Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16545results about "Film/foil adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

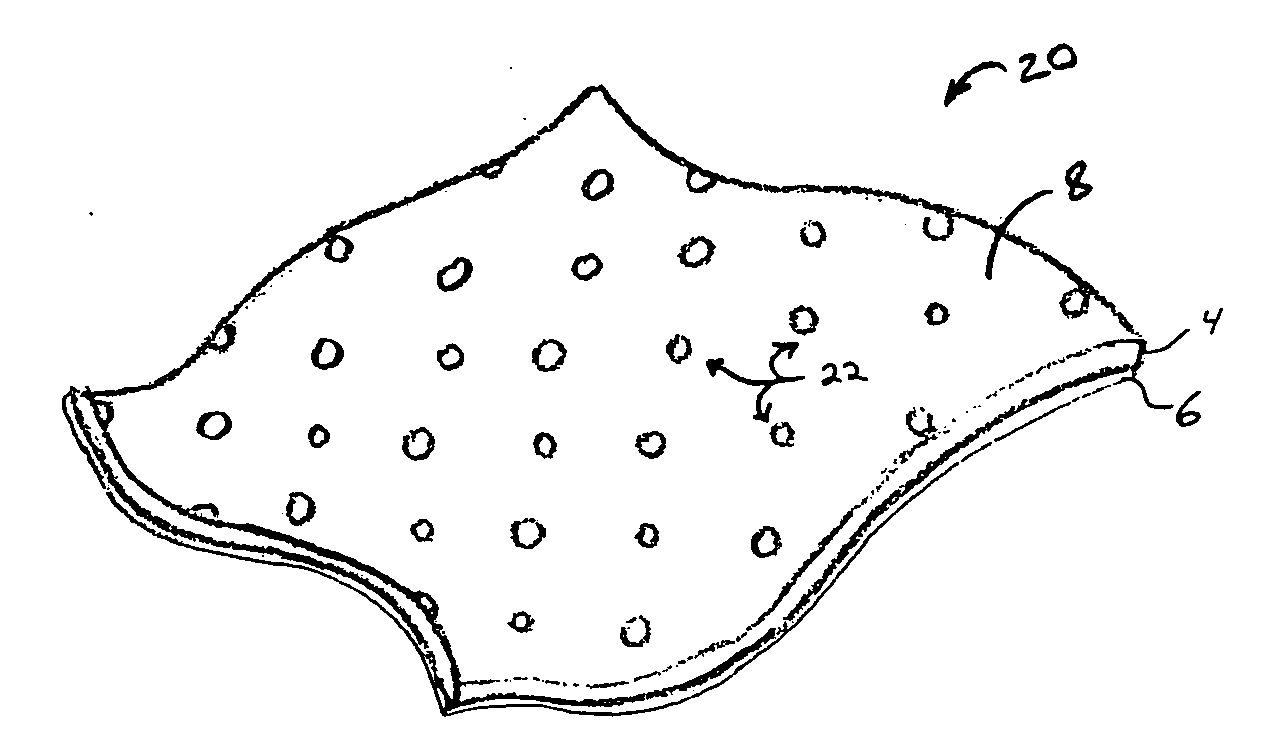

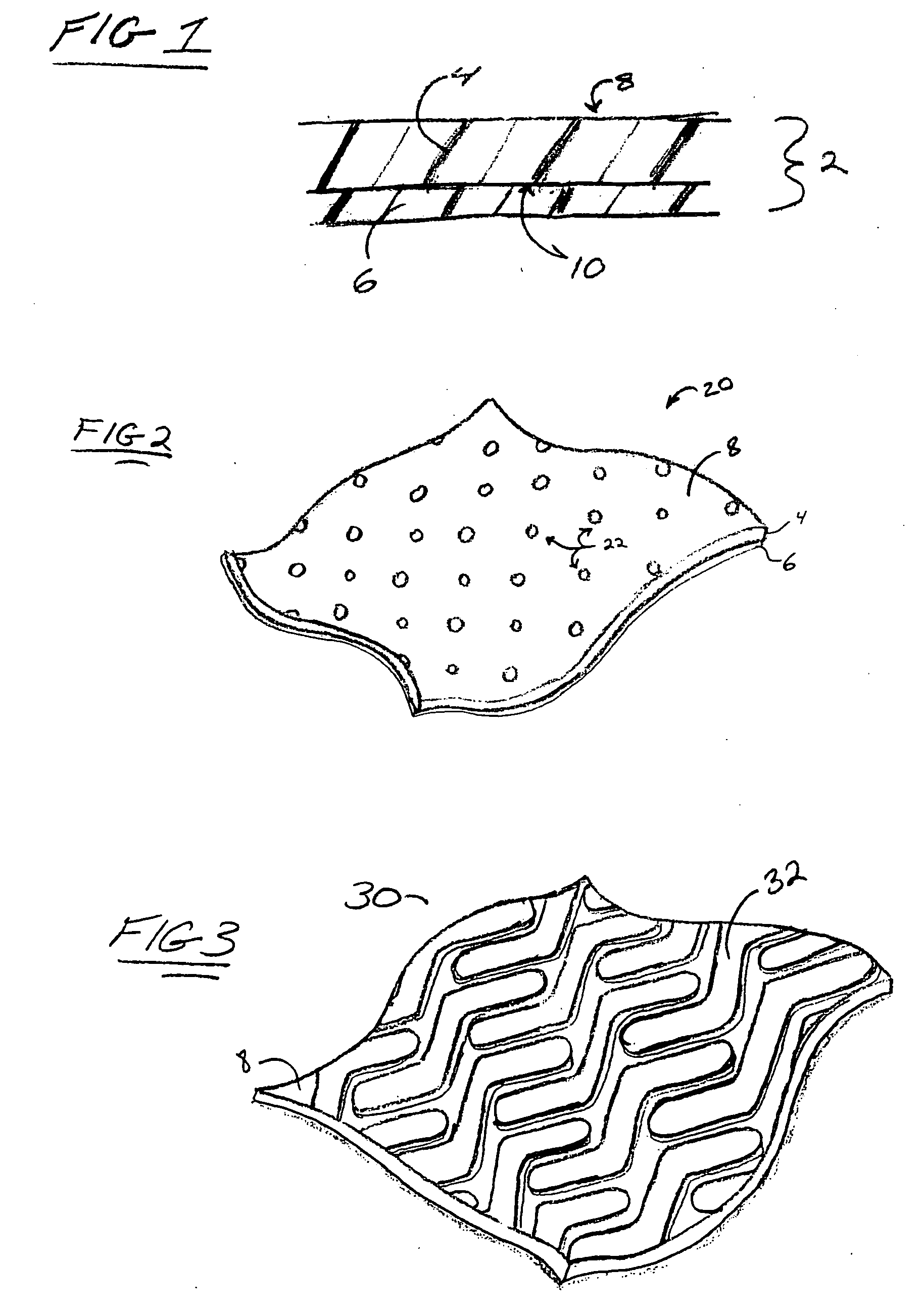

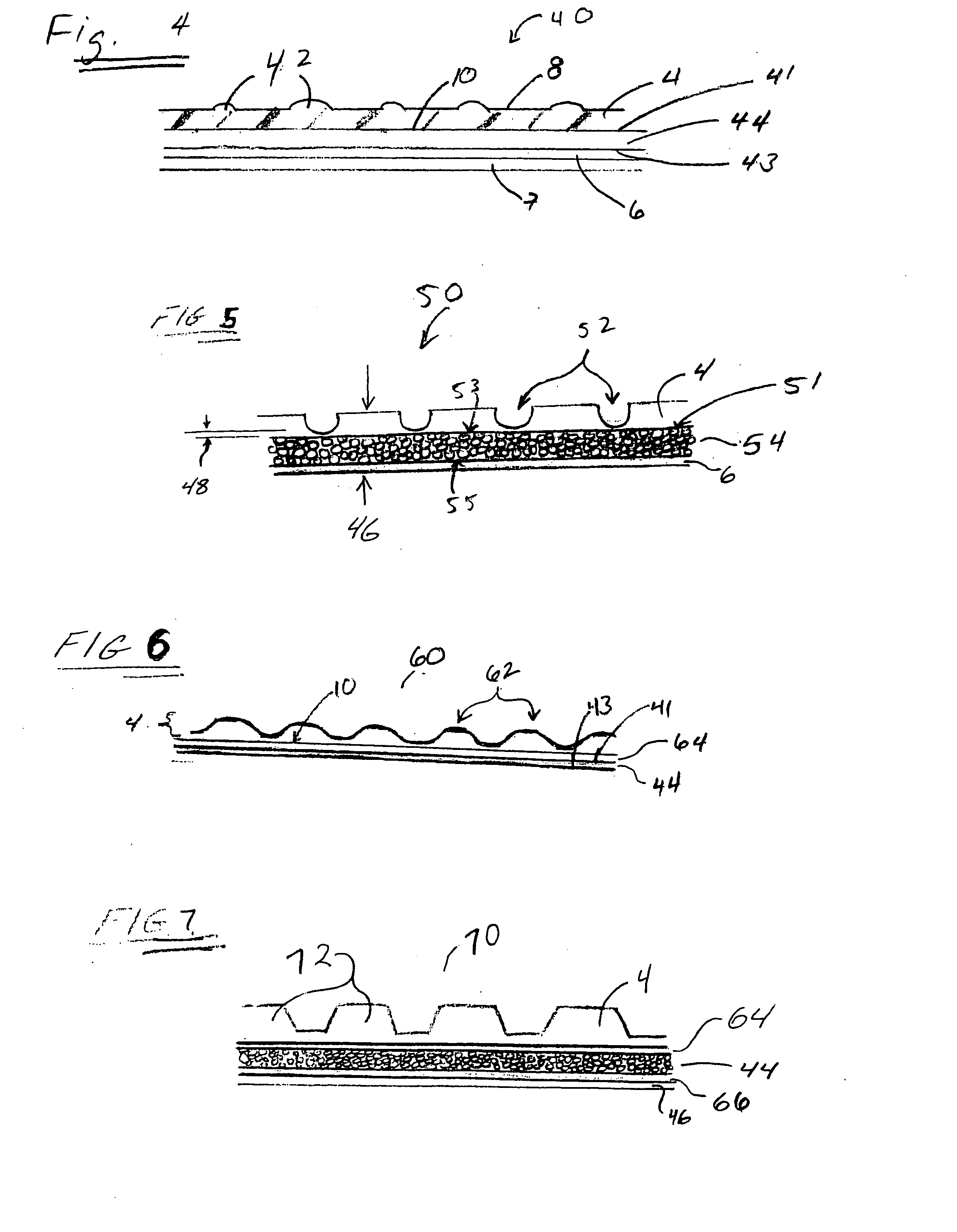

Air permeable pressure-sensitive adhesive tapes

InactiveUS20060154546A1Convenient to to manufactureEasy to useLamination ancillary operationsLayered product treatmentEngineeringPlastic film

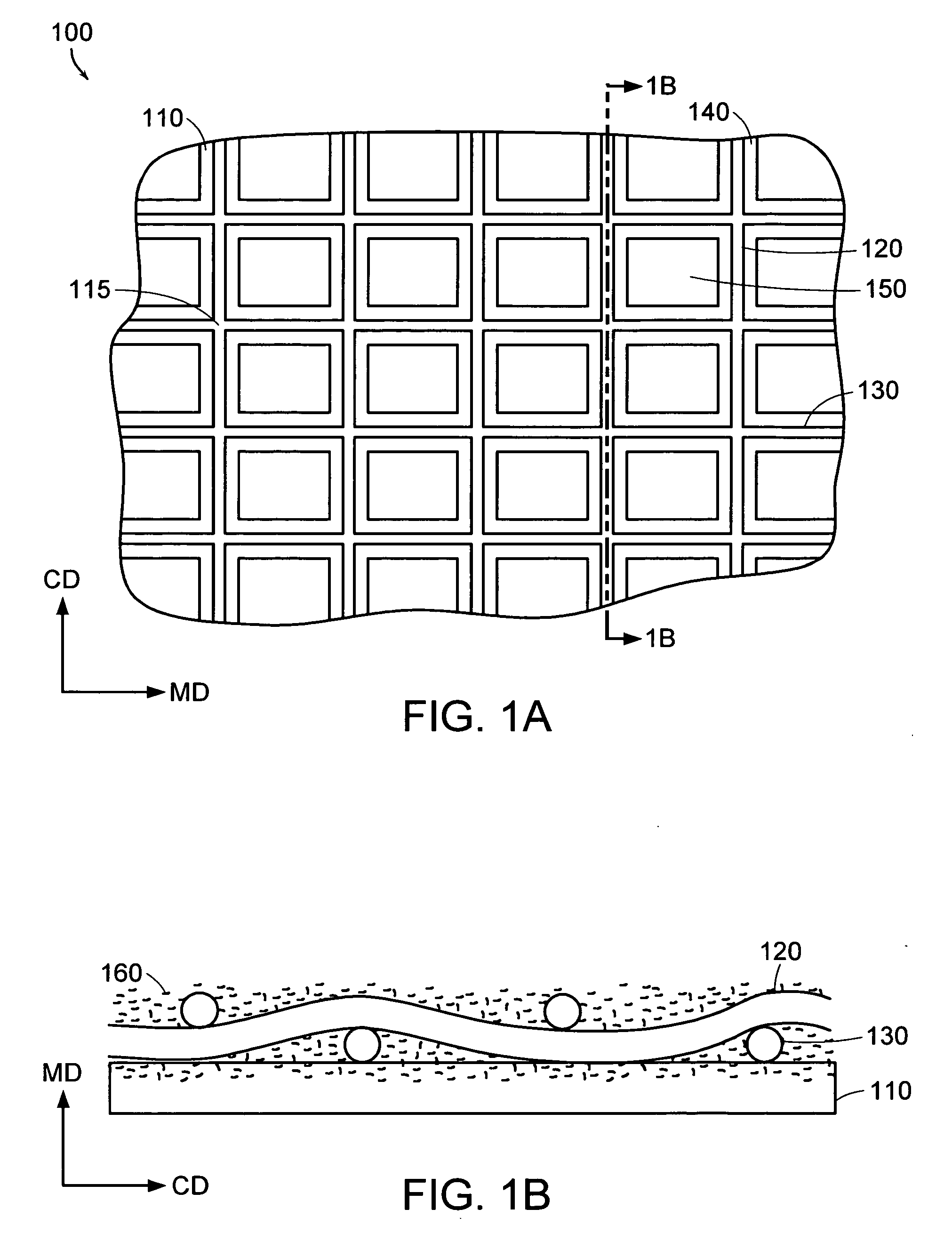

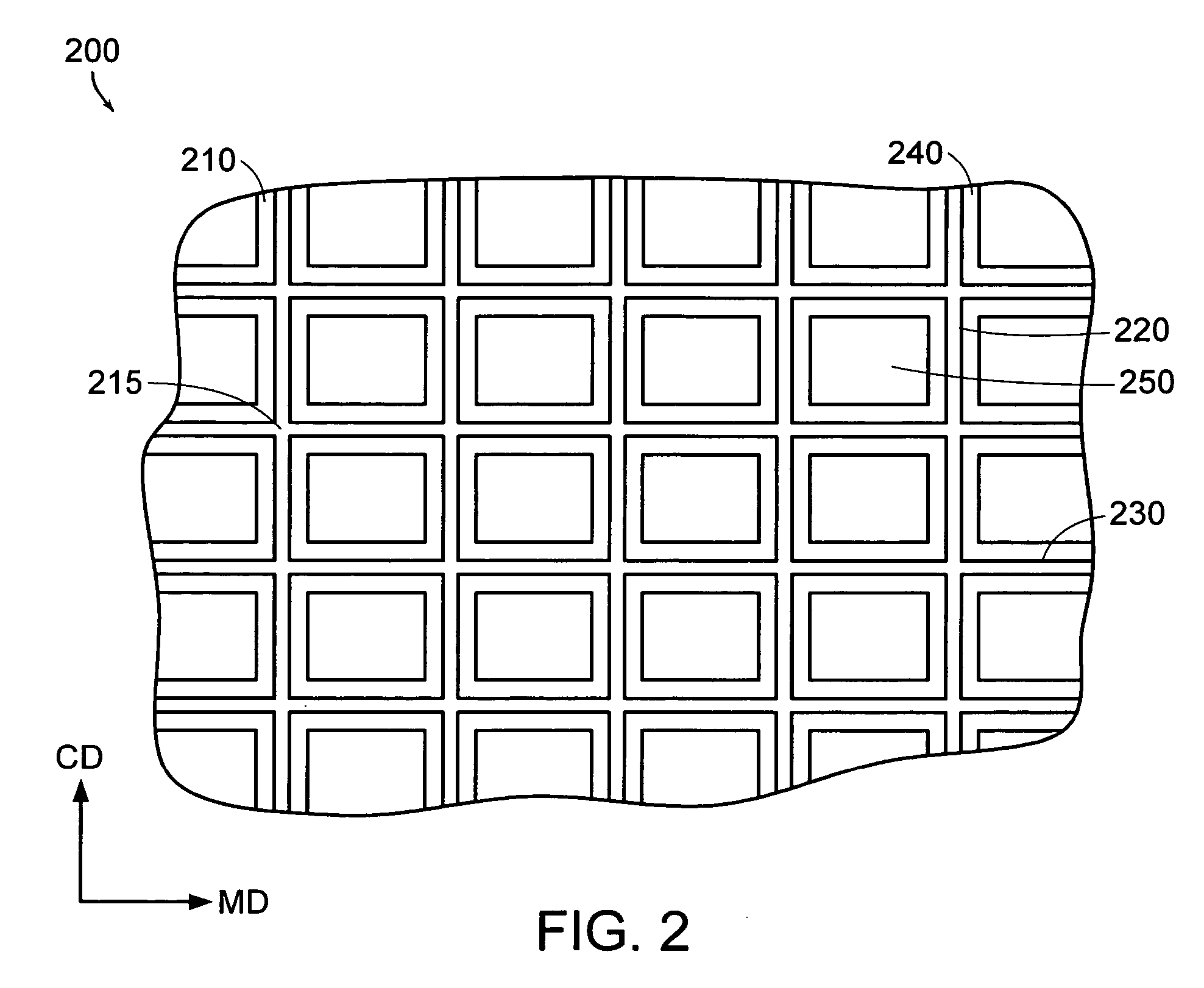

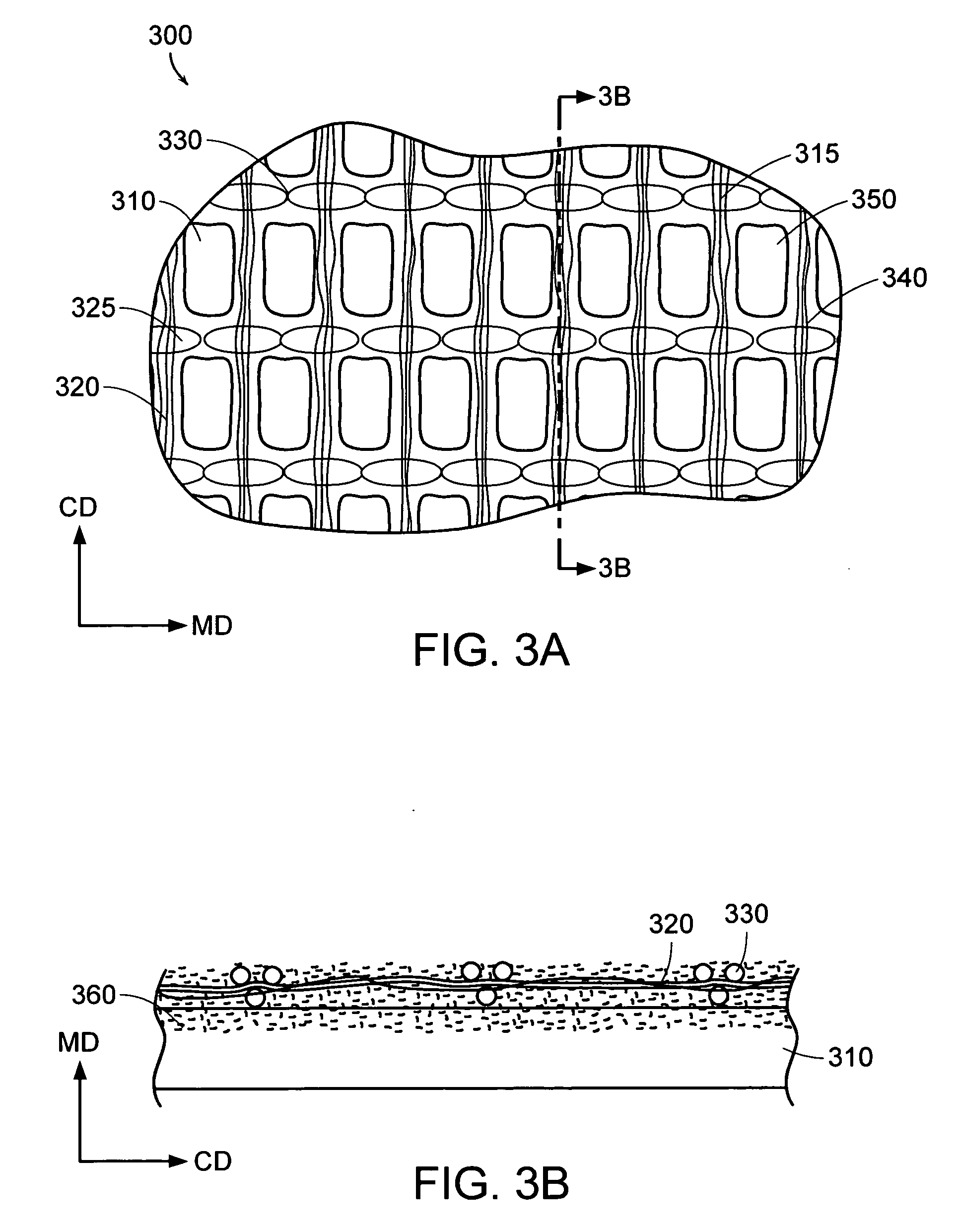

A vapor permeable article includes a porous backing substrate and an open fabric applied to one surface of the backing substrate. The open fabric has a greater porosity than that of the backing substrate. The open fabric may be a woven fabric comprising warp (MD) yarns and weft (CD) yarns, and the warp yarns may be of a lower denier than the weft yarns, so as to facilitate hand-tear of the assembled article. The open fabric is coated with an adhesive in such a manner that the open fabric remains porous and vapor permeable. The backing substrate can be a woven, knit or non-woven fabric, or a porous film, such as an apertured plastic film.

Owner:ANDOVER HEALTHCARE

Damage resistant glass article for use as a cover plate in electronic devices

InactiveUS20090197048A1Minimizing transportEasy to disassembleFilm/foil adhesivesSynthetic resin layered productsAnti-reflective coatingChemical Linkage

An alkali aluminosilicate glass article, said alkali aluminosilicate glass having a surface compressive stress of at least about 200 MPa, a surface compressive layer having a depth of at least about 30 μm, a thickness of at least about 0.3 mm and an amphiphobic fluorine-based surface layer chemically bonded to the surface of the glass. In one embodiment the glass has an anti-reflective coating applied to one surface of the glass between the chemically strengthened surface of the glass and the amphiphobic coating. In another embodiment the surface of the chemically strengthened glass is acid treated using a selected acid (e.g., HCL, H2SO4, HClO4, acetic acid and other acids as described) prior to placement of the amphiphobic coating or the anti-reflective coating.

Owner:CORNING INC

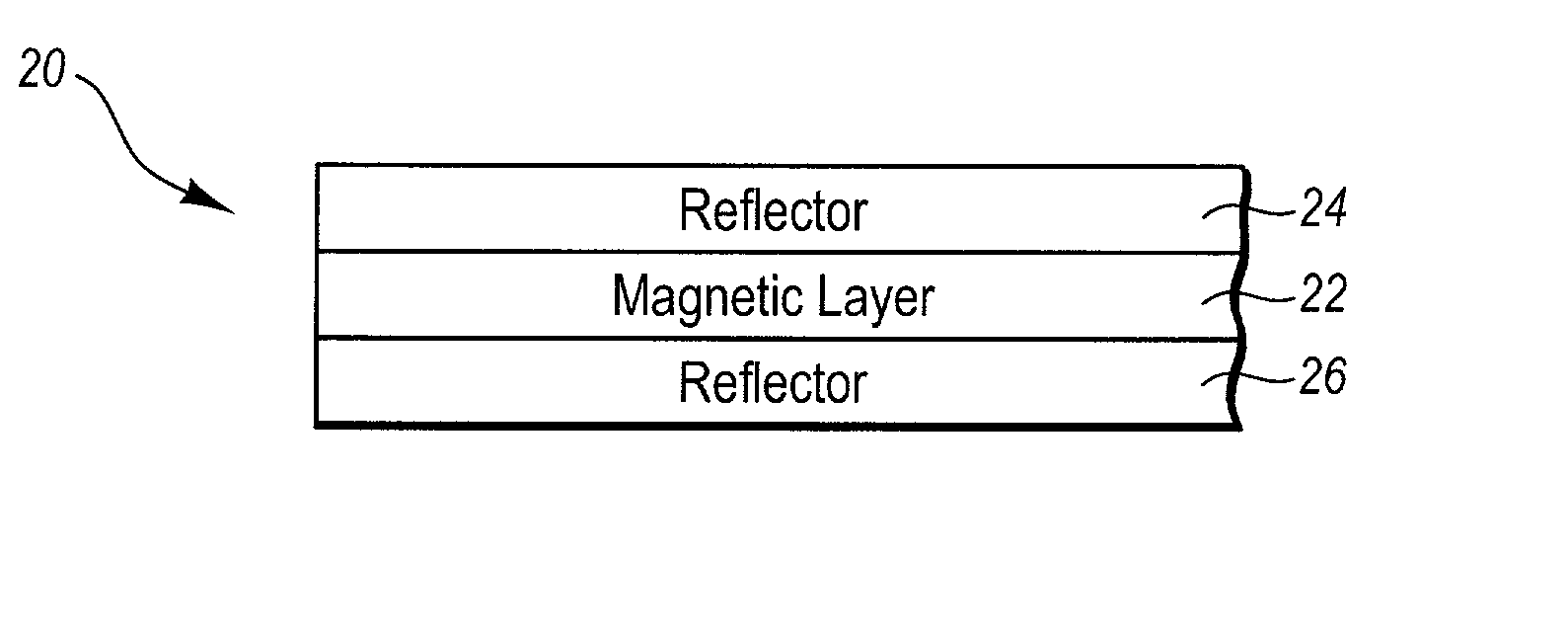

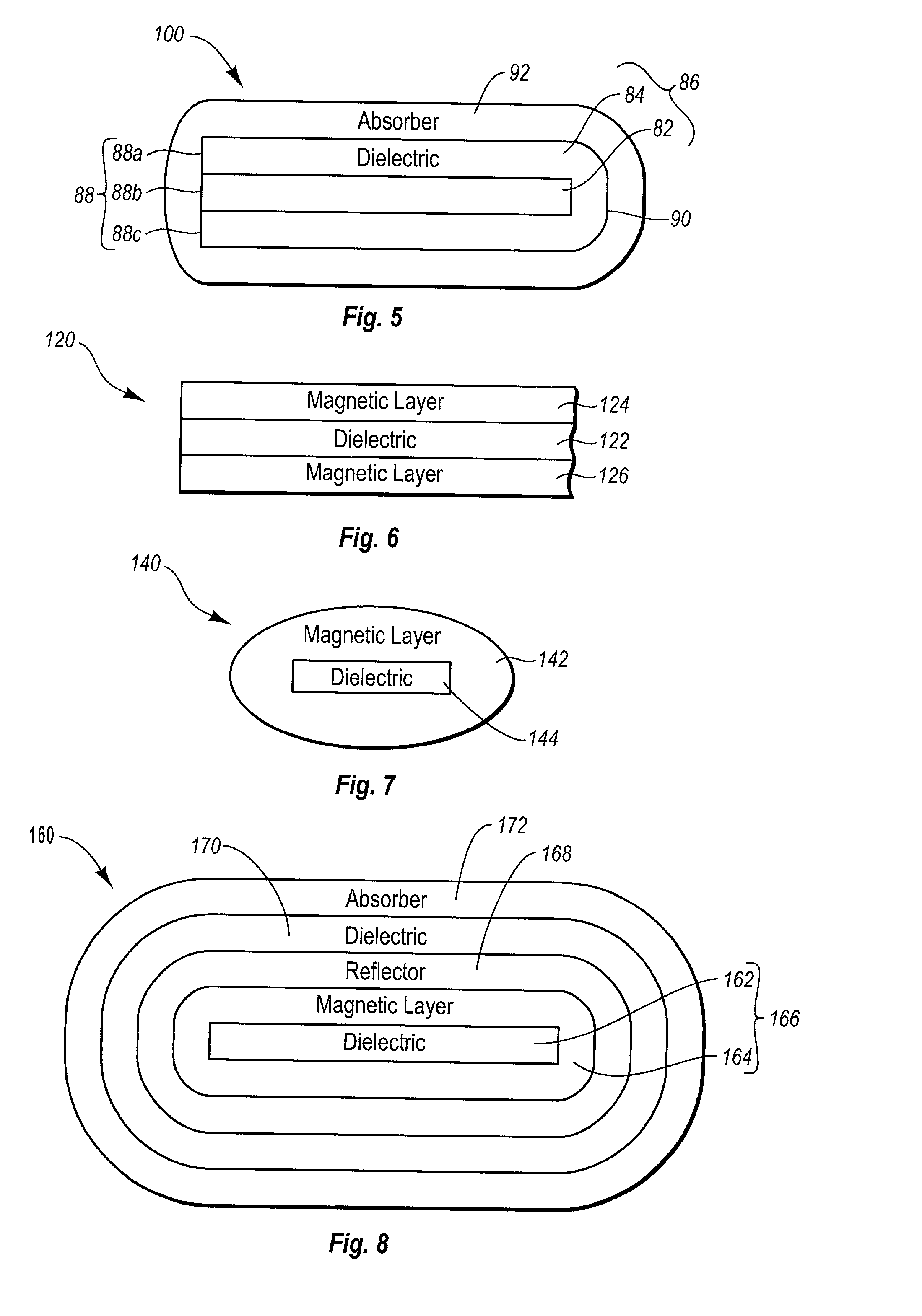

Multi-layered magnetic pigments and foils

InactiveUS20020160194A1High chromaIncreased durabilityPigment preparation by PVD/CVD methodsPattern printingLiquid mediumColor shift

Multilayered magnetic pigment flakes and foils are provided. The pigment flakes can have a symmetrical coating structure on opposing sides of a magnetic core, or can be formed with encapsulating coatings around the magnetic core. The magnetic core can be a magnetic layer between reflector or dielectric layers, a dielectric layer between magnetic layers, or only a magnetic layer. Some embodiments of the pigment flakes and foils exhibit a discrete color shift so as to have distinct colors at differing angles of incident light or viewing. The pigment flakes can be interspersed into liquid media such as paints or inks to produce colorant compositions for subsequent application to objects or papers. The foils can be laminated to various objects or can be formed on a carrier substrate.

Owner:FLEX PRODUCTS INC

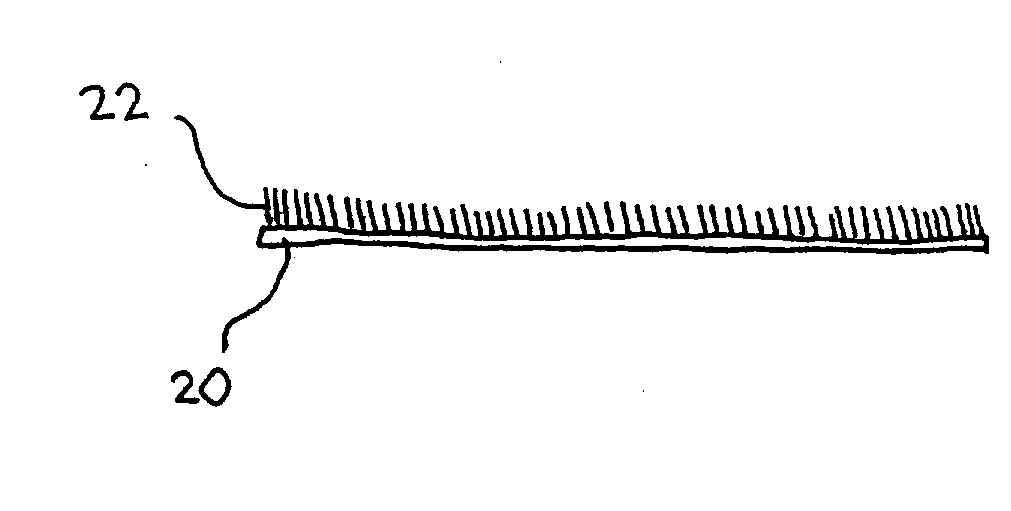

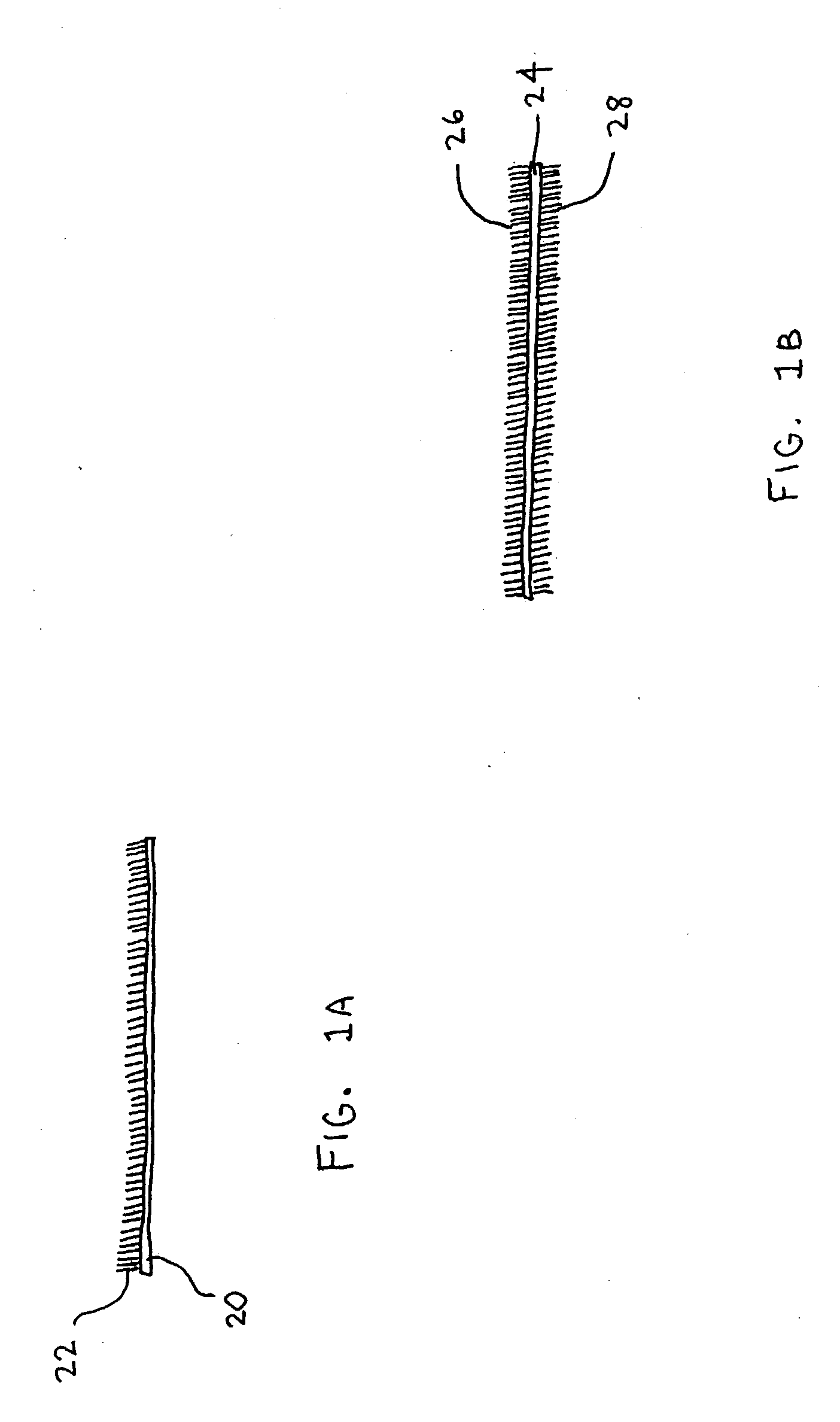

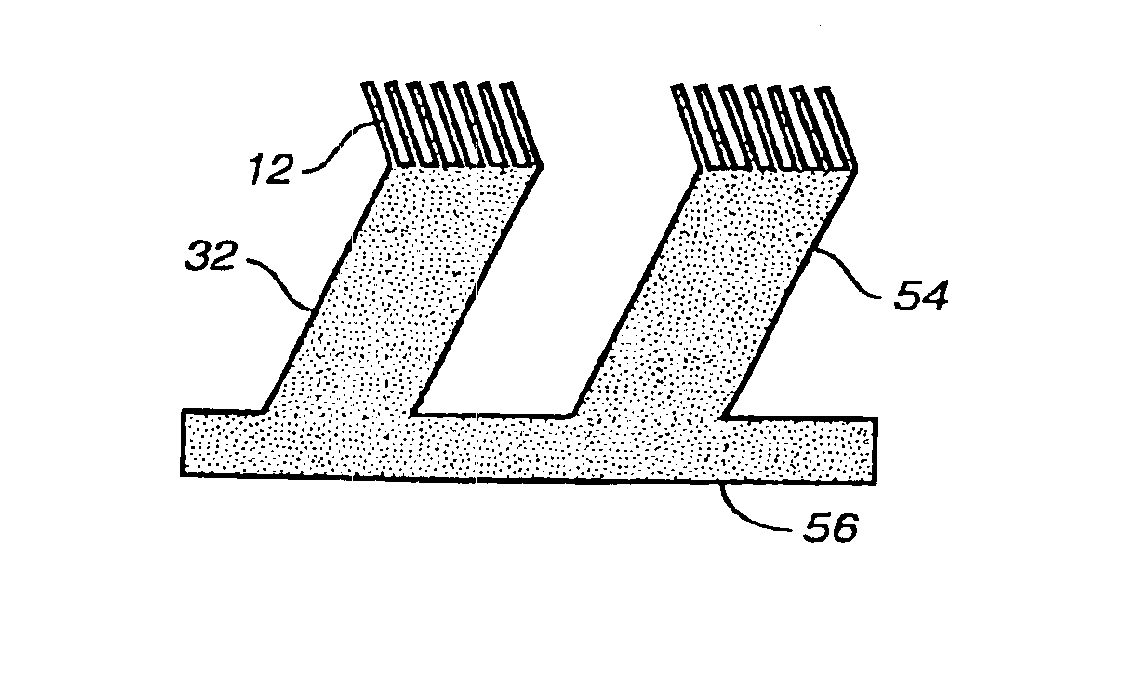

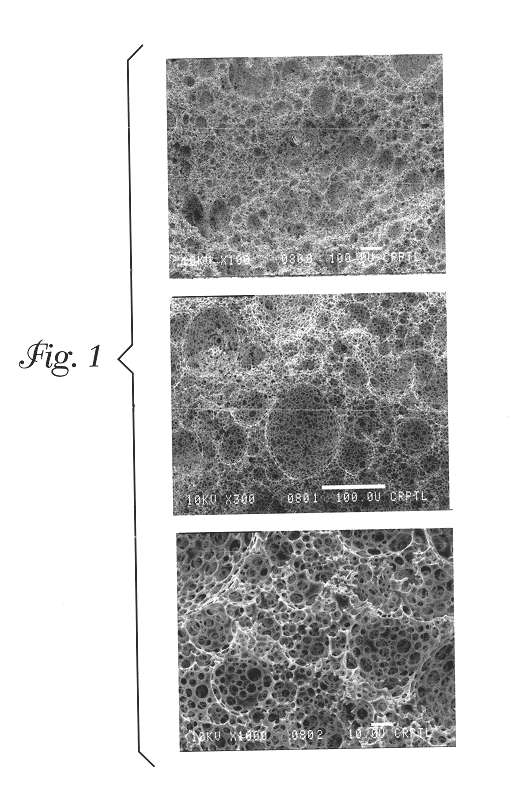

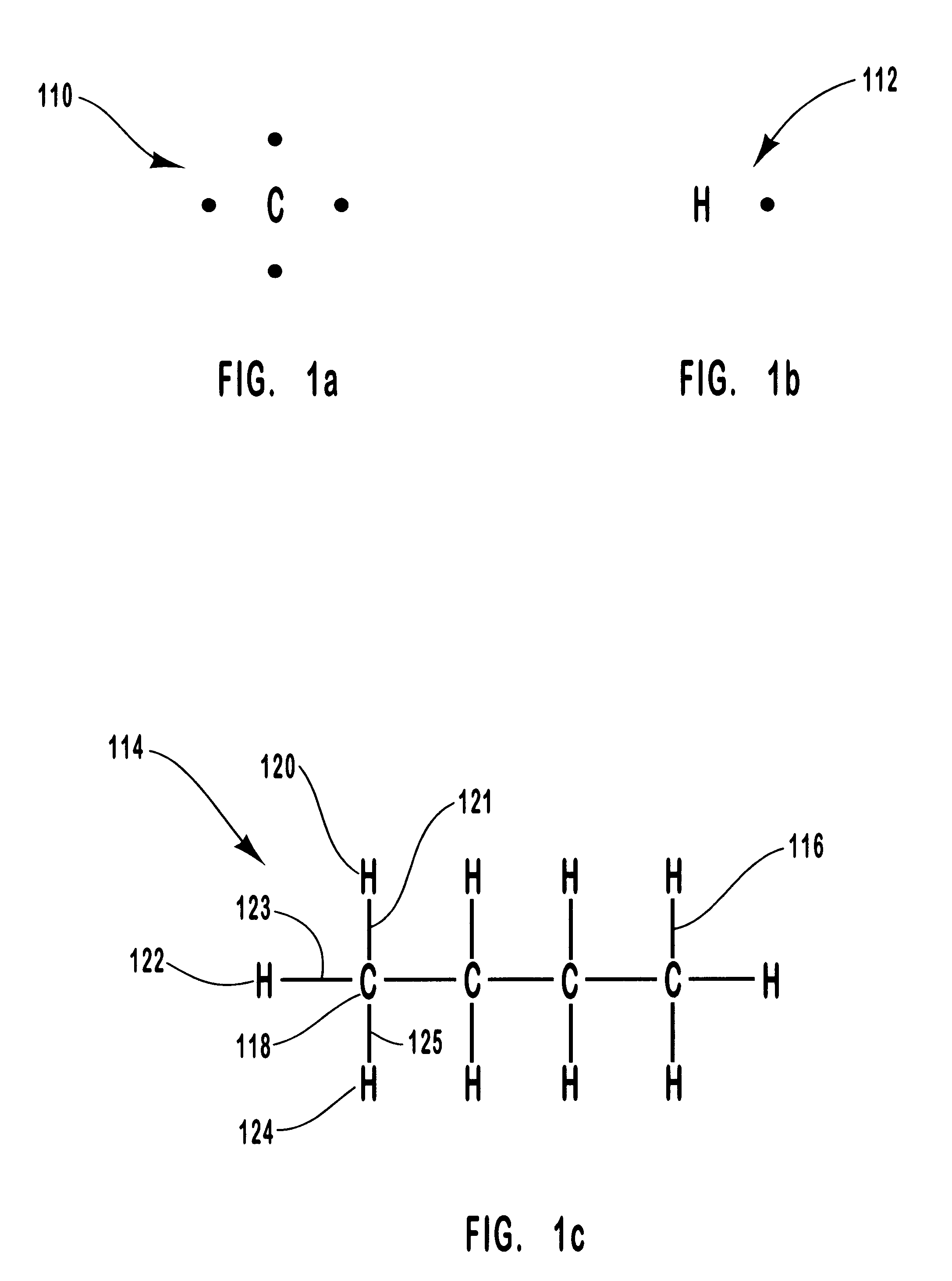

Fiber adhesive material

InactiveUS20040071870A1Improve adhesion performanceMaterial nanotechnologySemiconductor/solid-state device detailsDielectricFiber

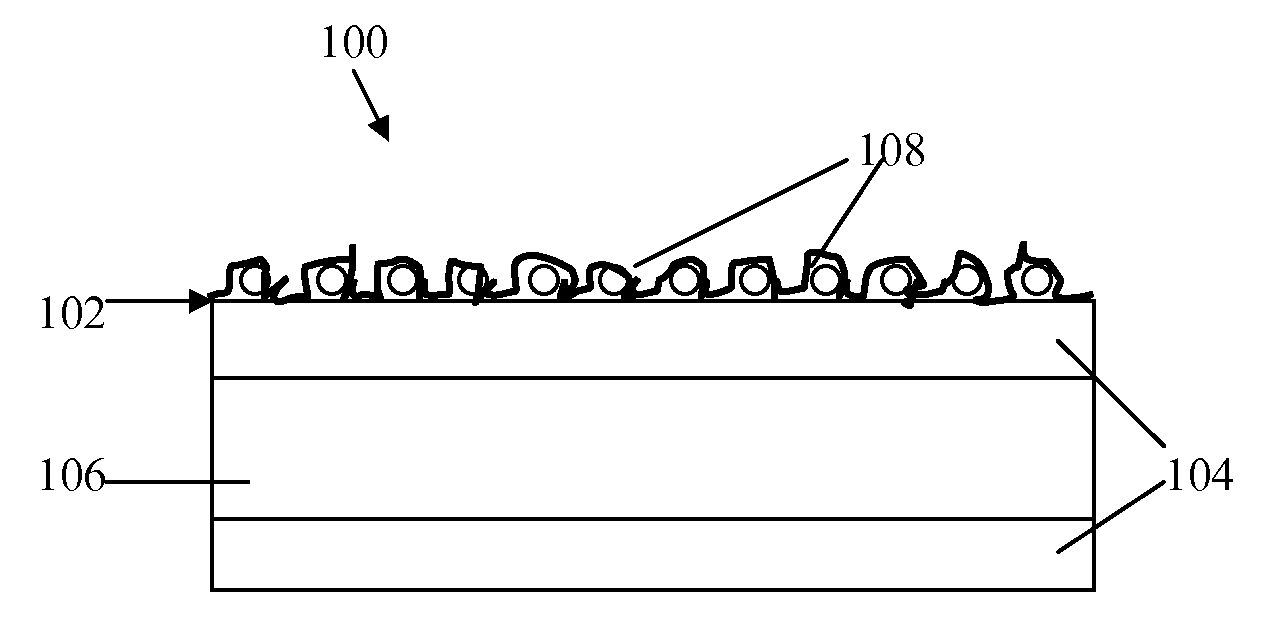

A fiber velvet comprising nano-size fibers or nanofibrils attached to micro-size fibers is disclosed. Methods of manufacturing the velvet as well as various uses of the velvet are also described. For example, the fiber velvet can be used as a thermal interface or as an adhesive material. The nanofibrils may be attached to a flat base or membrane, or may be attached to the tip portions of the micro-size or larger diameter fibers. Various attributes of the micro-size fibers and of the nano-size fibers, for example, geometry (e.g. size, length, packing density) material type (e.g. carbon, metal, polymer, or ceramic) and properties (e.g. conductivity, modulus, surface energy, dielectric constant, surface roughness) can be selected depending on the desired attributes of the fiber velvet. The nanofibrils have a diameter of less than about 1 micron, and may advantageously be formed from single walled and / or multi-walled carbon nanotubes.

Owner:KULR TECH

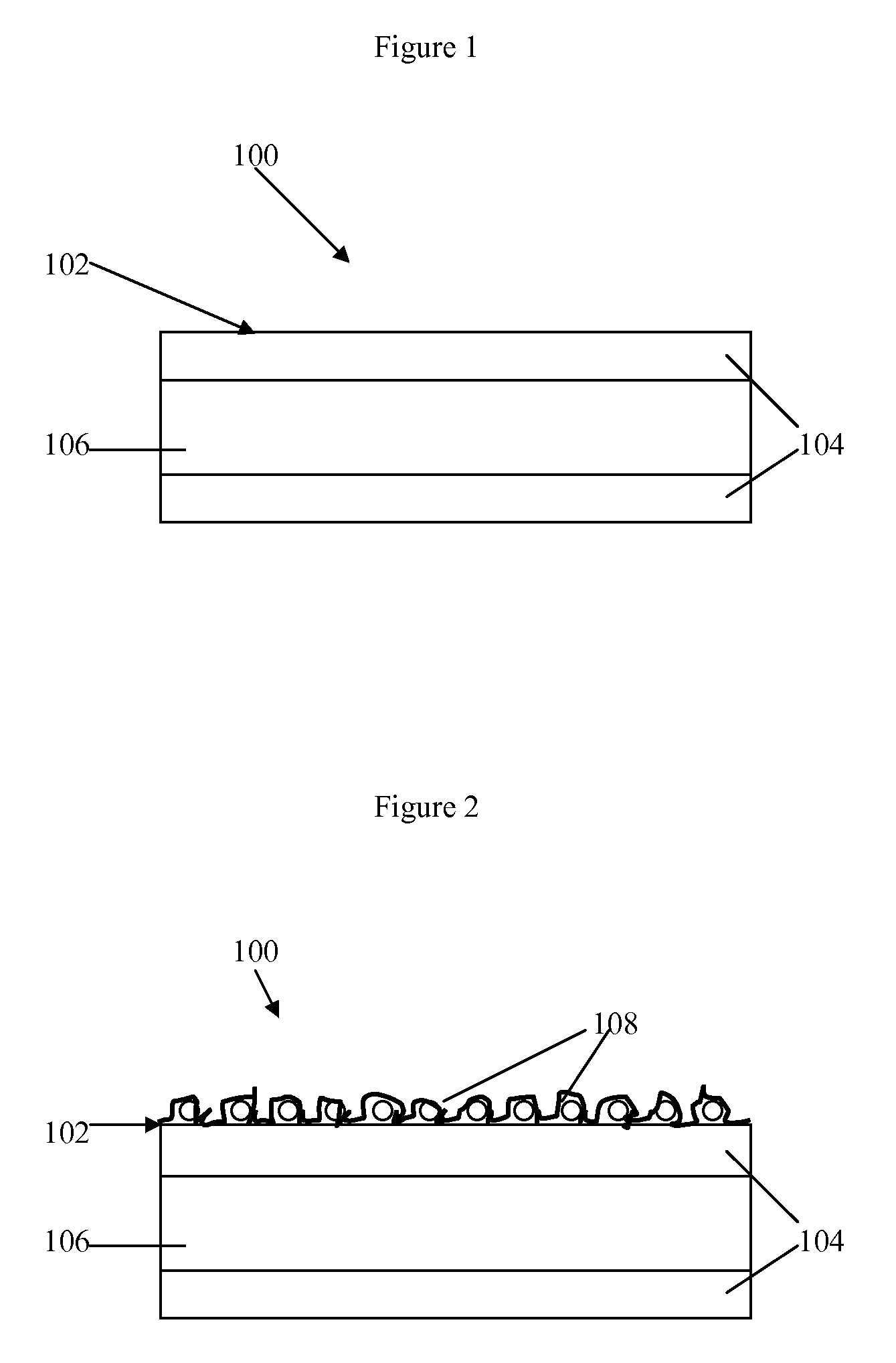

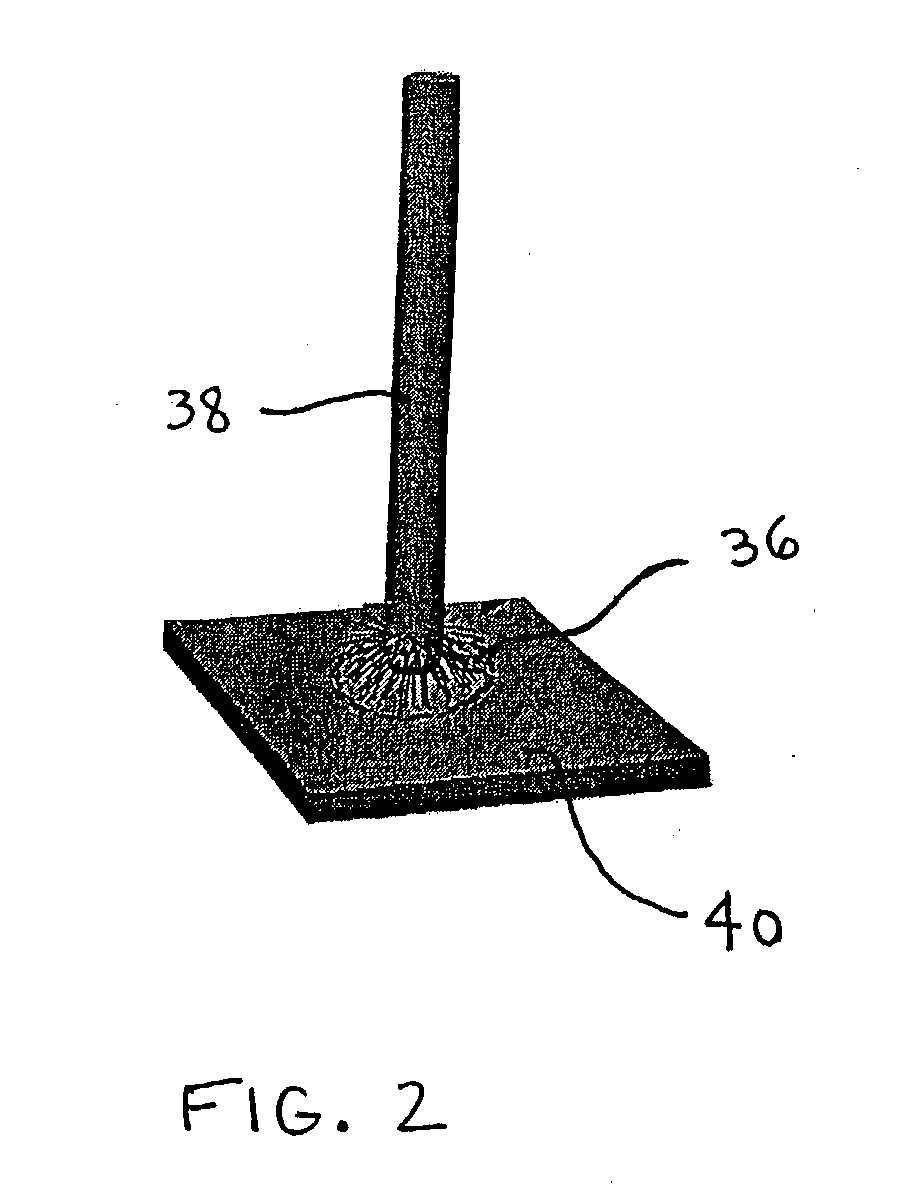

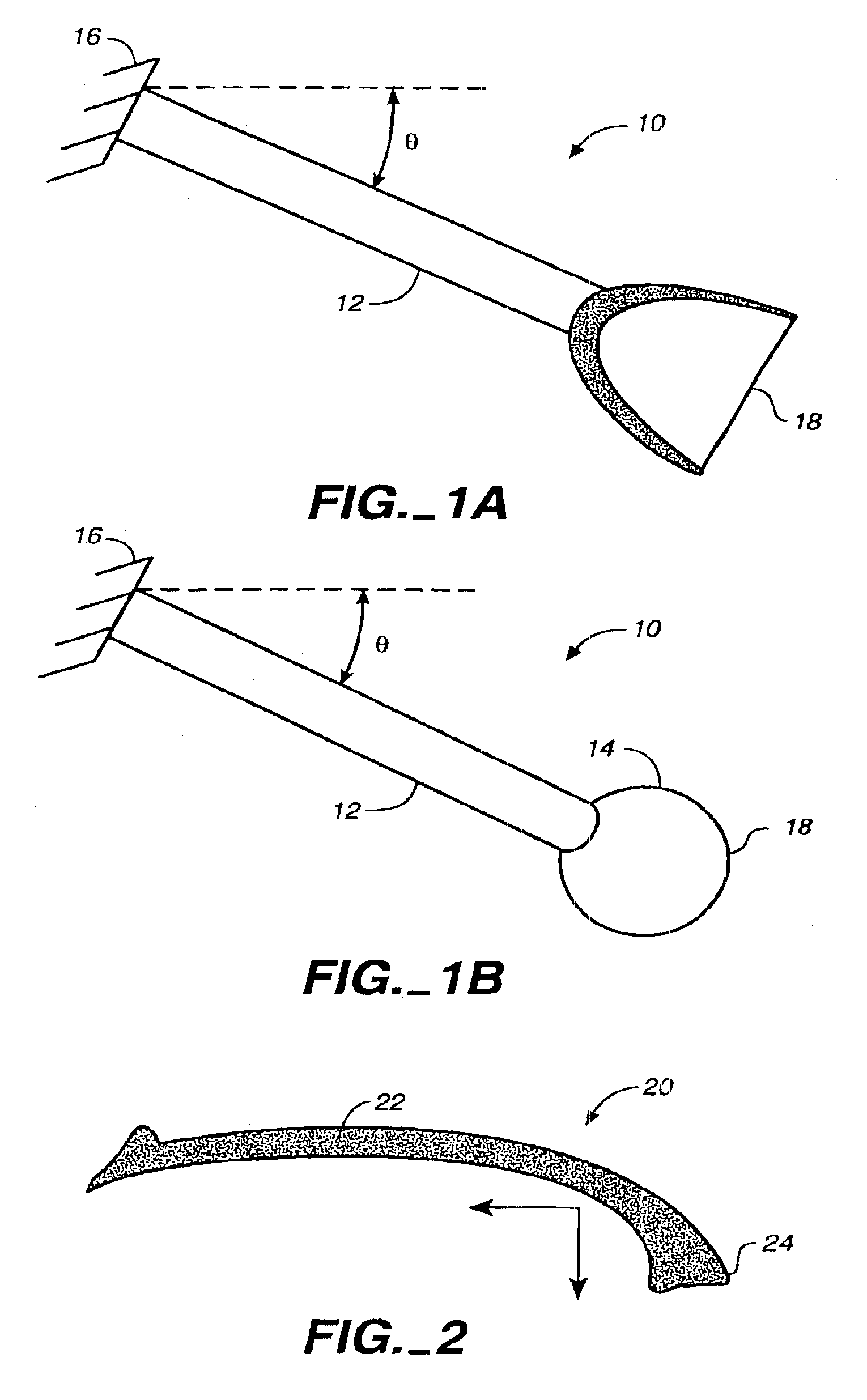

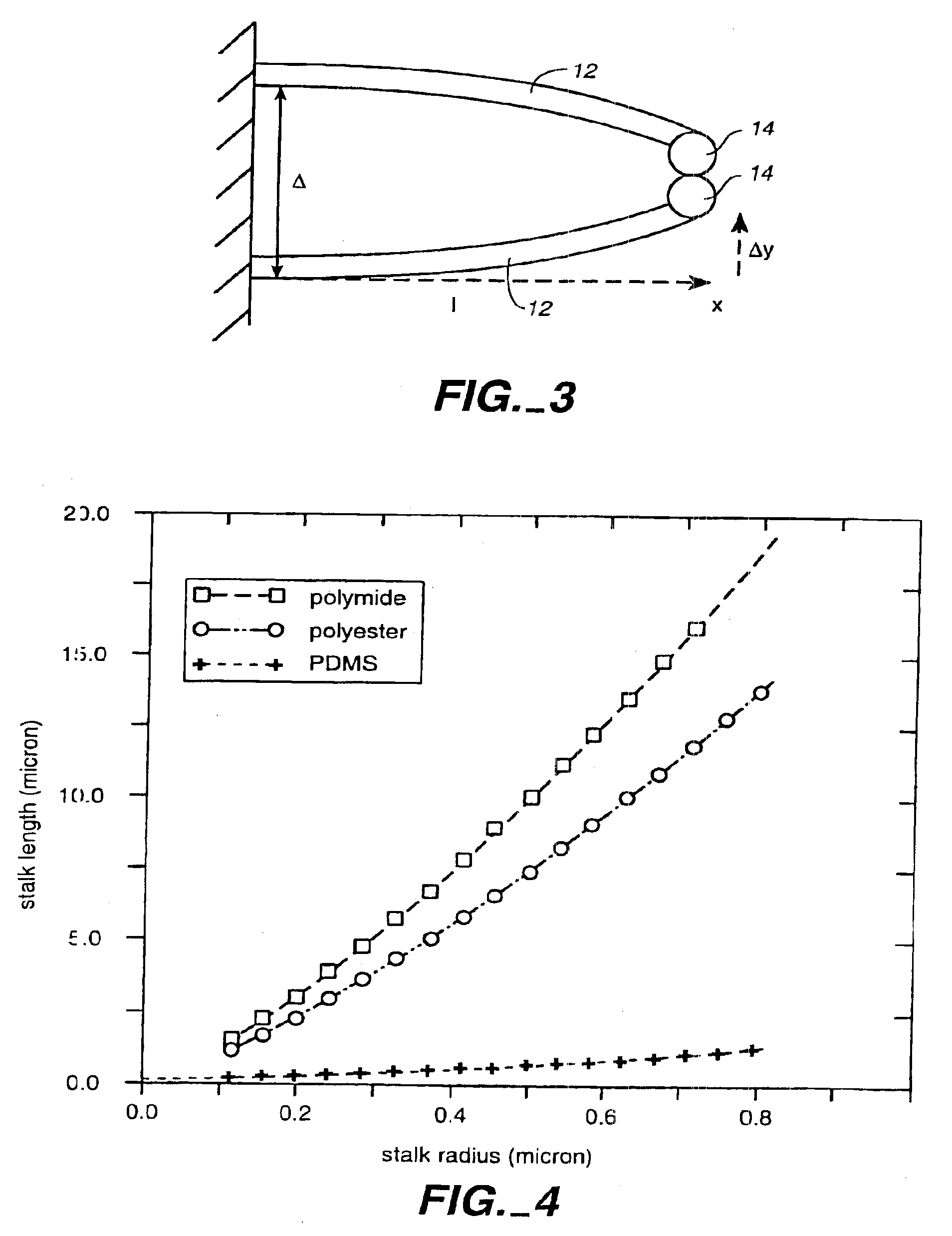

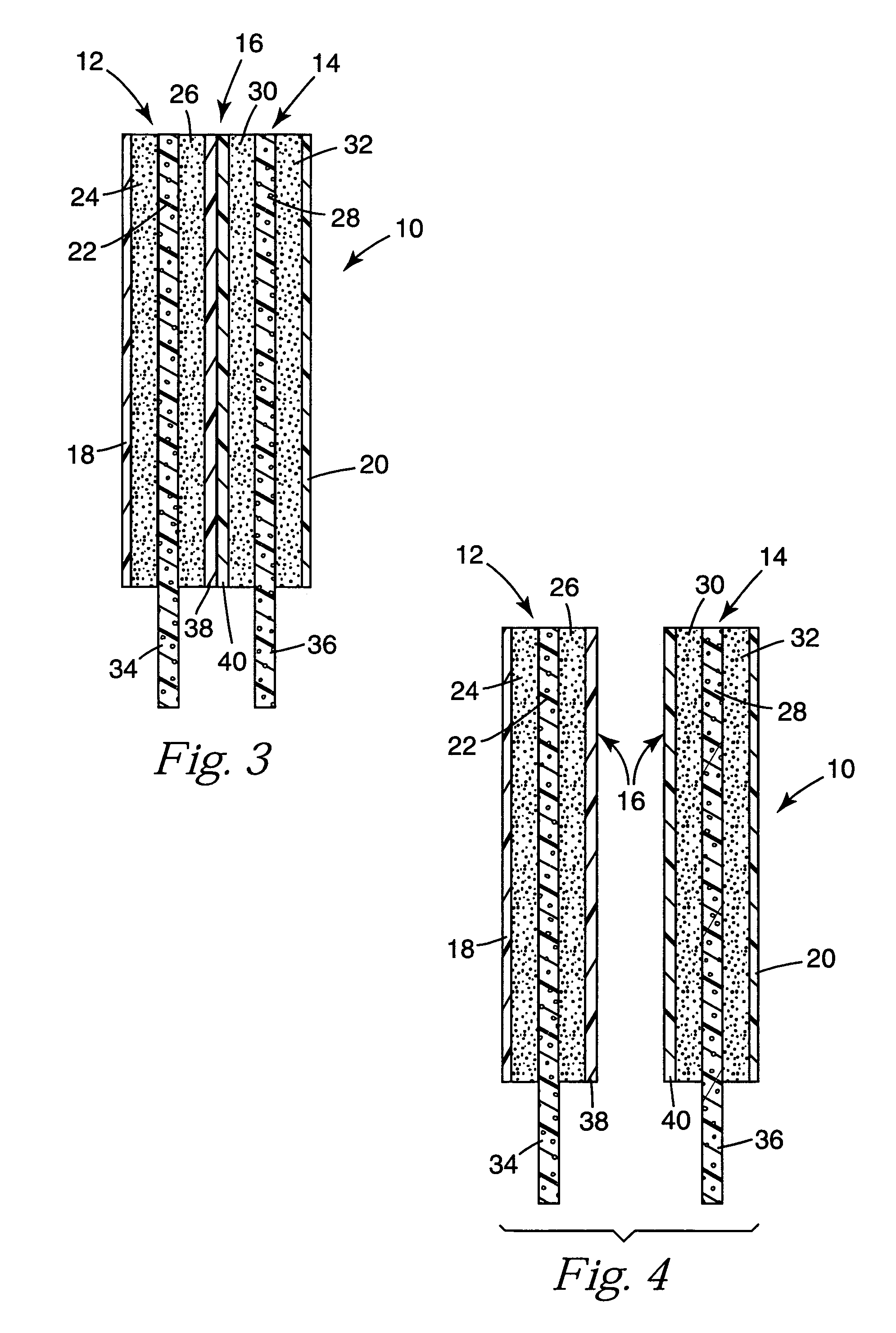

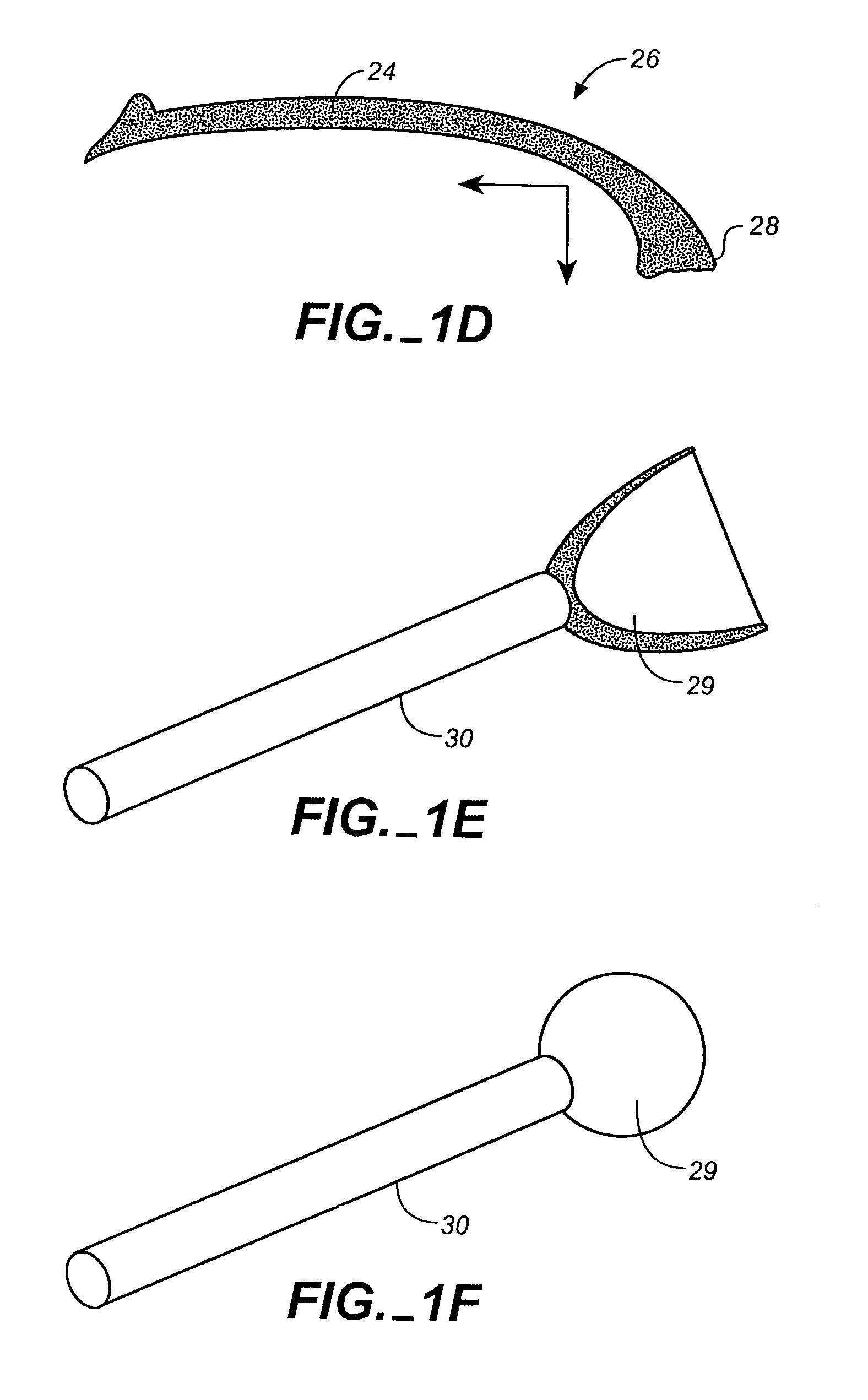

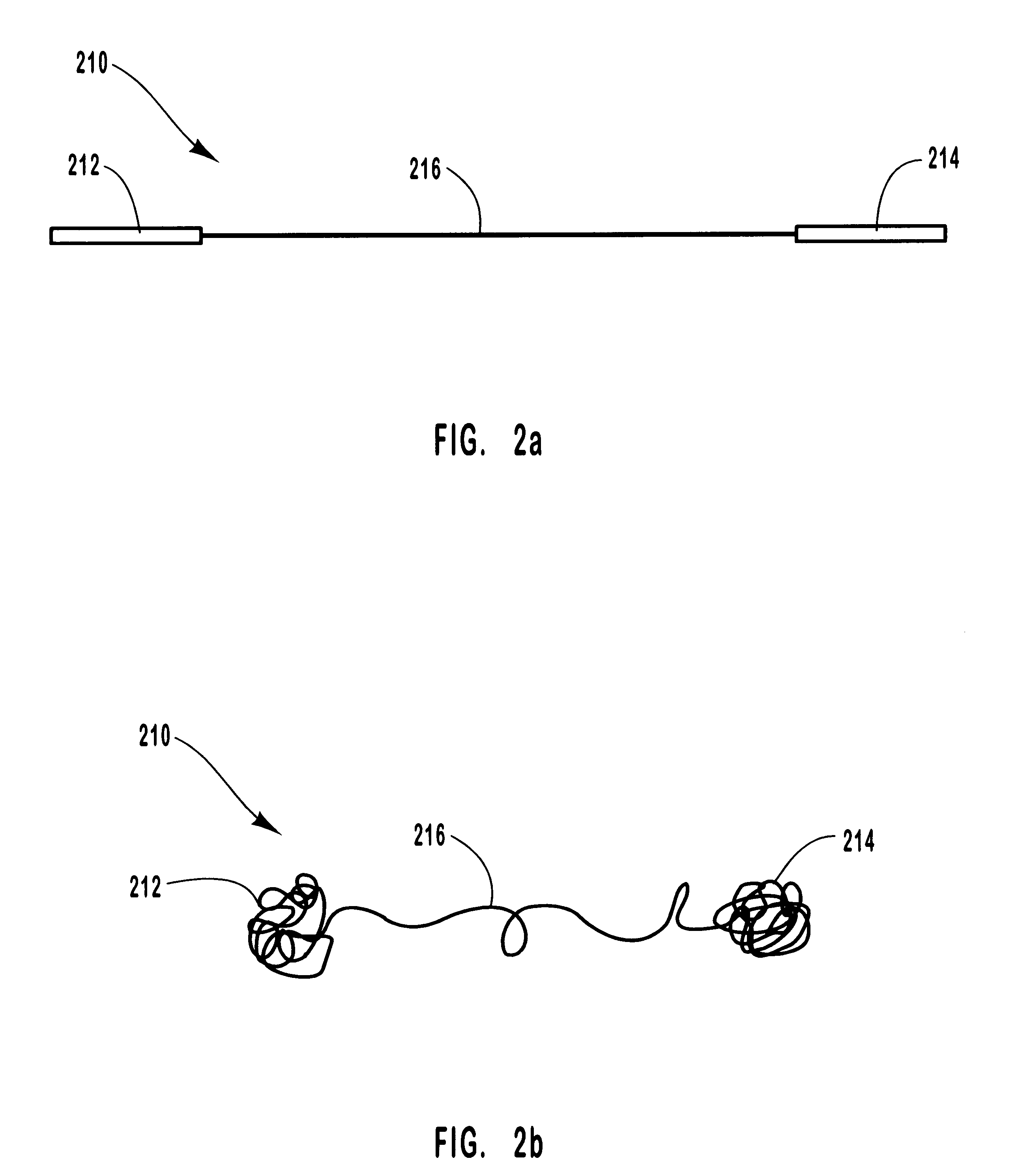

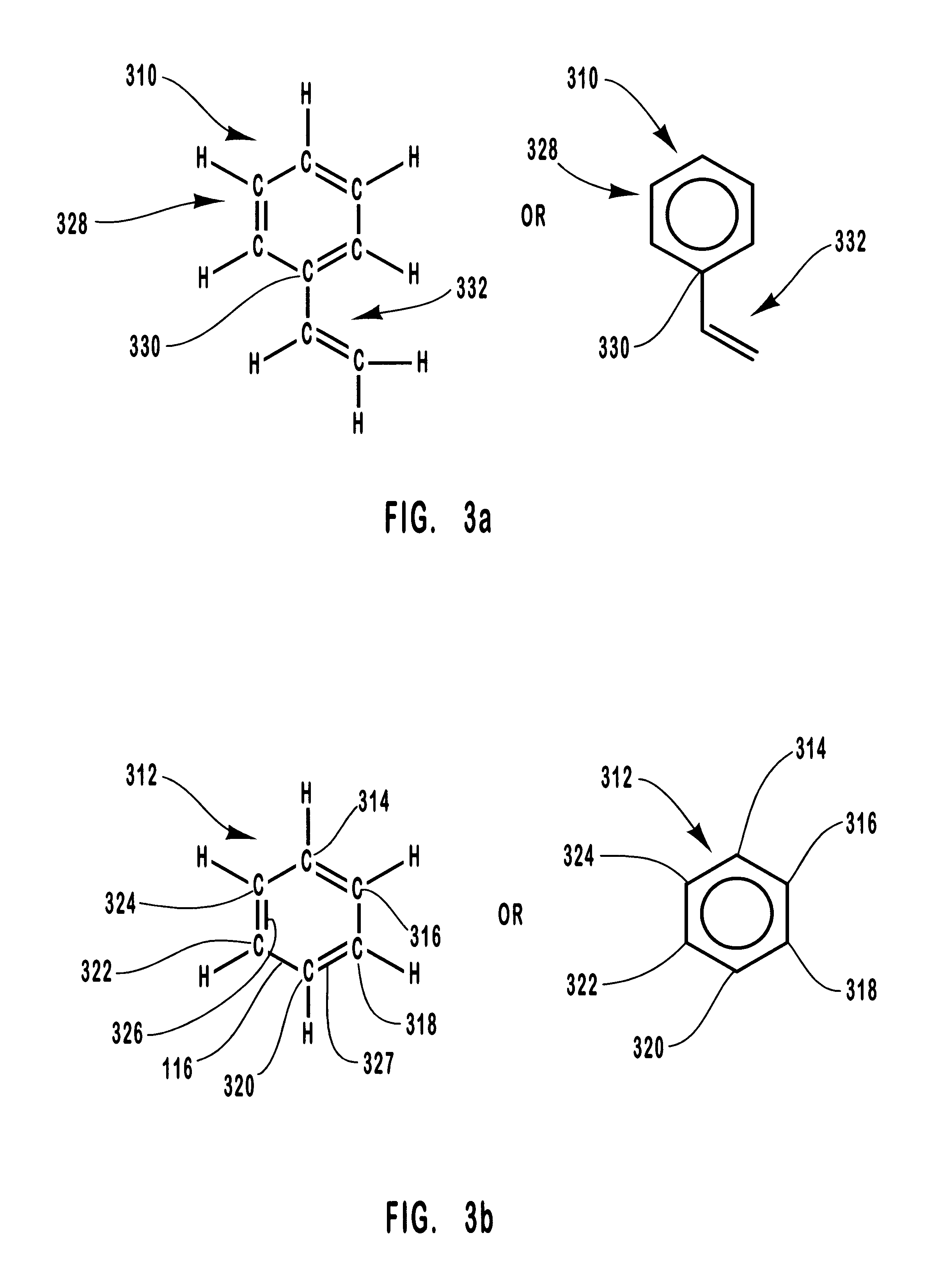

Adhesive microstructure and method of forming same

InactiveUS6872439B2Improve adhesionEasy to disengageSnap fastenersMaterial nanotechnologyMicroscopic scaleOblique angle

A fabricated microstructure comprising at least one protrusion capable of providing an adhesive force at a surface of between about 60 and 2,000 nano-Newtons. A stalk supports the protrusion at an oblique angle relative to a supporting surface. The microstructure can adhere to different surfaces.

Owner:RGT UNIV OF CALIFORNIA

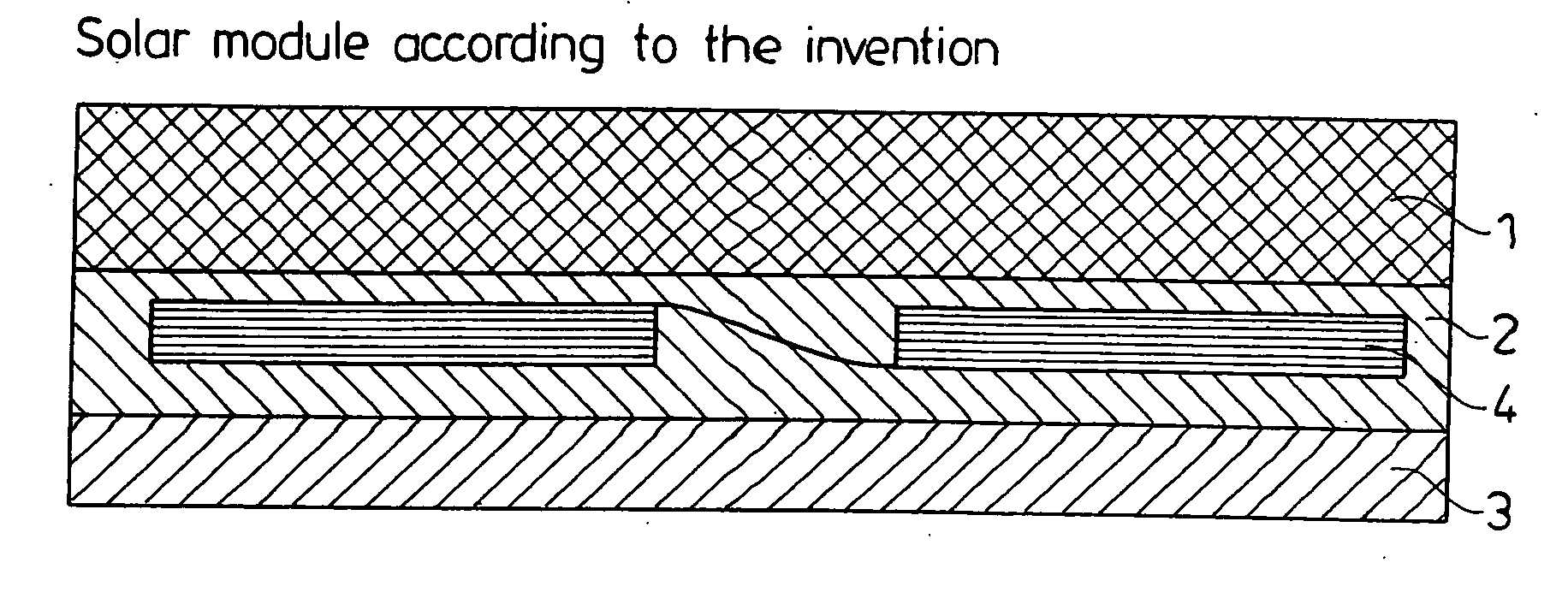

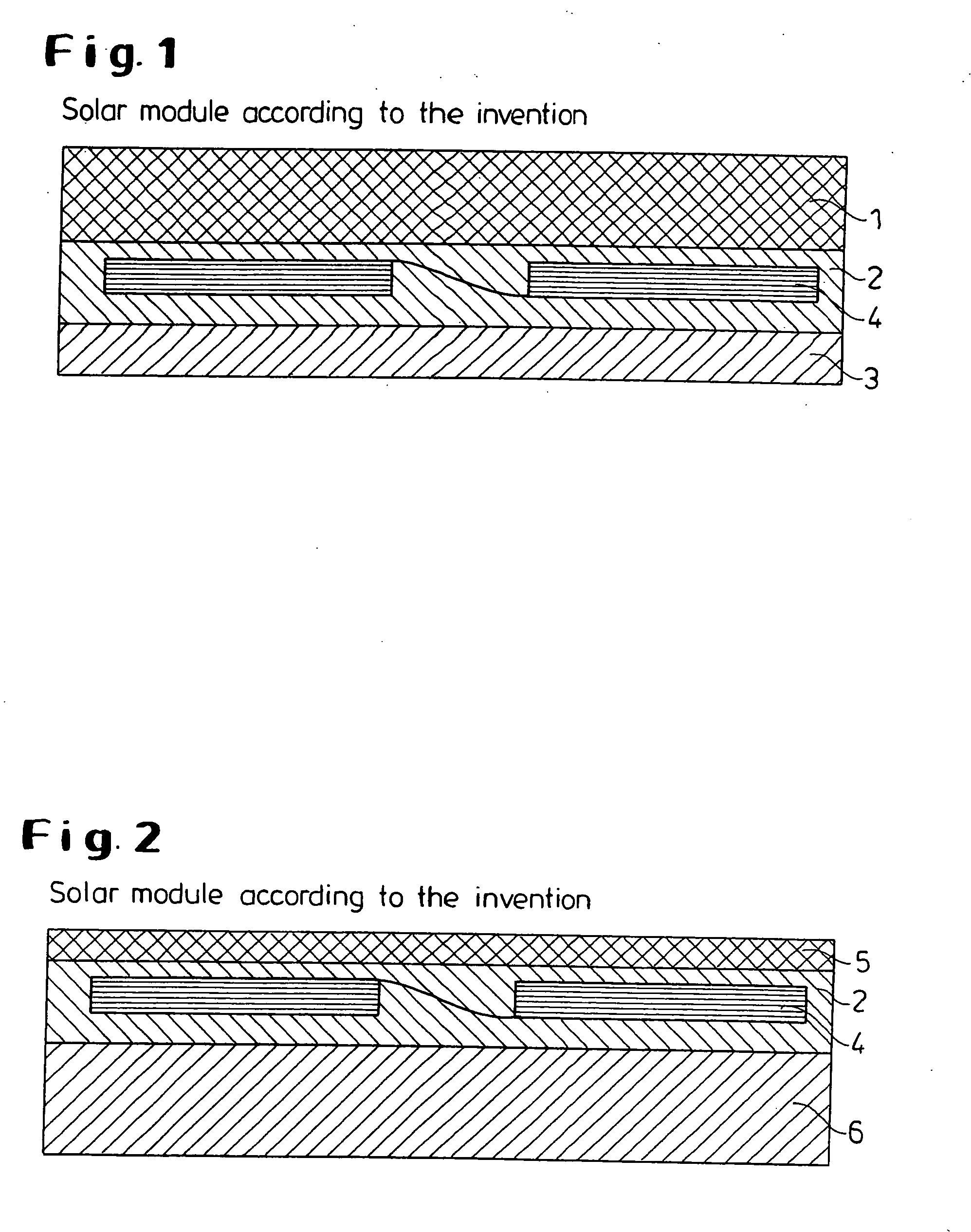

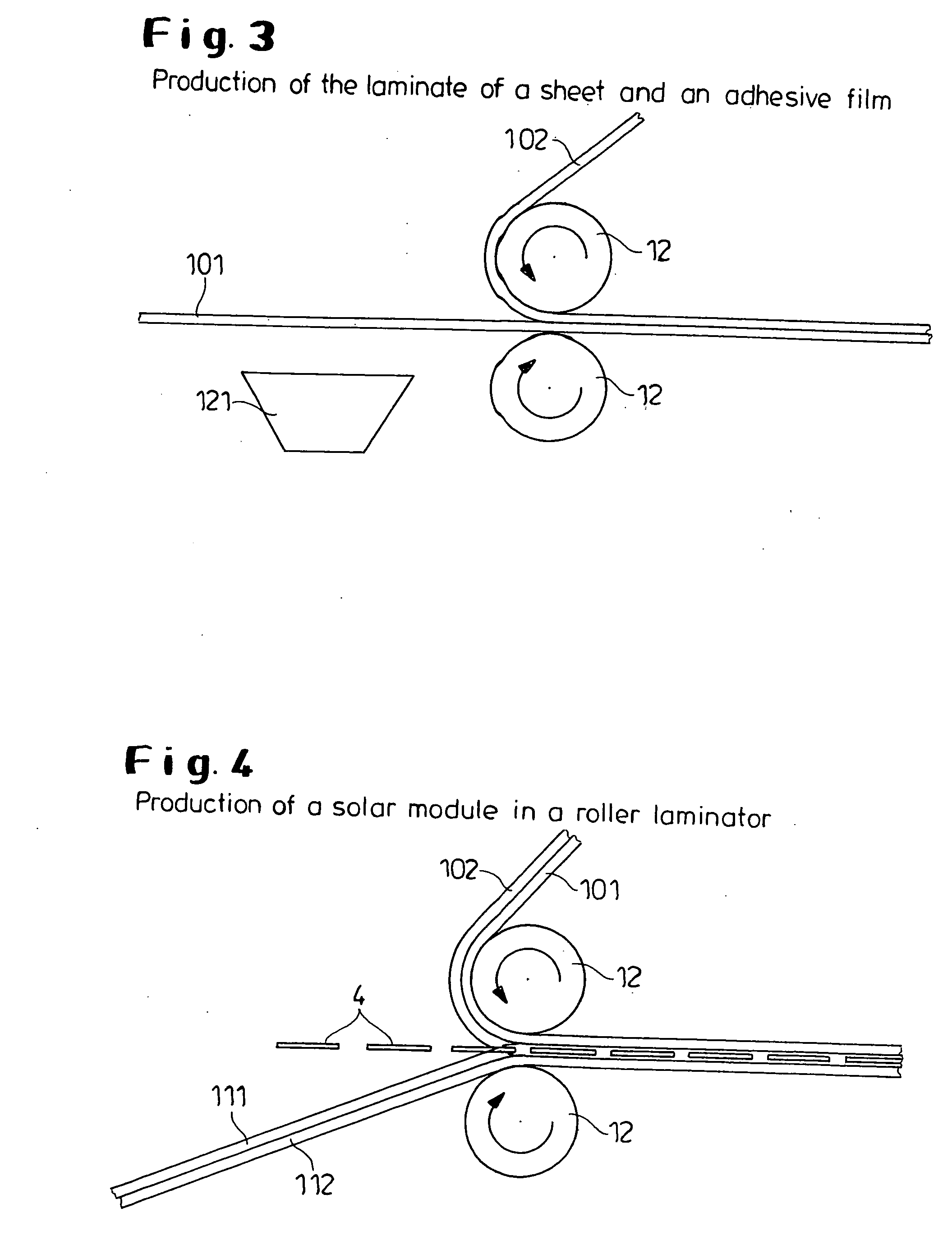

Photovoltaic modules with a thermoplastic hot-melt adhesive layer and a process for their production

InactiveUS20070131274A1Fast and inexpensive for productionReduce weightFilm/foil adhesivesPV power plantsHot-melt adhesiveChemistry

The invention relates to photovoltaic modules with a specific thermoplastic adhesive layer and the production thereof.

Owner:STOLLWERCK GUNTHER +5

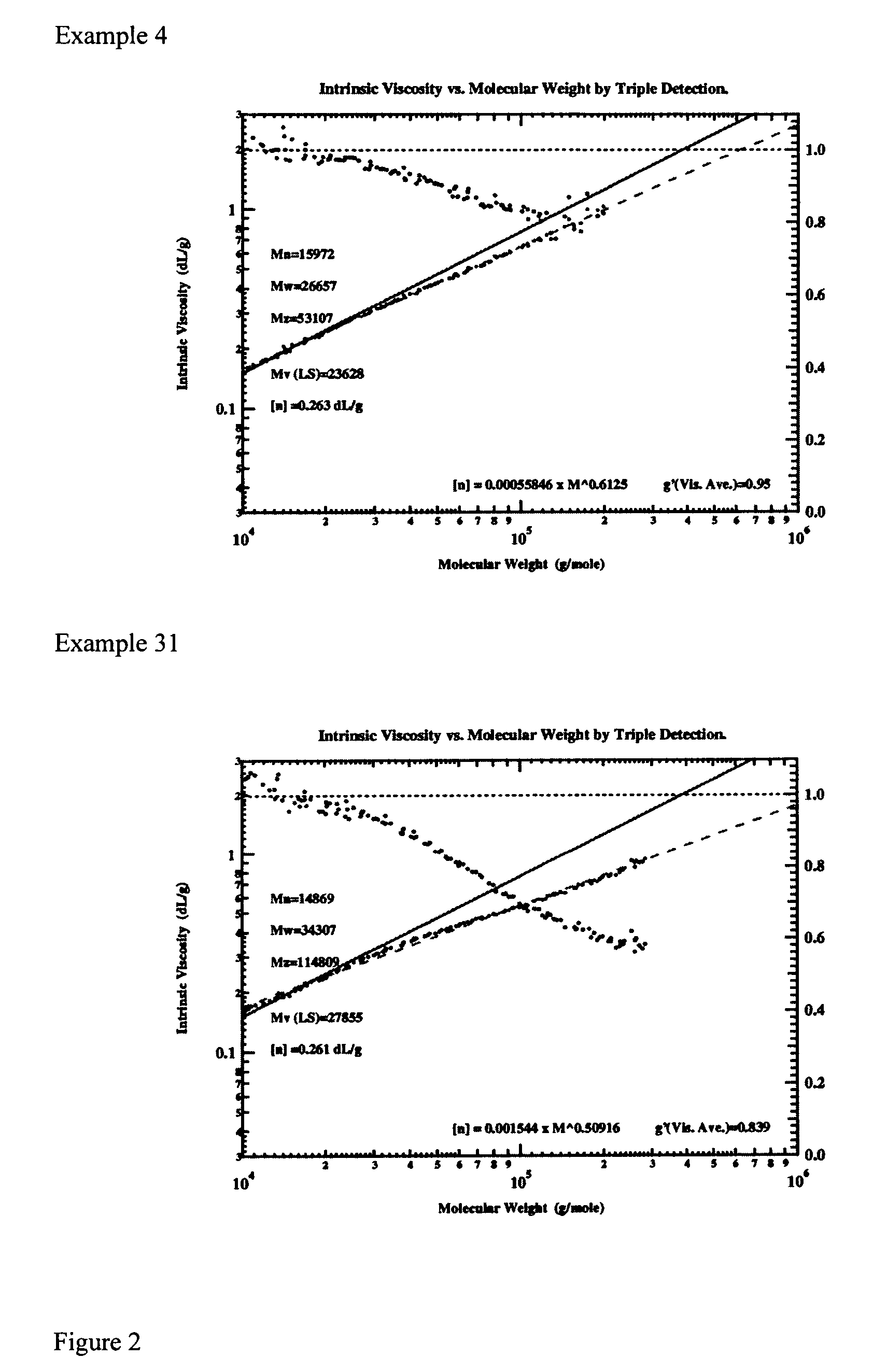

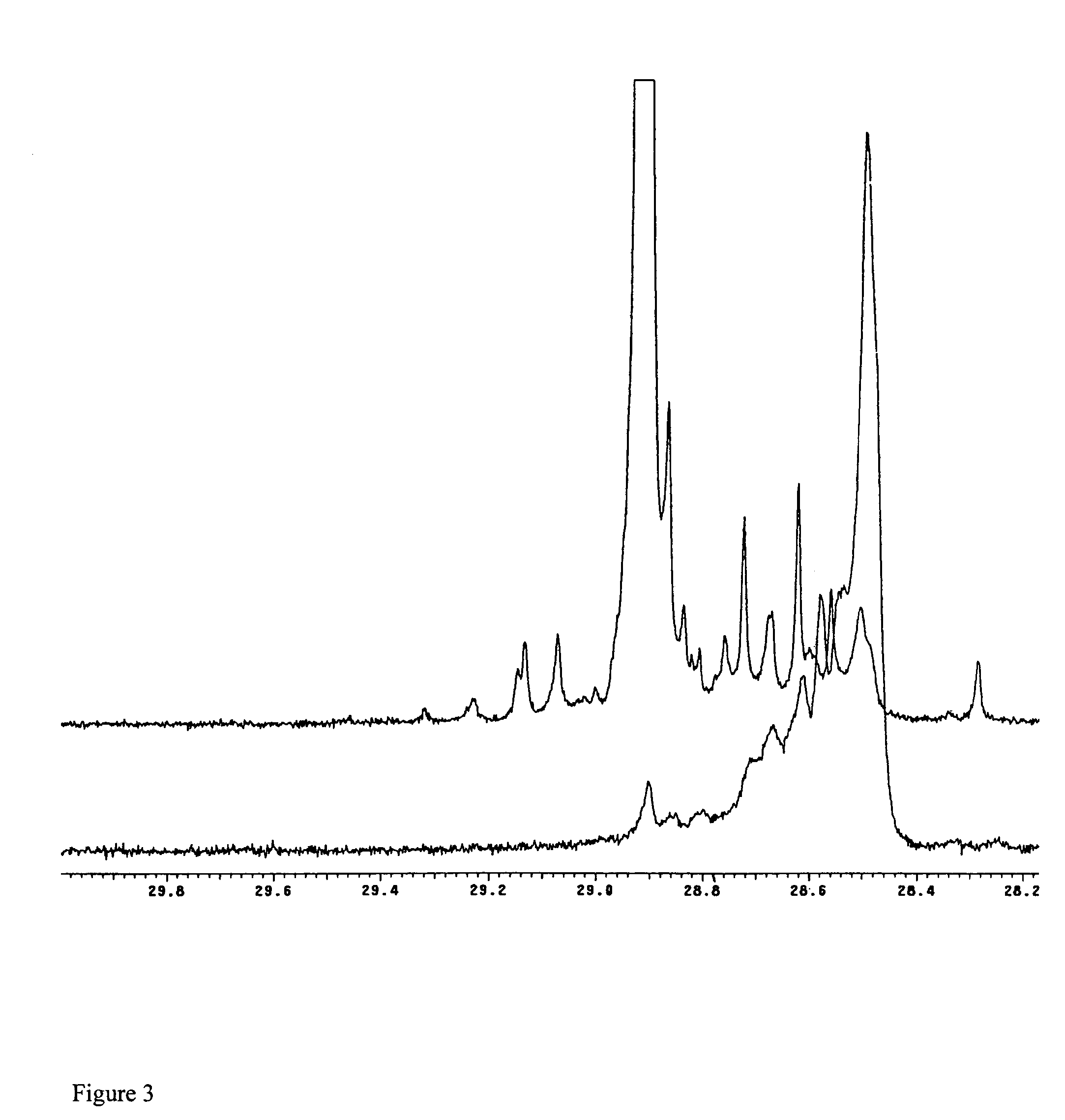

Mutliple catalyst system for olefin polymerization and polymers produced therefrom

This invention relates to a polymer of one or more C3 to C40 olefins, optionally one or more diolefins, and less than 15 mole % of ethylene, and polymerization processes for producing the same.

Owner:EXXONMOBIL CHEM PAT INC

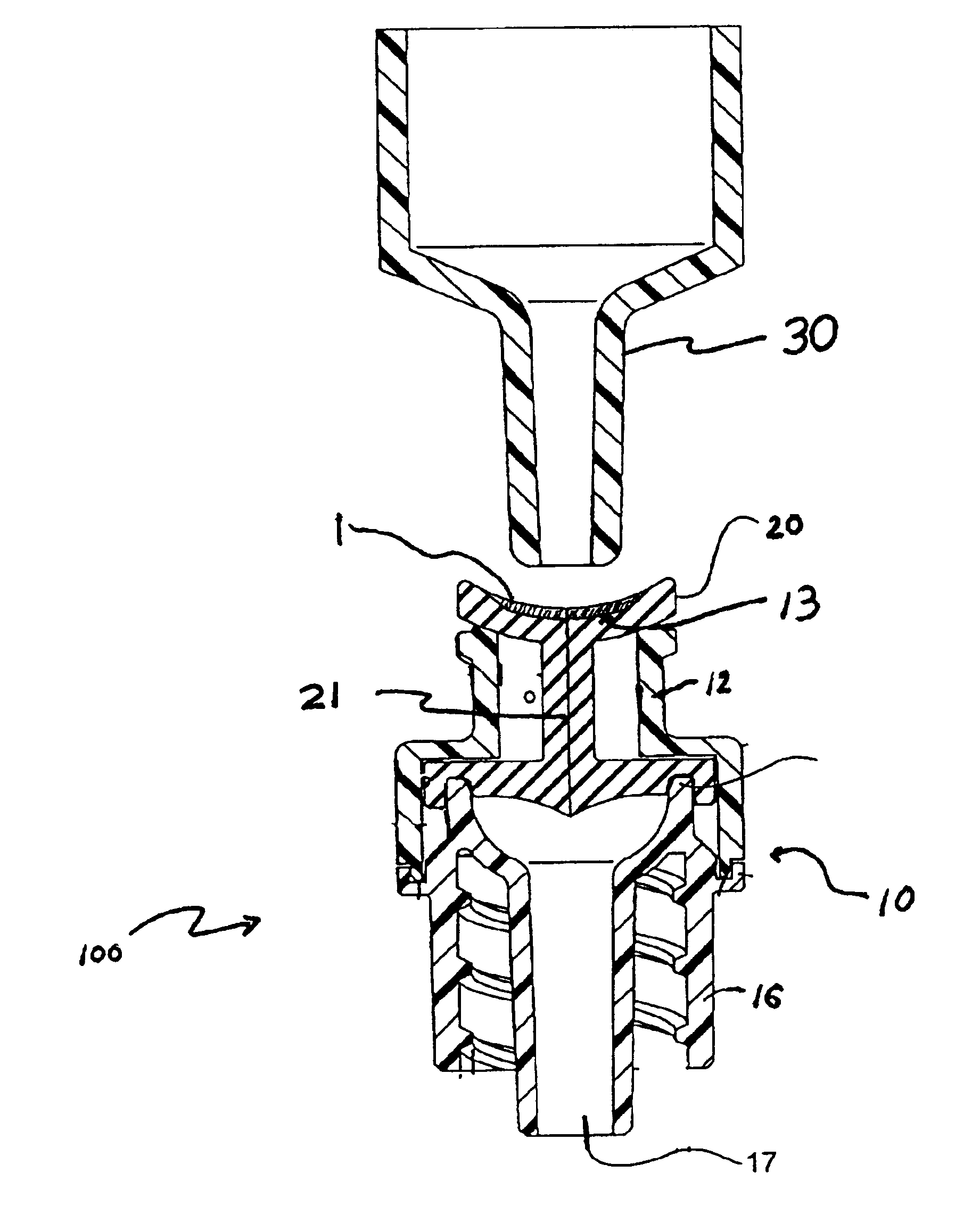

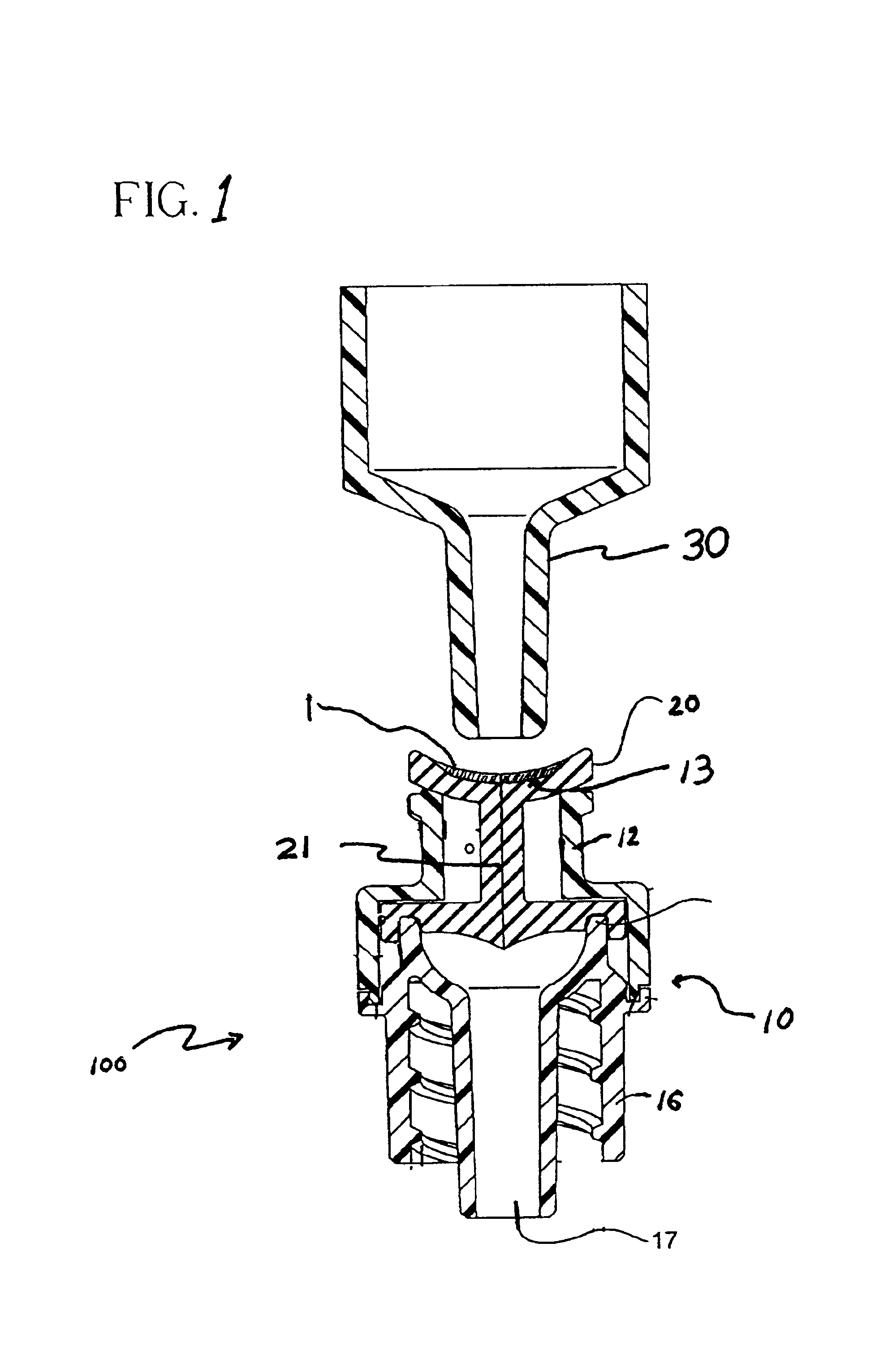

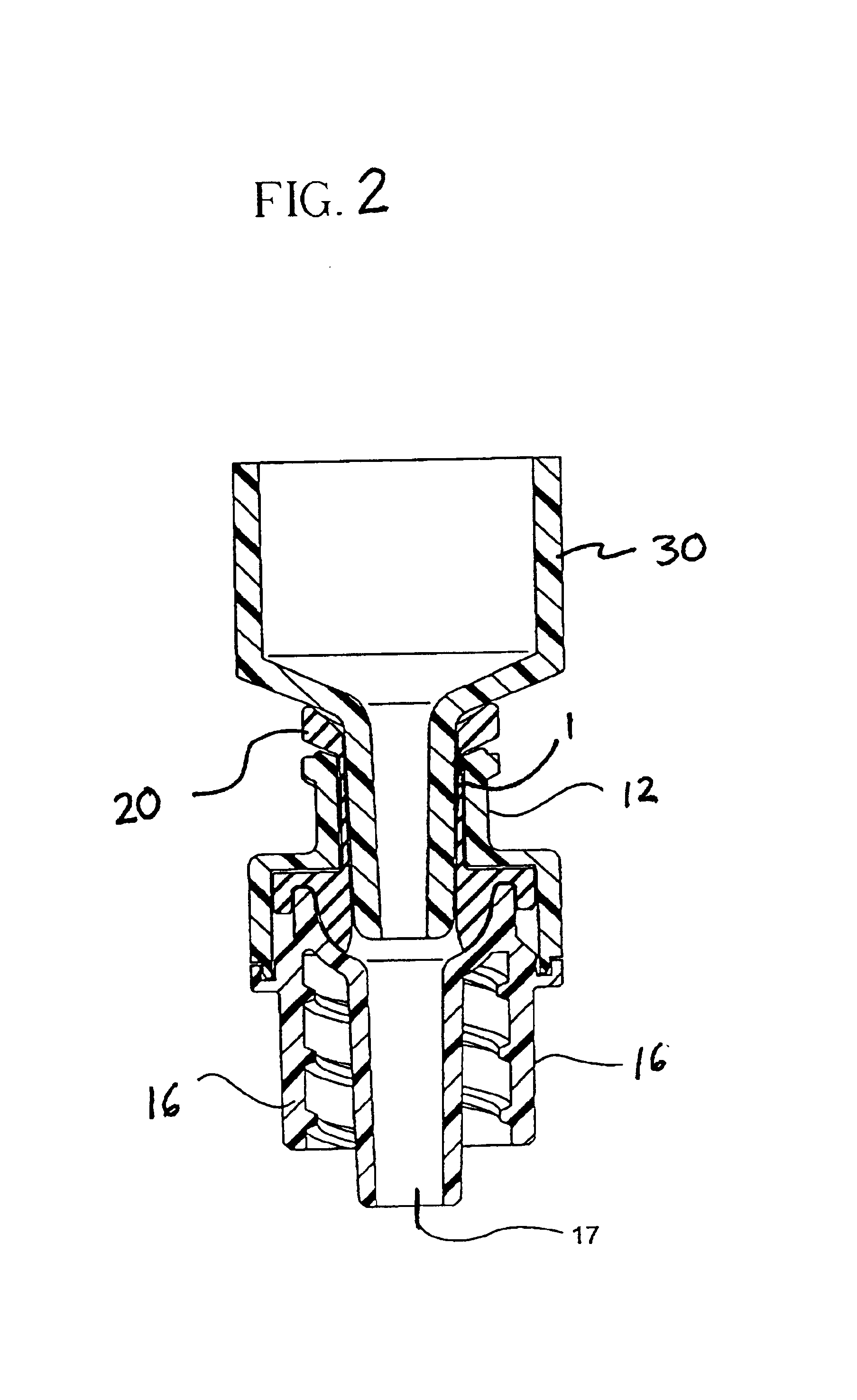

Lubricious coating for a medical device

InactiveUS6866656B2Reduce frictionNot degradedFilm/foil adhesivesSynthetic resin layered productsElastomerChemical Linkage

A lubrication system is disclosed which minimizes friction and that is useful for application on the surface of a flexible portion of a medical device. Such a lubrication system includes a lubricant that is able to move when the flexible portion of the medical device flexes and is biocompatible and is not degraded by the application of alcohol or other conventional medical sterilizing and cleaning agents. The lubricant is bonded to the surface of the flexible portion of the medical device. The lubrication system may be used on an elastomeric septum, such as a silicone rubber elastomer. The lubricant coating may be any type of coating that can be chemically bonded to the elastomer, such as di-paraxylene, poly-(p-xylene), polytetrafluoroethylene, or polyvinylpyrrolidone.

Owner:BECTON DICKINSON & CO

Process for producing modified epoxy resin

ActiveUS20070027233A1Reduce removalEasy to excludeFilm/foil adhesivesCircuit susbtrate materialsSolubilityPolymer chemistry

This invention provides a process for producing an epoxy resin composition having core / shell rubber particles (rubber-like polymer particles) dispersed in an epoxy resin, wherein an epoxy resin composition excellent in the dispersed state of rubber-like polymer particles in an epoxy resin with a reduced amount of contaminants is produced easily and efficiently. The epoxy resin composition having rubber-like polymer particles dispersed well in an epoxy resin with less contaminant is obtained by bringing an aqueous latex of rubber-like polymer particles (B) into contact with an organic medium (C) showing partial solubility in water, then bringing an organic medium (D) having lower partial solubility in water than that of the organic medium (C) into contact therewith to separate water substantially, to remove the rubber-like polymer particles as a dispersion (F) having the polymer particles dispersed in the organic medium, and mixing it with an epoxy resin (A), followed by distilling volatile components away.

Owner:KANEKA CORP

Bright metal flake

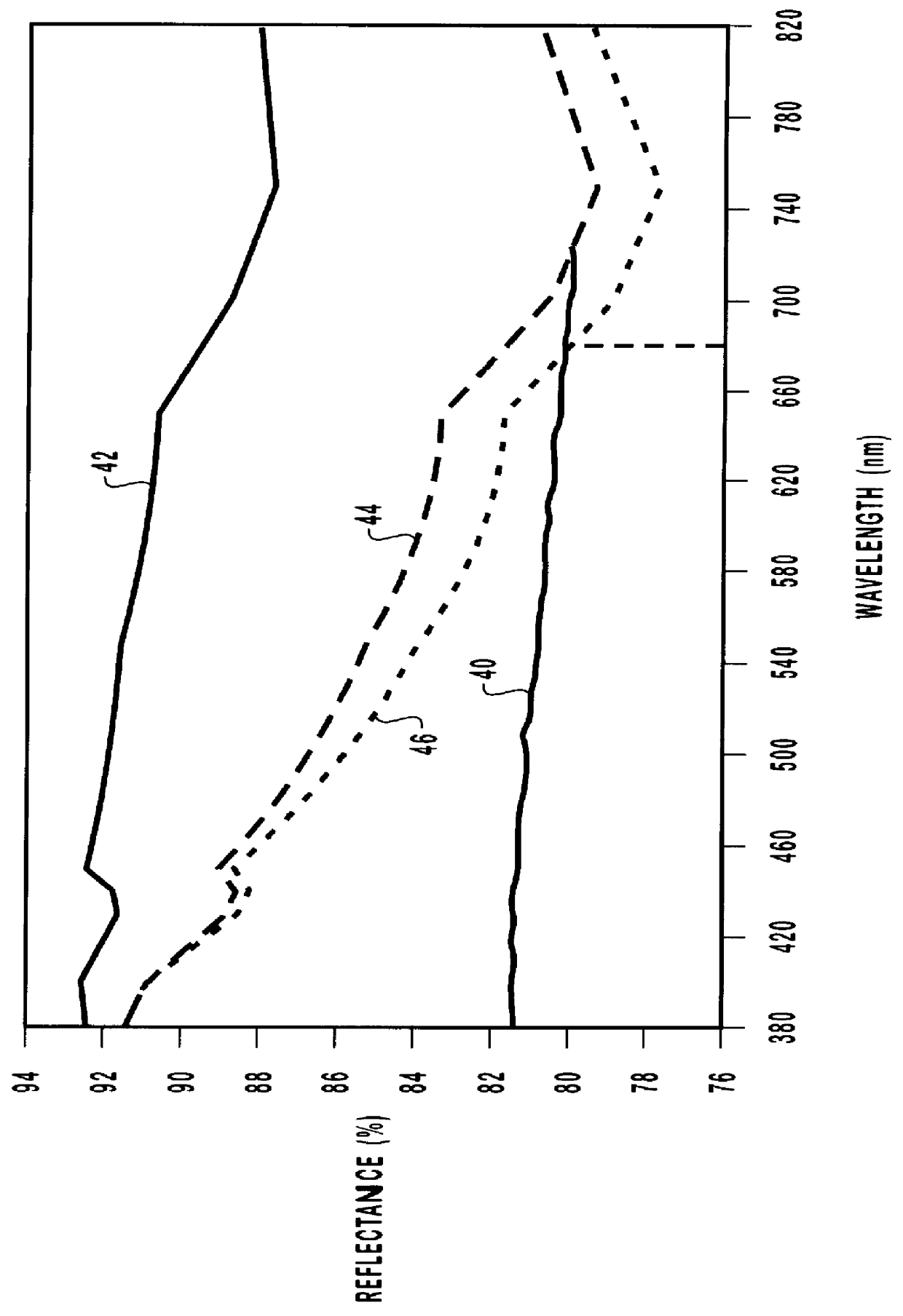

InactiveUS6013370AGood specular reflectance characteristicHigh aspect ratioPigmenting treatmentRecord information storageSilicon dioxideReflectivity

A rigid and brittle bright metal flake is formed of a central layer of a reflective material supported on both sides by dielectric layers. In a preferred embodiment, the metal layer is aluminum having a thickness of about 100 nm and the dielectrics are either silicon dioxide or magnesium fluoride, each having a thickness of about 100 nm. The result is a very thin three-layered metal flake about 300 nm thick that exhibits a uniaxial compressive strength of about 8 times a corresponding uniaxial tensile strength. As a result, the metal flake is then afforded the benefits of rigidity and brittle fracture during the manufacturing and applicational processes which ultimately provides favorable planar and specular reflectance characteristics in the visible wavelength range.

Owner:JDS UNIPHASE CORP

Gelatinous elastomer

An improved gelatinous elastomer is disclosed which uses an A-B-A triblock copolymer having a molecular weight in the range of 125,000 to 175,000, or about 150,000, and a plasticizer.

Owner:PURPLE INNOVATION LLC

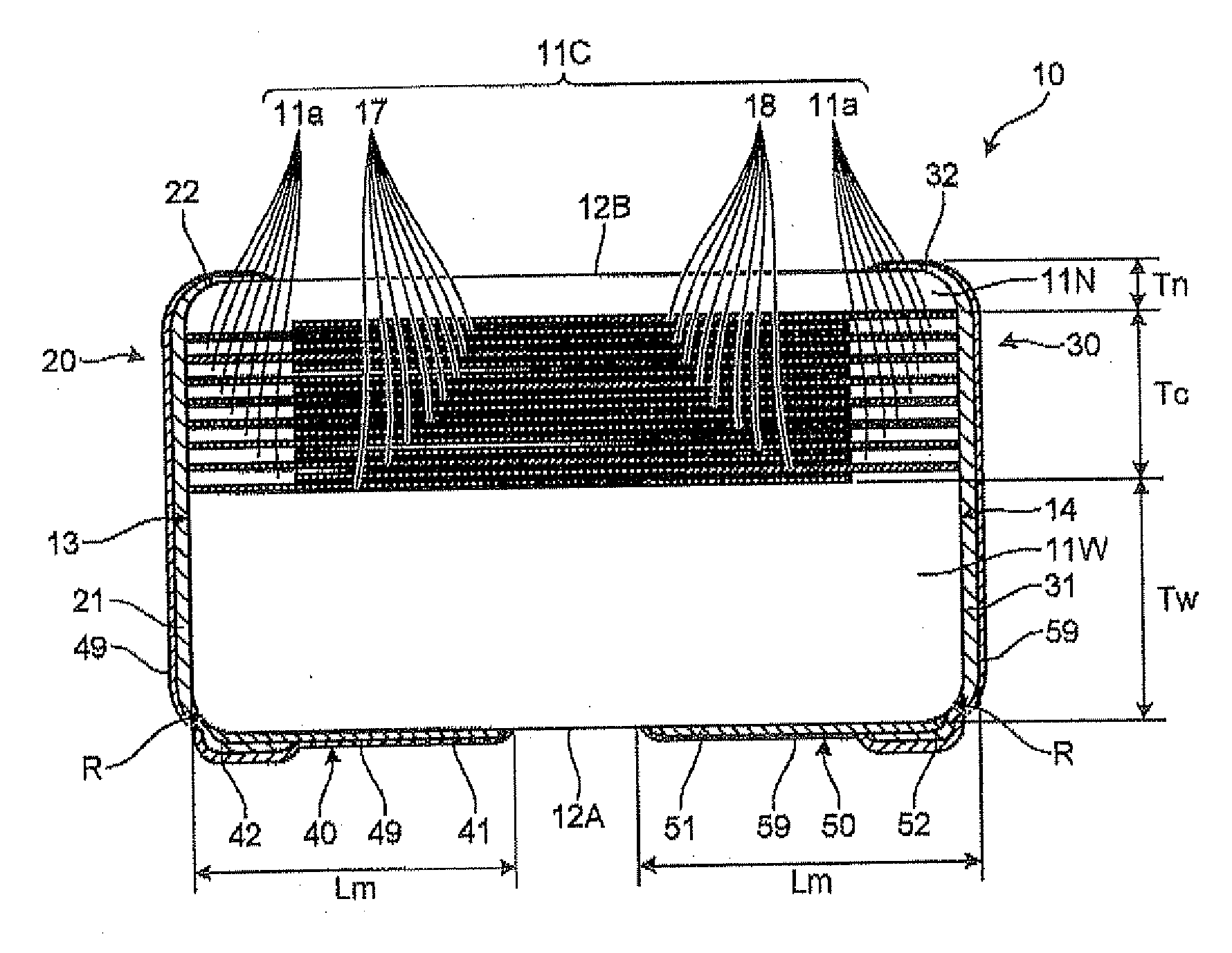

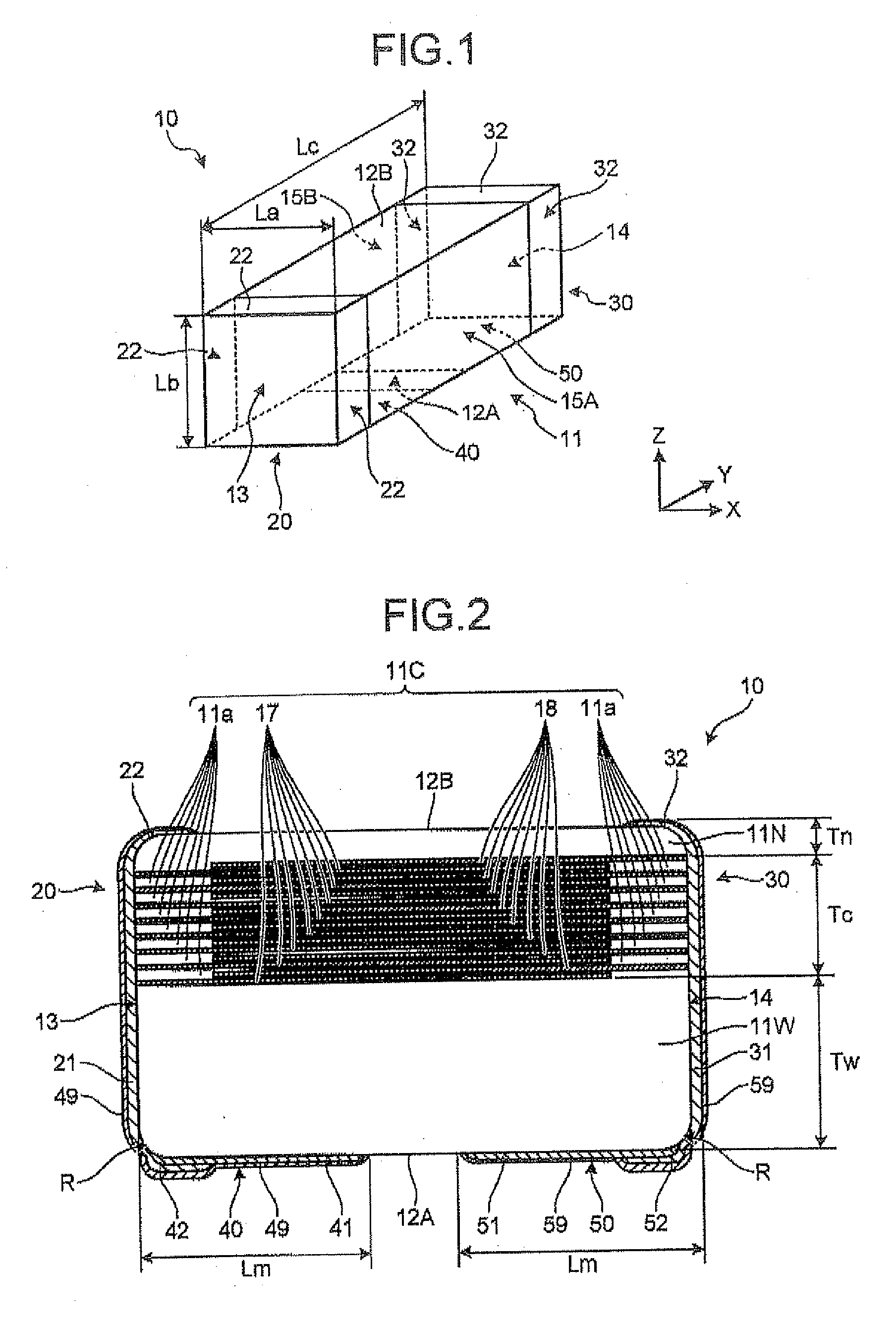

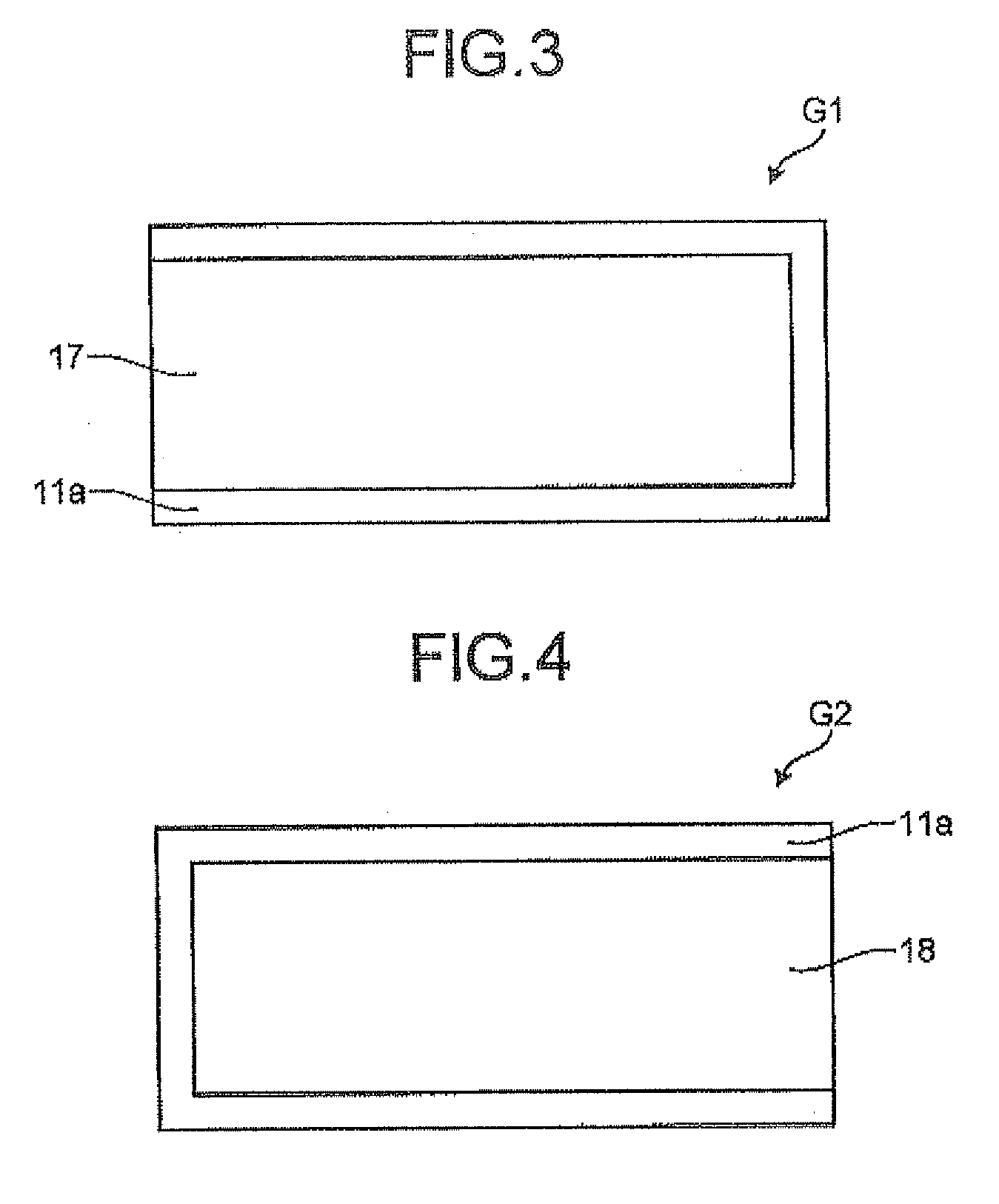

Multilayer capacitor and method for manufacturing the same

In a multilayer capacitor, a first dielectric layered product including a first body principal face is formed to be thicker than a second dielectric layered product including a second body principal face in a stacking direction thereof. A first external electrode and a second external electrode extend only to the first body principal face from a first body end face and a second body end face. Alternatively, the first external electrode and the second external electrode extend at least to the first body principal face from the first body end face and the second body end face and extend also to at least one of the second body principal face, a first body lateral face, and a second body lateral face.

Owner:TDK CORPARATION

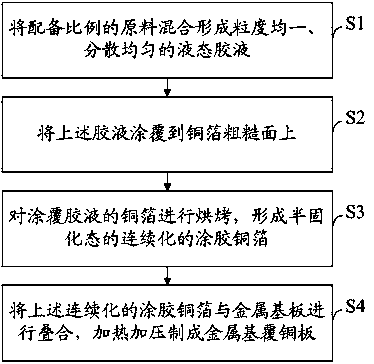

Epoxy resin composition, metal-based copper-clad plate and manufacturing method thereof

ActiveCN103694644AHigh thermal conductivityImprove thermal conductivityFilm/foil adhesivesLaminationEpoxyOrganic solvent

The invention discloses an epoxy resin composition, a metal-based copper-clad plate and a manufacturing method thereof. The epoxy resin composition comprises the following components by mass: 90-110 parts of epoxy resin, 10-50 parts of thermoplastic resin, 1-100 parts of a curing agent, 0.05-5 parts of a curing accelerant, 1-10 parts of an additive, 20-500 parts of heat conduction filler and 0-30 parts of an organic solvent. The metal-based copper-clad plate has the characteristic that 1, the heat conductivity is high; 2, the insulation property is high as the puncture-withstand voltage is higher than 6KV; 3, the anti-bending property is high, so that the metal-based copper-clad plate can be used for manufacturing a three-dimensional aluminum substrate; 4, the thickness of the insulation layer is uniform, the coating thickness tolerance can be controlled at + / - 2 microns, and the press-fit thickness tolerance can be controlled at + / - 5 microns, so that the performance of a product can be guaranteed; 5, the production efficiency is high; 6, the cost is low and is about 1 / 4-1 / 3 of the cost of an imported product.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

Medical electrode

An electrode providing electrical contact with a patient's skin includes a conductive member adapted for connection to an external electrical apparatus and a non-liquid water containing film for electrically interfacing to said patient's skin, the non-liquid film being electrically and mechanically connected to said conductive member. The non-liquid water containing film includes an electrically conductive organic polymer plasticized with a polyhydric alcohol with said organic polymer being derived from a monomeric mixture comprising from about 2 to 30 pph acrylic acid, 2 to 30 pph of a glycolvinylether and 0.01 to 1.5 pph of a crosslinking agent. Preferably the polyhydric alcohol is glycerol.

Owner:AXELGAARD MANUFACTURING COMPANY INC

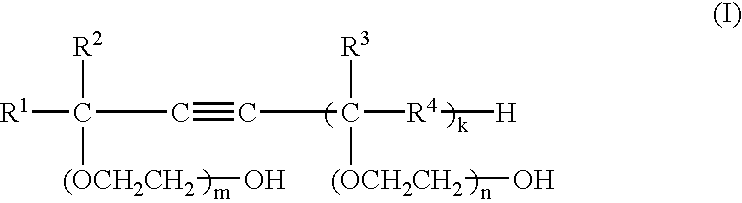

Water-soluble resin composition

InactiveUS6555607B1Improved coating propertiesEasy to diffuseFilm/foil adhesivesSemiconductor/solid-state device manufacturingResistAlcohol

A water-soluble resin composition comprising (1) a water-soluble resin, (2) a water-soluble crosslinking agent, (3) at least one of surface active agents selected from acetylene alcohols, acetylene glycols, polyethoxylates of acetylene alcohols and polyethoxylates of acetylene glycols, and (4) a solvent consisting of water or a mixture of water and a water-soluble solvent. This water-soluble resin composition is applied onto a resist pattern, then heated to crosslink by an acid supplied from the resist, followed by development to remove the non-crosslinked water-soluble resin coating layer. This water-soluble resin composition is excellent in coating characteristics on steps of resist patterns and in dimensional regulation upon fining of patterns so that resist patterns such as trench patterns and hole patterns can effectively be fined.

Owner:MERCK PATENT GMBH

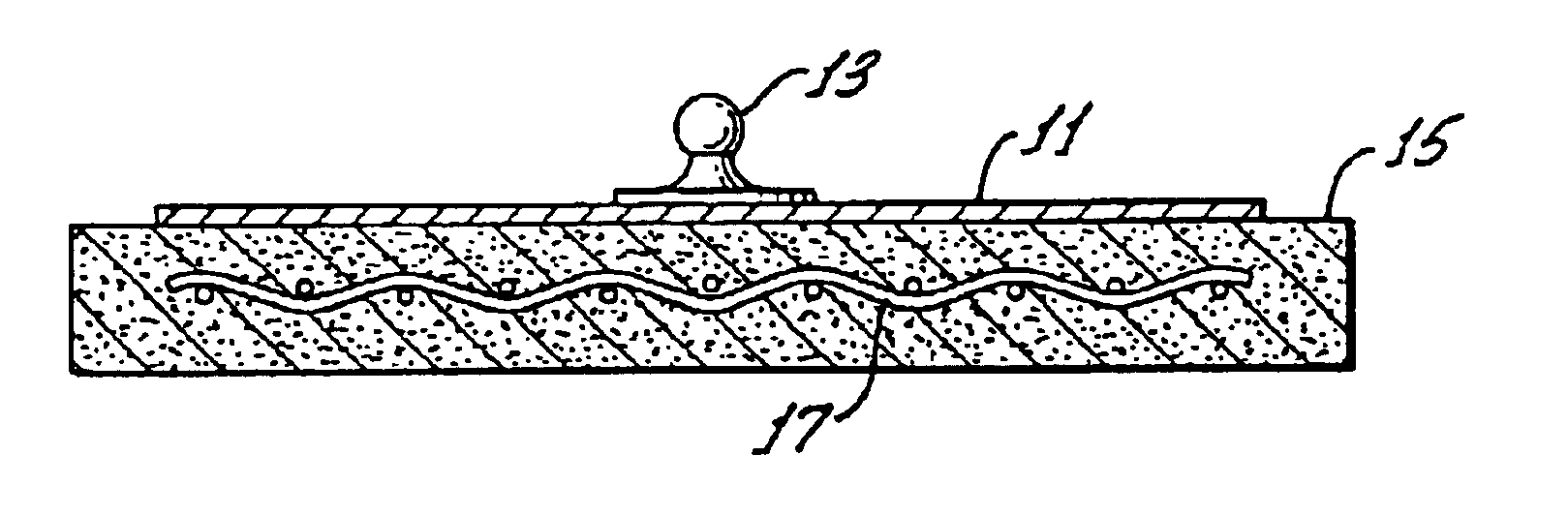

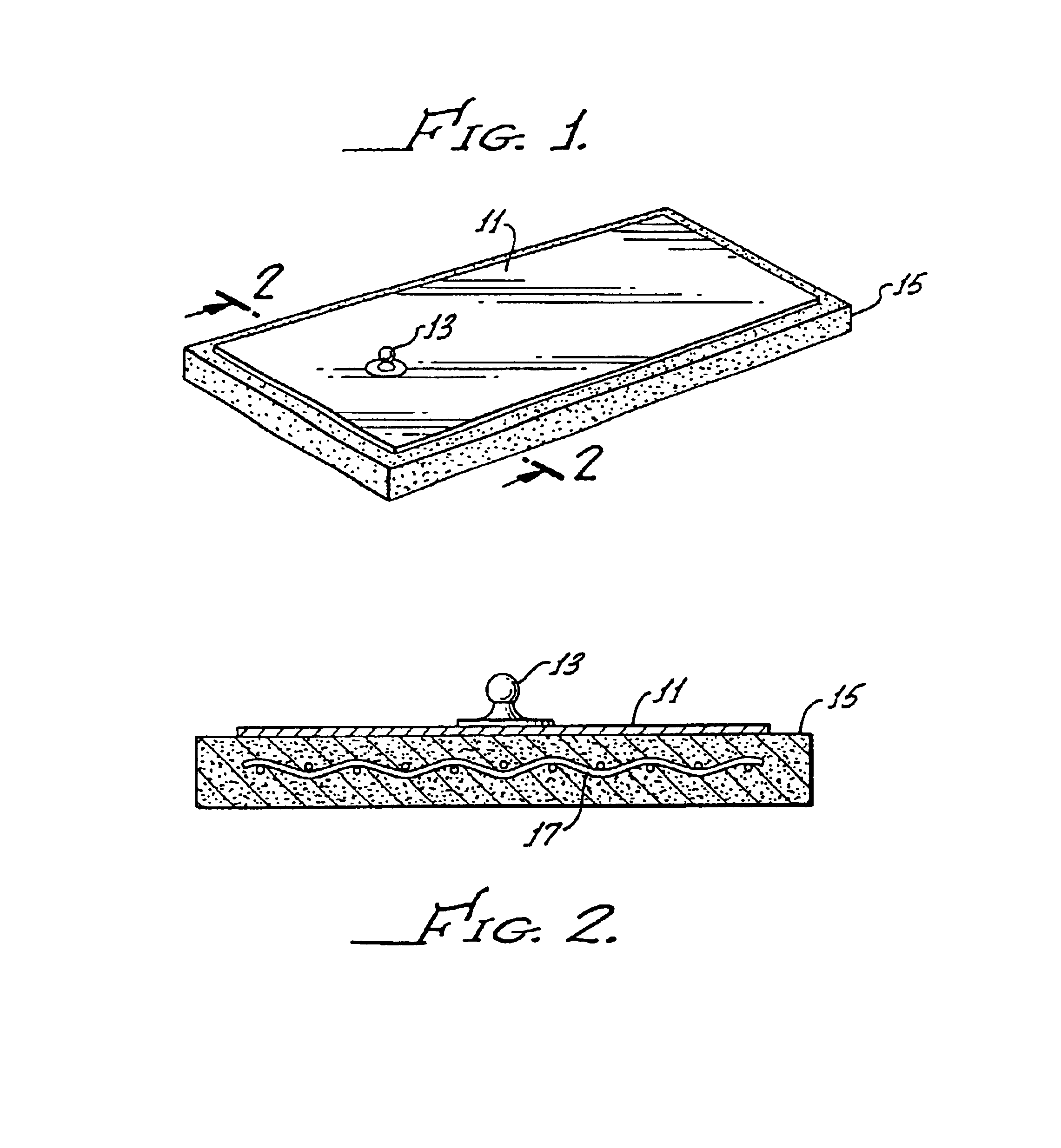

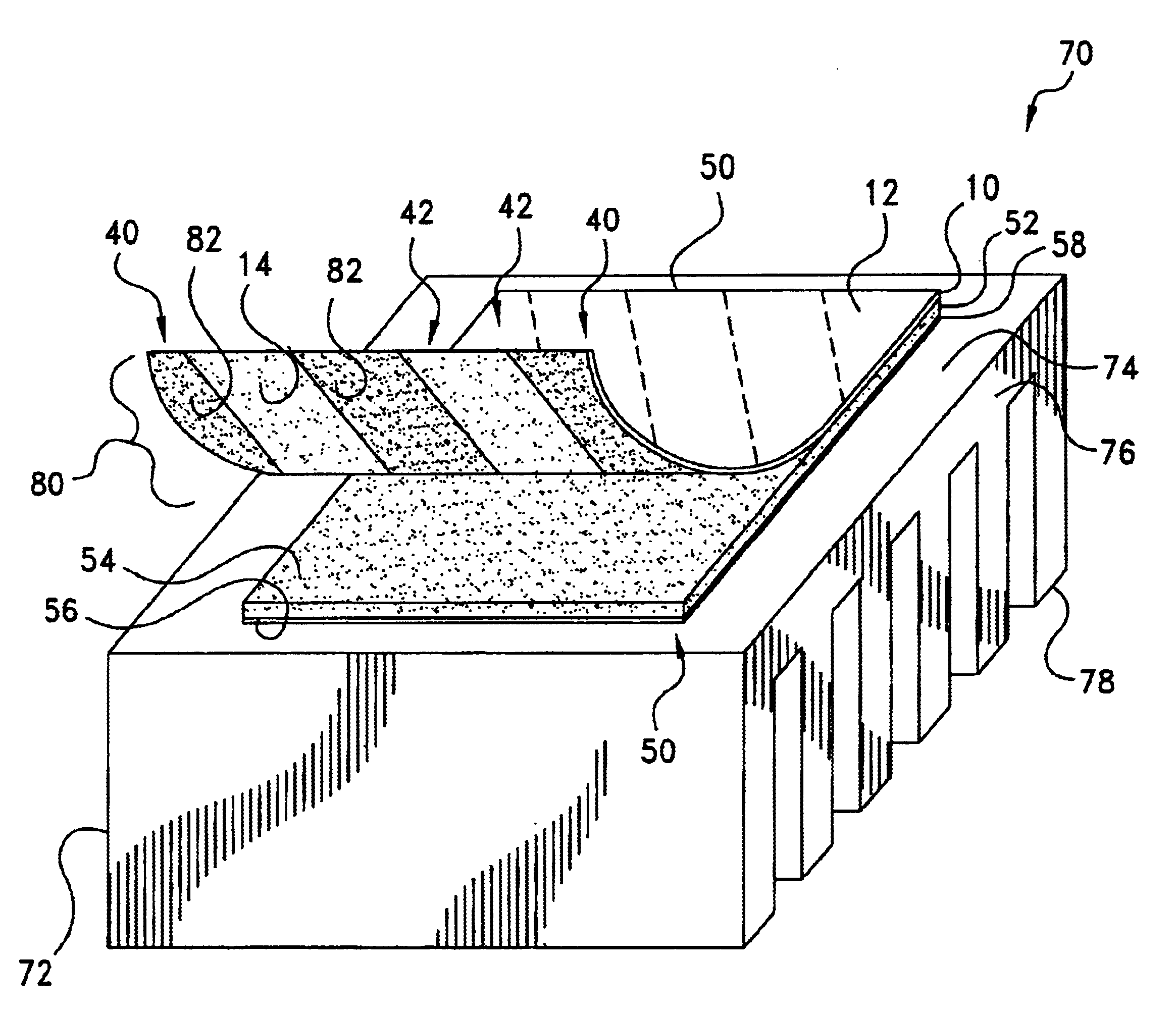

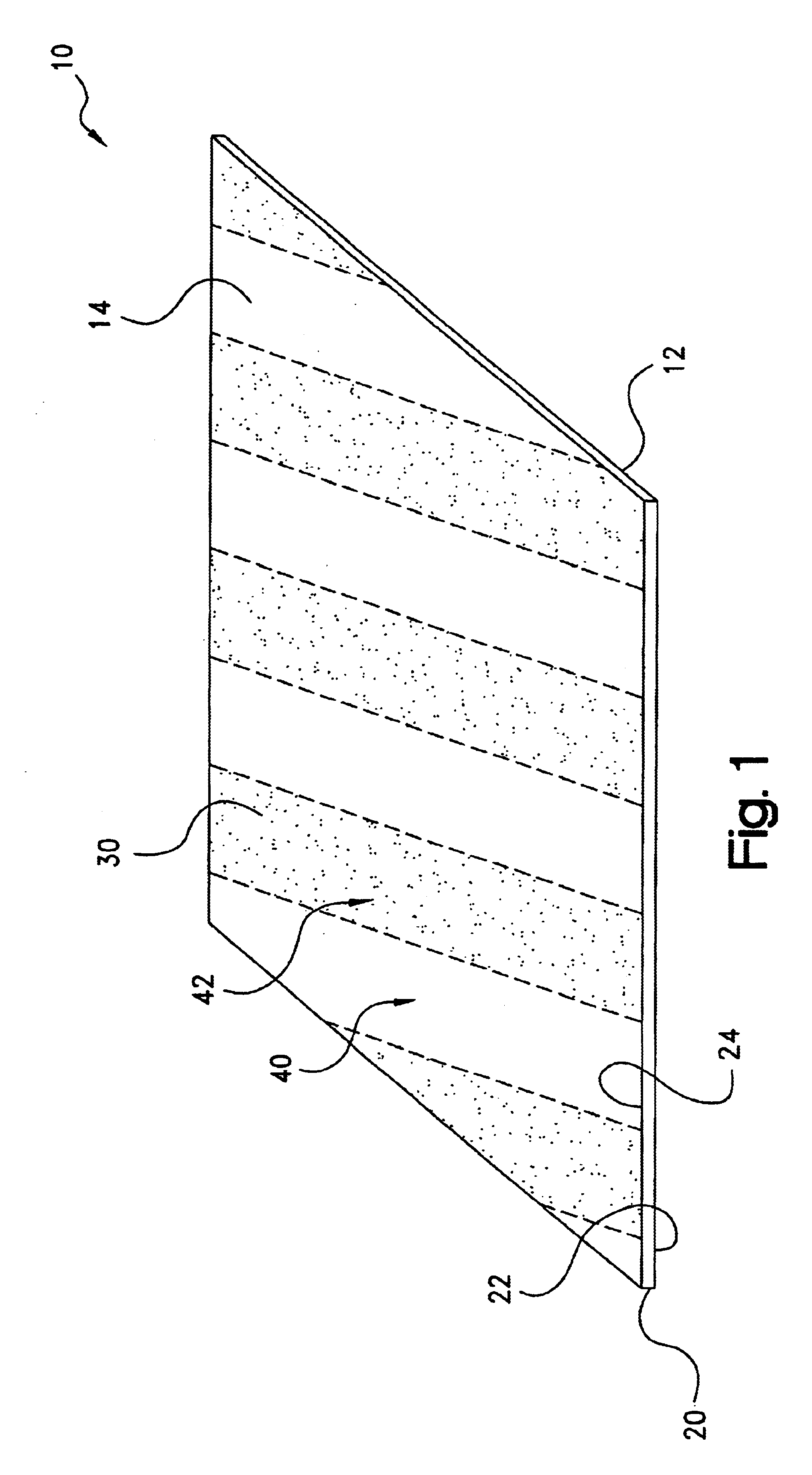

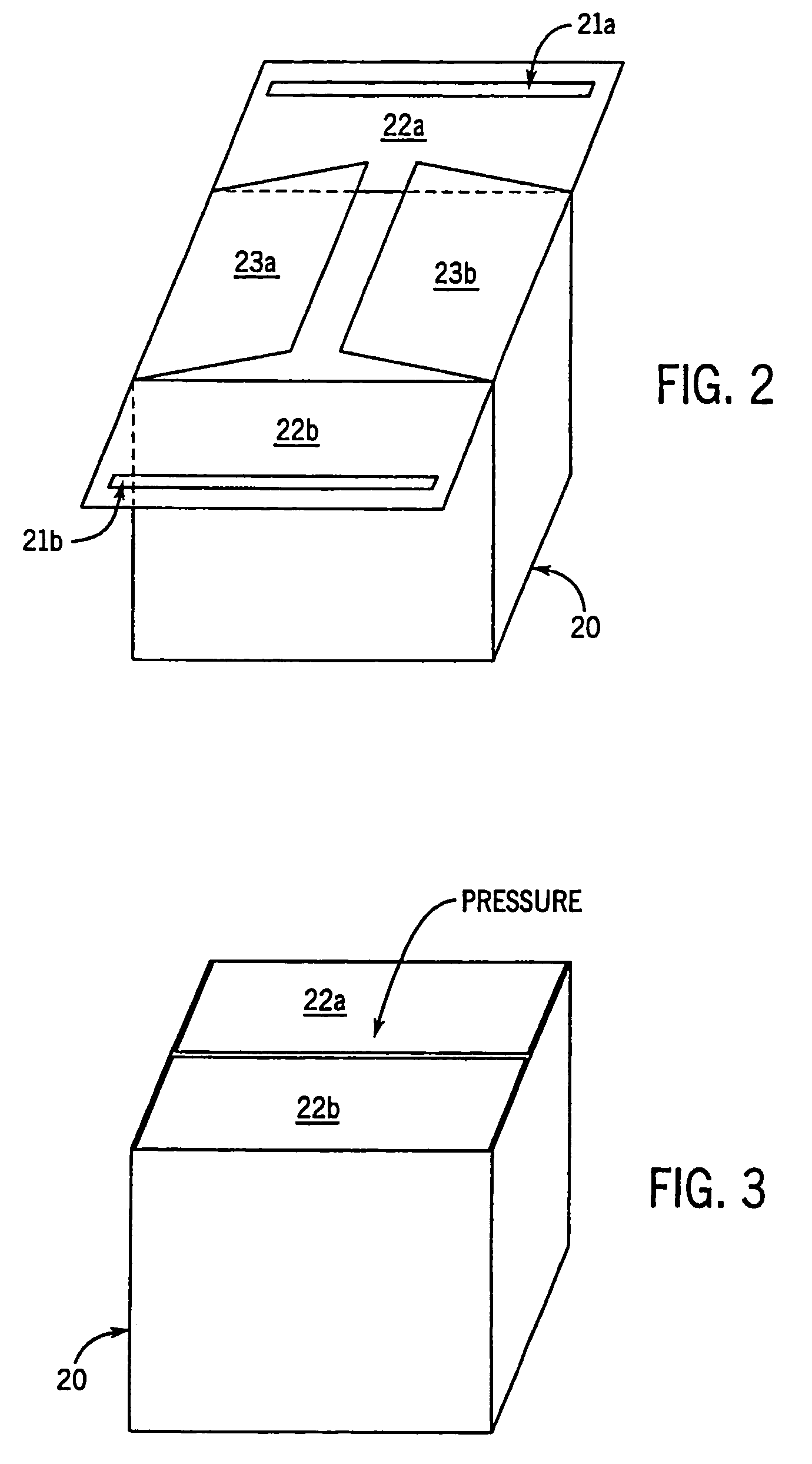

Thermal interface material having a zone-coated release linear

InactiveUS6644395B1Reduce generationIncrease physical strengthFilm/foil adhesivesSemiconductor/solid-state device detailsEngineeringConductive materials

A release liner particularly adapted for use with a layer of a thermal interface material having a first surface and a second surface which is bondable to the heat transfer surface of a thermal dissipation member. The liner has an exterior surface and an interior surface disposable in adhering contact with the first surface of the thermally-conductive material. The liner interior surface has one or more first zones defined thereon which exhibit a first release value relative to the first surface of the thermally-conductive material, and one or more second zones bordered by the first zones which exhibit a second release value relative to the first surface of the thermally-conductive material which is lower than the first release value of the first zones. With the second surface of the thermally-conductive material being bonded to the heat transfer surface of the thermal dissipation member, the release liner is removable from the first surface of the thermally-conductive material without substantial cohesive or adhesive failure thereof.

Owner:PARKER HANNIFIN CORP

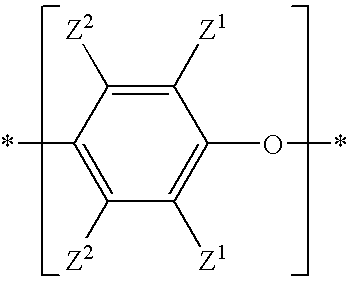

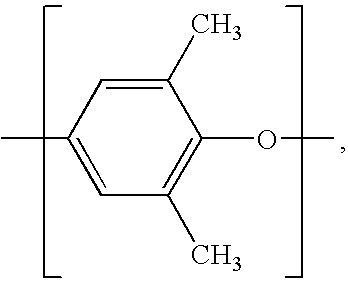

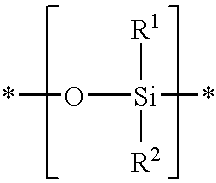

Poly(arylene ether) composition and extruded articles derived therefrom

A poly(arylene ether) composition includes a hydrogenated block copolymer of an alkenyl aromatic compound and a conjugated diene, a flame retardant, and a poly(arylene ether)-polysiloxane block copolymer reaction product that itself includes a poly(arylene ether)-polysiloxane block copolymer. The composition is useful for forming extruded articles, including insulation for wire and cable. The poly(arylene ether)-polysiloxane block copolymer contributes improved flame retardancy and, in many cases, improved physical properties to the composition.

Owner:SHPP GLOBAL TECH BV

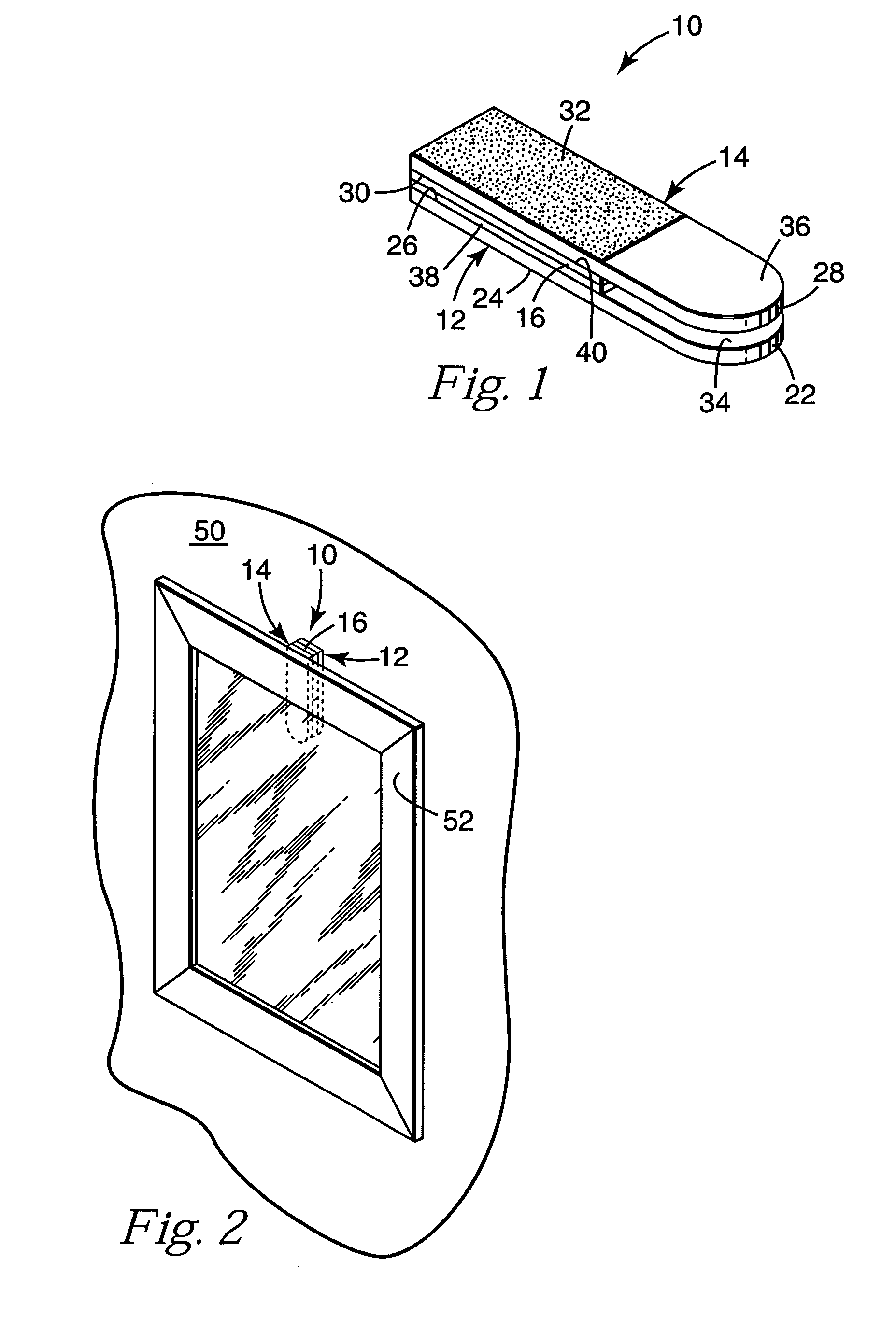

Removable adhesive tape laminate and separable fastener

An adhesive tape construction is removable from one or more objects to which it is adhered and which is reusably separable within its construction so that an object can be separated from another and subsequently reconnected with one another. The adhesive tape construction can be used to bond the other opposed surfaces of objects, including rigid objects such as a picture frame to a wall, where no portion of the adhesive tape construction projects from between the objects, and which subsequently affords easy separation of the objects without damage to either of them. More specifically, the adhesive tape construction includes a stretch release adhesive tape structure combined with a reusable connector surface.

Owner:3M INNOVATIVE PROPERTIES CO

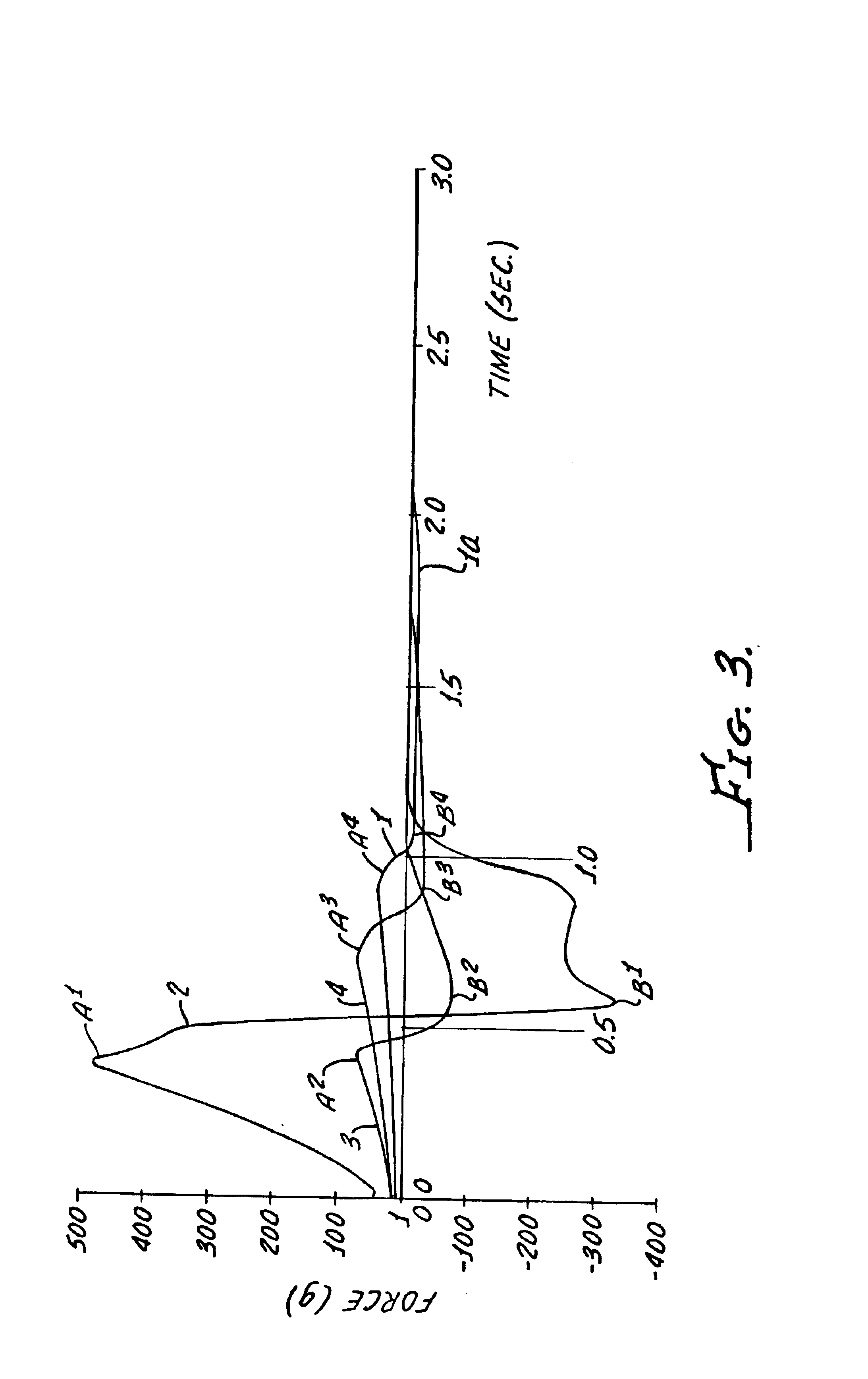

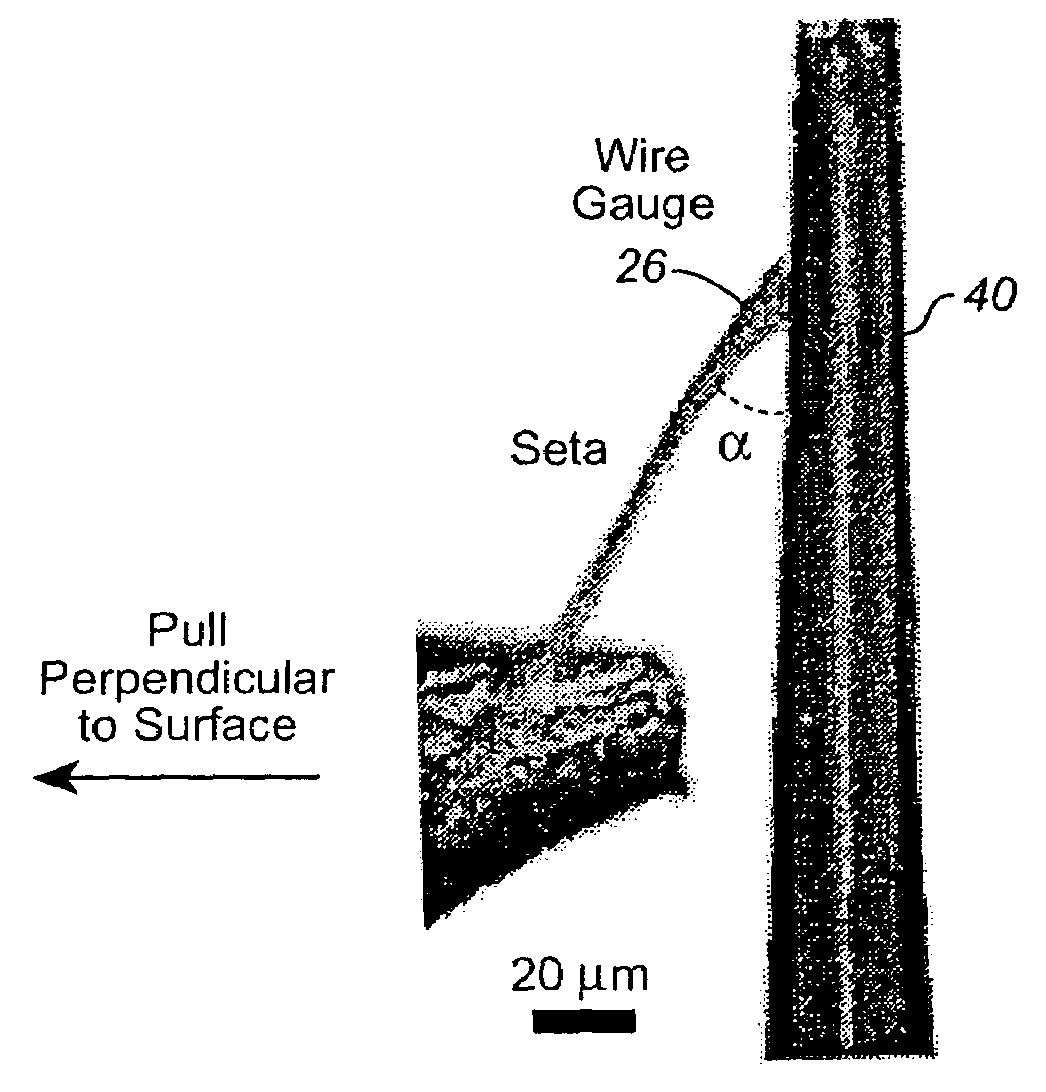

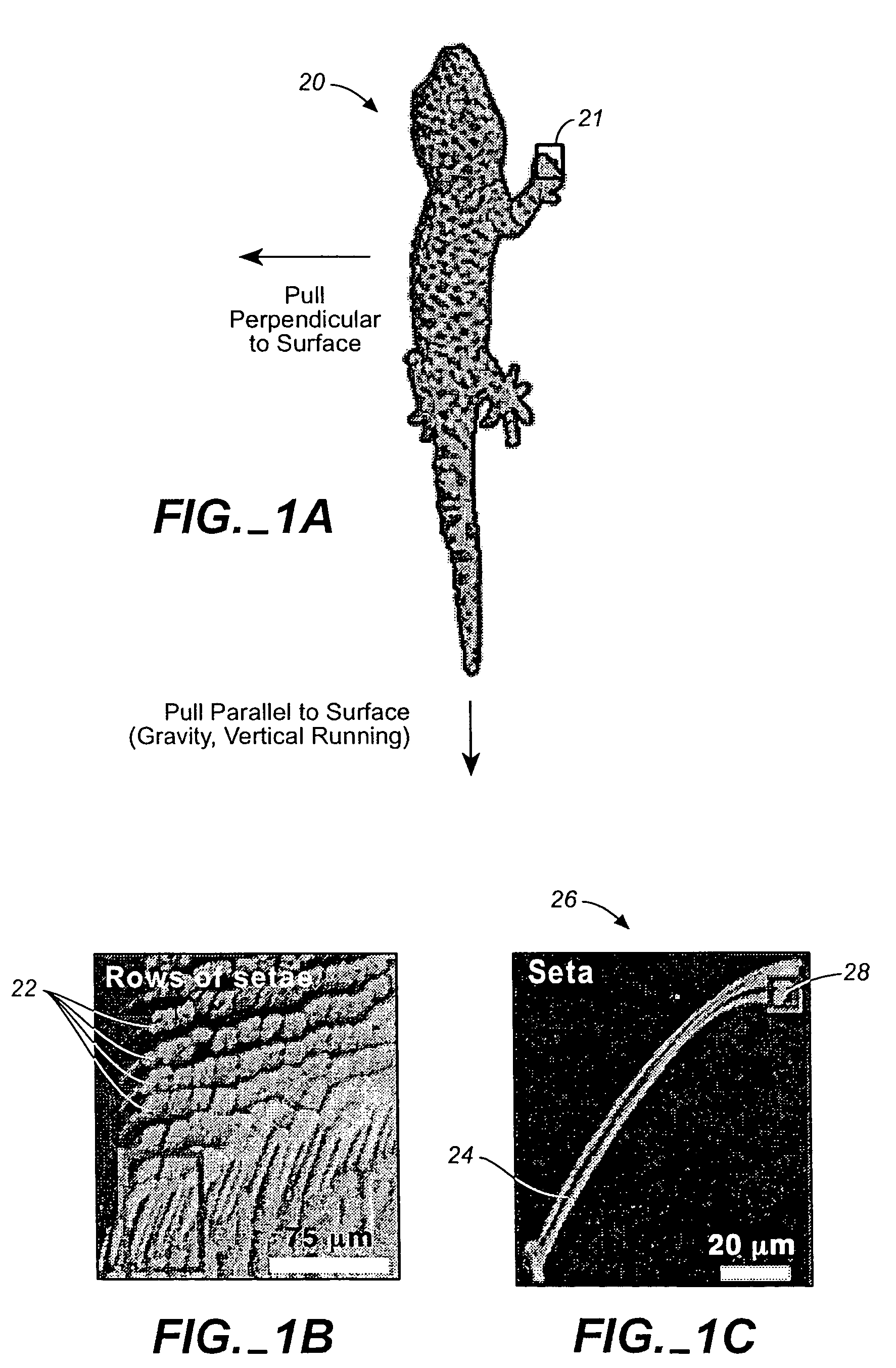

Adhesive microstructure and method of forming same

A method of forming an adhesive force includes removing a seta from a living specimen, attaching the seta to a substrate, and applying the seta to a surface so as to establish an adhesive force between the substrate and the surface. The seta is applied to the surface with a force perpendicular to the surface. The seta is then pulled with a force parallel to the surface so as to preload the adhesive force of the seta.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

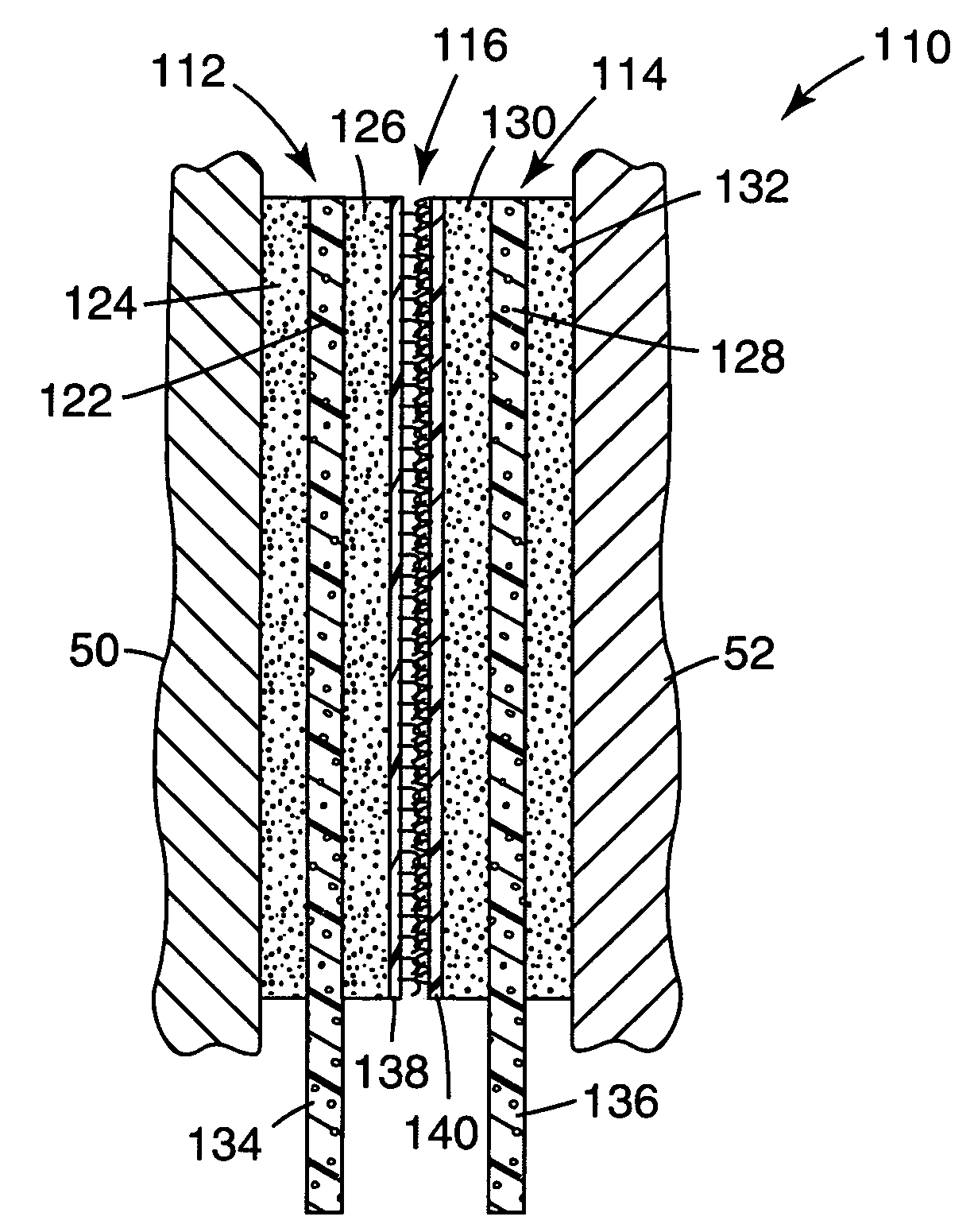

Cure on demand adhesives and window module with cure on demand adhesive thereon

InactiveUS6355127B1Improve stabilityHigh green strengthManual label dispensersGlass/slag layered productsActive agentSide chain

In one embodiment the invention is An adhesive composition comprisinga) a polymer having a flexible backbone and a reactive moiety capable of cross-linking,b) a particle comprising an active agent encapsulated in an encapsulating agent wherein the active agent comprises a catalyst for cross-linking of the reactive moiety, a curing agent for the reactive moiety, an accelerator for the curing reaction or a mixture thereof; and the encapsulating agent comprises a side chain crystallizable polymer wherein the active agent is not substantially extractable from the particle at ambient conditions in a first extraction after particle formation.This composition is used in binding two subtracters together.

Owner:ESSEX SPECIALITY PROD INC +1

Bi-layer hard mask for the patterning and etching of nanometer size MRAM devices

ActiveUS20120028373A1Inhibition formationAvoid formingFilm/foil adhesivesSemiconductor/solid-state device manufacturingEtchingEngineering

A composite hard mask is disclosed that prevents build up of metal etch residue in a MRAM device during etch processes that define an MTJ shape. As a result, MTJ shape integrity is substantially improved. The hard mask has a lower non-magnetic spacer, a middle conductive layer, and an upper sacrificial dielectric layer. The non-magnetic spacer serves as an etch stop during a pattern transfer with fluorocarbon plasma through the conductive layer. A photoresist pattern is transferred through the dielectric layer with a first fluorocarbon etch. Then the photoresist is removed and a second fluorocarbon etch transfers the pattern through the conductive layer. The dielectric layer protects the top surface of the conductive layer during the second fluorocarbon etch and during a substantial portion of a third RIE step with a gas comprised of C, H, and O that transfers the pattern through the underlying MTJ layers.

Owner:TAIWAN SEMICON MFG CO LTD

Silicone compositions, methods of manufacture, and articles formed therefrom

InactiveUS20070148409A1Balanced coefficient of frictionImprove gripSolesWater sport boardsHydrogenHydrogen atom

A silicone grip comprising a cured silicone film layer with a Shore A Durometer of less than or equal to about 60 wherein the silicone film layer is formed from a curable silicone composition comprising a catalyst that promotes cure of the silicone composition, a higher molecular weight organopolysiloxane having at least two alkenyl groups per molecule, a lower molecular weight organopolysiloxane having at least two alkenyl groups per molecule, and an organopolysiloxane having at least two silicon-bonded hydrogen atoms per molecule. The cured silicone layer is used in combination with an adhesive to provide a flexible and malleable grip, and / or in combination with a backing layer that can be solid or foamed.

Owner:WORLD PROPERTIES

Foams made by photopolymerization of emulsions

InactiveUS6573305B1High mechanical strengthFilm/foil adhesivesOptical articlesWater in oil emulsionPolymer chemistry

Owner:3M INNOVATIVE PROPERTIES CO

Hot Melt Adhesive Based on Olefin Block Copolymers

ActiveUS20110021103A1Improve spray characteristicsGood viscosity stabilityPersonal careLayered product treatmentCardboardCrystallinity

A hot melt adhesive composition, comprising a blend of components including about 5% to about 50% by weight of an olefin block copolymer; about 10% to about 70% by weight of a first tackifying resin having a softening point of at least about 95° C.; about 0 to 65% of a second tackifying resin that is different than the first tackifying resin; about 0% to about 60% by weight of a plasticizer; about 0% to about 20% by weight of an aromatic reinforcing resin having a softening point equal to or higher than 115° C.; about 0.1% to about 5% by weight of a stabilizer; and about 1% to about 40% by weight of a secondary polymer that is different from the olefin block copolymer, the first and second tackifying resins and the reinforcing resin, having relatively low crystallinity, which low crystallinity is equal to or less than 250 Joules / gram, wherein the components total 100% by weight of the composition, and the viscosity of the composition is equal to or less than about 20,000 mPa·s at 163° C. Laminates, especially those used in disposable soft goods, and methods of making such laminates using the hot melt adhesive composition are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

Block composites in soft compounds

ActiveUS8686087B2Modulus improvementImprove performanceFilm/foil adhesivesMixingMaterials sciencePolymer science

Owner:DOW GLOBAL TECH LLC

Hot melt adhesive composition based on a random copolymer of isotactic polypropylene and a secondary polymer

InactiveUS7262251B2Broad processibilityImprove thermal stabilityOther chemical processesFilm/foil adhesivesWaxPlasticizer

Owner:ATO FINDLEY

Elastomeric podalic pads

InactiveUS6187837B1Readily conformsSoft and deformableCosmetic preparationsImpression capsCushioningMicrosphere

Podalic foot pads of various shapes and configurations which utilize a padding material that is primarily an A-B-A triblock copolymer and a plasticizer. A-B diblock copolymers may be compounded into the padding material. An anti-bleed agent is preferably employed. The plasticizer may be a resin, mineral oil or otherwise. A detackifier may be employed such as grape seed oil or another slip agent. Antioxidants, pigments and micropsheres may be added to the material. The material has good cushioning properties.

Owner:PURPLE INNOVATION LLC

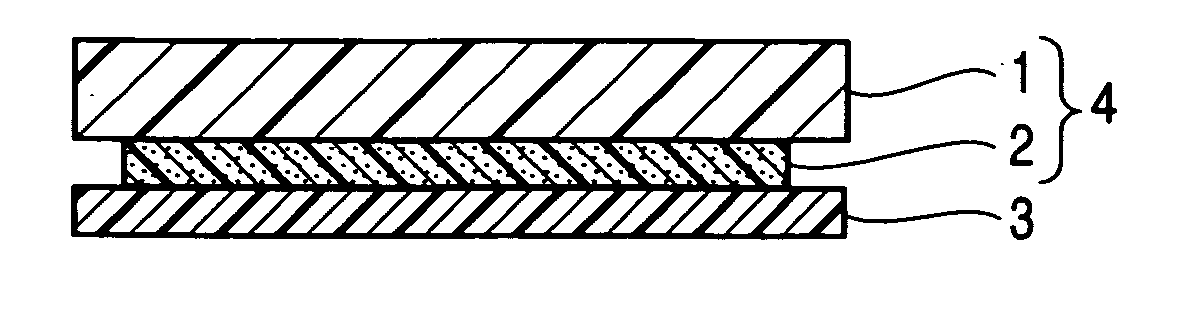

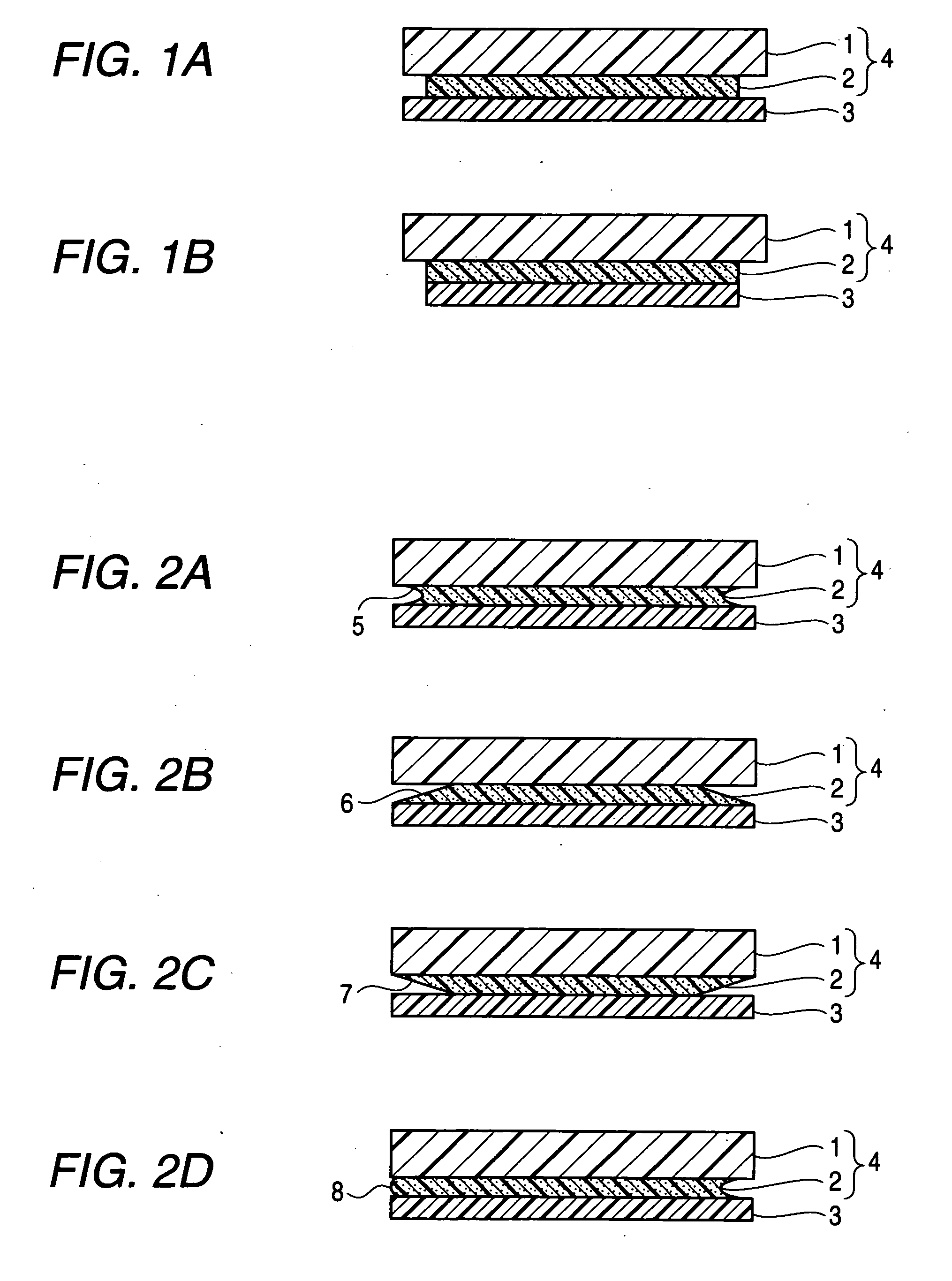

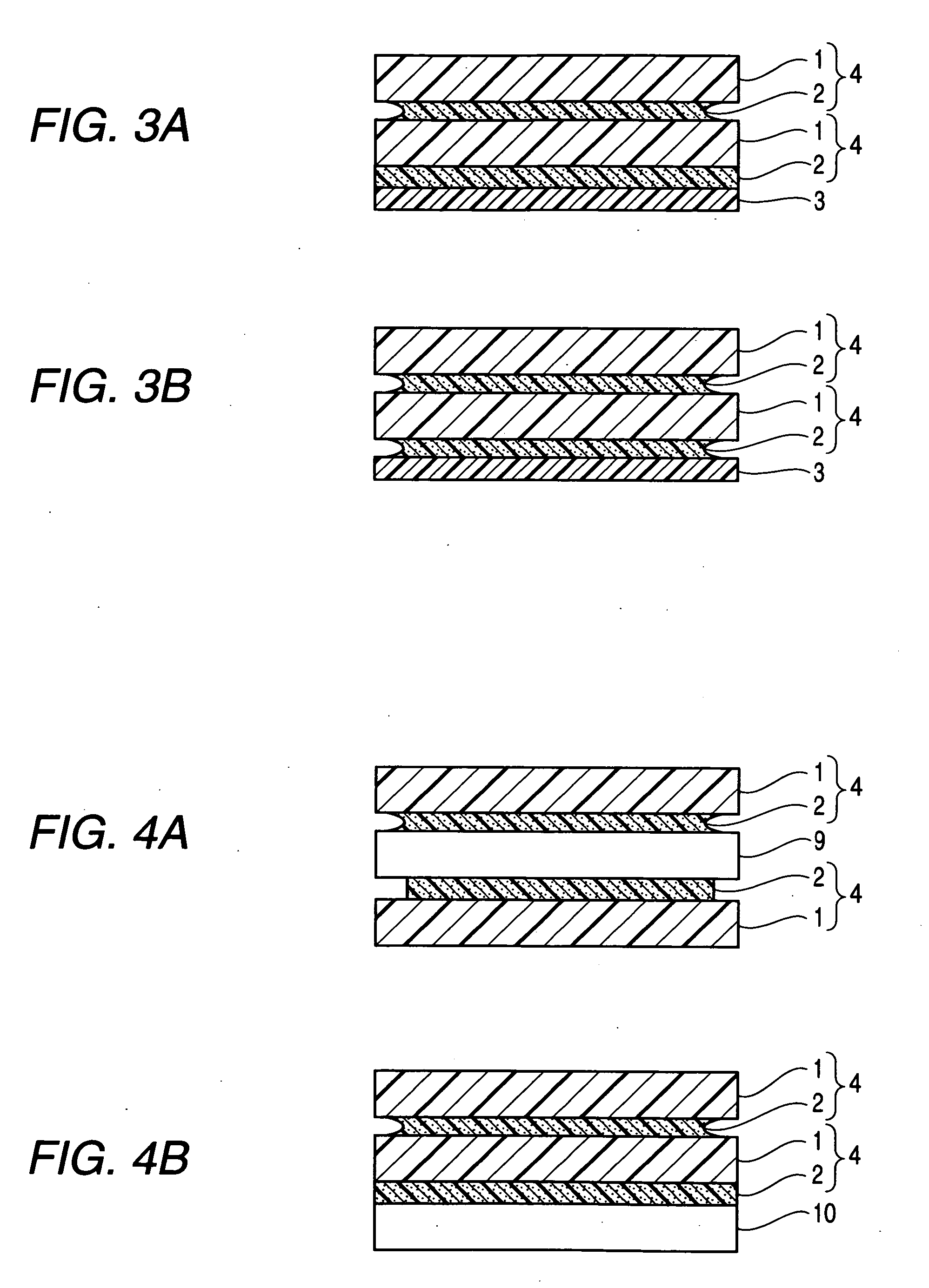

Adhesive optical film, method for manufacturing adhesive optical film and image display

ActiveUS20060108050A1More easilySimply easilyAdhesive articlesSolid-state devicesAdhesiveEngineering

An adhesive layer included in an adhesive-type optical film forms a portion located on the inside of a edge line of an optical film.

Owner:NITTO DENKO CORP

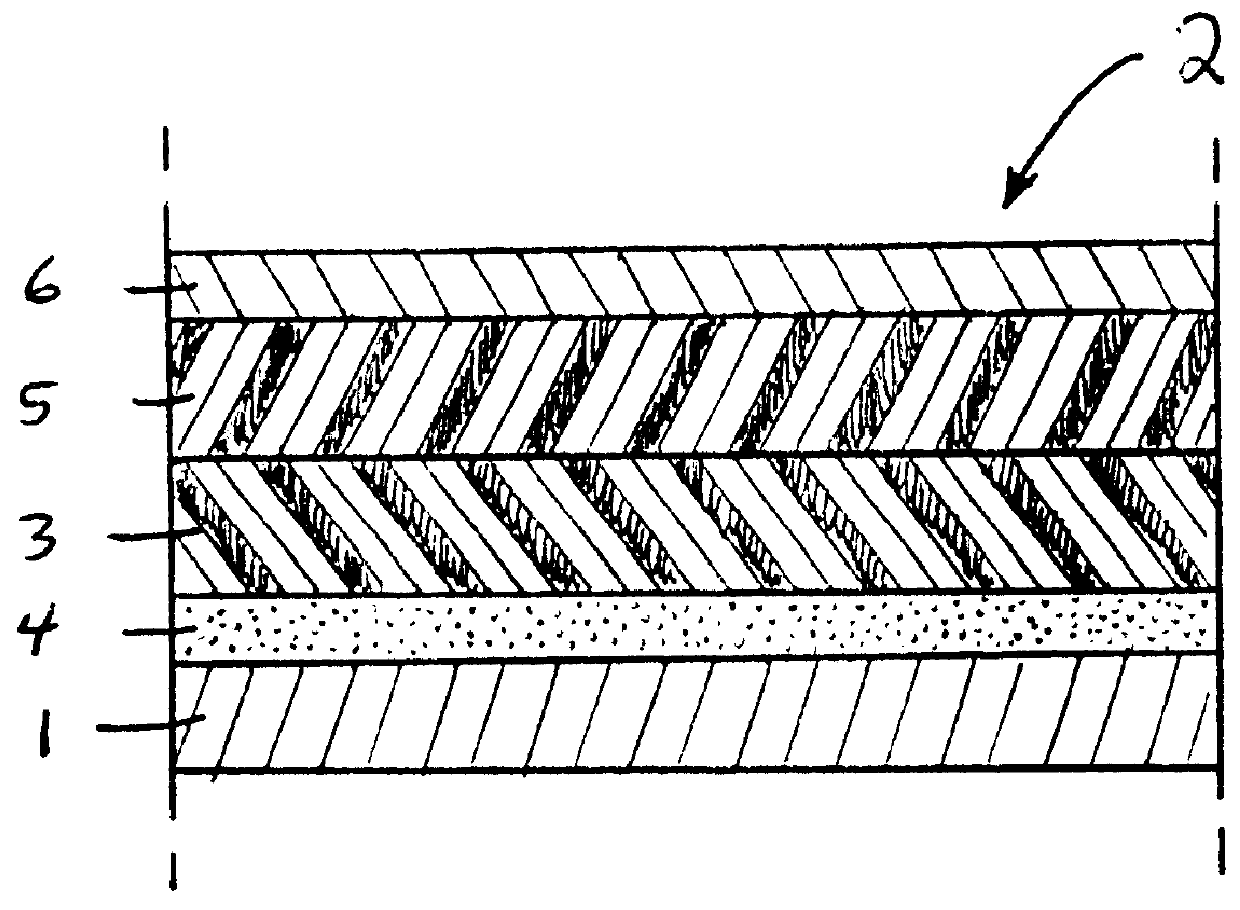

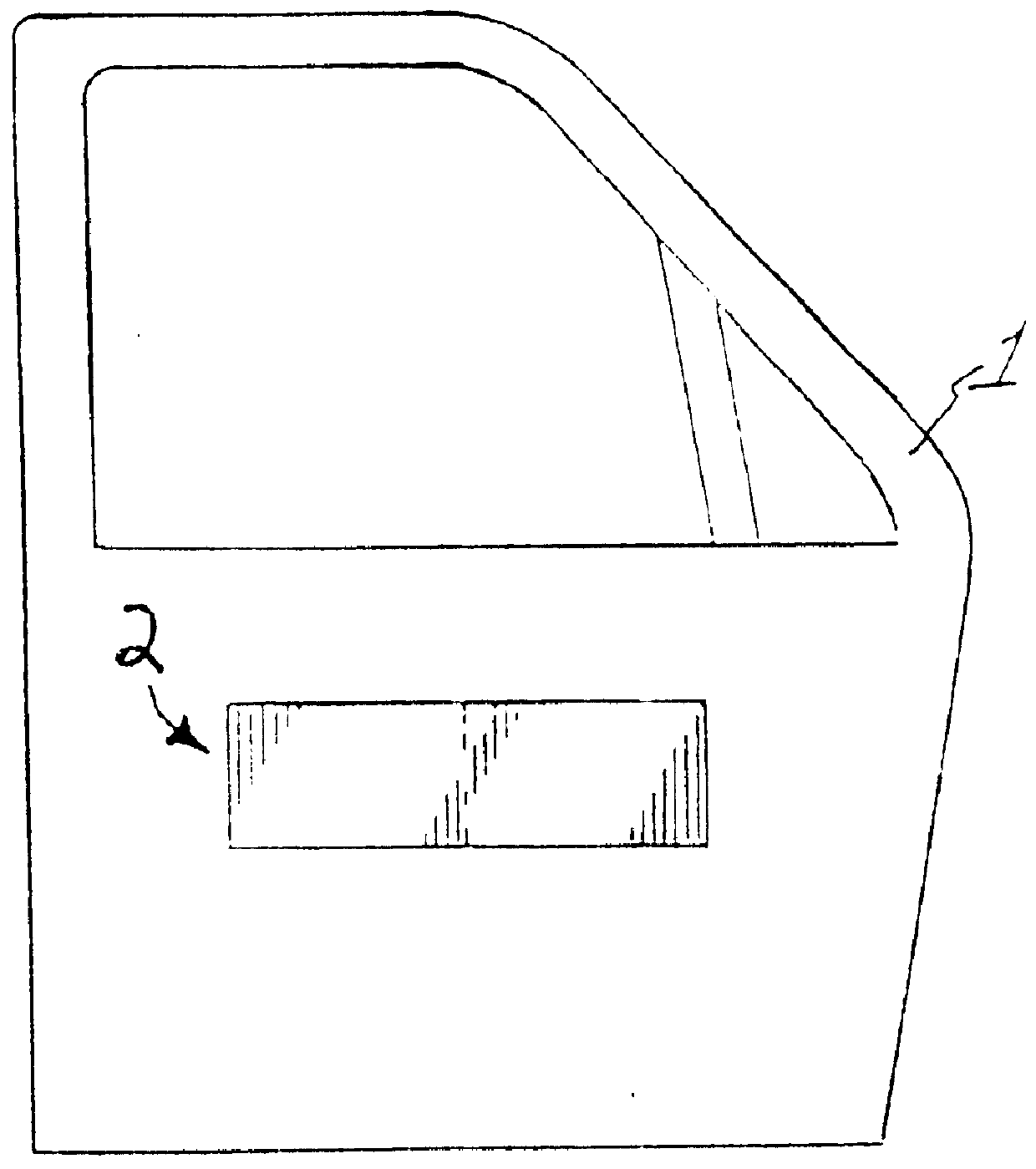

Reinforcement laminate

InactiveUSH2047H1High strength bondImprove the immunityFilm/foil adhesivesSynthetic resin layered productsEpoxyPolyol

A thermosettable adhesive is used to secure a laminate having a compliant layer (for example, a foamable composition containing a diene rubber), a layer comprised of a thermosettable resin capable of being cured to a rigid state, and an optional carrier layer (for example, a metal foil) to a substrate for the purpose of strengthening, stiffening, or otherwise reinforcing the substrate. The substrate may, for example, be a metal vehicle door. The thermosettable adhesive is comprised of at least one polyol such as a polyether polyol, at least one epoxy resin, and at least one polyisocyanate.

Owner:HENKEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com