Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Modifying surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of hydrophilizing materials

InactiveUS6863933B2Easy to controlGood removal effectInorganic/elemental detergent compounding agentsRadiation applicationsPolymer scienceNanoparticle

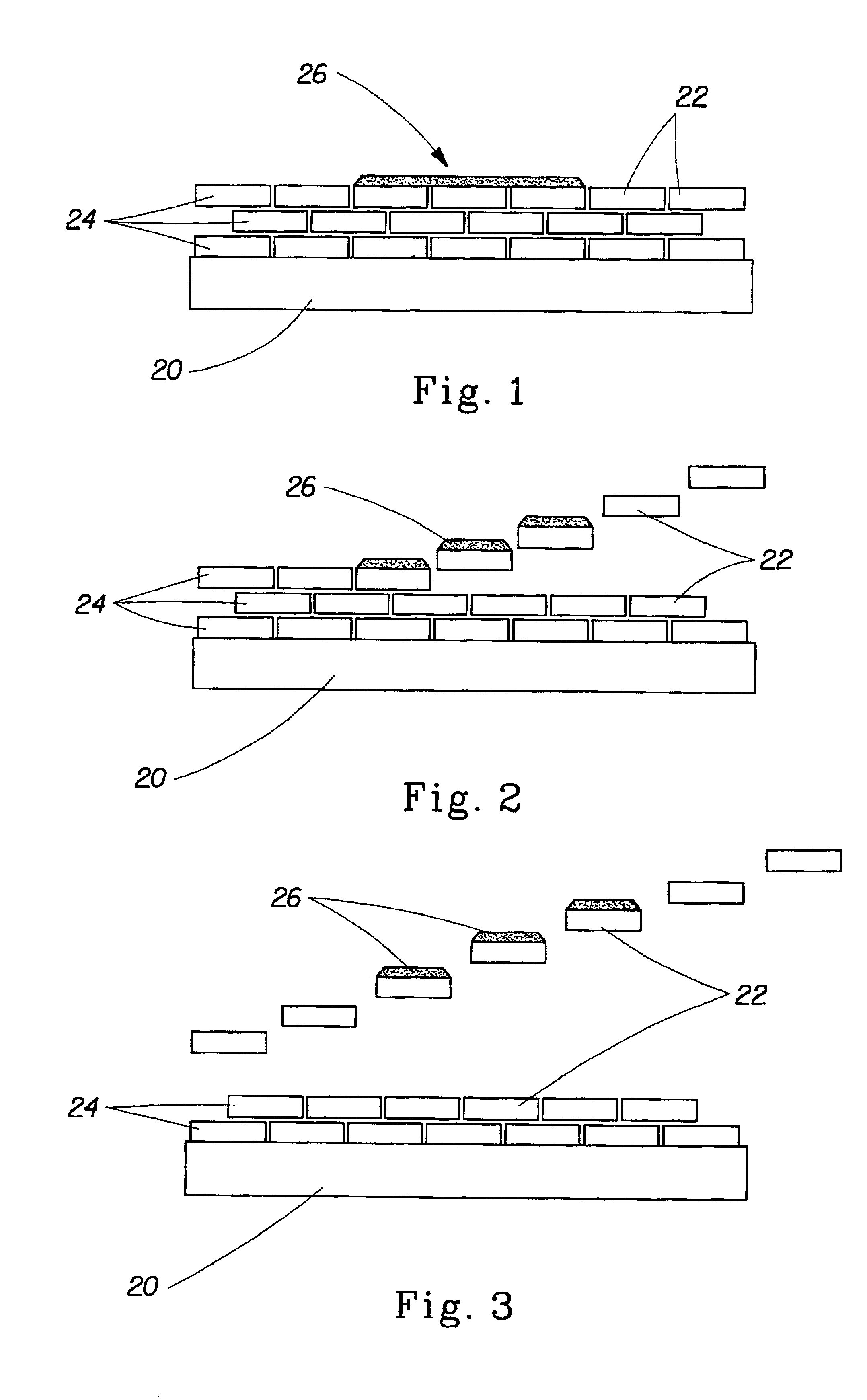

Coating compositions, methods and articles of manufacture comprising a nanoparticle system employing same to impart surface modifying benefits for all types of soft surfaces, and in some cases, hard surfaces, are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to the modified surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that, in some embodiments, may include at least one of the following improved surface properties: cleaning, wettability, liquid strike-through, comfort, stain resistance, soil removal, malodor control, modification of surface friction, reduced damage to abrasion and color enhancement, relative to the surfaces unmodified with such nanoparticle systems.

Owner:THE PROCTER & GAMBLE COMPANY

Enhancement of color on surfaces

InactiveUS6872444B2Easy to controlGood removal effectInorganic/elemental detergent compounding agentsPigmenting treatmentNanoparticleMaterials science

Coating compositions, methods and articles of manufacture comprising a nanoparticle system employing same to impart surface modifying benefits for all types of soft surfaces, and in some cases, hard surfaces, are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to the modified surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that, in some embodiments, may include at least one of the following improved surface properties: cleaning, wettability, liquid strike-through, comfort, stain resistance, soil removal, malodor control, modification of surface friction, reduced damage to abrasion and color enhancement, relative to the surfaces unmodified with such nanoparticle systems.

Owner:THE PROCTER & GAMBLE COMPANY

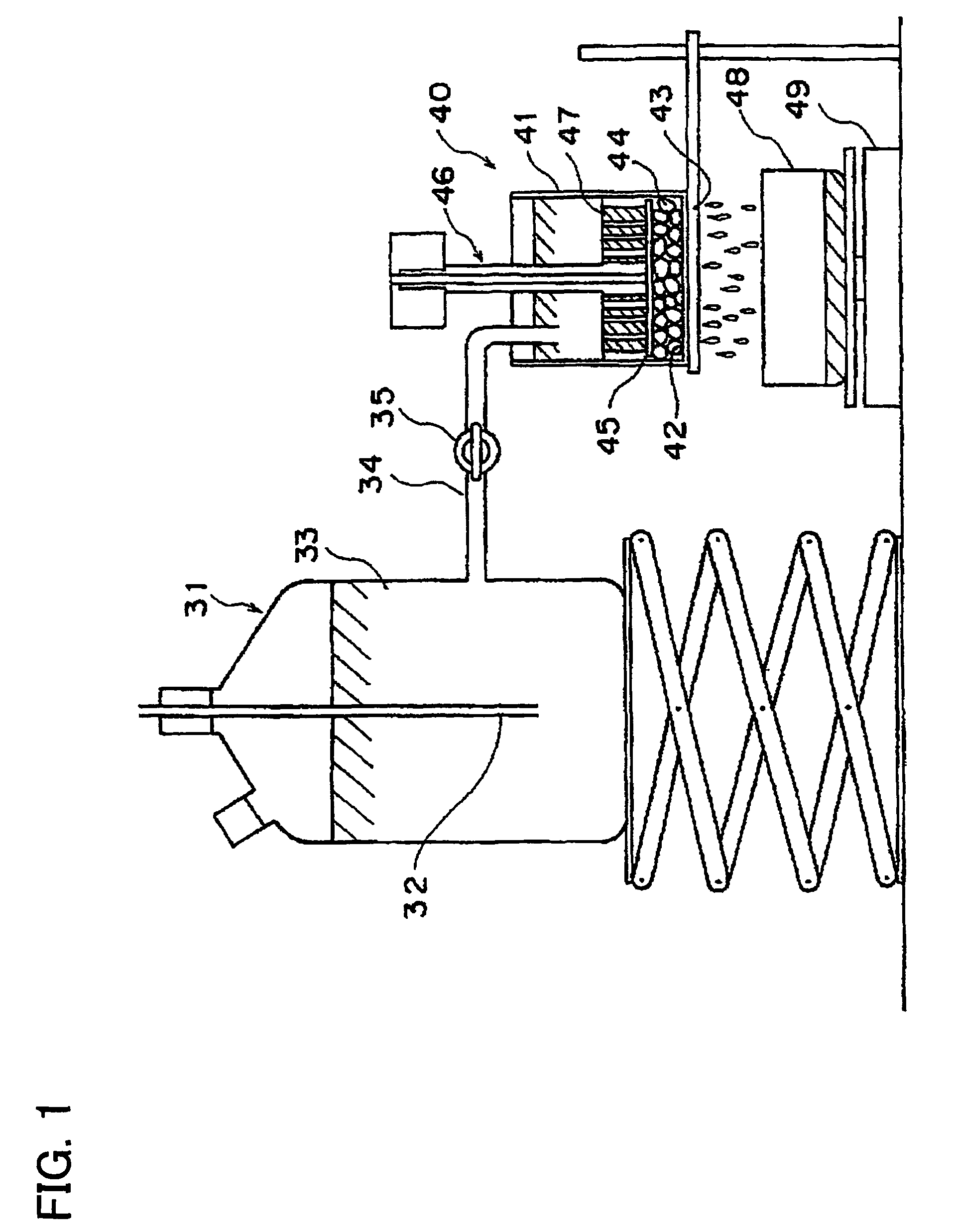

Water absorbent and producing method of same

ActiveUS20070123658A1Improve gel performanceMaintain good propertiesOther chemical processesAbsorbent padsCross-linkPolymer science

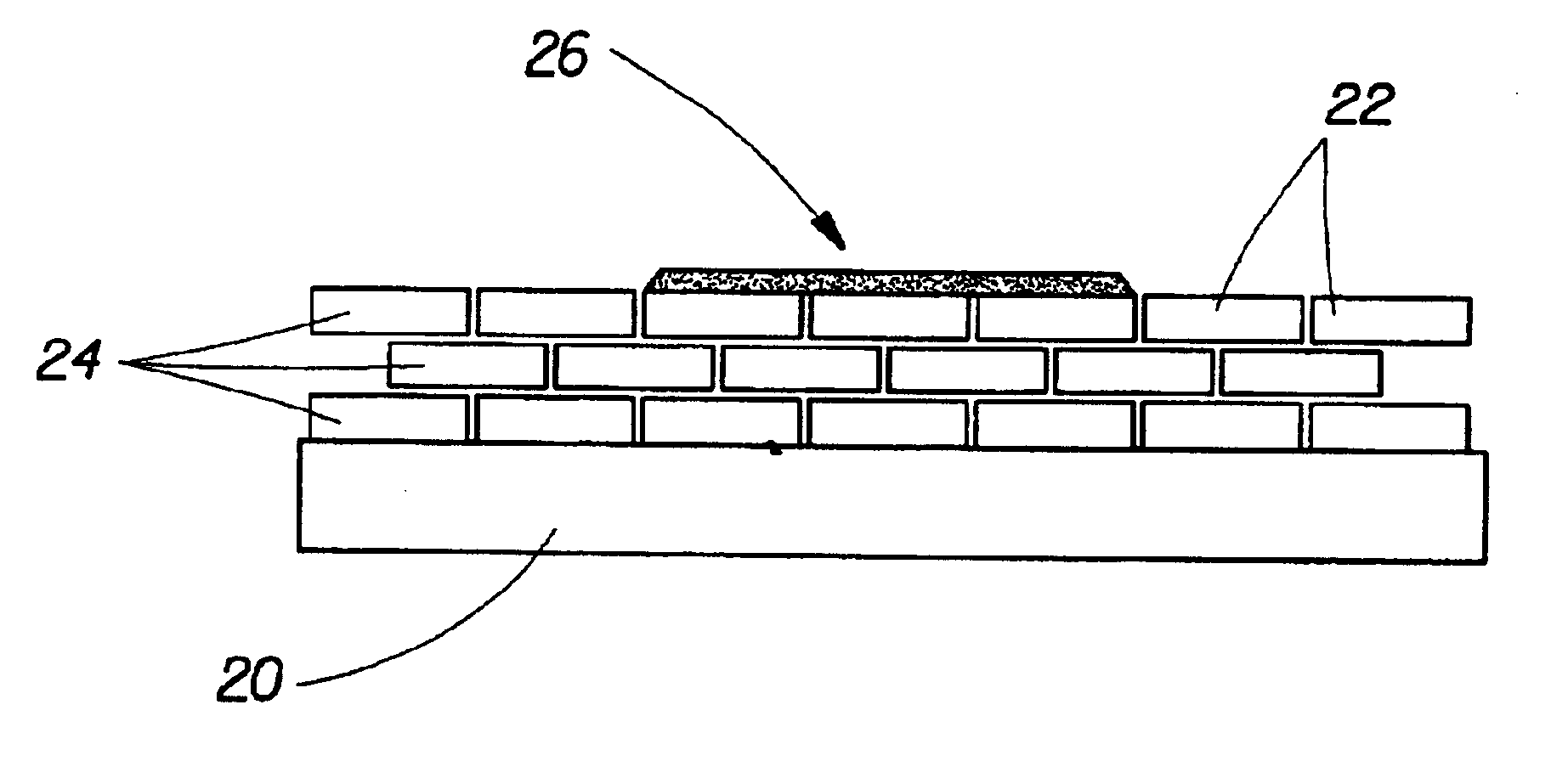

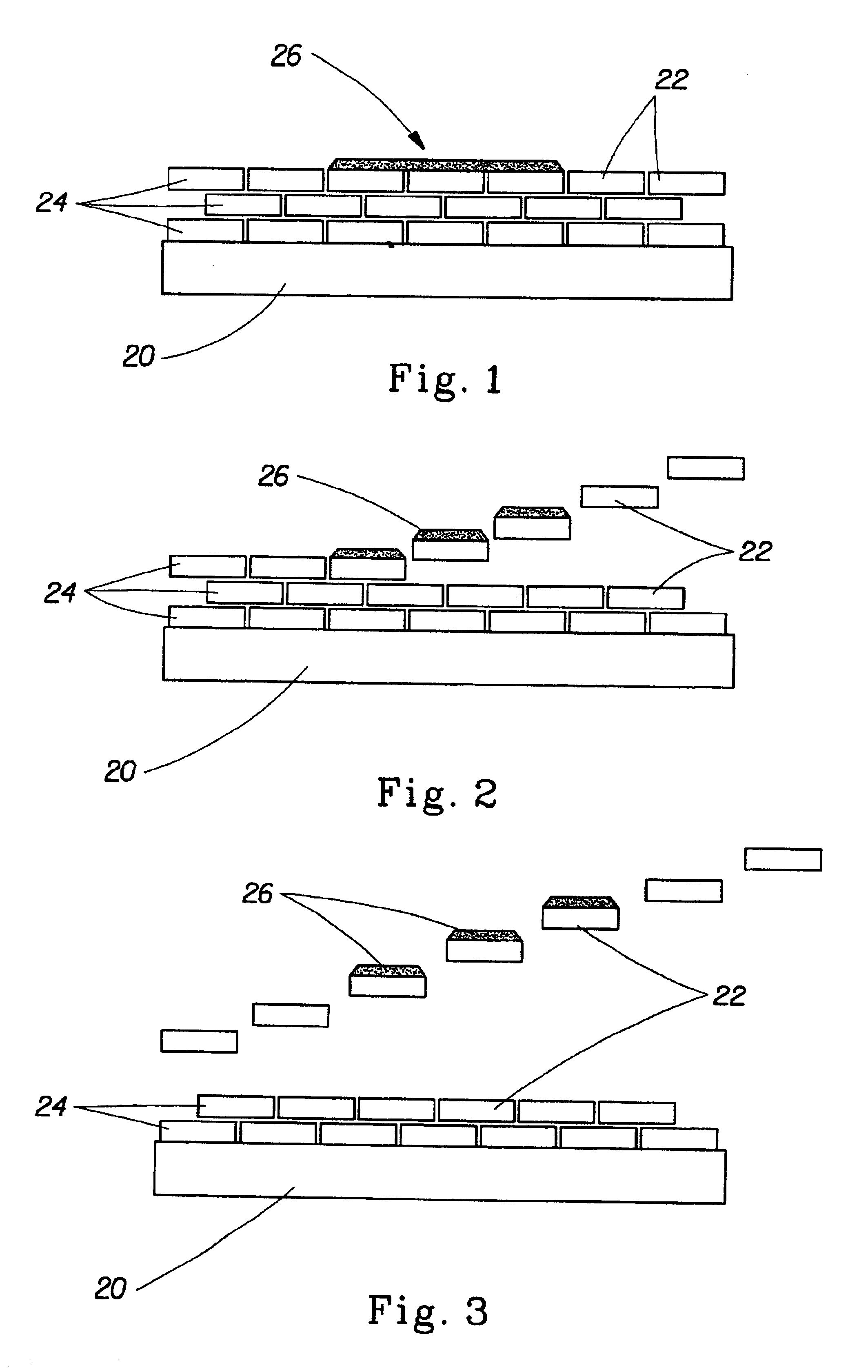

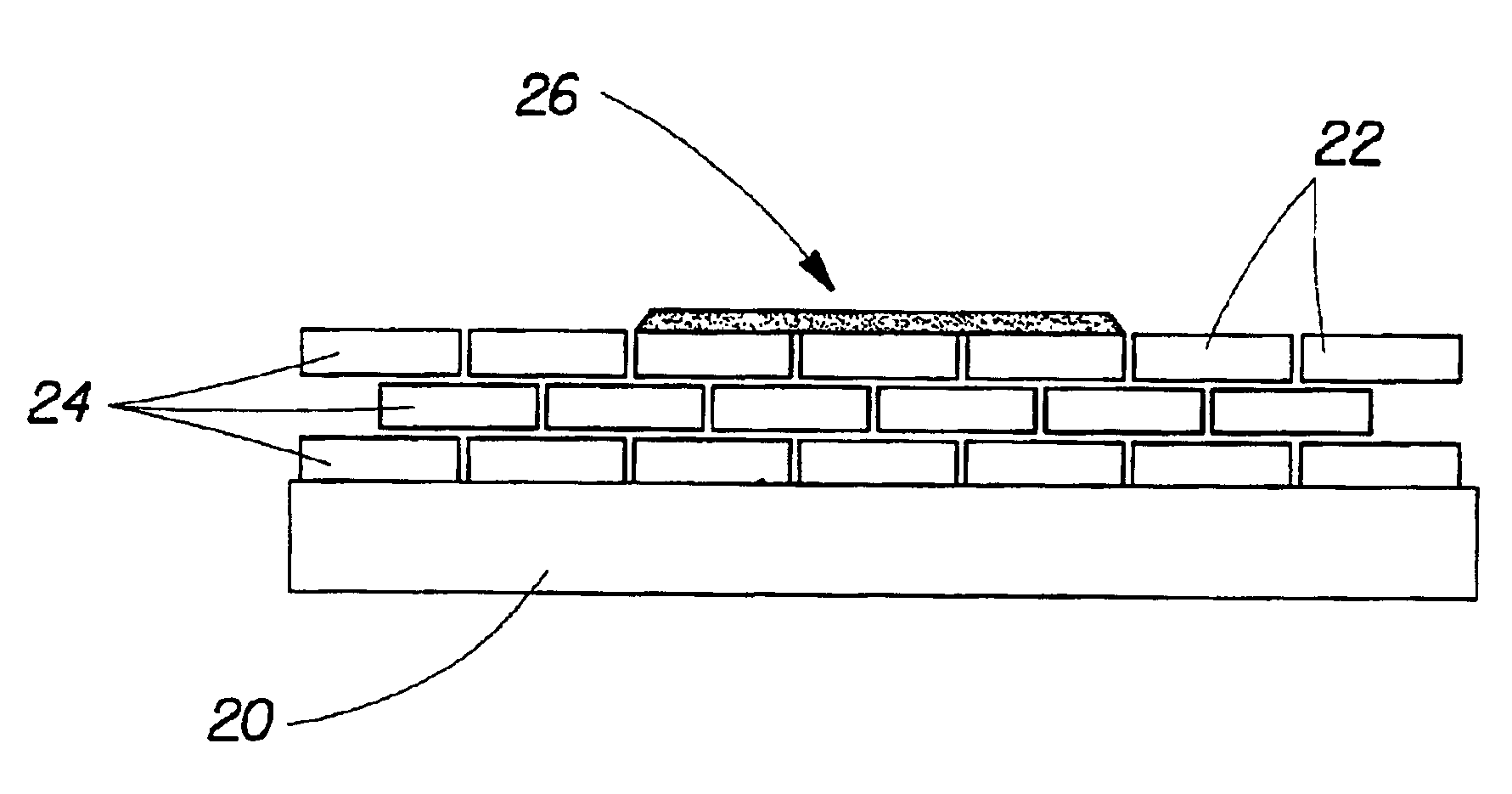

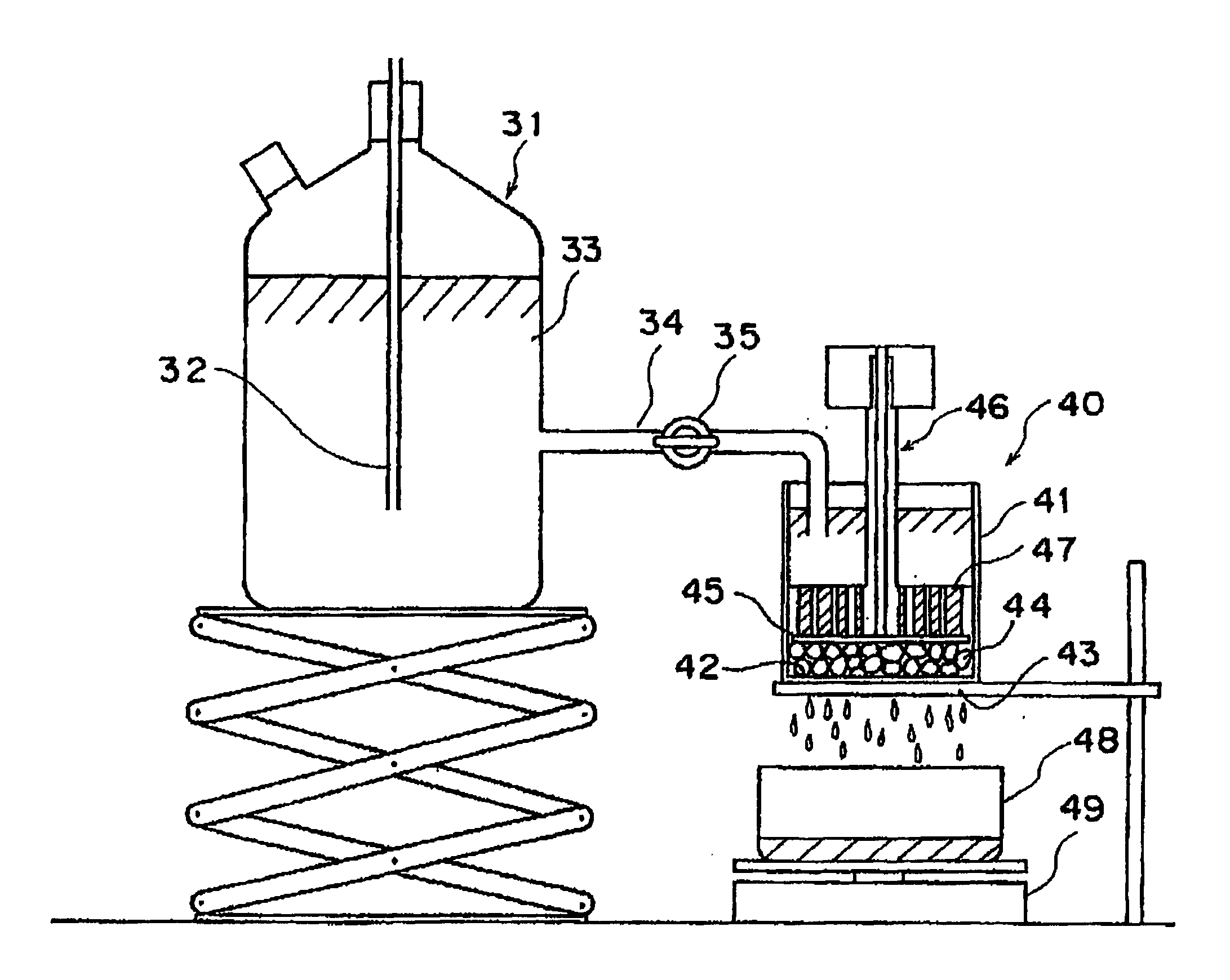

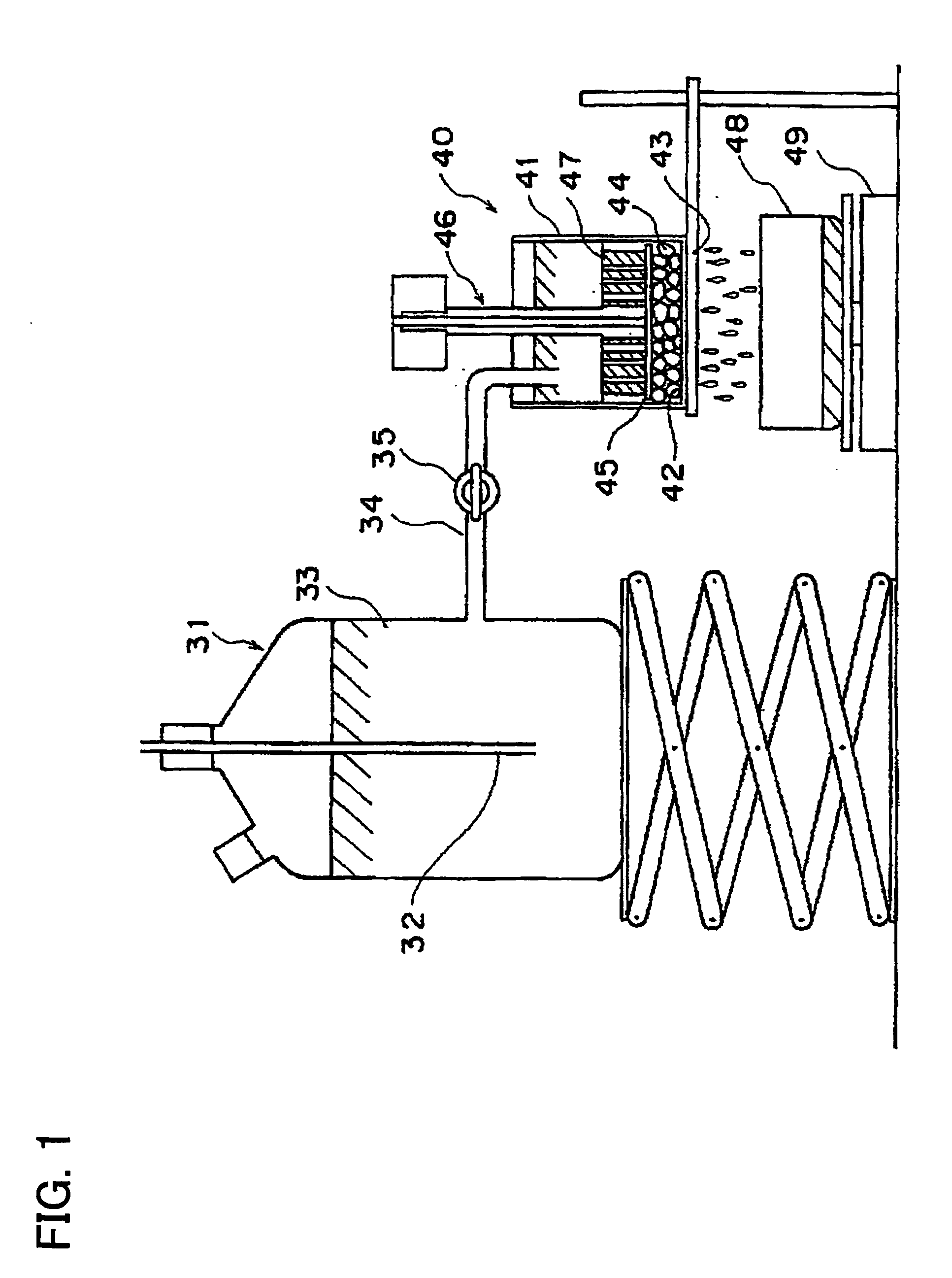

An object of the present invention is to provide a water absorbent having excellent gel properties and showing excellent properties when used in a water-absorbing material of a sanitary / hygienic material such as paper diaper. Moreover, another object of the present invention is to provide a water absorbent which is safe and excellent in liquid permeability, and in which an amount of liquid permeability improver for improving the liquid permeability is reduced. The water absorbent is made from a water-absorbing resin prepared by a specific polymerization method and having a high degree of cross-linking, a high liquid holding property and a high gel strength (its swelling pressure of gel layer of is 35 kdyne / cm2 or more). This water absorbent is further processed to have a particular particle size distribution (95 wt % or more of its particles are less than 850ƒÊm but not less than 106ƒÊm, and logarithmic standard deviation (ƒĐƒÄ) is in a range of 0.25 to 0.45) and then surface cross-linked. After that, a liquid permeability improver is added therein.

Owner:NIPPON SHOKUBAI CO LTD

Water absorbent and producing method of same

ActiveUS20100308263A1Improve gel performanceMaintain good propertiesOther chemical processesAbsorbent padsCross-linkPolymer science

An object of the present invention is to provide a water absorbent having excellent gel properties and showing excellent properties when used in a water-absorbing material of a sanitary / hygienic material such as paper diaper. Moreover, another object of the present invention is to provide a water absorbent which is safe and excellent in liquid permeability, and in which an amount of liquid permeability improver for improving the liquid permeability is reduced. The water absorbent is made from a water-absorbing resin prepared by a specific polymerization method and having a high degree of cross-linking, a high liquid holding property and a high gel strength (its swelling pressure of gel layer of is 35 kdyne / cm2 or more). This water absorbent is further processed to have a particular particle size distribution (95 wt % or more of its particles are less than 850ƒÊm but not less than 106ƒÊm, and logarithmic standard deviation (ƒĐƒÄ) is in a range of 0.25 to 0.45) and then surface cross-linked. After that, a liquid permeability improver is added therein.

Owner:NIPPON SHOKUBAI CO LTD

Rinsing fluid for lithography

InactiveUS7741260B2Effectively preventing pattern fallingModifying surfaceOrganic detergent compounding agentsNon-surface-active detergent compositionsSolventCarbon atom

Owner:TOKYO OHKA KOGYO CO LTD

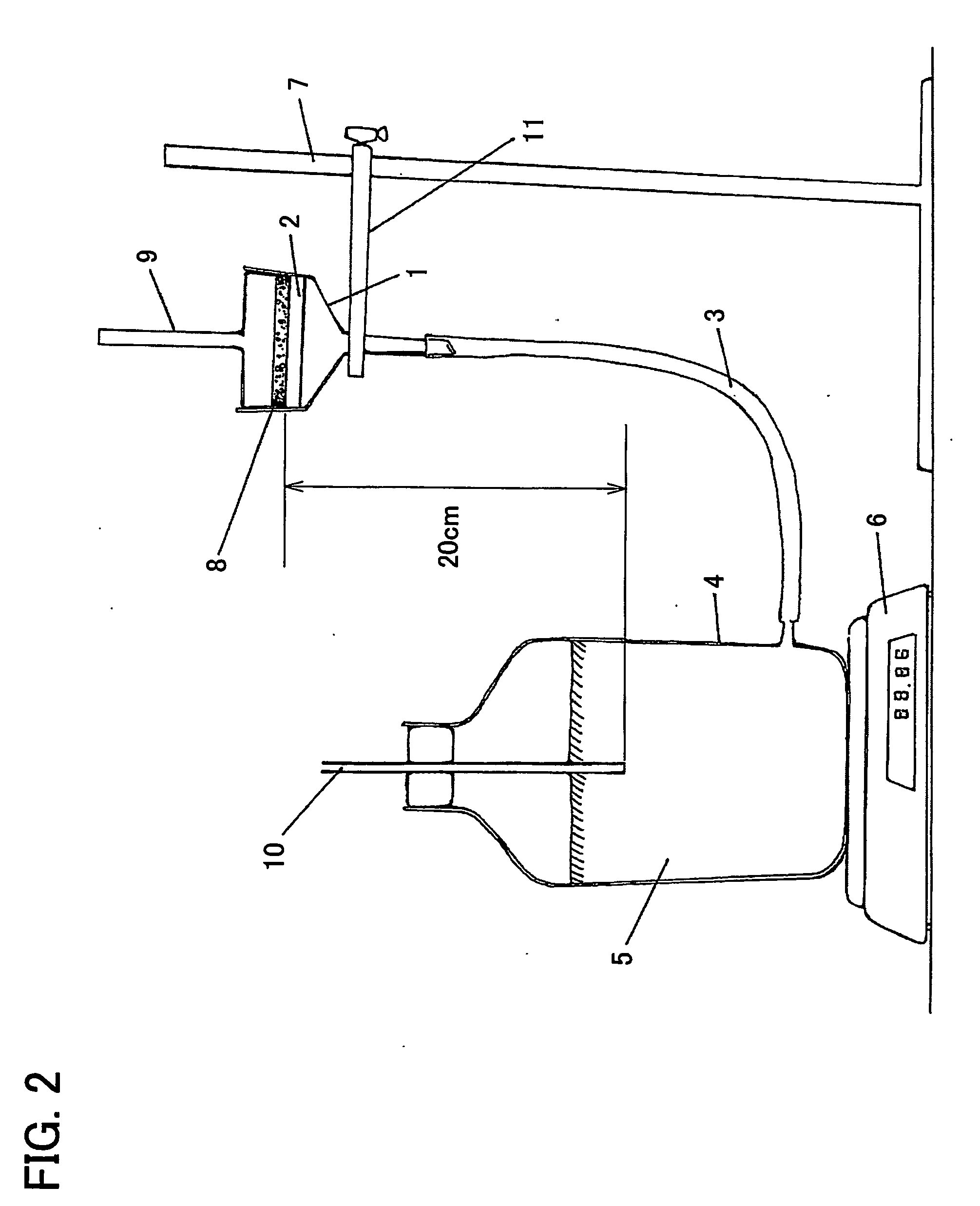

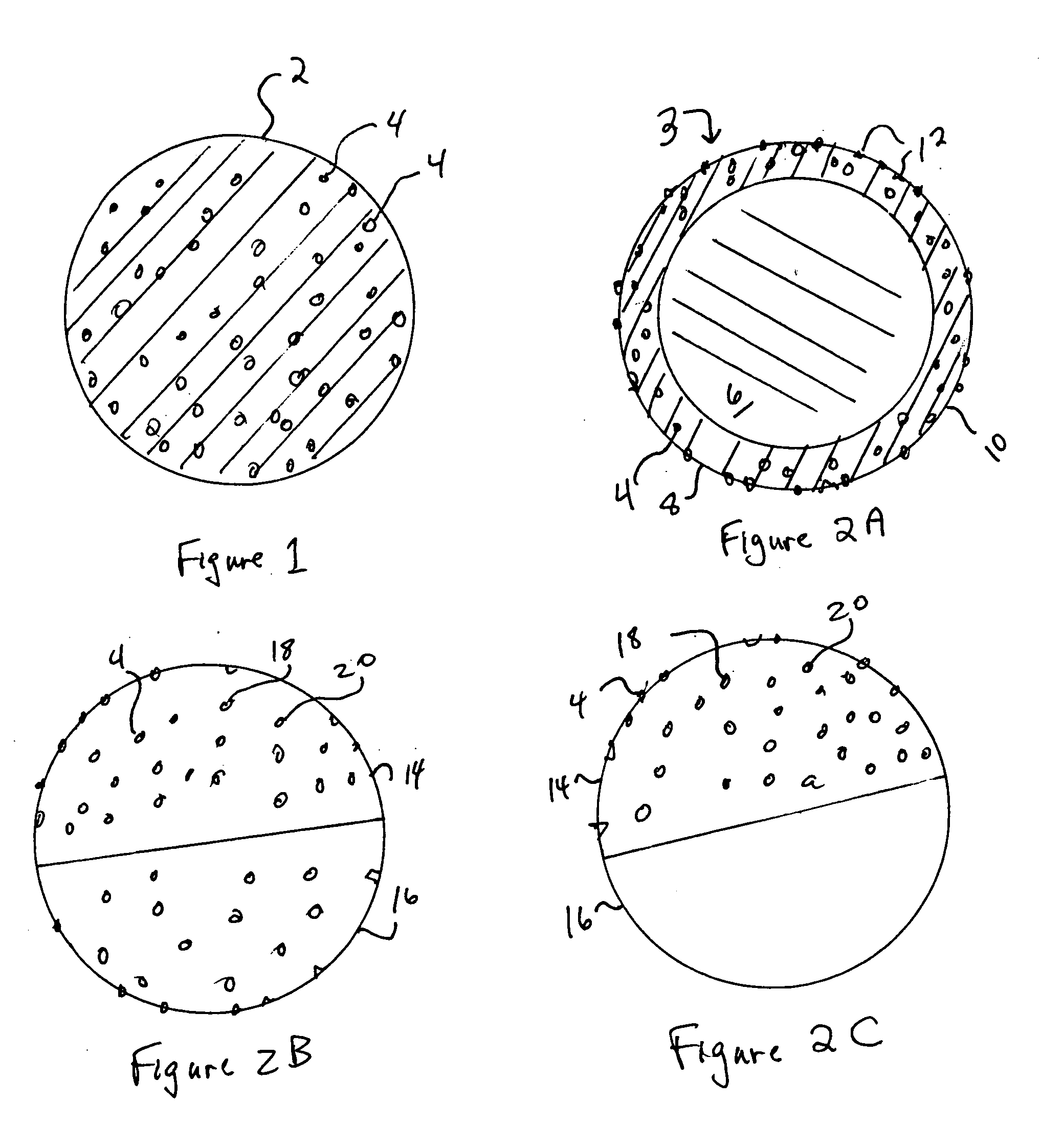

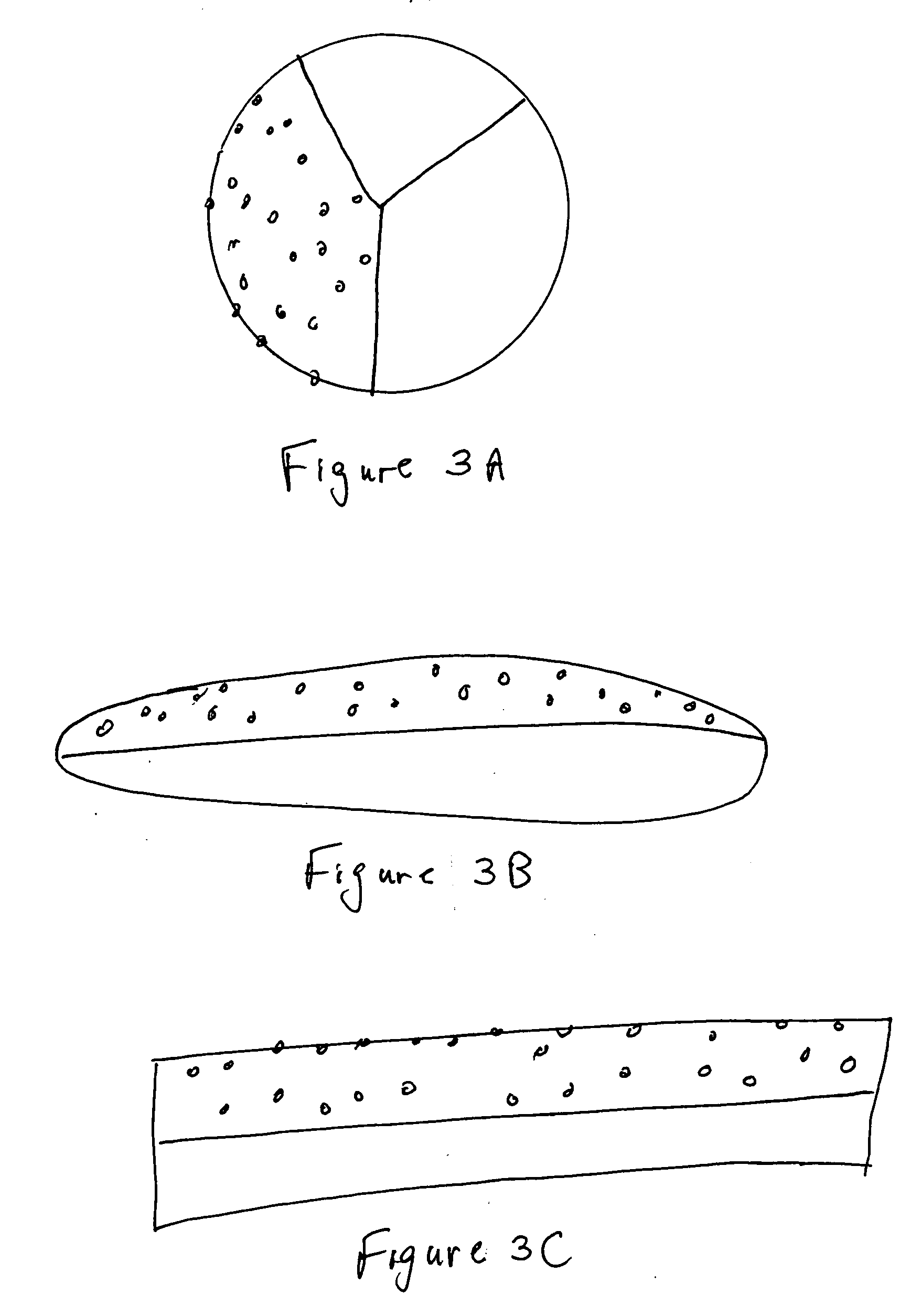

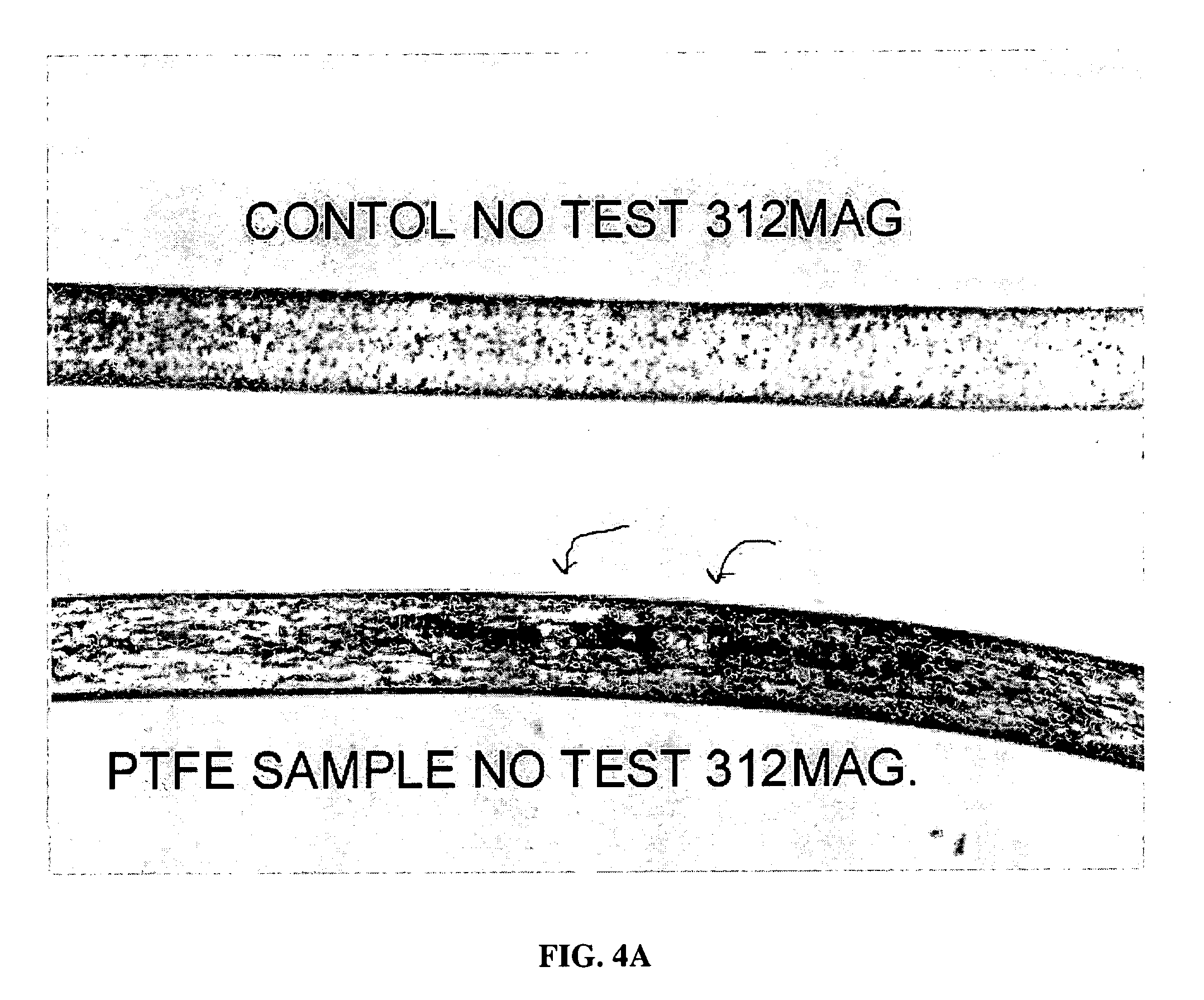

Synthetic fibers modified with PTFE to improve performance

InactiveUS20050100733A1Improve hydrophilicityImprove stain resistanceConjugated synthetic polymer artificial filamentsYarnPolyesterUV degradation

Synthetic plastic fibers are enhanced by inclusions therein of micro-polyester particles (4), preferably sized or otherwise optimized to enhance surface (10) characteristics (abrasion resistance, hydrophilicity, coating receptiveness, increase dullness), reduce UV degradation. The synthetic plastic matrix is preferably polyester but can be any synthetic plastic. The invention is preferentially implemented in multi-component fibers (e.g. core (6)-sheath (8) bi-component fibers (3)) with the inclusions entirely or primarily in one or some, but not all such components. The PTFE inclusions, sizing, concentration, morphology can be adjusted to optimize their enhancing effects, reduce costs and enhance throughput of fiber production. Co-inclusions can be made with the PTFE including anti-microbial and / or coloring agents and with synergistic effects.

Owner:FOSS MFG CO LLC

Methods for synthesizing precipitated silica and use thereof

InactiveUS20050228106A1Affects ionic strengthReduce ionic strengthMaterial nanotechnologySilicaLow ionic strengthColloid

The synthesis of precipitated silica having improved chemical and physical properties of use as a reinforcing filler in polymeric matrices is described. Improvements in the properties result from the synthesis of the silica al a reduced ionic strength. In particular, the use of silicia acid during synthesis, provides a solution of reduced ionic strength, which favors the formation of improved colloidal structure via increased aggregation and reduced agglomeration. In addition, the surface of the silica precipitate formed may be modified by the addition of surface modifying agents, during synthesis to further enhance the desired reinforcing properties of the precipitated silica. The invention also embodies polymeric compositions of improved tensile and elongation strengths, with the compositions including precipitated silica, synthesized at reduced ionic strengths and having modified surfaces, in combination with a polymeric compound.

Owner:UNIVERSITY OF CINCINNATI

Water absorbent and producing method of same

ActiveUS7803880B2Improve gel performanceMaintain good propertiesOther chemical processesAbsorbent padsCross-linkPolymer science

An object of the present invention is to provide a water absorbent having excellent gel properties and showing excellent properties when used in a water-absorbing material of a sanitary / hygienic material such as paper diaper. Moreover, another object of the present invention is to provide a water absorbent which is safe and excellent in liquid permeability, and in which an amount of liquid permeability improver for improving the liquid permeability is reduced. The water absorbent is made from a water-absorbing resin prepared by a specific polymerization method and having a high degree of cross-linking, a high liquid holding property and a high gel strength (its swelling pressure of gel layer of is 35 kdyne / cm2 or more). This water absorbent is further processed to have a particular particle size distribution (95 wt % or more of its particles are less than 850ƒÊm but not less than 106ƒÊm, and logarithmic standard deviation (ƒĐƒÄ) is in a range of 0.25 to 0.45) and then surface cross-linked. After that, a liquid permeability improver is added therein.

Owner:NIPPON SHOKUBAI CO LTD

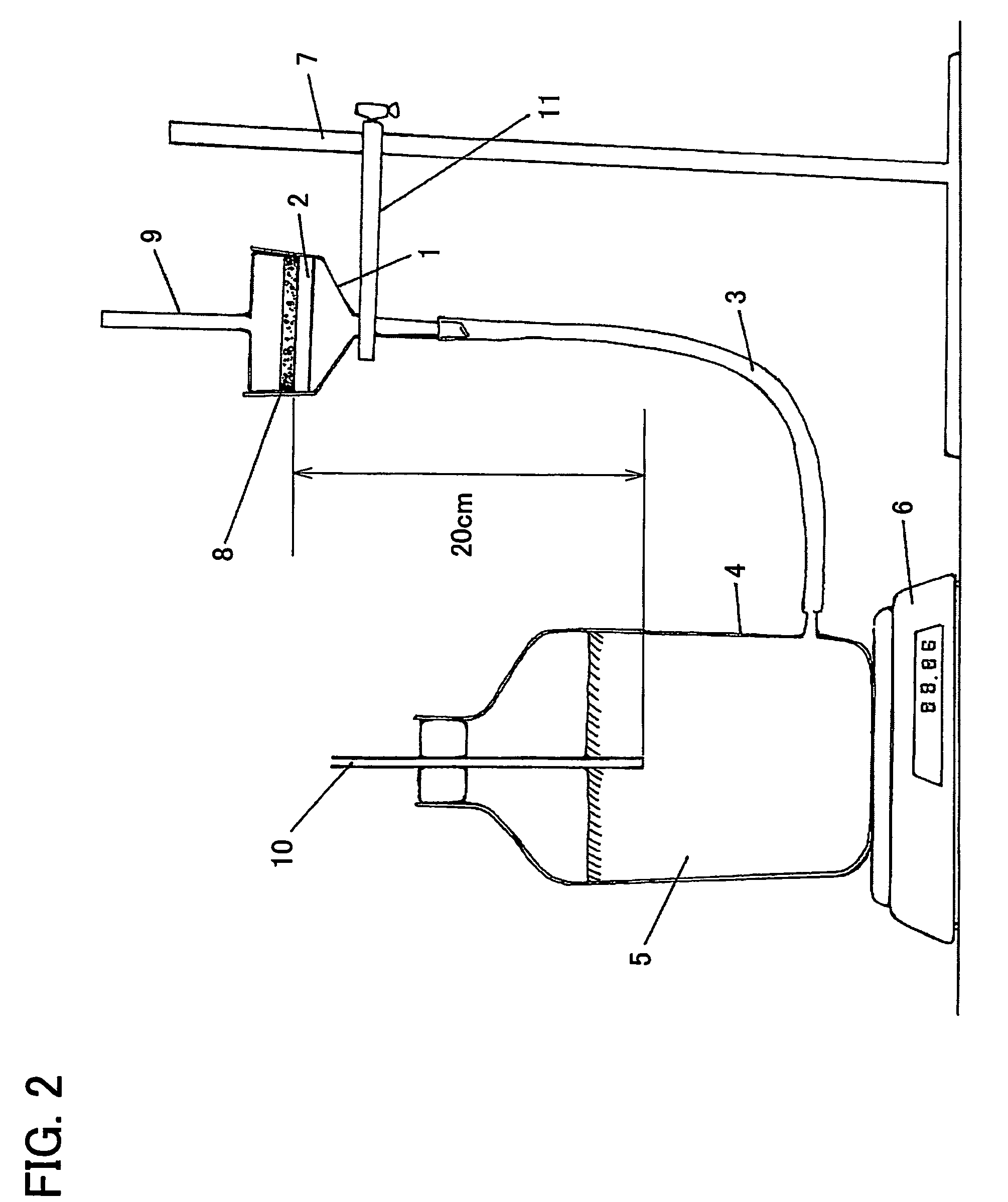

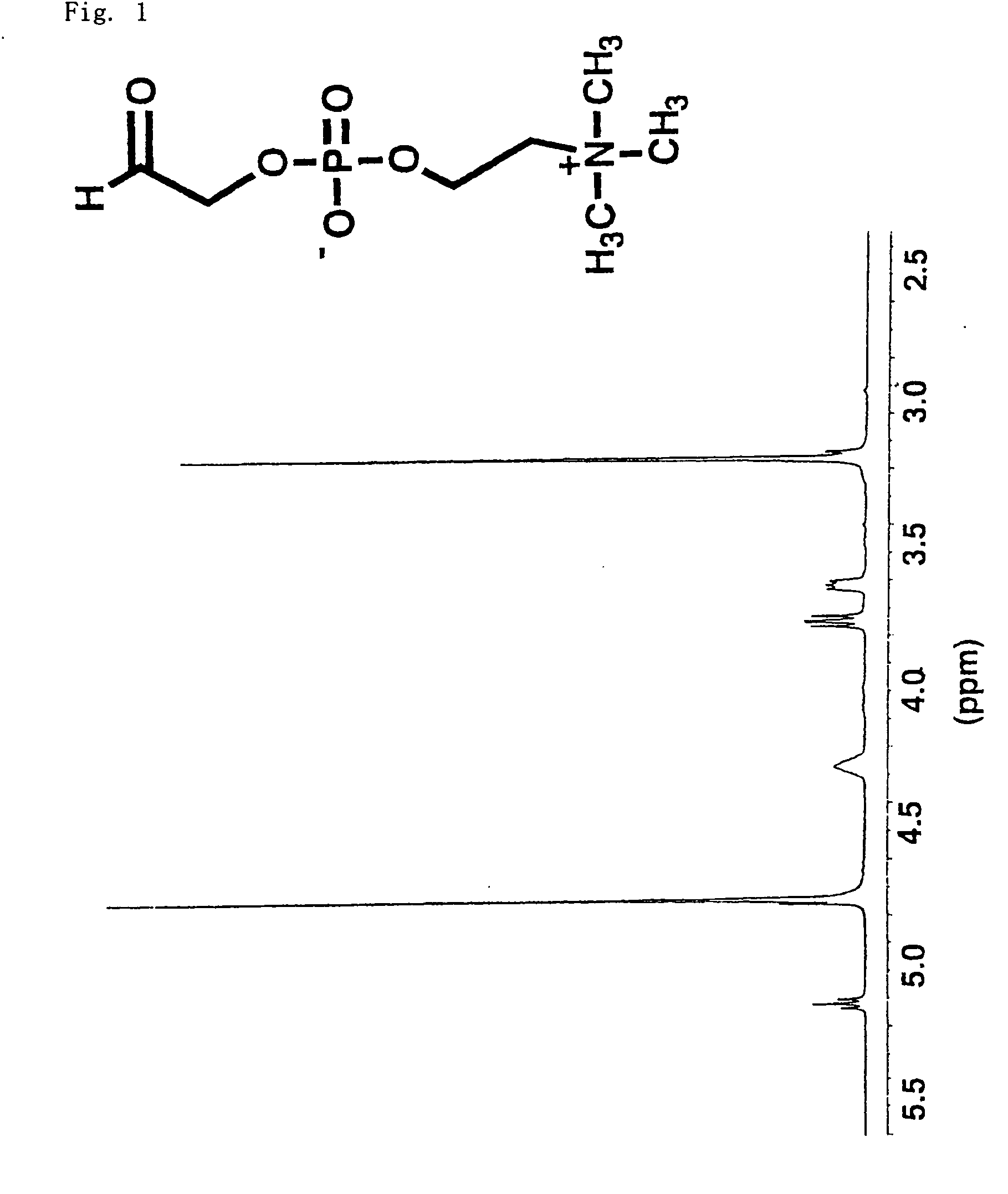

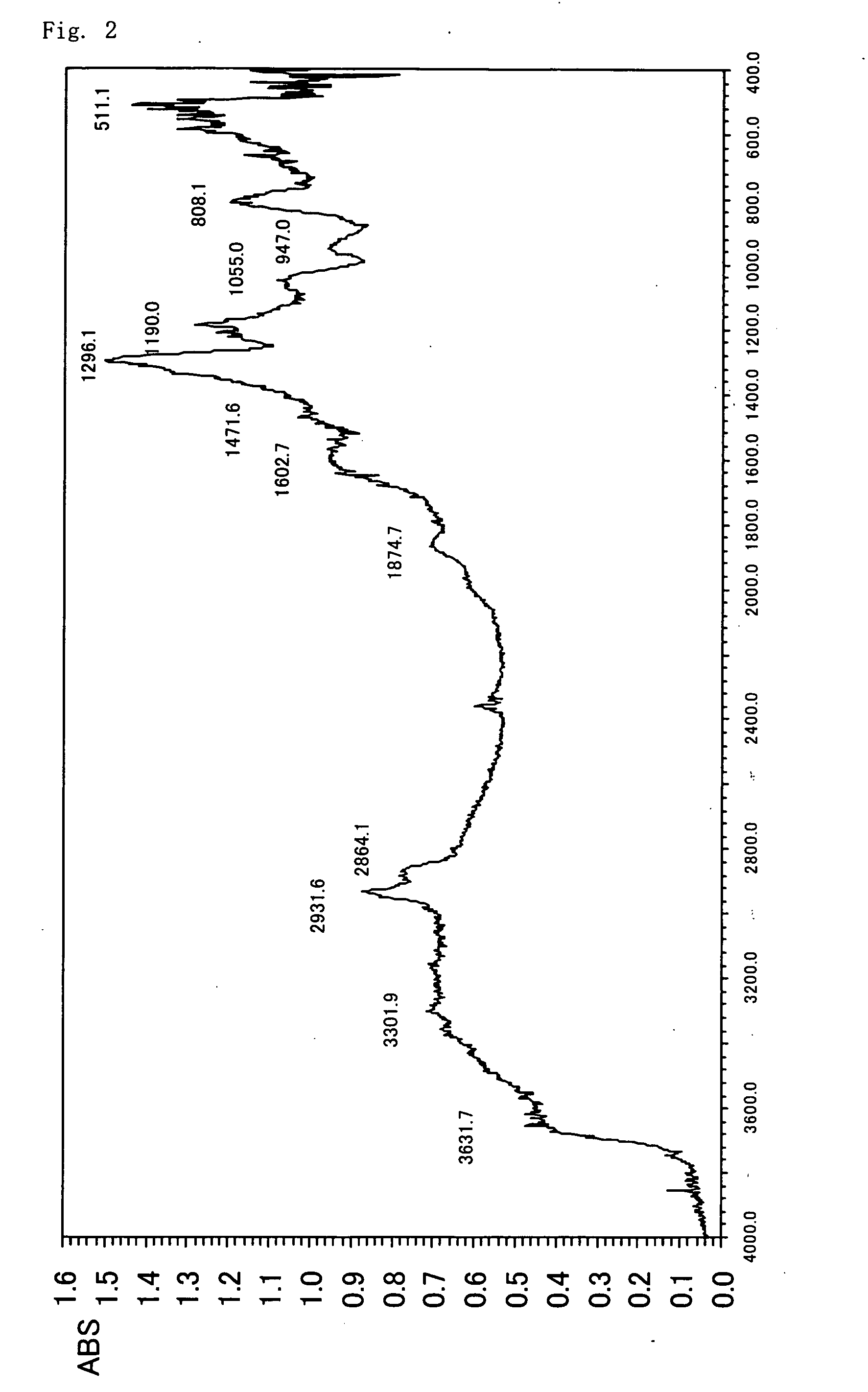

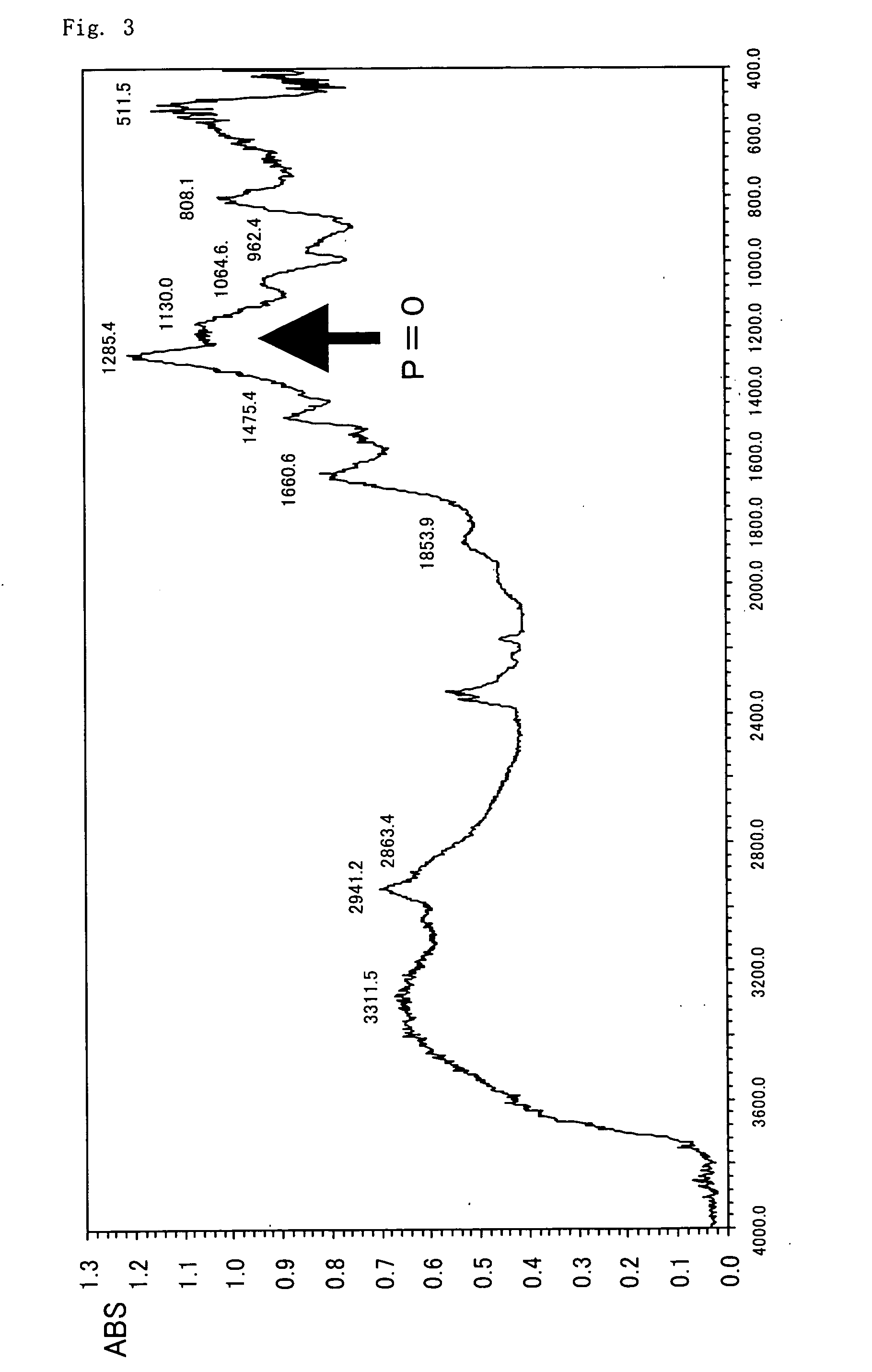

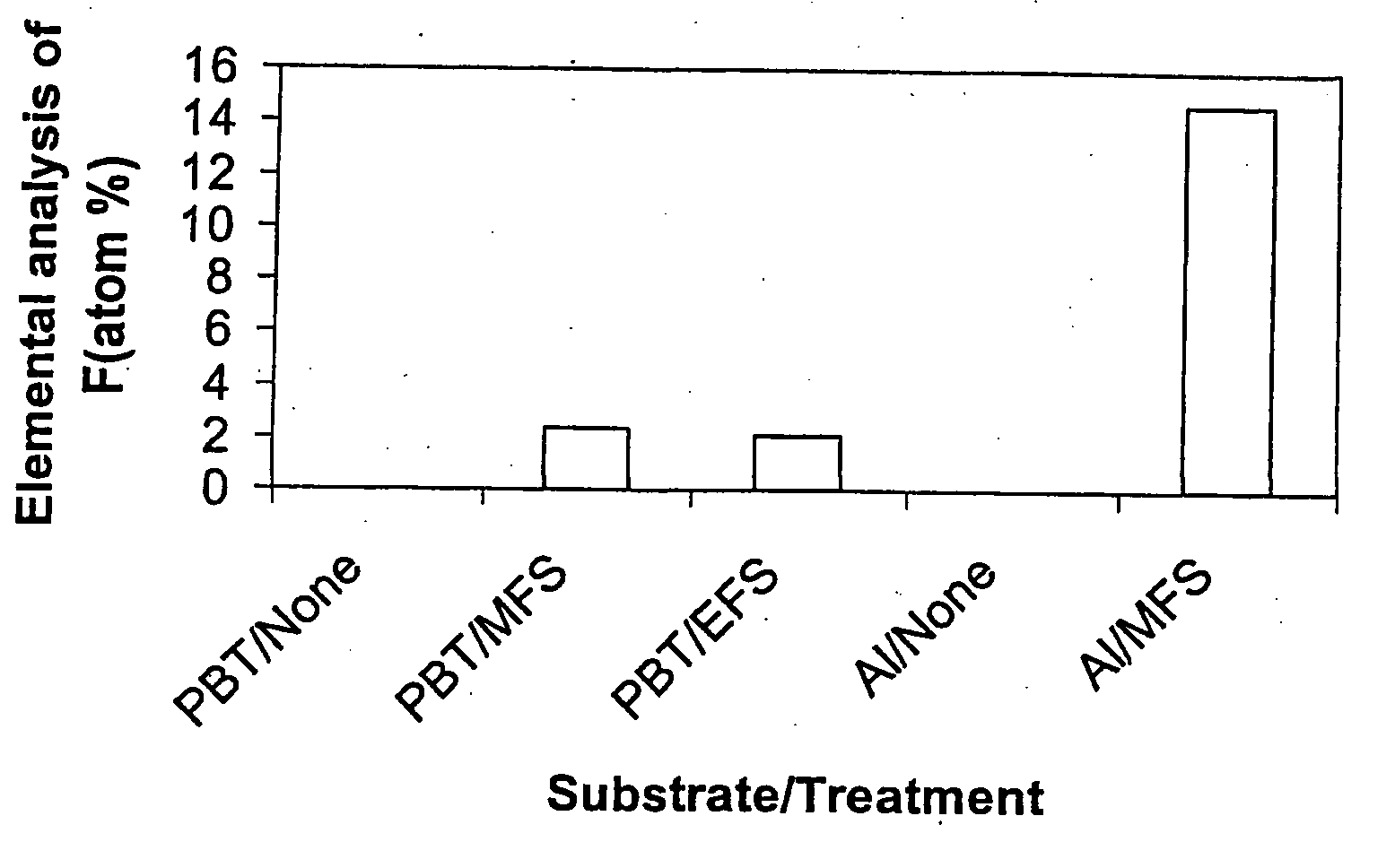

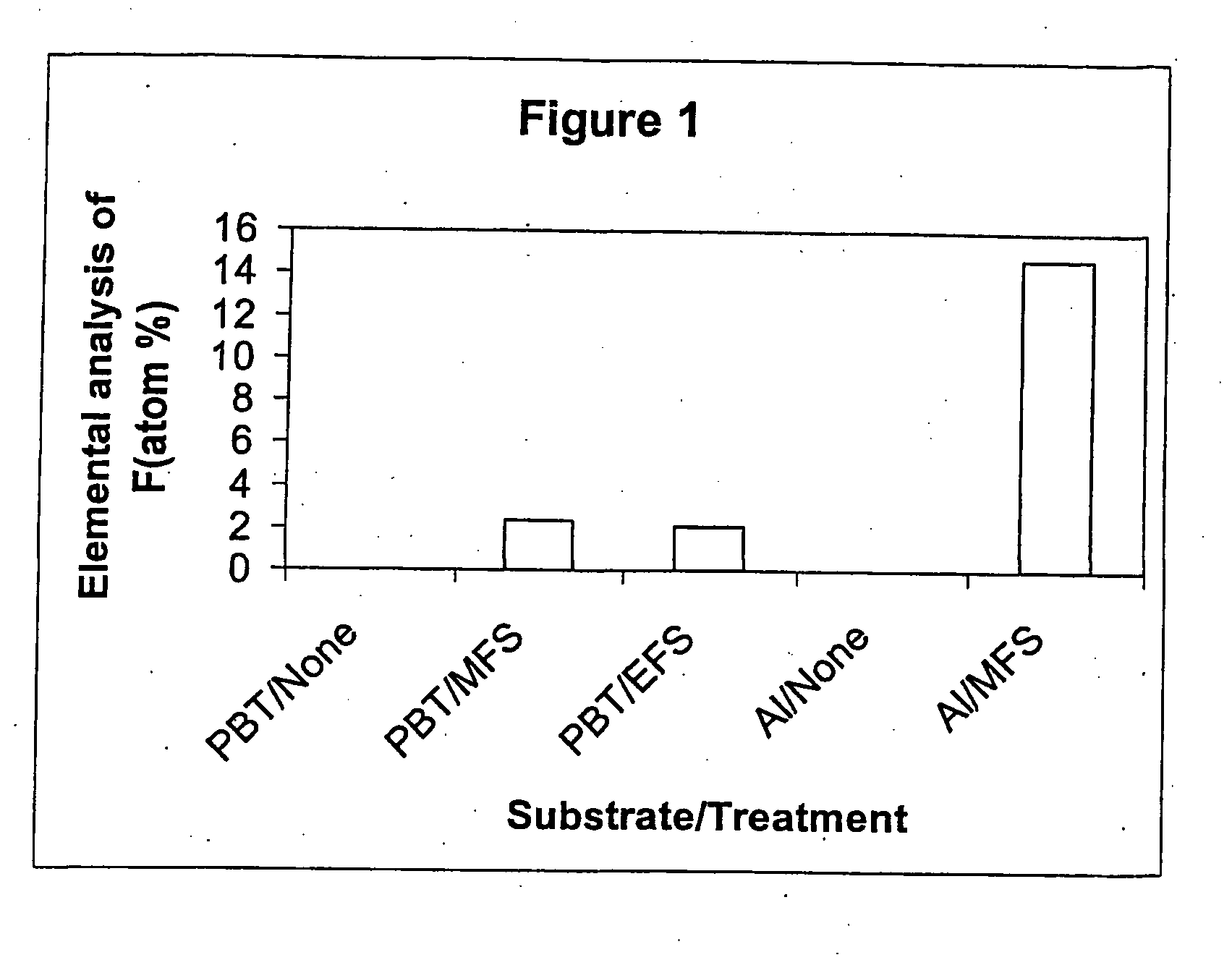

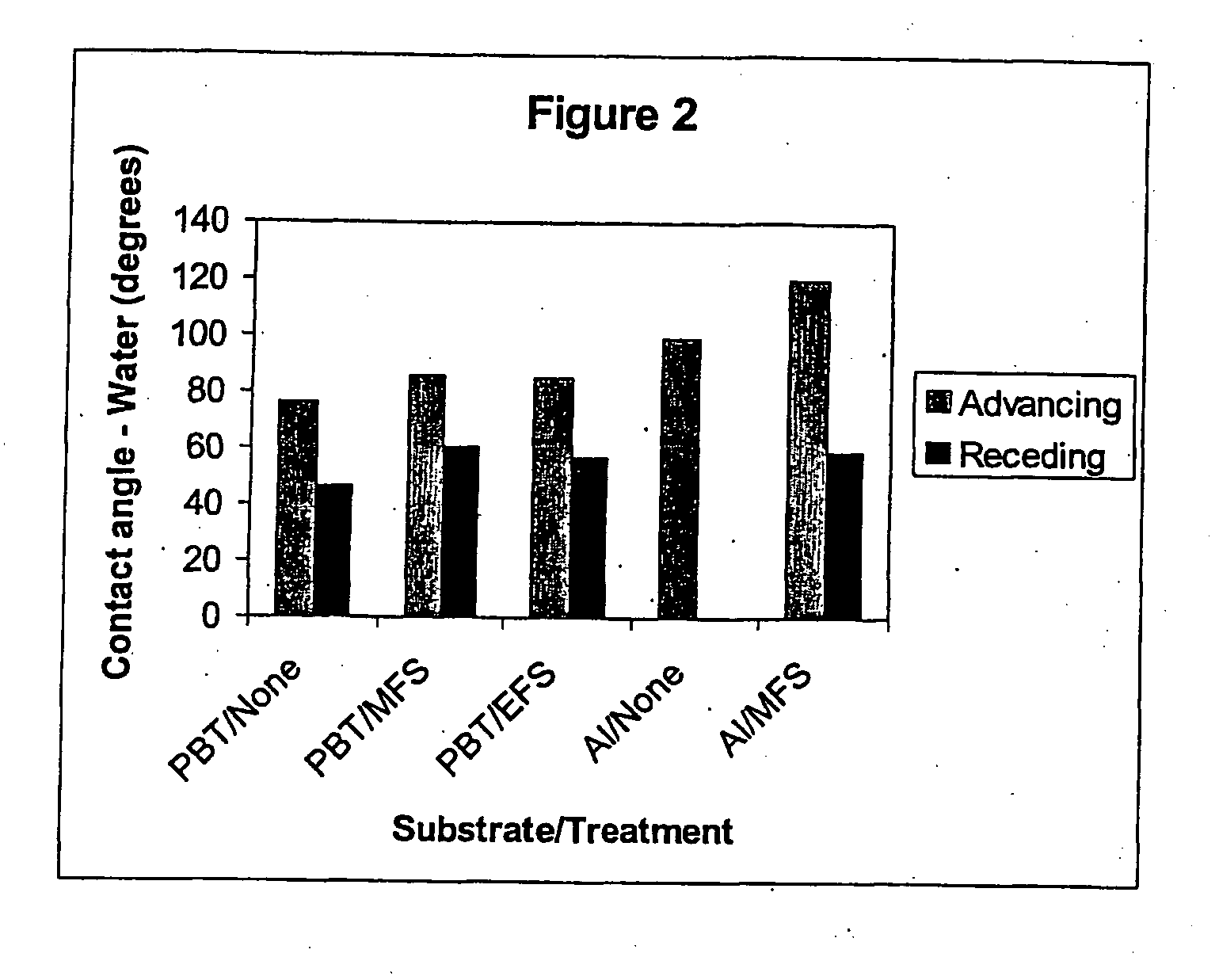

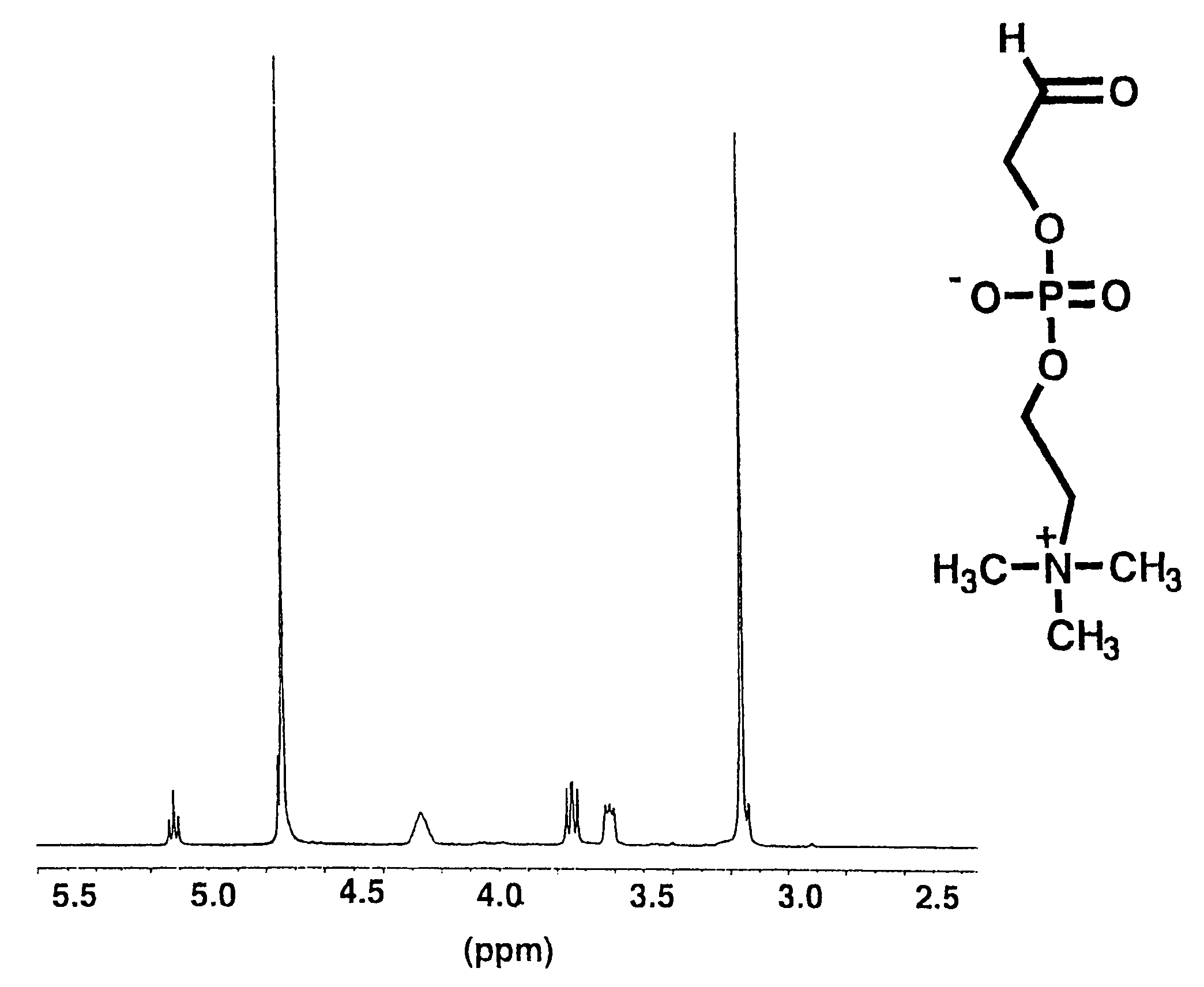

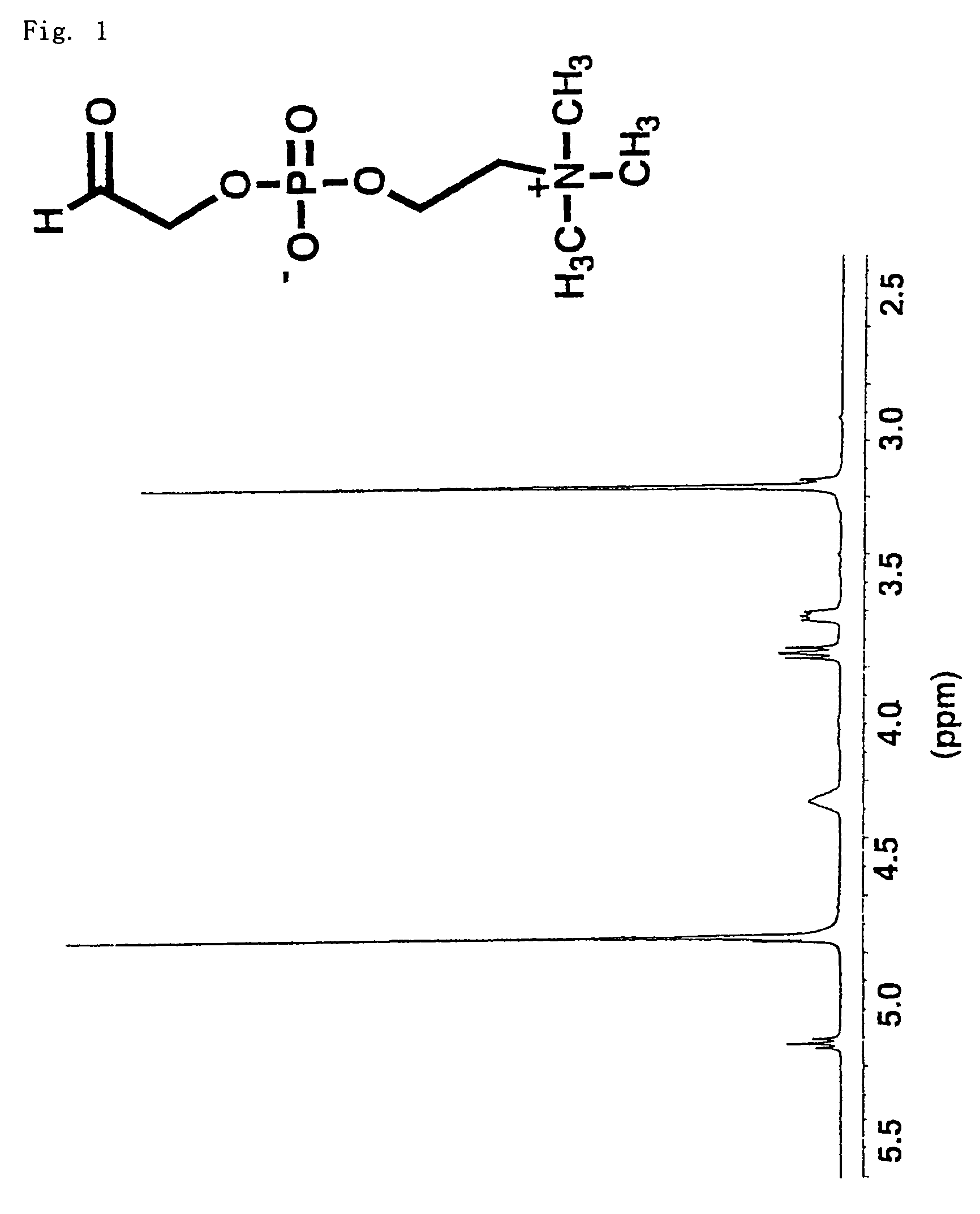

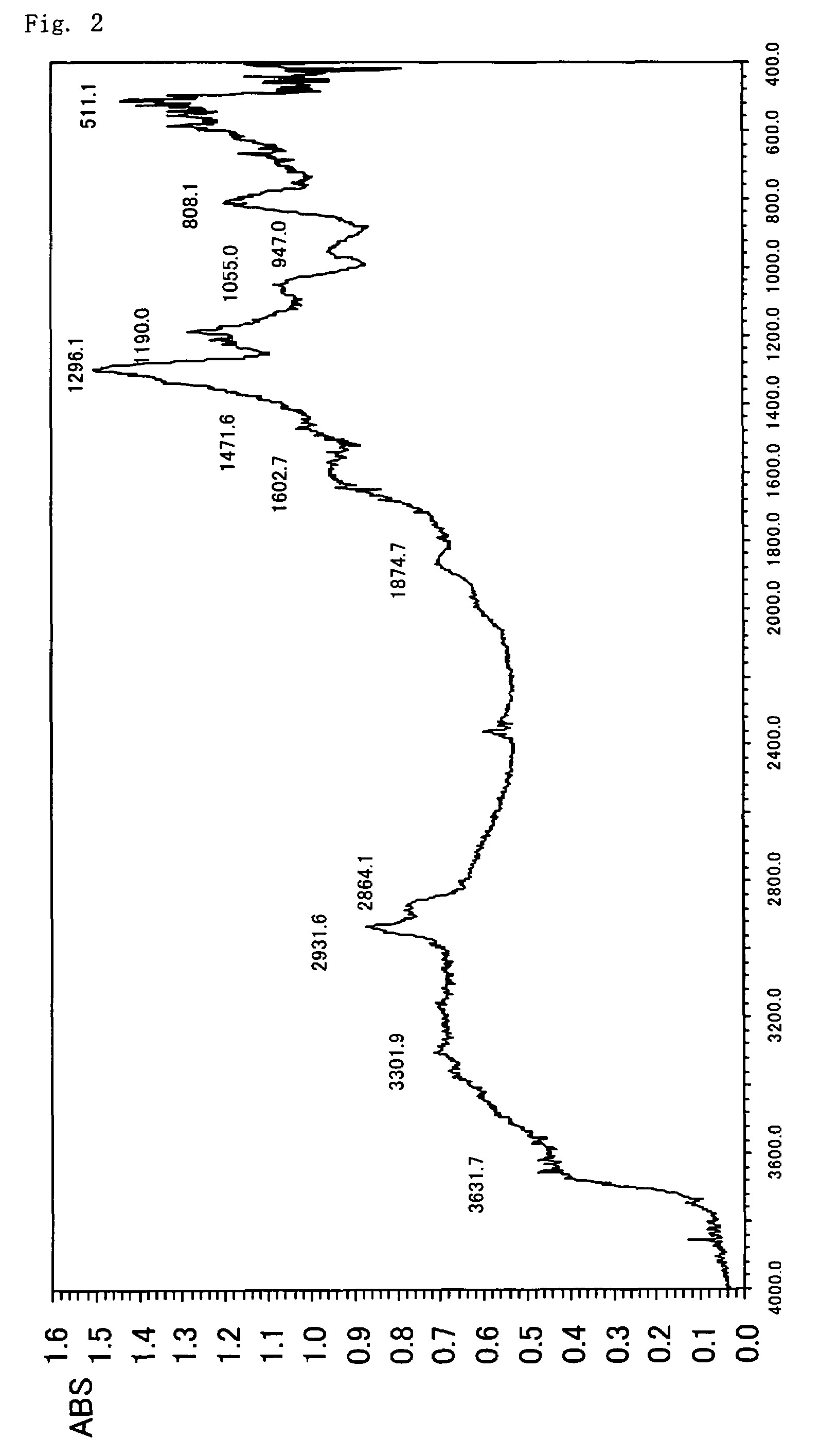

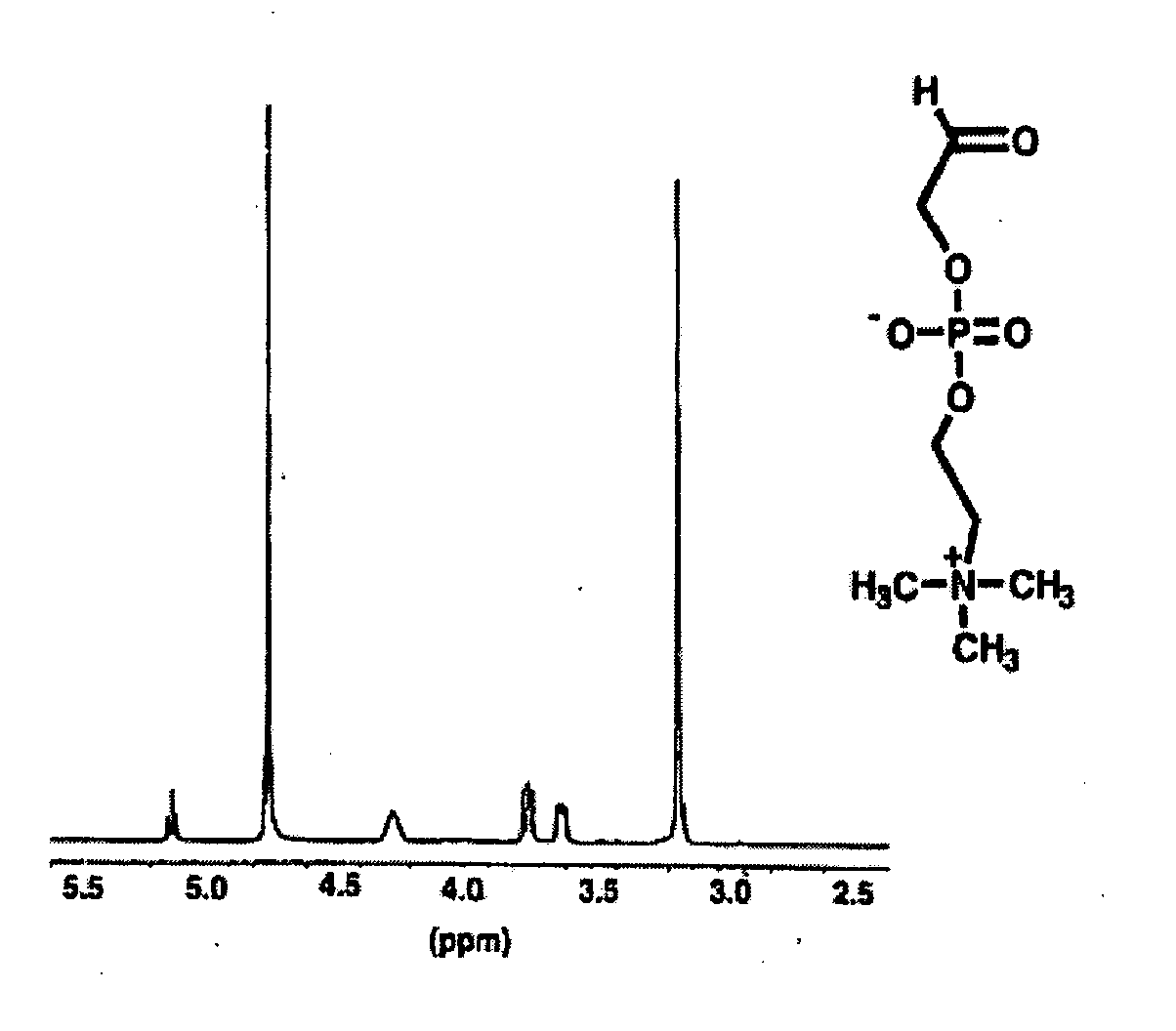

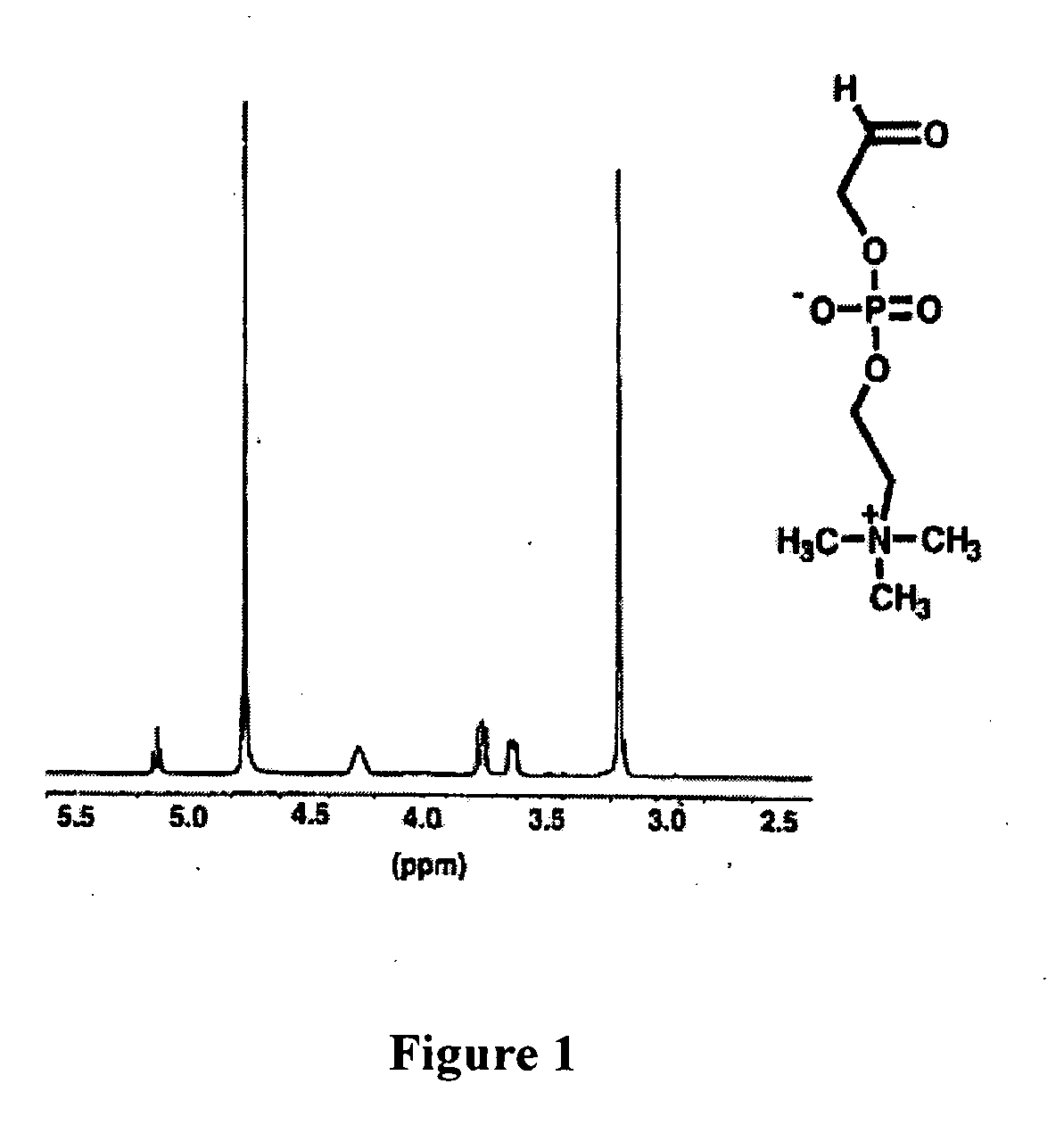

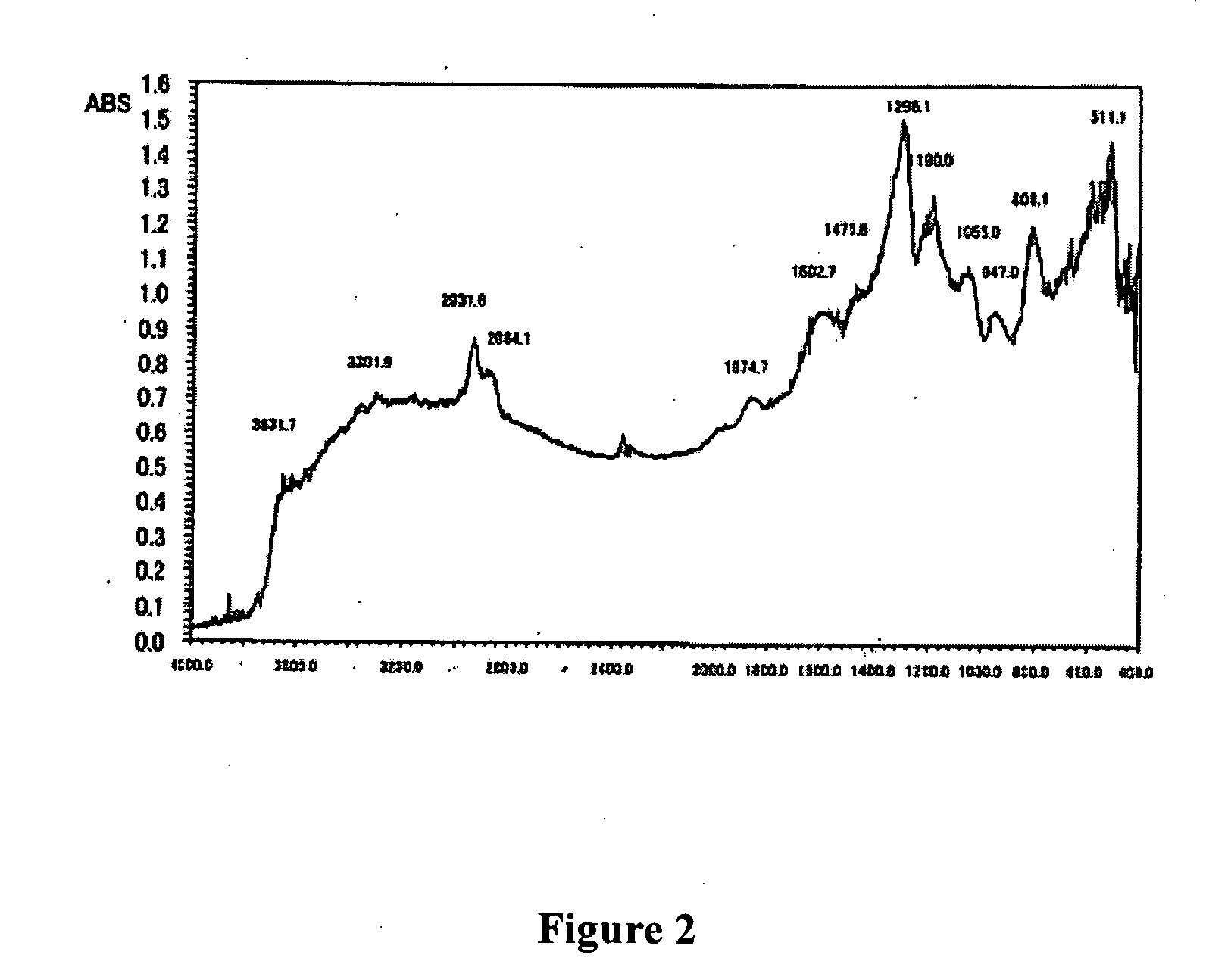

Method of modifying surface of material

InactiveUS20060060533A1Easy to adjustIncrease chanceIon-exchange process apparatusOther chemical processesPhosphorylcholinePhosphoric acid

A method for surface modification of a material by means of introducing the phosphorylcholine group represented by the following formula (1-1) onto the surface of the material by treating a material having amino groups with a chemical compound containing an aldehyde derivative obtained by the oxidative ring-opening reaction of glycerophosphorylcholine. The method of the present invention provides various materials such as medical materials having superior biocompatibility and hydrophilicity.

Owner:SANYO FINE IRICA TECH CO LTD

Surface modification process

InactiveUS20060083879A1Delayed reaction timeEfficient responsePharmaceutical delivery mechanismMedical devicesSurface modificationEngineering

Owner:BREWIS DEREK +2

Method of modifying surface of material

InactiveUS7560023B2Easy to adjustIncrease chanceIon-exchange process apparatusOther chemical processesChemical compoundPhosphorylcholine

A method for surface modification of a material by means of introducing the phosphorylcholine group represented by the following formula (1-1) onto the surface of the material by treating a material having amino groups with a chemical compound containing an aldehyde derivative obtained by the oxidative ring-opening reaction of glycerophosphorylcholine.The method of the present invention provides various materials such as medical materials having superior biocompatibility and hydrophilicity.

Owner:SANYO FINE IRICA TECH CO LTD

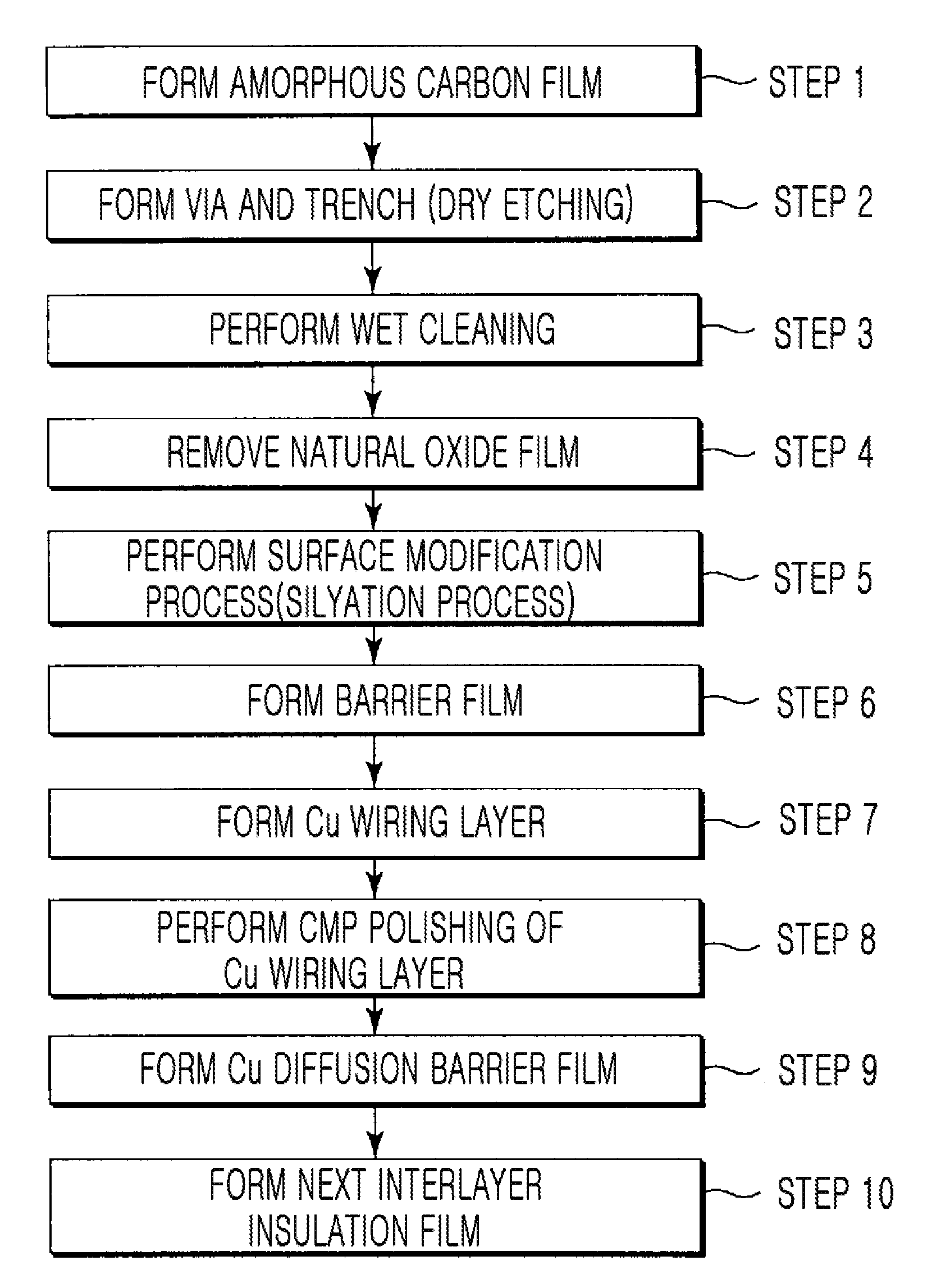

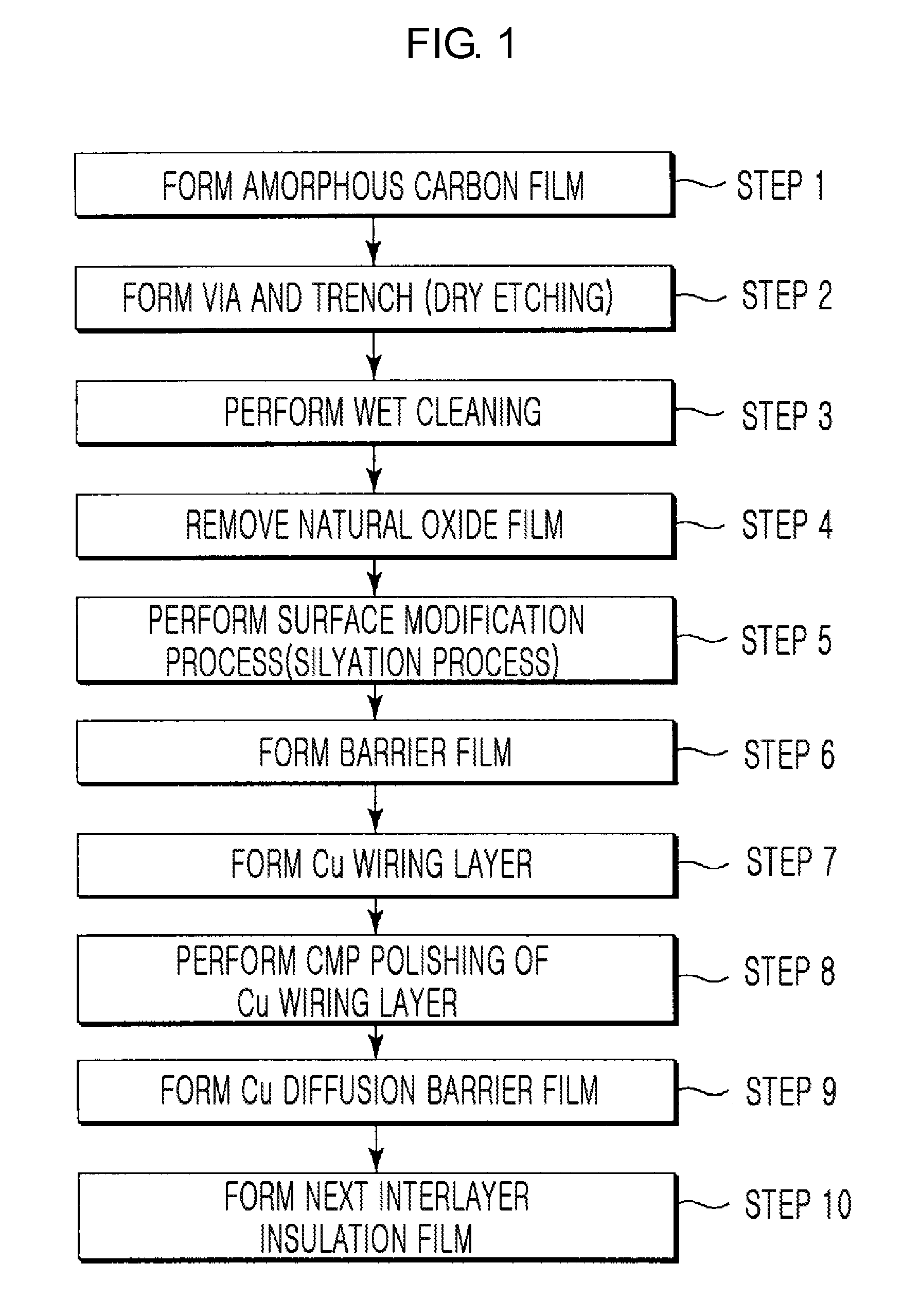

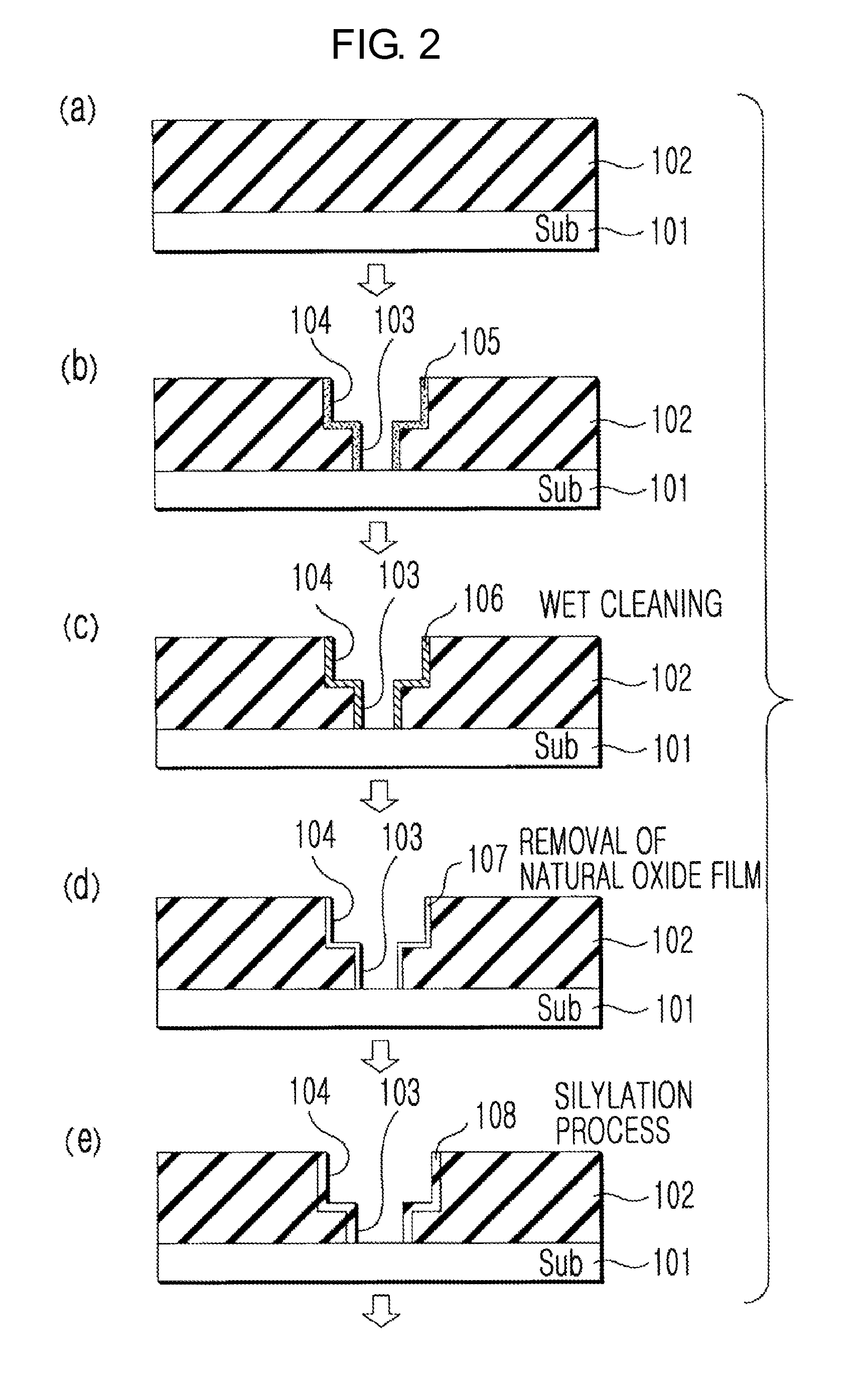

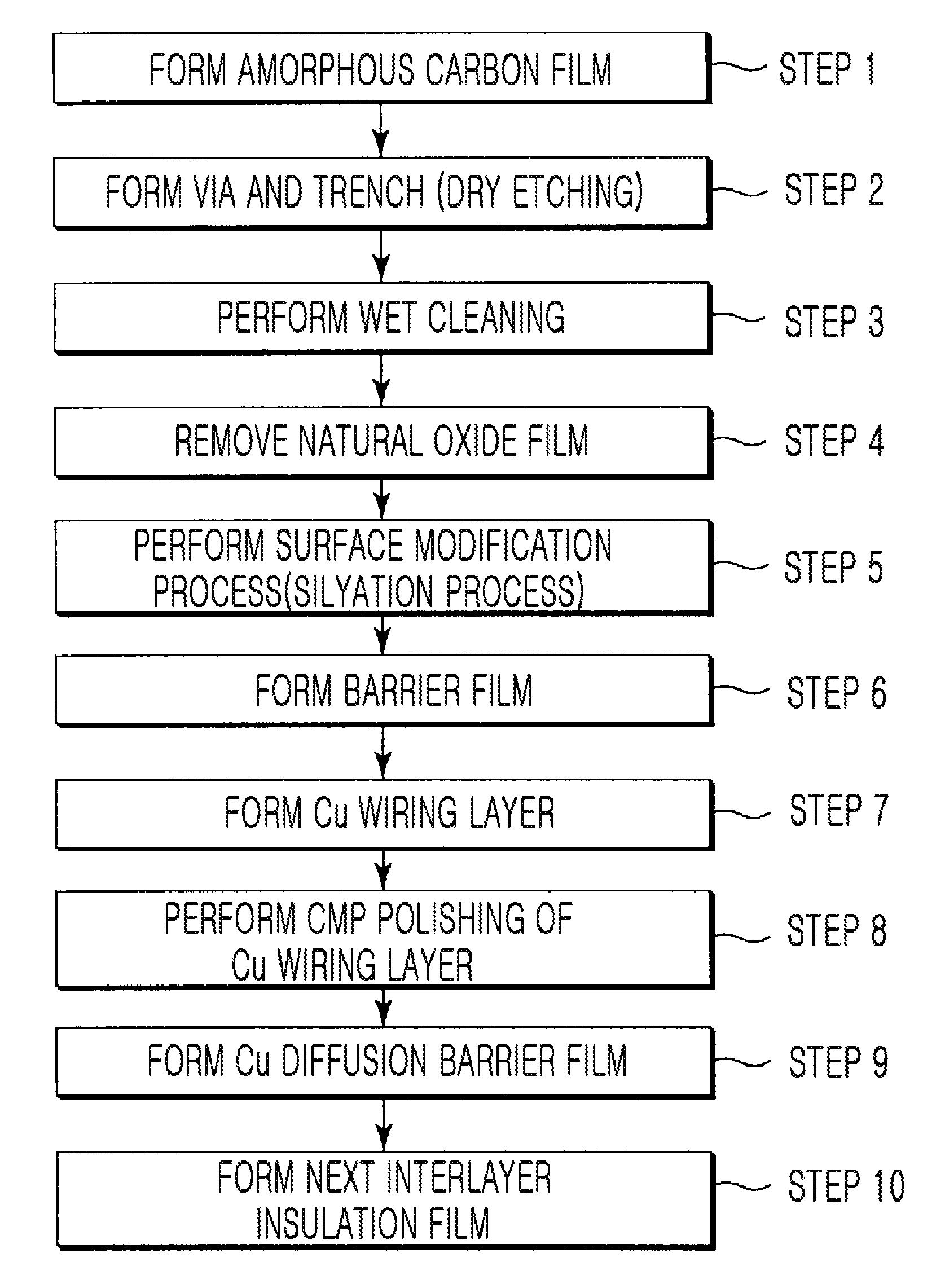

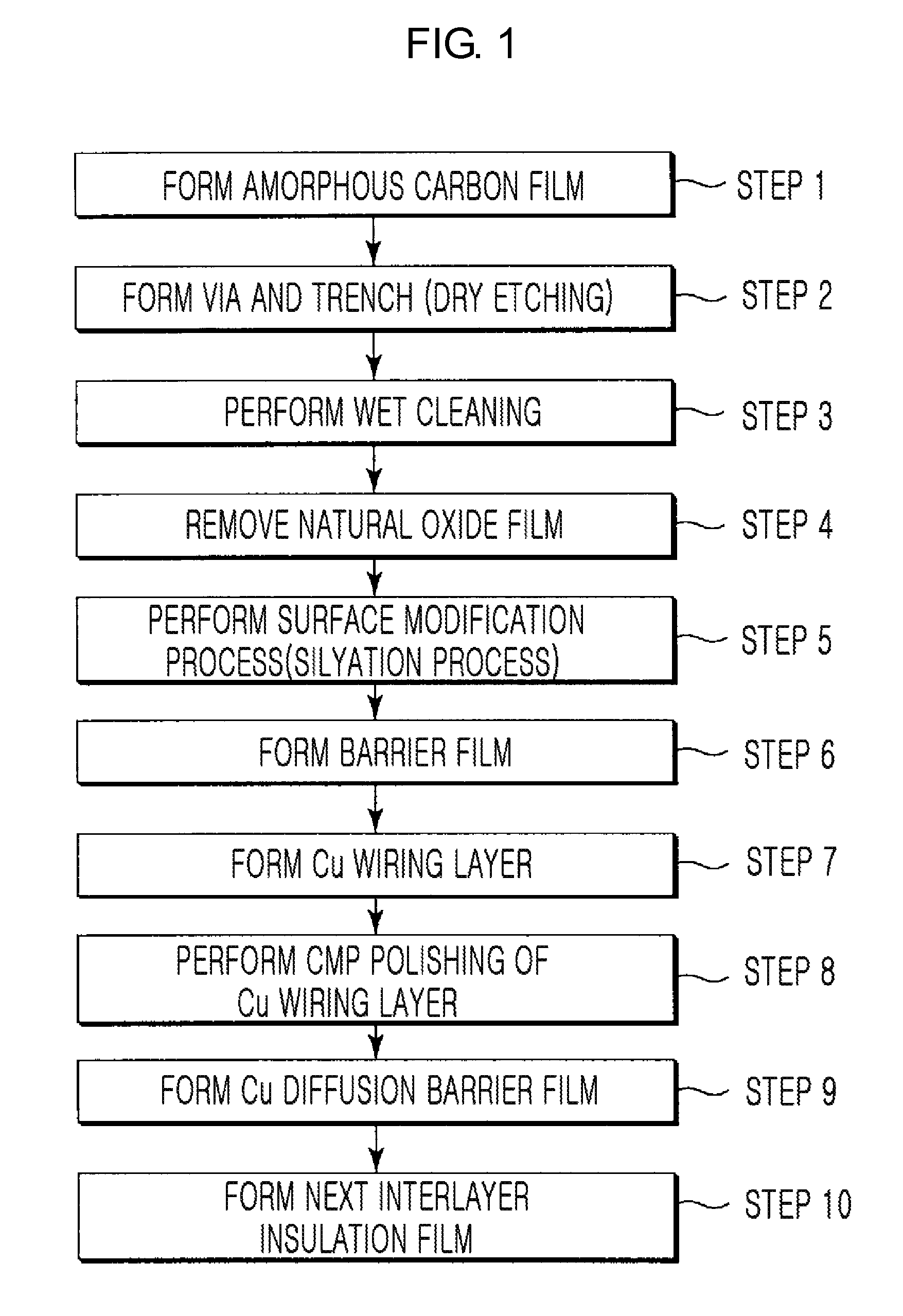

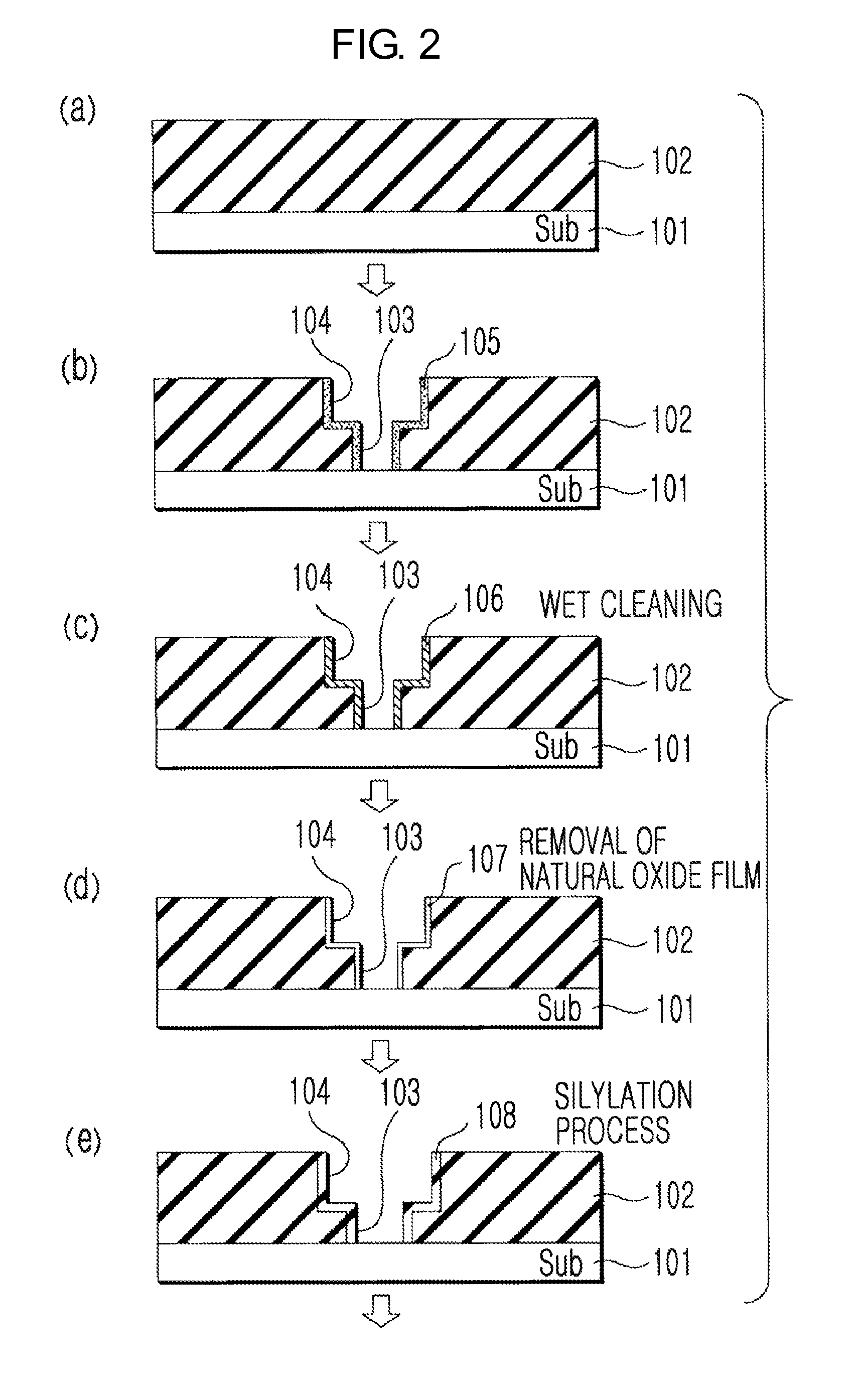

Method for processing amorphous carbon film, and semiconductor device manufacturing method using the method

InactiveUS20110053375A1Reduce adhesionPermittivitySilicon organic compoundsSemiconductor/solid-state device manufacturingCarbon filmSemiconductor

A method for processing an amorphous carbon film which has been formed on a substrate and wet-cleaned after being dry-etched includes preparing the substrate having the wet-cleaned amorphous carbon film and modifying a surface of the amorphous carbon film, before forming an upper layer on the wet-cleaned amorphous carbon film.

Owner:TOKYO ELECTRON LTD

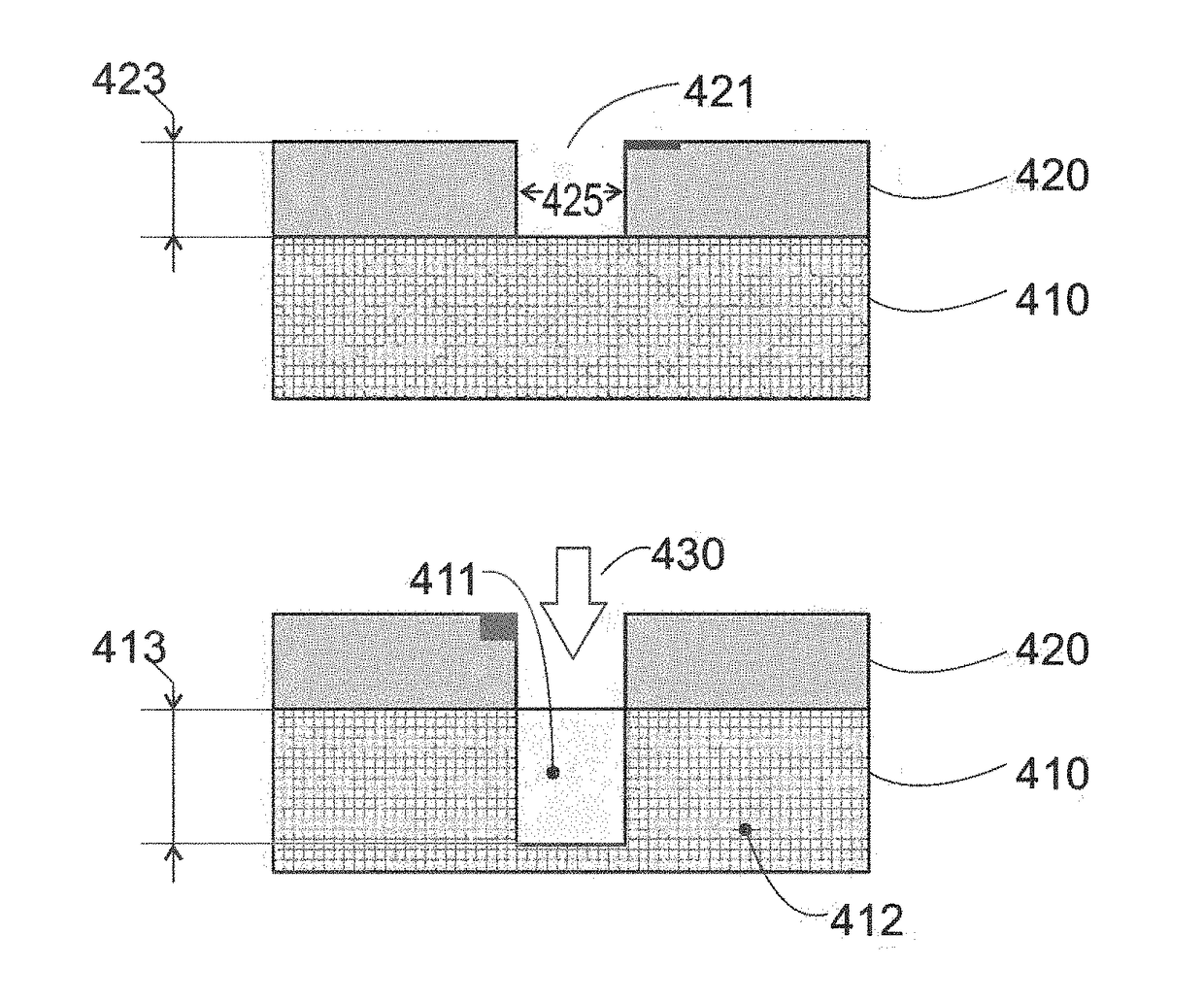

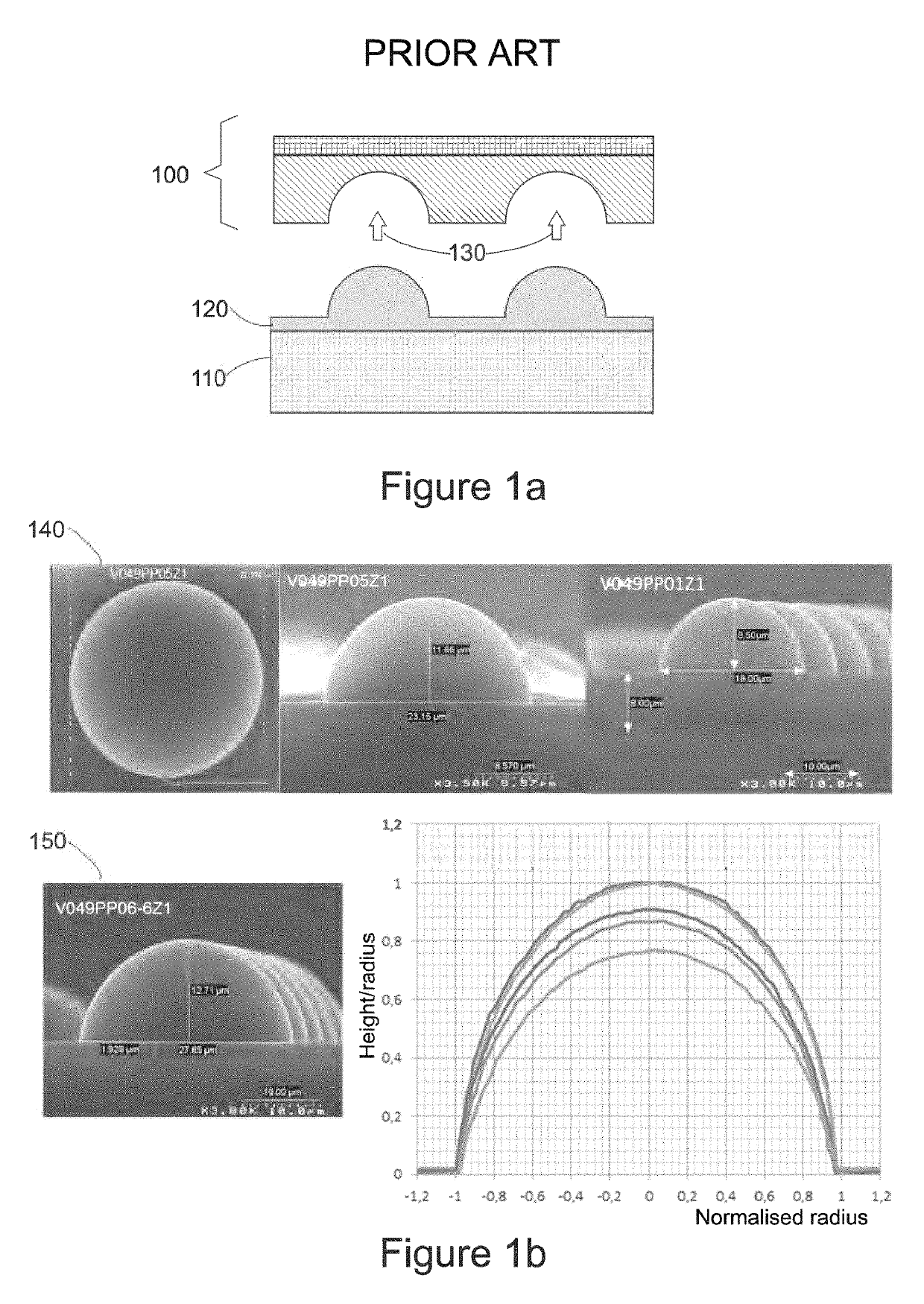

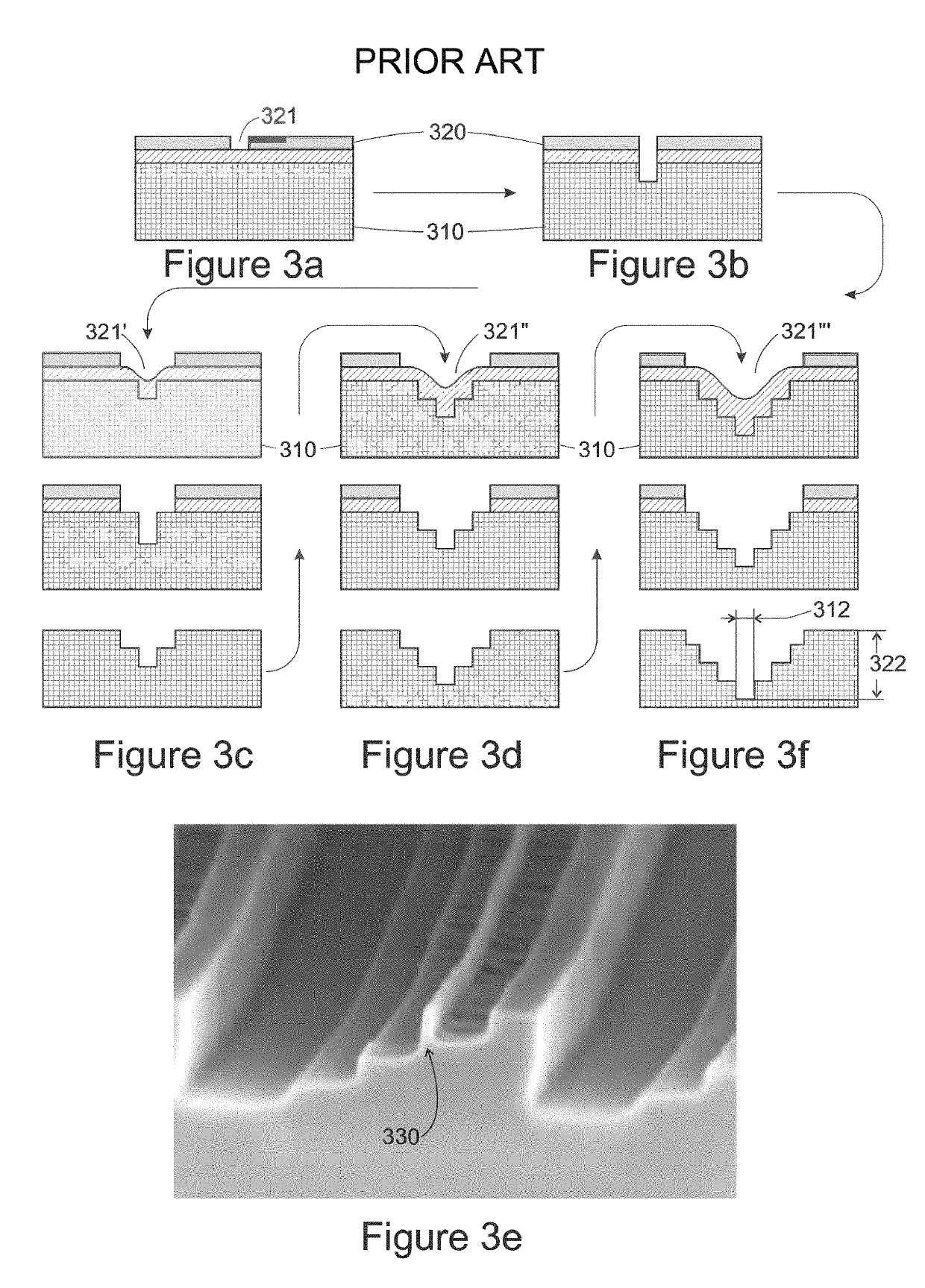

Method for creating patterns

ActiveUS20180001582A1Modifying surfaceImprove surface conditionDecorative surface effectsVacuum evaporation coatingComputer scienceIon implantation

The invention relates in particular to a method for creating patterns in a layer (410) to be etched, starting from a stack comprising at least the layer (410) to be etched and a masking, layer (420) on top of the layer (410) to be etched, the masking layer (420) having at least one pattern (421), the method comprising at least;a) a step of modifying at least one zone (411) of the layer (410) to be etched via ion implantation (430) vertically in line with said at least one pattern (421);b) at least one sequence of steps comprising:b1) a step of enlarging (440) the at least one pattern (421) in a plane in which the layer (410) to be etched mainly extends;b2) a step of modifying at least one zone (411″, 411″) of the layer (410) to be etched via ion implantation (430) vertically in line with the at least one enlarged pattern (421), the implantation being carried out over a depth less than the implantation depth of the preceding, modification step;)c) a step of removing (461, 462) the modified zones (411, 411′, 41″), the removal comprising a step of etching the modified zones (411, 411′, 411″) selectively with respect to the non-modified zones (412) of the layer (410) to be etched.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Rinsing Fluid for Lithography

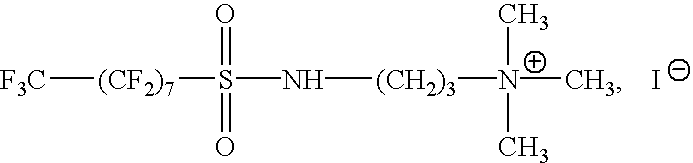

InactiveUS20080026975A1Effectively preventing pattern fallingModifying surfaceOrganic detergent compounding agentsNon-surface-active detergent compositionsHydrogenHydrogen atom

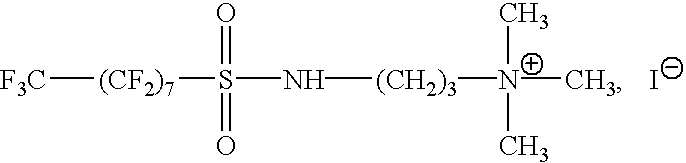

The invention provides a novel rinsing fluid which can convert an easily wettable resist pattern surface having a contact angle of 40° or below into one having a contact angle of 70° or above to inhibit pattern collapse effectively and thereby give high-quality products. The rinsing fluid consists of a solution containing at least one fluorine compound soluble in water or alcoholic solvents which is selected from among compounds represented by the general formula (I), those represented by the general formula (II), and those represented by the general formula: Rf′—COOH: wherein R1 and R2 are each optionally substituted C1-5 alkyl whose hydrogen atoms are partially or wholly replaced by fluorine, or R1 and R2 together with the SO2 groups to which they are bonded and the nitrogen atom may form a five- or six-membered ring; Rf is optionally substituted C1-5 alkyl whose hydrogen atoms are partially or wholly replaced by fluorine; m and n are each an integer of 2 or 3; and Rf′ is at least partially fluorinated alkyl having 8 to 20 carbon atoms.

Owner:TOKYO OHKA KOGYO CO LTD

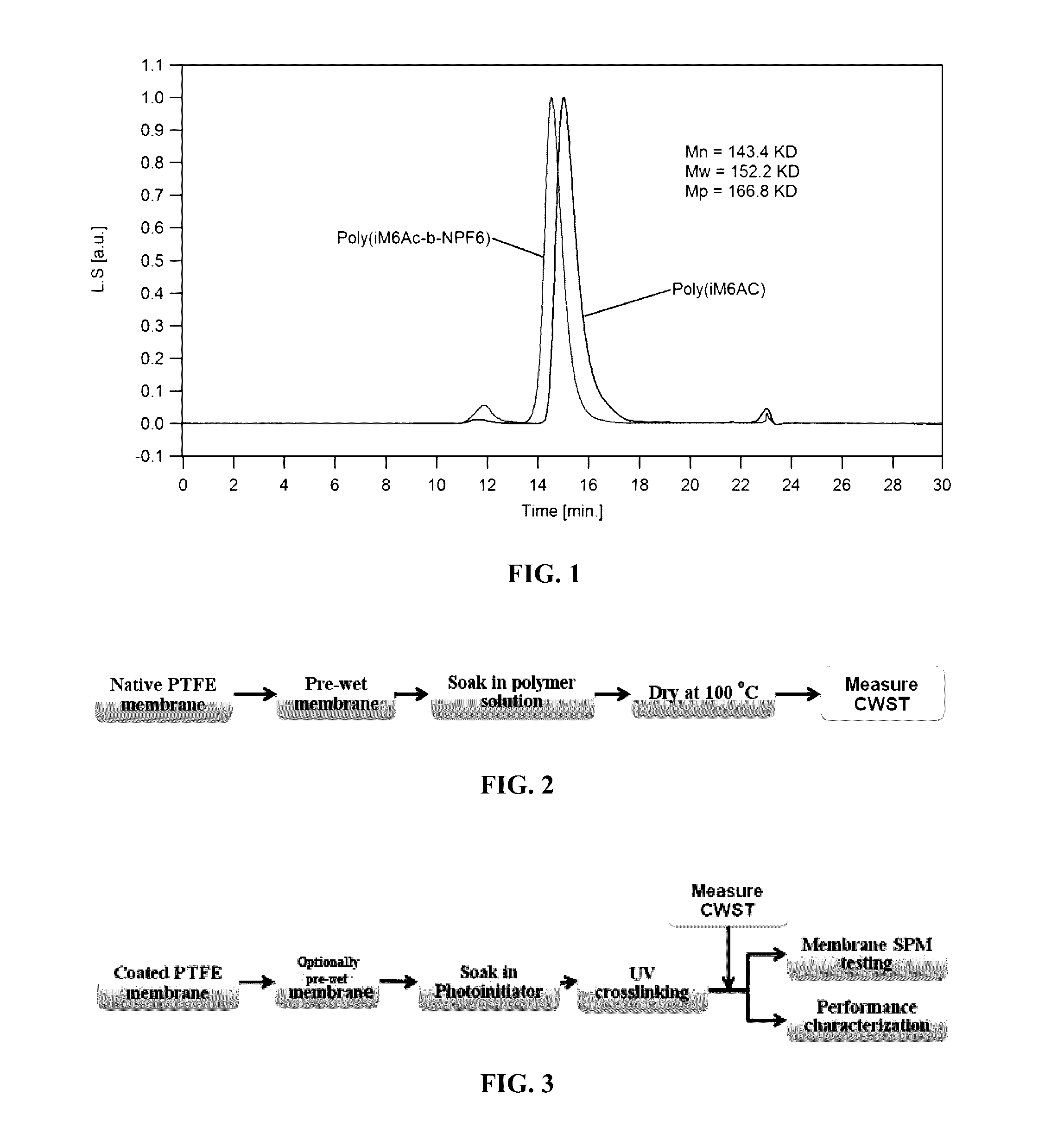

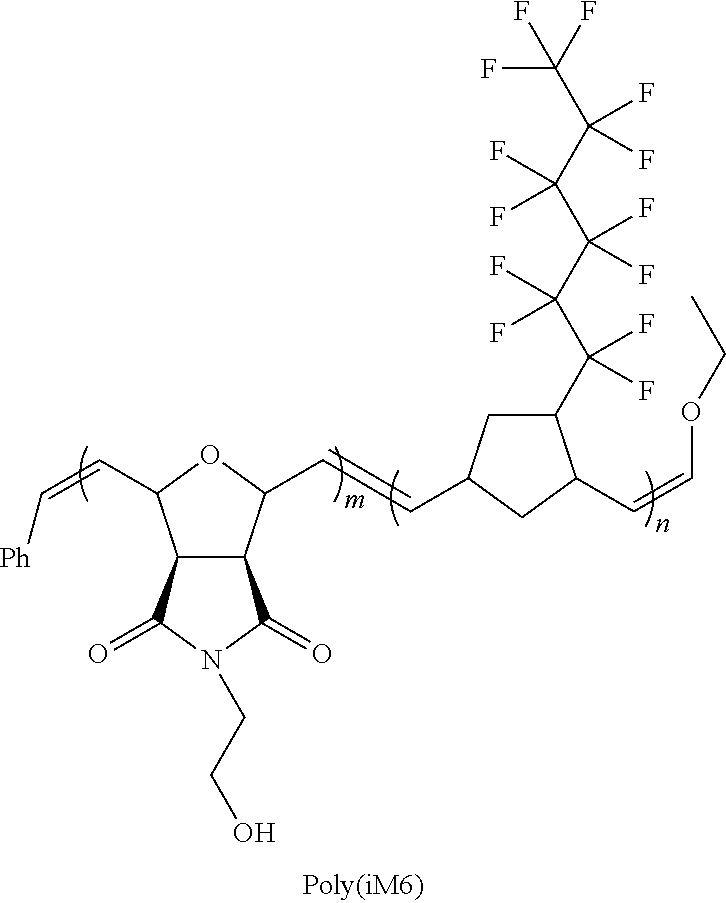

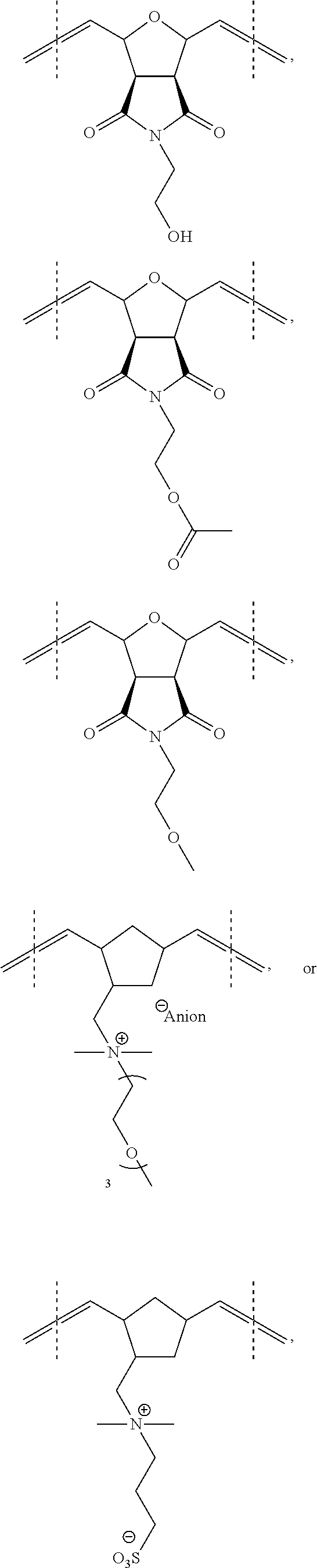

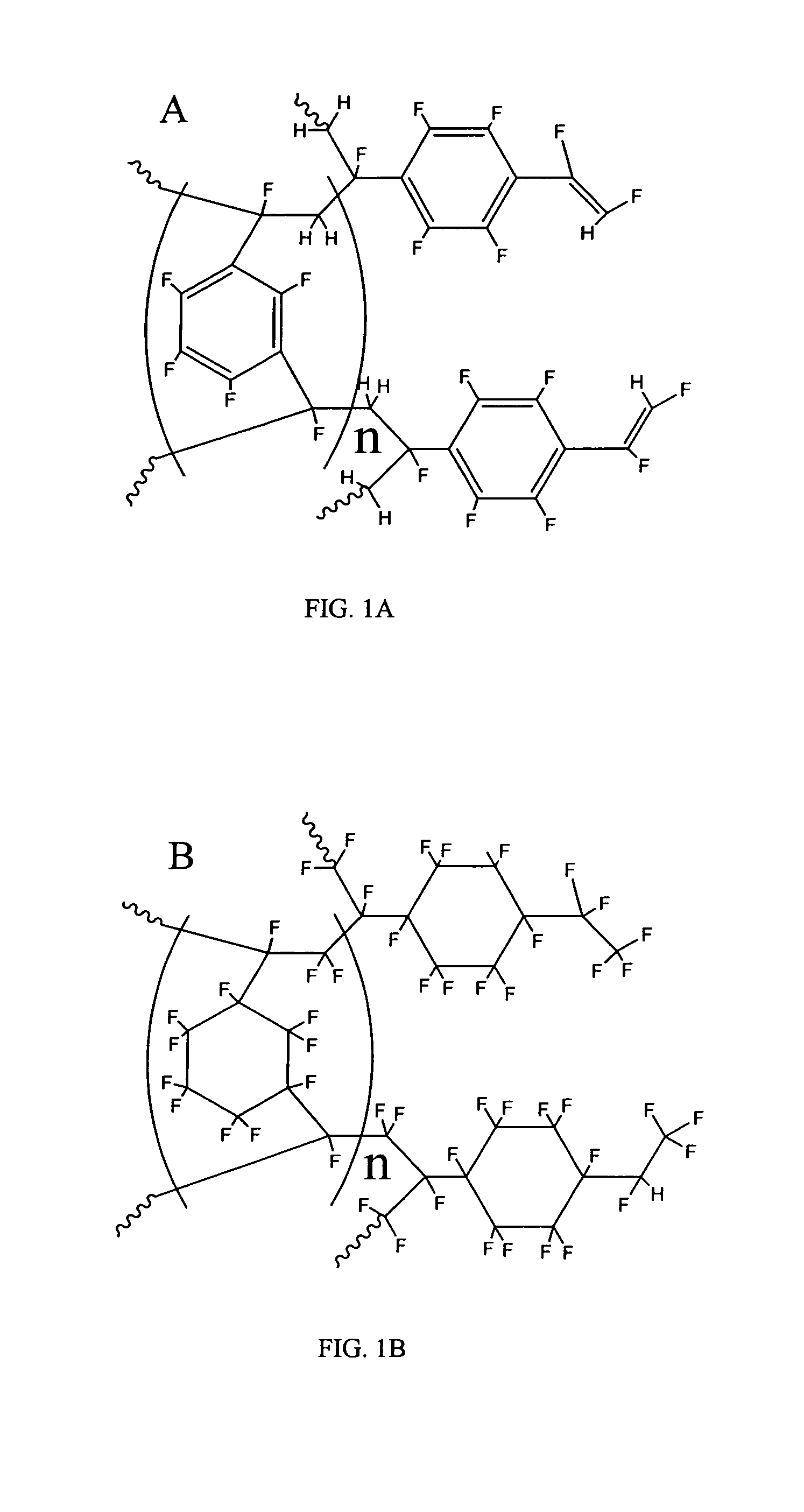

Hydrophilically modified fluorinated membrane (IV)

ActiveUS20160288062A1Modifying surfaceSemi-permeable membranesMembranesPolymer scienceMembrane surface

Disclosed are copolymers which are useful in hydrophilically modifying fluoropolymer membranes. An example of the copolymers is:Also disclosed are a method of preparing such copolymers, a method of modifying fluoropolymer membrane surfaces, and hydrophilic fluoropolymer porous membranes prepared from the copolymers.

Owner:PALL CORP

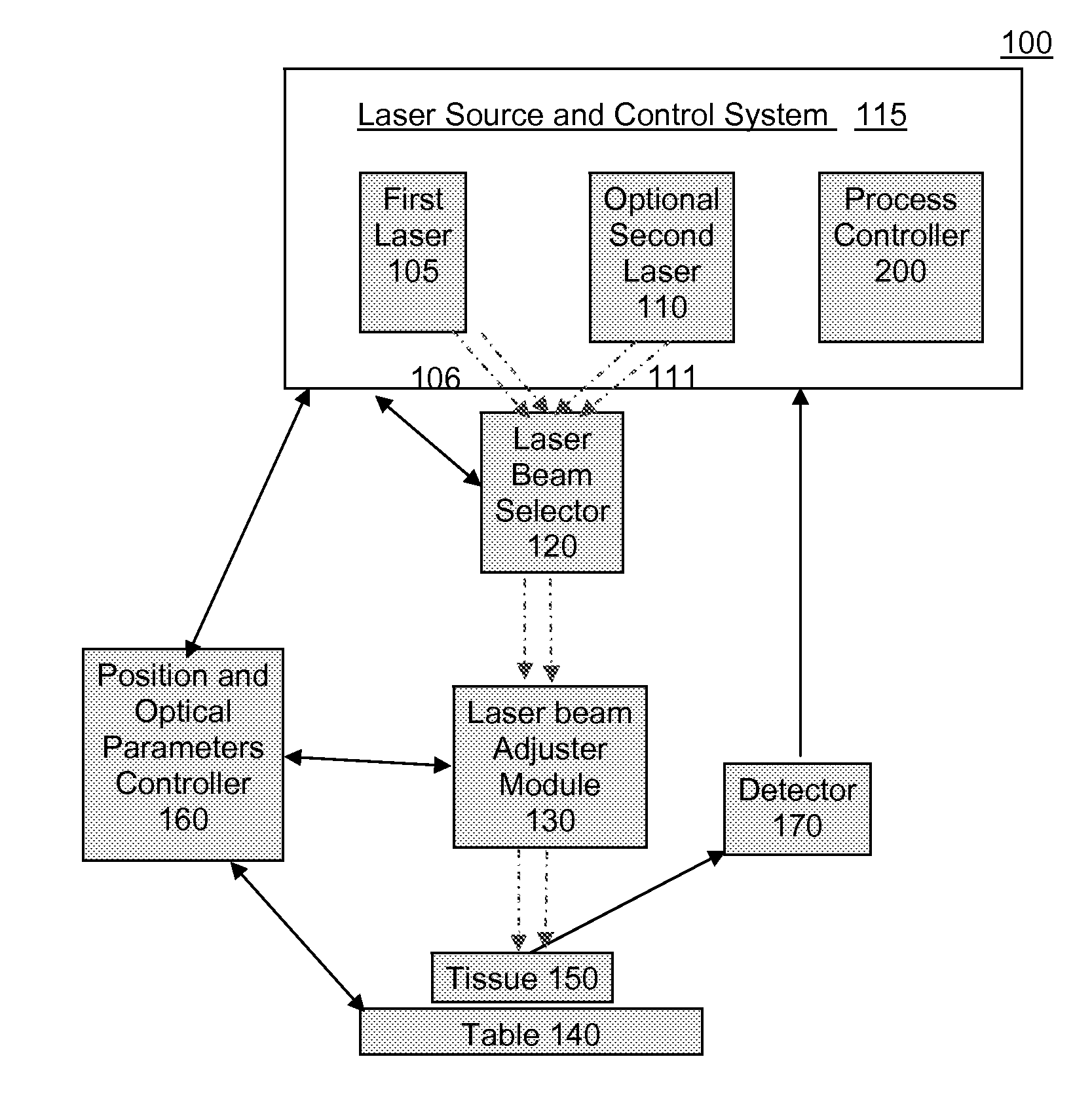

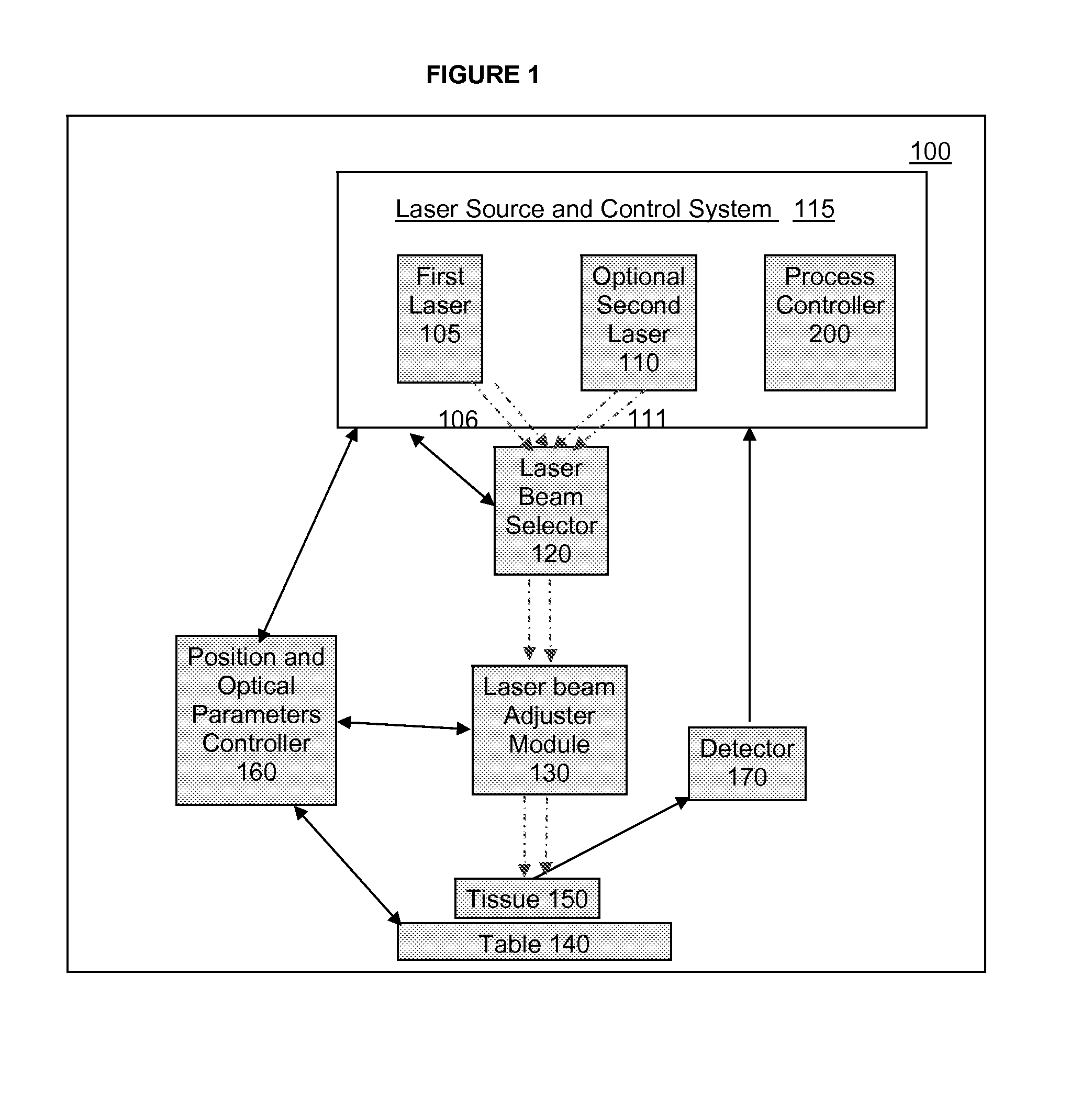

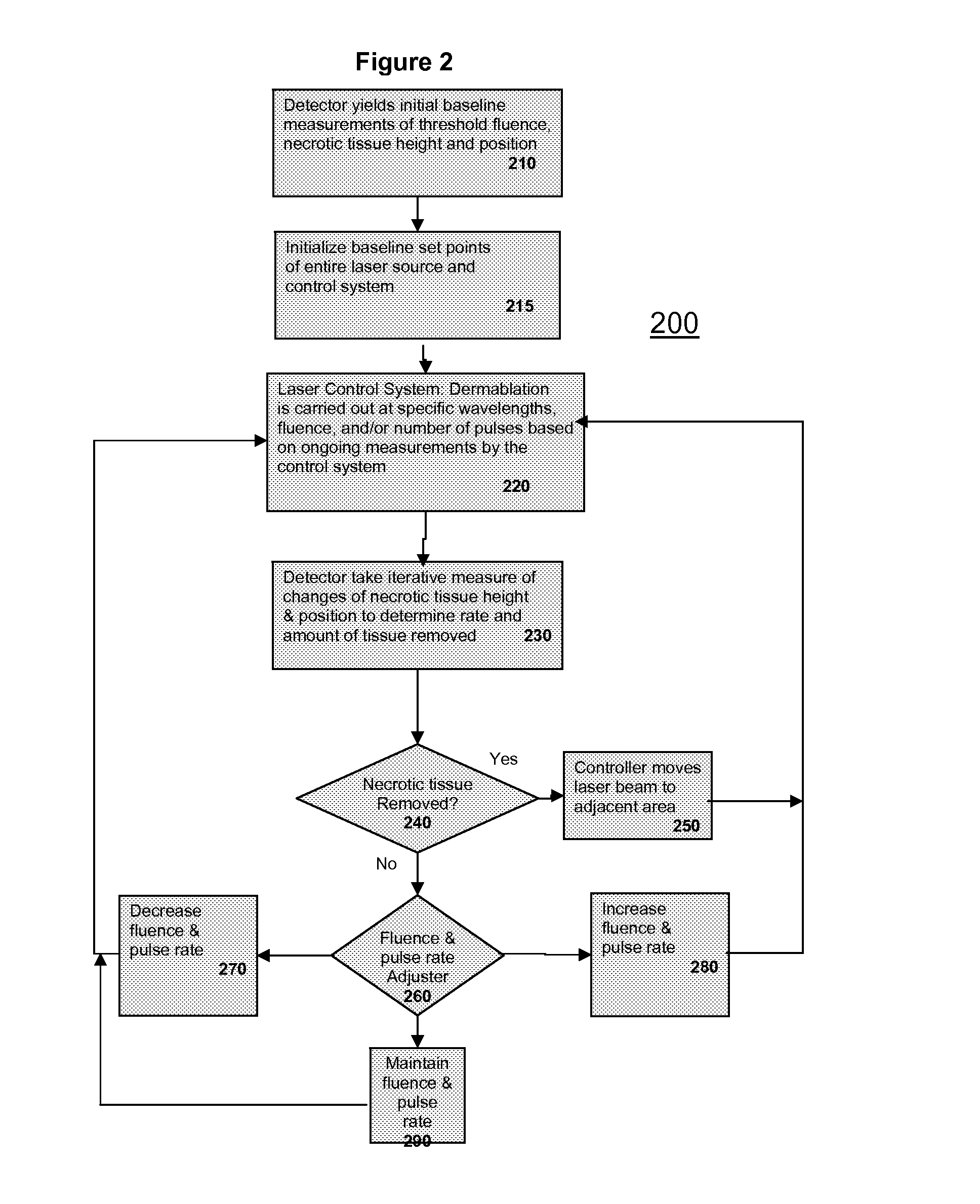

System and method for modification and/or smoothing of tissue with laser ablation

InactiveUS20130190742A1Not to damageModifying surfaceSurgical instrument detailsSharpeningLength wave

Disclosed is an improved system and method for efficiently removing tissue using laser ablation. A first laser emits a first laser beam with a variable first integrated fluence sufficient to ablate tissue. The first laser beam is movably positioned over one or more surfaces of the tissue and the first integrated fluence varies over different levels with position, so different thicknesses of tissue are ablated at different surface positions in order to modify the contour of the surface of the tissue. Modifications include tissue smoothing, removing, feathering, sharpening, and roughening. In one preferred embodiment the tissue is eschar that is removed, unveiling viable tissue. In alternate preferred embodiments, one or more additional lasers beams with different wavelengths, with integrated fluence sufficient to ablate tissue, are moved over the surface of the tissue until a second ablation reaches a second self-termination point, e.g., determined by affects of chemicals below the termination point that absorb the second laser beam without producing the temperature increase necessary for ablation to continue.

Owner:IBM CORP

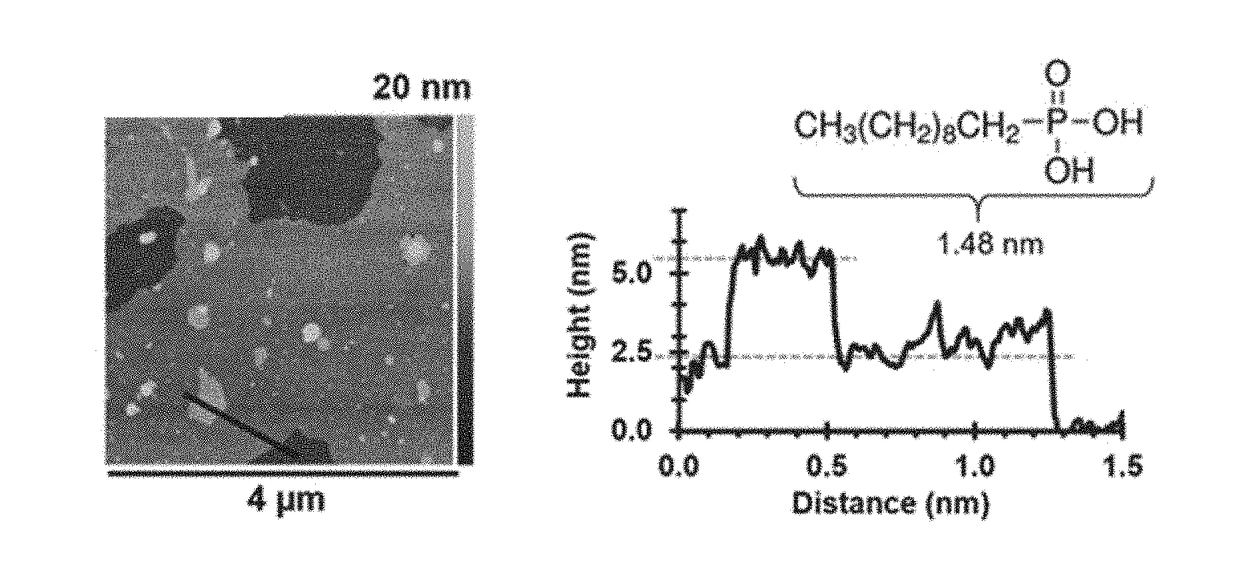

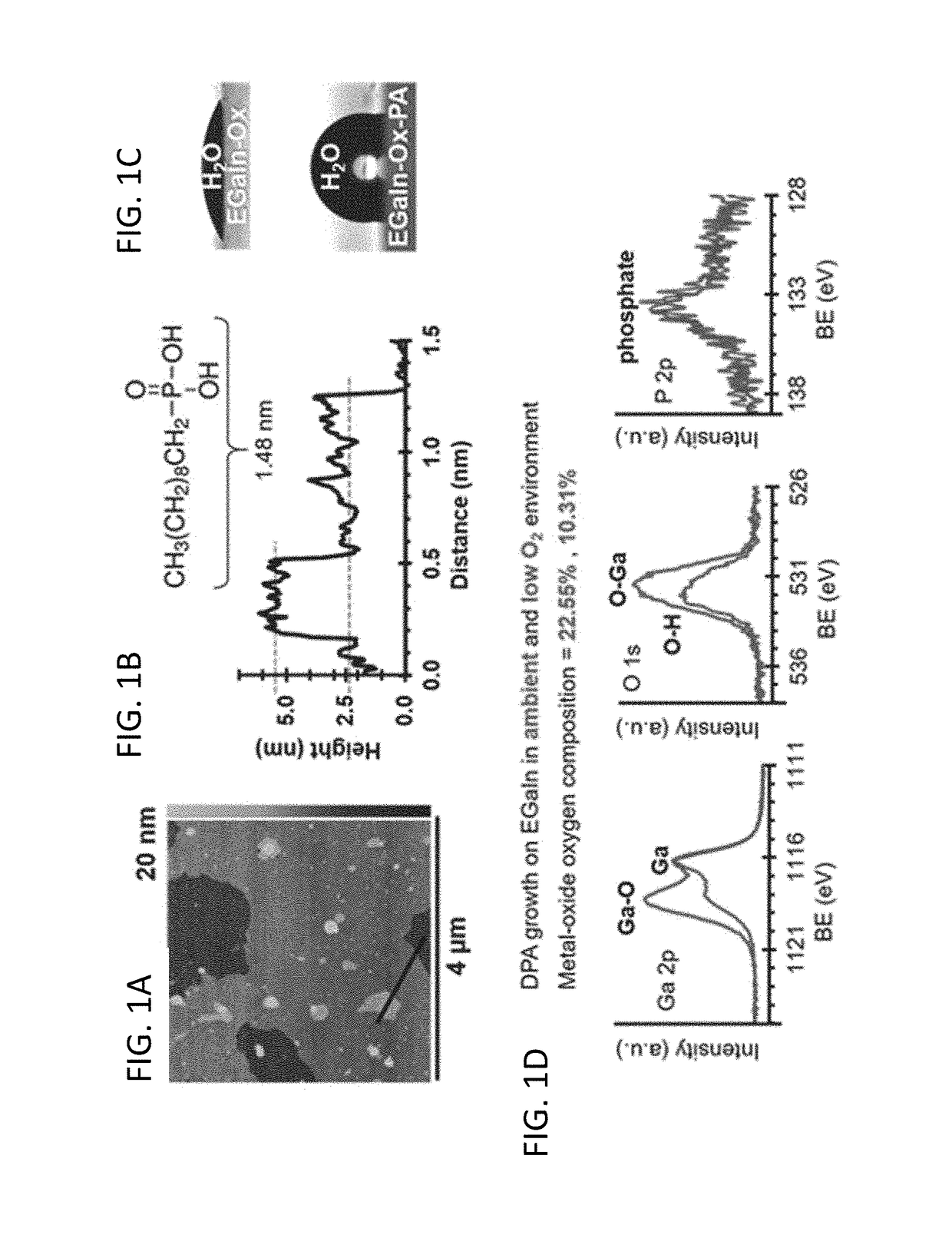

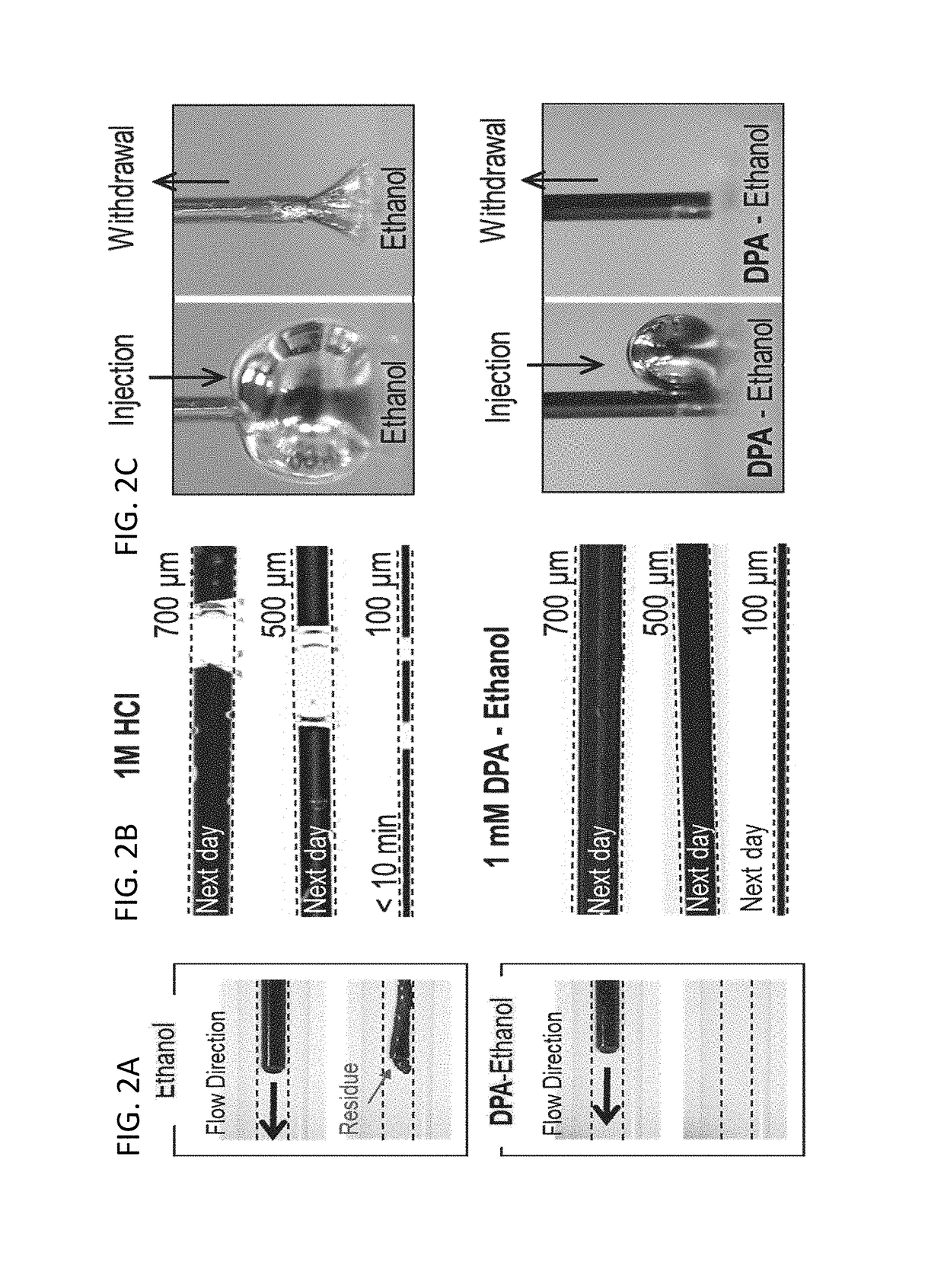

Liquid metal interfaces for flexible and reconfigurable electronics

ActiveUS10129975B1Control and mitigate undesirable side effectProduce flexible and reconfigurable electronicsLiquid conductorsCircuit security detailsIndiumLiquid metal

A reconfigurable electronic component comprising a channel having first and second ends and outer walls defining a lumen; a liquid phosphonic acid within the lumen; and a liquid metal within the lumen. A first electrical contact at the first end of the channel and a second electrical contact in communication with the lumen at the second end of the channel. A predetermined amount of a solvent and a liquid metal may be within the lumen, and the solvent may comprise ethanol. The liquid metal may be selected from the group consisting of eutectic gallium indium (EGaIn) and eutectic gallium-indium-tin alloys. The phosphonic acid may be selected from the group consisting of decylphosphonic acid (DPA), fluorobenzylphosphonic acid (FPA), and difluorobenzylphosphonic acid (DFPA). The first and second electrical contacts comprise copper. An overflow channel and a reservoir for the liquid metal and phosphonic acid may be in fluid communication with the lumen.

Owner:GOVERNMENT OF THE UNITED STATES AS REPRESENTED BY THE SEC OF THE AIR FORCE

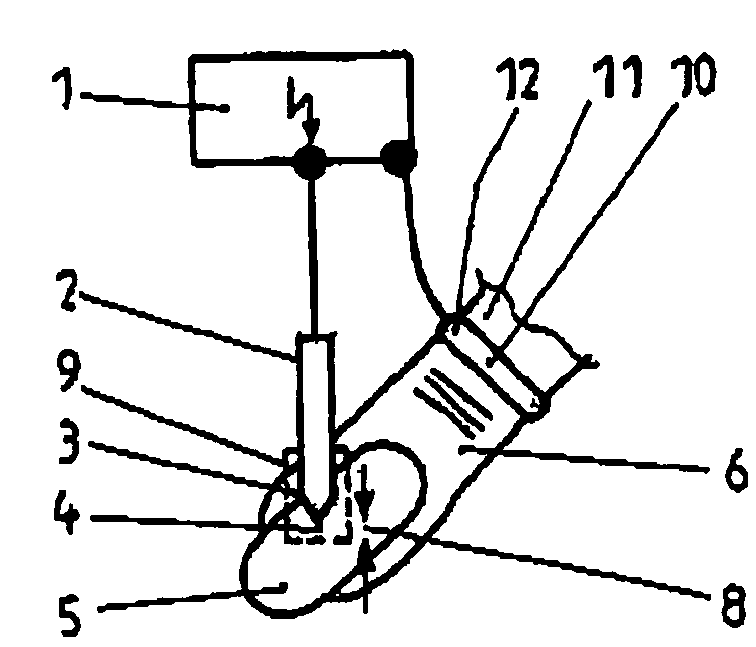

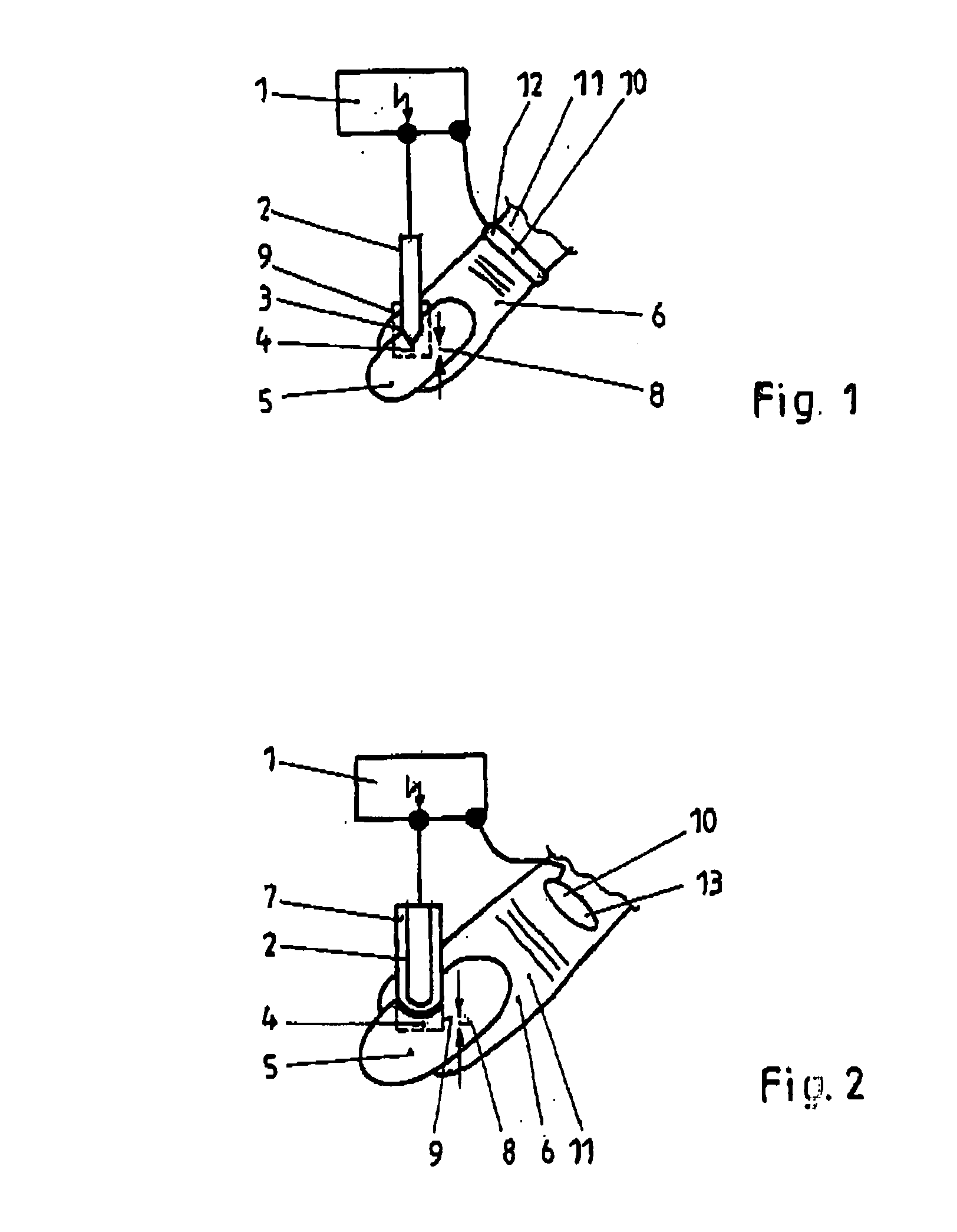

Apparatus for preparing a finger nail or a toe nail for a coating

ActiveUS7330755B2Easy to spreadStrongly stickElectrotherapySurgical instruments for heatingEngineeringAtmospheric pressure

Owner:VIOL WOLFGAG +1

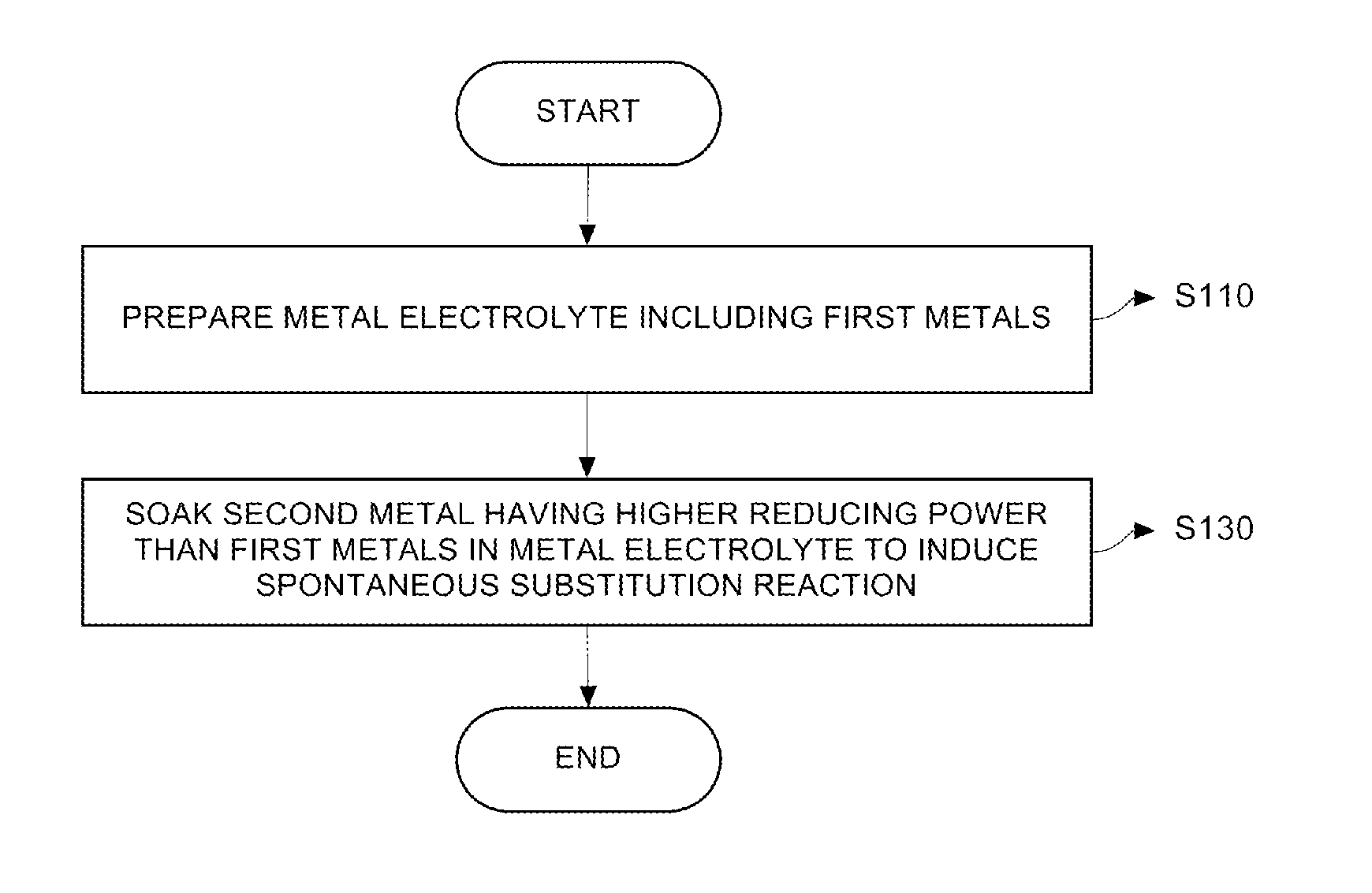

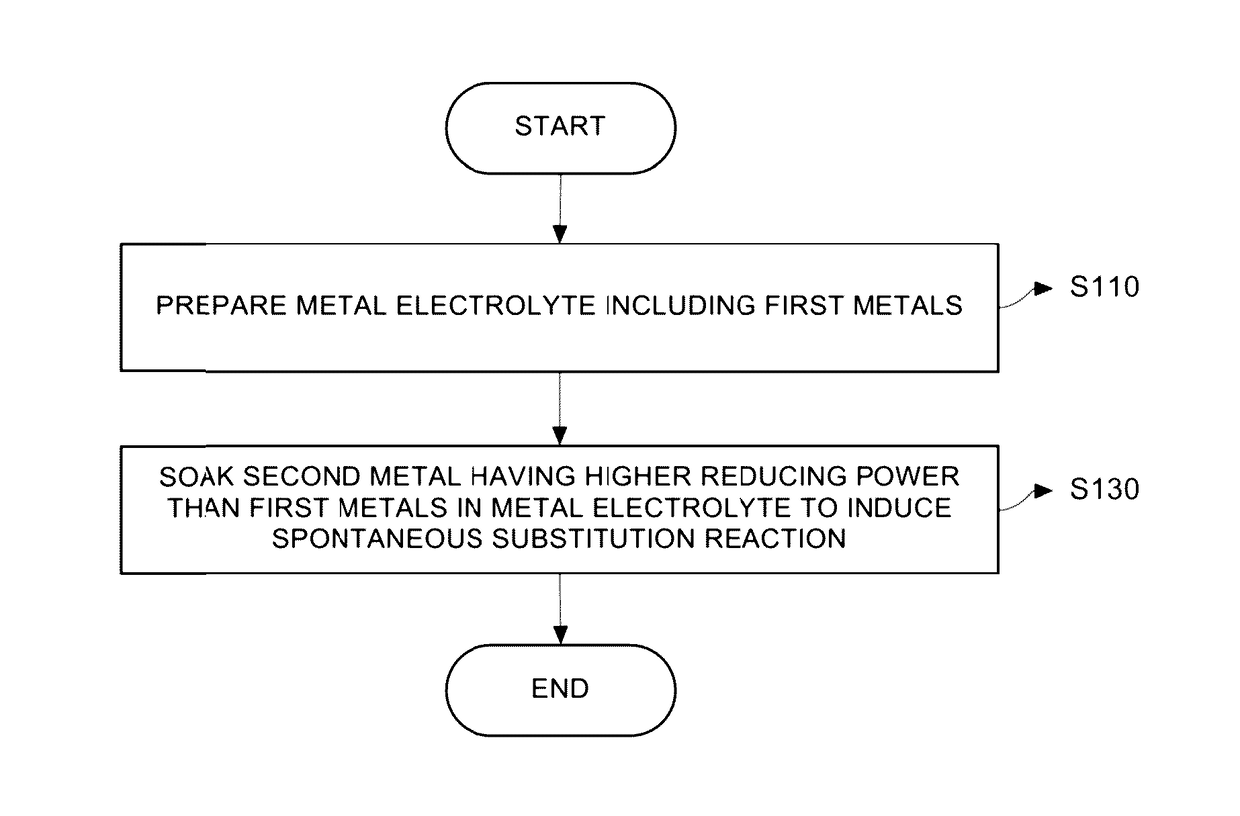

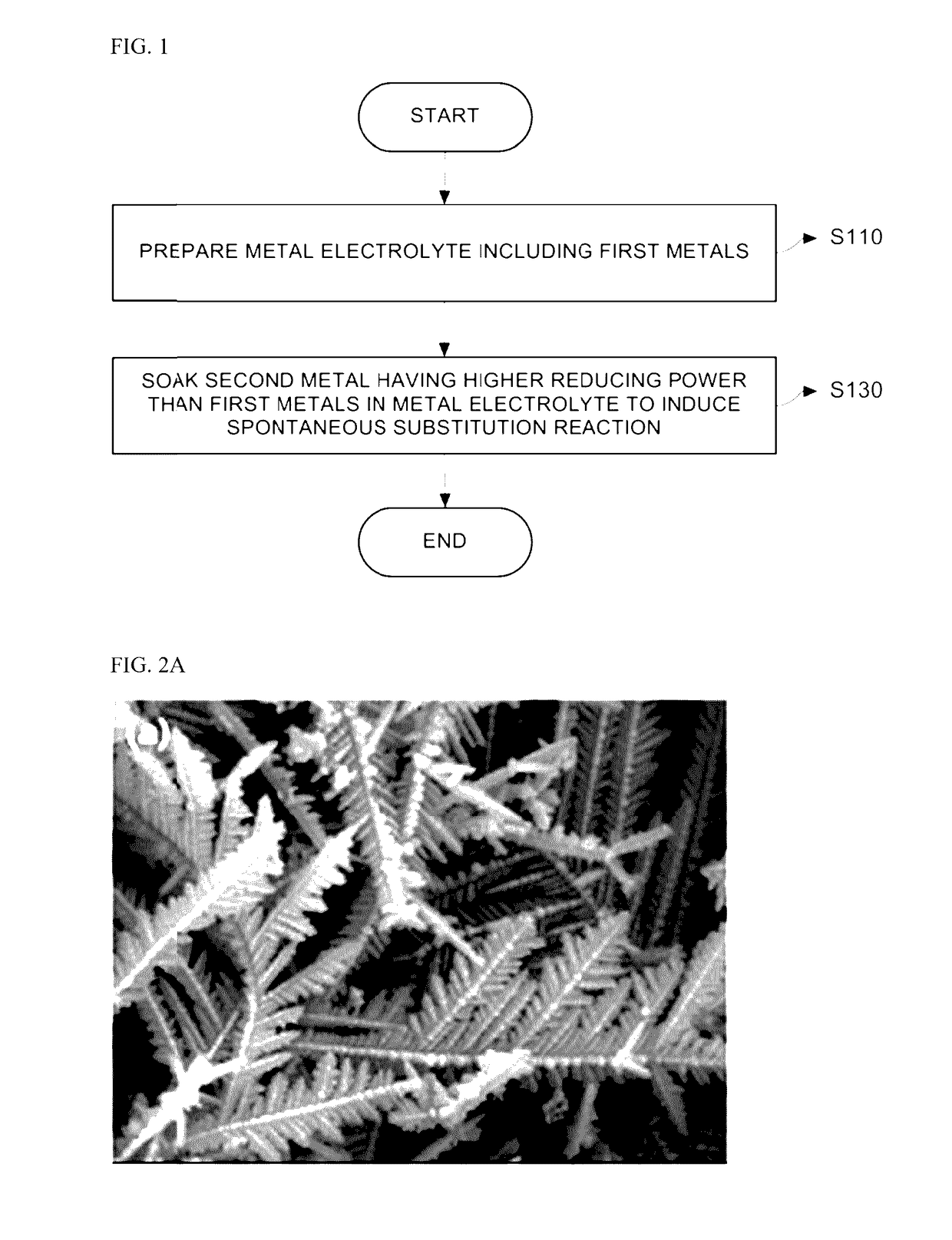

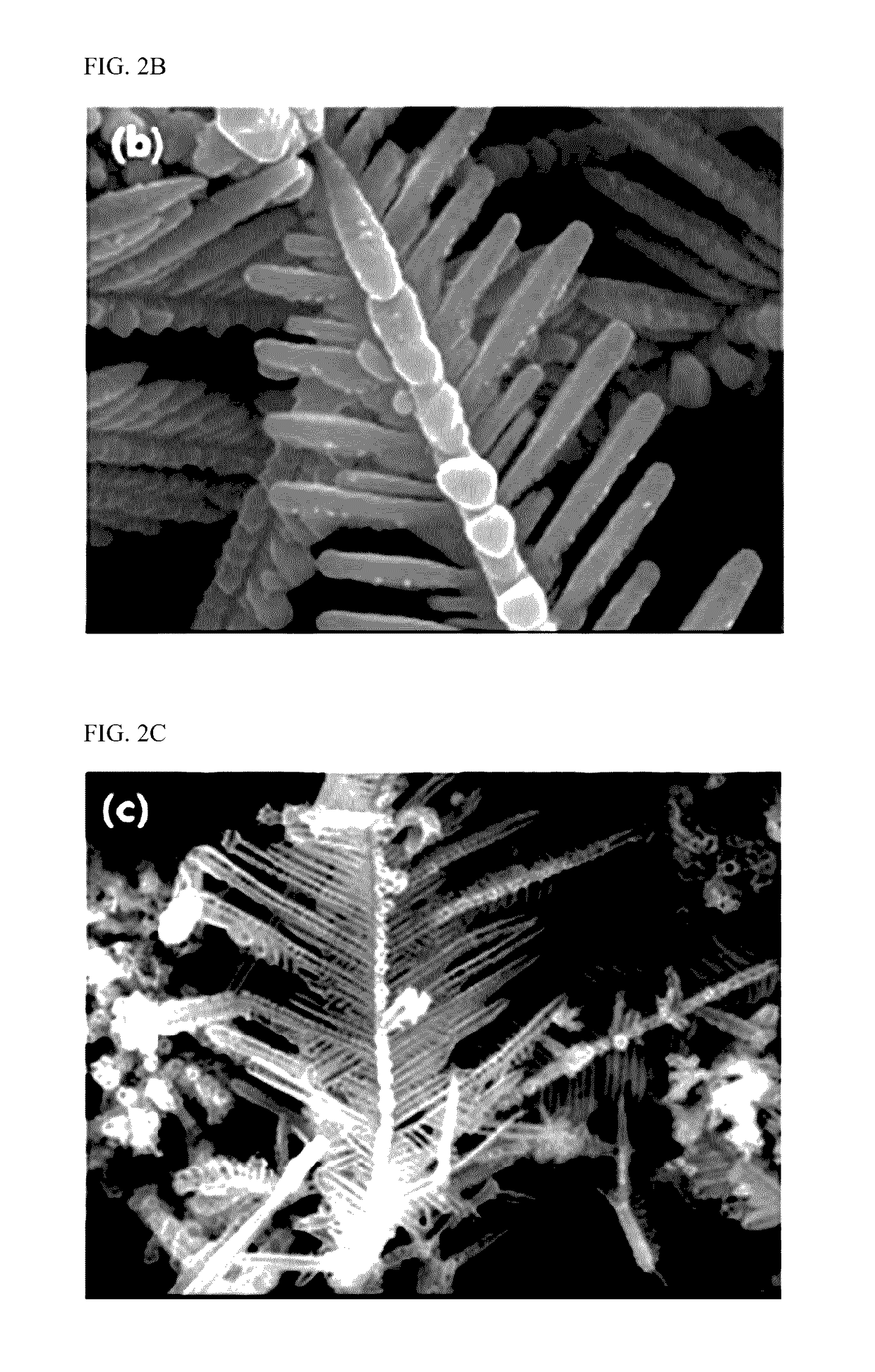

Method of manufacturing powder having high surface area

ActiveUS20140283650A1Short processing timeHigh surface areaMaterial nanotechnologyNanostructure manufactureIonMetal alloy

A method of manufacturing a powder having a high surface area is provided. According to the method of manufacturing a powder having a high surface area, a metal electrolyte in which metal ions of different kinds of first metals are dissociated is prepared. Subsequently, a metal alloy powder formed of the first metals is formed by soaking a second metal having a higher reducing power than the first metals in the metal electrolyte to induce a first spontaneous substitution reaction. Therefore, it is possible to form a powder having an improved specific surface area.

Owner:RES & BUSINESS FOUNDATION SUNGKYUNKWAN UNIV

Softening Strip for Controlling Stress in Joints at Very Low Temperatures

ActiveUS20170348954A1Thin bond lineReduce the amount of adhesionLamination ancillary operationsLaunch systemsEngineeringMechanical engineering

Owner:THE BOEING CO

Method Of Modifying Surface Of Material

ActiveUS20100285252A1Easy to adjustIncrease chancePretreated surfacesLoose filtering material filtersPhosphorylcholineChemical compound

A method for surface modification of a material by means of introducing the phosphorylcholine group represented by the following formula (1-1) onto the surface of the material by treating a material having amino groups with a chemical compound containing an aldehyde derivative obtained by the oxidative ring-opening reaction of glycerophosphorylcholine.The method of the present invention provides various materials such as medical materials having superior biocompatibility and hydrophilicity.

Owner:SHISEIDO CO LTD

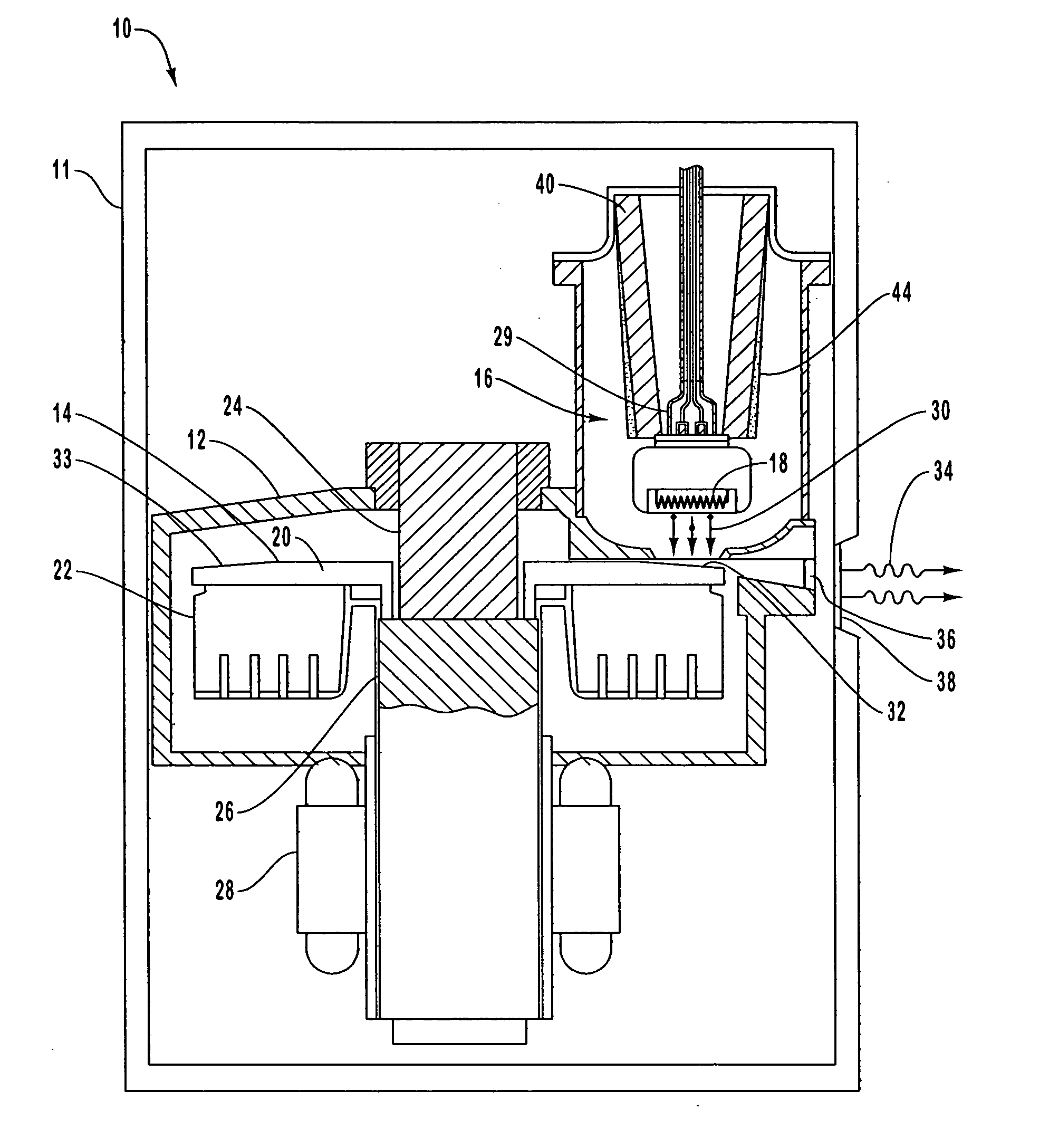

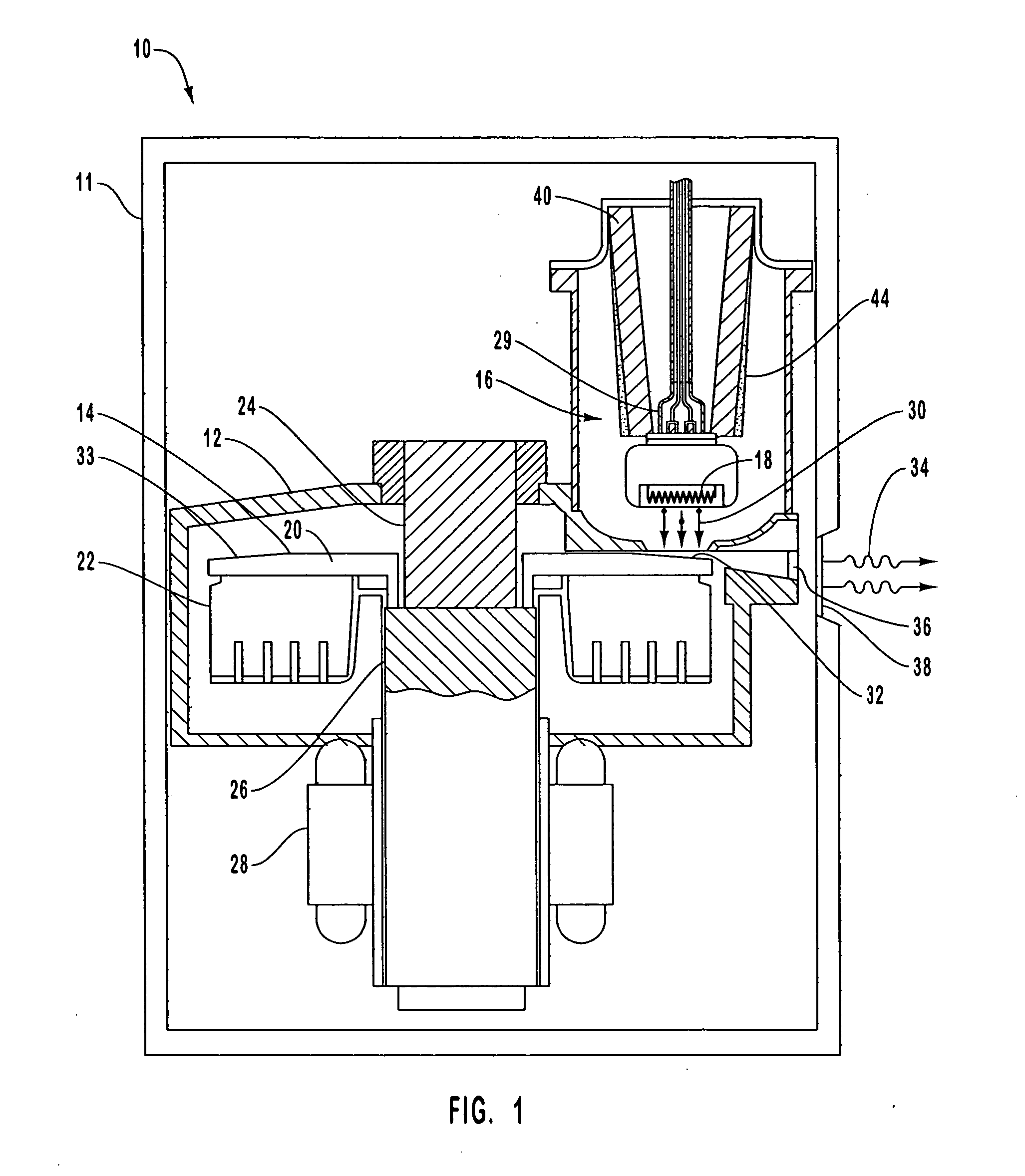

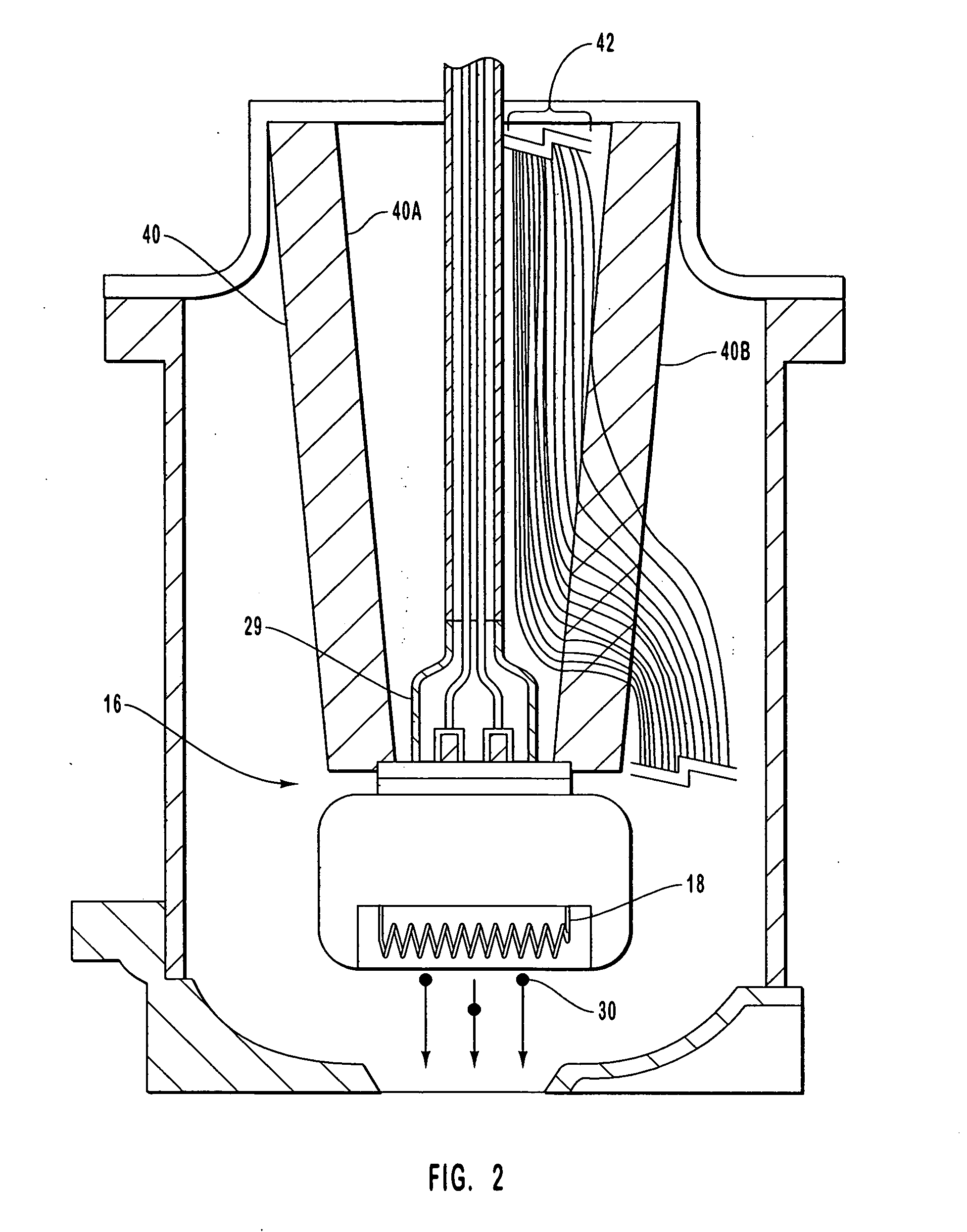

Apparatus and method for shaping high voltage potentials on an insulator

InactiveUS20050100659A1Improve conductivityGood surface conductivityX-ray tube electrodesCoatingsEngineeringHigh pressure

An apparatus and method for reducing the incidence of electric field stress on portions of insulating structures within high voltage devices is disclosed. Each of the embodiments disclosed herein modifies the conductive properties of the insulating structure surface in a non-uniform manner such that the distribution of voltage potential along the surface thereof is more fully equalized during operation of the high voltage device. This, in turn, reduces the per unit stress on the insulating structure caused by the electric field of the high voltage device. Though embodiments of the present invention are preferably directed to utilization in x-ray tube devices, a variety of high voltage devices may benefit from application of the disclosed matter.

Owner:VARIAN MEDICAL SYSTEMS

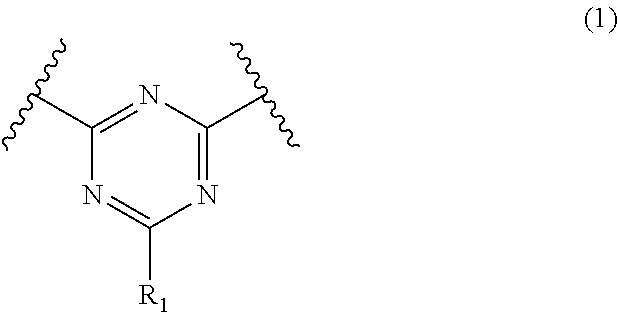

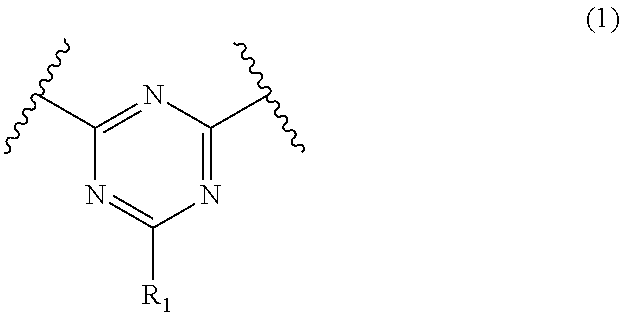

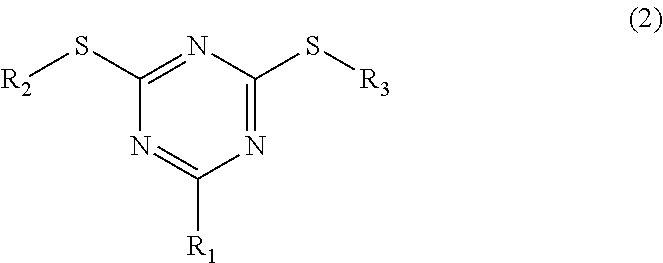

Organic-inorganic hybrid composition, and article and optical component including the same

An organic-inorganic hybrid composition including a polymer having a triazine ring structure in a main chain of the polymer (A);an inorganic particulate (B); and a surface-treating agent having a triazine ring structure represented by Formula (1)(C):wherein, in Formula (1), R1 is a carboxyl group, a phosphoric acid group, a sulfo group, or a substituted or unsubstituted alkyl group, a substituted or unsubstituted alkenyl group, a substituted or unsubstituted alkynyl group, a substituted or unsubstituted aryl group, a substituted or unsubstituted aralkyl group, or a substituted or unsubstituted amino group, wherein a number median diameter (Dn50) of the inorganic particulate (B) is greater than or equal to about 1 nm and less than or equal to about 20 nm.

Owner:SAMSUNG ELECTRONICS CO LTD

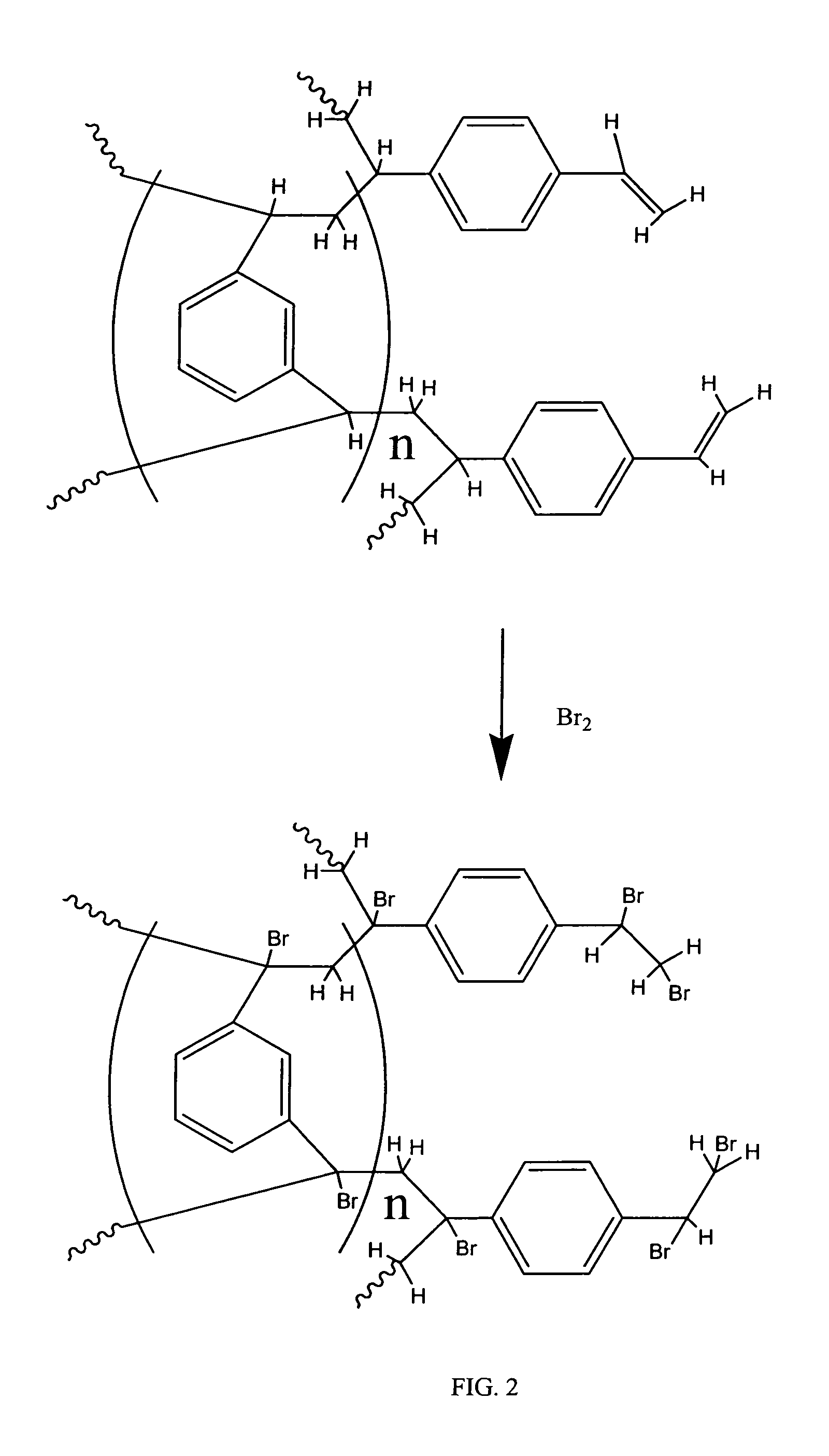

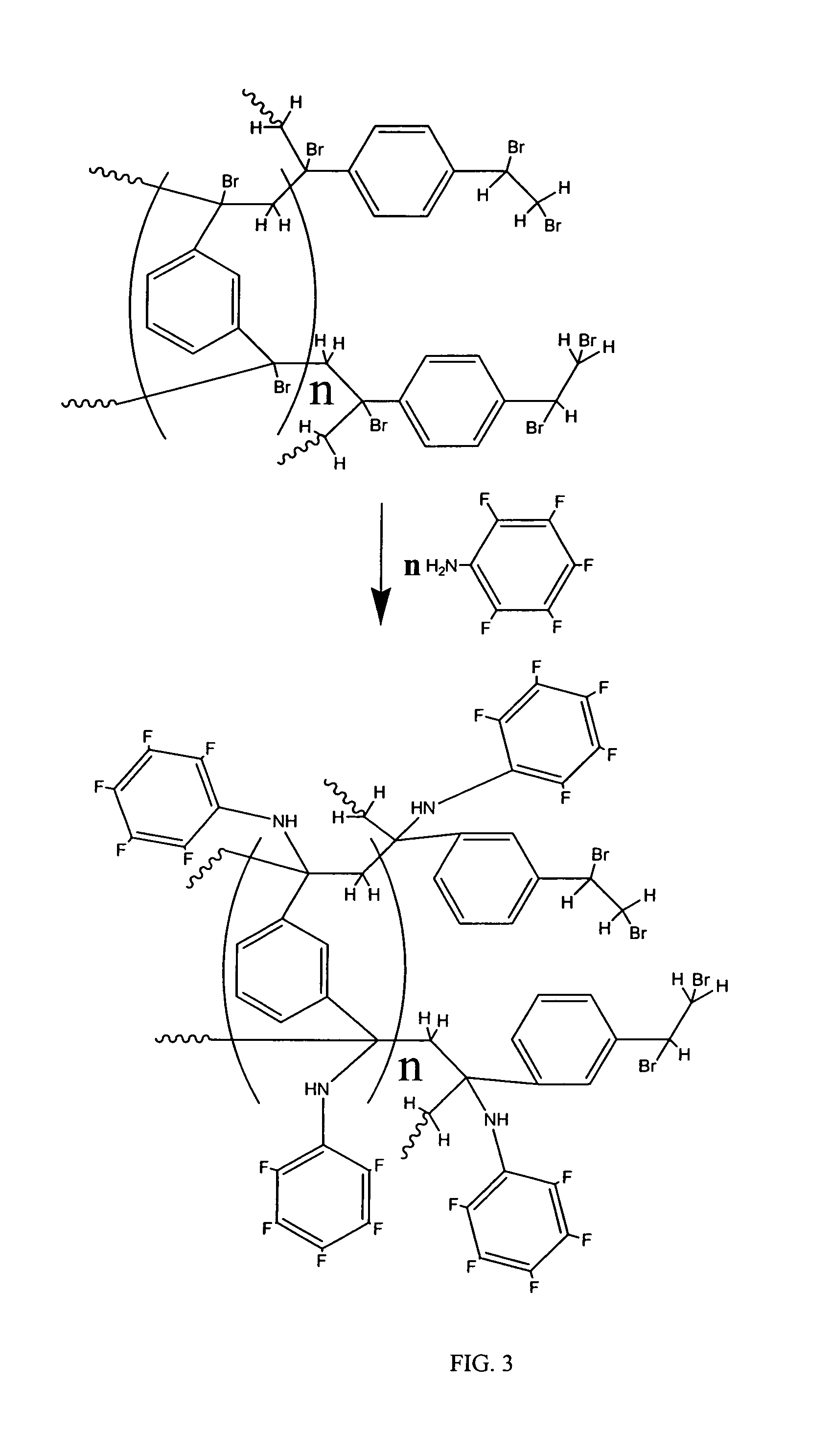

Coated polydivinylbenzene beads

InactiveUS7396883B1Rapid and but efficient separationLower average back pressureSolid sorbent liquid separationAnalyteThin layer

The present invention provides novel, polymeric supports, methods of making, and methods of using the supports, that have a fluorinated, amidated surface. The supports include polymeric microbeads, thin layers or membranes, plates, monoliths and the like. The supports are useful as packing materials for normal phase, reverse phase, and size exclusion chromatography, and provide high speed separation of analytes with excellent resolution. The fluorinated, amidated surface may include a composition comprising a plurality of repeating units, for example, having the following structure:

Owner:JORDI FLP

Method for processing amorphous carbon film, and semiconductor device manufacturing method using the method

InactiveUS8461047B2Reduce adhesionHigh dielectric constantSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon filmSemiconductor

A method for processing an amorphous carbon film which has been formed on a substrate and wet-cleaned after being dry-etched includes preparing the substrate having the wet-cleaned amorphous carbon film and modifying a surface of the amorphous carbon film, before forming an upper layer on the wet-cleaned amorphous carbon film.

Owner:TOKYO ELECTRON LTD

Apparatus for preparing a finger nail or a toe nail for a coating

ActiveUS20050143775A1Low costEasy to spreadElectrotherapySurgical instruments for heatingEngineeringHigh pressure

An apparatus for preparing a finger nail or a toe nail for a coating in that a gas discharge is ignited above the nail at atmospheric pressure comprises an electrode to be arranged above the nail, and a high voltage generator generating a high voltage to be applied to the electrode arranged above the nail for igniting the gas discharge between the electrode and the nail.

Owner:VIOL WOLFGAG +1

Method of manufacturing powder having high surface area

ActiveUS9676034B2Simple structureImprove directionalityMaterial nanotechnologyNanostructure manufactureMetal alloySubstitution reaction

A method of manufacturing a powder having a high surface area is provided. According to the method of manufacturing a powder having a high surface area, a metal electrolyte in which metal ions of different kinds of first metals are dissociated is prepared. Subsequently, a metal alloy powder formed of the first metals is formed by soaking a second metal having a higher reducing power than the first metals in the metal electrolyte to induce a first spontaneous substitution reaction. Therefore, it is possible to form a powder having an improved specific surface area.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

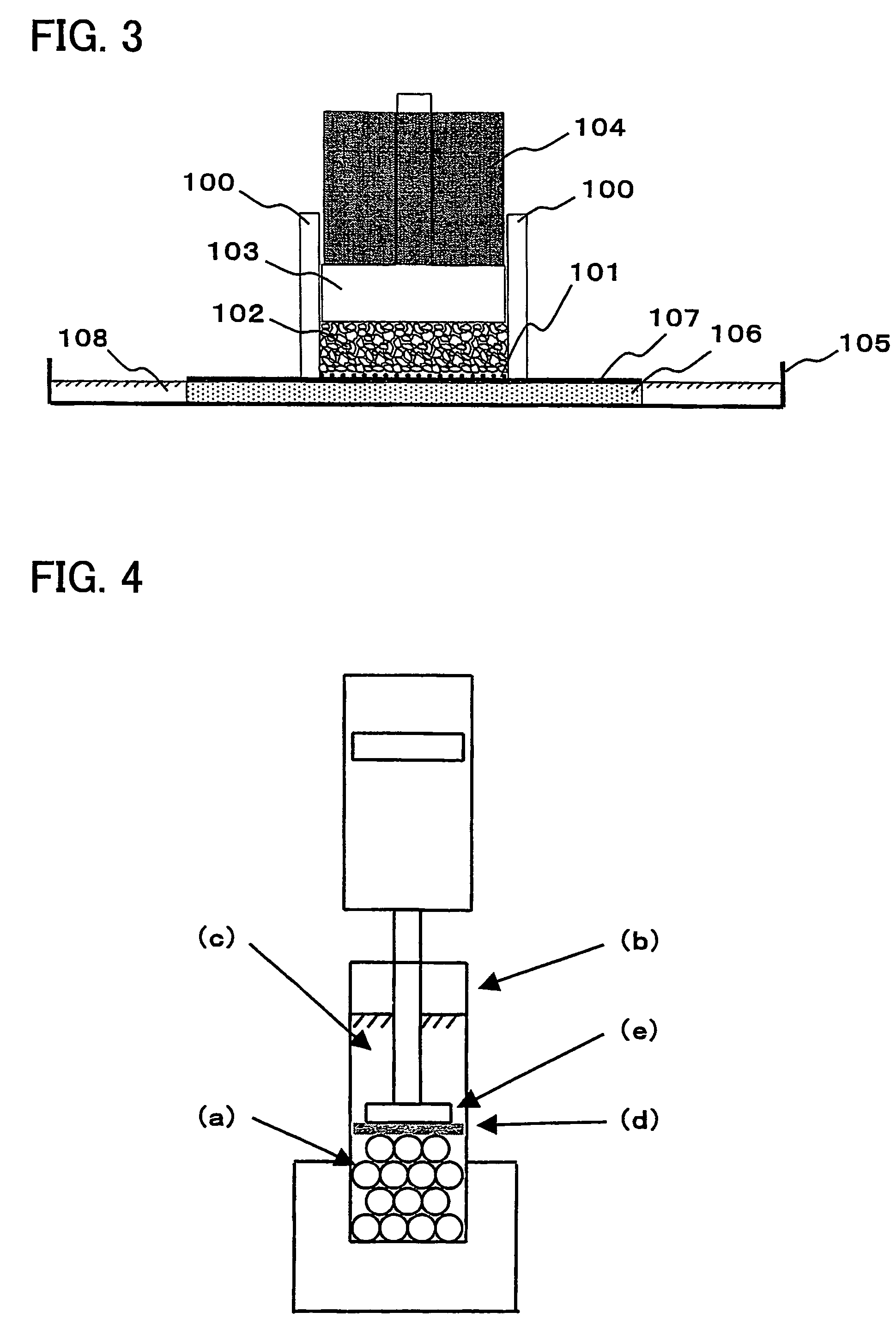

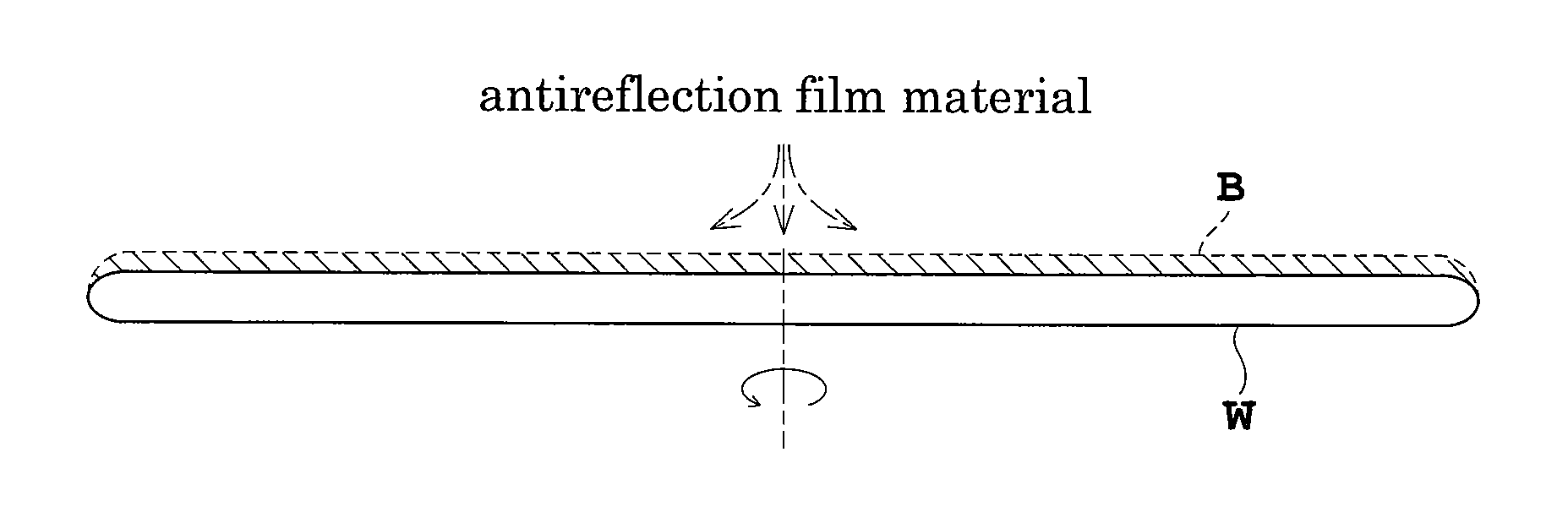

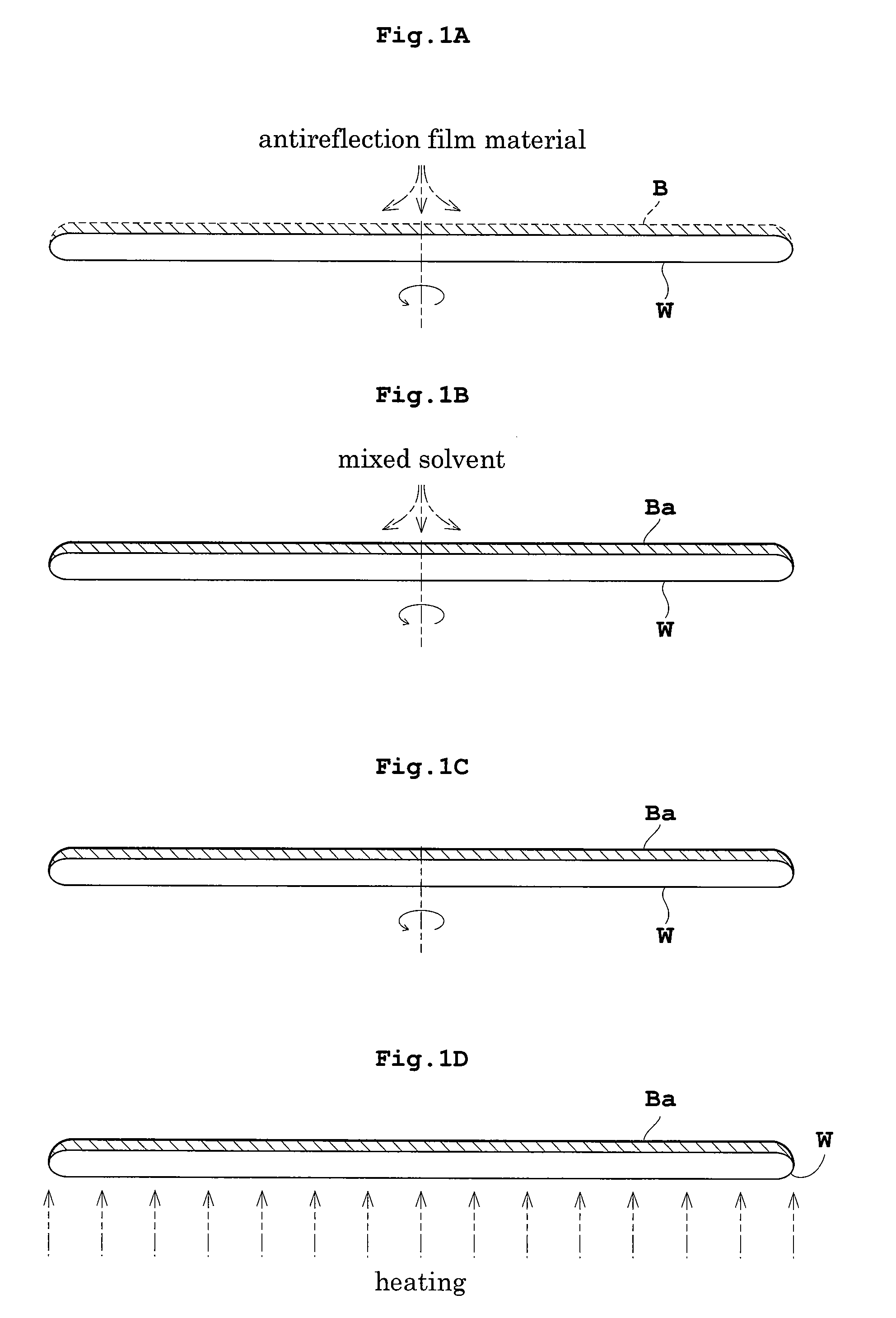

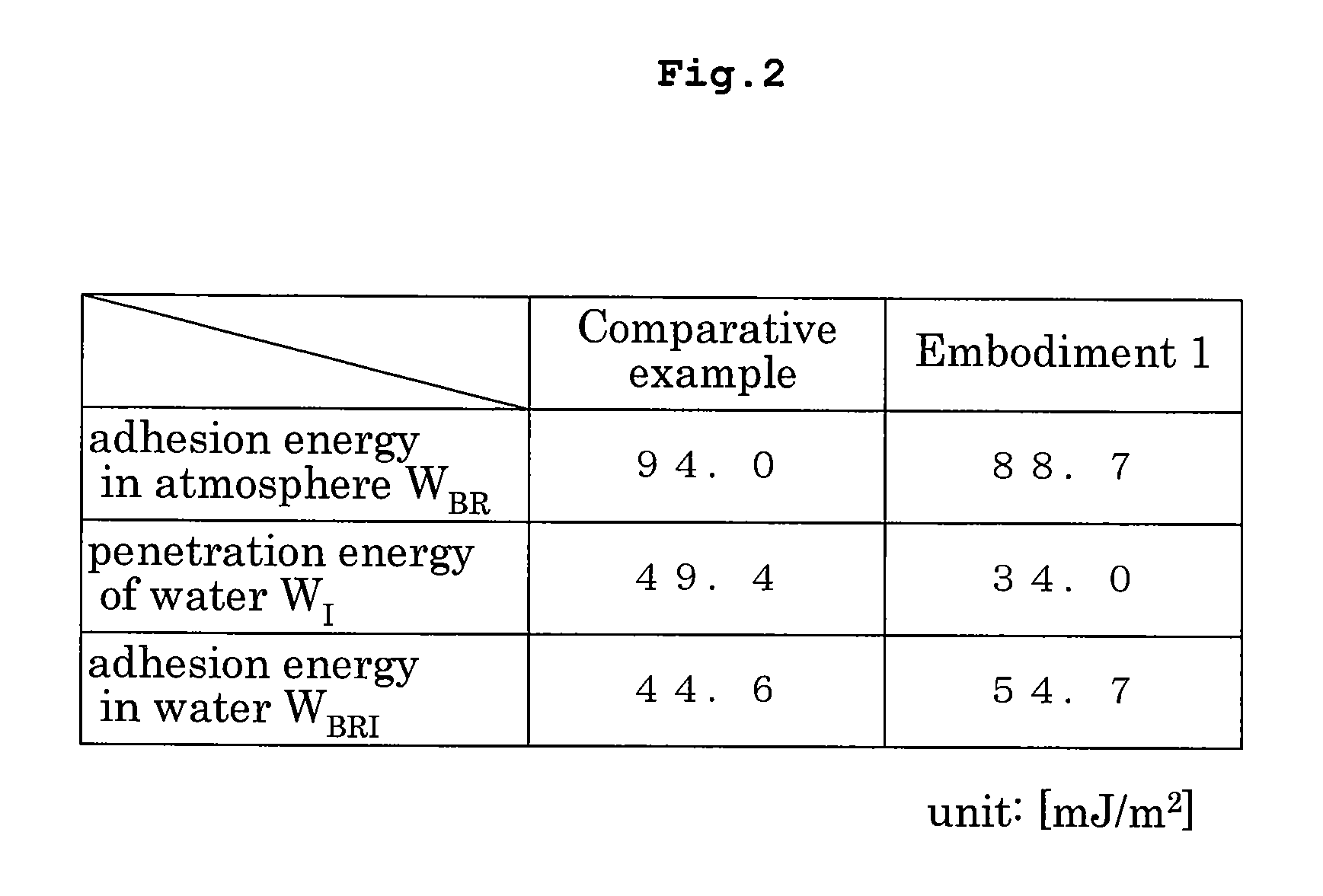

Antireflection film forming method, and substrate treating apparatus

InactiveUS20070183051A1Lower surface energyReduce hydrogen bondingPhotomechanical apparatusOptical elementsHydrogenOptoelectronics

A substrate is first spin-coated with an antireflection film material is carried out to the substrate to form antireflection film on the substrate. Next, a mixed solvent of HMDS and xylene is supplied in a predetermined quantity to the upper surface of the antireflection film, and is spin-dried in this state. The mixed solvent effects surface modifying treatment to reduce a hydrogen bonding component of surface energy of the antireflection film. Subsequently, the substrate receives heat treatment. This completes formation of the antireflection film on the substrate. As a result, the antireflection film has increased adhesion energy in water with respect to resist film, without impairing essential characteristics of the antireflection film.

Owner:SOKUDO CO LTD

Method for creating patterns

ActiveUS10336023B2Modifying surfaceGood size controlDecorative surface effectsVacuum evaporation coatingComputer scienceIon implantation

The invention relates in particular to a method for creating patterns in a layer (410) to be etched, starting from a stack comprising at least the layer (410) to be etched and a masking, layer (420) on top of the layer (410) to be etched, the masking layer (420) having at least one pattern (421), the method comprising at least:a) a step of modifying at least one zone (411) of the layer (410) to be etched via ion implantation (430) vertically in line with said at least one pattern (421);b) at least one sequence of steps comprising: b1) a step of enlarging (440) the at least one pattern (421) in a plane in which the layer (410) to be etched mainly extends;b2) a step of modifying at least one zone (411′, 411″) of the layer (410) to be etched via ion implantation (430) vertically in line with the at least one enlarged pattern (421), the implantation being carried out over a depth less than the implantation depth of the preceding, modification step;c) a step of removing (461, 462) the modified zones (411, 411′, 411″), the removal comprising a step of etching the modified zones (411, 411′, 411″) selectively with respect to the non-modified zones (412) of the layer (410) to be etched.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Methods of synthesizing precipitated silica and use thereof

InactiveUS7700062B2Affects ionic strengthImprove featuresMaterial nanotechnologySilicaIonic strengthColloid

The synthesis of precipitated silica having improved chemical and physical properties of use as a reinforcing filler in polymeric matrices is described. Improvements in the properties result from the synthesis of the silica al a reduced ionic strength. In particular, the use of silicia acid during synthesis, provides a solution of reduced ionic strength, which favors the formation of improved colloidal structure via increased aggregation and reduced agglomeration. In addition, the surface of the silica precipitate formed may be modified by the addition of surface modifying agents, during synthesis to further enhance the desired reinforcing properties of the precipitated silica. The invention also embodies polymeric compositions of improved tensile and elongation strengths, with the compositions including precipitated silica, synthesized at reduced ionic strengths and having modified surfaces, in combination with a polymeric compound.

Owner:UNIVERSITY OF CINCINNATI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com