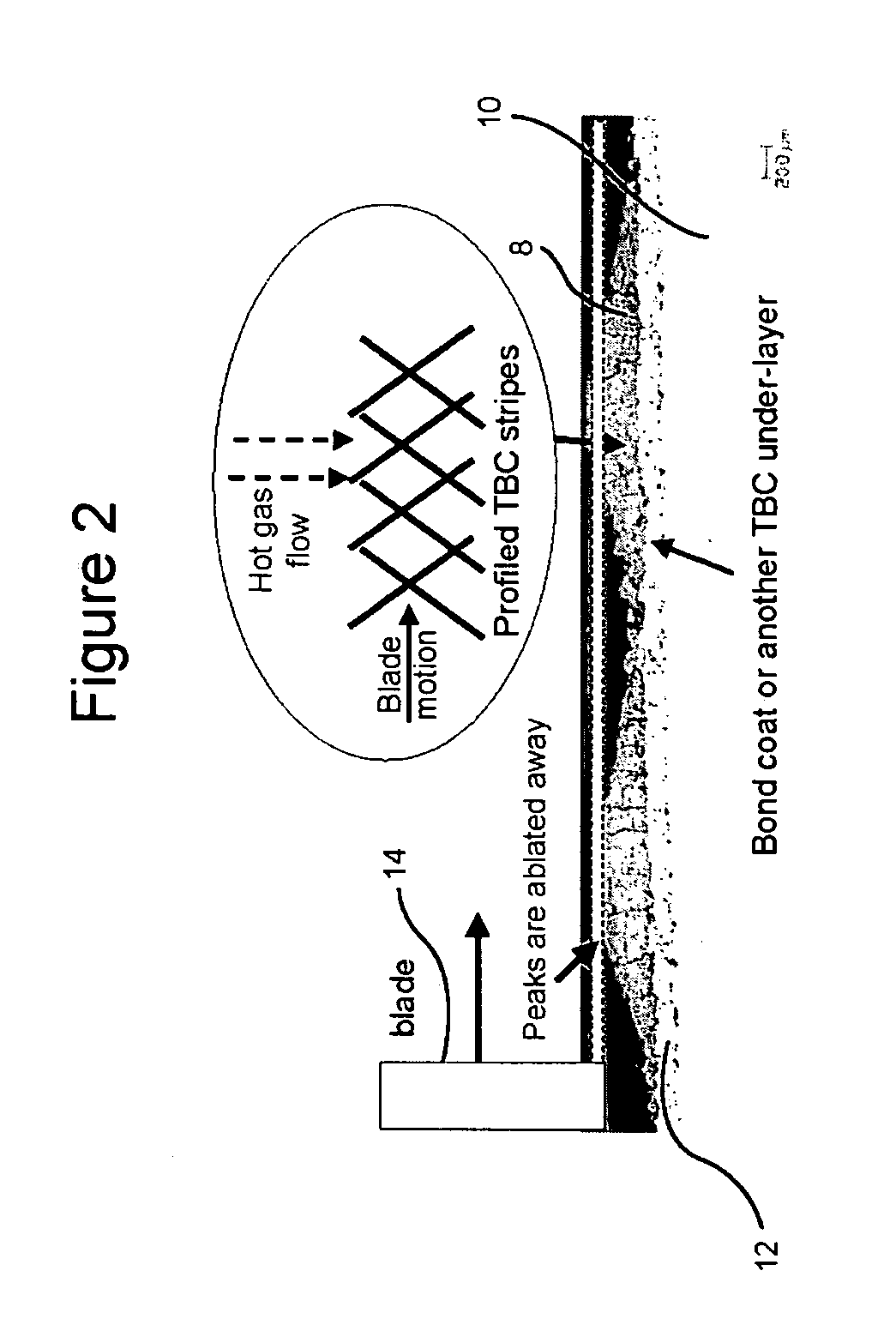

High temperature abradable coatings

InactiveUS6887528B2Solution to short lifeMolten spray coatingSpecial surfacesCeramic coatingMetallurgy

Method of producing a profiled abradable coating on a substrate in which an abradable ceramic coating composition is applied to a substrate using direct-write technology, or plasma sprayed onto the substrate through a mask or by use of a narrow foot-print plasma gun. These methods of producing abradable coatings are performed in the absence of a grid.

Owner:GENERAL ELECTRIC CO

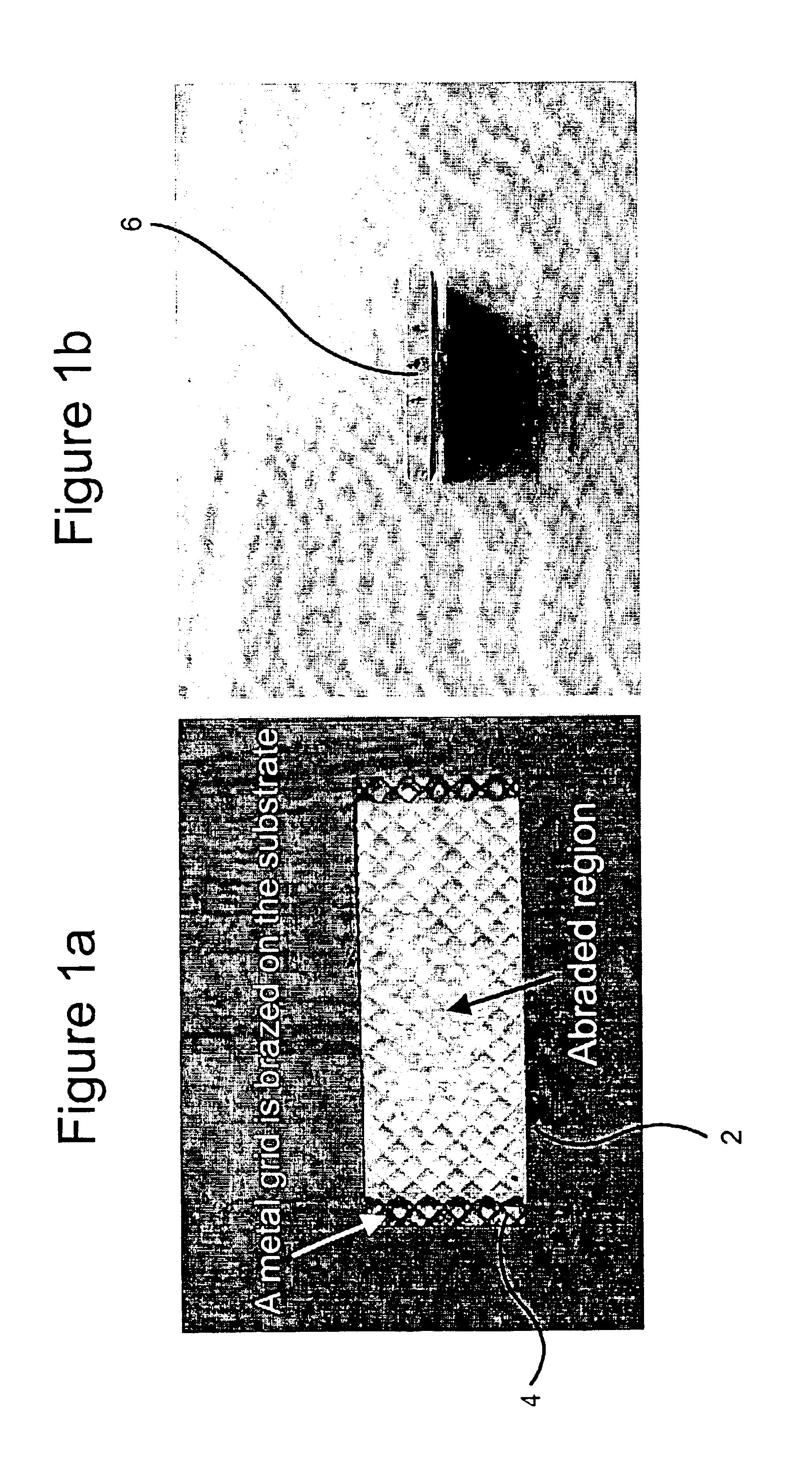

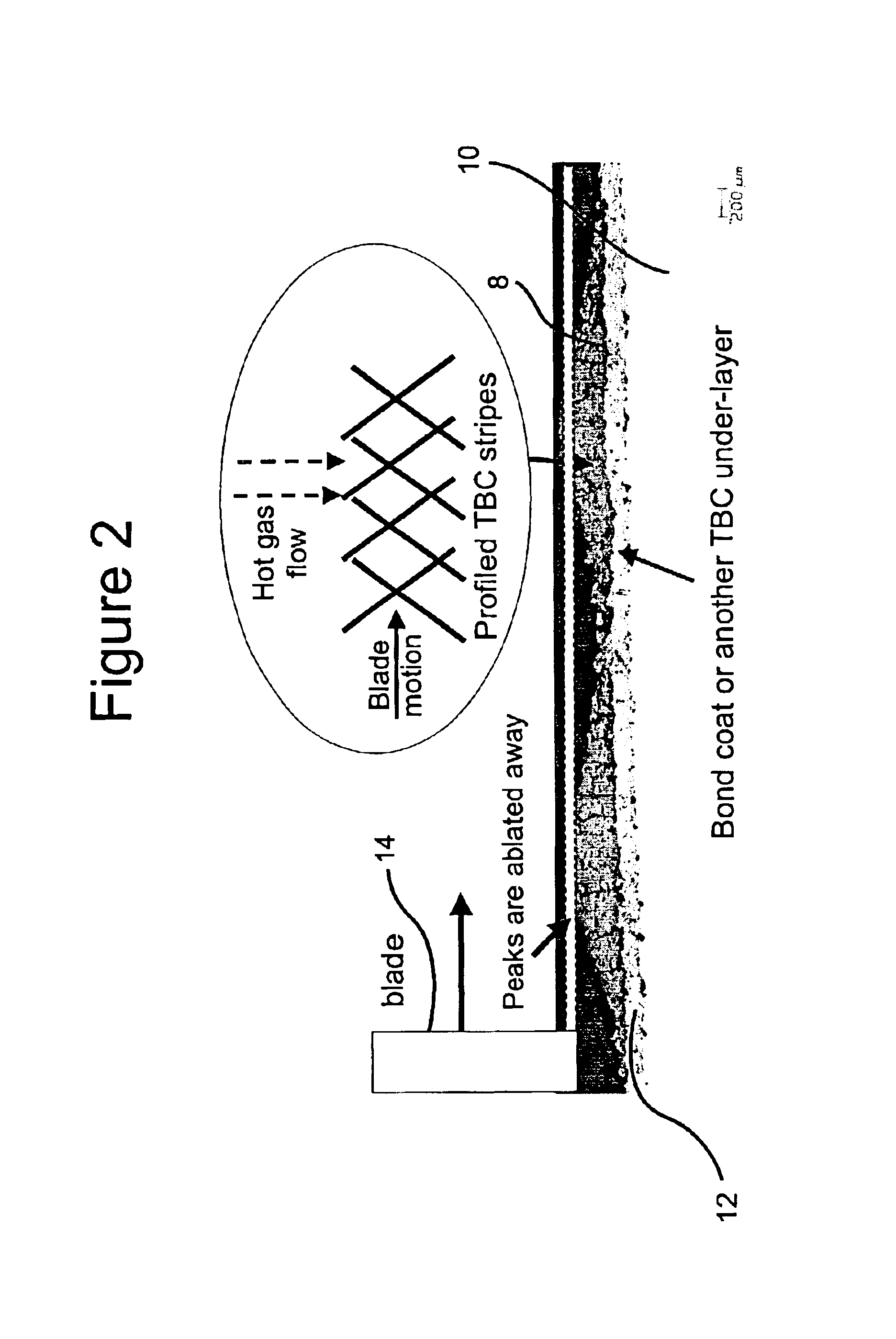

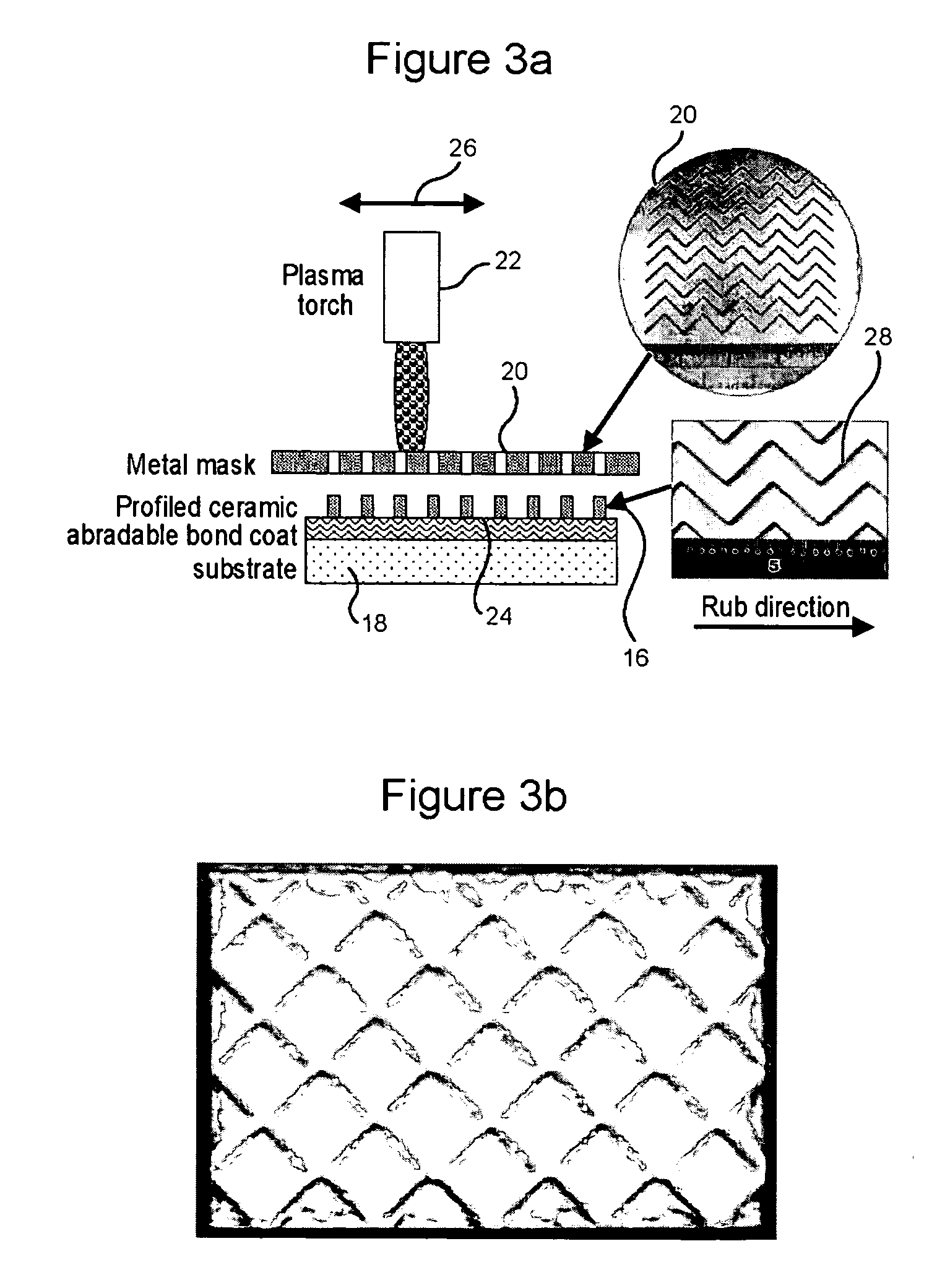

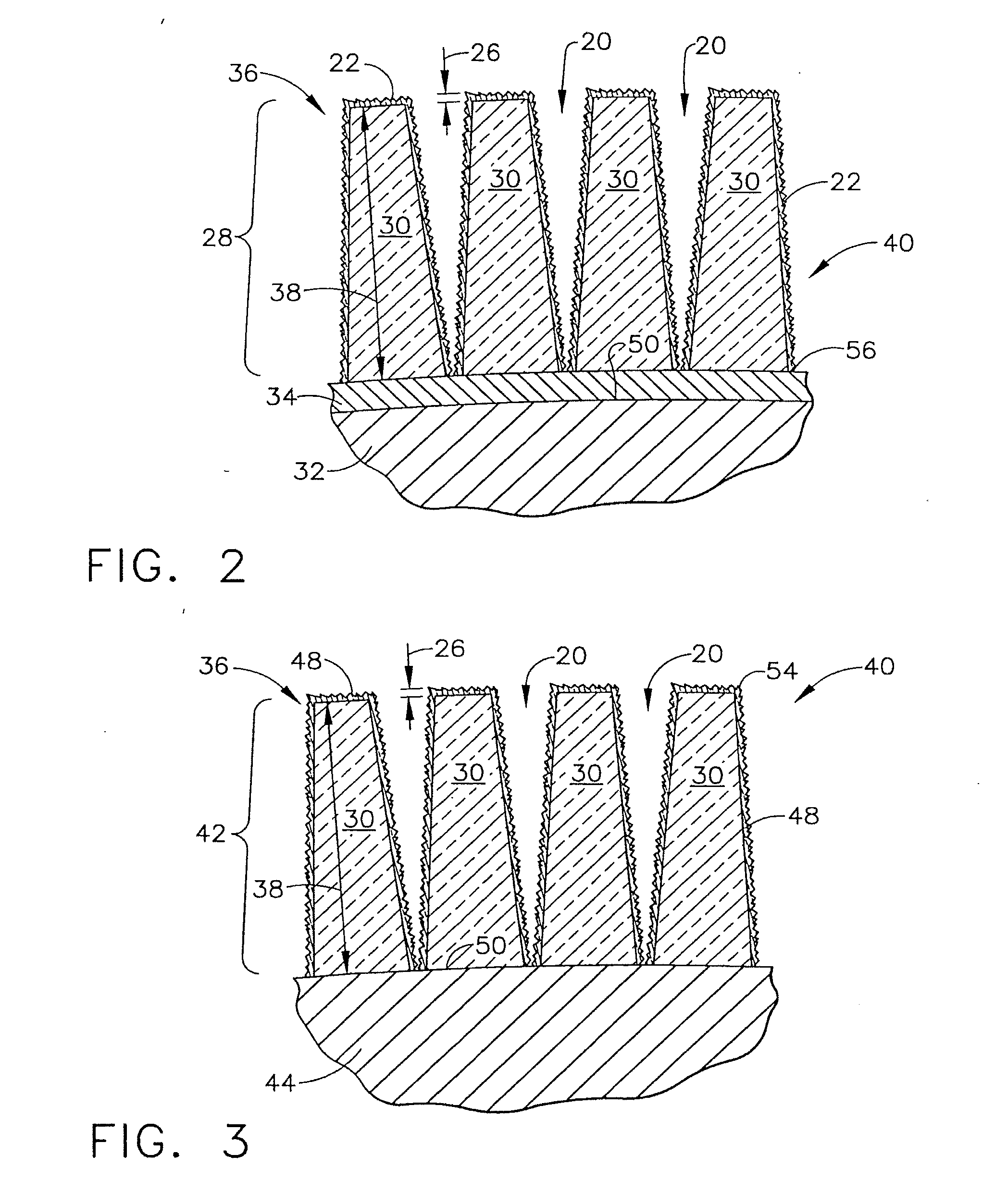

7FAstage 1 abradable coatings and method for making same

InactiveUS20050003172A1Minimal wearReduce gas leakageMolten spray coatingEngine manufactureLeading edgeGrid pattern

A method of applying a profiled abradable coating onto a substrate in which an abradable ceramic coating composition is applied to a metal substrate using one or more coating application techniques to produce a defined ceramic pattern without requiring a separate web or grid to be brazed onto the substrate. The invention is particularly designed to withstand the higher operating temperatures encountered with the stage 1 section of 7FA+e gas turbines to allow for increased coating life without significant deterioration in structural or functional integrity. Typically, the grid pattern coating begins approximately 0.431″ after the leading edge of the shroud, and ends approximately 1.60″ before the trailing edge of the shroud. In the case of diamond-shaped patterns, the grid pattern will be about 0.28″ long and 0.28″ wide, with an overall thickness of about 0.46.″ The coatings thus provide the required levels of abradability and leakage performance and may be applied as a chevron or diamond pattern with the shape oriented such that the diagonals run perpendicular and parallel to the sides of the shroud.

Owner:GENERAL ELECTRIC CO

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

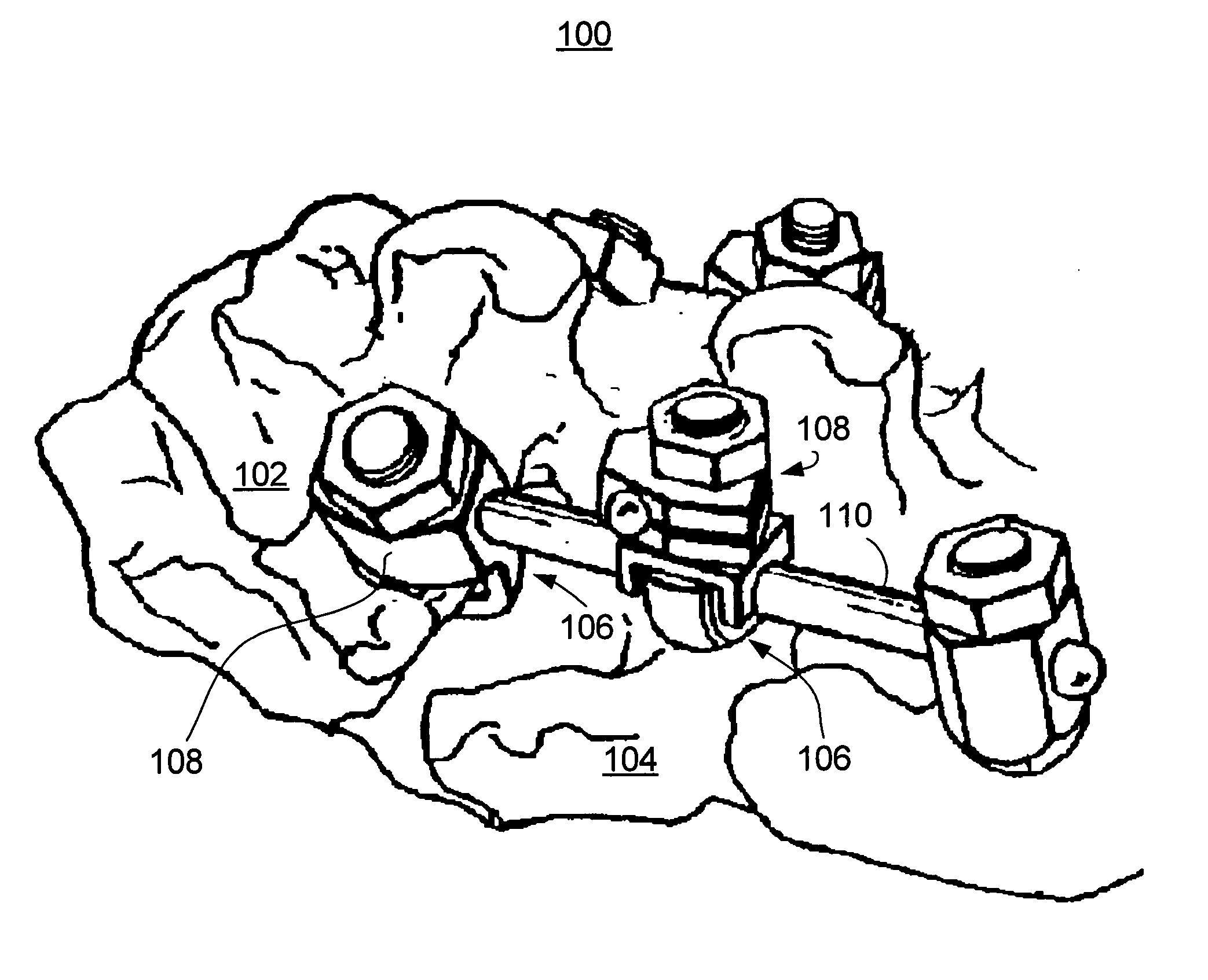

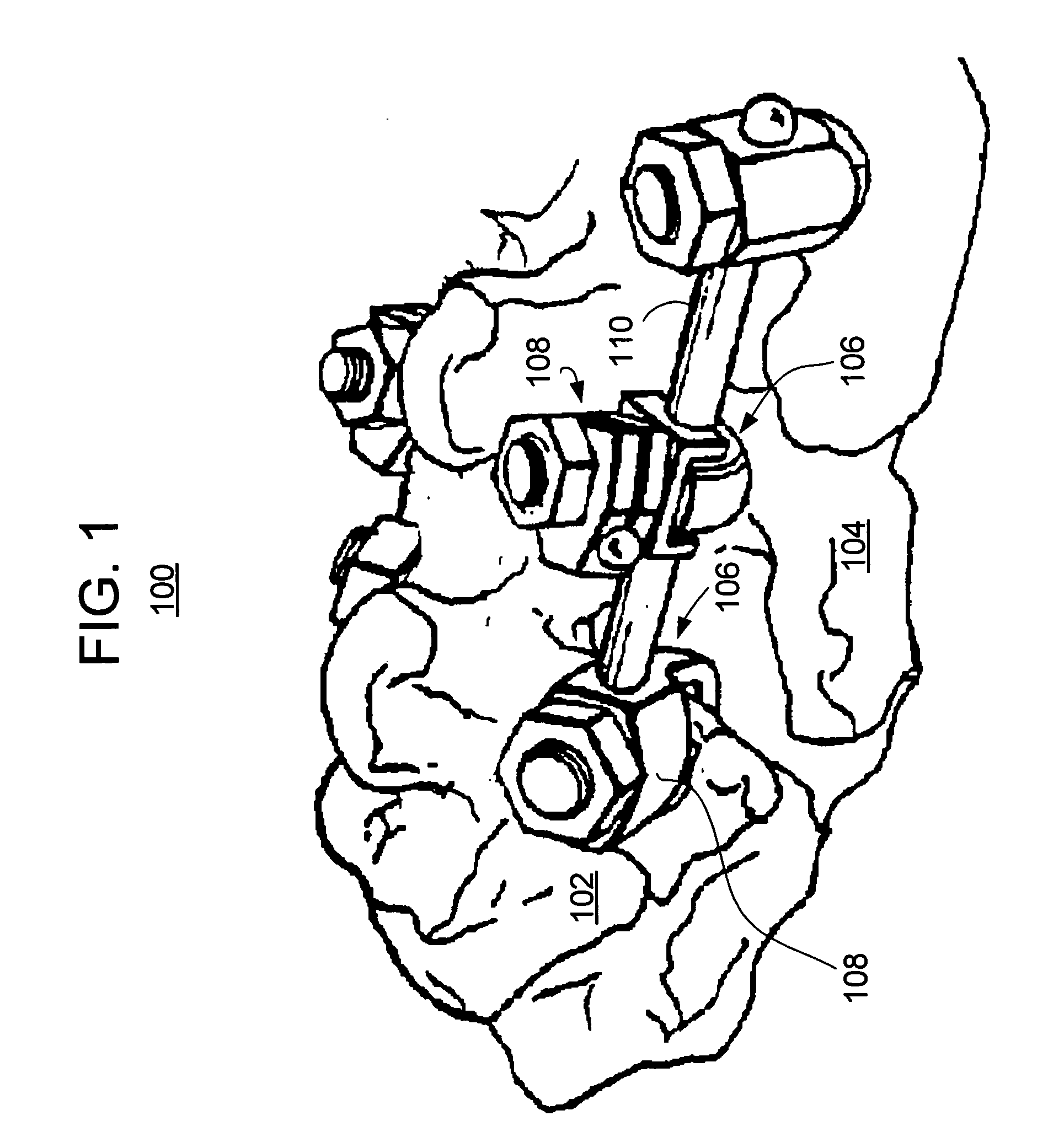

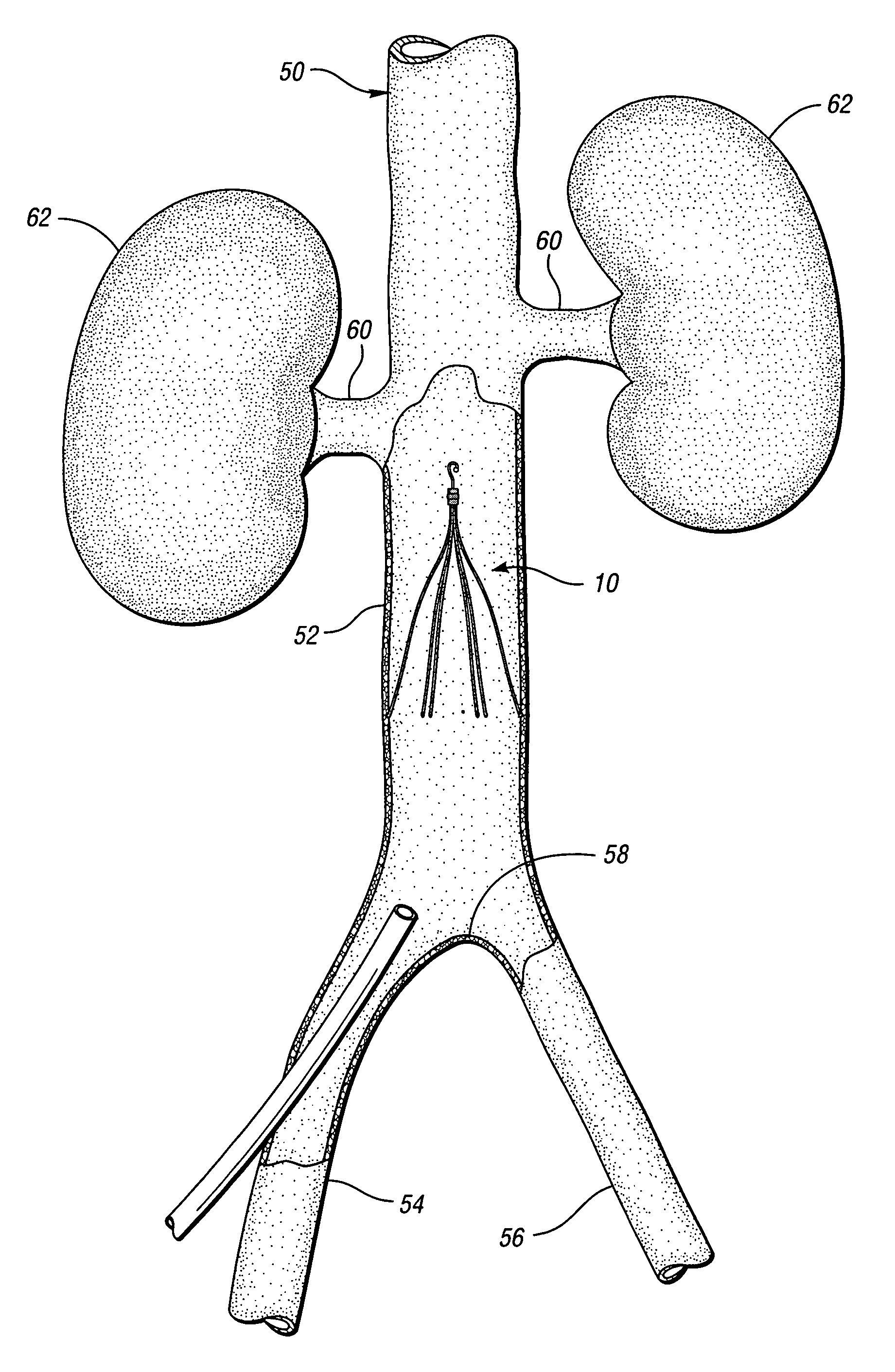

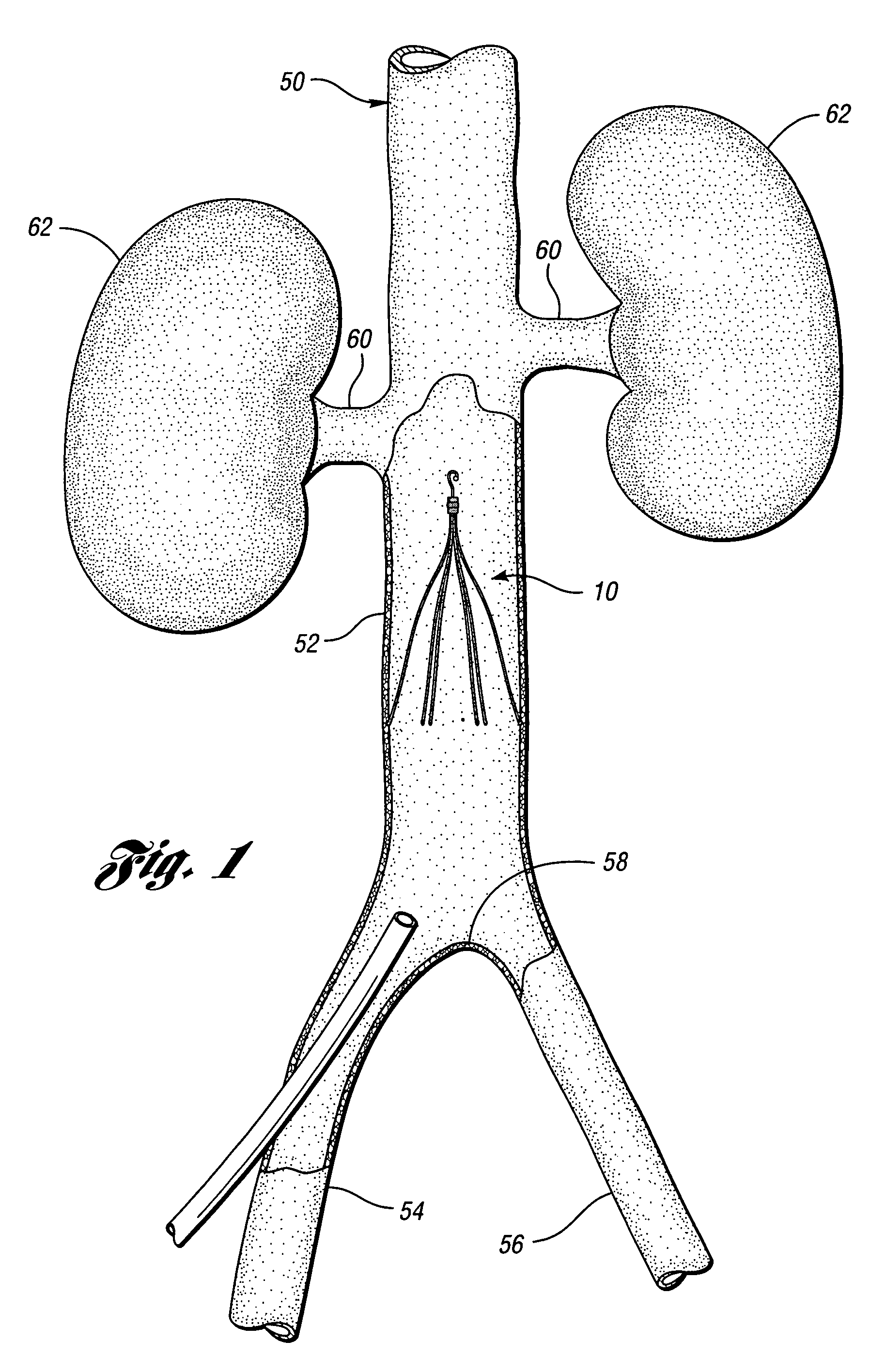

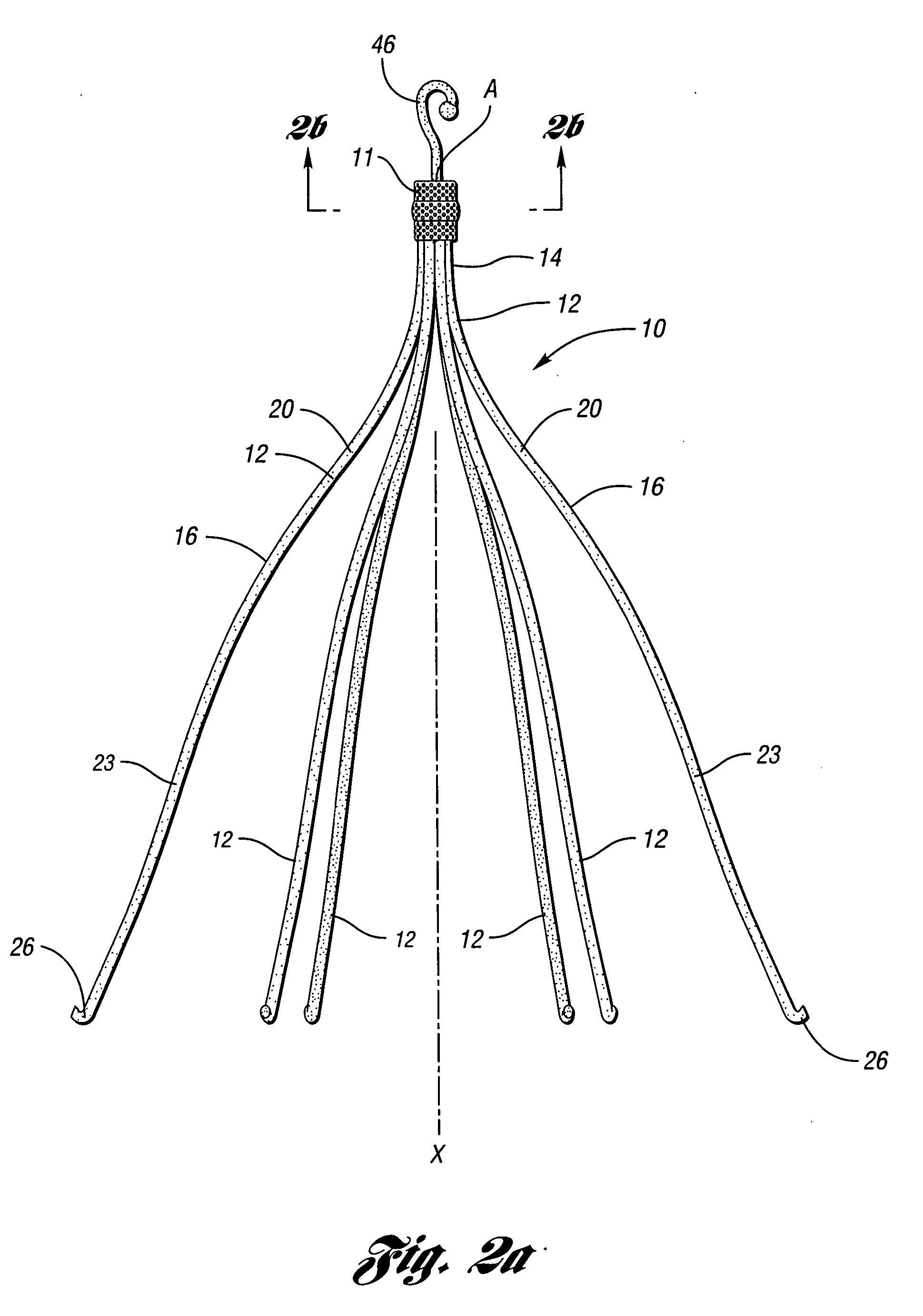

Anti-thrombus filter having enhanced identifying features

InactiveUS20060069405A1Easy to identifyReduced endotheliosis featureDiagnosticsSurgeryCeramic coatingThrombus

A removable filter for capturing thrombi in a body vessel. The filter has anti-thrombogenic, echogenic, and radiopaque features. The features of the filter provide for enhanced identifying and reduced endotheliosis in a body vessel of a patient. Generally, the anti-thrombogenic feature is preferably a fibrinolytic coating disposed on the filter to decrease the accumulation of fibrin thereon. The echogenic feature preferably is comprised of marks formed on the filter that give rise to reflections of ultrasound waves during ultrasonography. The radiopaque feature is preferably a polymeric coating, ceramic coating, or noble metal coating applied on the filter for enhanced fluoroscopy.

Owner:COOK INC

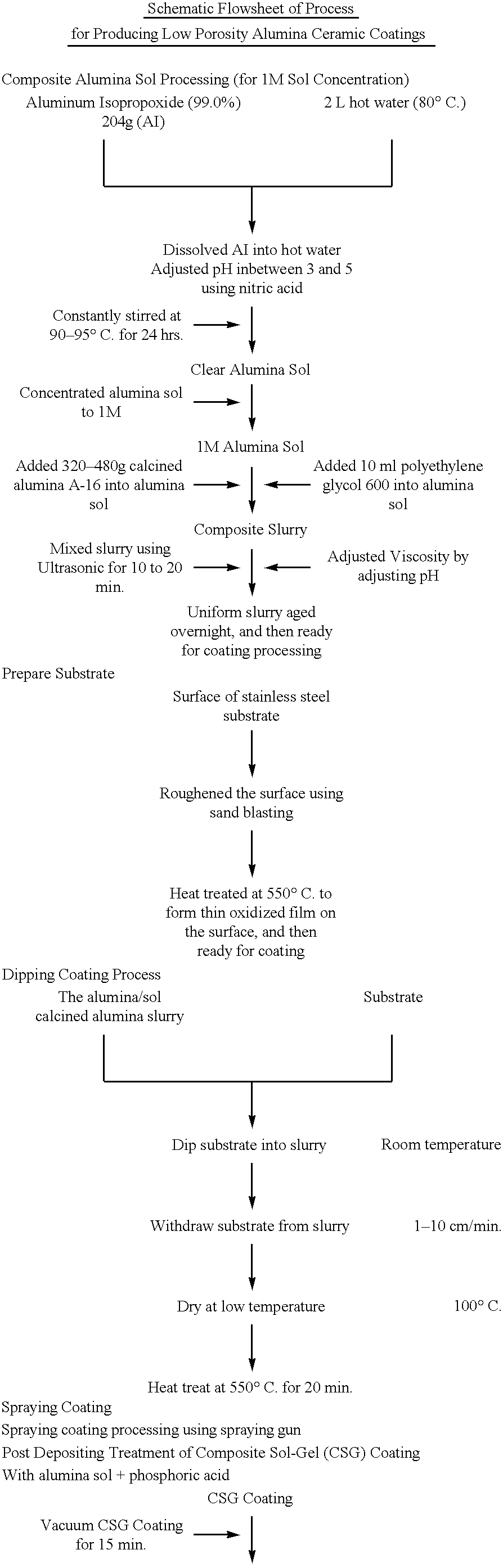

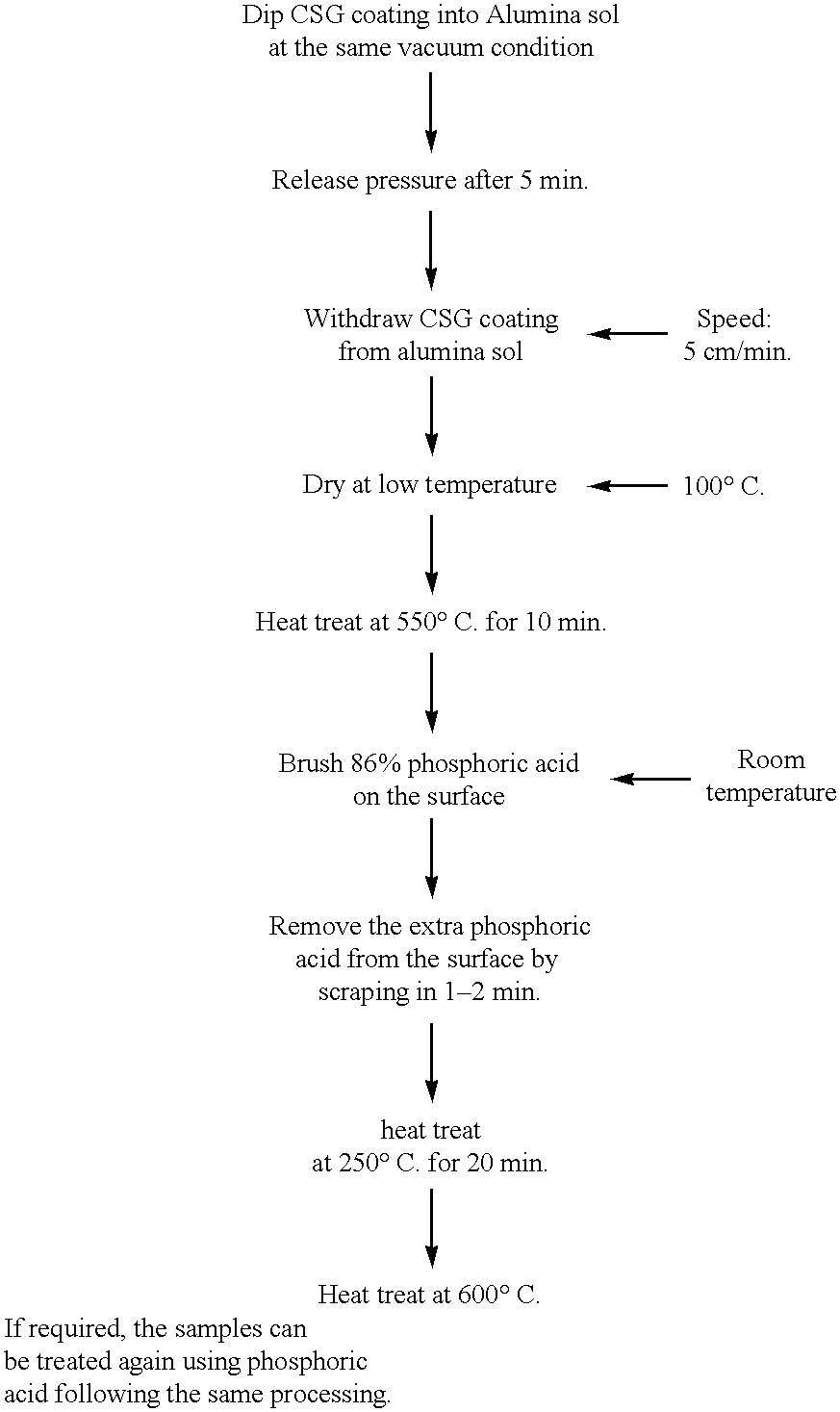

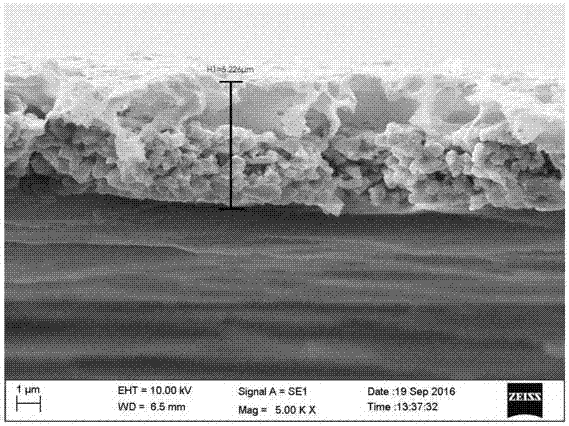

Process for making chemically bonded sol-gel ceramics

InactiveUS6284682B1Liquid/solution decomposition chemical coatingSuperimposed coating processPorosityCeramic coating

This invention relates to a novel method of decreasing porosity of ceramics produced by sol-gel processing. The process of preparing chemically bonded sol-gel ceramics comprises phosphating a sol-gel derived oxide or hydrated oxide and polymerizing the phosphated product with heat treatment. Such combined sol-gel / chemical bonding process can be used to fabricate dense, thick ceramics or ceramic coatings for a variety of applications, including high temperature corrosion protection, wear resistance, dielectric properties, non-sticky surfaces, bio-active ceramics, thermal barrier ceramics, non-wetted surfaces, and others.

Owner:THE UNIV OF BRITISH COLUMBIA

Fiber-reinforced high-temperature-resistant thermal insulation and heat preserving ceramic coating and preparation method thereof

InactiveCN102464933ADelivery barrierHigh surface strength of the coatingEpoxy resin coatingsCeramic coatingThermal insulation

The invention relates to a high-temperature-resistant thermal insulation and heat preserving ceramic coating and a preparation method thereof. The coating is prepared from the following raw materials in percentage by weight: 30-50 percent of film forming substance, 30-40 percent of high-temperature-resistant filler, 10-15 percent of hollow micro beads, 2-5 percent of thermal insulation fiber and 2-8 percent of aid and solvent. The coating has the toughness of an organic coating and the rigidity and hardness of an inorganic coating, has high adhesion, can be used at the high temperature of 400-1,200 DEG C for a long time, and is resistant to chemical reagents, acids, alkalis and oil. A coating film has high surface intensity, and can bear strong shear force without being damaged when a high-temperature pipeline is required to be connected mechanically. The coating has excellent heat preserving performance, and the surface temperature of a pipeline of 350 DEG C can be lowered to be below 100 DEG C by coating the coating outside the pipeline in the thickness of 4-6 millimeters. The coating can be widely applied to heat-resistant protection of the inner and outer surfaces of equipment such as high-temperature steam pipelines, metallurgy high-temperature furnaces, high-temperature valves, high-temperature containers and the like.

Owner:SHENYANG LIGONG UNIV

Scaffold for tissue engineering cartilage having outer surface layers of copolymer and ceramic material

InactiveUS6692761B2High mechanical strengthEfficient transportBiocideJoint implantsPolyesterPolytetramethylene terephthalate

A biodegradable, biocompatible porous matrix as a scaffold for tissue engineering cartilage is formed of a copolymer of a polyalkylene glycol and an aromatic polyester such as a polyethylene glycol / polybutylene terephtalate copolymer. A ceramic coating such as a calcium phosphate coating may be provided on the scaffold by soaking the scaffold in a solution containing calcium and phosphate ions. A composite scaffold which is preferably a two-layer system may be formed having an outer surface of a layer of the porous matrix formed of the copolymer, and an outer surface of a layer of a ceramic material. The composite scaffold may be prepared by casting the copolymer on top of the ceramic material in a mould. Cells are preferably seeded on the scaffold prior to implanting, and the scaffold may contain bioactive agents that are released on degradation of the scaffold in vivo.

Owner:OCTOPLUS SCI

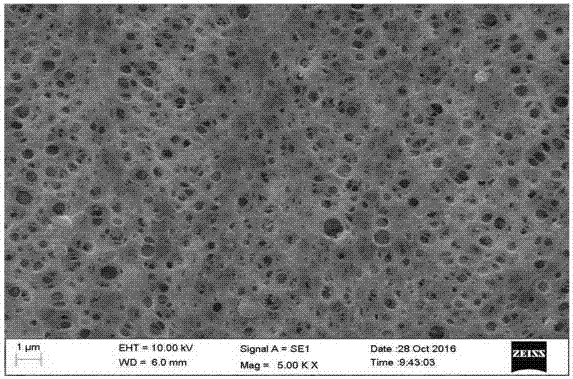

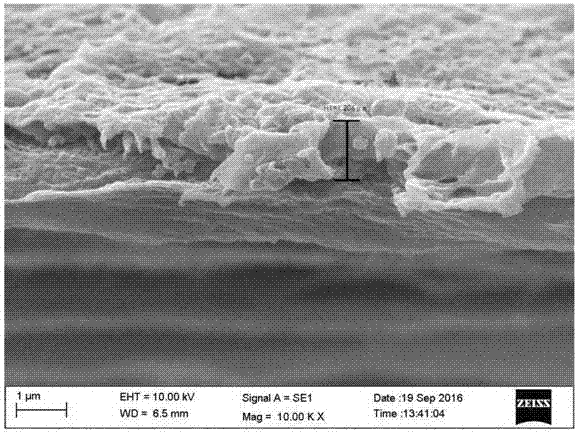

Ceramic and polymer composite coated lithium ion diaphragm and preparation method thereof

ActiveCN107275550AImprove ionic conductivityHigh bonding strengthCell component detailsSecondary cells servicing/maintenanceLithiumPolyolefin

The invention discloses a ceramic and polymer composite coated lithium ion diaphragm and a preparation method thereof. The ceramic and polymer composite coated lithium ion diaphragm comprises a polyolefin porous diaphragm, a ceramic coating coated on one side or the two sides of the diaphragm surface and a polymer coating coated on the ceramic surface or the diaphragm surface. The composite diaphragm prepared by the preparation method disclosed by the invention has the advantages that the heat resistance of the diaphragm is greatly improved, and the infiltration of an electrolyte is improved; the bonding strength of the diaphragm and a positive and negative pole piece is improved, so that the internal short-circuit caused by staggering between the diaphragm and an electrode is prevented; meanwhile, the hardness of a battery is improved, so that the safety performance of the battery is greatly improved. In the production process, the ceramic coating and the polymer coating are uniform in thickness and good in uniformity and facilitate continuous and large-scale production.

Owner:SHENZHEN SENIOR TECH MATERIAL

Bi-metal disc brake rotor and method of manufacturing

InactiveUS20070062768A1Avoid problemsImprove bindingNoise/vibration controlMetal rolling stand detailsCeramic coatingMaterials science

The invention provides a method for manufacturing a friction damped disc brake rotor, including the steps of: (A) providing a ceramic coating on an insert, wherein the insert has a body with tabs extending therefrom to hold the insert in a desired position within a mold; (B) washing the ceramic coating off of the tabs; (C) positioning the insert into the mold; and (D) casting a rotor cheek of the disc brake rotor in the mold around the insert such that a portion of each tab is bonded with the rotor cheek, and such that the coating is substantially non-bonded with the rotor cheek so that the coating provides a proper interfacial boundary between the body and the cheek for damping, and the at least partial bonding of each tab with the rotor cheek prevents corrosion-causing exterior elements from reaching the interfacial boundary when the friction damped disc brake rotor is in use.

Owner:GM GLOBAL TECH OPERATIONS LLC

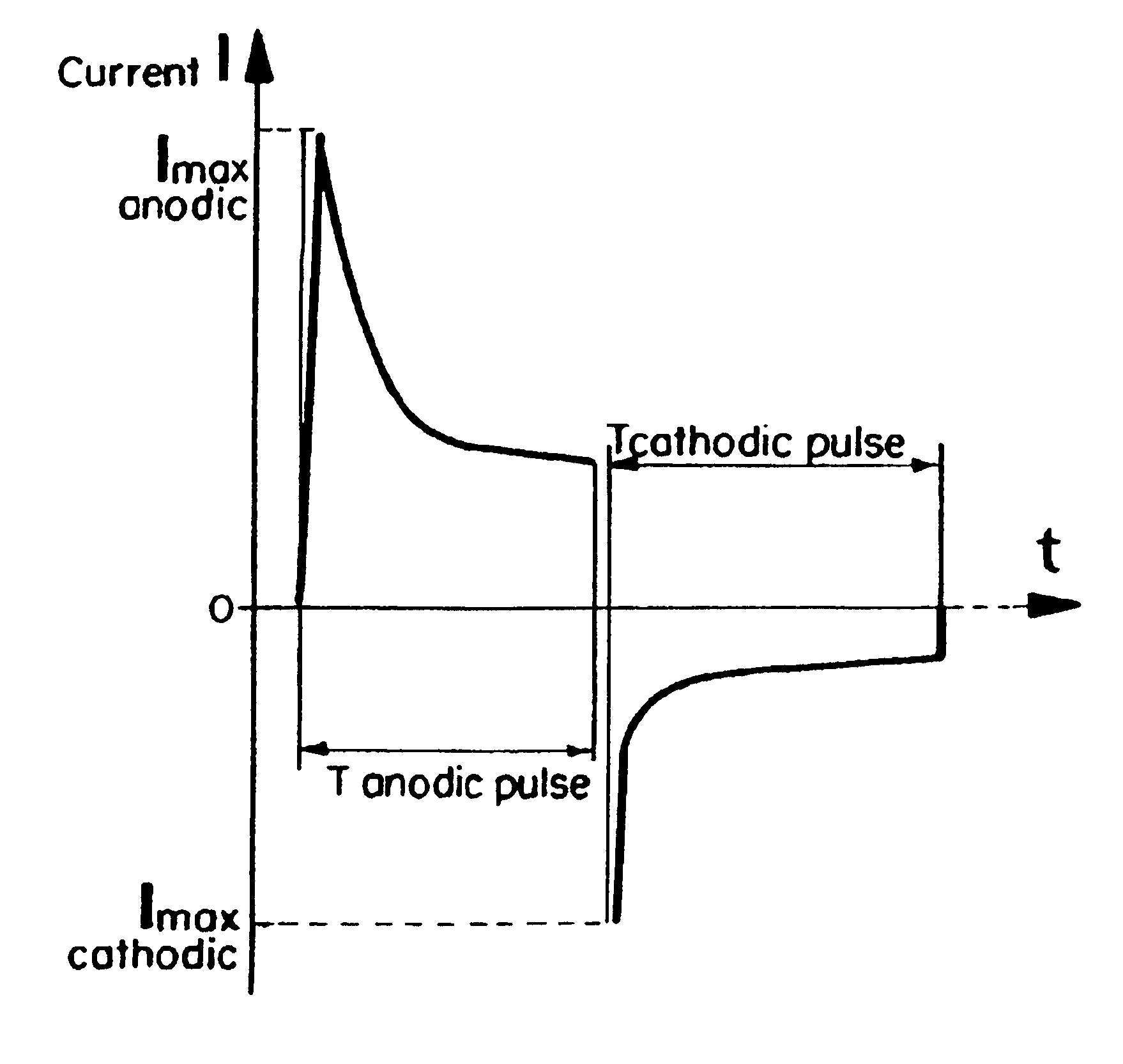

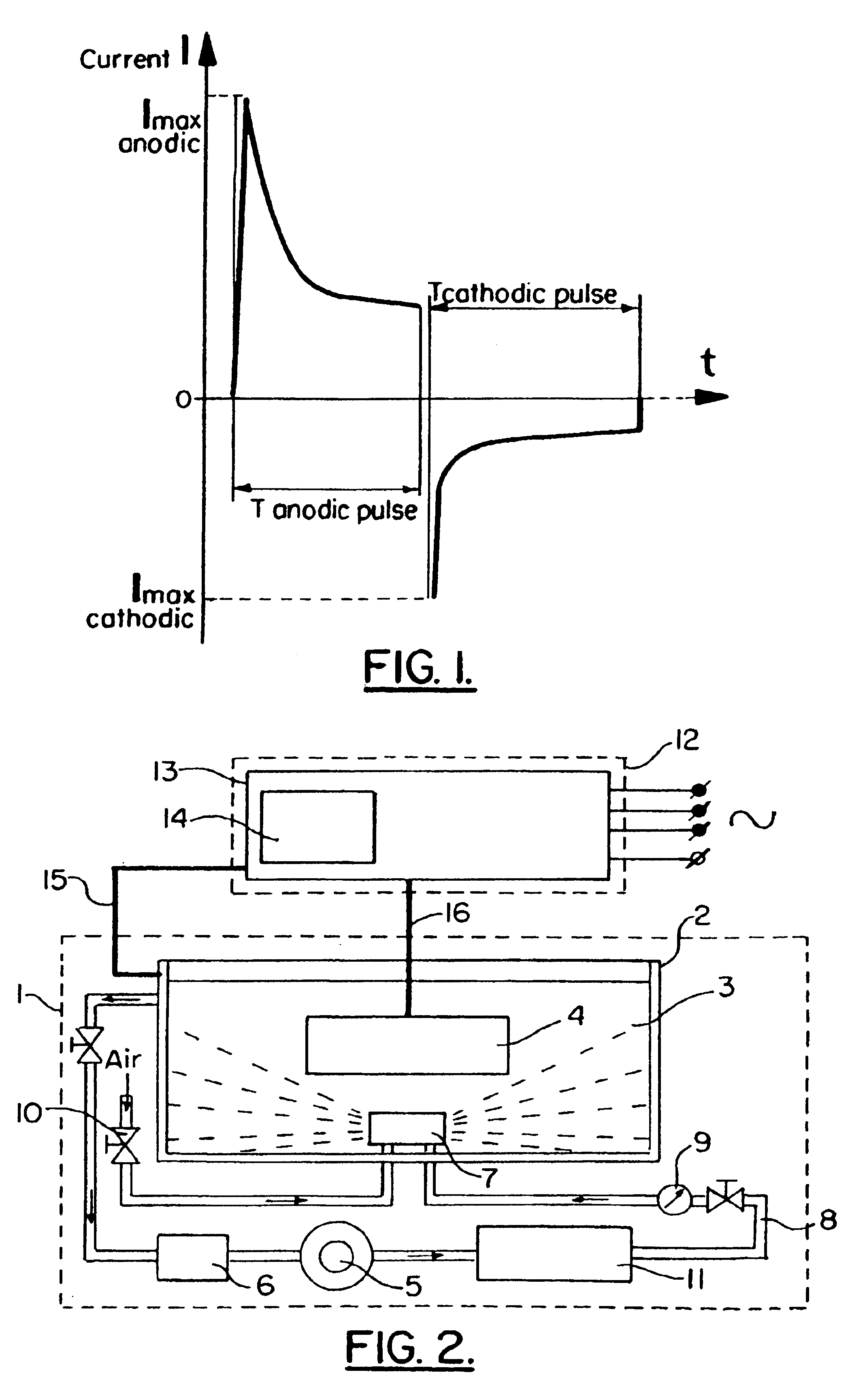

Process and device for forming ceramic coatings on metals and alloys, and coatings produced by this process

InactiveUS6896785B2Increase usageImprove adhesionAnodisationCellsPlasma electrolytic oxidationCeramic coating

Owner:KERONITE INT LTD

Article of manufacture and process for anodically coating an aluminum substrate with ceramic oxides prior to polytetrafluoroethylene or silicone coating

InactiveUS20050115840A1AnodisationElectrolytic inorganic material coatingCeramic coatingSilicone coating

Owner:HENKEL KGAA

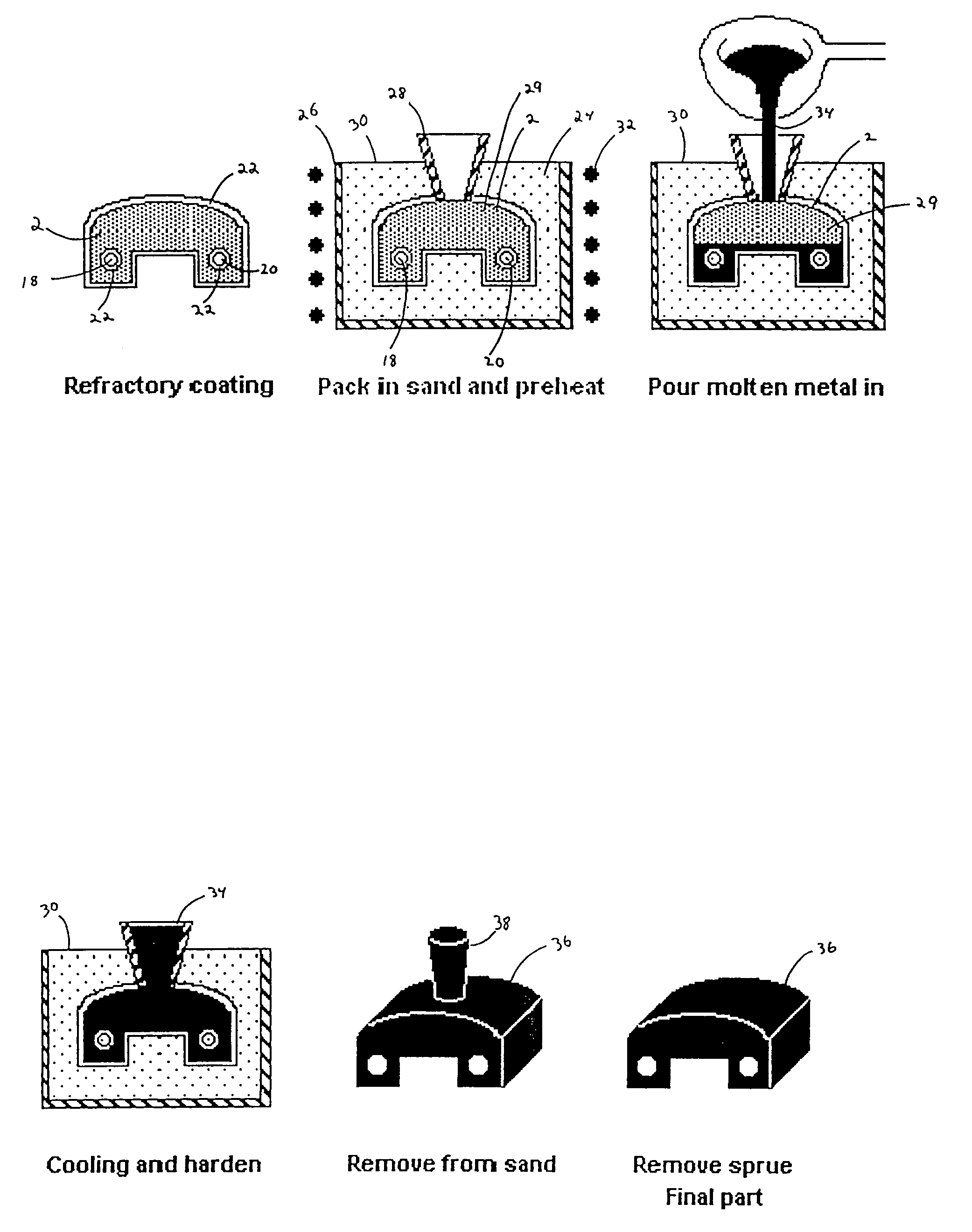

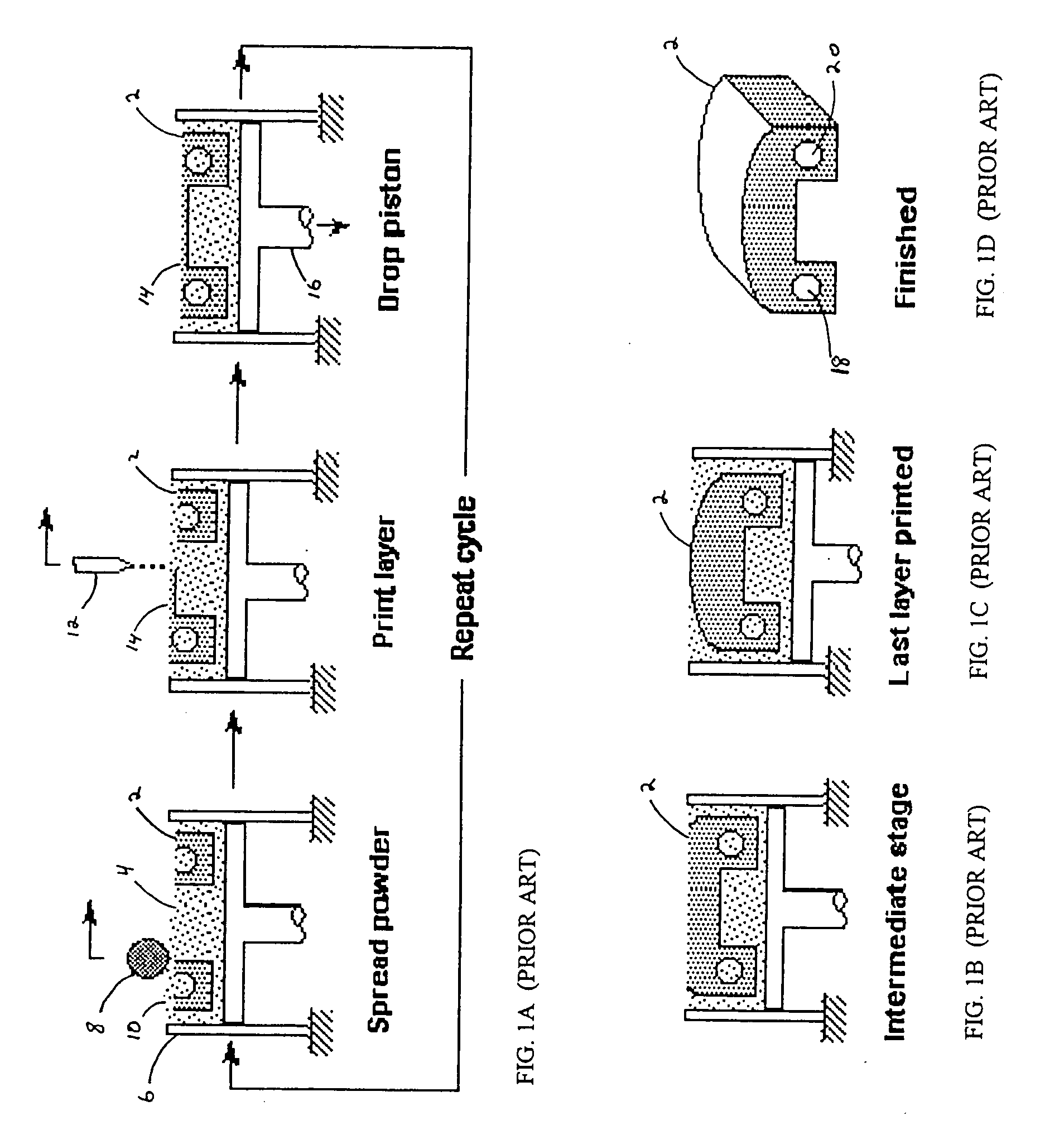

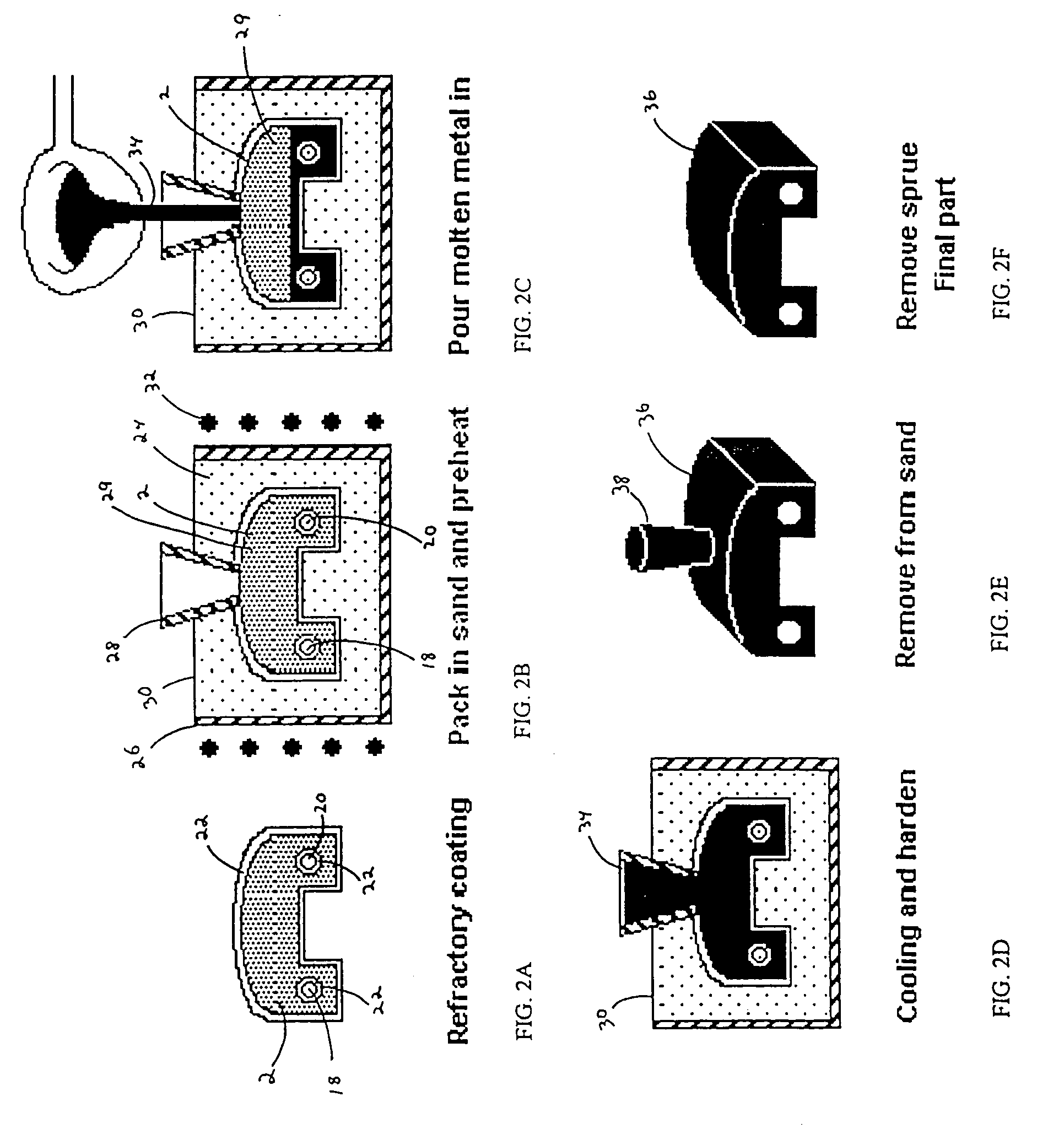

Novel casting process and articles for performing same

ActiveUS20040140078A1Fast technologyShort timeAdditive manufacturing apparatusFoundry mouldsCeramic coatingCasting mold

A method for producing a cast article comprises using a porous powder article as a sacrificial pattern. The porous powder article is preferably made using a rapid prototyping process. The porous powder article is used as a sacrificial pattern for a mold into which a molten metal is cast. Some embodiments include a step of proving the porous powder article with a ceramic coating. Methods of making molds and patterns using a porous powder article are also disclosed. The powder comprising the porous powder article may be a metal, ceramic or cermet. In some embodiments, the powder alloys with the molten casting metal. In some other embodiments, the powder and the casting metal form a composite. Sacrificial casting mold patterns comprising porous powder articles and casting molds comprising such sacrificial patterns are also disclosed.

Owner:THE EX ONE

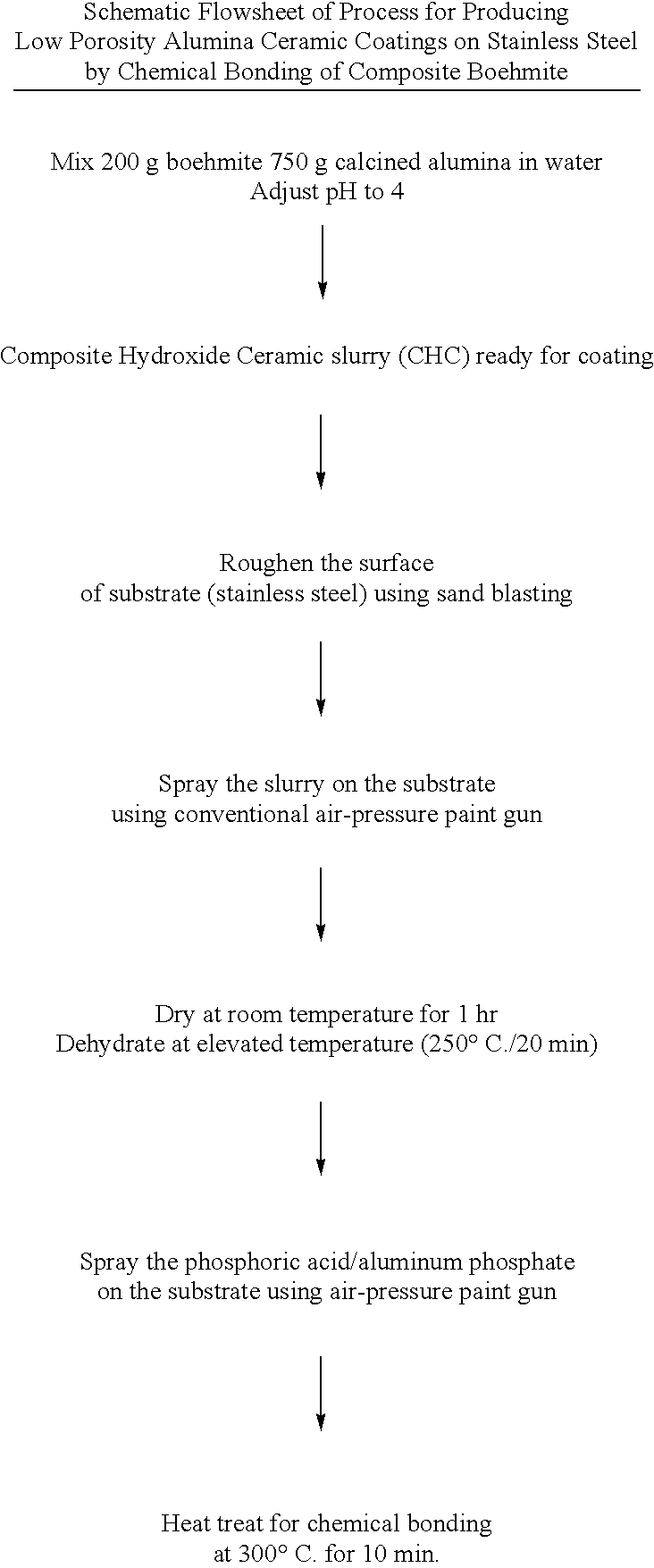

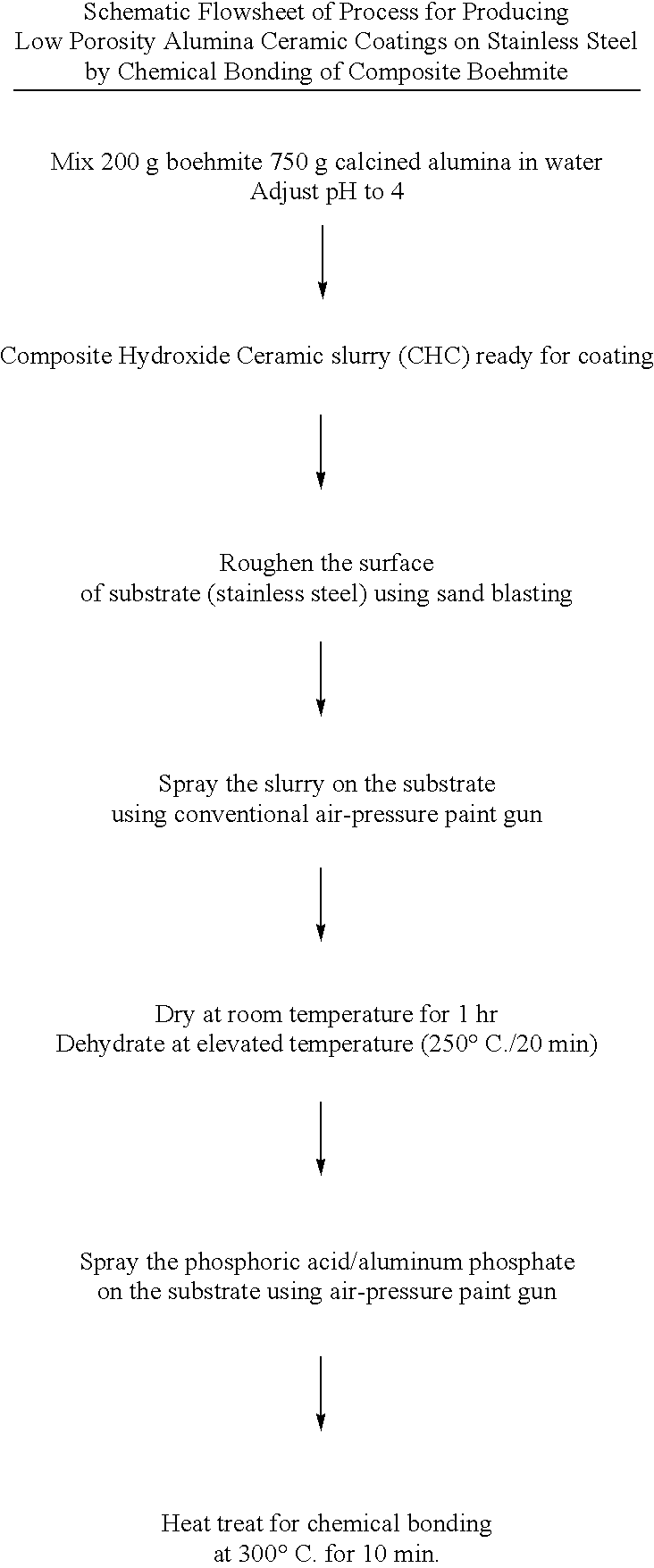

Process for making chemically bonded composite hydroxide ceramics

InactiveUS6770325B2Reduce reactivityMinimizes shrinkageImpression capsPretreated surfacesPhosphateCeramic coating

This invention relates to novel process of preparing chemically bonded composite hydroxide ceramics by exposing a thermally treated hydroxide ceramic to phosphate reagent and subsequent heat treating the resulting system to initiate a rapid chemical bonding reaction. Such combined hydroxide / chemical bonding process can be used to fabricate ceramics or ceramic coatings for a variety of high and low temperature applications, including corrosion protection, wear resistance, dielectric properties, metal reinforced ceramics, ceramic membranes, non-sticky surfaces, bio-active ceramics, thermal barrier ceramics, non-wetted surfaces, and others.

Owner:THE UNIV OF BRITISH COLUMBIA

Functionalization of porous materials by vacuum deposition of polymers

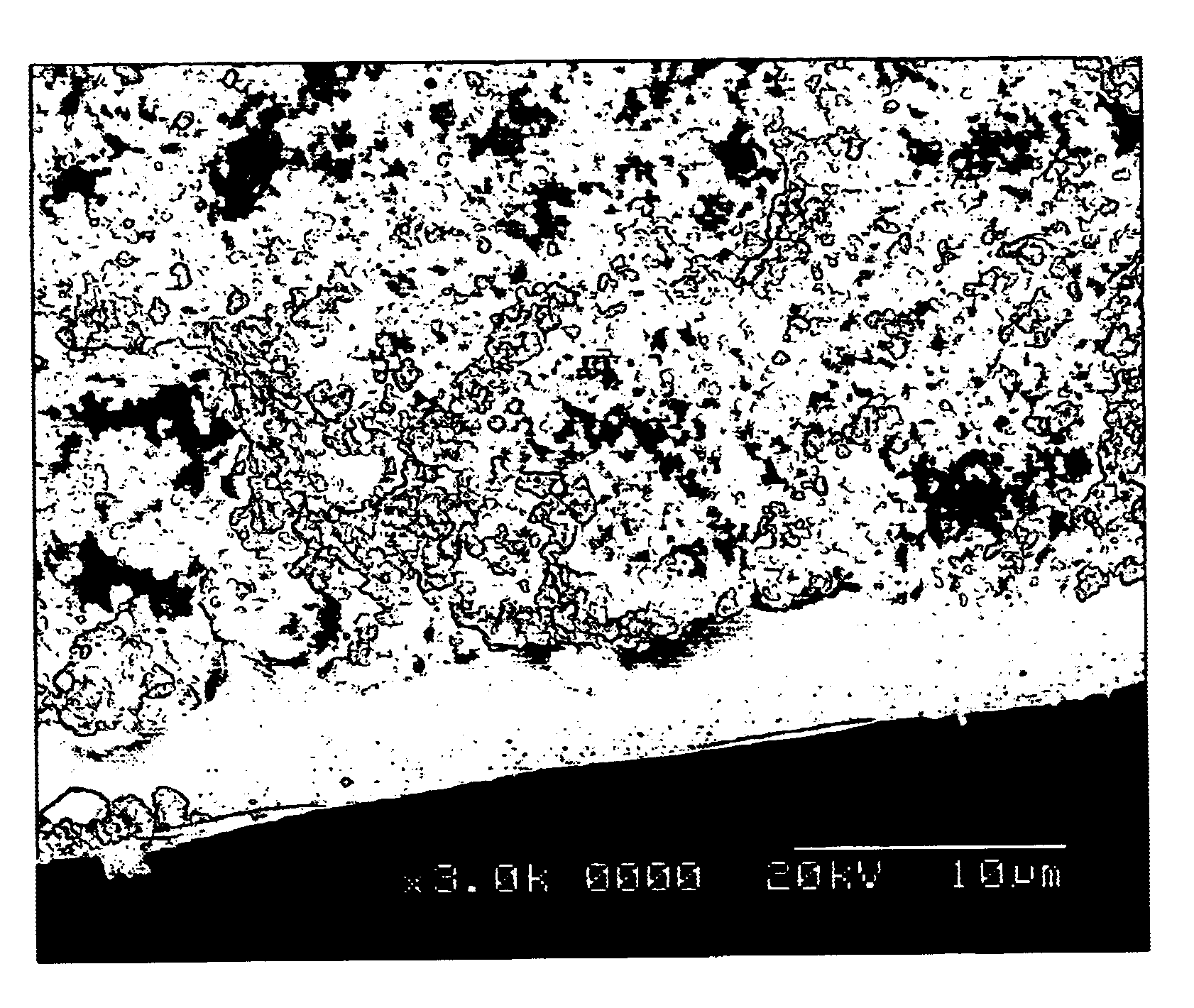

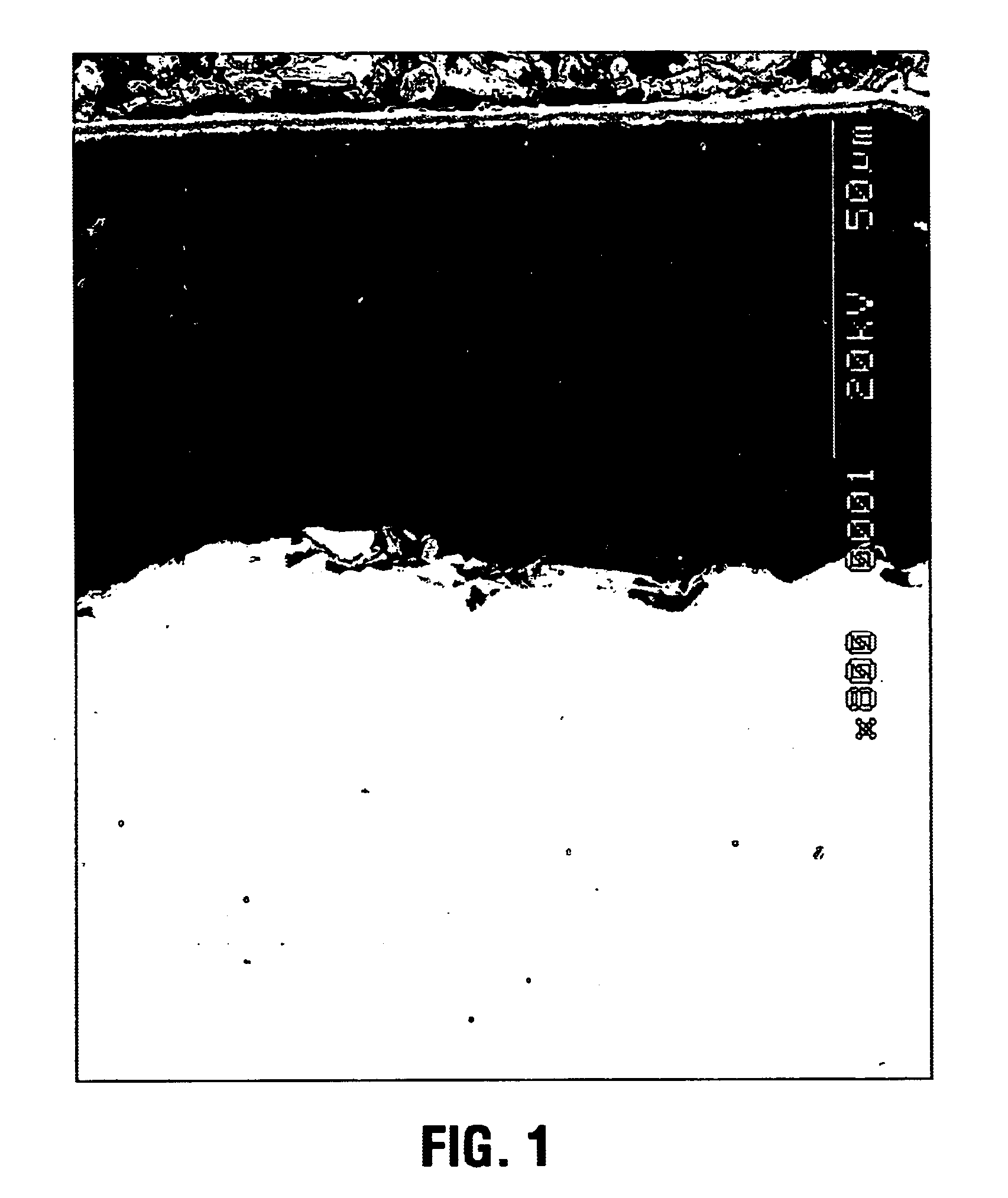

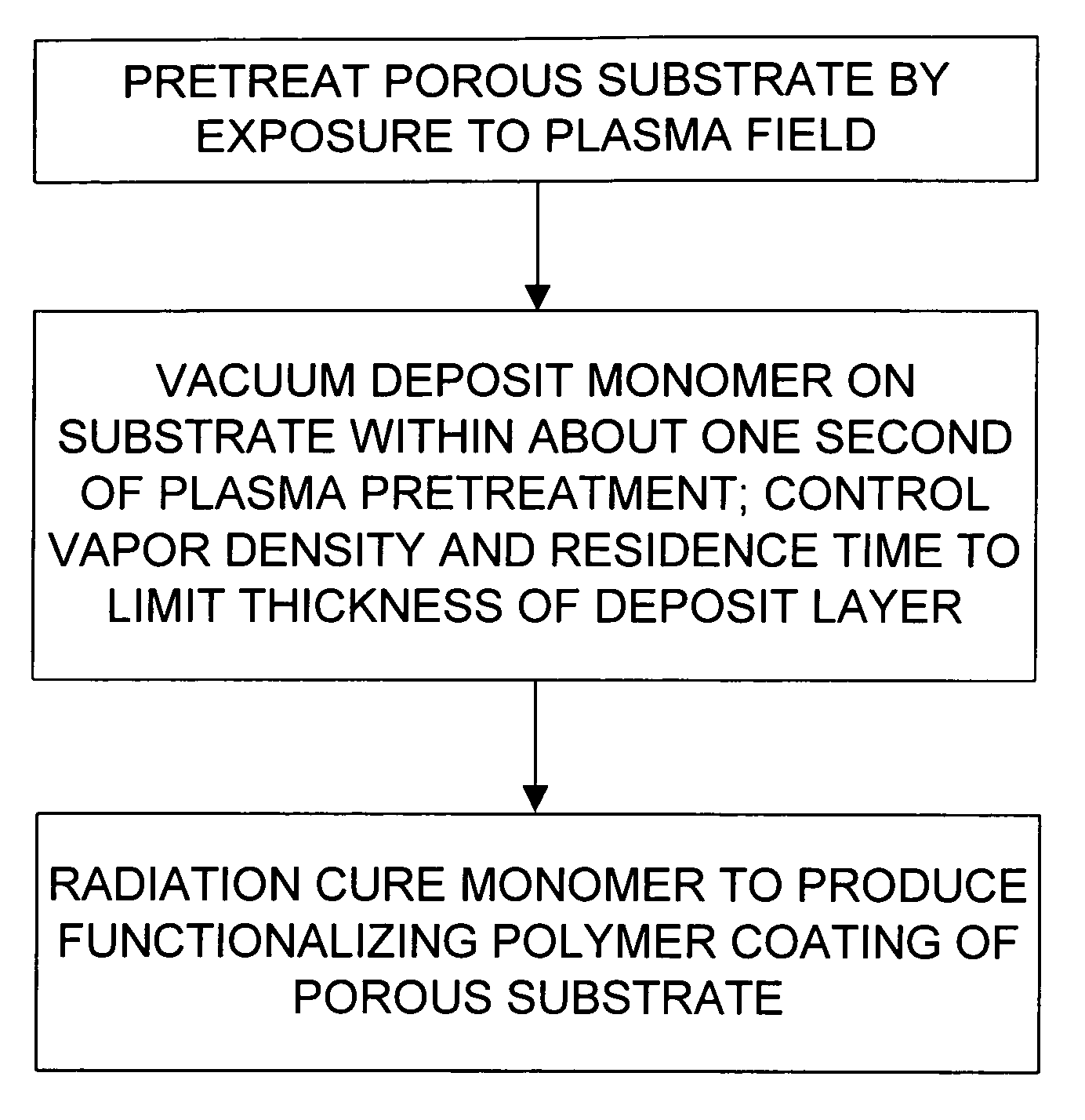

InactiveUS7157117B2Improve reflectivityReduced durabilitySemi-permeable membranesMembranesPorous substrateFiber

A porous substrate is pretreated in a plasma field and a functionalizing monomer is immediately flash-evaporated, deposited and cured over the porous substrate in a vacuum vapor-deposition chamber. By judiciously controlling the process so that the resulting polymer coating adheres to the surface of individual fibers in ultra-thin layers (approximately 0.02–3.0 μm) that do not extend across the pores in the material, the porosity of the porous substrate is essentially unaffected while the fibers and the final product acquire the desired functionality. The resulting polymer layer is also used to improve the adherence and durability of metallic and ceramic coatings.

Owner:SIGMA LAB OF ARIZONA

Ceramic membranes with improved adhesion to plasma-treated polymeric supporting material and their production and use

InactiveUS20080190841A1Overcome disadvantagesMembranesSemi-permeable membranesCeramic coatingCarbon chain

Owner:EVONIK DEGUSSA GMBH

Cerium oxide containing ceramic components and coatings in semiconductor processing equipment and methods of manufacture thereof

InactiveUS6830622B2Reduce corrosionReduce erosion rateLiquid surface applicatorsMolten spray coatingCeramic coatingCerium

Owner:LAM RES CORP

Heat reflective coated structural article

InactiveUS6872440B1Energy efficiencyLow costRecord information storageCeramic layered productsElastomerCeramic coating

The present invention relates to a heat reflective coated structural article comprising a heat reflective component and a coated structural article component which comprises a substrate having an ionic charge coated with a coating having essentially the same ionic charge. The coating of the coated structural article consists essentially of a filler material and a binder material wherein the binder material bonds the filler material together and to the substrate and wherein the coating does not bleed through the substrate. Nonlimiting examples of the heat reflective component include, elastomeric coatings, aluminum fiber coatings, acrylic and polyurethane coating systems, ceramic coatings insulating paints, metal pigment paints, metal pigment pastes and aluminum flakes. The heat reflective coated structural article of the present invention may be incorporated into commercial roofing products.

Owner:ELK PREMIUM BUILDING PROD

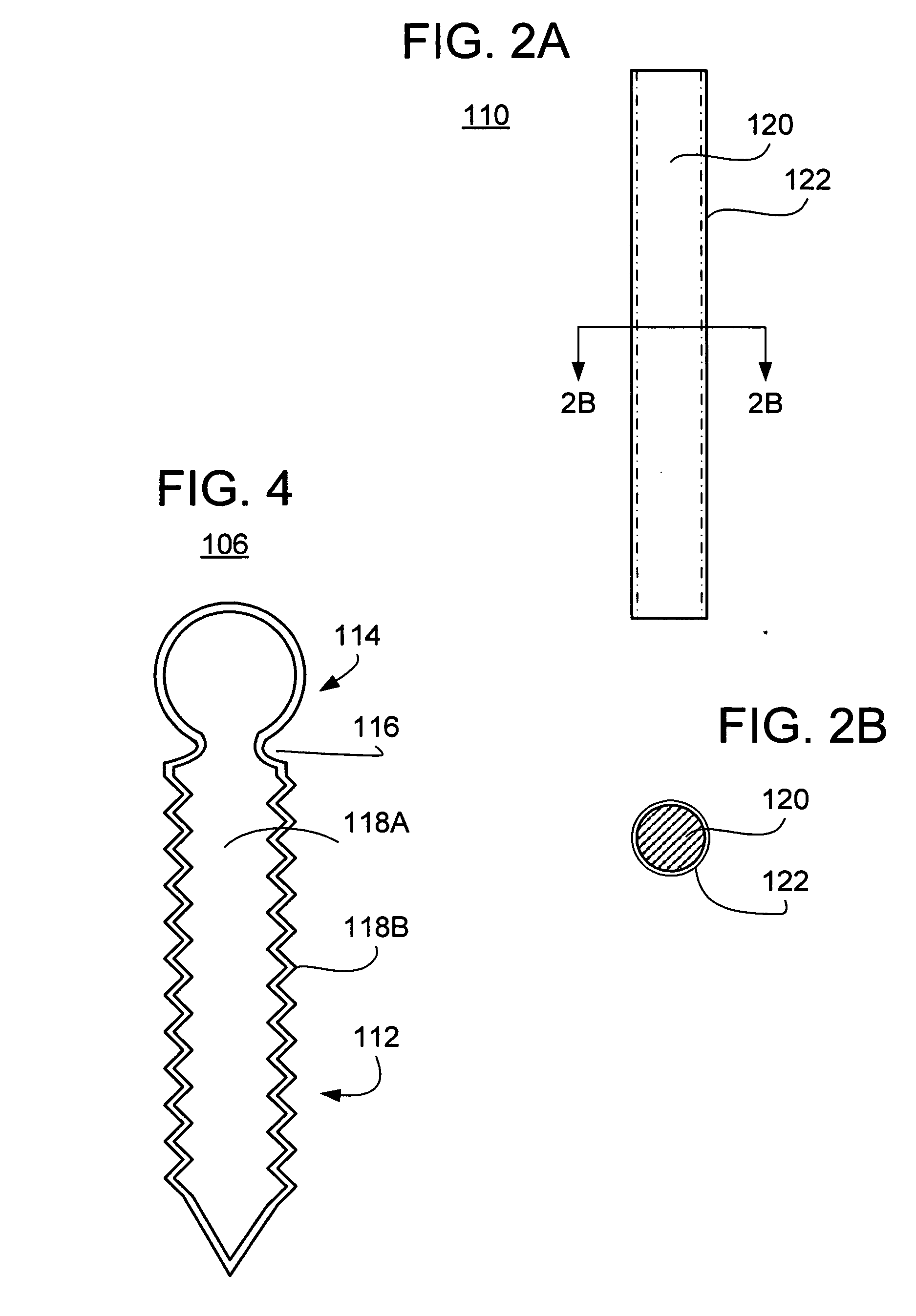

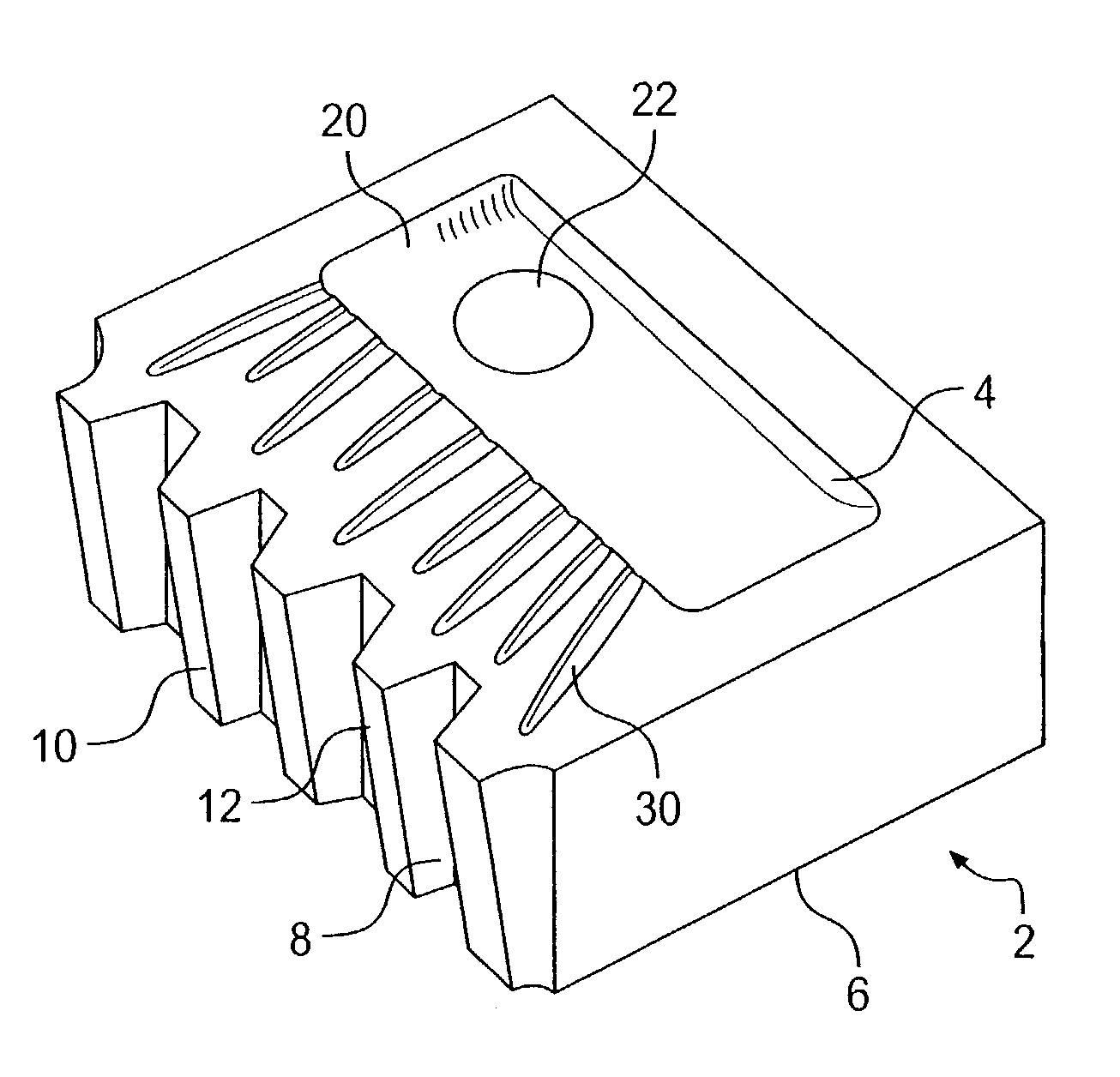

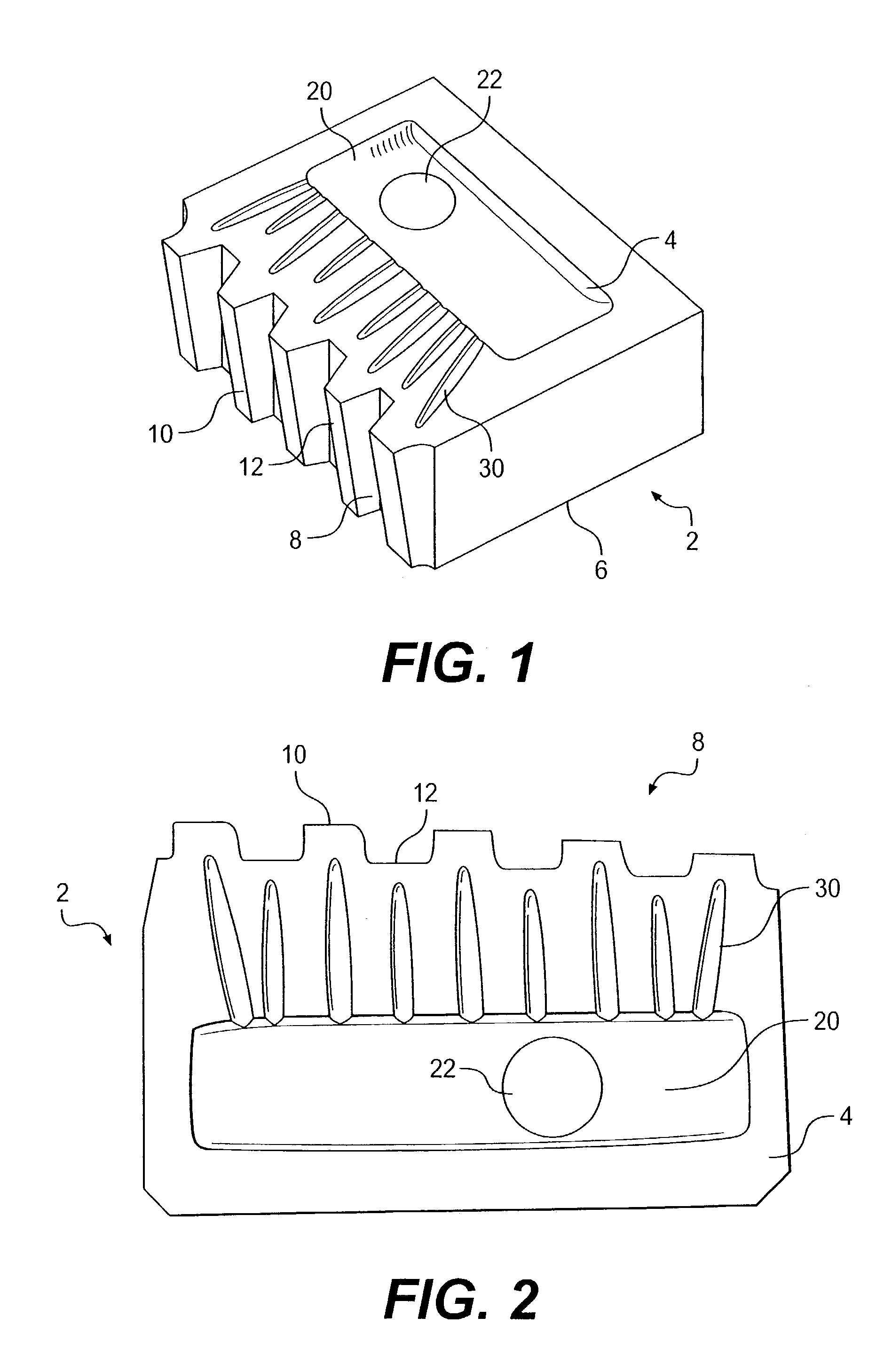

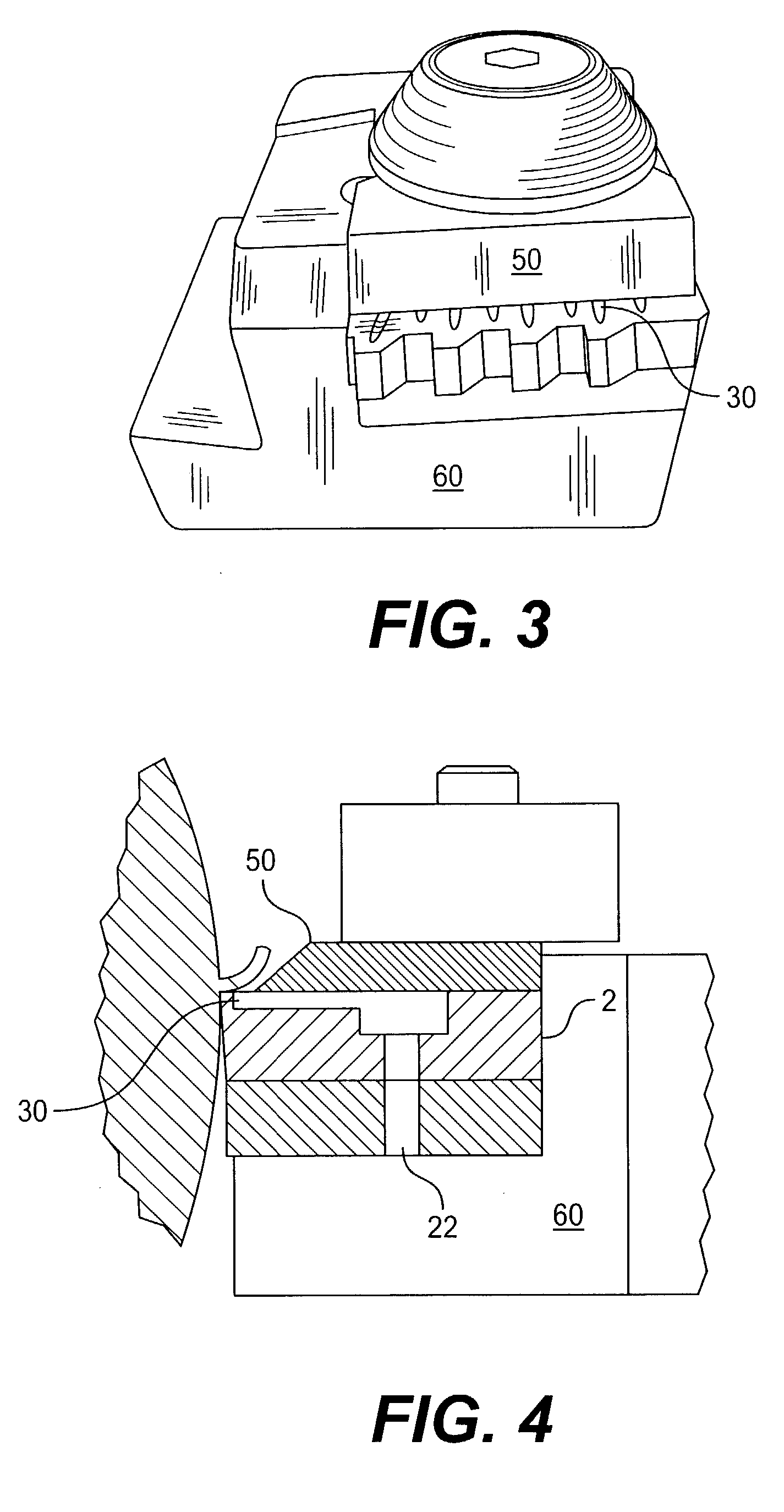

Threading insert with cooling channels

A metalworking apparatus includes a threading insert with a channel-less chip breaker and a holder for holding the threading insert. The threading insert includes (i) one cooling channel disposed on the top side of the threading insert for each crest and each valley, which terminates near the cutting region, and (ii) a ceramic coating on at least the cutting region of crests and valleys, with each cooling channel being uncoated.

Owner:SIDERCA S A L C ARGENTINA

Process for making chemically bonded composite hydroxide ceramics

InactiveUS20020107133A1Minimizes shrinkagePromote environmental protectionImpression capsPretreated surfacesPhosphateCeramic coating

This invention relates to novel process of preparing chemically bonded composite hydroxide ceramics by exposing a thermally treated hydroxide ceramic to phosphate reagent and subsequent heat treating the resulting system to initiate a rapid chemical bonding reaction. Such combined hydroxide / chemical bonding process can be used to fabricate ceramics or ceramic coatings for a variety of high and low temperature applications, including corrosion protection, wear resistance, dielectric properties, metal reinforced ceramics, ceramic membranes, non-sticky surfaces, bio-active ceramics, thermal barrier ceramics, non-wetted surfaces, and others.

Owner:THE UNIV OF BRITISH COLUMBIA

Zirconia toughened ceramic components and coatings in semiconductor processing equipment and method of manufacture thereof

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber comprises zirconia toughened ceramic material as an outermost surface of the component. The component can be made entirely of the ceramic material or the ceramic material can be provided as a coating on a substrate such as aluminum or aluminum alloy, stainless steel, or refractory metal. The zirconia toughened ceramic can be tetragonal zirconia polycrystalline (TZP) material, partially-stabilized zirconia (PSZ), or a zirconia dispersion toughened ceramic (ZTC) such as zirconia-toughened alumina (tetragonal zirconia particles dispersed in Al2O3). In the case of a ceramic zirconia toughened coating, one or more intermediate layers may be provided between the component and the ceramic coating. To promote adhesion of the ceramic coating, the component surface or the intermediate layer surface may be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

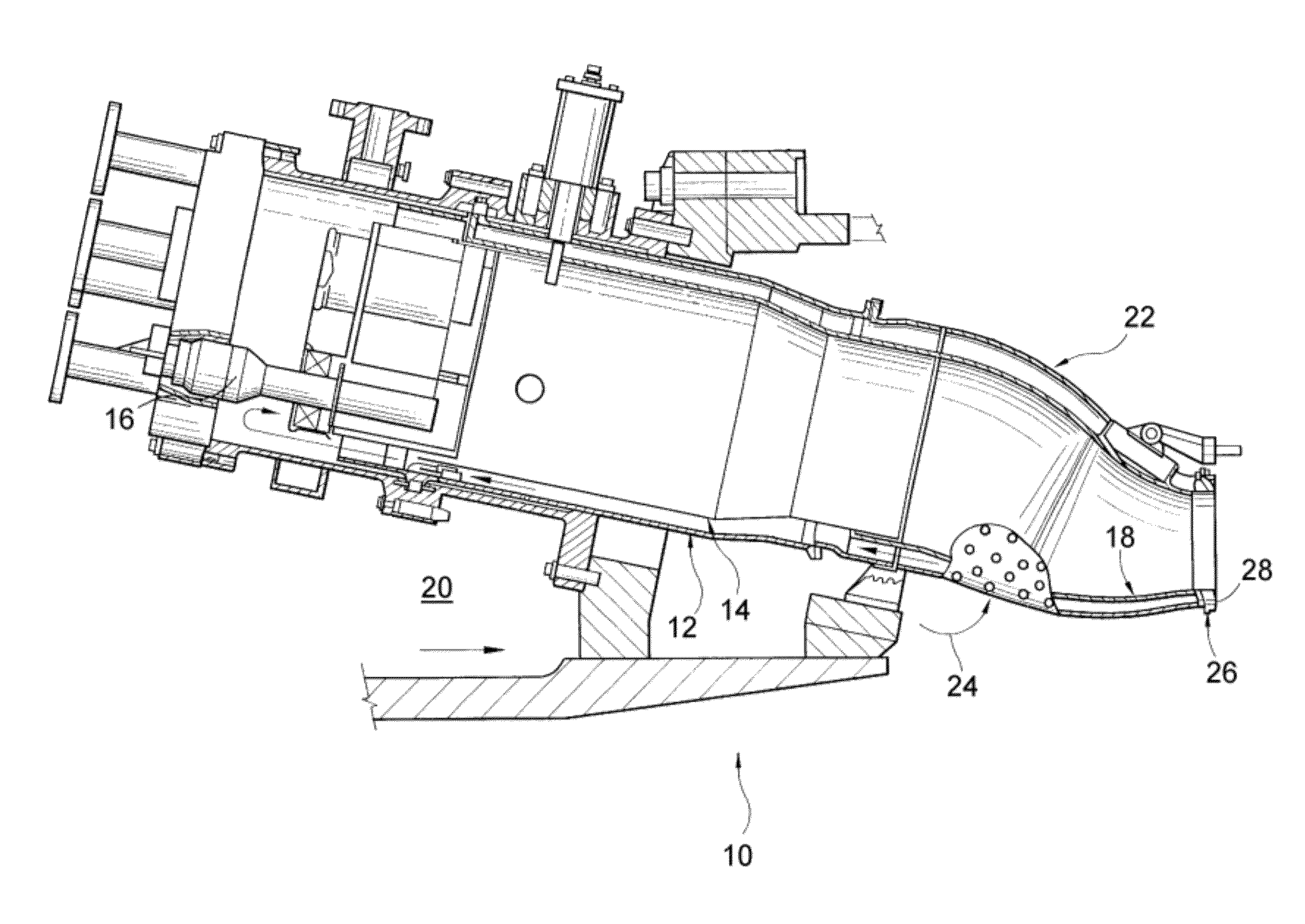

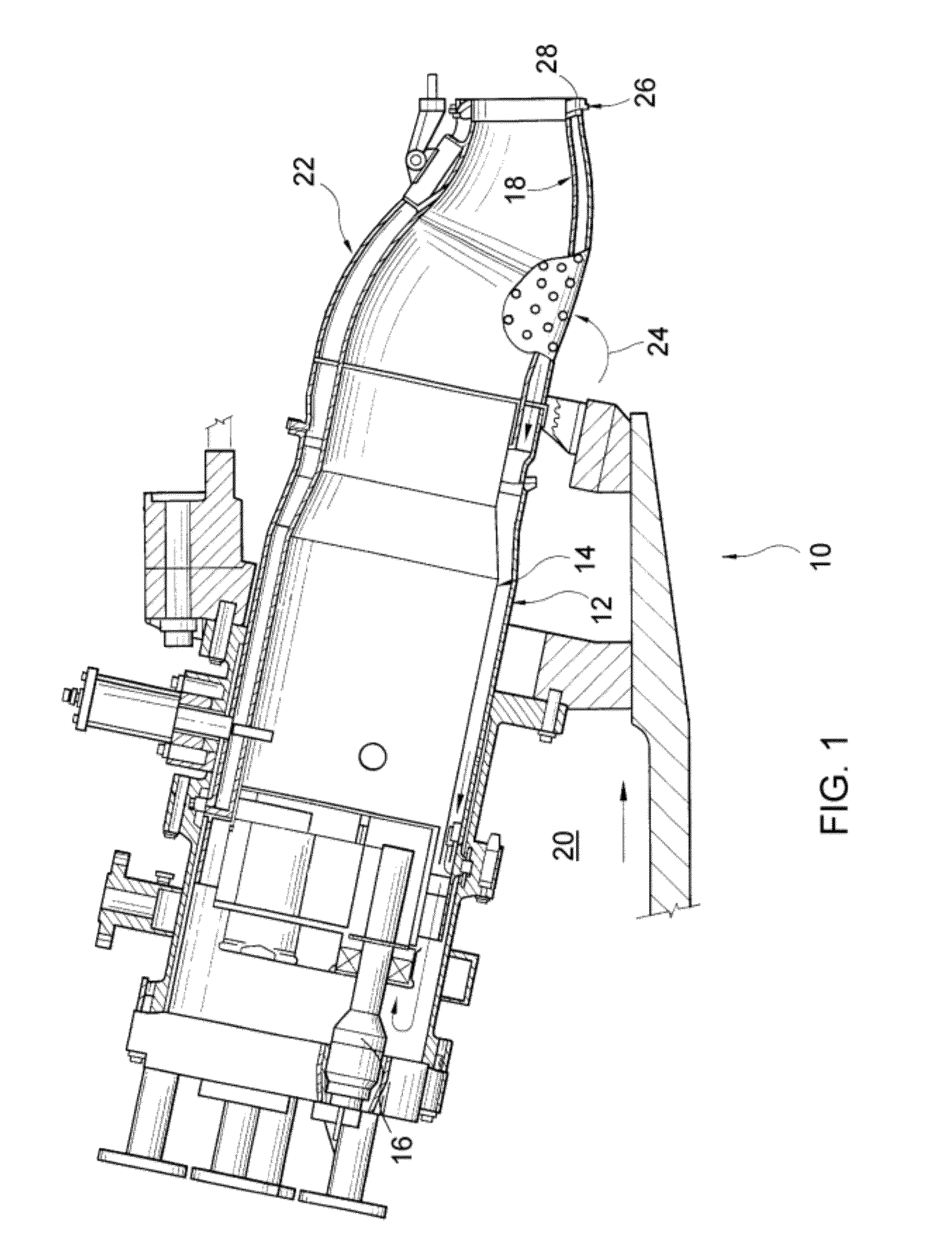

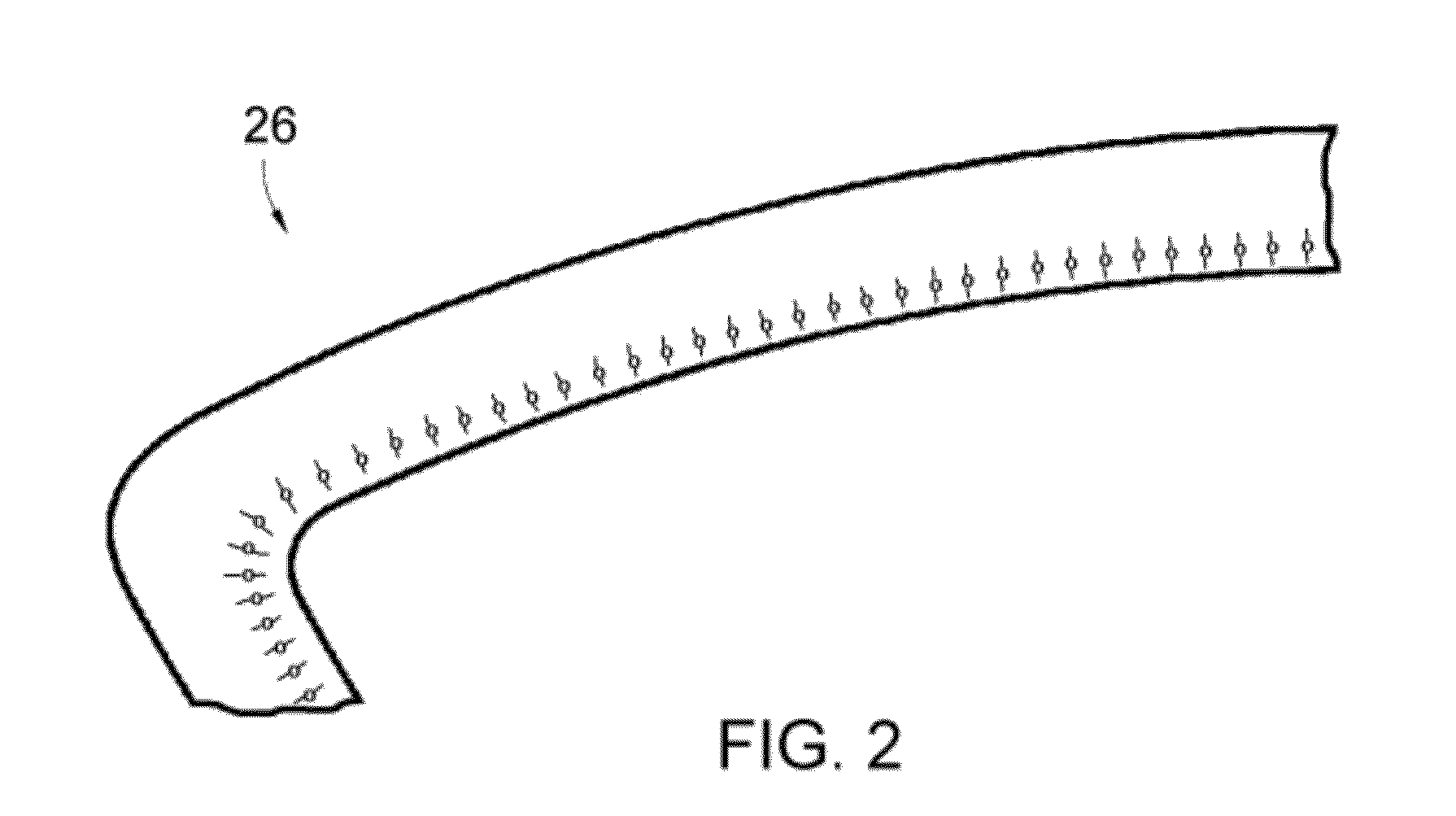

Method of repairing a transition piece of a gas turbine engine

A method of weld repairing an air-cooled aft frame of a transition piece of a gas turbine engine. The transition piece has an interior surface coated with a ceramic coating. The aft frame has a surface with cooling holes therein and from which cracks have propagated. The method includes removing the transition piece from the engine and, without removing the ceramic coating or the aft frame from the transition piece, weld repairing the cracks by performing a laser beam welding technique that deposits a filler material on the surface but does not close the cooling holes in the surface. The surface of the aft frame can be machined to remove excess filler material prior to re-installing the transition piece in a gas turbine engine.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com