Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2893 results about "Needle valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A needle valve is a type of valve with a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates.

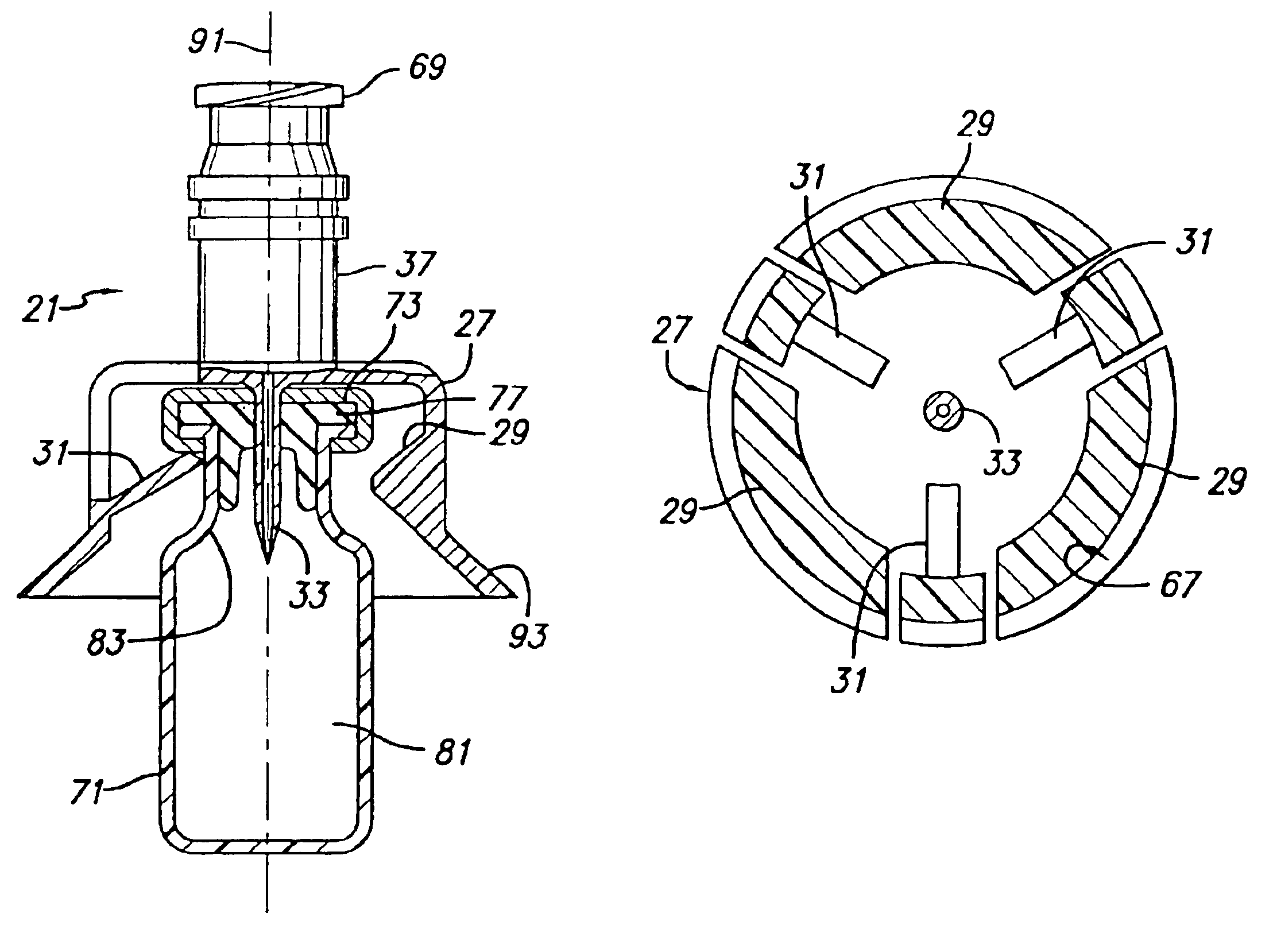

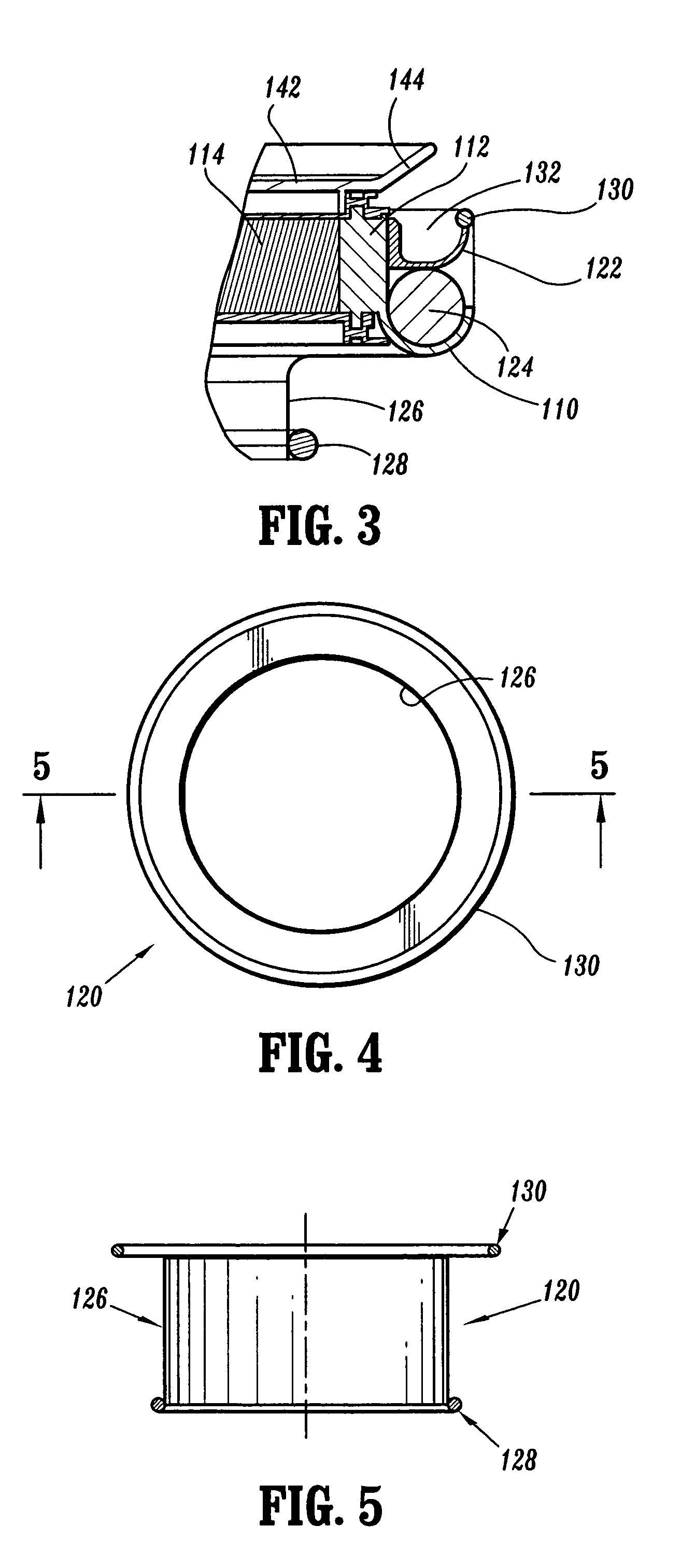

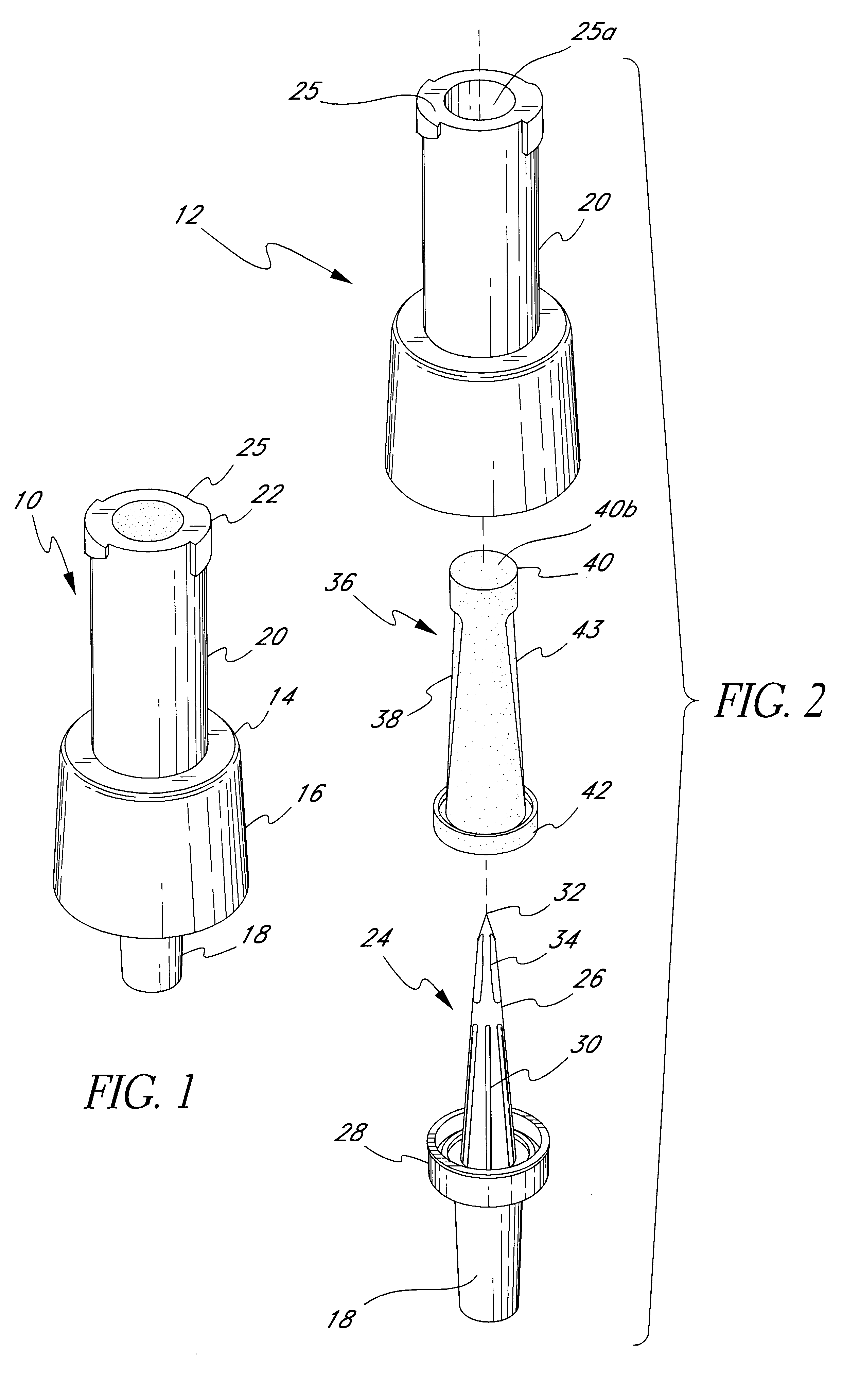

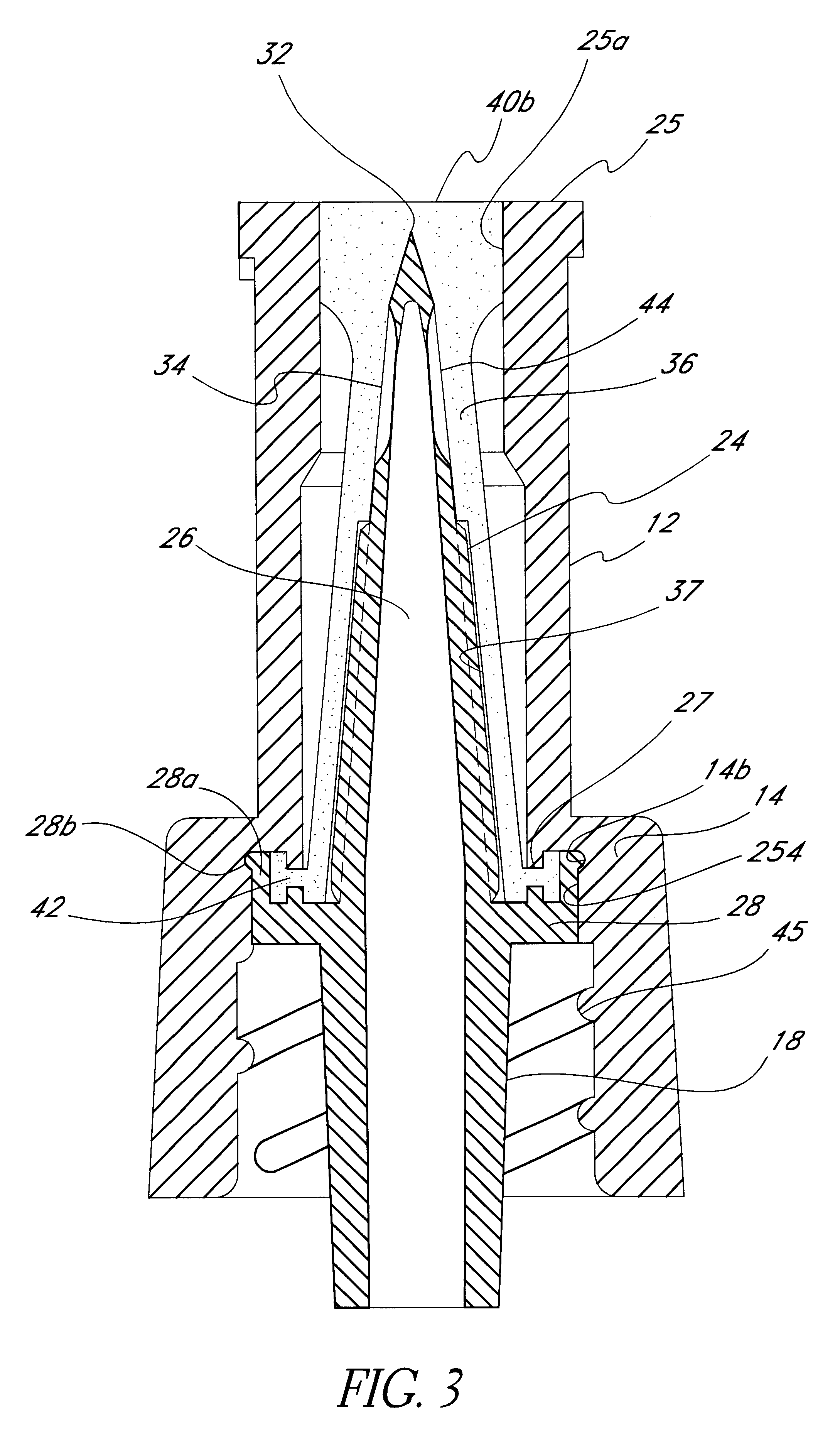

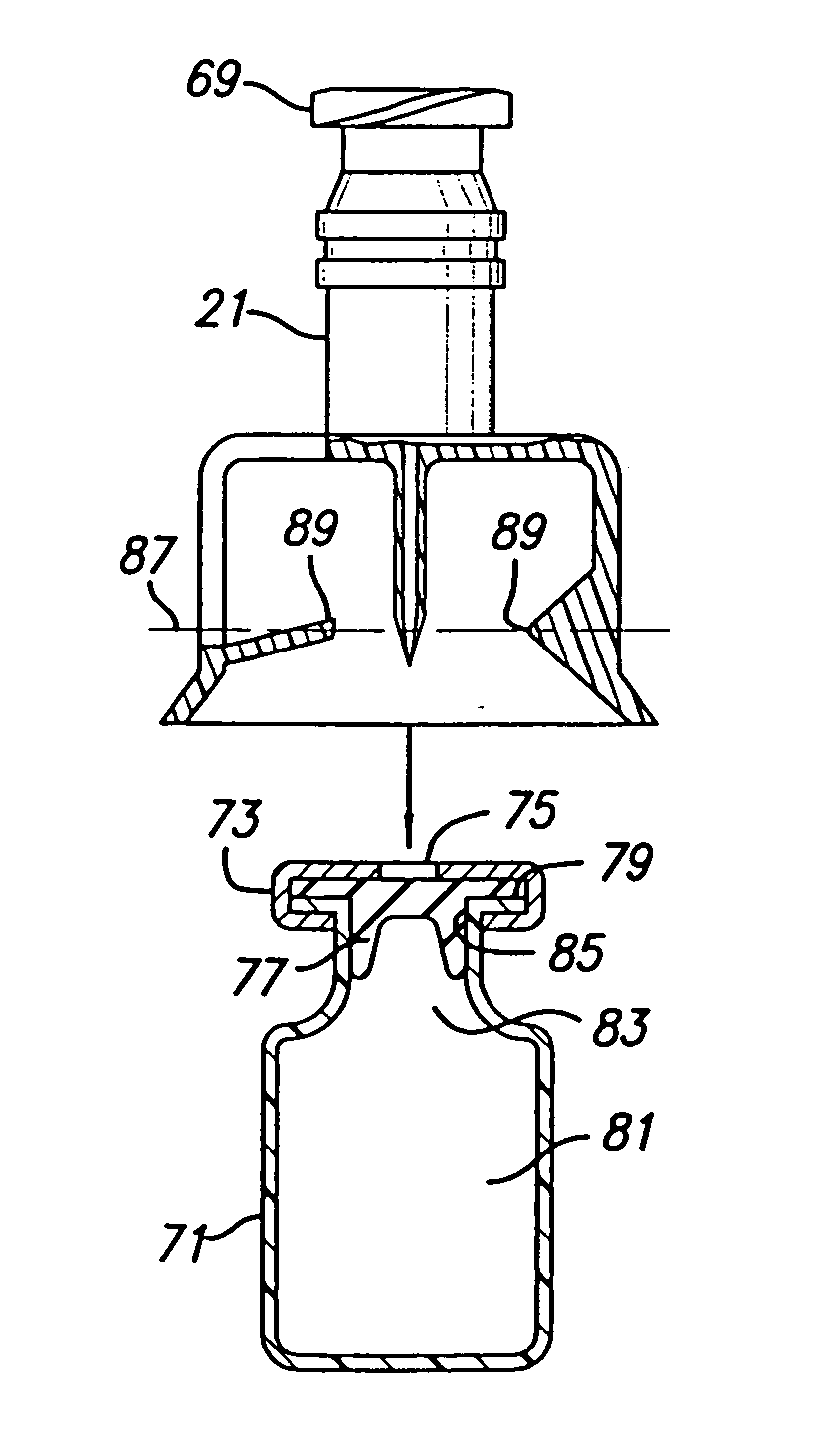

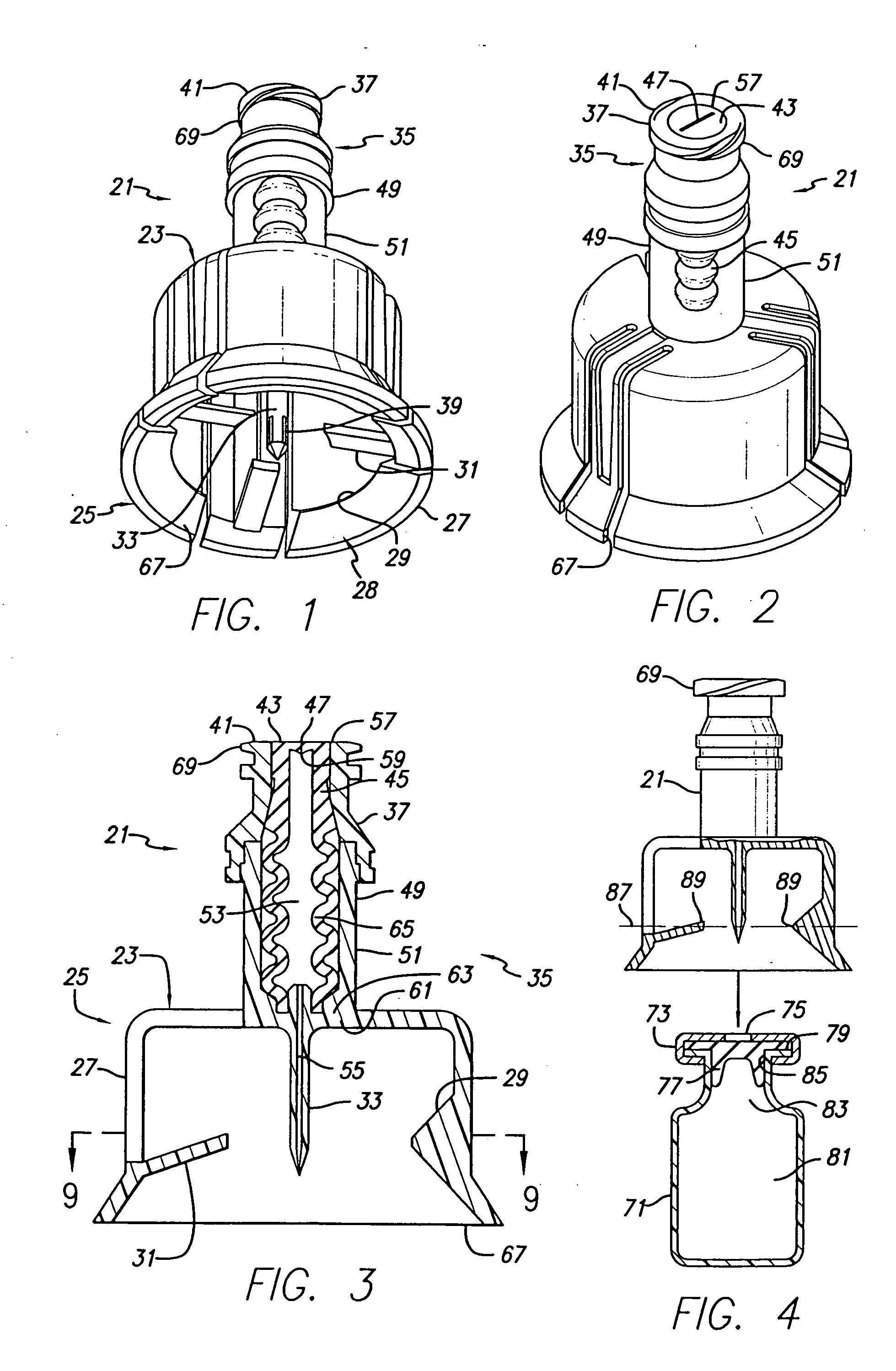

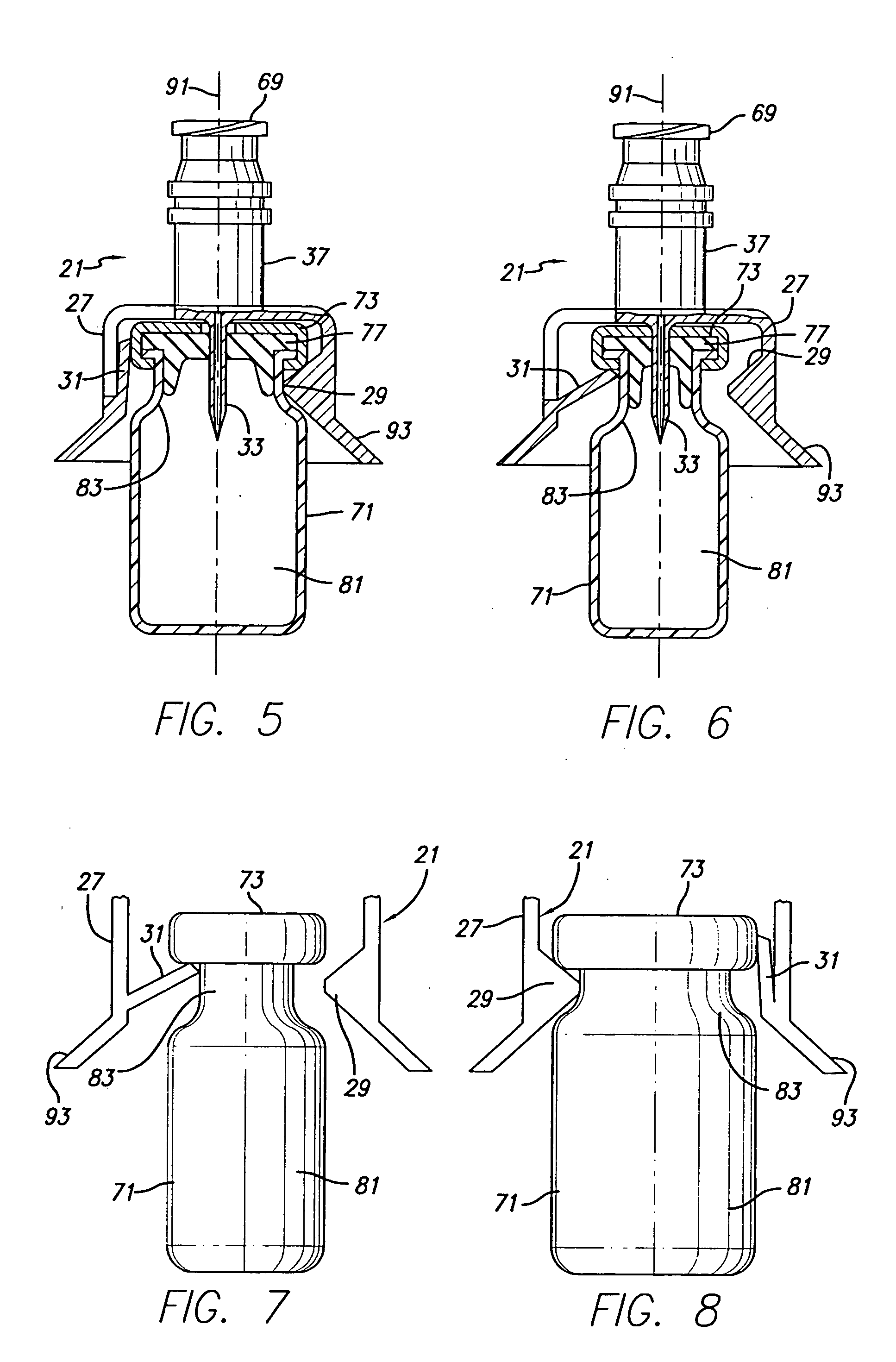

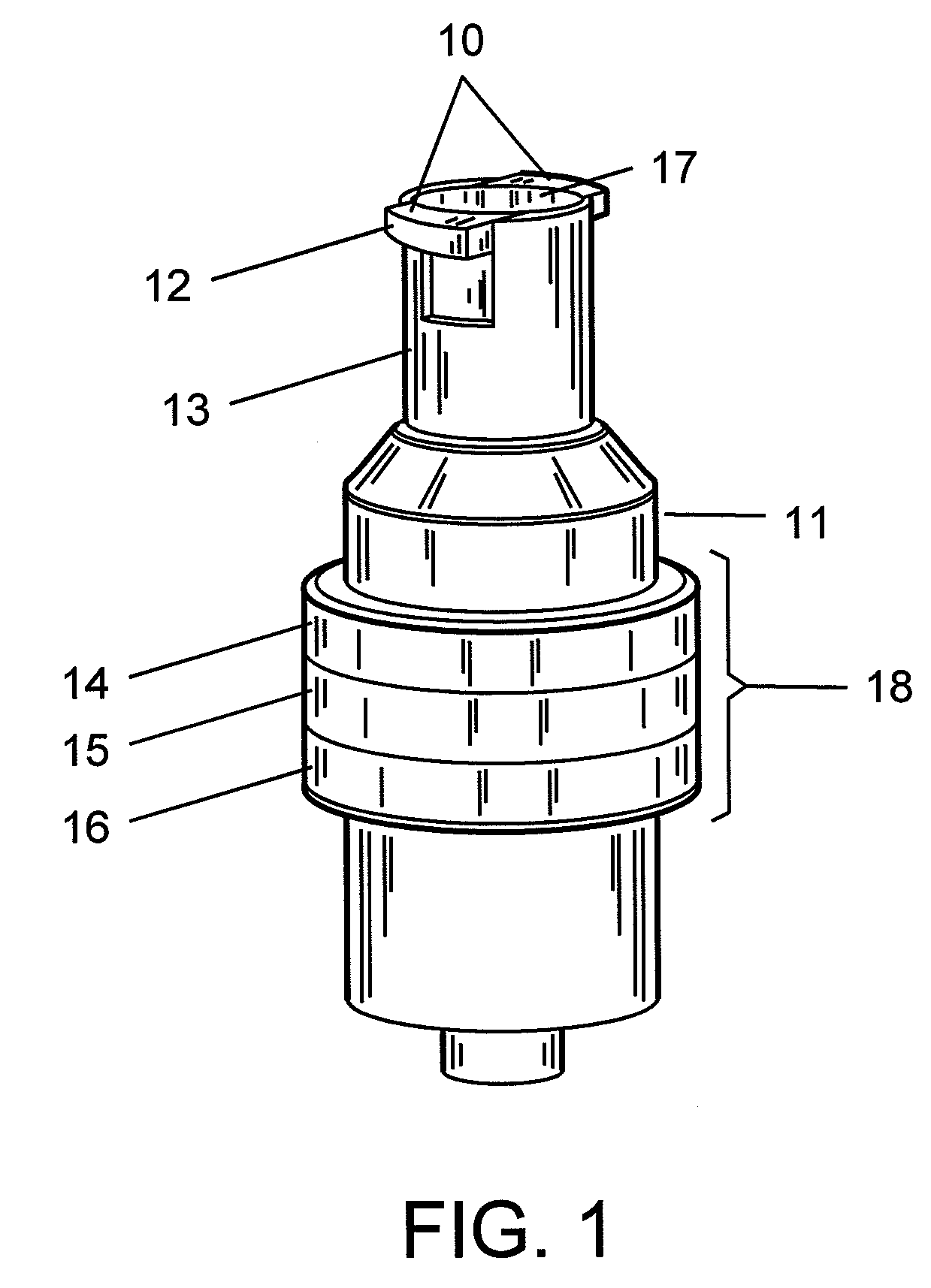

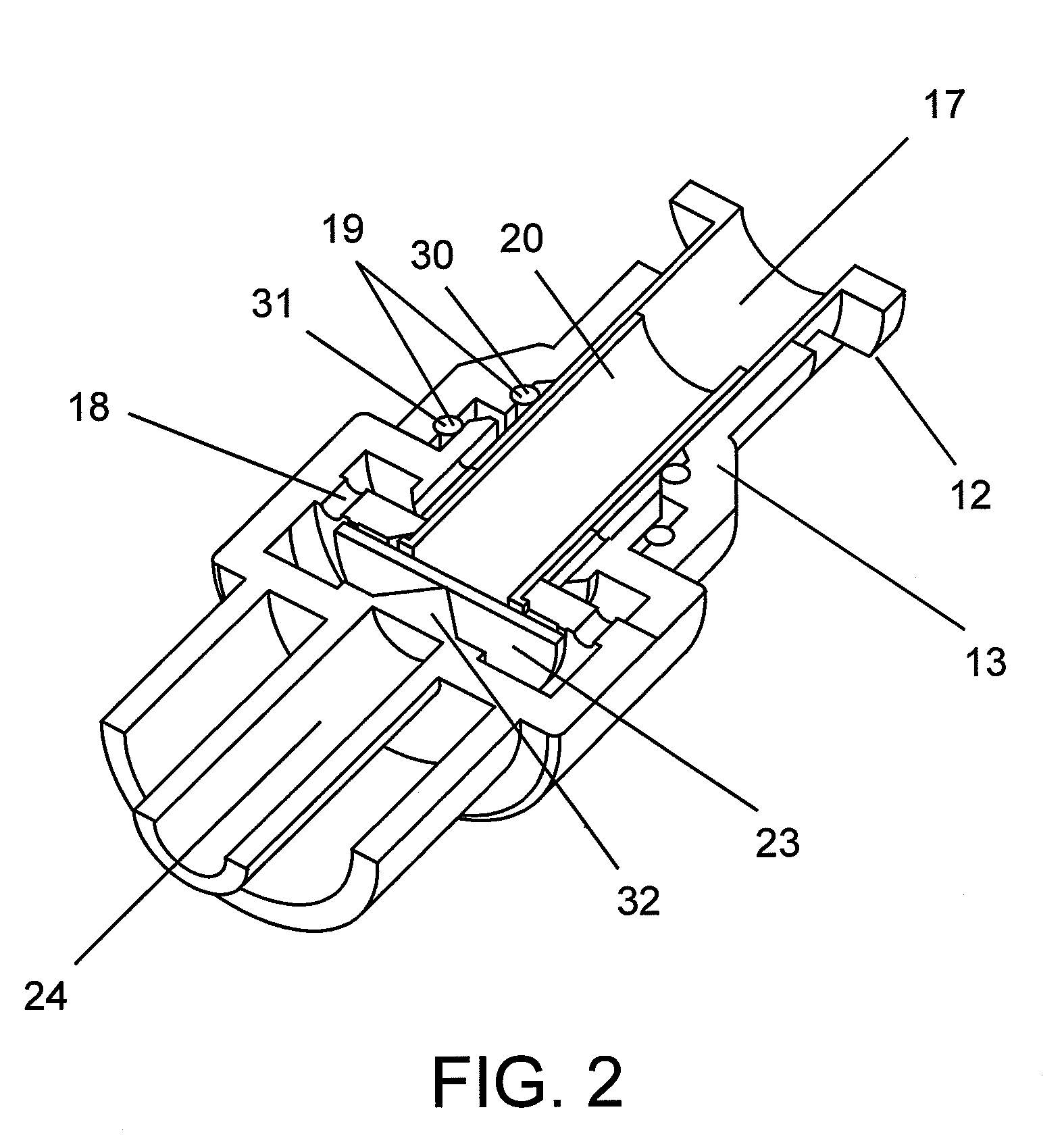

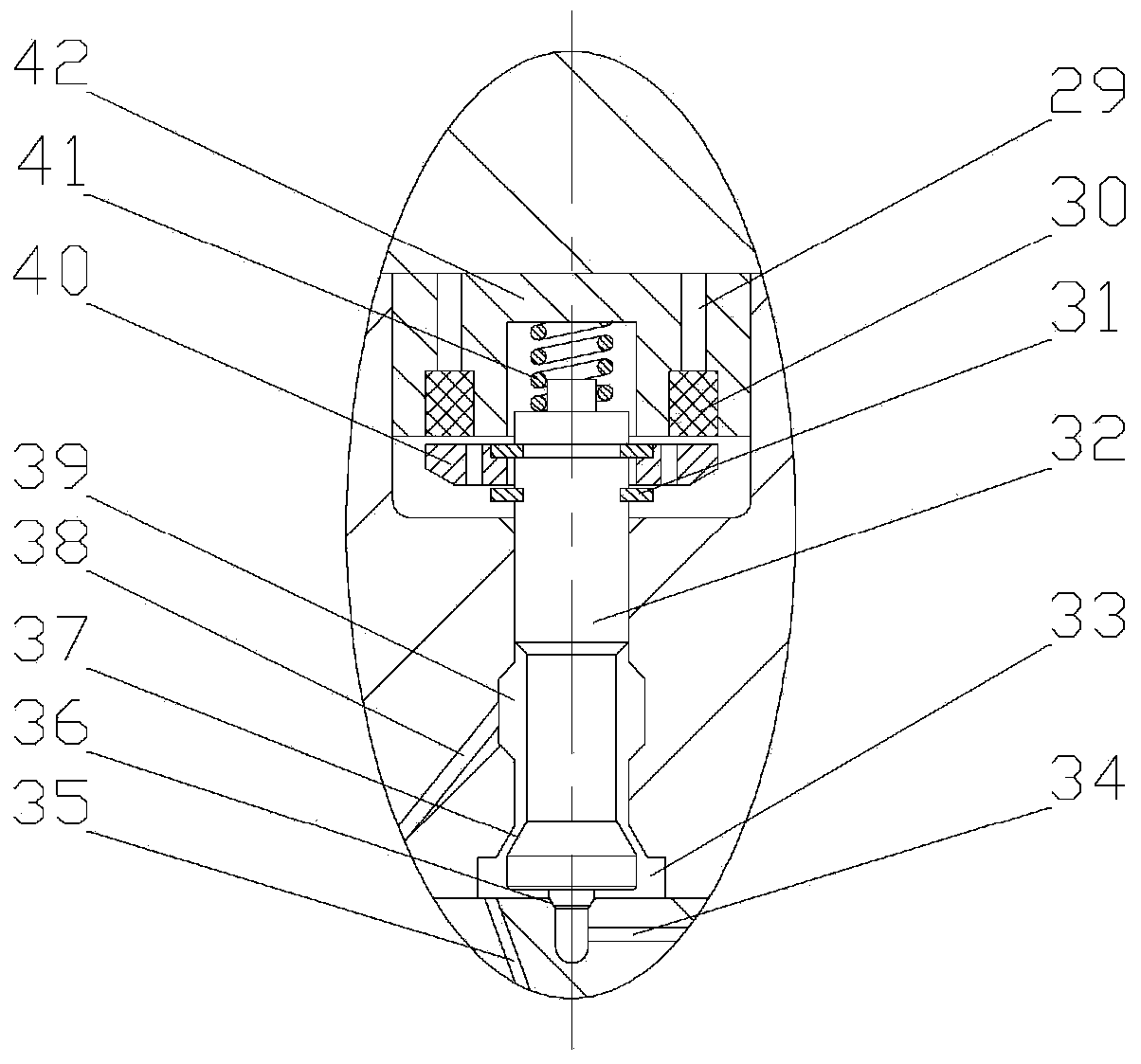

Vial adapter having a needle-free valve for use with vial closures of different sizes

A vial adapter having a needle-free valve, a sharpened cannula used to perforate a vial's rubber stopper, and a circular array of claws of different lengths to engage vial closures of different diameters. The array of claws includes a first set of claws each having a first length extending inwardly from the periphery of the housing of the adapter and a second set of claws alternating with the first set of claws and each having a longer length. The second set of claws are mounted so that they deflect and plastically deform out of the way in the case where the adapter is engaged with a vial that exceeds a predetermined size. The housing includes a shroud that is at least as long as the sharpened cannula to protect medical personnel who use the adapter from inadvertent punctures. The needle-free valve includes a resiliently deformable piston element with a naturally open bore. The interior of the piston provides a fluid flow path through the adapter. In one embodiment, the first set of claws of the adapter may be used with a vial closure of at approximately 20 mm in diameter and the second set of claws may be used with a vial closure of approximately 13 to 17 mm in diameter.

Owner:CAREFUSION 303 INC

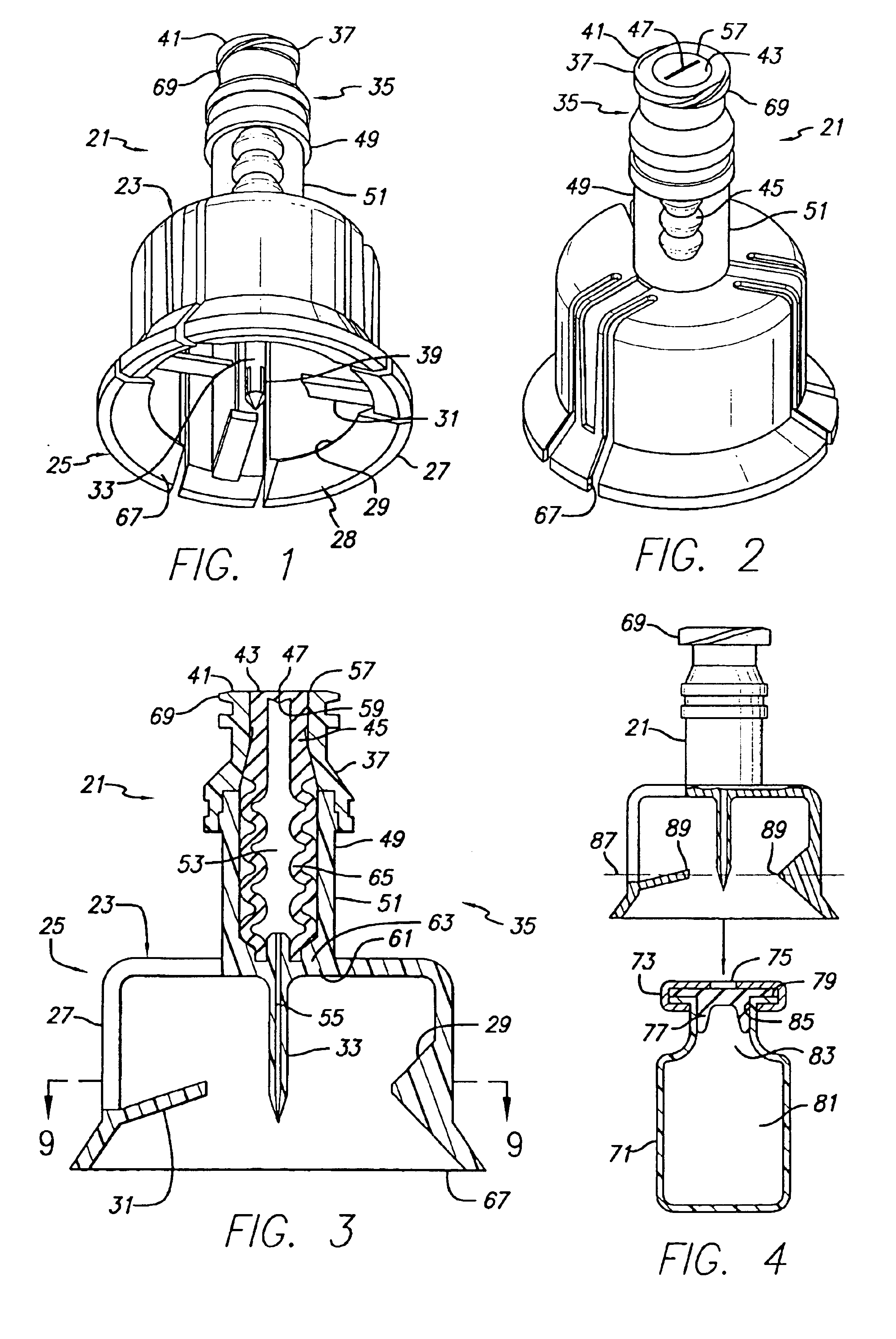

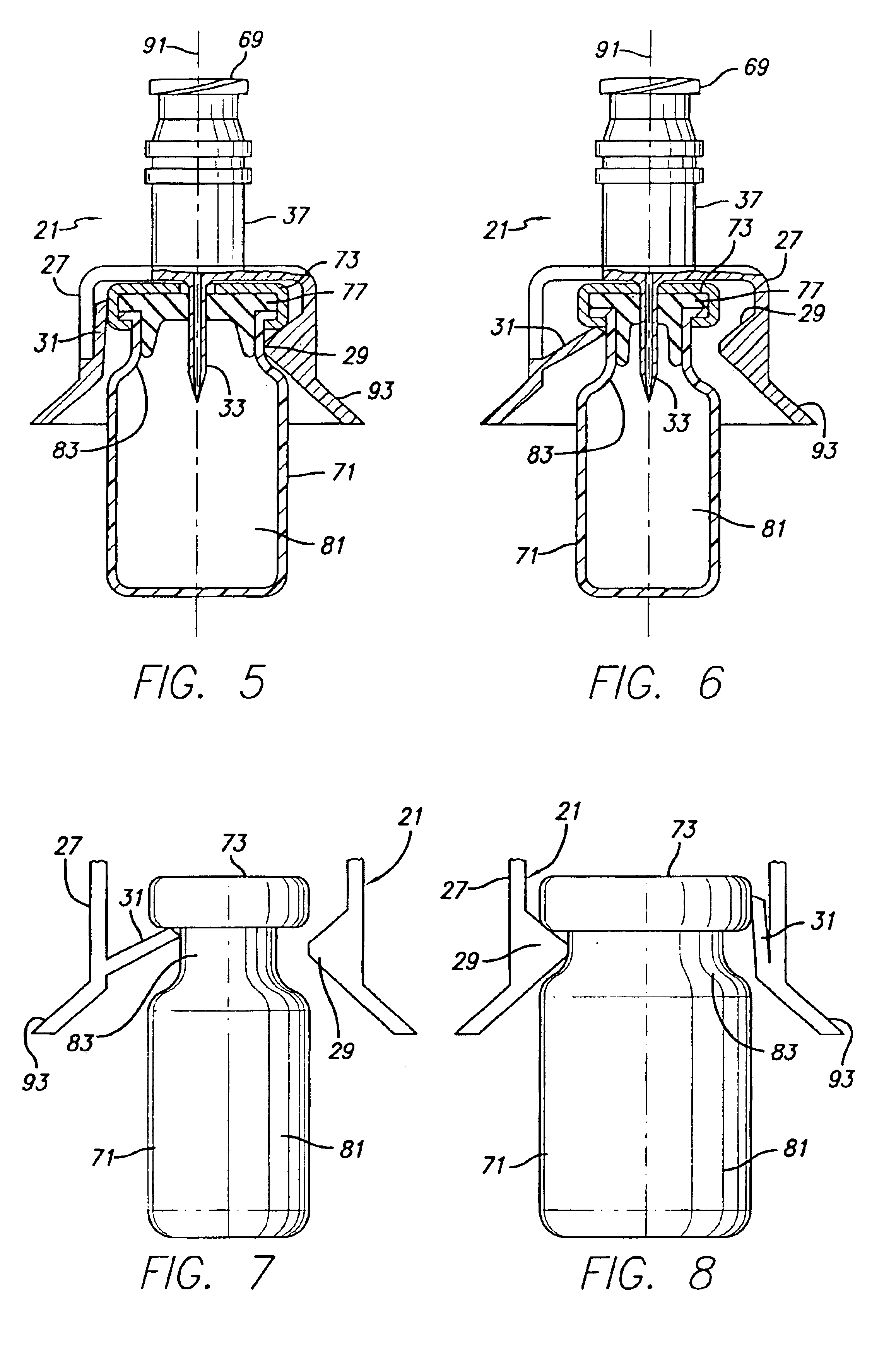

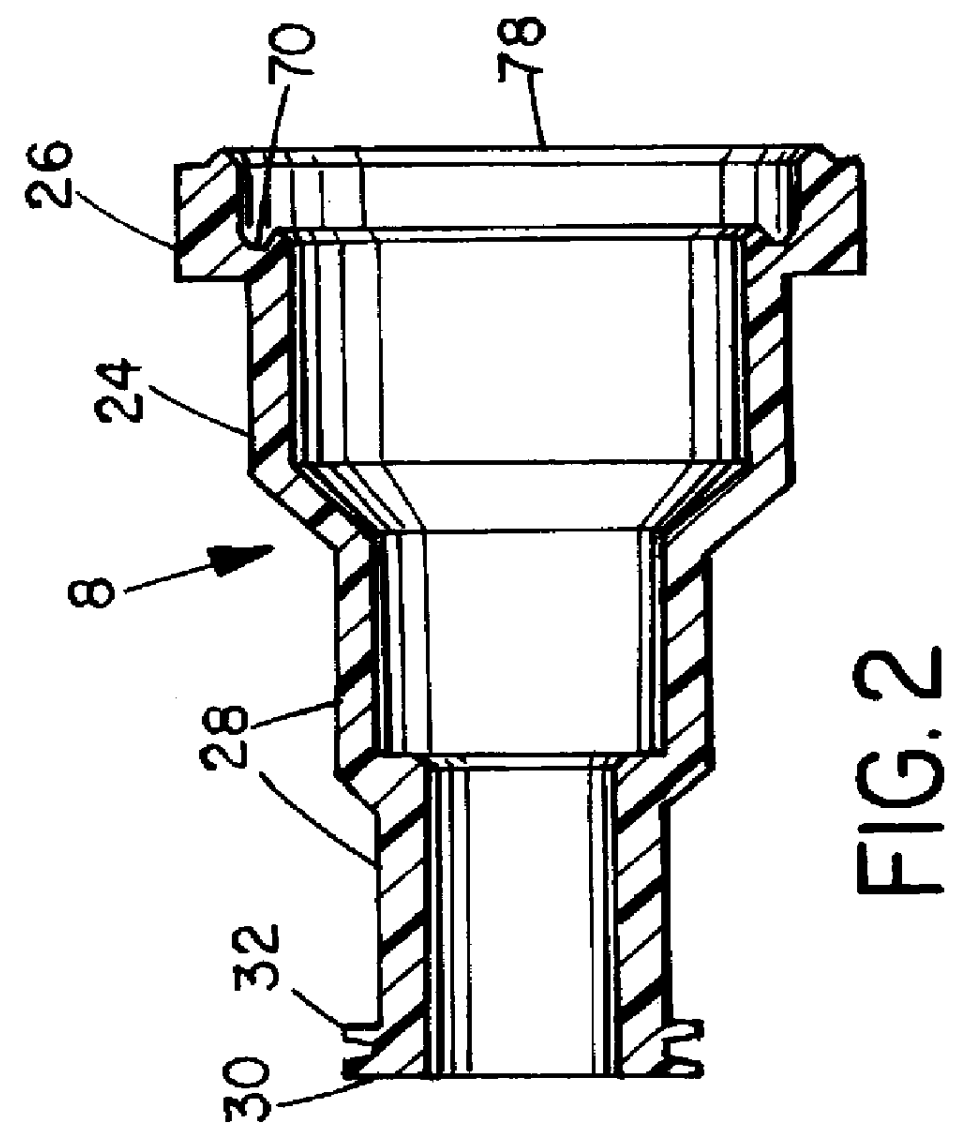

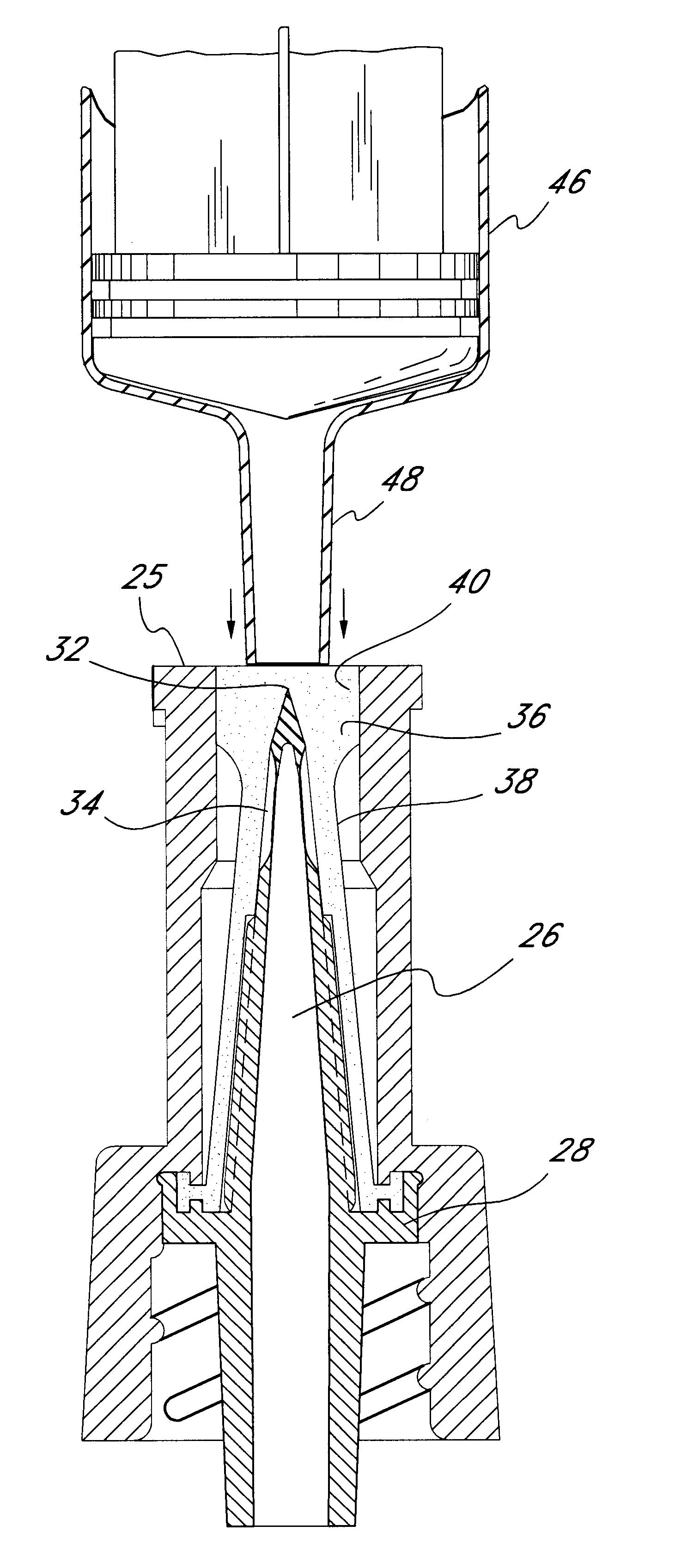

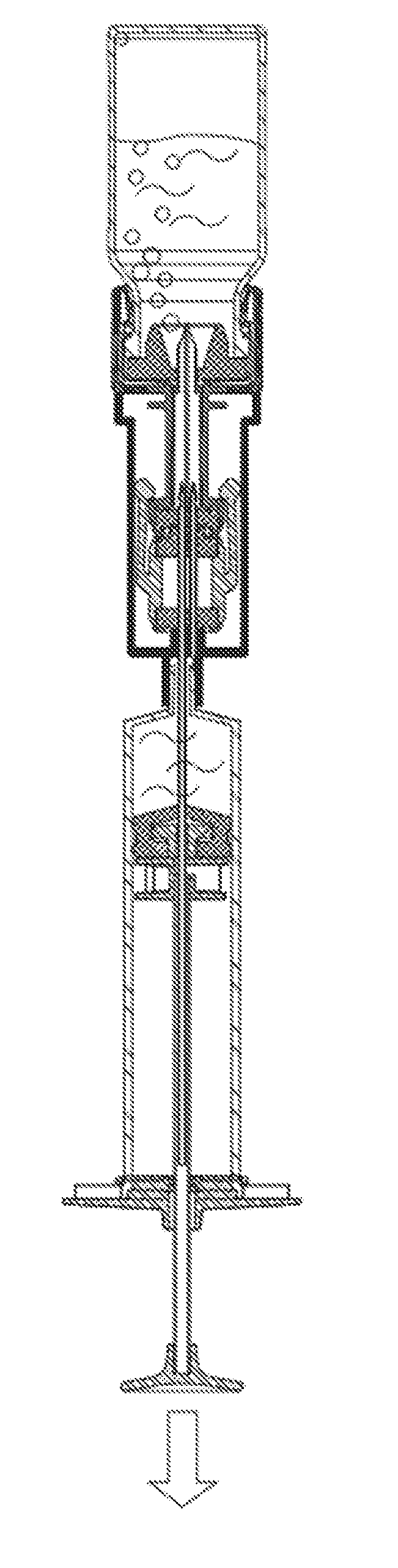

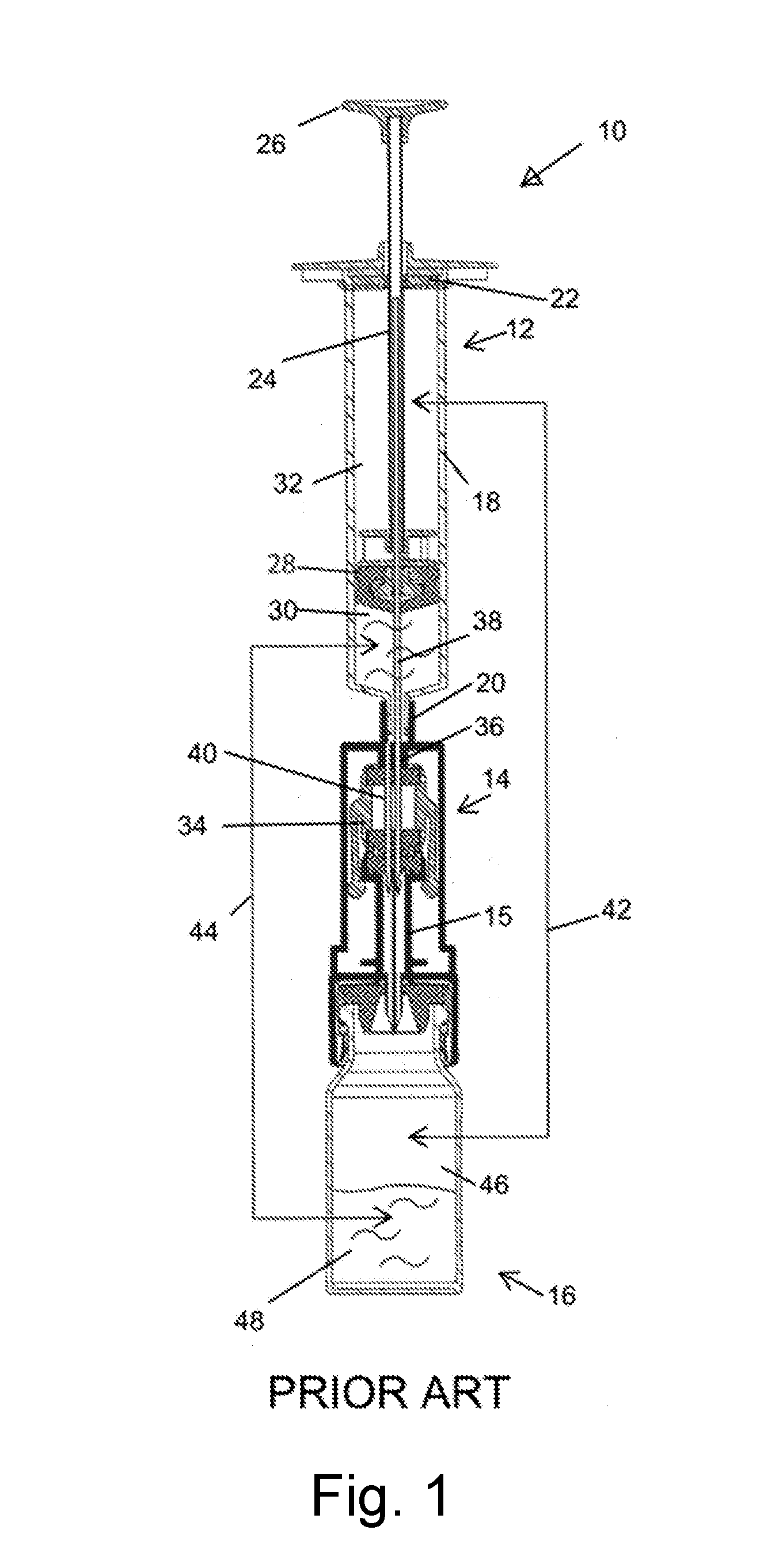

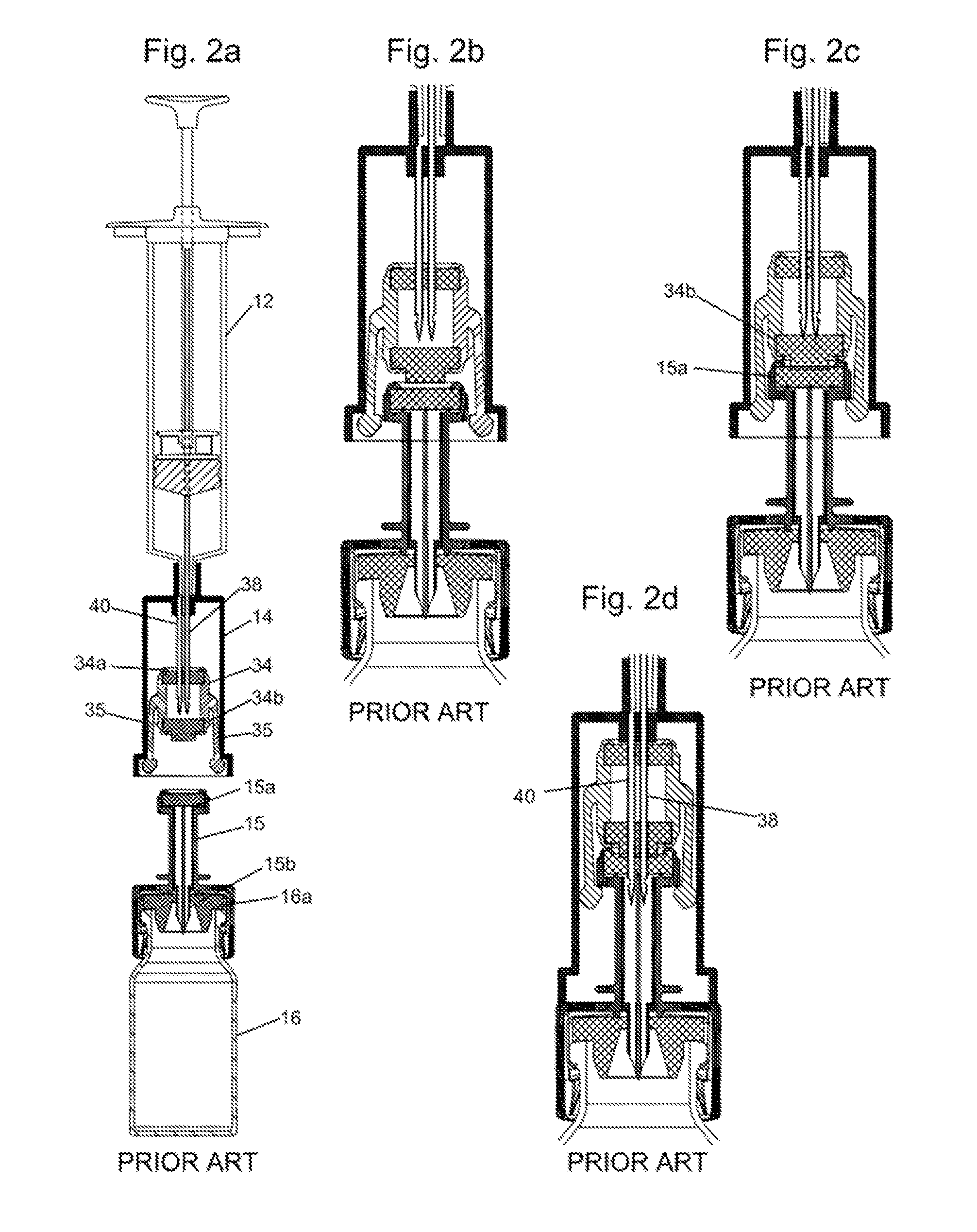

Needleless valve

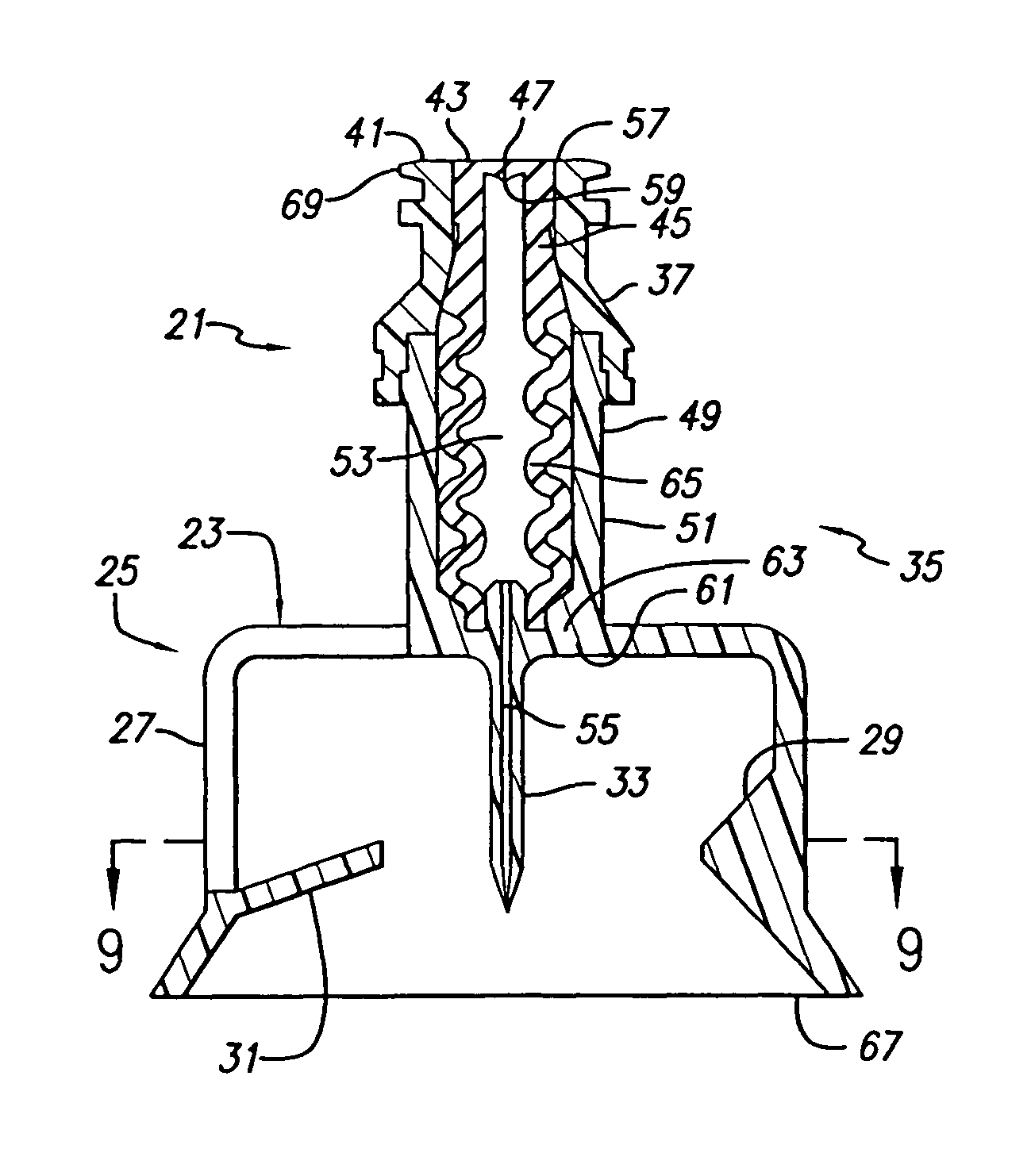

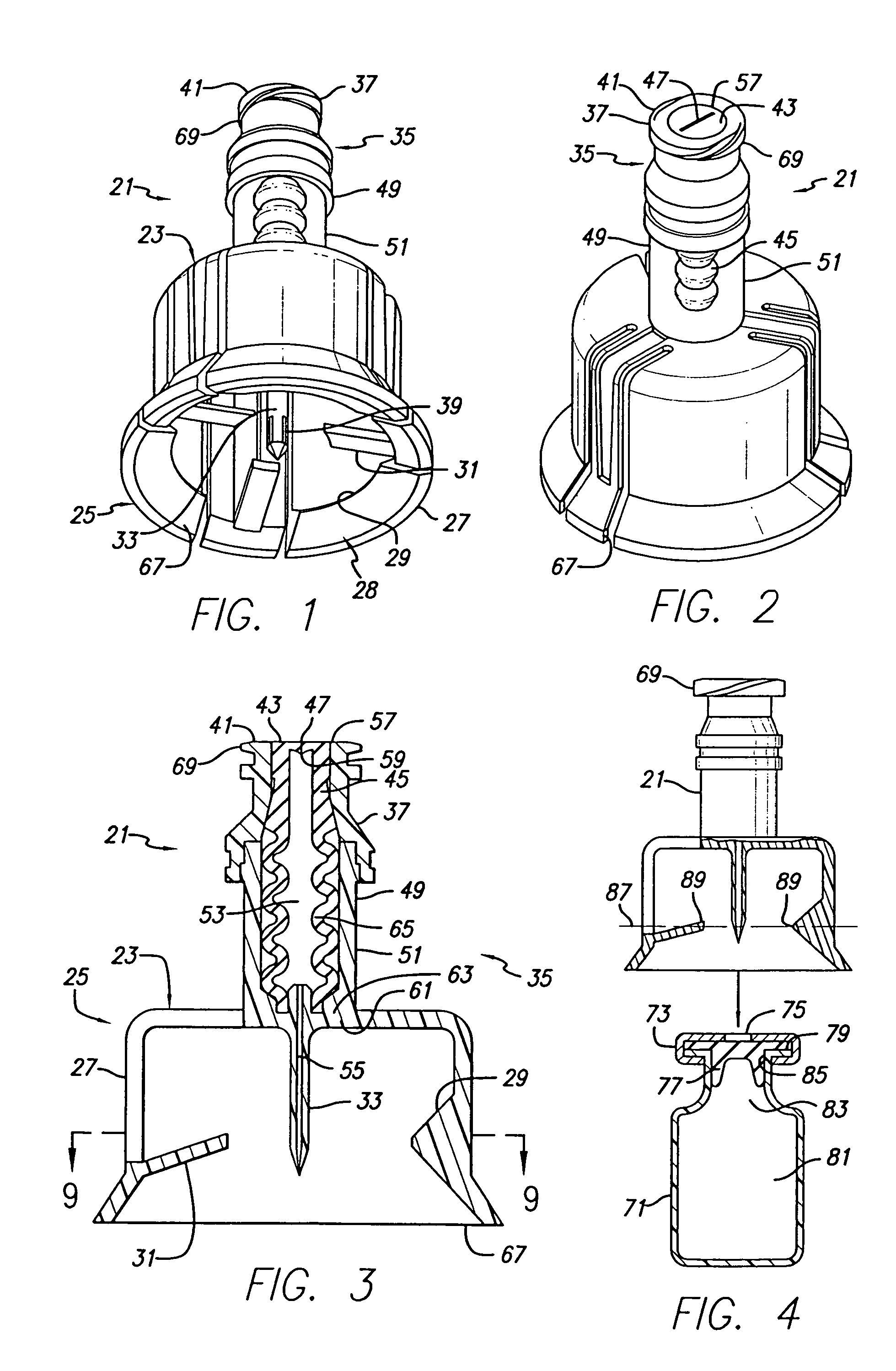

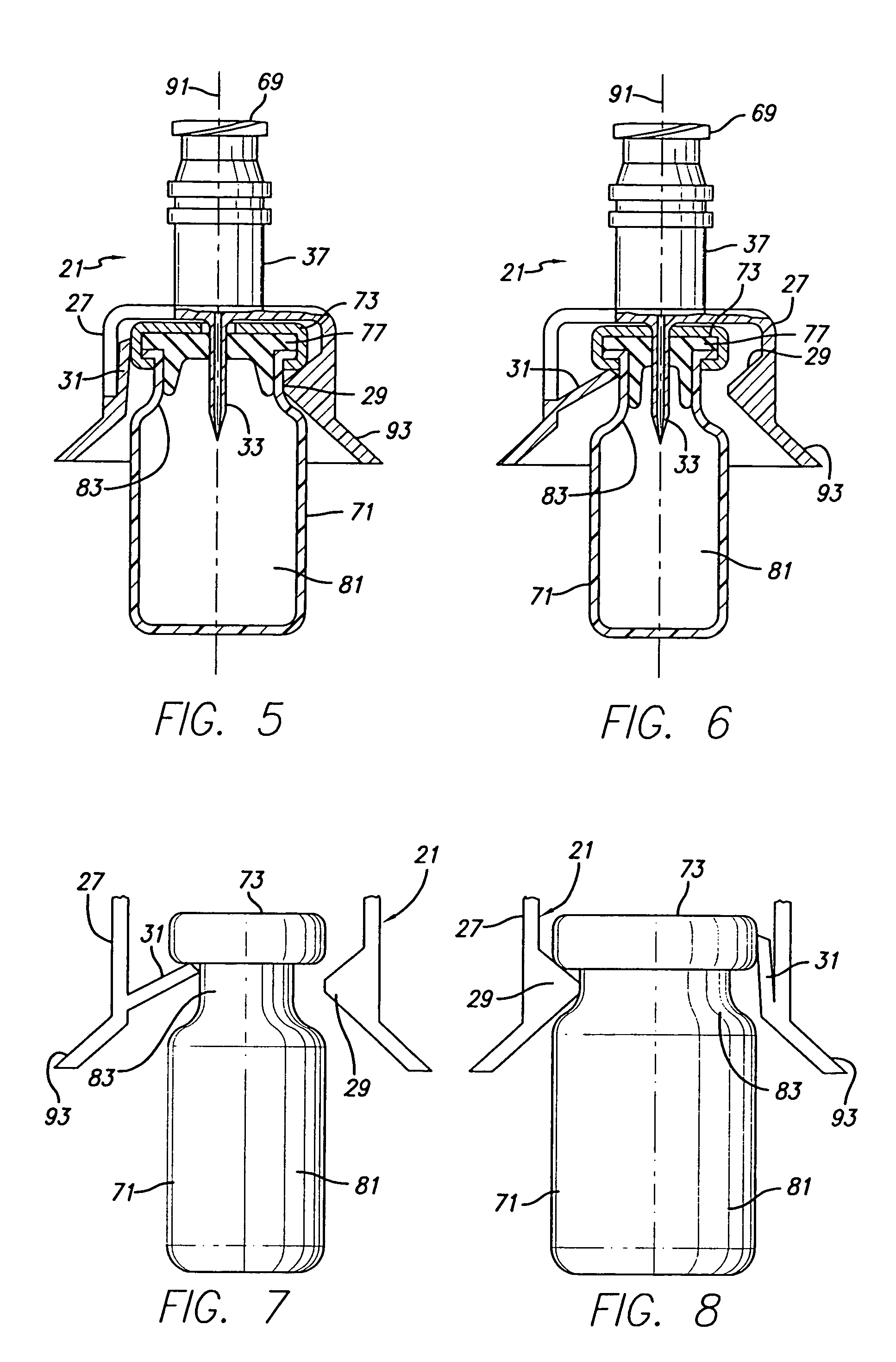

A needless valve is described which avoids the suctioning problems of the prior needleless devices upon deactivation and which preferably provides a positive self-purging effect. The valve is self-purging at the end of an administration cycle, avoiding clogging of attached catheters or other devices, and ensures that substantially all of liquid received into the valve is delivered to the receiver. The valve is also extremely simple in design and easy to construct and assemble, since it consists of only three pieces. The valve has a base with a connector for fluid communication attachment to tubing or other device, a solid elongated fluid channeling rod, and an internal fluid flow conduit; a flexible hollow expandable and contractible plug fitting over and moveable along the rod; and a tubular housing fitting over the plug and attached to the base. When the valve is activated by insertion of a nozzle of a fluid source, the rod and plug wall cooperate so that as the plug retracts along the rod, it is stretched and its interior expanded. Upon deactivation, the plug contracts, the interior volume decreases, and the resiling plug wall forces residual fliud within the valve to be expelled through the outlet, purging the residual fluid from the valve. No negative pressure is formed, so no suctioning of blood or other fluid from a patient or receiver occurs.

Owner:CAREFUSION 303 INC

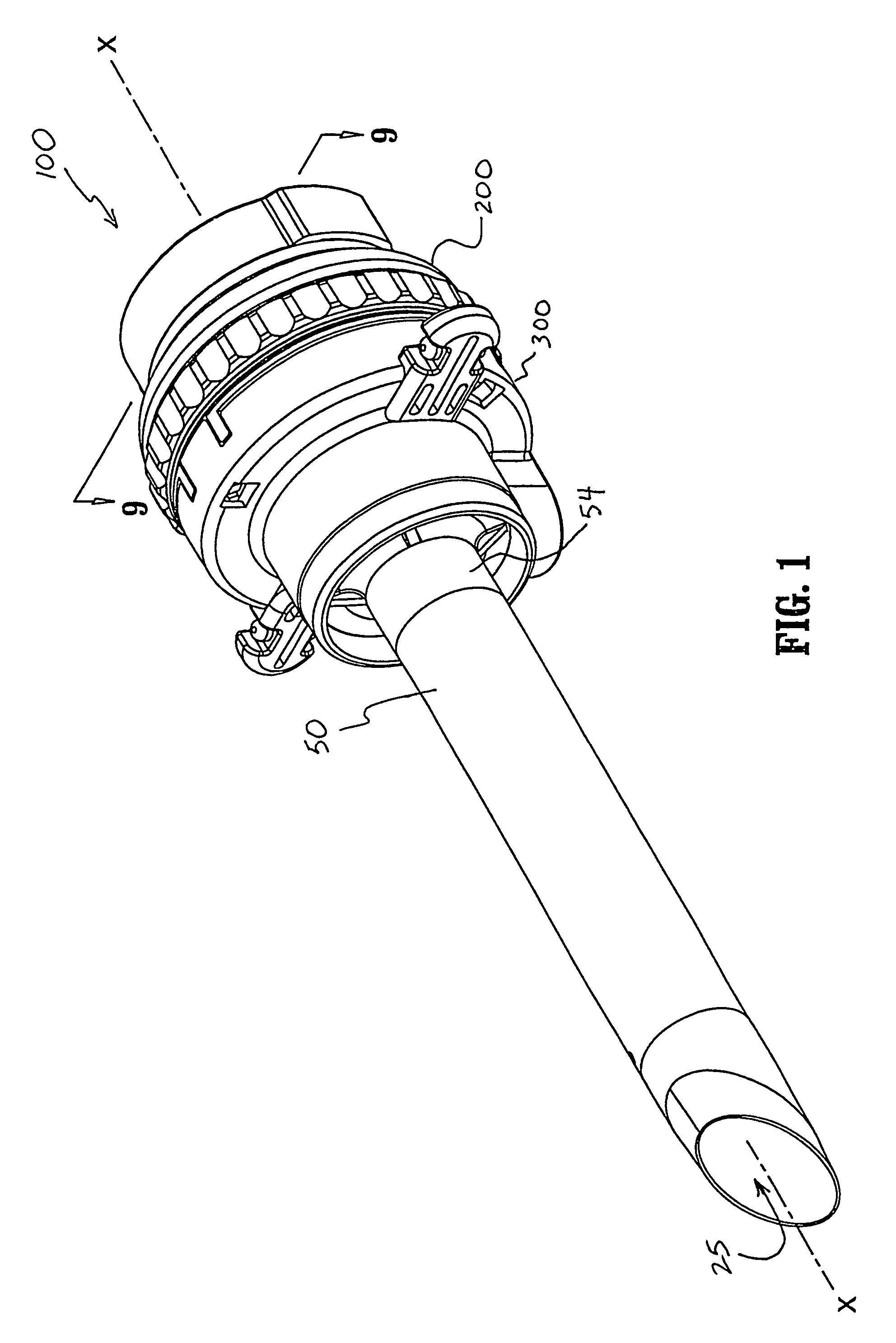

Surgical hand access apparatus

A surgical access apparatus adaptable to permit the sealed insertion of either the surgeon's hand and / or surgical instruments during laparoscopic and endoscopic surgical procedures includes an access housing defining a central longitudinal axis and having a longitudinal opening extending therethrough for passage of a surgeon's hand, a retractor base mounted to the access housing and having a flexible liner for positioning within the incision to engage tissue portions defining the incision, and a trocar adapter which is releasably mounted to the access housing. The trocar adapter includes a trocar sleeve positioned for reception within the longitudinal opening and a trocar valve adapted to receive a surgical instrument in fluid tight relation therewith. The access housing may include a seal adapted to form a seal about each of the surgeon's arm and the trocar sleeve. The seal is adapted to close in absence of the surgeon's arm or the trocar sleeve.

Owner:TYCO HEALTHCARE GRP LP

Vial adapter having a needle-free valve for use with vial closures of different sizes

Owner:CAREFUSION 303 INC

Needleless valve

A needless valve is described which avoids the suctioning problems of the prior needleless devices upon deactivation and which preferably provides a positive self-purging effect. The valve is self-purging at the end of an administration cycle, avoiding clogging of attached catheters or other devices, and ensures that substantially all of liquid received into the valve is delivered to the receiver. The valve is also extremely simple in design and easy to construct and assemble, since it consists of only three pieces. The valve has a base with a connector for fluid communication attachment to tubing or other device, a solid elongated fluid channeling rod, and an internal fluid flow conduit; a flexible hollow expandable and contractible plug fitting over and moveable along the rod; and a tubular housing fitting over the plug and attached to the base. When the valve is activated by insertion of a nozzle of a fluid source, the rod and plug wall cooperate so that as the plug retracts along the rod, it is stretched and its interior expanded. Upon deactivation, the plug contracts, the interior volume decreases, and the resiling plug wall forces residual fluid within the valve to be expelled through the outlet, purging the residual fluid from the valve. No negative pressure is formed, so no suctioning of blood or other fluid from a patient or receiver occurs.

Owner:CAREFUSION 303 INC

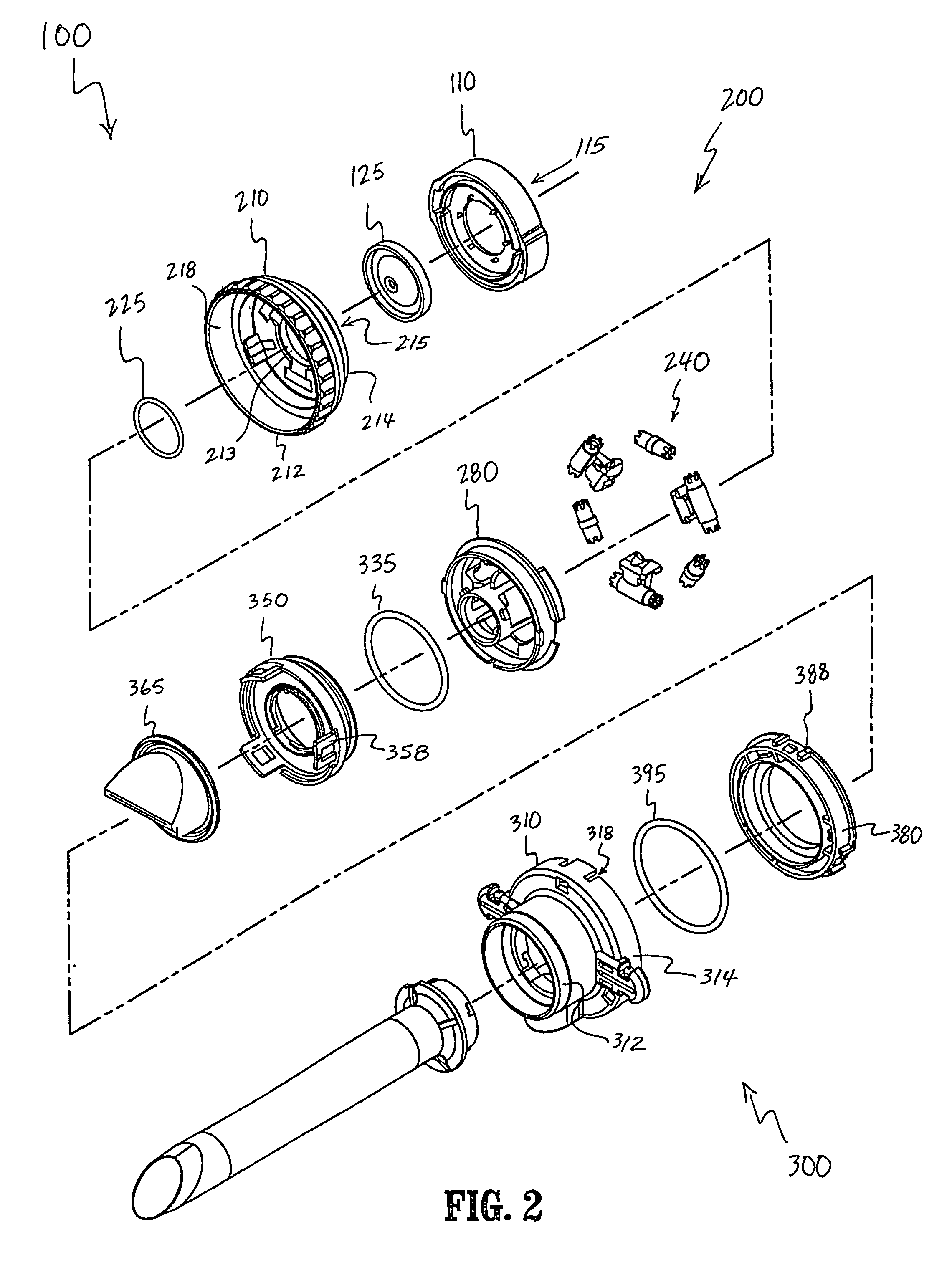

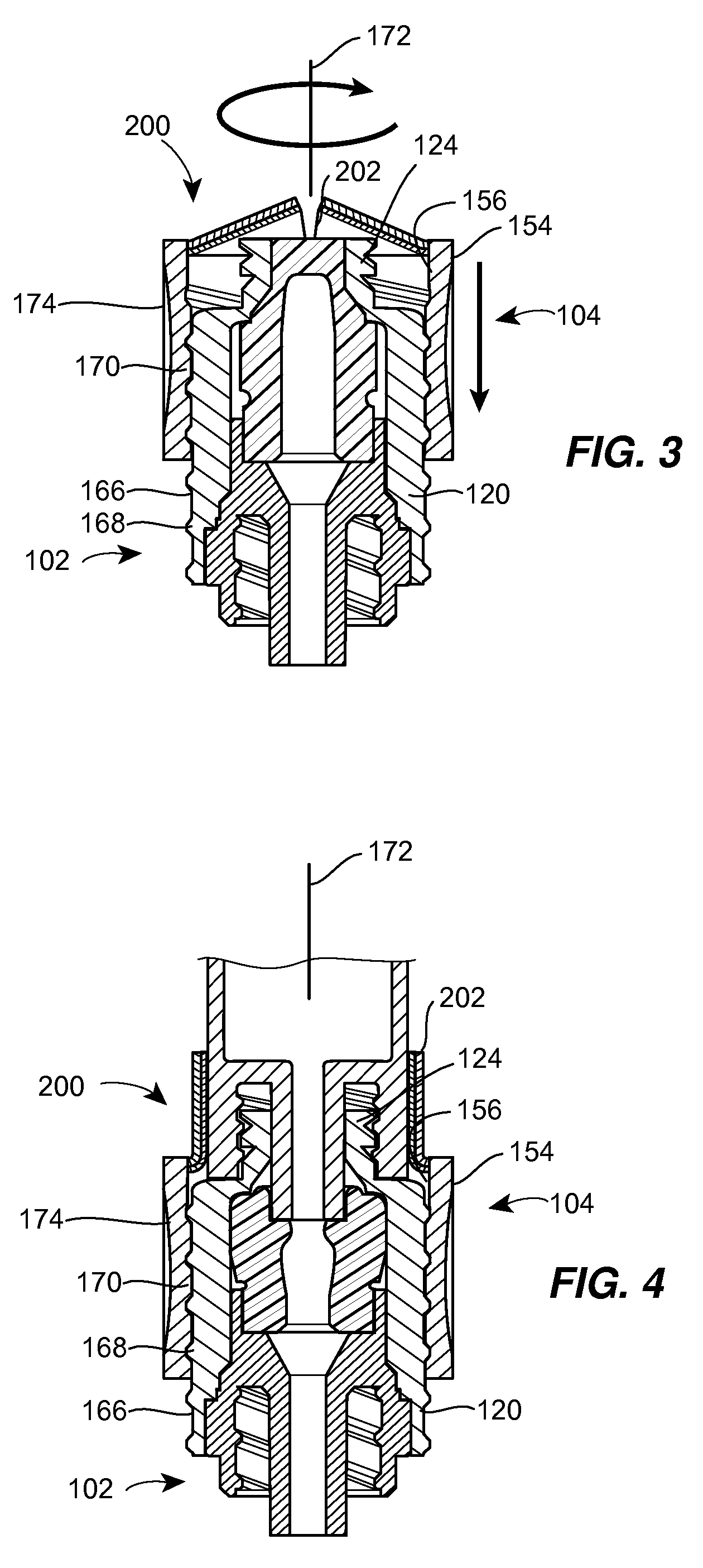

Valve assembly including diameter reduction structure for trocar

InactiveUS7025747B2Convenient introductionSmall sizeCannulasInfusion syringes% diameter reductionVALVE PORT

A valve assembly and diameter reduction structure for trocar employing a movable diameter reduction structure. The diameter reduction structure is positioned in proximity to a first seal and includes a plurality of stand off members movable between a first position, a second position, and a third position. The diameter reduction structure in the first position reduces the likelihood of the first seal losing its integrity by limiting excessive off-axis and angular movements of small diameter surgical instruments. When large diameter surgical instruments are positioned through the trocar, the diameter reduction structure pivots to accommodate the passage of larger diameter surgical instruments without any operational adjustments.

Owner:TYCO HEALTHCARE GRP LP

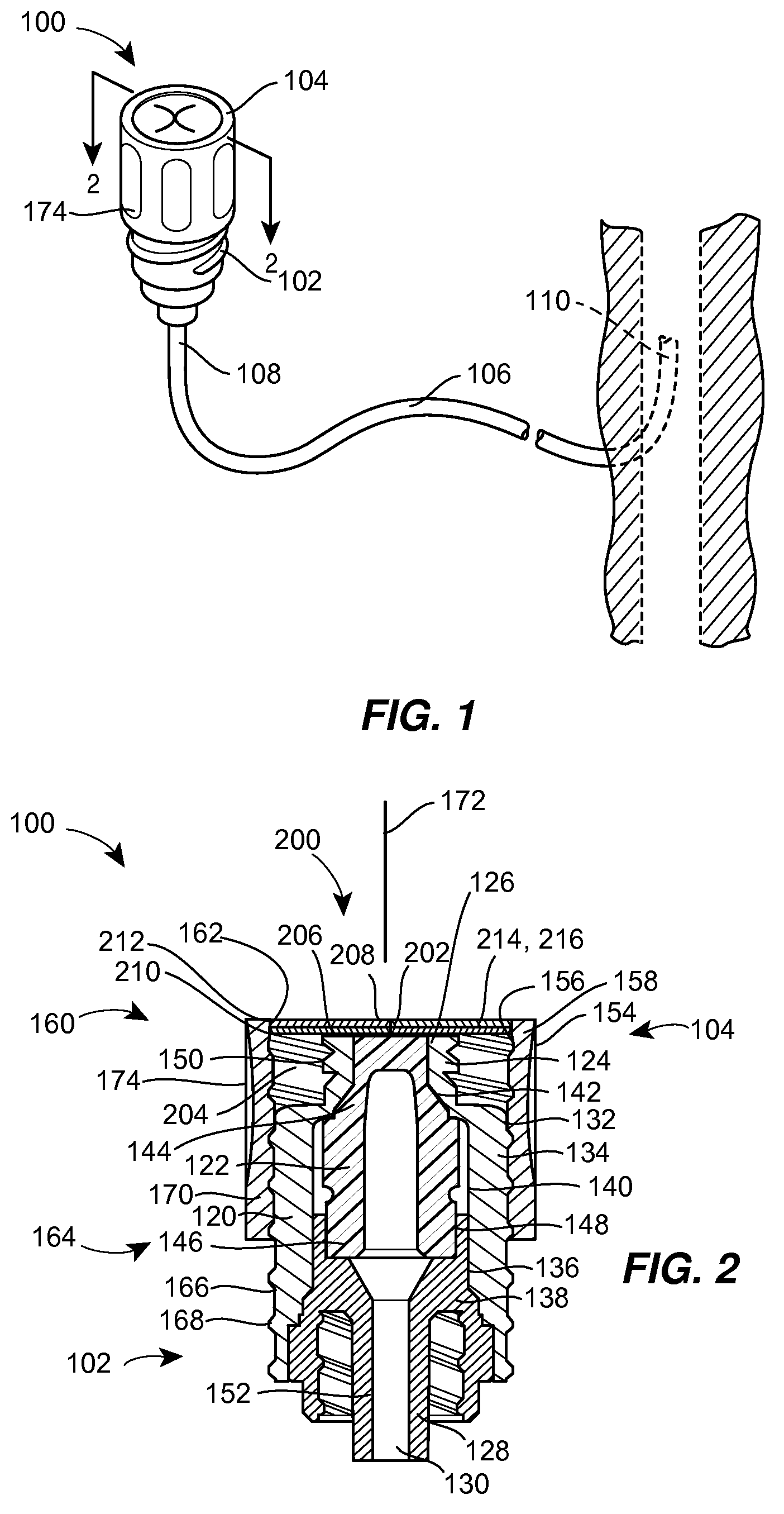

Barrier assembly for use with needleless connector

A needleless valve assembly includes a needleless connector having a housing with an inlet end with an inlet opening and an outlet end with an outlet opening, and a valve disposed in the housing to control passage between the openings. The assembly also includes a collar having an exterior surface and an interior surface, and a first end with a collar opening communicating between the interior surface and the exterior surface and a second end moveably attached to the housing. Further, the assembly includes a barrier disposed across the collar opening with a slit therethrough and including an anti-microbial material. The collar is moveable relative to the housing so that the inlet end of the housing depends past the exterior surface of the collar through the slit in the barrier. A kit may include the assembly and a catheter having a first end attached to the outlet opening.

Owner:BAXTER INT INC +1

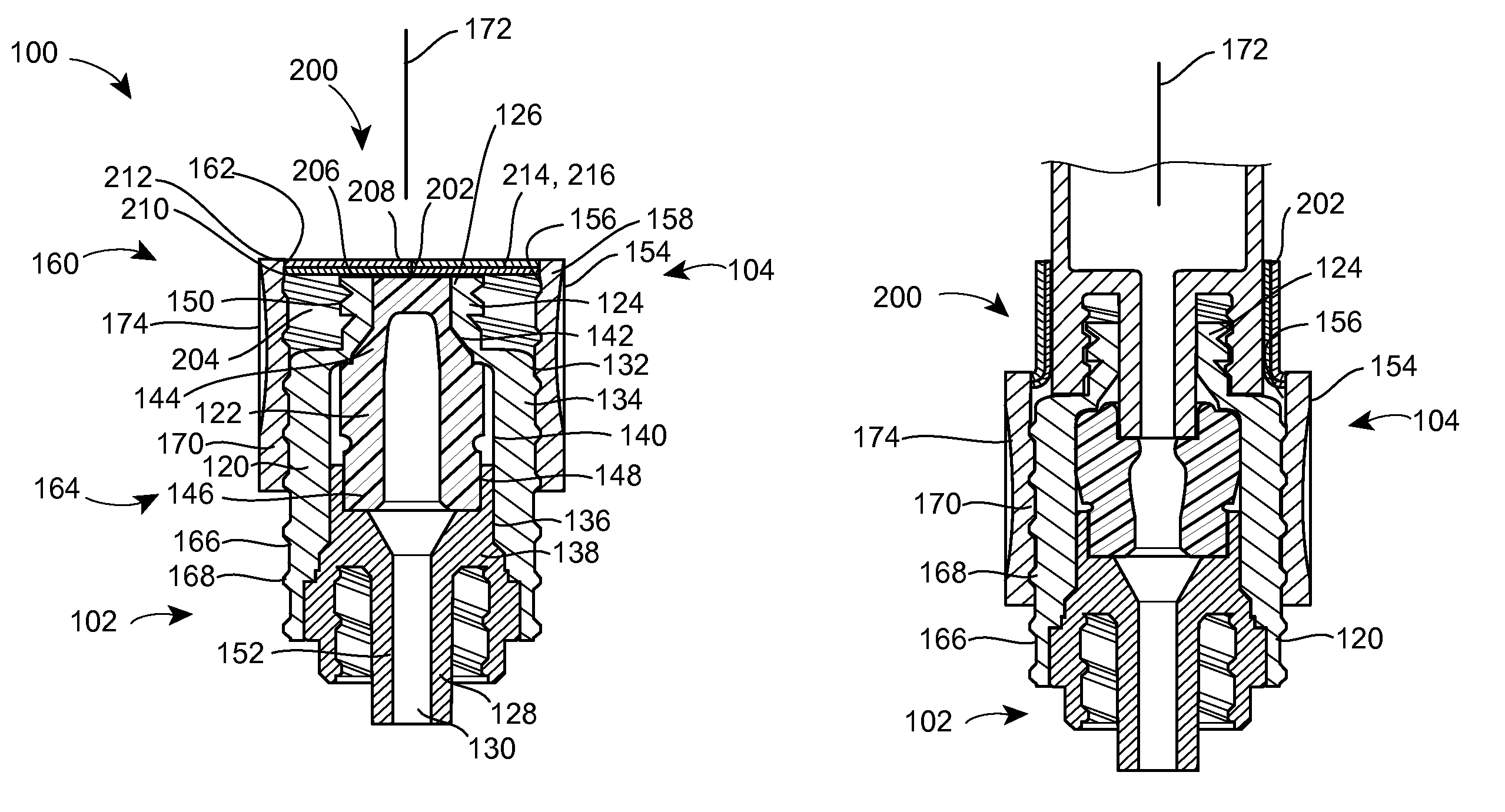

Medical valve

A closed system, needleless valve device includes a generally tubular body defining an internal cavity. On the proximal end of the body there is an opening which is preferably sufficiently large to receive an ANSI standard tip of a medical implement. The distal end of the body has a generally tubular skirt. The valve also includes a hollow spike having a closed tip. The spike includes at least one longitudinal 18-gauge hole located distal the tip, and is seated inside the cavity such that the tip is below the proximal end of the body. An annular support cuff is connected to the spike which seals off a portion of the cavity of the body such that an upper cavity containing the tip is defined. The valve also includes a plastic, resilient silicone seal which fills the upper cavity and opening and covers the tip of the spike so as to present a flush surface. An adaptor enables the valve to be attached to a resealable container.

Owner:ICU MEDICAL INC

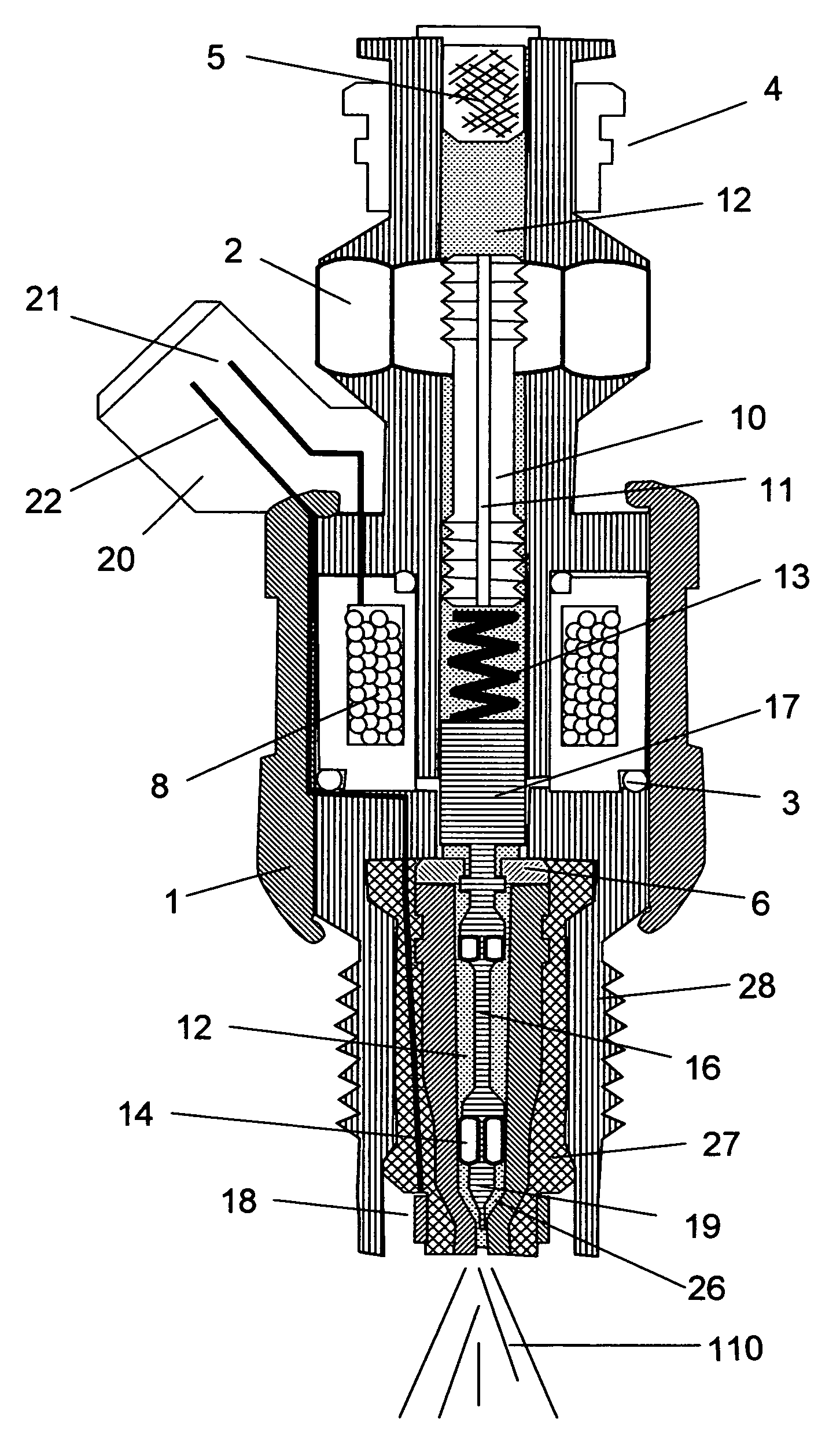

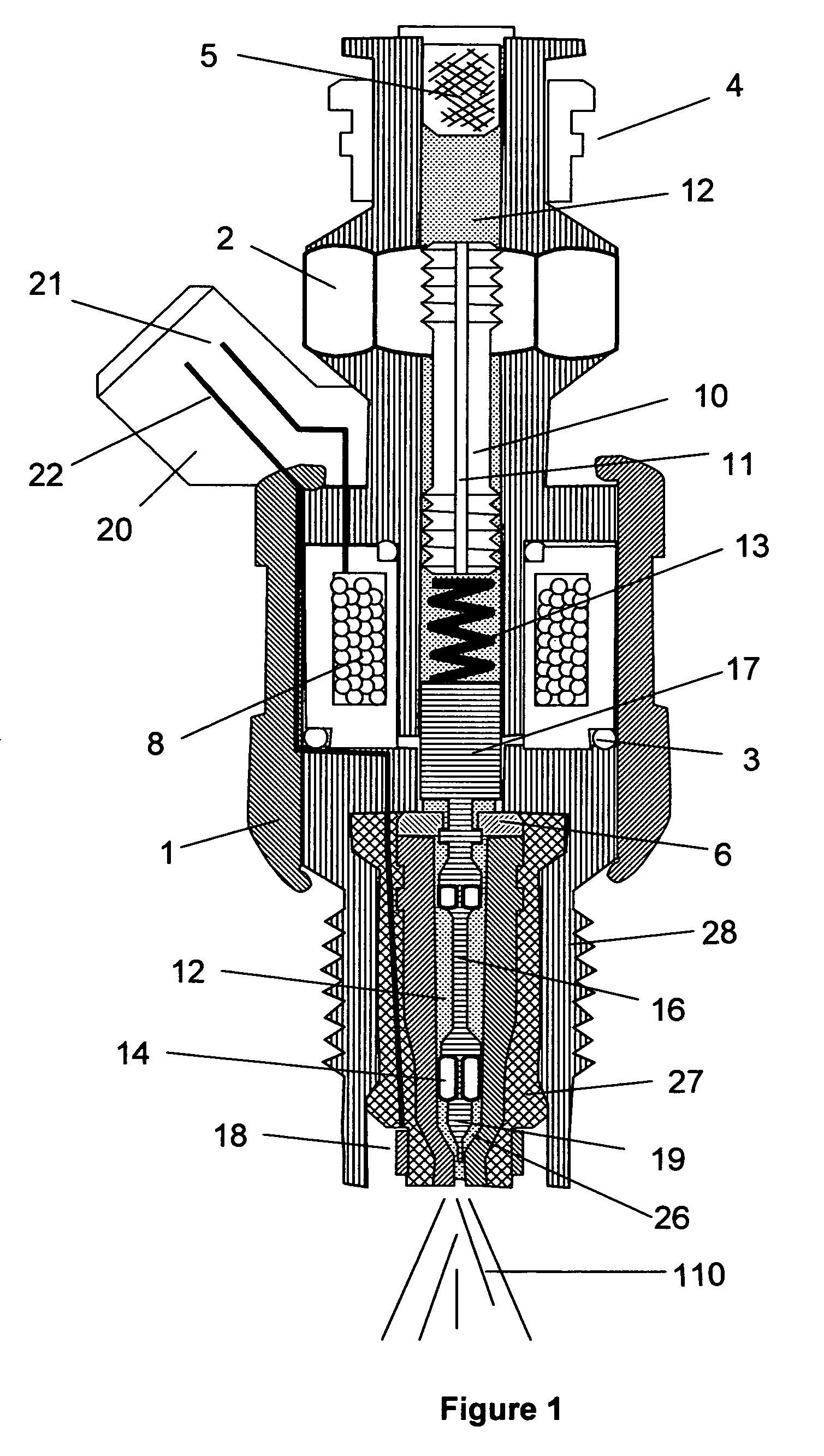

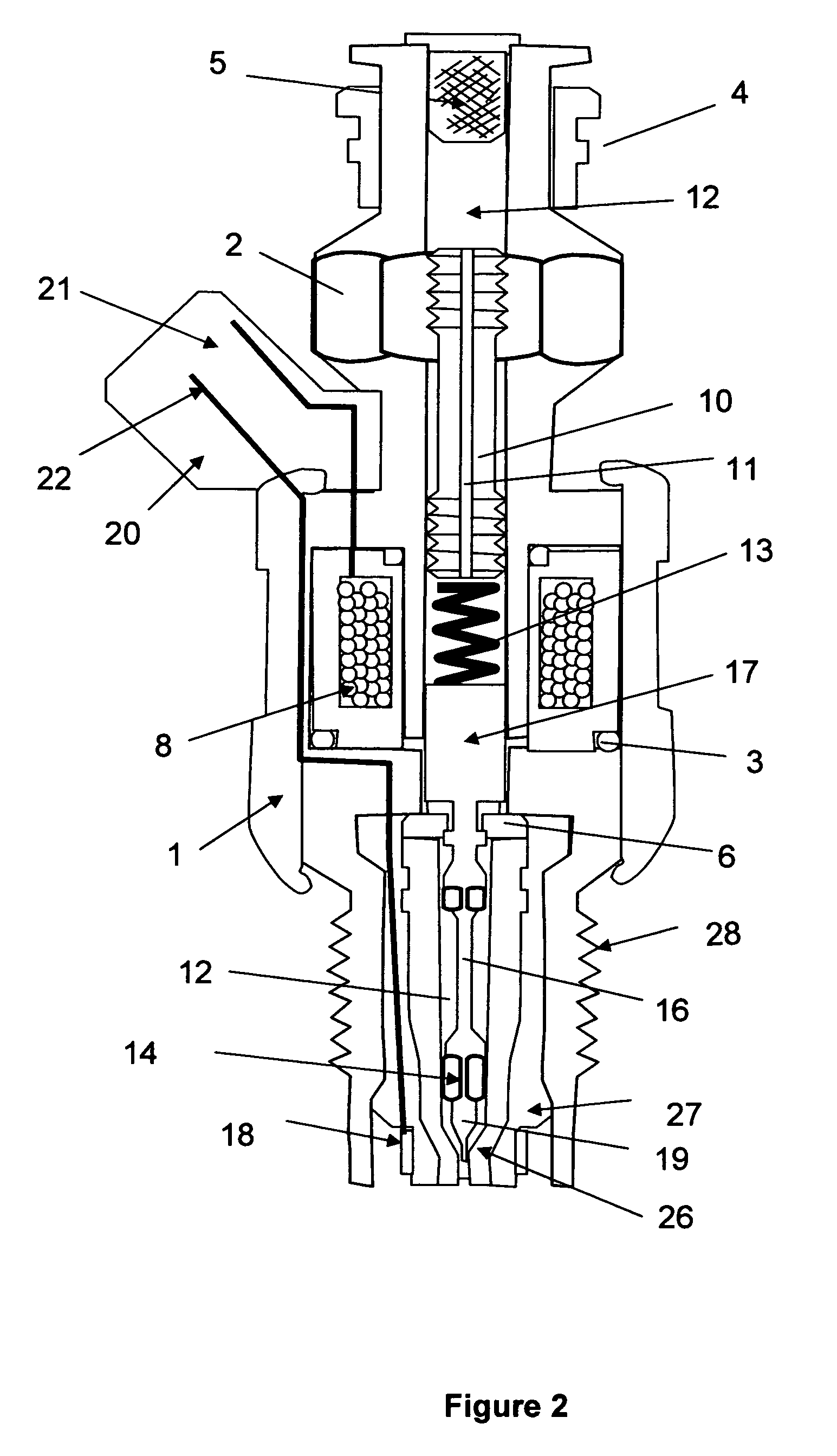

Fuel injector spark plug

InactiveUS6955154B1Eliminates excess fuel useRemove heatSparking plugsFuel injection apparatusCombustionEngineering

A spark plug and fuel injector combination. The spark plug has a central channel that funnels fuel into the lower portion of the spark plug, where it is superheated. A solenoid system causes a needle valve to rise up to allow a measured quantity of fuel to be injected into a cylinder through a nozzle, where it vaporizes upon exiting the spark plug. A spring releases the needle valve to close the nozzle. The spark plug also has an ignition ring on the base. The ignition ring produces an encompassing spark, which produces complete combustion of the vaporized fuel. This produces more power and better fuel economy.

Owner:DOUGLAS DENIS

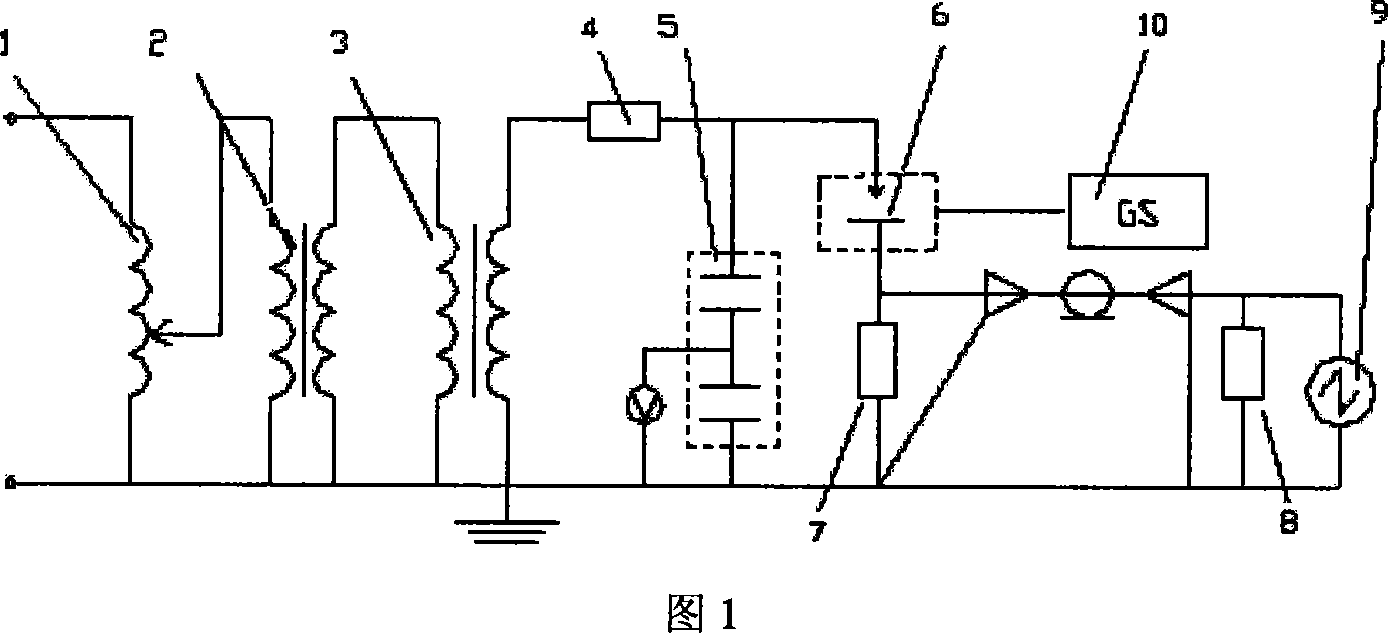

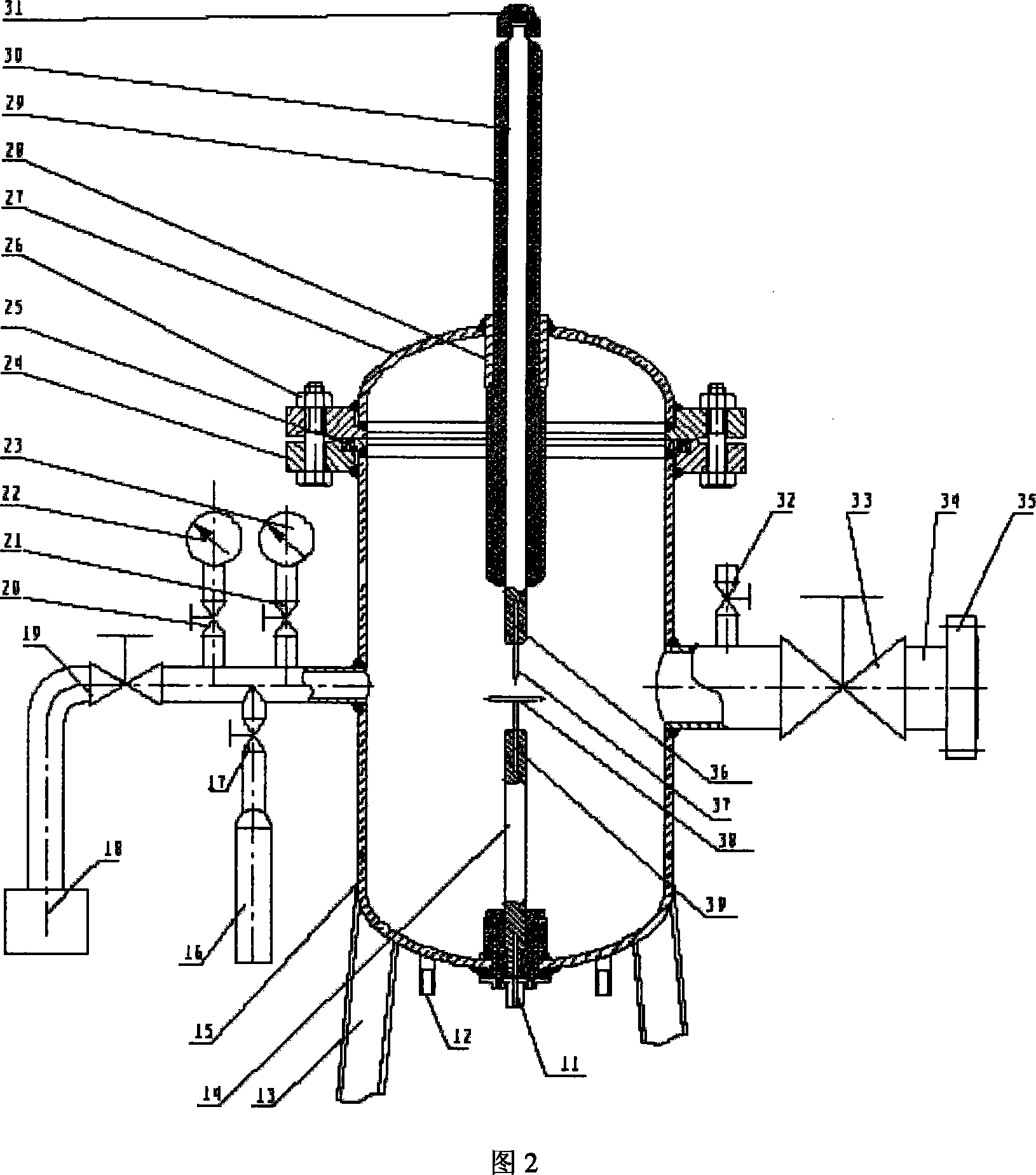

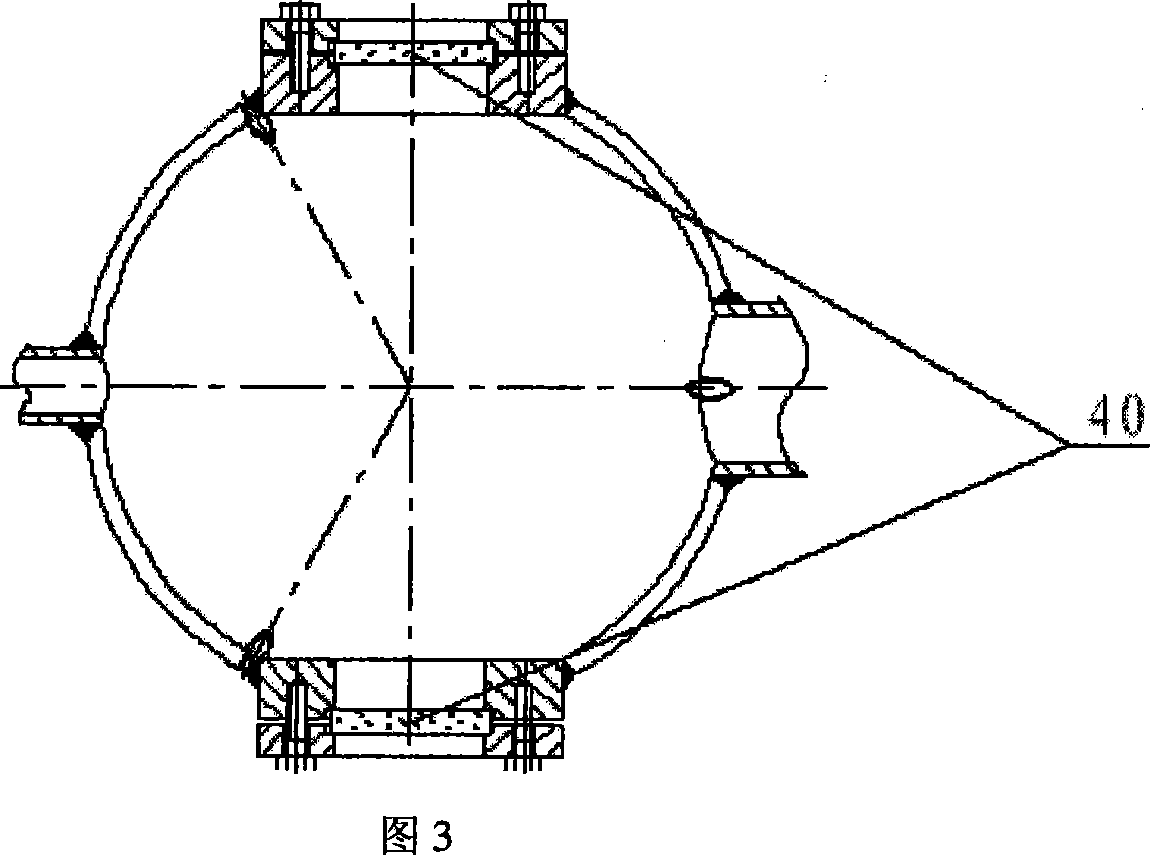

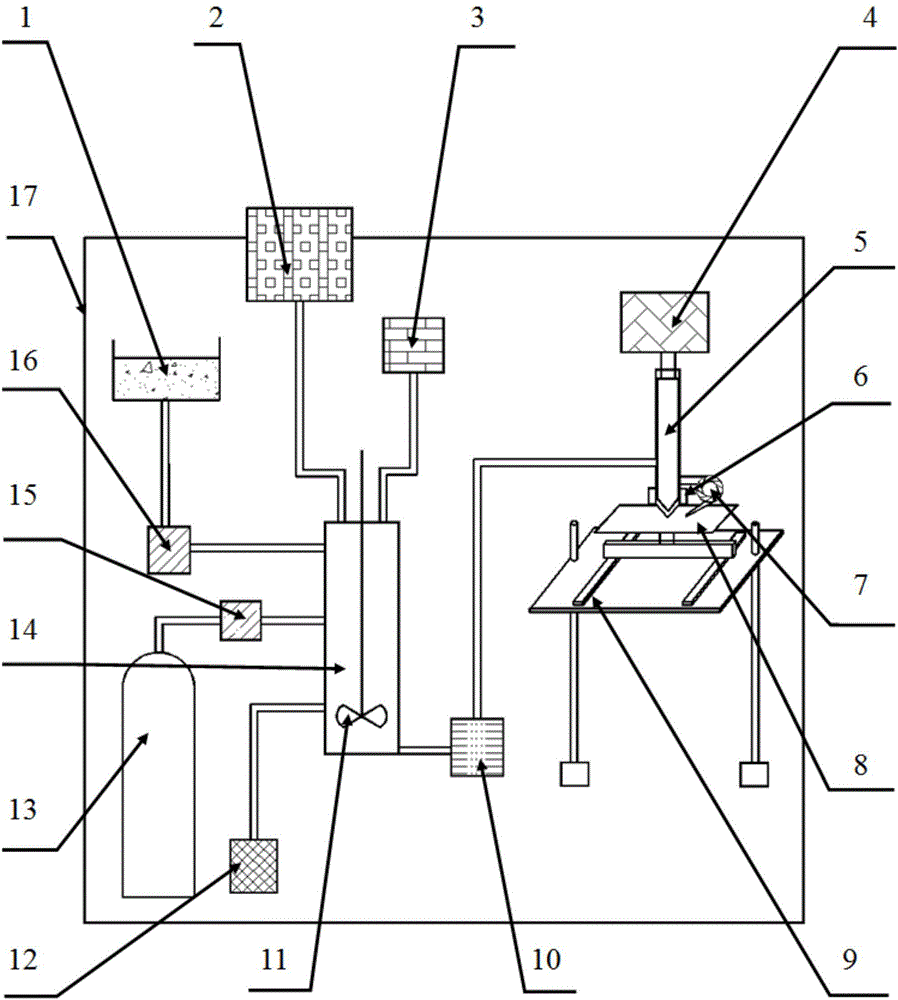

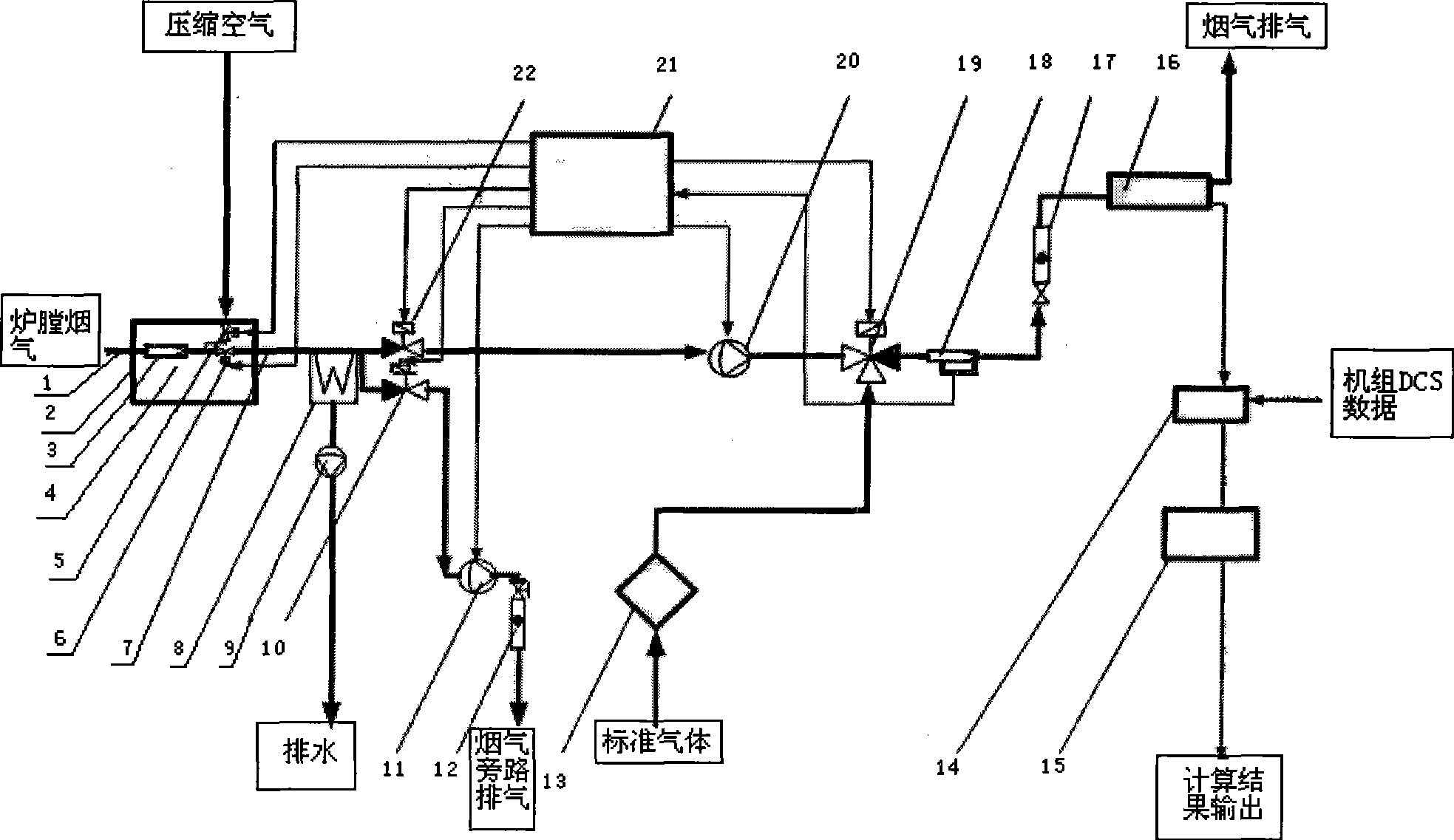

Sulfur hexafluoride discharge decomposed gas component analysis system and its usage method

InactiveCN101059485AImprove sealingGuaranteed validityComponent separationPreparing sample for investigationTransformerSulfur hexafluoride

A sulfur hexafluoride discharge decomposition gas component analysis system is composed of a pressure adjuster console 1, an insulation transformer 2, a non-blooming test transformer 3, a non-local-discharge protective resistance 4, a capacitor bleeder 5, a sulfur hexafluoride discharge decompose device 6, a non-inductive check resistance 7, a match resistance 8, an oscillometer 9, and a gas spectrometer 10. And the method comprises that (1), using a vacuum pump 18 to vacuum the sulfur hexafluoride discharge decompose device 6, (2), using an inlet needle valve 17 to feed SF6 gas into the sulfur hexafluoride discharge decompose device 6, (3), measuring maximum external test voltage and initial PD voltage, (4), generating PD under different electrodes, (5), collecting gas, (6), analyzing gas components, (7), collecting PD pulse signal wave shape, diagnosing accident and recognizing mode. The invention has wide application in research, teach, academy and industry, used in theory analysis and research of PD online state check of GIS device.

Owner:CHONGQING UNIV

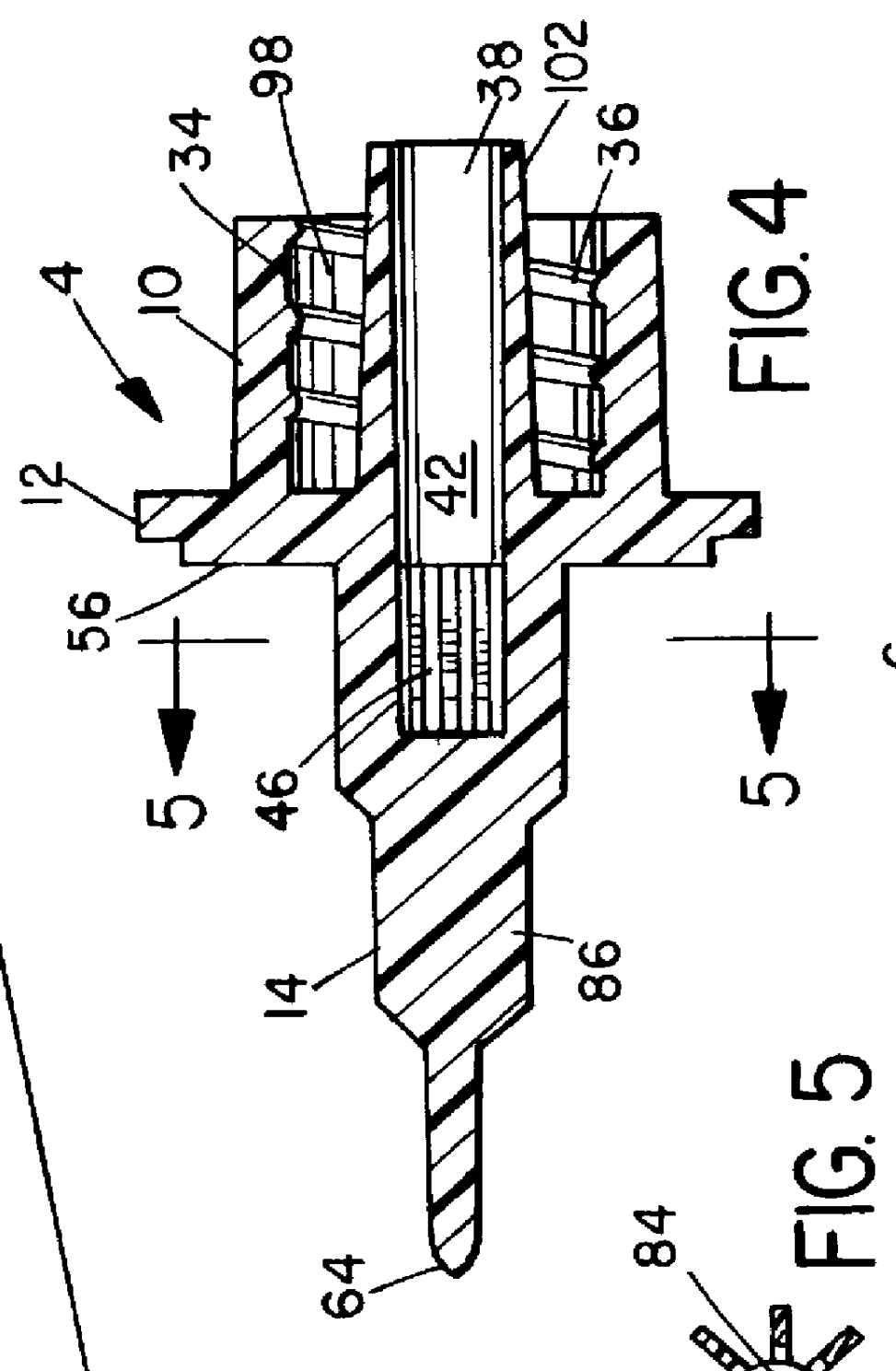

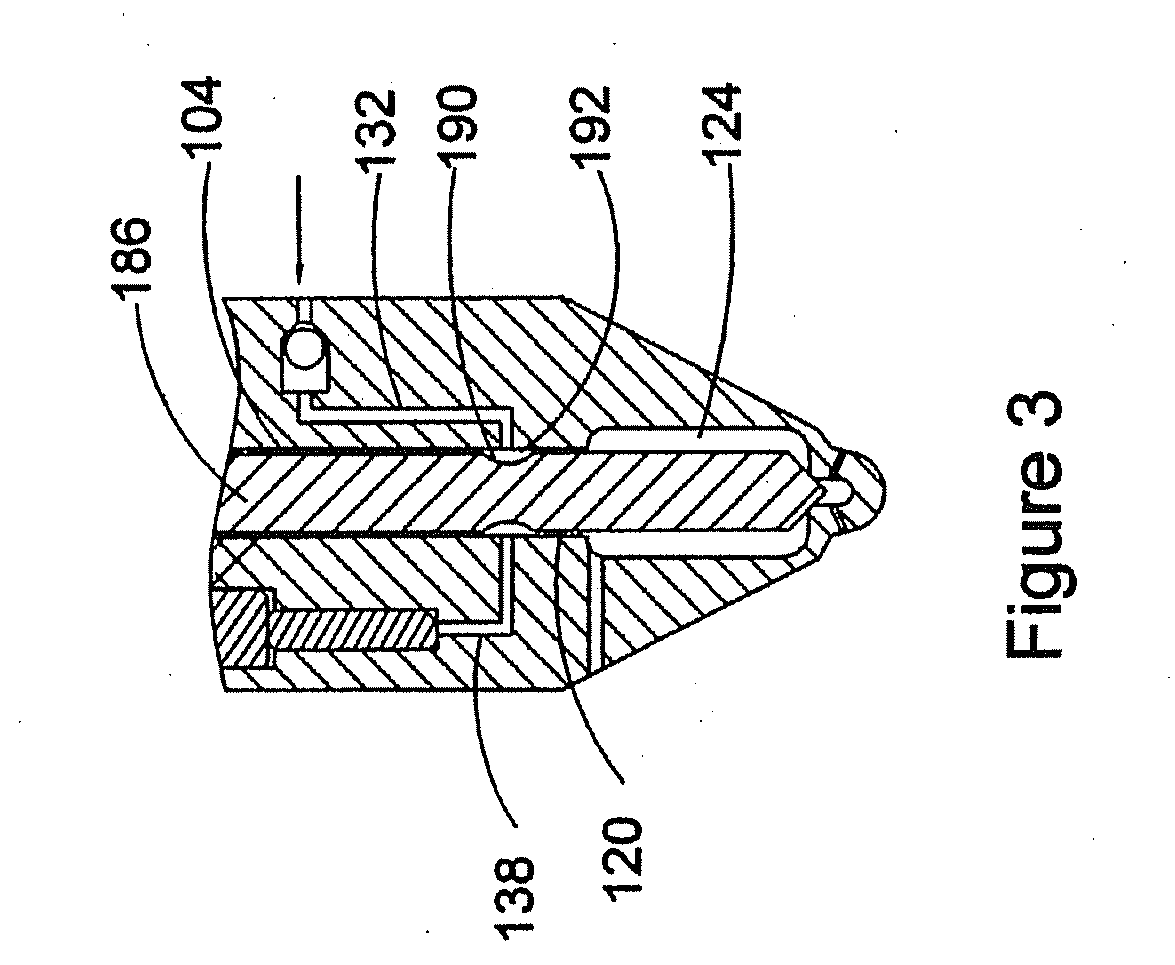

Vial adapter having a needle-free valve for use with vial closures of different sizes

A vial adapter having a needle-free valve, a sharpened cannula used to perforate a vial's rubber stopper, and a circular array of claws of different lengths to engage vial closures of different diameters. The array of claws includes a first set of claws each having a first length extending inwardly from the periphery of the housing of the adapter and a second set of claws alternating with the first set of claws and each having a longer length. The second set of claws are mounted so that they deflect and plastically deform out of the way in the case where the adapter is engaged with a vial that exceeds a predetermined size. The housing includes a shroud that is at least as long as the sharpened cannula to protect medical personnel who use the adapter from inadvertent punctures. The needle-free valve includes a resiliently deformable piston element with a naturally open bore. The interior of the piston provides a fluid flow path through the adapter. In one embodiment, the first set of claws of the adapter may be used with a vial closure of at approximately 20 mm in diameter and the second set of claws may be used with a vial closure of approximately 13 to 17 mm in diameter.

Owner:CAREFUSION 303 INC

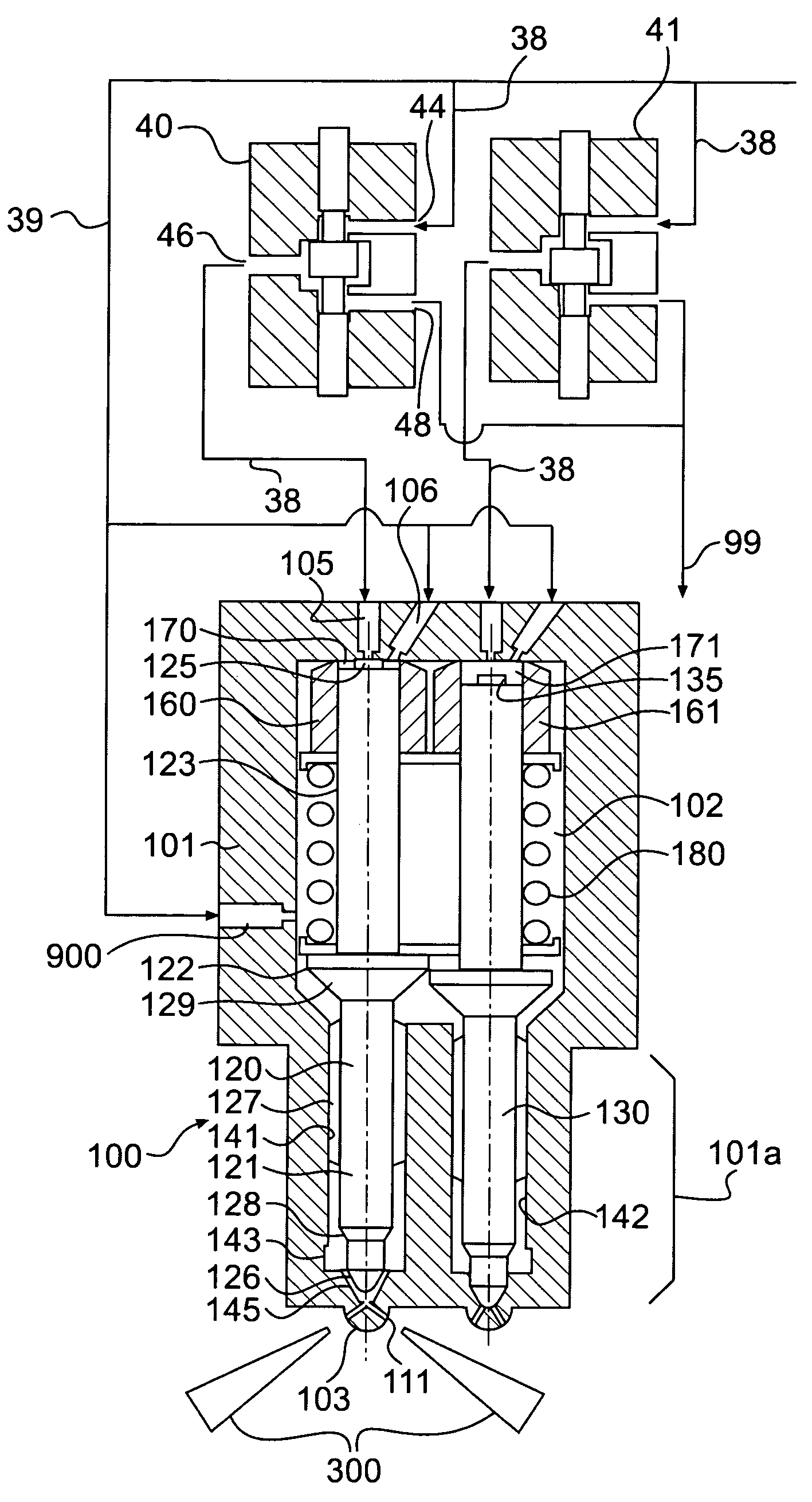

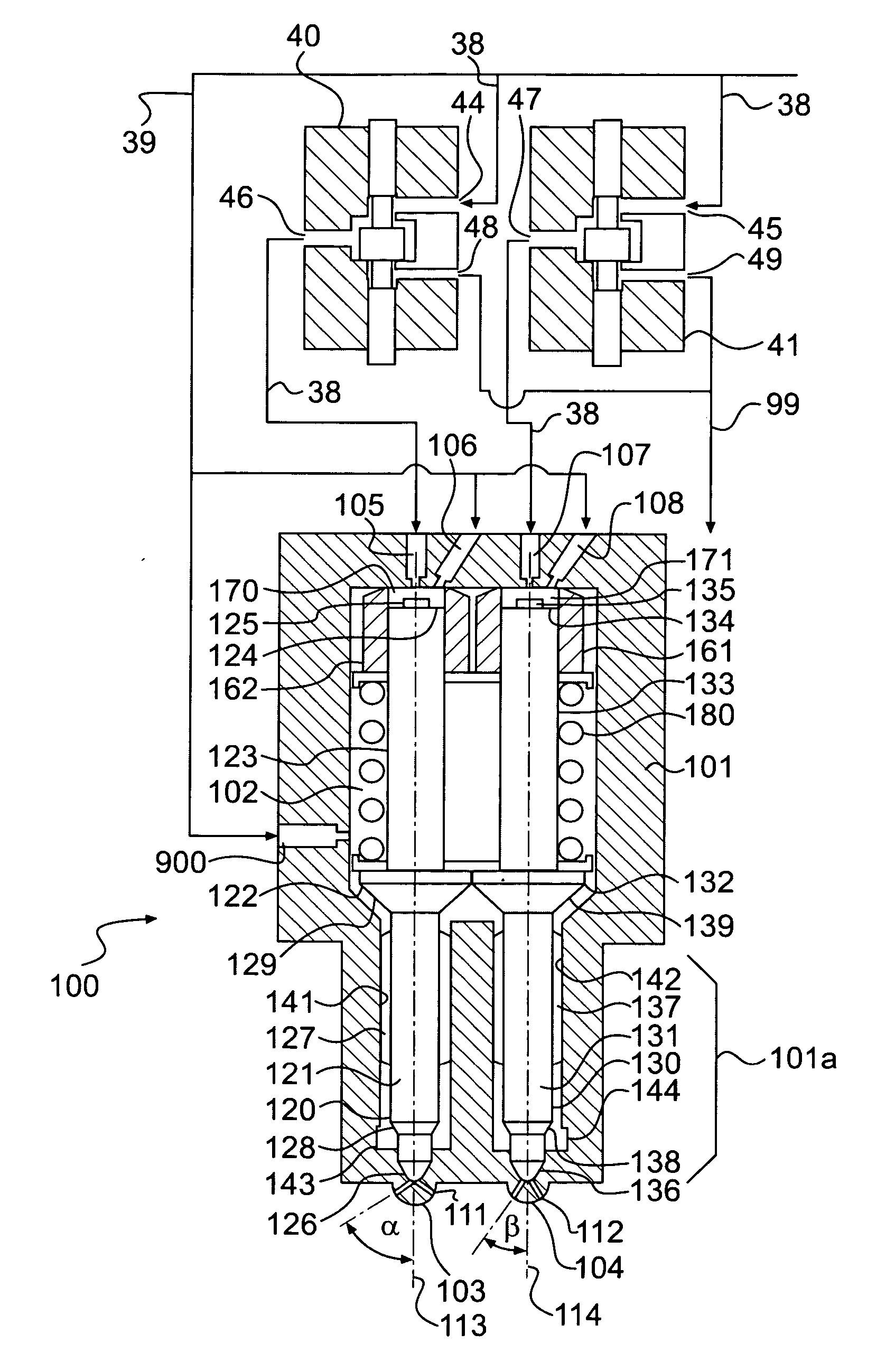

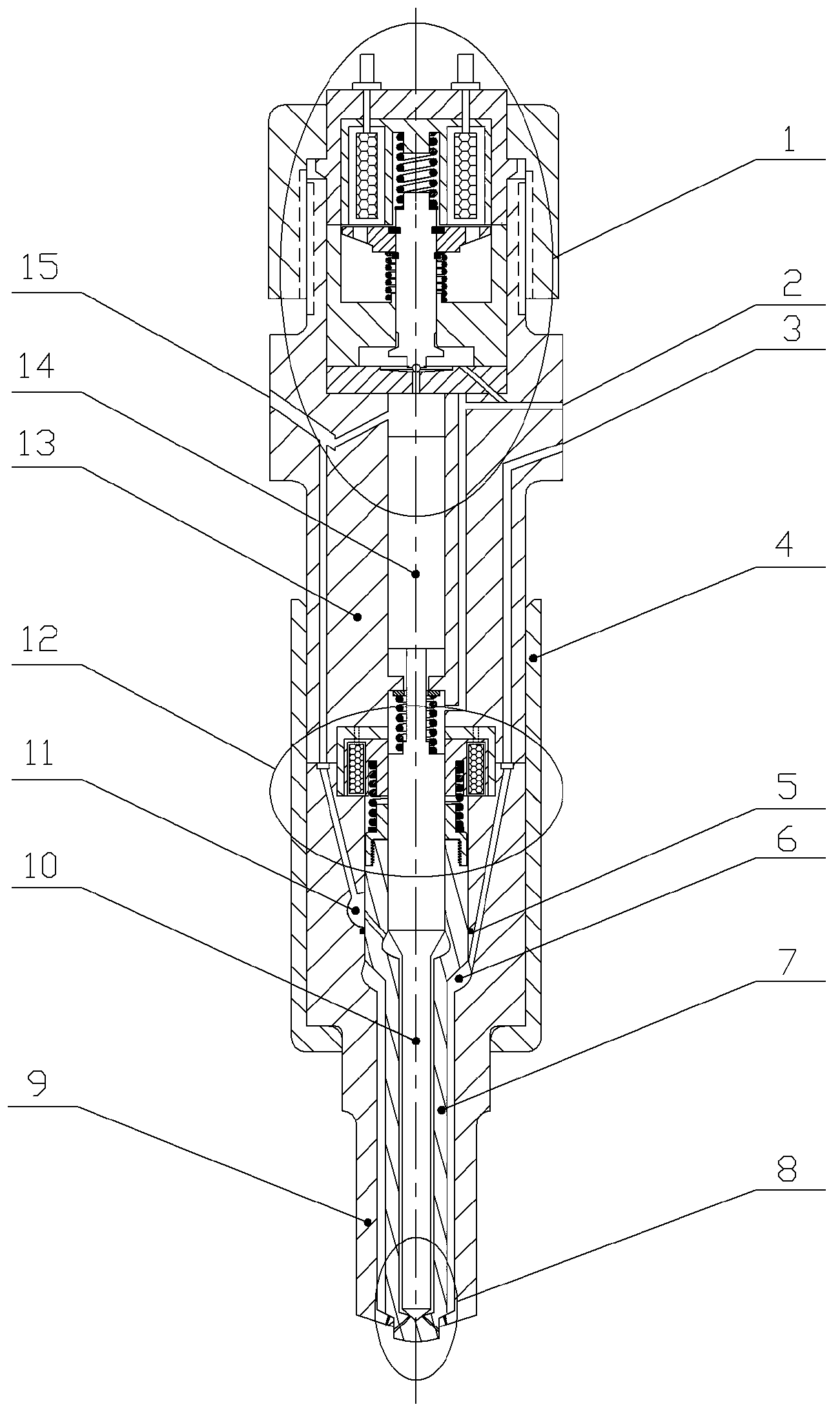

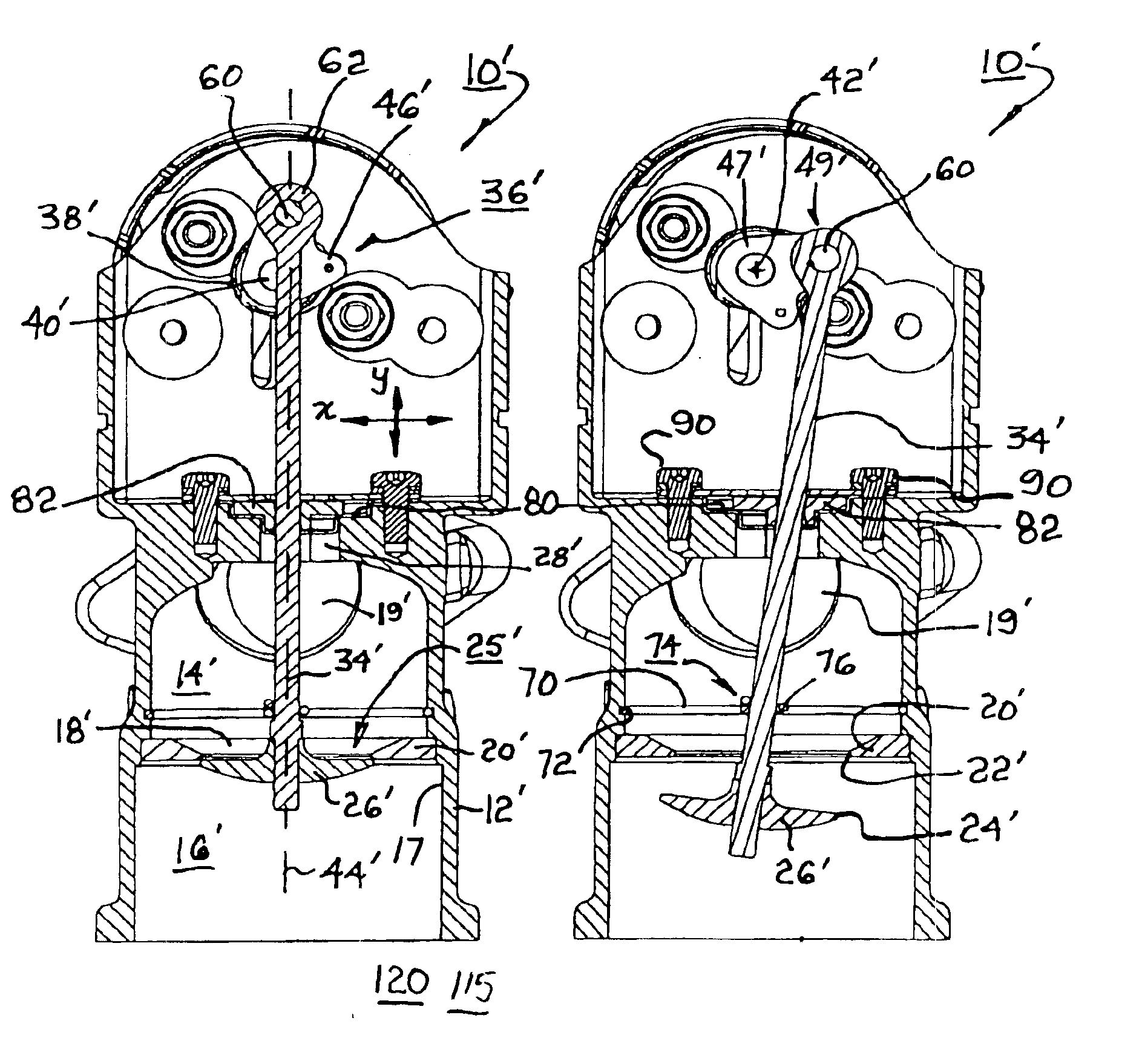

Twin needle valve dual mode injector

A fuel injector having an injector body defining a hollow interior configured to receive pressurized fuel, a first nozzle configured for providing a first fuel spray pattern, and a second nozzle configured for providing a second fuel spray pattern different from the first fuel spray pattern. The first and second nozzles may be configured to inject fuel supplied from a common source into a combustion space. The fuel injector may further include first and second needle valve members corresponding to the first and second nozzles, respectively. The first and second needle valve members may be positioned within the hollow interior of the injector body, with the second needle valve member being spaced from, but adjacent to the first needle valve member.

Owner:CATERPILLAR INC

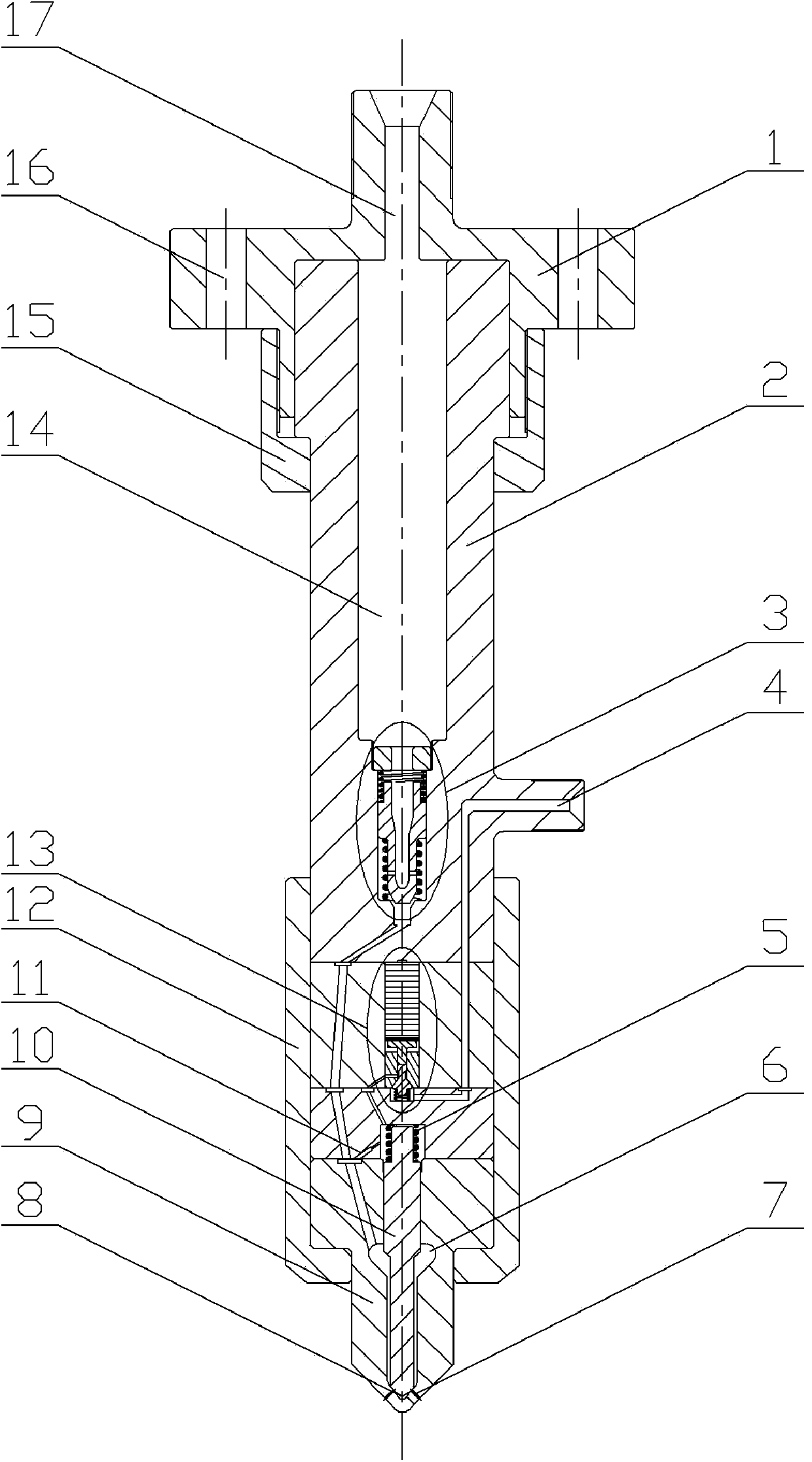

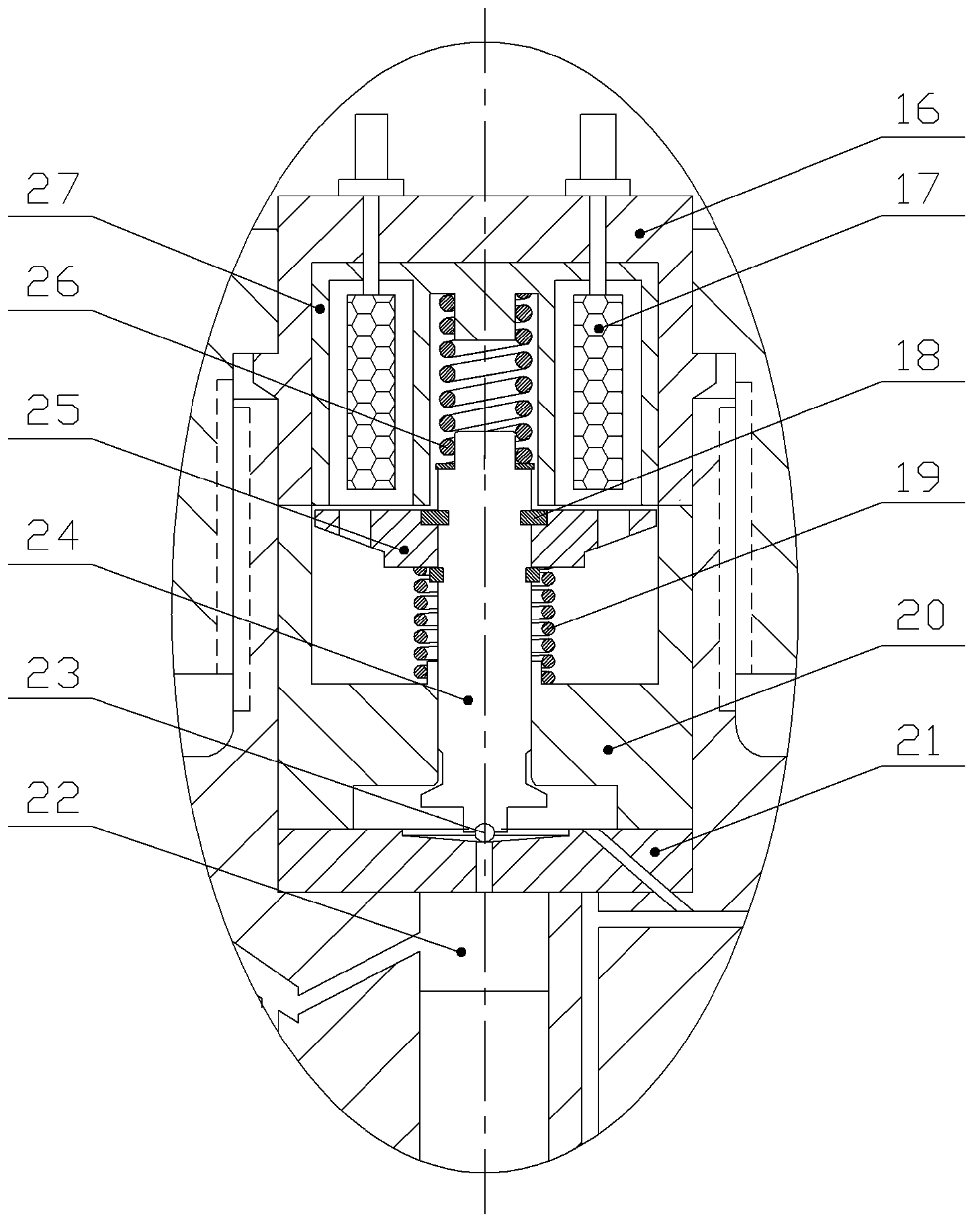

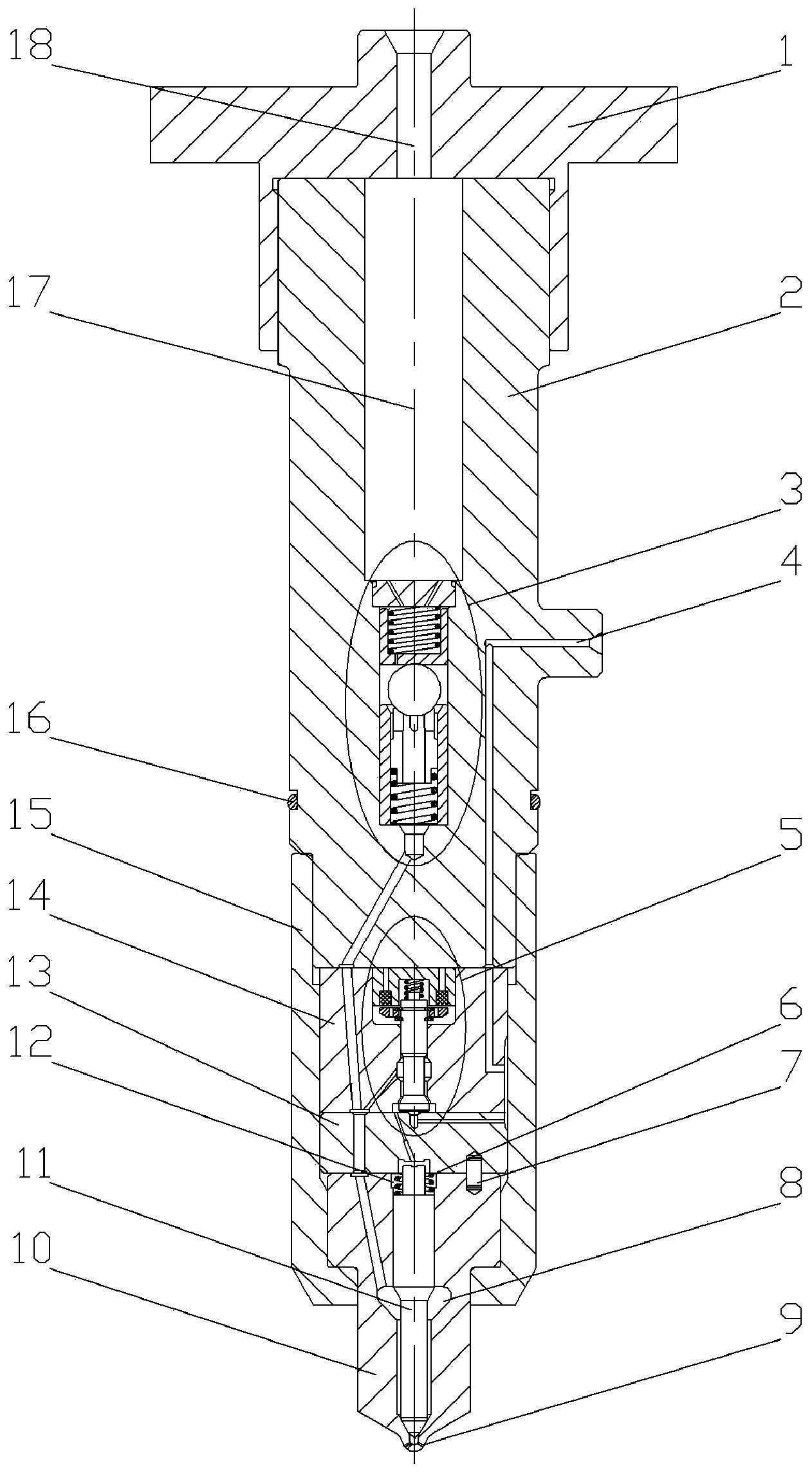

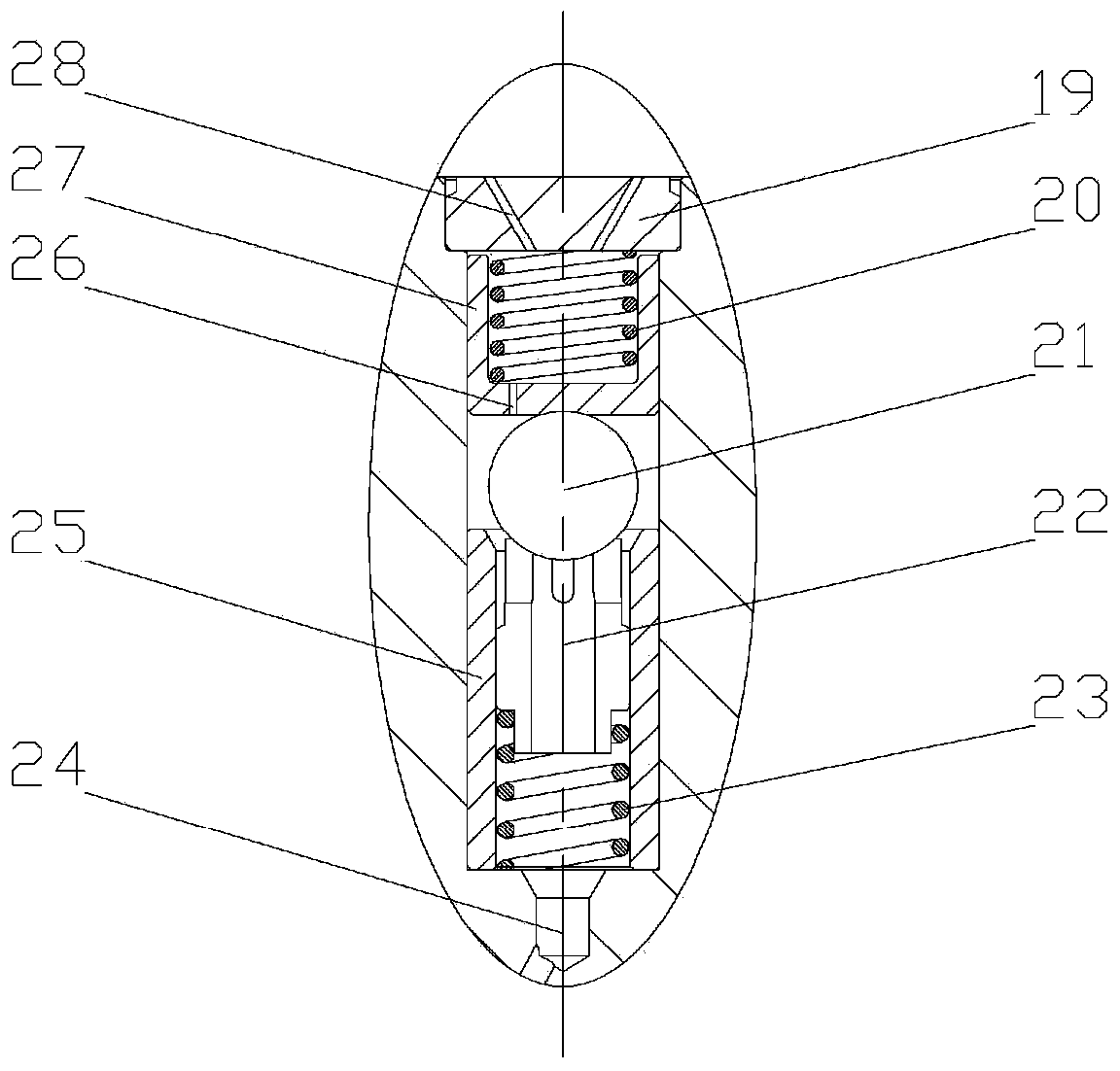

Piezoelectric control pressure accumulation and stabilization oil sprayer

ActiveCN104018969APrevent abnormal continuous fuel injectionImprove fuel injection stabilityFuel injection apparatusMachines/enginesNeedle valveElectricity

The invention provides a piezoelectric control pressure accumulation and stabilization oil sprayer which comprises an oil sprayer head, an oil sprayer body, a flow limiting component, a needle valve reset spring, a nozzle, a needle valve, a tightening cap, a piezoelectric control component and a locking sleeve. The flow limiting component structure is adopted, the situation that the economical efficiency of fuel oil is reduced due to the fact that the oil sprayer sprays oil abnormally and continuously can be effectively avoided, and work reliability of the oil sprayer is guaranteed. Pressure fluctuation caused in the fuel oil spraying process can be reduced through a pressure accumulation cavity in the oil sprayer body, and oil spraying stability can be controlled precisely. When the oil sprayer is used for a common-rail fuel oil system, the structural size of a common-rail pipe can be reduced, and therefore the strength requirement for common-rail pipe materials is lowered, the service life of the oil sprayer can be prolonged, and the space utilization rate of the oil sprayer can be improved. The needle valve is directly driven by a piezoelectric stack in the movement process, and is high in response speed, the control freedom degree is large, the oil spraying rule is flexible and variable, the dynamic property and economical efficiency of a diesel engine are effectively improved, and the diesel engine can meet the stricter emission regulation.

Owner:无锡格迪斯机械制造有限公司

Twin needle valve dual mode injector

A fuel injector having an injector body defining a hollow interior configured to receive pressurized fuel, a first nozzle configured for providing a first fuel spray pattern, and a second nozzle configured for providing a second fuel spray pattern different from the first fuel spray pattern. The first and second nozzles may be configured to inject fuel supplied from a common source into a combustion space. The fuel injector may further include first and second needle valve members corresponding to the first and second nozzles, respectively. The first and second needle valve members may be positioned within the hollow interior of the injector body, with the second needle valve member being spaced from, but adjacent to the first needle valve member.

Owner:CATERPILLAR INC

3D printing device and 3D printing method by utilizing supercritical carbon dioxide as solvent

ActiveCN104816478AIncrease profitAvoid emissionsAdditive manufacturing apparatusGas cylinderCarbon dioxide gas cylinder E

The invention discloses a 3D printing device and a 3D printing method by utilizing supercritical carbon dioxide as a solvent. The device mainly comprises a stock unit, an ejection unit, a three-dimensional molding platform unit and a raw material recycling unit, wherein the ejection unit comprises a gas pump, a needle valve, a cooling fan and a resistive heater; the stock unit comprises high polymer material powder, a powder pump, a carbon dioxide gas cylinder, a mixing tank, a liquefied booster pump, a heater, a liquid pump and a gas pump; the three-dimensional molding platform unit comprises an aluminum alloy molding platform and a three-dimensional ball screw sliding table module; and the raw material recycling unit comprises a closed box and a recovered gas pump. According to the method disclosed by the invention, the carbon dioxide gas is turned to be in a supercritical carbon dioxide state, and after the carbon dioxide gas is completely dissolved to produce supercritical carbon dioxide solution containing a high polymer material, the solution is conveyed into the ejection unit by virtue of the liquid pump. The supercritical carbon dioxide serves as a consumable carrier, so that more kinds of high polymer materials are applied to the field of 3D printing, and the overall performances of 3D printing supplies are improved.

Owner:BEIJING UNIV OF CHEM TECH

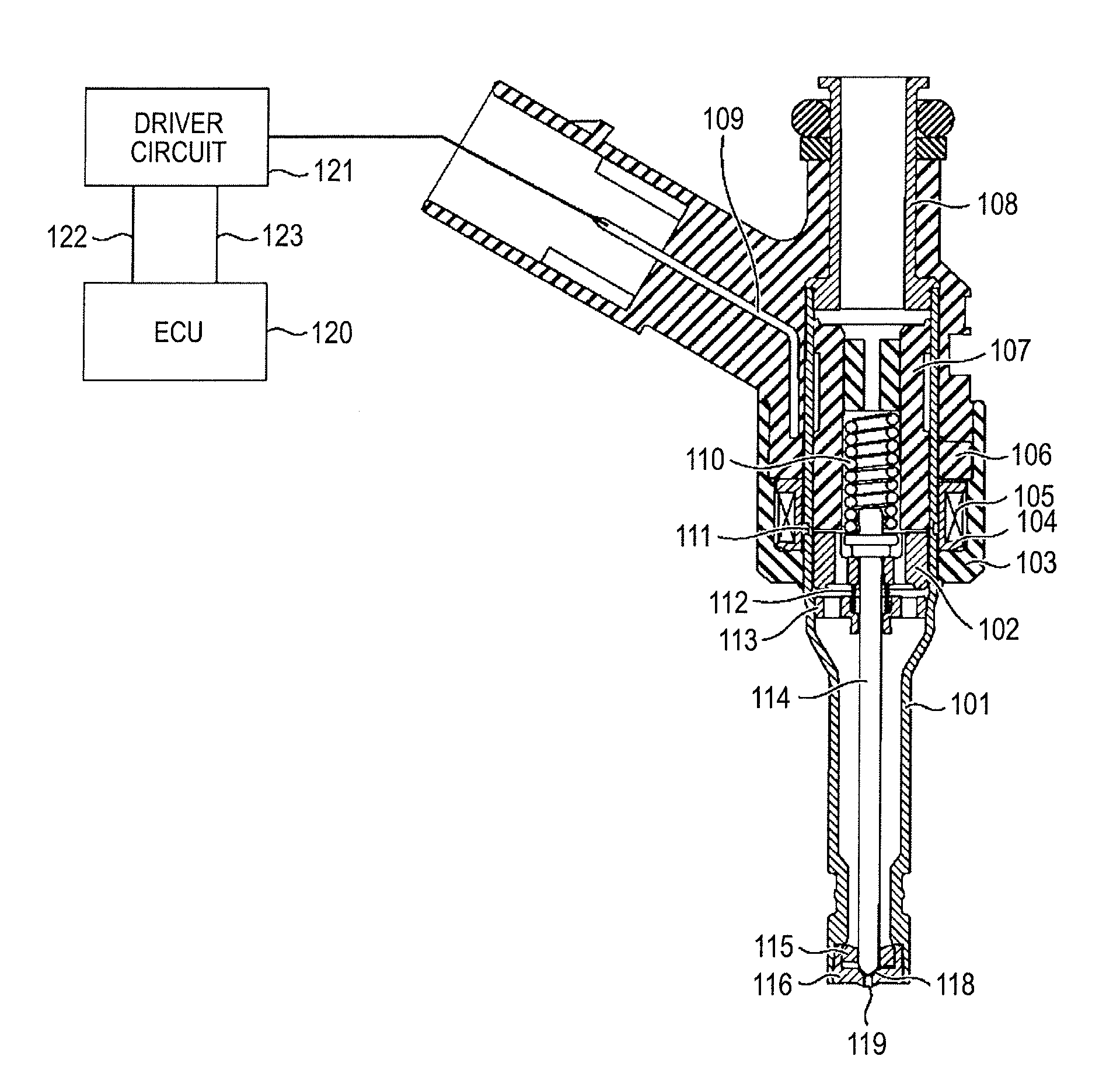

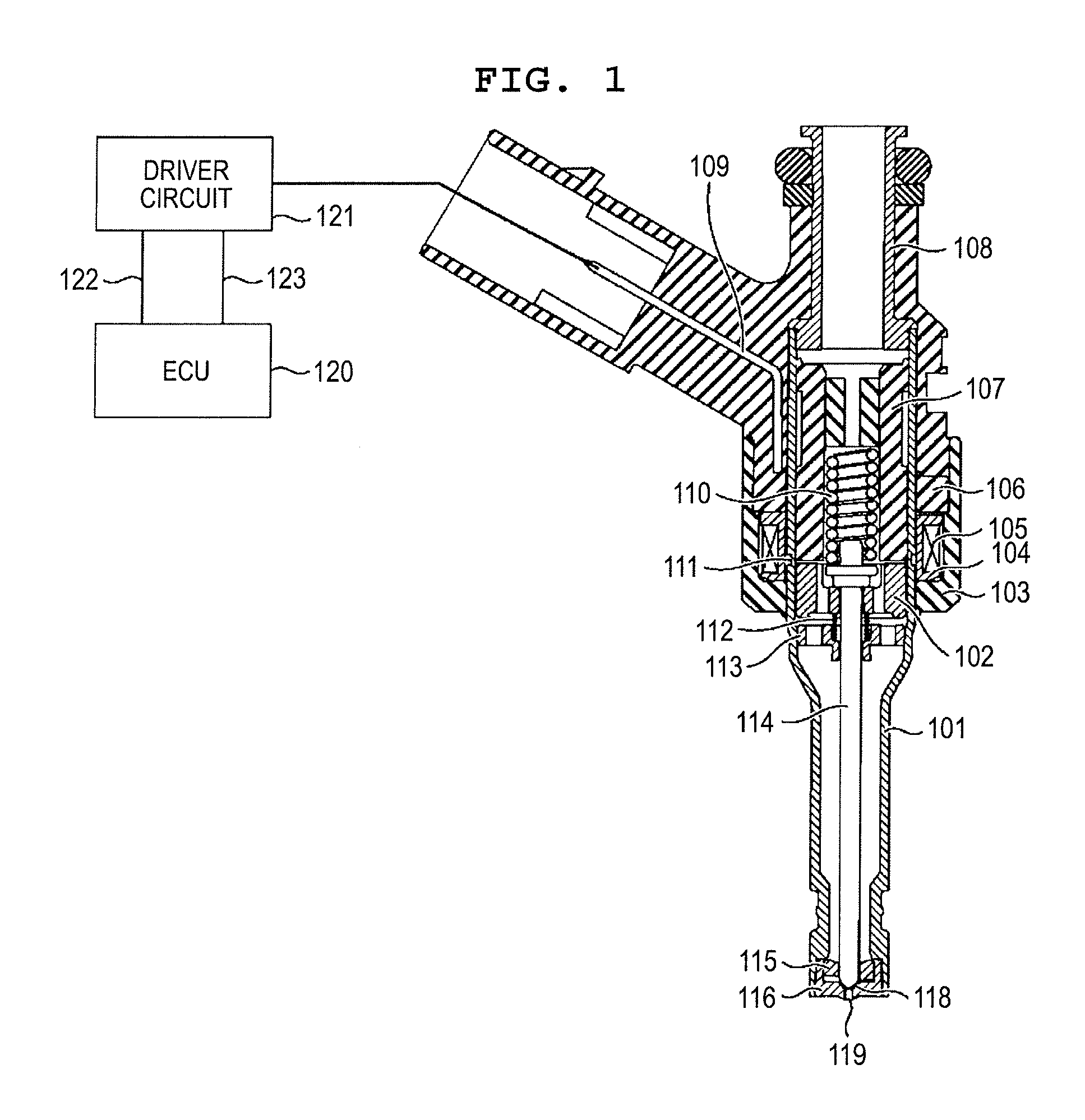

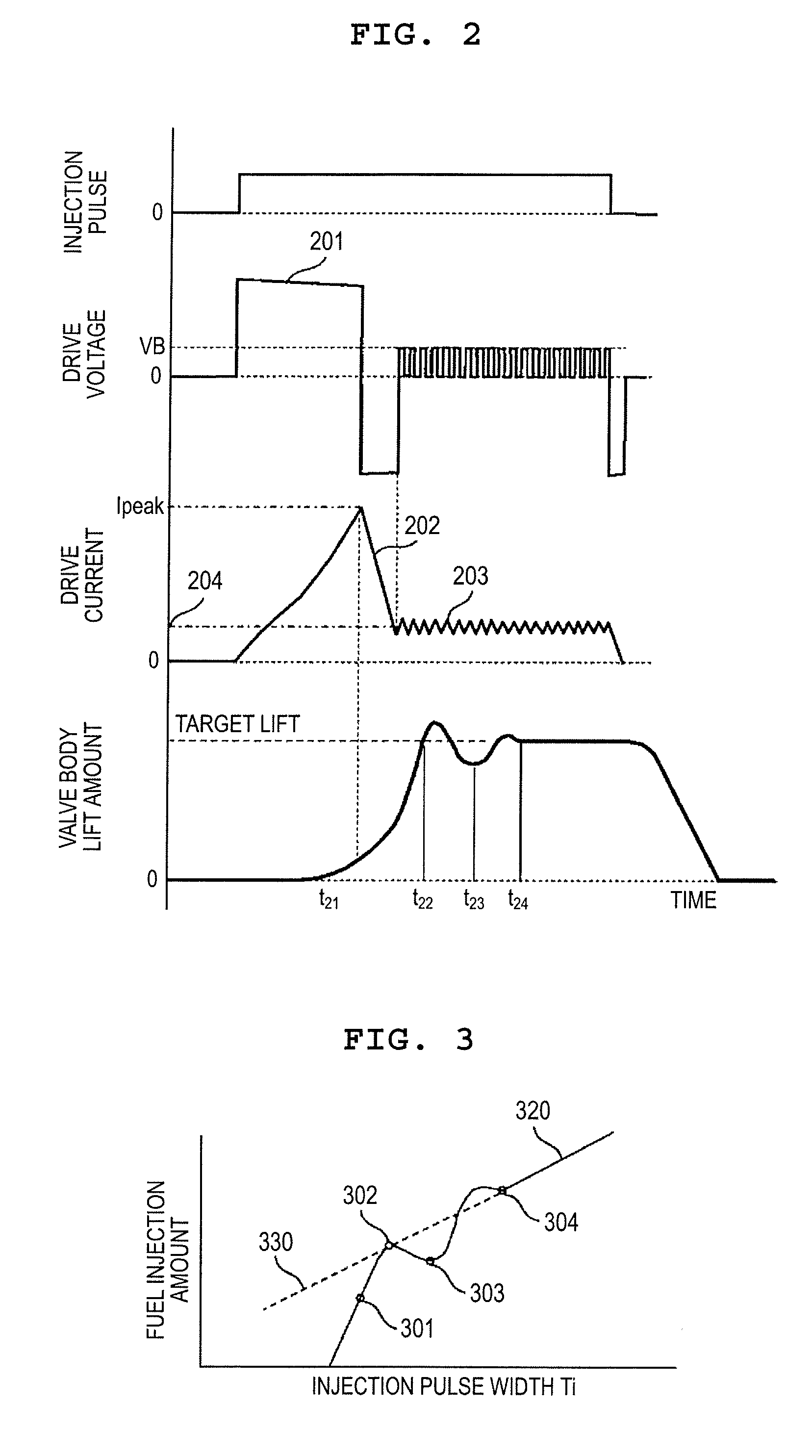

Fuel Injection Device

ActiveUS20120318883A1Low costReduces controllable amountElectrical controlWatering devicesExternal combustion engineEngineering

A method of controlling a fuel injection device that can control a small amount of injection is provided. A fuel injection device for use in an internal combustion engine, includes: a valve body that can open and close a fuel passage, a needle that transfers a force with the valve body, and executes valve opening / closing operation, and an electromagnet that includes a coil and a magnetic core provided as a driver for driving the needle, and a cylindrical nozzle holder disposed on an outer periphery of the magnetic core and the needle, in which a current is supplied to the coil to exert a magnetic attractive force between the magnetic core and the needle to open the valve body.

Owner:HITACHI ASTEMO LTD

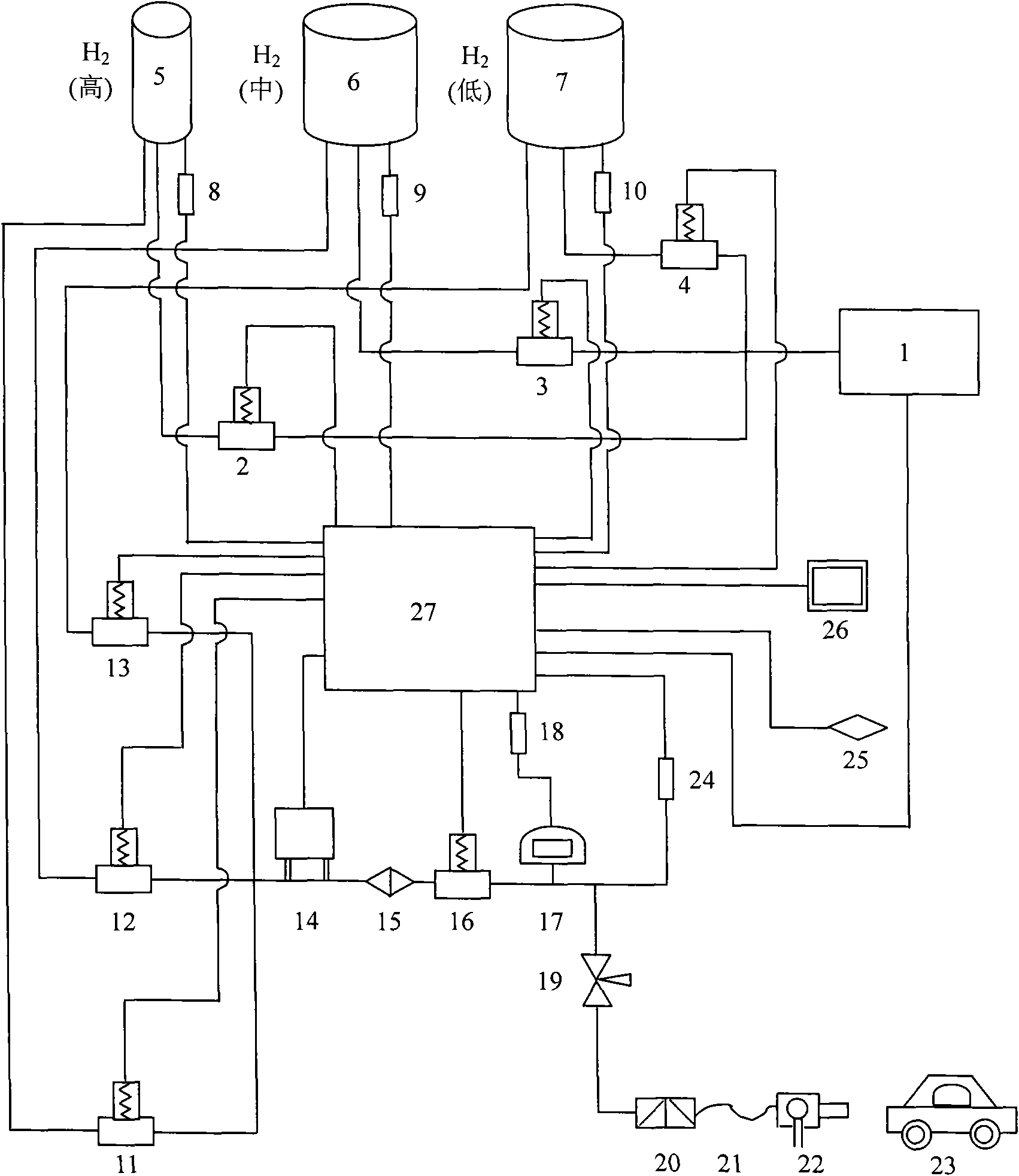

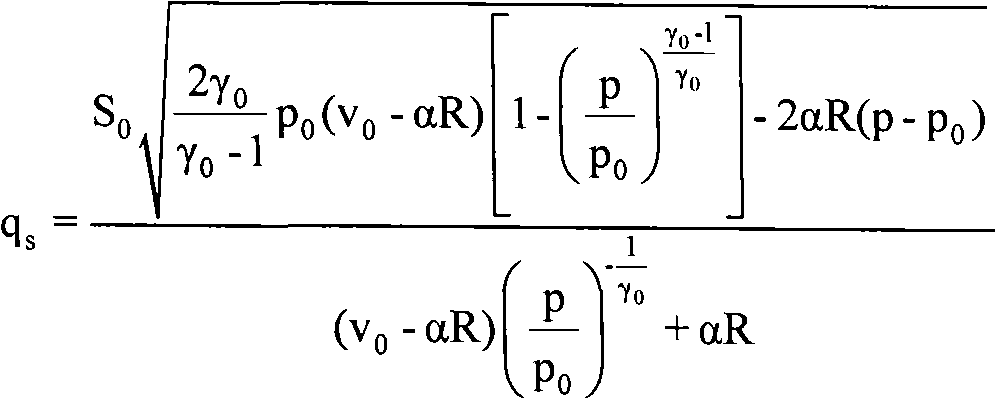

Hydrogen refueling station hydrogen optimizing filling method based on temperature rise and energy consumption control and system thereof

ActiveCN101832467AReduce energy consumptionLow energy operationContainer discharging methodsContainer filling under pressureNew energyProgrammable logic controller

The invention relates to the field of renewable, clean and environment-friendly new energy, aiming at providing a hydrogen refueling station hydrogen optimizing filling method based on temperature rise and energy consumption control and a system thereof. The method comprises the steps of: establishing a database arranged inside a programmable logic controller (PLC), and using the database to record the corresponding relationship between the corresponding filling initial condition and the opening value of a needle valve; according to the filling initial condition, using the PLC to inquire the opening value of the needle valve when hydrogen storage tanks with different pressure levels are used for taking gas; and according to the data inquired by the PLC, arranging the needle valve at the corresponding demarcated position, and carrying out the filling operation. The invention can run at the lower power consumption of a cooling device, ensures the temperature of a vehicle hydrogen storage container to be strictly controlled within the required range, and remarkably shortens the filling time, thus leading the whole system to effectively, safely and reliably fill high pressure hydrogen, and having the advantages of high gas taking efficiency, low power consumption and the like.

Owner:ZHEJIANG UNIV

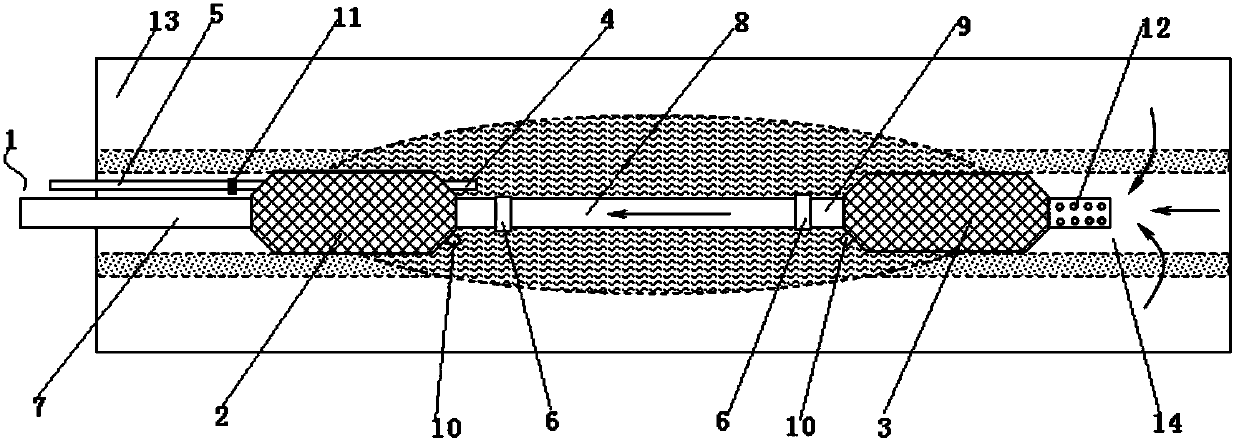

Under-pressure grouting hole sealing device and method for gas extraction drill air bag blocking

The invention relates to an under-pressure grouting and hole sealing device and method for gas extraction drill air bag blocking. The device is characterized in that the device comprises an extraction pipe, a first tip air bag, a second tip air bag, a slurry outlet pipe and a grouting pipe, wherein the extraction pipe is composed of a first extraction pipe body, a second extraction pipe body and a third extraction pipe body, the first extraction pipe body is sleeved with the first tip air bag, a one-way needle valve is arranged on the first tip air bag, the slurry outlet pipe with a one-way check valve arranged inside penetrates through the first tip air bag, the outer end of the slurry outlet pipe is communicated with the grouting pipe, the third extraction pipe body is sleeved with the second tip air bag, a one-way needle valve is arranged on the second tip air bag, the two ends of the second extraction pipe body are connected with one end of the first extraction pipe body and one end of the third extraction pipe body respectively, the tip of the other end of the third extraction pipe body is provided with a plurality of sieve holes which allow gas to inflow, and the first tip air bag and the second tip air bag are filled with expansion agents in advance. The device and the method can be widely applied to permanent hole sealing for coal mine underground gas extraction hole drilling.

Owner:NORTH CHINA INST OF SCI & TECH

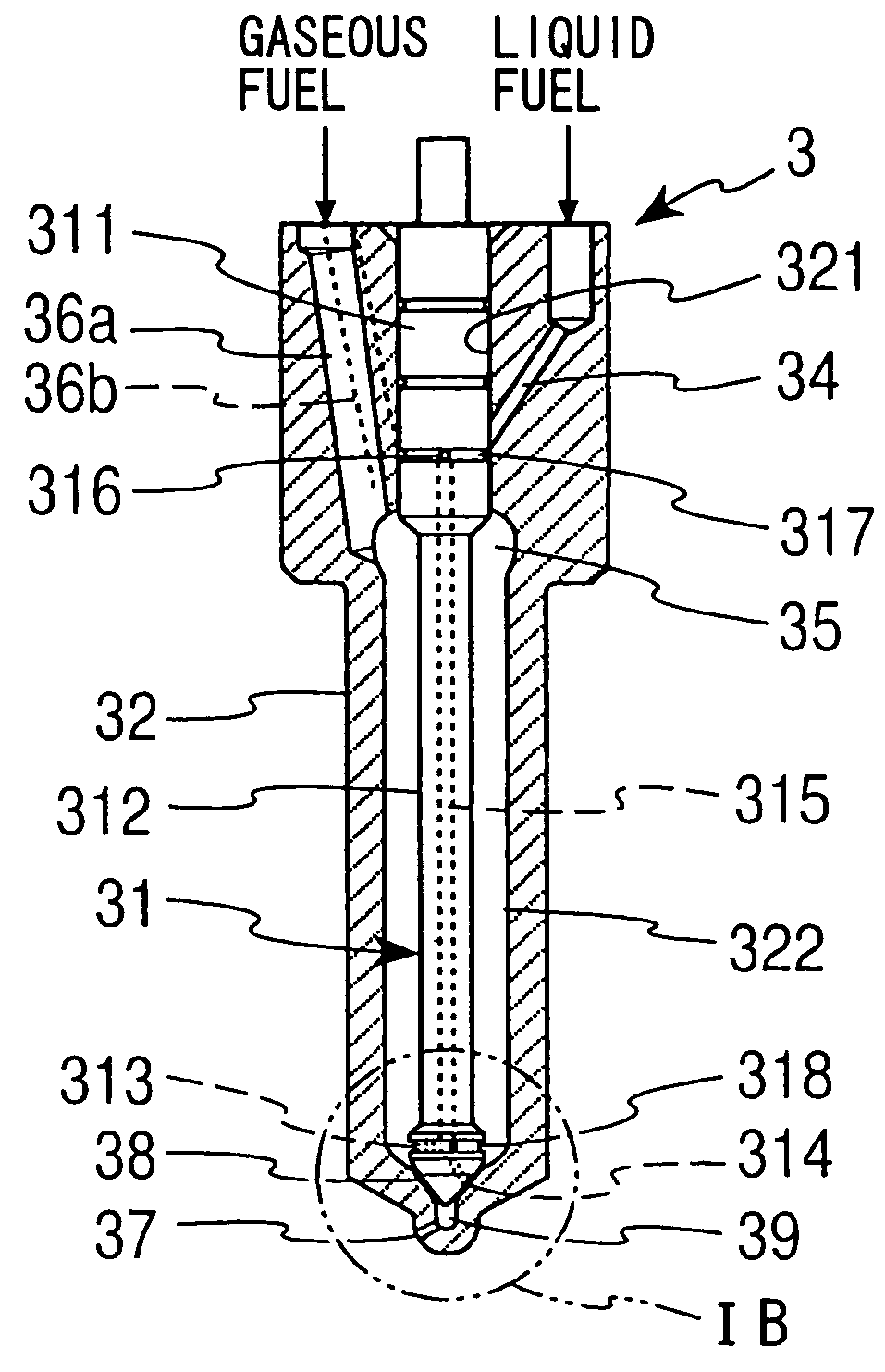

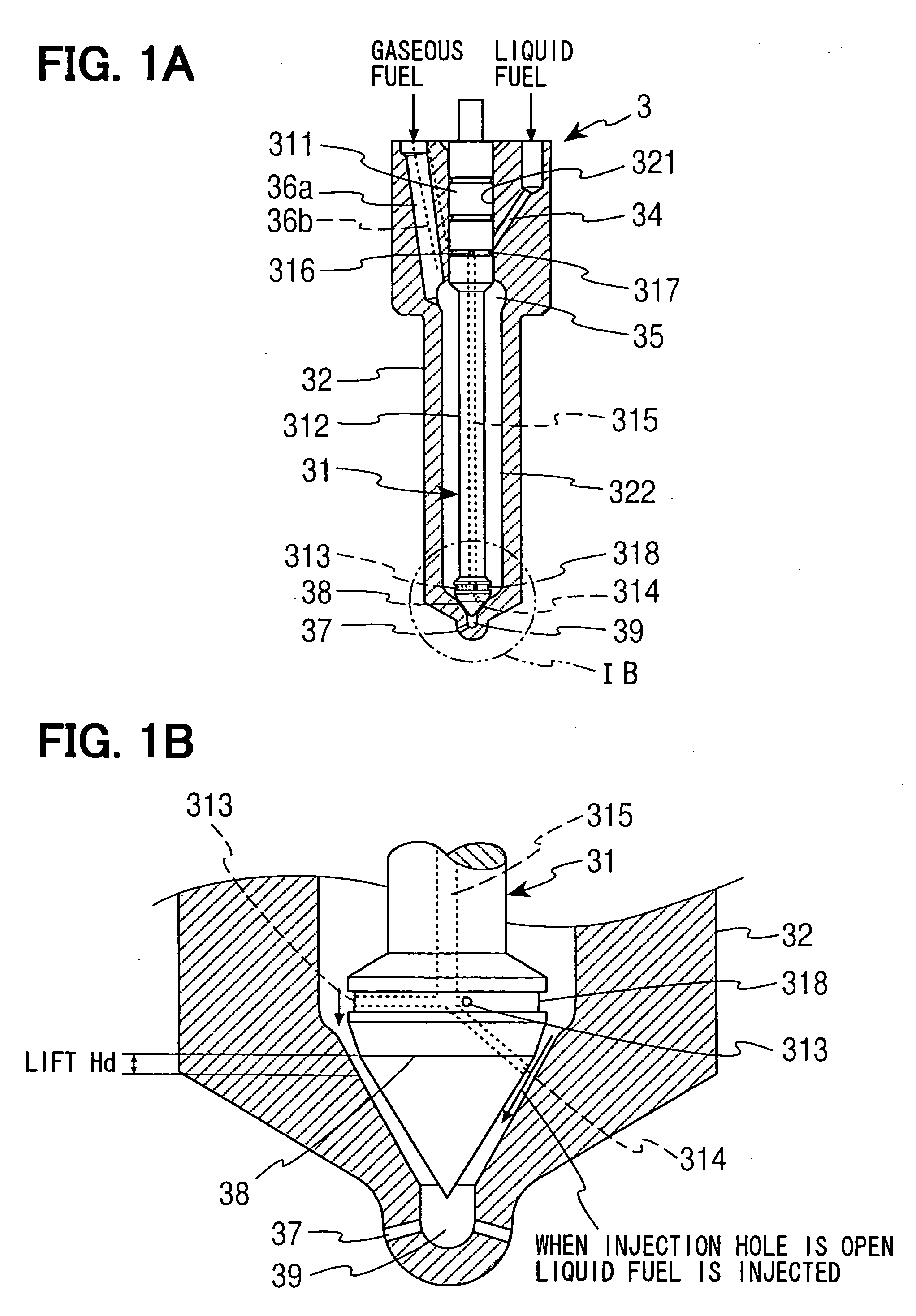

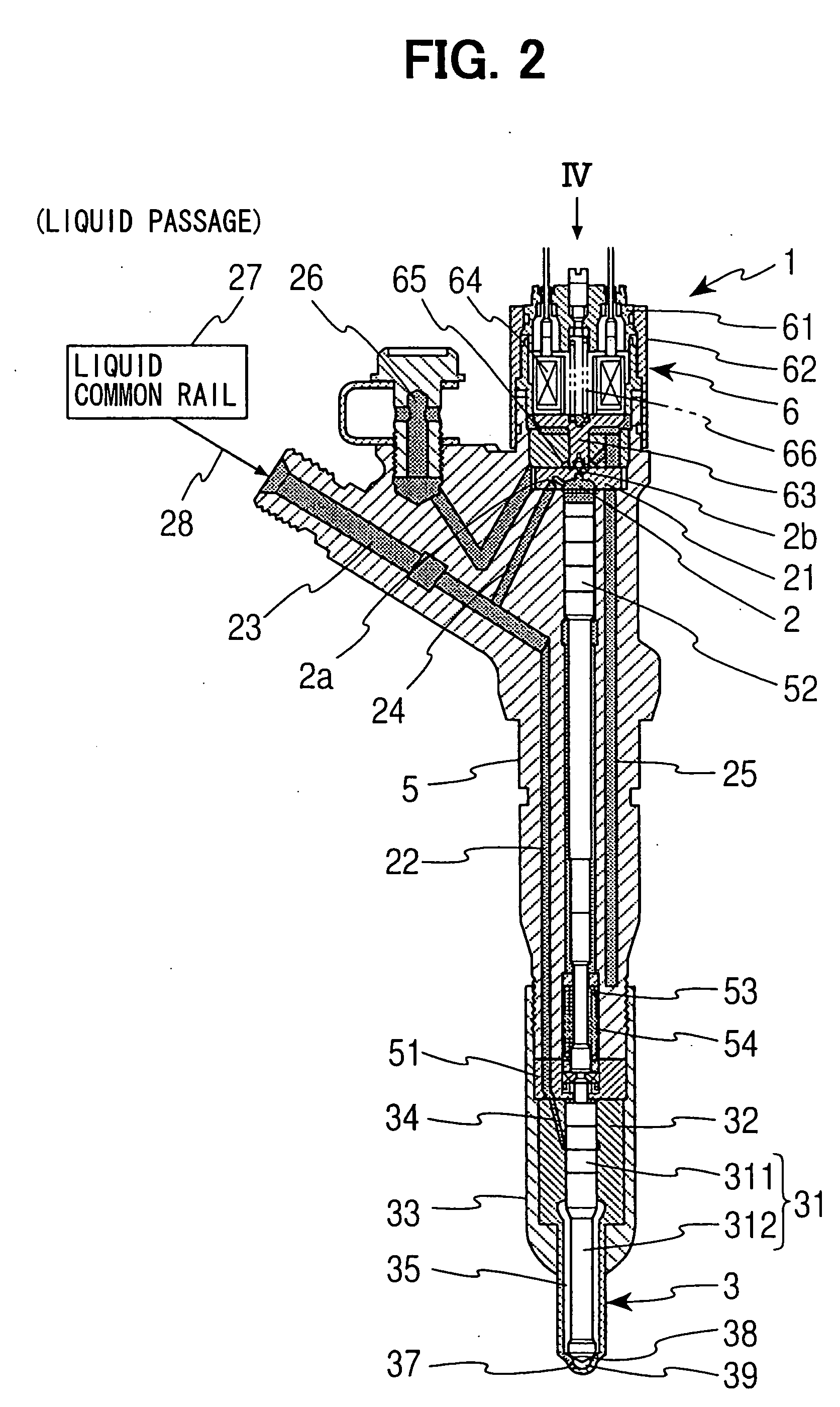

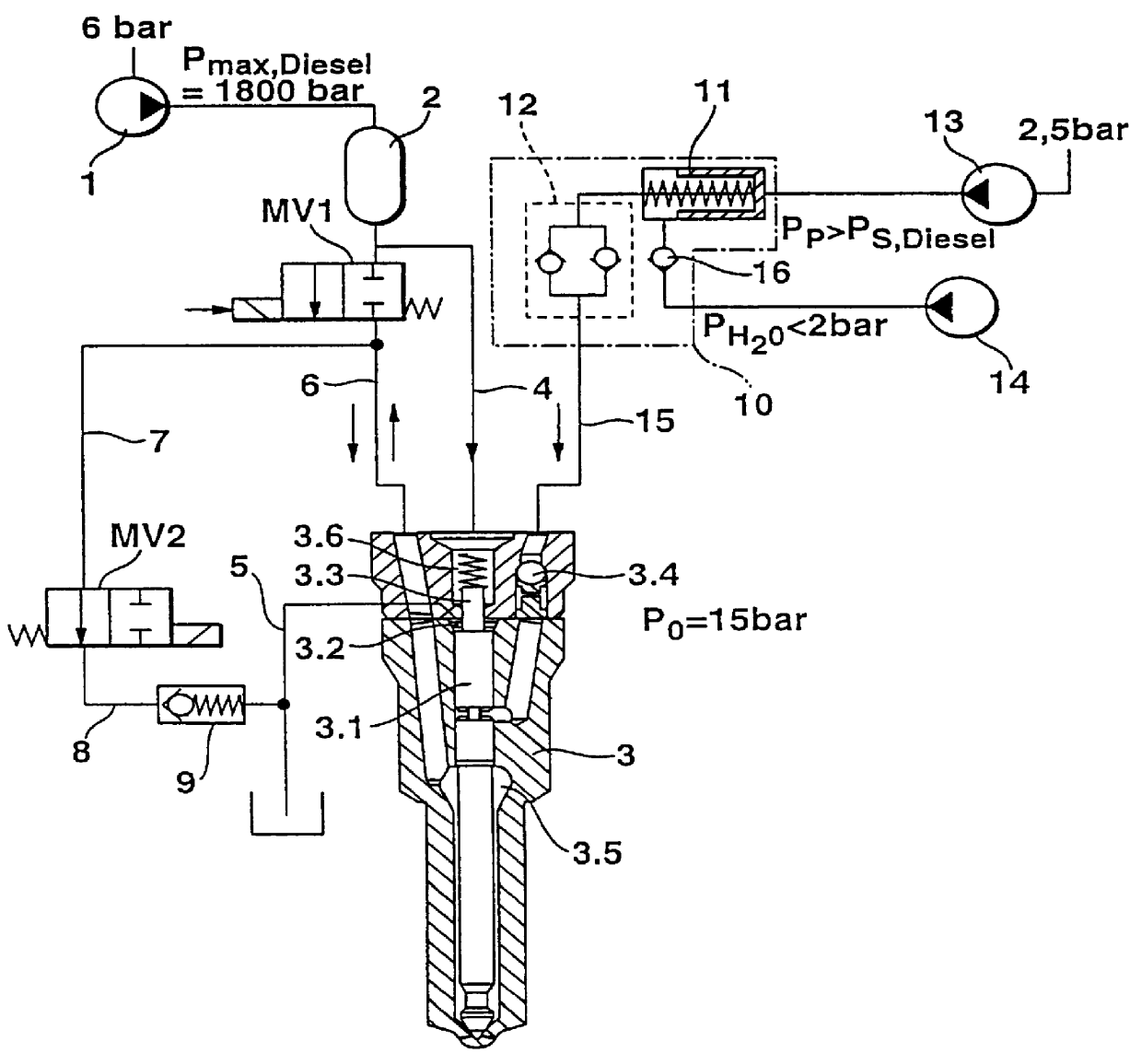

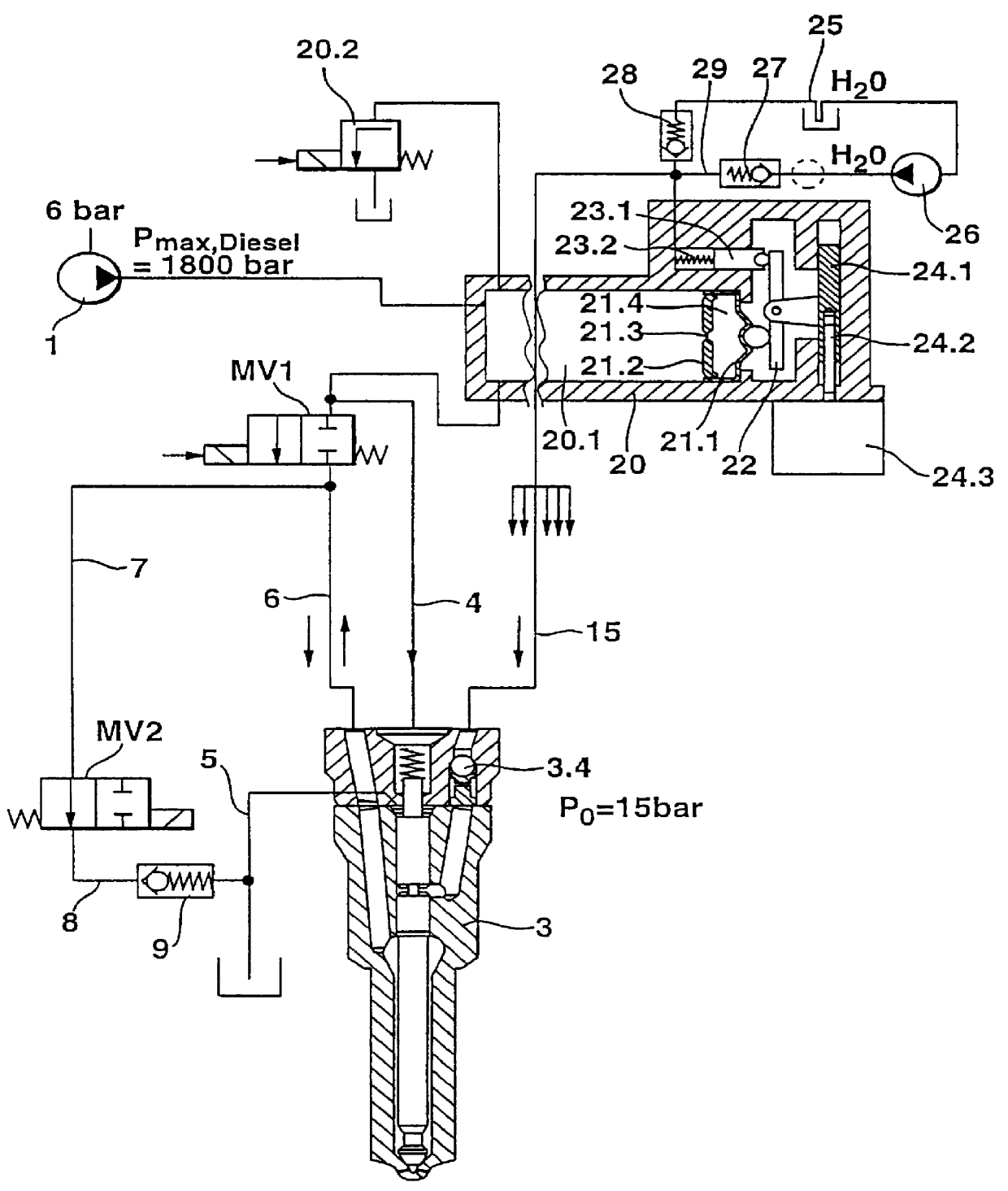

Fuel Injection Valve And Method For Co-Injecting A Liquid And A Gaseous Fuel Into The Combustion Chamber Of An Internal Combustion Engine

ActiveUS20110108631A1Prevent escapeInternal combustion piston enginesFuel supply apparatusIntensifierEngineering

A fuel injection valve co-injects a liquid and a gaseous fuel into the combustion chamber of an internal combustion engine. A solid needle regulates the injection of liquid and gaseous fuels from a cavity in the fuel injection valve into the combustion chamber when the needle is lifted to its open position. In preferred embodiments, liquid fuel is metered and pressurized in an intensifier's cylinder provided within the valve body and the liquid fuel is delivered through a restricted flow passage into the cavity where it mixes with the gaseous fuel. The restricted flow passage can be formed by a small passage formed in the valve body or an annular passage between the needle and the valve body.

Owner:WESTPORT FUEL SYST CANADA INC

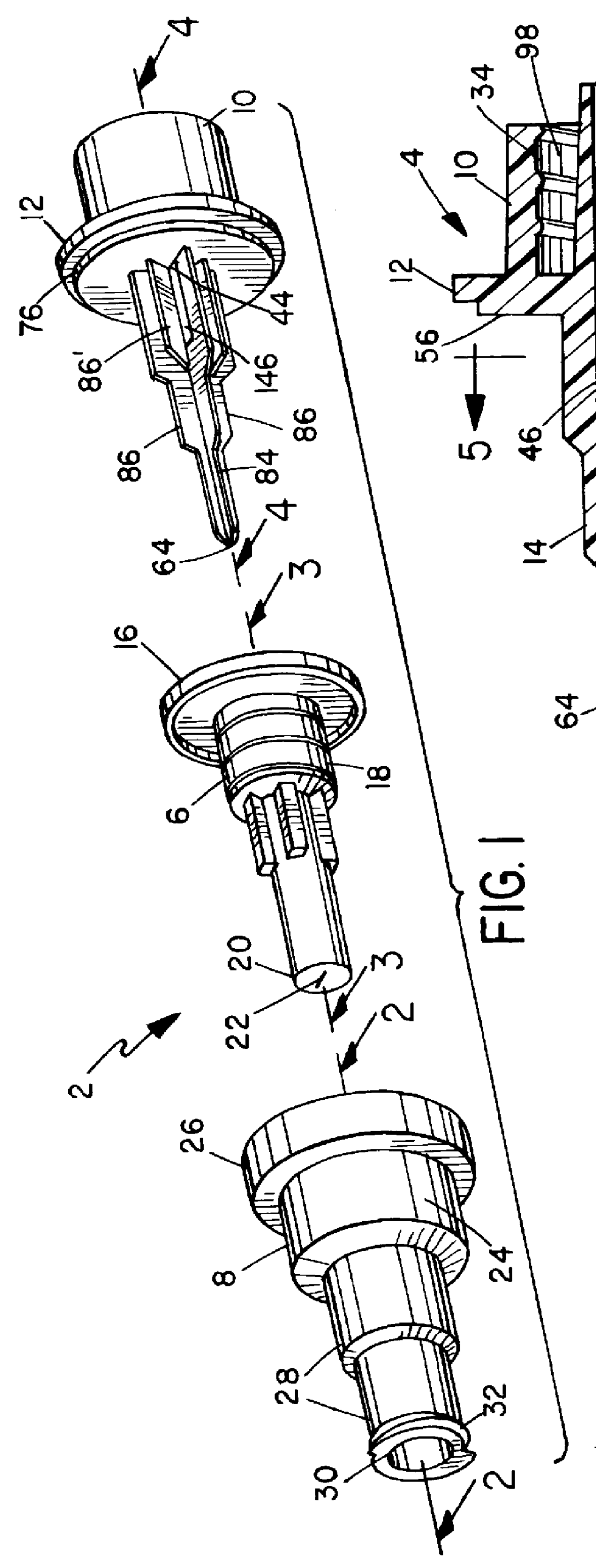

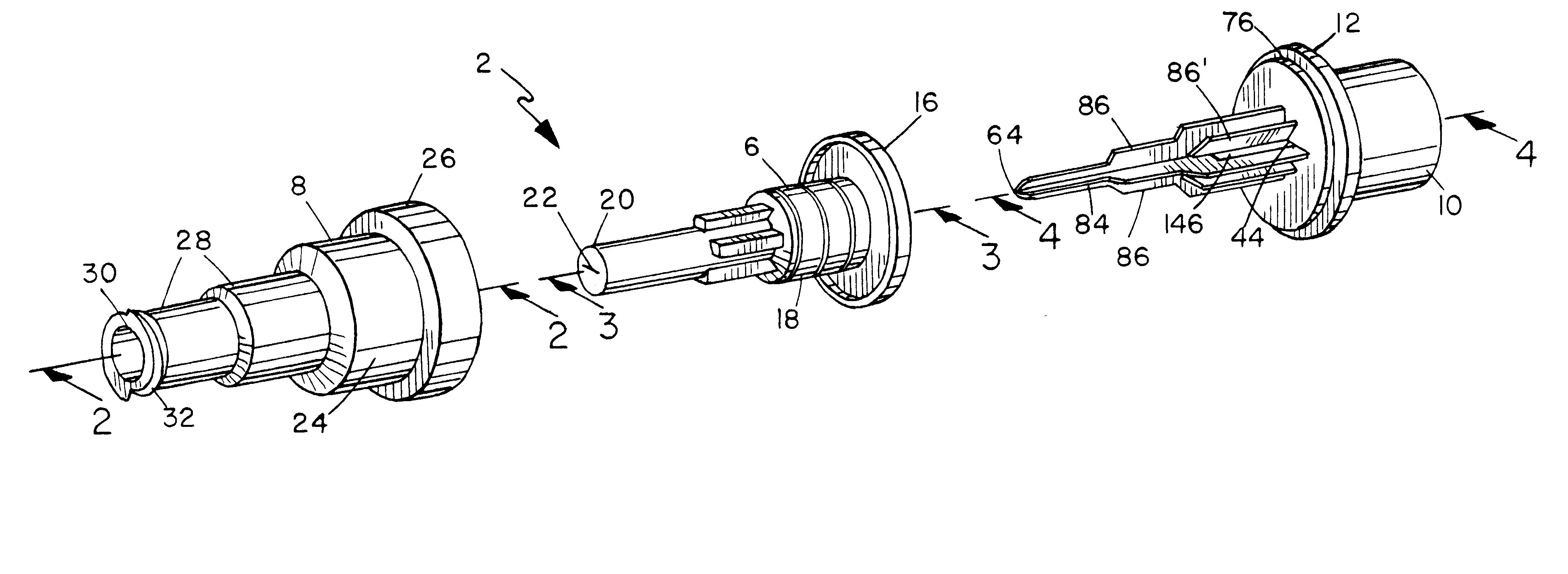

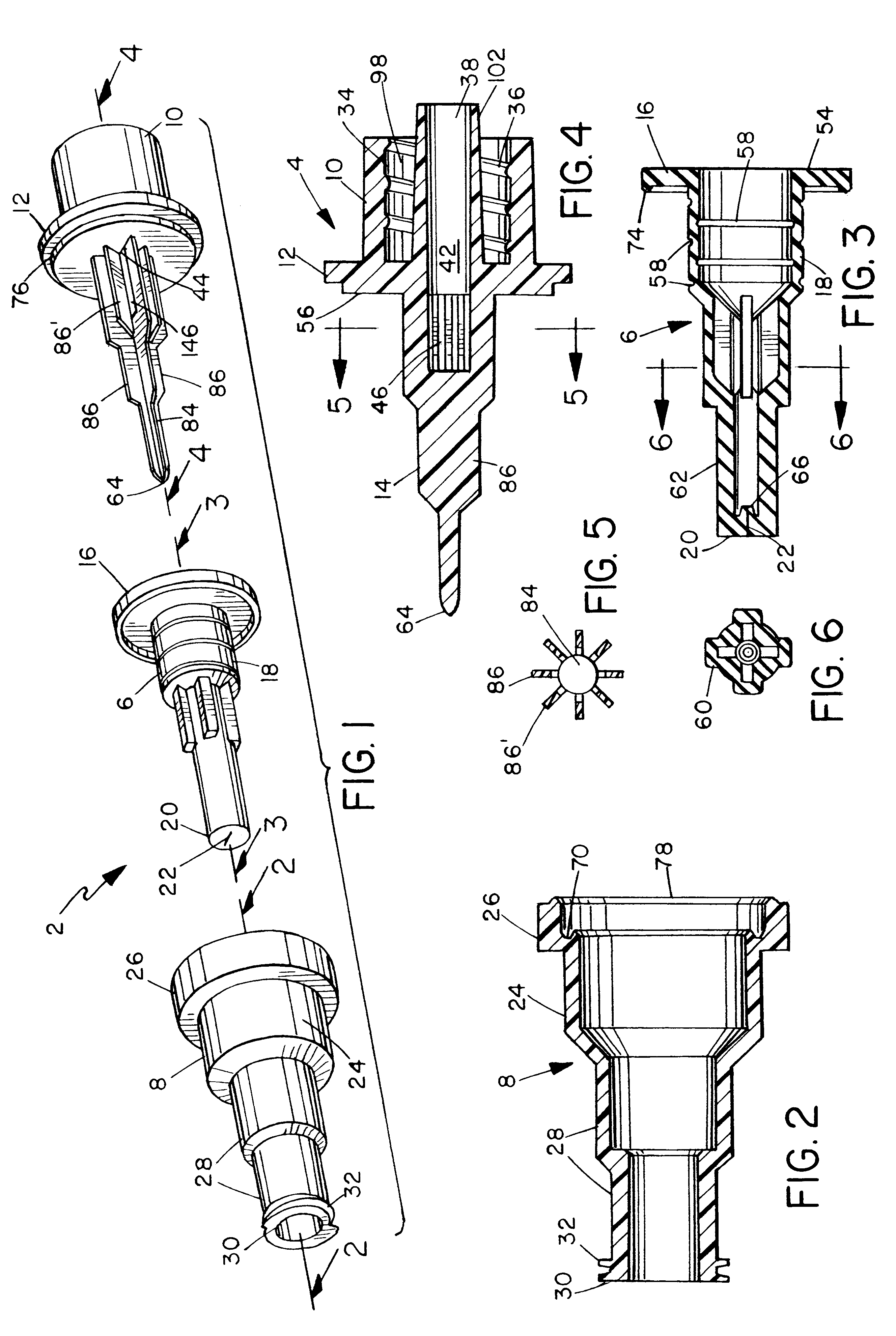

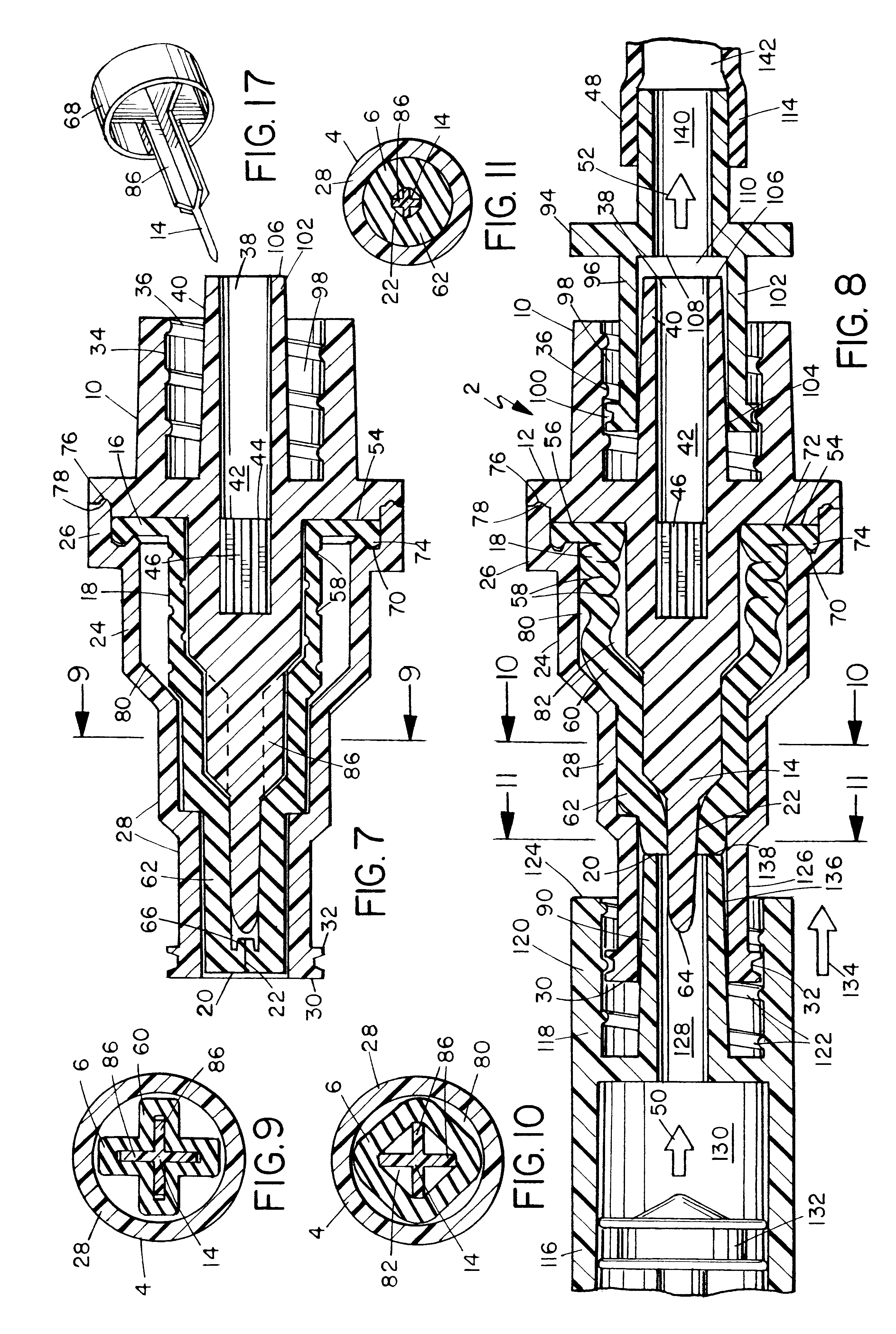

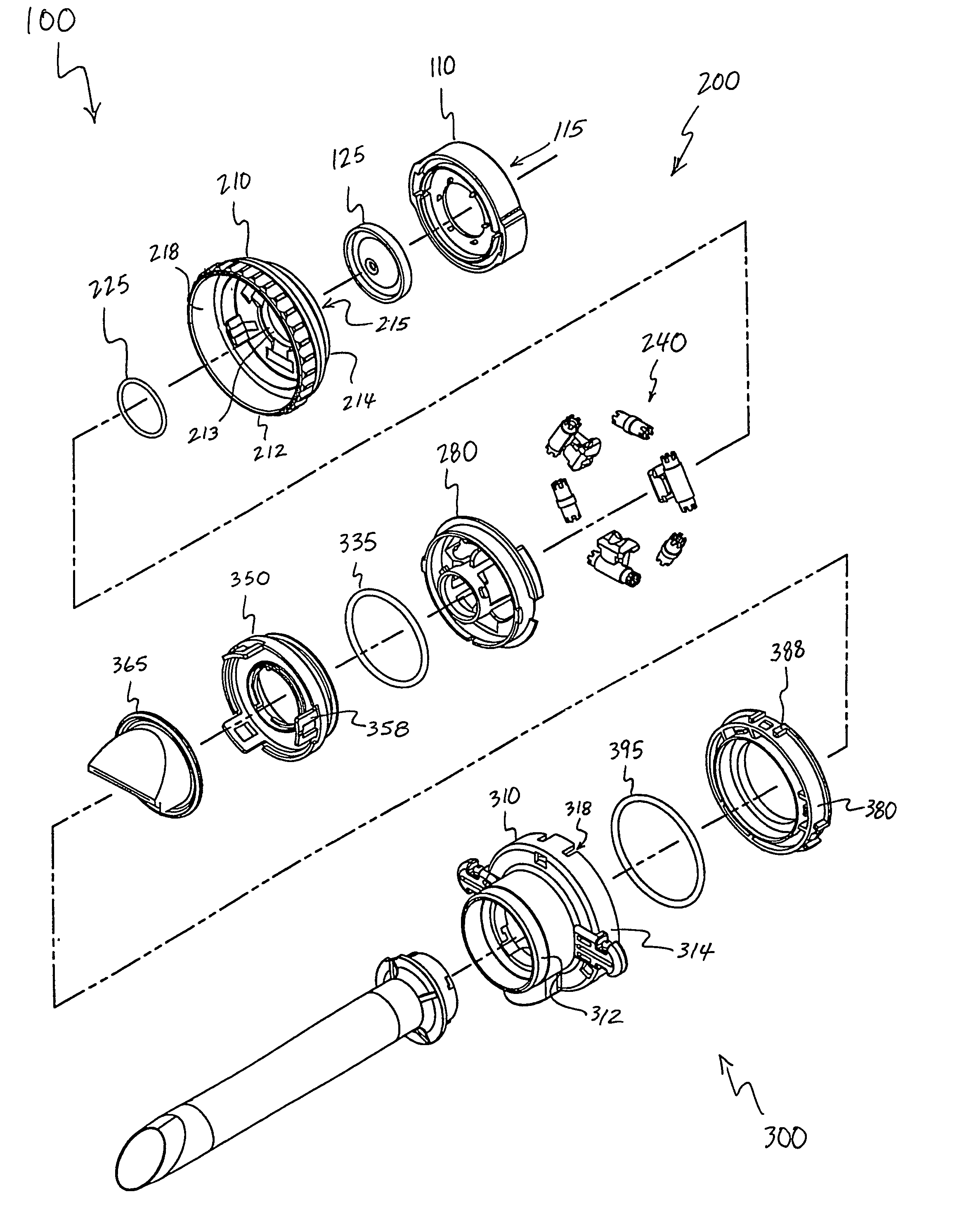

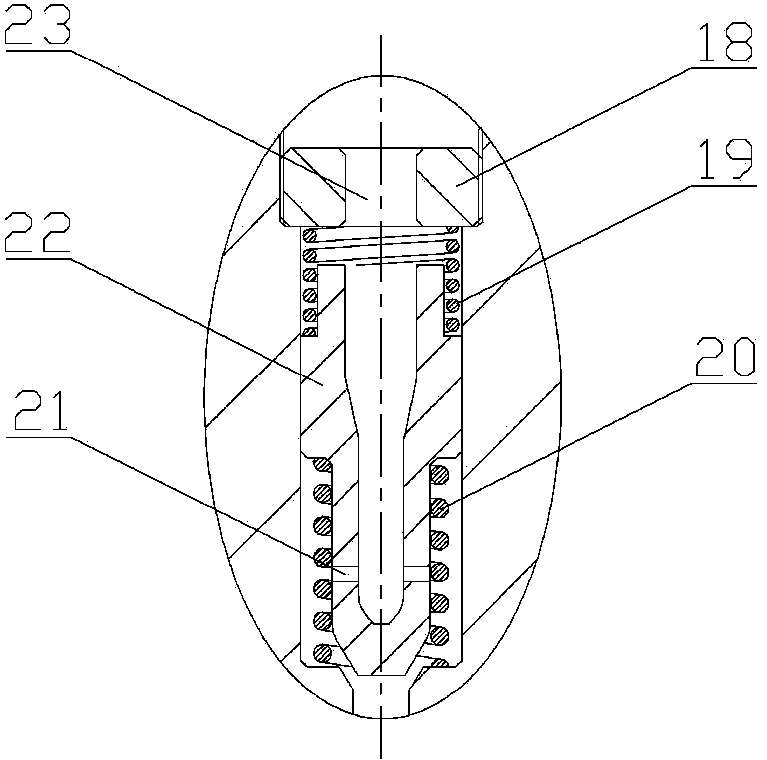

Needle valve and connectors for use in liquid transfer apparatuses

The invention is a needle valve and connectors for use in liquid transfer apparatuses. The needle valve of the invention is not the conventional type of needle valve known in the art that comprises a threaded valve stem, which allows very accurate control of the flow through the valve, and that uses elastic materials, such as rubber, as a sealing component. The needle valve of the invention comprises two components: the first component is a hollow needle having a smooth exterior surface and a port at the side of the cylindrical shaft, the second component is a seat made of rigid material e.g. plastic with low friction properties.

Owner:EQUASHIELD MEDICAL

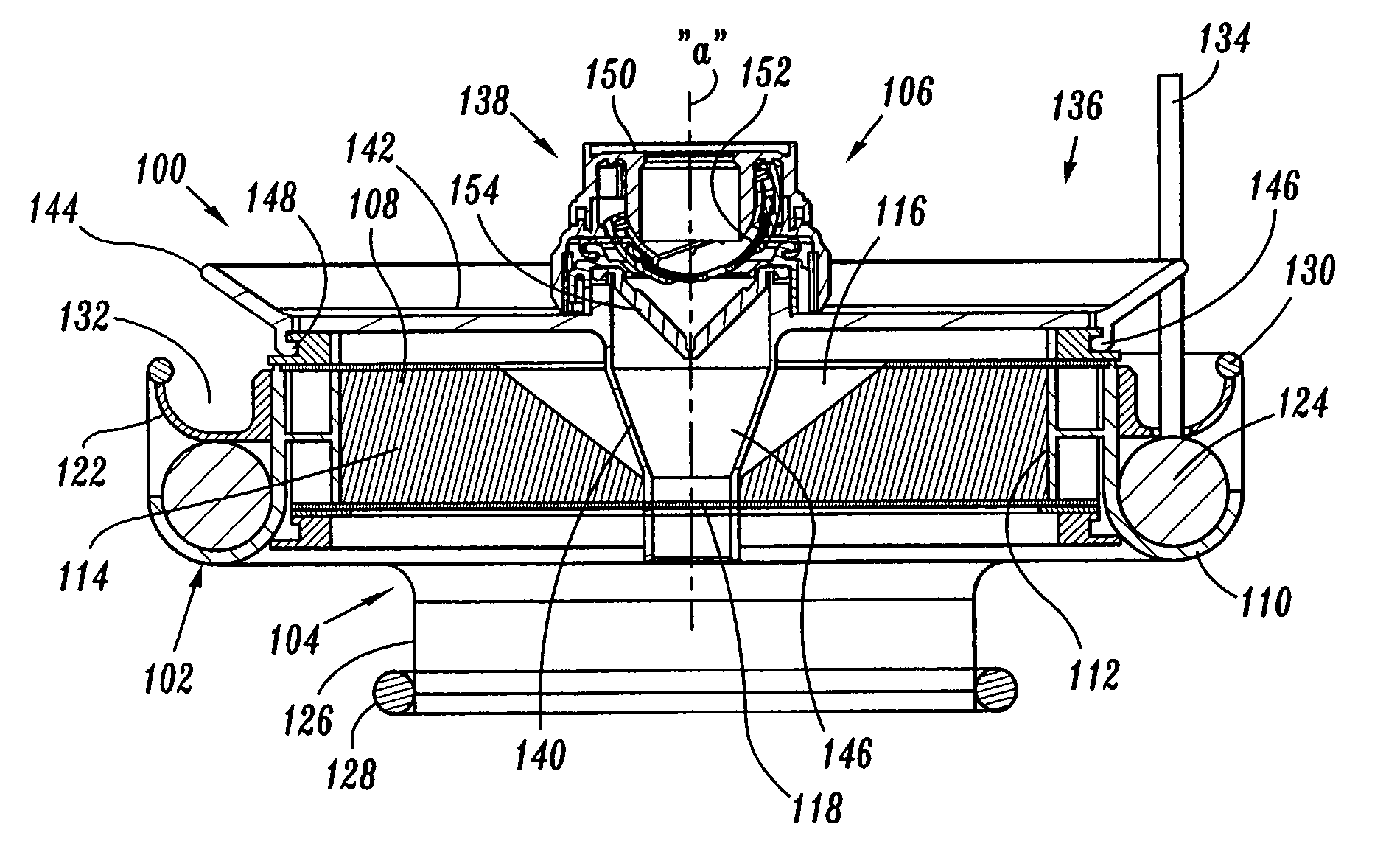

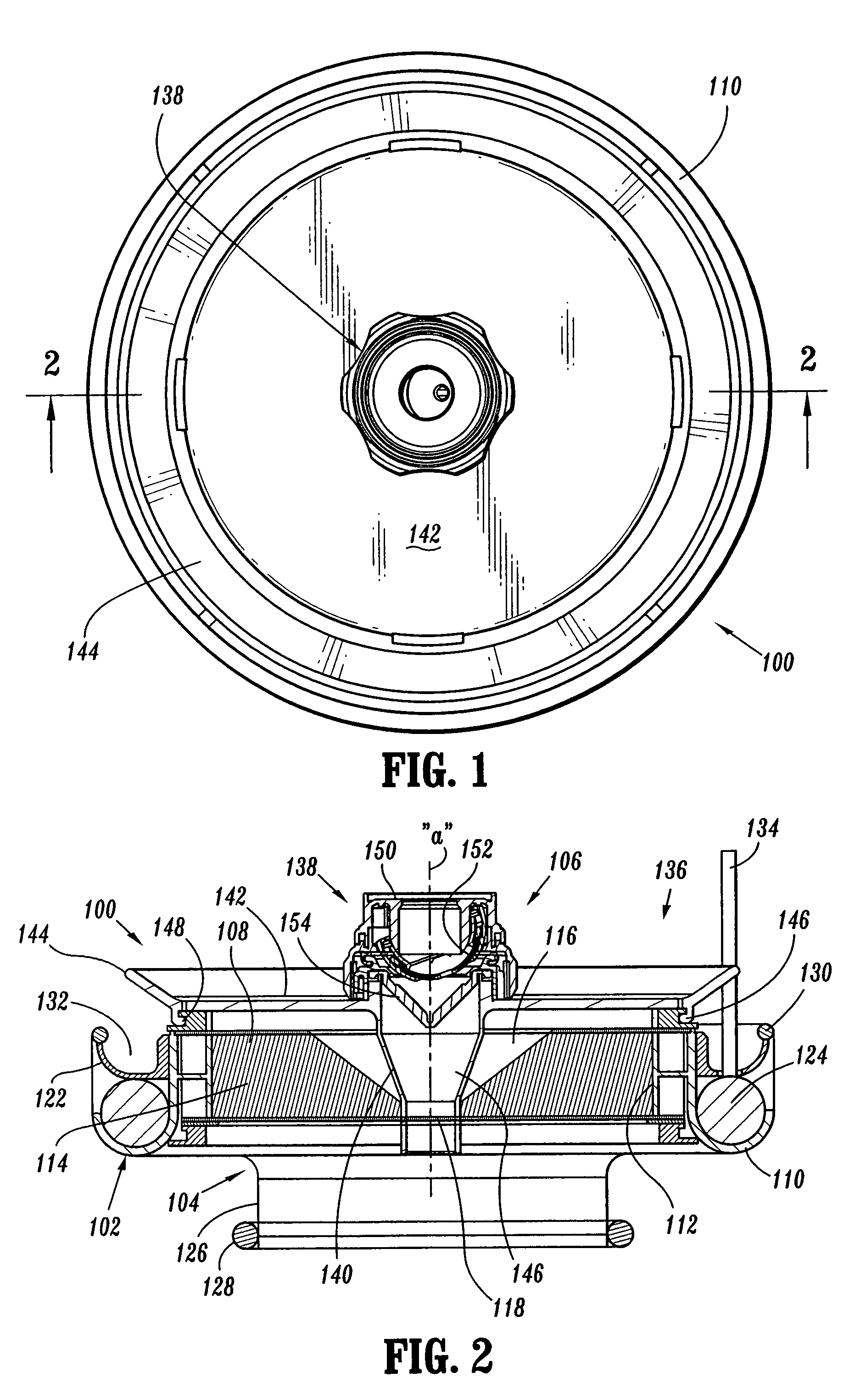

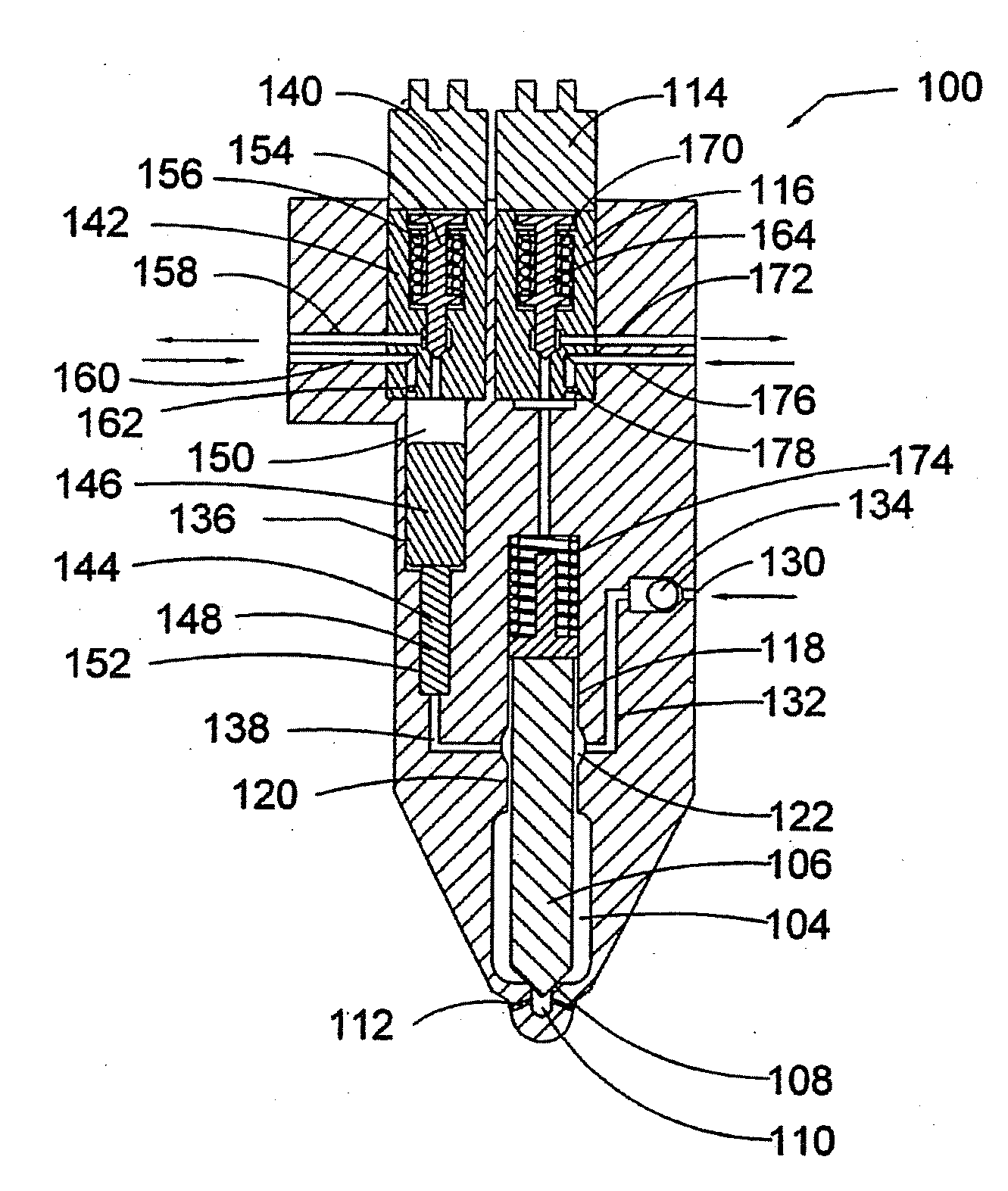

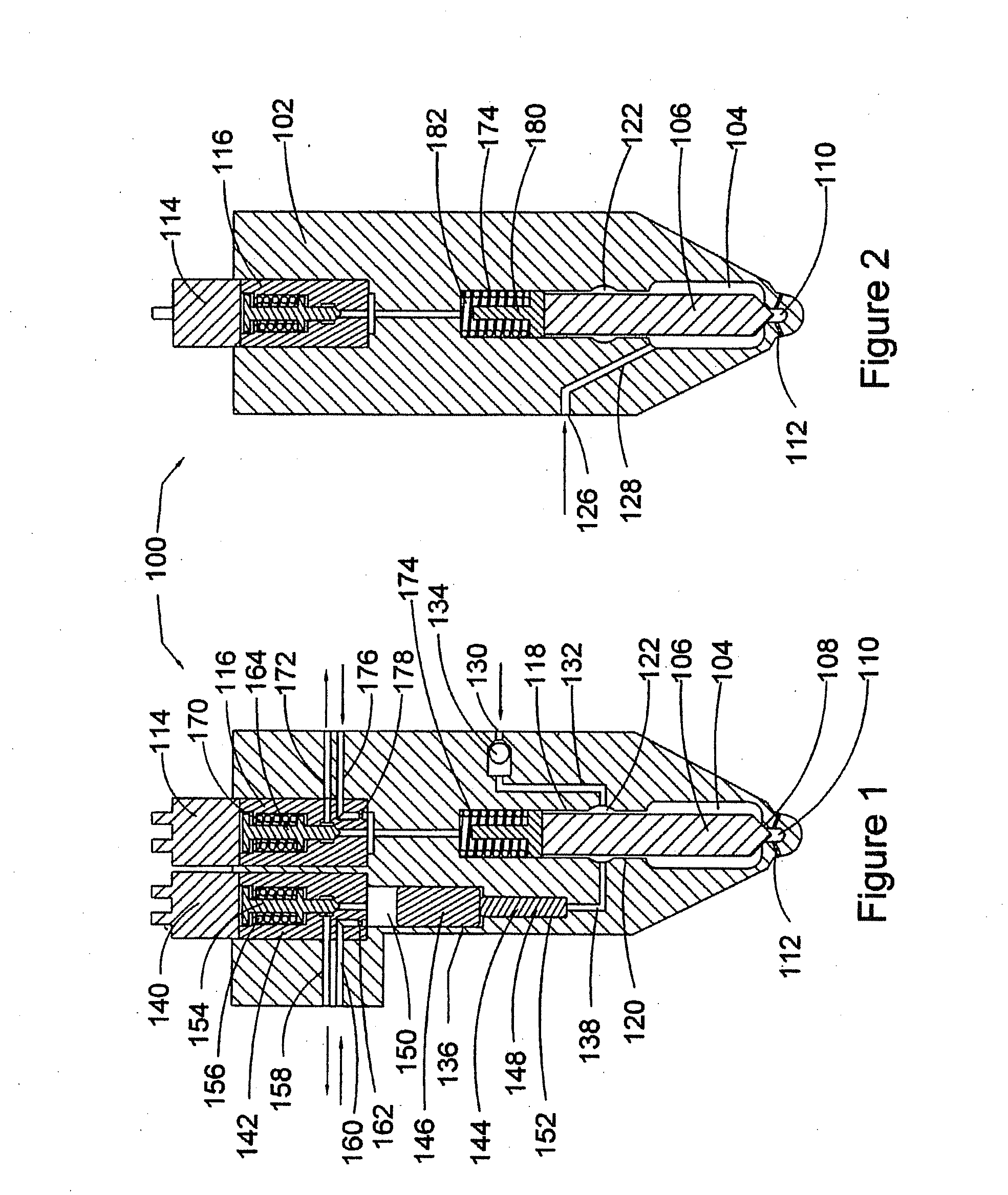

Gaseous fuel injector

InactiveUS20060086825A1Improve ignition performanceLimit wearInternal combustion piston enginesFuel supply apparatusWorking fluidEngineering

The injector includes a nozzle, a needle, a control chamber, a working fluid supply passage, an electric switching valve, a high-pressure gaseous fuel supply passage and a lubrication liquid fuel supply passage. The nozzle has an injection hole, through which high-pressure gaseous fuel is injected. The needle is axially reciprocably received in the nozzle to open and close the injection hole. The needle includes a sliding portion and a valve portion. The control chamber applies a pressure to the needle. The working fluid supply passage supplies liquid fuel to the control chamber. The electric switching valve controls an inflow / outflow of the liquid fuel to / from the control chamber. The high-pressure gaseous fuel supply passage supplies the high-pressure gaseous fuel to the injection hole. The lubrication liquid fuel supply passage supplies the liquid fuel from the working fluid supply passage to the sliding portion and the valve portion.

Owner:DENSO CORP

Dual Fuel Injector With Hydraulic Lock Seal And Liquid Leak Purge Strategy

InactiveUS20130098333A1Inhibit migrationPrevent movementInternal combustion piston enginesFuel supply apparatusCommon railEngineering

A dual fuel system includes a dual fuel injector that has disposed therein a gaseous nozzle chamber fluidly connected to a gaseous fuel inlet, and a liquid nozzle chamber fluidly connected to the liquid fuel inlet. The dual fuel injector also includes a hydraulic lock seal with an annular volume of liquid fuel surrounding a guide segment of a gas needle valve member for inhibiting migration of gaseous fuel into the liquid fuel. A liquid fuel common rail is fluidly connected to a liquid fuel inlet. A check valve is fluidly positioned between the gaseous fuel common rail and the gaseous nozzle chamber of the dual fuel injector for blocking liquid fuel leaked into a gaseous nozzle chamber through the hydraulic lock seal from entering the gaseous fuel common rail.

Owner:CATERPILLAR INC

Underwater gas transportation pipeline leakage detection experiment platform

InactiveCN102322570AMonitor pressure fluctuationsMonitor output gas flow changesPipeline systemsGas cylinderEngineering

The invention discloses an underwater gas transportation pipeline leakage detection experiment platform. The experiment platform comprises a gas transportation device, a detection system, a water tank environment and a pipeline framework, wherein the gas transportation device comprises a programmable logic controller (PLC) module, an air compressor, a gas transportation hose, a first gas pressuresensor, a first gas circuit one-way valve, a first pressure meter, a second gas circuit one-way valve, a high-pressure gas storage bottle, a gas input hose and a gas output hose; the detection systemcomprises a detection module, a second gas pressure sensor and a gas flow meter; the water tank environment comprises a sound insulation material, a water tank, silt, a first movable support rod, a second pressure meter, a safety valve, a clapboard, a third pressure meter, a second movable support rod and a wave maker; the pipeline framework comprises a first pressure reducing valve, a needle valve, a high-pressure gas transportation pipeline, a fixing bracket and a second pressure reducing valve; and the detection module can detect leakage information and transmit the leakage information to a remote control center. The experiment platform can be used for simulating an underwater environment during an underwater pipeline leakage detection experiment, and has high simulation authenticity.

Owner:CHINA JILIANG UNIV

Luer-type needle-free valve fitting with bypass

Embodiments of luer-type needle-free valve devices are disclosed. One of the novel aspects of the invention is its ability to transform from an open state to a closed state. The open position eliminates the potential for a differential pressure to exist between the volume connected to the inlet and outlet of the valve fitting. The closed position enables the device to maintain a differential pressure between the volume connected to the inlet and outlet of the valve fitting. The invention is useful in manufacturing sterile medical devices by allowing all surfaces to communicate with the sterilizing agent when the valve is in an open configuration when it is in a closed position.

Owner:CYTYC CORP

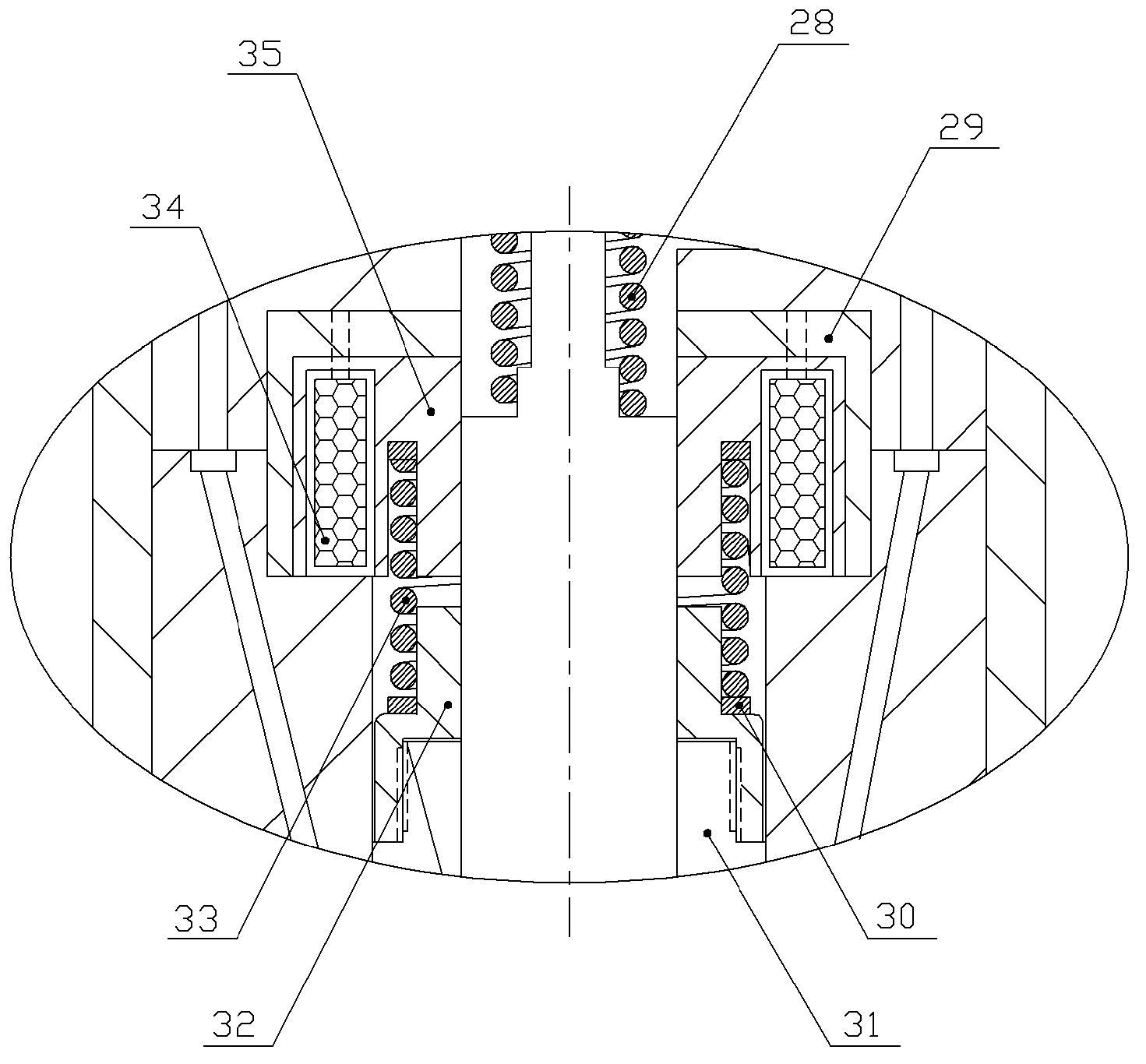

Dual-fuel electric control monomer ejector

ActiveCN102705120AControl individual injectionRealize individual jettingFuel injection apparatusMachines/enginesControl roomElectric control

The invention aims at providing a dual-fuel electric control monomer ejector, which comprises an ejector body, and a control diesel oil electromagnetic valve, a control natural gas electromagnetic valve, a control piston, a needle valve, a needle valve offsetting spring and a nozzle which are arranged in the ejector body, wherein the ejector body is provided with a diesel oil inlet, an oil discharge port and a natural gas inlet, a control room, an oil storage room and a gas storage room are arranged in the ejector, the diesel oil inlet is respectively communicated with the control room, the oil storage room and a fuel pipe of an engine, the natural gas inlet is communicated with the gas storage room, the control diesel oil electromagnetic valve is arranged above the control room, a control piston is arranged below the control room and is connected with the needle valve, the control natural gas electromagnetic valve is arranged outside the needle valve, the nozzle is arranged on the lower end of the ejector body, and the needle valve offsetting spring is arranged between the needle valve and the ejector body. According to the invention, less lean mixture of fuel ignition air and natural gas is ejected at an initial ejection stage, the ejection performance of the fuel and the atomizing effect are improved, and emission and economy of the engine are improved.

Owner:HARBIN ENG UNIV

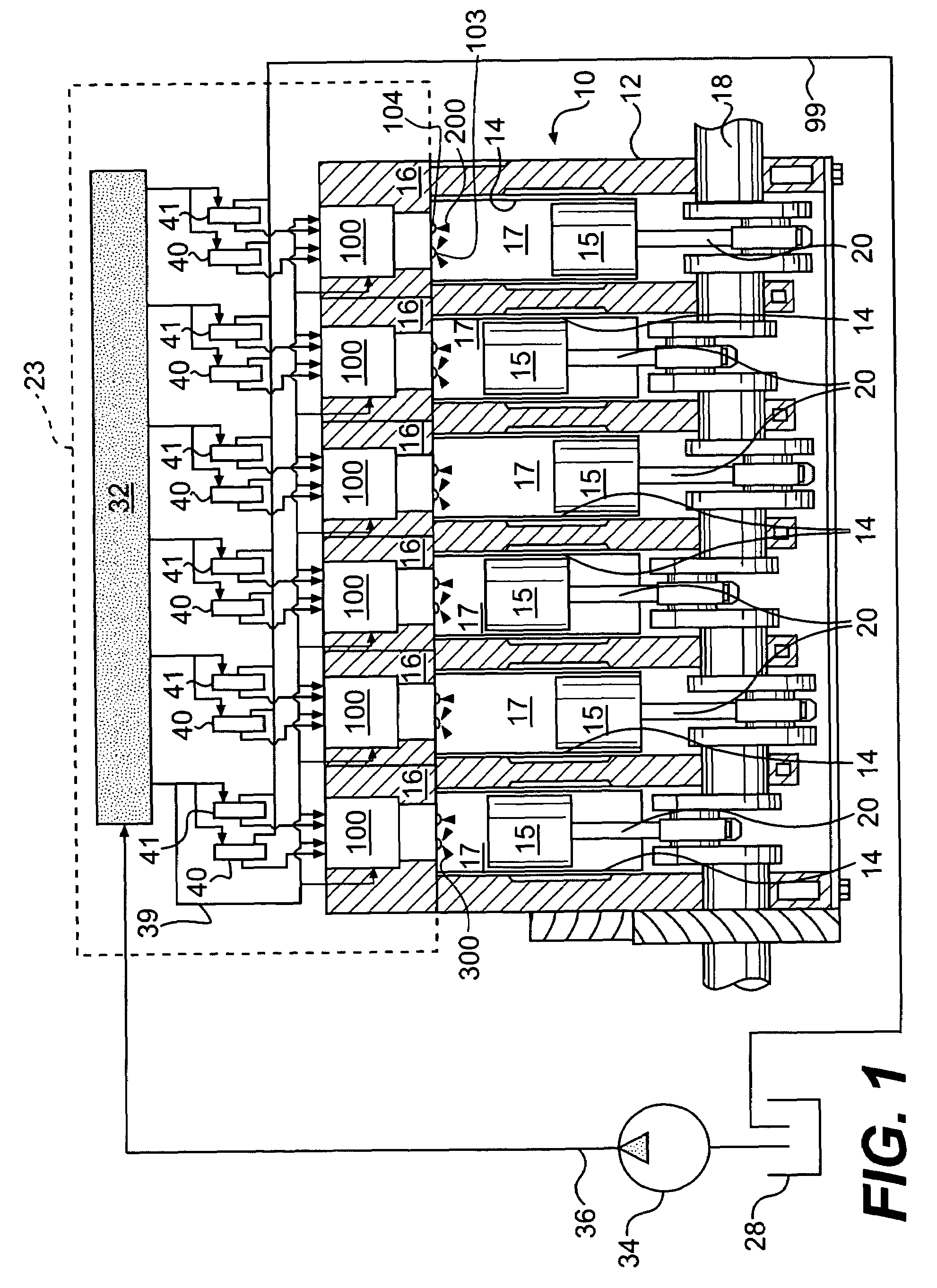

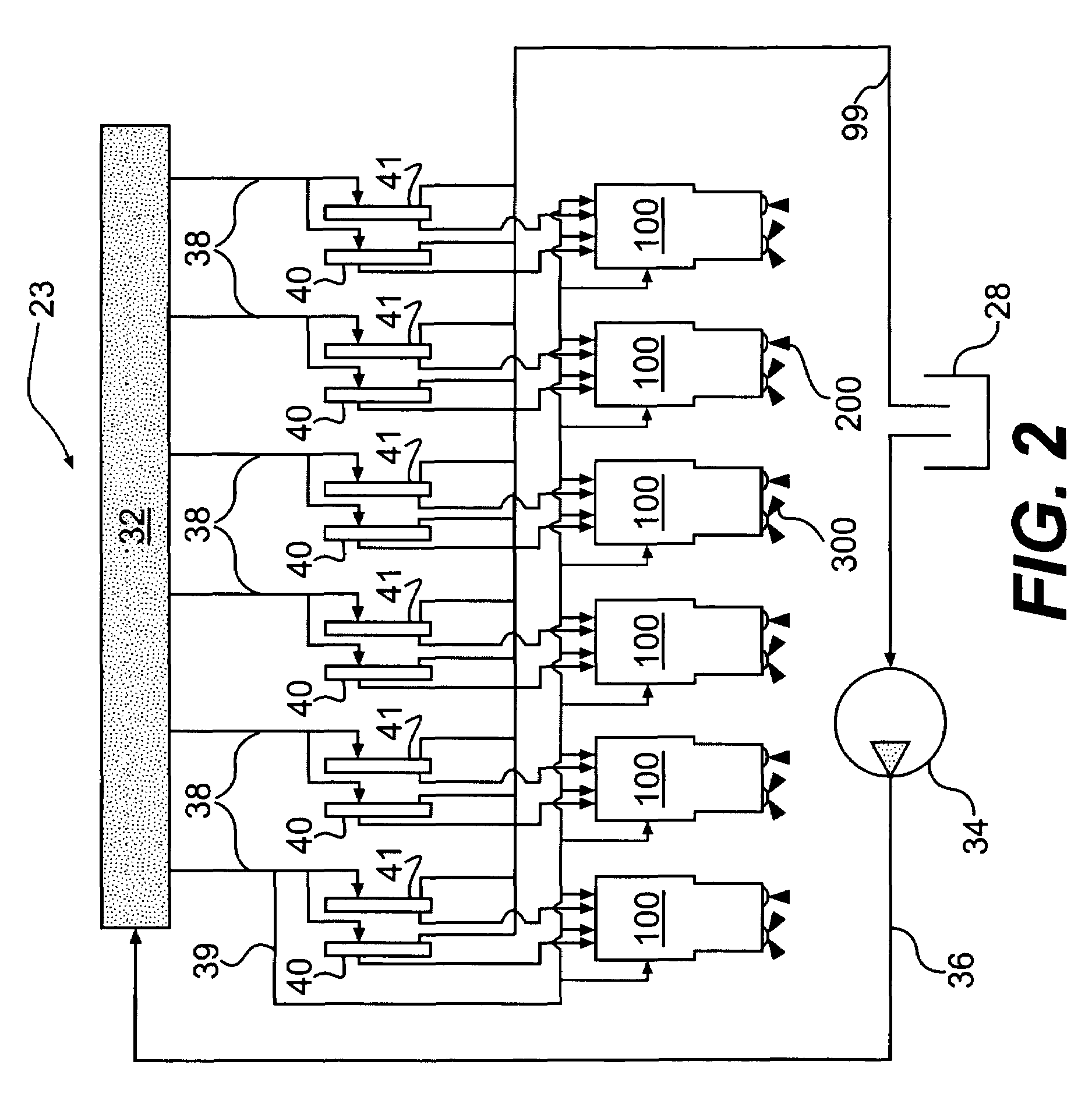

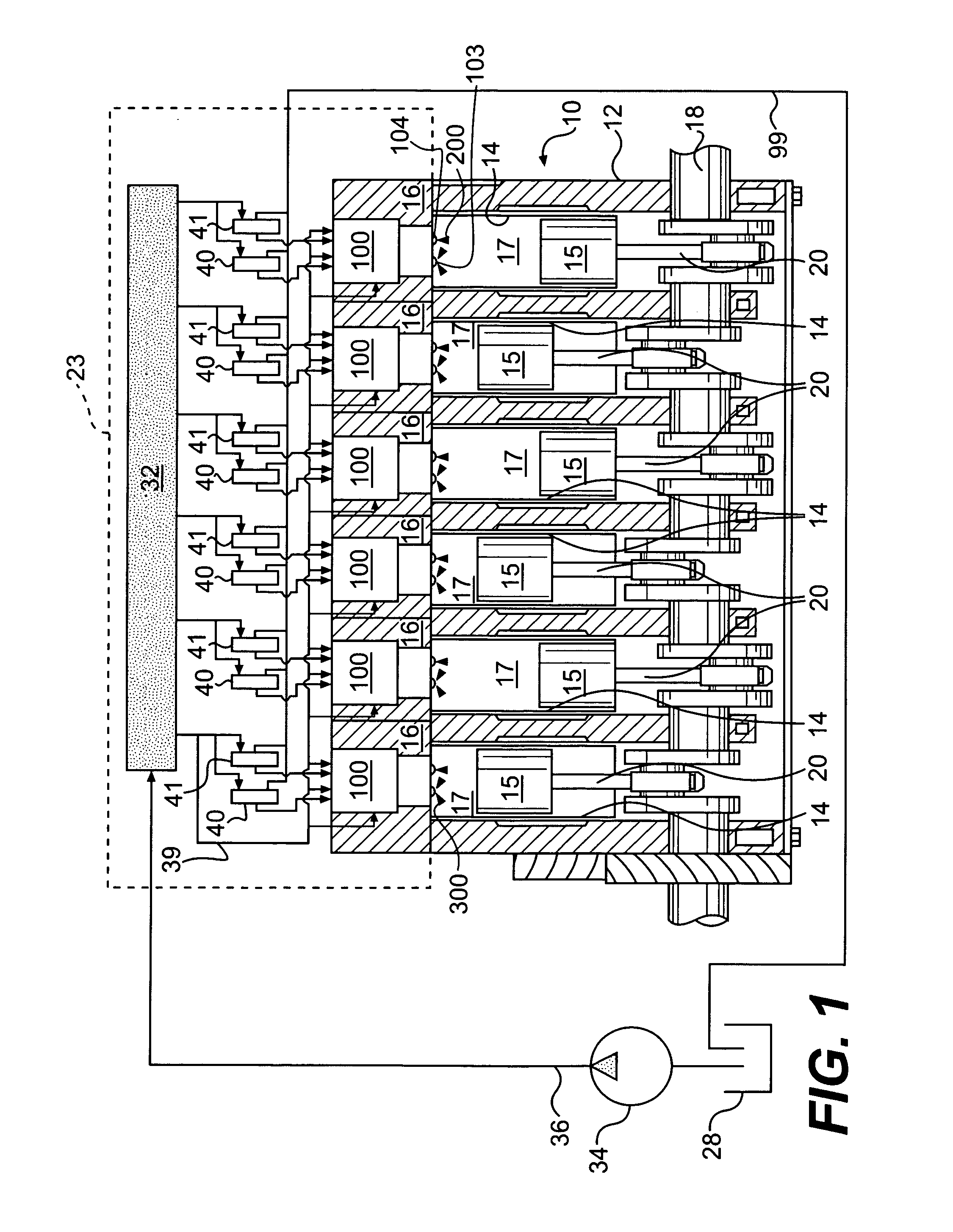

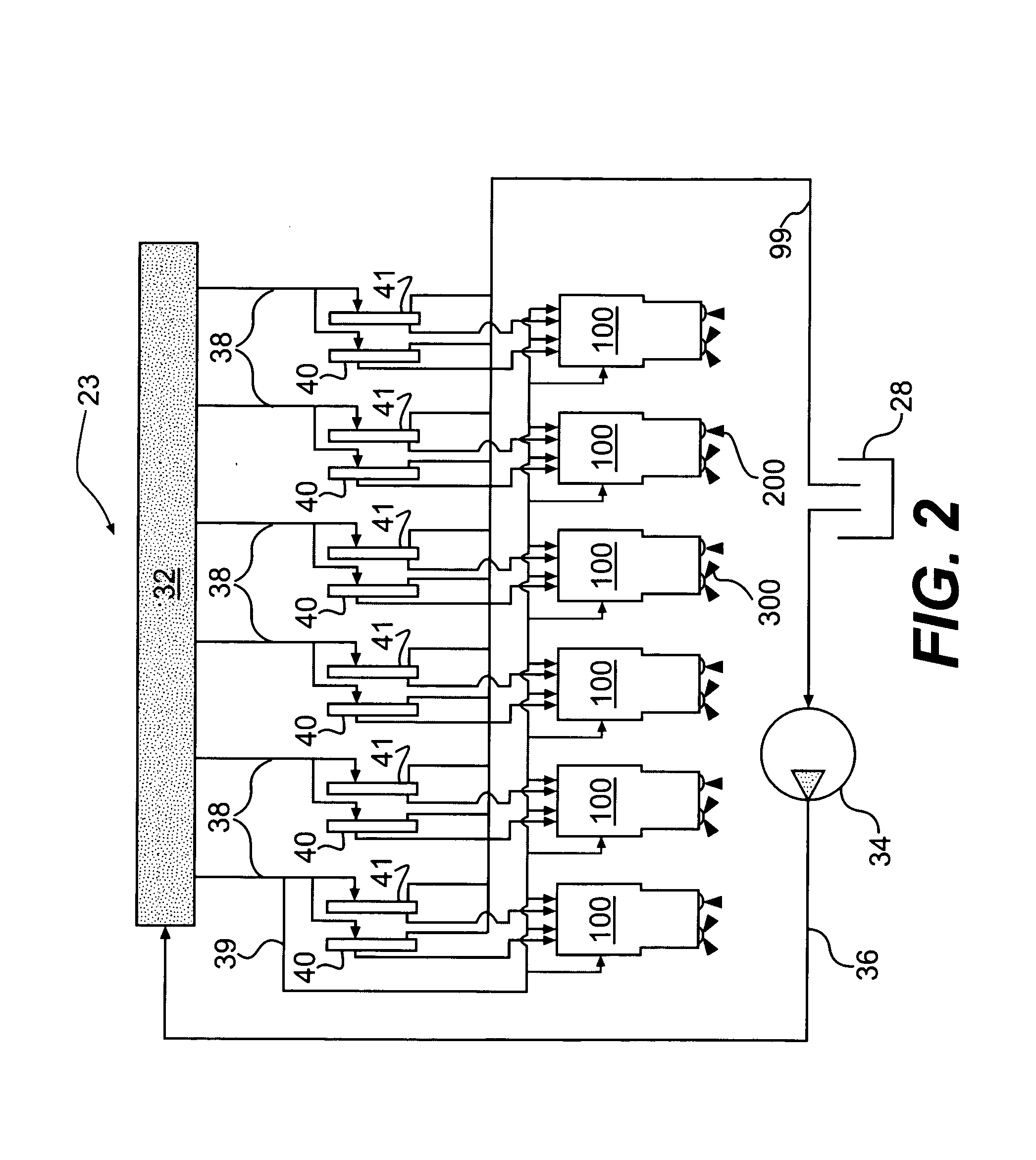

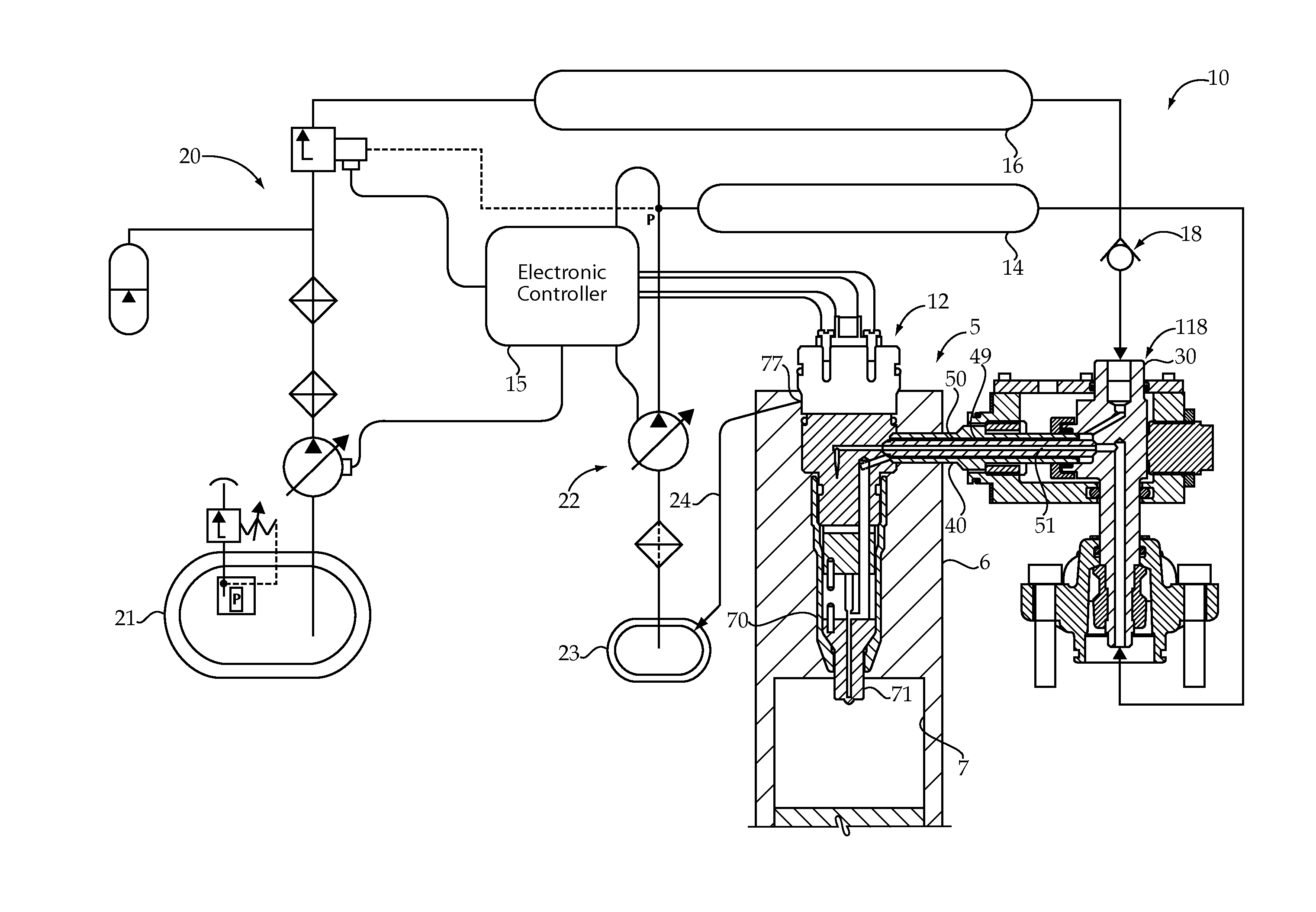

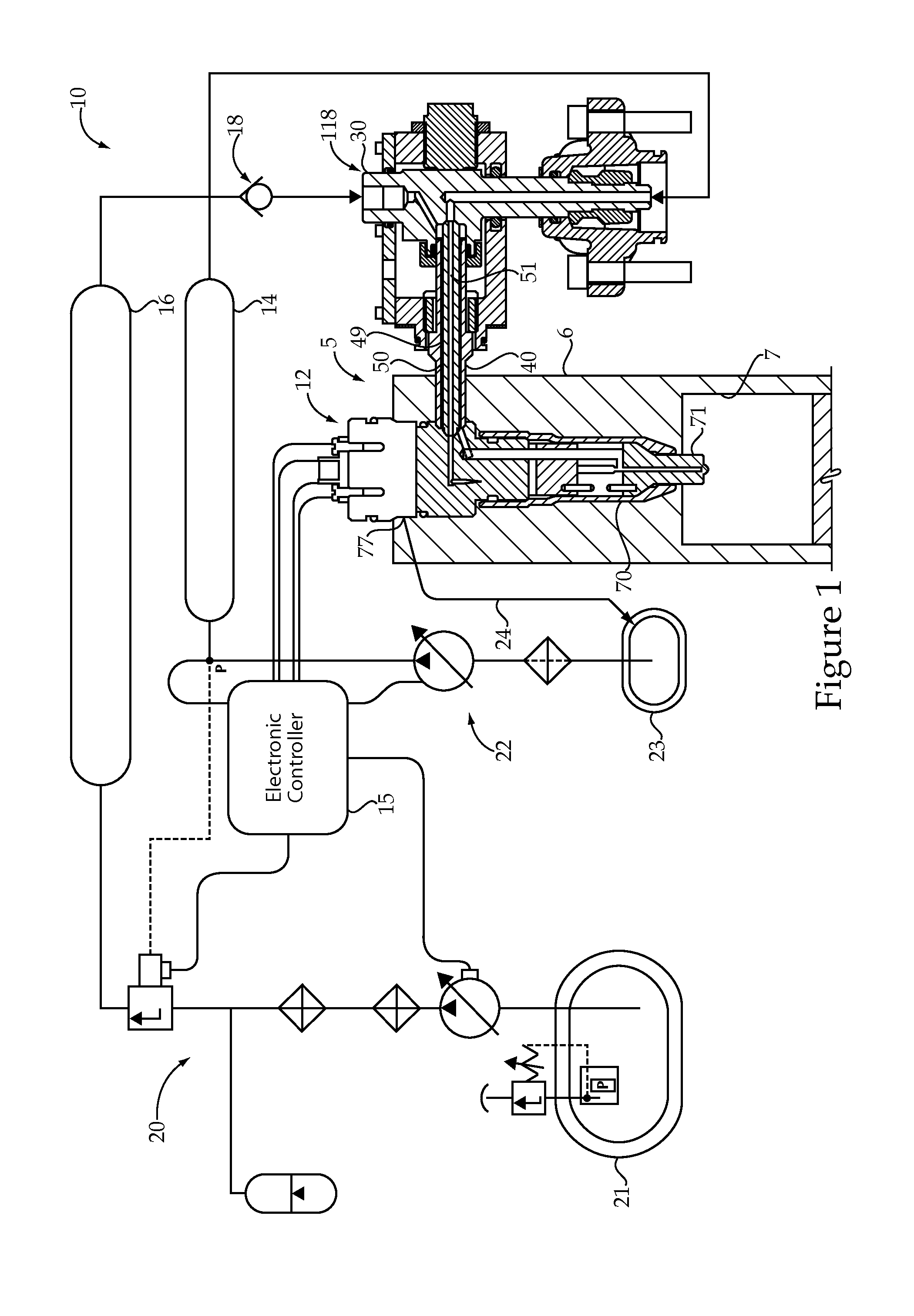

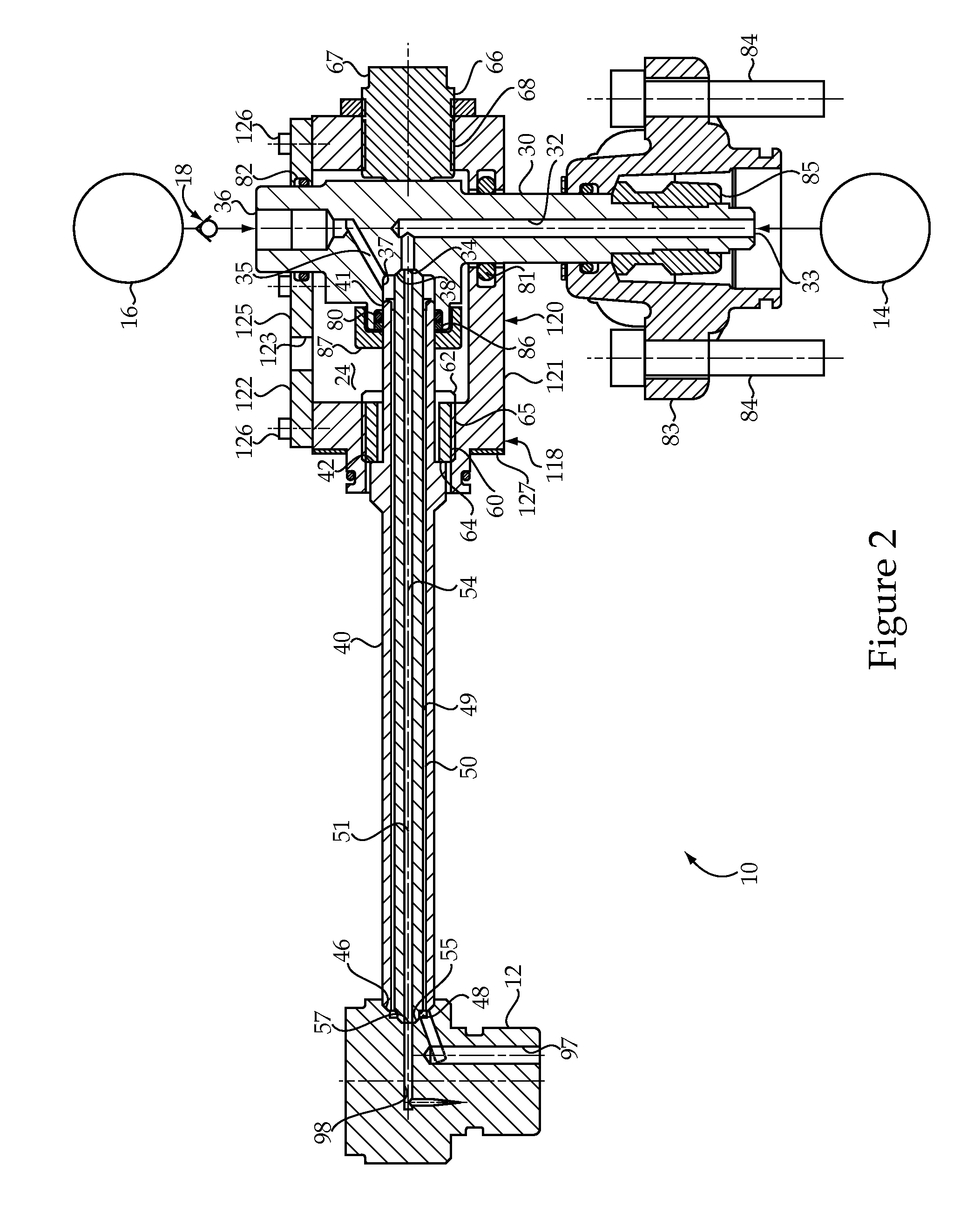

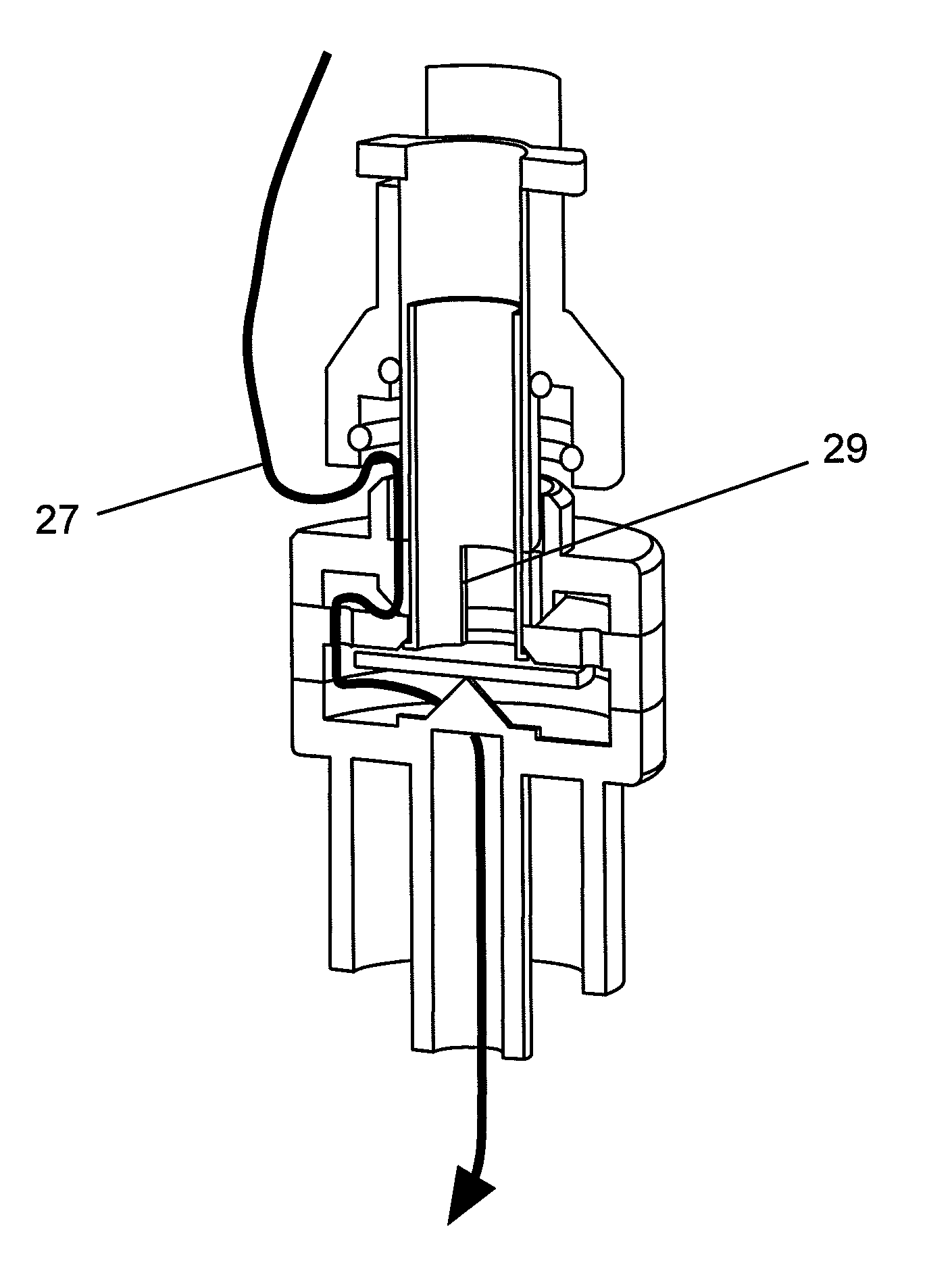

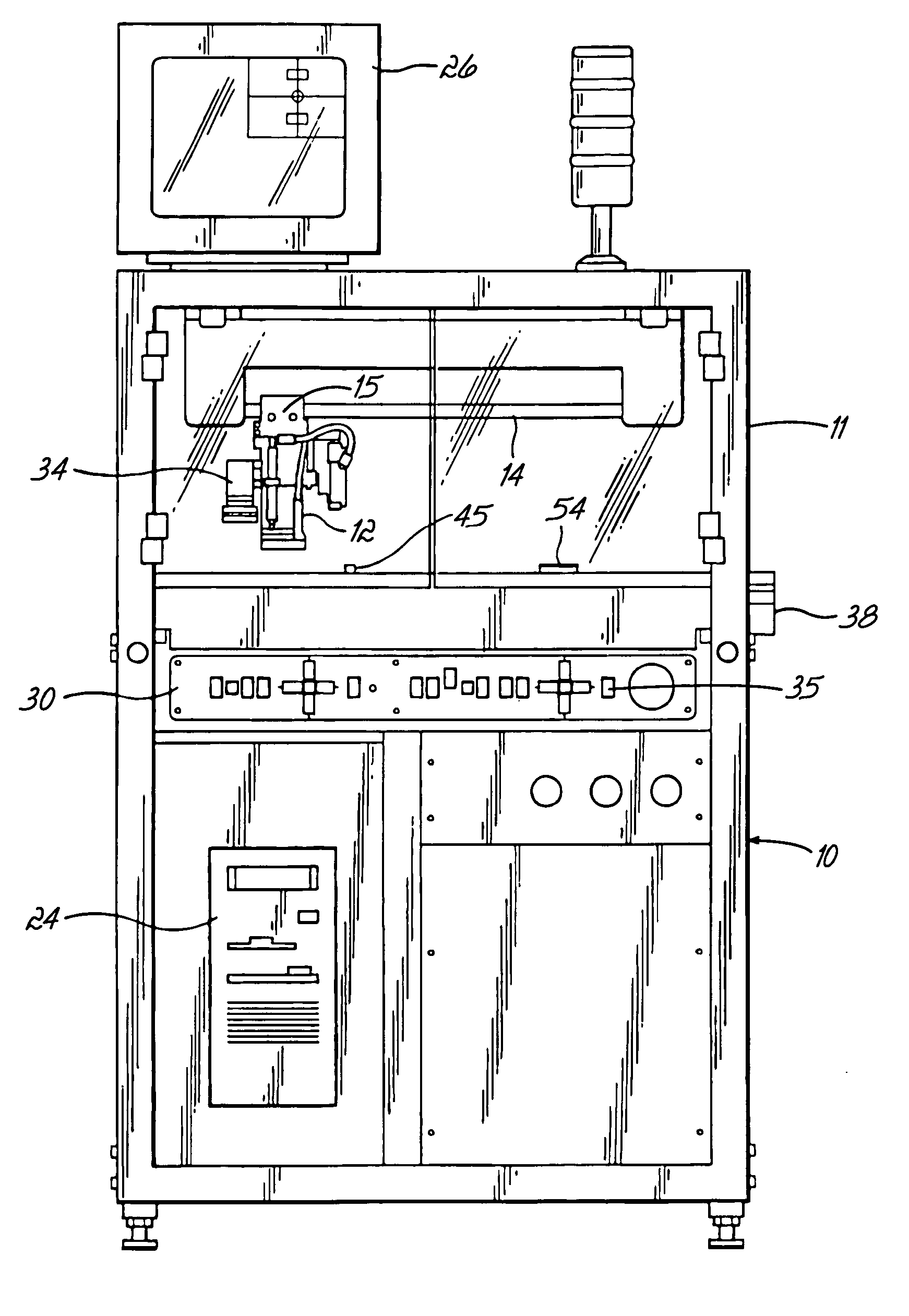

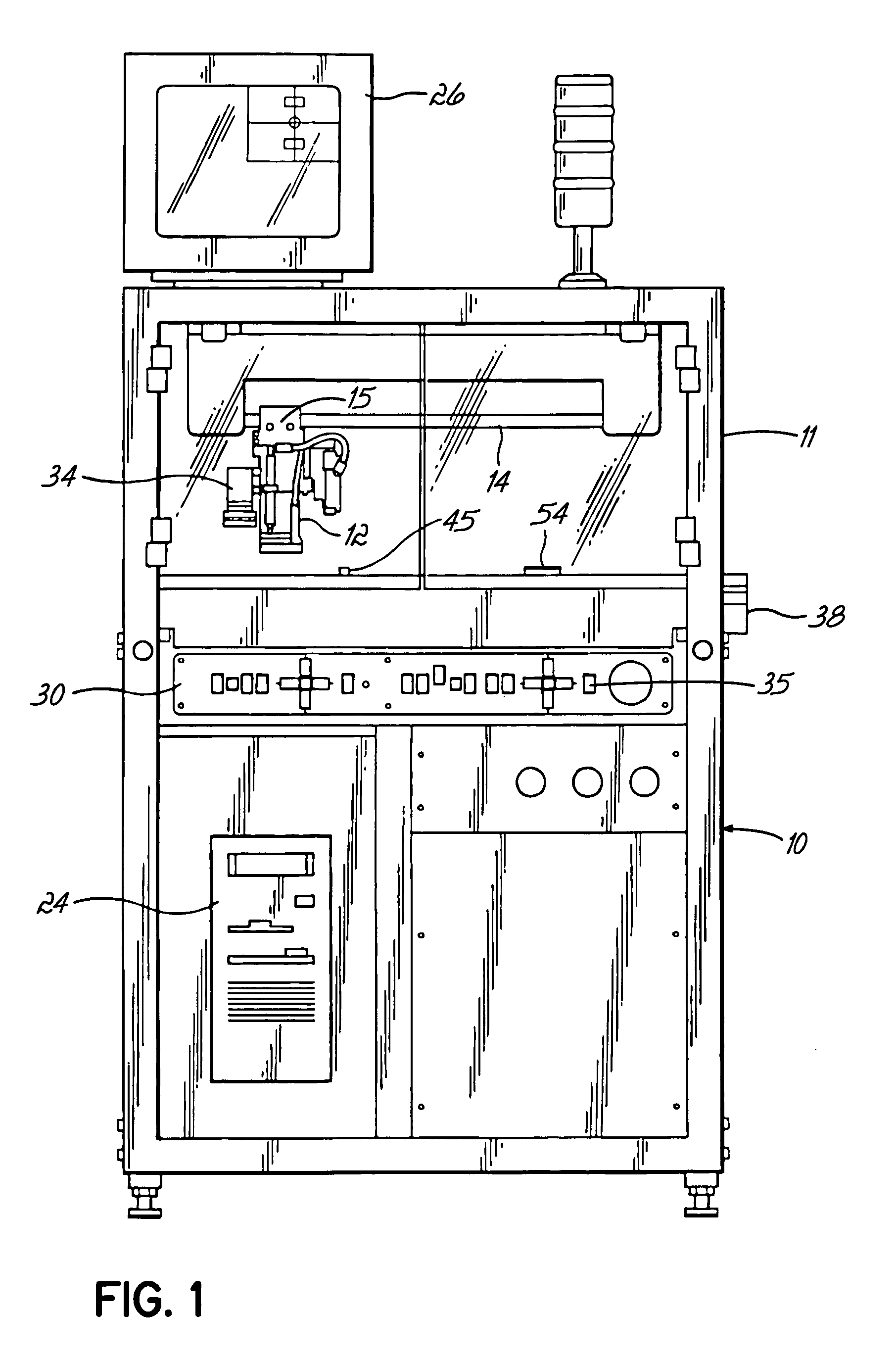

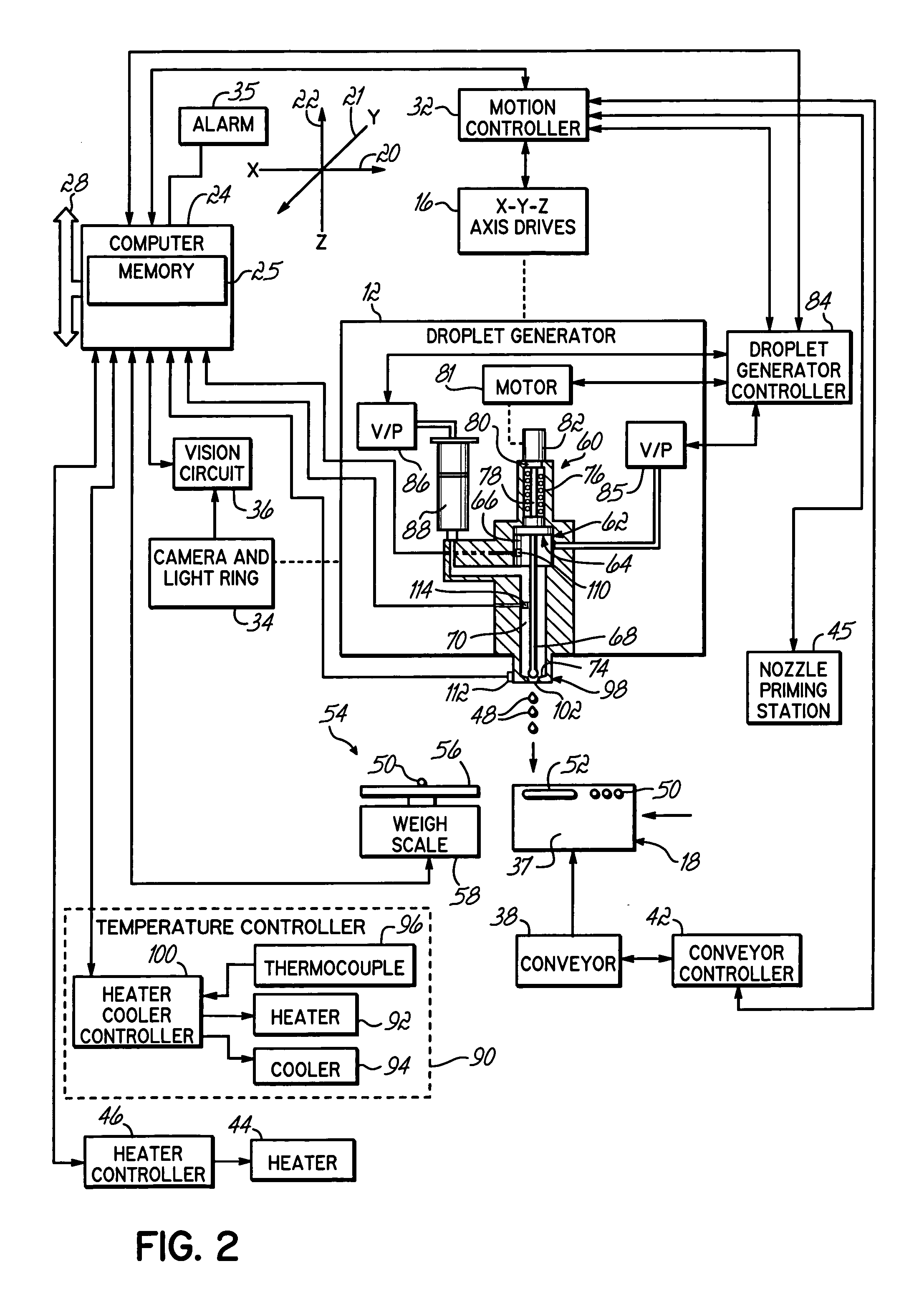

Viscous material dispensing systems with parameter monitoring and methods of operating such systems

InactiveUS20070069041A1Self-acting watering devicesLiquid transferring devicesElectronic controllerControl system

Systems and methods for dispensing or jetting a viscous material. The systems include an electronic controller and a jetting dispenser operatively coupled with the electronic controller. The systems further include at least one sensor that senses a system dispensing parameter and communicates an output signal representing the sensed parameter to the electronic controller for controlling system operation. In pneumatically-actuated jetting dispensers, a sensor may sense the fluid pressure in the air cavity of the pneumatic actuator. In jetting dispensers with a movable needle valve, a sensor may sense the displacement of the needle shaft. In other jetting dispensers, a sensor may sense the vibration of the jetting dispenser.

Owner:NORDSON CORP

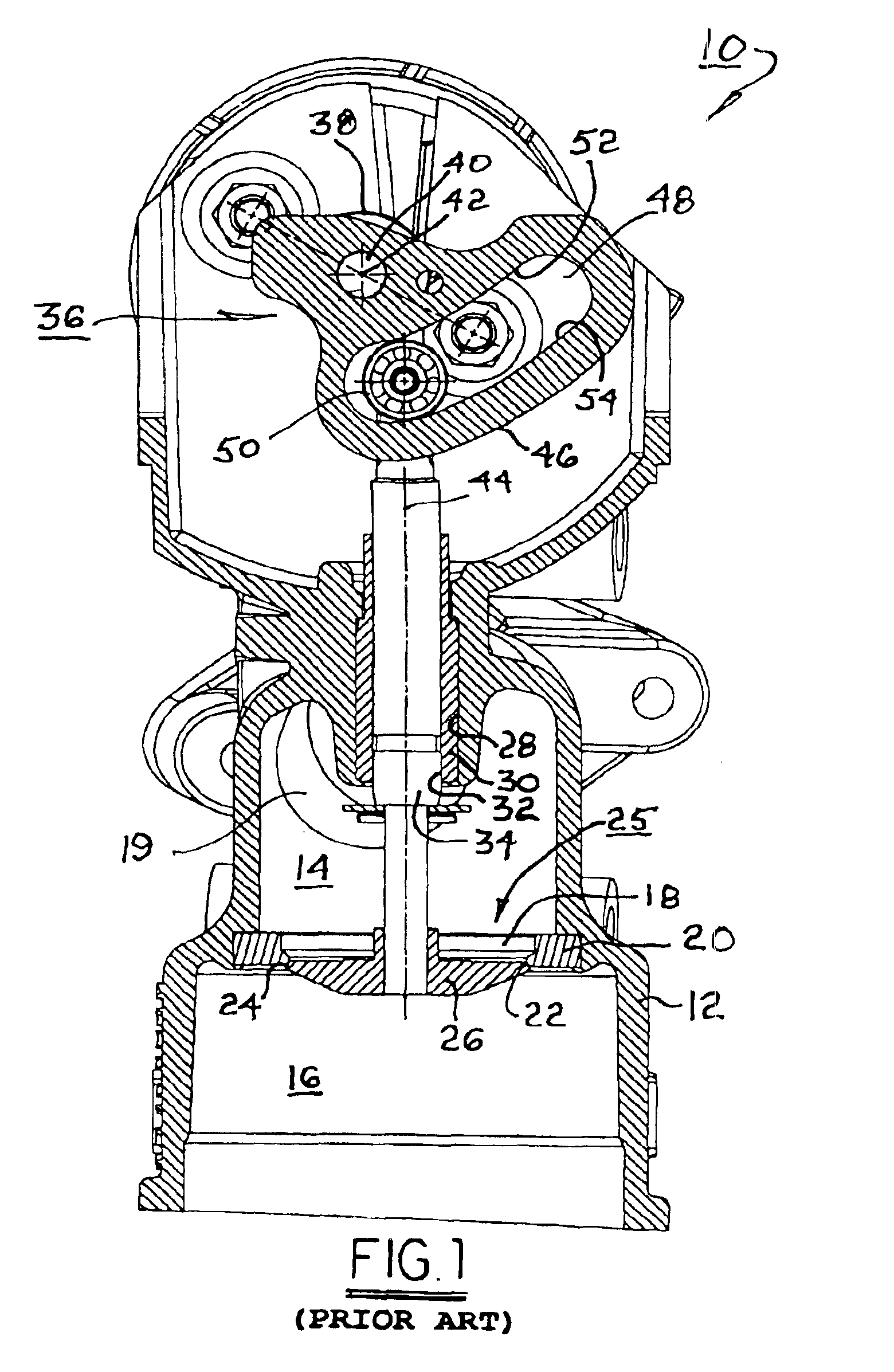

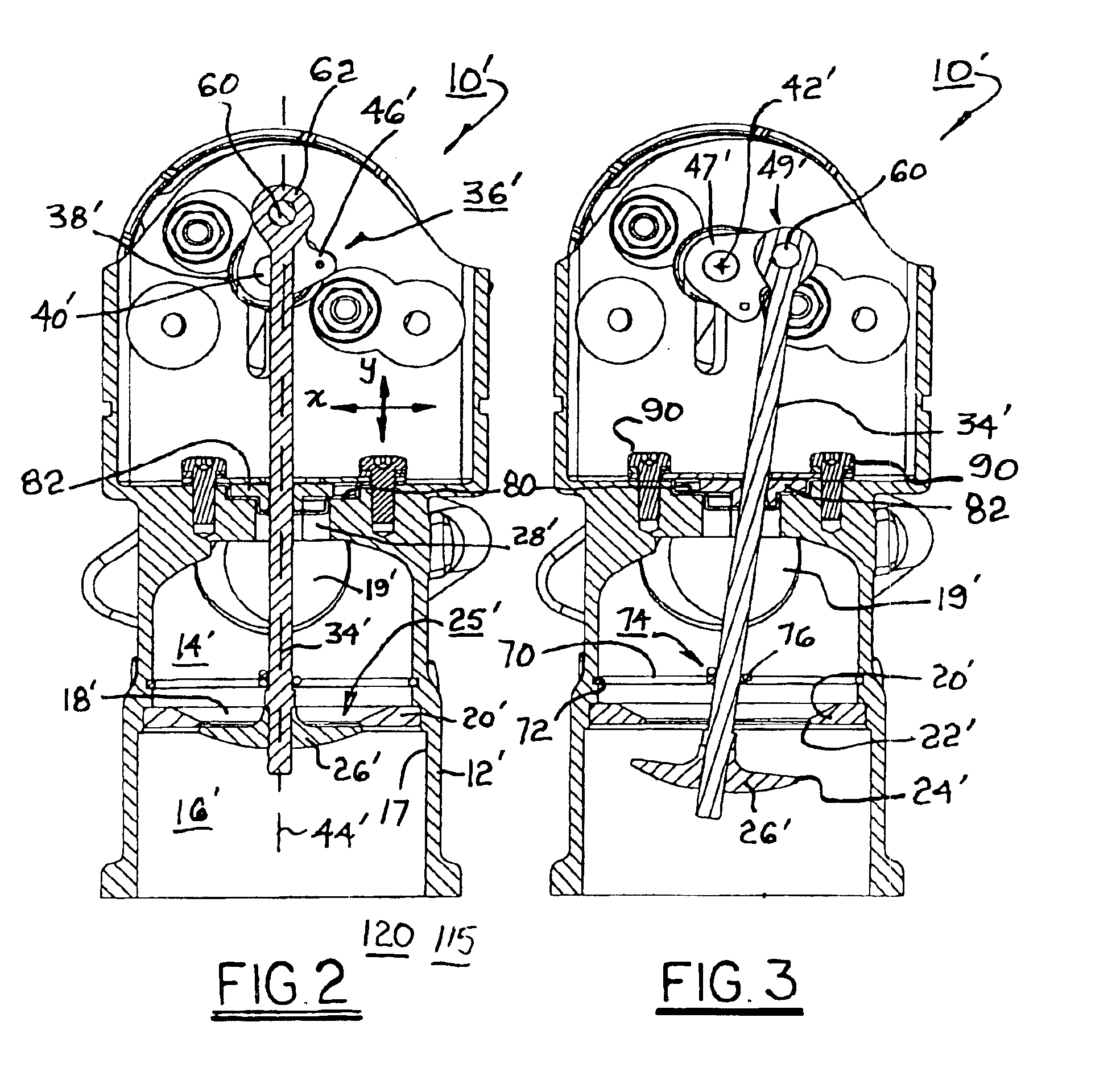

Rotary-actuator EGR valve having compliant seal/bushing

InactiveUS6886546B1Improve sealingInhibit wearOperating means/releasing devices for valvesNon-fuel substance addition to fuelAs DirectedReciprocating motion

A rotary arm-actuated pintle valve assembly having a pintle valve seat, a pintle shaft, and a valve head forming a pintle valve for regulating flow of gas through a valve body. The shaft extends through a port in a wall of the body. A rotary-arm actuator mounted to the body includes an oscillating motor and shaft. An arm mounted on the motor shaft engages the outer end of the pintle shaft and causes the pintle shaft to reciprocate to open and close the valve. The port permits the pintle to move back and forth radially during actuation of the valve. A floating bearing assembly at the port receives the pintle and slides back and forth as directed by the pintle, all the while maintaining a pneumatic seal around the pintle. A centering element is provided within the valve body to guide the pintle in mating the head with the seat.

Owner:DELPHI TECH INC

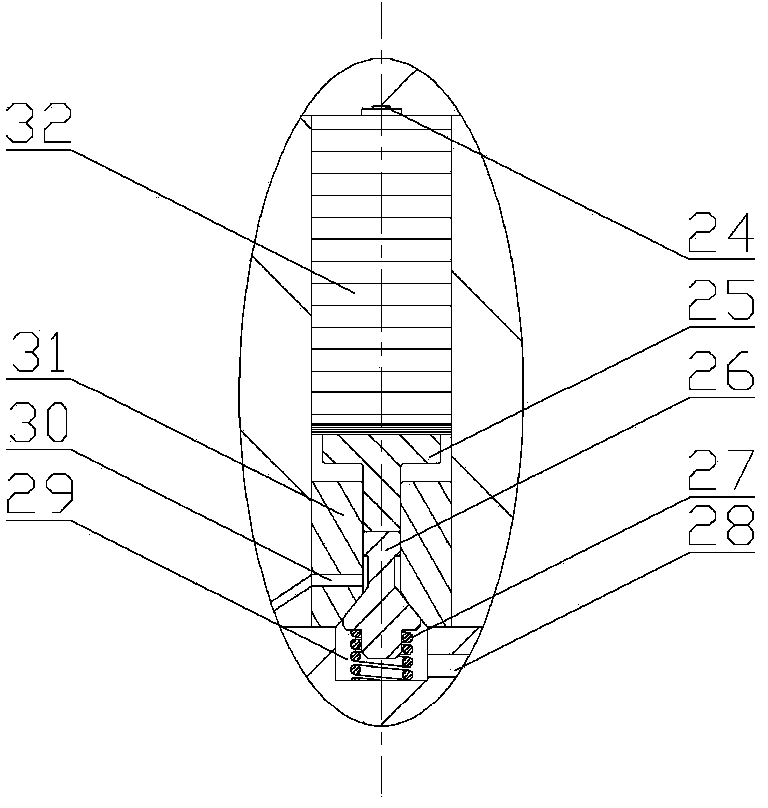

Pressure accumulation flow-limiting type electromagnetic control oil sprayer

ActiveCN104018966APrevent abnormal continuous fuel injectionGuaranteed reliabilityFuel injection apparatusMachines/enginesSprayerFuel oil

The invention provides a pressure accumulation flow-limiting type electromagnetic control oil sprayer which comprises an oil sprayer head, an oil sprayer body, a flow limiting component, an electromagnetic valve component, a needle valve reset spring, a locating pin, a nozzle, a needle valve, a needle valve limiting block, a valve seat, a tightening cap and a sealing ring. A pressure accumulation cavity is formed in the oil sprayer body, the pressure accumulation cavity is respectively communicated with a main oil inlet in the oil sprayer head and a first oil passing hole in the limiting block, the flow limiting component is arranged in the oil sprayer body, the lower end of the flow limiting component is communicated with a fuel oil channel in the oil sprayer body, the needle valve cavity is communicated with a second oil cavity through a fourth oil inlet in the needle valve limiting block, a first oil cavity is communicated with a high-pressure fuel oil path in the oil sprayer body through a third oil inlet in the vale seat, an oil drainage opening is communicated with an oil return opening through a low-pressure oil path in the oil sprayer body, and the needle valve limiting block is used as a spring seat of the needle valve reset spring to be arranged at the upper end of the needle valve. The pressure accumulation flow-limiting type electromagnetic control oil sprayer is high in response speed, high in control precision, flexible in oil spraying rule and stable in work in the small oil spraying quantity spraying process.

Owner:HARBIN ENG UNIV

High temperature corrosion on-line monitoring system for boiler water-cooled wall

The invention discloses a boiler water-cooling wall high-temperature corrosion online monitoring system, comprising a sampling system and a sampling control and disposing system, wherein, the sampling system comprises a fume sampling probe pipe; a fume sampling probe heat-preservation box of a temperature control device is arranged behind the fume sampling probe pipe; an electric heating pipe and a quick cooling device are connected behind the probe heat-preservation box; two branches are connected behind the electric heating pipe and the quick cooling device, wherein, one branch is a fume branch and the other branch is sequentially connected with a sample air separation electromagnetic valve, a sample air sampling pump, a calibration / sampling three-way electromagnetic valve, a 0.1Mum ceramic filter, a sample air adjusting needle valve, a flowmeter and a fume analysis gauge; the sampling control and disposing system comprises a PLC which can control the running of the sampling system, a data collector which is connected with the fume analysis gauge by a data wire and an industry control machine which is connected with the data collector by the data wire. The boiler water-cooling wall high-temperature corrosion online monitoring system can achieve the object of online monitoring the high-temperature corrosion speed of the boiler water-cooling wall and provides safety evaluation basis of the heated surface for the combustion optimization of the boiler.

Owner:JIANGSU FRONTIER ELECTRIC TECH +1

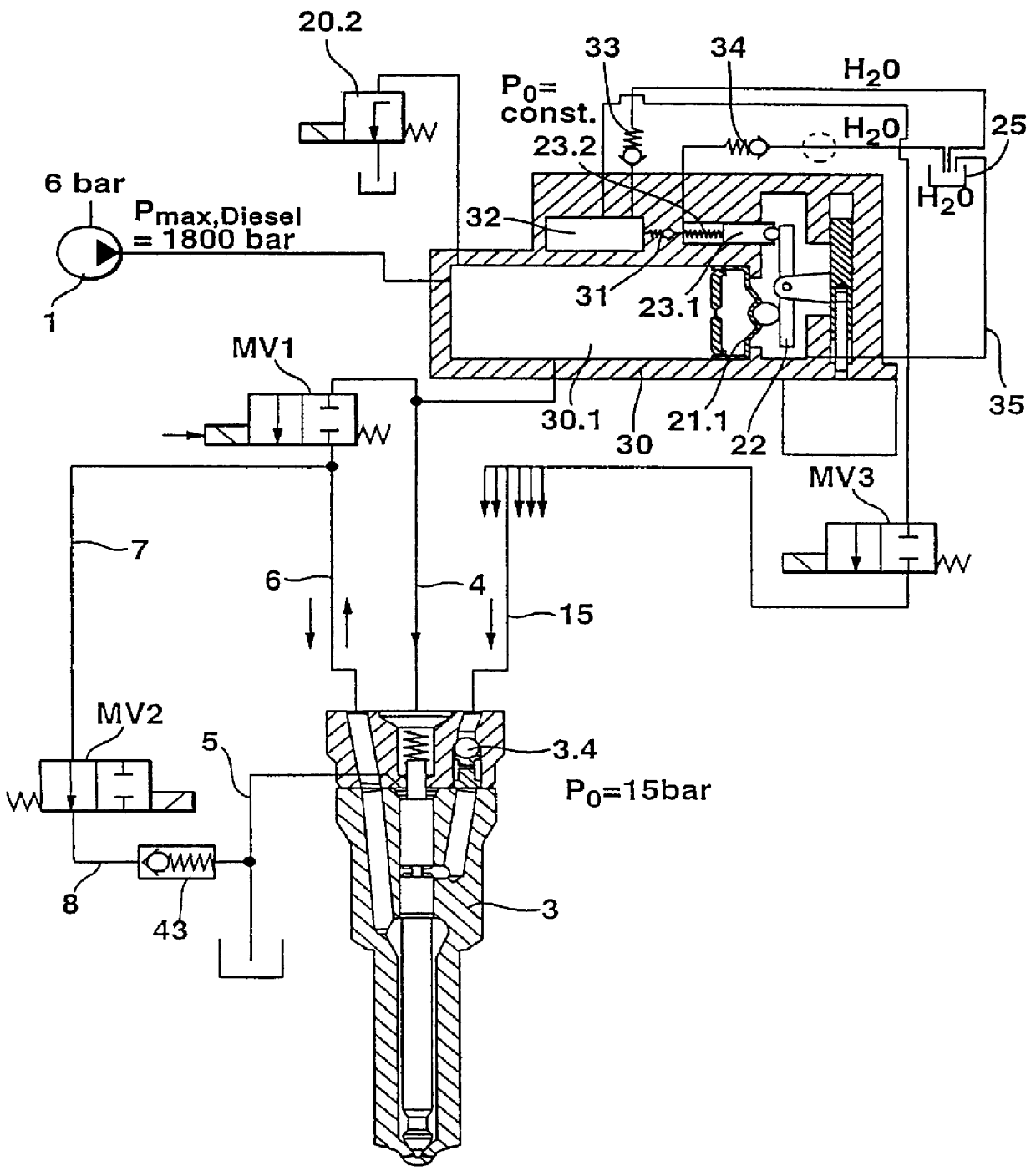

Fuel injection system for an internal combustion engine

InactiveUS6067964AAccurate supervisionHigh degreeCombustion enginesFuel injecting pumpsCommon railEngineering

PCT No. PCT / DE98 / 02771 Sec. 371 Date Jul. 23, 1999 Sec. 102(e) Date Jul. 23, 1999 PCT Filed Sep. 18, 1998 PCT Pub. No. WO99 / 20893 PCT Pub. Date Apr. 29, 1999A fuel injection system having a common rail pressure reservoir filled with high-pressure fuel and having a dual-fuel injector for a bi-fluid injection of fuel and an additive fluid into an internal combustion engine. The system includes a first 2 / 2-way valve in the injection line between the common rail pressure reservoir and a pressure chamber encompassing the injector needle of the dual-fuel injector as well as a second 2 / 2-way valve, whose inlet is connected via a supply line to the injection line at a point between the first 2 / 2-way valve and the pressure chamber, and whose outlet is connected to the low-pressure fuel side by way of an outlet line. As a result, the otherwise conventional 3 / 2-way solenoid control valves, which are significantly more complex technically, can be replaced by more reasonably priced 2 / 2-way valves. At the same time, this raises the possibility of shifting the quantity metering for additive fluid to a single metering valve that serves an entire group of injectors.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com