Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3277results about How to "Fine surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

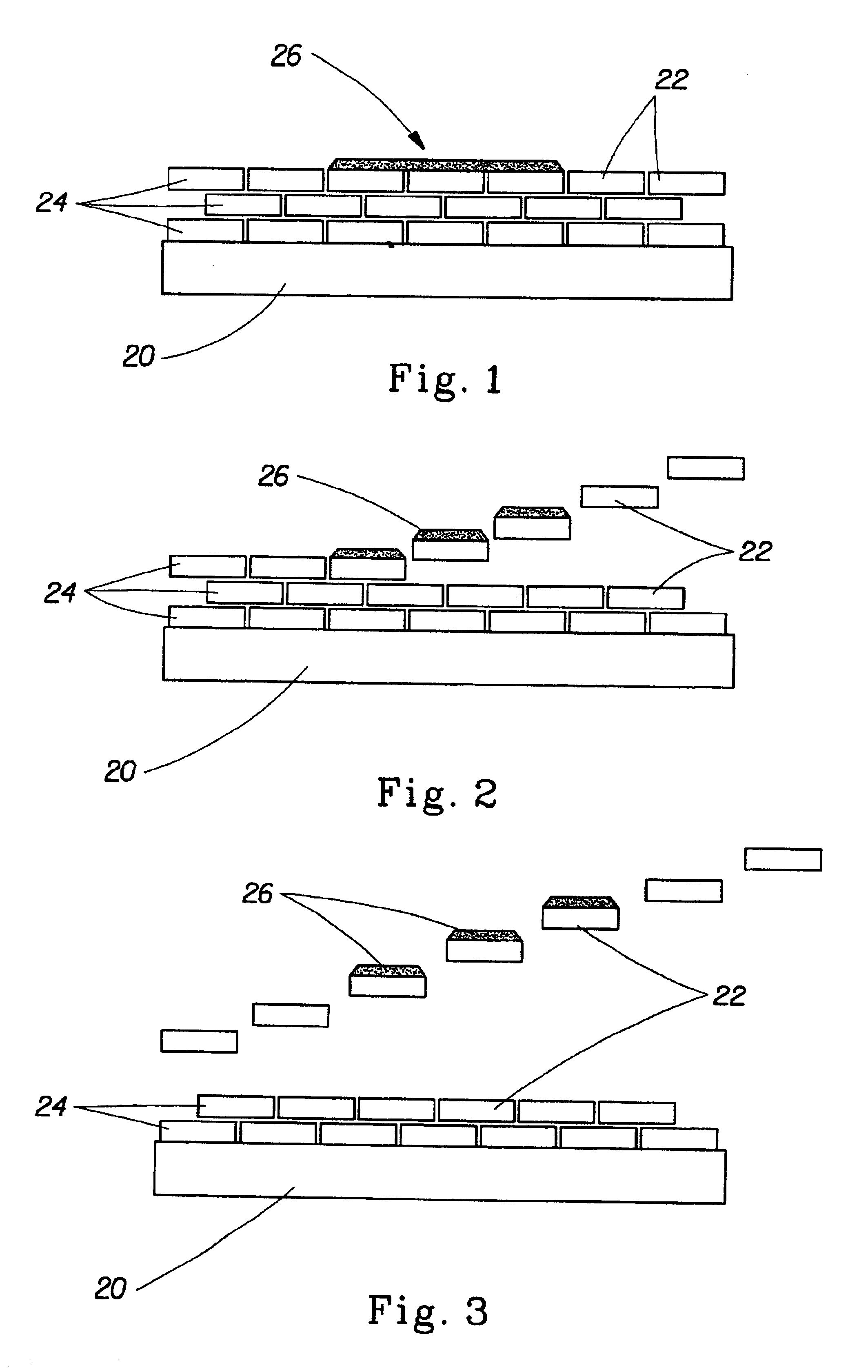

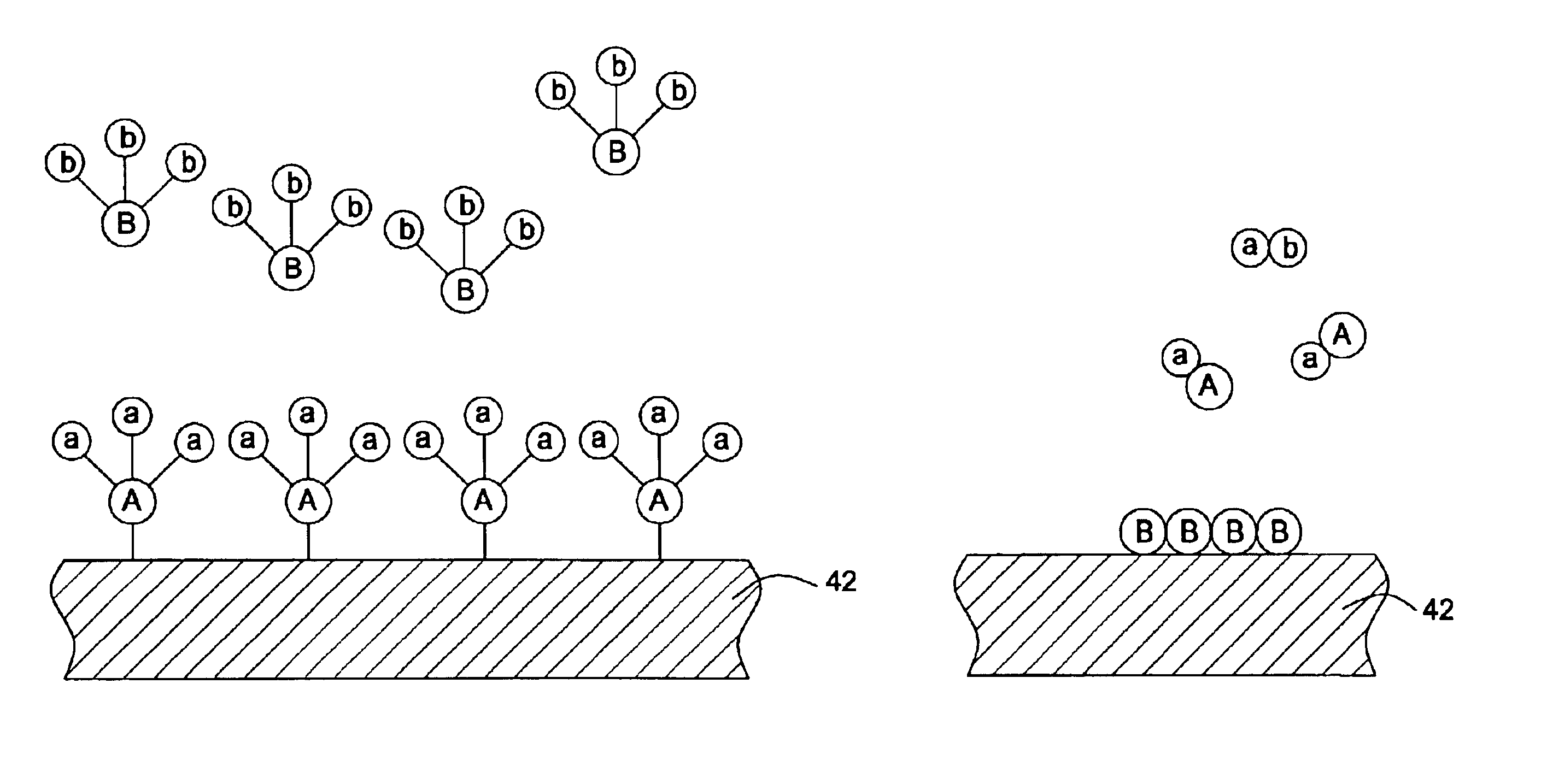

Method of hydrophilizing materials

InactiveUS6863933B2Easy to controlGood removal effectInorganic/elemental detergent compounding agentsRadiation applicationsPolymer scienceNanoparticle

Coating compositions, methods and articles of manufacture comprising a nanoparticle system employing same to impart surface modifying benefits for all types of soft surfaces, and in some cases, hard surfaces, are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to the modified surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that, in some embodiments, may include at least one of the following improved surface properties: cleaning, wettability, liquid strike-through, comfort, stain resistance, soil removal, malodor control, modification of surface friction, reduced damage to abrasion and color enhancement, relative to the surfaces unmodified with such nanoparticle systems.

Owner:THE PROCTER & GAMBLE COMPANY

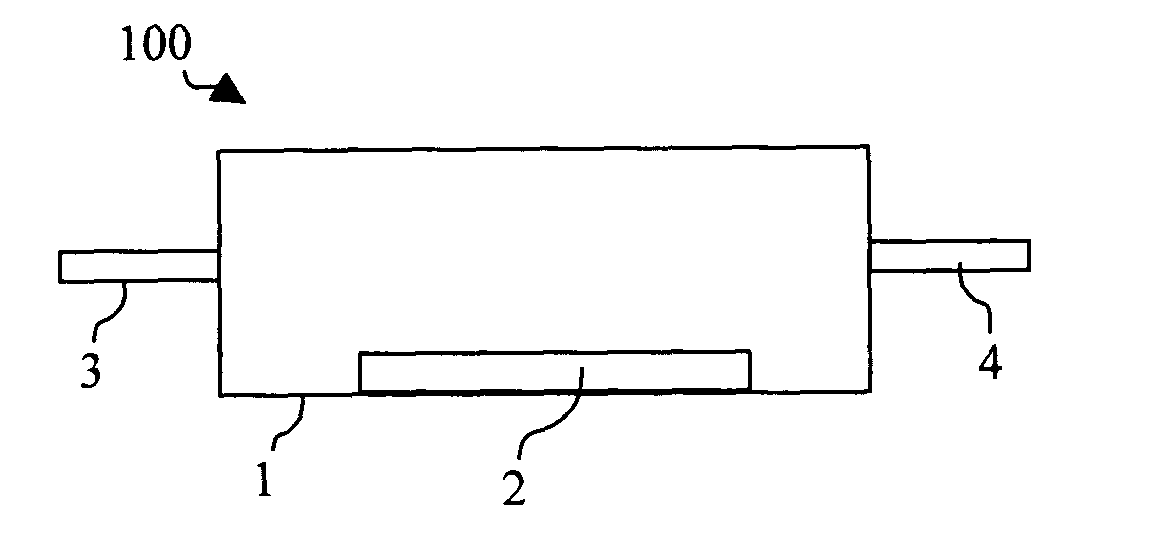

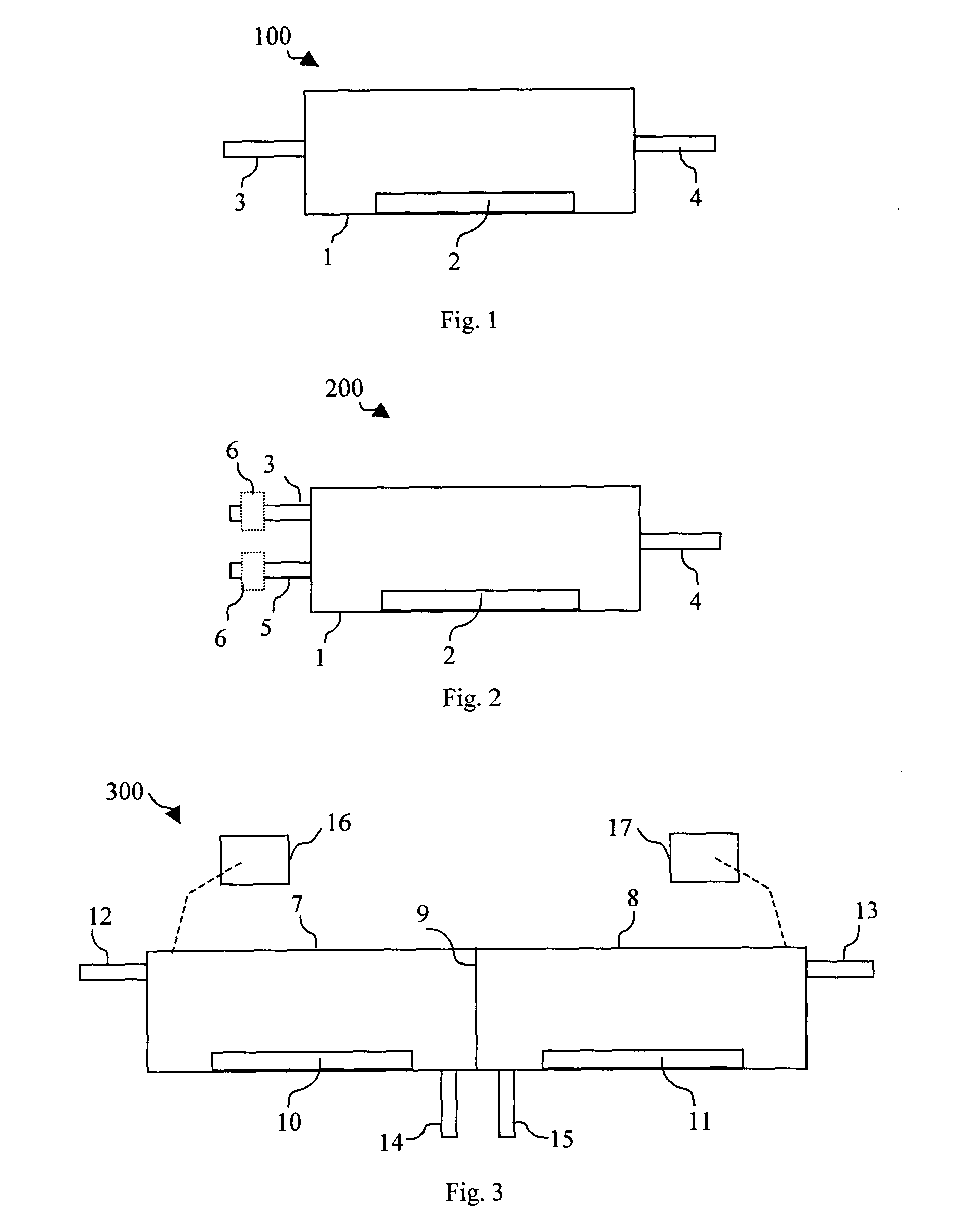

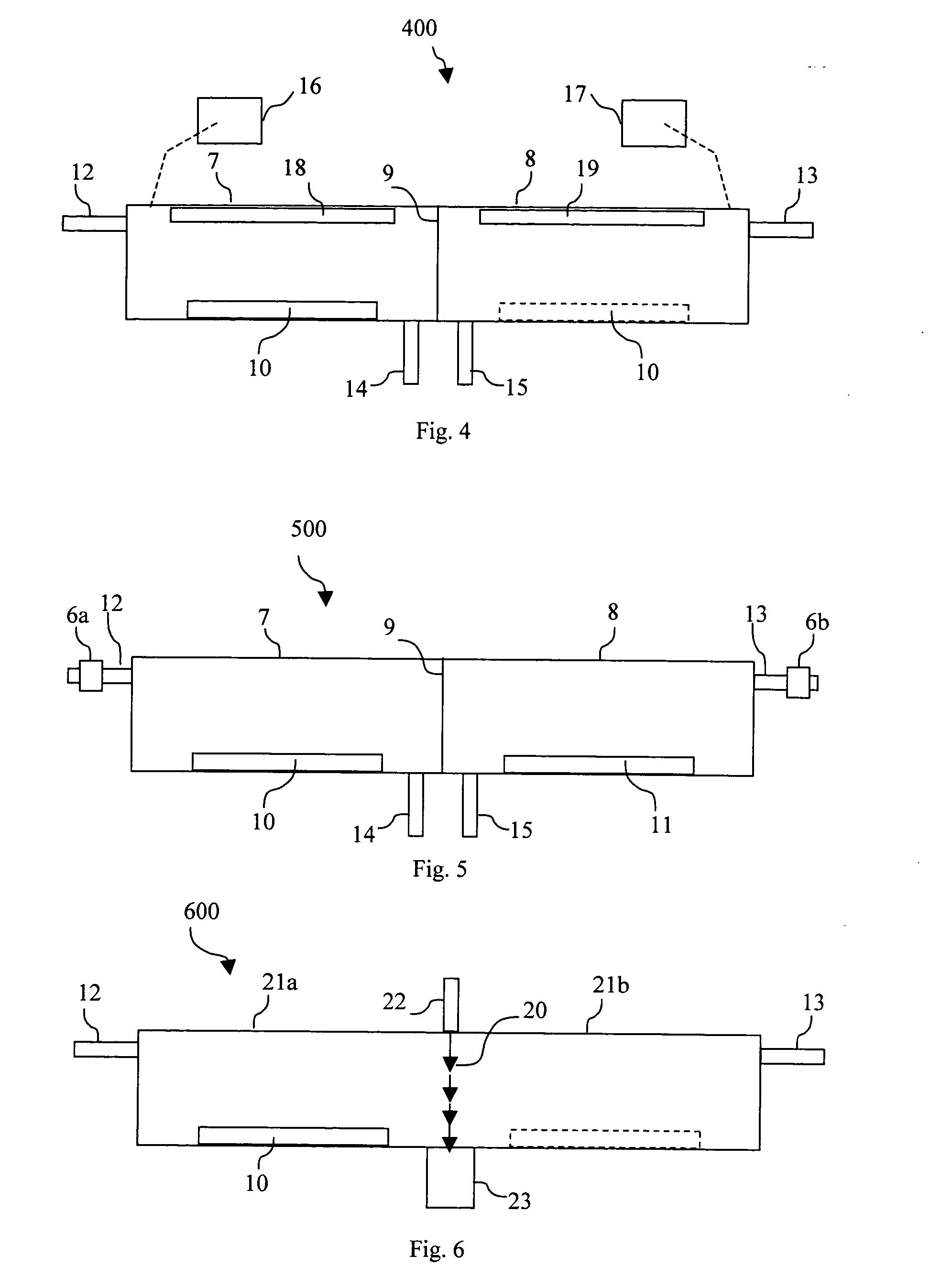

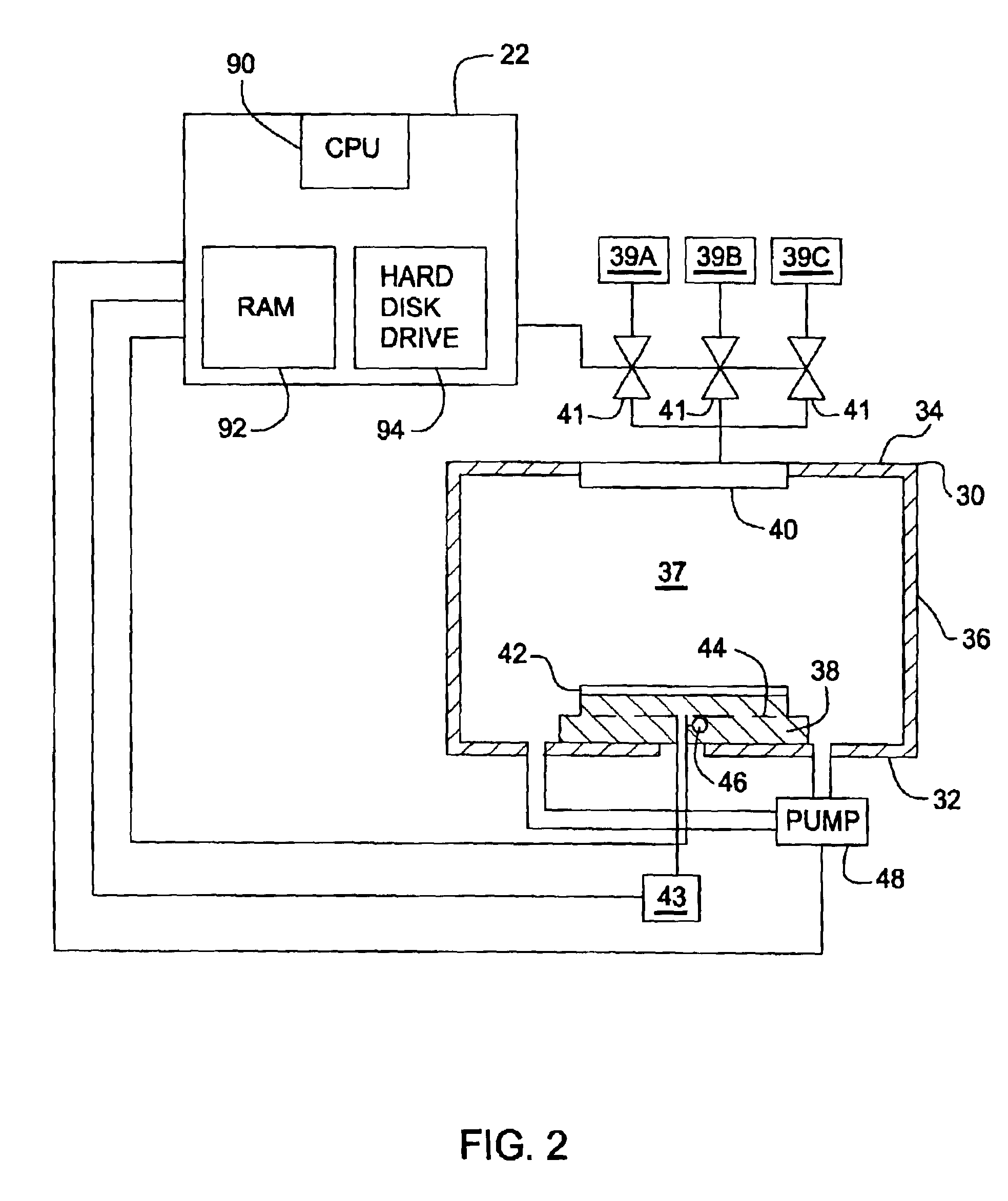

Safe liquid source containers

ActiveUS20050066893A1Excessive pressure increaseEncouraging capillary migrationCarburetting airMixing methodsPorous membraneEngineering

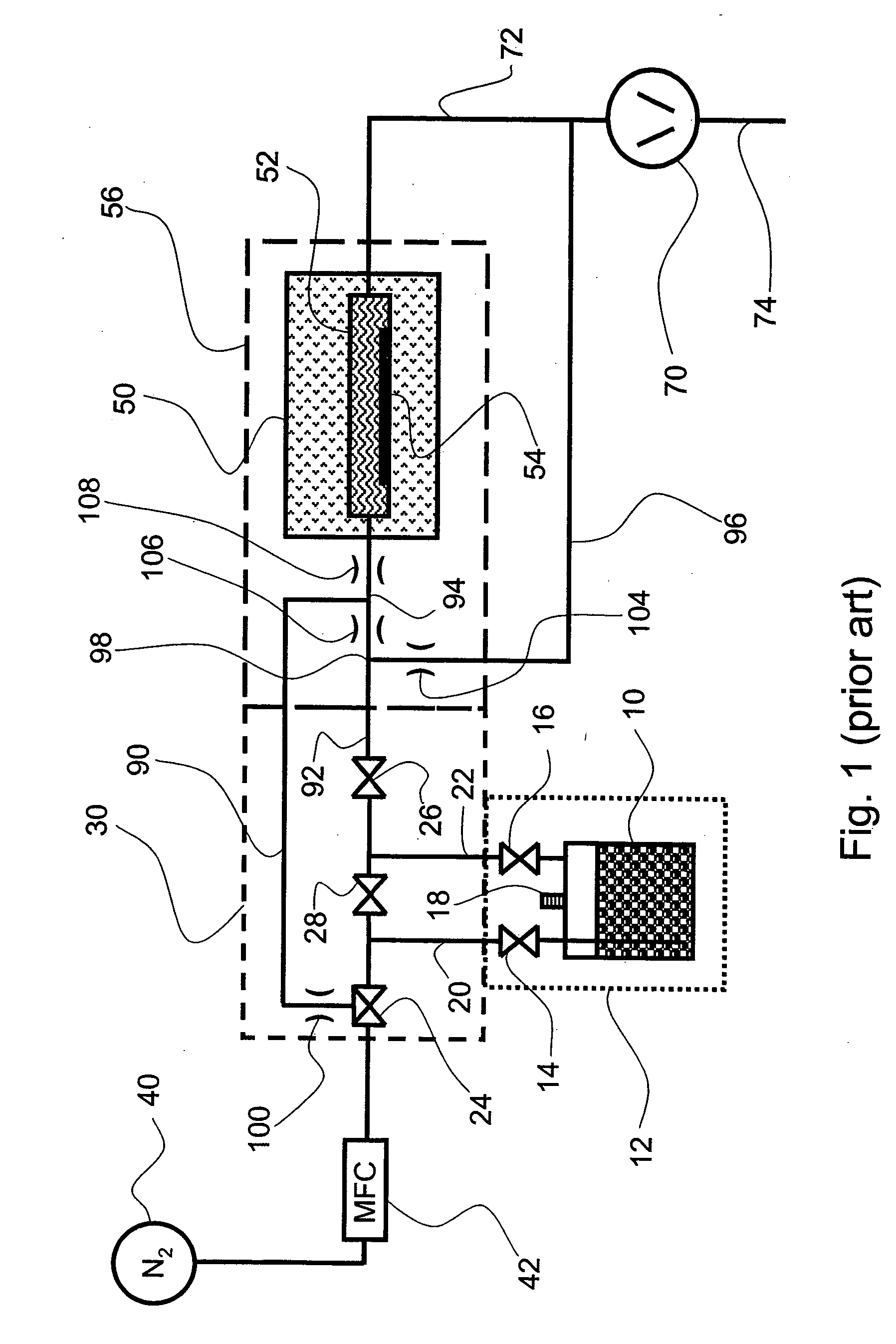

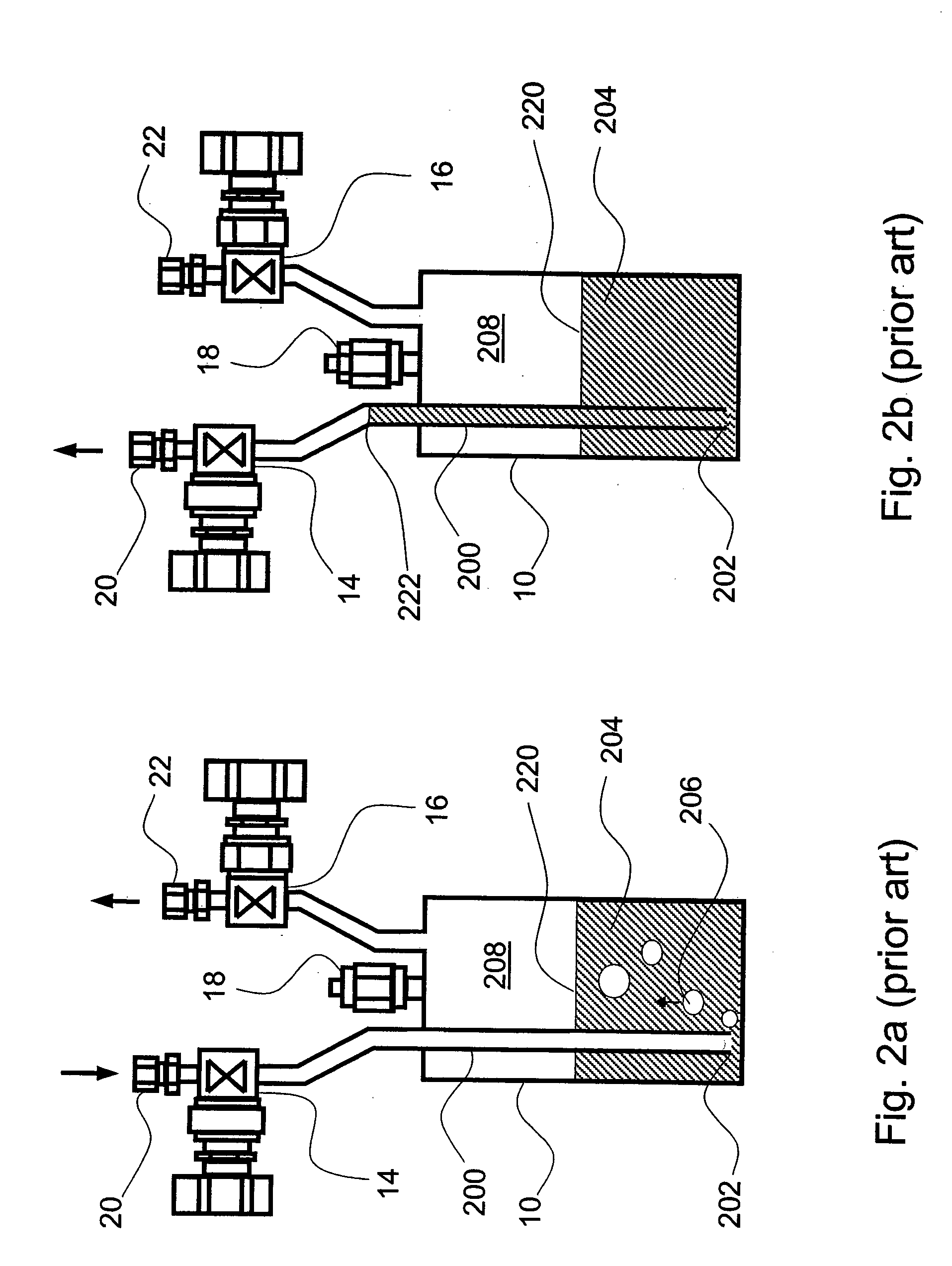

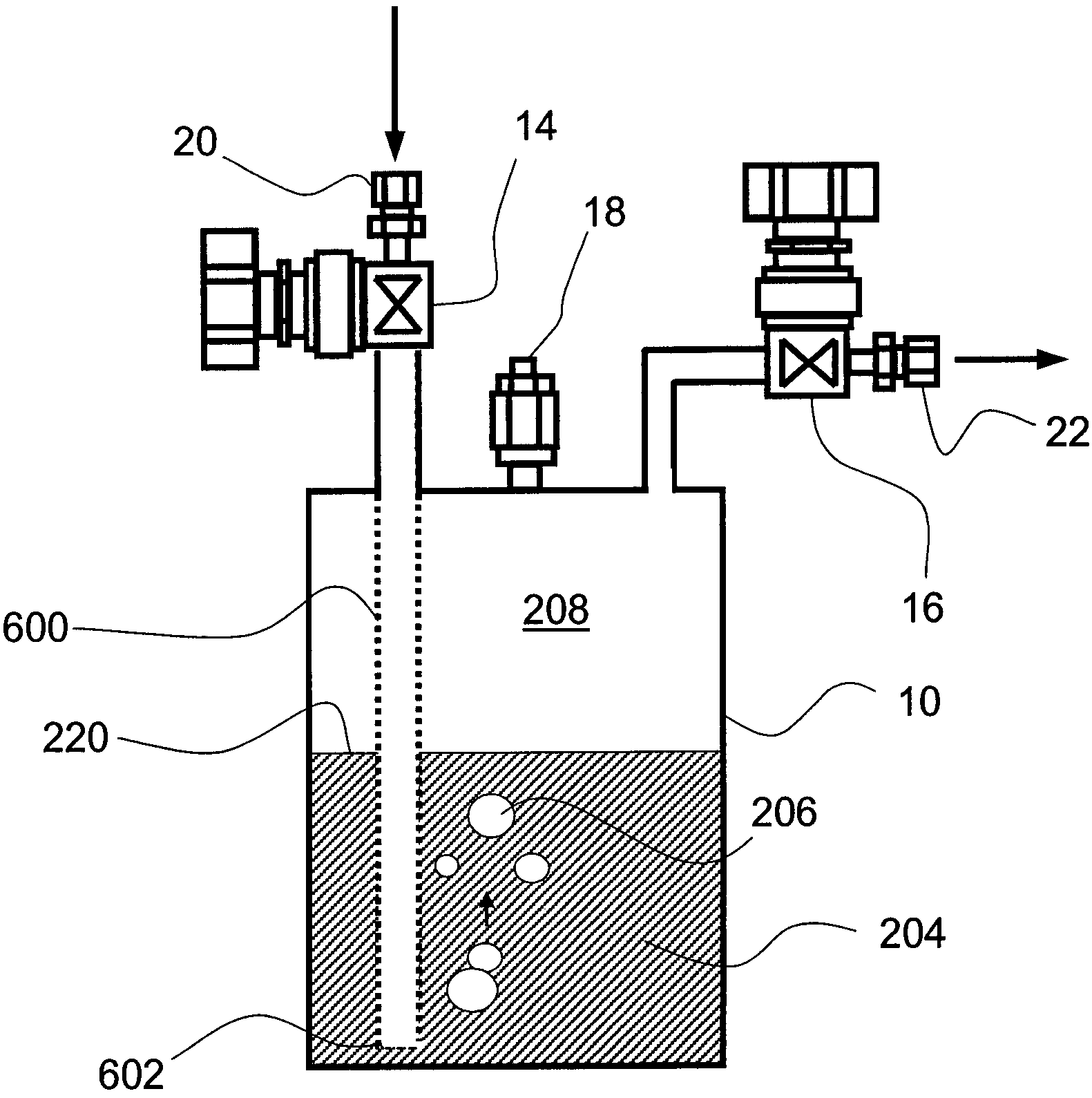

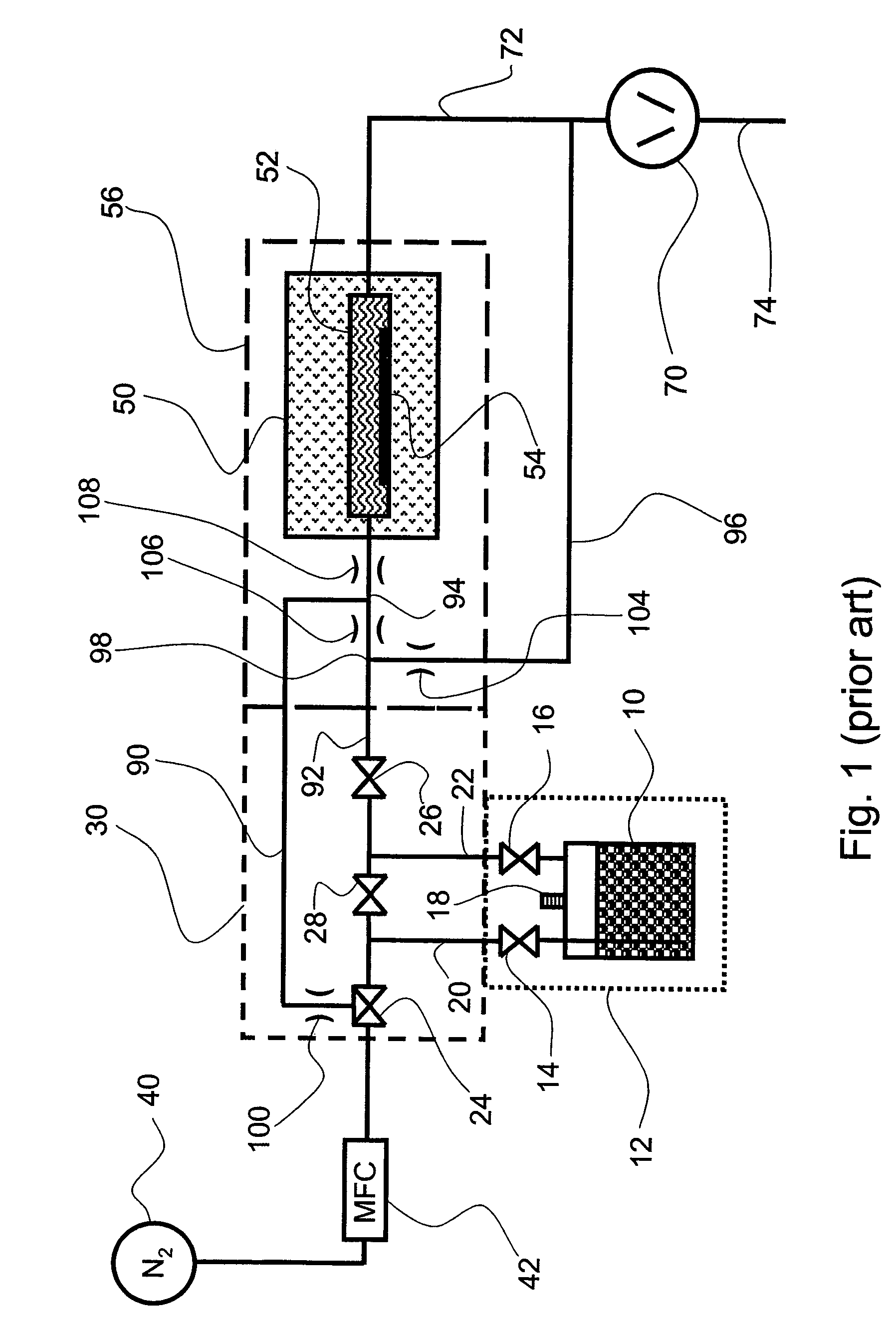

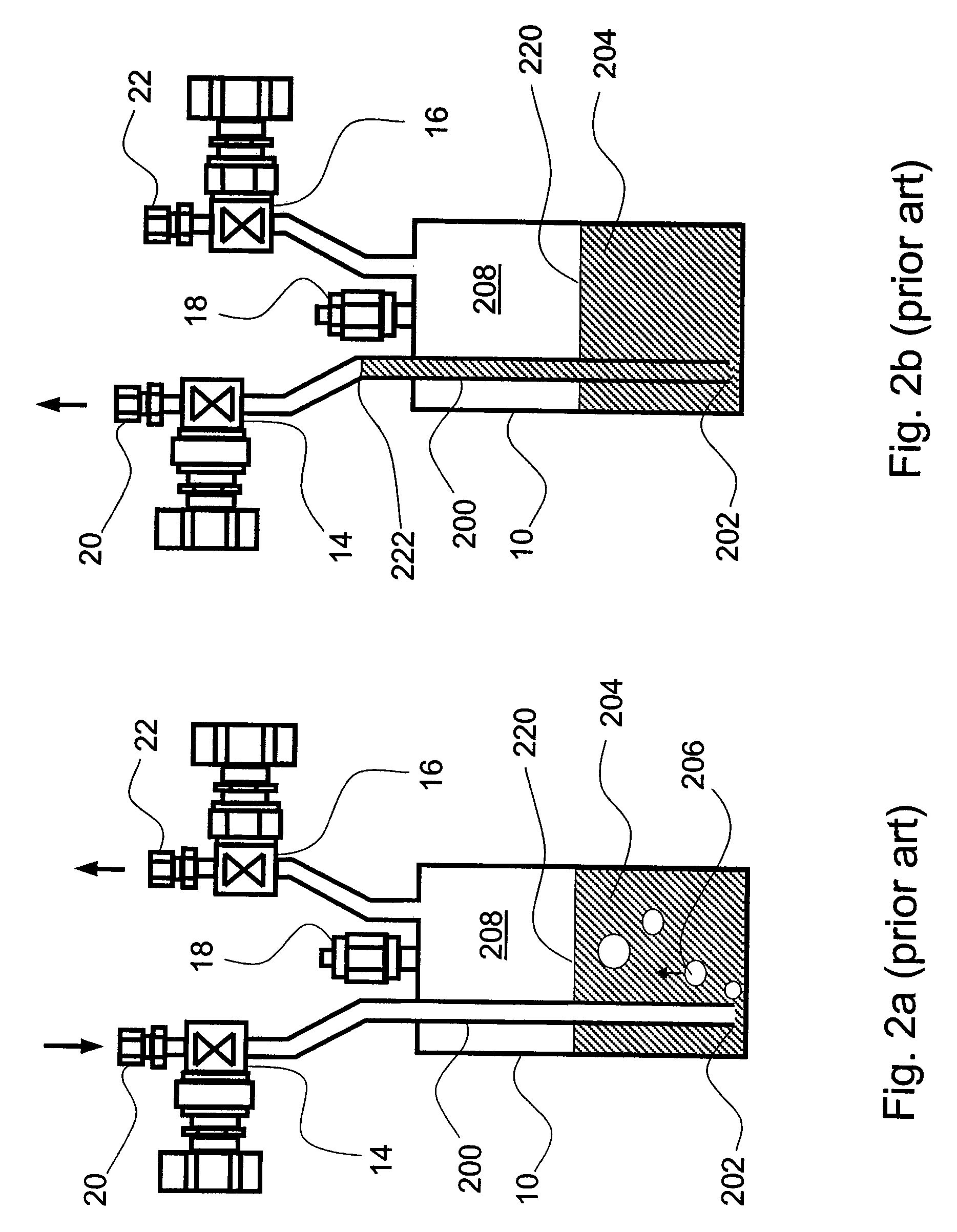

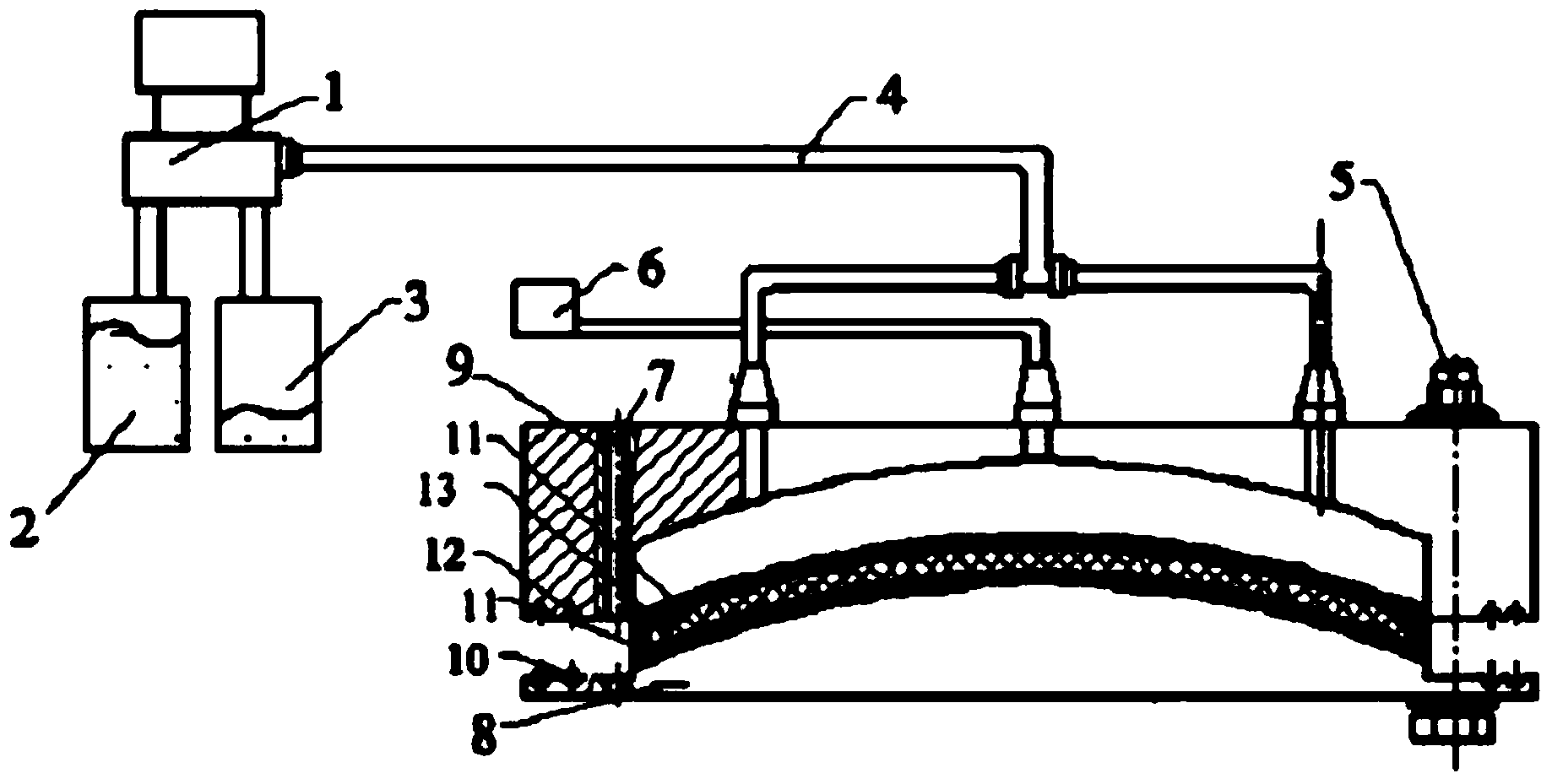

Containers for providing vapor phase reactant from liquid sources include bubbler designs and designs in which carrier gas flows over the liquid surface. Among the bubbler arrangements, a bypass conductance is provided to release excess pressure from the gas volume inside the container, or an enlarged bubbler tube is provided with a volume sufficient to accommodate all possible liquid backflow without having the liquid exit the container. Among the overflow designs, flow dividers provide a tortuous path for the gas to increase the time exposure of carrier gas packets to the evaporating liquid surface. The flow dividers can be microporous to encourage capillary action, thereby increasing the evaporating surface. The tortuous gas flow path can be separated from the liquid phase by a breathable semi-porous membrane that permits vapor phase reactant to pass through but prohibits liquid from passing in the other direction.

Owner:ASM INTERNATIONAL

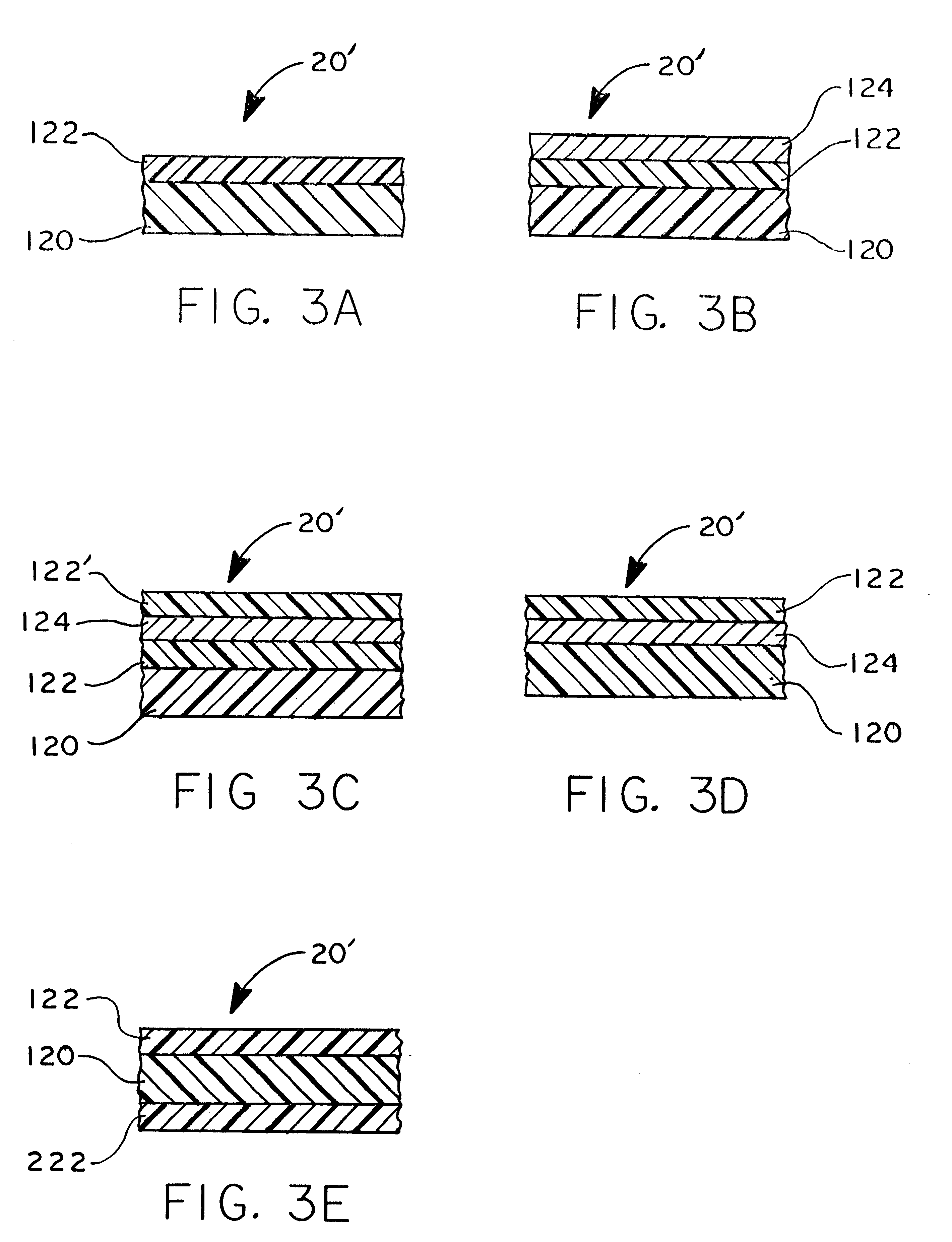

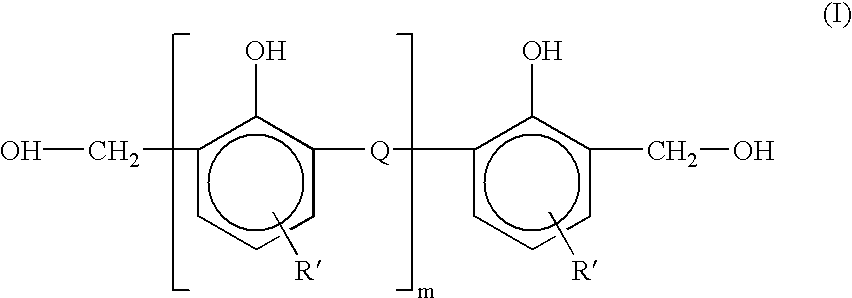

Method of forming a hybrid polymer film

InactiveUS6214422B1Fine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-liked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

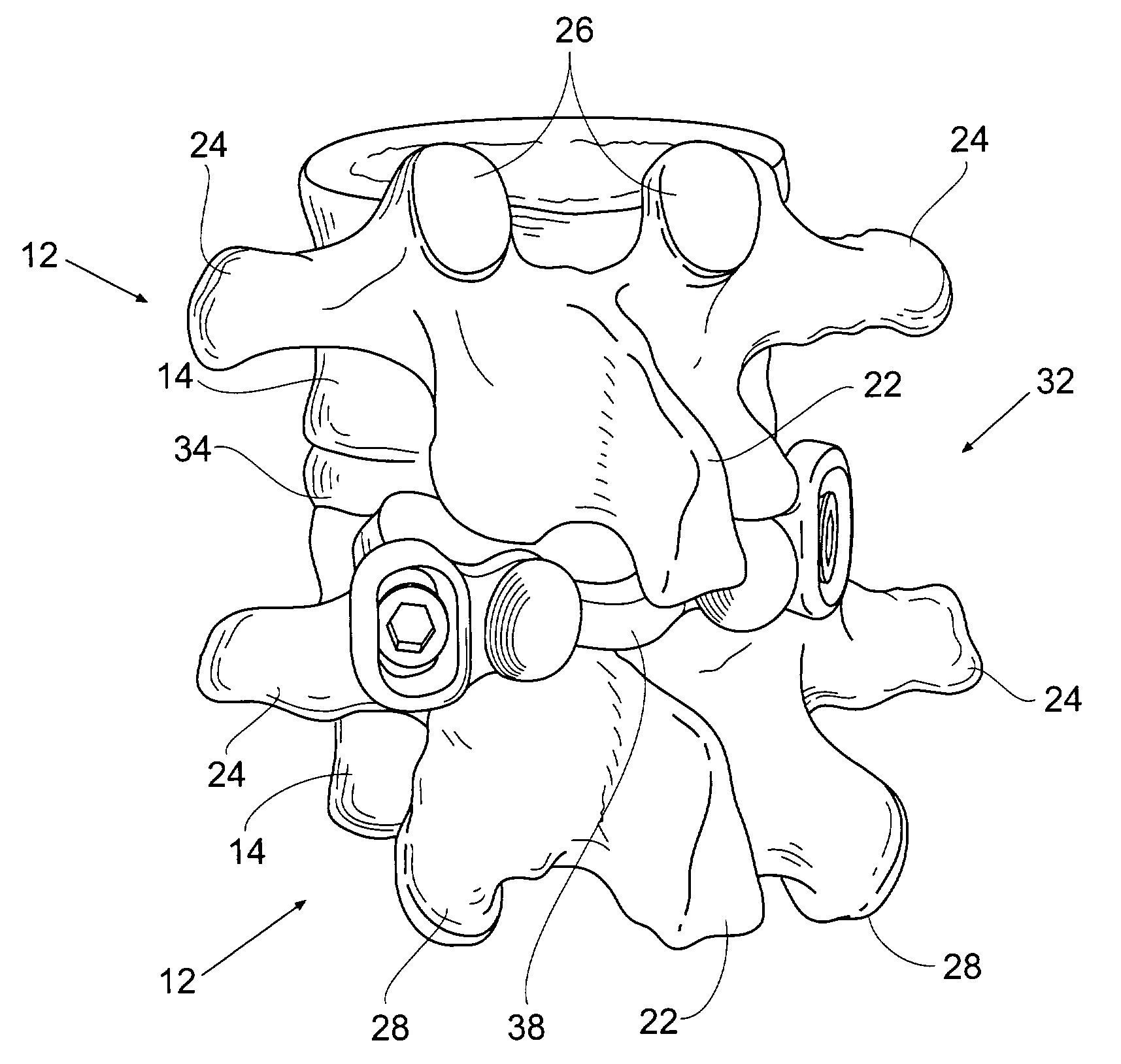

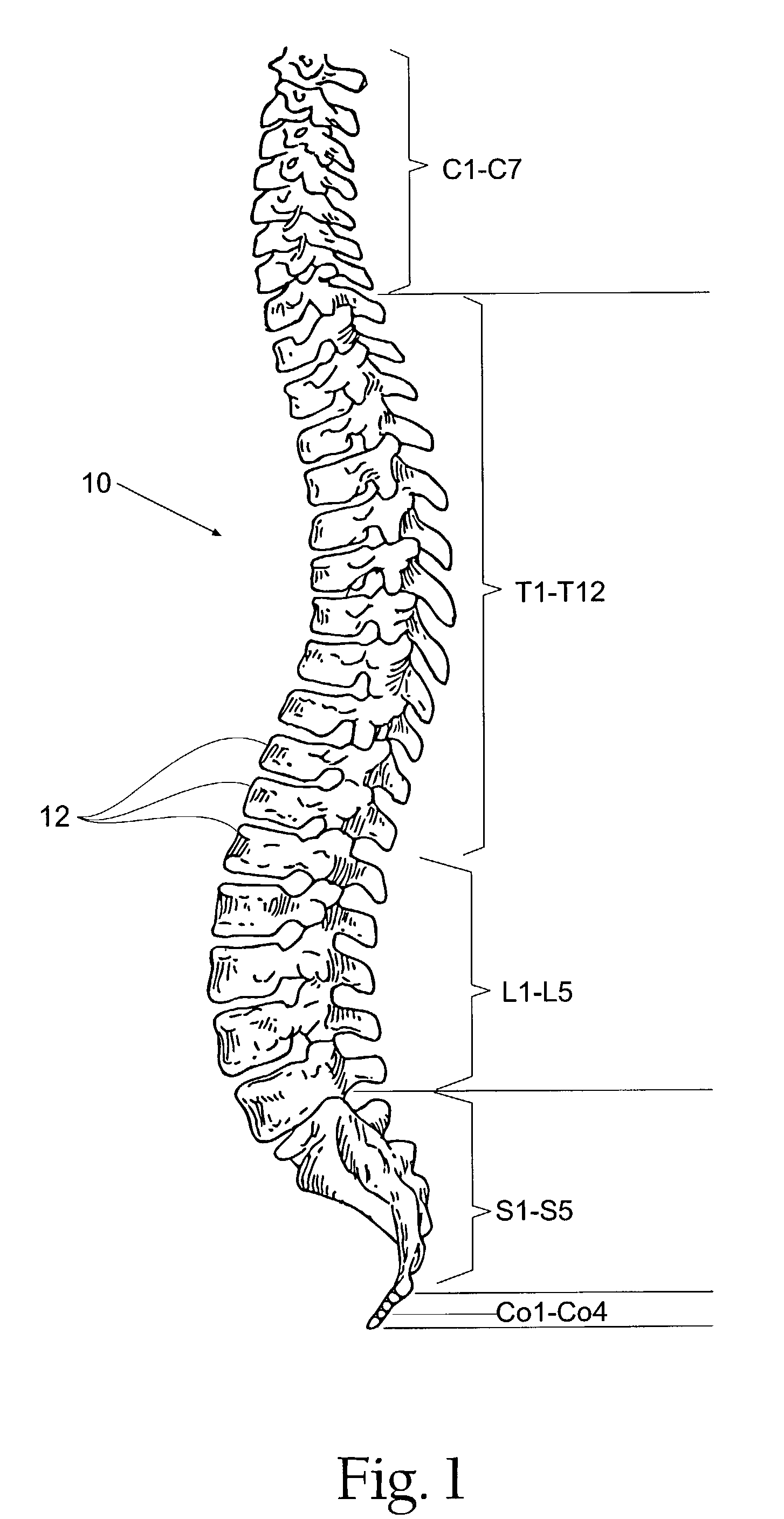

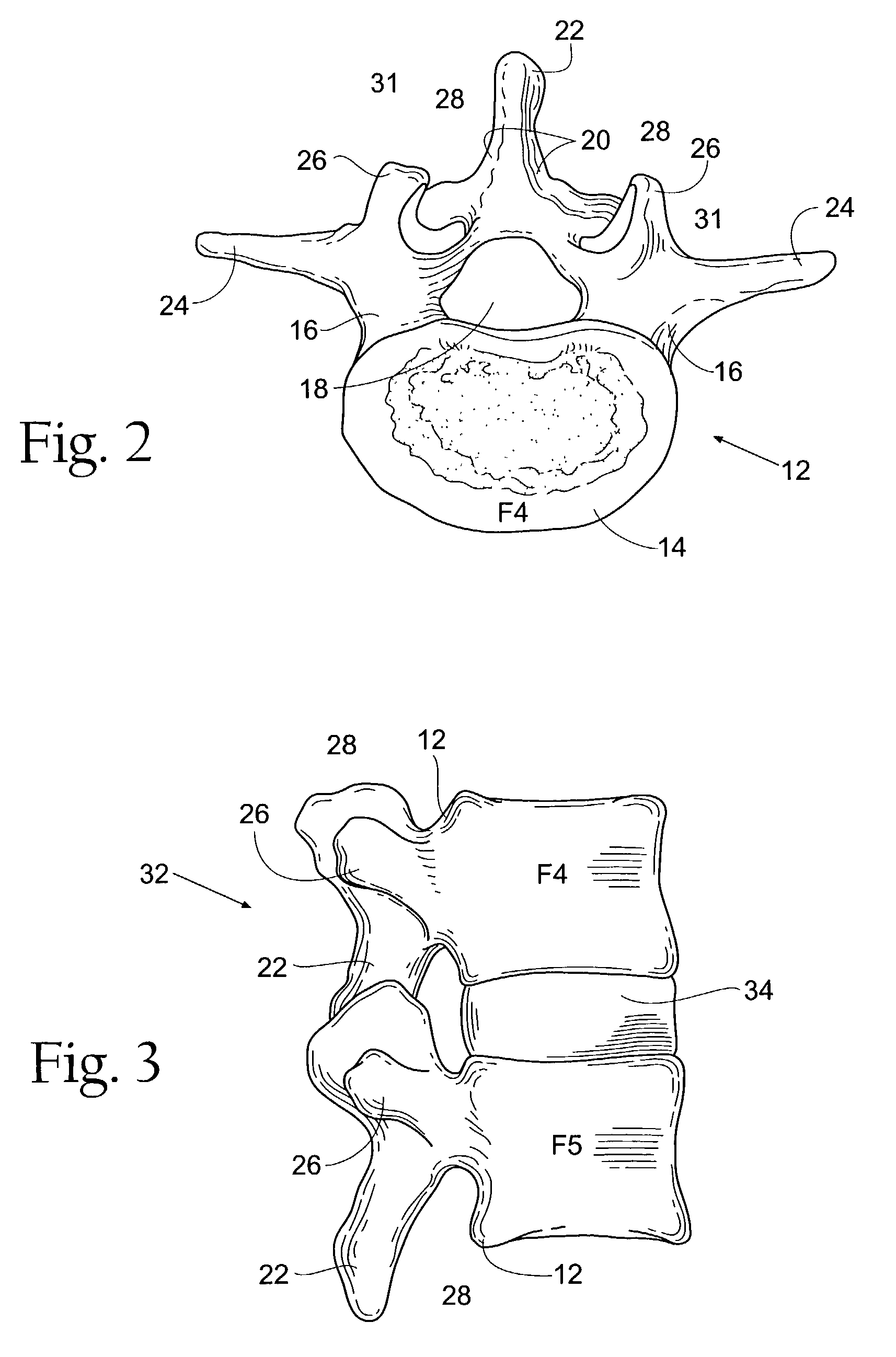

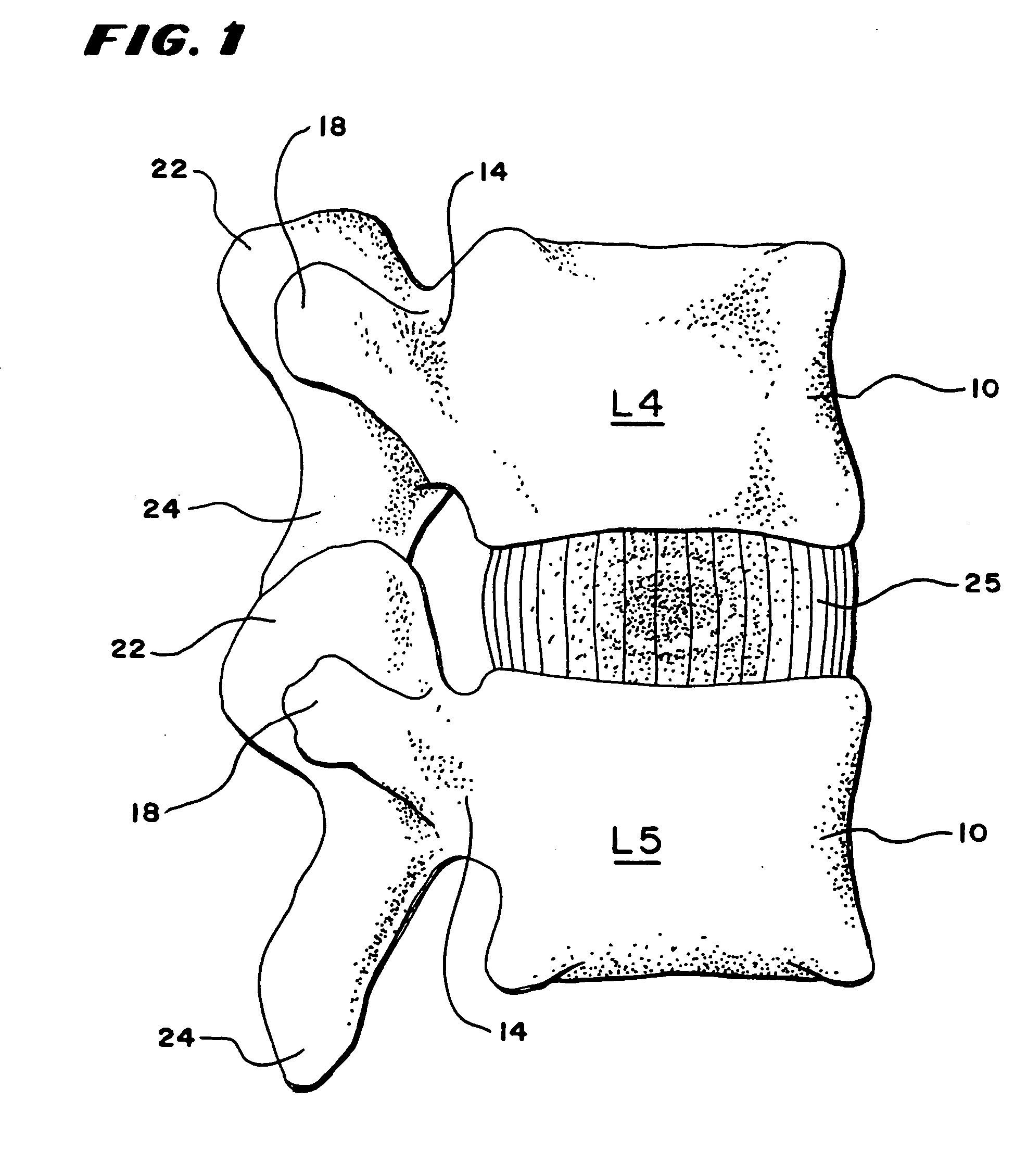

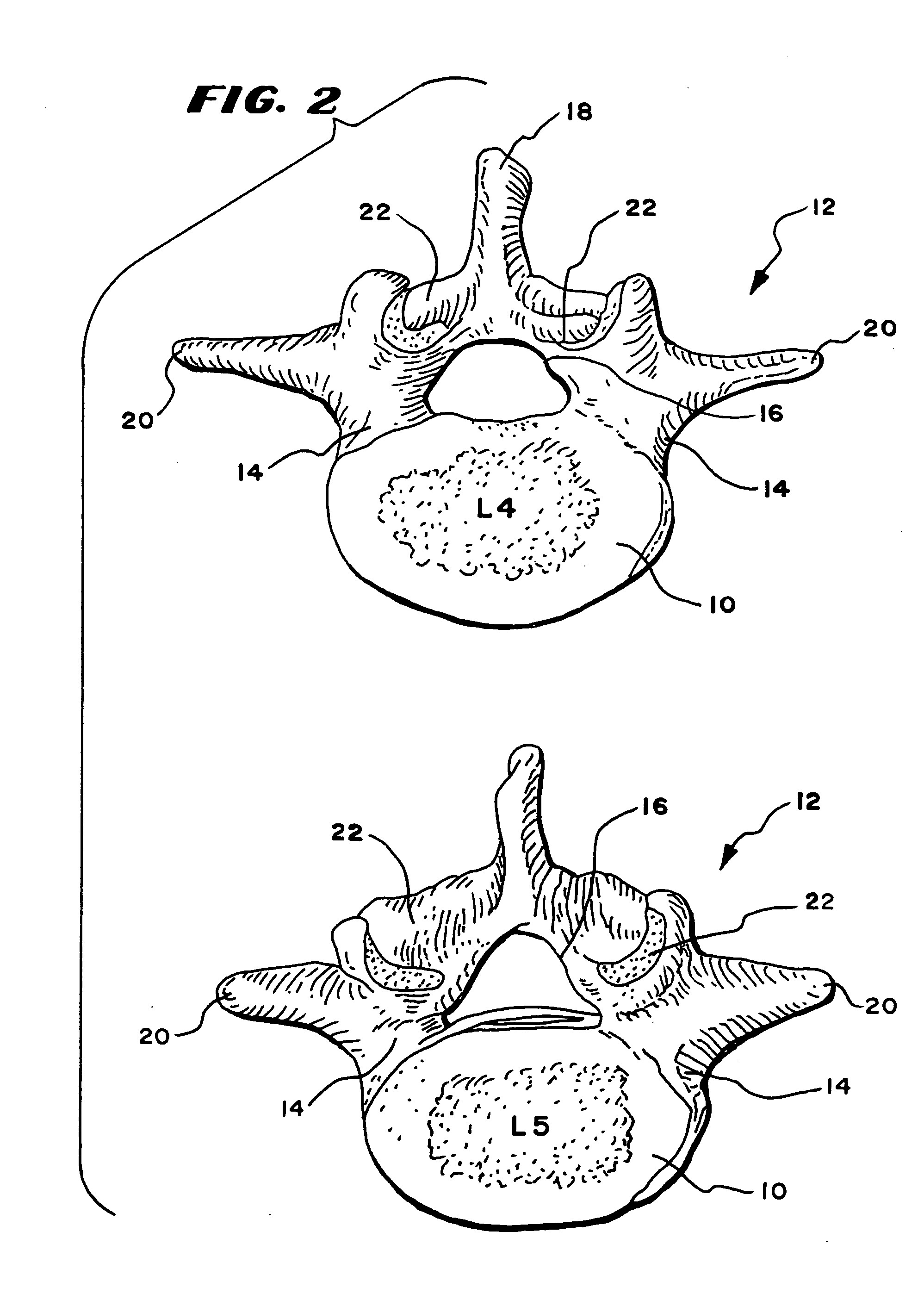

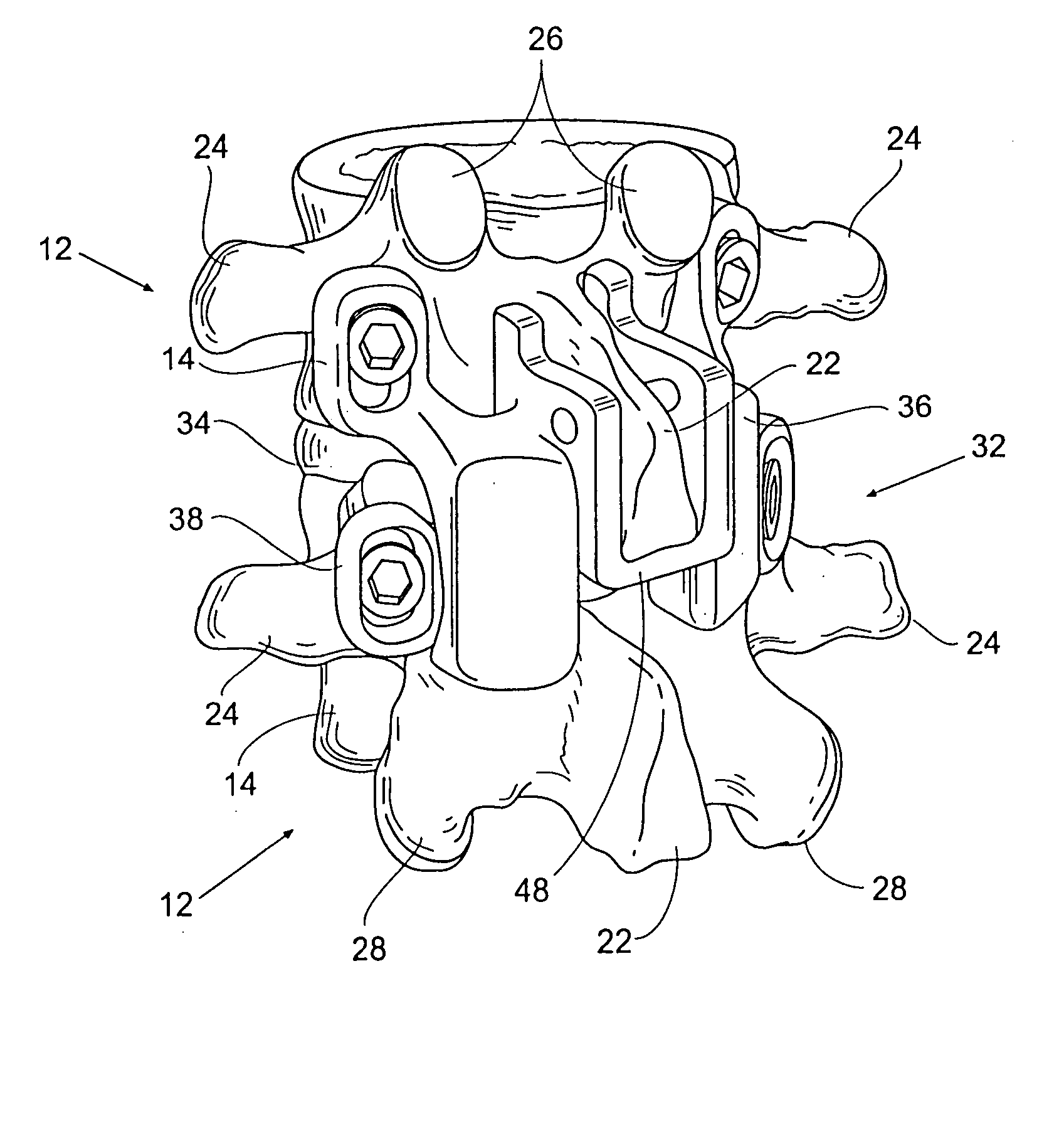

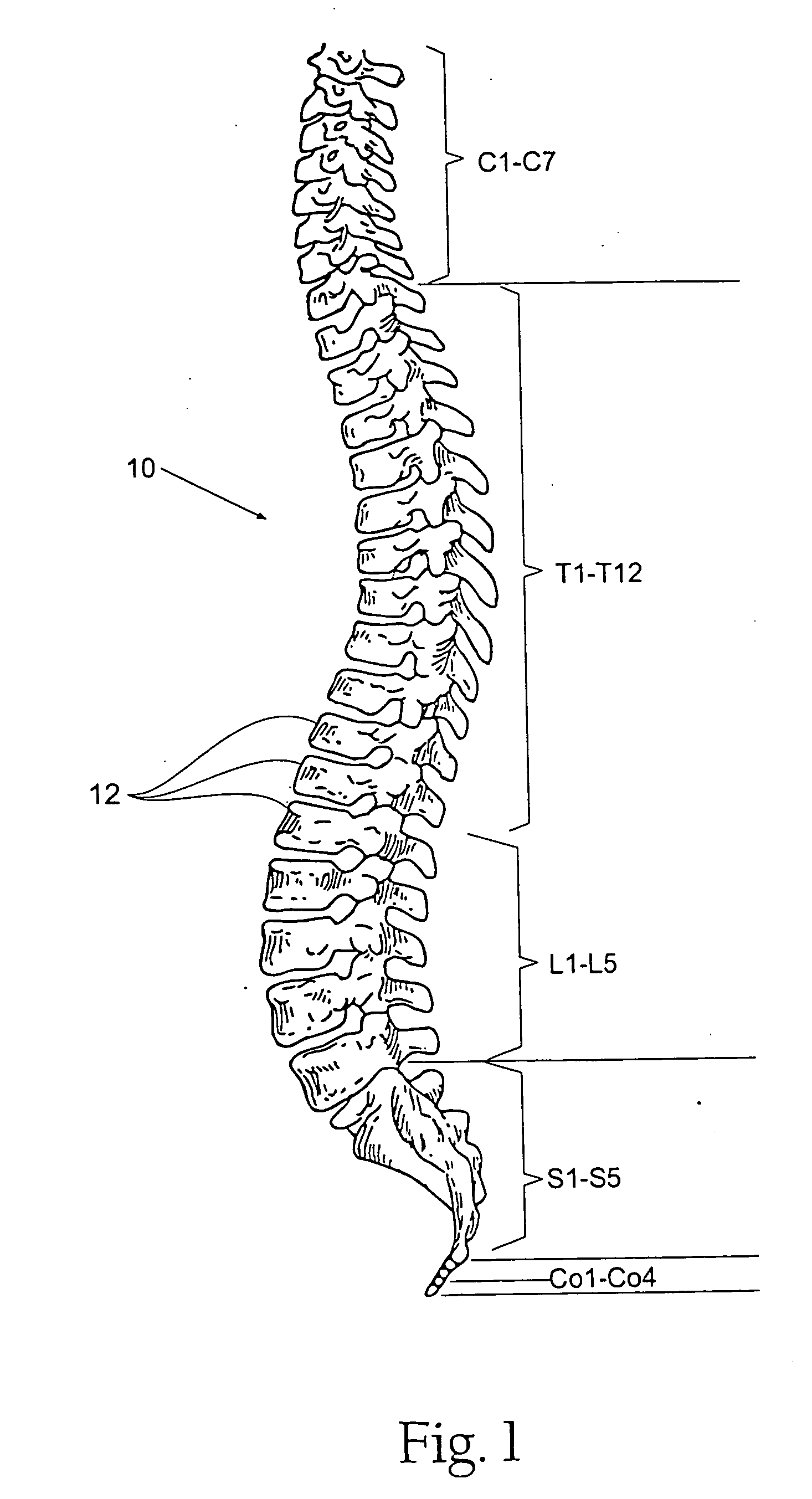

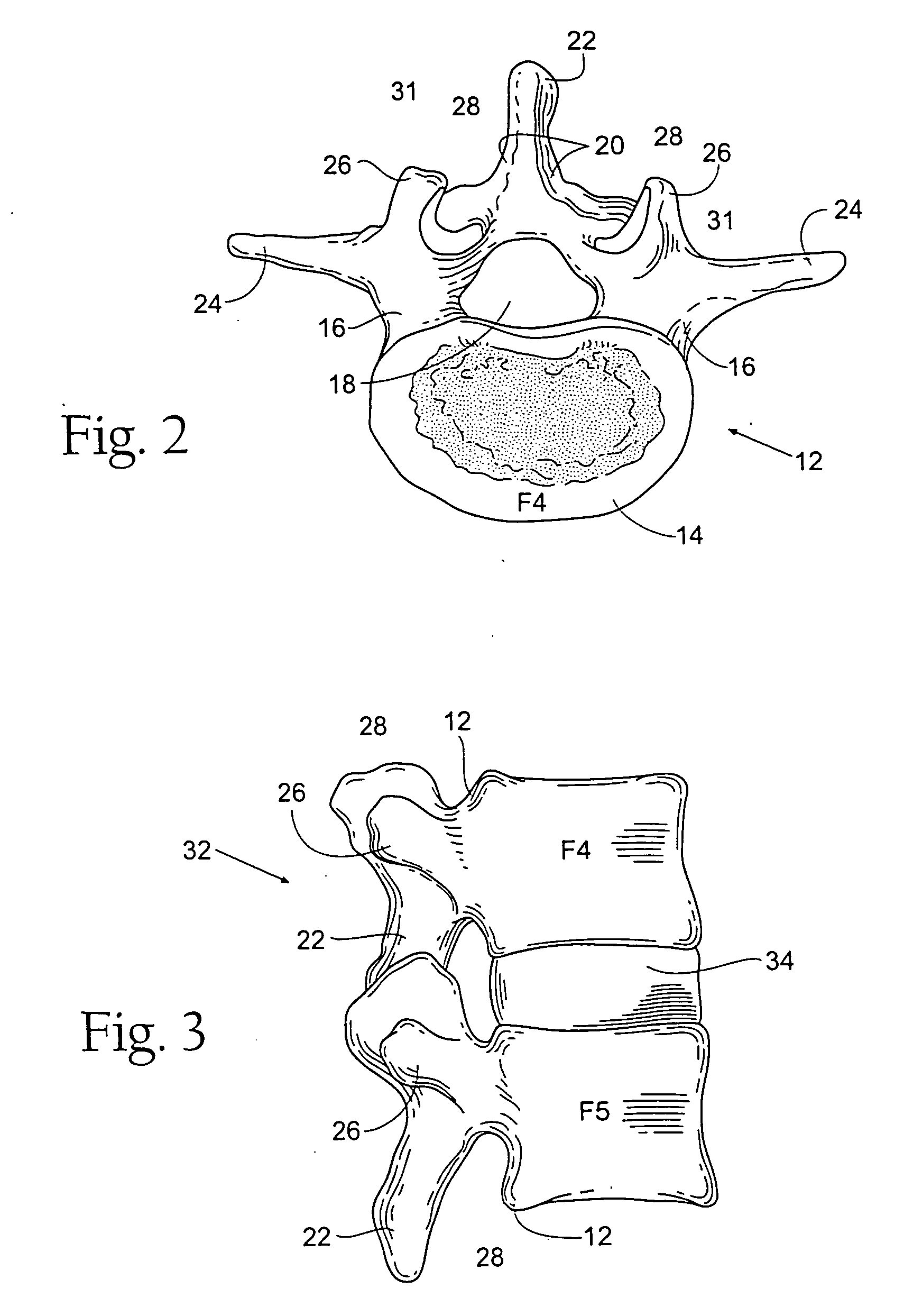

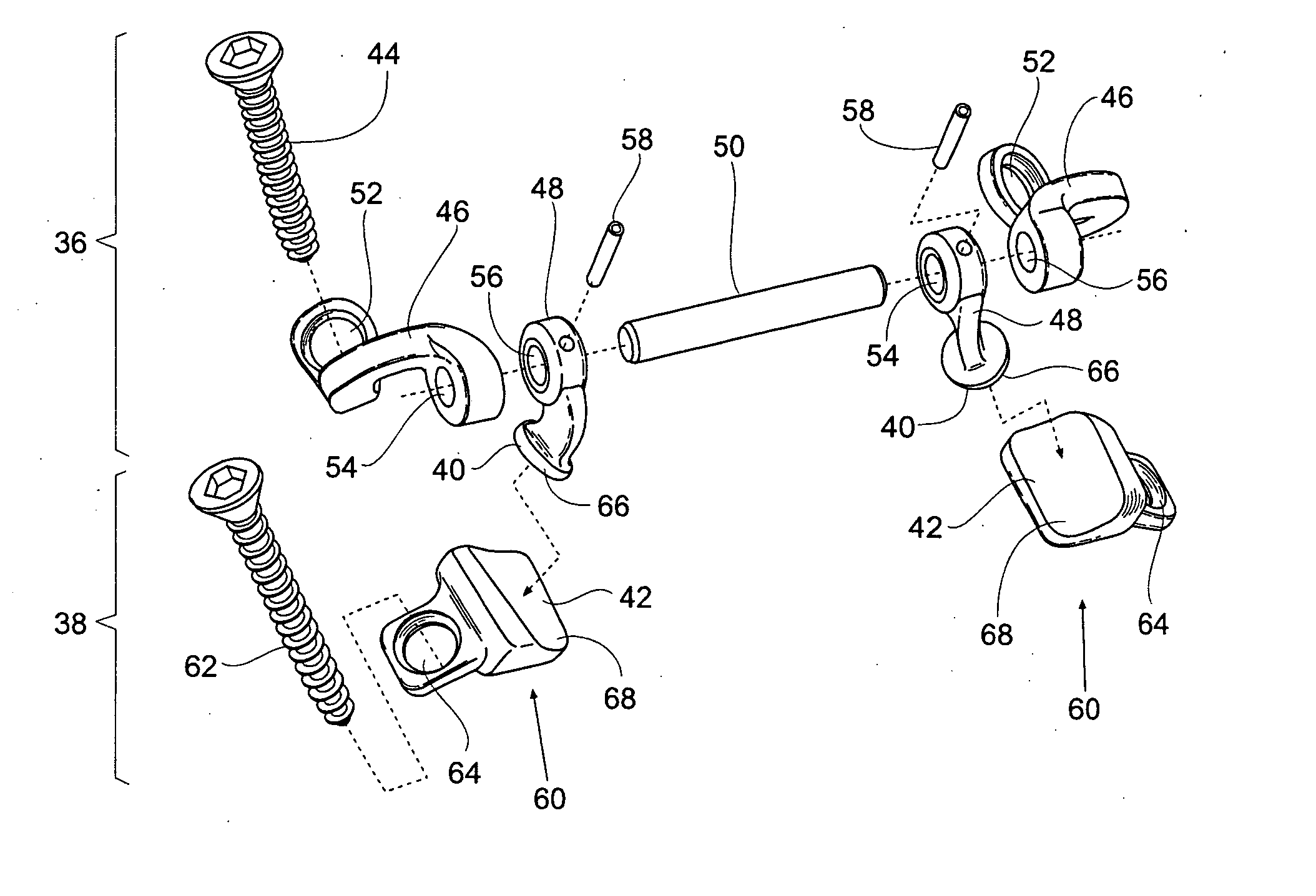

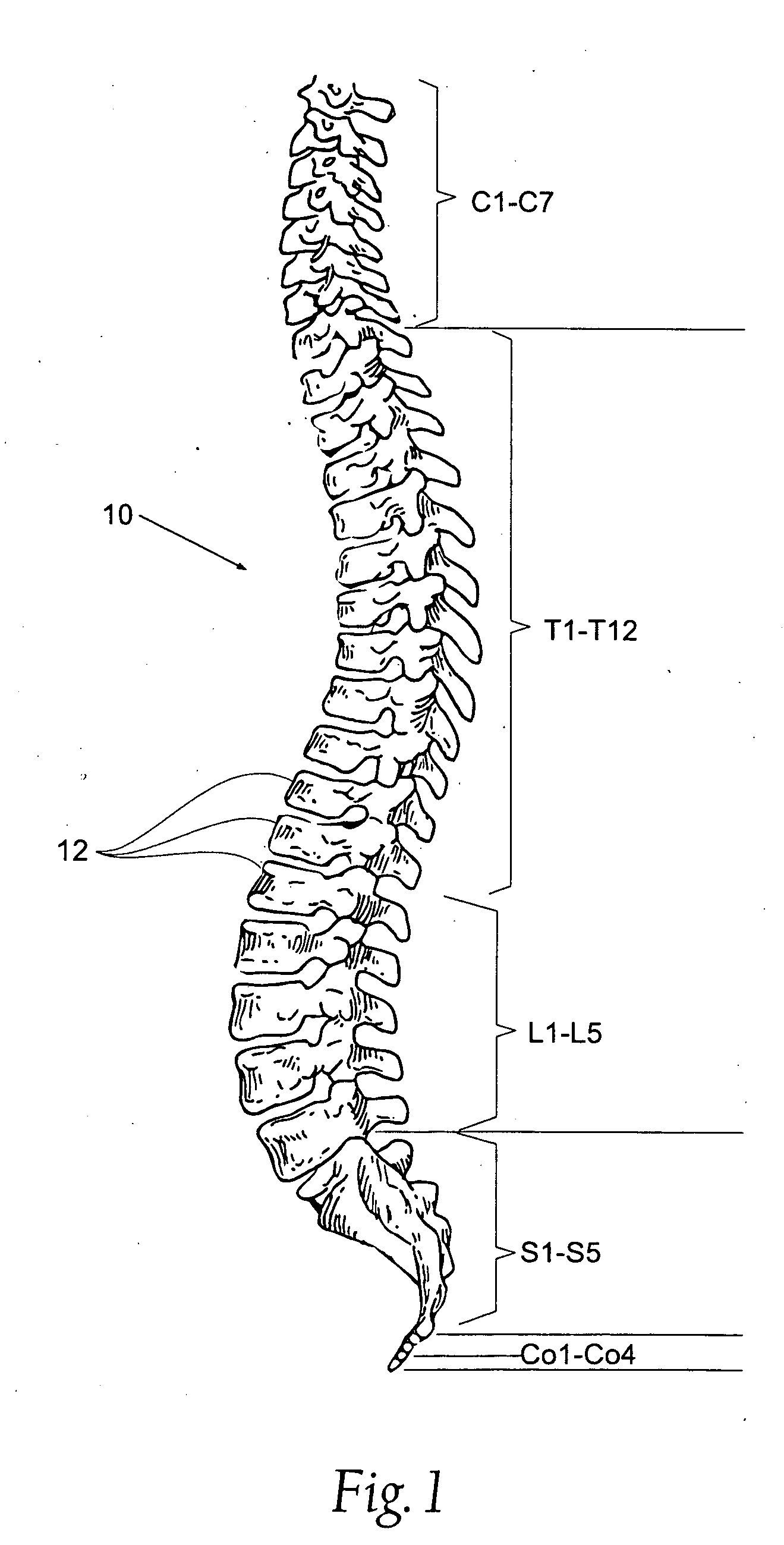

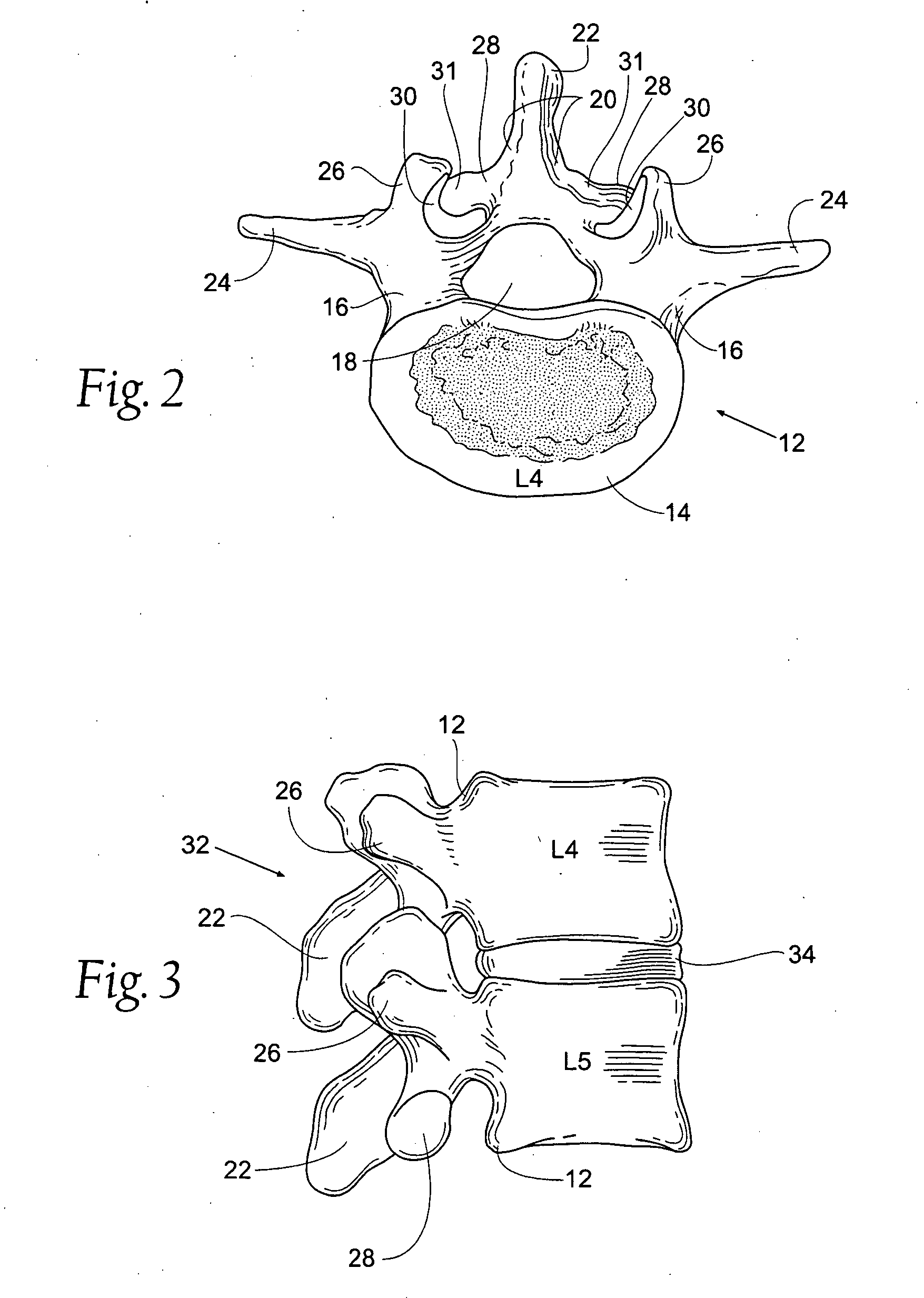

Prostheses, systems and methods for replacement of natural facet joints with artificial facet joint surfaces

InactiveUS6974478B2Desired range of mobilityLessen and alleviate spinal painSuture equipmentsInternal osteosythesisArticular surfacesSpinal column

Cephalad and caudal vertebral facet joint prostheses and methods of use are provided. The prostheses provide an artificial facet joint structure including an artificial articular configuration unlike the preexisting articular configuration. The radii and material stress values of the prostheses are configured to sustain contact stress. The cephalad prosthesis provides for posterior-anterior adjustment. Both prostheses permit lateral adjustment and adjustment to accomodate interpedicle distance. Further, the prostheses may be customized to provide a pre-defined lordotic angle and a pre-defined pedicle entry angle.

Owner:GLOBUS MEDICAL INC

Safe liquid source containers

ActiveUS7156380B2Encouraging capillary migrationFine surfaceCarburetting airMixing methodsPorous membraneProduct gas

Containers for providing vapor phase reactant from liquid sources include bubbler designs and designs in which carrier gas flows over the liquid surface. Among the bubbler arrangements, a bypass conductance is provided to release excess pressure from the gas volume inside the container, or an enlarged bubbler tube is provided with a volume sufficient to accommodate all possible liquid backflow without having the liquid exit the container. Among the overflow designs, flow dividers provide a tortuous path for the gas to increase the time exposure of carrier gas packets to the evaporating liquid surface. The flow dividers can be microporous to encourage capillary action, thereby increasing the evaporating surface. The tortuous gas flow path can be separated from the liquid phase by a breathable semi-porous membrane that permits vapor phase reactant to pass through but prohibits liquid from passing in the other direction.

Owner:ASM INTERNATIONAL

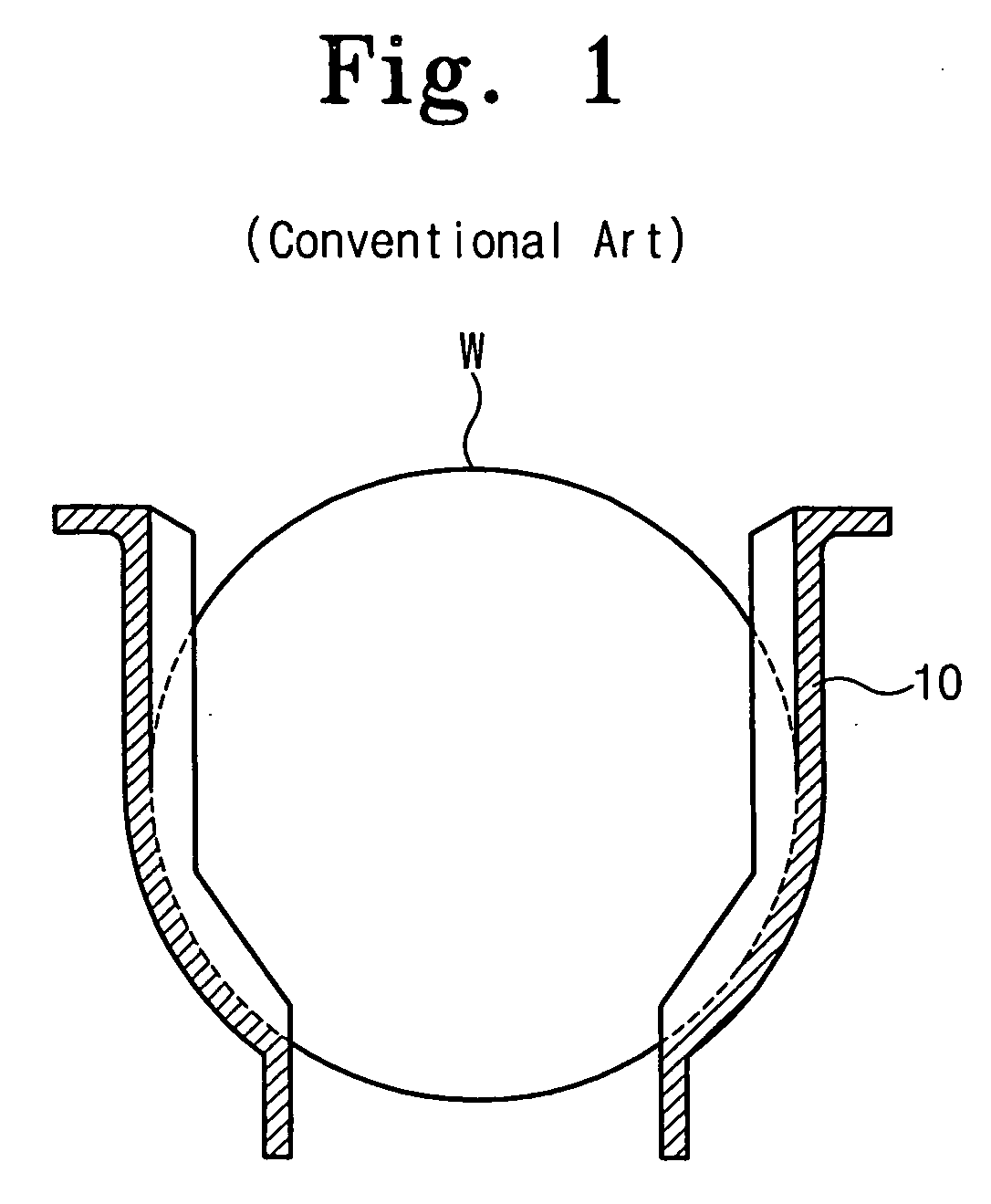

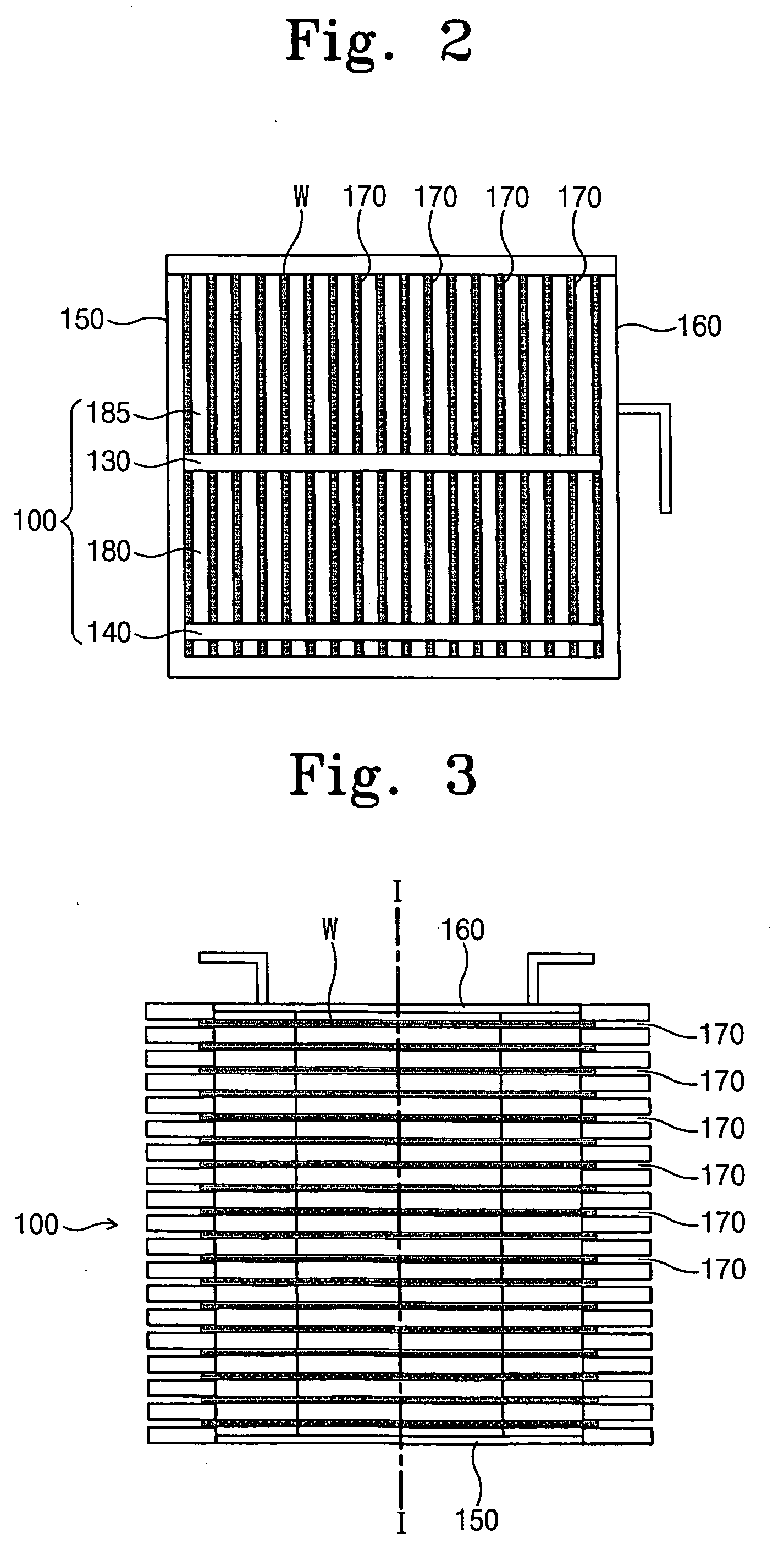

Wafer carrier for minimizing contacting area with wafers

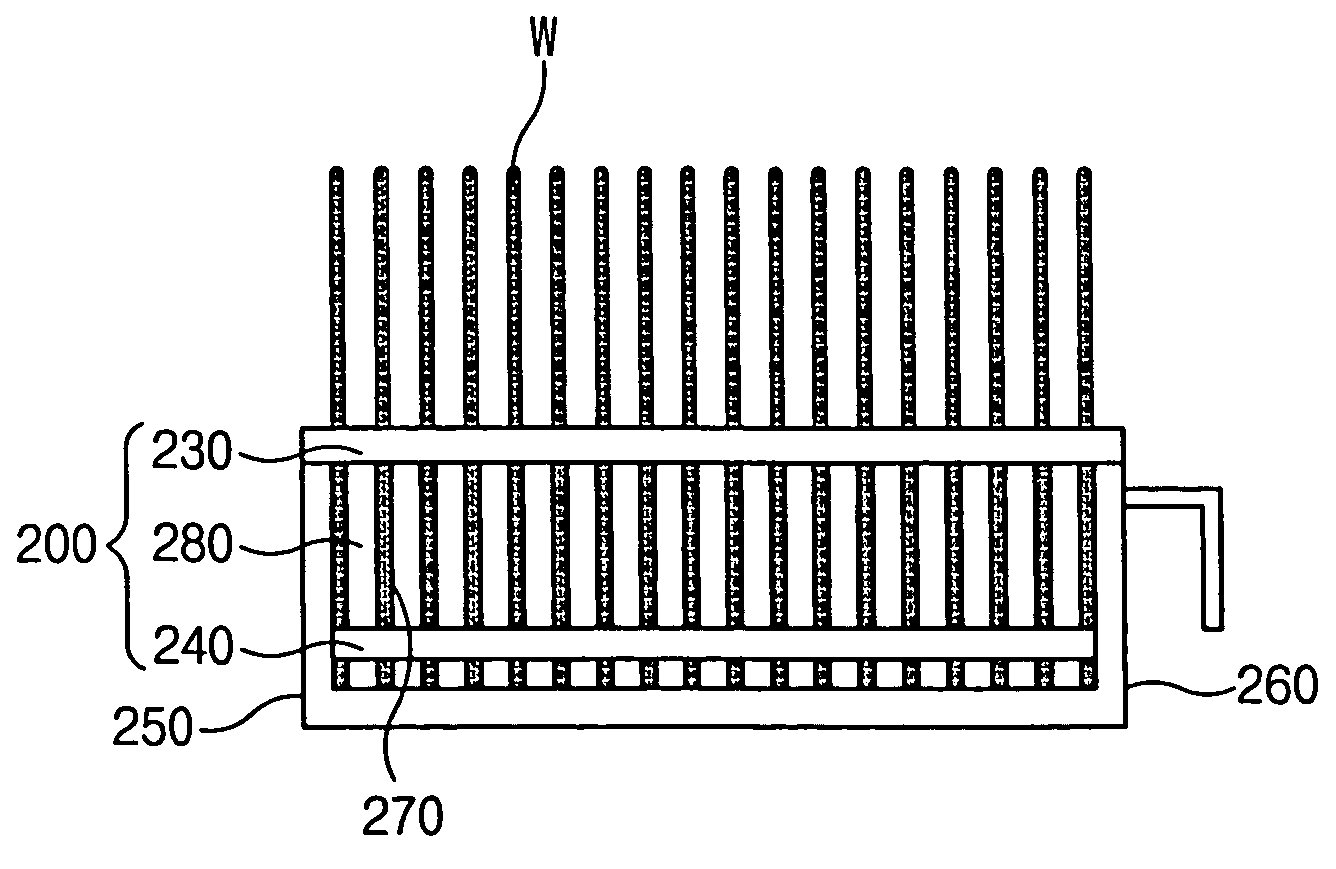

InactiveUS20060216942A1Reduce direct contact areaReduce generationSemiconductor/solid-state device manufacturingPackaging toiletriesEngineeringFront and back ends

A wafer carrier is provided. The wafer carrier includes a storage holding member for storing a plurality of wafers and includes a plurality of open portions. The wafer carrier further includes a front fixing plate and a rear fixing plate disposed at a front and a rear end of the storage holding member, respectively. The front and rear fixing plates each face a side of at least one of the plurality of wafers. Moreover, left and right edges of the plurality of wafers stored in the storage holding member are exposed by the plurality of open portions.

Owner:SAMSUNG ELECTRONICS CO LTD

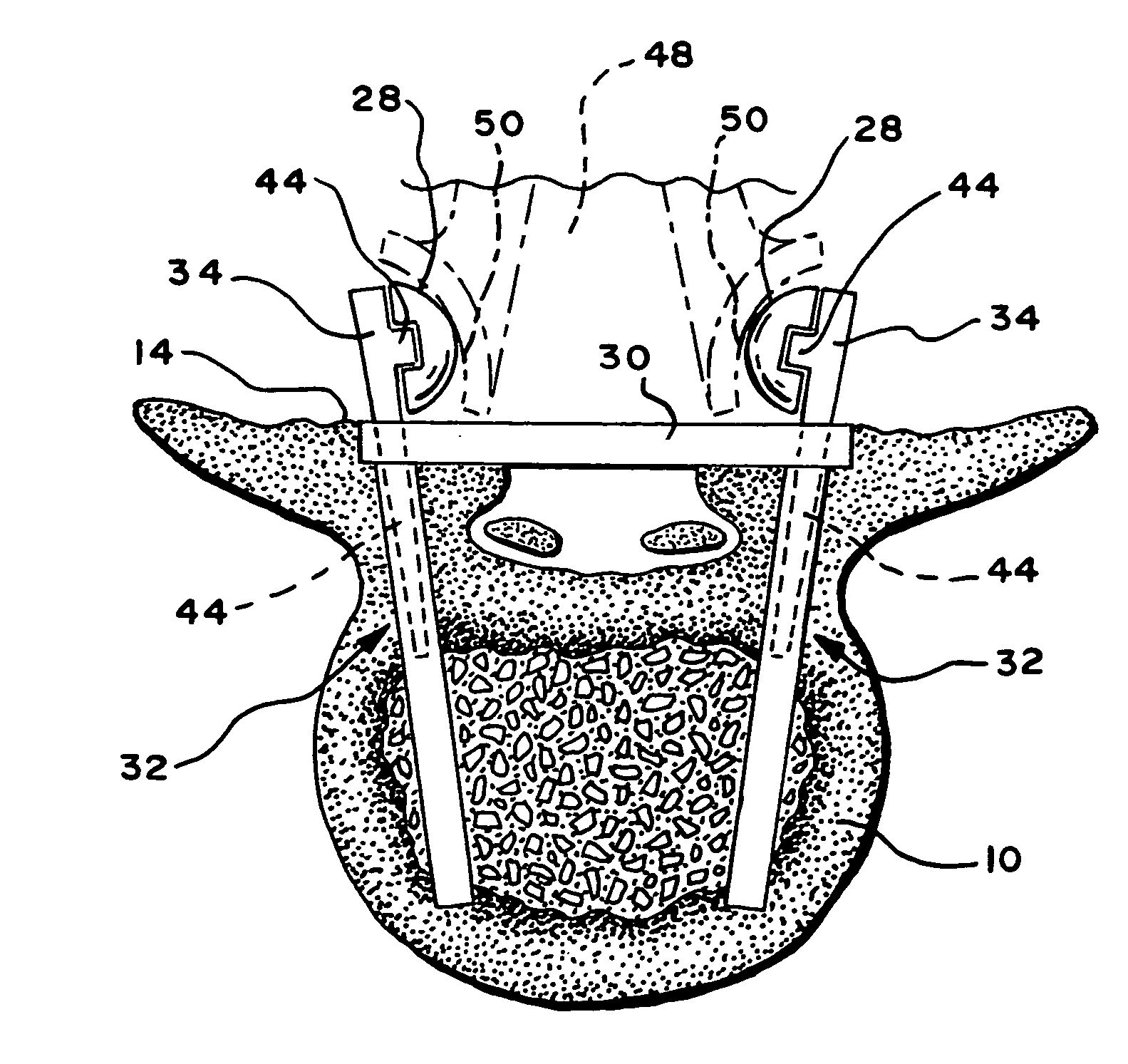

Facet arthroplasty devices and methods

InactiveUS20050043799A1Alleviating and eliminating painIncidence can be reduced and eliminatedInternal osteosythesisBone implantProsthesisFacet arthroplasty

Surgically installed prostheses replace either the caudal portion of a natural facet joint, the cephalad portion of a natural facet joint, or both. The prostheses are readily attached to the pedicles of a vertebral body and support at least one element that defines an artificial facet joint structure. The caudal facet joint structure is sized and located to articulate with the cephalad facet joint structure. Together, the prostheses form a total facet replacement system. The system is suitable for use in virtually all levels of the spine.

Owner:FACET SOLUTIONS

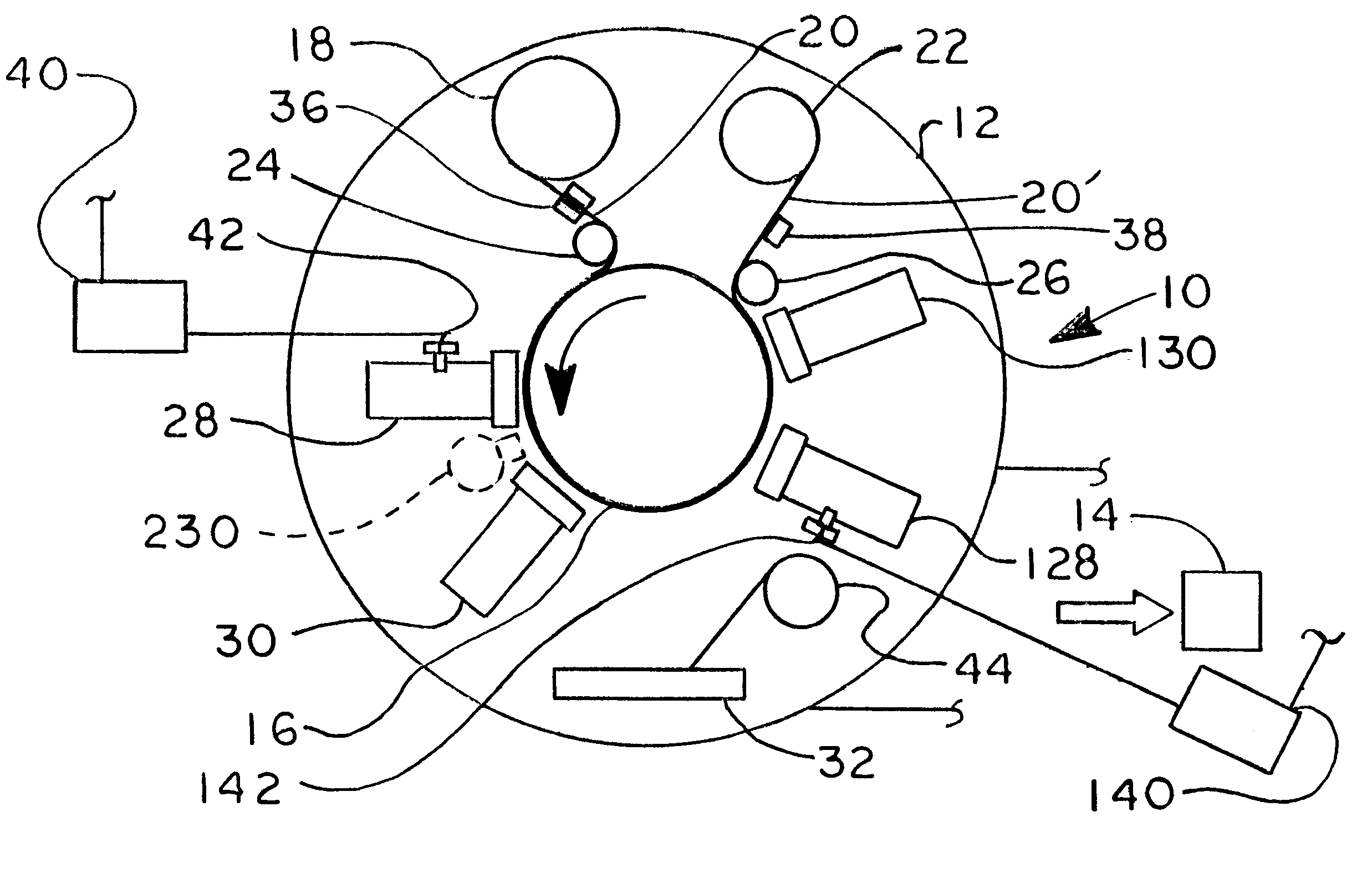

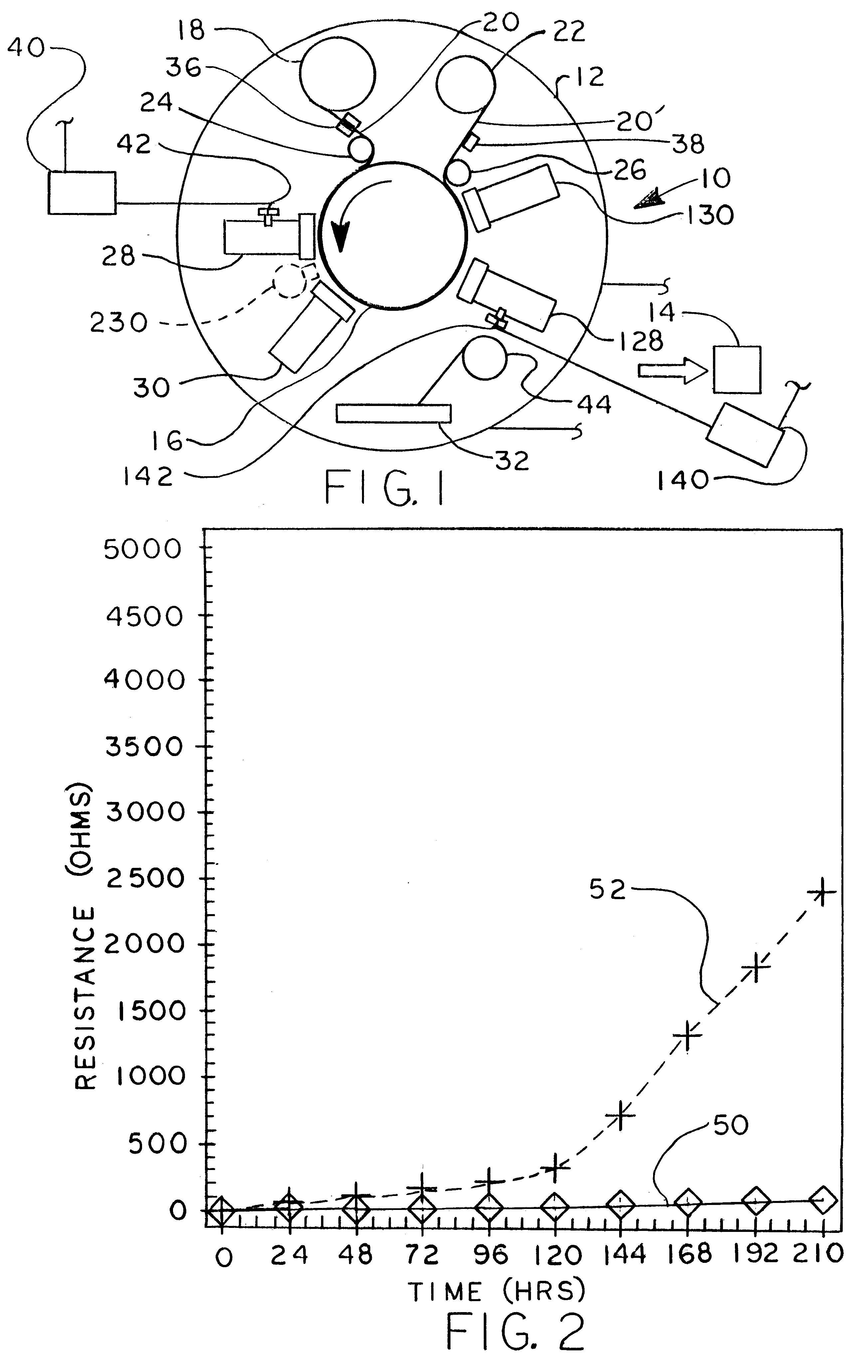

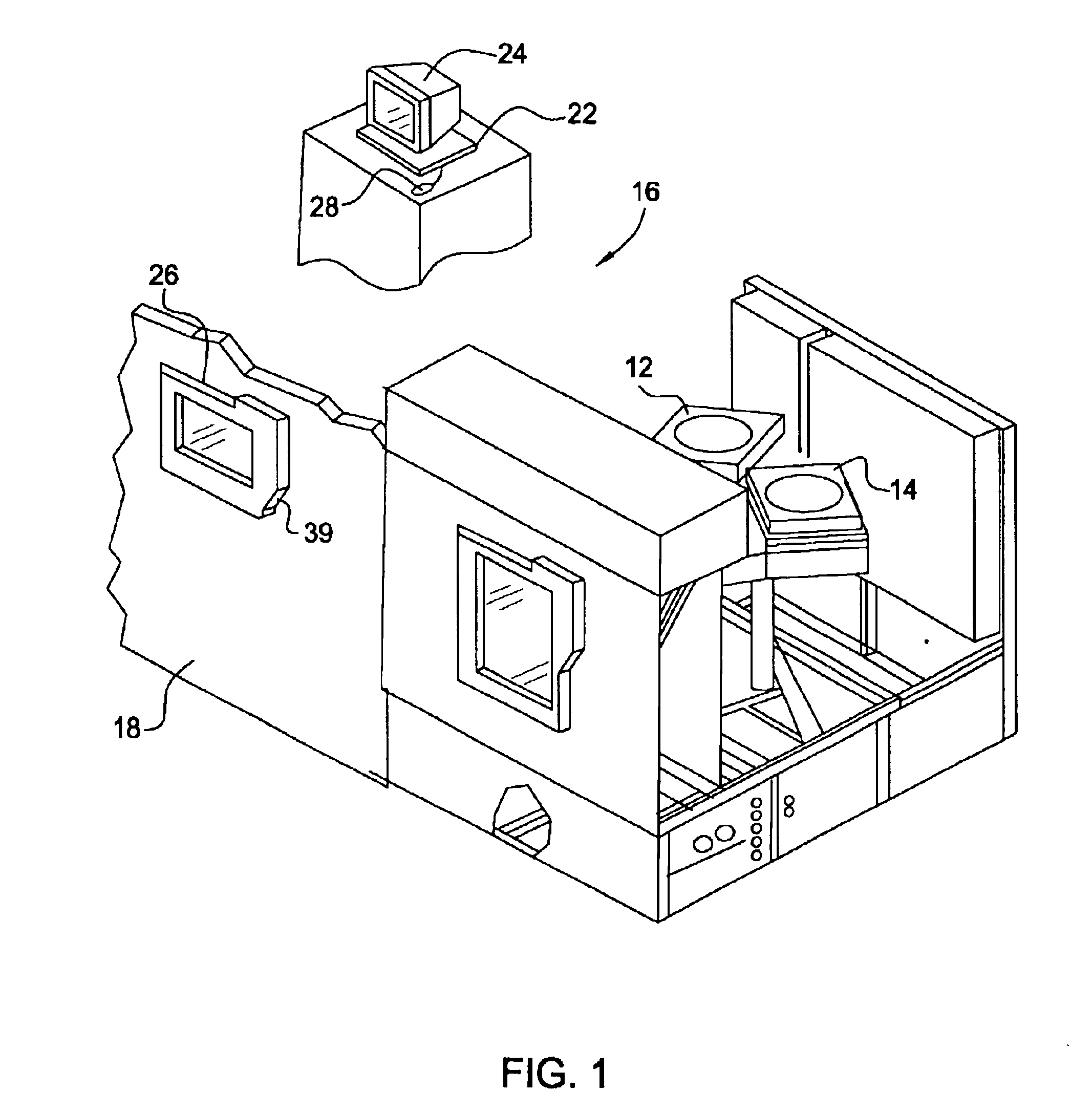

Atmospheric pressure molecular layer CVD

InactiveUS20050084610A1Reducing physisorptionHigh purityChemical vapor deposition coatingChemical physicsControl system

An Atomic Layer CVD process and apparatus deposits single and or multiple minelayers of material sequentially at atmospheric pressure. Sequential monolayer depositions are separated in time and in space by combinations of physical barriers and / or gas curtains and / or by physical movement of substrates from one deposition chamber or location to another Pulse and / or continuous flows of reactant and purge gases are used in alternate embodiments of the present invention. Reactant injection, purge gas flow and exhaust flows at separated deposition chambers or locations are controlled by coordination of dedicated gas manifolds and control systems for each spatially or temporally separated deposition process or location.

Owner:SELITSER SIMON I

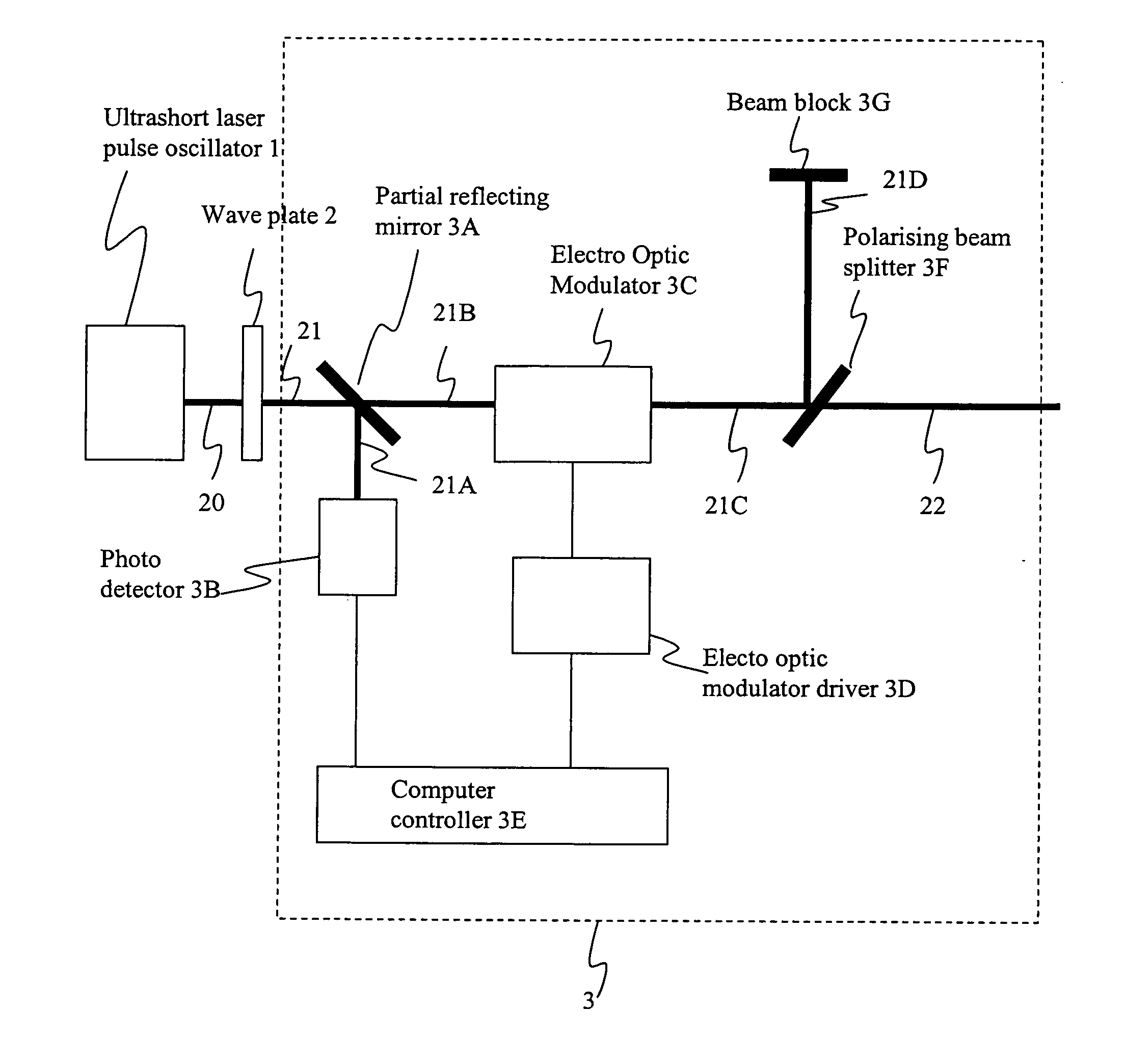

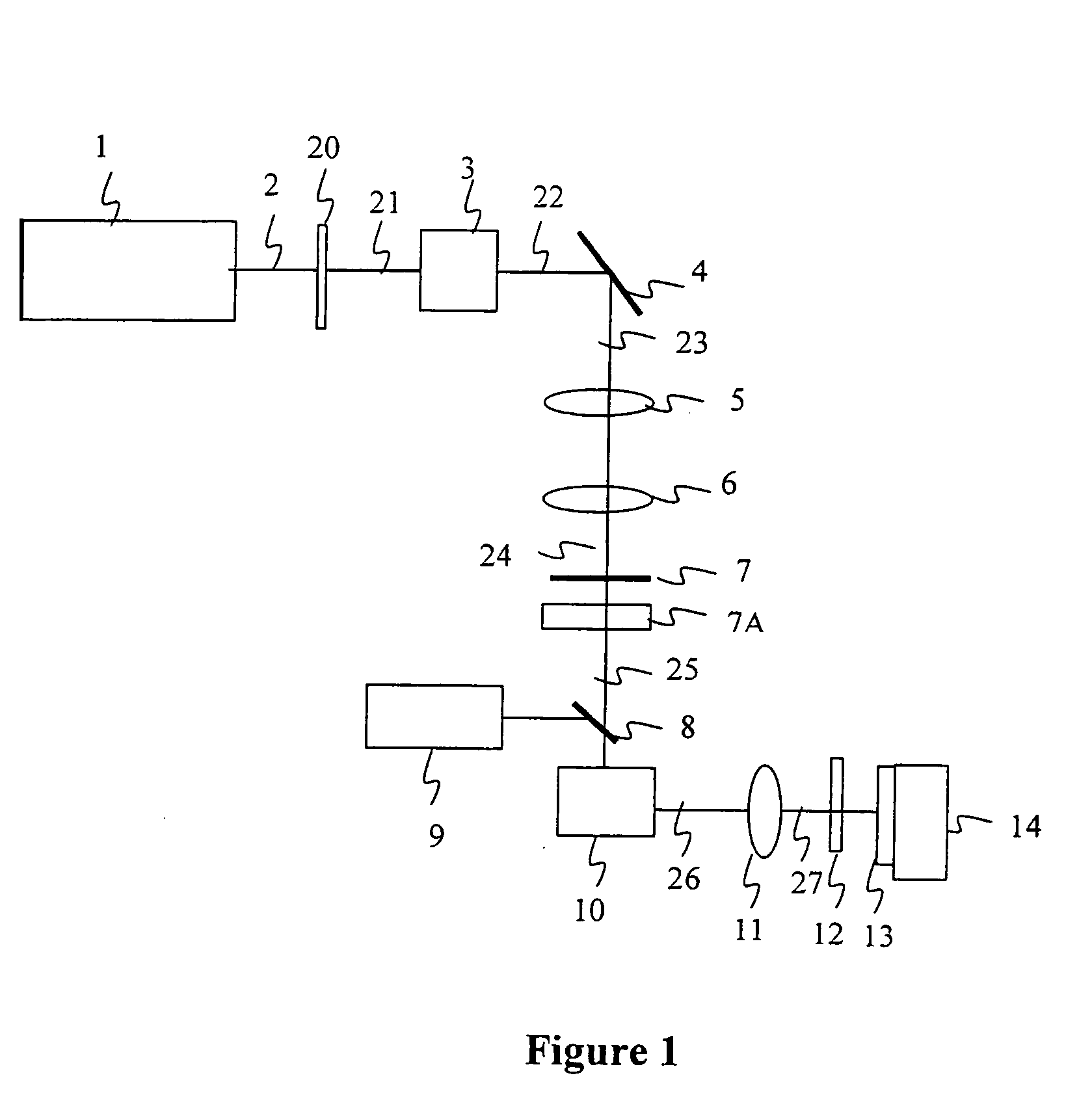

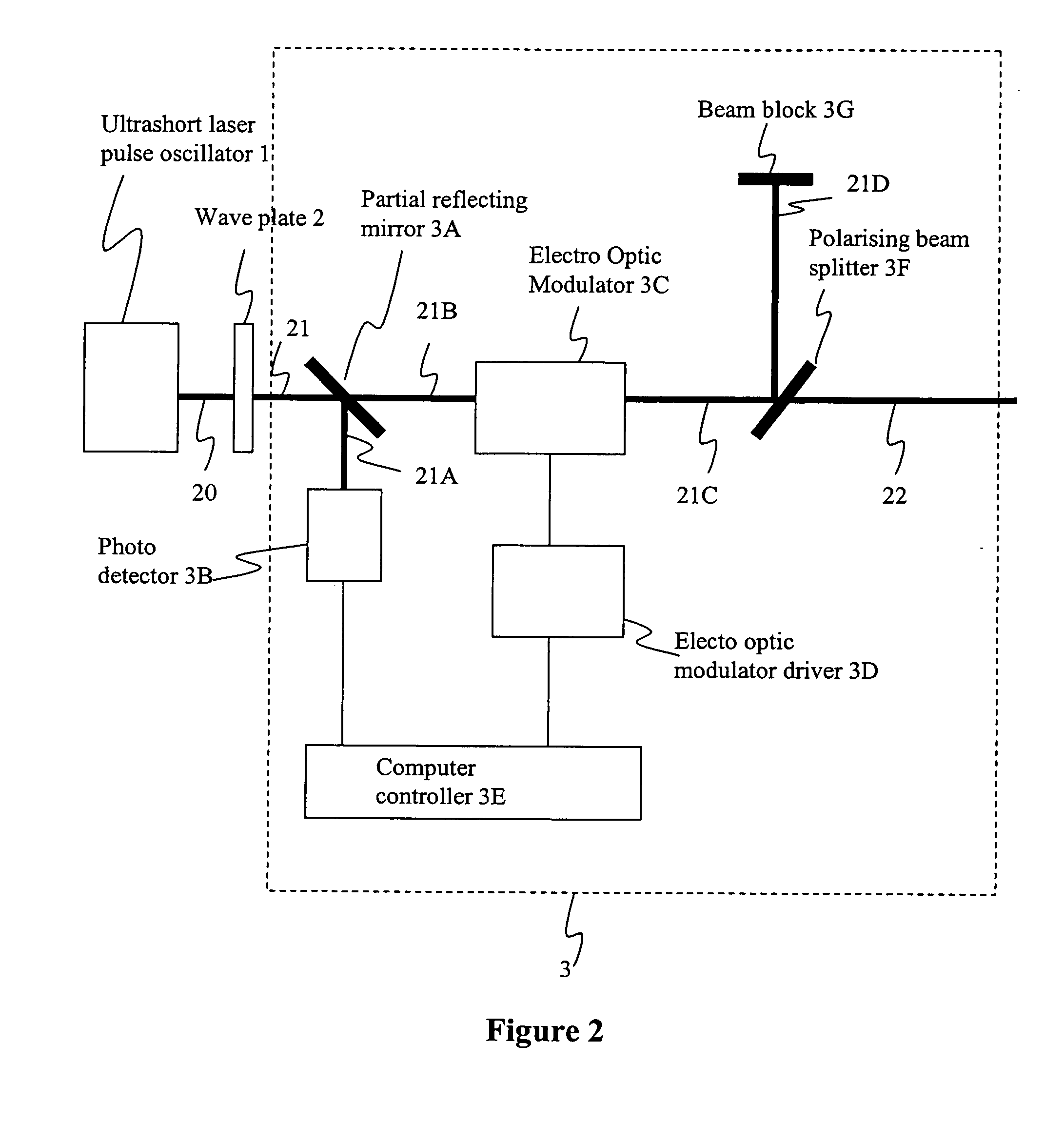

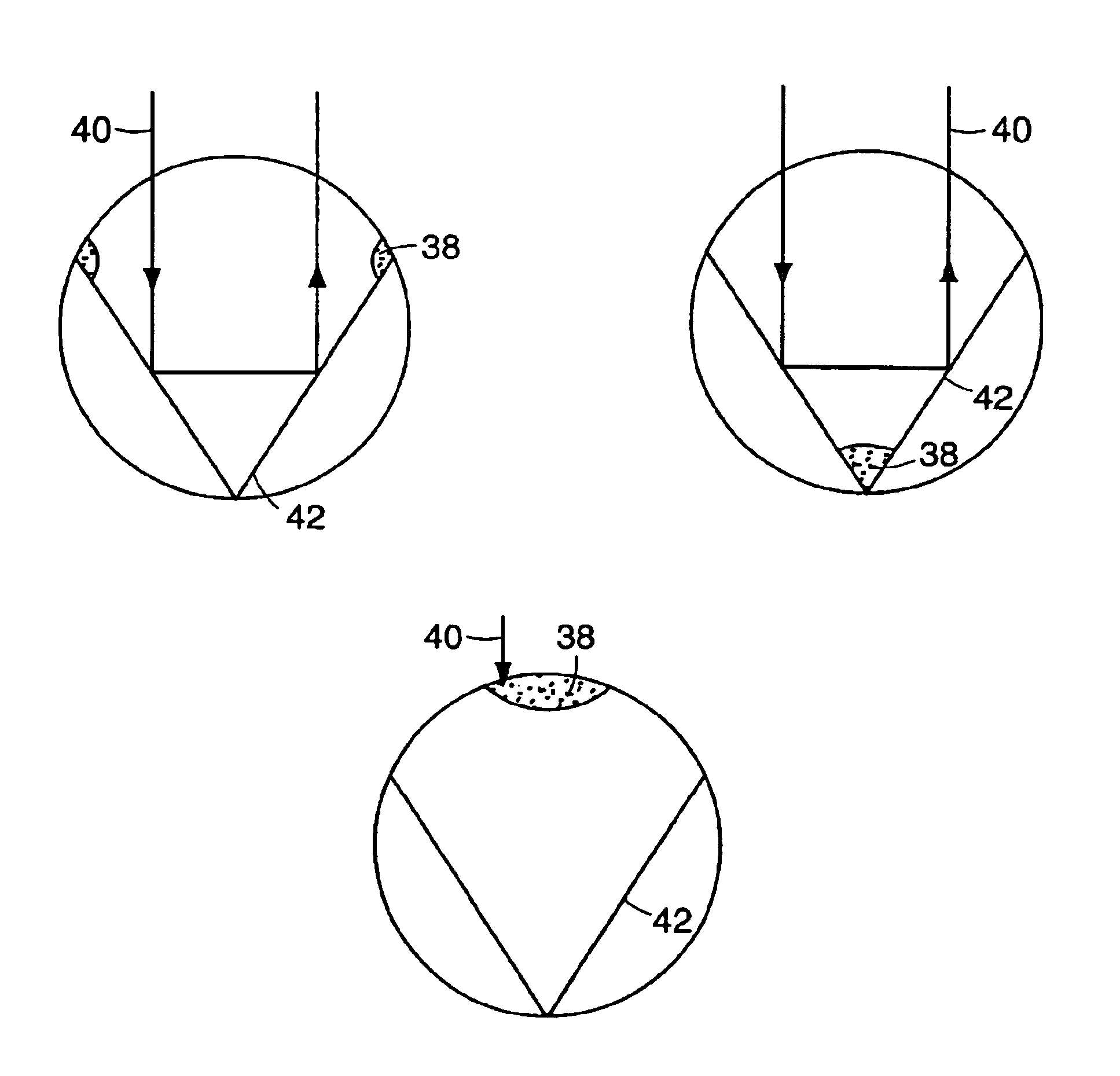

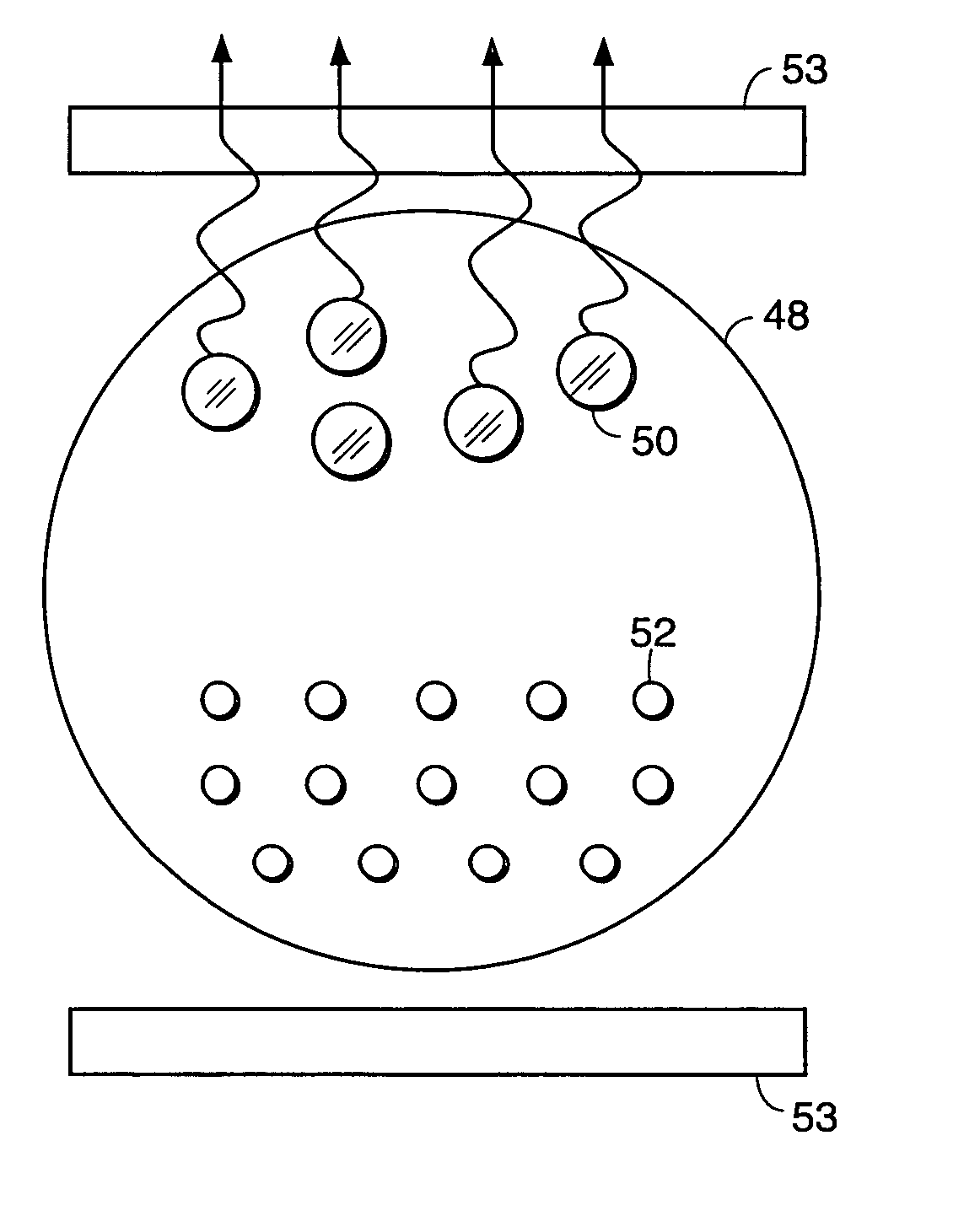

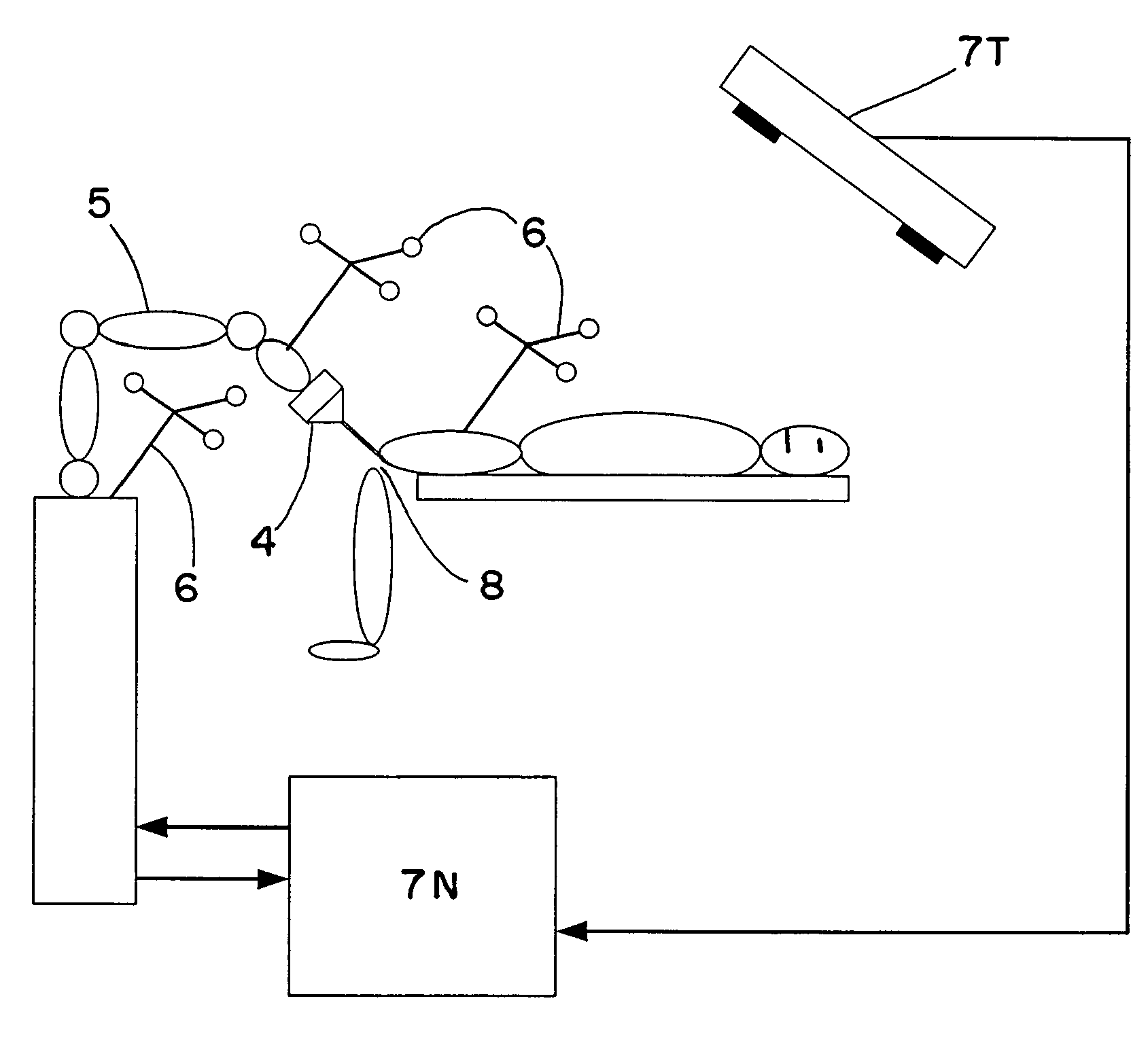

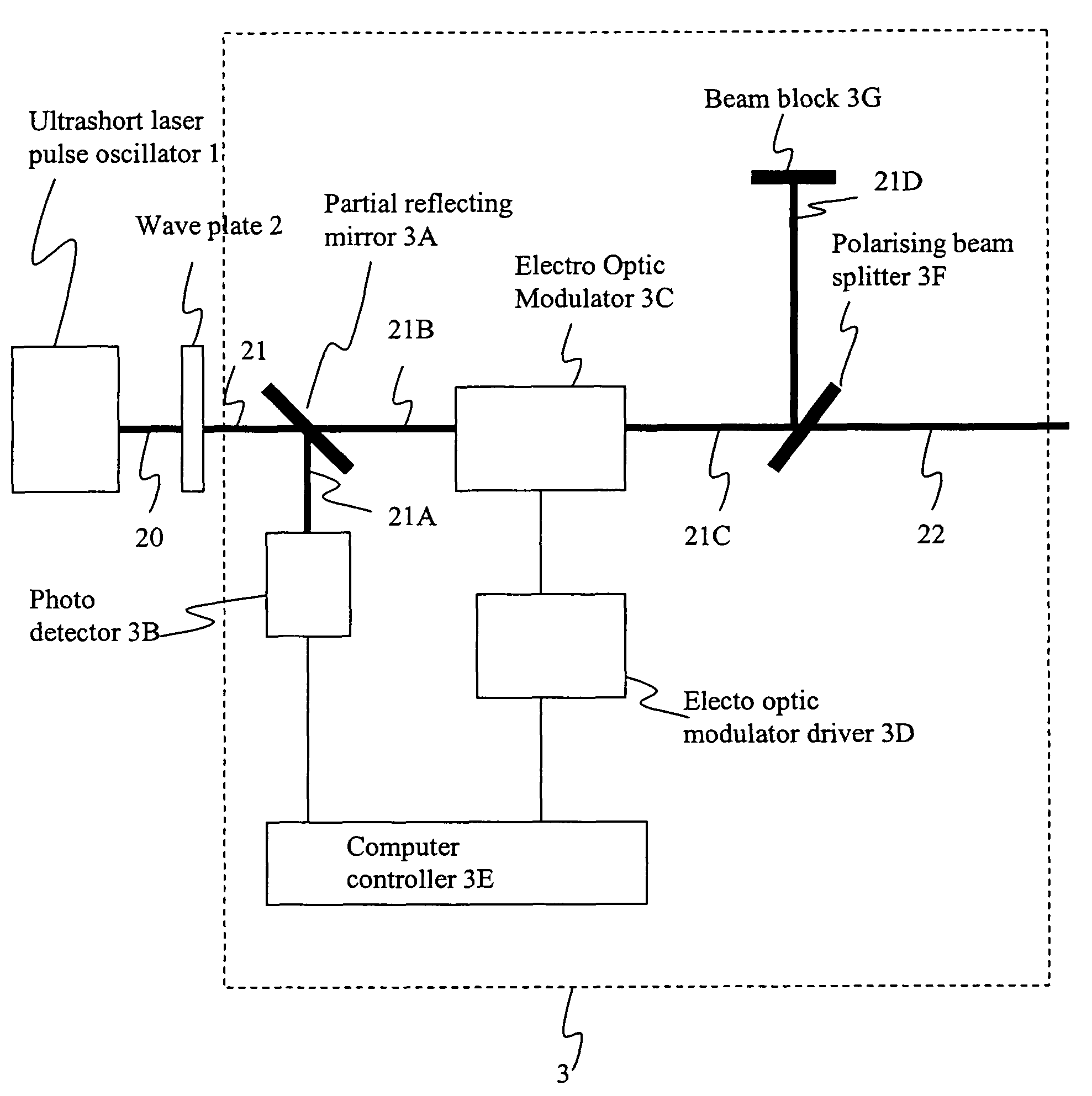

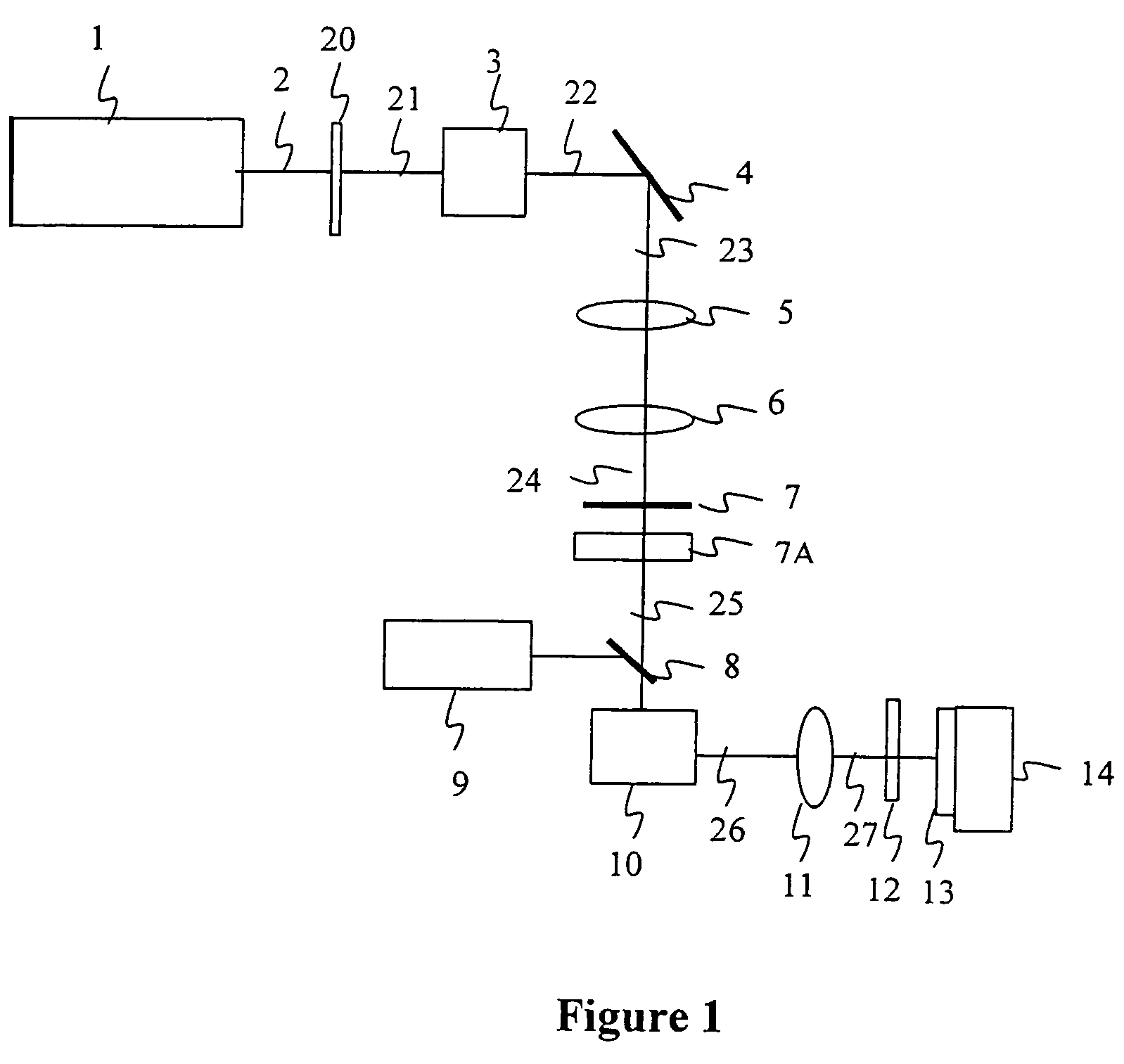

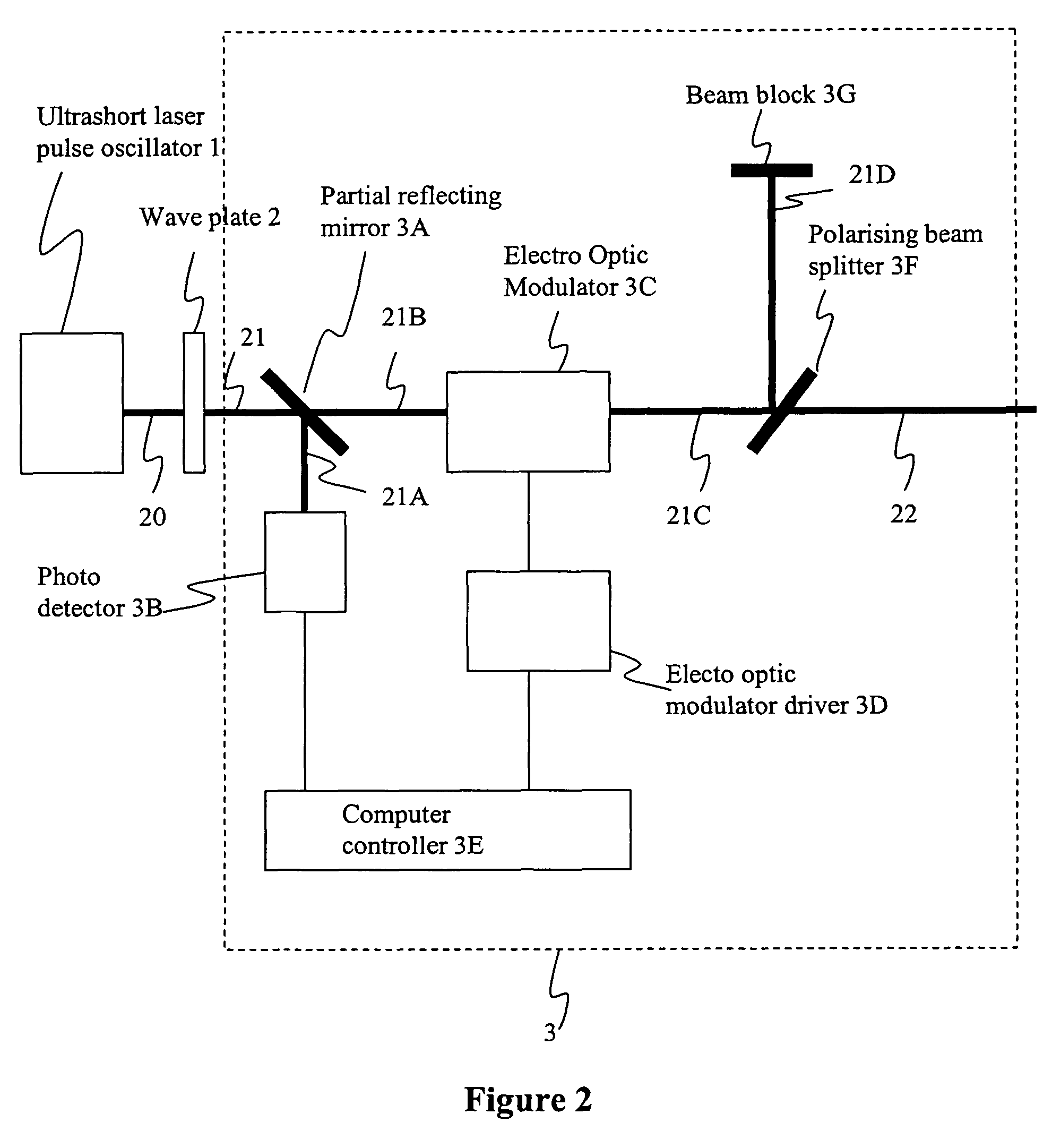

Method and apparatus for dicing of thin and ultra thin semiconductor wafer using ultrafast pulse laser

InactiveUS20050274702A1Improve inner wall qualityImprove surface qualityWelding/soldering/cutting articlesMetal working apparatusPicosecond laserFacula

The present invention relates to the apparatus, system and method for dicing of semiconductor wafers using an ultrafast laser pulse of femtosecond and picosecond pulse widths directly from the ultrafast laser oscillator without an amplifier. Thin and ultrathin simiconductor wafers below 250 micrometer thickness, are diced using diode pumped, solid state mode locked ultrafast laser pulses from oscillator without amplification. The invention disclosed has means to avoid / reduce the cumulative heating effect and to avoid machine quality degrading in multi shot ablation. Also the disclosed invention provides means to change the polarization state of the laser beam to reduce the focused spot size, and improve the machining efficiency and quality. The disclosed invention provides a cost effective and stable system for high volume manufacturing applications. An ultrafast laser oscillator can be a called as femtosecond laser oscillator or a picosecond laser oscillator depending on the pulse width of the laser beam generated.

Owner:LASERFACTURING

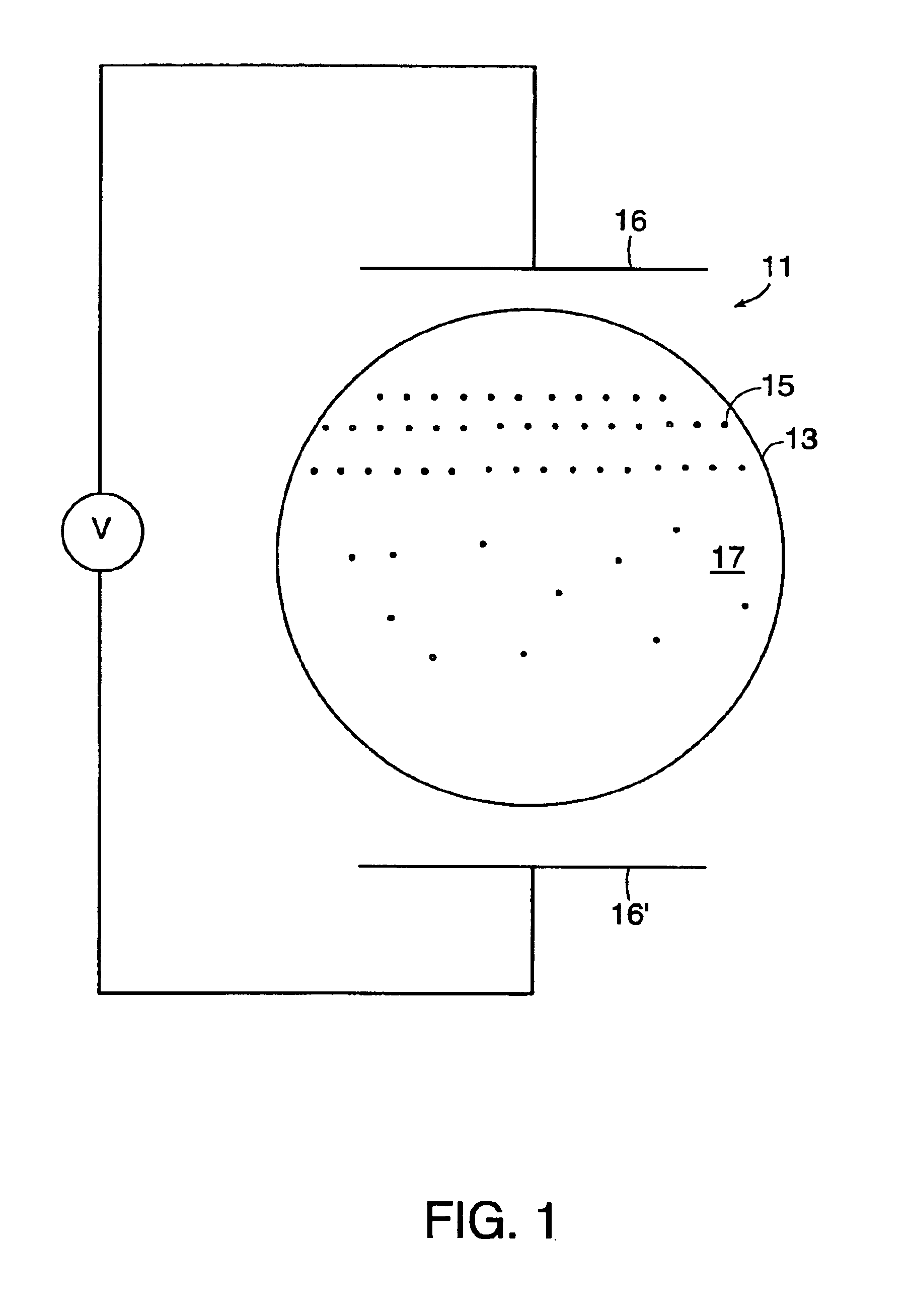

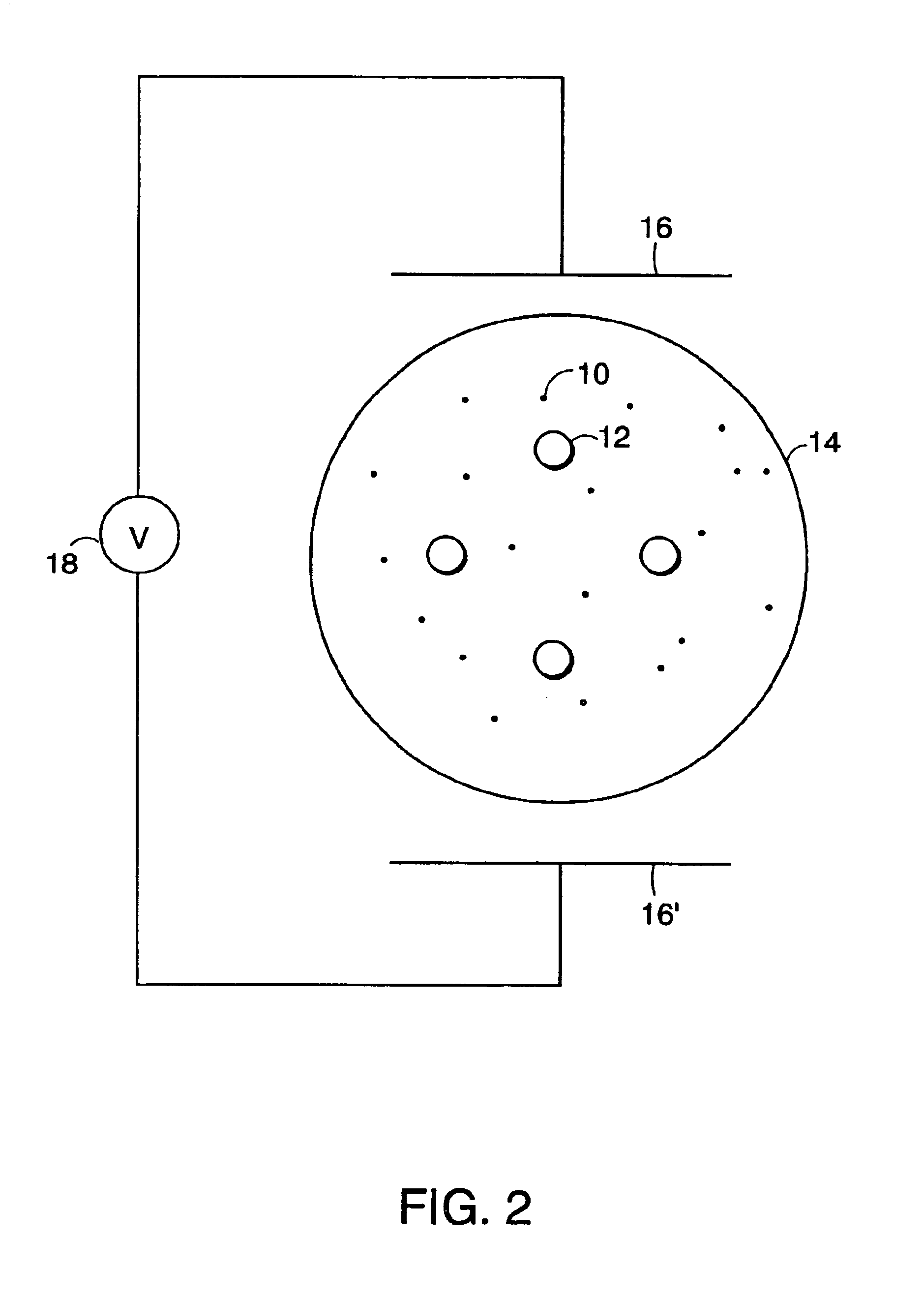

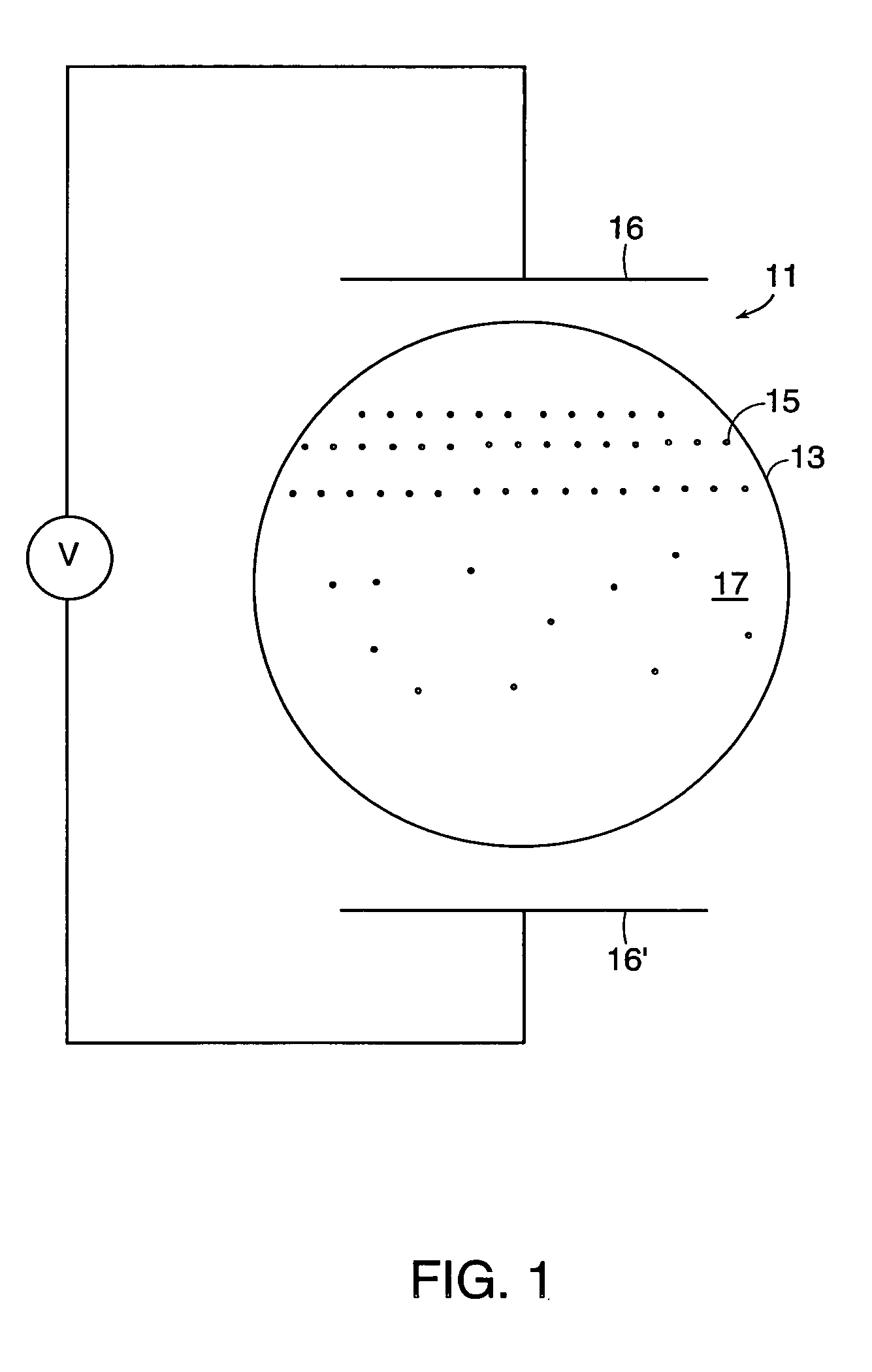

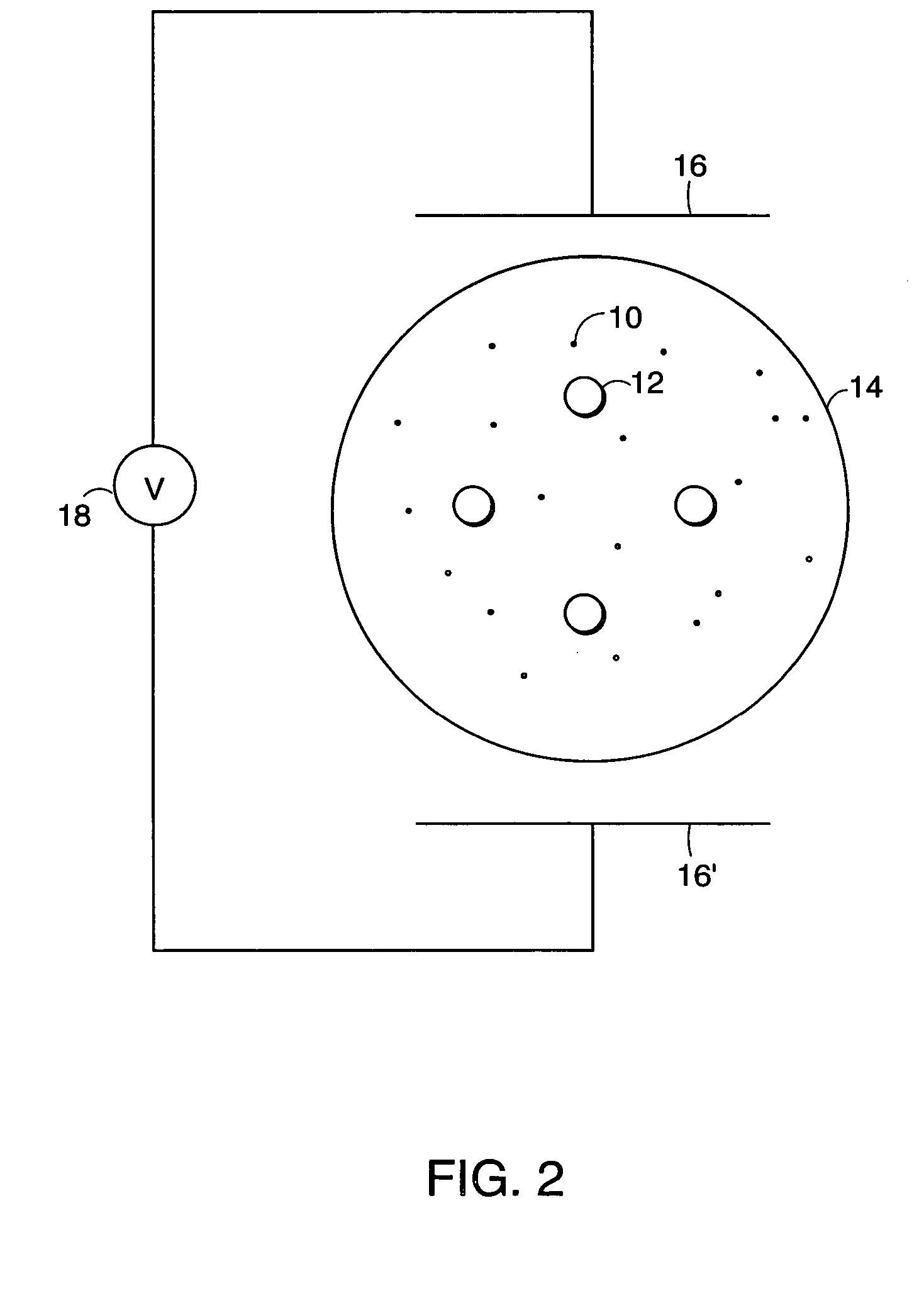

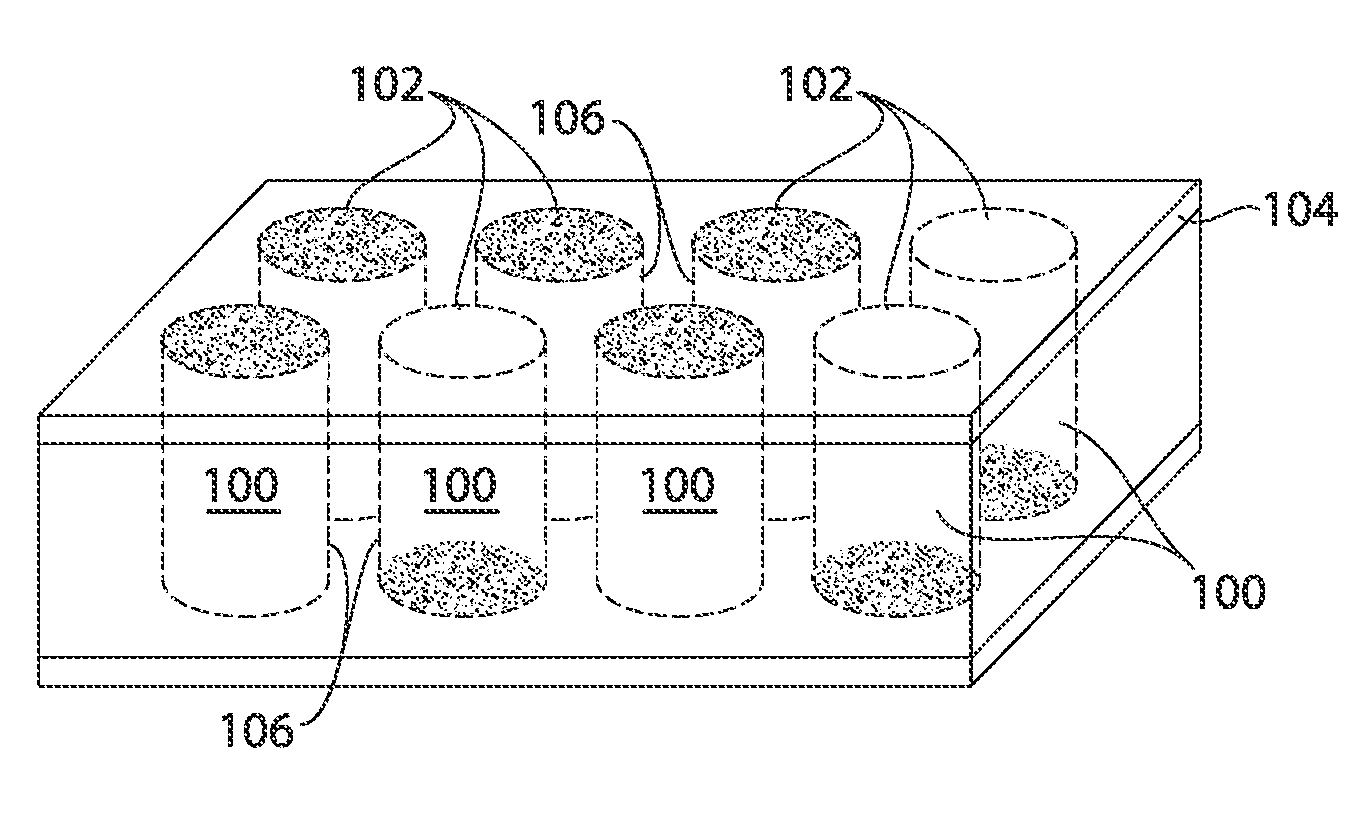

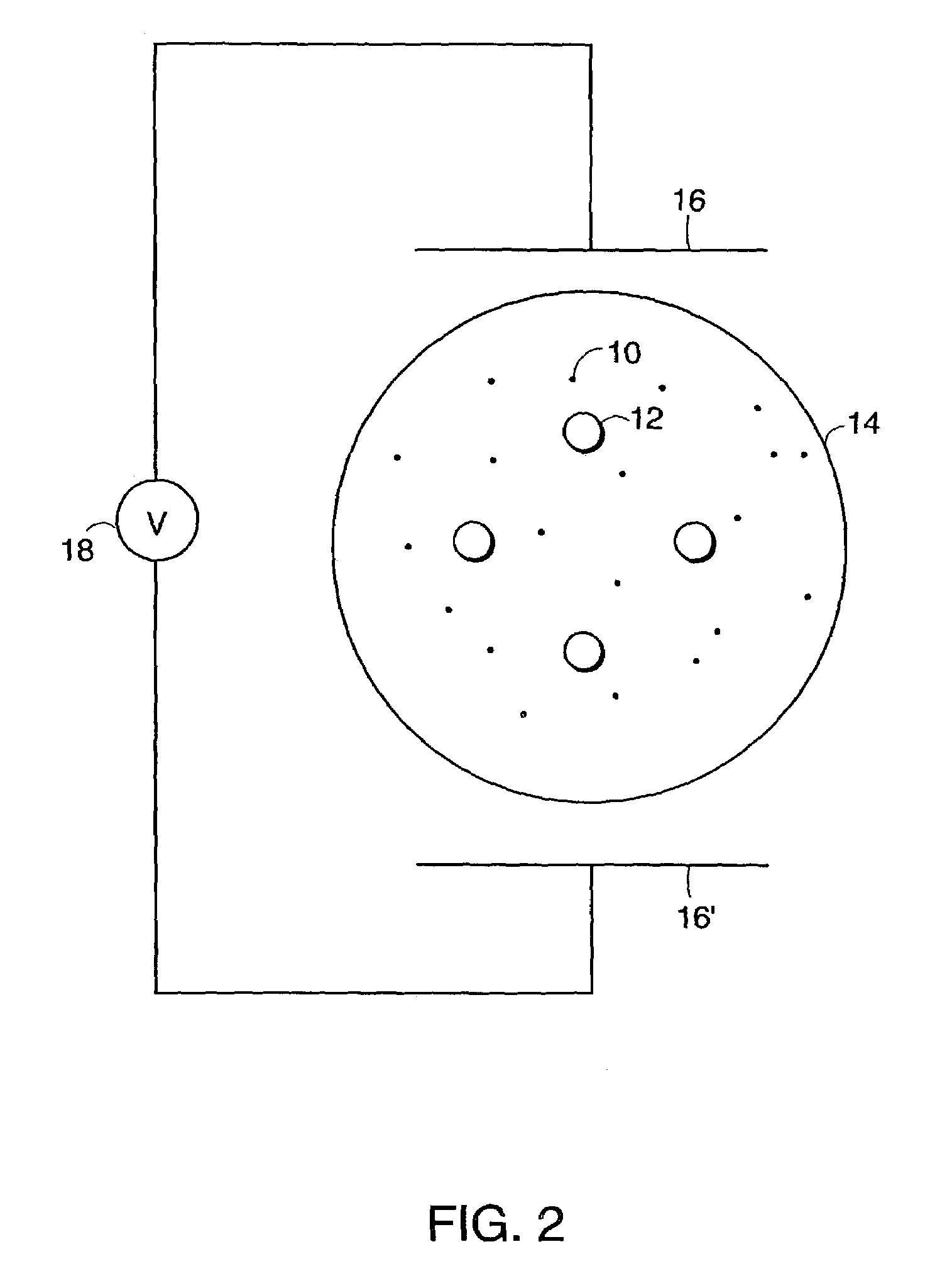

Retroreflective electrophoretic displays and materials for making the same

InactiveUS7071913B2High level controlDisorientingMechanical clocksStatic indicating devicesCelluloseOptical property

Disclosed herein are novel electrophoretic displays and materials useful in fabricating such displays. In particular, novel encapsulated displays are disclosed. Particles encapsulated therein are dispersed within a suspending, or electrophoretic, fluid. This fluid may be a mixture of two or more fluids or may be a single fluid. The displays may further comprise particles dispersed in a suspending fluid, wherein the particles contain a liquid. In either case, the suspending fluid may have a density or refractive index substantially matched to that of the particles dispersed therein. Finally, also disclosed herein are electro-osmotic displays. These displays comprise at least one capsule containing either a cellulosic or gel-like internal phase and a liquid phase, or containing two or more immiscible fluids. Application of electric fields to any of the electrophoretic displays described herein affects an optical property of the display.

Owner:E INK CORPORATION

Implantable device for facet joint replacement

InactiveUS20050267579A1Desired range of mobilityLessen and alleviate spinal painInternal osteosythesisBone implantFacet joint structureProsthesis

Cephalad and caudal vertebral facet joint prostheses and methods of use are provided. The prostheses provide an artificial facet joint structure including an artificial articular configuration unlike the preexisting articular configuration. The radii and material stress values of the prostheses are configured to sustain contact stress. The cephalad prosthesis provides for posterior-anterior adjustment. Both prostheses permit lateral adjustment and adjustment to accomodate interpedicle distance. Further, the prostheses may be customized to provide a pre-defined lordotic angle and a pre-defined pedicle entry angle.

Owner:FACET SOLUTIONS

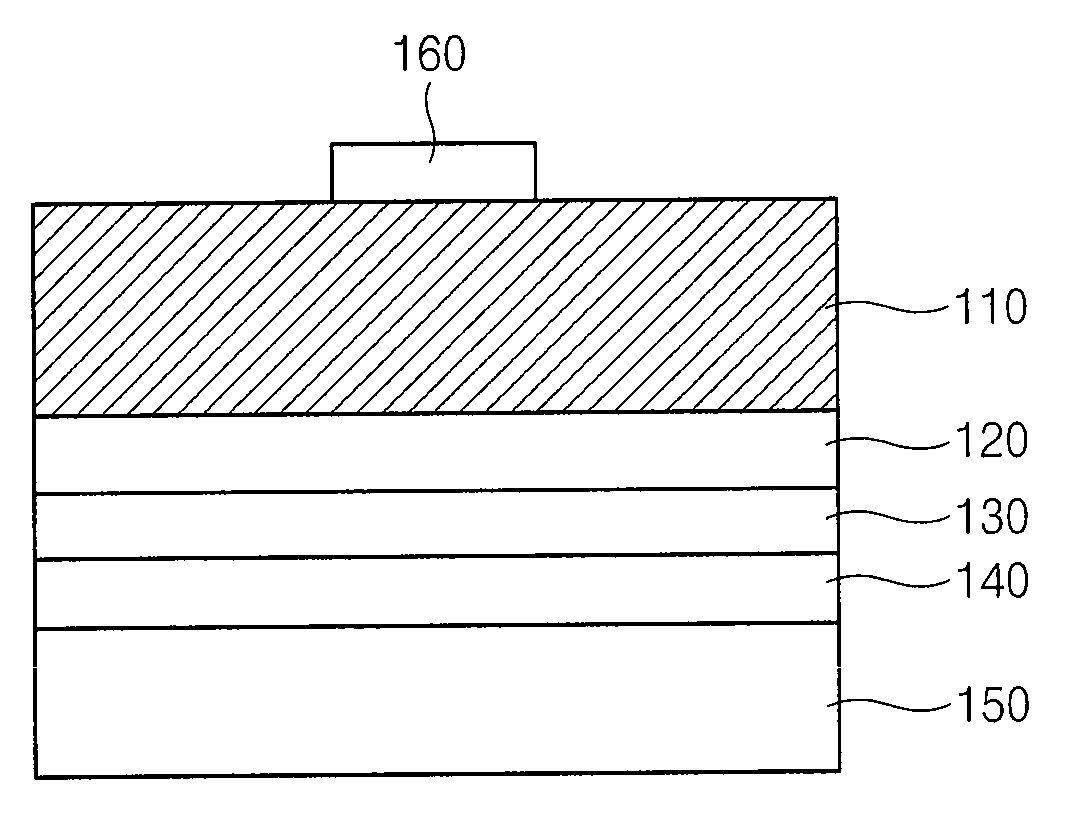

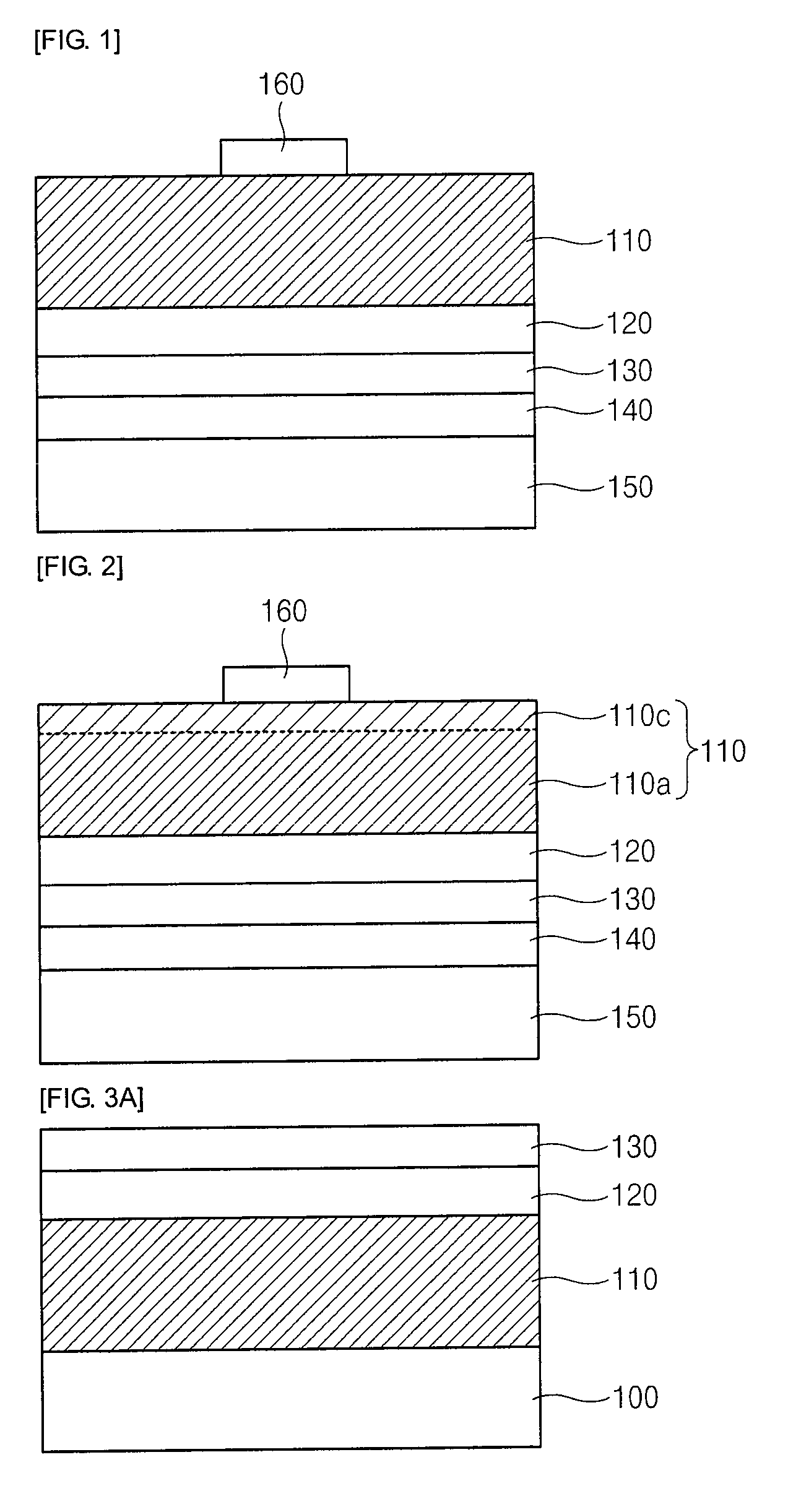

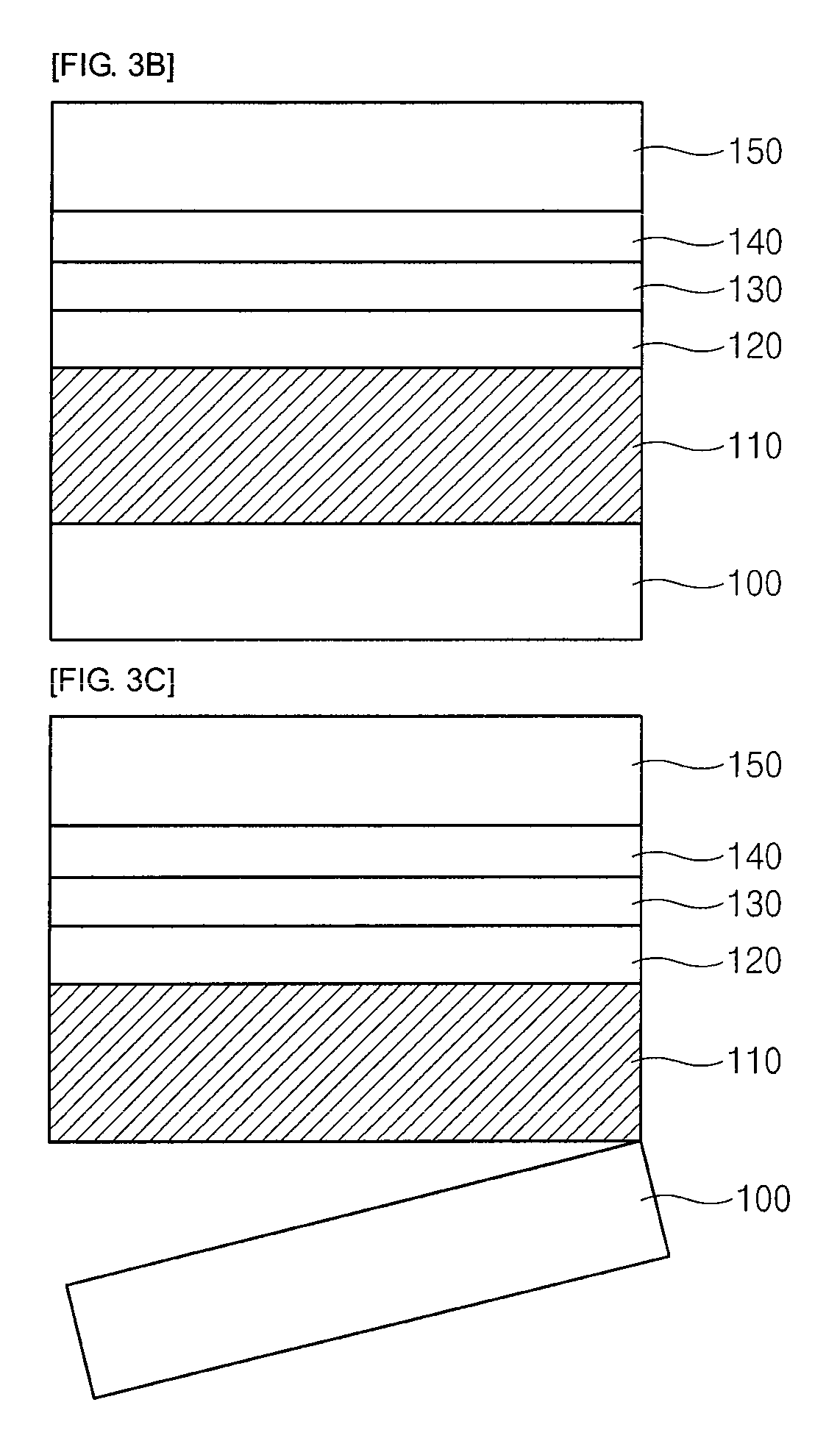

Vertical light emitting diode and method of manufacturing the same

ActiveUS20090221110A1Fine surfaceImprove thermal stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesActive layerLight-emitting diode

Provided is a vertical LED including an n-electrode; an n-type GaN layer formed under the n-electrode, the n-type GaN layer having a surface coming in contact with the n-electrode, the surface having a Ga+N layer containing a larger amount of Ga than that of N; an active layer formed under the n-type GaN layer; a p-type GaN layer formed under the active layer; a p-electrode formed under the p-type GaN layer; and a structure support layer formed under the p-electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

Retroreflective electrophoretic displaya and materials for making the same

InactiveUS20050035941A1High level controlDisorientingMechanical clocksStatic indicating devicesChemistryElectric field

Disclosed herein are novel electrophoretic displays and materials useful in fabricating such displays. In particular, novel encapsulated displays are disclosed. Particles encapsulated therein are dispersed within a suspending, or electrophoretic, fluid. This fluid may be a mixture of two or more fluids or may be a single fluid. The displays may further comprise particles dispersed in a suspending fluid, wherein the particles contain a liquid. In either case, the suspending fluid may have a density or refractive index substantially matched to that of the particles dispersed therein. Finally, also disclosed herein are electro-osmotic displays. These displays comprise at least one capsule containing either a cellulosic or gel-like internal phase and a liquid phase, or containing two or more immiscible fluids. Application of electric fields to any of the electrophoretic displays described herein affects an optical property of the display.

Owner:E INK CORPORATION

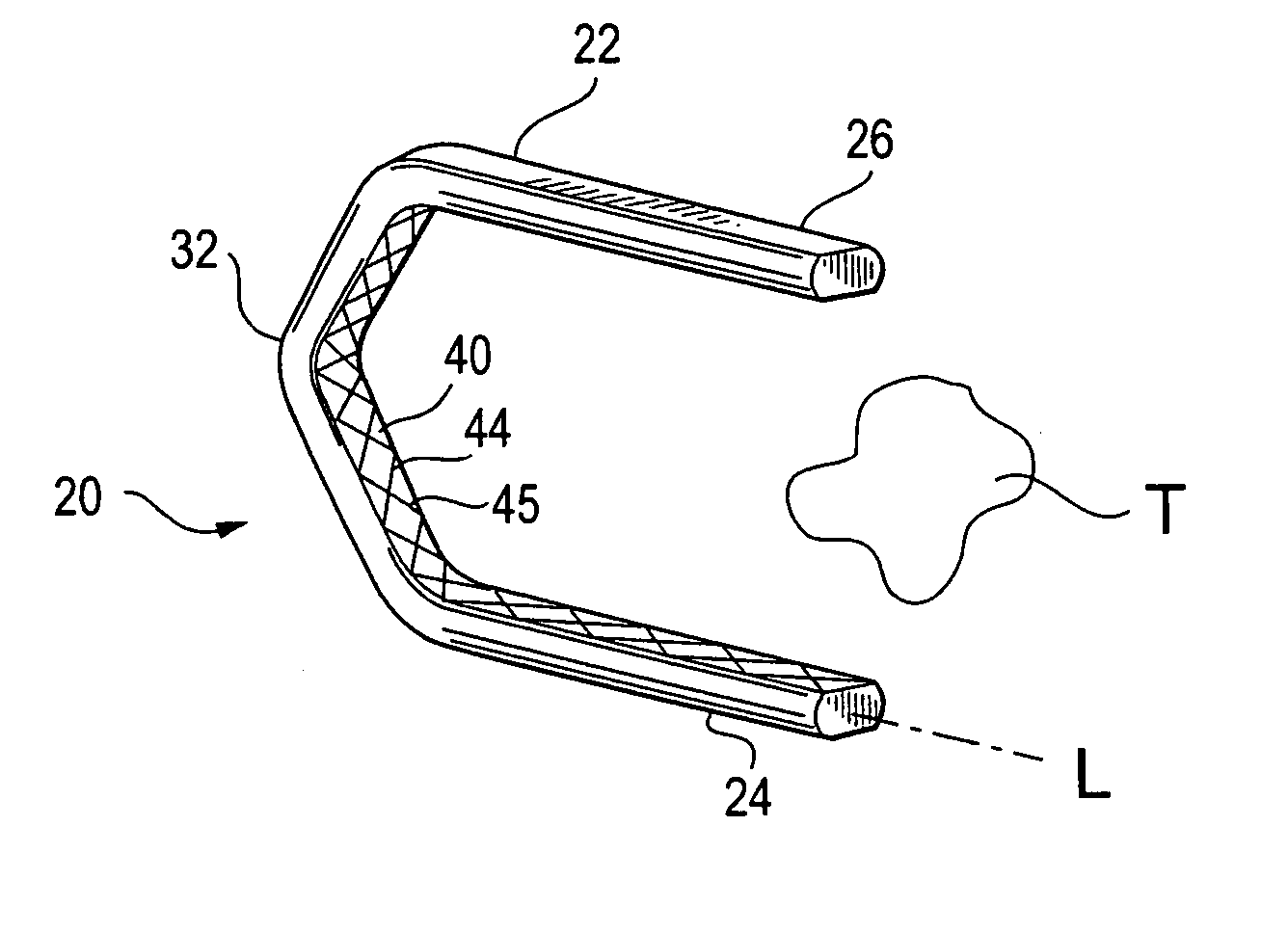

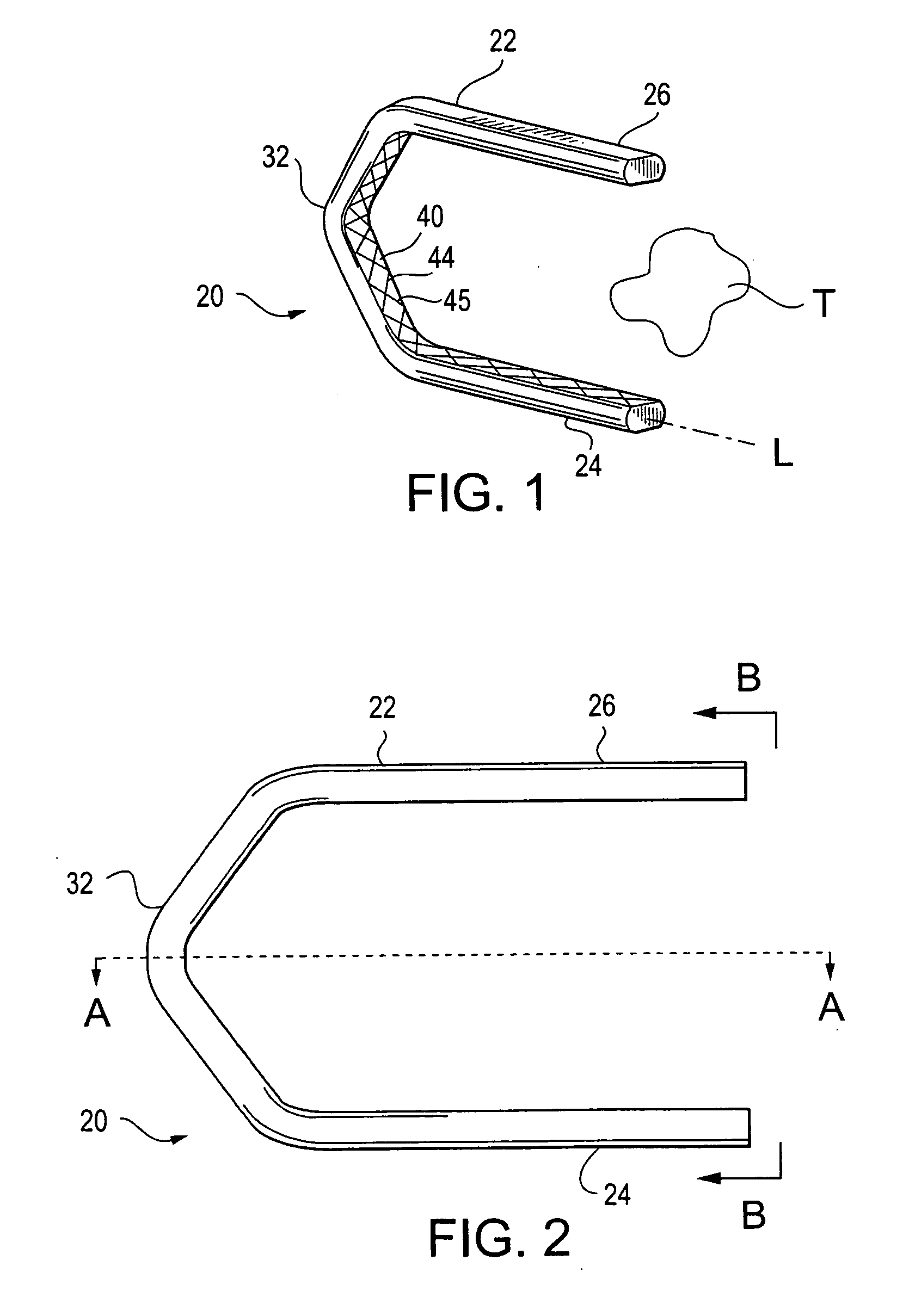

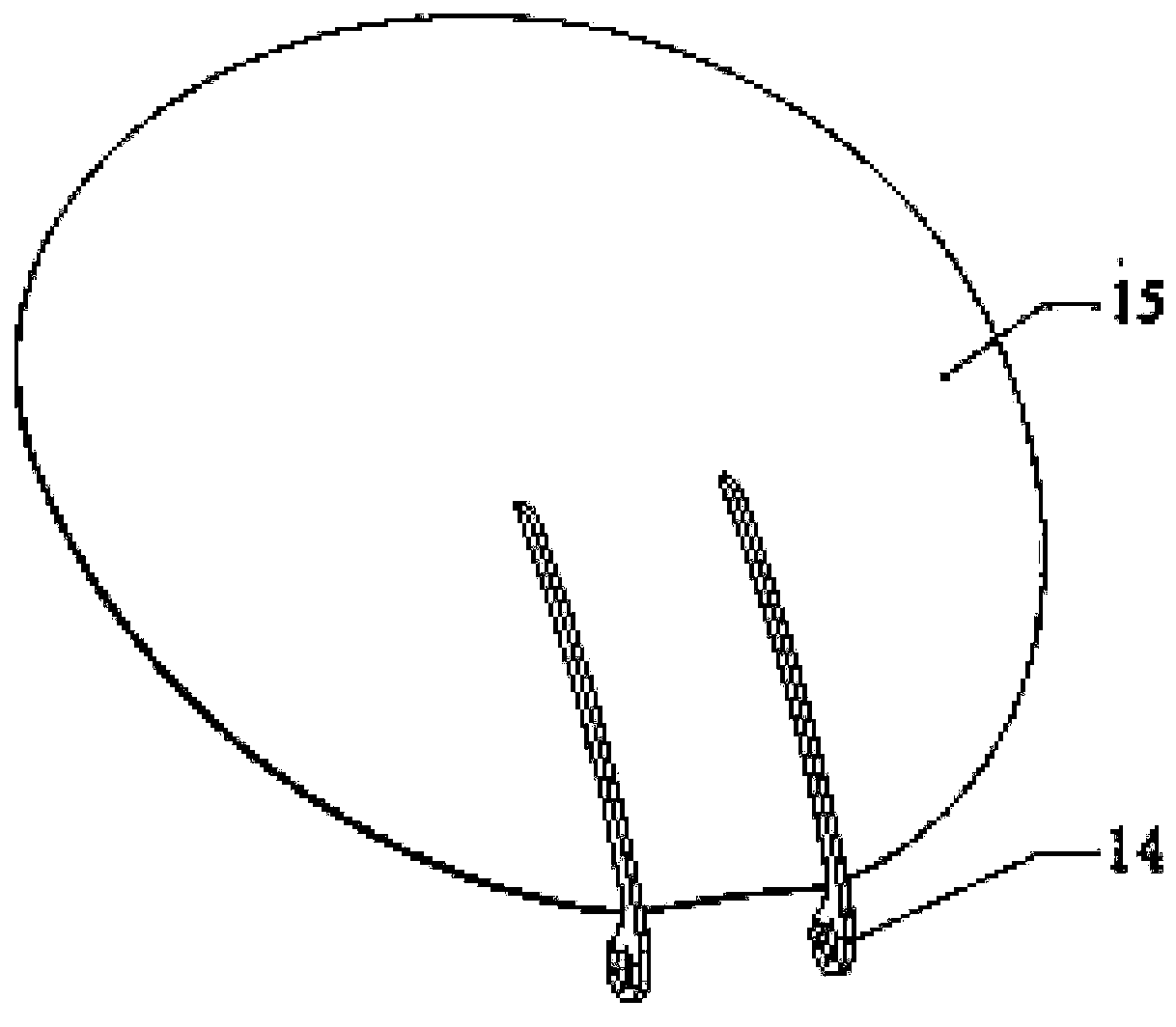

Clip with enhanced gripping arrangement

A surgical clip includes a connecting member having a two ends and a pair of legs. Each leg extends from one end of the connecting member. A generally diamond-shaped pattern is formed on a portion of the inner surface of at least one of the connecting member and the pair of legs. The generally diamond-shaped pattern is formed as the result of generally perpendicular diagonal grooves.

Owner:MICROLINE PENTAX

Non-spherical cavity electrophoretic displays and methods and materials for making the same

InactiveUS7109968B2High level controlEasy to chargeStatic indicating devicesNanoinformaticsCelluloseOptical property

Disclosed herein are novel electrophoretic displays and materials useful in fabricating such displays. In particular, novel encapsulated displays are disclosed. Particles encapsulated therein are dispersed within a suspending, or electrophoretic, fluid. This fluid may be a mixture of two or more fluids or may be a single fluid. The displays may further comprise particles dispersed in a suspending fluid, wherein the particles contain a liquid. In either case, the suspending fluid may have a density or refractive index substantially matched to that of the particles dispersed therein. Finally, also disclosed herein are electro-osmotic displays. These displays comprise at least one capsule containing either a cellulosic or gel-like internal phase and a liquid phase, or containing two or more immiscible fluids. Application of electric fields to any of the electrophoretic displays described herein affects an optical property of the display.

Owner:E INK CORPORATION

Prostheses, systems and methods for replacement of natural facet joints with artificial facet joint surfaces

InactiveUS20050119748A1Secure durable attachmentProcess safety and stabilityInternal osteosythesisBone implantFacet joint prosthesisArticular surfaces

Cephalad and caudal vertebral facet joint prostheses and methods of use are provided. A pair of fixation elements are adapted to be secured within a vertebra in an orientation that best assures a secure and durable attachment to cortical and / or cancellous bone. Artificial facet joint surfaces are mounted on the fixation elements, either directly or with the aid of a support. The artificial facet joint structure may be carried by an arm. The artificial facet joint structure is adapted for articulation with a complementary natural or artificial facet joint structure. Bilateral prostheses may by coupled by a brace to further secure and stabilize the prostheses.

Owner:GLOBUS MEDICAL INC

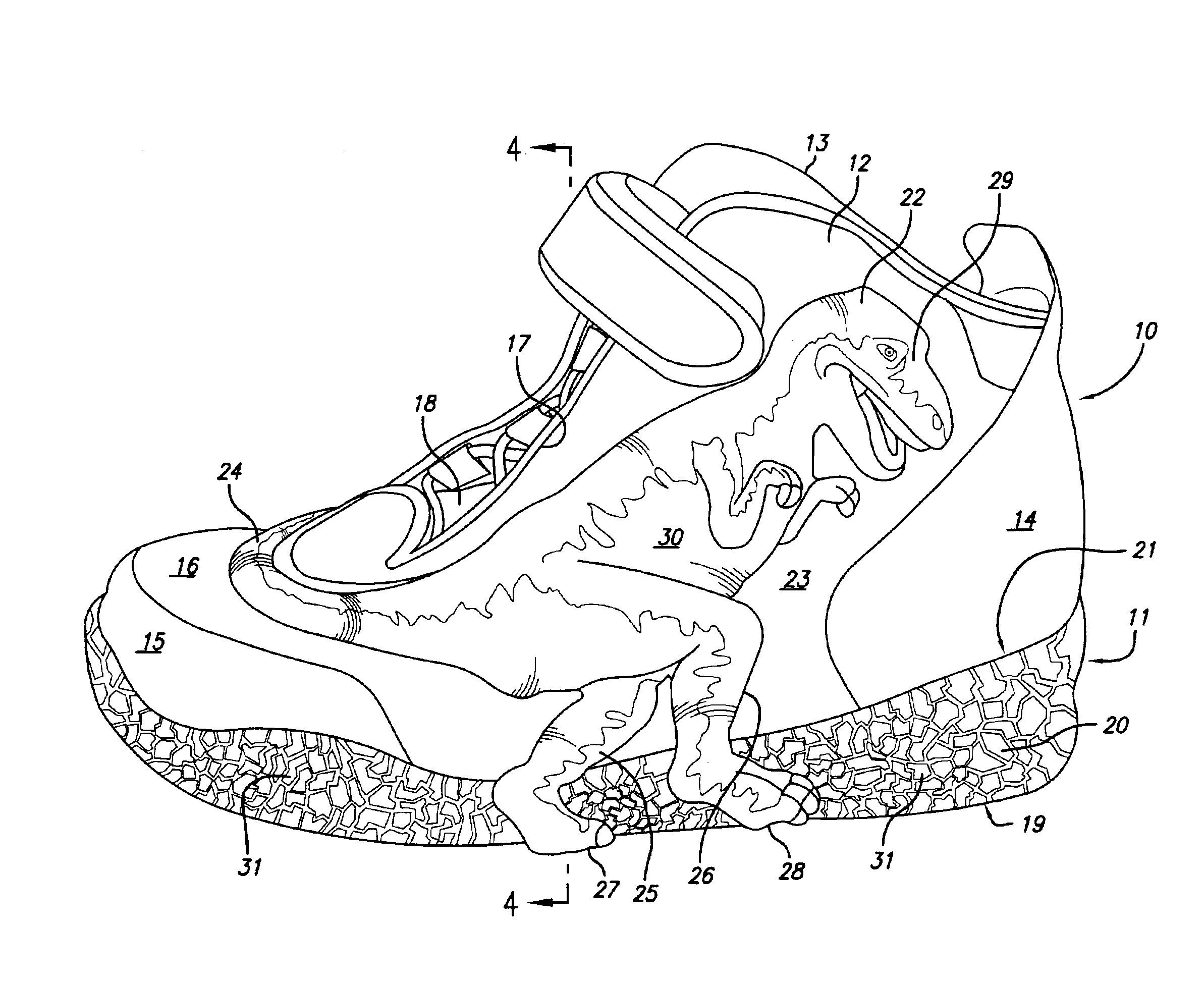

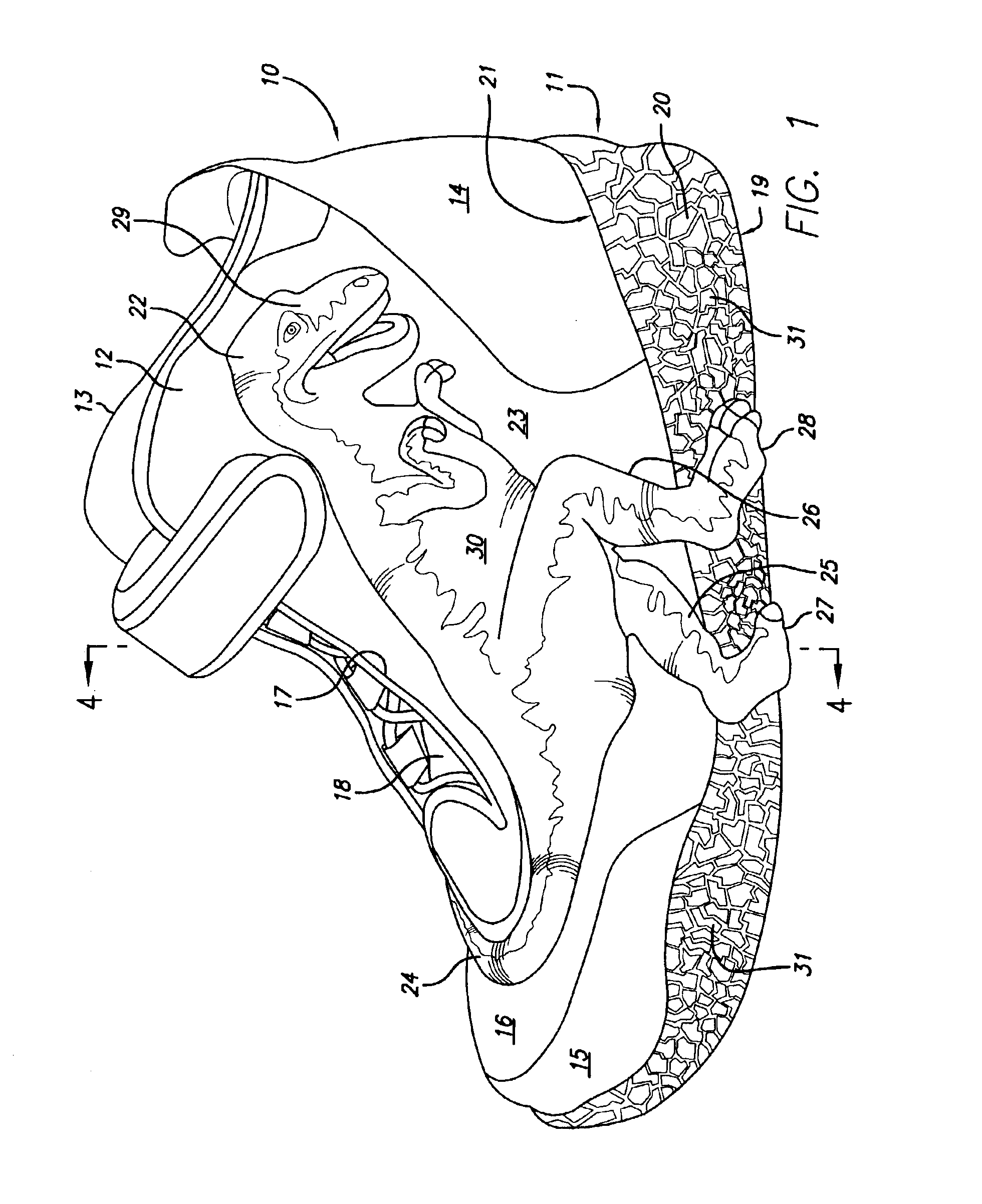

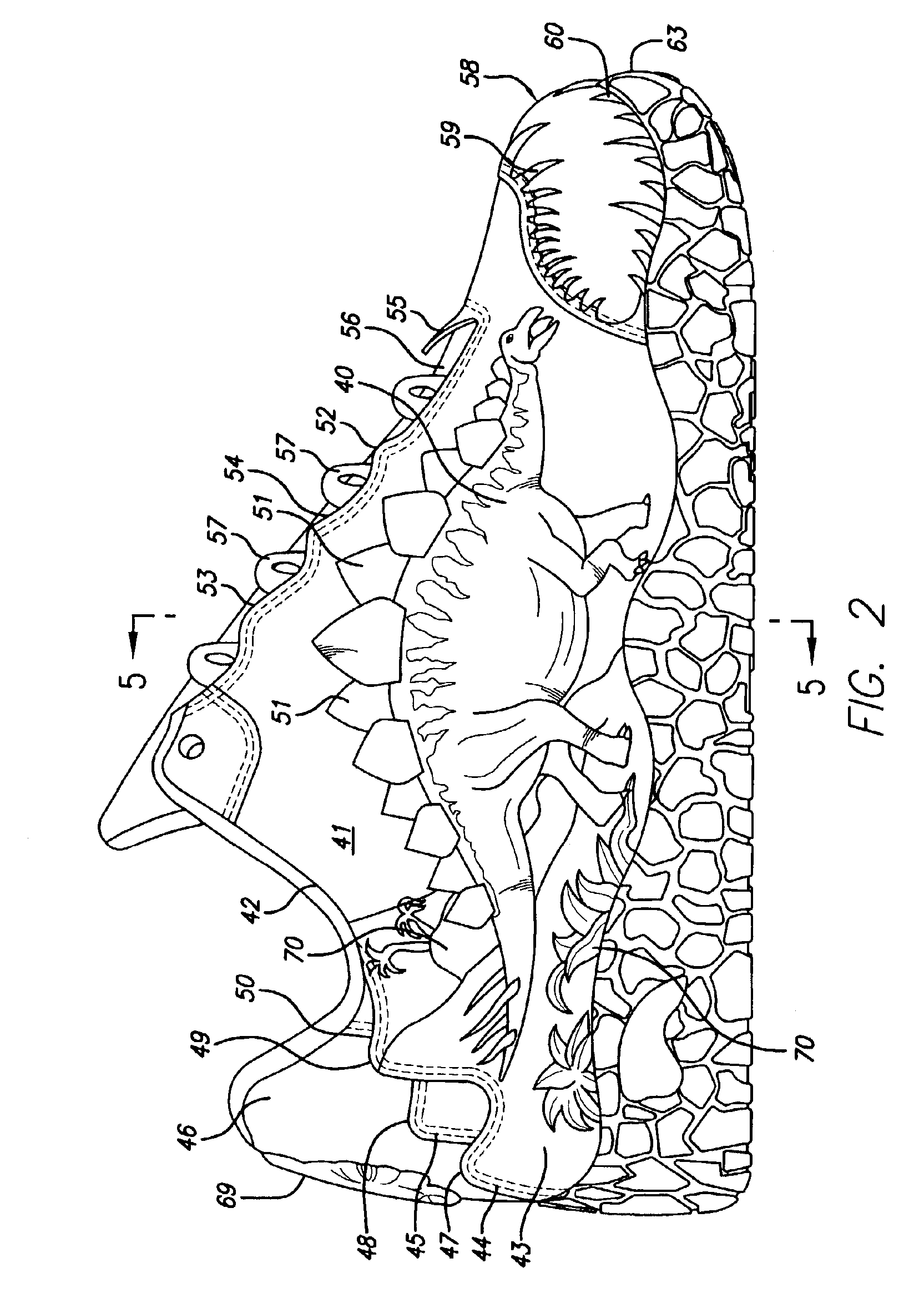

Footwear with surrounding ornamentation

InactiveUS6957504B2Enhances surround art themeImproved footwearSolesUpperElectrical and Electronics engineering

A shoe upper has an outside surface having a first ornamental theme, the first theme being formed in three dimensions, with artwork coincident with the three dimensional effect. An outsole below the shoe upper includes a bottom surface for engagement with a walking surface; a peripheral area extending about the bottom and mating with the upper. The upper surface is for engagement with a bottom of the upper. The bottom surface and the peripheral area have a surface with a second ornamental theme. The first ornamental theme and the second ornamental theme are thematically related so as to create a surrounding ornamentation of the footwear.

Owner:SCULPTED FOOTWEAR

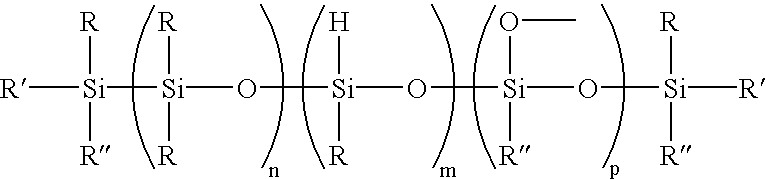

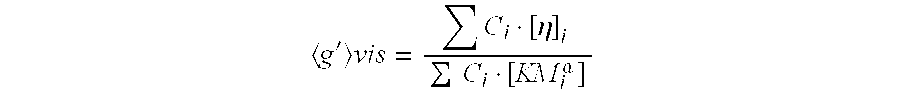

Thermoplastic elastomers having improved processing and physical property balance

InactiveUS6451915B1Without deleteriously sacrificing mechanical propertyEasy to processThermoplasticPolymer science

A thermoplastic elastomer formed by a process comprising the steps of dynamically vulcanizing a rubber within a mixture that includes the rubber, from about 10 to about 80 percent by weight of a thermoplastic resin based upon the total weight of the rubber and the thermoplastic combined, and from about 1 to about 25 percent by weight of a polymeric processing additive based upon the total weight of the rubber and the thermoplastic combined, where the polymeric processing additive is a linear polyolefin resin that has an melt flow rate that is greater than about 1,000 dg / min, a diene-modified polyolefin polymer that has an melt flow rate that is greater than about 1,000 dg / min, from about 0.005 to about 2.00 mole percent polymeric units deriving from dienes, and a viscosity average branching index that is from about 0.4 to about 0.95, or a mixture of the linear polyolefin resin and the diene-modified polyolefin polymer, where the step of dynamically vulcanizing the rubber results in vulcanized rubber having a crosslink density of about 40 to about 180 mole per milliliter of rubber.

Owner:CELANESE INT CORP

Consolidated body fluid testing device and method

InactiveUS20030109777A1Increase flowSufficient supplyCatheterSensorsTest fixtureBiomedical engineering

A body fluid testing device includes a body member and a tissue penetrator carried by the body member. A test strip holder is carried by the body member, and a test strip is carried by the test strip holder. The test strip is capable of receiving a body fluid thereon and processing the body fluid into a form suitable for yielding test results relating to the content of the body fluid.

Owner:KLOEPFER DR HANS

Planning method and system for free-form implant modification

ActiveUS7742801B2Increase configuration flexibilityFunction increaseAnalogue computers for chemical processesComputerised tomographsFree formControl data

A method for planning a bone implant ascertains a condition of a bone to be treated, and identifies a dysfunctional part of the bone. A free-form area then can be ascertained and registered, wherein the free-form area lies below the dysfunctional part. A control data set then is produced that forms the basis for ablating the bone on the ascertained free-form area.

Owner:SMITH & NEPHEW ASIA PACIFIC PTE LTD +2

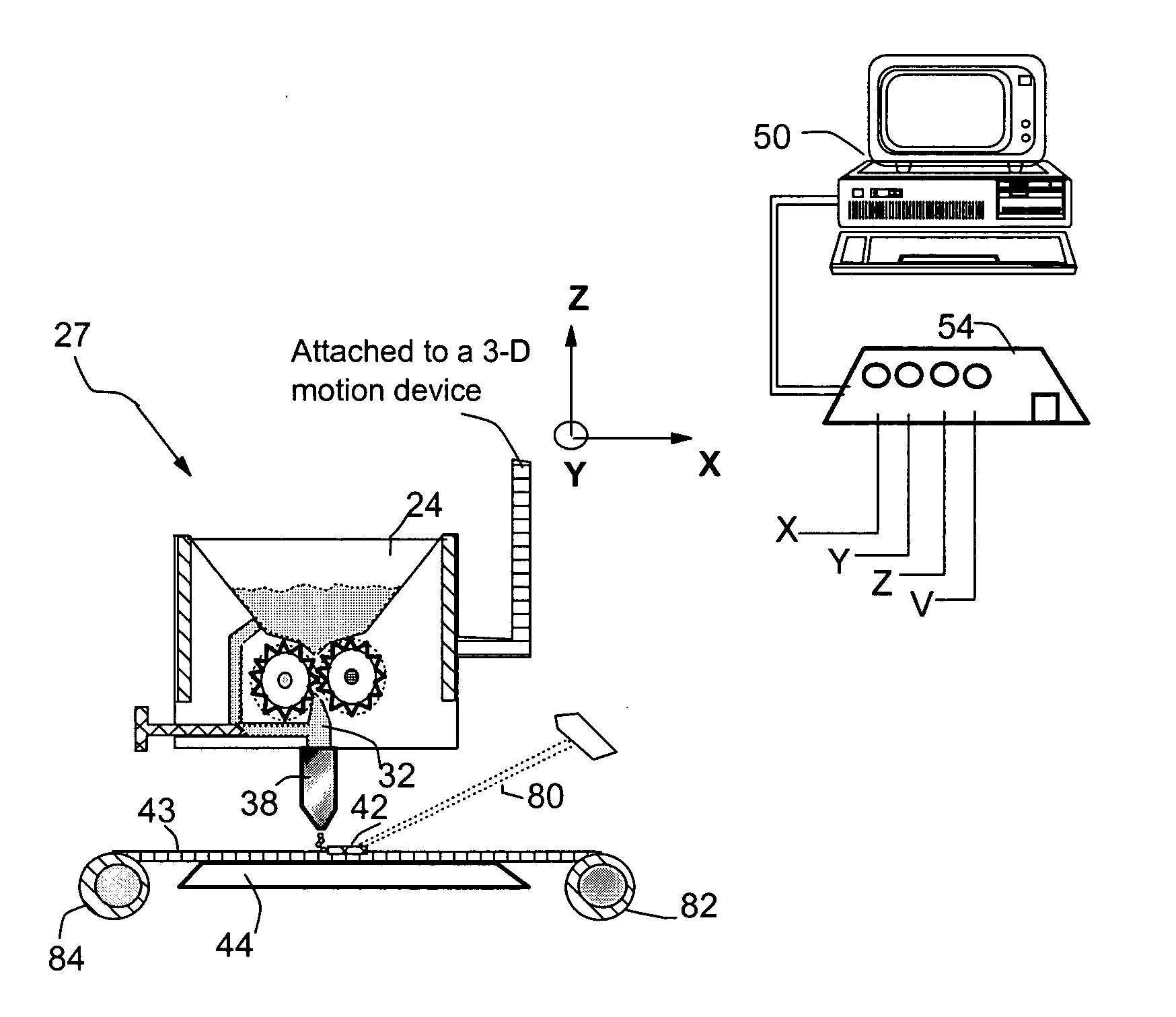

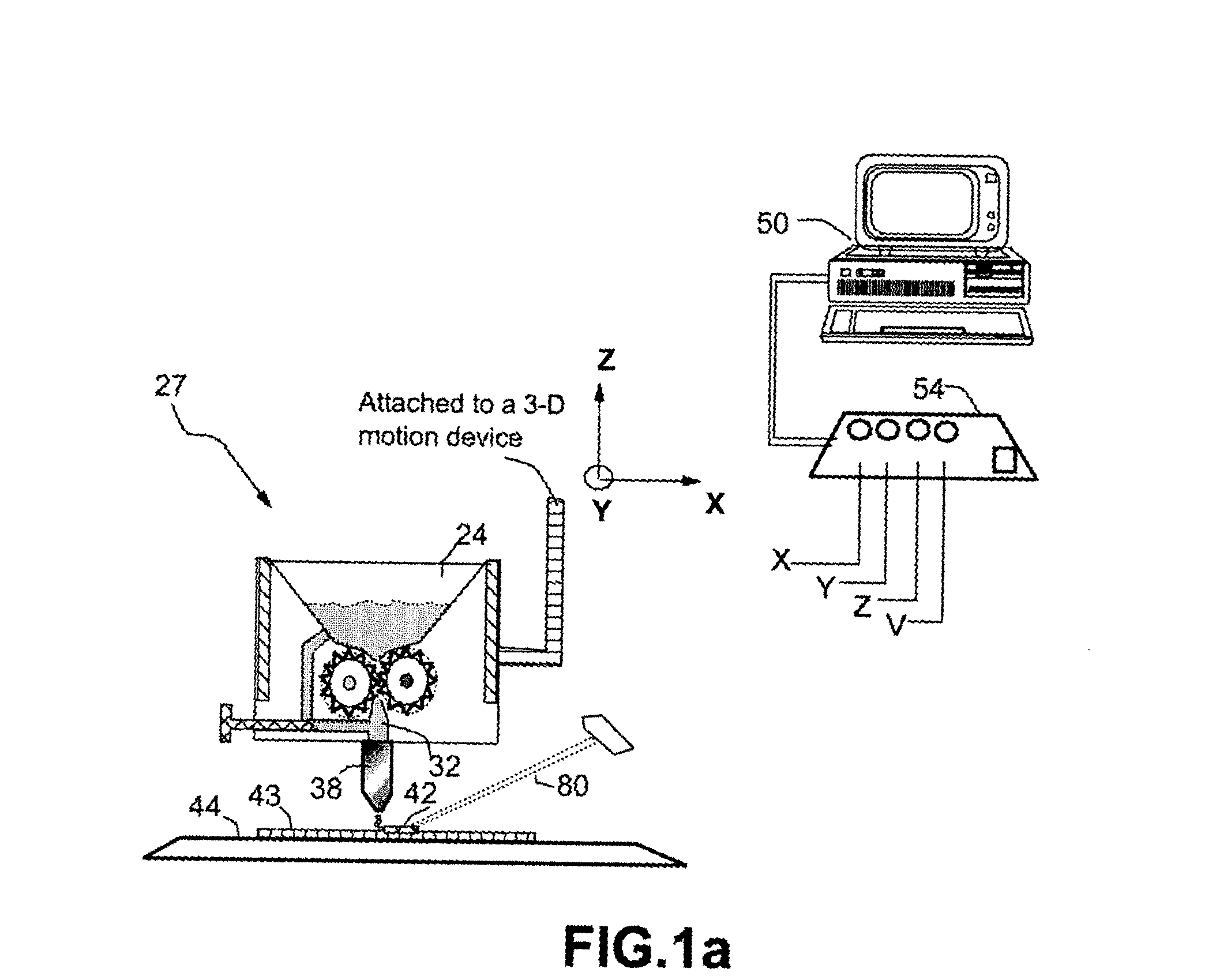

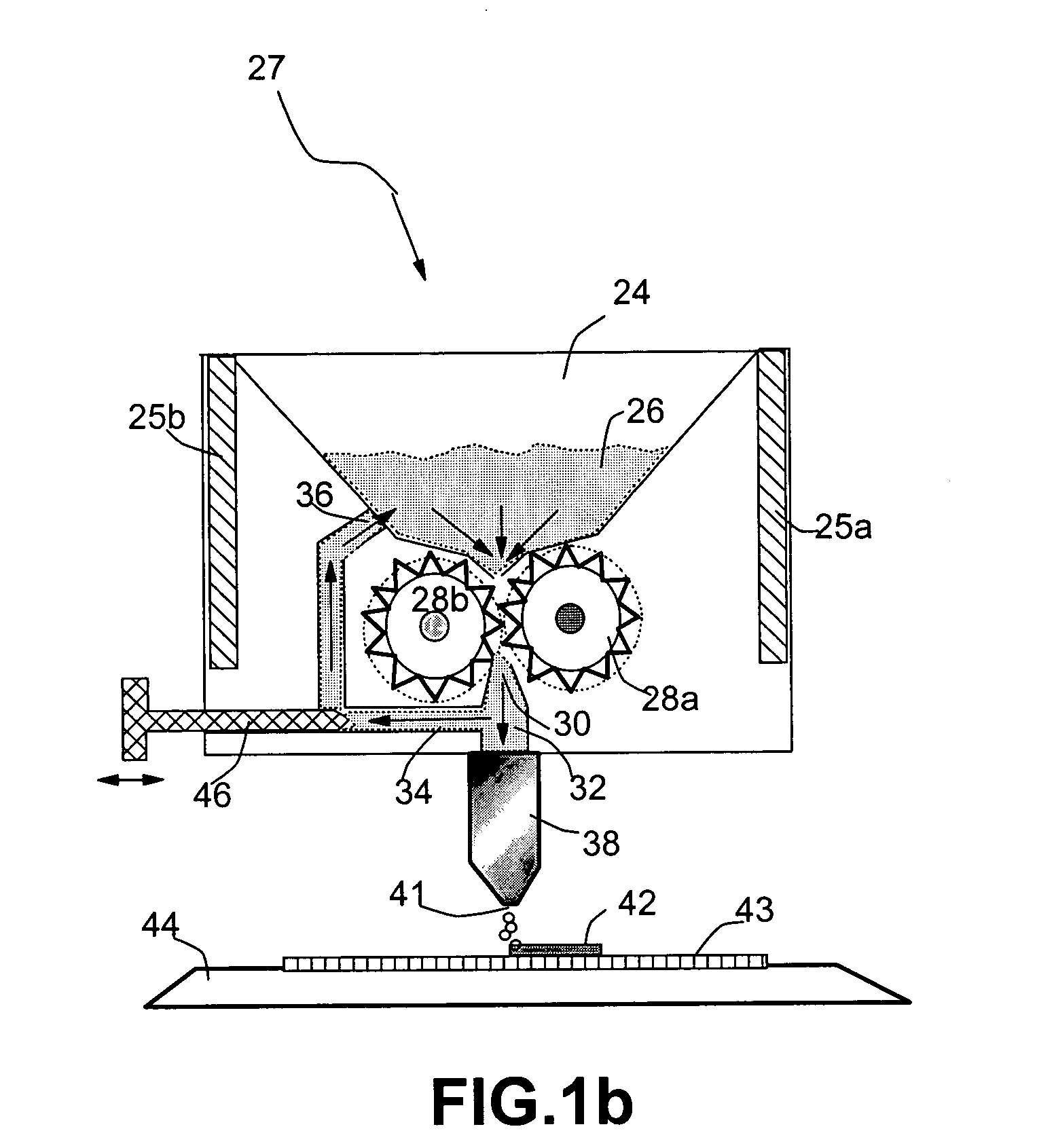

Direct write process and apparatus

ActiveUS20050015175A1Fast preparationIncrease back pressureRecording apparatusAdditive manufacturing apparatusDielectricControl signal

A direct write process and apparatus for fabricating a desired circuit component onto a substrate surface of a microelectronic device according to a computer-aided design (CAD). The process includes (a) providing a support member by which the device is supported while being fabricated; (b) providing a chamber for containing a precursor fluid material under a substantially constant pressure differential relative to the ambient pressure, with the precursor fluid material having a viscosity no less than 10 cps; (c) operating an inkjet-based dispensing head with a control valve or actuator for dispensing and depositing minute droplets of the precursor fluid material onto the substrate surface; (d) energy- or heat-treat the deposited precursor fluid material for converting it to the desired active or passive component; and (e) operating a machine controller for generating control signals in response to the CAD coordinates for controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing and depositing of the precursor material to form the desired component. The process is useful for depositing a wide range of component materials onto an electronic device, including conductor, resistor, capacitor, dielectric, inductor, antenna, solar cell electrode, battery electrode, interconnect, superconductor, sensor, and actuator element materials.

Owner:NANOTEK INSTR GRP LLC

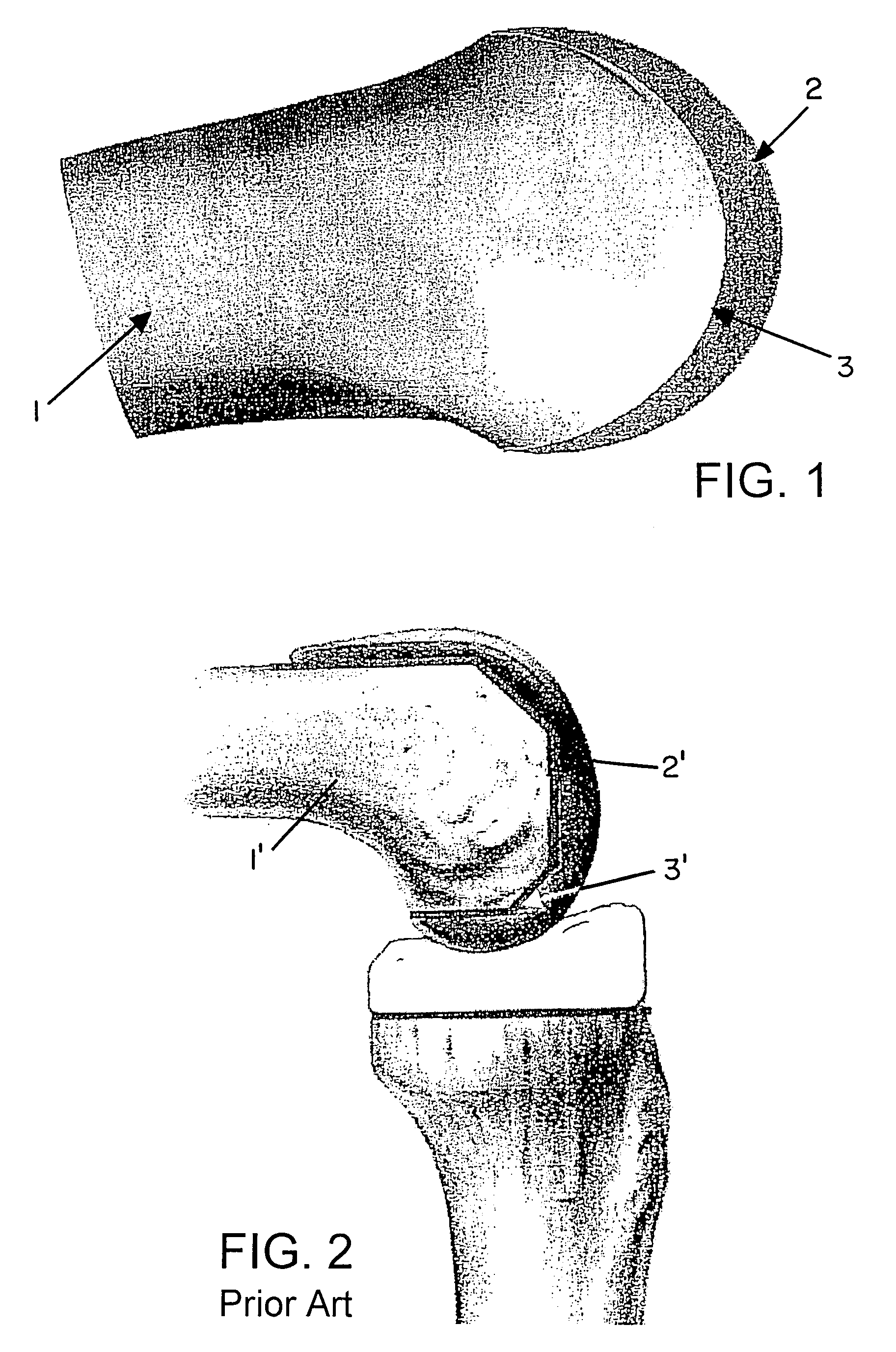

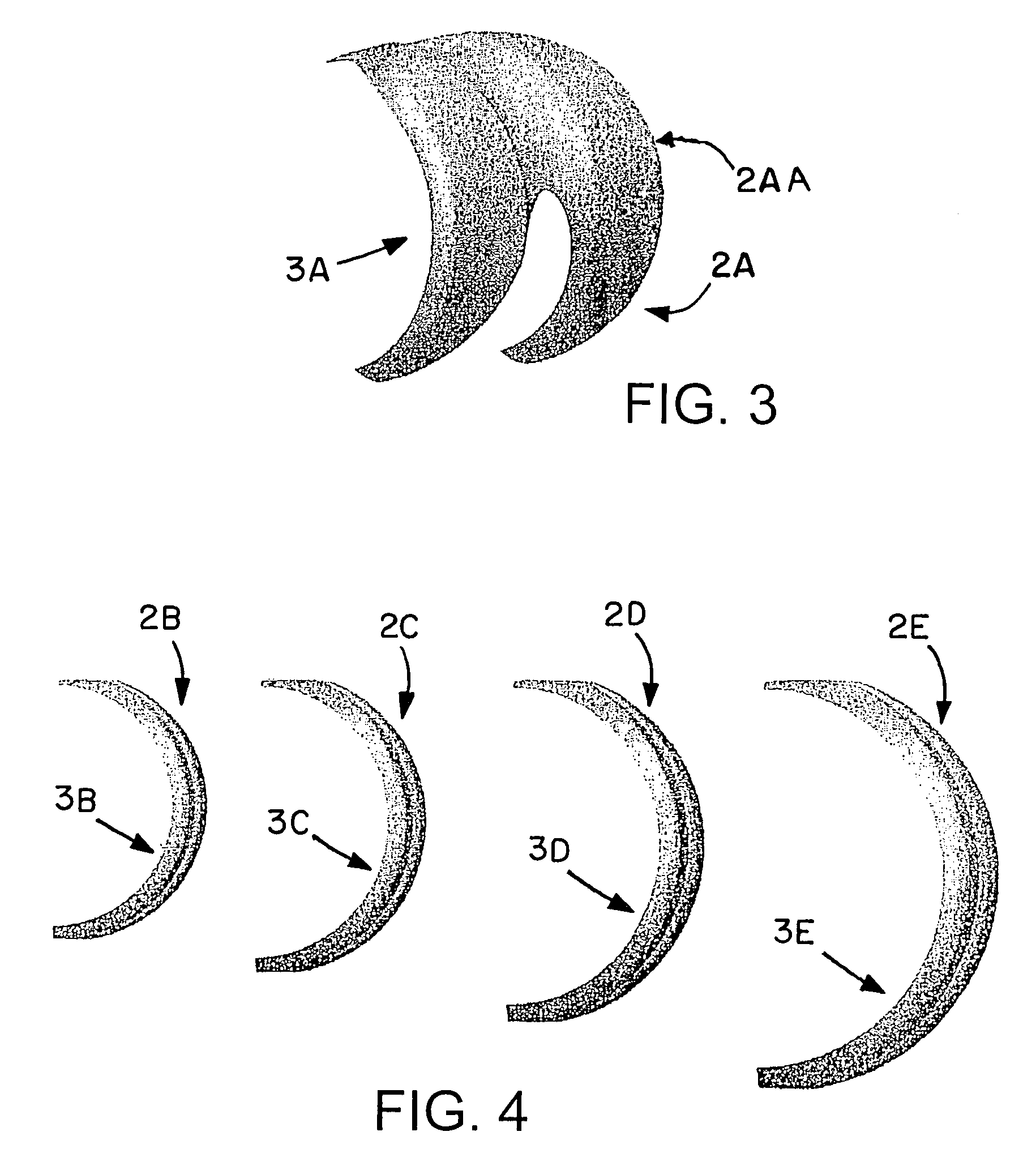

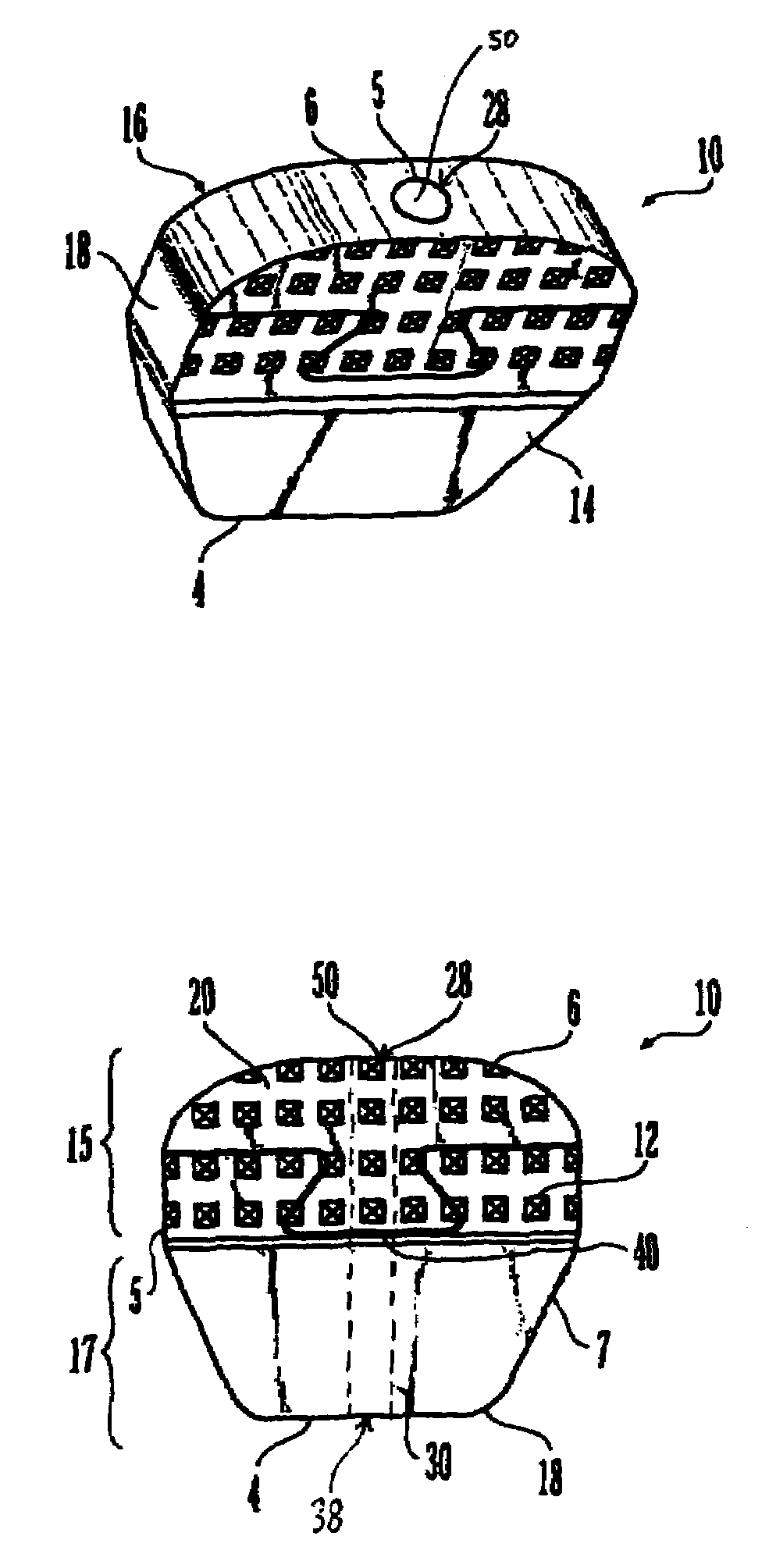

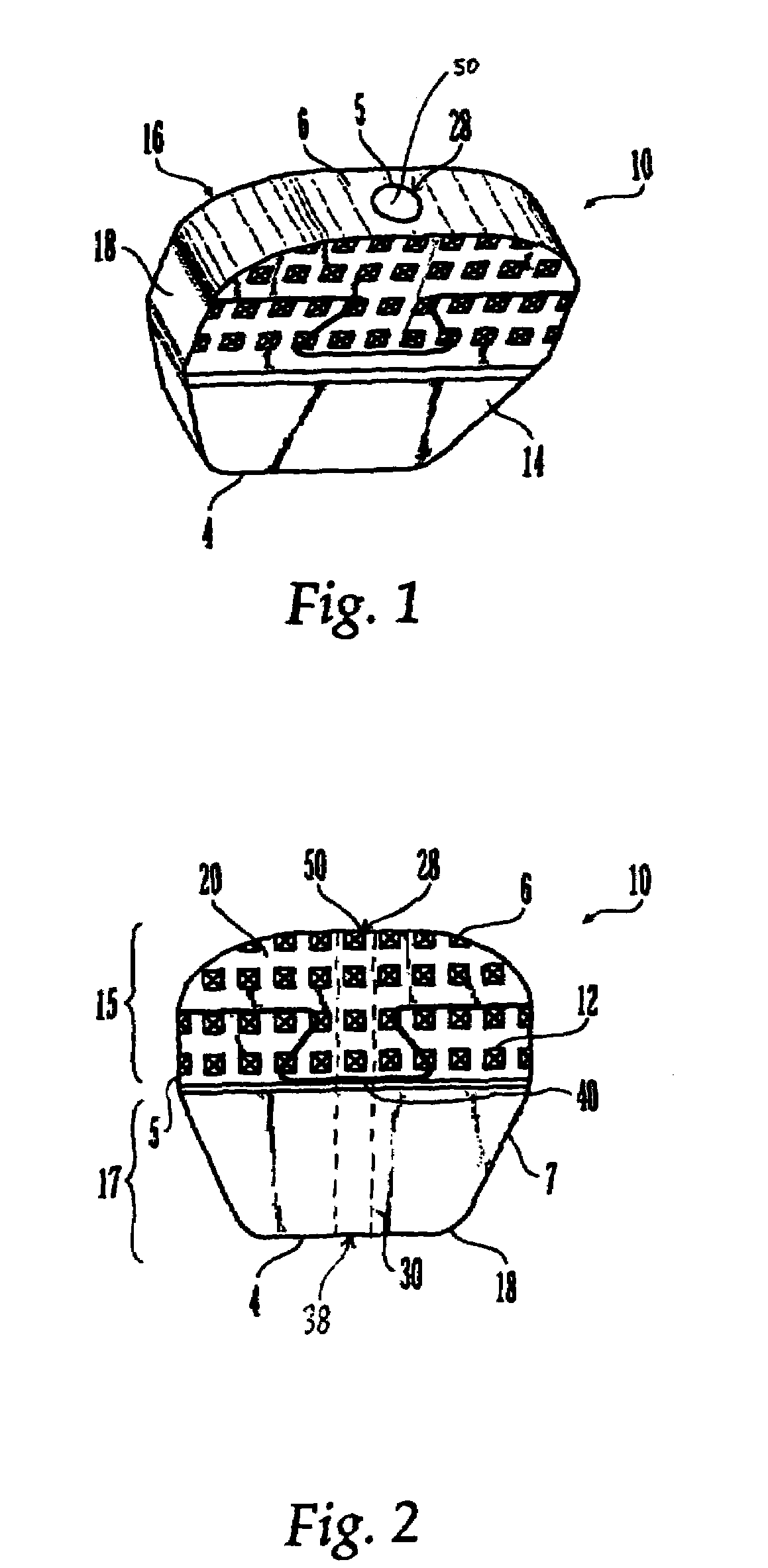

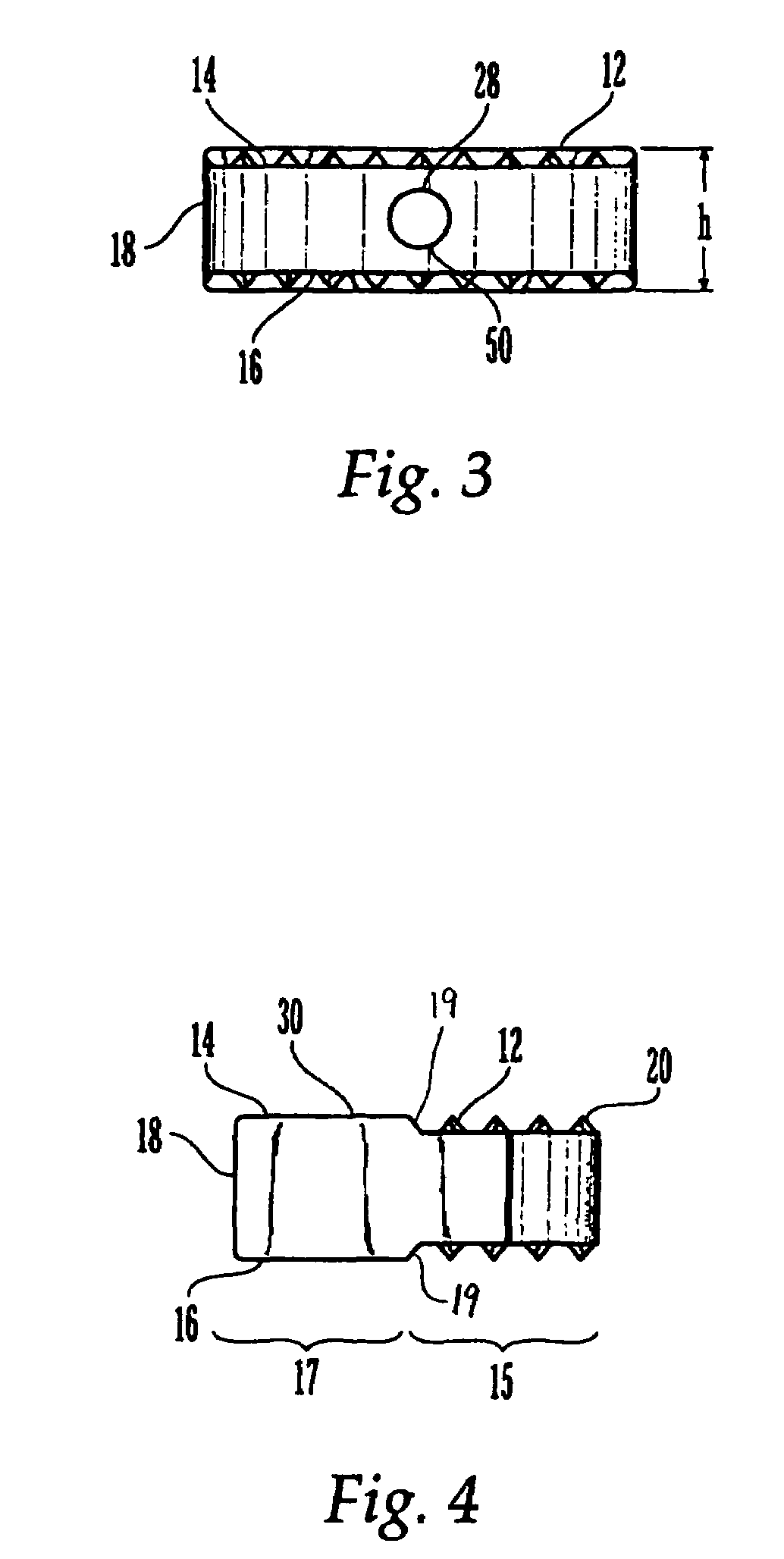

Multipiece allograft implant

ActiveUS7226482B2Promote new bone growthKeeping the implant from being displacedBone implantJoint implantsBone CortexIntervertebral fusion

Owner:SYNTHES USA

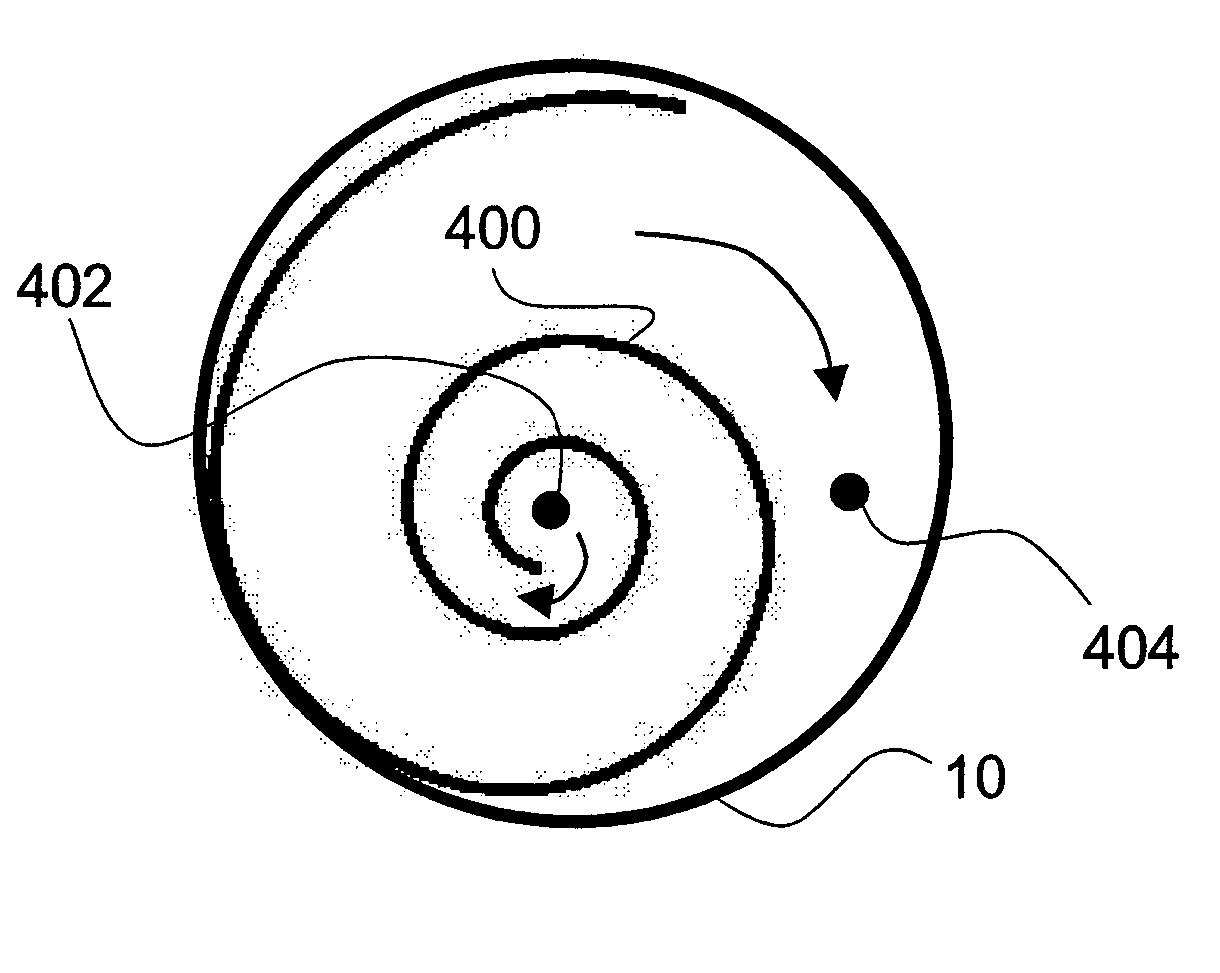

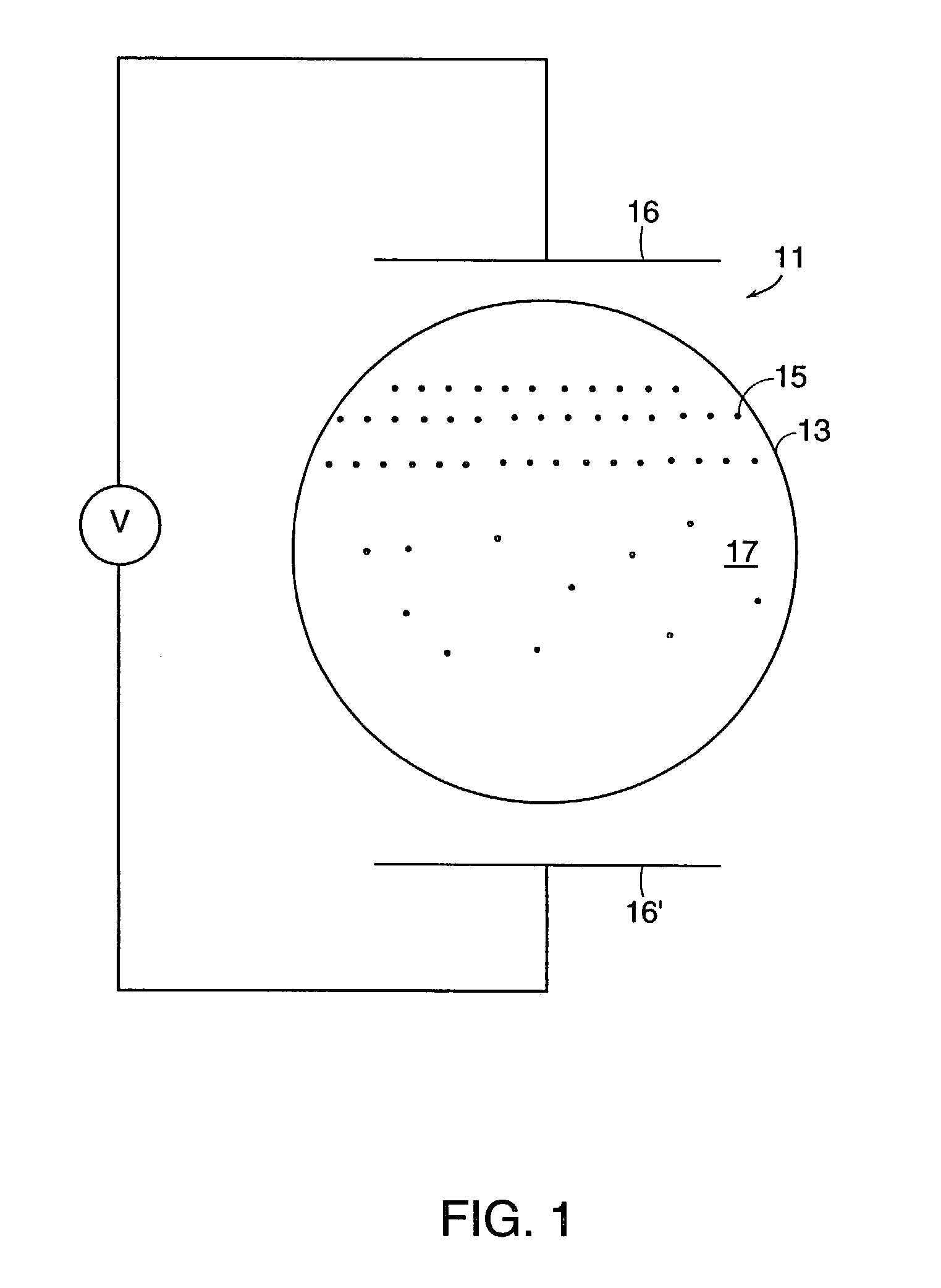

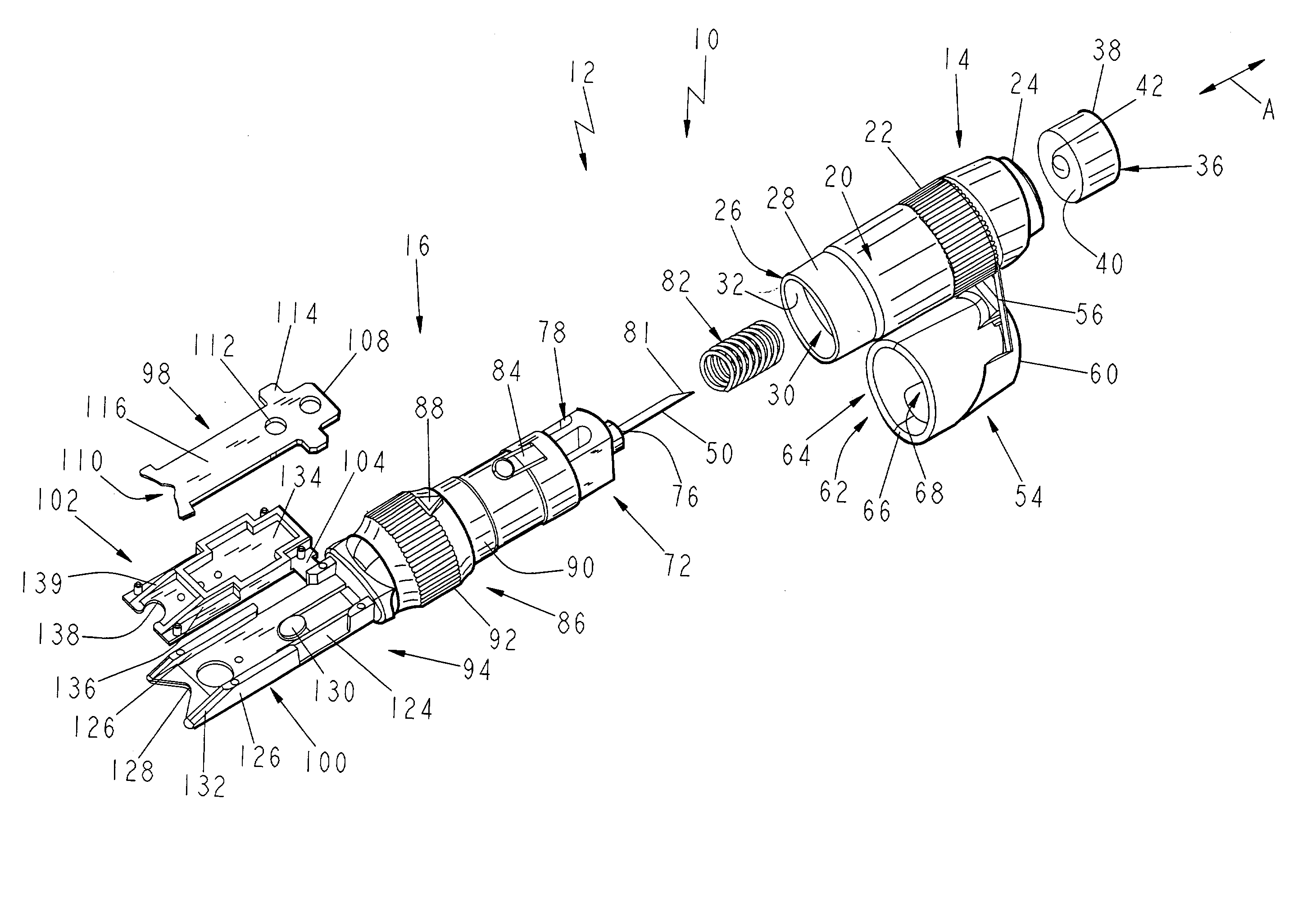

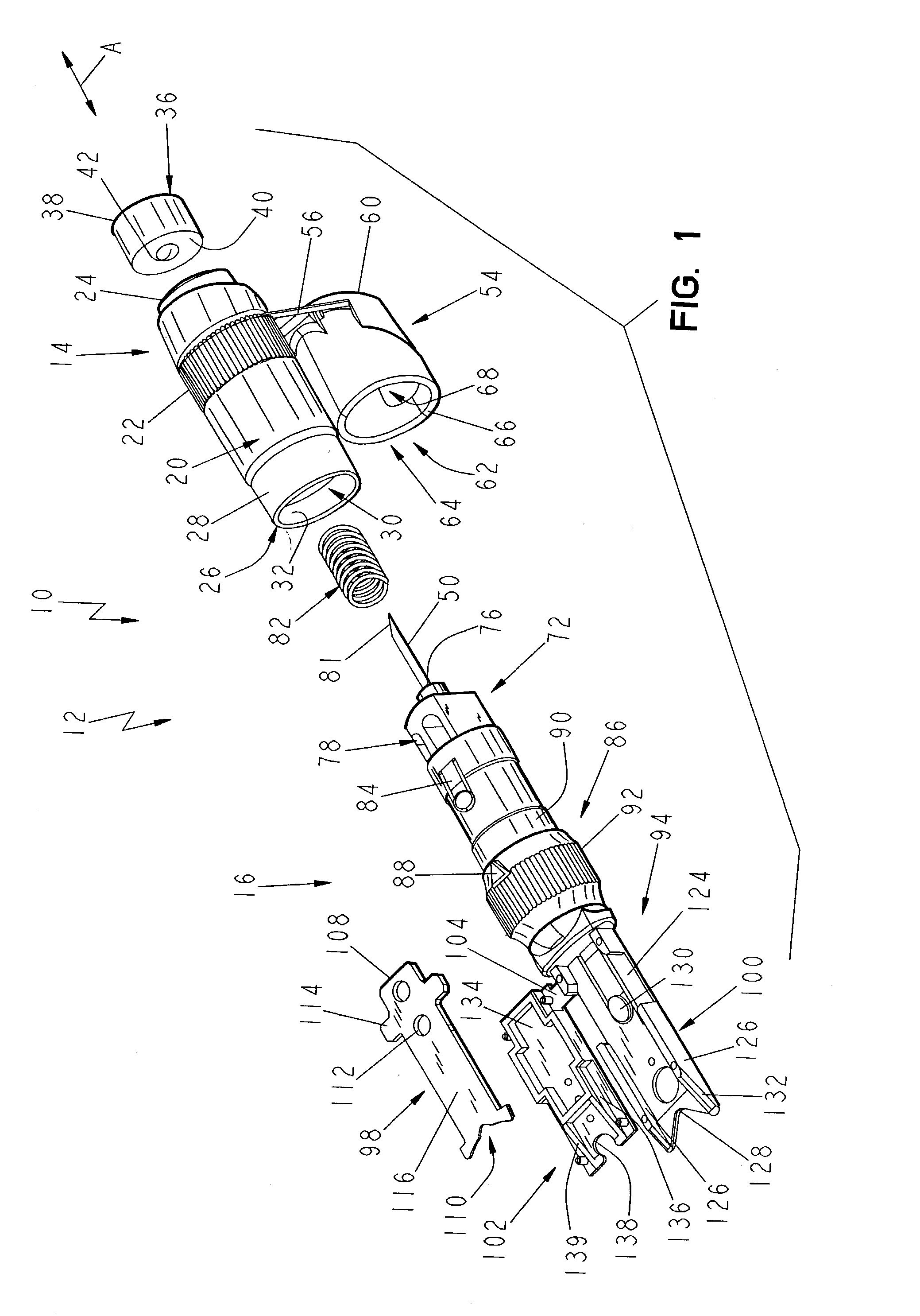

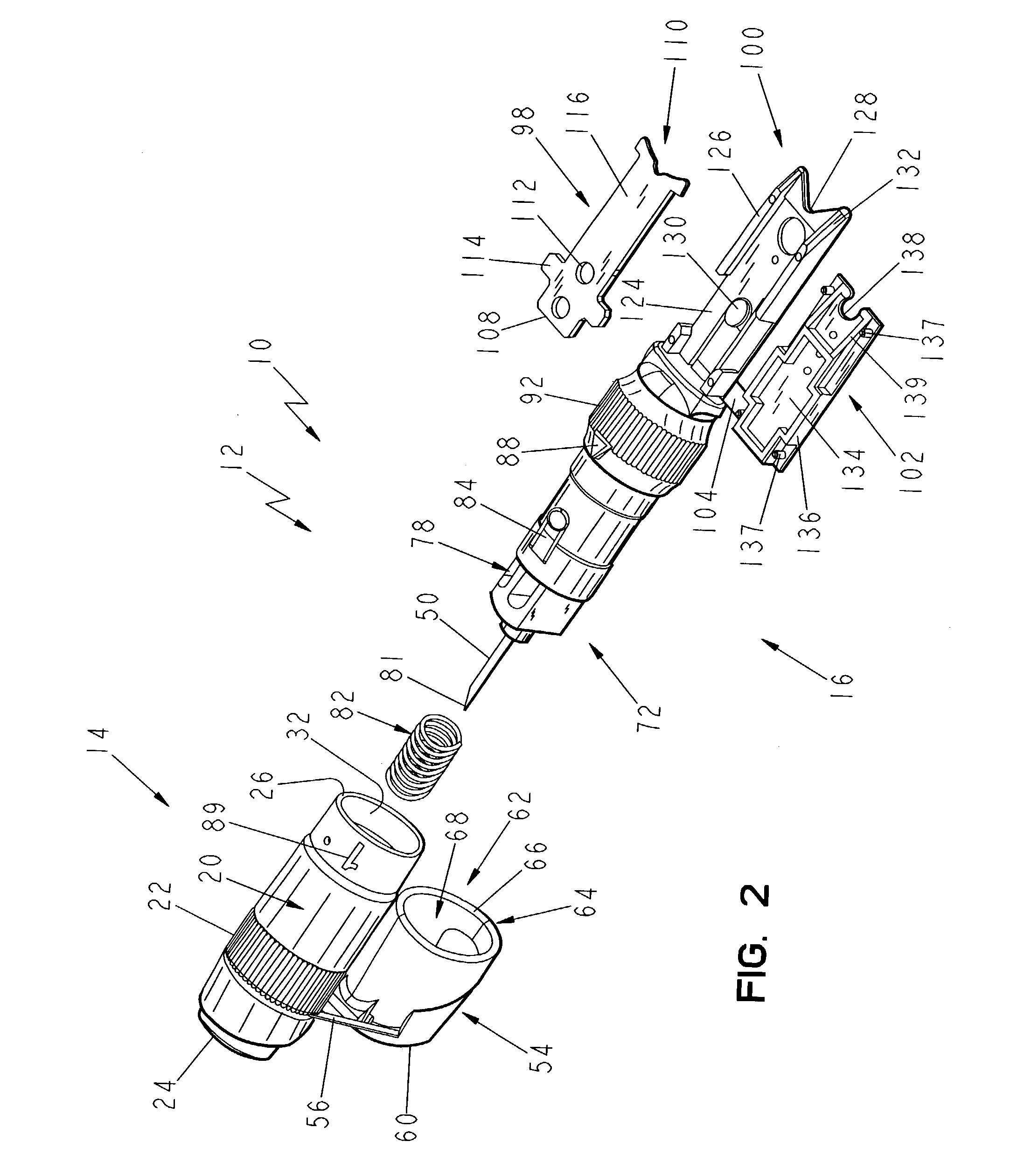

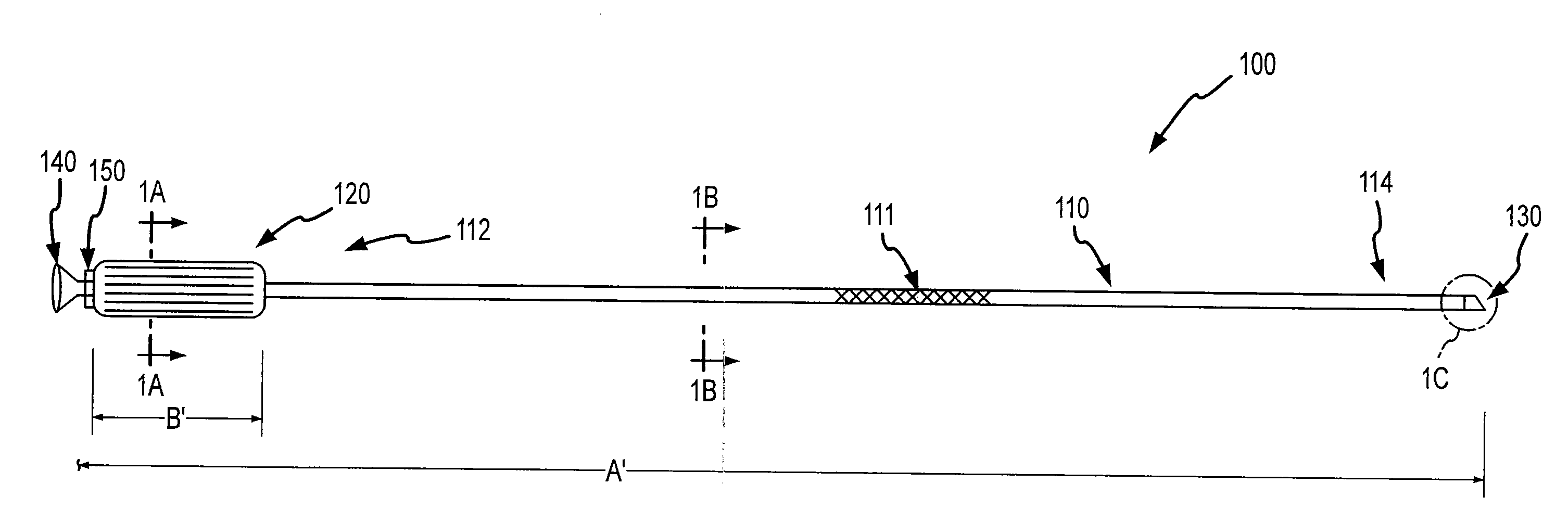

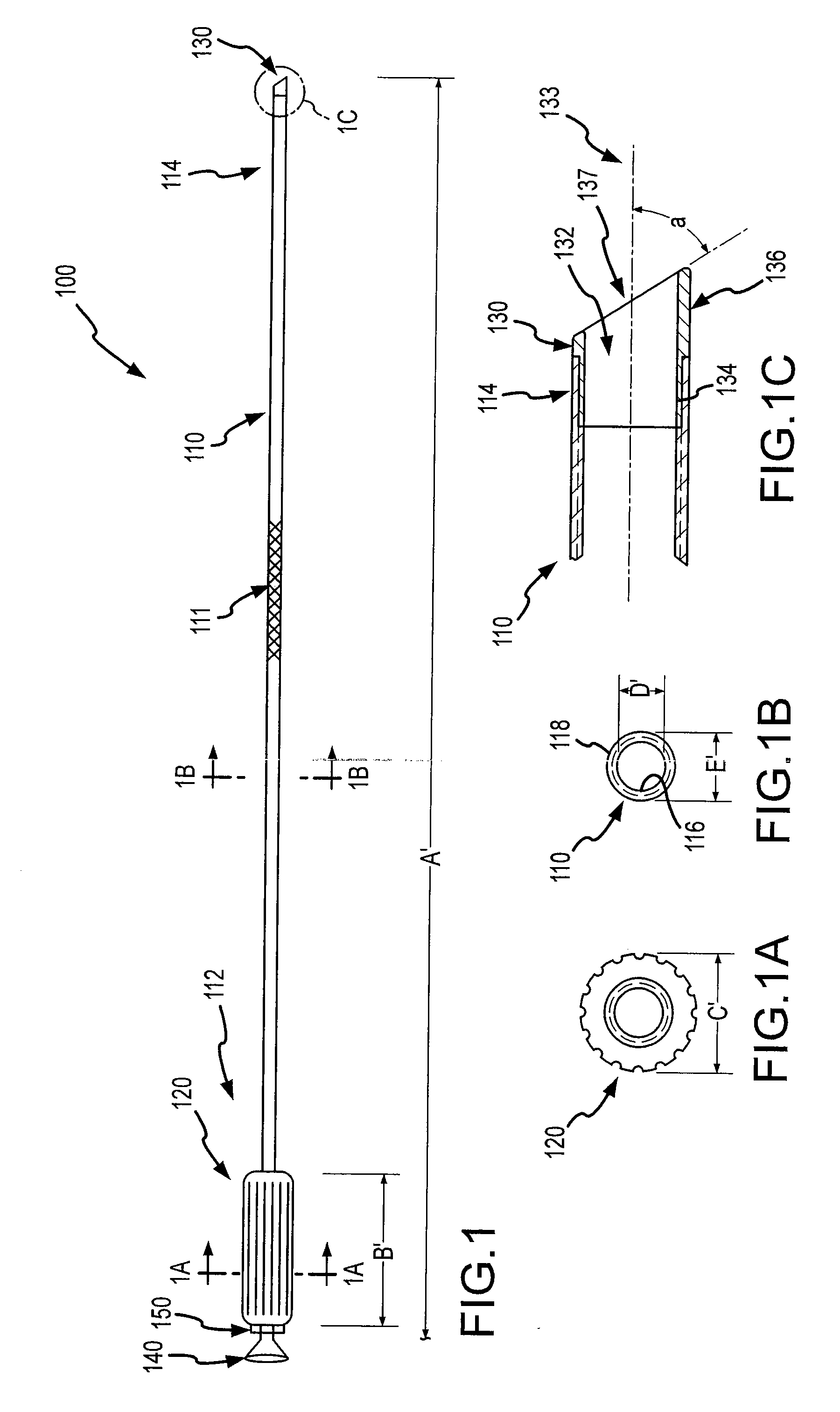

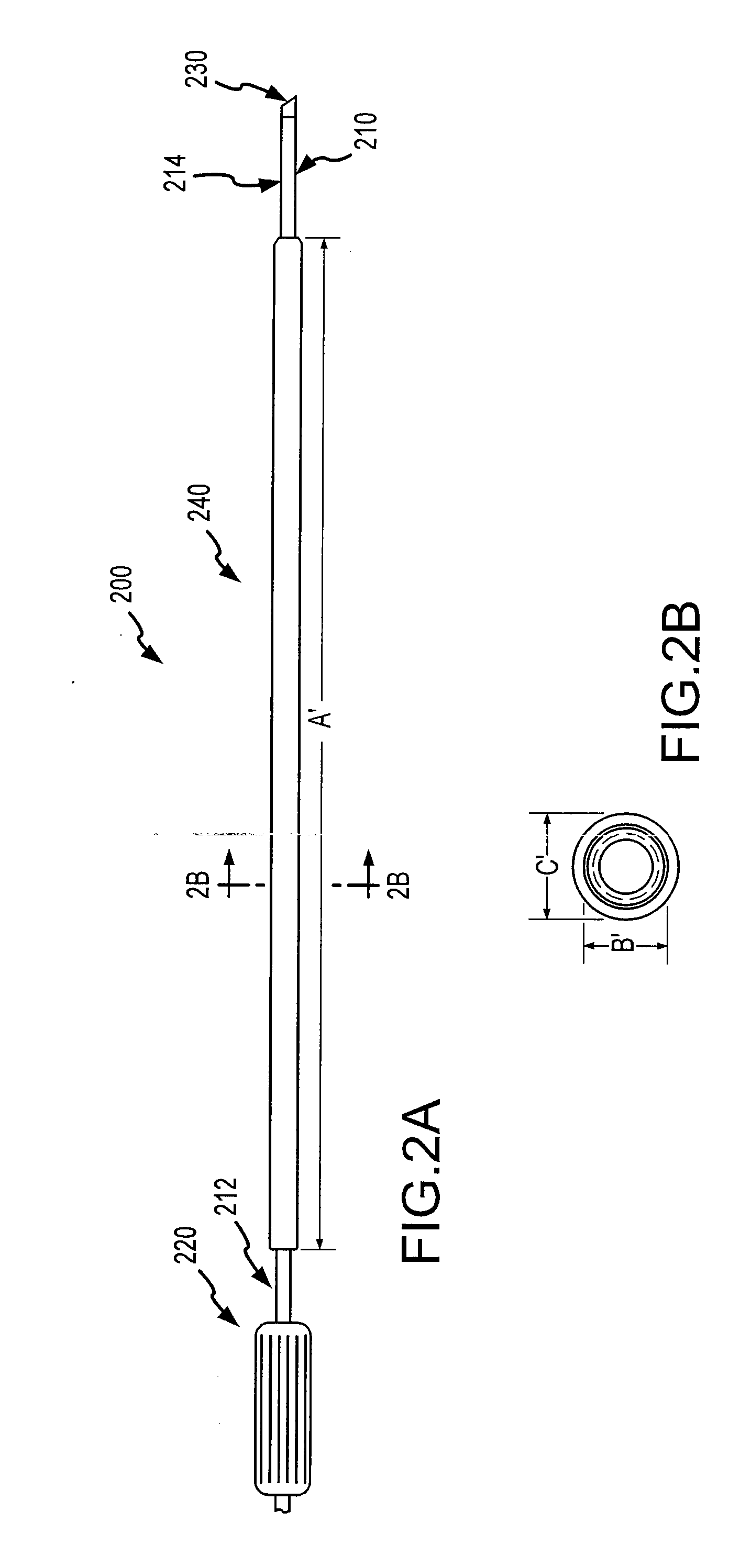

Tissue Separating Systems and Methods

ActiveUS20080154296A1Smooth connectionReduce morbidityTransvascular endocardial electrodesBlunt dissectorsEngineeringBiomedical engineering

Systems and methods for separating an object such as a pacing lead from a patient tissue involve a flexible and torqueable shaft having an internal lumen sized to receive the object, and a hard separating mechanism for separating the object from the tissue. Typically the shaft and separating mechanism are advanced along or toward the object, and the separating mechanism is contacted with the tissue. The shaft is rotated to effect separation between the object and the tissue. The systems and methods are well suited for use in cardiac pacing or defibrillator lead explant procedures.

Owner:SPECTRANETICS

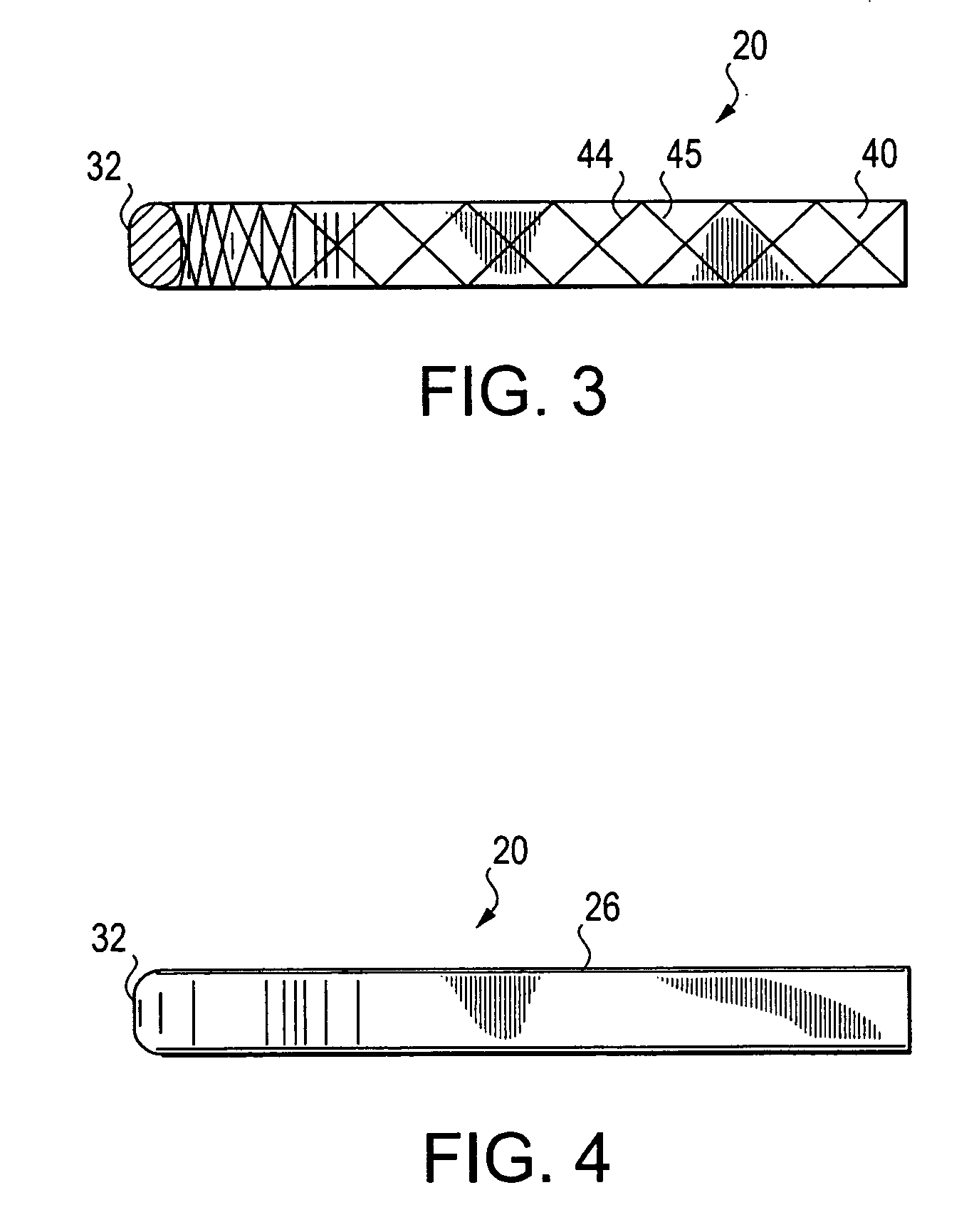

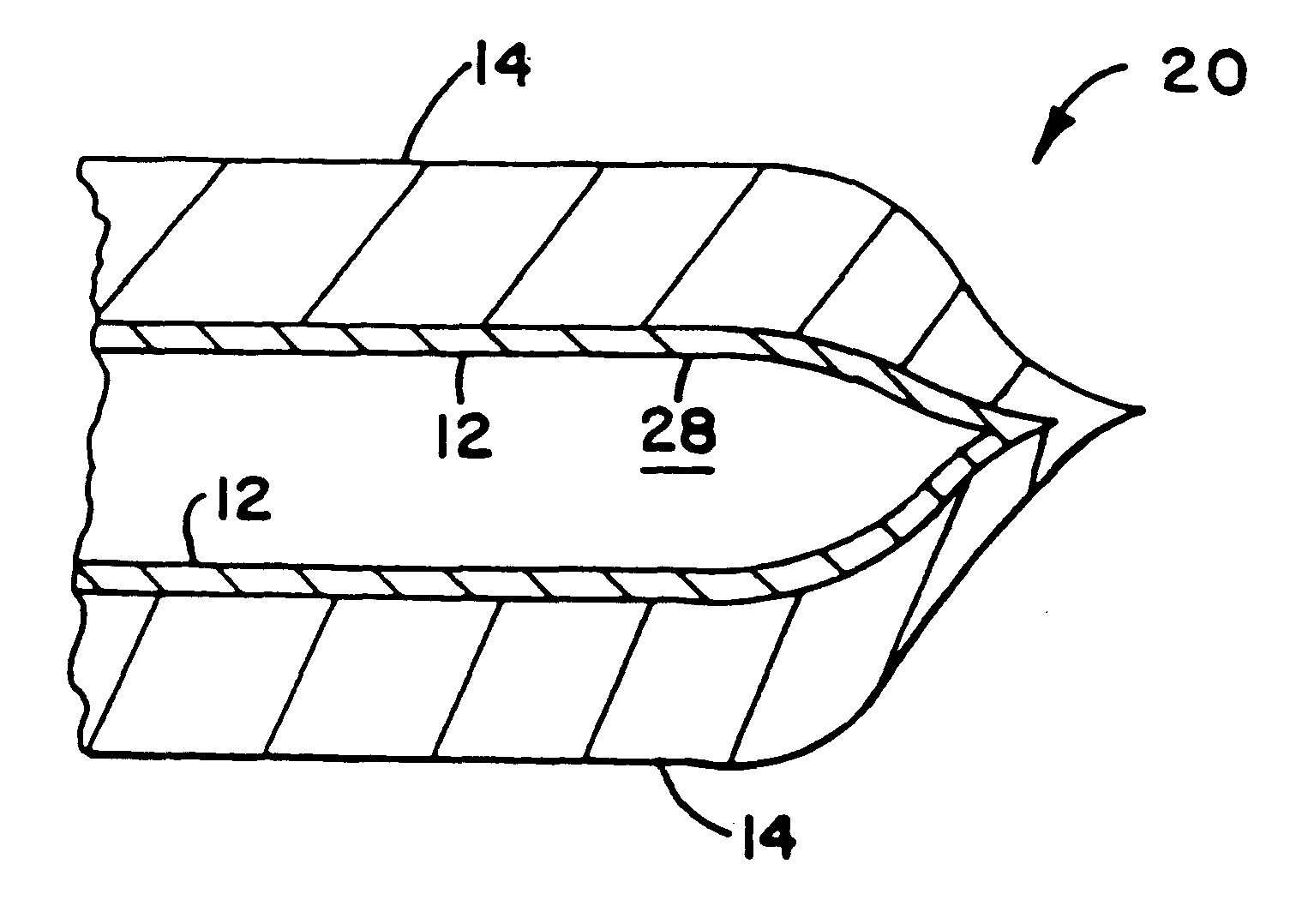

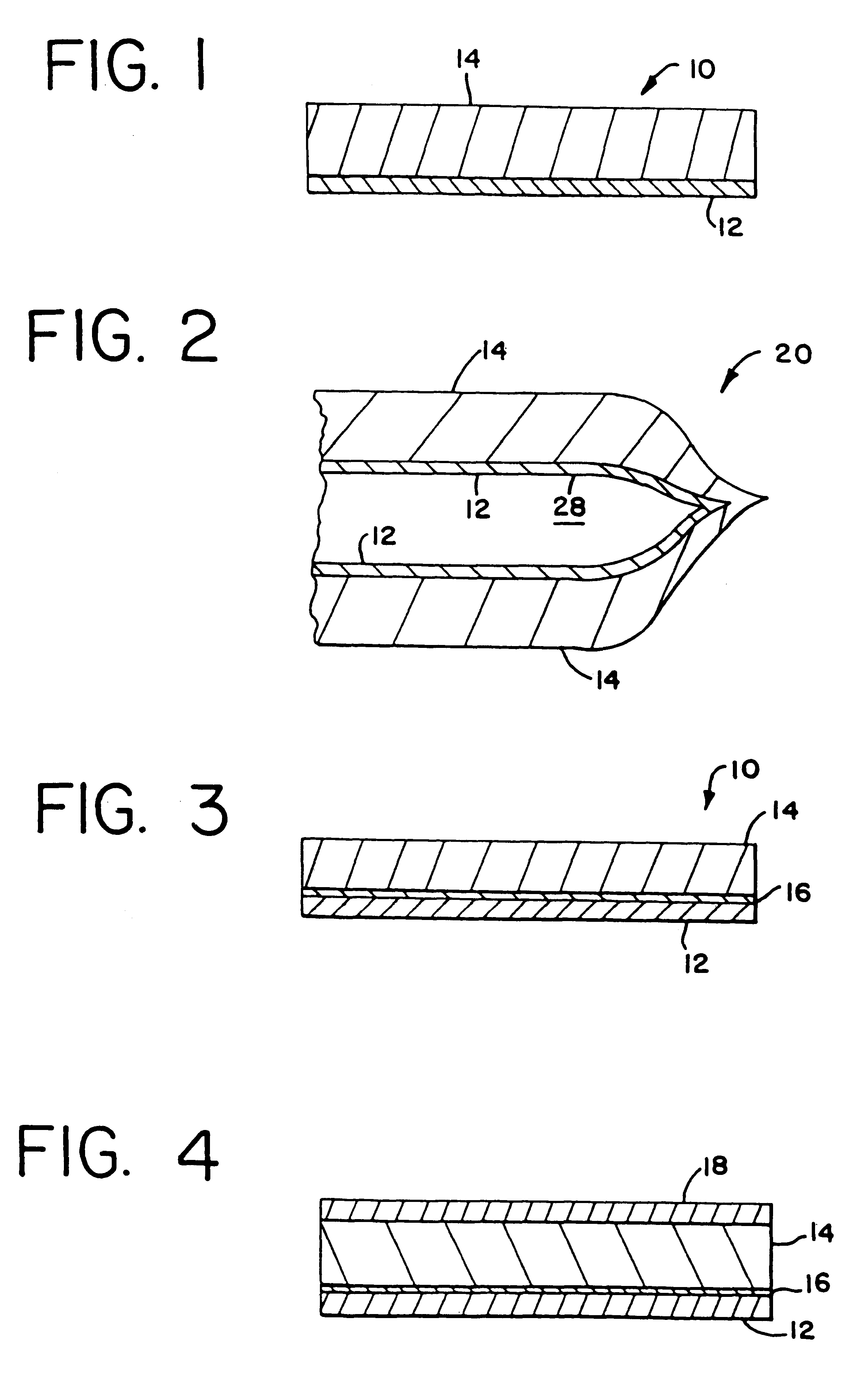

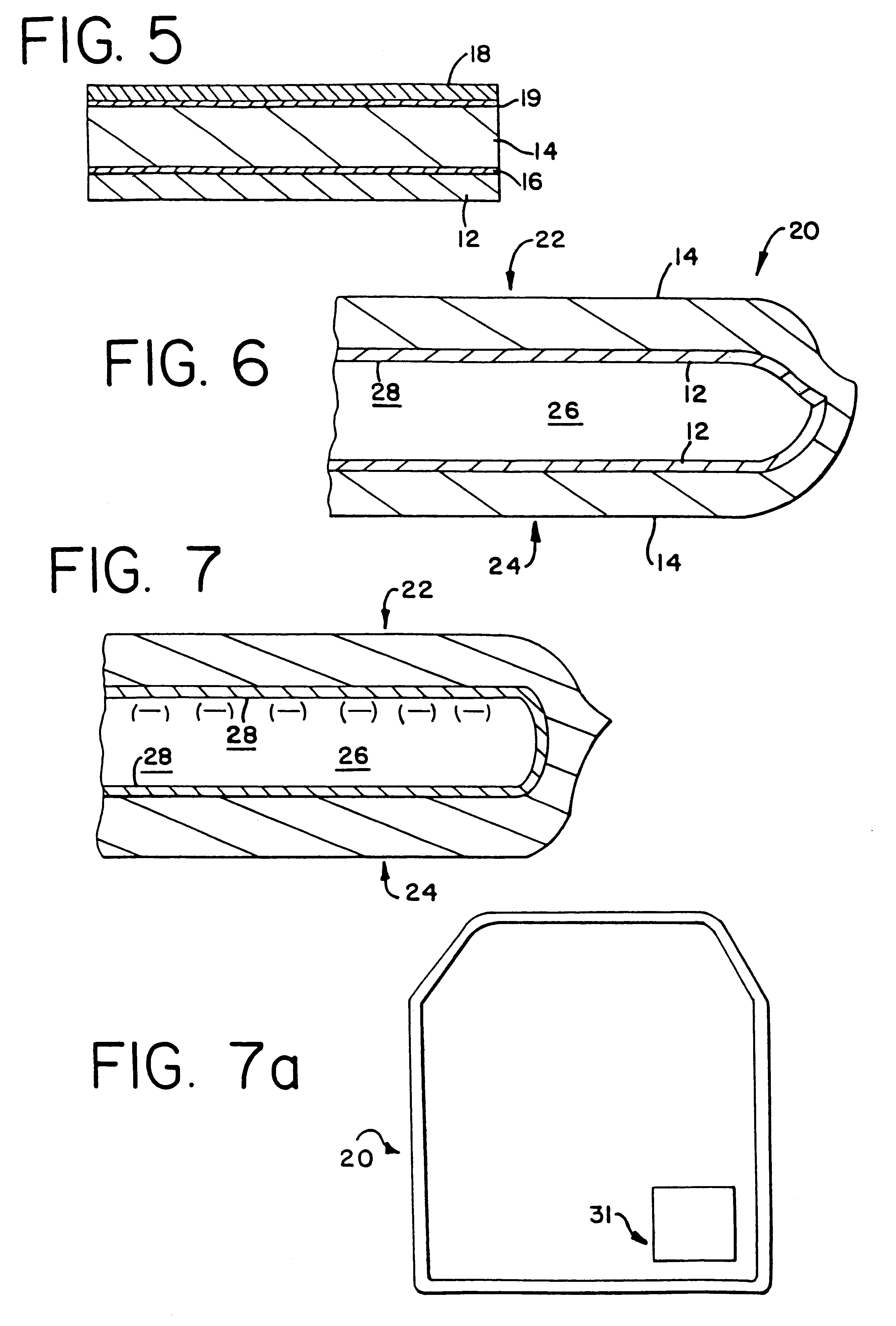

Multilayer gas-permeable container for the culture of adherent and non-adherent cells

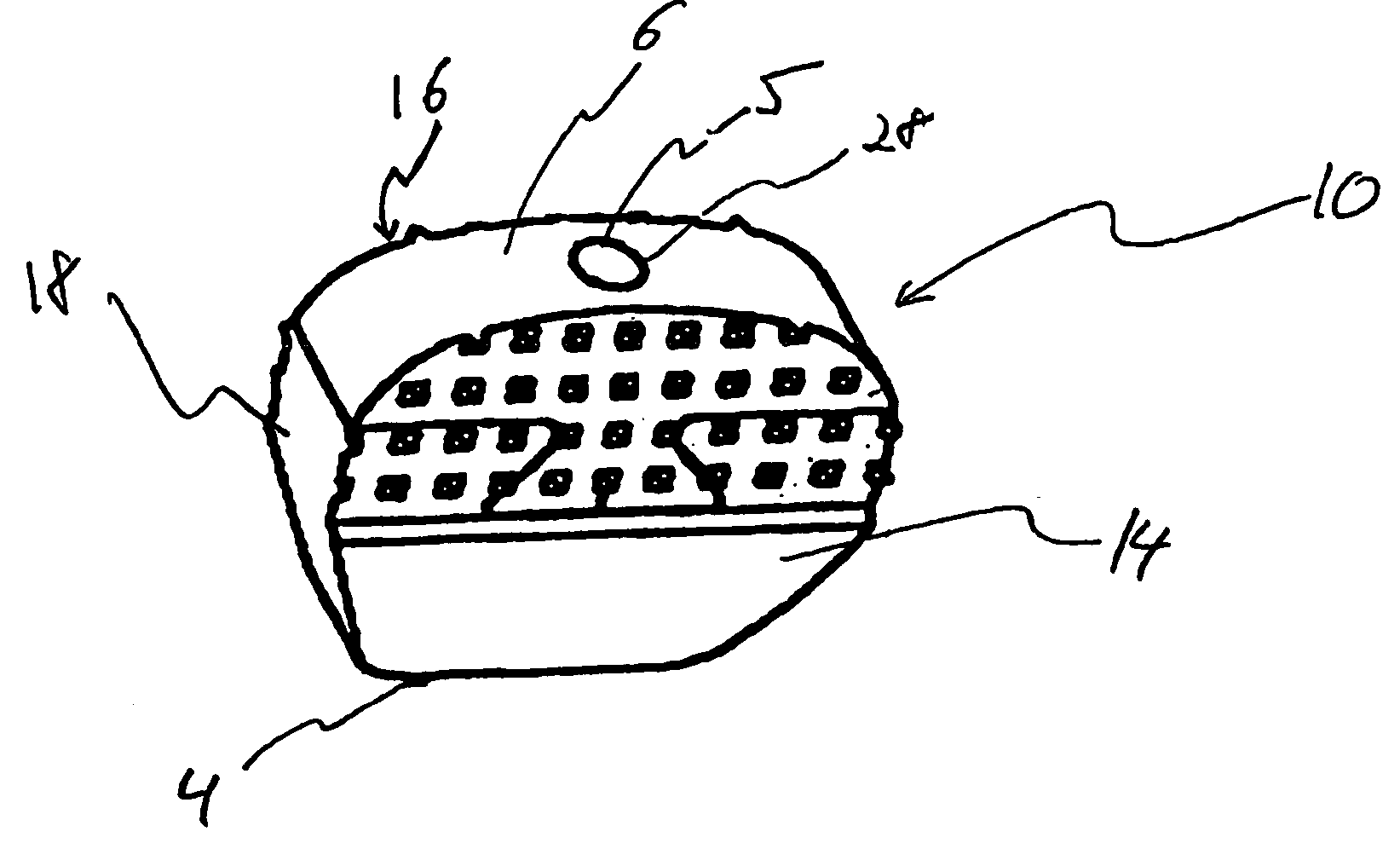

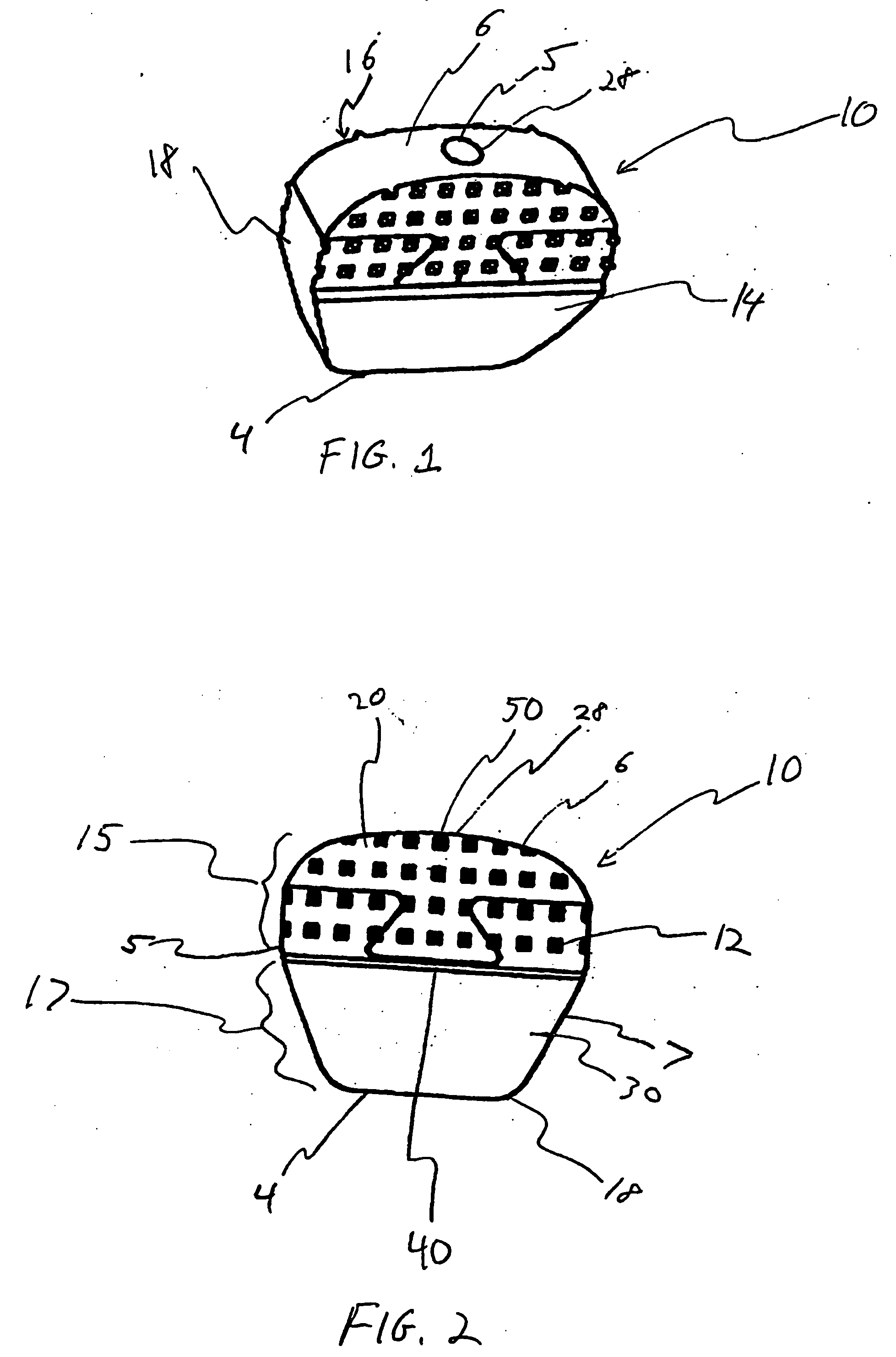

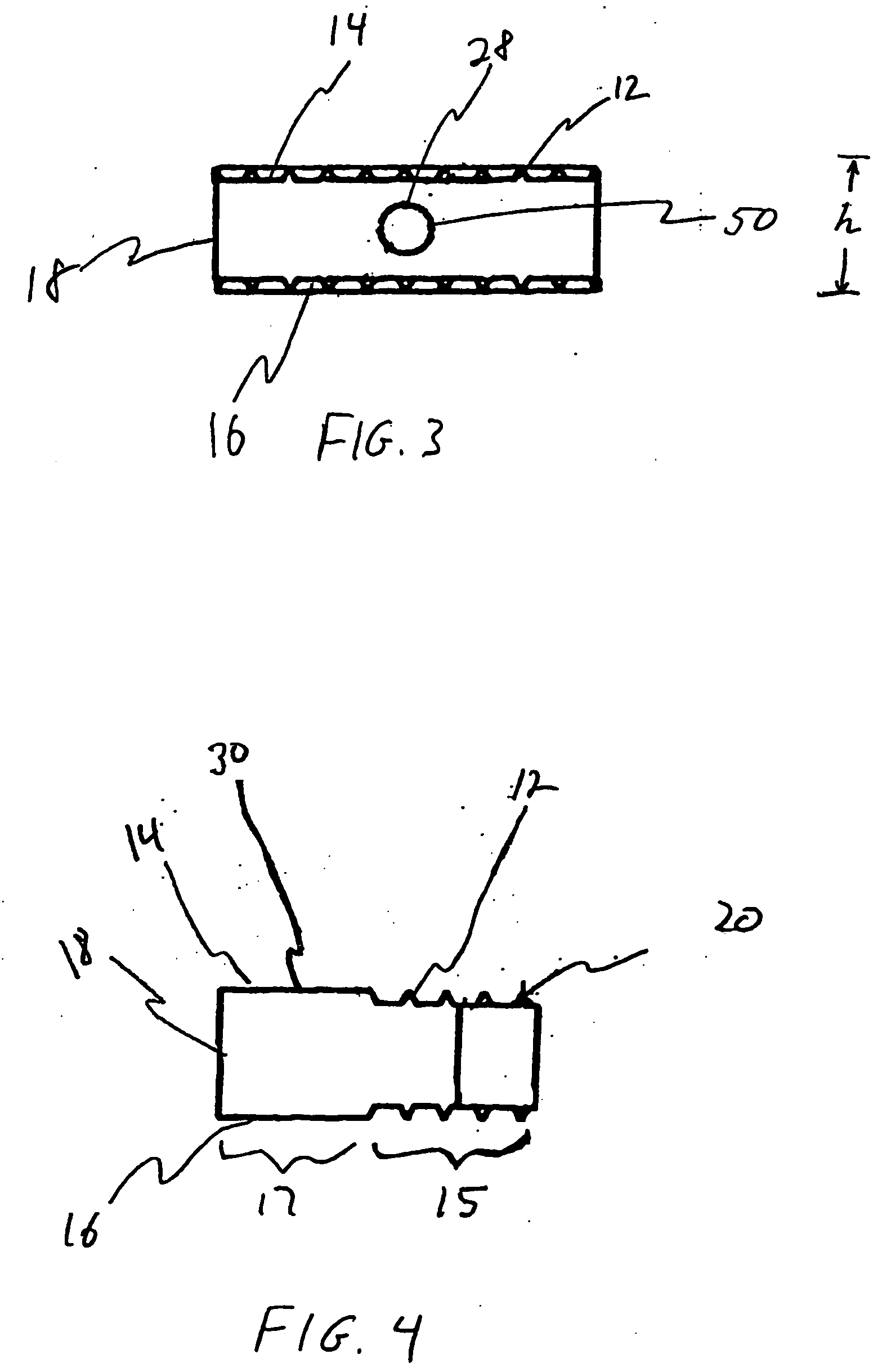

InactiveUS6297046B1Promote cell growthStrength and resistanceBioreactor/fermenter combinationsBiological substance pretreatmentsPolyolefinPolystyrene

A multi-layer, flexible, gas-permeable film (10) suitable for forming a cell culture container (20), the film (10) comprising a first layer (12) composed of a polystyrene having a thickness within the range of 0.0001 inches to about 0.0010 inches and, a second layer (14) adhered to the first layer (12) composed of a polyolefin having a thickness within the range of 0.004 inches to about 0.015 inches.

Owner:BAXTER INT INC

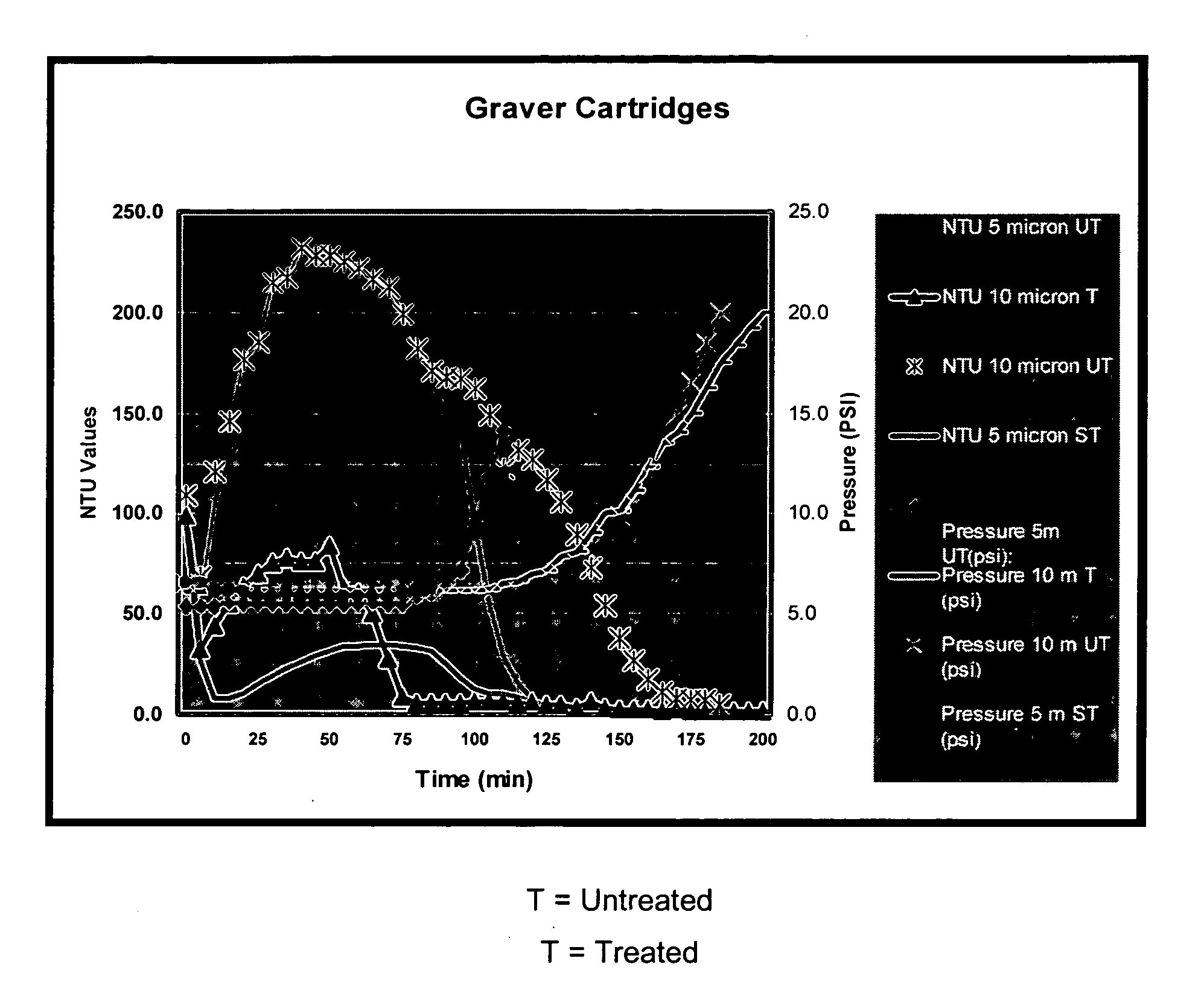

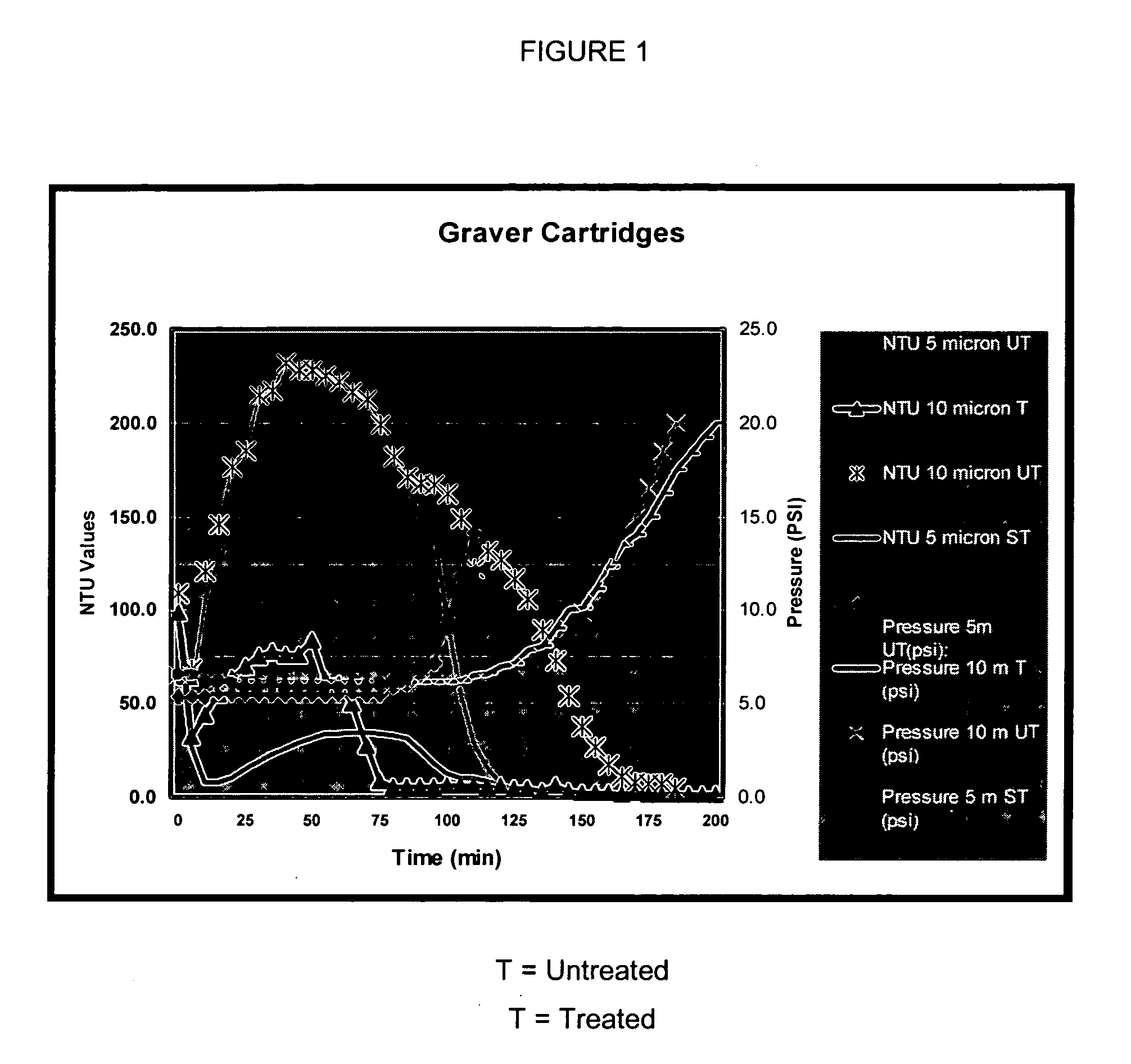

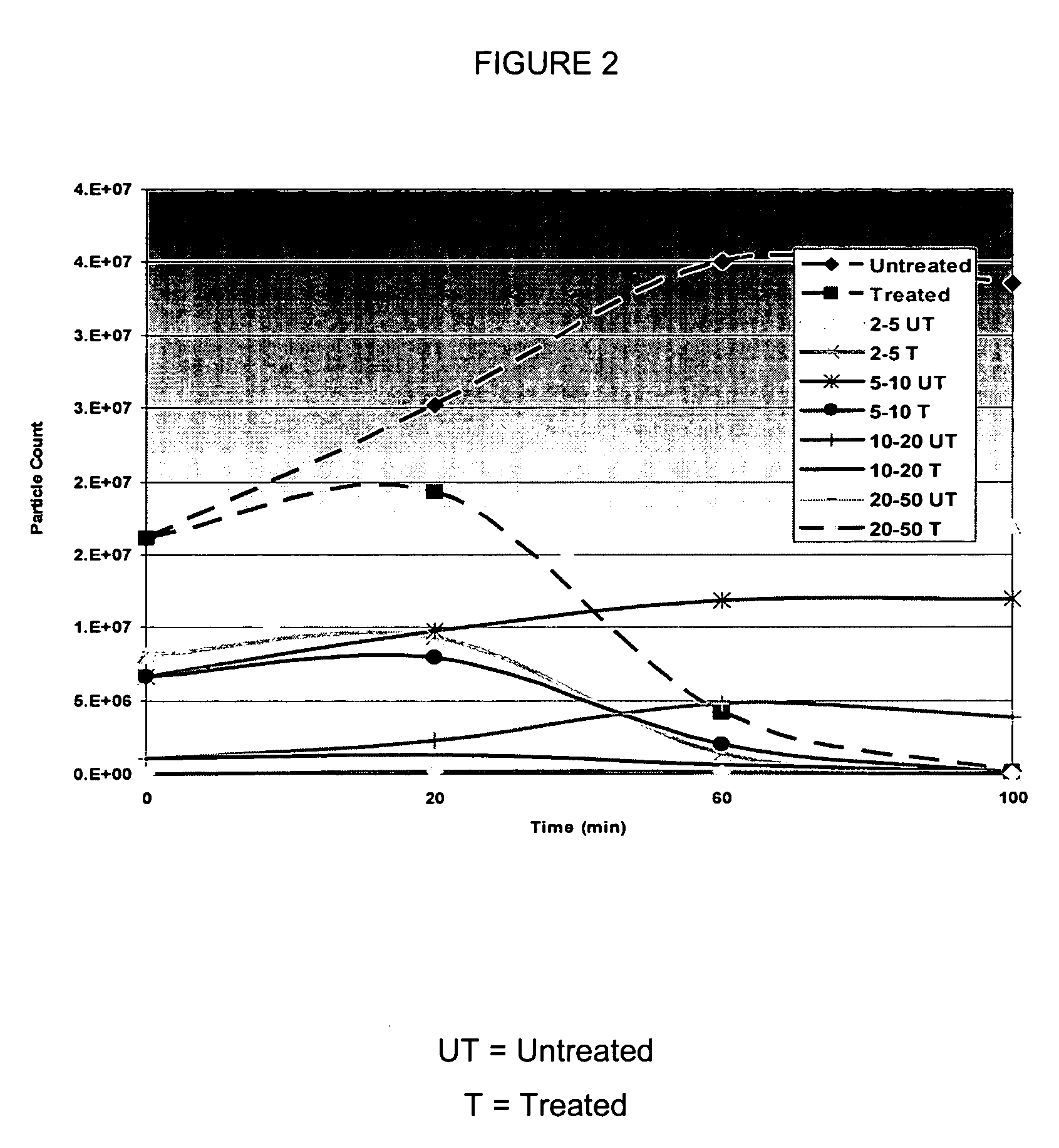

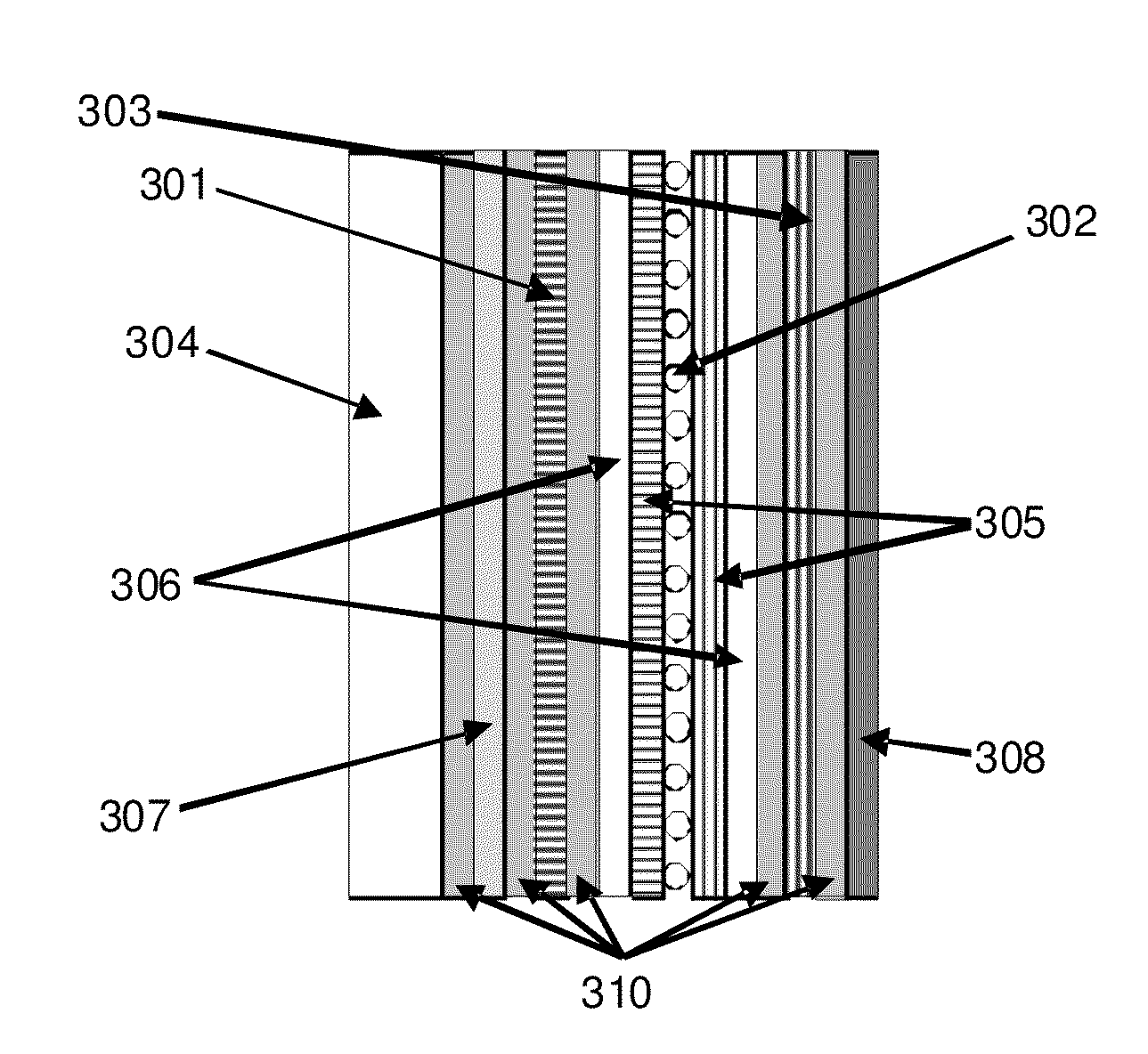

Coated filter media

InactiveUS20060231487A1Fine surfaceImprove abilitiesSemi-permeable membranesIsotope separationPolymer scienceFilter media

The invention relates to a coating composition on the surface of a filtration media. In particular, the invention relates to a coating composition for a filtration media comprising at least one polymer; at least one crosslinking agent; and optionally at least one compatabilizing agent.

Owner:THE LUBRIZOL CORP

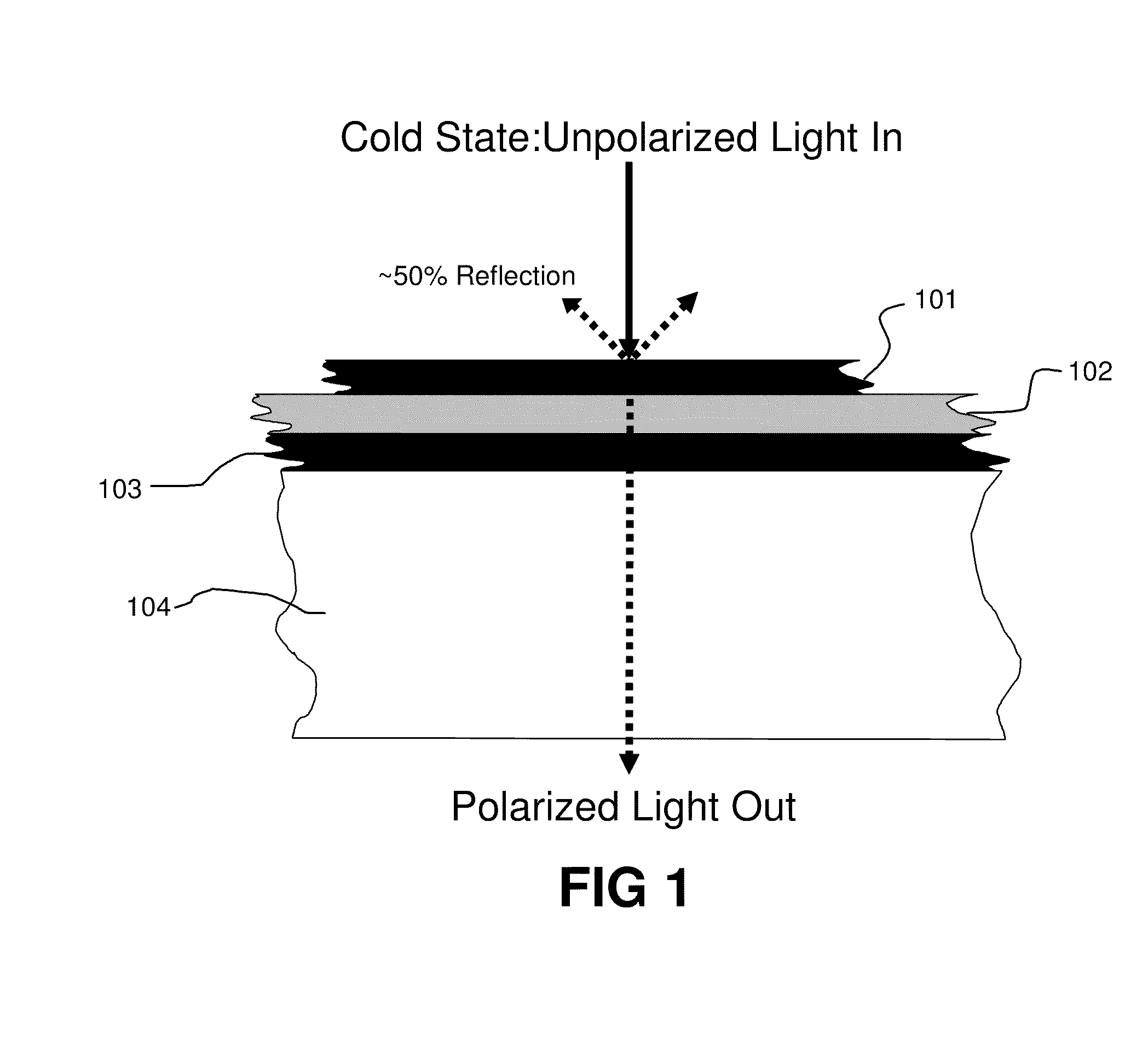

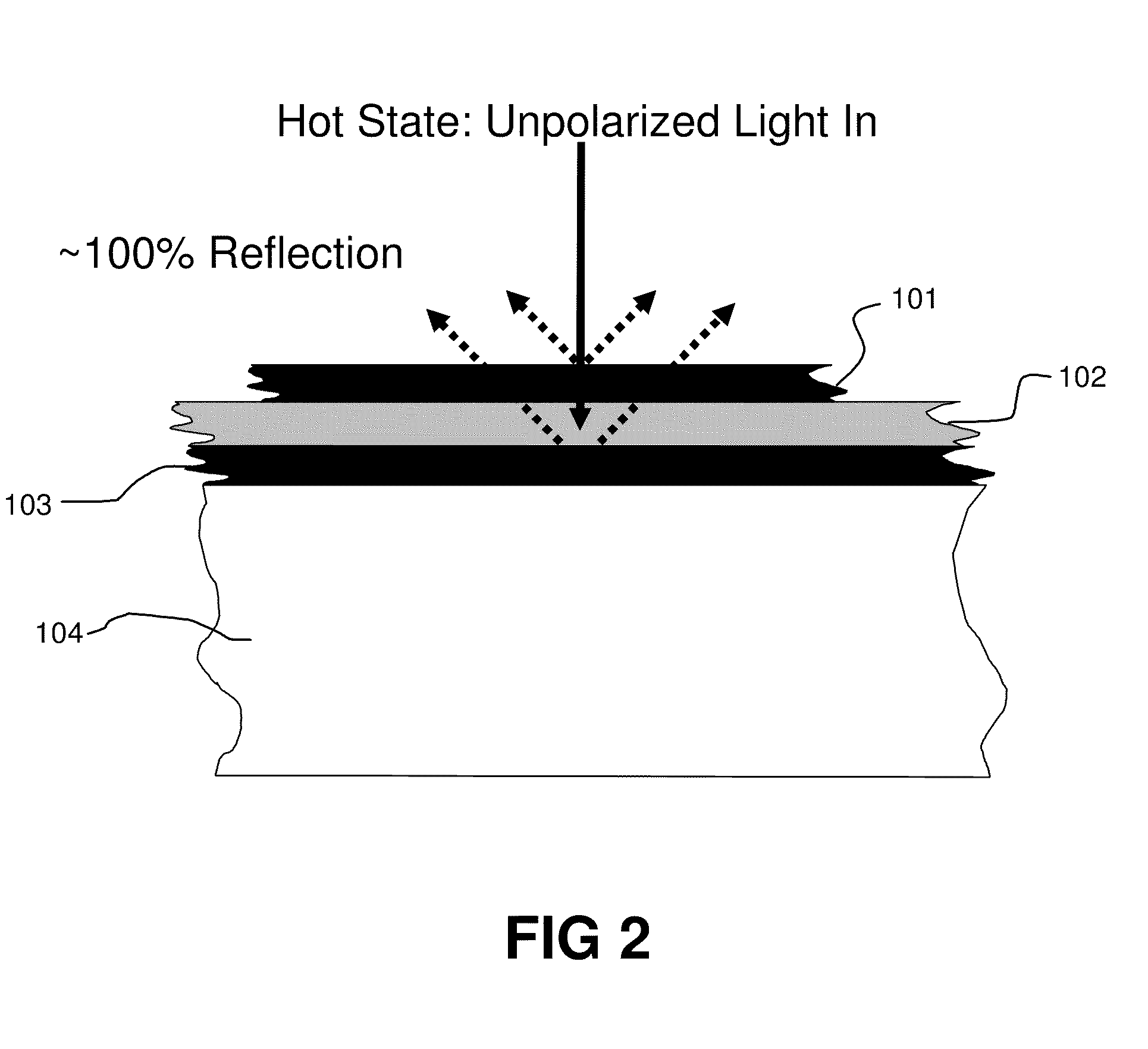

Methods for Fabricating Thermochromic Filters

InactiveUS20100045924A1Easy and less-expensive to manufactureEasy to installSolar heating energySolar heat collector controllersSelective reflectionElectrical polarity

Thermochromic liquid crystal filters are fabricated by providing two polarizers oriented at offset polarity with respect to each other; providing alignment structures adjacent the inner surfaces of the polarizers; placing a plurality of spacers between the polarizers; and filling a space created by the spacers with a thermotropic liquid crystal that acts as a wave block in an isotropic state and acts as a depolarizer in a nematic state. Alternatively, the filters can be created by encapsulating a thermochromic liquid crystal with a polymer material to form a flexible film and orienting the thermochromic liquid crystal in the polymer material to create a structure that functions as a thermochromic optical filter. Such filters can control the flow of light and radiant heat through selective reflection, transmission, absorption, and / or re-emission. The filters have particular application in passive or active light-regulating and temperature-regulating films, materials, and devices, and particularly as construction materials.

Owner:RAVENBRICK

Method and apparatus for depositing tungsten after surface treatment to improve film characteristics

InactiveUS6936538B2Reduce fluorine contentHigh resistivitySolid-state devicesSemiconductor/solid-state device manufacturingChemical speciesNucleation

A method and system to form a refractory metal layer over a substrate includes introduction of a reductant, such as PH3 or B2H6, followed by introduction of a tungsten containing compound, such as WF6, to form a tungsten layer. It is believed that the reductant reduces the fluorine content of the tungsten layer while improving the step coverage and resistivity of the tungsten layer. It is believed that the improved characteristics of the tungsten film are attributable to the chemical affinity between the reductants and the tungsten containing compound. The chemical affinity provides better surface mobility of the adsorbed chemical species and better reduction of WF6 at the nucleation stage of the tungsten layer. The method can further include sequentially introducing a reductant, such as PH3 or B2H6, and a tungsten containing compound to deposit a tungsten layer. The formed tungsten layer can be used as a nucleation layer followed by bulk deposition of a tungsten layer utilizing standard CVD techniques. Alternatively, the formed tungsten layer can be used to fill an aperture.

Owner:APPLIED MATERIALS INC

Method and apparatus for dicing of thin and ultra thin semiconductor wafer using ultrafast pulse laser

InactiveUS7804043B2Minimize heating effectImprove machine qualityWelding/soldering/cutting articlesMetal working apparatusPicosecond laserBeam polarization

The present invention relates to the apparatus, system and method for dicing of semiconductor wafers using an ultrafast laser pulse of femtosecond and picosecond pulse widths directly from the ultrafast laser oscillator without an amplifier. Thin and ultrathin semiconductor wafers below 250 micrometer thickness, are diced using diode pumped, solid state mode locked ultrafast laser pulses from oscillator without amplification. The invention disclosed has means to avoid / reduce the cumulative heating effect and to avoid machine quality degrading in multi shot ablation. Also the disclosed invention provides means to change the polarization state of the laser beam to reduce the focused spot size, and improve the machining efficiency and quality. The disclosed invention provides a cost effective and stable system for high volume manufacturing applications. An ultrafast laser oscillator can be a called as femtosecond laser oscillator or a picosecond laser oscillator depending on the pulse width of the laser beam generated.

Owner:LASERFACTURING

Multipiece allograft implant

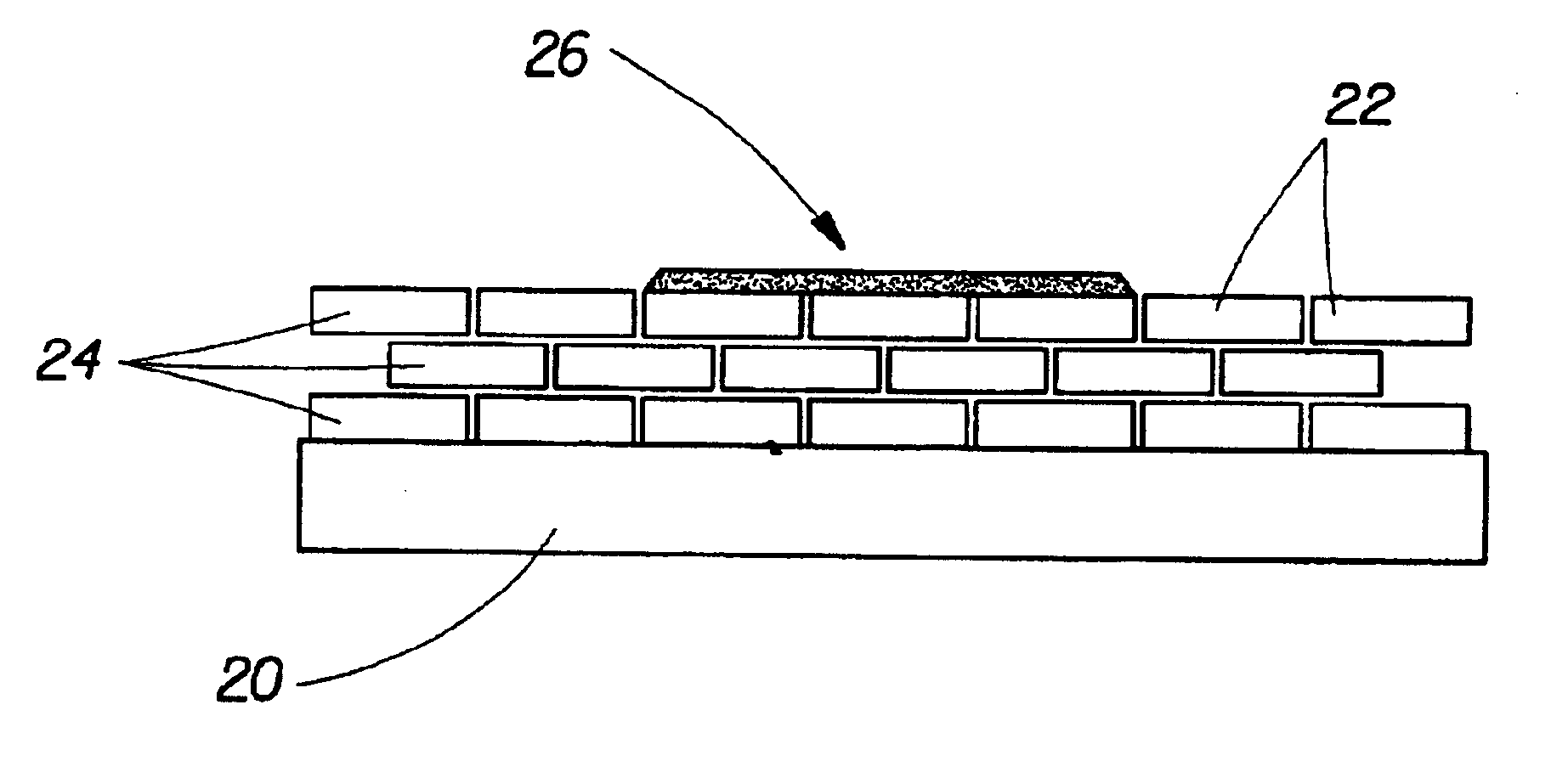

ActiveUS20050113918A1Fine surfacePromote new bone growthBone implantJoint implantsBone CortexIntervertebral fusion

An allogenic implant for use in intervertebral fusion is formed from two parts. The first part, composed of cortical bone, provides mechanical strength to the implant, allowing the proper distance between the vertebrae being treated to be maintained. The second part, composed of cancellous bone, is ductile and promotes the growth of new bone between the vertebrae being treated and the implant, thus fusing the vertebrae to the implant and to each other. The implant is sized and shaped to conform to the space between the vertebrae. Teeth formed on the superior and inferior surfaces of the implant prevent short-term slippage of the implant.

Owner:SYNTHES USA

Manufacturing method for carbon fiber antenna surface

The invention relates to a manufacturing method for a carbon fiber antenna surface. The manufacturing method comprises the following steps of 1, prefabricating a die; 2, polishing the die; 3, chemically electroplating the die; 4, measuring the precision, and clearing away impurities; 5, coating a demolding agent; 6, paving carbon fiber cloth on a male die; 7, paving PVC foams on the surface of the male die; 8, paving carbon fiber cloth on the surface of the male die; 9, assembling the male die and a female die, and sealing and fastening the male die and the female die; 10, vacuumizing to enable the vacuum degree in the die to be smaller than -0.096MPa; 11, injecting epoxy resin and a solidifying agent from a material inlet of the female die; 12, sticking a layer of glass paper to the outer surface of a blank after the appearance gets through inspection and is qualified; 13, performing perforation and assembling; and 14, obtaining the carbon fiber antenna surface after the product is qualified through inspection. The carbon fiber antenna surface manufactured by the manufacturing method is smooth, and the precision can reach 0.1R.M.S; and due to normal-temperature solidification, energy is saved, and the cost is lowered.

Owner:XIAN TUOFEI COMPOSITE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com