Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11184 results about "Filling materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Today, several dental filling materials are available. Teeth can be filled with gold; porcelain; silver amalgam (which consists of mercury mixed with silver, tin, zinc, and copper); or tooth-colored, plastic, and materials called composite resin fillings. There is also a material that contains glass particles and is known as glass ionomer. This material is used in ways similar to the use of composite resin fillings.

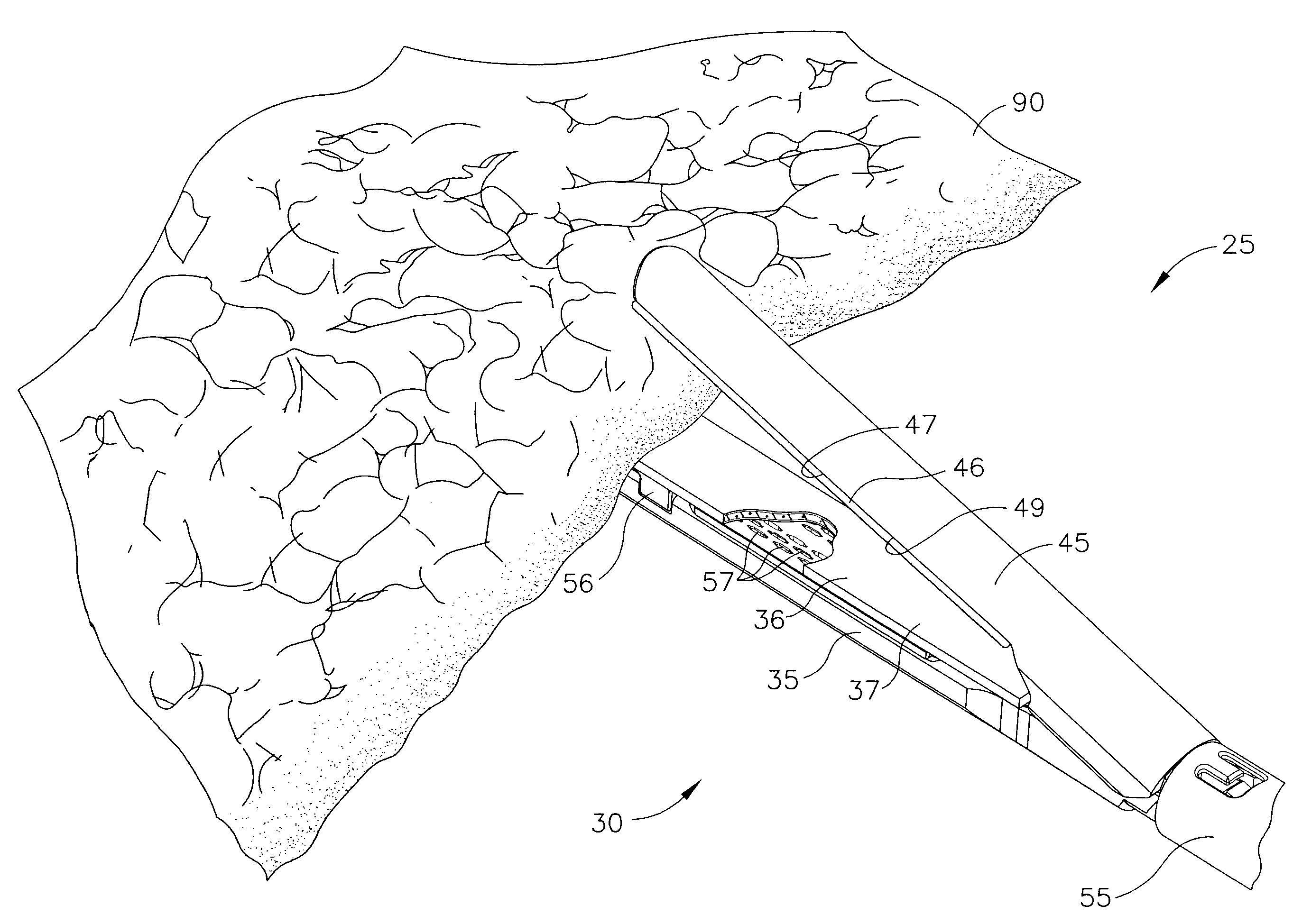

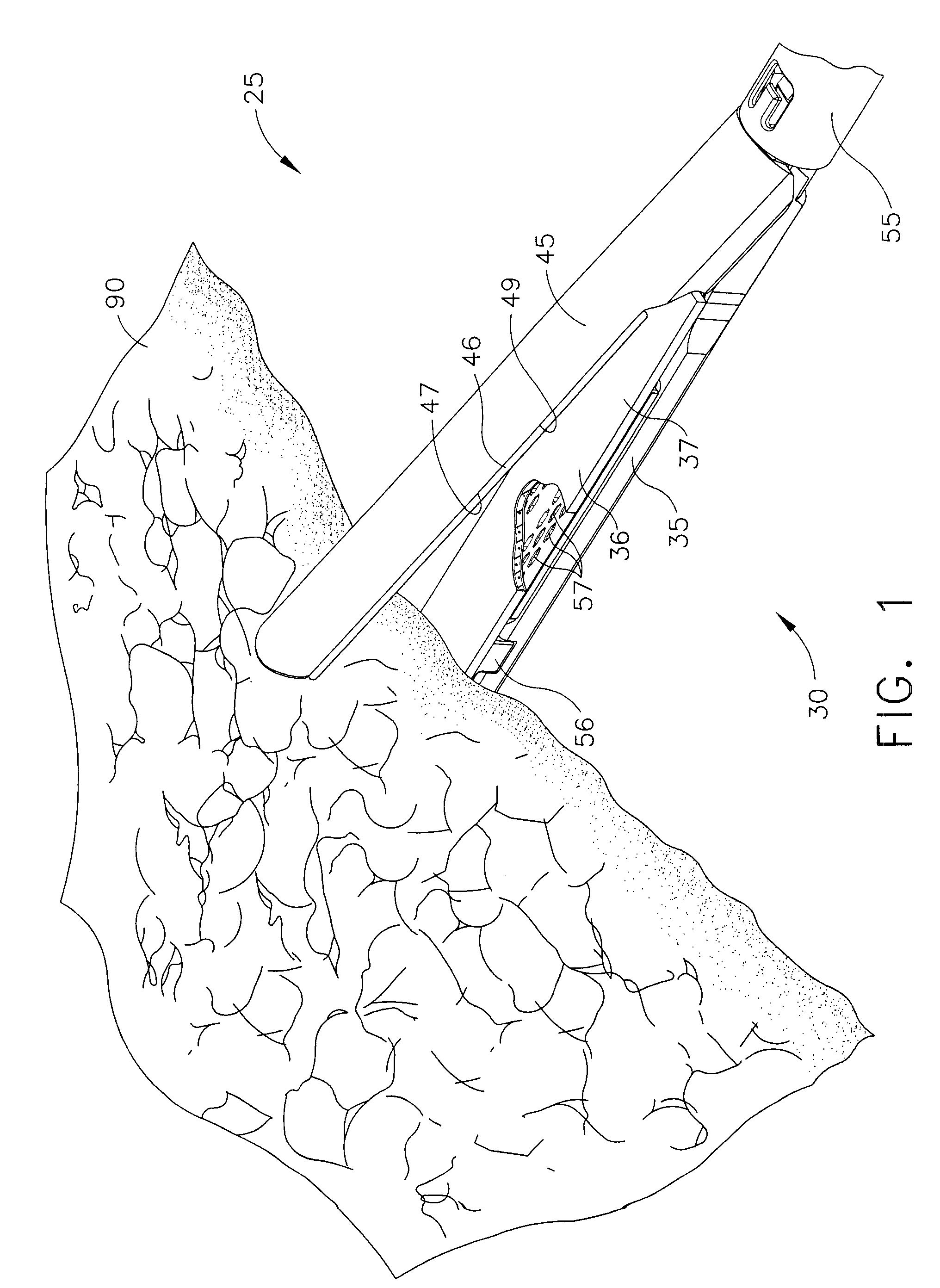

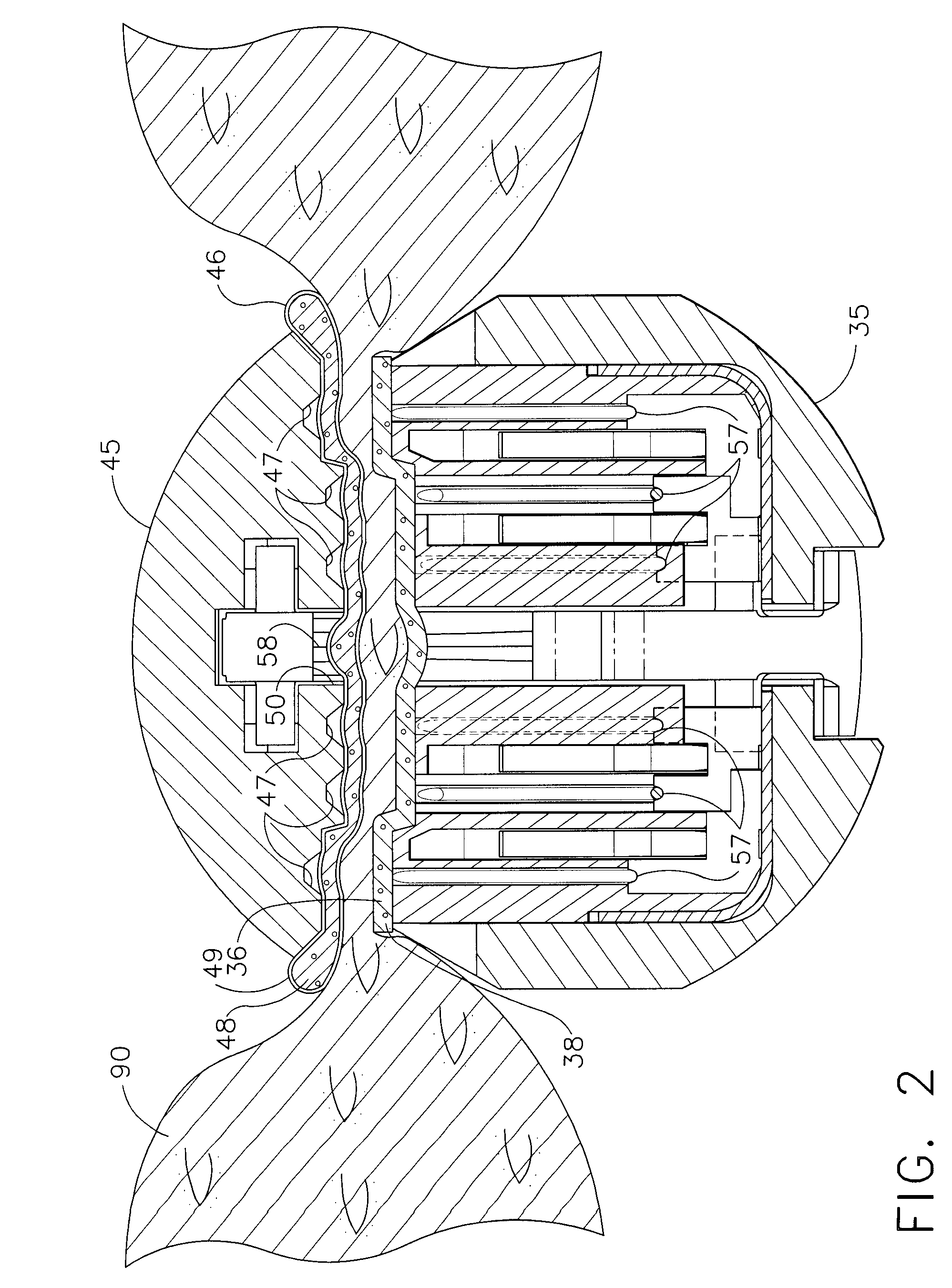

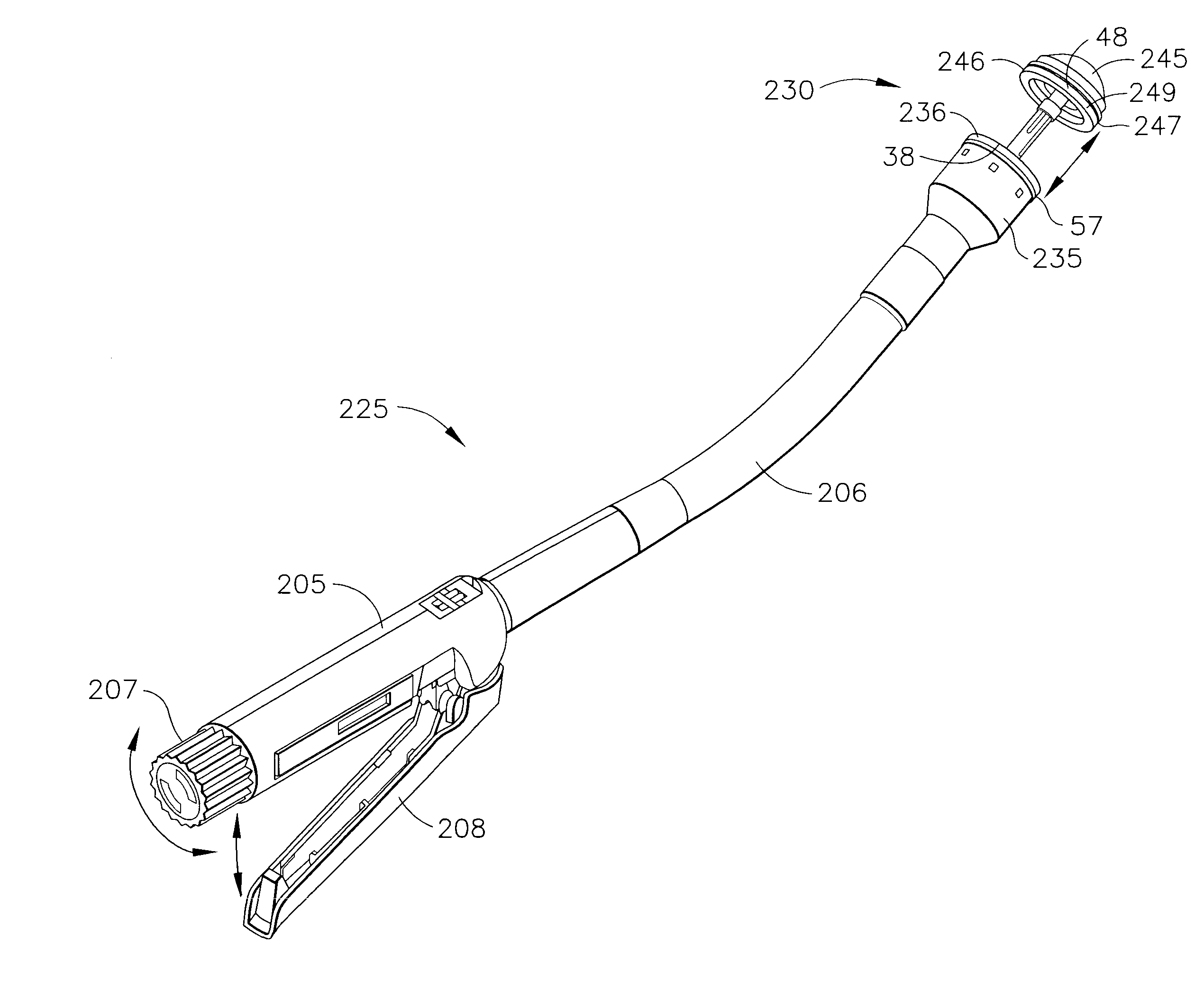

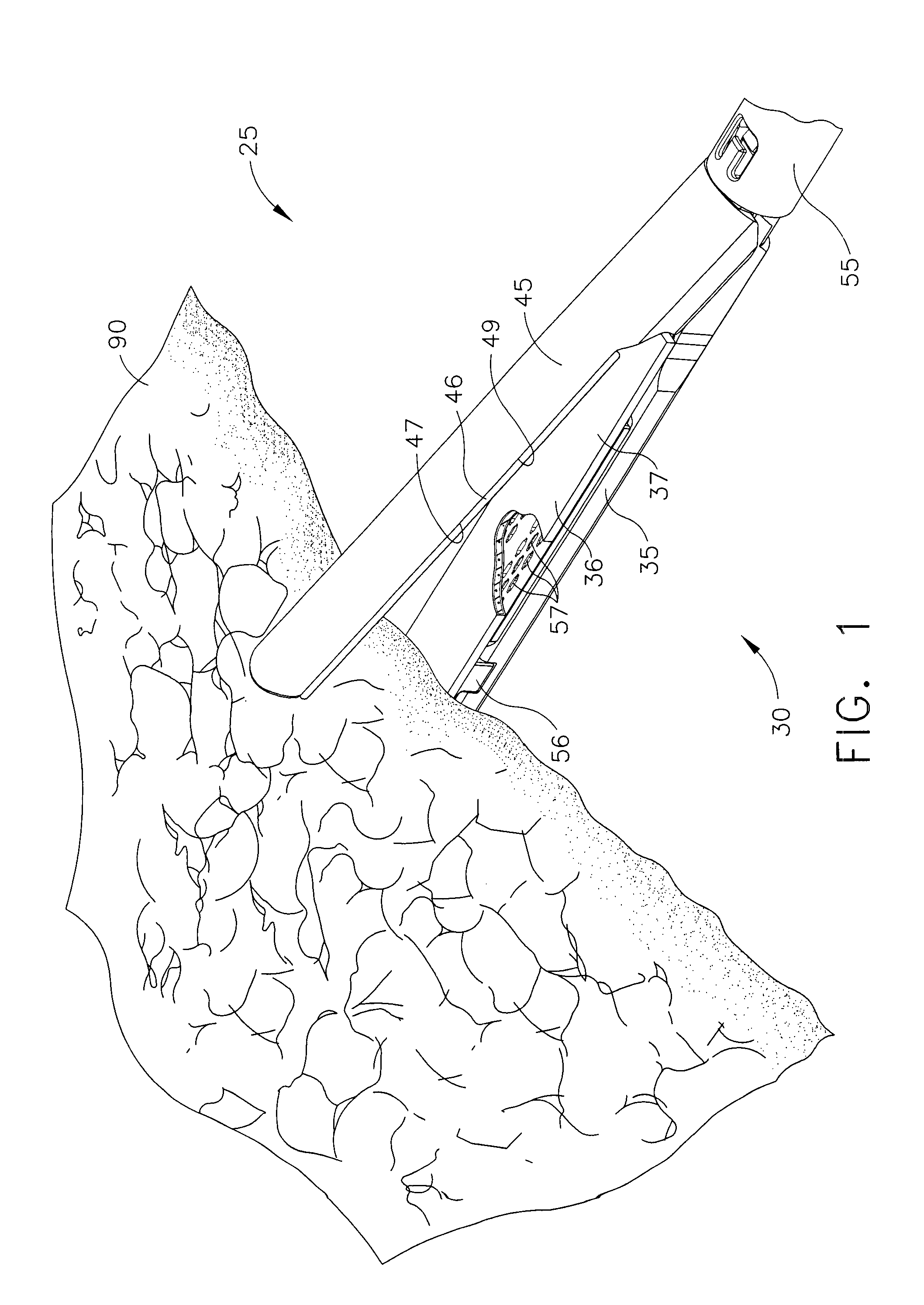

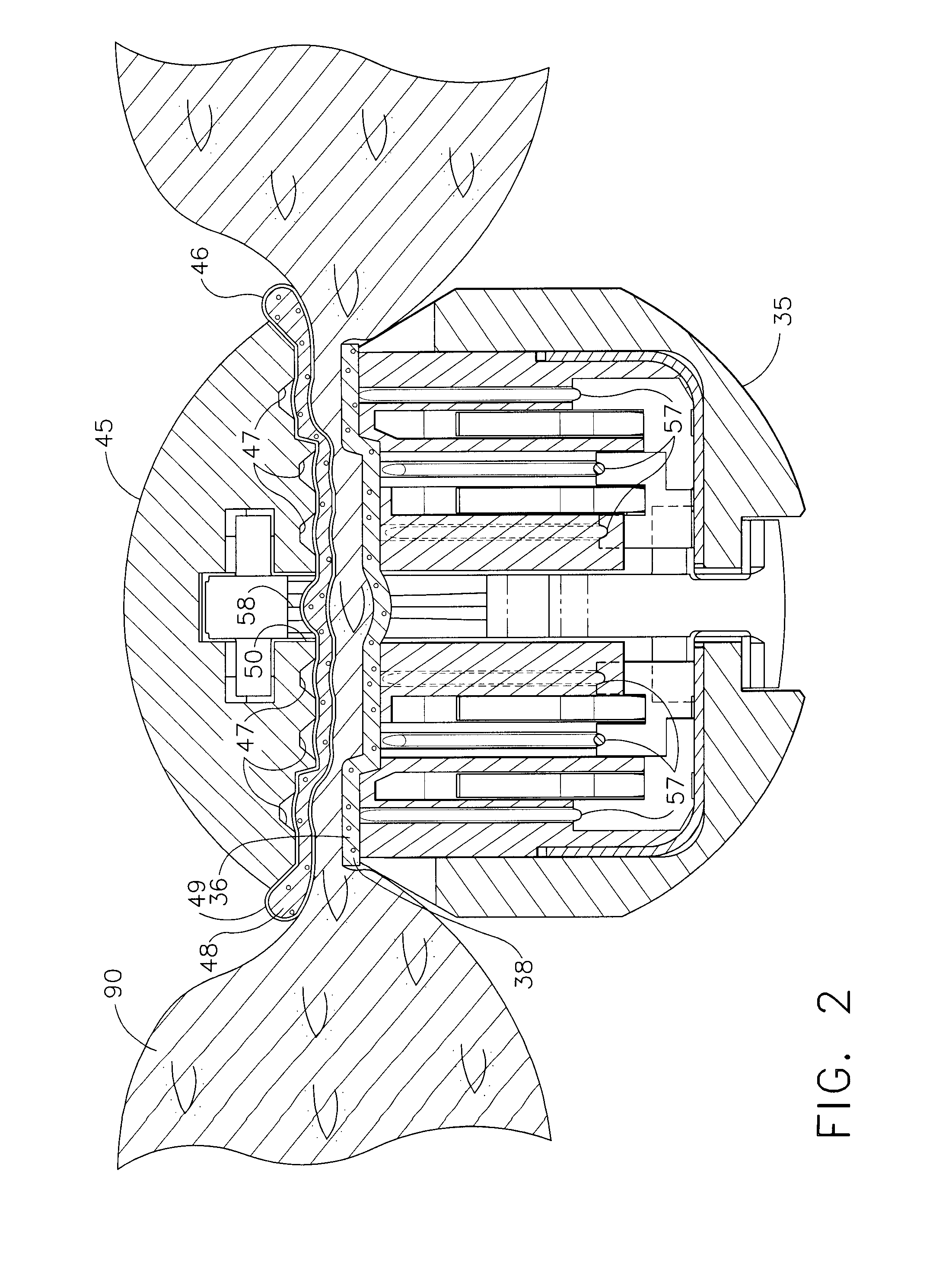

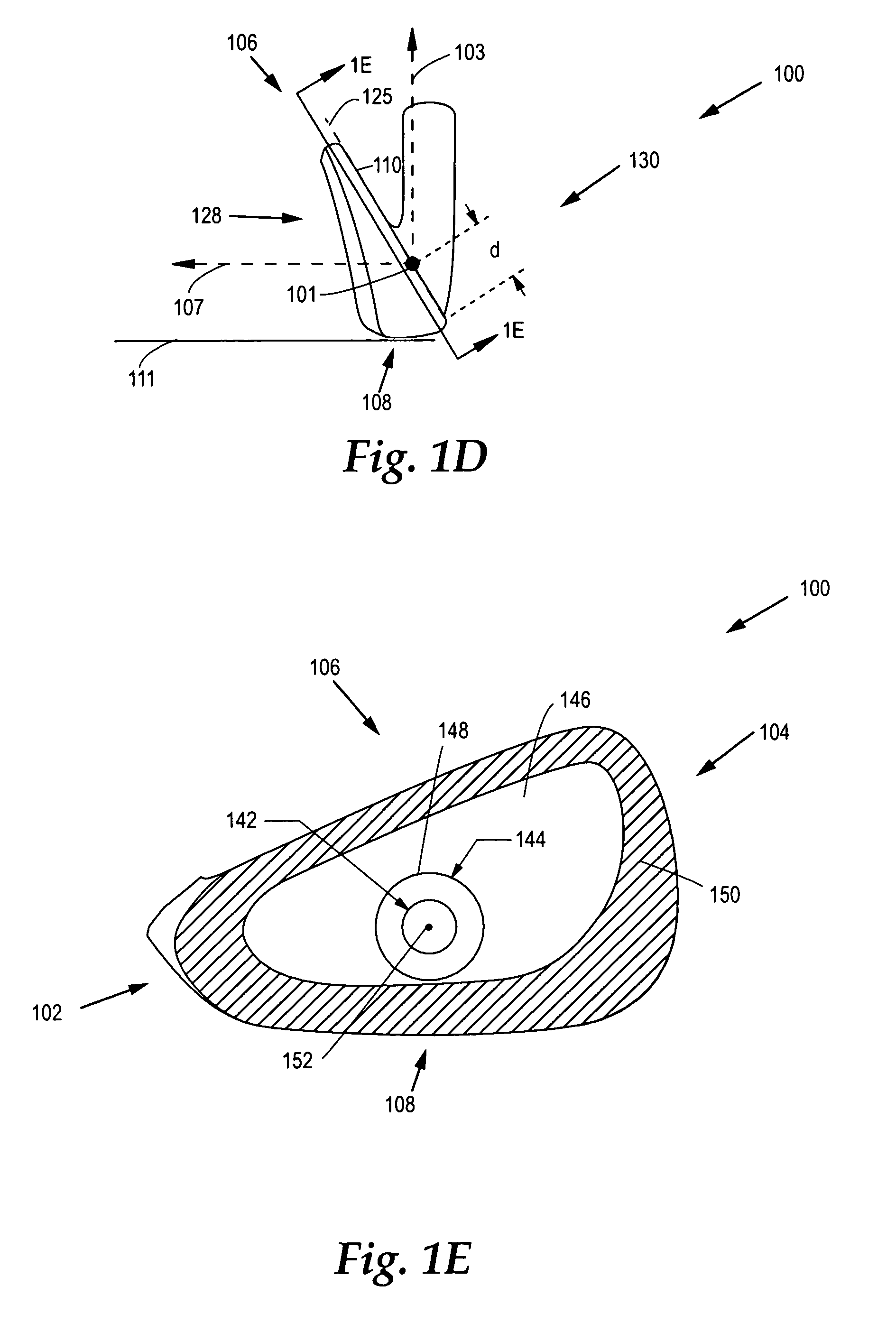

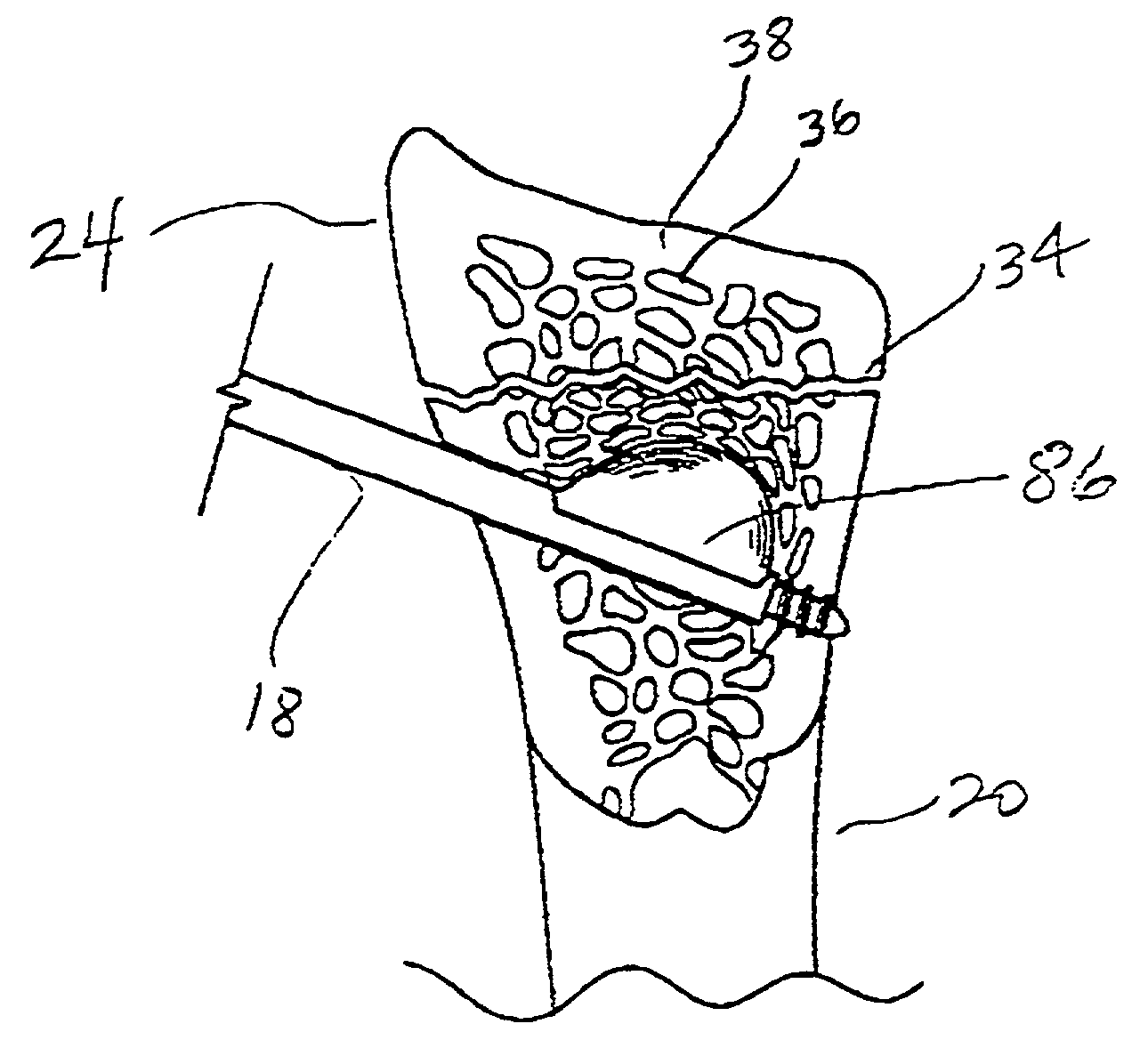

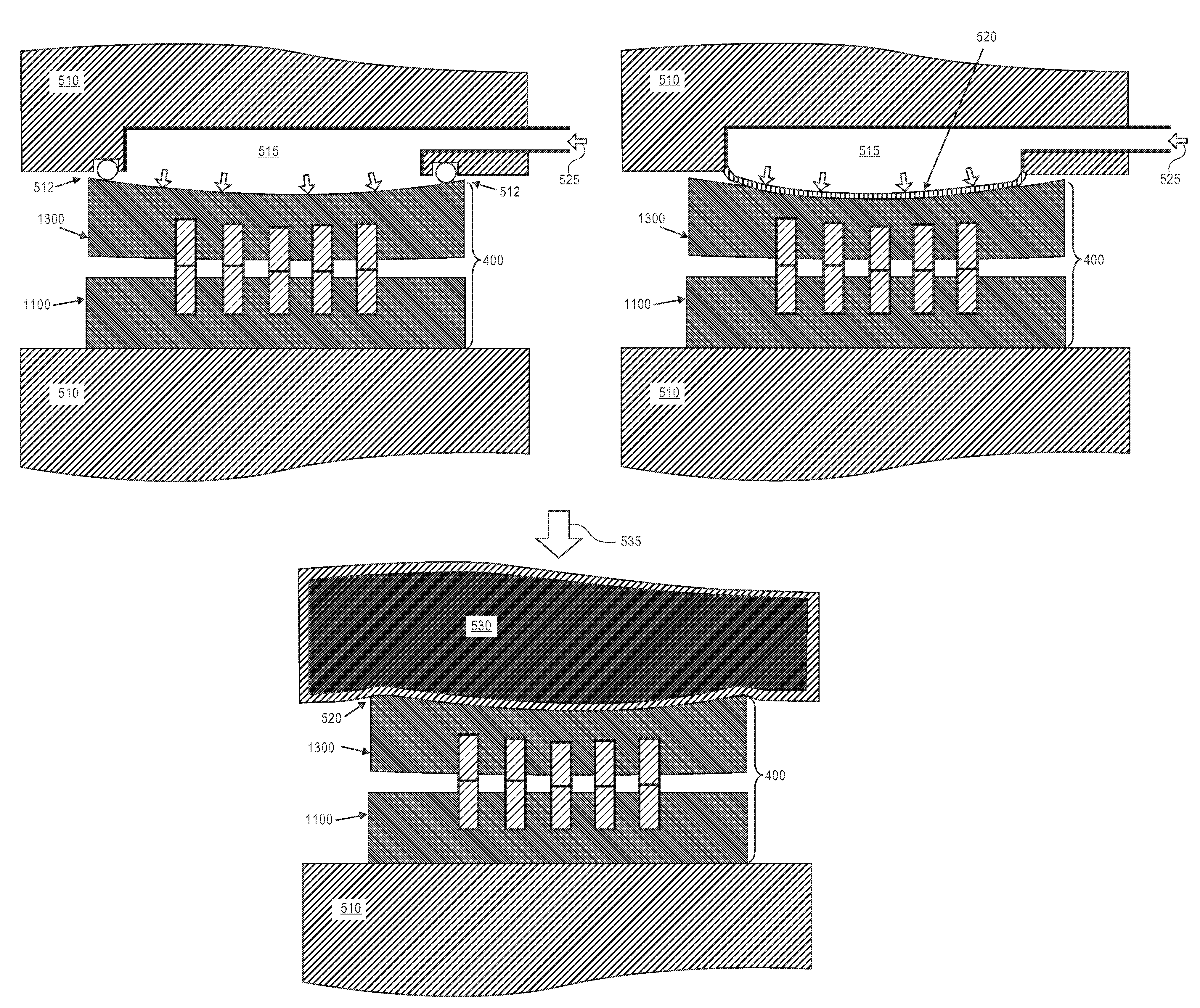

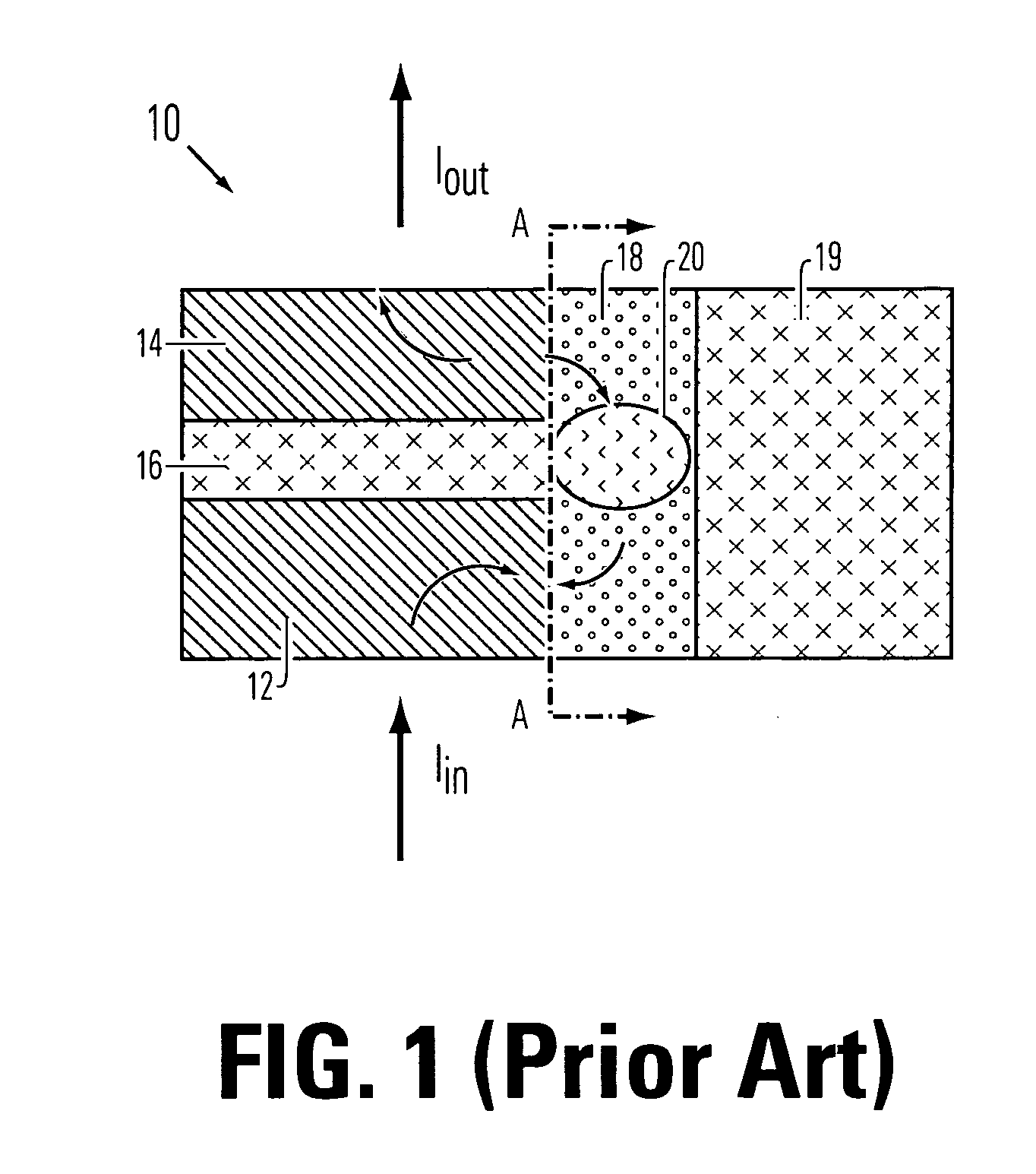

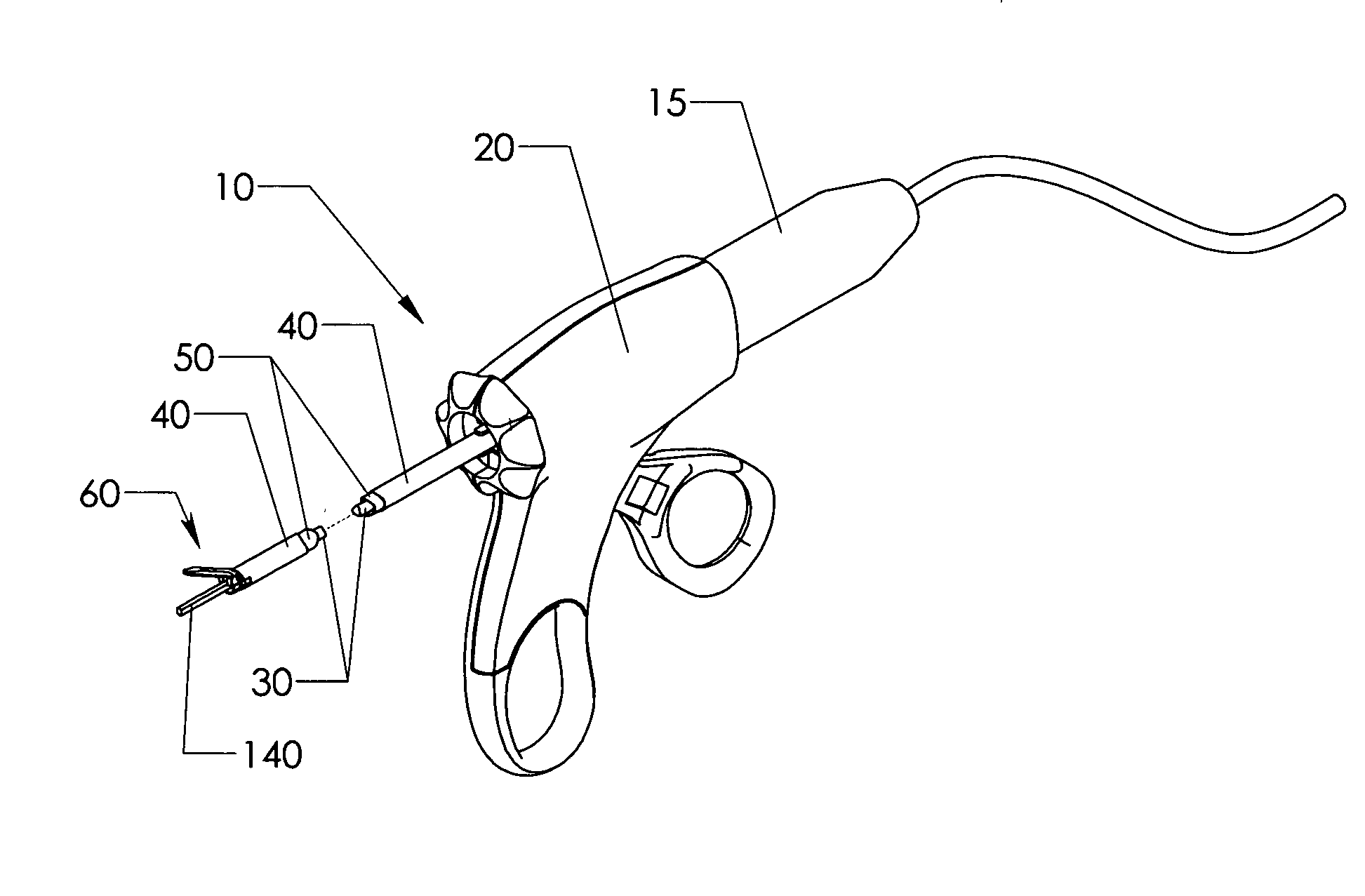

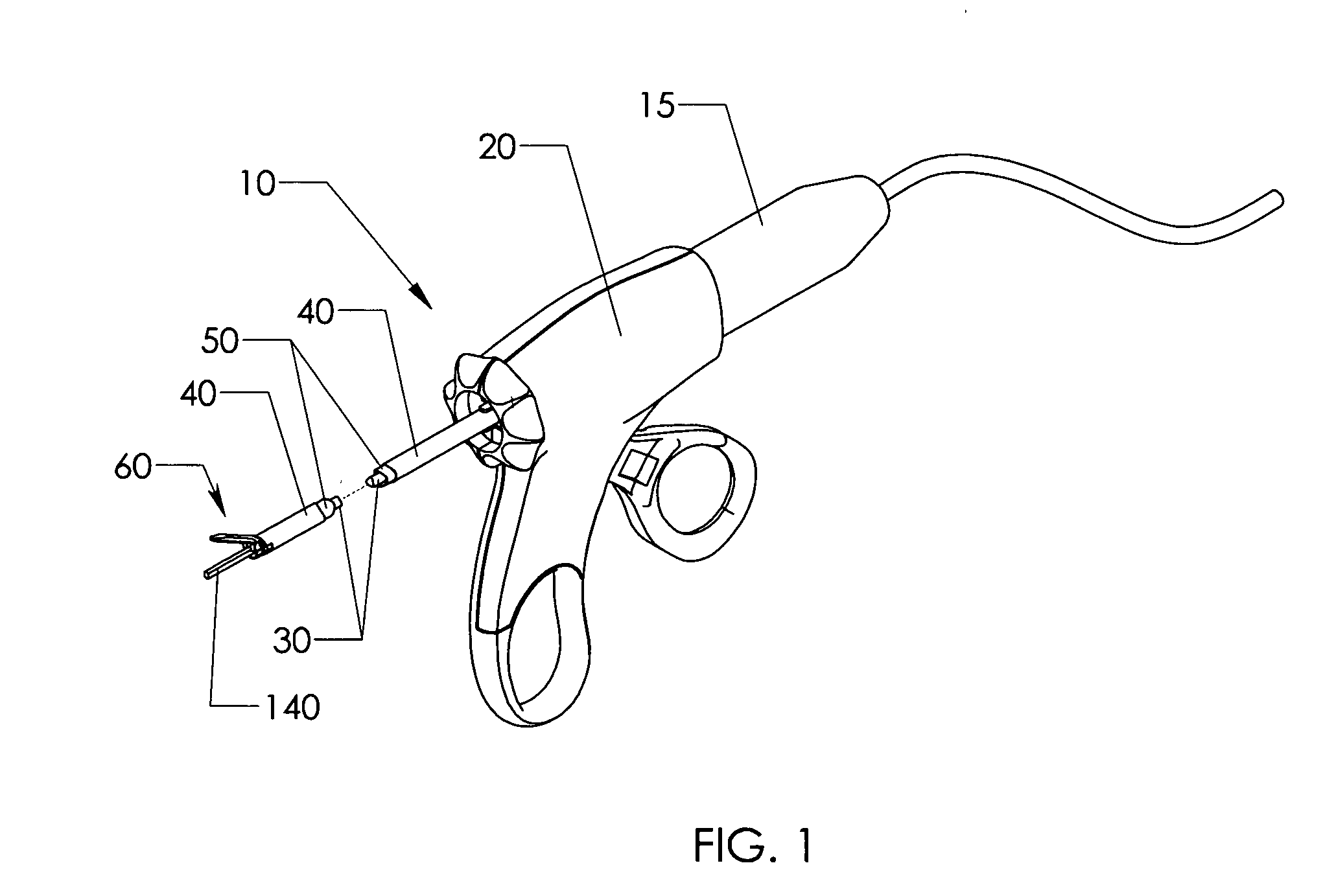

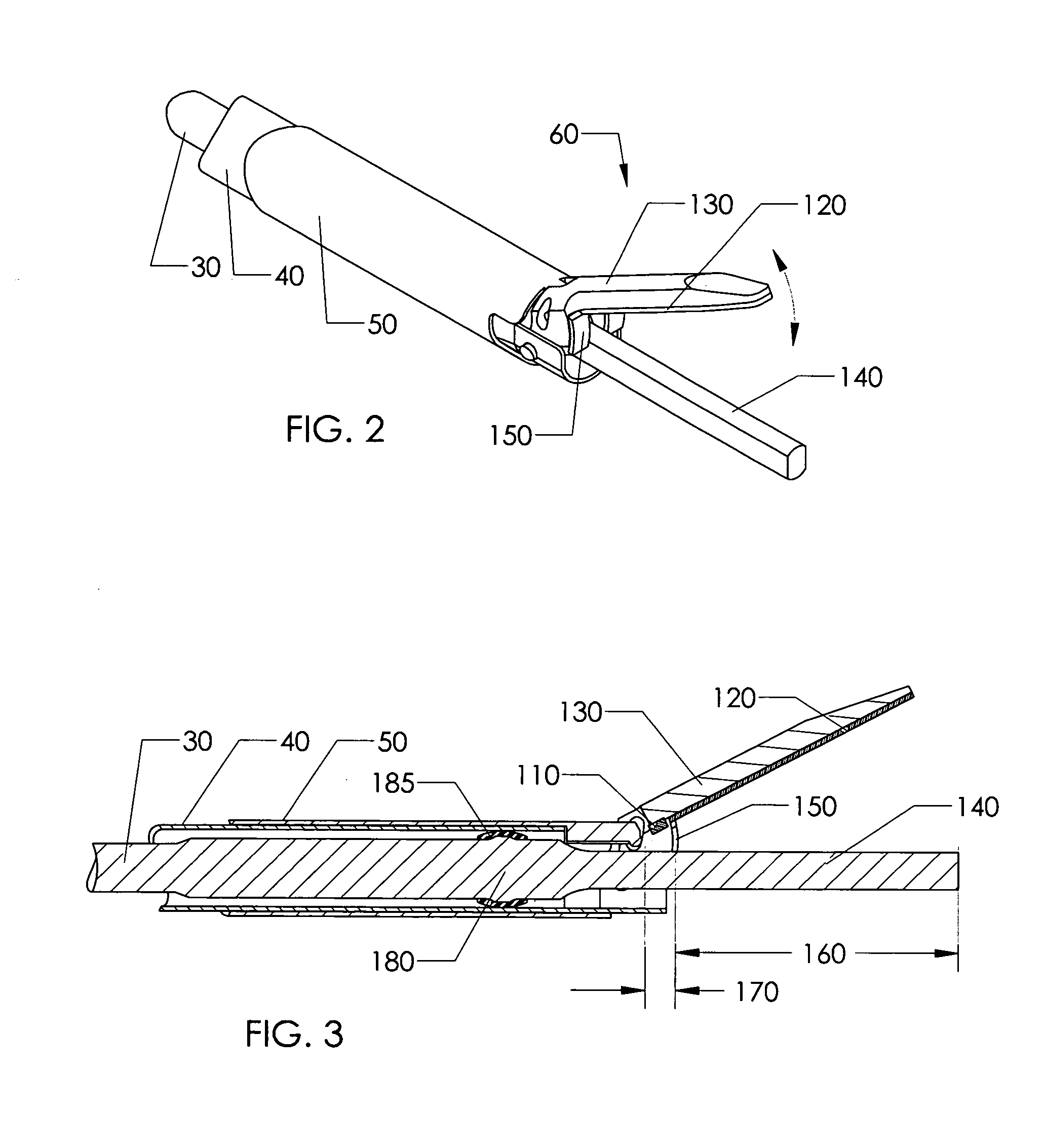

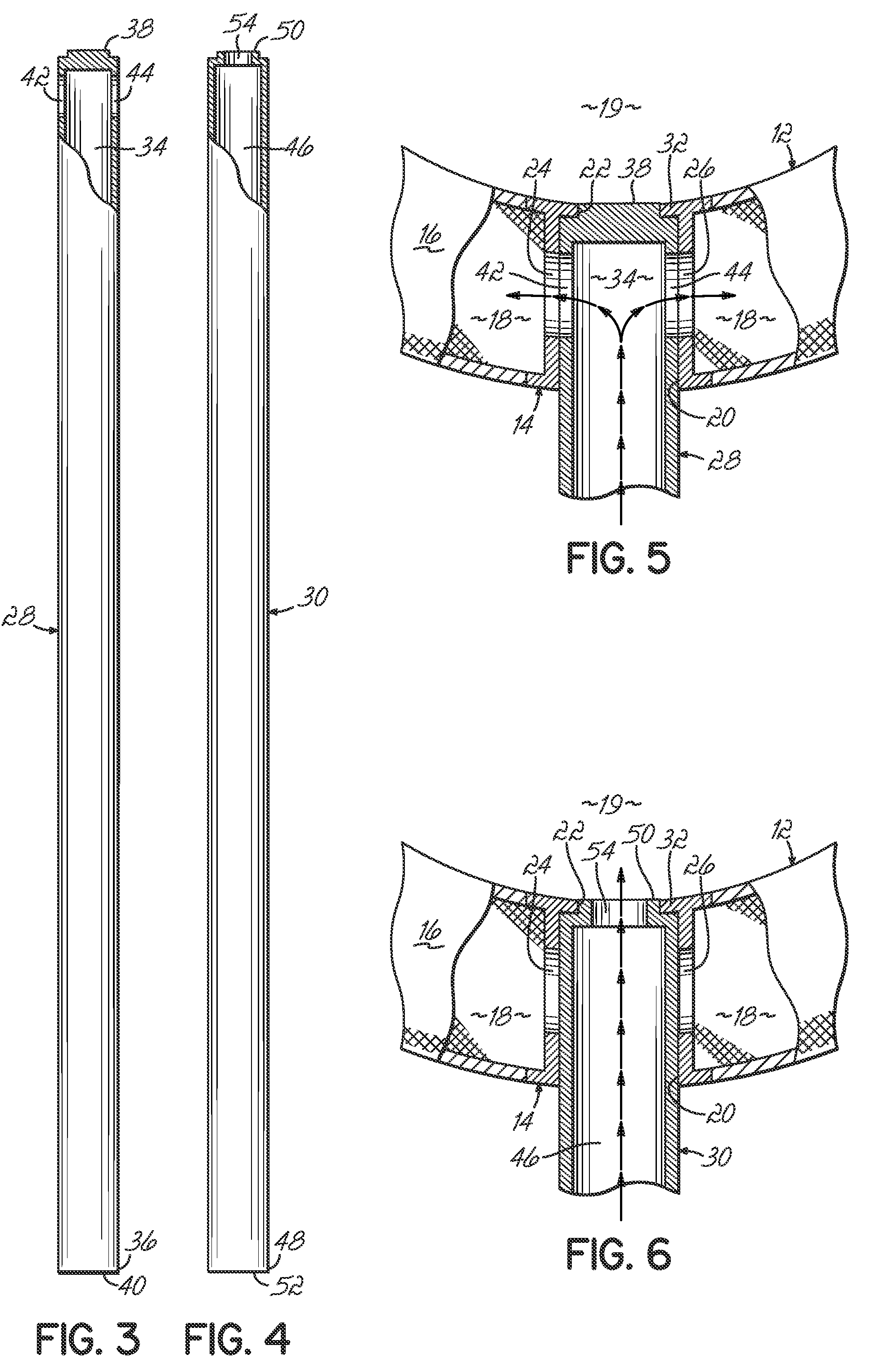

Surgical fastening device with initiator impregnation of a matrix or buttress to improve adhesive application

A material comprising a matrix or a buttress is impregnated with an adhesive initiator and is used with a surgical stapling device and an adhesive. The tissue and material are stapled together, and a knife in the surgical stapling device cuts the tissue and the material. The adhesive is applied across the cut and sets up or polymerizes to seals the cut when the adhesive contacts the adhesive initiator. The surgical stapling device can place the staples in a linear, arcuate, or circular array, and can anastomose luminal tissue. The methods of use can include stapling luminal tissue end to end, stapling two portions of material onto ether side of tissue, and stapling two portions of tissue onto a portion of material. Additionally, a portion of adhesive filed material can be stapled onto one side of portion of tissue and the adhesive initiator impregnated material can be stapled onto the other. Cutting the material and tissue provides a path for the adhesive across the cut, and catalyzes the adhesive from contact with the adhesive initiator.

Owner:ETHICON ENDO SURGERY INC

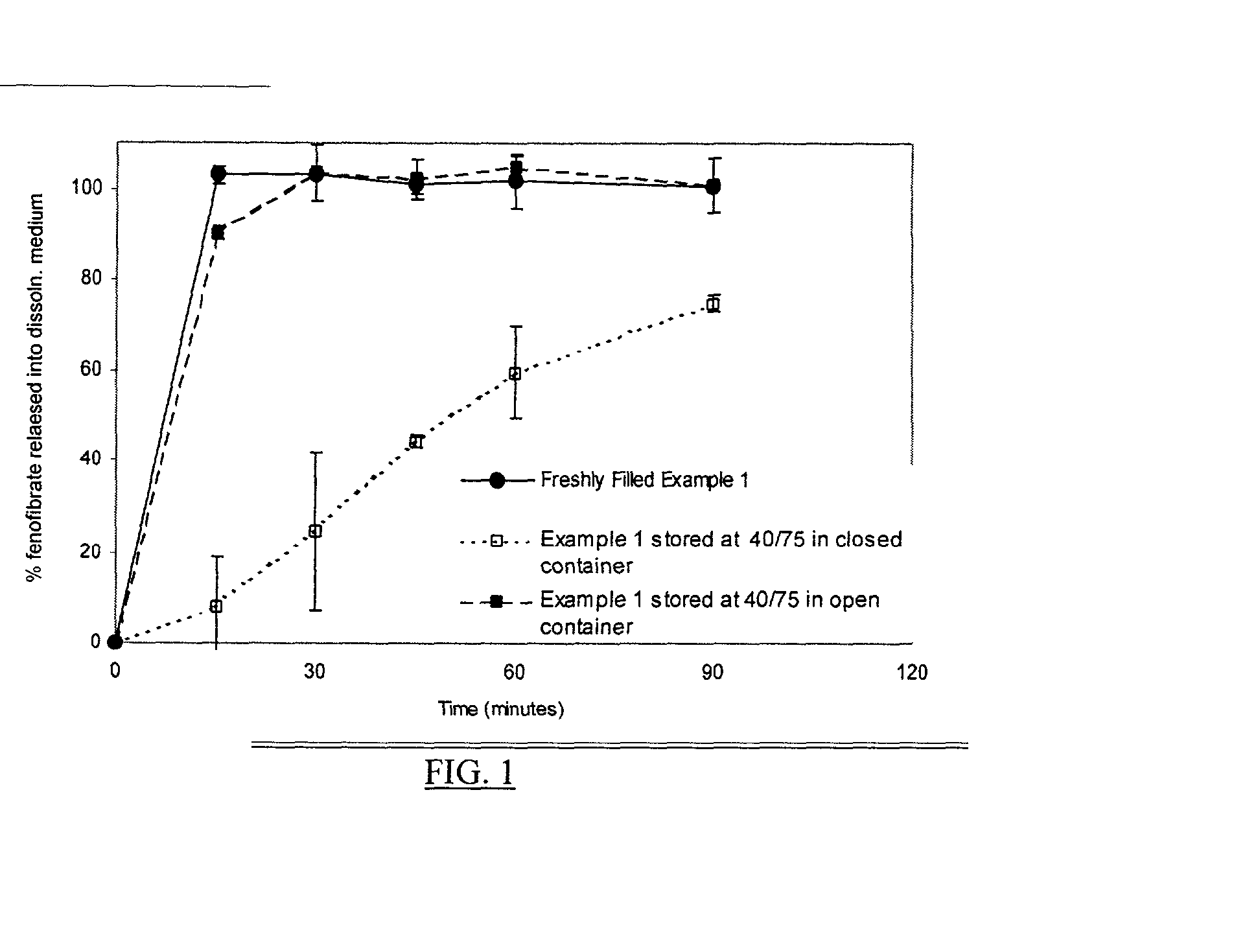

Pharmaceutical dosage forms for highly hydrophilic materials

Pharmaceutical dosage forms having a highly hydrophilic fill material and a shell encapsulating the fill material are disclosed and described. Generally, the shell has at least one plasticizing agent therein in order to provide the shell with an effective plasticity. In one aspect, the shell may have included therein an amount of plasticizing agent that is sufficient to provide the shell with an effective plasticity upon migration of a portion of the plasticizing agent into the fill material. In another aspect, the plasticizing agent may have a solubility in the fill material of less than about 10% w / w. In yet another aspect, a combination of a plasticizing agent, and a plasticizing agent having a solubility in the fill material of less than about 10% w / w, may be presented in a total amount sufficient to provide the shell with an effective plasticity upon migration of plasticizing agent into the fill material.

Owner:LIPOCINE

Surgical Fastening Device With Initiator Impregnation of a Matrix or Buttress to Improve Adhesive Application

A material comprising a matrix or a buttress is impregnated with an adhesive initiator and is used with a surgical stapling device and an adhesive. The tissue and material are stapled together, and a knife in the surgical stapling device cuts the tissue and the material. The adhesive is applied across the cut and sets up or polymerizes to seals the cut when the adhesive contacts the adhesive initiator. The surgical stapling device can place the staples in a linear, arcuate, or circular array, and can anastomose luminal tissue. The methods of use can include stapling luminal tissue end to end, stapling two portions of material onto ether side of tissue, and stapling two portions of tissue onto a portion of material. Additionally, a portion of adhesive filed material can be stapled onto one side of portion of tissue and the adhesive initiator impregnated material can be stapled onto the other. Cutting the material and tissue provides a path for the adhesive across the cut, and catalyzes the adhesive from contact with the adhesive initiator.

Owner:ETHICON ENDO SURGERY INC

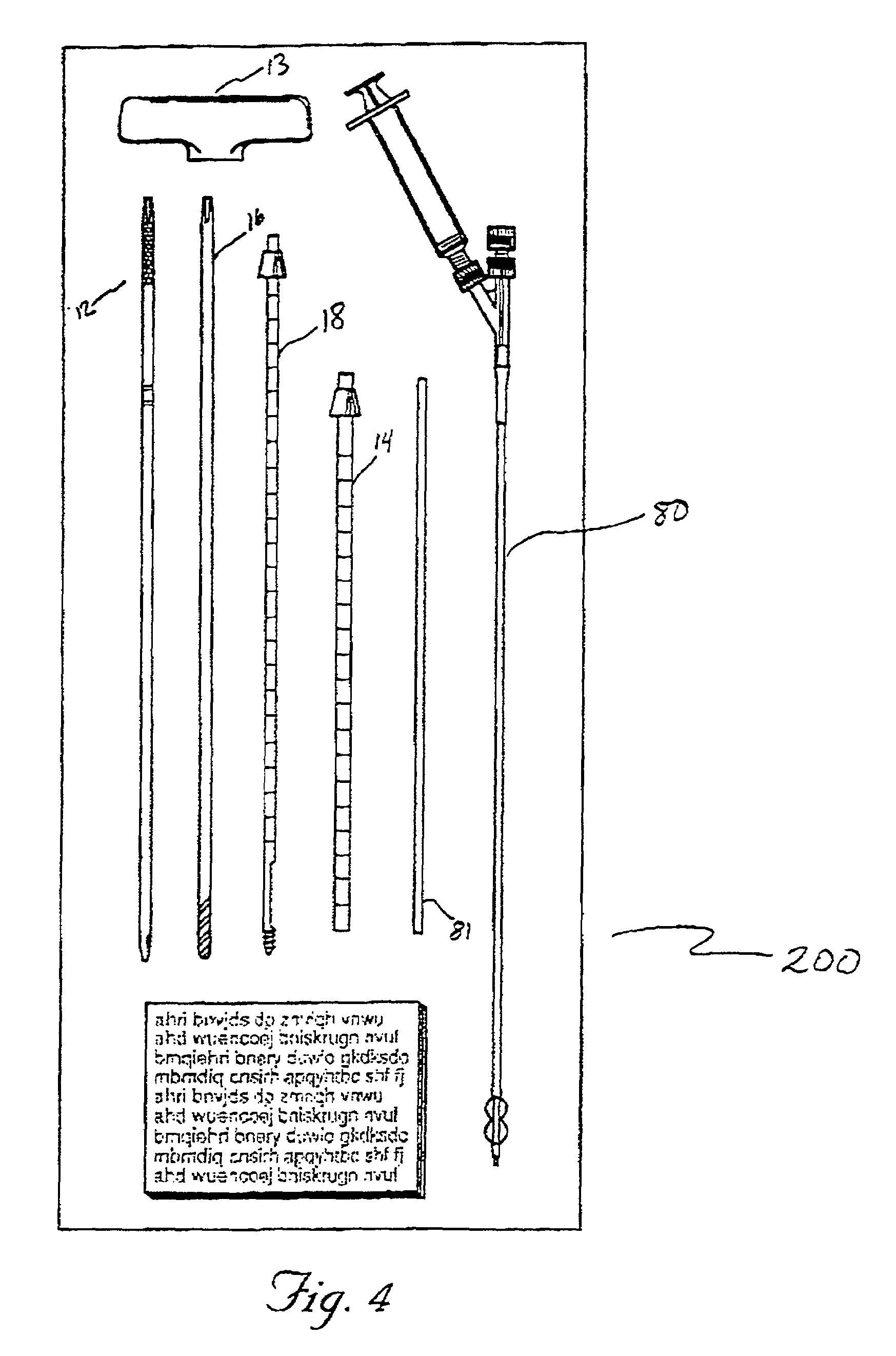

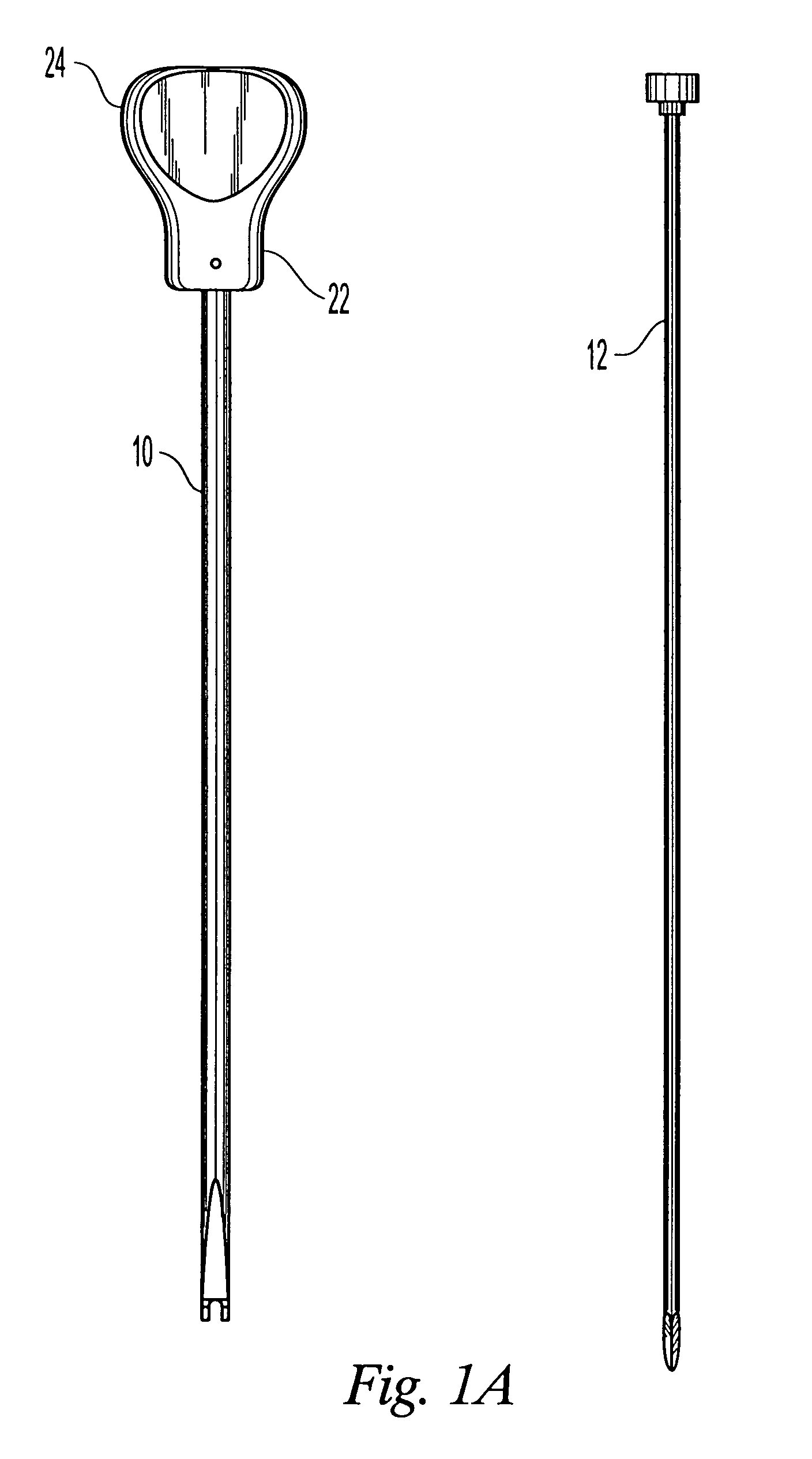

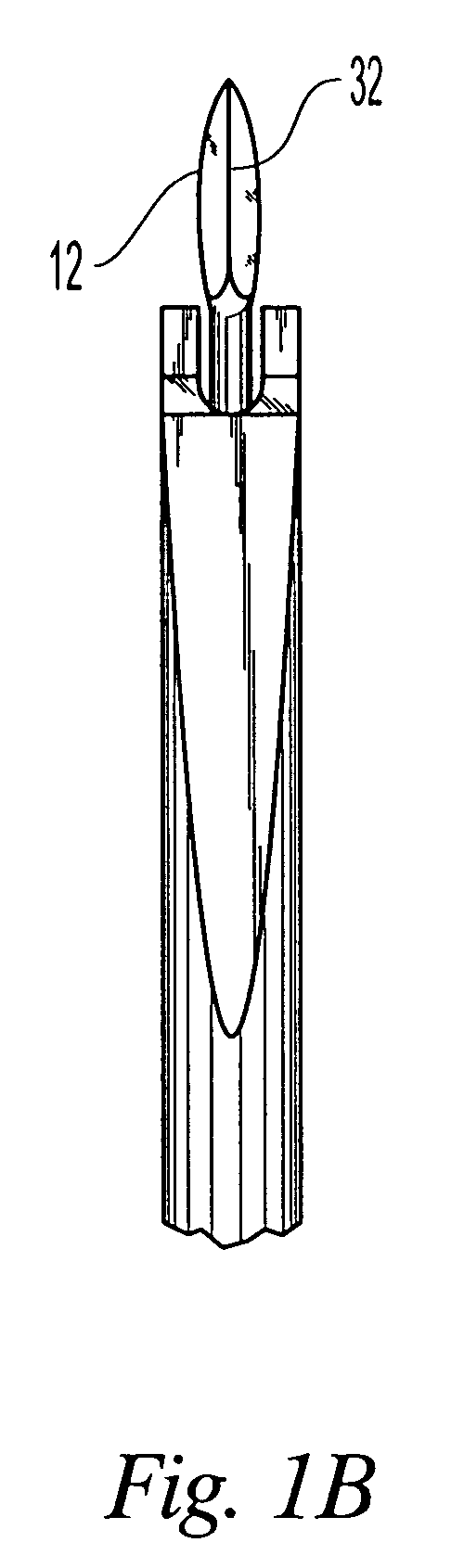

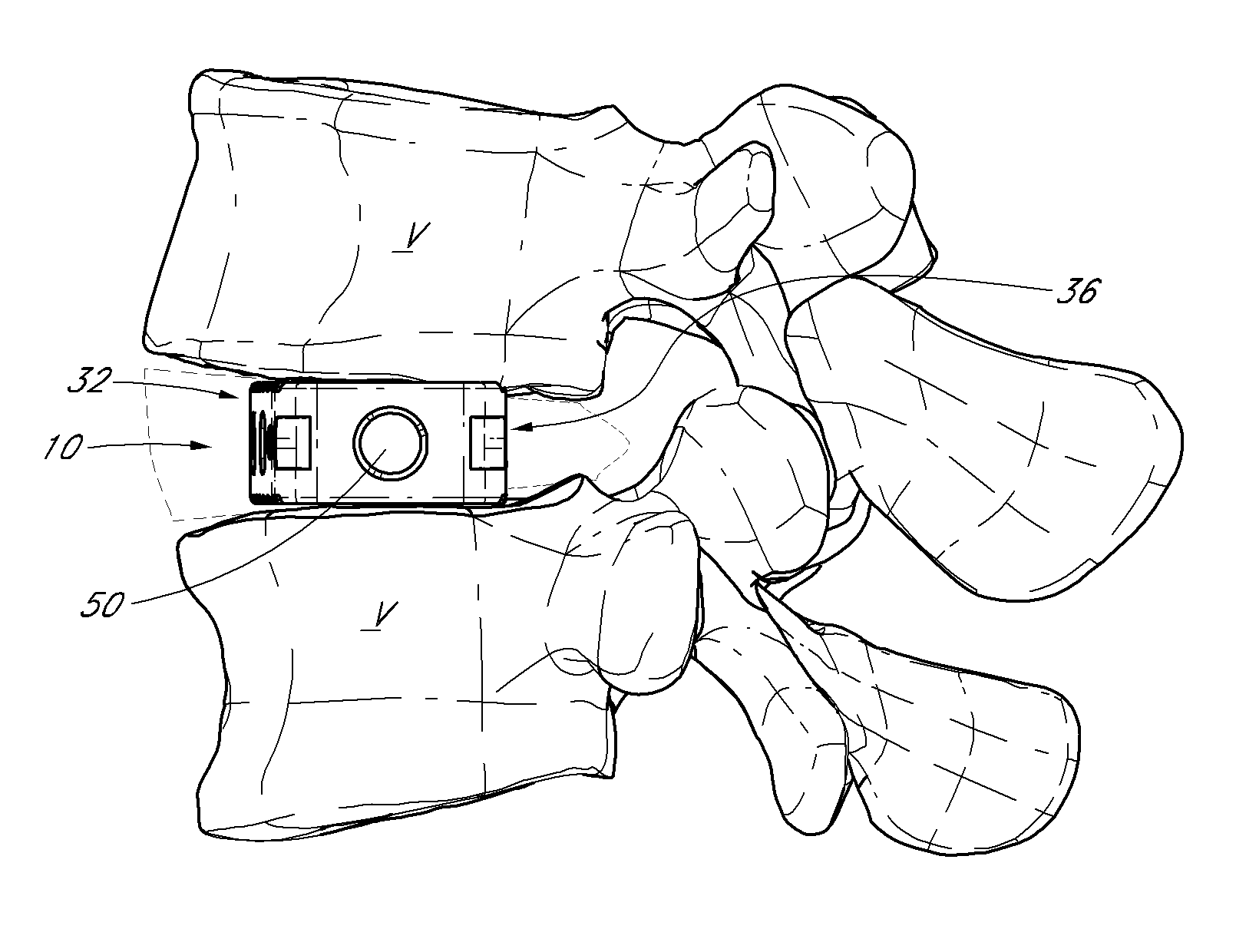

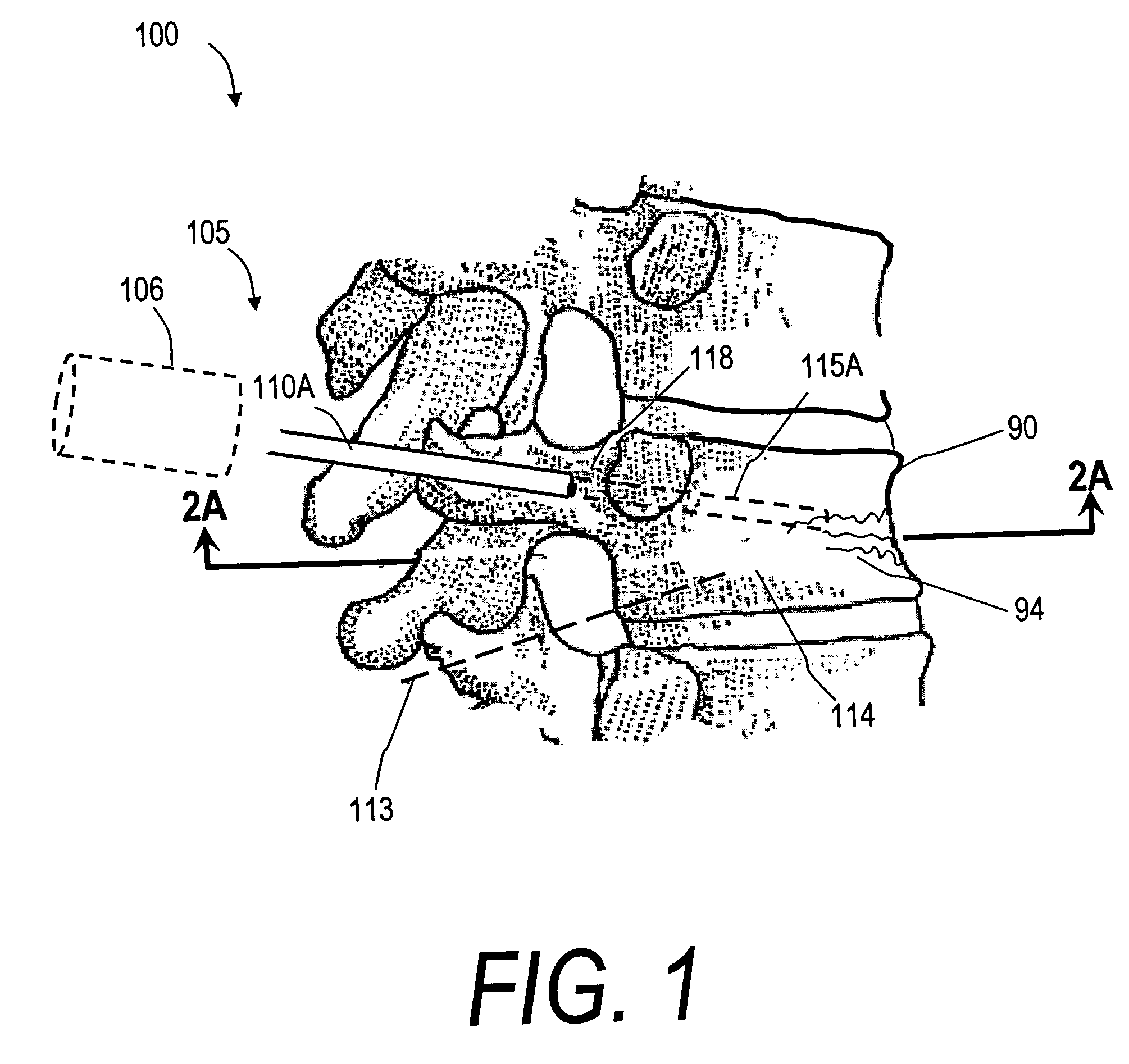

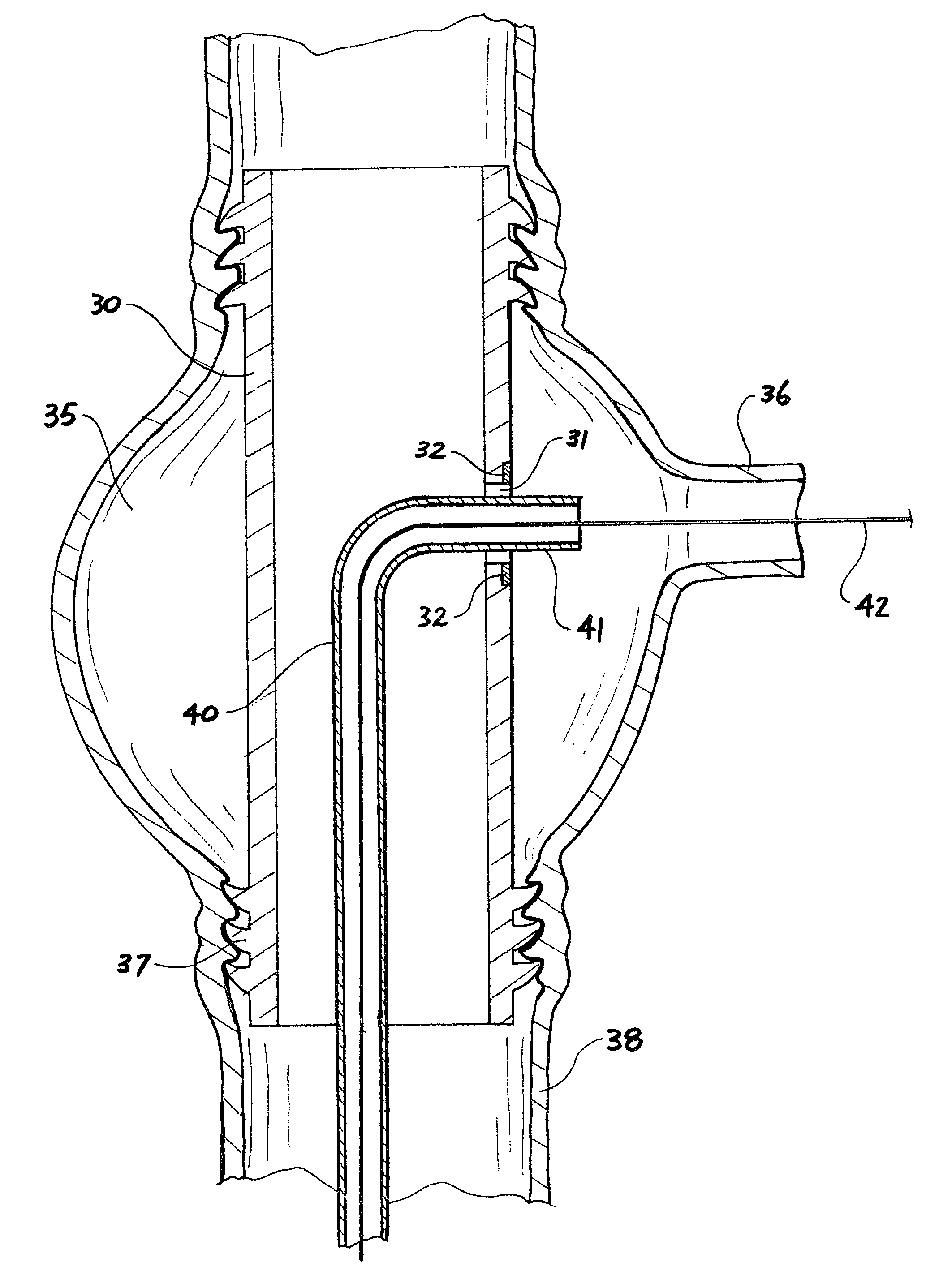

Inflatable device for use in surgical protocol relating to fixation of bone

InactiveUS6981981B2Improve clinical outcomesWorsen conditionSurgical furnitureInternal osteosythesisFilling materialsCancellous bone

Systems for treating a bone, e.g. a vertebral body, having an interior volume occupied, at least in part, by cancellous bone provide a first tool, a second tool, and a third tool. The first tool establishes a percutaneous access path to bone. The second tool is sized and configured to be introduced through the percutaneous access path to form a void that occupies less than the interior volume. The third tool places within the void through the percutaneous access path a volume of filling material. Related methods for treating a bone, e.g. a vertebral body, having an interior volume occupied, at least in part, by cancellous bone provide establishing a percutaneous access path to bone. A tool is introduced through the percutaneous access path and manipulated to form a void that occupies less than the interior volume. A volume of filling material is then placed within the void through the percutaneous access path.

Owner:ORTHOPHOENIX

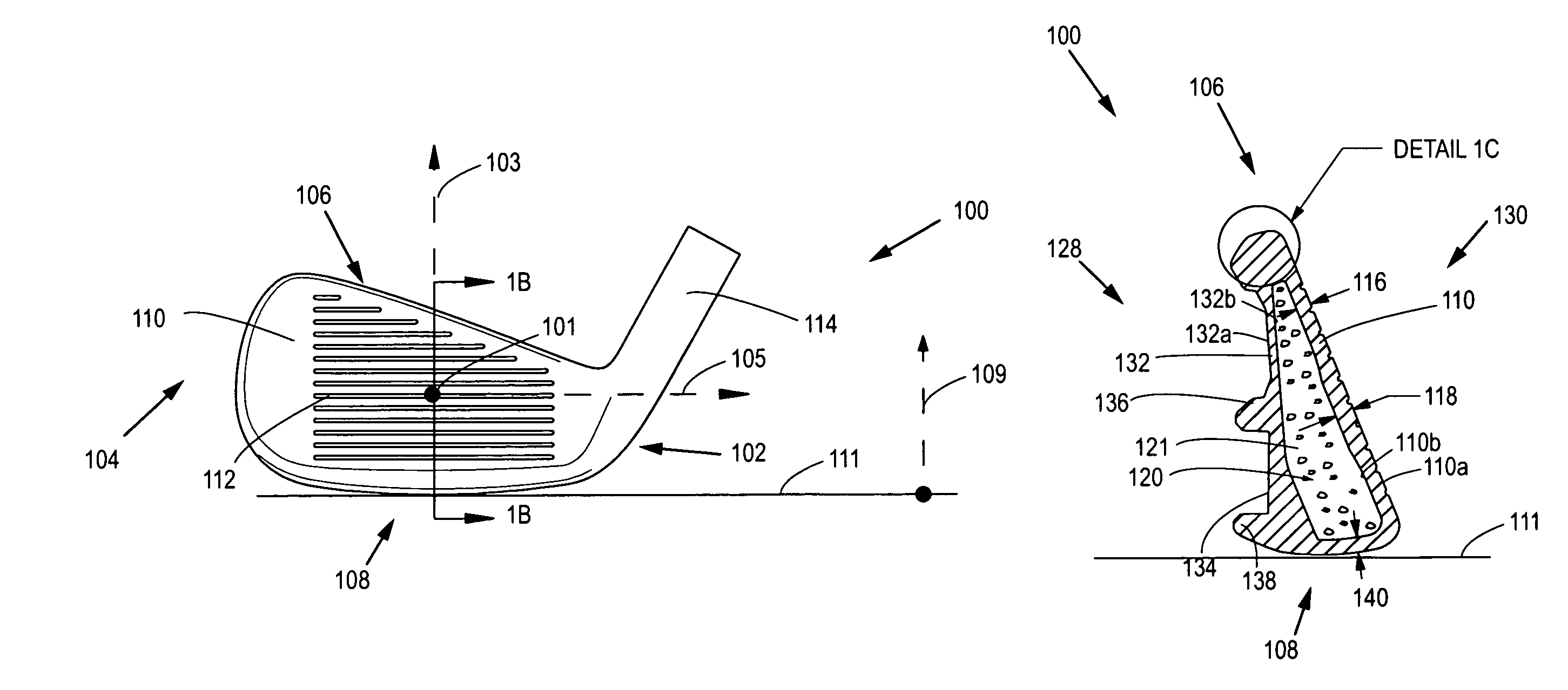

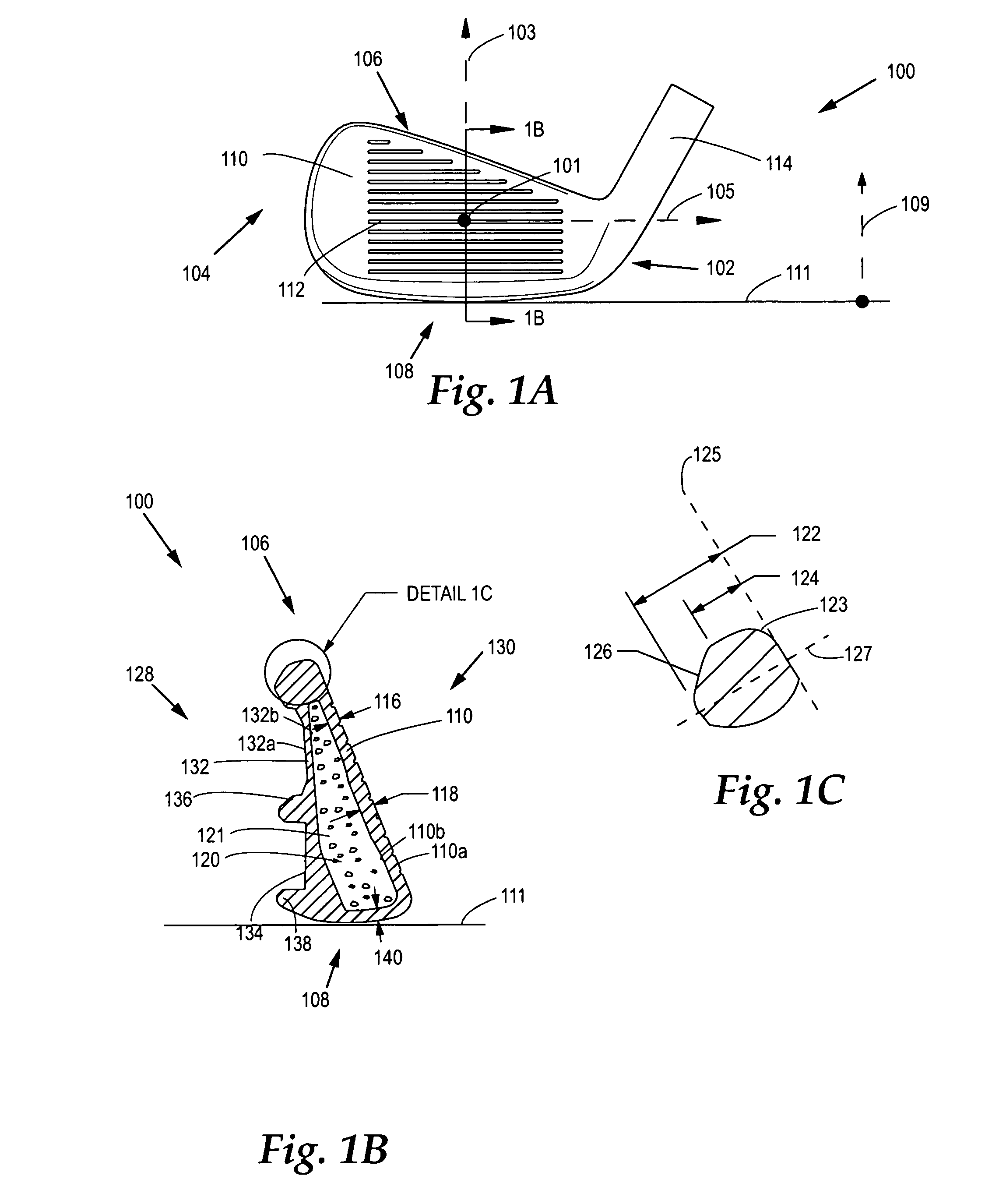

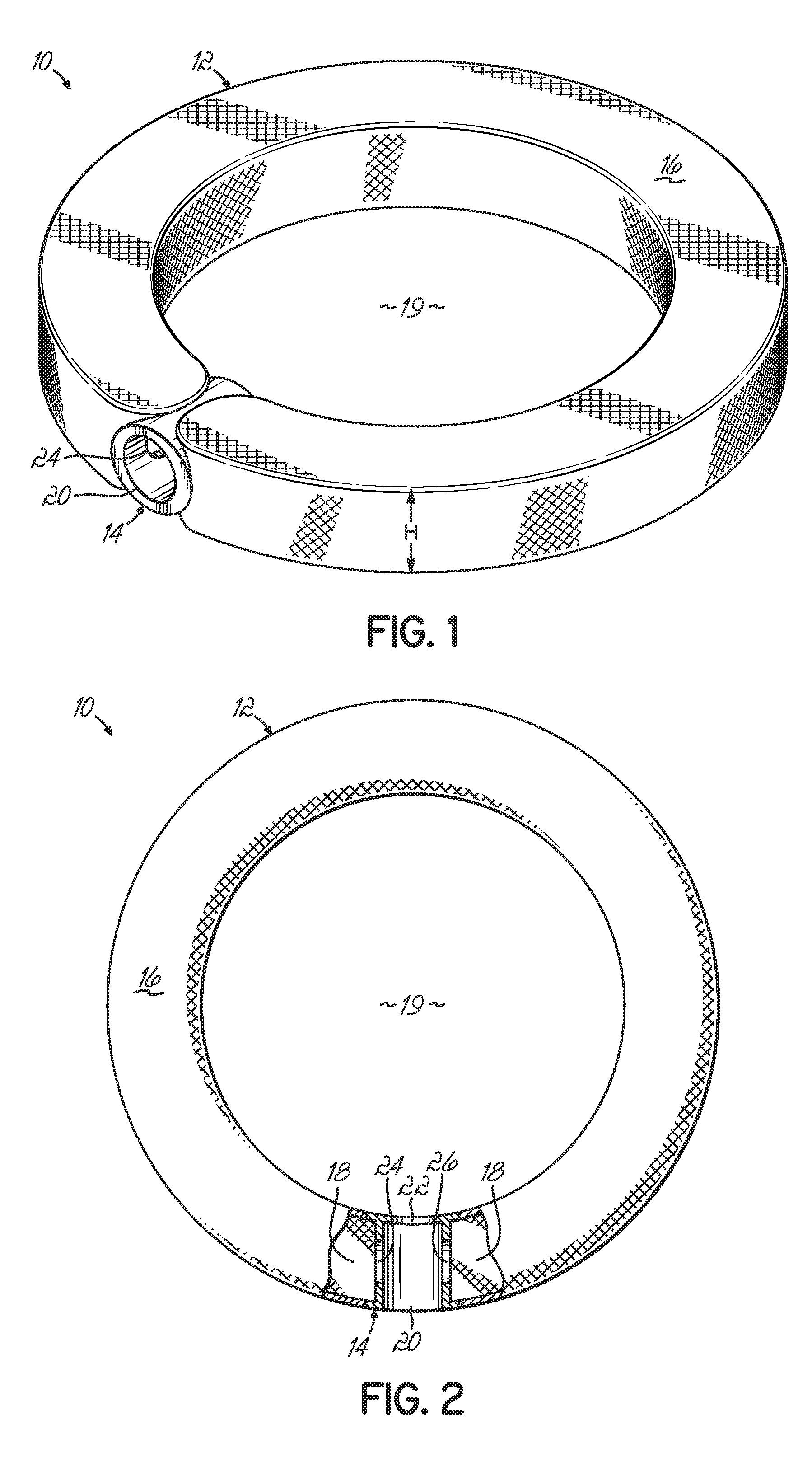

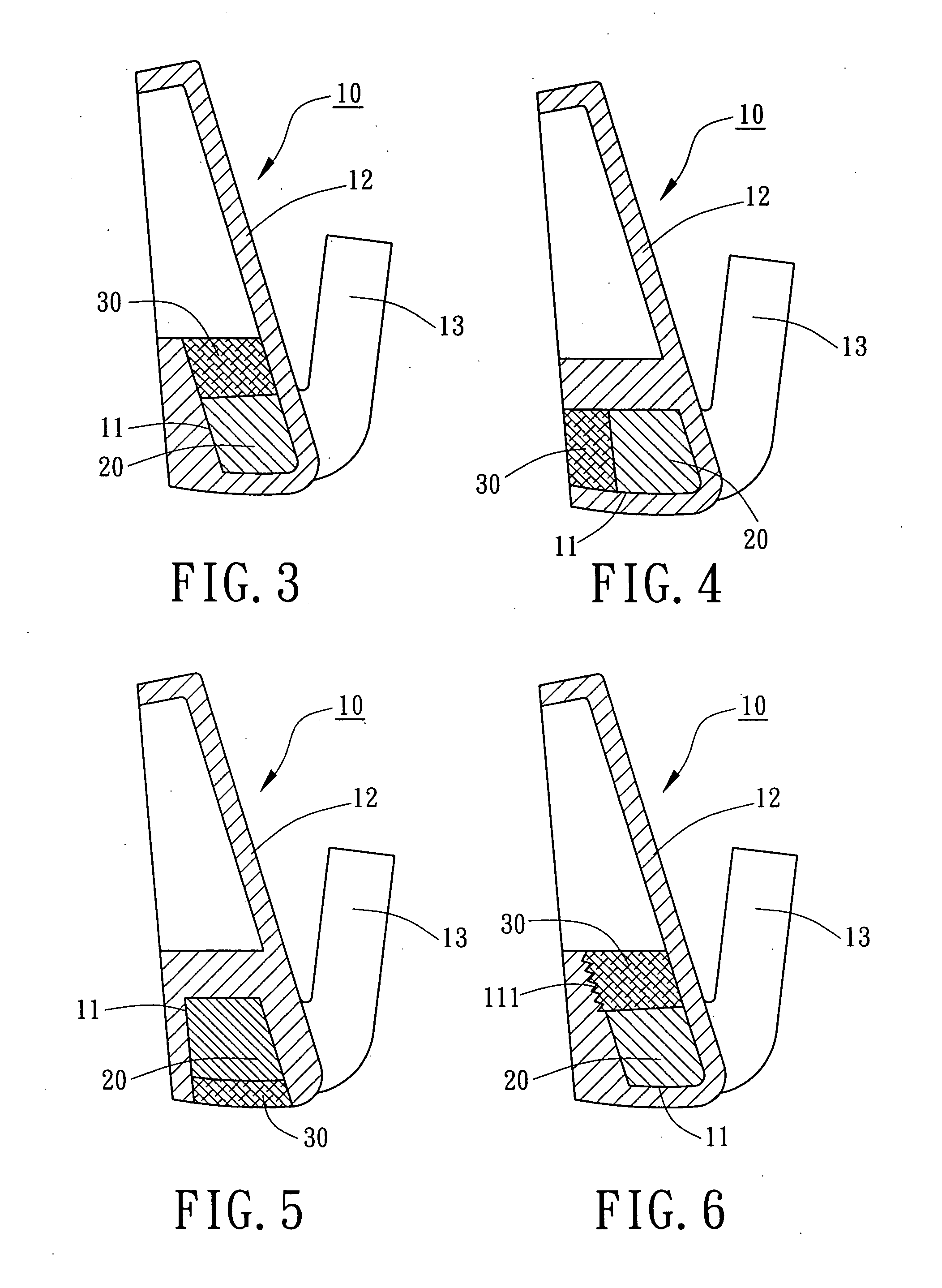

Golf club head

An iron-type golf club head is disclosed having a heel portion, a sole portion, a toe portion, a top-line portion, a front portion, a rear portion, and a striking face. A back wall is also disclosed in the rear portion enclosing a portion of the rear portion to create an enclosed cavity. The cavity is defined by at least a rear surface of the striking face, an inner back wall surface, and the sole portion. A plug and a filler material is located within the enclosed cavity. The filler material surrounds the plug and is configured to hold the plug in place. The plug is lighter than the filler material.

Owner:TAYLOR MADE GOLF

Non-gelatin substitutes for oral delivery capsules, their composition and process of manufacture

Gelatin-free capsule for use in oral administration of medicines, cosmetic or bath applications, or dietary supplements can be prepared from compositions comprisinga) 8-50% by weight of water-dispersible or water-soluble plasticizer,b) 0.5 to 12% by weight kappa-carrageenan,c) 0 to 60% dextrins, andd) 1% to 95% by weight water,with the kappa-carrageenan comprising at least 50% by weight of all gums forming or contributing to formation of thermoreversible gels in the composition. A capsule for oral administration or cosmetic application may comprise a fill material to be administered to a patient or subject and a capsule, the capsule comprising an aqueous based film comprisinga) water-dispersible or water-soluble plasticizer, andb) carrageenan,with the carrageenan comprising at least 50% or 75% by weight of kappa-carrageenan, and the carrageenan comprising at least 50% or 75% by weight of all gums which form or contribute to the formation of thermoreversible gels. A process for forming the capsules may comprise heating the composition, casting or extruding the composition into a film, gelling the composition by cooling, associating a fill material with the gelled composition (usually as a film) and sealing the film about the fill material.

Owner:PATHEON SOFTGELS INC

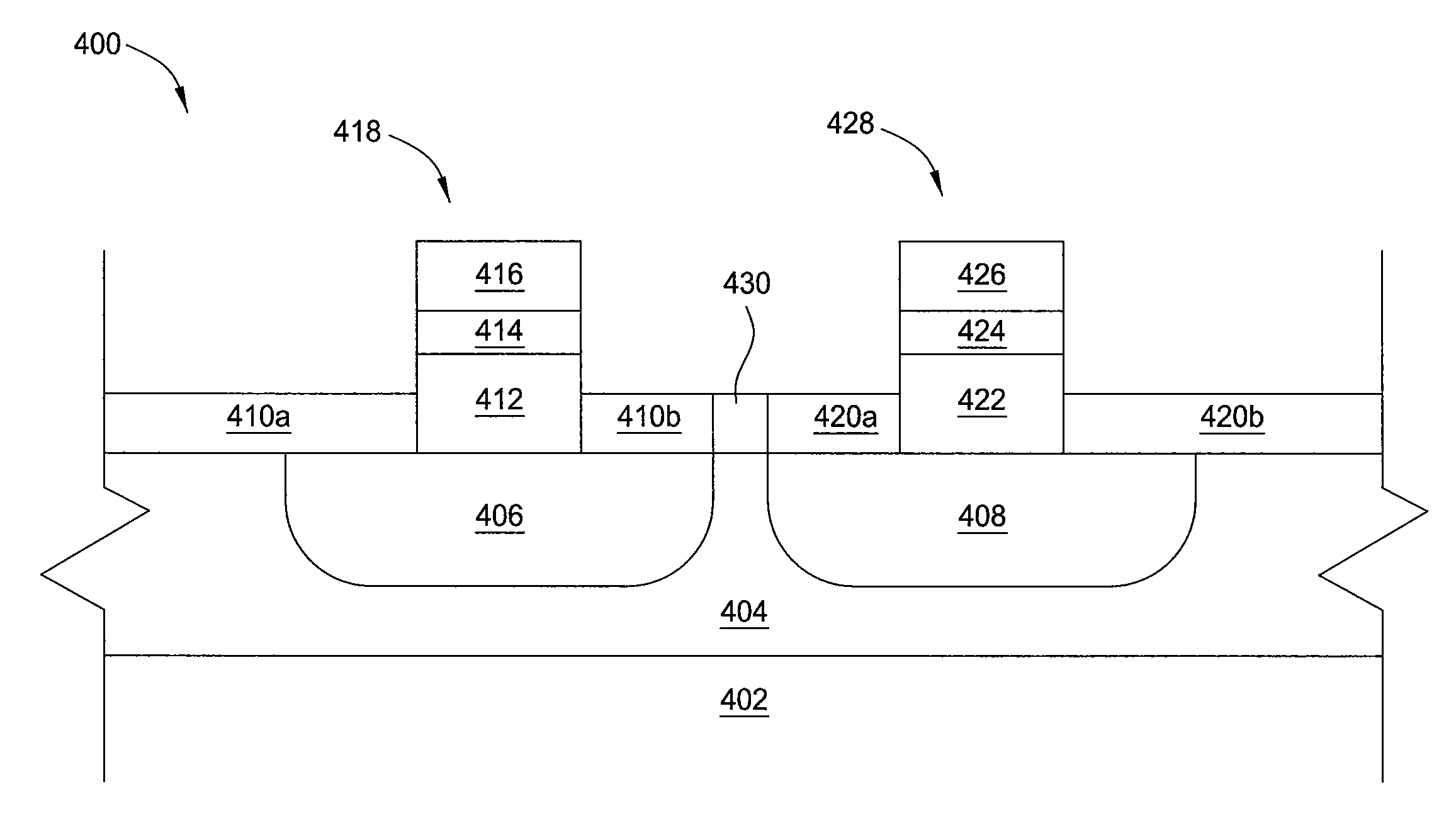

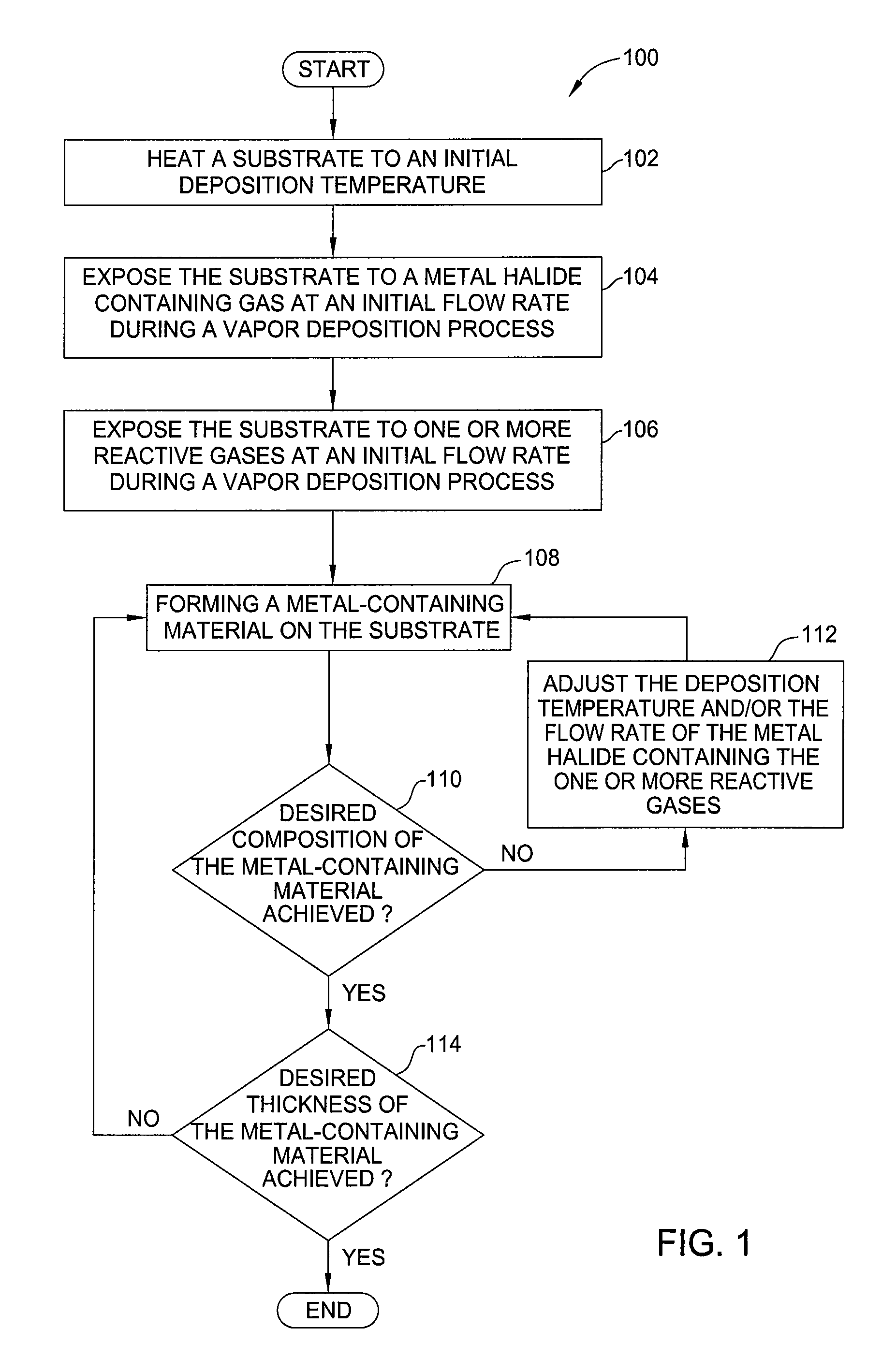

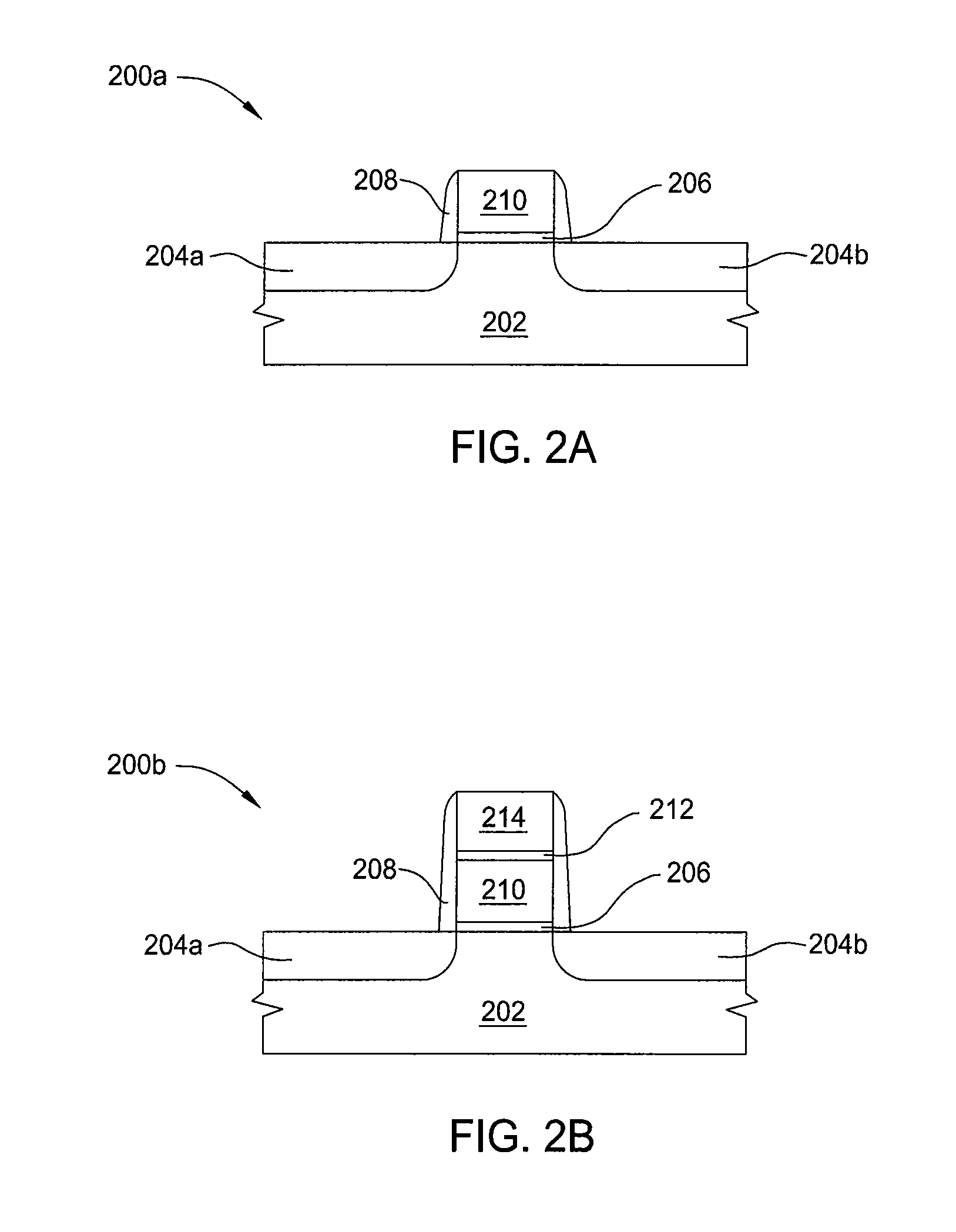

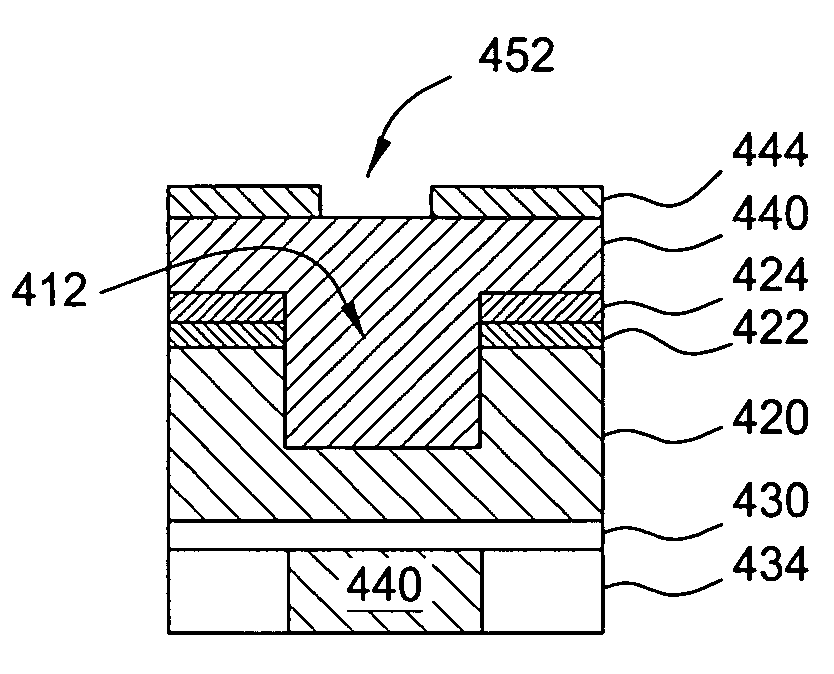

Nmos metal gate materials, manufacturing methods, and equipment using CVD and ald processes with metal based precursors

ActiveUS20110263115A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseMetallic materials

Embodiments of the invention generally provide methods for depositing metal-containing materials and compositions thereof. The methods include deposition processes that form metal, metal carbide, metal silicide, metal nitride, and metal carbide derivatives by a vapor deposition process, including thermal decomposition, CVD, pulsed-CVD, or ALD. In one embodiment, a method for processing a substrate is provided which includes depositing a dielectric material having a dielectric constant greater than 10, forming a feature definition in the dielectric material, depositing a work function material conformally on the sidewalls and bottom of the feature definition, and depositing a metal gate fill material on the work function material to fill the feature definition, wherein the work function material is deposited by reacting at least one metal-halide precursor having the formula MXY, wherein M is tantalum, hafnium, titanium, and lanthanum, X is a halide selected from the group of fluorine, chlorine, bromine, or iodine, and y is from 3 to 5.

Owner:APPLIED MATERIALS INC

Use of glucomannan hydrocolloid as filler material in prostheses

A prosthetic device for implantation into a mammalian body comprised of a non-absorbable biocompatible flexible material shell or sac filled with various biocompatible gel filler materials. The gel filler materials are comprised of biocompatible glucomannan obtained from konjac hydrocolloid flour and other biocompatible hydrocolloids, producing a natural look and feel for the prosthetic implants, especially reconstructive prostheses such as breast implants.

Owner:KONJAC TECH

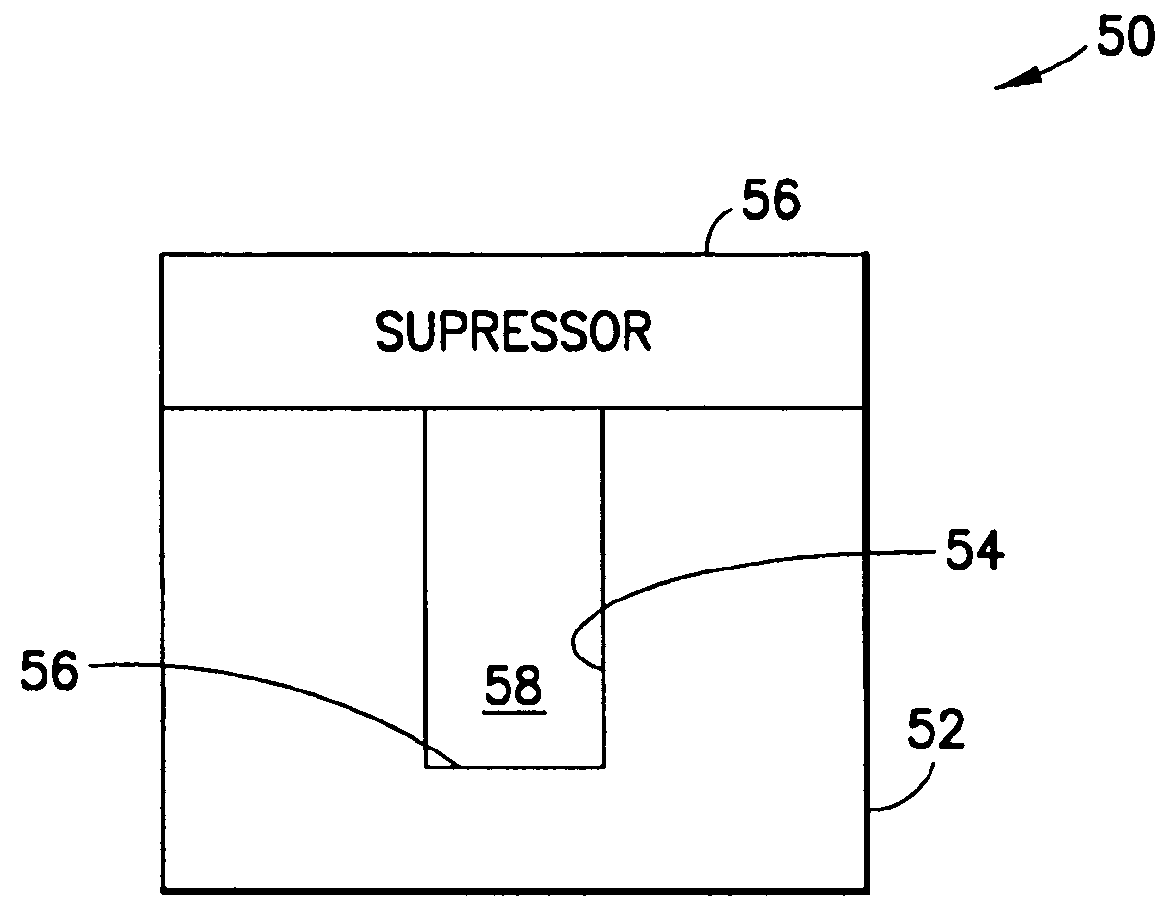

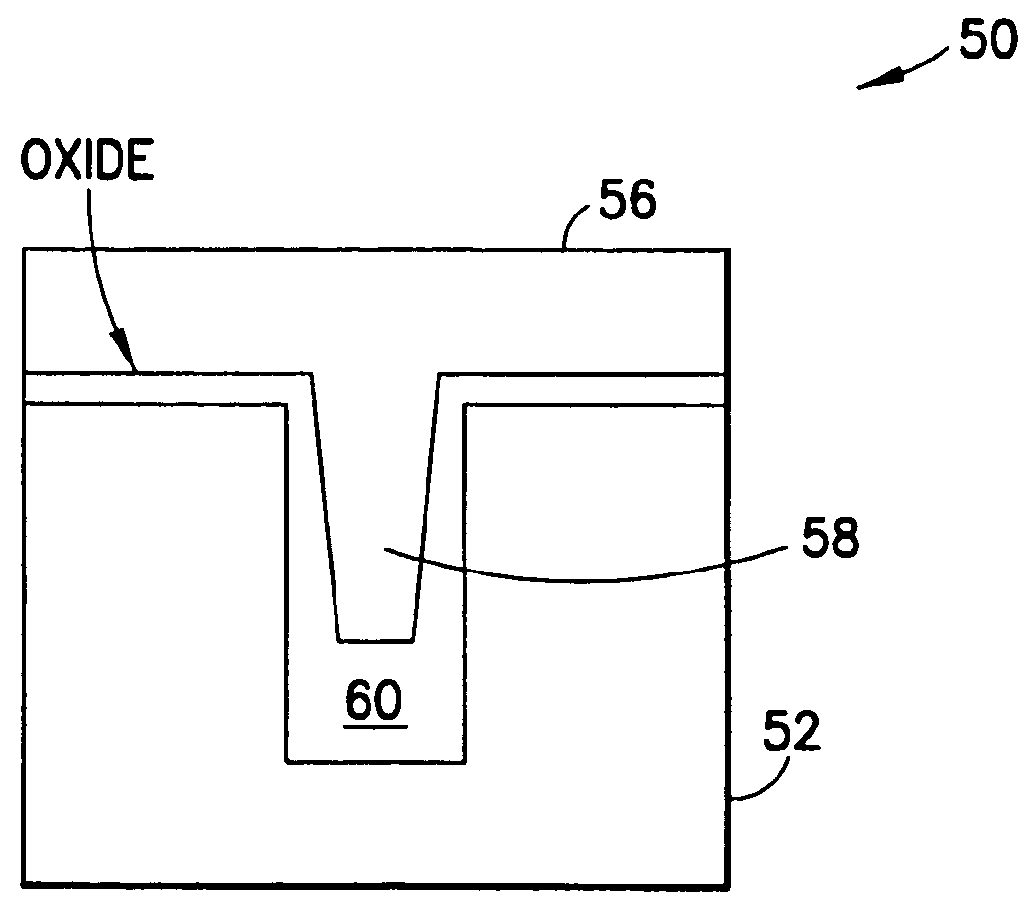

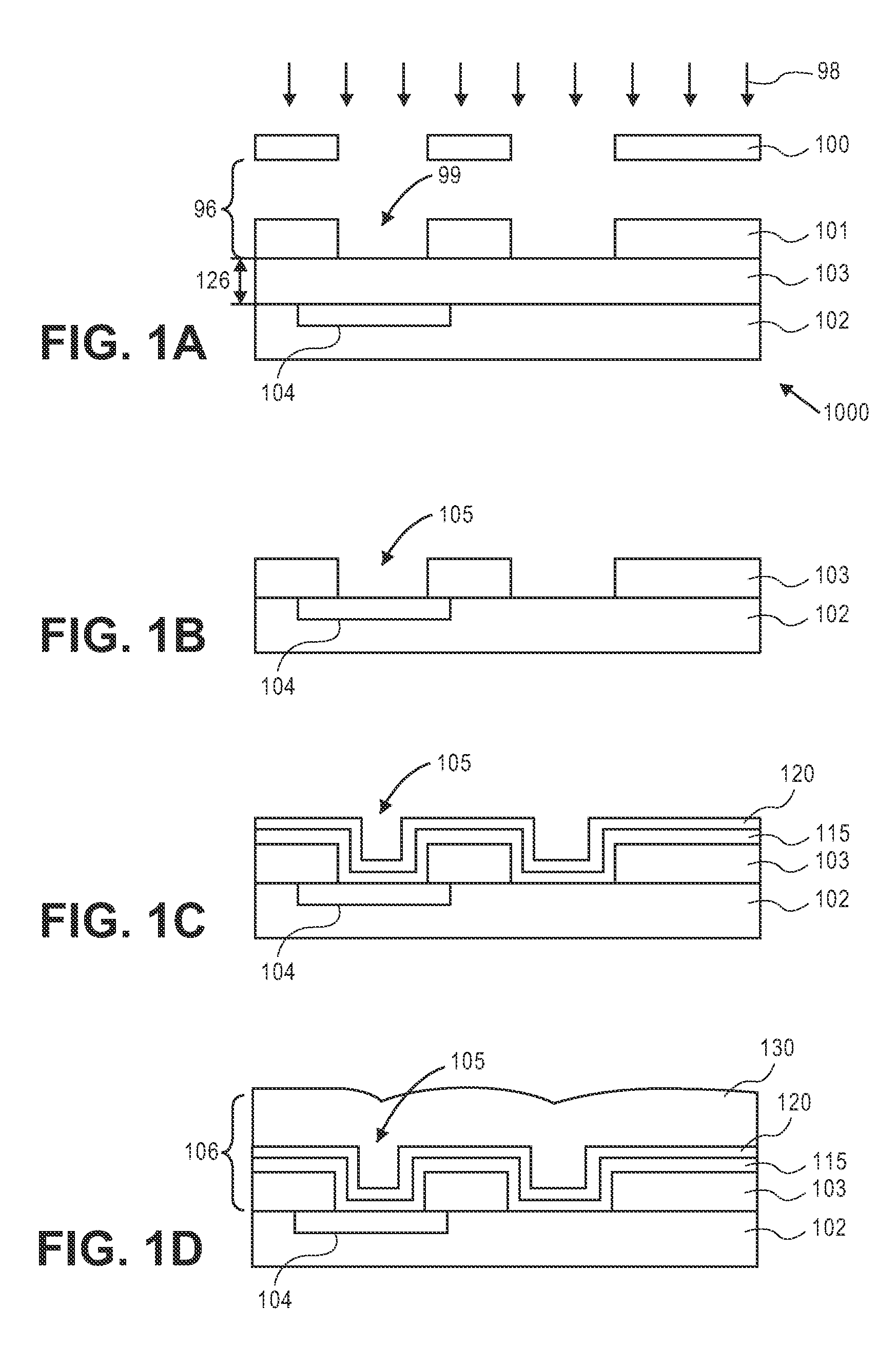

Precursors for silicon dioxide gap fill

ActiveUS9337054B2Adverse seam effectSemiconductor/solid-state device manufacturingChemical vapor deposition coatingFilling materialsVolumetric Mass Density

A full fill trench structure is described, including a microelectronic device substrate having a high aspect ratio trench therein and filled with silicon dioxide of a substantially void-free character and substantially uniform density throughout its bulk mass. A method of manufacturing a semiconductor product also is described, involving use of specific silicon precursor compositions for forming substantially void-free and substantially uniform density silicon dioxide material in the trench. The precursor fill composition may include silicon and germanium, to produce a microelectronic device structure including a GeO2 / SiO2 trench fill material. A suppressor component may be employed in the precursor fill composition, to eliminate or minimize seam formation in the cured trench fill material.

Owner:ENTEGRIS INC

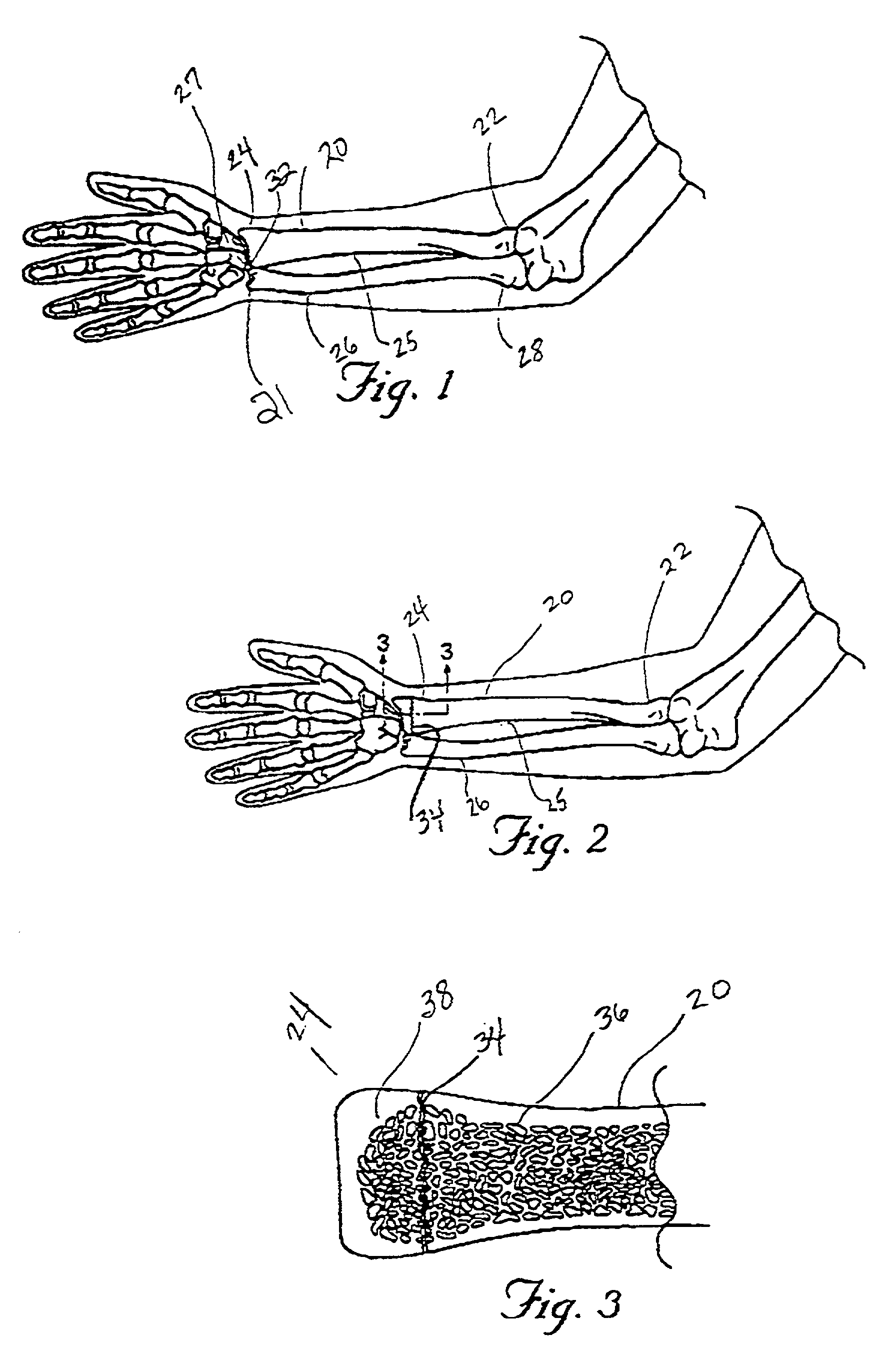

Systems and methods for reducing fractured bone using a fracture reduction cannula

InactiveUS7153306B2Relieve painRaise the possibilitySurgical furnitureSurgical needlesFracture reductionFilling materials

Systems and methods provide for the fixation of osteoporotic and non-osteoporotic long bones, especially Colles' fractures. A cannula having a circumferential opening is inserted into cancellous bone and directed such that the circumferential opening faces the fracture. The cannula is further adapted to receive an expandable structure, the expandable structure being inserted through the cannula until it is in registration with the circumferential opening. The expandable structure is expanded through the circumferential opening into cancellous bone and toward the fracture. The expansion of the expandable structure through the circumferential opening toward the fracture causes compression of cancellous bone and moves fractured cortical bone, thus creating a cavity proximal to the fracture. The cavity is then filled with a flowable bone filling material and the material allowed to harden.

Owner:ORTHOPHOENIX

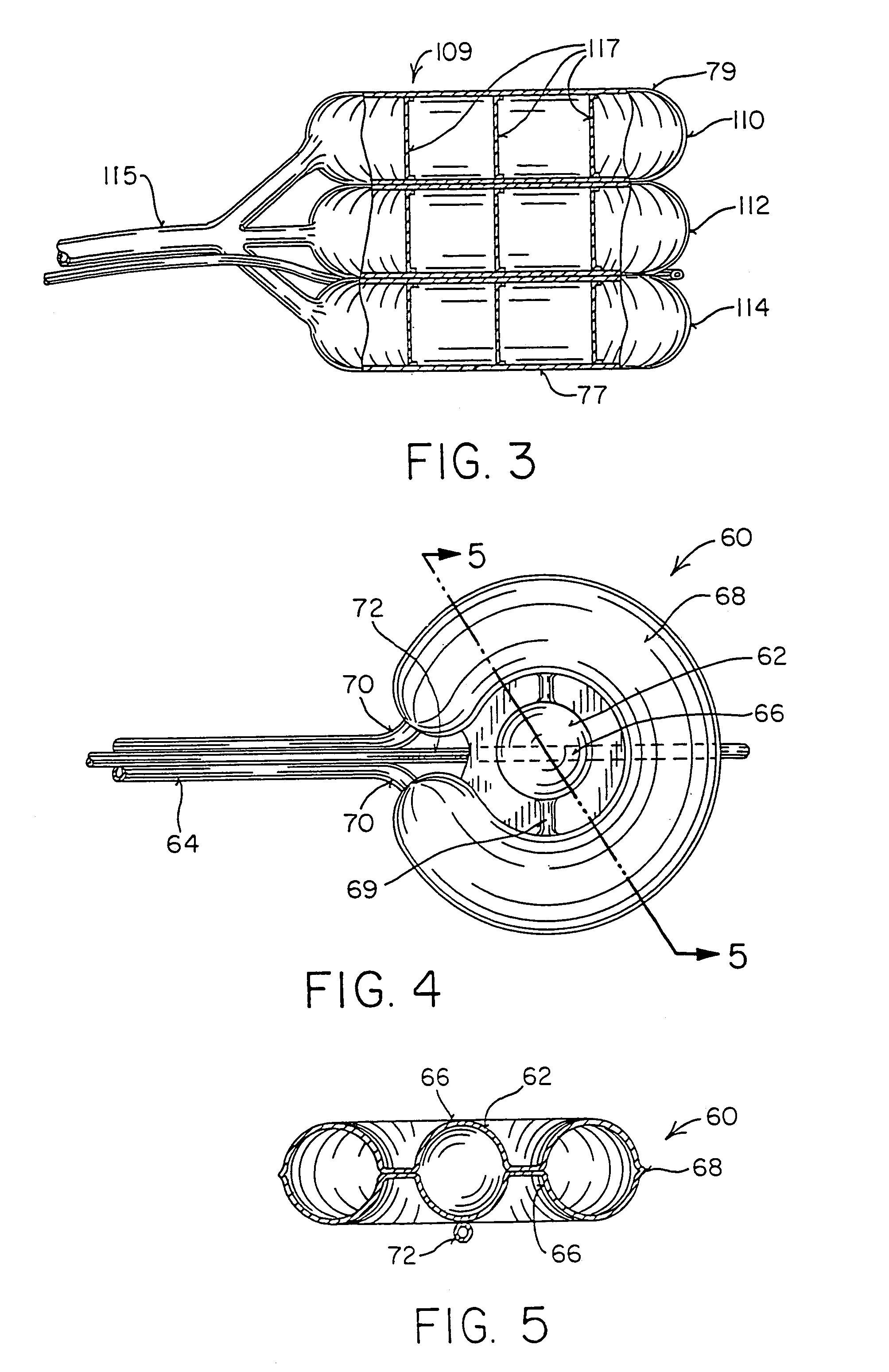

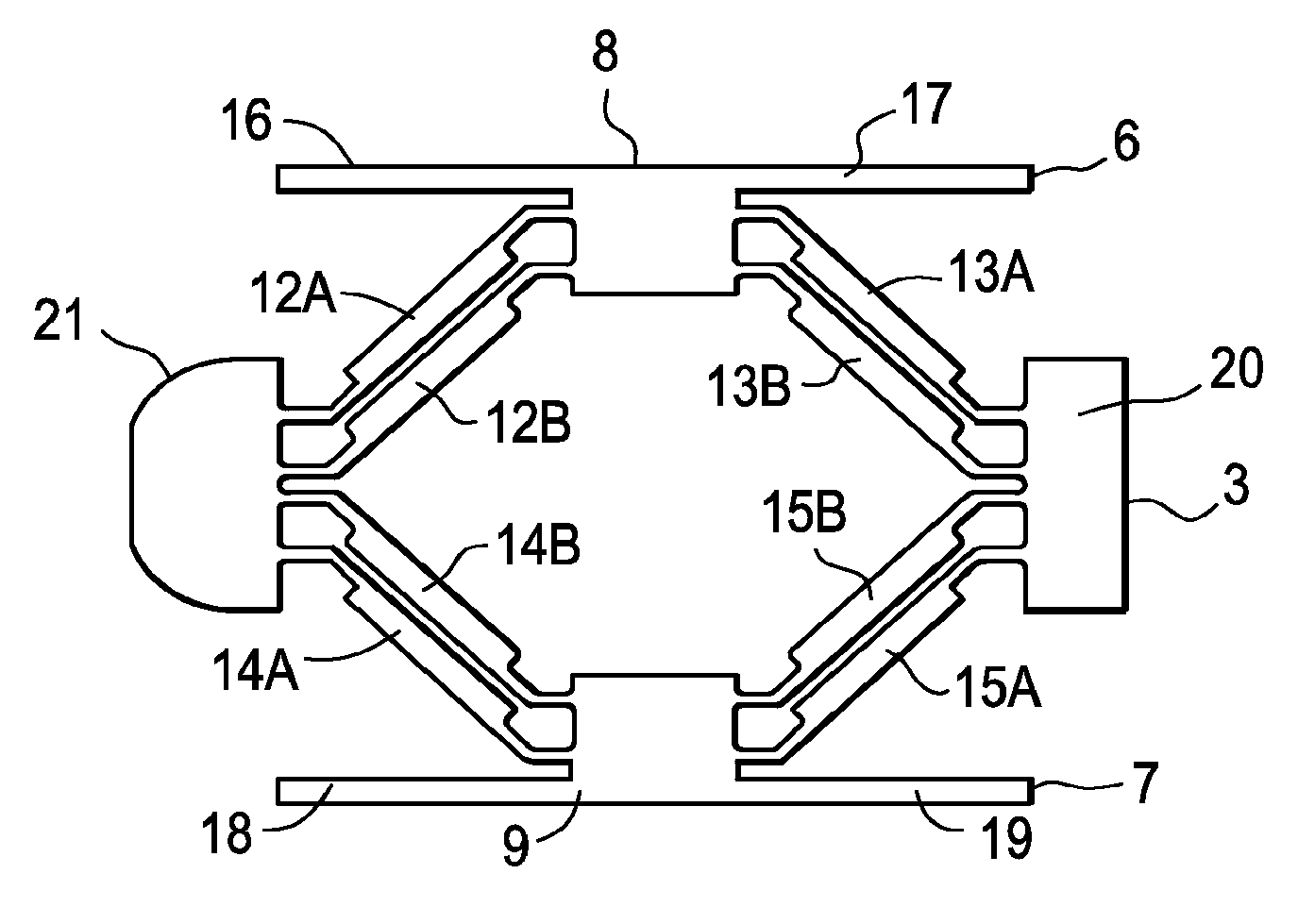

Methods and apparatuses for bone restoration

ActiveUS7846206B2Reduce stressReduce injection pressureInternal osteosythesisBone implantAnatomical structuresRestoration method

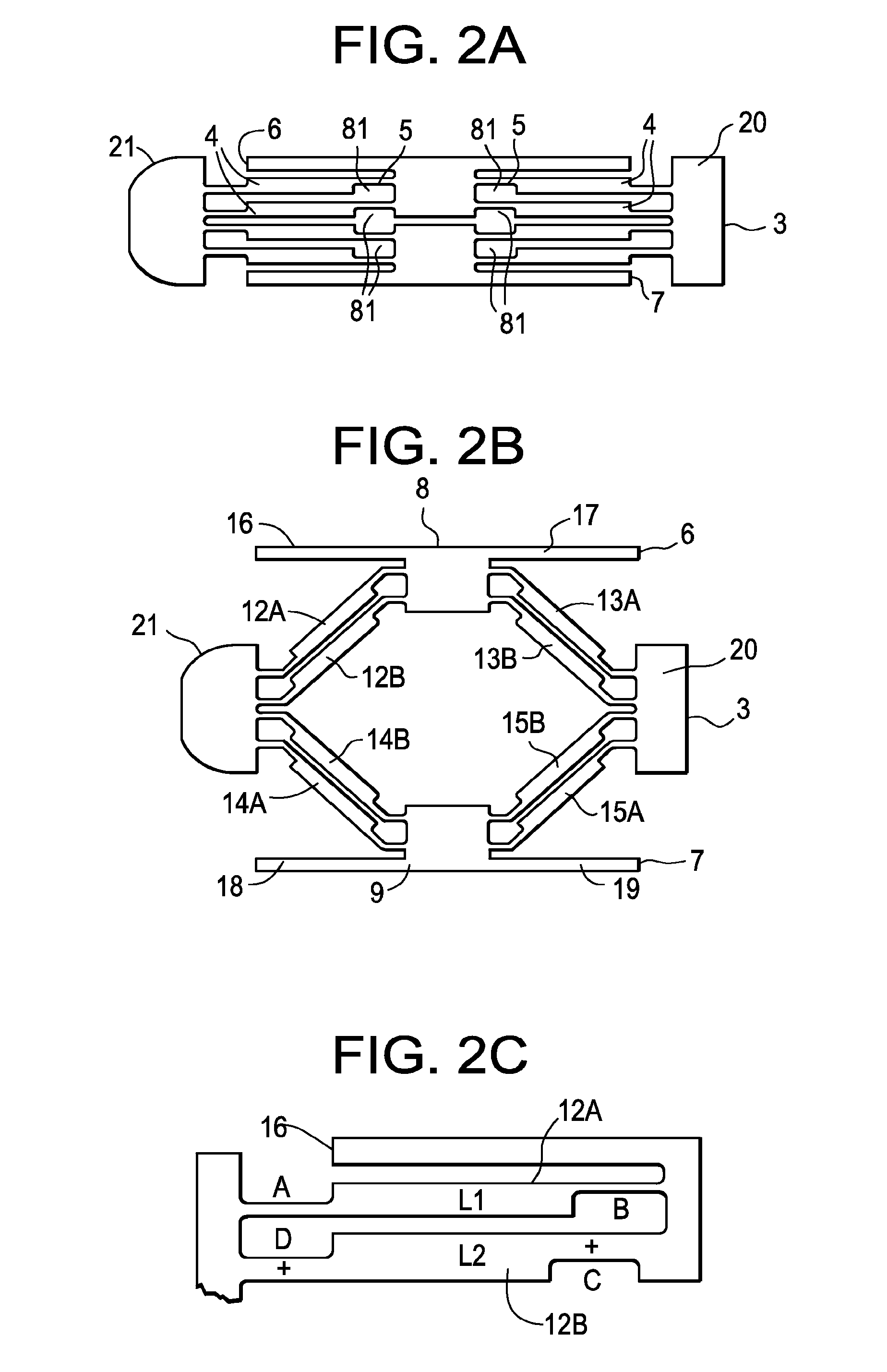

Methods and apparatuses for restoration of human or animal bone anatomy, which may include introduction, into a bone of an expansible implant capable of expansion in a single determined plane, positioning the expansible implant in the bone in order to correspond the single determined plane with a bone restoration plane and opening out the expansible implant in the bone restoration plane. A first support surface and a second support surface spread tissues within bone. The embodiments of the invention may also include injecting a filling material around the implant.

Owner:STRYKER EUROPEAN OPERATIONS LIMITED

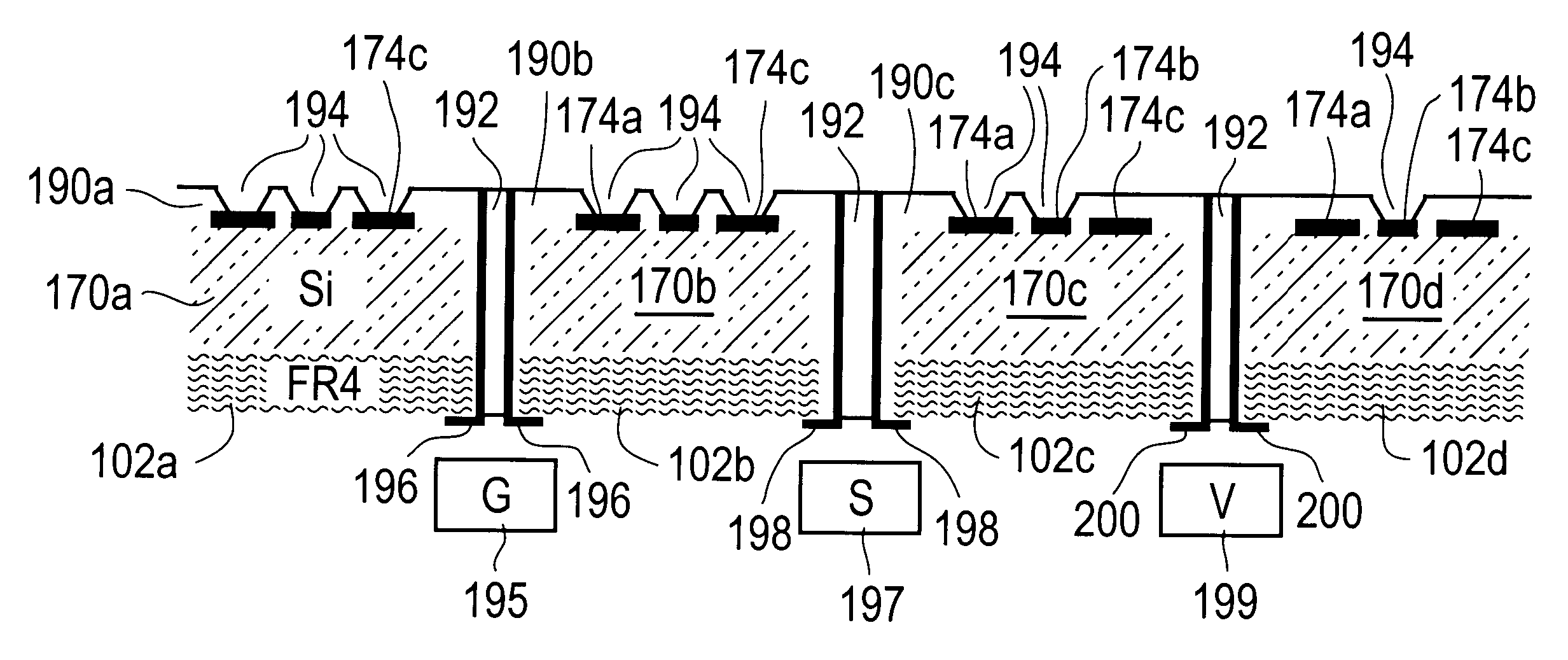

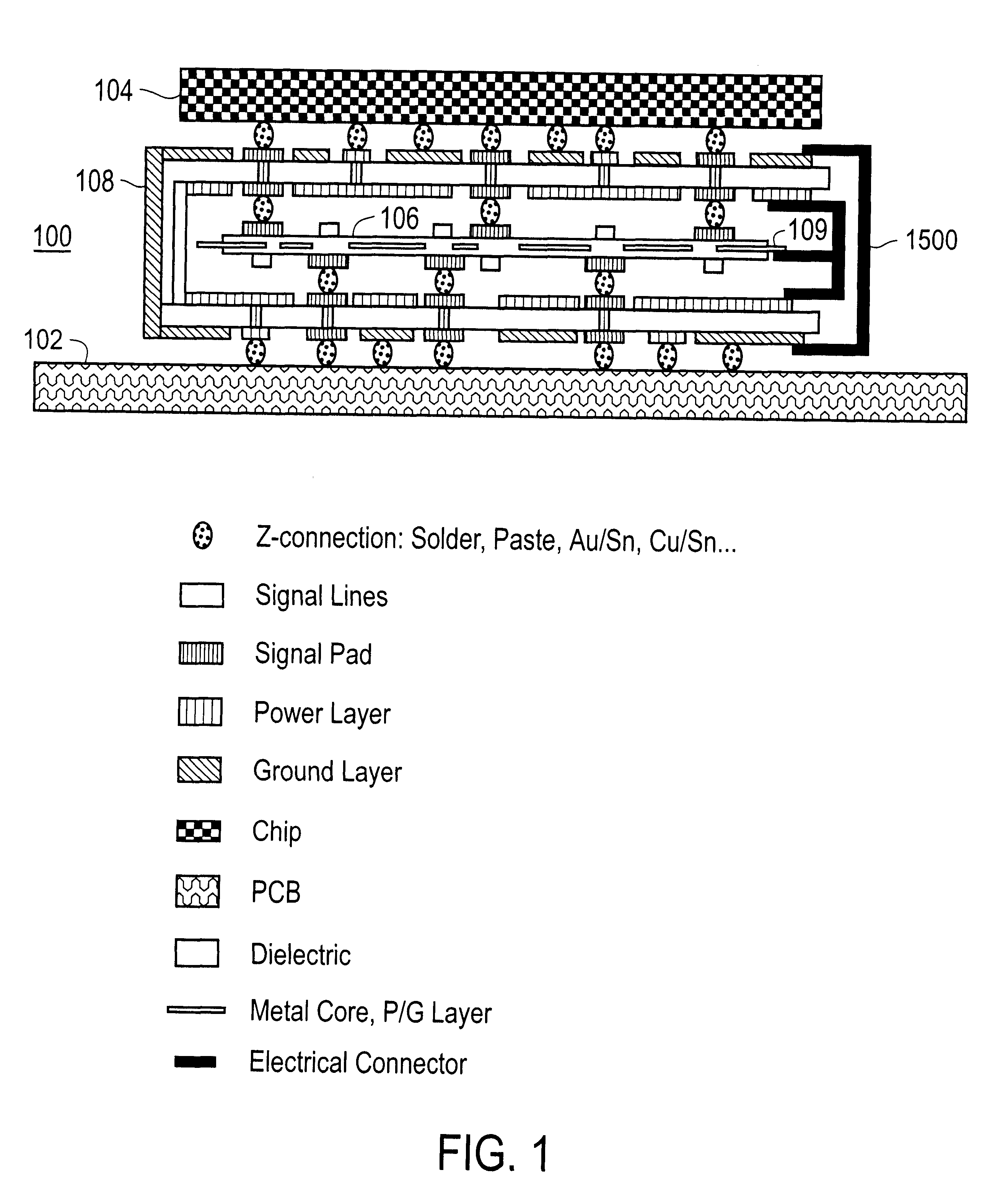

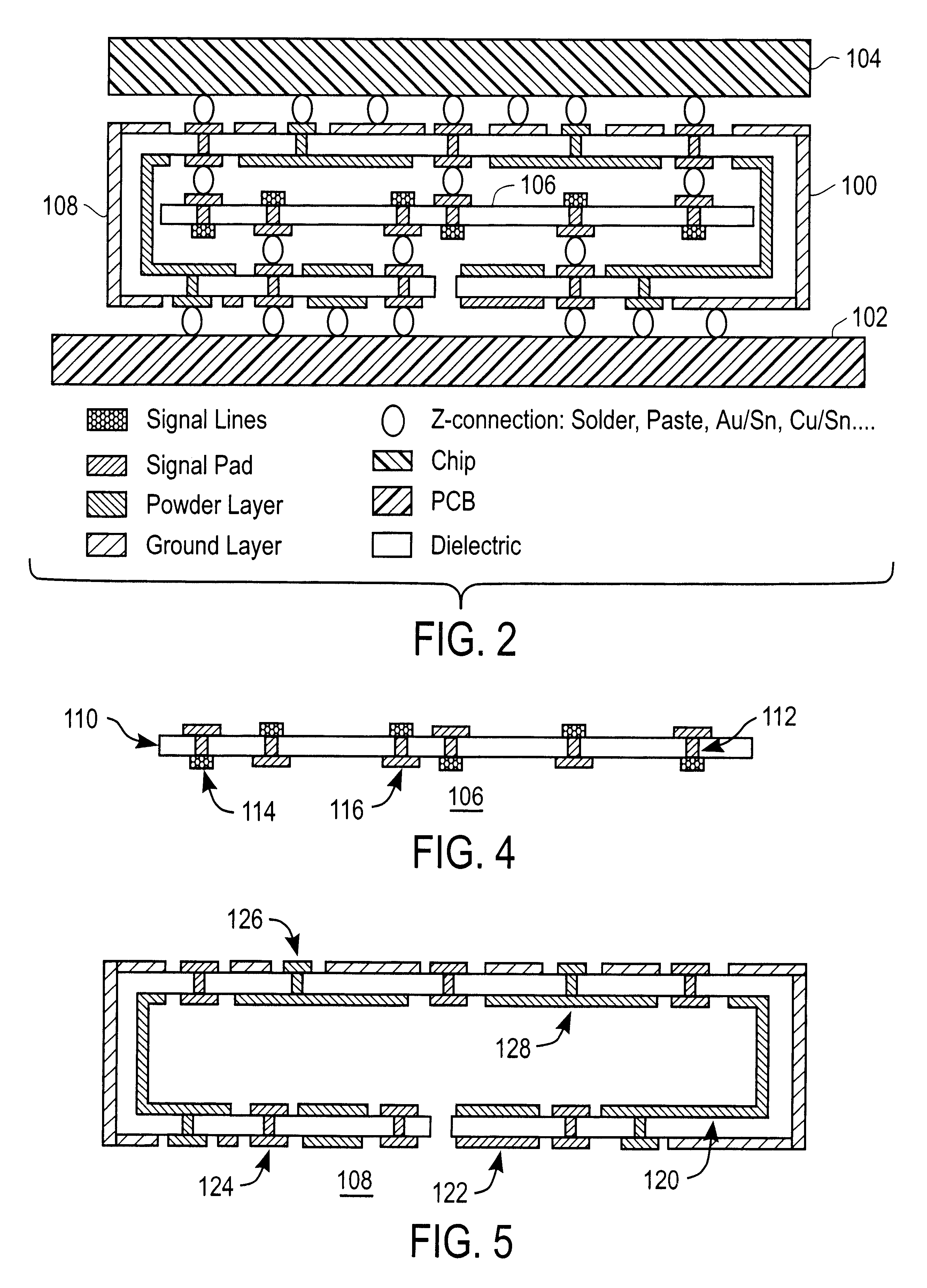

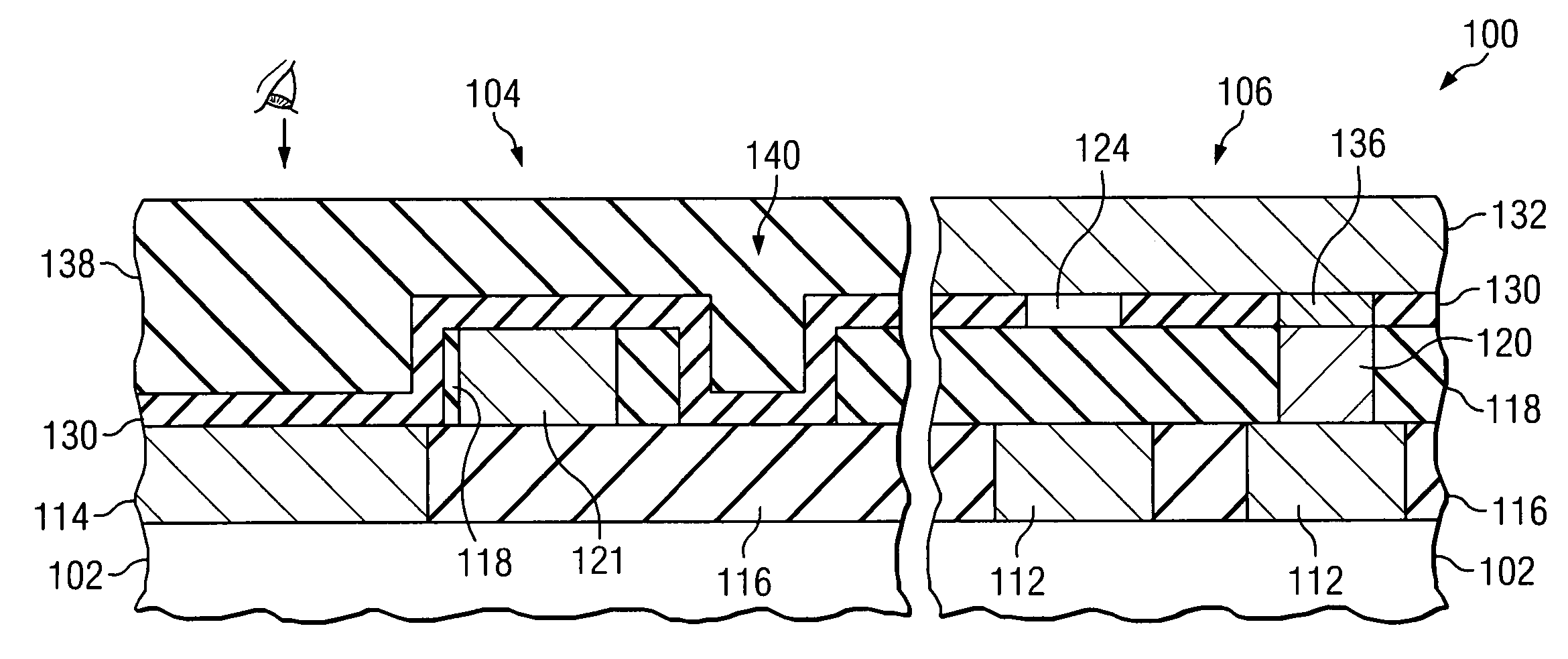

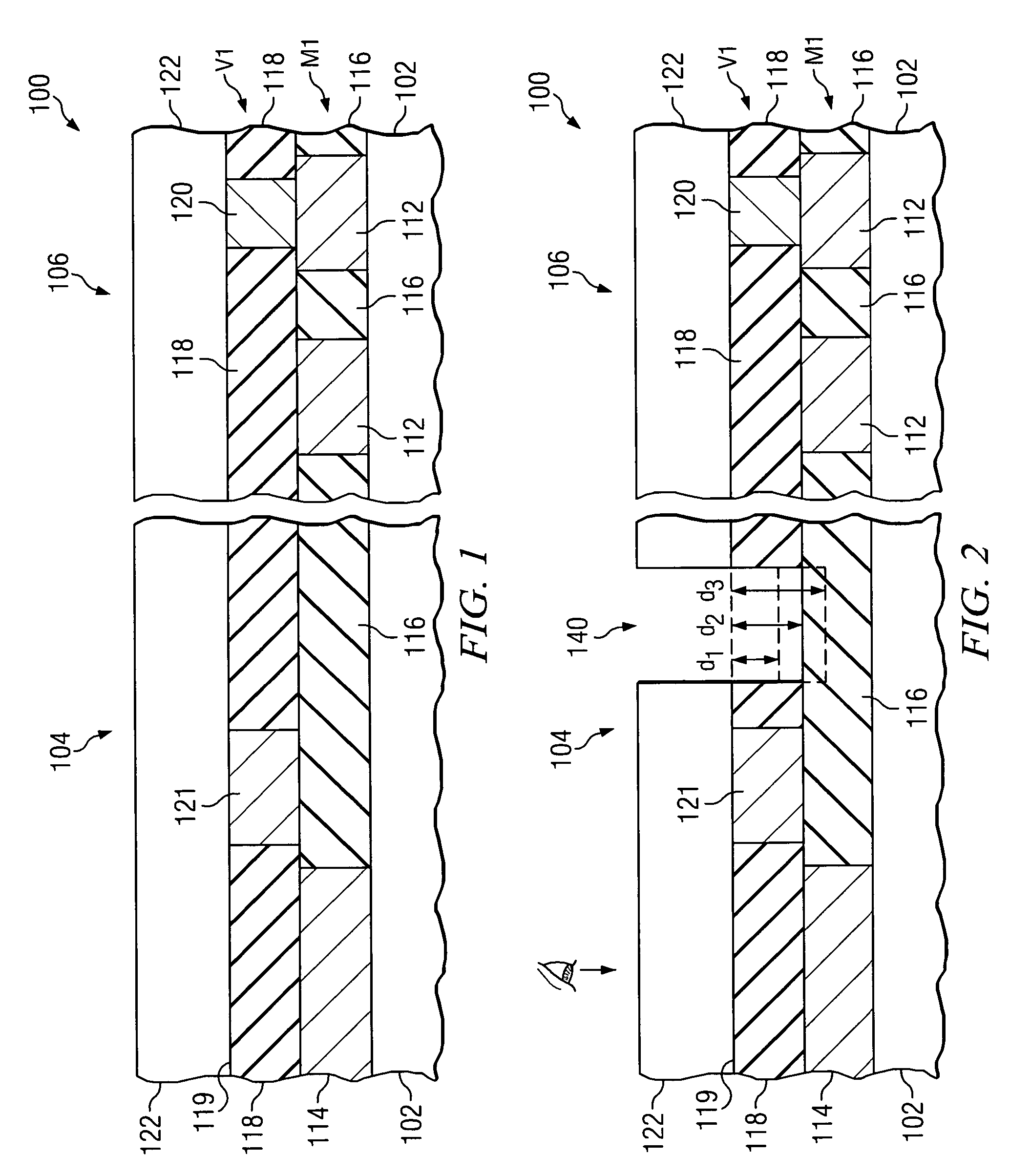

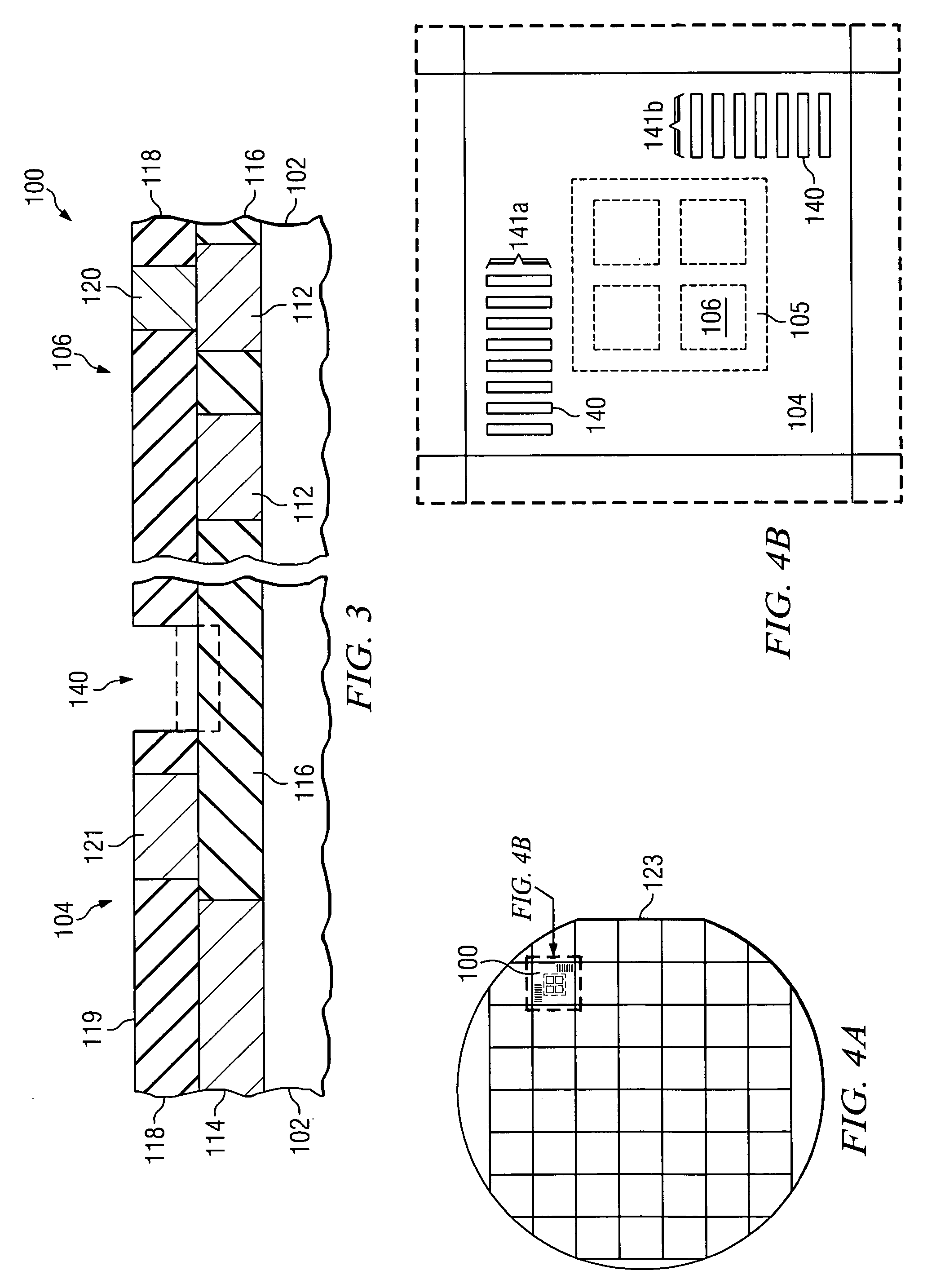

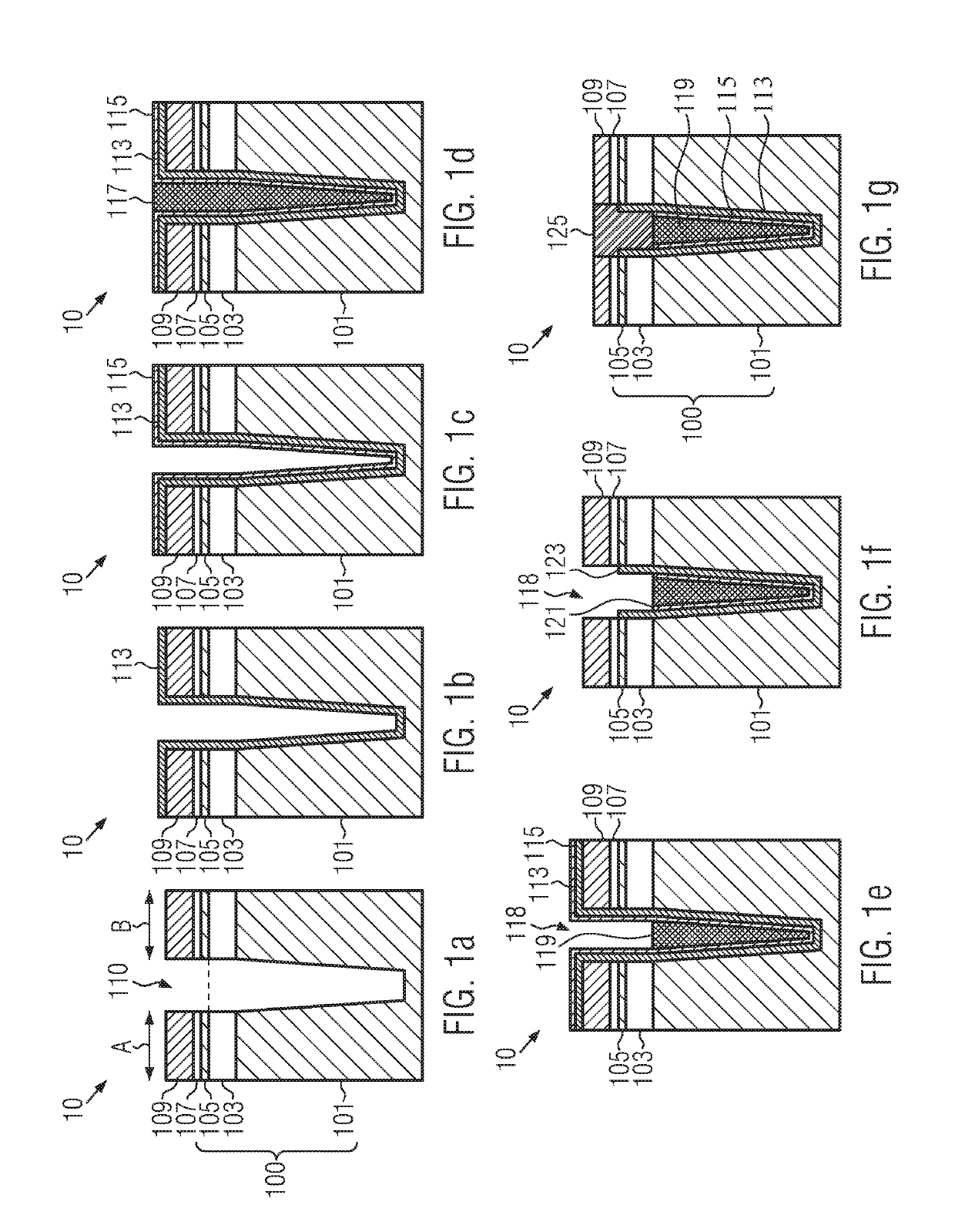

Composite interposer and method for producing a composite interposer

InactiveUS6521530B2Cross-talk/noise/interference reductionSemiconductor/solid-state device detailsEpoxyFilling materials

A composite interposer for providing power and signal connections between an integrated circuit chip or chips and a substrate. The interposer includes a signal core formed from a conductive power / ground plane positioned between two dielectric layers. A method for fabricating a composite interposer comprising disposing a silicon layer on a substrate, and selectively etching the silicon layer down to the substrate to develop silicon openings with a silicon profile, and to expose part of the substrate. Vias are formed through the exposed part of the substrate. The method additionally includes filling the vias and the silicon openings with a filler material (e.g., a high-aspect-ratio-capable photodefinable epoxy polymer) to form filled silicon openings and filled vias, forming first openings through the filled silicon openings and through the filled vias, forming second opening through filler material to expose semiconductor devices on the silicon layer, and interconnecting electrically, through the first openings and through the second openings, the exposed semiconductor devices with pads disposed against a bottom of the substrate.

Owner:FUJITSU LTD

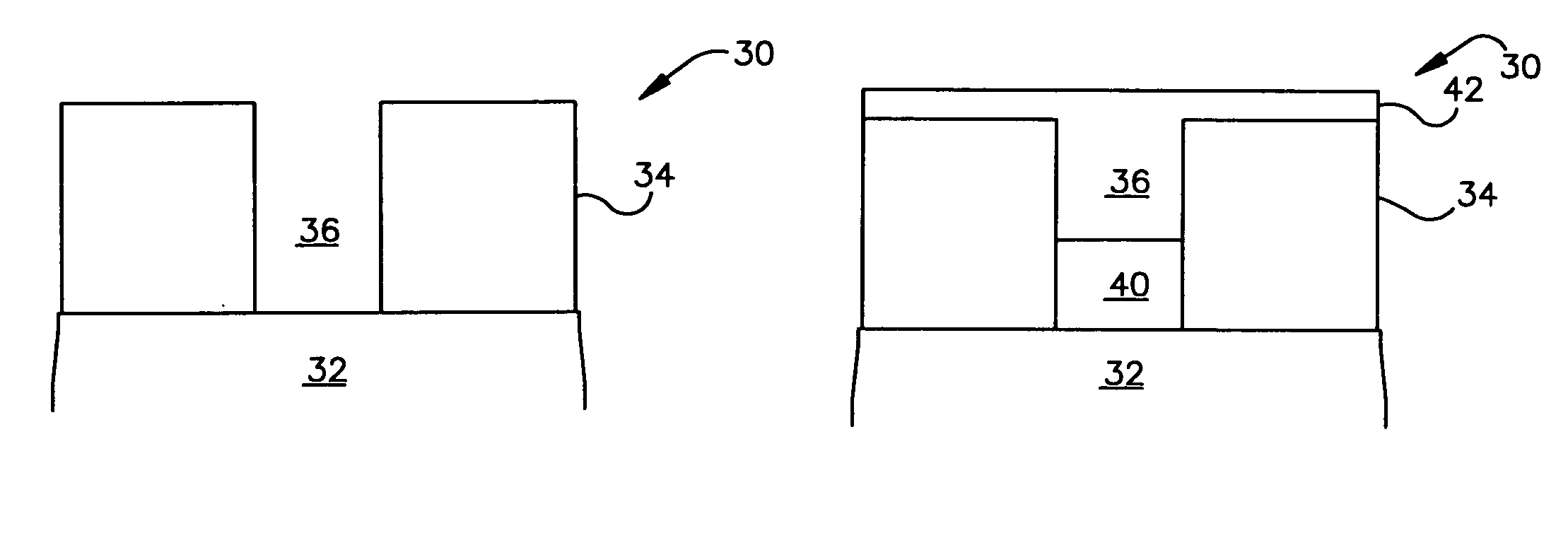

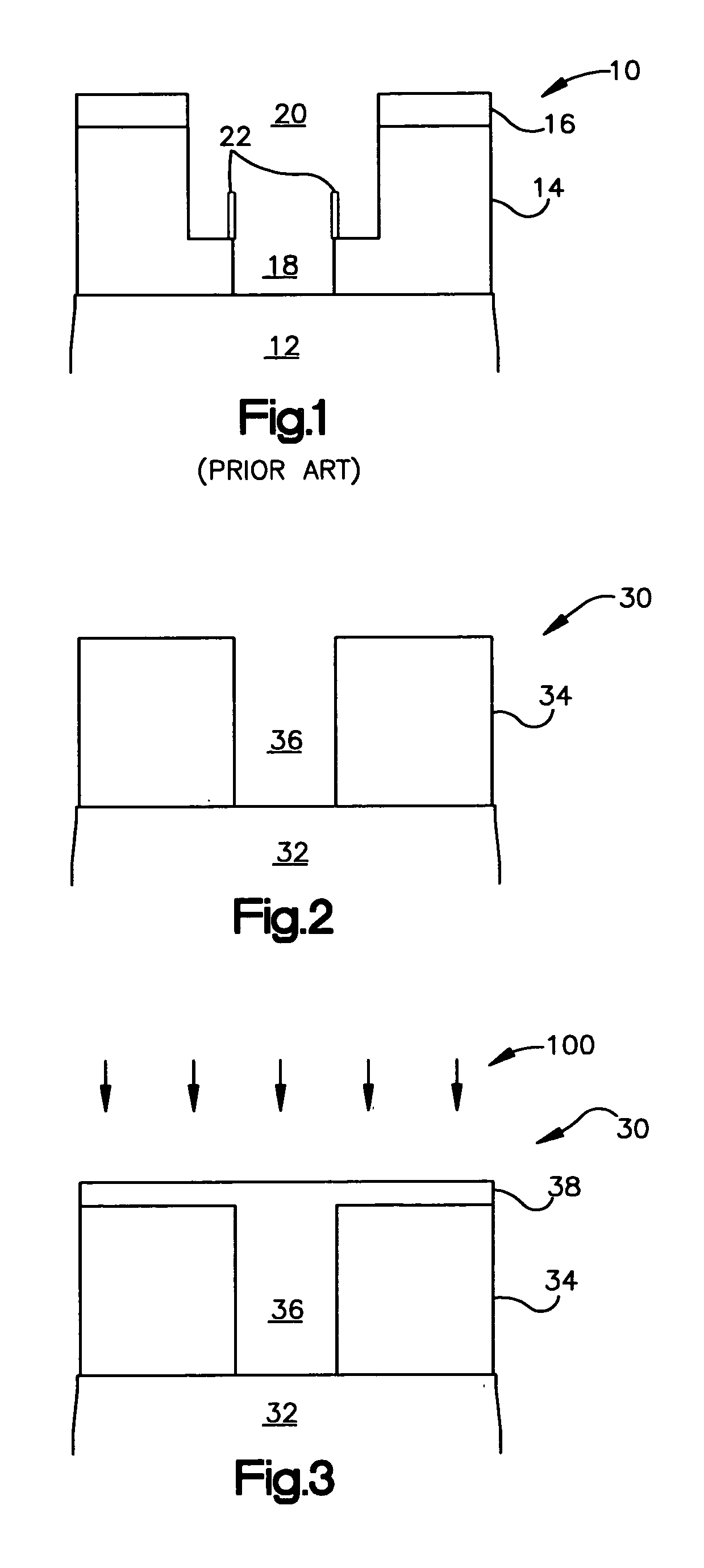

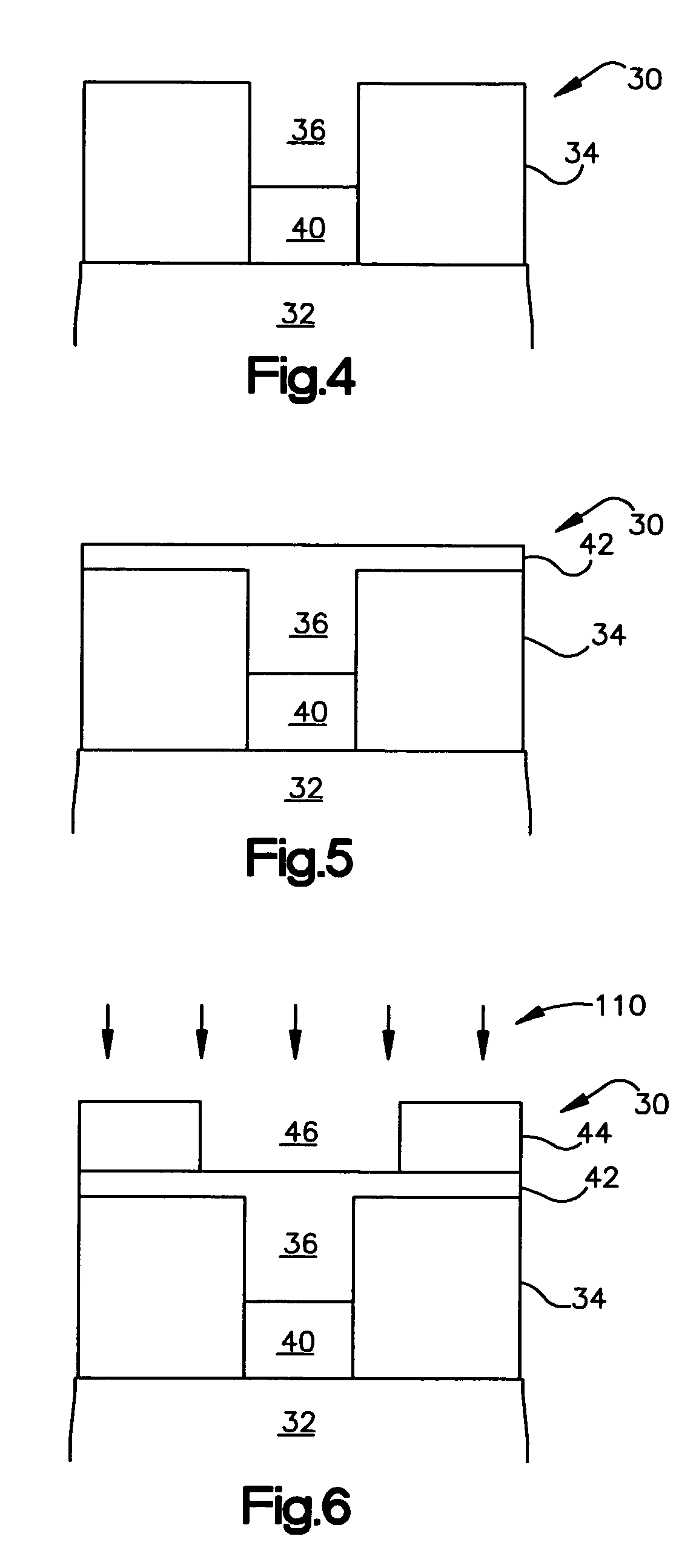

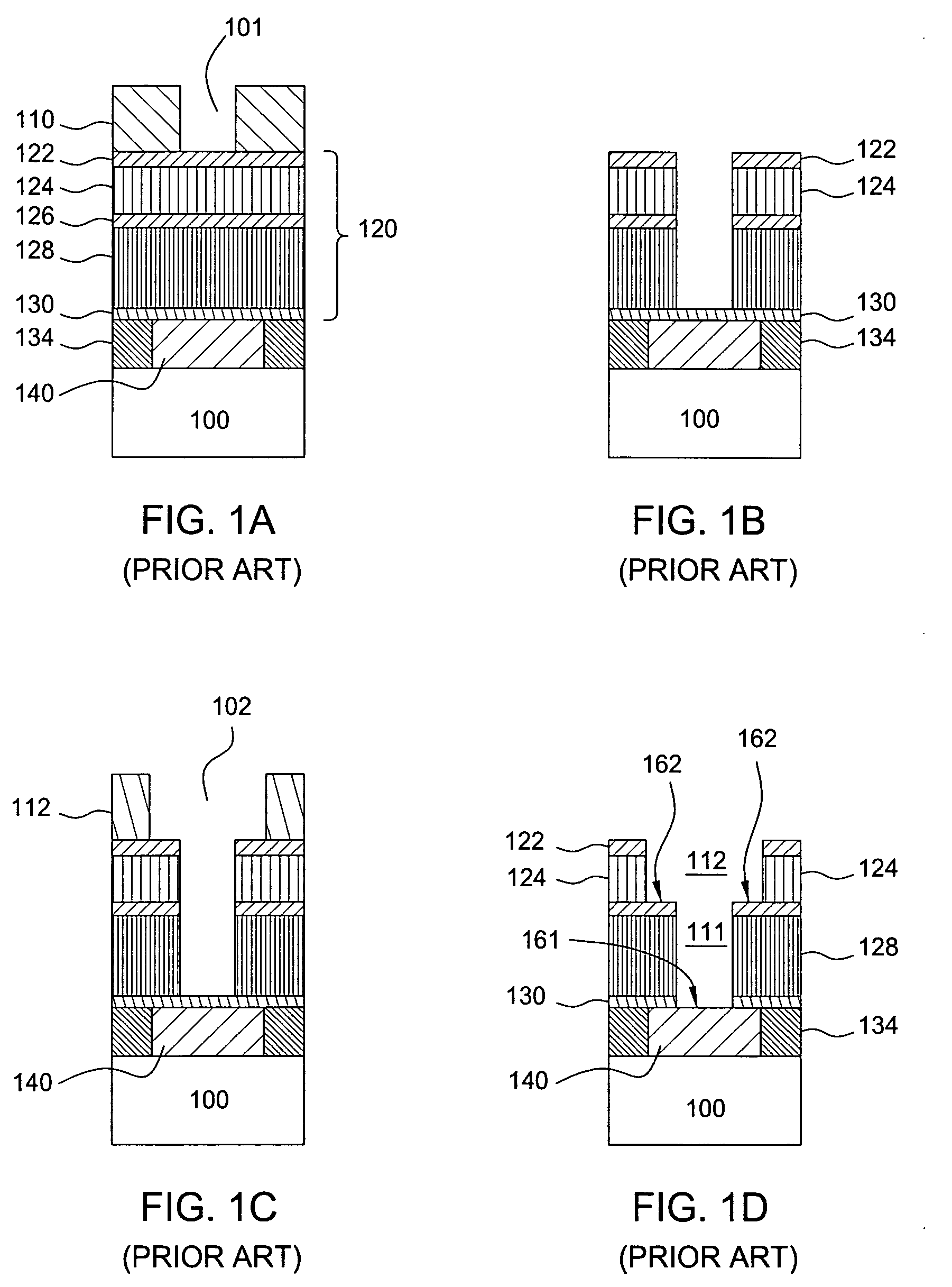

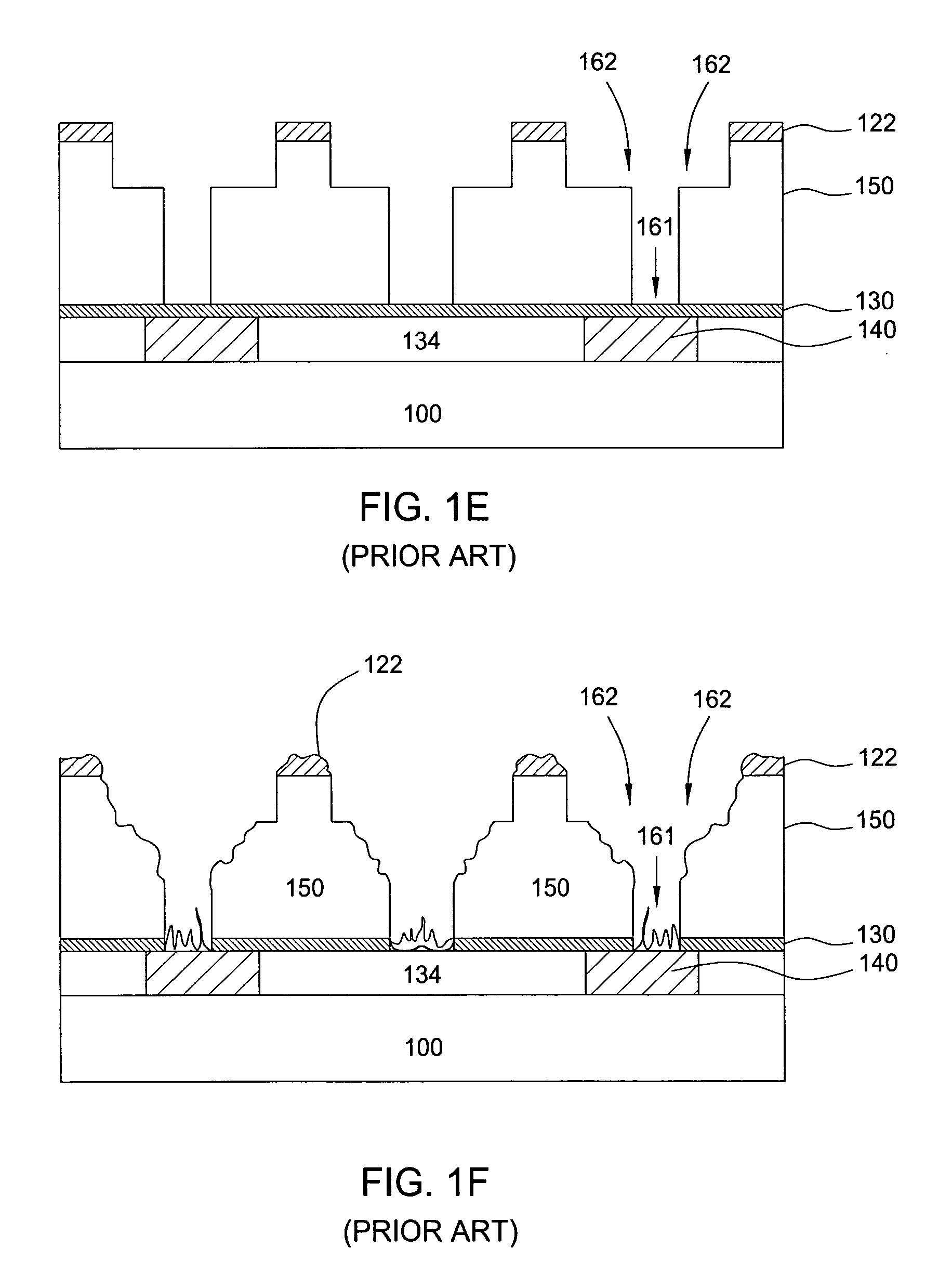

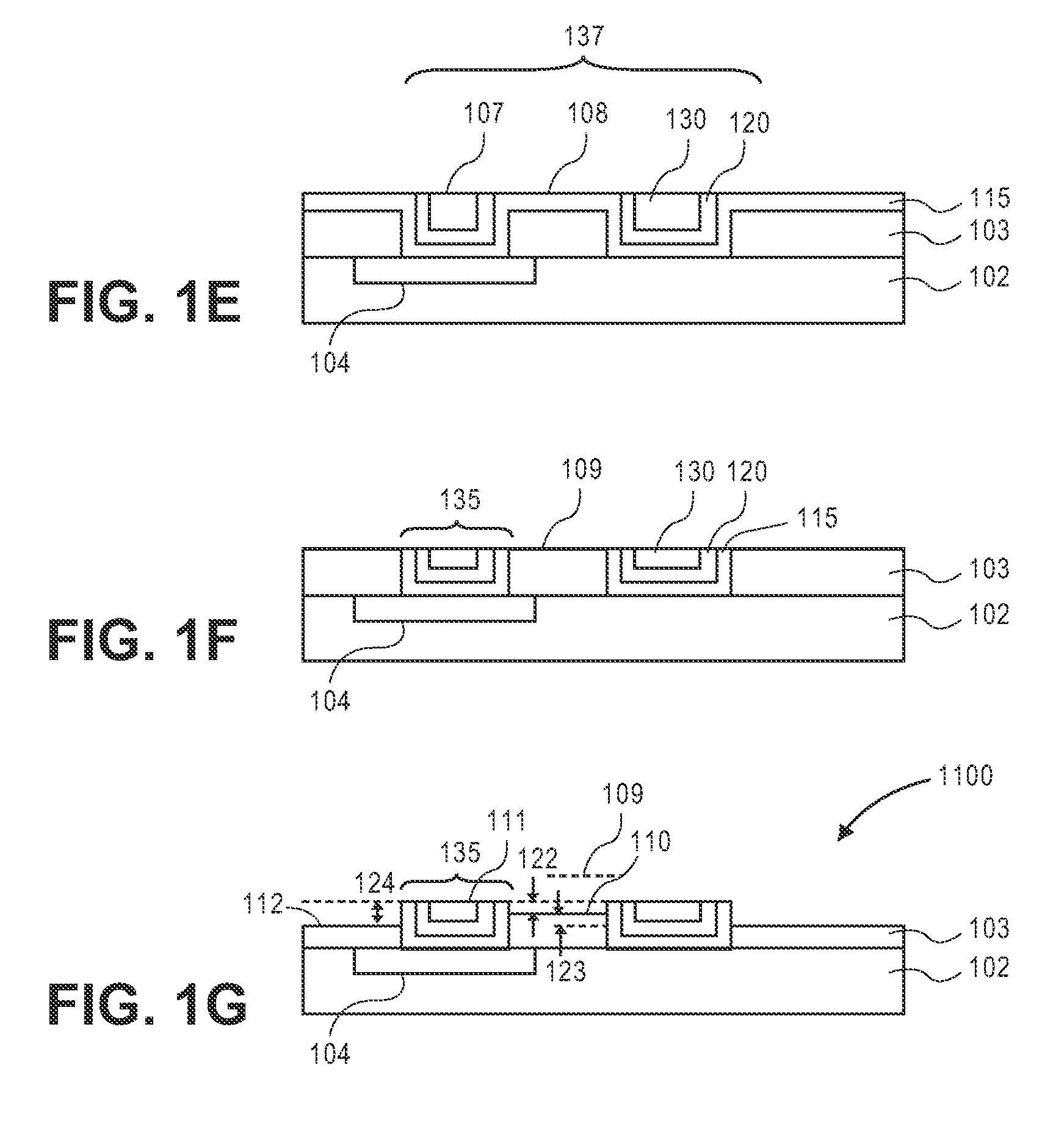

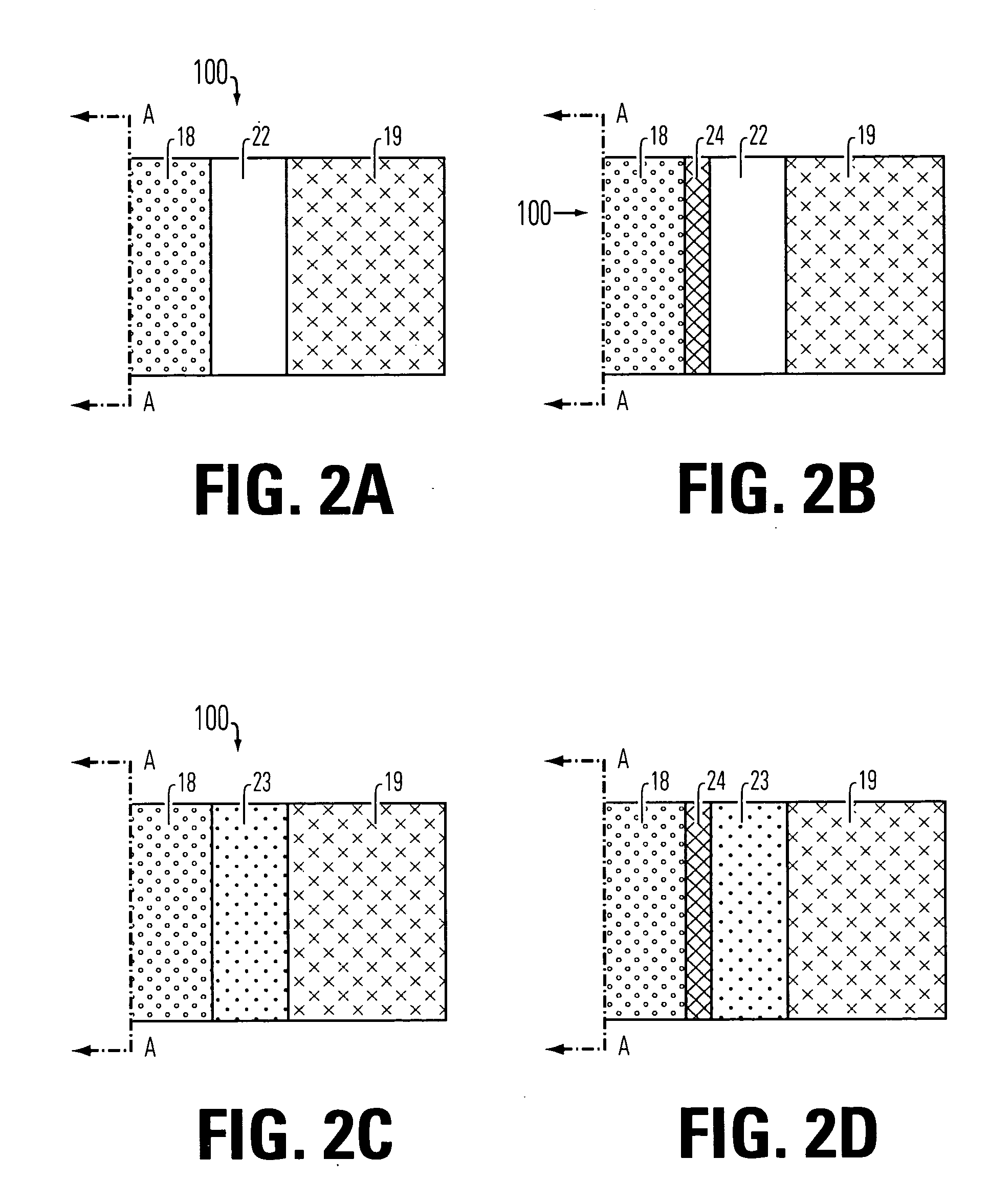

Method of eliminating etch ridges in a dual damascene process

ActiveUS20060024956A1Inhibition formationSemiconductor/solid-state device manufacturingAnti-reflective coatingFilling materials

A dual damascene process employs a via fill material (38) with an etch rate that is within 60% of an etch rate that an underlying dielectric layer (34) etches for a given dielectric etch chemistry in which a trench (48) and via (50) are being formed. In one embodiment, an organic via fill material plug (40) is employed in conjunction with a bottom anti-reflective coating (BARC) material layer (42). Both the organic via fill material plug (40) and the BARC material layer (42) are selected to have a material with an etch rate that within 60% of an etch rate that an underlying dielectric layer (34) etches for a given dielectric etch chemistry in which the trench (48) and via (50) are formed.

Owner:TEXAS INSTR INC

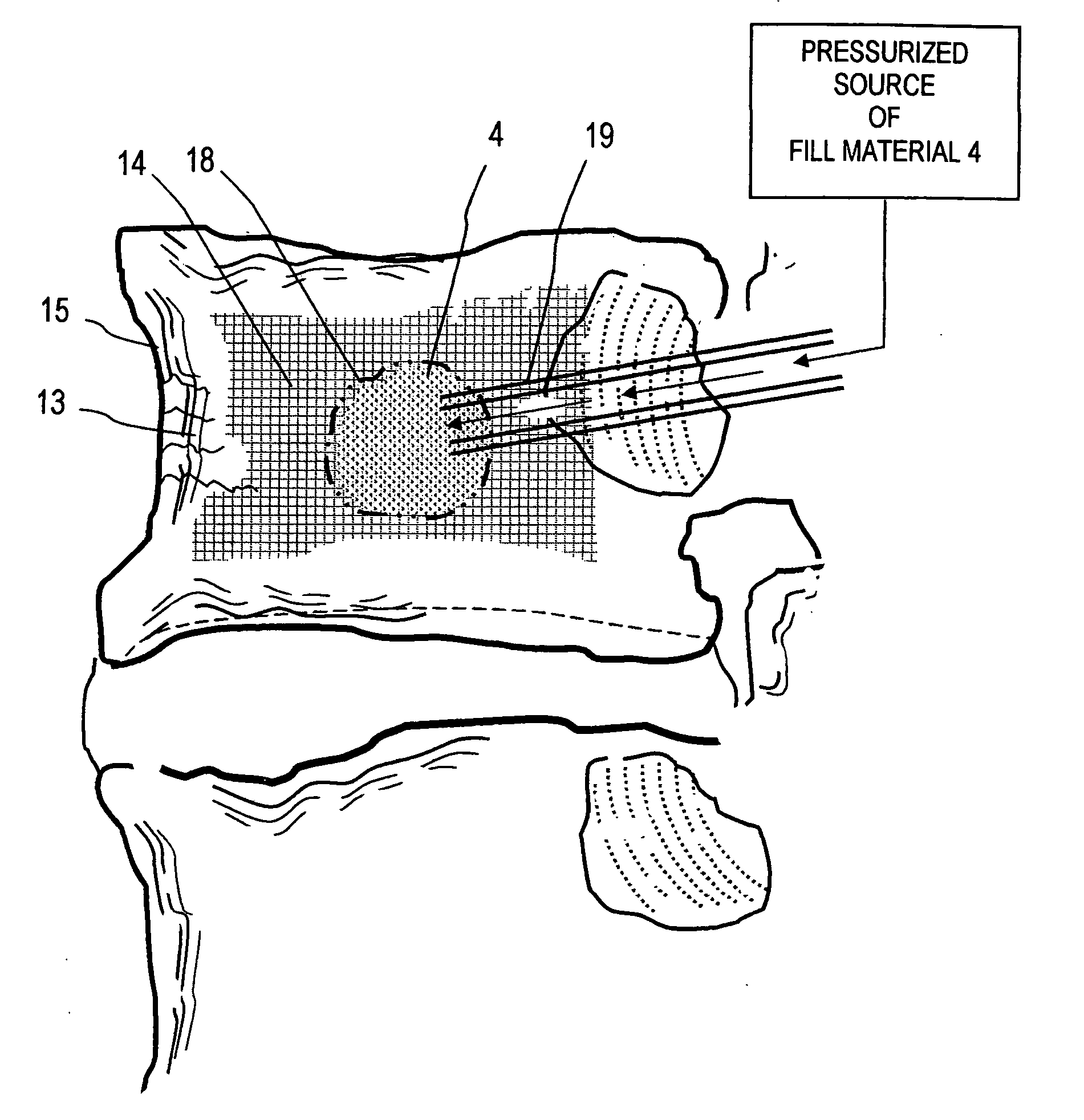

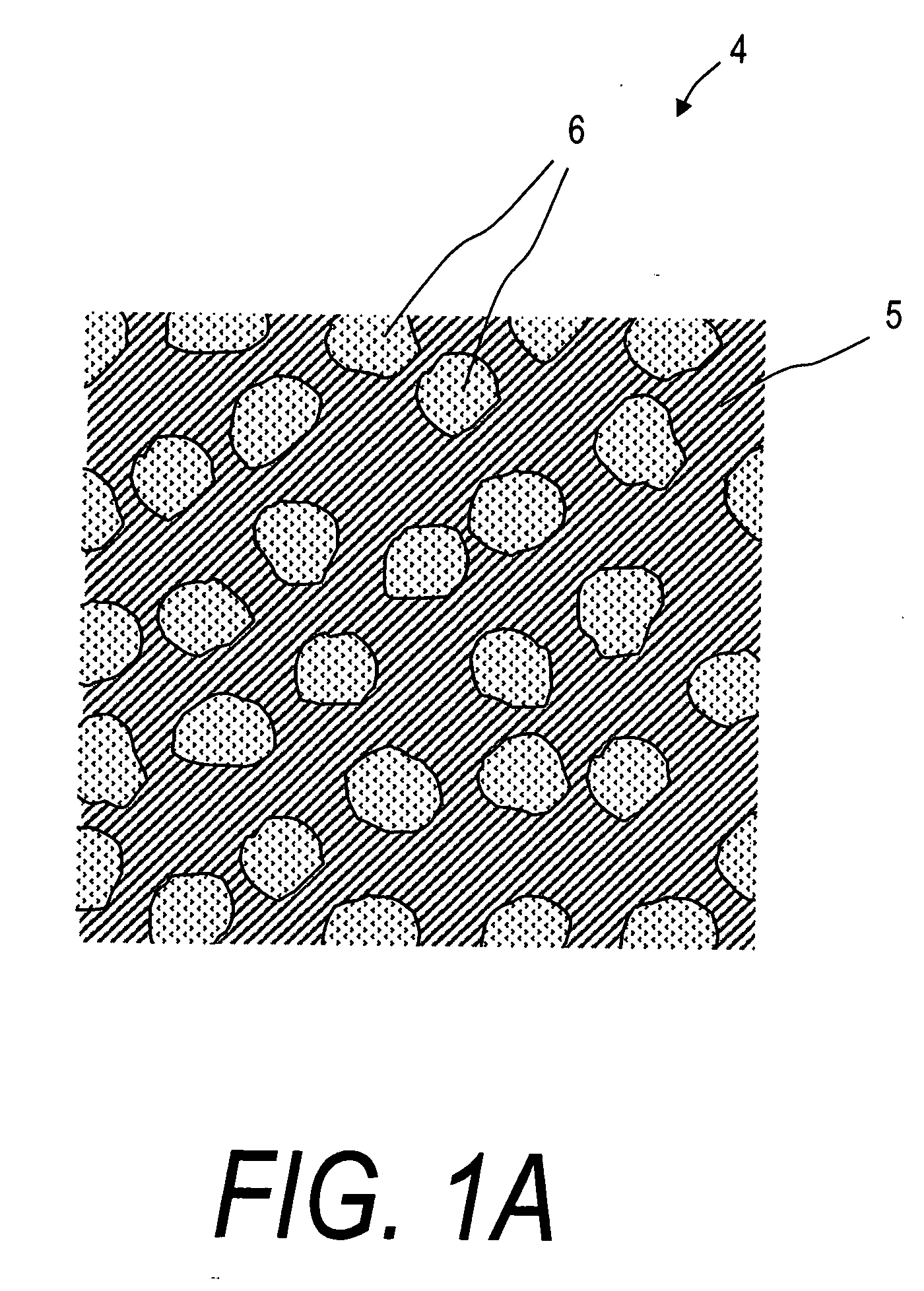

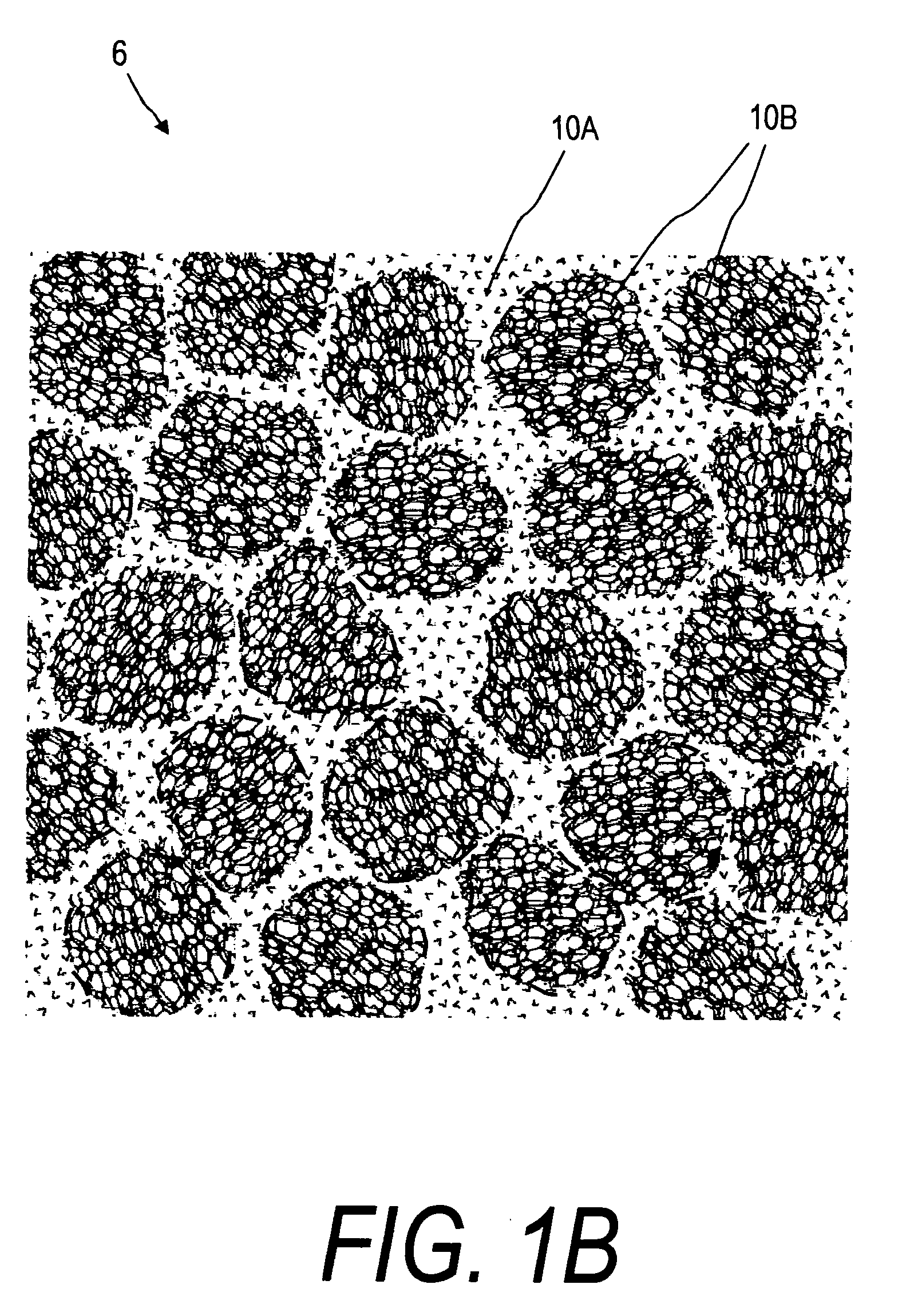

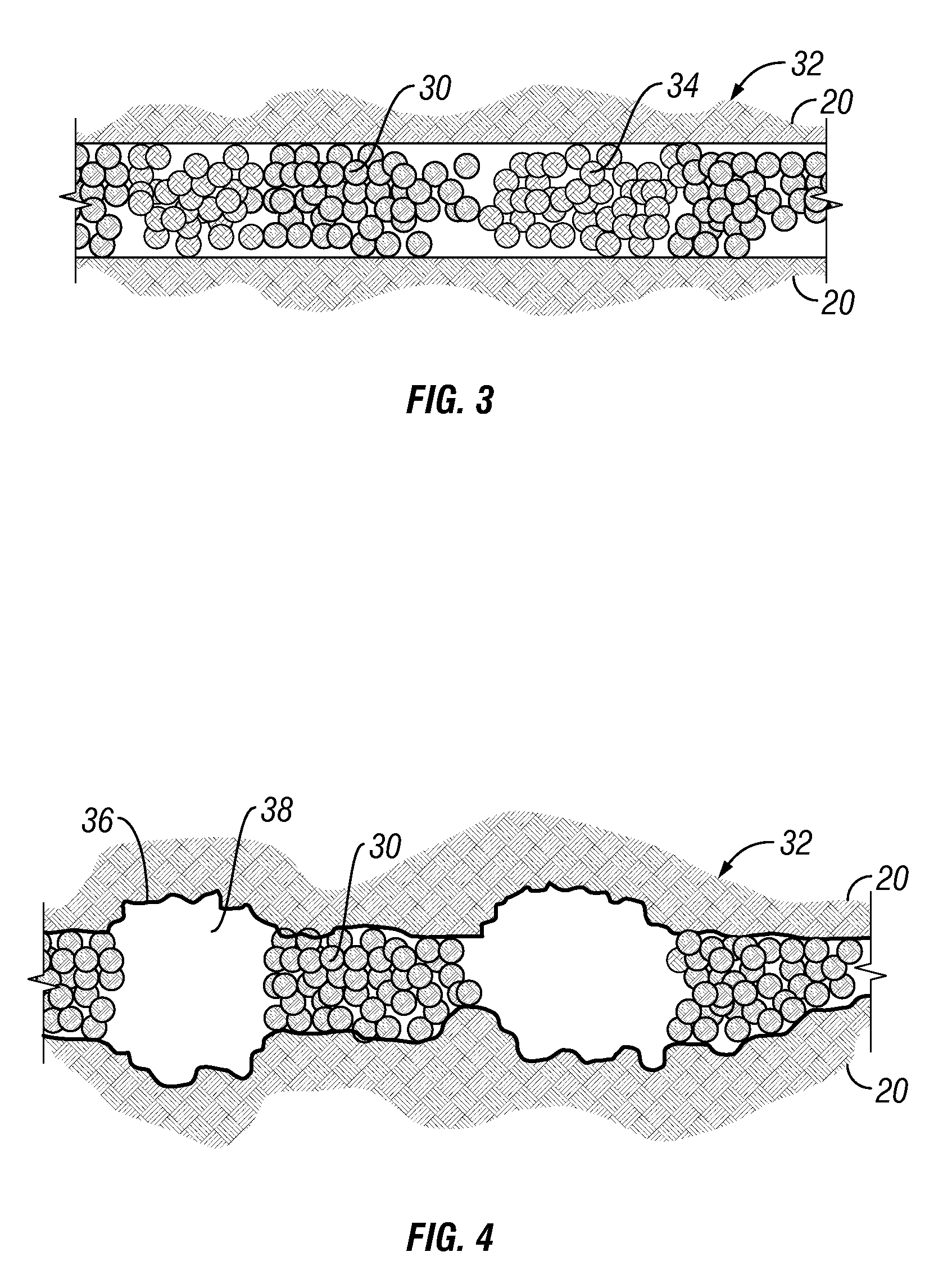

Composites and methods for treating bone

A system and method for treating bone abnormalities including vertebral compression fractures and the like. In one vertebroplasty method, a fill material is injected under high pressures into cancellous bone wherein the fill material includes a flowable bone cement component and an elastomeric polymer component that is carried therein. The elastomer component can further carry microscale or mesoscale reticulated elements. Under suitable injection pressures, the elastomeric component ultimately migrates within the flowable material to alter the apparent viscosity across the plume of fill material to accomplish multiple functions. For example, the differential in apparent viscosity across the fill material creates a broad load-distributing layer within cancellous bone for applying retraction forces to cortical bone endplates. The differential in apparent viscosity also transitions into a flow impermeable layer at the interface of cancellous bone and the flowable material to prevent extravasion of the flowable bone cement component.

Owner:DFINE INC

Dual damascene fabrication with low k materials

The invention provides methods and apparatuses for fabricating a dual damascene structure on a substrate. First, trench lithography and trench patterning are performed on the surface of a substrate to etch a low-k dielectric material layer to a desired etch depth to form a trench prior to forming of a via. The trenches can be filled with an organic fill material and a dielectric hard mask layer can be deposited. Then, via lithography and via resist pattering are performed. Thereafter, the dielectric hard mask and the organic fill material are sequentially etched to form vias on the surface of the substrate, where the trenches are protected by the organic fill material from being etched. A bottom etch stop layer on the bottom of the vias is then etched and the organic fill material is striped. As a result, the invention provides good patterned profiles of the via and trench openings of a dual damascene structure.

Owner:APPLIED MATERIALS INC

Alignment of MTJ stack to conductive lines in the absence of topography

InactiveUS7223612B2Convenient lengthIncrease patternSemiconductor/solid-state device detailsSolid-state devicesLithography processLithographic artist

A scheme for aligning opaque material layers of a semiconductor device. Alignment marks are formed in a via level of the semiconductor device. The alignment marks are formed using a separate lithography mask, and may have about the same length as vias formed in the via layer. The alignment marks comprise trenches that are not filled with material and are not exposed to a CMP process. An opaque material layer is deposited, and depressions are formed in the opaque material layer over the alignment mark trenches. The depressions in the opaque material layer are used to align a lithography process to open the opaque material layer over alignment marks in an underlying metallization layer. The alignment marks in the metallization layer are then used to align the lithography process used to pattern the opaque material layer.

Owner:POLARIS INNOVATIONS LTD

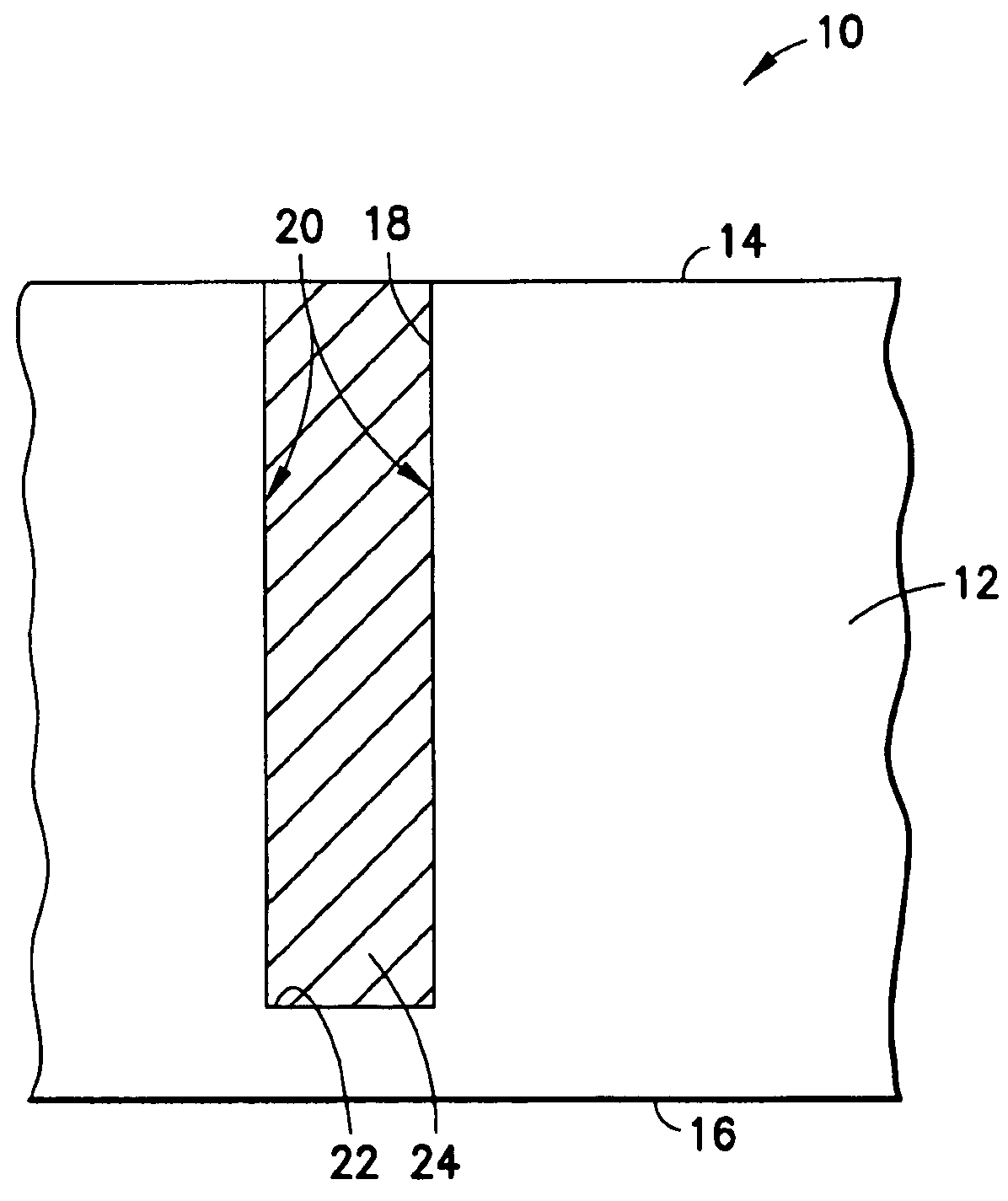

Front-end-of-line device structure and method of forming such a front-end-of-line device structure

ActiveUS10483154B1Well formedSemiconductor/solid-state device manufacturingSemiconductor devicesFilling materialsFront end of line

In various aspects, the present disclosure relates to device structures and a method of forming such a device structure. In some illustrative embodiments herein, a device is provided, including a semiconductor substrate having a first trench formed therein, and a first trench isolation structure formed in the first trench. The first trench isolation structure includes first and second insulating liners formed adjacent inner surfaces of the first trench, wherein the first insulating liner is in direct contact with inner surfaces of the first trench and the second insulating liner is formed directly on the first insulating liner, and a first insulating filling material which at least partially fills the first trench. In some aspects, a thickness of the first insulating liner is greater than a thickness of the second insulating liner.

Owner:GLOBALFOUNDRIES US INC

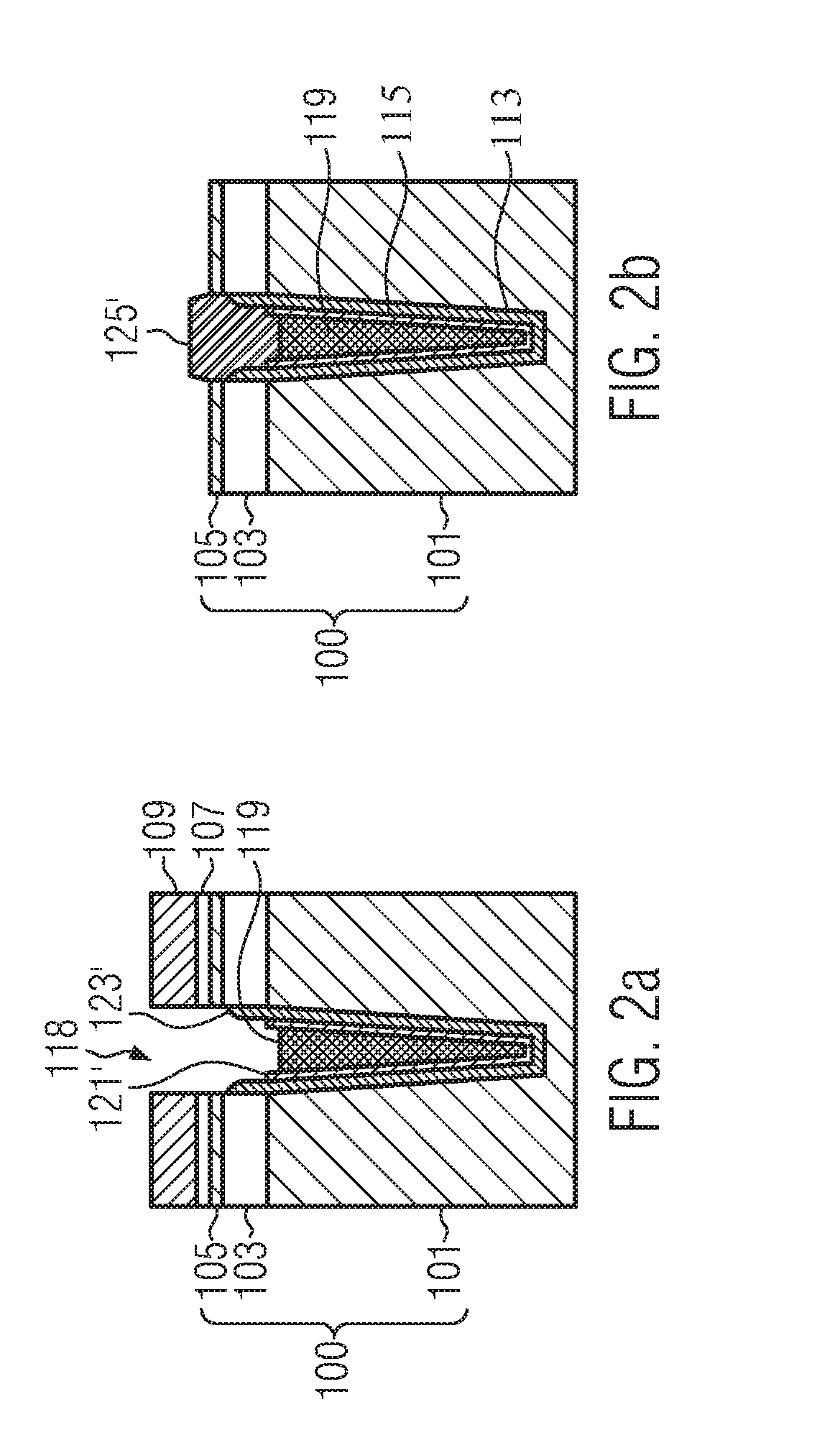

Wafer bonding with highly compliant plate having filler material enclosed hollow core

ActiveUS7307005B2Solid-state devicesSemiconductor/solid-state device manufacturingFilling materialsWafer bonding

The present invention discloses a method that includes: providing two wafers; forming raised contacts on the two wafers; aligning the two wafers; bringing together the raised contacts; locally deflecting the two wafers; and bonding the raised contacts.The present invention also discloses a bonded-wafer structure that includes: a first wafer, the first wafer being locally deflected, the first wafer including a first raised contact; and a second wafer, the second wafer being locally deflected, the second wafer including a second raised contact, wherein the second raised contact is bonded to the first raised contact.

Owner:TAHOE RES LTD

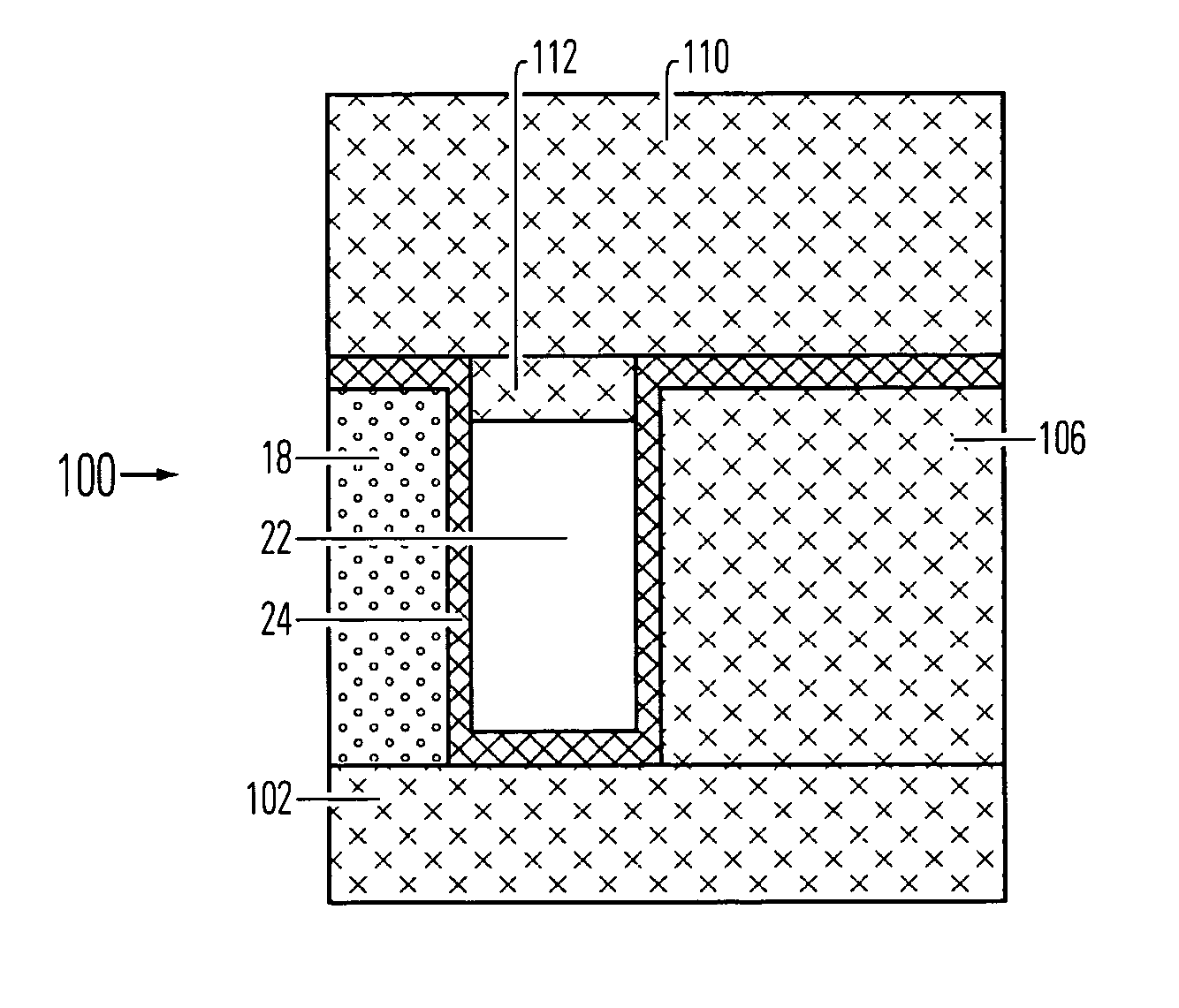

Thermal isolation for an active-sidewall phase change memory cell

ActiveUS20070115794A1Improve insulation performanceMechanical recordingRecord information storageDielectricThermal isolation

A phase change memory device with improve thermal isolation. The device includes an electrode stack, including a first and second electrode elements, generally planar in form, separated by and in mutual contact with a dielectric spacer element, wherein the electrode stack includes a side surface; a phase change element having a bottom surface in contact with the electrode stack side surface, including electrical contact with the first and second electrode elements; and dielectric fill material surrounding and encasing the memory device, wherein the dielectric fill material is spaced from the phase change element, such that the phase change element and the dielectric fill material define a cavity adjacent the phase change element, and wherein the cavity contains a low pressure environment.

Owner:MACRONIX INT CO LTD

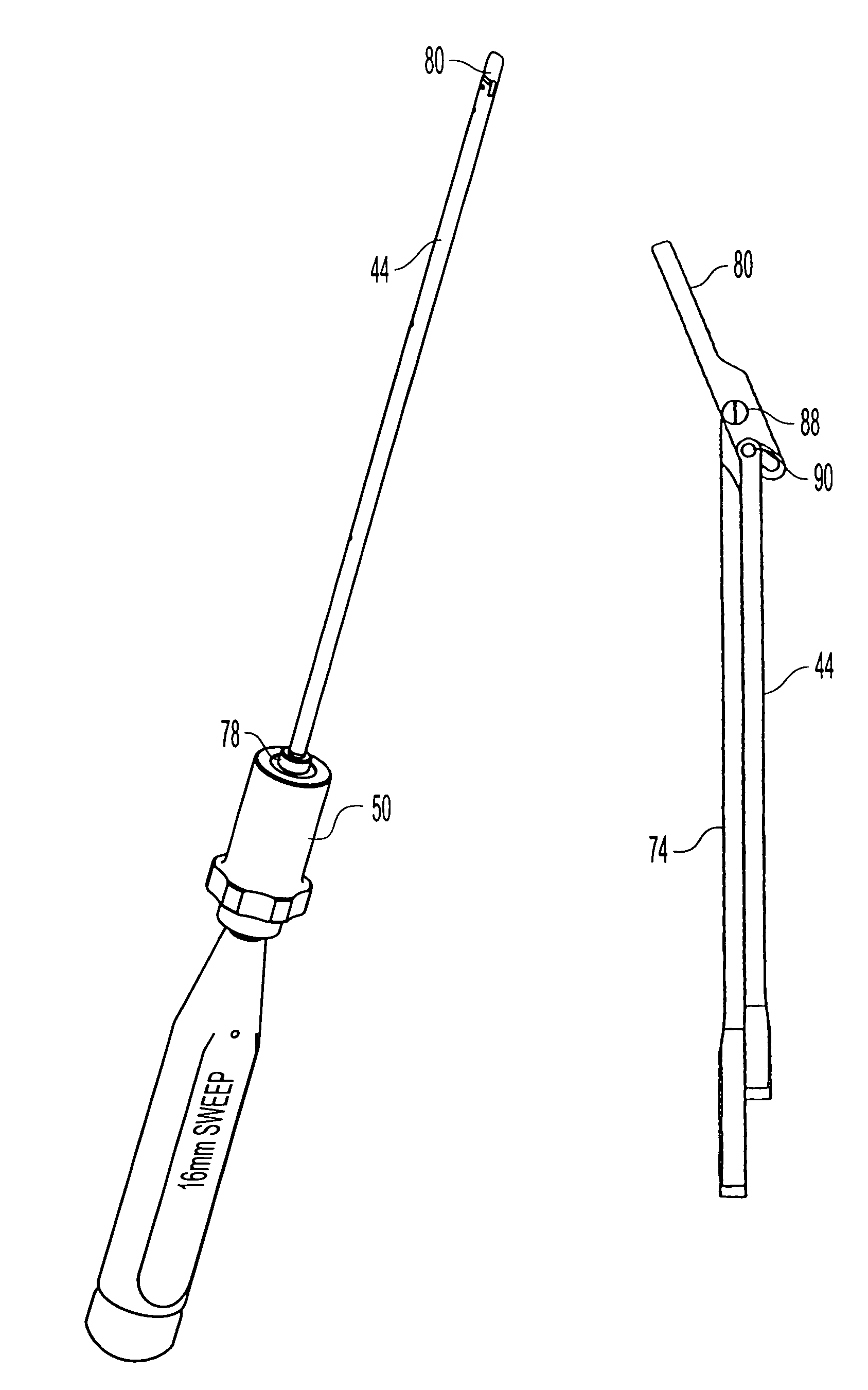

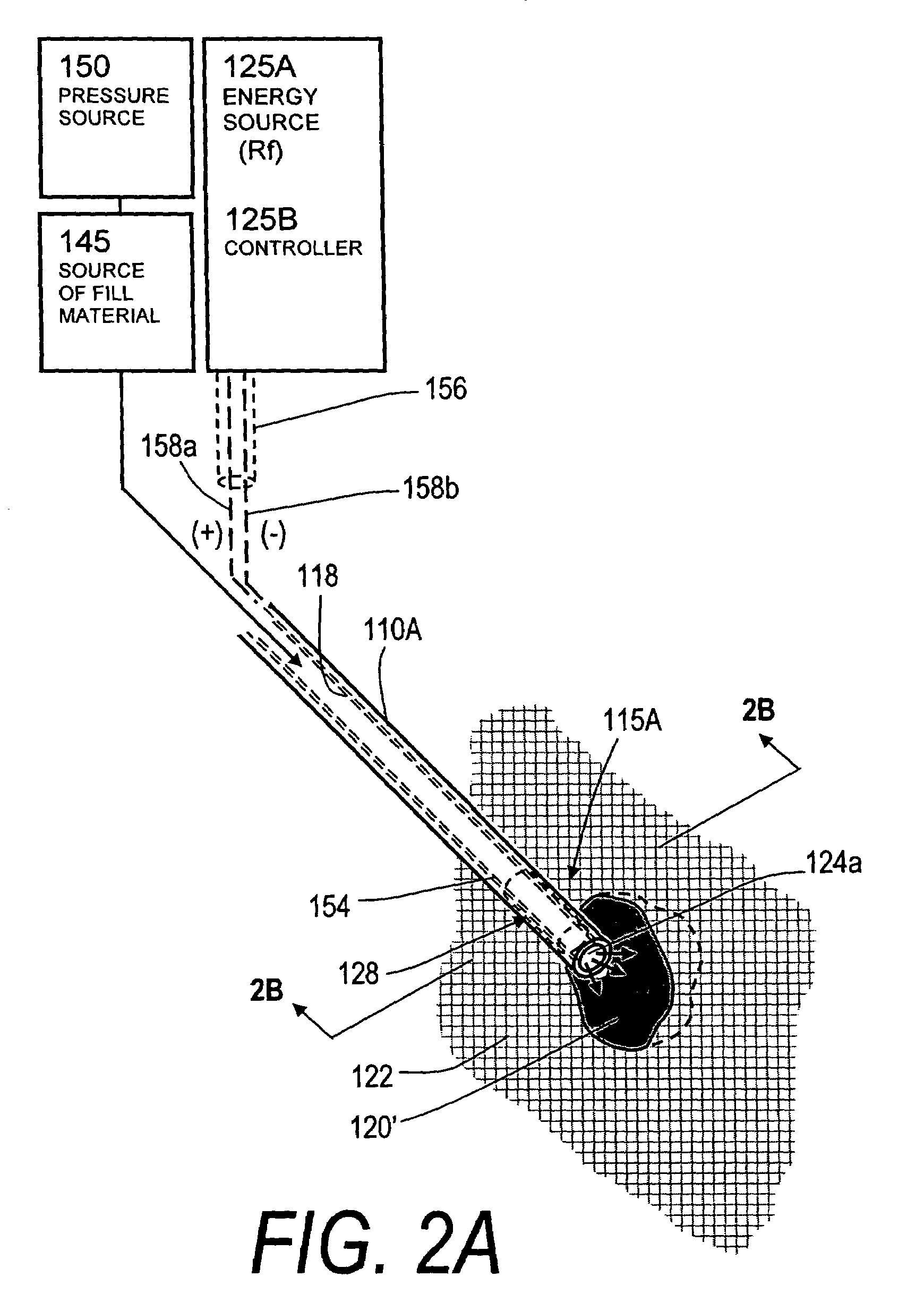

Tools and methods for creating cavities in bone

InactiveUS7476226B2Small diameterPrevent movementInternal osteosythesisJoint implantsFilling materialsBiomedical engineering

Tools for use in the creation of cavities in bones. The tools include a probe, a cannula that provides percutaneous passageway to the interior of the treated bone, a bone tamp, and a system for delivering bone filler material into the cavity. The bone tamp has a shaft that is inserted into the bone through the cannula. The end of the shaft that is inserted into the bone may have a flapper tip that extends out of axial alignment with the shaft upon deployment by the physician. Once the tip is deployed, the bone tamp can be rotated to form the cavity. The cavity may then be treated with a medicament, filled with bone filler material, or both. Other tools and materials described herein may be used to lift or restore the treated bone closer to its natural anatomy.

Owner:SYNTHES USA

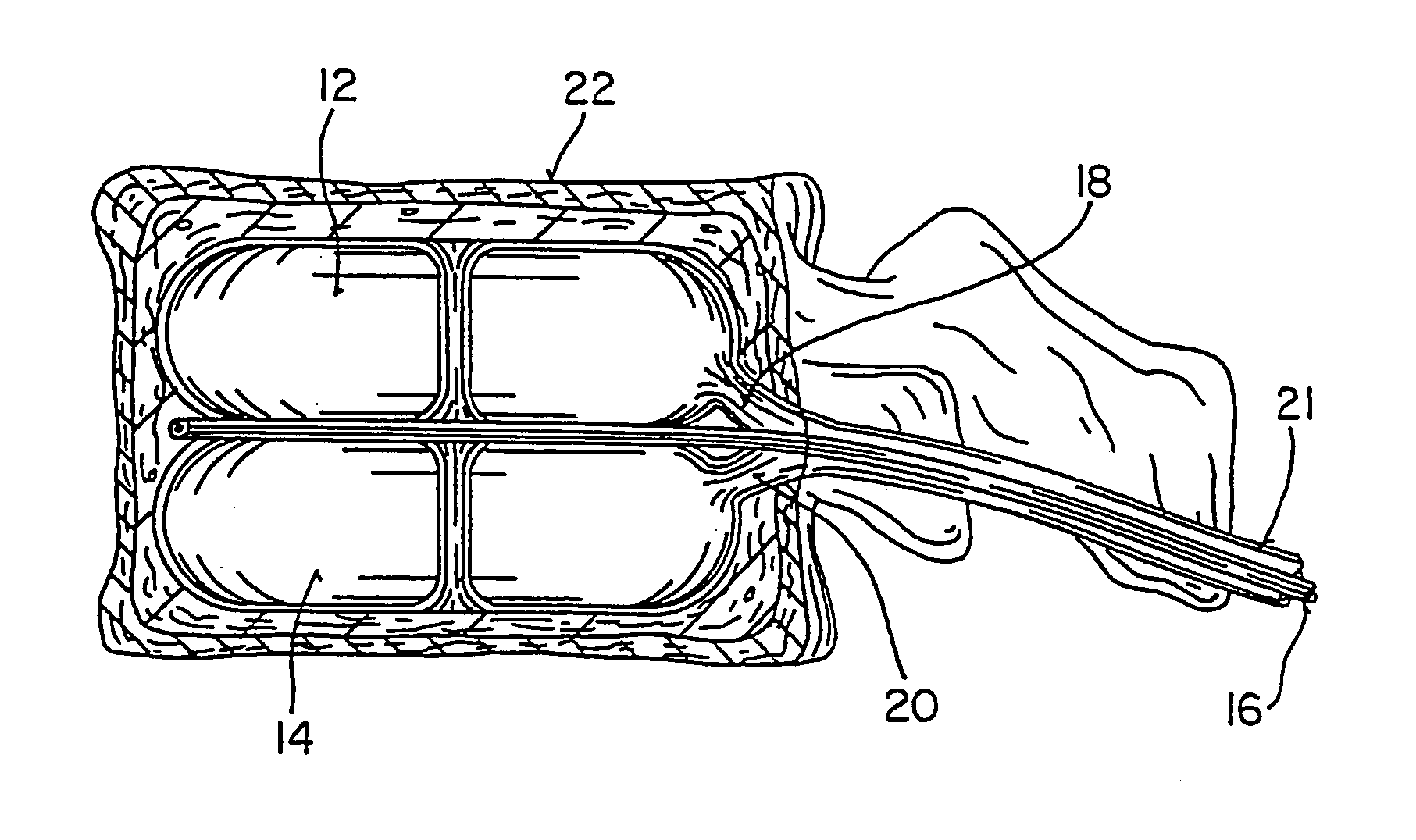

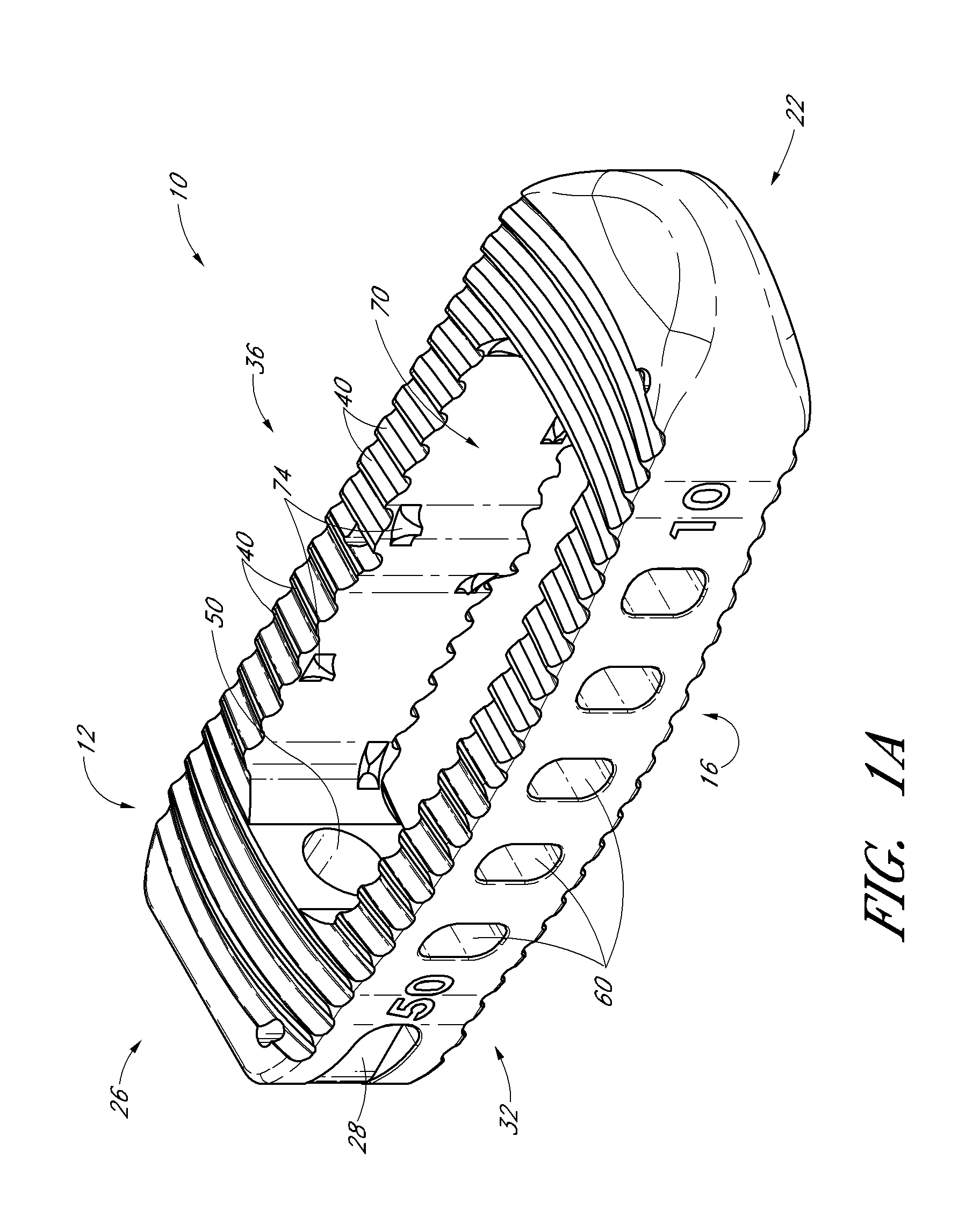

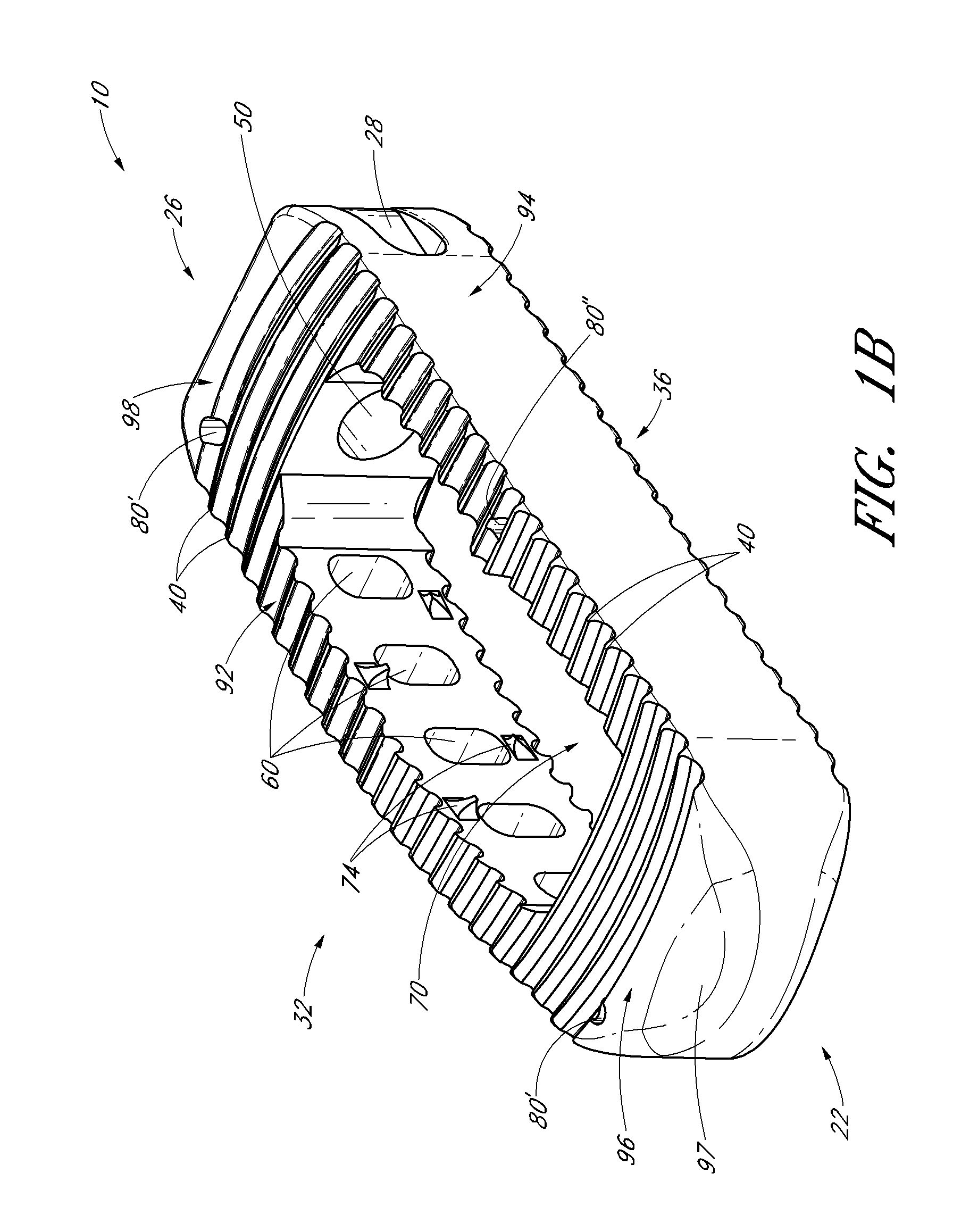

Intervertebral implants and graft delivery systems and methods

ActiveUS20110230970A1Reduce the likelihood of migrationBone implantJoint implantsFilling materialsSpinal implant

According to some embodiments, a method for promoting spinal fusion using a spinal implant comprises providing a spinal implant, wherein the spinal implant comprises an anterior wall, a posterior wall and two lateral walls configured to extend between the anterior wall and the posterior wall. In some embodiments, the spinal implant further comprises at least one internal chamber generally positioned between the anterior wall, the posterior wall and the two lateral walls, wherein the internal chamber being is adapted to receive at least one graft and / or other fill material. In some arrangements, the anterior wall of the spinal implant comprises at least one opening or hole that places the internal chamber in fluid communication with an exterior area or portion of the spinal implant. In one embodiment, at least one of the two lateral walls comprises an access port. The method additionally includes positioning the spinal implant between two adjacent vertebrae of a patient and directing at least one graft and / or other fill material into the internal chamber of the spinal implant through the access port. In some embodiments, at least a portion of the graft and / or other fill material delivered into the internal chamber is configured to exit through the one or more of the openings of the anterior wall.

Owner:SPINE HLDG LLC

Ultrasonic shears stop pad

InactiveUS20090264909A1Negative frictional effectImprove wear resistanceSurgical scissorsSurgical bladeFilling materials

An ultrasonic-surgical-shears stop pad has a stop-pad body including a base material and at least one filler material. An alternate ultrasonic-surgical-shears stop pad has a stop-pad body adjacent to tissue pad. An ultrasonic surgical shears includes an ultrasonic surgical blade and a clamping arm which is operable to open and close toward the blade and which has a transversely and resiliently flexible distal tip. An alternate ultrasonic surgical shears includes an ultrasonic surgical blade, a clamping arm operable to open and close toward the blade, and a stop pad attached to the clamping arm and having a blade contact surface, wherein at least a portion of the stop pad is resiliently flexible in a direction substantially perpendicular to the blade contact surface.

Owner:ETHICON ENDO SURGERY INC

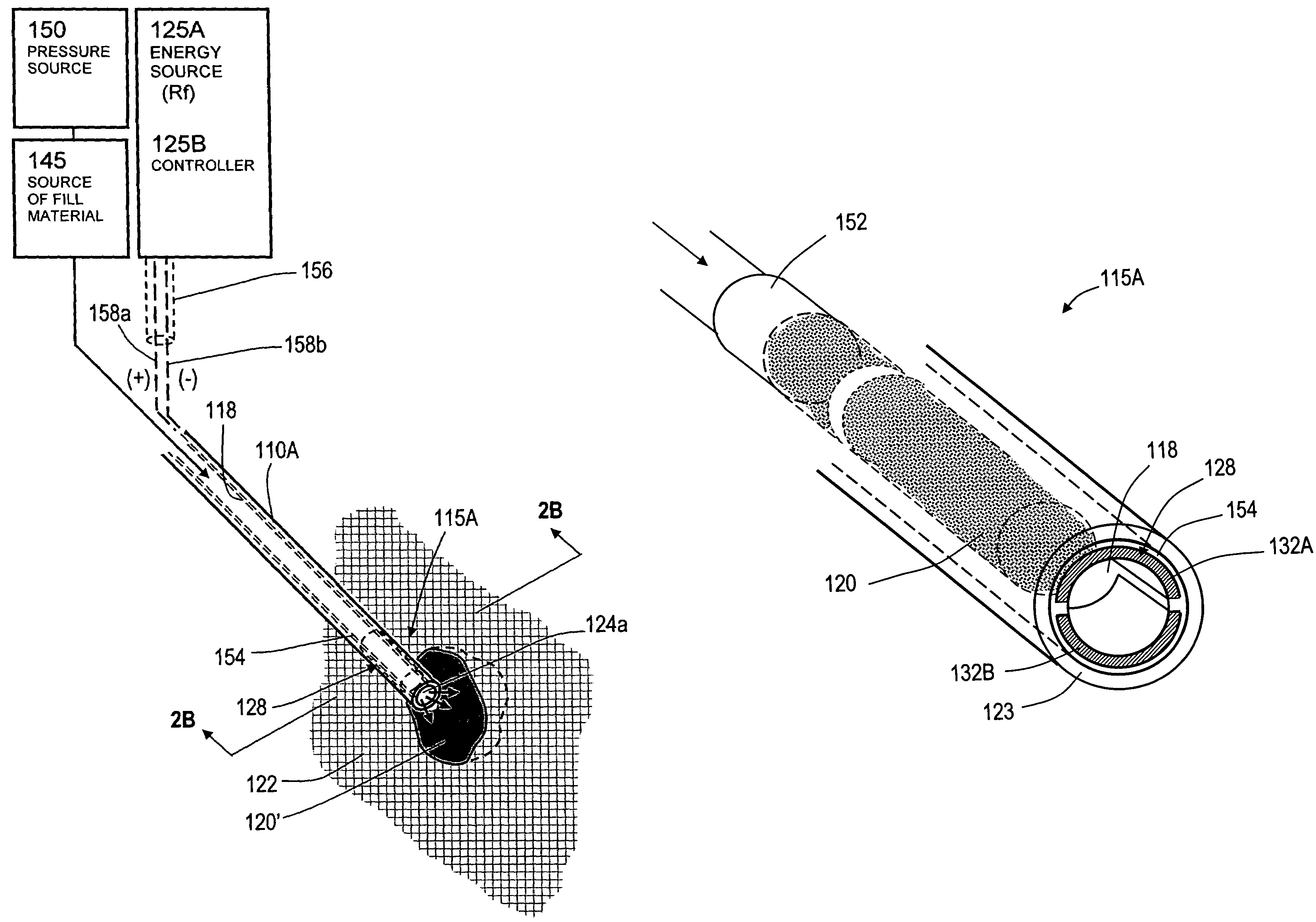

Bone treatment systems and methods

ActiveUS7559932B2Inhibit migrationSpinal implantsFastenersFilling materialsVertebra compression fracture

The present invention relates in certain embodiments to medical devices for treating osteoplasty procedures such as vertebral compression fractures. More particularly, embodiments of the invention relate to instruments and methods for controllably restoring vertebral body height by controlling the geometry of fill material introduced into cancellous bone. An exemplary system utilizes Rf energy in combination a conductive bone fill material for polymerizing the surface of the inflow plume to control the geometry of the fill material and the application of force caused by inflows of fill material. In another embodiment, method of treating bone includes injecting a volume of fill material into a bone and selectively modifying a viscosity of a selected portion of the bone filler to control the direction of flow of the fill material within the bone. A system for treating bone using this method includes an introducer for delivering fill material into the bone and an energy source selectively coupleable to the fill material to alter the viscosity of the fill material as it flows out of the introducer.

Owner:DFINE INC

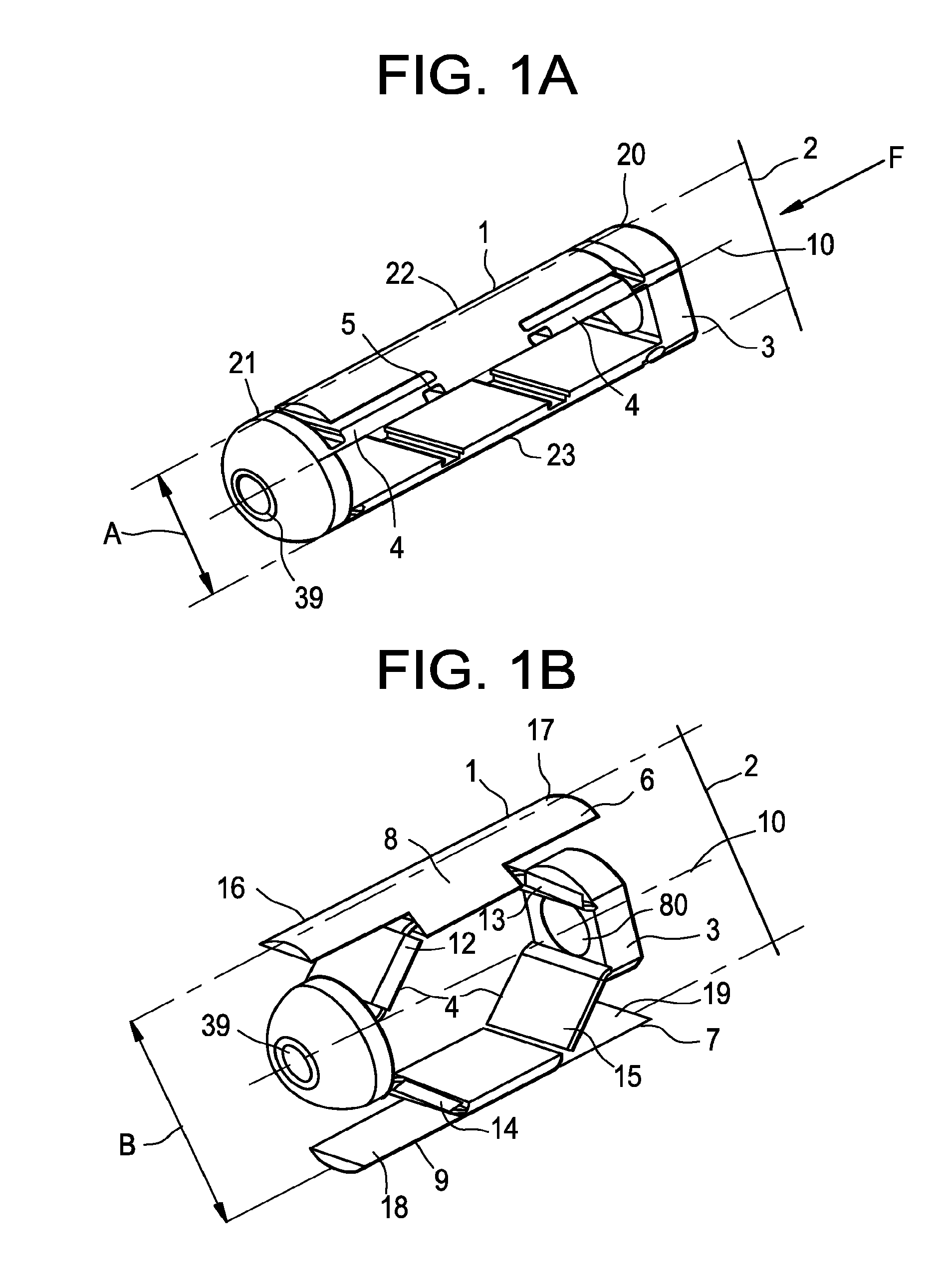

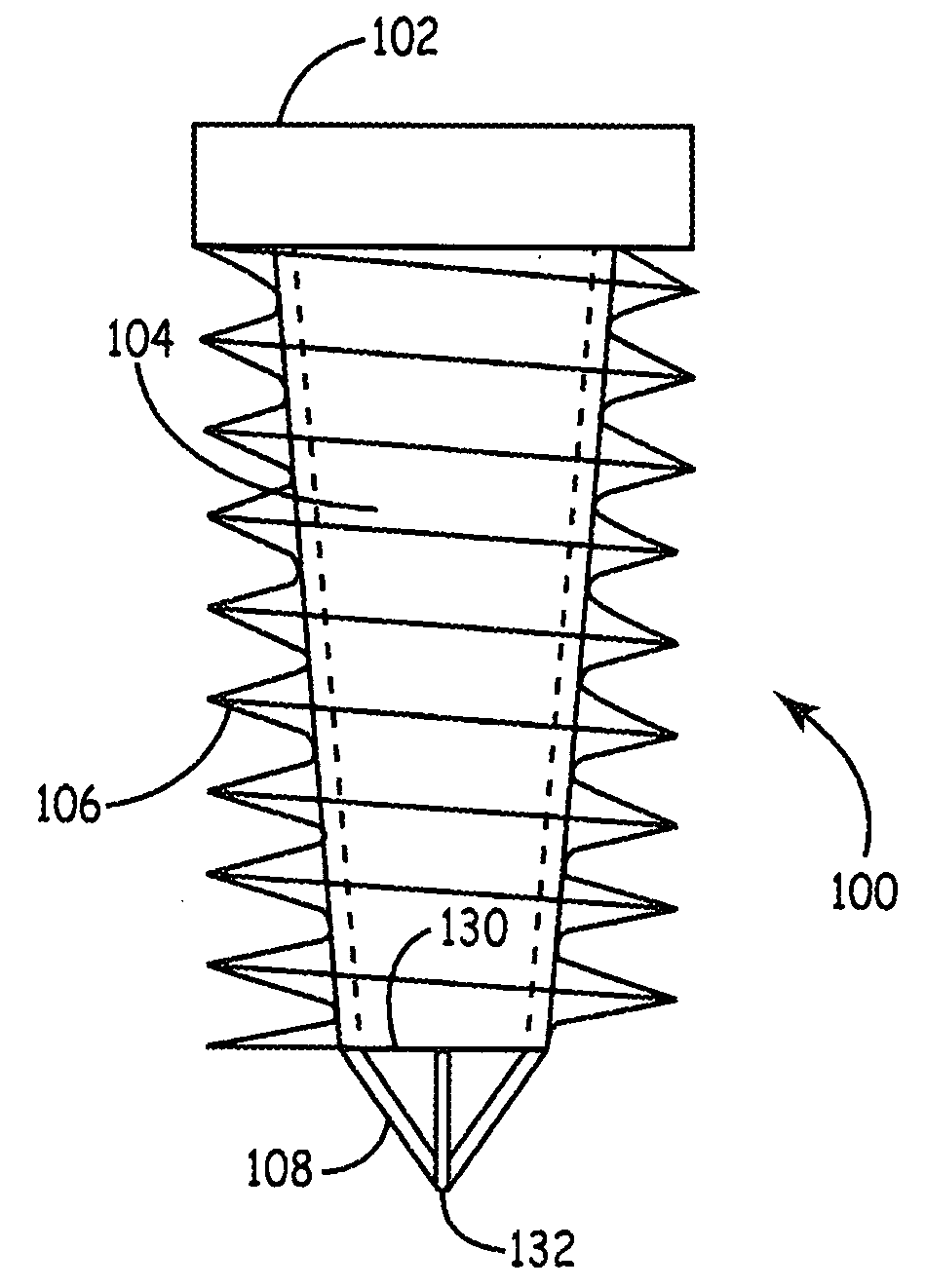

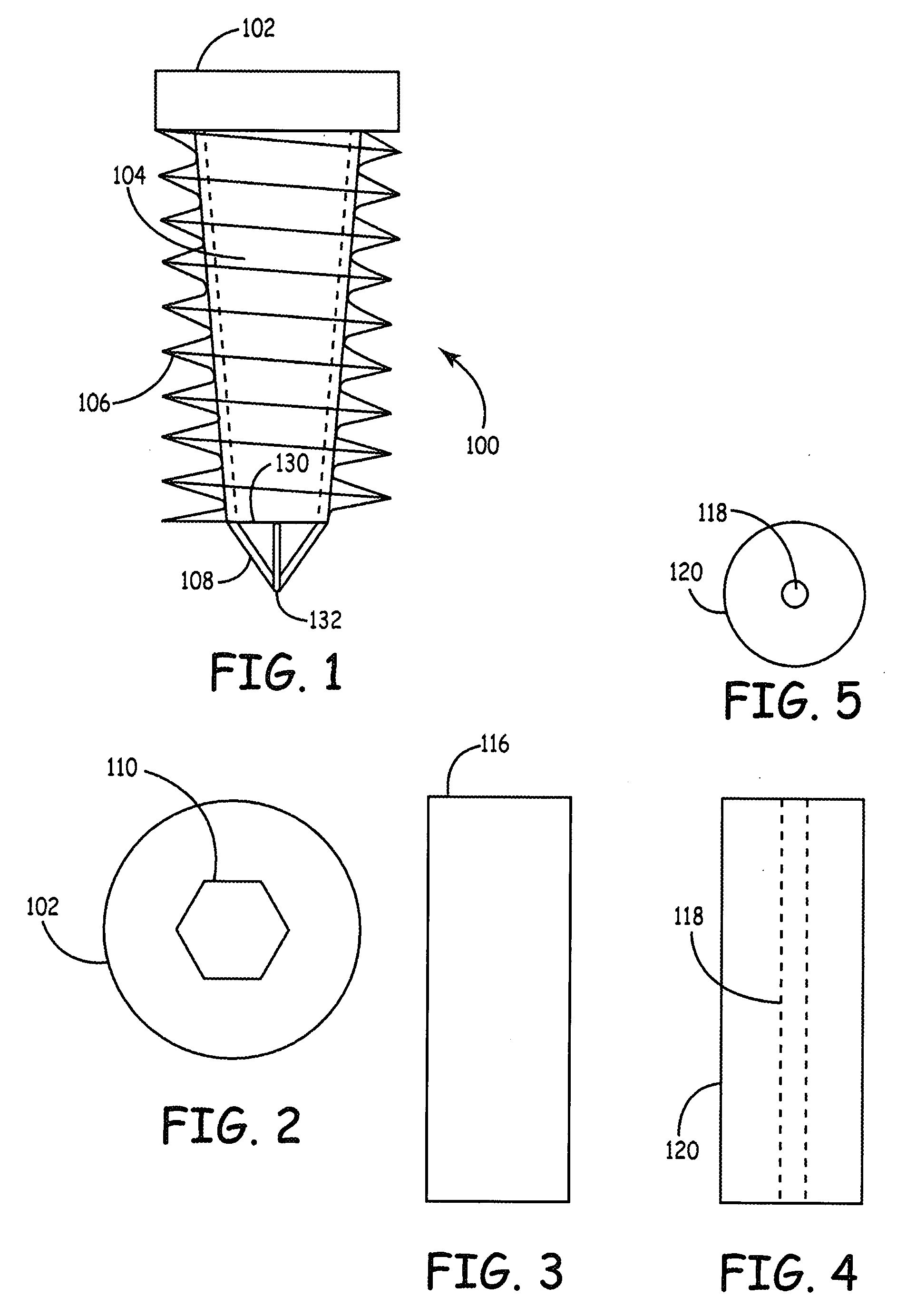

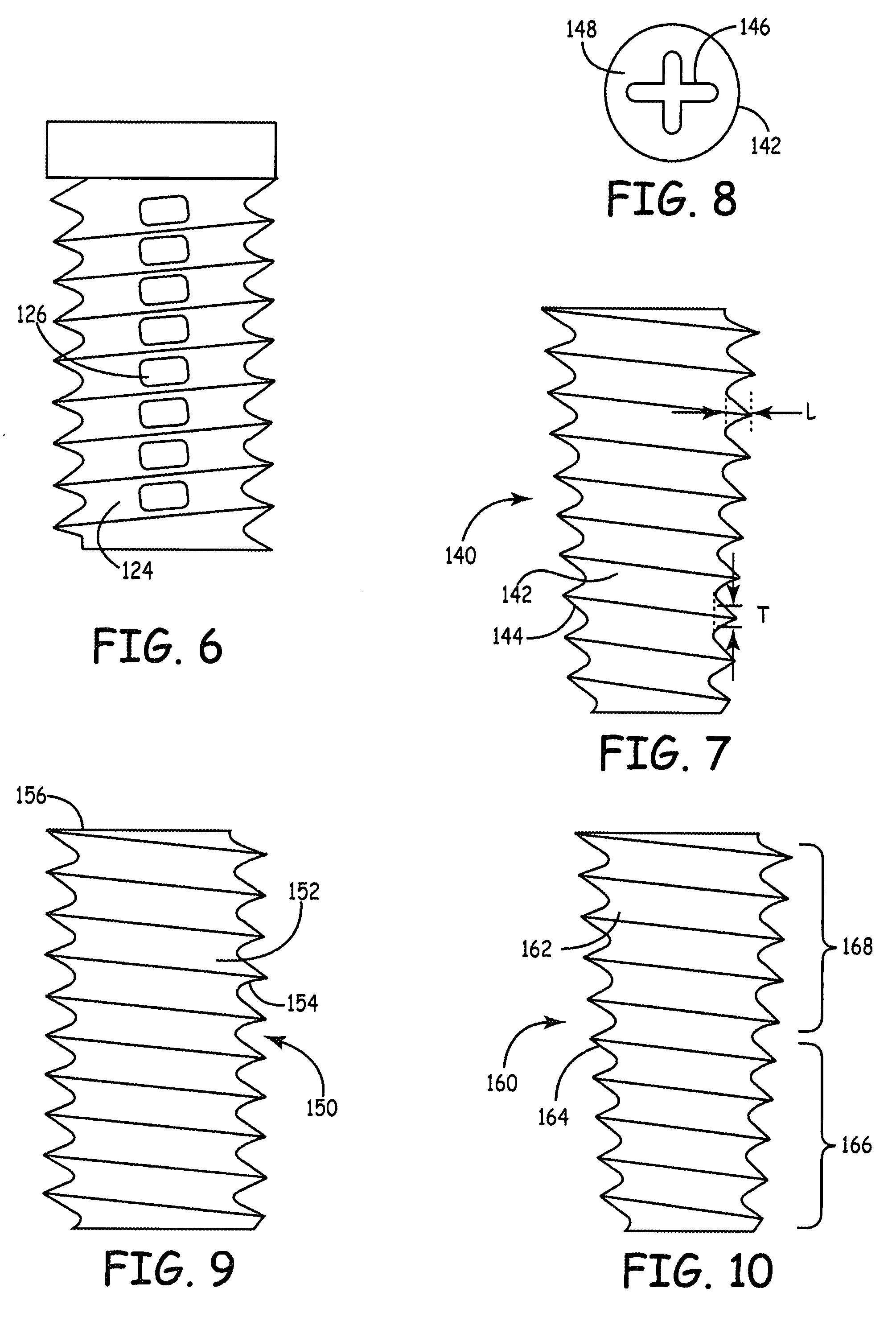

Bone screws and particular applications to sacroiliac joint fusion

Procedures for the fusion of the sacroiliac joint advantageously make use of an implant selected to distract the joint upon insertion and to maintain or increase tension upon insertion. The implant can have a varying structure along its length. In some method described herein for fusing the sacroiliac joint using an implant, an implant is screwed into the sacroiliac joint between the sacrum bone and the iliac bone. The implant comprises a shaft, a tool engagement flange at top end of the shaft, a pointed tip comprising no more than about 20 percent of the length of the screw, and threads spiraling around the shaft. For screws of particular interest, the volume displacement perpendicular to the shaft increases at least about 5 percent from a point adjacent the tip to a point near the top of the shaft. Some of the desirable screw designs can be used in other orthopedic application, especially situations involving varying bone hardness. Useful filler material can be formed from a blend of bone powder and bioactive agents.

Owner:ILION MEDICAL

Minimally invasive interbody device and method

Methods and devices for insertion between adjacent vertebrae in a spine following removing at least a portion of a nucleus from within a disc. In one embodiment, the device includes a member having a flexible wall surrounding an internal volume and a coupler that is secured to the flexible wall. The member is adapted to expand when filled with a first filler material to form an interior cavity. The coupler has a first access point, a second access point, a first coupler side hole, and an optional second coupler side hole. The first and second access points are adapted to removably receive one or more fill tubes. The fill tubes cooperate with the first and optional second coupler side holes to direct the first filler material into the internal volume and a second filler material into the interior cavity.

Owner:ZIMMER SPINE INC

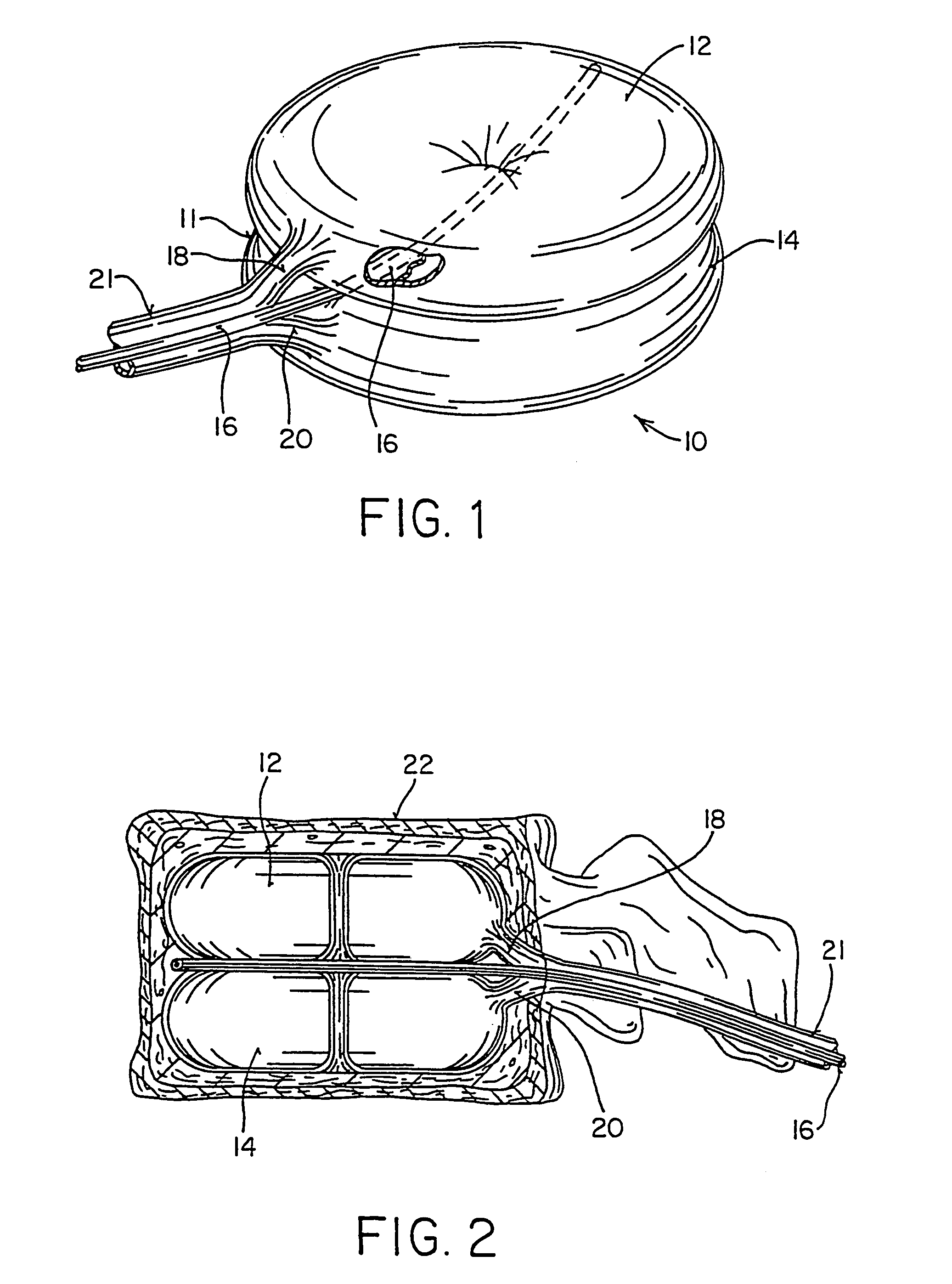

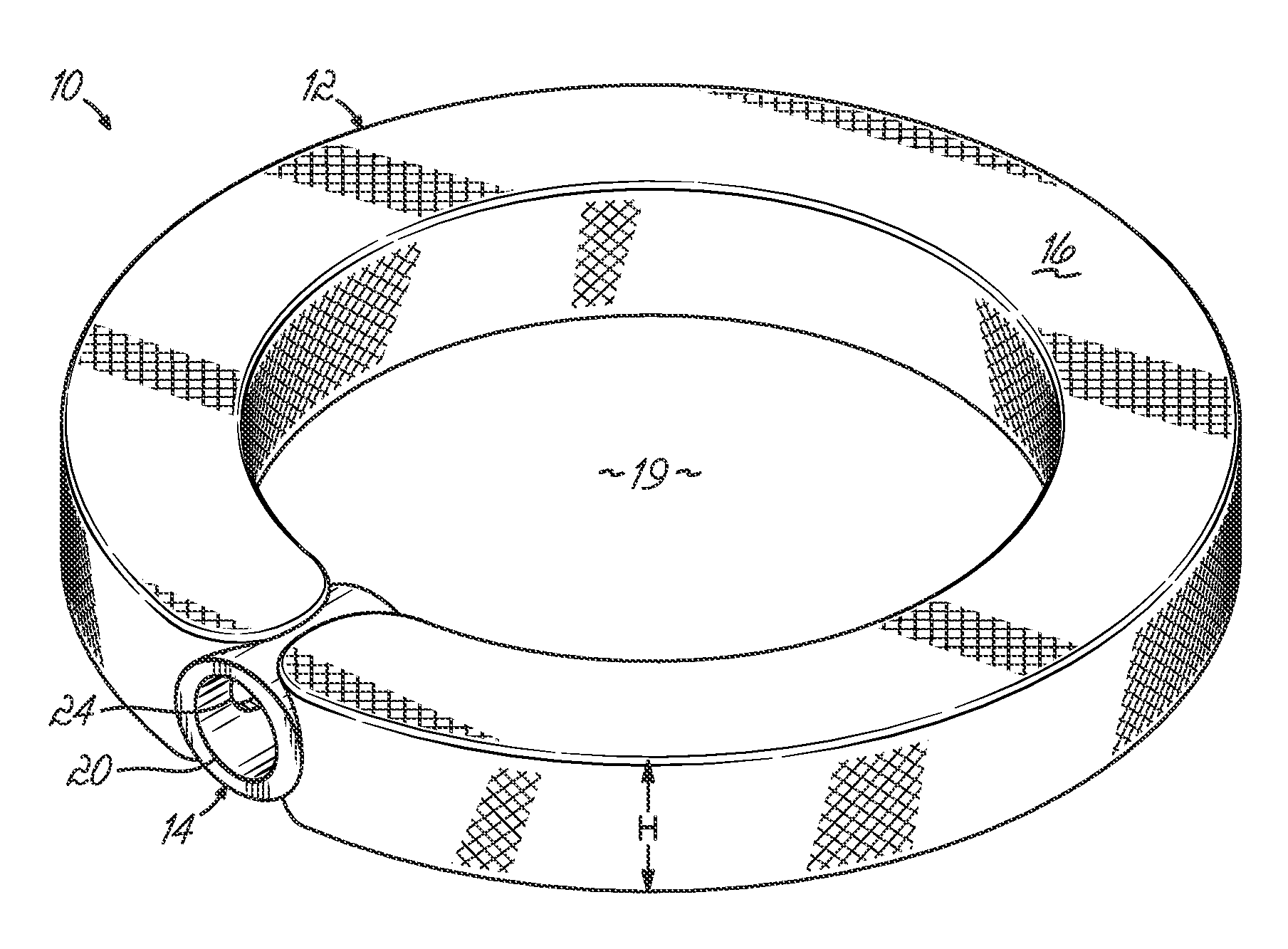

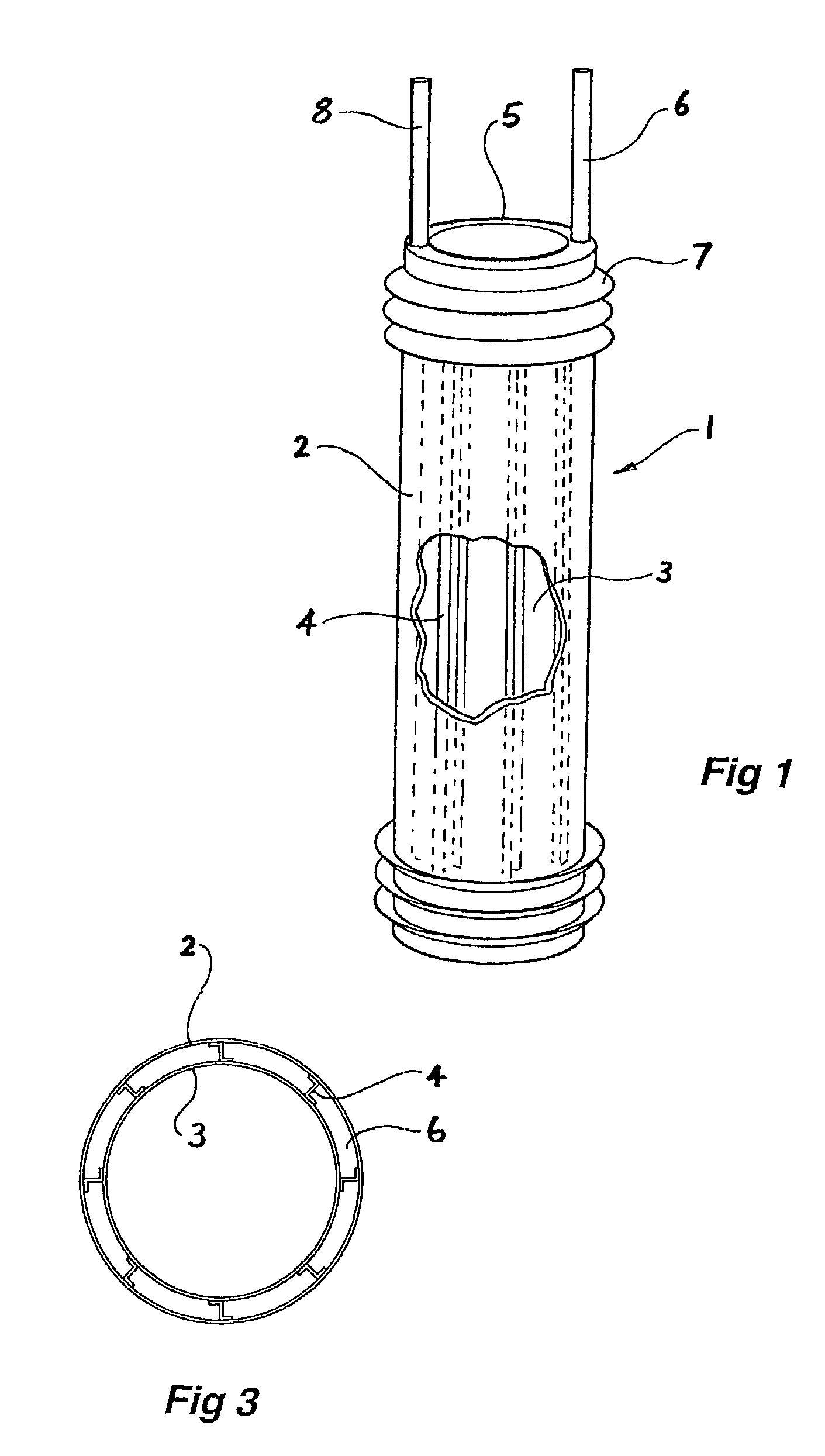

Endoluminal graft

ActiveUS7108715B2Appropriate structural strengthReduce structural strengthStentsBalloon catheterFilling materialsBalloon catheter

A graft (1) which is in the form of an inflatable member adapted to be formed into a predetermined and / or selected shape when deployed in situ by filling with a filler material (6) which can be made rigid in situ and deployed on a balloon catheter (12). The deployment balloon (13) is formed from a non-compliant material.

Owner:COOK MEDICAL TECH LLC +1

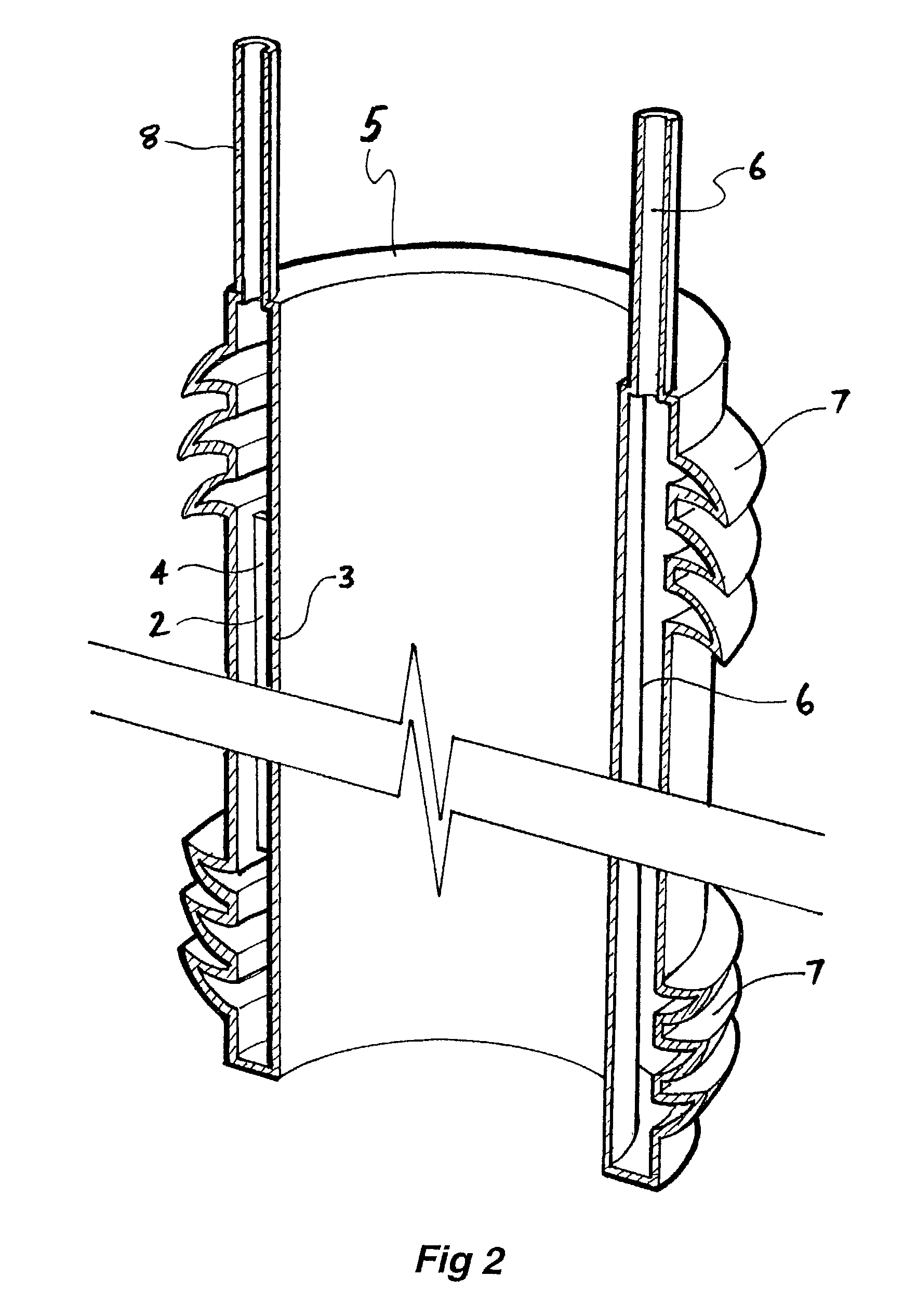

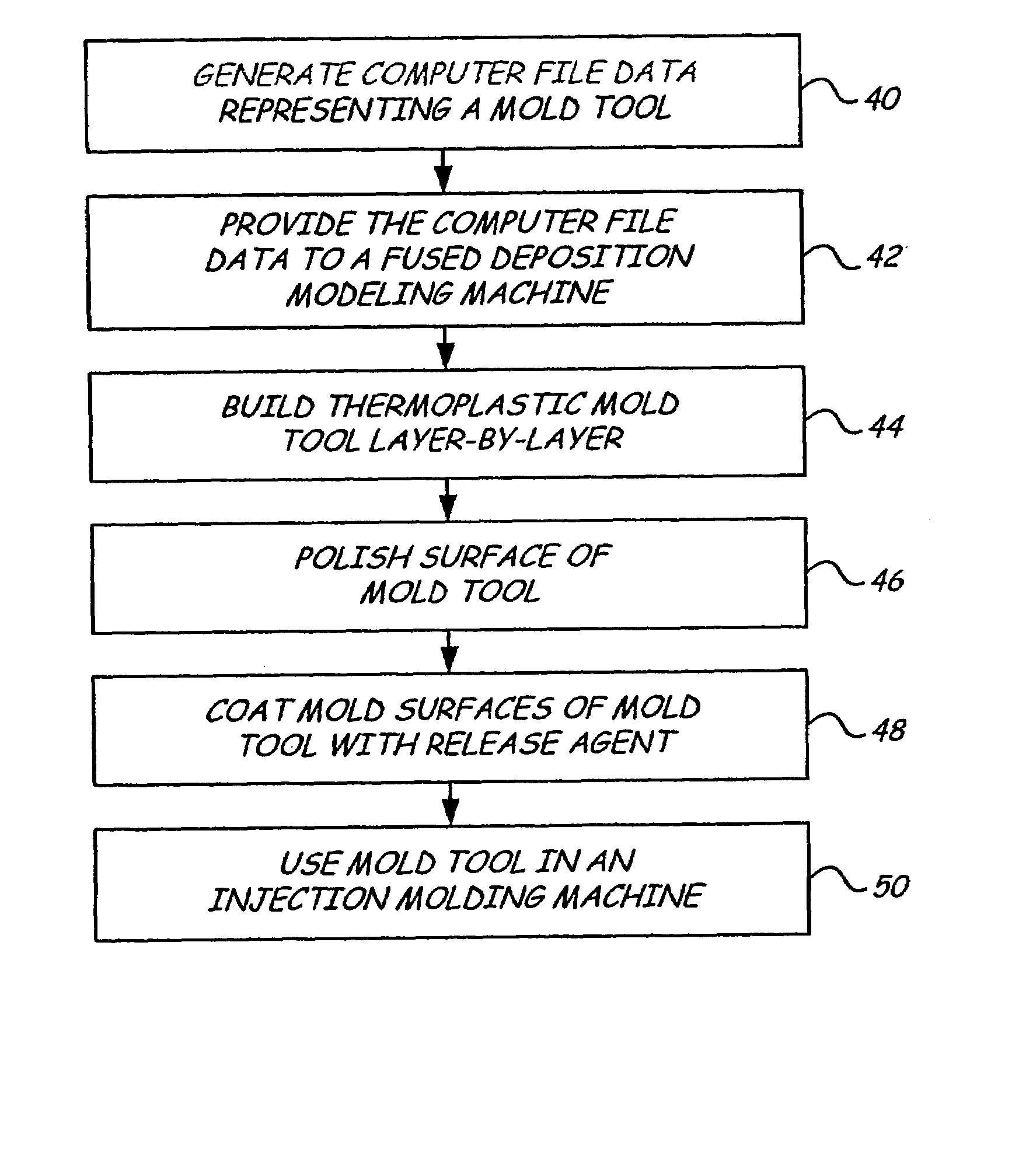

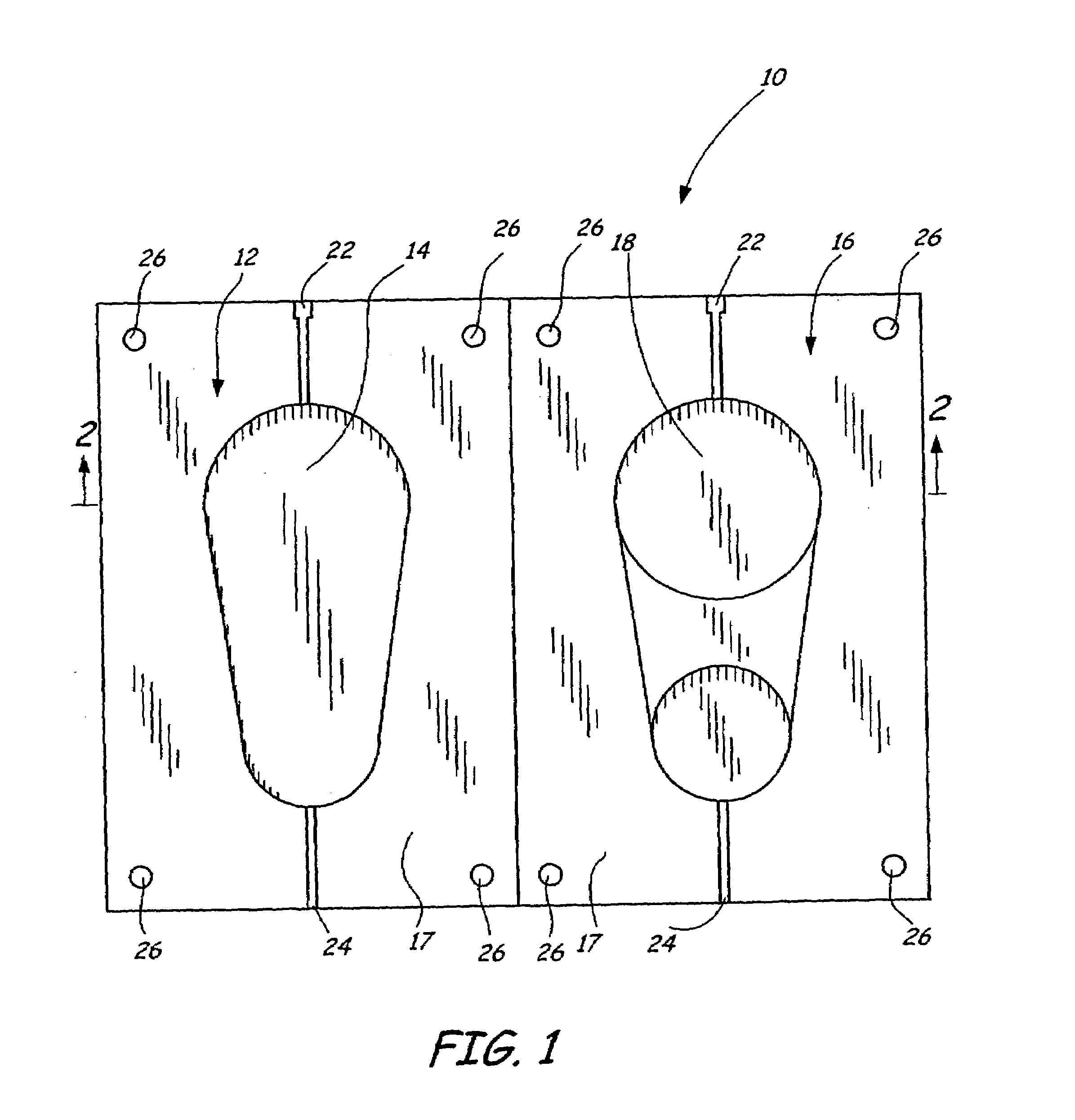

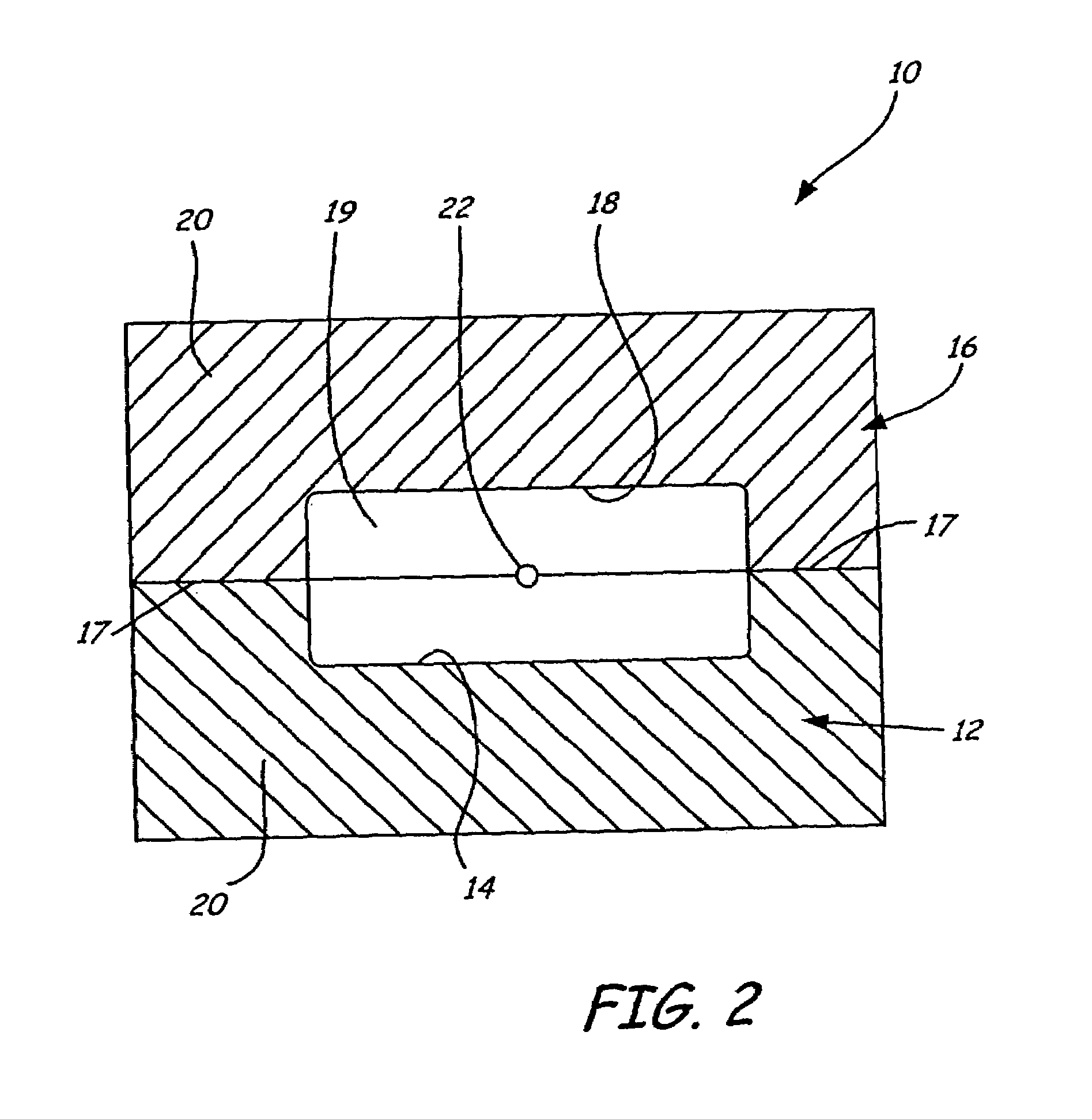

Layered deposition bridge tooling

InactiveUS7255821B2Additive manufacturing apparatusAdditive manufacturing with liquidsFilling materialsInjection molding machine

Disclosed is a method for making a prototype plastic injection molded part from a mold tool (10) built by fused deposition modeling. The mold tool (10) is built by depositing roads of a molten thermoplastic resin in layers in a predetermined pattern defined by computer file data representing the inverse of the desired prototype molded part, and is used in an injection molding machine without the addition of any reinforcement fill material or layers to create the prototype part. The disclosed method provides prototype plastic injection molded parts within a twenty-four hour time period.

Owner:STRATSYS INC

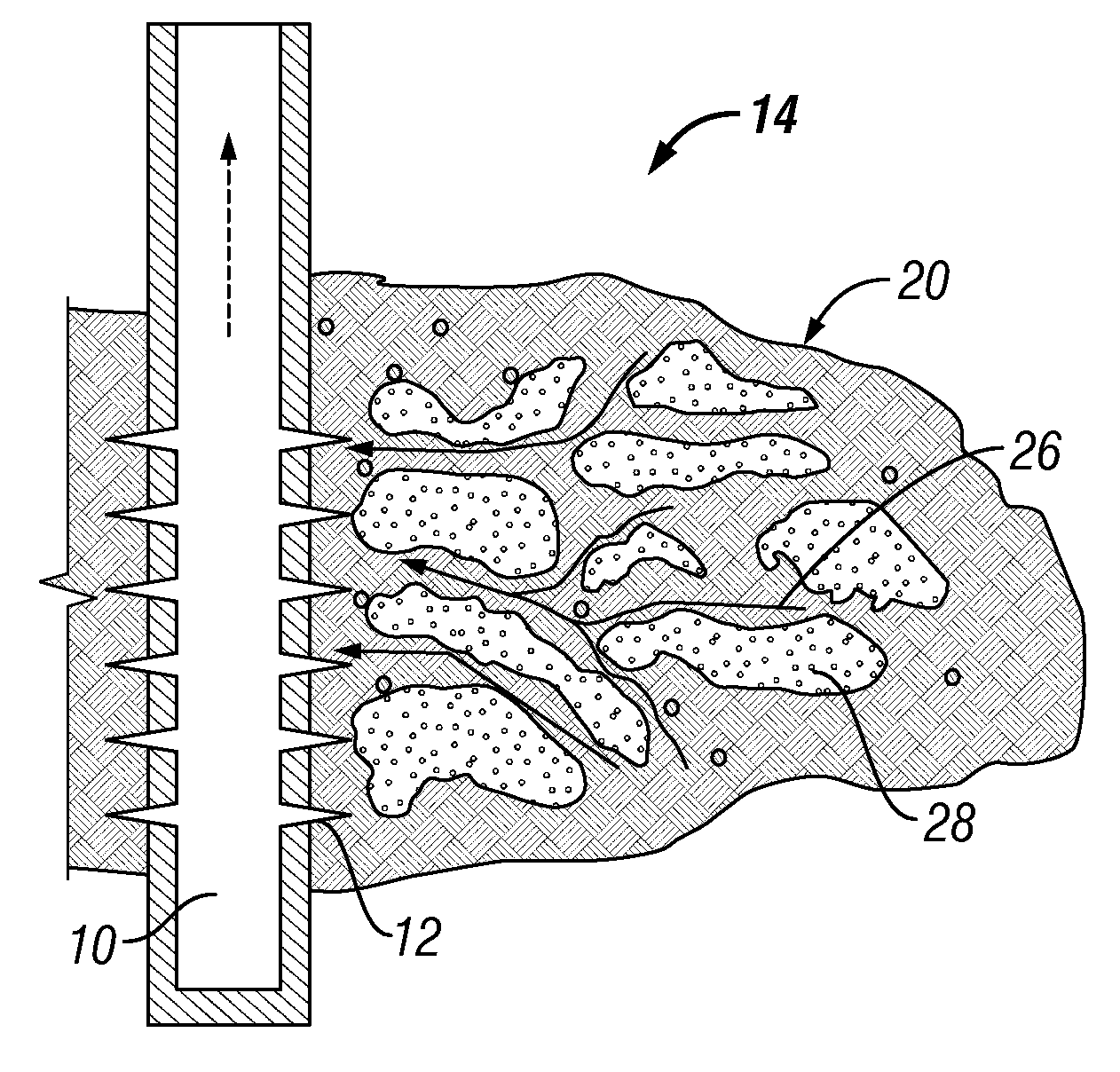

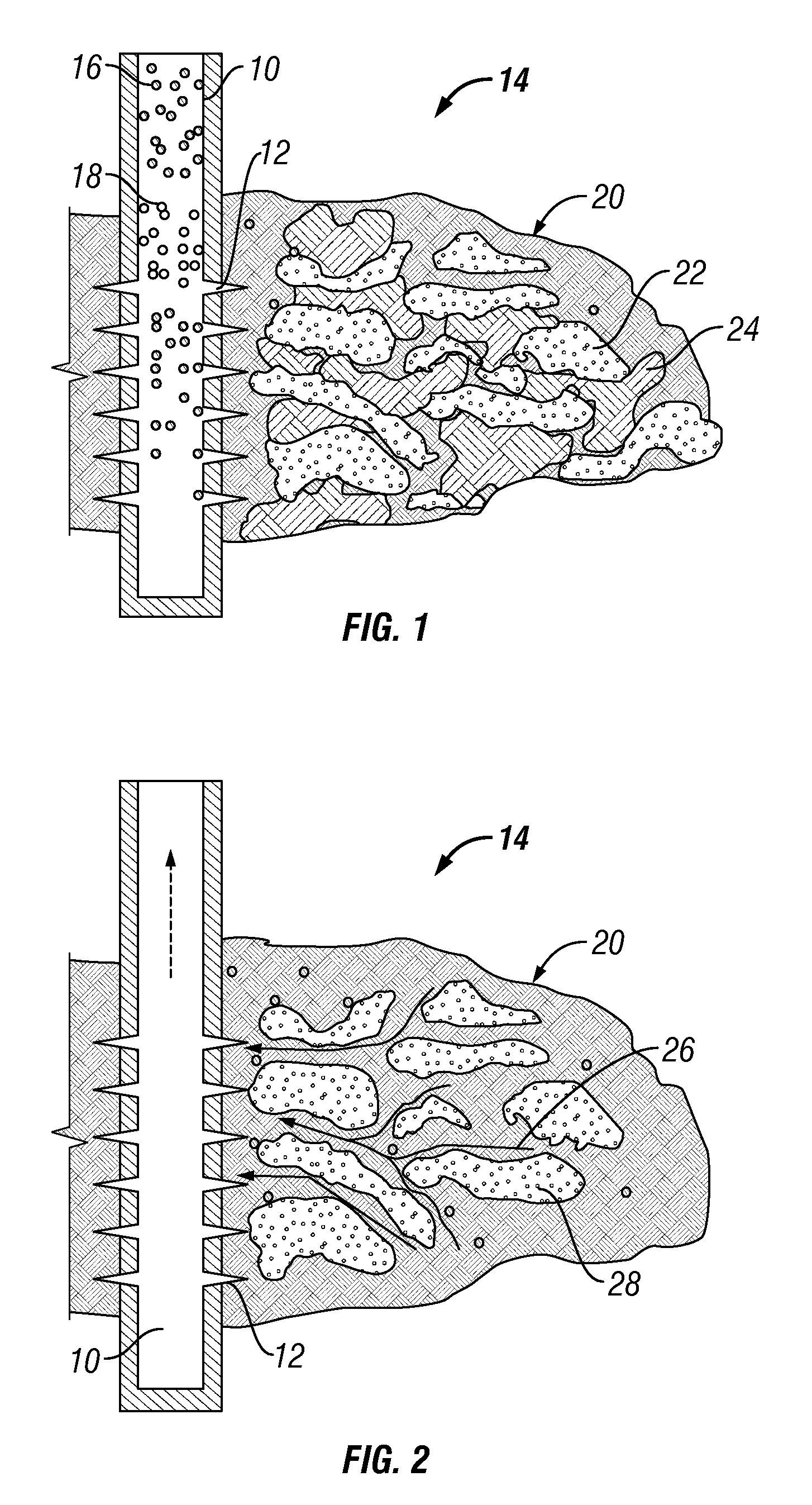

Heterogeneous proppant placement in a fracture with removable channelant fill

InactiveUS7581590B2Segregation can be facilitatedEasy to integrateFluid removalDrilling compositionFiberFilling materials

A method of heterogeneous proppant placement in a subterranean fracture is disclosed. The method comprises injecting well treatment fluid including proppant (16) and proppant-spacing filler material called a channelant (18) through a wellbore (10) into the fracture (20), heterogeneously placing the proppant in the fracture in a plurality of proppant clusters or islands (22) spaced apart by the channelant (24), and removing the channelant filler material (24) to form open channels (26) around the pillars (28) for fluid flow from the formation (14) through the fracture (20) toward the wellbore (10). The proppant and channelant can be segregated within the well treatment fluid, or segregated during placement in the fracture. The channelant can be dissolvable particles, initially acting as a filler material during placement of the proppant in the fracture, and later dissolving to leave the flow channels between the proppant pillars. The well treatment fluid can include fibers to provide reinforcement and consolidation of the proppant and, additionally or alternatively, to inhibit settling of the proppant in the treatment fluid.

Owner:SCHLUMBERGER TECH CORP

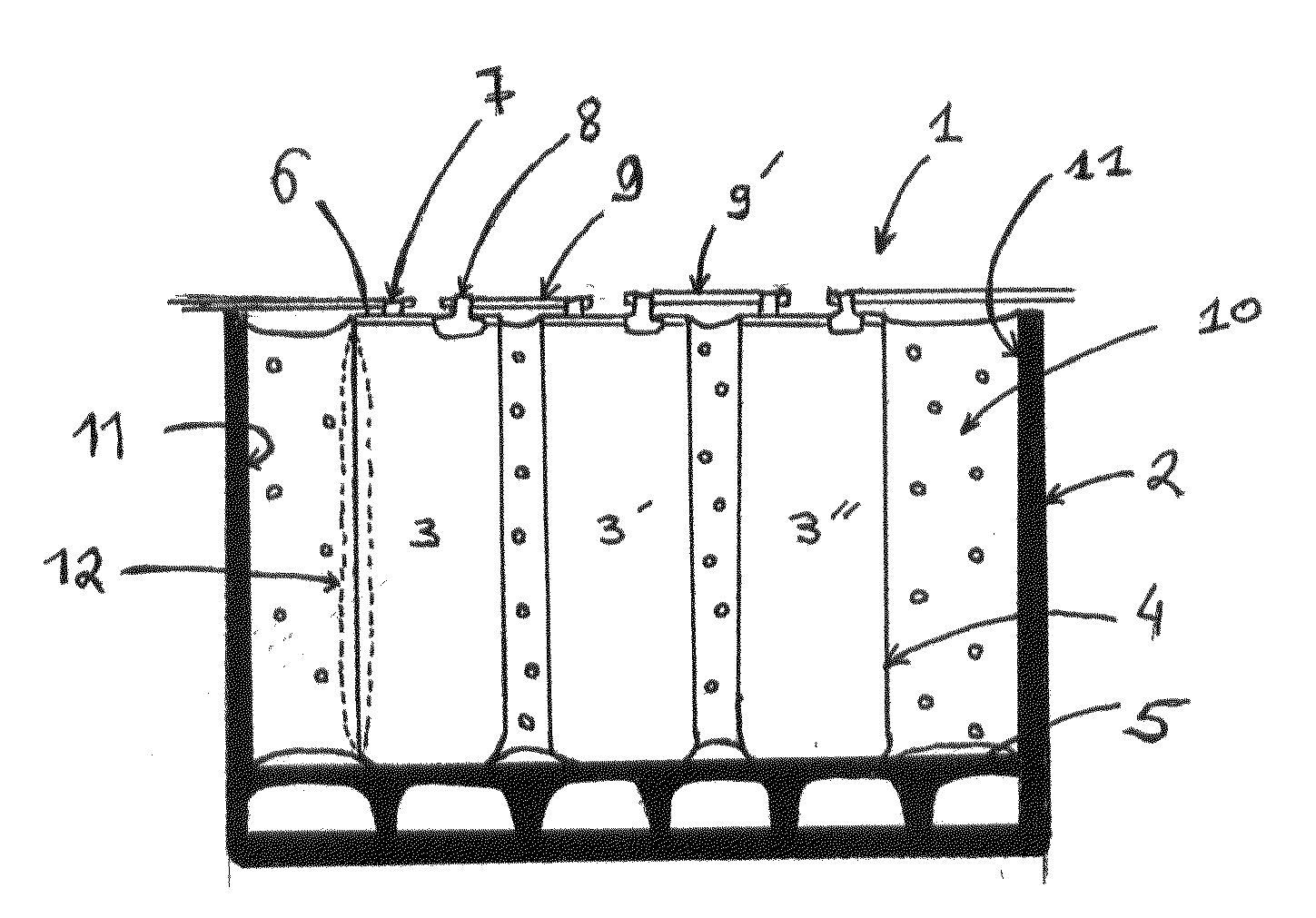

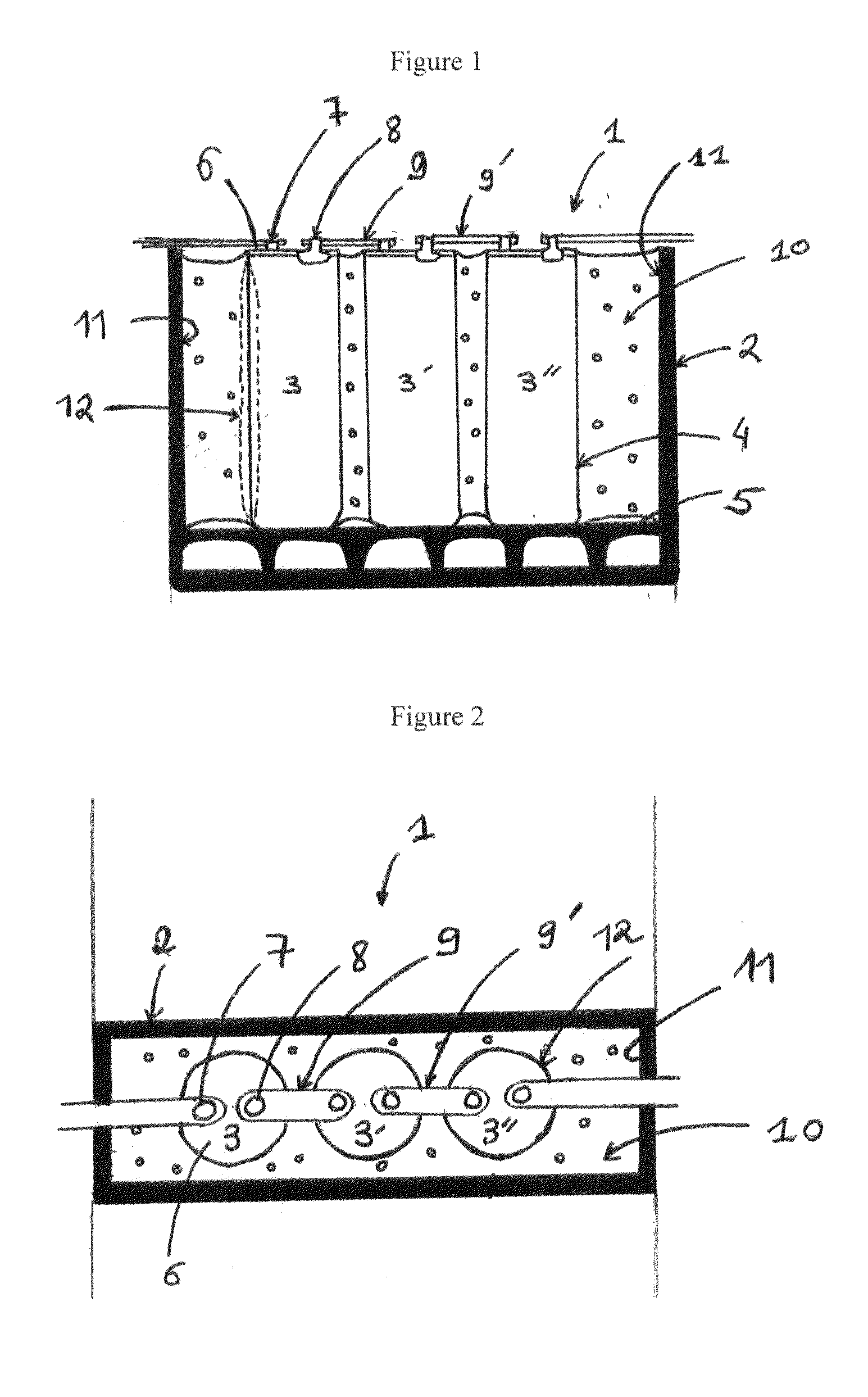

Battery of electrochemical generators comprising a foam as inter-generator filler material

InactiveUS20120003508A1Improve securityFinal product manufactureSmall-sized cells cases/jacketsPorosityLithium

A battery of lithium electrochemical generators including a casing; a plurality of lithium electrochemical generators housed in the casing, each generator including a container; a rigid, flame-retardant foam with closed porosity formed of an electrically insulating material filling the space between the inner wall of the casing and the free surface of the side wall of the container of each electrochemical generator, the foam covering the free surface of the side wall of the container of each electrochemical generator over a length representing at least 25% of the height of the container.

Owner:SAFT GRP SA

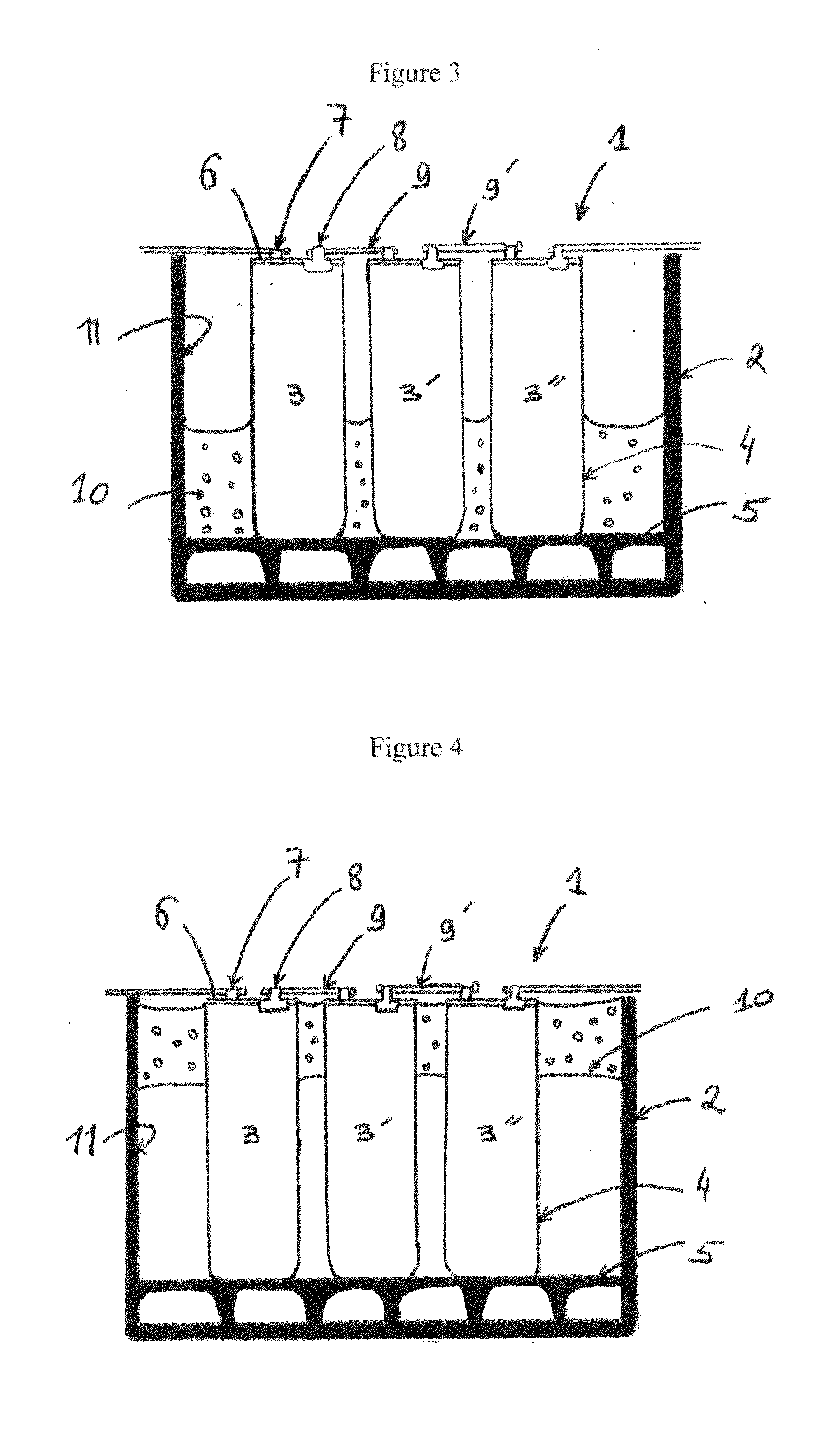

Combination of a golf club head and a weight member

InactiveUS20050096151A1Rapid and simplified processGood effectGolf clubsRacket sportsFilling materialsEngineering

A golf club head includes a recession in a sole thereof. A weight member is mounted in a recession of the golf club head for adjusting the center of gravity of the golf club head. A filling material seals the recession and buries / fixes the weight member in the recession. The filling material simplifies the process for mounting the weight member and absorbs vibrations generated as a result of striking a golf ball.

Owner:NELSON PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com