DLC infrared anti-refiection protective film and method for producing the same

An anti-reflection and protective film technology, applied in sputtering plating, ion implantation plating, coating, etc., can solve the problem of narrow transmission band and achieve less interference, anti-reflection effect and good wear and corrosion resistance , easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1

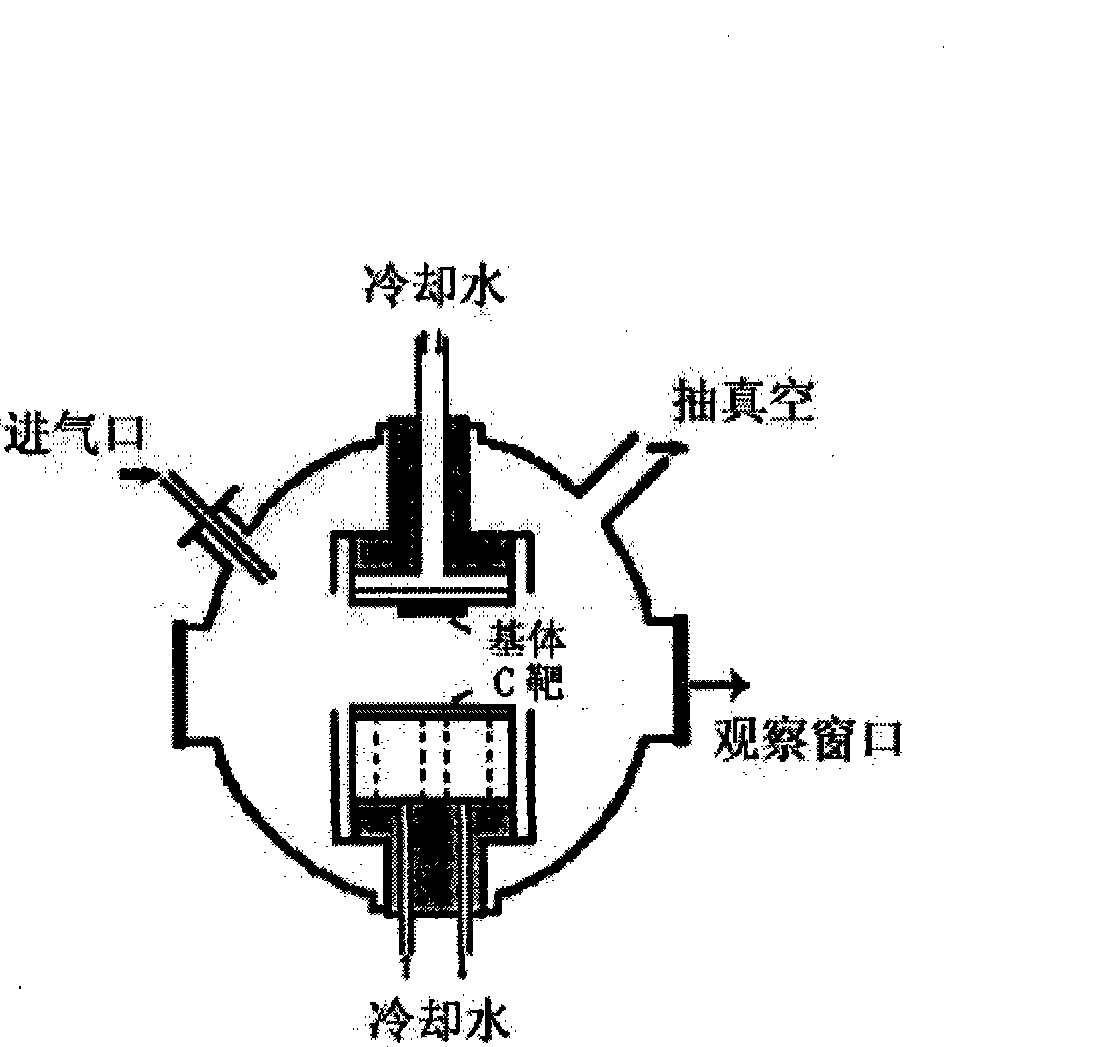

[0019] In the experiment, the intermediate frequency unbalanced magnetron sputtering method was used, and the CH 4 The mixed gas of Ar and Ar is used as discharge gas to deposit DLC bilayer film on ZnSe substrate. The IF frequency used is 40kHz with a duty cycle of 80%. CH 4 and Ar gas are sent into the vacuum chamber from the gas inlet, and the ratio of the two gases is controlled by a needle valve. The vacuum degree during film deposition is 0.1-2Pa by mechanical pump and molecular pump. During deposition, CH 4 The positive ions generated by the ionization of Ar and Ar bombard the graphite target under the action of an electric field, and the sputtered C and CH 4 The hydrocarbon plasma produced by decomposition generates a DLC film on the ZnSe substrate. The ZnSe substrate needs to be pretreated by polishing and cleaning before being placed in the vacuum chamber; after being placed in the vacuum chamber, ion beam sputtering or backsputtering is used to further remove su...

Embodiment (2

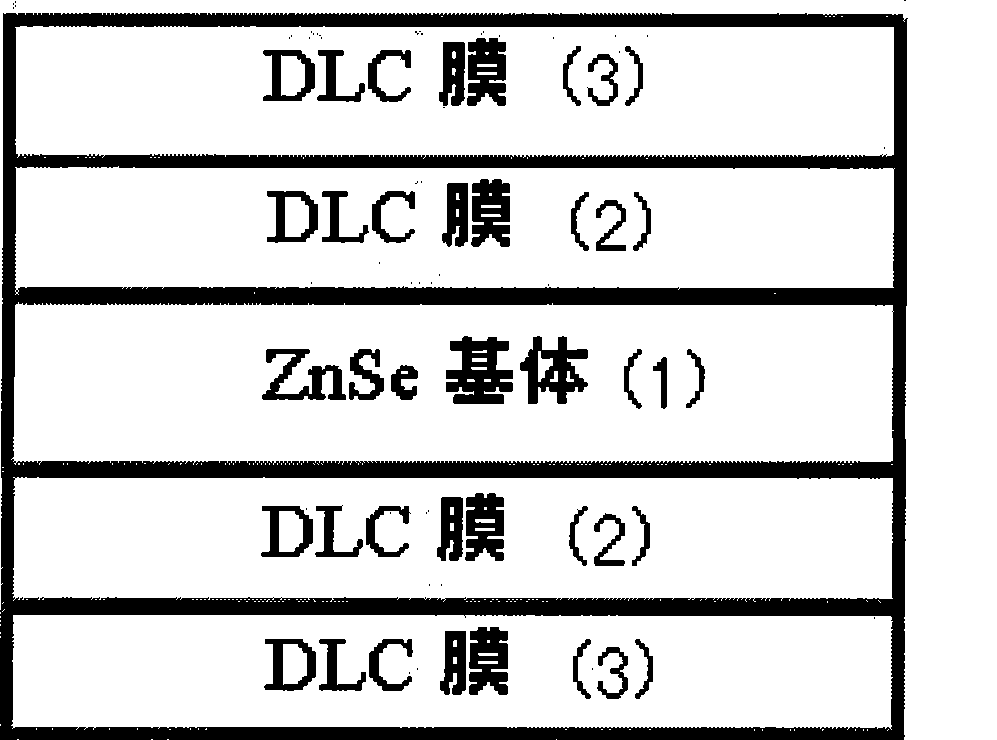

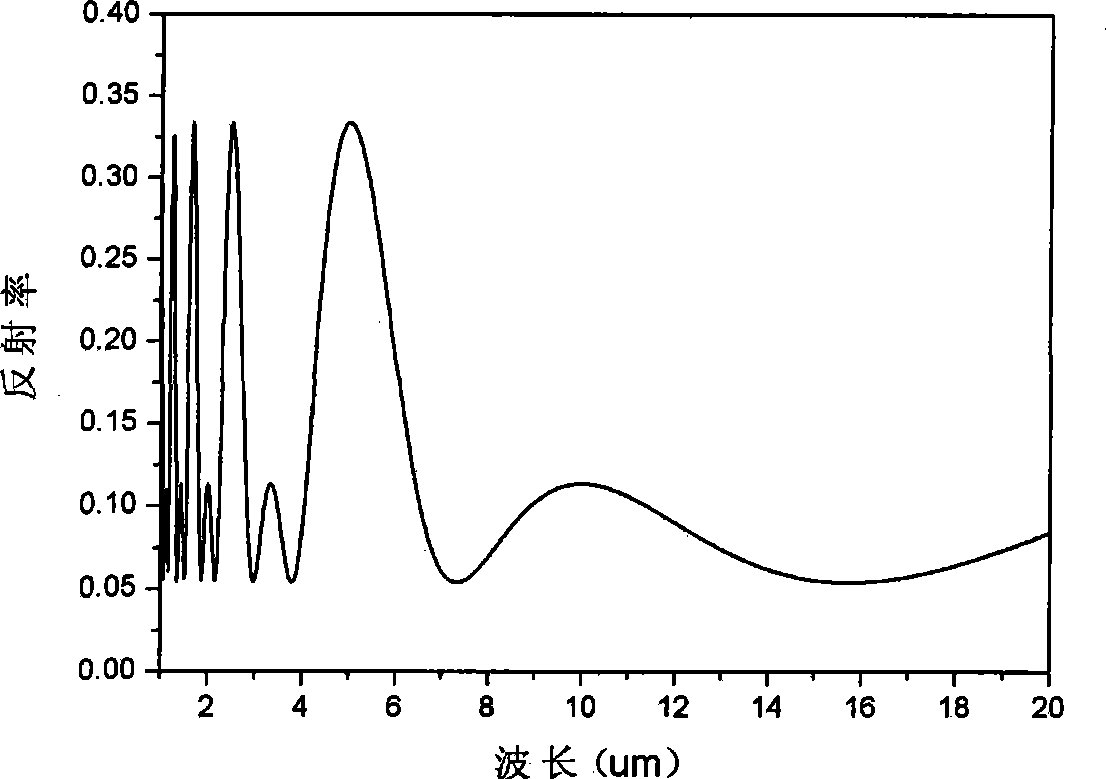

[0022] With 10 μm as the center anti-reflection wavelength, first prepare a high refractive index DLC film 2 with a refractive index of 2.1 on one side of the ZnSe substrate (refractive index 2.5), with a thickness of ~1.2 μm; The DLC film 3 with a ratio of 1.7 has a thickness of ~1.5 μm. The same DLC double-layer film was prepared on the other side of the ZnSe substrate according to the above method. The change curve of reflectivity with wavelength is as follows: Figure 3 Show. Depend on Figure 3 can See, in the wavelength range of 1.0-20 μm, the minimum reflectance of the film system reaches 5.4% (~7.3 μm and 15.7 μm); in the wavelength range of 6.5-20 μm, the reflectance curve is relatively flat, with an average reflectance of 8%, compared with The reflectance before the anti-reflection protective film is not coated is reduced by 25%; the average reflectance is 8% in the wavelength range of 2.7-4.2 μm, which is 25% lower than that before the anti-reflection protective ...

Embodiment (3

[0024] With 10.5 μm as the center anti-reflection wavelength, first prepare a high refractive index DLC film 2 with a refractive index of 2.5 on one side of the Ge substrate (refractive index 4.0), with a thickness of ~1.0 μm; then prepare on the high refractive index DLC film 2 The DLC film 3 with a refractive index of 1.7 has a thickness of ~1.5 μm. The same DLC bilayer film was prepared on the other side of the Ge substrate as described above. The curve of its reflectivity as a function of wavelength is shown in Figure 4 shown. It can be seen from the figure that at ~7.7μm and ~16.5μm, the film system achieves zero reflectivity; the reflectivity of the film system in the wavelength range of 13-21μm is ≤10%; the reflectivity of the film system in the wavelength range of 7.0-23μm ≤20%. The anti-reflection range is wide, and the effect is ideal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com