Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1487 results about "Valve actuator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A valve actuator is the mechanism for opening and closing a valve. Manually operated valves require someone in attendance to adjust them using a direct or geared mechanism attached to the valve stem. Power-operated actuators, using gas pressure, hydraulic pressure or electricity, allow a valve to be adjusted remotely, or allow rapid operation of large valves. Power-operated valve actuators may be the final elements of an automatic control loop which automatically regulates some flow, level or other process. Actuators may be only to open and close the valve, or may allow intermediate positioning; some valve actuators include switches or other ways to remotely indicate the position of the valve.

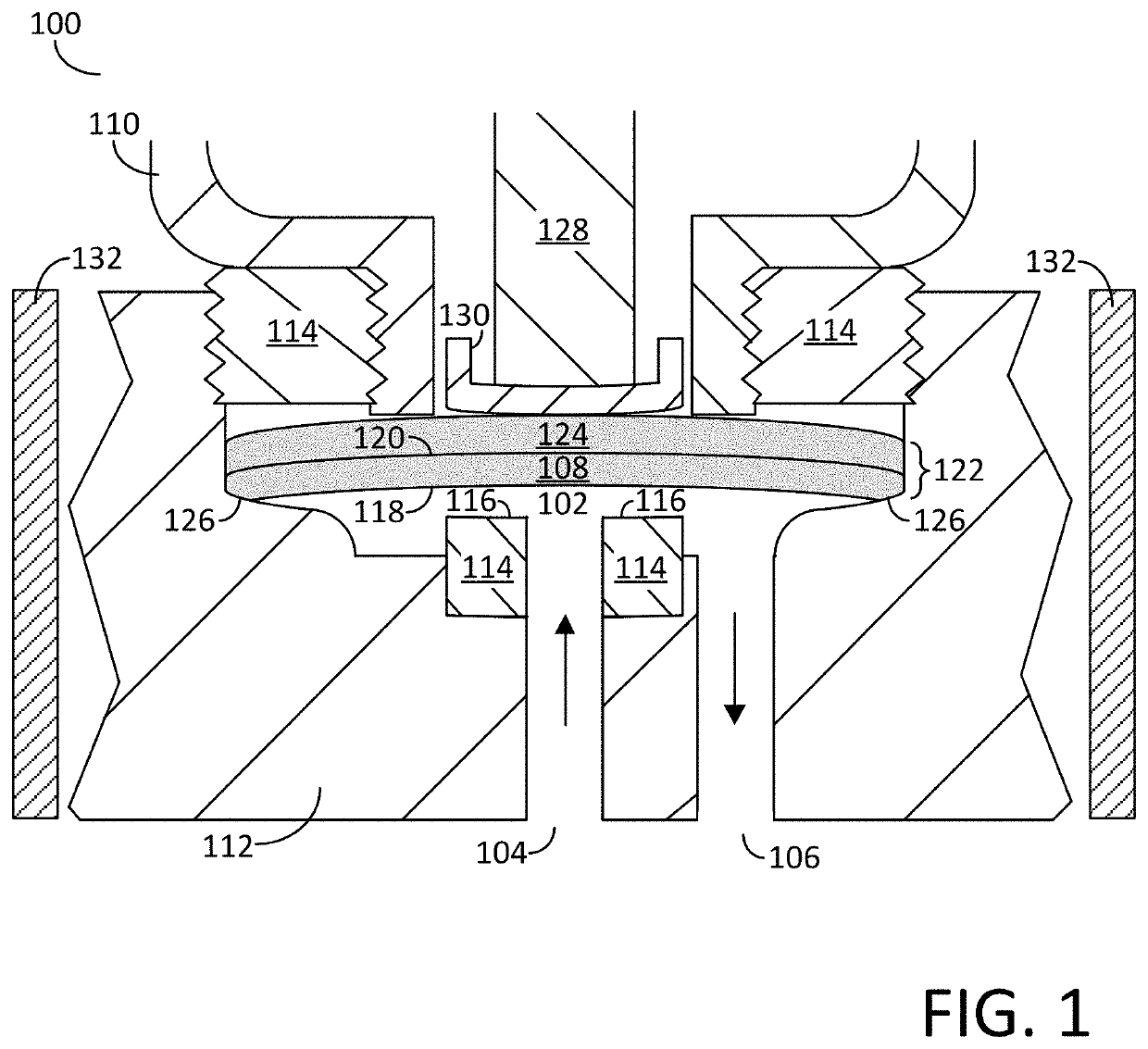

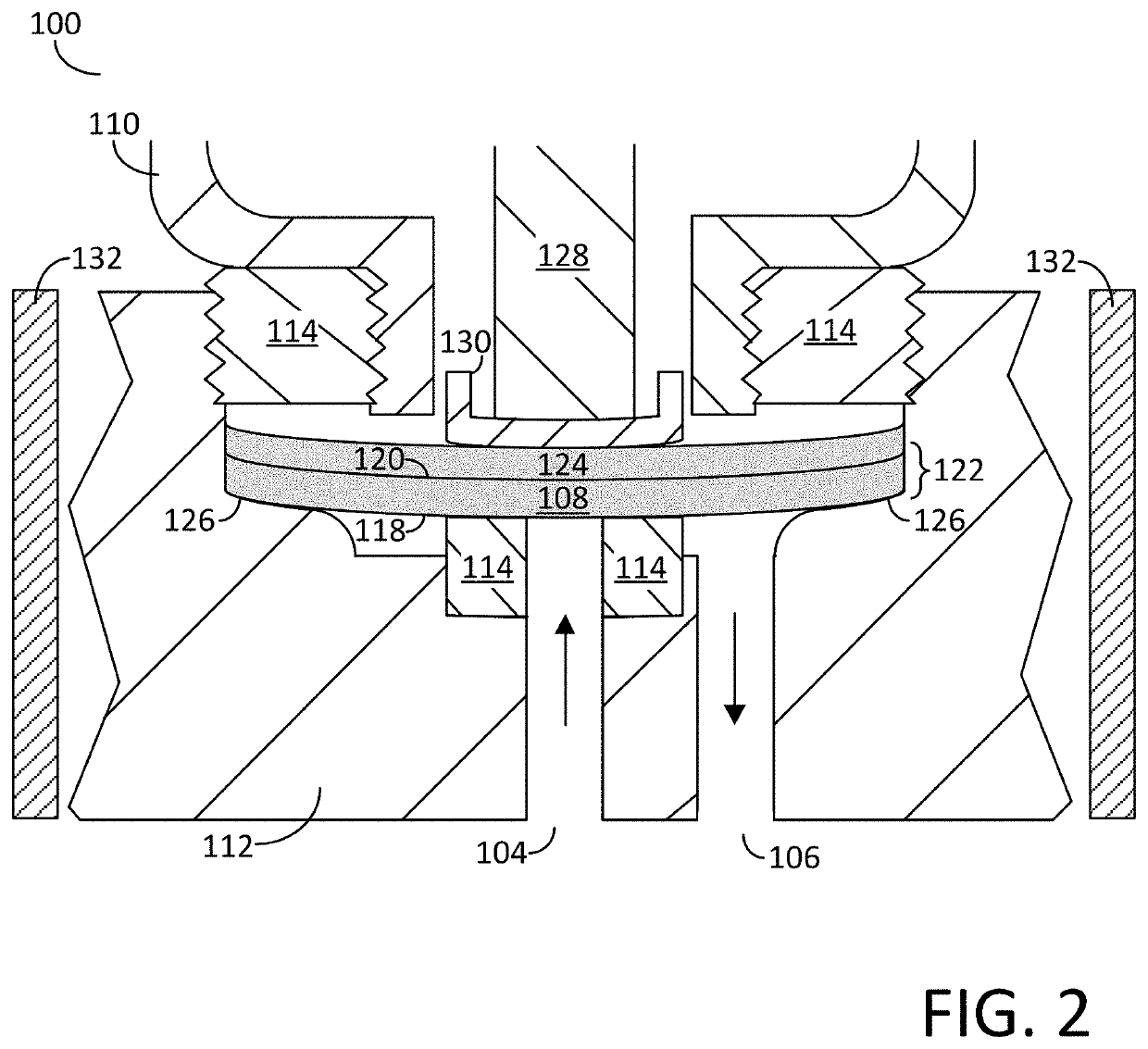

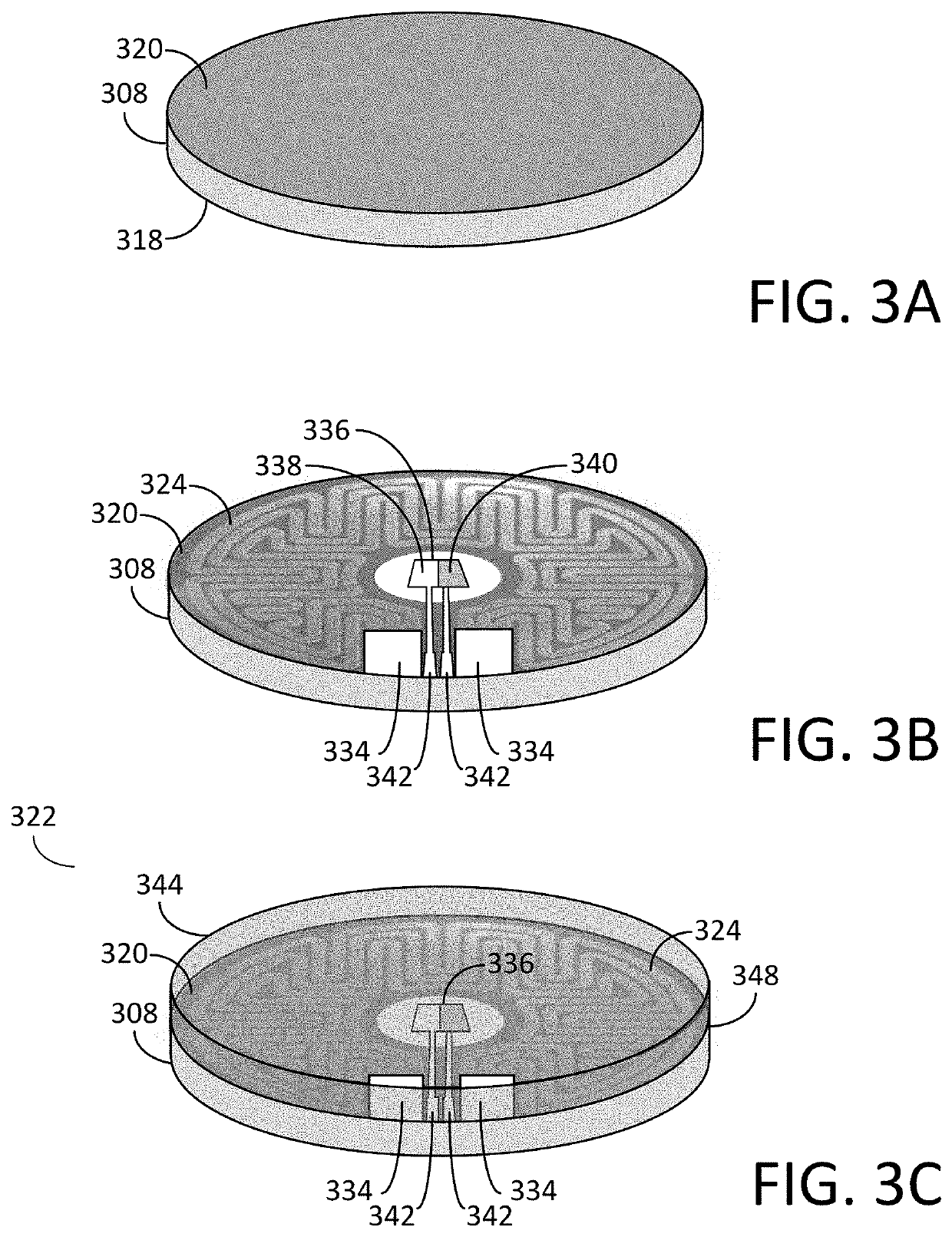

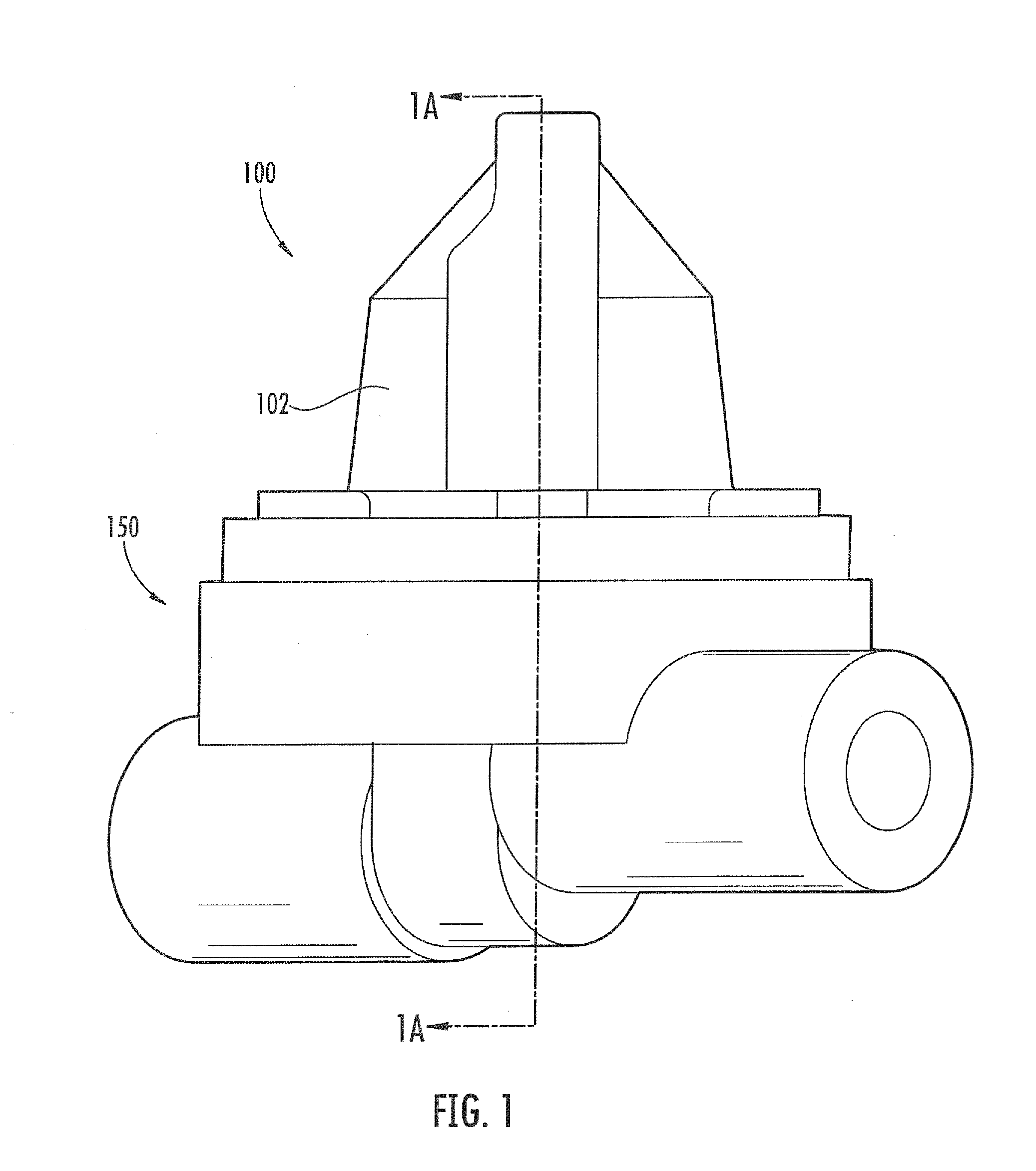

Diaphragm valves, valve components, and methods for forming valve components

ActiveUS20200018421A1Diaphragm valvesOperating means/releasing devices for valvesValve actuatorEngineering

A diaphragm valve is disclosed. The diaphragm valve may include, a valve body comprising a valve channel, the valve channel including an inlet channel and an outlet channel. The diaphragm valve may also include, a valve seat adjacent to the valve channel and a flexible diaphragm comprising a wetted surface and an opposing non-wetted surface, the flexible diaphragm being disposed adjacent to the valve channel. The diaphragm valve may also include, a flexible heater disposed over the non-wetted surface of the flexible diaphragm, and a valve actuator that is operable to operable to move the wetted surface of the flexible diaphragm into and out of contact with the valve seat. Valve components including a flexible heater and methods for forming such valve components are also disclosed.

Owner:ASM IP HLDG BV

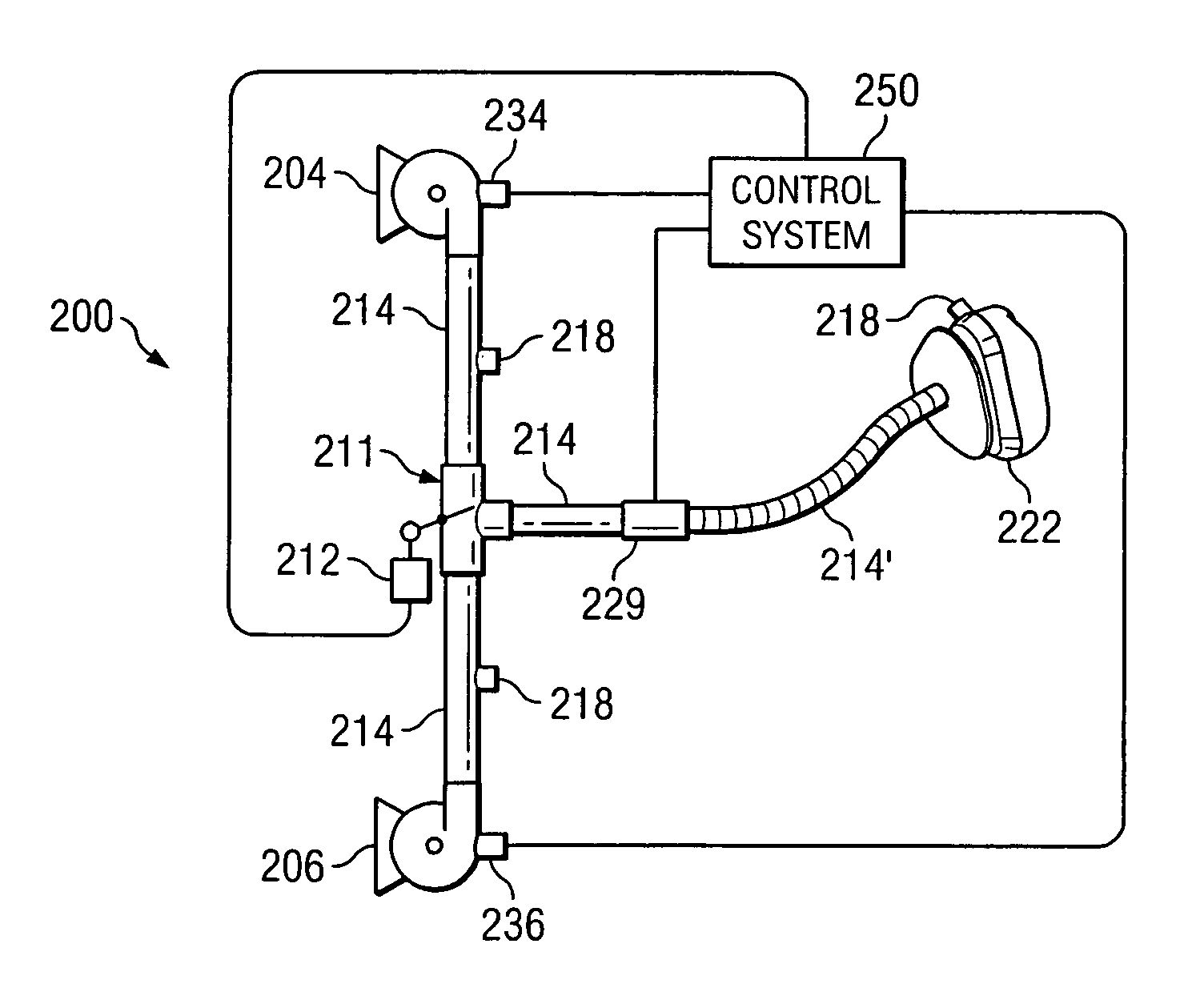

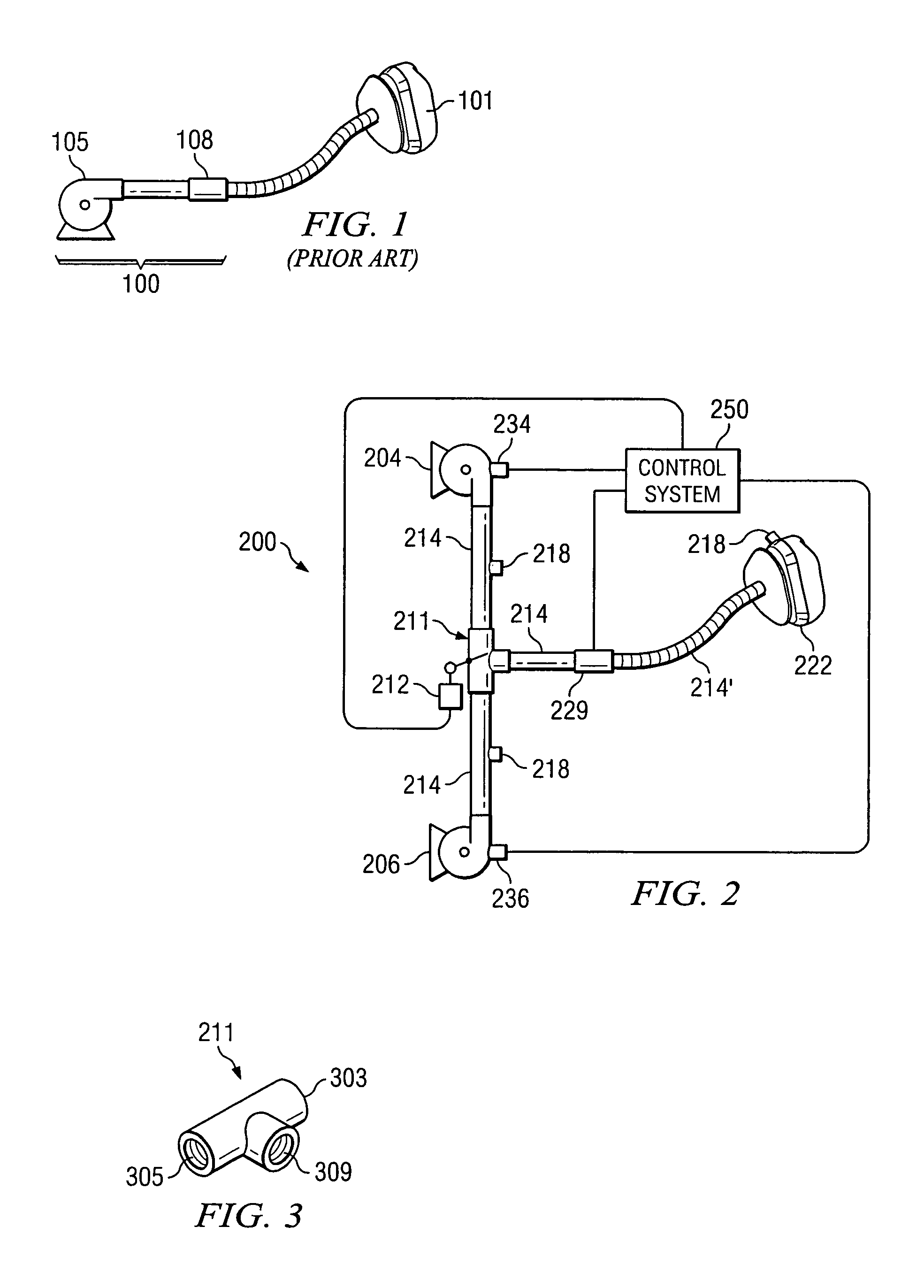

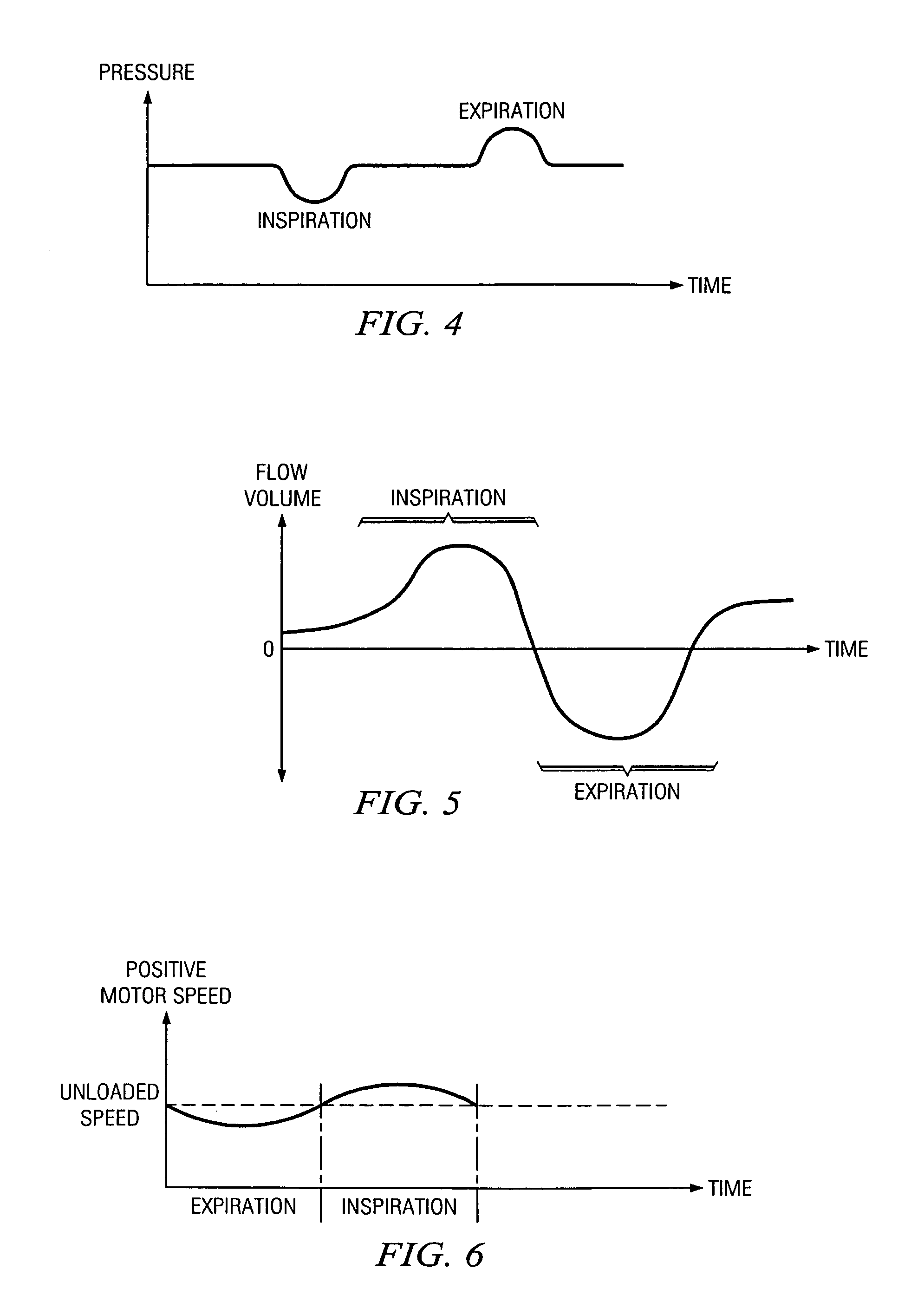

Ventilator with dual gas supply

InactiveUS7077131B2Minimize the differenceOperating means/releasing devices for valvesRespiratory masksRelative pressureValve actuator

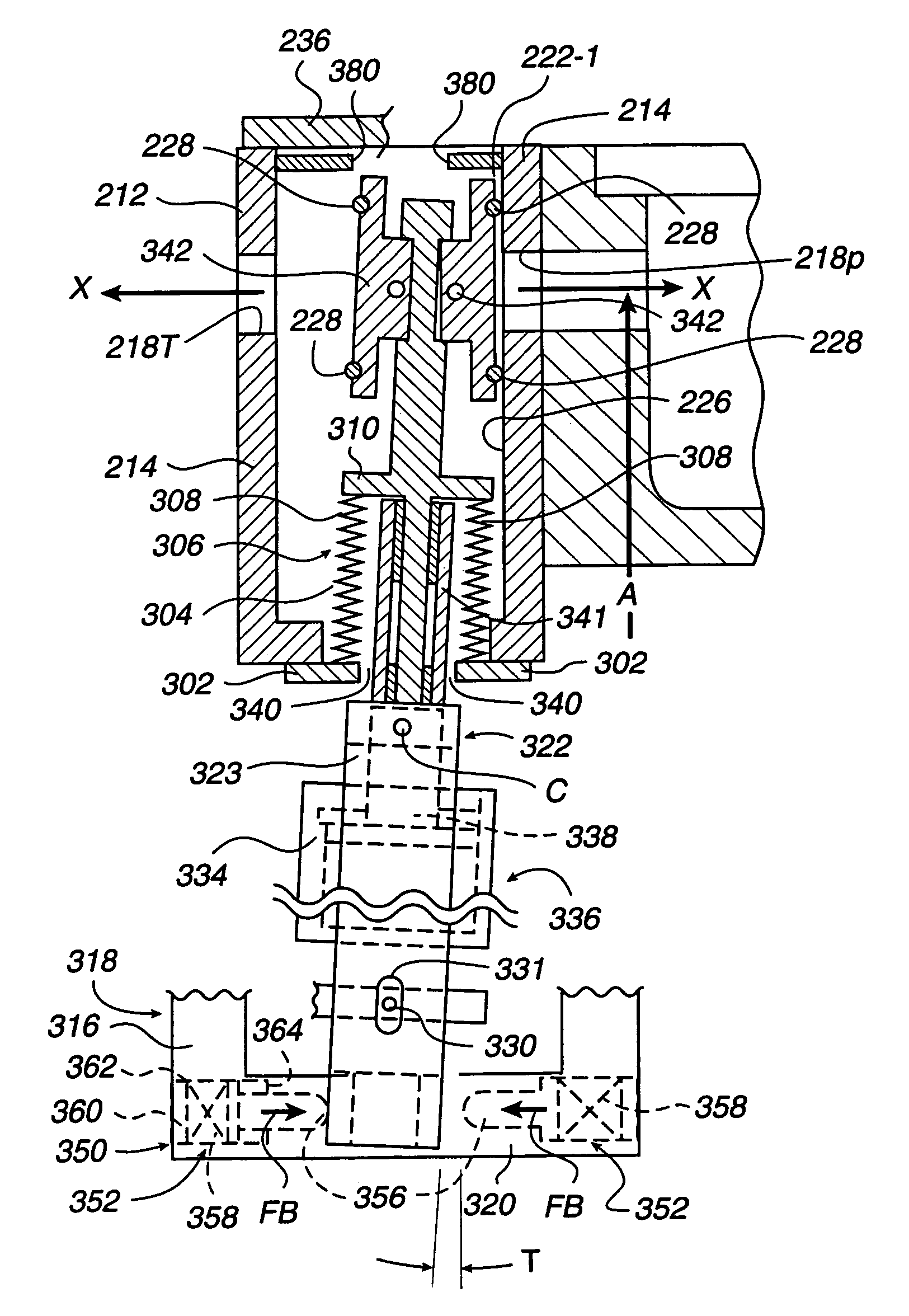

A method of pressure regulation and a ventilator are provided. The ventilator includes a positive relative pressure gas supply, a negative relative pressure gas supply, and a diverter valve. The diverter valve includes a positive pressure port connected to the positive relative pressure gas supply, a negative pressure port connected to the negative relative pressure gas supply, and a gas supply port communicating with a gas delivery device. The ventilator preferably further includes a feedback sensor that detects a gas supply difference between a gas supply and a predetermined gas supply and generates a feedback signal that is substantially related to the gas supply difference. The ventilator preferably further includes a diverter valve actuator communicating with the diverter valve and operating the diverter valve to communicate the positive relative pressure gas supply and the negative relative pressure gas supply to the gas supply port of the diverter valve based upon the feedback signal.

Owner:TYCO HEALTHCARE GRP LP

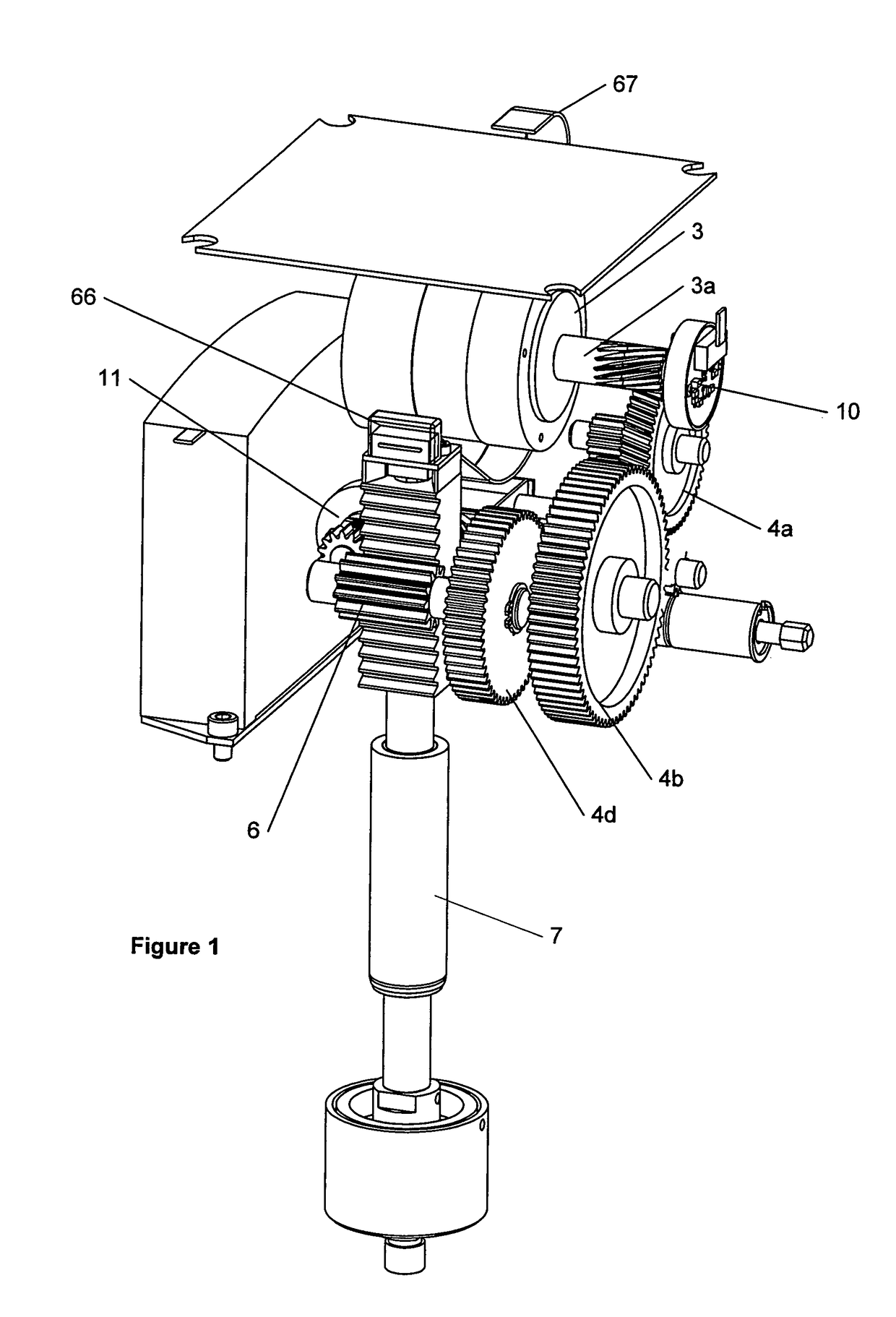

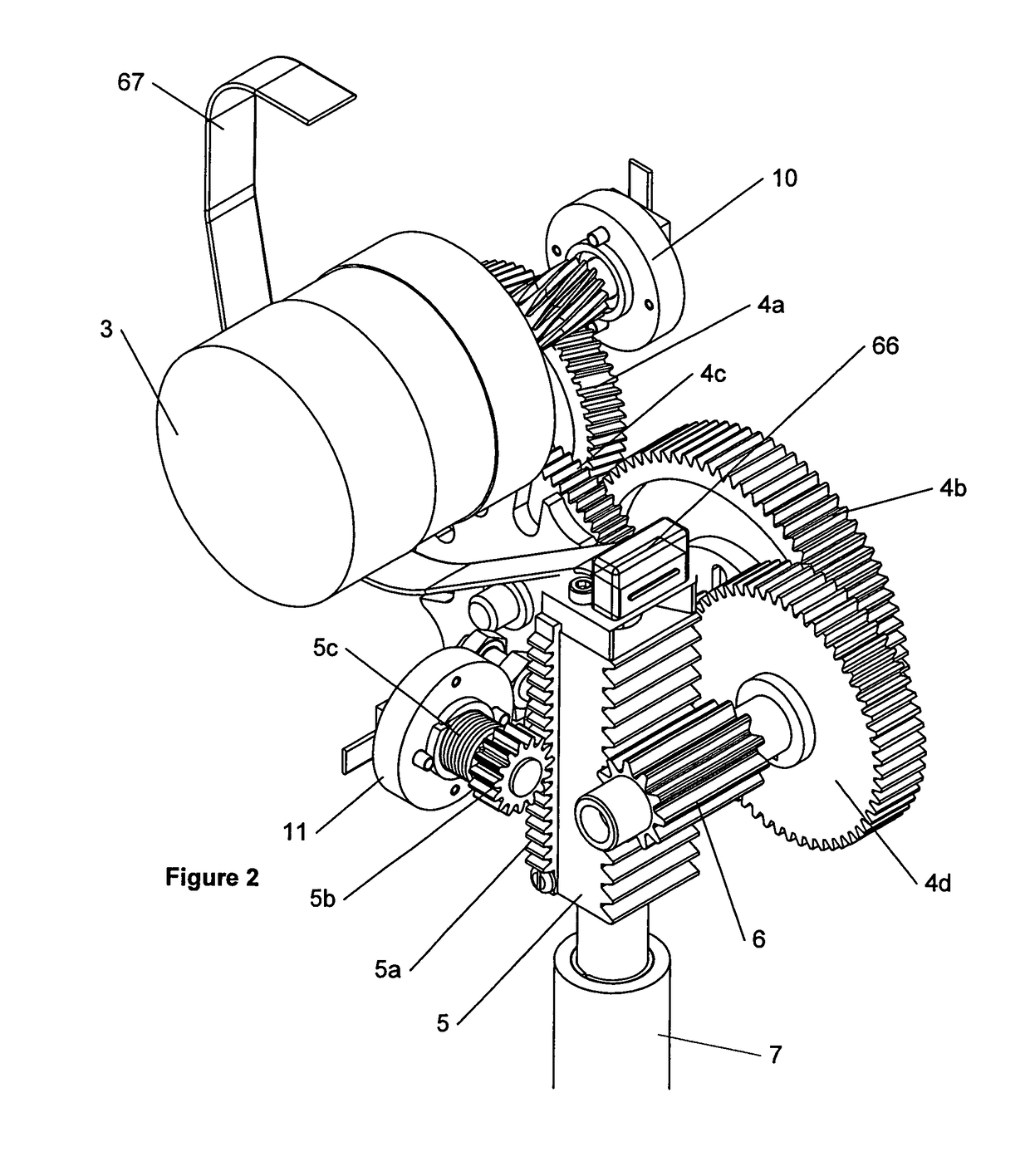

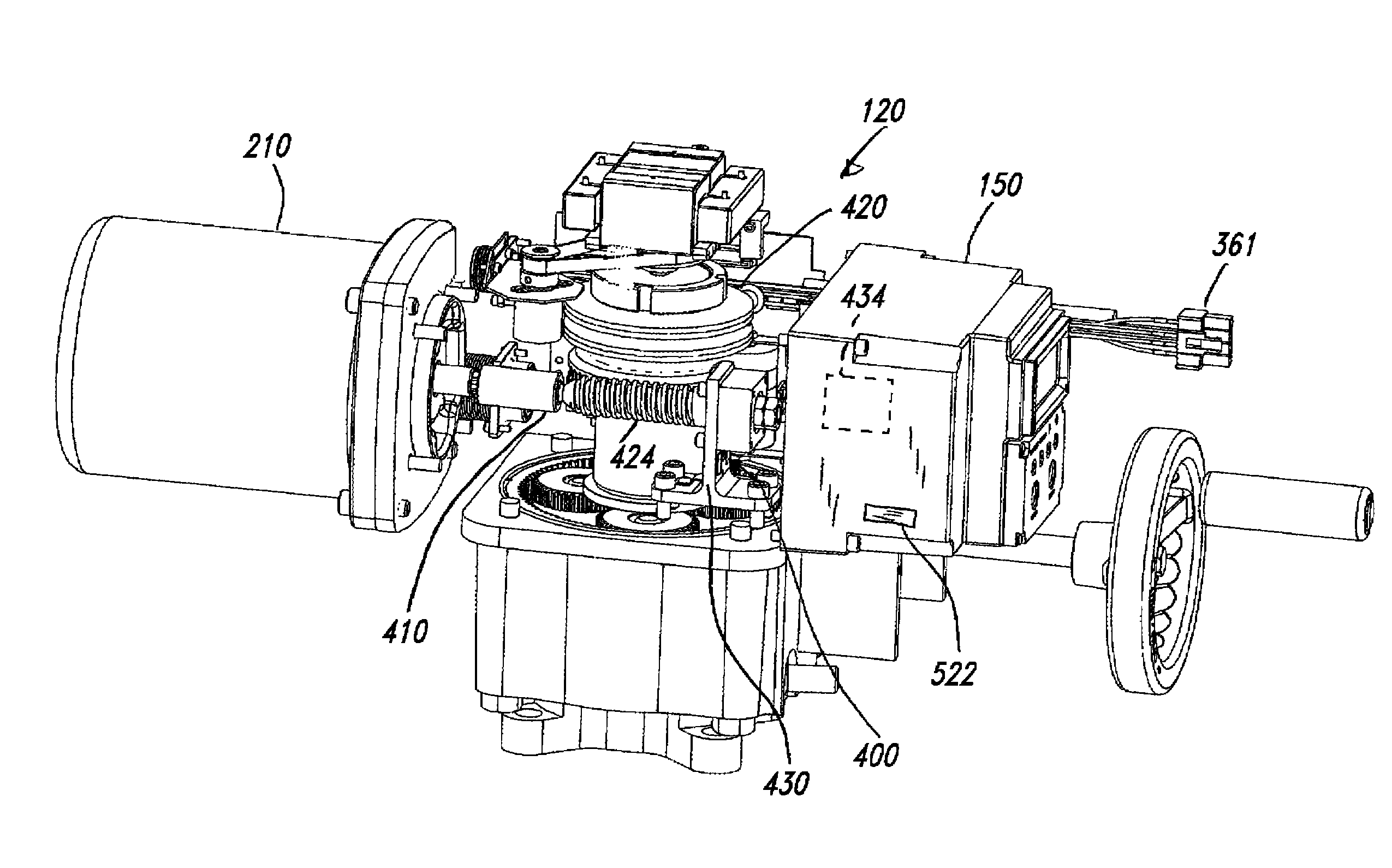

Valve actuators

ActiveUS8118276B2Low costImprove accuracySafety arrangmentsOperating means/releasing devices for valvesMotor speedValve actuator

A valve actuator having an electric drive motor with a motor shaft and having an output shaft linked to the motor shaft to drive movement of a valve, the actuator further having a control system arranged to provide a first closed loop control of the actuator output shaft and including a controller coupled to a first position sensor to sense the position of the actuator output shaft, and to a second position sensor to sense the position of the motor shaft and to enable determination of the speed of the motor shaft, the control system being configured to respond to sensed signals from the first and second sensors and adjust the motor speed / position accordingly.

Owner:ROTORK CONTROLS LTD

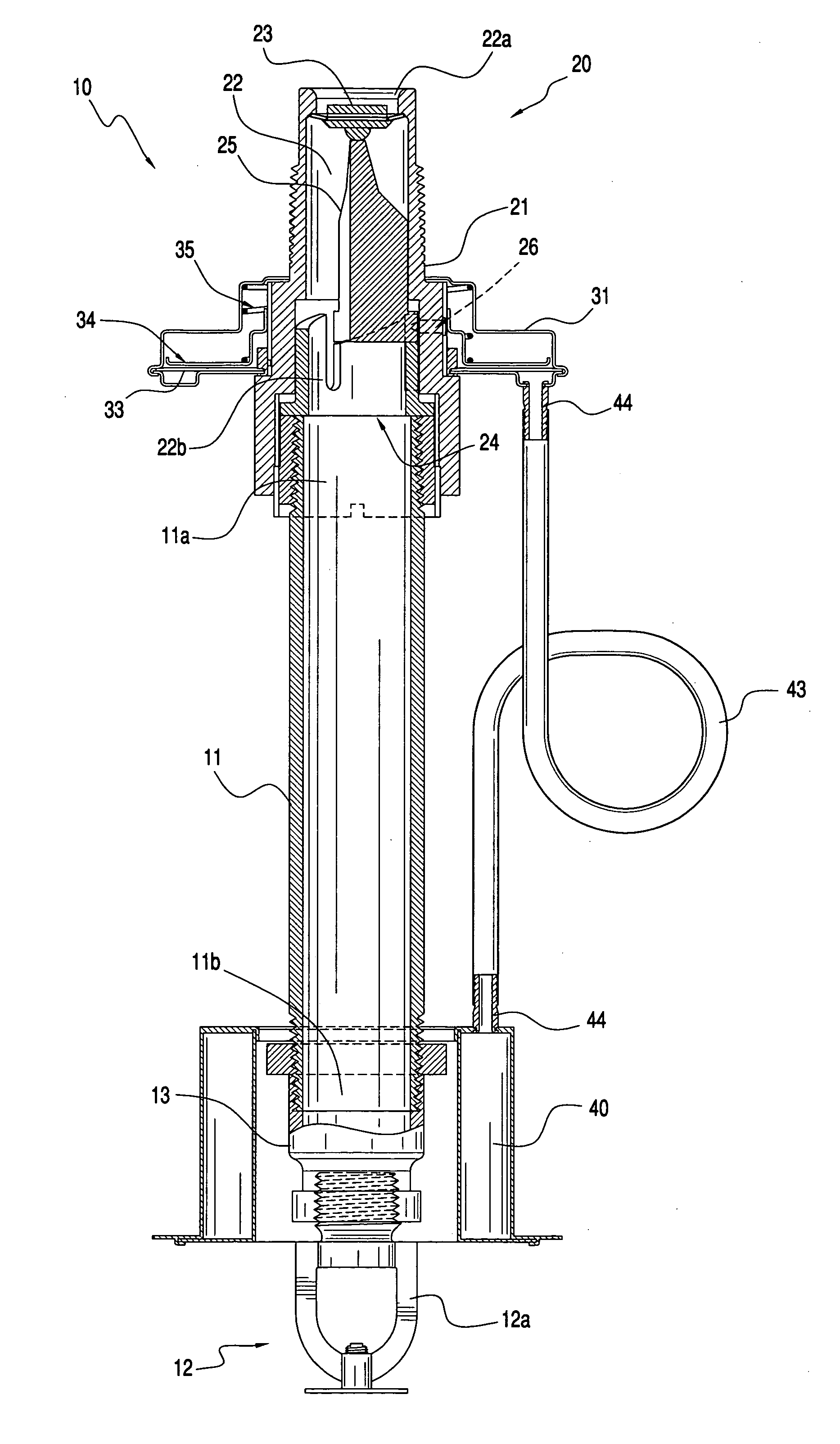

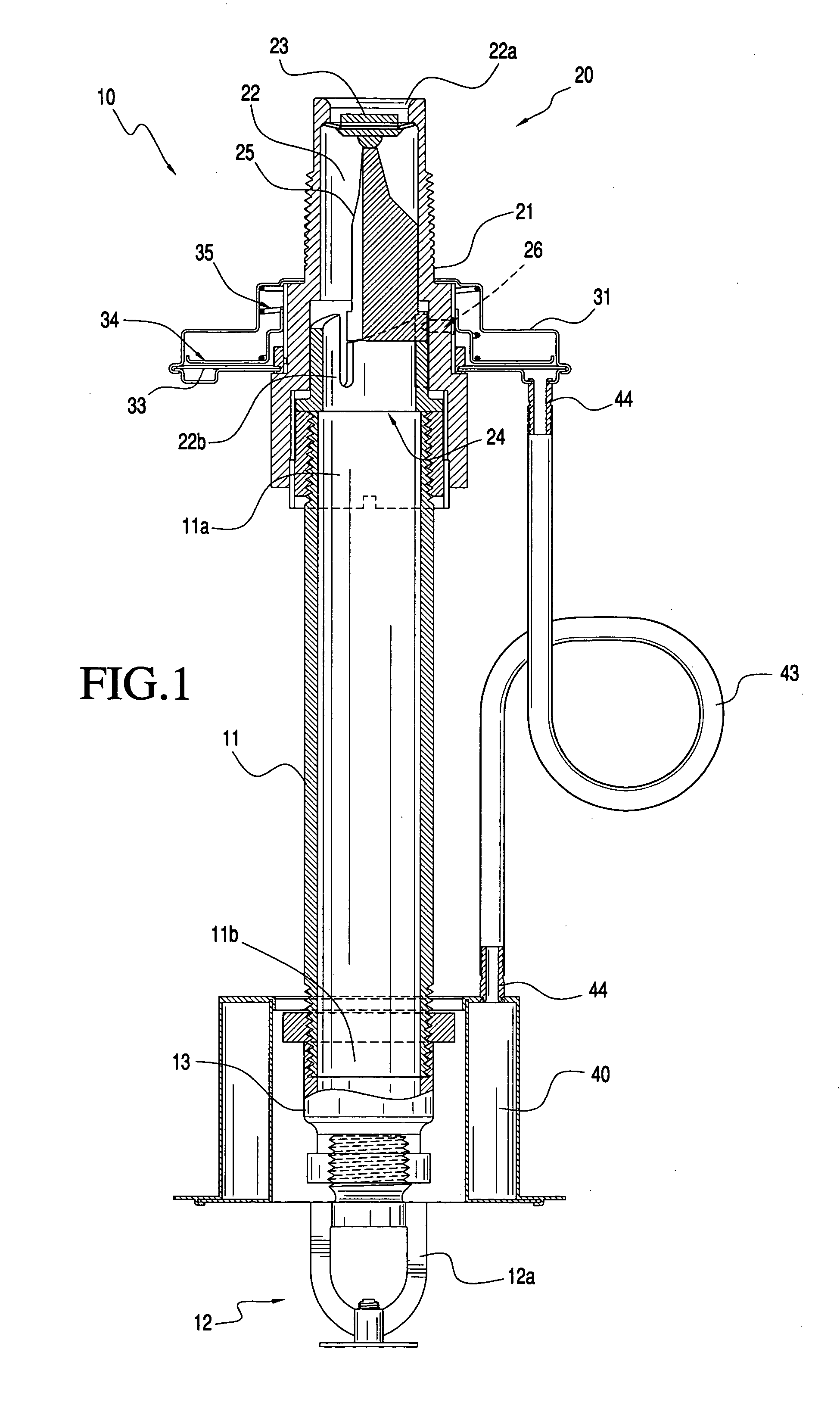

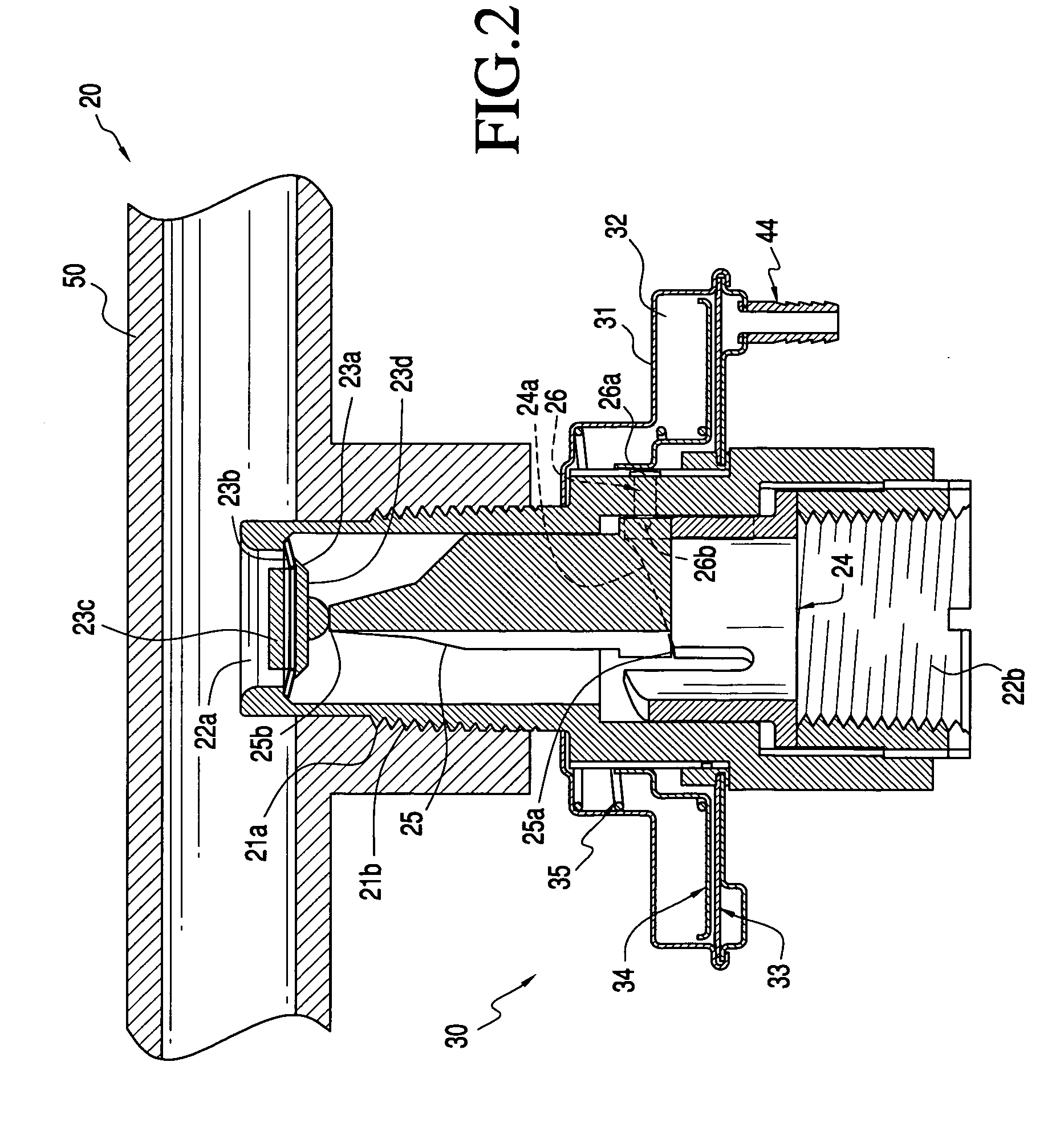

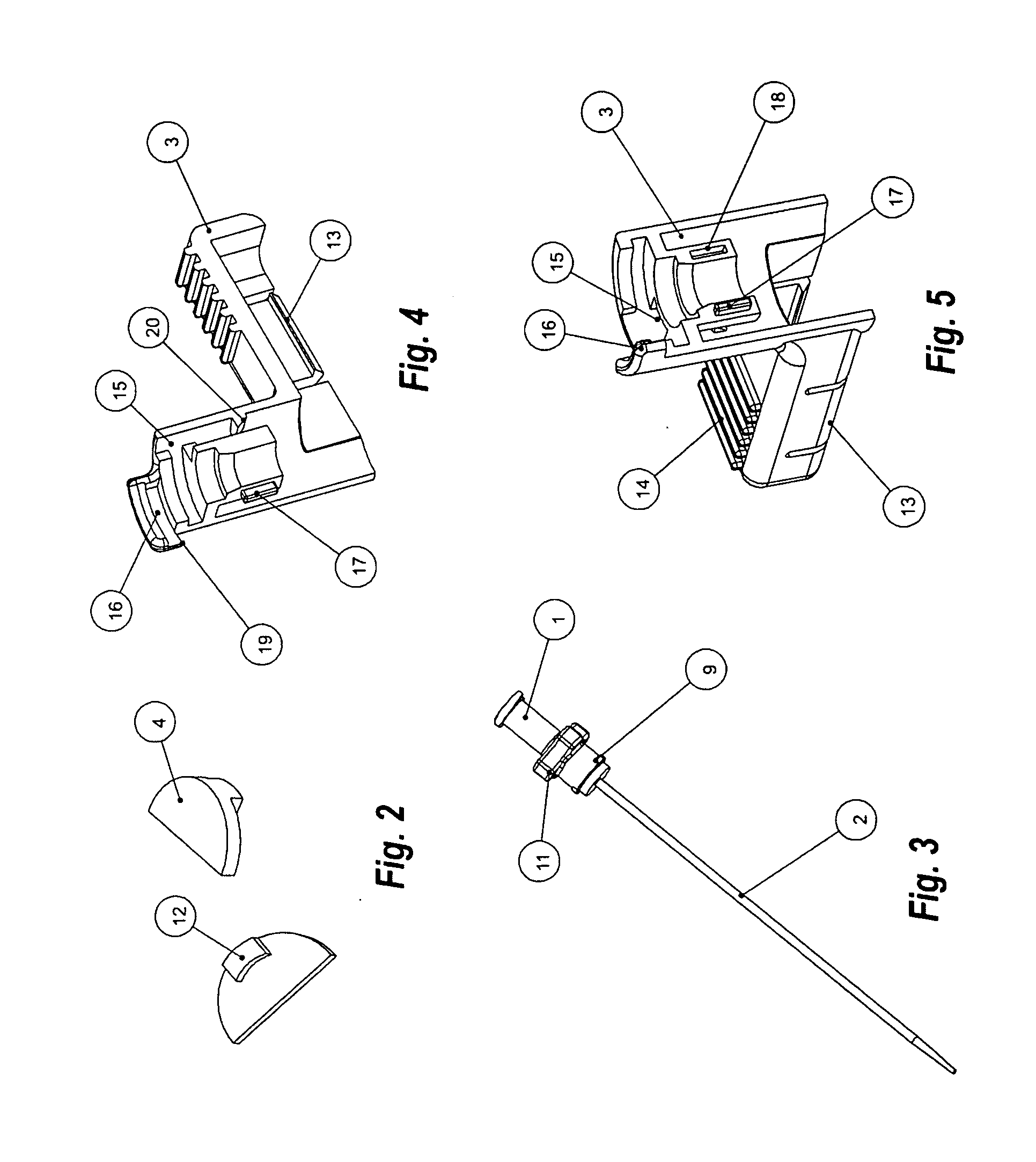

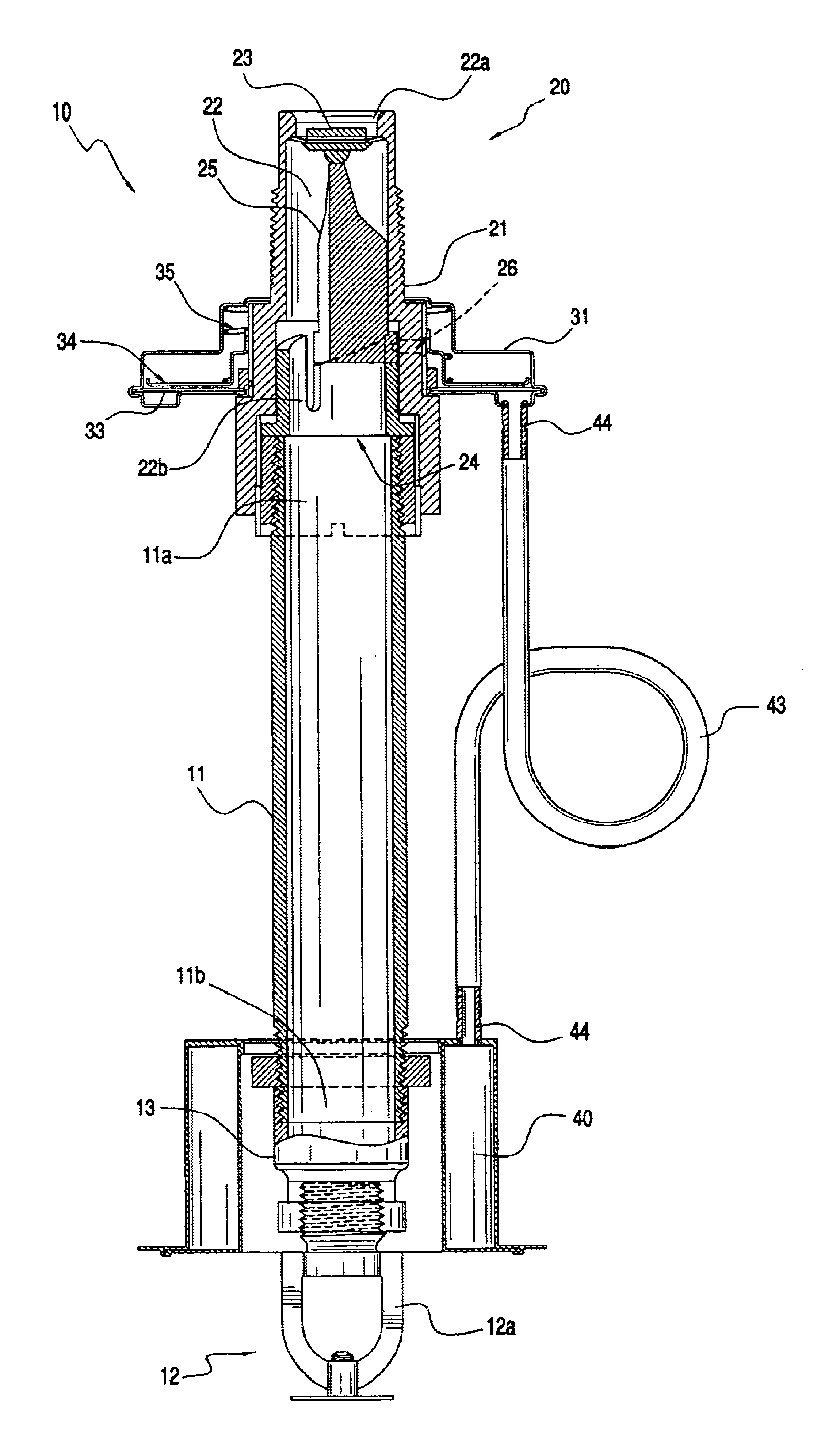

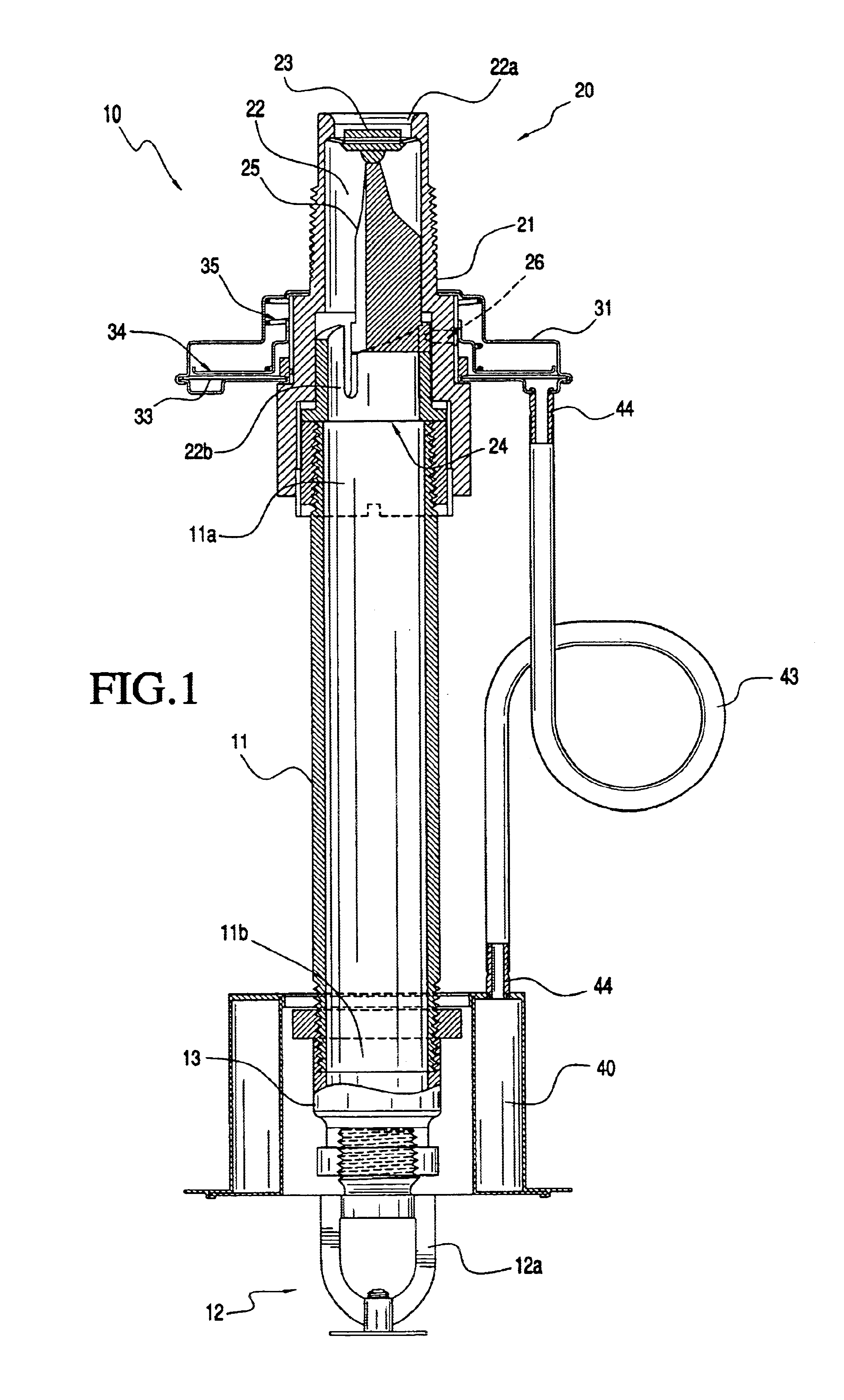

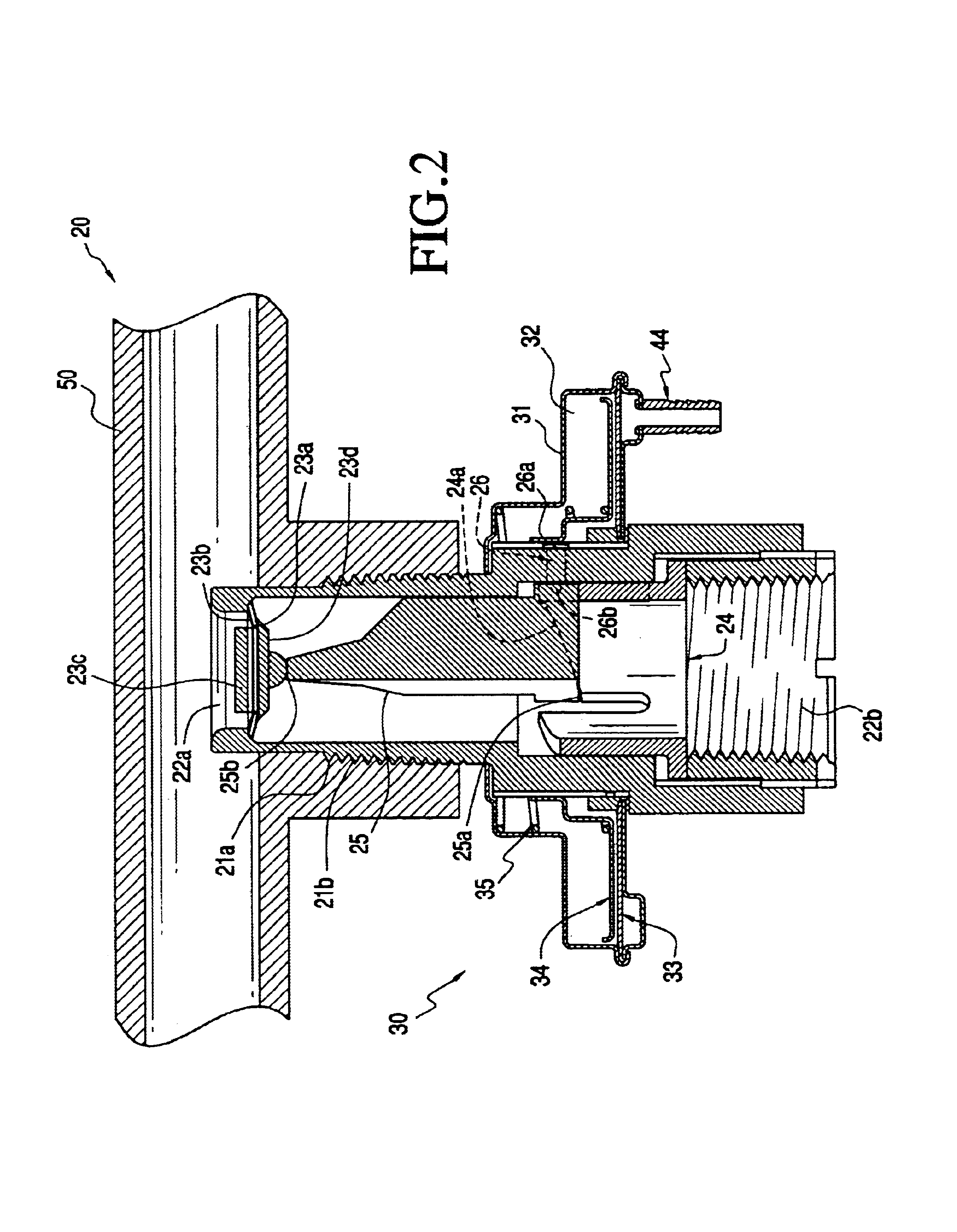

Multi-chamber, sequential dose dispensing syringe

A valve assembly is disclosed which effectively partitions a syringe into proximal and distal chambers to provide a multi-chamber, sequentially dispensing syringe apparatus. The valve assembly may be effectively used with a variety of standard, currently available commercial syringes and pre-filled syringes. Incorporated in the valve assembly is a valved stopper having a valve (which may be a slit valve), an impact sensor which opens the valve upon impact between the valve assembly and internal distal end of the syringe and a gas separator which separates liquid from gas disposed in the proximal chamber to assure gas is not delivered therefrom. The valve assembly is displaced as a plunger of the syringe is displaced via communication through fluid in the proximal chamber of the syringe. The actuator has a latching feature which latches the valve to an open state after being opened by the impact sensor. The gas separator has a proximally disposed orifice which facilitates priming. The valve assembly may be made from two parts. One part, a valved stopper, may be molded from the same rubber based material used in syringe plunger stoppers. The second part, the valve actuator, may be injection molded as a single part. A synthetic resinous material which is compatible with manufacture of living hinges my be used for the second part. Multiple valve assemblies may be used in a single syringe barrel.

Owner:INFUSIVE TECH LLC

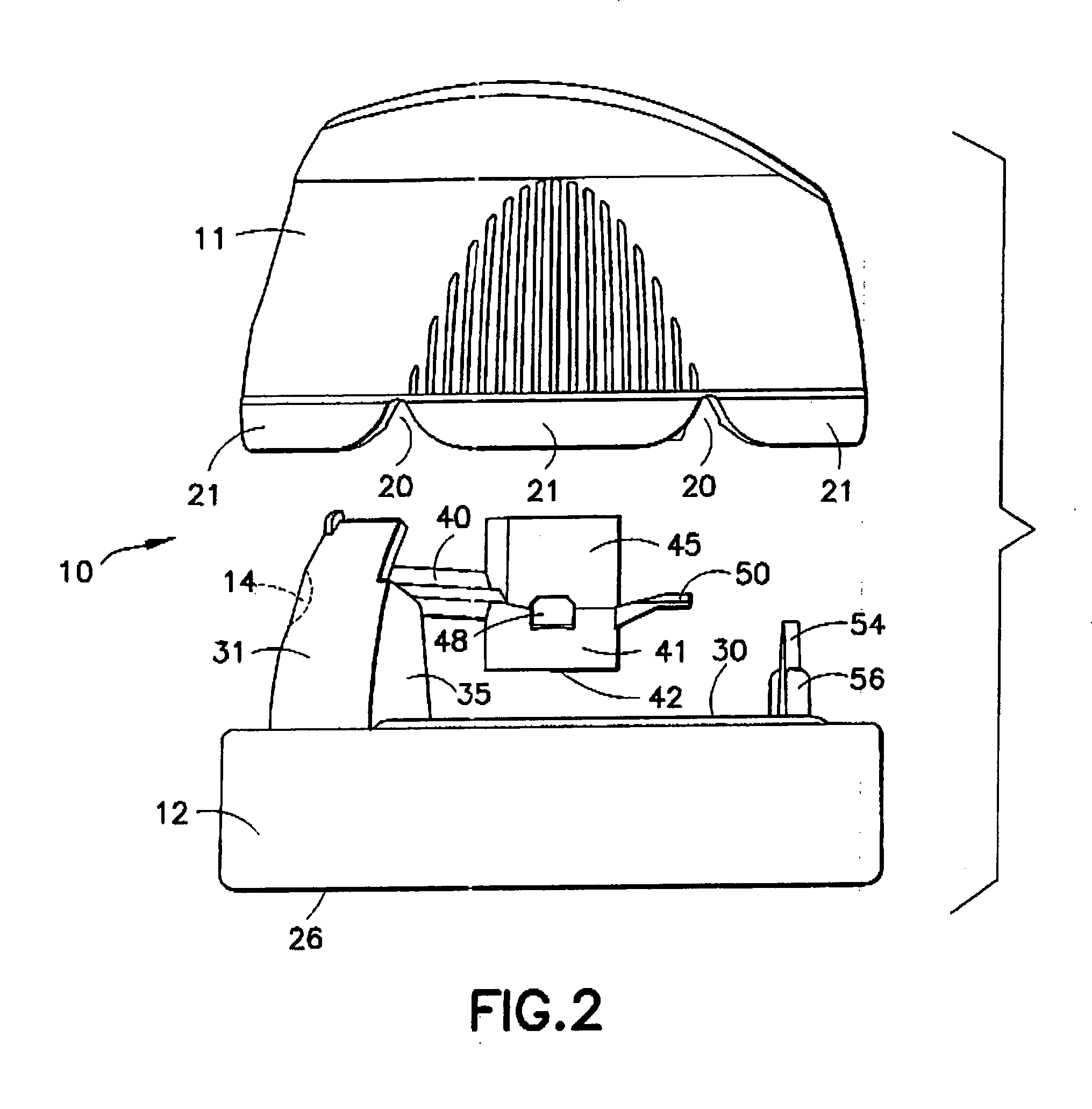

Sprinkler assembly

InactiveUS20050121206A1High performance and economical and reliableEqualizing valvesFire rescueFluid controlValve actuator

A sprinkler assembly for controlling a fire situation includes at least one fluid conduit defining a flow passage including an inlet for receiving a fluid from a fluid source and at least one outlet for discharging the fluid, and a dispensing mechanism such as an open or closed sprinkler head for distributing water to a selected location. A fluid control apparatus is provided including a valve assembly having a valve seal which is moveable between a closed position blocking fluid flow through the conduit and an open position causing fluid flow through the conduit. The fluid control apparatus further includes an actuating mechanism including a valve actuator which is operatively connected to the valve assembly for causing movement of the valve seal to the open position upon release of the sealing force. A sensing mechanism is operatively connected to the valve assembly, the sensing mechanism being thermodynamically responsive to at least one of heat, smoke, infrared radiation and ultraviolet radiation emitted by a heat source.

Owner:DOLAN KEVIN MICHAEL

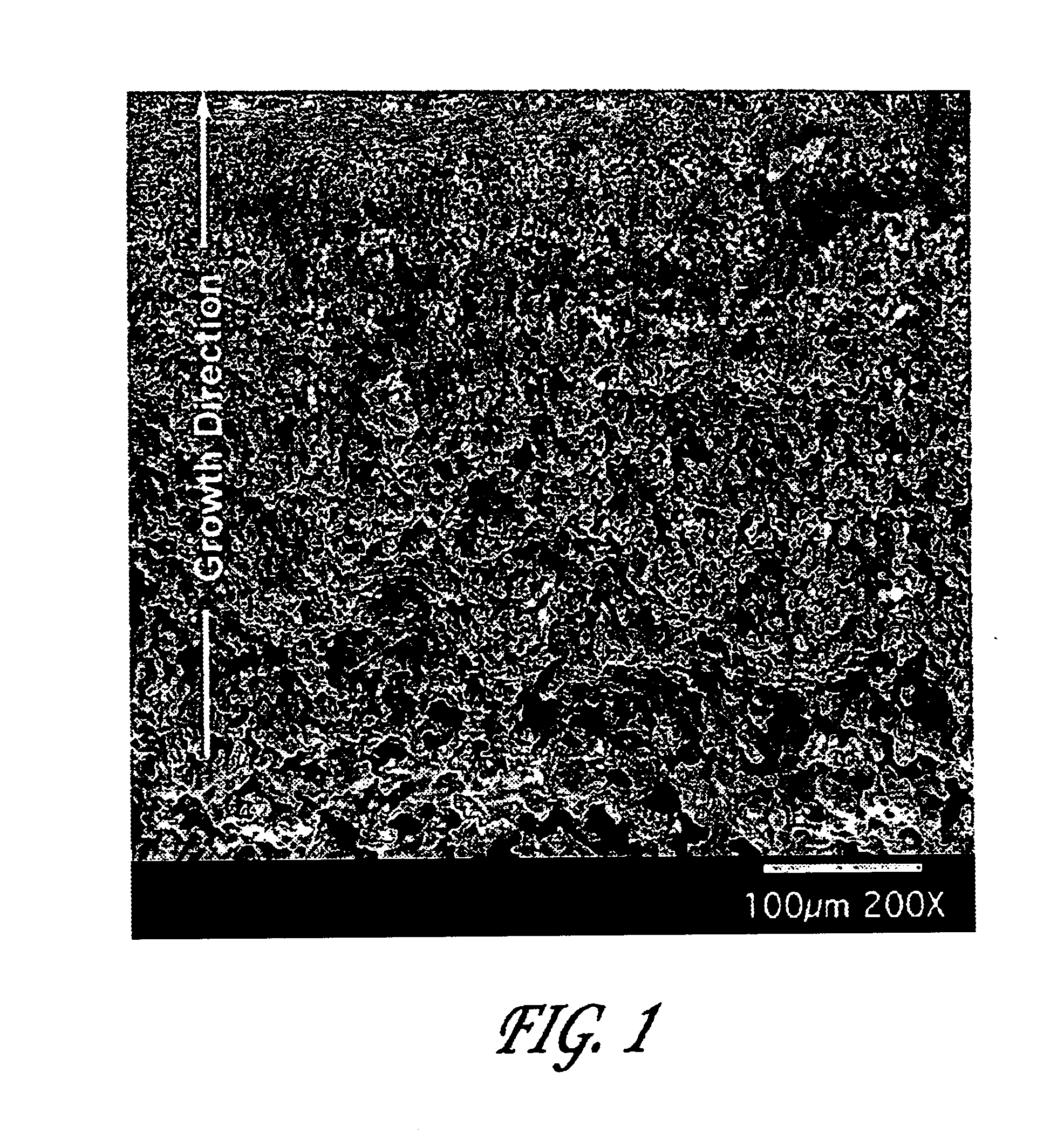

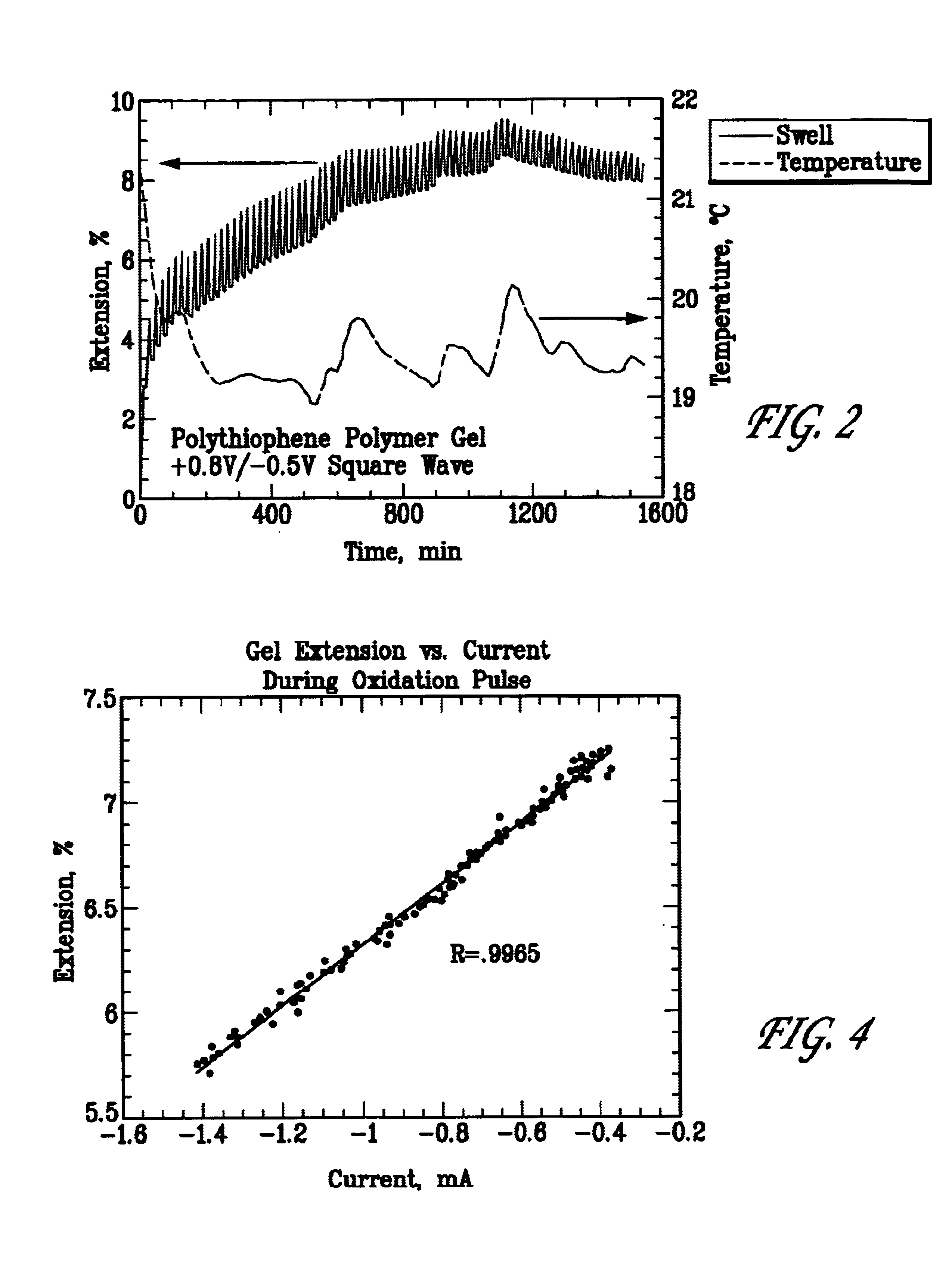

Actuator device utilizing a conductive polymer gel

InactiveUS6685442B2Operating means/releasing devices for valvesCircuit elementsElastomerConductive polymer

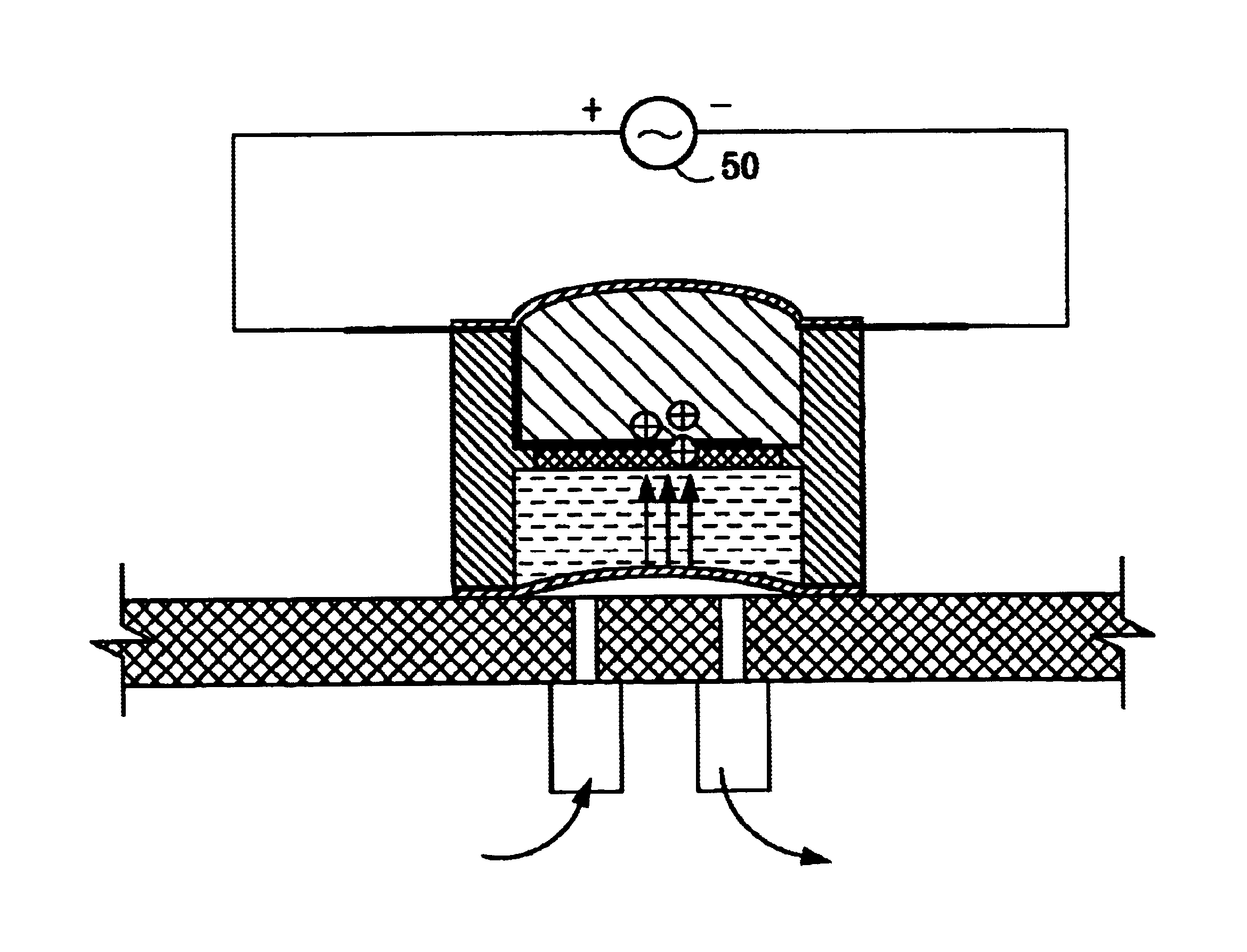

A valve actuator based on a conductive polymer gel is disclosed. A nonconductive housing is provided having two separate chambers separated by a porous frit. The conductive polymer is held in one chamber and an electrolyte solution, used as a source of charged ions, is held in the second chamber. The ends of the housing a sealed with a flexible elastomer. The polymer gel is further provide with electrodes with which to apply an electrical potential across the gel in order to initiate an oxidation reaction which in turn drives anions across the porous frit and into the polymer gel, swelling the volume of the gel and simultaneously contracting the volume of the electrolyte solution. Because the two end chambers are sealed the flexible elastomer expands or contracts with the chamber volume change. By manipulating the potential across the gel the motion of the elastomer can be controlled to act as a "gate" to open or close a fluid channel and thereby control flow through that channel.

Owner:SANDIA NAT LAB

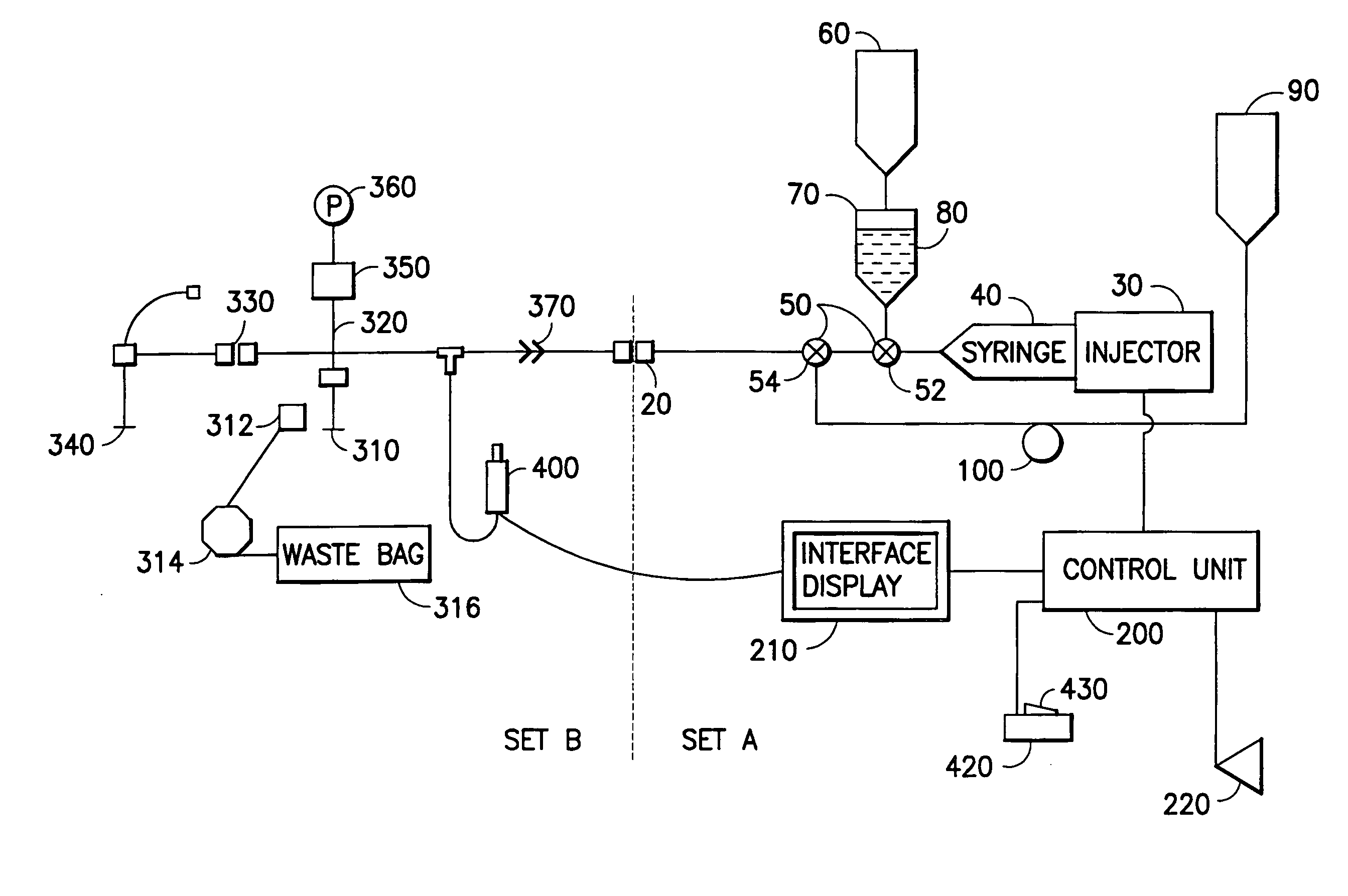

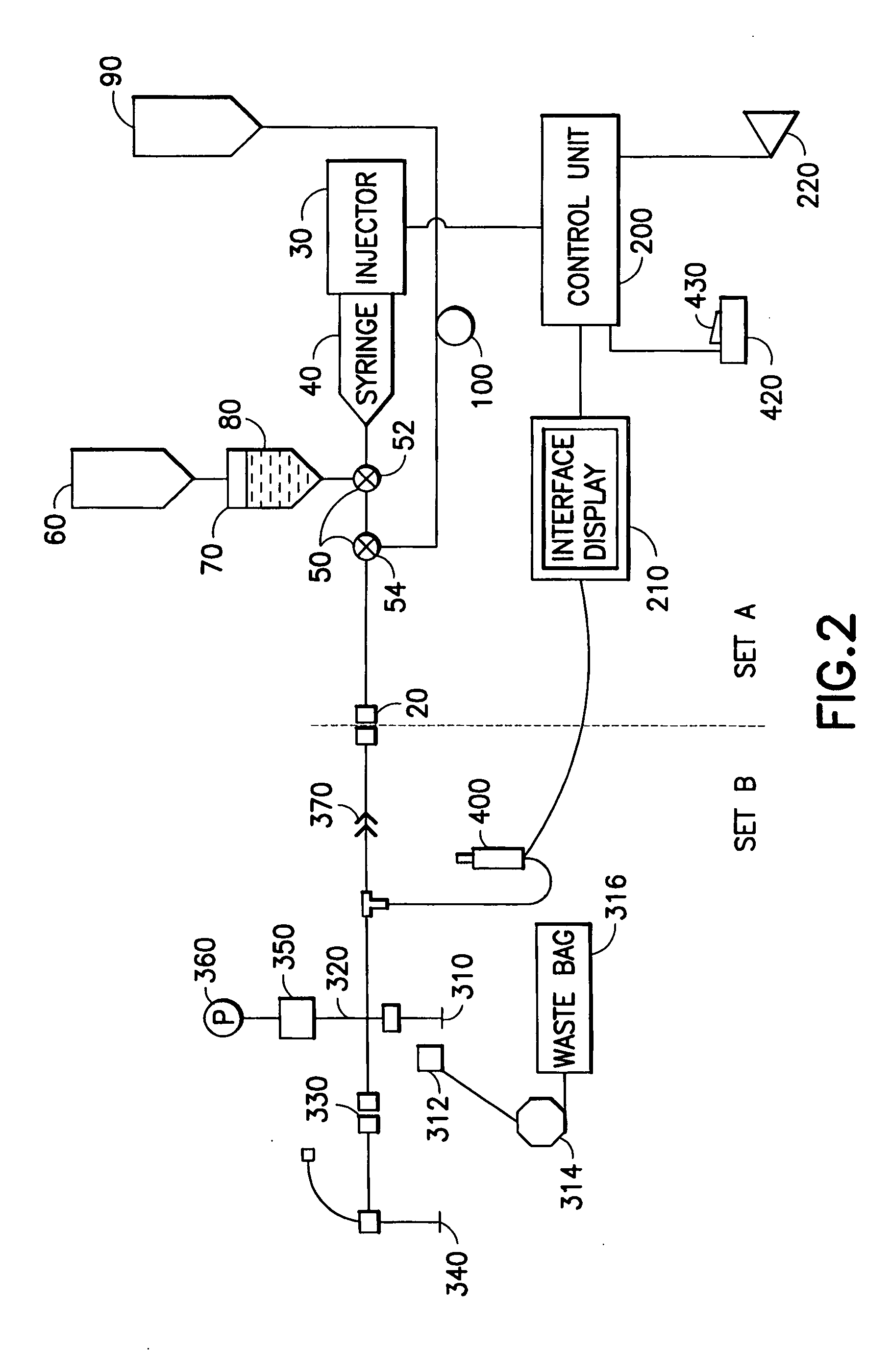

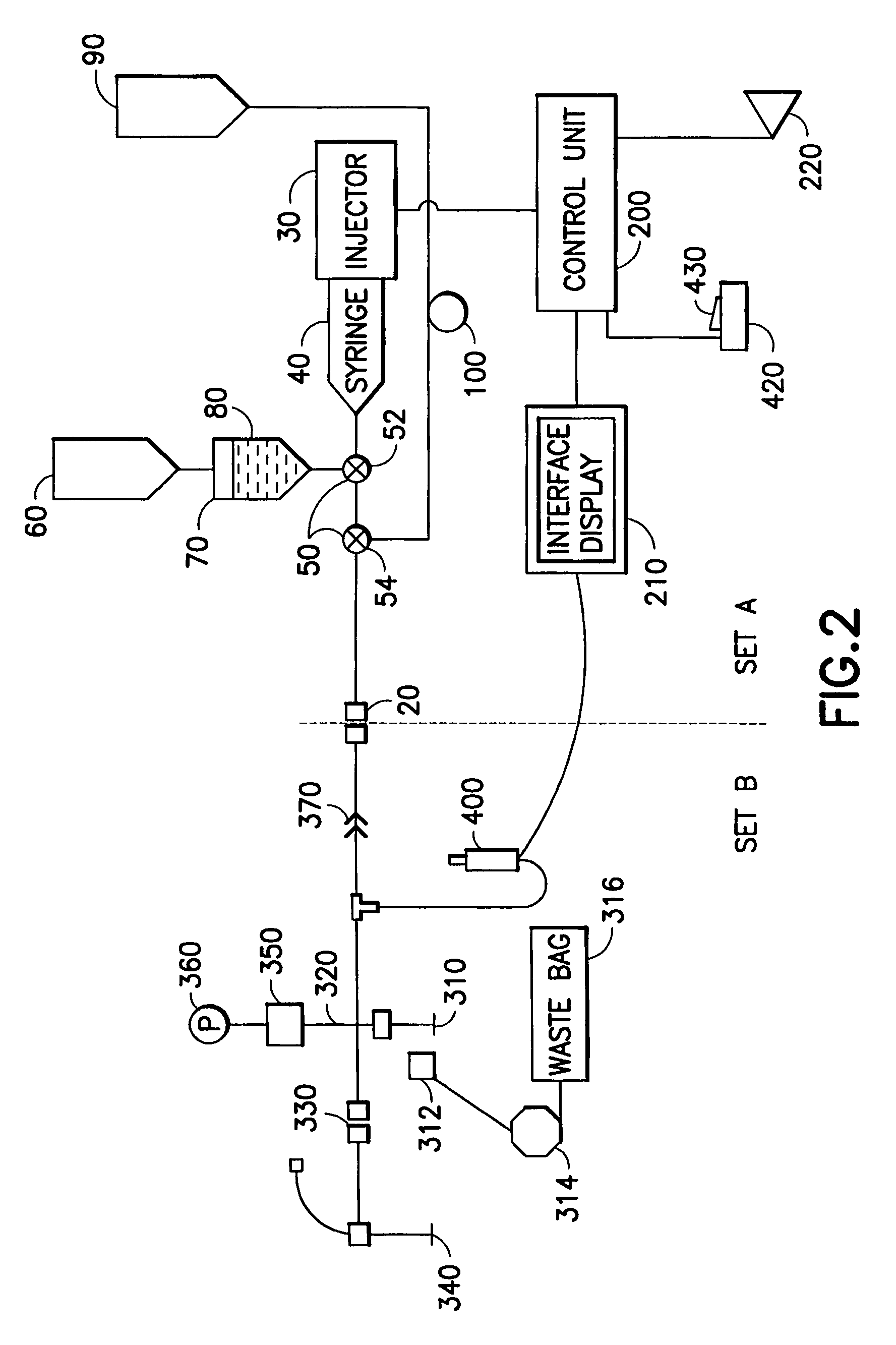

Fluid delivery system, fluid control device, and methods associated with the fluid delivery system and fluid control device

ActiveUS20050234407A1Reduce and eliminate flowReduce fluid pressureInfusion syringesPharmaceutical delivery mechanismFluid controlValve actuator

The fluid delivery system generally includes a source of injection fluid, a pump device a fluid path set disposed between the source of injection fluid and the pump device, and a fluid control device. The fluid path set includes a multi-position valve. The fluid control device is operatively associated with the fluid path set and includes a valve actuator adapted to operate the multi-position valve. The valve actuator is adapted to close the multi-position valve to isolate the pump device from a patient and stop flow of the injection fluid to the patient at substantially any pressure or flow rate generated by the pump device for delivering a sharp bolus of the injection fluid to the patient. The valve actuator is generally adapted to selectively place the pump device in fluid communication with the source of injection fluid for supplying the injection fluid to the pump device and the patient.

Owner:BAYER HEALTHCARE LLC

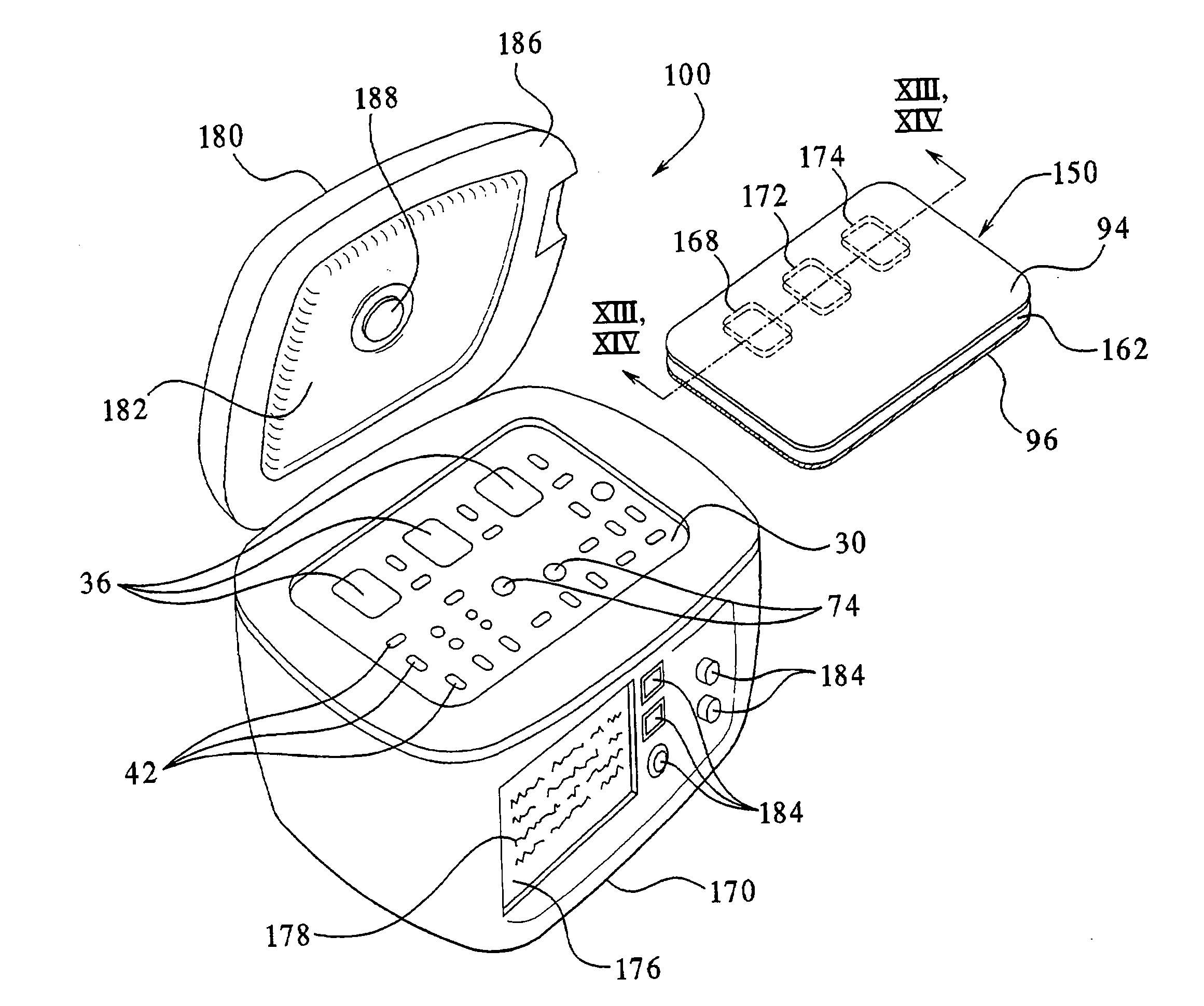

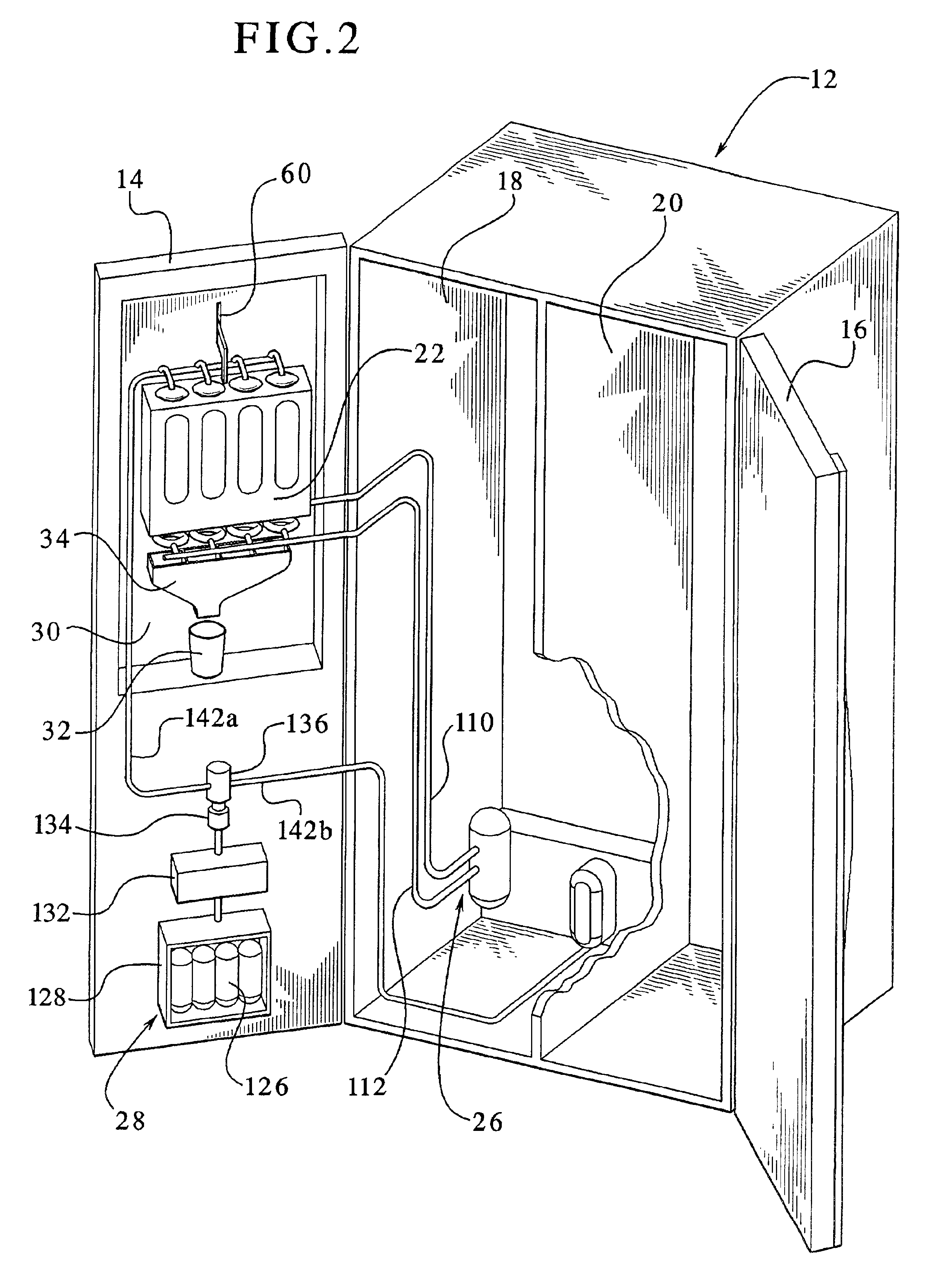

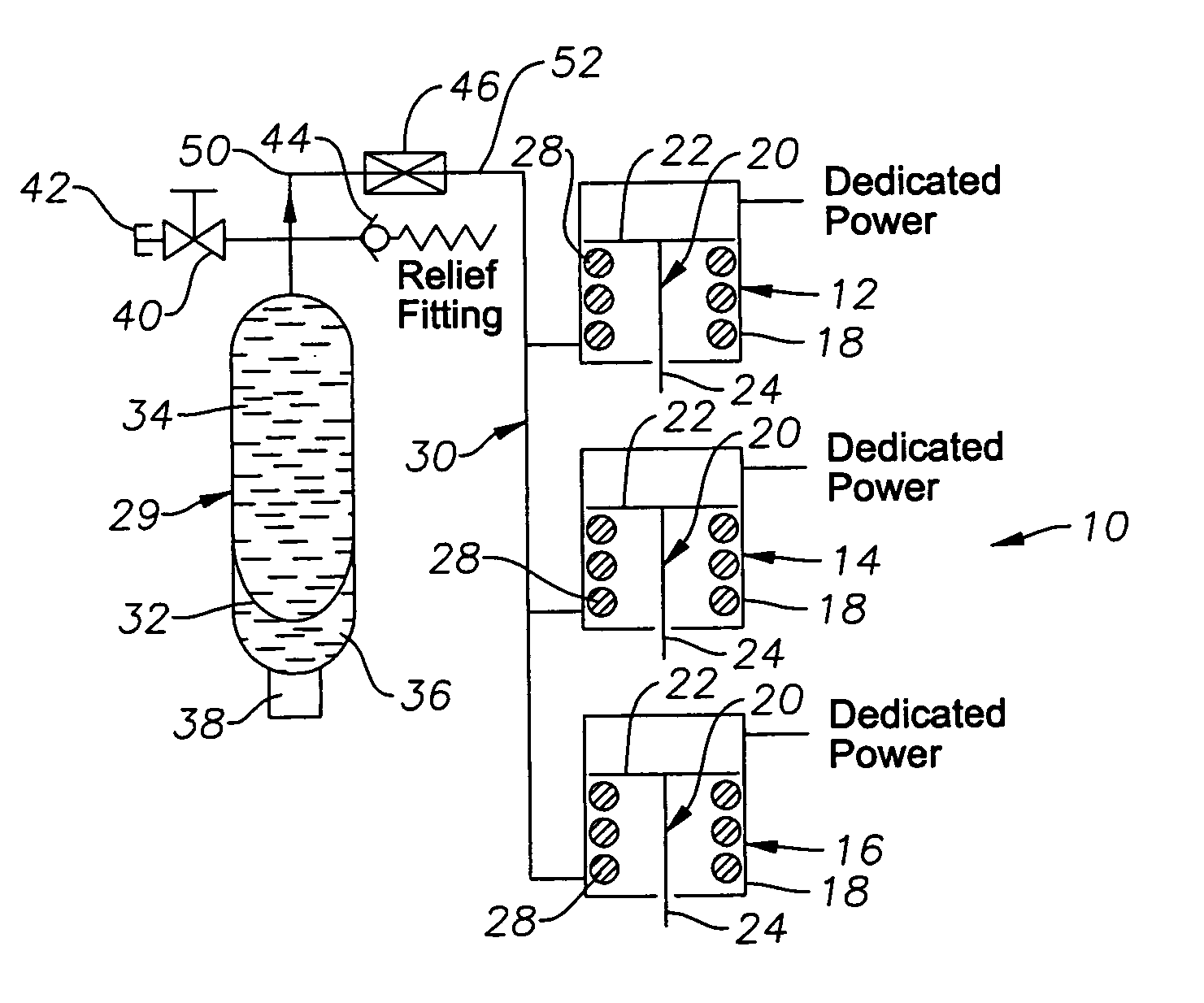

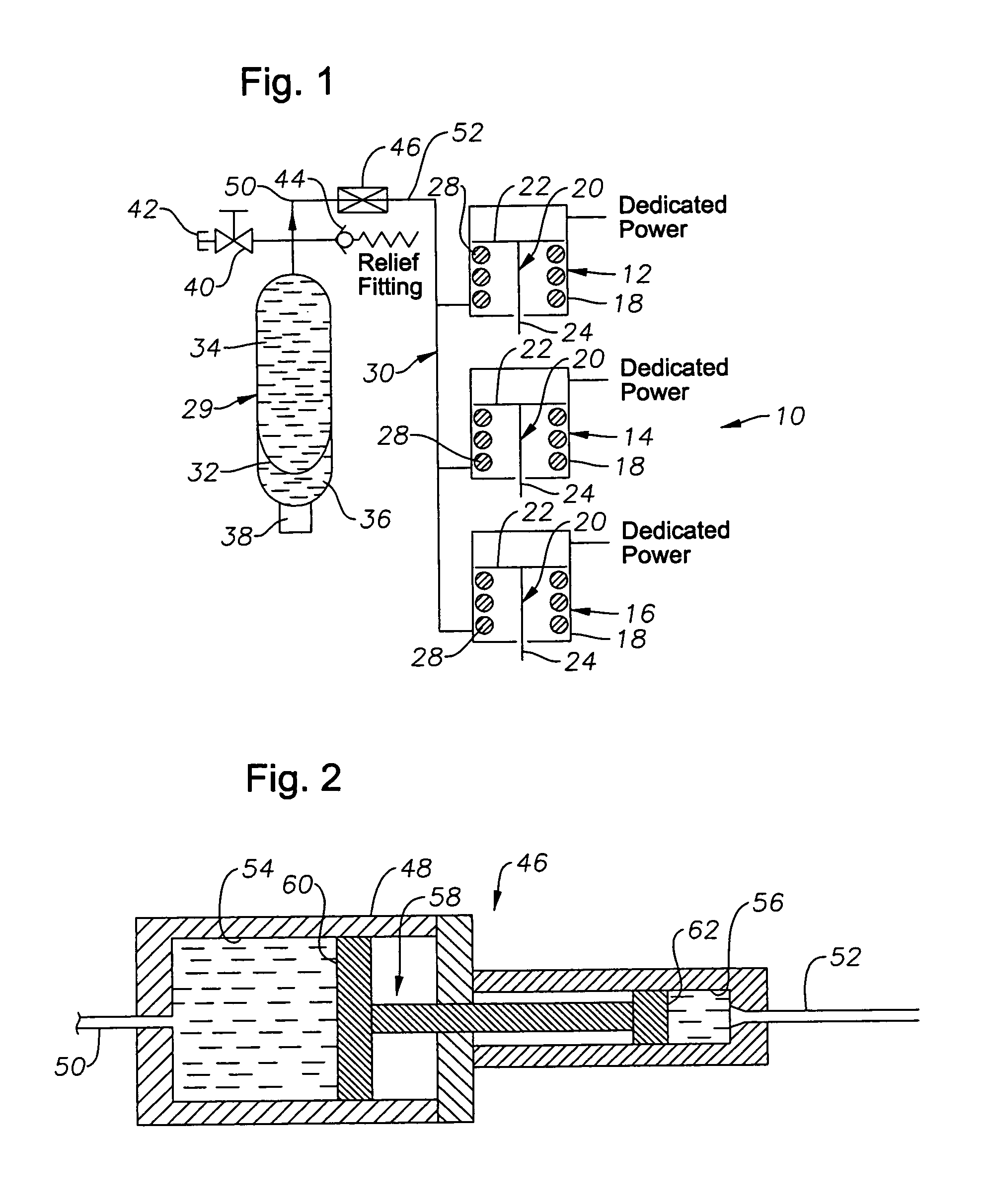

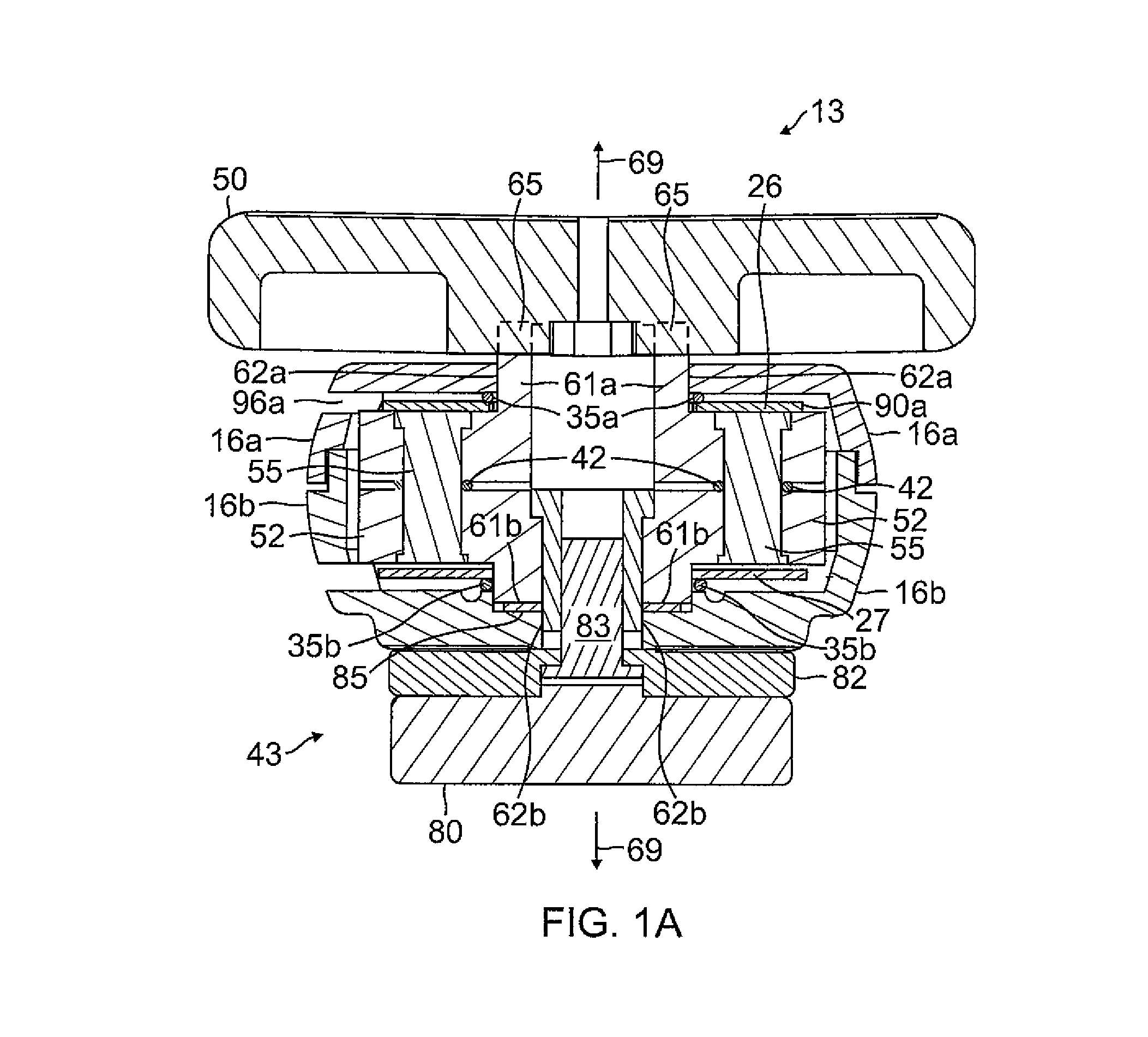

System including machine interface for pumping cassette-based therapies

A dialysis machine includes: a hardware unit including at least one pump actuator, at least one valve actuator and a cassette interface, the cassette interface including: (i) a plate that abuts the cassette; (ii) at least one pump aperture defined by the plate; (iii) at least one pump head moveable out of and retractable into the at least one pump aperture to operate a pumping portion of the cassette; (iv) at least one valve aperture defined by the plate; (v) at least one valve apparatus moveable out of and retractable into the at least one valve aperture to operate a valve portion of the cassette; (vi) at least one sensor aperture defined by the plate; and (vii) at least one sensor located in the least one sensor aperture, the at least one sensor operable with a sensor portion of the cassette.

Owner:BAXTER HEALTHCARE SA +1

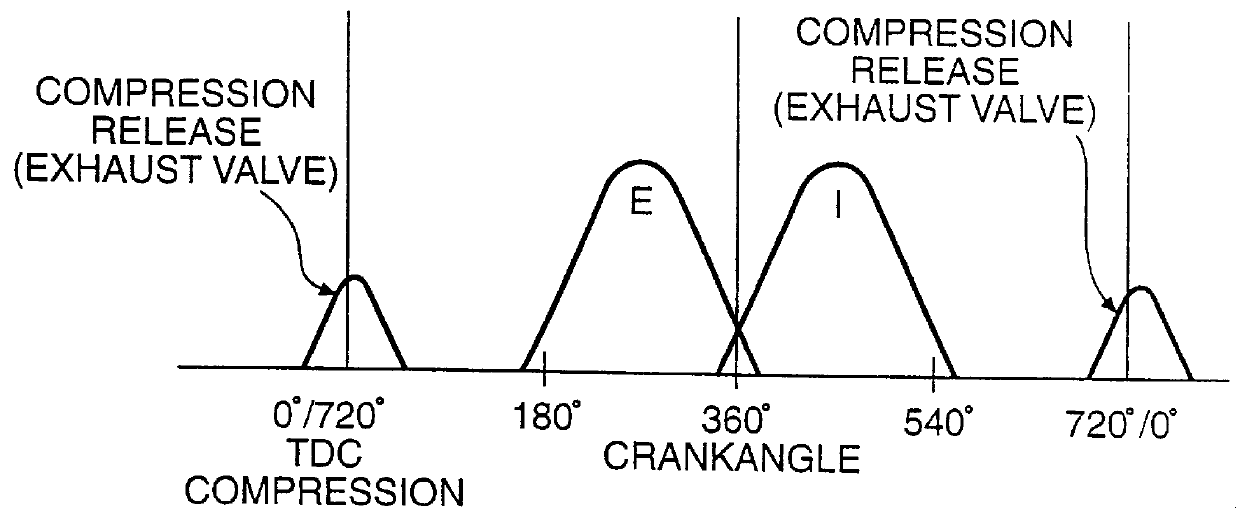

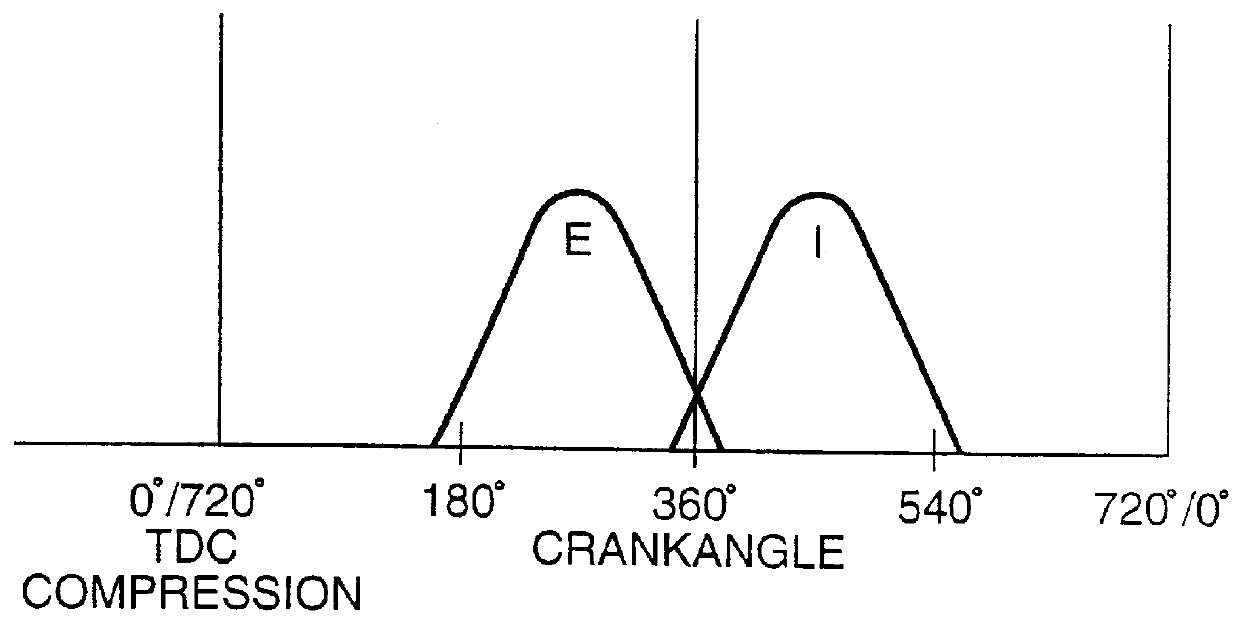

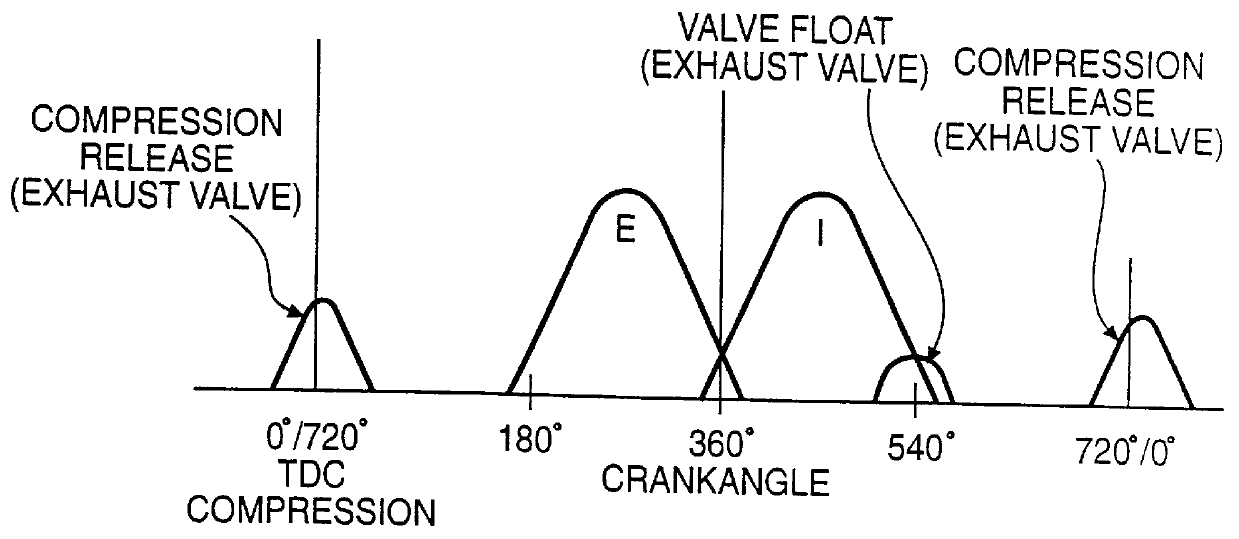

Method and apparatus to accomplish exhaust air recirculation during engine braking and/or exhaust gas recirculation during positive power operation of an internal combustion engine

InactiveUS6082328AHigh retarding powerEasy to operateValve arrangementsNon-fuel substance addition to fuelStored energyExternal combustion engine

A method and apparatus for carrying out variable timing exhaust gas recirculation is disclosed for use during both positive power and retarding operation of an internal combustion engine. Motion or energy is derived from an engine component and stored as potential energy. The stored energy is selectively applied to a valve actuator to carry out exhaust gas recirculation in an engine cylinder. The energy derived from the engine may be stored and selectively applied to the valve actuator with an electronically controlled trigger valve. The valve actuator may be a slave piston having an inner core and an outer sleeve capable of opening the valve of the cylinder in response to independent exhaust gas recirculation and compression release hydraulic systems.

Owner:DIESEL ENGINE RETARDERS

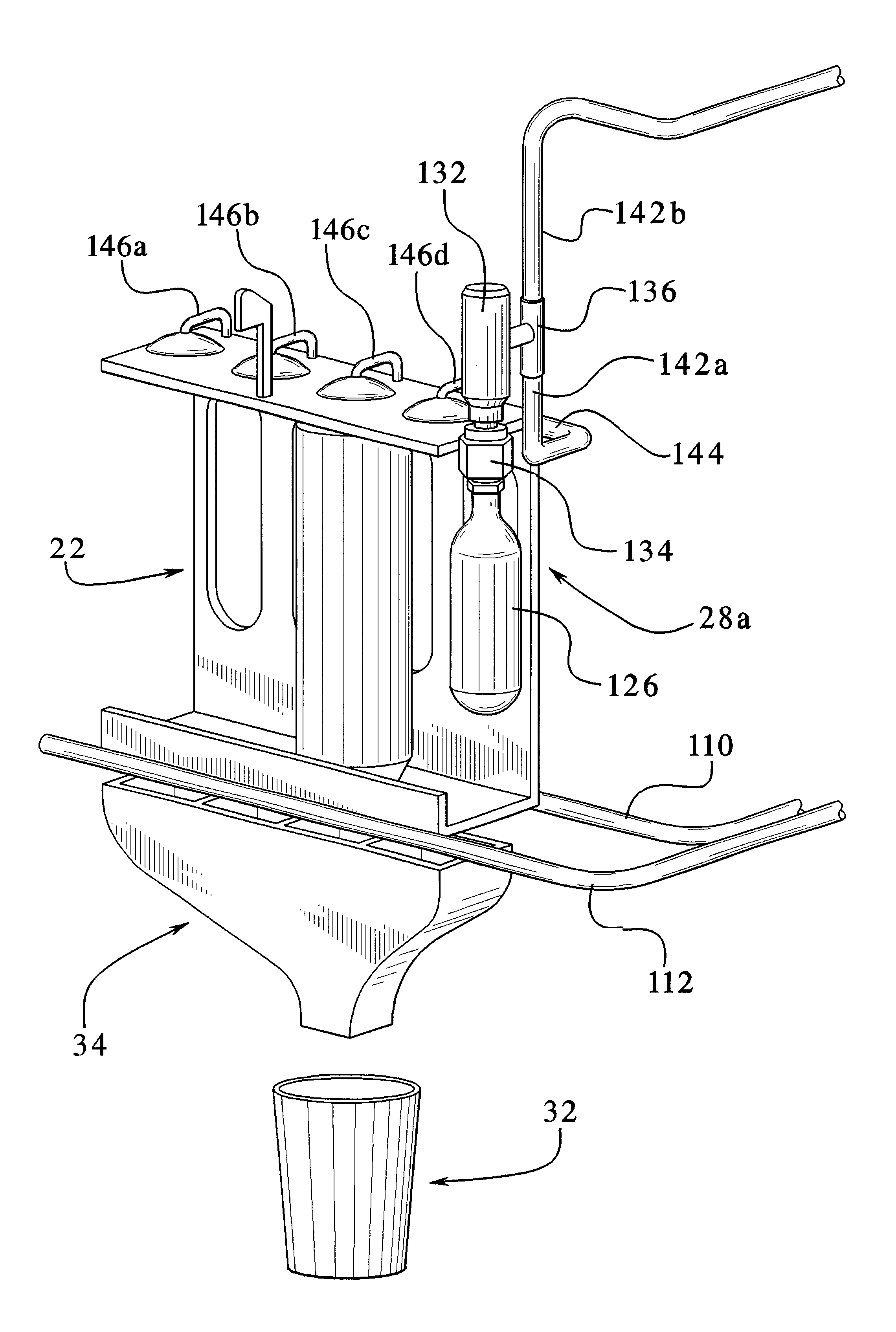

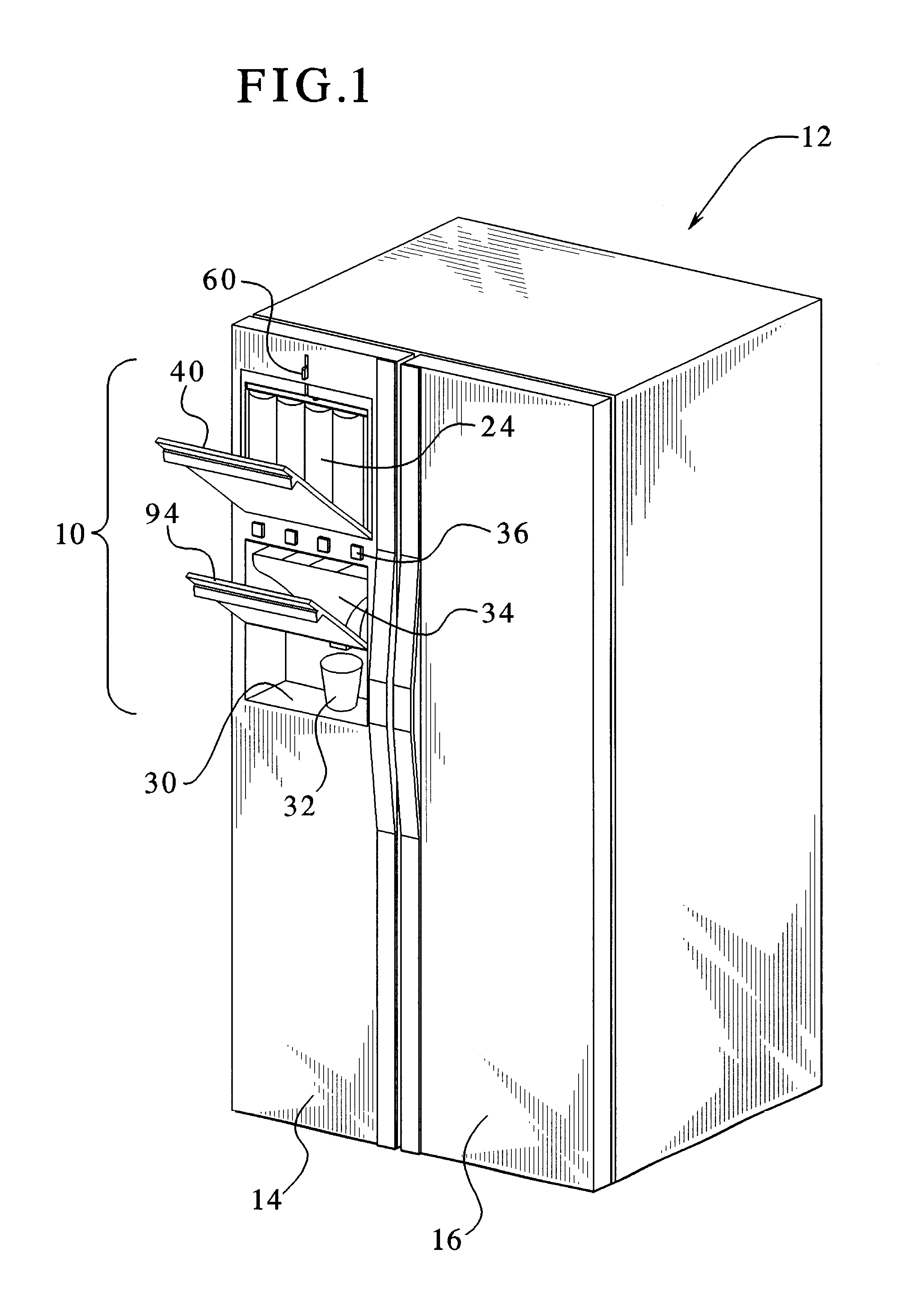

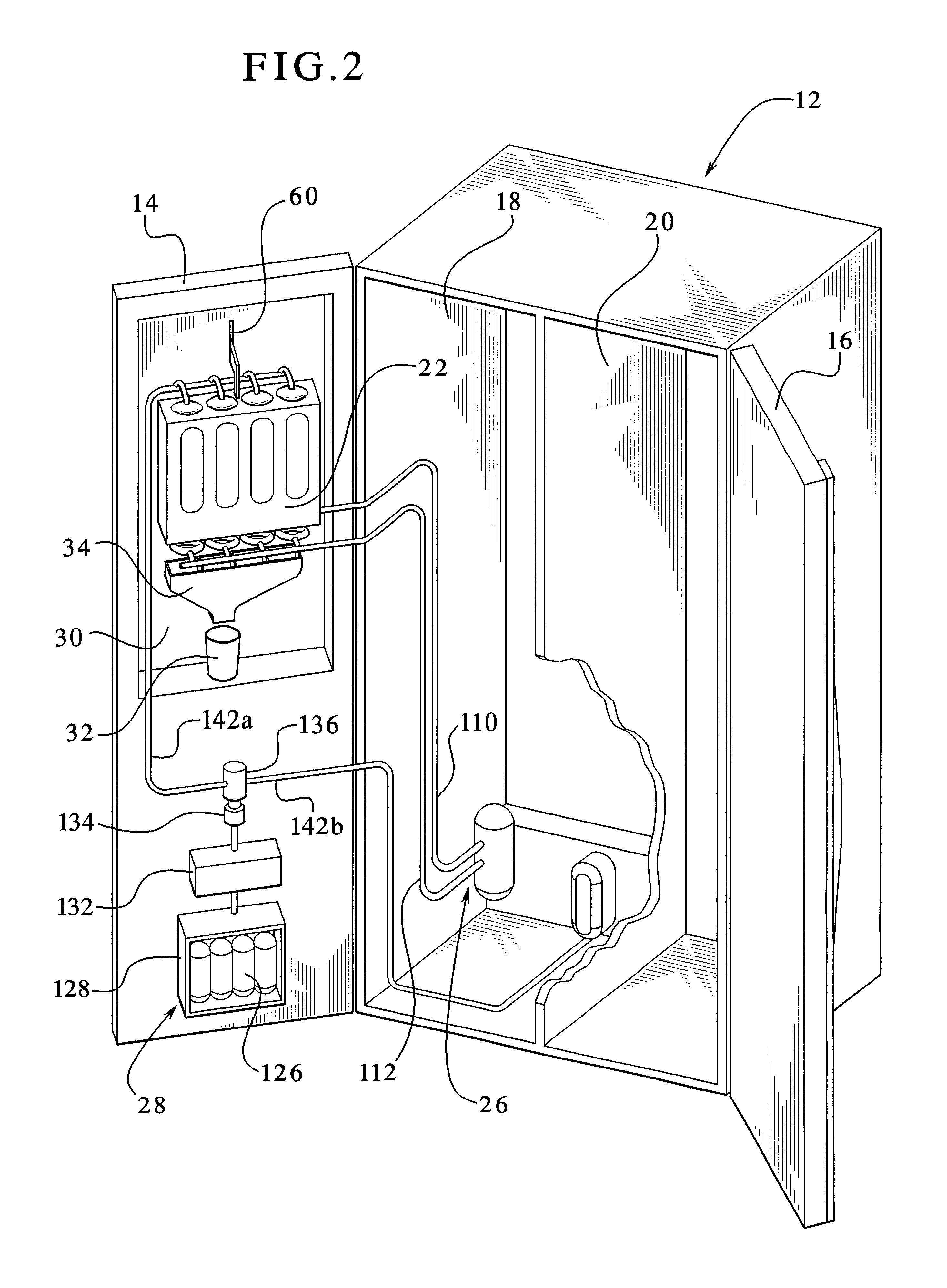

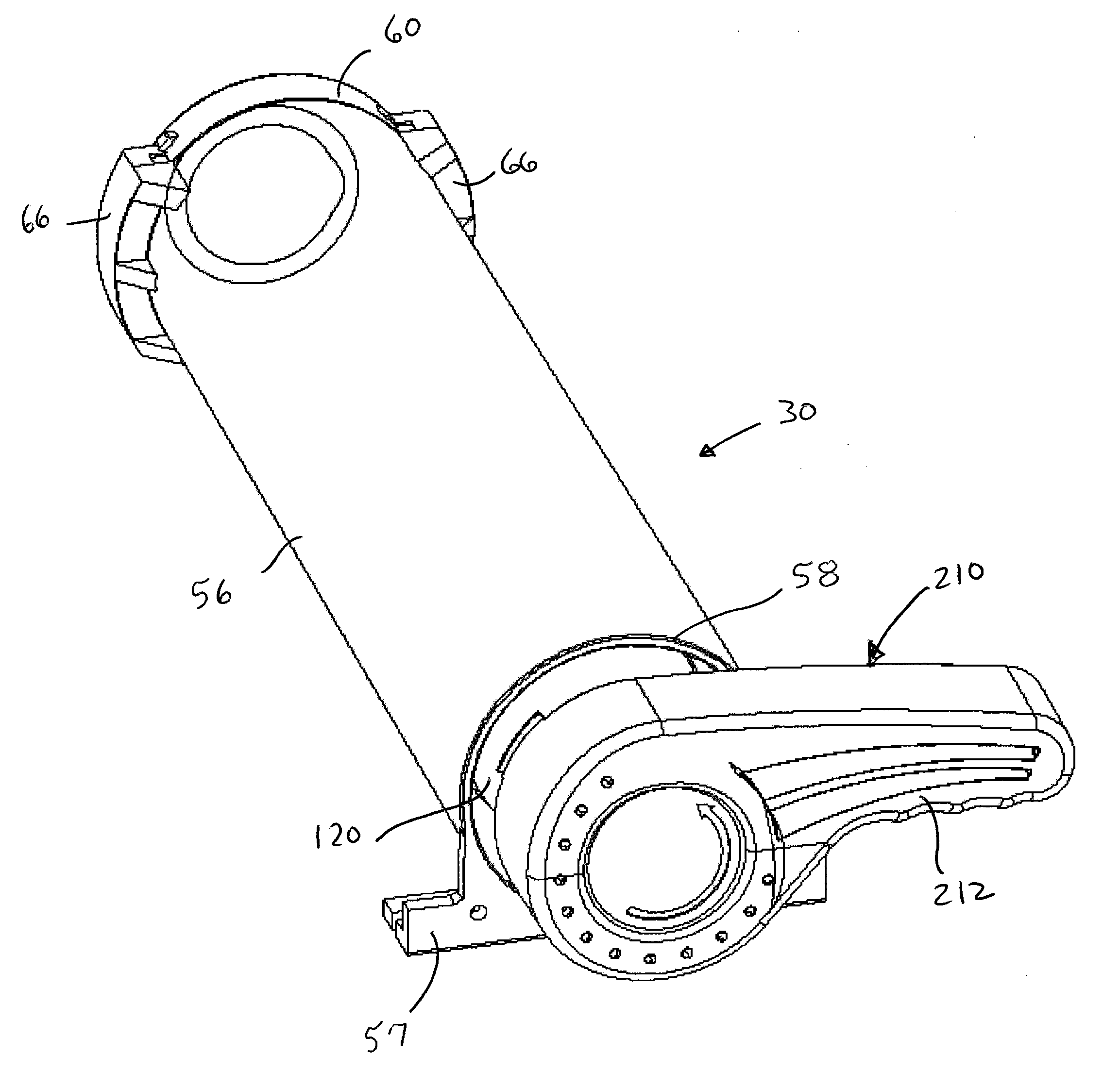

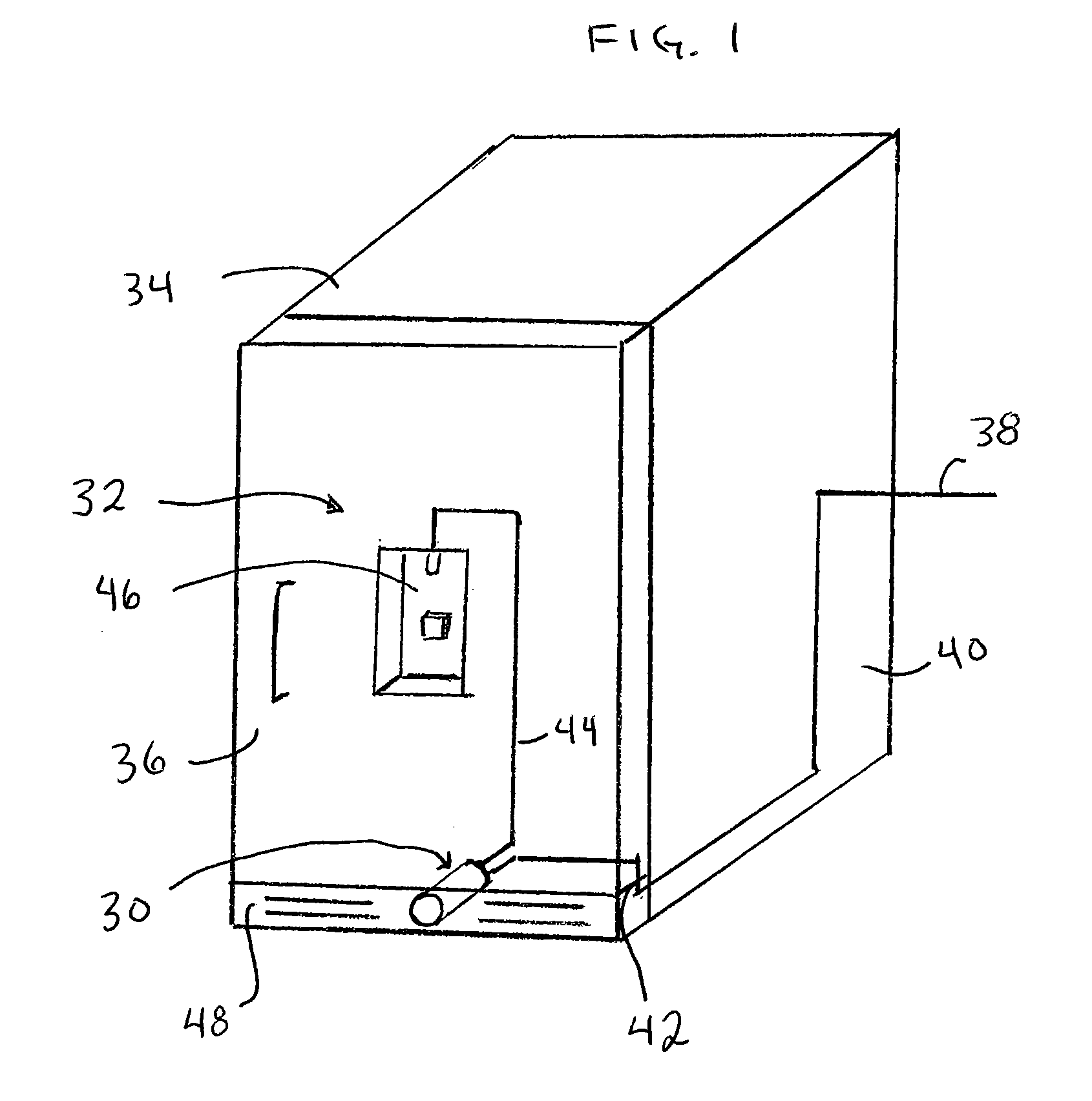

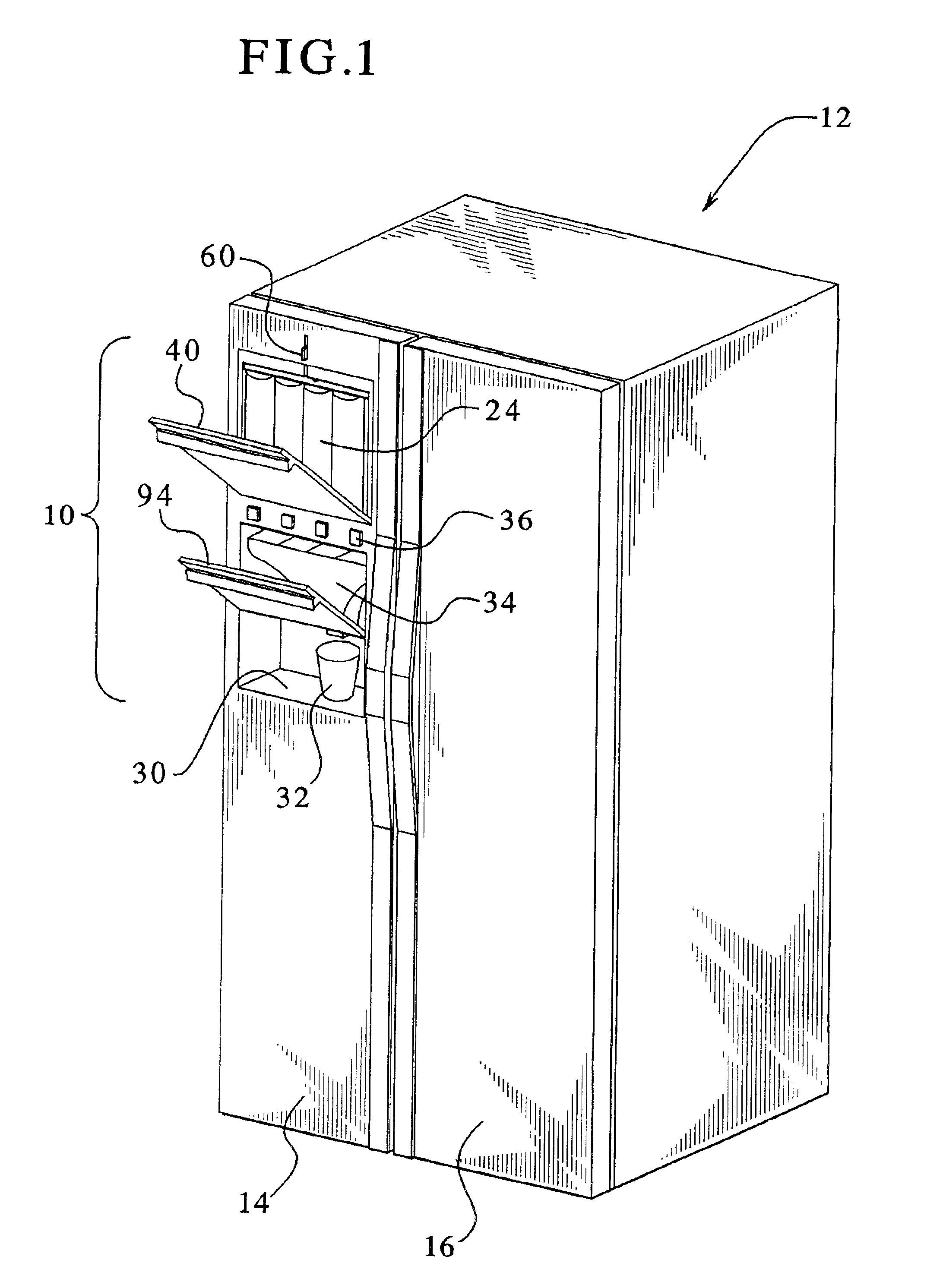

Beverage dispensing apparatus having fluid director

InactiveUS6896159B2Reliable consistent controlEasy to controlLighting and heating apparatusLiquid flow controllersValve actuatorEngineering

The present invention provides a beverage dispensing apparatus for a residential refrigerator. The beverage dispensing apparatus includes a drink supplier including a drink supply canister holder for holding a plurality of drink supply canisters, a plurality of valve actuators for causing the drink supply to be selectively released from the drink supply canisters, a water supplier for selectively supplying carbonated water and non-carbonated water for producing the beverages, a gas supplier for supplying CO2 gas to carbonate the carbonated water provided by the water supplier and for supplying CO2 gas or other gas for pressurizing the drink supply canisters to provide a consistent flow rate of the drink supply from the drink supply canisters, a fluid director for facilitating the mixing of the drink supply from one of the drink supply canisters and the carbonated or non-carbonated water from the water supplier and one or more beverage requesters for enabling users to request one of a plurality of beverages.

Owner:BEVERAGE WORKS

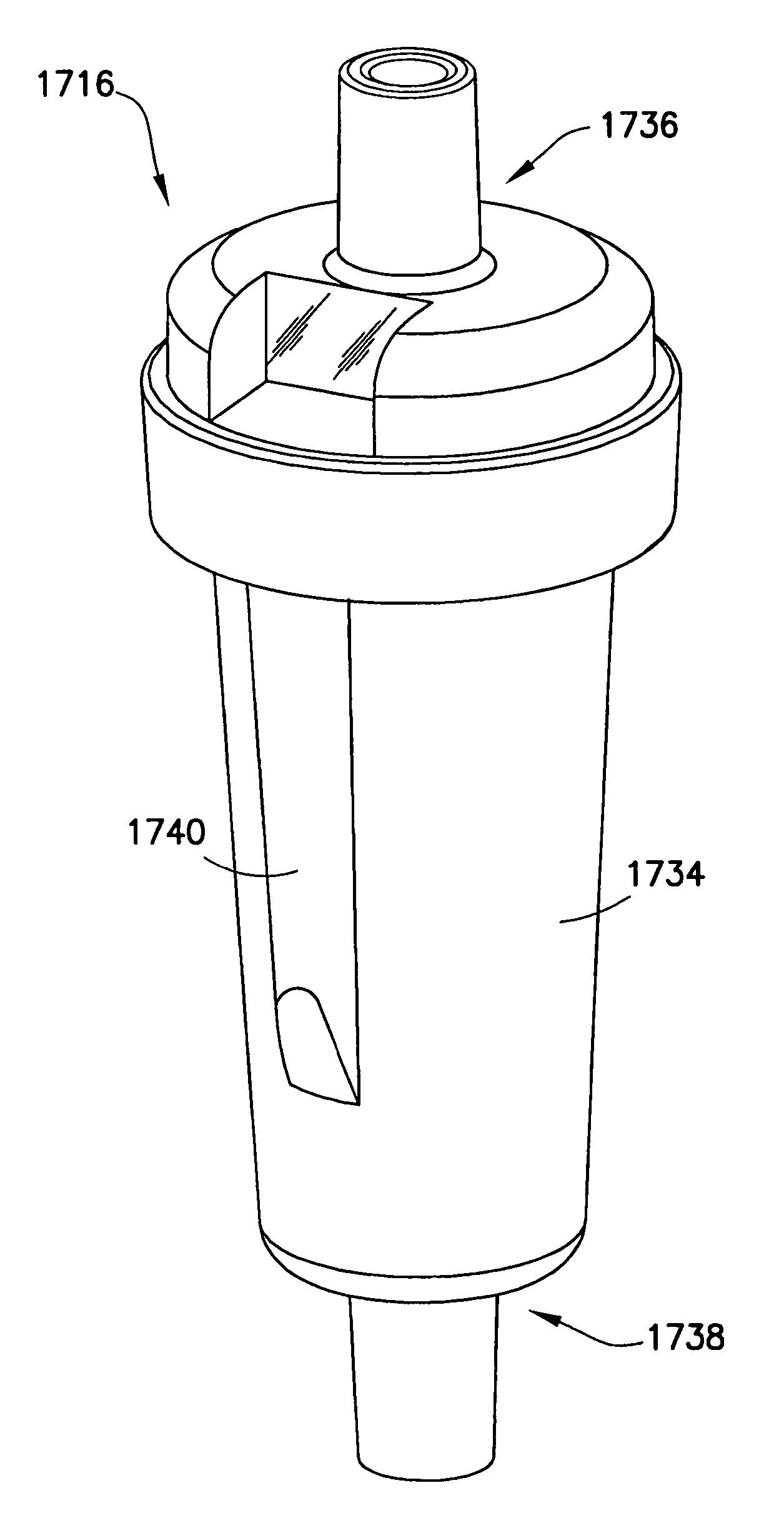

Water Filter Cartridge and Valve with Autobypass Feature

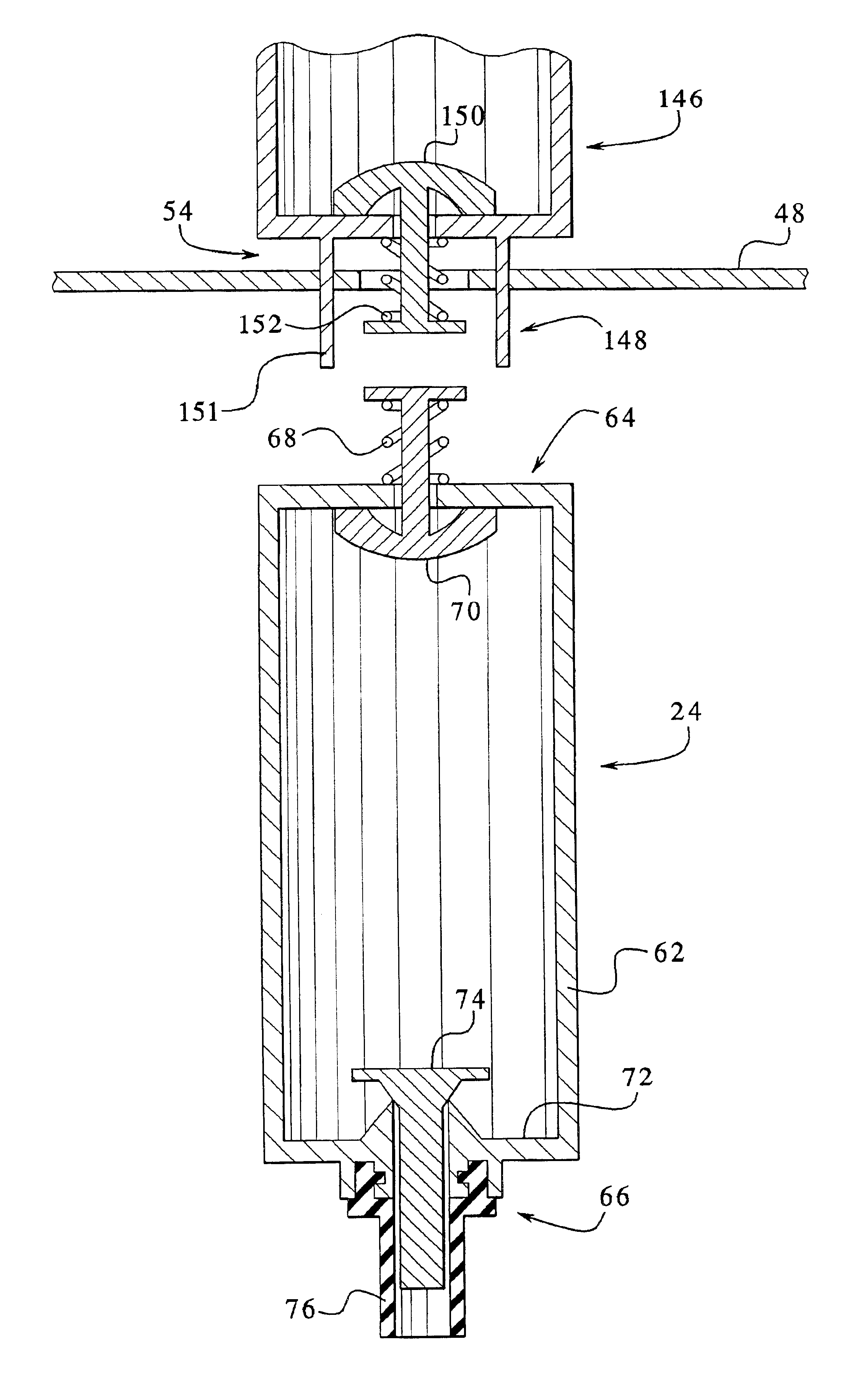

InactiveUS20080000820A1Avoid communicationSemi-permeable membranesOperating means/releasing devices for valvesWater filterValve actuator

A liquid filter cartridge system includes a housing, a valve body, a valve actuator, a filter, an inlet passage having a portion extending through each of the valve body and the valve actuator and into the filter, and an outlet passage having a portion leading out of the filter, and extending through each of the valve actuator and the valve body. An interface is located between the inlet passage portions in the valve actuator and the filter and an interface is located between the outlet passage portions in the valve actuator and the filter. The inlet passage interface and the outlet passage interface may lie in the same plane as each other. They may each comprise a face seal comprising an axial seal between the valve actuator and the filter. They may each comprise a seal between the valve actuator and the filter, wherein the two seals are sealed via compression and not via sliding contact.

Owner:WHIRLPOOL CORP

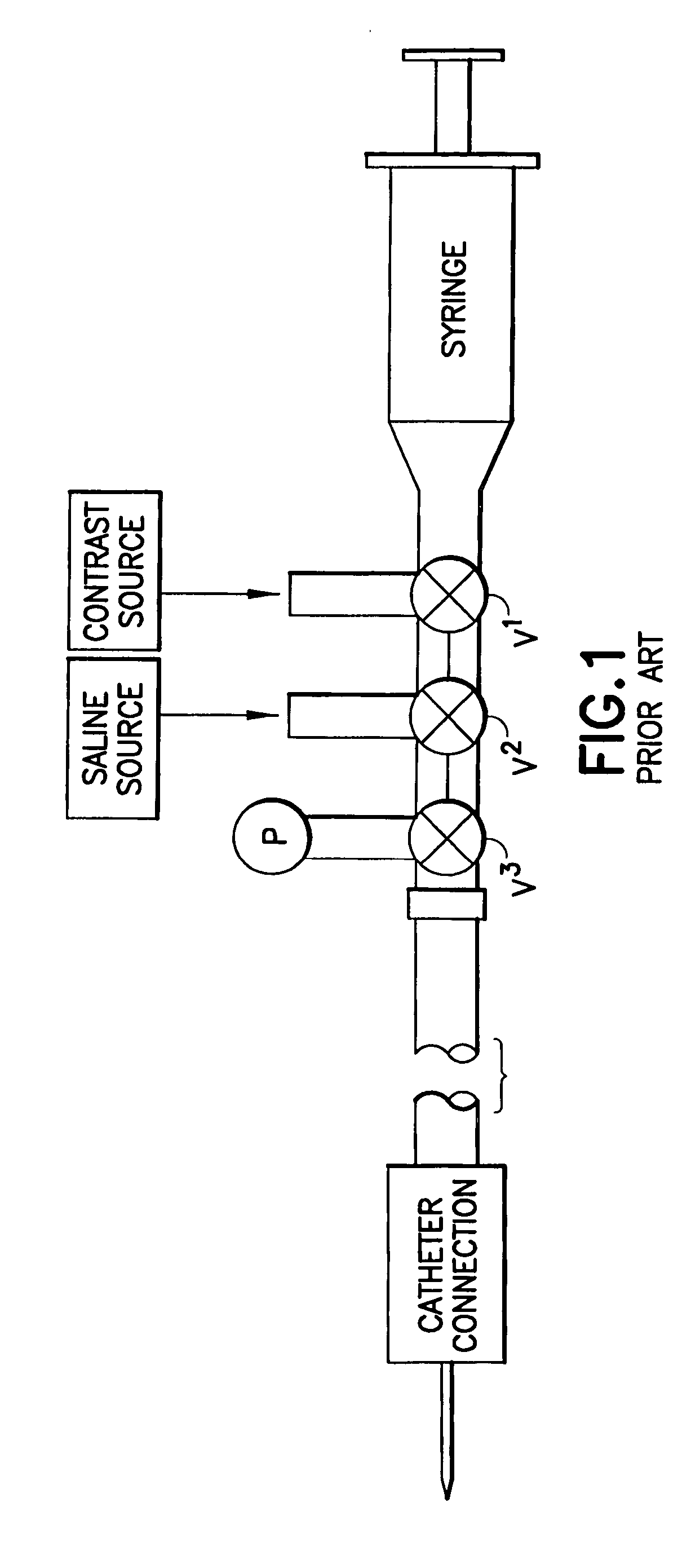

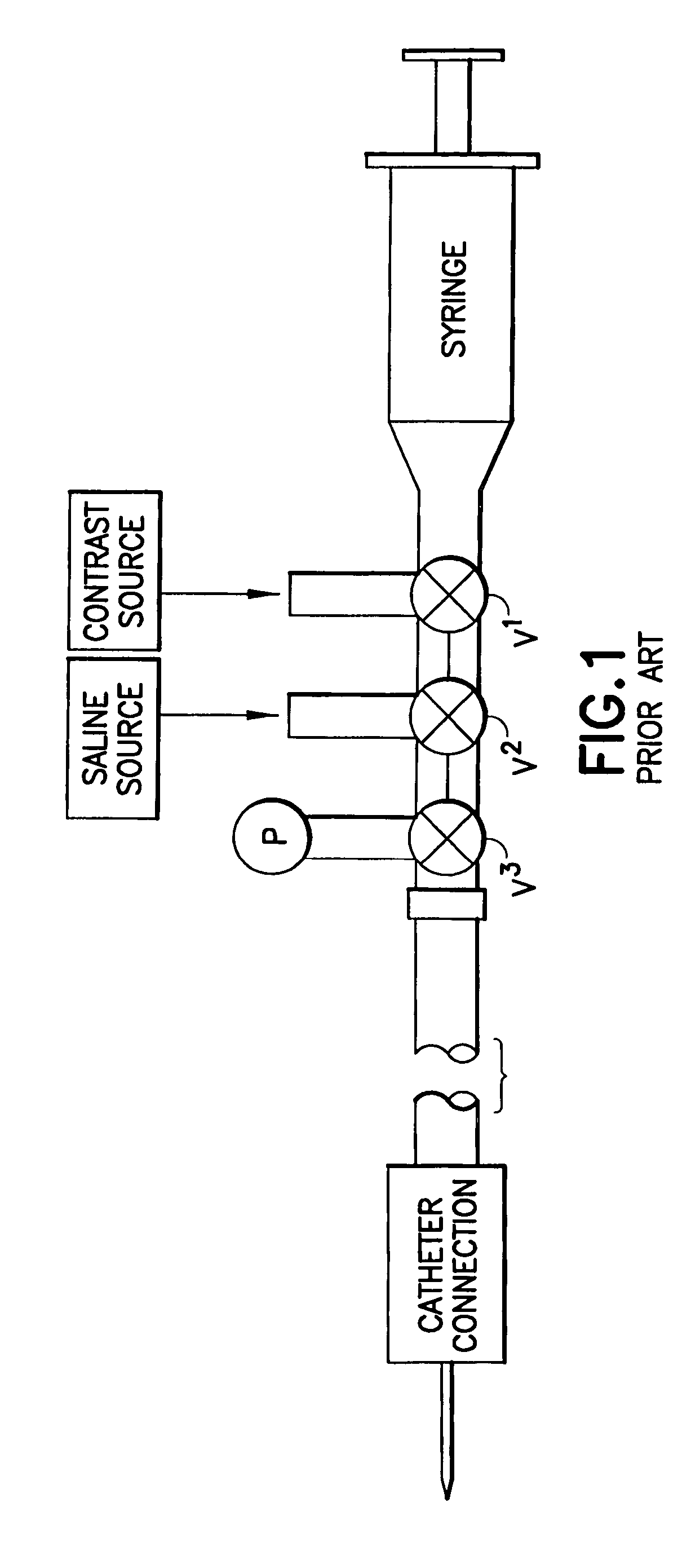

Fluid delivery system having a fluid level sensor and a fluid control device for isolating a patient from a pump device

ActiveUS7556619B2Reduce and eliminate flowReduce fluid pressureInfusion syringesMedical devicesFluid controlValve actuator

The fluid delivery system generally includes a source of injection fluid, a pump device a fluid path set disposed between the source of injection fluid and the pump device, and a fluid control device. The fluid path set includes a multi-position valve. The fluid control device is operatively associated with the fluid path set and includes a valve actuator adapted to operate the multi-position valve. The valve actuator is adapted to close the multi-position valve to isolate the pump device from a patient and stop flow of the injection fluid to the patient at substantially any pressure or flow rate generated by the pump device for delivering a sharp bolus of the injection fluid to the patient. The valve actuator is generally adapted to selectively place the pump device in fluid communication with the source of injection fluid for supplying the injection fluid to the pump device and the patient.

Owner:BAYER HEALTHCARE LLC

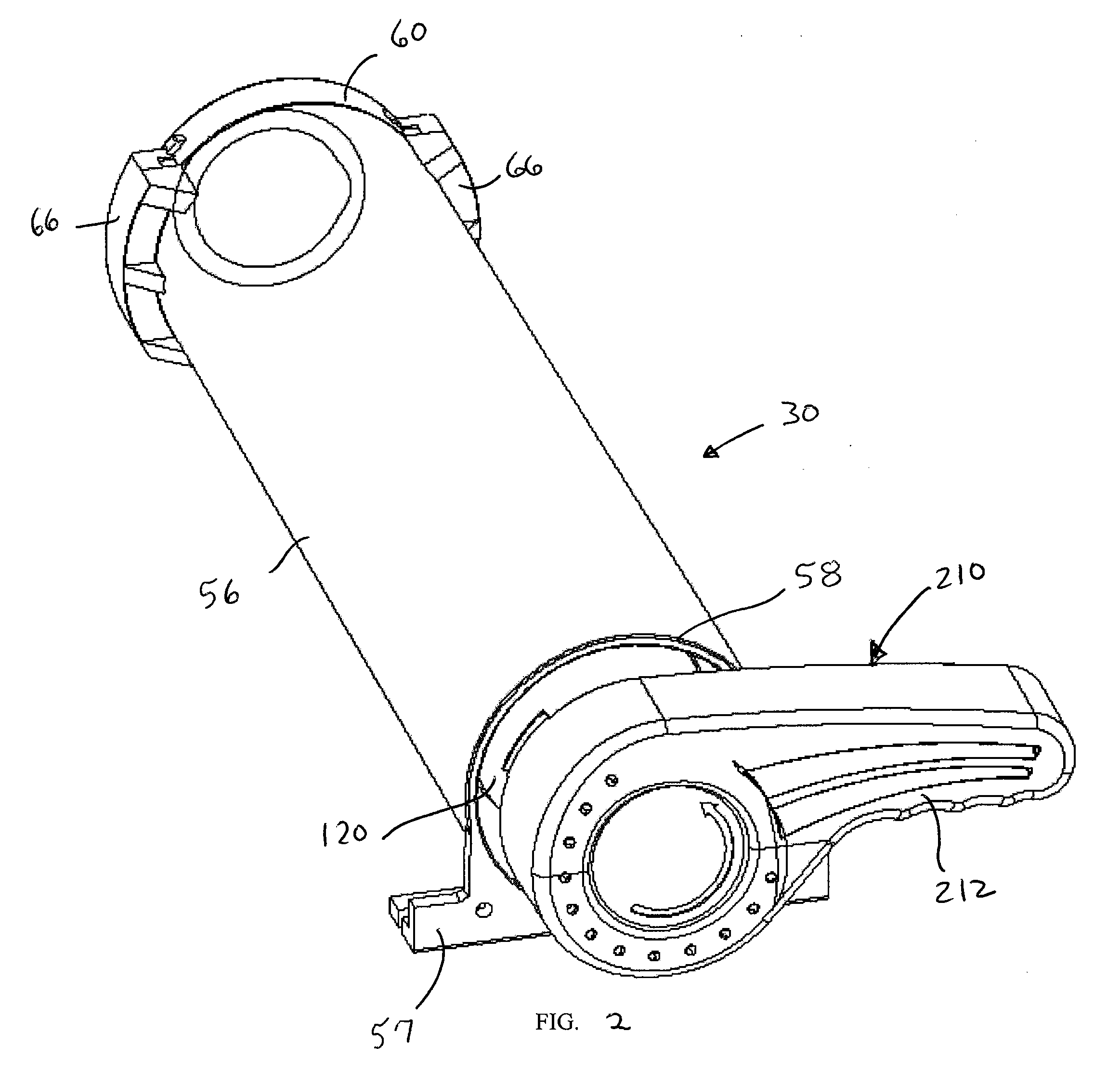

Valve actuator assembly and methods of using the same

ActiveUS8342478B1Operating means/releasing devices for valvesPipeline systemsValve actuatorControl theory

Valve systems include a valve and a valve actuator assembly for operating the valve. The valve actuator assembly includes a controller that uses stored information and signals from a sensor to open and close the valve. The controller can manipulate, analyze, evaluate, store, and communicate information related to the history of the valve, performance of the valve, valve settings, and the like. The controller can send information to a replacement controller or a replacement valve actuator assembly. Various types of wired and wireless connections can establish communication between the controller and the replacement controller or replacement valve actuator assembly.

Owner:TRI TEC MFG

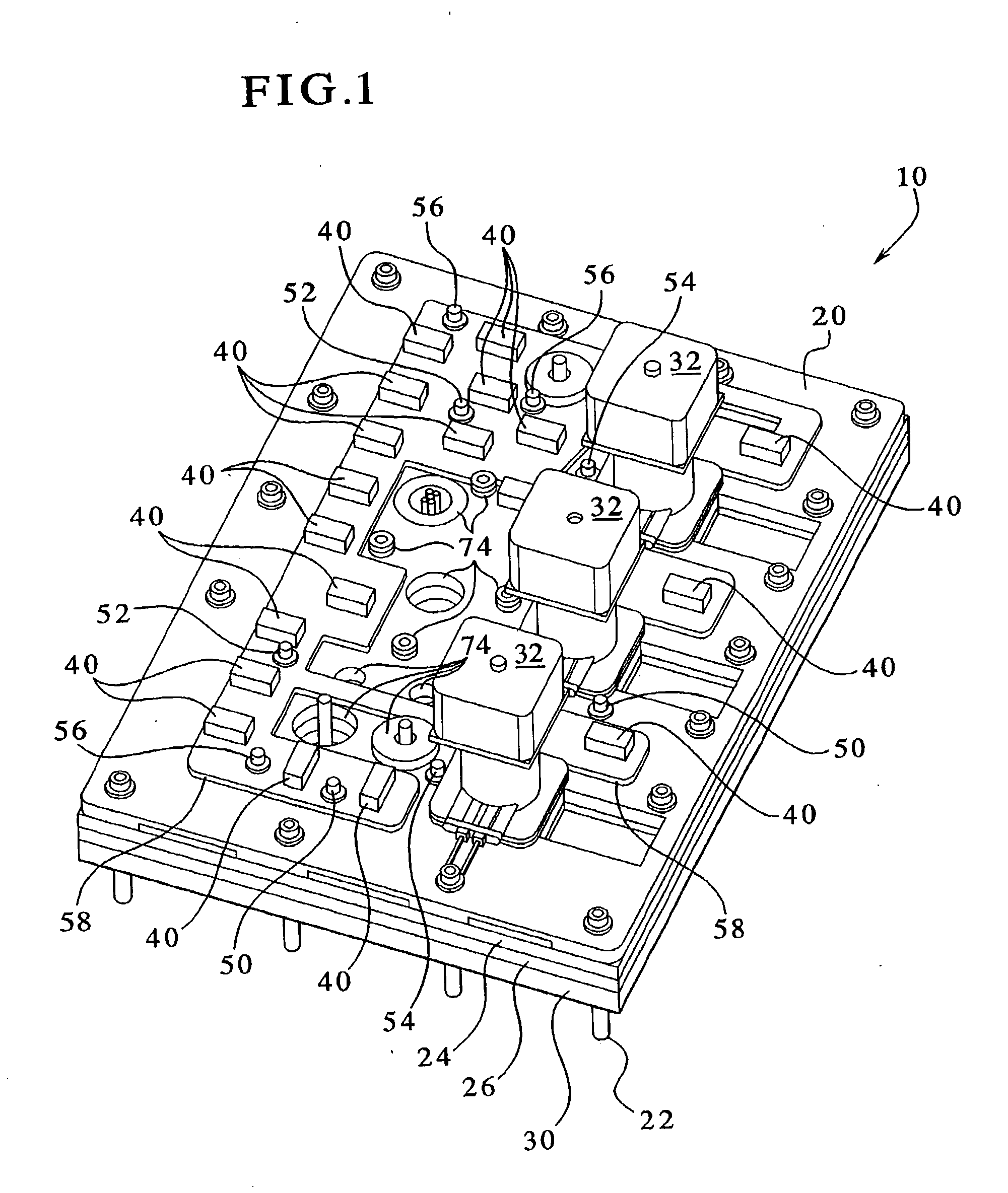

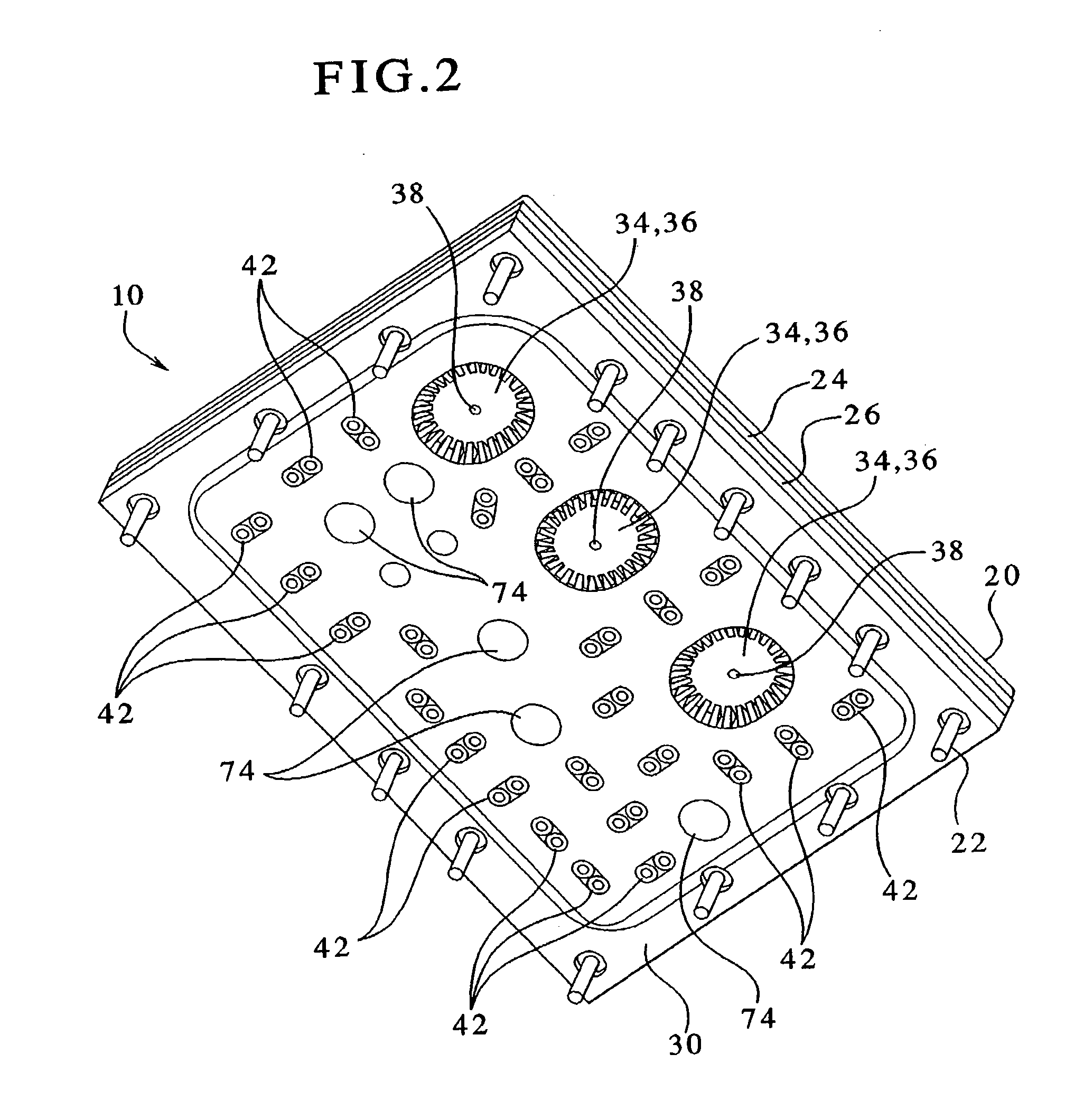

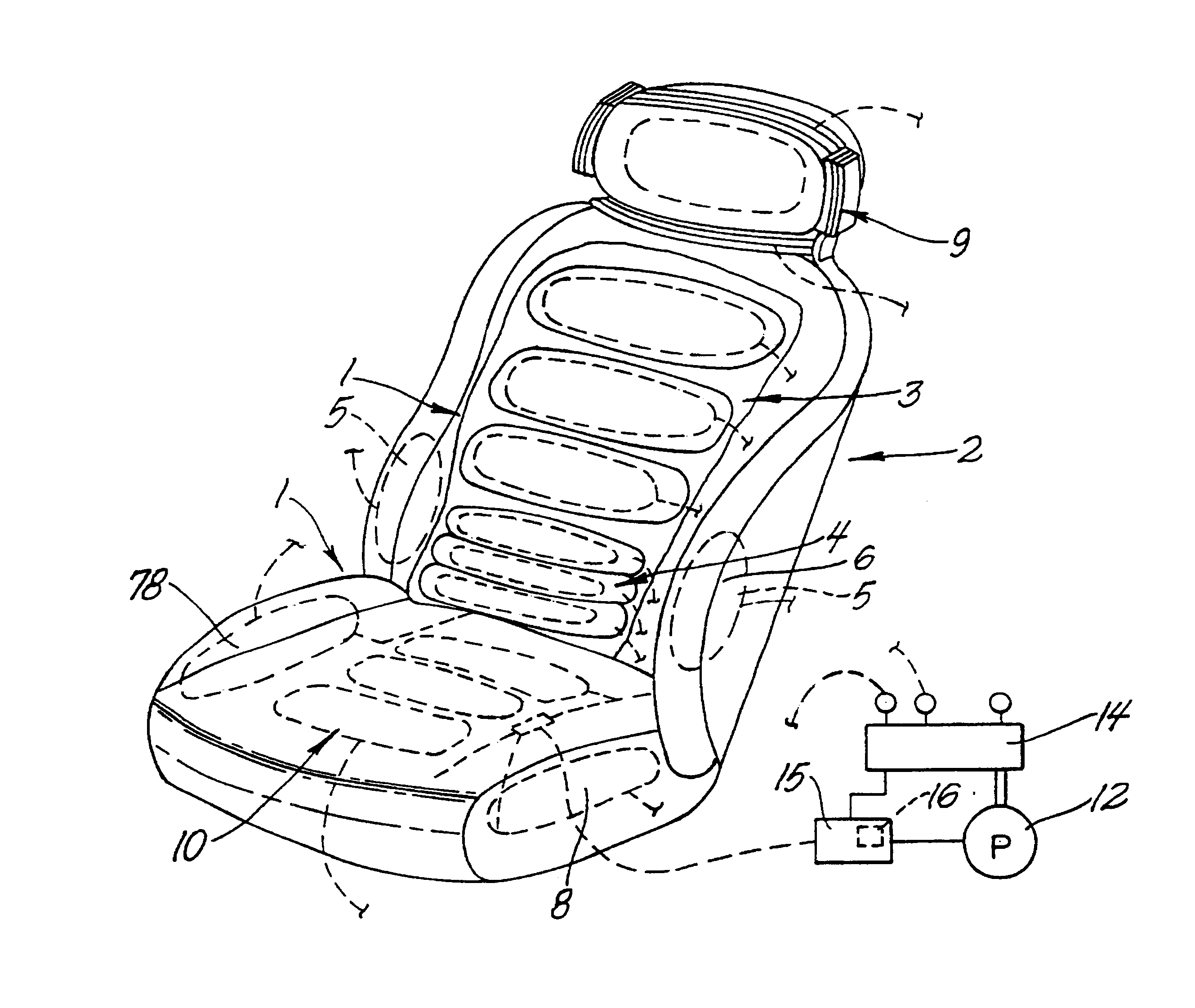

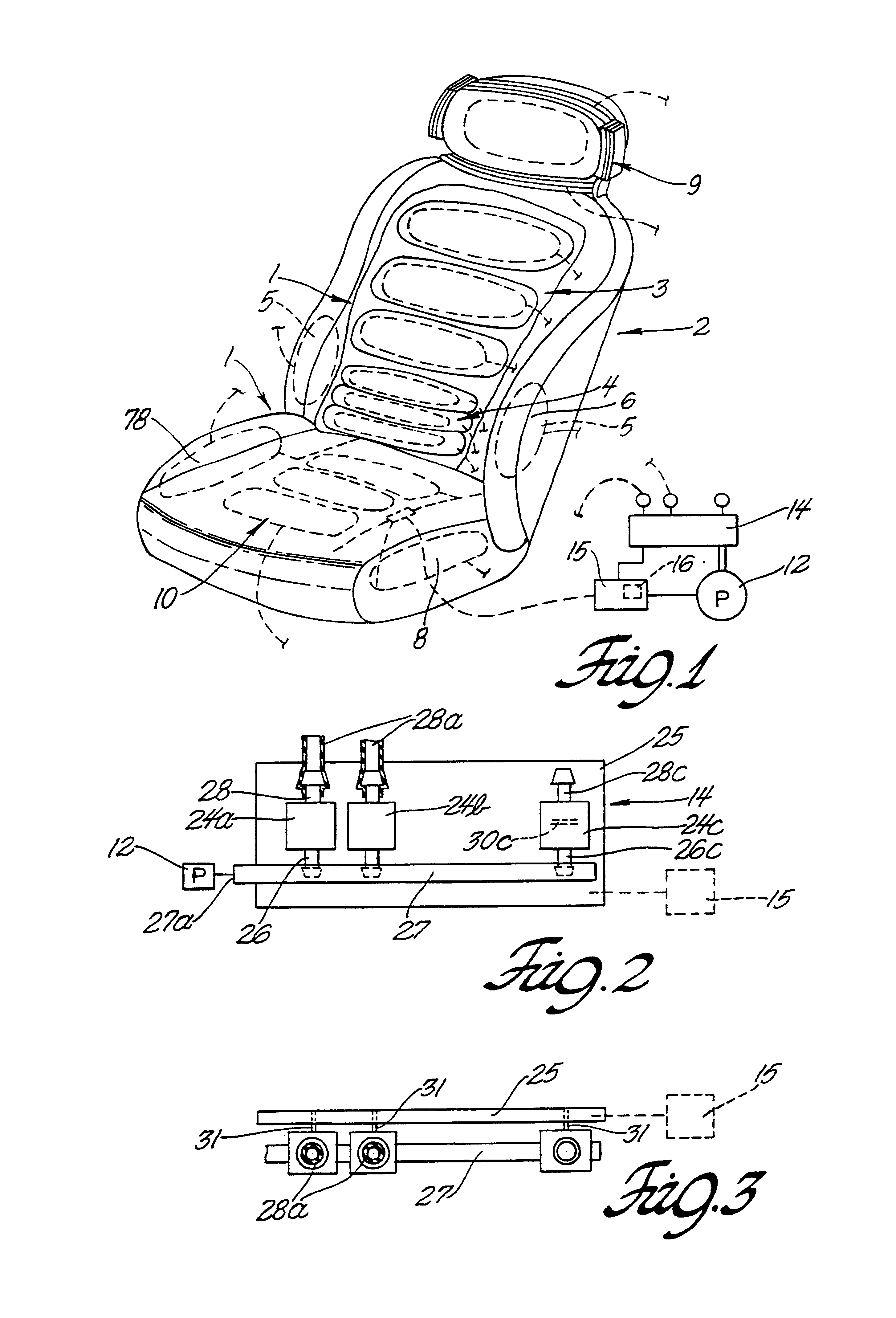

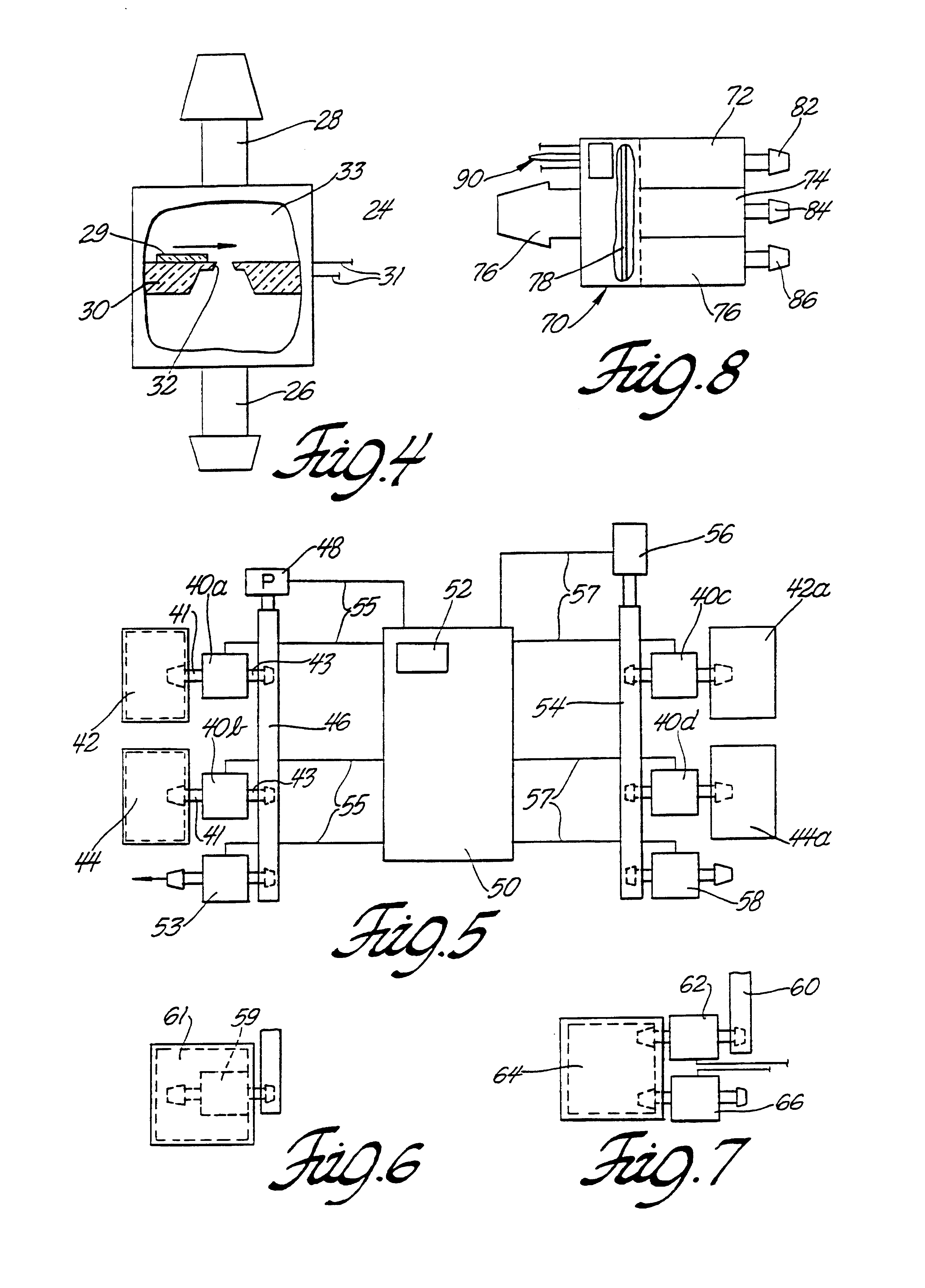

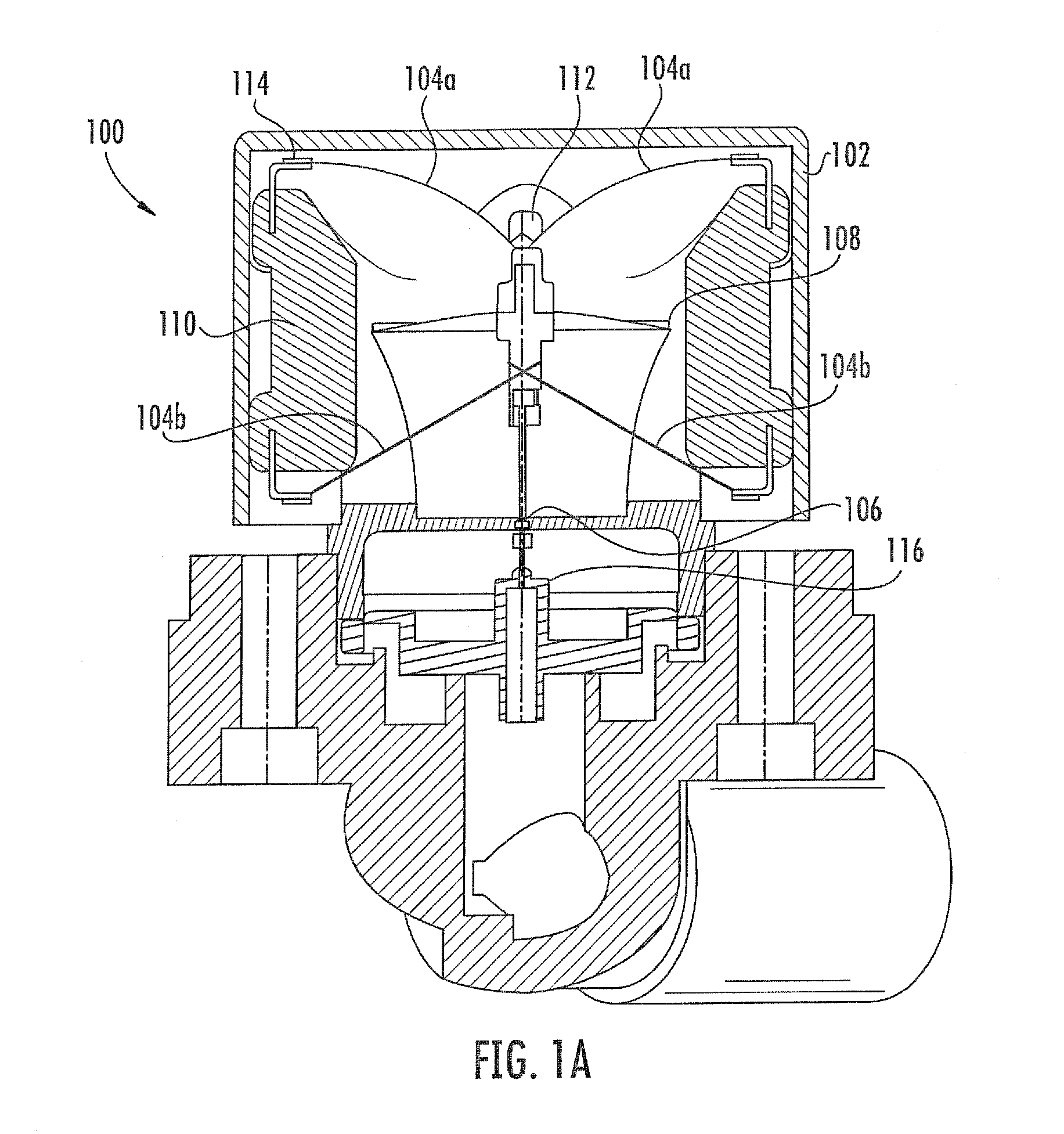

Microvalve controller for pneumatically contoured support

A pneumatic support system and controller combination including pressurizable expandable chambers (1); a source of pressure and an exhaust characterized by: a unitary manifold assembly (14) including a circuit board (25); a manifold (27) and one or more microvalves (24) having a silicon based valve actuator responsive to a signal for controlling flow from said manifold with respect to one or more expandable chambers.

Owner:KONGSBERG AUTOMOTIVE SP ZOO

Drink supply canister for beverage dispensing apparatus

InactiveUS6857541B1Reliable consistent controlEasy to controlLighting and heating apparatusLiquid flow controllersValve actuatorEngineering

Owner:BEVERAGE WORKS

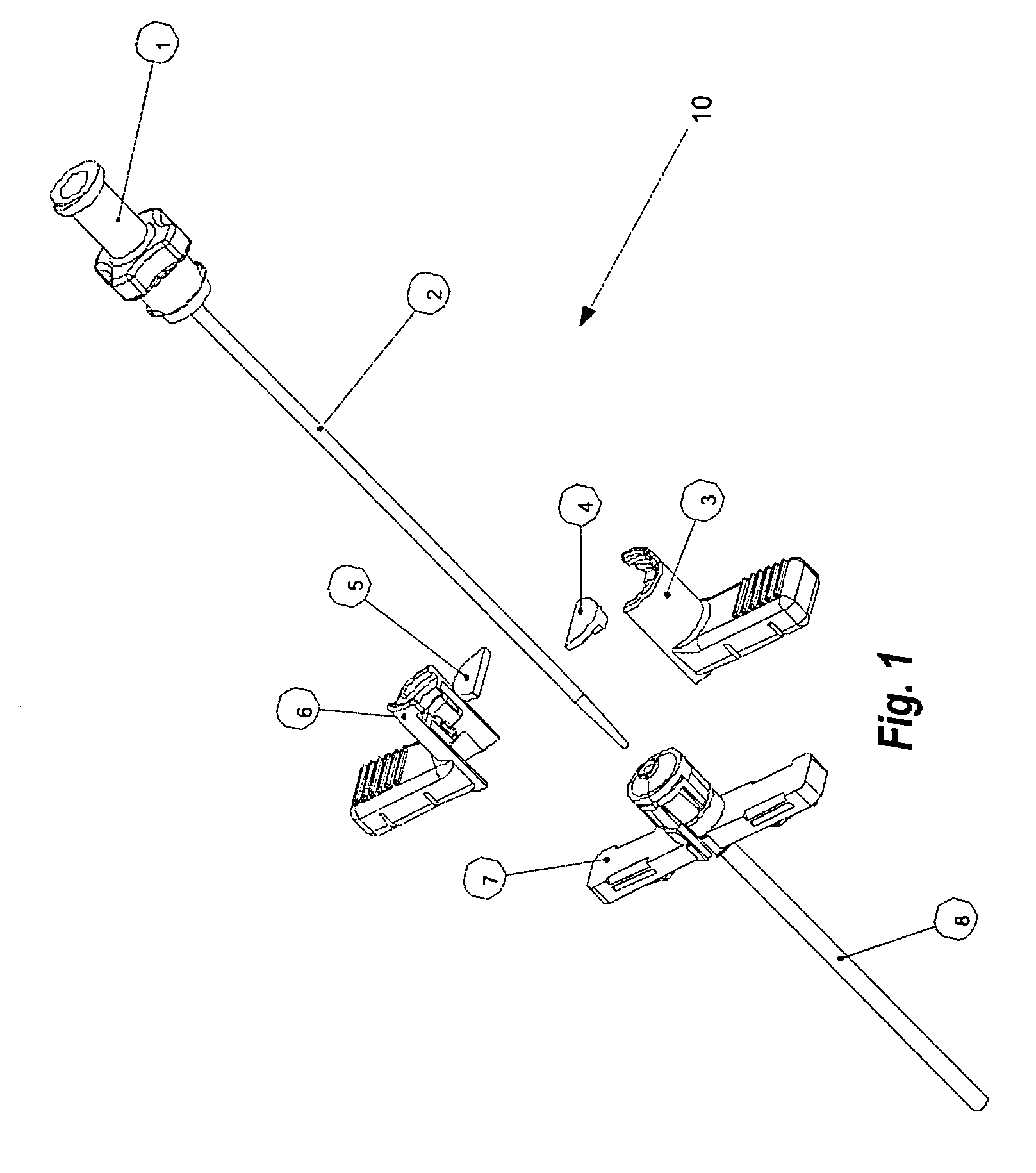

Reduced friction catheter introducer and method of manufacturing and using the same

ActiveUS20090177163A1Reduced and eliminated frictional forceGuide needlesInfusion syringesValve actuatorEngineering

Tear-away sheath introducers for catheters, methods for making such introducers, and methods for using such introducers are described. The sheath introducers contain movable valves that are encapsulated in a movable housing that allows the valve to move along the axis of the introducer. As the movable valve and housing travel along the axis, a portion of the hub protrudes past the valve and is exposed. As well, the sheath introducers can also contain a stationary valve and housing that can be opened to expose a portion of the hub when a conduit penetrates the stationary valve. The conduit can include a one-way valve actuator that can penetrate and open the valve, yet remain attached to a portion of the introducer when the introducer is split for removal from a patient. In both instances, the protruding portion of the hub contains a friction-free pathway for a catheter into the sheath introducer.

Owner:CR BARD INC

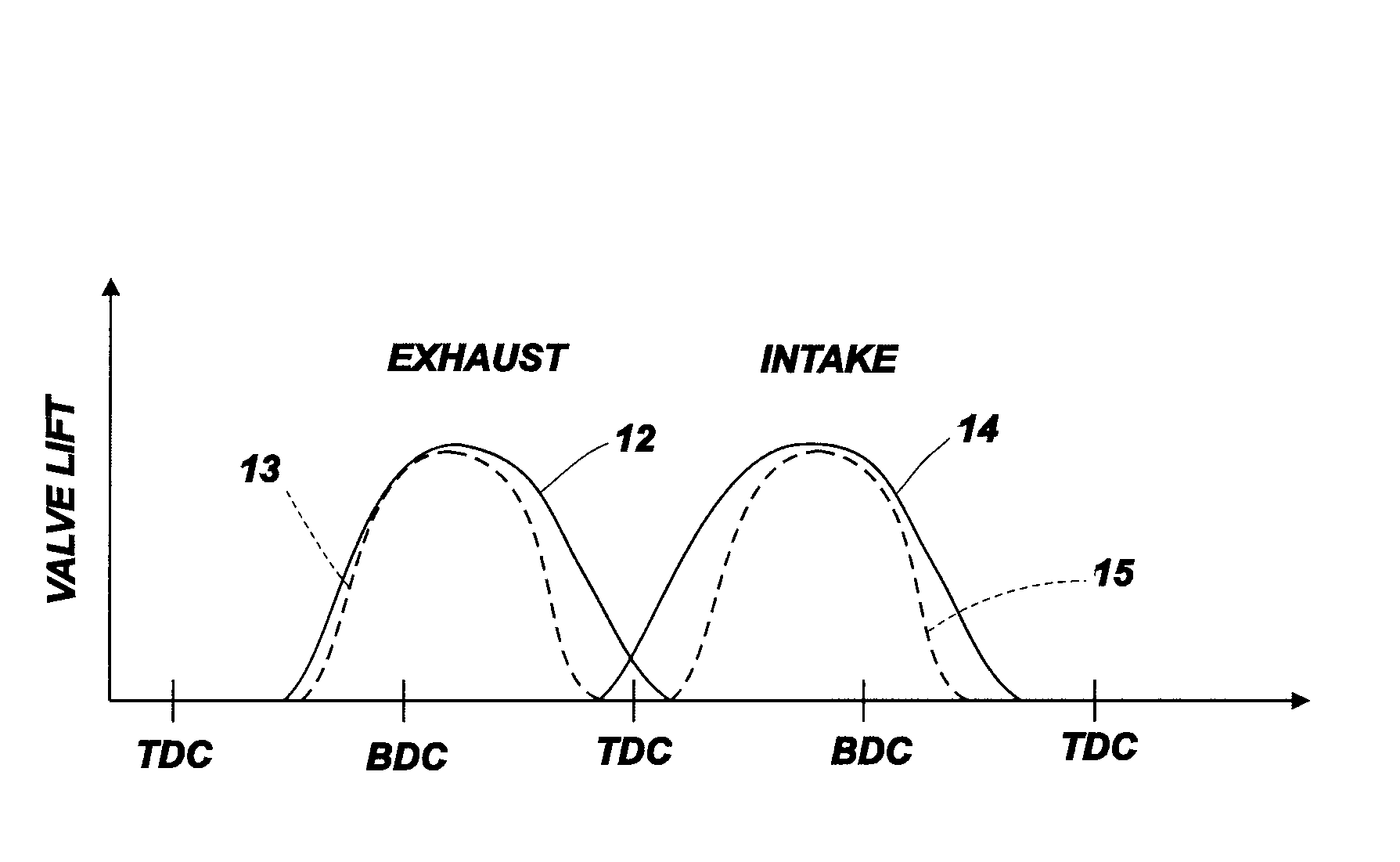

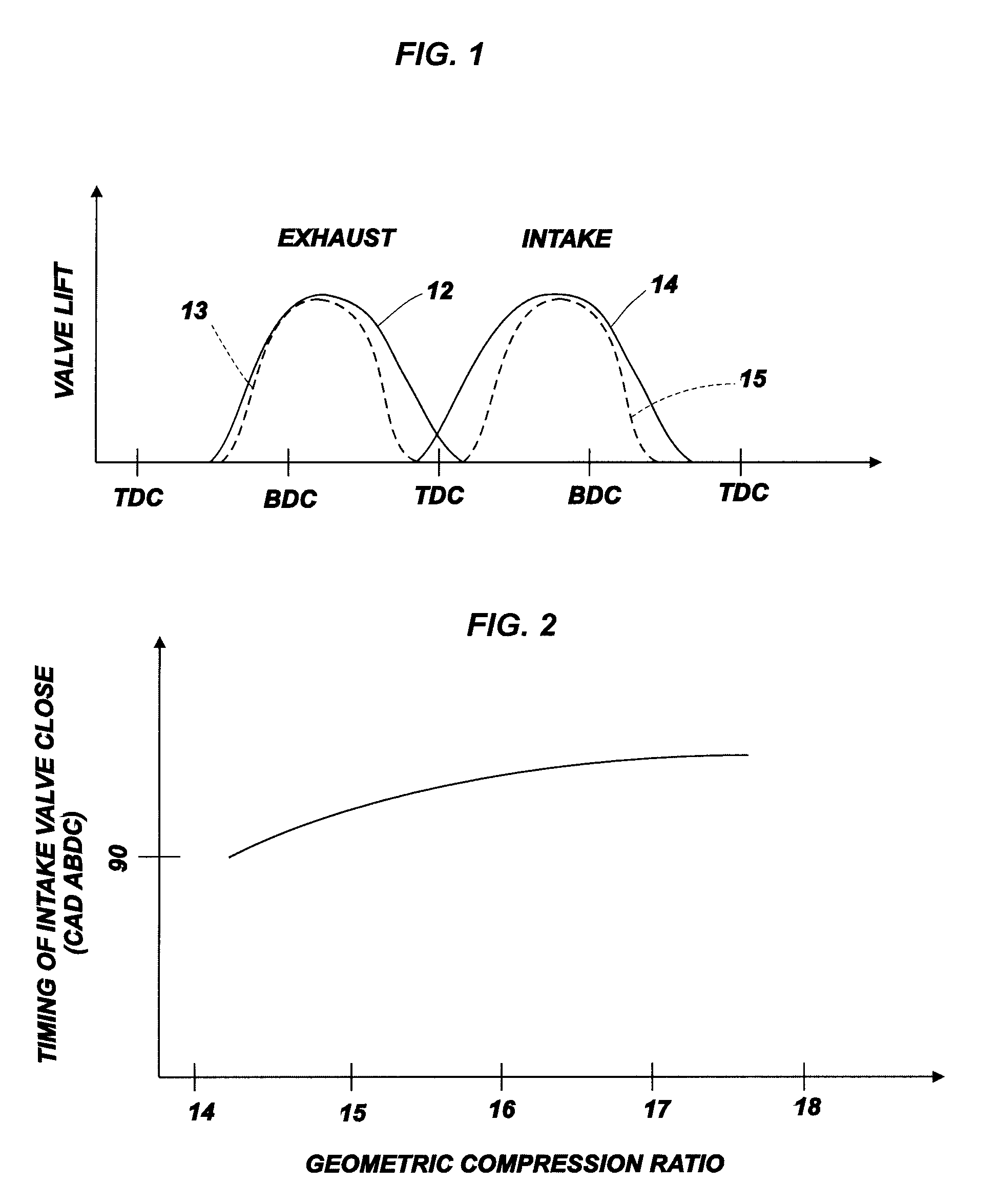

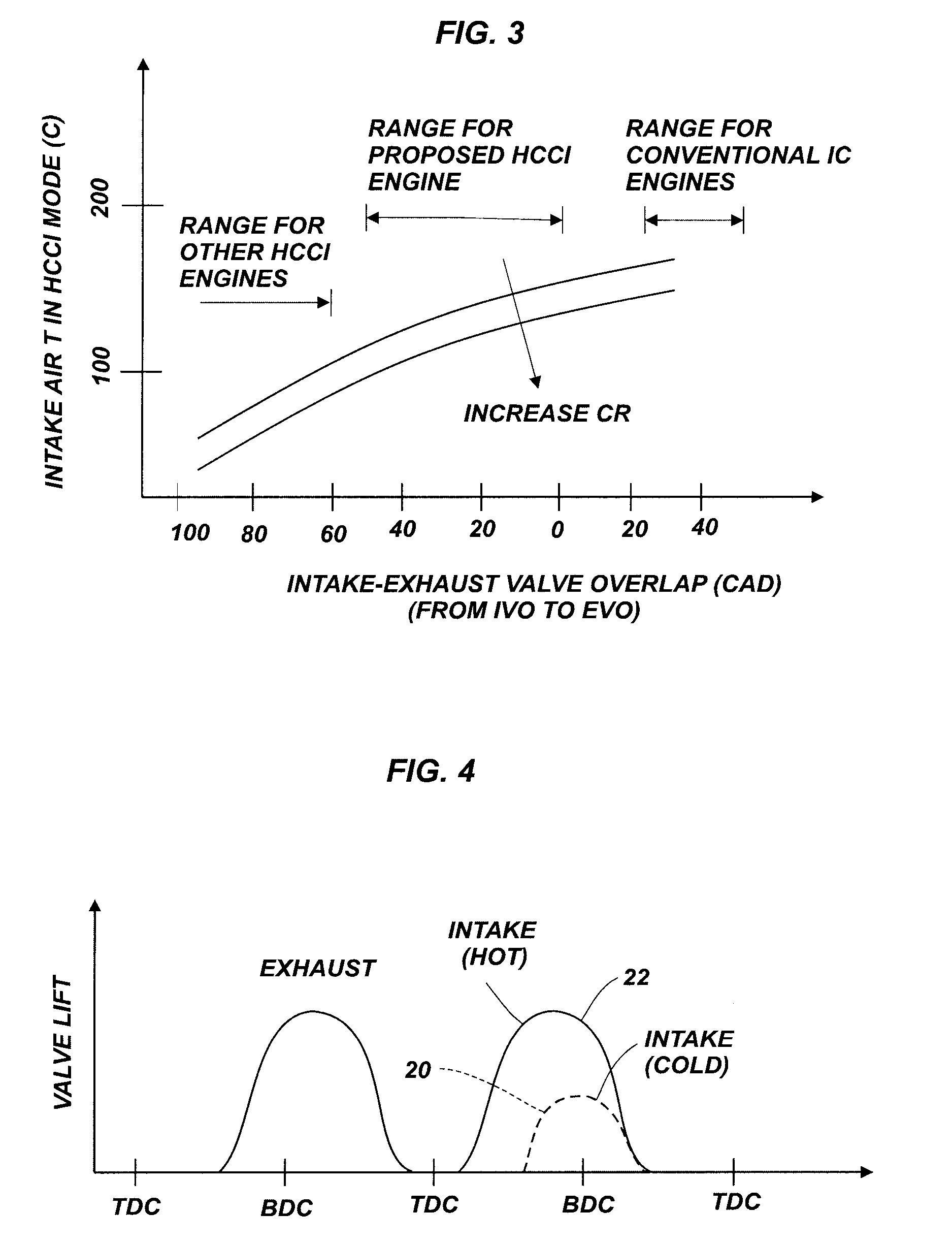

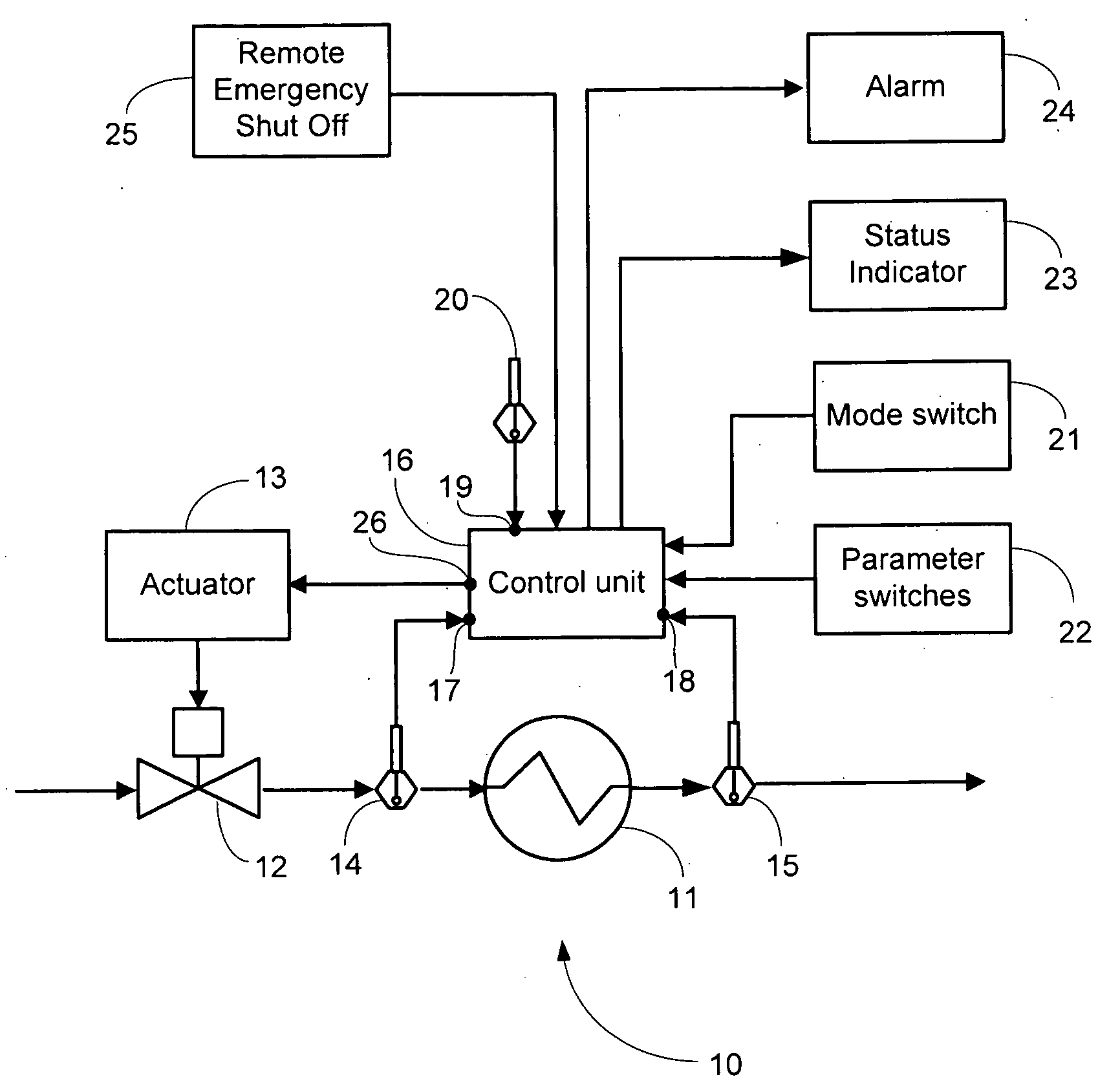

Method and apparatus for controlling operation of dual mode hcci engines

InactiveUS20050183693A1Overcome deficienciesOvercomes drawbackValve arrangementsElectrical controlTemperature controlExhaust valve

An intake and exhaust system for a dual mode HCCI engine, which provides superior intake temperature control and homogeneity for engine operation in SI and HCCI modes, as well as during transition between SI and HCCI modes and vice-versa. The system includes adjusted intake cam movement event lengths for intake valve operation at specified modes of operation. The system further includes at least one cam profile switching device operatively connected to intake and exhaust valves in an engine for controlling event length, maximum lift, and valve opening / closing timings for the intake and exhaust valves. The system yet further includes a bifurcated intake system and camless valve actuators for controlling intake valves for facilitating operation in SI or HCCI modes, as well as transition between SI and HCCI modes and vice-versa.

Owner:FORD GLOBAL TECH LLC

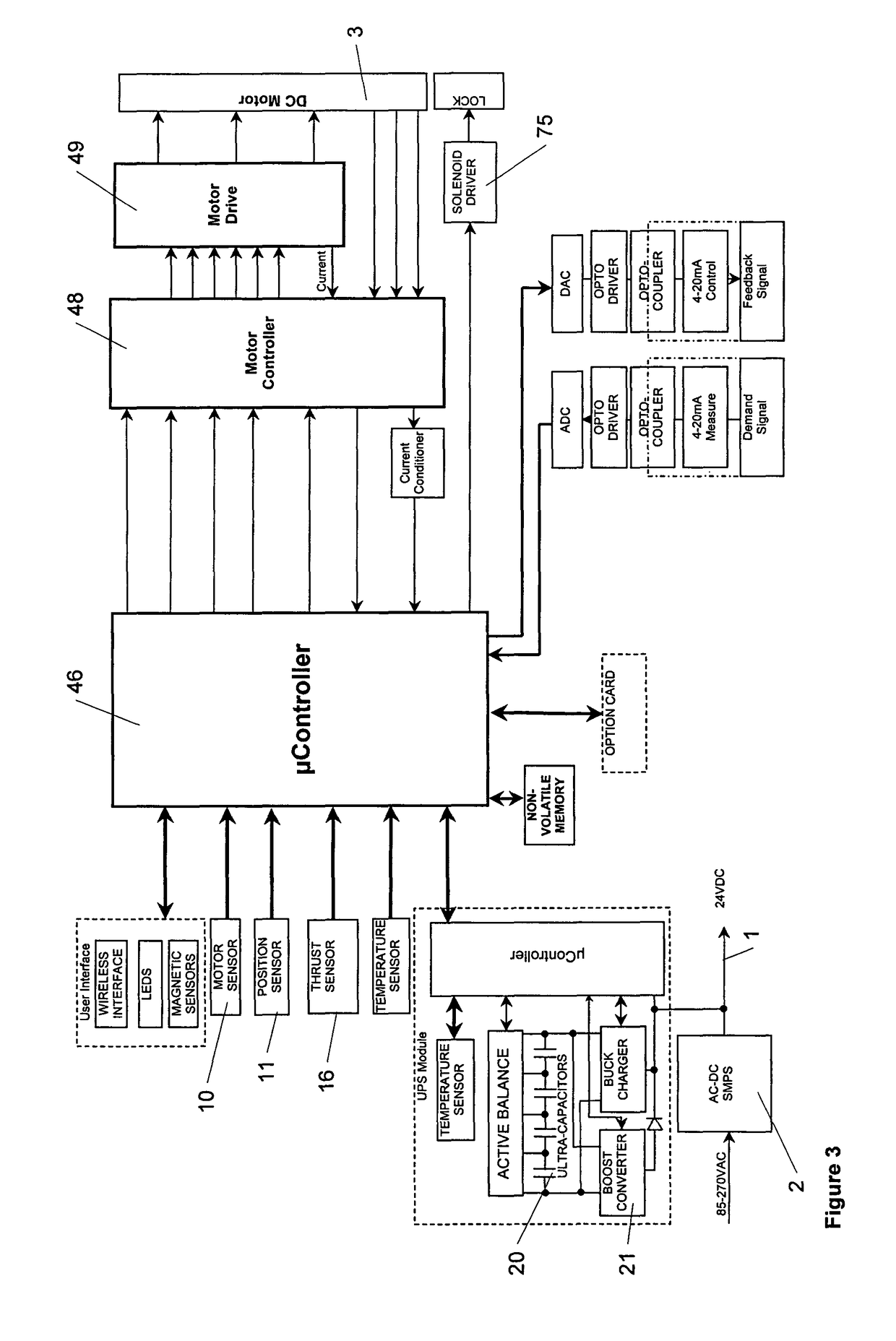

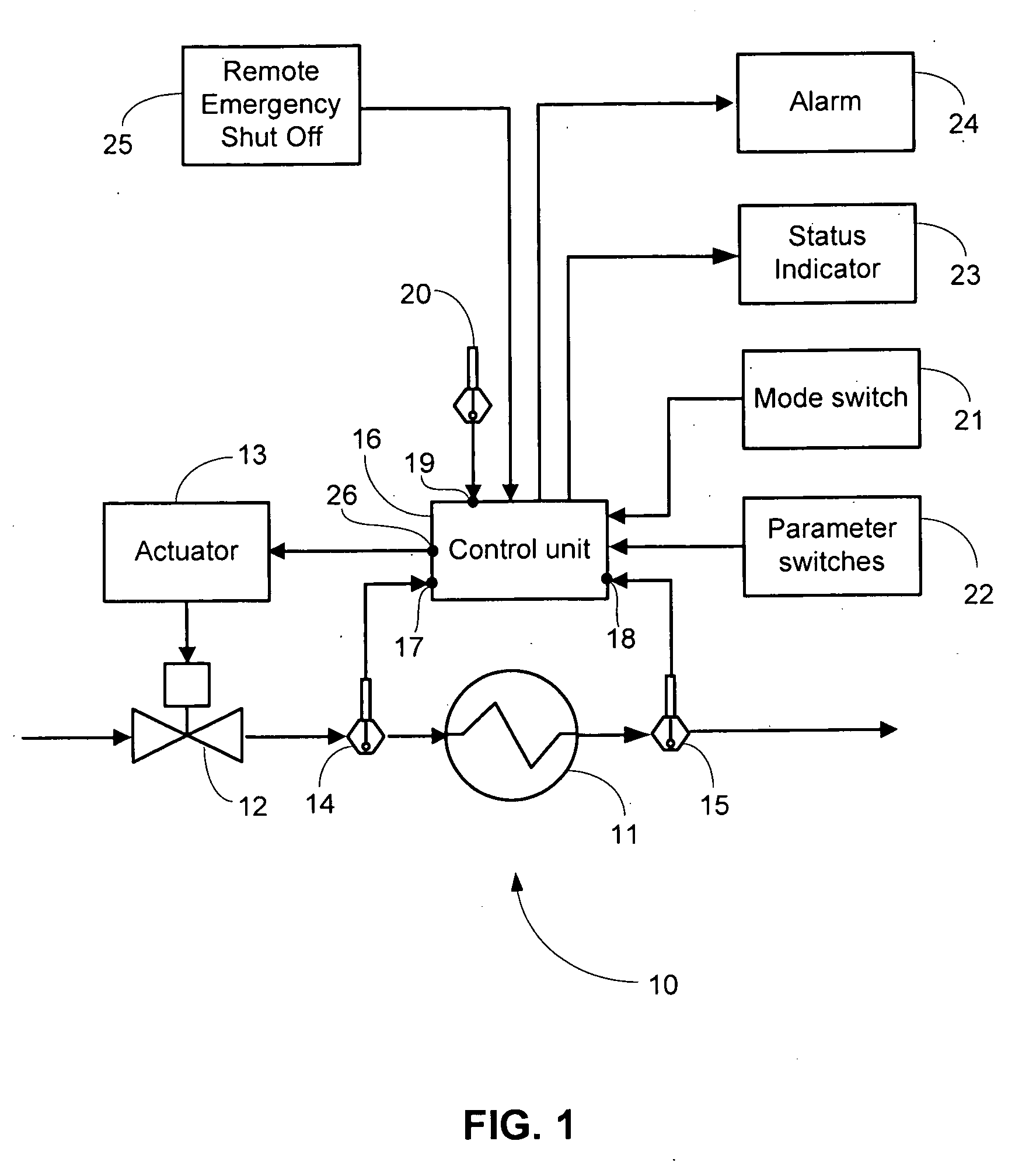

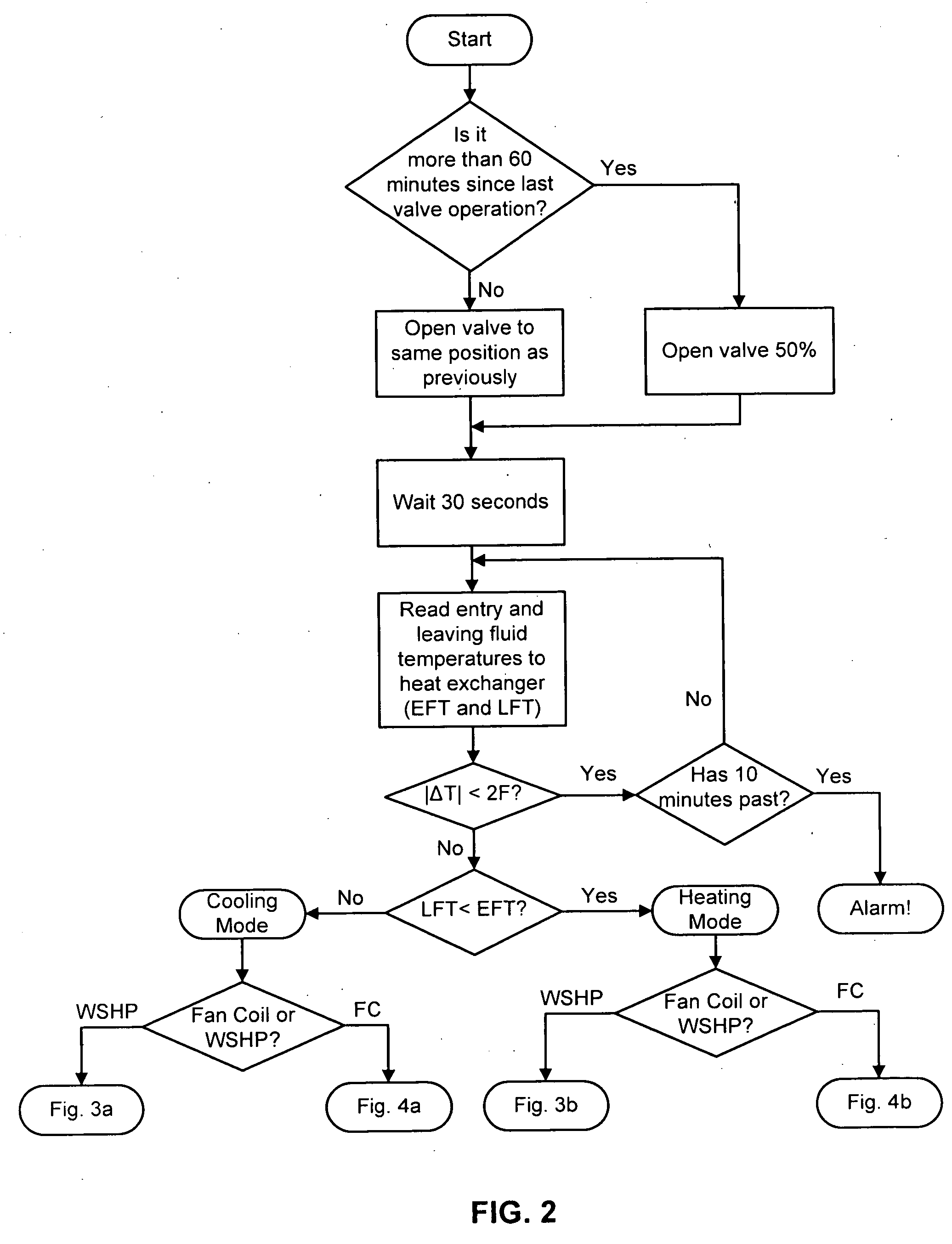

Standalone flow rate controller for controlling flow rate of cooling or heating fluid through a heat exchanger

InactiveUS20090314484A1Improve performanceSave energyTemperatue controlControl flowPlate heat exchanger

A standalone flow rate controller for controlling flow rate of cooling or heating fluid through a heat exchanger by providing a control signal to a flow valve actuator so as to open or close a flow valve in response thereto. A first temperature sensor measures an entry temperature of the cooling or heating fluid flowing into the heat exchanger and a second temperature sensor measures an exit temperature of the cooling or heating fluid flowing out of the heat exchanger. A control unit is responsive to a temperature difference between the entry temperature and the exit temperature for adjusting the control signal so as maintain the temperature difference substantially constant.

Owner:AKZ TECH

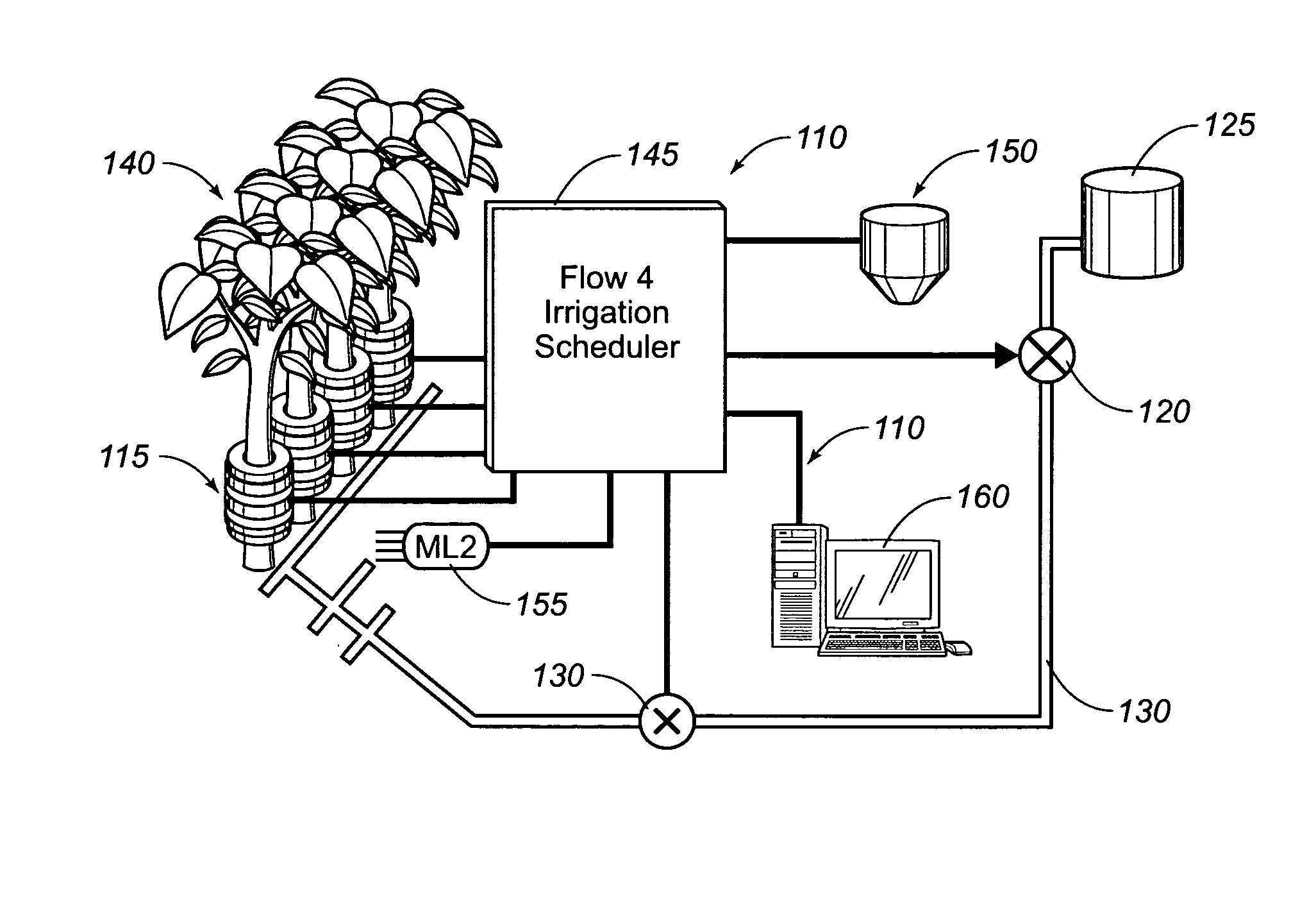

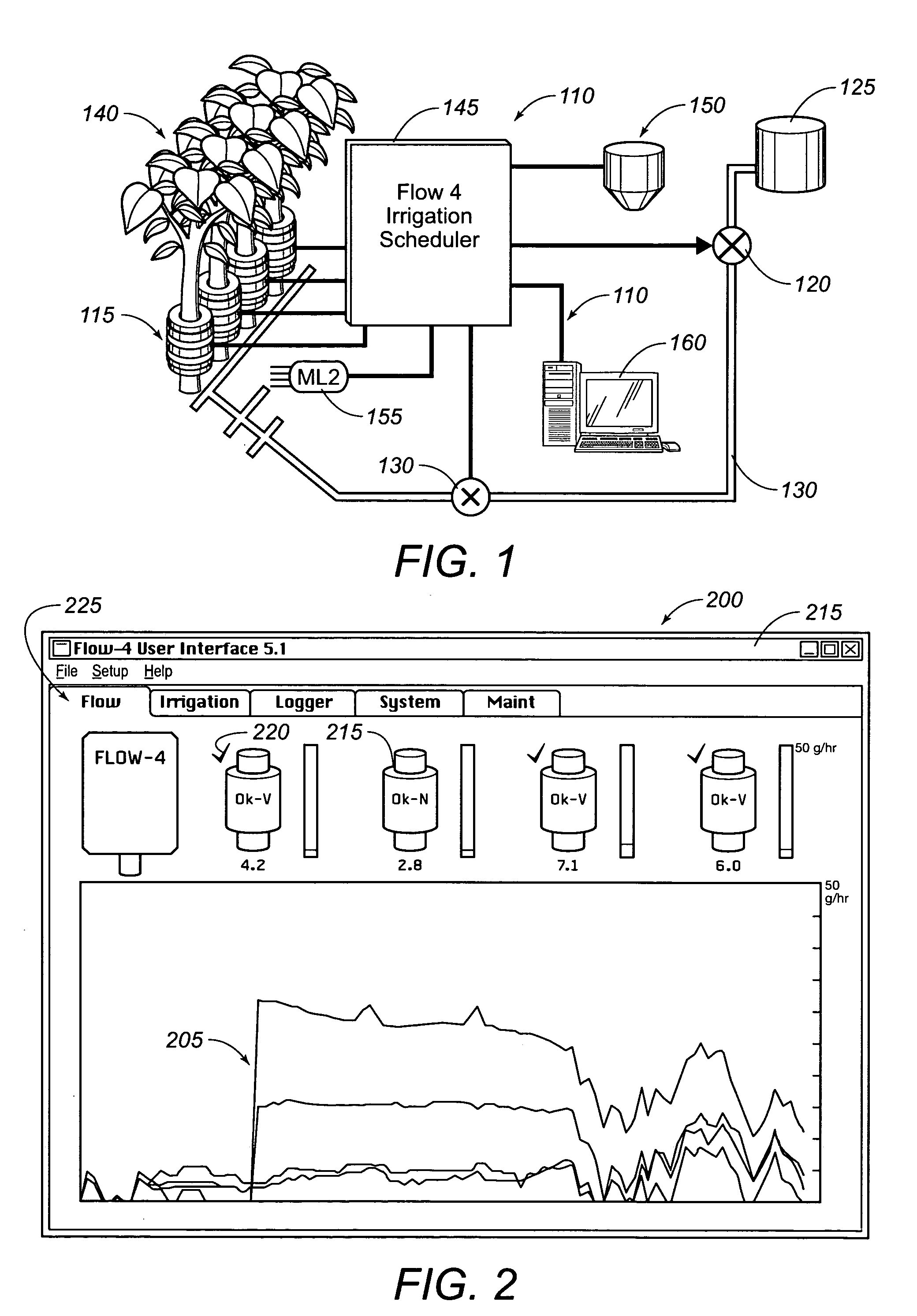

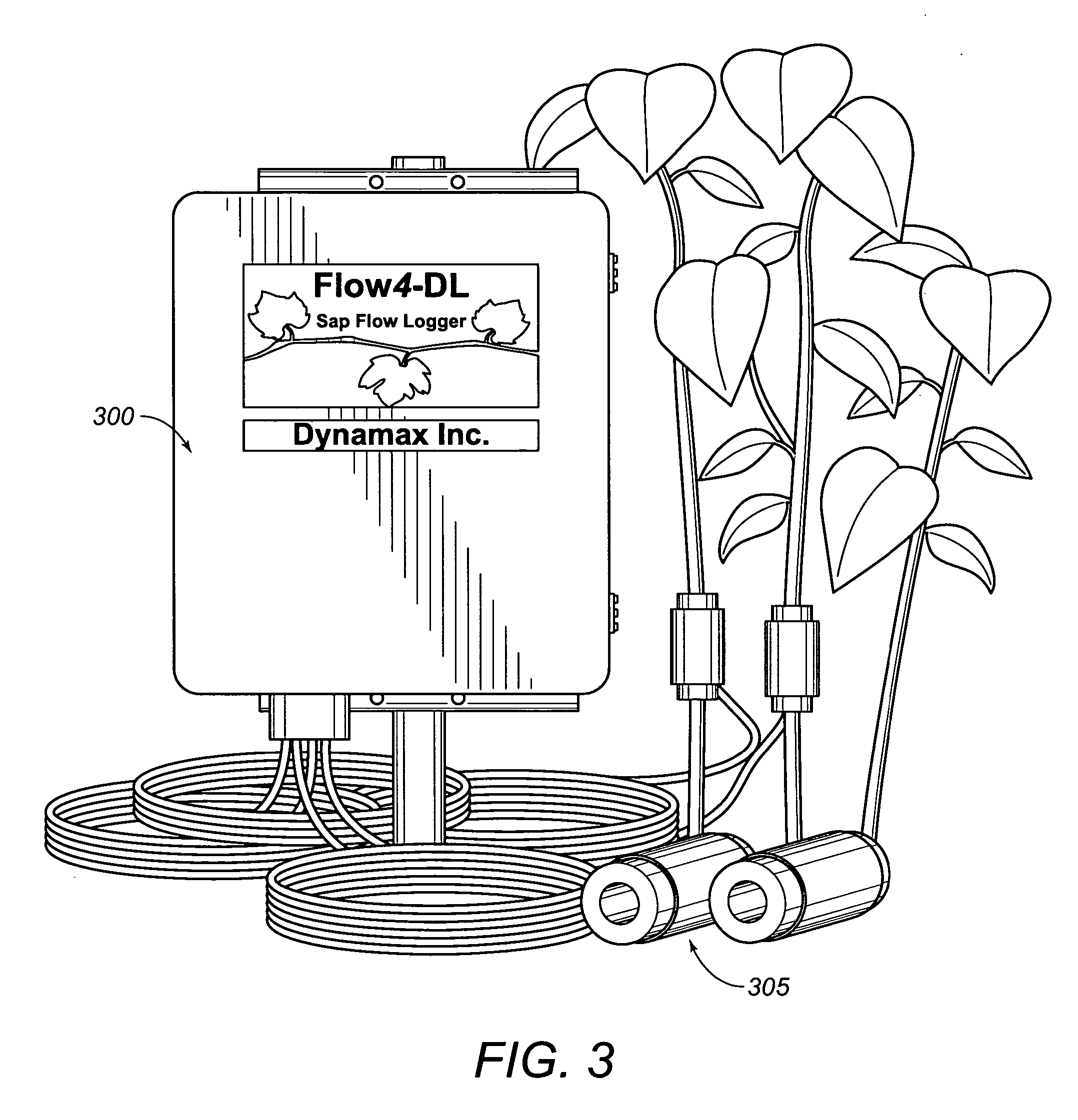

Integrated sap flow monitoring, data logging, automatic irrigation control scheduling system

ActiveUS7280892B2Accurate measurementReduce errorsSelf-acting watering devicesWatering devicesClosed loopUser interface

An integrated system for monitoring sap flow and simultaneously performing data-logging and automatically scheduling irrigation in a field; comprising a plurality of in situ sap flow gauges that perform its comprehensive computer-controlled tasks in the field being irrigated. This plurality of sap flow gauge can be detached from and reattached to a like plurality of plant stems as appropriate. A scaling mechanism is used to calculate crop water usage in variously-sized fields. An integrated portable computer apparatus is programmed to perform a plurality of actions including sap flow monitoring via a controller and data-logger; data-logging and automatic irrigation scheduling; a plurality of sap flow gauges; an automatic rain gage; a water meter; an irrigation valve actuator; and any auxiliary and independent weather or soil monitoring sensors. The system is connected to a PC, mounted in a weatherproof enclosure, and powered by rechargeable battery, solar panel, or AC mains power with battery backup. Computerized monitoring and control procedures are initialized via a custom-developed graphical user interface. At any predetermined interval set by a user, the depth or volume of water required to balance transpiration losses is calculated and irrigation is then automatically triggered. The system affords closed loop control with water flow from soil through plant to atmosphere and from irrigation—and having the benefit of a feedback loop.

Owner:BAVEL MICHAEL VAN

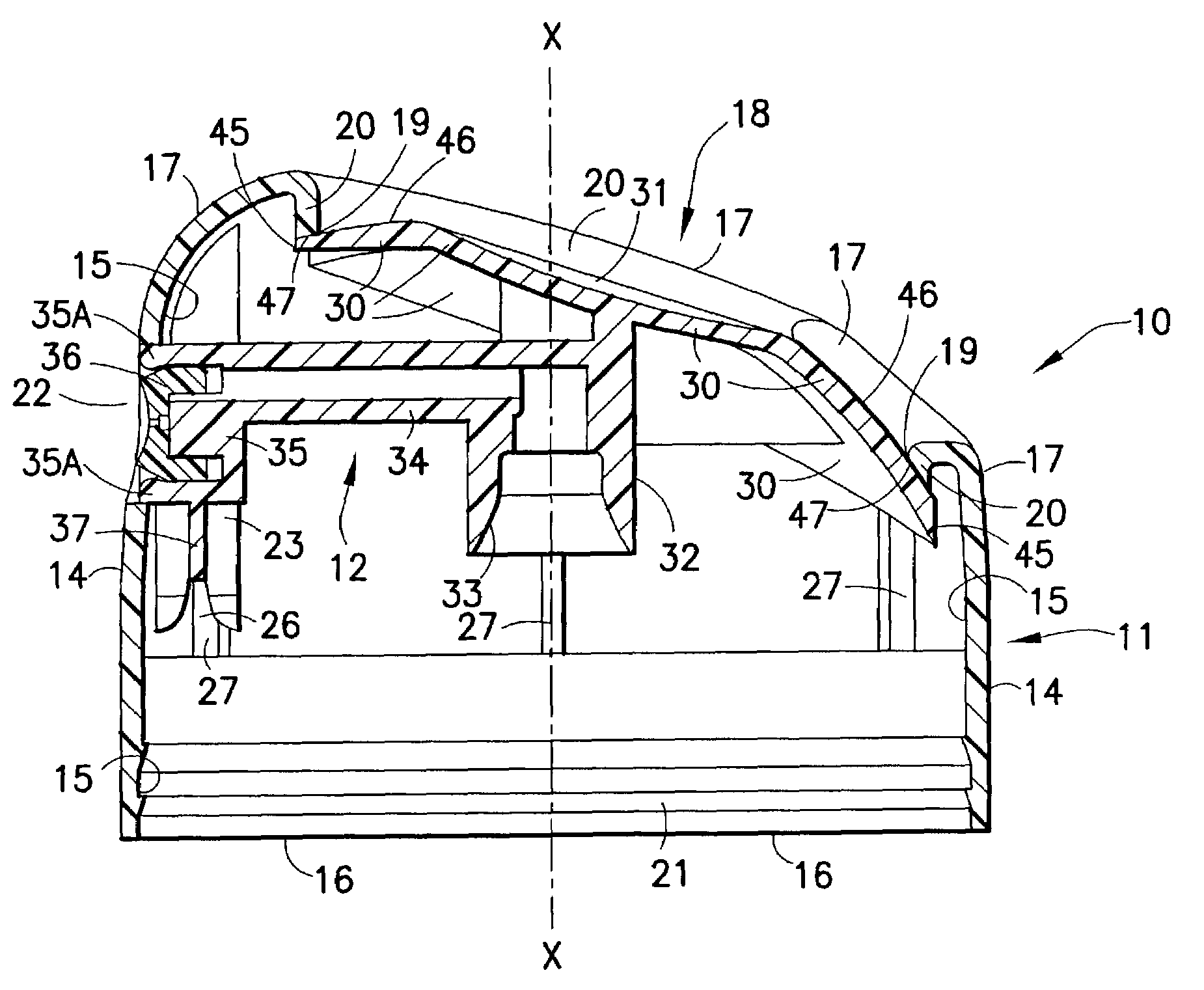

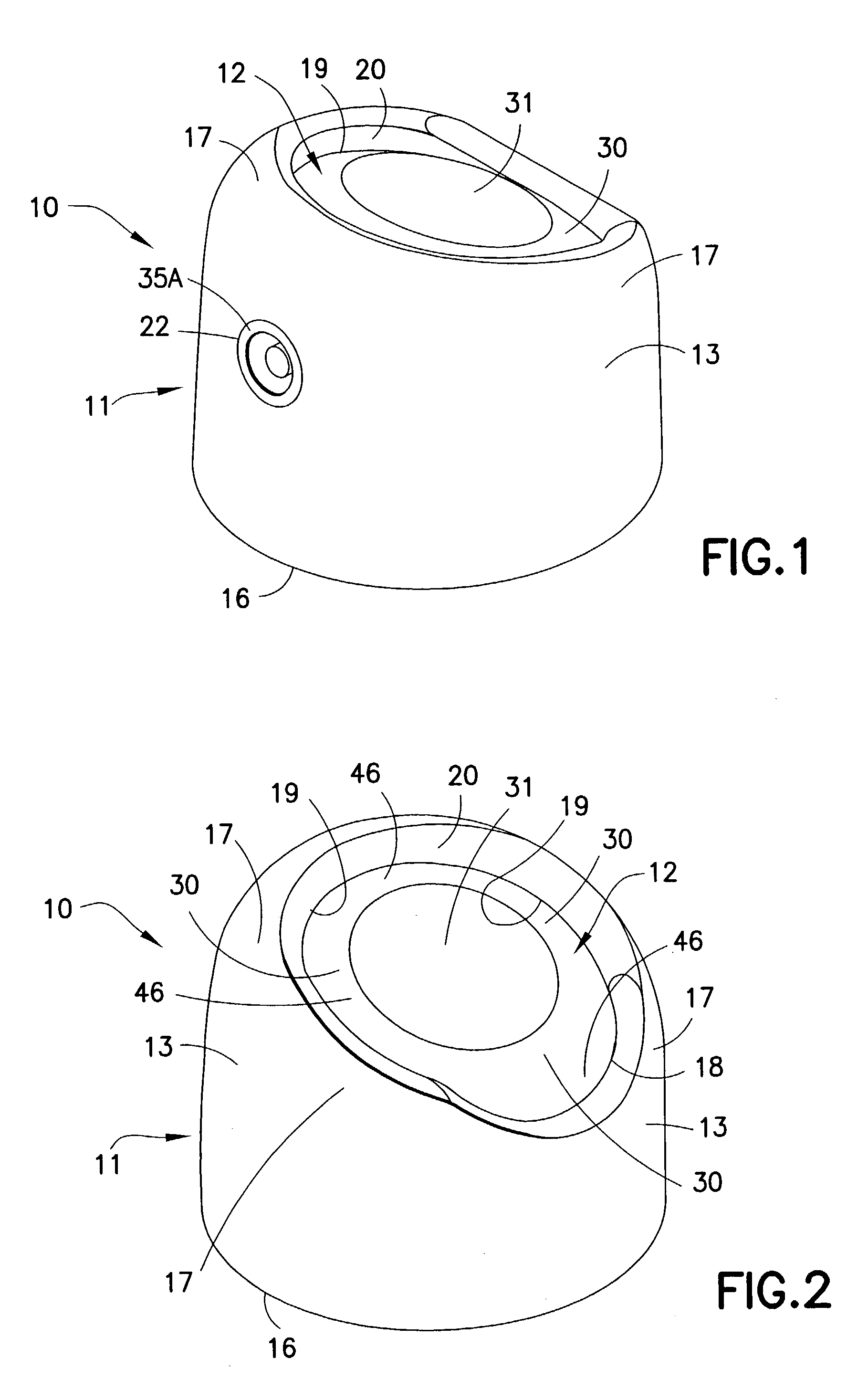

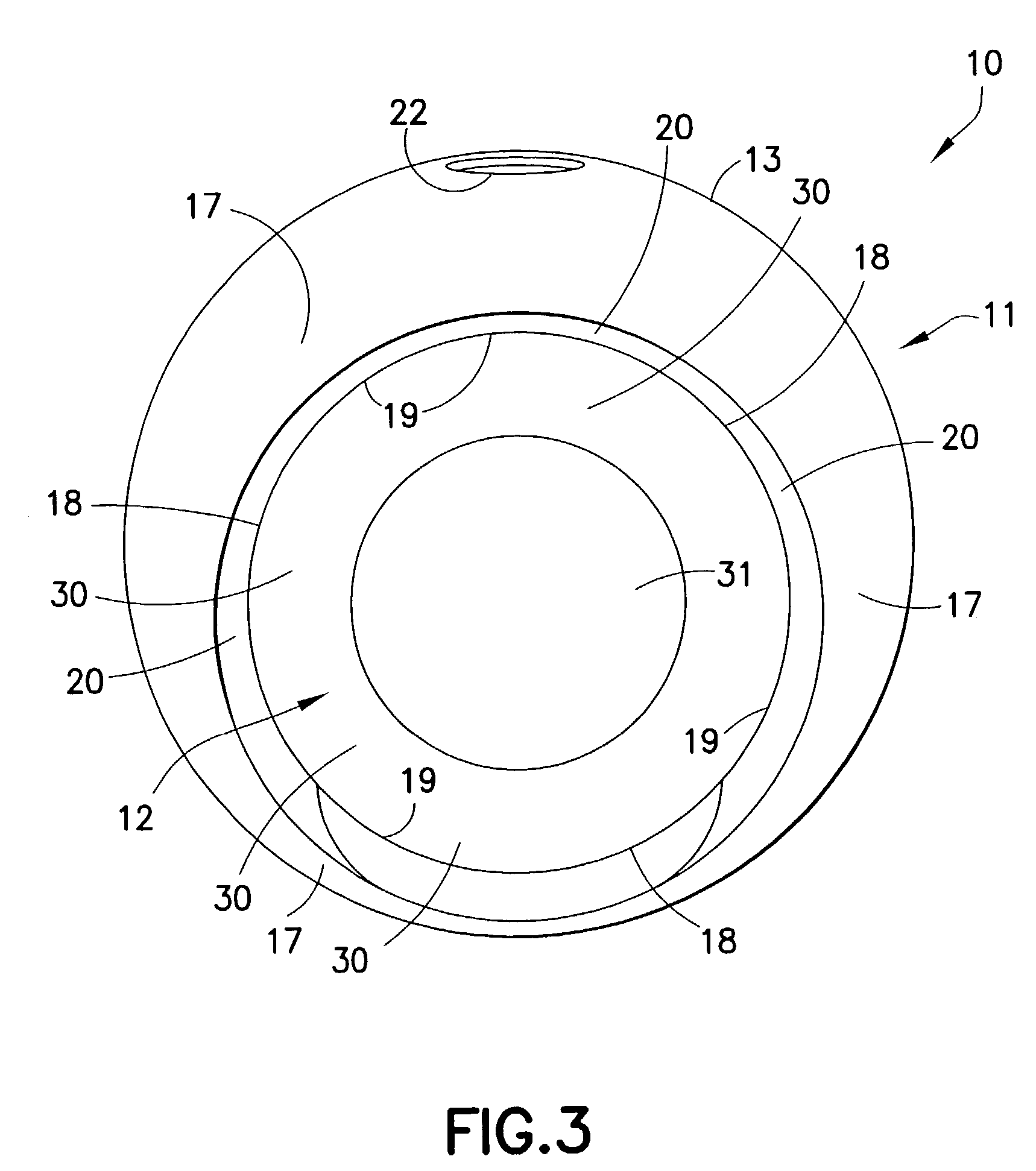

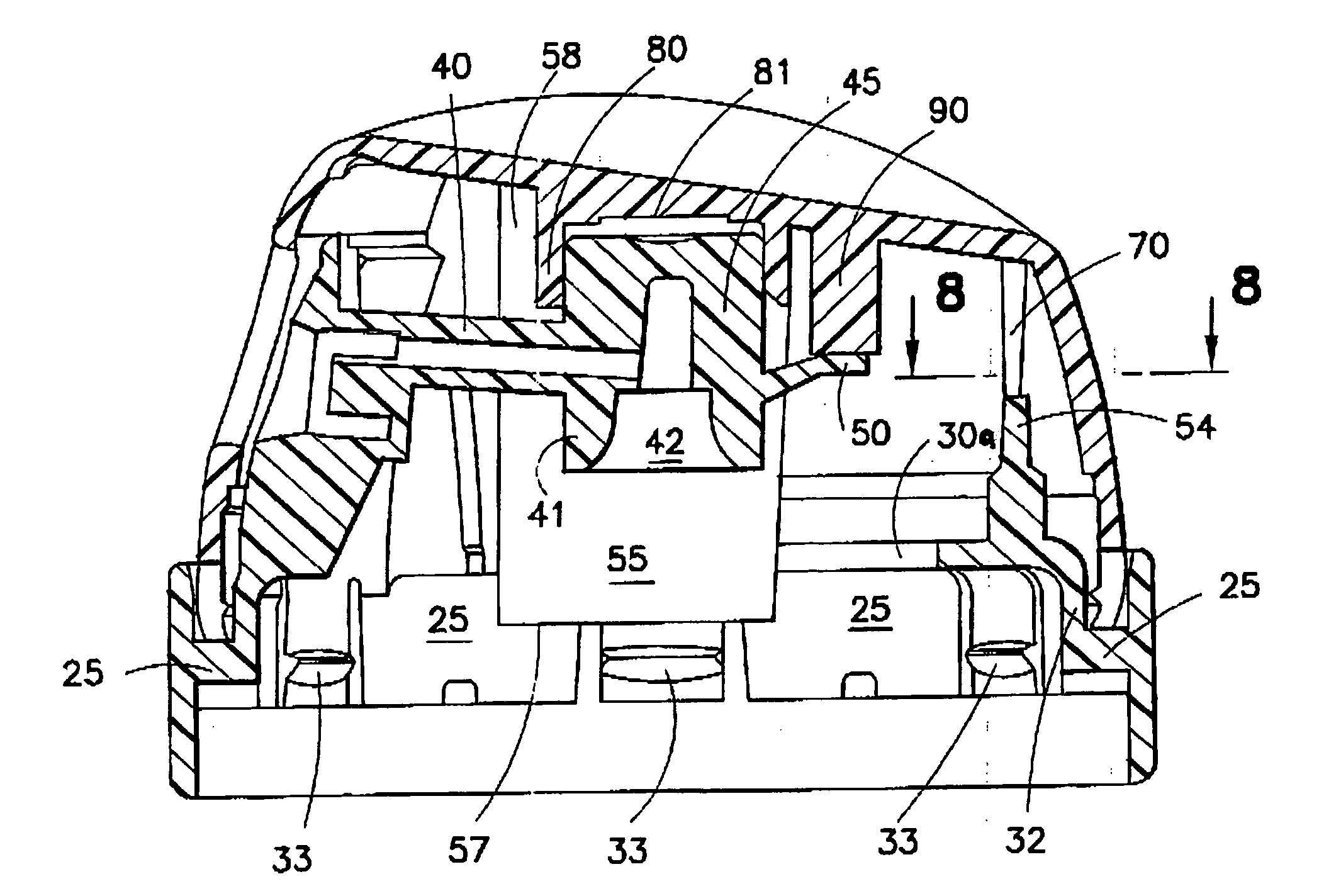

Gapless aerosol valve actuator

InactiveUS7104427B2Strong constructionEasy to assembleClosure using stoppersLiquid transferring devicesValve actuatorEngineering

An aerosol valve actuator with a discrete shell-like enclosure and a discrete, bottom mounted, actuating member with finger actuating pad. An opening with a perimeter, in the upper portion of the enclosure, is closed in non-actuated position by the finger pad which has a greater perimeter than the opening perimeter. The finger pad has an upper surface with a portion adjacent its perimeter which underlies and contacts the enclosure upper portion directly adjacent its opening leaving no discernable gap. The finger pad cannot be pushed upwardly through the opening to create a “smiling” effect. The actuating member is connected to the enclosure interior side wall, and has a nozzle outer end snap fit and extending into and filling an enclosure side wall product dispensing opening to prevent spray noise entering the enclosure and being intensified.

Owner:PRECISION VALVE CORP

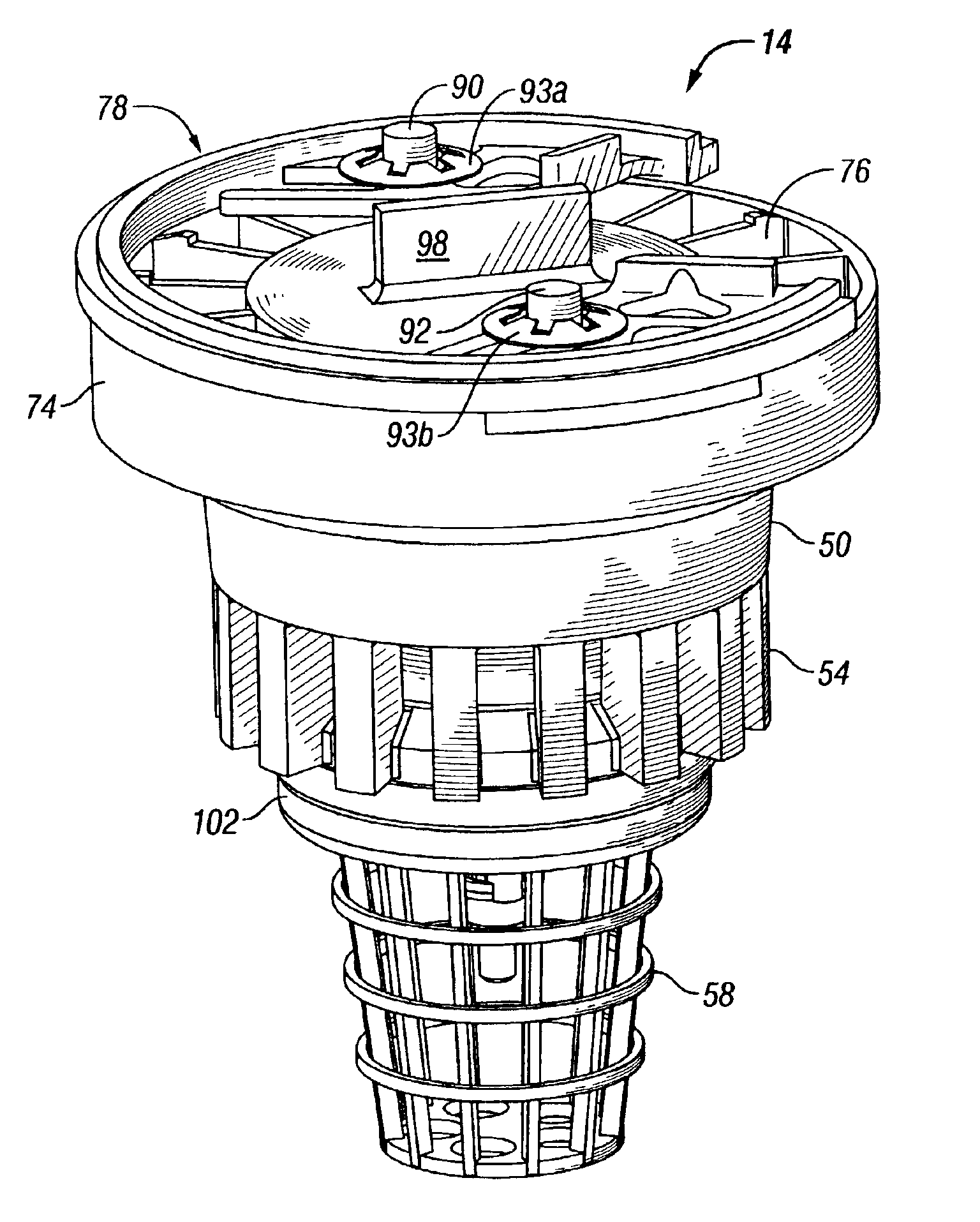

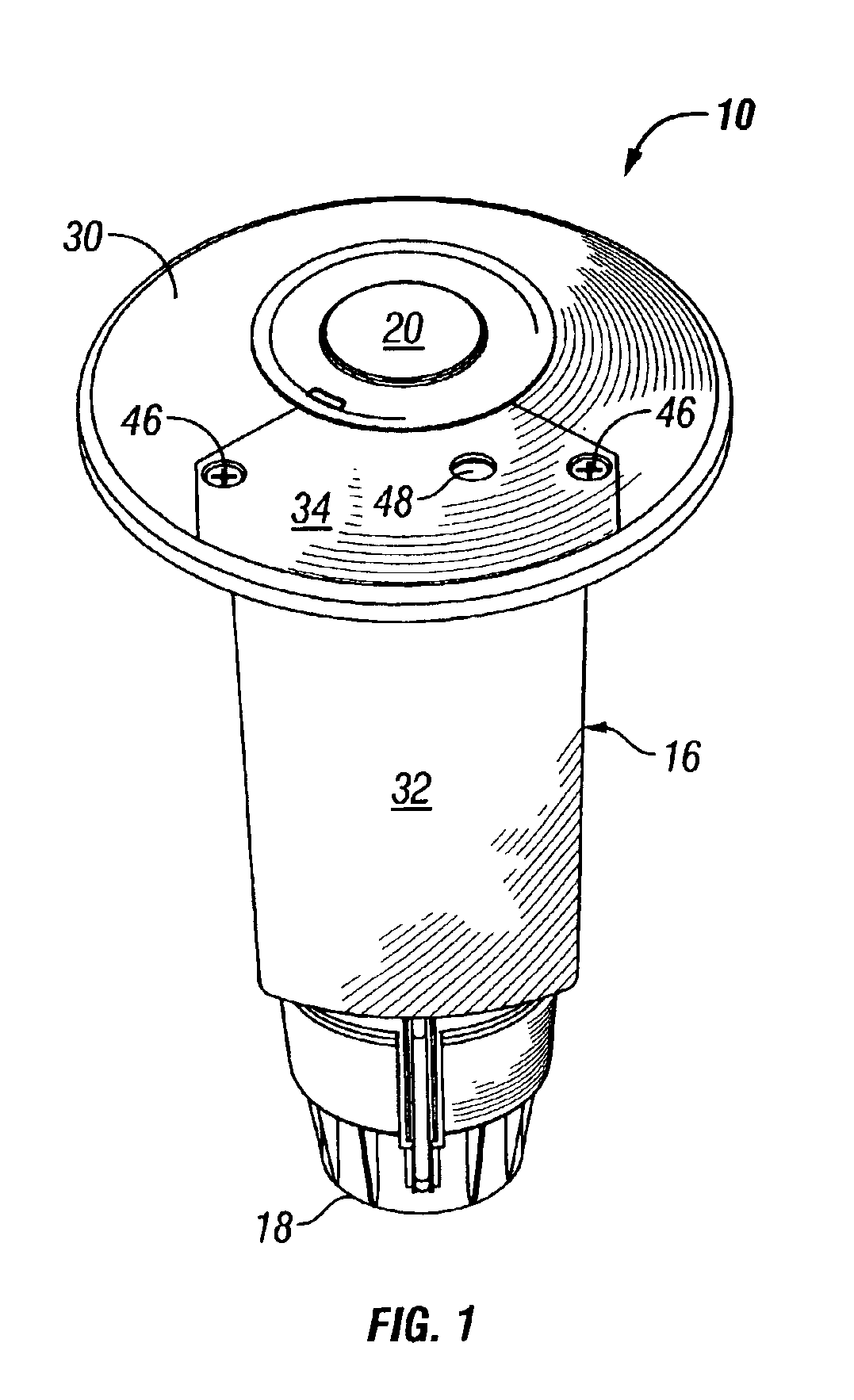

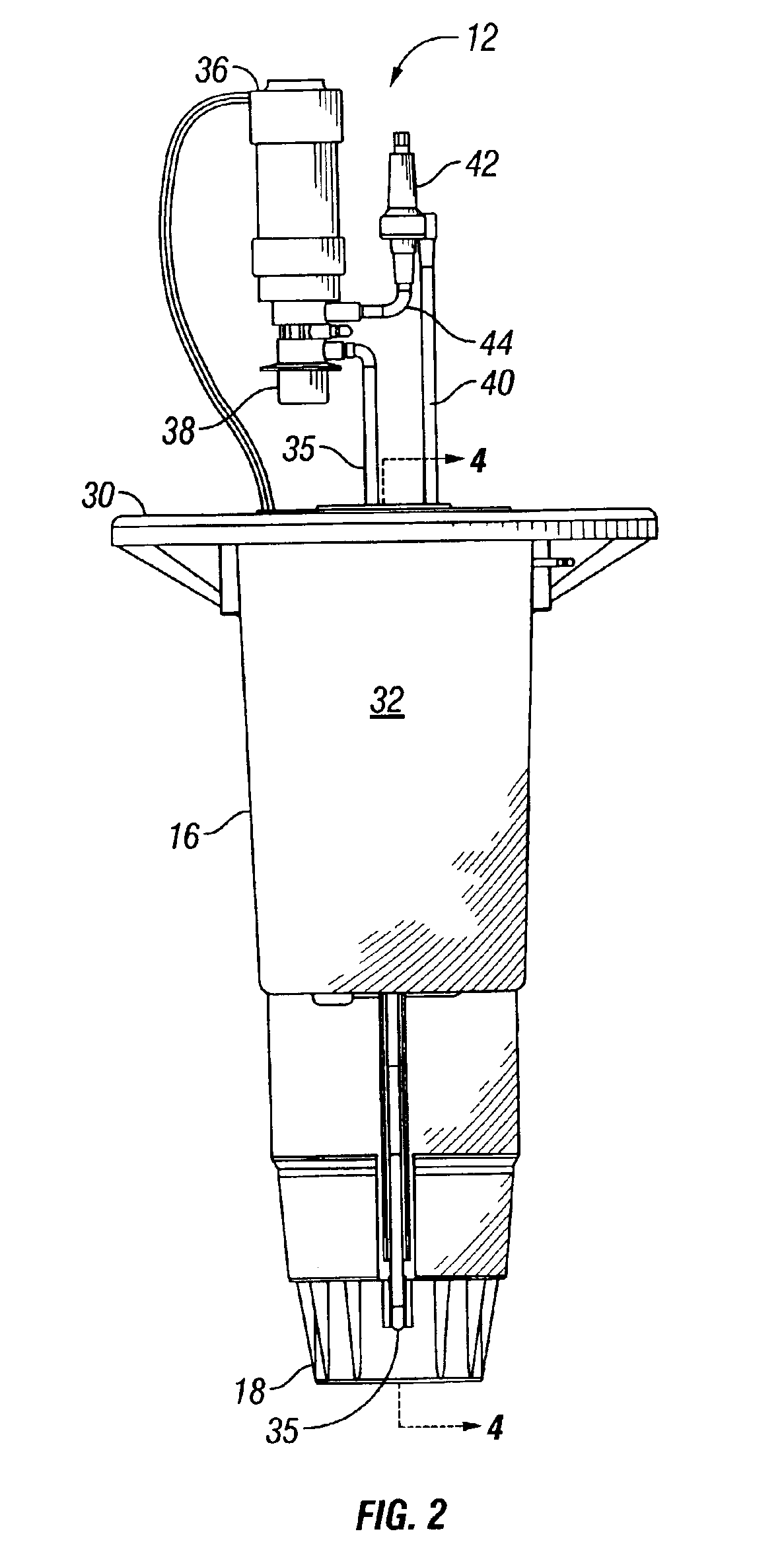

Self-camming snap ring for pop-up sprinkler with top serviceable diaphragm valve module

InactiveUS6854664B2Promote repairEasy to replaceCandle holdersLighting support devicesValve actuatorWater flow

A diaphragm valve module is mounted in the lower end of the outer housing of a pop-up rotor type sprinkler for controlling the flow of water through an inlet in response to actuation of a valve actuator component. A resilient deformable semi-circular snap ring is mounted on top of the module and has a pair of opposing peripheral annular portions. Upon removal of the sprinkler riser, the snap ring can be disengaged from an annular groove formed in the interior wall of the outer housing by manually squeezing the annular portions together. This permits removal of the module for repair or replacement. The annular portions of the snap ring are formed with angled slots that receive projections that extend from the cover of the module to produce a camming movement that uniformly retracts the snap ring out of the annular groove to more readily permit removal of the module.

Owner:HUNTER INDUSTRIES

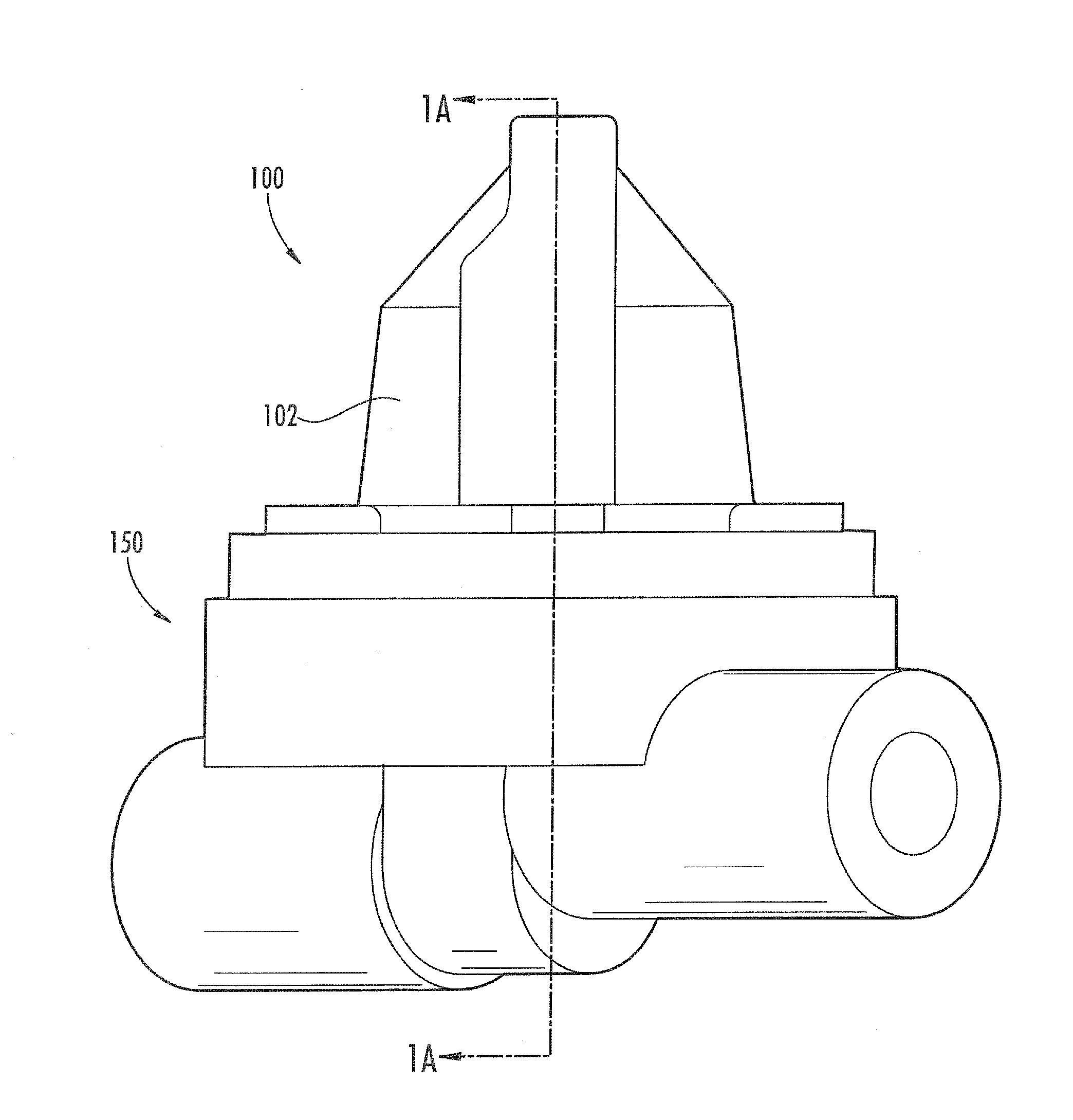

Memory alloy-actuated apparatus and methods for making and using the same

InactiveUS20120151913A1Reduce operating costsLess ecologically damaging wasteOperating means/releasing devices for valvesMechanical power devicesValve actuatorShape-memory alloy

Actuator apparatus having a multi-stable element actuated by memory alloy actuating elements. In one embodiment, the multi-stable actuator comprises a bistable (two-state) diaphragm element adapted to alternate between two stable configurations via forces exerted on the diaphragm by more than one memory alloy filaments in response to thermal activation. The bistable diaphragm element is coupled to a magnetic actuator element resident on a dry portion of a valve fitting, while a plunger actuated by the magnetic actuator element is resident on a wet portion of a valve fitting. Methods for making and using the bistable actuator apparatus are also disclosed.

Owner:AUTOSPLICE SYST

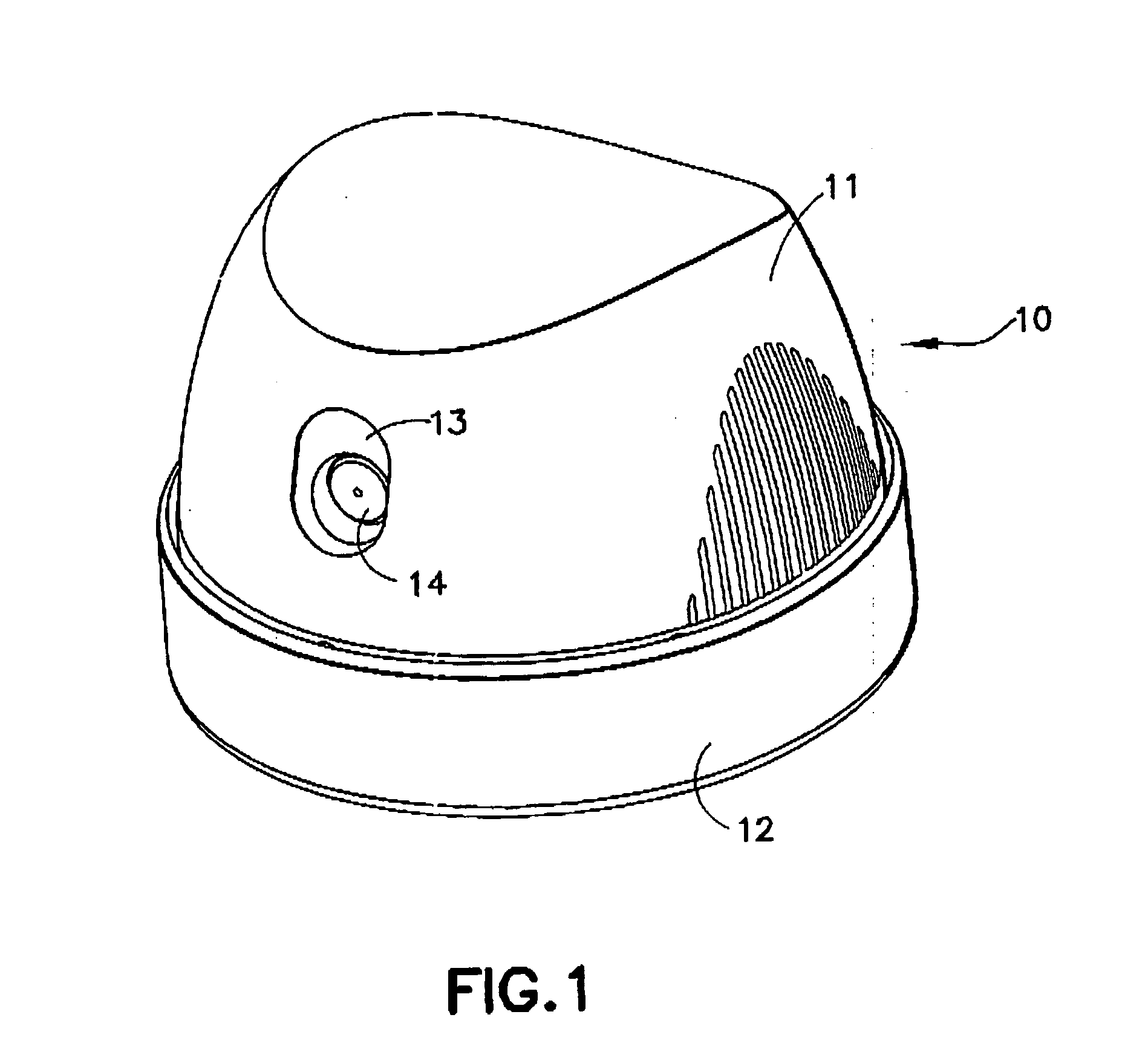

Locking aerosol dispenser

ActiveUS20080164285A1Avoid confusionPrevent rattlingDecorative coversClosure decorative/protective coversValve actuatorShort stem

An aerosol valve actuator with a top portion rotatable on a bottom portion. The entire top portion in one rotatable position is depressible vertically to actuate the valve. A click post and clicking rib provide a single click in each direction of rotation. Flanges on top and bottom portions interact to stop rotation as soon as each click occurs. Plastic springs interact with spring biasing members only when the top portion is in actuating position, and assure return of the actuator top portion to full upward position for rotation after actuation of even a short-stemmed valve. Downwardly extending flexible connecting flanges connect the actuator top and bottom portions. The top portion has a lower periphery with a plurality of upwardly extending indentations to overlie lateral ribs in the lower portion in actuation position. The top and bottom portions have interfitting cylinders to stabilize the top portion and maintain verticality.

Owner:PRECISION VALVE CORP

Subsea actuator assemblies and methods for extending the water depth capabilities of subsea actuator assemblies

InactiveUS7108006B2Improved hydraulic pressure compensation systemIncrease fluid pressureOutboard propulsion unitsEqualizing valvesOcean bottomPressure transmission

A hydraulic pressure compensation system for valve actuator assemblies is described having particular application for subsea wellhead installations. The compensation system includes at least one valve actuator assembly having a housing that retains a reciprocable piston therewithin. The piston is spring biased into its fail safe configuration. The valve actuator assembly is hydraulically associated with an accumulator reservoir that defines a closed fluid reservoir and an open fluid reservoir that is exposed to ambient pressures. The two chambers are separated by a membrane. The valve actuator assembly is also operationally associated with a fluid pressure intensifier that boosts the ambient pressure of the accumulator so that an increased fluid pressure may be transmitted to the actuator assembly to bias the actuated valve toward its fail safe configuration. In a described embodiment, the fluid pressure intensifier comprises a housing that defines a chamber having a fluid inlet and fluid outlet. A dual-headed piston is moveably retained within the housing. The piston has an enlarged piston face and a reduced size piston face. Fluid pressure entering the fluid inlet is exerted upon the enlarged piston face, and due to the difference of piston face sizes, an increased pressure is transmitted out of the fluid outlet.

Owner:VETCO GRAY

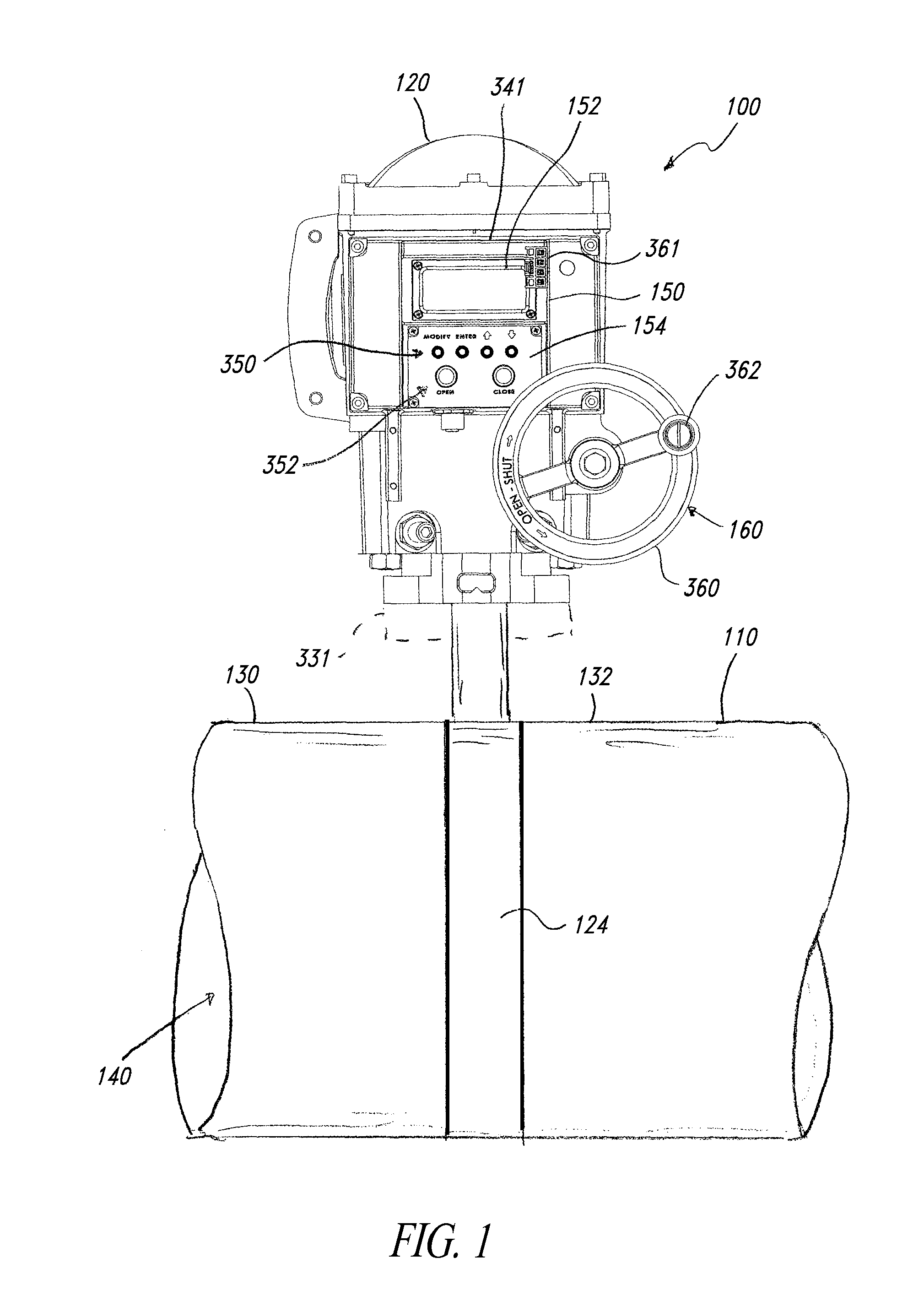

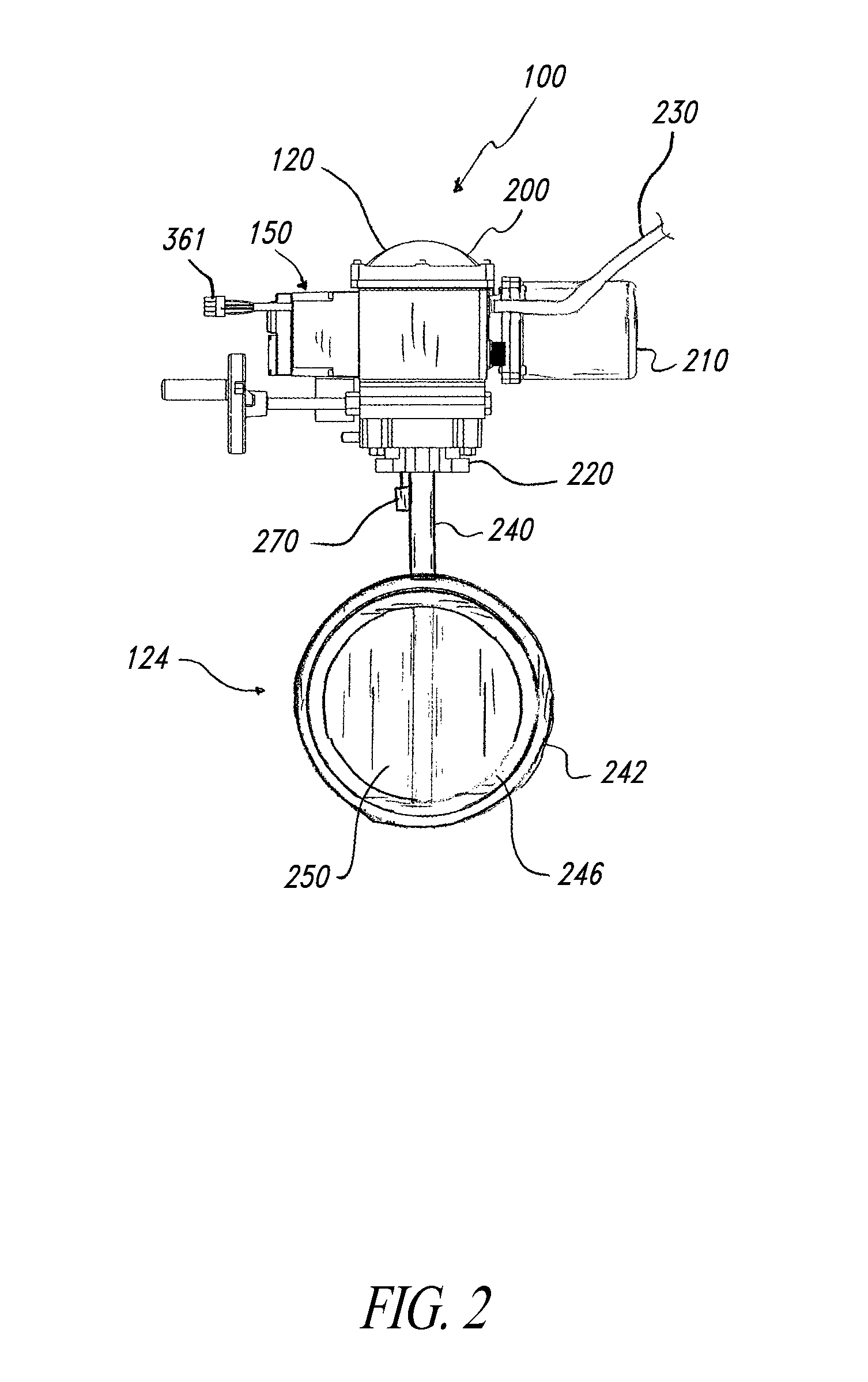

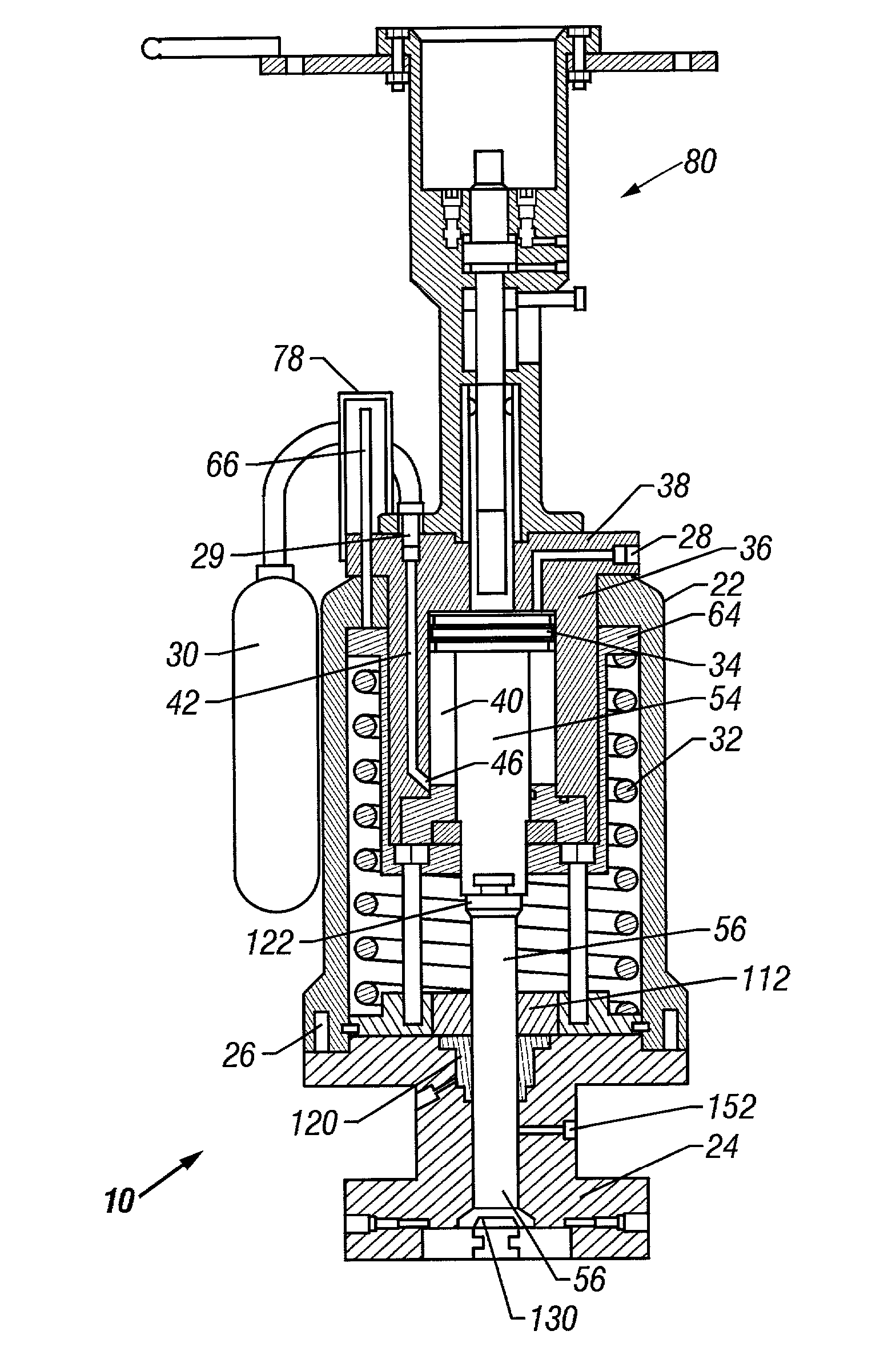

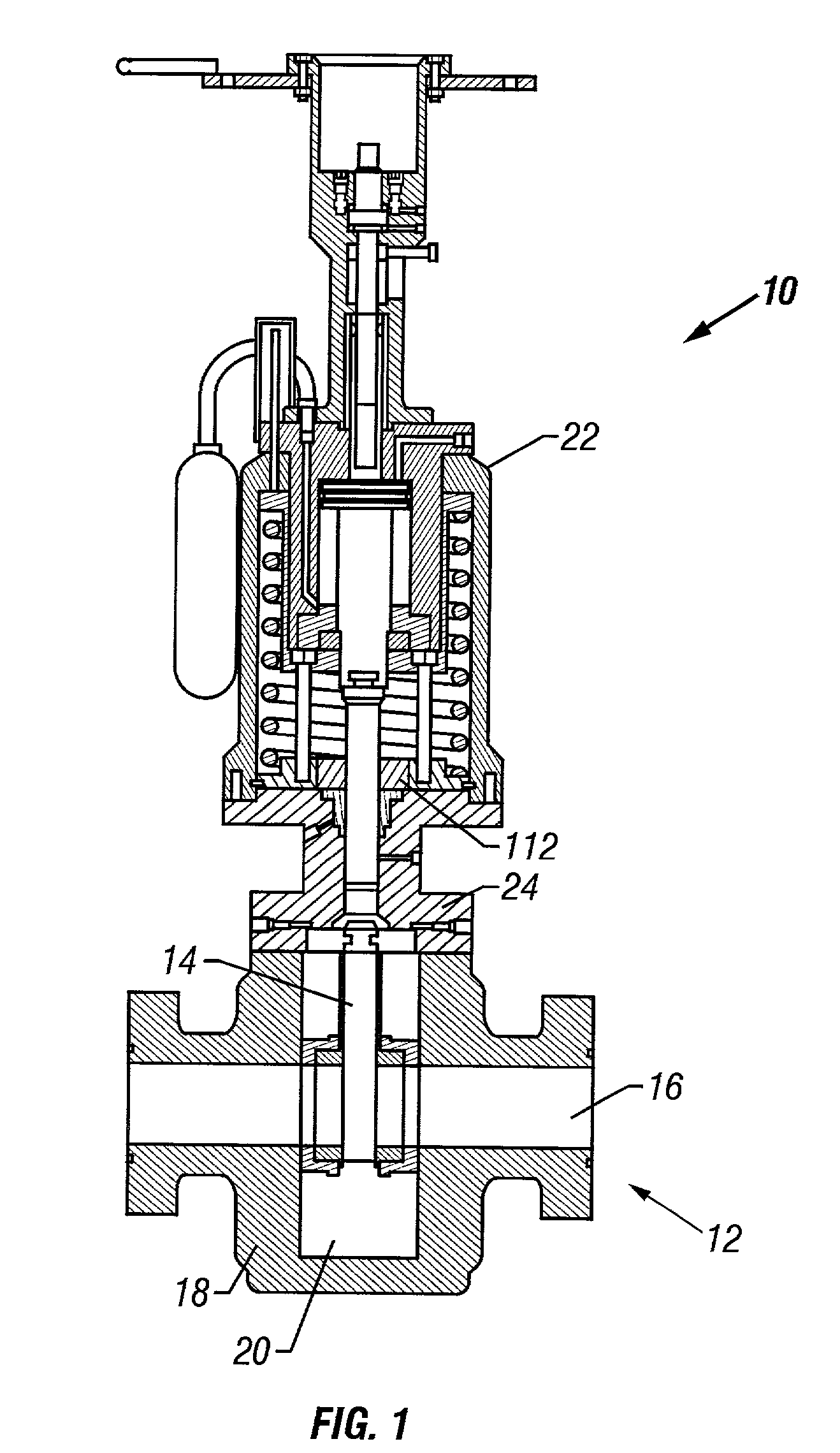

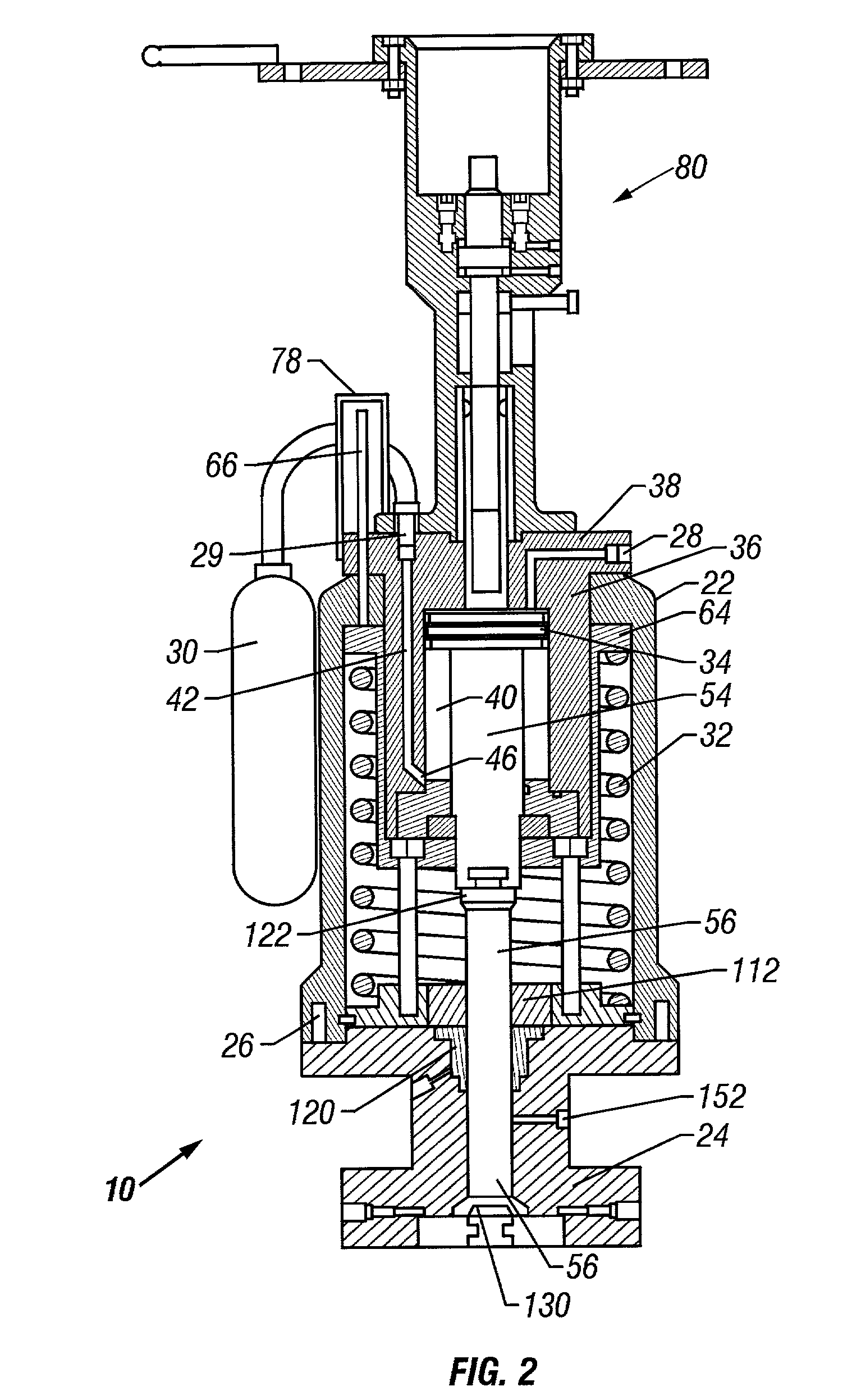

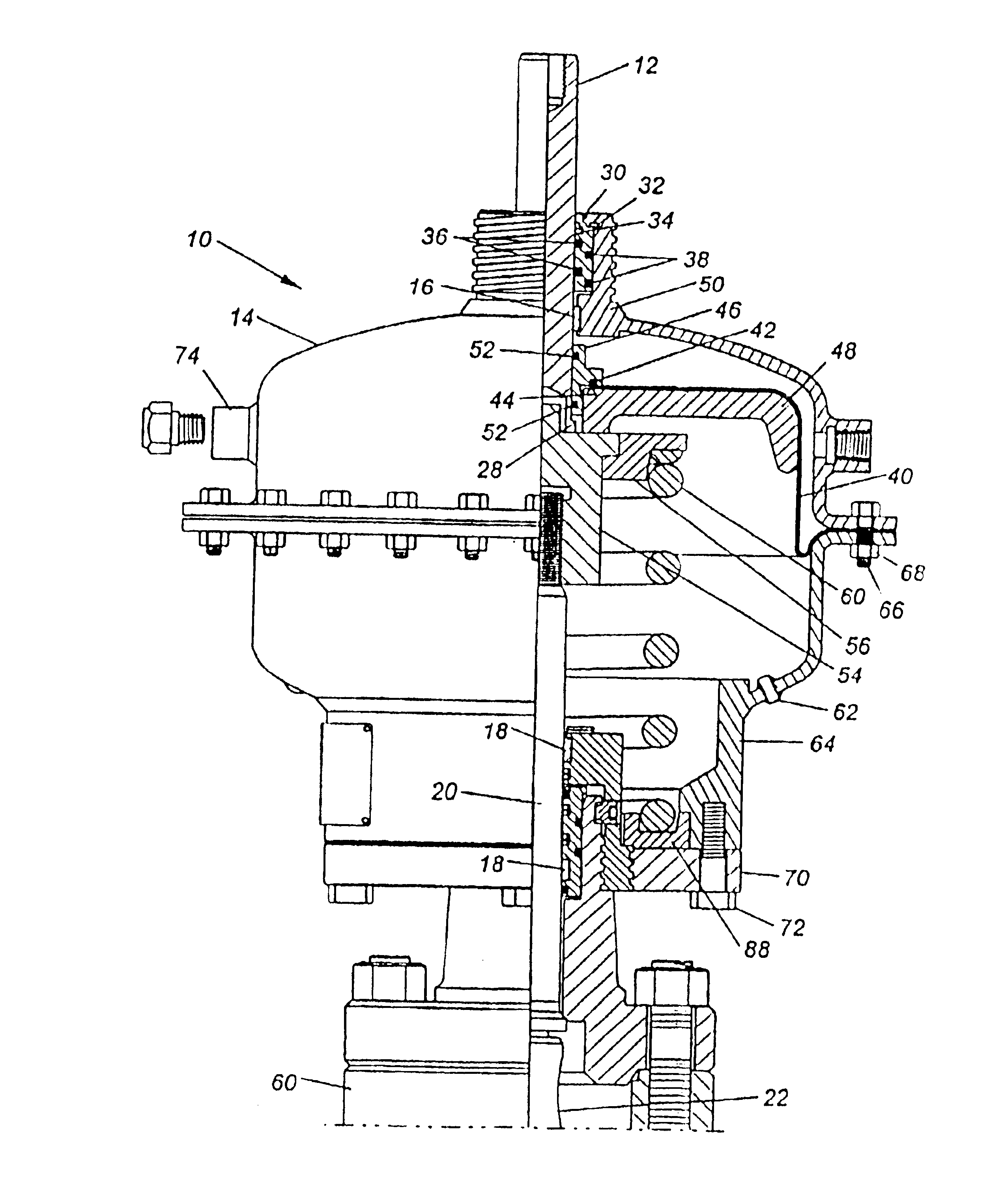

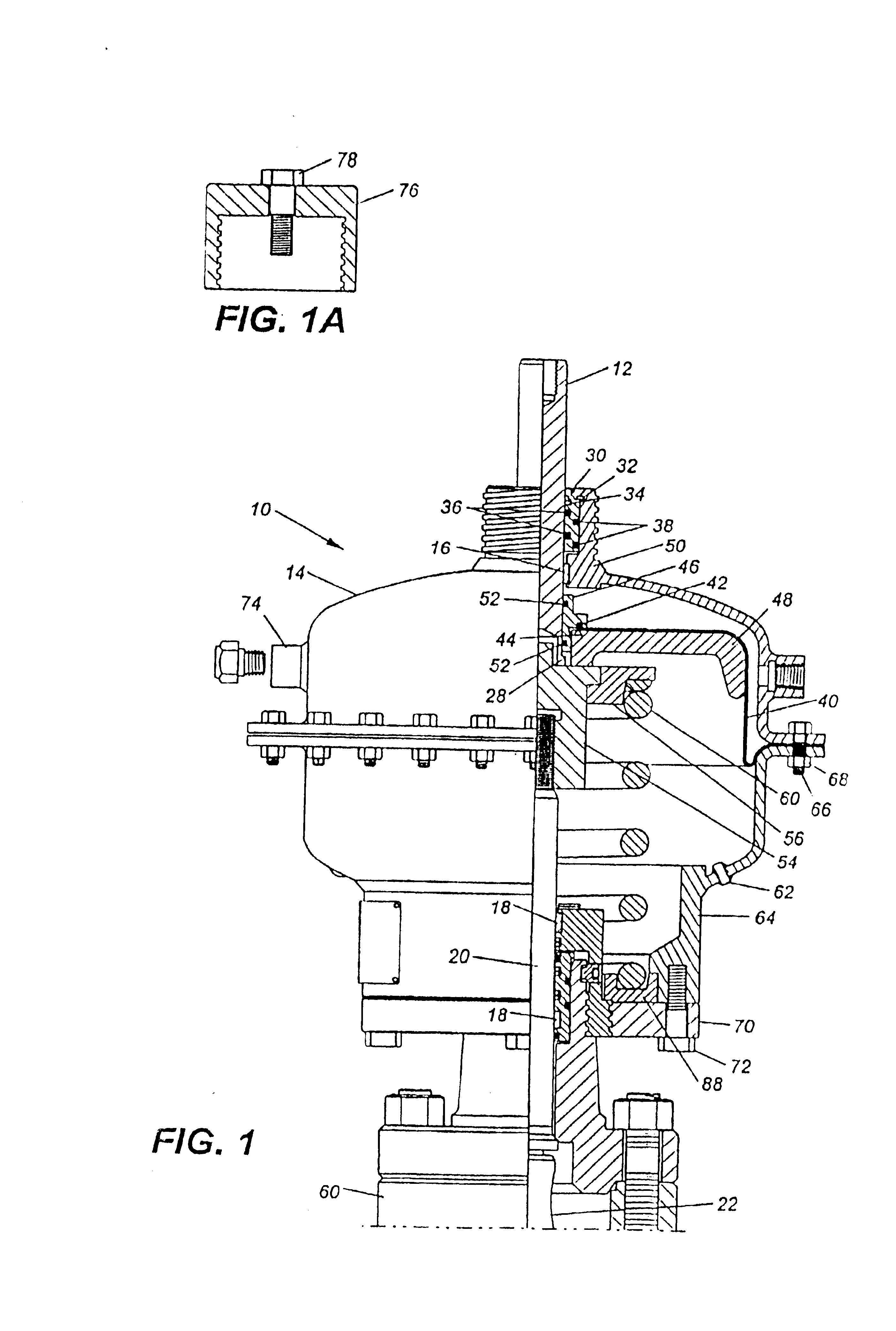

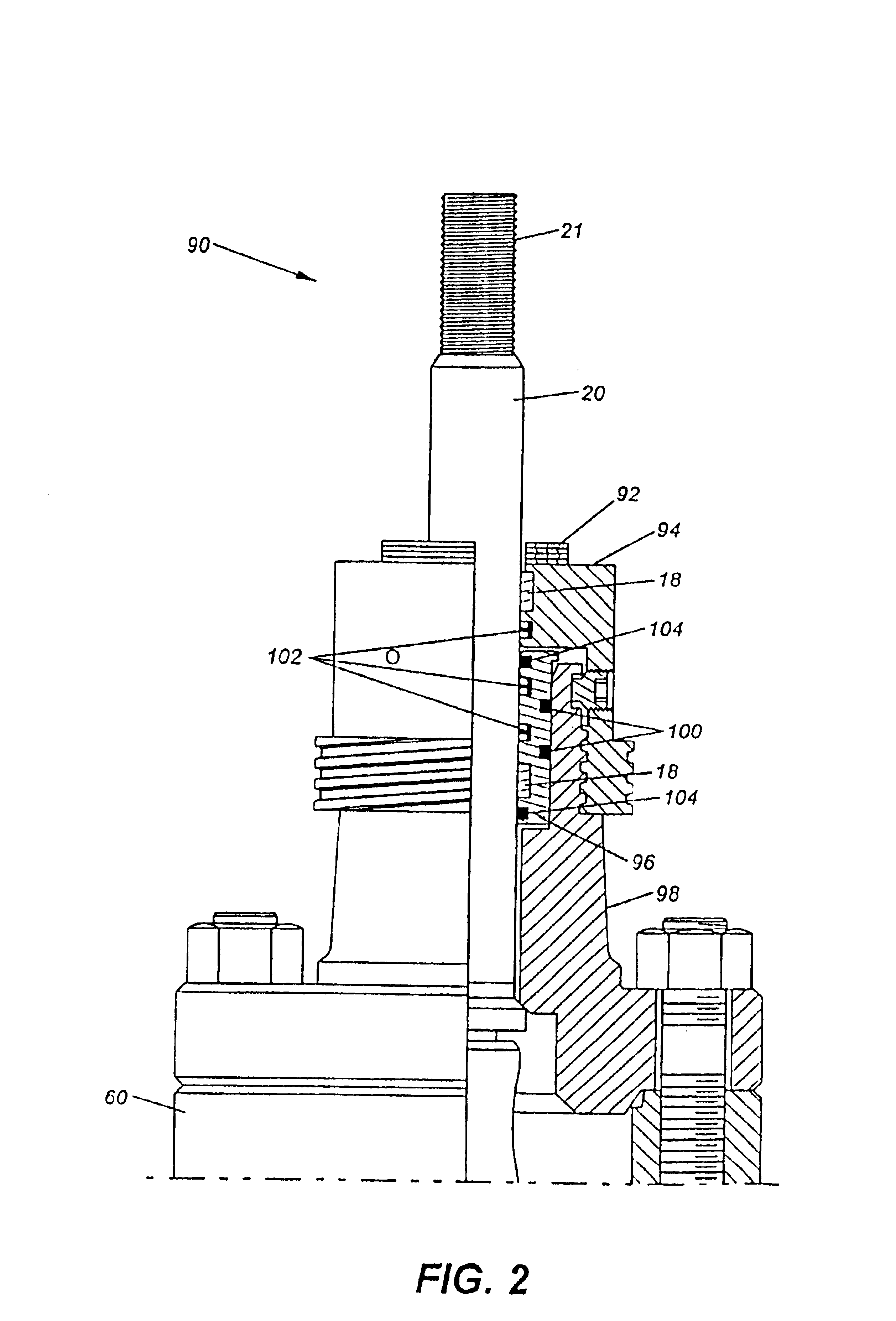

Valve actuator and method

InactiveUS20020124889A1Easy to configureLow profileOperating means/releasing devices for valvesPipeline systemsValve actuatorValve stem

A subsea actuator and method is disclosed that includes all moving components mounted in a compact, concentric configuration. The subsea actuator is highly reliable and will operate at depth even with zero valve body cavity pressure. A preferably cup-shaped spring pusher is provided in telescoping relationship to the hydraulic chamber. A piston position indicator is provided which is connected externally to the hydraulic piston cylinder to avoid the possibility of hydraulic leaks due to the piston indicator. A manual override may be provided with a manual override indicator. The manual override indicator has a shorter travel length than the manual override operating stem to thereby reduce the overall length of the manual override assembly. The driving stem provides a removable connection to the hydraulic piston from the top of the actuator housing and a quick disconnect permits disconnection of the driving stem from the valve stem. In a preferred embodiment, upper and lower t-slot connections are utilized in the driving stem assembly. In a preferred embodiment, two back seat valves are removably secured to the driving stem to engage respective seats and provide additional sealing around the driving stem so as to prevent leakage between the valve chamber and actuator housing chamber. The high tension spring does not need to be removed to perform maintenance, and all wear items and seals are readily accessible. Change or replacement of the stem packing is made from the top of the bonnet to avoid dissasembling the bonnet to valve body connection. Pre-load bolts are used to adjustably preload the tension in the return spring. The height / weight of the actuator is significantly reduced as compared to prior art subsea valve actuators.

Owner:WORLDWIDE OILFIELD MACHINE INC

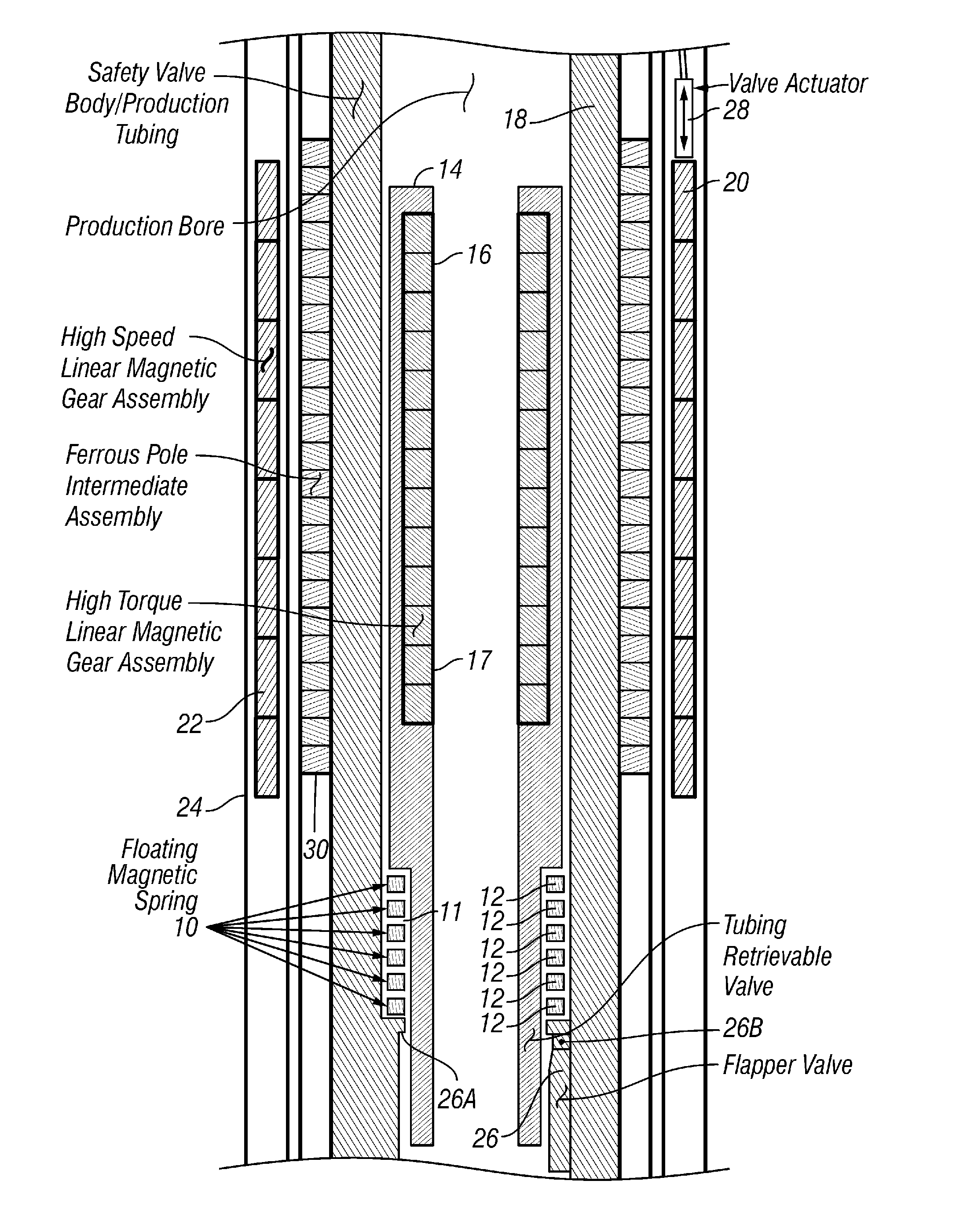

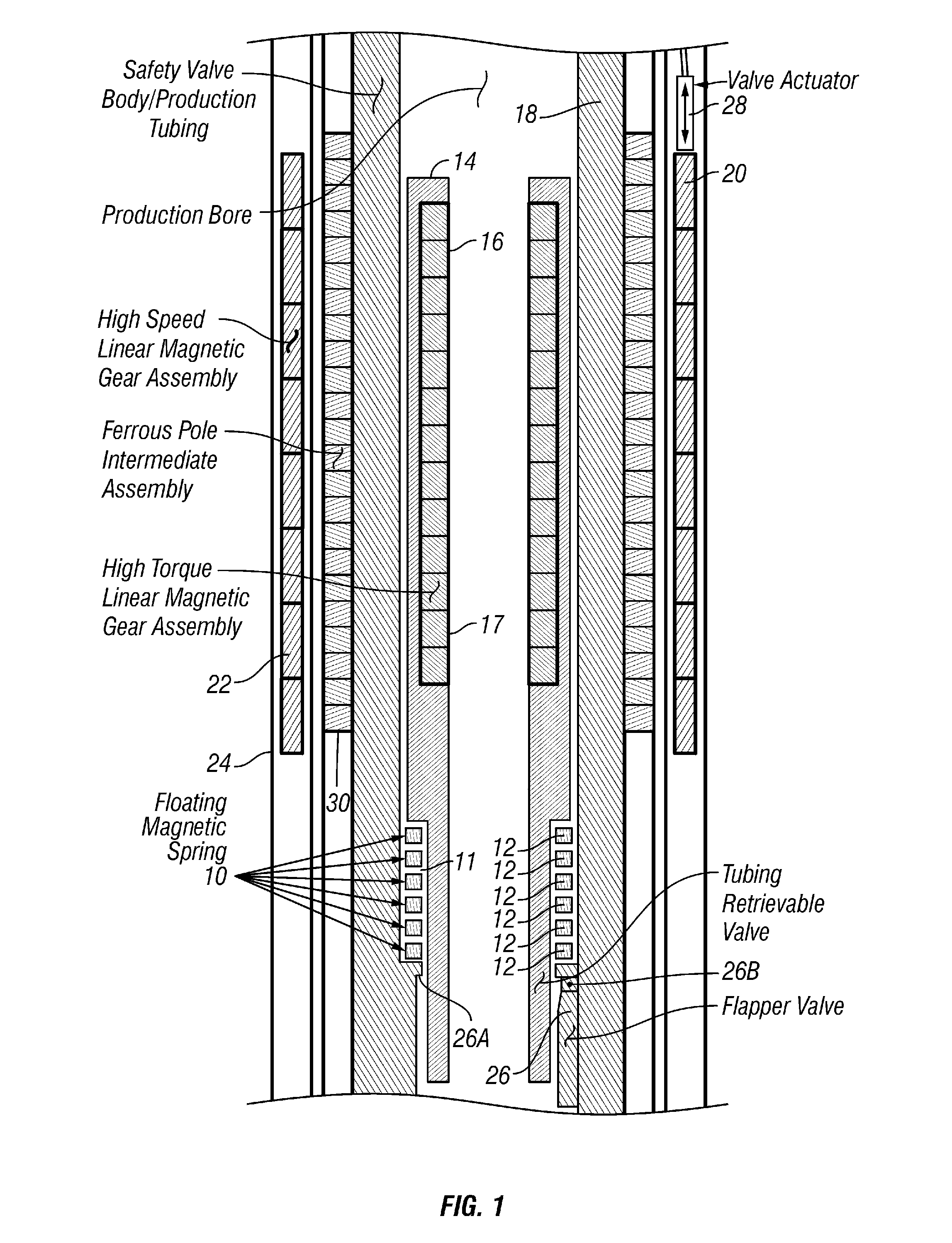

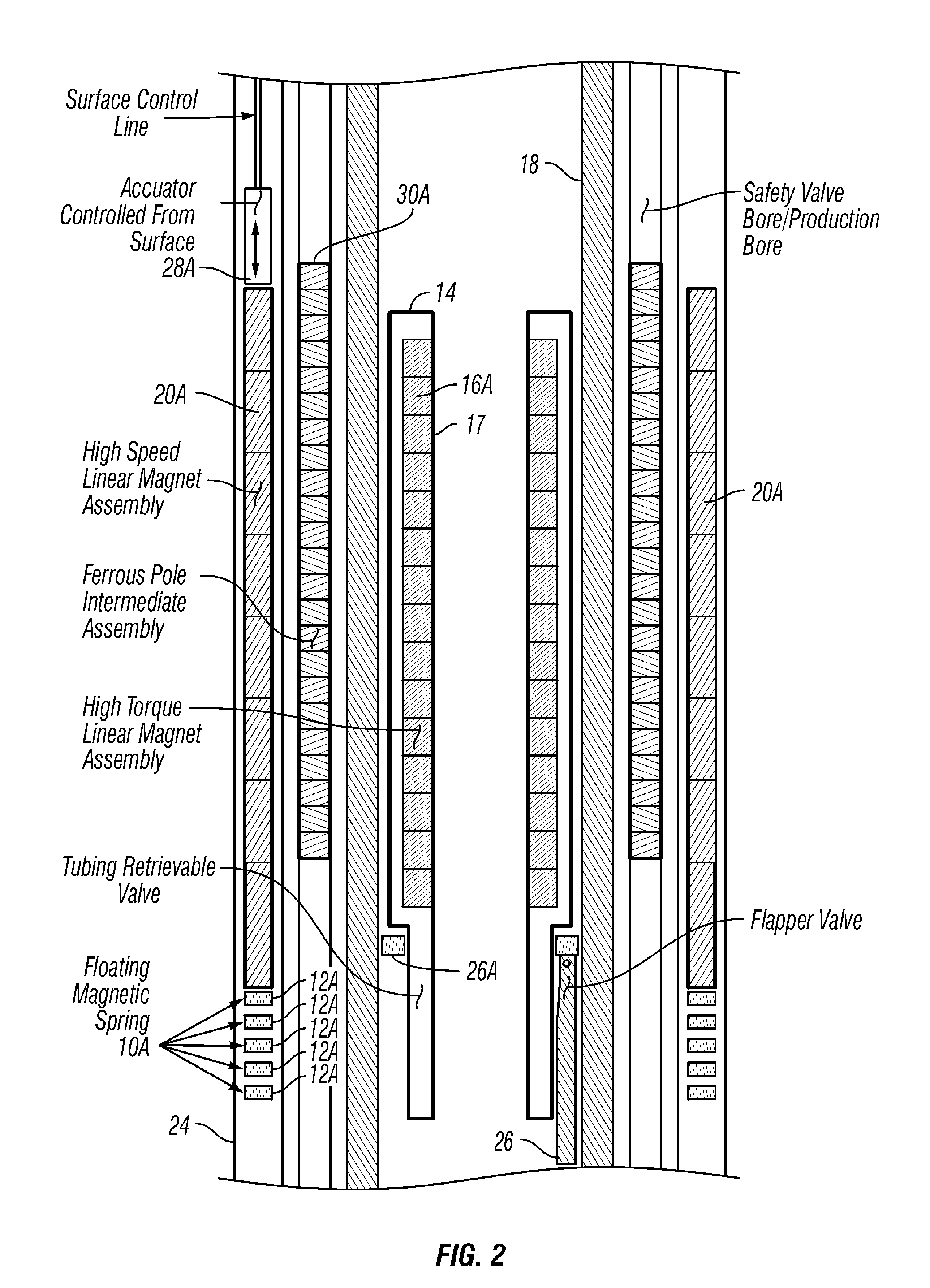

Wellbore Valve Having Linear Magnetically Geared Valve Actuator

InactiveUS20070289734A1Operating means/releasing devices for valvesFluid removalValve actuatorMotion transfer

A wellbore valve includes a valve operator arranged to move axially along an interior of the wellbore, the valve operator arranged to operate a valve. A valve actuator is disposed proximate the valve operator. The valve actuator is arranged to move from one longitudinal position to another. A linear magnetic gear is coupled at an input element thereof to the valve actuator. The gear is coupled at an output element thereof to the valve operator such that motion of the valve actuator is transferred to the valve operator.

Owner:MAGNOMATICS LTD

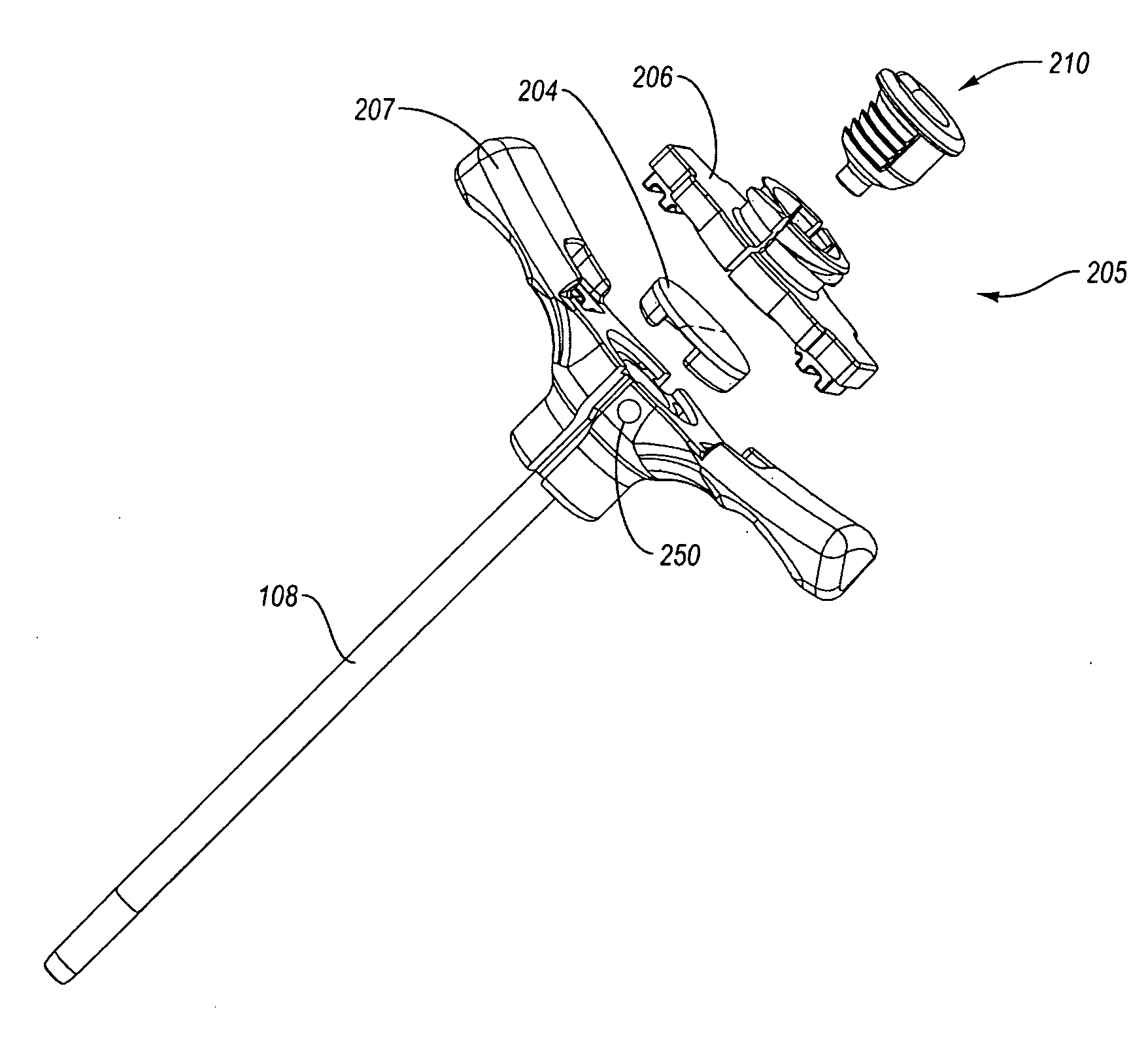

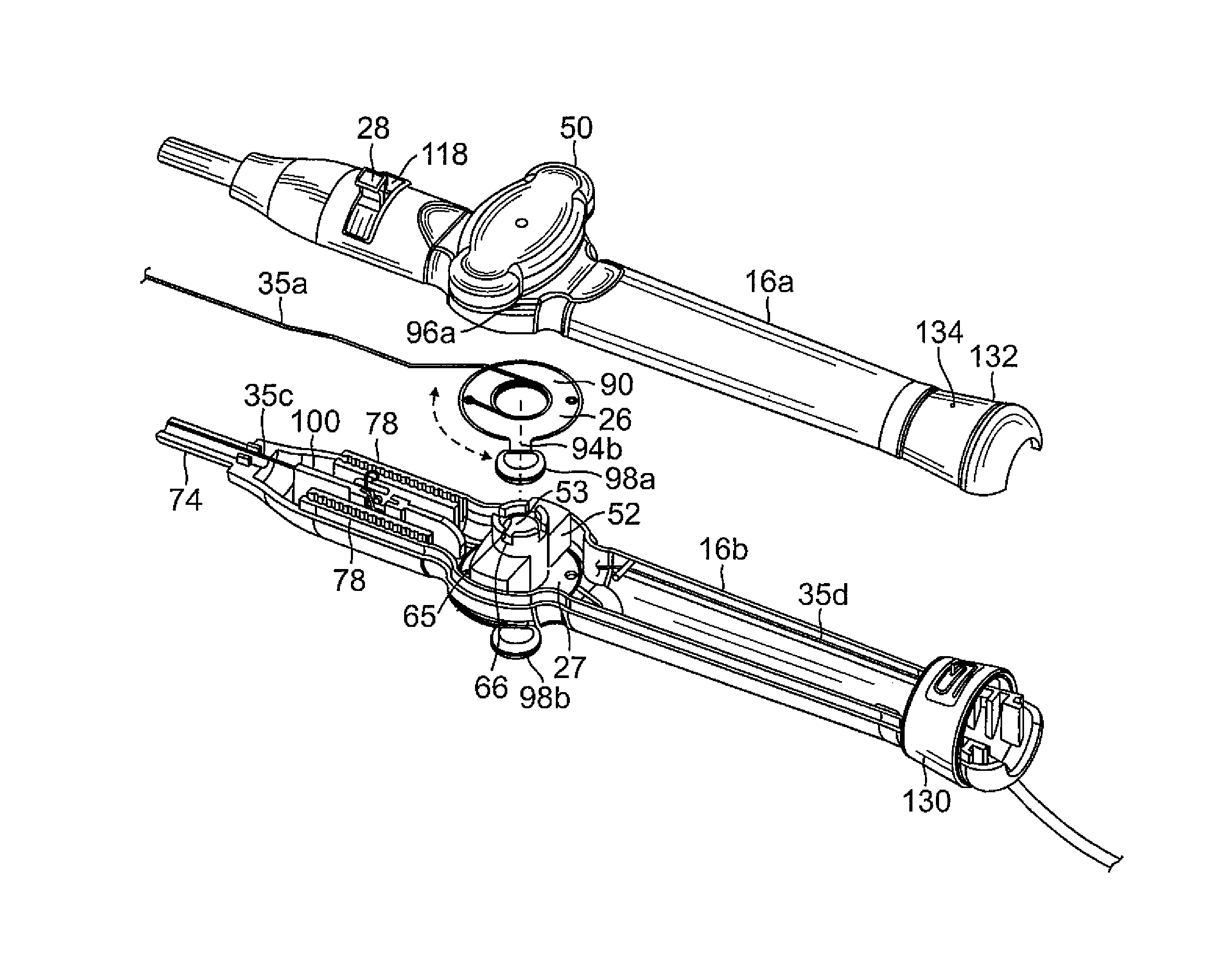

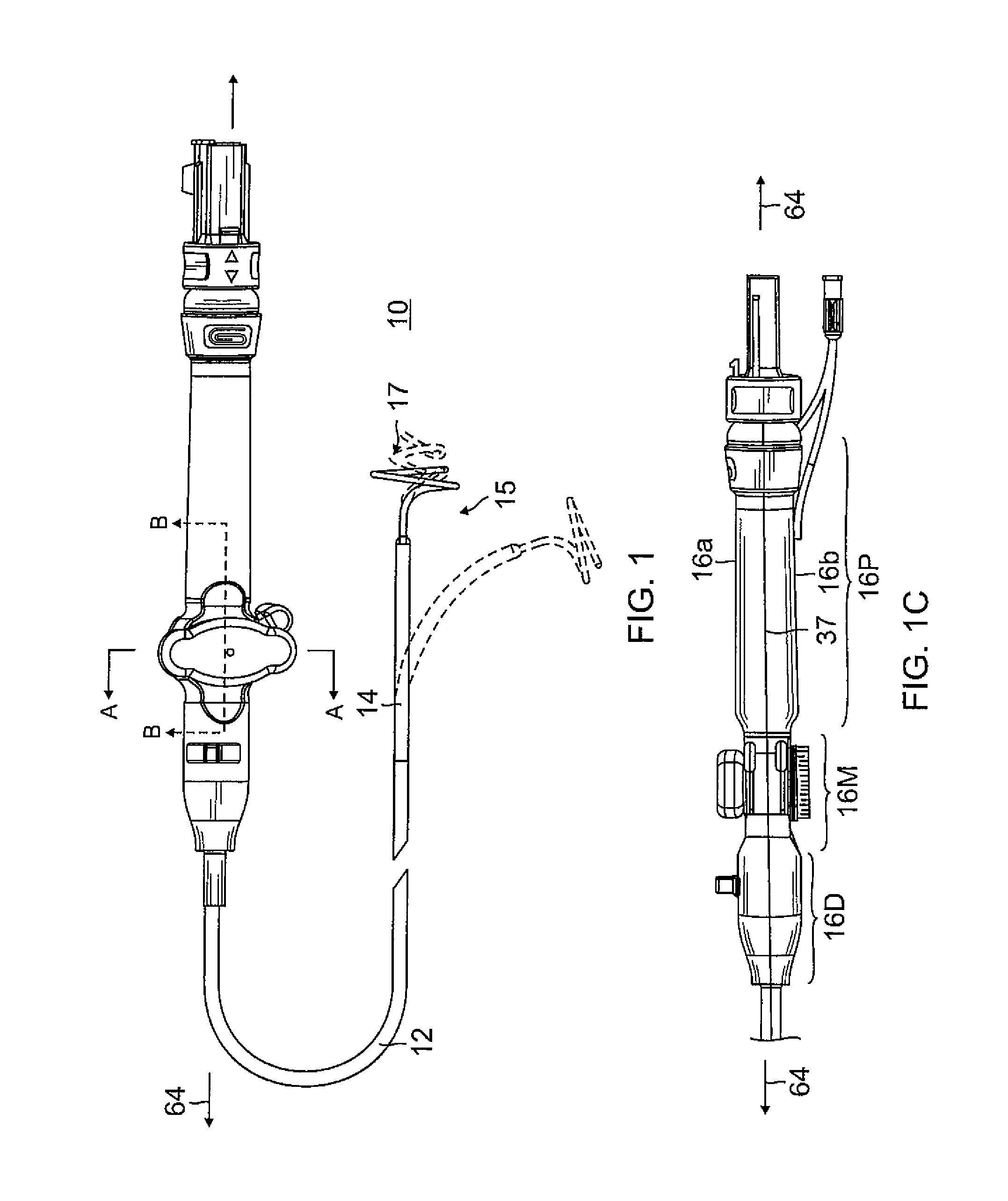

Medical device control handle with multiple puller wires

A medical device control handle or catheter includes deflection assembly and at least one of the following: a disk actuator, a lever actuator and a ring actuator for actuating additional puller wires in manipulation of multiple features of the medical device or catheter independently of each other. The disk actuator has a common rotational axis with but is rotationally independent of the deflection assembly. The lever actuator has a separate rotational axis. The ring is mounted outside of the control handle and rotatable relative to the control handle to actuate another puller wire for manipulating another feature of the catheter.Each of the disk, lever and ring actuators are of a design that allows existing control handles and catheters to be readily modified to include these actuators.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

Sprinkler assembly

InactiveUS6851482B2High performance and economical and reliableEconomical and reliableSpray nozzlesTobacco devicesFluid controlValve actuator

A sprinkler assembly for controlling a fire situation includes at least one fluid conduit defining a flow passage including an inlet for receiving a fluid from a fluid source and at least one outlet for discharging the fluid, and a dispensing mechanism such as an open or closed sprinkler head for distributing water to a selected location. A fluid control apparatus is provided including a valve assembly having a valve seal which is moveable between a closed position blocking fluid flow through the conduit and an open position causing fluid flow through the conduit. The fluid control apparatus further includes an actuating mechanism including a valve actuator which is operatively connected to the valve assembly for causing movement of the valve seal to the open position upon release of the sealing force. A sensing mechanism is operatively connected to the valve assembly, the sensing mechanism being thermodynamically responsive to at least one of heat, smoke, infrared radiation and ultraviolet radiation emitted by a heat source.

Owner:DOLAN KEVIN MICHAEL

Valve actuator apparatus

InactiveUS6854704B1Inexpensive to constructSimple yet reliable in constructionSpindle sealingsOperating means/releasing devices for valvesValve actuatorTorque transmission

A valve actuator apparatus and method comprises an operator housing secured to a bonnet assembly. The bonnet assembly is secured to the valve body, and includes a bonnet stem movably within a bonnet housing for moving a gate within the valve body to open and close the valve. A downstop member is fixably secured to the bonnet stem and engages removable stem spacers which are added or removed to obtain a selected bonnet stem drift setting. The operator housing connects to a base ring that surrounds the bonnet housing and rotates to allow positioning of a fluid port in the operator housing. The operator housing may removed and replaced without altering the bonnet stem drift adjustment. A top shaft extends from the operator housing and rotates with respect to the bonnet stem to prevent torque transmission from the top shaft to the bonnet stem. A replaceable sealing cartridge sealingly supports the top shaft for axial movement within the operator housing.

Owner:SAFOCO

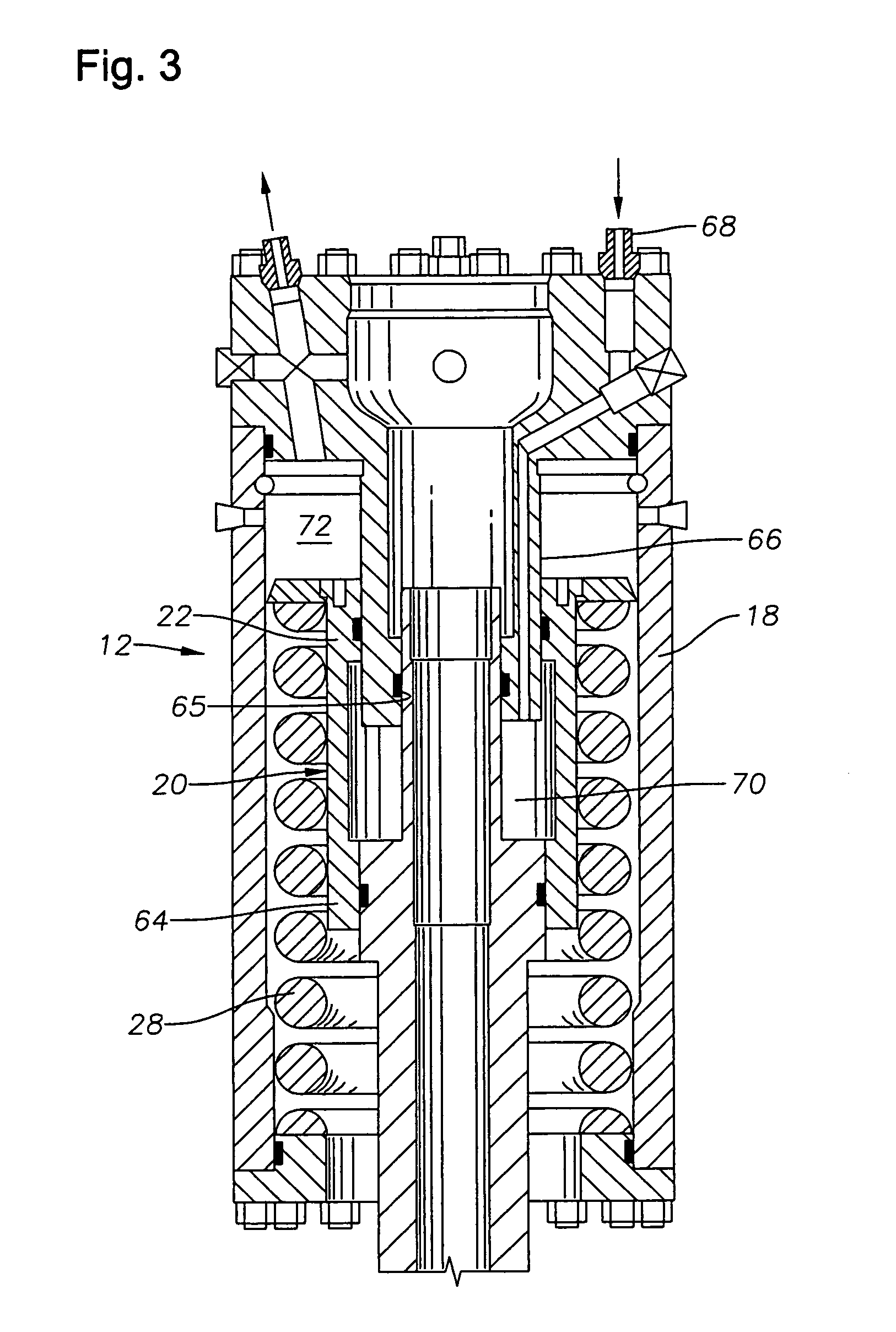

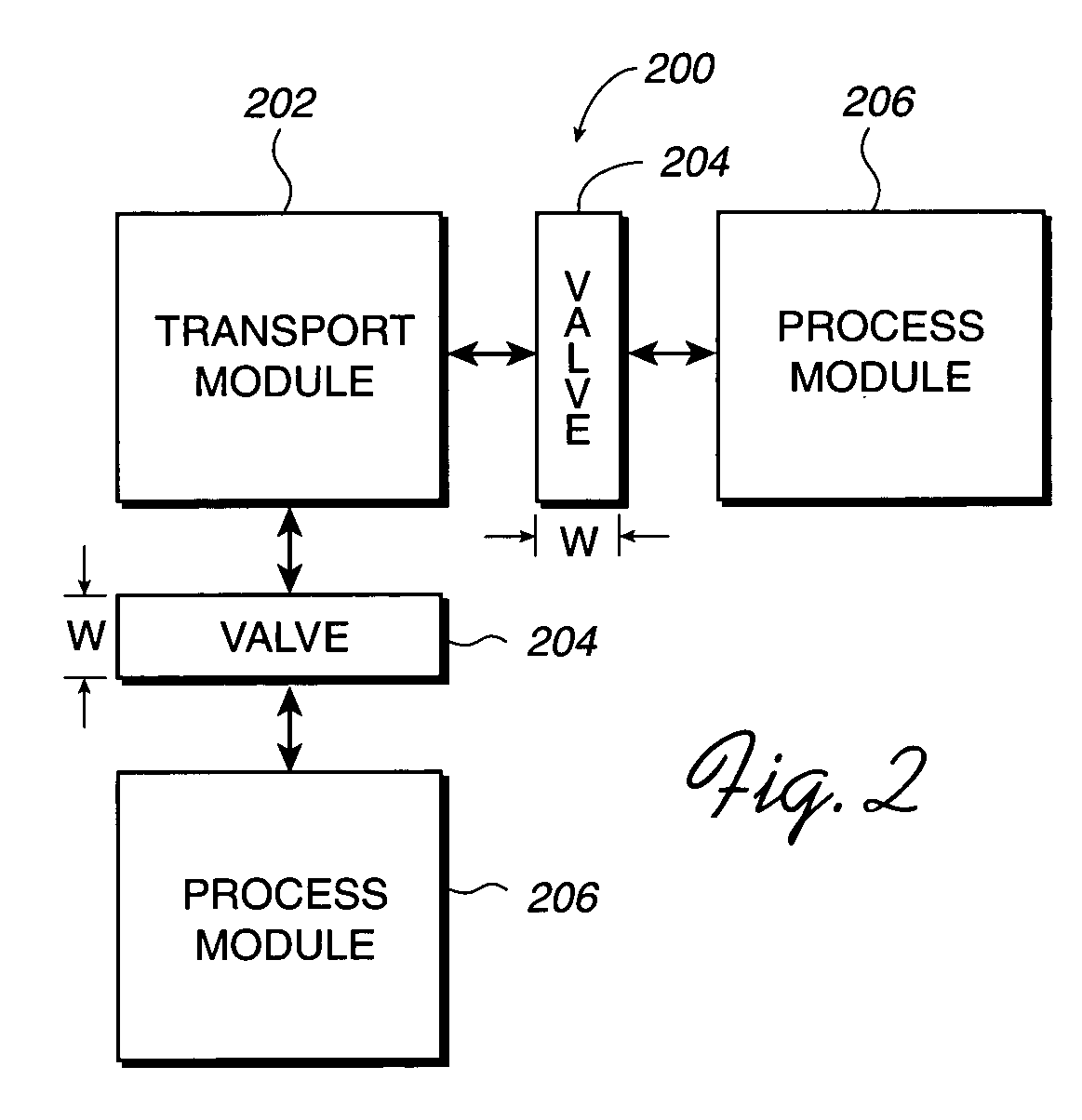

Unitary slot valve actuator with dual valves

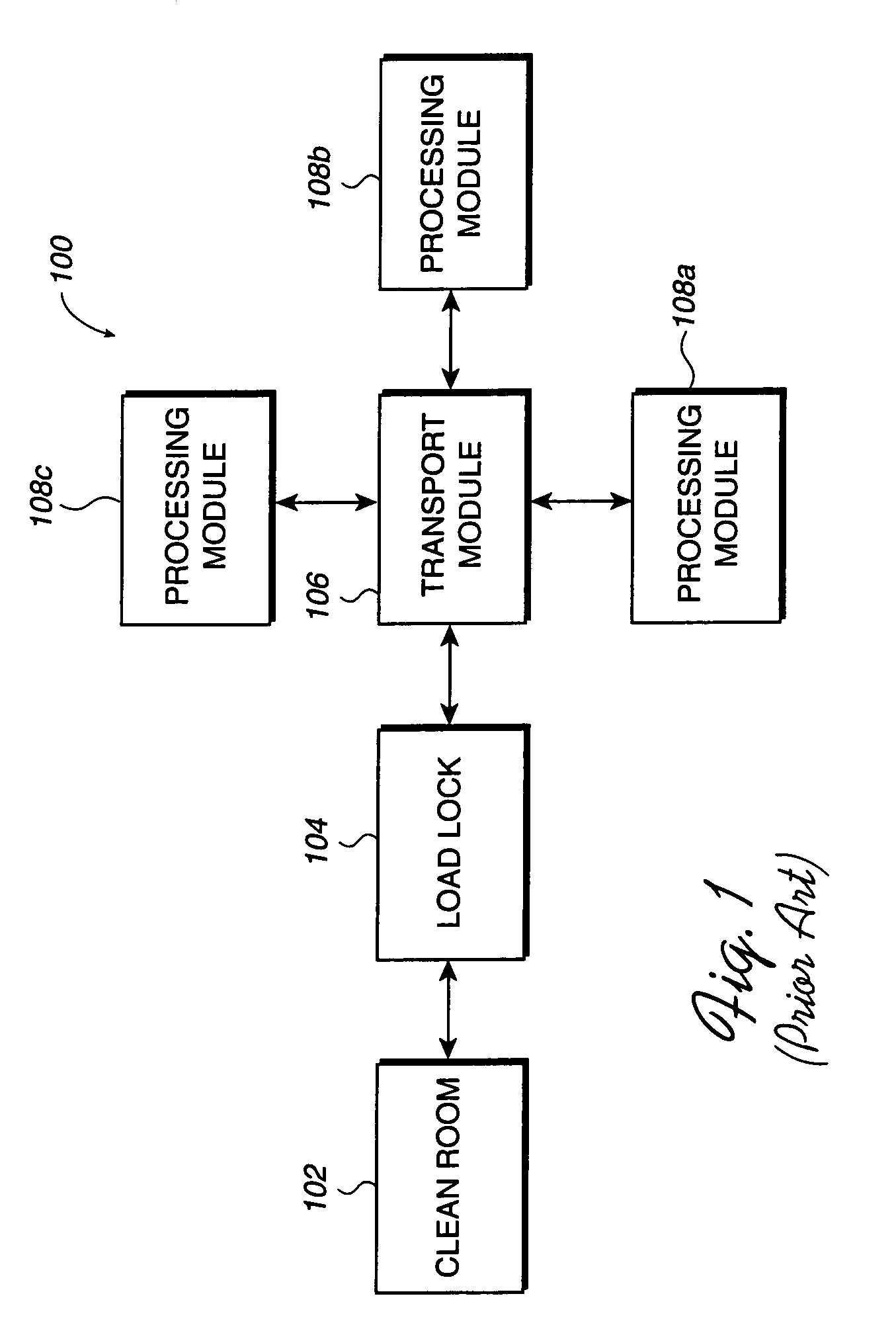

InactiveUS6913243B1Easy maintenanceSubstantial period is avoidedSemiconductor/solid-state device manufacturingCharge manipulationValve actuatorProcess module

A unitary slot valve actuator is in a vacuum body between adjacent vacuum chambers, such as a process module and a transport module. Separate valves are provided on the unitary actuator for each of two valve body slots, each body slot being closed or opened according to the position of the unitary actuator. The separate valves allow a vacuum condition to be maintained in the transport module while an adjacent process module is open to the atmosphere for servicing. The unitary actuator allows access to an open valve for servicing the open valve by way of a resilient bias assembly that releasably holds the valves in an open, but not vertically-spaced, position relative to the respective slots. The open valves are easily reached by a gloved hand of a service worker. A separate actuator motor moves the unitary actuator with the valves vertically down from the open position and away from the slots to expose seal surfaces around the slots for cleaning.

Owner:LAM RES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com