Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5067 results about "Fluorocarbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorocarbons, sometimes referred to as perfluorocarbons or PFCs, are, strictly speaking, organofluorine compounds with the formula CₓFy, i.e. they contain only carbon and fluorine, though the terminology is not strictly followed. Compounds with the prefix perfluoro- are hydrocarbons, including those with heteroatoms, wherein all C-H bonds have been replaced by C-F bonds. Fluorocarbons can be perfluoroalkanes, fluoroalkenes and fluoroalkynes and perfluoroaromatic compounds. Fluorocarbons and their derivatives are used as fluoropolymers, refrigerants, solvents, and anesthetics.

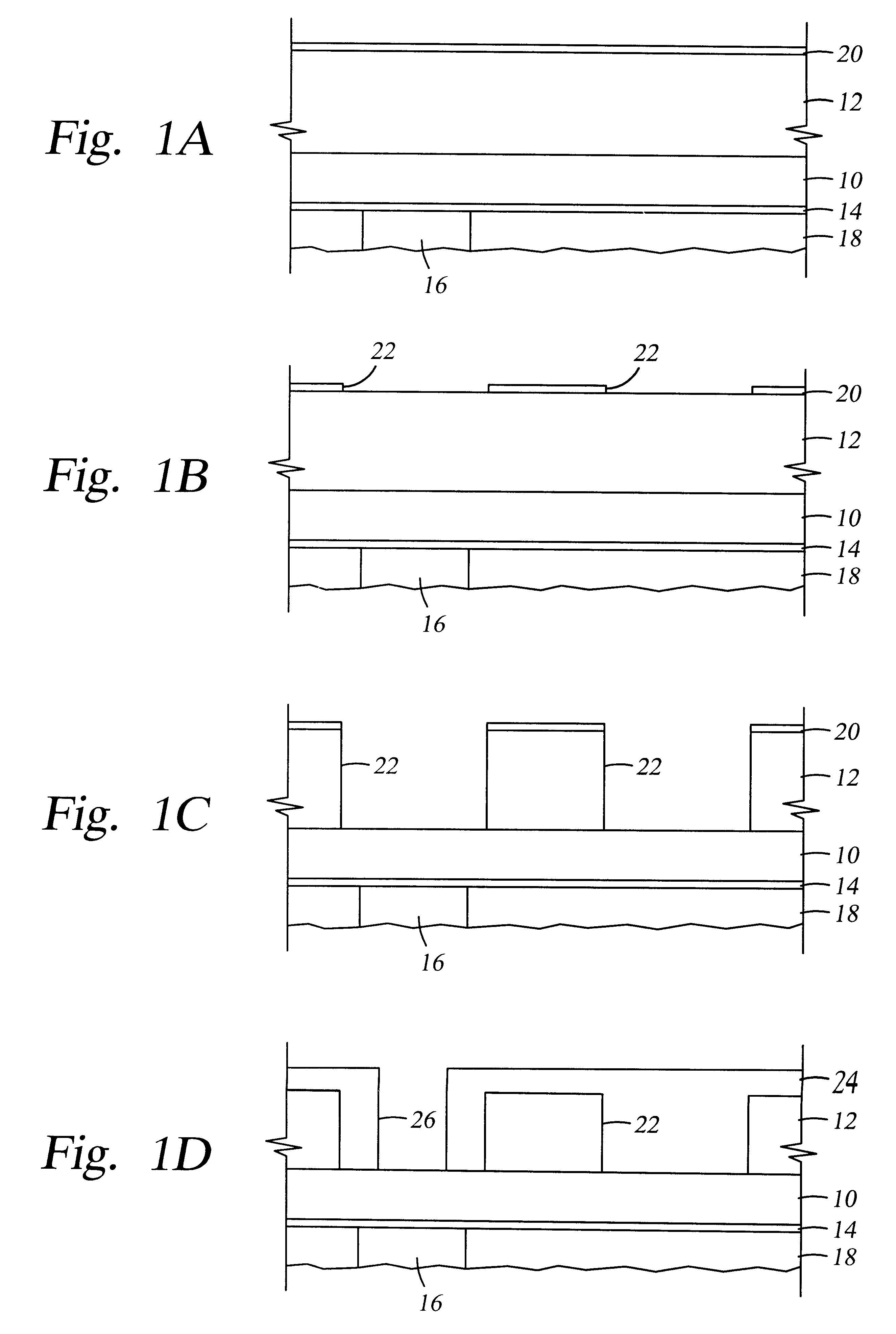

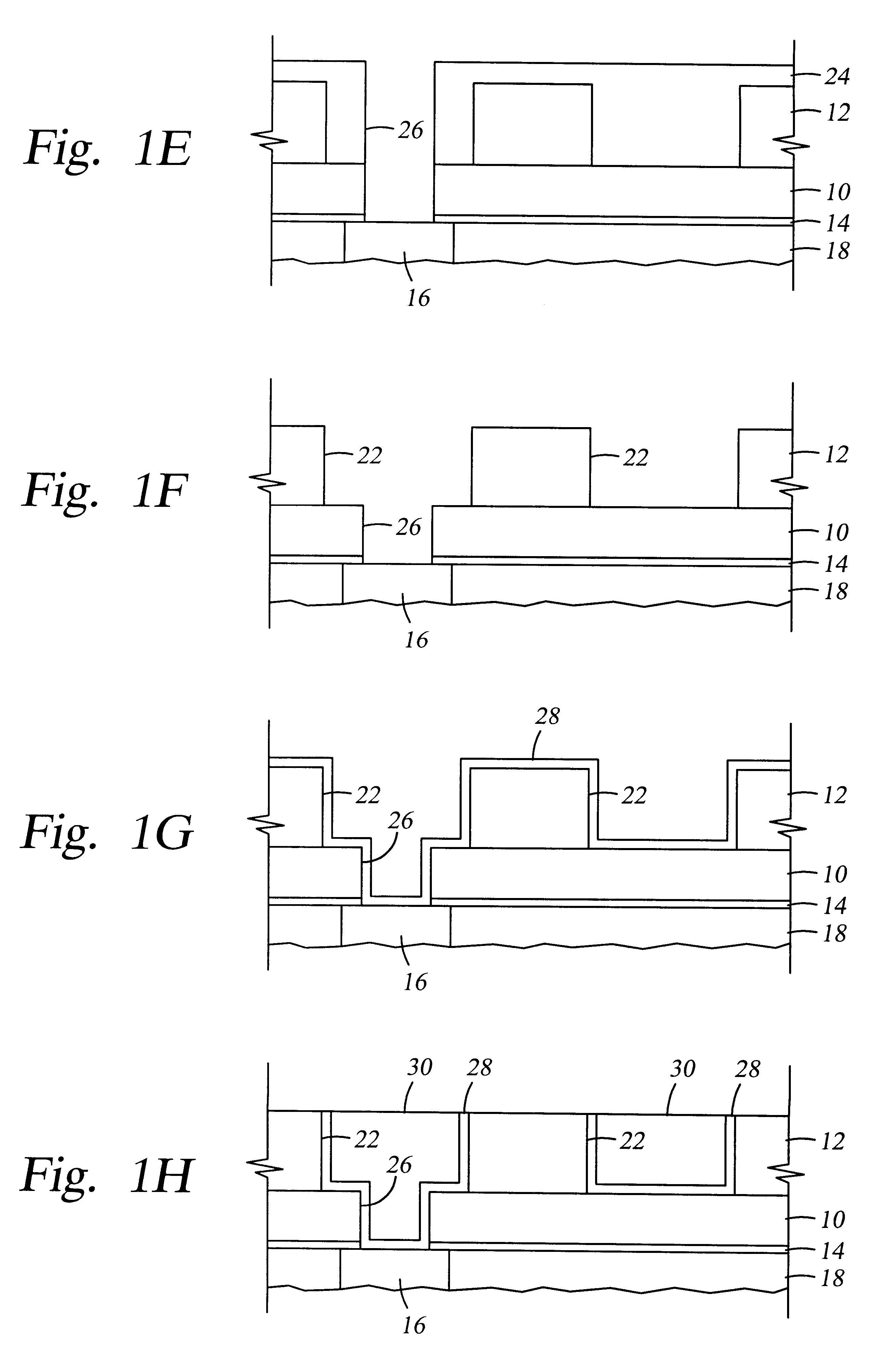

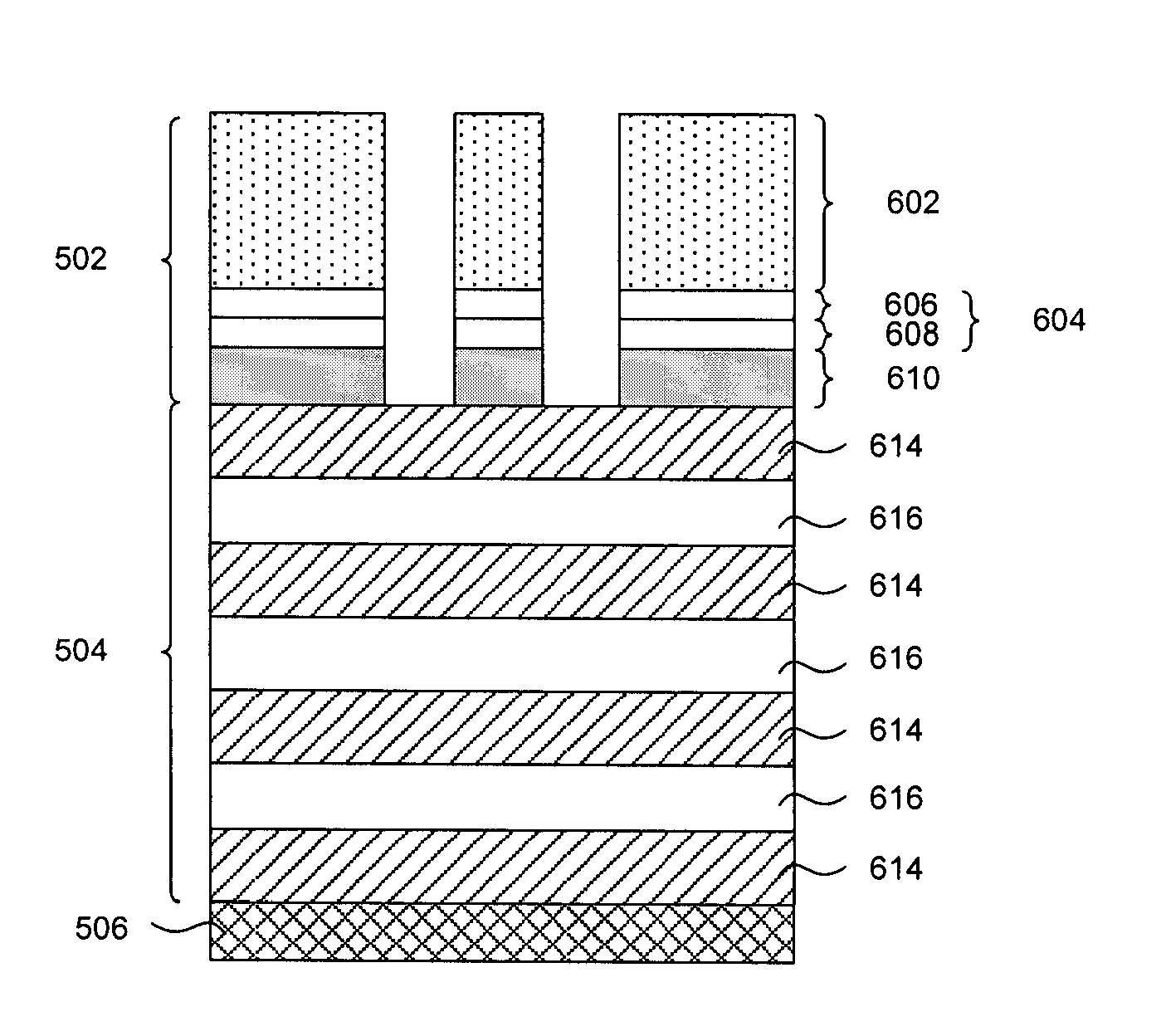

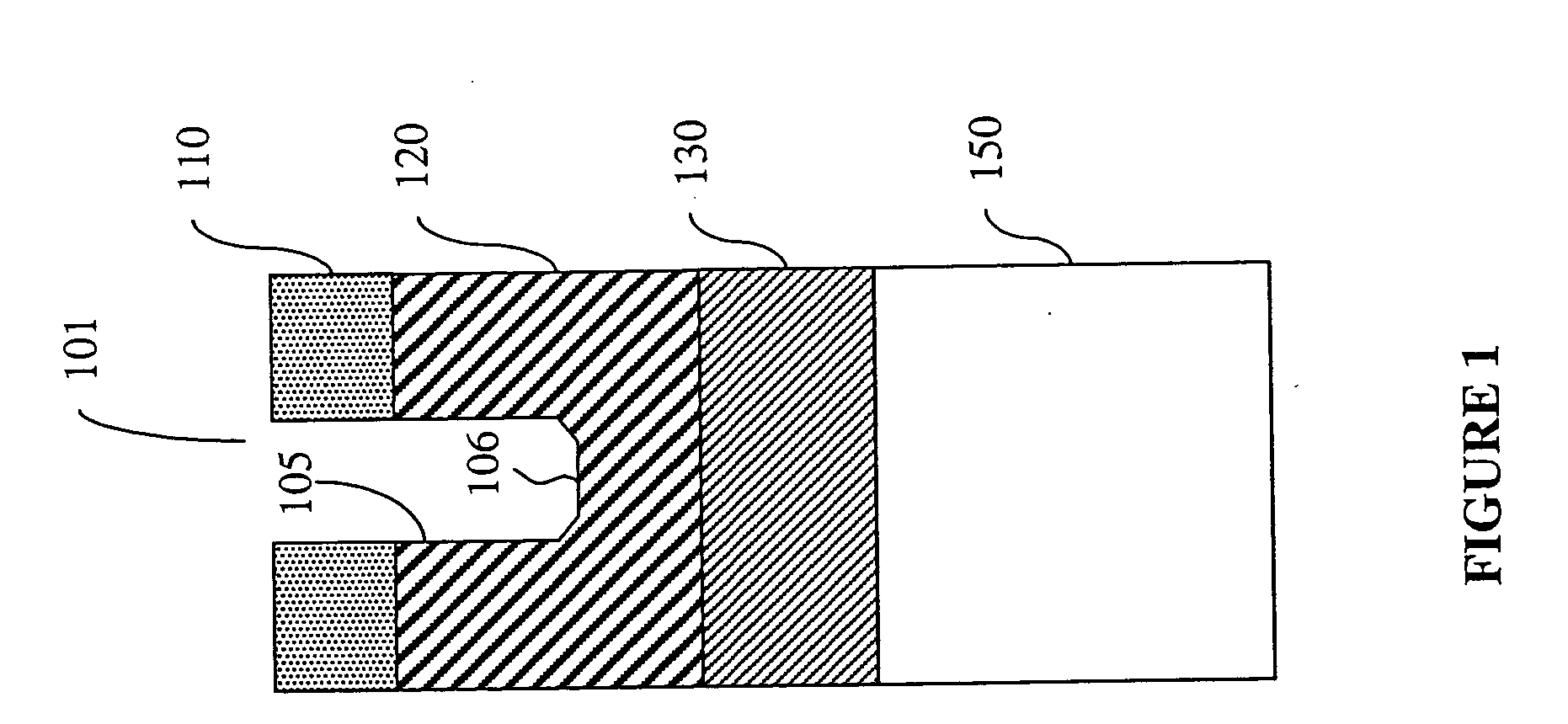

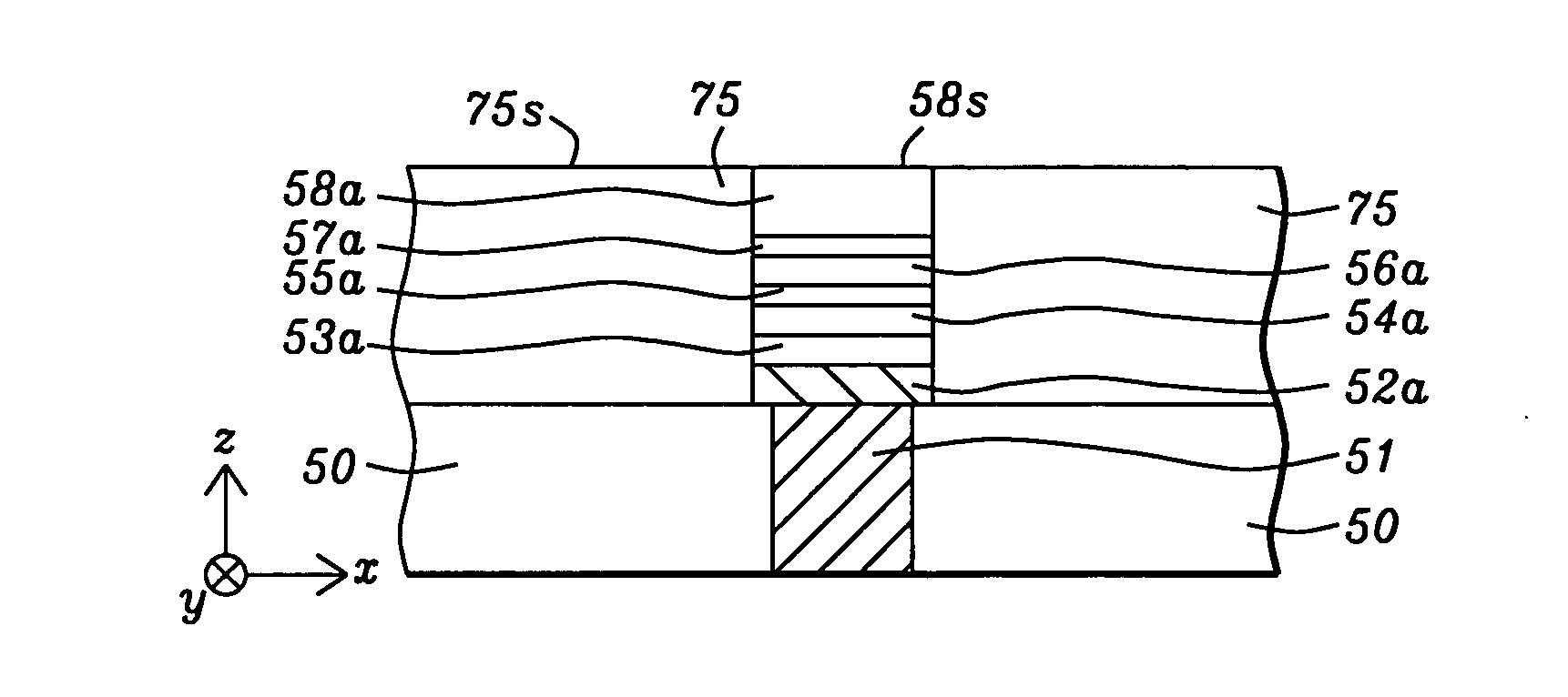

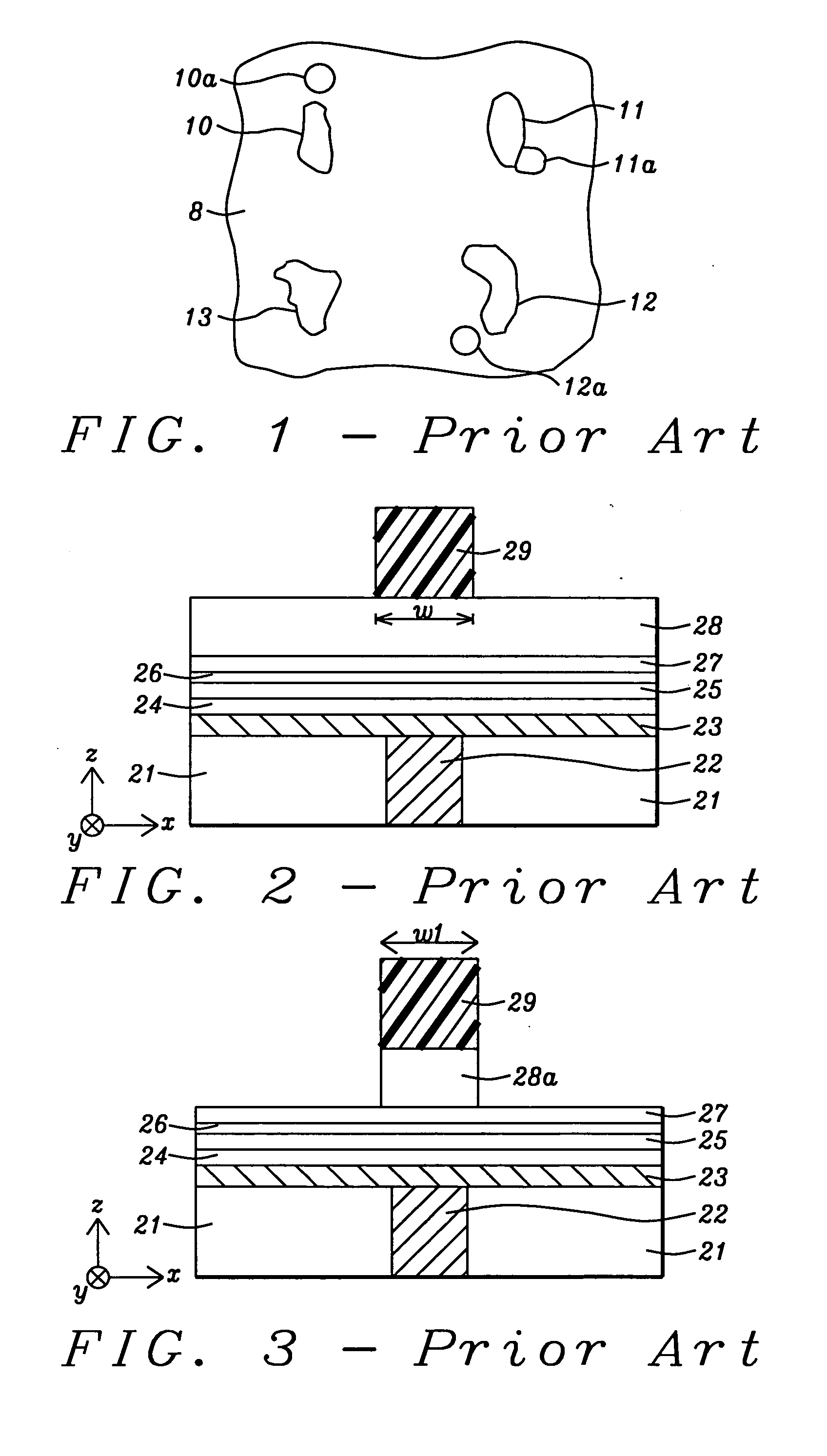

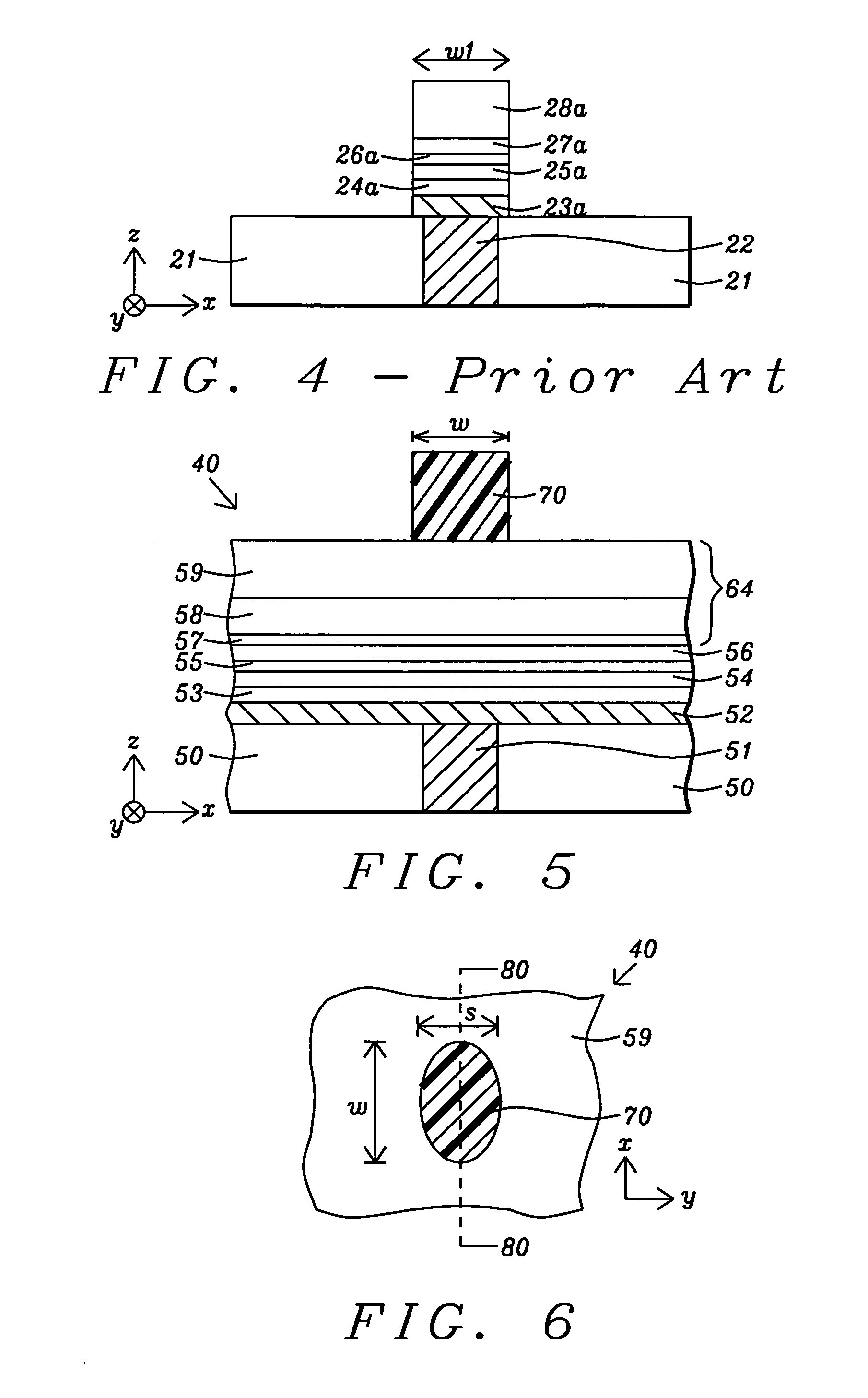

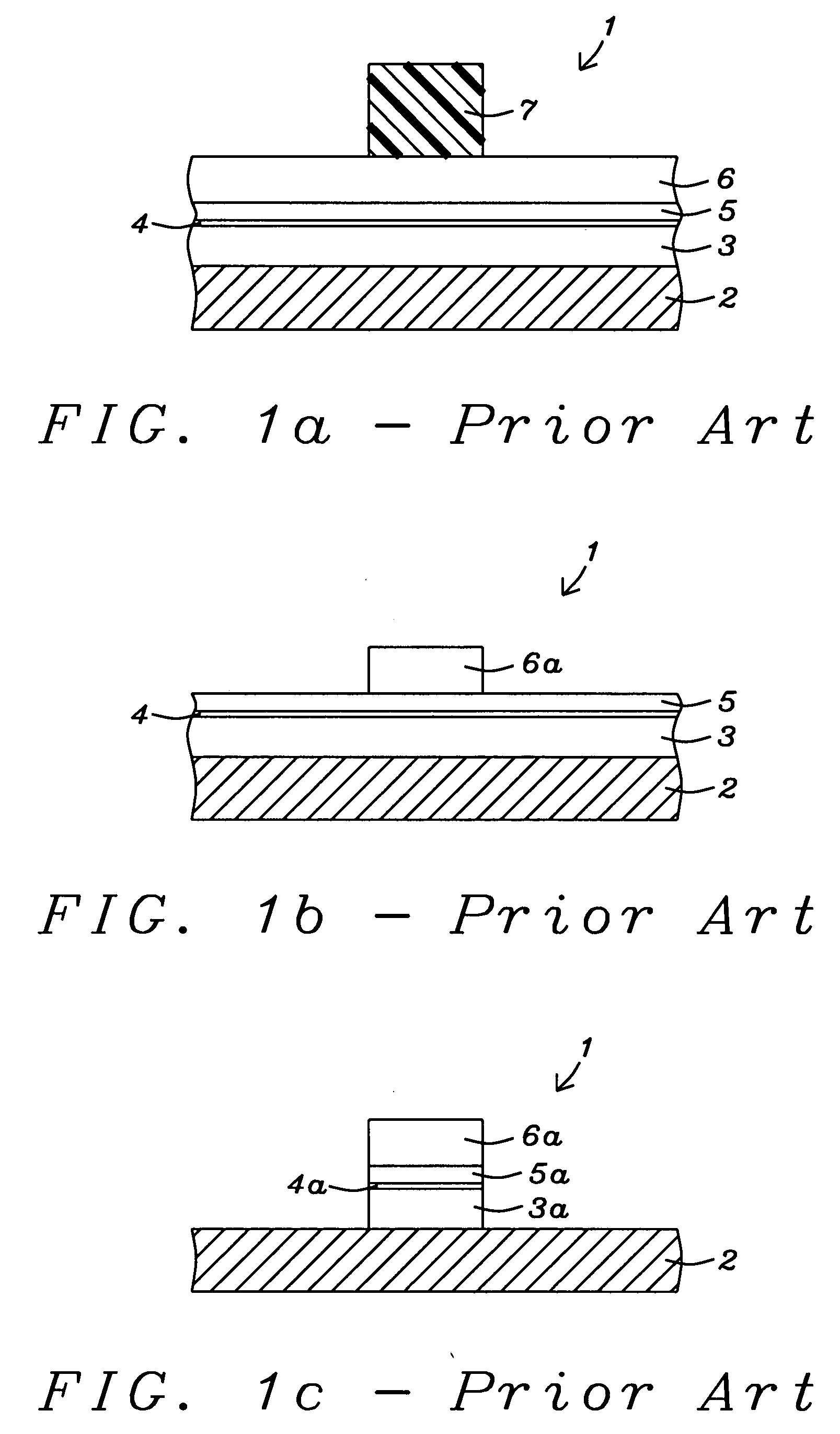

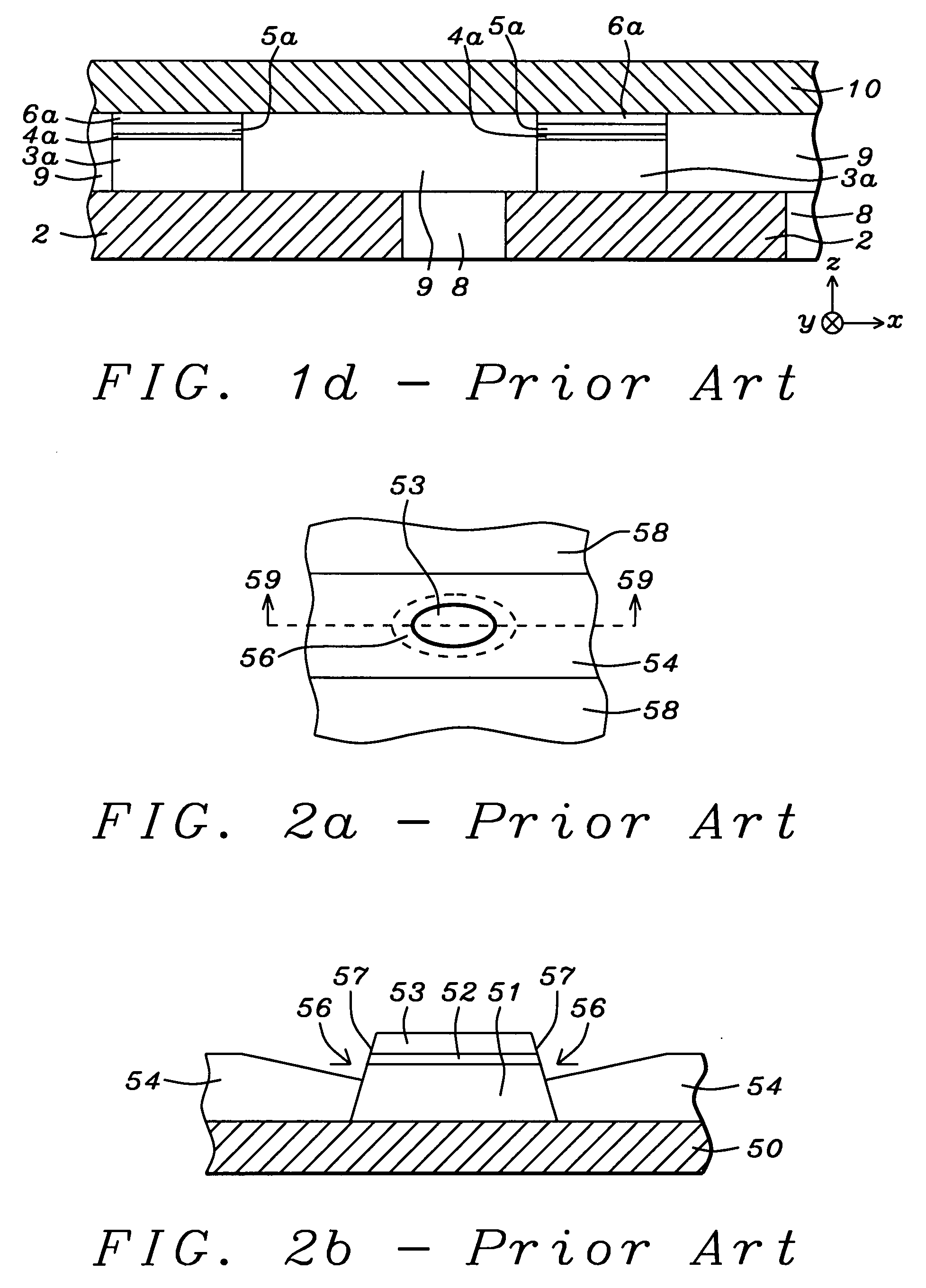

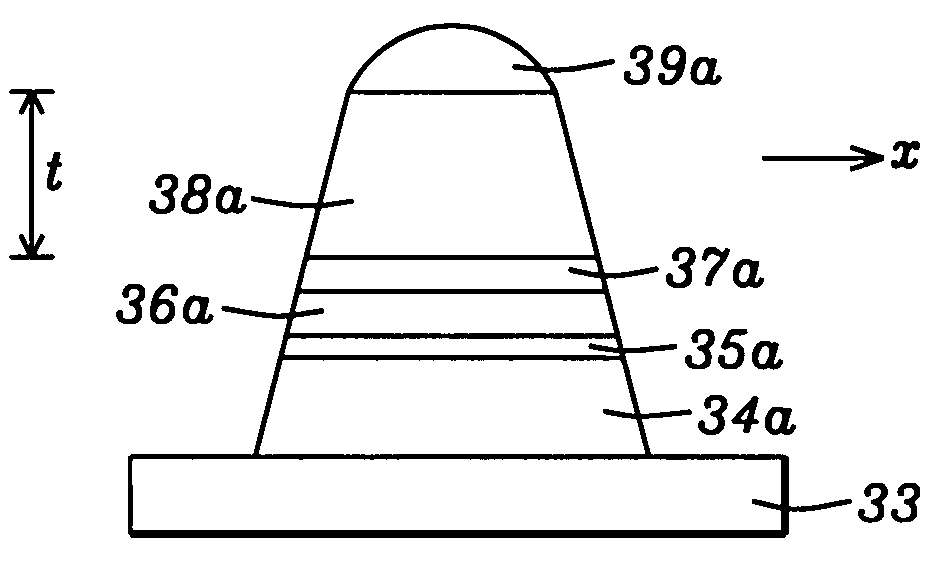

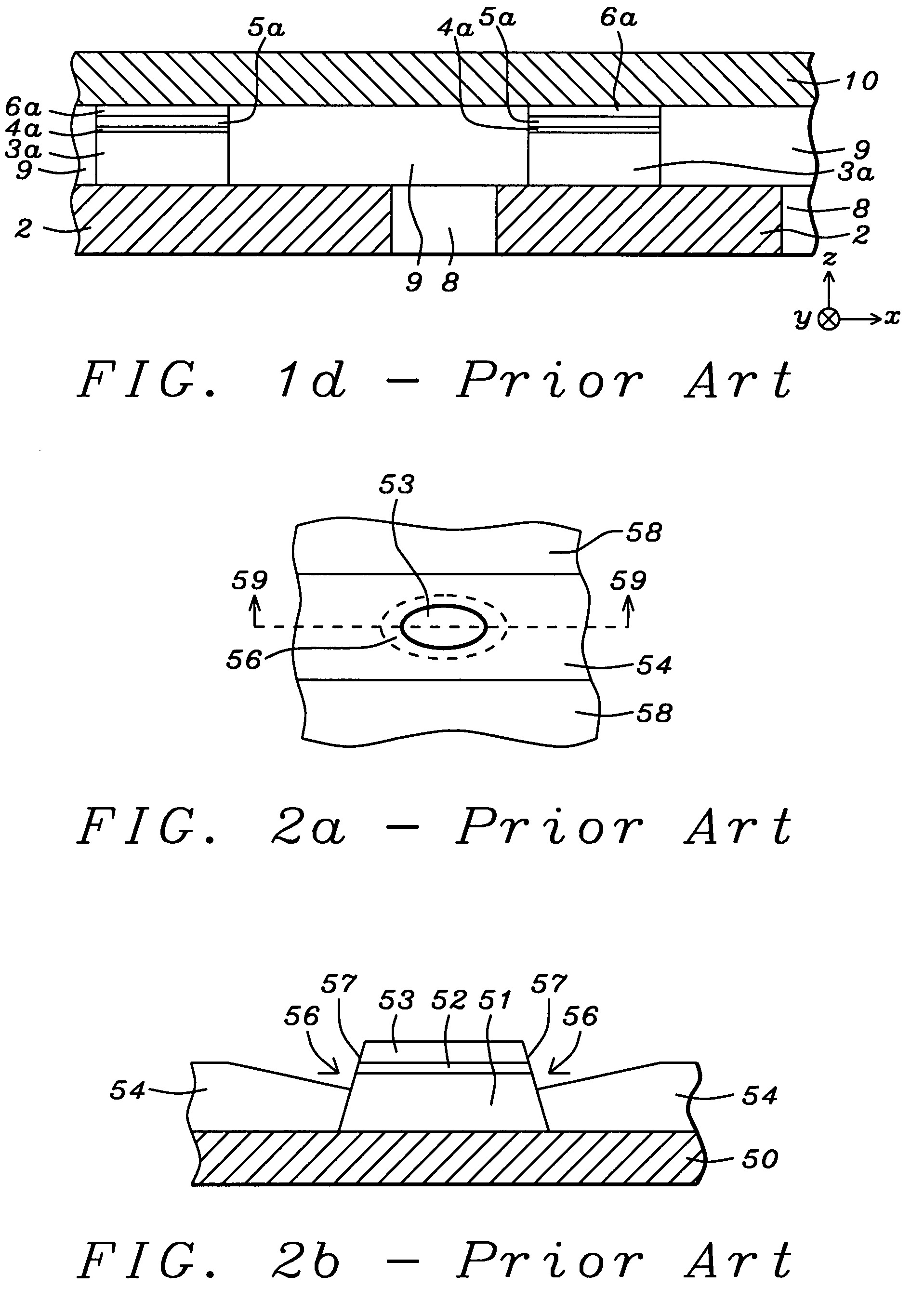

Integrated low K dielectrics and etch stops

InactiveUS6340435B1Decorative surface effectsSemiconductor/solid-state device detailsHydrogenFluorocarbon

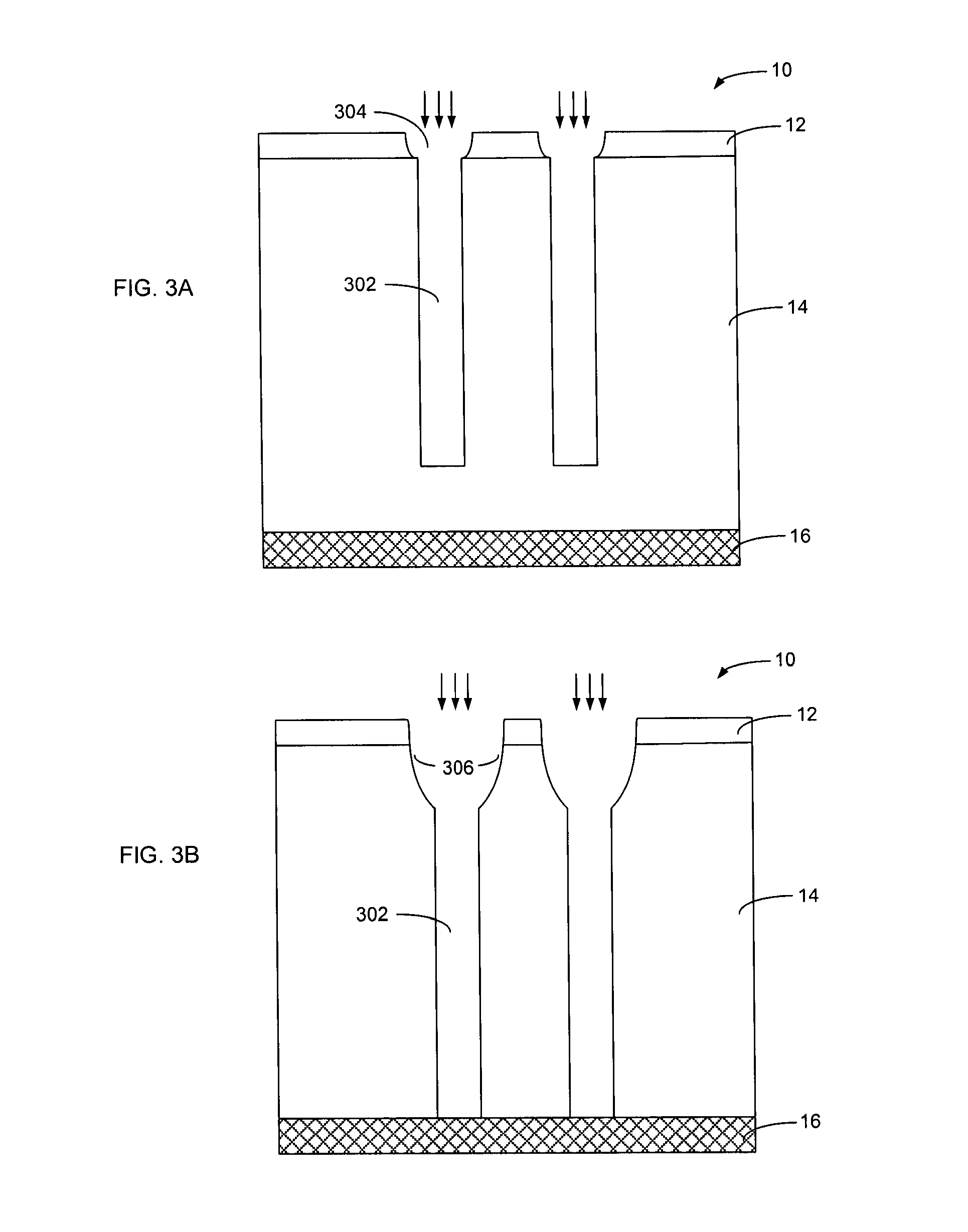

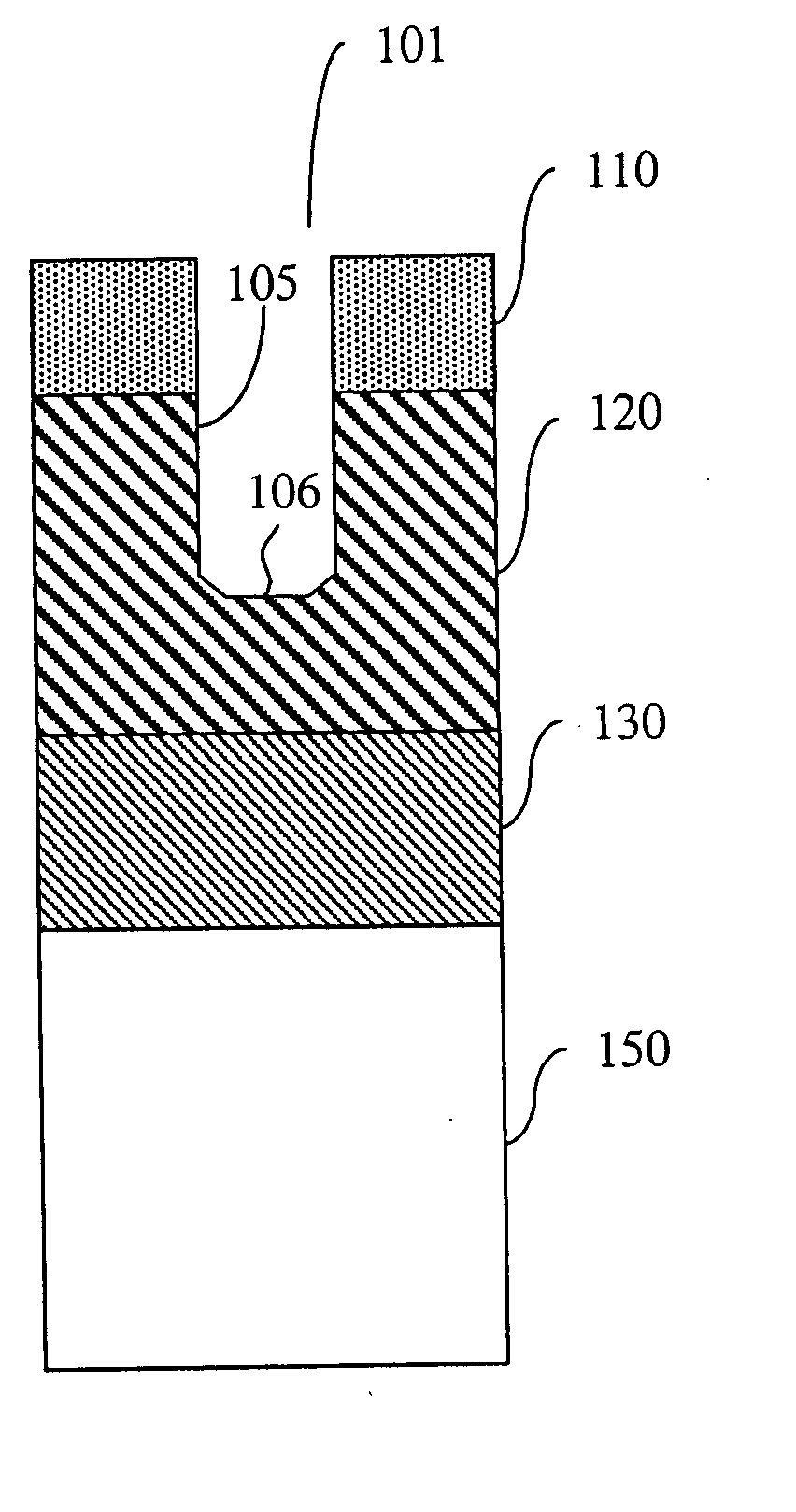

A method of depositing and etching dielectric layers having low dielectric constants and etch rates that vary by at least 3:1 for formation of horizontal interconnects. The amount of carbon or hydrogen in the dielectric layer is varied by changes in deposition conditions to provide low k dielectric layers that can replace etch stop layers or conventional dielectric layers in damascene applications. A dual damascene structure having two or more dielectric layers with dielectric constants lower than about 4 can be deposited in a single reactor and then etched to form vertical and horizontal interconnects by varying the concentration of a carbon:oxygen gas such as carbon monoxide. The etch gases for forming vertical interconnects preferably comprises CO and a fluorocarbon, and CO is preferably excluded from etch gases for forming horizontal interconnects.

Owner:APPLIED MATERIALS INC

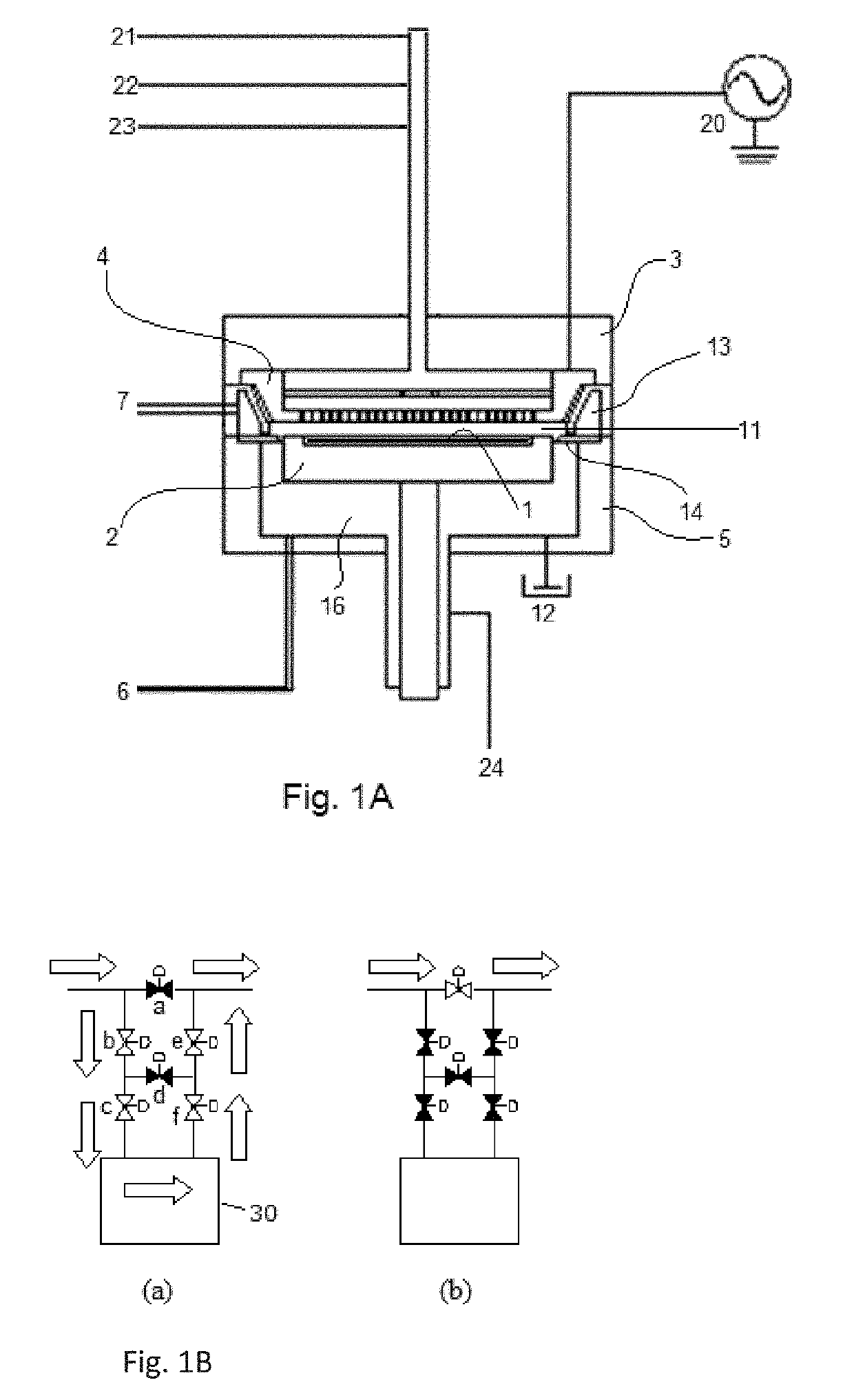

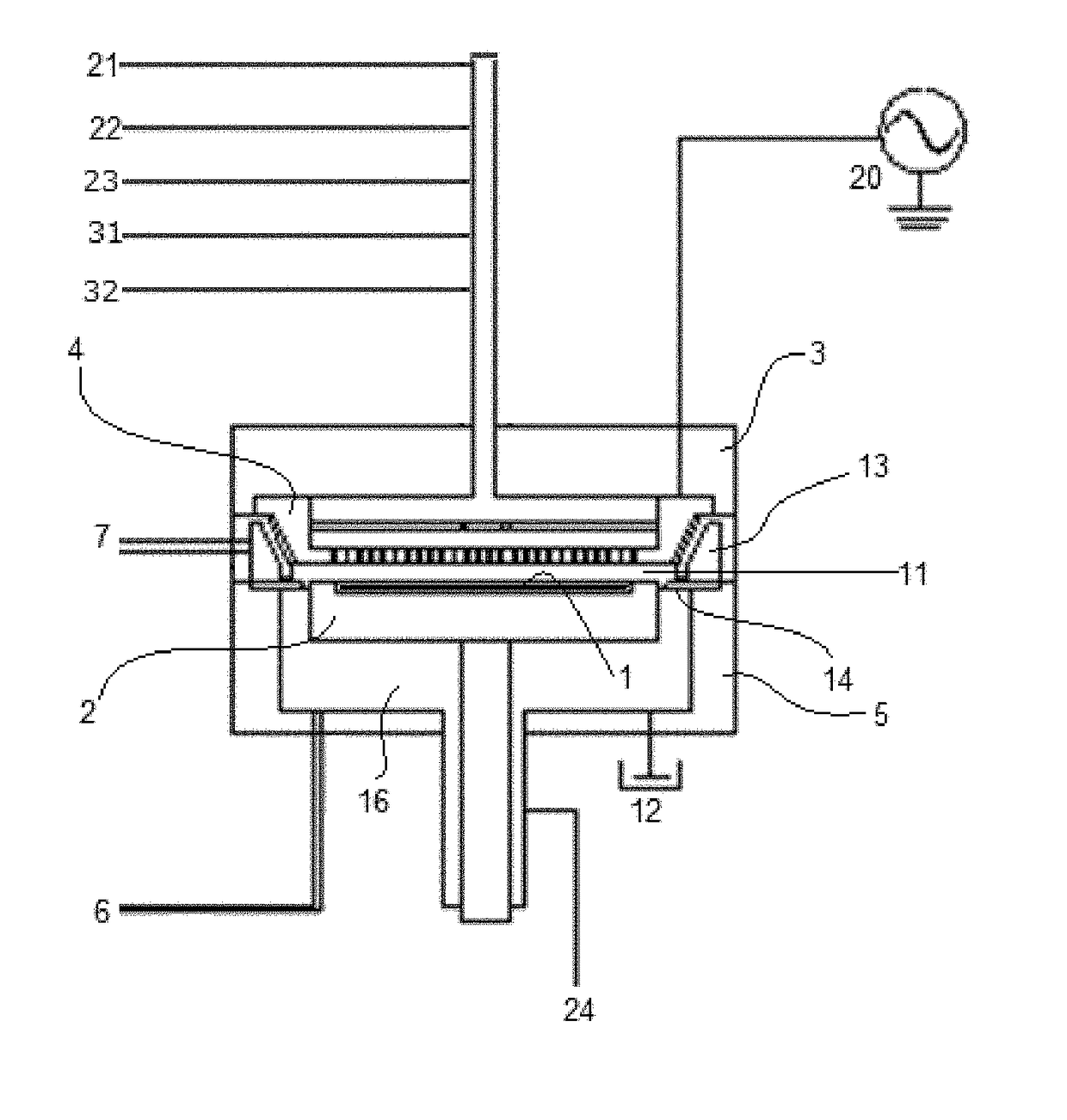

Plasma reactor apparatus with multiple gas injection zones having time-changing separate configurable gas compositions for each zone

ActiveUS8231799B2Electric discharge tubesVacuum gauge using ionisation effectsGas compositionEngineering

Owner:APPLIED MATERIALS INC

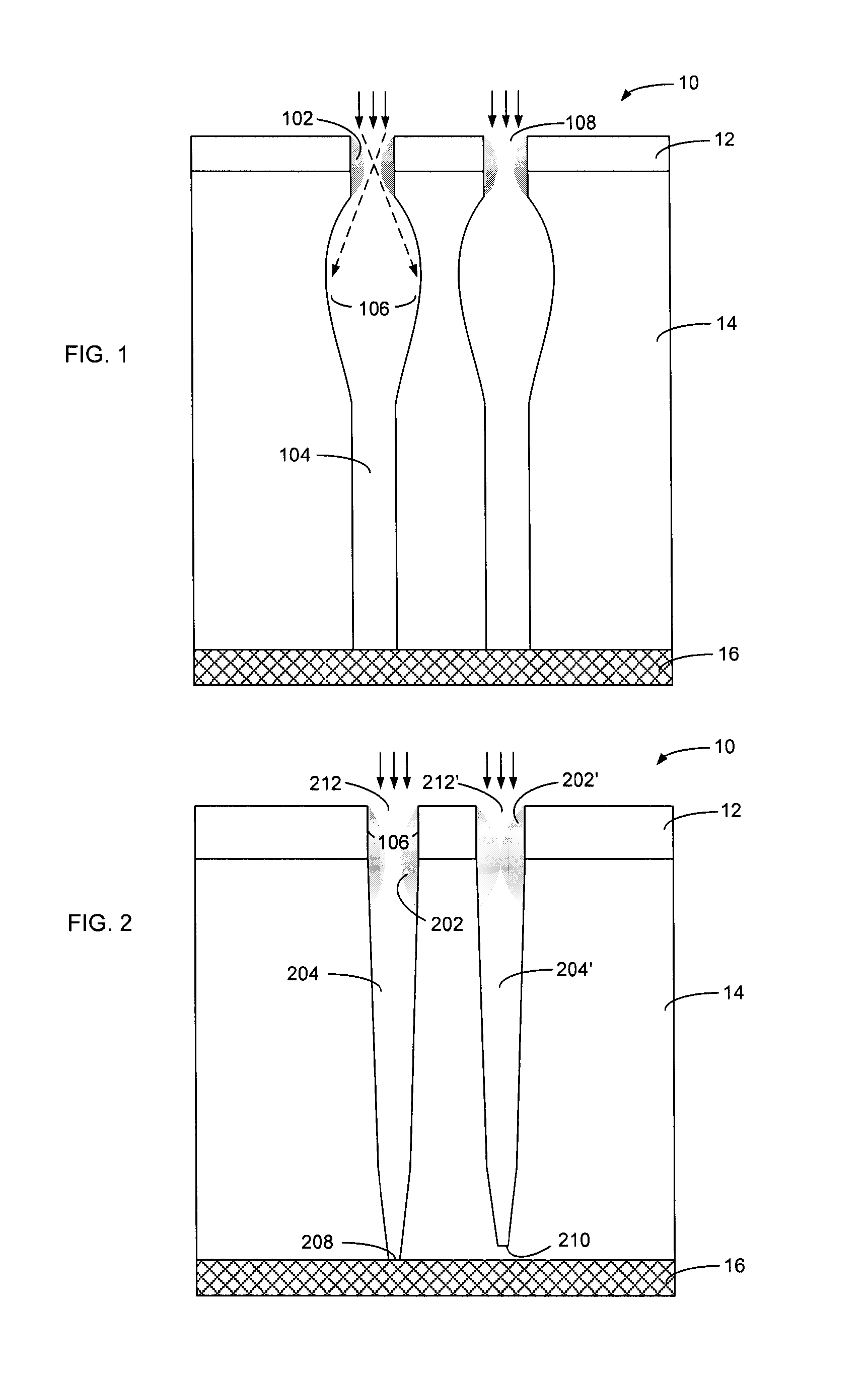

Method of etching high aspect ratio features in a dielectric layer

Methods of etching HAR features in a dielectric layer are described. In one embodiment, a substrate is provided into an etch chamber. The substrate has a patterned mask disposed on a dielectric layer formed thereon where the patterned mask has openings. A gas mixture is provided into the etch chamber, the gas mixture includes CO, O2, a fluorocarbon gas, and an optional inert gas. A plasma is formed from the gas mixture. Features are etched in the dielectric layer through the openings in the presence of the plasma

Owner:APPLIED MATERIALS INC

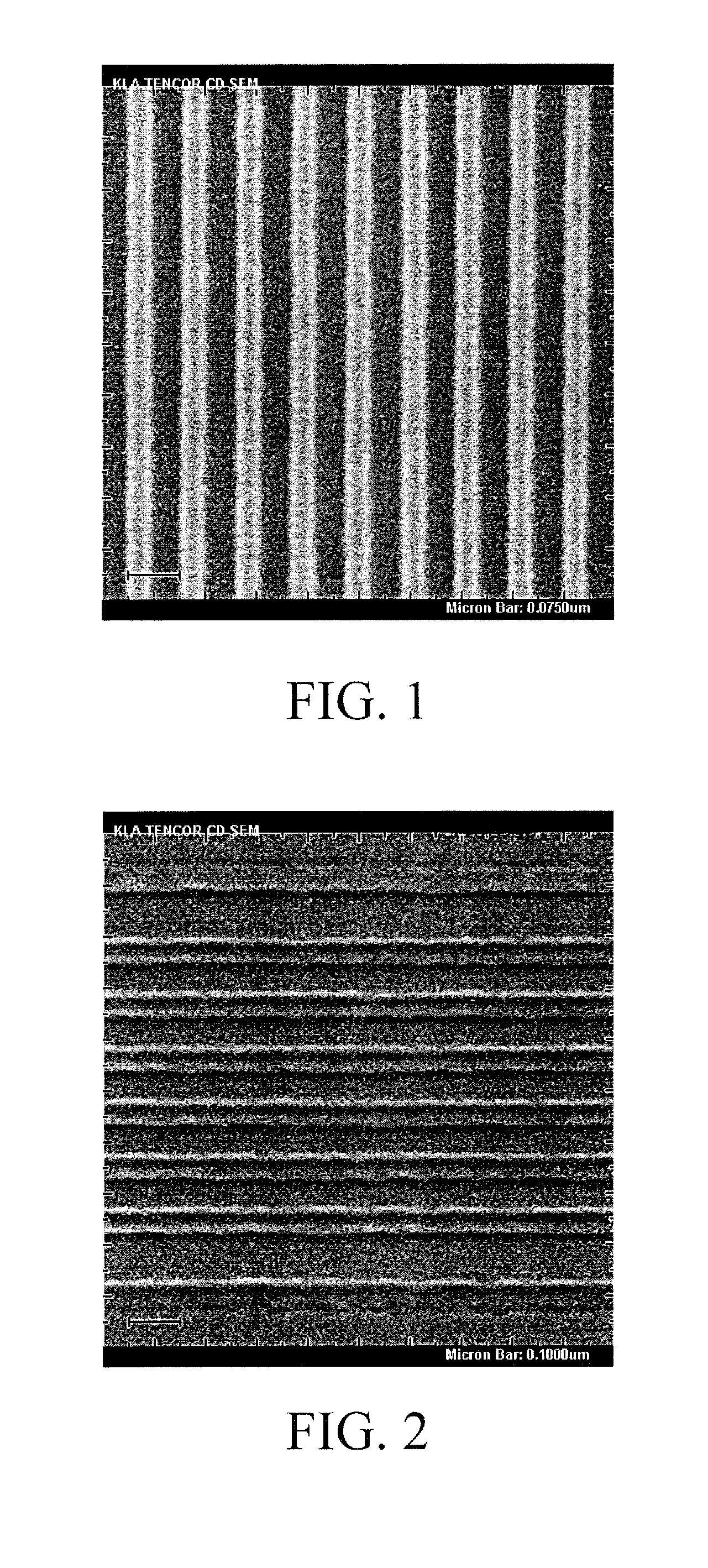

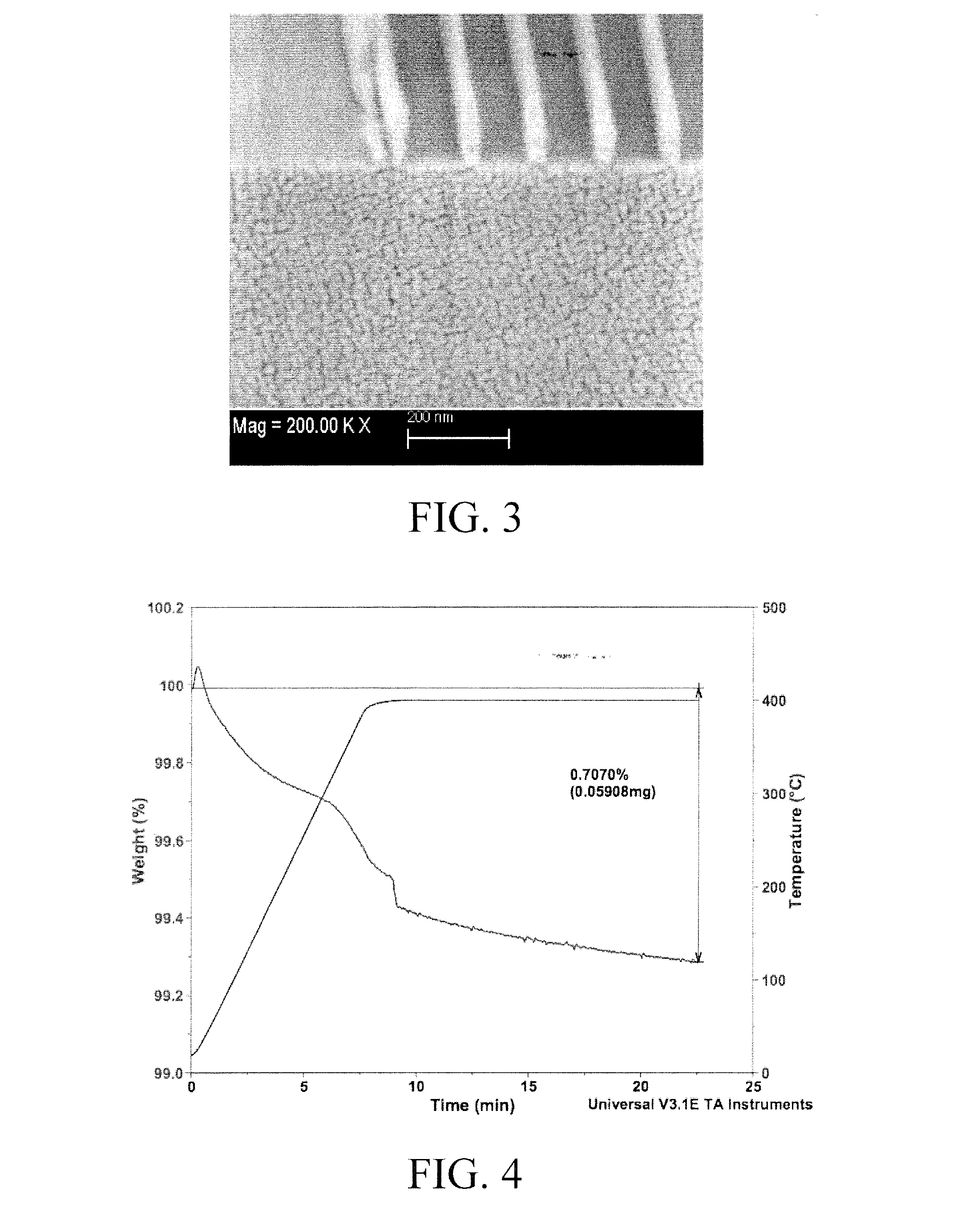

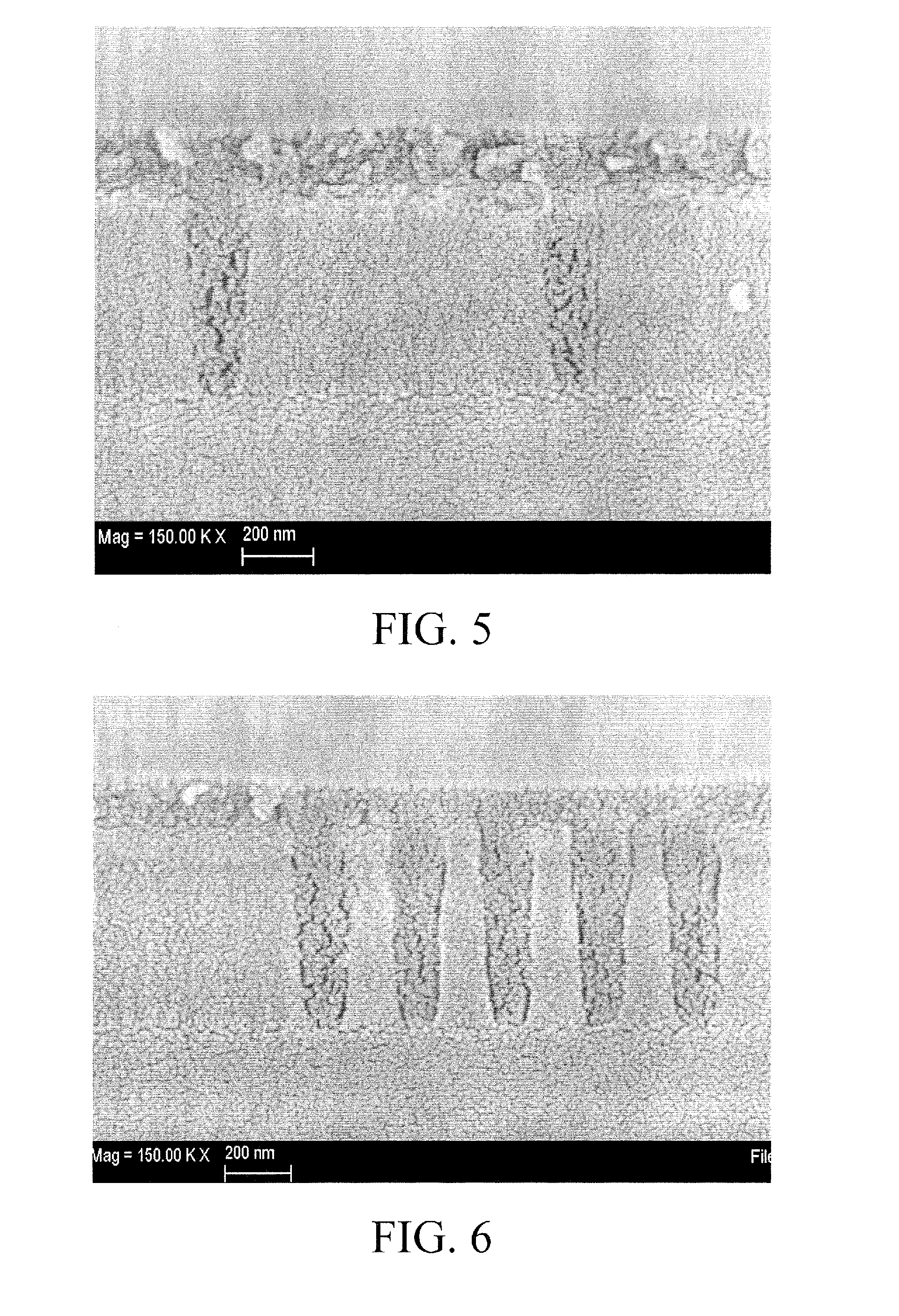

Spin-on carbon compositions for lithographic processing

The invention described herein is directed towards spin-on carbon materials comprising polyamic acid compositions and a crosslinker in a solvent system. The materials are useful in trilayer photolithography processes. Films made with the inventive compositions are not soluble in solvents commonly used in lithographic materials, such as, but not limited to PGME, PGMEA, and cyclohexanone. However, the films can be dissolved in developers commonly used in photolithography. In one embodiment, the films can be heated at high temperatures to improve the thermal stability for high temperature processing. Regardless of the embodiment, the material can be applied to a flat / planar or patterned surface. Advantageously, the material exhibits a wiggling resistance during pattern transfer to silicon substrate using fluorocarbon etch.

Owner:BREWER SCI

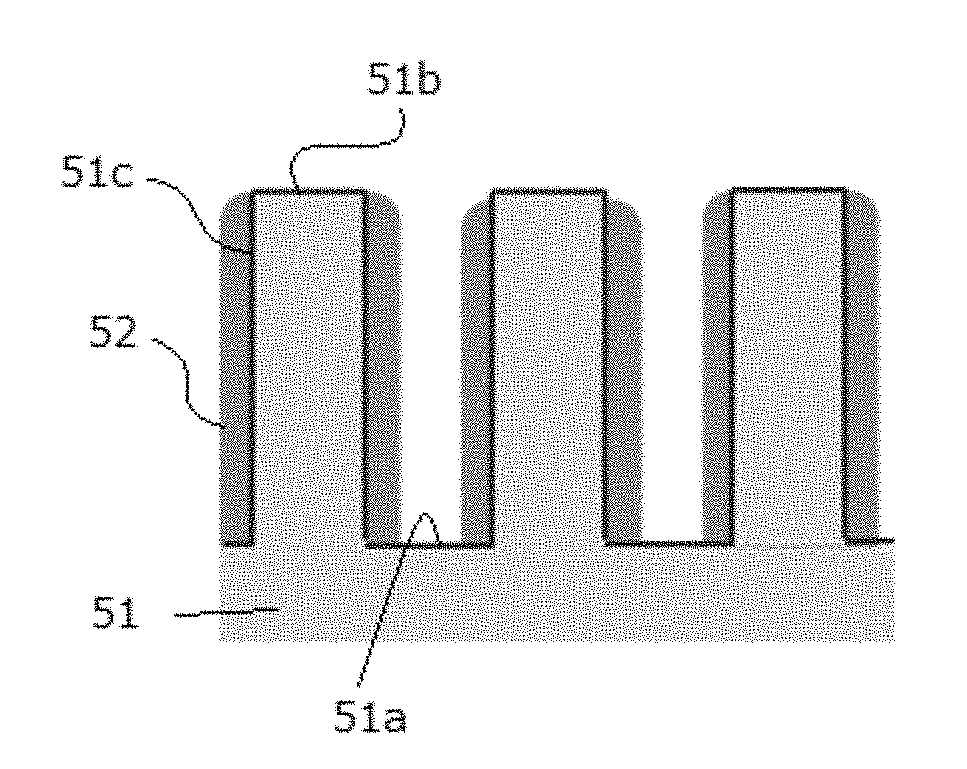

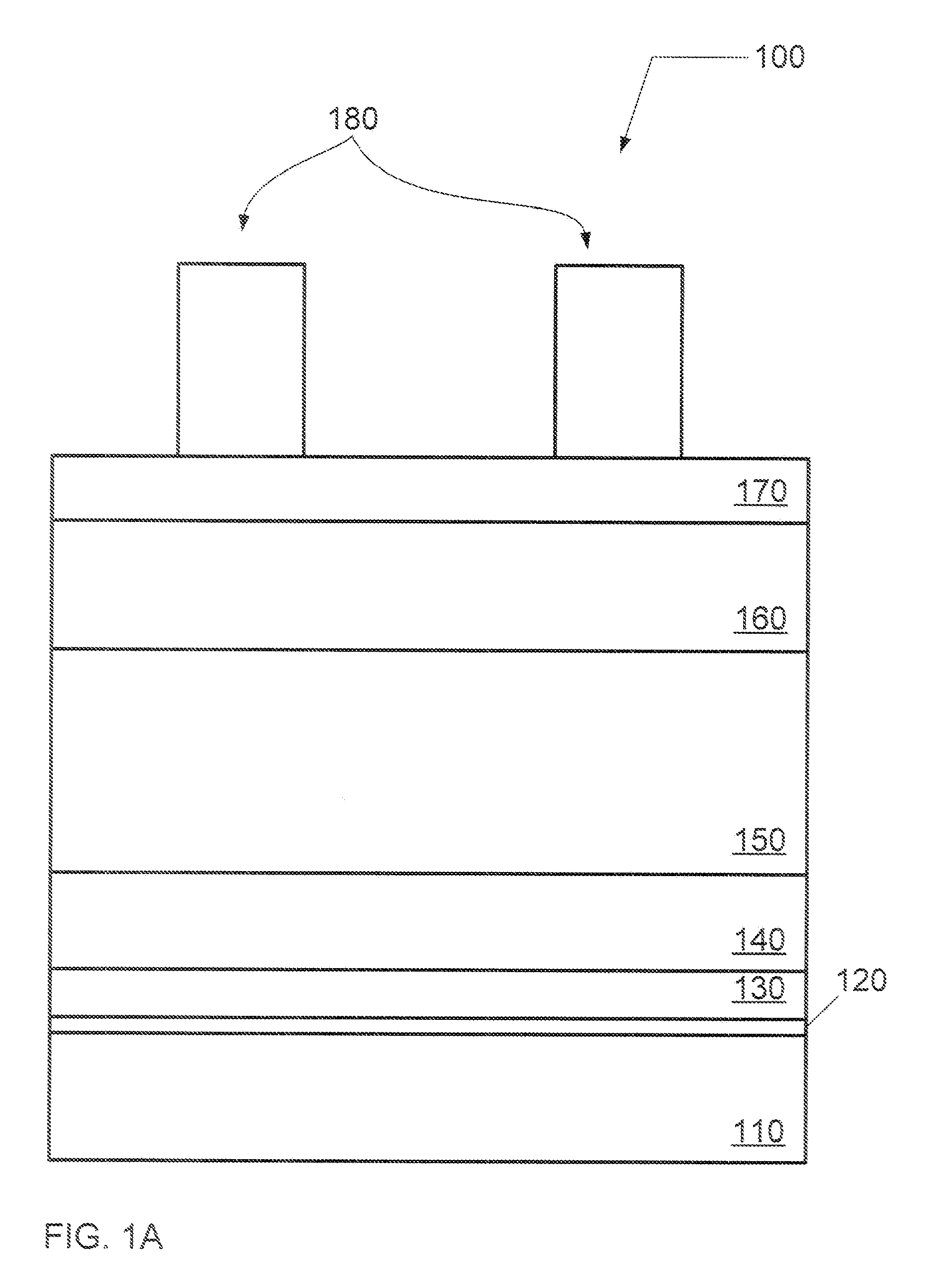

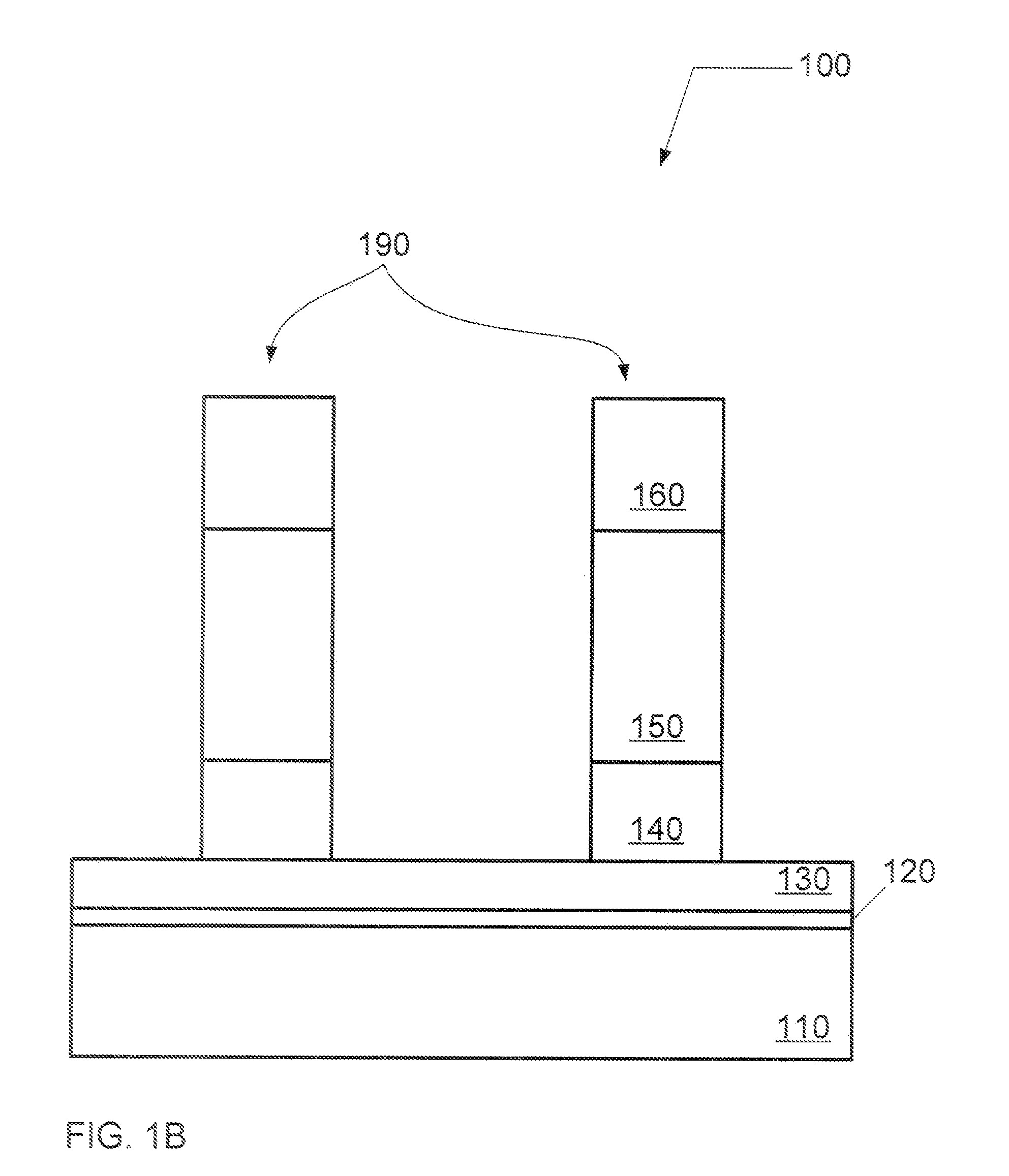

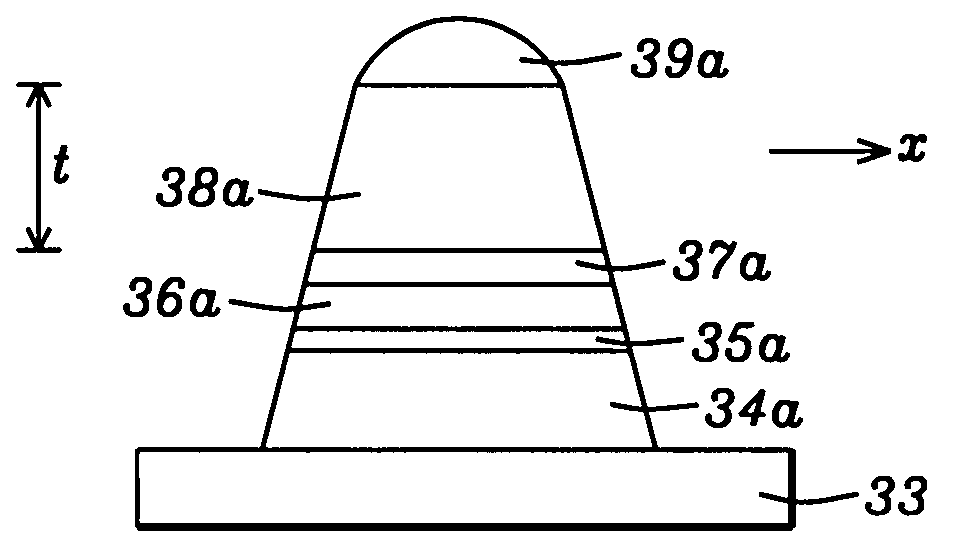

Method for forming spacers using silicon nitride film for spacer-defined multiple patterning

ActiveUS20170316940A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSurface patternSilanes

A method of forming spacers for spacer-defined multiple pattering (SDMP), includes: depositing a pattern transfer film by PEALD on the entire patterned surface of a template using halogenated silane as a precursor and nitrogen as a reactant at a temperature of 200° C. or less, which pattern transfer film is a silicon nitride film; dry-etching the template using a fluorocarbon as an etchant, and thereby selectively removing a portion of the pattern transfer film formed on a top of a core material and a horizontal portion of the pattern transfer film while leaving the core material and a vertical portion of the pattern transfer film as a vertical spacer, wherein a top of the vertical spacer is substantially flat; and dry-etching the core material, whereby the template has a surface patterned by the vertical spacer on a underlying layer.

Owner:ASM IP HLDG BV

Selective etching of carbon-doped low-k dielectrics

InactiveUS20050026430A1High selectivityReducing micro-loadingDecorative surface effectsVacuum evaporation coatingPlasma etchingChemistry

The present invention includes a process for selectively etching a low-k dielectric material formed on a substrate using a plasma of a gas mixture in a plasma etch chamber. The gas mixture comprises a fluorine-rich fluorocarbon or hydrofluorocarbon gas, a nitrogen-containing gas, and one or more additive gases, such as a hydrogen-rich hydrofluorocarbon gas, an inert gas and / or a carbon-oxygen gas. The process provides a low-k dielectric to a photoresist mask etching selectivity ratio greater than about 5:1, a low-k dielectric to a barrier / liner layer etching selectivity ratio greater about 10:1, and a low-k dielectric etch rate higher than about 4000 Å / min.

Owner:APPLIED MATERIALS INC

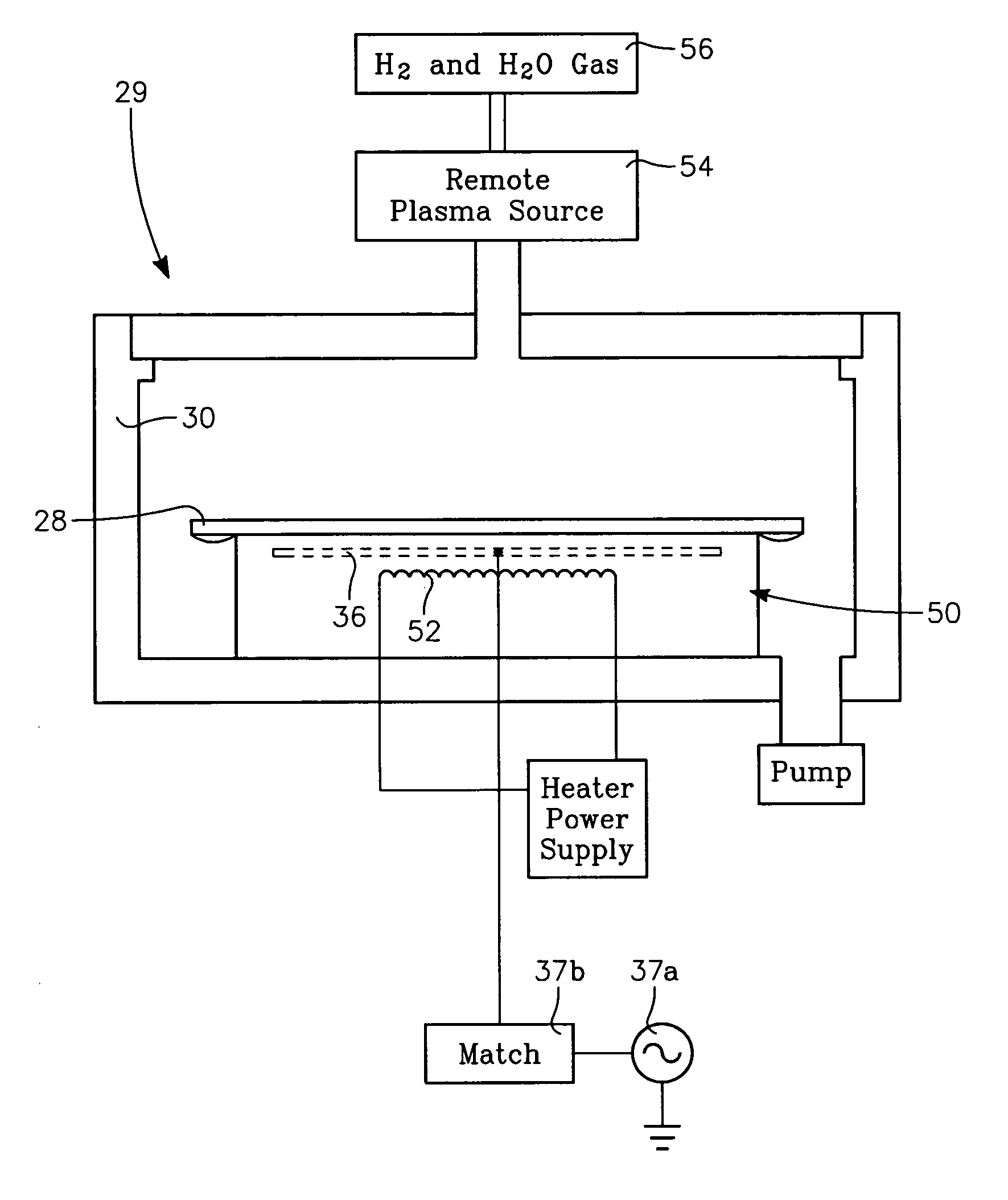

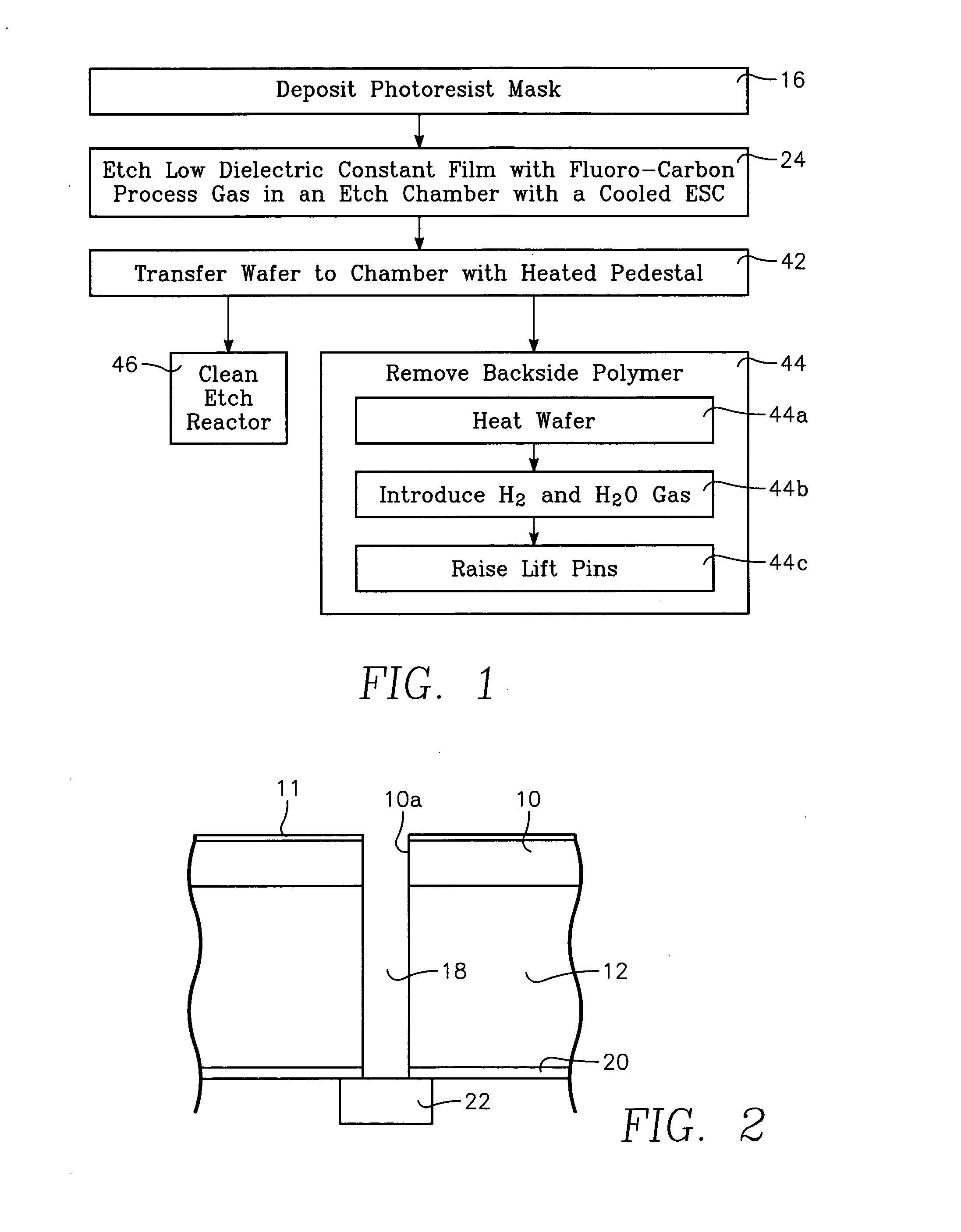

Plasma dielectric etch process including ex-situ backside polymer removal for low-dielectric constant material

A plasma etch process for etching a porous carbon-doped silicon oxide dielectric layer using a photoresist mask is carried out first in an etch reactor by performing a fluorocarbon based etch process on the workpiece to etch exposed portions of the dielectric layer while depositing protective fluorocarbon polymer on the photoresist mask. Then, in an ashing reactor, polymer and photoresist are removed by heating the workpiece to over 100 degrees C., exposing a peripheral portion of the backside of said workpiece, and providing products from a plasma of a hydrogen process gas to reduce carbon contained in polymer and photoresist on said workpiece until the polymer has been removed from a backside of said workpiece. The process gas preferably contains both hydrogen gas and water vapor, although the primary constituent is hydrogen gas. The wafer (workpiece) backside may be exposed by extending the wafer lift pins.

Owner:APPLIED MATERIALS INC

Method to form a contact hole

InactiveUS20050181588A1Reduce duplicationSemiconductor/solid-state device manufacturingCompound (substance)Fluorocarbon

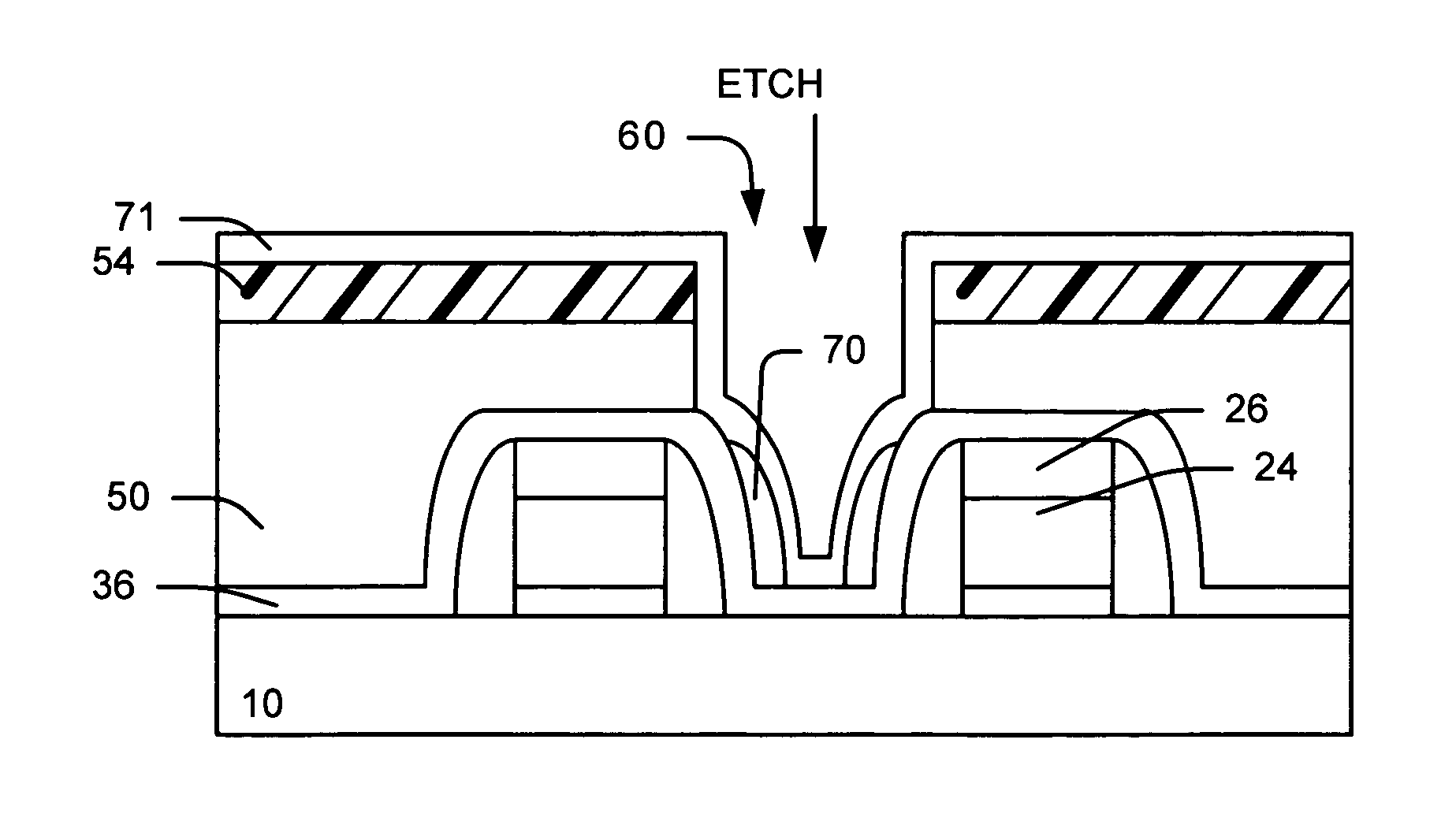

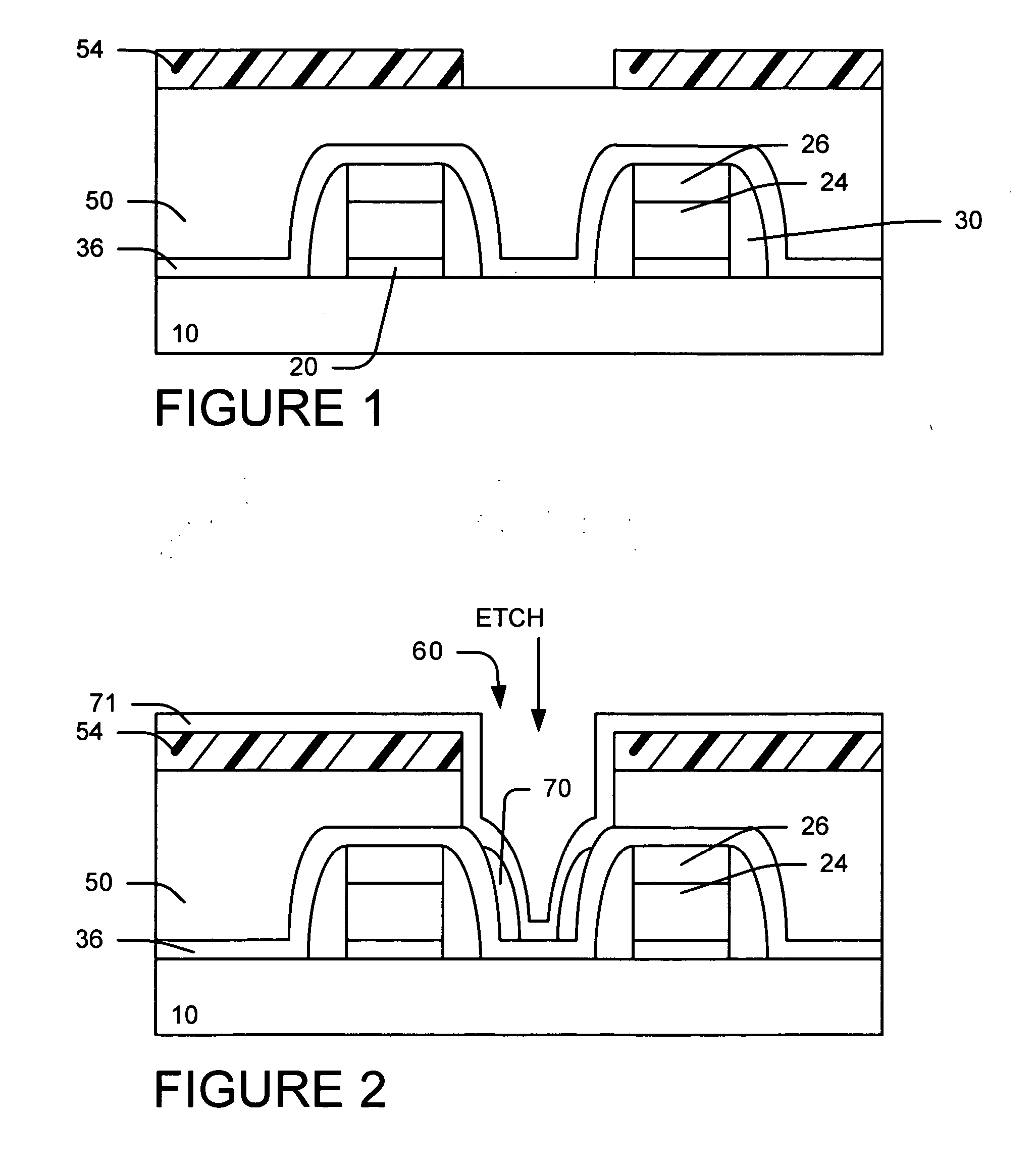

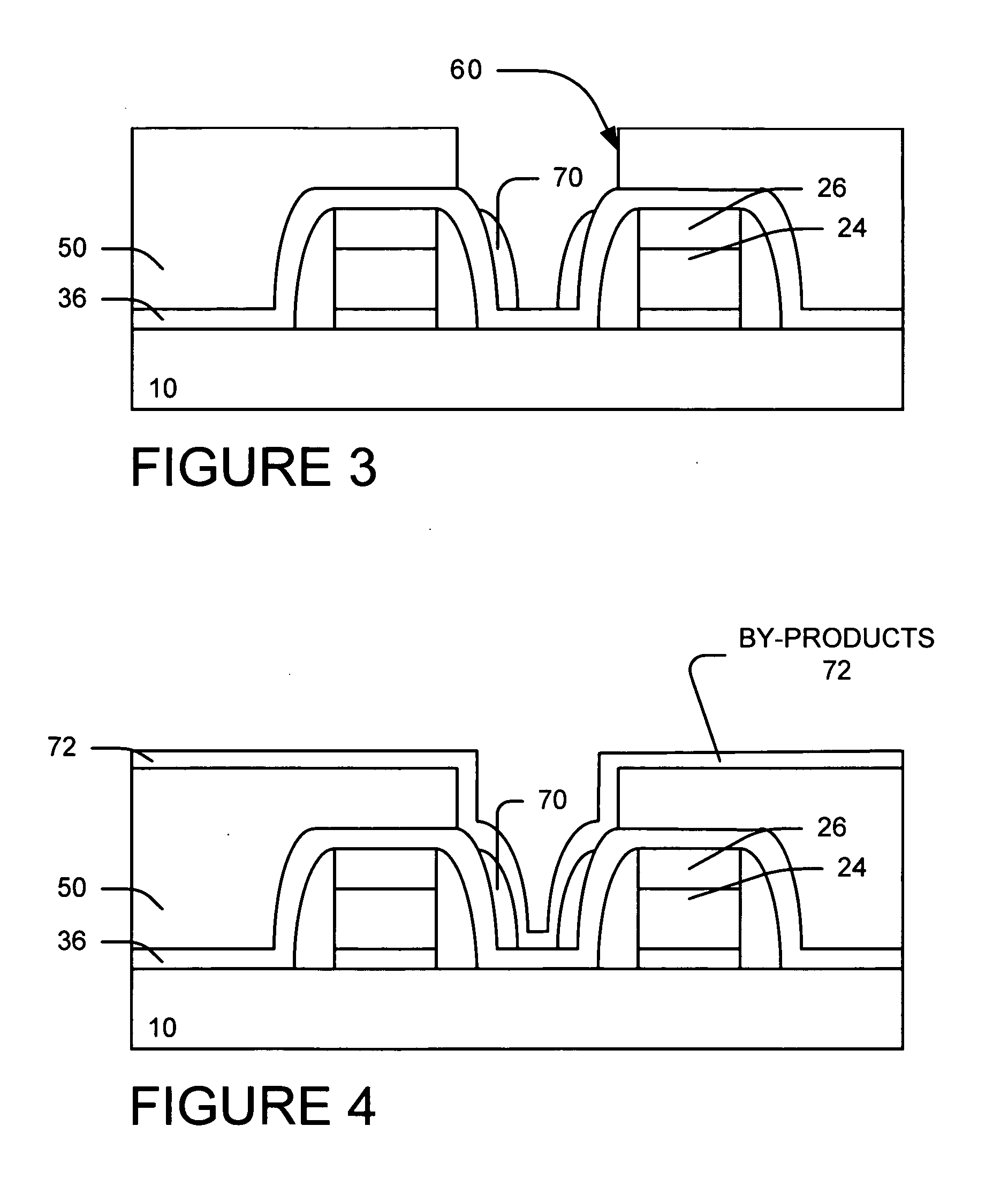

A example method of forming of a contact hole by removing residue and oxide spacer beside a nitride spacer after a CF containing etch. We provide a gate structure with nitride spacers on the sidewalls of the gate. We provide a dielectric layer (oxide) over the substrate and gate structure. We form a contact photoresist pattern over the oxide dielectric layer. We etch the oxide dielectric layer using fluorocarbons (CxFy) to form contact openings and residual spacer. The photoresist is striped. Preferably, a NF3 and N2 and H2 plasma treatment is performed to deposit a byproducts layer over the residual spacer. The byproducts layer and residual spacer are removed preferably using one of the following processes: (1) heat (2) DI rinse or (3) IR or UV radiation.

Owner:TAIWAN SEMICON MFG CO LTD

Method for forming spacers using silicon nitride film for spacer-defined multiple patterning

ActiveUS10468251B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingFluorocarbonDry etching

A method of forming spacers for spacer-defined multiple pattering (SDMP), includes: depositing a pattern transfer film by PEALD on the entire patterned surface of a template using halogenated silane as a precursor and nitrogen as a reactant at a temperature of 200° C. or less, which pattern transfer film is a silicon nitride film; dry-etching the template using a fluorocarbon as an etchant, and thereby selectively removing a portion of the pattern transfer film formed on a top of a core material and a horizontal portion of the pattern transfer film while leaving the core material and a vertical portion of the pattern transfer film as a vertical spacer, wherein a top of the vertical spacer is substantially flat; and dry-etching the core material, whereby the template has a surface patterned by the vertical spacer on a underlying layer.

Owner:ASM IP HLDG BV

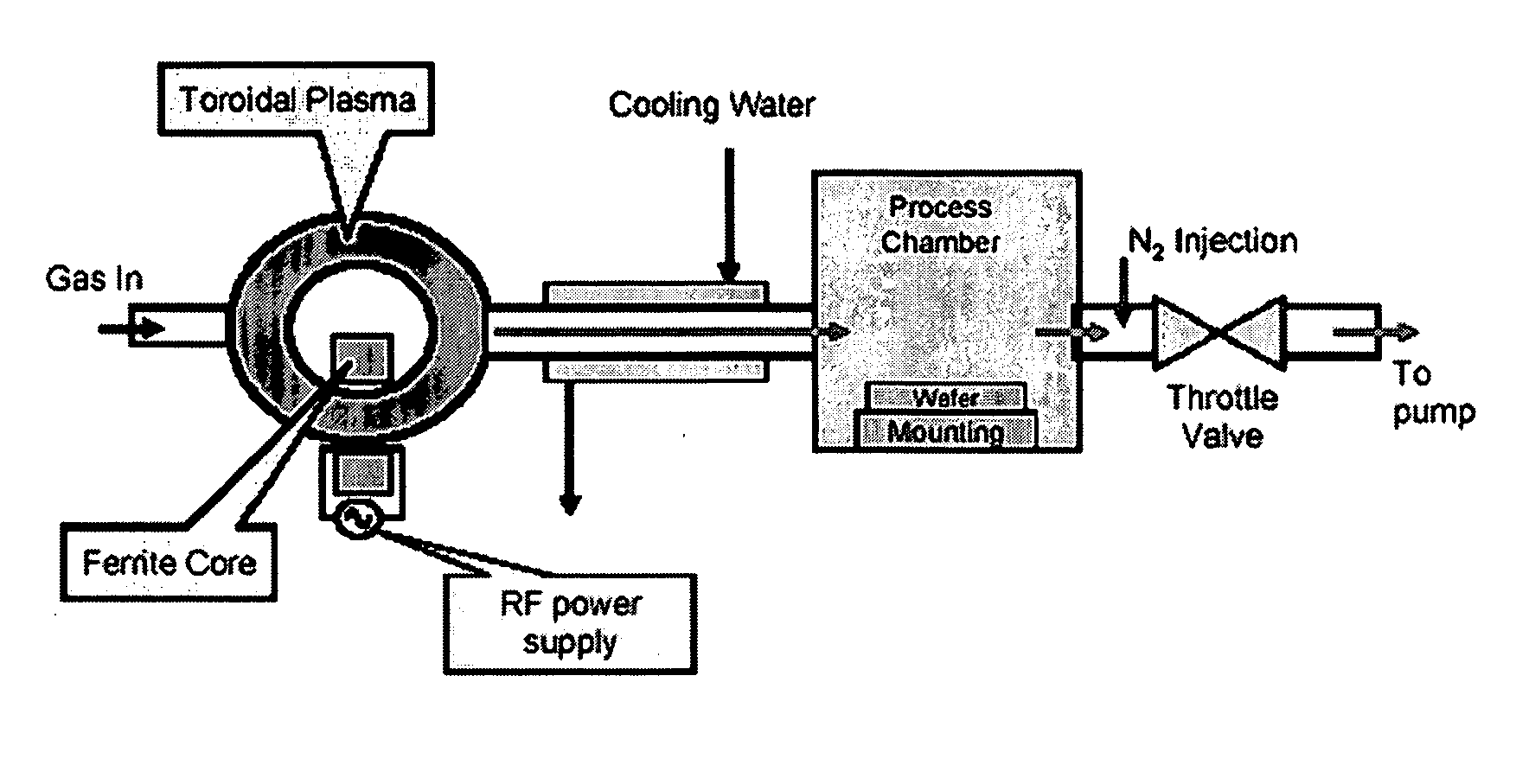

Remote chamber methods for removing surface deposits

The present invention relates to an improved remote plasma cleaning method for removing surface deposits from a surface, such as the interior of a deposition chamber that is used in fabricating electronic devices. The improvement involves a fluorocarbon rich plasma pretreatment of interior surface of the pathway from the remote chamber to the surface deposits.

Owner:MASSACHUSETTS INST OF TECH +1

Method of using NF3 for removing surface deposits from the interior of chemical vapor deposition chambers

InactiveUS20070107750A1Efficient methodElectrostatic cleaningChemical vapor deposition coatingRemote plasmaOxygen

The present invention relates to a remote plasma cleaning method for removing surface deposits from a surface, such as the interior of a depositions chamber that is used in fabricating electronic devices. The process involves activating a gas stream comprising an oxygen source, NF3, and a fluorocarbon and contacting the activated gas mixture with surface deposits to remove the surface deposits.

Owner:MASSACHUSETTS INST OF TECH

Method and system for dry etching a metal nitride

InactiveUS20080230519A1Decorative surface effectsSemiconductor/solid-state device manufacturingTitanium nitrideProcess composition

A method and system of etching a metal nitride, such as titanium nitride, is described. The etching process comprises introducing a process composition having a halogen containing gas, such as Cl2, HBr, or BCl3, and a fluorocarbon gas having the chemical formula CxHyFz, where x and z are equal to unity or greater and y is equal to 0 or greater.

Owner:TOKYO ELECTRON LTD

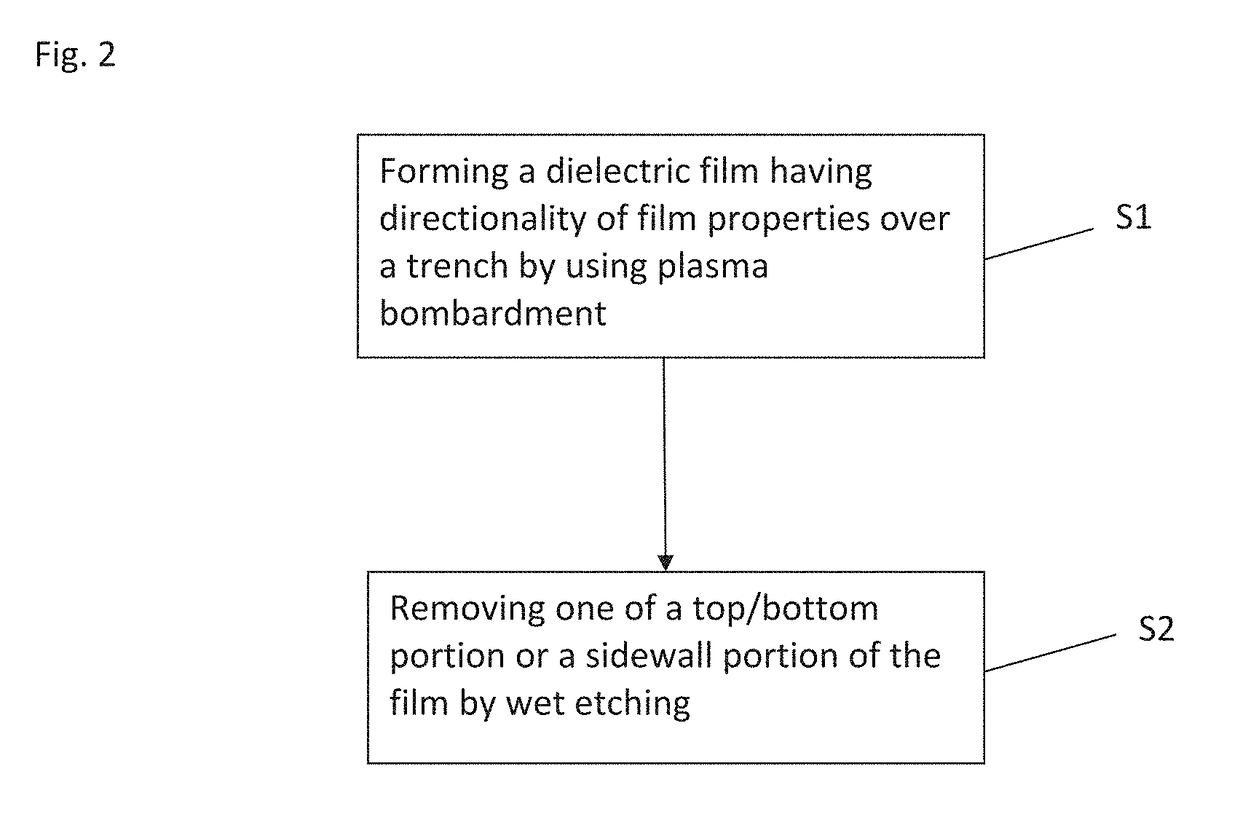

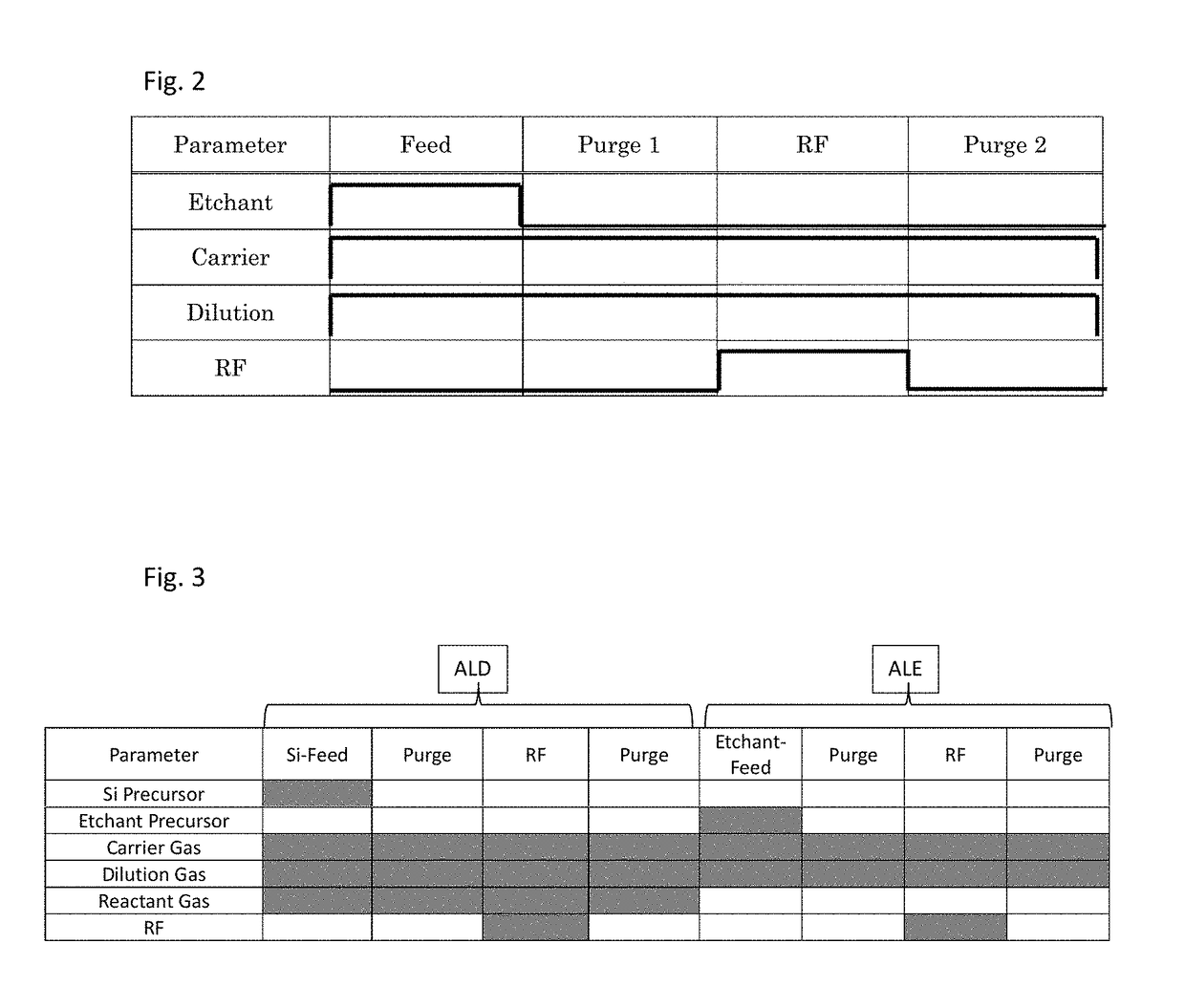

Method of atomic layer etching using functional group-containing fluorocarbon

ActiveUS20170186621A1Improve in-plane uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingSelf limitingNoble gas

Owner:ASM IP HLDG BV

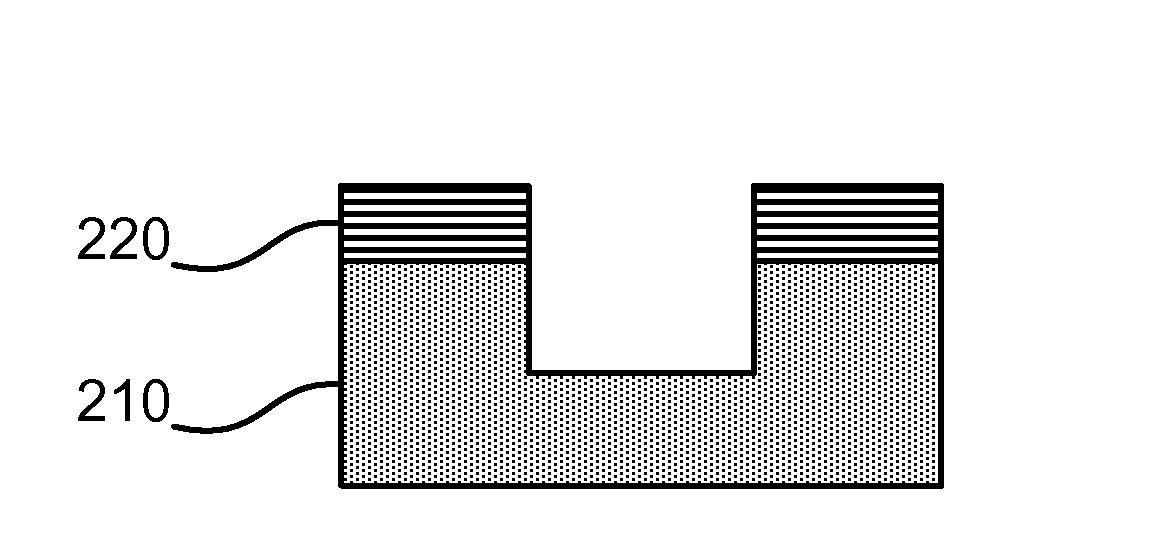

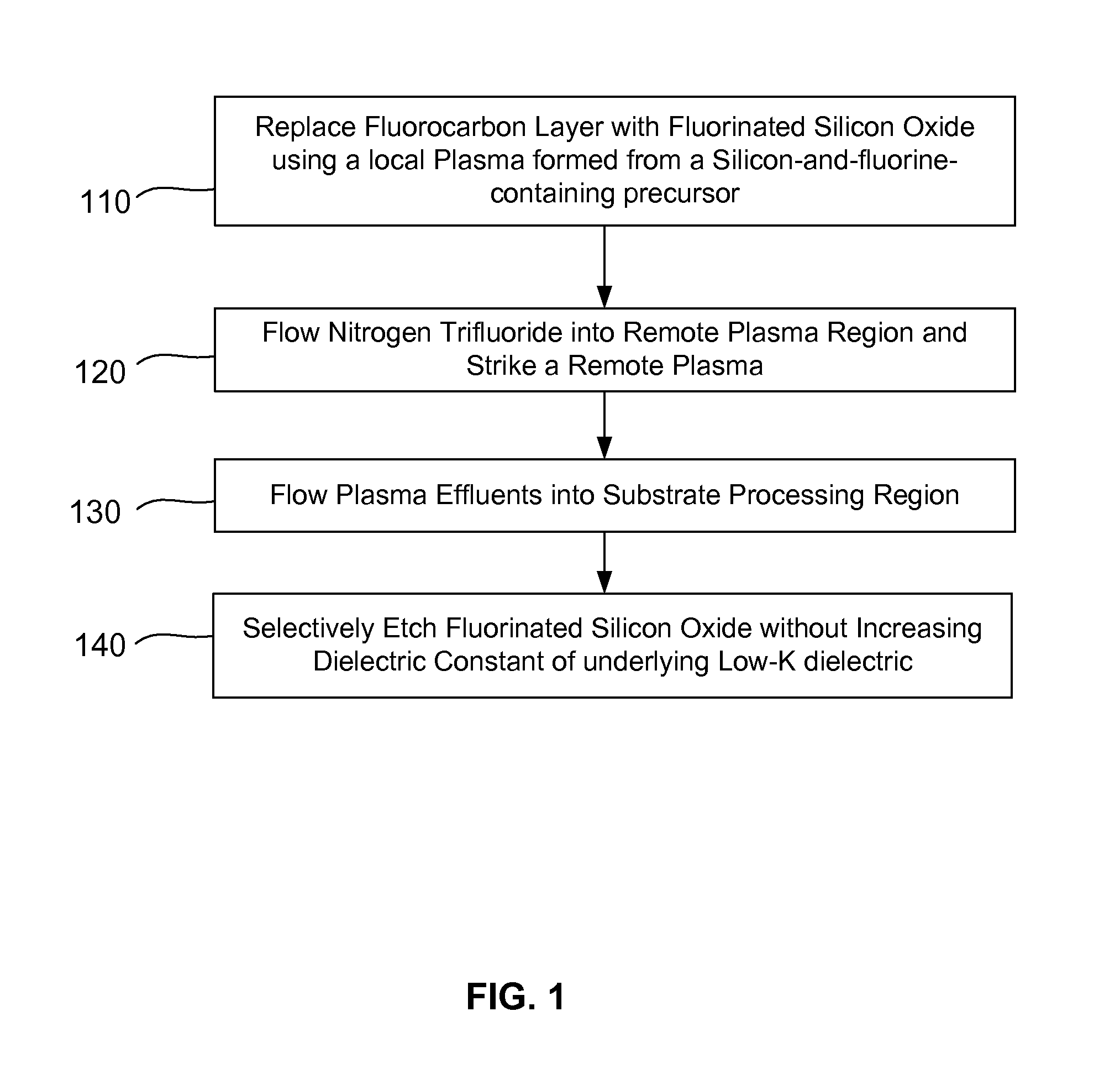

Delicate dry clean

ActiveUS20140342532A1High selectivityAvoid exposureSemiconductor/solid-state device manufacturingOxygenCompanion animal

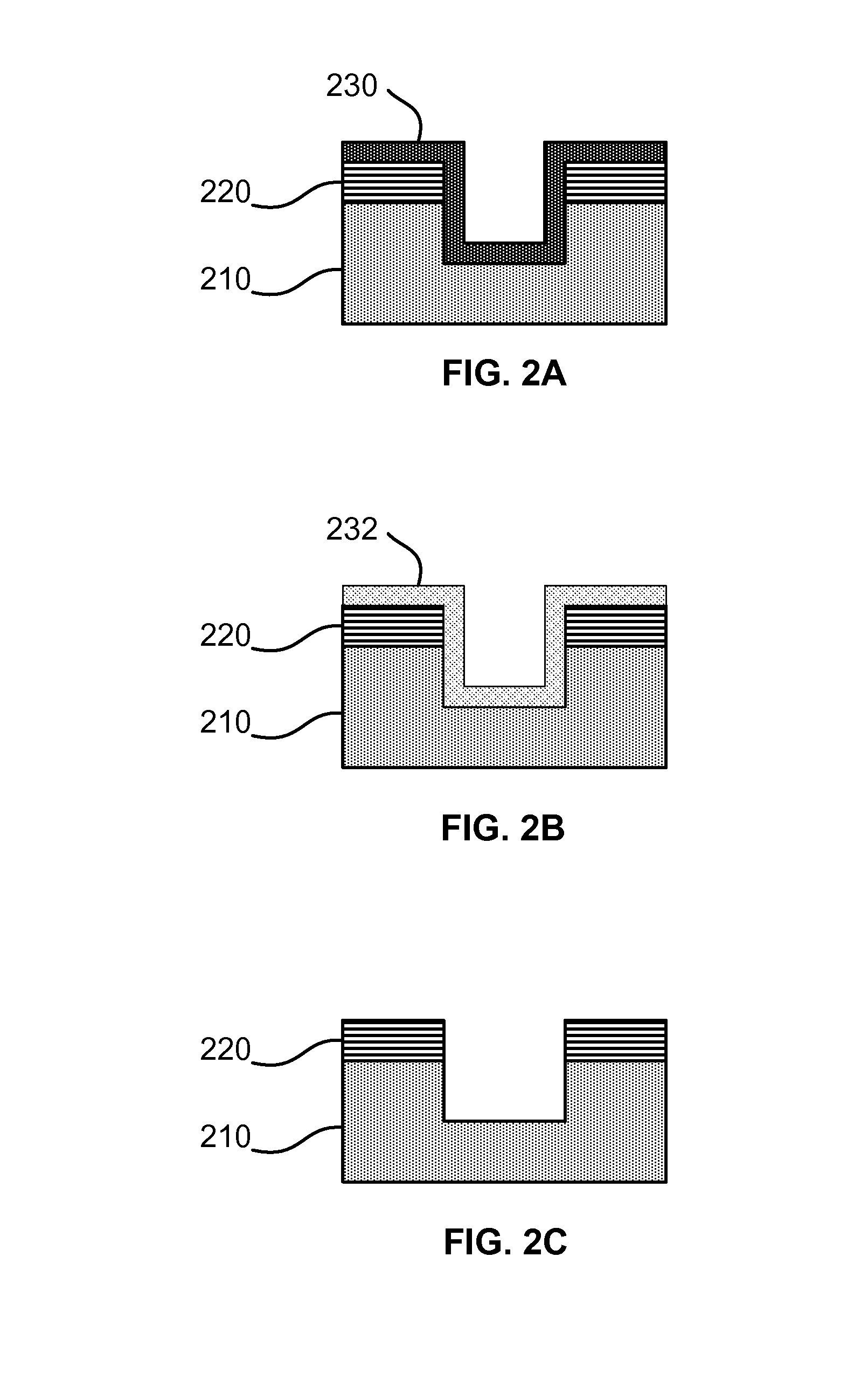

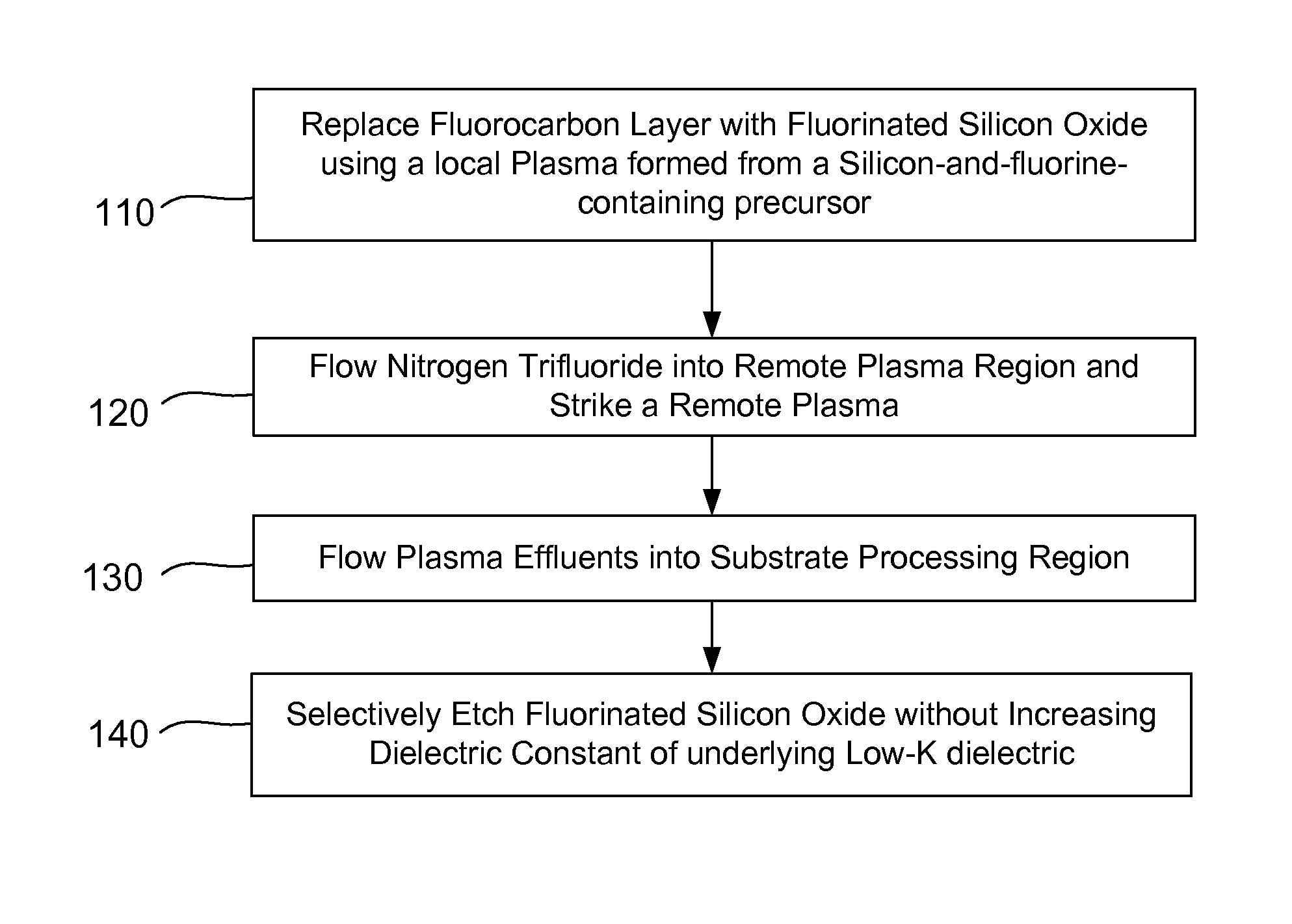

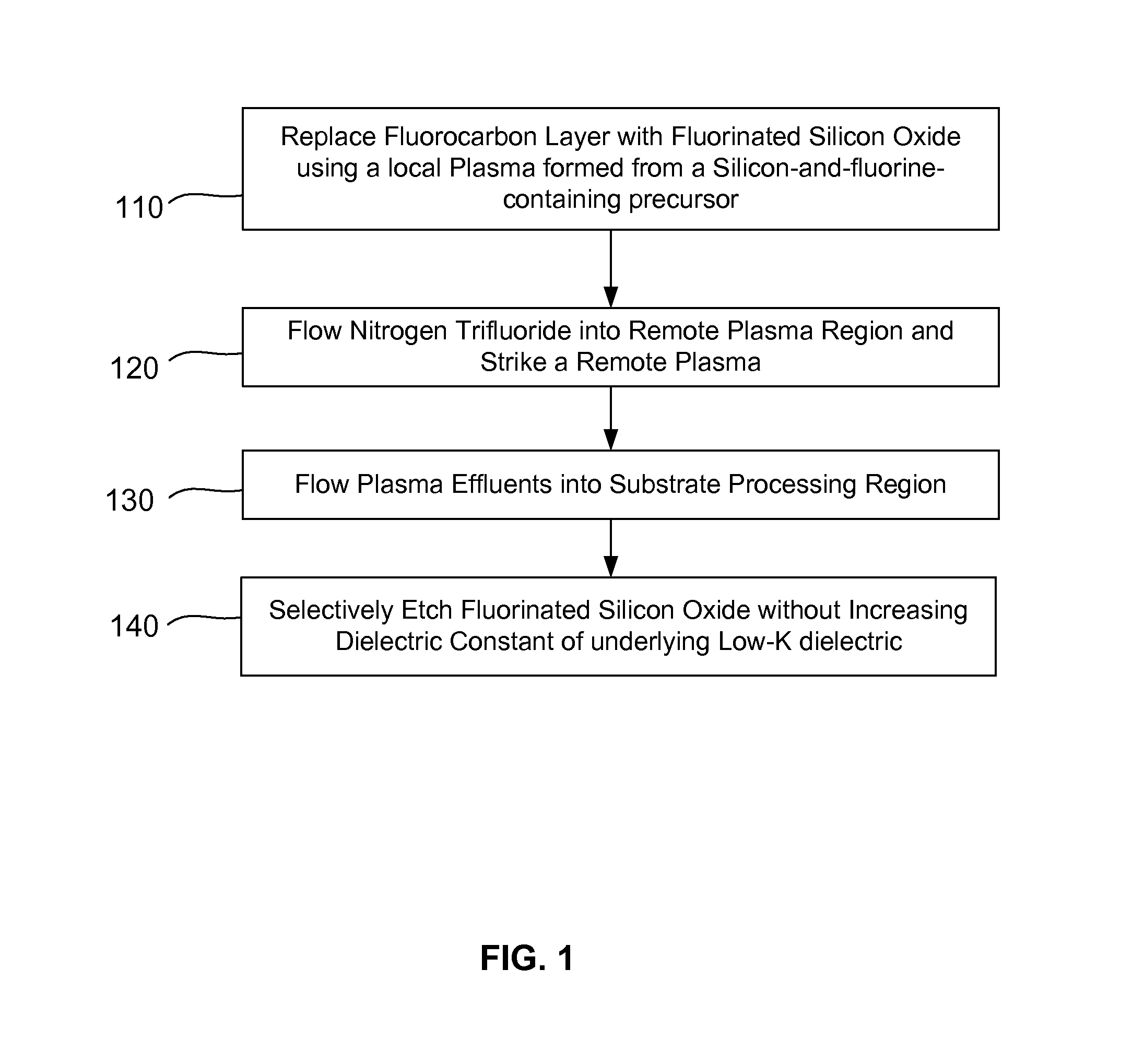

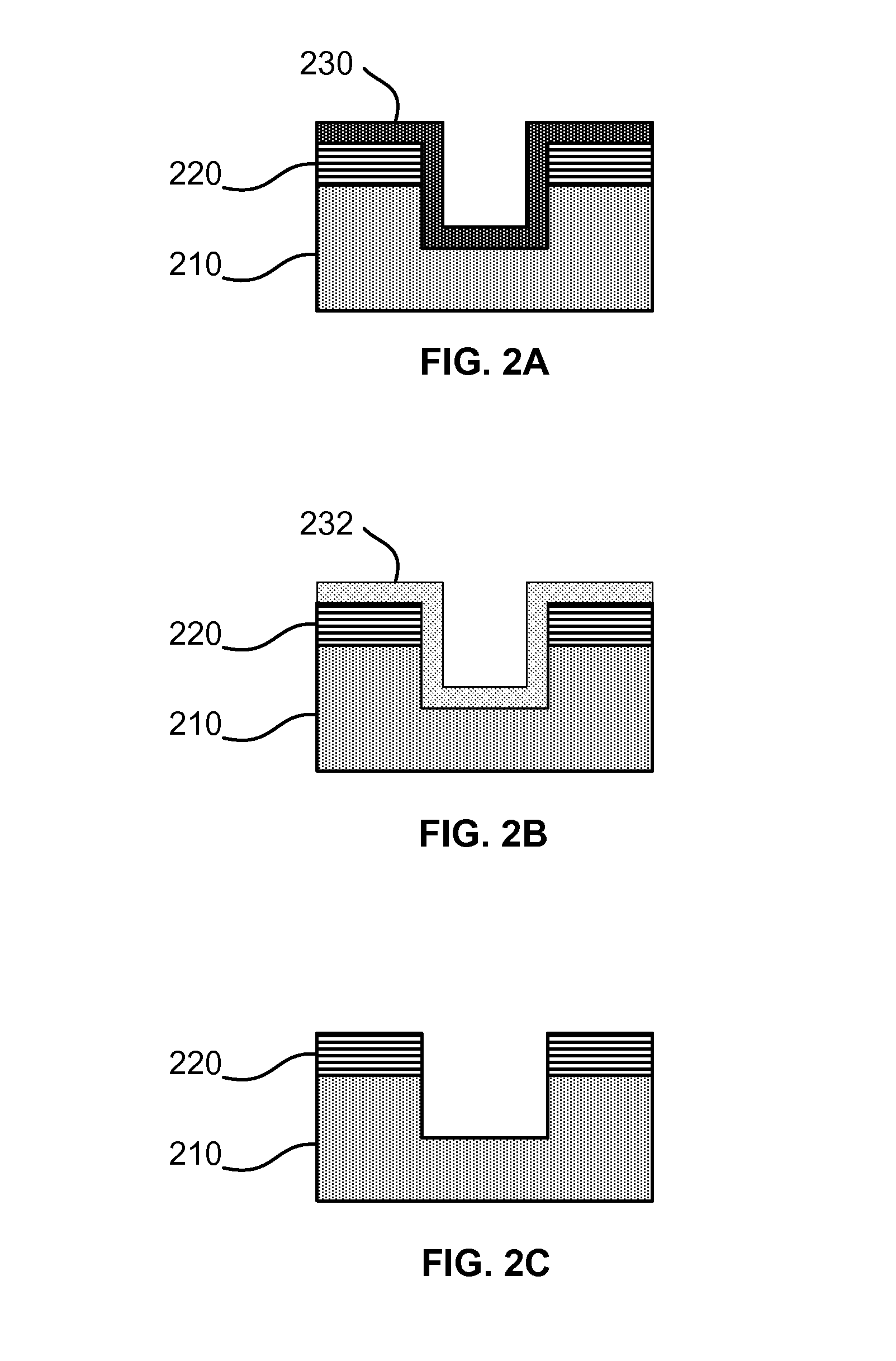

A method of selectively removing fluorocarbon layers from overlying low-k dielectric material is described. These protective plasma treatments (PPT) are delicate alternatives to traditional post-etch treatments (PET). The method includes sequential exposure to (1) a local plasma formed from a silicon-fluorine precursor followed by (2) an exposure to plasma effluents formed in a remote plasma from a fluorine-containing precursor. The remote plasma etch (2) has been found to be highly selective of the residual material following the local plasma silicon-fluorine exposure. The sequential process (1)-(2) avoids exposing the low-k dielectric material to oxygen which would undesirably increase its dielectric constant.

Owner:APPLIED MATERIALS INC

Delicate dry clean

ActiveUS8895449B1High selectivityAvoid exposureDecorative surface effectsSemiconductor/solid-state device manufacturingOxygenCompanion animal

A method of selectively removing fluorocarbon layers from overlying low-k dielectric material is described. These protective plasma treatments (PPT) are delicate alternatives to traditional post-etch treatments (PET). The method includes sequential exposure to (1) a local plasma formed from a silicon-fluorine precursor followed by (2) an exposure to plasma effluents formed in a remote plasma from a fluorine-containing precursor. The remote plasma etch (2) has been found to be highly selective of the residual material following the local plasma silicon-fluorine exposure. The sequential process (1)-(2) avoids exposing the low-k dielectric material to oxygen which would undesirably increase its dielectric constant.

Owner:APPLIED MATERIALS INC

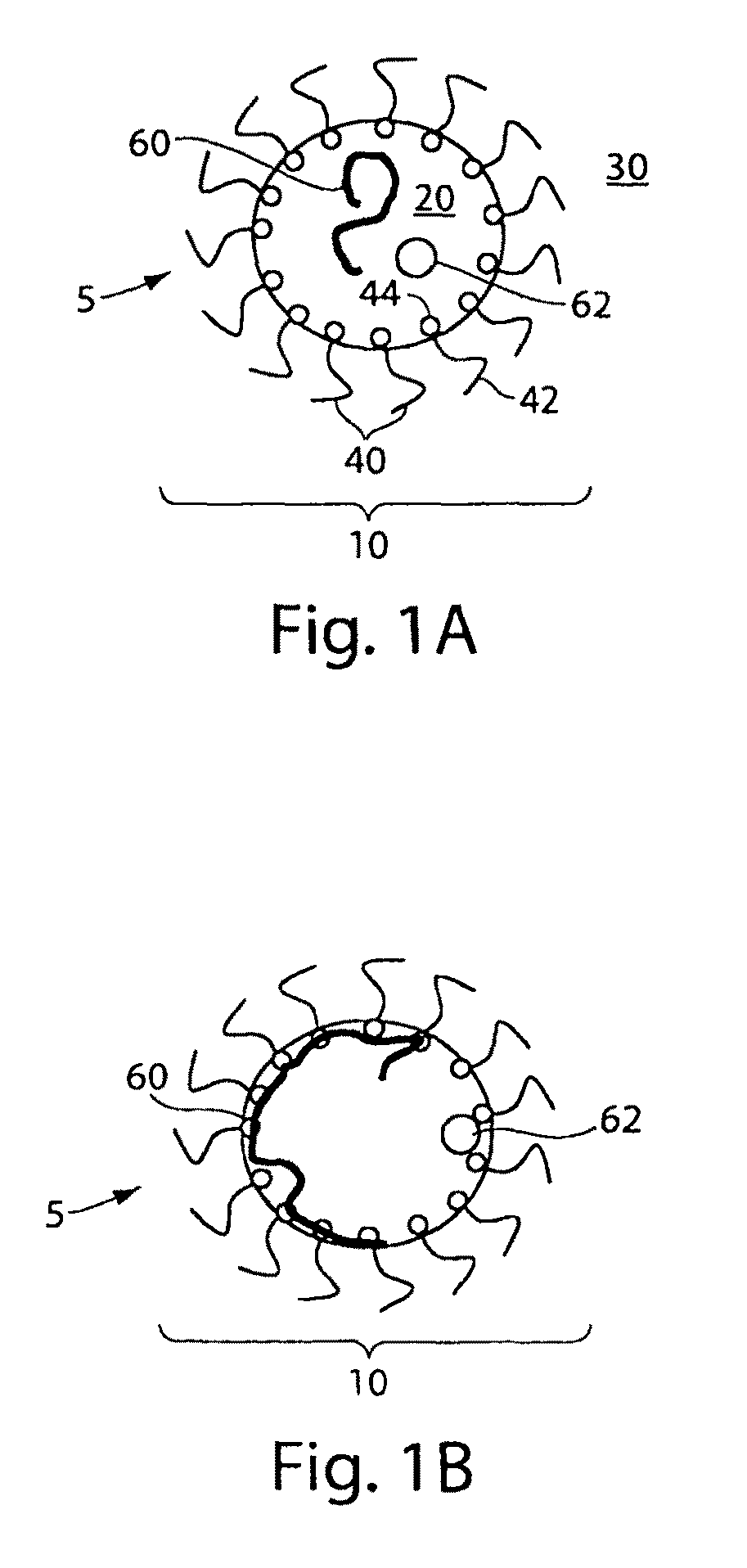

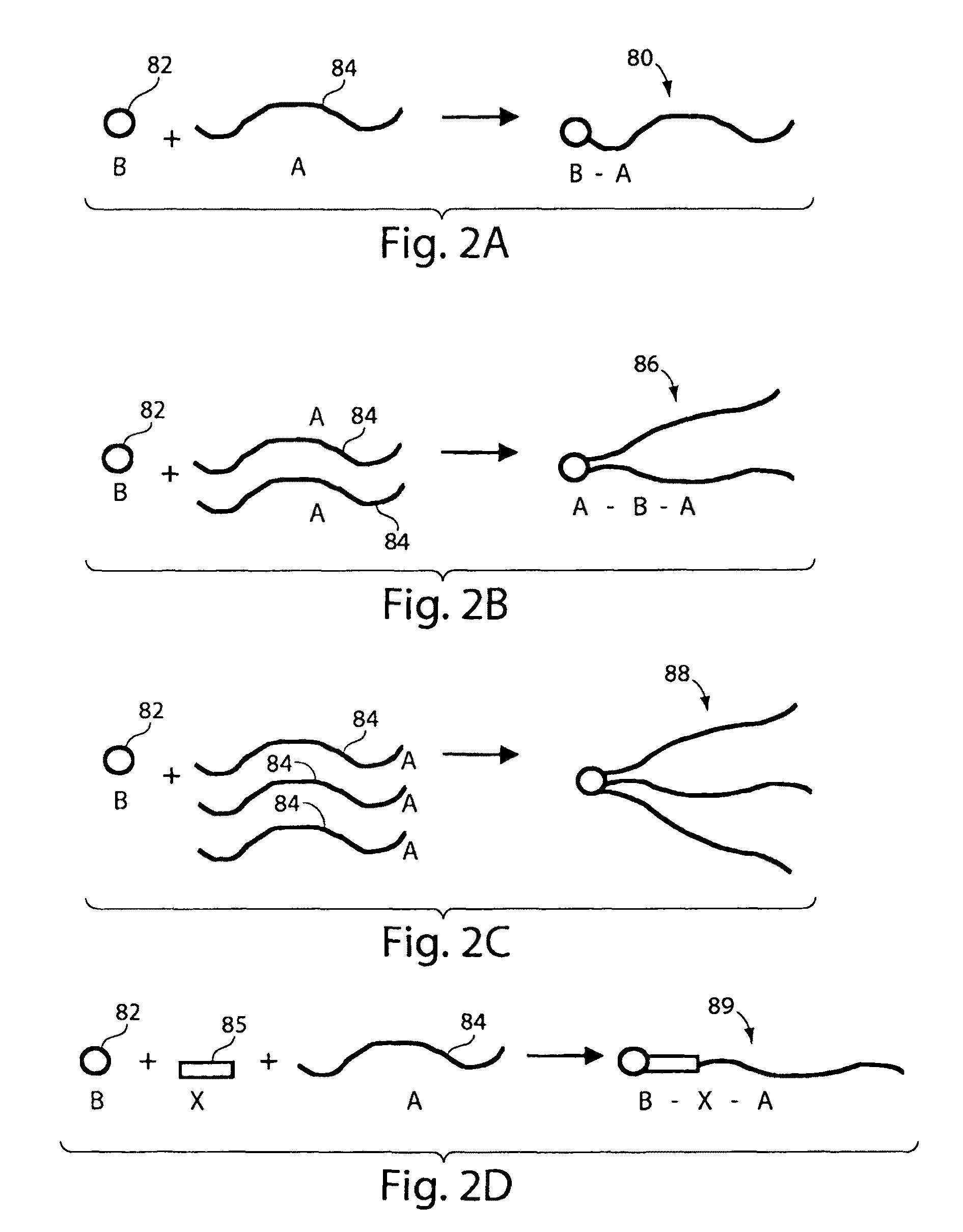

Fluorocarbon emulsion stabilizing surfactants

Surfactants (e.g., fluorosurfactants) for stabilizing aqueous or hydrocarbon droplets in a fluorophilic continuous phase are presented. In some embodiments, fluorosurfactants include a fluorophilic tail soluble in a fluorophilic (e.g., fluorocarbon) continuous phase, and a headgroup soluble in either an aqueous phase or a lipophilic (e.g., hydrocarbon) phase. The combination of a fluorophilic tail and a headgroup may be chosen so as to create a surfactant with a suitable geometry for forming stabilized reverse emulsion droplets having a disperse aqueous or lipophilic phase in a continuous, fluorophilic phase. In some embodiments, the headgroup is preferably non-ionic and can prevent or limit the adsorption of molecules at the interface between the surfactant and the discontinuous phase. This configuration can allow the droplet to serve, for example, as a reaction site for certain chemical and / or biological reactions. In another embodiment, aqueous droplets are stabilized in a fluorocarbon phase at least in part by the electrostatic attraction of two oppositely charged or polar components, one of which is at least partially soluble in the dispersed phase, the other at least partially soluble in the continuous phase. One component may provide collodial stability of the emulsion, and the other may prevent the adsorption of biomolecules at the interface between a component and the discontinous phase. Advantageously, surfactants and surfactant combinations of the invention may provide sufficient stabilization against coalescence of droplets, without interfering with processes that can be carried out inside the droplets.

Owner:BIO RAD LAB INC +2

Blowing agents for forming foam comprising unsaturated fluorocarbons

Owner:EI DU PONT DE NEMOURS & CO

Bi-layer hard mask for the patterning and etching of nanometer size MRAM devices

ActiveUS20120028373A1Inhibition formationAvoid formingFilm/foil adhesivesSemiconductor/solid-state device manufacturingEtchingEngineering

A composite hard mask is disclosed that prevents build up of metal etch residue in a MRAM device during etch processes that define an MTJ shape. As a result, MTJ shape integrity is substantially improved. The hard mask has a lower non-magnetic spacer, a middle conductive layer, and an upper sacrificial dielectric layer. The non-magnetic spacer serves as an etch stop during a pattern transfer with fluorocarbon plasma through the conductive layer. A photoresist pattern is transferred through the dielectric layer with a first fluorocarbon etch. Then the photoresist is removed and a second fluorocarbon etch transfers the pattern through the conductive layer. The dielectric layer protects the top surface of the conductive layer during the second fluorocarbon etch and during a substantial portion of a third RIE step with a gas comprised of C, H, and O that transfers the pattern through the underlying MTJ layers.

Owner:TAIWAN SEMICON MFG CO LTD

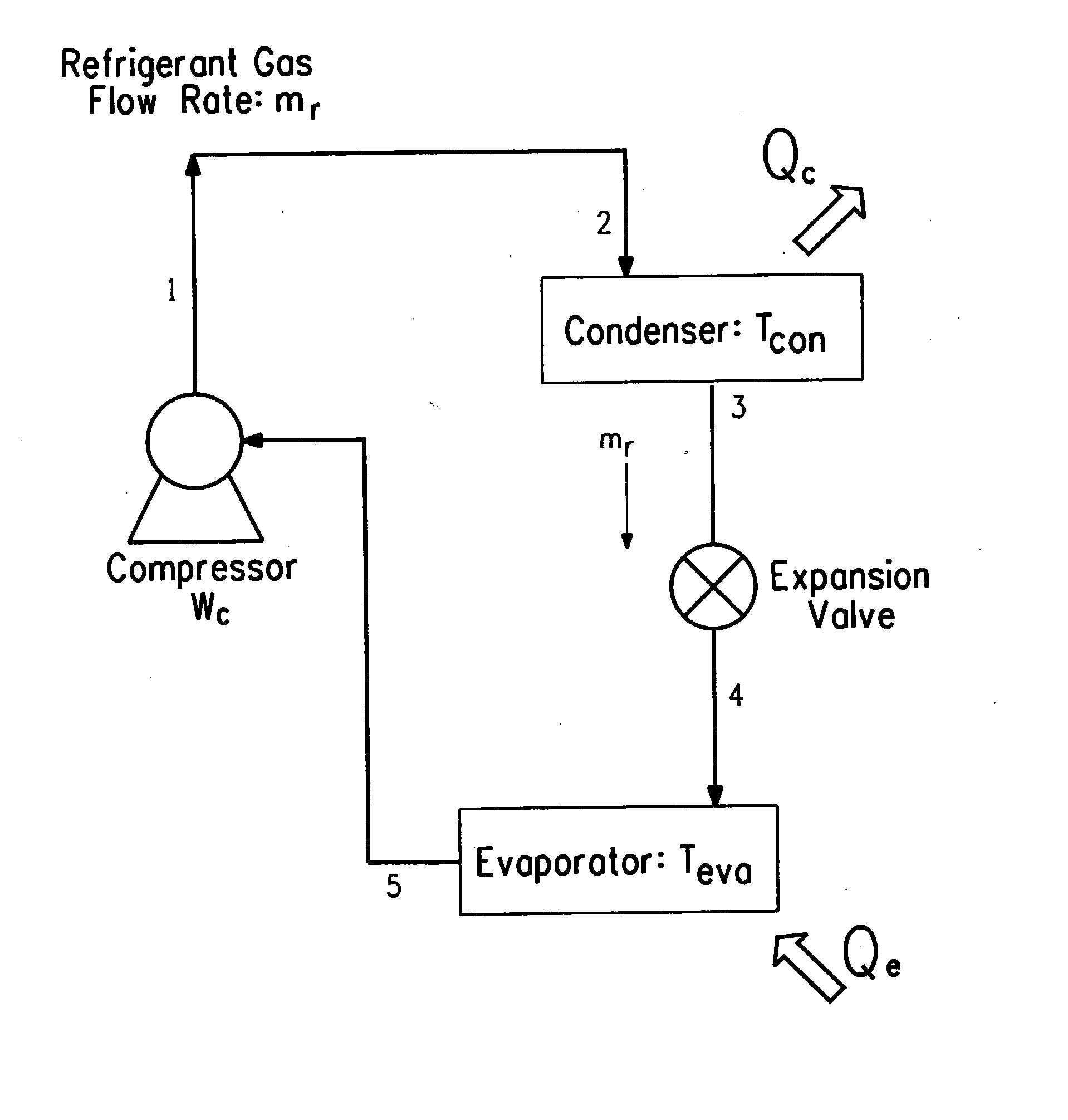

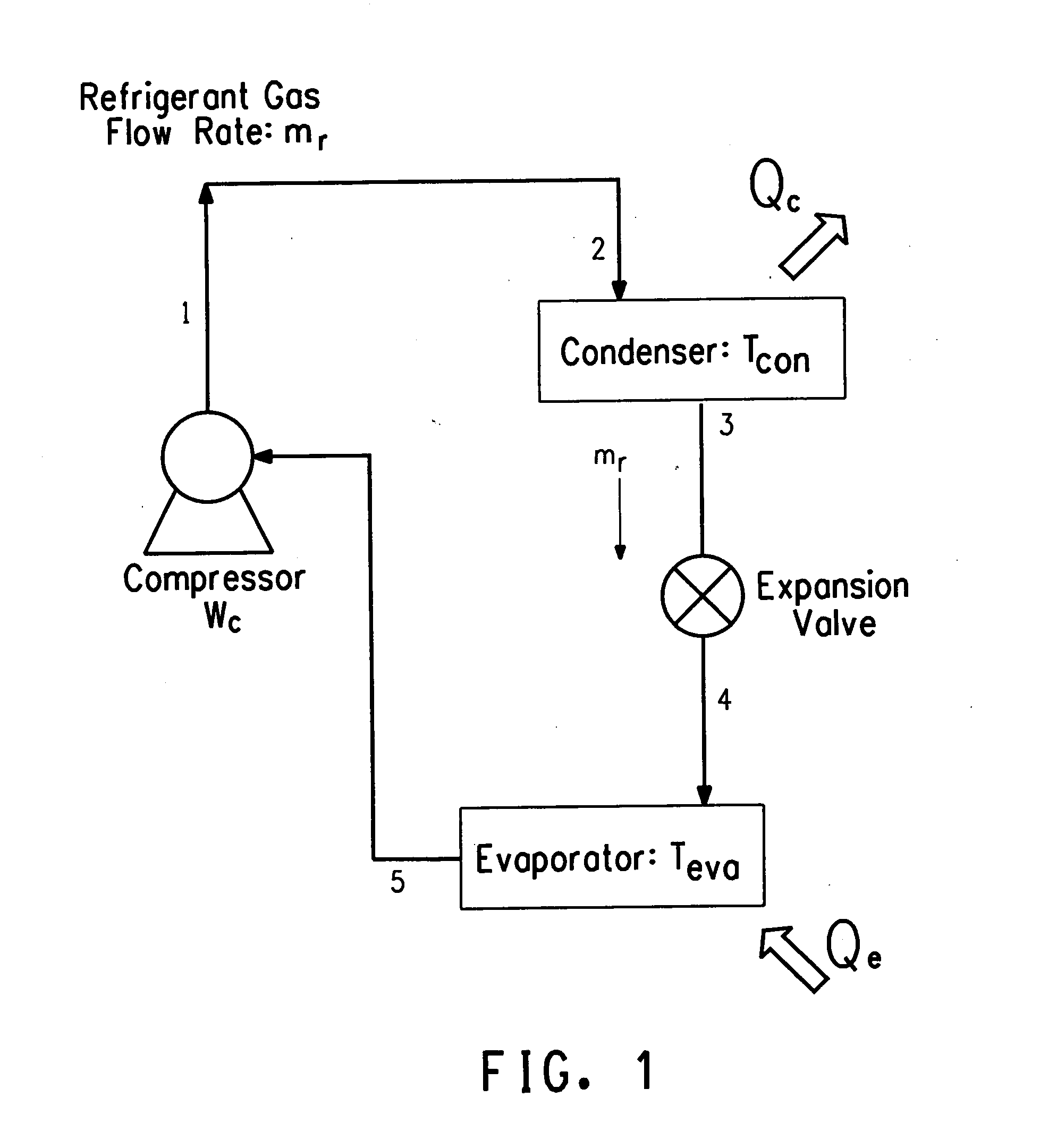

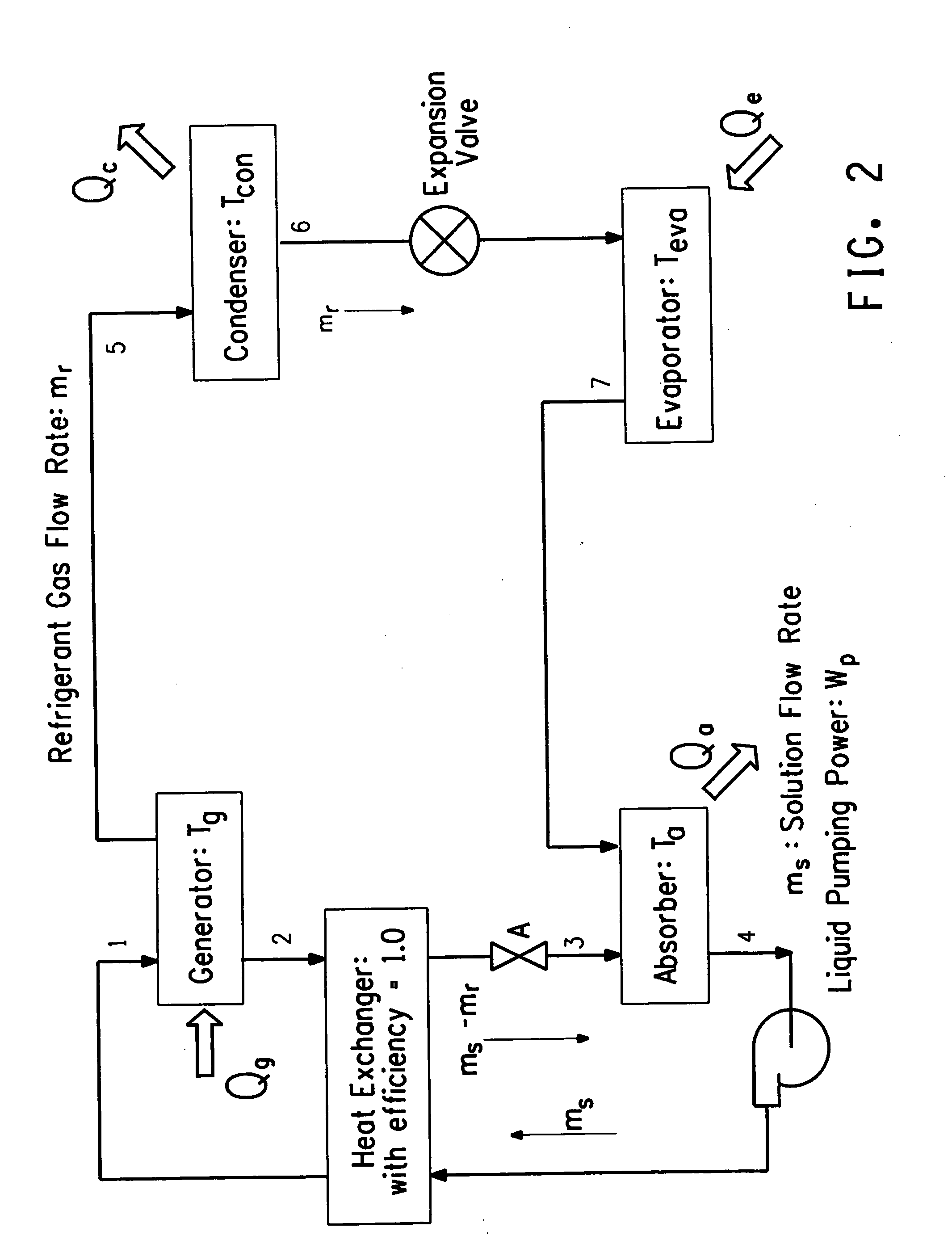

Hybrid vapor compression-absorption cycle

InactiveUS20070019708A1Limit scopeCompression machines with non-reversible cycleThermometers using electric/magnetic elementsFluorocarbonRefrigerant

The present invention relates to a hybrid vapor compression-absorption cooling or heating system and apparatus containing a refrigerant pair comprising at least one refrigerant and at least one ionic liquid. The present invention also provides for the performance of a hybrid vapor compression-absorption cycle that utilizes refrigerants and absorbents such as fluorocarbon gases in fluorinated ionic liquids. The present invention also provides a method of cooling by the execution of a hybrid vapor compression-absorption cycle using a refrigerant pair comprising at least one refrigerant and at least one ionic liquid. The present invention also provides a method of heating by the execution of a hybrid vapor compression-absorption cycle using a refrigerant pair comprising at least one refrigerant and at least one ionic liquid.

Owner:EI DU PONT DE NEMOURS & CO

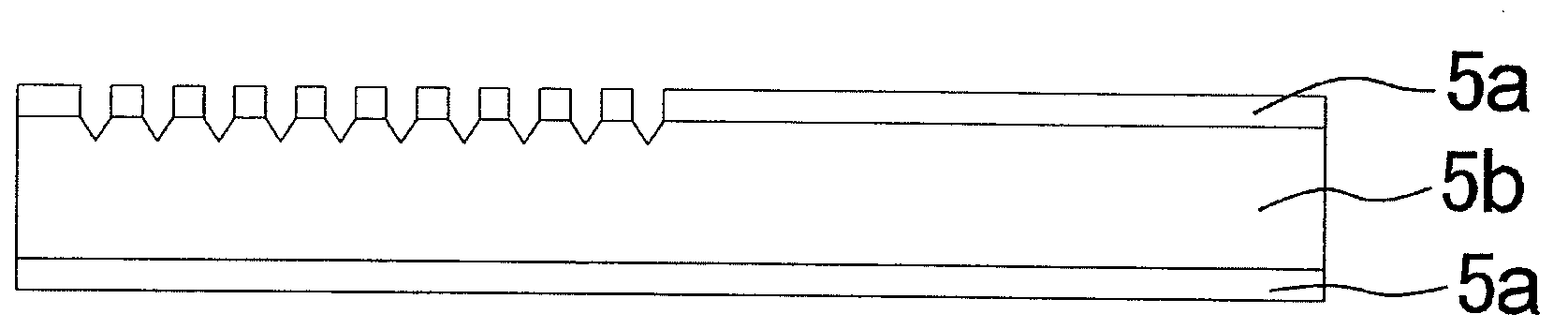

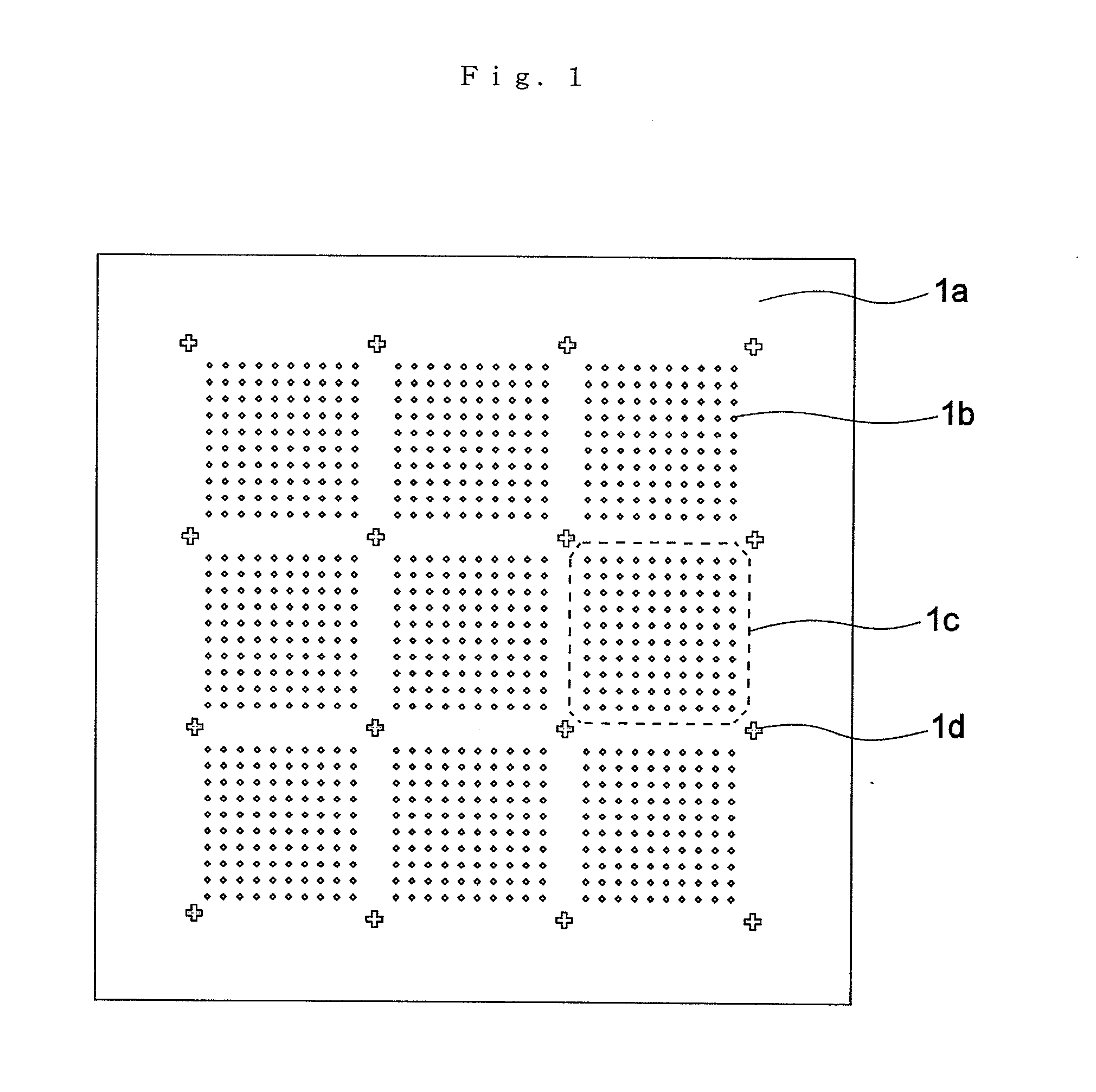

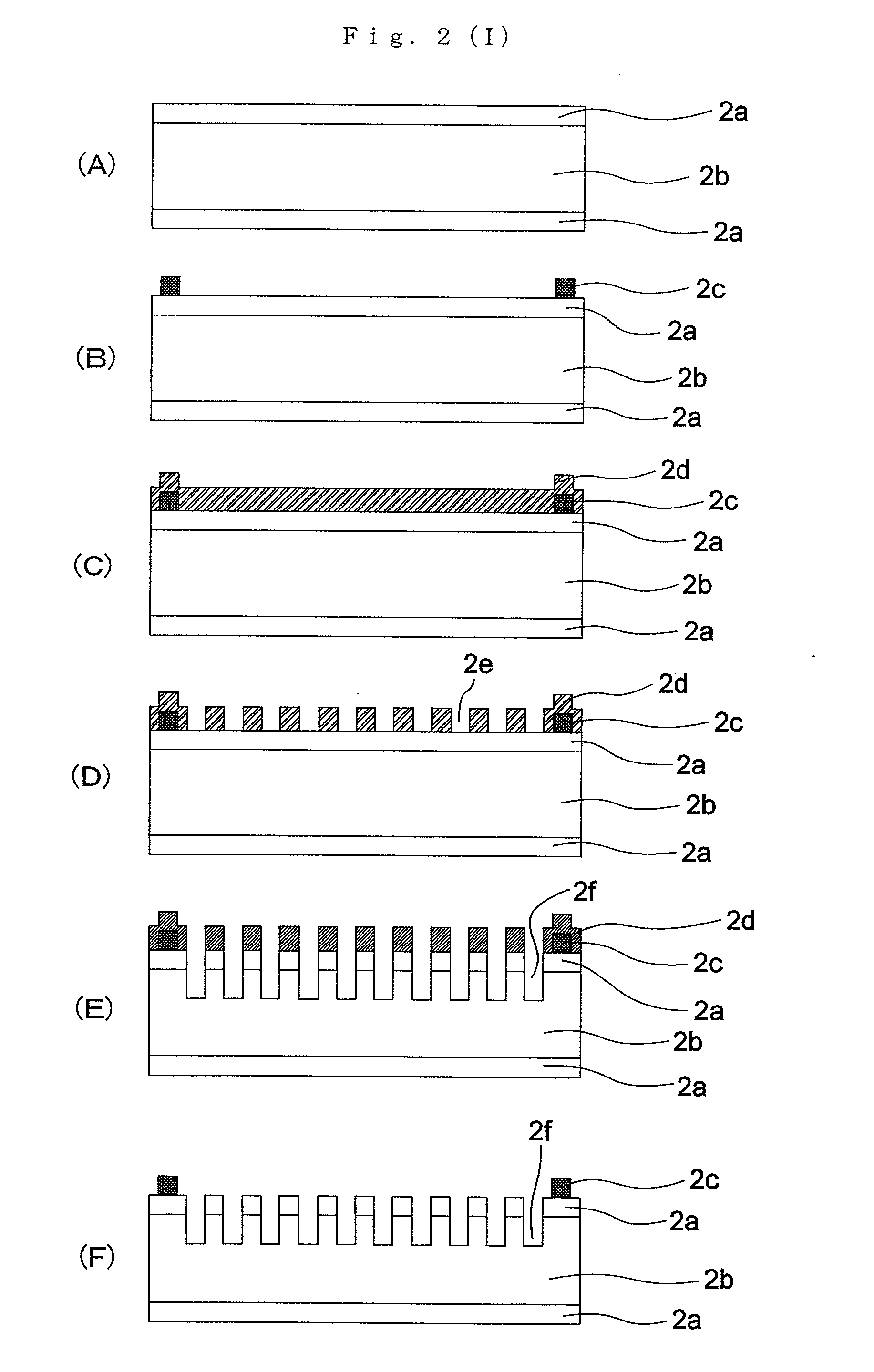

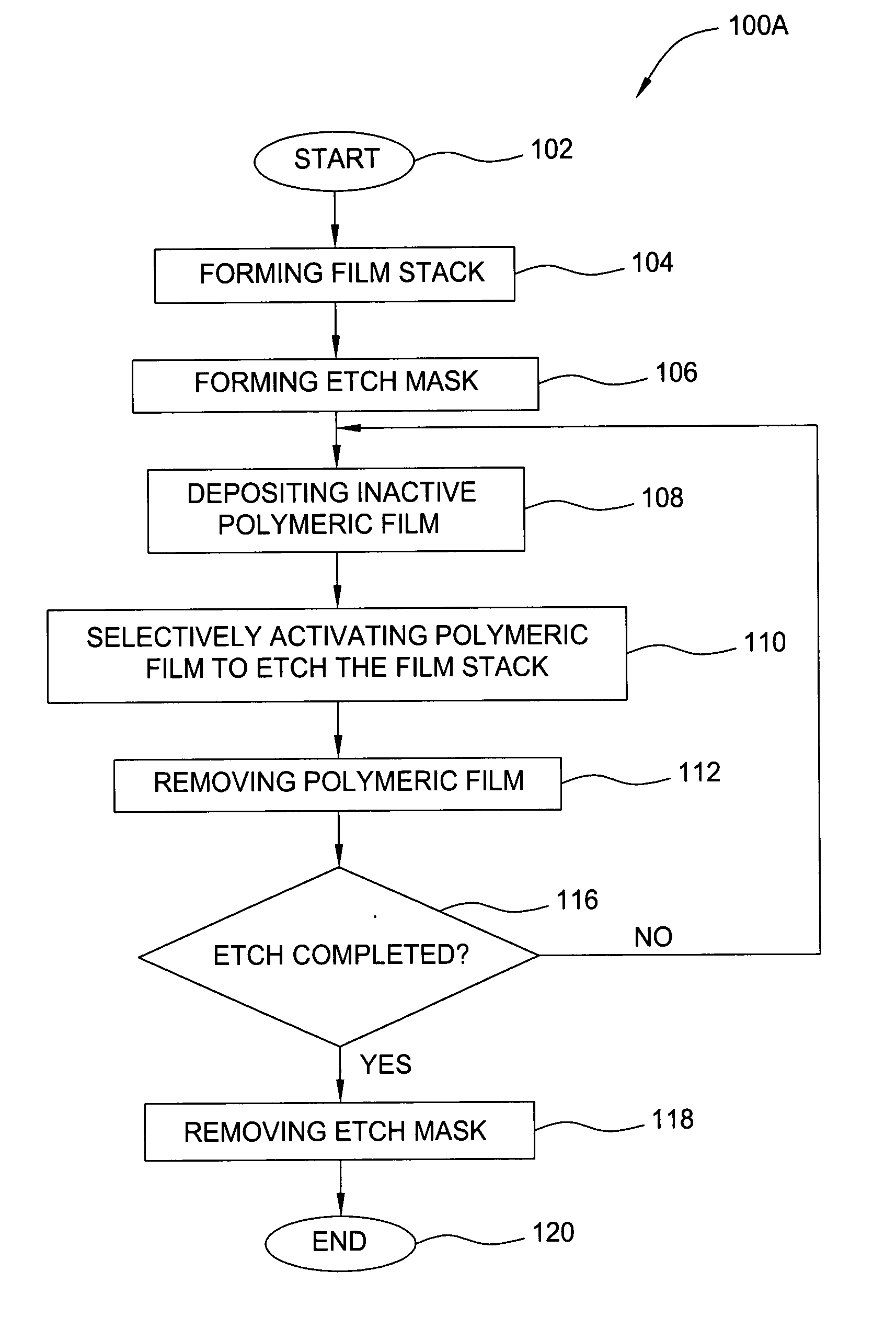

Microwell array chip and method of manufacturing same

ActiveUS20110195496A1Sequential/parallel process reactionsGenetic material ingredientsFluorocarbonSilicon

The present invention is directed to a microwell array chip made of silicon and having multiple microwells. Each microwell is used to store a single specimen organic cell. Each microwell is of a size and shape holding just one organic cell, and the interior surface of the microwells are coated with a fluorocarbon film.

Owner:BLINK BIOMEDICAL SAS

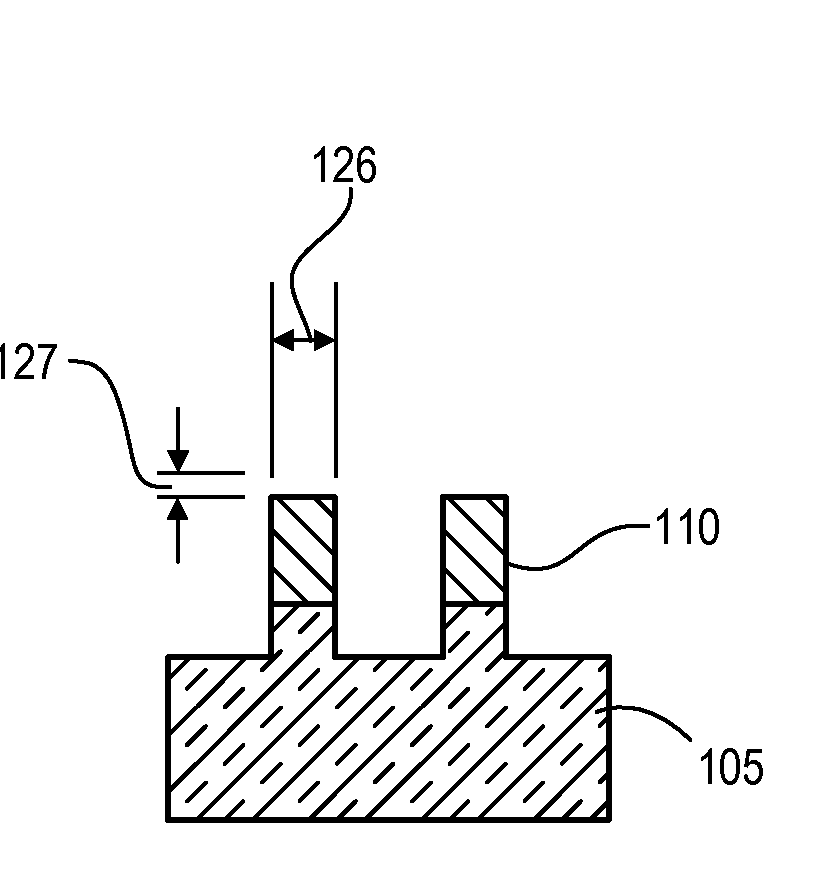

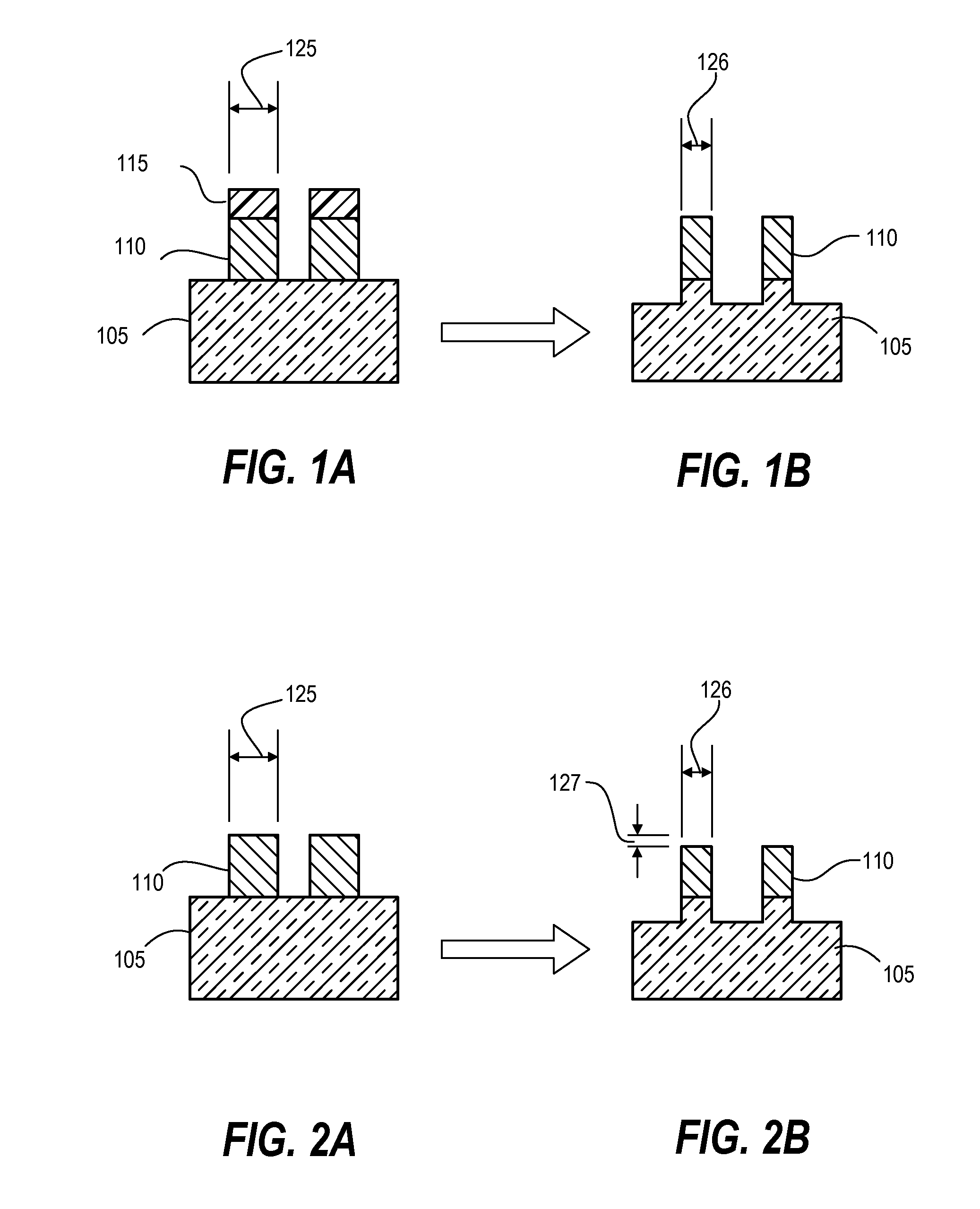

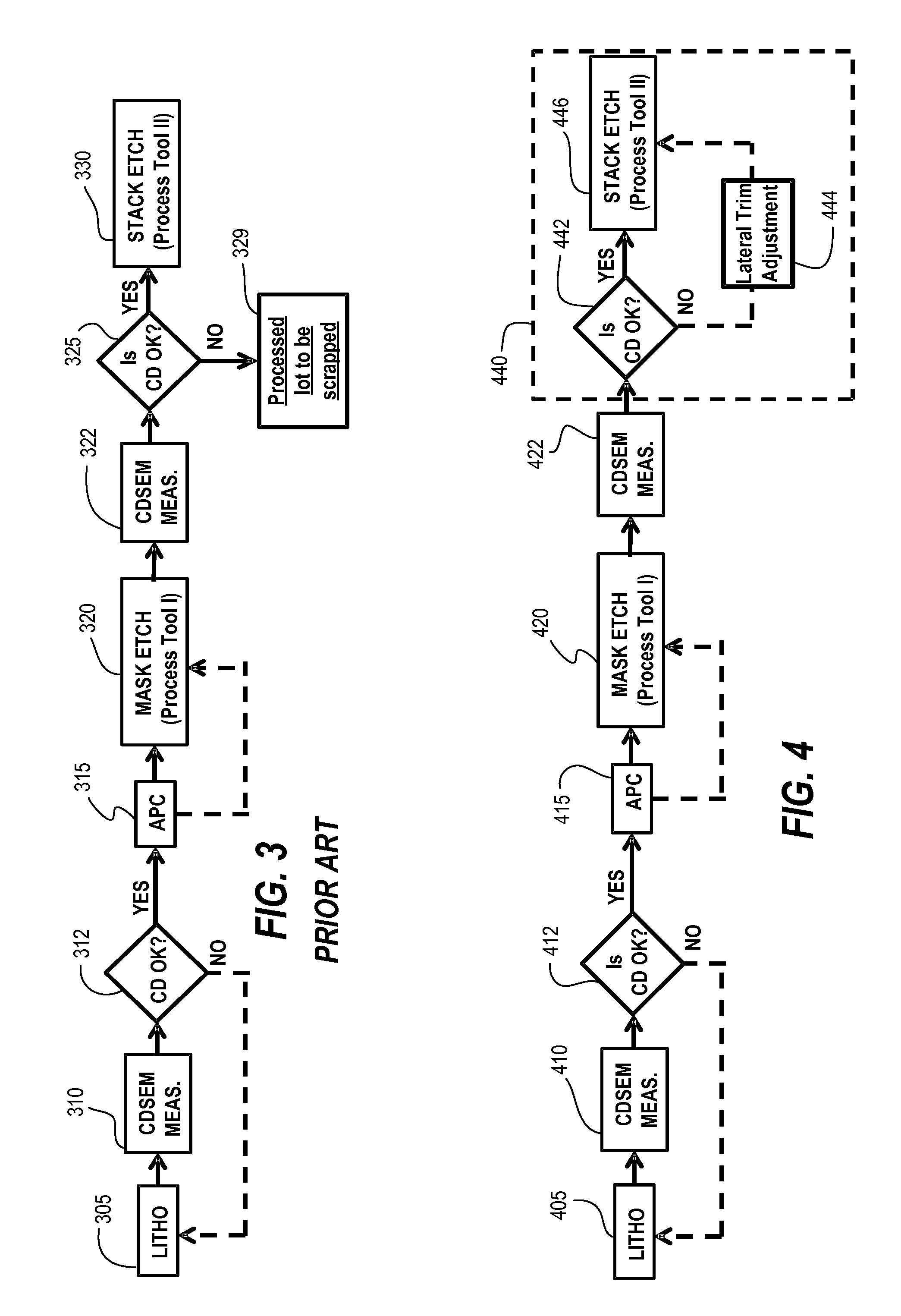

Method for Laterally Trimming a Hardmask

ActiveUS20150064918A1Reduce decreaseReduced dimensionSemiconductor/solid-state device manufacturingDielectricFluorocarbon

Techniques herein include methods for controllable lateral etching of dielectrics in polymerizing fluorocarbon plasmas. Methods can include dielectric stack etching that uses a mask trimming step as part of a silicon etching process. Using a fluorocarbon mixture for dielectric mask trimming provides several advantages, such as being straightforward to apply and providing additional flexibility to the process flow. Thus, techniques herein provide a method to correct or tune CDs on a hardmask. In general, this technique can include using a fluorine-based and a fluorocarbon-based, or fluorohydrocarbon-based, chemistry for creating a plasma, and controlling a ratio of the two chemistries. Without the hardmask trim method disclosed herein, if a hardmask CD is not on target, then a wafer is scrapped. With hard-mask trim capability in silicon etch as disclosed herein, a given CD can be re-targeted to eliminate wafer-scraps.

Owner:TOKYO ELECTRON LTD

Methods for making foams using blowing agents comprising unsaturated fluorocarbons

Owner:THE CHEMOURS CO FC LLC

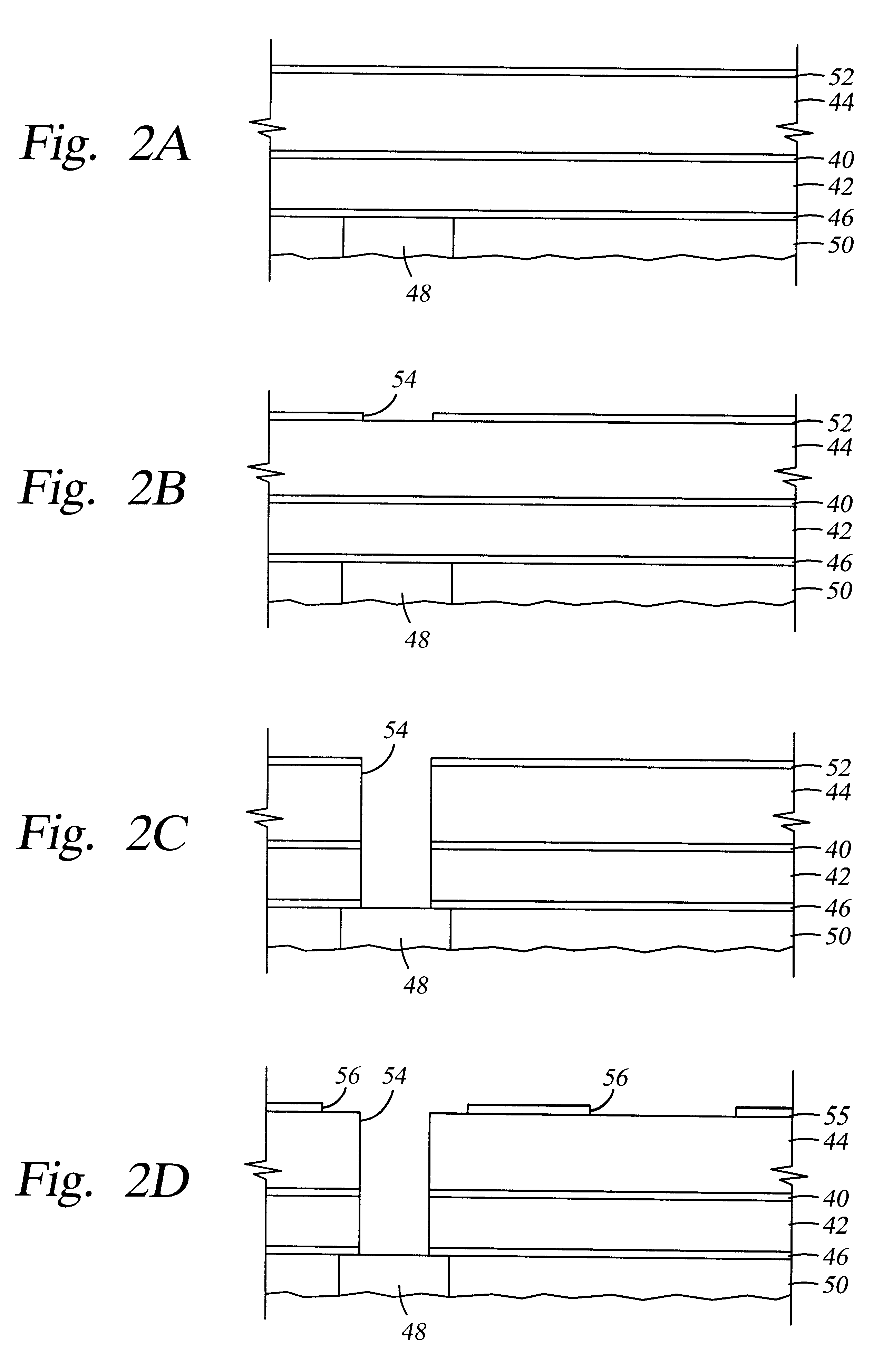

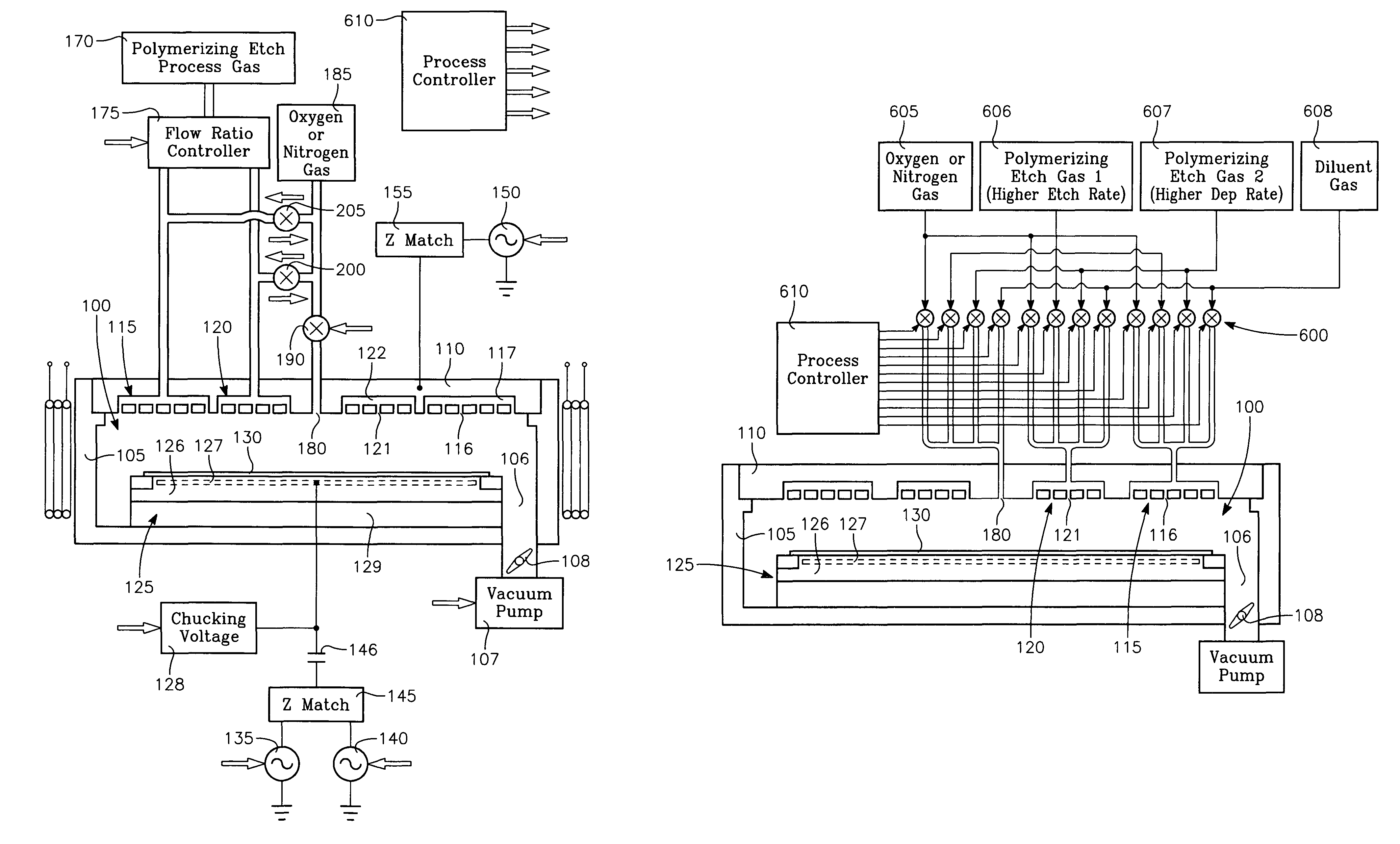

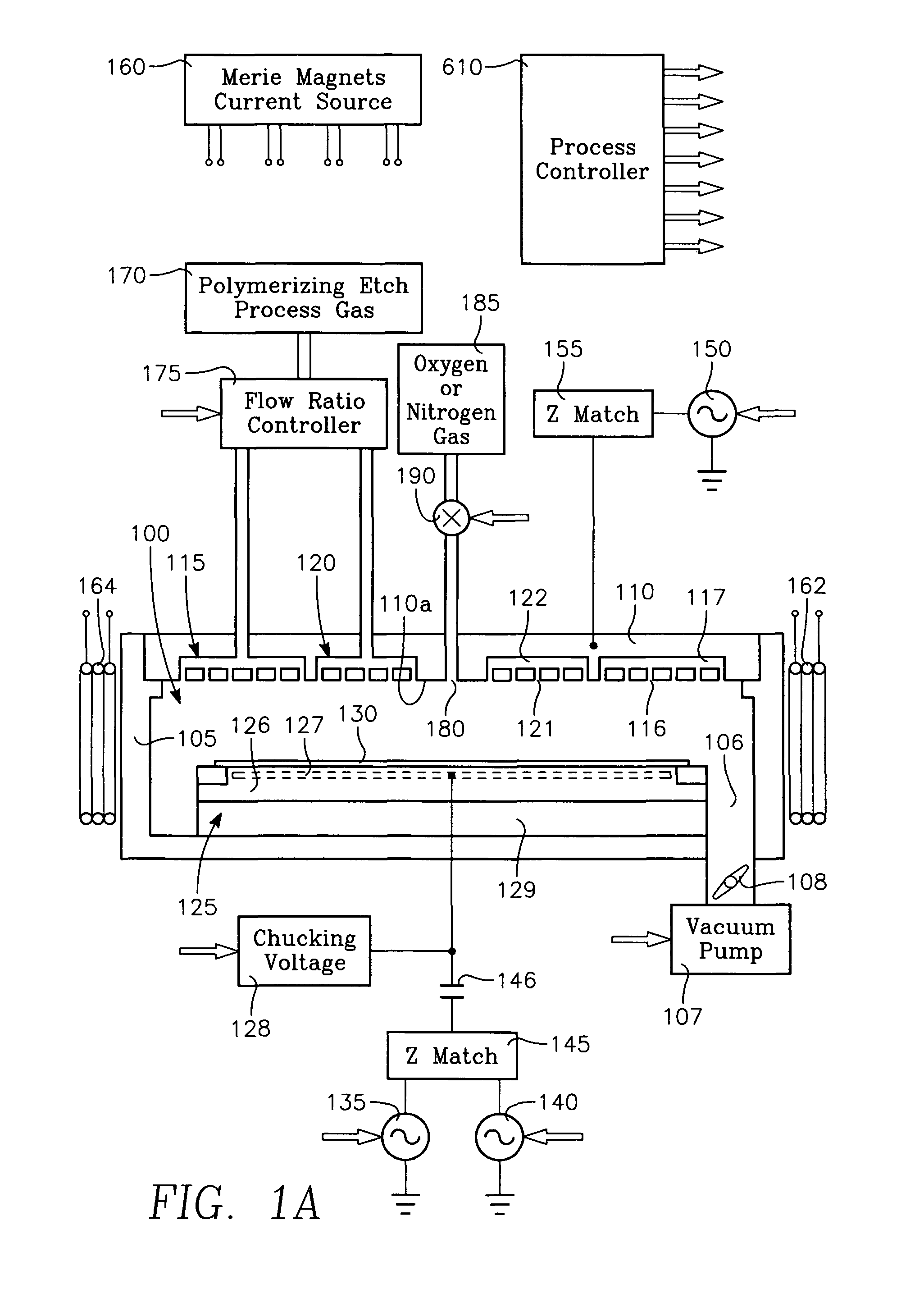

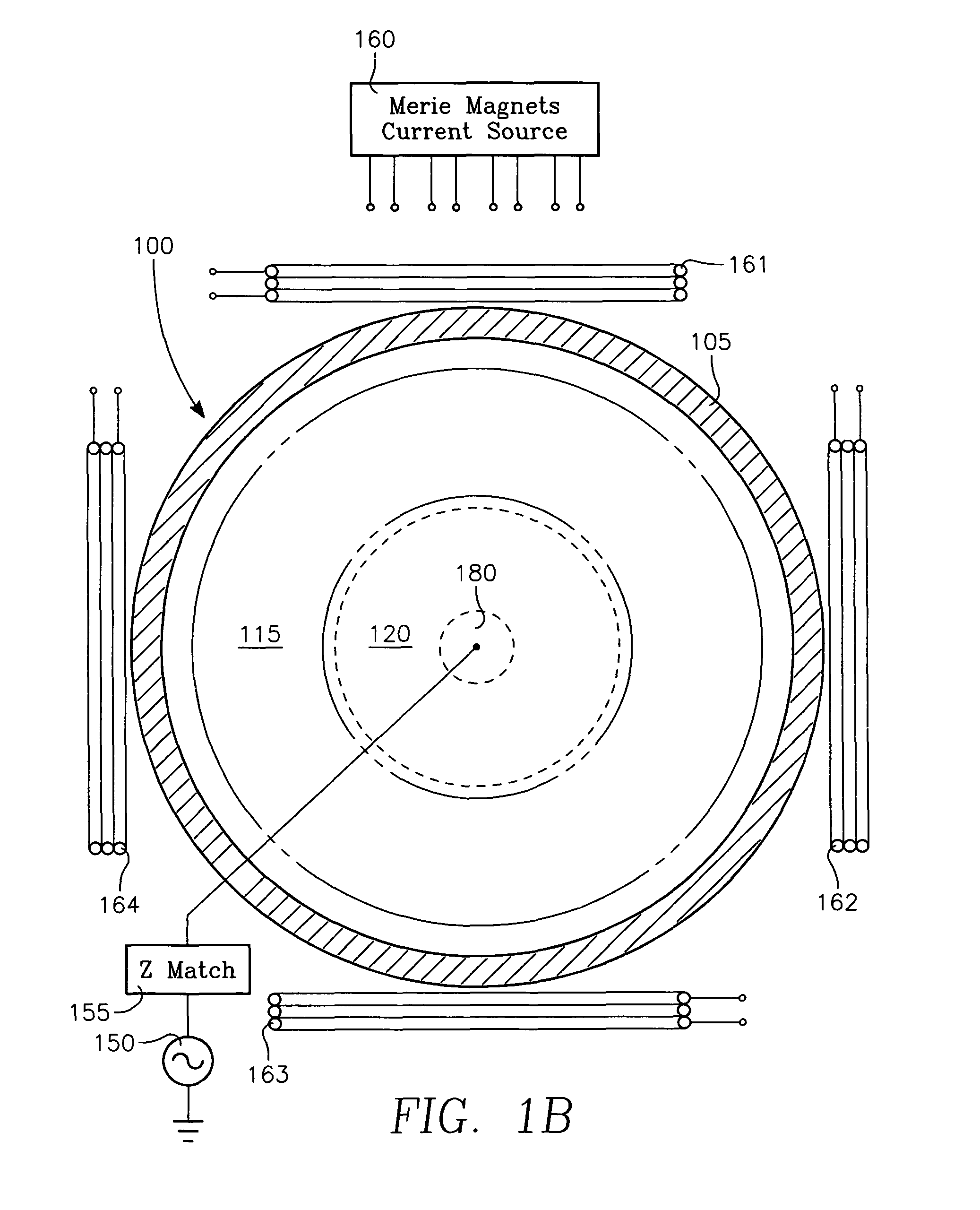

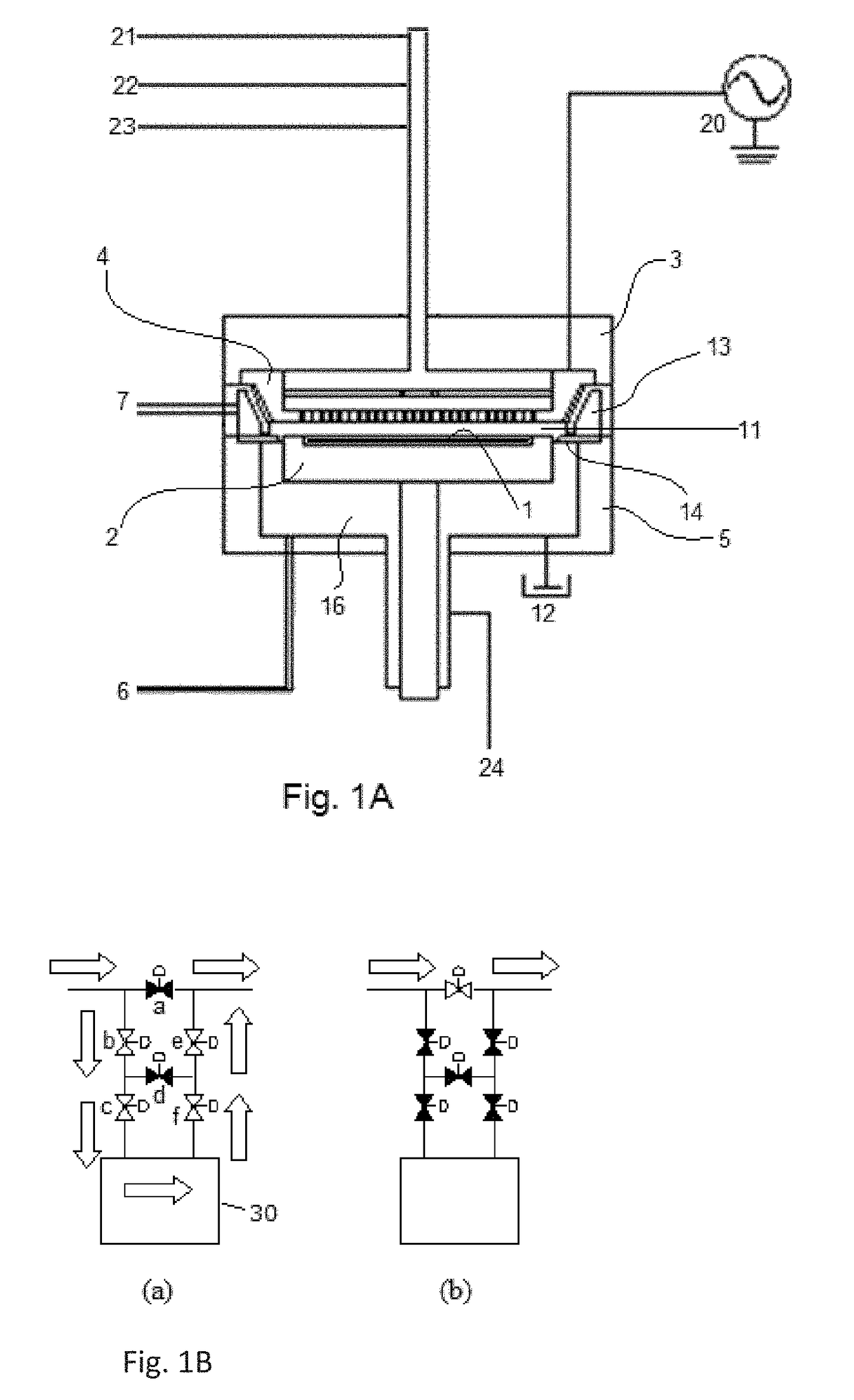

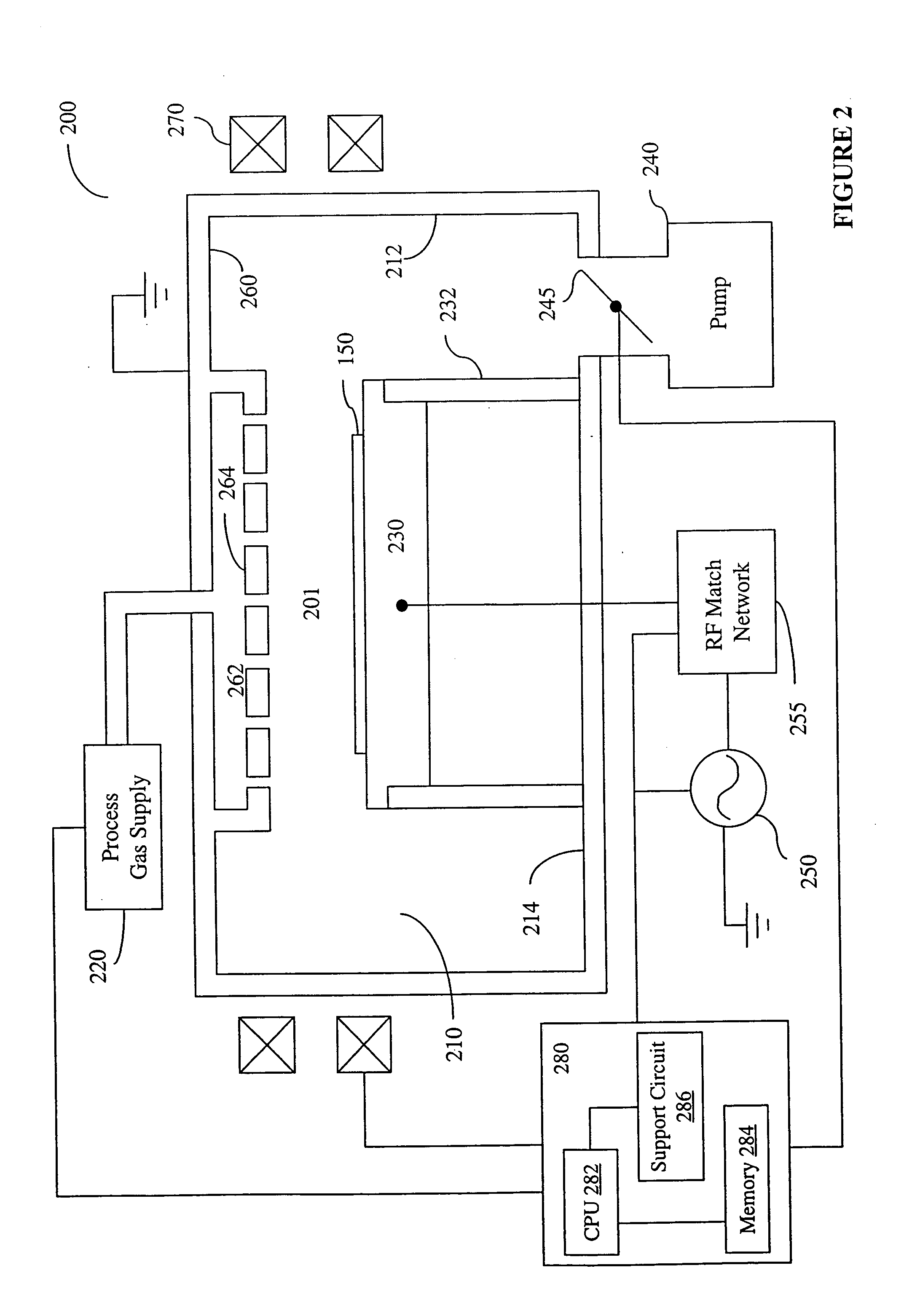

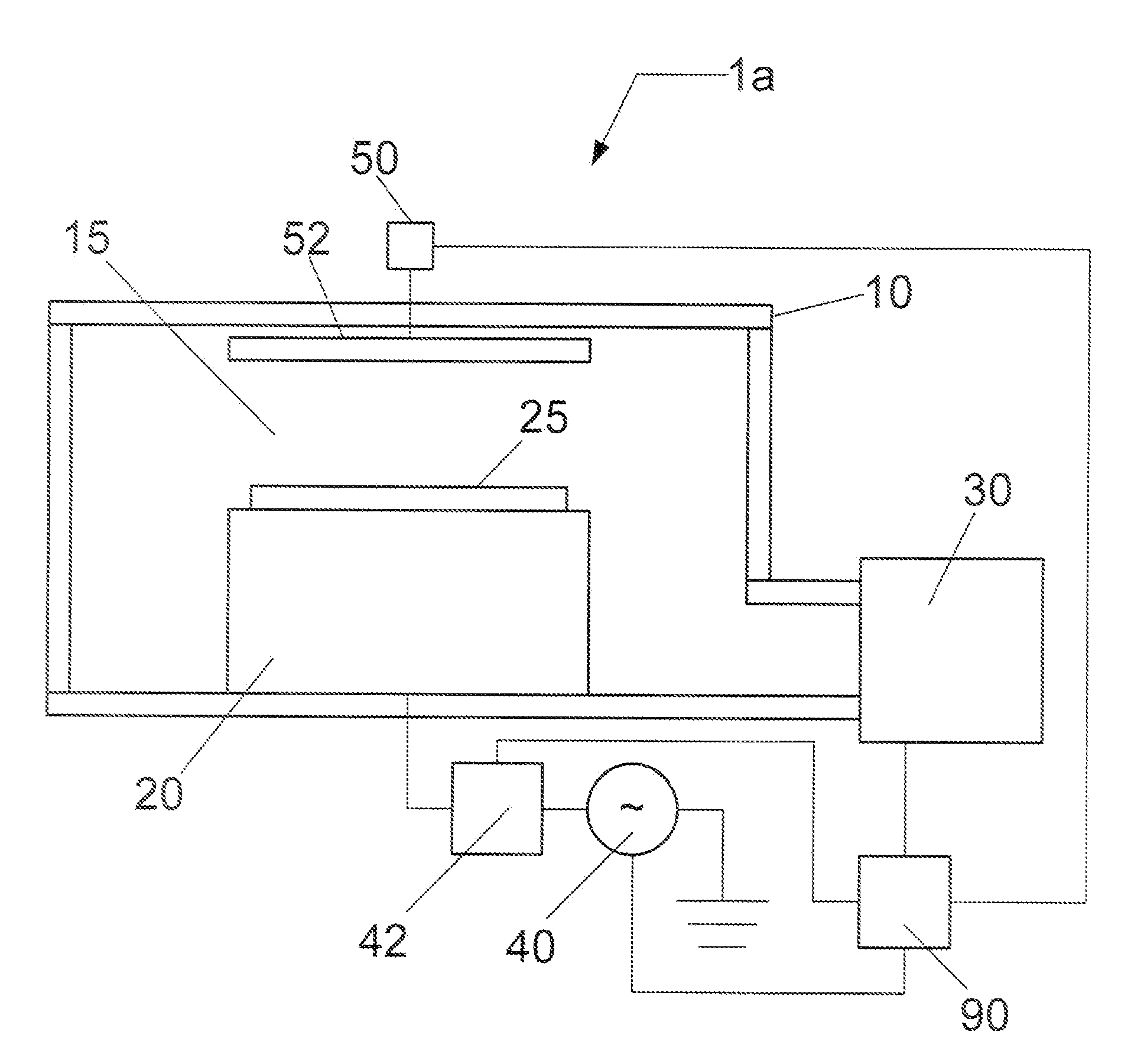

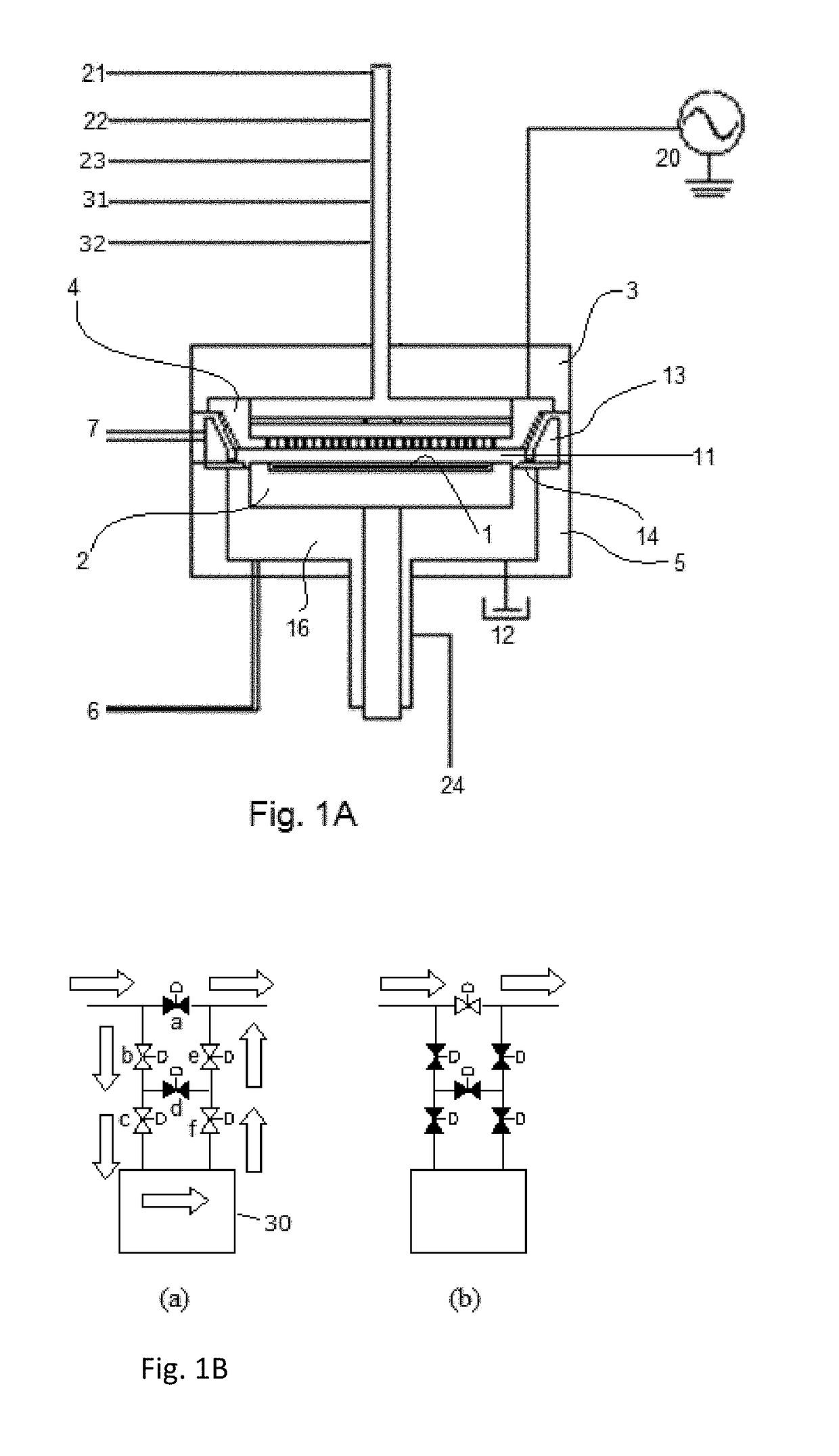

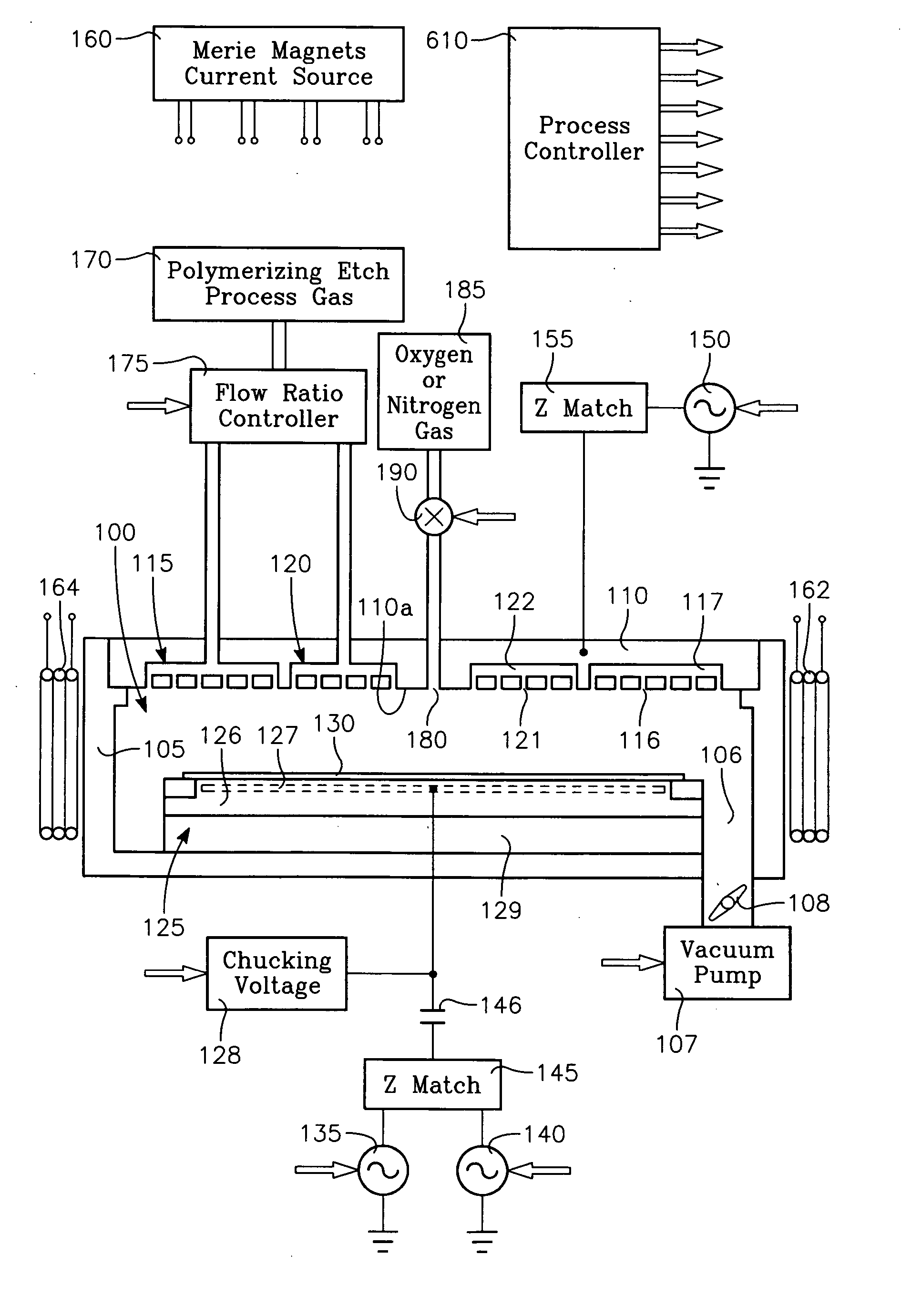

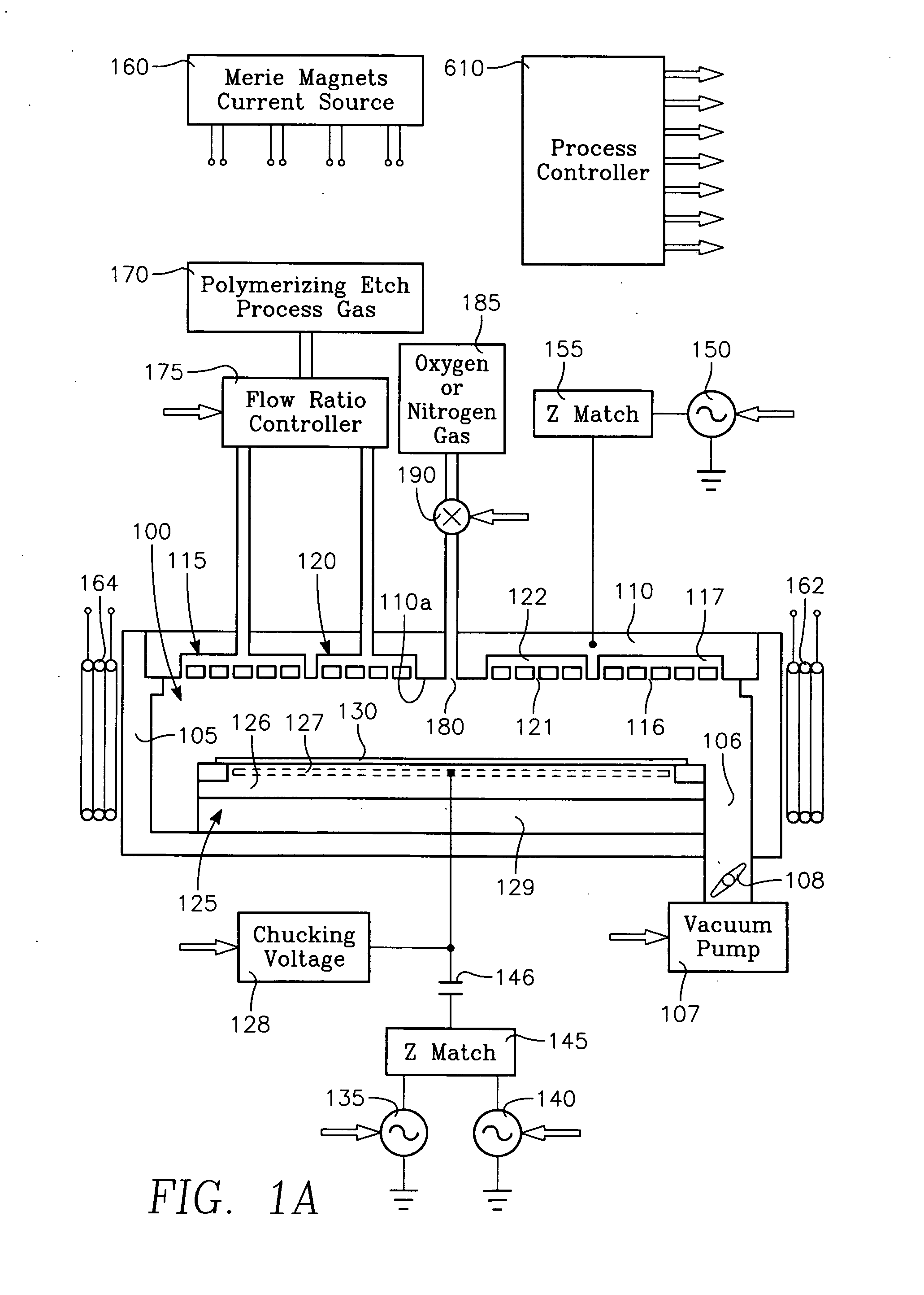

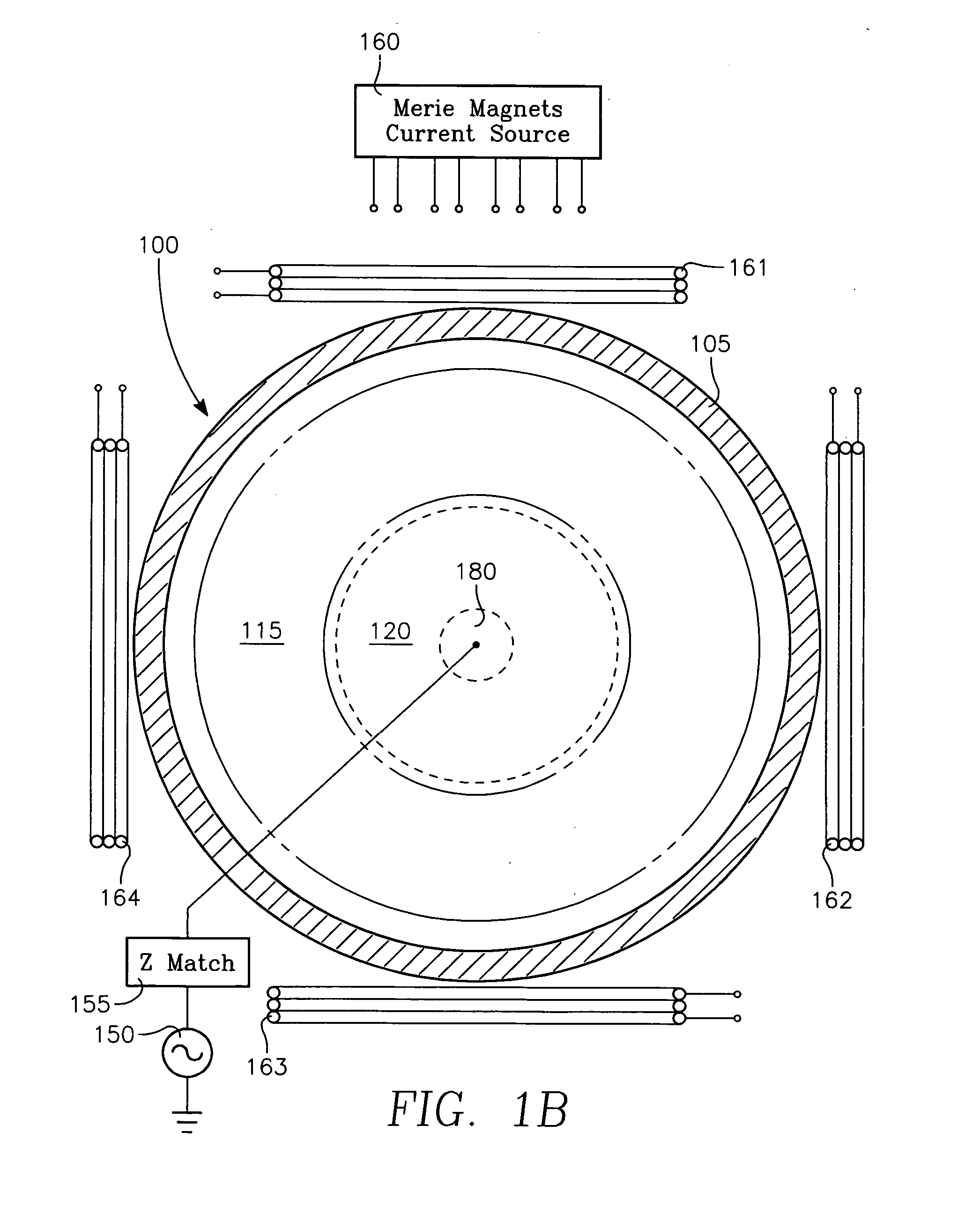

Plasma reactor apparatus with multiple gas injection zones having time-changing separate configurable gas compositions for each zone

ActiveUS20070251642A1Electric discharge tubesVacuum gauge using ionisation effectsGas compositionOxygen

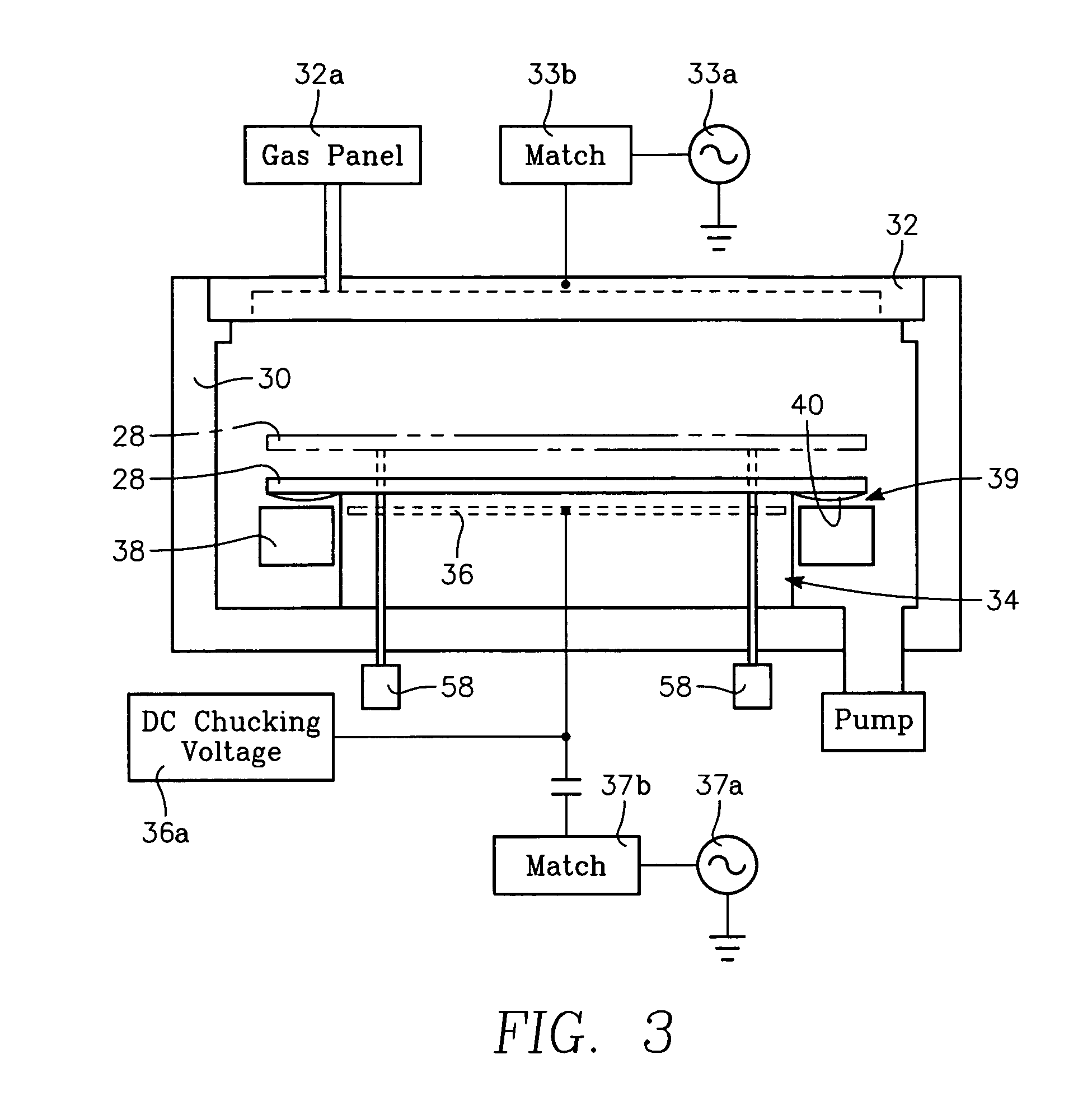

A plasma reactor for processing a workpiece such as a semiconductor wafer has a housing defining a process chamber, a workpiece support configured to support a workpiece within the chamber during processing and comprising a plasma bias power electrode. The reactor further includes plural gas sources containing different gas species, plural process gas inlets and an array of valves capable of coupling any of said plural gas sources to any of said plural process gas inlets. The reactor also includes a controller governing said array of valves and is programmed to change the flow rates of gases through said inlets over time. A ceiling plasma source power electrode of the reactor has plural gas injection zones coupled to the respective process gas inlets. In a preferred embodiment, the plural gas sources comprise supplies containing, respectively, fluorocarbon or fluorohydrocarbon species with respectively different ratios of carbon and fluorine chemistries. They further include an oxygen or nitrogen supply and a diluent gas supply. The controller is programmed to produce flow of different process gas species or mixtures thereof through different ones of said plural gas injection zones. The controller is further programmed to change over time the species content of the gases flowing through different ones of said plural gas injection zones.

Owner:APPLIED MATERIALS INC

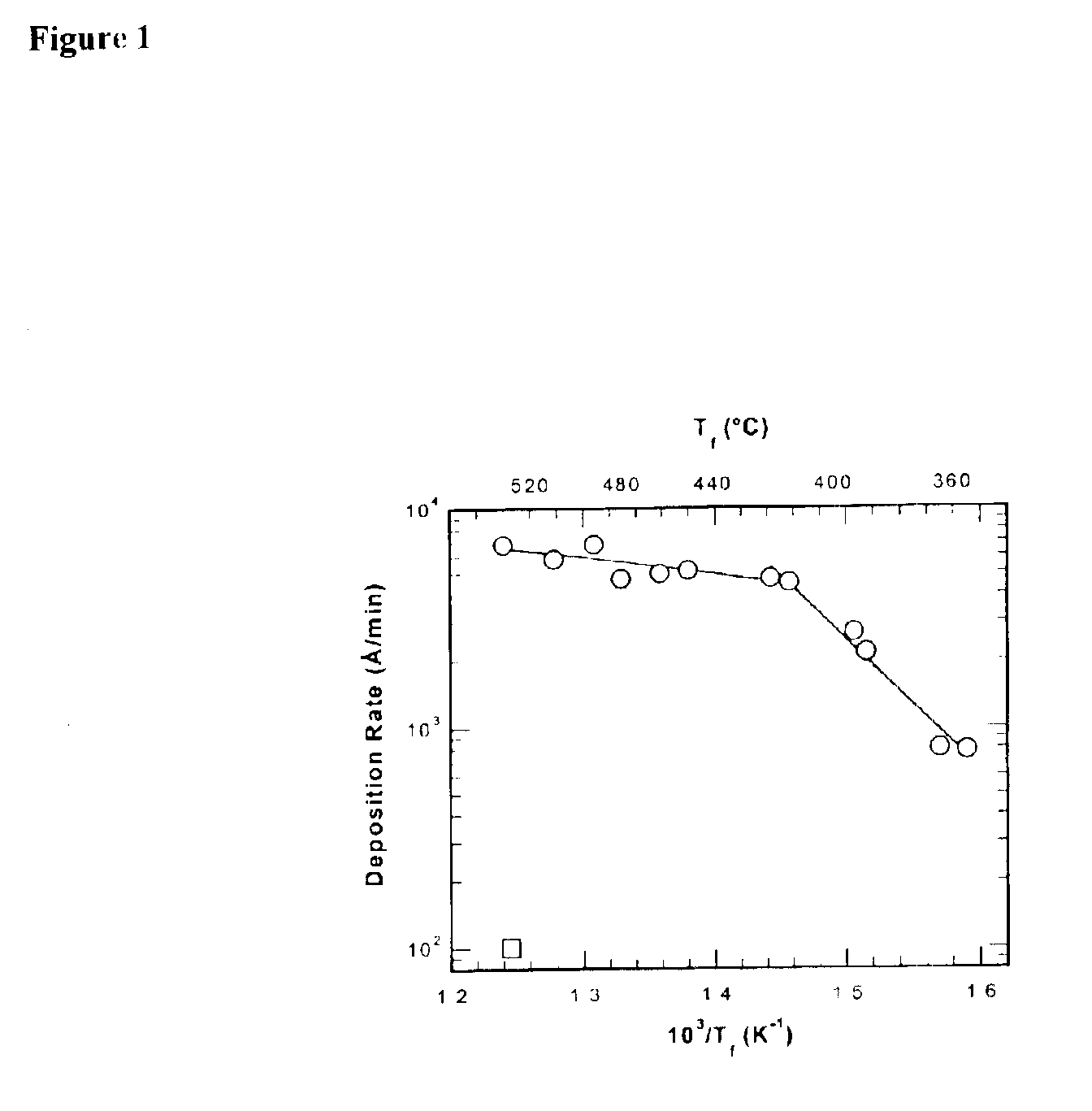

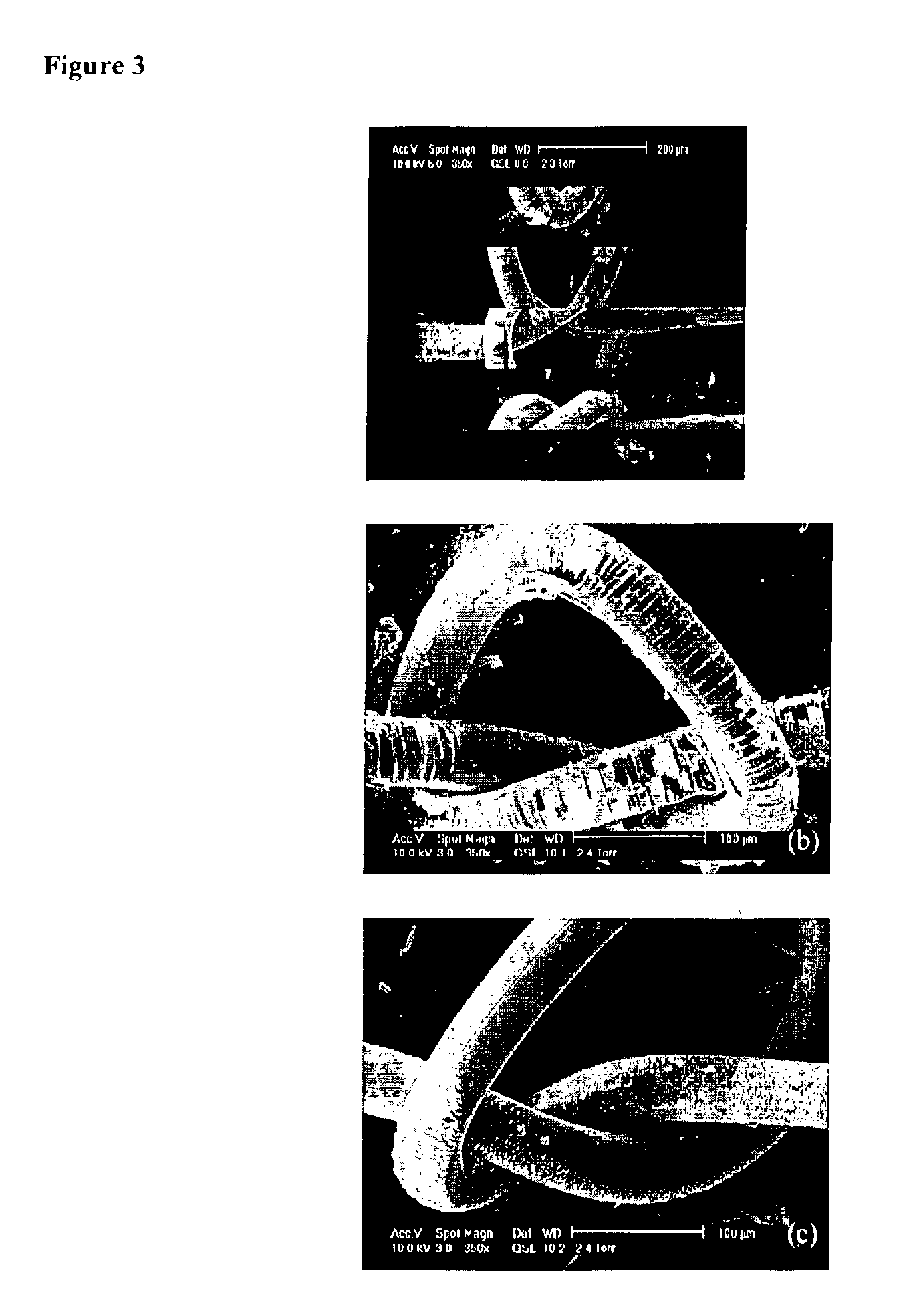

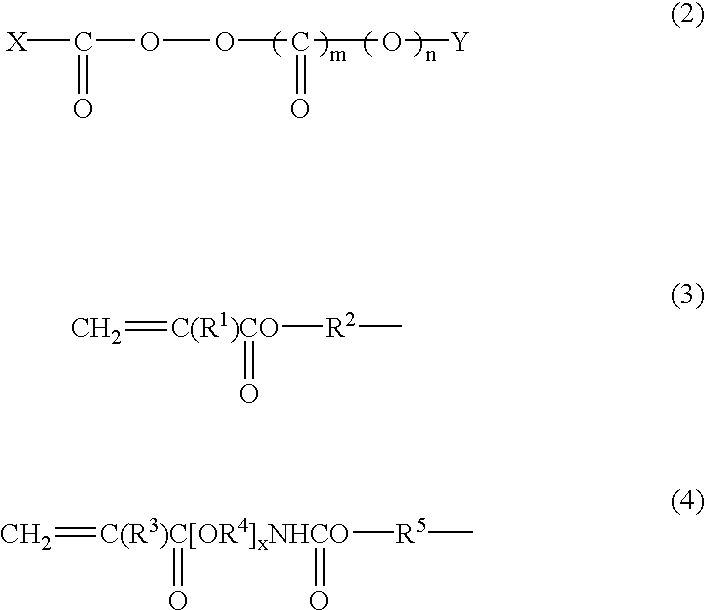

Fluorocarbon-organosilicon copolymers and coatings prepared by hot-filament chemical vapor deposition

InactiveUS6887578B2Synthetic resin layered productsCellulosic plastic layered productsGas phaseX-ray

Hot-filament chemical vapor deposition has been used to deposit copolymer thin films consisting of fluorocarbon and siloxane groups. The presence of covalent bonds between the fluorocarbon and organosilicon moieties in the thin film has been confirmed by Infrared, X-ray Photoelectron (XPS) and solid-state 29Si, 19F, and 13C Nuclear Magnetic Resonance (NMR) spectroscopy. The film structure consists of chains with linear and cyclic siloxane groups and CF2 groups as repeat units.

Owner:MASSACHUSETTS INST OF TECH

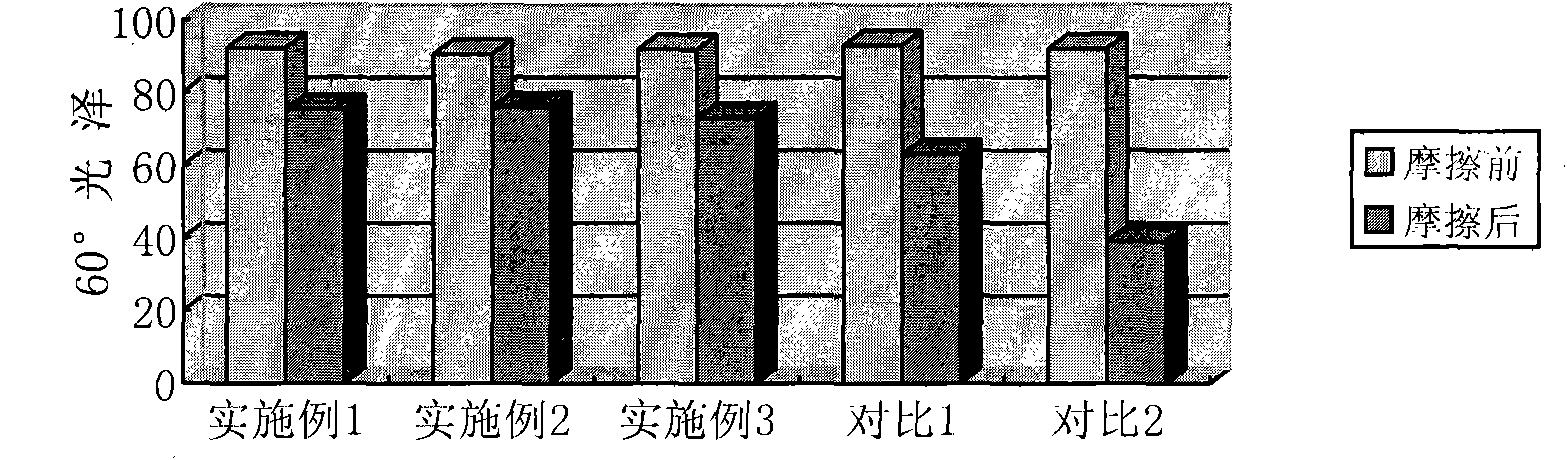

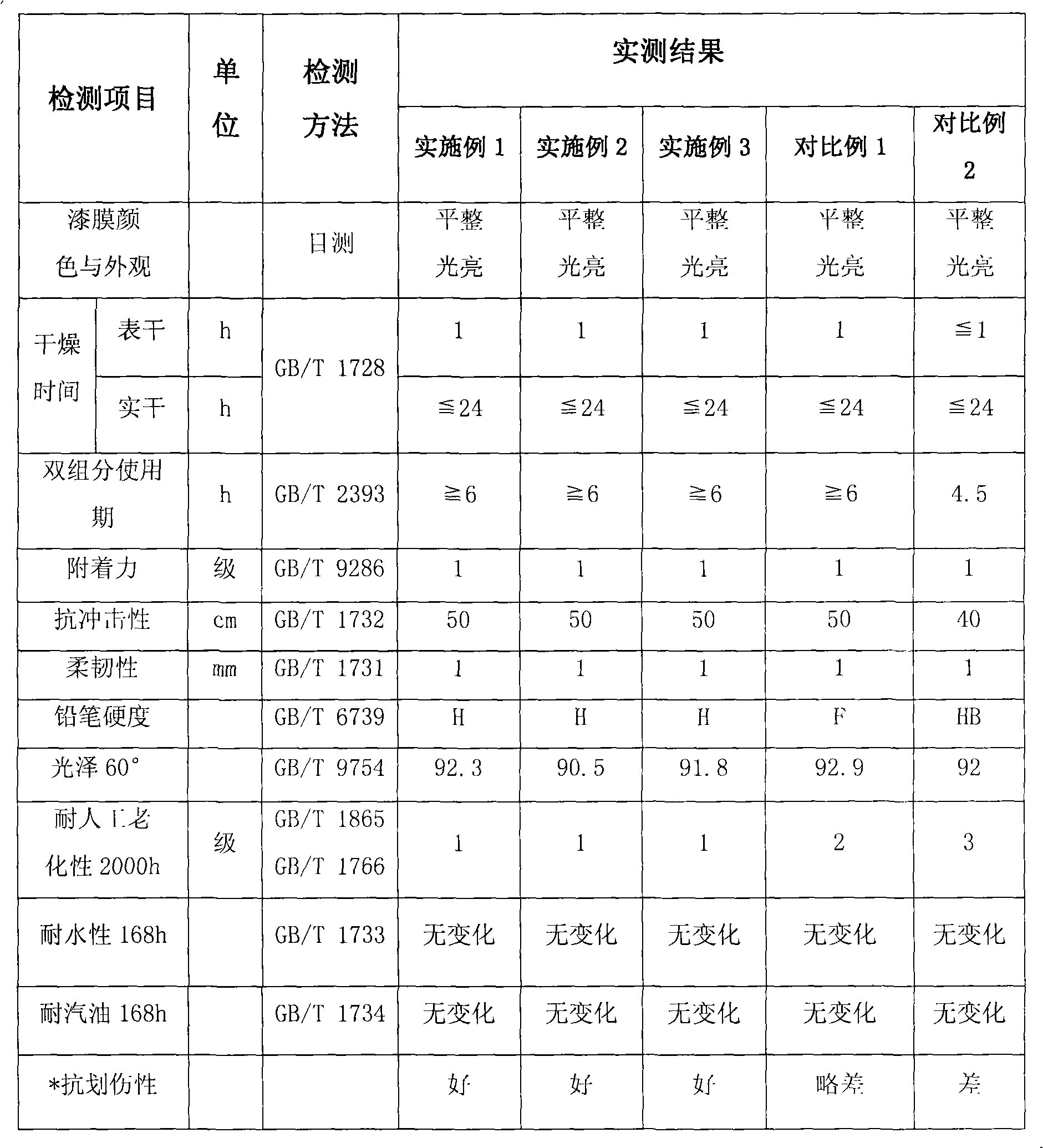

Wear-resisting scratch-resisting weather-proof polyurethane coating and preparation method thereof

ActiveCN101792639AImprove scratch resistanceGood weather resistancePolyurea/polyurethane coatingsPolyester coatingsScavengerAcrylic resin

The invention relates to a double-component polyurethane coating and a preparation method thereof. The coating comprises a component A and a component B, wherein the component A comprises hydroxyl-containing acrylic resin, fluorocarbon resin, polyester resin, non-nanoscale titanium white, nanometer titanium dioxide, nanometer silicon dioxide and various auxiliary agents; and the component B comprises polyisocyanate curing agent, solvent and moisture scavenger. The component A and the component B are mixed at the weight ratio of 4:1-5:1 to obtain the polyurethane coating. The coating has excellent wear resistance, scratch resistance and weather proofness, has favorable decoration, and is suitable for coating the surfaces of rapid trains, automobiles and the like which have higher requirements on decoration and physiochemical performance.

Owner:DE LAITTERN ENVIRONMENTAL COATING BEIJING

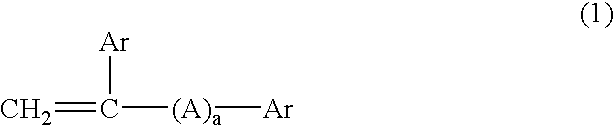

Composite hard mask for the etching of nanometer size magnetic multilayer based device

ActiveUS20090078927A1Prevent electrical shortingAvoid shortingLayered productsSemiconductor/solid-state device manufacturingBit lineEtching

A composite hard mask is disclosed that enables sub-100 nm sized MTJ cells to be formed for advanced devices such as spin torque MRAMs. The hard mask has a lower non-magnetic metallic layer such as Ru to magnetically isolate an overlying middle metallic spacer such as MnPt from an underlying free layer. The middle metallic spacer provides a height margin during subsequent processing to avoid shorting between a bit line and the MTJ cell in the final device. An upper conductive layer may be made of Ta and is thin enough to allow a MTJ pattern in a thin overlying photoresist layer to be transferred through the Ta during a fluorocarbon etch without consuming all of the photoresist. The MTJ pattern is transferred through the remaining hard mask layers and underlying MTJ stack of layers with a second etch step using a C, H, and O etch gas composition.

Owner:TAIWAN SEMICON MFG CO LTD

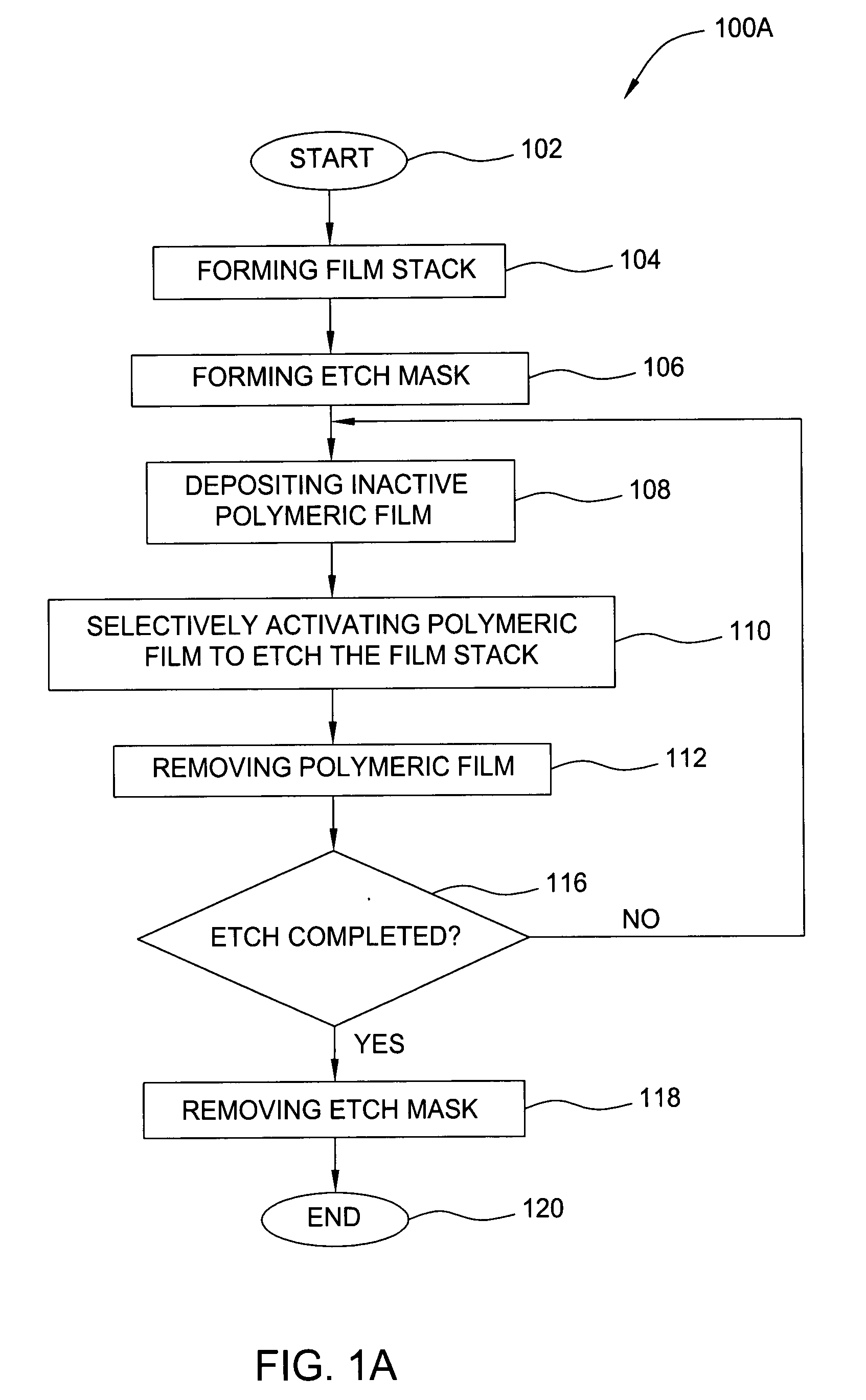

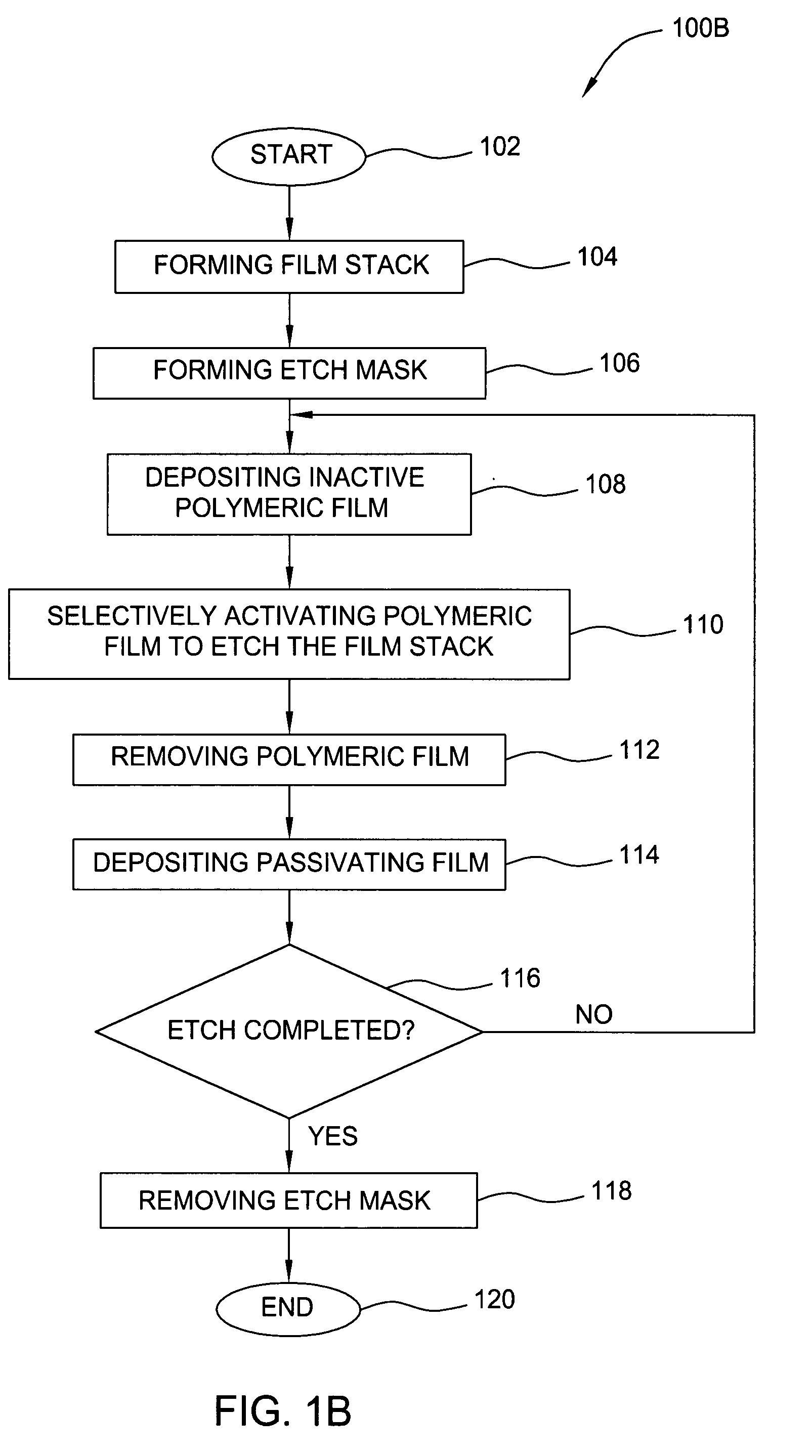

Method for plasma etching a dielectric layer

A method of etching a dielectric layer formed on a substrate including a sequence of processing cycles, wherein each cycle comprises steps of depositing an inactive polymeric film, activating the film to etch the structure, and removing the film is disclosed. In one embodiment, the method uses a fluorocarbon gas to form the polymeric film and a substrate bias to activate such film.

Owner:APPLIED MATERIALS INC

Composite hard mask with upper sacrificial dielectric layer for the patterning and etching of nanometer size MRAM devices

ActiveUS8722543B2Avoid formingPrevent electric shortingSemiconductor/solid-state device manufacturingGalvano-magnetic device manufacture/treatmentEtchingNon magnetic

A composite hard mask is disclosed that prevents build up of metal etch residue in a MRAM device during etch processes that define an MTJ shape. As a result, MTJ shape integrity is substantially improved. The hard mask has a lower non-magnetic spacer, a middle conductive layer, and an upper sacrificial dielectric layer. The non-magnetic spacer serves as an etch stop during a pattern transfer with fluorocarbon plasma through the conductive layer. A photoresist pattern is transferred through the dielectric layer with a first fluorocarbon etch. Then the photoresist is removed and a second fluorocarbon etch transfers the pattern through the conductive layer. The dielectric layer protects the top surface of the conductive layer during the second fluorocarbon etch and during a substantial portion of a third RIE step with a gas comprised of C, H, and O that transfers the pattern through the underlying MTJ layers.

Owner:TAIWAN SEMICON MFG CO LTD

Thermopolymerizable composition for battery use

InactiveUS6562513B1Good storage stabilityHigh strengthCell electrodesFinal product manufactureMeth-Carbonate ester

The present invention provides (1) a thermopolymerizable composition containing a thermopolymerizable compound having (meth)acrylate having a moiety consisting of oxyalkylene, fluorocarbon, oxyfluorocarbon and / or carbonate group within the molecule, an electrolyte salt, an organic polymerization initiator having no benzene ring, and a polymerization retarder having vinyl group within the molecule, (2) a solid electrolyte obtained by heat-curing the composition, (3) a primary battery, a secondary battery and an electric double-layer capacitor each using the solid electrolyte, and processes for manufacturing the same.

Owner:SHOWA DENKO KK

Composite hard mask for the etching of nanometer size magnetic multilayer based device

ActiveUS7696551B2Avoid shortingImprove etch selectivitySemiconductor/solid-state device manufacturingGalvano-magnetic device manufacture/treatmentBit lineEtching

A composite hard mask is disclosed that enables sub-100 nm sized MTJ cells to be formed for advanced devices such as spin torque MRAMs. The hard mask has a lower non-magnetic metallic layer such as Ru to magnetically isolate an overlying middle metallic spacer such as MnPt from an underlying free layer. The middle metallic spacer provides a height margin during subsequent processing to avoid shorting between a bit line and the MTJ cell in the final device. An upper conductive layer may be made of Ta and is thin enough to allow a MTJ pattern in a thin overlying photoresist layer to be transferred through the Ta during a fluorocarbon etch without consuming all of the photoresist. The MTJ pattern is transferred through the remaining hard mask layers and underlying MTJ stack of layers with a second etch step using a C, H, and O etch gas composition.

Owner:TAIWAN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com