Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

686results about How to "Improve anti-reflection effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing large area antireflective microtextured surfaces

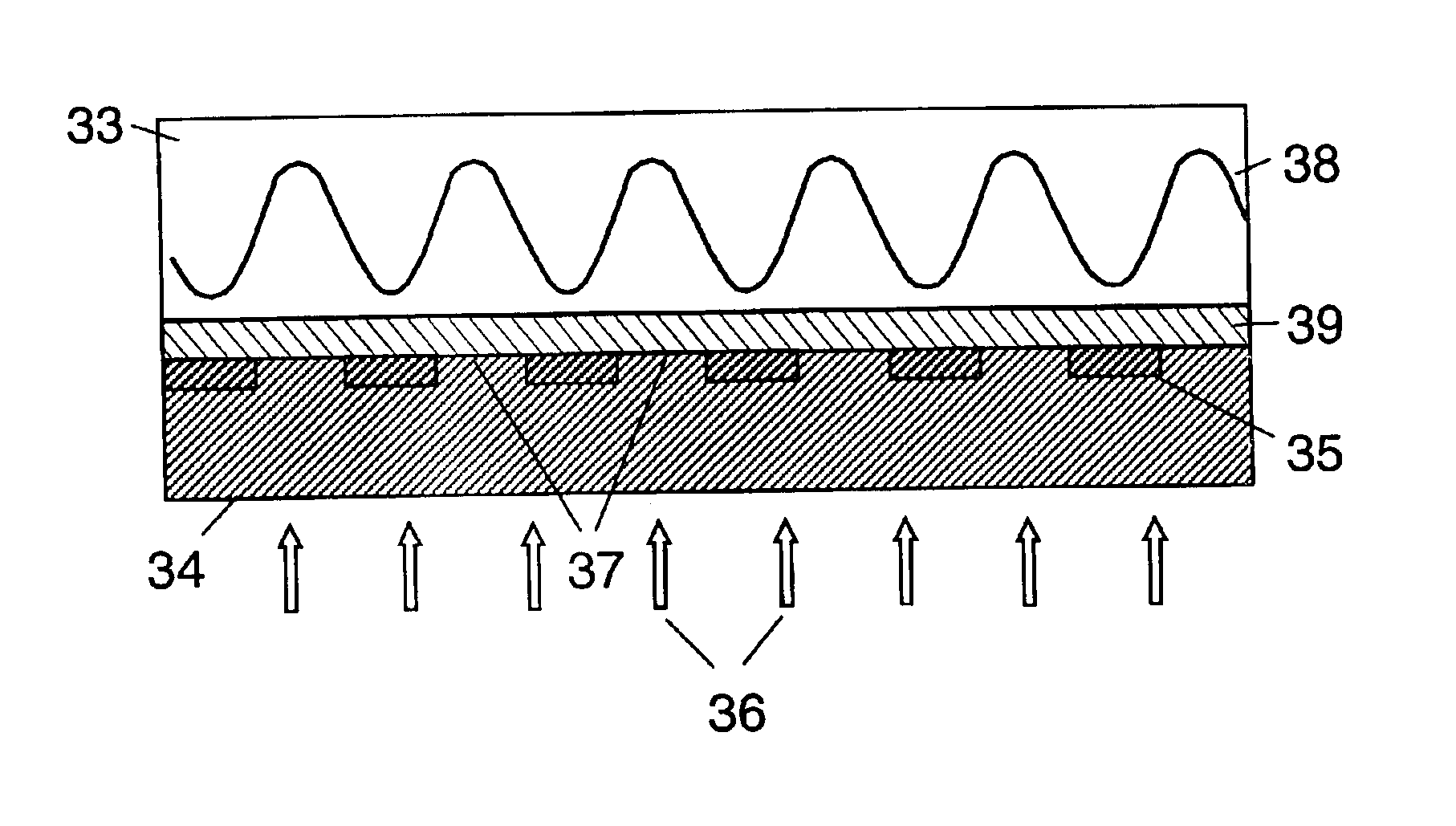

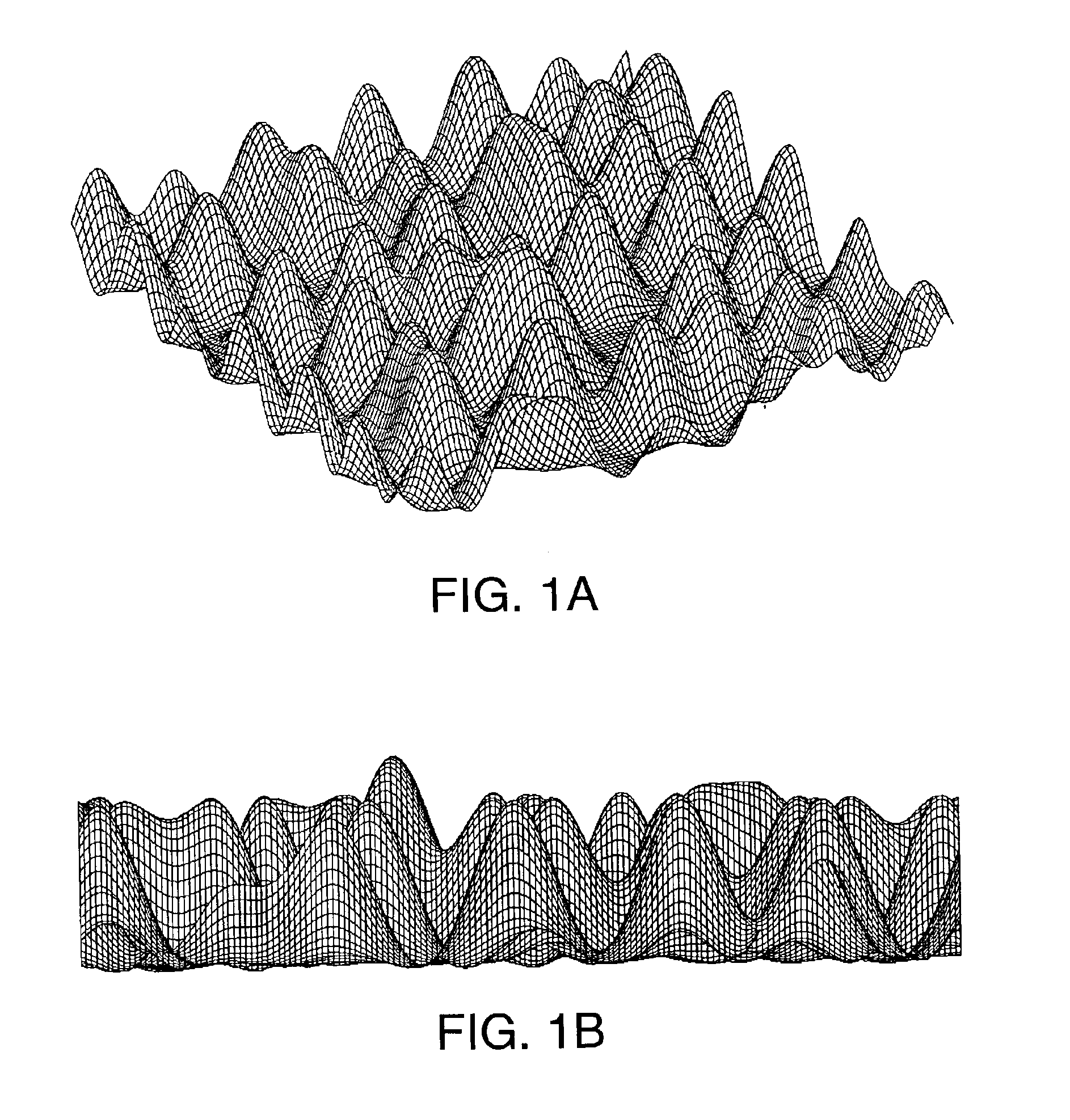

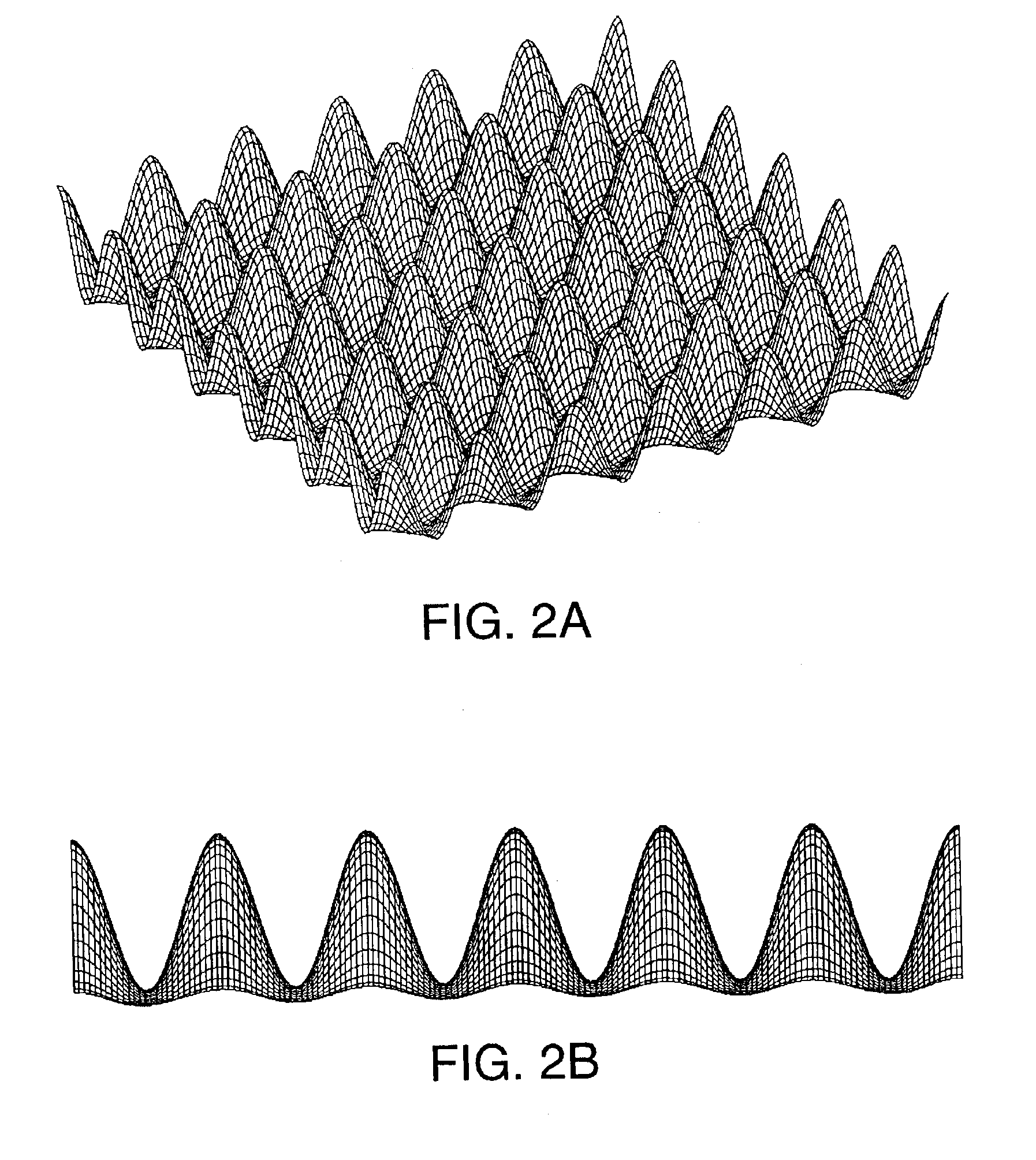

InactiveUS6958207B1Improve anti-reflection effectSlow replicationDiffusing elementsPhotomechanical exposure apparatusResistUltraviolet lights

A method employing a photolithography mask for producing microtextured antireflective surfaces is disclosed. The photolithography mask is used during the exposure of photoresist to a pattern of ultraviolet light. The exposed photoresist is subsequently processed to obtain a microtextured surface possessing antireflective properties. The antireflective surface profile comprises an array of sub-micron protuberances that may reside in a periodic arrangement, a quasiperiodic arrangement, or in an arbitrary non-periodic arrangement. The antireflective surface is designed for visible light. It may be scaled-up to large areas, and is suitable for replication into inexpensive polymer materials.

Owner:KHUSNATDINOV NIYAZ +1

Hard coat film, polarizing plate, and image display

ActiveUS20090214871A1Deterioration in brittlenessHigh surface hardnessMaterial nanotechnologyStarch dervative coatingsOrganic solventPolyrotaxane

A hard coat film includes a transparent plastic film substrate; and a hard coat layer, wherein the hard coat layer is formed of a composition for forming a hard coat layer, the composition containing the following component (A), component (B), and an organic solvent:Component (A): a polyrotaxane,Component (B): a monomer having two or more ethylenically unsaturated groups.

Owner:FUJIFILM CORP

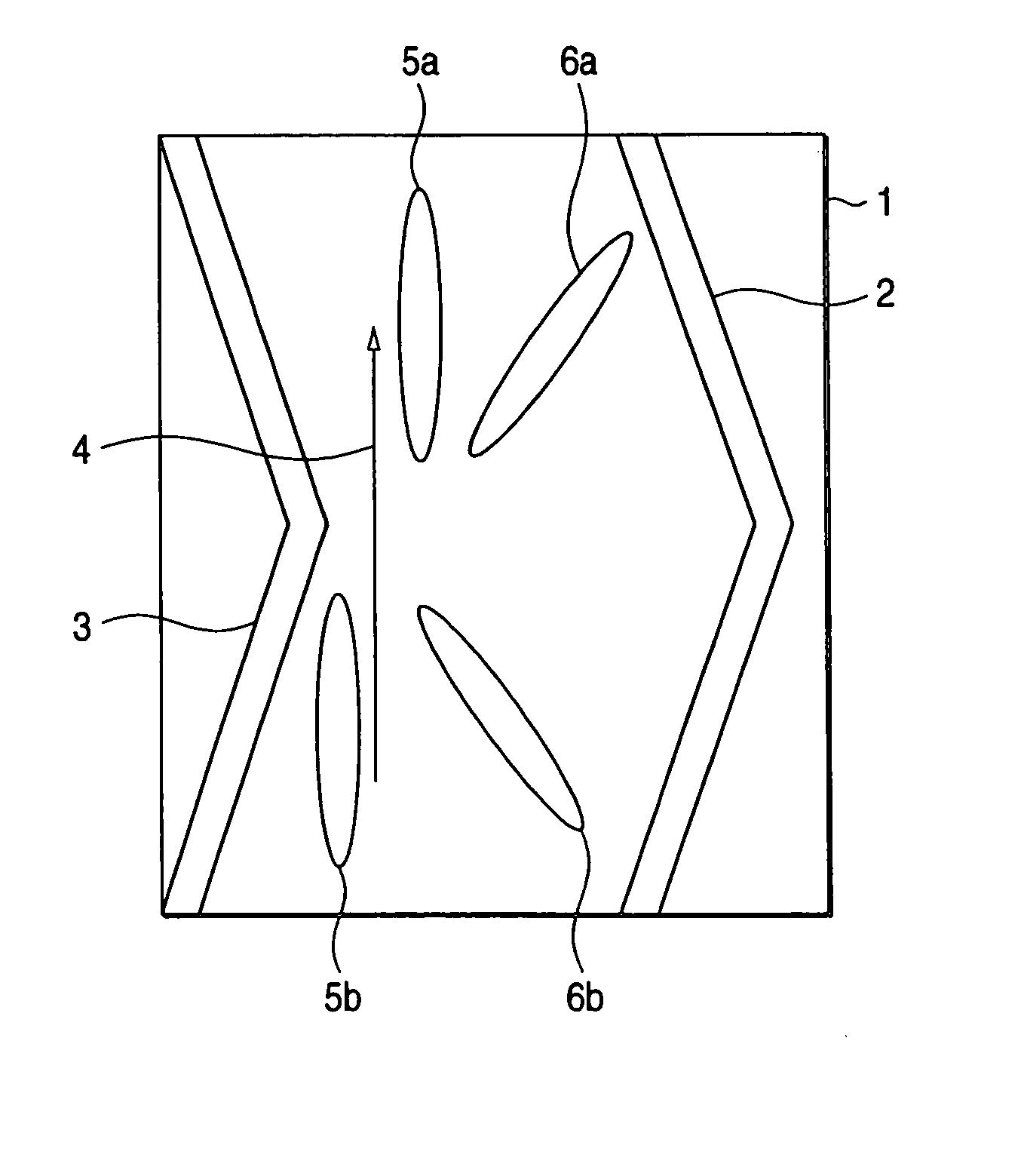

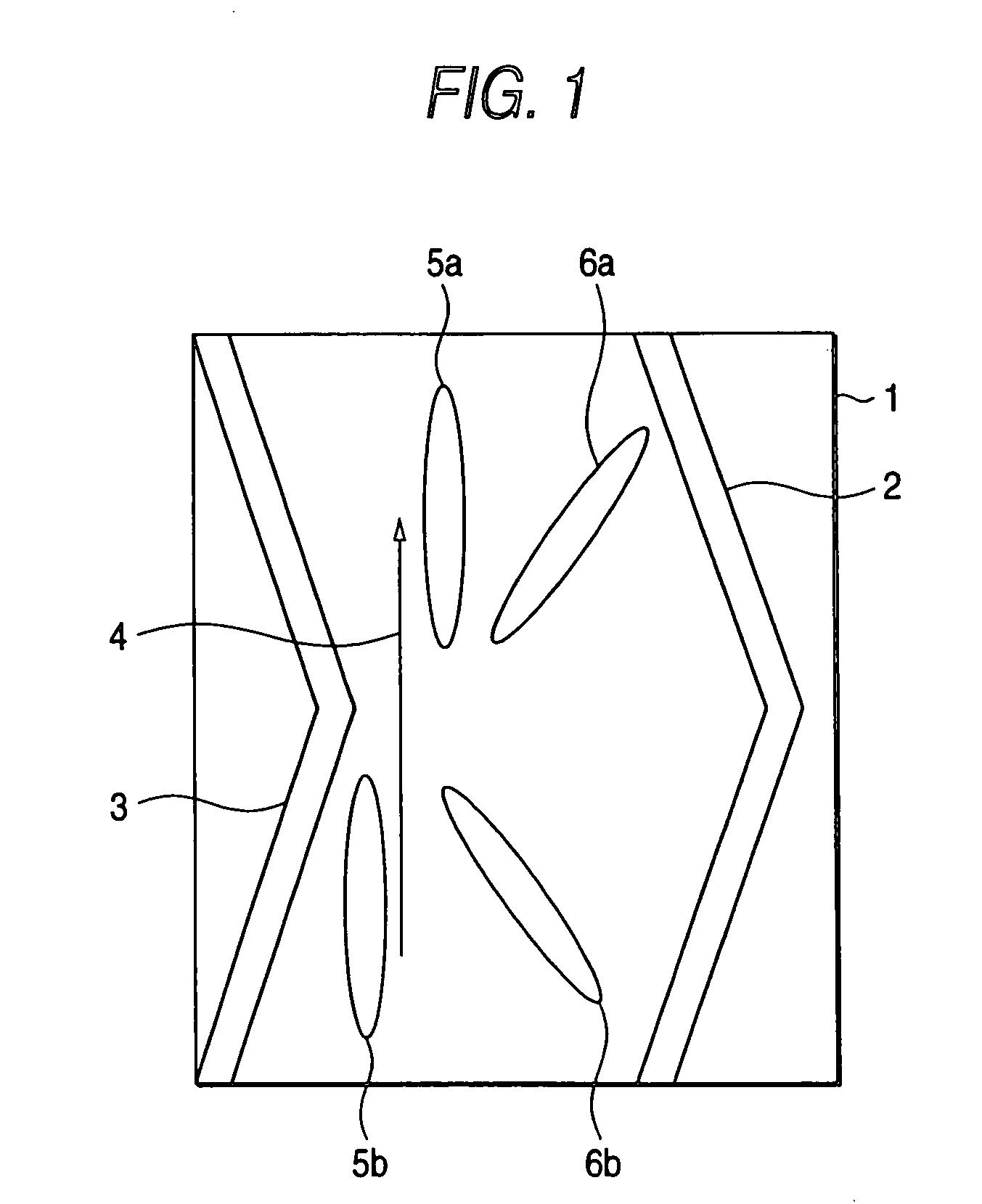

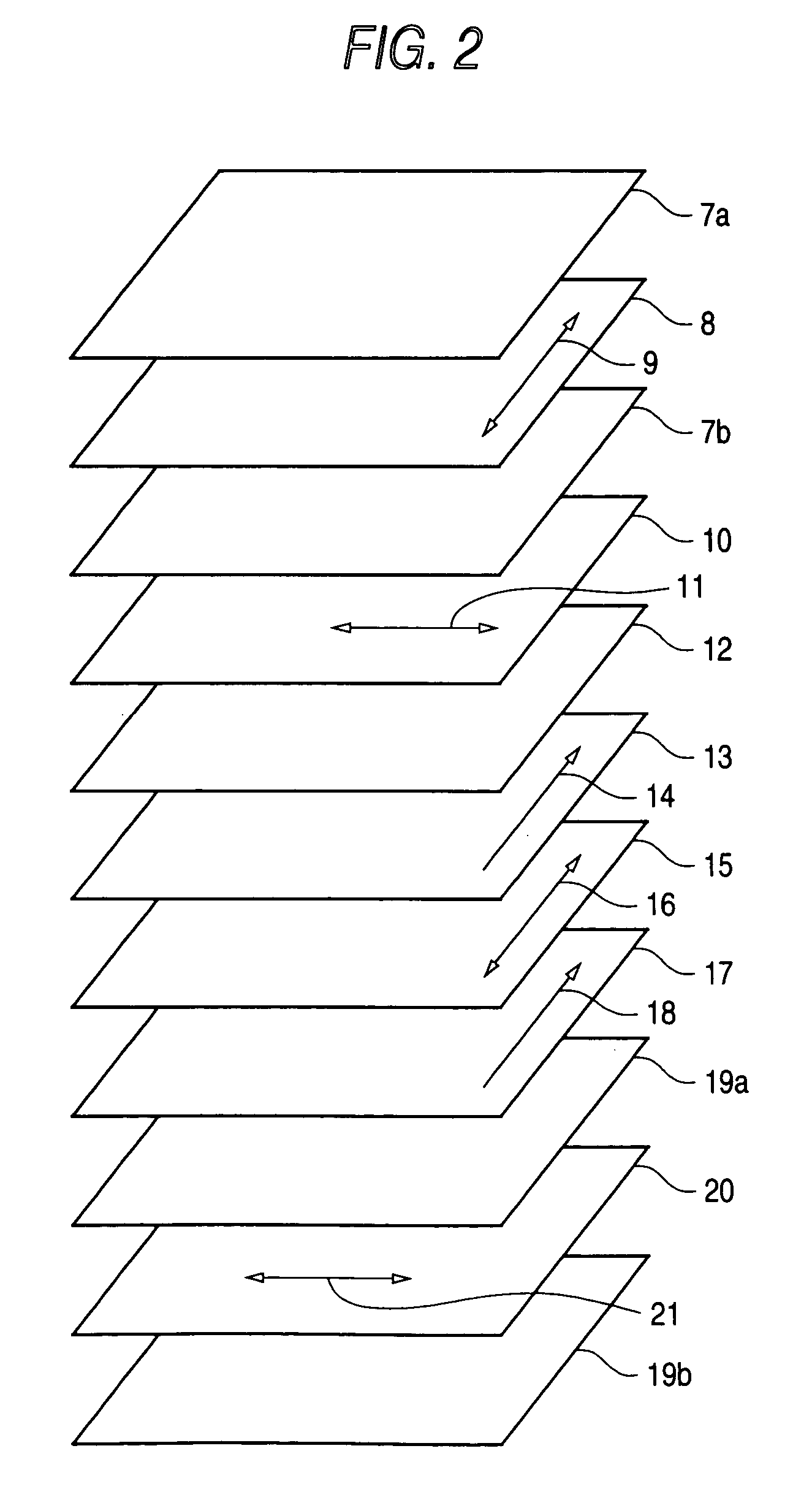

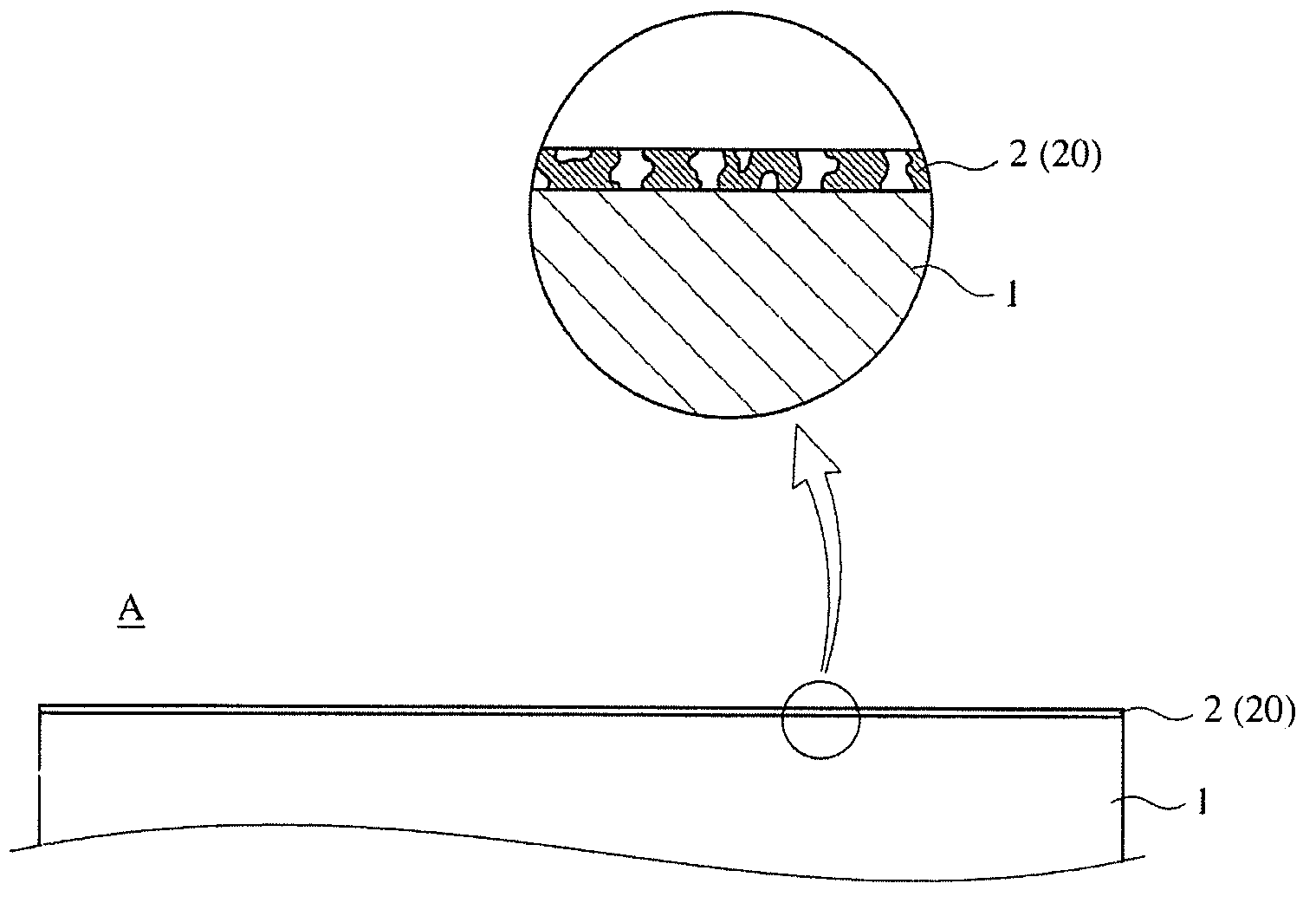

Liquid crystal display device

ActiveUS20060215079A1Improve anti-reflection effectReduce decreaseNon-linear opticsCrystallographyTectorial membrane

A liquid crystal display device comprising: a first protective film; a first polarizing film; an optical compensation region; a liquid crystal cell comprising a liquid crystal layer and a pair of substrates sandwiching the liquid crystal layer; a second polarizing film; and a second protective layer, in this order, wherein at a black display, liquid crystal molecules in the liquid crystal layer are aligned in parallel with surfaces of said pair of substrates, an antiglare layer is provided to at least one of the first protective film and the second protective layer, and the antiglare layer has a haze value attributable to internal scattering of from 5 to 35%, and a haze value attributable to surface scattering of from 1 to 10%.

Owner:FUJIFILM CORP

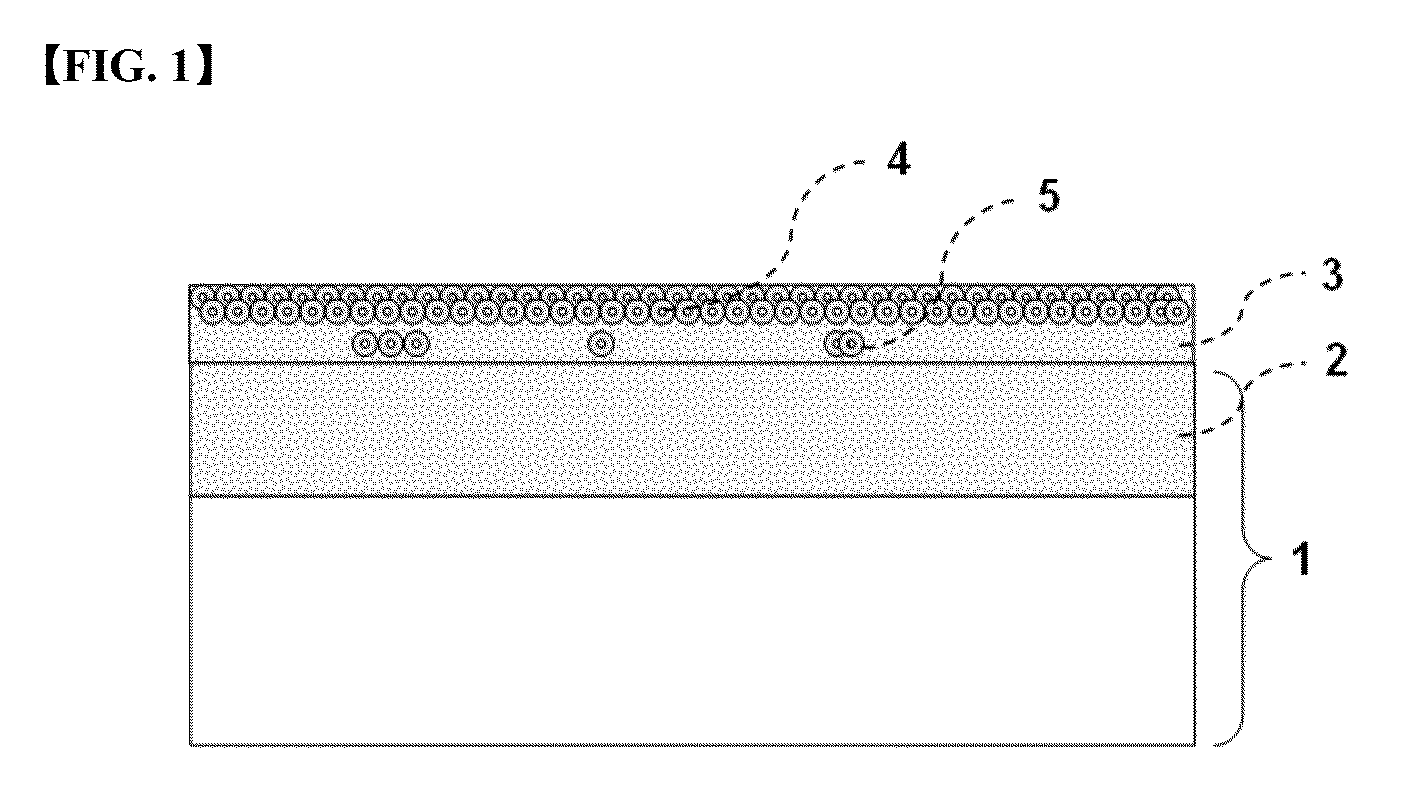

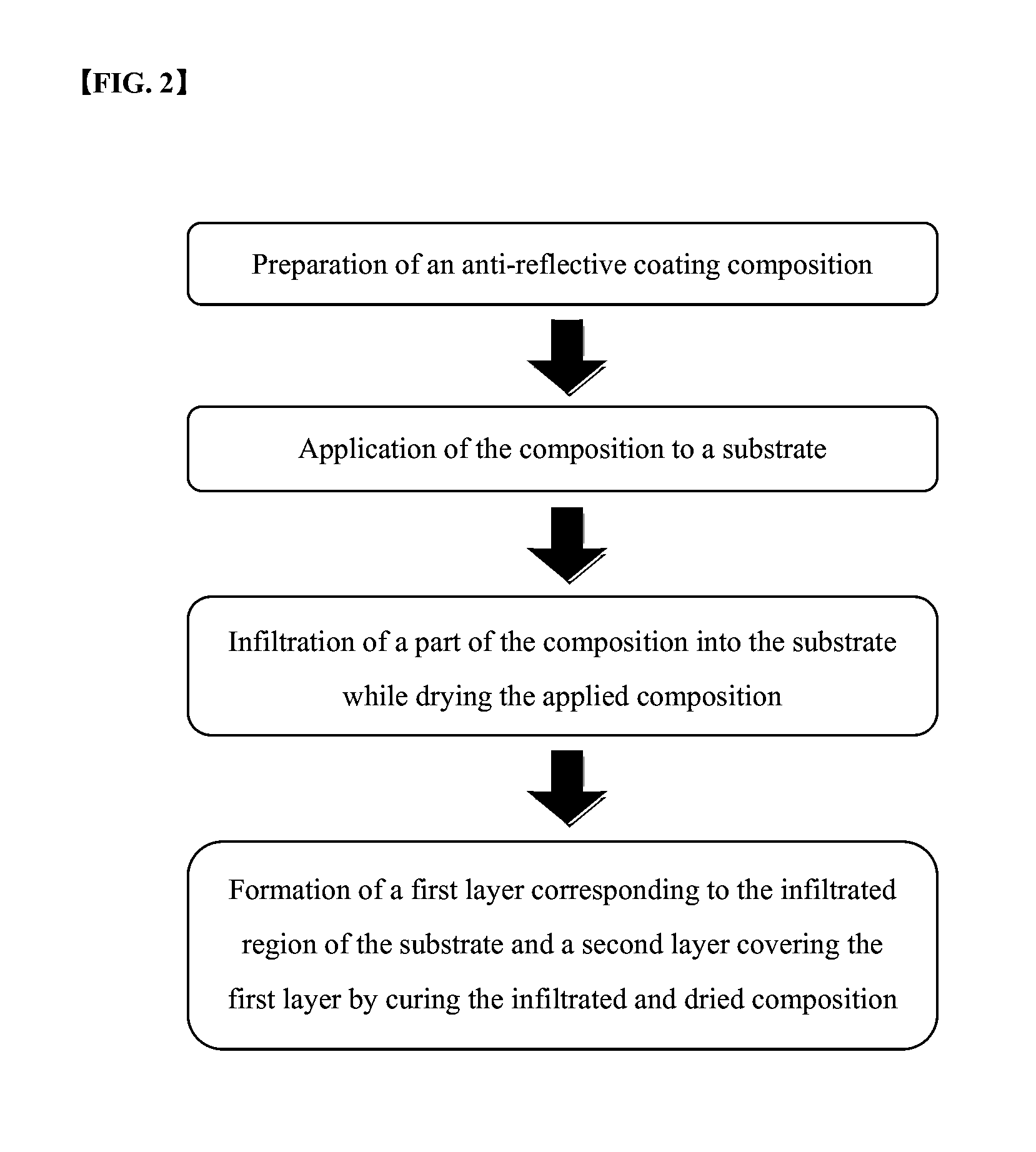

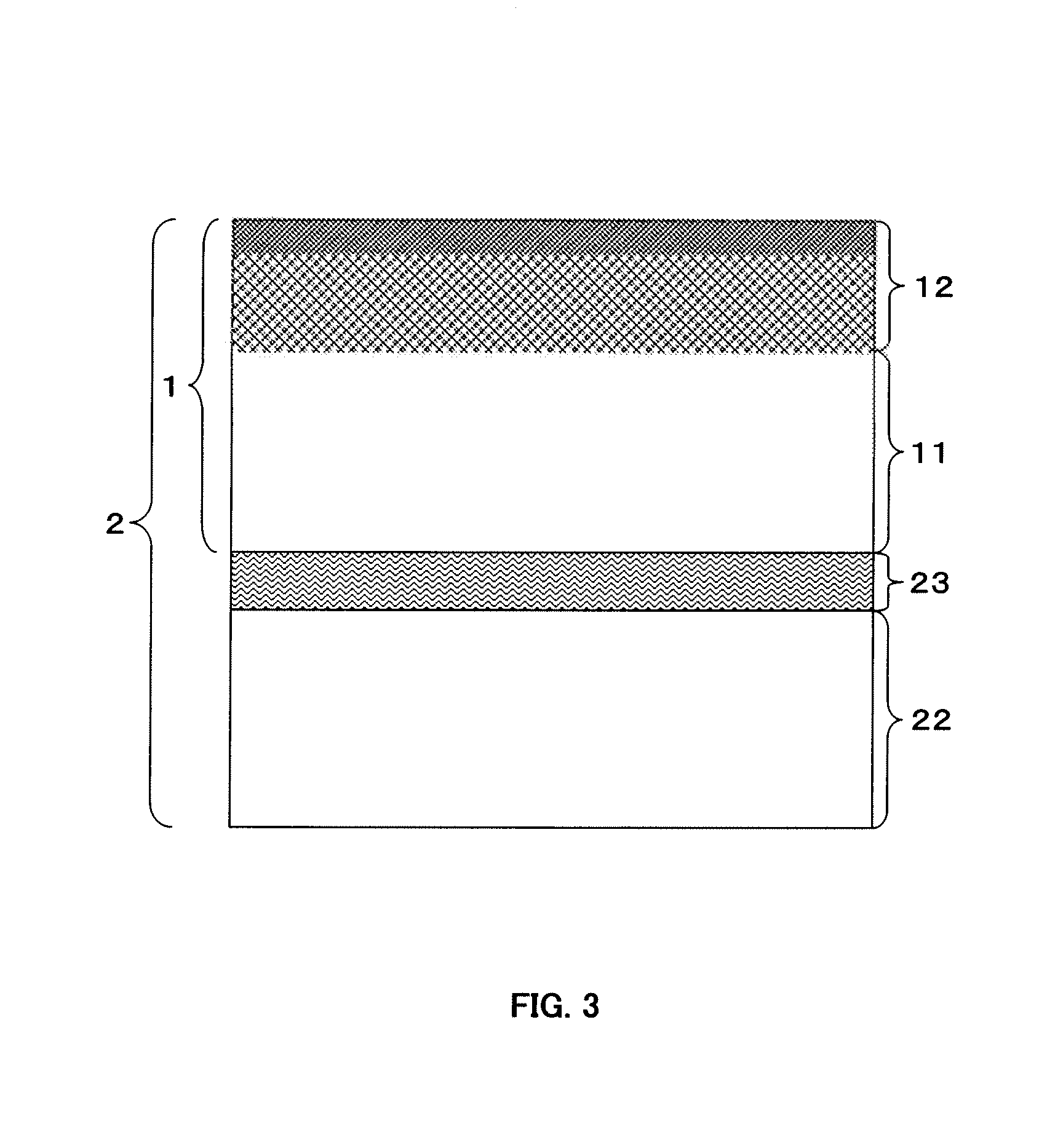

Anti-reflection coating and its production method

ActiveUS20090220774A1Improve anti-reflection effectImprove adhesionMaterial nanotechnologyLayered productsRefractive indexMesoporous silica

An anti-reflection coating comprising a mesoporous silica coating composed of mesoporous silica nano-particles formed on a substrate or a dense coating formed on the substrate, the mesoporous silica coating having a refractive index of more than 1.10 and 1.35 or less.

Owner:PENTAX RICOH IMAGING CO LTD +1

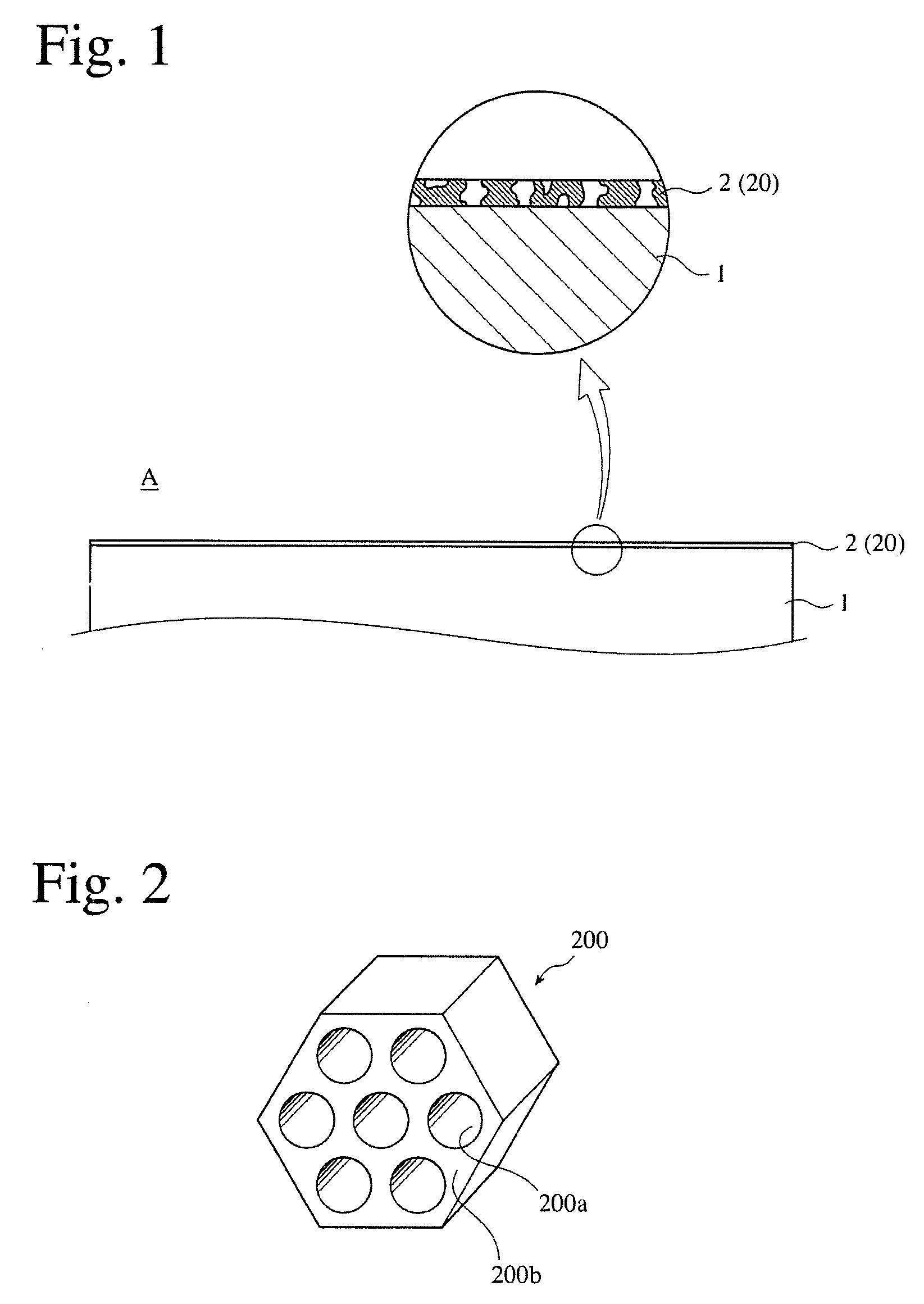

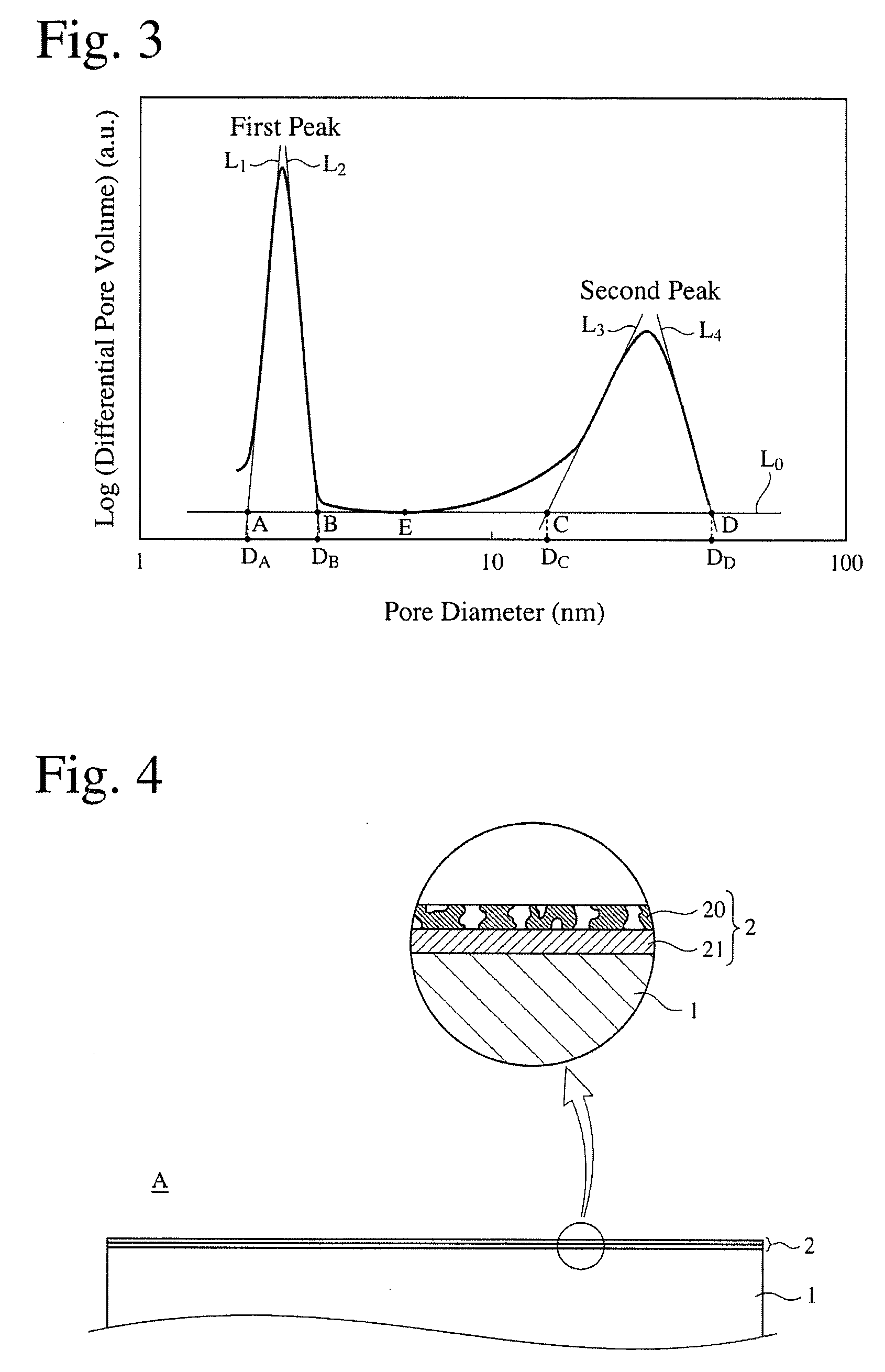

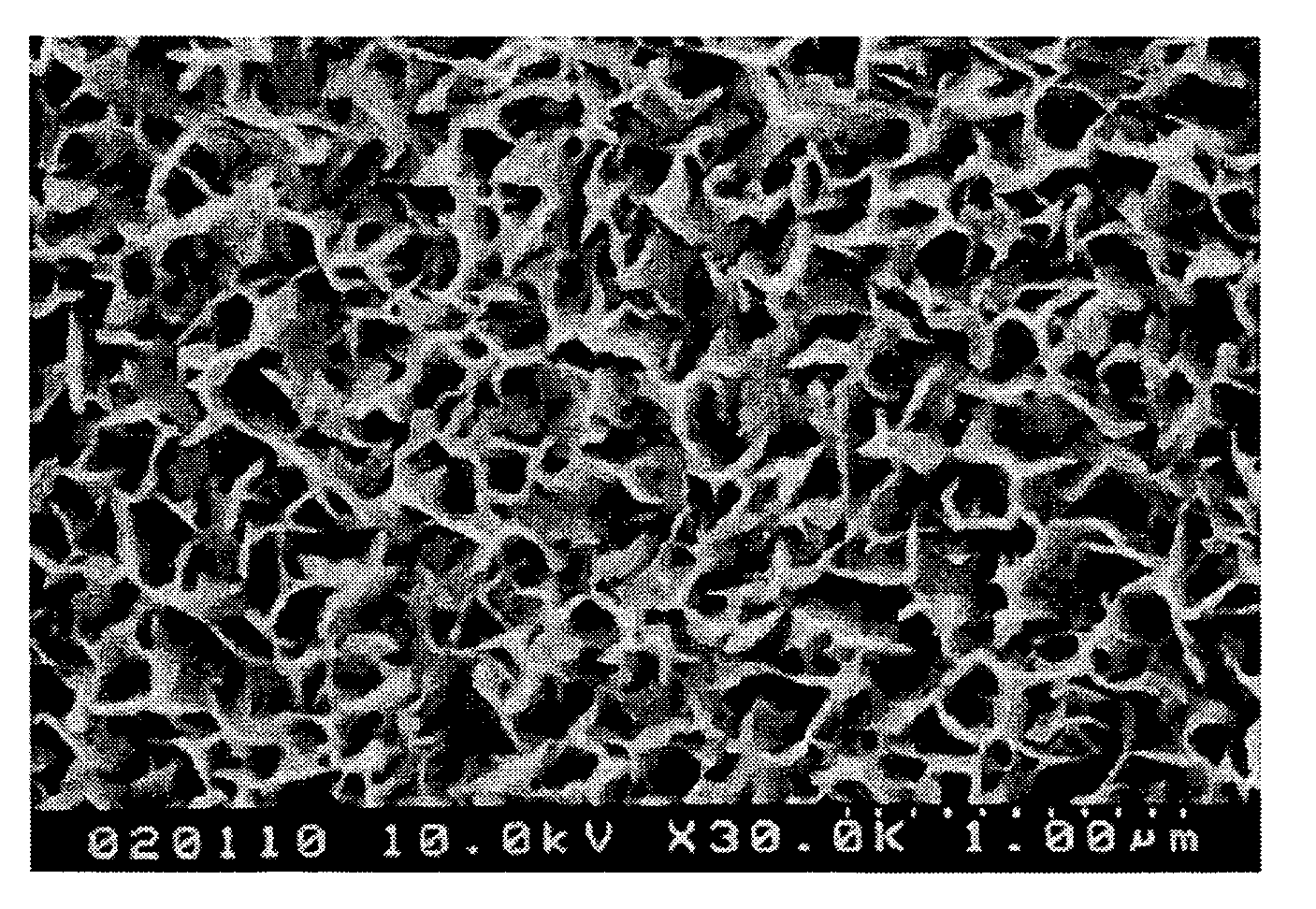

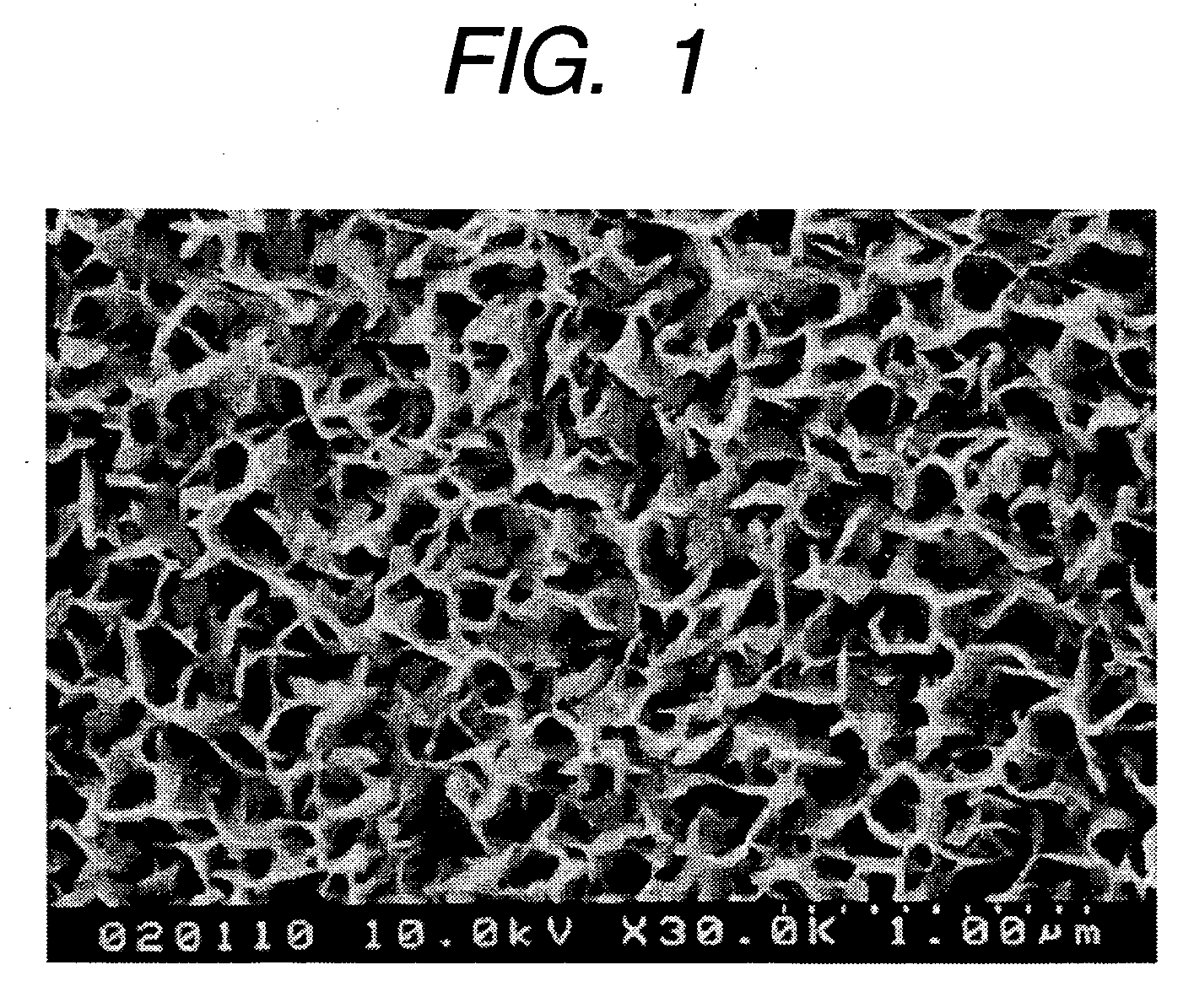

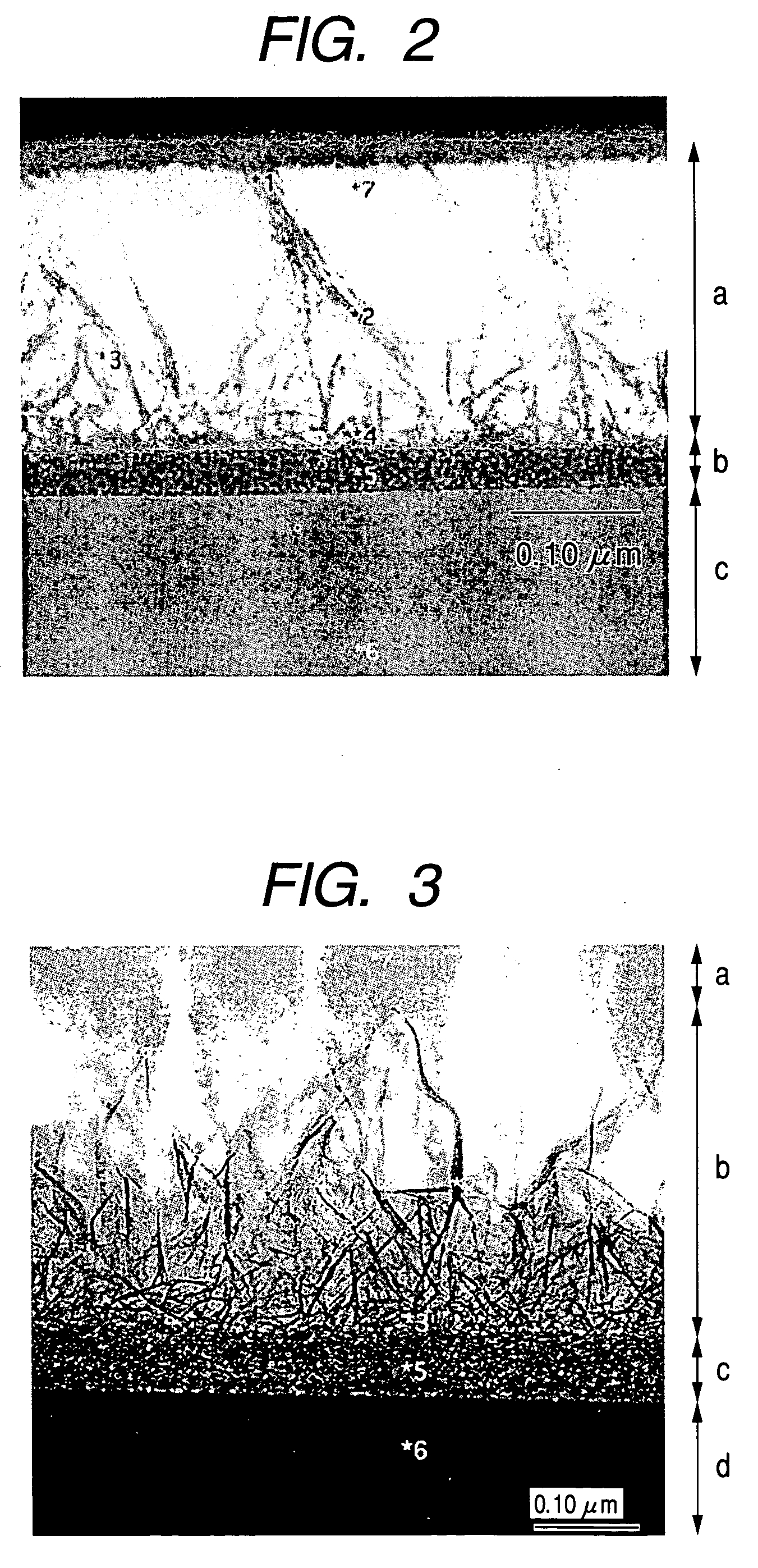

Film and antireflection film having fine irregularities on surface, production method for the same, and optical member using the same

InactiveUS20050233113A1Improve anti-reflection effectReduce reflectionDiffusing elementsLayered productsZirconia silicaZinc compounds

A transparent antireflection film, including fine irregularities mainly composed of alumina, and a transparent thin film layer supporting the fine irregularities, in which the transparent thin film layer contains at least one selected from the group consisting of zirconia, silica, titania, and zinc oxide. A production method for the aforementioned transparent antireflection film, including: forming a multicomponent film using an application liquid containing at least one compound selected from the group consisting of a zirconium compound, a silicon compound, a titanium compound, and a zinc compound, and at least an aluminum compound; and subjecting the multicomponent film to warm water treatment.

Owner:PUBLIC UNIVERSITY CORPORATION OSAKA CITY UNIVERSITY +1

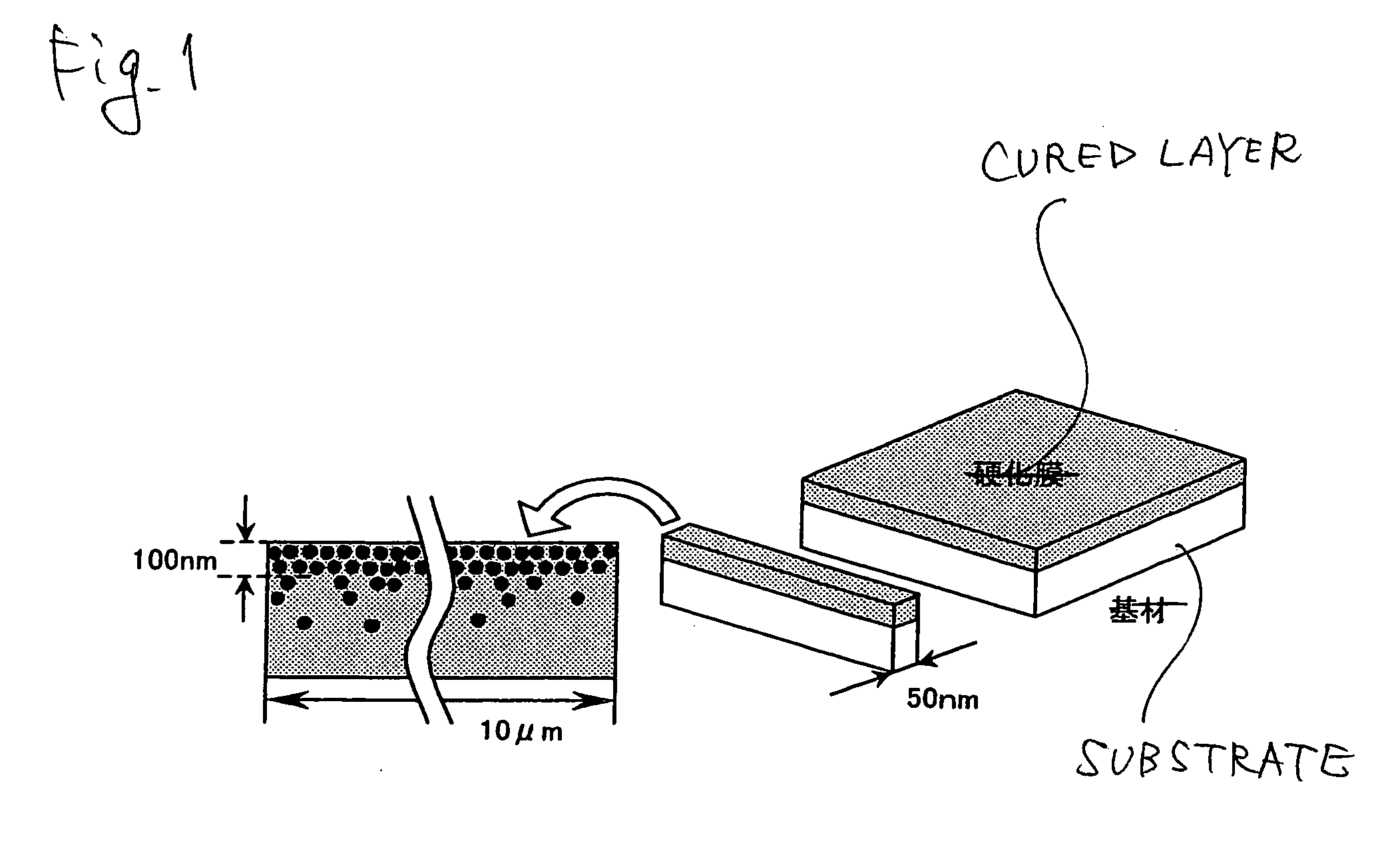

Optical film, polarizing plate and image display device

InactiveUS20070047087A1Improve anti-reflection effectImprove scratch resistanceOptical elementsRefractive indexPlastic film

An optical film comprises: a transparent plastic film substrate; and a cured layer having a dry thickness of 100 nm or more, formed by coating a curable composition comprising: a low refractive index fine particle having a refractive index of 1.50 or less; and a binder, wherein the low refractive index fine particle is unevenly distributed in the cured layer to a surface portion on the side opposite the transparent plastic film substrate.

Owner:FUJIFILM CORP

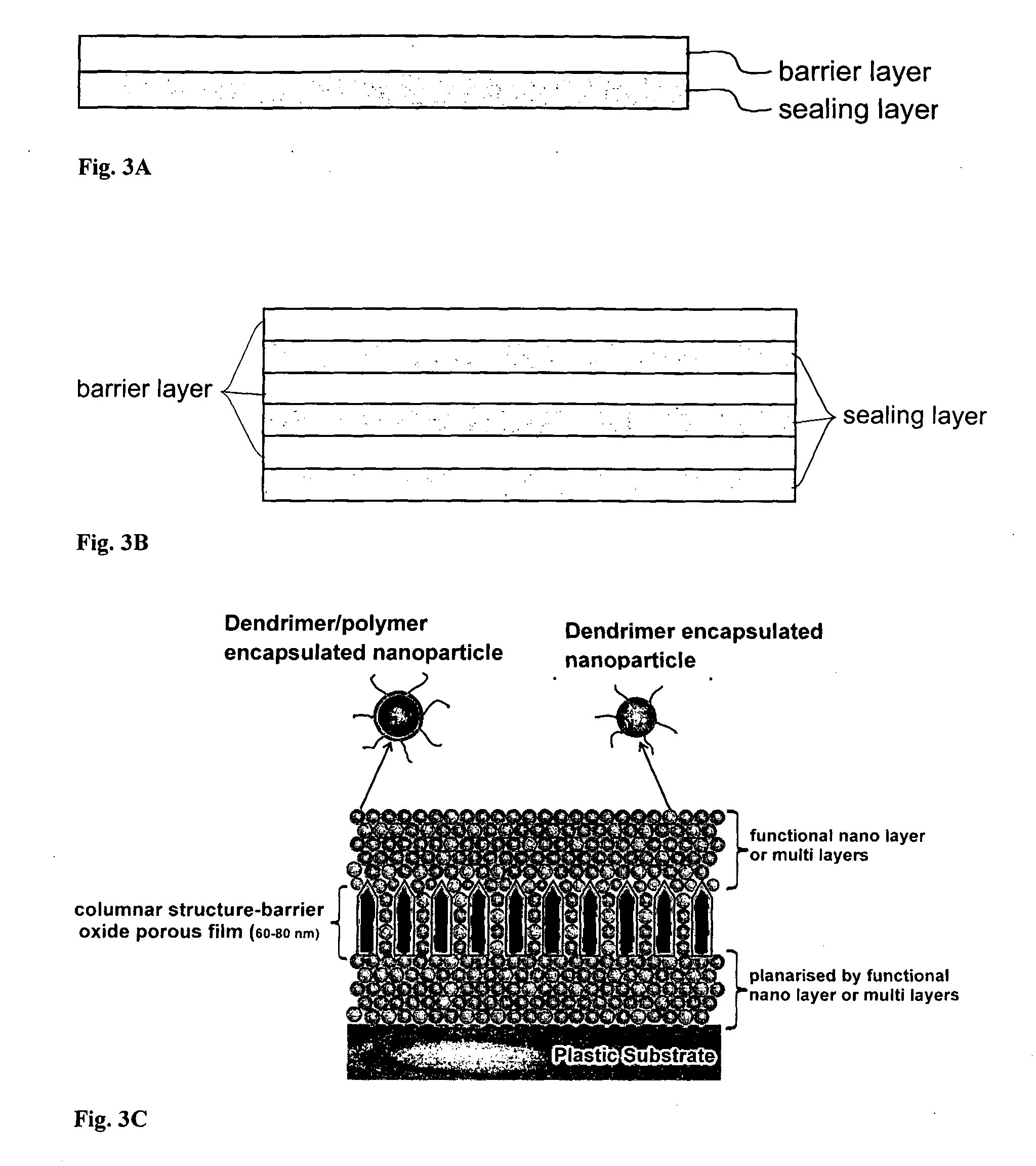

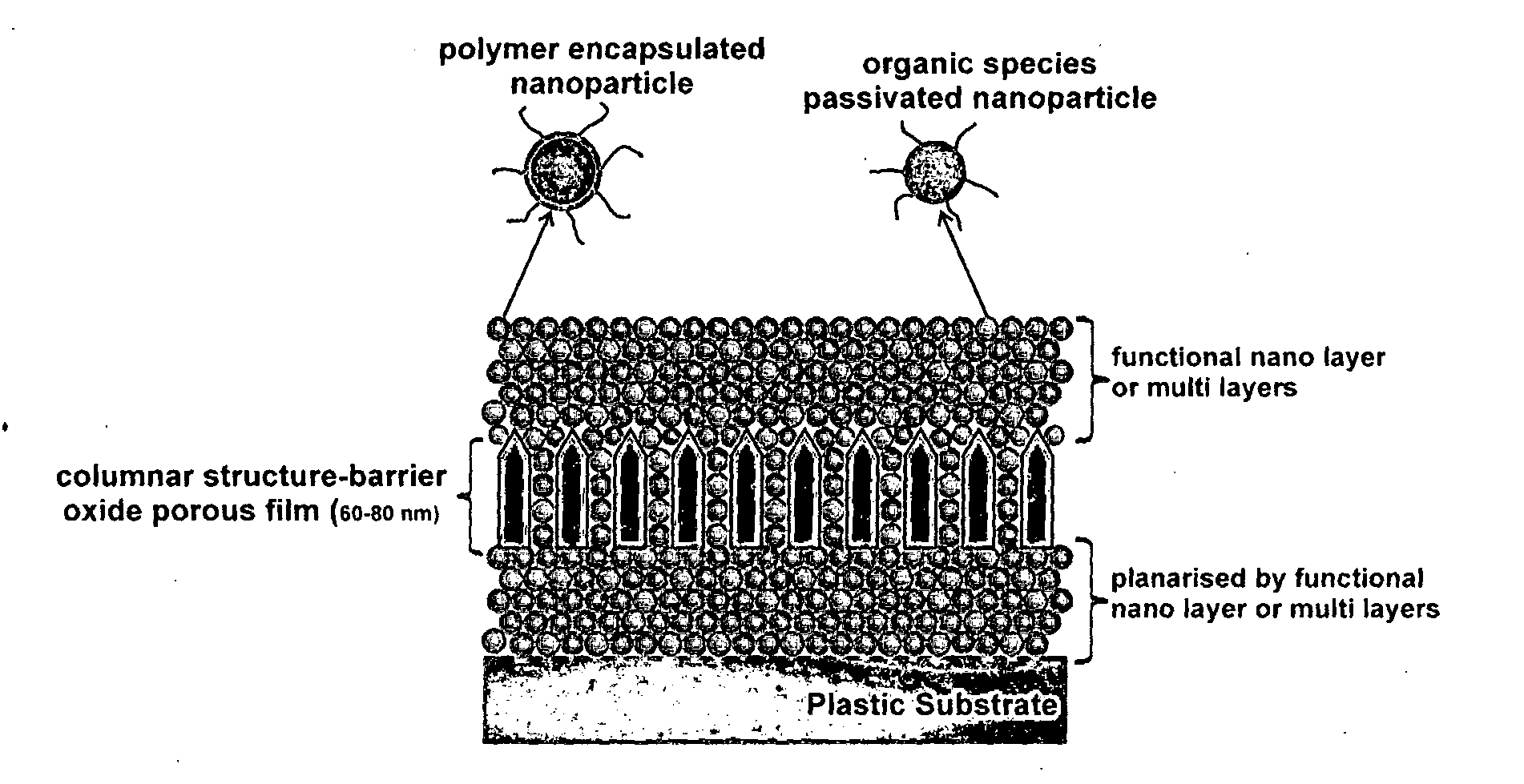

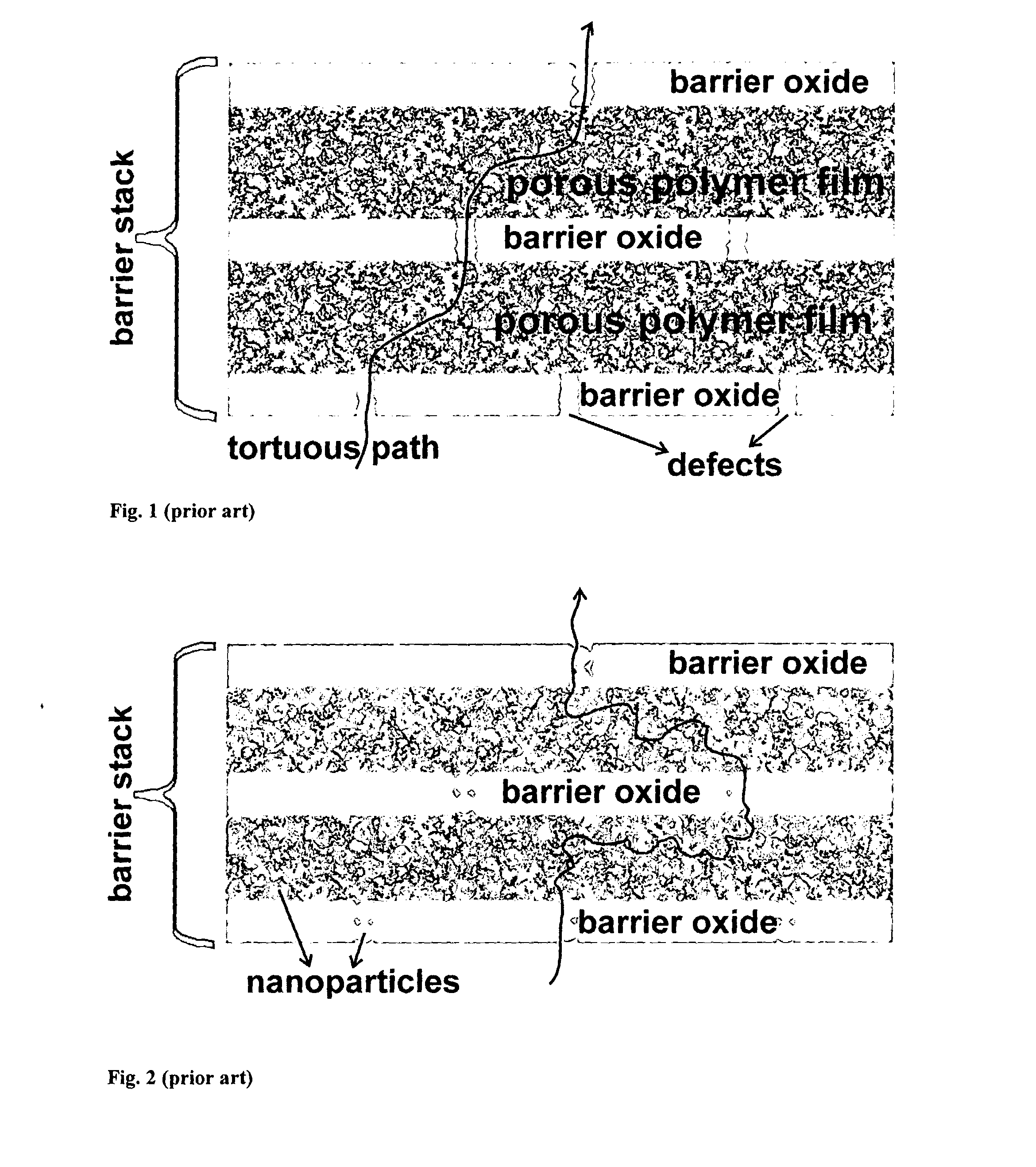

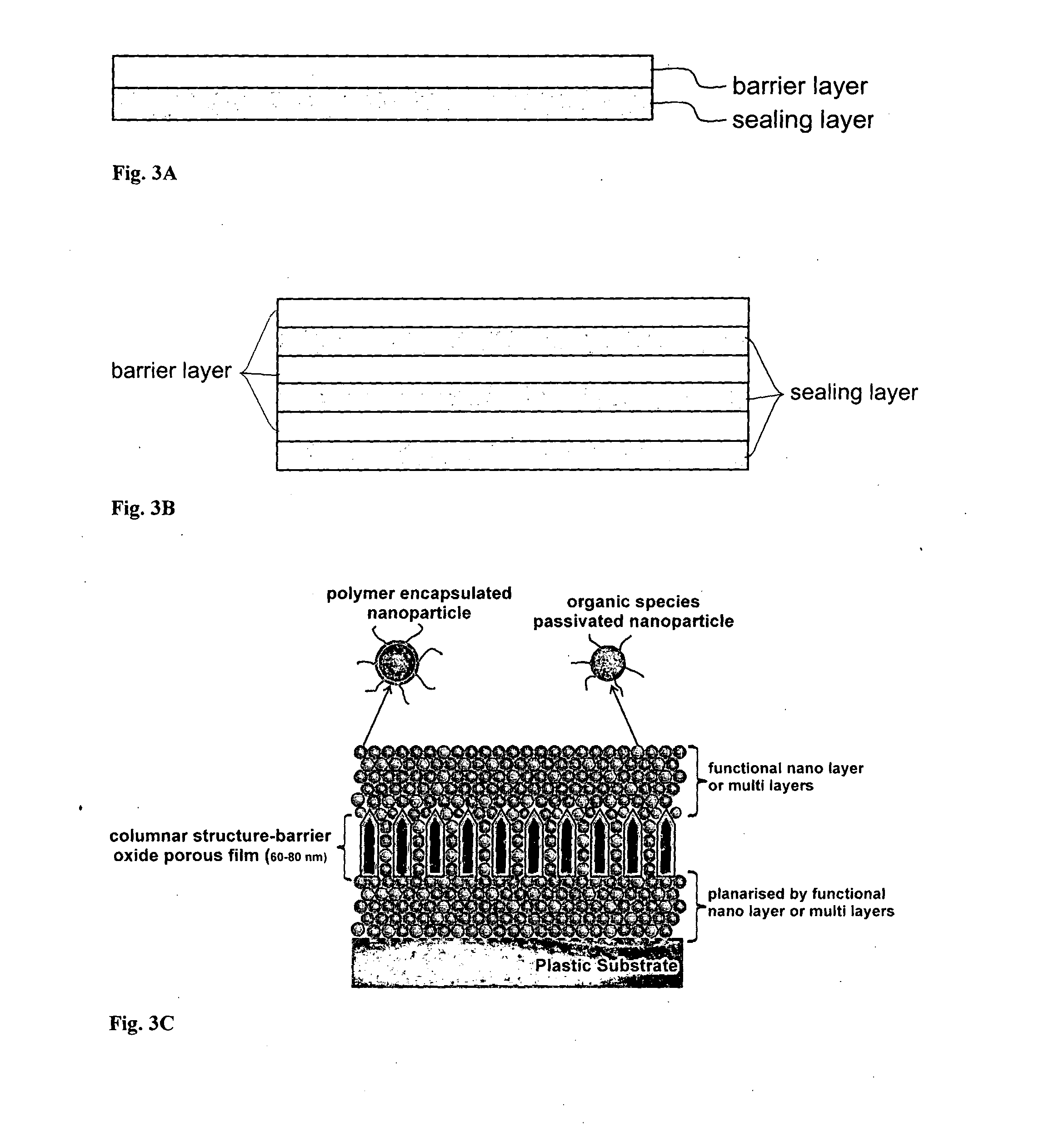

Encapsulation barrier stack comprising dendrimer encapsulated nanop articles

InactiveUS20160088756A1Reduce porosityHigh bonding strengthMaterial nanotechnologyFinal product manufacturePermeationMoisture

Disclosed is an encapsulation barrier stack, capable of encapsulating a moisture and / or oxygen sensitive article and comprising a multilayer film, wherein the multilayer film comprises: one or more barrier layer(s) having low moisture and / or oxygen permeability, and one or more sealing layer(s) arranged to be in contact with a surface of the at least one barrier layer, thereby covering defects present in the barrier layer, wherein the one or more sealing layer(s) comprise(s) a plurality of dendrimer encapsulated nanoparticles, the nanoparticles being reactive in that they are capable of interacting with moisture and / or oxygen to retard the permeation of moisture and / or oxygen through the defects present in the barrier layer.

Owner:TERA BARRIER FILMS

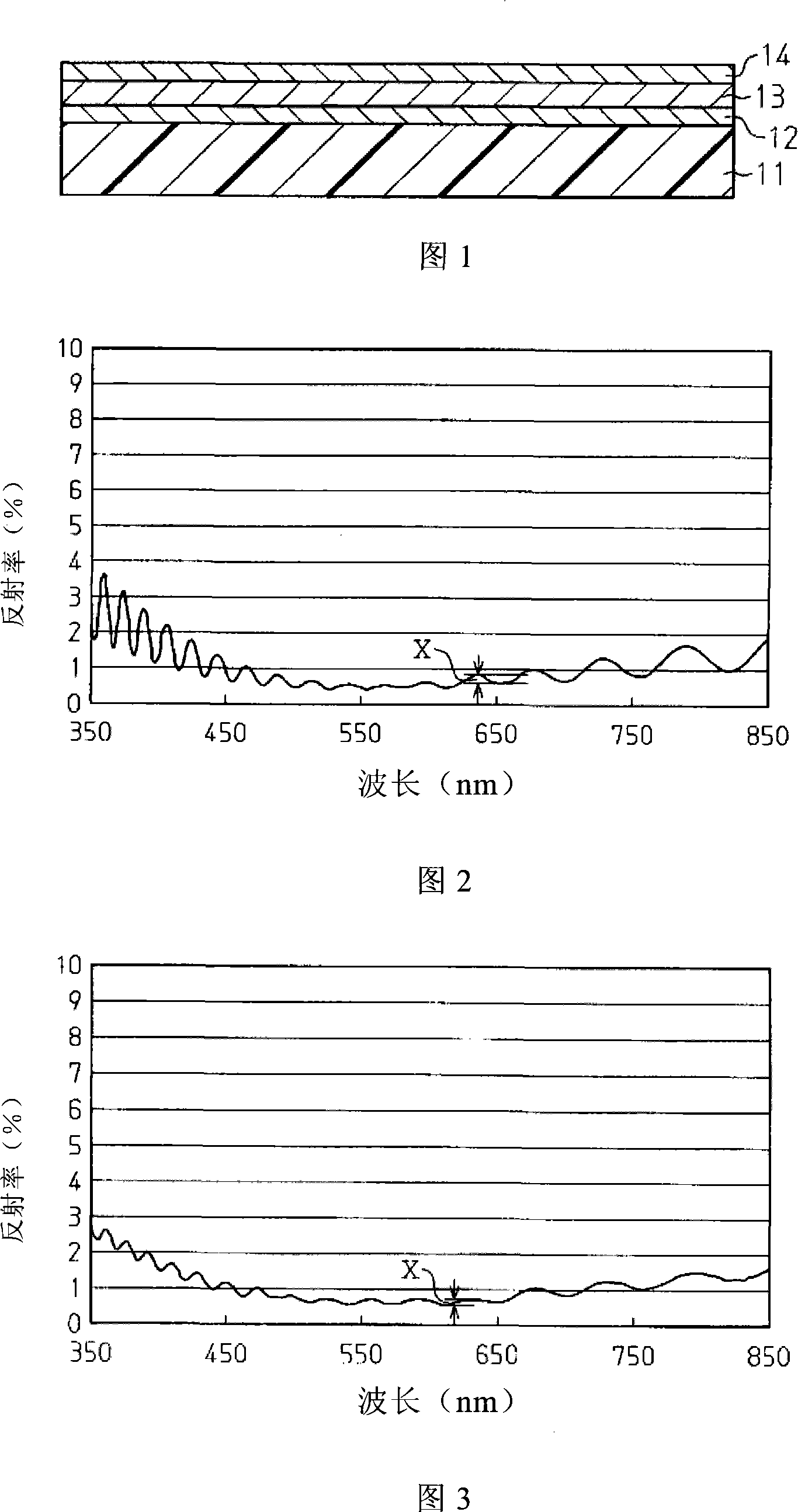

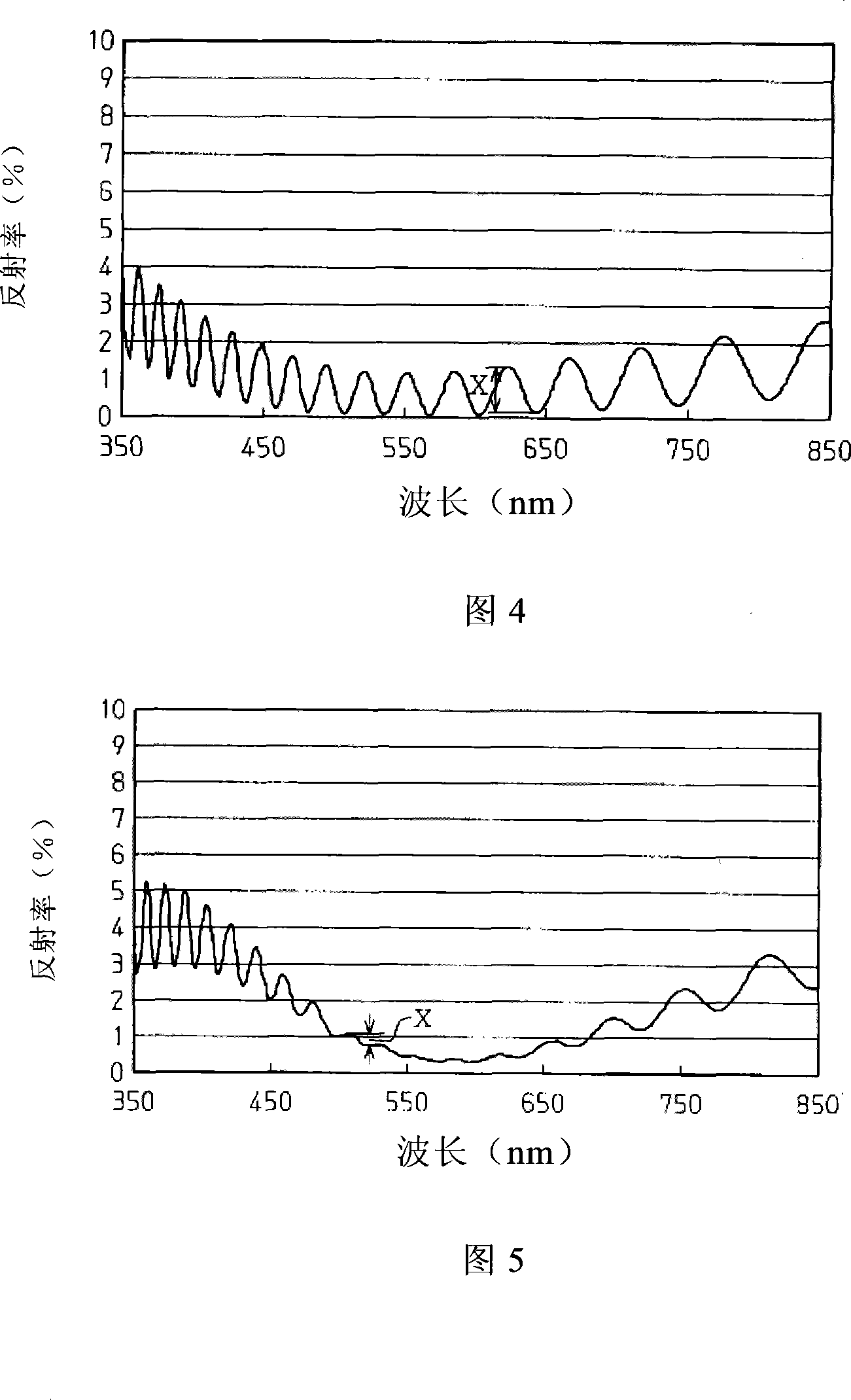

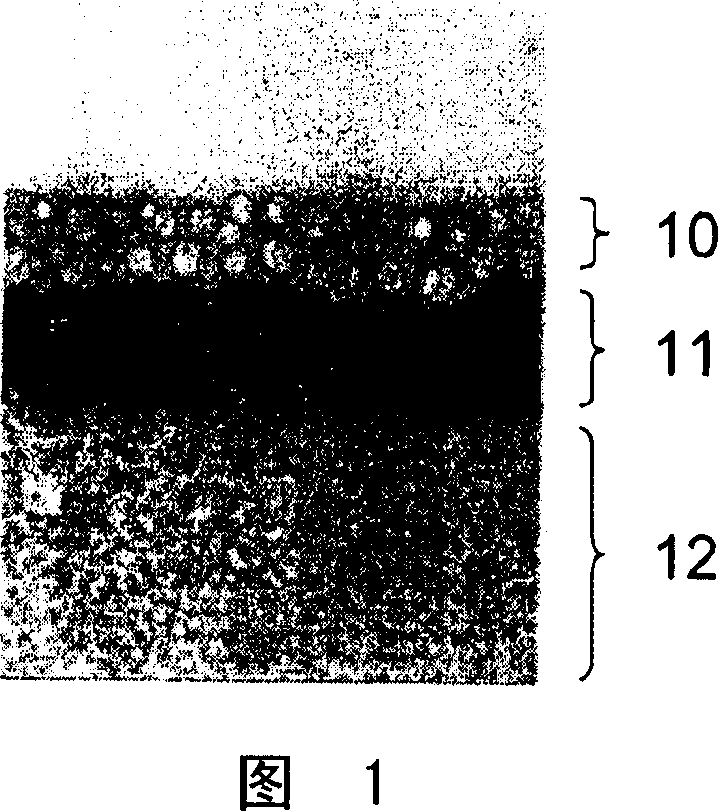

Reflection decreasing material, and electronic image displaying device using it

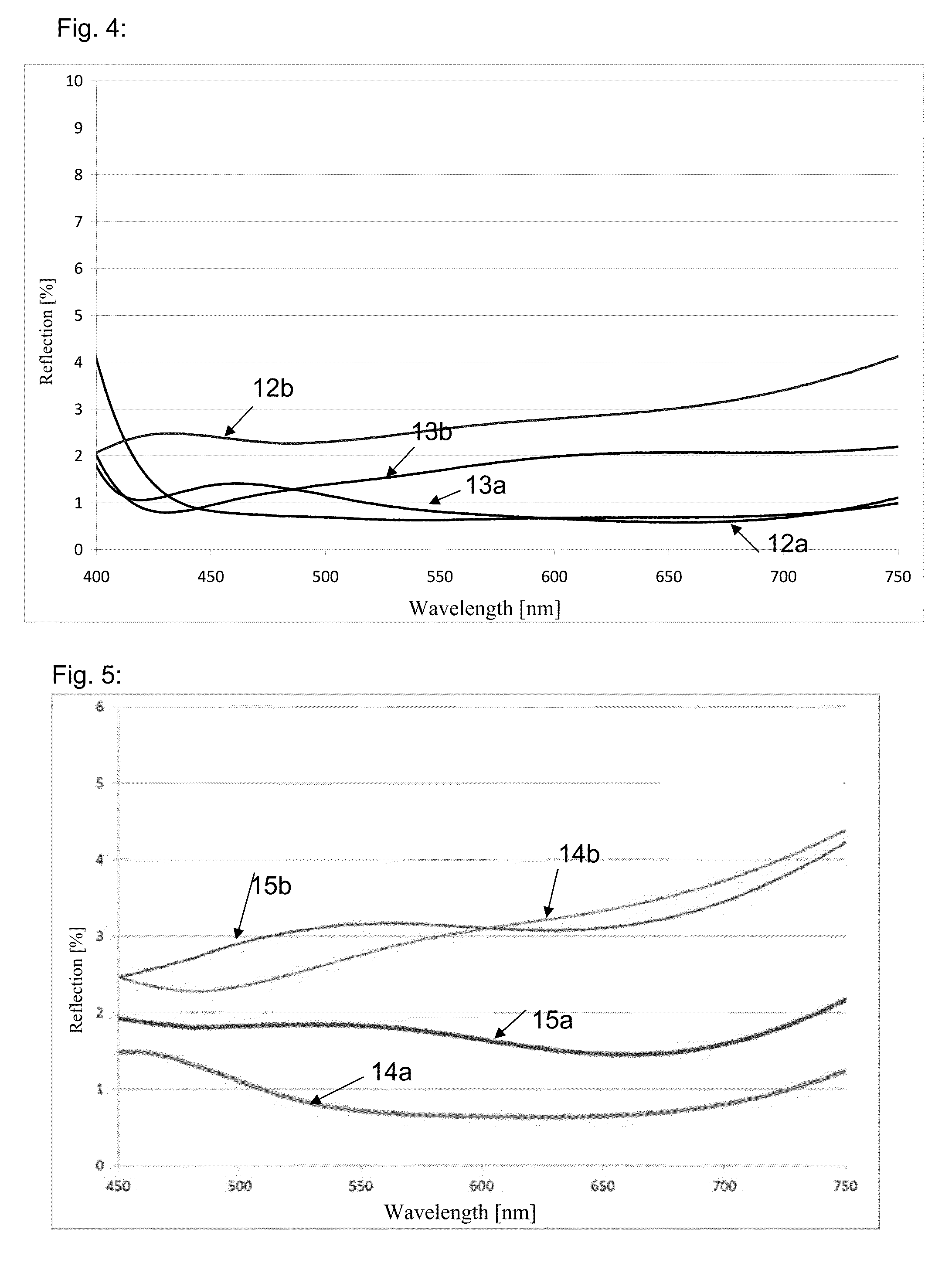

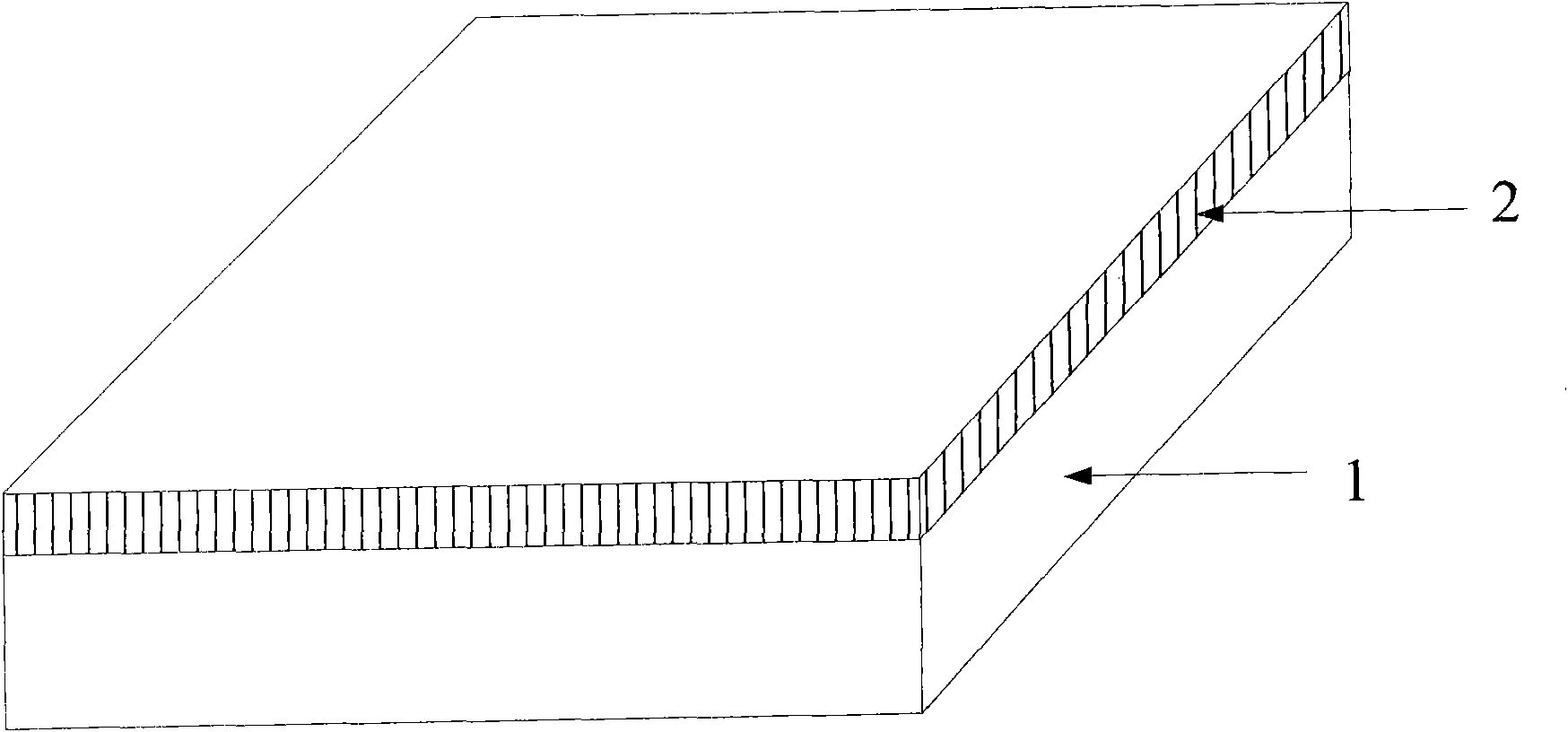

ActiveCN101019043AImprove anti-reflection effectGlass/slag layered productsCoatingsLuminosityMaximum amplitude

There is provided a reflection-reducing layered film which simultaneously improves the reflection preventing ability and suppresses coloring. The reflection-reducing layered film includes: an interference layer (12) layered on a transparent resin film (11), a hard code layer (13) layered on the interference layer (12), and a reflection-reducing layer (14) layered on the hard code layer (13). This reflection-reducing layered film satisfies the following requirements and can simultaneously improve the reflection preventing ability and suppress the coloring. [i] The maximum amplitude of the reflectance curve in the wavelength area of 500 nm to 650 nm is not greater than 1%. [ii] The luminosity reflectance Y for the CIE standard illuminant D65 is not greater than 2%. [iii] The ab chroma Cab for the CIE standard illuminant D65 is not greater than 10.

Owner:HIGASHIYAMA FILM CO LTD

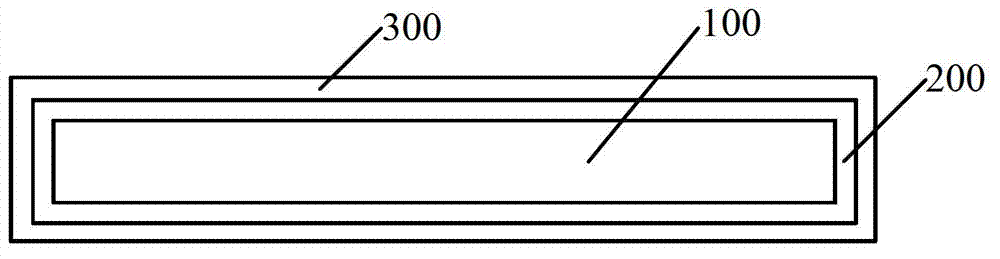

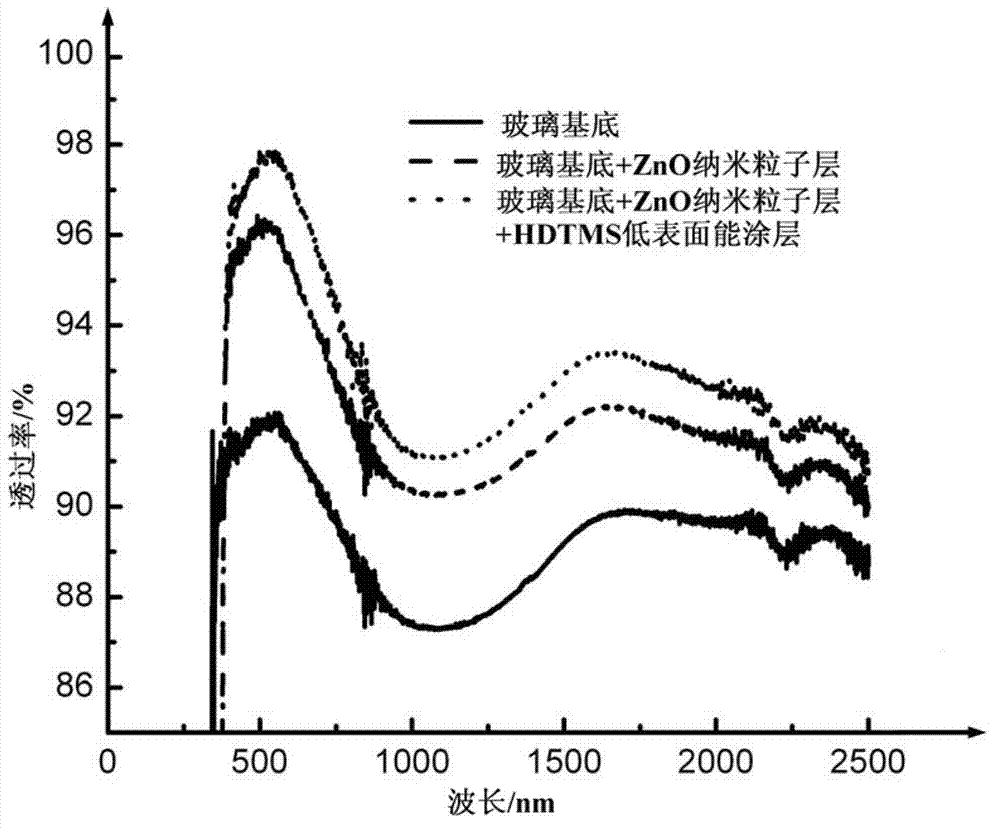

Super-hydrophobic anti-reflection substrate and its manufacturing method

InactiveCN102815052AIncrease the angle of incidenceAchieve superhydrophobic self-cleaningSynthetic resin layered productsCeramic layered productsSurface energyTransmittance

Disclosed are a super-hydrophobic anti-reflection substrate and its manufacturing method. The super-hydrophobic anti-reflection substrate comprises: a basement, an antireflective film positioned on the surface of the basement and a low surface energy coating positioned on the surface of the antireflective film, wherein the antireflective film has a moth eye structure. The manufacturing method of the super-hydrophobic anti-reflection substrate comprises the following steps of: providing the basement; forming the antireflective film having the moth eye structure on the surface of the basement; and forming the low surface energy coating on the surface of the antireflective film. Light transmittance of the antireflective film can be further raised through formation of the low surface energy coating on the surface of the antireflective film.

Owner:SAINT-GOBAIN GLASS FRANCE

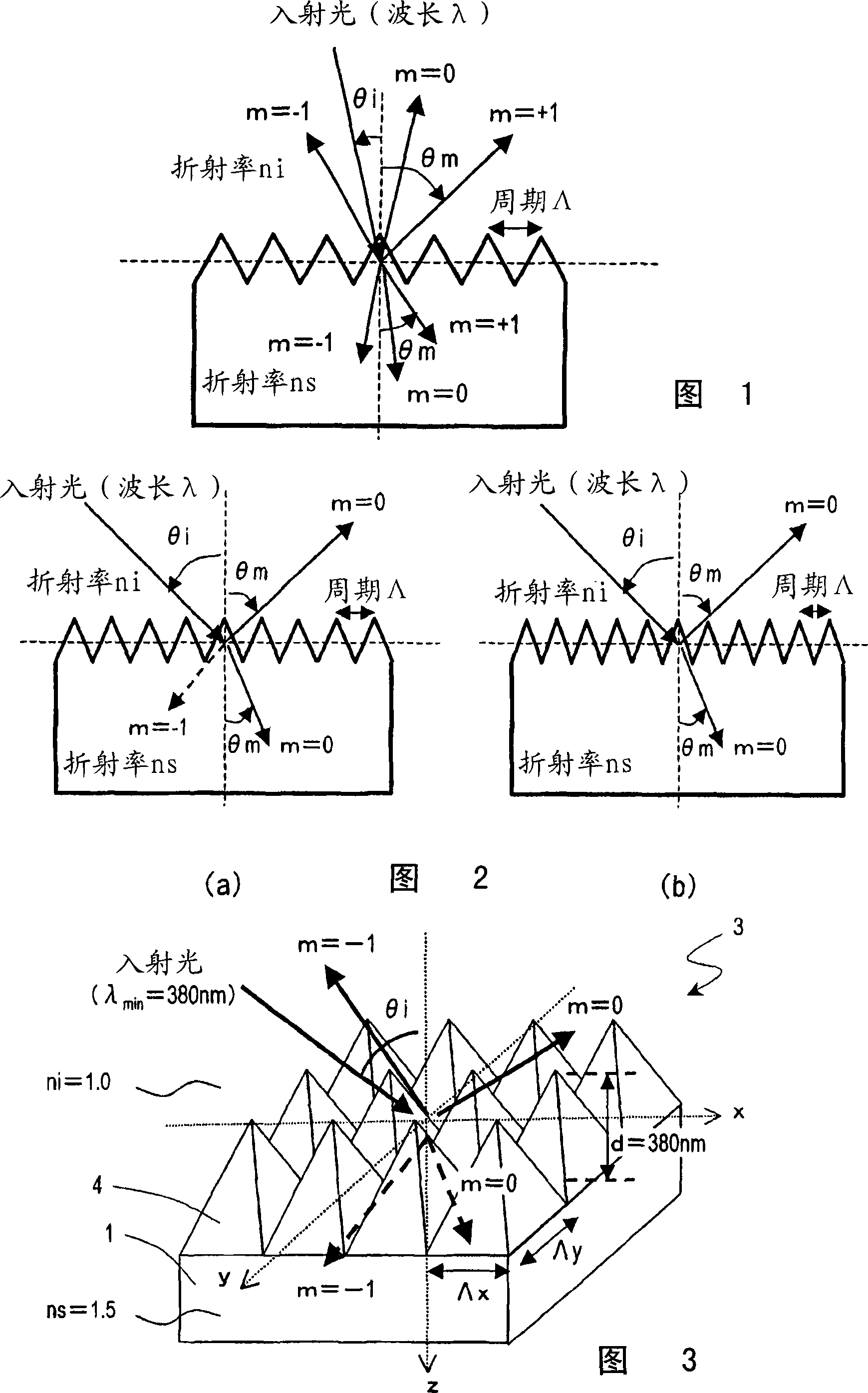

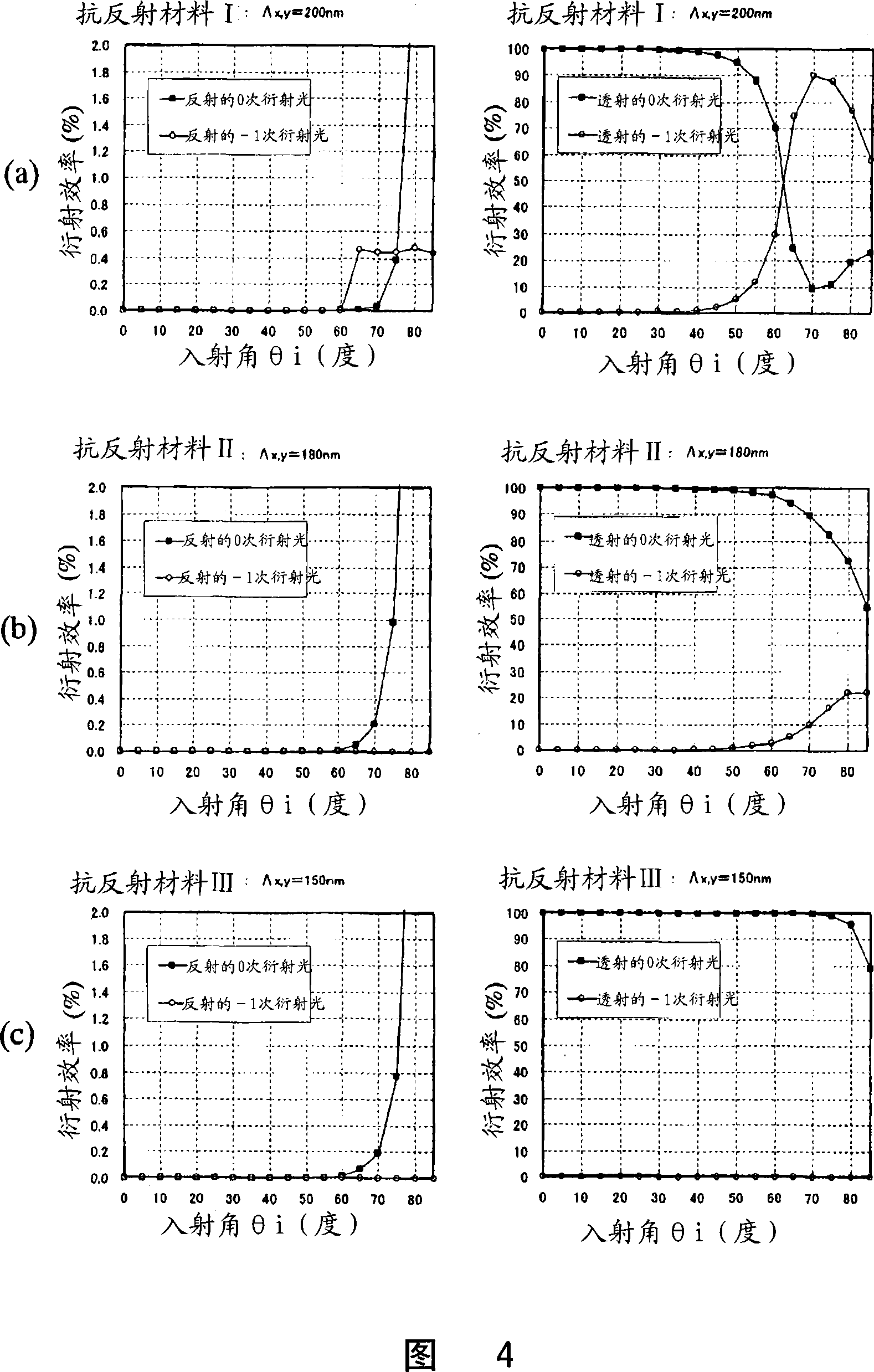

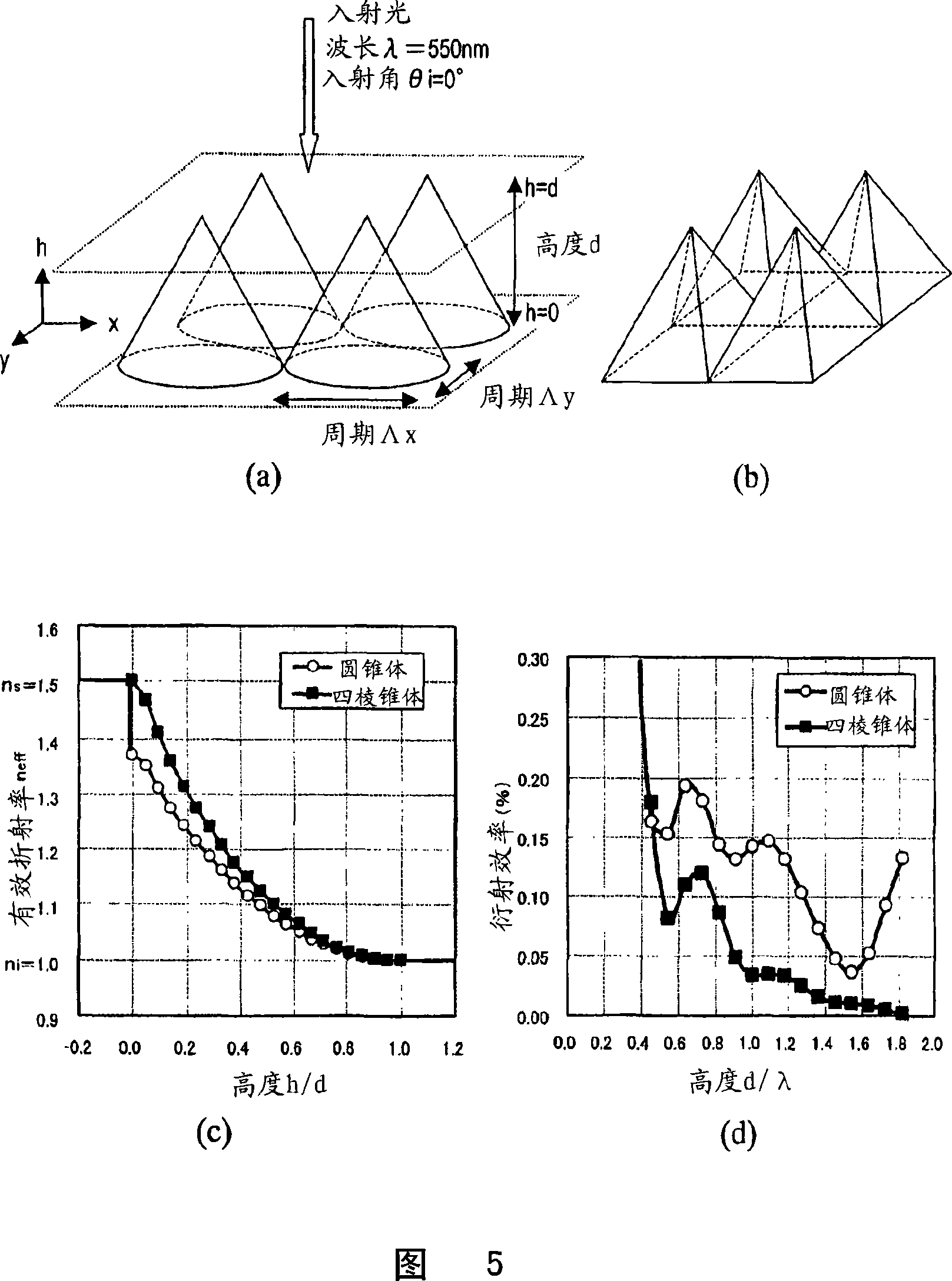

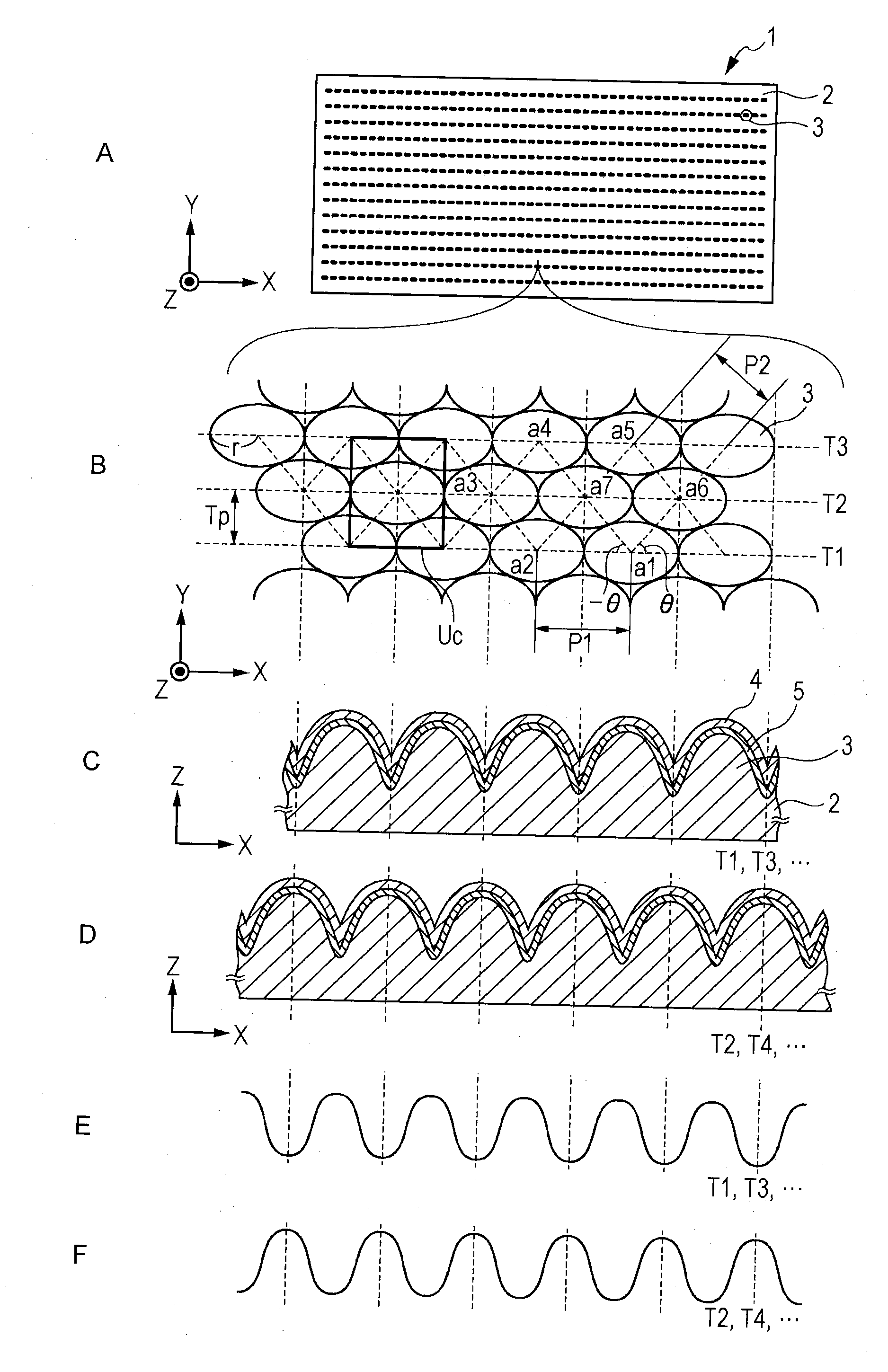

Antireflective member, optical element, display device, method of making stamper and method of making antireflective member using the stamper

ActiveCN101088030ASuppression of regular reflectionImprove anti-reflection effectLayered productsCoatingsSurface patternAngle of incidence

An antireflective member according to the present invention has an uneven surface pattern, in which unit structures are arranged in x and y directions at respective periods that are both shorter than the shortest wavelength of an incoming light ray, on the surface of a substrate and satisfies the following inequality (1): lambda, / lambda ) . . ., where lambda is the shortest wavelength of the incoming light ray, theta i is the largest angle of incidence of the incoming light ray, ni is the refractive index of an incidence medium, lambda is the period of the uneven surface pattern in the x direction, and lambda is the period of the pattern in the y direction. As a result, diffraction of short-wave light components can be reduced in a broad wavelength range.

Owner:SHARP KK

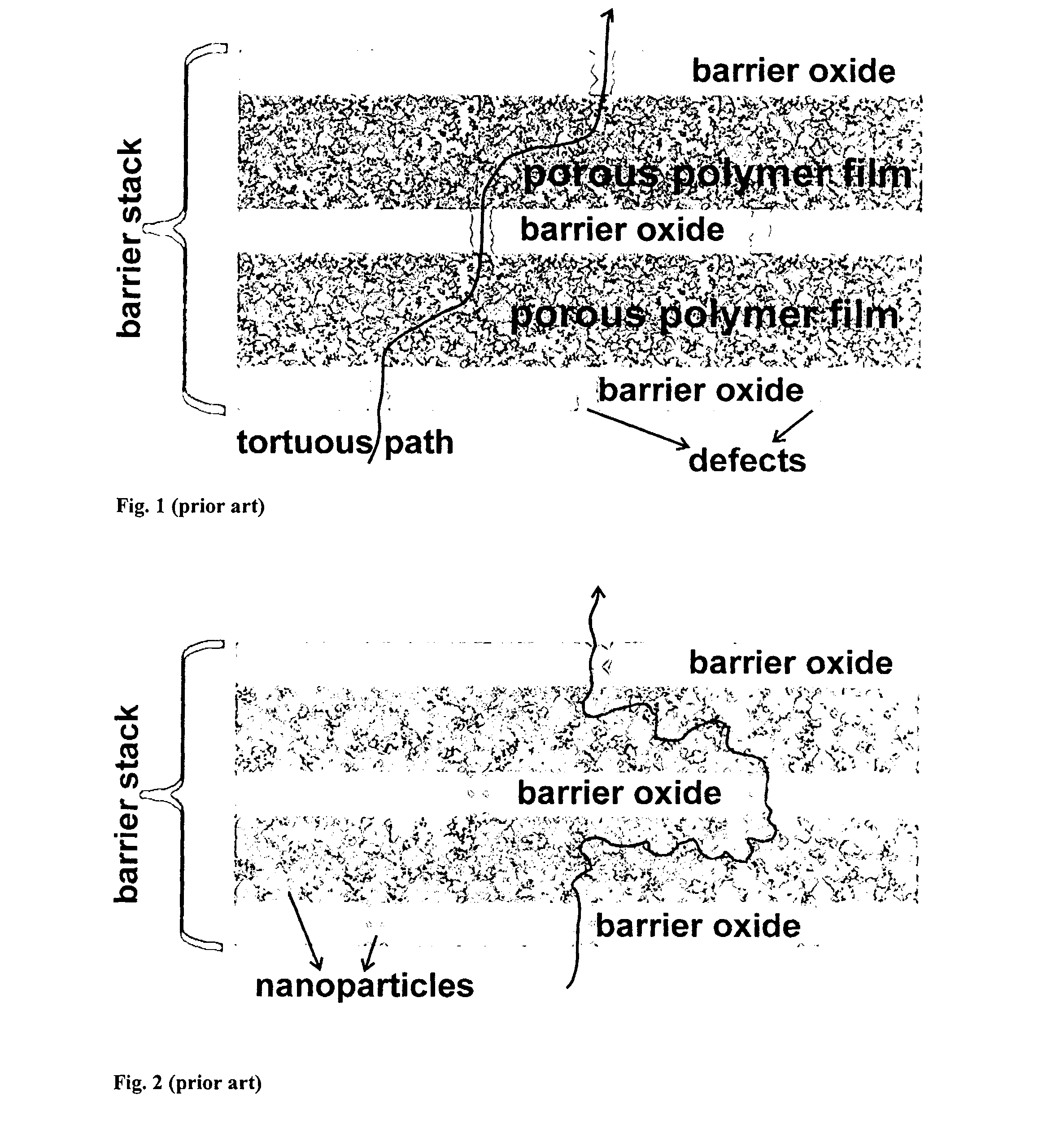

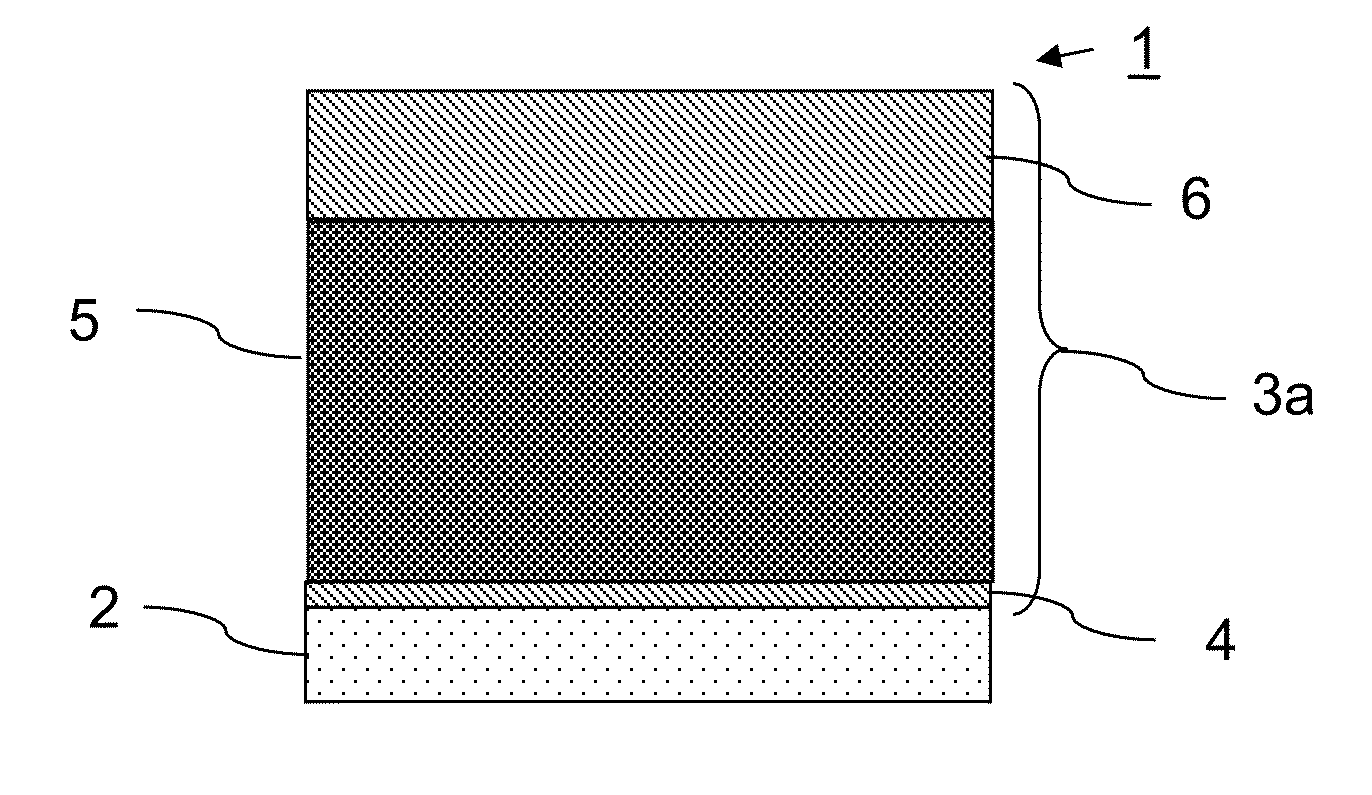

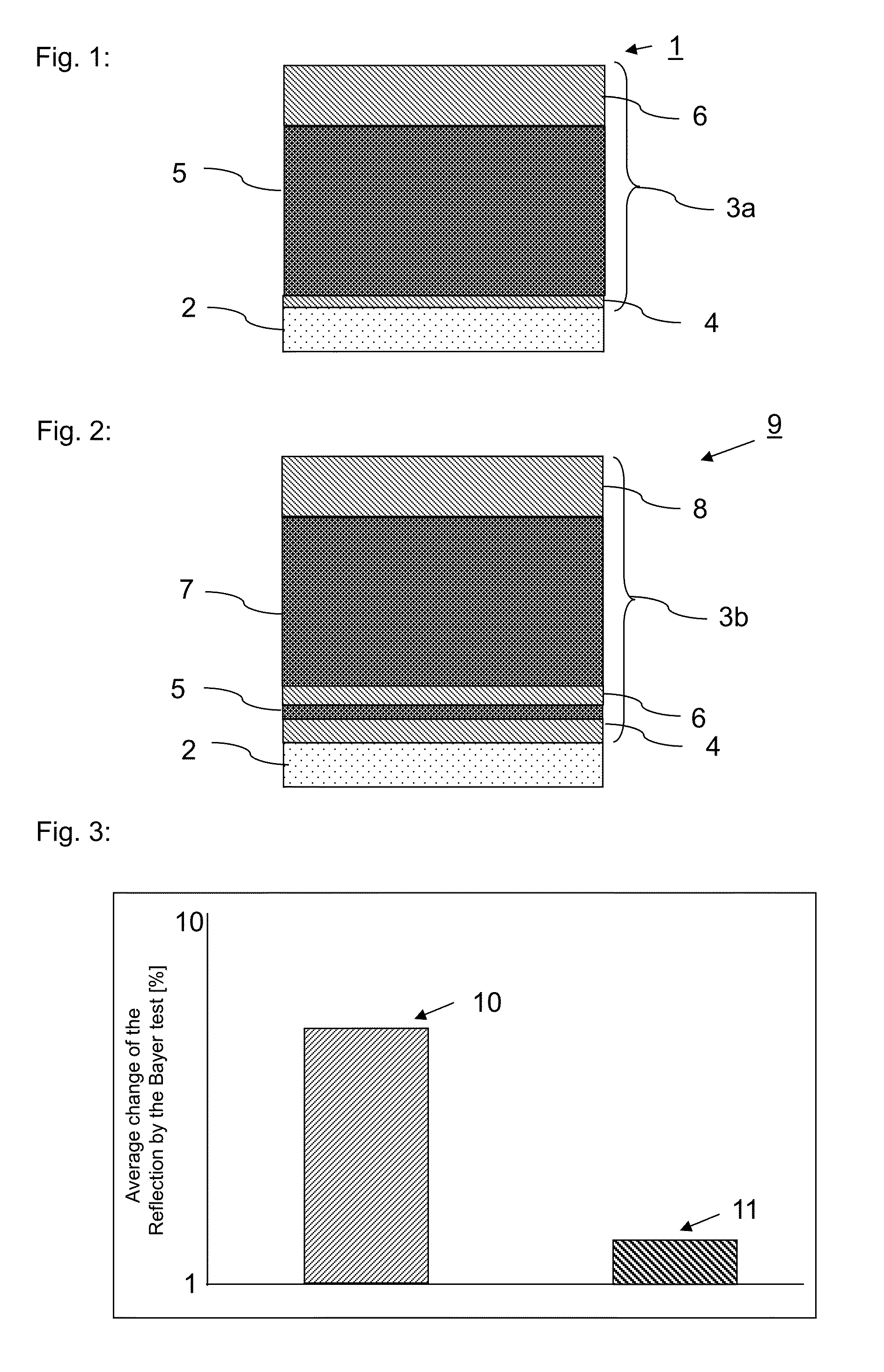

Encapsulation barrier stack

InactiveUS20140252342A1Minimise lateral diffusionImprove anti-reflection effectMaterial nanotechnologyFinal product manufactureCross-linkNanoparticle

Disclosed is an encapsulation barrier stack, capable of encapsulating a moisture and / or oxygen sensitive article and comprising a multilayer film, wherein the multilayer film comprises: one or more barrier layer(s) having low moisture and / or oxygen permeability, and one or more sealing layer(s) arranged to be in contact with a surface of the at least one barrier layer, thereby covering defects present in the barrier layer, wherein the one or more sealing layer(s) comprise(s) a plurality of encapsulated nano-particles, the nanoparticles being reactive in that they are capable of interacting with moisture and / or oxygen to retard the permeation of moisture and / or oxygen through the defects present in the barrier layer. The encapsulation of the particles can be obtained by polymerising a polymerisable compound (a monomeric or a polymeric compound with polymerisible groups or) cross-linking a cross-linkable compound on the surface of the reactive nanoparticles.

Owner:AGENCY FOR SCI TECH & RES

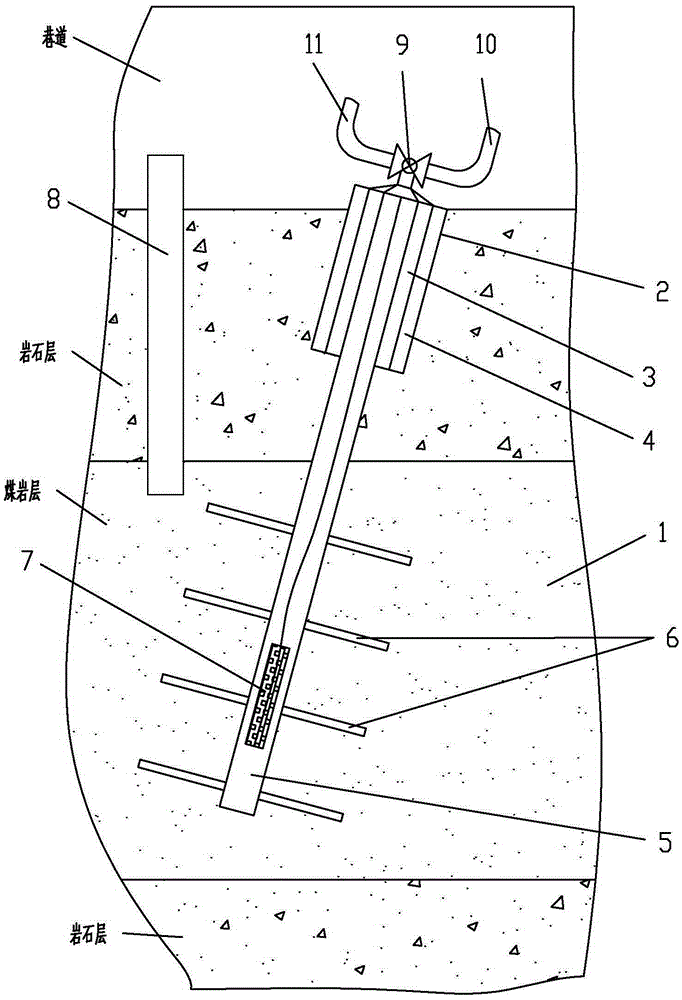

High-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology

InactiveCN105332684AAccurately determine the scope of influenceWide variety of sourcesFluid removalGas removalHigh pressure waterHigh pressure

The invention discloses a high-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology. The high-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology comprises the following steps: ground stress state determination, hole sealing section drilling and sealing, hole drilling and slitting, charging, water injection hole sealing, high-pressure water burst crack starting, supercritical or liquid CO2 fracturing and gas extraction. A ceramsite proppant is mixed in the supercritical or liquid CO2, in a continuous fracturing process of the liquid CO2, extension conditions of burst cracks can be monitored in real time by a microseism monitoring instrument, and fracturing is stopped after an expected effect of extension in a set range is achieved. During guided slitting, slitting can be carried out step by step after holes are drilled according to the number of slits and a set distance between each two adjacent slits, and a mode of drilling holes and slitting alternately can also be adopted. The high-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology has the advantages that the permeability of a low-permeability coal bed gas reservoir can be increased effectively, construction amount is reduced, and coal bed gas extraction efficiency is high.

Owner:CHONGQING UNIV

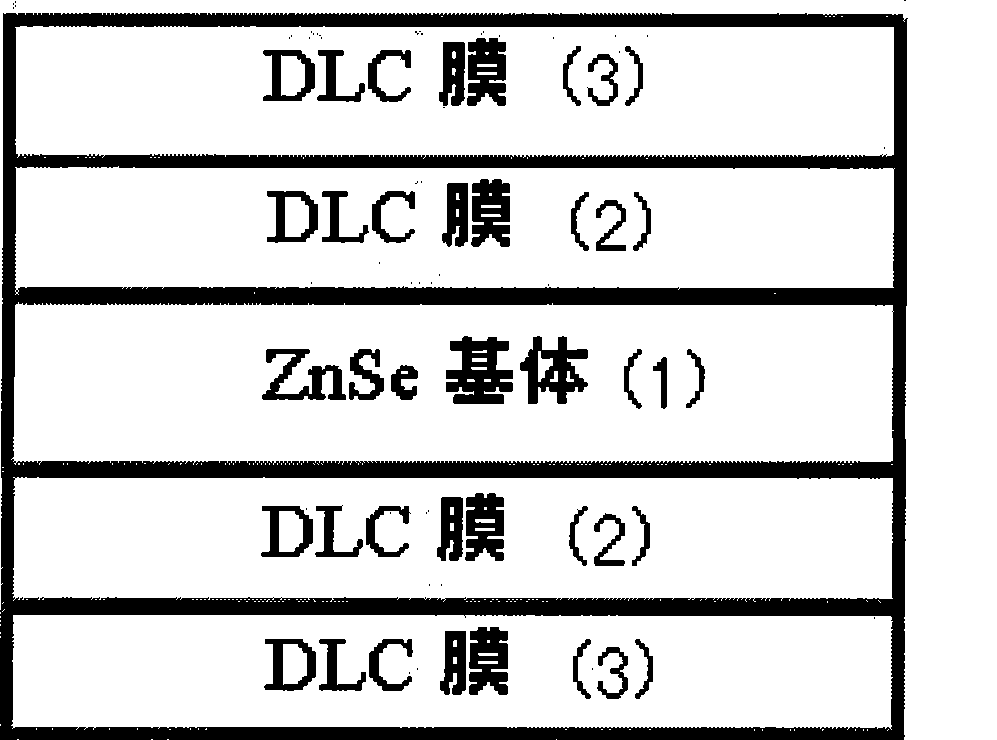

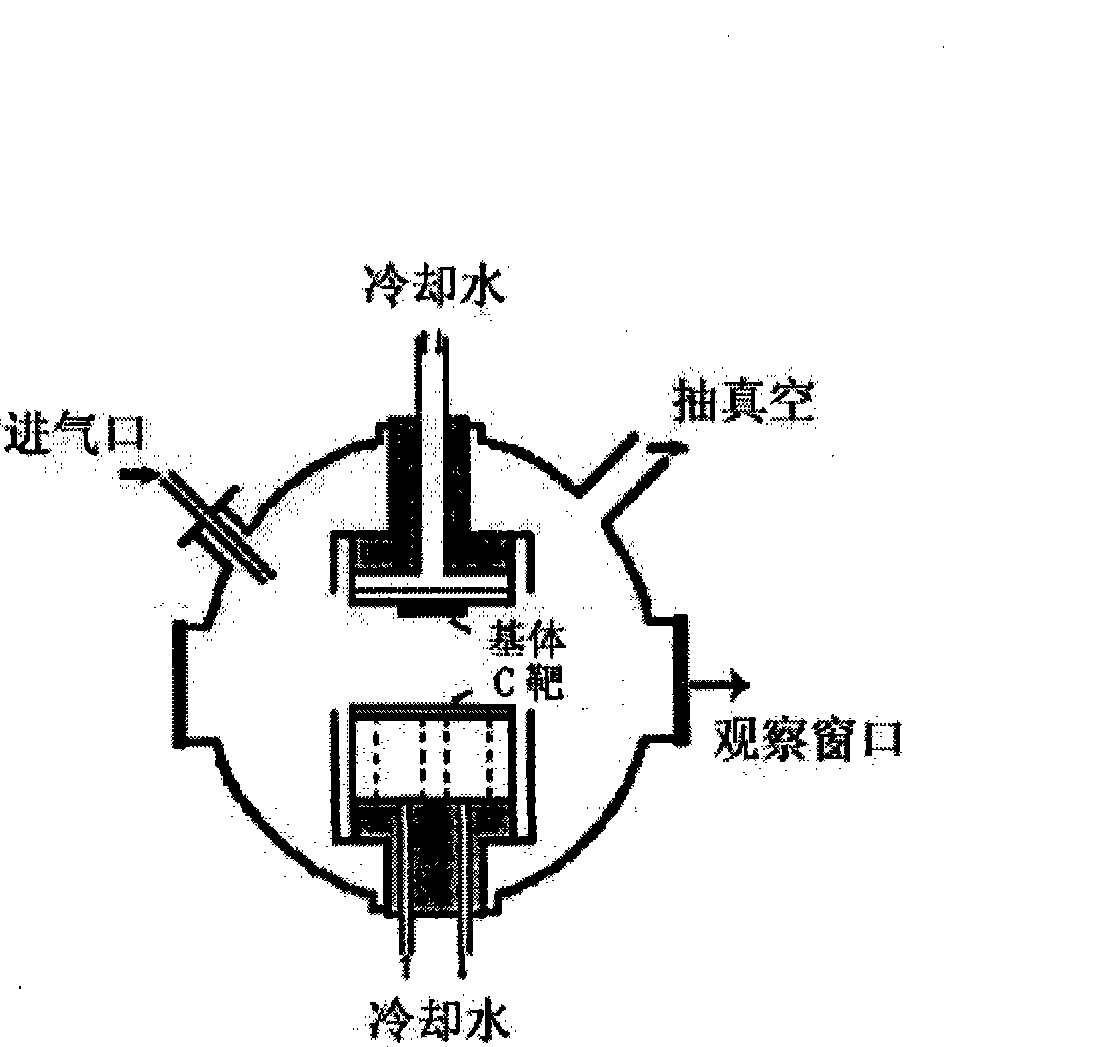

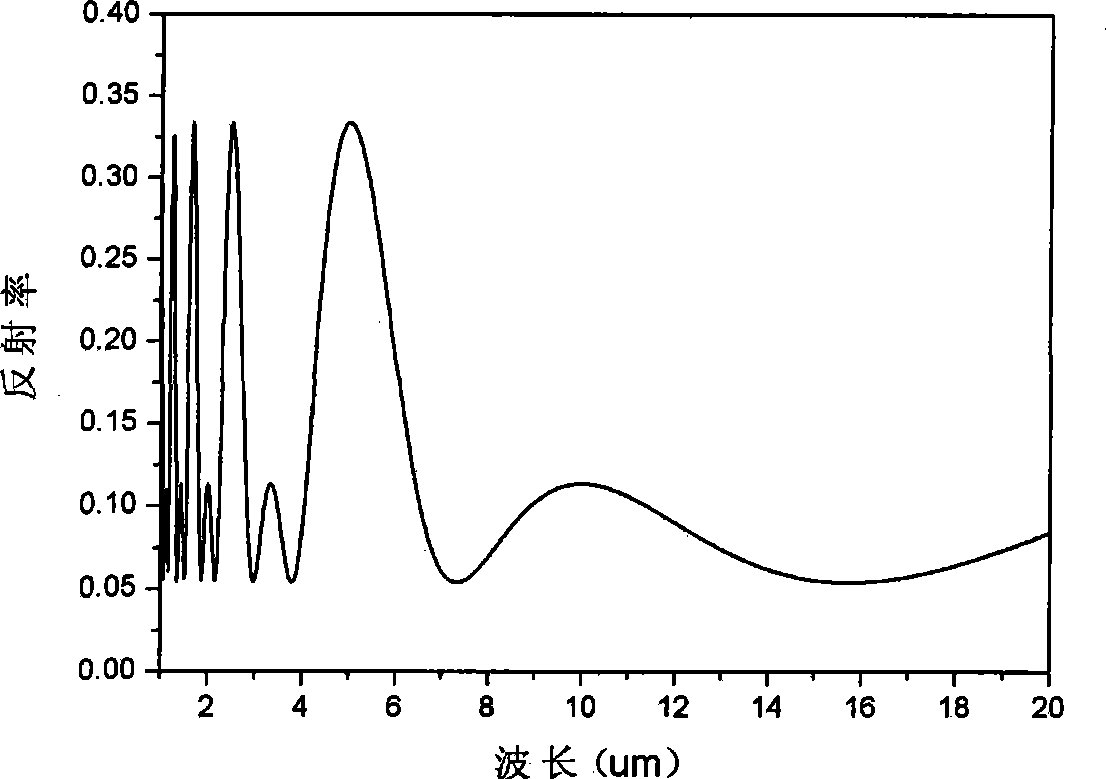

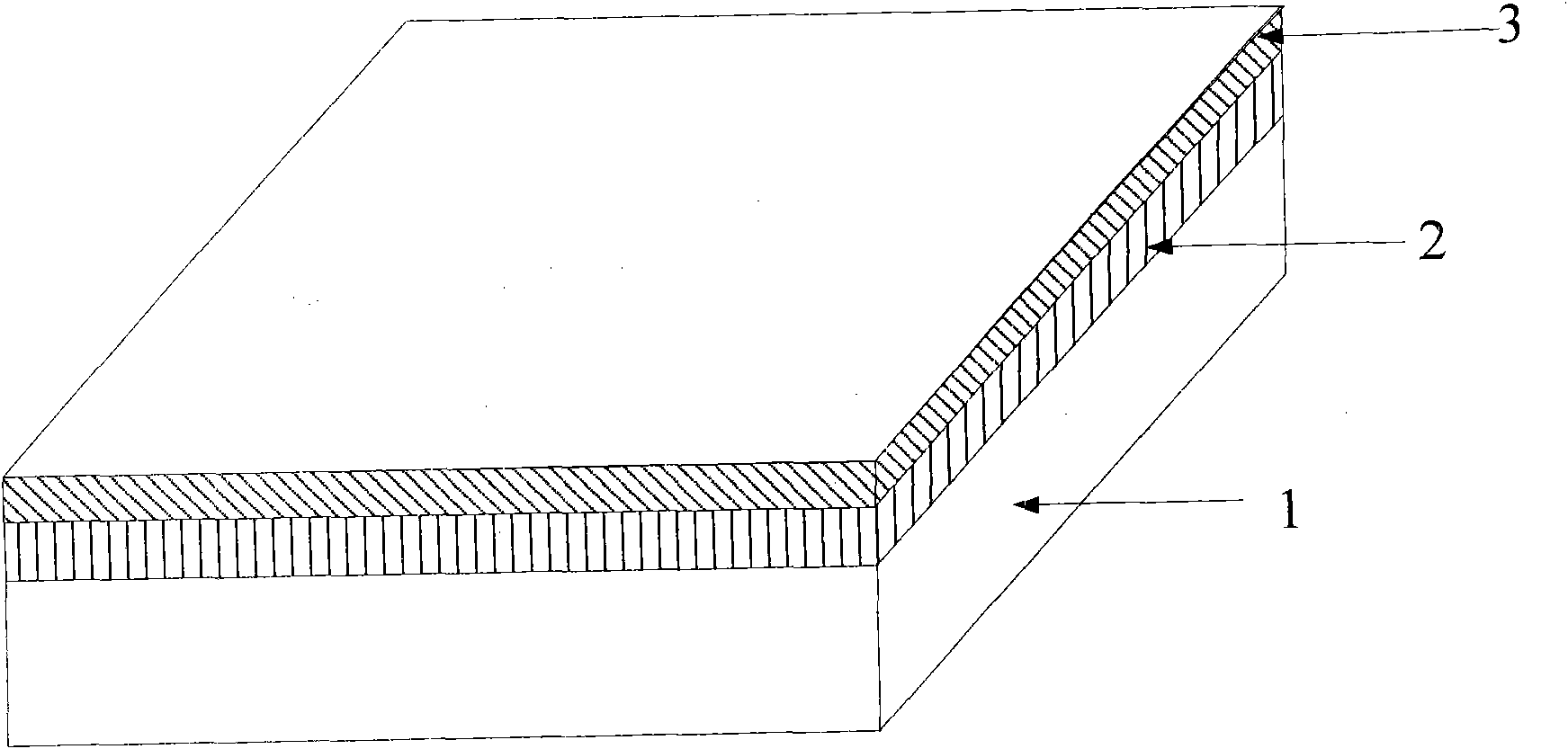

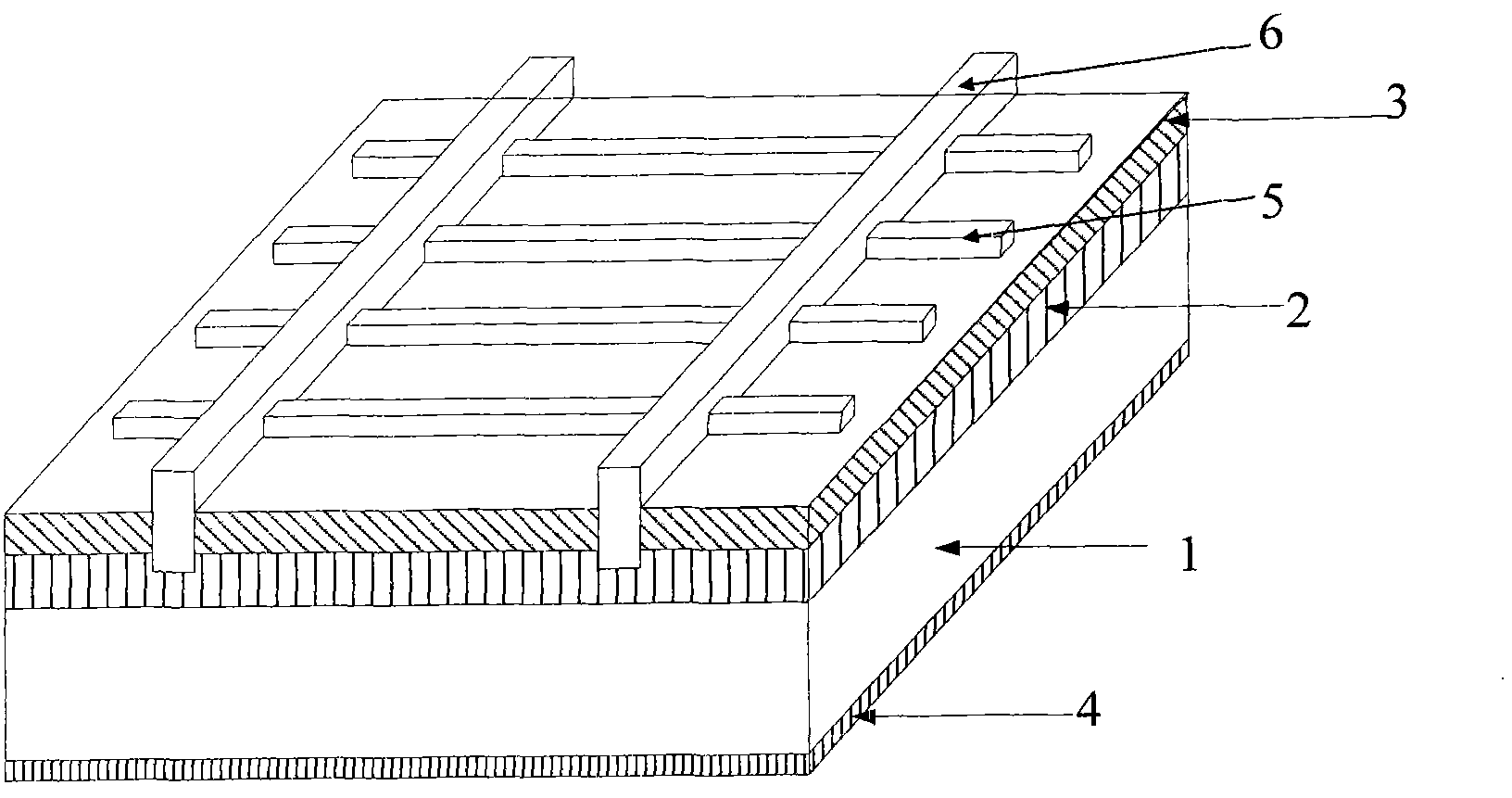

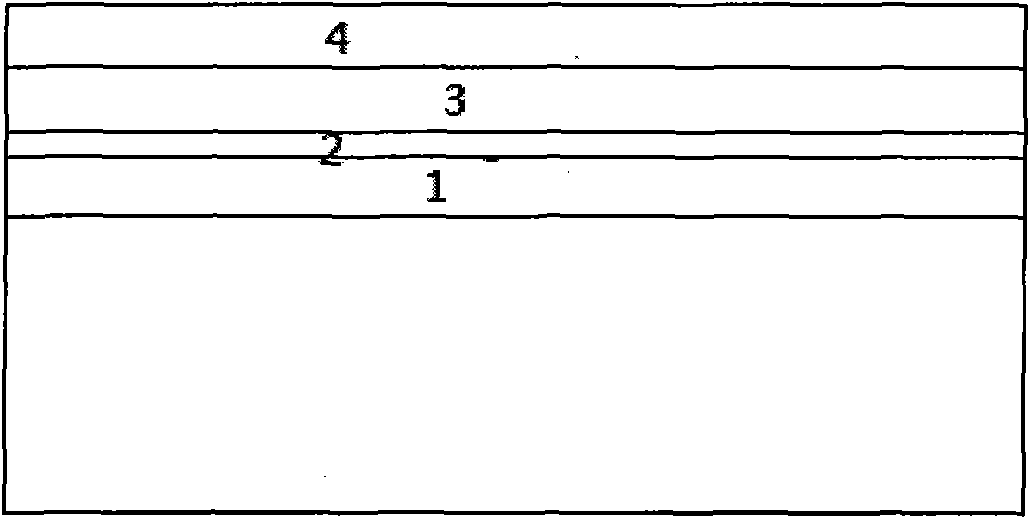

DLC infrared anti-refiection protective film and method for producing the same

InactiveCN101464528AEasy to controlReduce distractionsVacuum evaporation coatingSputtering coatingDiamond-like carbonRadio frequency magnetron sputtering

The invention relates to a DLC infrared anti-reflection protective film and a preparation method thereof. The infrared anti-reflection protective film has the anti-reflection effect at a wider infrared band and simultaneously ensures that an optical element after being filmed has the capacity of abrasion and corrosion resistance. The infrared anti-reflection protective film adopts the structure that a double-layer film is prepared on ZnSe(1); and the refractive index n1 of a first layer of high refractive index film is 1.8 to 2.5, and the thickness d1 thereof is within the scope of about 0.25 Lambada / n1; the refractive index n2 of a second layer of high refractive index film is 0.1 less than that of the first layer of high refractive index film at least, and the thickness d2 thereof is within the scope of about 0.25 Lambada / n (wherein, Lambada is the anti-reflection central wavelength of the infrared anti-reflection film). The preparation method comprises the step of depositing diamond like carbon (DLC) anti-reflection film on double sides or single side of a transparent basal body by adopting the unbalanced intermediate frequency or radio frequency magnetic control sputtering method and taking graphite as a target source, and hydrocarbon and Ar mixed gas or pure Ar as auxiliary discharge gas. Two layers of DLC films with different refractive indexes are prepared through controlling depositing parameters; and the thickness required for each film is obtained through controlling the time. The method has the advantages of convenient control of the depositing parameters of the films, less interference among the depositing parameters, and better anti-reflection effect and abrasion and corrosion resistance.

Owner:SICHUAN UNIV

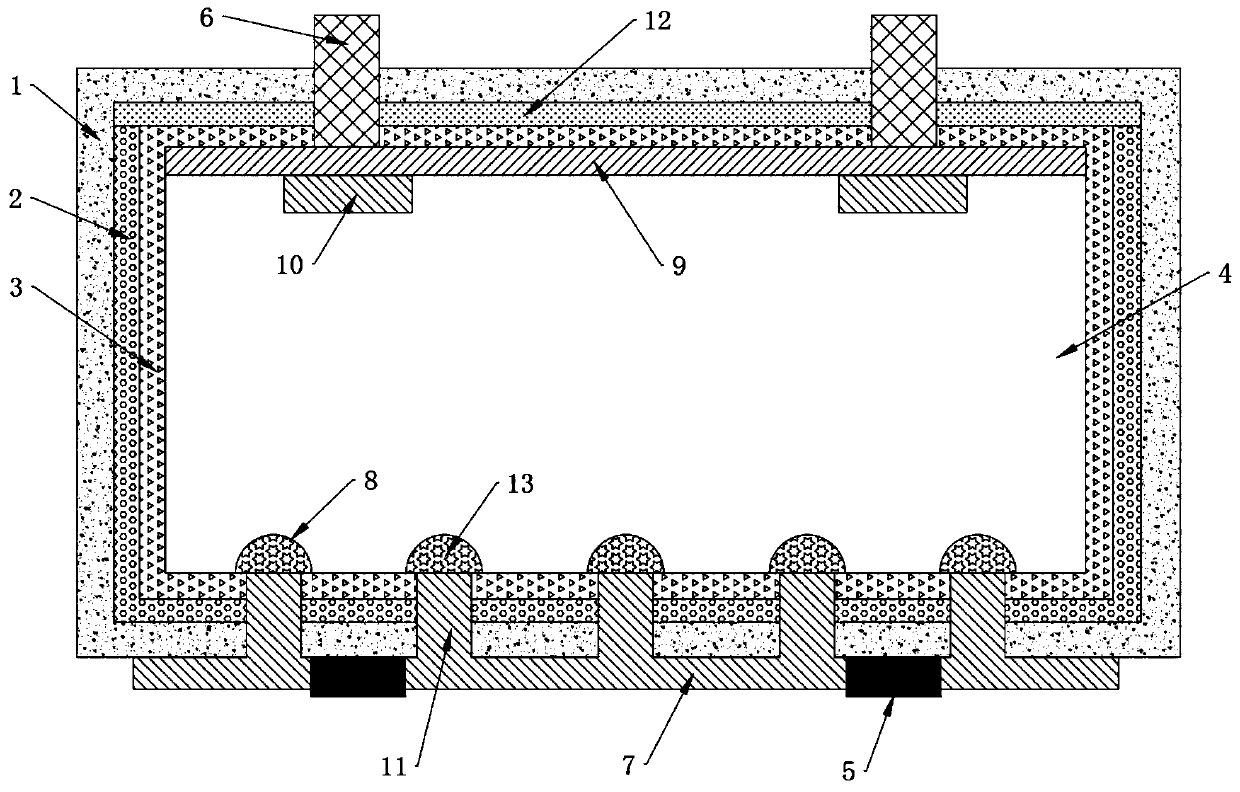

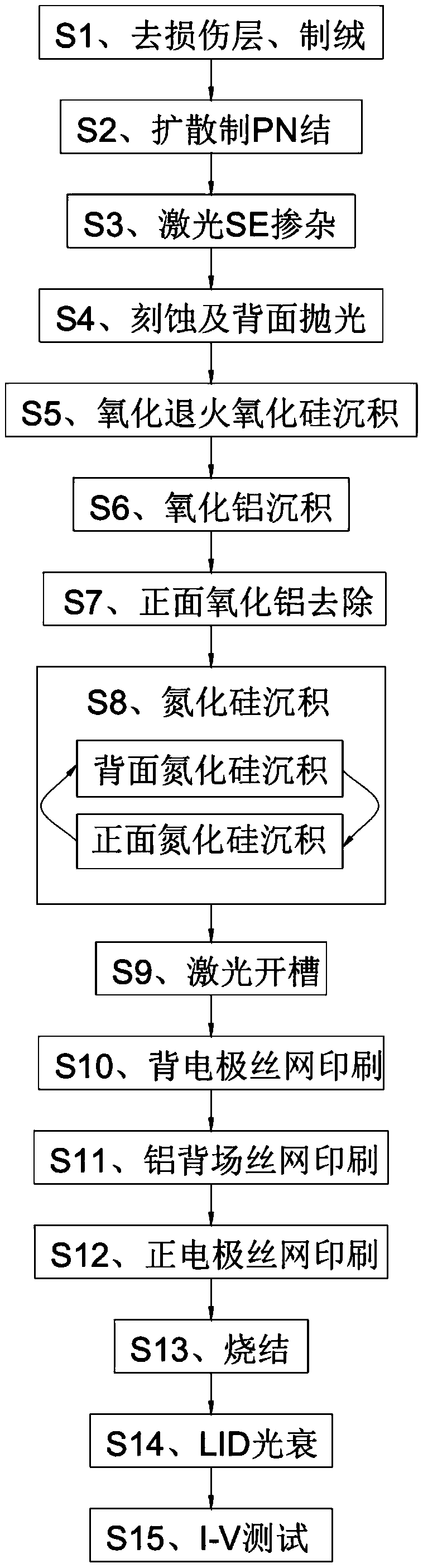

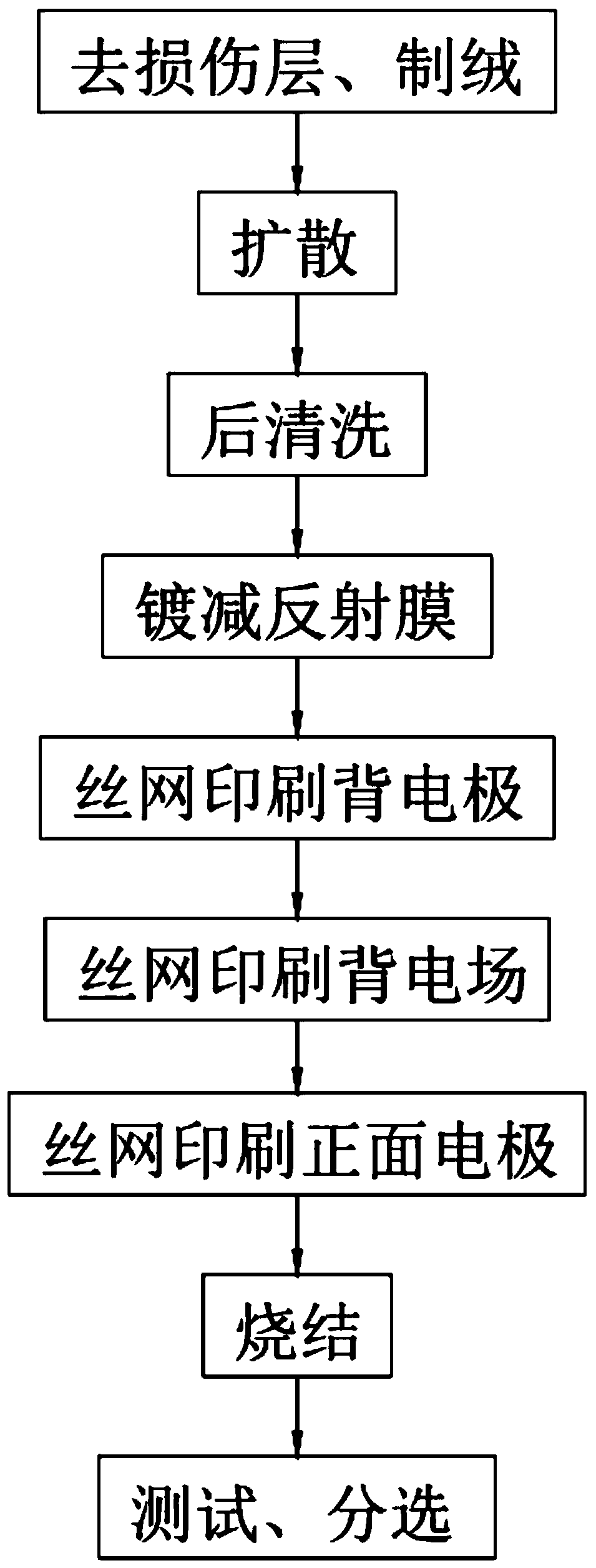

Solar cell with composite dielectric passivation layer structure and preparation process thereof

PendingCN110459615AIncrease short circuit currentIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationDielectricRefractive index

The invention discloses a solar cell with a composite dielectric passivation layer structure and a preparation process thereof. A silicon oxide film, an alumina film and a silicon nitride or silicon oxynitride film are deposited in turn on the front, back and sides of a p-type silicon substrate to form a composite dielectric film on the whole surface, and windows are opened locally to lead electrodes out. Through aluminum oxide, silicon dioxide, silicon oxynitride, silicon nitride with different refractive indexes and a back surface passivation layer with a laminated structure of the materials, the back surface recombination rate is greatly reduced, the back reflectivity is improved, the CTM of a module is reduced, and the light attenuation and heat-assisted light attenuation and the anti-PID performance of the cell are improved. The structure can be made on a boron / gallium-doped p-type monocrystalline silicon, p-type polycrystalline silicon or p-type monocrystalline-silicon-like substrate, and a passivation method based on the composite dielectric film passivation structure can be used to manufacture PERC cells, double-sided PERC+ cells and imbricate PERC cells. Based on the preparation process steps and sequence, the corresponding preparation mode and the process parameter range of the laminated structure, the making of the cell can be well completed.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID +2

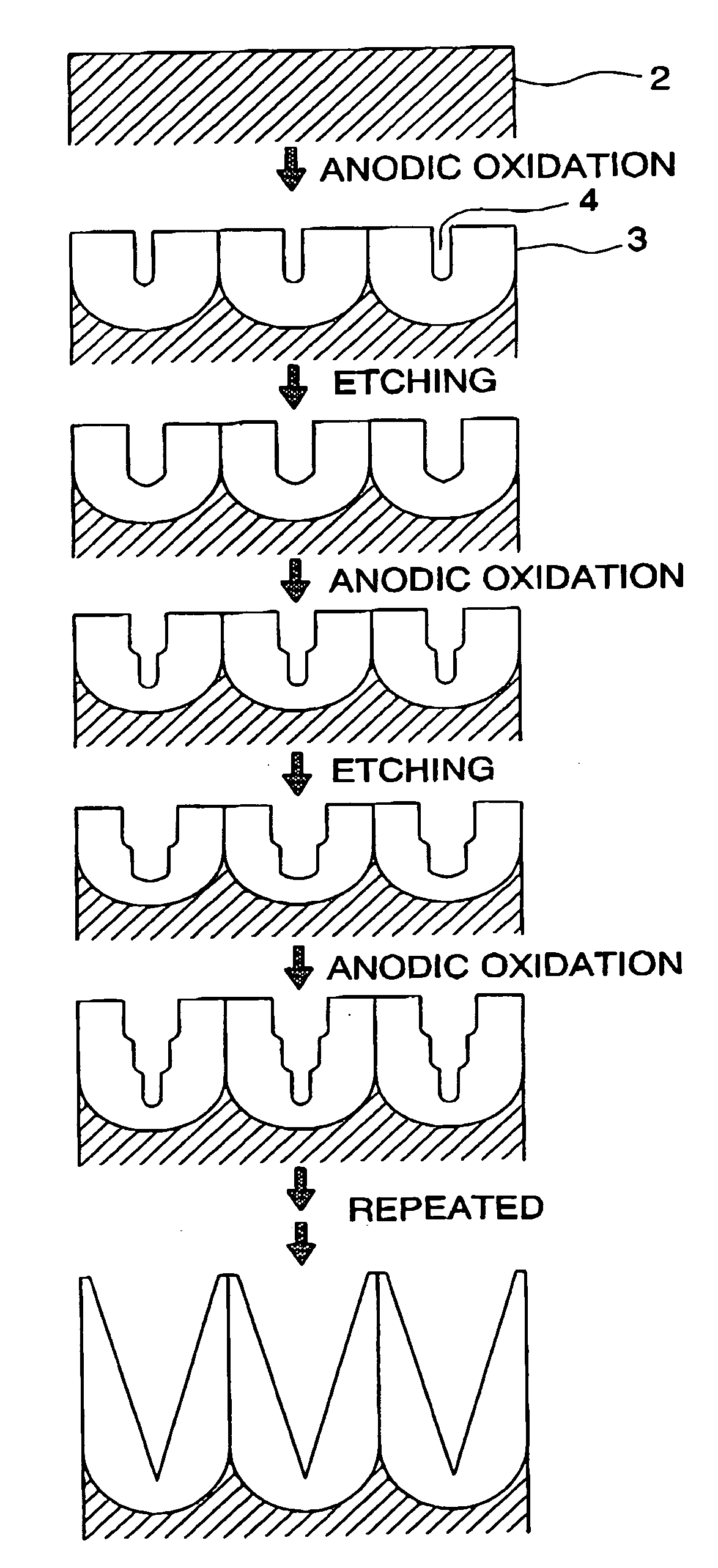

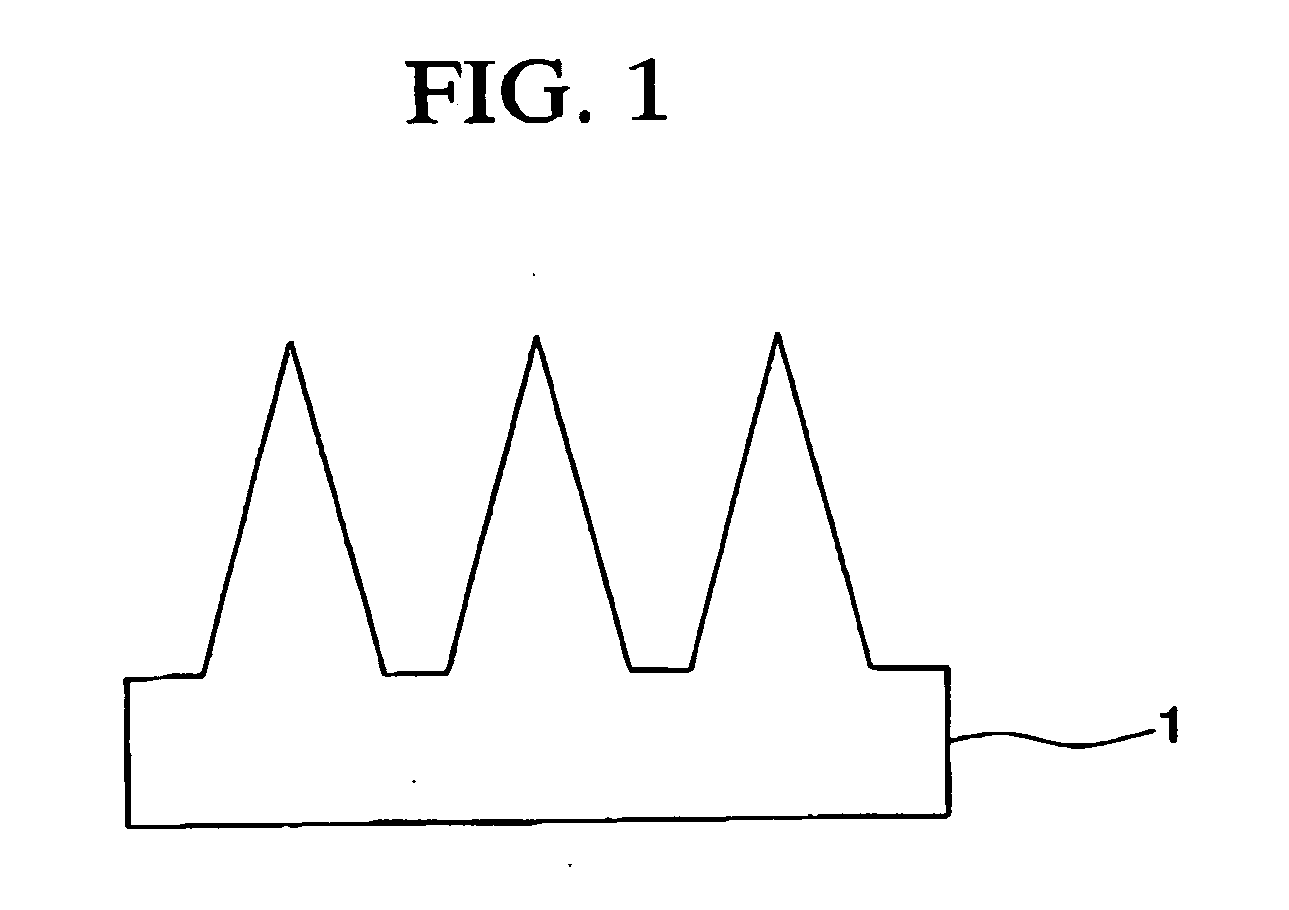

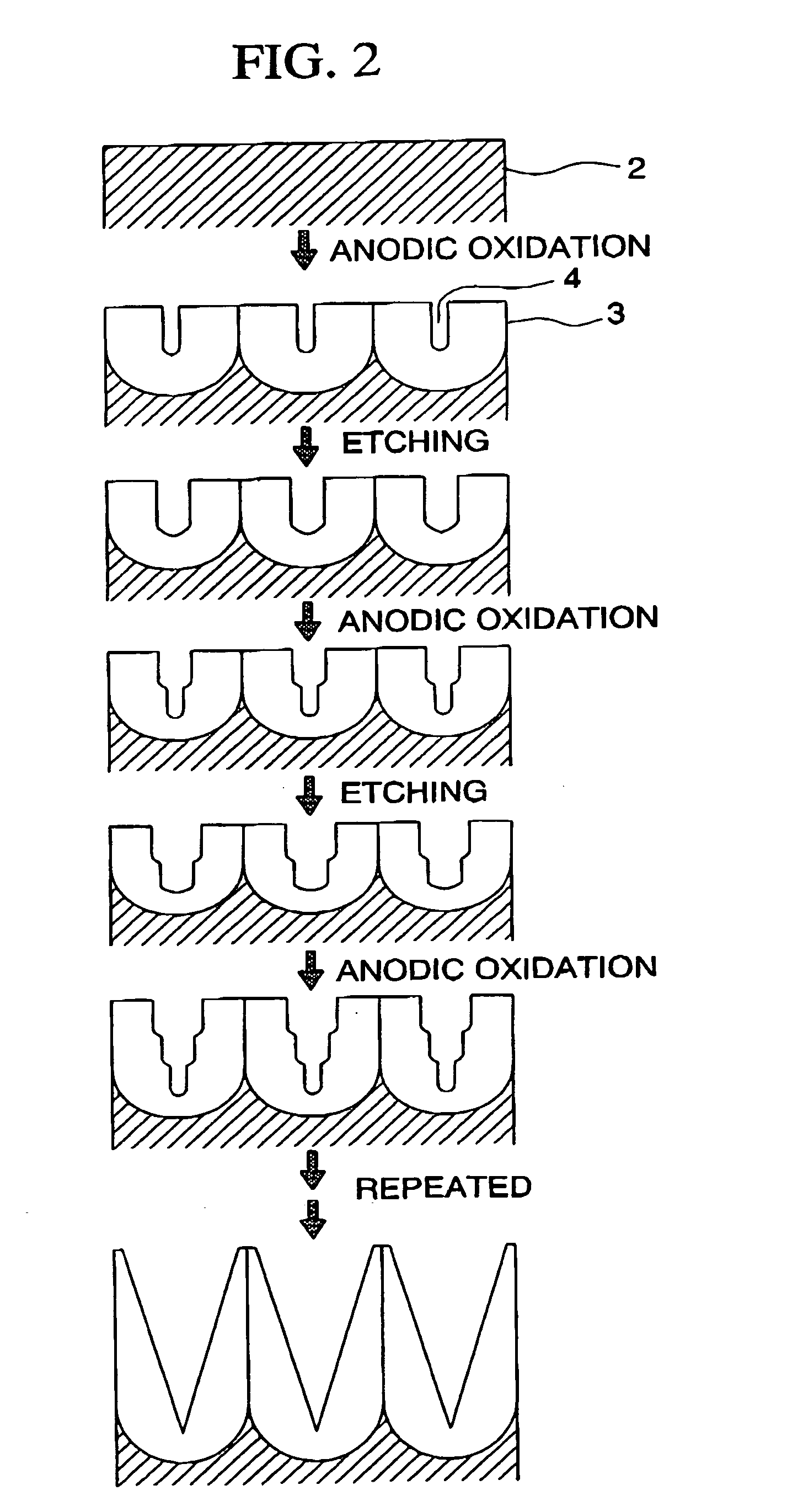

Anti-reflective film and production method thereof, and stamper for producing anti-reflective film and production method thereof

ActiveUS20070289874A1Reduce reflectionWell formedAnodisationConfectioneryShell moldingRefractive index

In this method for producing an anti-reflective film, pores are formed on a surface of a polymer molding material to continuously change a refractive index and then reduce reflectance, in which anodic oxidized porous alumina, in which pores having a tapered shape and whose pore diameter continuously changes, are formed by repeating anodic oxidation at about the same formation voltage and pore diameter enlargement treatment, is used as a mold, or a stamper, which is produced by using the anodic oxidized porous aluminum as a mold, is used as a mold.

Owner:KANAGAWA INST OF IND SCI & TECH

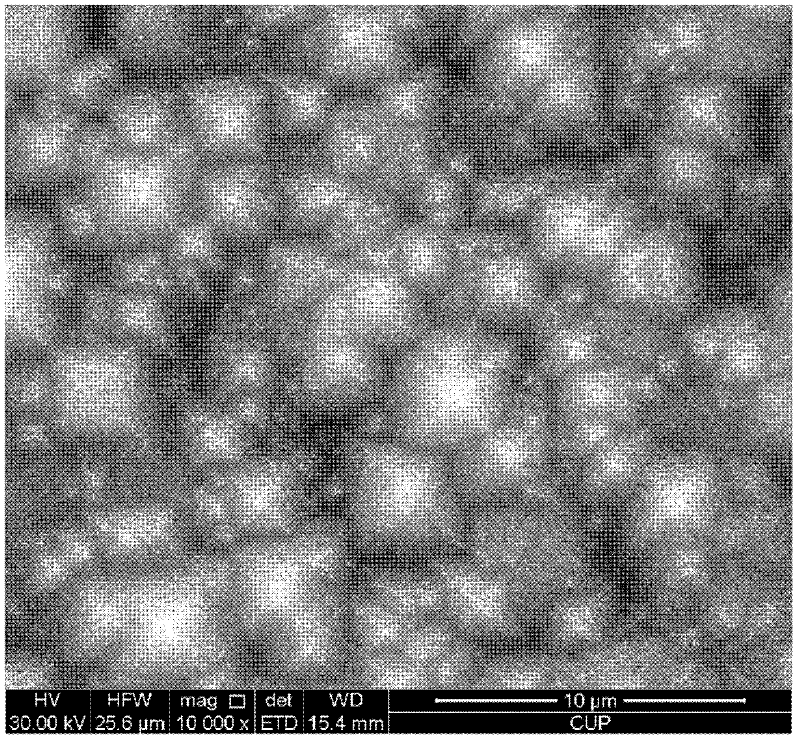

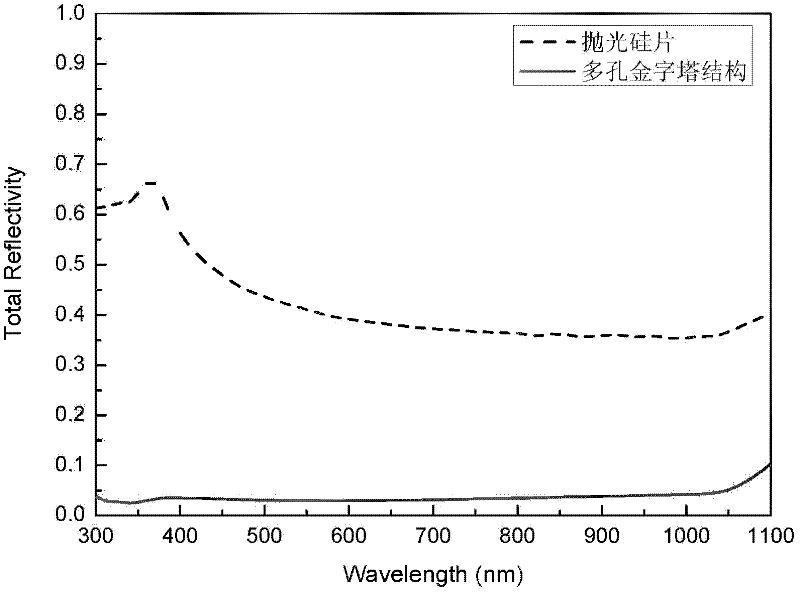

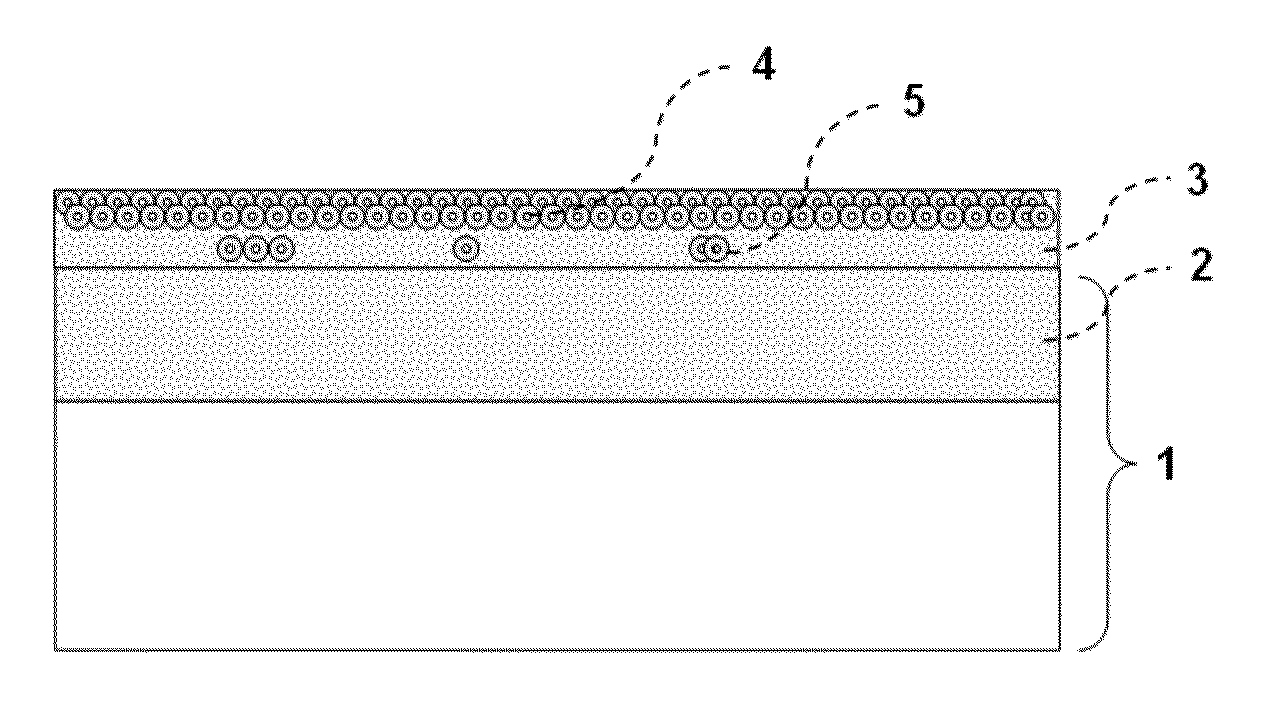

Preparation method of porous pyramid silicon surface light-trapping structure for solar cells

ActiveCN102299207AGood repeatabilityLow costAfter-treatment detailsFinal product manufactureReflectivityEtching

The invention discloses a method for manufacturing a porous pyramid-type silicon surface light trapping structure for a solar cell and belongs to the technical field of solar cell. The method comprises the following steps of: after cleaning a silicon wafer, manufacturing a pyramid structure surface by using an alkali etching technology; and manufacturing the porous pyramid-type surface light trapping structure by combining a noble metal nanoparticle catalyzing and etching process. The average reflectivity of a porous pyramid-type silicon surface light trapping structure manufactured by the method within a spectral range of 300 to 1000nm is reduced to 3.3 percent, so that a new technical measure is provided for improving the efficiency of a silicon solar cell; and when the method is used, the conventional alkali etching process and the noble metal nanoparticle assistant etching process are comprehensively utilized, the characteristics of a wet etching method are kept, and a higher anti-reflective effect of the silicon surface is achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Anti-reflective coating film

ActiveUS20130215514A1Improve interface adhesionImprove scratch resistanceSynthetic resin layered productsPretreated surfacesAnti-reflective coatingMaterials science

Owner:LG CHEM LTD

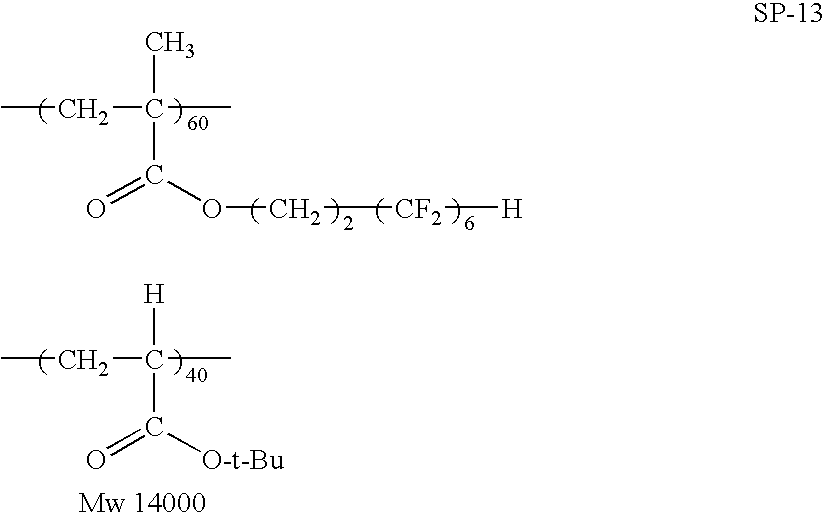

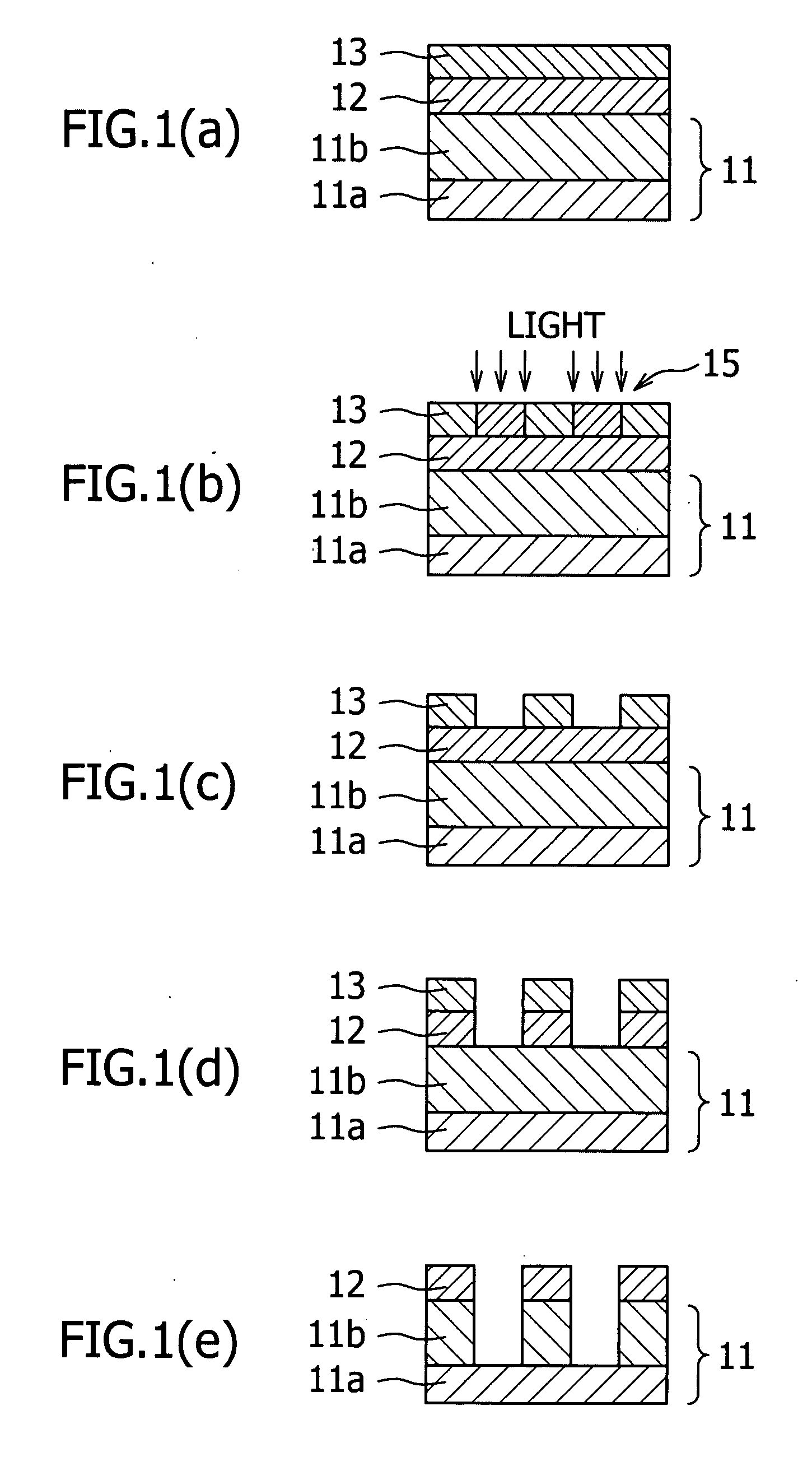

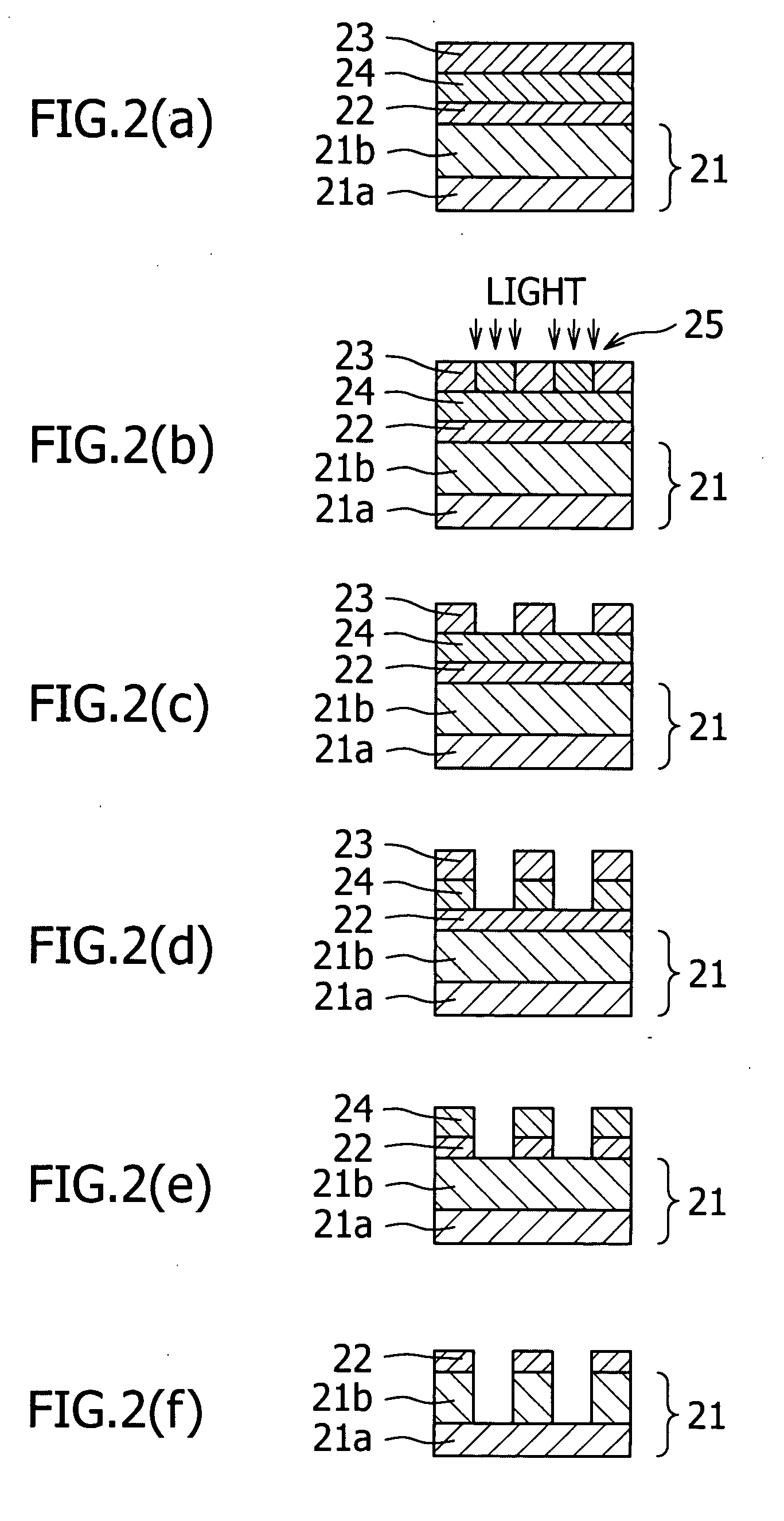

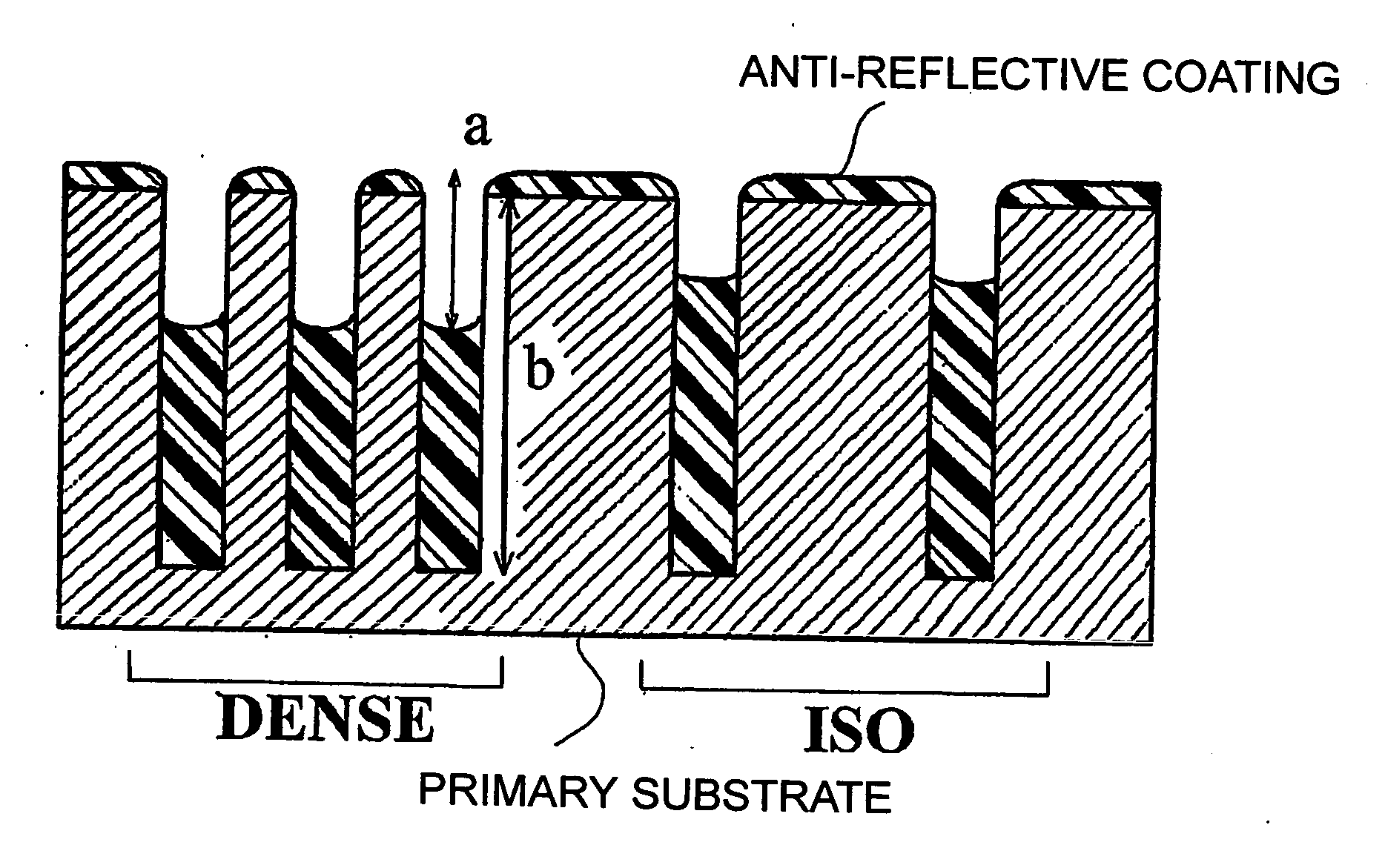

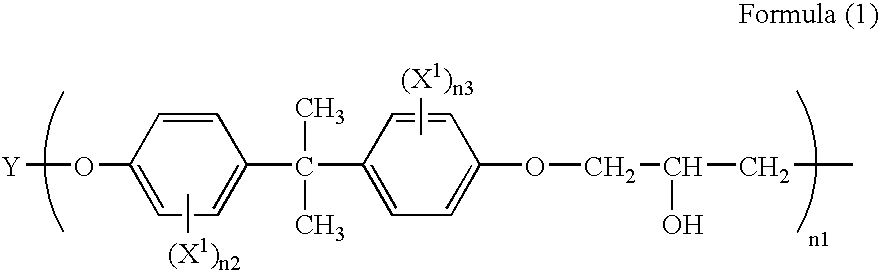

Resist lower layer material, resist lower layer substrate comprising the material and method for forming pattern

ActiveUS20080032231A1Reduce harmful effectHigh precisionPhotosensitive materialsRadiation applicationsResistChemistry

Provided is a method for forming a resist lower layer material for use in a multilayer resist process, especially two-layer resist process or three-layer resist process, having a function of neutralizing an amine contaminant from a substrate, thereby reducing a harmful effect such as trailing skirts of a resist pattern of an upper layer resist. Specifically, there is provided a material for forming a lower layer of a chemically amplified photoresist layer comprising a crosslinkable polymer and a thermal acid generator that can generate an acid by heating at 100° C. or greater and is represented by the general formula (1a):R1CF2SO3−(R2)4N+, (1a)as well as a resist lower layer substrate comprising a resist lower layer formed using said material.

Owner:SHIN ETSU CHEM IND CO LTD

Preparation method of wear-resistant antireflective coating comprising mesopores, and wear-resistant antireflective coating comprising mesopores

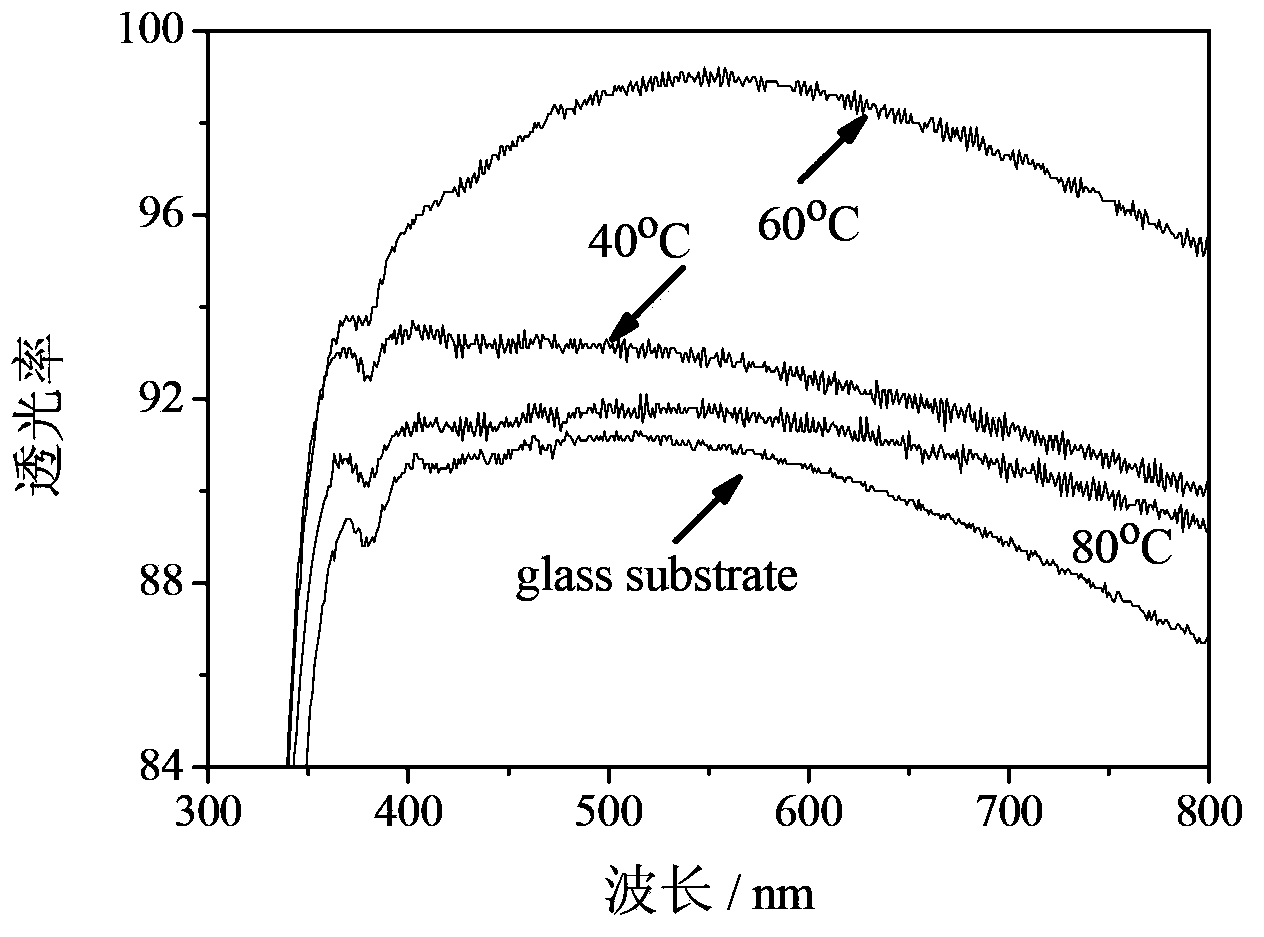

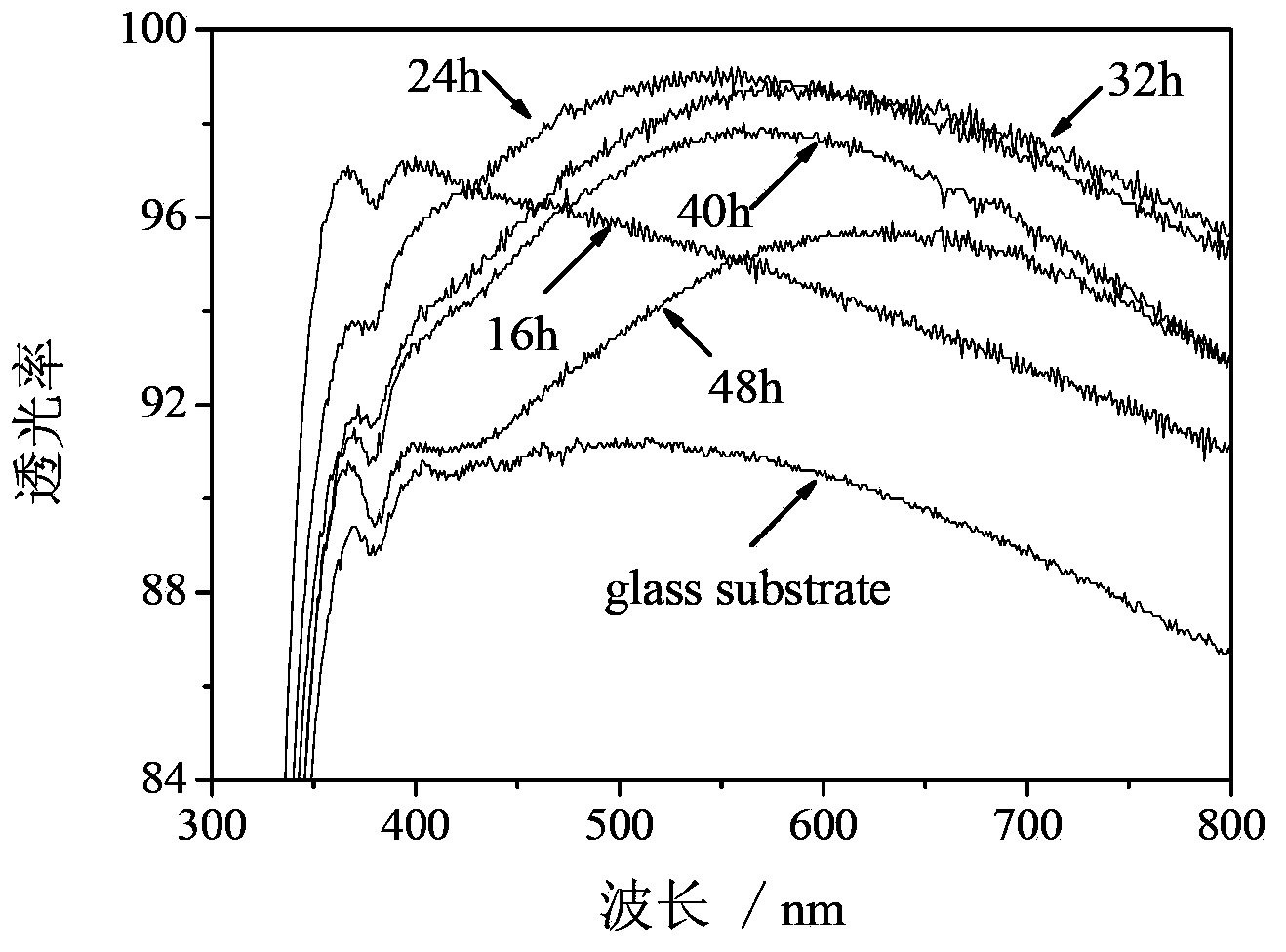

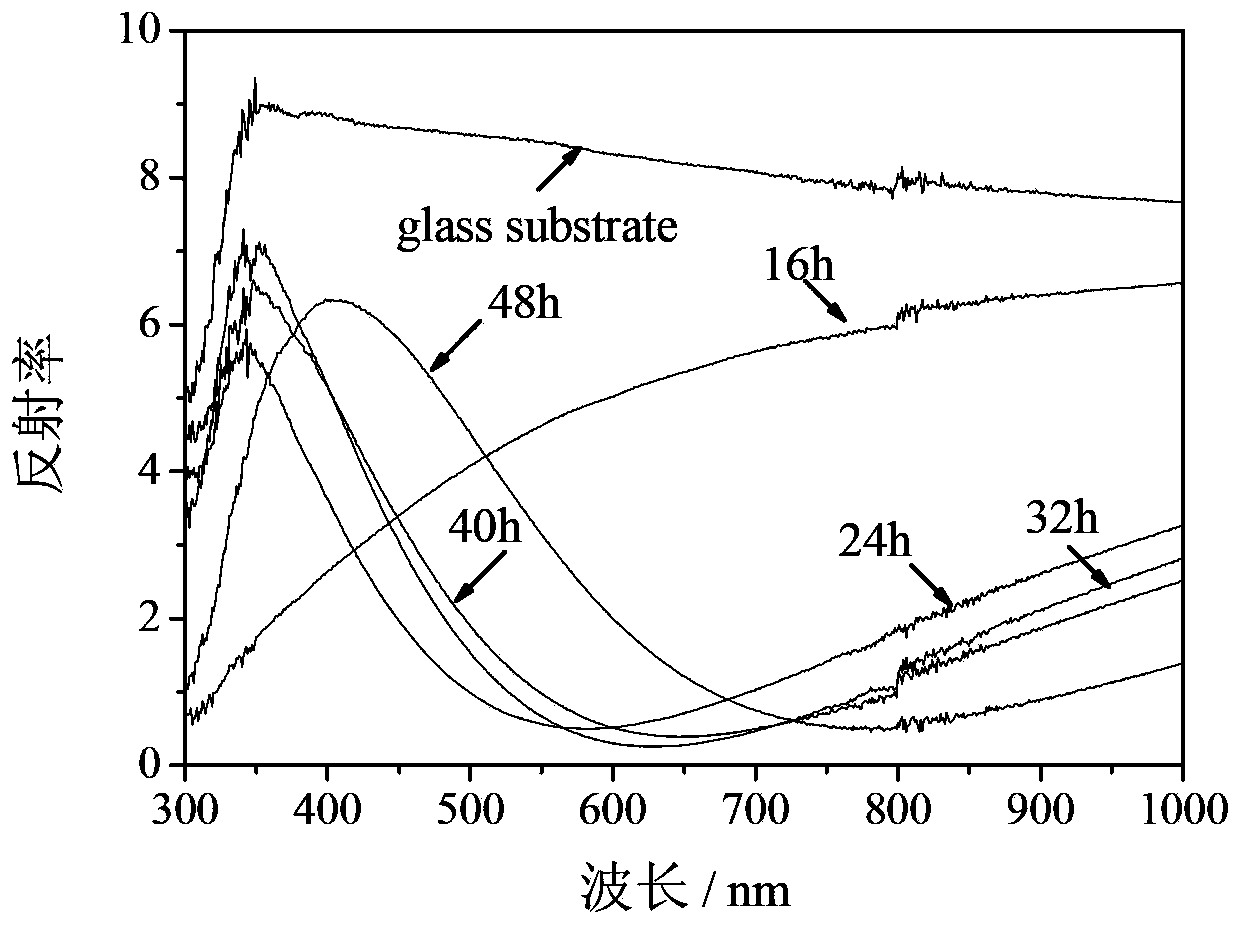

The invention belongs to the technical field of nano-grade material preparation, and especially relates to a preparation method of a wear-resistant antireflective coating comprising mesopores, and a wear-resistant antireflective coating comprising mesopores prepared with the method. According to the invention, a cheap and easy-to-obtain common glass sheet is adopted as a substrate; tetraethyl orthosilicate, ammonia water, anhydrous ethanol, cetyl trimethyl ammonium bromide and water are adopted as raw materials; with a simple solution deposition method, a sealed reaction is carried out for 16-48h in a baking oven with a temperature of 40-80 DEG C; and a templating agent CTAB is removed with a calcination method, such that the wear-resistant antireflective coating comprising mesopores is obtained. The glass sheet coated with the coating can endure scratch test with a 6H pencil. Light transmittance of the glass sheet coated with the coating can be improved from 91.3% to 99.4%. The wear-resistant antireflective coating preparation method is simple, and cost is low. The obtained wear-resistant antireflective coating has the advantages of excellent performances, good durability, wide application range, and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

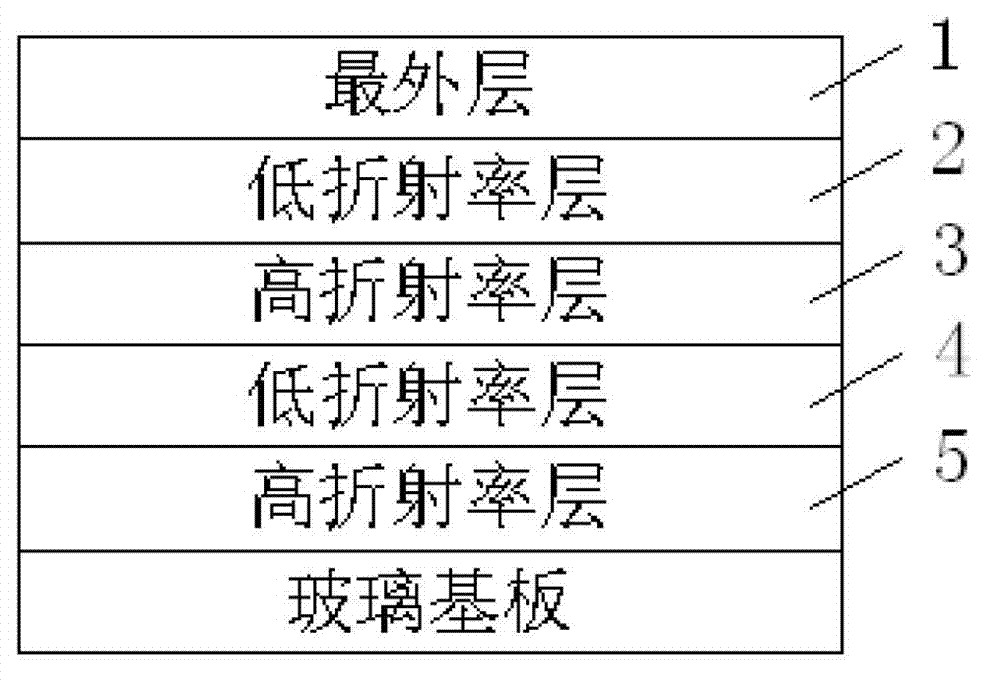

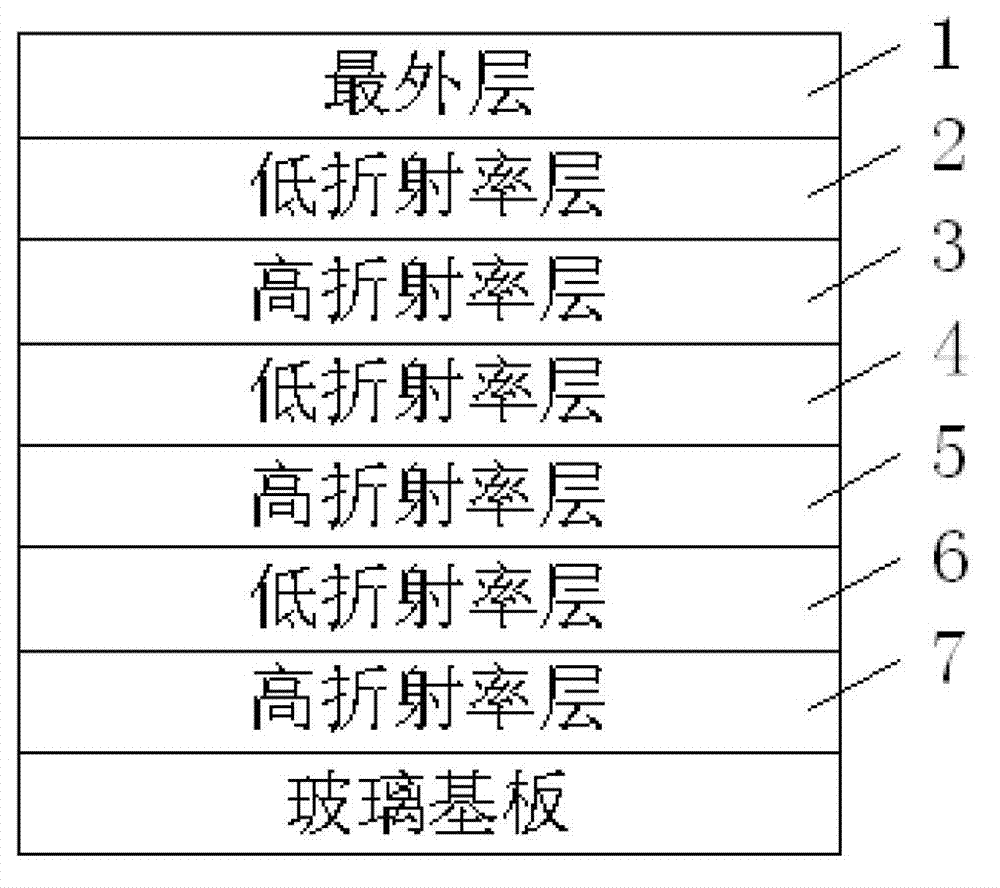

Aid-base resistance anti-reflection coated glass

ActiveCN102922825AGood acid and alkali resistanceImprove anti-reflection effectGlass/slag layered productsHydrogen fluorideRefractive index

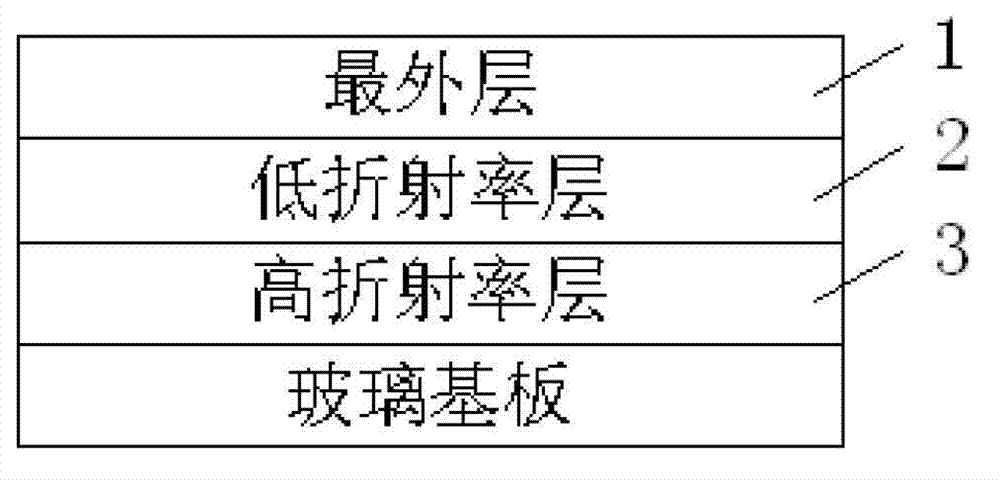

The invention relates to anti-reflection coated glass, in particular to aid-base resistance anti-reflection coated glass. The aid-base resistance anti-reflection coated glass comprises a glass base board and an anti-reflection film arranged on the surface of the glass base board, wherein the anti-reflection film is composed of high refractive index layers and low refractive index layers arranged in staggered and overlapped mode. The aid-base resistance anti-reflection coated glass is characterized in that three layers in the anti-reflection film are an outmost layer, a second layer and a third layer in sequence from the outmost layer to the inner. The outmost layer is 1.9-2.4 in refractive index and 3-20nm in geometry thickness and is chosen from a nitride of silicon (Si) or at least one of oxides of titanium (Ti), zirconium (Zr) and hydrogen fluoride (Hf). The second layer is 1.4-1.7 in refractive index and 50-85nm in geometry thickness. The third layer is 1.9-2.5 in refractive index and 100-180nm in geometry thickness. The aid-base resistance anti-reflection coated glass has the advantages that the anti-reflection film is provided not only with good aid-base resistance, but also with good mechanical tolerance and a good anti-reflection effect, and the anti-reflection film is coated on a single face of glass so that reflectivity of the glass can be reduced by more than 2% and even by more than 3%.

Owner:FUYAO GLASS IND GROUP CO LTD

Hard Anti-reflective coatings and manufacturing and use thereof

InactiveUS20150355382A1Crystal formation can be enhancedImprove mechanical propertiesLayered productsVacuum evaporation coatingAnti-reflective coatingCrystal structure

A coated substrate is provided with a scratch-resistant anti-reflective coating. The anti-reflective coating is designed as an optical interference coating that has at least two low refractive index layers and at least one high refractive index layer. The high refractive index layer is a transparent hard material layer and includes crystalline aluminum nitride with a hexagonal crystal structure with a (001) preferred orientation. The low refractive index layers include SiO2. The low refractive index layers and high refractive index layers are arranged alternately.

Owner:SCHOTT AG

Method for preparing colorful film for protecting solar cell thin grid line metal electrode by adopting mask

InactiveCN101834230ANot easily oxidizedGuaranteed electrical conductivityFinal product manufactureSemiconductor devicesButt jointMetal electrodes

The invention relates to a method for preparing a colorful film for protecting a solar cell thin grid line metal electrode by adopting a mask. In the method, after a solar cell is prepared, a mask is utilized to cover a main grid line metal electrode on the front surface of the solar cell, a film is coated on the area which is not covered by the mask for the second time, and a dielectric layer for protecting the thin grid line metal electrode is prepared to form a structure comprising the dielectric layer, the thin grid line metal electrode and a passivation layer. The method can protect the thin grid line metal electrode against easy oxidation, and the main grid line metal electrode can be normally connected by welding rods. The passivation effect of the front surface can be enhanced through optimizing the passivation layer; the reflectivity of the front surface of the solar cell can be reduced and color regulation can be realized through regulating the dielectric layer; and characters, figures, graphics and the like can be displayed on the front surface of the solar cell through changing a mask pattern. In addition, the secondary film coating method is convenient to be in butt joint with the traditional crystalline silicon solar cell preparation process and is easy for industrialization.

Owner:SUN YAT SEN UNIV

Electrically conductive optical element, touch panel, information input device, display device, solar cell, and stamper for producing electrically conductive optical element

InactiveUS20120160560A1Improve anti-reflection effectConductive layers on insulating-supportsLayered productsTouch panelElectrically conductive

An electrically conductive optical element is provided with a substrate having a surface, structures which are convex portions or concave portions in the shape of a cone and which are arranged in large numbers on the surface of the substrate with a minute pitch less than or equal to the wavelength of the visible light, and a transparent, electrically conductive layer disposed on the structures. The aspect ratio of the structure is 0.2 or more, and 1.3 or less, the transparent, electrically conductive layer has a surface following the structures, the average layer thickness Dm1 of the transparent, electrically conductive layer at the top portion of the structure is 80 nm or less, and the surface resistance of the transparent, electrically conductive layer is within the range of 50Ω / □ or more, and 500Ω / □ or less.

Owner:DEXERIALS CORP

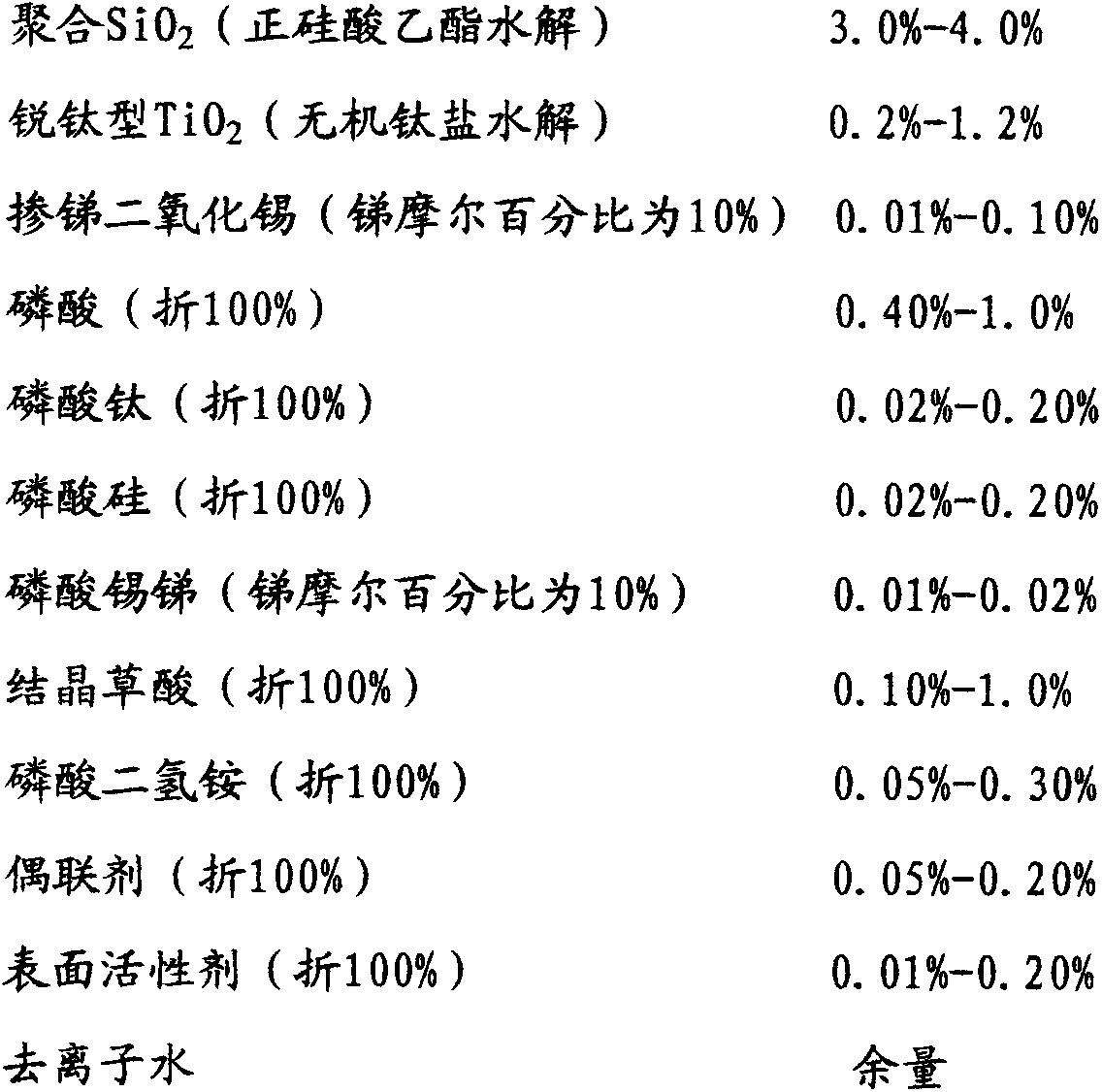

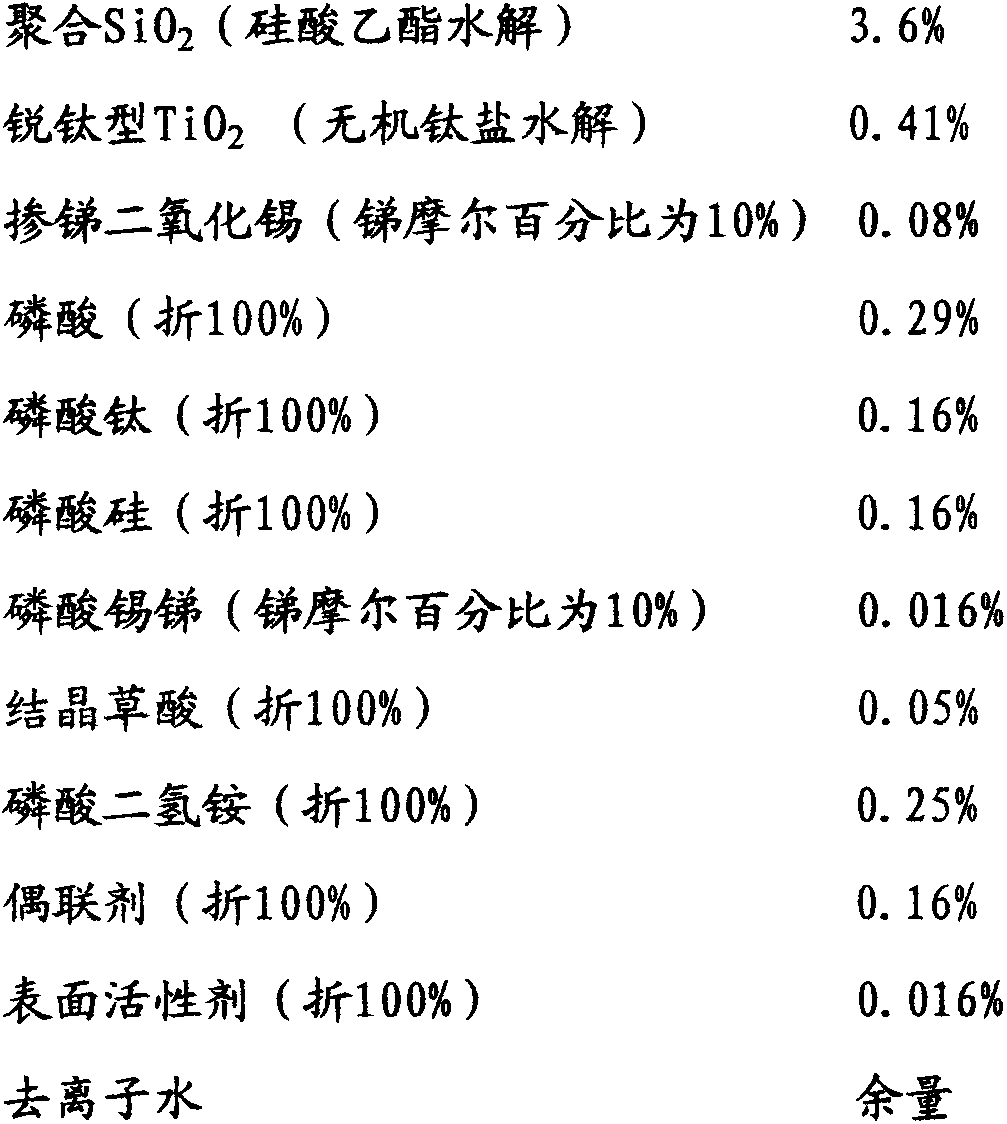

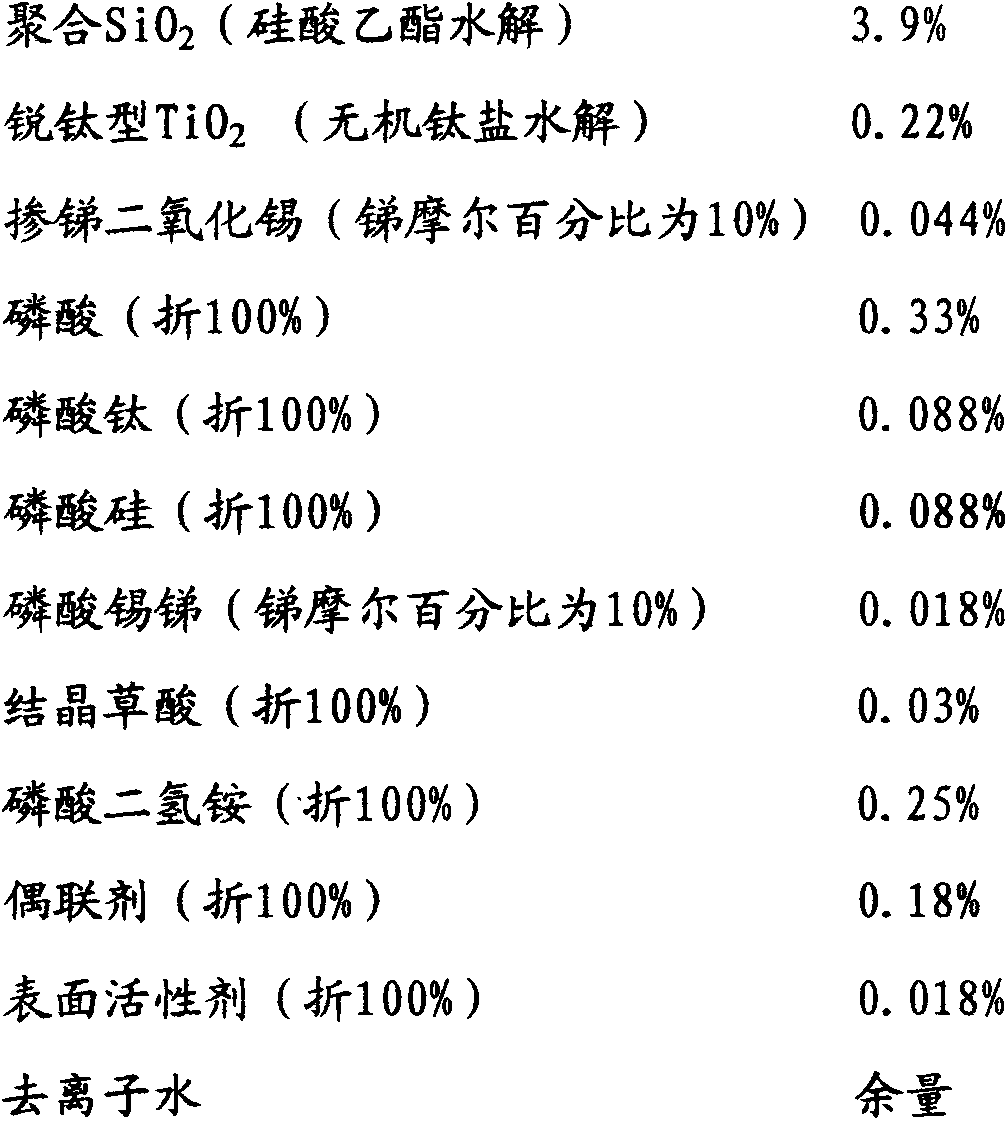

Solar glass self-cleaning antireflection paint and production method thereof

The invention discloses solar glass self-cleaning antireflection paint and a production method thereof. In the solar glass self-cleaning antireflection paint, poly silicon dioxide is used as a main antireflection component, low reflection titanium dioxide is used as an auxiliary antireflection component and a photocatalyst, antimony doped tin oxide, titanium phosphate, silicon phosphate, phosphoric acid and antimony doped tin phosphate are used as a self-cleaning synergist, an antistat and an antireflection membrane enhancer, and deionized water is used as a solvent. The production method comprises the step: a porous silicon dioxide shell generated through ethyl silicate hydrolysis is covered with the anatase titanium dioxide photocatalyst, the antimony doped stannic oxide antistat and other synergist components. The problem that antireflection performance and the self-cleaning performance of conventional solar glass self-cleaning antireflection paint can offset each other is solved, the power generating efficiency of a solar cell can be improved and stabilized greatly, and the maintenance management cost of the solar cell can be reduced.

Owner:TIANJIN VOCATIONAL INST

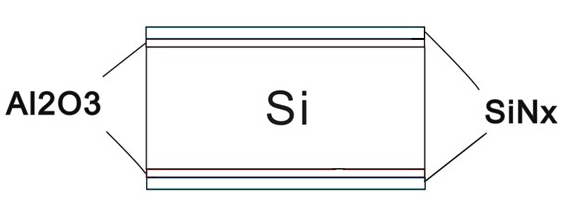

Composite passivated anti-reflection film used for crystalline silicon solar battery and preparation method thereof

InactiveCN102157570AImprove anti-reflection effectImprove passivation effectFinal product manufactureChemical vapor deposition coatingElectrical batteryEngineering

The invention discloses a composite passivated anti-reflection film used for a crystalline silicon solar battery and a preparation method thereof. The composite passivated anti-reflection film consists of a silicon oxide (SiO2) layer, an amorphous alumina (a-Al2O3) layer and an amorphous silicon nitride (a-Si1-xNx) layer which are arranged on the emitter on a light receiving surface of the crystalline silicon solar battery in turn. The preparation method comprises the following steps of: preparing an a-Al2O3 layer on the emitter on the light receiving surface of the crystalline silicon solar battery by a plasma enhanced chemical vapor deposition (PECVD) process or an atomic layer deposition (ALD) process; forming the SiO2 layer between the emitter layer and the a-Al2O3 layer by an annealing process; and preparing the a-Si1-xNx layer on the a-Al2O3 layer by the PECVD process. The composite passivated anti-reflection film has the advantages that: the a-Si1-xNx anti-reflection film has a good anti-reflection effect; the a-Al2O3 / SiO2 composite passivated film has double effects of chemical passivation and field passivation and has a good passivation effect; the a-Si1-xNx / a-Al2O3 / Si2O composite passivated anti-reflection film has high thermal stability and is compatible with a subsequent battery preparation process; and the anti-ultraviolet (UV) performance is high.

Owner:上海太阳能电池研究与发展中心

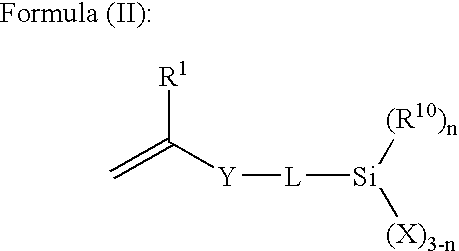

Siloxane coating material, optical articles and process for the production of siloxane coating materials

ActiveCN1969023AGood storage stabilityInhibit secondary aggregationAntifouling/underwater paintsSynthetic resin layered productsHigh surfaceHardness

The invention provides a coating material containing silica fine particles, a siloxane compound, and a curing agent and giving an even coating film in the case it is used for forming a coating film. The invention gives a siloxane-based coating material excellent in storage stability and giving high surface hardness of a coating film when the coating material is used for forming the coating film. The invention also provides an optical article excellent in anti-reflection property and scratching resistance.

Owner:TORAY IND INC

Anti-Reflection Film, Manufacturing Method Thereof, Polarizing Plate and Transmission Type LCD

InactiveUS20100227085A1Good optical performanceLow production costLiquid crystal compositionsLayered productsOptical propertyRefractive index

The present invention provides an anti-reflection film which has excellent optical properties at a low production cost. The anti-reflection film of the present invention has a low refractive index hard coat layer having low refractive index particles and a binder matrix which is formed by curing an ionizing radiation curable material on a transparent substrate. It is a feature of the anti-reflection film of the present invention that the low refractive index hard coat layer has two optically distinguishable layers from the transparent substrate side, namely, an intermediate layer and a localized layer wherein the low refractive index particles are localized, and the refractive index and optical thickness of the localized layer are in the range of 1.29-1.43 and in the range of 100-200 nm, respectively.

Owner:TOPPAN PRINTING CO LTD

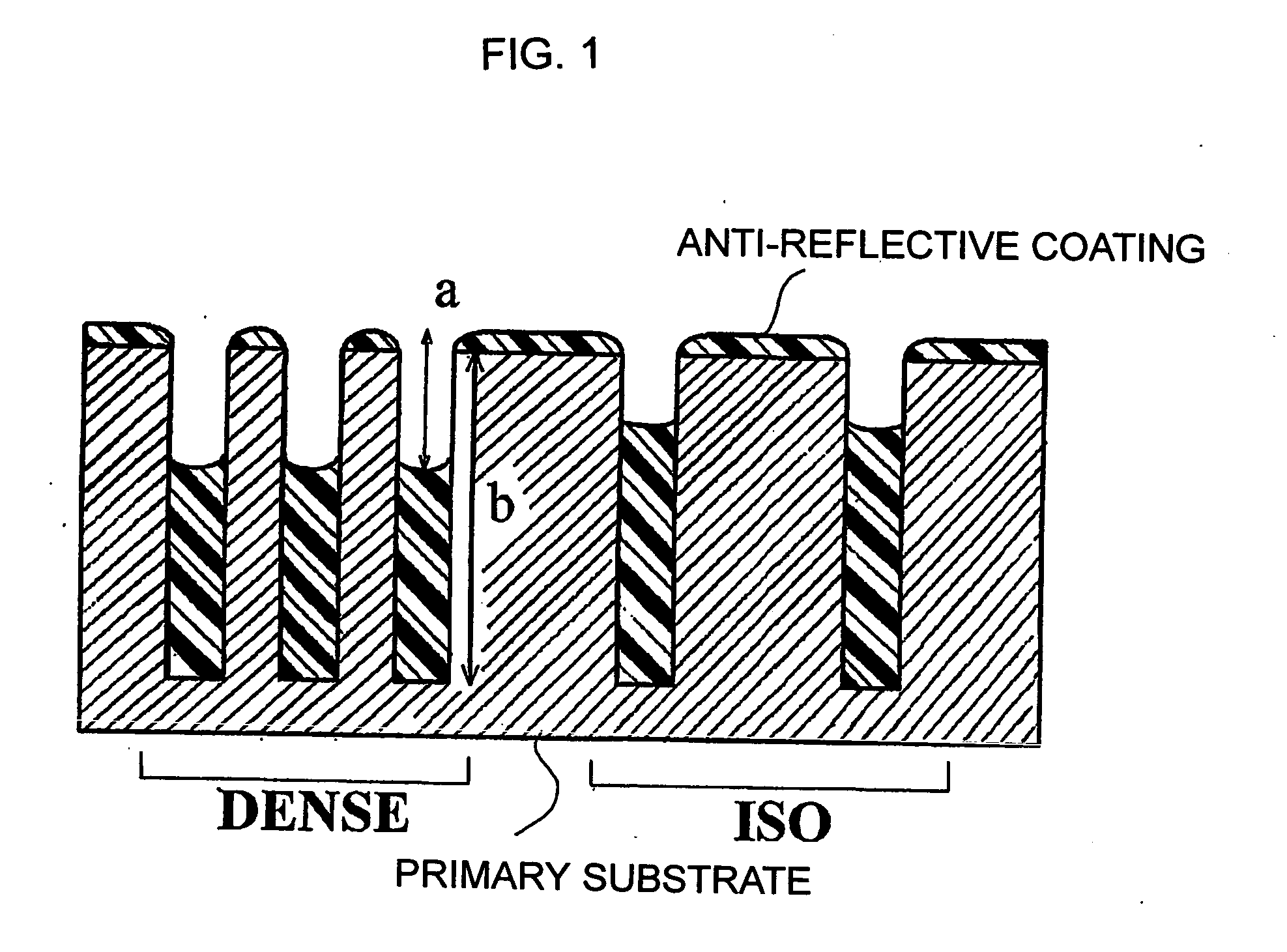

Composition for forming anti-reflective coating for use in lithography

ActiveUS20050008964A1High planarizationLarge dry etching rateSemiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersAnti-reflective coatingLithography process

The present invention relates to a composition for forming anti-reflective coating for use in a lithography process in manufacture of a semiconductor device which comprises polymer (A) having a weight average molecular weight of 5,000 or less, and a polymer (B) having a weight average molecular weight of 20,000 or more. The composition provides an anti-reflective coating for use in a lithography which is excellent in step coverage on a substrate with an irregular surface, such as hole or trench, has a high anti-reflection effect, causes no intermixing with a resist layer, provides an excellent resist pattern, and has a higher dry etching rate compared with the resist layer.

Owner:NISSAN CHEM IND LTD

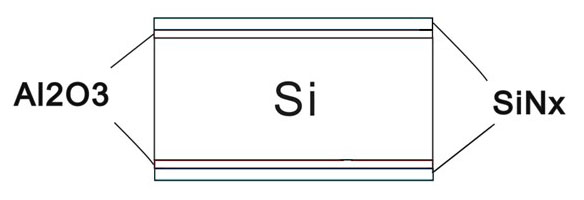

Double-layer passivating method for crystalline silicon solar battery

InactiveCN102064237AEasy to growEasy to industrializeFinal product manufactureVacuum evaporation coatingHydrogenThermal chemical vapor deposition

The invention discloses a double-layer passivating method for a crystalline silicon solar battery, comprising the following steps: (1) selecting a silicon chip, cleaning, and polishing or texturing; (2) growing Al2O3 on the silicon chip obtained in step (1) by an ALD (atomic layer deposition) or PECVD (plasma enhanced chemical vapor deposition) method, wherein the refractive index is 1.5-1.7, the thickness is 10-80nm; (3) growing SiNx on the silicon chip obtained in step (2) by the PECVD or PVD (physical vapor deposition) method, wherein the refractive index is 1.9-2.2, the thickness is 30-150nm; and (4) annealing the sample obtained in step (3) at the temperature of 200-600 DEG C in the atmosphere of N2 or a hydrogen argon gas mixture for 1-30 minutes to obtain a double-layer passivated dielectric film. The passivating method provided by the invention can reduce the surface recombination velocity of the silicon chip to below 10cm / s, can be well applied to surface passivation of a crystalline silicon solar battery, and obtains high conversion efficiency.

Owner:ALTUSVIA ENERGY TAICANG

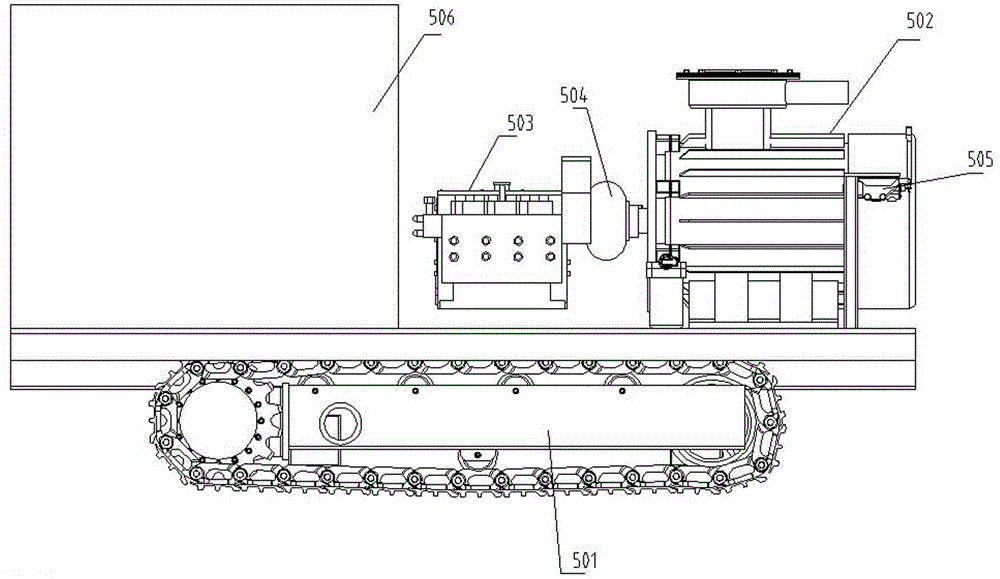

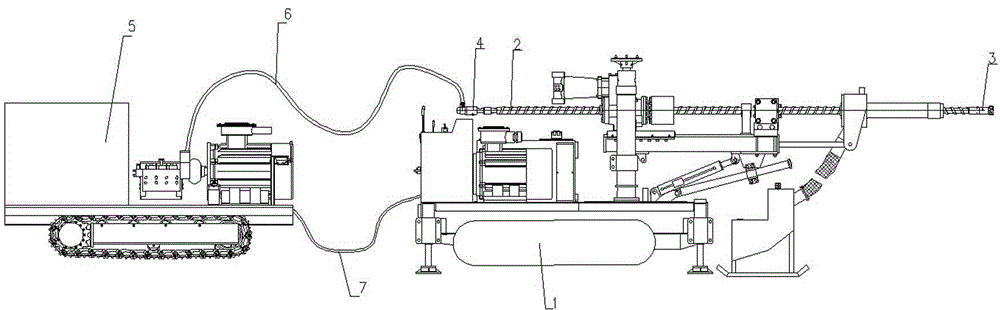

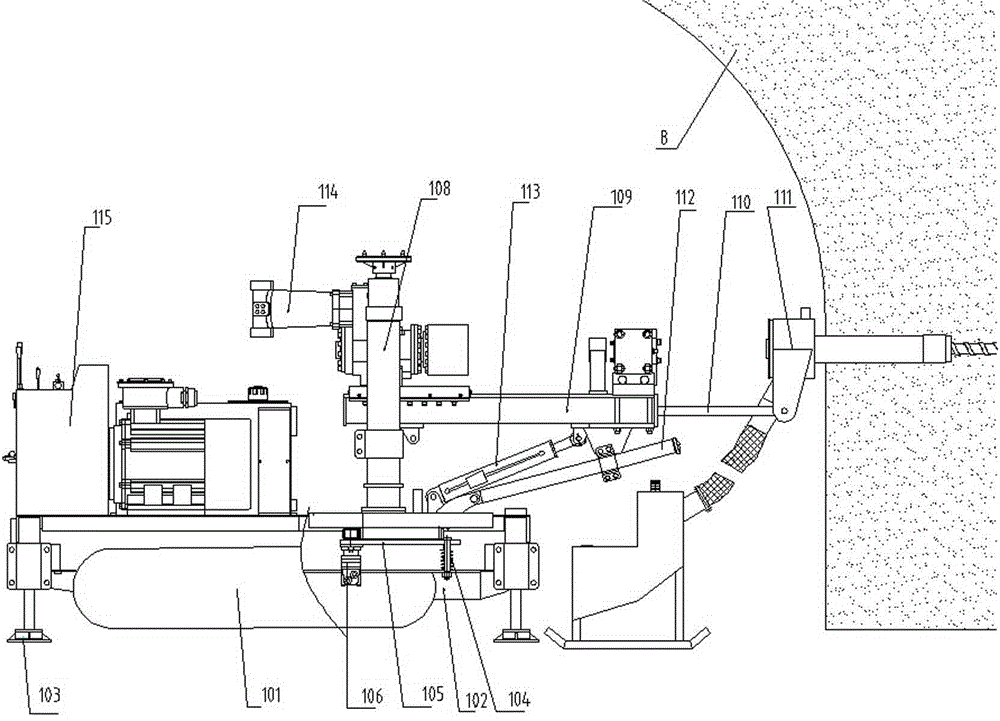

Coal mine downhole crawler type drilling and punching integrated equipment

ActiveCN104895484ASafe and efficient productionImprove extraction efficiencyConstructionsBorehole drivesPunchingDual purpose

Coal mine downhole crawler type drilling and punching integrated equipment comprises a crawler type hydraulic drilling machine, a high-pressure-resistant sealing drill stem, a drilling and punching dual-purpose drill bit, a high-pressure rotation connector and a high-pressure water pump station, wherein the body of the high-pressure-resistant sealing drill stem penetrates and is fixed in the power head inner hole of the crawler type hydraulic drilling machine, a power head provides rotation speed and torque to the body of the high-pressure-resistant sealing drill stem, one end of the high-pressure-resistant sealing drill stem is connected with the high-pressure water pump station through the high-pressure rotation connector, the high-pressure water pump station provides high-pressure water needed by punching, the other end of the high-pressure-resistant sealing drill stem is connected with the drilling and punching dual-purpose drill bit, and hydraulic operations can be performed after drilling without replacing the drill bit. The coal mine downhole crawler type drilling and punching integrated equipment has the advantages that streamlined operations of coal mine downhole gas pressure relief, drilling and punching can be completed by the equipment, safe and efficient production of outburst mines is guaranteed, coal seam coal and gas outburst danger is eliminated, a regional pre-drainage gas drilling construction period is shortened, coal seam drilling and punching and gas extraction efficiency are increased, and gas disaster prevention and control cost is reduced.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com