Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

755 results about "Normal phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The normal phase is as a gas, since at normal conditions (temperature and pressure) that is the form in which it is found. It transitions to other phases: liquid, then solid, the same way all other elements do … by cooling and/or decreasing the pressure in a way...

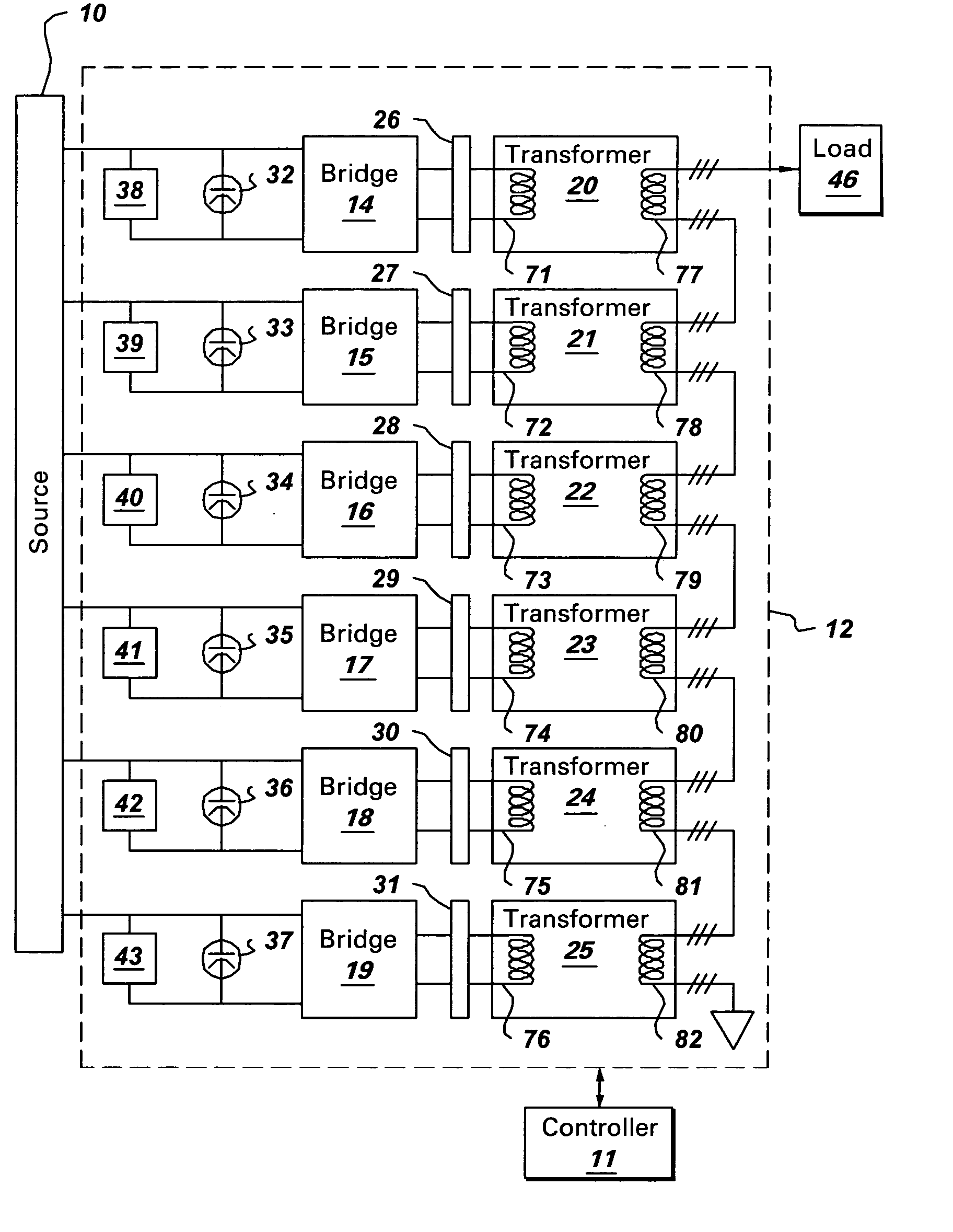

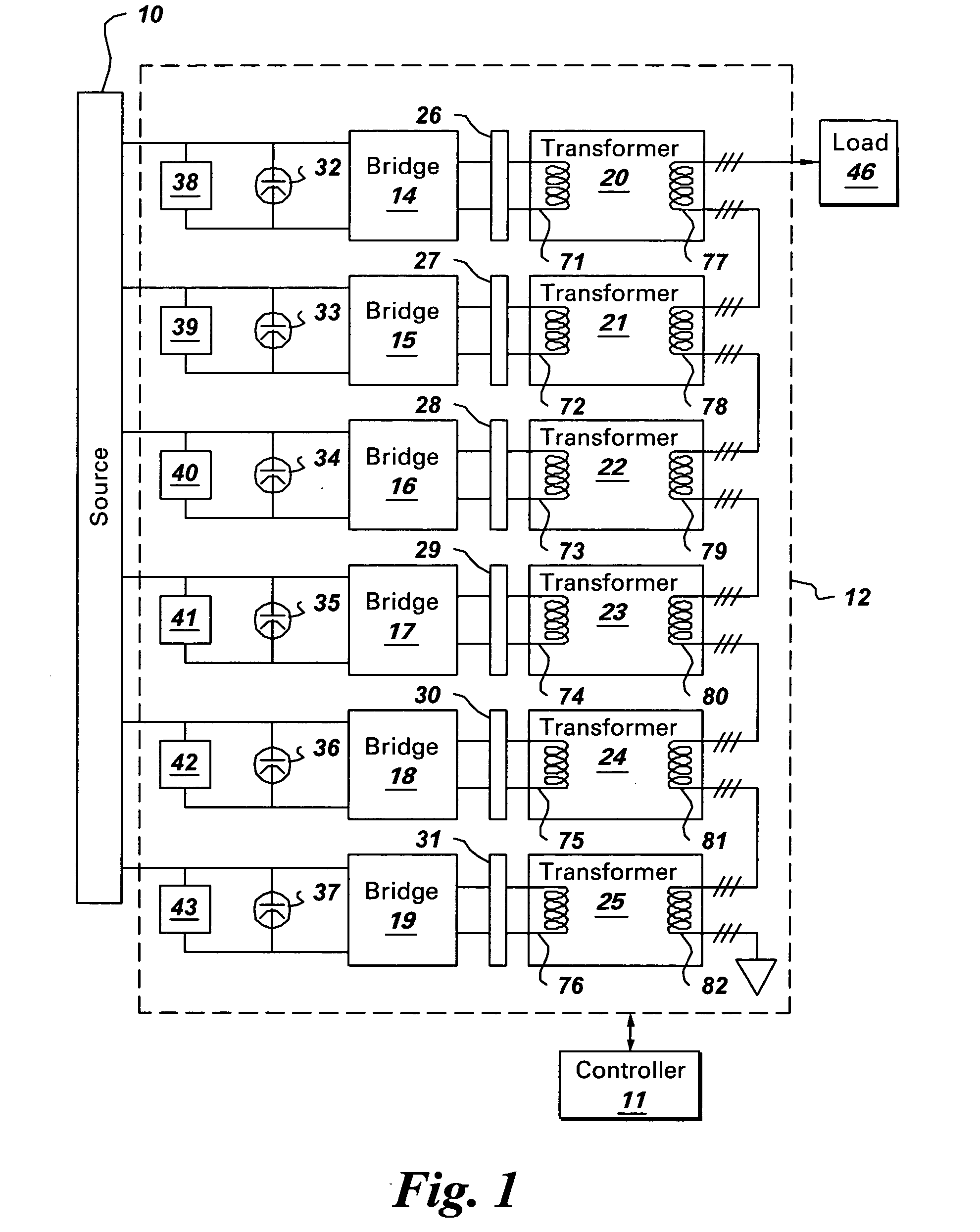

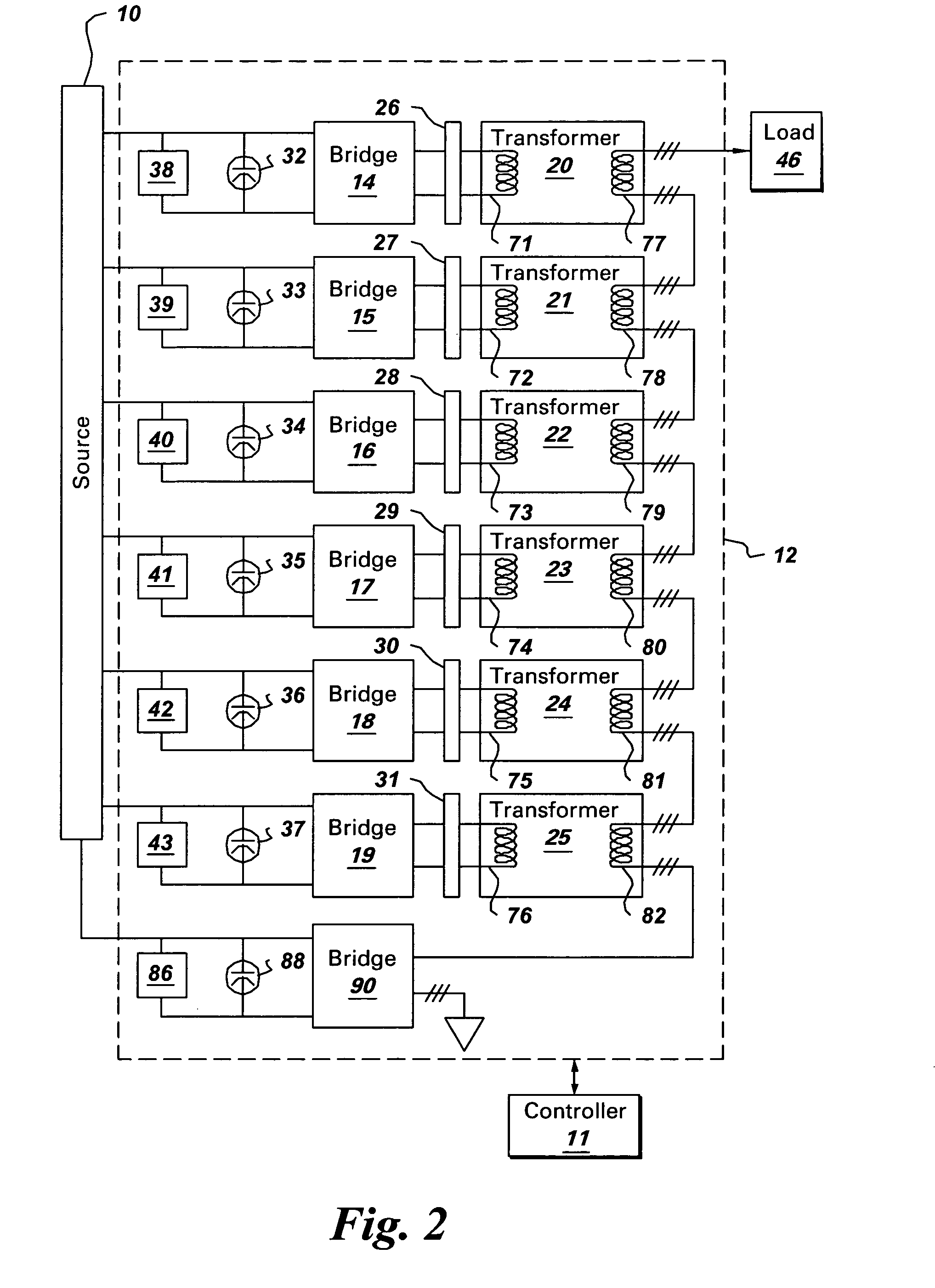

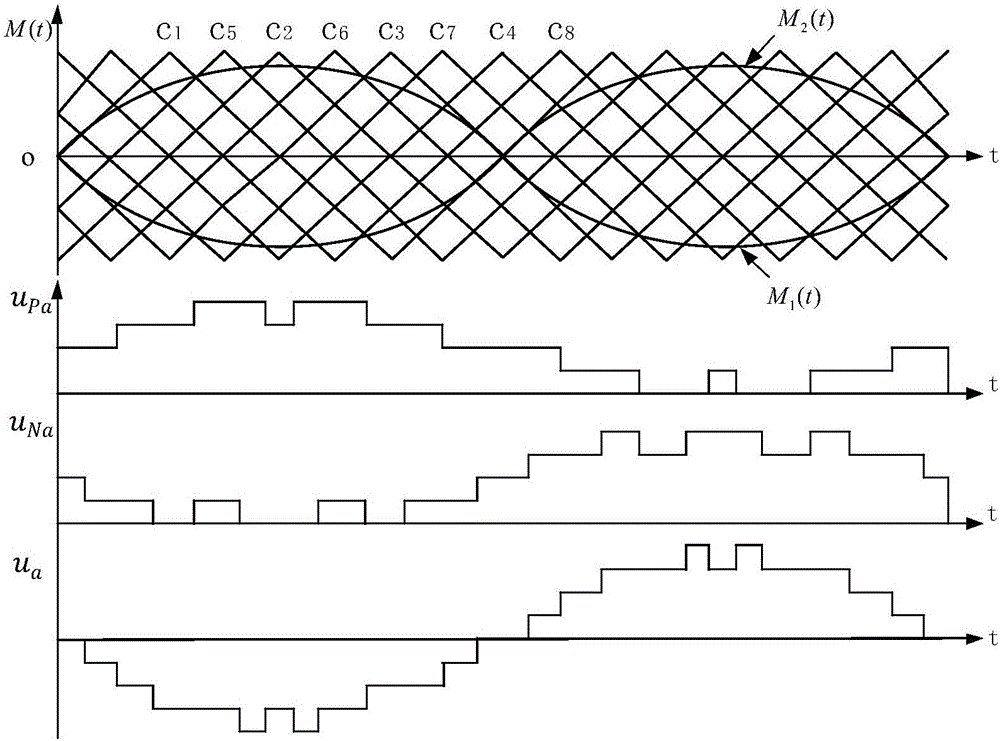

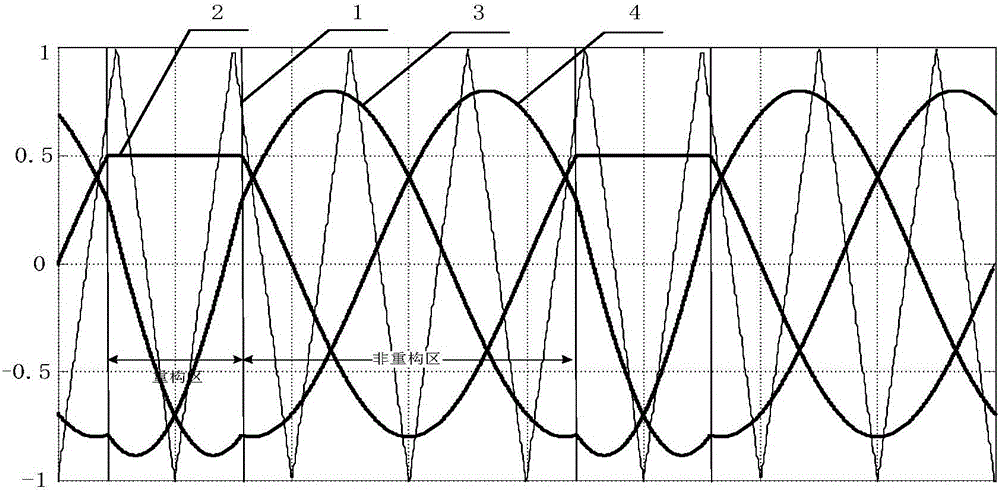

Power converter system and method

A power converter system for supplying an output voltage is provided. The power converter system is adapted to operate in a normal mode and a fault mode. The system comprises a plurality of bridges and a plurality of transformers. The system further comprises a plurality of dc link capacitors, each coupled across a corresponding bridge. The system also includes a controller adapted for, during the normal mode, switching each bridge with a respective normal phase shift. During the fault mode, the controller is adapted for switching each of the remaining ones of the bridges with a respective adjusted phase shift to generate the output voltage. During the fault mode, at least one of the plurality of bridges is bypassed.

Owner:GENERAL ELECTRIC CO

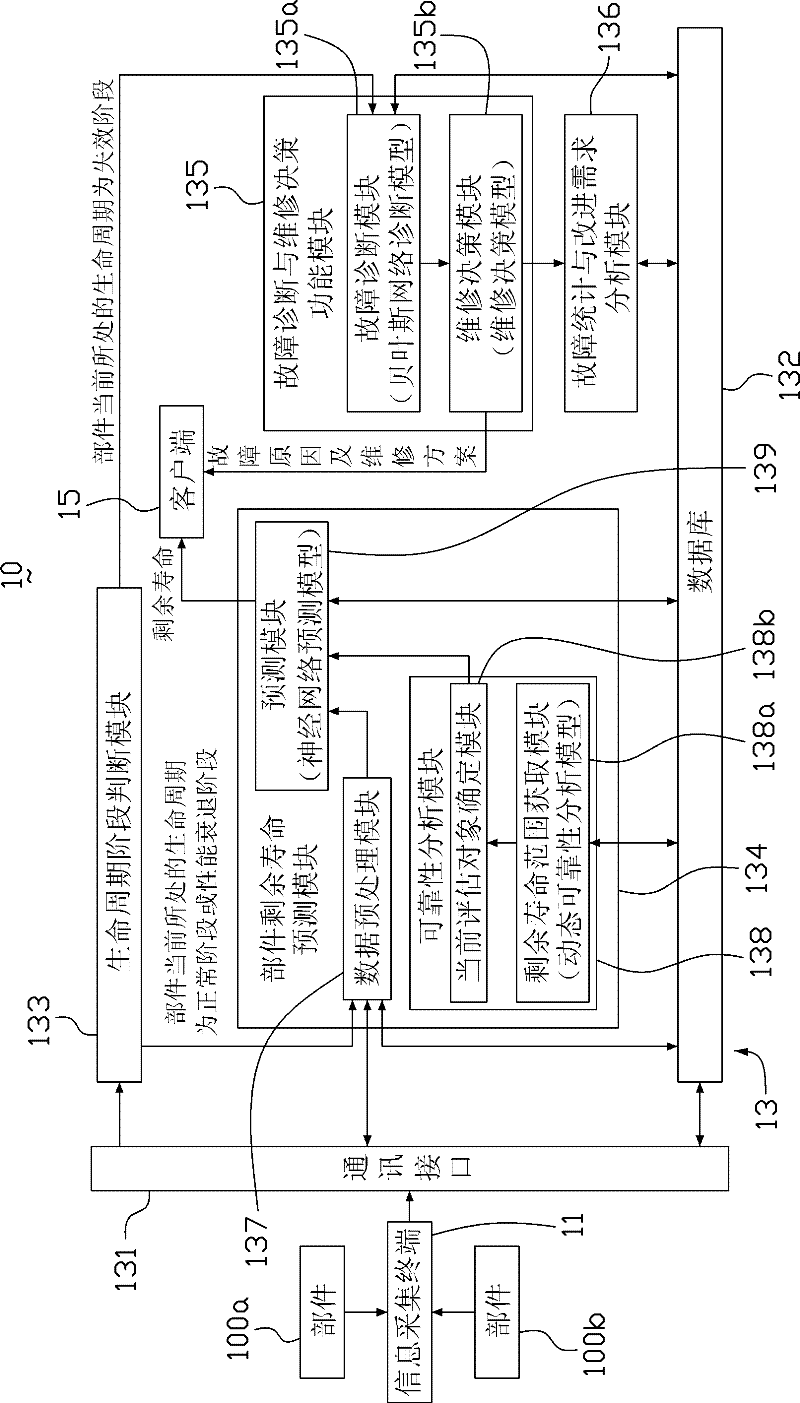

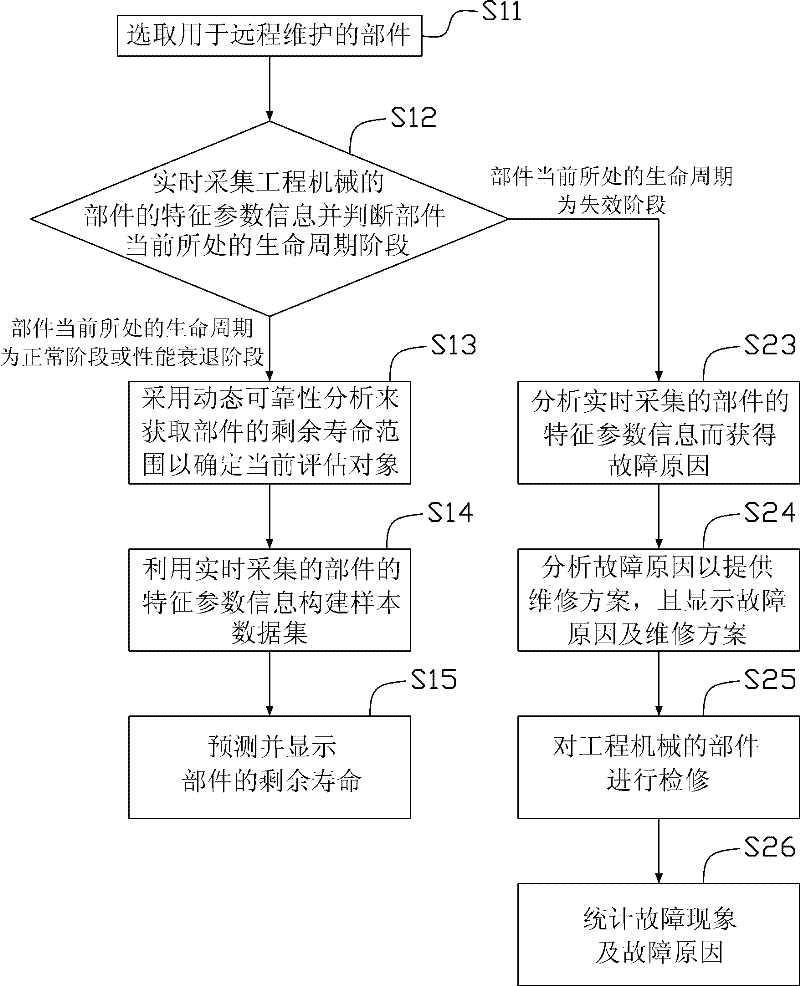

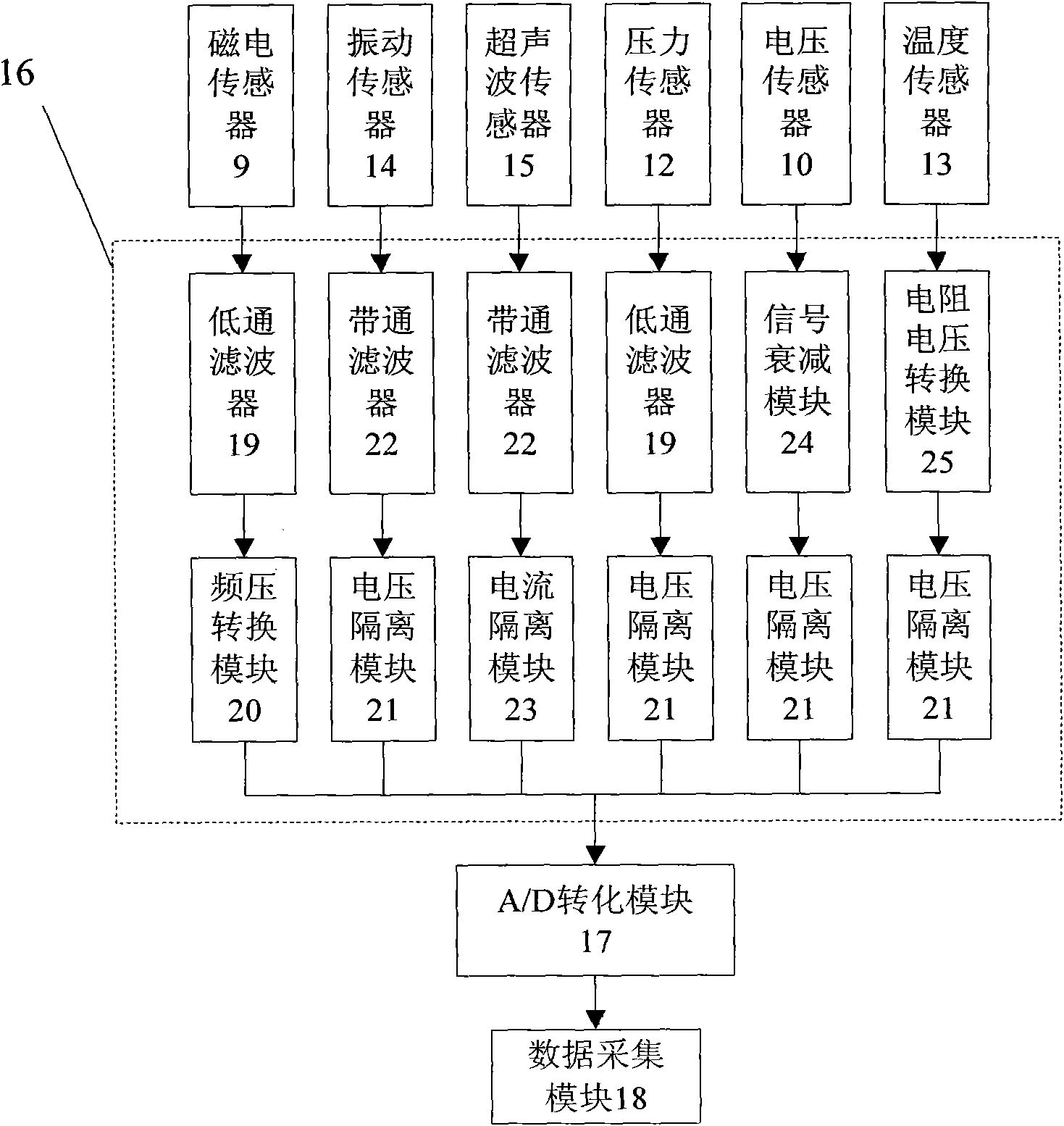

Remote maintenance decision system of engineering machinery and method thereof

ActiveCN102495549AGuaranteed safe operationTimely replacementAdaptive controlDecision systemLife time

The invention relates to a remote maintenance decision system of engineering machinery and a method thereof. The system comprises an information acquisition terminal, a client and a maintenance decision center. The information acquisition terminal acquires characteristic parameter information of a part of the engineering machinery in real time. The maintenance decision center comprises a life cycle phase determination module, a part residual life prediction module and a fault diagnosis and maintenance decision function module. The life cycle phase determination module receives the real-time characteristic parameter information and determines a present life cycle phase of the part. The part residual life prediction module carries out residual life prediction on the part at a normal phase or a performance decline phase. The fault diagnosis and maintenance decision function module carries out fault reason diagnosis on the part at a failure phase and provides a maintenance scheme. The client displays a residual life, or a fault reason and the maintenance scheme of the part. According to the system and the method of the invention, the life prediction or the fault diagnosis can be carried out on the part, and remote maintenance is carried out on the engineering machinery.

Owner:中科云谷科技有限公司

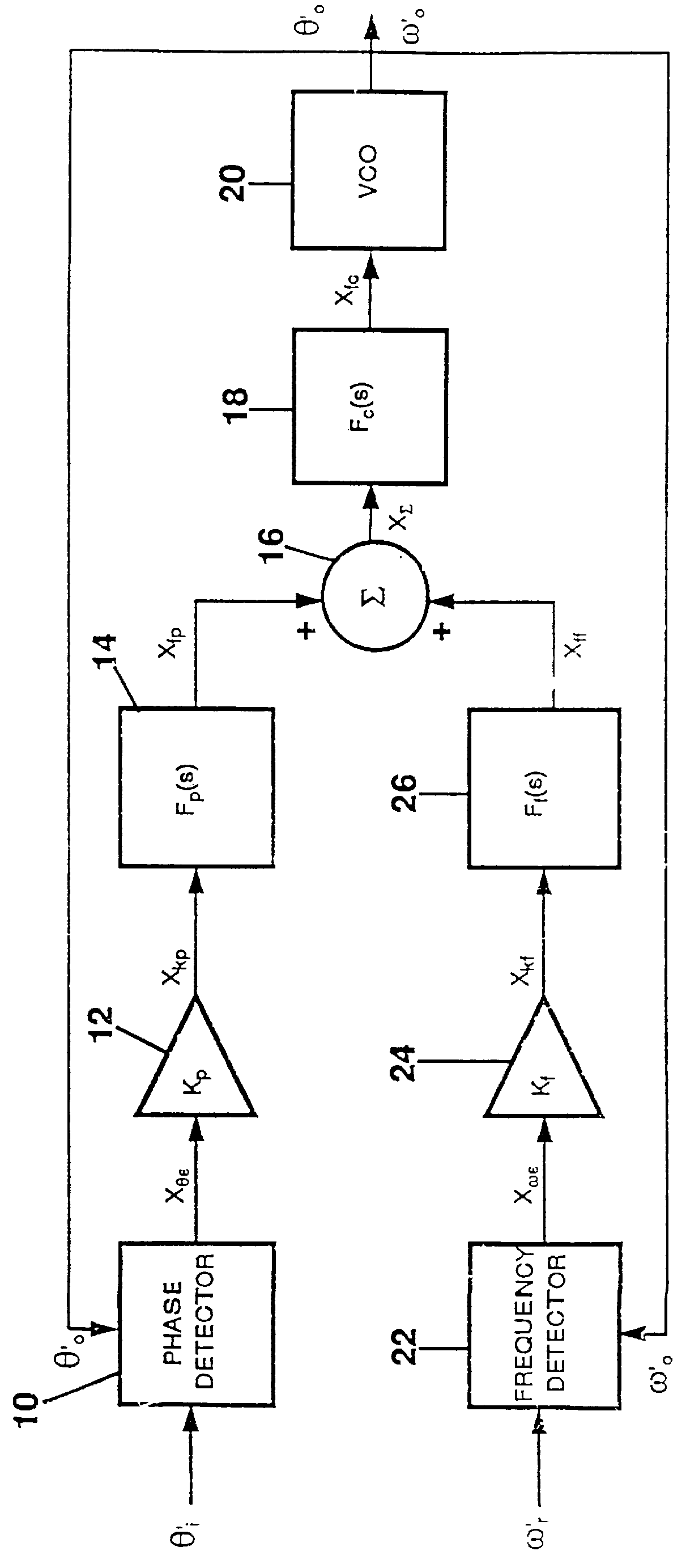

Steered frequency phase locked loop

InactiveUS6031428APulse automatic controlFrequency-modulated carrier systemsPhase detectorFrequency detection

PCT No. PCT / AU95 / 00793 Sec. 371 Date Sep. 30, 1997 Sec. 102(e) Date Sep. 30, 1997 PCT Filed Nov. 28, 1995 PCT Pub. No. WO96 / 17435 PCT Pub. Date Jun. 6, 1996A Steered Frequency Phase Lock Loop (SFPLL) comprises a phase loop that functions like a normal phase locked loop (PLL) and locks to the input signal, and a frequency loop that uses a reference frequency to influence the phase loop and effectively confines the output frequency of the phase loop and the SFPLL to be in a range of frequencies close to the reference frequency. The reference frequency is chosen to be very close to the input signal frequency that it is desired the SFPLL lock to. The SFPLL comprises a phase detector (10), a frequency detector (22), first and second gain components (12, 24), first, second and third filter components (14, 18, 26), a summer (16) and a voltage controlled oscillator (VCP)(20). By a judicious choice of the gains in the phase and frequency loops the SFPLL can be designed so that the range of frequencies to which the SFPLL will lock can be confined to an arbitrarily small region around the reference frequency ( omega 'r). Applications of the SFPLL include demodulation in CW modulation systems and timing recovery from NRZ data. Three advantages of the SFPLL are that the output frequency is equal or close to the reference frequency when no input signal is present, and the range of frequencies to which the SFPLL can lock is confined to a region around the reference frequency, and the phase and frequency instabilities of the VCO can be reduced.

Owner:CURTAIN UNIV OF TECH

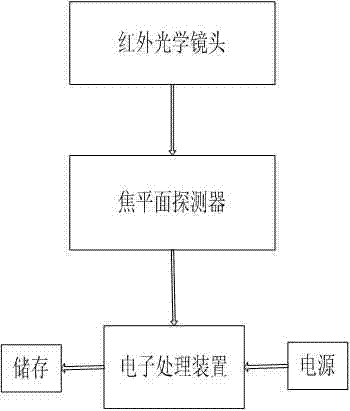

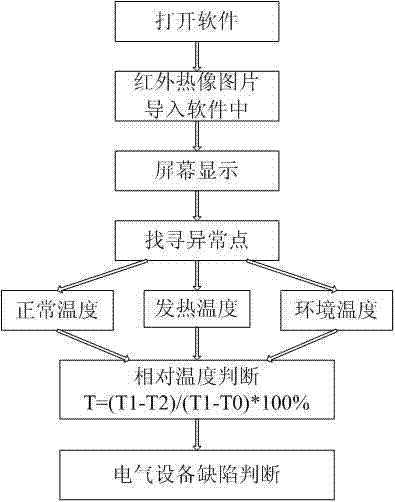

Infrared image automatic fault identifying method for high-voltage equipment

ActiveCN102928742AAutomatic identification of red hot faultsRadiation pyrometryFault locationImaging processingTemperature difference

The invention discloses an infrared image automatic fault identifying method for high-voltage equipment. Firstly, electric equipment in need of detection is selected and a temperature image of the electric equipment is obtained; secondly, a heating point, heating a point temperature T1 and a normal phase temperature T2 of the electric equipment are obtained through processing of the temperature image; thirdly, a relative temperature is calculated in combination with an environment reference temperature T0 to judge a running condition and fault information of the electric equipment. In the infrared image automatic fault identifying method for the high-voltage equipment, the running condition and the fault information of the electric equipment on a high-voltage transmission wire are monitored on the basis of an infrared image processing technology, a temperature heating abnormal point is detected according to an infrared temperature image processing technology, a heating temperature, a normal temperature, an environment temperature and the relative temperature of an abnormal point are calculated and then the running condition and the fault information of the electric equipment are automatically judged according to a relative temperature difference judging method; in this case, quick on-line detection of the running condition of the electric equipment is realized.

Owner:MAINTENANCE BRANCH OF STATE GRID CHONGQING ELECTRIC POWER +1

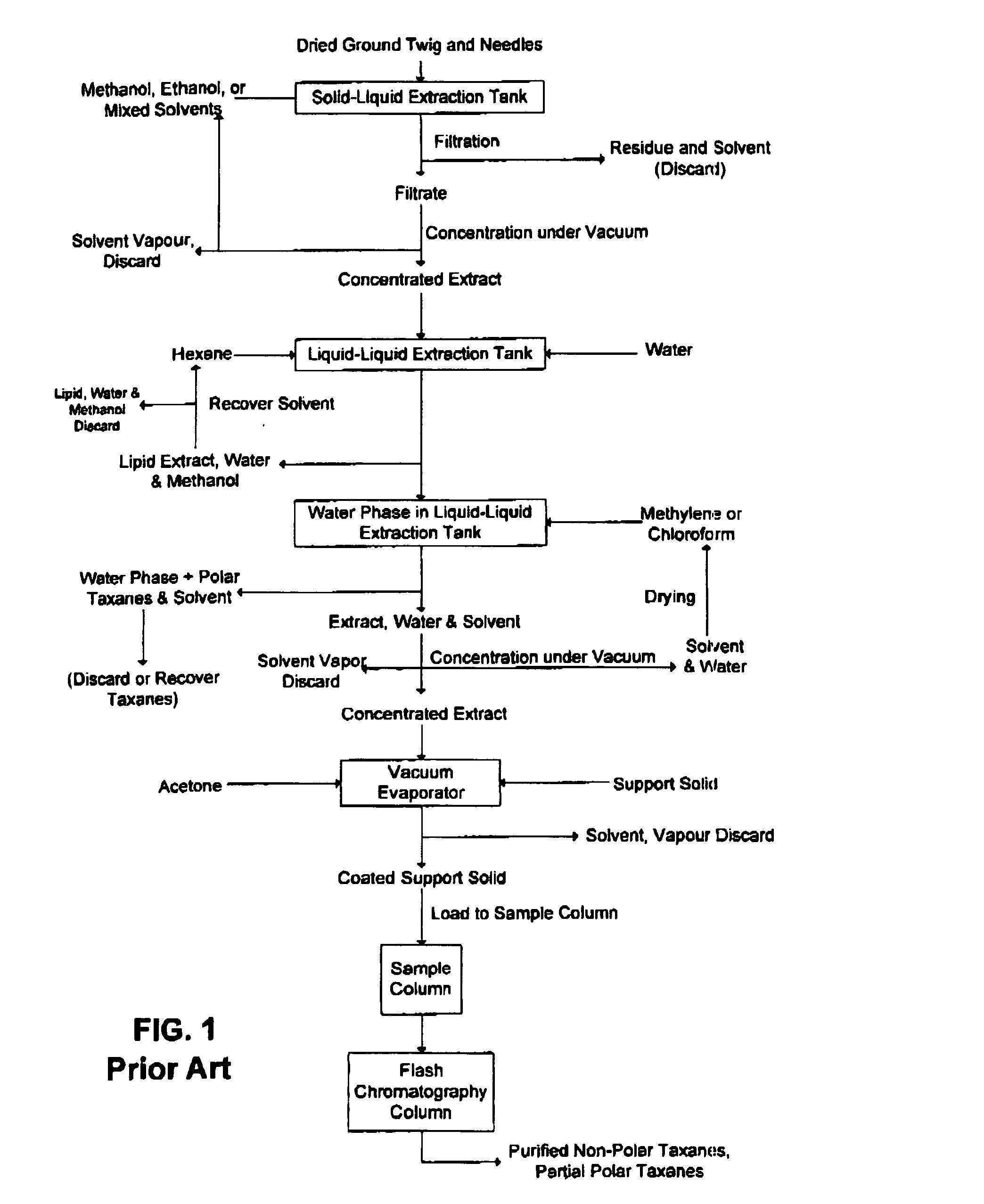

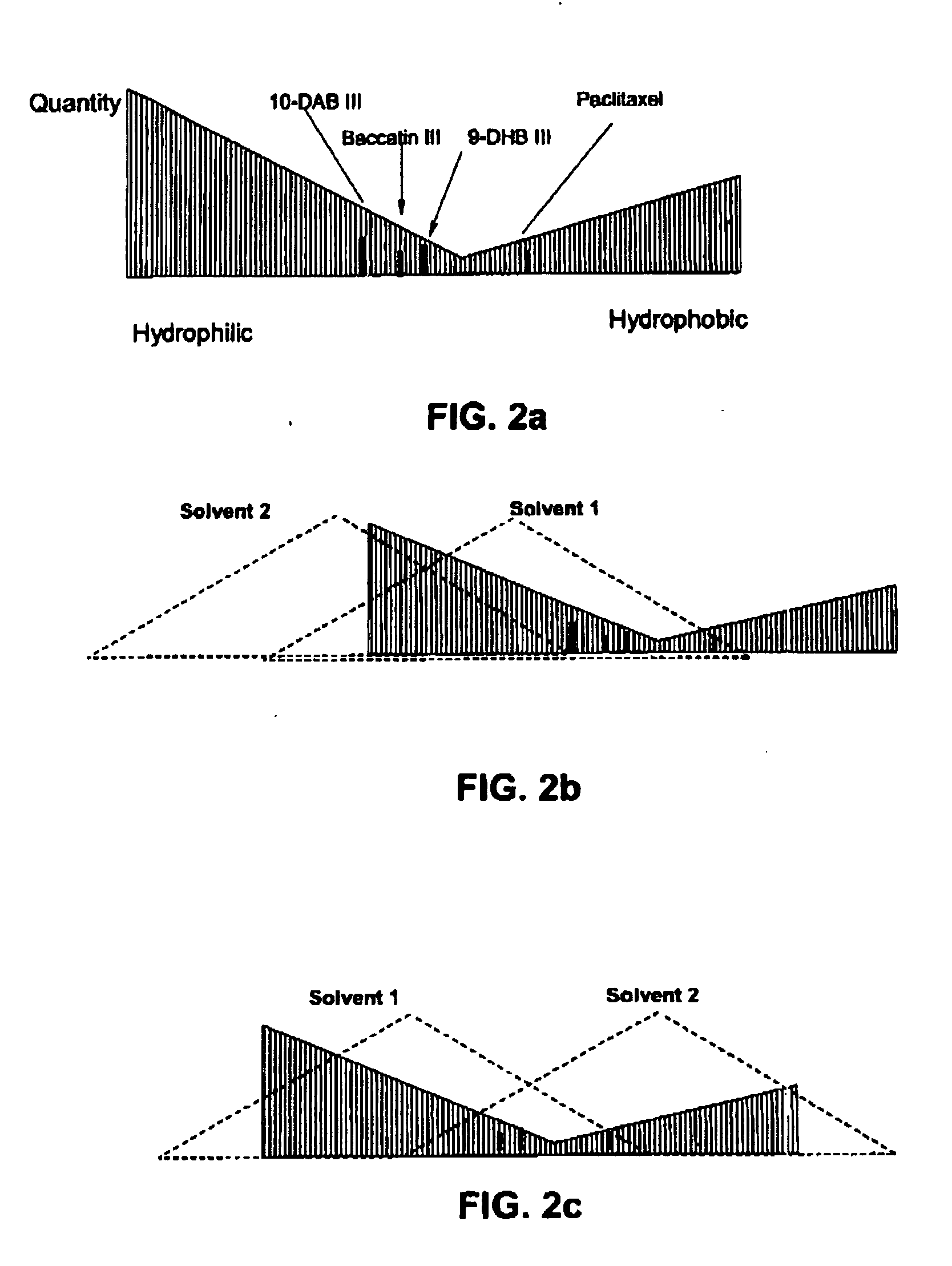

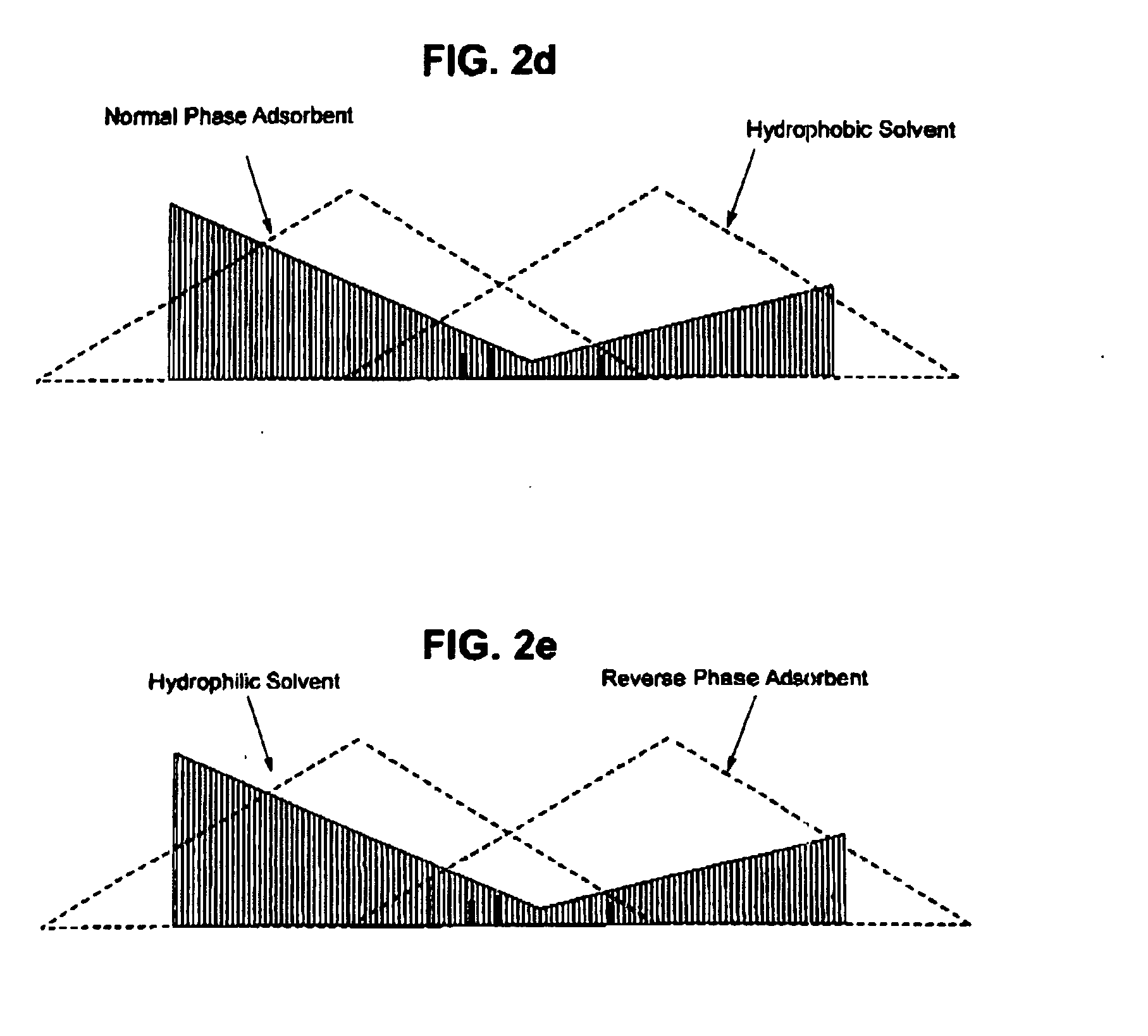

Process for extracting taxanes

A method of extracting taxane products from biomass, which involves feeding the biomass into an pressurized liquid extraction unit and contacting the biomass with a halogenated C1 to C2 alkane solvent at a temperature of 100° C. or less and at sufficient pressure to keep the solvent in liquid form, to extract a stream of taxanes and solvent. The stream of taxanes and solvent are then cooled arid the solvent is stripped from the taxanes. The taxanes are finally passed through either a normal phase liquid chromatograph or a reverse phase liquid chromatograph.

Owner:OTTAWA UNIV OF

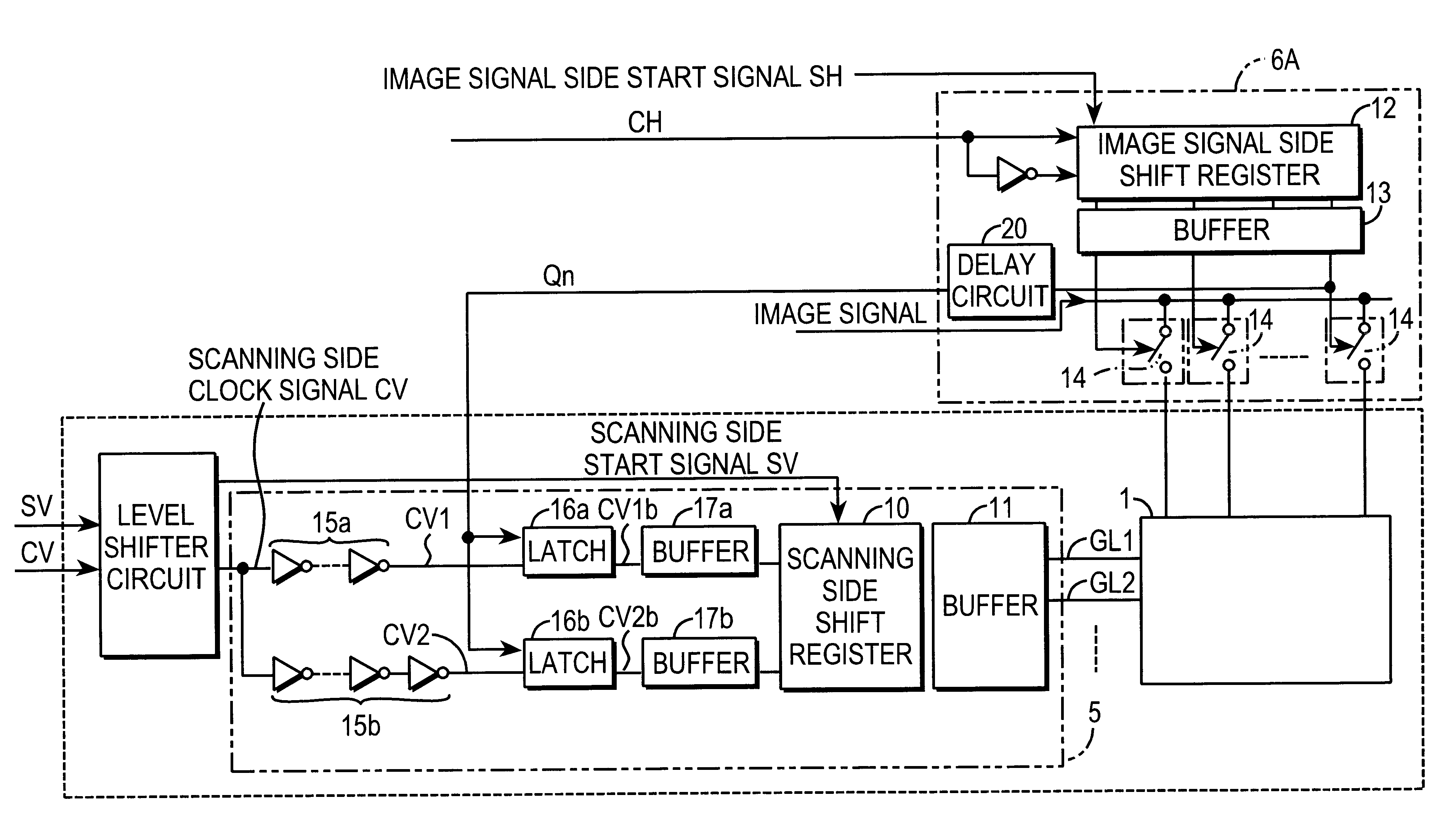

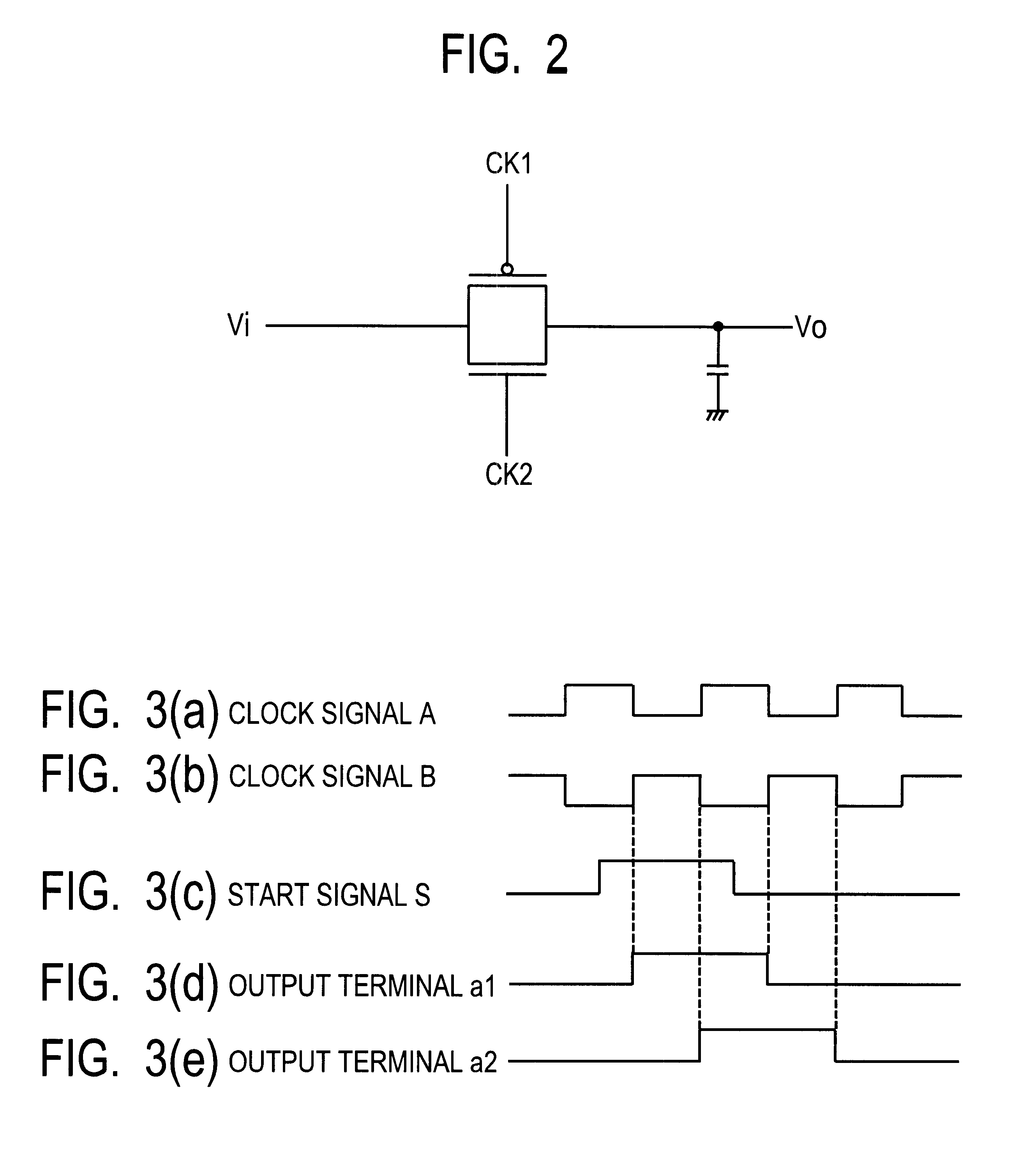

Motion circuit and on-board driver circuit for liquid crystal display panel employing the motion circuit

InactiveUS6373458B1Reduce generationStable circuit operations with no malfunctionsCathode-ray tube indicatorsDigital storageDriver circuitShift register

The motion circuit of the present invention is an on-board driver circuit which is composed of polycrystal silicon semiconductor layers formed on a substrate, and which is provided with a first latch circuit for latching one of a normal phase and reverse phase clock signals having a clock skew using a clock signal and for outputting it to a shift register, and a second latch circuit for latching the other one of the normal phase and reverse phase clock signals using a clock signal and for outputting to the shift register. The latch operations of the first and second latch circuits are timed to make the two clock signals have reverse polarities. Consequently, it is realized to provide a motion circuit performing stable circuit operations without malfunctions, by preventing the occurrence of the fail phenomenon due to a skew between the normal phase and reverse phase clock signals which drive the shift register. It is also realized to provide an on-board driver circuit for a liquid crystal display panel by employing the motion circuit.

Owner:TOSHIBA MATSUSHITA DISPLAY TECH

Circuit and method for correcting offset voltage of comparator

ActiveCN103036538AHigh precisionHigh speedMultiple input and output pulse circuitsElectric variable regulationVoltage generatorComputer module

The invention discloses a circuit and a method for correcting offset voltage of a comparator. The circuit for correcting the offset voltage of the comparator comprises the comparator, an output latch, a selecting module, a first substrate voltage generator and a second substrate voltage generator, wherein two input ends of the comparator are connected with working voltage or common mode level (VCM), a normal phase output end of the comparator is connected with the selecting module or a first output end (VOUT+) of the circuit of correcting the offset voltage of the comparator through the output latch, a reversal phase output end of the comparator is connected with the selecting module or a second output end (VOUT-) of the circuit of correcting the offset voltage of the comparator through the output latch, an input end of the first substrate voltage generator and an input end of the second substrate voltage generator are both connected with the selecting module, an output end of the first substrate voltage generator outputs a first variable voltage (VB+) to a metal oxide semiconductor (MOS) of a normal phase input end of the comparator and an output end of the second substrate voltage generator outputs a second variable voltage (VB+) to a metal oxide semiconductor (MOS) of a reversal phase input end of the comparator. The circuit for correcting the offset the voltage of the comparator and the method for correcting the offset voltage of the comparator has the advantages of being capable of rapidly achieving large-scale and high-precision correct because digital correction is applied and simultaneously correcting the substrate voltage of two input pipes, and more flexible.

Owner:NATIONZ TECH INC

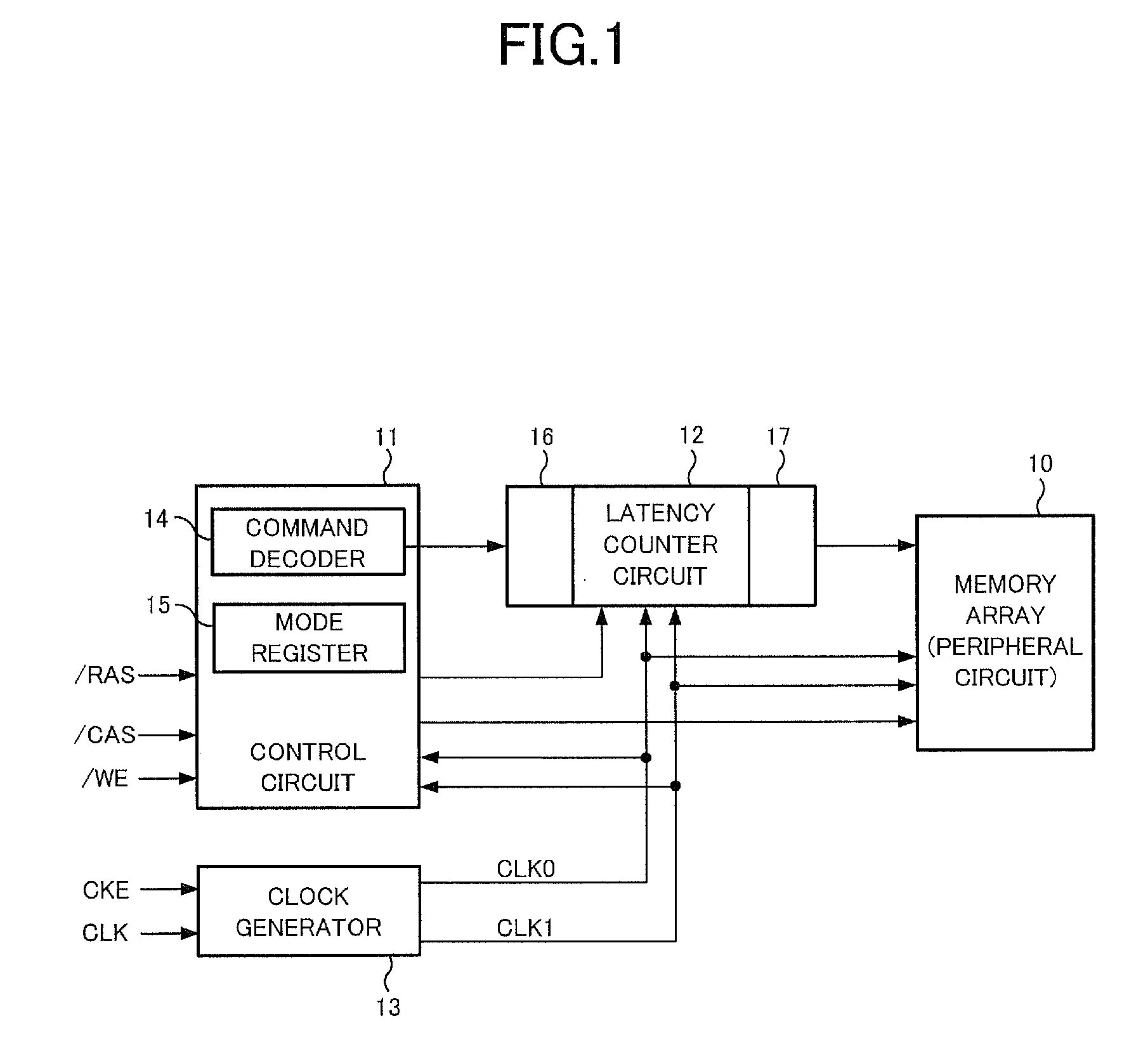

Semiconductor device having latency counter

InactiveUS20100177589A1Total current dropCurrent consumptionDigital storageControl circuitComputer science

A semiconductor device includes a latency setting circuit setting the latency, an input command circuit outputting a normal-phase (reverse-phase) command signal obtained by capturing an input command signal using a normal-phase (reverse-phase) clock, first and second counter circuits each including latch circuits sequentially shifting the normal-phase (reverse-phase) command signal based on the normal-phase (reverse-phase) clock, a selector circuit controlling a signal path so that the normal-phase (reverse-phase) command signal is transmitted through the first (second) counter circuit when an even latency is set and the normal-phase (reverse-phase) command signal is transmitted so as to be shifted from the first (second) counter circuit to the second (first) counter circuit when an odd latency is set, and a control circuit controlling so that the latch circuits of the first (second) counter circuit are activated in response to the input command signal and stopped after an operation period is elapsed.

Owner:LONGITUDE SEMICON S A R L

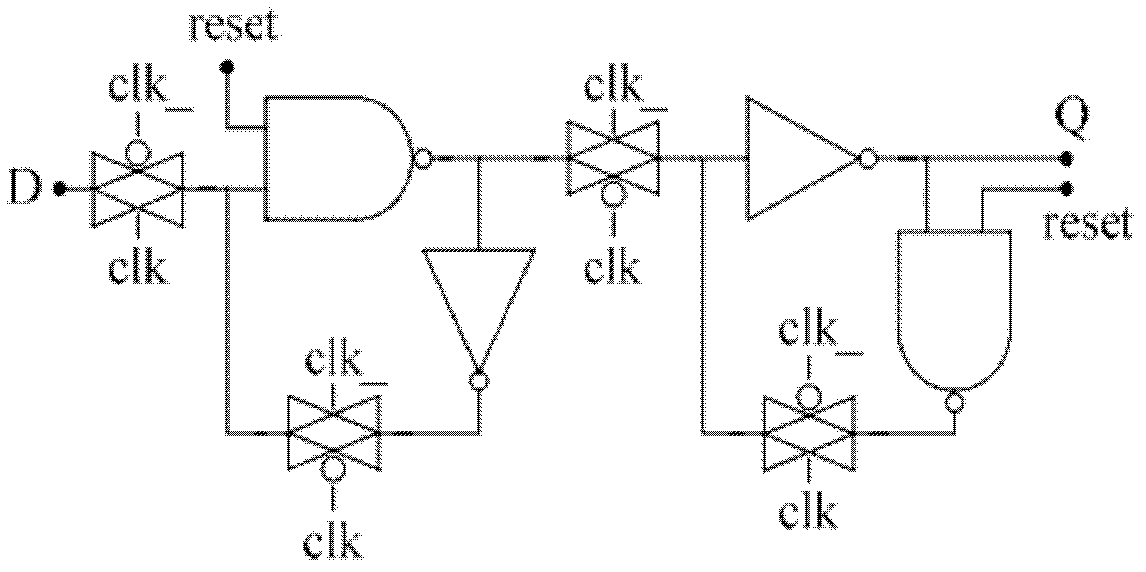

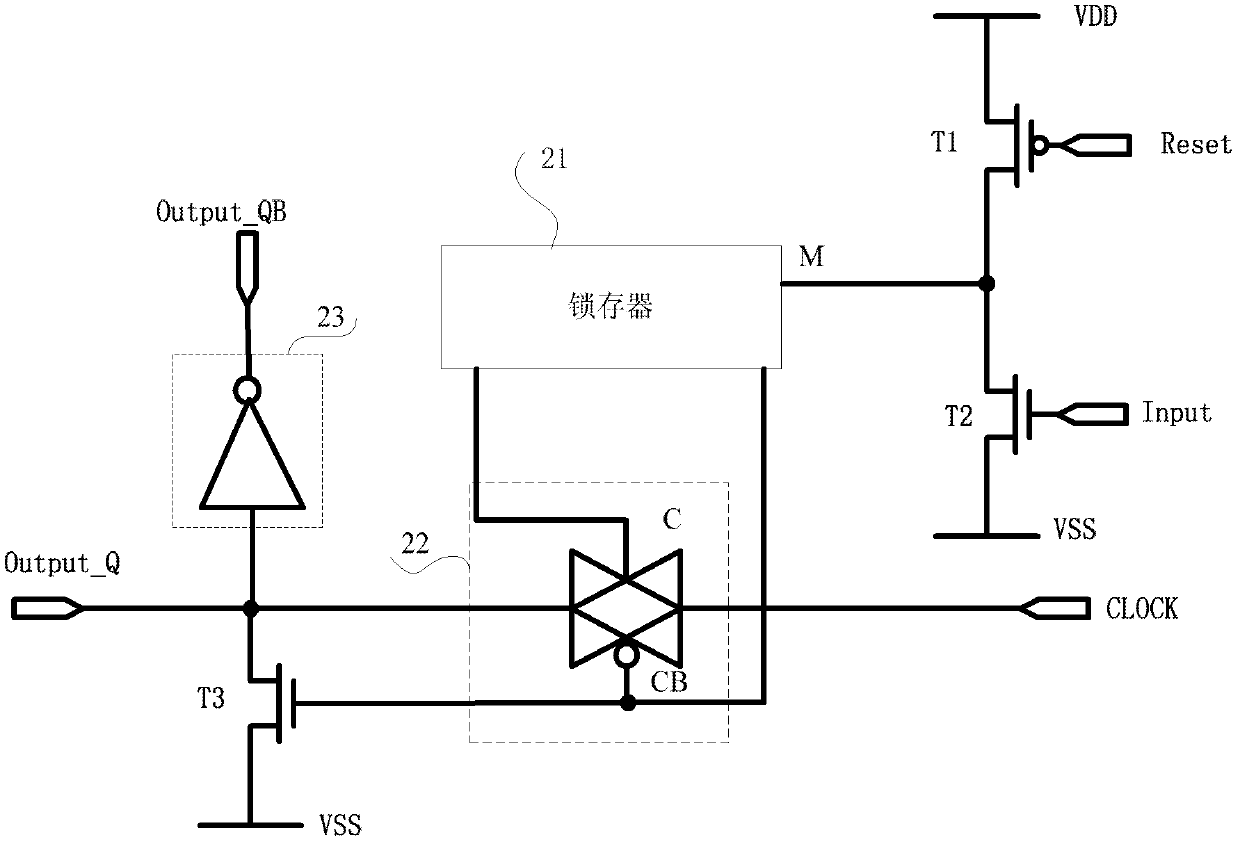

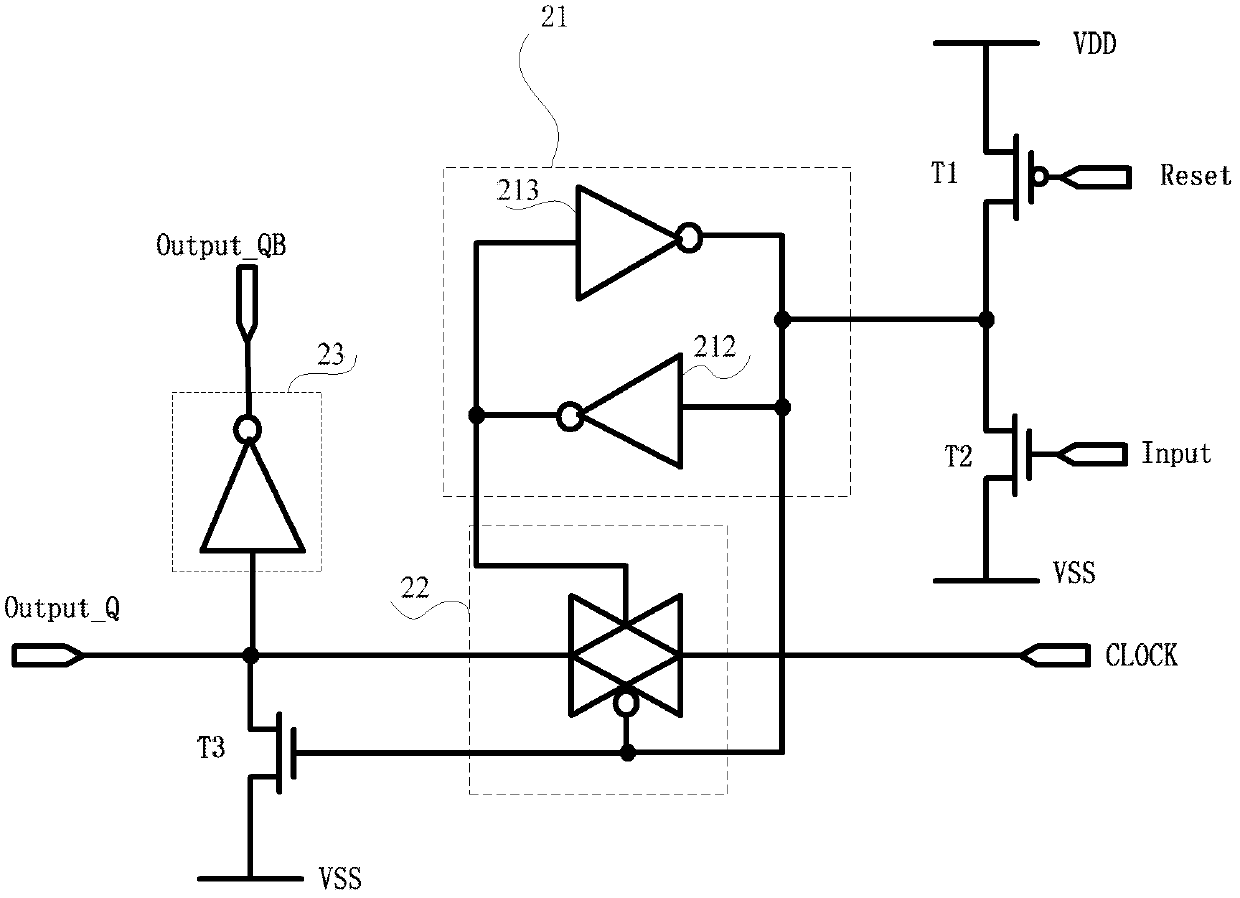

Shift register, grid driving device and display device

ActiveCN102708816AAchieve shiftStatic indicating devicesDigital storageShift registerTransmission gate

The invention provides a shift register, a grid driving device and a display device. The shift register comprises a latch, a transmission gate, a first thin film transistor, a second thin film transistor, a third thin film transistor and a first inverter, wherein a grid of the first thin film transistor is connected with a reset terminal of the shift register, a drain of the first thin film transistor is respectively connected with a drain of the second thin film transistor and an input terminal of the latch, a grid of the second thin film transistor is connected with an input terminal of theshift register, a grid of the third thin film transistor is connected with an inverted output terminal of the latch, a drain of the third thin film transistor is connected with an input terminal of the first inverter, an output terminal of the transmission gate is connected with the drain of the third thin film transistor, an input terminal of the transmission gate is connected with a clock signal input terminal, the drain of the third thin film transistor is connected with a normal phase output terminal of the shift register, and an output terminal of the first inverter is connected with an inverted output terminal of the shift register. The shift register can realize signal shift by the aid of one latch.

Owner:BOE TECH GRP CO LTD +1

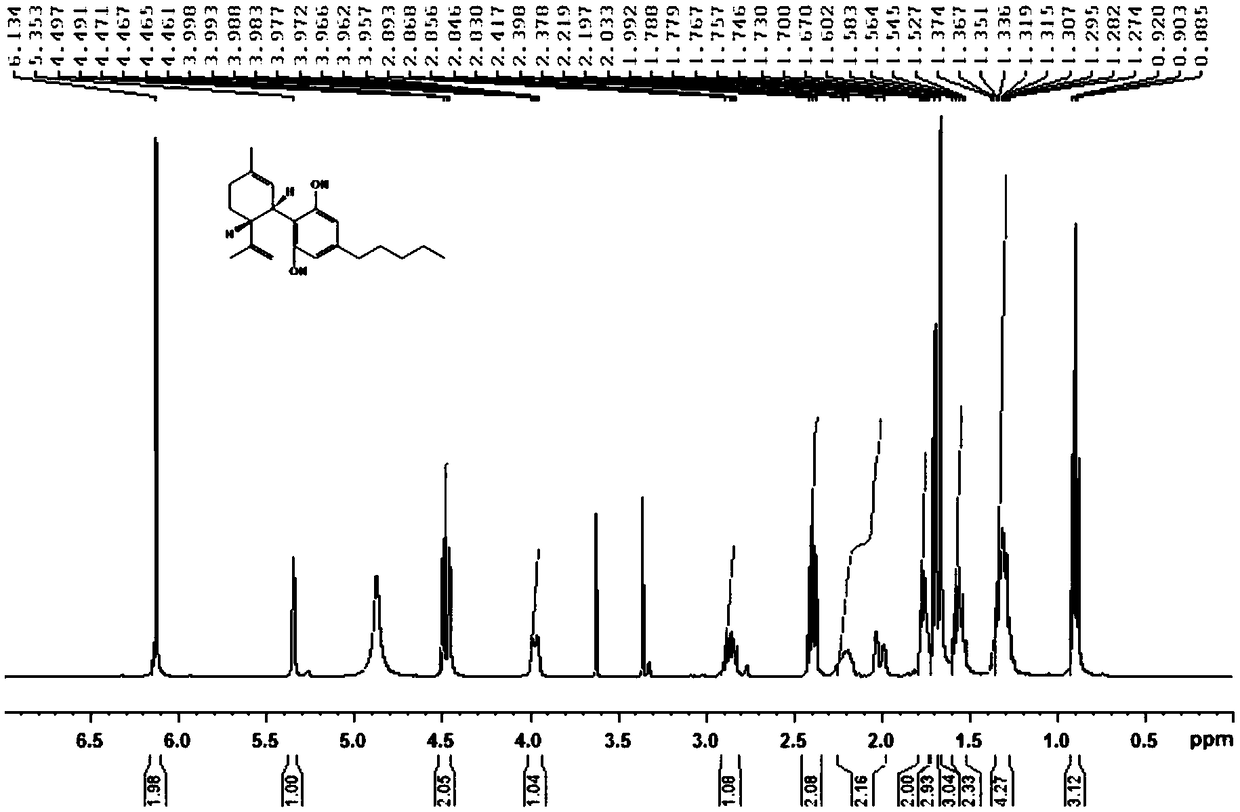

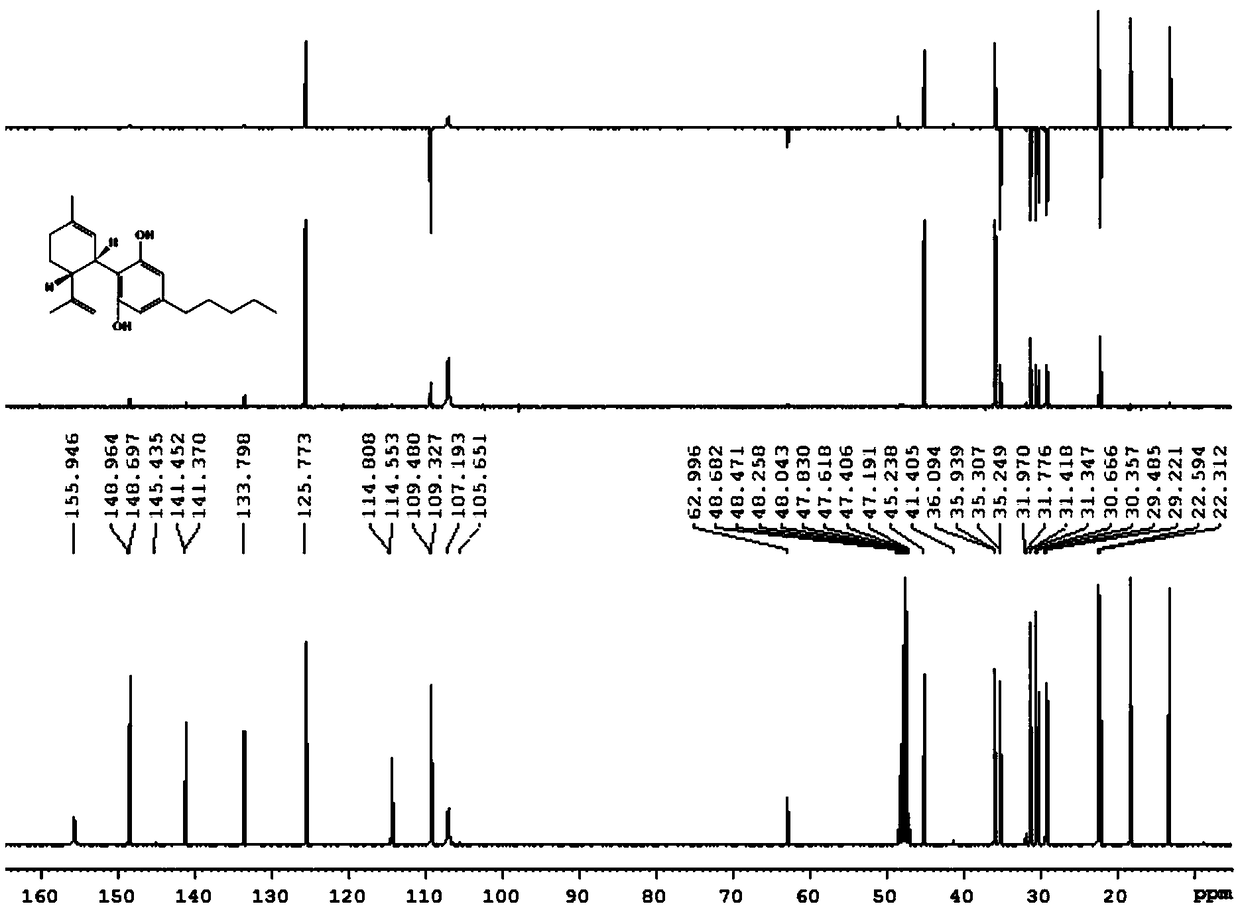

Method for separating and extracting cannabidiol from industrial cannabis plants

InactiveCN109369344AReduce typesE-buyOrganic chemistryOrganic compound preparationChemical structureSolvent

The invention discloses a method for separating and extracting cannabidiol from industrial cannabis plants. The method comprises the following steps: leaching and concentration of the plants, extraction, normal phase column chromatography, and reverse phase column chromatography. The method has the following advantages of determining the polarity based on the chemical structure characteristic of cannabidiol, selecting suitable extraction solvents according to the principle that like dissolves like, and carrying out two times of simple column chromatography isolation on extract which is obtained through extraction, thereby obtaining a required product. The separation process is simple, the cycle time is short, the number of varieties of the solvents used for formulating the polarity is small, the solvents are easy to purchase, and the solvents in the steps of extraction, column chromatography and the like can be recycled and reused, so that the solvent consumption is low and the cost isgreatly reduced. The cannabidiol separated out does not need to be repurified by high-cost and high-efficiency preparative liquid chromatography. The method has high extraction efficiency, and is convenient to implement, economical, rapid and simple in operation.

Owner:YUNNAN MINZU UNIV

Shifting register unit, driving method thereof, grid drive circuit and display device

ActiveCN105513524AImprove noise reductionStatic indicating devicesDigital storageShift registerControl signal

The invention provides a shifting register unit, a driving method thereof, a grid drive circuit and a display device. The shifting register unit comprises a pull-up node control module, a pull-down node control module, a grid drive signal output end and a grid drive signal output module. The grid drive signal output module is connected with a pull-up node, a pull-down node, a normal phase clock signal input end and the grid drive signal output end. The pull-down node control module is connected with the pull-down node and an inverse phase clock signal input end. The shifting register unit further comprises a noise reduction module which is connected with a noise reduction control signal output end and the grid drive signal output end. The noise reduction module controlled by a noise reduction control signal is adopted with the existing grid drive signal output module to control grid drive signal denoising, and the noise reduction effect is improved.

Owner:BOE TECH GRP CO LTD +1

Methods and compositions for chromatography

InactiveUS6942804B2Easy to createIon-exchange process apparatusOther chemical processesProcess scaleChromatographic separation

The present invention is directed to methods and compositions for separating and isolating target molecules. In particular, the present invention comprises devices, such as CCDs, that contain particles without the need for support structures. Chromatography separation techniques, including but not limited to, ion exchange, size separation, affinity chromatography, ion exclusion, ligand exchange, reversed phase and normal phase partitioning, are used in the CCD. Methods also include low, medium and high pressure liquid chromatography. Such methods can be used for analytical, semi-preparative processes, initial clarification, preparative filtration and process scale applications.

Owner:SARTORIUS STEDIM NORTH AMERICA INC

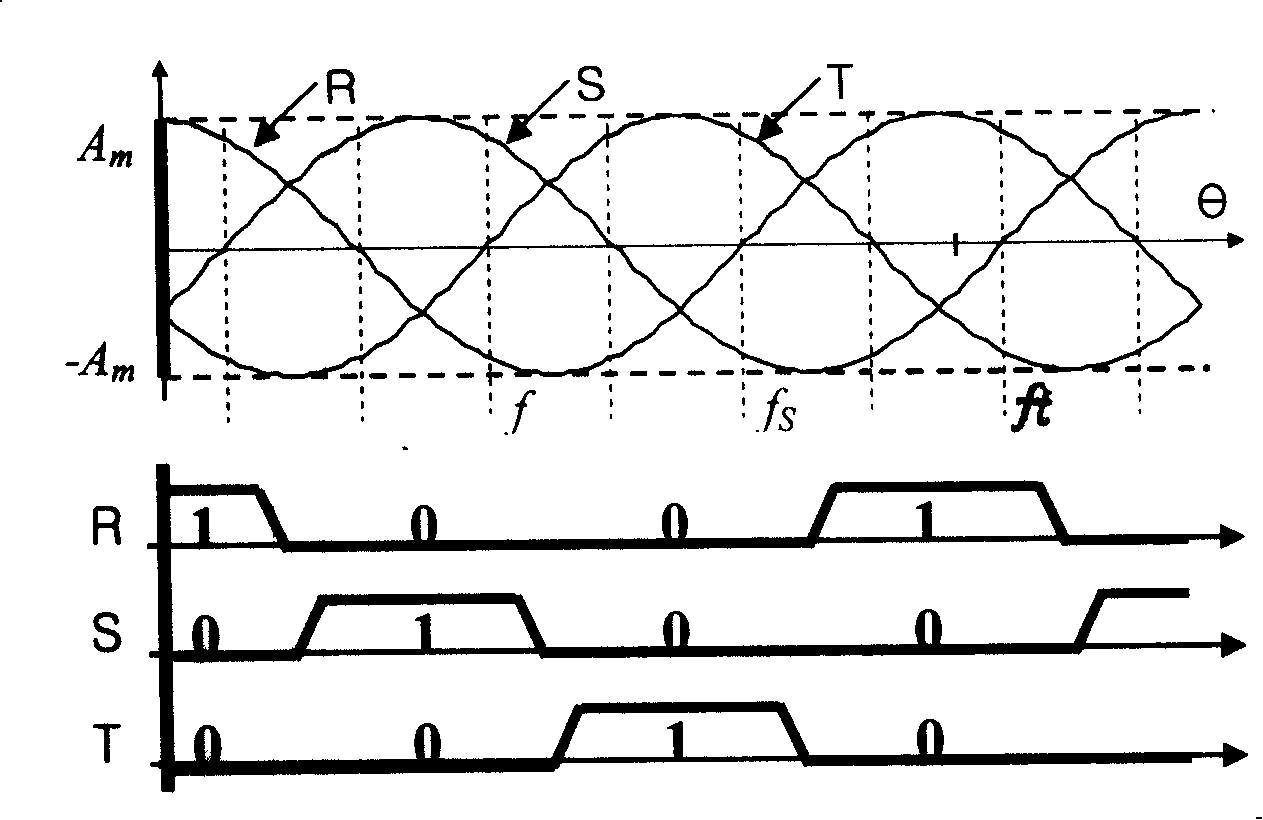

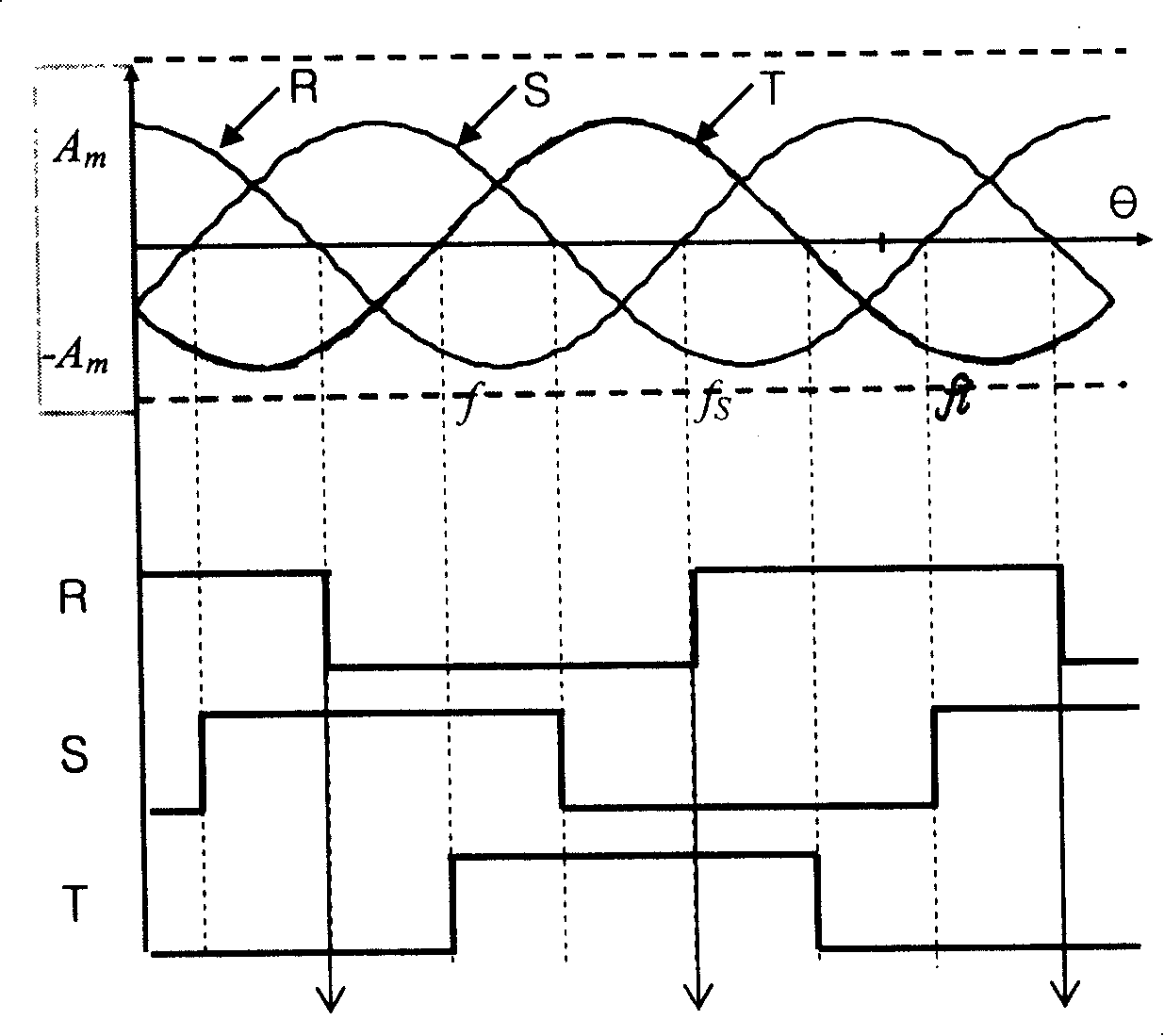

Compressor three phase voltage phase sequence detection method

InactiveCN101210944AEffective protectionLow costEmergency protective circuit arrangementsPhase sequence/synchronism indicationThree-phaseEngineering

The invention discloses a method for detecting phase sequence and lacking phase of three-phase alternating current for an air conditioner compressor, which comprises the following steps of: (1) falling edge determination stage for subjecting an air conditioner compressor to square wave shaping by using three-phase alternating current for determining a falling edge of one phase of the three-phase alternating current used for the air conditioner compressor; (2) delay comparison stage for detecting and delay-comparing the levels of the other two phases of alternating currents in the three-phase alternating current after square wave treatment according to the determined falling edge of the one phase of square wave as the reference; and (3) determination stage for determining whether the three-phase alternating current has error phase sequence, lacked phase or normal phase sequence. The three-phase current phase sequence detection logic adopted by the invention can accurately determine the phase sequence or phase lacking by detecting the voltages of the other two phases when meeting the falling edge, thus effectively protecting the compressor at low cost.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

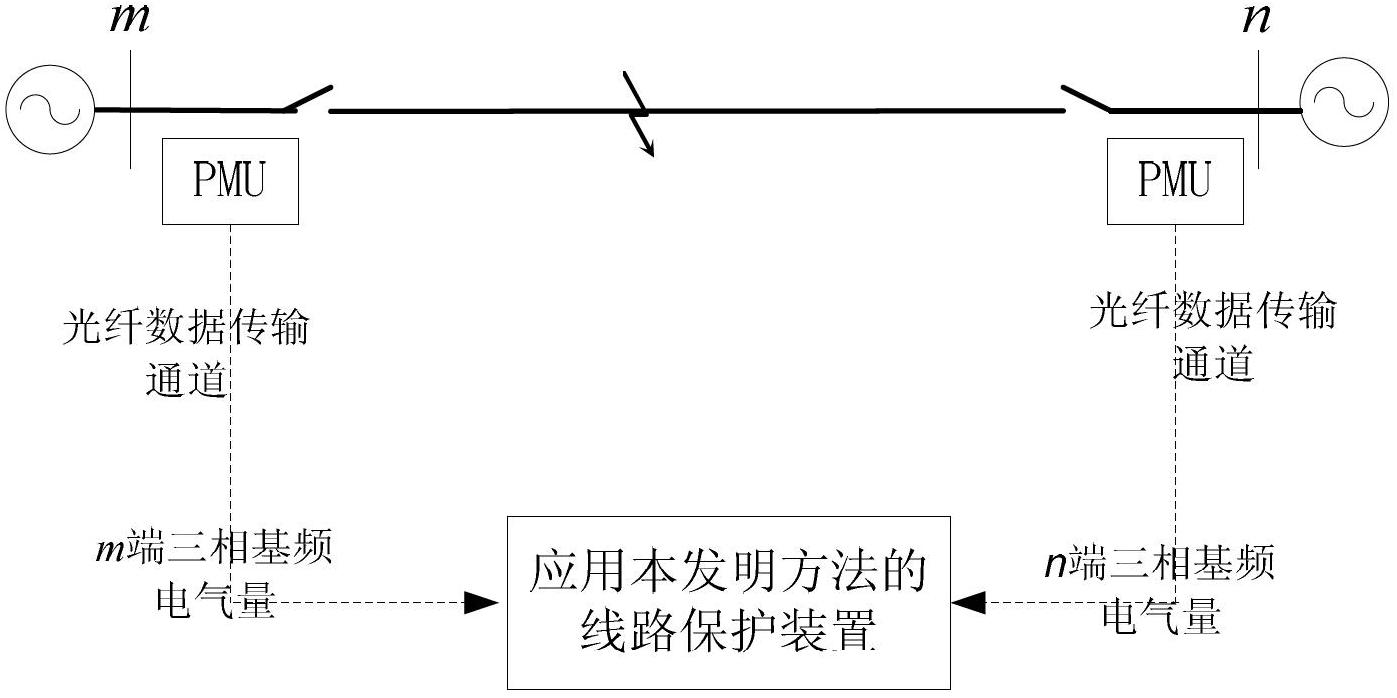

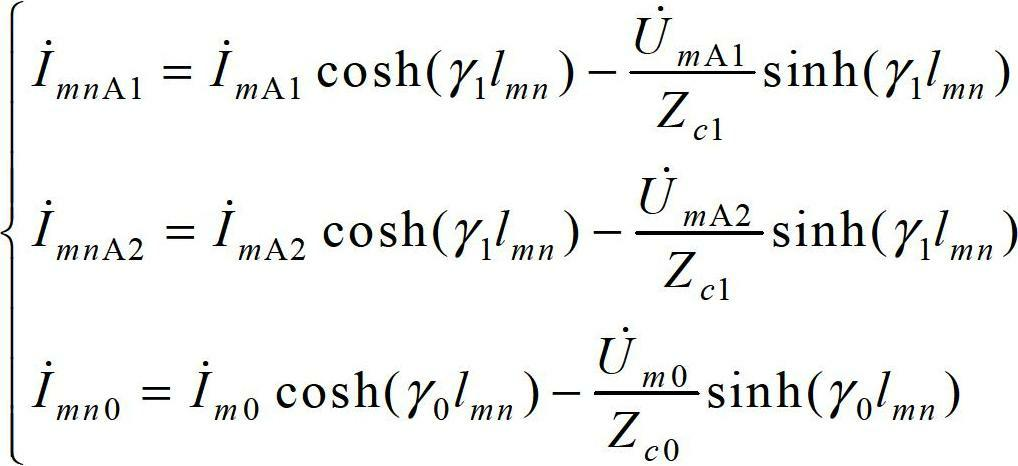

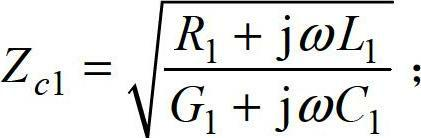

Ultra high-voltage alternating current transmission line protection method based on all-component differential coefficient matrix

ActiveCN102694375AAccurate identificationReliable actionEmergency protective arrangements for automatic disconnectionDifferential coefficientHigh resistance

The invention discloses an ultra high-voltage alternating current transmission line protection method based on an all-component differential coefficient matrix, comprising the following steps that the fundamental frequency electric amount on both ends of an ultra high-voltage alternating current transmission line is measured; the positive, negative and zero sequence current amount on the other end is calculated from that on one end of the line with a long line equation; the fundamental frequency current amount on the other end is calculated through a symmetrical component method; and then a differential coefficient matrix is calculated. A fault type is judged according to the values of all elements of the differential coefficient matrix, and a fault phase is enabled to be correctly tripped. The method is applicable to protecting the whole fault process of the ultra high-voltage alternating current transmission line; and particularly when the ultra high-voltage alternating current transmission line has a single-phase high-resistance grounding short-circuit fault, the method can accurately identify and correctly trip the fault phase, and circuit breakers on both ends of other two normal phase lines are reliable without working.

Owner:STATE GRID CORP OF CHINA +1

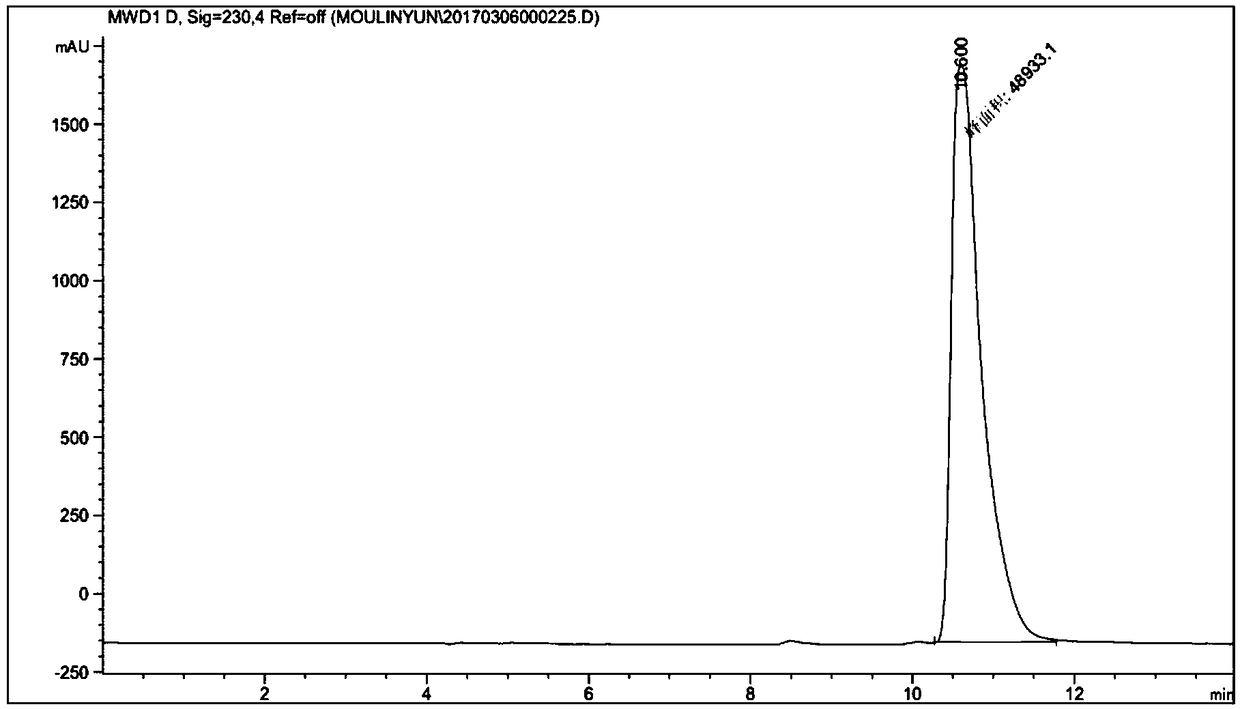

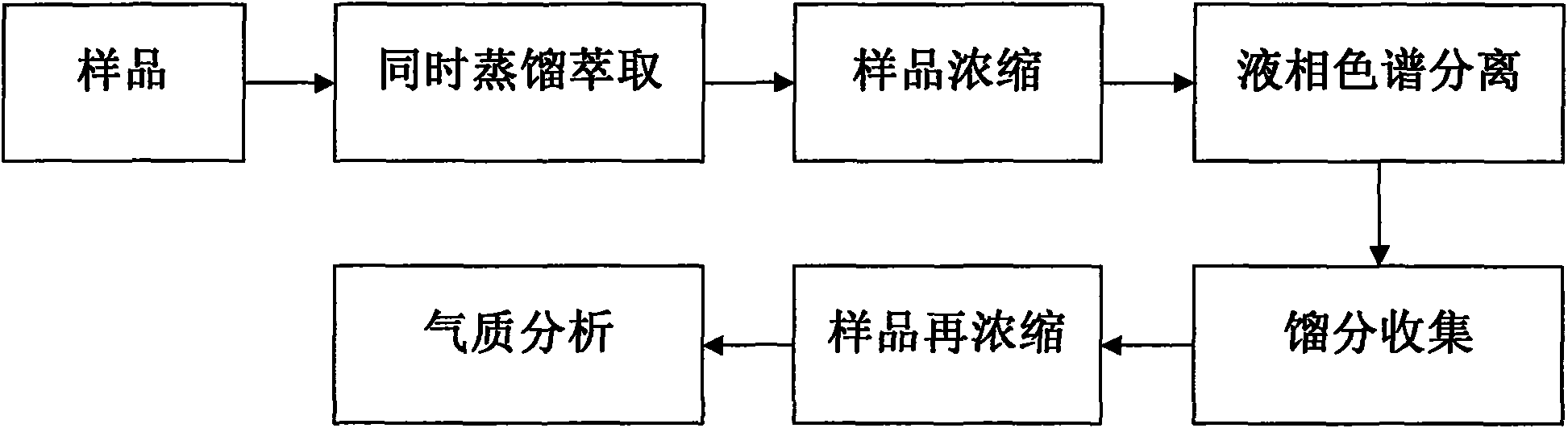

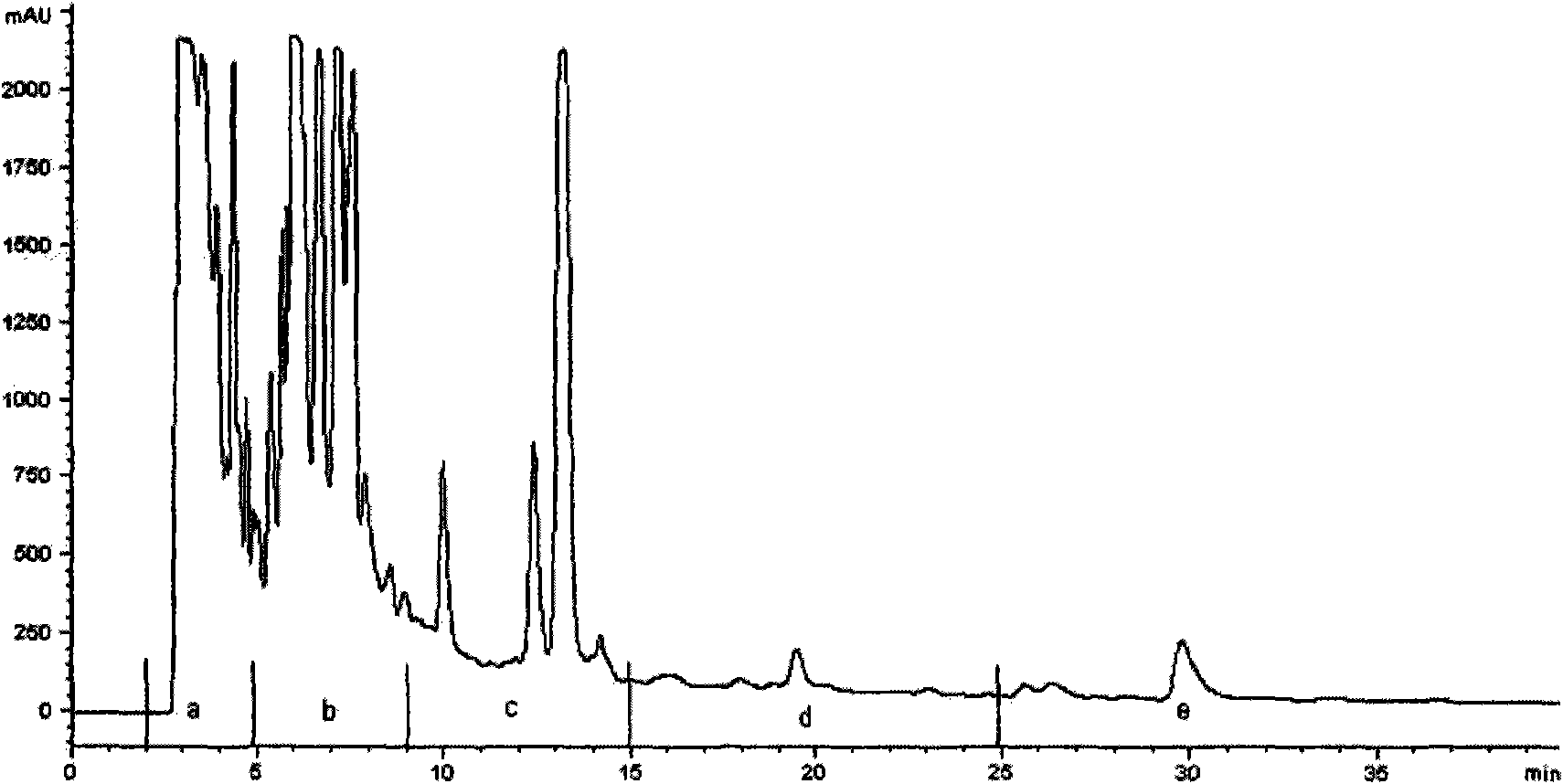

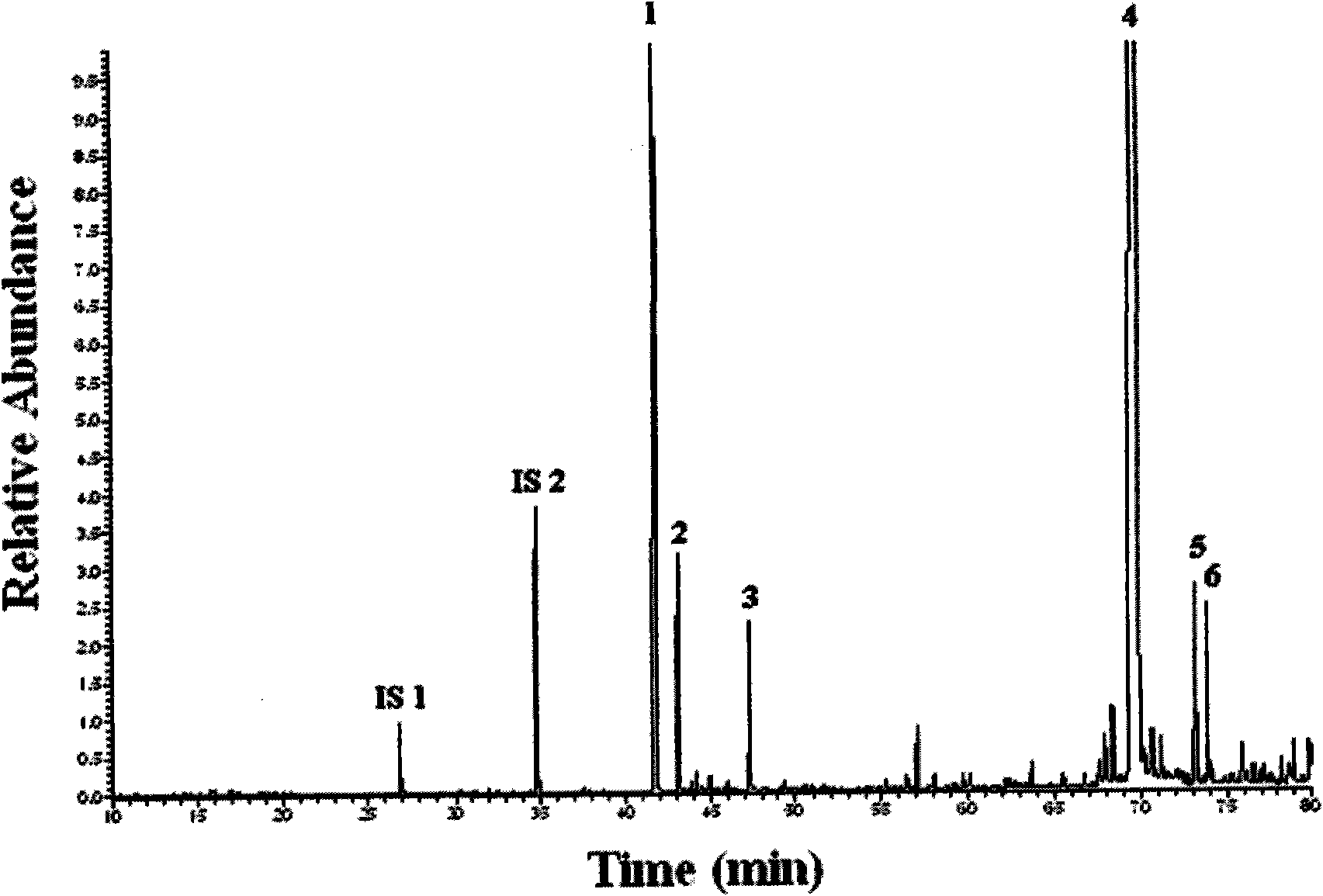

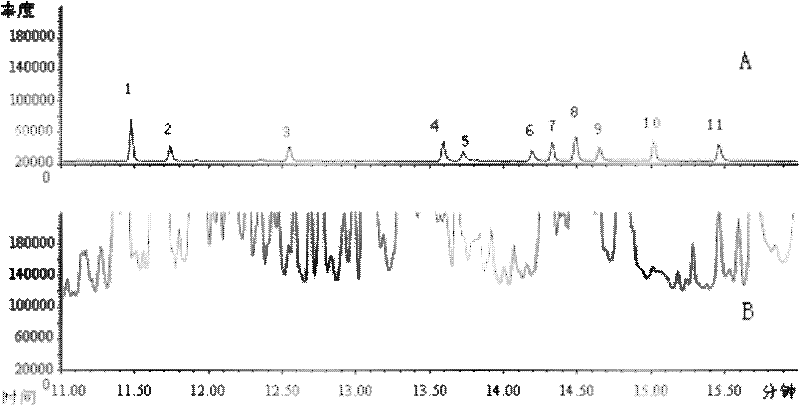

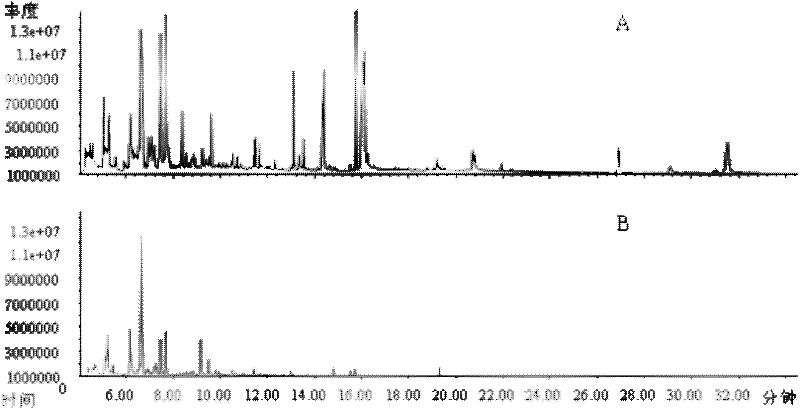

Method for separating and analyzing volatile and semi-volatile flavor components in tobacco by using liquid chromatography-gas chromatography/mass spectrometry technology

A method for separating and analyzing volatile and semi-volatile flavor components in tobacco by using liquid chromatography-gas chromatography / mass spectrometry technology comprises the following steps: 1. taking a given weight of tobacco products and extracting the volatile and semi-volatile flavor components from the tobacco by simultaneously adopting distillation and extraction; 2. concentrating the extracted samples with a concentrator; 3. carrying out group component separation on the concentrated extracted samples by normal-phase liquid chromatography and collecting distillates by different time sections; and 4. concentrating the collected distillates by the concentrator and respectively entering a gas chromatography-mass spectrometer (GC-MS) for detailed analysis. Compared with theprior art, the method of the invention can effectively extract the volatile and semi-volatile flavor components from the tobacco, carry out group component separation on the extract liquor by normal-phase liquid chromatography, then carry out accurate GC-MS qualitative and quantitative analysis on each group component according to different boiling points, not only has good selectivity and high separation efficiency but also ensures more accurate qualitative and quantitative analysis of each component.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Semiconductor device having latency counter

InactiveUS20090290445A1Current consumptionSufficient margin for a counting operationDigital storageControl signalControl circuit

A semiconductor device includes a latency setting circuit setting the latency, an input command circuit outputting a normal-phase (reverse-phase) command signal obtained by capturing an input command signal using a normal-phase (reverse-phase) clock, first and second counter circuits each including latch circuits for sequentially shifting the normal-phase (reverse-phase) command signal based on the normal-phase (reverse-phase) clock, a selector circuit controlling a signal path so that the normal-phase (reverse-phase) command signal is transmitted through the first (second) counter circuit when an even latency is set and the normal-phase (reverse-phase) command signal is transmitted so as to be shifted from the first (second) counter circuit to the second (first) counter circuit when an odd latency is set, and a control circuit controlling so that the latch circuits of the first (second) counter circuit are activated in response to the input command signal and stopped after an operation period is elapsed.

Owner:LONGITUDE SEMICON S A R L

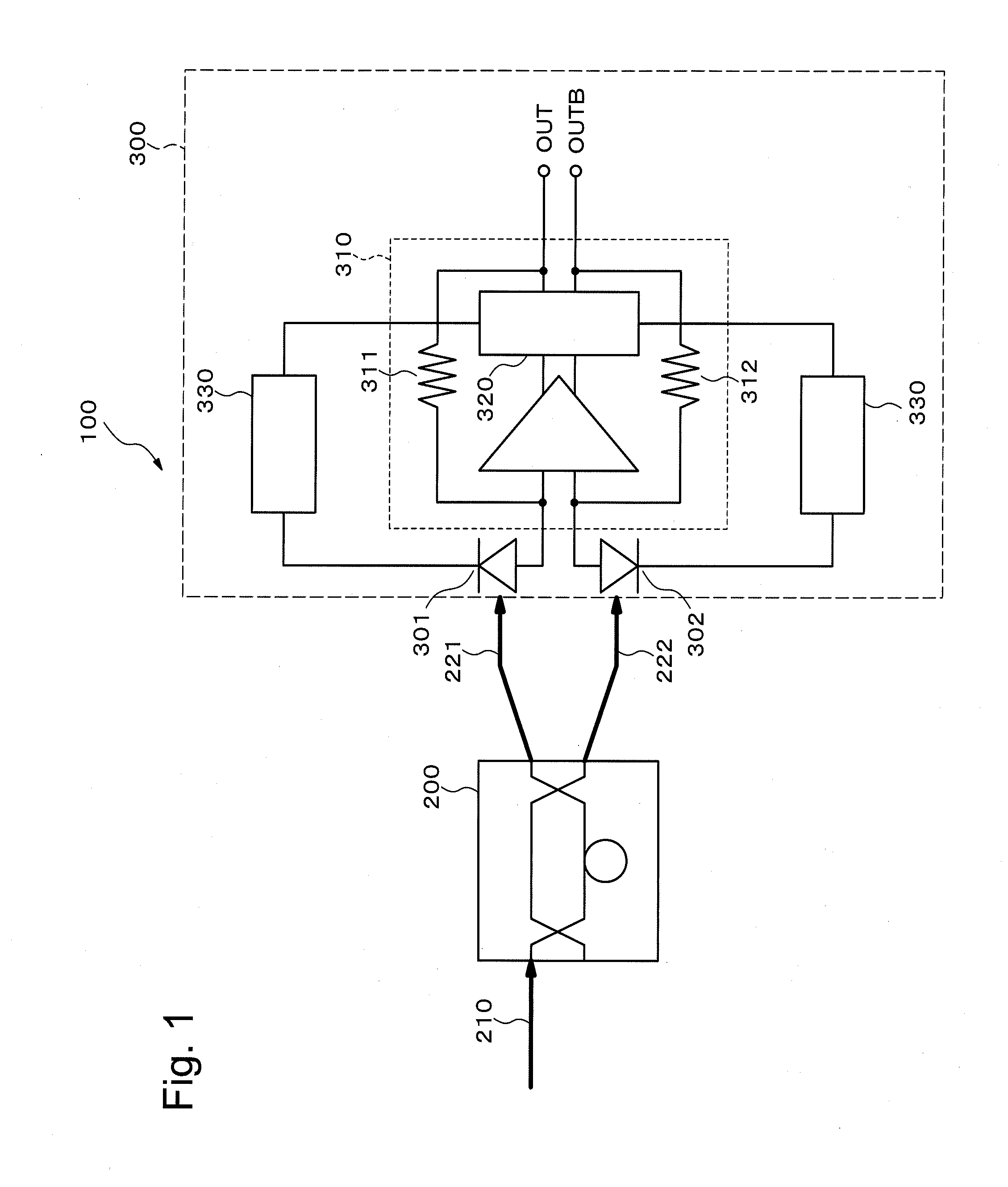

Optical receiver, optical reception device, and correction method for optical received intensity

ActiveUS20130028596A1Correct differenceTransmission monitoringElectromagnetic receiversTransimpedance amplifierUltimate tensile strength

In the optical receiver available for the RZ-DPSK modulation system, the difference in the received intensity due to the difference in the intensity or optical path of the optical signal cannot be corrected automatically, therefore, an optical receiver according to an exemplary aspect of the invention includes a first photodiode receiving a normal phase optical signal from a first output of a 1-bit delayed interferometer and outputting a positive signal; a second photodiode receiving a reversed phase optical signal from a second output of the 1-bit delayed interferometer and outputting a complementary signal; a differential transimpedance amplifier inputting the positive signal and the complementary signal and including a closed feedback loop for each input of the positive signal and the complementary signal; a level adjustment unit adjusting a signal level in the closed feedback loop; a photoelectric current detection unit detecting a photoelectric current generated in each of the first photodiode and the second photodiode; and wherein the level adjustment unit adjusts the signal level on the basis of an output of the photoelectric current detection unit.

Owner:NEC CORP

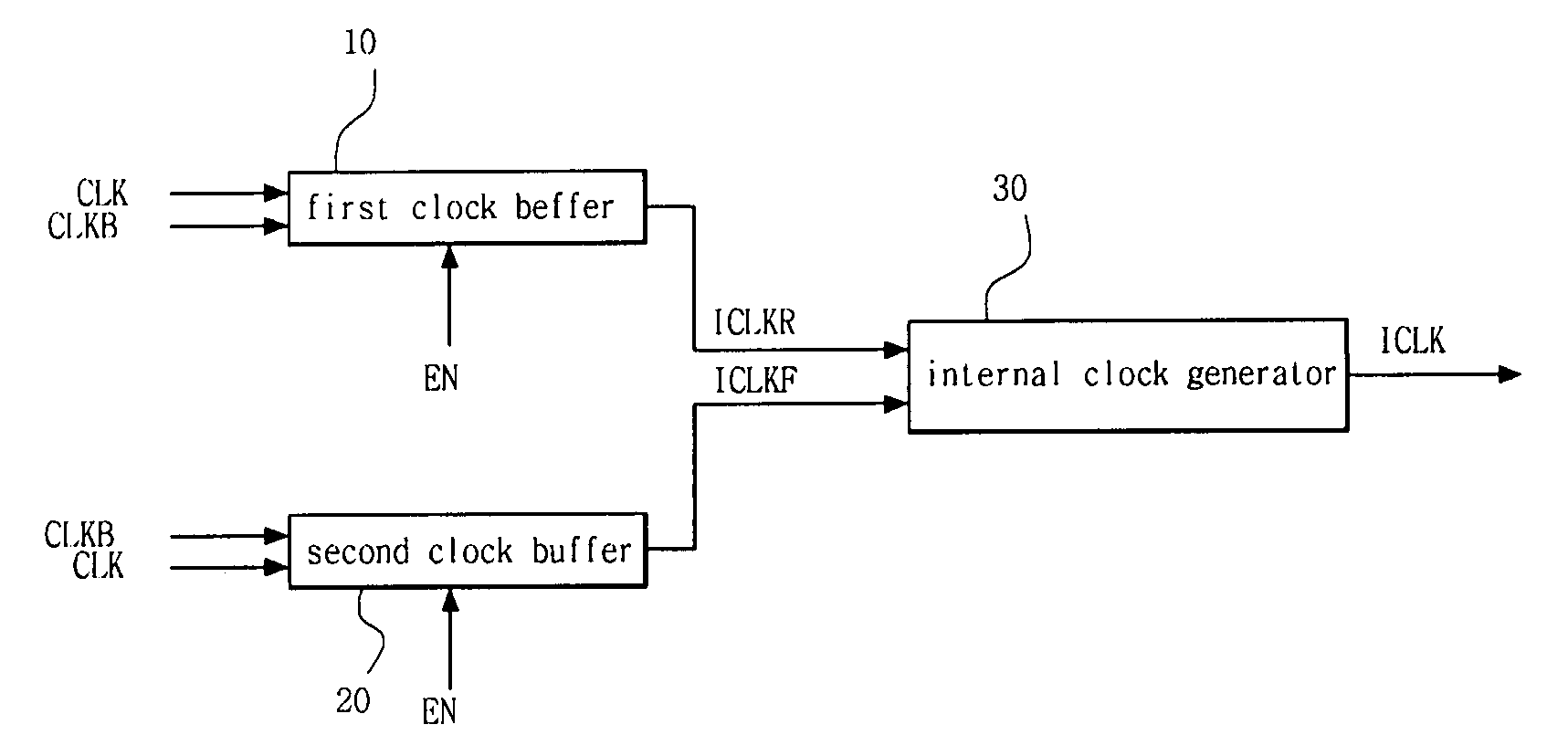

Clock buffer circuit of semiconductor device

InactiveUS20080201596A1Digital storageGenerating/distributing signalsDuty cycle distortionClock generator

A clock buffer circuit of a semiconductor device is disclosed which receives an external clock signal and generates an internal clock signal with no duty distortion. The clock buffer circuit includes a first clock buffer for receiving and buffering a normal-phase clock signal, a second clock buffer for receiving and buffering a reverse-phase clock signal, and an internal clock generator for generating an internal clock signal in response to output signals from the first and second clock buffers.

Owner:SK HYNIX INC

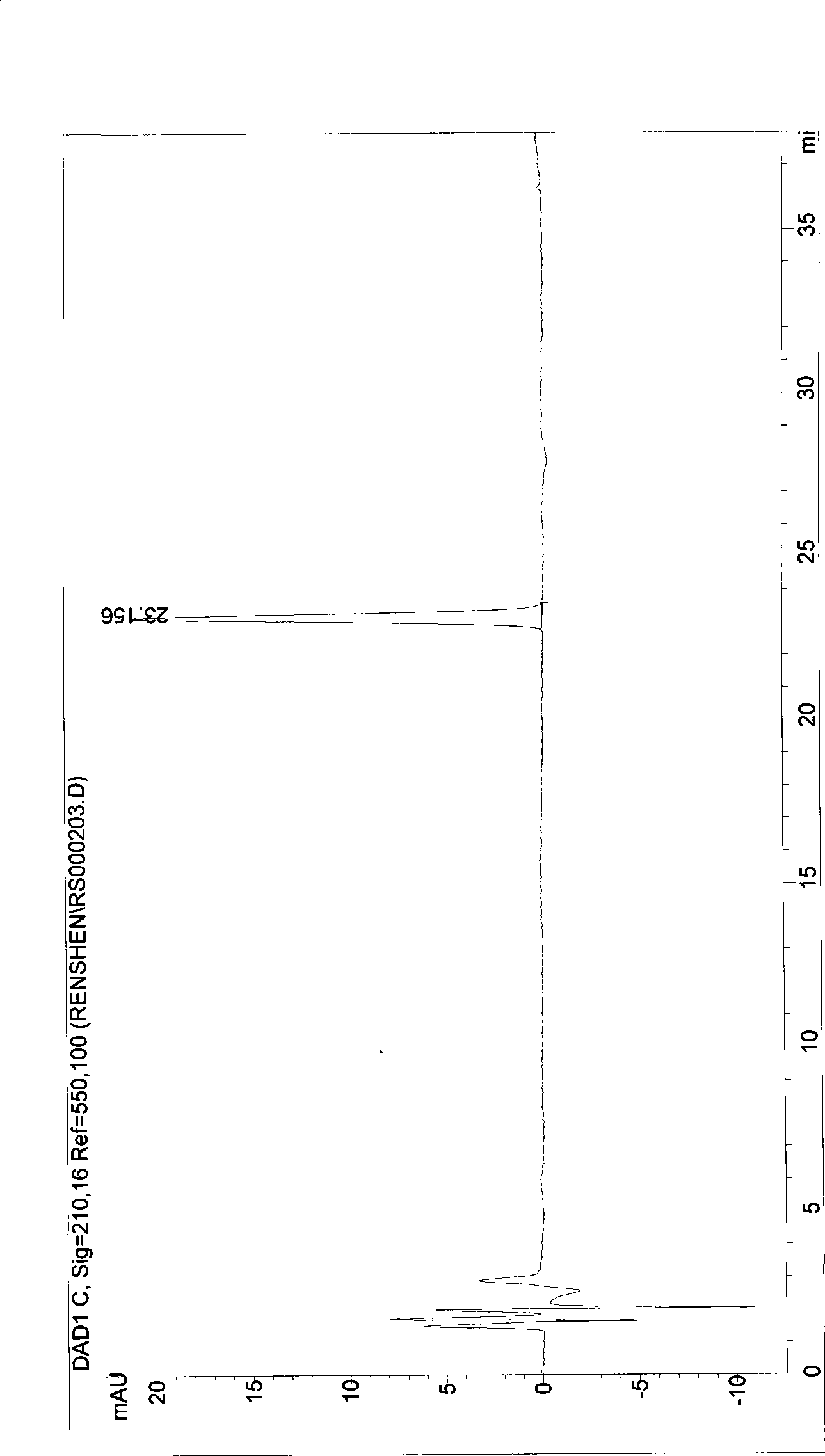

Ginseng saponin Rg1 and Rb1 in pseudo-ginseng and preparation of total saponin thereof

The invention belongs to the medicine technical filed, in particular to a preparation method of monomeric compound ginsenoside Rg1, ginsenoside Rb1 and total arasaponin and the application in the medicine field thereof. The fresh medicinal material, the dried medicinal material and the medicinal material on the market of Panax notoginseng are taken as the raw materials; according to the polarity and the solubility property of a compound, separation and purification are carried out by adopting the solvent extraction method, the crystallization process and the chromatography and total arasaponin powder is prepared by combining the common drying means, such as decompression concentration drying, freeze drying, vacuum drying and the like; by carrying out one or more methods of recrystal, normal phase, opposite phase silica gel column chromatography, daiamid column chromatography and sephadex chromatography and the like on the powder, the ginsenoside Rg1 and the ginsenoside Rb1 monomers are prepared. The medicines which take the ginsenoside Rg1 and the ginsenoside Rb1 monomers or the total arasaponin as the active ingredients can be used for preventing and / or curing the senile dementia, the neurodegenerative diseases, the cerebrovascular disorder, various dysmnesia, the central lesion and other diseases.

Owner:YUNNAN JECUI BIOTECH

A continuous extraction method of effective ingredients from fruitbodies of Cordyceps militaris

InactiveCN101007025AHigh purityNo pollution in the processBulk chemical productionPlant ingredientsAdditive ingredientBULK ACTIVE INGREDIENT

The invention disclosed a way to successively extract active ingredients from carpohole of north aweto. The invention adopts super critical CO2 to extract sterin substances, precipitating with alcohol to get nucleoside substances with cordycepin and Cordyceps polyose, separating with normal phase low pressure gel silica chromatography to get crude cordycipin, preparative reversed-phase high-performance liquid chromatography to get cordycepin crystal with high purity. The invention can not only successively extract sterin substances and Cordyceps polyose (CM-1) from the carpohole of north aweto, it can also get the cordycepin metamer; it is not applicable to small experiments but also applicable to industrial production. Since the producers can extract many substances by one treatment of carpohole, the invention can not only decrease the industrial cost but also make the biggest economic returns.

Owner:SHANGHAI ELITE AGRI SCI TECH GROUP +1

Transformation controller for charging and discharging lithium ion accumulator as well as transformation control method thereof

InactiveCN101355260AReduce volumeReduce weightBatteries circuit arrangementsDc-dc conversionLithiumDriver circuit

The invention discloses a transform controller and a transform control method for the charging-discharging of a lithium-ion storage battery. The transform controller comprises an auxiliary power supply connected with a shutoff signal SD1 which is externally input, and a main circuit, wherein a storage battery end of the main circuit is connected with a drain electrode of a switch tube S1 and a source electrode of a switch tube S2 through a power inductor; a drain electrode of the switch tube S2 is connected with a bus end, and control electrodes of the switch tube S1 and the switch tube S2 are connected with the output of a driving circuit; the input of the driving circuit is connected with an output end of a driving signal PWM of a switching circuit; an input end of the switching circuit is respectively connected with an external switching control signal SD2, a charging feedback signal FB1 output by a constant current-to-constant voltage auxiliary circuit, a discharging feedback signal FB2 output by a discharging sampling unit of the bus end, and a normal phase driving signal PWMA output by a control circuit; the other output end of the switching circuit outputs a feedback signal FB to the control circuit; and an input end of the constant current-to-constant voltage auxiliary circuit is connected with a voltage sampling signal Vb and a current sampling signal Ib which are output by a charging sampling unit of the storage battery end.

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP NO 771 RES INST

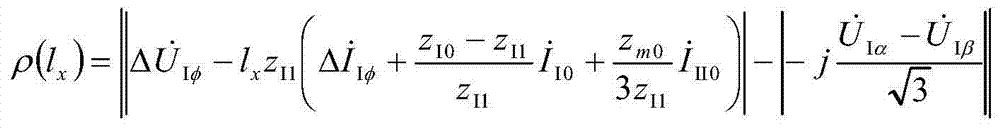

SV network sampling-based double-circuit line single-phase earth fault distance measurement method

ActiveCN103869221AEliminate fault distance measurement accuracyEliminates effects on distance-to-fault measurement accuracyFault locationElectrical resistance and conductancePhase currents

The invention discloses an SV network sampling-based double-circuit line single-phase earth fault distance measurement method which is used for measuring the fault phase voltage mutational volume, the fault phase current mutational volume, the zero-sequence current and the other two normal phase voltages of an I-circuit line at the protection mounting position of a double-circuit line on the same pole, and measuring the zero-sequence current of a II-circuit line; calculating the fault phase voltage when the I-circuit line operates normally, sequentially calculating the positioning vector function of each point on the I-circuit line of the double-circuit line on the same pole until the full length of the I-circuit line of the double-circuit line on the same pole, and selecting the distance between the point with the smallest positioning vector function value on the I-circuit line of the double-circuit line on the same pole and the protection mounting position of the double-circuit line on the same pole as the fault distance. According to the method, the voltage of the circuit before the fault does not need to be remembered, and a voltage protection loop of the circuit before the fault does not need to be set; the influence of the zero-sequence mutual inductive impedance among the lines, the transition resistance and the load current on the precision of measurement of the fault distance is eliminated, and no fault distance measurement dead zone exists in protecting the single phase grounding fault of the outlet single-circuit line.

Owner:STATE GRID PUTIAN ELECTRIC POWER SUPPLY +2

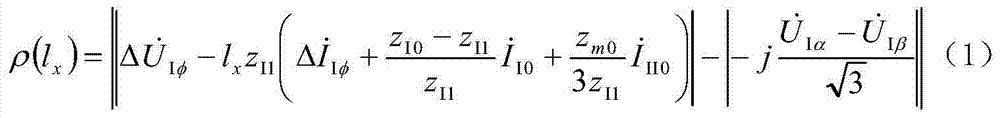

Method for diagnosing turn-to-turn short circuit of permanent magnet fault-tolerant motor

InactiveCN101221206ACapture fault signatureSolve the problem of online fault diagnosisDynamo-electric machine testingFault tolerancePower analysis

The invention discloses a diagnosis method for inter-turn short trouble of a permanent magnetic motor with fault tolerance, which is characterized in that the method comprises the following steps: (a) the method implements the transient power analysis of motor windings, and if the number of the windings that have short trouble is no less than 10, the method decides whether a trouble happens by computing the mean value change of the transient power before and after the trouble happens, if the number of the windings that have short troubles is less than 10, the method turns to next step; (b) the method takes the derivation of the first-order complex Gaussian wavelet function as the wavelet function, analyzes and locates the unsteady signal of the inter-turn short trouble; (c) the method compares the transformation situations of the wavelet modulus maximum value of the transient power signal in a trouble phase and in a normal phase, and if the situations are the same, the method decides that no trouble exists; if the situation are different, the method decides that the inter-turn short trouble exists. By adopting the modulus maximum value of the complex Gaussian wavelet, the invention can markedly observe a distortion point of the transient power before and after an inter-turn short trouble happens, accurately capture trouble characteristics when the inter-turn short trouble happens in the motor, and solve the difficult problems of the online trouble diagnosis of the inter-turn short trouble of small turns of a stator winding in a permanent magnetic motor.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Power converter system and method

A power converter system for supplying an output voltage is provided. The power converter system is adapted to operate in a normal mode and a fault mode. The system comprises a plurality of bridges and a plurality of transformers. The system further comprises a plurality of dc link capacitors, each coupled across a corresponding bridge. The system also includes a controller adapted for, during the normal mode, switching each bridge with a respective normal phase shift. During the fault mode, the controller is adapted for switching each of the remaining ones of the bridges with a respective adjusted phase shift to generate the output voltage. During the fault mode, at least one of the plurality of bridges is bypassed.

Owner:GENERAL ELECTRIC CO

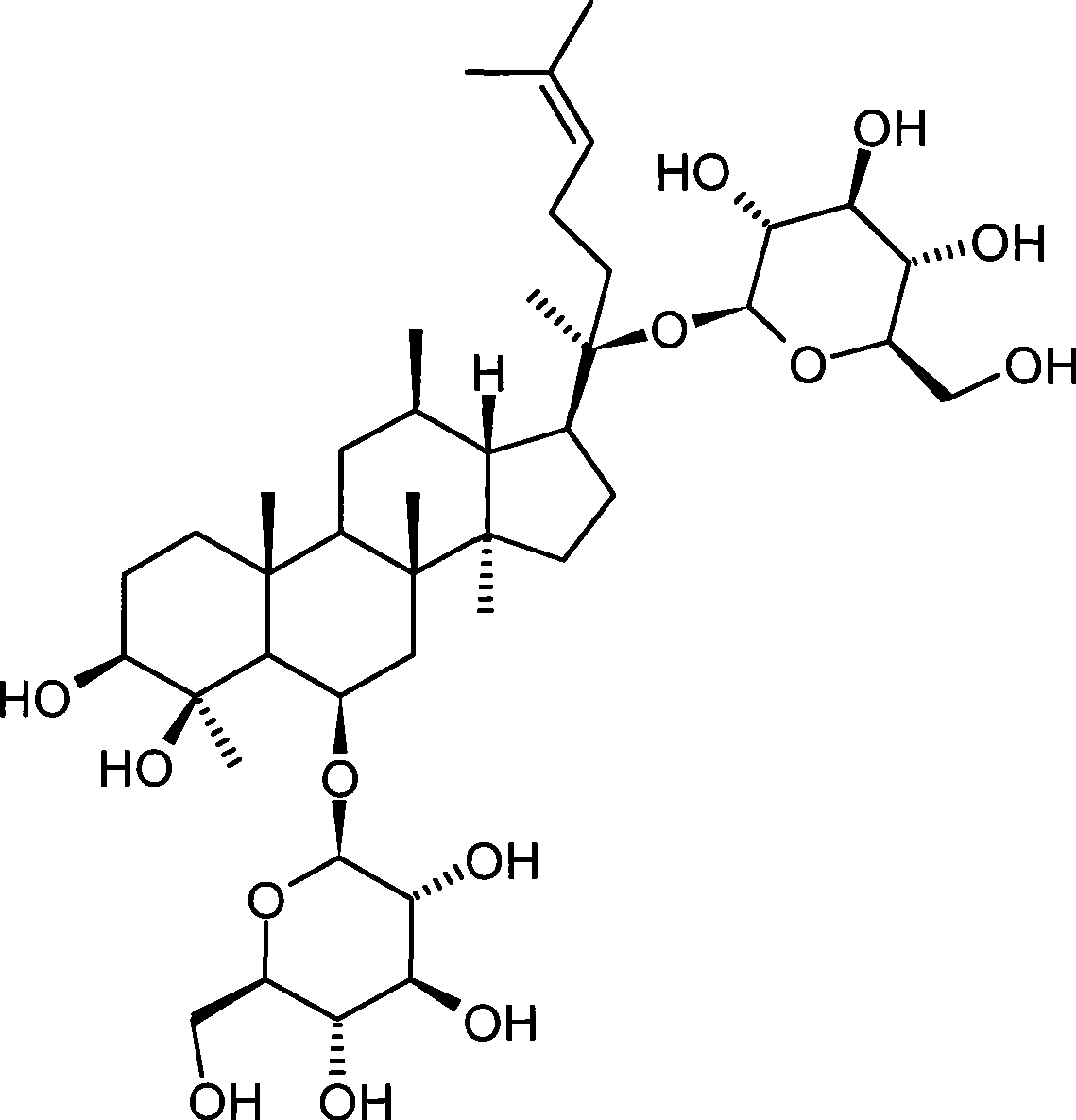

Preparation of high-purity Momordica grosvenori mogroside V

The invention discloses a preparation method of grosvenor momordica glycoside V with high purity, which has steps as follows: 1) the grosvenor momordica glycoside is dissolved in methanol and then filtered to obtain a filtrate; 2) acetone is added in the obtained filtrate for sedimentation and a sediment can be obtained by filtering; 3) the sediment is adsorbed by a normal phase silica gel column; 4) the adsorbed normal phase silica gel column is eluted by using a mixing solution of low carbon chain ester and ethanol as an elution agent, and elution liquid is collected; and 5) the grosvenor momordica glycoside V with high purity can be obtained by recycling and crystallizing the elution agent in the elution liquid. Compared with the prior art of twice column adsorbing methods of the normal phase silica gel column and expensive opposite phase silica gel column, the preparation method only needs separation and elution of the normal phase silica gel column once to obtain the grosvenor momordica glycoside V with good quality and purity of more than 98 percent. Compared with the prior art, the preparation method of the grosvenor momordica glycoside V with high purity is simpler in technique, shortens the production cycle and reduces the production operation difficulties and production cost.

Owner:桂林市振达生物制药有限公司

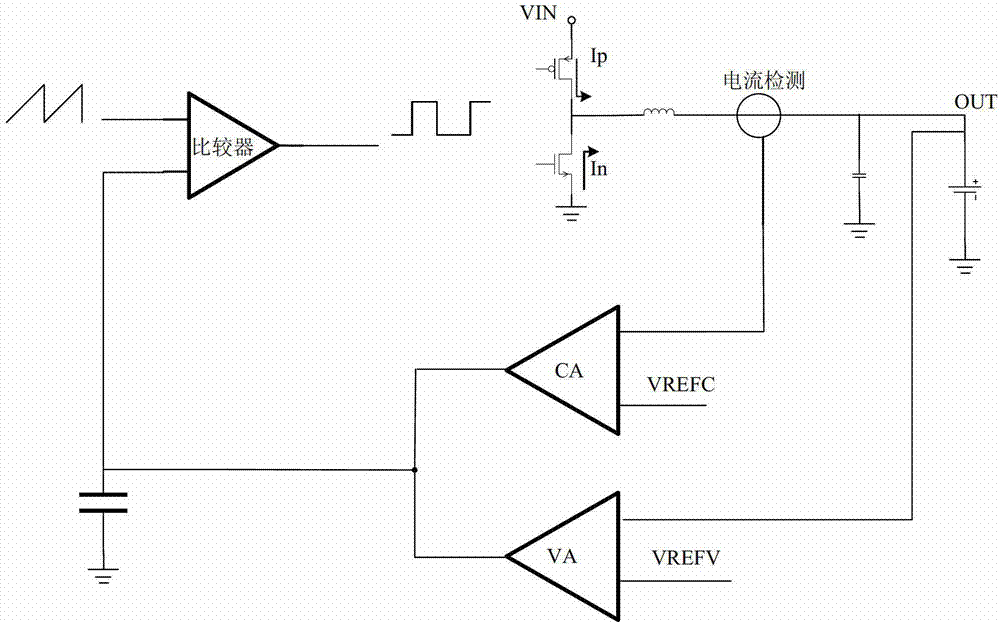

Constant-current constant-voltage charge control circuit

InactiveCN102969765AEasy to implementAccurate settingBatteries circuit arrangementsElectric powerMOSFETEngineering

The invention discloses a constant-current constant-voltage charge control circuit. The circuit comprises a first metal oxide semiconductor field effect transistor (MOSFET), a second MOSFET, an inductor, a capacitor, a comparator, a first error amplifier, a second error amplifier, a voltage clamp circuit and a first compensating network, wherein the inverted input end of the first error amplifier is connected to the positive end of a battery and the normal phase input end of the first error amplifier is connected to a first reference voltage; one end of the voltage clamp circuit is connected to the output end of the first error amplifier and the other end of the voltage clamp circuit is connected to the normal phase input end of the second error amplifier; the inverted phase input end of the second error amplifier is connected to the signal output end of a current detecting unit connected in series onto a current path of the inductor; the output end of the second error amplifier is connected to the input end of the comparator; and the other input end of the comparator is connected with a sawtooth generator, and the first compensating network is connected between the inverted phase input end and the output end of the second error amplifier. According to the circuit, an external capacitor is not needed, the clamp value is set accurately, the circuit is simple, and the cost is low.

Owner:深圳鼎信芯微电子有限公司

Composite solid-phase extraction column used in vegetable pesticide removing, and preparation method thereof

InactiveCN102489249AEasy to fillShort purification timeOther chemical processesPreparing sample for investigationPesticide residueFilling materials

The invention relates to a composite solid-phase extraction column used in vegetable pesticide removing. Graphitized carbon black and florisil are filled in a solid-phase extraction hollow pipe, such that the solid-phase extraction column is obtained. A mass ratio of the florisil to the graphitized carbon black is 1:1-5:1. The invention is suitable for normal-phase extractions of low-pole or middle-pole pesticide compounds, and is especially suitable for organic phosphorus pesticide residue removing of colored vegetables and vegetables with relatively complicated groundmass. Compared to other solid-phase extraction columns with single filling materials, the solid-phase extraction column provided by the invention is advantaged in faster and more convenient processing process, large adsorption capacity, and low solvent dosage. The prices of the florisil and the graphitized carbon black are not high. Commercialized solid-phase extraction hollow pipes are adopted. The preparation method is simple, and is suitable for batch productions.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Dynamic latch comparator

InactiveCN102957405AKick back noise reductionMultiple input and output pulse circuitsElectronic switchingNegative phaseComparators circuits

The invention relates to the field of latch comparator circuit structures and discloses a dynamic latch comparator. The dynamic latch comparator comprises a first switch circuit and a second switch circuit which are controlled by a normal phase latch signal, and a third switch circuit and a fourth switch circuit which are controlled by a negative phase latch signal, wherein the first switch circuit is connected between the regeneration node of a first positive feedback anode and the output end of a first input pipe; the second switch circuit is connected between the regeneration node of a second positive feedback anode and the output end of a second input pipe; the third switch circuit is connected between the output end of the first input pipe and a ground / power supply; and the fourth switch circuit is connected between the output end of the second input pipe and the ground / power supply. According to the invention, four switch circuits are added on the basis of the existing dynamic latch to stabilize the electric potential at the output end of the input pipe at a resetting period and a regeneration period, so that the kickback noise can be effectively reduced on the basis of low power consumption.

Owner:ANYKA (GUANGZHOU) MICROELECTRONICS TECH CO LTD

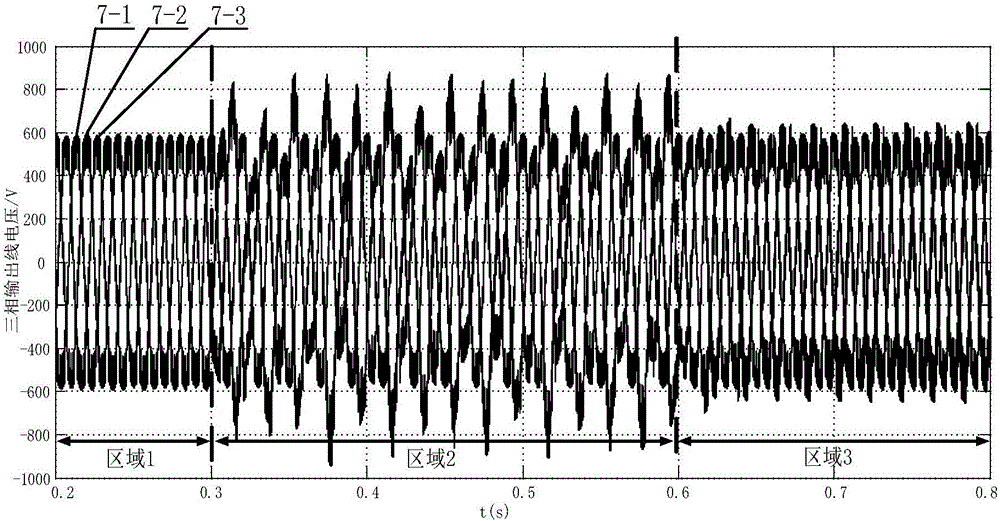

Fault-tolerant control method for MMC (modular multilevel converter) system without redundant submodules

InactiveCN106787885AReduce the number of resectionsAchieve three-phase symmetrical outputAc-dc conversionCapacitanceCapacitor voltage

A fault-tolerant control method for an MMC (modular multilevel converter) system without redundant submodules is a method for fault ride-through control in the situation that redundant submodules of an MMC system are used up, but the system does not allow shutdown for overhauling. According to the method, firstly, the positions of fault submodules are detected, the fault submodules are removed through a bypass switch, and other normal submodules are not processed; modulating waves of fault phases are subjected to amplitude limiting according to the number of the fault submodules, a zero-sequence voltage value is calculated, and capacitor voltage of remaining normal submodules of the fault-phase bridge arms is sequenced again; finally, zero-sequence voltage is injected to modulating waves of other normal phases, recombination of the modulating waves is realized, and balance of voltage of output lines is guaranteed. According to the fault-tolerant control method, migration of neutral points of a system is avoided, the equipment reliability is enhanced, the operation efficiency is improved, and ceaseless and stable running of the system is maintained. The invention applies to the field of electrotechnics.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

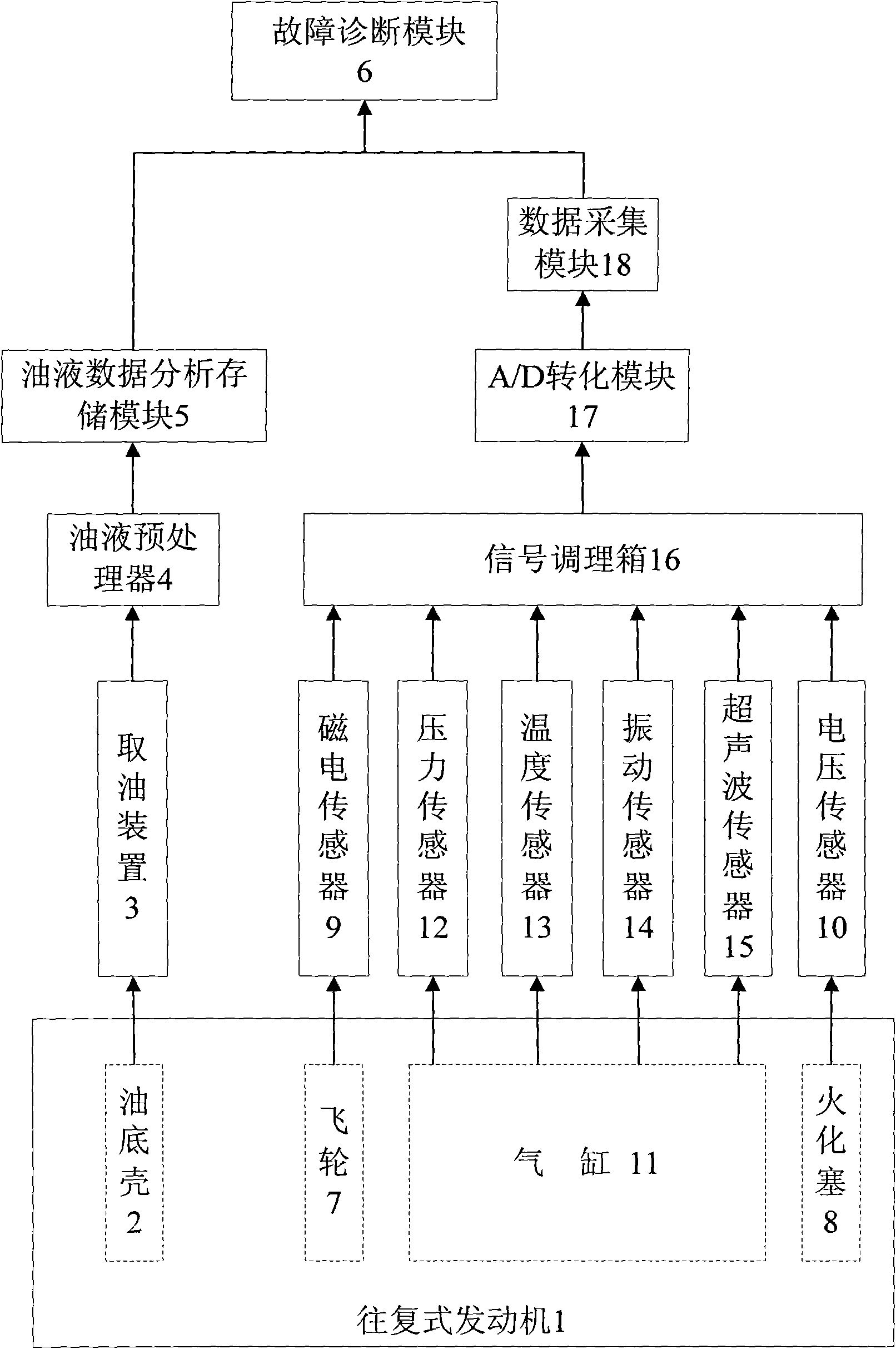

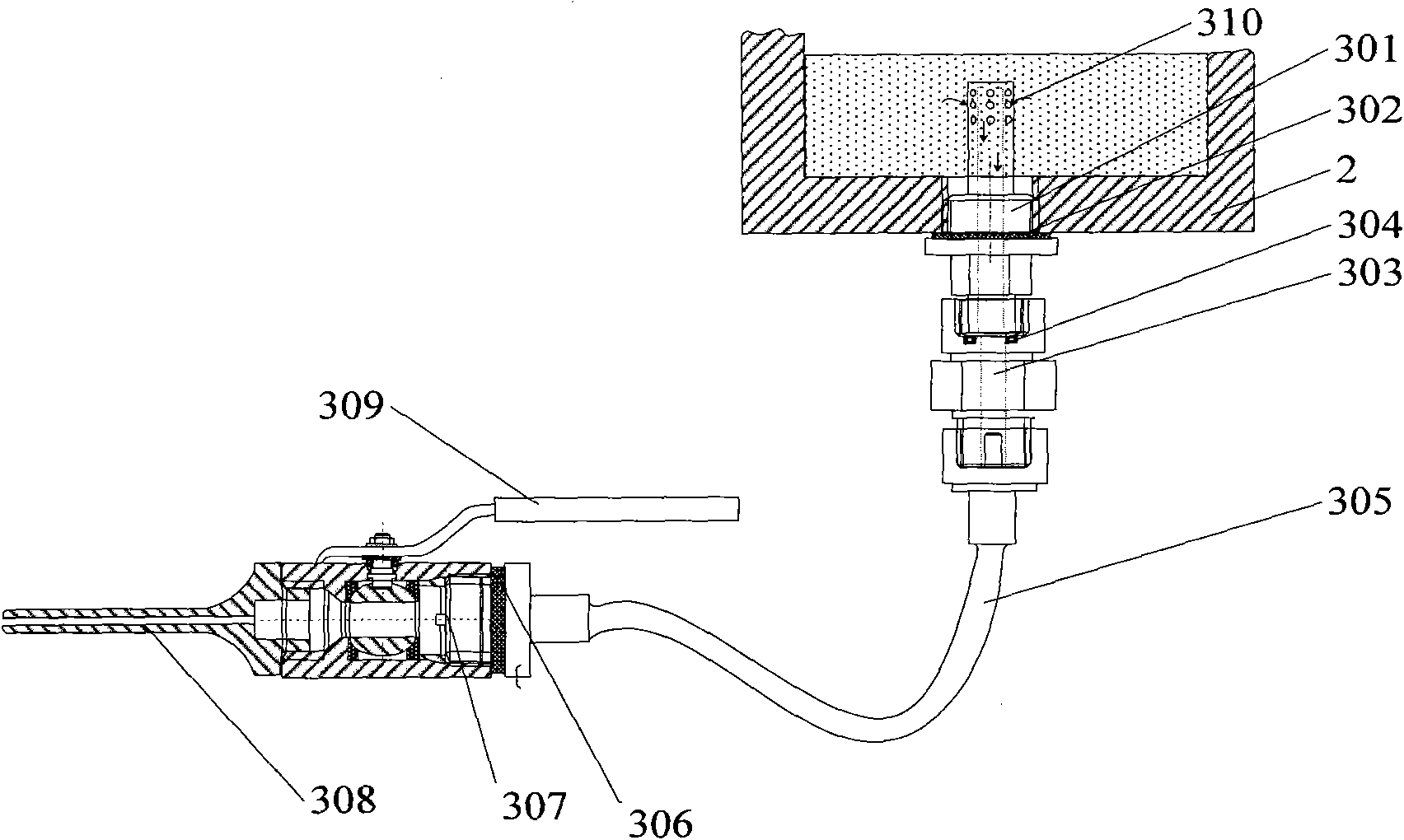

Failure diagnosis method of power equipment

InactiveCN101798957AHigh degree of integrationSatisfy Failure PredictionMachines/enginesEngine componentsData acquisitionPower equipment

The invention relates to a failure diagnosis method of power equipment, comprising the following steps: (1) installing a failure monitoring and predicting system comprising a reciprocating engine, an oil extraction device, an oil preprocessor, an oil data analyzing and storing module, a failure diagnosis module, a magnetoelectric sensor, a voltage sensor, a pressure sensor, a temperature sensor, a vibration sensor, an ultrasonic wave sensor, a signal conditioning box, an analog-to-digital conversion module and a data acquisition module; (2) judging whether the acquired data exceed the upper limit of the threshold values of the normal phase and the amplitude according to the oil analysis data and the data acquired by each sensor, if not, continuing operating the equipment, if so, carrying out phase deviation and amplitude data quantifying; (3) establishing a fuzzy evaluation matrix of the amplitude and the phase signal according to a fuzzy evaluation method; and (4) carrying out failure diagnosis on various acquired data according to the fuzzy evaluation matrix. The invention has overall acquisition means, can satisfy the failure predicting and monitoring functions and has high diagnosis precision. The invention can be widely applied to various reciprocating machines.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com