Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1355 results about "Anti-reflective coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

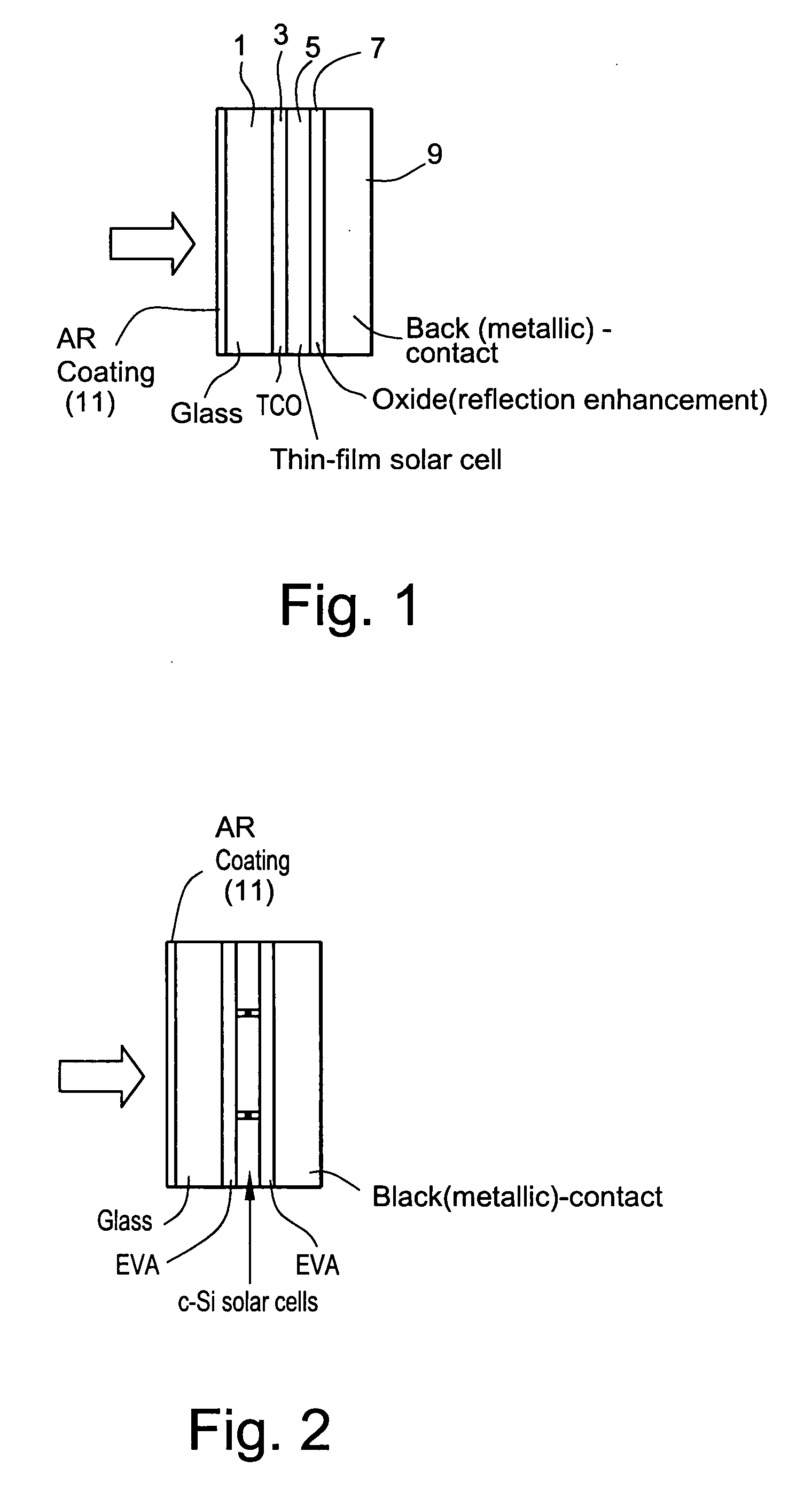

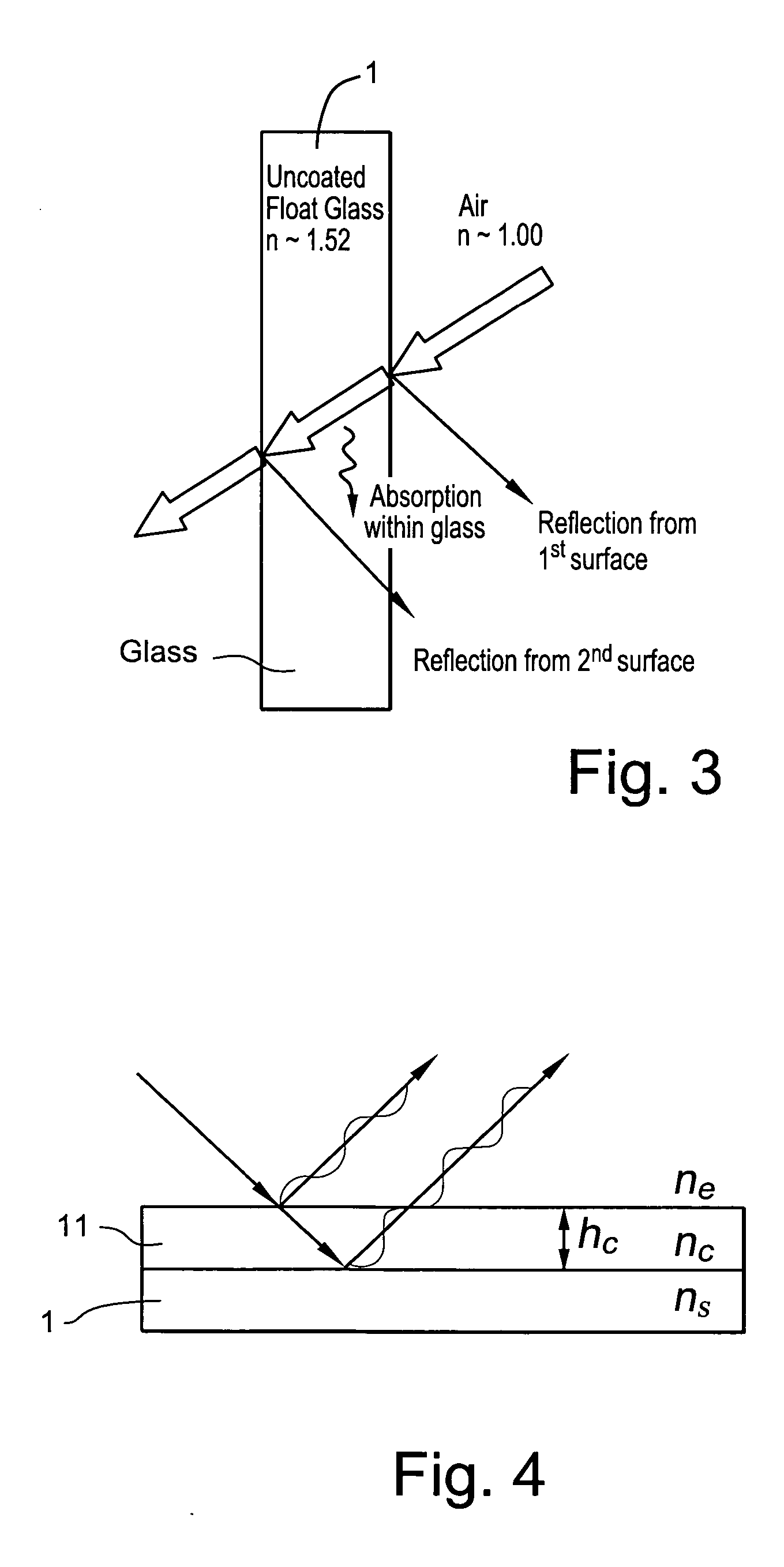

An antireflective or anti-reflection (AR) coating is a type of optical coating applied to the surface of lenses and other optical elements to reduce reflection. In typical imaging systems, this improves the efficiency since less light is lost due to reflection. In complex systems such as telescopes and microscopes the reduction in reflections also improves the contrast of the image by elimination of stray light. This is especially important in planetary astronomy. In other applications, the primary benefit is the elimination of the reflection itself, such as a coating on eyeglass lenses that makes the eyes of the wearer more visible to others, or a coating to reduce the glint from a covert viewer's binoculars or telescopic sight.

Damage resistant glass article for use as a cover plate in electronic devices

InactiveUS20090197048A1Minimizing transportEasy to disassembleFilm/foil adhesivesSynthetic resin layered productsAnti-reflective coatingChemical Linkage

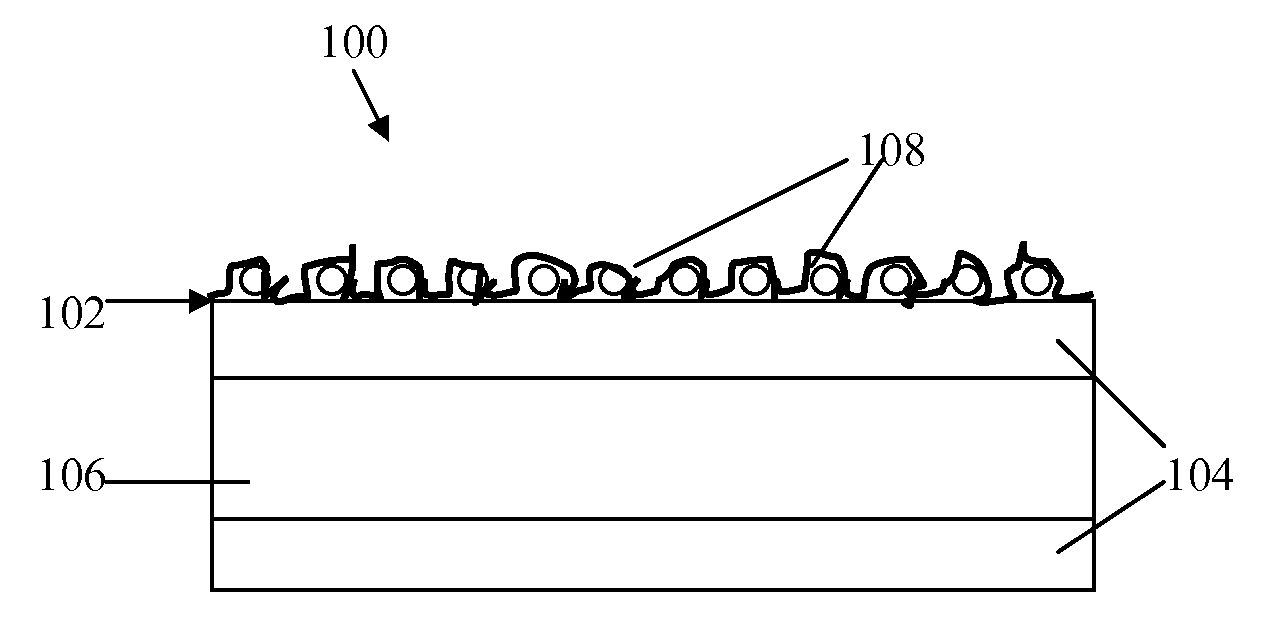

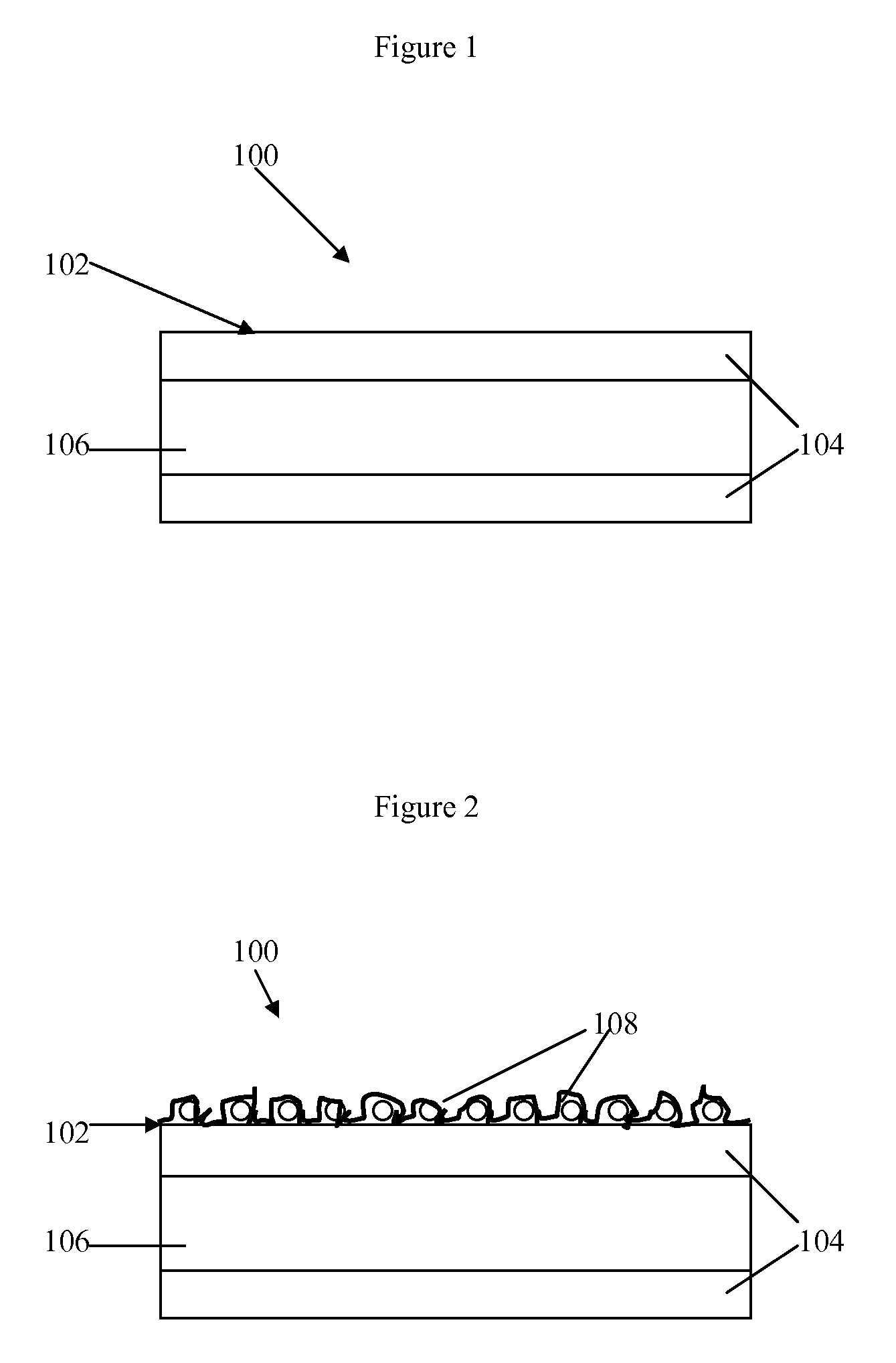

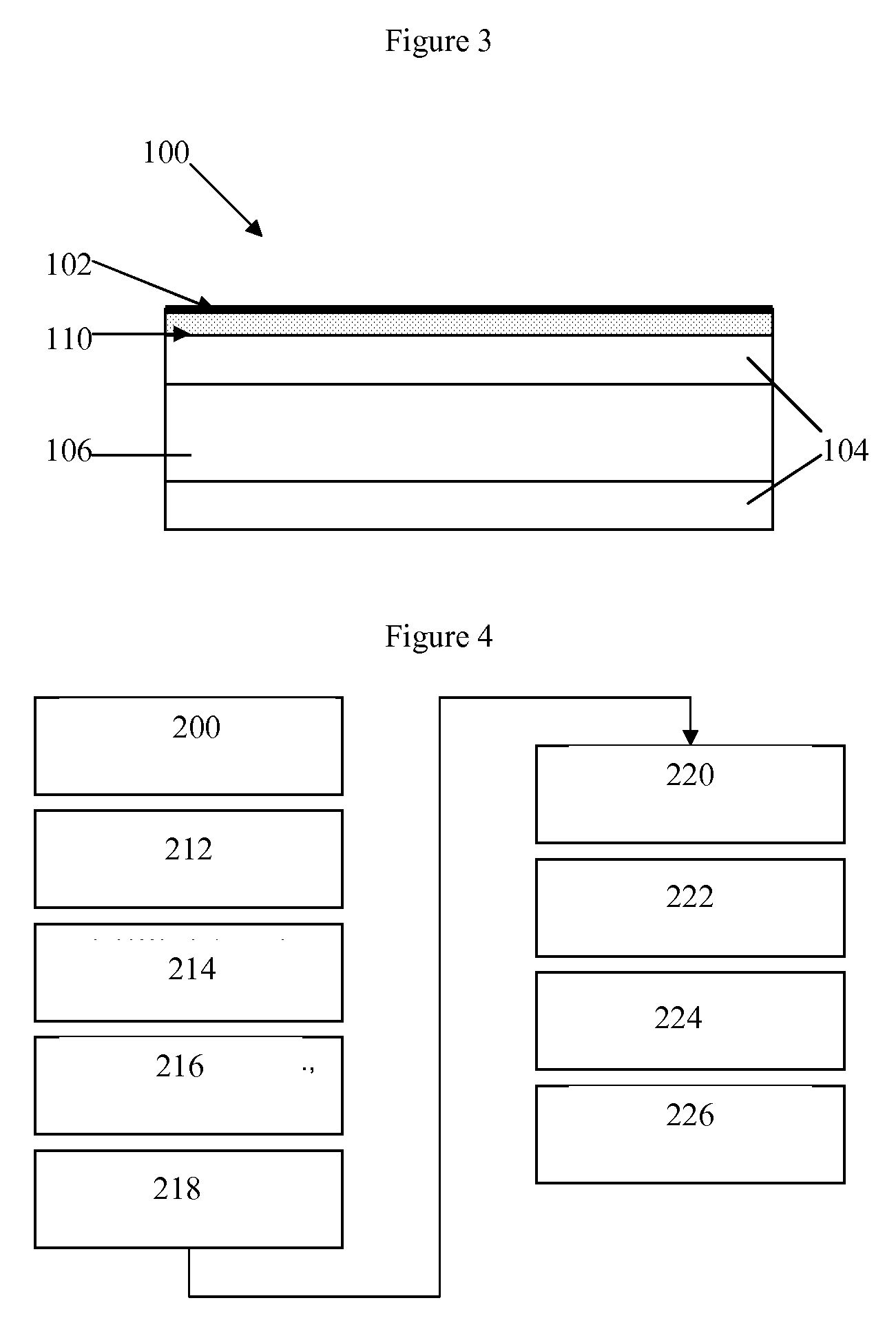

An alkali aluminosilicate glass article, said alkali aluminosilicate glass having a surface compressive stress of at least about 200 MPa, a surface compressive layer having a depth of at least about 30 μm, a thickness of at least about 0.3 mm and an amphiphobic fluorine-based surface layer chemically bonded to the surface of the glass. In one embodiment the glass has an anti-reflective coating applied to one surface of the glass between the chemically strengthened surface of the glass and the amphiphobic coating. In another embodiment the surface of the chemically strengthened glass is acid treated using a selected acid (e.g., HCL, H2SO4, HClO4, acetic acid and other acids as described) prior to placement of the amphiphobic coating or the anti-reflective coating.

Owner:CORNING INC

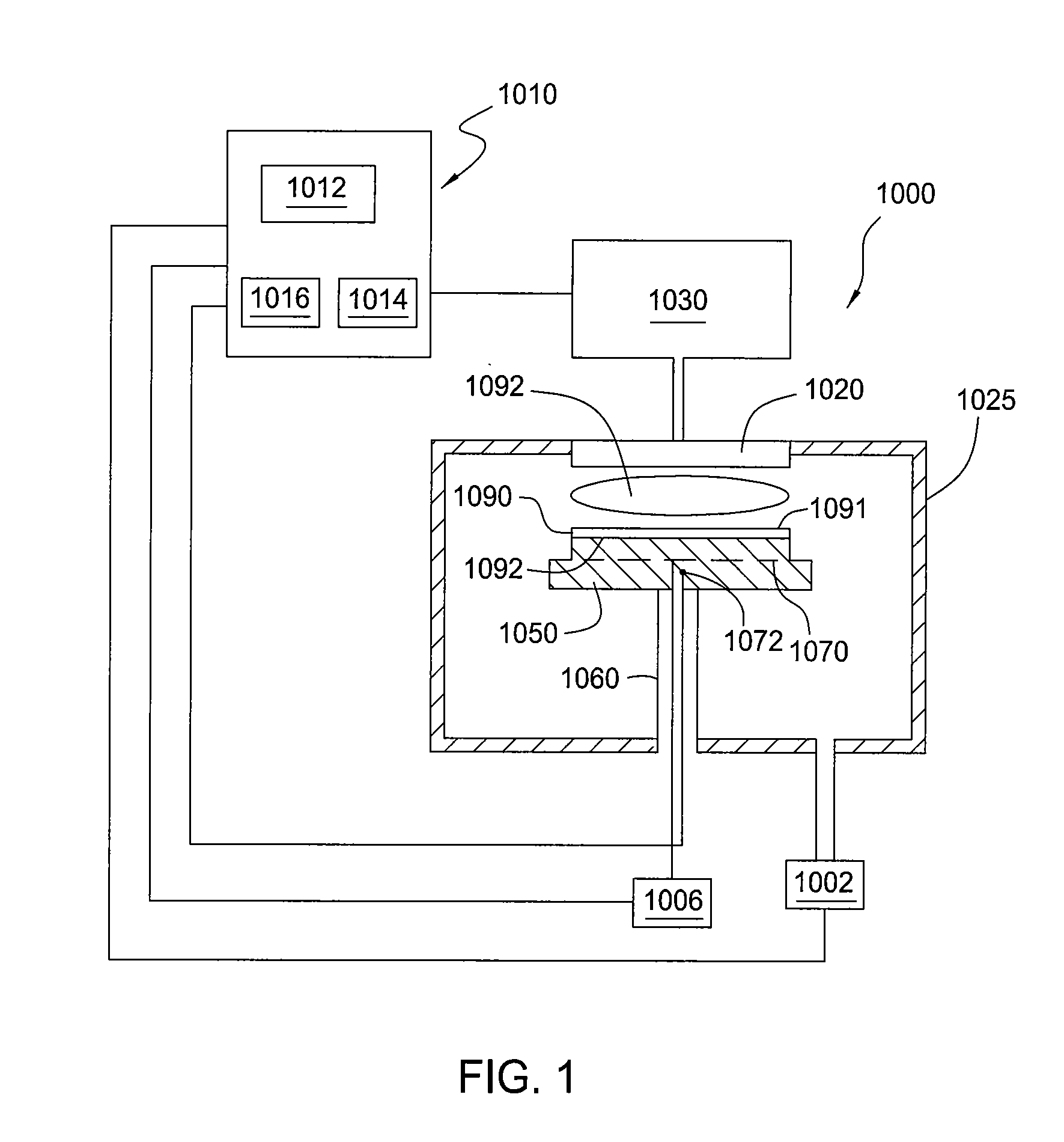

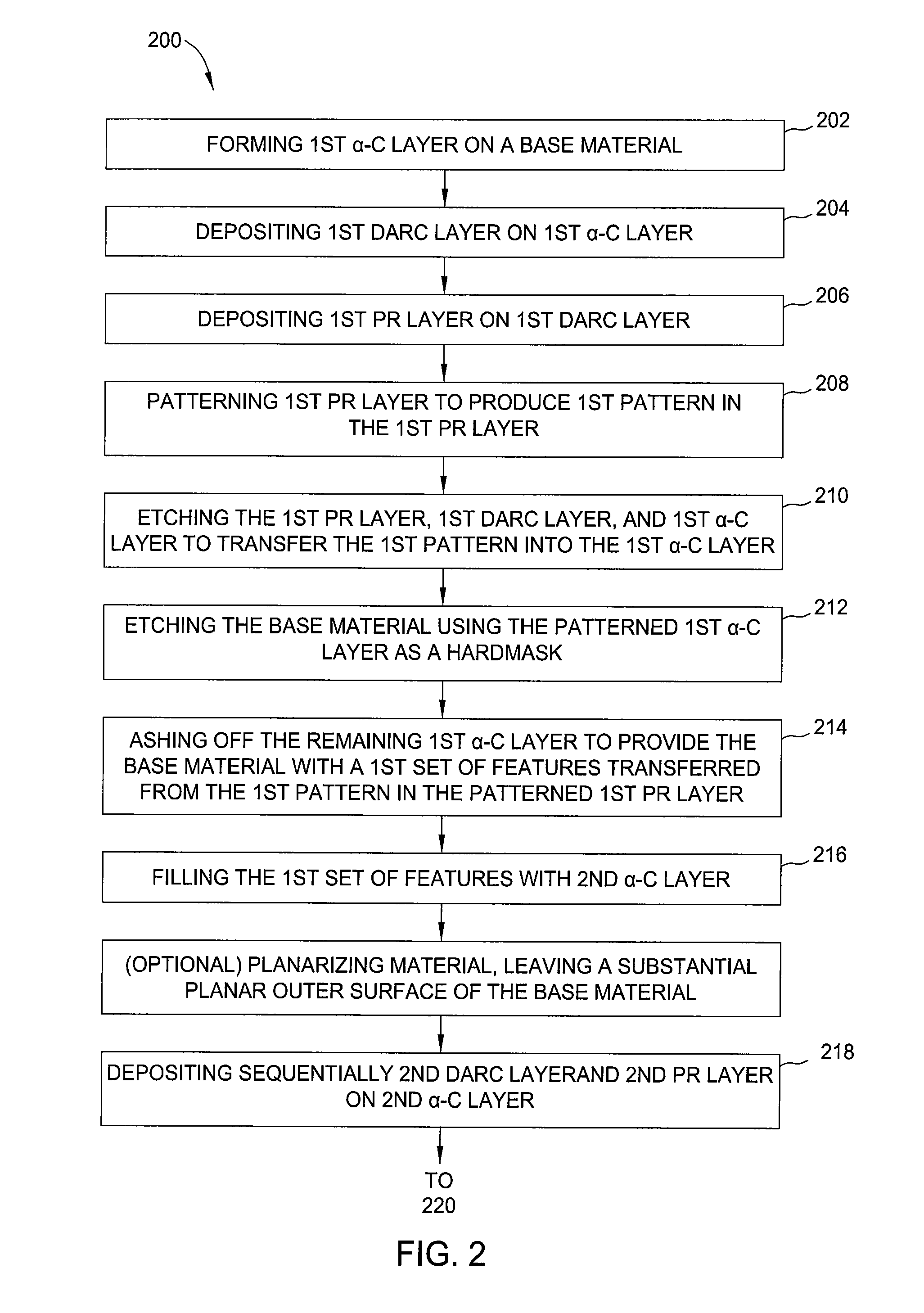

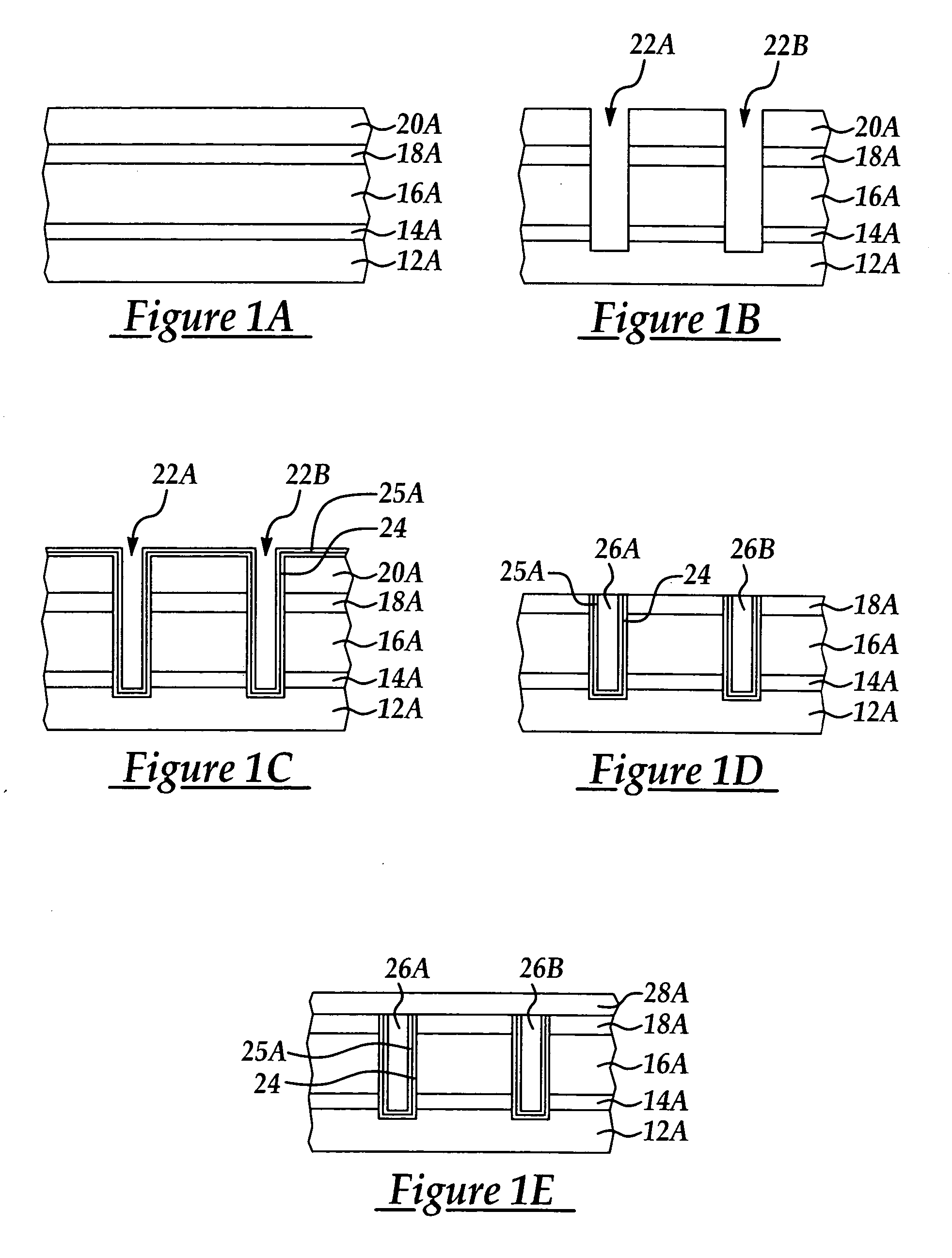

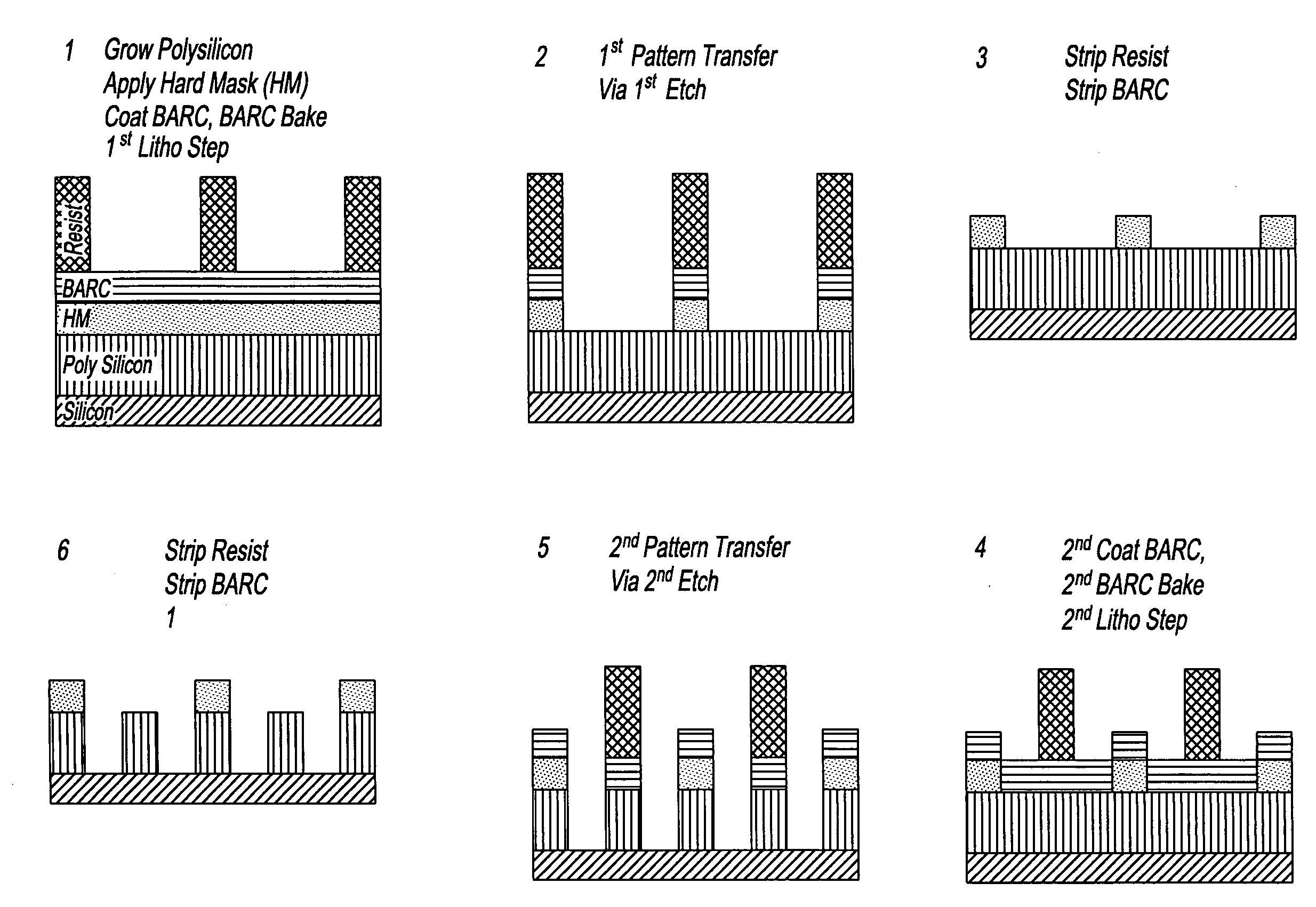

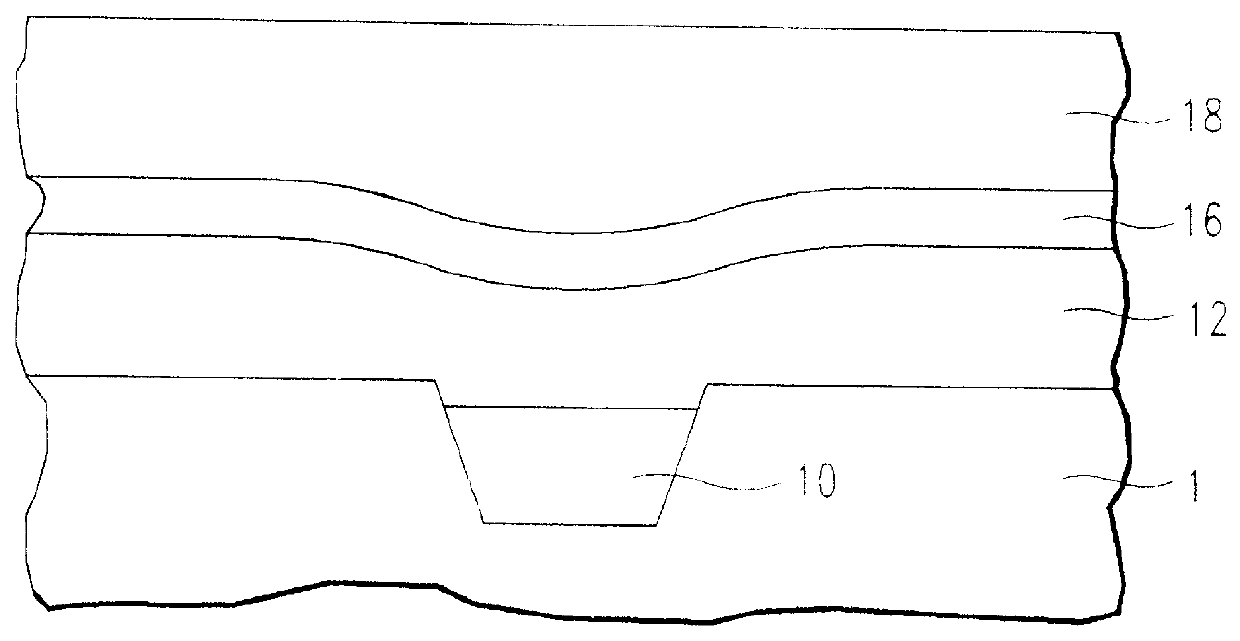

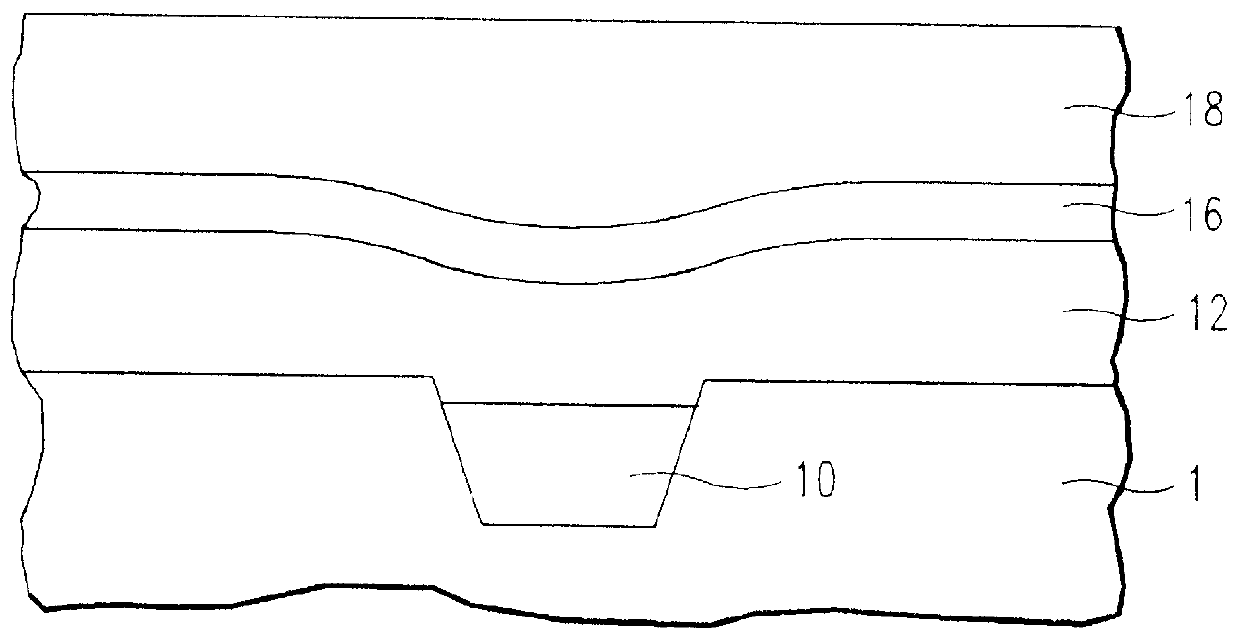

Planarizing etch hardmask to increase pattern density and aspect ratio

InactiveUS20110291243A1Easy to disassembleAdd depthSemiconductor/solid-state device detailsSolid-state devicesAnti-reflective coatingEngineering

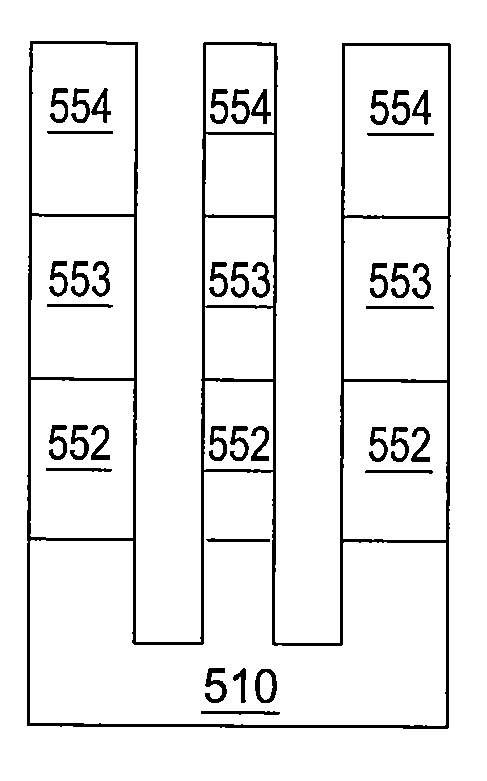

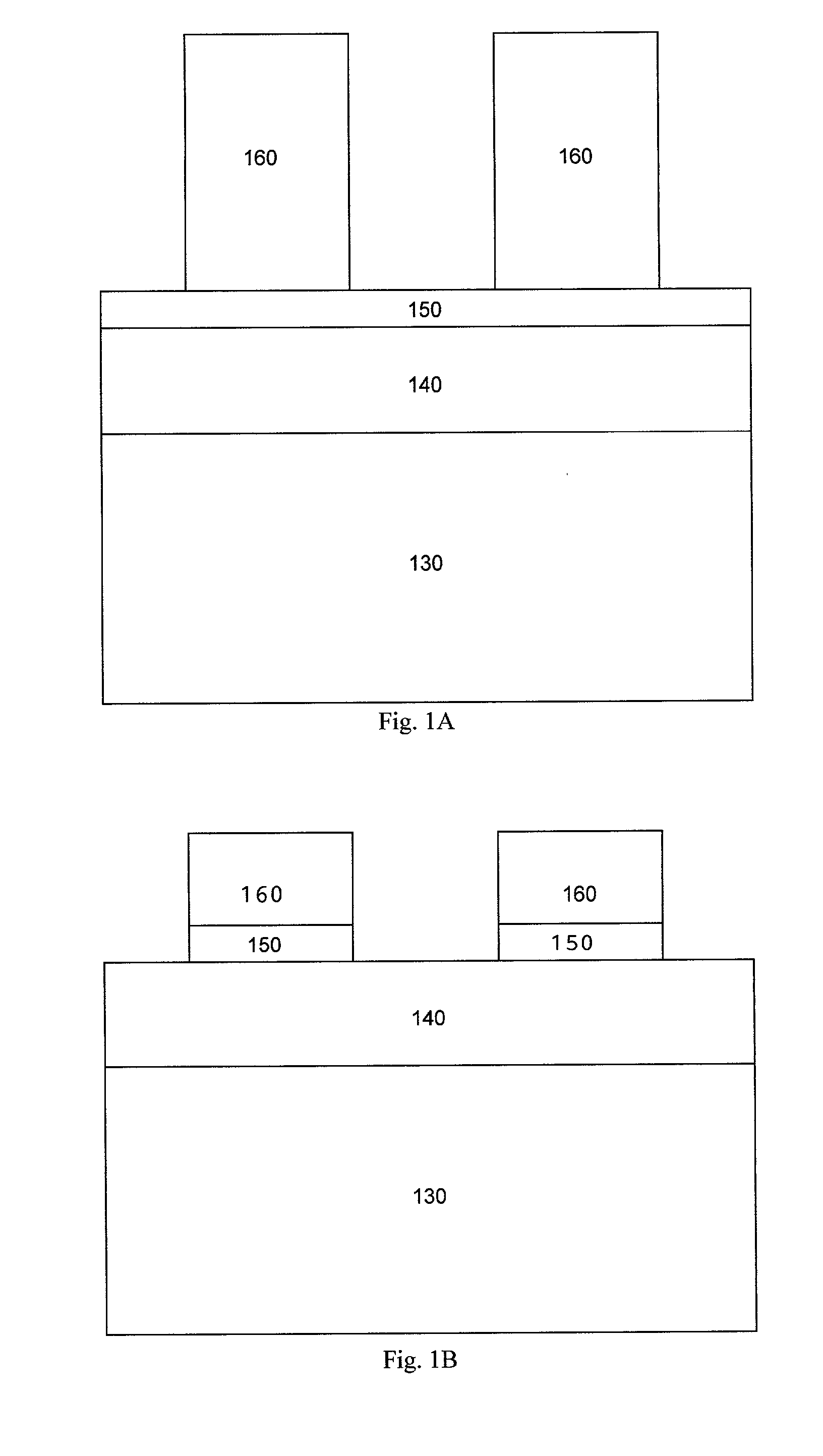

Methods for manufacturing a semiconductor device in a processing chamber are provided. In one embodiment, a method includes depositing over a substrate a first base material having a first set of interconnect features, filling an upper portion of the first set of interconnect features with an ashable material to an extent capable of protecting the first set of interconnect features from subsequent processes while being easily removable when desired, planarizing an upper surface of the first base material such that an upper surface of the ashable material filled in the first set of interconnect features is at the same level with the upper surface of the first base material, providing a substantial planar outer surface of the first base material, depositing a first film stack comprising a second base material on the substantial planar outer surface of the first base material, forming a second set of interconnect features in the second base material, wherein the second set of interconnect features are aligned with the first set of interconnect features, and removing the ashable material from the first base material, thereby extending a feature depth of the semiconductor device by connecting the second set of interconnect features to the first set of interconnect features. In another embodiment, a method includes providing a base material having a first film stack deposited thereon, wherein the base material is formed over the substrate and having a first set of interconnect features filled with an amorphous carbon material, the first film stack comprising a first amorphous carbon layer deposited on a surface of the base material, a first anti-reflective coating layer deposited on the first amorphous carbon layer, and a first photoresist layer deposited on the first anti-reflective coating layer, and patterning a portion of the first photoresist layer by shifting laterally a projection of a mask on the first photoresist layer relative to the substrate a desired distance, thereby introducing into the first photoresist layer a first feature pattern to be transferred to the underlying base material, wherein the first feature pattern is not aligned with the first set of interconnect features.

Owner:APPLIED MATERIALS INC

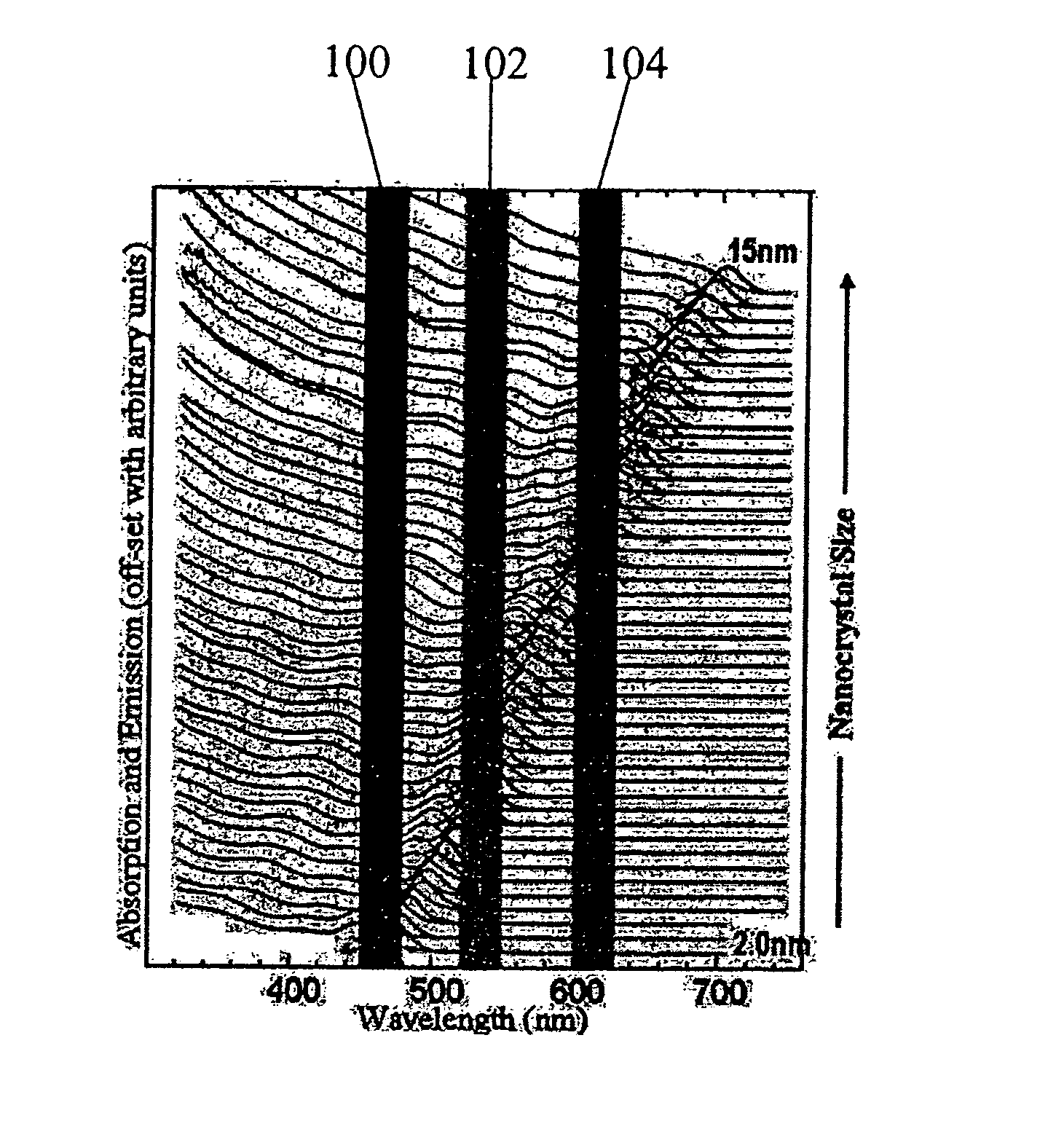

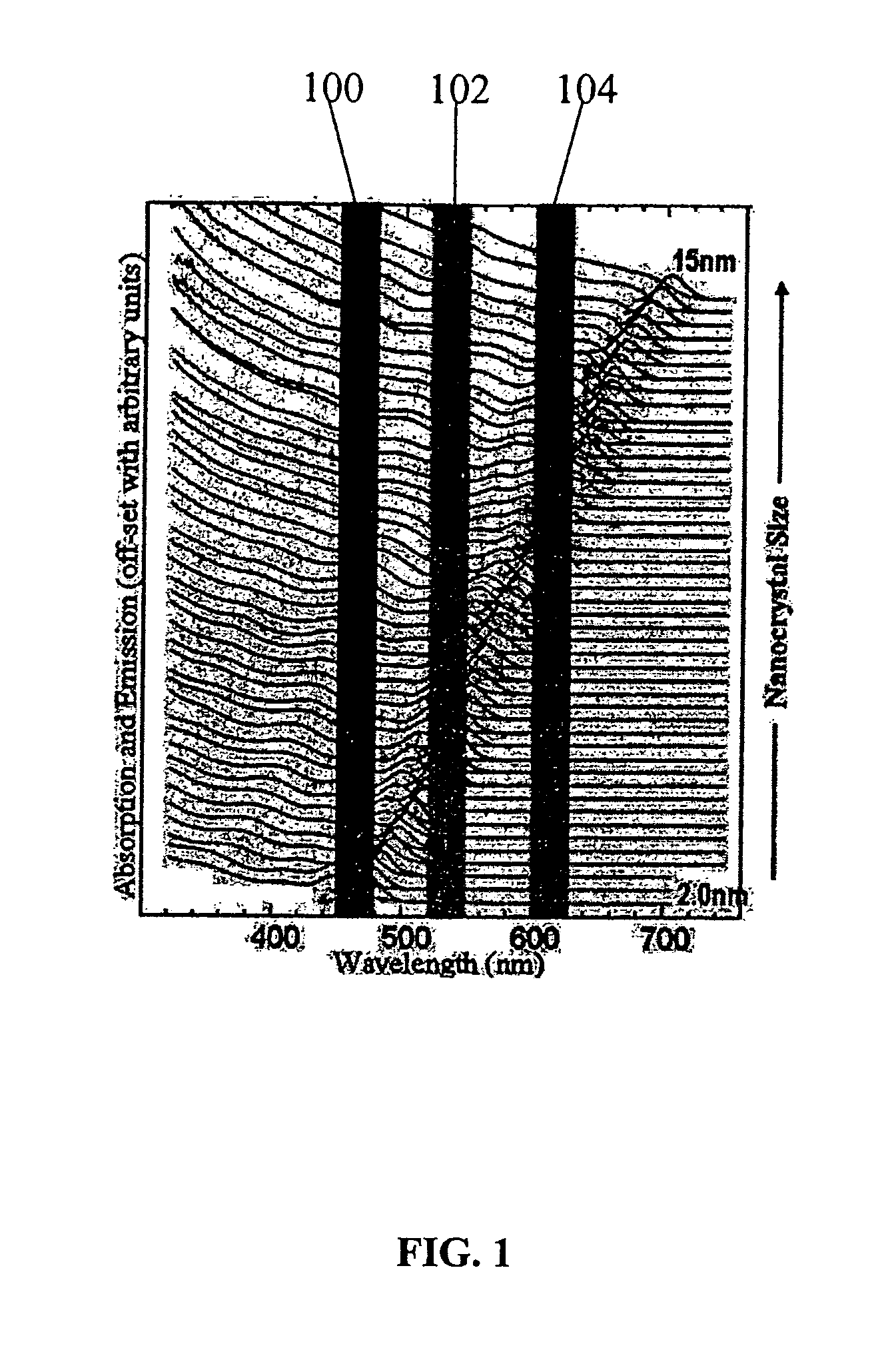

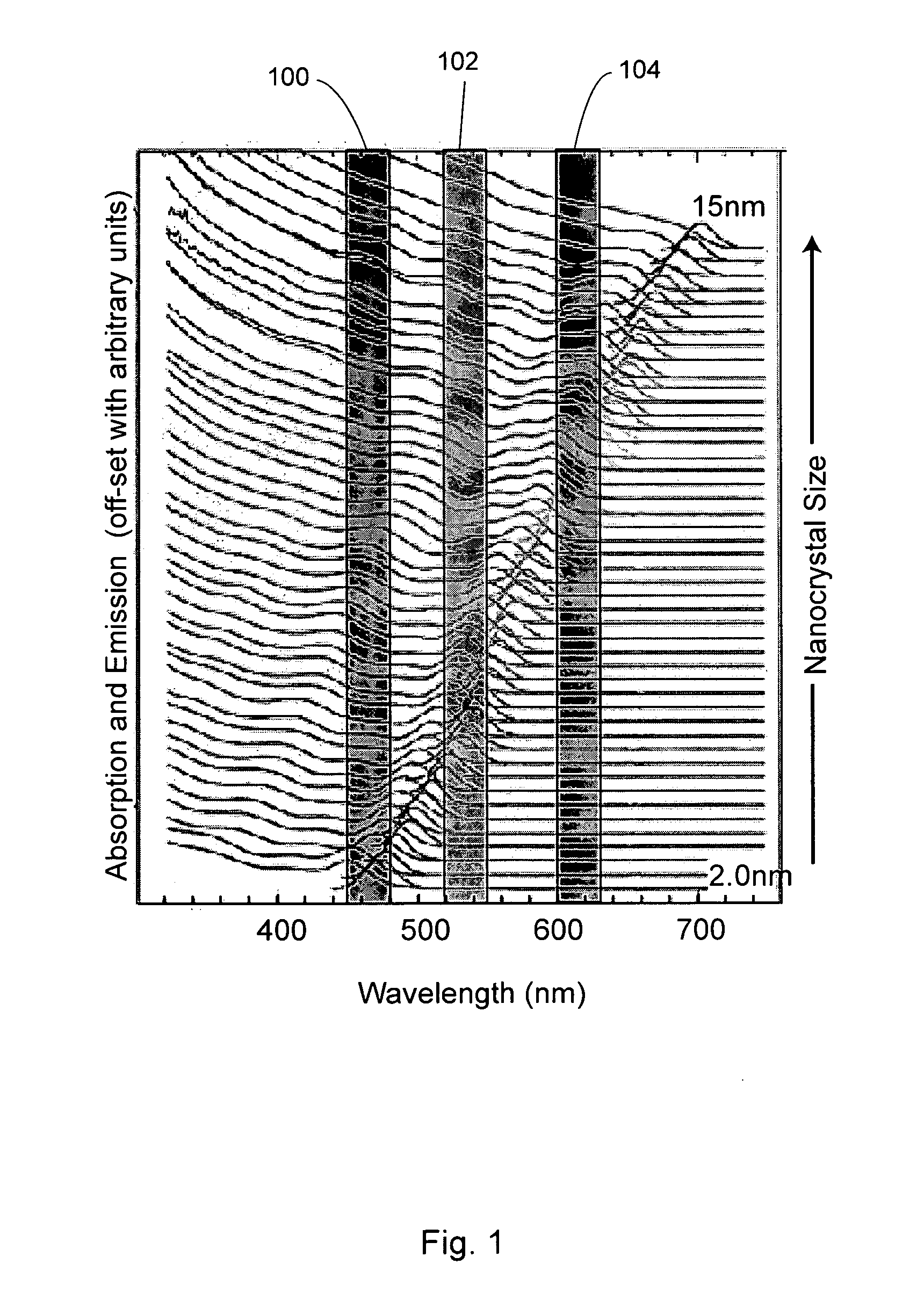

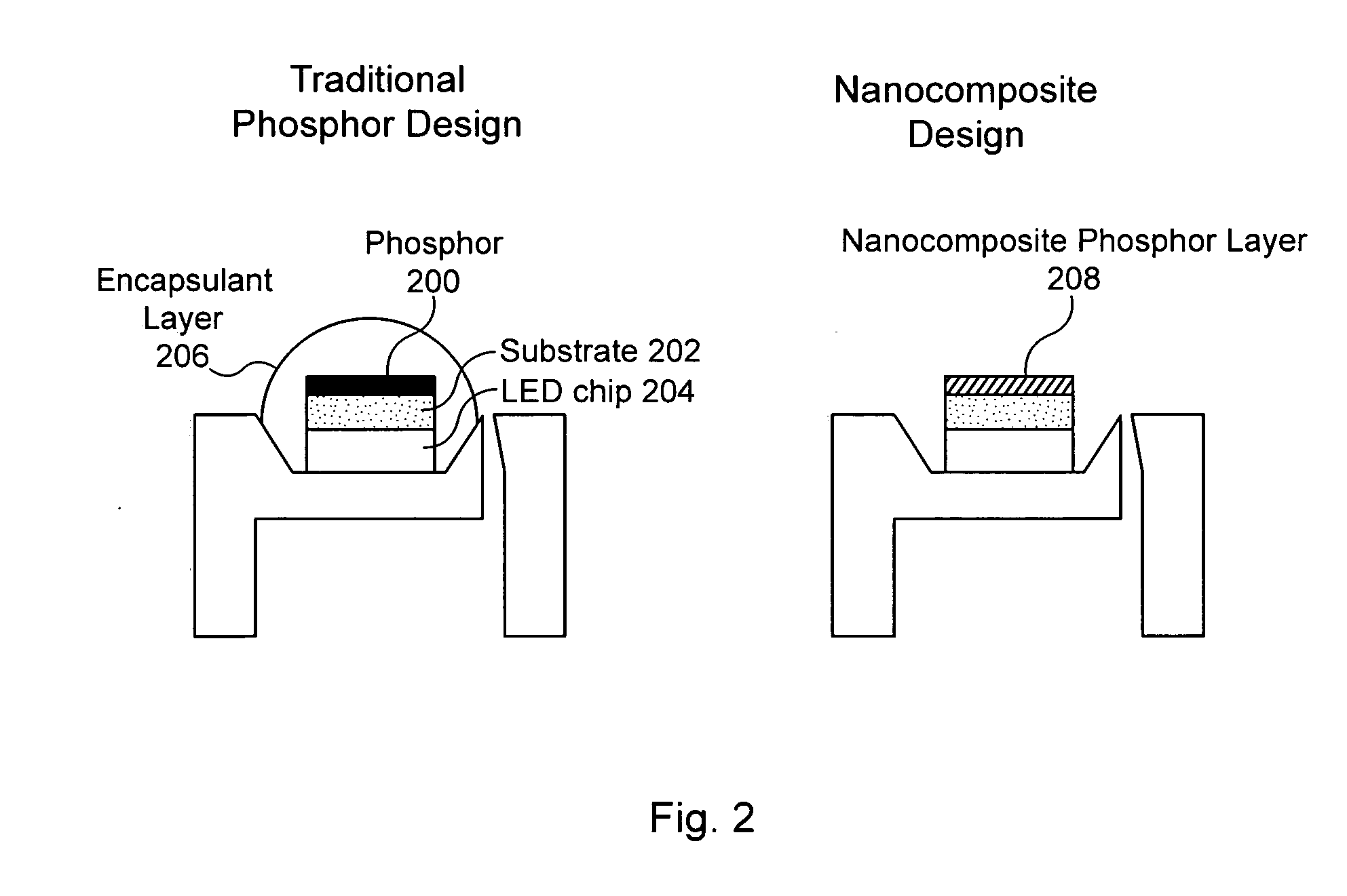

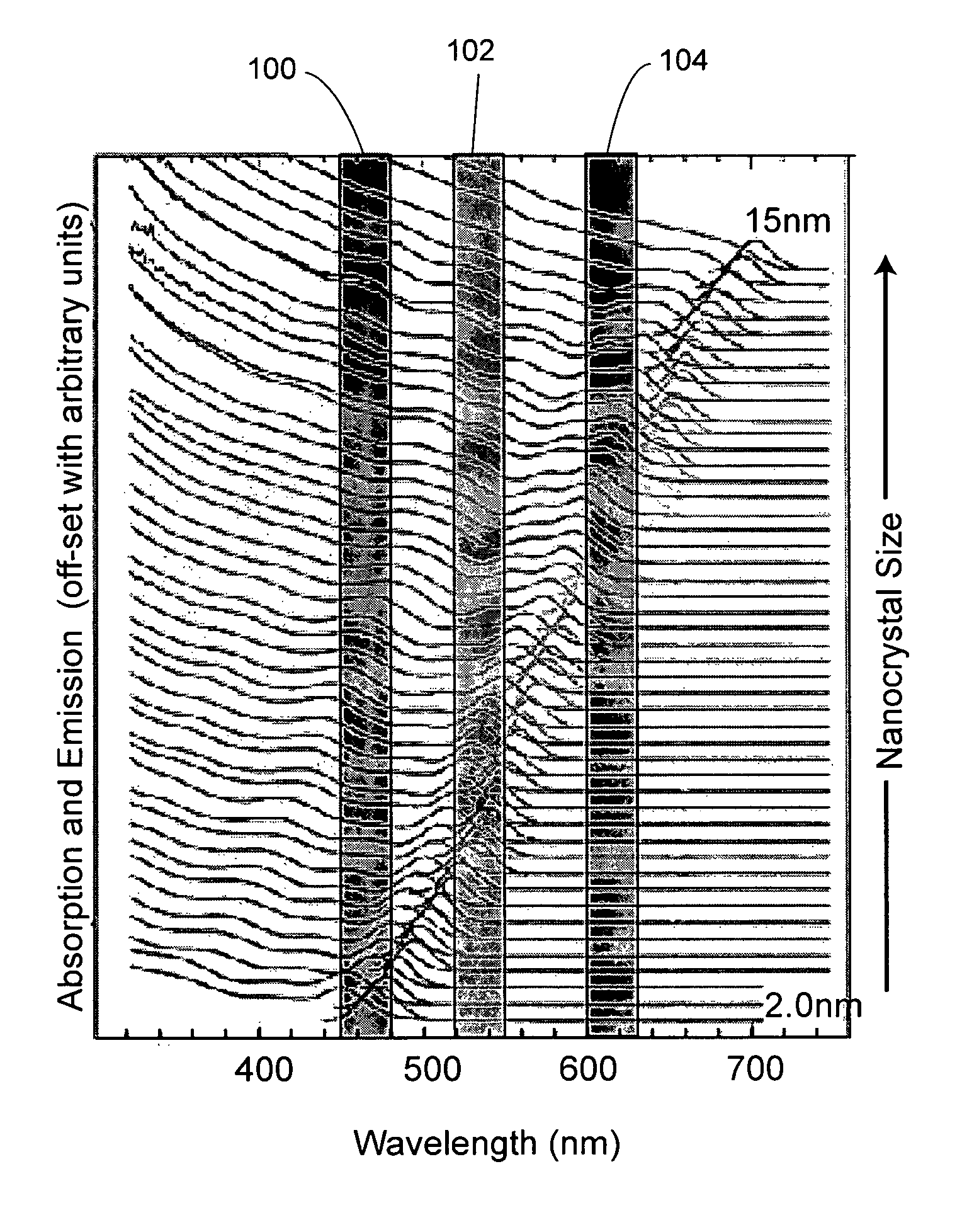

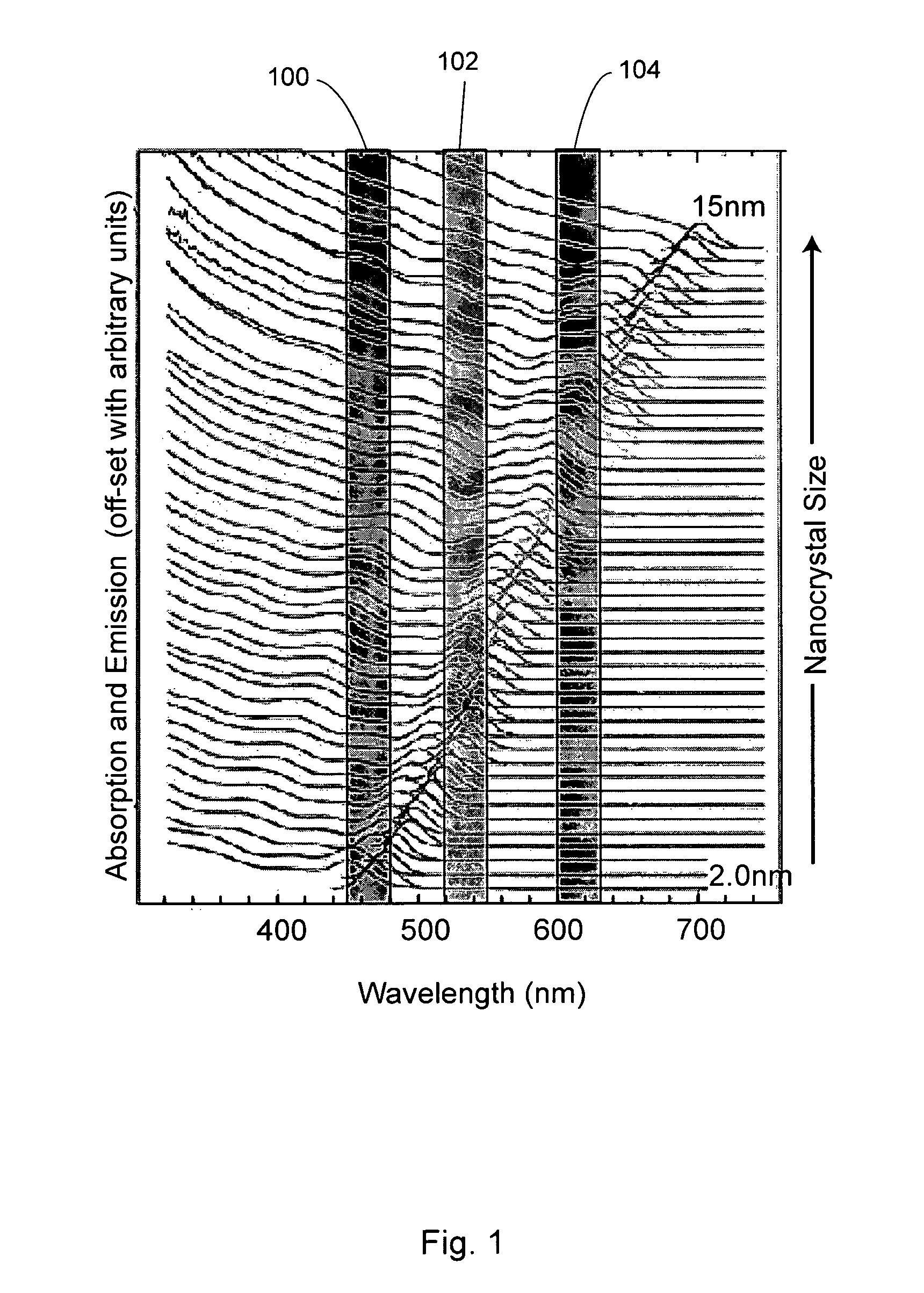

Nanocrystal doped matrixes

ActiveUS20070034833A1Good miscibilityInhibit aggregationMaterial nanotechnologyIndividual molecule manipulationAnti-reflective coatingSemiconductor nanocrystals

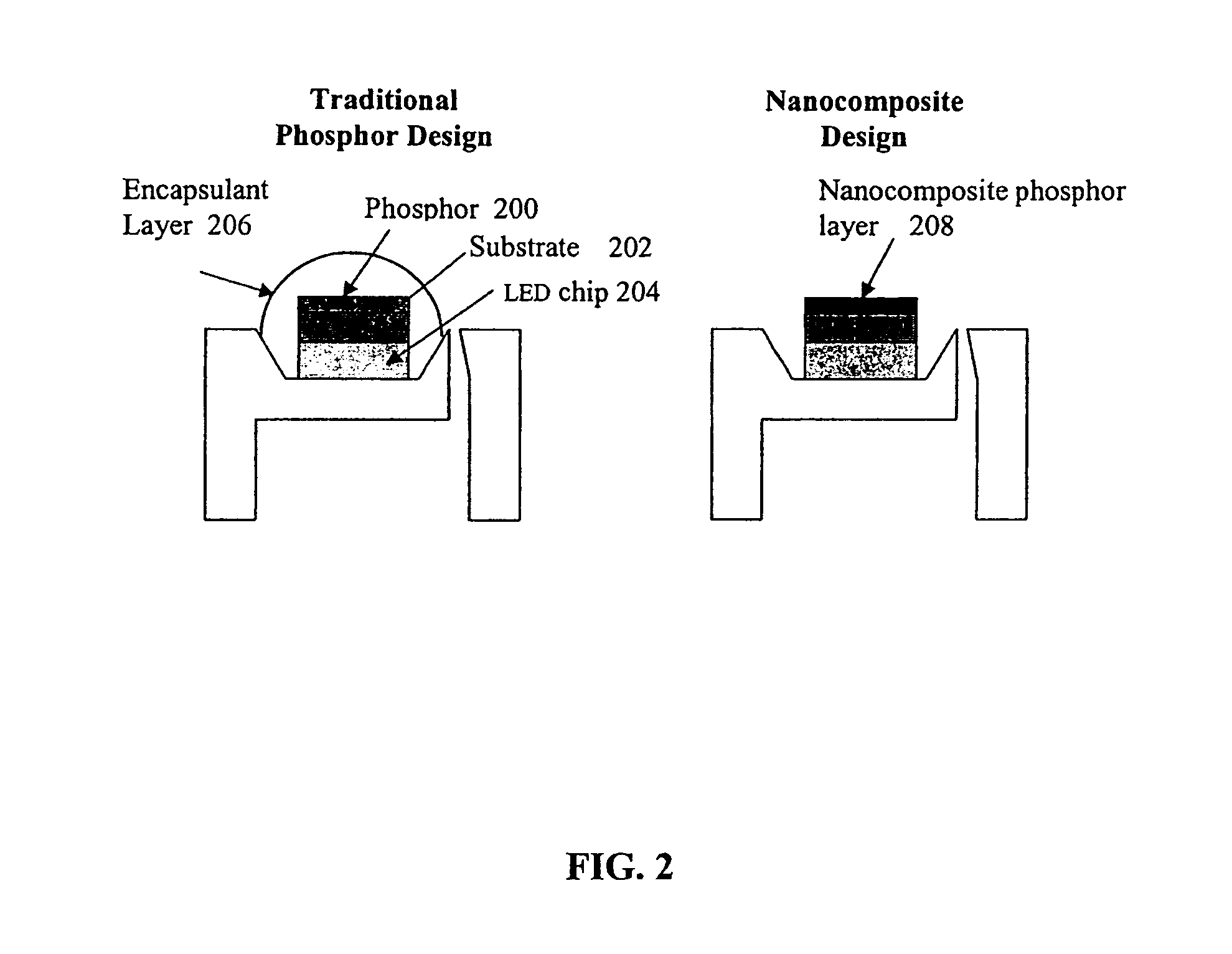

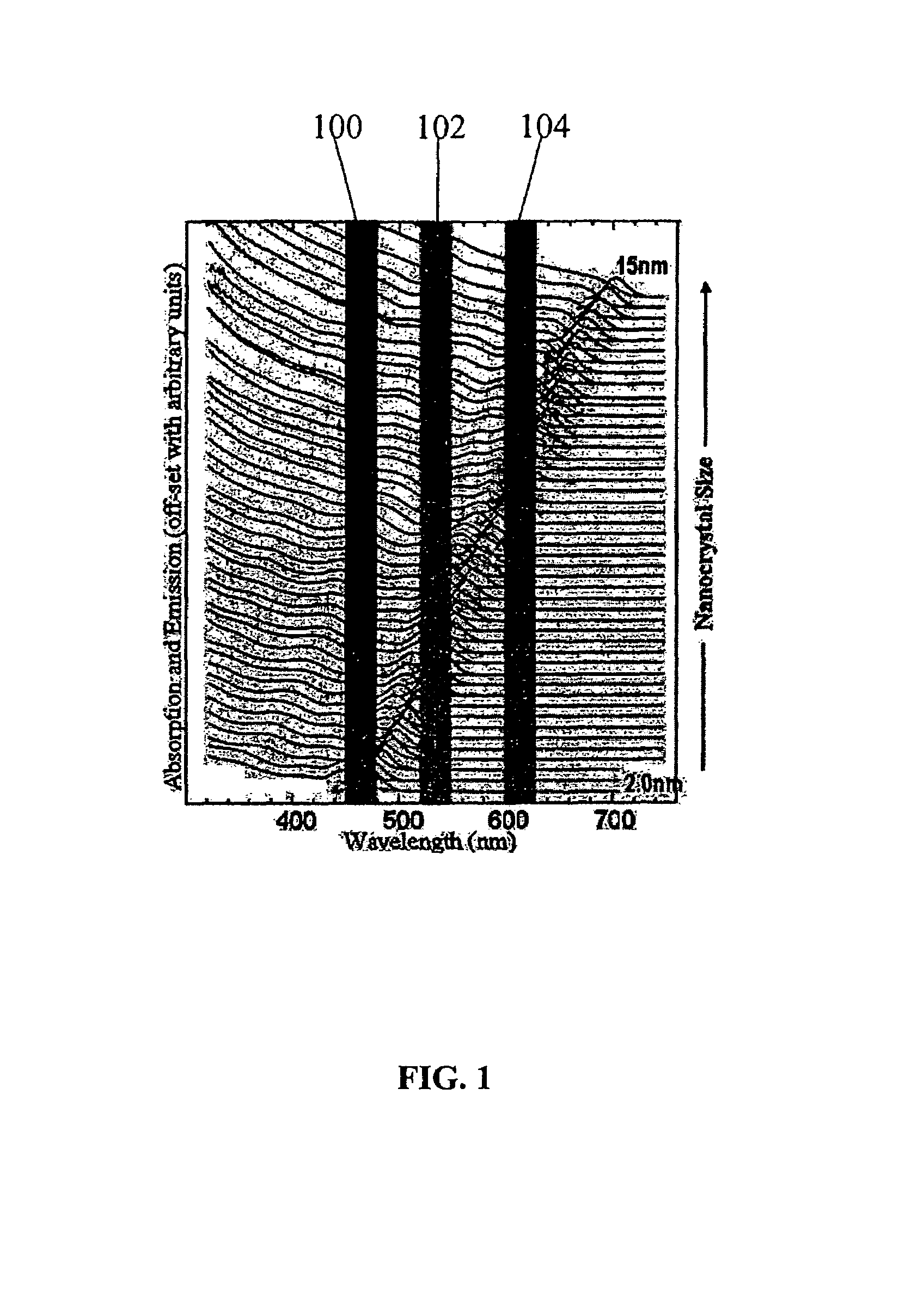

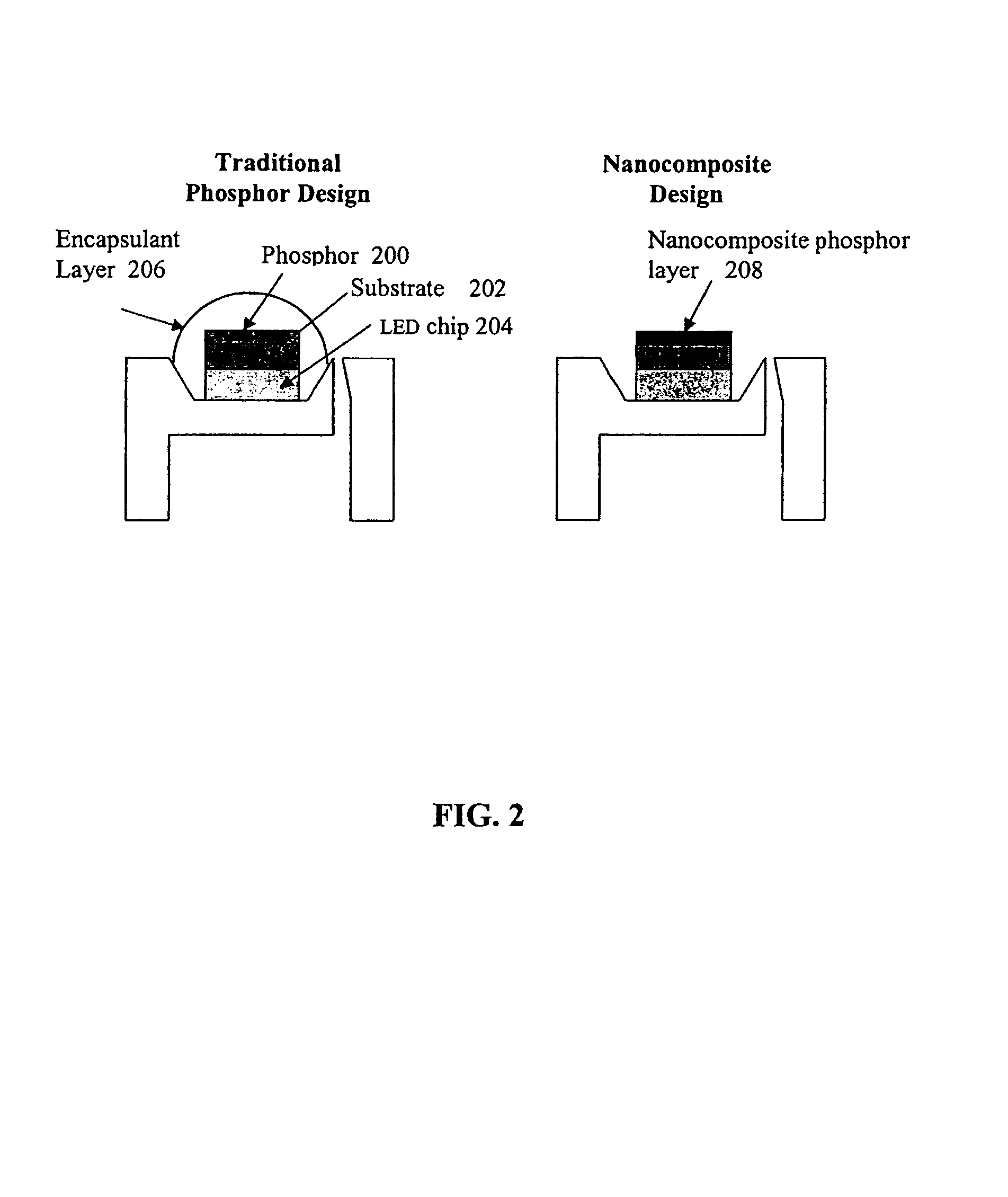

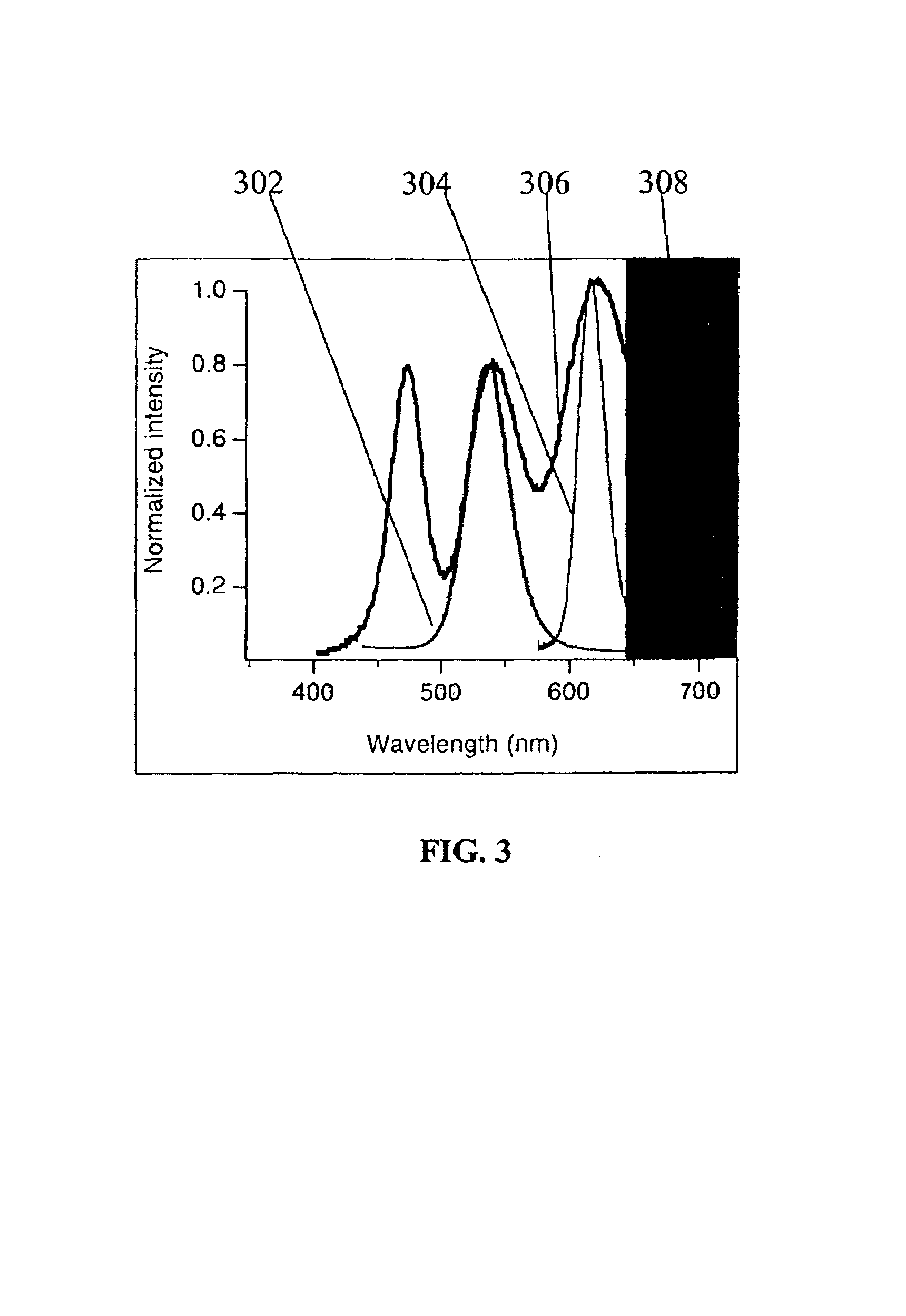

Matrixes doped with semiconductor nanocrystals are provided. In certain embodiments, the semiconductor nanocrystals have a size and composition such that they absorb or emit light at particular wavelengths. The nanocrystals can comprise ligands that allow for mixing with various matrix materials, including polymers, such that a minimal portion of light is scattered by the matrixes. The matrixes of the present invention can also be utilized in refractive index matching applications. In other embodiments, semiconductor nanocrystals are embedded within matrixes to form a nanocrystal density gradient, thereby creating an effective refractive index gradient. The matrixes of the present invention can also be used as filters and antireflective coatings on optical devices and as down-converting layers. Processes for producing matrixes comprising semiconductor nanocrystals are also provided. Nanostructures having high quantum efficiency, small size, and / or a narrow size distribution are also described, as are methods of producing indium phosphide nanostructures and core-shell nanostructures with Group II-VI shells.

Owner:SAMSUNG ELECTRONICS CO LTD

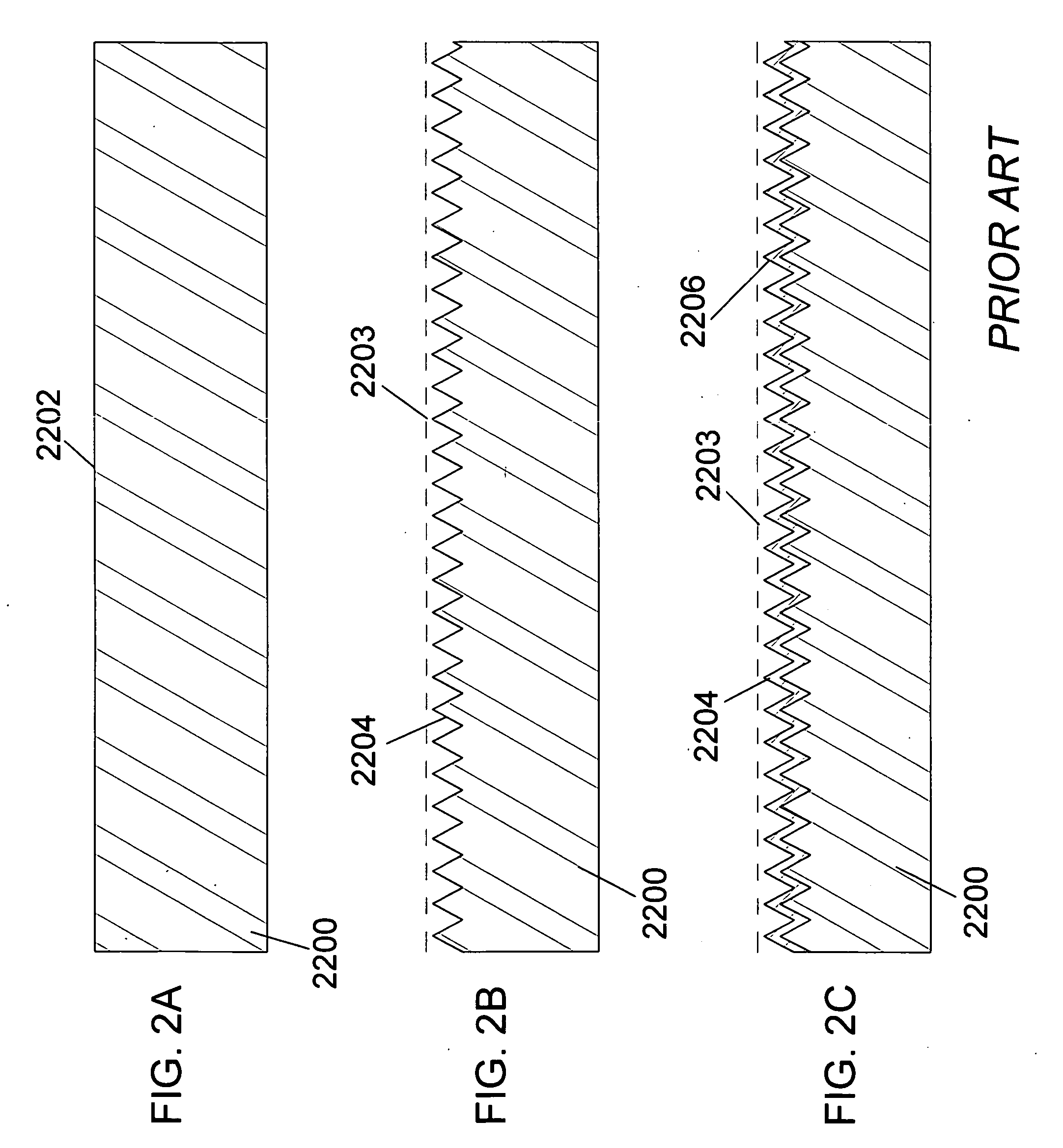

Antireflective coatings comprising poly(oxyalkylene) colorants

InactiveUS6048662AReduce the amplitudeImprove anti-reflectionPhotosensitive materialsRadiation applicationsCounterionThin layer

This invention relates to antireflective coatings comprising polymeric polyoxyalkylenated colorants. More particularly, the present invention relates to antireflective coatings for utilization in forming thin layers between reflective substrates and photoresist coatings. Such antireflective coatings are very useful and beneficial within the production and fabrication of semiconductors through photolithographic procedures due to the liquid, non-crystallizing nature of polyoxyalkylenated colorants, and the lack of potentially damaging counterions, metals, and / or electrolytes within the inventive antireflective colored coatings. The inventive coatings may also be applied on lenses, mirrors, and other optical components. Methods of forming such antireflective coatings are also contemplated within this invention.

Owner:MILLIKEN & CO

Nanocrystal doped matrixes

ActiveUS7645397B2Good miscibilityInhibit aggregationMaterial nanotechnologyIndividual molecule manipulationAnti-reflective coatingQuantum efficiency

Owner:SAMSUNG ELECTRONICS CO LTD

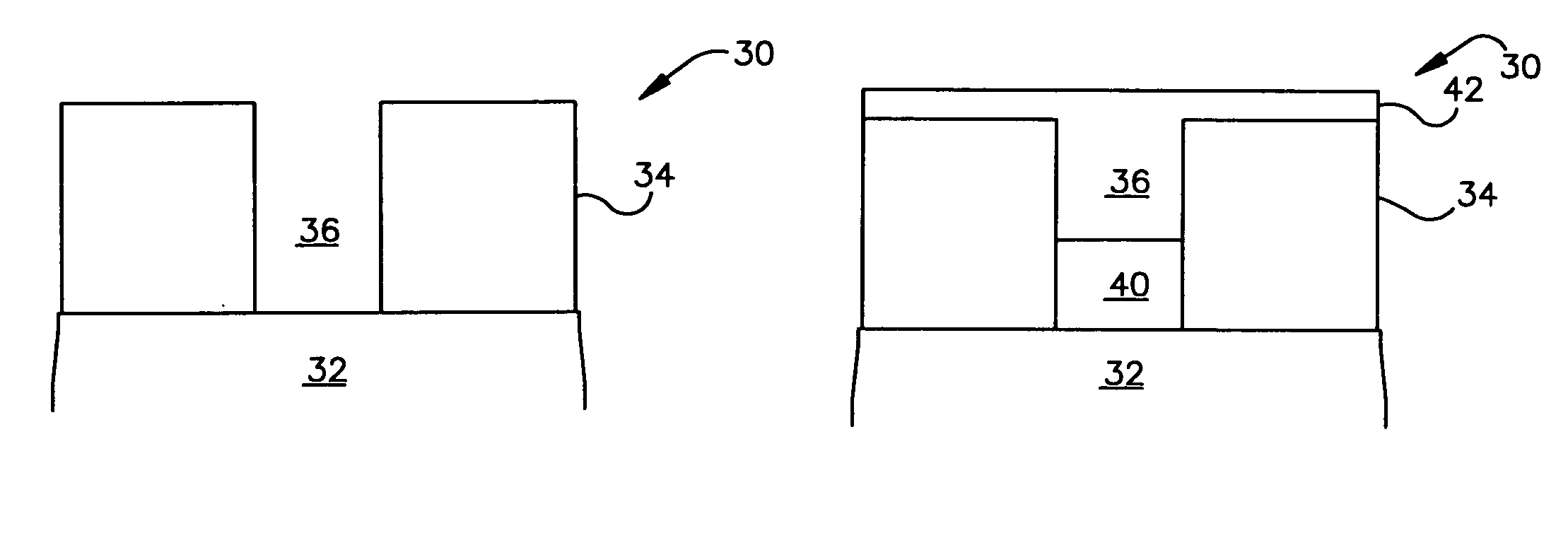

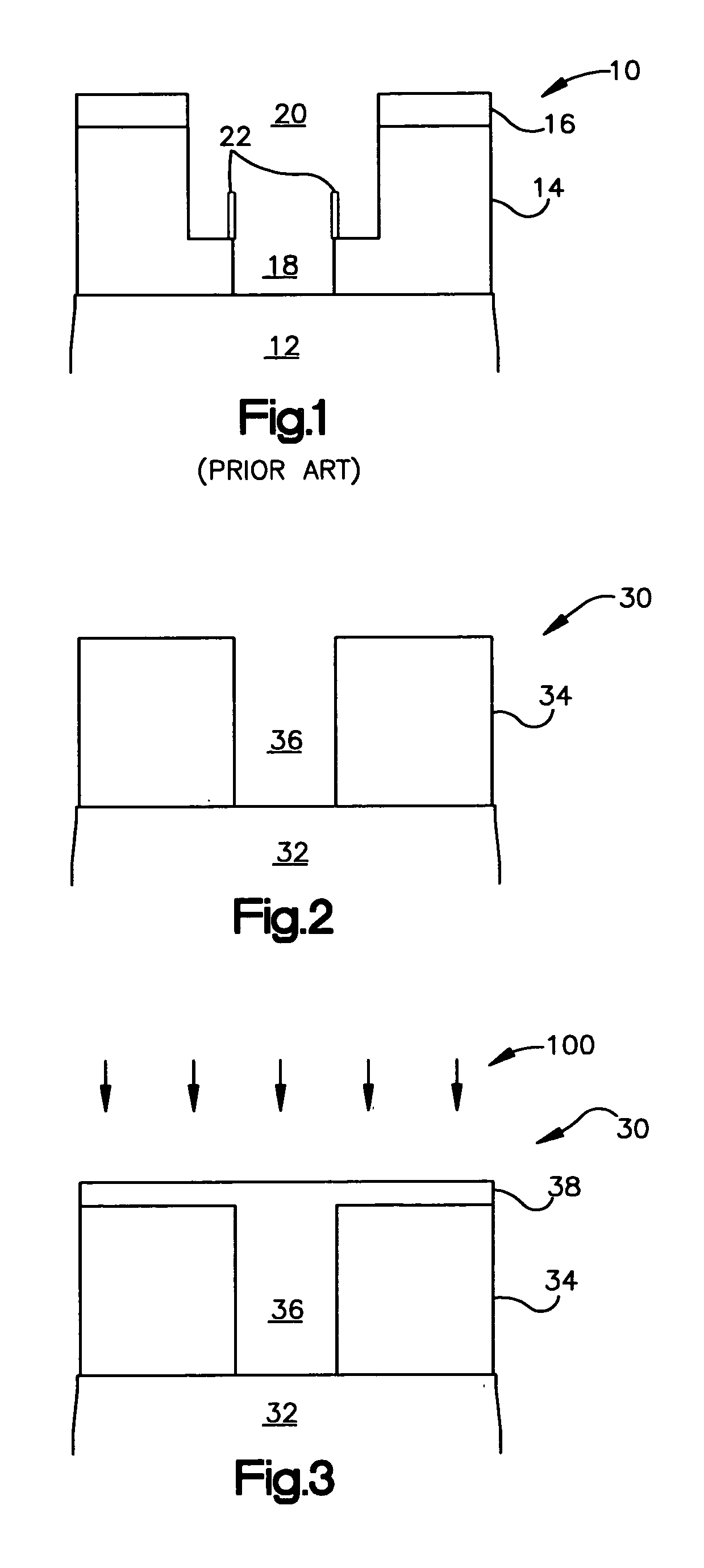

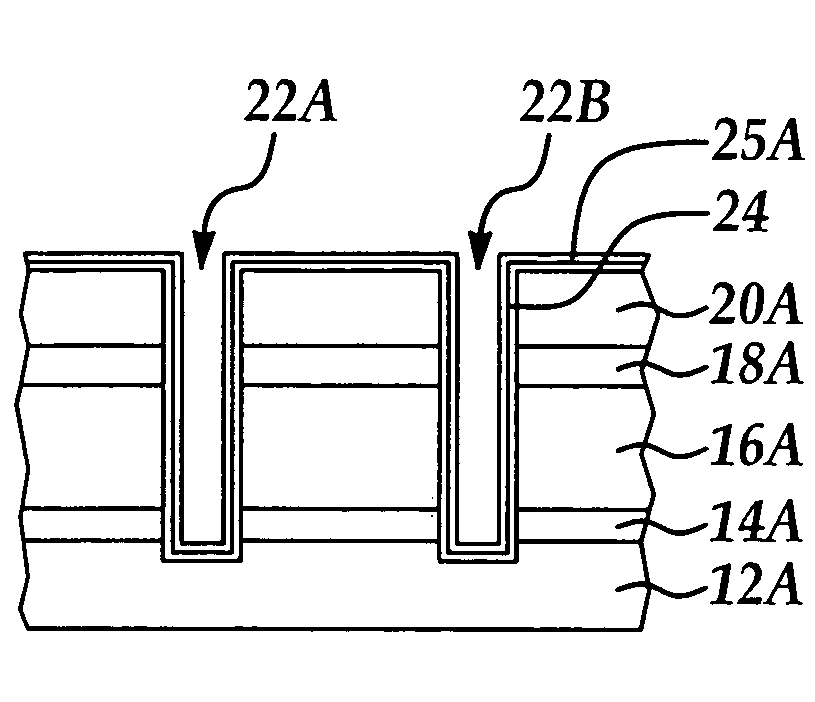

Method of eliminating etch ridges in a dual damascene process

ActiveUS20060024956A1Inhibition formationSemiconductor/solid-state device manufacturingAnti-reflective coatingFilling materials

A dual damascene process employs a via fill material (38) with an etch rate that is within 60% of an etch rate that an underlying dielectric layer (34) etches for a given dielectric etch chemistry in which a trench (48) and via (50) are being formed. In one embodiment, an organic via fill material plug (40) is employed in conjunction with a bottom anti-reflective coating (BARC) material layer (42). Both the organic via fill material plug (40) and the BARC material layer (42) are selected to have a material with an etch rate that within 60% of an etch rate that an underlying dielectric layer (34) etches for a given dielectric etch chemistry in which the trench (48) and via (50) are formed.

Owner:TEXAS INSTR INC

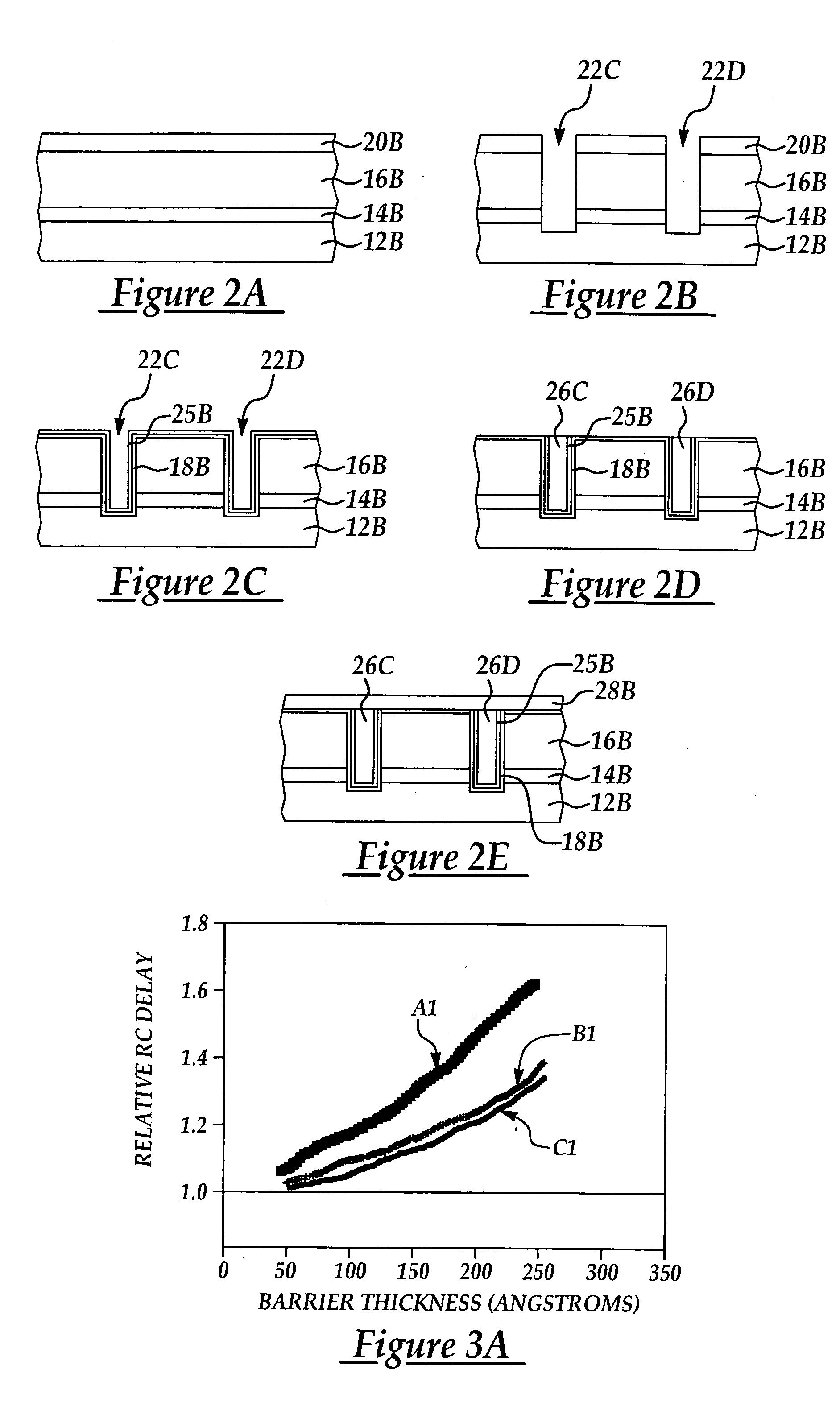

Copper damascene barrier and capping layer

InactiveUS20060024954A1Improve electrical performanceSemiconductor/solid-state device manufacturingAnti-reflective coatingEngineering

A method for forming a damascene with improved electrical properties and resulting structure thereof including providing at least one dielectric insulating layer overlying a first etch stop layer; forming an anti-reflectance coating (ARC) layer prior to a photolithographic patterning process; forming at least one opening extending through a thickness portion of the at least one dielectric insulating layer and first etch stop layer according to said photolithographic patterning and an etching process; blanket depositing a barrier layer including material selected from the group consisting of silicon carbide and silicon oxycarbide to line the at least one opening; blanket depositing a refractory metal liner over the barrier layer; blanket depositing at least one metal layer to fill the at least one opening; and, removing at least the at least one metal layer overlying the at least one opening level according to a chemical mechanical polish (CMP) process.

Owner:WU ZHEN CHENG +3

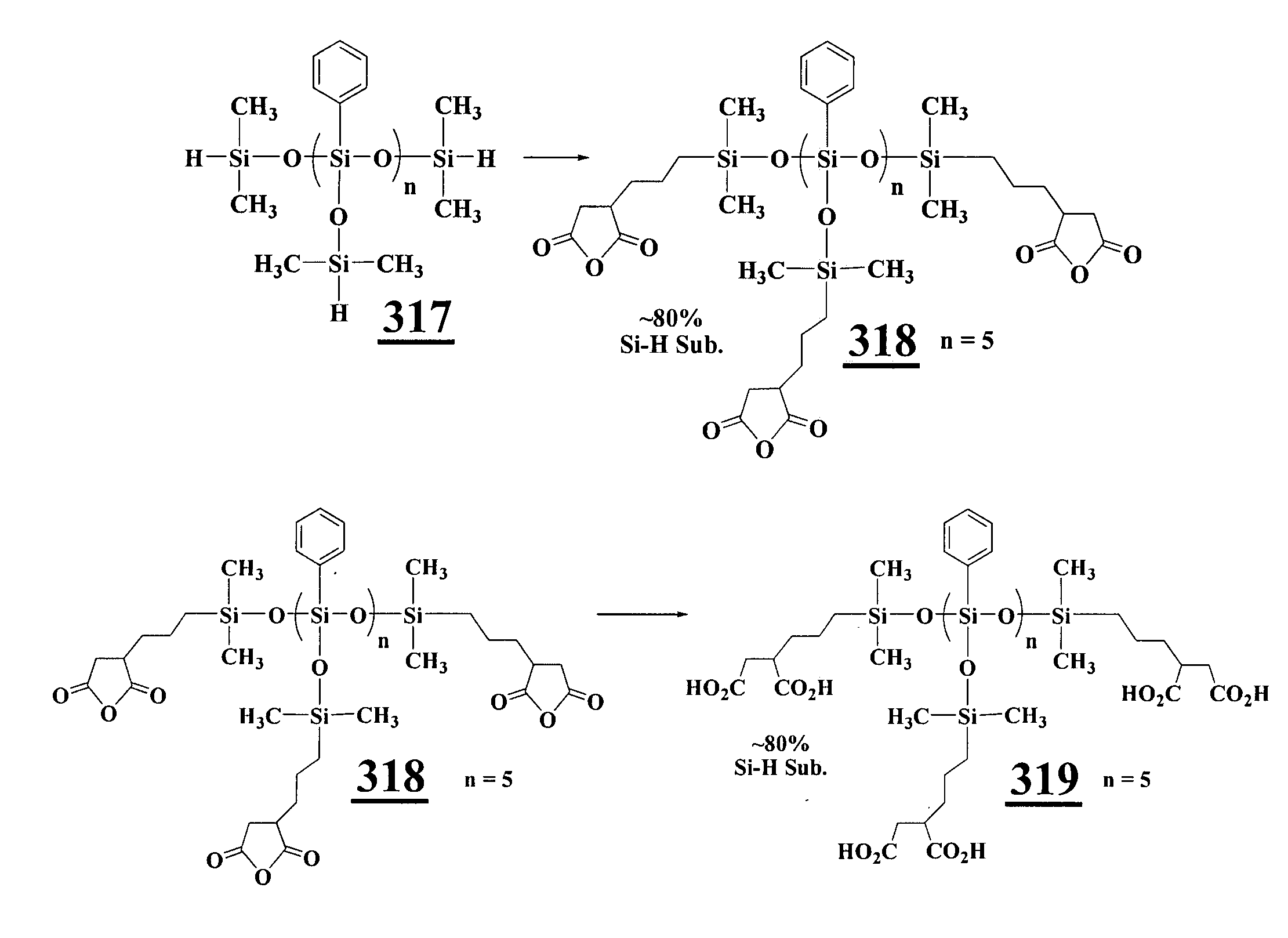

Functionalized matrixes for dispersion of nanostructures

ActiveUS20100276638A1High quantum yieldFacilitate device fabricationMaterial nanotechnologyGroup 4/14 element organic compoundsAnti-reflective coatingVolumetric Mass Density

Matrixes doped with semiconductor nanocrystals are provided. In certain embodiments, the semiconductor nanocrystals have a size and composition such that they absorb or emit light at particular wavelengths. The nanocrystals can comprise ligands that allow for mixing with various matrix materials, including polymers, such that a minimal portion of light is scattered by the matrixes. The matrixes are optionally formed from the ligands. The matrixes of the present invention can also be utilized in refractive index matching applications. In other embodiments, semiconductor nanocrystals are embedded within matrixes to form a nanocrystal density gradient, thereby creating an effective refractive index gradient. The matrixes of the present invention can also be used as filters and antireflective coatings on optical devices and as down-converting layers. Processes for producing matrixes comprising semiconductor nanocrystals are also provided. Nanostructures having high quantum efficiency, small size, and / or a narrow size distribution are also described, as are methods of producing indium phosphide nanostructures and core-shell nanostructures with Group II-VI shells.

Owner:NANOSYS INC

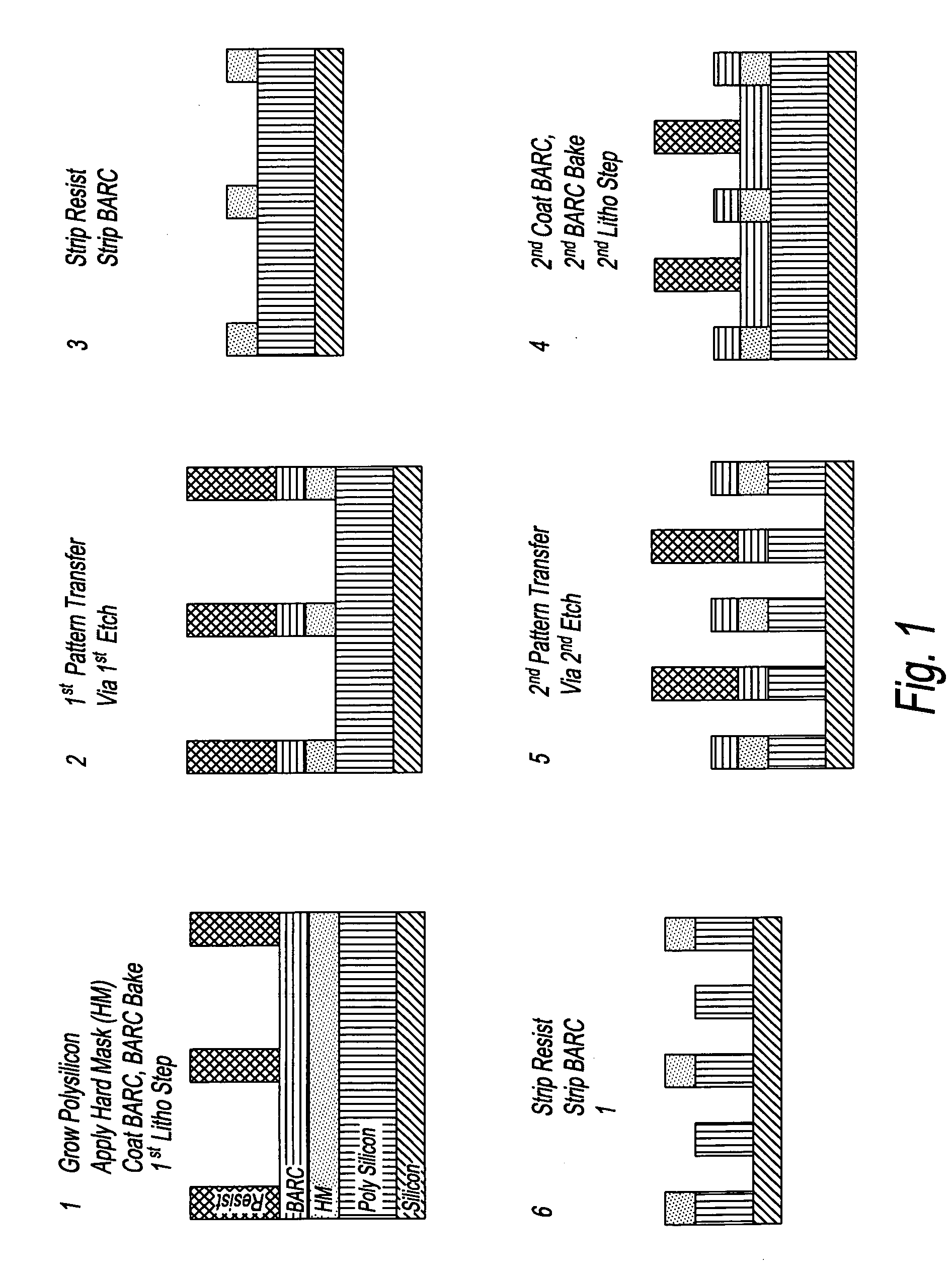

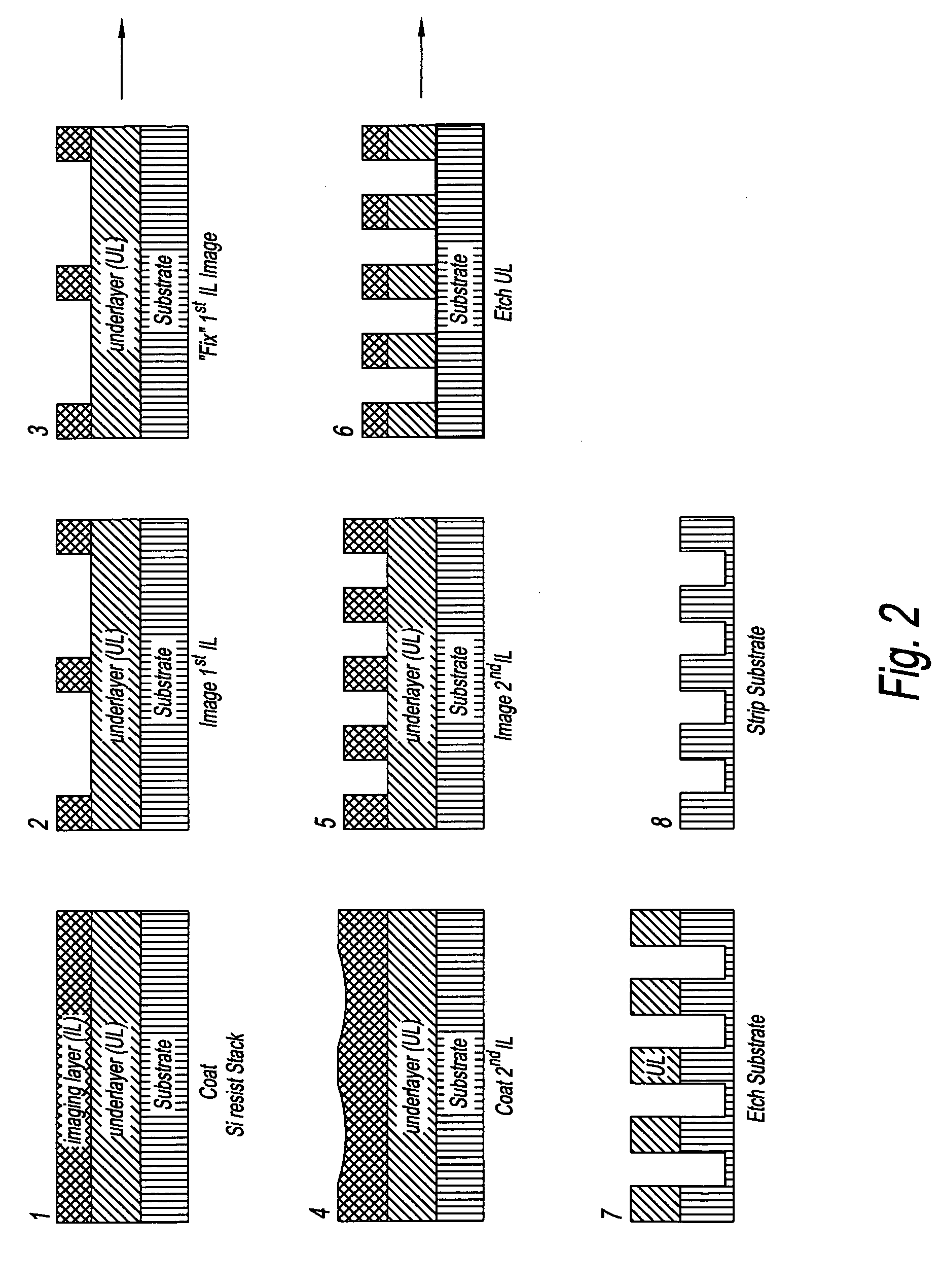

Device manufacturing process utilizing a double patterning process

InactiveUS20080199814A1Photomechanical apparatusSemiconductor/solid-state device manufacturingSolubilityAnti-reflective coating

Manufacturing semiconductor device by steps of:a) providing substrate with antireflective coating or underlayer,b) applying first photosensitive composition over substrate,c) exposing first composition to radiation to produce first pattern,d) developing exposed first composition to produce an imaged bilayer stack,e) rinsing the stack,f) applying fixer to the stack,g) applying optional bake,h) rinsing the stack,i) applying second optional bake,j) applying second photosensitive composition onto the stack to produce multilayer stack,k) exposing second composition to produce second pattern offset from first pattern,l) developing exposed second composition to produce multilayer stack, andm) rinsing multilayer stack;the photosensitive compositions have photoacid generator and substantially aqueous base insoluble polymer whose solubility increases upon treatment with acid and further comprises an anchor group, and the fixer is a polyfunctional compound reactive with anchor group, but does not contain silicon and the substrate stays within a lithographic cell from at least first coating step until at least after final exposure.

Owner:FUJIFILM ELECTRONICS MATERIALS US

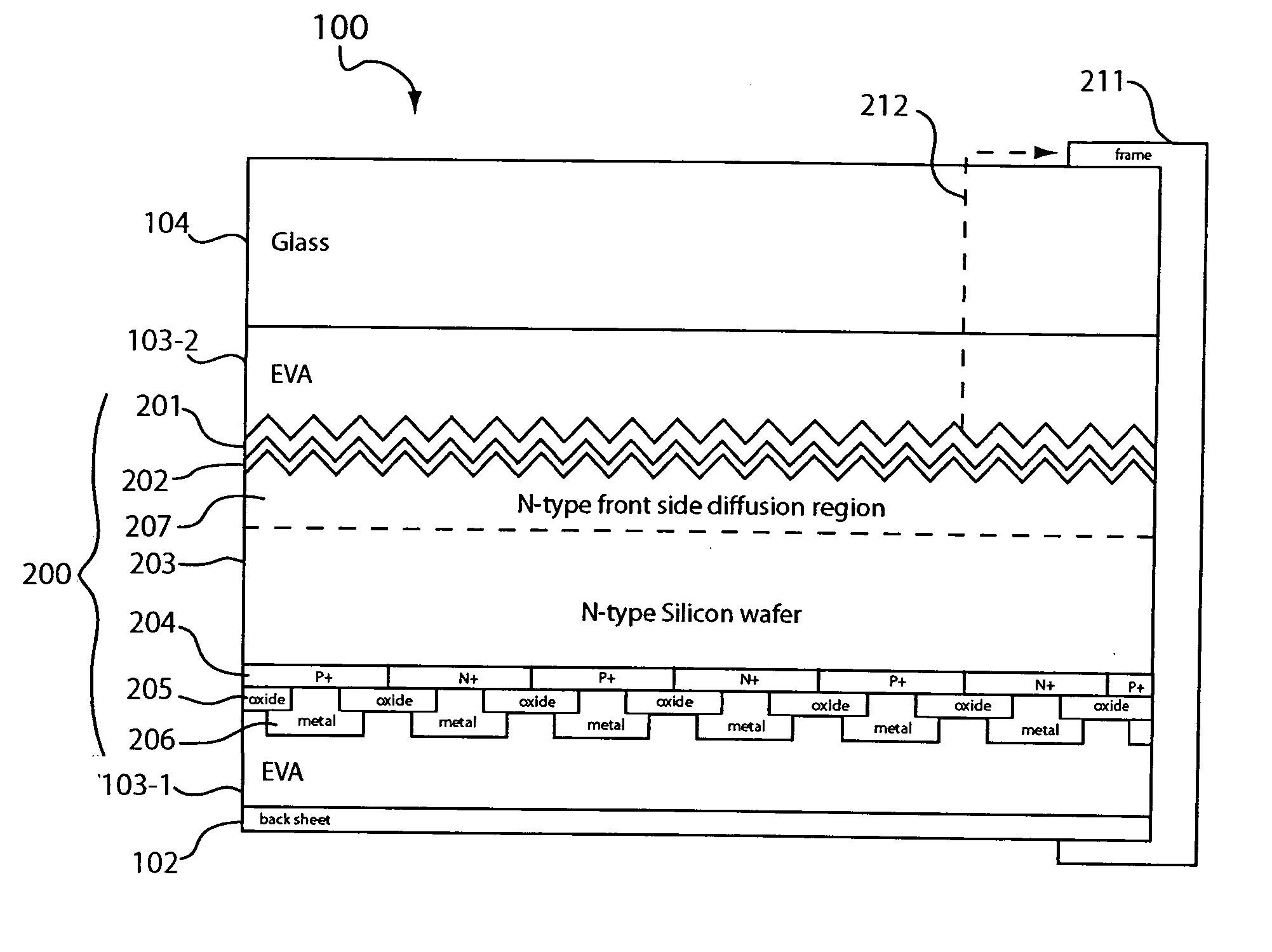

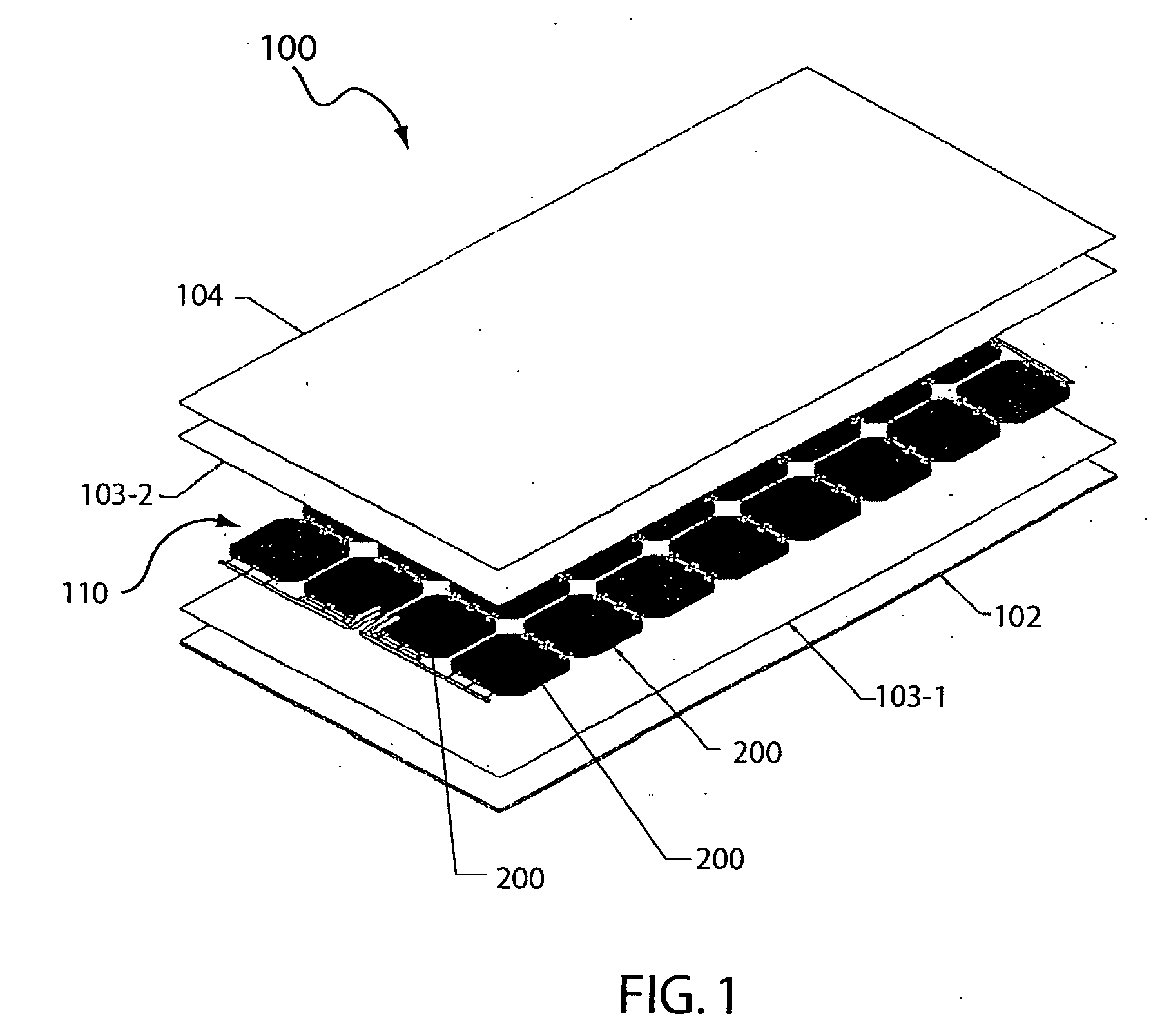

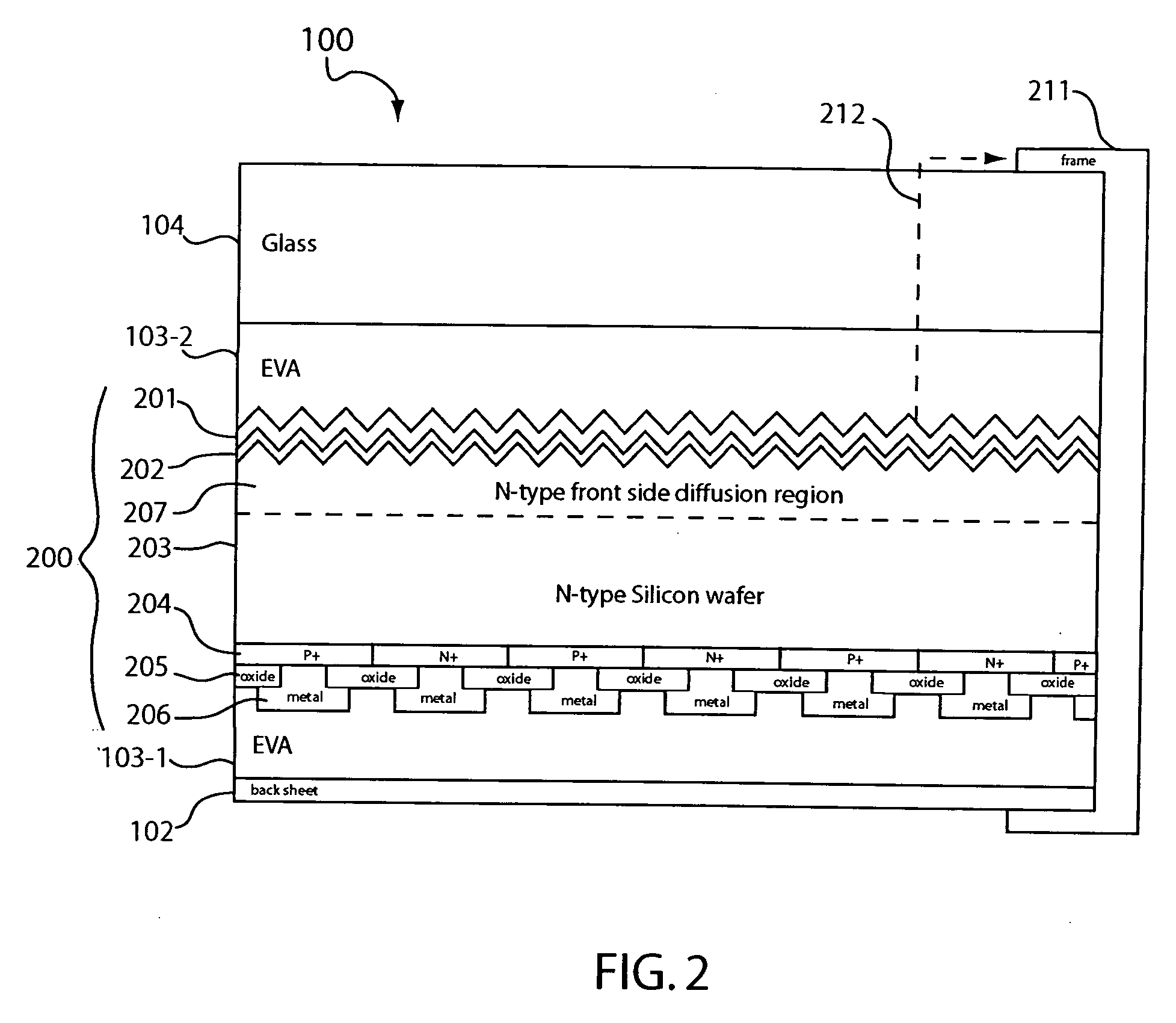

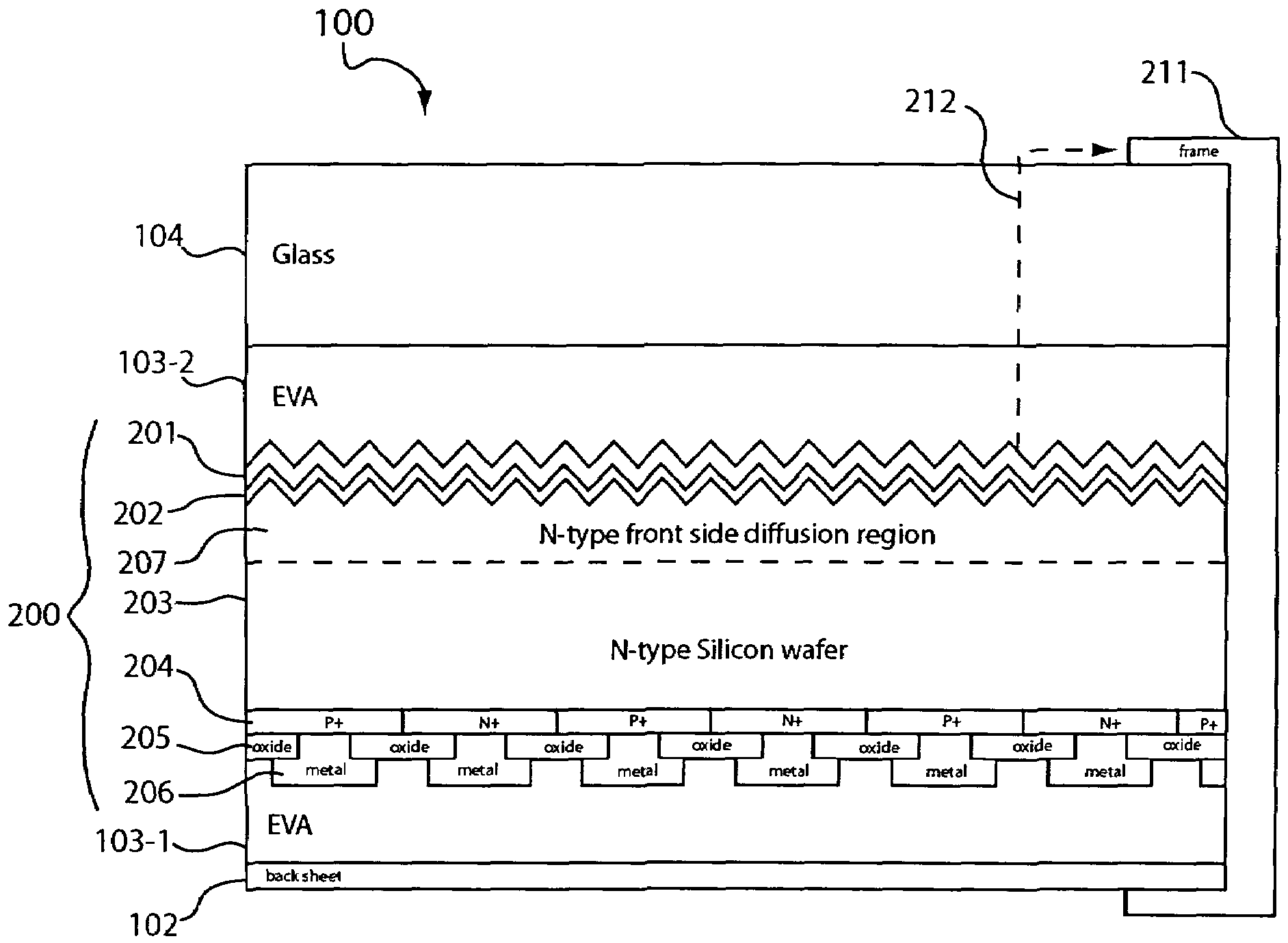

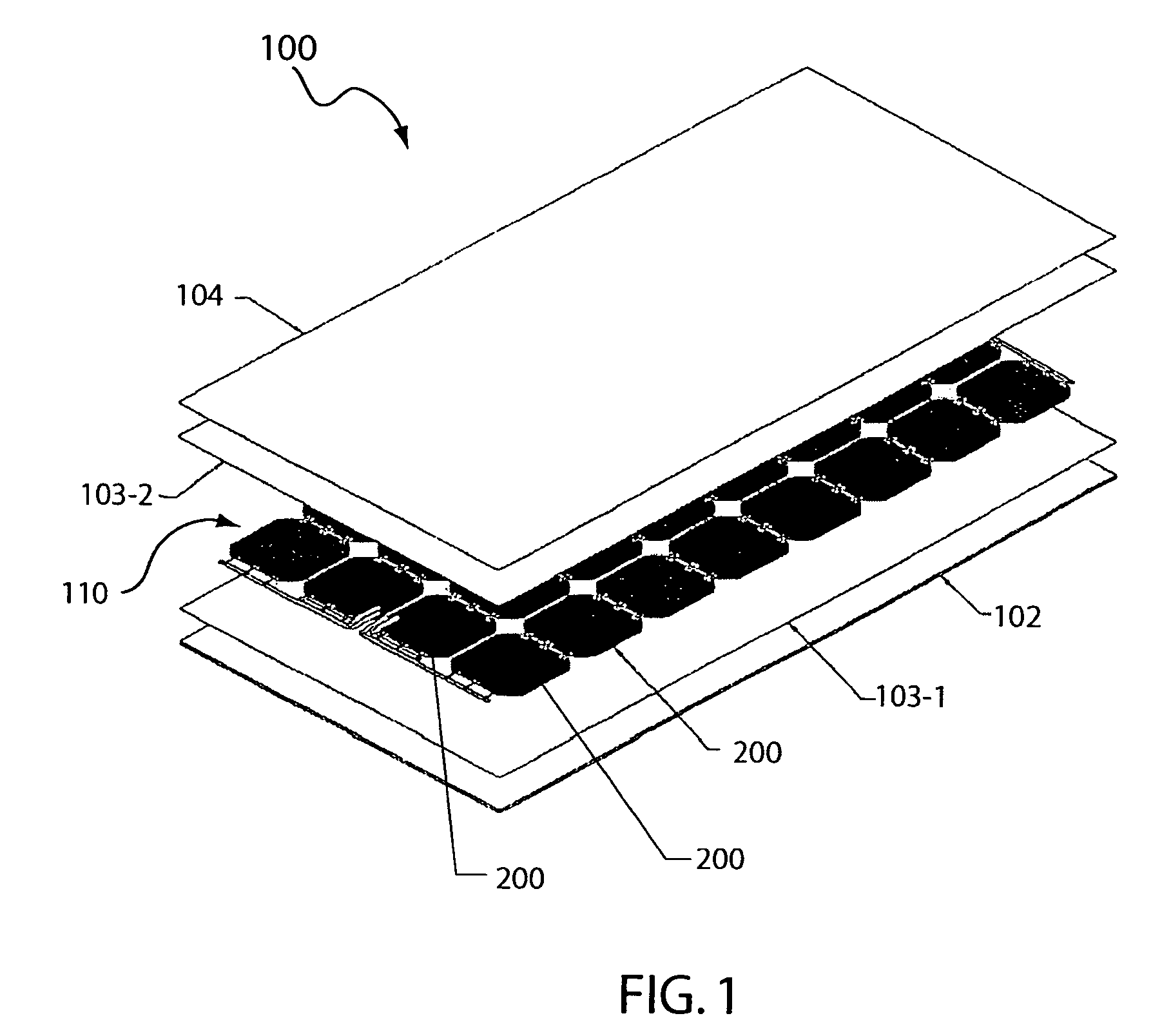

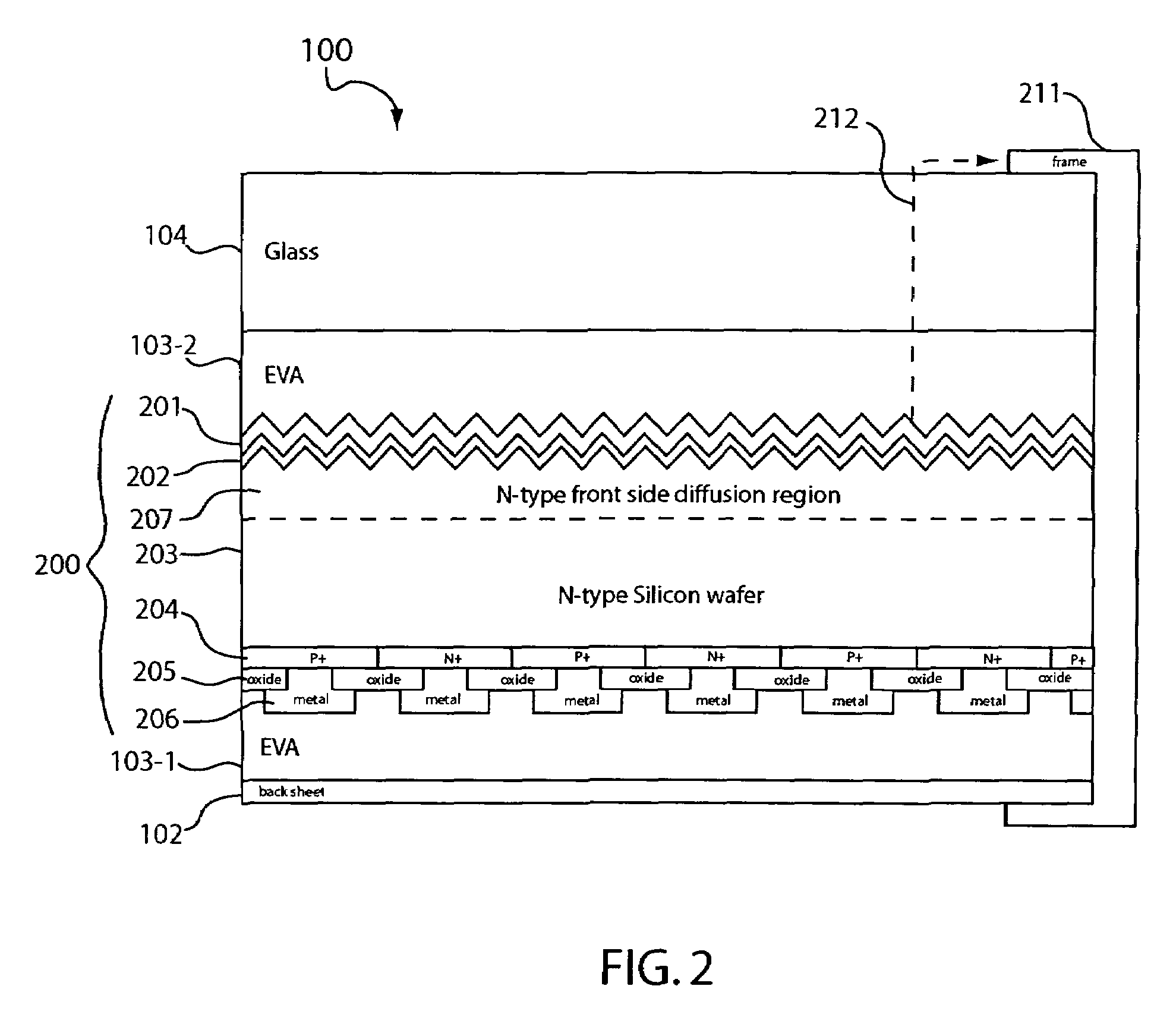

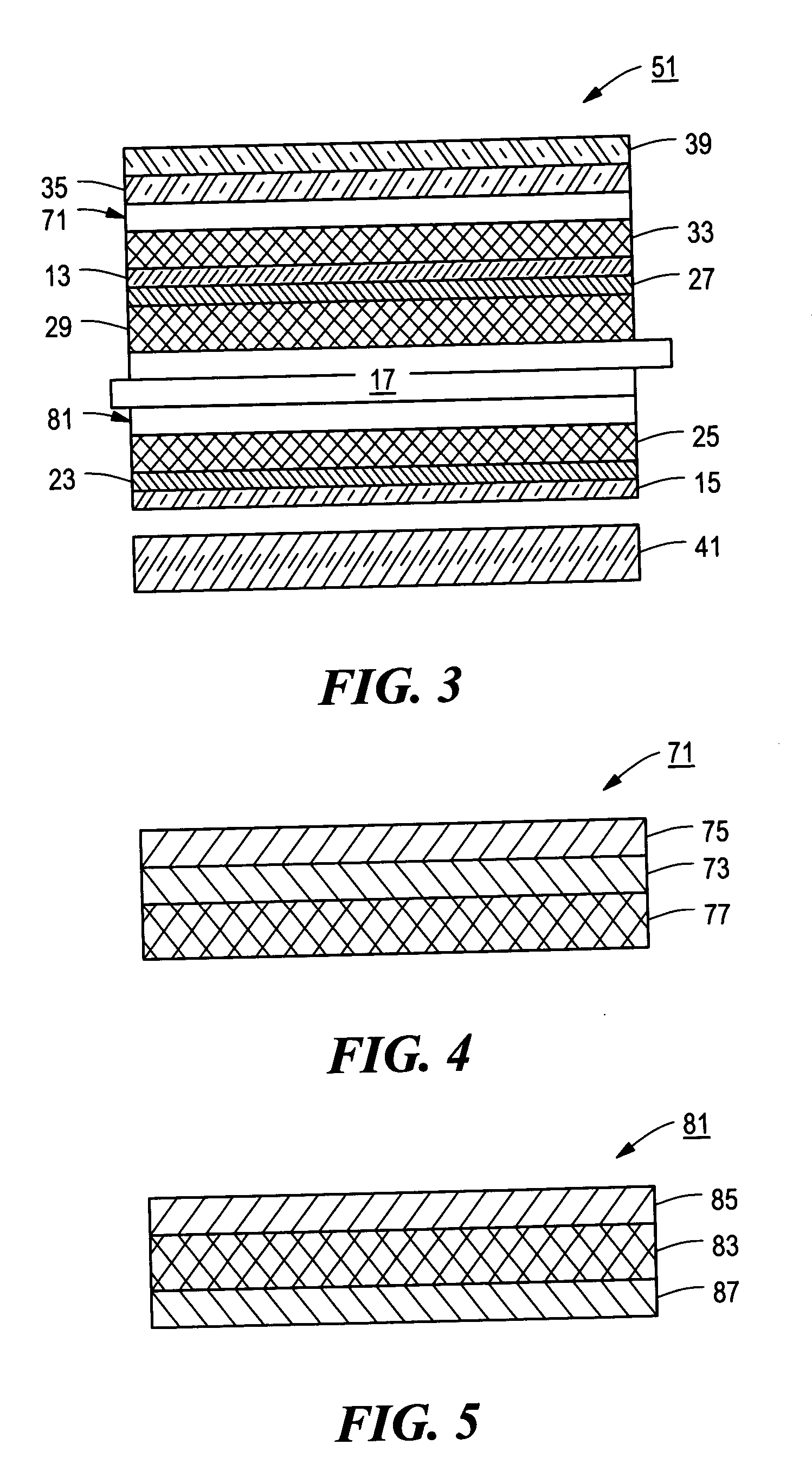

Preventing harmful polarization of solar cells

ActiveUS20060196535A1Harmful solar cell polarization may also be preventedHarmful solar cell polarization is prevented or minimizedPV power plantsSingle network parallel feeding arrangementsAnti-reflective coatingConductive materials

In one embodiment, harmful solar cell polarization is prevented or minimized by providing a conductive path that bleeds charge from a front side of a solar cell to the bulk of a wafer. The conductive path may include patterned holes in a dielectric passivation layer, a conductive anti-reflective coating, or layers of conductive material formed on the top or bottom surface of an anti-reflective coating, for example. Harmful solar cell polarization may also be prevented by biasing a region of a solar cell module on the front side of the solar cell.

Owner:MAXEON SOLAR PTE LTD +1

Thermosetting anti-refective coatings

Anti-reflective coating compositions having improved etch rate, inter alia, are prepared from certain acrylic polymers and copolymers, such as, glycidyl methacrylate reacted with non-polycyclic carboxylic acid dyes and non-polycyclic phenolic dyes, all light absorbing at a wavelength of 193 nm.

Owner:BREWER SCI

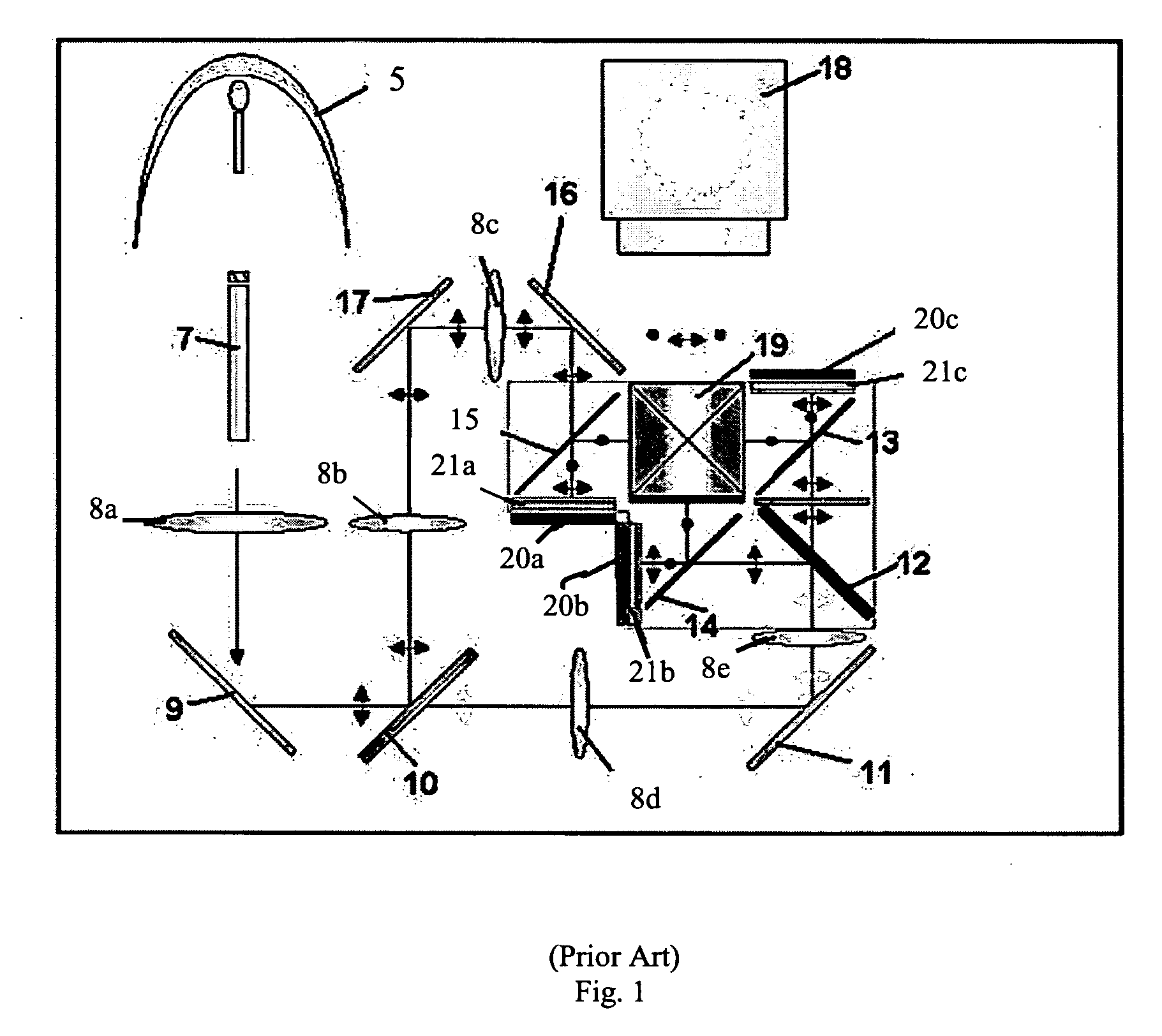

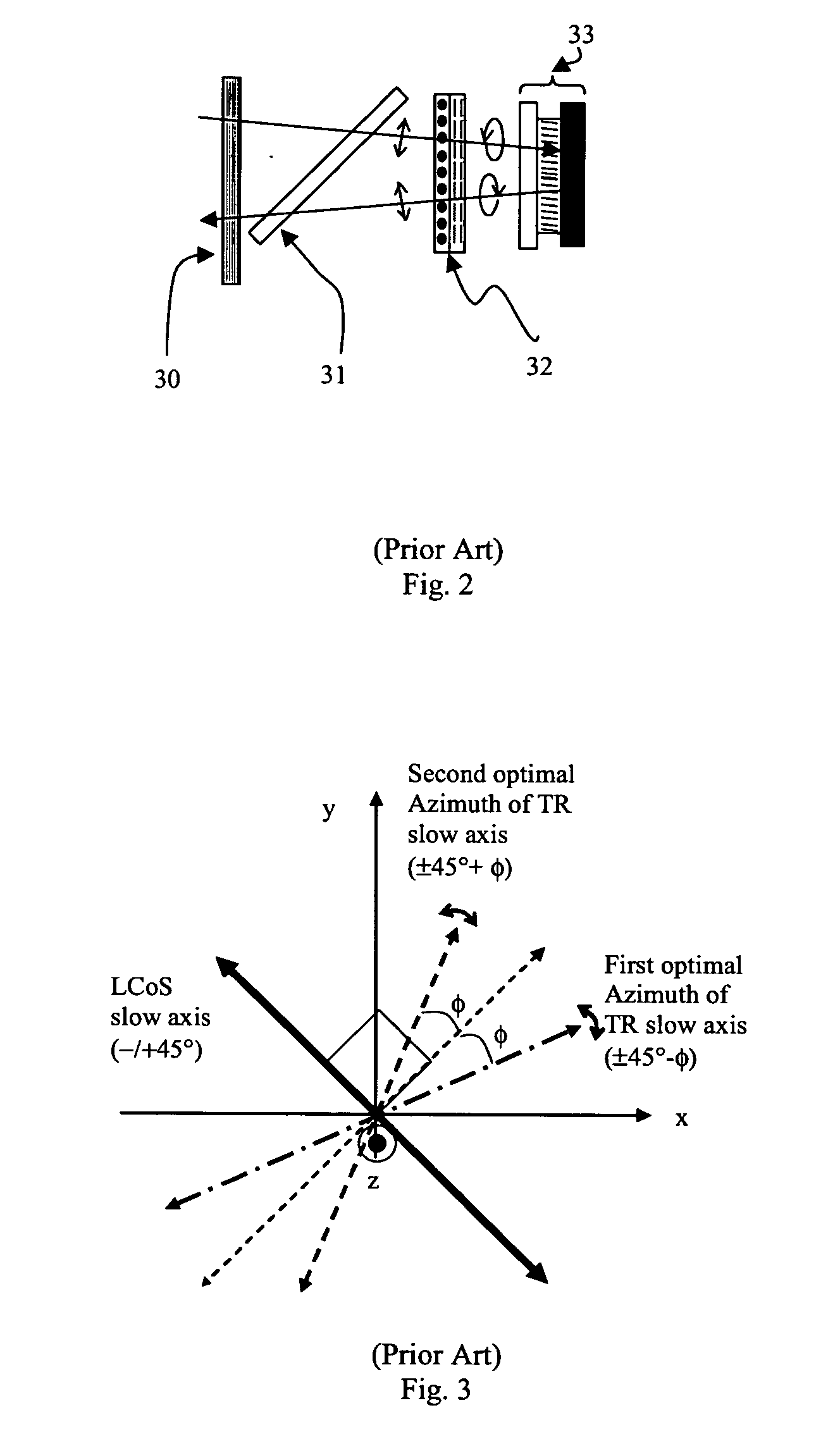

Grating trim retarders

InactiveUS20070070276A1Improve image contrastEasily integrated into oneColor television detailsNon-linear opticsIn planeZeroth order

A grating trim retarder fabricated from a form-birefringent multi-layer dielectric stack including at least one anti-reflection coating and supported on a transparent substrate is provided. The form-birefringent dielectric stack includes an axially-inhomogeneous element in the form of a −C-plate grating and a transversely-inhomogeneous element in the form of an A-plate grating. Each of the −C-plate and the A-plate gratings are fabricated with dimensions to form a zeroth order sub-wavelength grating structure. Fabricating the grating trim retarder with anti-reflection coatings and / or a segment where the −C-plate and A-plate grating overlap enables the in-plane and out-of-plane retardances to be tailored independently according to the desired application.

Owner:VIAVI SOLUTIONS INC

Preventing harmful polarization of solar cells

ActiveUS7554031B2Harmful solar cell polarization may also be preventedHarmful solar cell polarization is prevented or minimizedPV power plantsSingle network parallel feeding arrangementsAnti-reflective coatingConductive materials

In one embodiment, harmful solar cell polarization is prevented or minimized by providing a conductive path that bleeds charge from a front side of a solar cell to the bulk of a wafer. The conductive path may include patterned holes in a dielectric passivation layer, a conductive anti-reflective coating, or layers of conductive material formed on the top or bottom surface of an anti-reflective coating, for example. Harmful solar cell polarization may also be prevented by biasing a region of a solar cell module on the front side of the solar cell.

Owner:MAXEON SOLAR PTE LTD +1

Thin Films and Methods of Making Them

InactiveUS20020197831A1Increase productionImprove device yieldTransistorMaterial nanotechnologyAnti-reflective coatingSilicon membrane

<heading lvl="0">Abstract of Disclosure< / heading> Thin, smooth silicon-containing films are prepared by deposition methods that utilize a silicon-containing precursor. In preferred embodiments, the methods result in Si-containing films that are continuous and have a thickness of about 150 Åor less, a surface roughness of about 5 Å rms or less, and a thickness non-uniformity of about 20% or less. Preferred silicon-containing films display a high degree of compositional uniformity when doped or alloyed with other elements. Preferred deposition methods provide improved manufacturing efficiency and can be used to make various useful structures such as wetting layers, HSG silicon, quantum dots, dielectric layers, anti-reflective coatings (ARC s), gate electrodes and diffusion sources.

Owner:ASM IP HLDG BV

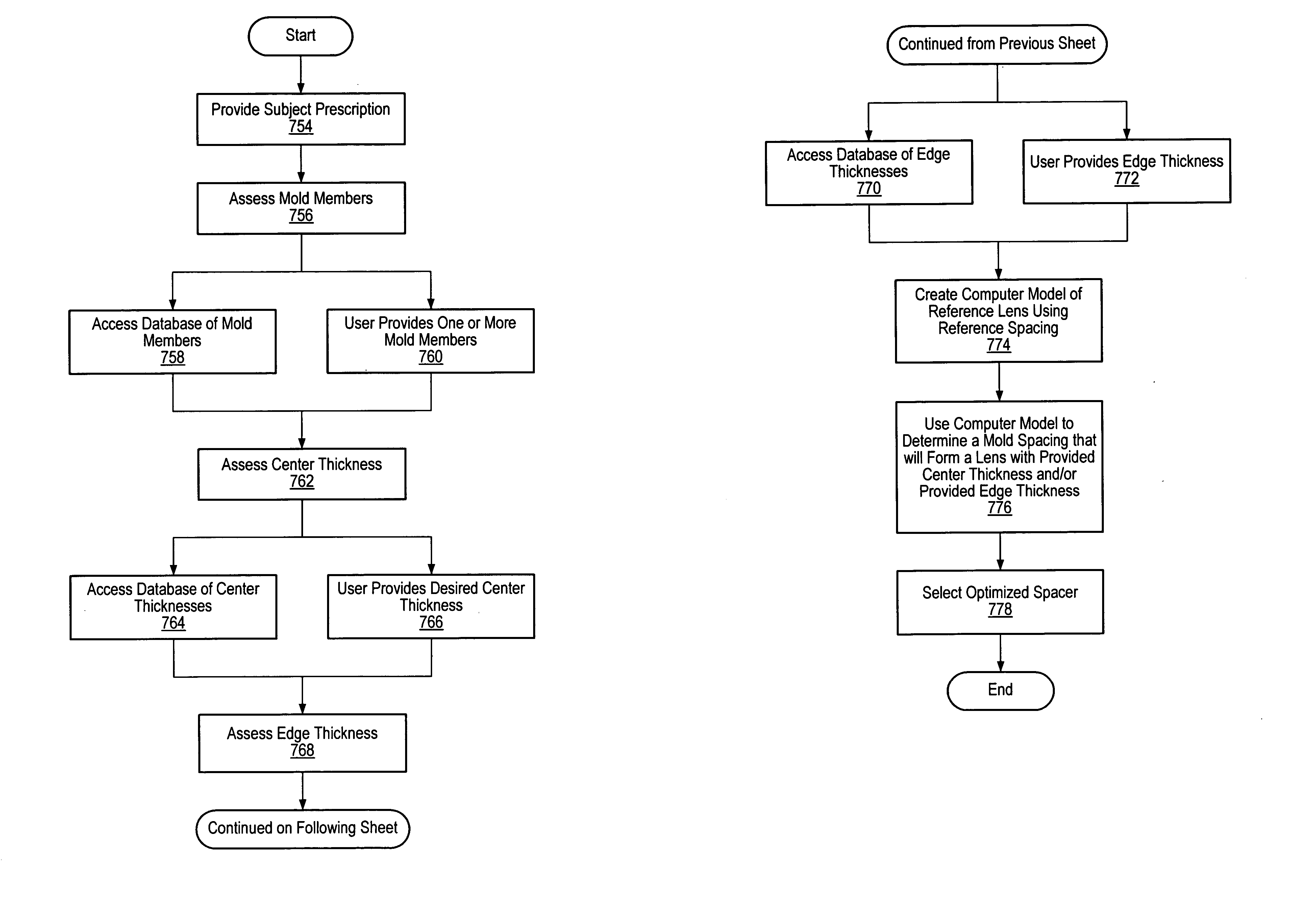

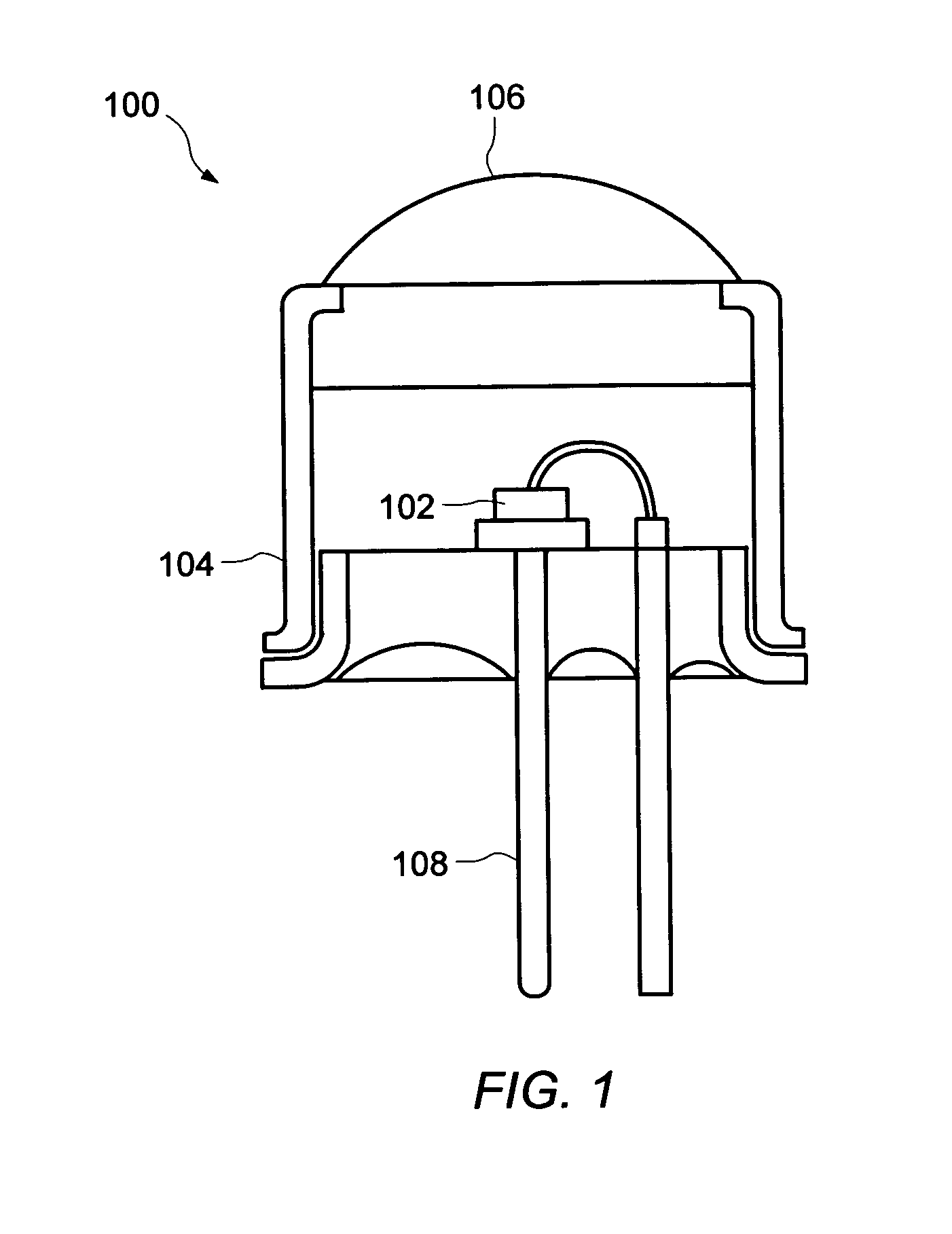

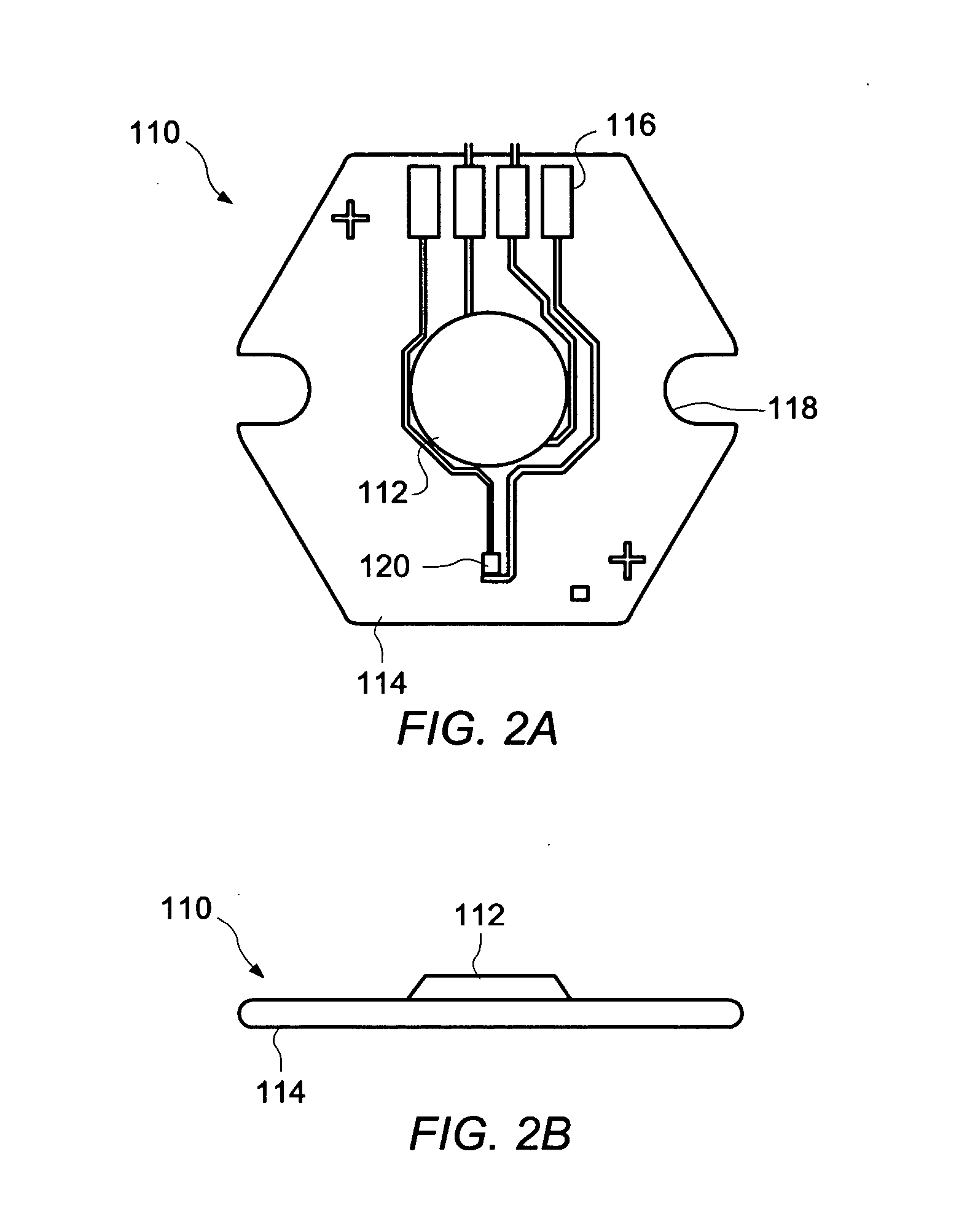

Lens forming systems and methods

Described herein are methods and systems for forming lenses. In one embodiment, systems for use in forming eyeglass lenses are described that include one or more LED lights. The LED lights may be used to cure lens forming compositions and coating compositions. In other embodiments, methods of determining an appropriate spacing for mold members are described. In other embodiments, methods of forming anti-reflective coatings, photochromic coatings, hardcoat coatings, and combinations thereof, on eyeglass lenses, are described.

Owner:VISION DYNAMICS

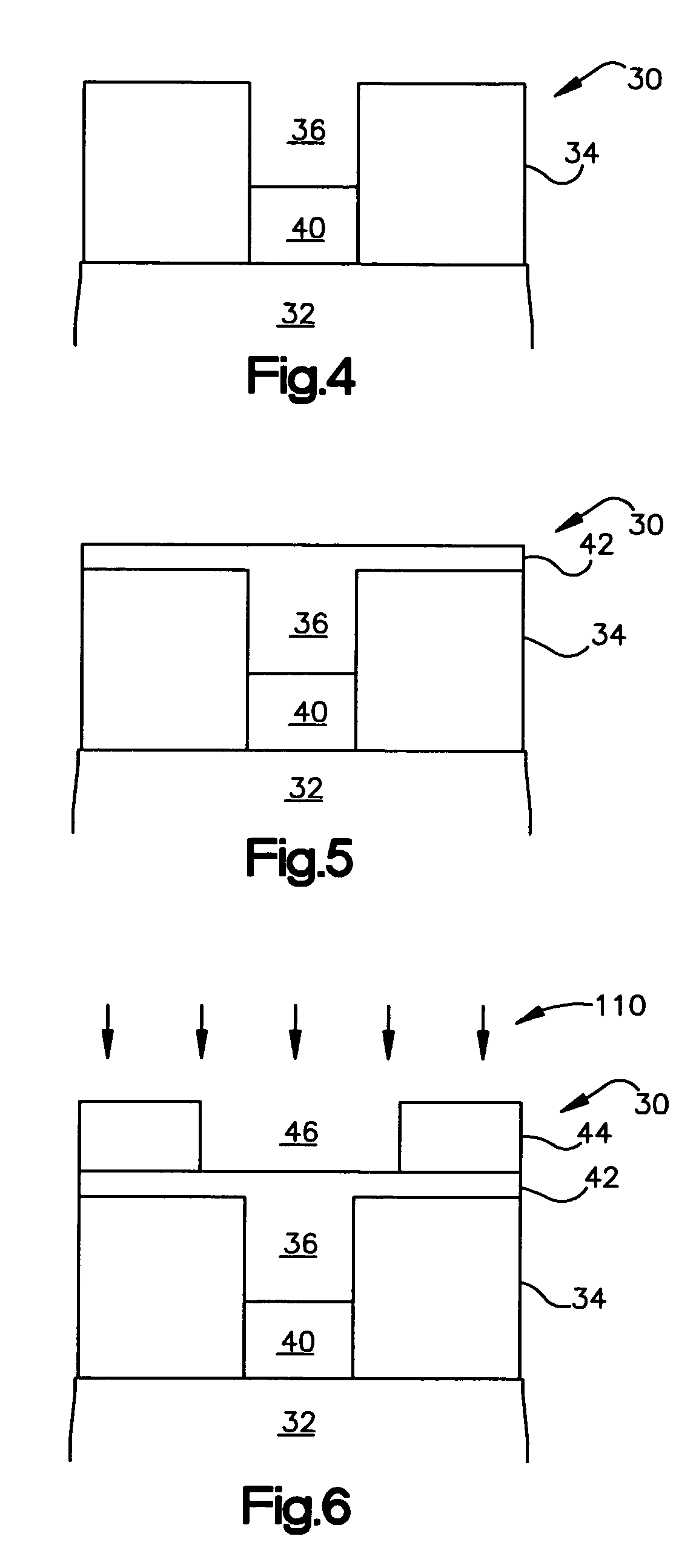

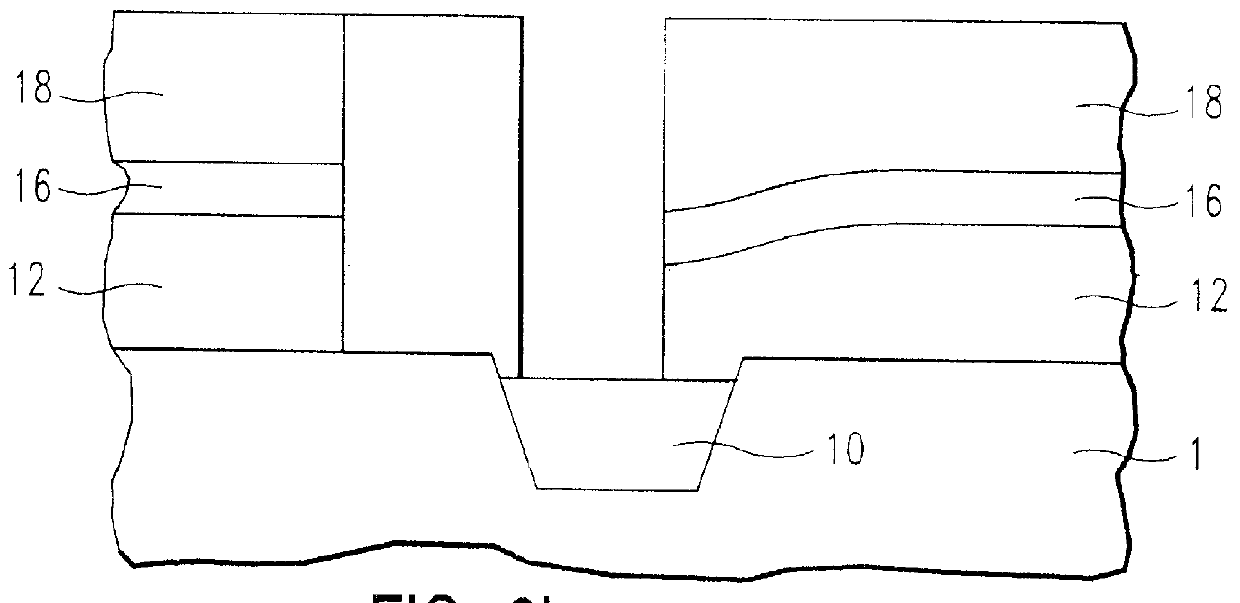

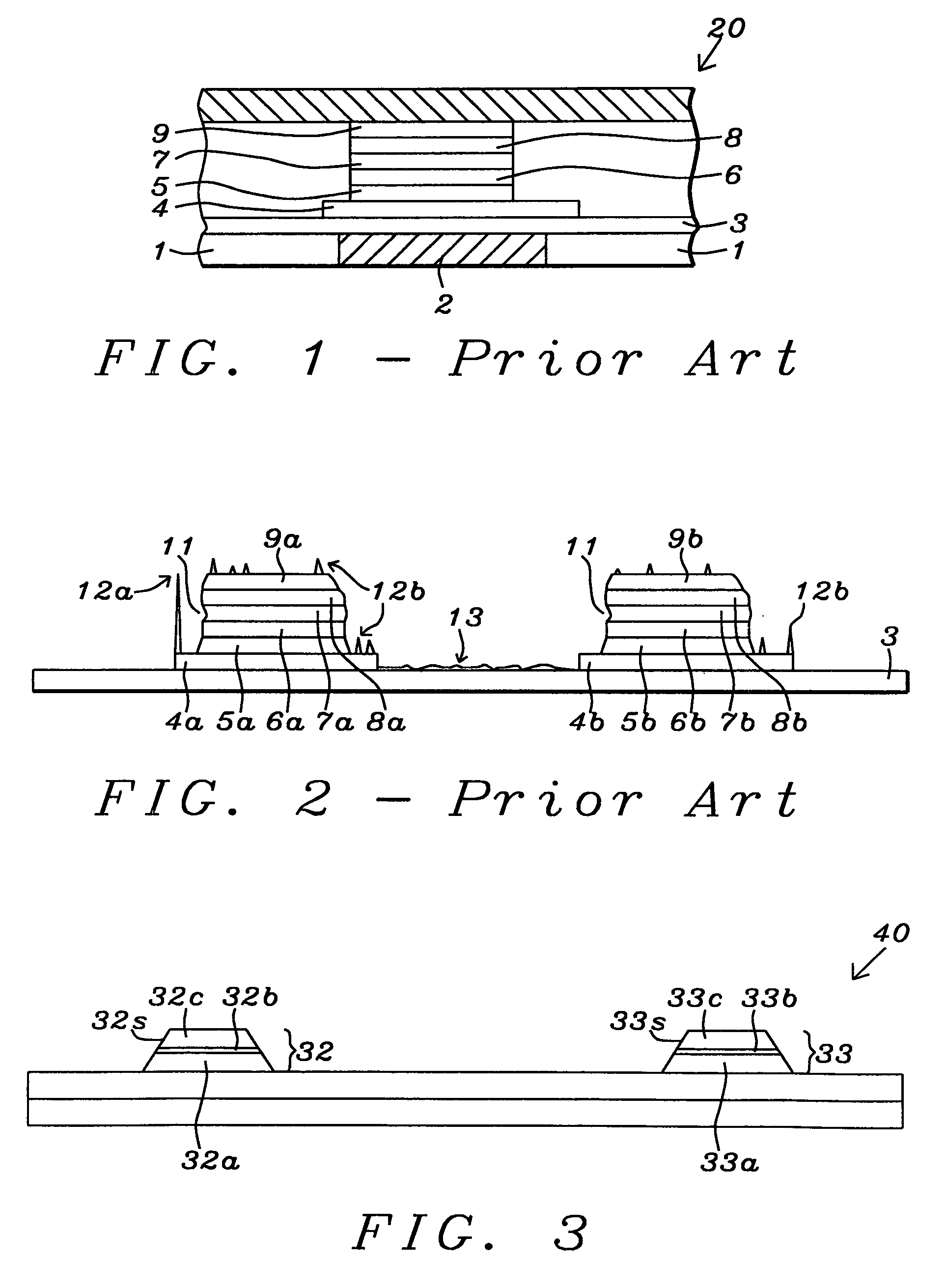

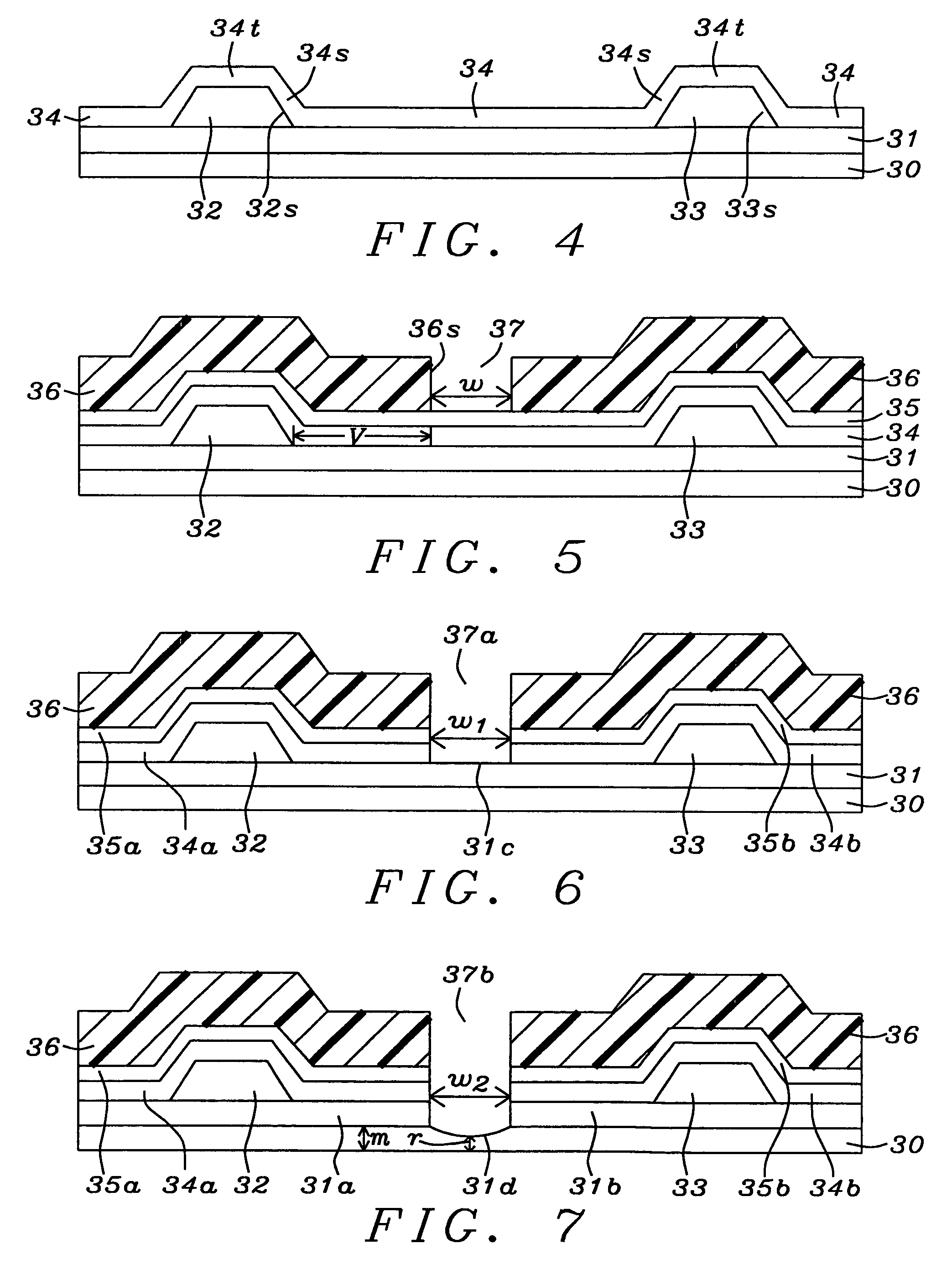

Process for defining a pattern using an anti-reflective coating and structure therefor

InactiveUS6030541ADecorative surface effectsSemiconductor/solid-state device manufacturingAnti-reflective coatingPhotoresist

A pattern in a surface is defined by providing on the surface a hard mask material; depositing an anti-reflective coating on the hard mask material; applying a photoresist layer on the anti-reflective coating; patterning the photoresist layer, anti-reflective layer and hard mask material; and removing the remaining portions of the photoresist layer and anti-reflective layer; and then patterning the substrate using the hard mask as the mask. Also provided is a structure for defining a pattern in a surface which comprises a surface having a hard mask material thereon; an anti-reflective coating located on the hard mask material; and a photoresist located on the anti-reflective coating. Also provided is an etchant composition for removing the hard mask material which comprises an aqueous composition of HF and chlorine.

Owner:IBM CORP

Functionalized matrices for dispersion of nanostructures

ActiveUS8283412B2Good miscibilityInhibit aggregationMaterial nanotechnologyGroup 4/14 element organic compoundsAnti-reflective coatingSemiconductor nanocrystals

Matrixes doped with semiconductor nanocrystals are provided. In certain embodiments, the semiconductor nanocrystals have a size and composition such that they absorb or emit light at particular wavelengths. The nanocrystals can comprise ligands that allow for mixing with various matrix materials, including polymers, such that a minimal portion of light is scattered by the matrixes. The matrixes are optionally formed from the ligands. The matrixes of the present invention can also be utilized in refractive index matching applications. In other embodiments, semiconductor nanocrystals are embedded within matrixes to form a nanocrystal density gradient, thereby creating an effective refractive index gradient. The matrixes of the present invention can also be used as filters and antireflective coatings on optical devices and as down-converting layers. Processes for producing matrixes comprising semiconductor nanocrystals are also provided. Nanostructures having high quantum efficiency, small size, and / or a narrow size distribution are also described, as are methods of producing indium phosphide nanostructures and core-shell nanostructures with Group II-VI shells.

Owner:SHOEI CHEM IND CO LTD

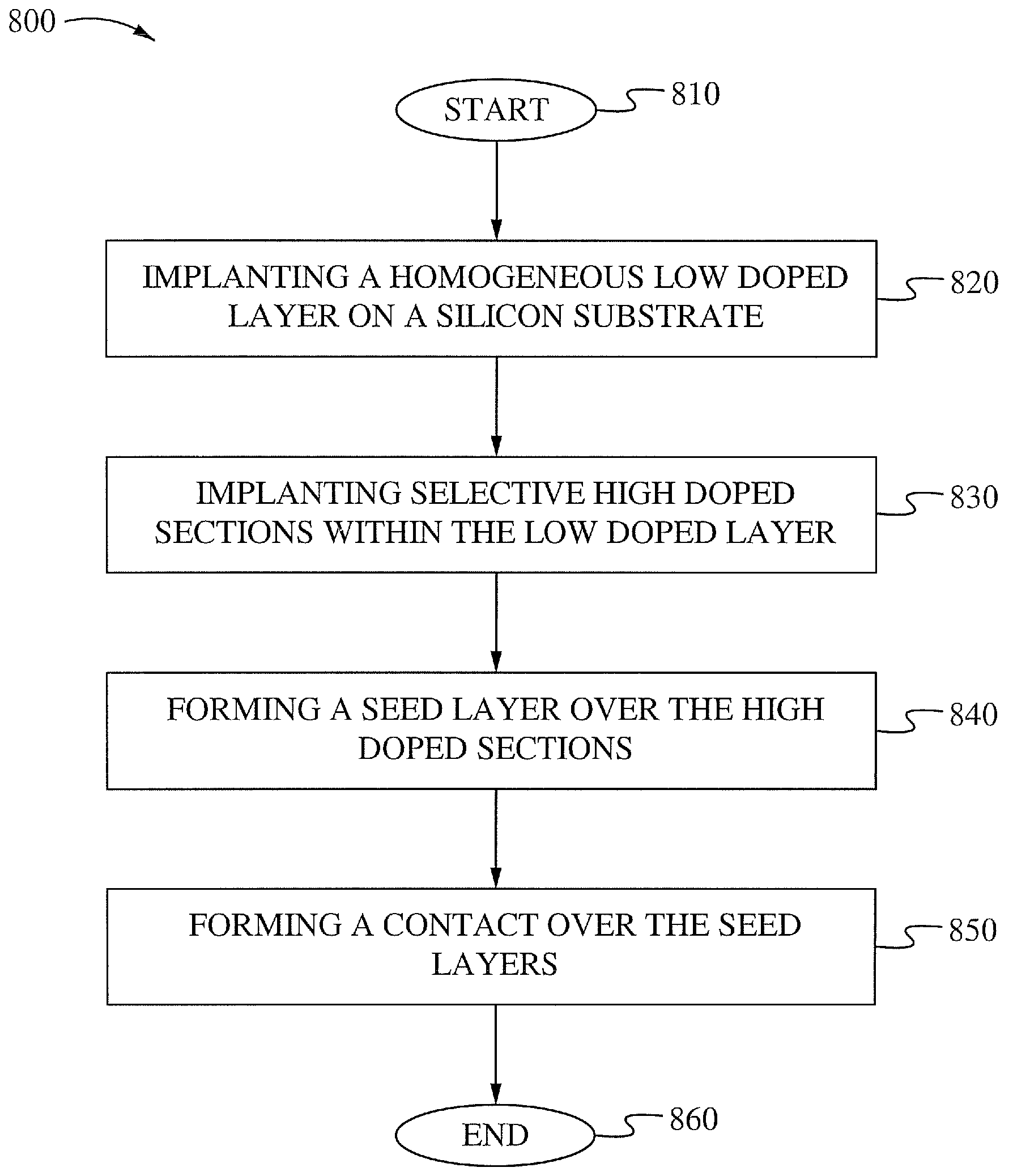

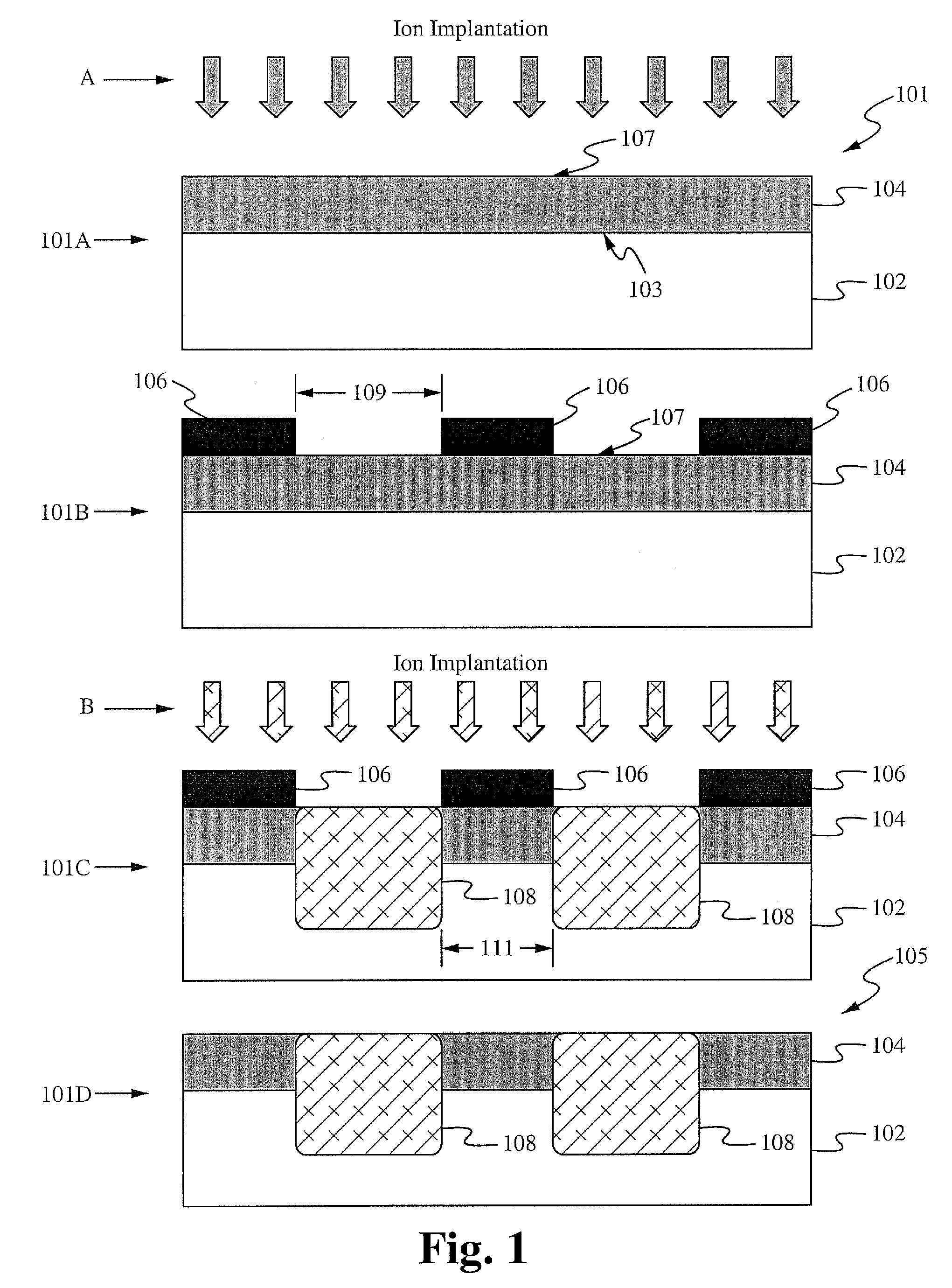

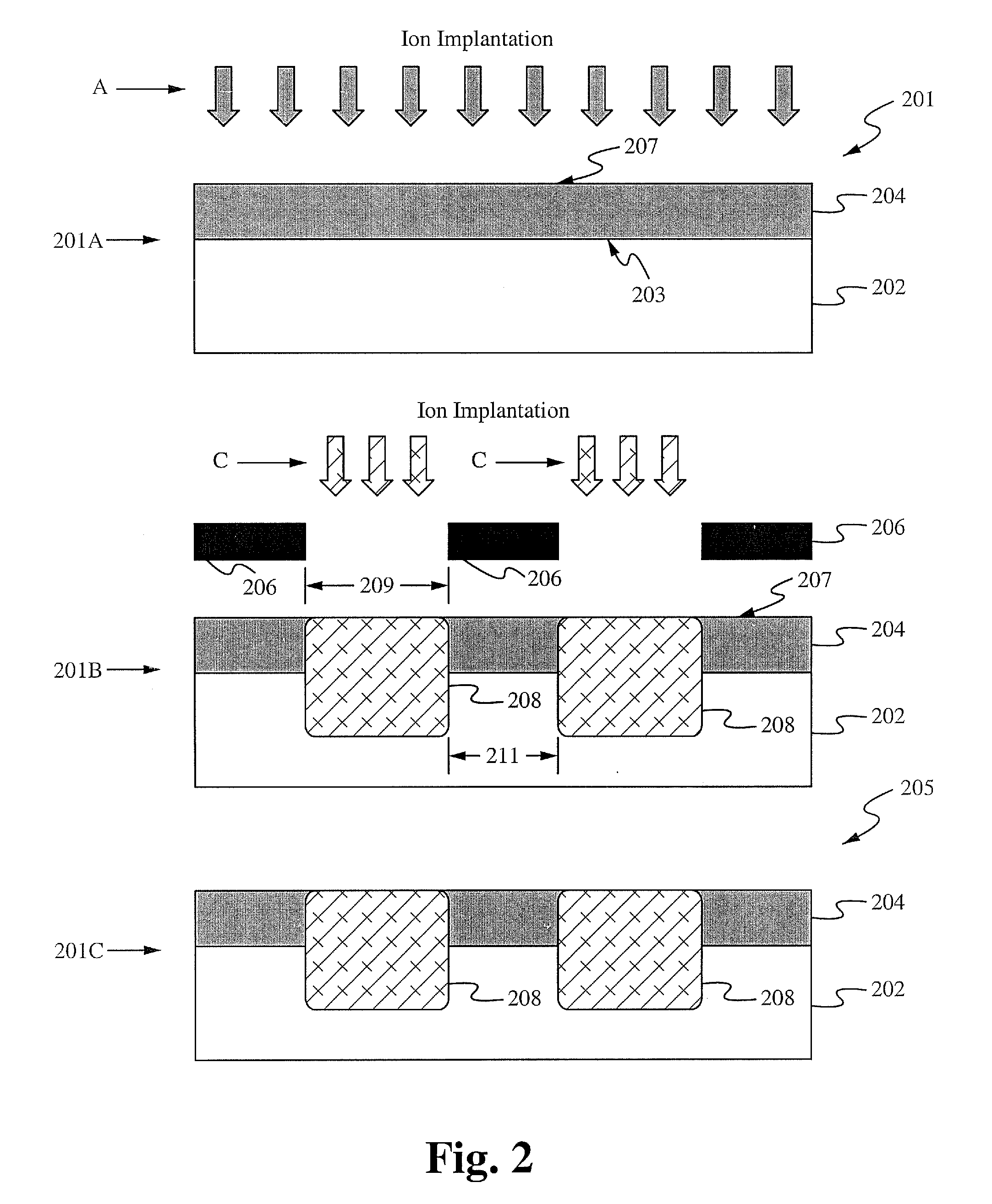

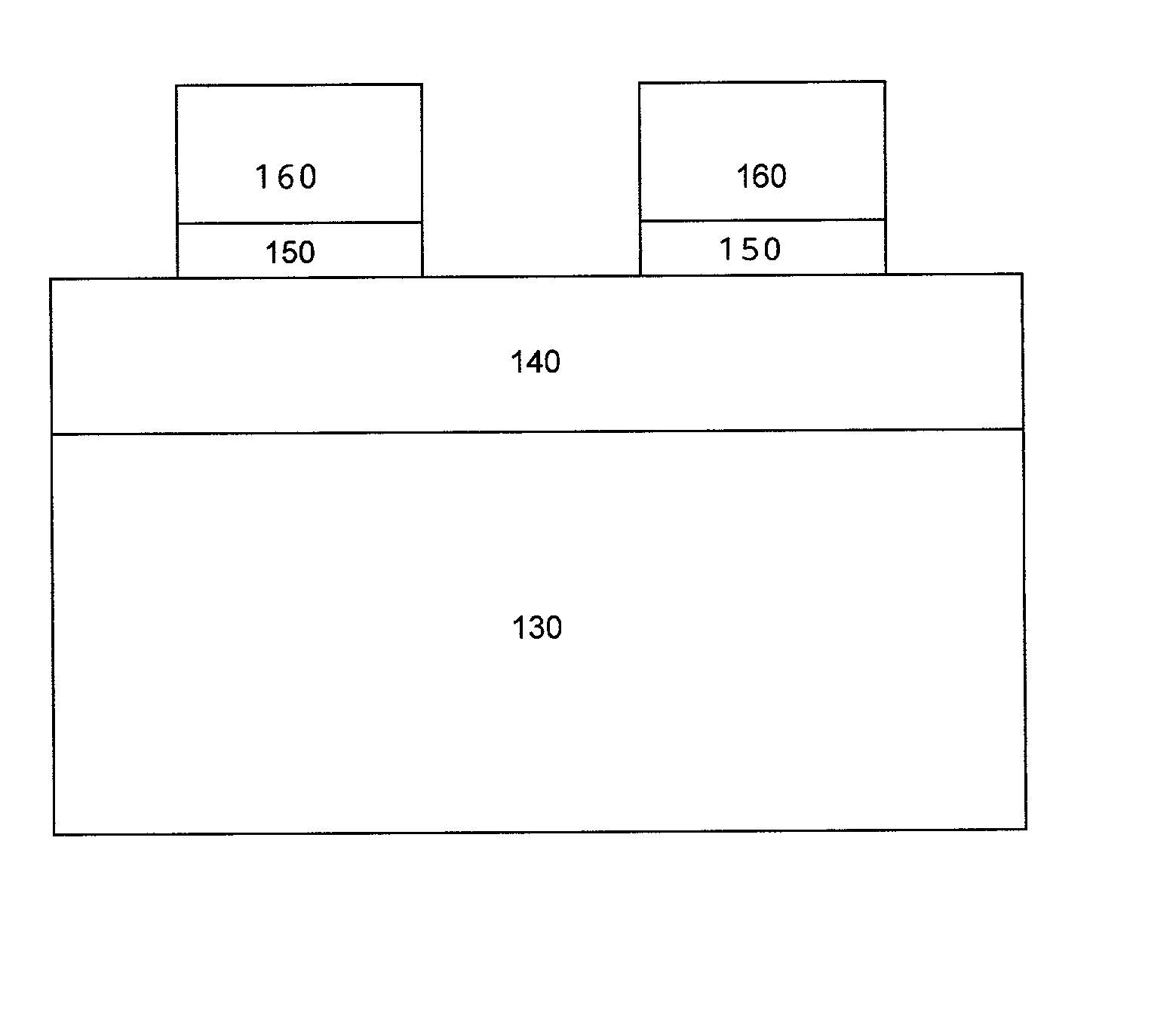

Solar cell fabrication using implantation

InactiveUS20090308439A1Low temperature annealingLower temperature annealingFinal product manufactureSemiconductor/solid-state device manufacturingAnti-reflective coatingDopant

A solar cell device and method of making are provided. The device includes a silicon substrate including a preexisting dopant. A homogeneous lightly doped region is formed on a surface of the silicon substrate to form a junction between the preexisting dopant and the lightly doped region. A heavily doped region is selectively implanted on the surface of the silicon substrate. A seed layer is formed over the heavily doped region. A metal contact is formed over the seed layer. The device can include an anti-reflective coating. In one embodiment, the heavily doped region forms a parabolic shape. The heavily doped regions can each be a width on the silicon substrate a distance in the range 50 to 200 microns. Also, the heavily doped regions can be laterally spaced on the silicon substrate a distance in the range 1 to 3 mm from each other. The seed layer can be a silicide. The silicon substrate can include fiducial markers configured for aligning the placement of the heavily doped regions during an ion implantation process.

Owner:INTEVAC

Bottom electrode etching process in MRAM cell

ActiveUS8334213B2Not to damageImprove device yieldDecorative surface effectsSolid-state devicesBit lineWater based

A BE patterning scheme in a MRAM is disclosed that avoids damage to the MTJ array and underlying ILD layer while reducing BE-BE shorts and BE-bit line shorts. A protective dielectric layer is coated over a MTJ array before a photoresist layer is coated and patterned on the dielectric layer. The photoresist pattern is transferred through the dielectric layer with a dielectric etch process and then through the BE layer with a metal etch that includes a certain amount of overetch to remove metal residues. The photoresist is stripped with a sequence involving immersion or spraying with an organic solution followed by oxygen ashing to remove any other organic materials. Finally, a second wet strip is performed with a water based solution to provide a residue free substrate. In another embodiment, a bottom anti-reflective coating (BARC) is inserted between the photoresist and dielectric layer for improved critical dimension control.

Owner:TAIWAN SEMICON MFG CO LTD

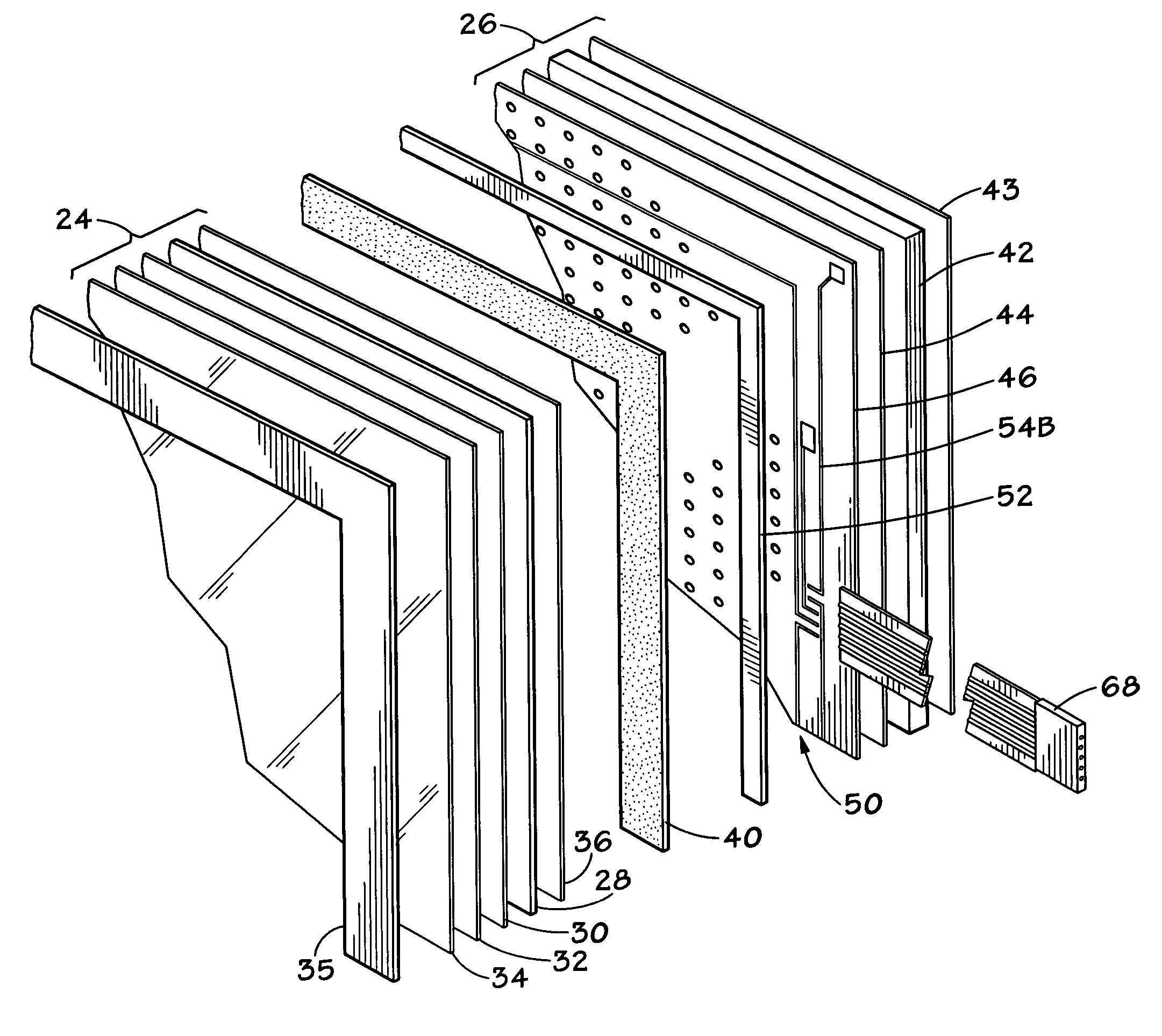

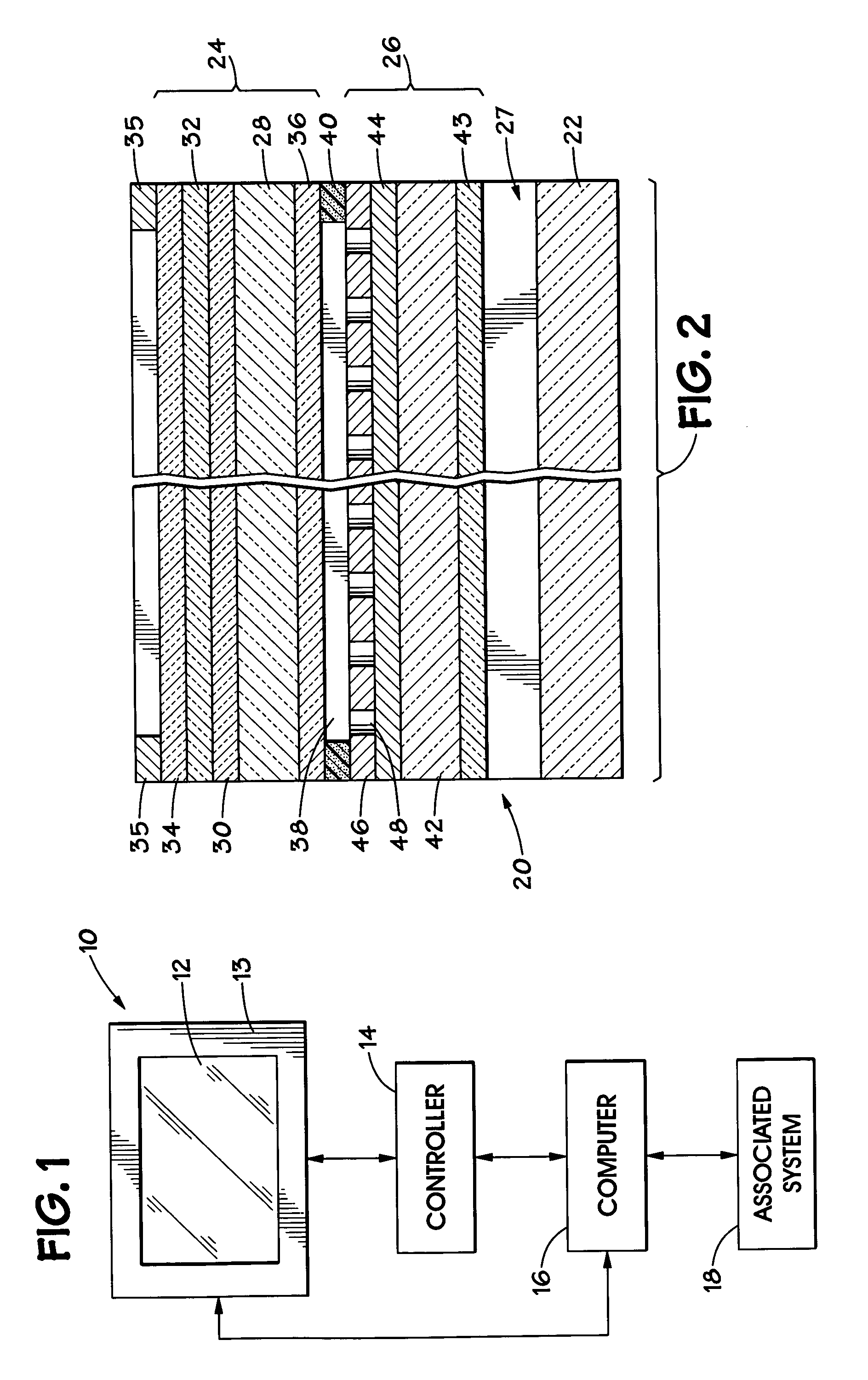

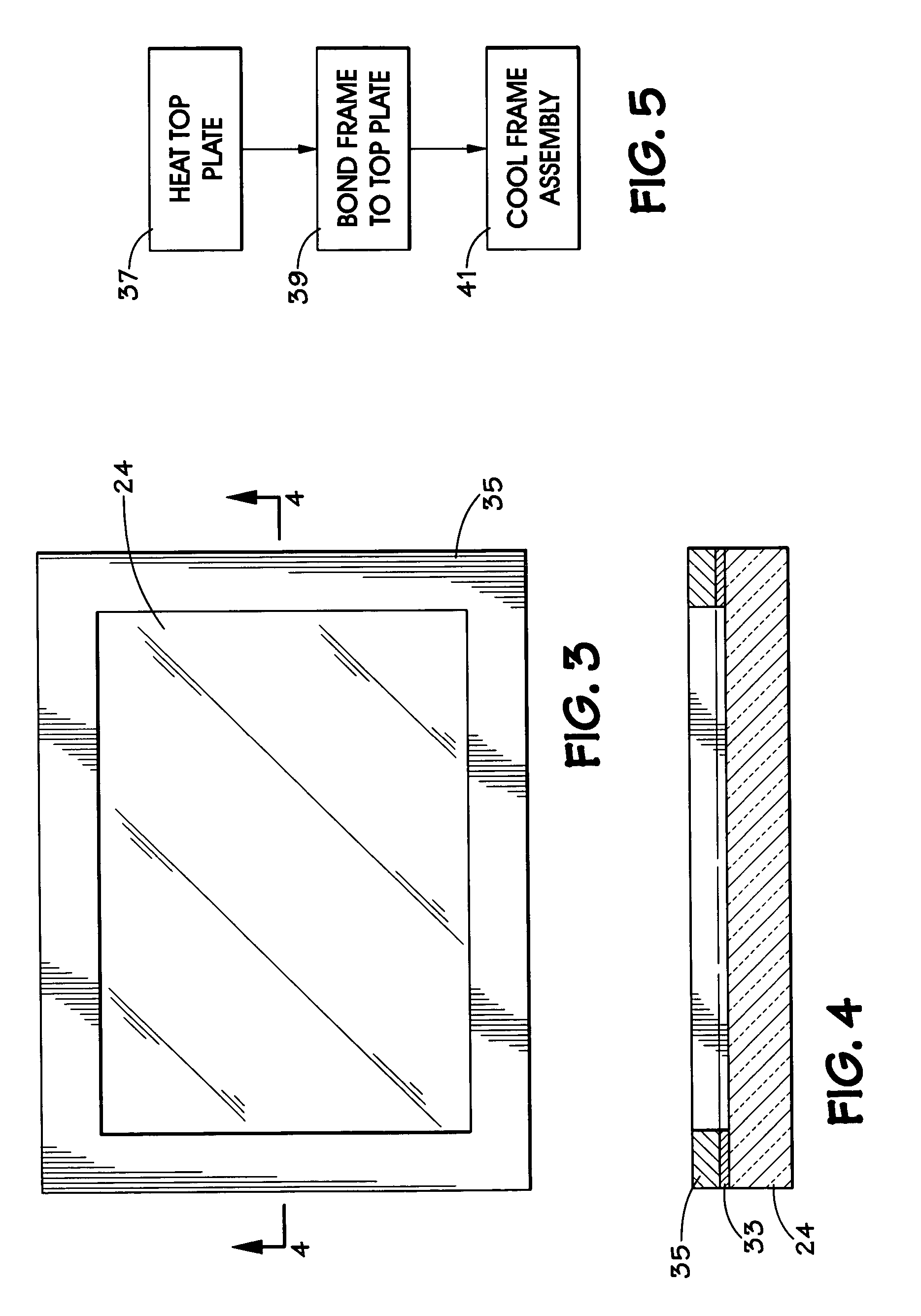

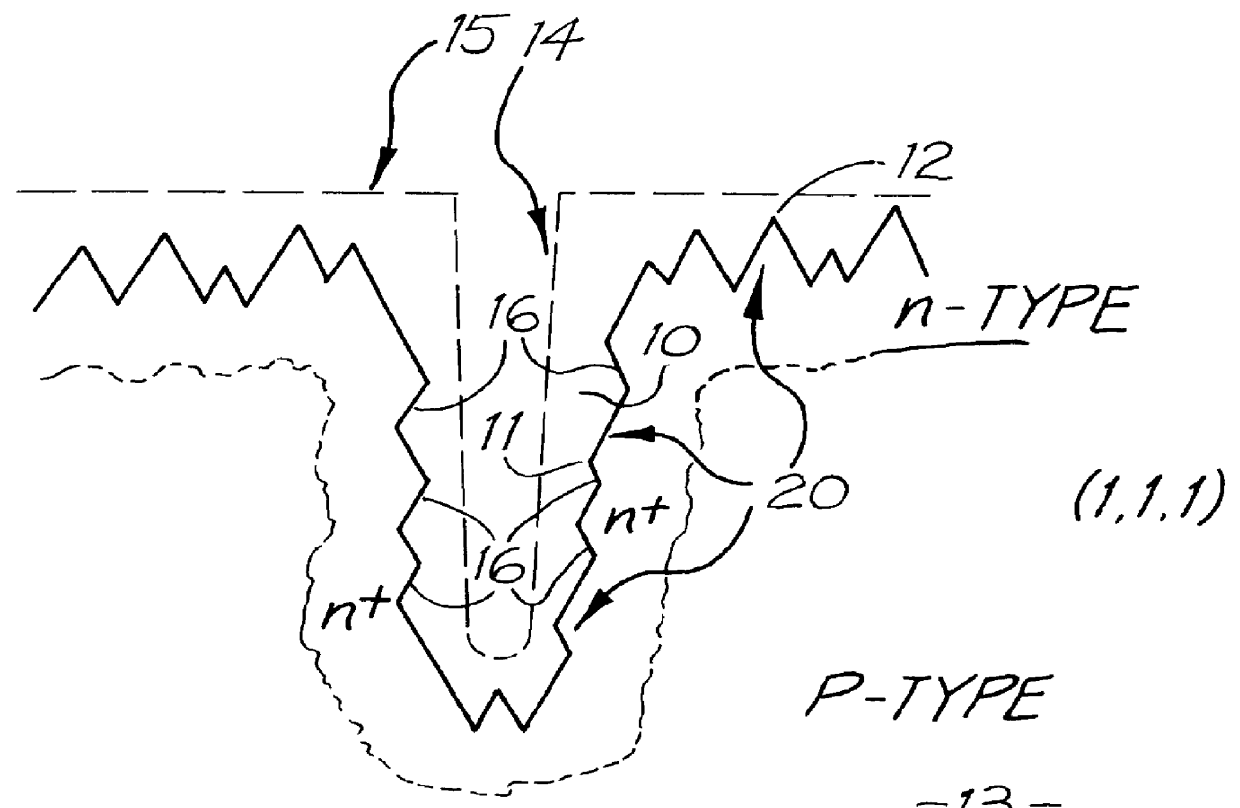

Resistive touch panel using removable, tensioned top layer

Sunlight can damage a conventional touch screen display and cause the display to be quite difficult to read. Furthermore, conventional touch screen displays are easily damaged, and, once damaged, the entire touch screen is replaced. To address these concerns, a touch panel includes anti-reflective coatings on the surfaces of the top plate and the base plate that are open to the air. These coatings substantially reduce reflections and make the touch screen easier to read in direct sunlight. In particular, the anti-reflective coating used on the upper surface of the base plate is dielectric in nature to reduce reflectivity even further. This dielectric coating includes openings to an underlying conductive layer so that an electrical contact is made when a user deflects the top plate into the base plate. Also, the top plate may be detachably coupled to the base plate, advantageously by double stick adhesive tape, so that only the top plate is replaced when damaged. In one embodiment, the top plate is placed in tension within a frame to prevent wrinkling. Furthermore, a resistive voltage divider may be fabricated on the base plate. The resistive voltage divider may include a substantially continuous strip of resistive material disposed on the conductive layer of the base plate, and a plurality of conductive traces disposed on the dielectric layer of the base plate and coupled to the resistive material in selected locations.

Owner:L 3 COMM CORP

Composition and process for post-etch removal of photoresist and/or sacrificial anti-reflective material deposited on a substrate

ActiveUS20050197265A1Cationic surface-active compoundsOrganic detergent compounding agentsAnti-reflective coatingPhotoresist

A composition and process for removing photoresist and / or sacrificial anti-reflective coating (SARC) materials from a substrate having such material(s) thereon. The composition includes a base component, such as a quaternary ammonium base in combination with an alkali or alkaline earth base, or alternatively a strong base in combination with an oxidant. The composition may be utilized in aqueous medium, e.g., with chelator, surfactant, and / or co-solvent species, to achieve high-efficiency removal of photoresist and / or SARC materials in the manufacture of integrated circuitry, without adverse effect on metal species on the substrate, such as copper, aluminum and / or cobalt alloys, and without damage to SiOC-based dielectric materials employed in the semiconductor architecture.

Owner:ENTEGRIS INC

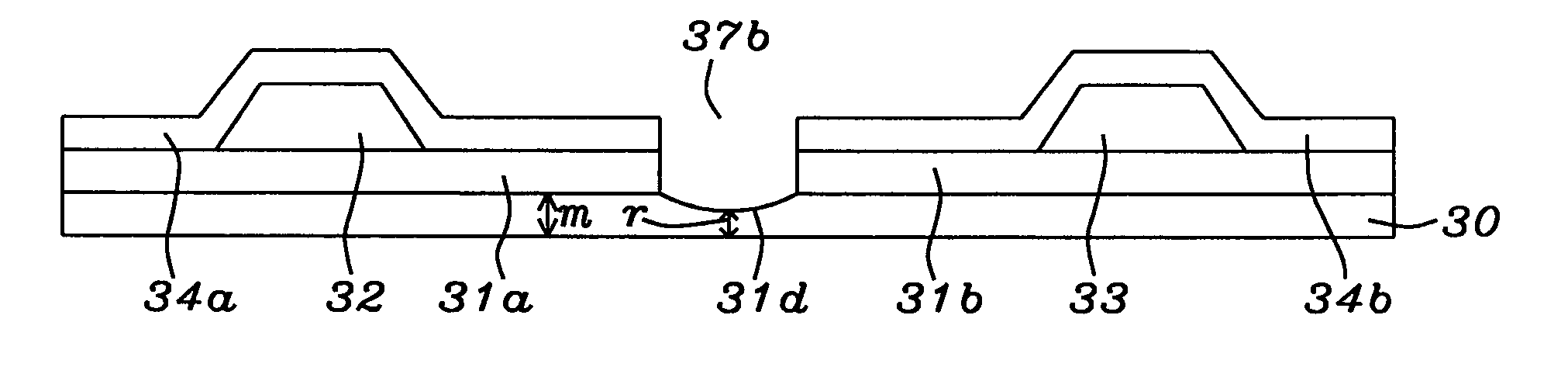

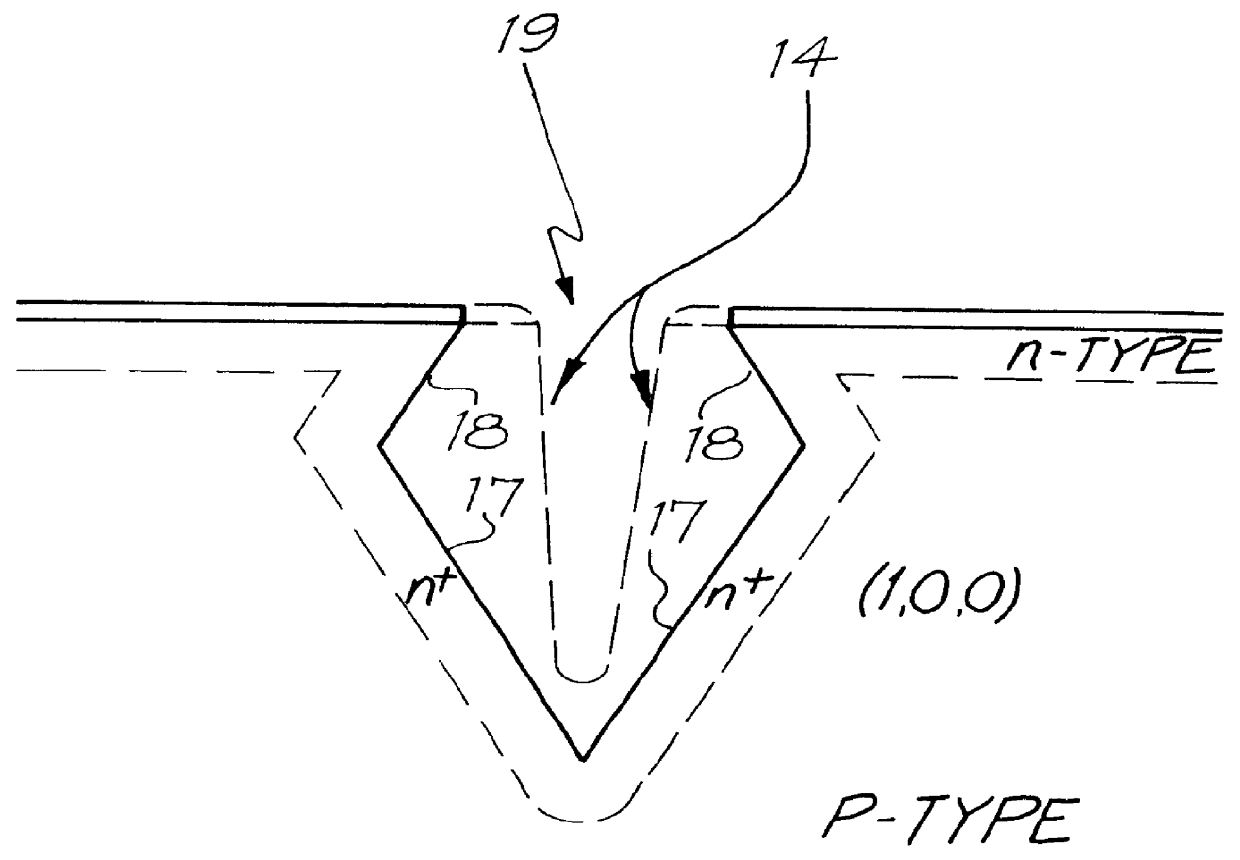

Metallization of buried contact solar cells

InactiveUS6162658AThin coatingFinal product manufactureSemiconductor/solid-state device manufacturingAnti-reflective coatingThin layer

The present invention makes use of geometry of grooves formed in a substrate, to allow a dielectric layer to be deposited with some regions of the grooves having a substantially thinner layer deposited than top surfaces of the substrate. These regions of reduced thickness dielectric within the grooves are then prematurely etched by an appropriate chemical, or other, etchant capable of controllably etching away the dielectric layer, with the result that in these regions the silicon surface can be exposed and plated by a metallization while the top surface remains protected by the dielectric material. The remaining dielectric material can optionally be required to act as an anti-reflective coating. The invention is applicable in making buried contact solar cells.

Owner:UNISEARCH LTD

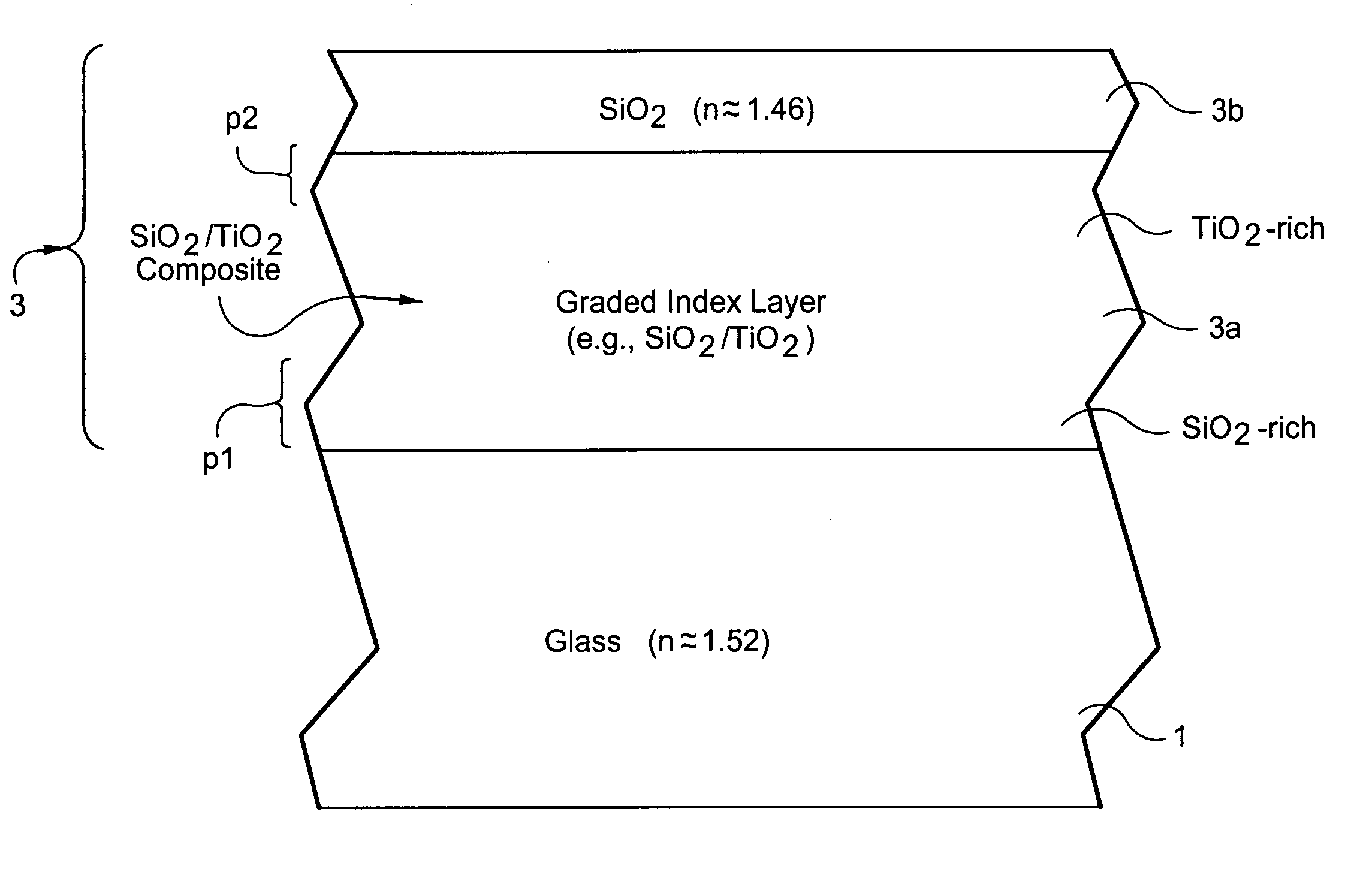

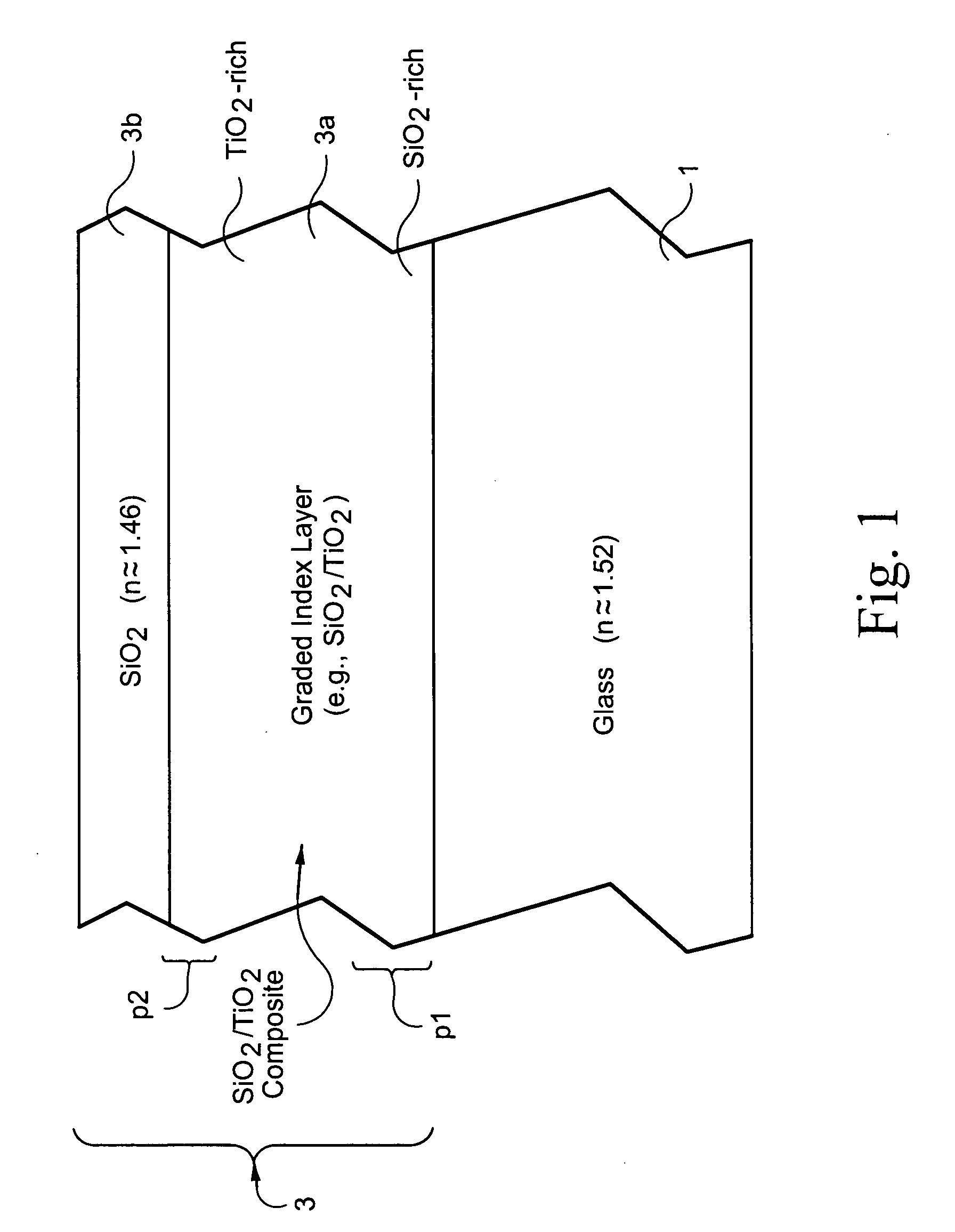

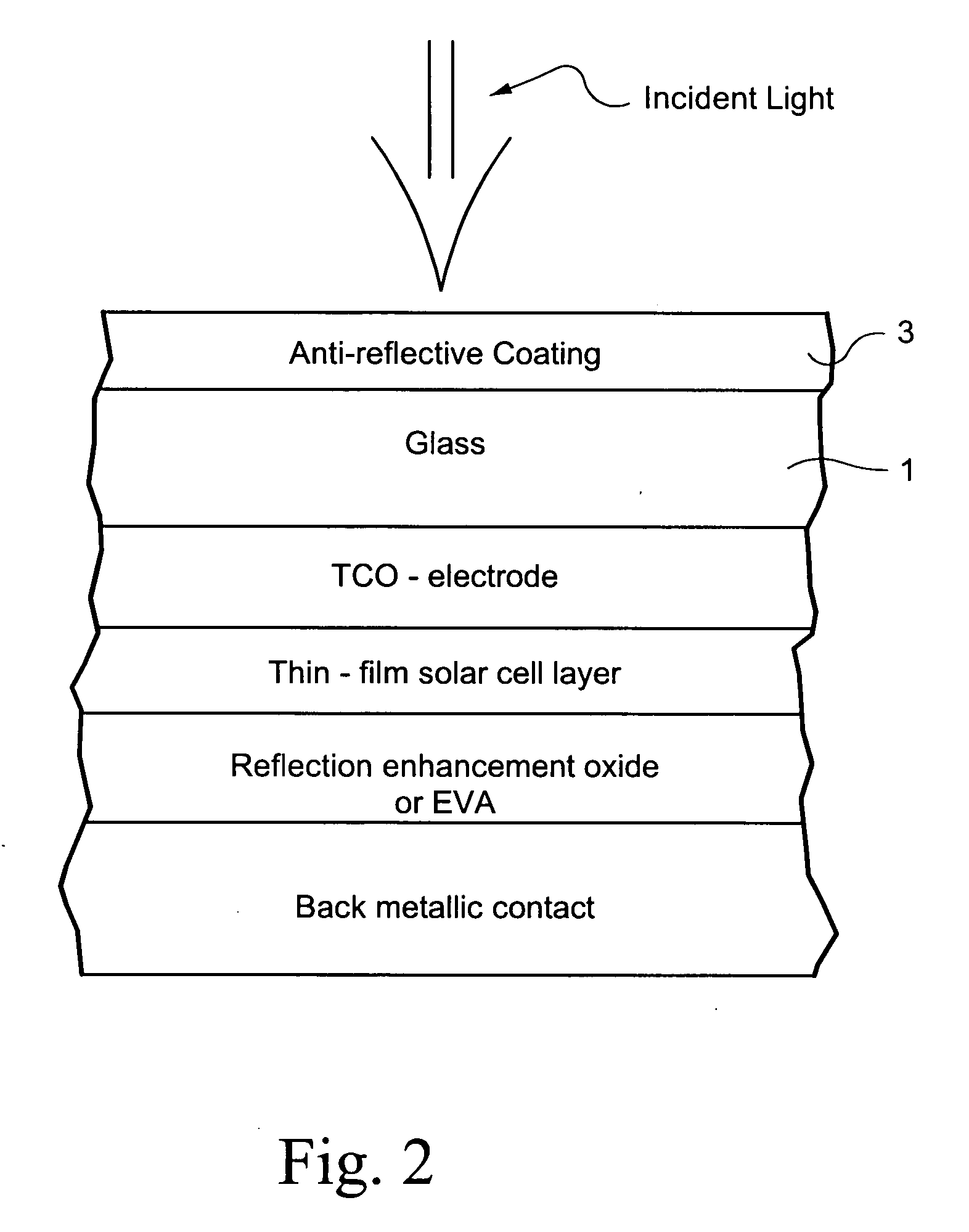

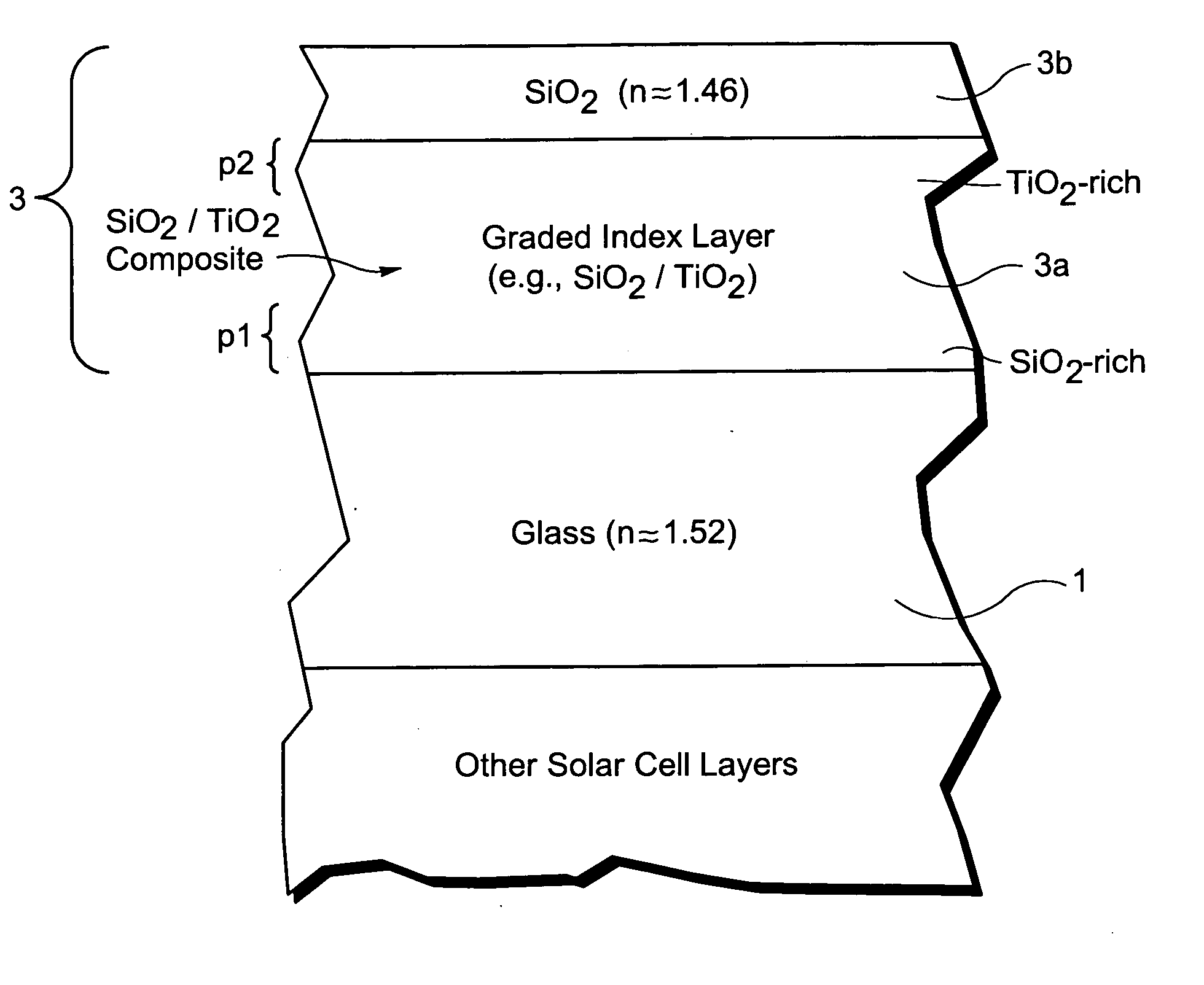

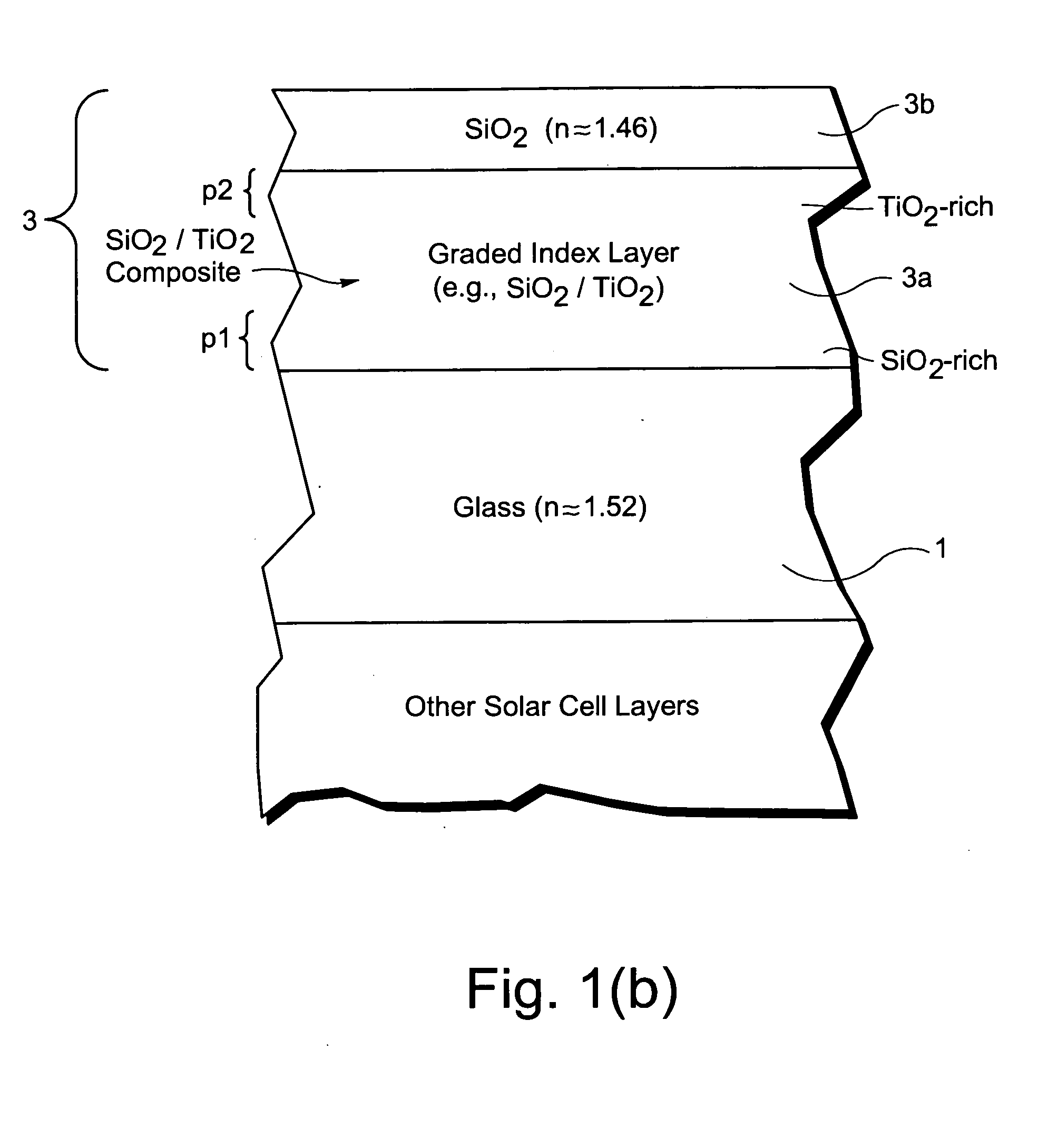

Solar cell with antireflective coating with graded layer including mixture of titanium oxide and silicon oxide

InactiveUS20070116966A1Synthetic resin layered productsGlass/slag layered productsAnti-reflective coatingRefractive index

There is provided a coated article (e.g., solar cell) that includes an improved anti-reflection (AR) coating. This AR coating functions to reduce reflection of light from a glass substrate, thereby allowing more light within the solar spectrum to pass through the incident glass substrate. In certain example embodiments, the AR coating includes a graded base layer having a varying refractive index value, and an overcoat layer which may be provided for destructive interference purposes.

Owner:GUARDIAN GLASS LLC

Etch pattern definition using a CVD organic layer as an anti-reflection coating and hardmask

InactiveUS20020086547A1Highly effective hard mask propertyHigh resolutionSemiconductor/solid-state device manufacturingSemiconductor devicesAnti-reflective coatingOrganic layer

A multilayer antireflective hard mask structure is disclosed. The structure comprises: (a) a CVD organic layer, wherein the CVD organic layer comprises carbon and hydrogen; and (b) a dielectric layer over the CVD organic layer. The dielectric layer is preferably a silicon oxynitride layer, while the CVD organic layer preferably comprises 70-80% carbon, 10-20% hydrogen and 5-15% nitrogen. Also disclosed are methods of forming and trimming such a multilayer antireflective hard mask structure. Further disclosed are methods of etching a substrate structure using a mask structure that contains a CVD organic layer and optionally has a dielectric layer over the CVD organic layer.

Owner:APPLIED MATERIALS INC

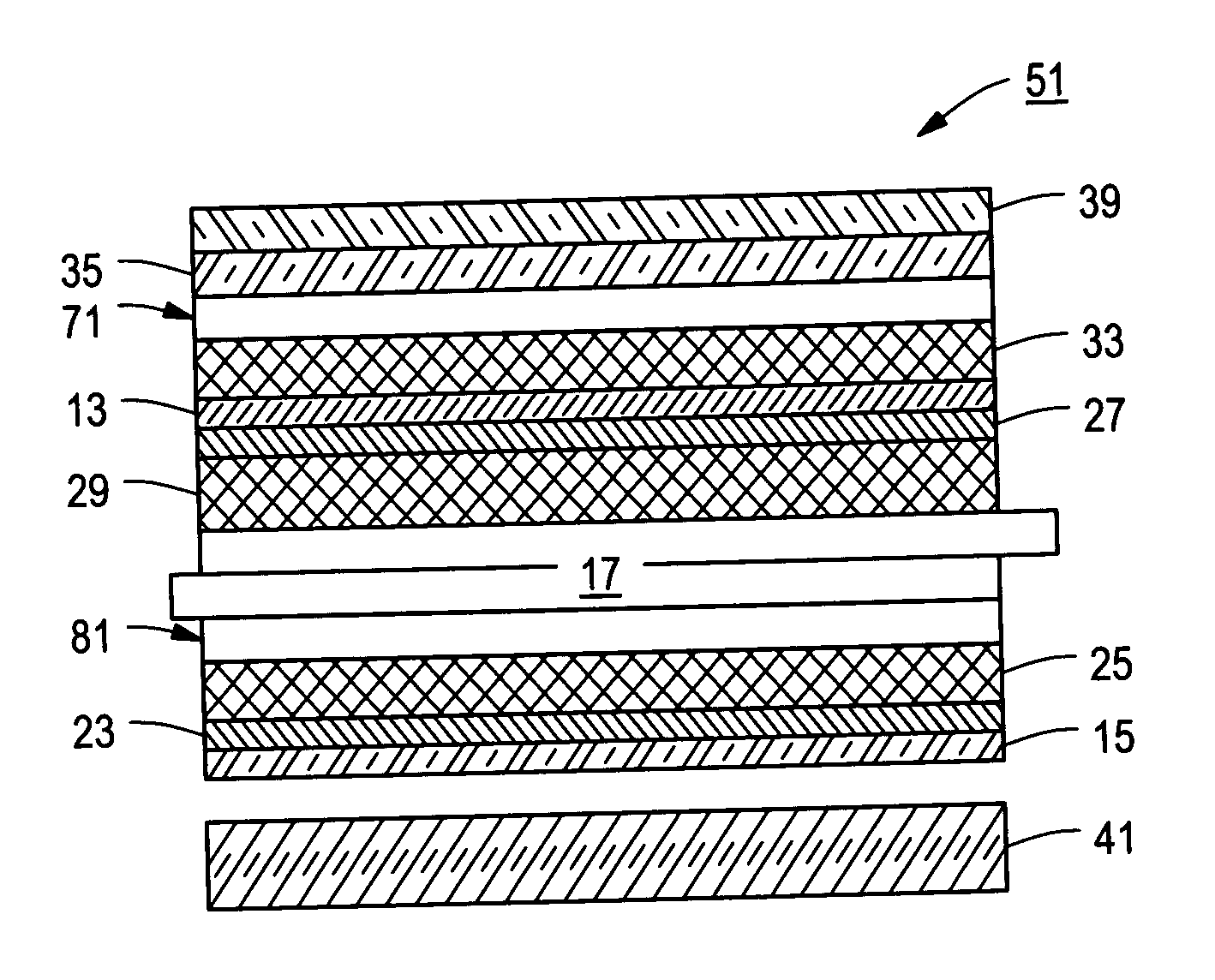

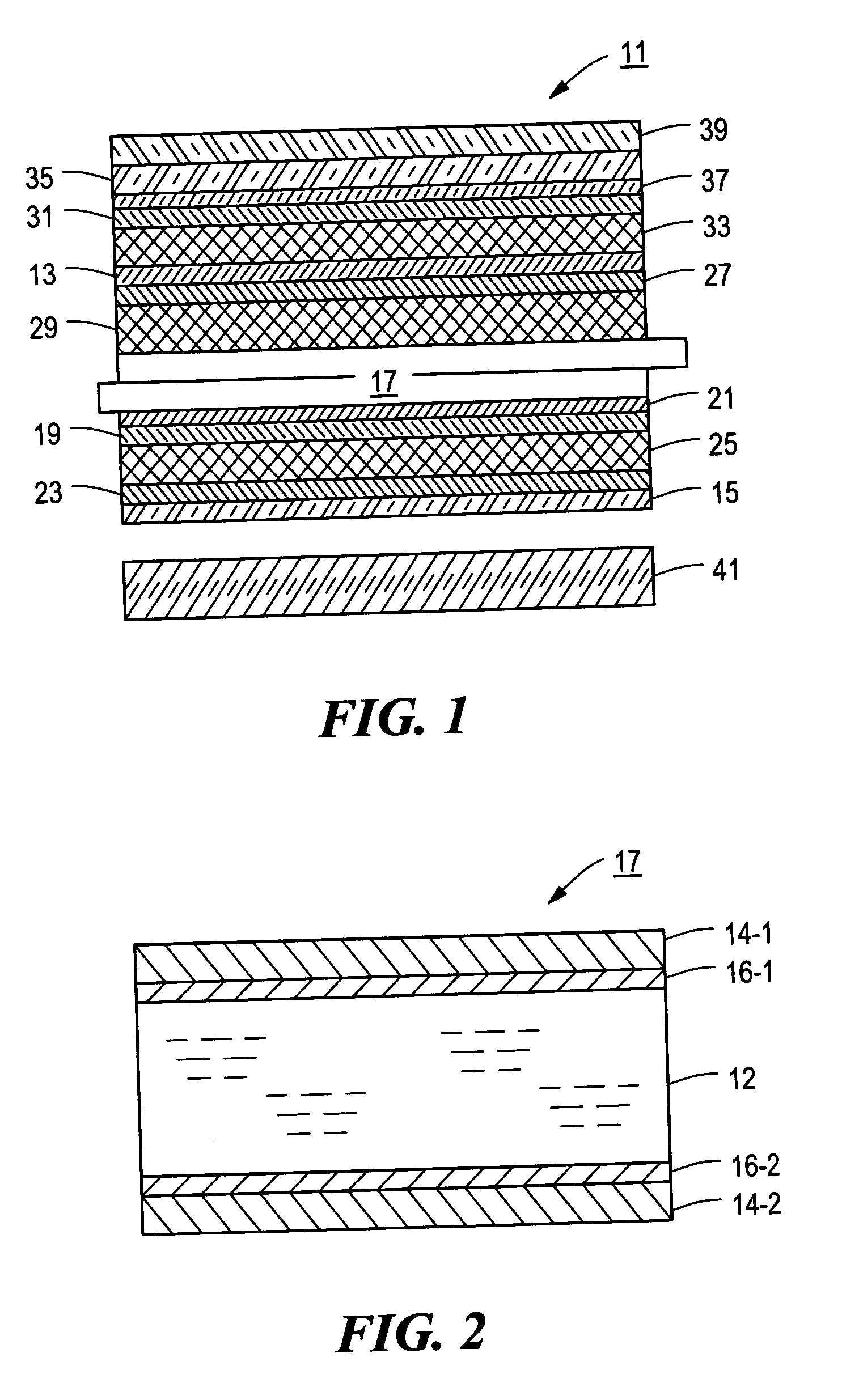

Super bright low reflectance liquid crystal display

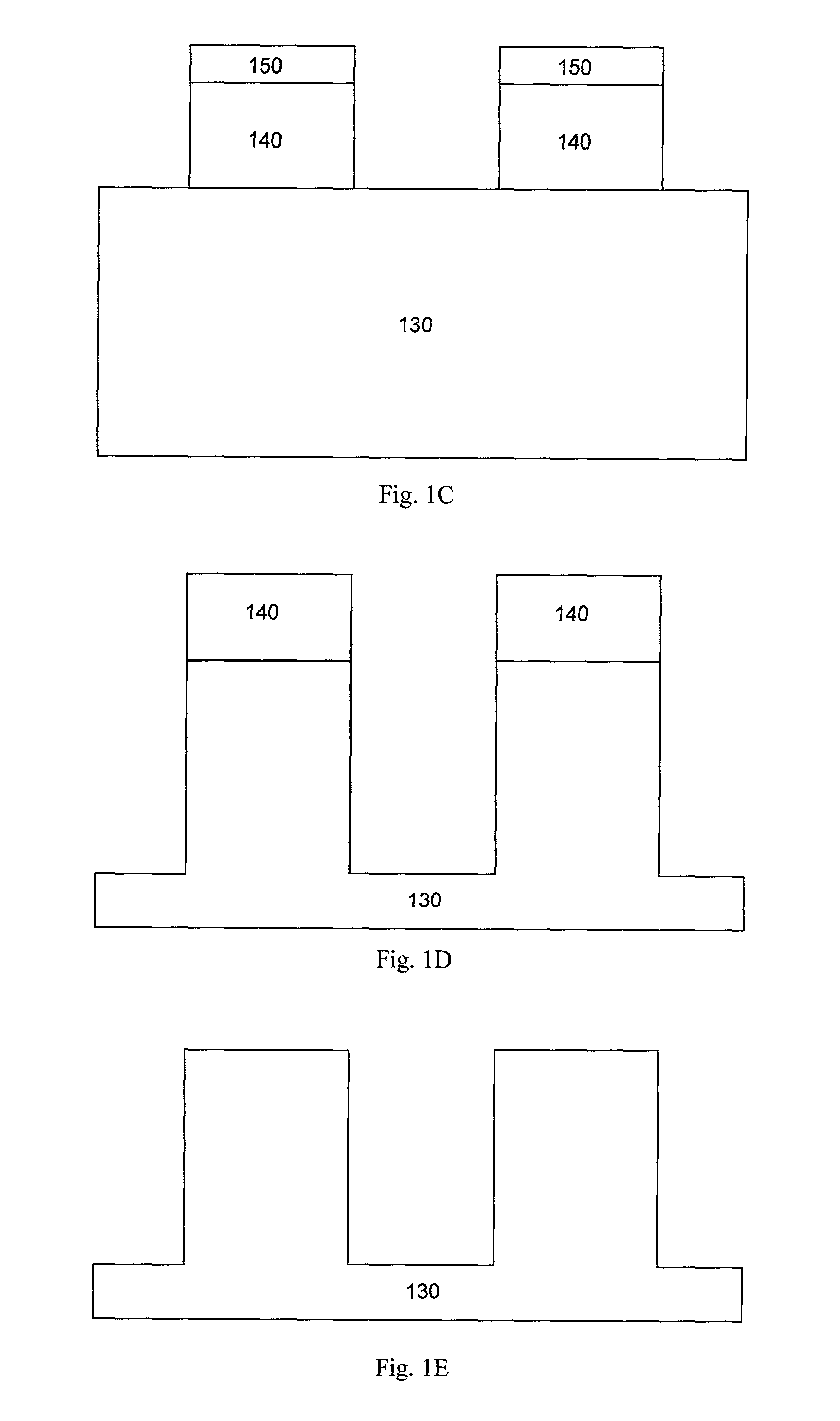

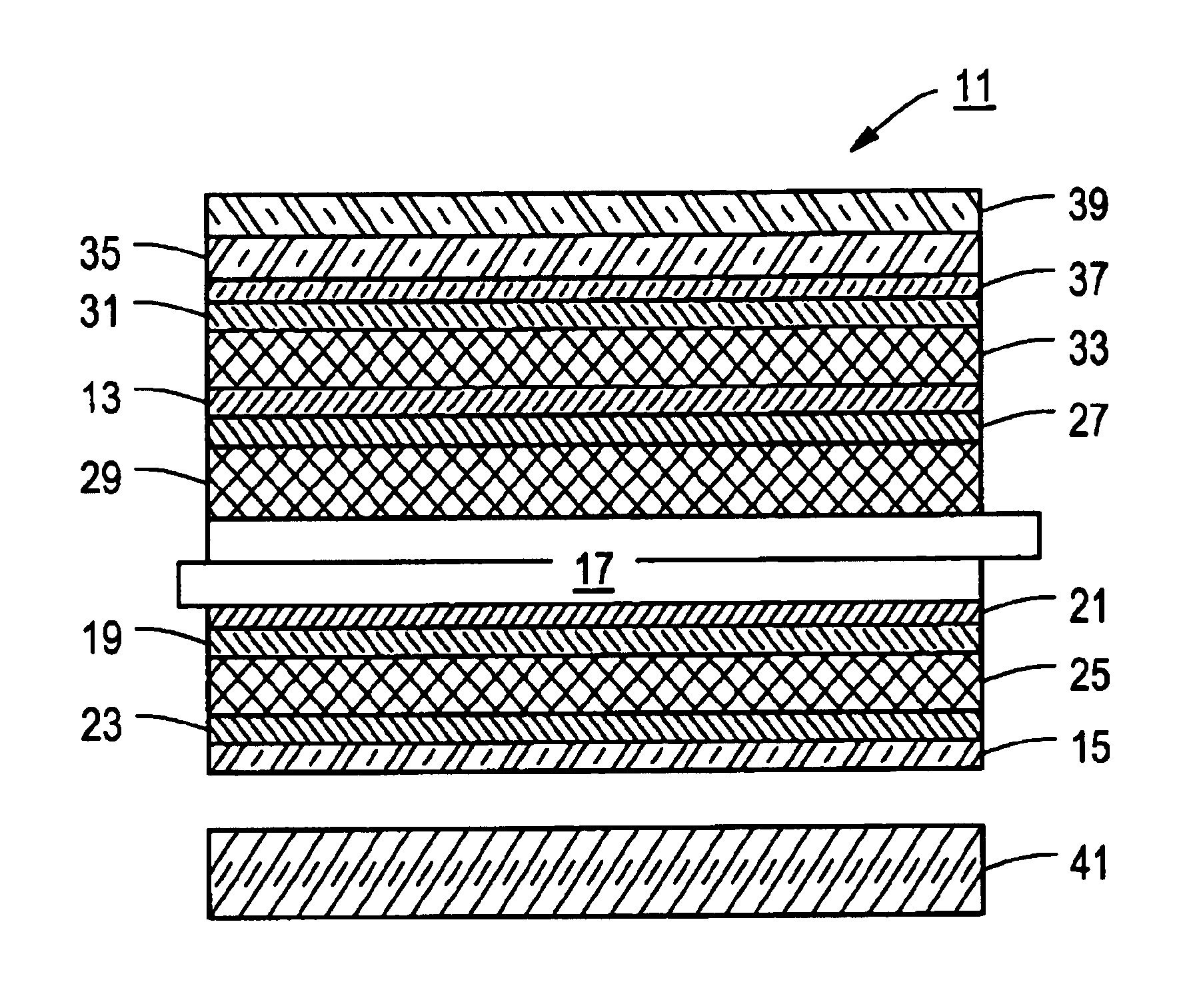

InactiveUS6933991B2Reduce the amount requiredImprove viewing characteristicsStatic indicating devicesPolarising elementsOptical bondingPolarizer

A liquid crystal display (LCD) exhibiting enhanced optical viewing performance. In a preferred embodiment, the LCD comprises a liquid crystal display panel, the liquid crystal display panel comprising a pair of transparent substrates, liquid crystal material sandwiched between the transparent substrates and transparent electrodes positioned between the liquid crystal material and the transparent substrates. The LCD also comprises a rear polarizer assembly comprising a compensation film, a polarizer mounted on the rear surface of the compensation film, and a first index-matched, pressure sensitive adhesive (PSA) mounted on the front surface of the compensation film, the PSA being adhered to the rear surface of the LCD panel. The LCD also comprises a front polarizer assembly, the front polarizer assembly comprising a front polarizer, a compensation film mounted on the rear surface of the front polarizer and an index-matched PSA mounted on the front surface of the front polarizer. The front polarizer is crossed relative to the rear polarizer. The front polarizer assembly may be adhered to the front of the LCD panel with a second index-matched, optical bonding material or may be spaced therefrom by an air gap. A transparent cover is mounted on the second index-matched PSA. The transparent cover is preferably a plastic plate. The plastic plate may be textured to reduce glare or may have an anti-reflection coating or an anti-reflection film applied to the front surface thereof. Instead of a plastic plate, the transparent cover may be a glass plate or a touch panel.

Owner:VIA OPTRONICS

Method of making solar cell/module with porous silica antireflective coating

InactiveUS20070074757A1Improved anti-reflection (AR) coatingReduce reflectionCoatingsPhotovoltaic energy generationColloidal silicaAnti-reflective coating

A solar cell includes an improved anti-reflection (AR) coating provided on an incident glass substrate. In certain example embodiments, the AR coating includes a layer comprising porous silica. The porous nature of the silica inclusive layer permits the refractive index (n) of the silica inclusive layer to be reduced, thereby decreasing reflection and permitting more radiation to make its way to the active layer(s) of the solar cell. In certain example embodiments, a coating solution may be formed by mixing a colloidal silica solution and a polymeric silica solution, then applying the coating solution to a substrate and curing the same in order to form an AR coating.

Owner:GUARDIAN GLASS LLC

High density plasma CVD process for making dielectric anti-reflective coatings

InactiveUS6060132ASemiconductor/solid-state device manufacturingSpecial surfacesResistAnti-reflective coating

An improved process for preparing nitrogen containing substrates selected from the group consisting of silicon oxynitride, silicon nitride and titanium nitride films and silicon dioxide cap films characterized by prevent resist contamination when used as dielectric anti-reflective coatings, using a high density plasma CVD system, comprising: providing a processing chamber holding a wafer in a vacuum sufficient to enable O2 to be used as an oxygen source without risk of explosion in a plasma generating region of the processing chamber; introducing a gaseous mixture selected from the group consisting of SiH4 / O2 / N2 or SiH4 / O2 / N2 / Ar into the processing chamber; and subjecting the processing chamber to a RF electrical signal of sufficient frequency to create a high density plasma in the plasma generating region of said processing chamber, whereby said wafer is processed by resulting high density plasma generated by said RF electrical signal.

Owner:POLARIS INNOVATIONS LTD

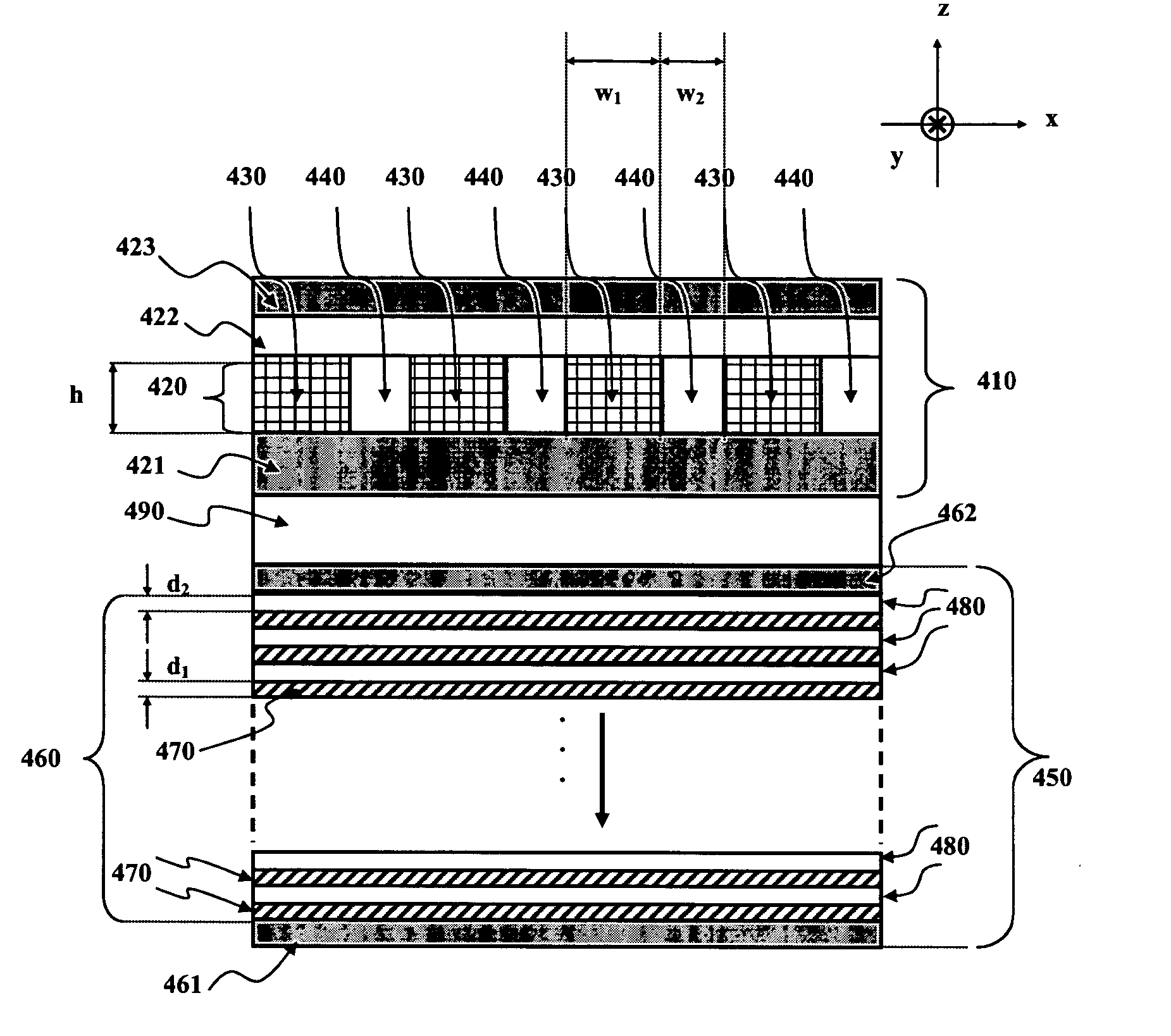

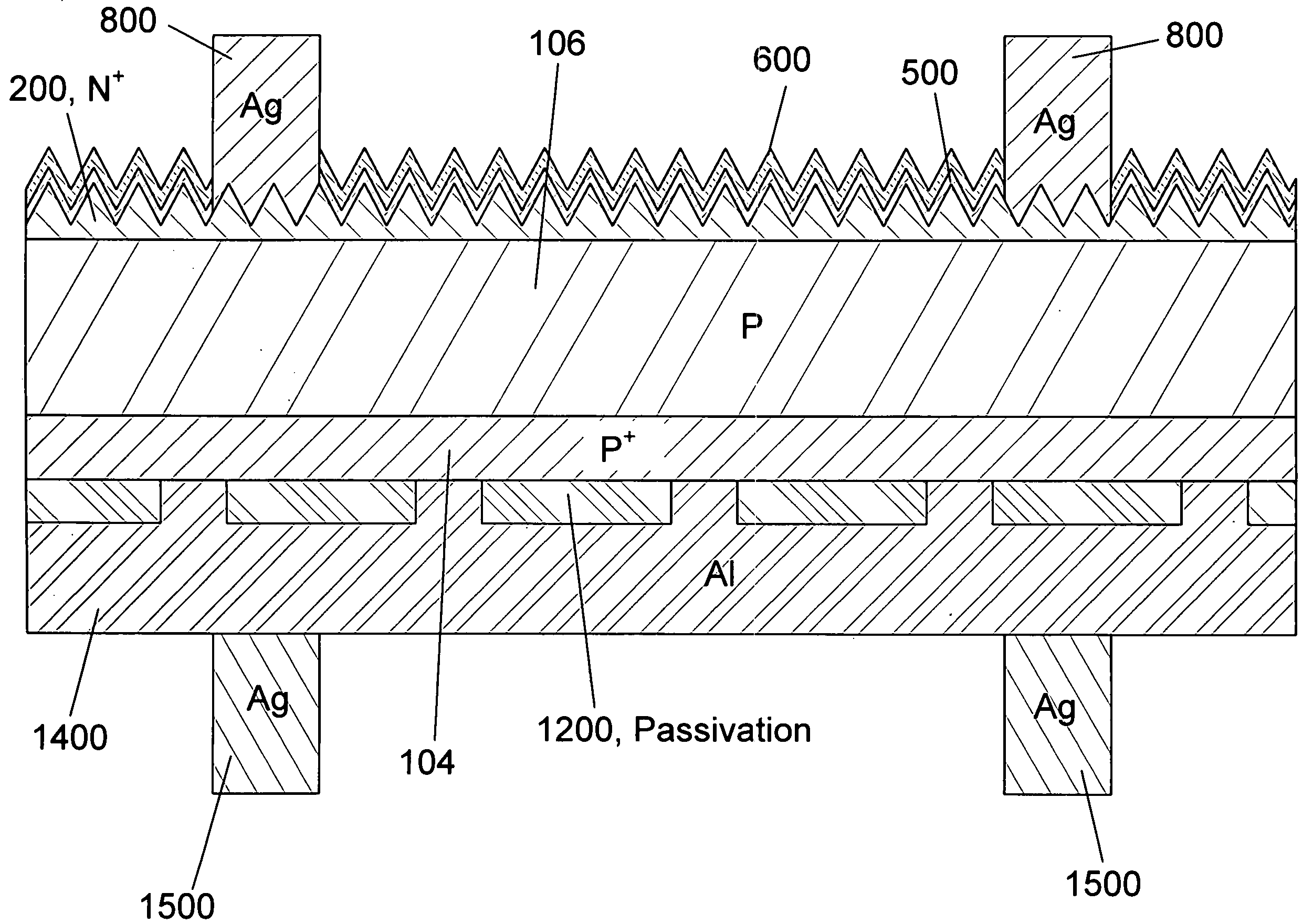

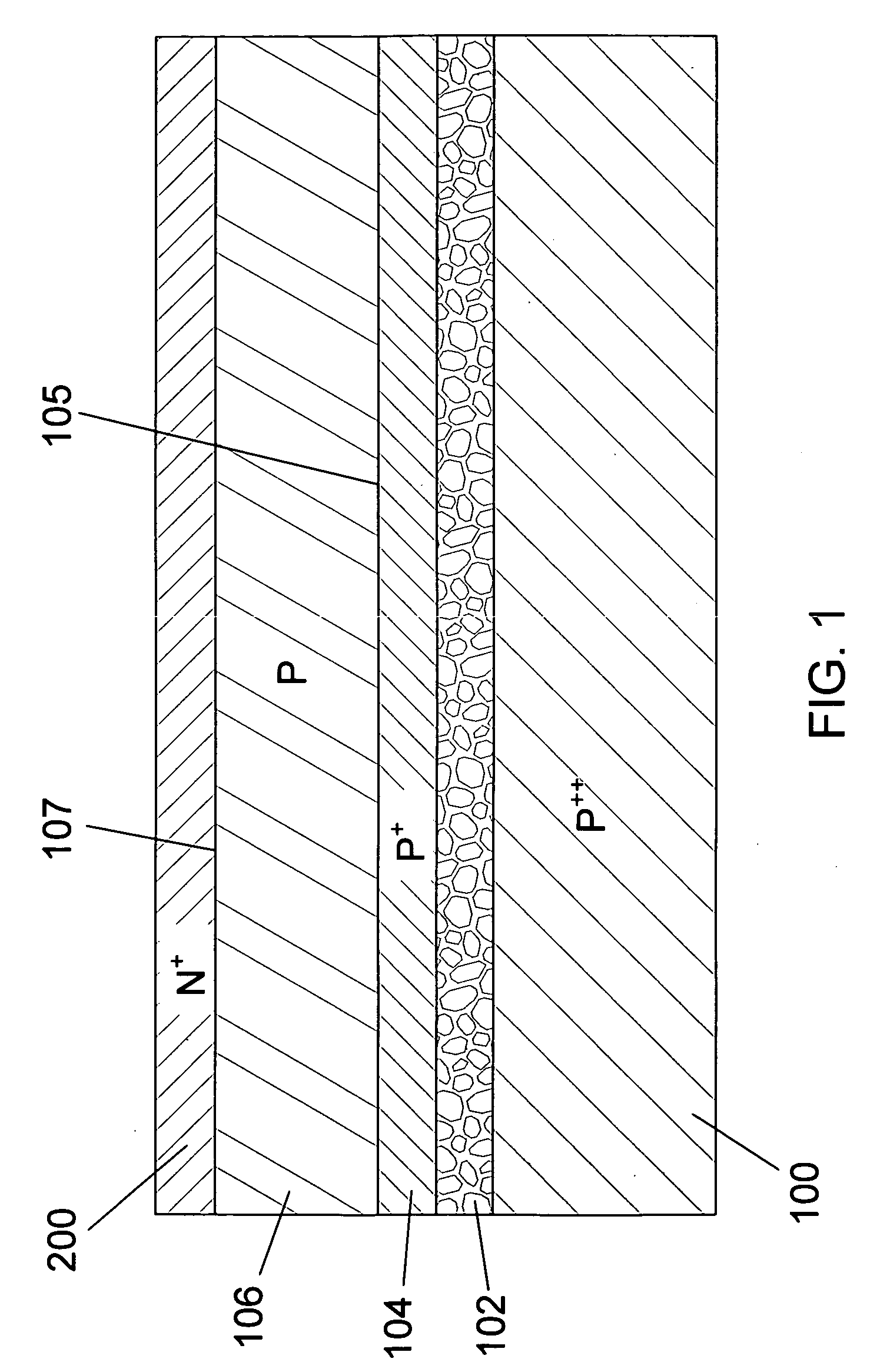

Thin two sided single crystal solar cell and manufacturing process thereof

InactiveUS20100108134A1High quality epitaxial growthImprove material qualitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationAnti-reflective coatingPorous layer

A design and manufacturing method for a photovoltaic (PV) solar cell less than 100 μm thick are disclosed. A porous silicon layer is formed on a wafer substrate. Portions of the PV cell are then formed using diffusion, epitaxy and autodoping from the substrate. All front side processing of the solar cell (junctions, passivation layer, anti-reflective coating, contacts to the N+-type layer) is performed while the thin epitaxial layer is attached to the porous layer and substrate. The wafer is then clamped and exfoliated. The back side of the PV cell is completed from the region of the wafer near the exfoliation fracture layer, with subsequent removal of the porous layer, passivation, patterning of contacts, deposition of a conductive coating, and contacts to the P+-type layer. During manufacturing, the cell is always supported by either the bulk wafer or a wafer chuck, with no processing of bare thin PV cell

Owner:CRYSTAL SOLAR INC

Super bright low reflectance liquid crystal display

InactiveUS20060001800A1Reduce the amount requiredImprove viewing characteristicsStatic indicating devicesPolarising elementsOptical bondingAnti-reflective coating

A liquid crystal display (LCD) exhibiting enhanced optical viewing performance. In a preferred embodiment, the LCD comprises a liquid crystal display panel, the liquid crystal display panel comprising a pair of transparent substrates, liquid crystal material sandwiched between the transparent substrates and transparent electrodes positioned between the liquid crystal material and the transparent substrates. The LCD also comprises a rear polarizer assembly comprising a compensation film, a polarizer mounted on the rear surface of the compensation film, and a first index-matched, pressure sensitive adhesive (PSA) mounted on the front surface of the compensation film, the PSA being adhered to the rear surface of the LCD panel. The LCD also comprises a front polarizer assembly, the front polarizer assembly comprising a front polarizer, a compensation film mounted on the rear surface of the front polarizer and an index-matched PSA mounted on the front surface of the front polarizer. The front polarizer is crossed relative to the rear polarizer. The front polarizer assembly may be adhered to the front of the LCD panel with a second index-matched, optical bonding material or may be spaced therefrom by an air gap. A transparent cover is mounted on the second index-matched PSA. The transparent cover is preferably a plastic plate. The plastic plate may be textured to reduce glare or may have an anti-reflection coating or an anti-reflection film applied to the front surface thereof. Instead of a plastic plate, the transparent cover may be a glass plate or a touch panel.

Owner:VIA OPTRONICS GMBH

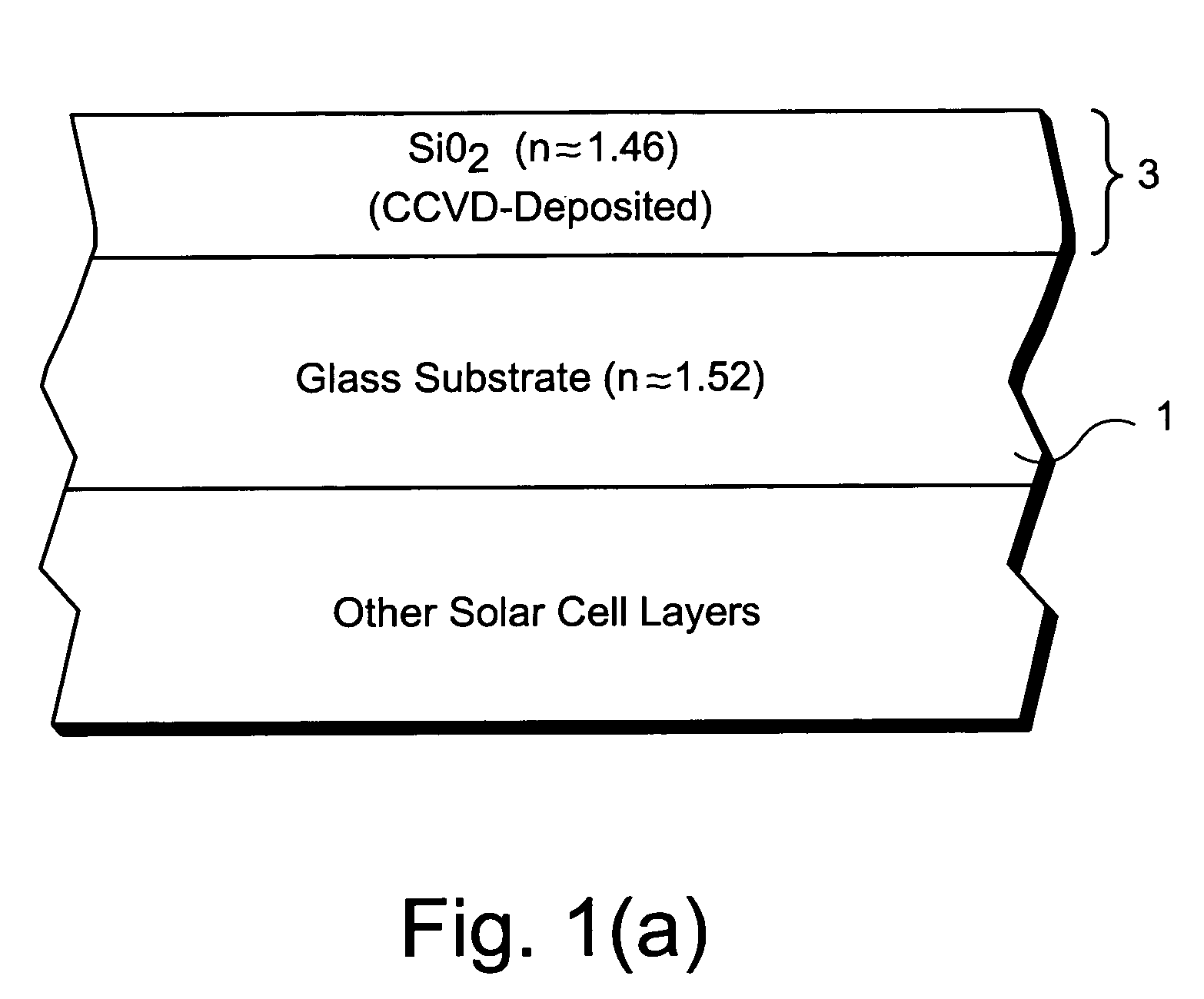

Method of making solar cell with antireflective coating using combustion chemical vapor deposition (CCVD) and corresponding product

InactiveUS20070113881A1Improved anti-reflection (AR) coatingReduce light reflectionPV power plantsSolid-state devicesAnti-reflective coatingSolar cell

There is provided a coated article (e.g., solar cell) that includes an improved anti-reflection (AR) coating. This AR coating functions to reduce reflection of light from a glass substrate, thereby allowing more light within the solar spectrum to pass through the incident glass substrate. In certain example embodiments, the AR coating is at least partially formed by flame pyrolysis.

Owner:GUARDIAN GLASS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com