Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20219 results about "Valve seat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The valve seat in an internal combustion gasoline or diesel engine is the surface against which an intake or an exhaust valve rests during the portion of the engine operating cycle when that valve is closed. The valve seat is a critical component of an engine in that if it is improperly positioned, oriented, or formed during manufacture, valve leakage will occur which will adversely affect the engine compression ratio and therefore the engine efficiency, performance (engine power and engine torque), exhaust emissions, and engine life.

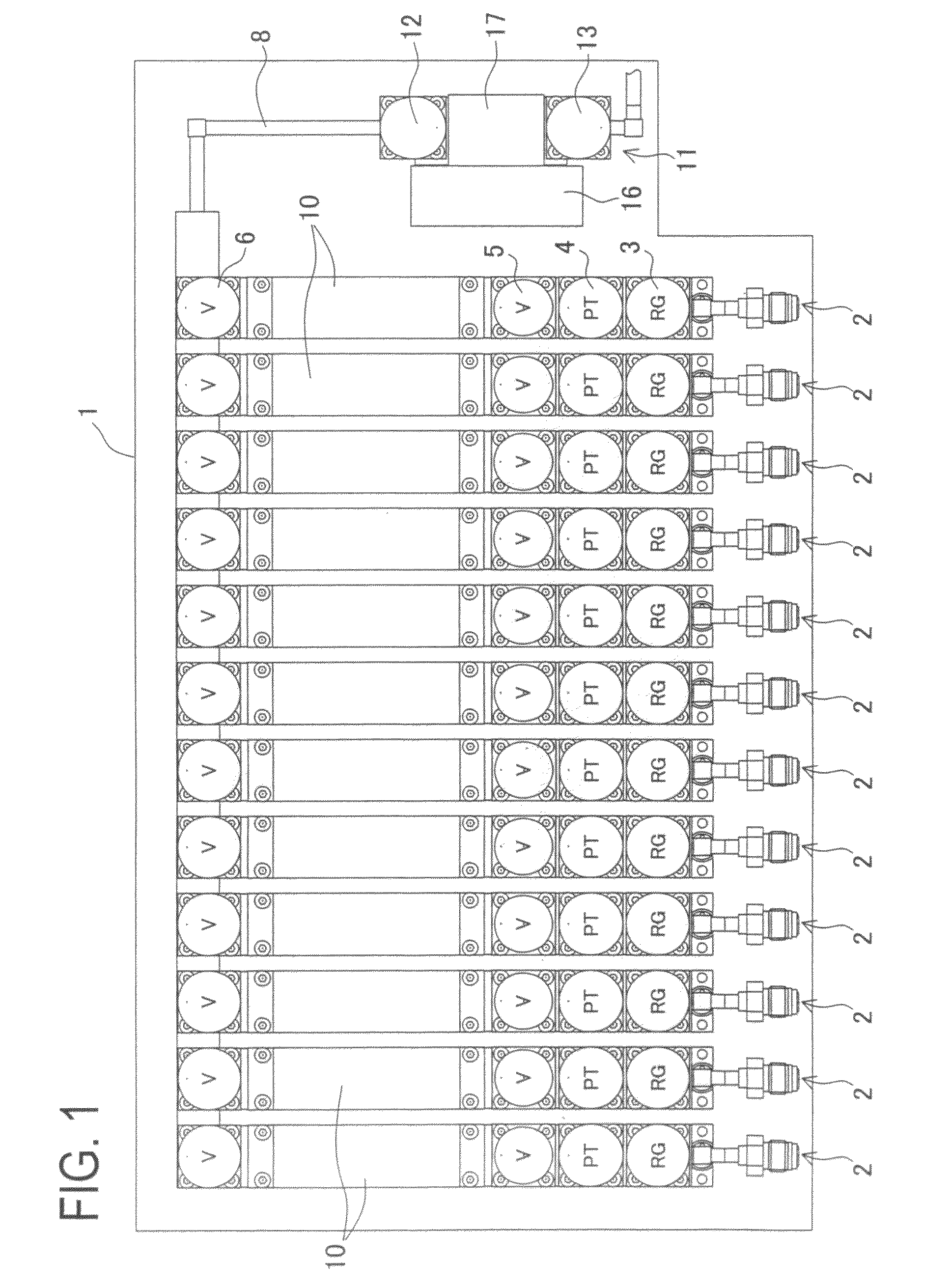

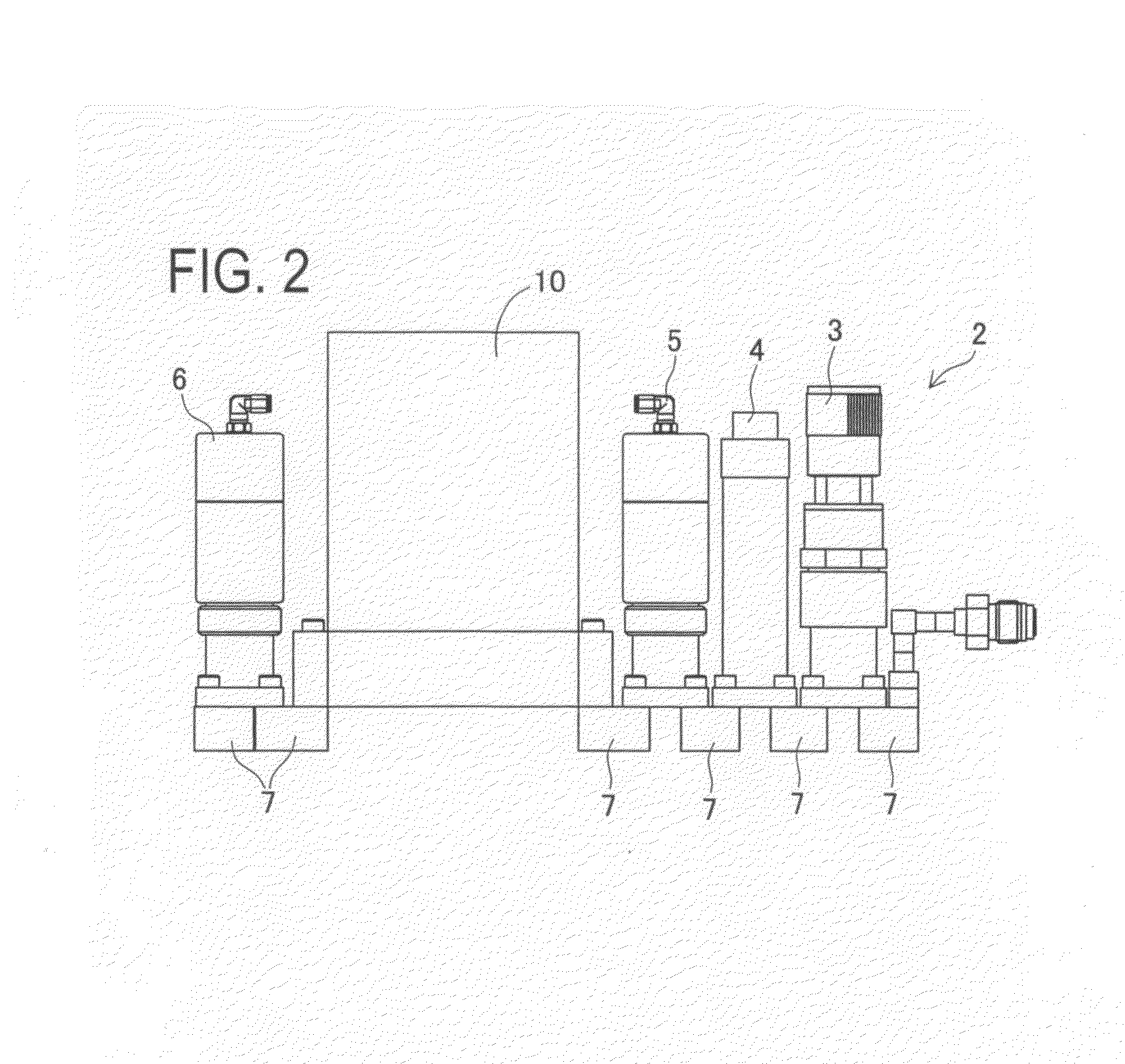

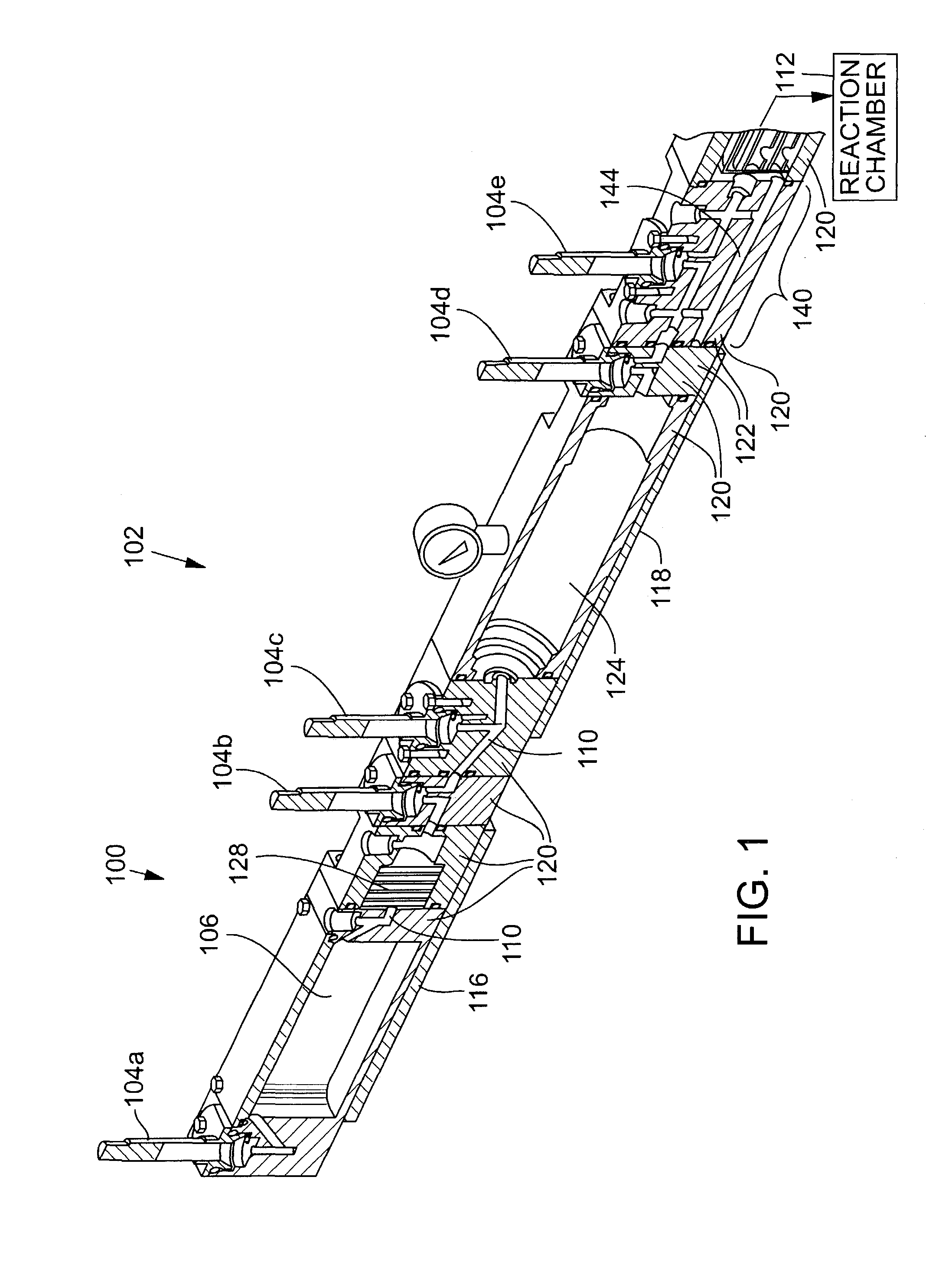

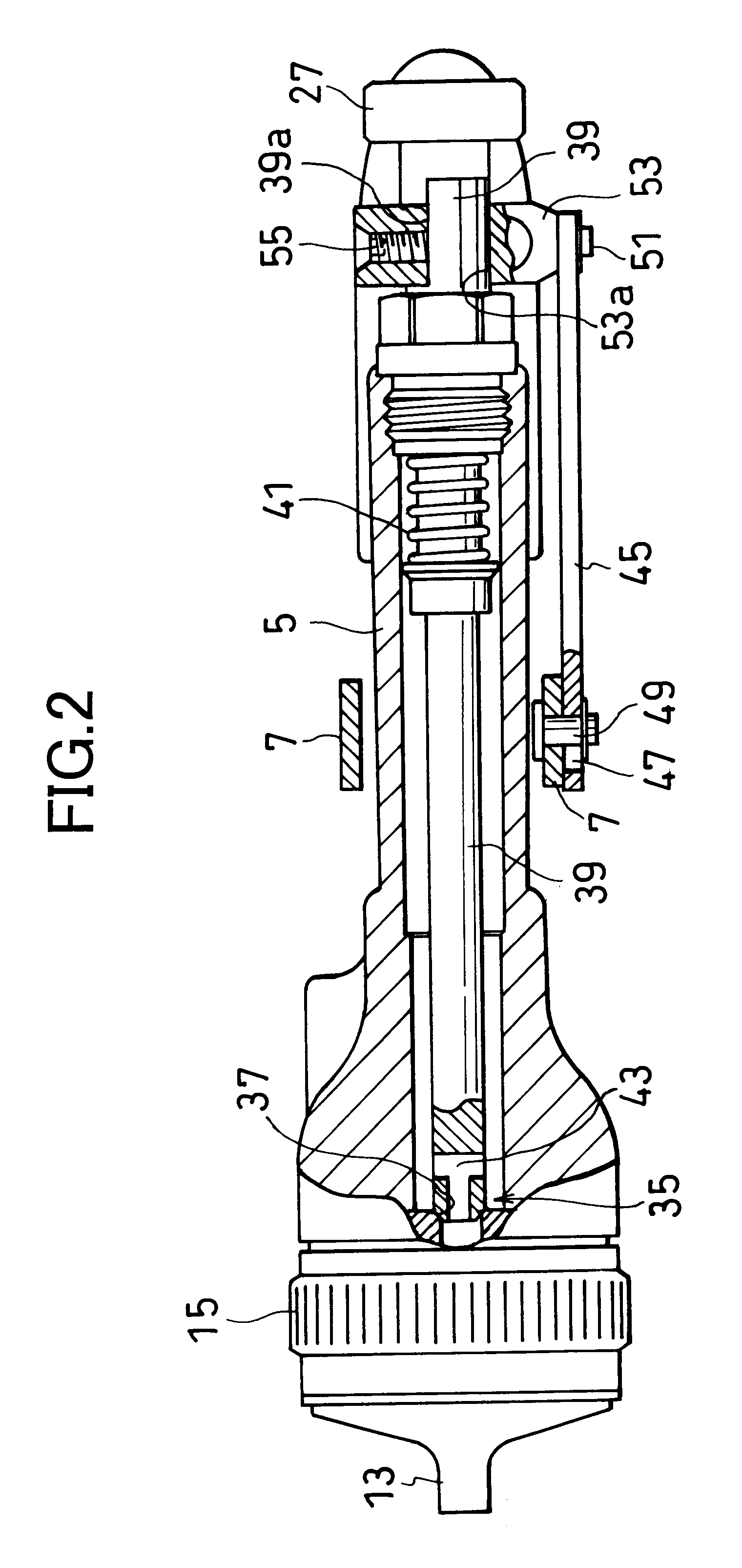

Gas flow rate verification unit

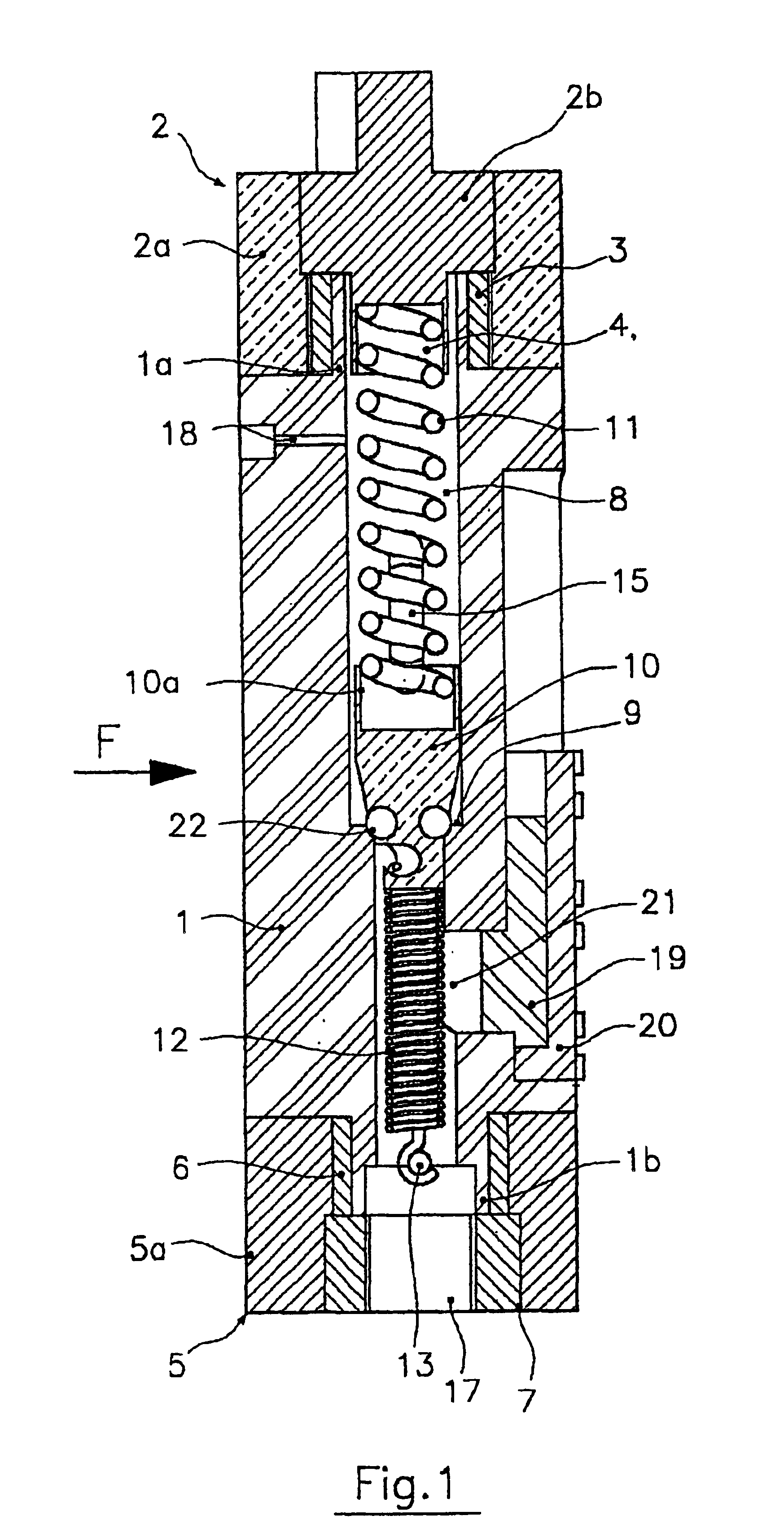

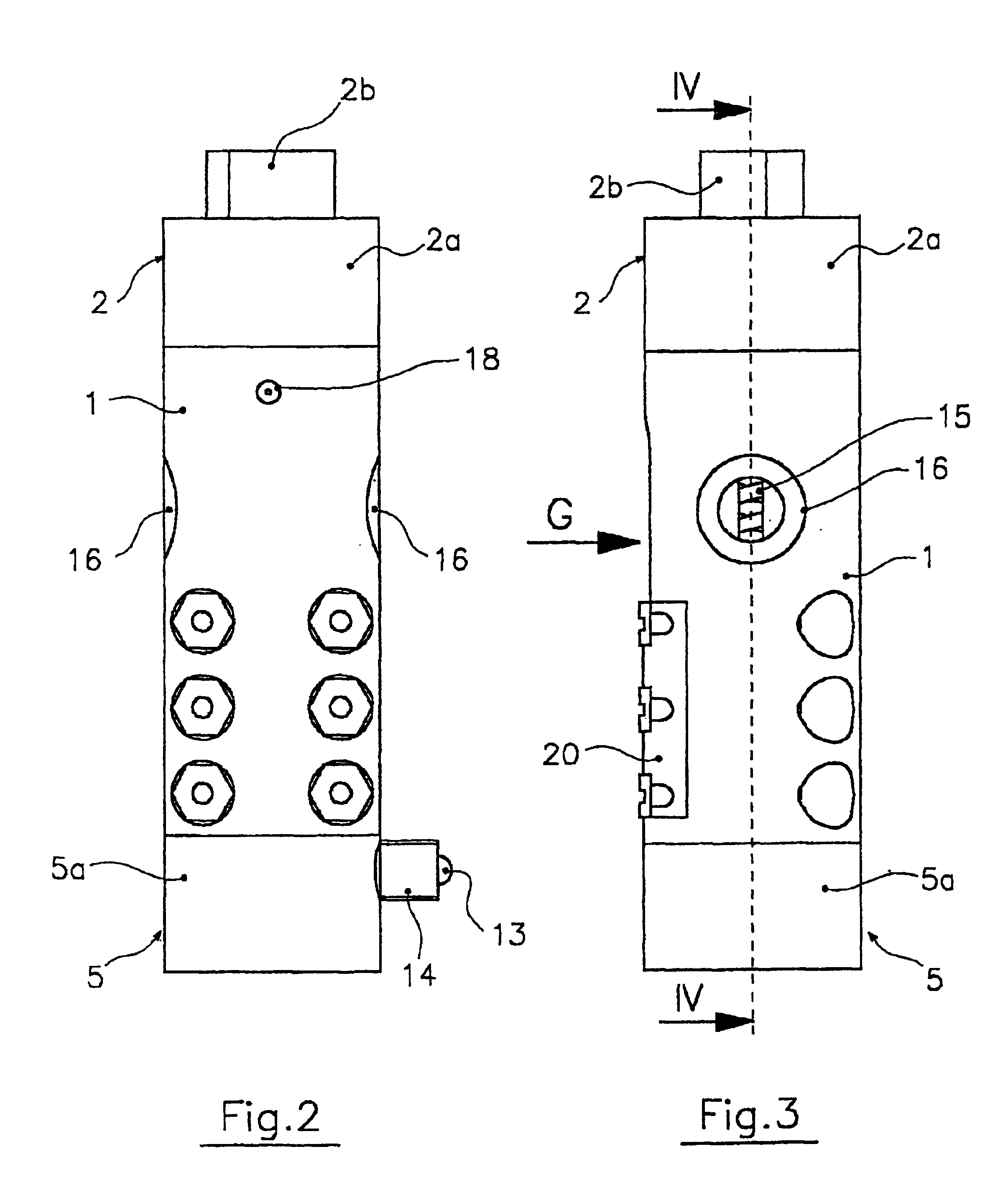

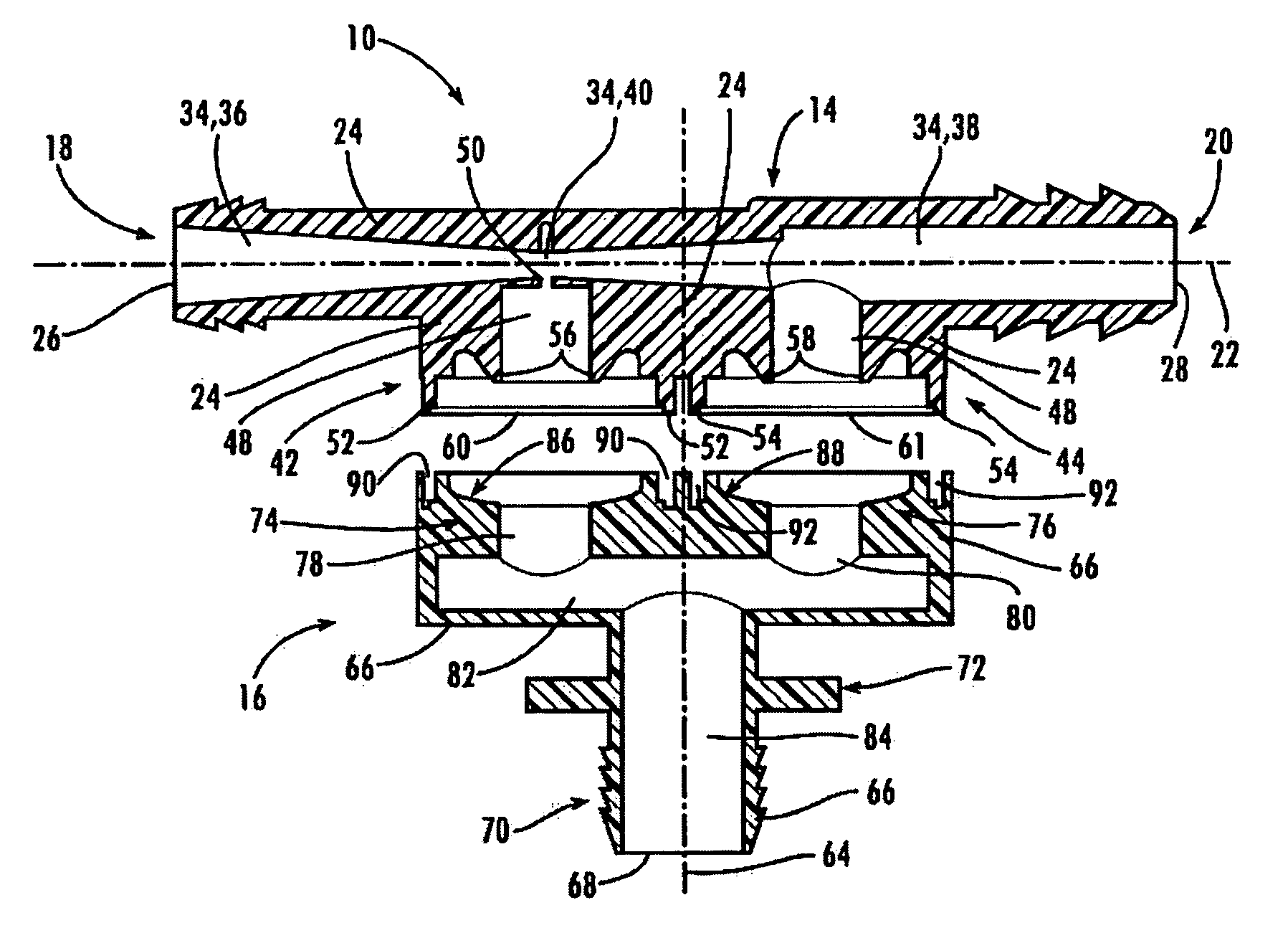

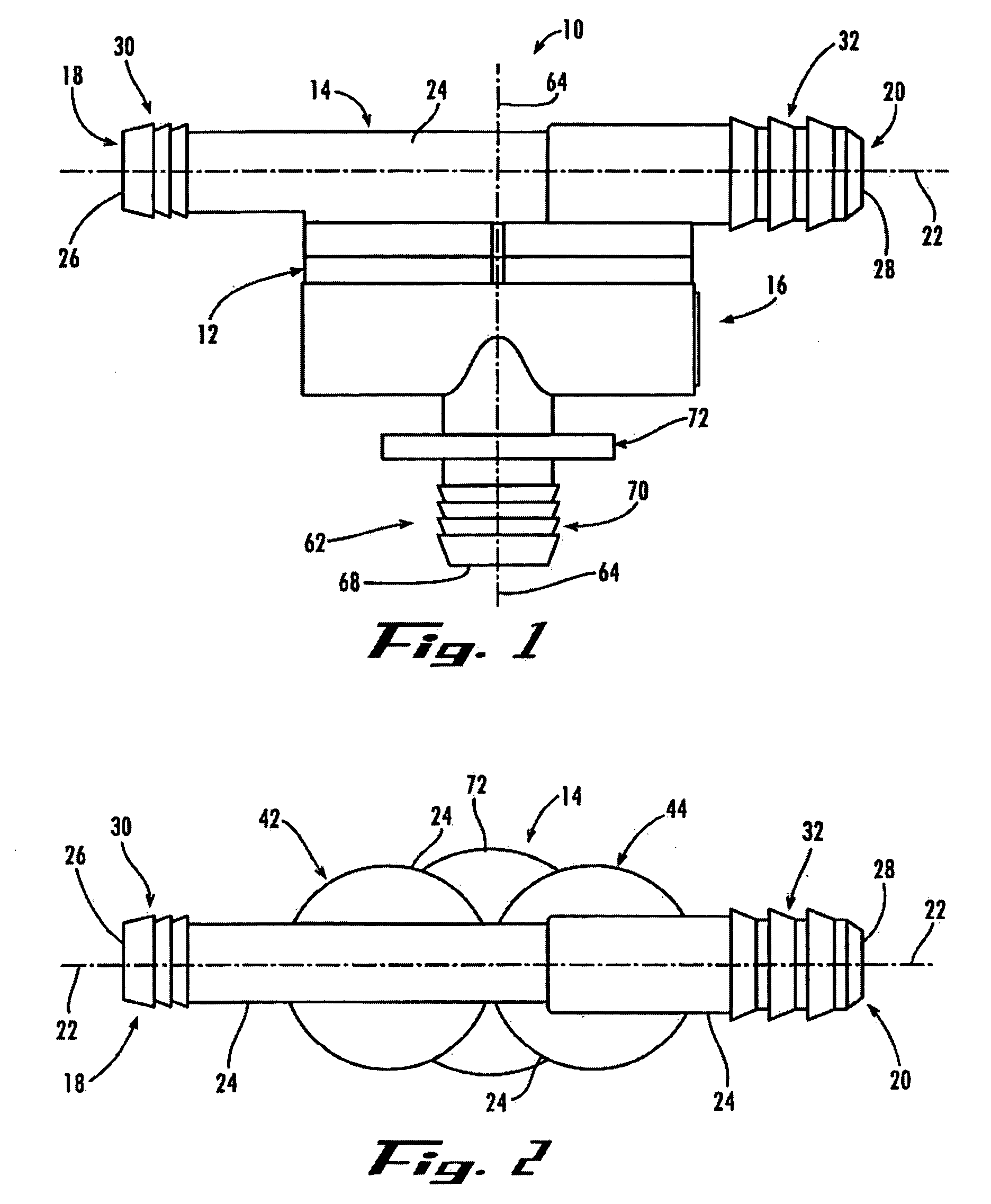

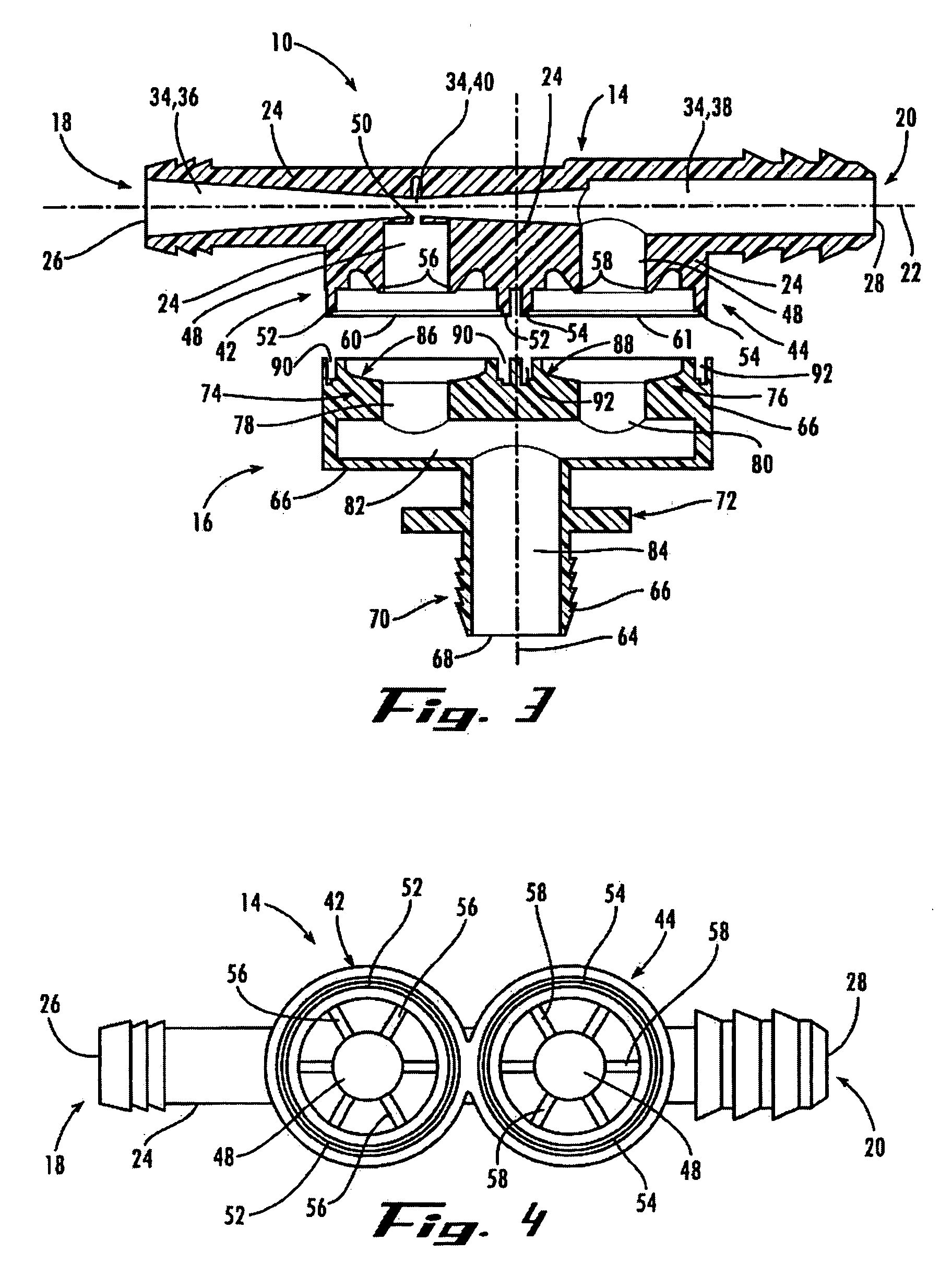

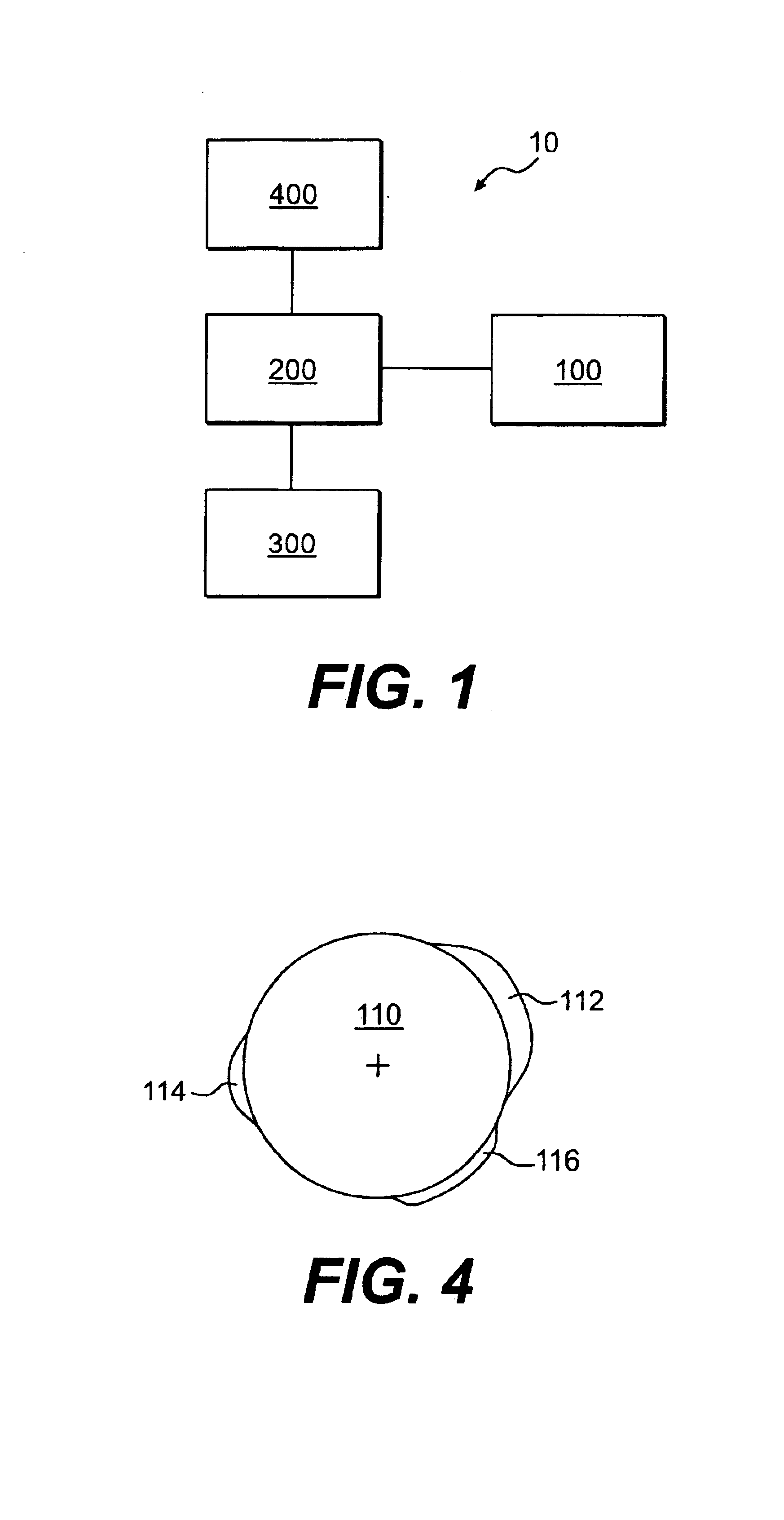

ActiveUS7716993B2Increase flow rateUniform pressureMultiple way valvesPipeline systemsEngineeringGas supply

A gas flow rate verification unit capable of enhancing reliability of gas flow rate verification. The gas flow rate verification unit has a first cutoff valve that is connected to a flow rate control device and to which gas is inputted, a second cutoff valve for discharging the gas, a communication member for allowing the first cutoff valve and the second cutoff valve to communicate with each other, a pressure sensor for detecting the pressure of the gas supplied between the first cutoff valve and the second cutoff valve, a temperature detector for detecting the temperature of the gas supplied between the first cutoff valve and the second cutoff valve, and a control means for verifying the flow of the gas flowing in the flow control device, the verification being performed by using both the result of the pressure detected by the pressure sensor and the result of the temperatures detected by the temperature detector. The volume (Vk) between the valve seat of the first cutoff valve and the valve seat of the second cutoff valve is equal to or less than the volume (Ve) between the outlet of the flow control device and the valve seat of the first cutoff valve.

Owner:CKD

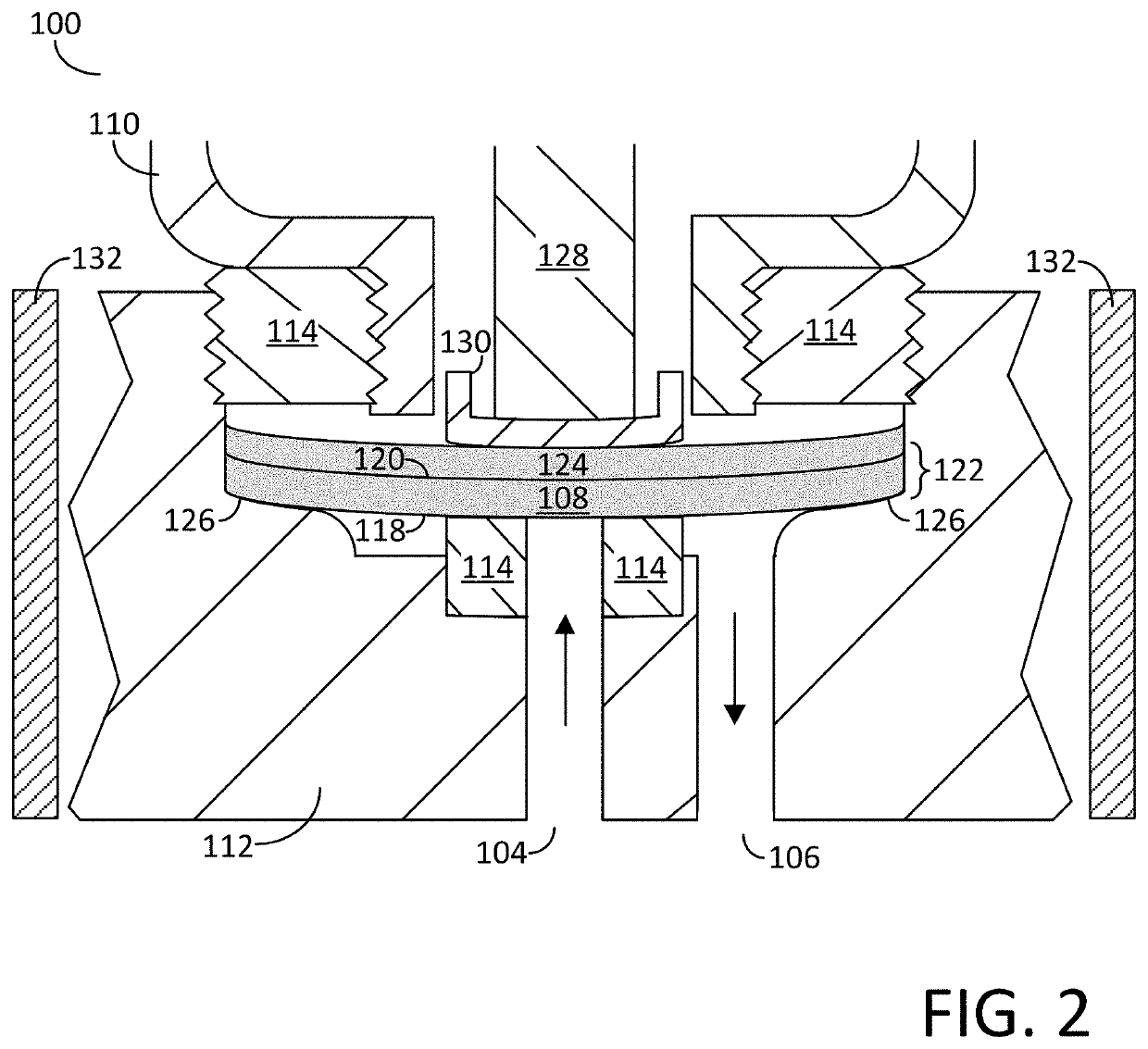

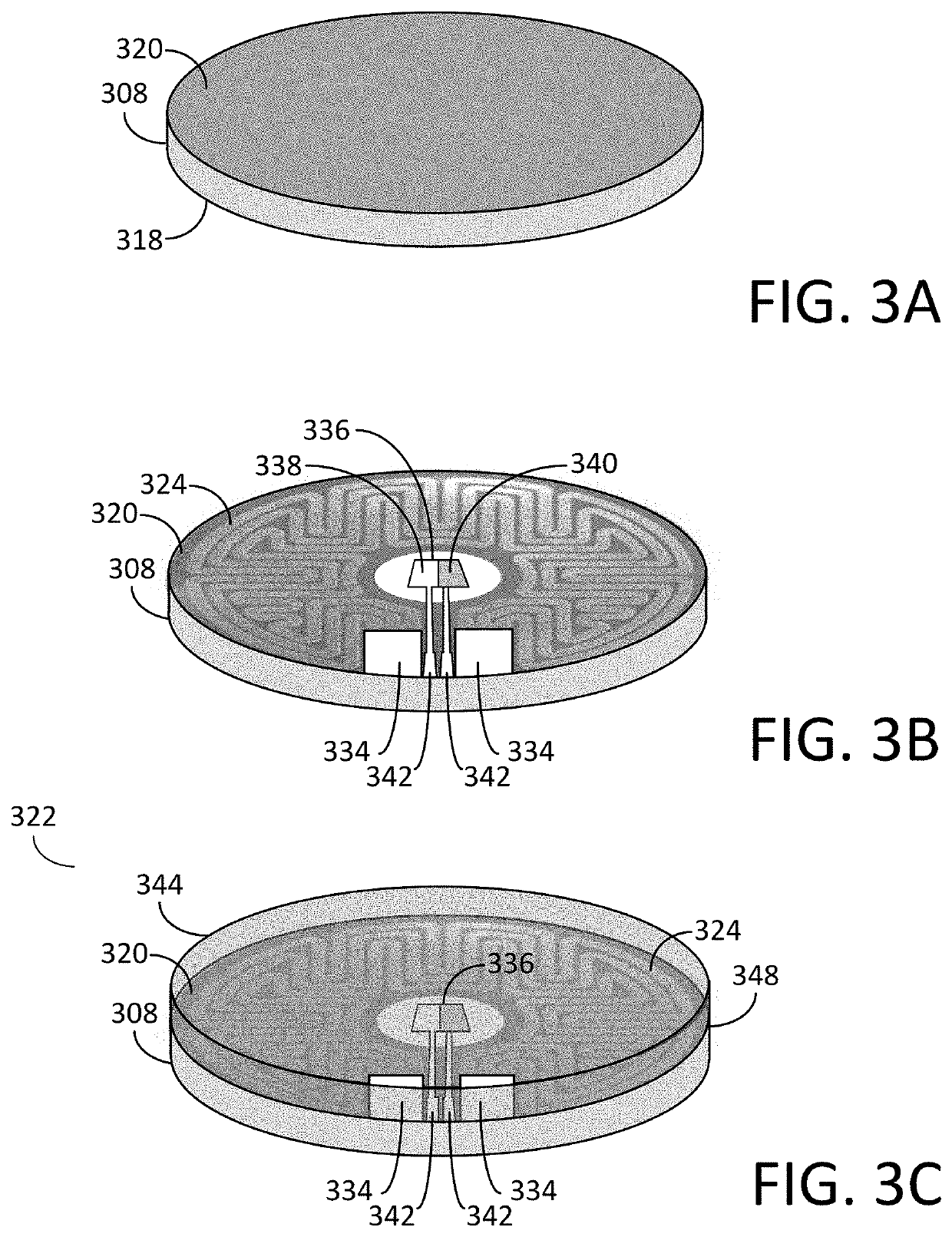

Diaphragm valves, valve components, and methods for forming valve components

ActiveUS20200018421A1Diaphragm valvesOperating means/releasing devices for valvesValve actuatorEngineering

A diaphragm valve is disclosed. The diaphragm valve may include, a valve body comprising a valve channel, the valve channel including an inlet channel and an outlet channel. The diaphragm valve may also include, a valve seat adjacent to the valve channel and a flexible diaphragm comprising a wetted surface and an opposing non-wetted surface, the flexible diaphragm being disposed adjacent to the valve channel. The diaphragm valve may also include, a flexible heater disposed over the non-wetted surface of the flexible diaphragm, and a valve actuator that is operable to operable to move the wetted surface of the flexible diaphragm into and out of contact with the valve seat. Valve components including a flexible heater and methods for forming such valve components are also disclosed.

Owner:ASM IP HLDG BV

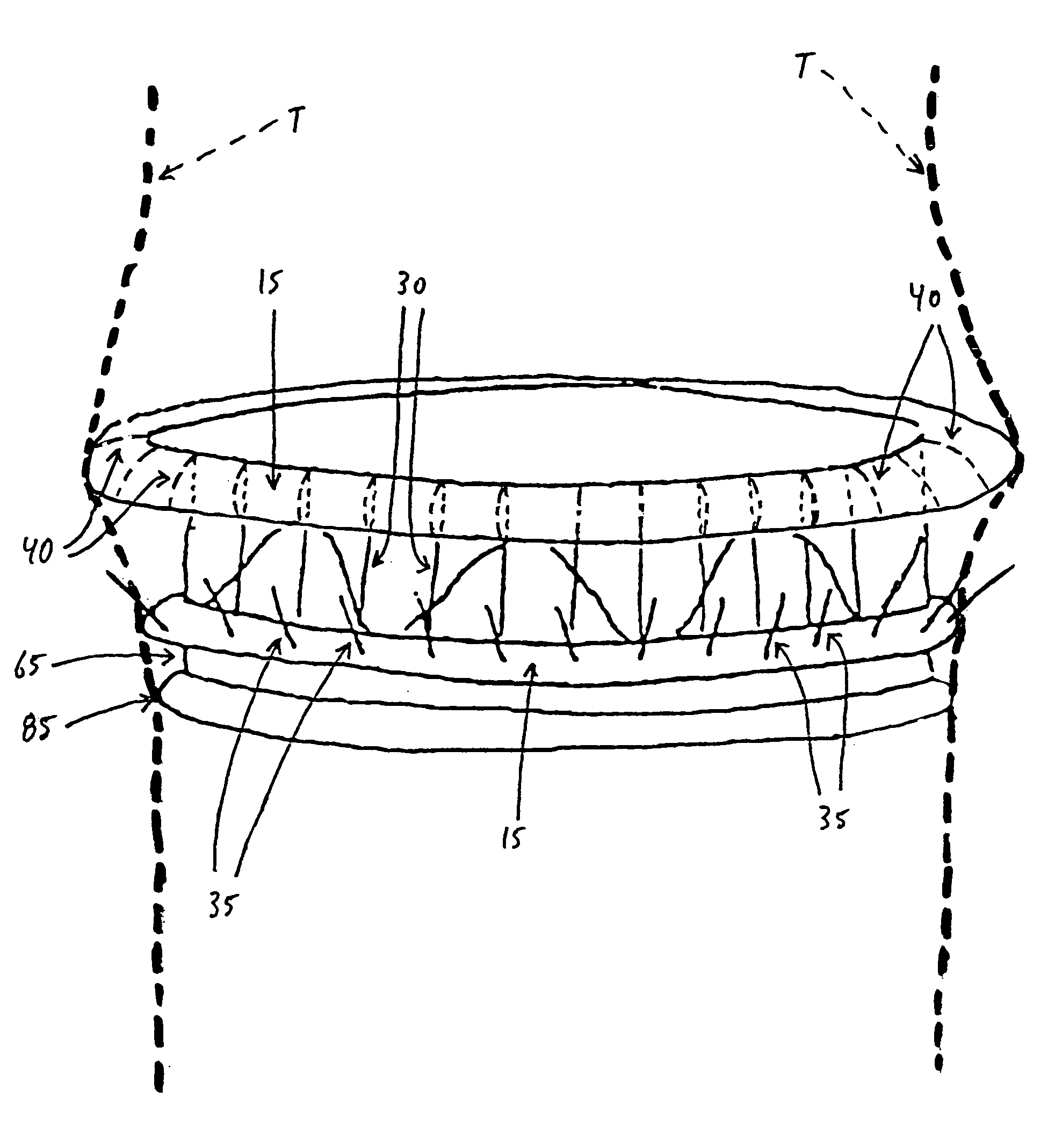

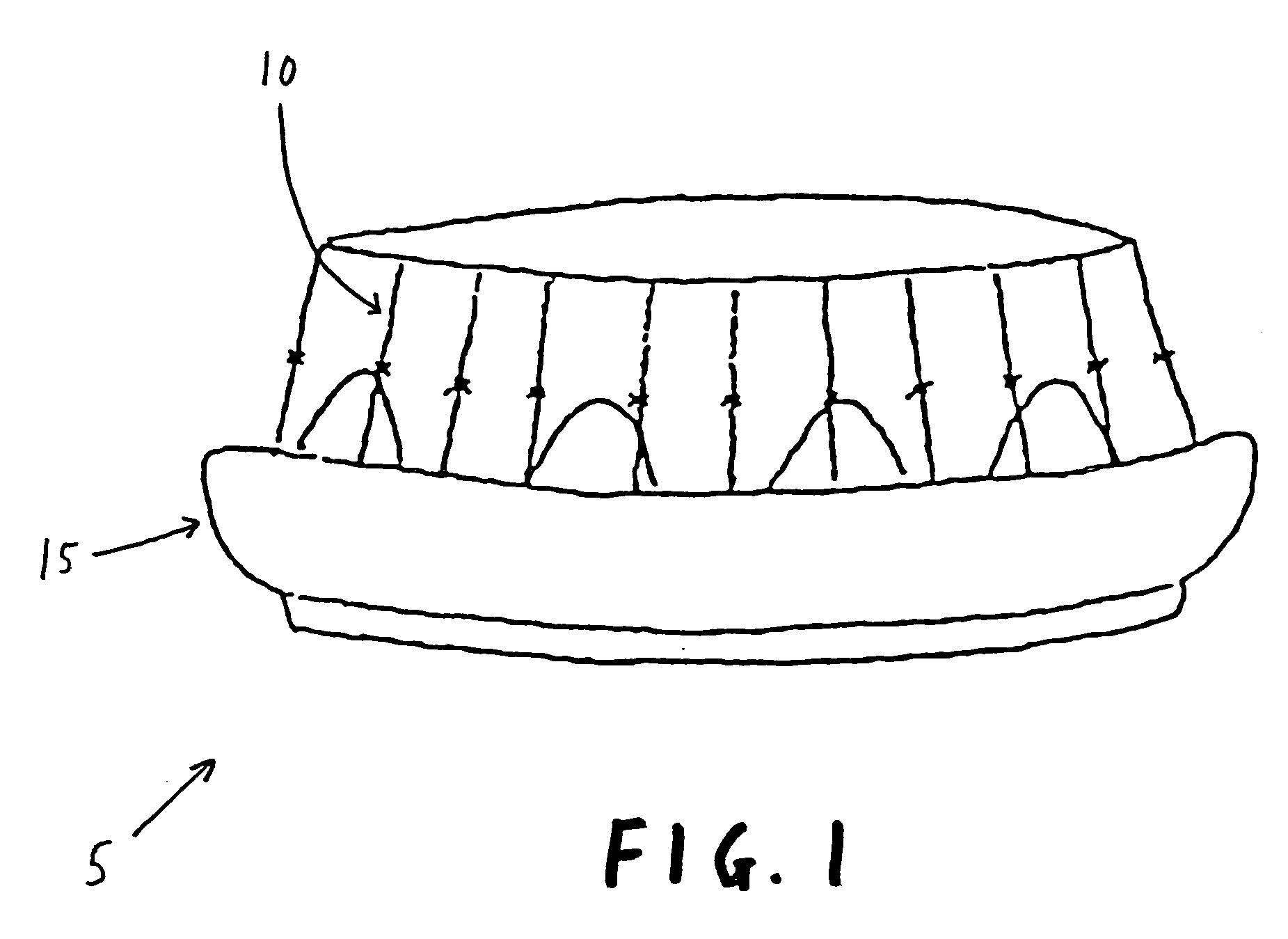

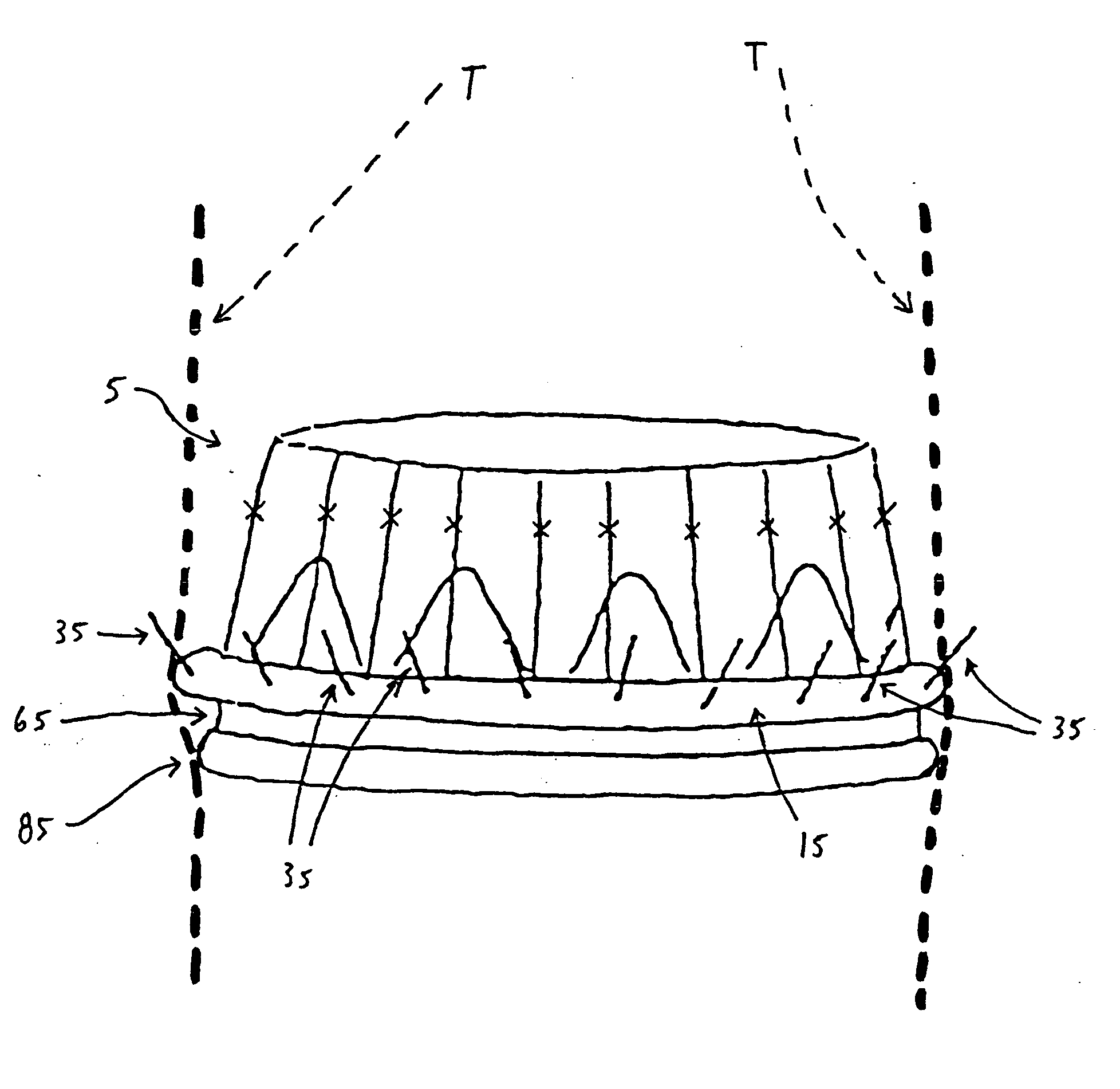

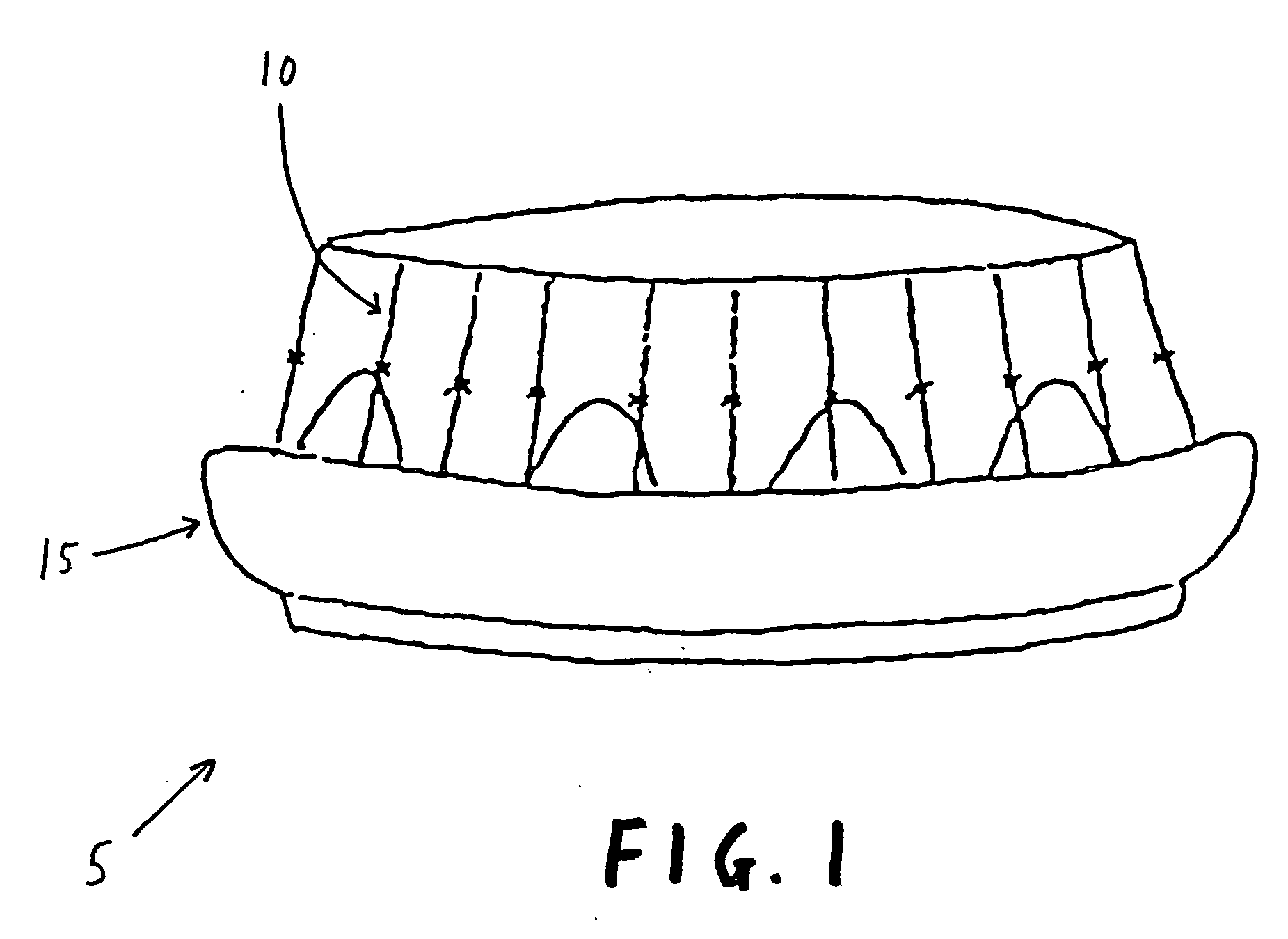

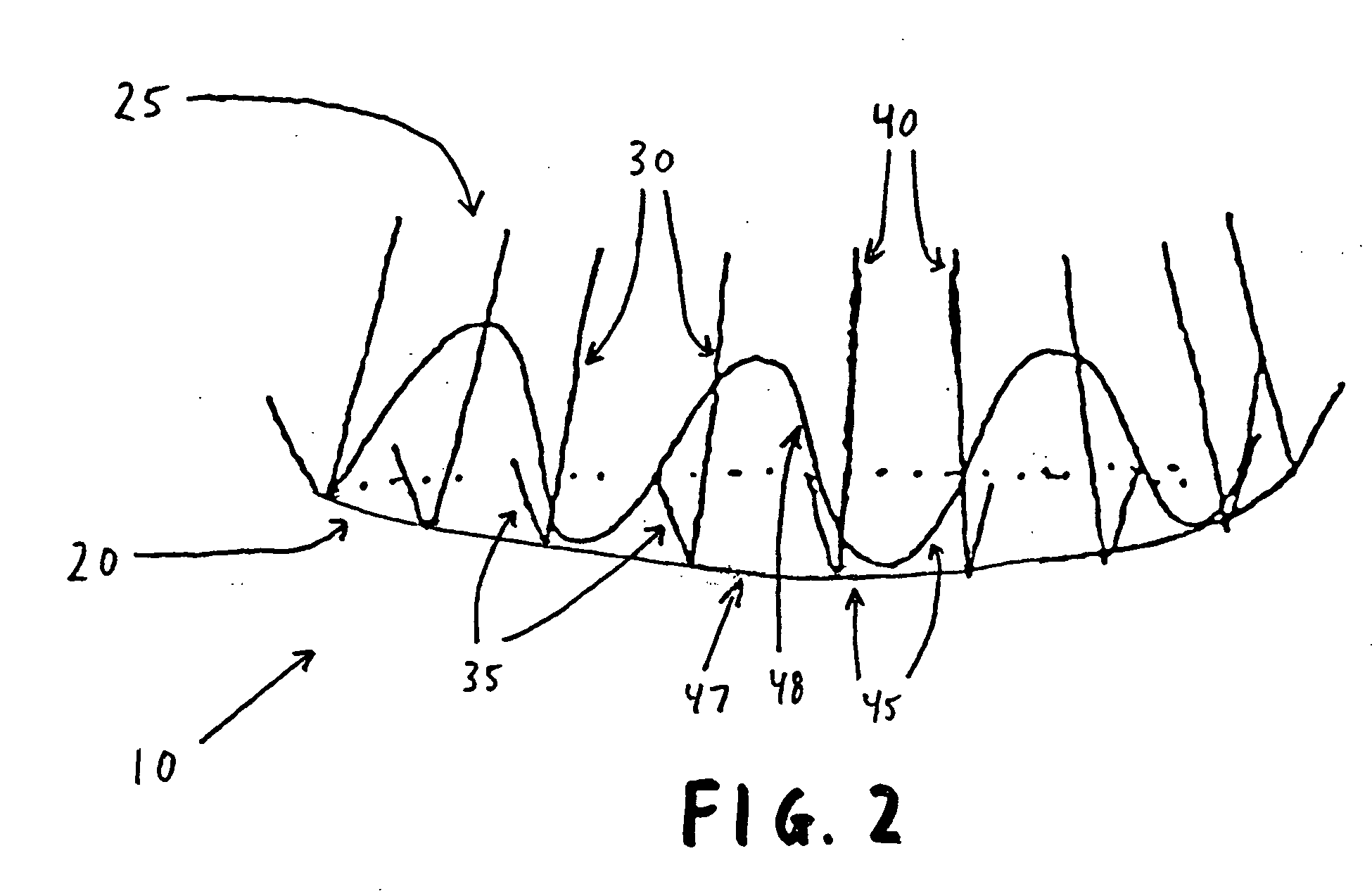

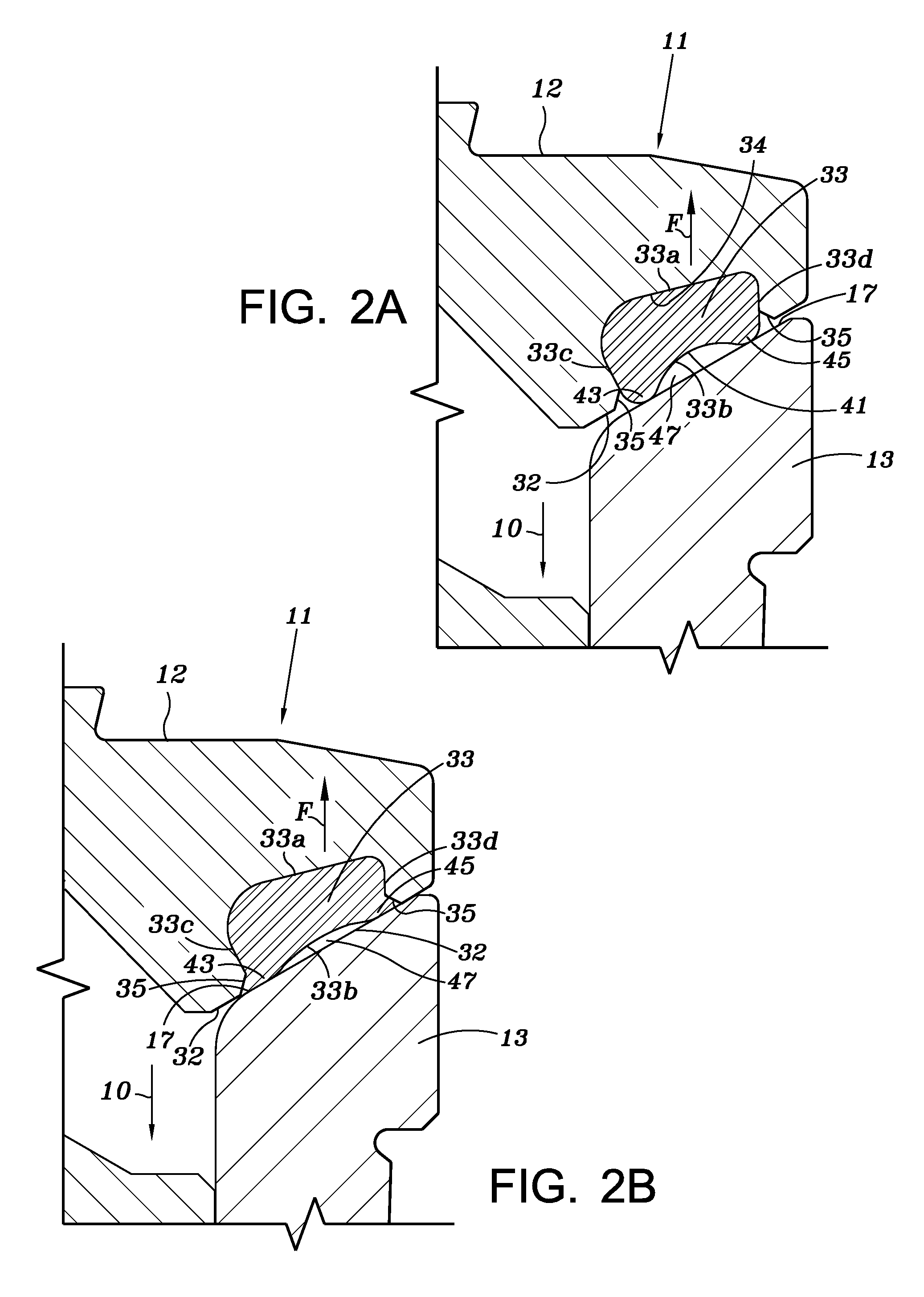

Fixation band for affixing a prosthetic heart valve to tissue

InactiveUS7300463B2Quickly and easily and conveniently affixingHeart valvesProsthetic valveProsthesis

Owner:MEDTRONIC INC

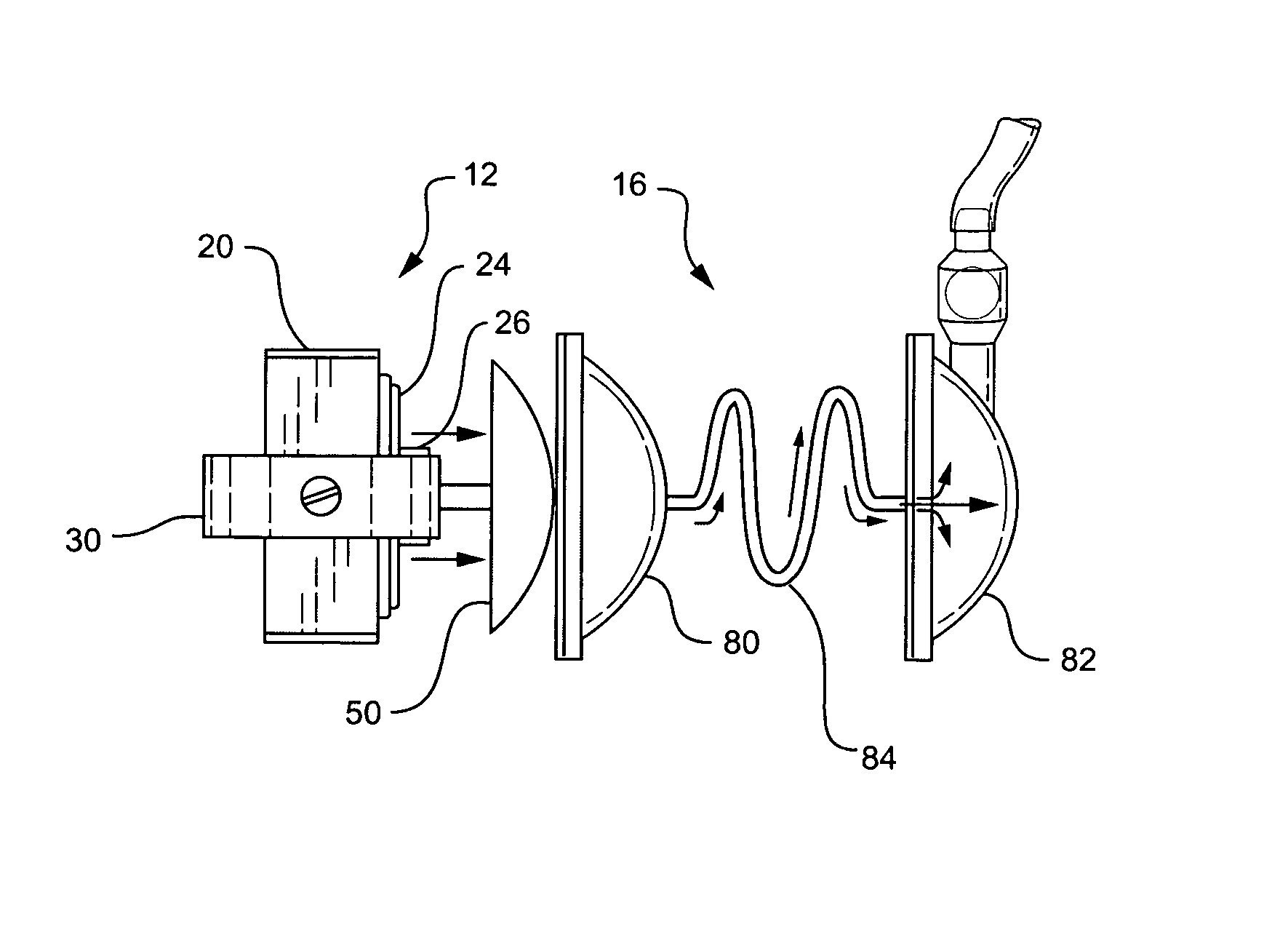

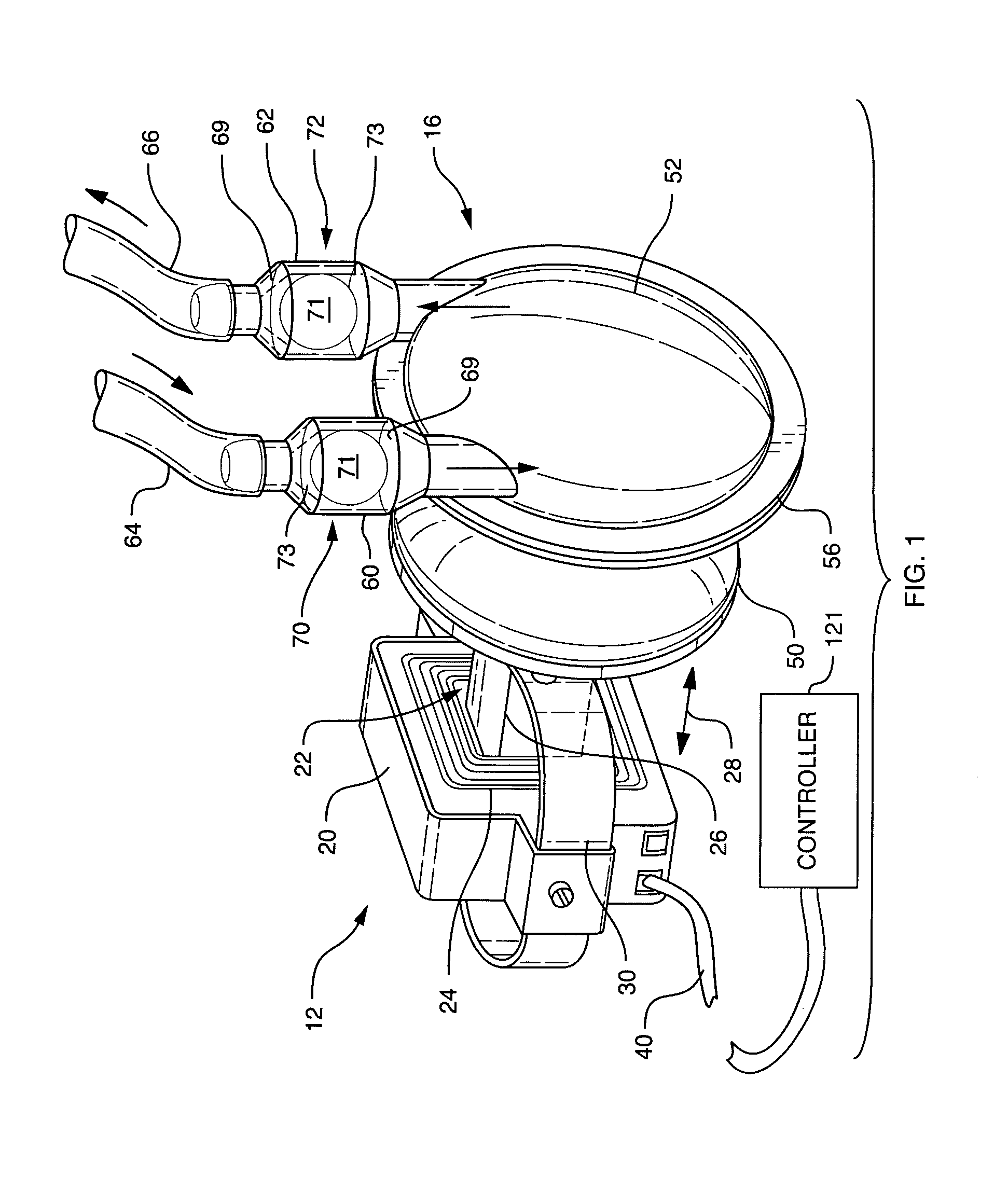

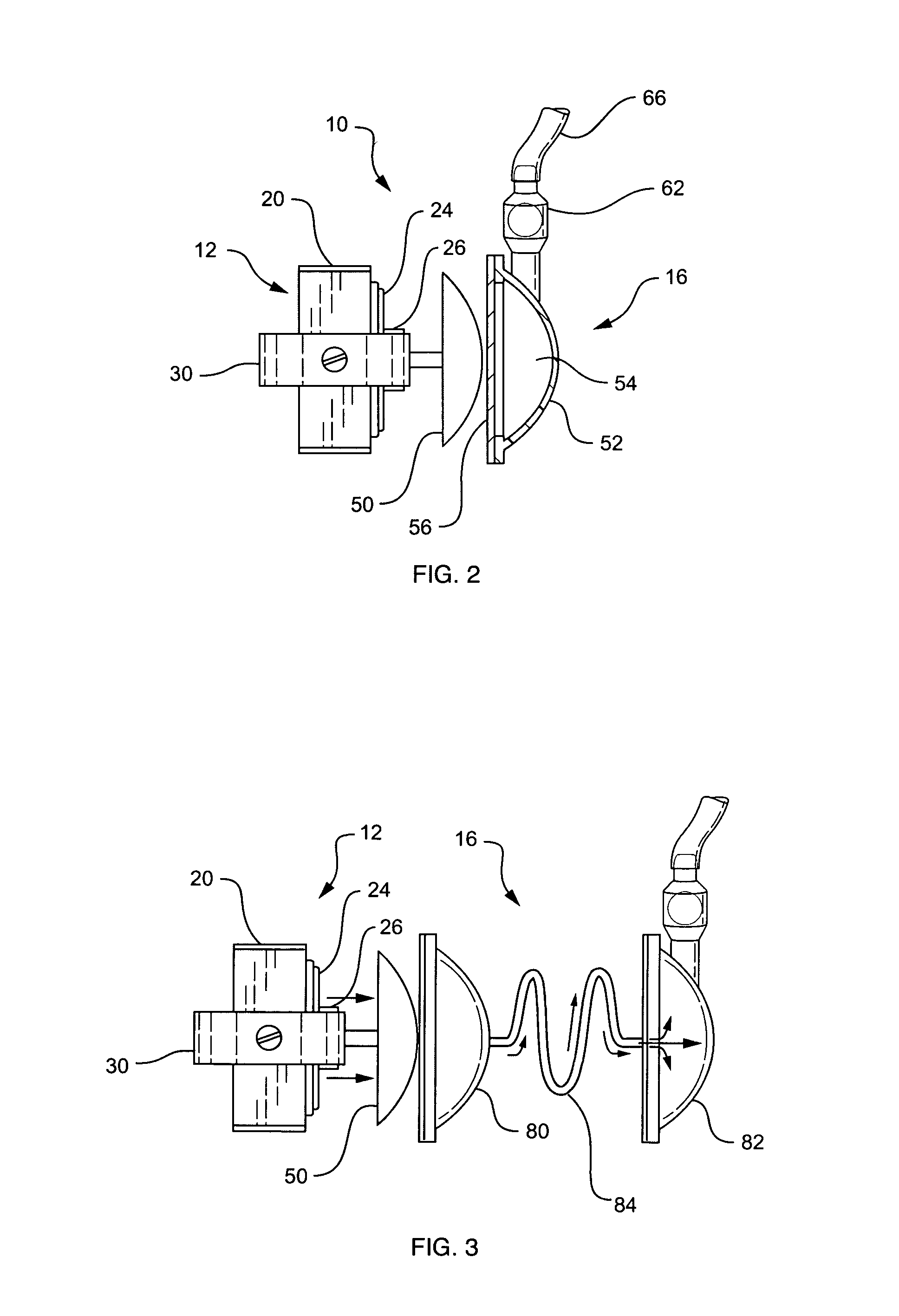

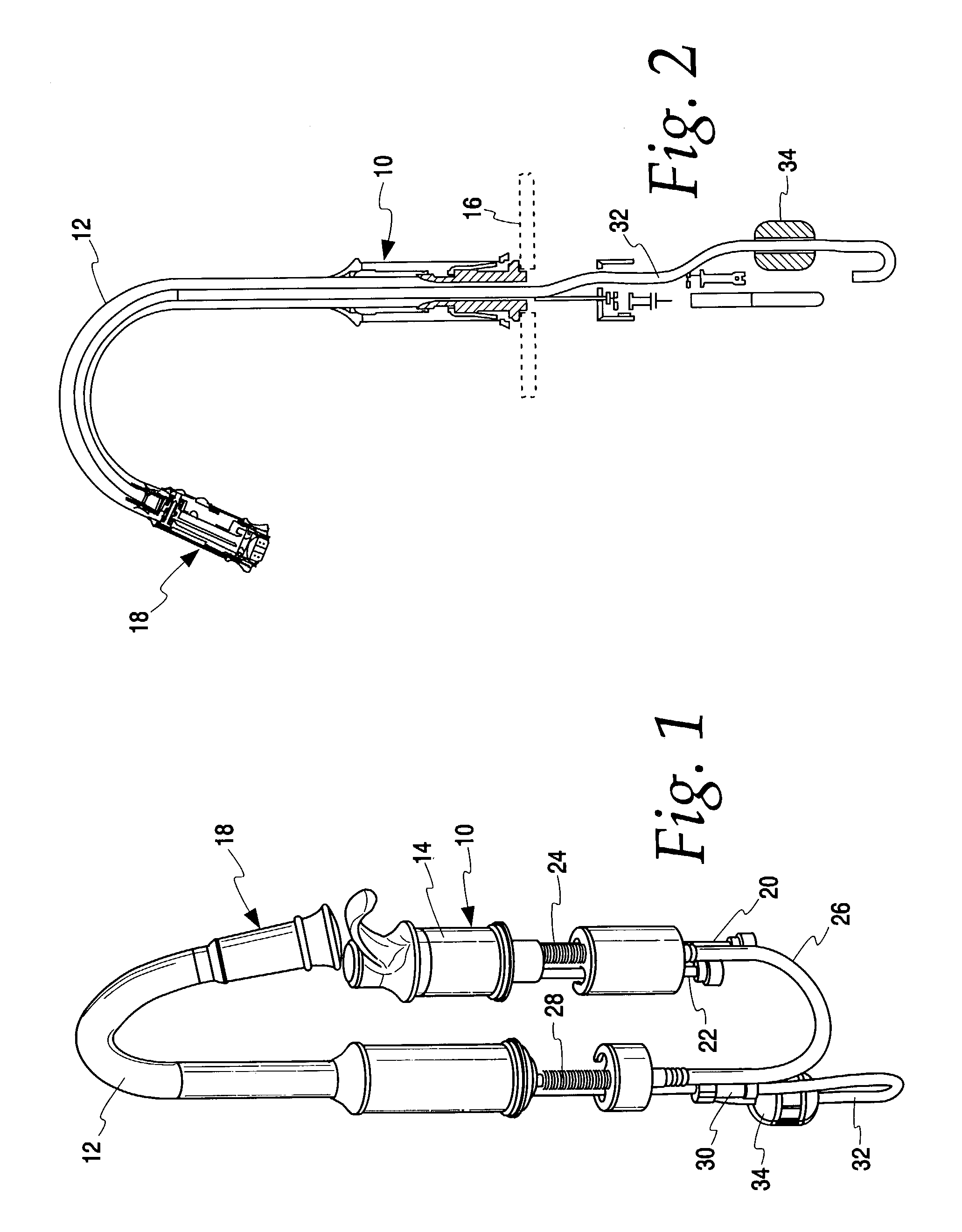

Fluid pump

ActiveUS7238165B2ElectrocardiographyOther blood circulation devicesEngineeringCardiopulmonary bypass time

A pumping system 10 provides a physiological pulsatile flow and includes controller 121, a pump drive head 50 coupled to a motor 12 and a fluid housing 52 having at least one port 60. The port 60 includes a ball valve retainer region 69, a valve seat 73, and an occluder ball 71 disposed in the ball valve retainer region 69. During operation, the motor 12 forces the fluid in and out the fluid housing 52 and causes the occluder ball 71 to move from a first position whereby the fluid cannot pass through the port 60, to a second position whereby the fluid moves annular to and generally around the occluder ball 71. This movement creates a slight flow reversal that “breaks up” any blood clots that may form. The pumping system may be used as part of a cardiopulmonary bypass system, a ventricular assist device (VAD) and / or a heart pump.

Owner:DESIGN MENTOR

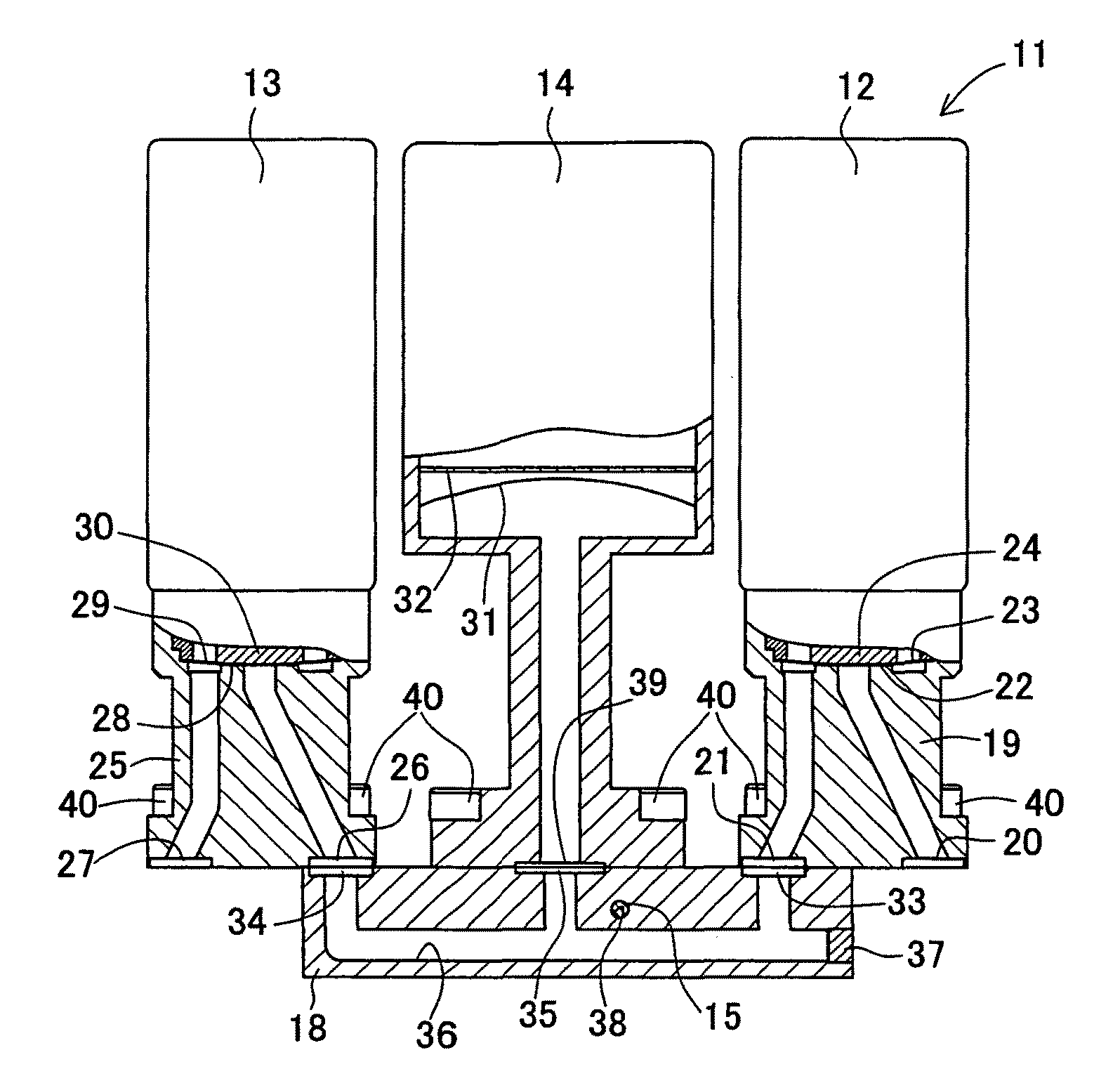

Diaphragm valve with reliability enhancements for atomic layer deposition

InactiveUS7021330B2Improve heat transfer performanceInhibiting condensingDiaphragm valvesOperating means/releasing devices for valvesEnhanced heat transferDiaphragm valve

A shut-off type diaphragm valve adapted for use in an atomic layer deposition system includes a valve seat having an annular seating surface that surrounds an inlet of the valve and extends radially therefrom. The seating surface contacts a substantial portion of the first side of a flexible diaphragm when the diaphragm is closed, to facilitate heat transfer and counteract dissipative cooling of the diaphragm, thereby inhibiting condensation of a medium flowing through the valve passage. The seating surface is preferably flat and smooth, to prevent shearing of an elastomeric diaphragm. For a plastic diaphragm, a ring-shaped seating ridge may extend from the seating surface to cause localized permanent deformation of the diaphragm and enhanced sealing, while still allowing a substantial portion of the diaphragm to contact the seating surface for enhanced heat transfer. Valve speed enhancements and other reliability enhancing features are also described.

Owner:BENEQ OY

Proportional valve with shape memory alloy actuator

InactiveUS6840257B2Limited sizeReduce weightTemperature control without auxillary powerOperating means/releasing devices for valvesClosed loopAlloy

A proportional valve is disclosed for controlling the outlet pressure of a fluid flowing therethrough. The valve comprises a valve body having an inlet port and an outlet port for the fluid. The valve also has an inner chamber, within which there is formed a valve seat that may be opened and closed variably by a shutter axially movable from and towards the valve seat. Movement of the shutter is controlled by a shape memory alloy (SMA) actuating member operating antagonistically to an elastic member, the temperature of the fluid being lower than the transition temperature of the shape memory alloy. The actuating member and the elastic member are connected to the body valve at opposite sides relative to the valve seat. A power control circuit is also provided for circulating an electric current through the actuating member so as to heat the same by Joule effect from a temperature lower than the transition temperature to one that is higher. At least one vent hole is formed in the valve body for putting a portion of the chamber upstream of the valve seat into fluid communication with the outside or a collection network. The actuating member is housed in that portion of chamber corresponding to the inlet port of the fluid, whereby a continuous flow of fluid around the actuating member is ensured for accelerating the cooling process. A closed-loop control circuit for the power control circuit controls the circulating current as a function of a pressure signal generated by fluid pressure sensing means and in such a way as to offset the retarding effect produced by the fluid during heating of the actuating member.

Owner:ARENA ALBERTO +2

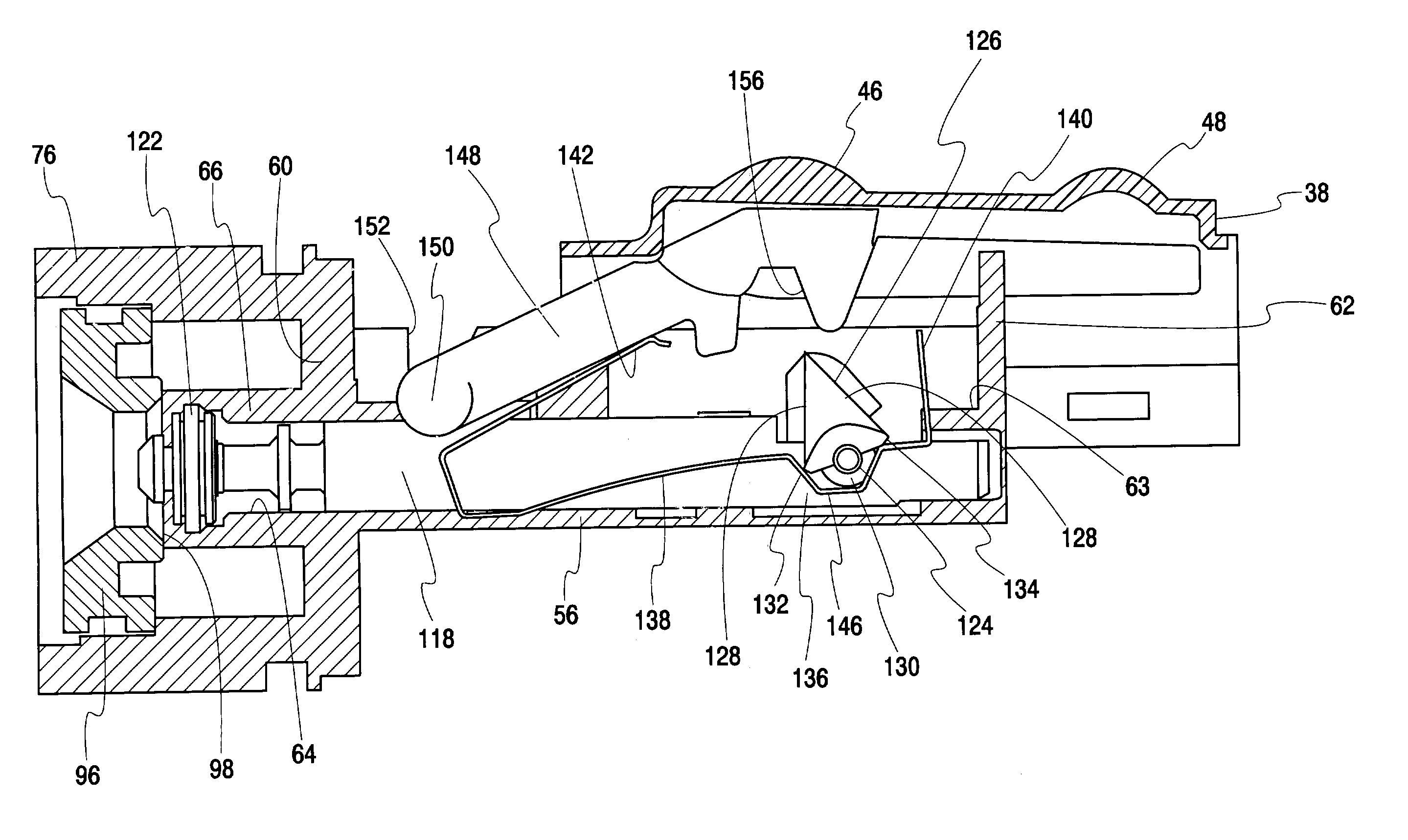

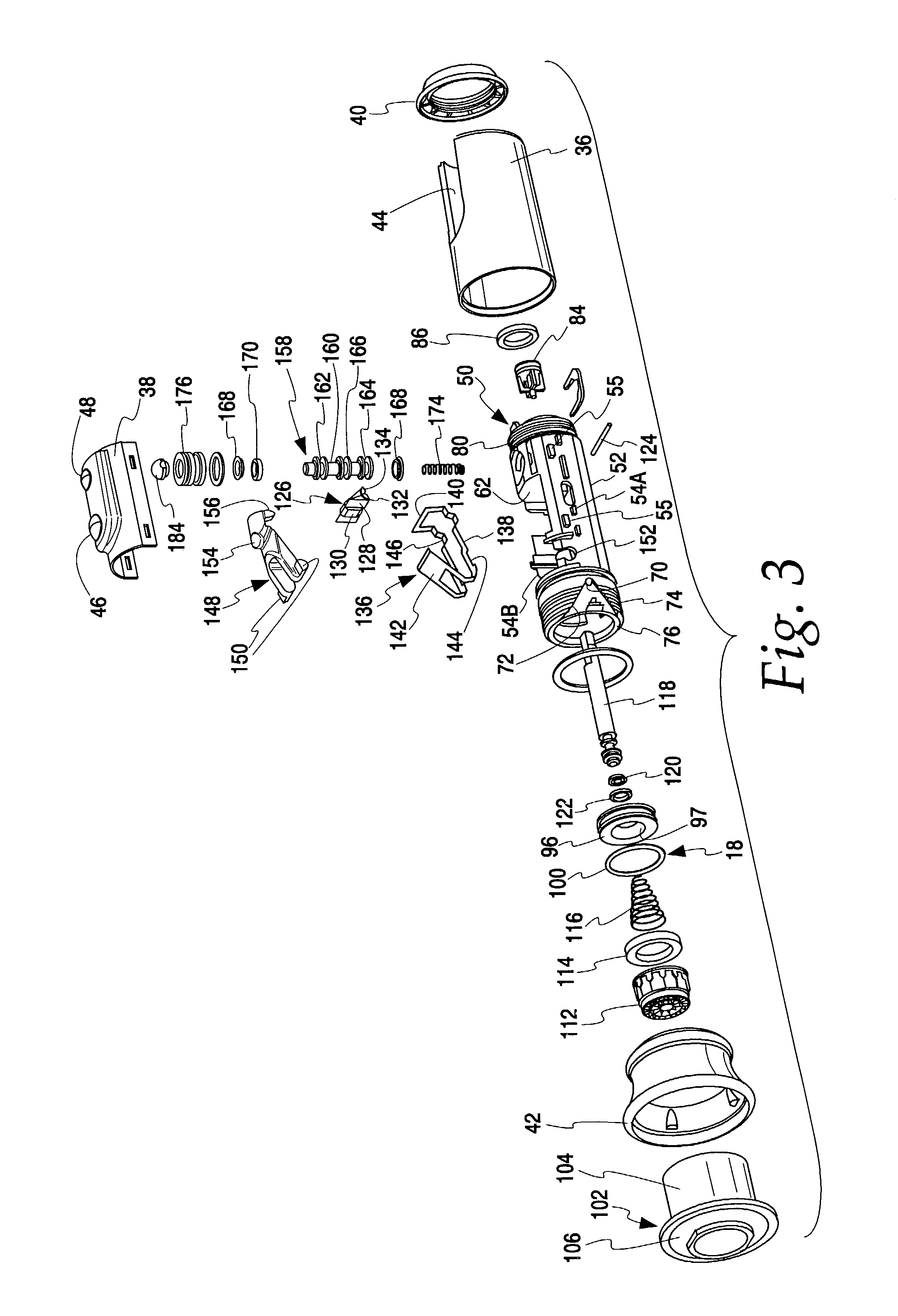

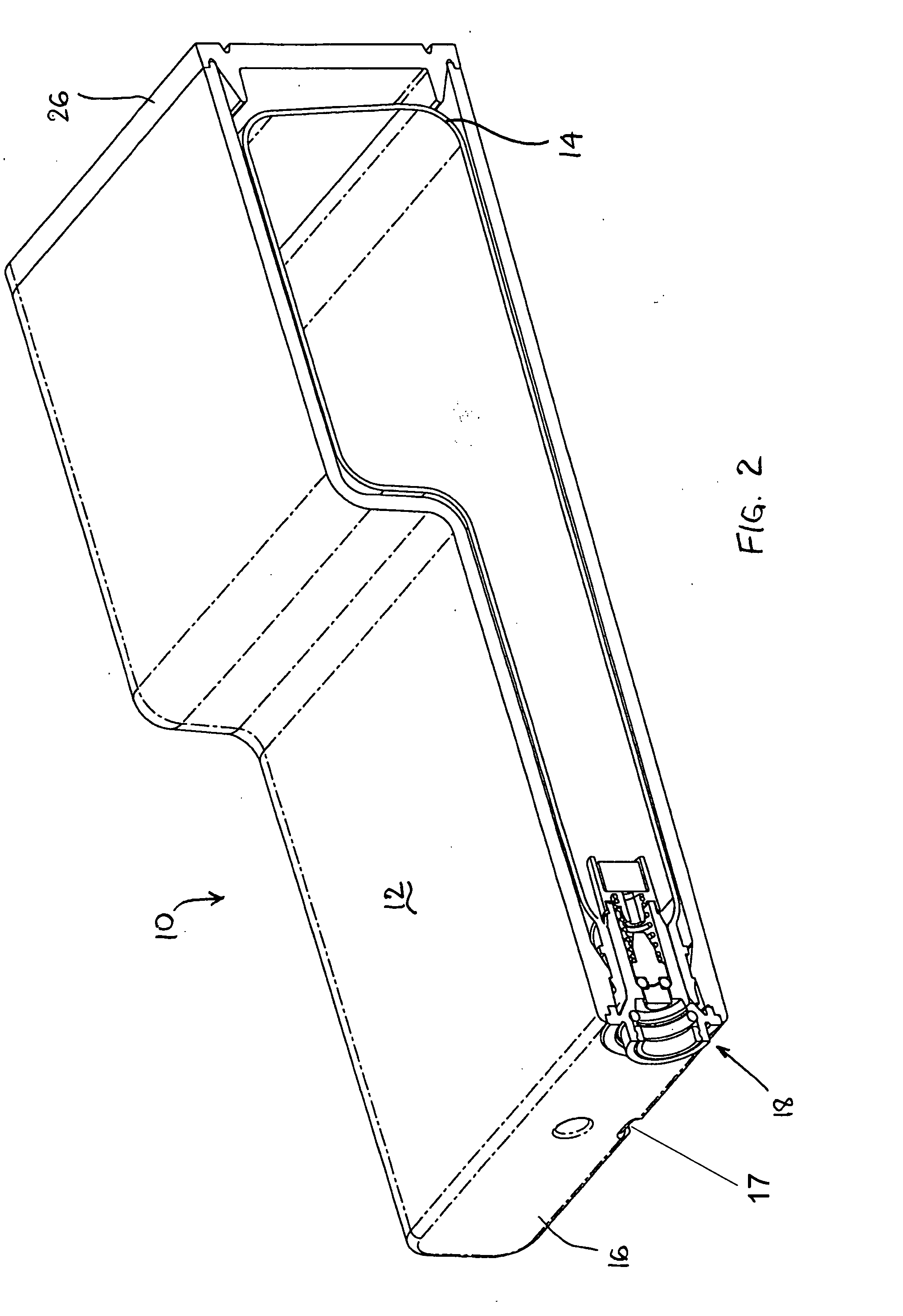

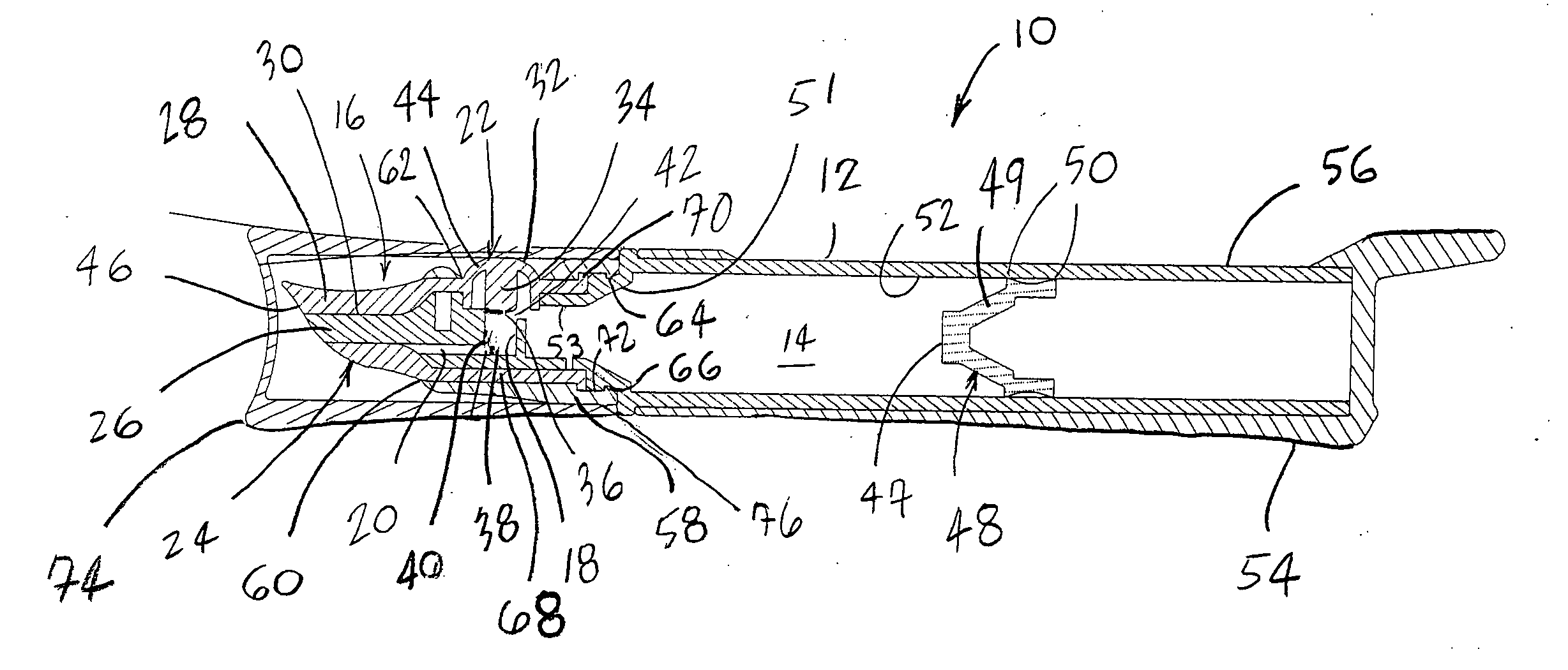

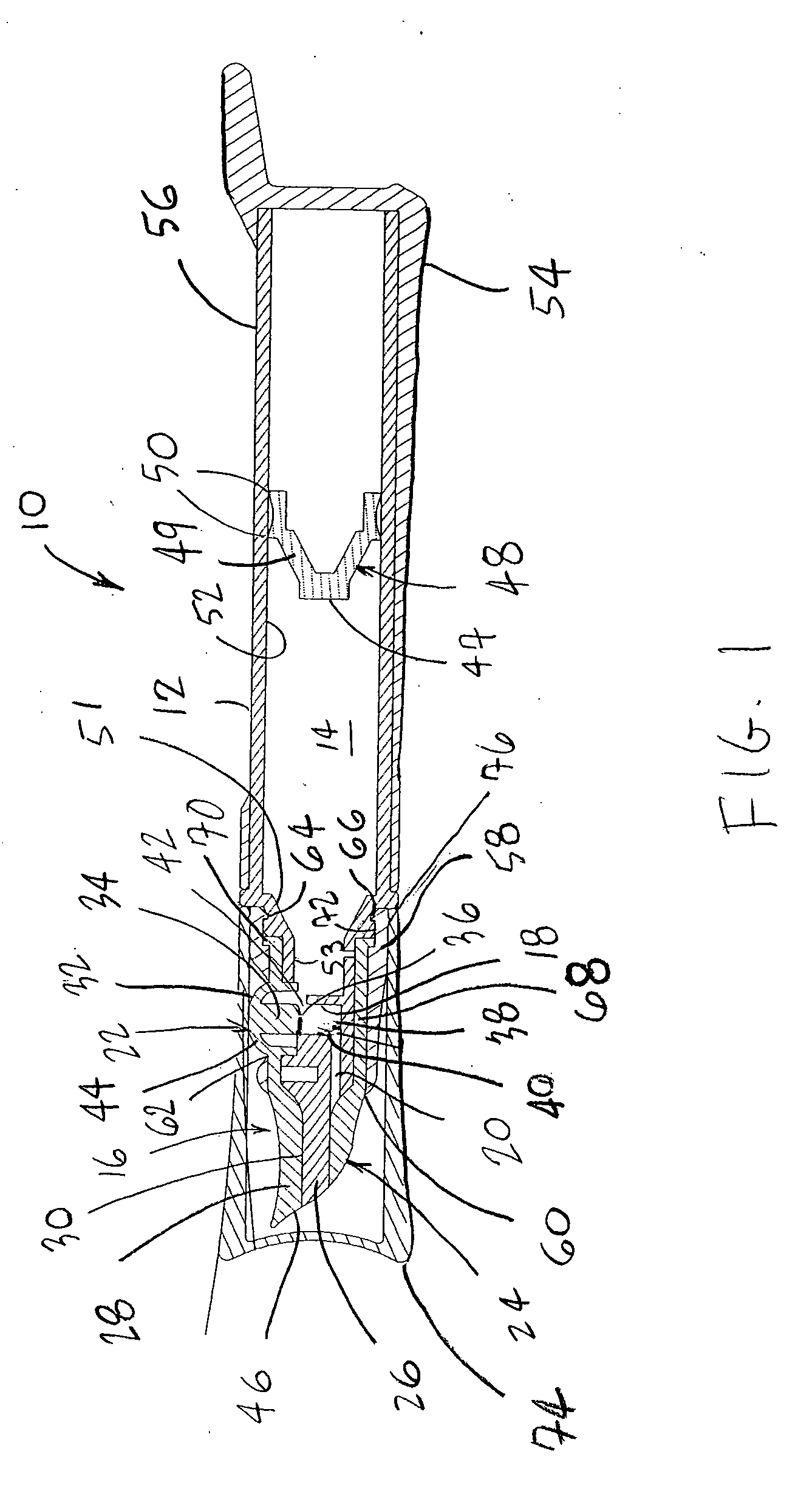

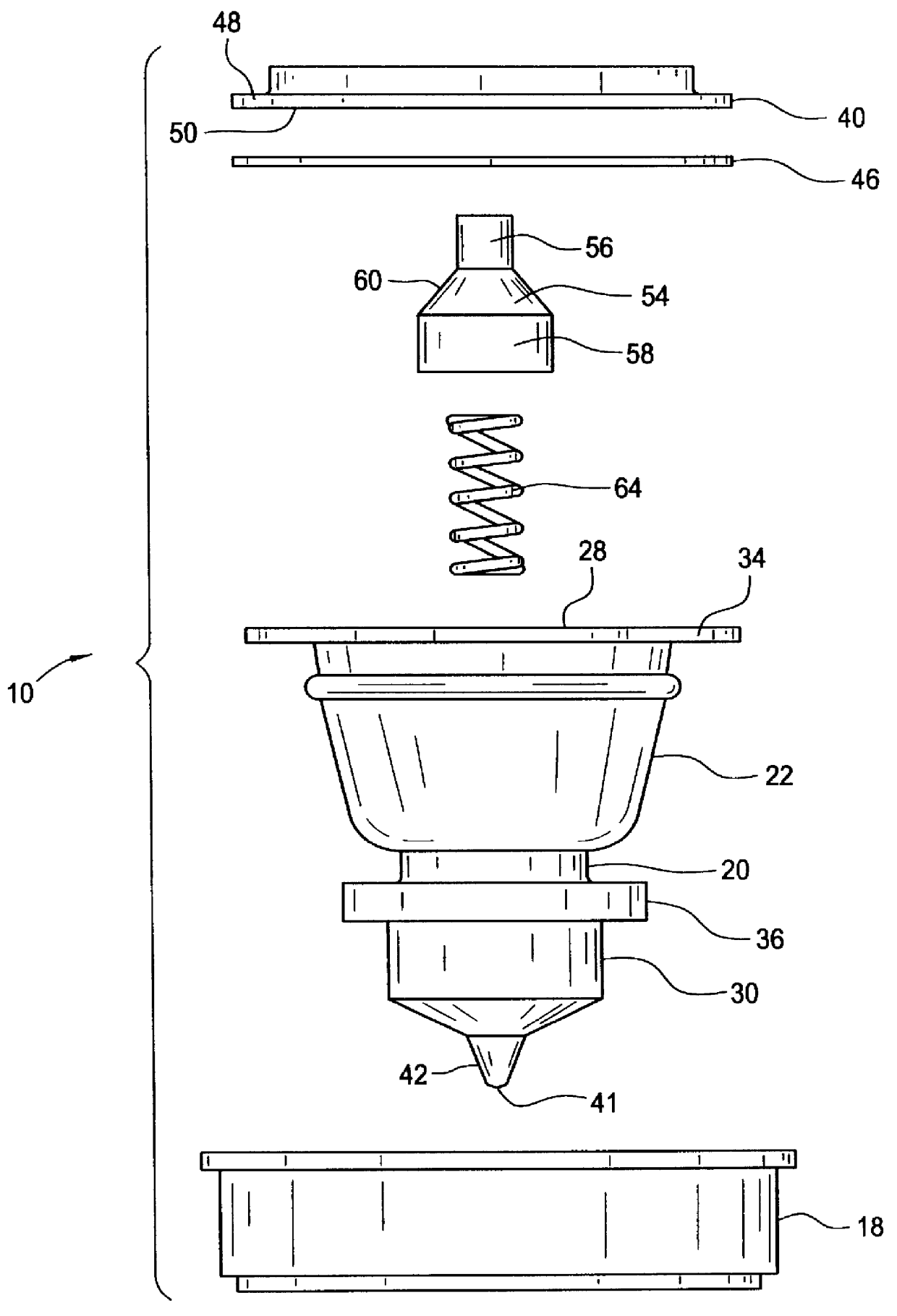

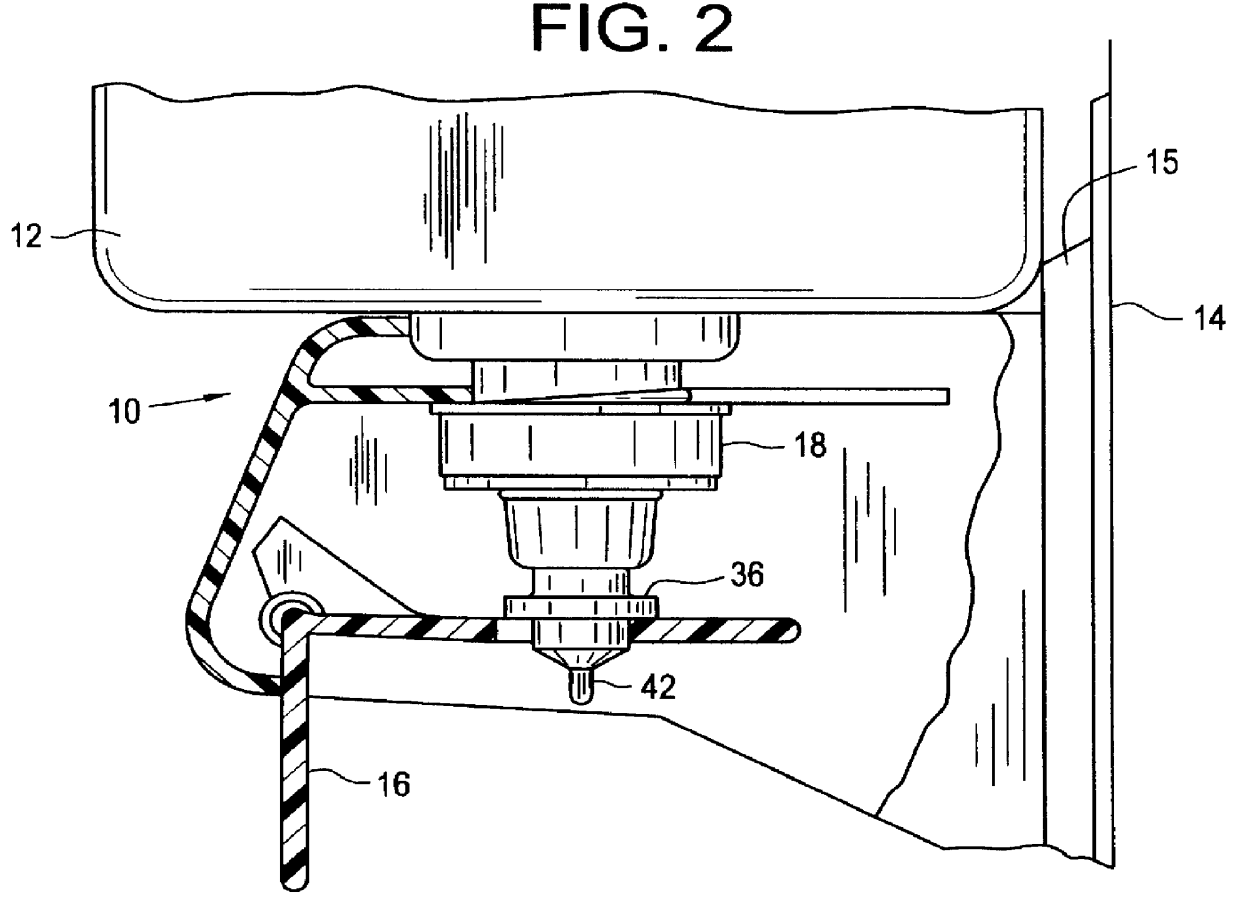

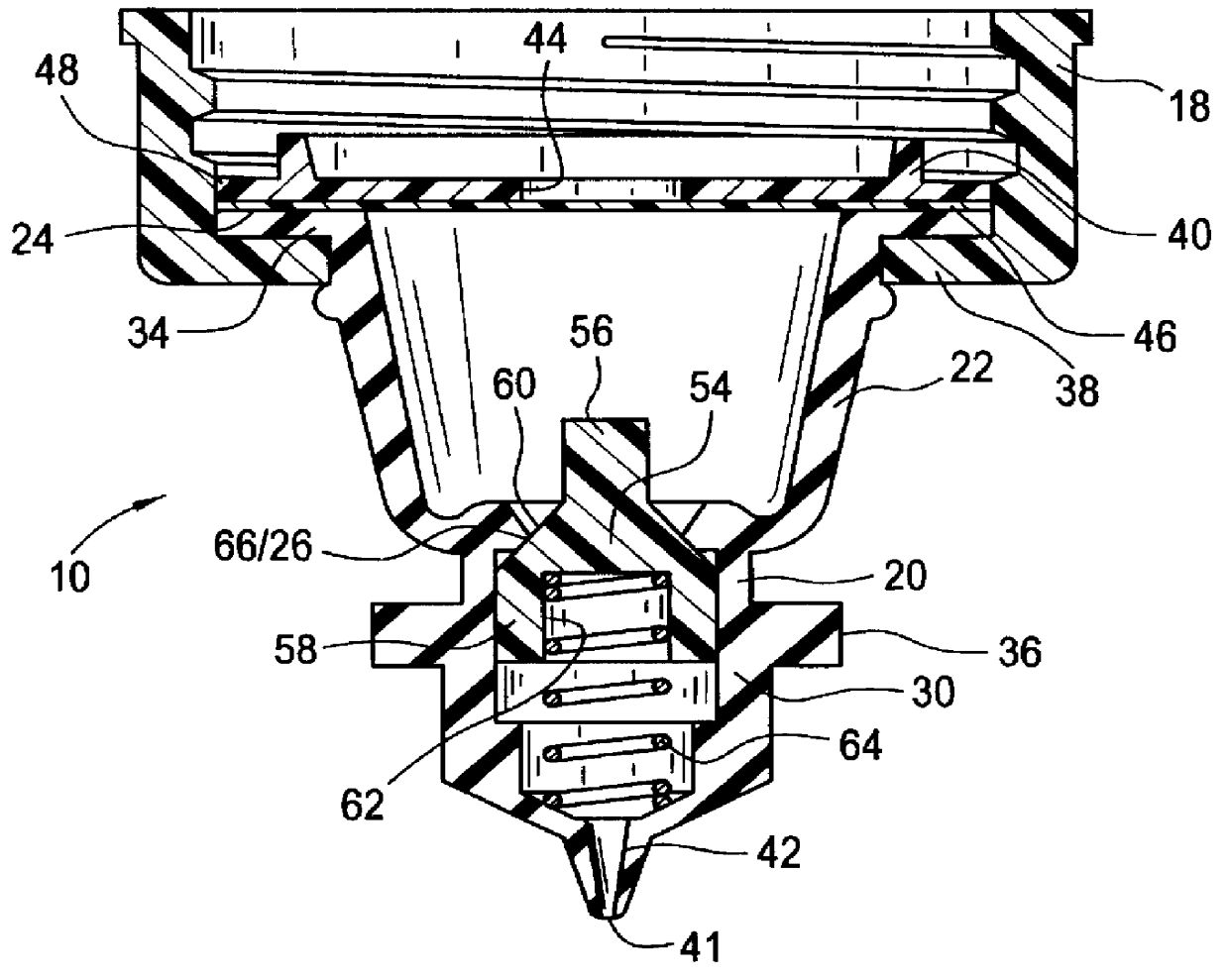

Pullout spray head with single-button mode selector

A spray head for a faucet or the like has a wand body defining a flow path from an inlet to first and second outlets. Diverter seats are provided so a face seal on a diverter spool can direct flow to the first or second outlet. The spool is positioned by a trigger acting on cam surfaces formed on a toggle. A spring biases the toggle to one of two stable states. Movement of the spool by the trigger causes the toggle to change states so subsequent actuation of the trigger causes the spool to move in the opposite direction. The wand body also has a pause button that reciprocates in a chamber that is part of the flow path. The chamber includes a valve seat and the pause button has a spool having a face seal that is engageable with the valve seat to shut off flow through the spray head. A return spring causes separation of the pause button's face seal upon release of pressure on the pause button. The pause button's seals in the chamber are arranged to have equal diameters and thus provide balanced hydraulic forces on the spool.

Owner:MOEN INC

Fluid End for Frac Pump

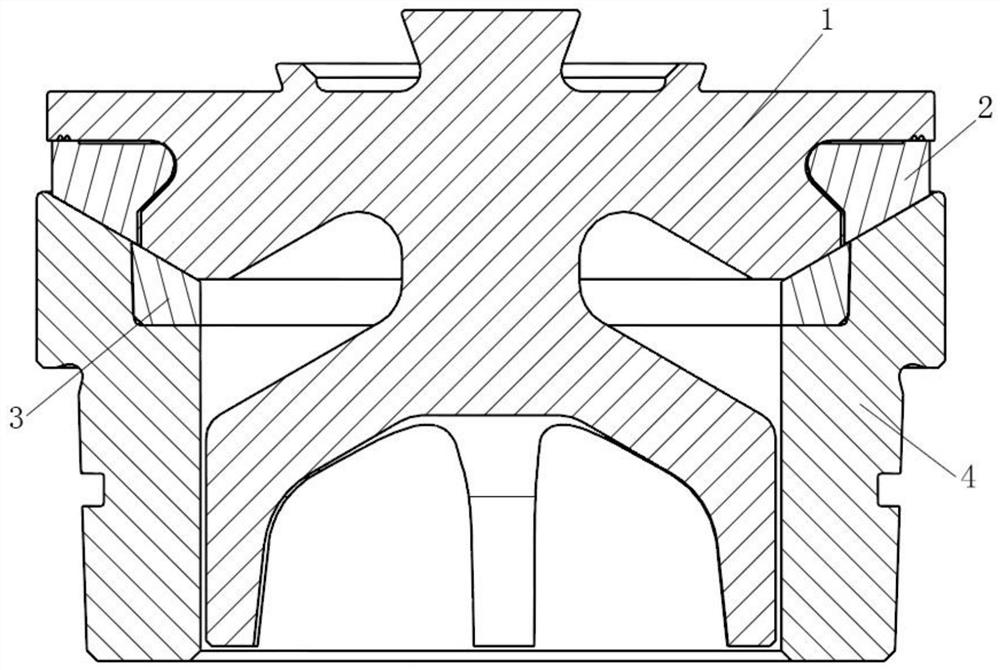

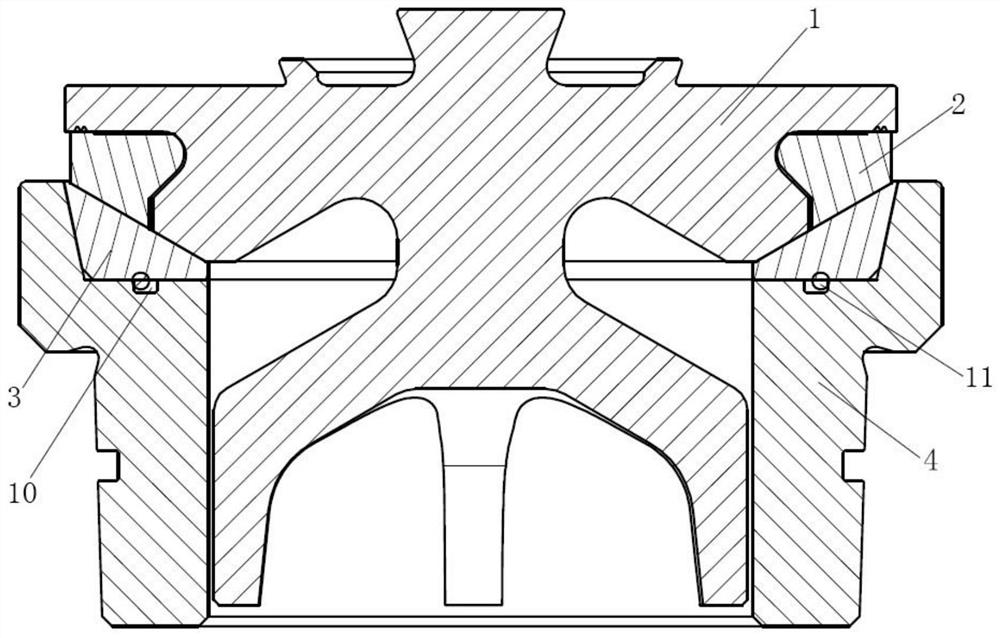

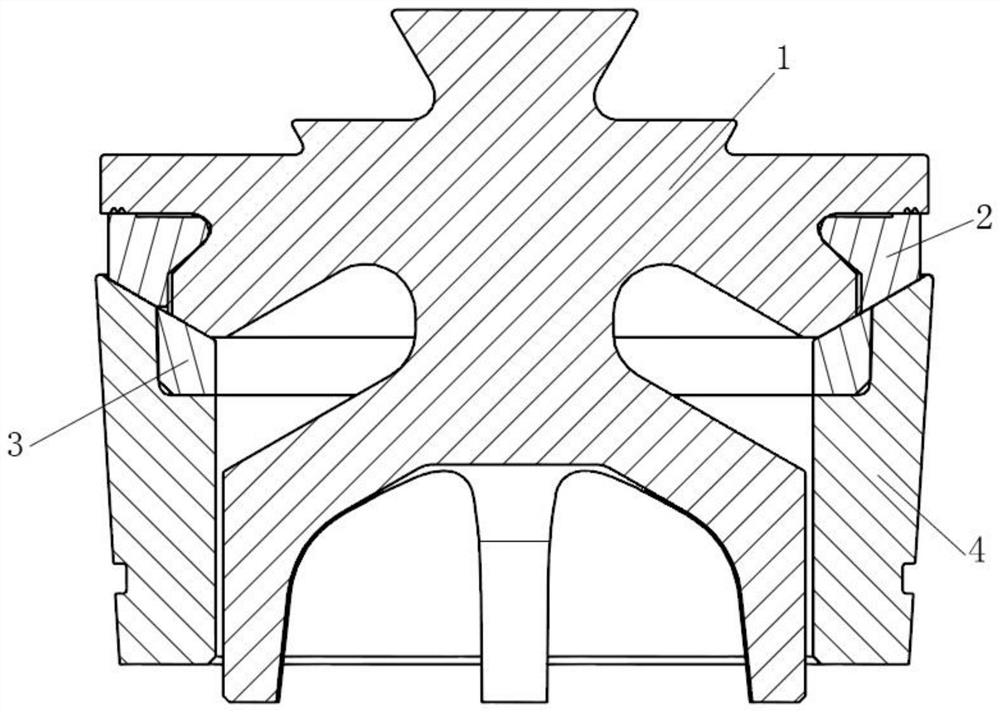

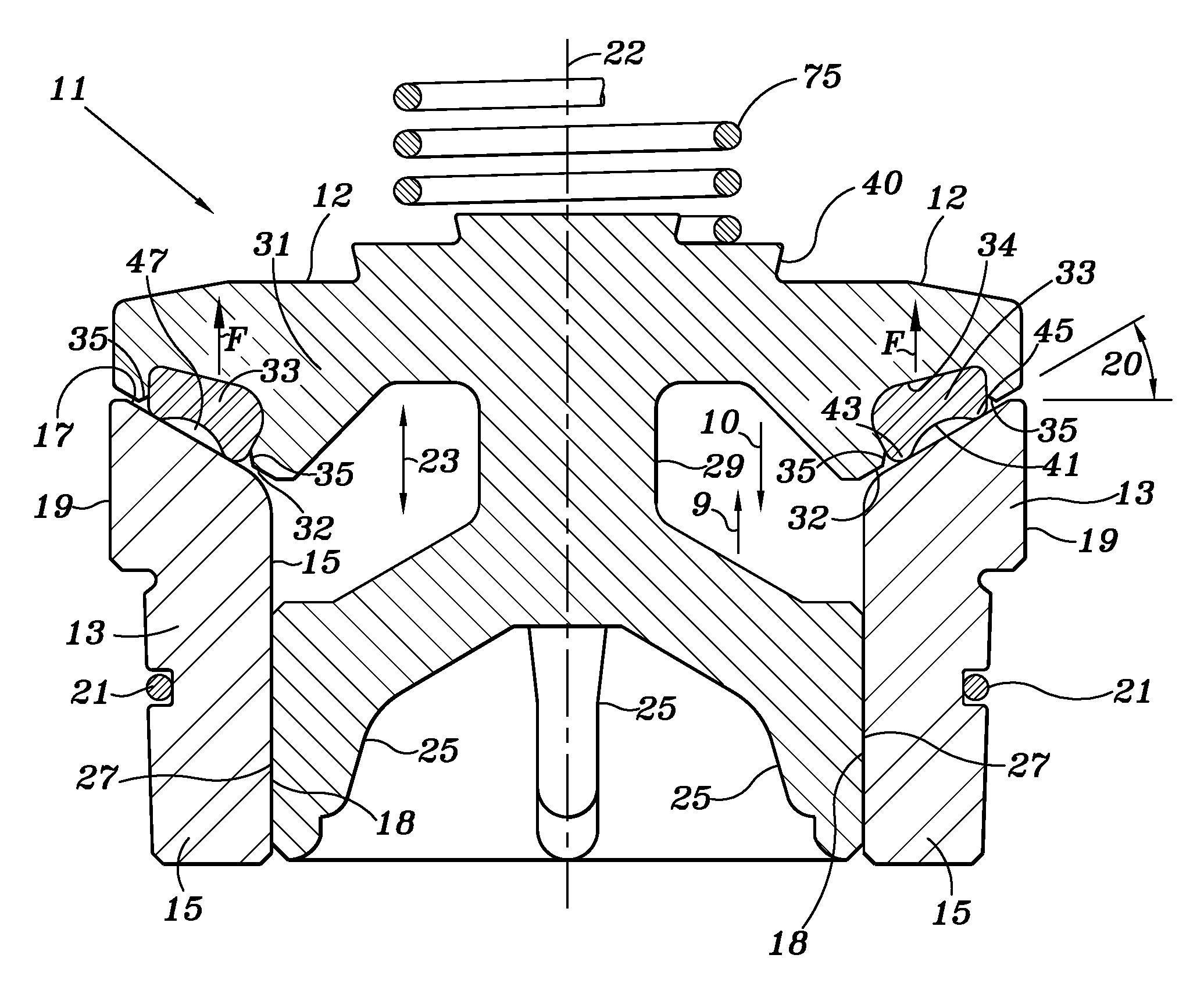

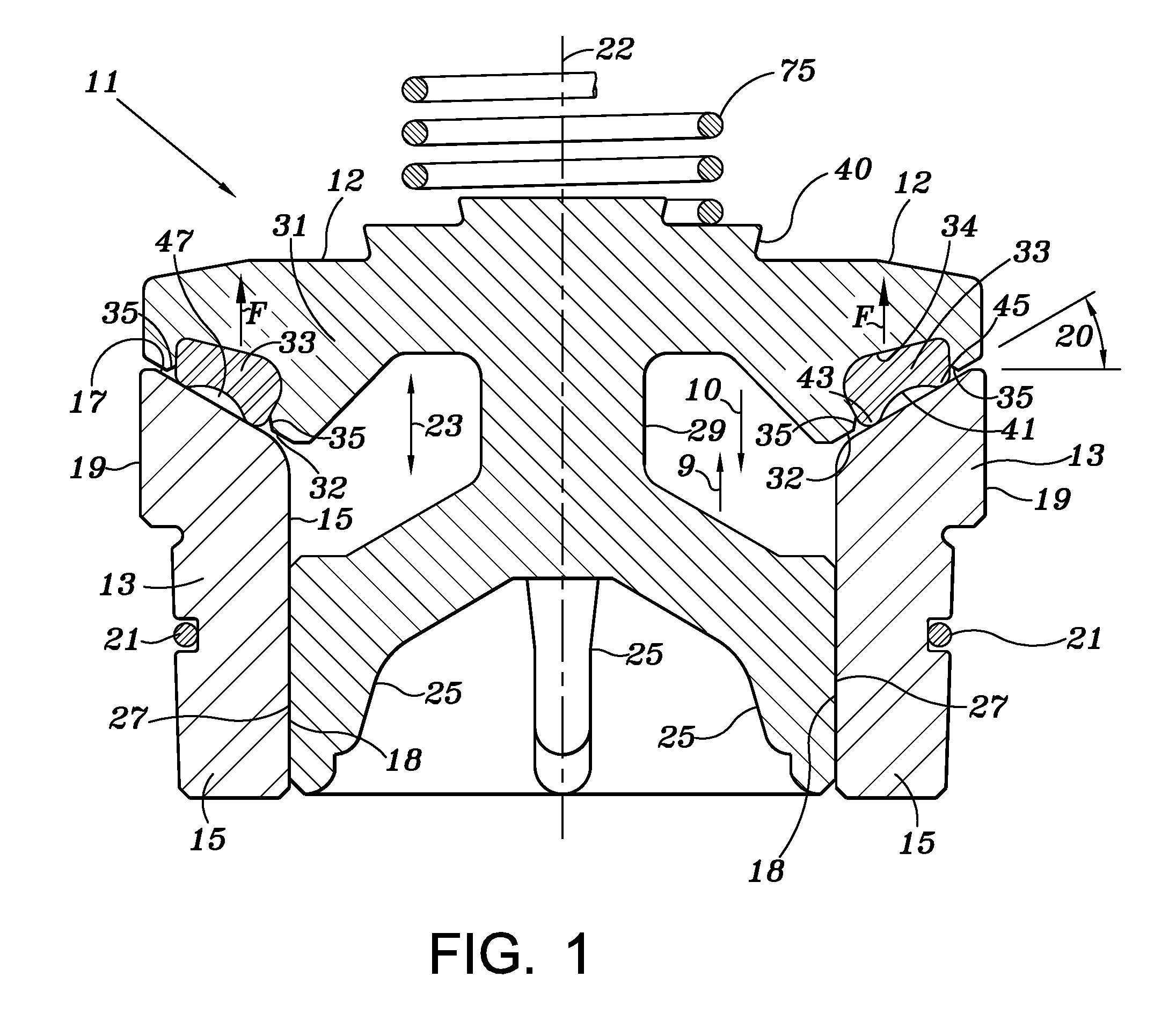

ActiveUS20190011051A1Reduce the cross-sectional areaReduce the possibilityPositive displacement pump componentsFlexible member pumpsEngineeringValve seat

Frac pumps have valve seats and bodies. The valve seats comprise a cylindrical body and an annular seat surface. The body has an axial passage and external threads adapted to engage internal threads in a fluid end block of the frac pump. The annular seat surface is at an end of the body and is adapted to engage a valve body. The valve bodies comprise a head and a compressible seal. The head provides a valve surface adapted to engage the valve seat. The compressible seal is carried on the head radially inward of the valve surface and is adapted to engage the valve seat.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

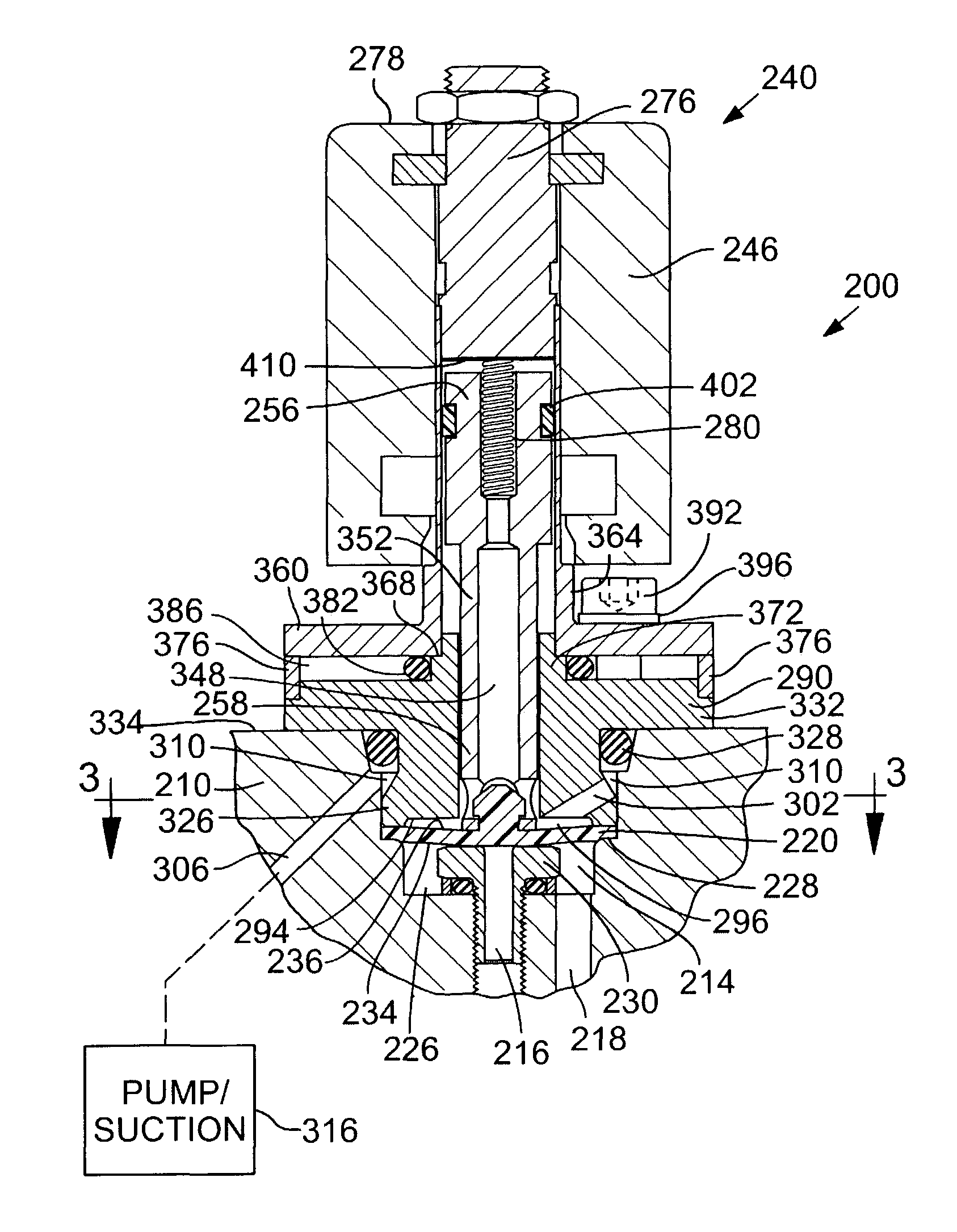

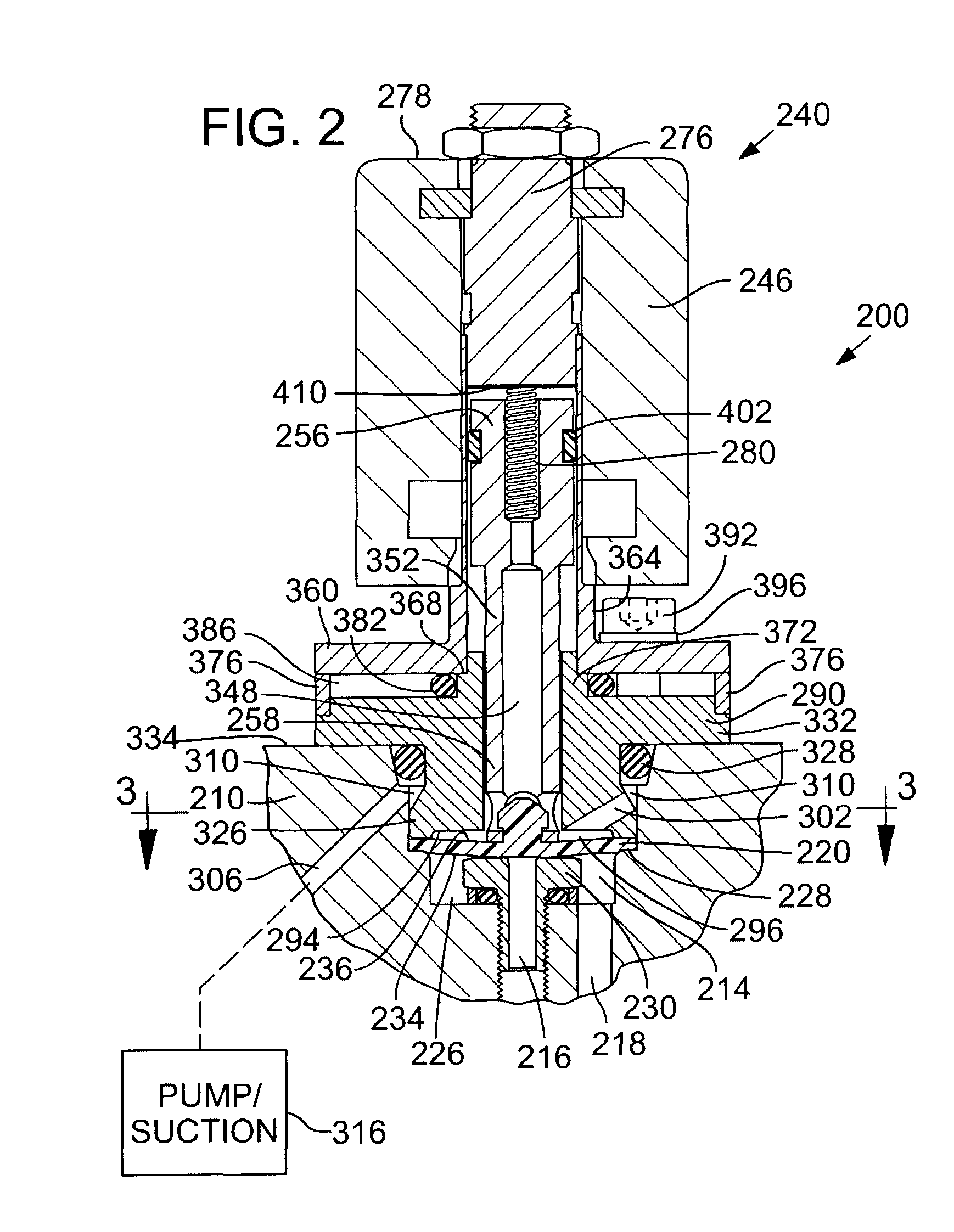

Injection port valve

Injection port valves are generally discussed herein and more particularly to port valves that have a valve housing with a nozzle having an inlet opening, a body section, a skirt section, an interior cavity, and a valve seat at an intersection of the first nozzle and the body section in the interior cavity. A piston may be positioned within the interior cavity of the valve housing having a body section having an exterior surface, an upper piston section, a seal surface, and a piston cavity, and wherein the body section includes a wall layer that emits lubricant from within the wall layer to the exterior surface. A nut, which may be a Luer nut, having a flow passage in communication with a discharge nozzle having a discharge lumen may be attached to an end of the skirt section of the valve housing to thereafter connect to an infusion line. A spring can be positioned within the piston cavity and abutting against the nut, wherein when used, the spring being in a first position when the seal surface of the piston is abutted against the valve seat of the valve housing, and the spring being in a second position when the seal surface of the piston is separated from the valve seat.

Owner:B BRAUN MEDICAL

Fixation band for affixing a prosthetic heart valve to tissue

InactiveUS20050261765A1Quickly and easily and conveniently affixingHeart valvesProsthetic valveProsthesis

A fixation band has a tubular frame and a tube, wherein the tubular frame comprises longitudinally-extending members having a hook on its distal end and fixation means on its proximal end. The tubular frame preferably comprises a laterally-extending member for stabilization. The tube is positioned inside longitudinally-extending members and a sewing cuff is formed in the tube distal to the distalmost end of the longitudinally-extending members. A standard prosthetic valve can be secured to the fixation band by suturing the prosthetic valve's sewing cuff to the fixation band's sewing cuff and the prosthetic valve can be advanced to a valve seat. By pulling the tubular frame proximally, the hooks pass into surrounding tissue so that the fixation band and prosthetic valve are fixed against proximal movement. The fixation means then secure the fixation band to the surrounding tissue so that the prosthetic valve is fixed against distal movement.

Owner:MEDTRONIC INC

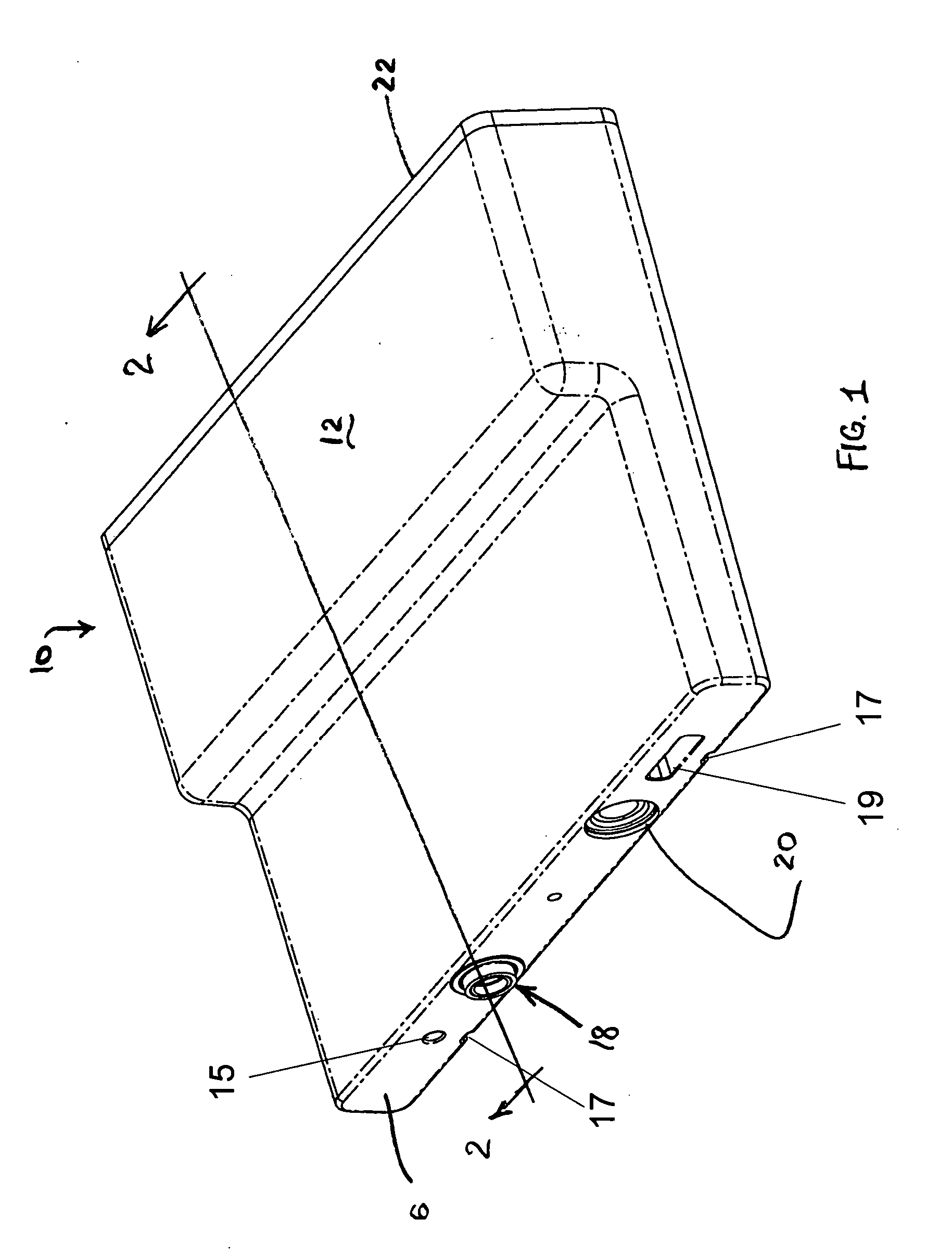

Fuel cell supply having fuel compatible materials

The present invention is directed to a fuel cell supply for a fuel cell having an outer casing, a liner member containing methanol, and a valve component comprising a valve body member and a slidable body member disposed inside the valve body member. The slidable body member is normally biased toward a valve seat surface to seal the valve component and the slidable body member can be moved away from the valve seat surface to open the valve component. The liner member, the valve body member and the slidable body member are made from at least two different materials and wherein at least one of the members compatible with methanol. Hence, each component can be selected from material(s) that is substantially optimal for its function in the fuel supply.

Owner:INTELLIGENT ENERGY LTD

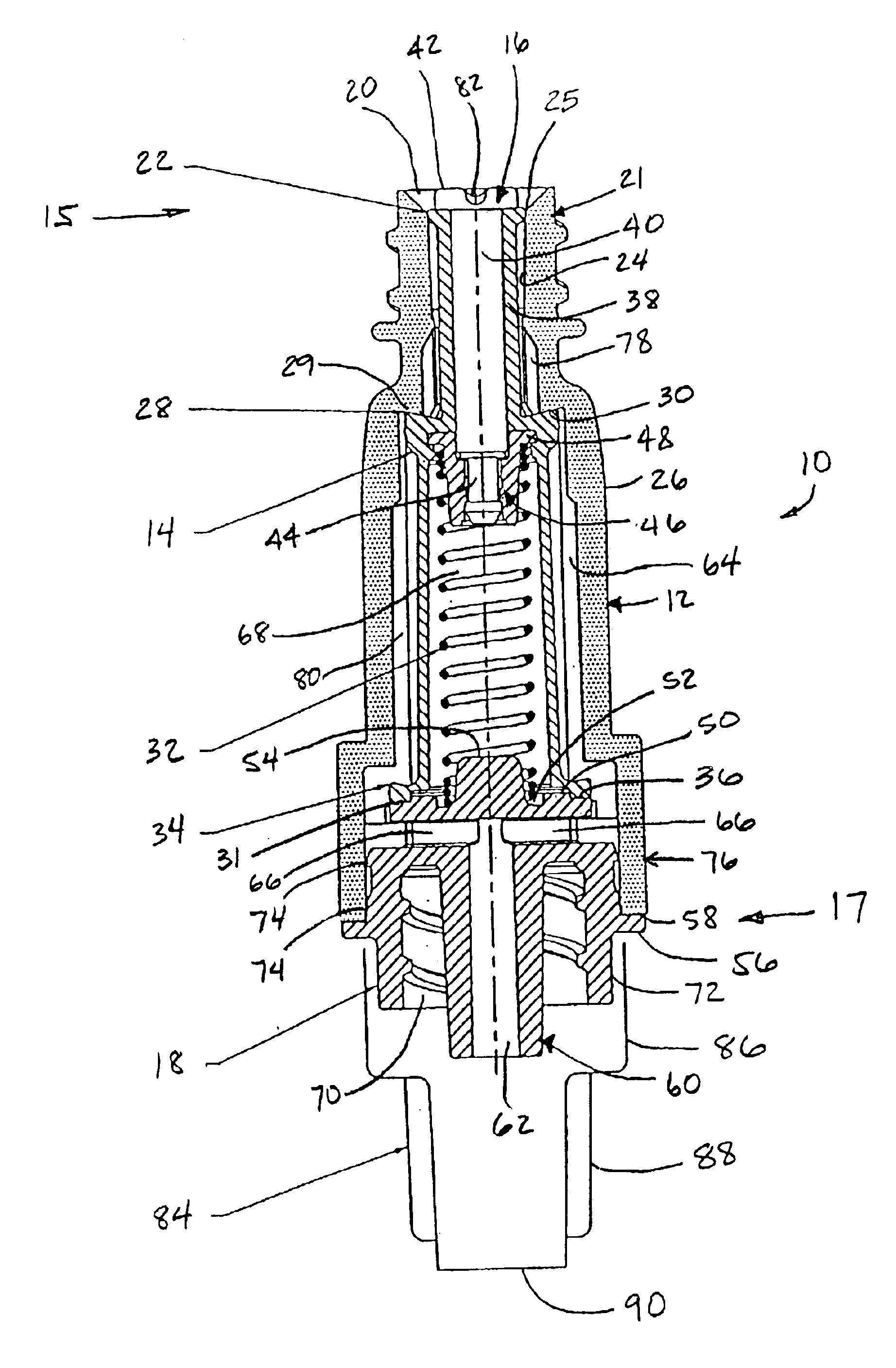

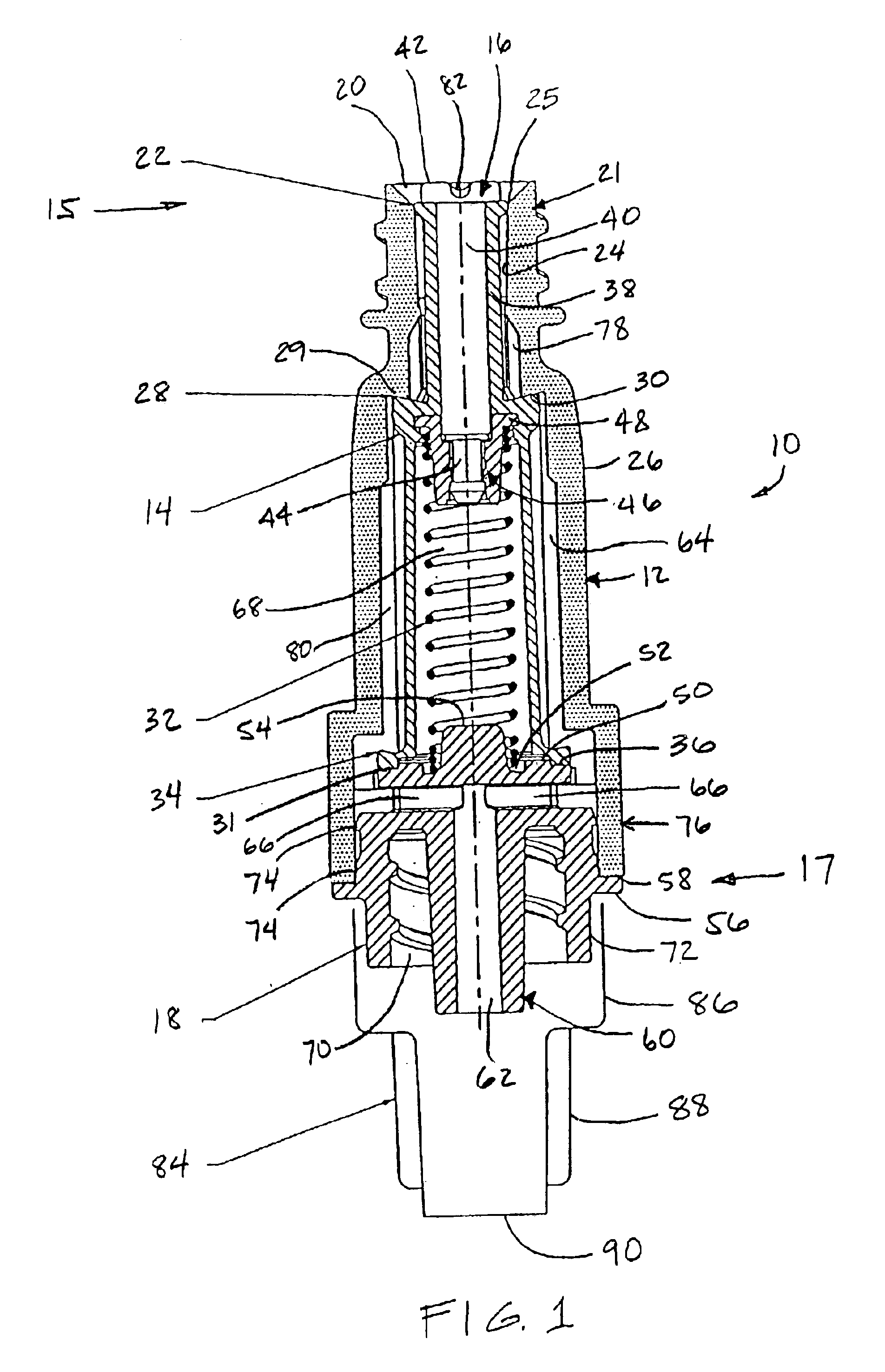

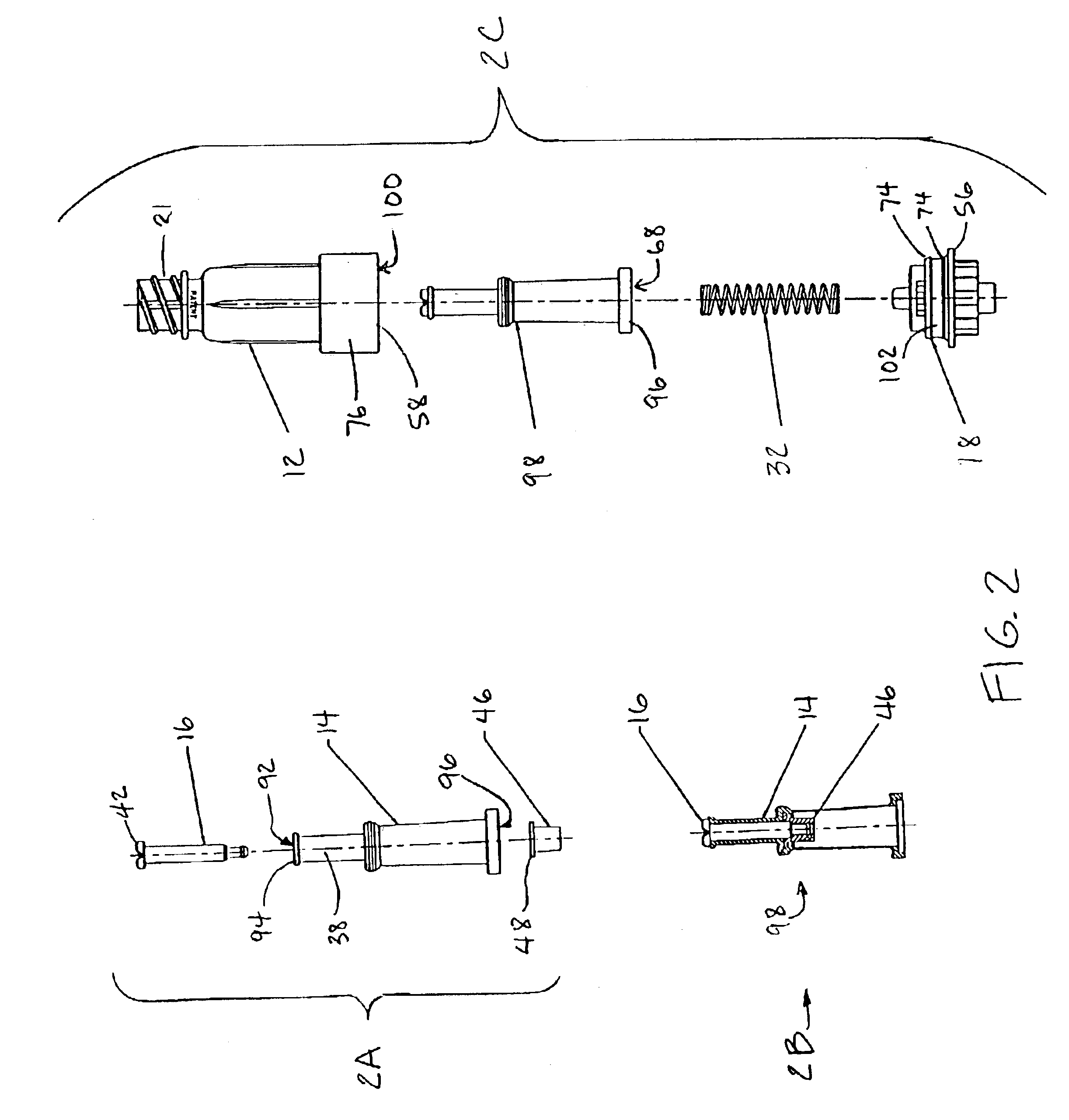

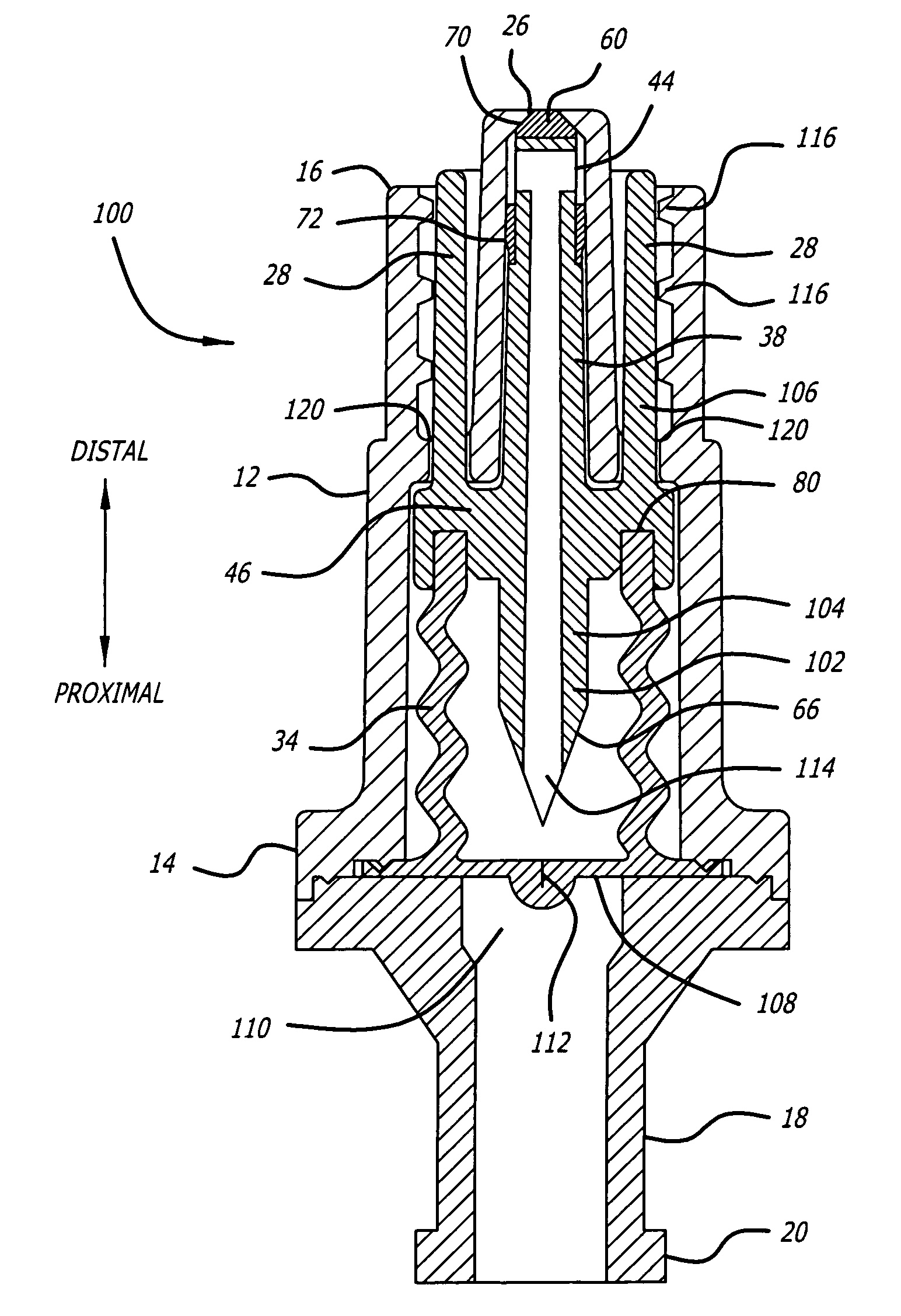

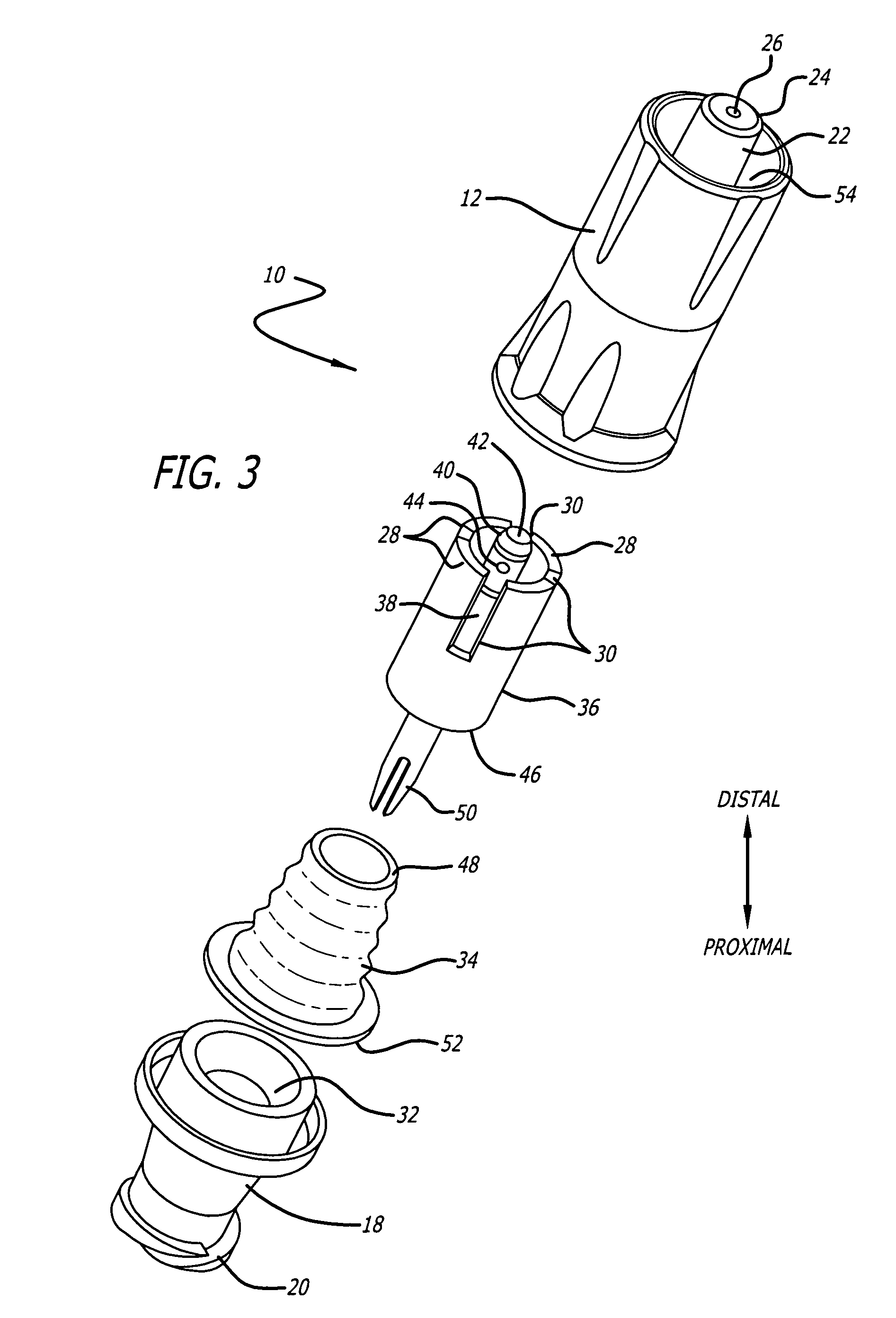

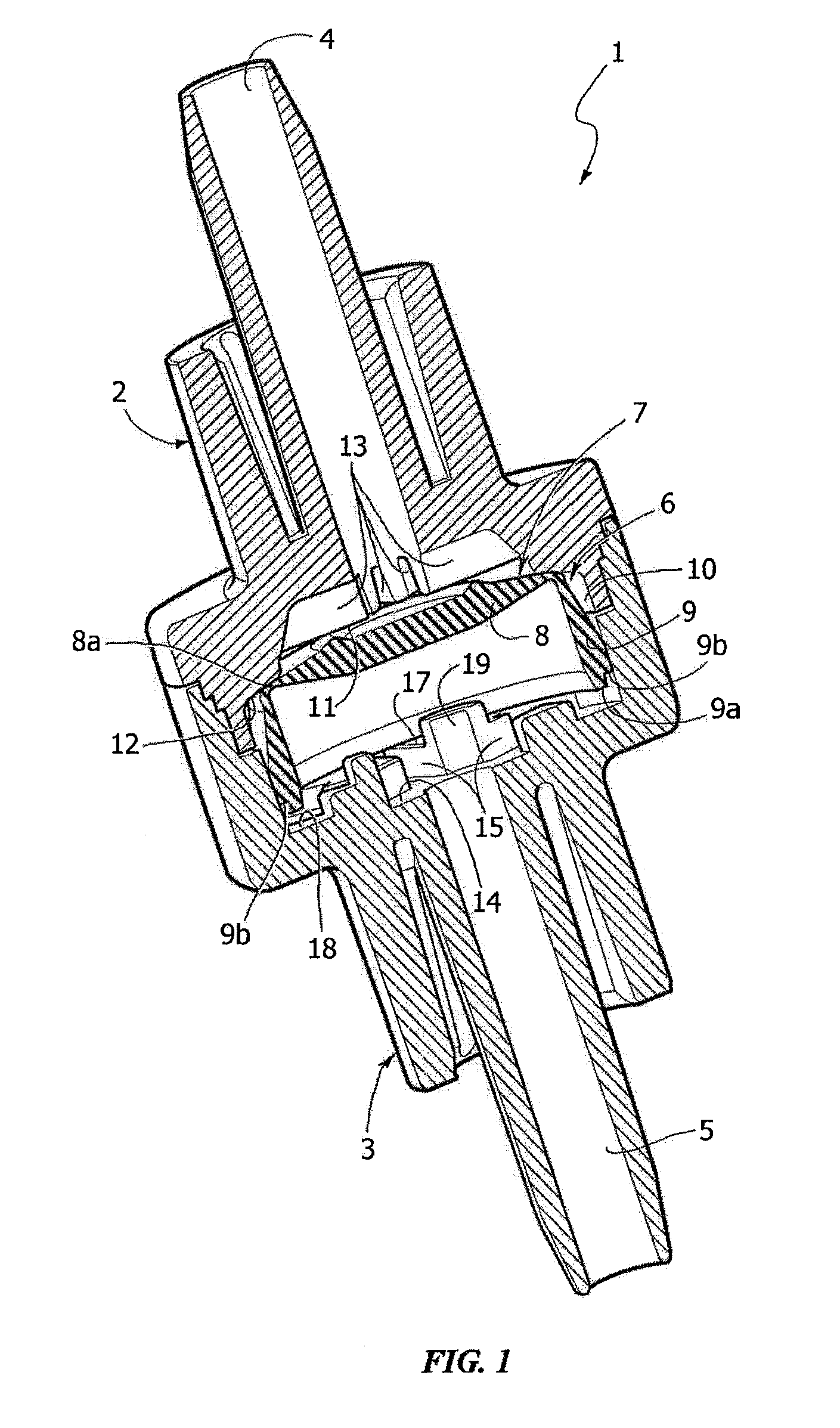

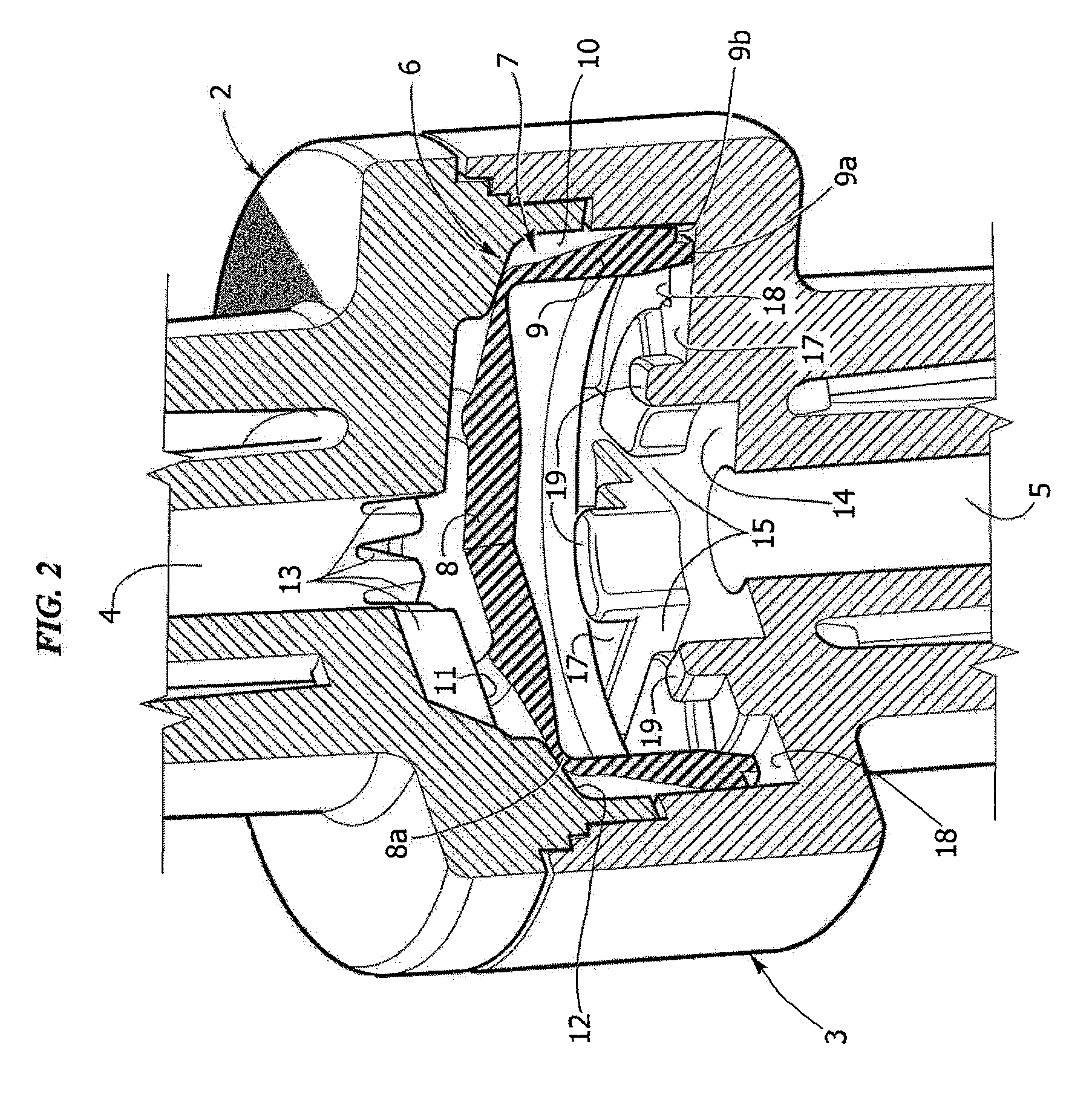

Self-sealing male Luer connector with multiple seals

A self-sealing male Luer connector attaches to any standard female Luer valve to open a flow channel between the two. The self-sealing male Luer connector includes a rigid housing having a distal end with a rigid male Luer connector and a proximal end at which a proximal seal is formed. The distal end of the housing includes a valve seat. Located within the housing is a resilient biasing member that biases an actuator into contact with the valve seat to prevent fluid flow through the male connector. Upon engagement with a female connector, the actuator is moved in the proximal direction to open the distal valve and then the proximal seal. A partial vacuum is formed within the male connector upon disengagement with the female connector that draws any fluids on the external surface of the distal end of the male Luer connector into the male tip.

Owner:CAREFUSION 303 INC

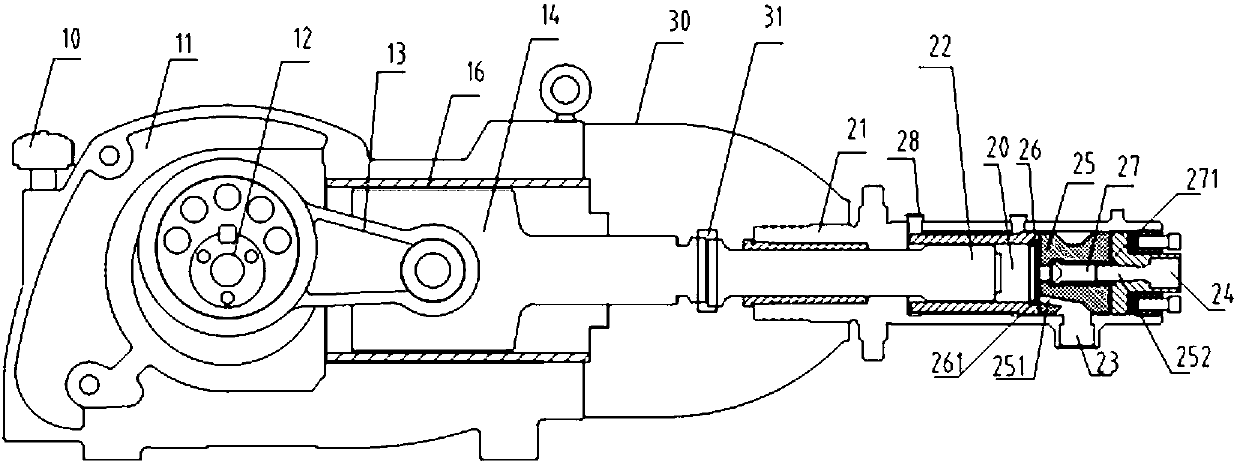

Plunger pump used for pumping ultralow-temperature liquid nitrogen

InactiveCN102889191ASolve the problem of easy heat absorption and vaporizationReduce deliveryPumpsPositive-displacement liquid enginesReciprocating motionEngineering

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

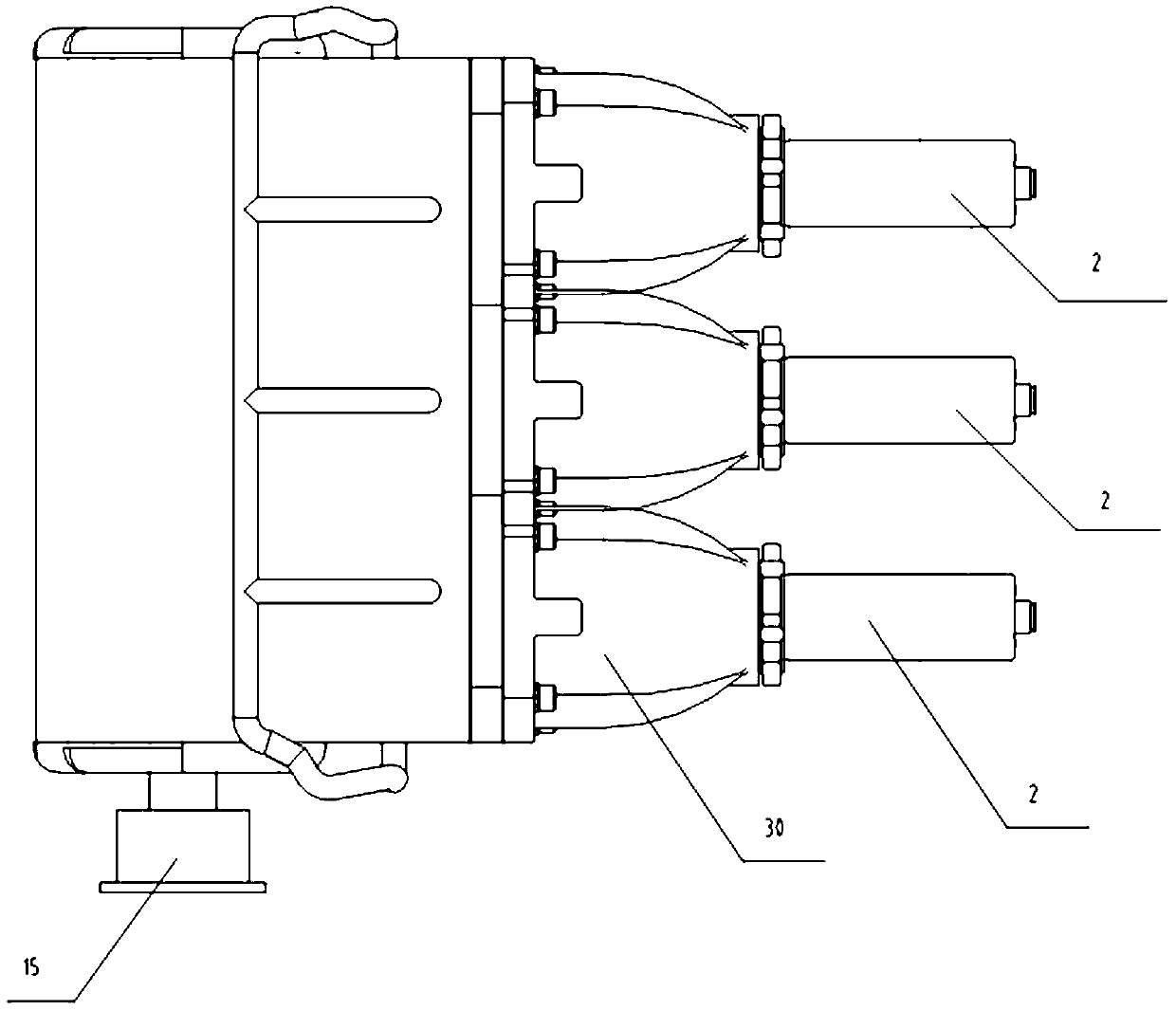

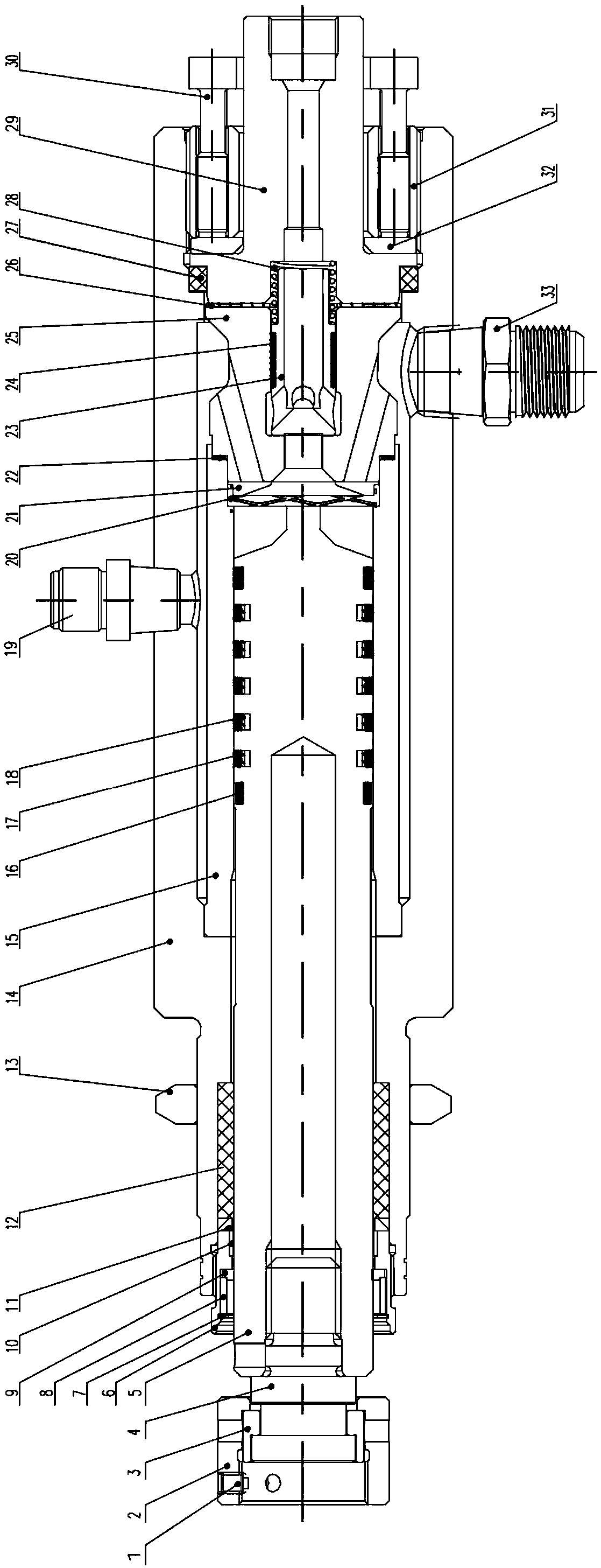

Cold end of low-temperature high-pressure plunger pump

InactiveCN109404274ASolve the problem of being unable to pump low temperature and high pressure liquid nitrogenHigh conveying medium temperaturePositive displacement pump componentsFluid removalHigh pressureLiquid nitrogen

The invention belongs to the technical field of low-temperature high-pressure plunger pumps, and particularly relates to a cold end of a low-temperature high-pressure plunger pump. The cold end comprises a cold end shell body, a plunger and a cylinder sleeve, wherein the plunger is arranged inside the cylinder sleeve, the cylinder sleeve is located inside the cold end shell body, a connecting locking device is arranged at the front end of the cold end shell body, the cold end shell body comprises a left cavity and a right cavity which communicate with each other, the right cavity internally comprises the cylinder sleeve, a valve set and a discharging flange, and the valve set comprises a valve seat, a high-pressure valve arranged in the valve seat and a low-pressure valve arranged betweenthe cylinder sleeve and the valve seat. According to the cold end of the low-temperature high-pressure plunger pump, the novel valve set structure adopts metal sealing, continuous opening and closingof the high-pressure valve and the low-pressure valve are achieved, and normal-pressure ultralow-temperature liquid nitrogen is converted into high-pressure low-temperature liquid nitrogen and is discharged so that the requirement for high-frequency opening and closing can be met, the characteristics of being low in conveying medium temperature and high in output pressure are achieved, and the problem that a common plunger pump cannot pump the low-temperature and high-pressure liquid nitrogen is solved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

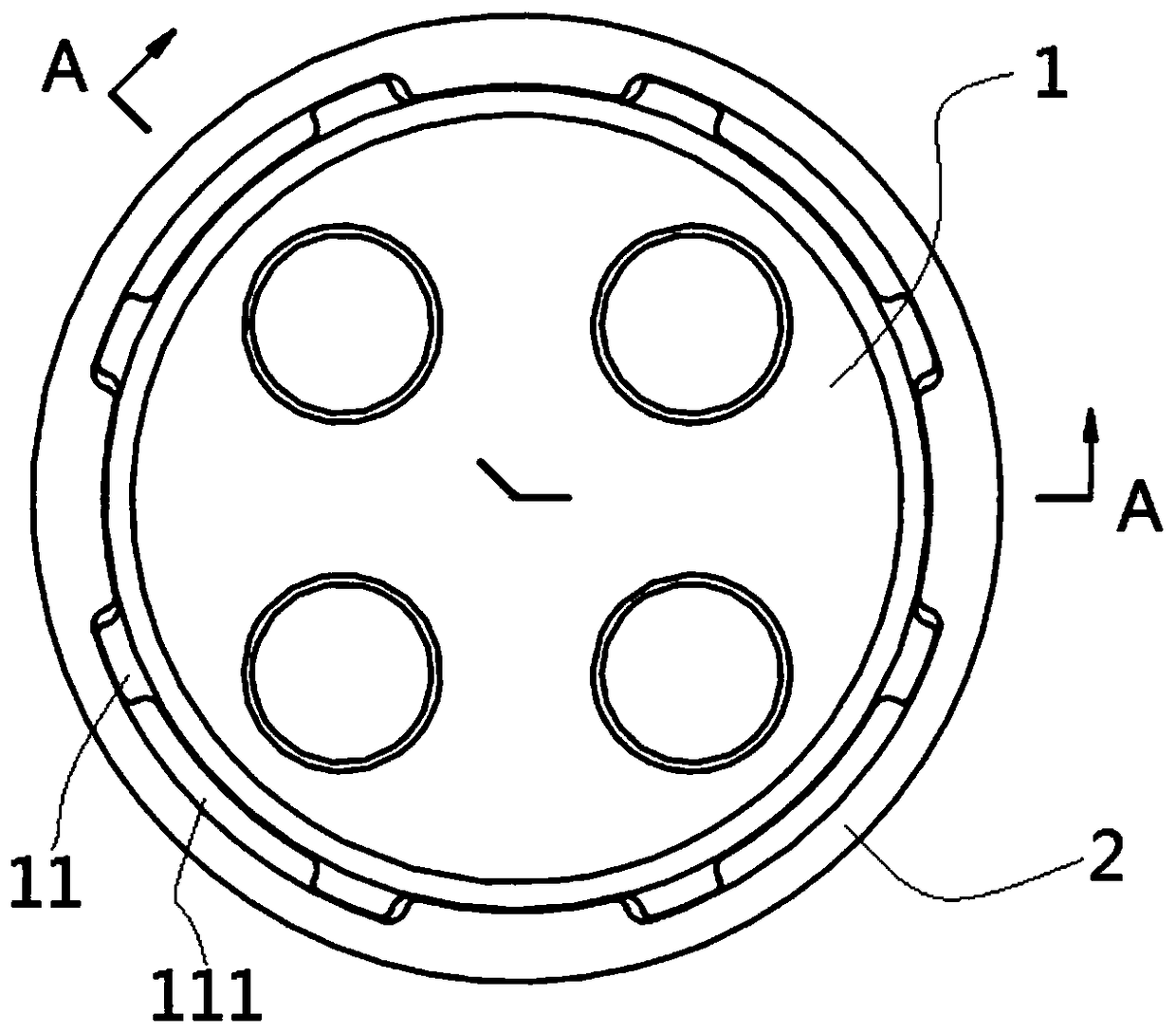

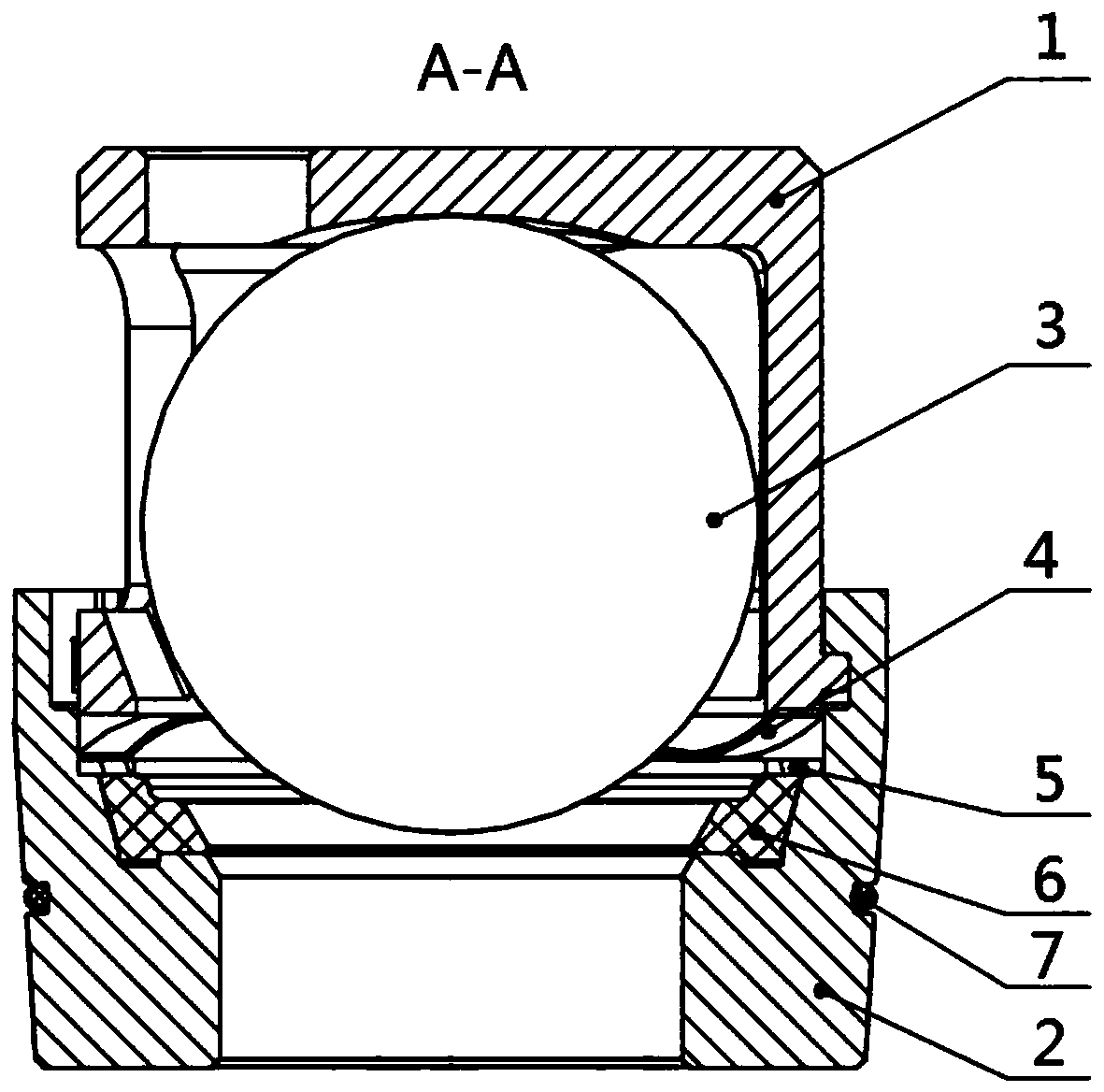

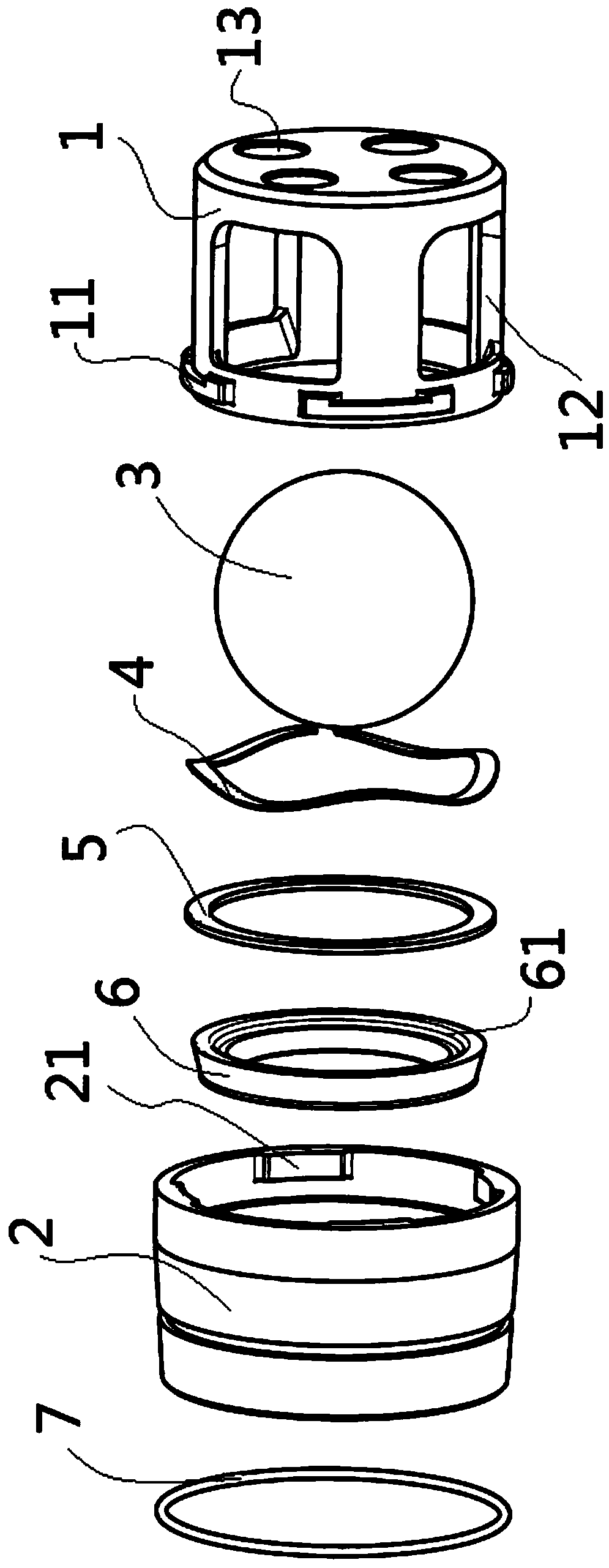

Ball-type valve assembly structure

PendingCN109058092AEasy to disassembleEasy to separatePositive displacement pump componentsLiquid fuel engine componentsSteel ballEngineering

The invention relates to a ball-type valve assembly structure, and belongs to the technical field of oil-gas exploitation equipment. The ball-type valve assembly structure comprises a valve seat, valve rubber arranged on the inner side of the valve seat, a steel ball positioned above the valve rubber, and a ball cage positioned outside the steel ball, a first clamping piece is arranged on the lower portion of the outer side of the ball cage, a second clamping piece matched with the first clamping piece is arranged on the upper portion of the inner side of the valve seat, and an elastic piece is arranged between the valve seat and the ball cage. The ball-type valve assembly structure has the advantages that the valve seat is connected with the ball cage through a clamping groove structure so that the situations that the clamping stagnation occurs and dismounting is difficult due to sand particle entering can be avoided, and the working efficiency of dismounting and checking a pump can be improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

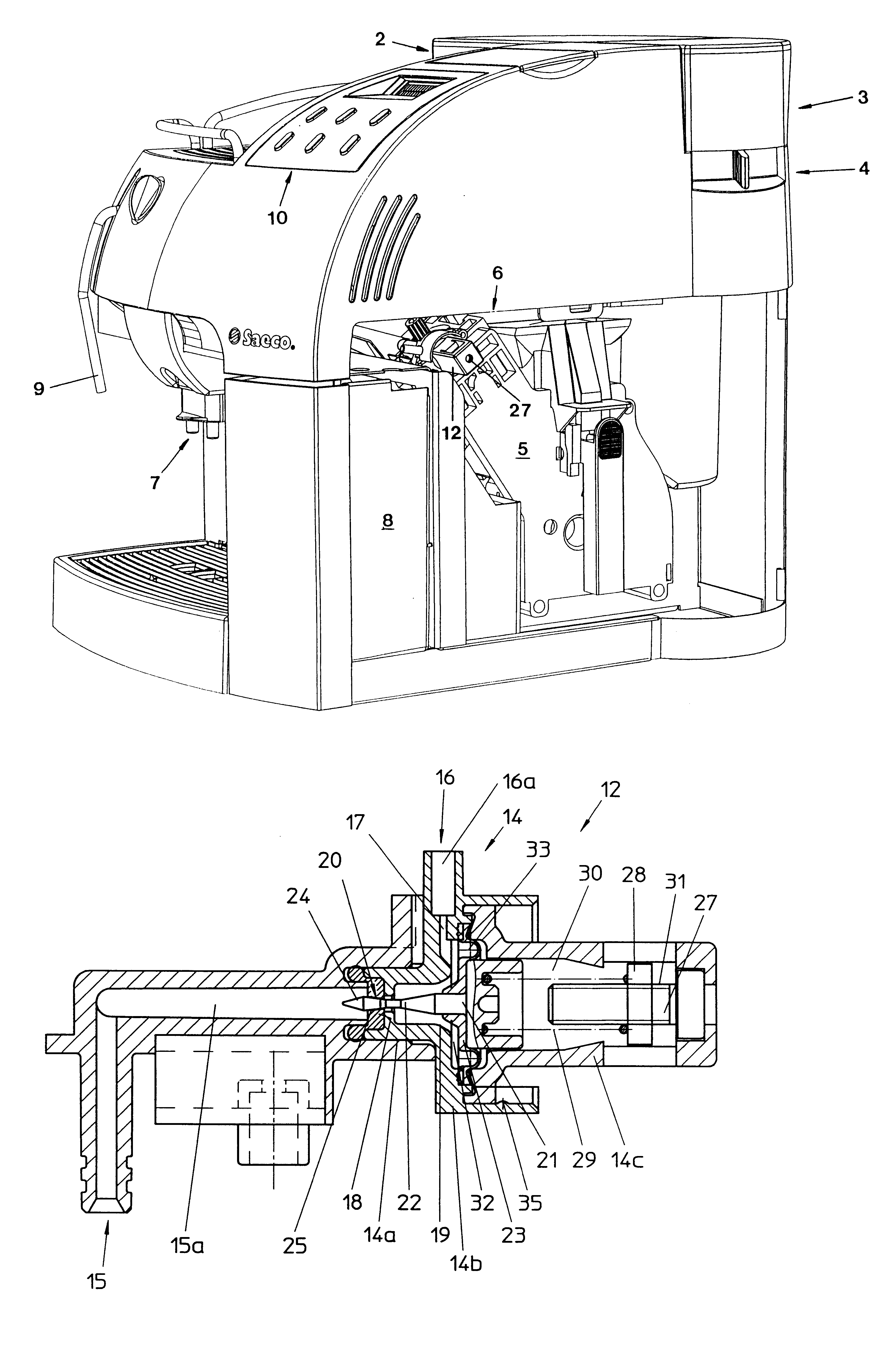

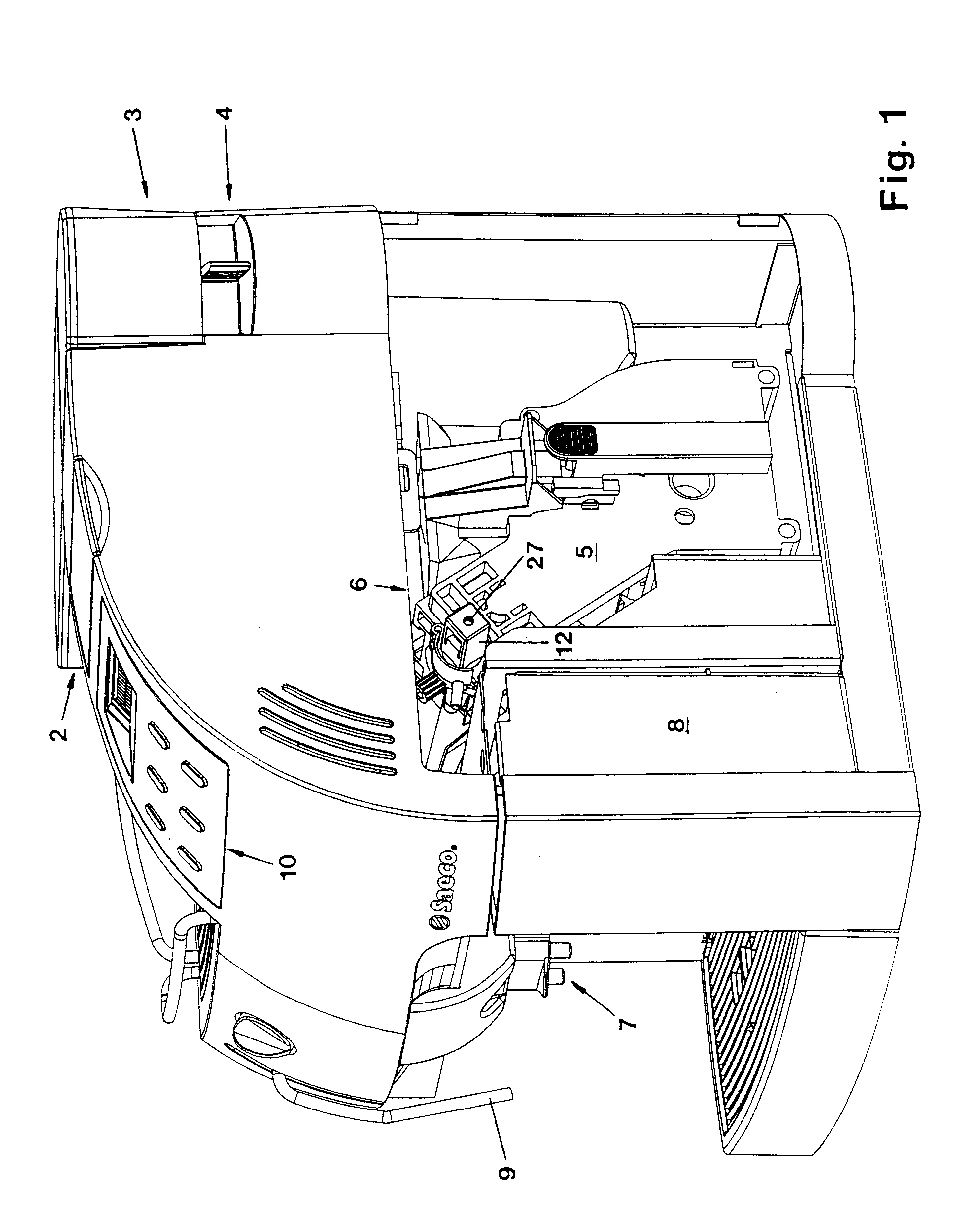

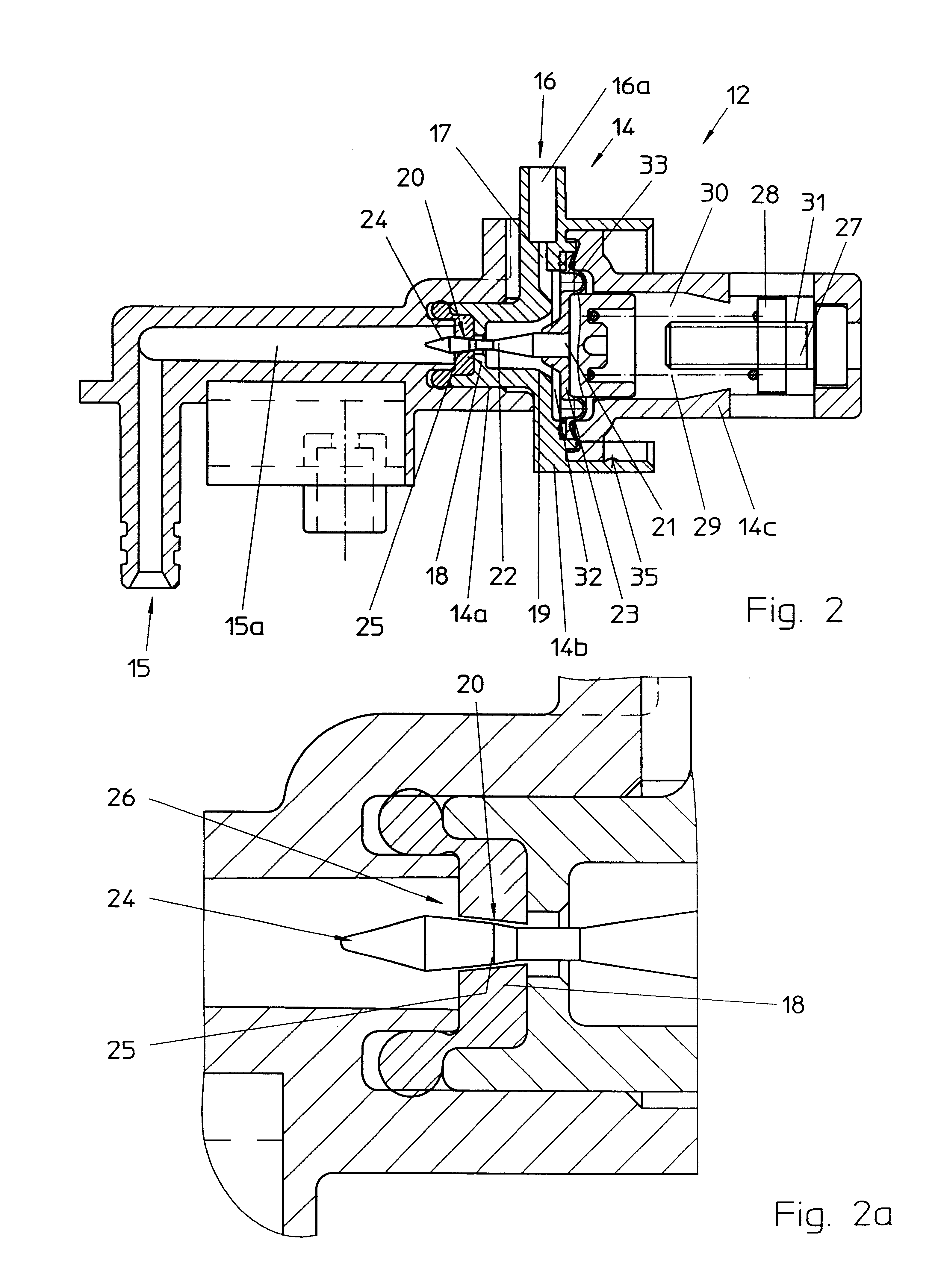

Coffee machine

Owner:KONINK PHILIPS ELECTRONICS NV

Long-service-life split type valve seat

PendingCN111664087AExtended service lifeHigh hardnessPositive displacement pump componentsLiquid fuel engine componentsWorking pressureStructural engineering

The invention discloses a long-service-life split type valve seat. The long-service-life split type valve seat comprises linings and bases. The linings are embedded into the outlet ends of the bases.The linings are matched with a valve body for use. Each lining is a tungsten carbide alloy. The long-service-life split type valve seat has the beneficial effects that the valve seat is composed of the linings and the bases, the linings are made of a hard alloy material, the hardness, the strength, the wear resistance and the corrosion resistance of the linings are improved, and the service life of the valve seat is greatly prolonged; the valve seat is of a split structure, once abrasion occurs, only the linings or the bases need to be replaced, integral replacement is not needed, maintenanceis convenient, the time and labor are saved, and meanwhile the production cost of an oil and gas field is reduced; the appropriate diameter sizes of the linings can be selected according to the working pressure, the conveying medium, the degree of abrasion of the valve body to the valve seat and the like in actual working conditions, and the application range is wide; the linings and the bases arein various shapes and can be combined according to actual working condition requirements, and the applicability is high.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

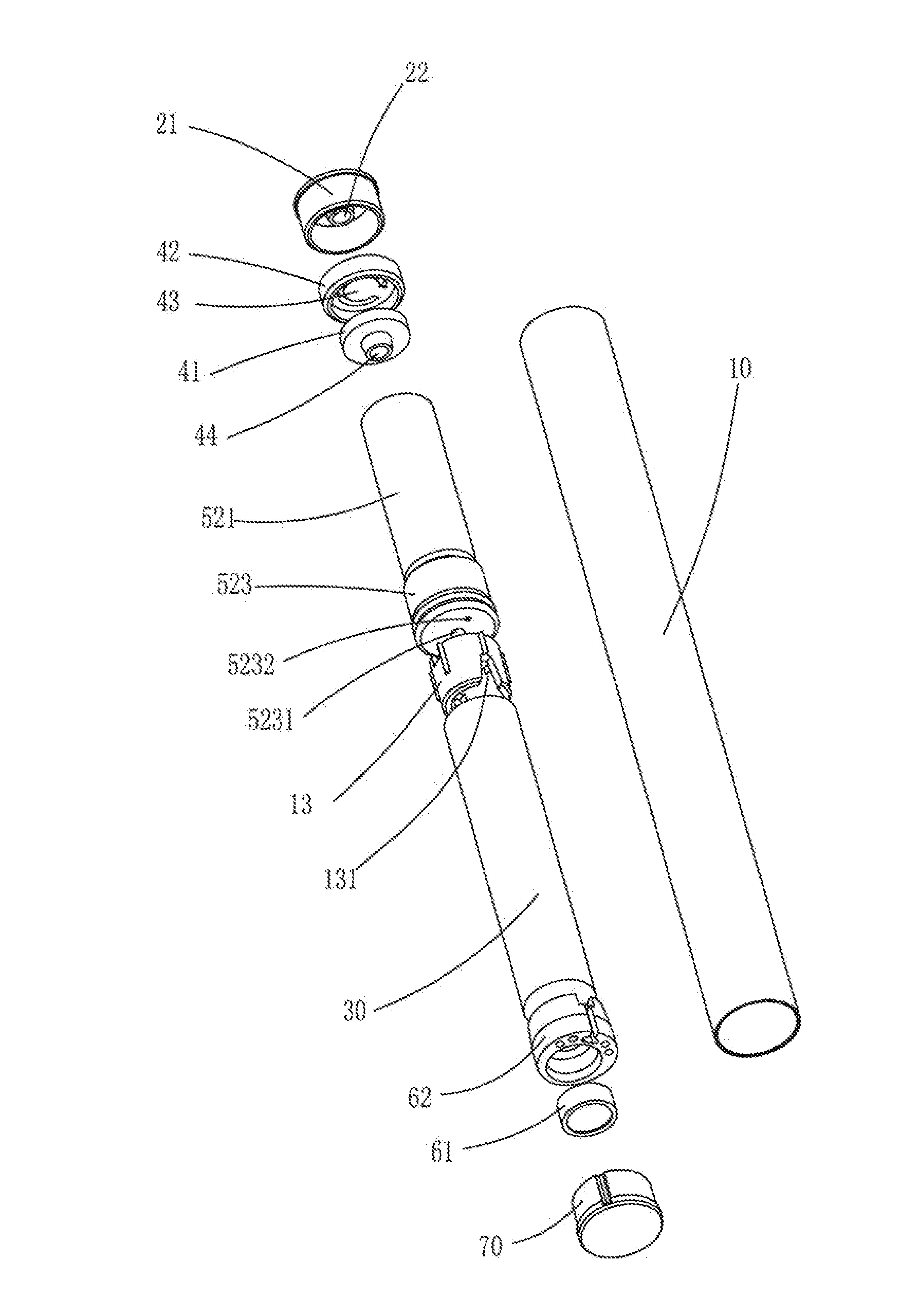

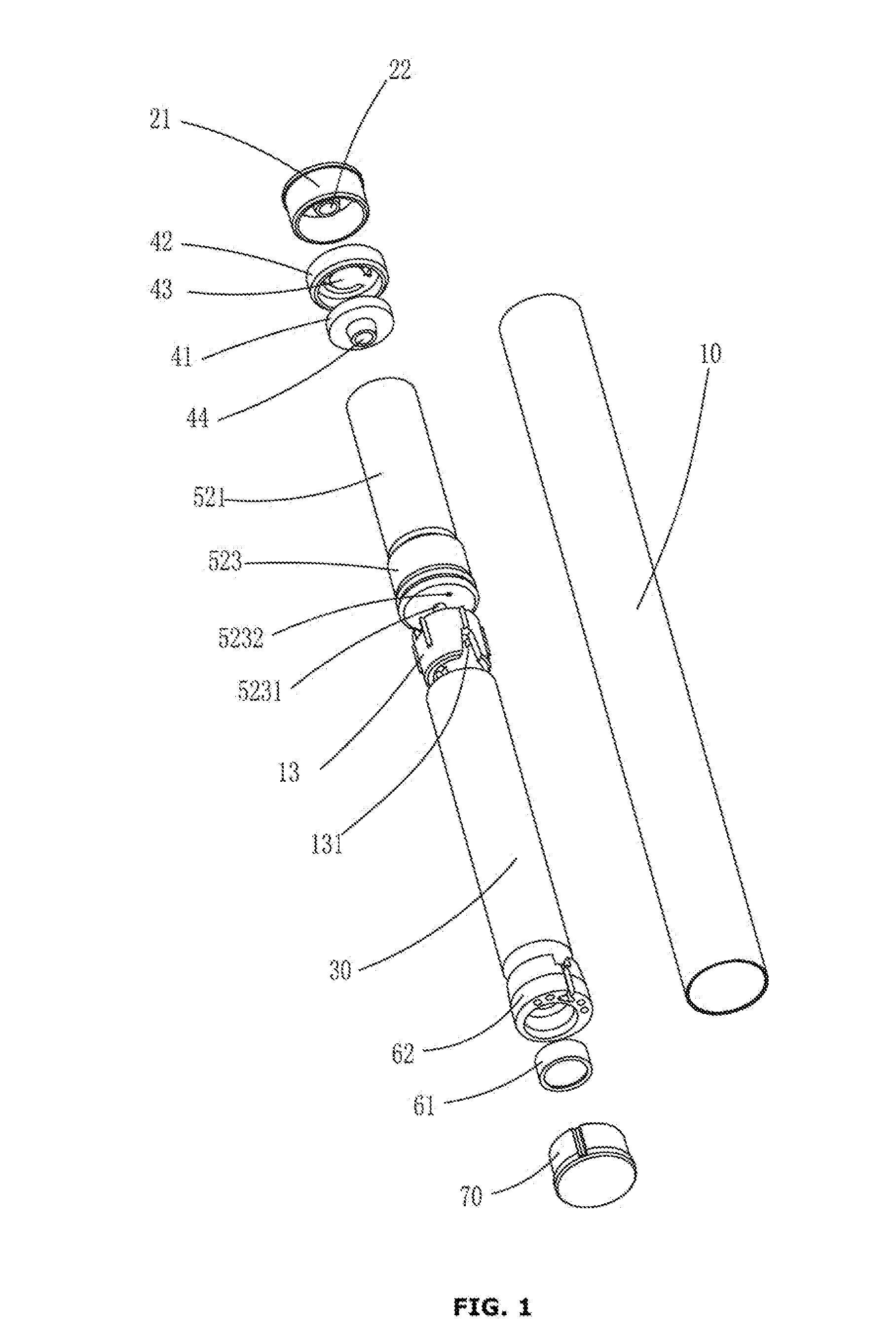

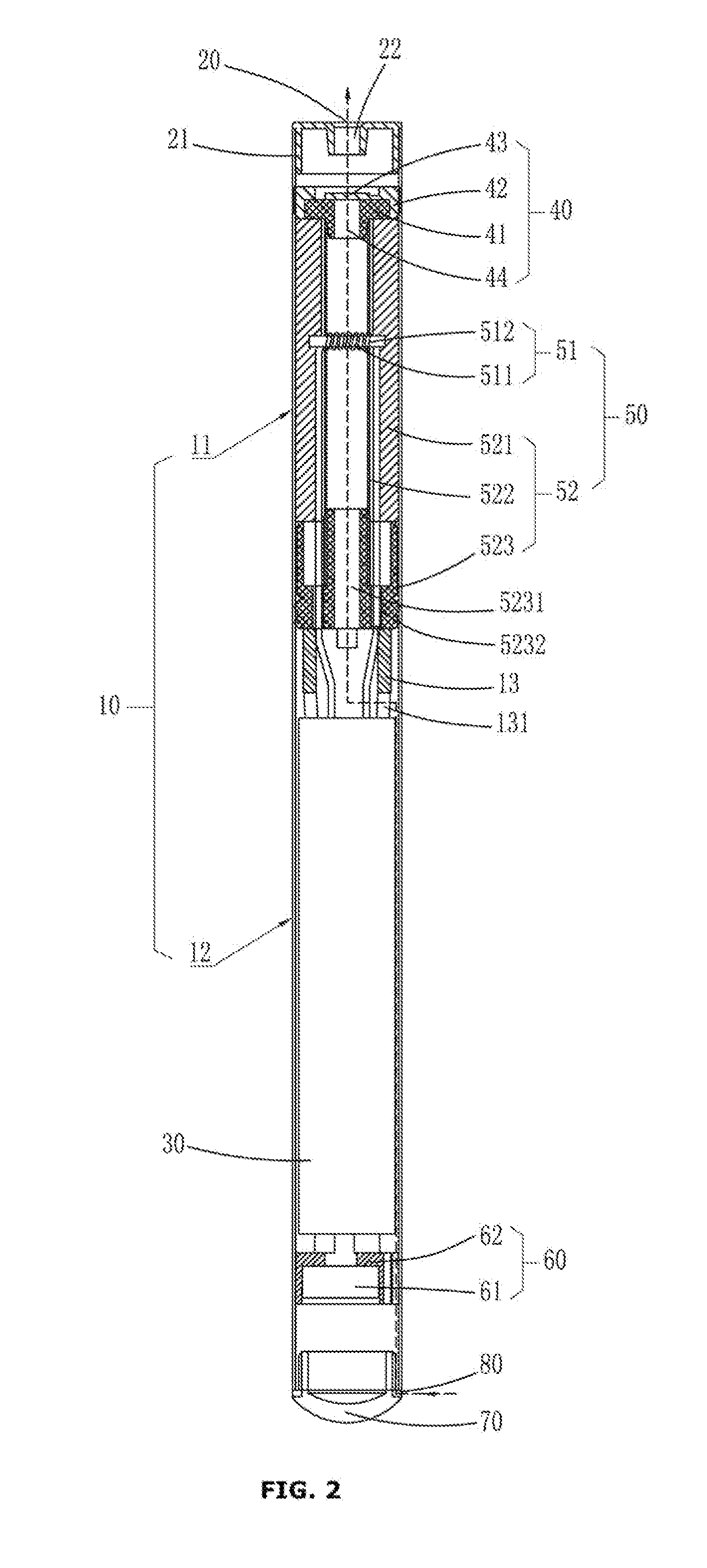

Electronic cigarette and electronic cigarette device thereof

Disclosed are an electronic cigarette and an electronic cigarette device thereof, the electronic cigarette (100) comprising a main rod body (10), one end of the main rod body (10) being provided with a suction nozzle (20) and the other end being internally provided with a battery (30), wherein a one-way valve (40) is further provided in the main rod body (10) between the suction nozzle (20) and the battery (30) for providing a gas passage when inhaling gas and shutting off the gas passage when exhaling gas; the one-way valve (40) comprises a valve seat (42) with two penetrating ends, and a valve core (41) and a valve flap (43) mounted inside the valve seat (42); the valve seat (42) or the valve core (41) is provided with a gas guide hole (44); and the valve flap (43) is affixed to an orifice at one end of the gas guide hole (44) and generates elastic deformation corresponding to the operation of inhaling or exhaling gas so as to control the open or closed state of the gas guide hole. The electronic cigarette (100) has a function of controlling a one-way gas passage, providing the gas passage when inhaling gas and shutting off the gas passage when exhaling gas.

Owner:SHENZHEN KIMSEN TECH CO LTD

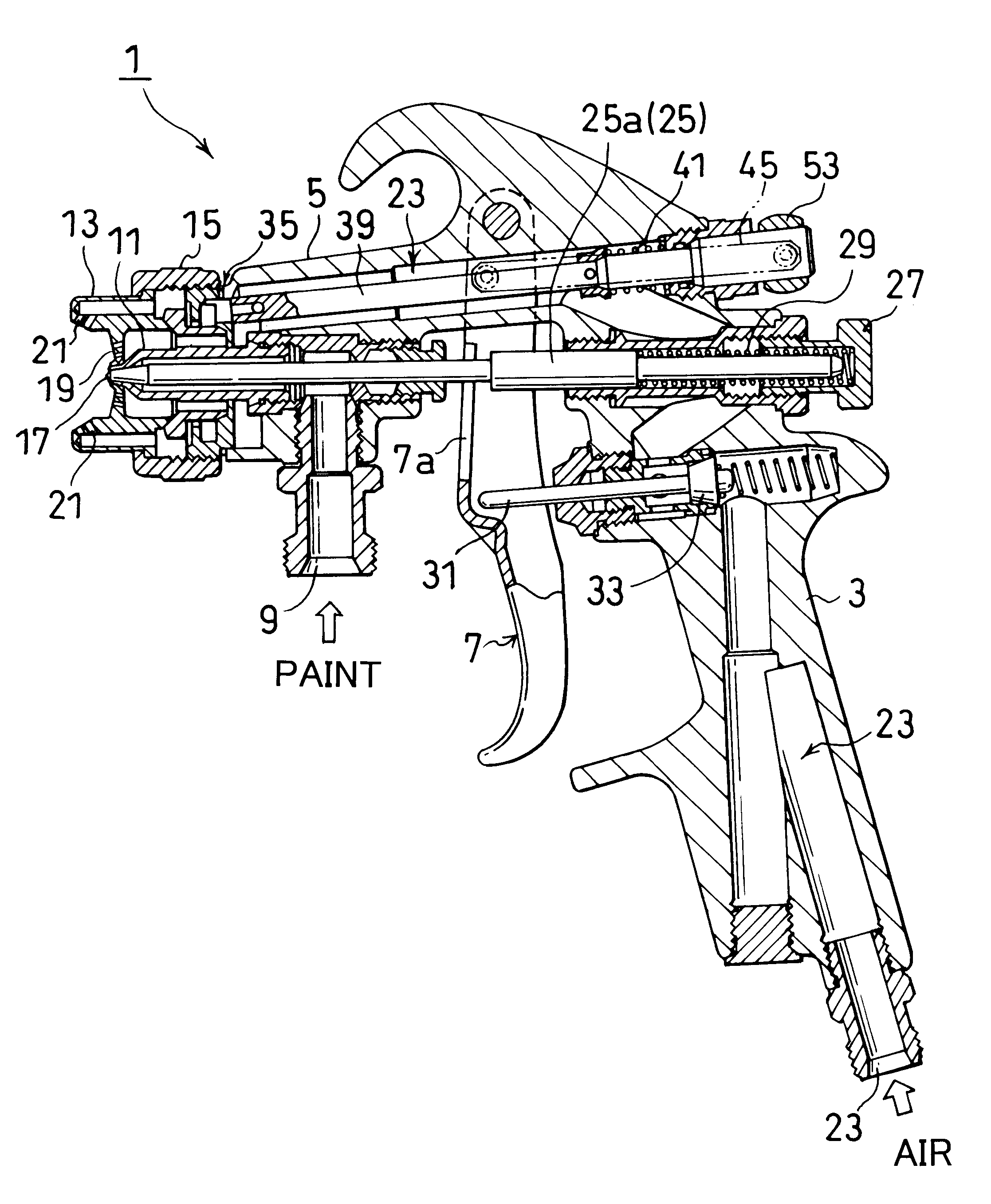

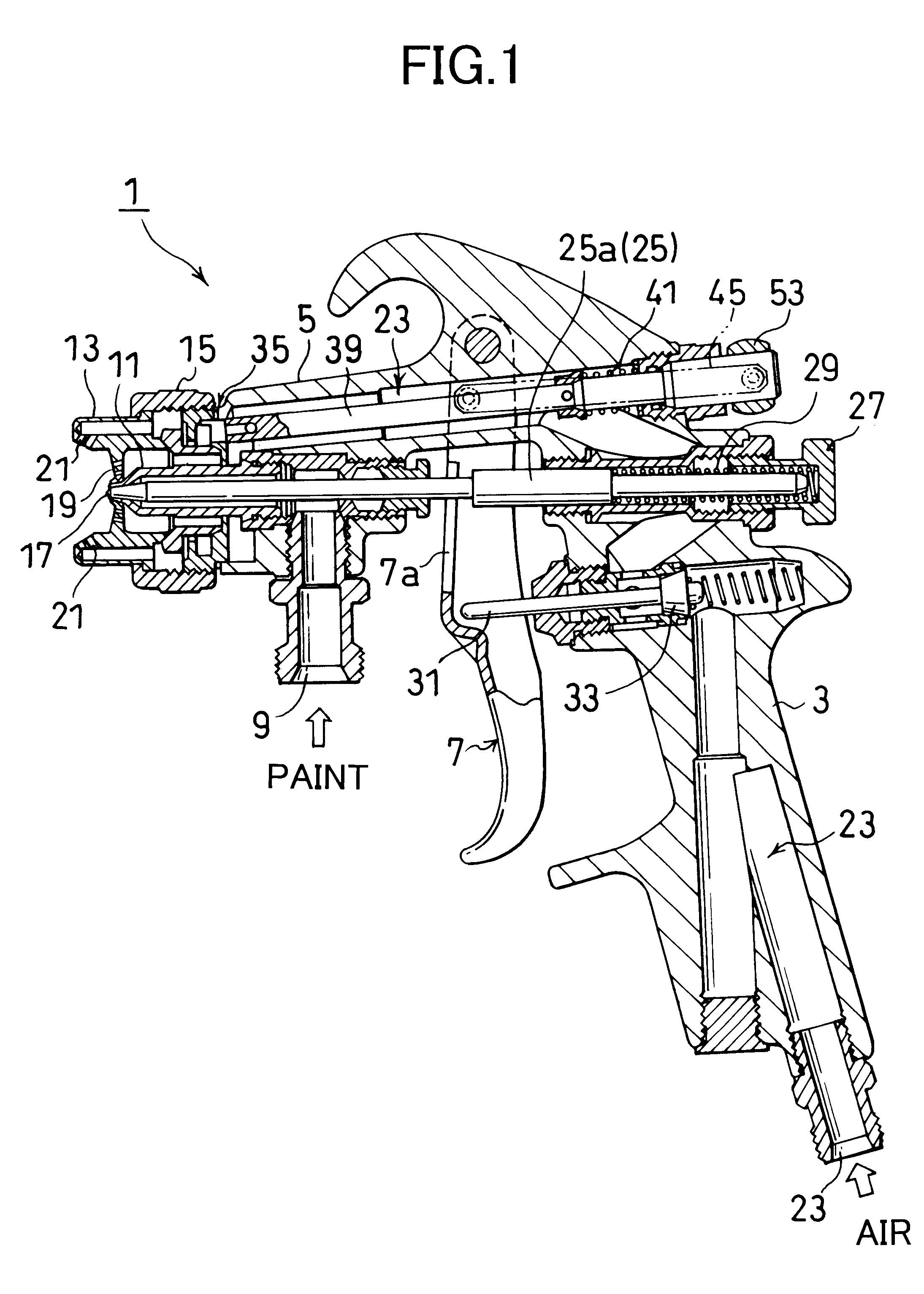

Aerosol spray gun

InactiveUS6402058B2Reduce in quantityLiquid spraying apparatusGaseous fuel burnerAerosol sprayCoupling

An aerosol spray gun used selectively in two spraying modes of small and large patterns is provided. The aerosol spray gun has a throttle valve, an air duct, and a coupling link. The throttle valve has an internal air duct for supplying pressurized air to a patterning air outlet which shapes a paint spraying stream jetted out from the aerosol spray gun, and has a movable valve element to which a compressed spring applies force to open the valve. The air duct created at the tip of the movable valve element supplies a small volume of air from the internal air duct to the patterning air outlet while the movable valve element seats on a valve seat. The coupling link, coupling the movable valve element to the trigger, has an elongated hole to disconnect the trigger from the movable valve element without cooperative relation between them from an initial stage where an operator begins to squeeze the trigger to an intermediate stage before the operator fully squeezes the trigger.

Owner:CARLISLE FLUID TECH RANSBURG JAPAN KK

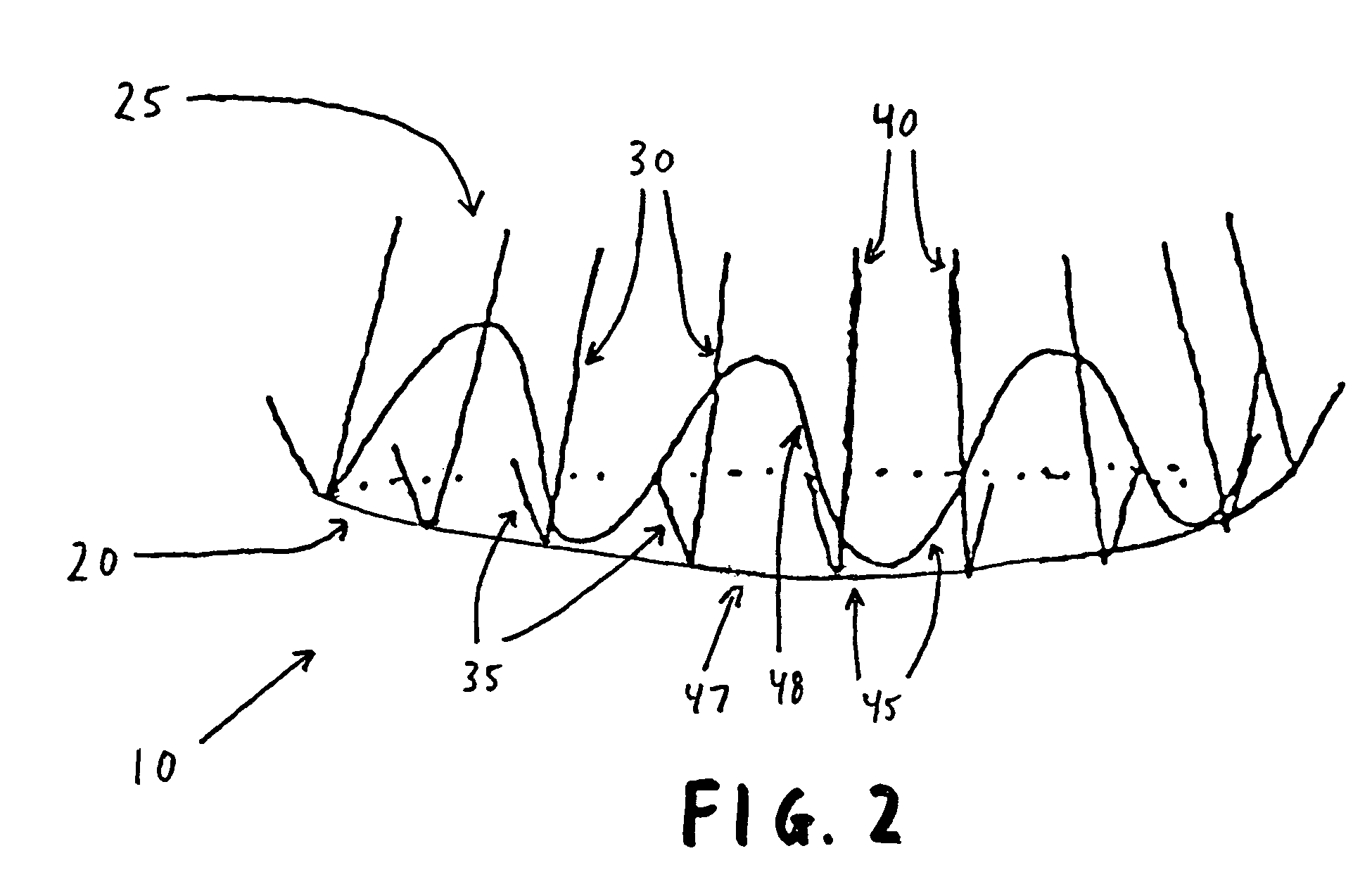

Laterally-actuated dispenser with one-way valve for storing and dispensing metered amounts of substances

InactiveUS20060065677A1Reduce in quantityReduce complexitySolid materialCosmetic containersEngineeringActuator

A dispenser for dispensing a substance, such as a pharmaceutical, ophthalmic, dermatological, cosmeceutical, cosmetic or other product, has a body defining a variable-volume storage chamber for storing the product. A dispensing portion of the dispenser is connected with the body and defines a bore coupled in fluid communication with the storage chamber for receiving substance therefrom, and an outlet aperture coupled in fluid communication with the bore. A one-way valve of the dispenser includes an axially-extending valve seat and an axially-extending flexible valve cover seated on the valve seat and defining a normally-closed, axially-extending seam therebetween forming a fluid-tight seal between the valve cover and valve seat. The flexible valve cover is movable relative to the valve seat and the seam is connectable in fluid communication with the outlet aperture to allow the passage of substance through the seam and out of the dispenser. The dispenser further comprises an actuator and piston assembly including a piston receivable within the bore, a manually-engageable actuator connected to the piston for moving the piston between first and second positions relative to the bore to dispense substance within the bore through the outlet aperture, and an integral, dome-shaped spring coupled to at least one of the piston and the actuator for biasing the piston in a direction from one of the first and second positions toward the other.

Owner:MEDINSTILL DEV

Vacuum enhancing check valve

InactiveUS20060016477A1Reducing vehicle 's costReduce complexityBraking action transmissionRatio controlEngineeringCheck valve

A vacuum enhancing check valve for direct connection to a vehicle brake booster which increases the partial vacuum provided thereto and restricts possible air back flow into the brake booster. The valve comprises a venturi for reducing the pressure of air induced to flow between a first air inlet and an air outlet by a partial vacuum at a vehicle engine's intake manifold. By significantly reducing the air pressure, the valve enhances the partial vacuum available for provision to the brake booster. The venturi is also in air communication with a second air inlet directly attachable to the brake booster such that the air pressure at the second air inlet tends toward the enhanced partial vacuum within the venturi. A valve seat and seal member within the valve are cooperative to allow air flow from the second air inlet toward the venturi, but not in the reverse direction.

Owner:FORD GLOBAL TECH LLC

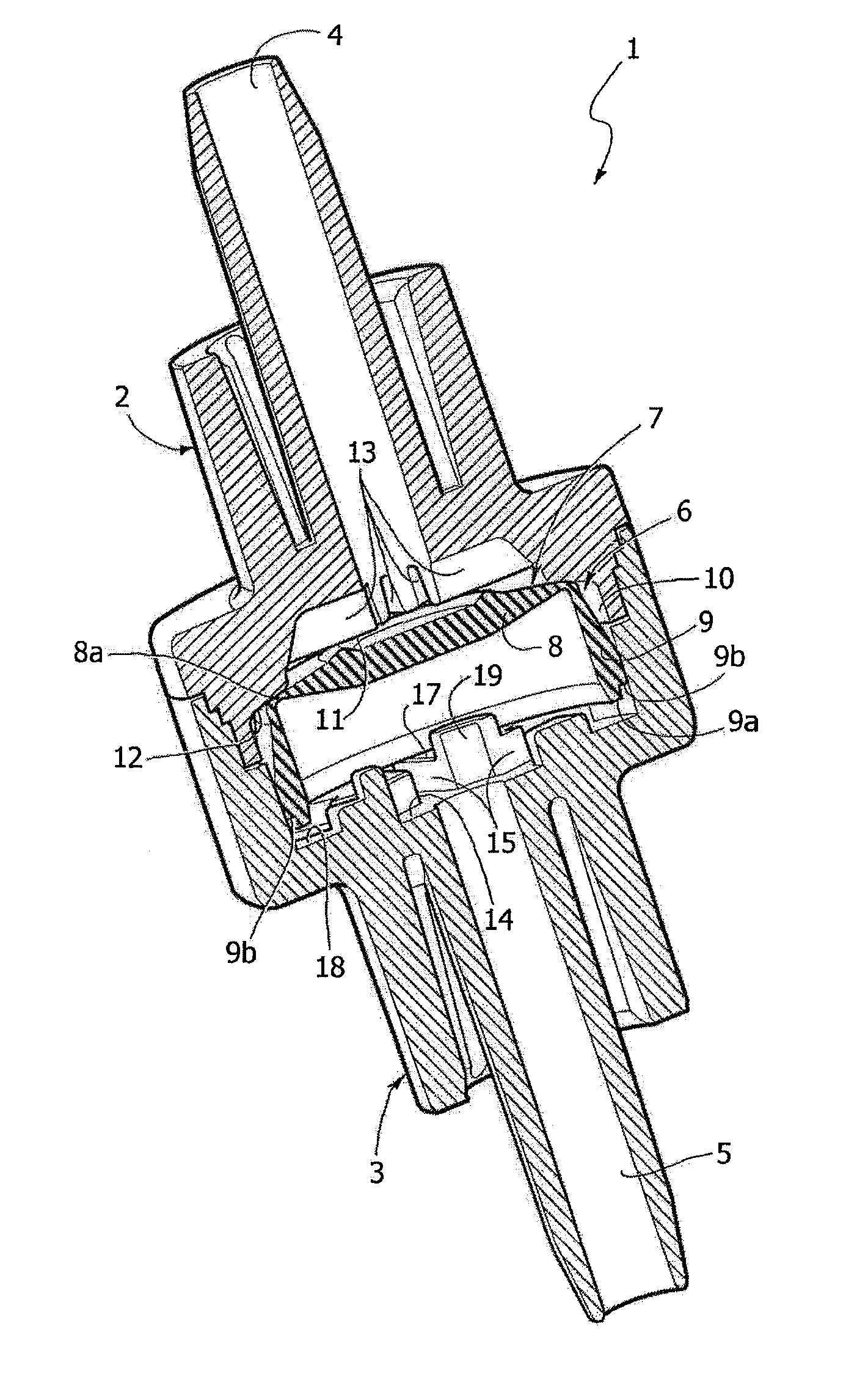

One-way valve for medical infusion lines and the like

A check valve for medical infusion lines and the like, includes a diaphragm made of elastic material set between a first tubular connector and a second tubular connector. The diaphragm includes an end wall of a cup-shaped element, having an outer peripheral edge of which is normally pressed in seal contact against an annular valve seat with a conical surface of the first tubular connector under an axial thrust exerted by a side wall of the cup-shaped element. A free edge of the side wall of the cup-shaped element is set resting against a transverse surface of the second tubular connector only in regions corresponding to angular portions of the latter separated by non-resting angular portions.

Owner:IND BORLA

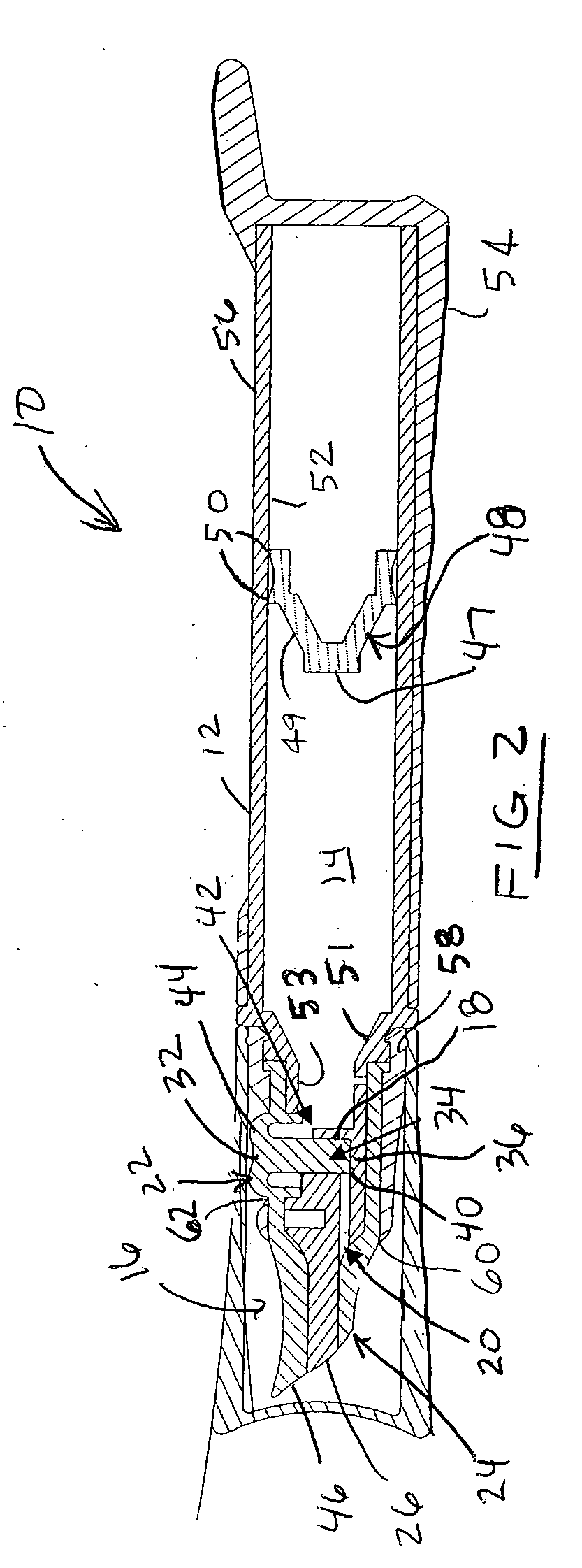

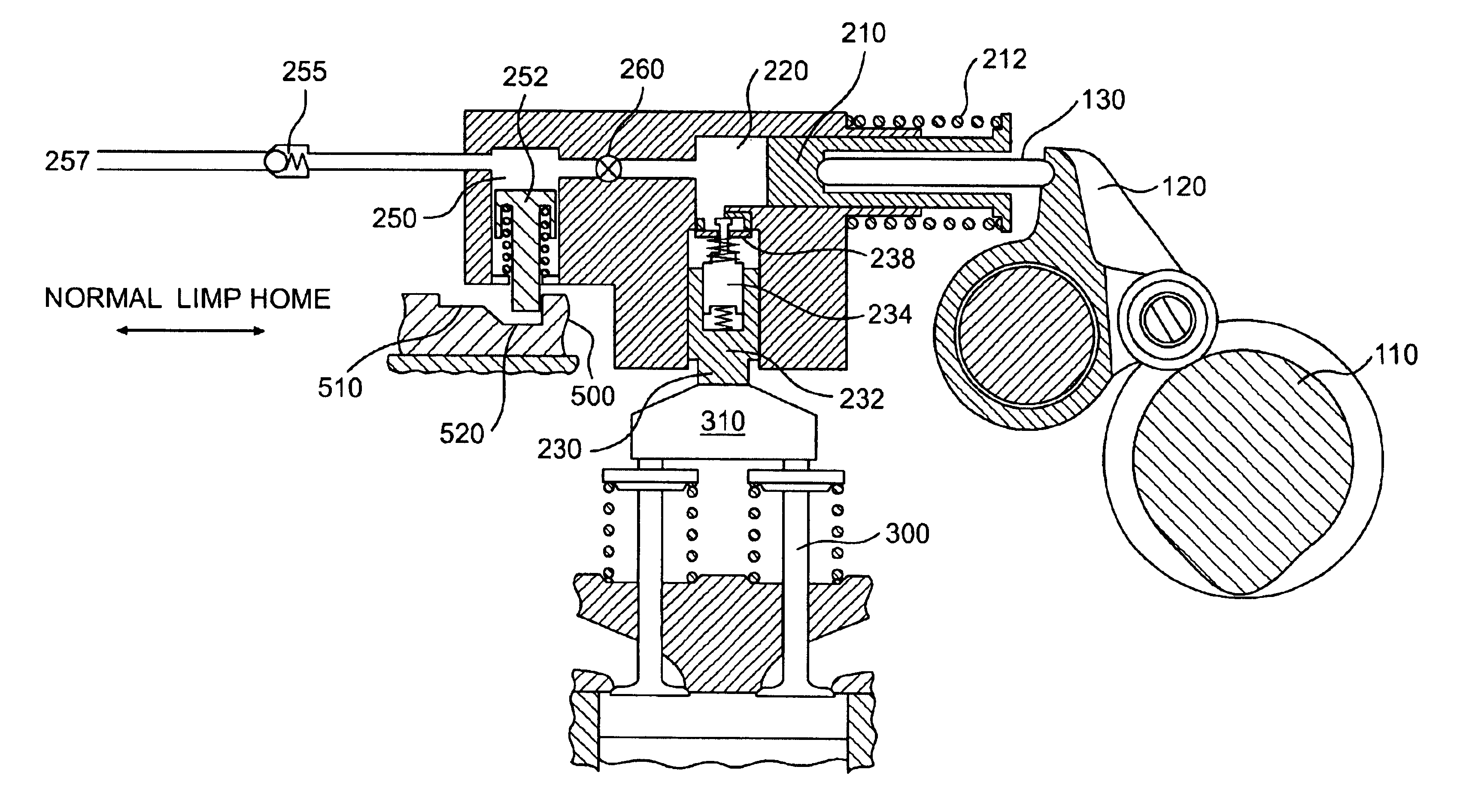

Thermal bypass valve with pressure relief capability

ActiveUS20100126594A1Relieve excessive stressIncrease dependenceTemperature control without auxillary powerOperating means/releasing devices for valvesEngineeringActuator

A by-pass valve for a heat exchanger circuit that includes a cooler has a chamber and ports for flow of fluid into and out of this chamber. A thermally sensitive actuator is mounted in the chamber and can extend or retract in dependence on its body temperature as influenced by temperature of the fluid. A by-pass valve seat is arranged in a valve housing along with a by-pass valve member movable by the actuator into or out of engagement with the seat. A relief valve is mounted in the chamber and has a relief valve member movable between closed and open positions in order to close or open pressure relief ports. This relief valve member is biased towards the closed position. Excessive pressure build up in an end section of the chamber causes the relief valve member to move to its open position.

Owner:DANA CANADA CORP

Fluid dispensing valve assembly

InactiveUS6053370AReduce manufacturing costEasy to useClosuresLiquid transferring devicesEngineeringCheck valve

A dispenser for dispensing charges of fluid from a container and applicable to a mouth of the container with the container in an inverted position and the mouth down. The dispenser includes a body formed of resilient elastomeric material having a hollow annular upper part having a flexible, resilient annular wall and an upper and lower end and constituting a bellows which is downwardly expansible and upwardly contractible by flexing of the annular wall. The body has integral with the bellows a lower part having a discharge port. The dispenser includes a first check valve at an entry end of the bellows operable for flow of fluid into the bellows on expansion thereof and operable to block flow of fluid from the pump member out of its upper end on contraction thereof. A second valve is operable for dispensing the charge of fluid from the bellows down into the outlet nozzle on contraction of the bellows and to block flow out of the bellows outlet on expansion of the bellows. The second check valve has a valve seat member at the intake of the bellows and outlet nozzle, has at least one outlet port below the valve and a spring biased to keep the poppet valve seated against the valve seat such that the fluid is expelled through the poppet valve, outlet nozzle, and outlet port on contraction of the pump member.

Owner:KOLLER ENTERPRISES +1

Check valve for a piston pump in a fluid circulation system

The invention relates to a check valve with a tubular valve housing in which a valve ball is received. To make a large flow cross section available and to prevent closure by the valve ball when the check valve is fully open, a perforated disk is press-fitted between longitudinally extending guide ribs of the valve housing and a circumferential wall of the valve housing there is an interstice as an outflow opening, which is not closed even the valve ball contacts the perforated disk. The valve housing is made by stamping, in which the guide ribs and a valve seat are made in one operation and are thereby aligned exactly with one another. In this way, a small radial play of the valve ball can be realized.

Owner:ROBERT BOSCH GMBH

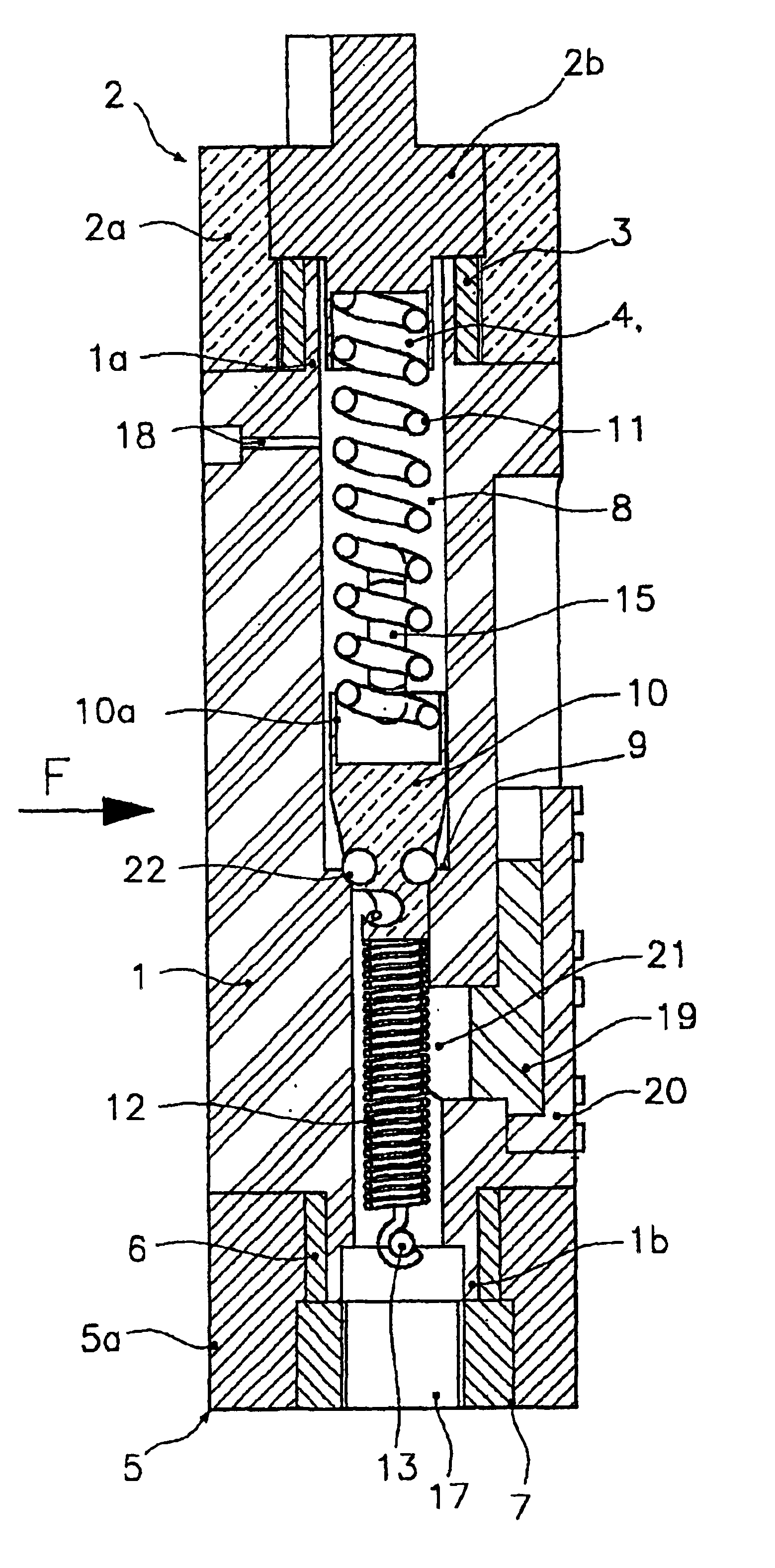

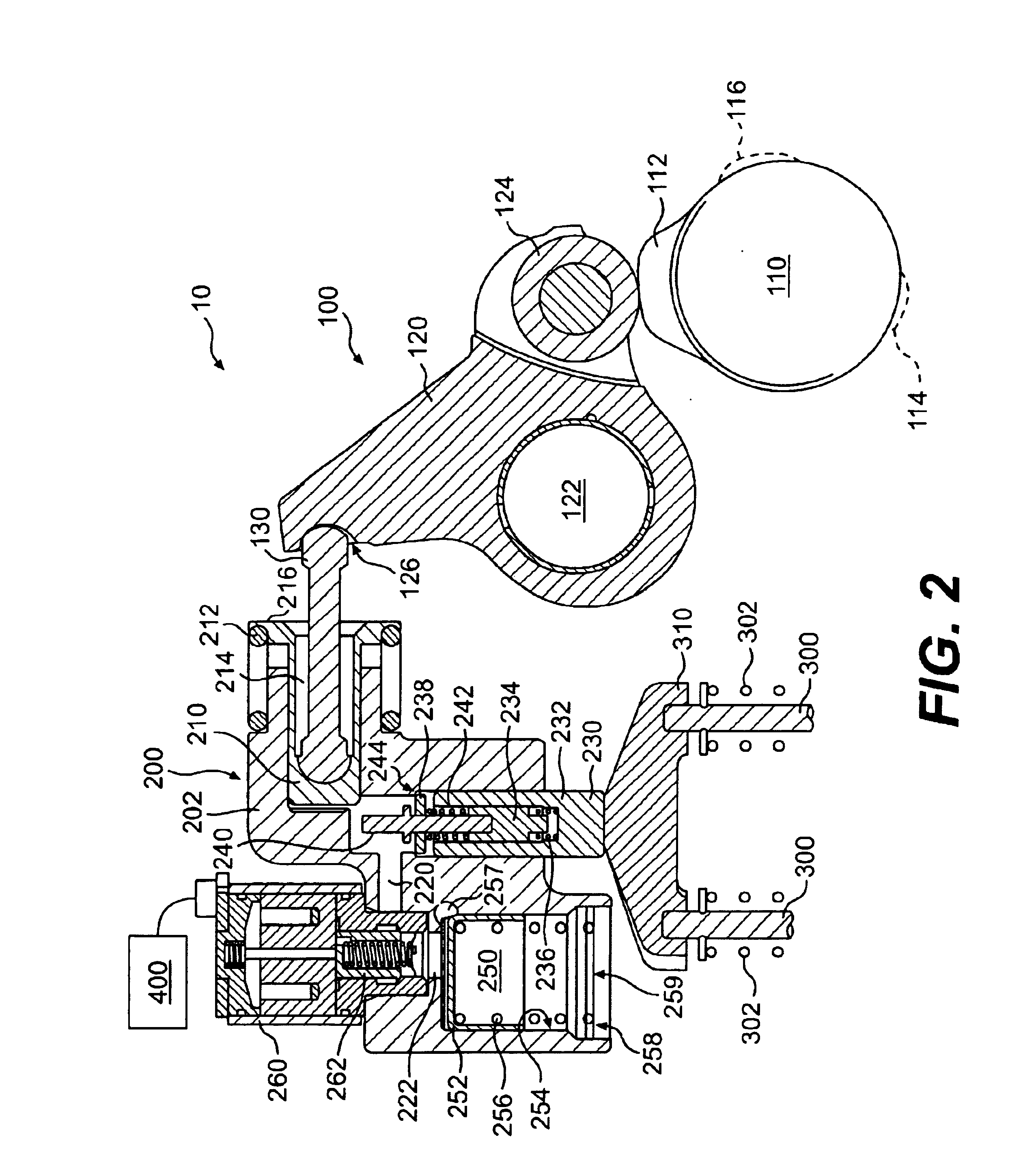

Compact lost motion system for variable valve actuation

InactiveUS6883492B2Wide rangeNon-fuel substance addition to fuelInternal combustion piston enginesVariable valve timingHydraulic circuit

Lost motion systems and methods for providing engine valves with variable valve actuation for engine valve events are disclosed. The system may include a master piston hydraulically linked to a slave piston, and a dedicated cam operatively connected to the master piston. The slave piston may be disposed substantially perpendicular to the master piston in a common housing. The slave piston is adapted to actuate one or more engine valves. The slave piston may incorporate an optional valve seating assembly into its upper end. A trigger valve may be operatively connected to the master-slave hydraulic circuit to selectively release and add hydraulic fluid to the circuit.

Owner:JACOBS VEHICLE SYST

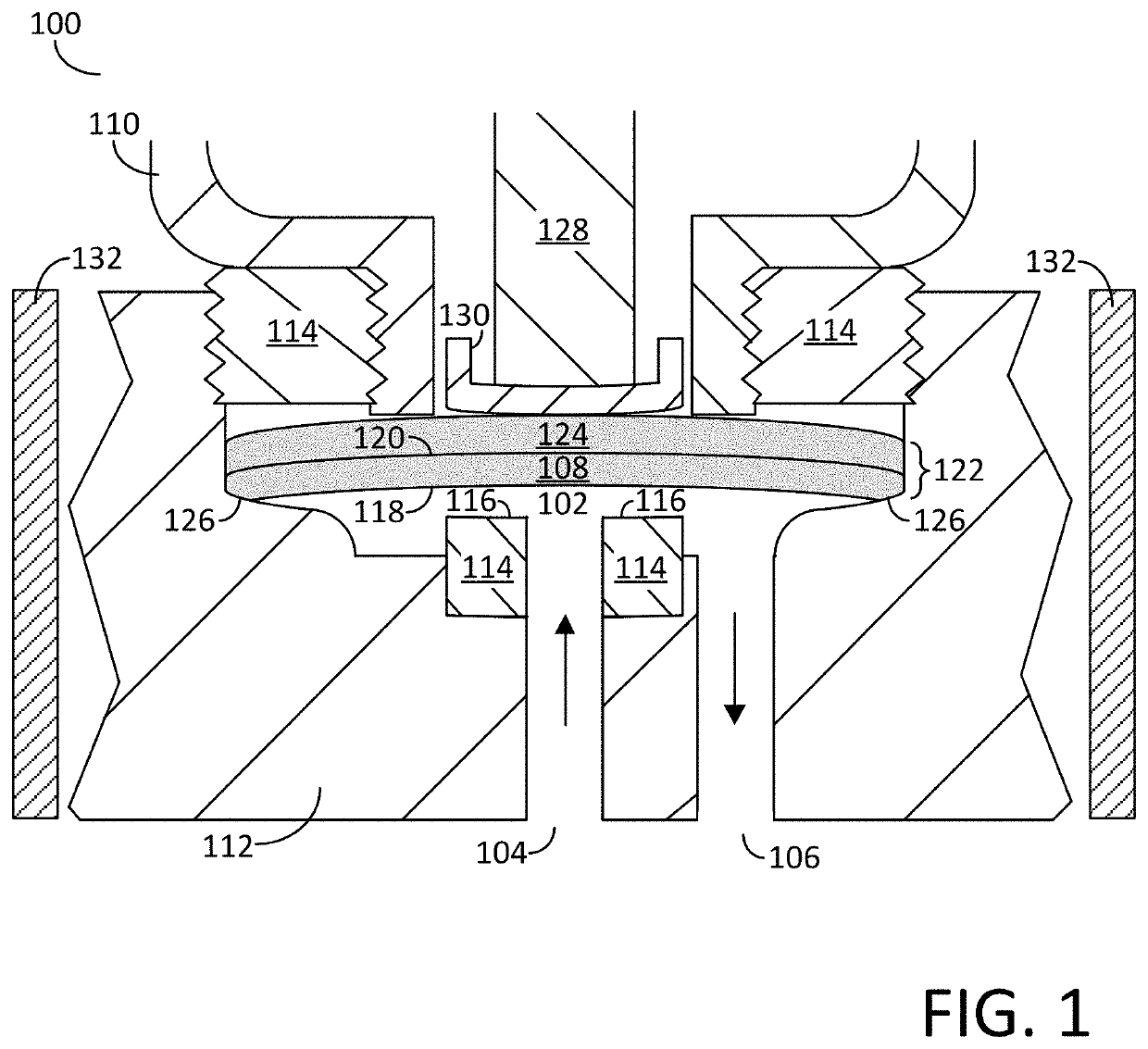

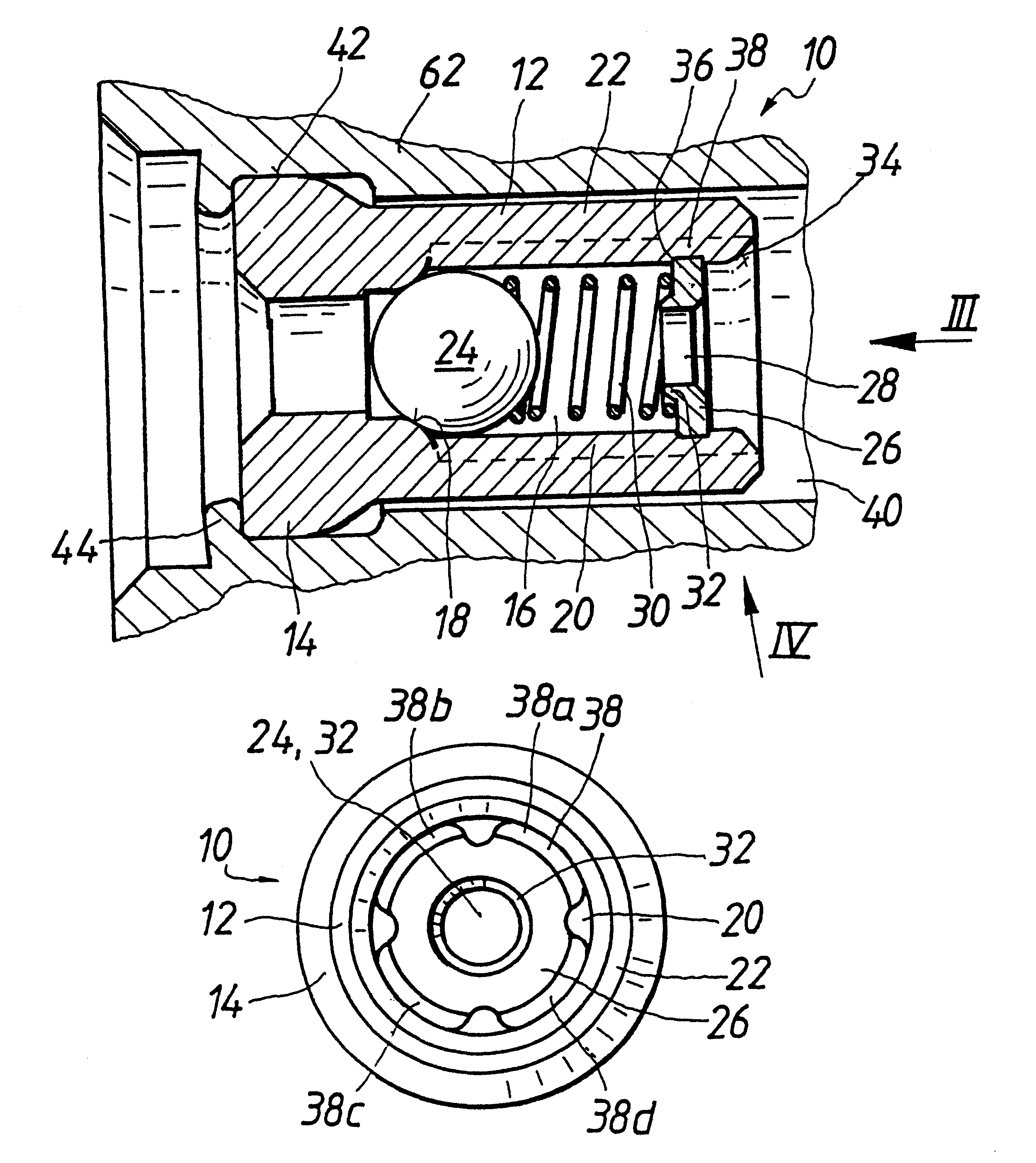

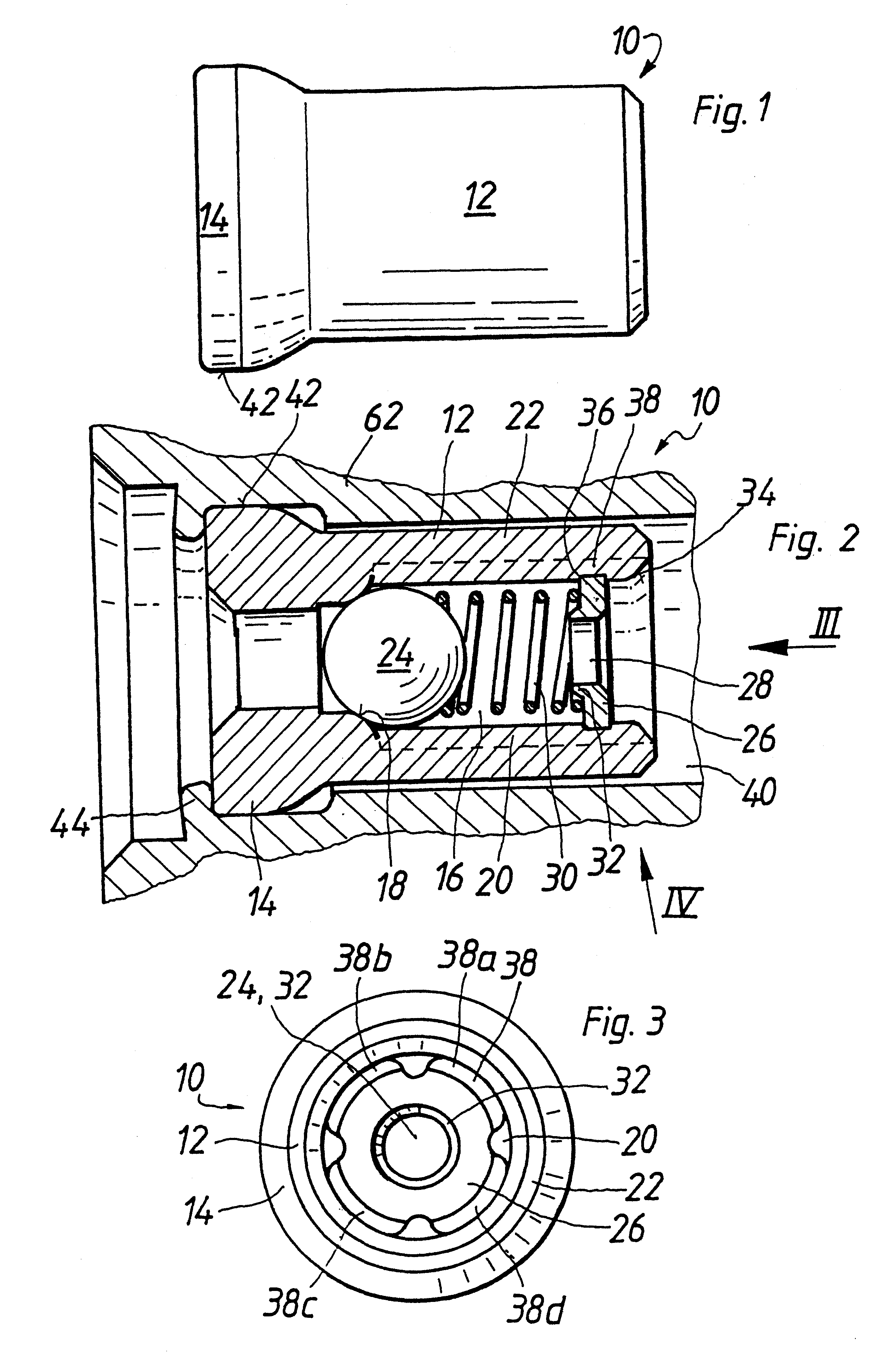

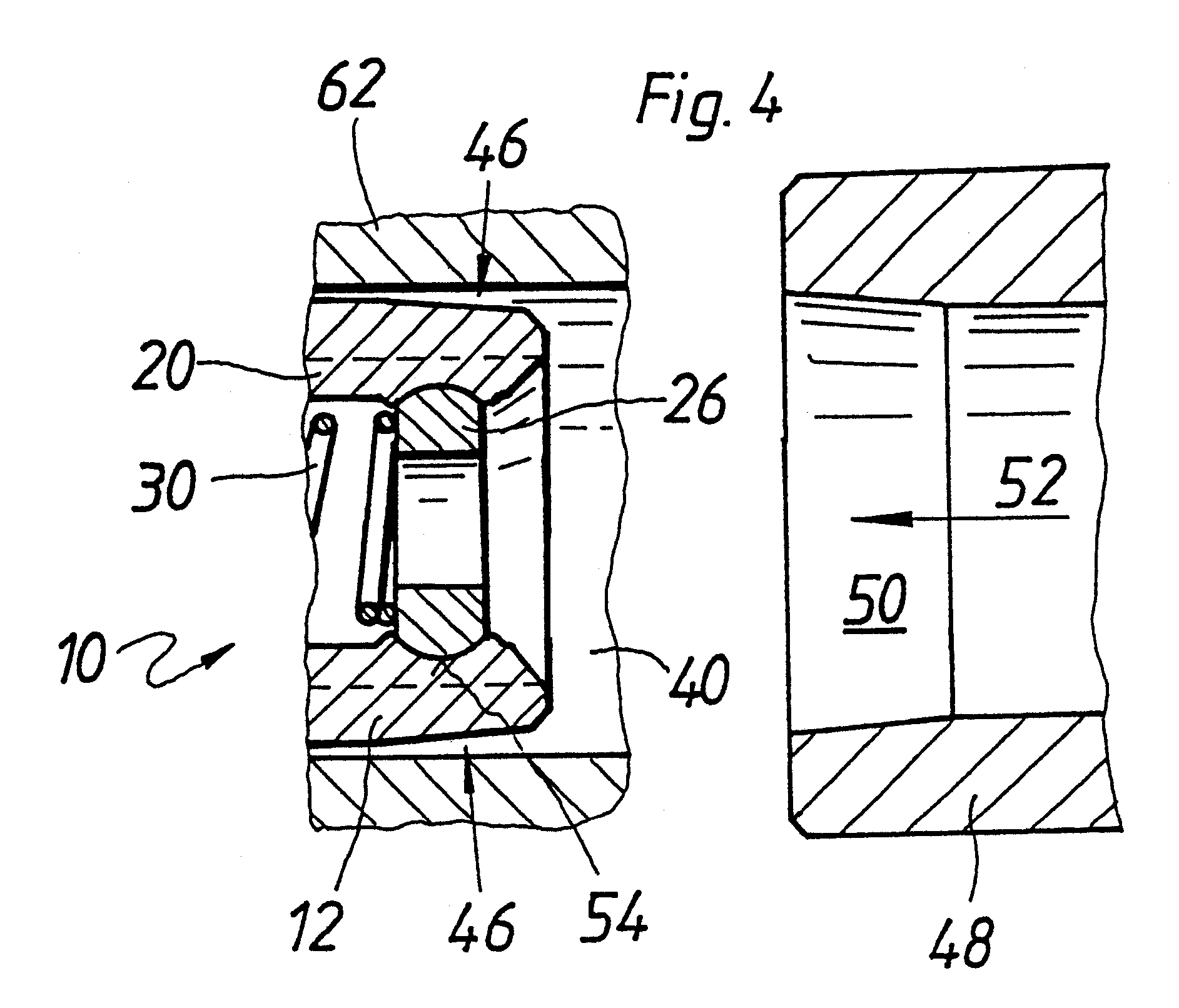

Preconfigured seal for valve assemblies

InactiveUS20130020521A1Shorten speedReduce impactCheck valvesMetal-working apparatusEngineeringValve seat

A valve assembly is disclosed herein having a valve member and a valve seat body. The valve member is reciprocatingly movable into and out of engagement with the valve seat body. The assembly further includes at least one deformable seal positioned to be at the situs of engagement of the valve member with the valve seat body. The at least one seal is preconfigured with a recess facing the situs to form a pocket to trap fluid therein as the valve member approaches the engagement, which reduces the velocity of the valve member moving toward the engagement and reduces the impact force of the valve member on the valve seat body. Furthermore, the fluid disposed within the pocket also reduces the axial load on the valve member and valve seat body.

Owner:S P M FLOW CONTROL

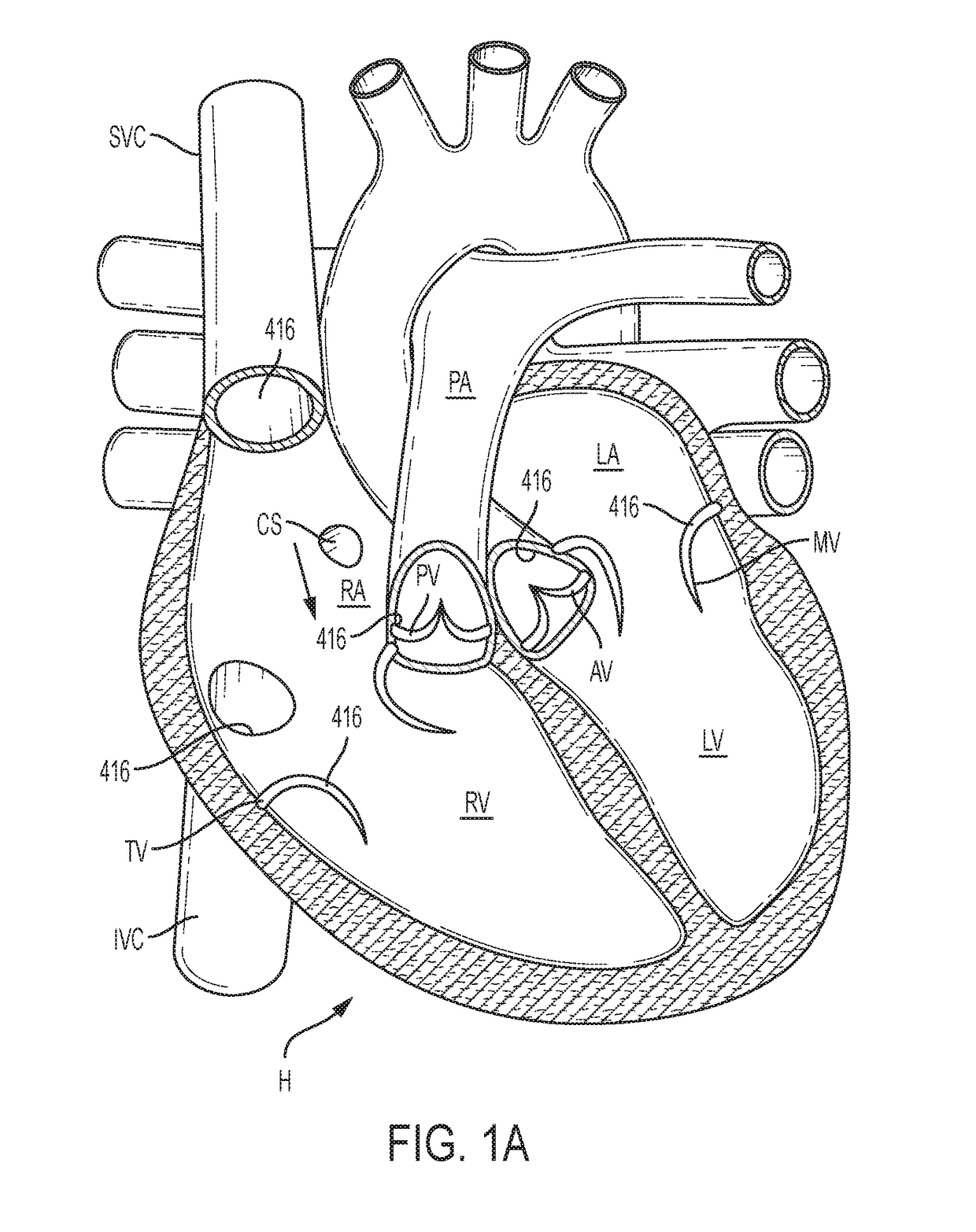

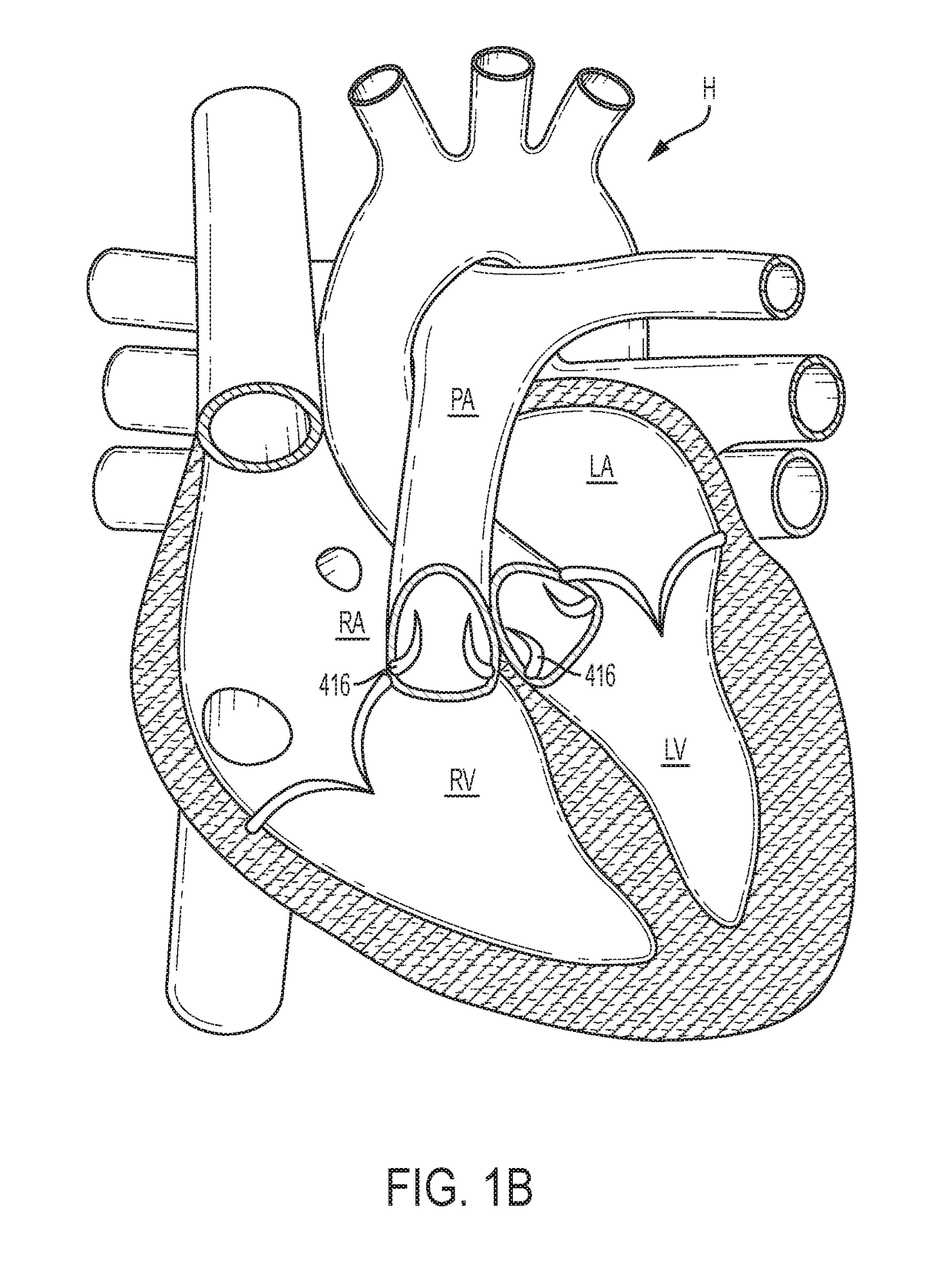

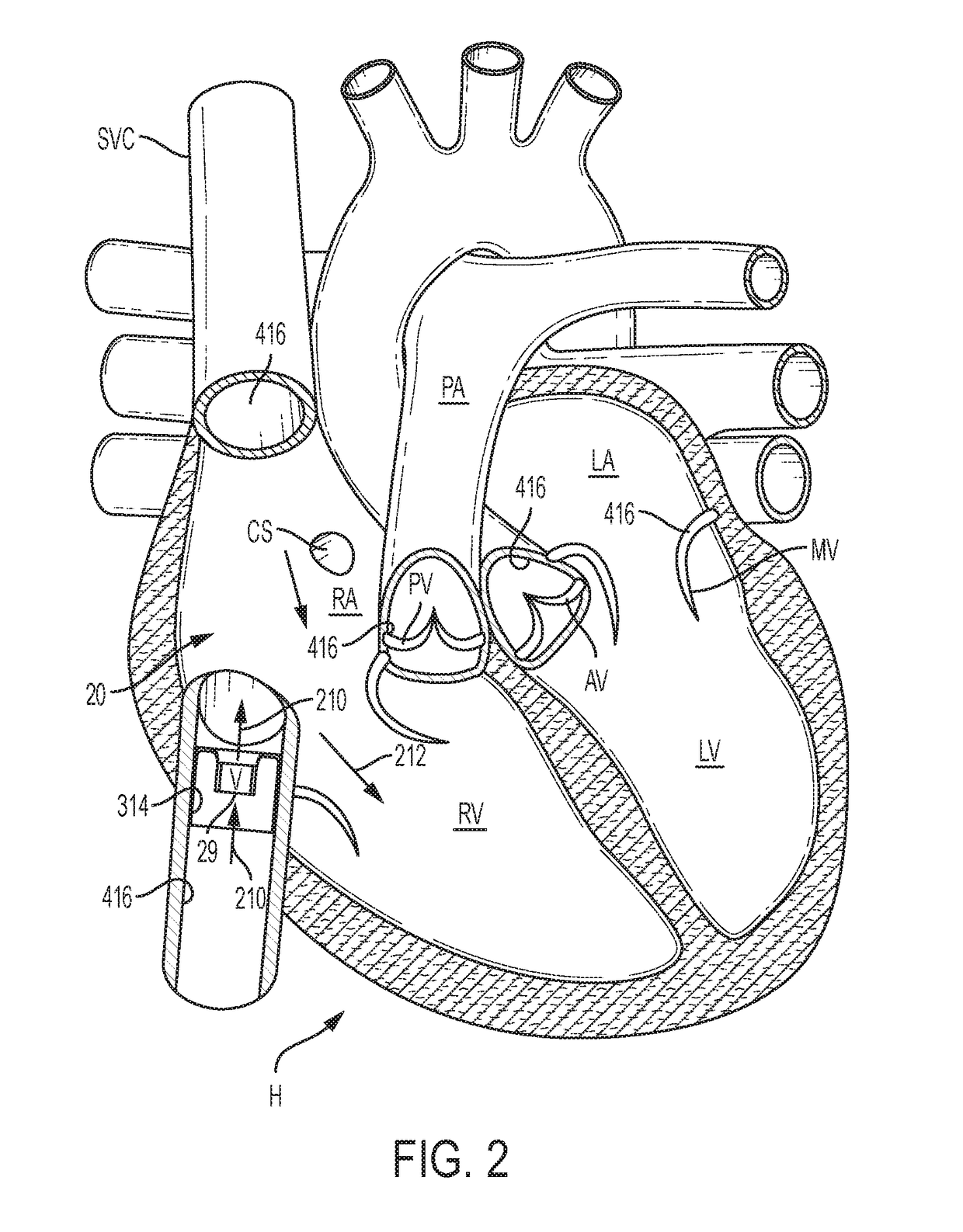

Docking stations for transcatheter valves

Docking stations for transcatheter valves are described. The docking stations can include an expandable frame, at least one sealing portion, and a valve seat. The expandable frame can be configured to conform to an interior shape of a portion of the circulatory system when expanded inside the circulatory system. The sealing portion can be configured to contact an interior surface of the circulatory system to create a seal. The valve seat can be connected to the expandable frame and can be configured to support an expandable transcatheter valve. The docking stations are adaptable to different anatomies / locations to allow implantation of a transcatheter valve in a variety of anatomies / locations.

Owner:EDWARDS LIFESCIENCES CORP

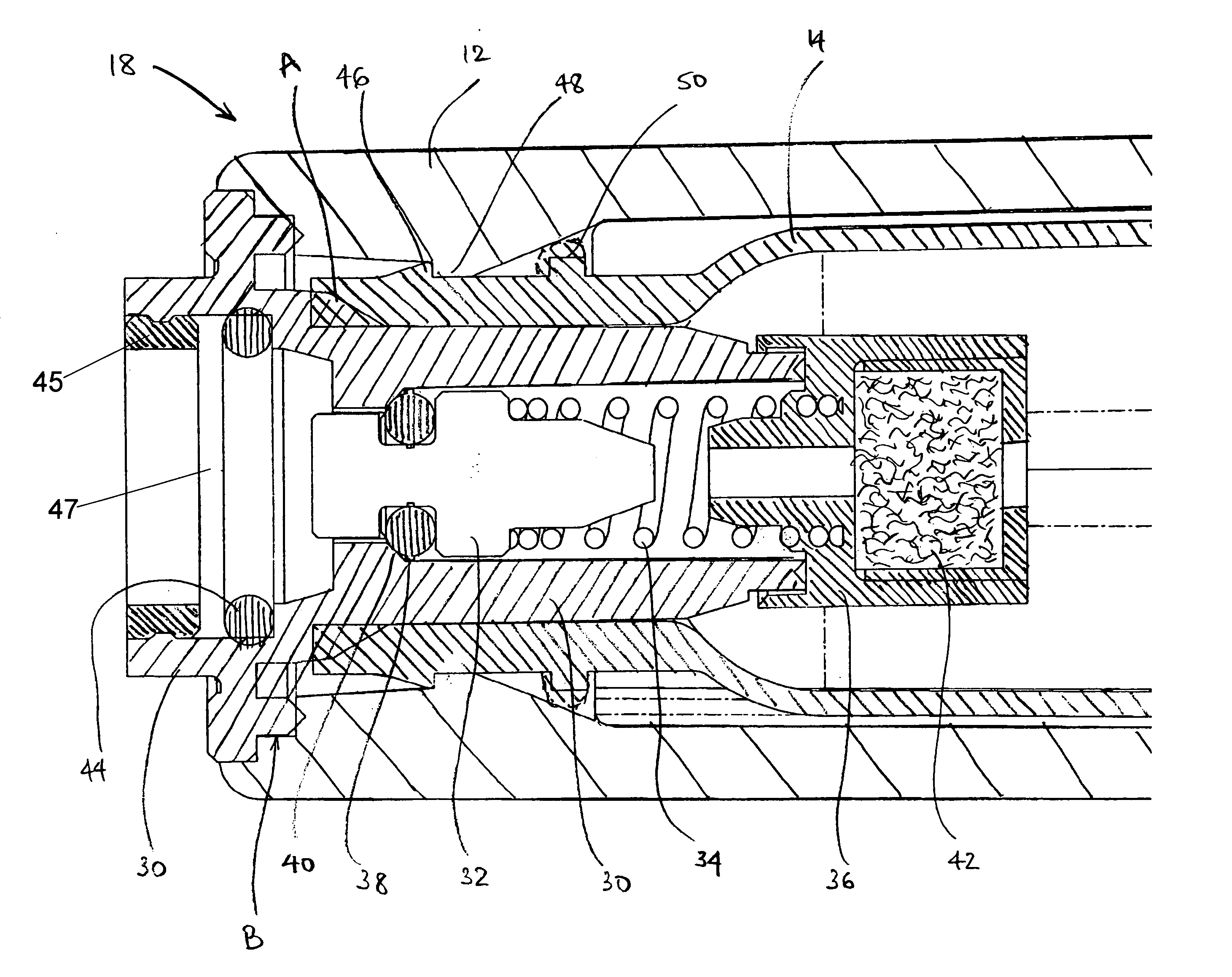

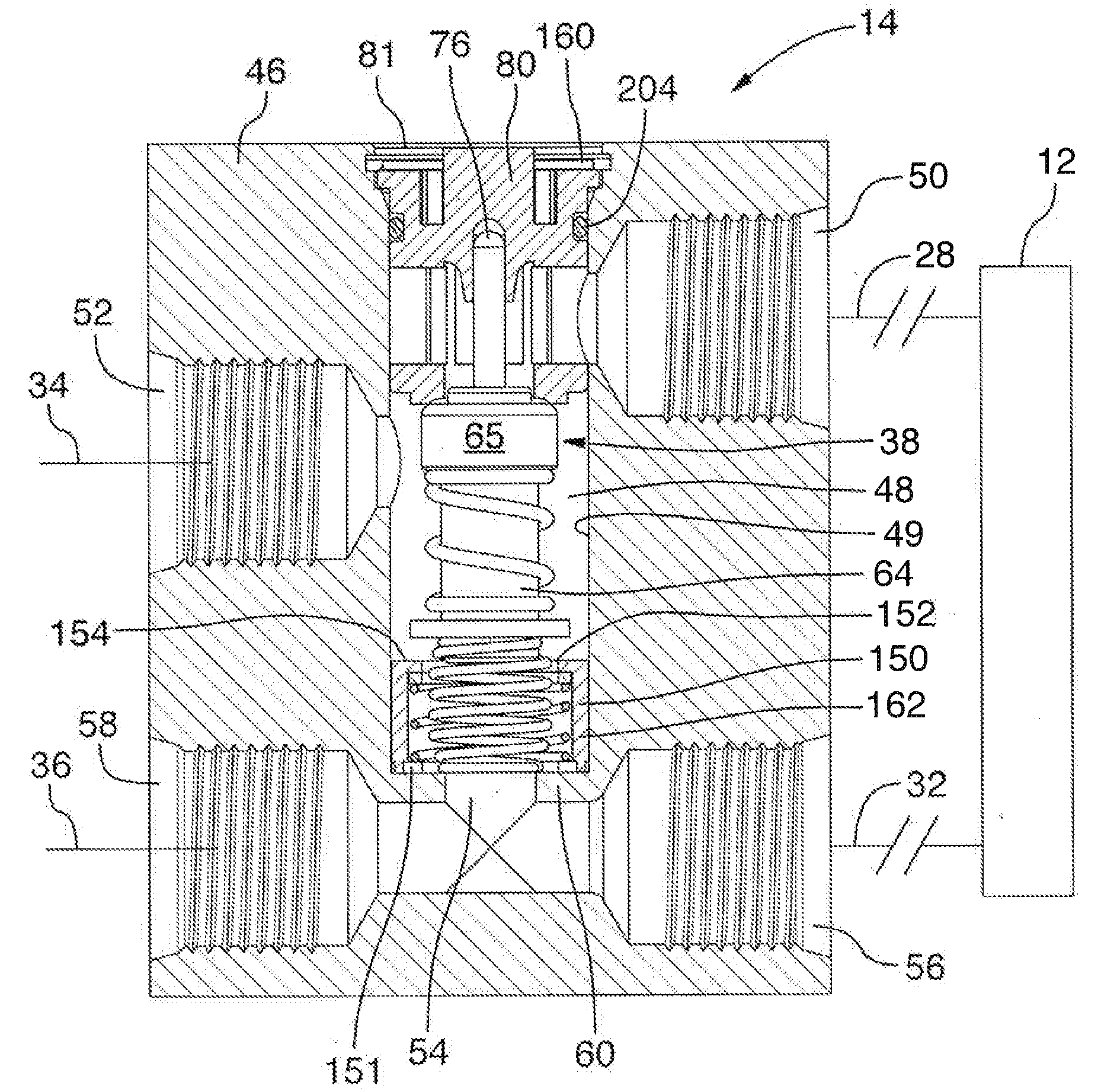

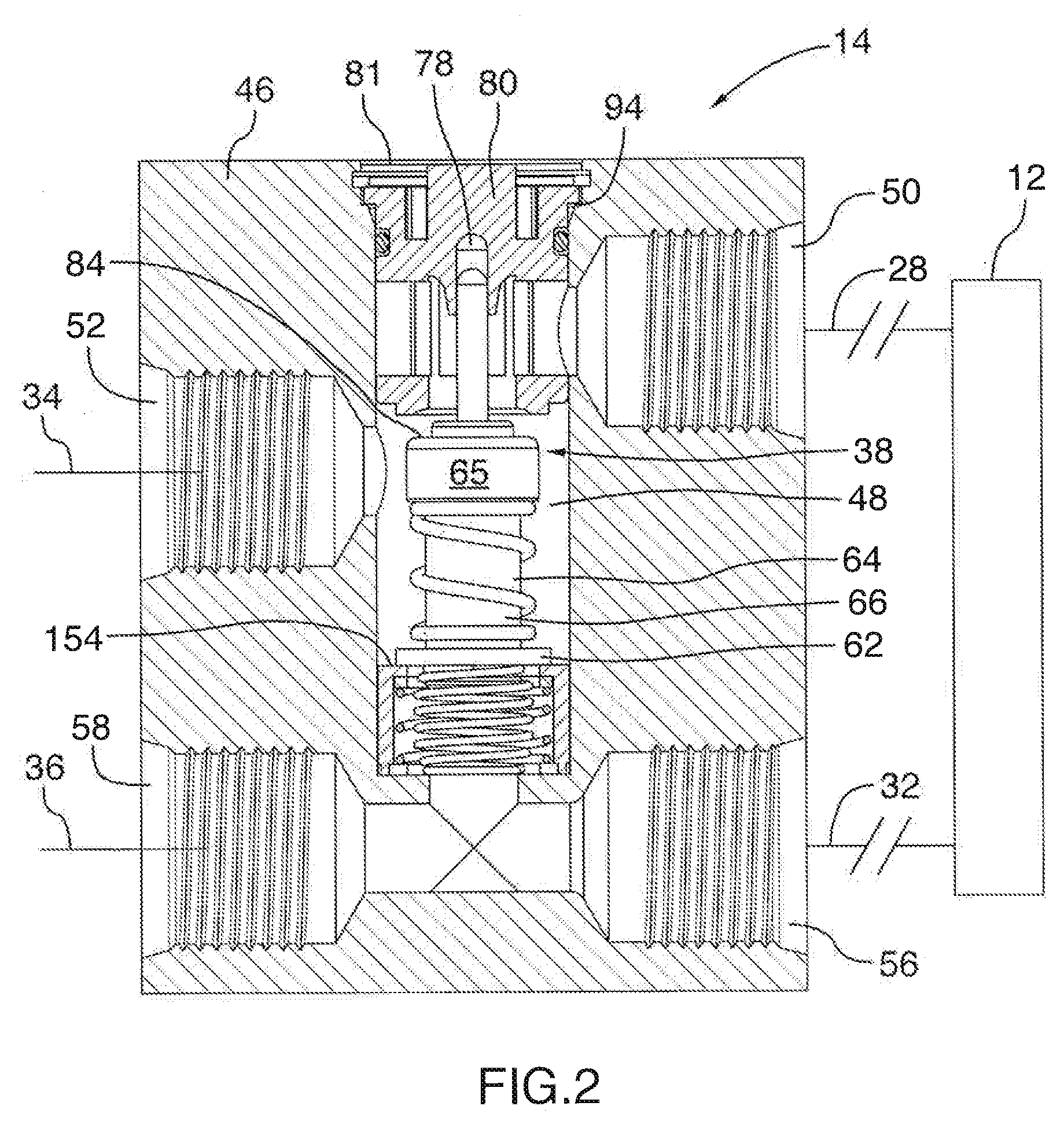

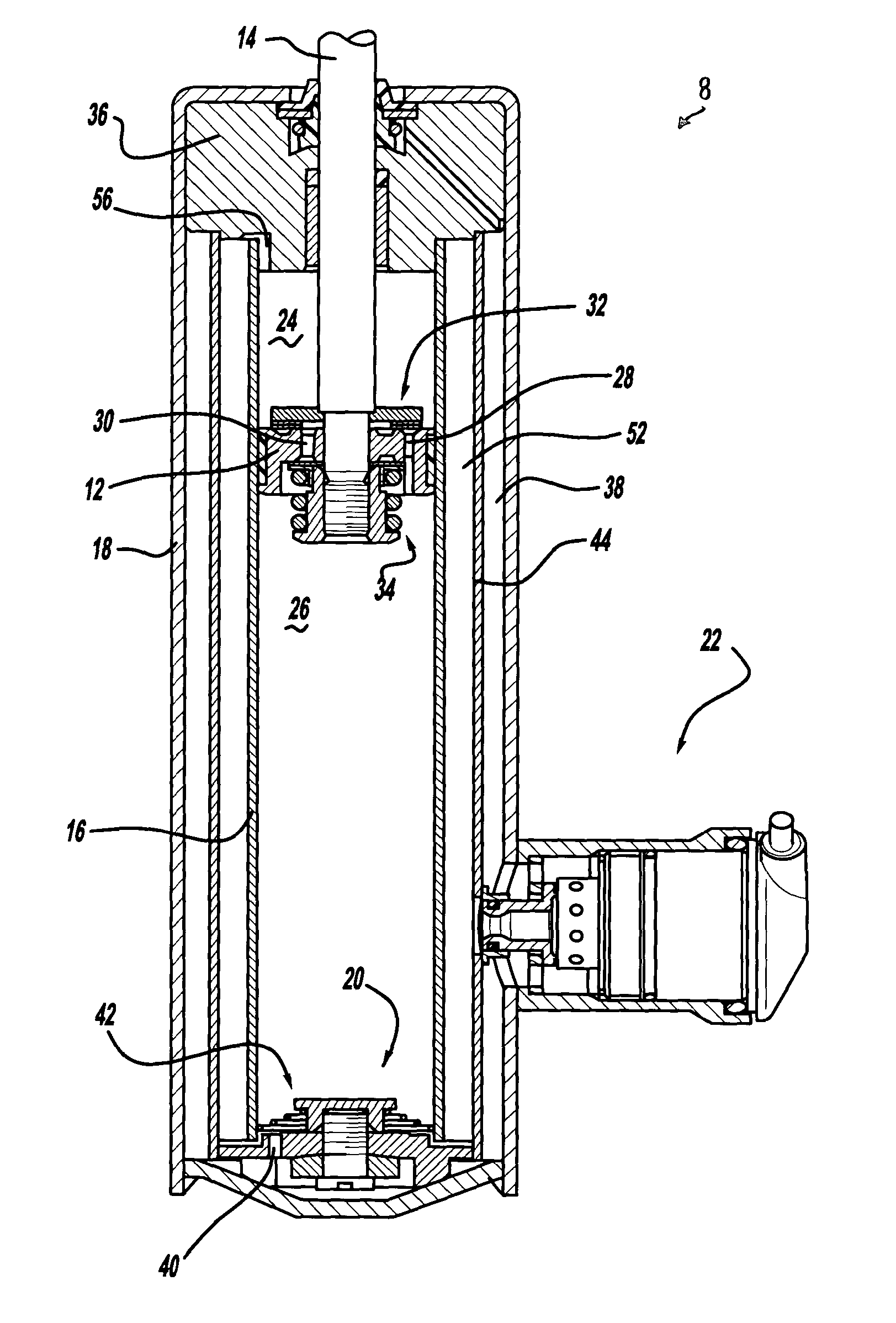

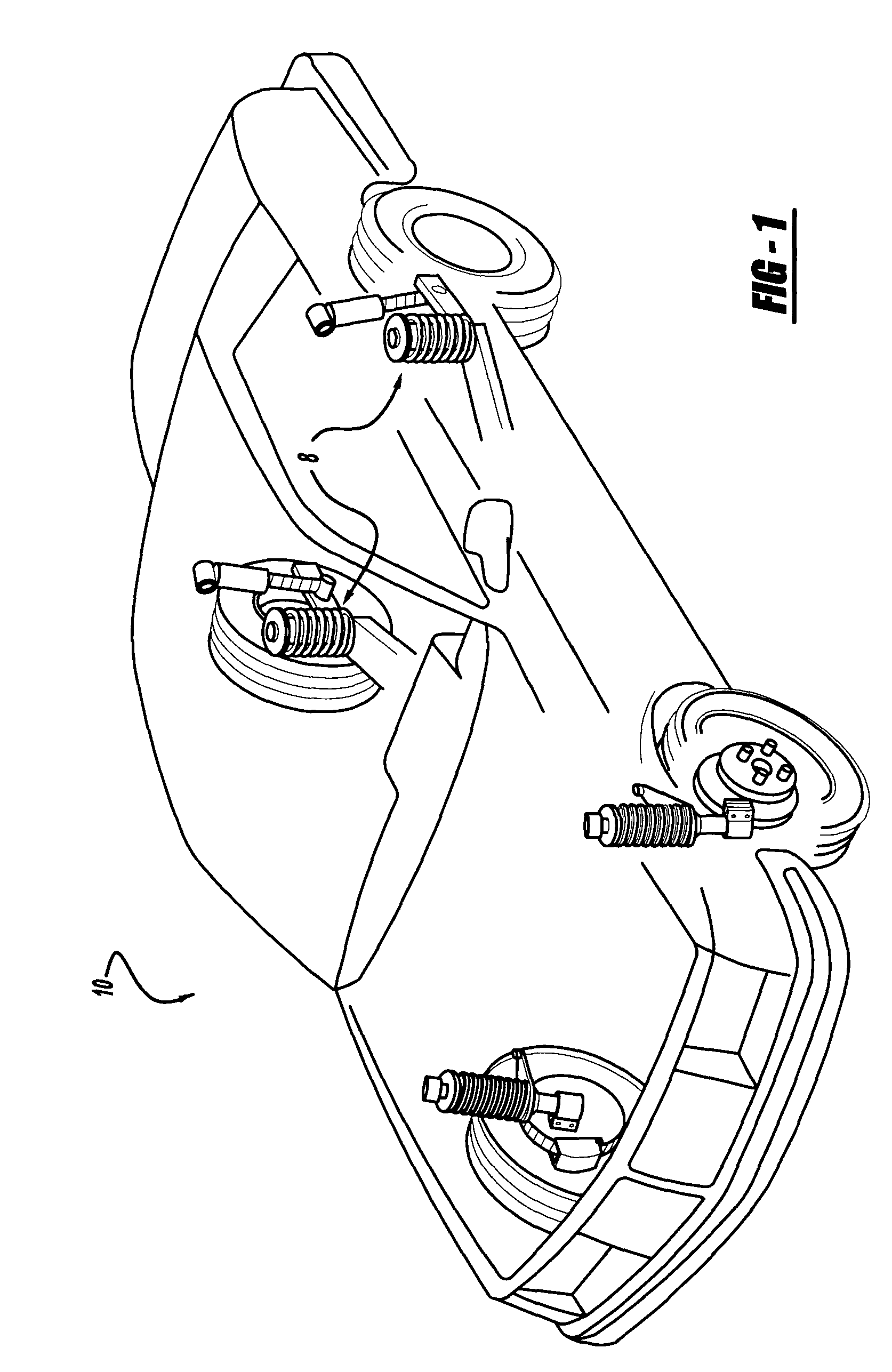

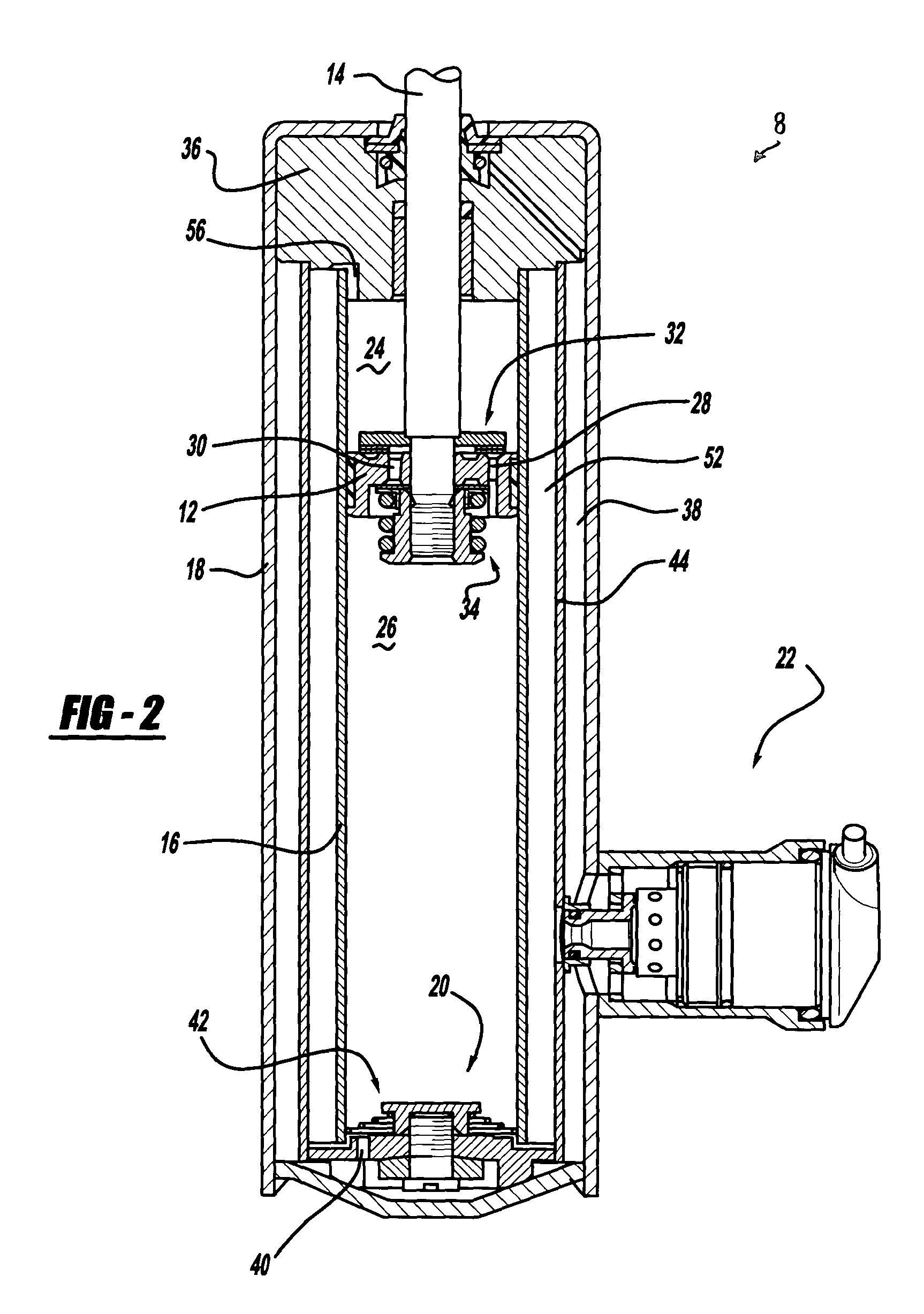

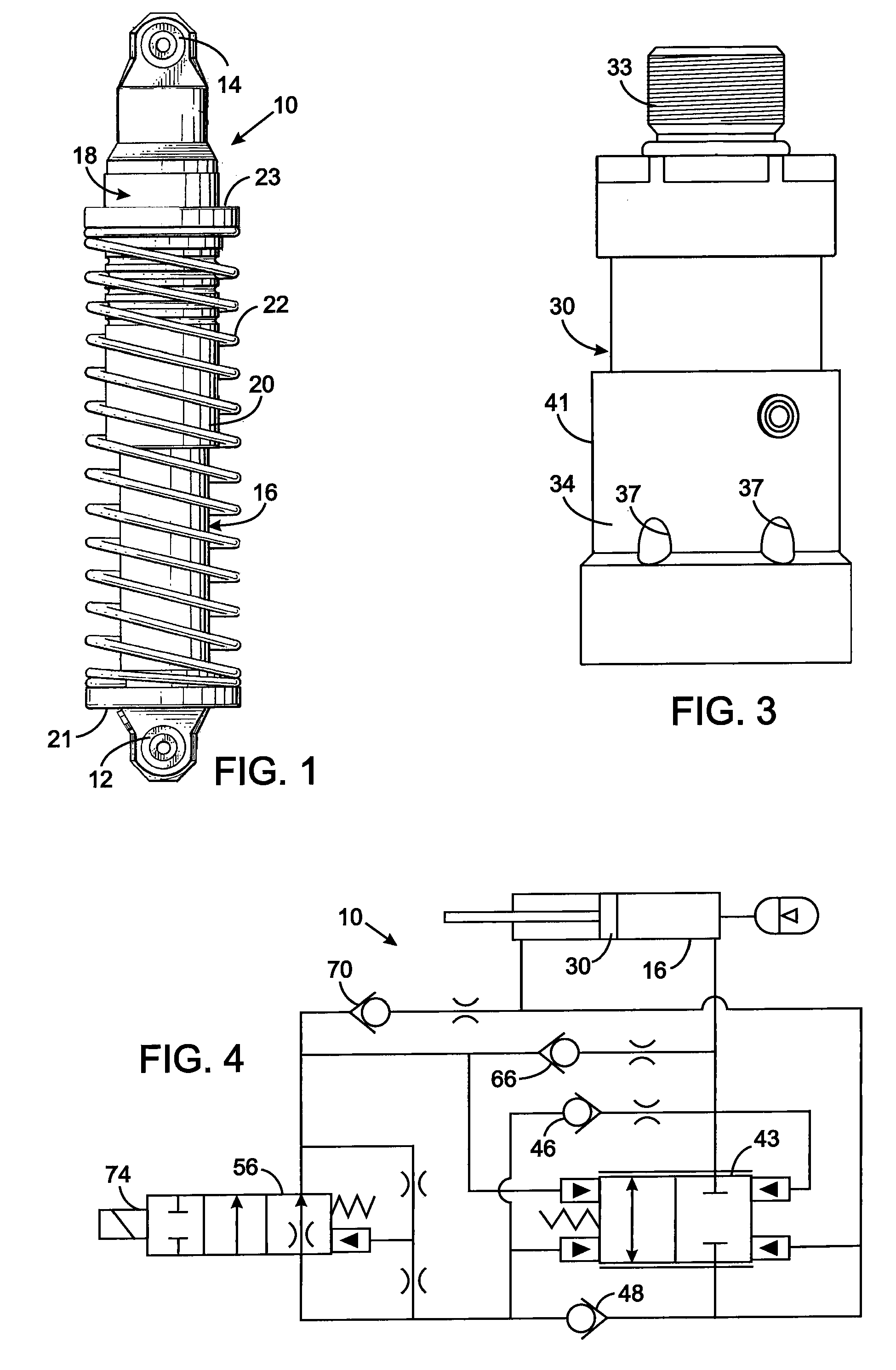

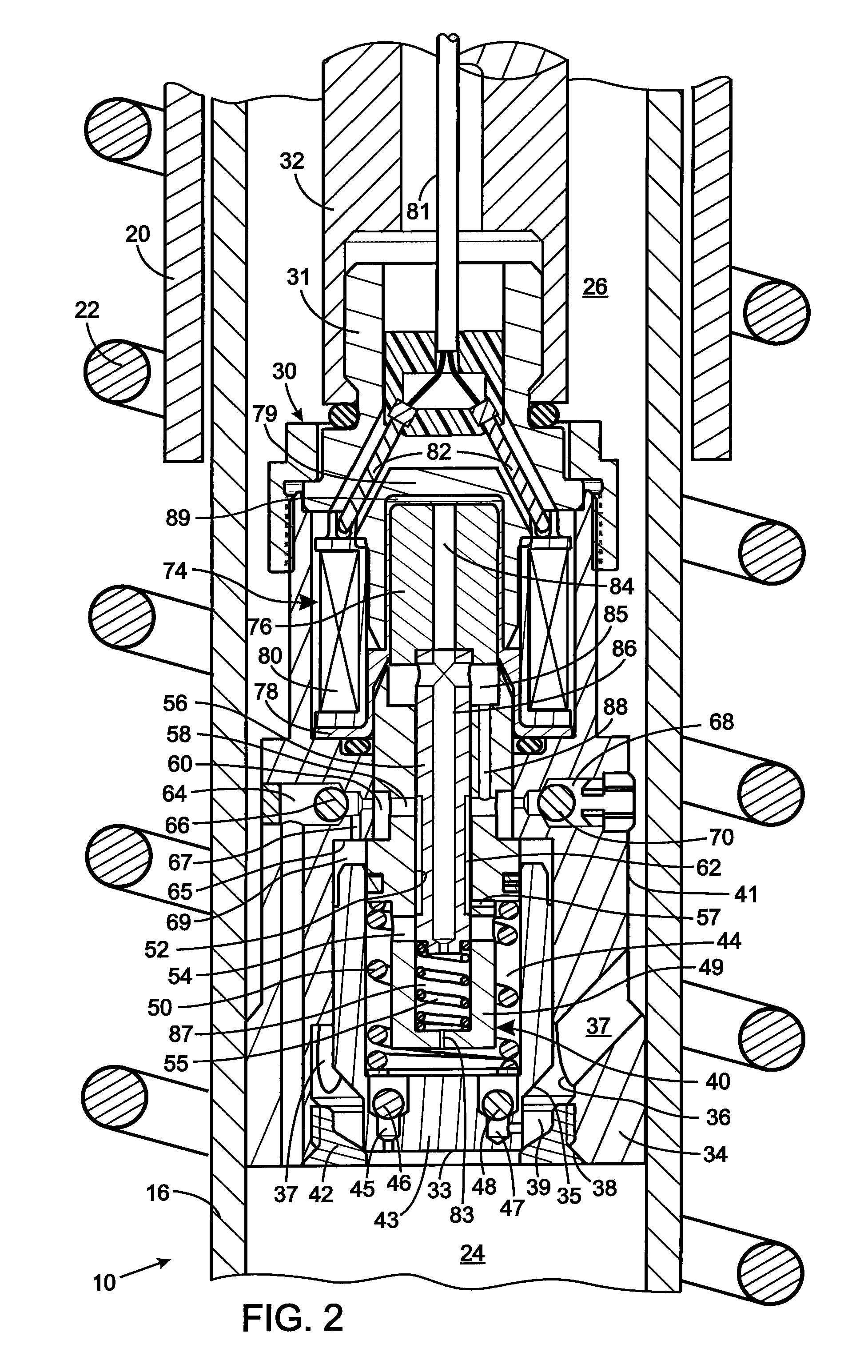

Adjustable damper with control valve, mounted in an external collar

A shock absorber according to the present invention includes a pressure tube having a working chamber disposed therewithin. A piston is slidably disposed within the working chamber and divides the working chamber into an upper working chamber and a lower working chamber. An intermediate tube is disposed around the pressure tube and the working chamber to define an intermediate chamber. A reserve tube is disposed around the intermediate tube. A collar is attached to the intermediate tube. The collar is defined by a shoulder portion extending generally lateral to the intermediate tube and a radial neck portion extending generally perpendicularly to the intermediate tube. An external control valve includes a valve seat received within the collar in an installed position. The external control valve is attached to the reserve tube.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

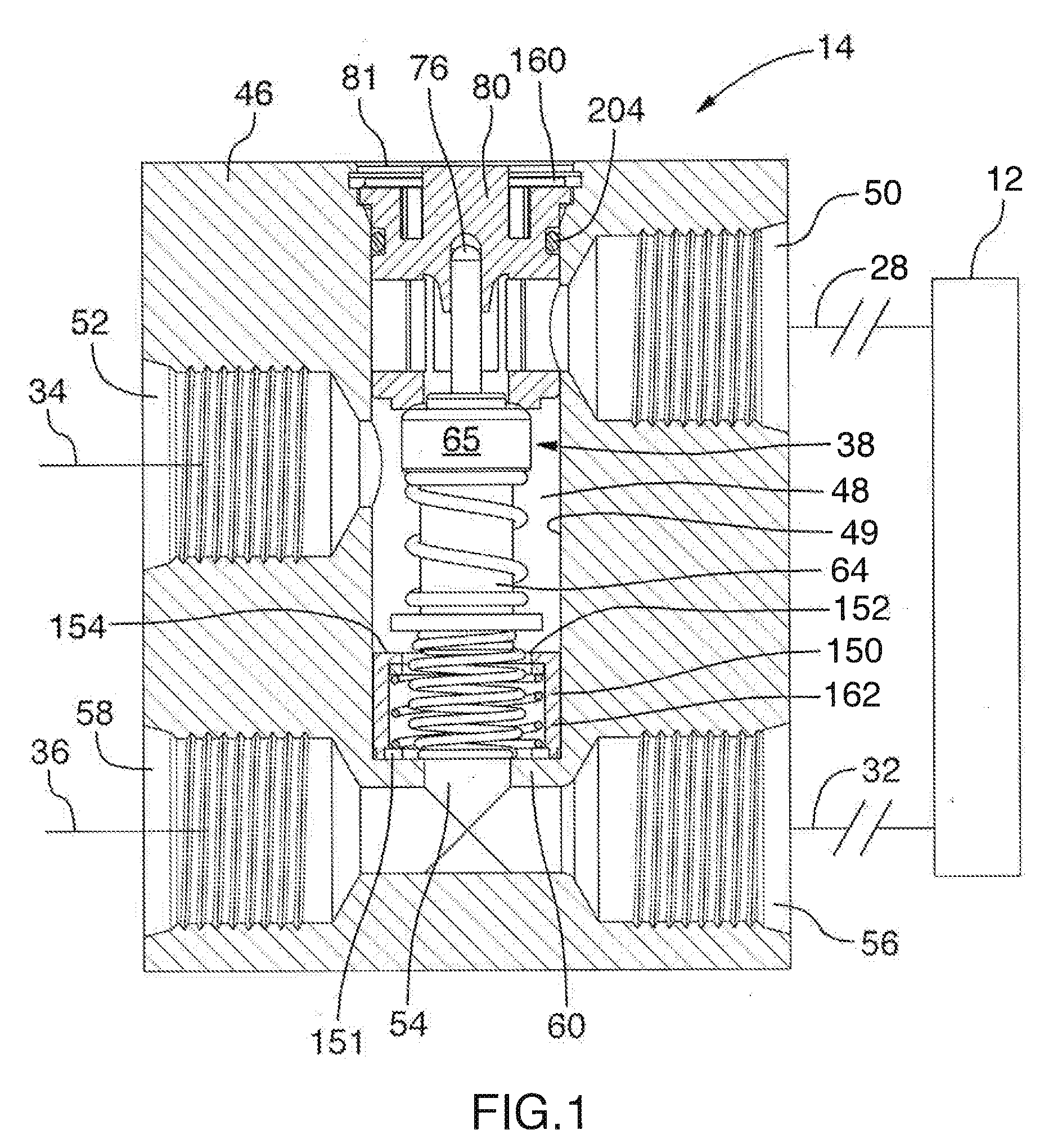

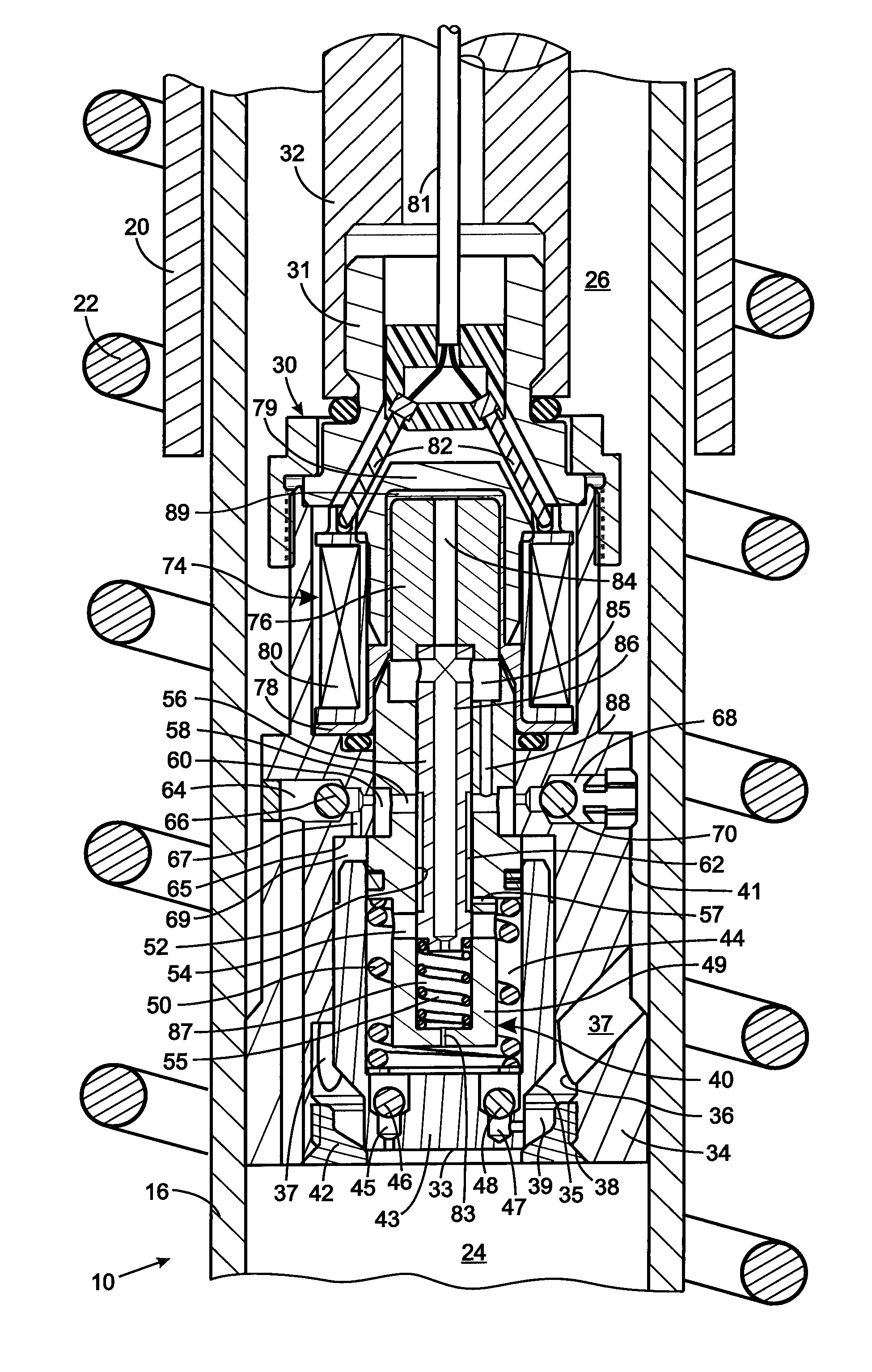

Piston With An Integral Electrically Operated Adjustment Valve For A Hydraulic Vibration Damper

A vibration damper includes a cylinder within which a piston is slidably received thereby defining compression and rebound chambers. The piston has a bore with a valve seat through which fluid flows between those chambers. A poppet selectively engages the valve seat and forms a pilot chamber an opposite side of the poppet from the valve seat. The greater pressure within the compression or rebound chambers is applied by a first logic arrangement to the pilot chamber and a pilot spool control a fluid flow between the pilot chamber and a pressure cavity in the piston body. A second logic arrangement connects the pressure cavity to either the compression and rebound chamber which has the lesser pressure. A solenoid that moves the pilot valve element to control pressure in the pilot chamber and thus the amount that the poppet moves to allow fluid flow through the piston.

Owner:HUSCO AUTOMOTIVE HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com