Wear-resisting scratch-resisting weather-proof polyurethane coating and preparation method thereof

A polyurethane coating and weather-resistant technology, which is applied in polyurea/polyurethane coatings, polyester coatings, coatings, etc., can solve the problems of reducing paint film, etc., and achieve excellent weather resistance, high gloss, decorative properties, and good scratch resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

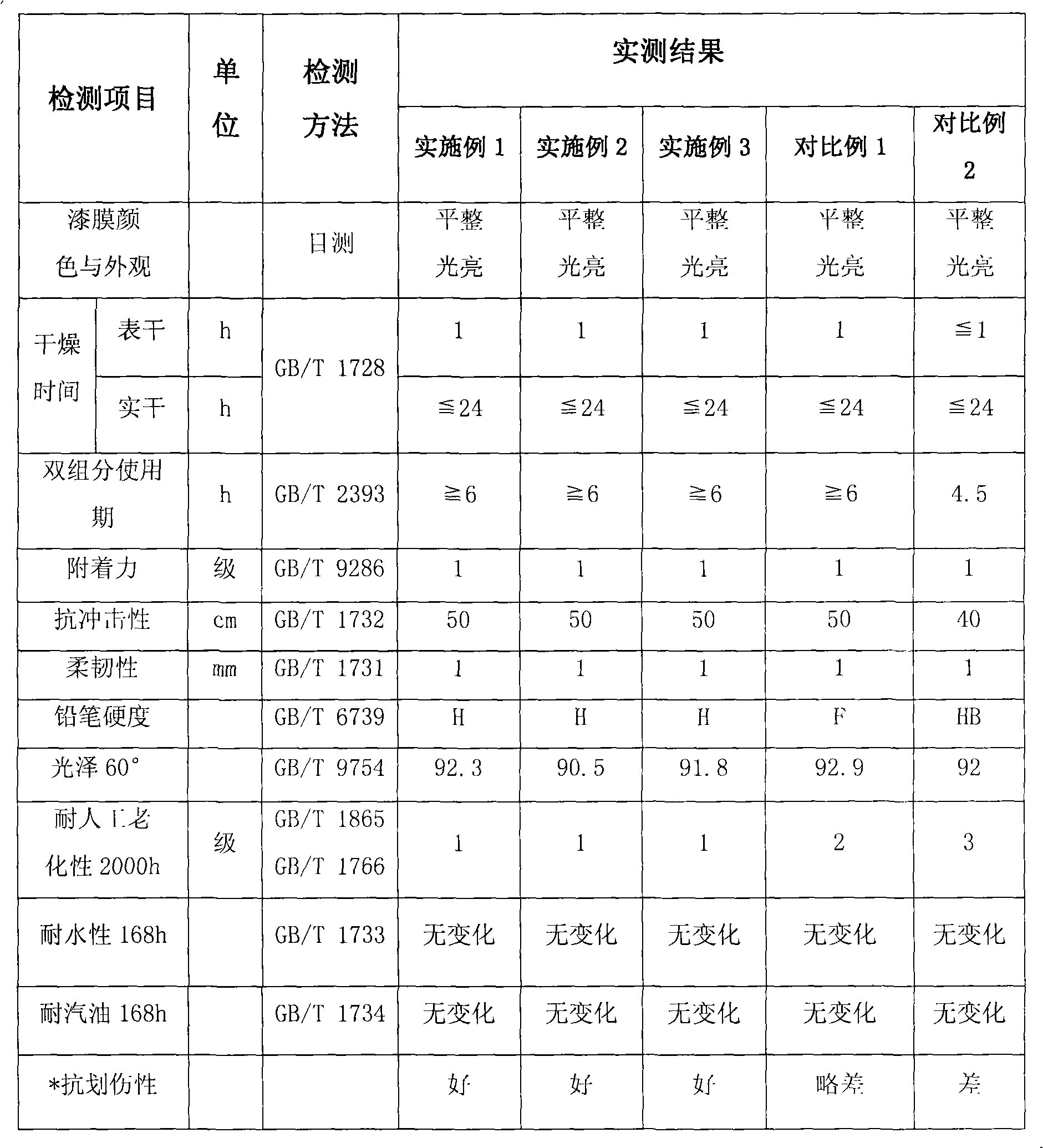

Embodiment 1

[0061] In Example 1, the raw materials are all commercially available products, the hydroxyl-containing acrylic resin in component A is Desmophen A870BA of Bayer, the polyester resin is Desmophe 670BA, and the fluorocarbon resin is selected from Dalian Zhenbang F-100; The nano-scale titanium dioxide is DuPont R-960 rutile titanium dioxide, the nano-titanium dioxide is VK-TO6S nano-rutile titanium dioxide from Hangzhou Wanjing New Material Co., Ltd., and the nano-silica is nano-silica dispersion from BYK BYK-3650; the dispersant is BYK-110 from BYK; the defoamer and leveling agent are BYK-066N and BYK-358N from the company; the light stabilizer is Tinuvin292 from Ciba; the catalyst is OMG The environmentally friendly catalyst Kat 0245; the polyisocyanate curing agent in the B component is Bayer's Desmodur N 3390BA / SN and Desmodur Z 4470MPA / X. The dehydrating agent is selected from Additive TI of OMG Company.

[0062] Preparation of wear-resistant, scratch-resistant and weather...

Embodiment 2

[0093] In component A of Example 2, the fluorocarbon resin is JF-2X from Changshu Zhonghao; the nano-silica is Degussa modified hydrophobic fumed silica AEROSIL R9200. AEROSIL R9200 is a hydrophobic fumed silica treated with special chemical and mechanical methods. This silica does not contain primary particles but exists in the form of agglomerates. OMG Company PaintAdditive OL 17 was added as the leveling agent, and the other raw materials were the same as in Example 1.

[0094] The preparation of embodiment 2:

[0095] A component comprises the composition of following parts by weight, based on the total weight of A component:

[0096] Hydroxy-containing acrylic resin: Desmophen A870BA 28.5

[0097] Fluorocarbon resin JF-2X 19.5

[0098] Polyester resin Desmophe 670BA 6.00

[0099] Rutile titanium dioxide R-960 22.0

[0100] Nano rutile titanium dioxide VK-TO6S 1.00

[0101] Hydrophobic fumed silica R9200 4.75

[0102] Dispersant: BYK-110 1.15

[0103] Leveling agen...

Embodiment 3

[0128] In the component A of Example 3, the fluorocarbon resin was selected from JF-2X of Changshu Zhonghao; the nano-silica was selected from Degussa modified hydrophobic fumed silica dispersion as AERODISP 1030, and the others were the same as in Example 2.

[0129] The preparation of embodiment 3:

[0130] A component comprises the composition of following parts by weight, based on the total weight of A component:

[0131] Hydroxy-containing acrylic resin: Desmophen A870BA 28.5

[0132] Fluorocarbon resin JF-2X 19.5

[0133] Polyester resin Desmophe 670BA 6.0

[0134] Non-nanometer rutile titanium dioxide R-960: 22.0

[0135] Nano rutile titanium dioxide VK-TO6S 1.0

[0136] Hydrophobic gas phase dioxide dispersion AERODISP 1030 10.0

[0137] Dispersant: BYK-110 0.50

[0138] Leveling agent: BYK-358N 0.3

[0139] Paint Additive OL 17 0.2

[0140] Defoamer: BYK-066N 0.2

[0141] Anti-settling agent: BYK-410 0.3

[0142] Light stabilizer: Tinuvin 292 1.3

[0143] C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com